Patents

Literature

12930results about How to "High crystallinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

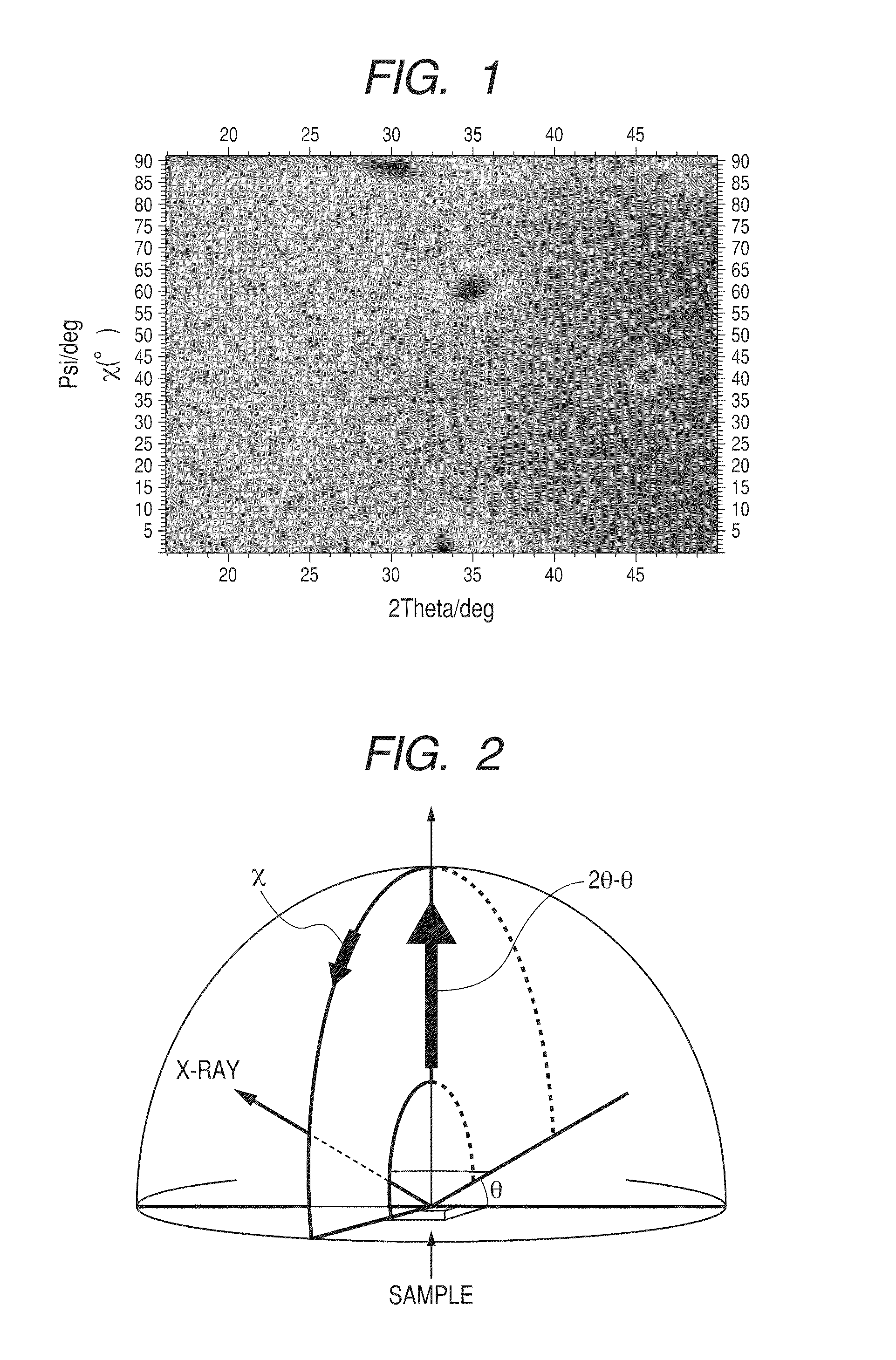

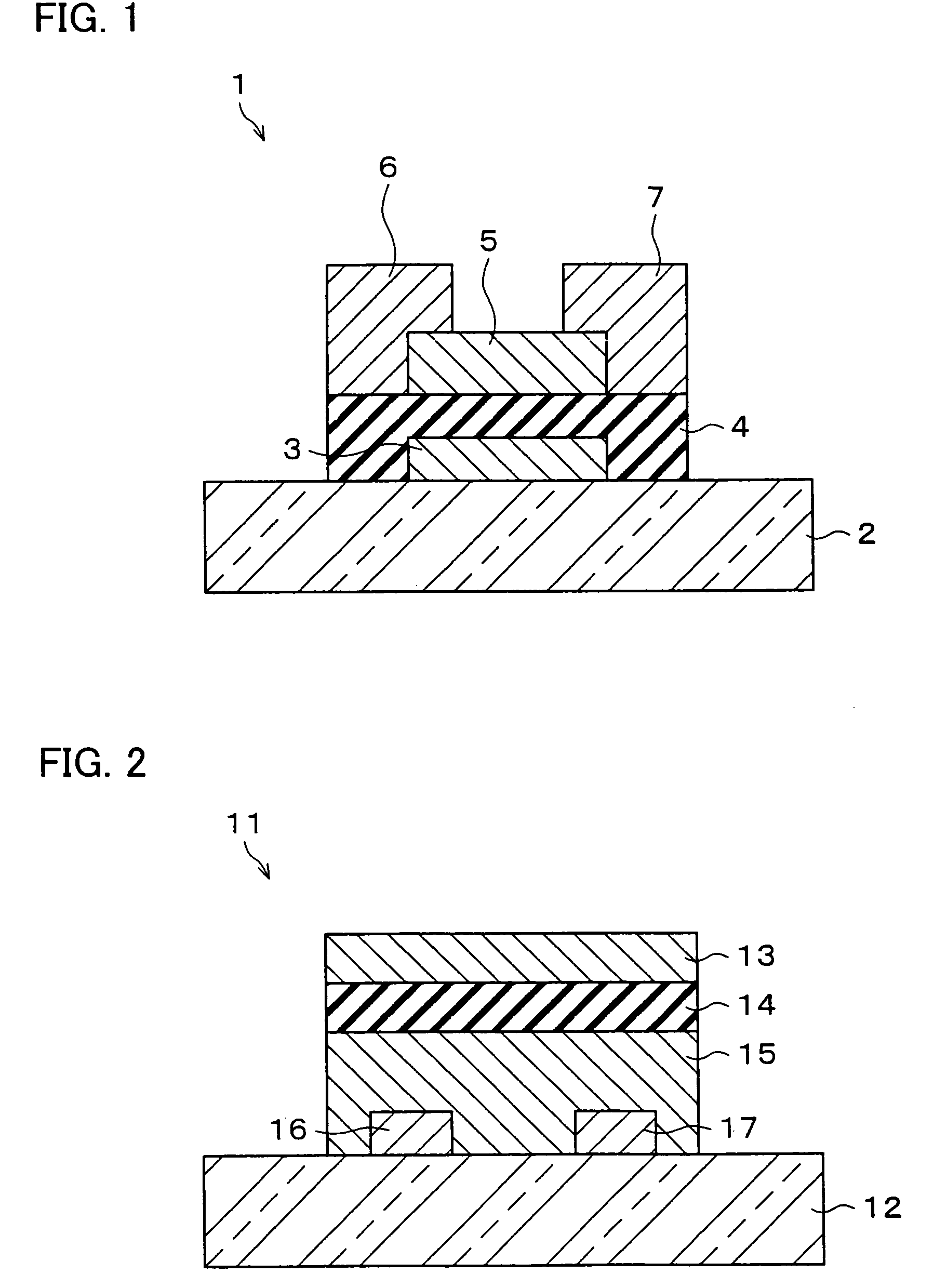

Method for forming ZnO film, method for forming ZnO semiconductor layer, method for fabricating semiconductor device, and semiconductor device

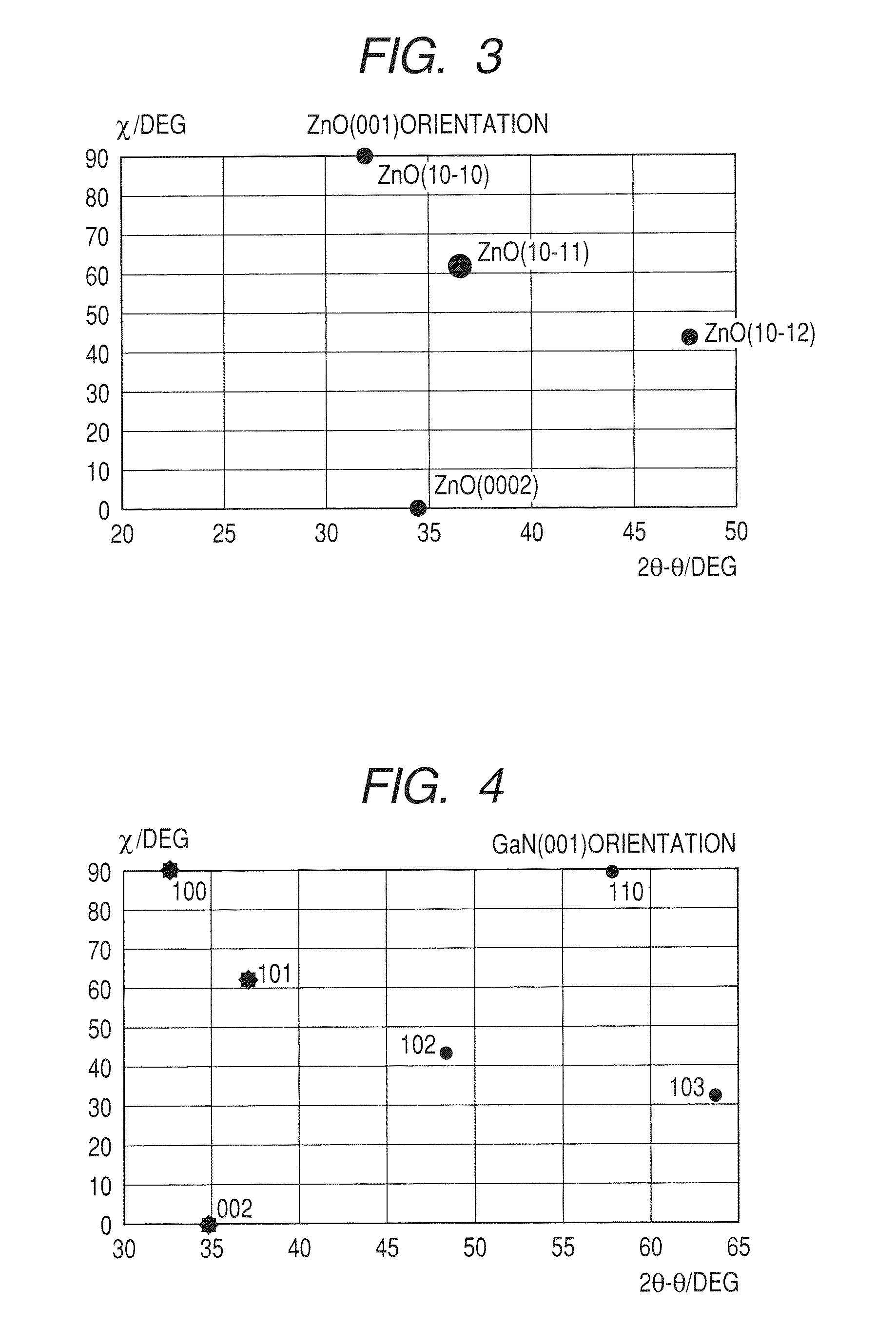

InactiveUS7049190B2High crystallinityLow costTransistorPolycrystalline material growthX-rayElectrical resistivity and conductivity

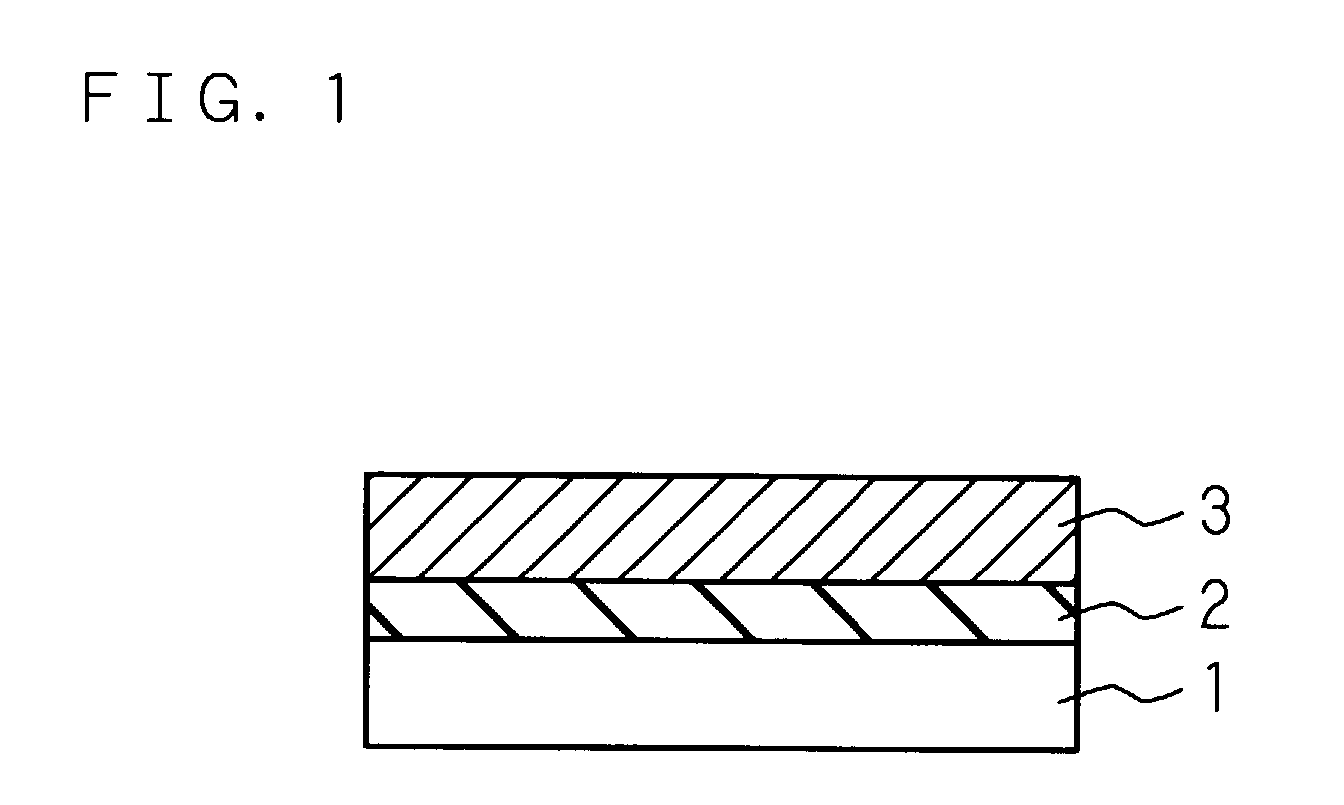

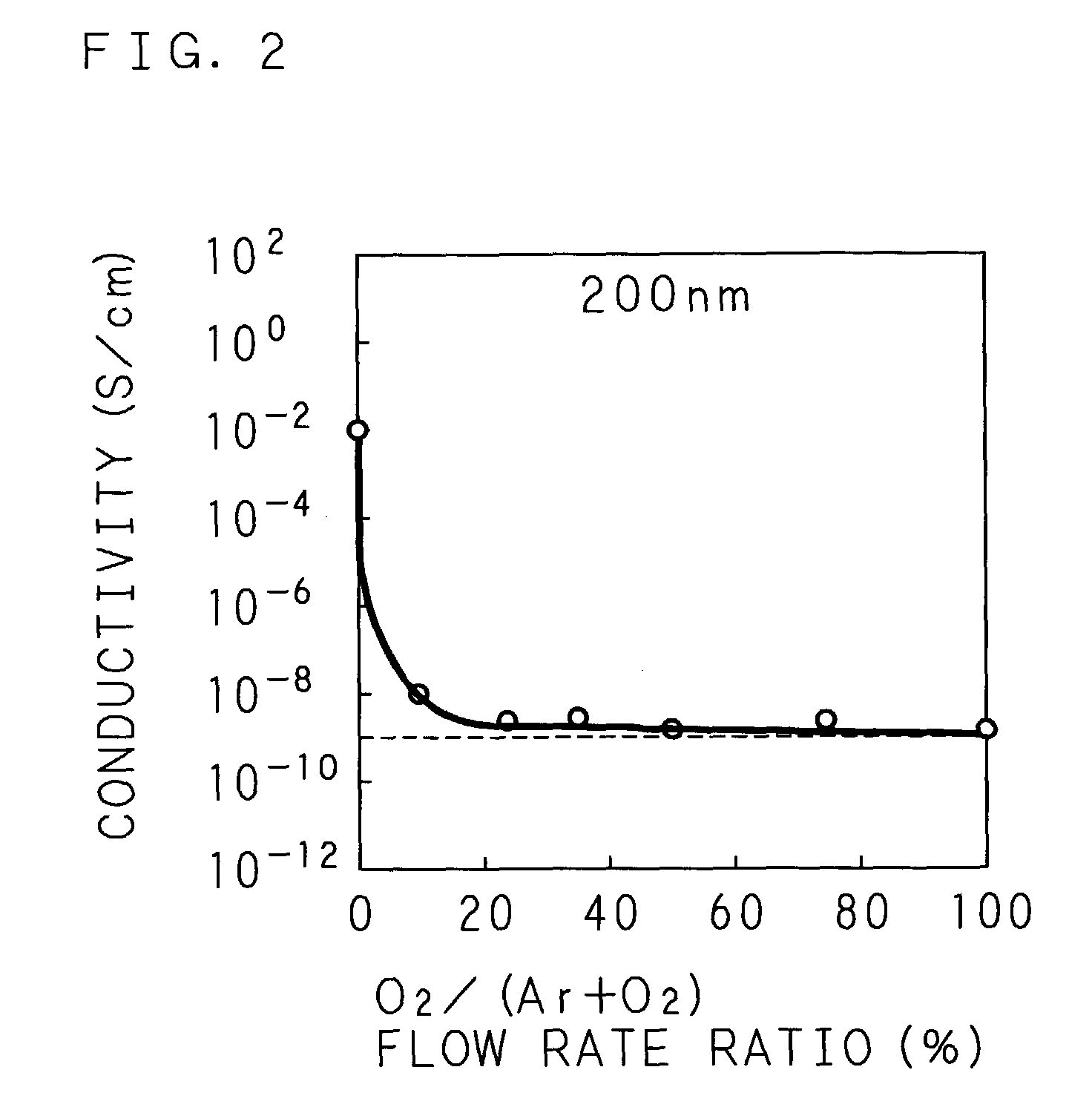

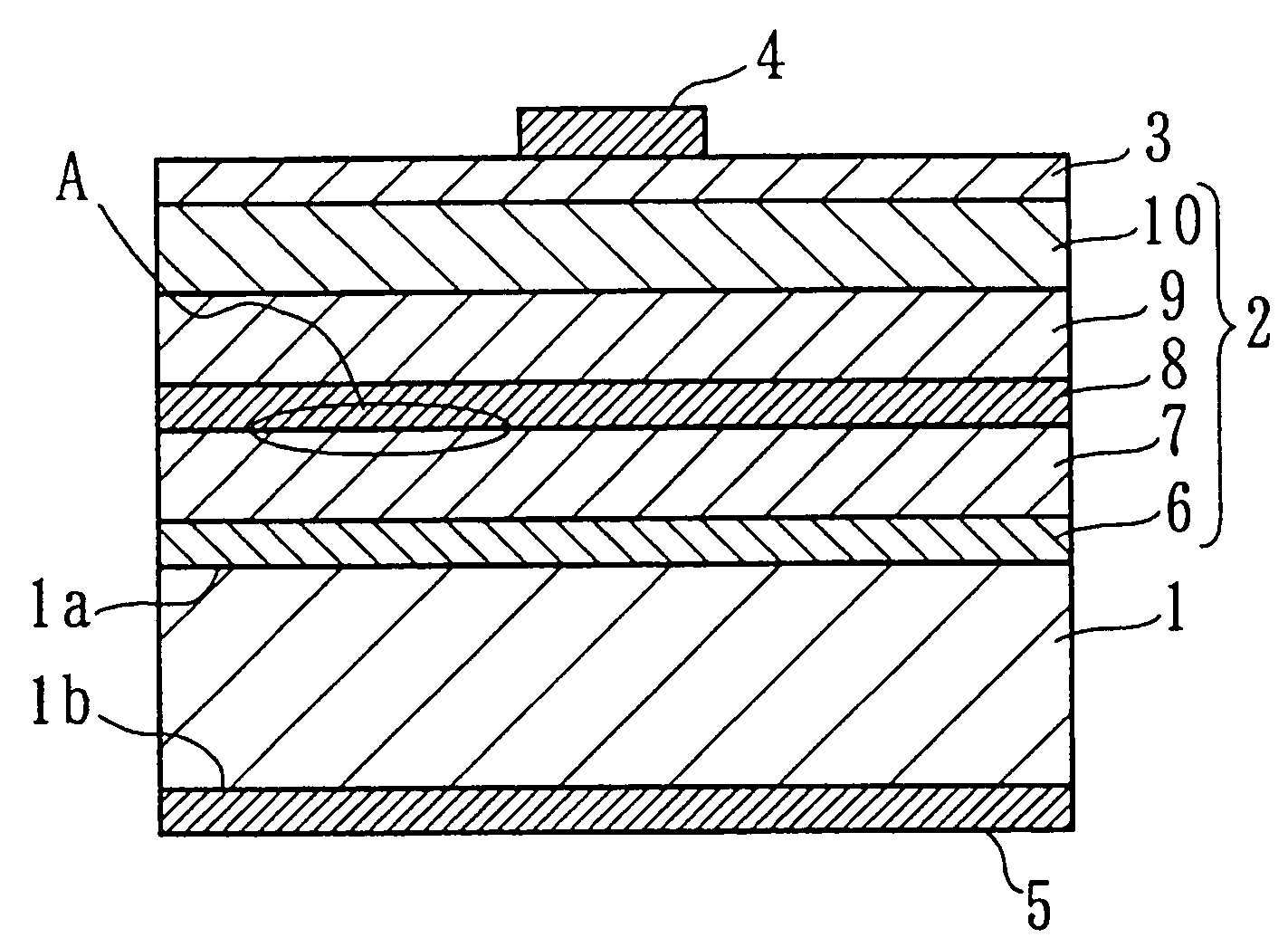

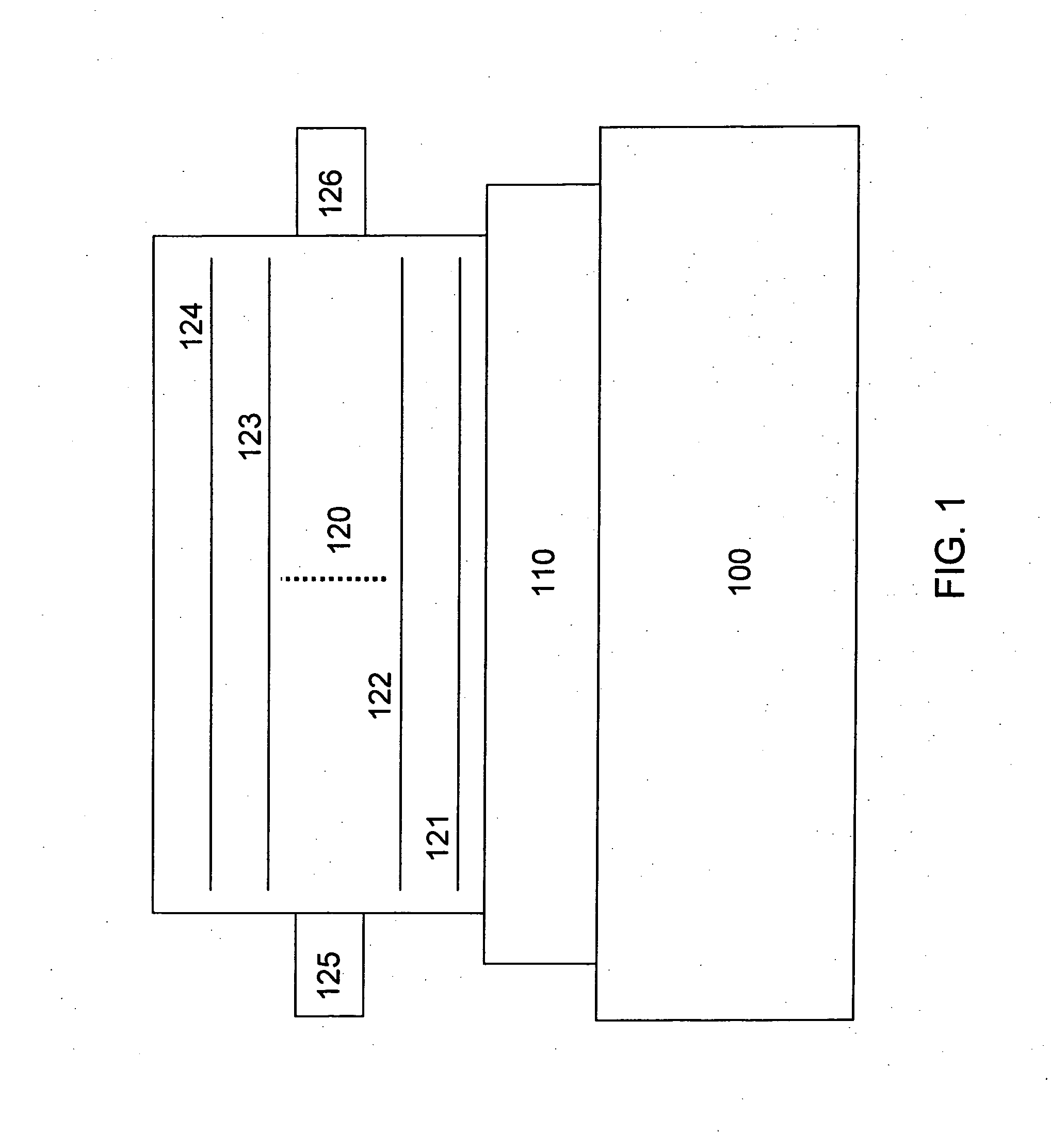

A ZnO buffer layer having an electric conductivity of 1×10−9 S / cm or lower or alternatively a ZnO buffer layer having a diffraction peak of a crystal face other than (002) and (004) in X-ray diffraction is formed on a substrate by sputtering. A ZnO semiconductor layer is formed on the ZnO buffer layer. The ZnO semiconductor layer is formed under the condition that the flow rate ratio of an oxygen gas in a sputtering gas is lower than that in the formation of the ZnO buffer layer.

Owner:SANYO ELECTRIC CO LTD

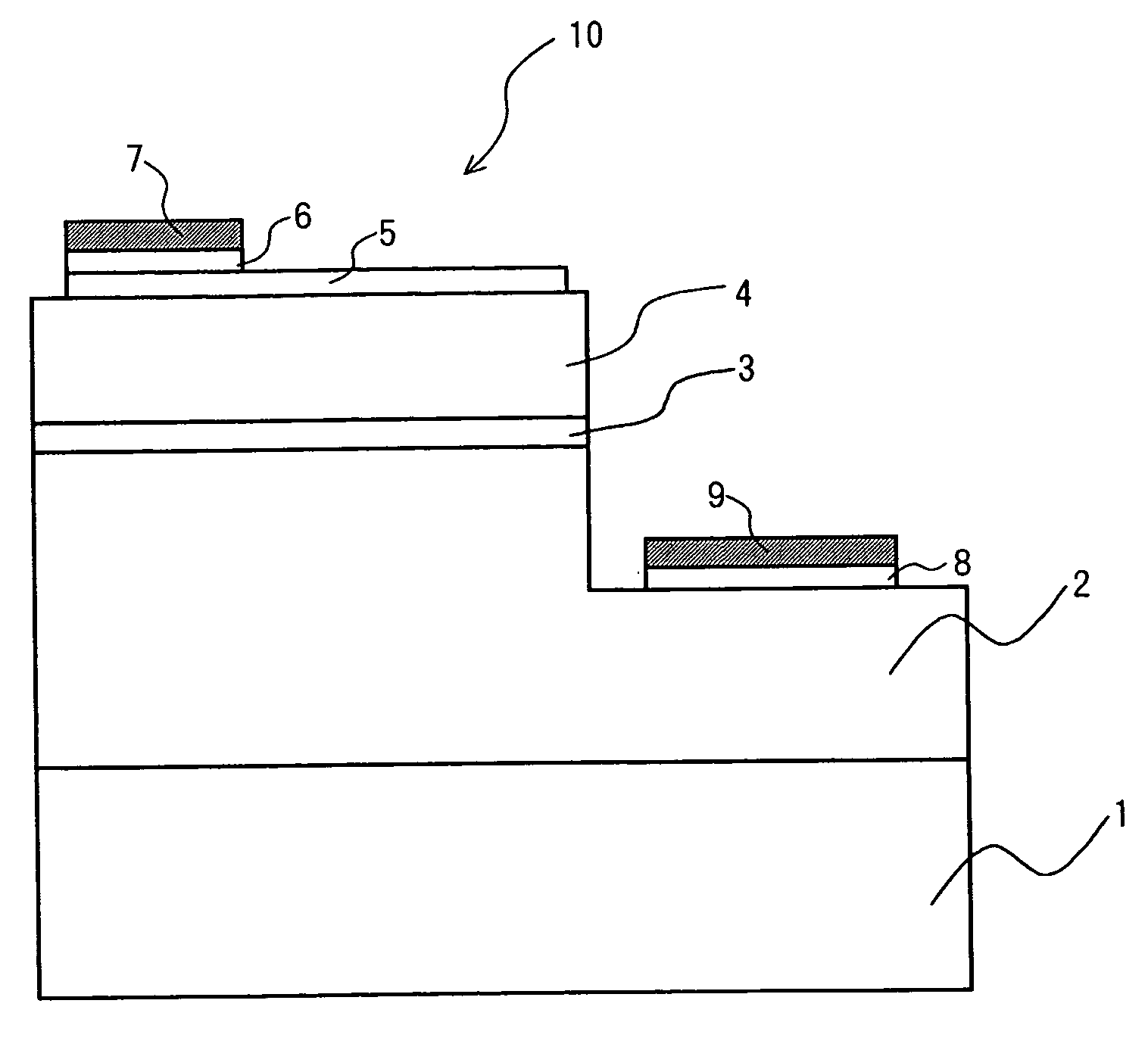

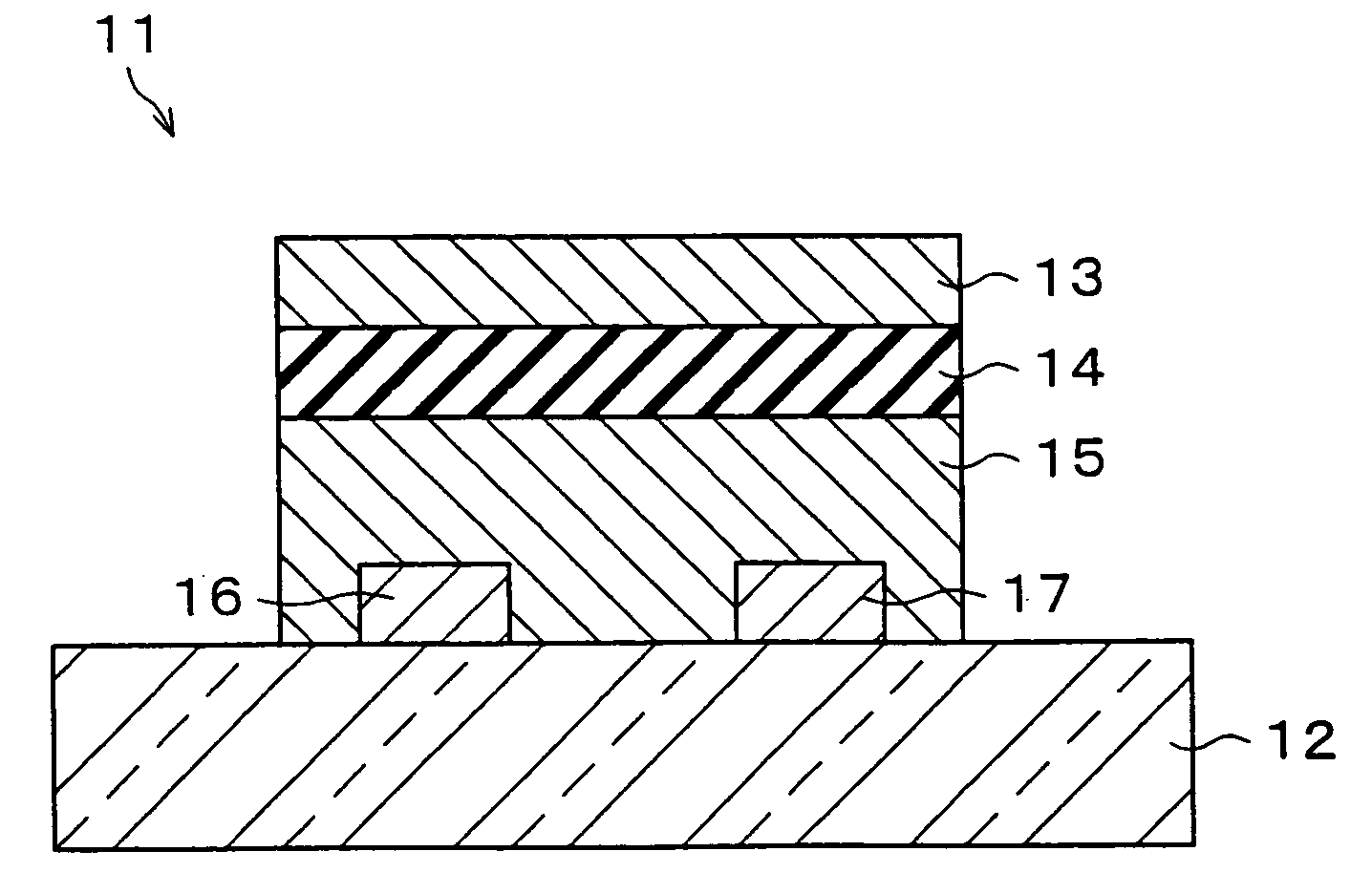

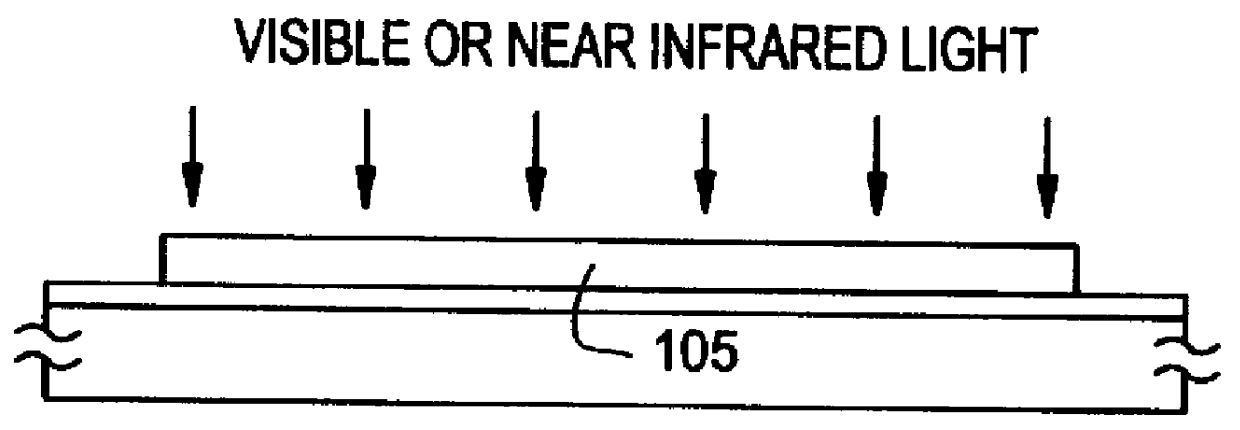

Semiconductor device in which zinc oxide is used as a semiconductor material and method for manufacturing the semiconductor device

ActiveUS7501293B2Improve surface smoothnessHigh crystallinityTransistorLaser detailsSemiconductor materialsDevice material

