Patents

Literature

1081results about How to "Large hole volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver-containing, sol/gel derived bioglass compositions

Silver-containing, sol-gel derived bioactive glass compositions and methods of preparation and use thereof are disclosed. The compositions can be in the form of particles, fibers and / or coatings, among other possible forms, and can be used, for example, for treating wounds, improving the success of skin grafts, reducing the inflammatory response and providing anti-bacterial treatments to a patient in need thereof. Anti-bacterial properties can be imparted to implanted materials, such as prosthetic implants, sutures, stents, screws, plates, tubes, and the like, by incorporating the compositions into or onto the implanted materials. The compositions can also be used to prepare devices used for in vitro and ex vivo cell culture.

Owner:IMPERIAL INNOVATIONS LTD

Porous metal organic framework material based on transition metal cobalt and preparation method thereof

InactiveCN102962036AGood application effectIncrease surface areaOther chemical processesGaseous fuelsMetal-organic frameworkCobalt

The invention relates to a porous metal organic framework material based on transition metal cobalt and a preparation method thereof. The metal organic framework material is a compound with supramolecular porous network structure and formed by self-assembly of metal ions and organic ligands through coordination complexation. The porous cobalt-based metal organic framework material contains one or more metal ions, and one or more organic ligands; and at least one of the metal ions is Co (II). The porous cobalt-based organic framework material has excellent selective adsorption on CH4 in a separation process of CH4 and N2; and the advantage of adsorption selectivity on CH4 is particularly evident under low pressure. The material is particularly suitable for development and recovery of oil field gas, coal bed methane and biogas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of low-temperature selective catalytic reduction (SCR) catalyst by removing NOx from flue gas

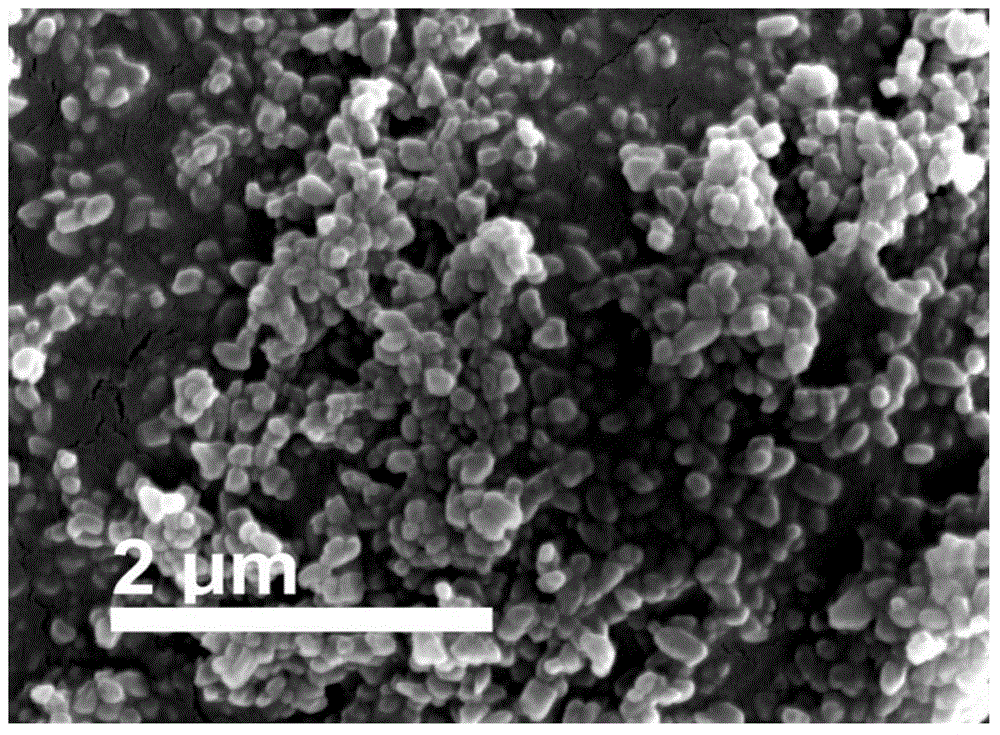

ActiveCN102008956AIncrease the areaLarge hole volumeNitrous oxide captureDispersed particle separationComposite oxideCoprecipitation

The invention provides a preparation method of a selective catalytic reduction (SCR) catalyst Mn-Ce-M / TiO2 by removing NOx from flue gas, wherein M represents one or more of composite oxides, namely Fe, Co, Cu, Cr, Zr and Al, the molar ratio of the elements is Ti: Mn: Ce: M =1:(0.005-1):(0.005-1):(0-1). In the invention, an improved coprecipitation method is adopted, and an intermediate compound, namely titanium nitrate Ti(NO3)4 is taken as a precursor of TiO2, thus the influence of the other impurities in the precipitation process is overcome; by changing the dispersing homogeneous degree of MnOx and CeO2 on the surface of a carrier TiO2, the activity of the catalyst is improved and the temperature of the SCR reaction is reduced; by adjusting the preparation condition of the TiO2 precursor, the sulfur resistance and water resistance of the catalyst are improved completely; and by adding the elements, such as Fe, Co, Cu, Cr, Zr and Al and the like, the activity and resistance of the catalyst are further modified.

Owner:GUODIAN SCI & TECH RES INST +1

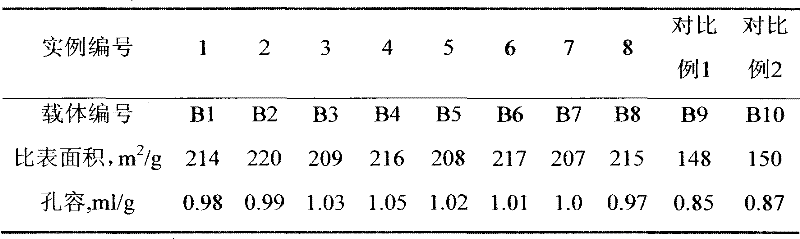

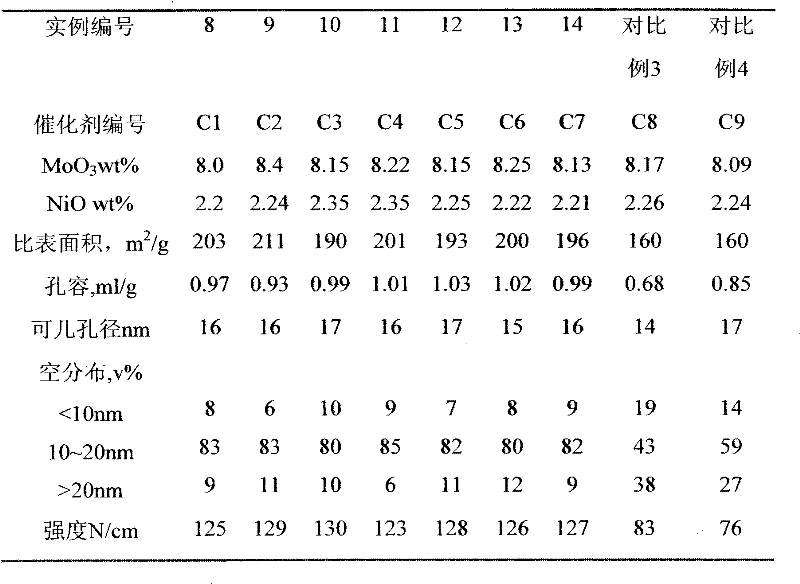

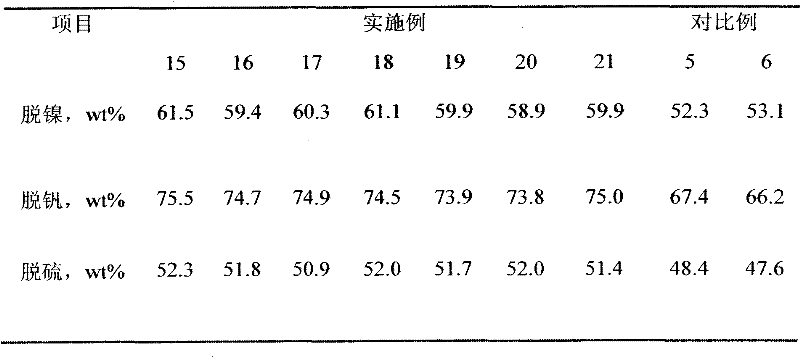

Preparation methods for macroporous alumina carrier and hydrodemetallization catalyst