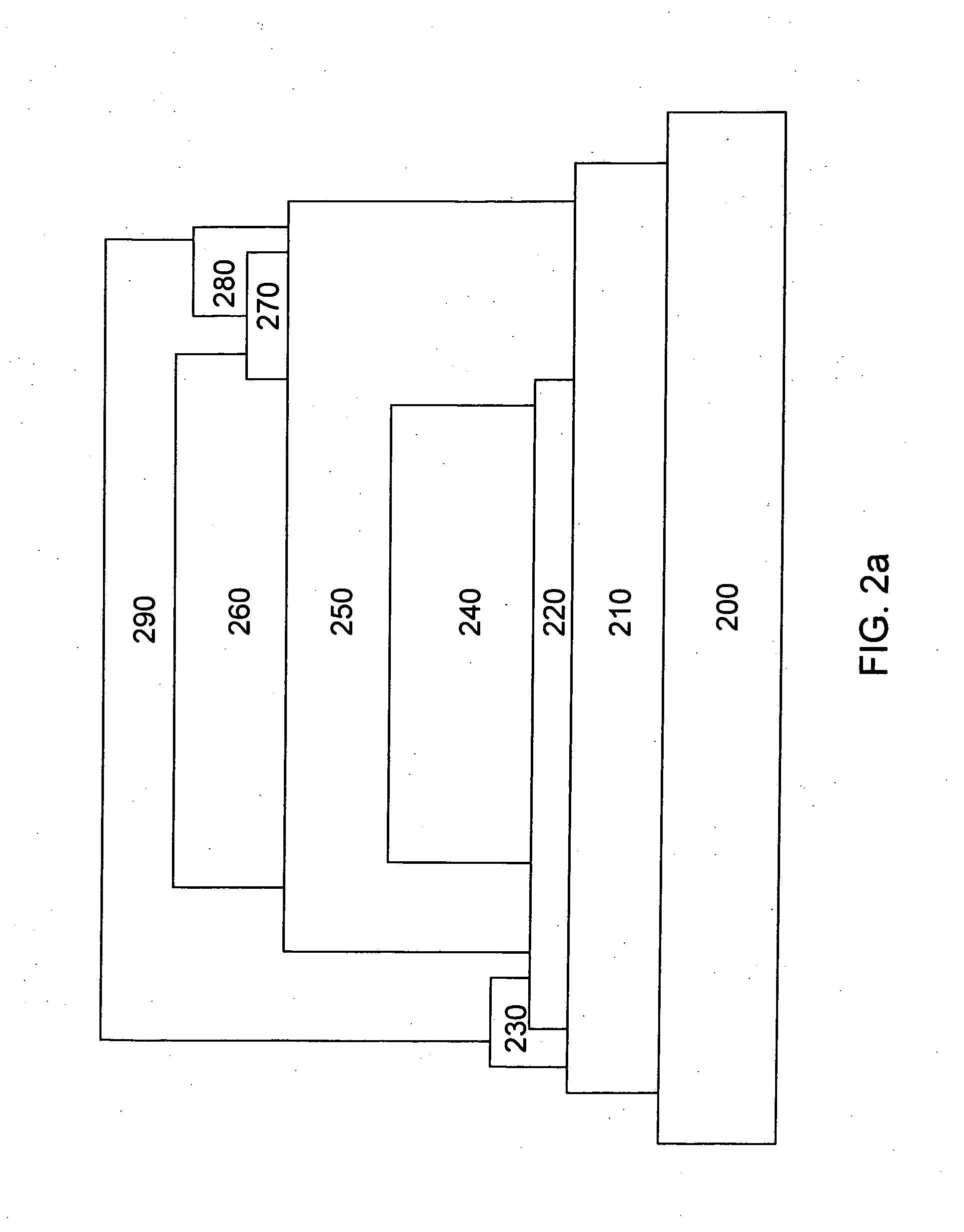

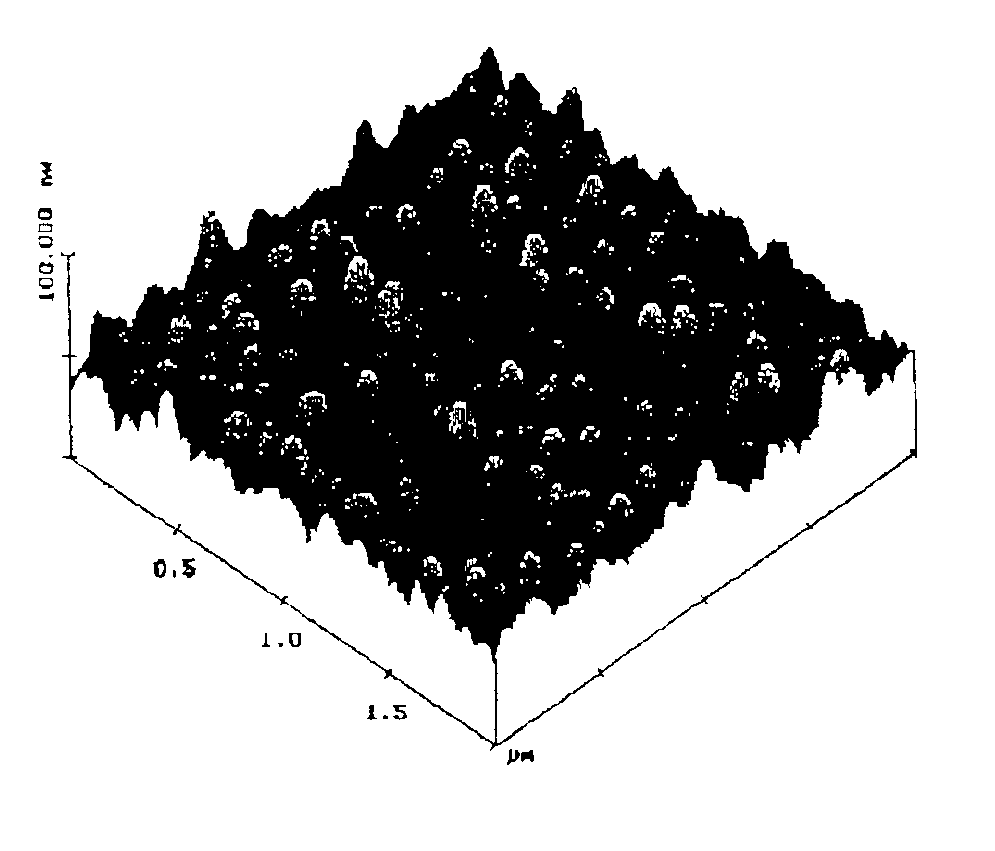

A semiconductor device having excellent crystallinity and excellent electric characteristics includes a ZnO thin film having excellent surface smoothness. ZnO-based thin films (an n-type contact layer, an n-type clad layer, an active layer, a p-type clad layer, and a p-type contact layer) primarily including ZnO are formed sequentially by an ECR sputtering method or other suitable method on a zinc-polar surface of a ZnO substrate. A transparent electrode and a p-side electrode are formed by an evaporation method or other suitable method on a surface of the p-type contact layer, and an n-side electrode is formed on an oxygen-polar surface of the ZnO substrate.

Owner:MURATA MFG CO LTD

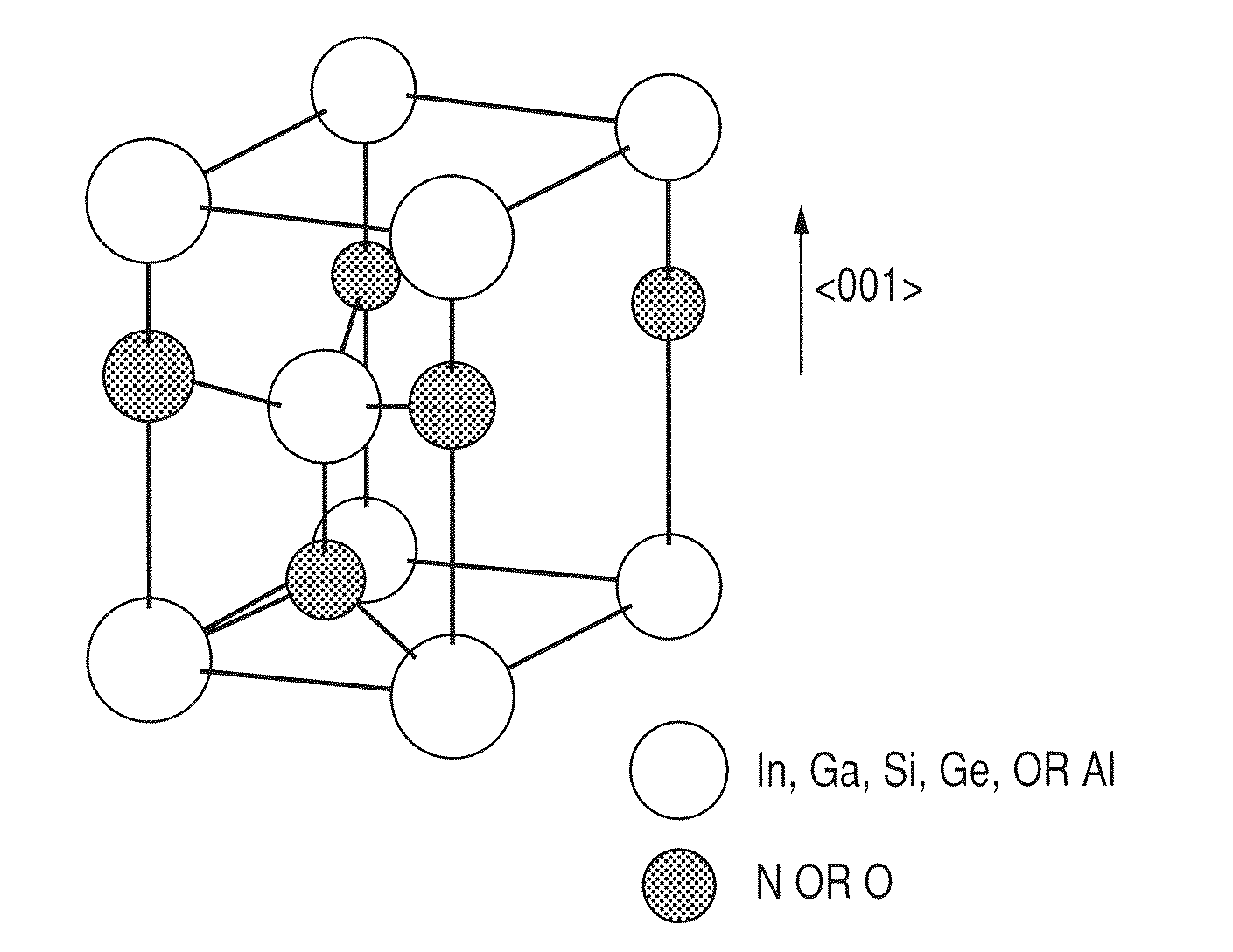

Substrate for growing wurtzite type crystal and method for manufacturing the same and semiconductor device

ActiveUS20100092800A1Low costHigh crystallinityPolycrystalline material growthVacuum evaporation coatingNitrideSemiconductor

A laminated structure comprises a first layer comprising a crystal with six-fold symmetry, and a second layer comprising a metal oxynitride crystal formed on the first layer, wherein the second layer comprises at least one element selected from the group consisting of In, Ga, Si, Ge and Al, N, O and Zn, as main elements, and wherein the second layer has in-plane orientation.

Owner:CANON KK

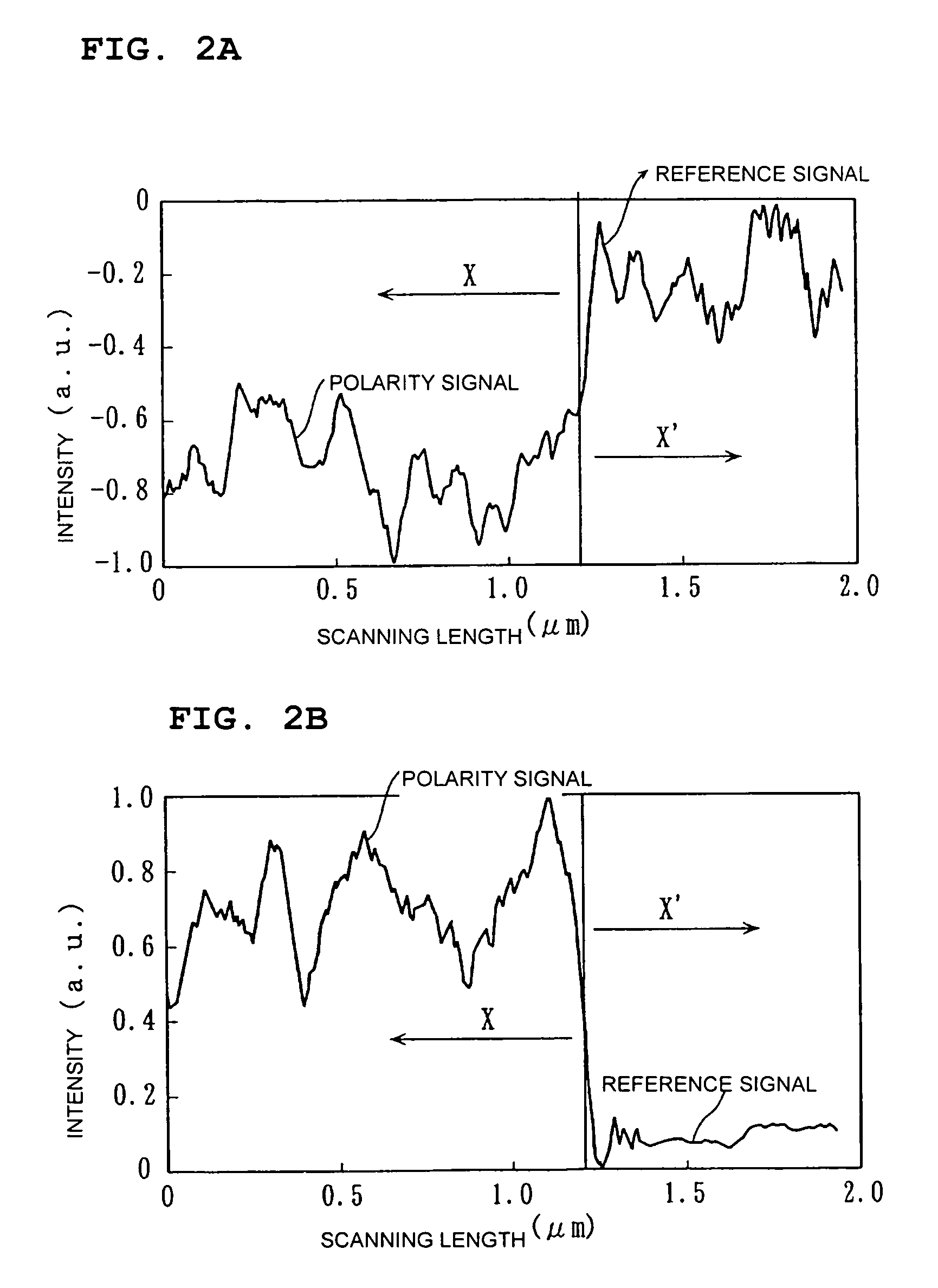

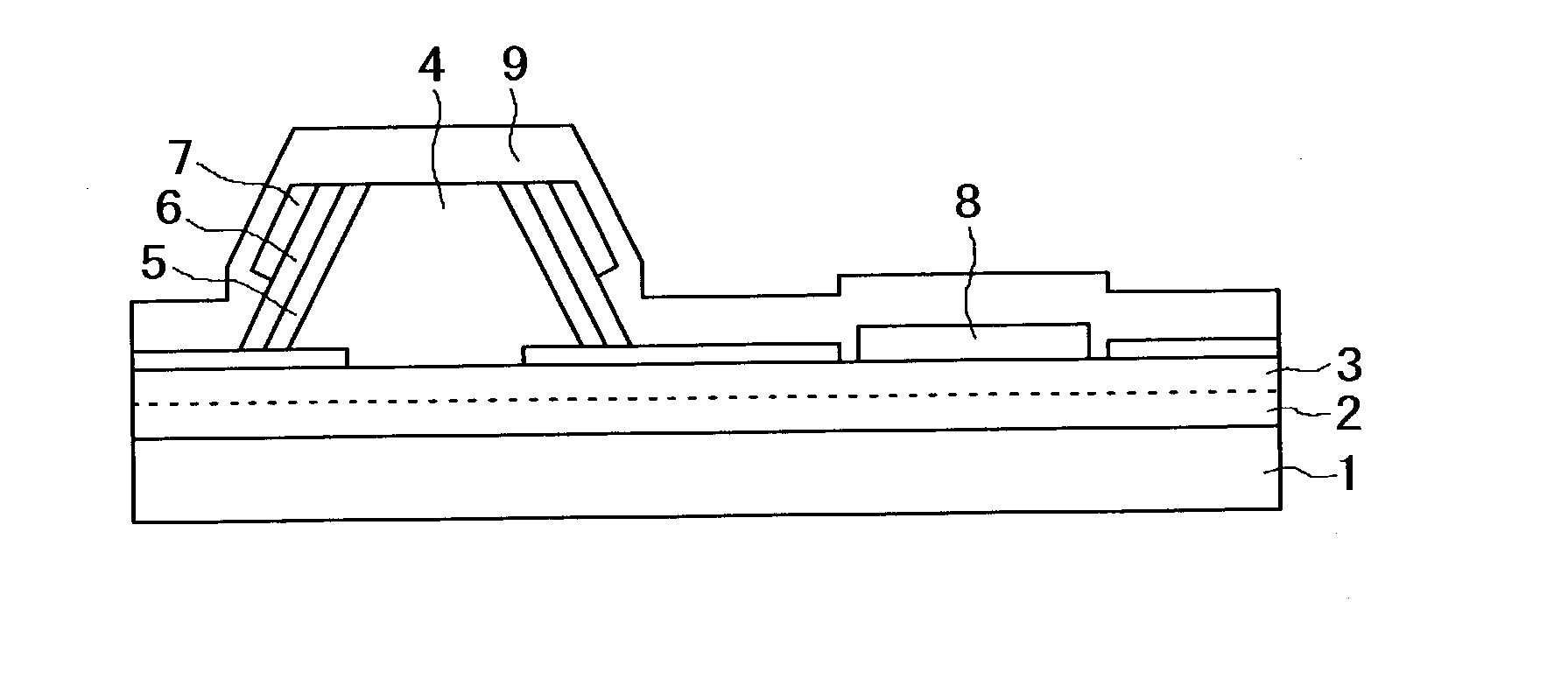

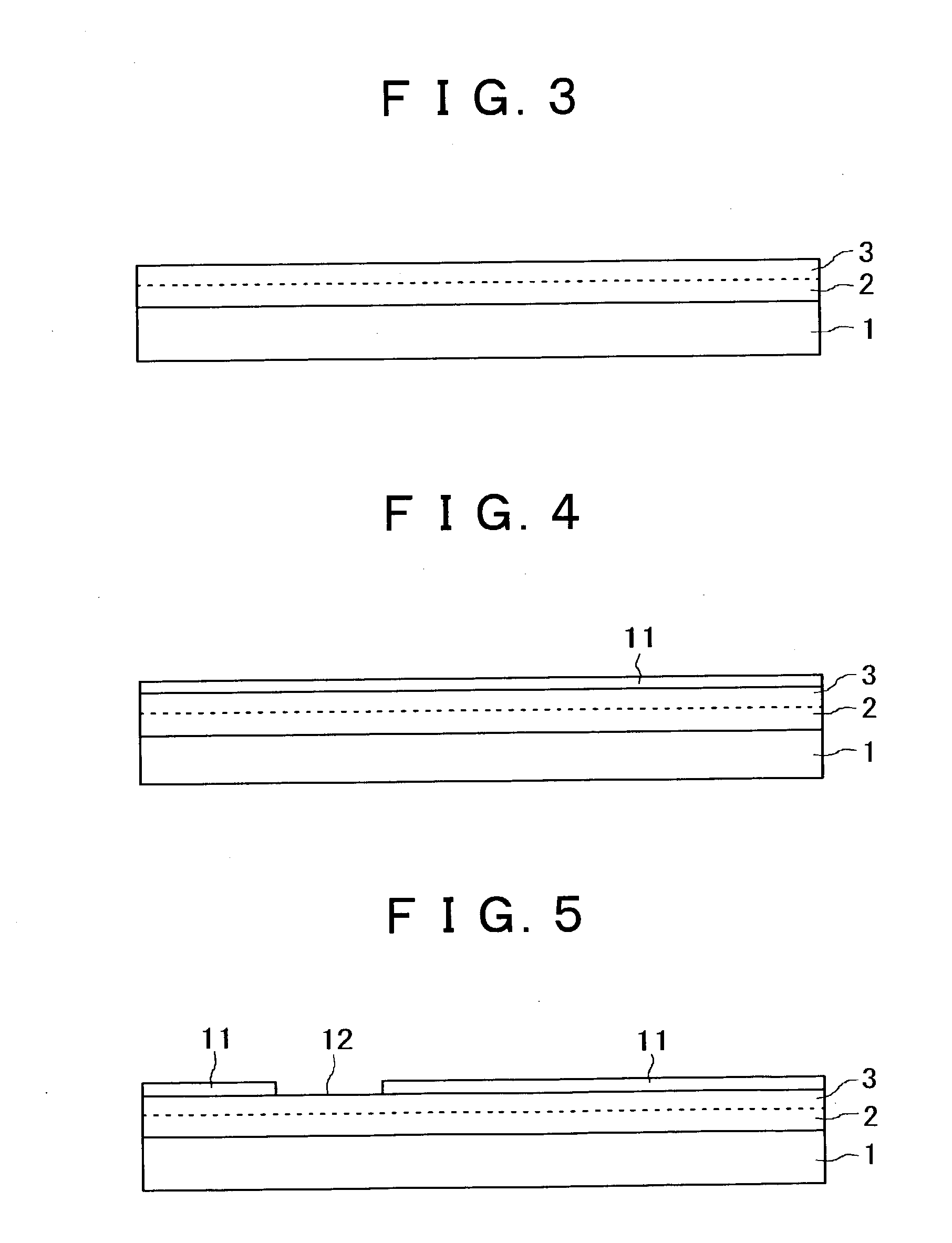

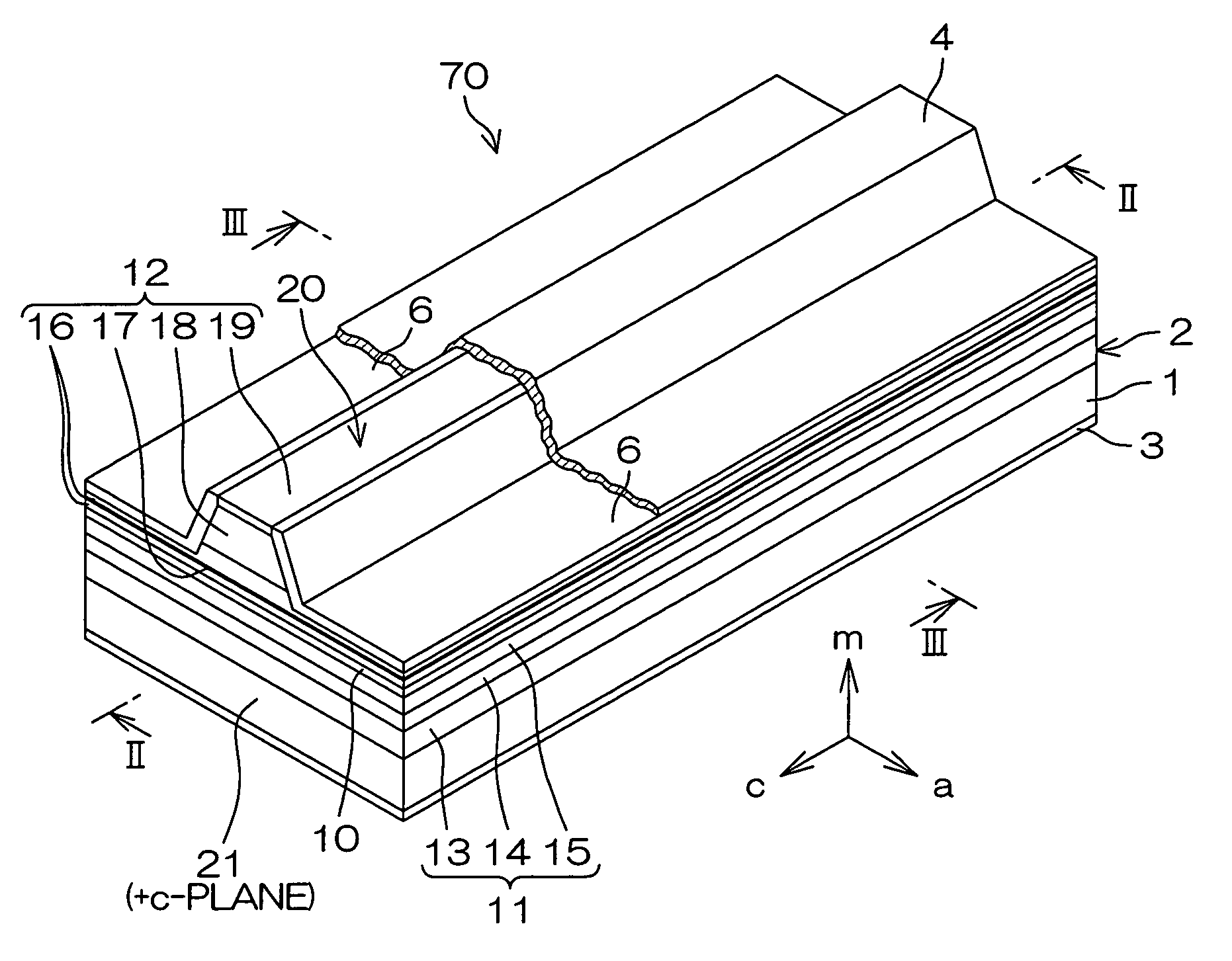

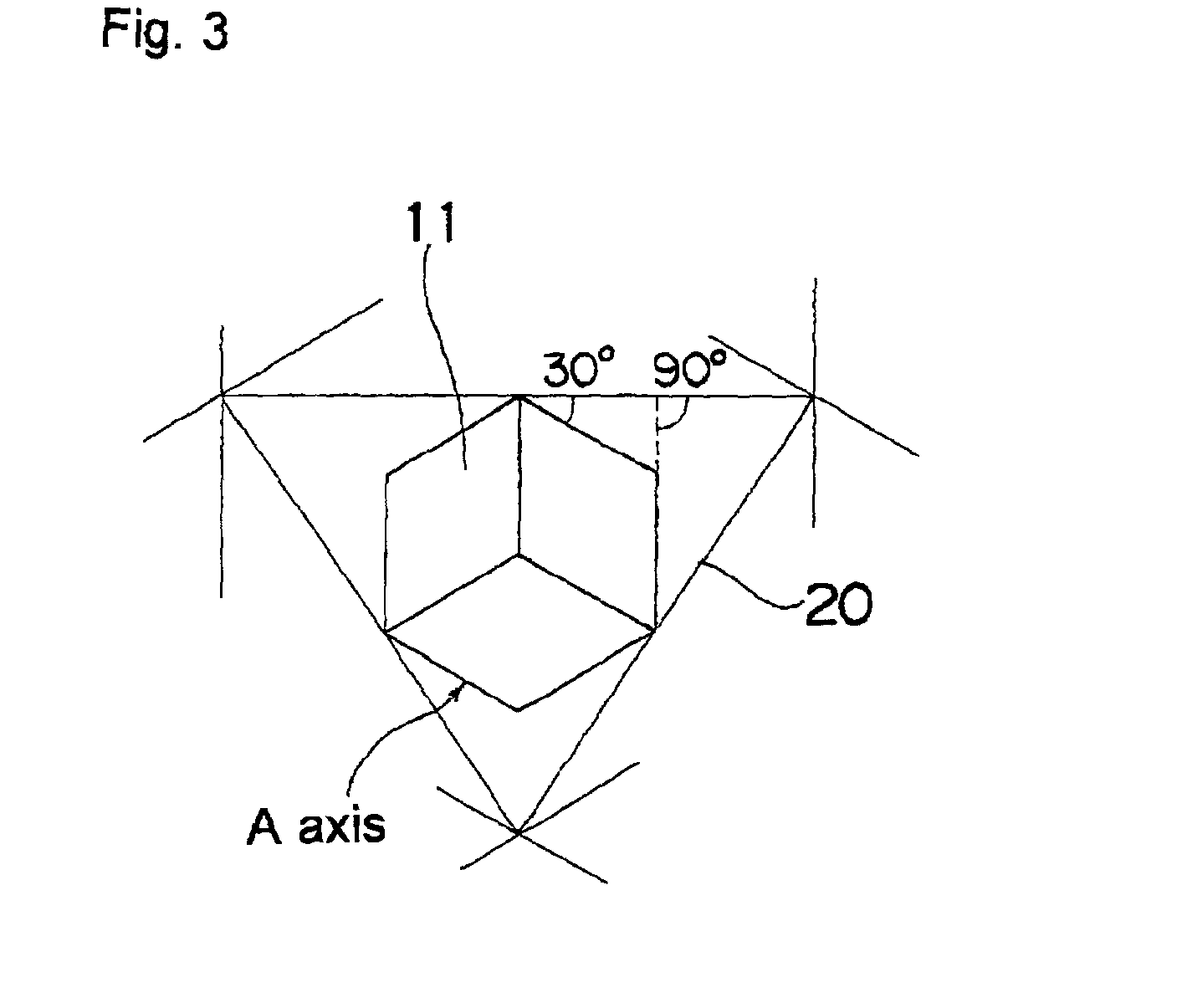

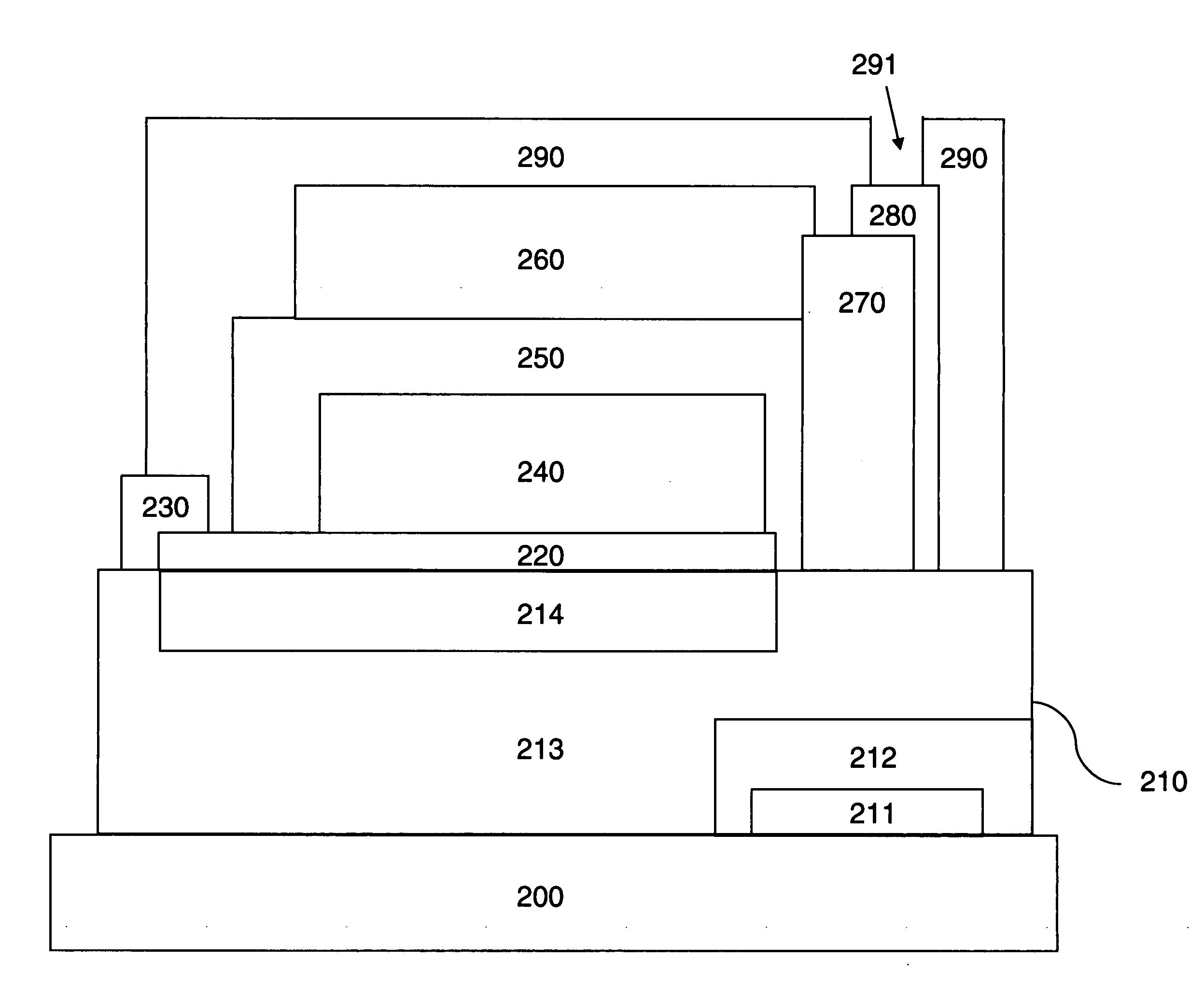

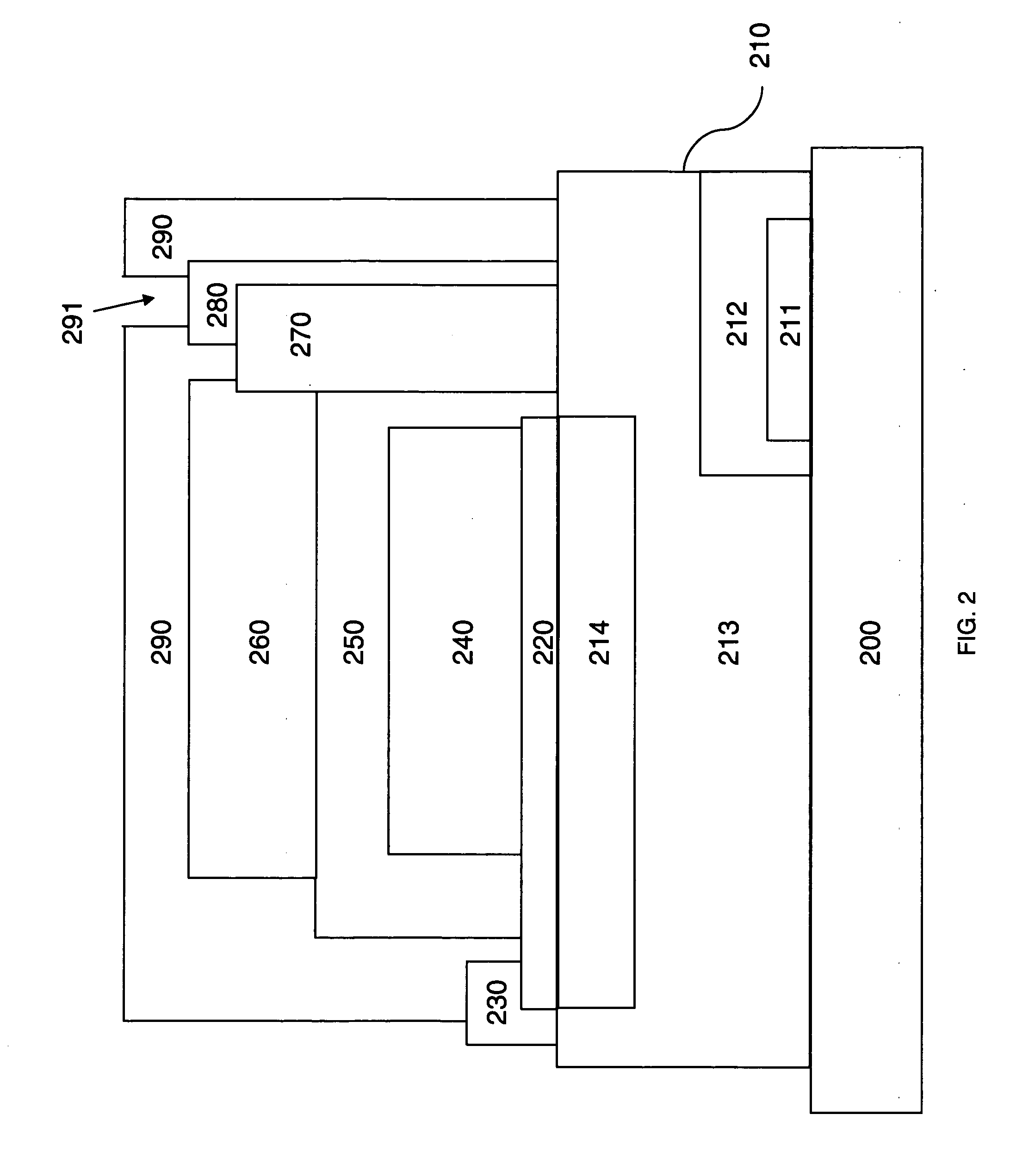

Semiconductor light emitting device and fabrication method thereof

InactiveUS6967353B2Improve luminous efficiencyIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingCrystal planeActive layer

A semiconductor light emitting device includes a crystal layer formed on a substrate, the crystal layer having a tilt crystal plane tilted from the principal plane of the substrate, and a first conductive type layer, an active layer, and a second conductive type layer, which are formed on the crystal layer in such a manner as to extend within planes parallel to the tilt crystal plane, wherein the device has a shape formed by removing the apex and its vicinity of the stacked layer structure formed on the substrate. Such a semiconductor light emitting device is excellent in luminous efficiency even if the device has a three-dimensional device structure. The present invention also provides a method of fabricating the above semiconductor light emitting device.

Owner:SAMSUNG ELECTRONICS CO LTD

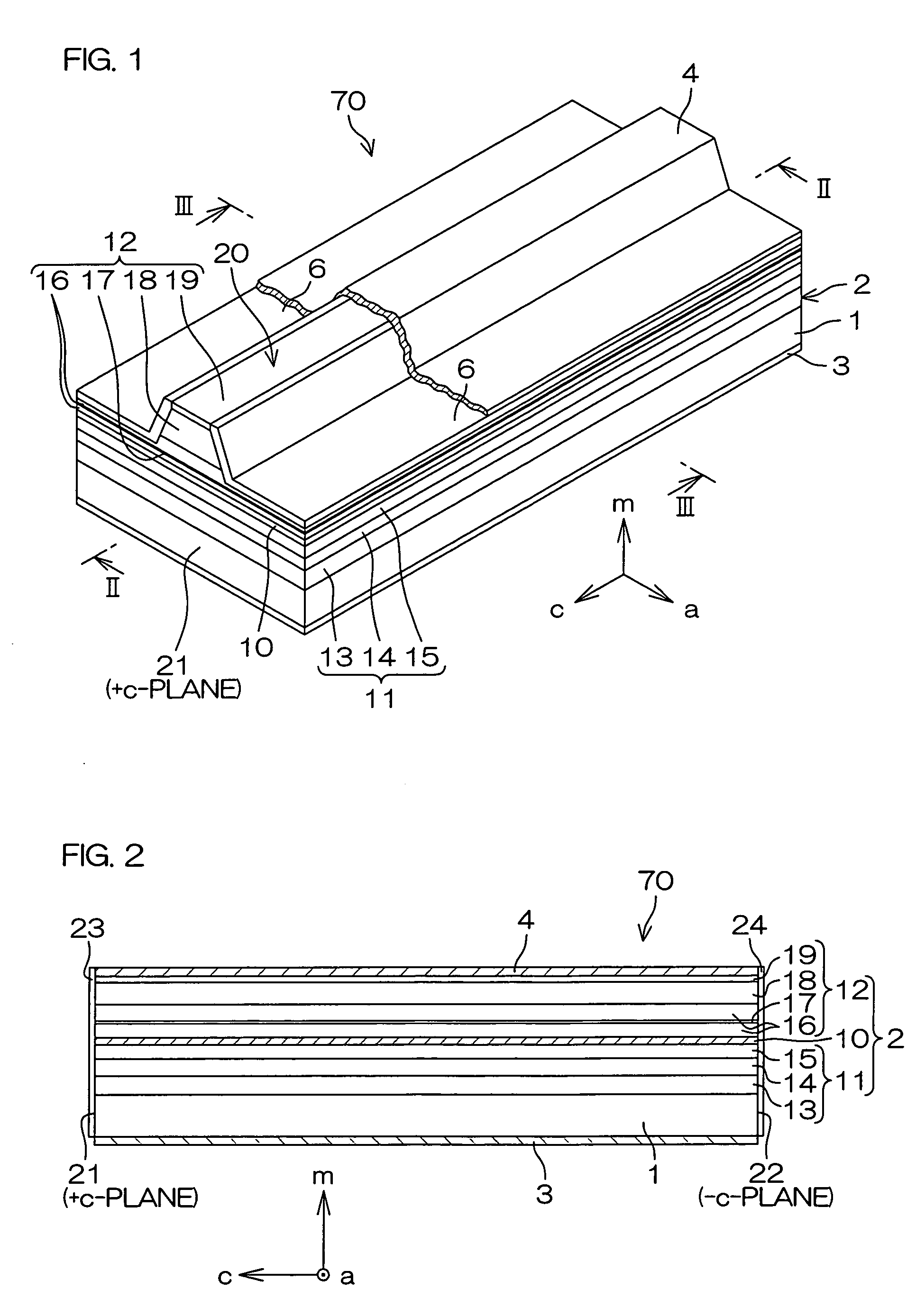

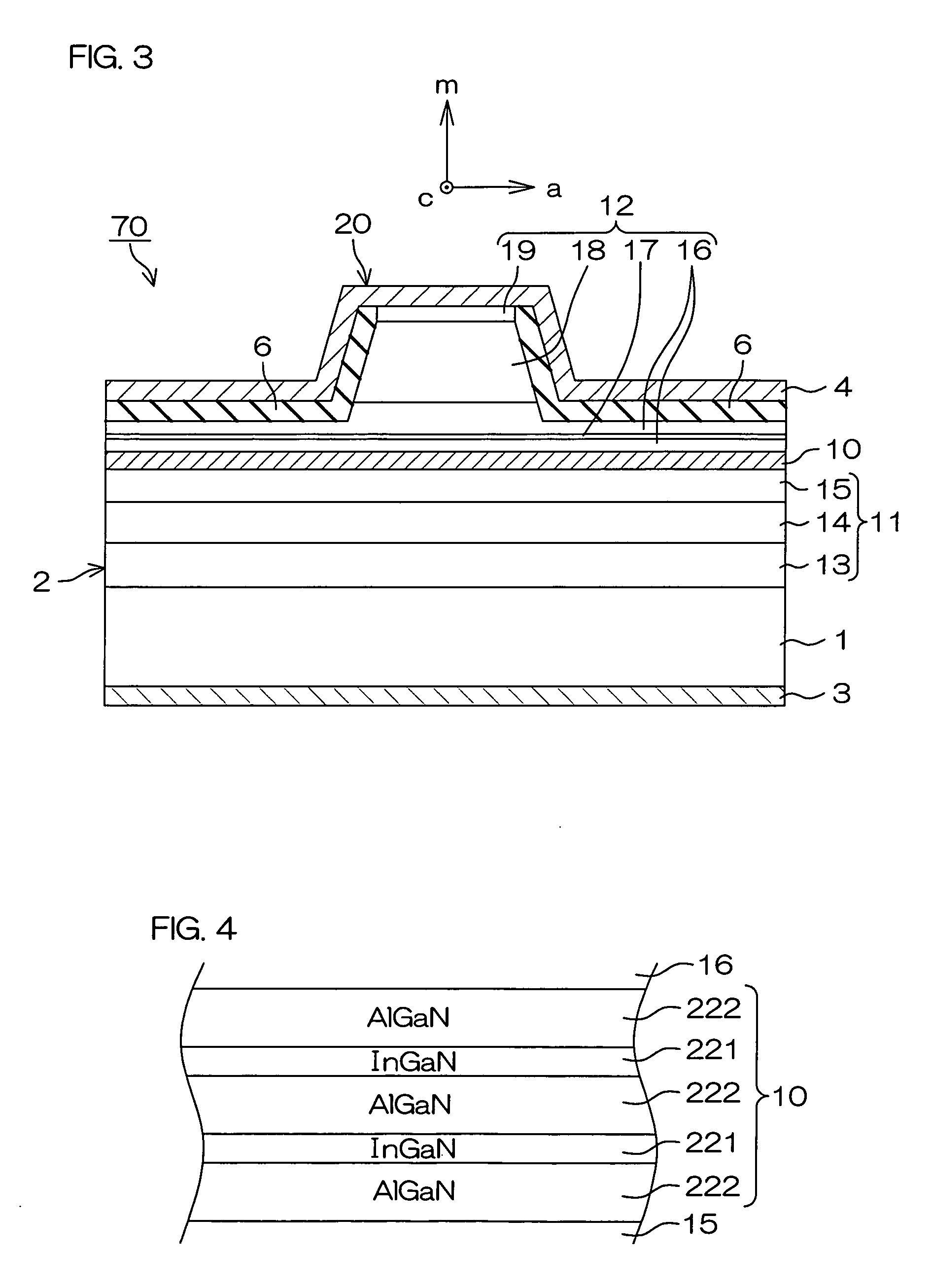

Semiconductor laser device

InactiveUS20100195687A1Improve energy efficiencyTotal current dropLaser detailsLaser active region structureActive layerNitride semiconductors

A semiconductor laser device has a semiconductor laser diode structure made of group III nitride semiconductors having major growth surfaces defined by nonpolar planes or semipolar planes. The semiconductor laser diode structure includes a p-type cladding layer and an n-type cladding layer, a p-type guide layer and an n-type guide layer held between the p-type cladding layer and the n-type cladding layer, and an active layer containing In held between the p-type guide layer and the n-type guide layer. The In compositions in the p-type guide layer and the n-type guide layer are increased as approaching the active layer respectively. Each of the p-type guide layer and the n-type guide layer may have a plurality of InxGa1-xN layers (0≦x≦1). In this case, the plurality of InxGa1-xN layers may be stacked in such order that the In compositions therein are increased as approaching the active layer.

Owner:ROHM CO LTD

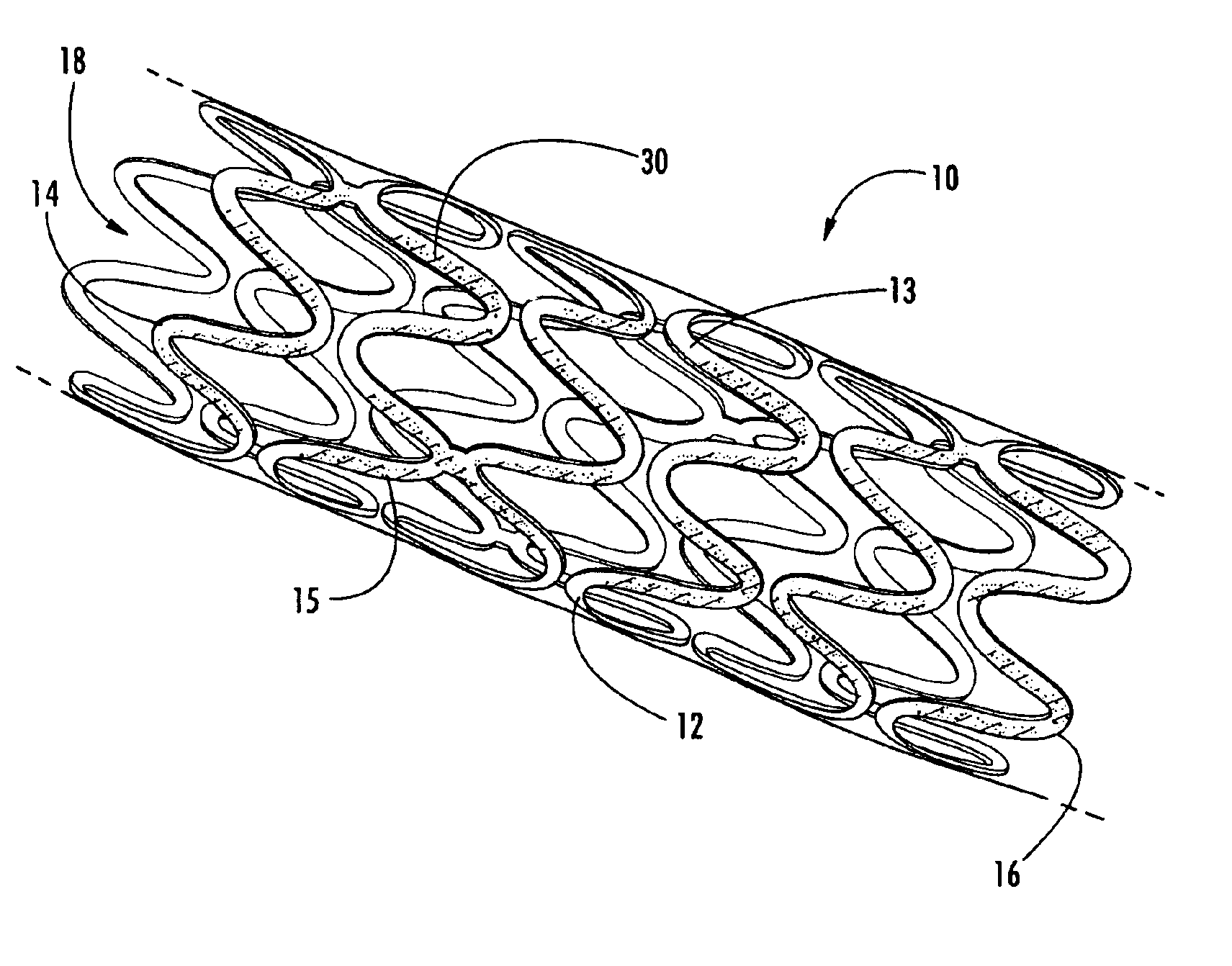

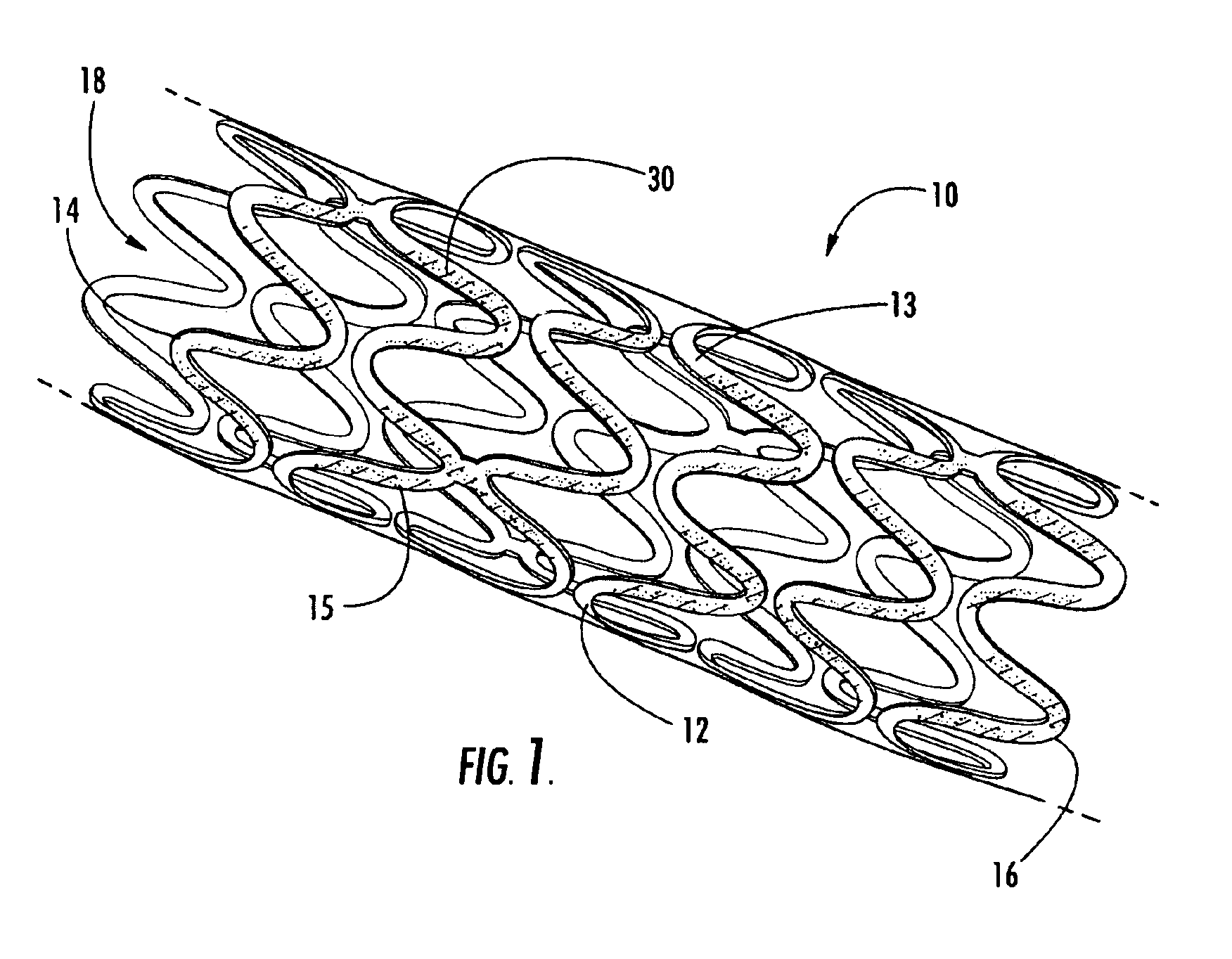

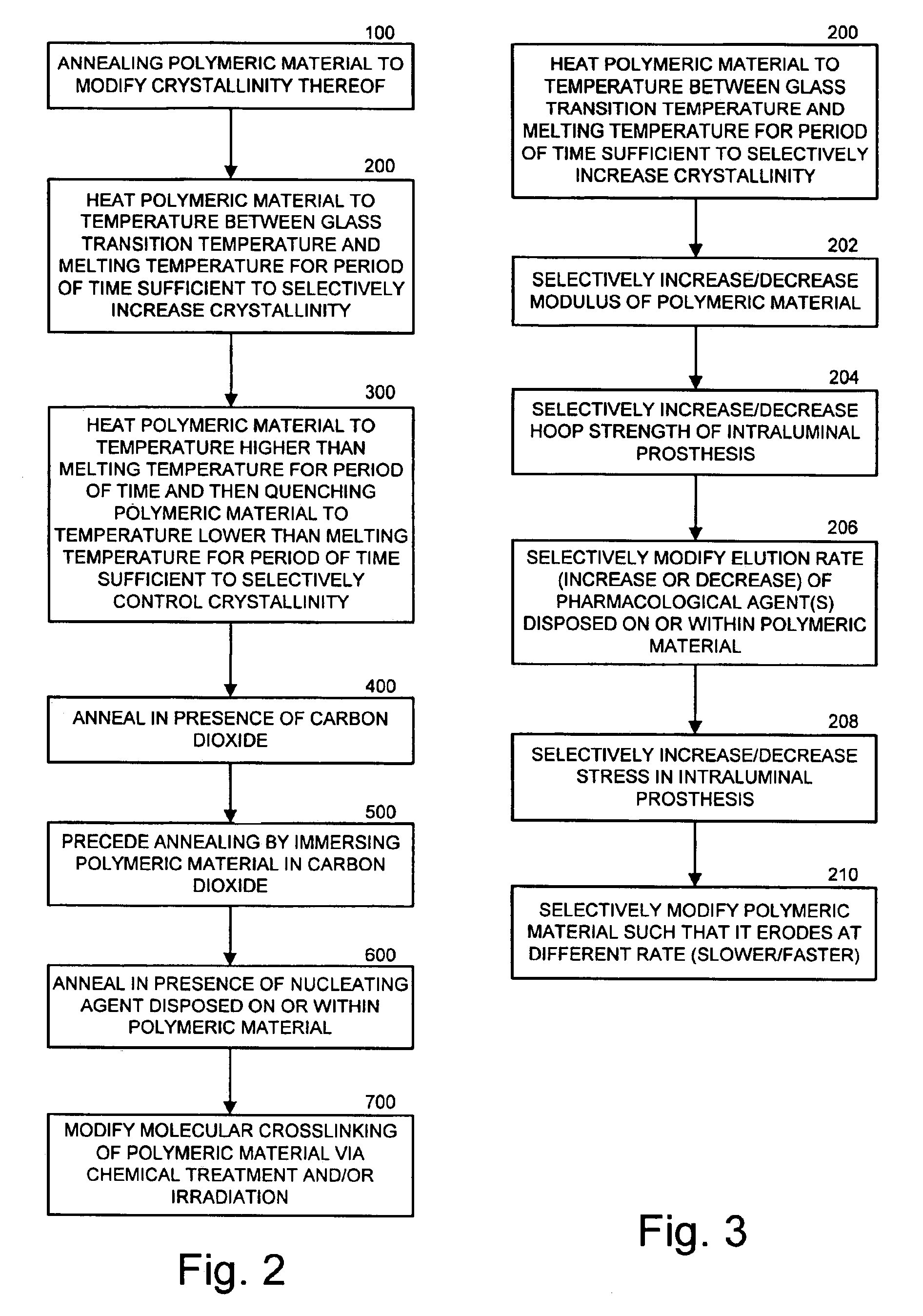

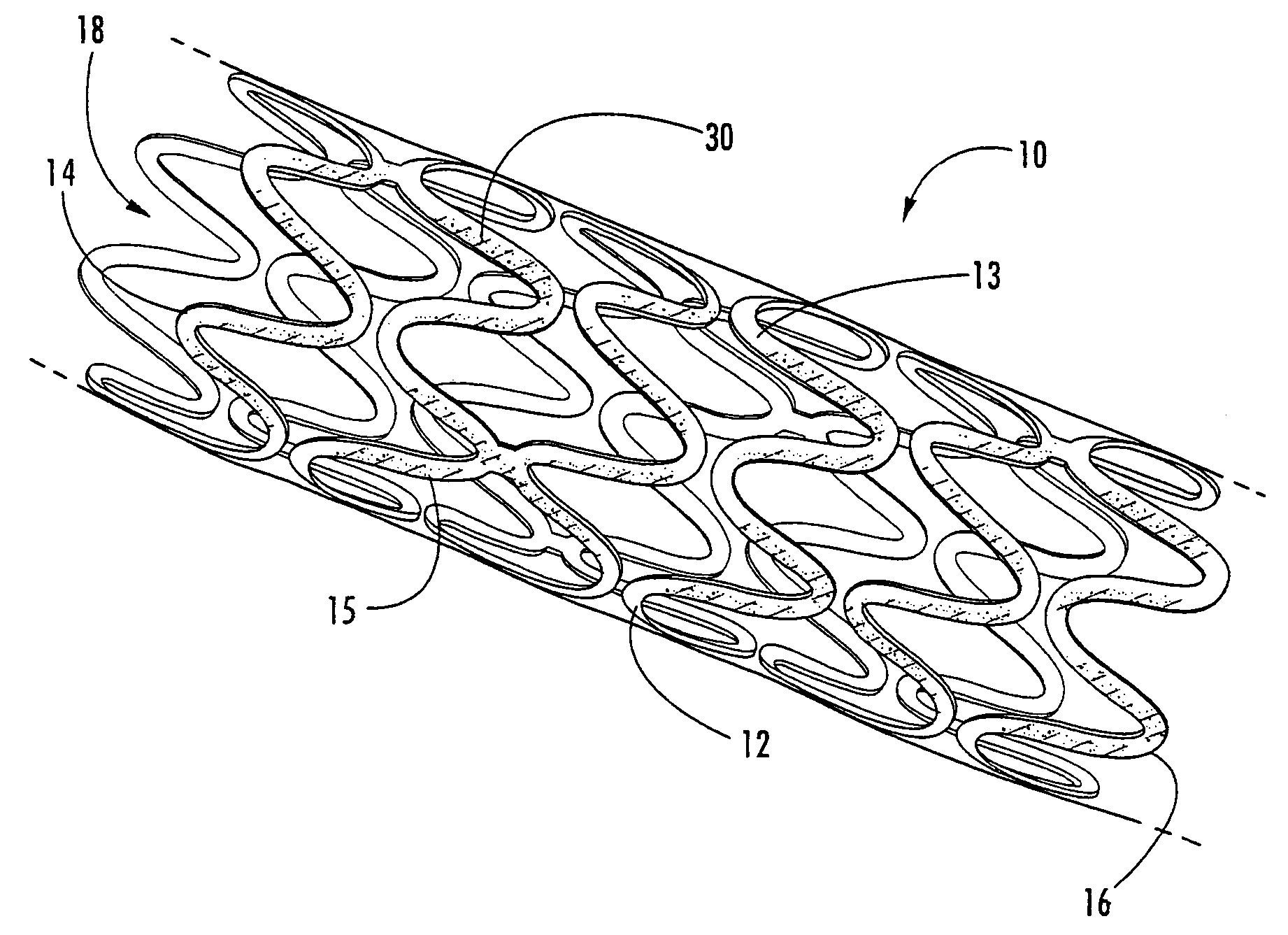

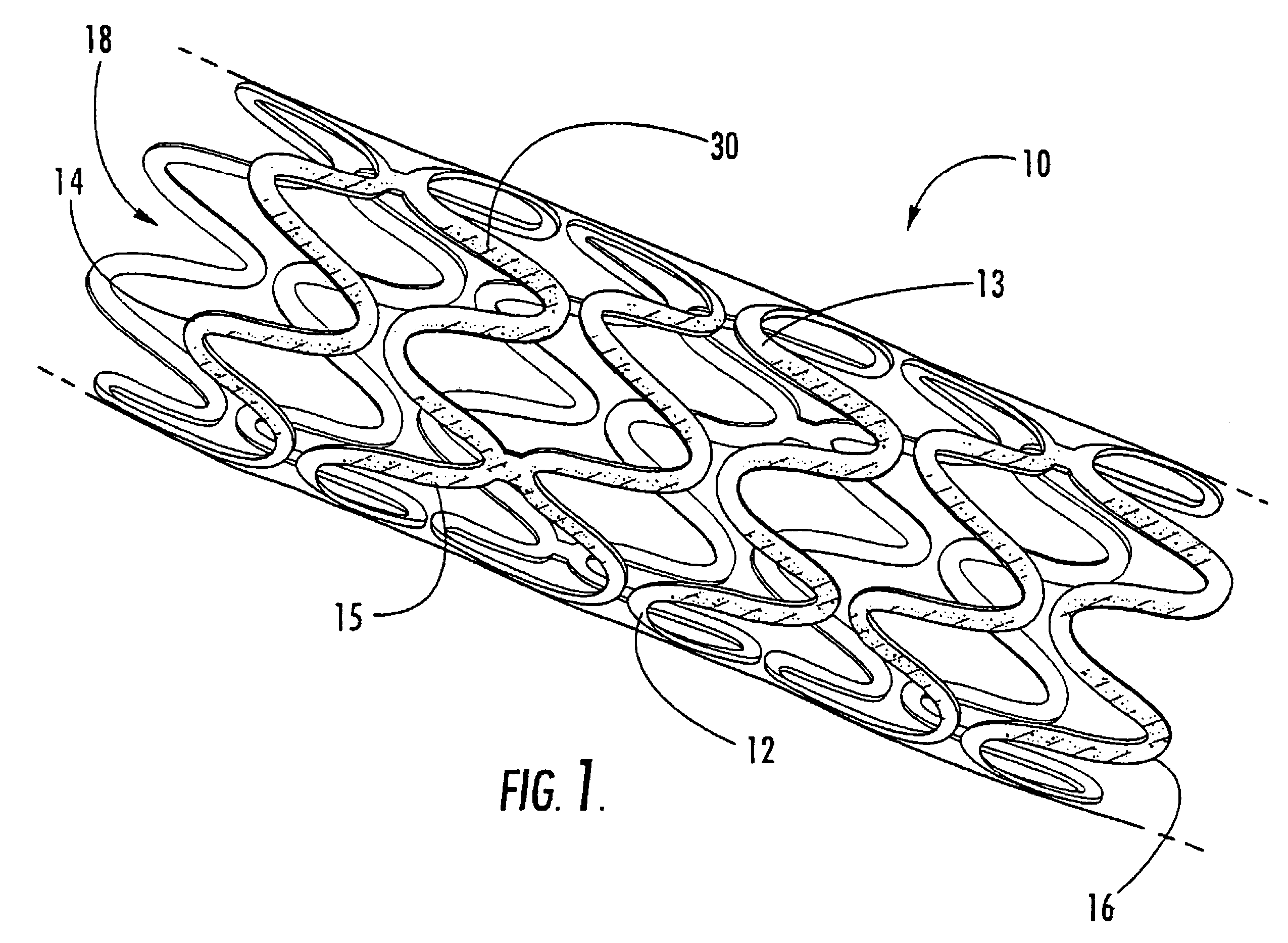

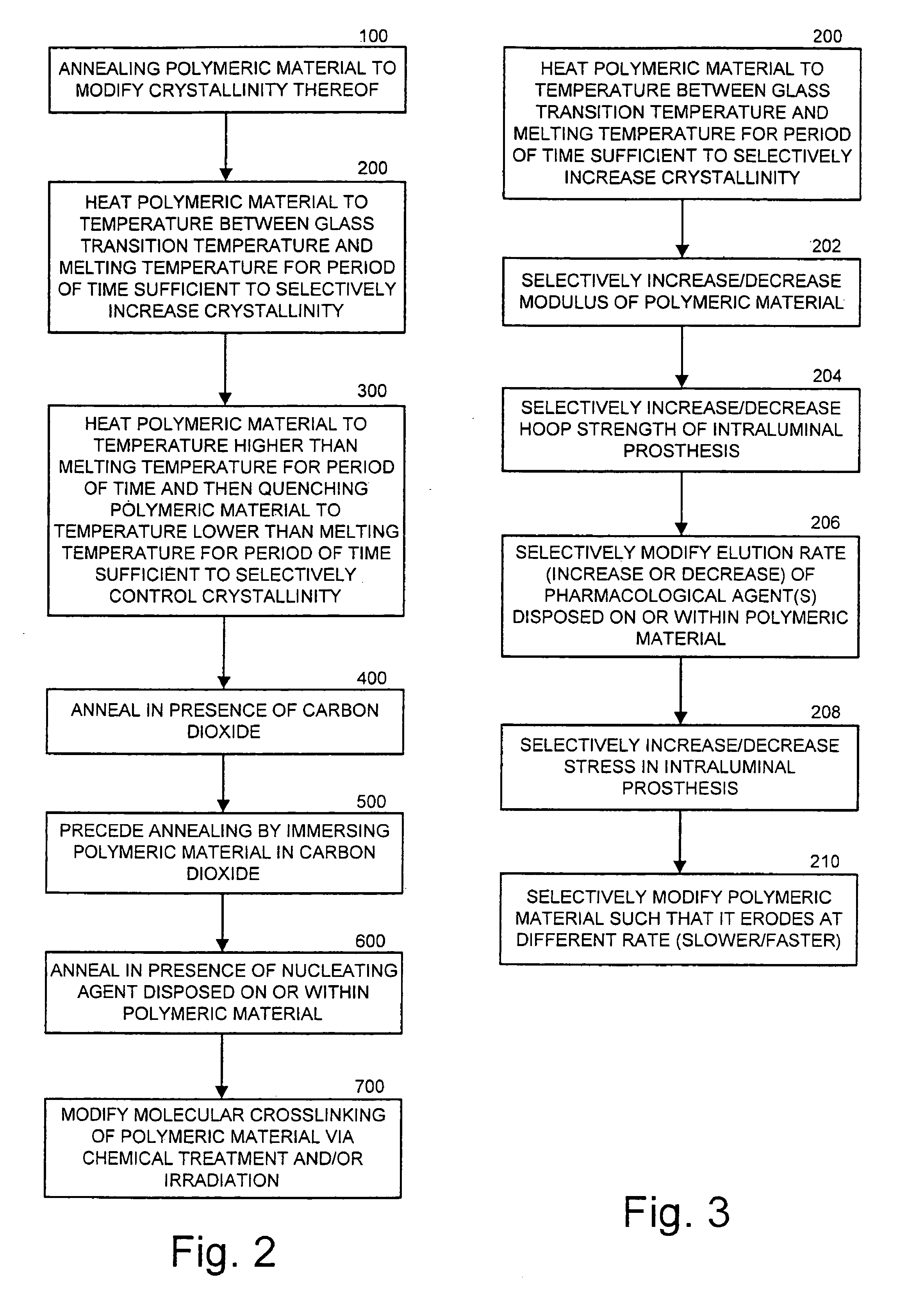

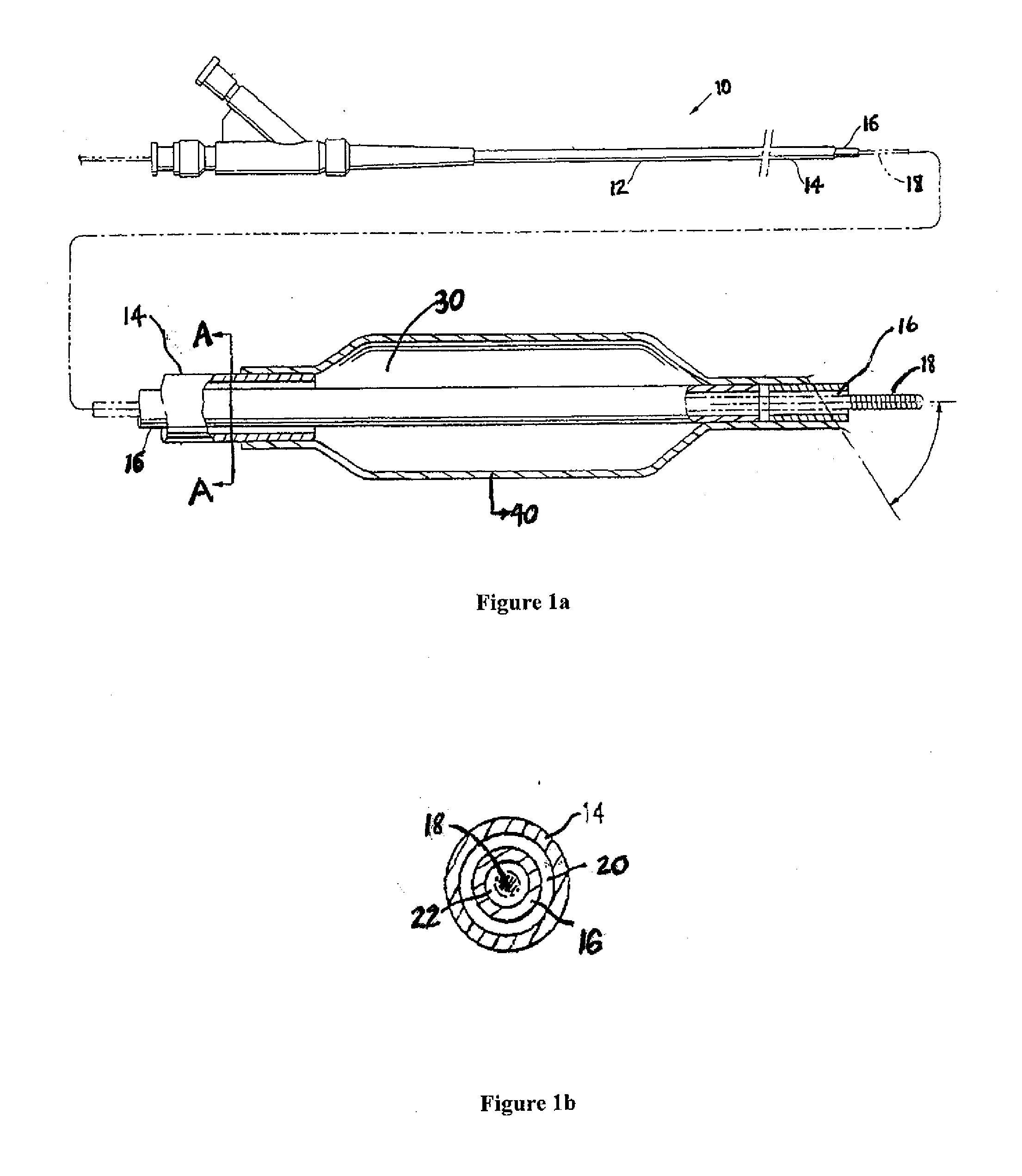

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

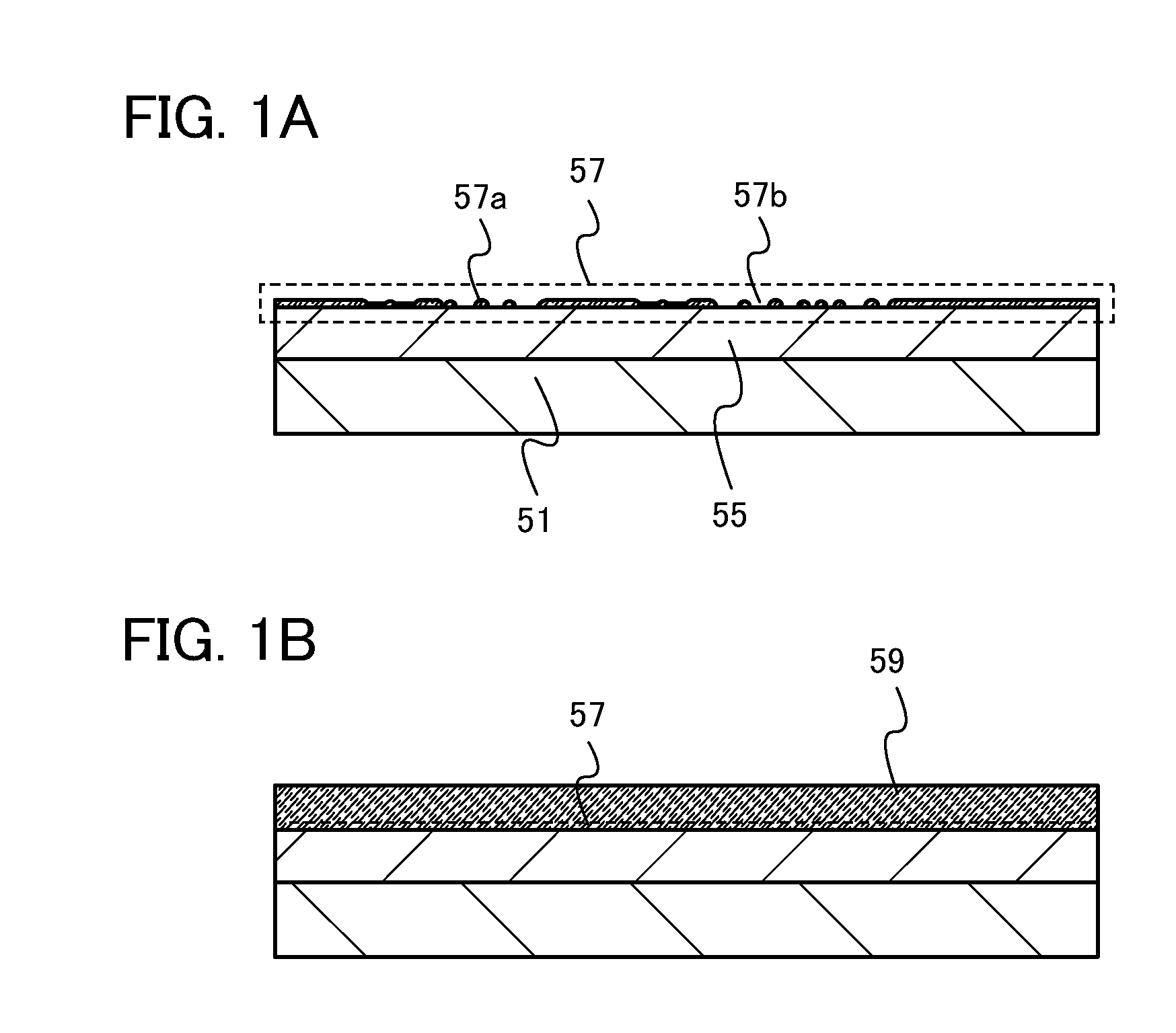

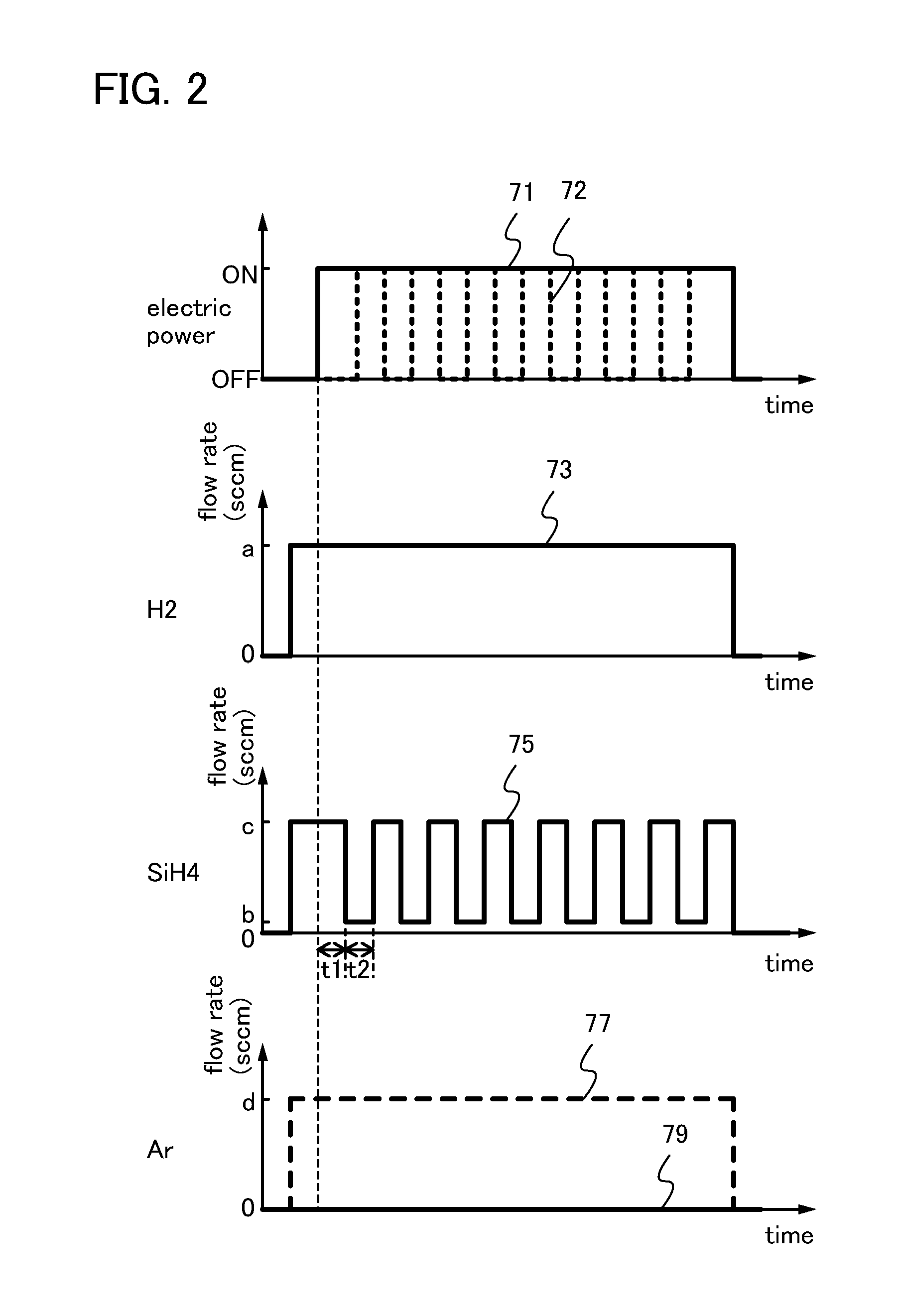

Method for manufacturing semiconductor device

InactiveUS20110318888A1High crystallinityExcellent electrical propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenEngineering