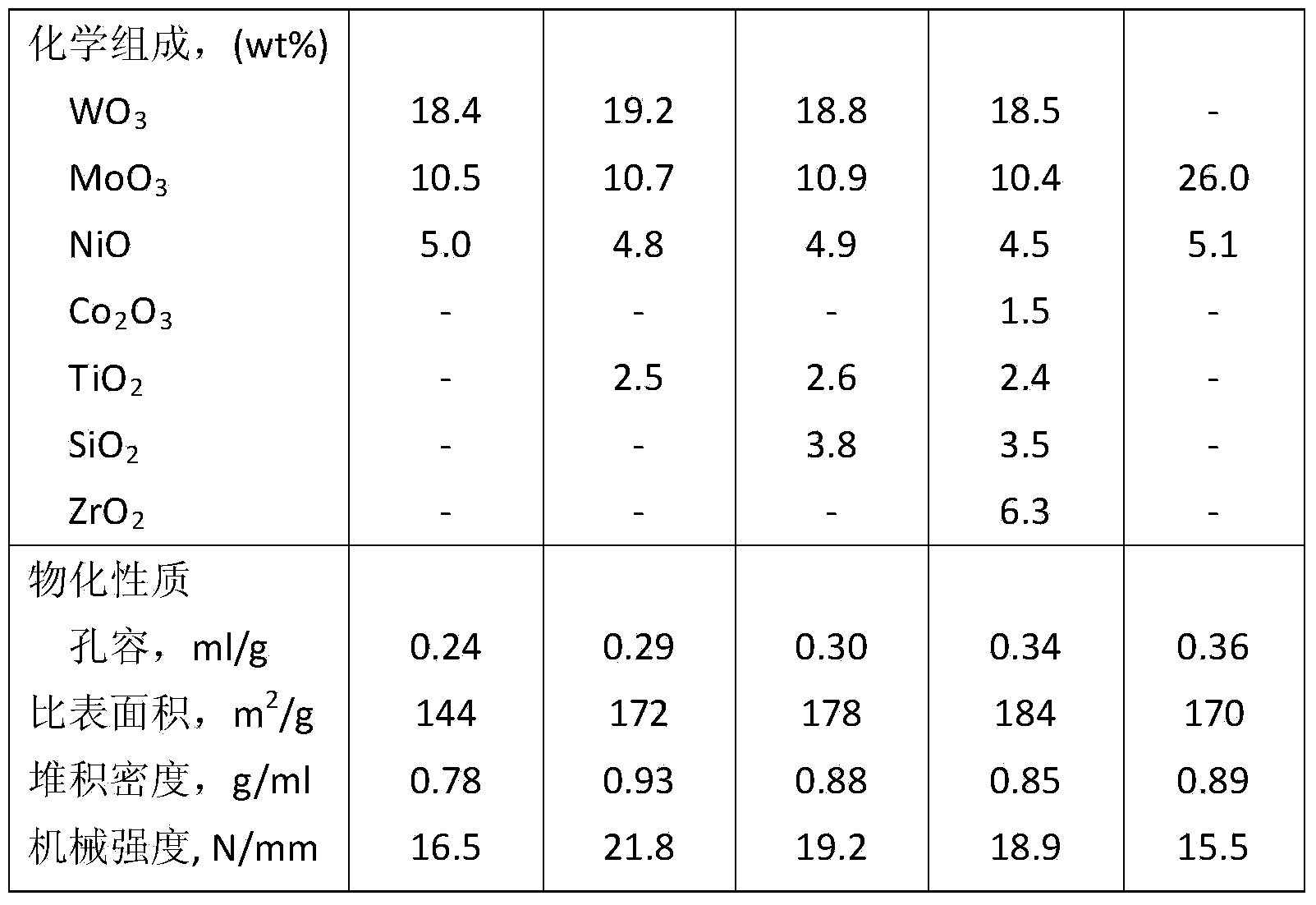

ActiveCN102441437AModerate mechanical strengthModerate bulk densityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteMetal catalyst

The invention discloses preparation methods for a macroporous alumina carrier and a hydrodemetallization catalyst. The preparation method for the macroporous alumina carrier includes the following steps: (1) dry pseudoboehmite gel powder is hydrothermally processed under high pressure; (2) the dry pseudoboehmite gel powder obtained in step 1 is kneaded into a plastic, and pore-expanding agent is added in step 1 or step 2; (3) the plastic obtained in step 2 is shaped, the shaped material is dried and baked, and thereby the macroporous alumina carrier is obtained. The impregnation method is adopted to prepare the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared by the method has large pore volume and pore diameter, centrally distributed pores, moderate mechanical strength and high activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