A method for manufacturing a semiconductor device comprises the steps of forming a seed over the insulating film by introducing hydrogen and a deposition gas into a first treatment chamber under a first condition and forming a microcrystalline semiconductor film over the seed by introducing hydrogen and the deposition gas into a second treatment chamber under a second condition: a second flow rate of the deposition gas is periodically changed between a first value and a second value; and a second pressure in the second treatment chamber is higher than or equal to 1.0×102 Torr and lower than or equal to 1.0×103 Torr.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method for fabricating the same

InactiveUS6077731AImprove featuresPromote crystallizationTransistorSolid-state devicesCrystalline siliconSemiconductor

A novel and very useful method for forming a crystal silicon film by introducing a metal element which promotes crystallization of silicon to an amorphous silicon film and for eliminating or reducing the metal element existing within the crystal silicon film thus obtained is provided. The method for fabricating a semiconductor device comprises steps of intentionally introducing the metal element which promotes crystallization of silicon to the amorphous silicon film and crystallizing the amorphous silicon film by a first heat treatment to obtain the crystal silicon film; eliminating or reducing the metal element existing within the crystal silicon film by implementing a second heat treatment within an oxidizing atmosphere; eliminating a thermal oxide film formed in the previous step; and forming another thermal oxide film on the surface of the region from which the thermal oxide film has been eliminated by implementing another thermal oxidation.

Owner:SEMICON ENERGY LAB CO LTD

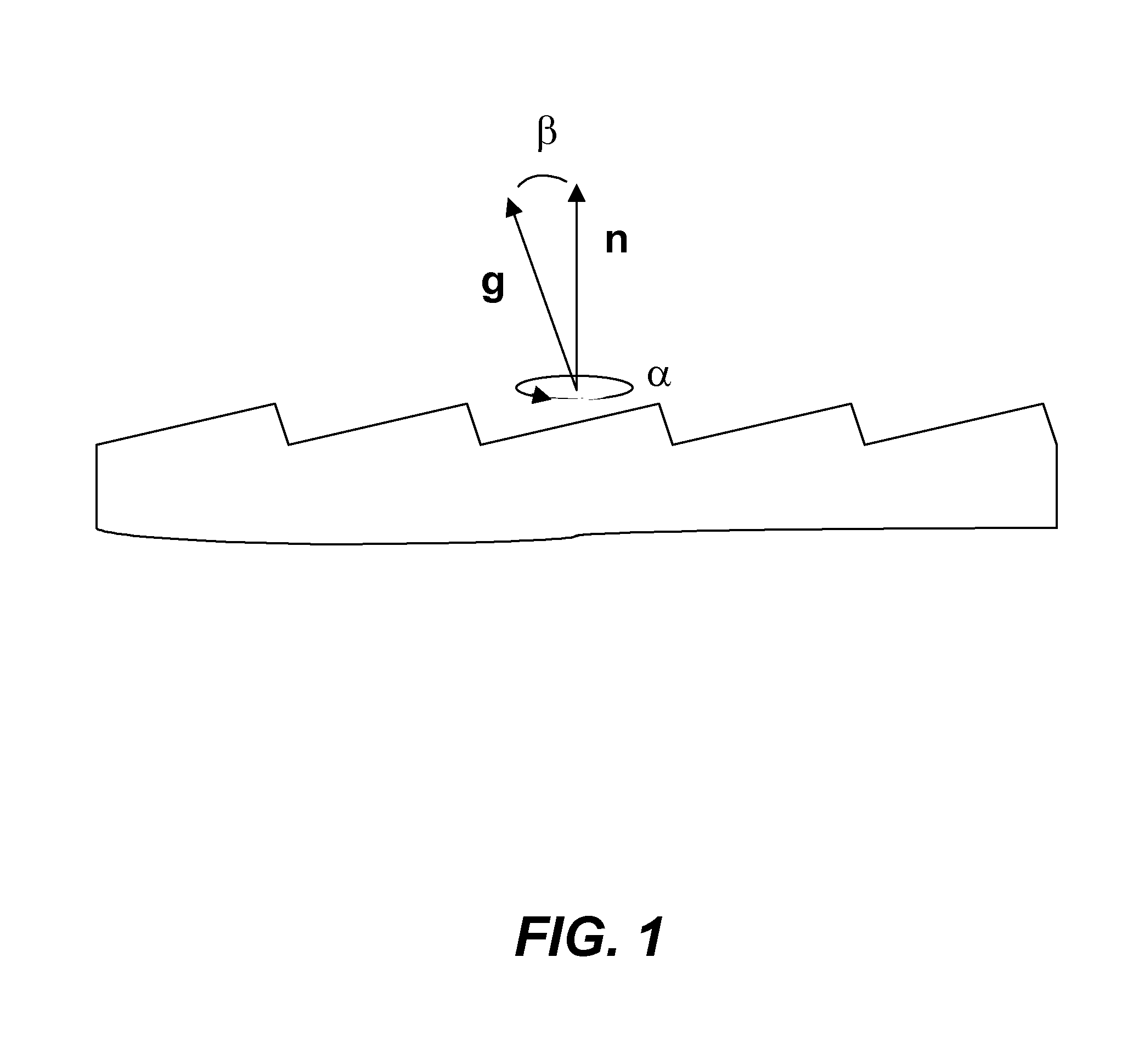

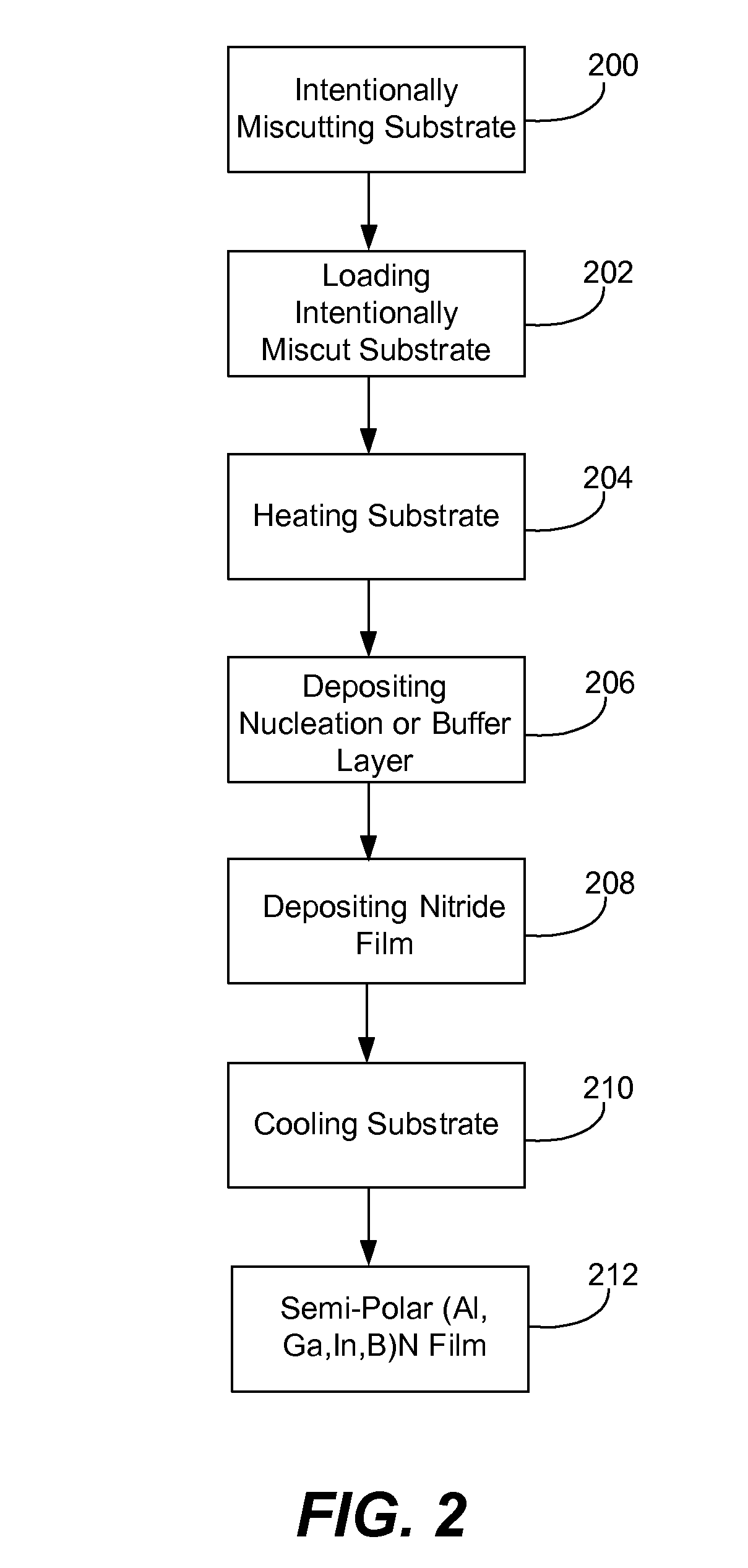

Method for improved growth of semipolar (Al,In,Ga,B)N

ActiveUS7691658B2Reduce symmetryImprove propertiesPolycrystalline material growthSolid-state devicesHydrogenNitrogen

A method for improved growth of a semipolar (Al,In,Ga,B)N semiconductor thin film using an intentionally miscut substrate. Specifically, the method comprises intentionally miscutting a substrate, loading a substrate into a reactor, heating the substrate under a flow of nitrogen and / or hydrogen and / or ammonia, depositing an InxGa1−xN nucleation layer on the heated substrate, depositing a semipolar nitride semiconductor thin film on the InxGa1−xN nucleation layer, and cooling the substrate under a nitrogen overpressure.

Owner:JAPAN SCI & TECH CORP

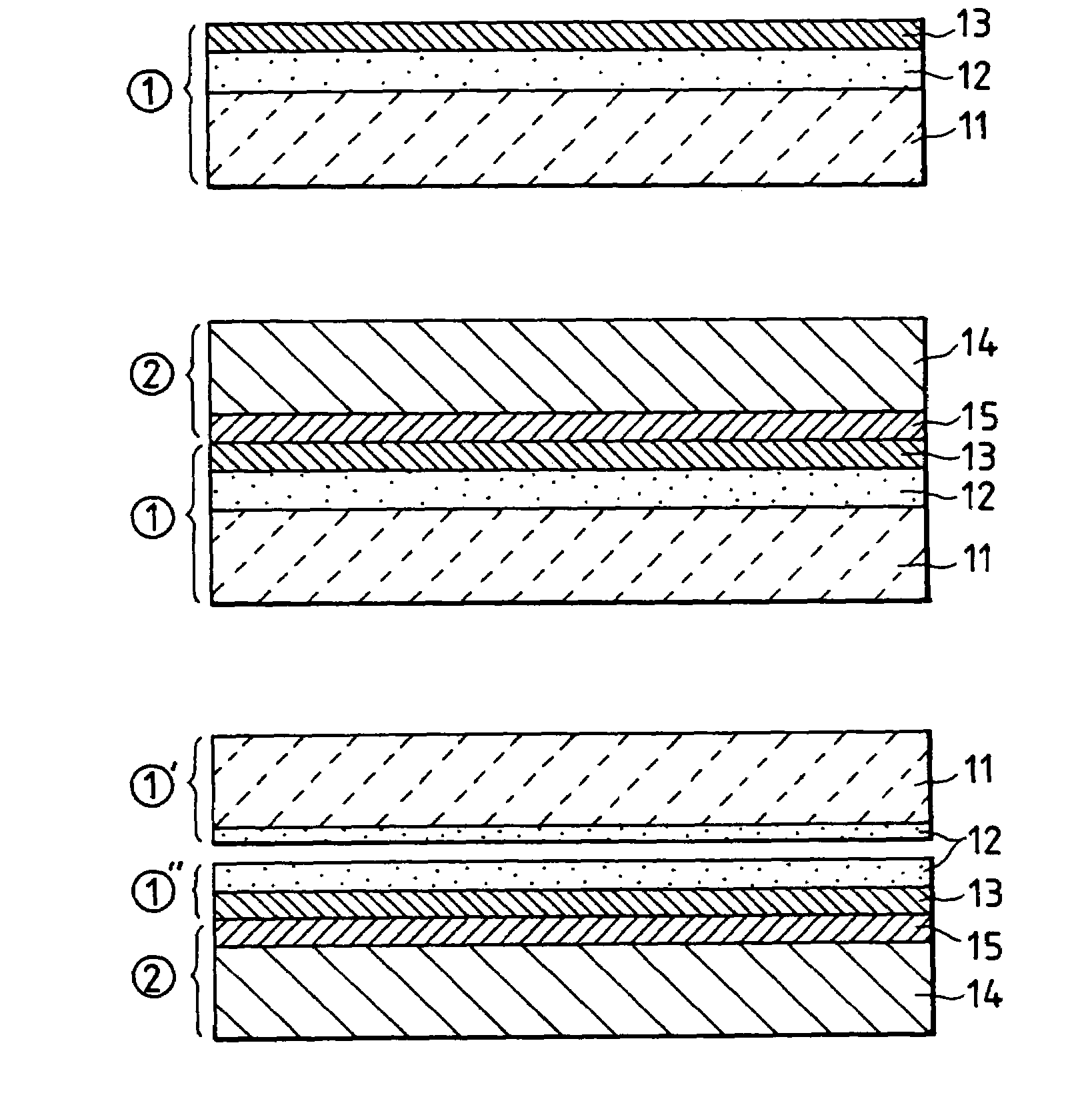

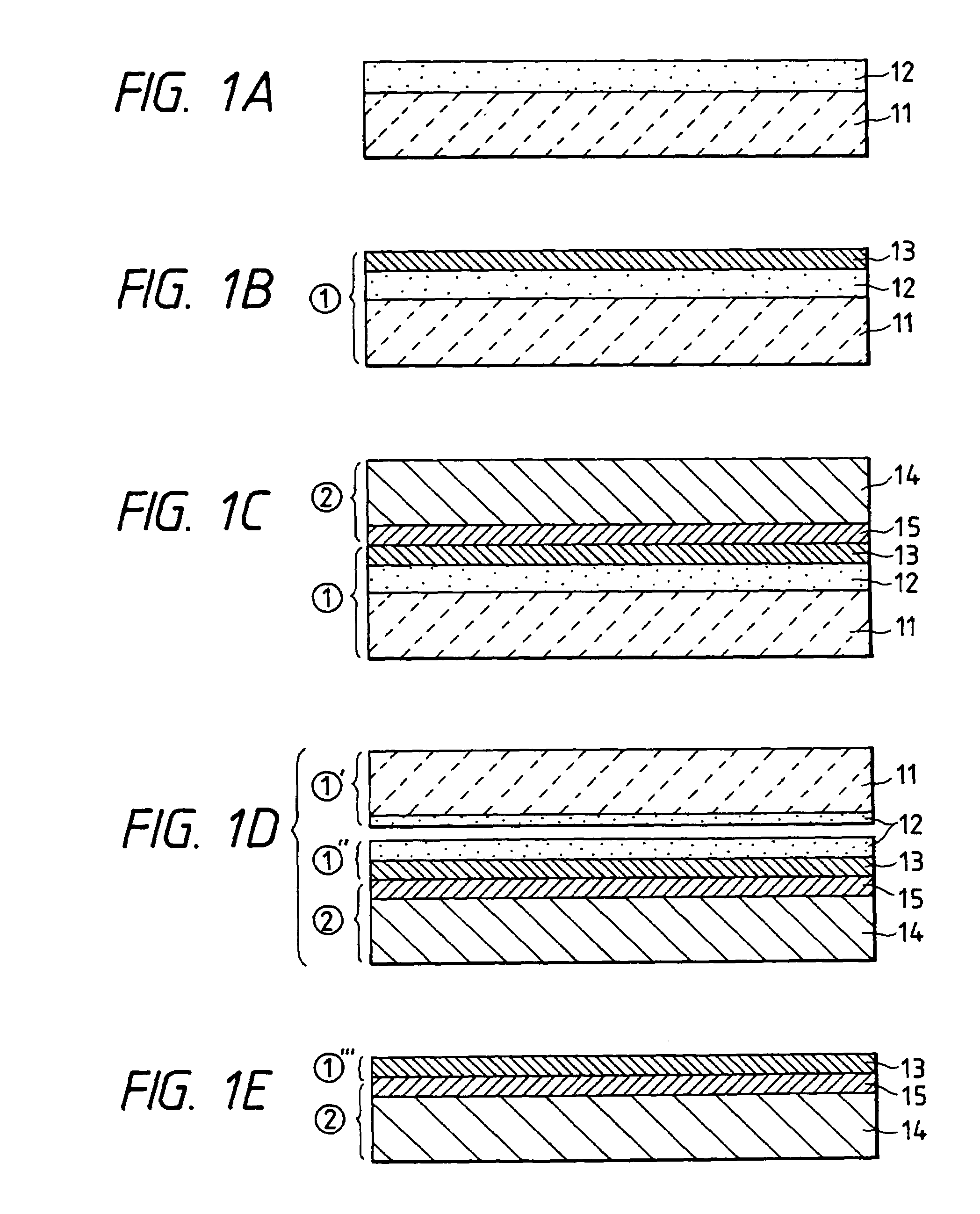

Process for production of semiconductor substrate

InactiveUS7148119B1Improve productivityLow costSemiconductor/solid-state device detailsSolid-state devicesPorous layerSemiconductor

A process for producing a semiconductor substrate is provided which comprises steps of forming a porous layer on a first substrate, forming a nonporous monocrystalline semiconductor layer on the porous layer of the first substrate, bonding the nonporous monocrystalline layer onto a second substrate, separating the bonded substrates at the porous layer, removing the porous layer on the second substrate, and removing the porous layer constituting the first substrate.

Owner:CANON KK

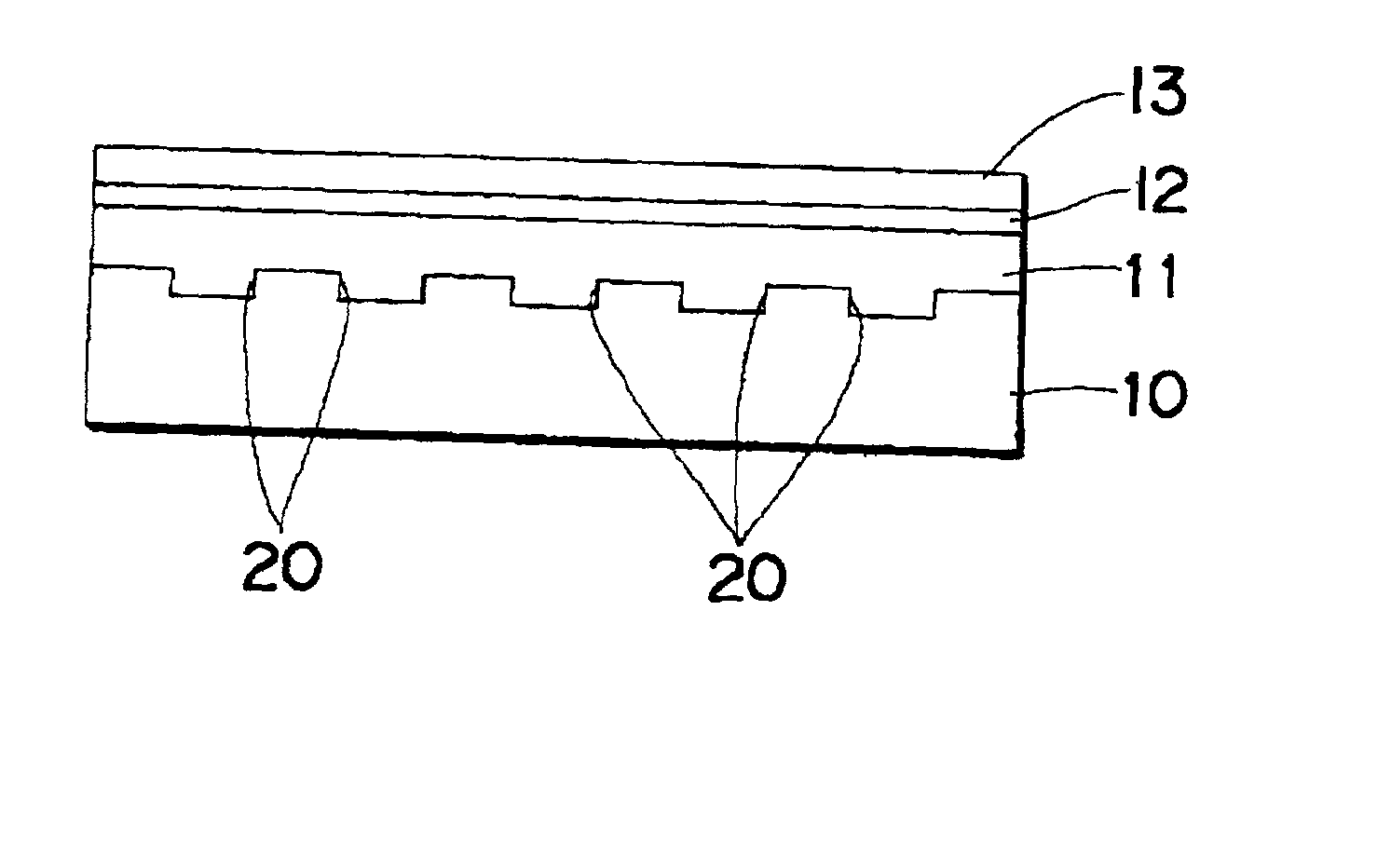

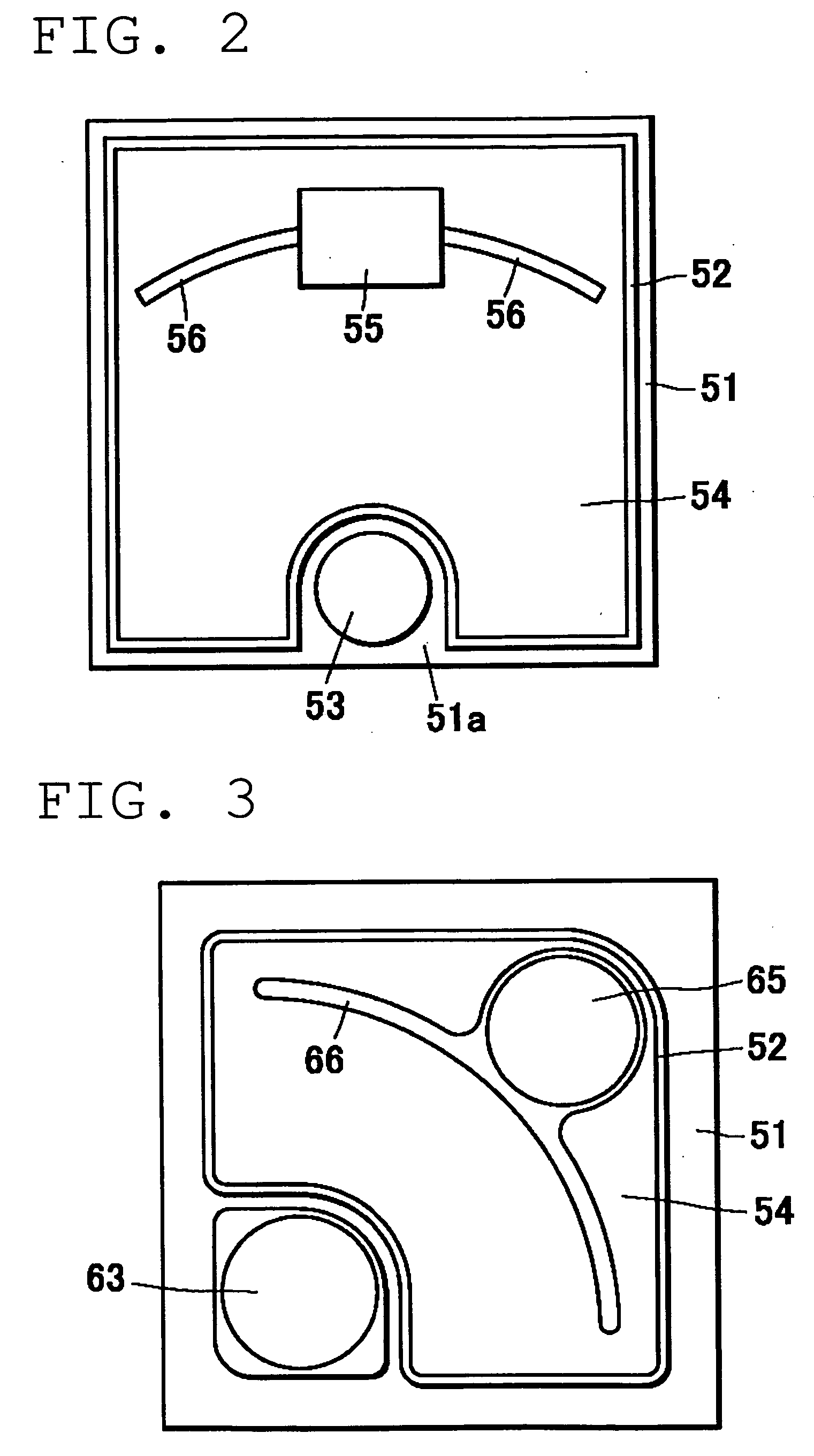

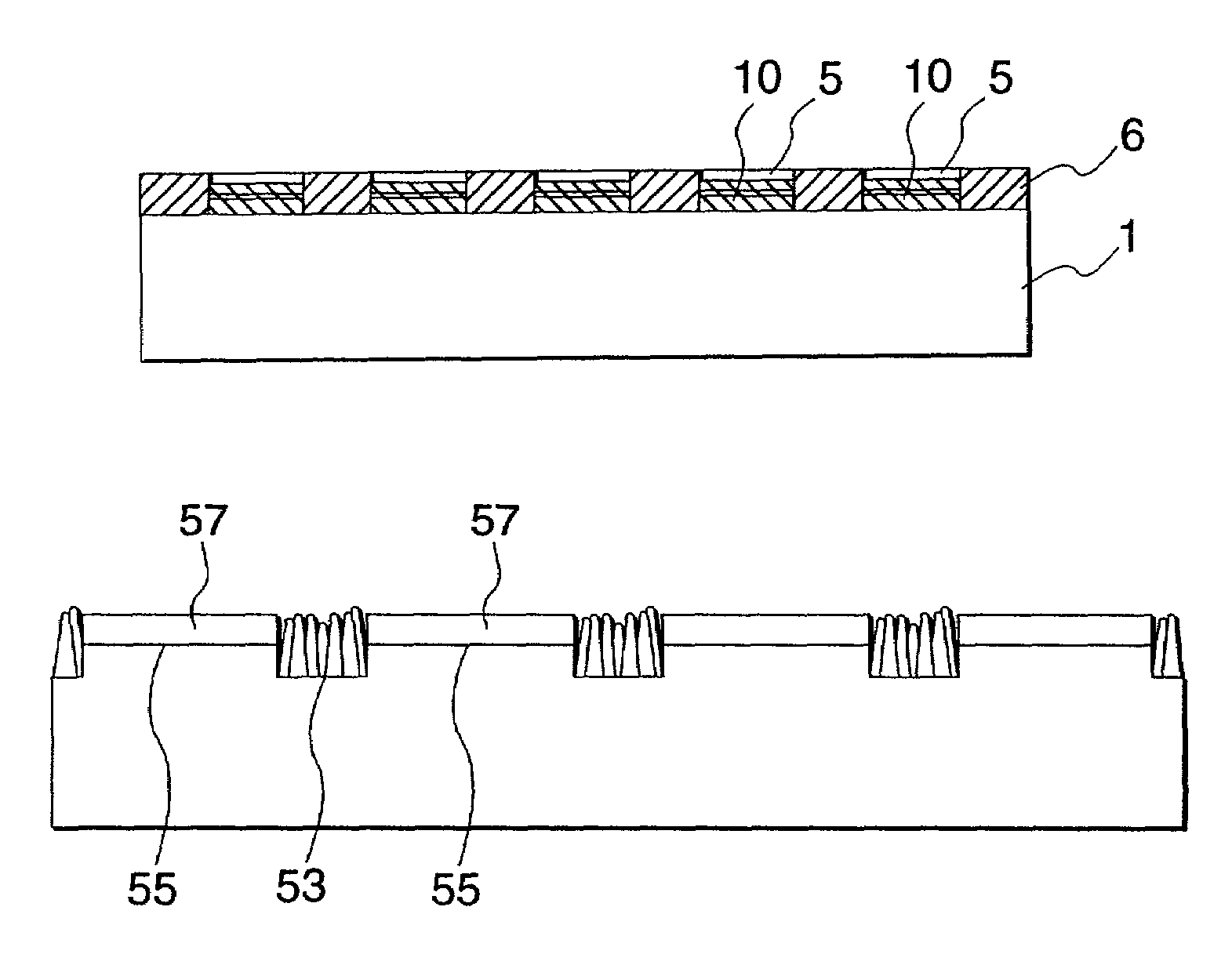

Semiconductor light emitting device

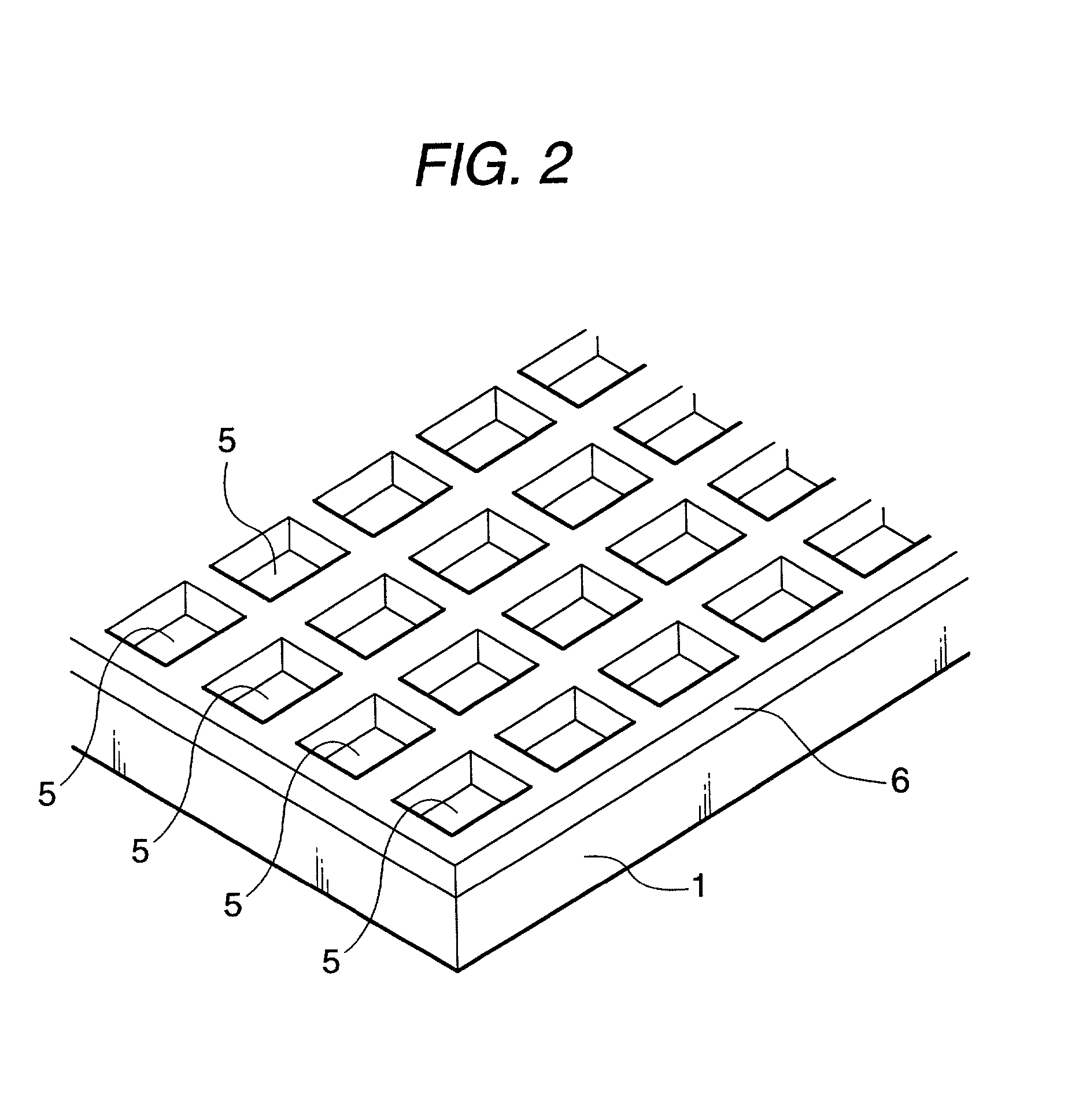

InactiveUS20030057444A1Blocking may occurAvoid defectsSemiconductor/solid-state device detailsSolid-state devicesQuantum efficiencyCrystallographic defect

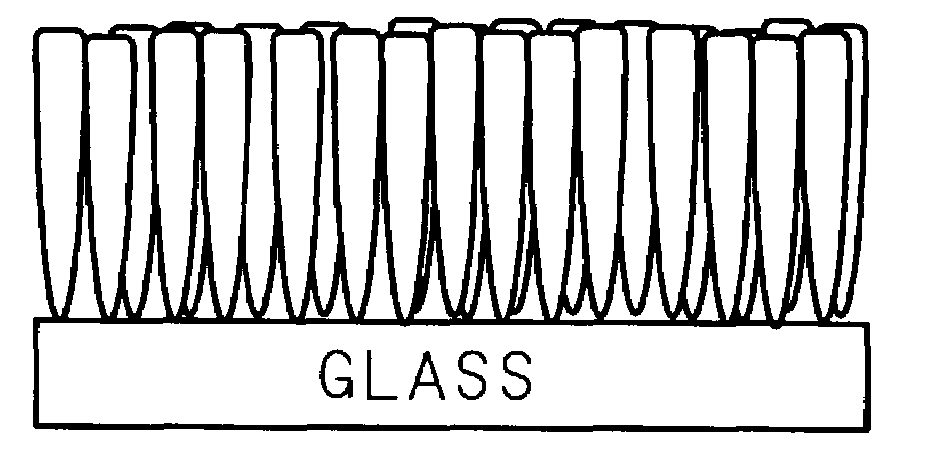

A high external quantum efficiency is stably secured in a semiconductor light emitting device. At least one recess and / or protruding portion is created on the surface portion of a substrate for scattering or diffracting light generated in a light emitting region. The recess and / or protruding portion has a shape that prevents crystal defects from occurring in semiconductor layers.

Owner:NICHIA CORP

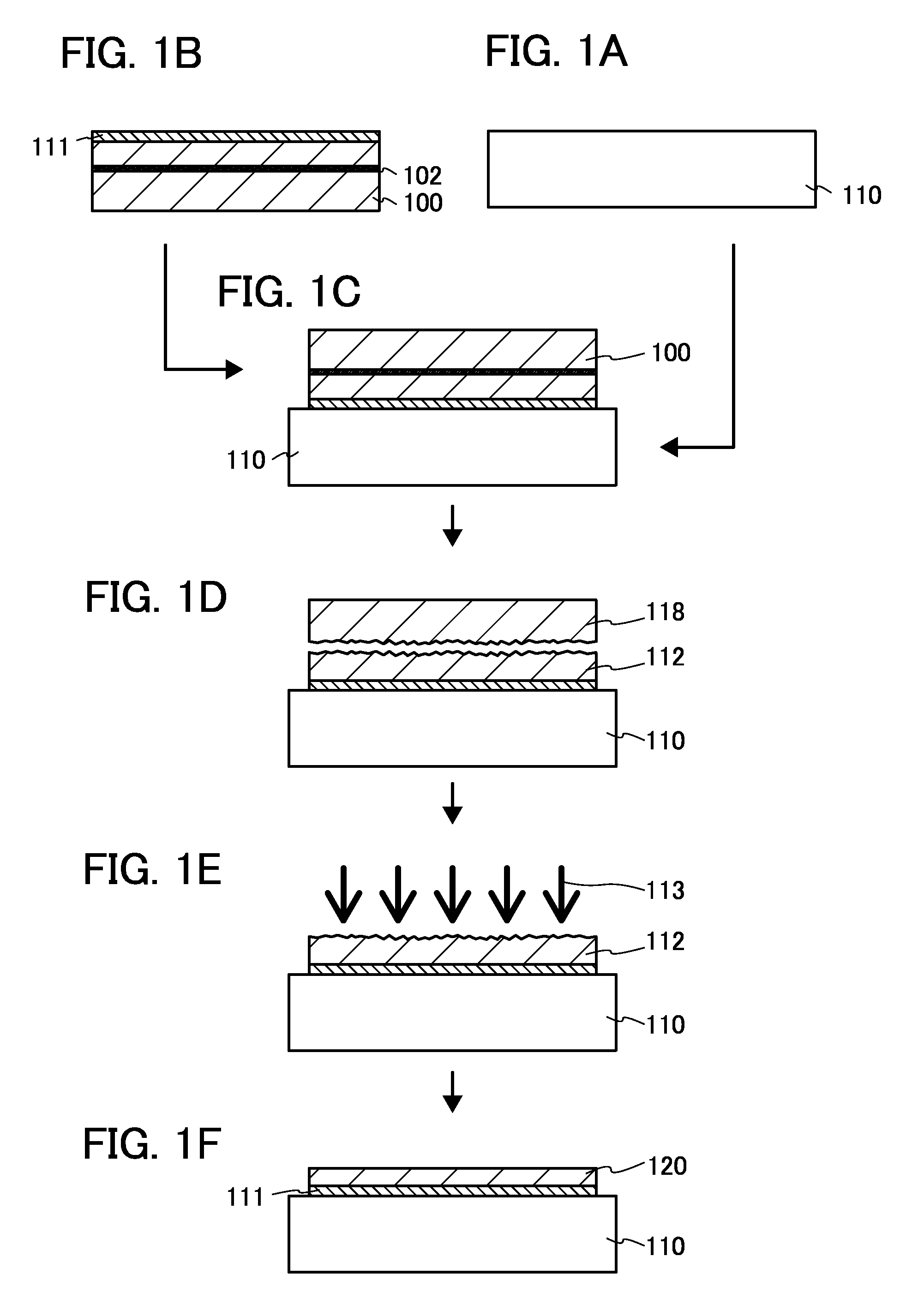

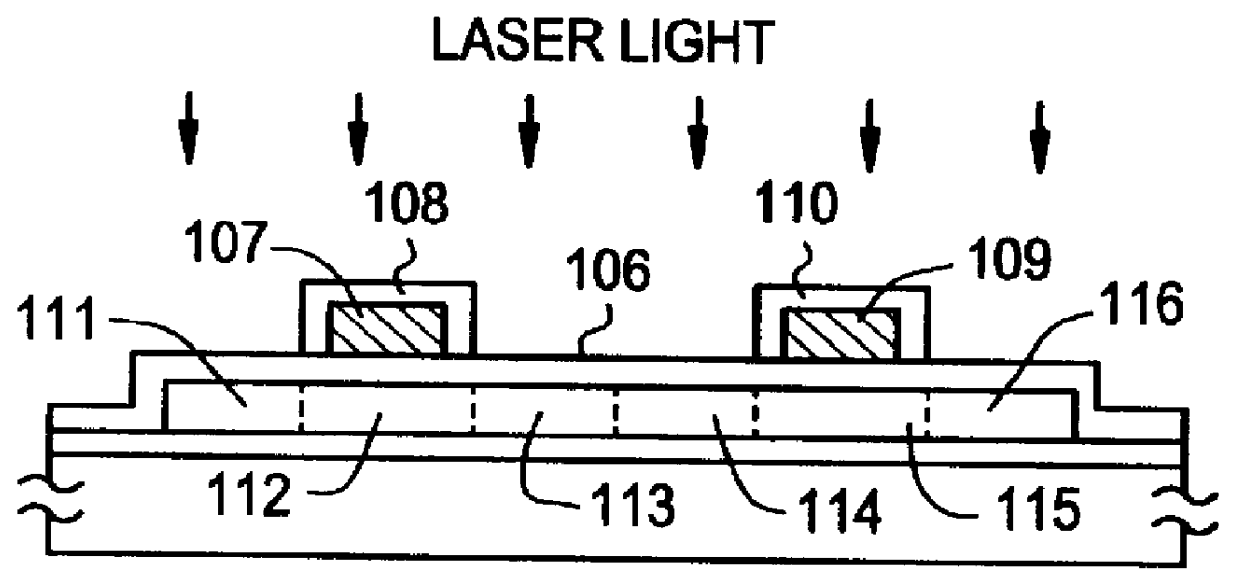

Semiconductor device and method for manufacturing the same

InactiveUS20090263942A1Favorable crystallinitySmall valueSolid-state devicesSemiconductor/solid-state device manufacturingEmbrittlementN channel

A single crystal semiconductor substrate including an embrittlement layer is attached to a base substrate with an insulating layer interposed therebetween, and the single crystal semiconductor layer is separated at the embrittlement layer by heat treatment; accordingly, a single crystal semiconductor layer is fixed over the base substrate. The single crystal semiconductor layer is irradiated with a laser beam so that the single crystal semiconductor layer is partially melted and then is re-single crystallized, whereby crystal defects are removed. In addition, an island-shaped single crystal semiconductor layer for forming an n-channel transistor is channel-doped using a photomask and then is etched back using the photomask so that the island-shaped single crystal semiconductor layer for forming an n-channel transistor is thinner than the island-shaped single crystal semiconductor layer for forming a p-channel transistor.

Owner:SEMICON ENERGY LAB CO LTD

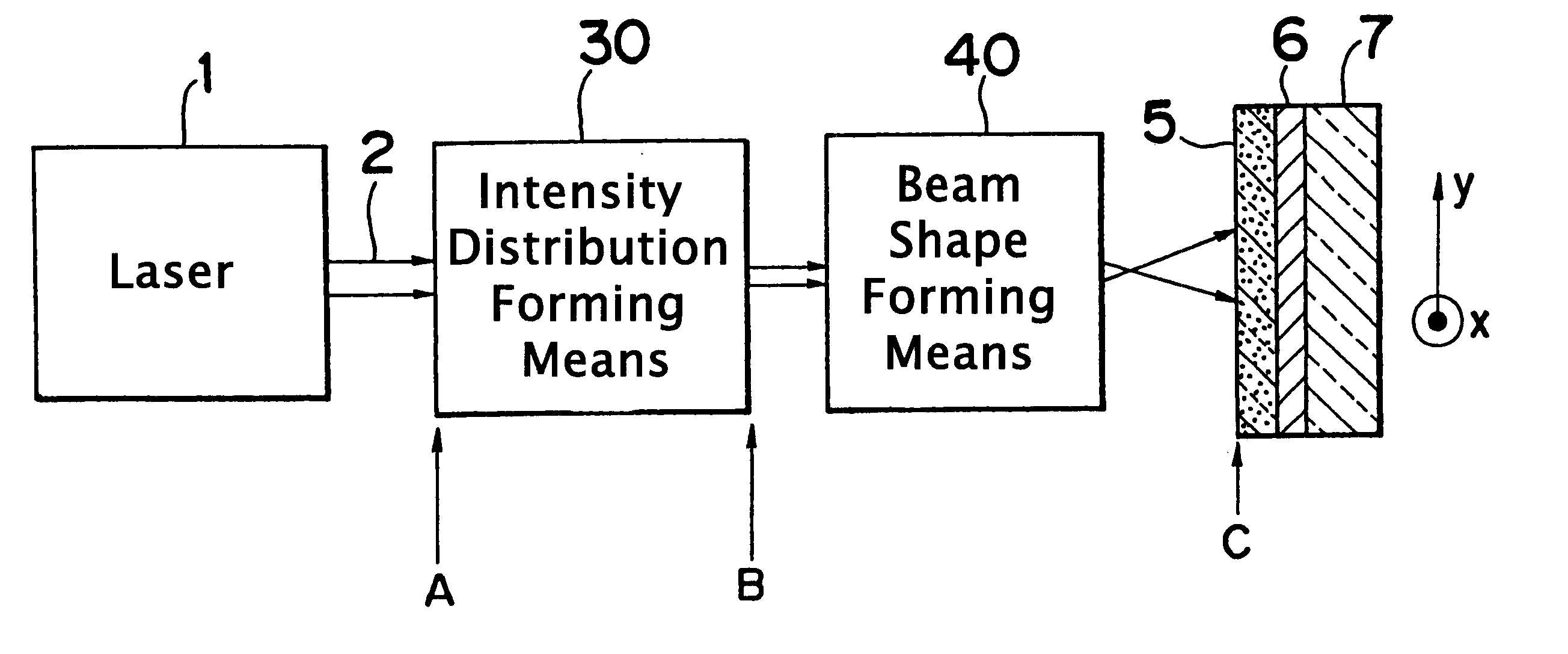

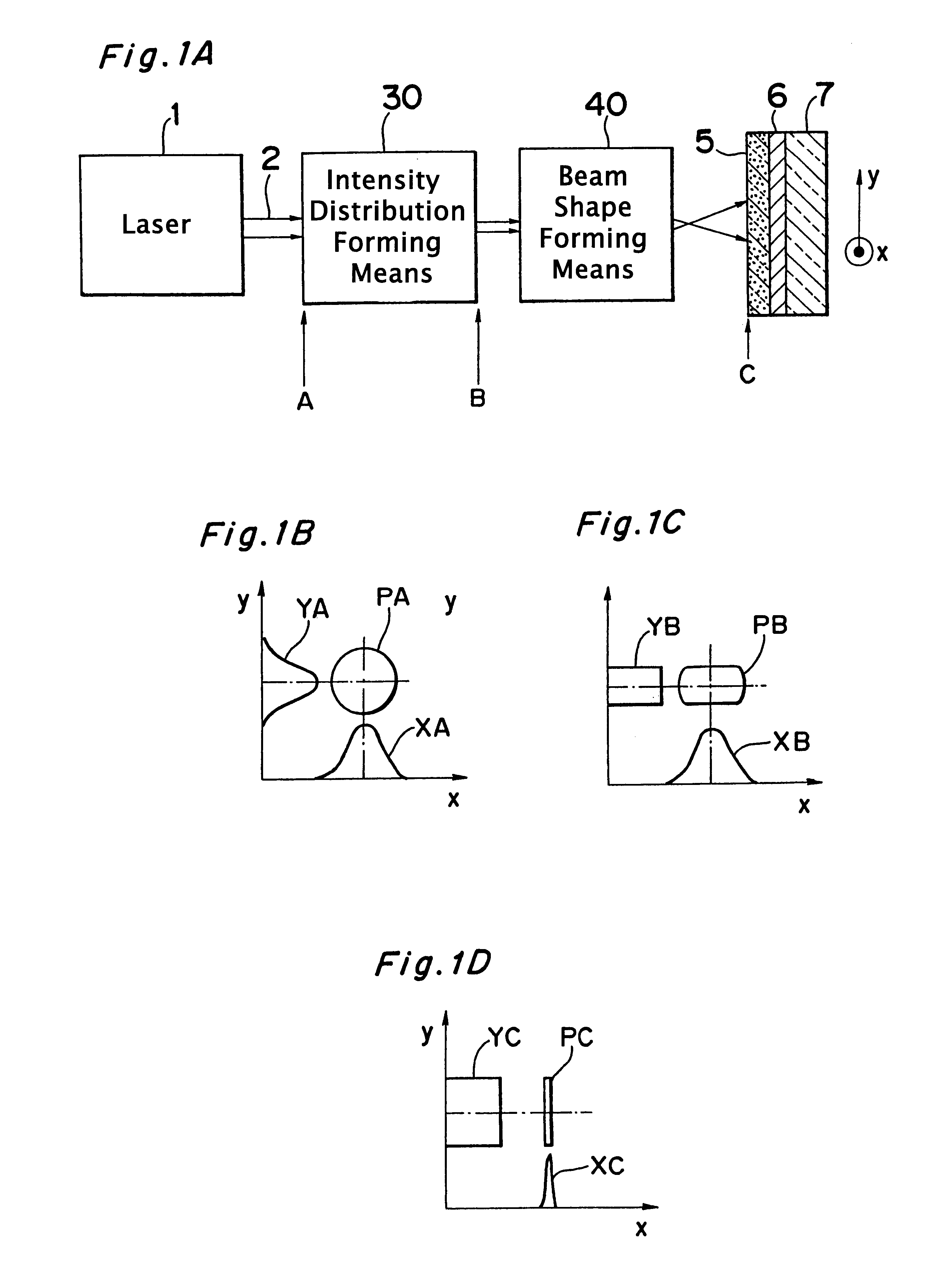

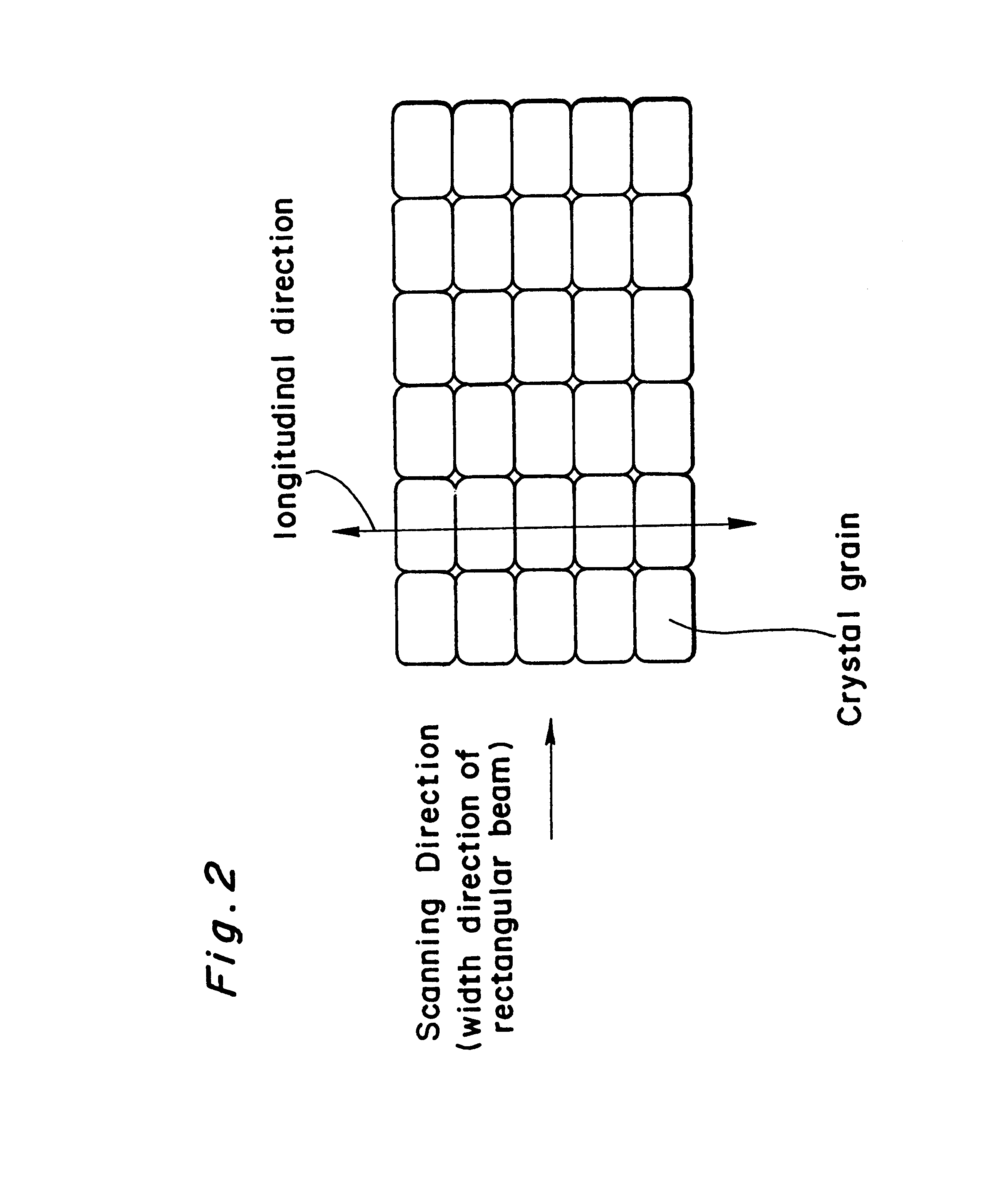

Optical system and apparatus for laser heat treatment and method for producing semiconductor devices by using the same

InactiveUS6437284B1High crystallinityReduced lattice defectsSemiconductor/solid-state device manufacturingMetal working apparatusLight beamOptoelectronics

An optical system that controls laser beam spot profile for forming a high performance thin film by a laser heat treatment process is provided. In the optical system that irradiates a rectangular laser beam on a film formed on a substrate, intensity distribution forming, apparatus makes the intensity distribution uniform in the longitudinal direction while maintaining the properties of the laser beam 2 such as directivity in the direction of shorter side, making it possible to concentrate the light to a limit permitted by the nature of the laser beam and achieve the maximum intensity gradient on the film disposed on the substrate. Thus a steep temperature distribution can be generated on the film disposed on the substrate and, as a result, high performance thin film can be formed.

Owner:MITSUBISHI ELECTRIC CORP

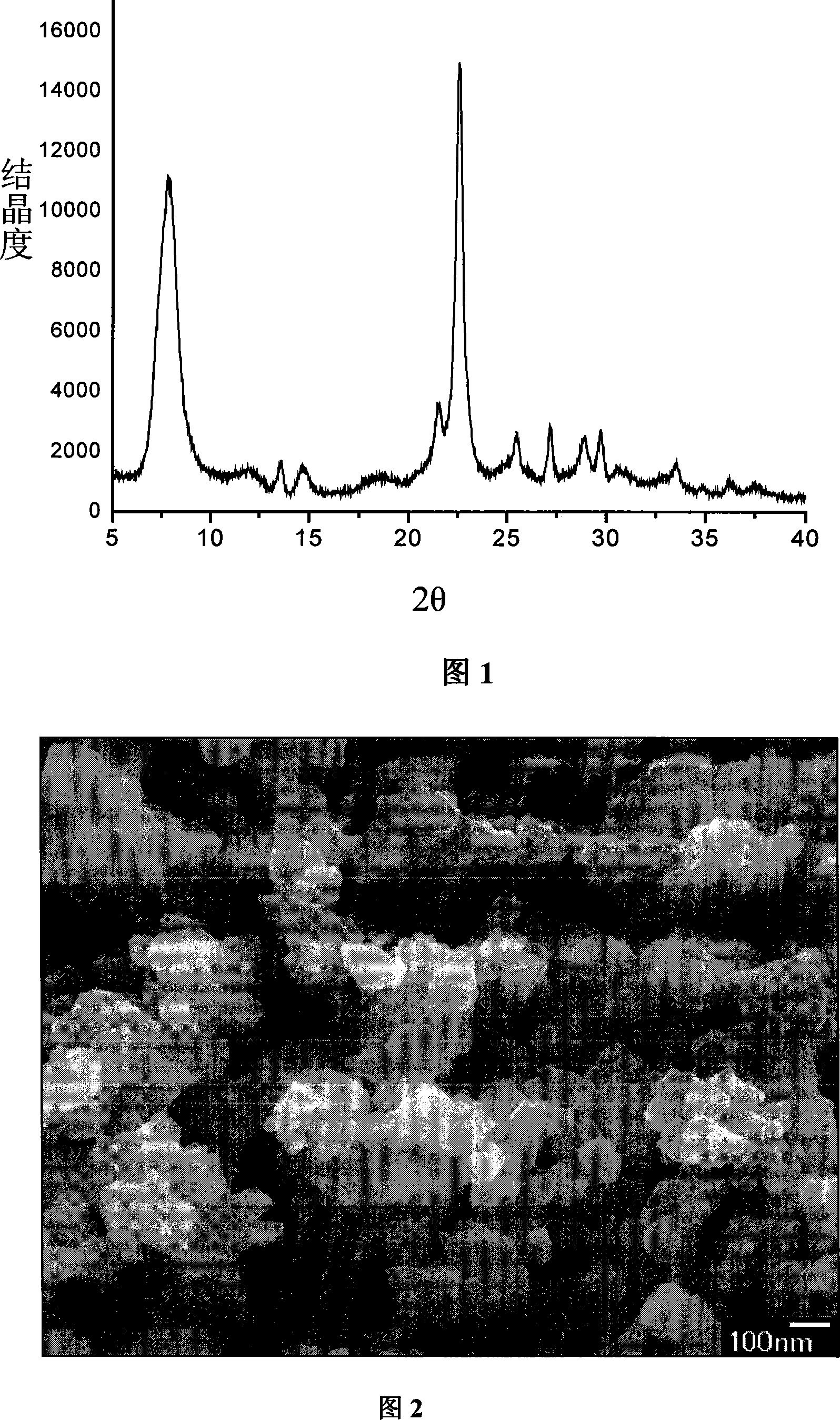

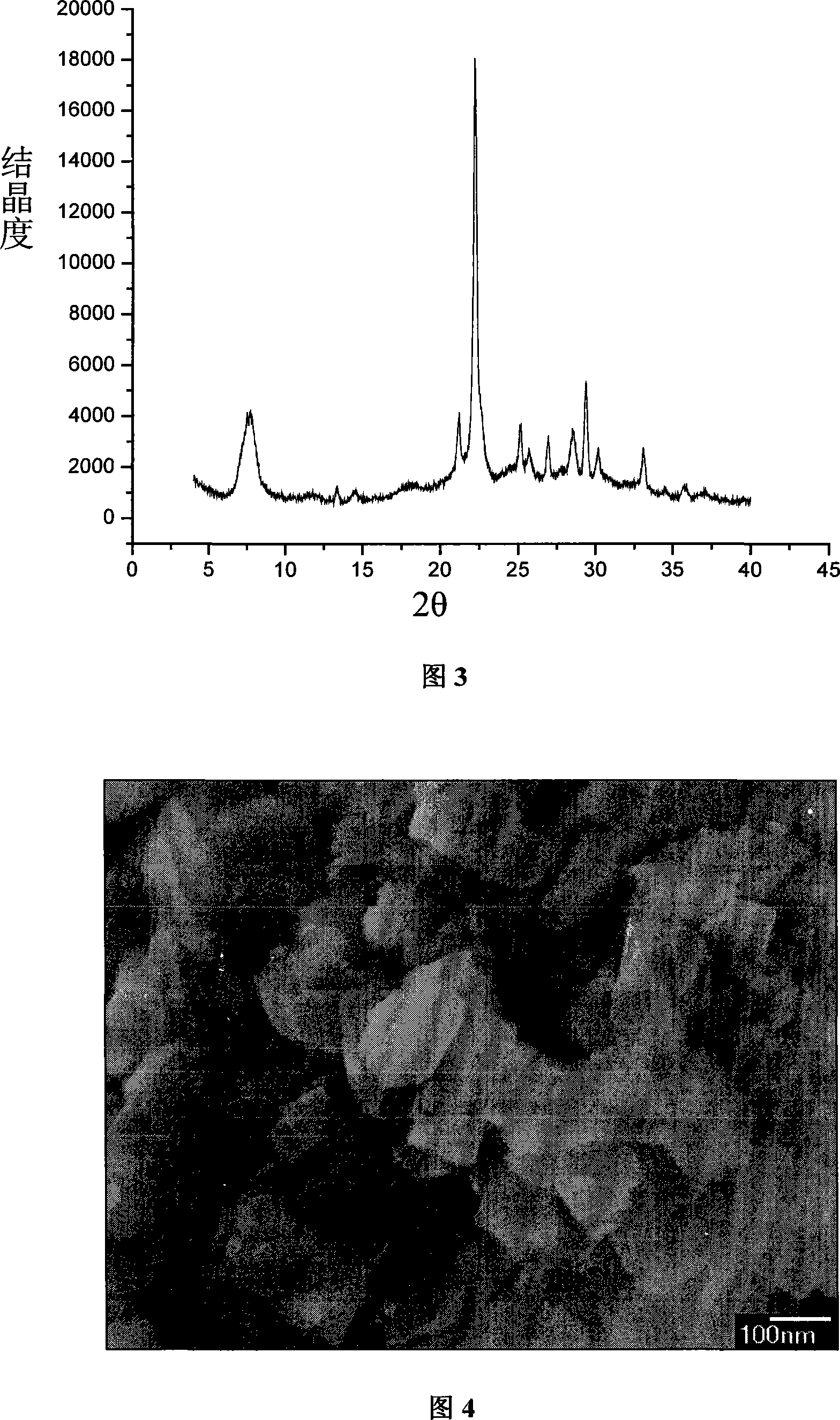

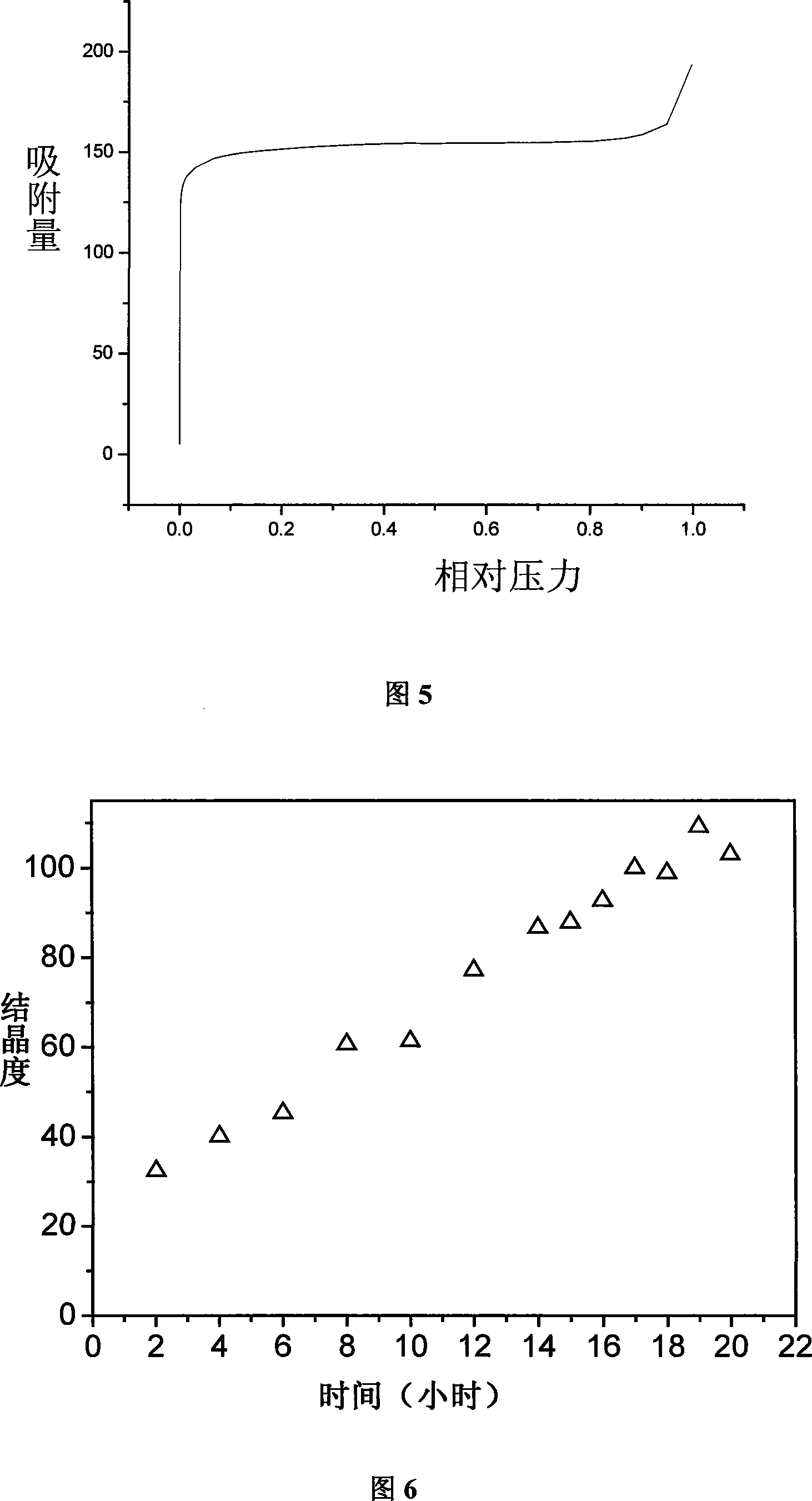

Method for synthesizing Beta molecular sieve by organic-free template

InactiveCN101249968AFast crystallization rateSynthesis fastCrystalline aluminosilicate zeolitesMolecular sieveAlumina gel

The invention relates to a method of synthesizing Beta molecular sieve without organic templates, which belongs to the technical field of catalytic chemistry. The steps of the invention comprise mixing alkali oxide sources, alumina sources, silica sources and water, stirring and synthesizing initial silica-alumina gel, then adding with Beta zeolite crystal seed, crystallizing 12-24 hours under the temperature of 100-180 DEG C and hydro-thermally synthesizing the Beta molecular sieve, SiO2 / Al2O3 of the Beta zeolite crystal seed equals 22-25, and the quality of addition quantity is 5%-20% of the silica sources. The method of the invention suits requirements of applying zeolite molecular sieve in industry, not only can directly synthesize high crystallinity crystal of the Beta molecular, but also can increase crystallizing speed of the molecular and reduce manufacturing cost. Because the synthesis process doesn't use any organic templates without roasting, thereby a pore path is unimpeded, and environmental pollution and relatively consumption are avoided.