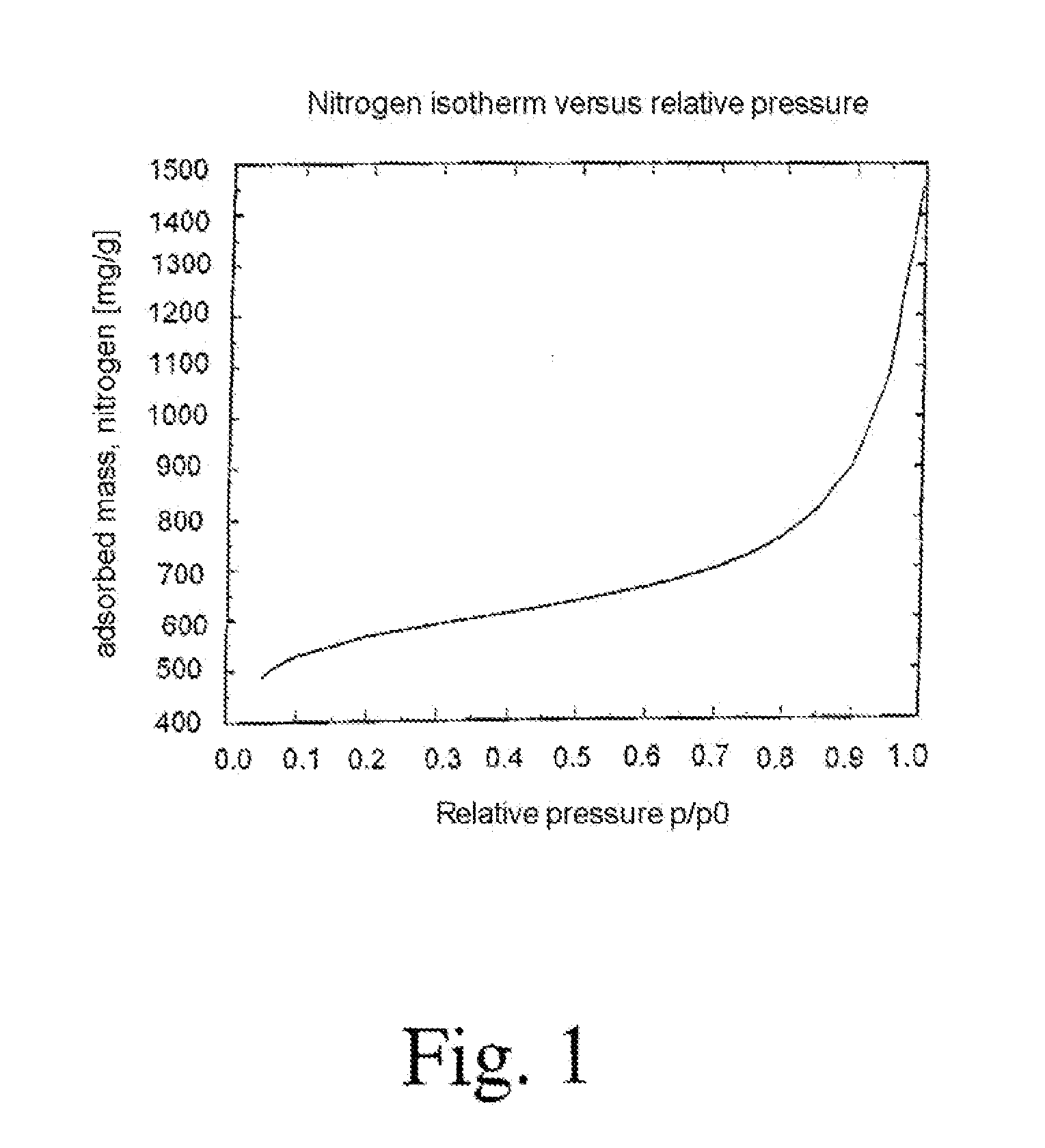

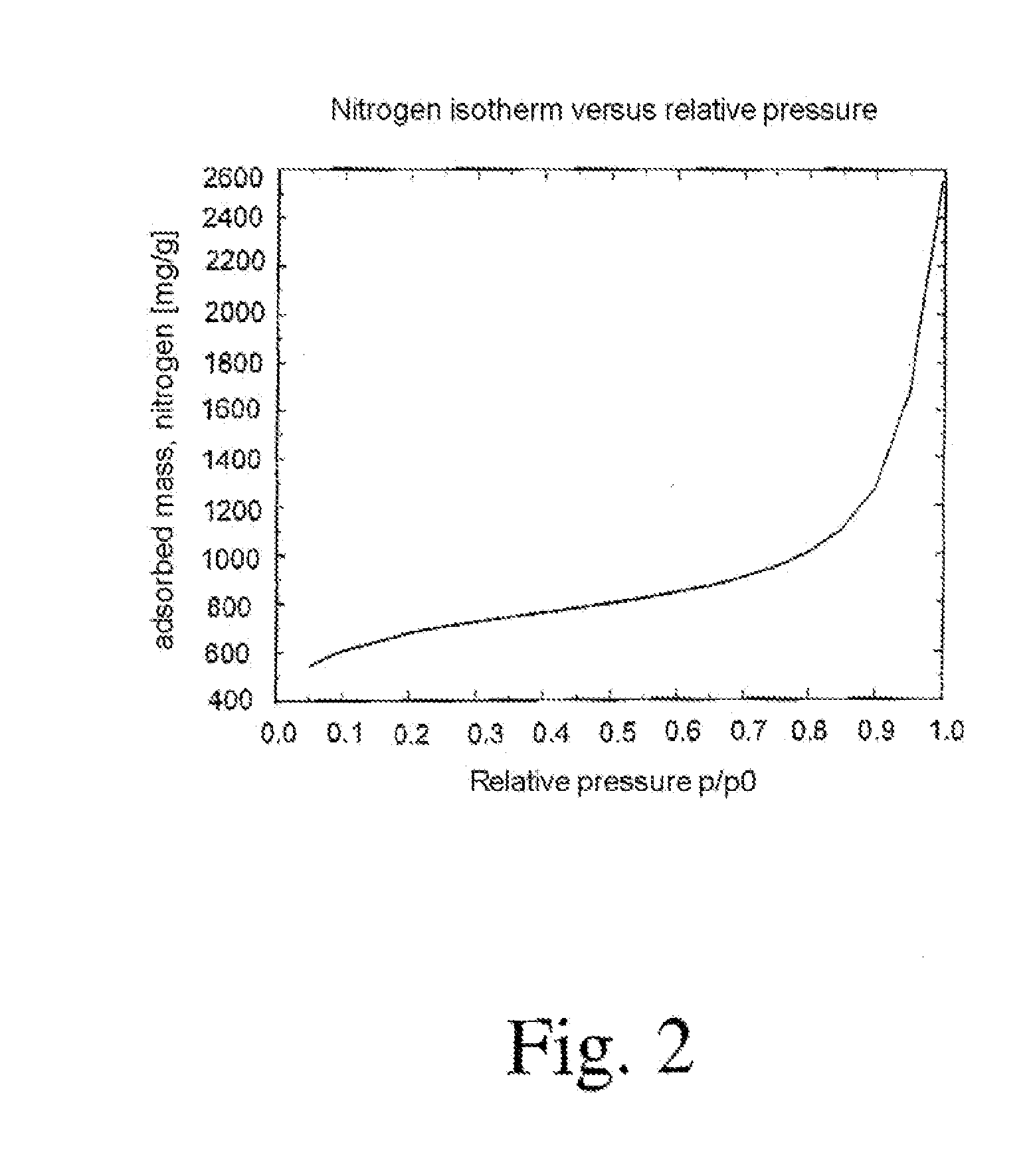

High-performance adsorbents based on activated carbon having high meso- and macropososity

InactiveUS20120172216A1High porosityLarge hole volumeChemical protectionHeat protectionActivated carbonSorbent

The invention concerns high-performance adsorbents based on activated carbon of high meso- and macroporosity which are present in the form of discrete grains of activated carbon, whereinat least 55% of the total pore volume of the high-performance adsorbents are formed by pores (i.e. meso- and macropores) having pore diameters of more than 20 Å,the high-performance adsorbents have a measure of central tendency pore diameter of more than 25 Å, andthe high-performance adsorbents have a BET surface area of at least 1250 m2 / g.These high-performance adsorbents are obtainable by a novel process comprising specific two-stage activation, and have, in addition to the aforementioned properties, an excellent abrasion and bursting resistance, so that they are useful for a multiplicity of different applications.

Owner:BLUCHER GMBH

Preparation method of double-hole-structure alumina supporter

ActiveCN102861617ALarge hole volumeNo overheating phenomenonCatalyst carriersMaterials scienceAmmonium bicarbonate

The invention discloses a preparation method of a double-hole-structure alumina supporter. The preparation method comprises the steps of weighing a certain quantity of pseudo-boehmite dry glue powders, evenly mixing the pseudo-boehmite dry glue powder with a certain quantity of peptizing agent and extrusion-auxiliary agent, then adding a certain quantity of ammonium bicarbonate aqueous solution in materials, mixing and nipping obtained materials into a plasticizer, squeezing into stripes and molding, placing molded materials in a sealing container, and roasting to prepare the alumina supporter after hydro-thermal treatment. The temperature of the hydro-thermal treatment is 70-120 DEG C, and the treatment time is 5-10 hours. Roasting is carried out at the temperature of 600-750 DEG C for 2-4 hours. The mass concentration of an ammonium bicarbonate solution is 40%-80%, the adding quantity of the ammonium bicarbonate solution is calculated according to NH<4+> and Al<3+>, and a molar ratio of the NH<4+> to Al<3+> is (0.5-1):1. According to the preparation method, the preparation procedure is simple, the prepared alumina supporter is in double-hole distribution and has good mechanical strength, and the preparation method is suitable to the field of preparation of heavy oil and residual oil hydrodemetallization catalysts and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

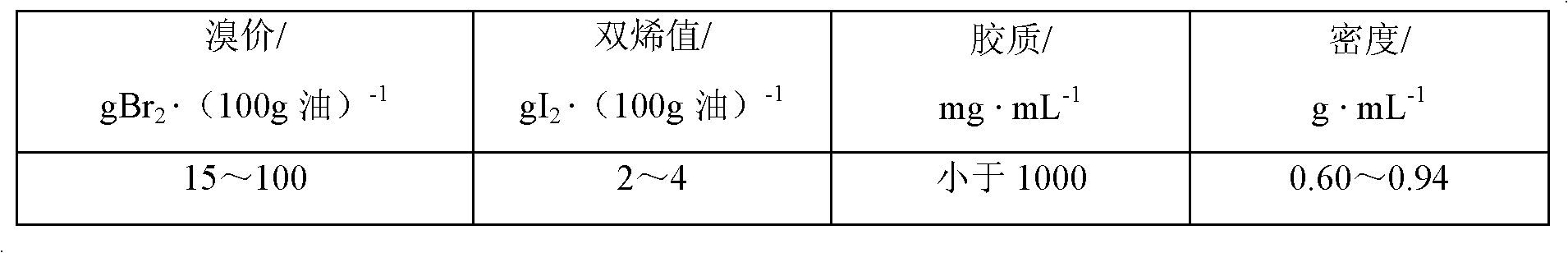

Hydrogenation catalyst, its process and use

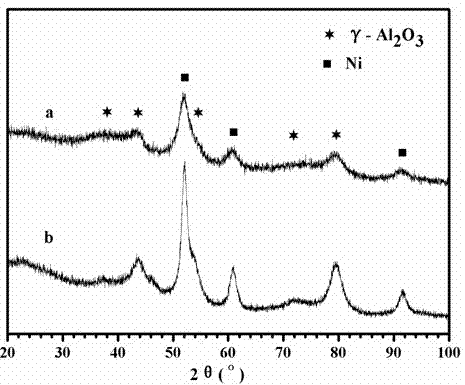

ActiveCN1644656AIncrease surface areaLarge hole volumeRefining by selective hydrogenationAluminium hydroxideNickel compounds

A hydrogenation catalyst and its preparation and use are disclosed. The said catalyst consists of NiO 10-30wt.% and Al2O3 70-90wt.%, obtained by: drying quasi-hydrated aluminum oxide powder, passing steam to ream, roasting to have macroporous aluminum oxide carrier, dipping it in a solvent containing nickel compound, filtering, drying, roasting to form the final product. It is suitable for fractional oil containing dialkene and styrene and their derivatives to directly prepare solvent with high aromatic hydrocarbon and gasoline with high octane level by hydrogenation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

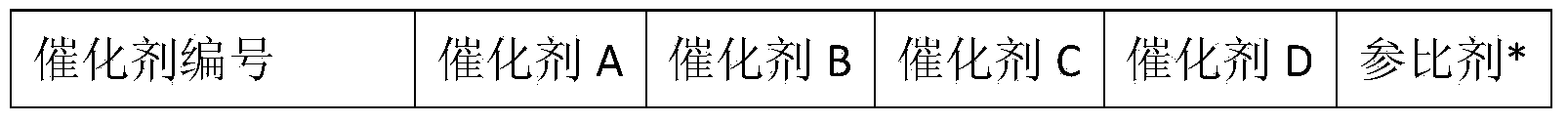

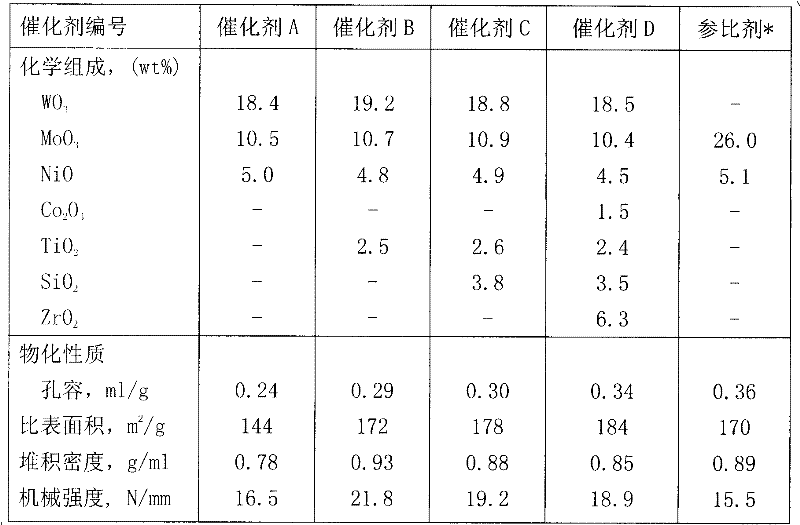

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

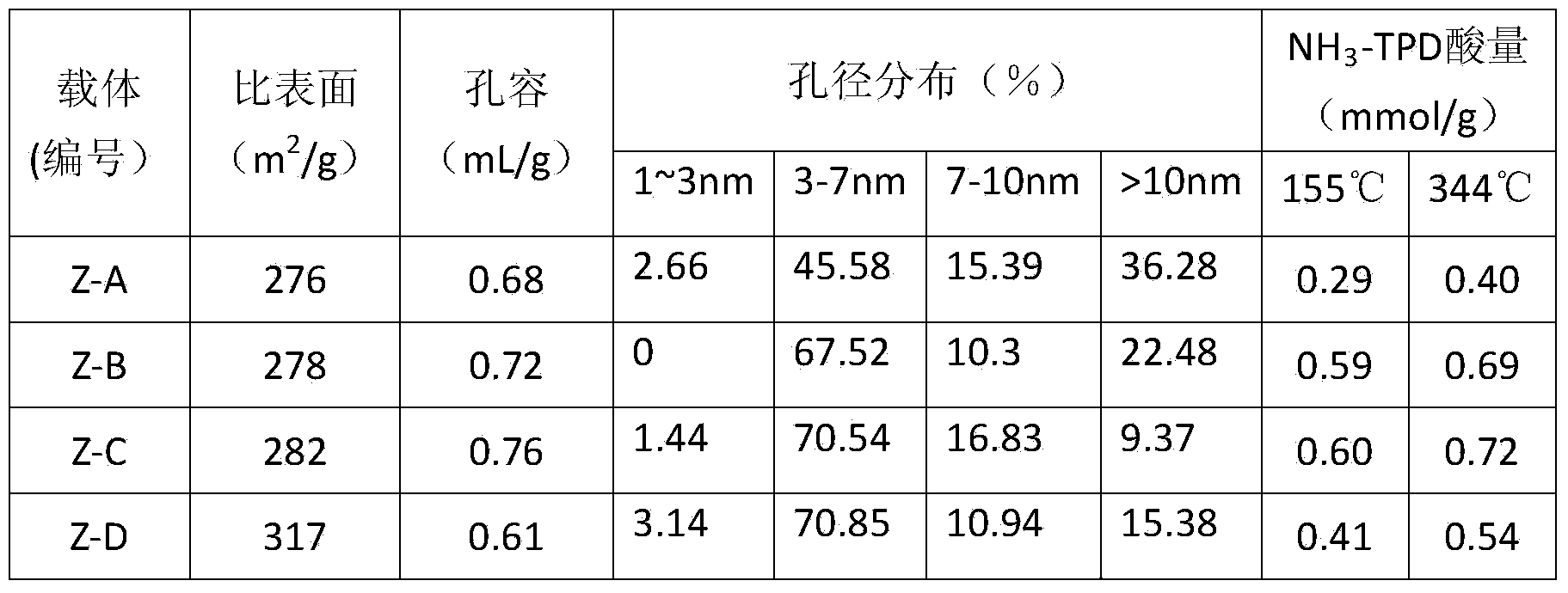

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for preparing hydro-demetalization catalyst for heavy oil

ActiveCN102441368AConcentrated hole distributionControl product propertiesCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPore distributionChemistry

The invention discloses a method for preparing a hydro-demetalization catalyst for heavy oil. The method comprises the following steps of: firstly, preparing an alumina carrier, then, loading active metal components by using an immersion method, and obtaining the final hydro-demetalization catalyst after drying and roasting, wherein the process for preparing the alumina carrier comprises the following steps of: (1) evenly mixing pseudoboehmite dry colloidal powder with an extrusion aid, and then, adding an aqueous solution in which a physical pore-expanding agent and a chemical pore-expandingagent are dissolved, wherein the physical pore-expanding agent is a carbohydrate, and the chemical pore-expanding agent is phosphoric acid, phosphate or borate; (2) evenly mixing the materials prepared in the step (1), and then, forming; and (3) drying and roasting the materials prepared in the step (2) so as to prepare the alumina carrier. The hydro-demetalization catalyst for the heavy oil, prepared by the method disclosed by the invention, has the advantages of larger pore volume, larger pore diameter, concentrated pore distribution, good mechanical strength, and higher activity and higheractivity stability in the process of the hydro-demetalization for the heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of porous nano metal organic framework material

ActiveCN104892518AIncrease surface areaLarge hole volumeMaterial nanotechnologyOther chemical processesSulfurMetal-organic framework

The invention aims to provide a preparation method and application of a porous nano metal organic framework material, and is characterized in that the preparation method comprises the steps: adding a metal ion, an organic ligand, a surfactant and a nanocrystalline guide agent or a reagent forming the nanocrystalline guide agent into a growth medium, forming a framework structure through chemical complexation, crystallizing, filtering, washing, drying, and finally obtaining the porous nano metal organic framework material. The addition amount of the surfactant is 0-30% of the molar concentration of the metal ion; the metal ion is one or more of Cu<II>, Al<III>, Mg<II>, Fe<III>, Ni<II>, Co<II> and Zn<II>; the organic ligand has at least one atom independently selected from oxygen, sulfur and nitrogen and can be subjected to coordinated complexation to the metal ion through the atom. The method not only can effectively suppress the size of MOFs materials, but also easily improves size homogeneity and synthetic efficiency of the product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

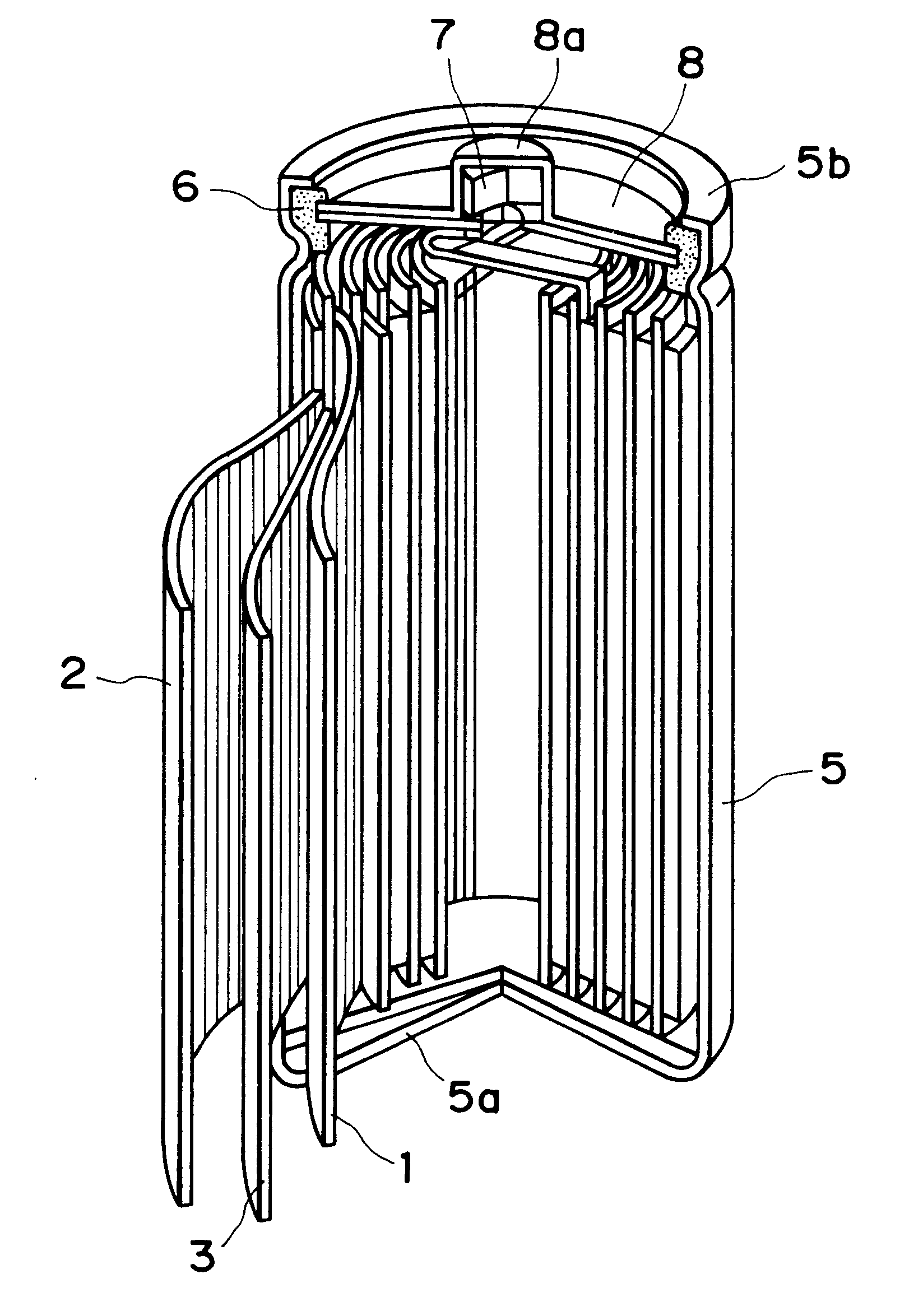

Carbonaceous electrode material for secondary battery and process for production thereof