Owner:JILIN UNIV

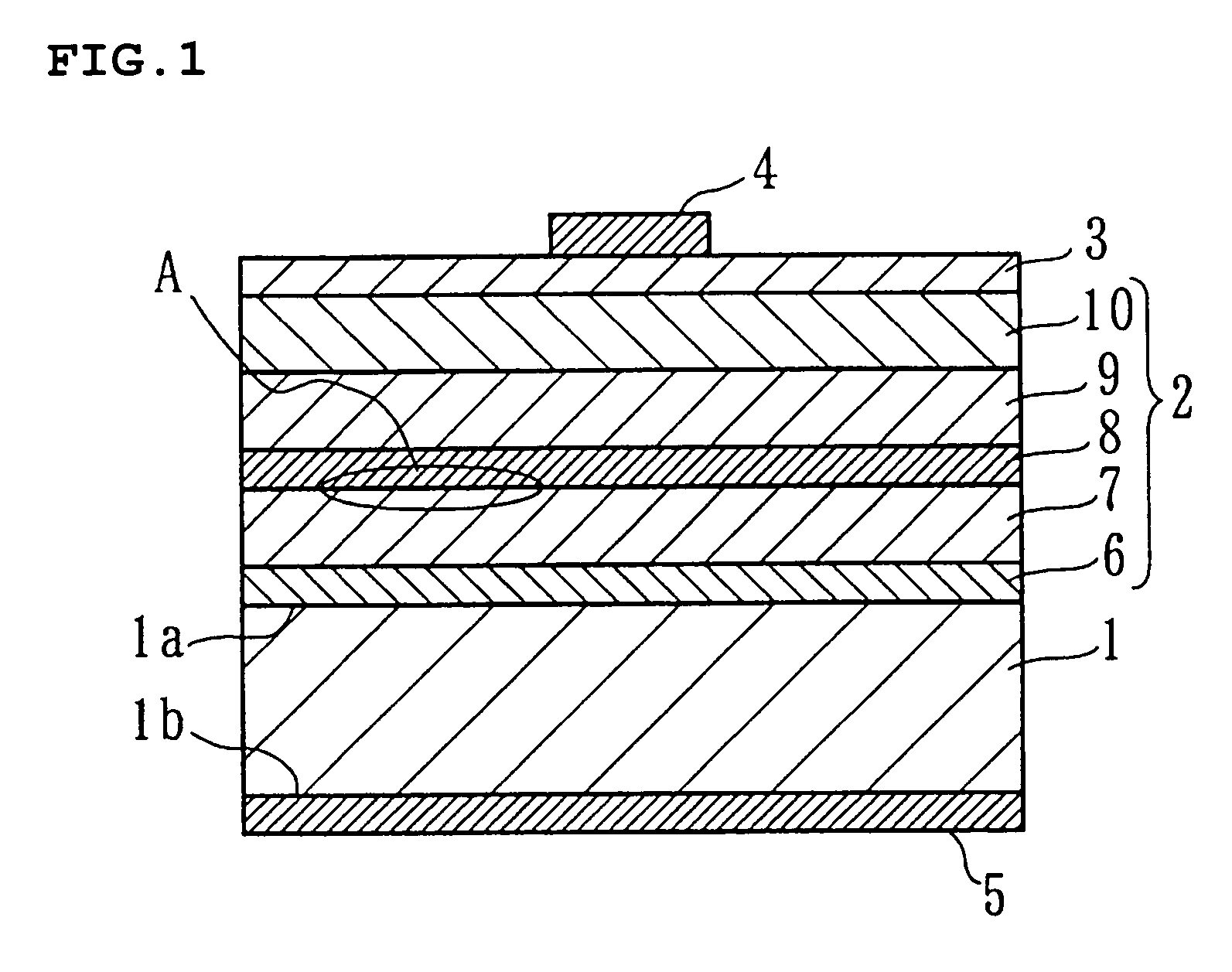

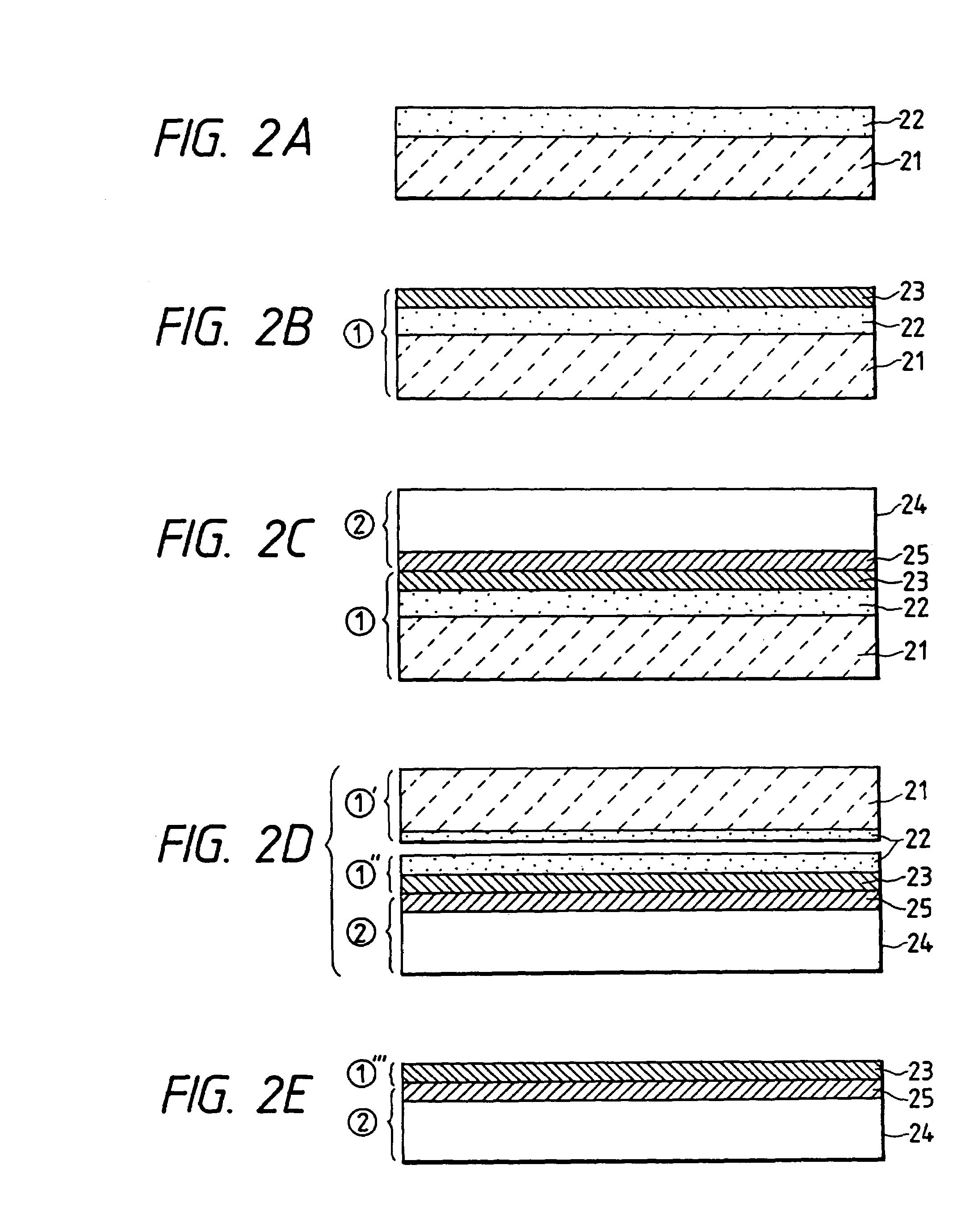

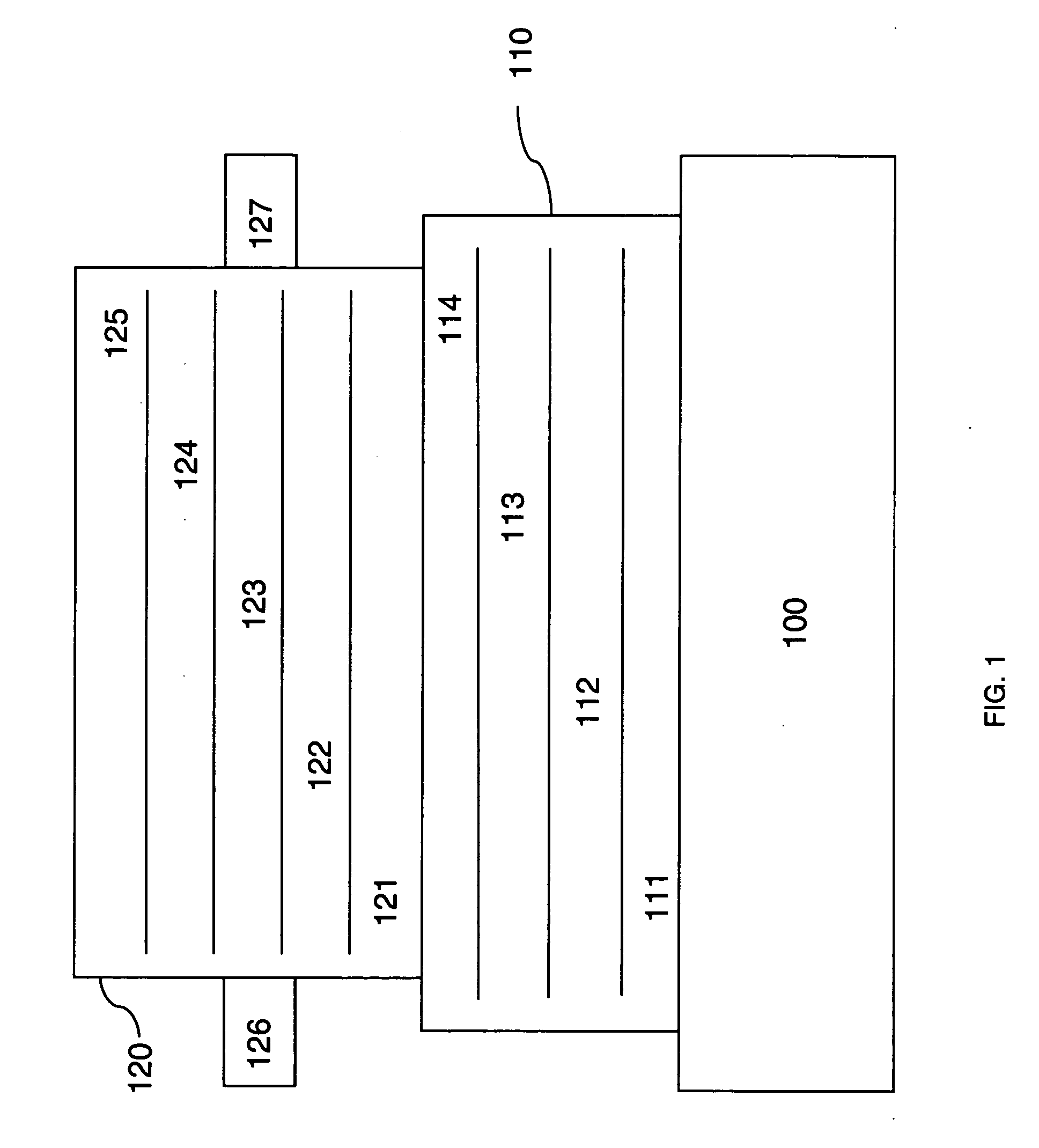

Electrochemical apparatus with barrier layer protected substrate

ActiveUS20060286448A1Inhibited DiffusionEfficient separationFinal product manufactureElectrode carriers/collectorsElectrochemistrySilicon

The present invention relates to apparatus, compositions and methods of fabricating high performance thin-film batteries on metallic substrates, polymeric substrates, or doped or undoped silicon substrates by fabricating an appropriate barrier layer composed, for example, of barrier sublayers between the substrate and the battery part of the present invention thereby separating these two parts chemically during the entire battery fabrication process as well as during any operation and storage of the electrochemical apparatus during its entire lifetime. In a preferred embodiment of the present invention thin-film batteries fabricated onto a thin, flexible stainless steel foil substrate using an appropriate barrier layer that is composed of barrier sublayers have uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for a LiCoO2 positive cathode.

Owner:SAPURAST RES

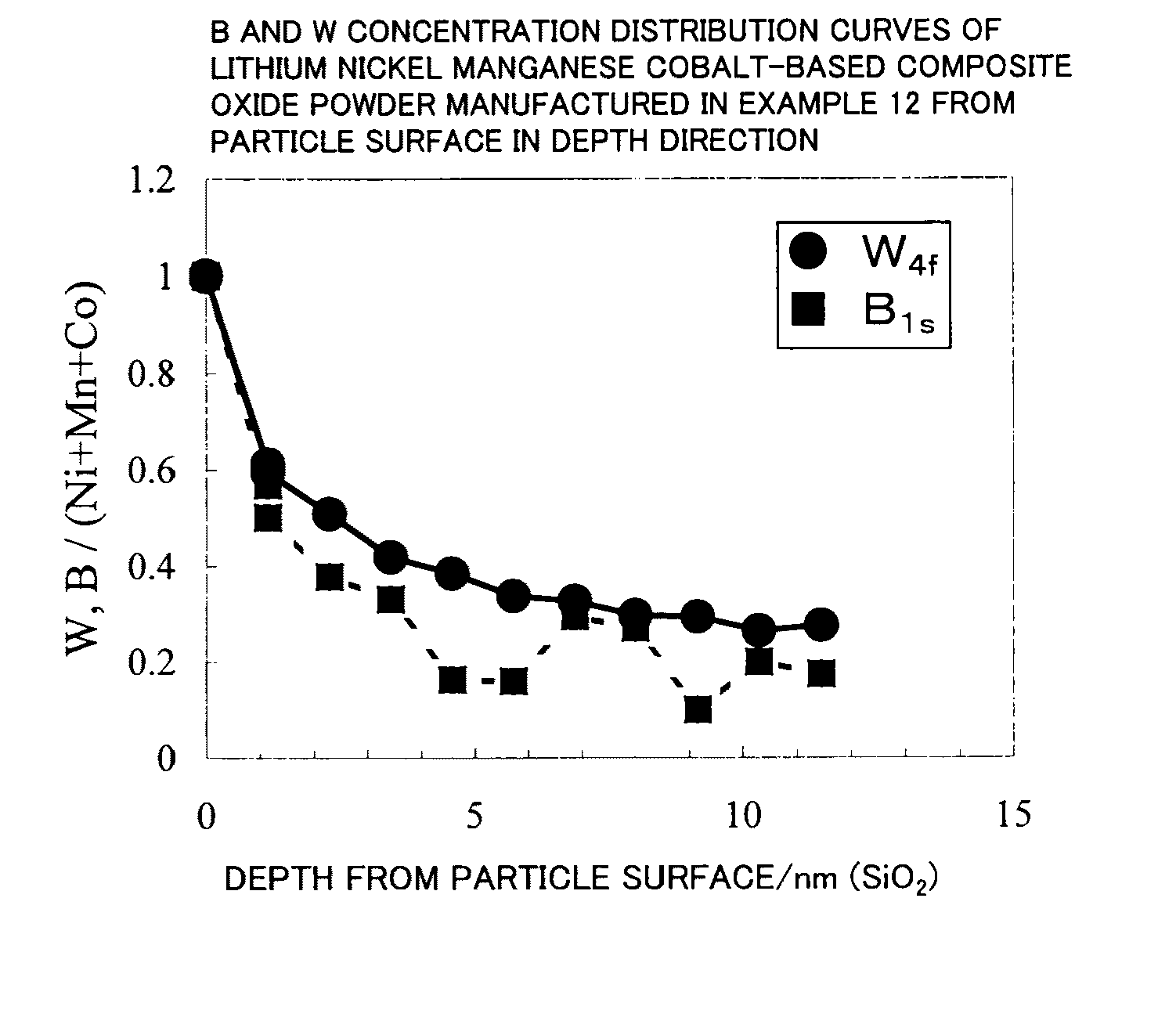

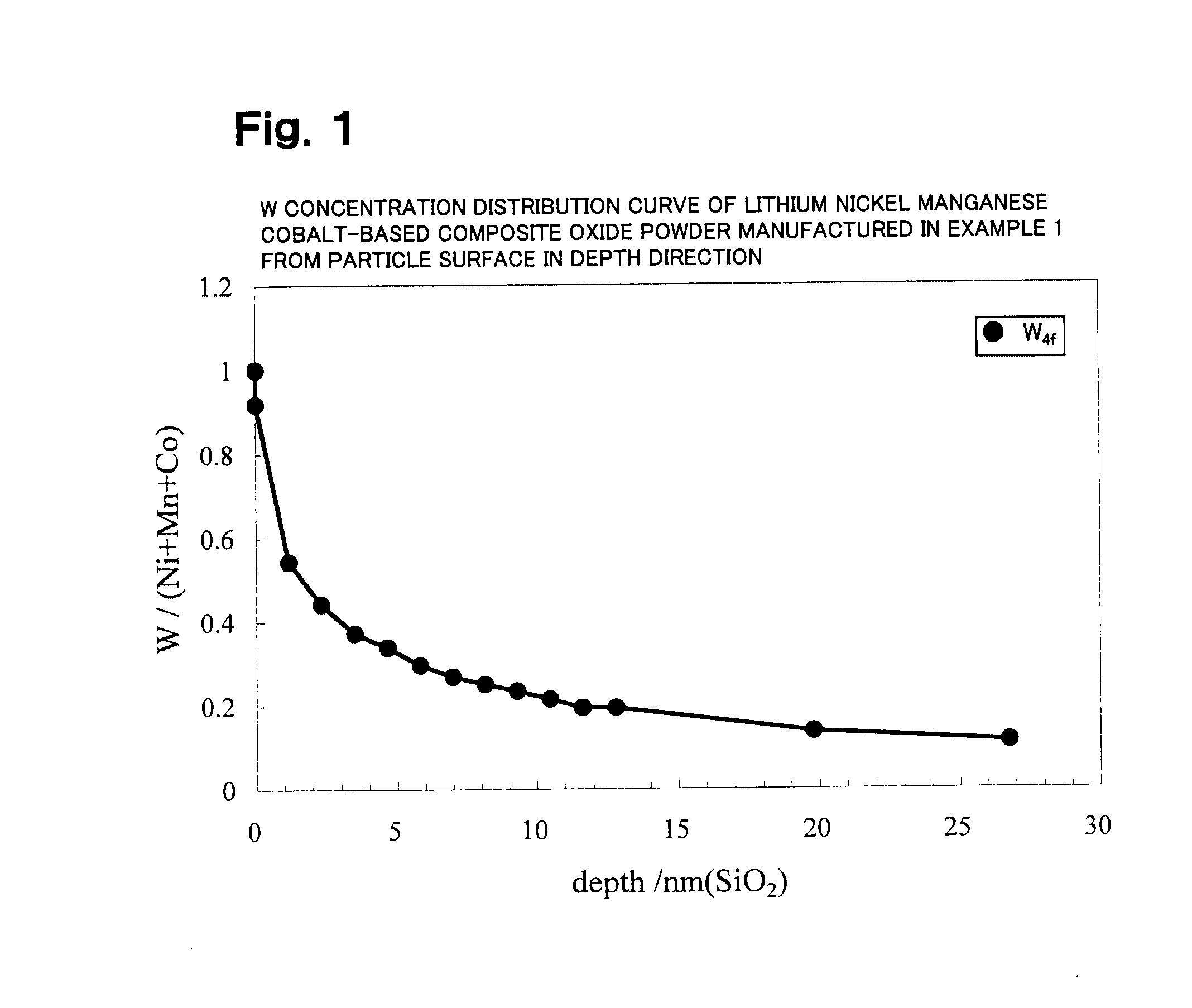

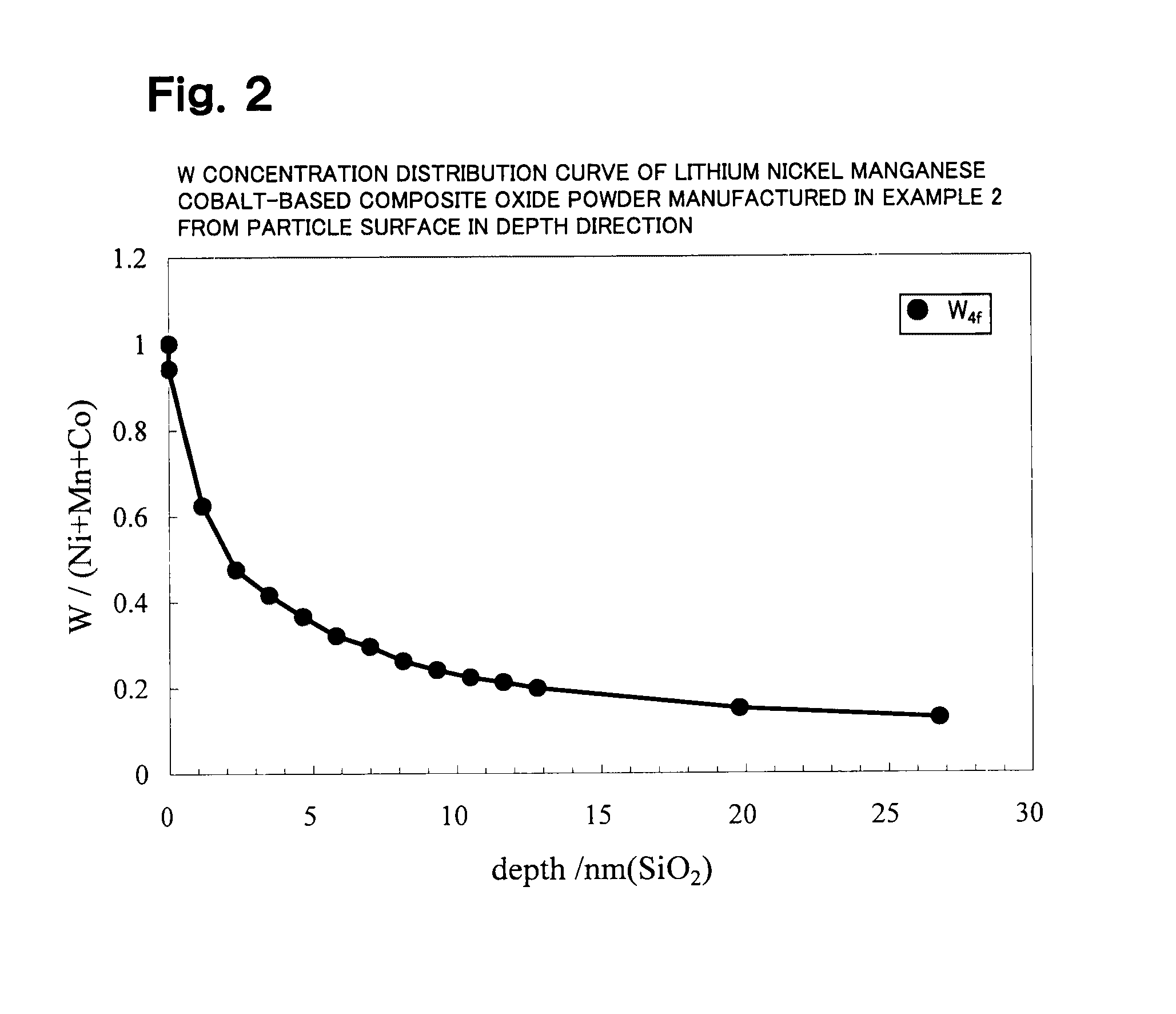

Lithium transition metal-based compound powder, method for manufacturing the same, spray-dried substance serving as firing precursor thereof, and lithium secondary battery positive electrode and lithium secondary battery using the same

ActiveUS20100209771A1Improve load characteristicsHigh densityMaterial nanotechnologyAlkaline accumulatorsLithiumHigh density

A lithium transition metal-based compound powder for a lithium secondary battery positive electrode material that can achieve both improvements of load characteristics such as rate and output characteristics and a higher density is a lithium transition metal-based compound powder containing, as a main component, a lithium transition metal-based compound that has a function of allowing elimination and insertion of lithium ions, and including a crystal structure belonging to a layer structure, wherein primary particles are aggregated to form secondary particles, the ratio A / B of a median diameter A of the secondary particles to an average diameter (average primary particle diameter B) is in the range of 8 to 100, and 0.01≦FWHM(110)≦0.5 where FWHM(110) is the half width of a (110) diffraction peak present near a diffraction angle 2θ of 64.5° in a powder X-ray diffraction analysis using a CuKα line.

Owner:MITSUBISHI CHEM CORP

Semiconductor light emitting device

A semiconductor light emitting device with improved efficiency in extracting light is provided. The semiconductor light emitting device comprises a first conductive type semiconductor layer, a light emitting layer, and a second conductive semiconductor layer stacked in this order, electrodes respectively connected to the first and second conductive semiconductor layers, the electrode connected to the second conductive type semiconductor layer comprising a lower conductive oxide film and an upper conductive oxide film disposed on the lower conductive oxide film, and a metal film disposed only on the upper conductive oxide film. The upper and lower conductive oxide films comprise an oxide including at least one element selected from the group consisting of zinc (Zn), indium (In), tin (Sn), and magnesium (Mg).

Owner:NICHIA CORP

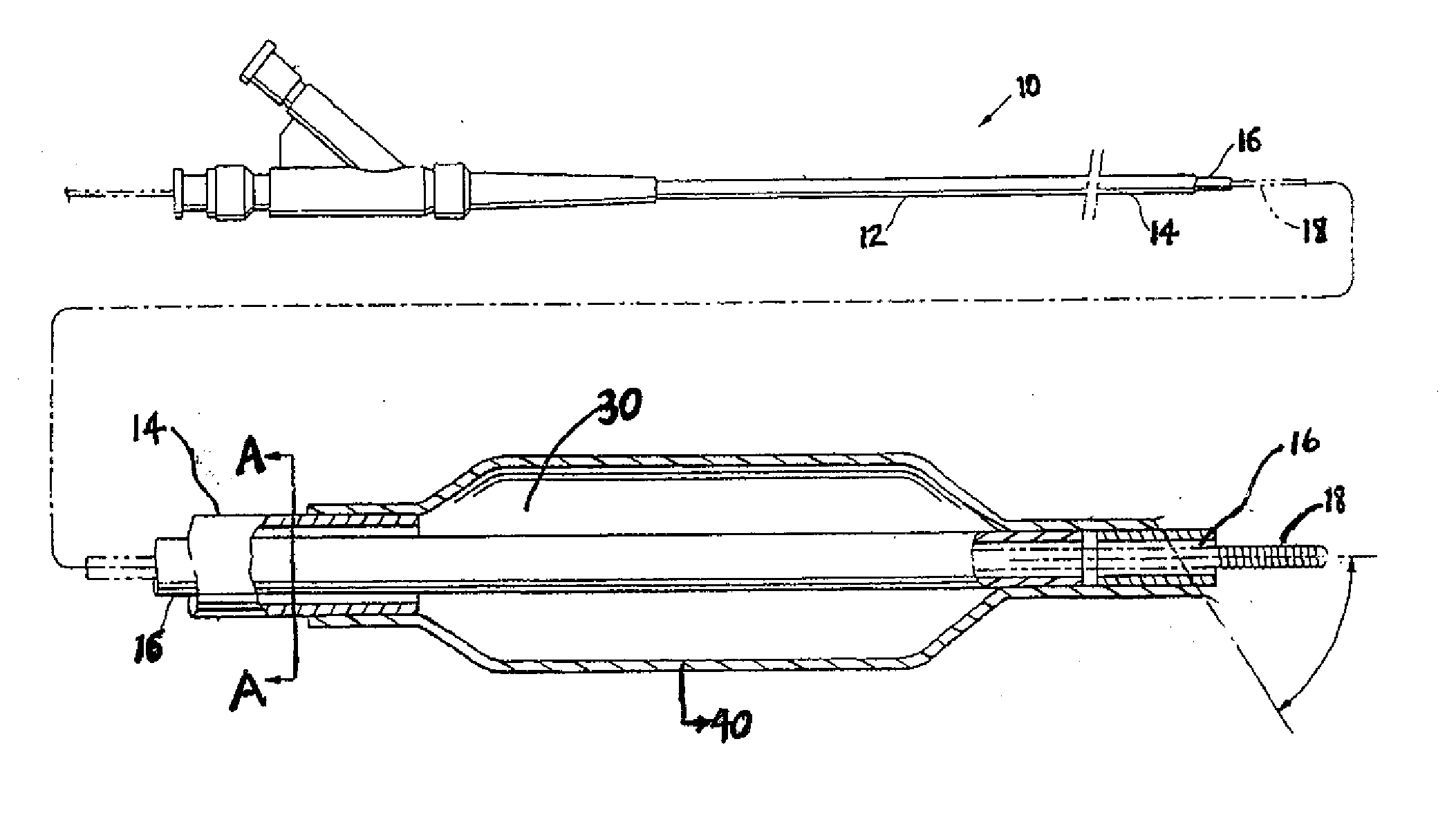

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

InactiveUS7919162B2High modulusEnhanced hoop strengthStentsSynthetic resin layered productsProsthesisCrystallinity

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

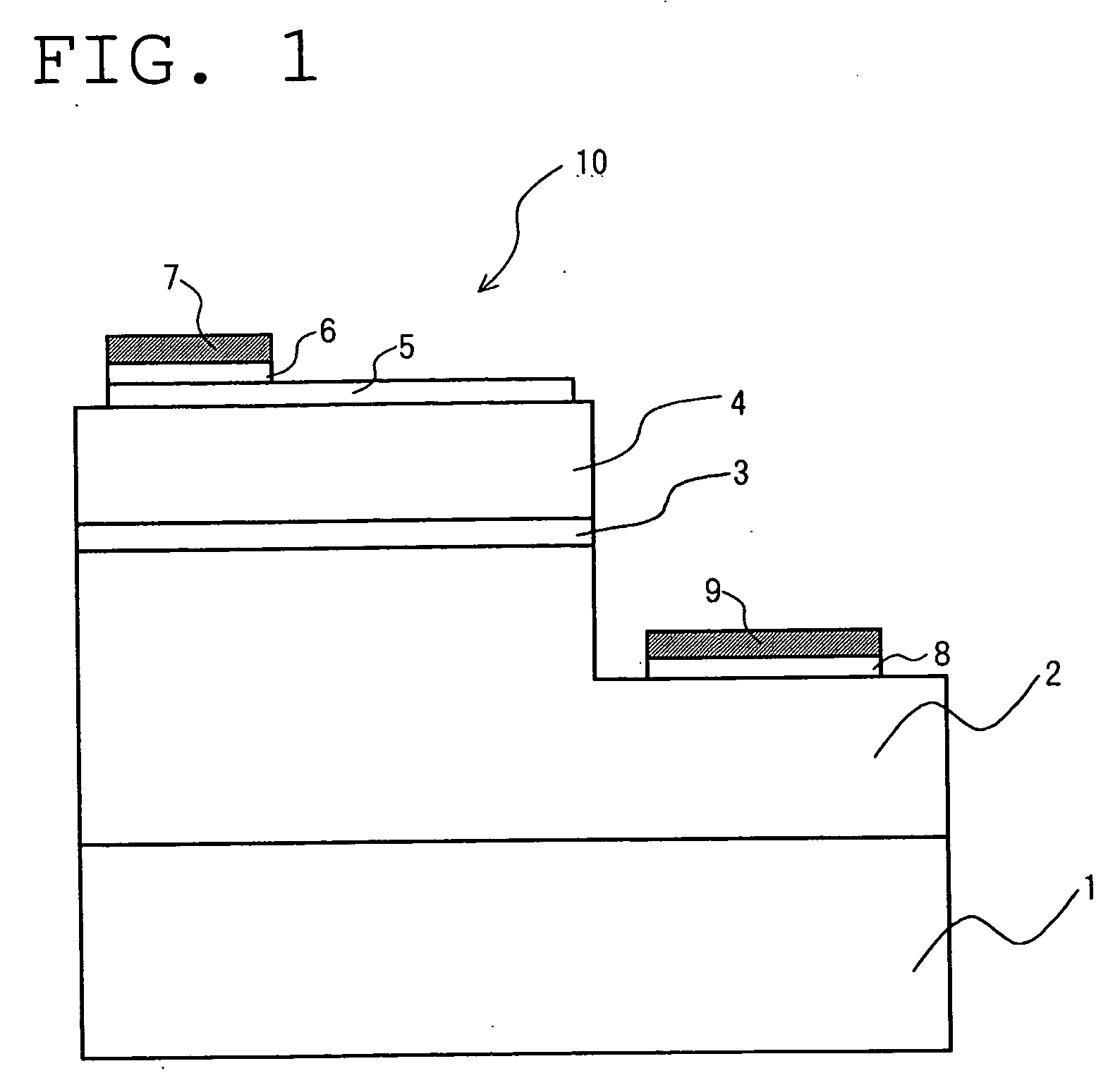

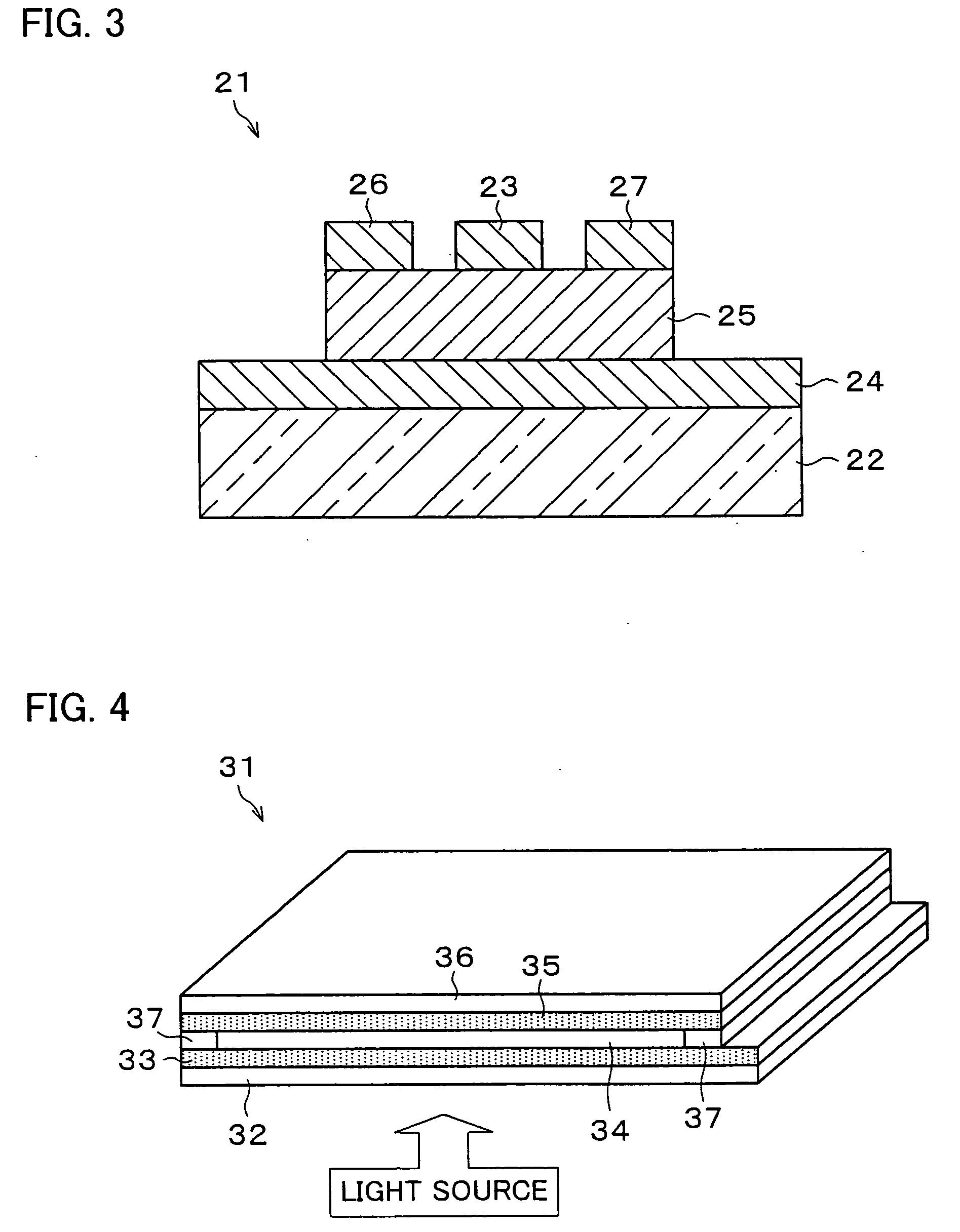

Semiconductor device and display comprising same

InactiveUS20050173734A1Improve performanceVersatile techniqueTransistorSemiconductor/solid-state device detailsMOSFETDevice material

In an inverse-stagger MOSFET (1), a gate insulating layer (4) made of amorphous aluminum oxide is so formed as to face a channel layer (5) which serves as the semiconductor layer, and which is made of zinc oxide. With this arrangement, a defect level at an interface between the channel layer (5) and the gate insulating layer (4) is reduced, thereby obtaining performance equivalent to that of a semiconductor apparatus in which all the layered films are crystalline. This technique is applicable to a staggered MOSFET and the like, and has high versatility.