InactiveUS6303249B1Small non-dedoping capacityLarge capacityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsPotassiumSolvent

A carbonaceous electrode having improved capacities for doping and dedoping of a cell active substance, such as lithium, and suitable for a non-aqueous solvent-type secondary battery, is constituted by a carbonaceous material having a pore volume of at least 0.55 ml / g of pores having a pore diameter of at most 5 mum as measured by mercury injection method, a potassium content of at most 0.5 wt. % as measured by fluorescent X-ray analysis, and a specific surface area of at most 100 m2 / g as measured by nitrogen adsorption BET method. The carbonaceous material is advantageous produced by carbonizing a carbon precursor of plant origin having a potassium content of at most 0.5 wt. % as measured by fluorescent X-ray analysis, in contact with a stream of an inert gas optionally containing a halogen gas at a temperature of 700-1500° C.

Owner:KUREHA KAGAKU KOGYO KK

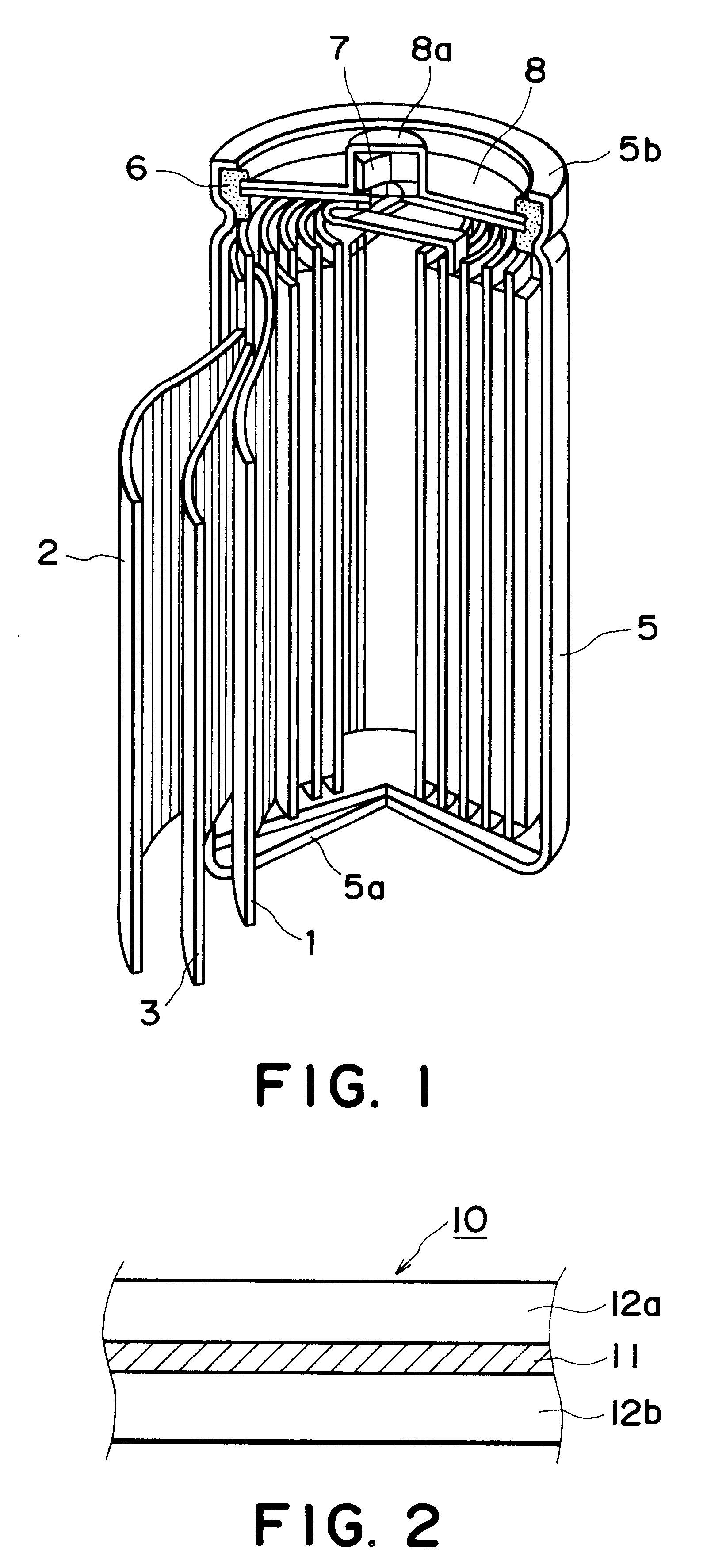

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

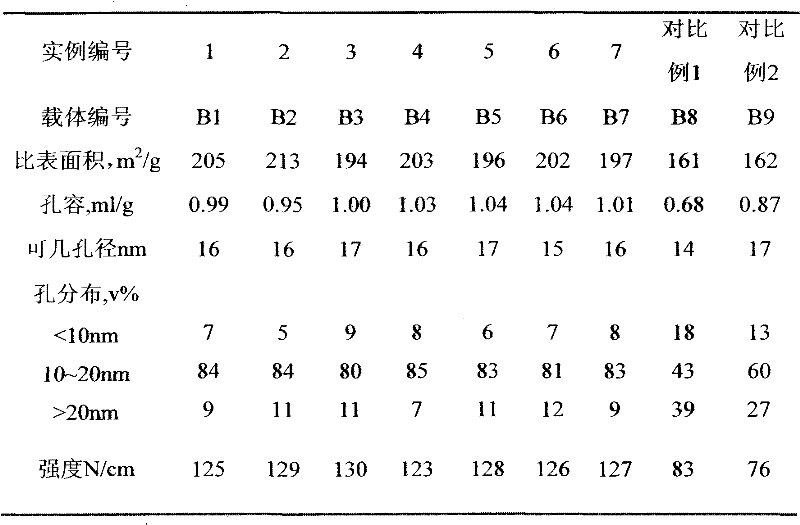

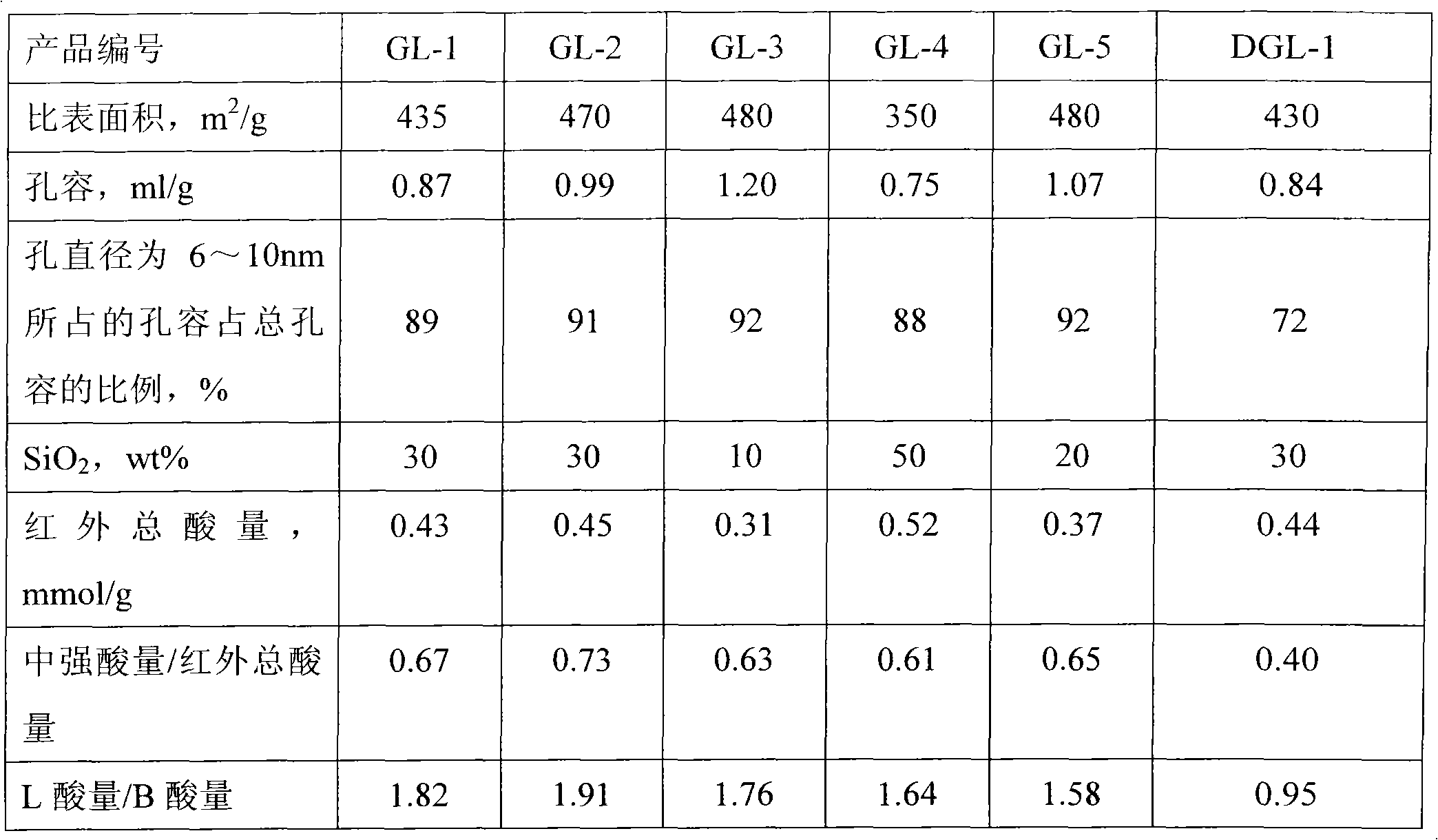

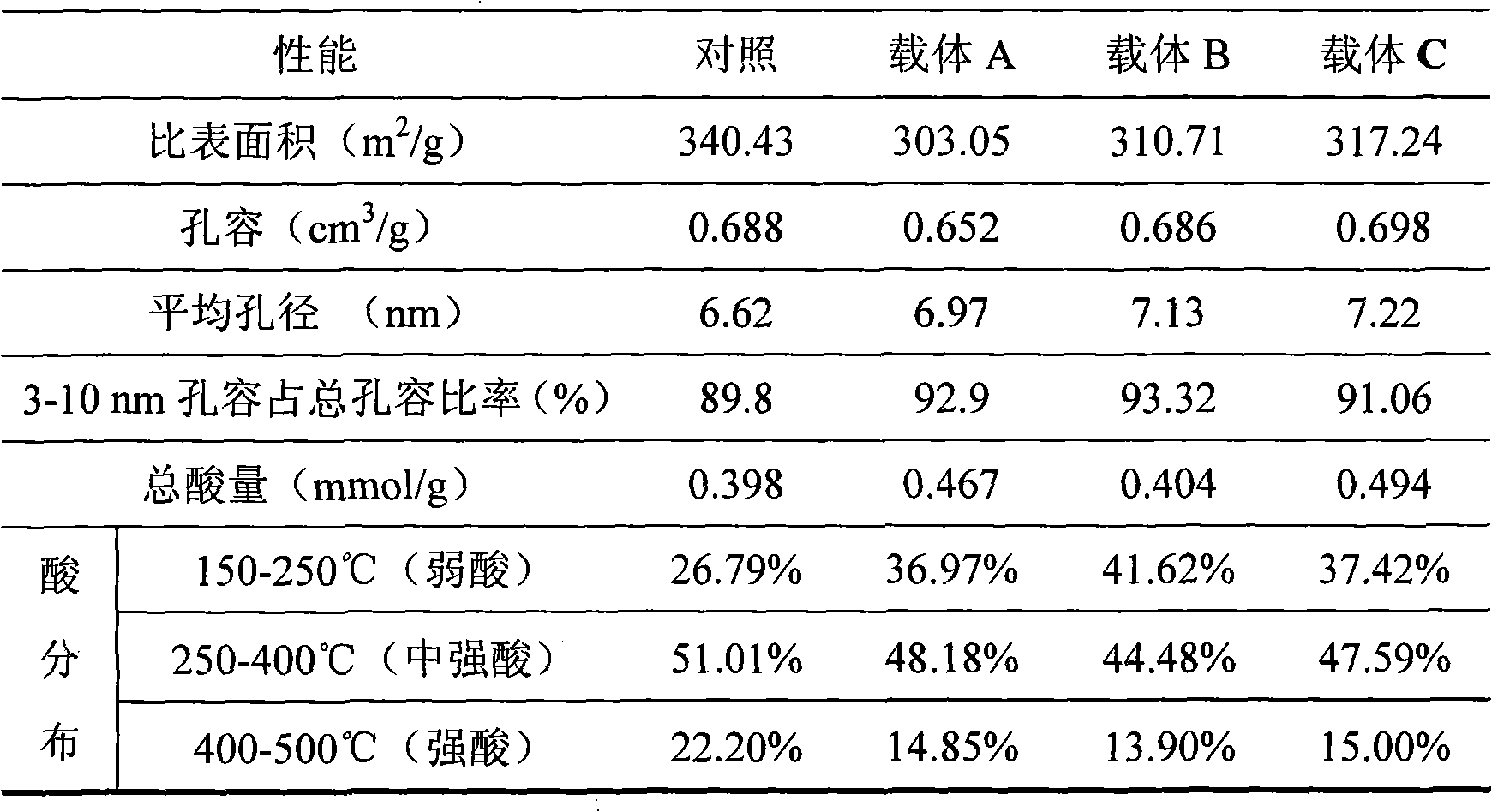

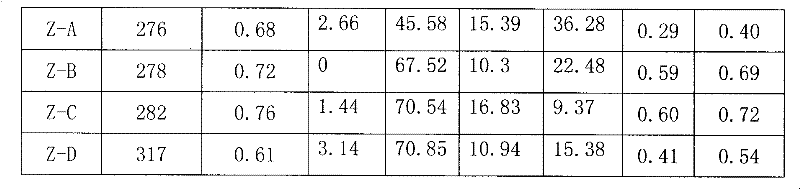

Amorphous silicon aluminium and preparation method thereof

ActiveCN102039197ASimple processEasy to controlCatalyst carriersCatalytic crackingPore distributionStrong acids

The invention discloses an amorphous silicon aluminium and a preparation method thereof. In the invention, hydro-thermal treatment is carried out on amorphous silicon aluminium obtained by a carbonization method, so that the amorphous silicon aluminium has higher specific surface area and bigger pore volume, the pore distribution is more intensive, and the pore volume the pore diameter of which is 6-10nm accounts for 80-95% of the total pore volume; meanwhile, the acid distribution of the amorphous silicon aluminium is improved; the amount of moderately strong acid and L acid is improved to effectively prevent raw material modules from excessively cracking, which is favourable for improving the selectivity of a target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

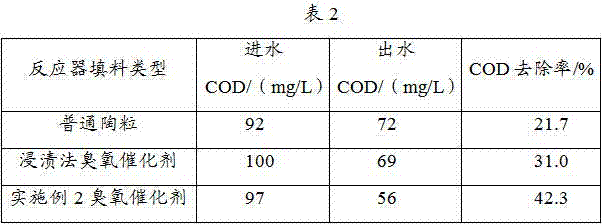

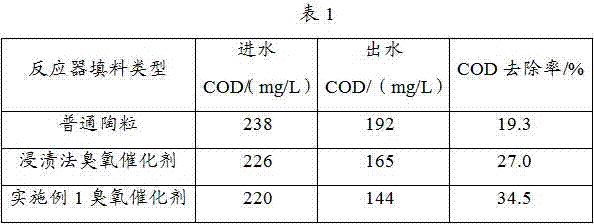

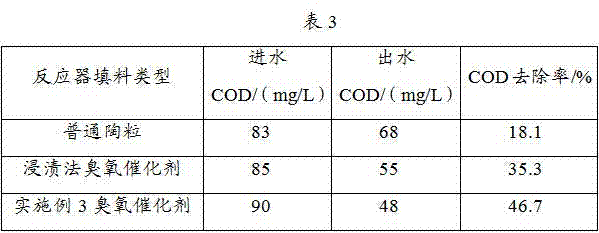

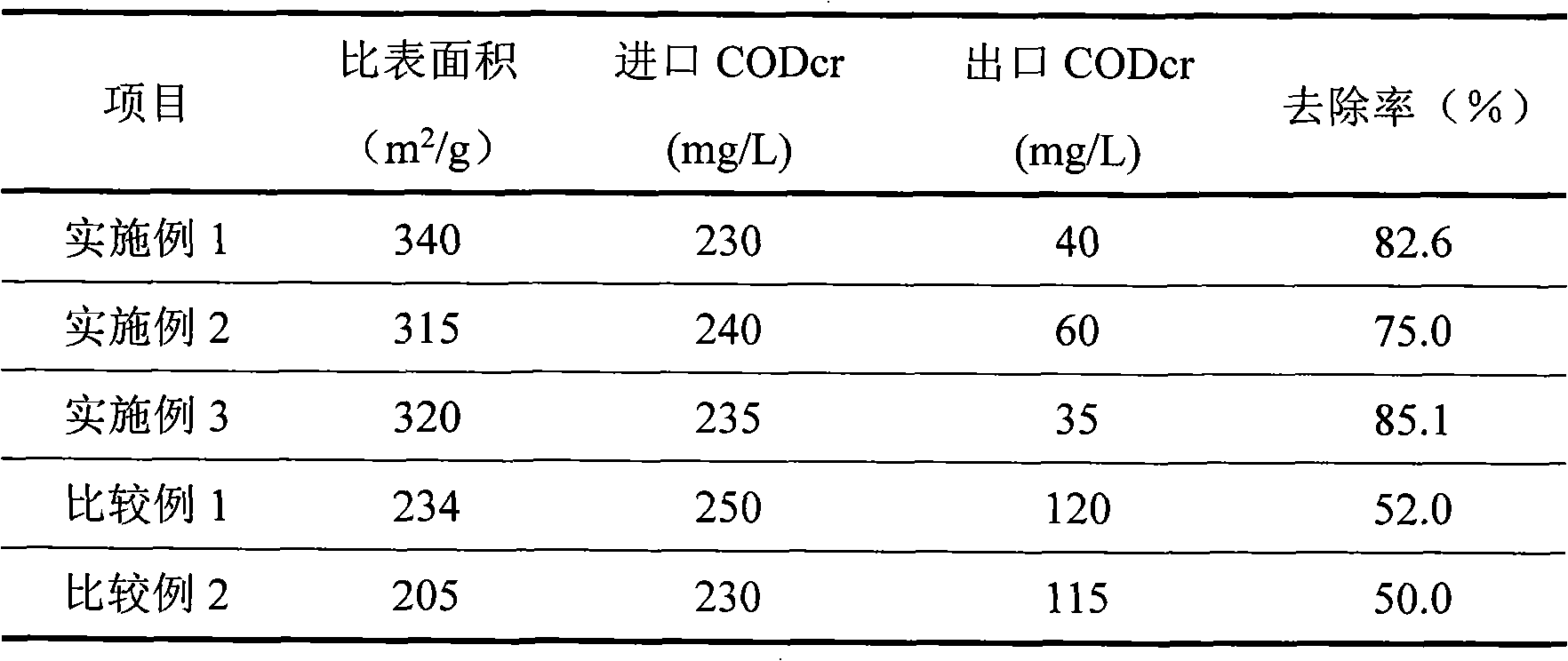

Ozone catalyst preparation method

ActiveCN104759286AImprove adhesion strengthAvoid churnMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemistryActive component

The invention provides an ozone catalyst preparation method which includes following steps: (1) mixing amorphous aluminum oxide powder, a catalyst powder and a pore-forming agent to form a catalytic mixture; (2) starting a pelletizer, feeding the amorphous aluminum oxide powder thereinto and spraying-in a binding agent to form aluminum oxide mother pellets; (3) feeding the aluminum oxide mother pellets and the catalytic mixture into the pelletizer and spraying-in a binding agent to form a catalyst formed pellet body; and (4) drying and roasting the catalyst formed pellet body to obtain the ozone catalyst. According to the method, the catalyst mixture is formed by mixing the amorphous aluminum oxide powder, the catalyst powder and the pore-forming agent. When the catalyst mixture is sintered onto the outer layer of the aluminum oxide mother pellets, a higher adhesive strength of the catalyst mixture is achieved since the components of the catalyst mixture and the aluminum oxide mother pellets are similar, thereby preventing loss of active components. Meanwhile, the ozone catalyst is ensured that the active components therein are effectively utilized, thereby reducing the production cost of the catalyst.