Owner:MASASHI KAWASAKI +2

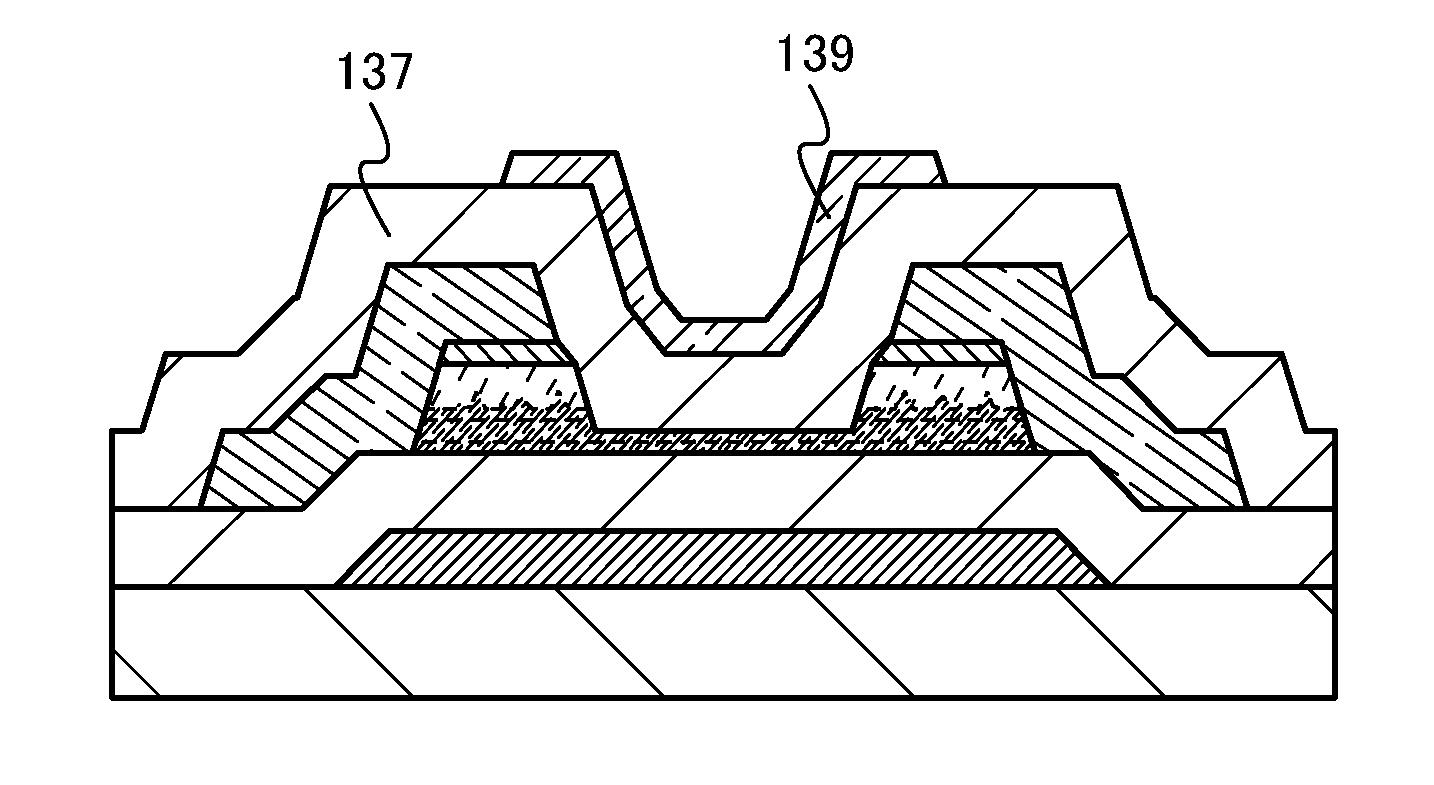

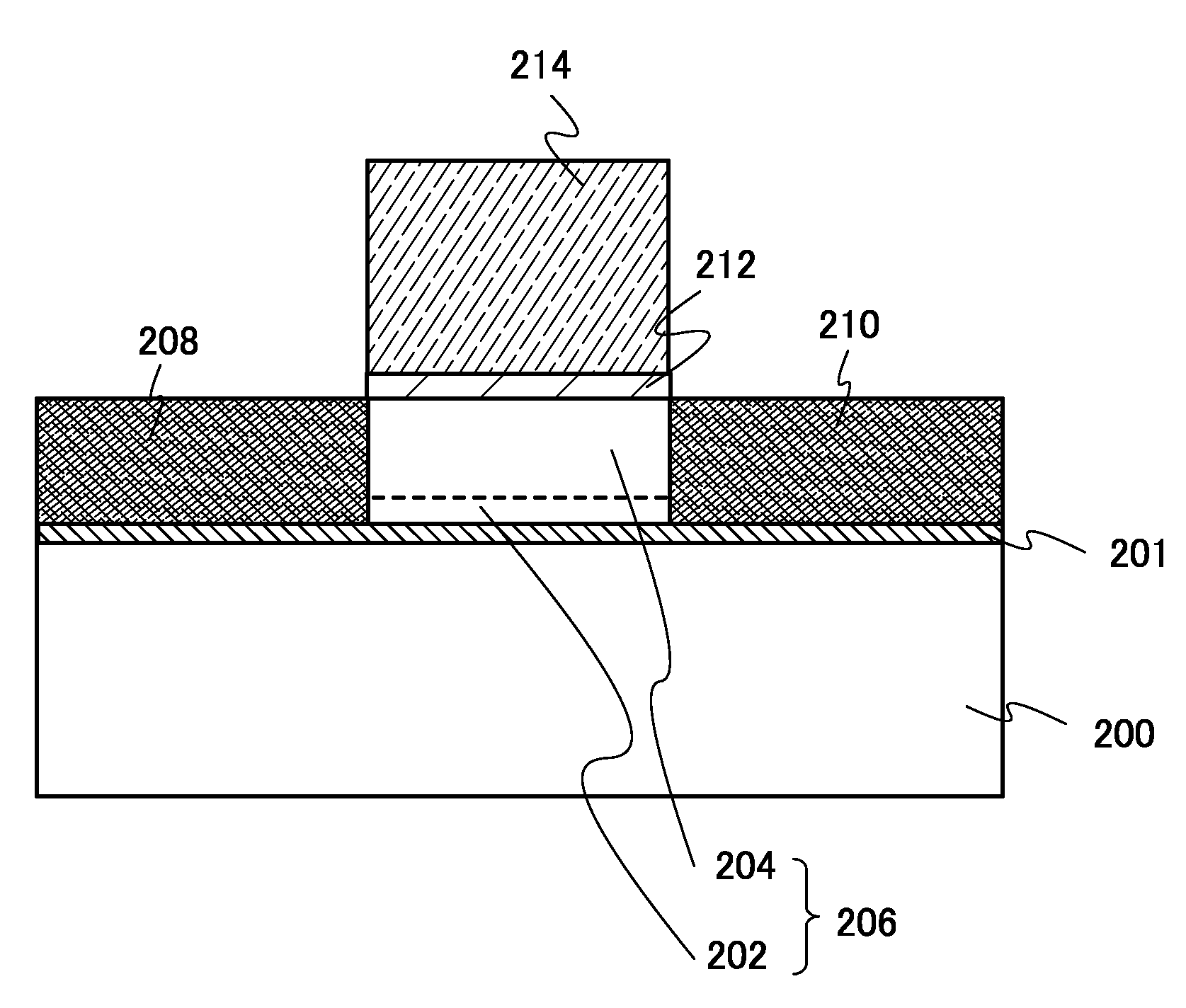

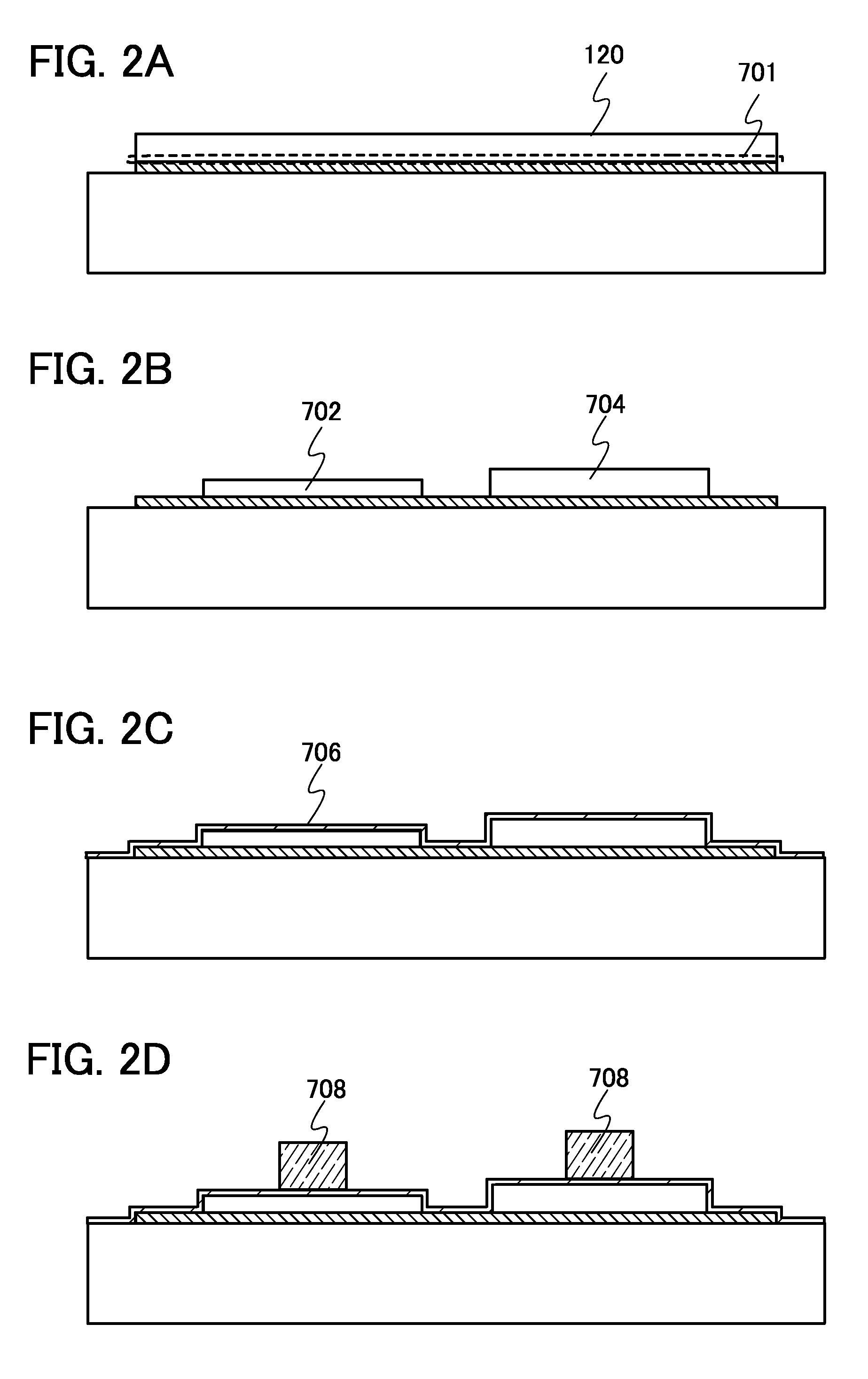

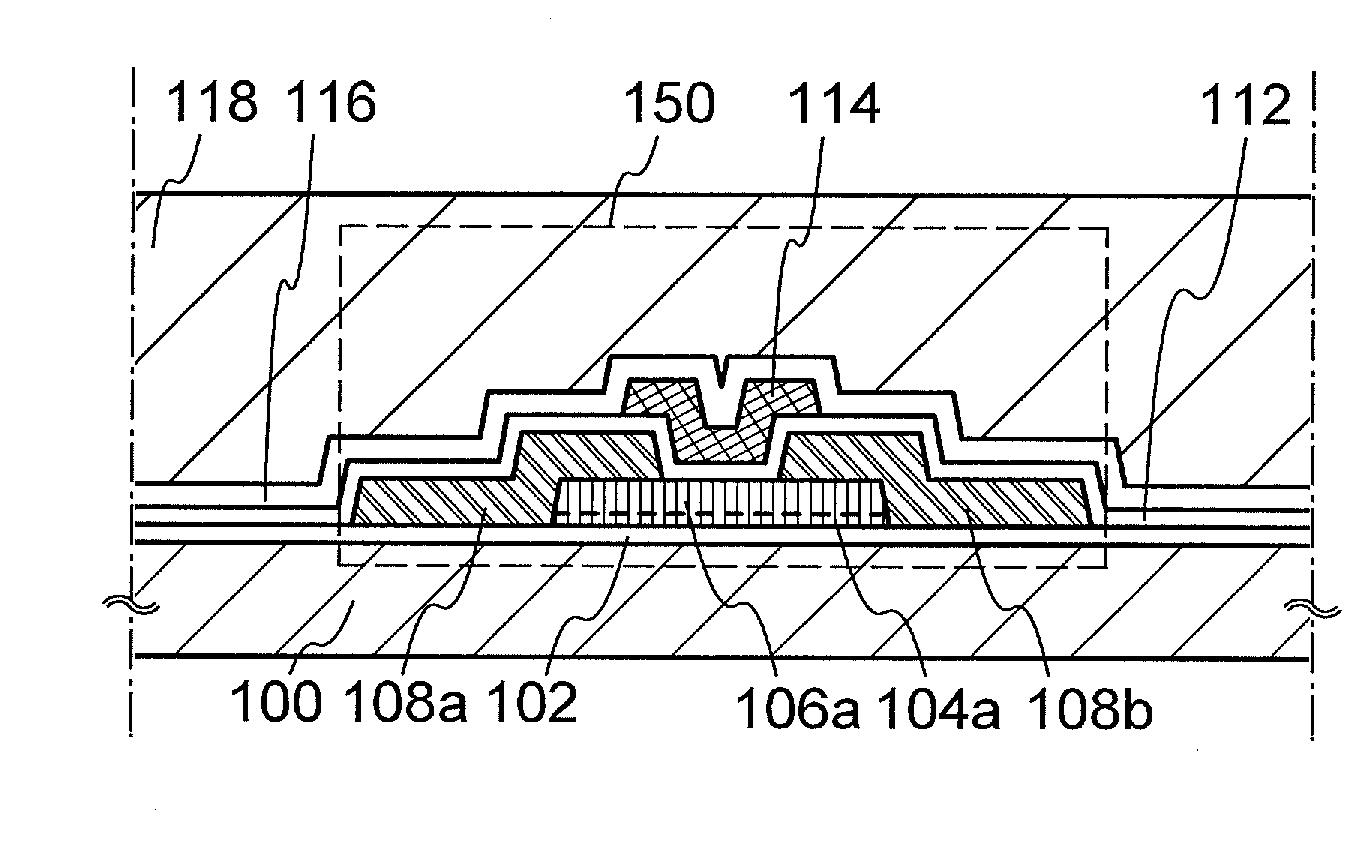

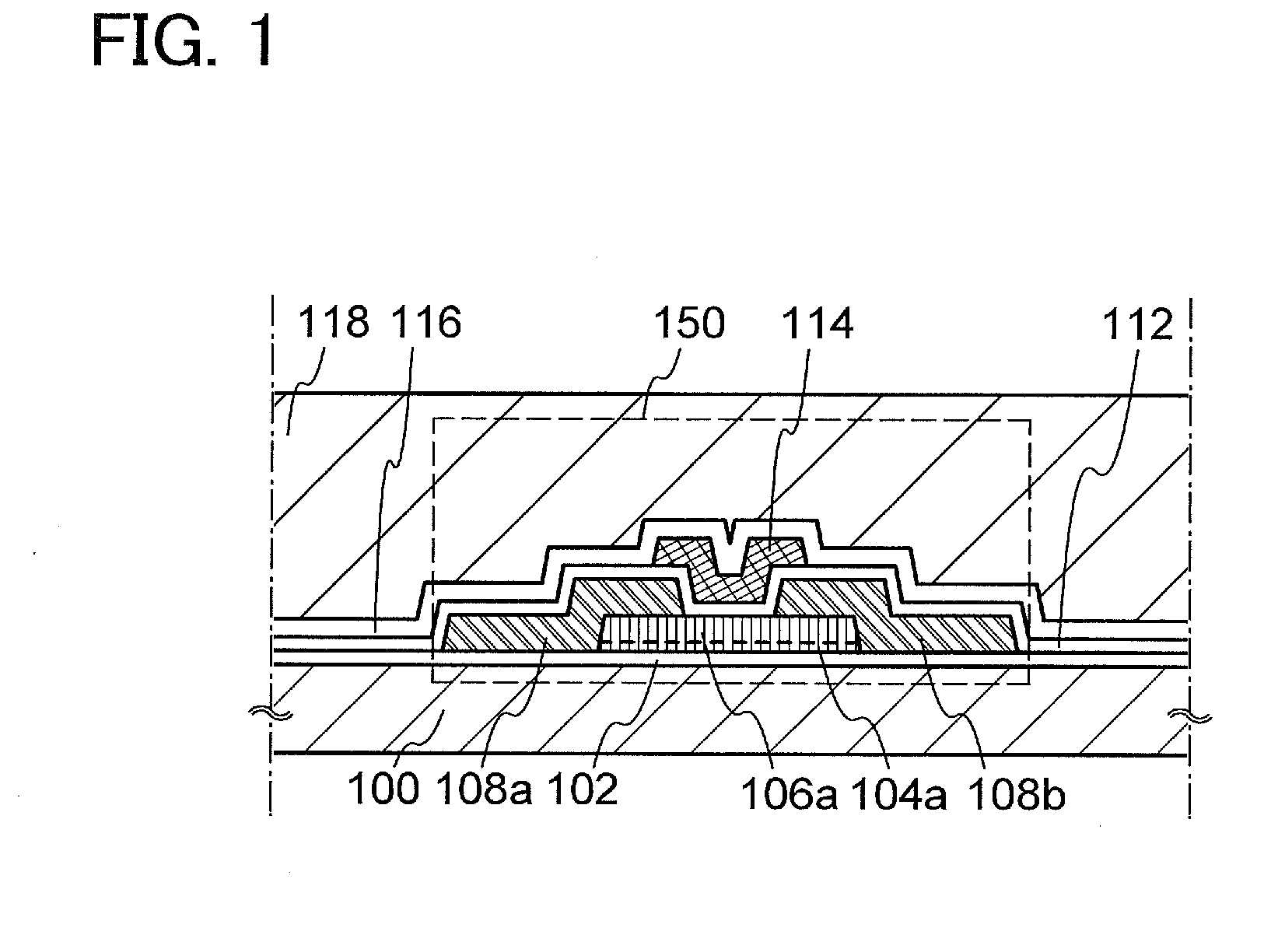

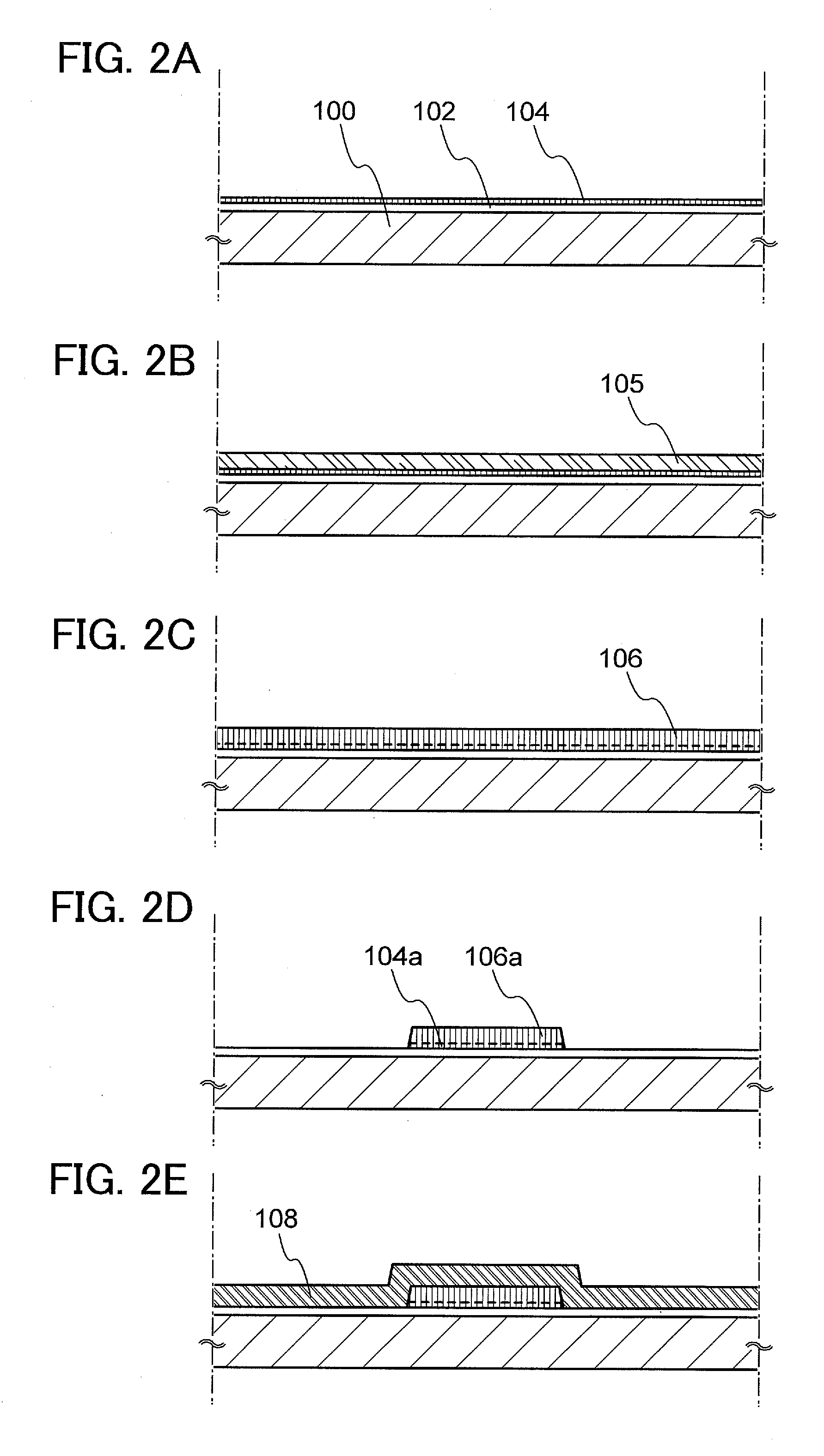

Semiconductor device and manufacturing method thereof

InactiveUS20110151618A1High field-effect mobilityLess variationSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor deviceOxide semiconductor

An oxide semiconductor layer with excellent crystallinity is formed to enable manufacture of transistors with excellent electrical characteristics for practical application of a large display device, a high-performance semiconductor device, etc. By first heat treatment, a first oxide semiconductor layer is crystallized. A second oxide semiconductor layer is formed over the first oxide semiconductor layer. By second heat treatment, an oxide semiconductor layer including a crystal region having the c-axis oriented substantially perpendicular to a surface is efficiently formed and oxygen vacancies are efficiently filled. An oxide insulating layer is formed over and in contact with the oxide semiconductor layer. By third heat treatment, oxygen is supplied again to the oxide semiconductor layer. A nitride insulating layer containing hydrogen is formed over the oxide insulating layer. By fourth heat treatment, hydrogen is supplied at least to an interface between the second oxide semiconductor layer and the oxide insulating layer.

Owner:SEMICON ENERGY LAB CO LTD

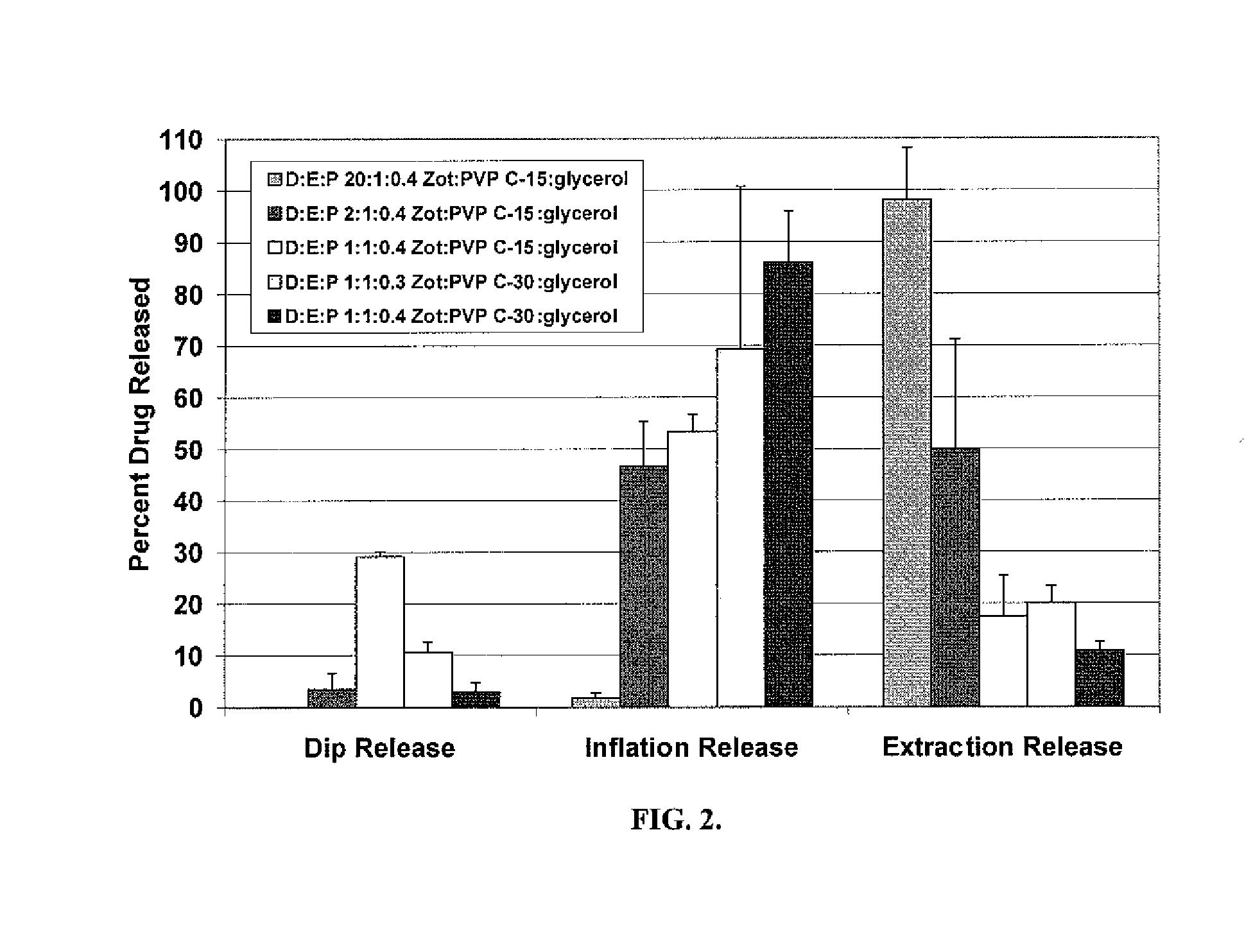

Coatings with tunable molecular architecture for drug-coated balloon

InactiveUS20110143014A1Low elastic modulusLow release rateStentsBalloon catheterDissolutionNuclear medicine

A drug delivery balloon is provided, the a balloon having an outer surface, and a tunable coating disposed on at least a length of the balloon surface. The tunable coating includes a first therapeutic agent and a first excipient, and can include a second therapeutic agent and a second excipient. The first and second therapeutic agents have different dissolution rates during balloon inflation and therefore provide a coating that is tunable.