Owner:SUZHOU QINGRAN ENVIRONMENTAL PROTECTION TECH

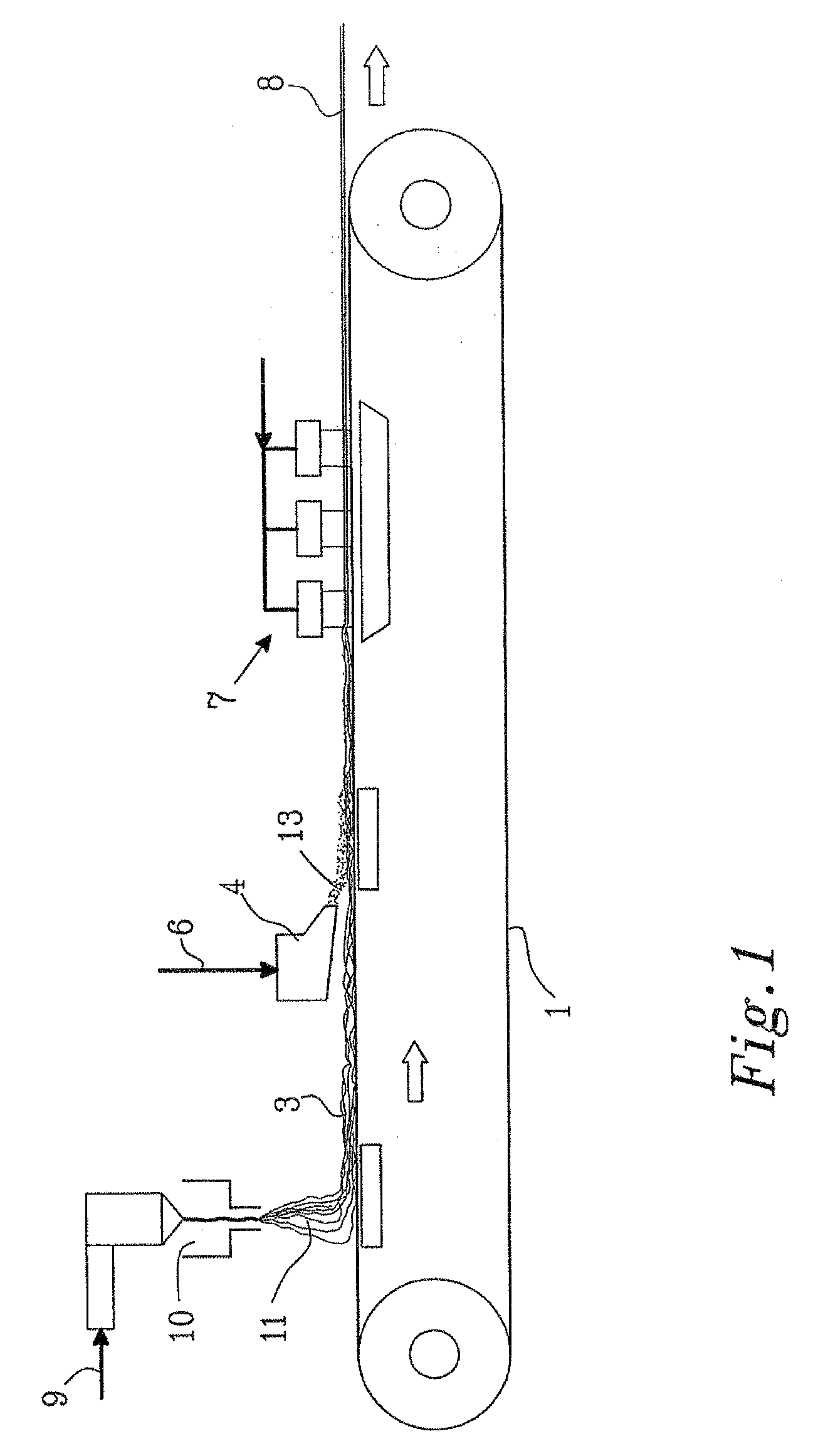