Owner:ABBOTT CARDIOVASCULAR

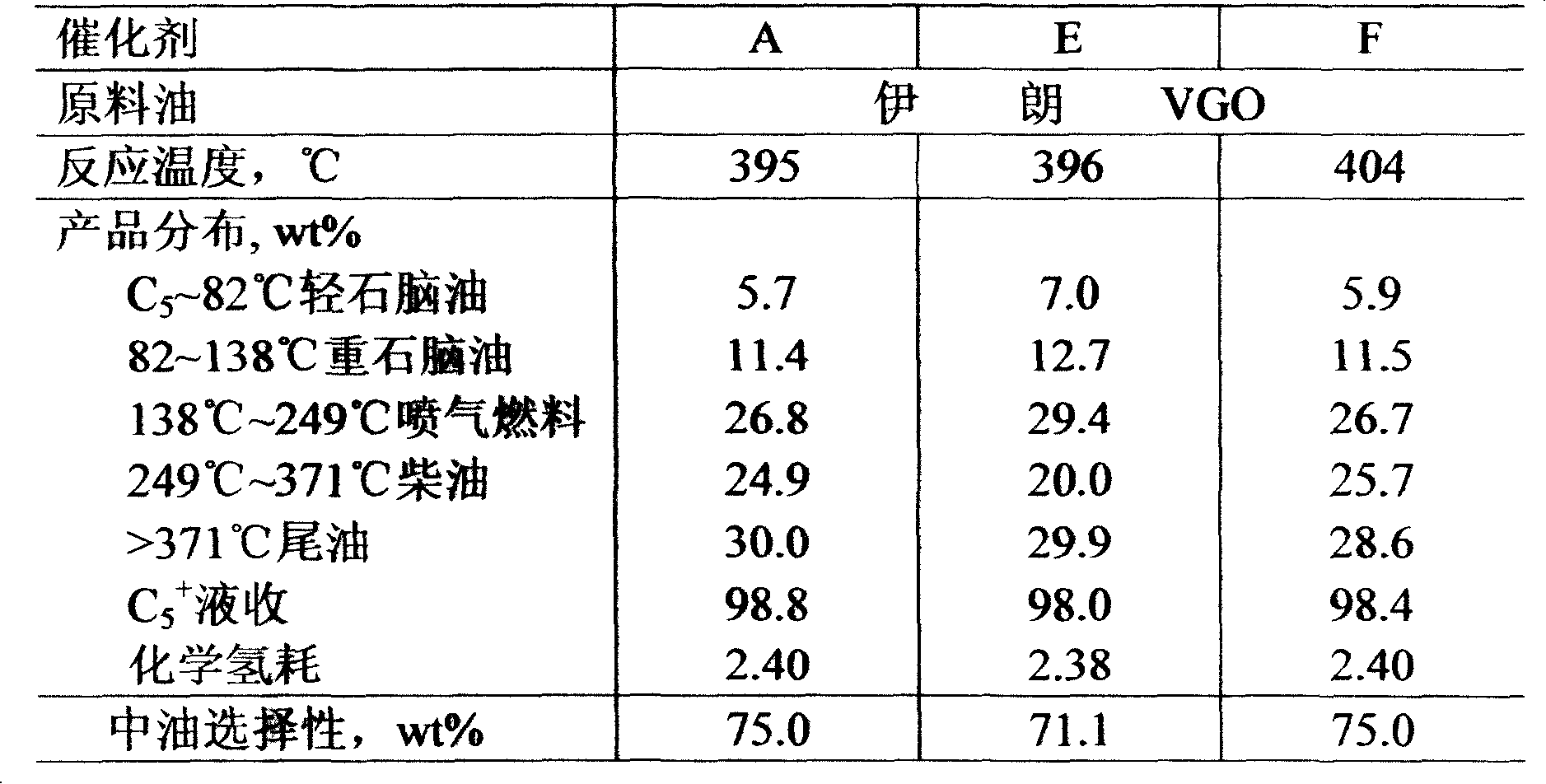

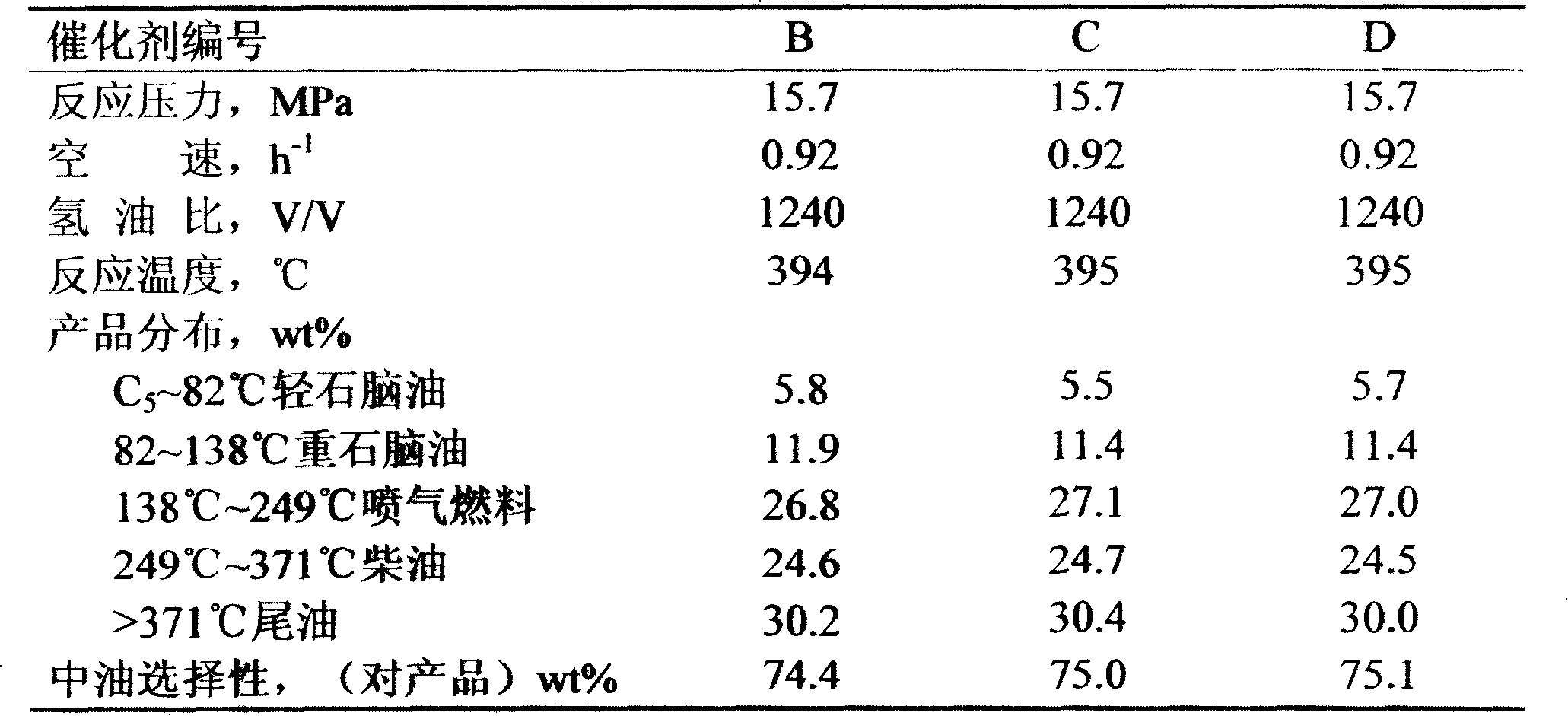

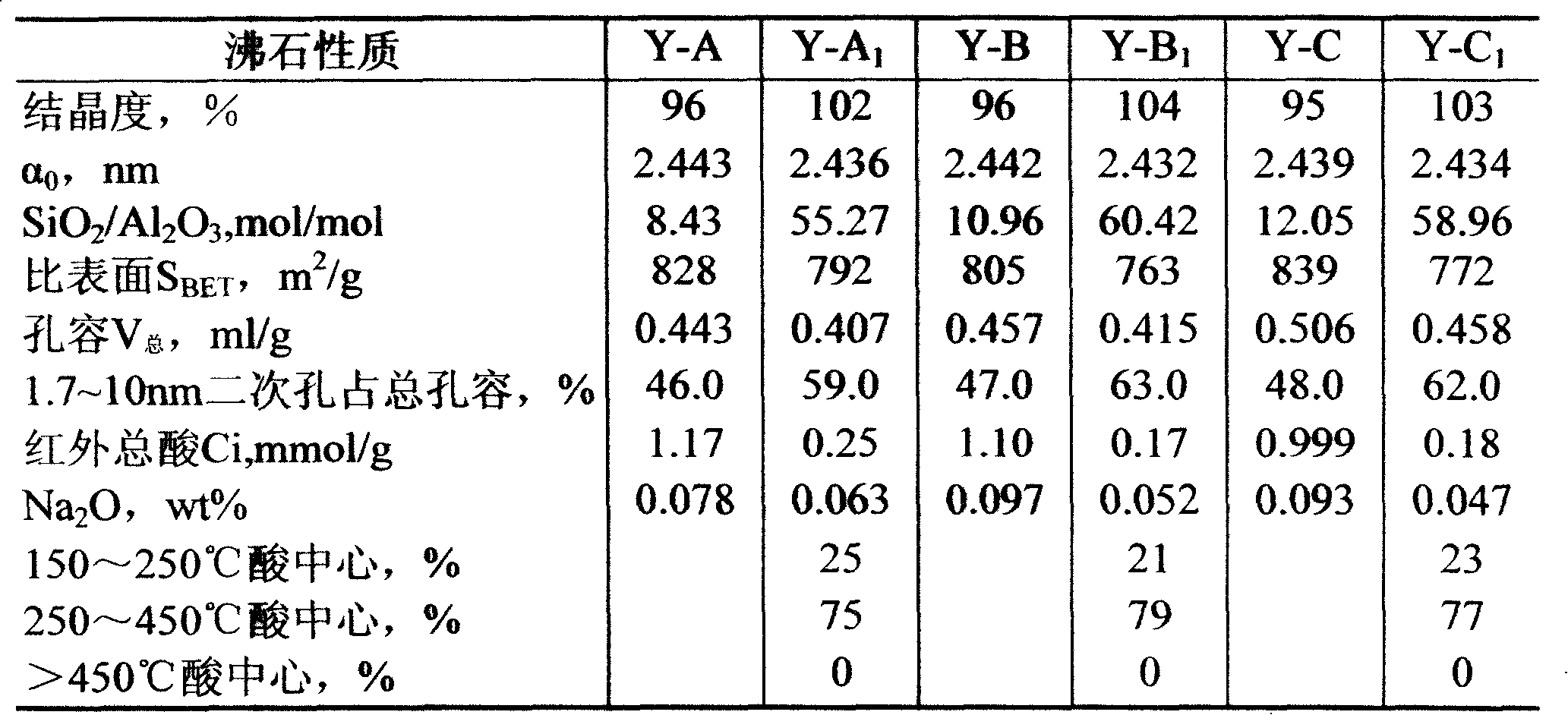

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

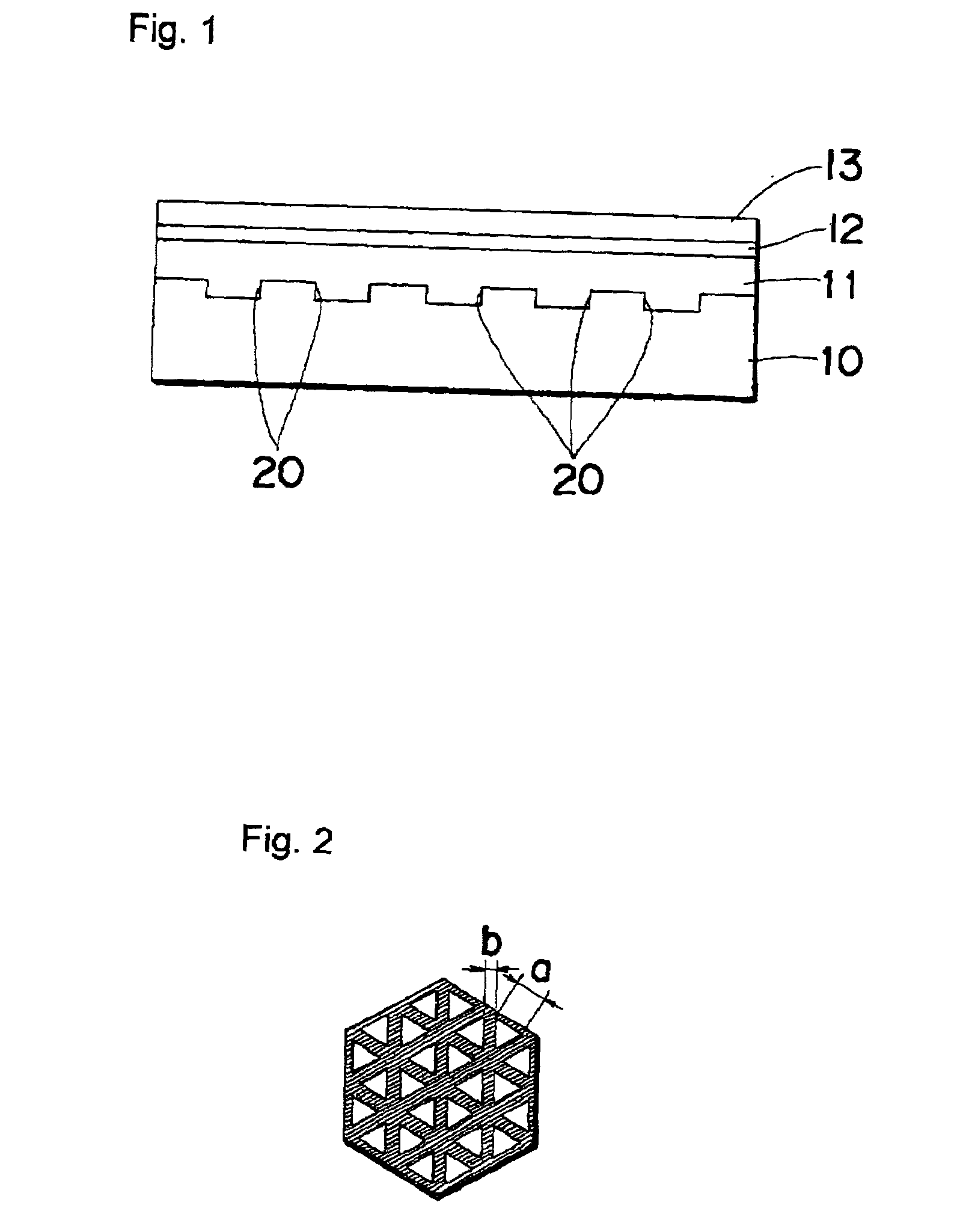

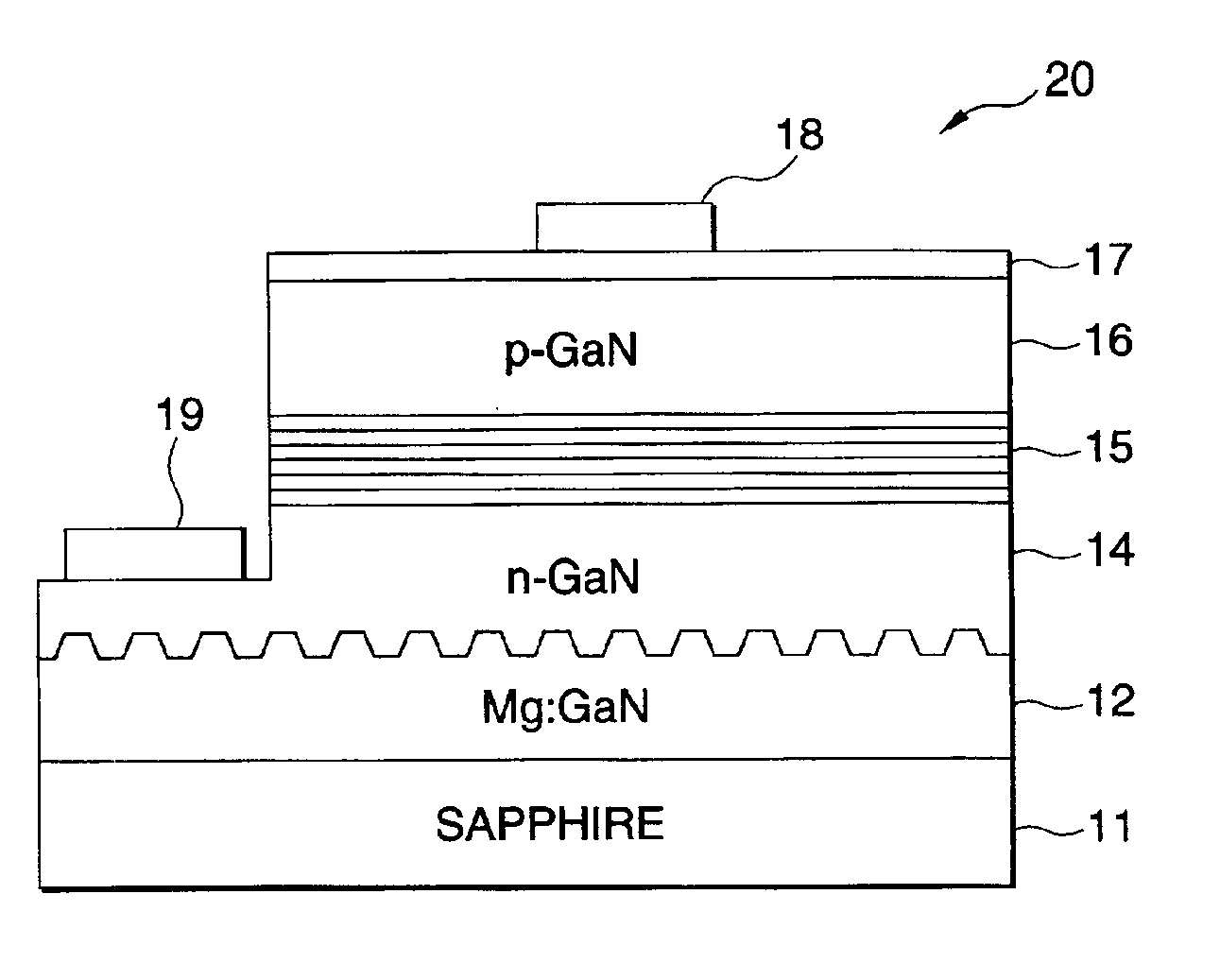

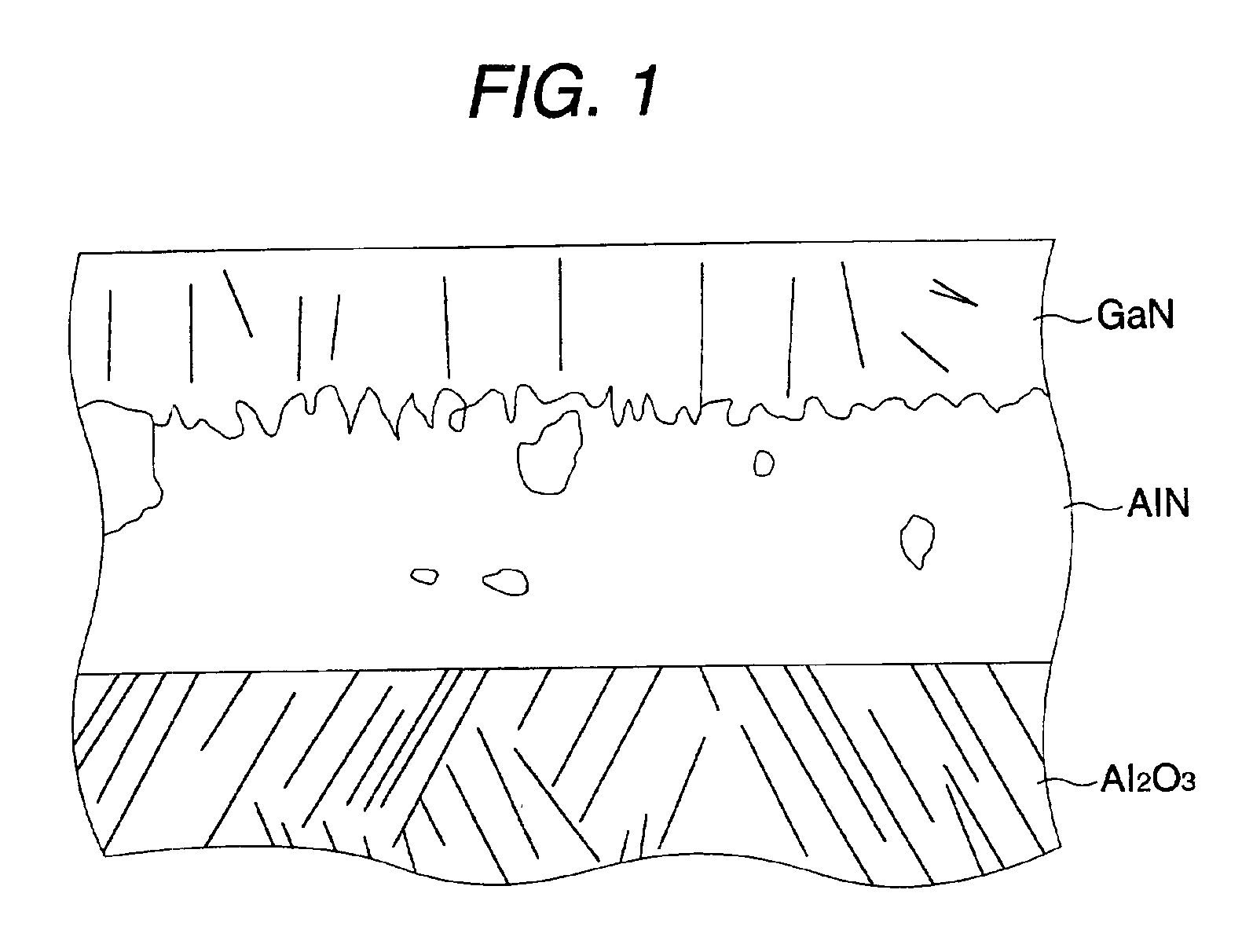

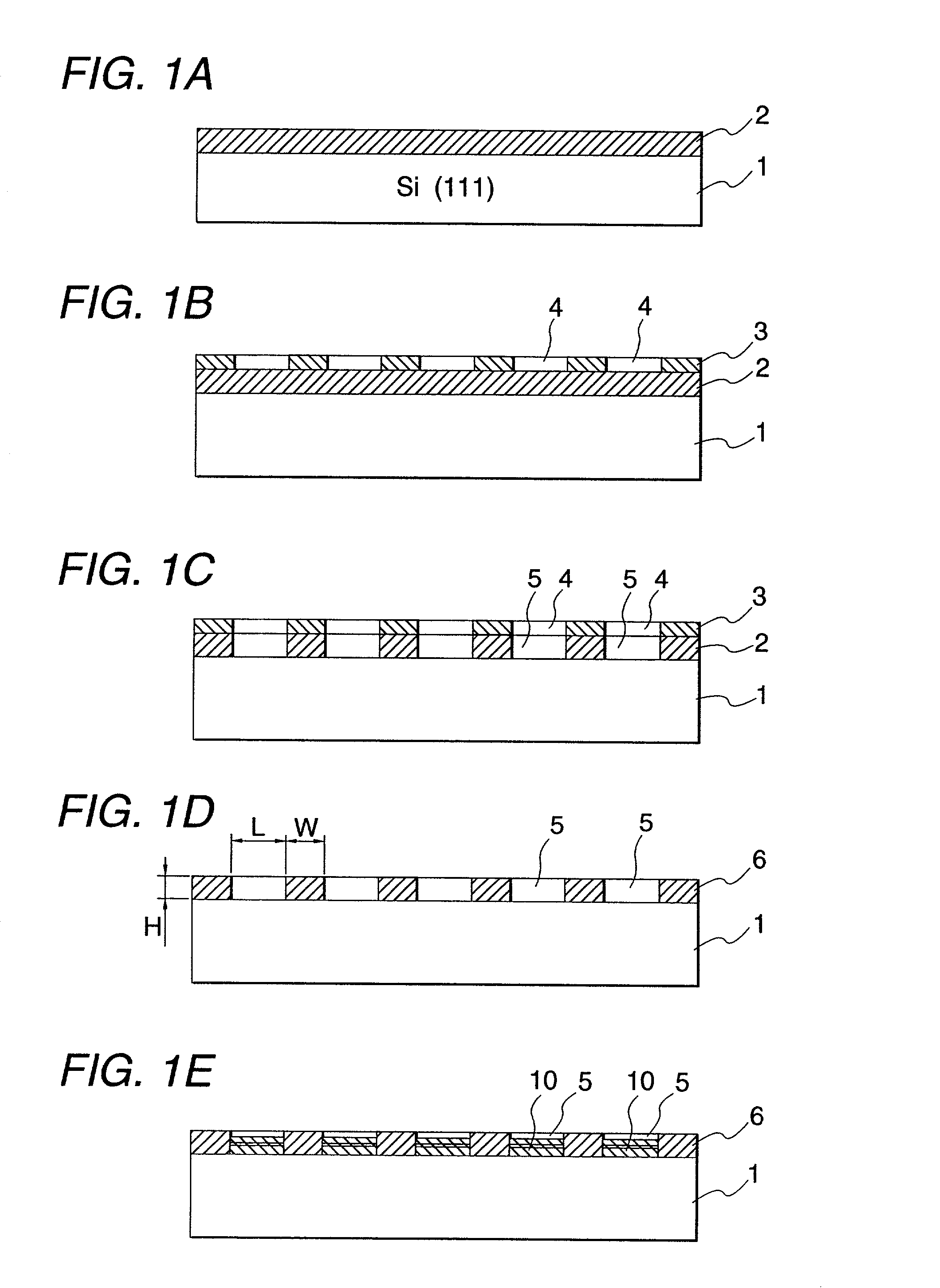

Group III nitride compound semiconductor device and method for producing the same

InactiveUS6841808B2Shorten production timeReduce laborSolid-state devicesSemiconductor/solid-state device manufacturingLateral overgrowthNitride

An AlN layer having a surface of a texture structure is formed on a sapphire substrate. Then, a growth suppressing material layer is formed on the AlN layer so that the AlN layer is partially exposed to the outside. Then, group III nitride compound semiconductor layers are grown on the AlN layer and on the growth suppressing material layer by execution of an epitaxial lateral overgrowth method. Thus, a group III nitride compound semiconductor device is produced. An undercoat layer having convex portions each shaped like a truncated hexagonal pyramid is formed on a substrate. Group III nitride compound semiconductor layers having a device function are laminated successively on the undercoat layer.

Owner:TOYODA GOSEI CO LTD

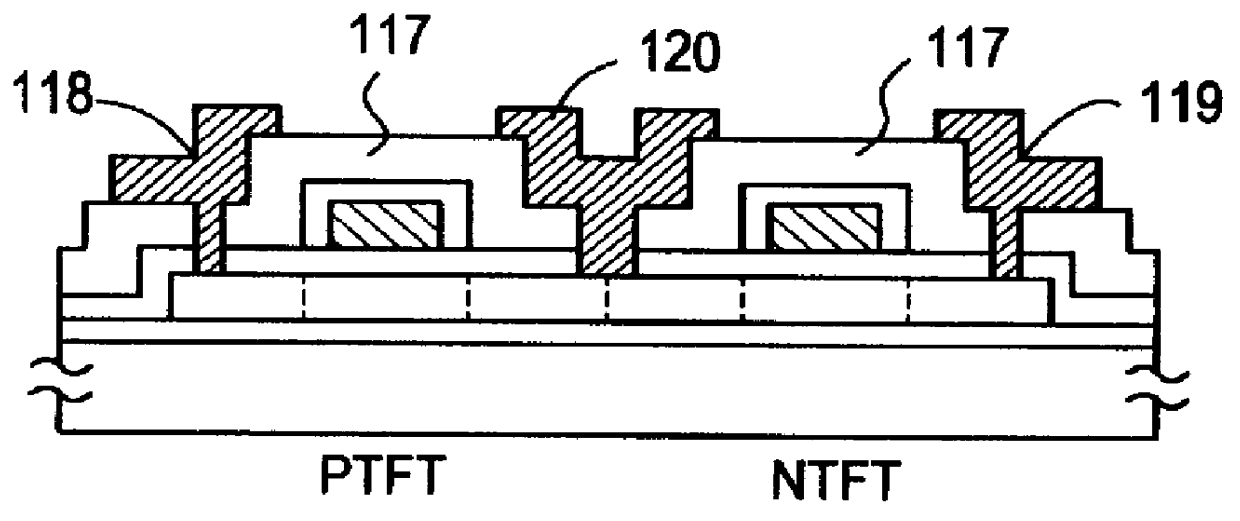

Process for fabricating semiconductor device

InactiveUS6051453AReduce the temperatureCrystal character can be improvedTransistorSolid-state devicesAmorphous siliconNear infrared radiation

A process for fabricating a semiconductor device comprising the step of, after patterning the silicon film crystallized to a low degree by thermally annealing an amorphous silicon film into an island by etching, irradiating an intense light of a visible light or a near infrared radiation to effect a short-period annealing (RTA) to the silicon film of low crystallinity. Thus, the crystallinity of the silicon film is improved and the silicon film is densified in a short-period.

Owner:SEMICON ENERGY LAB CO LTD

Preparation of multi-position doped lithium iron phosphate positive electrode material and application thereof

ActiveCN101339994AWide range of materialsIncrease base capacityElectrode manufacturing processesPhosphorus compoundsElectricityLithium iron phosphate

The invention discloses a preparation method of a multi-place doped lithium iron phosphate anode material and an application thereof, which belong to the technical field of the preparation of electrochemical power materials. The multi-place doped lithium iron phosphate anode material is expressed by the following formula: Li1-xAxFe1-yByP1-zCzO4Ddelta, wherein, at least two of x, y, x and delta can not be expressed zero at the same time. Multi-place doped anode material lithium iron phosphate powder which is used in a secondary lithium-ion battery and has good crystallization performance and even composition is prepared by adopting a solid phase method and a simple mixing and drying process; compared with the method doping in a certain crystal lattice place, the multi-place doped anode material lithium iron phosphate powder has wide doping material source, which can greatly improve the basic capacity and cycling electrical performance of matrix and is applied to a stable industrialized production and non-high-purity materials. The multi-place lithium iron phosphate of the invention is taken as the anode material and is usually used in the secondary lithium-ion battery and the secondary lithium-ion battery is taken as a power source.

Owner:甘肃大象能源科技有限公司

Electrochemical apparatus with barrier layer protected substrate

InactiveUS20080003496A1High crystallinityMore flexibleCell electrodesBattery isolationDiffusion barrierElectrochemistry

The present invention relates generally to fabricating well performing thin-film batteries onto metallic substrates, polymeric substrates, and doped and undoped silicon substrates. More specifically, the invention may include fabricating an appropriate diffusion barrier layer between the substrate and the battery part of the present invention that separates said two parts chemically during the entire battery fabrication process and the operation and storage conditions of the electrochemical apparatus during its entire lifetime. In one embodiment of the present invention, thin-film batteries fabricated onto a thin, flexible, stainless steel foil substrate using an appropriate diffusion layer show uncompromised electrochemical performance compared to thin-film batteries fabricated onto ceramic substrates when using a 700° C. post-deposition anneal process for the LiCoO2 positive cathode.

Owner:SAPURAST RES

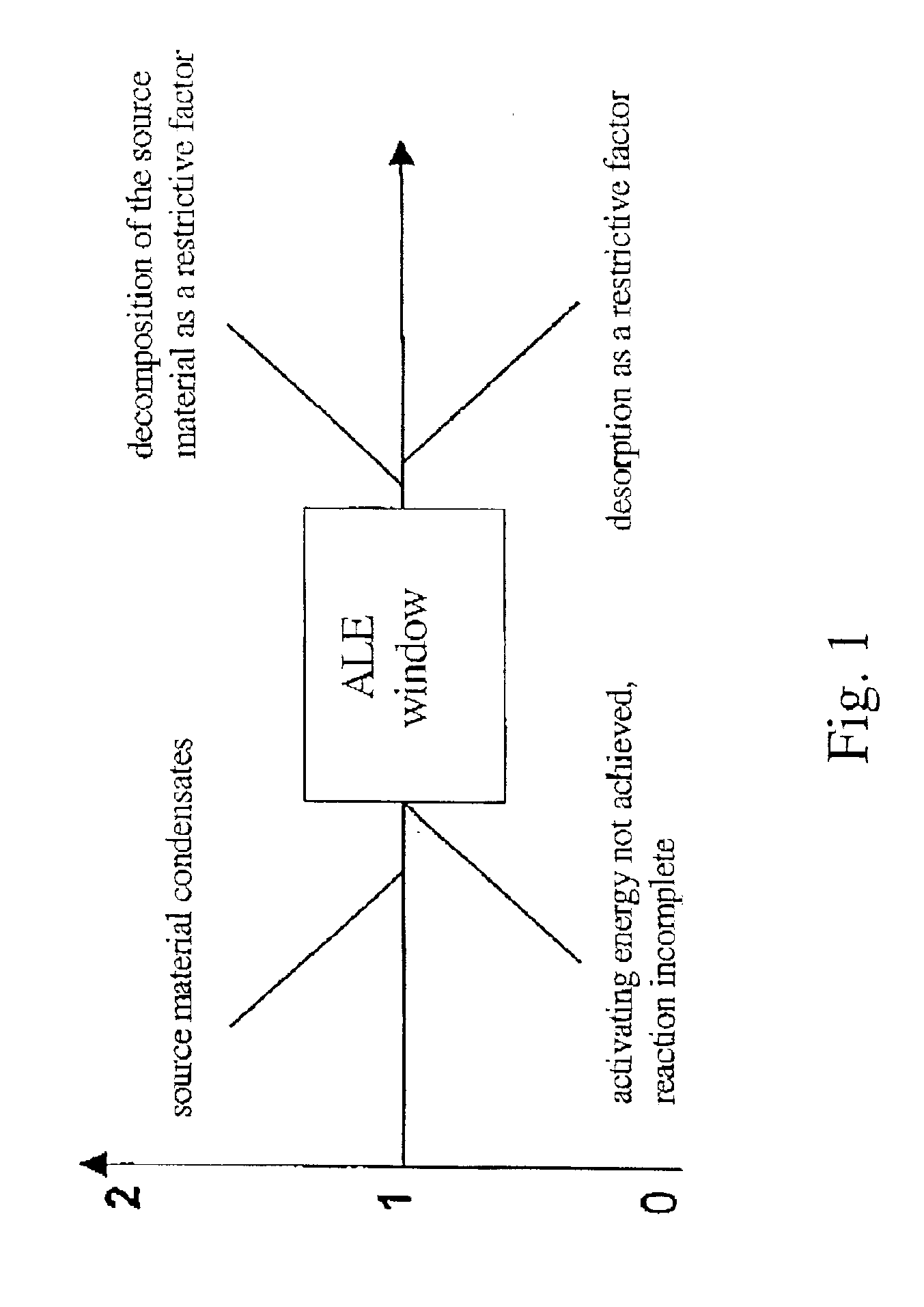

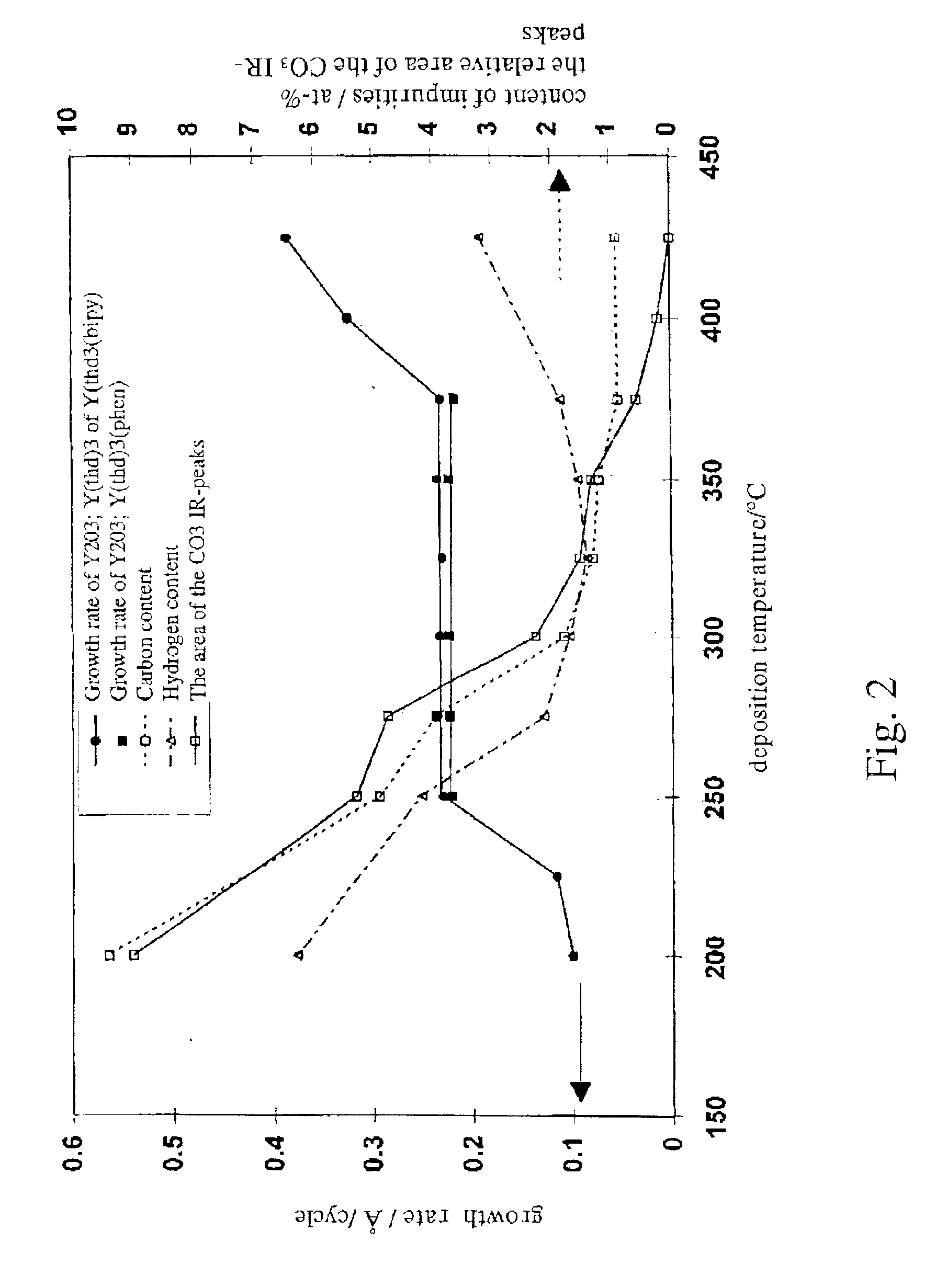

Method of depositing rare earth oxide thin films

InactiveUS6858546B2Increase probabilityIncrease ratingsPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureGadolinium

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds of rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

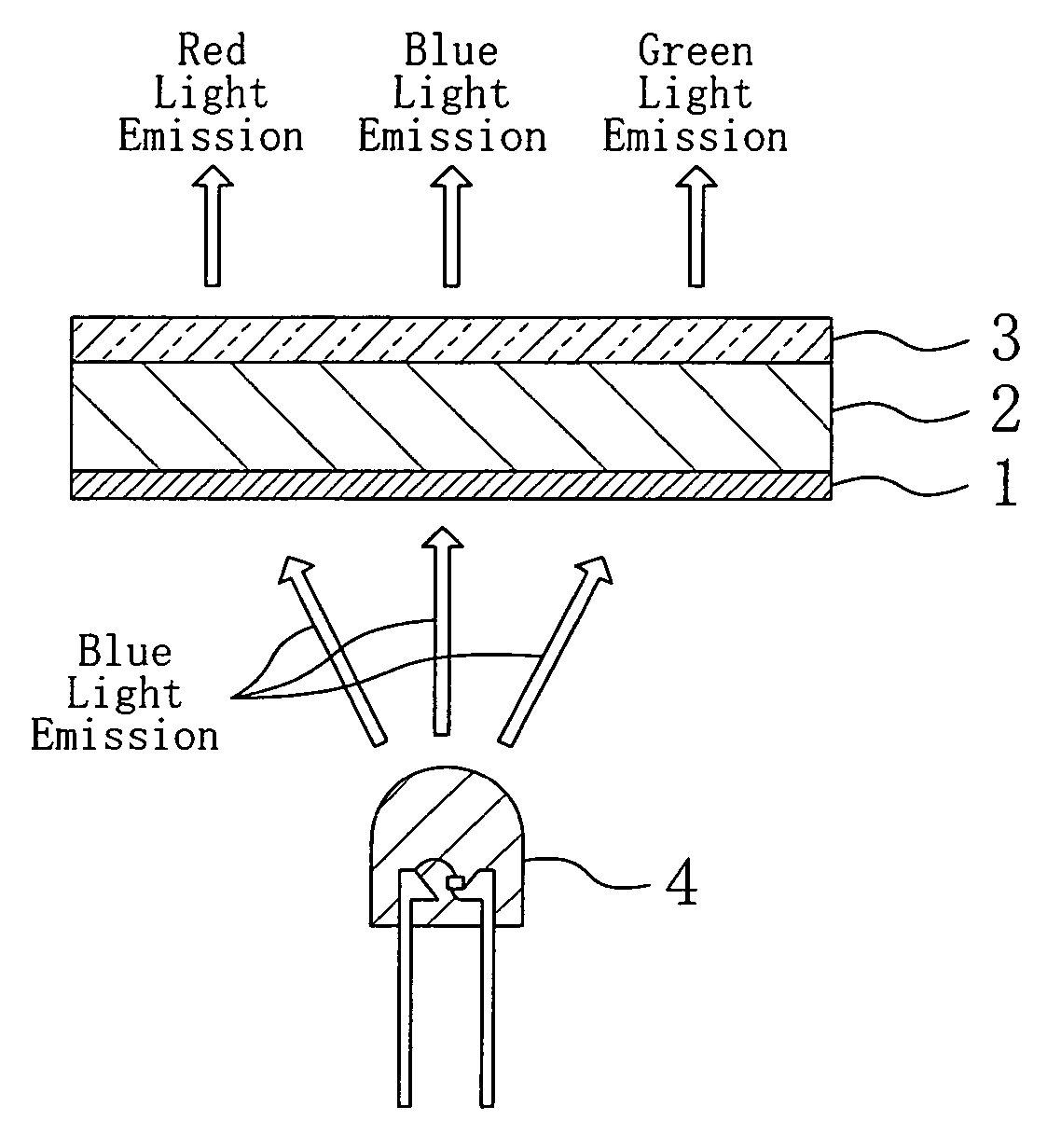

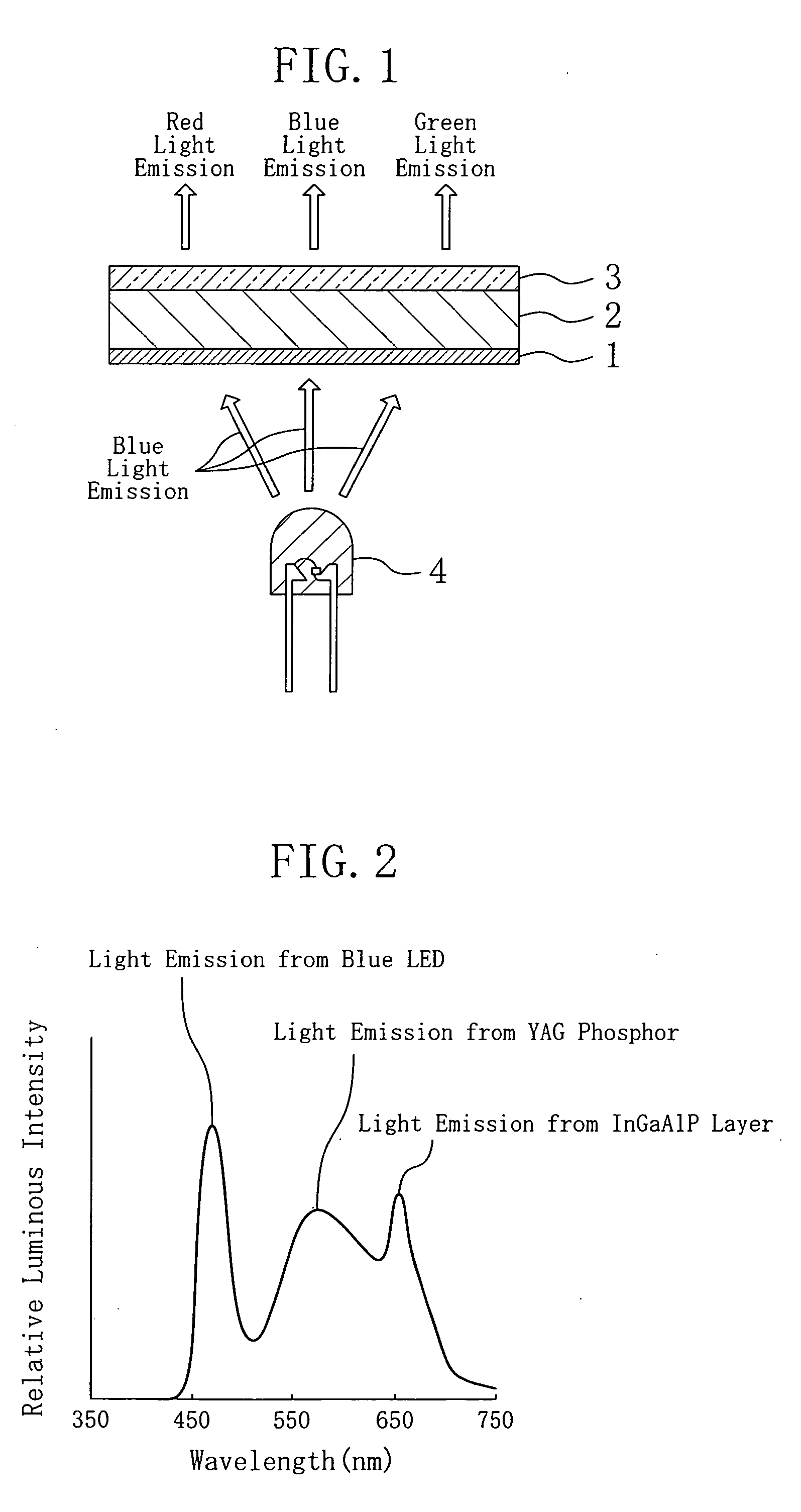

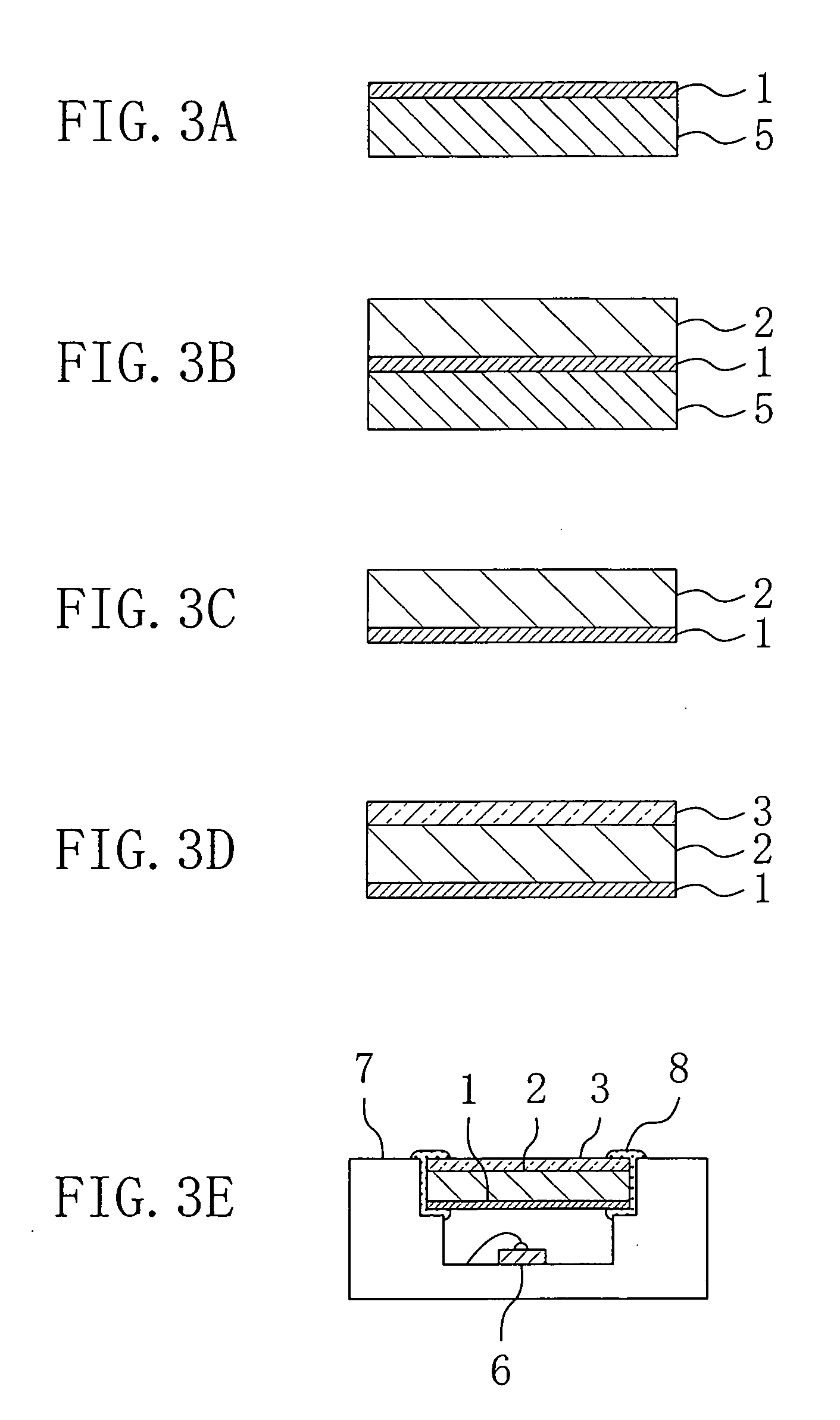

Phosphor, semiconductor light emitting device, and fabrication method thereof

ActiveUS20050051790A1High crystallinityIncrease brightnessSolid-state devicesBulk negative resistance effect devicesPhosphorUltraviolet lights

A phosphor that emits white light due to excitation by a light emitting diode capable of emitting blue or ultraviolet light includes: a substrate that allows transmission of visible light; and a semiconductor layer formed on the substrate.

Owner:PANASONIC CORP

Amorphous silica-alumina, a carrier combination and a hydrocracking catalyst containing the same, and processes for the preparation thereof

InactiveUS6399530B1Increase surface areaLarge hole volumeMolecular sieve catalystsHydrocarbon oil crackingSilicon dioxideHigh activity

An acidic amorphous silica-amumina has a large specific surface area and a large pore volume. A carrier complex and a hydrotreating catalyst containing acidic amorphous silica-alumina, in particular a hydrocracking catalyst containing acidic amorphous silica-alumina in combination with a modified zeolite-Y, treats petroleum hydrocarbon materials to produce middle distillates. The amorphous silica-alumina has a SiO2 content of 10-50 wt. %, a specific surface area of 300-600 m2 / g, a pore volume of 0.8-1.5 ml / g and an IR acidity of 0.25-0.60 mmol / g. The catalyst shows a relatively high activity and mid-distillate selectivity and can be particularly used in hydrocracking process for producing mid-distillates with a higher yield.

Owner:CHINA PETROCHEMICAL CORP +1

Group III nitride compound semiconductor device and method for producing the same

InactiveUS6982435B2Substrate surface efficientlyEfficiently formedLaser detailsSolid-state devicesNitrideSubstrate surface

A group III nitride compound semiconductor device is produced according to the following manner. A separation layer made of a material which prevents group III nitride compound semiconductors from being grown thereon is formed on a substrate. Group III nitride compound semiconductors is grown on a surface of the substrate uncovered with the separation layer while keeping the uncovered substrate surface separated by the separation layer.

Owner:TOYODA GOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com