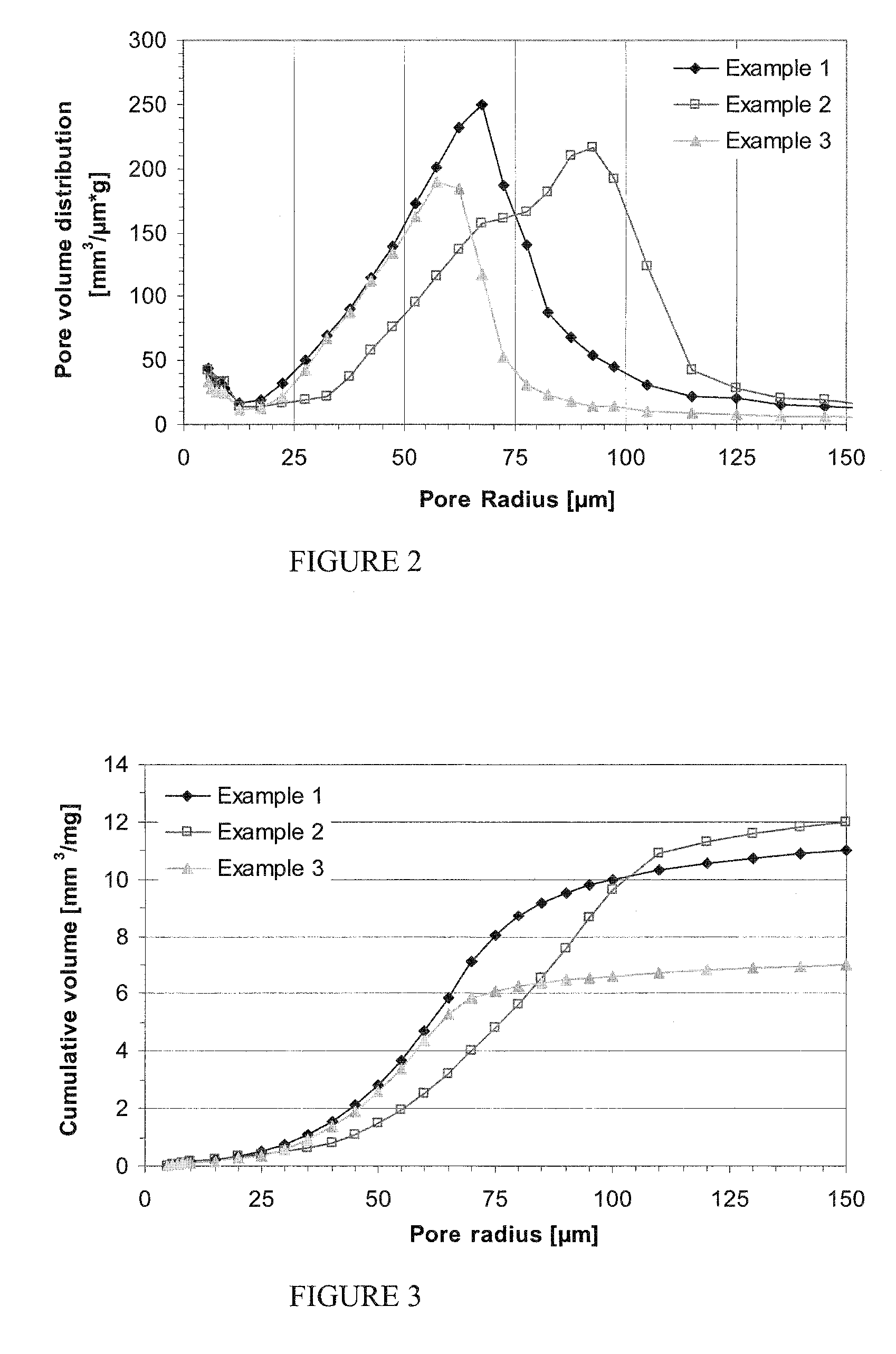

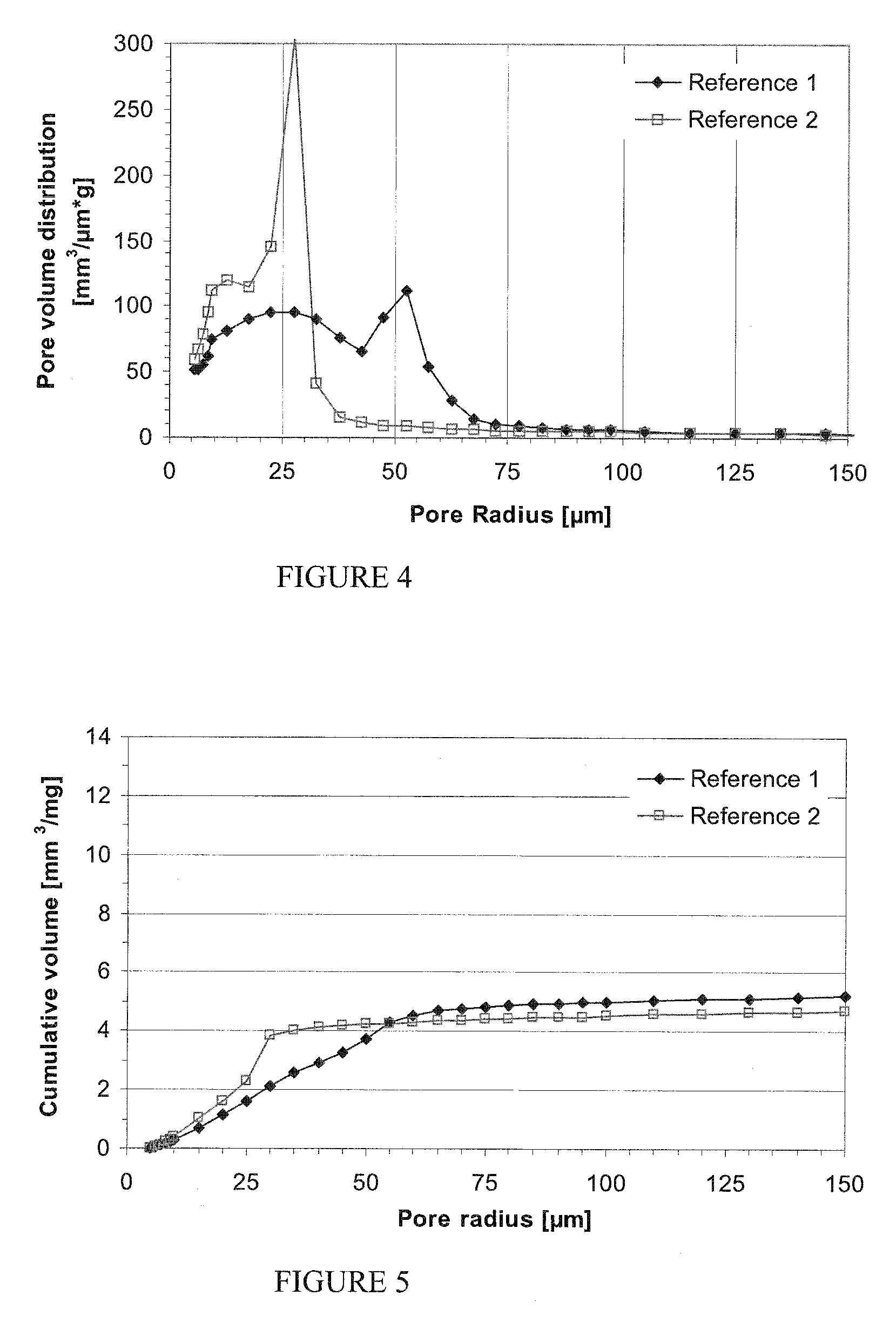

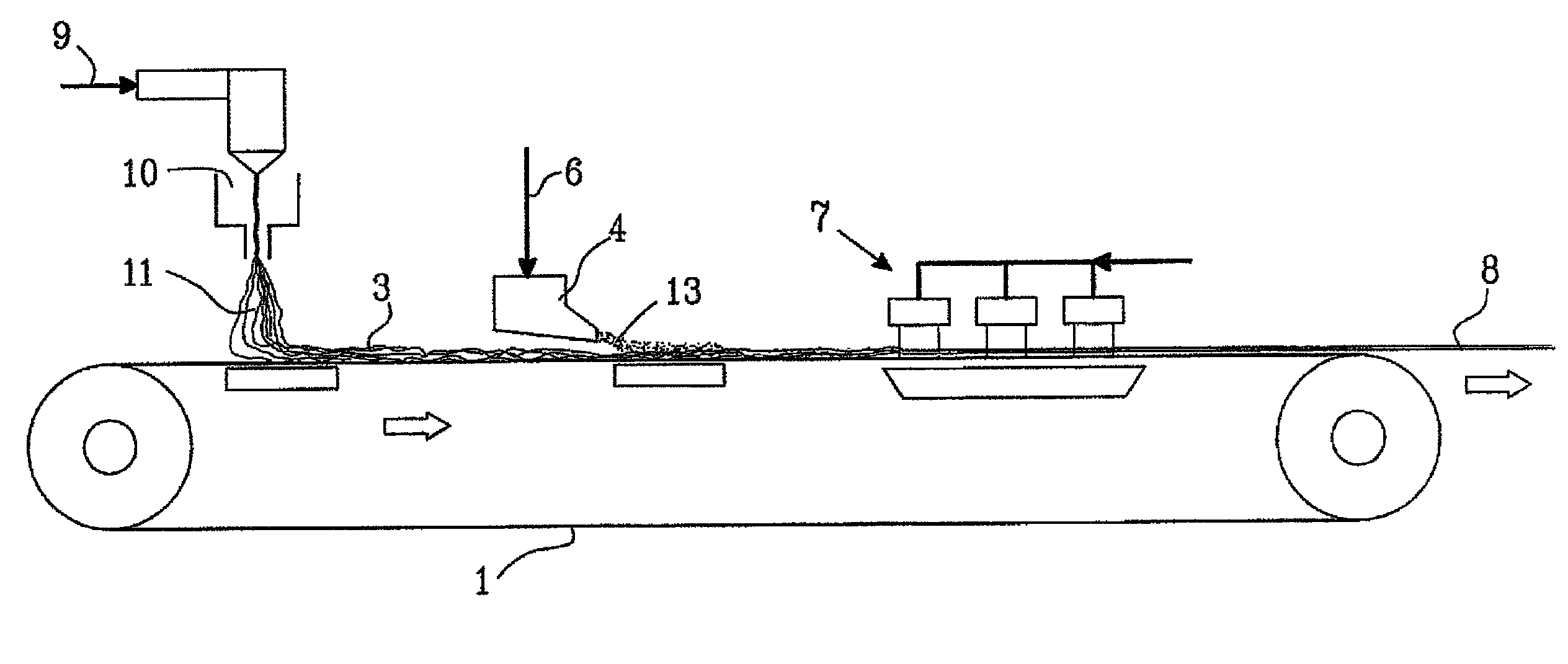

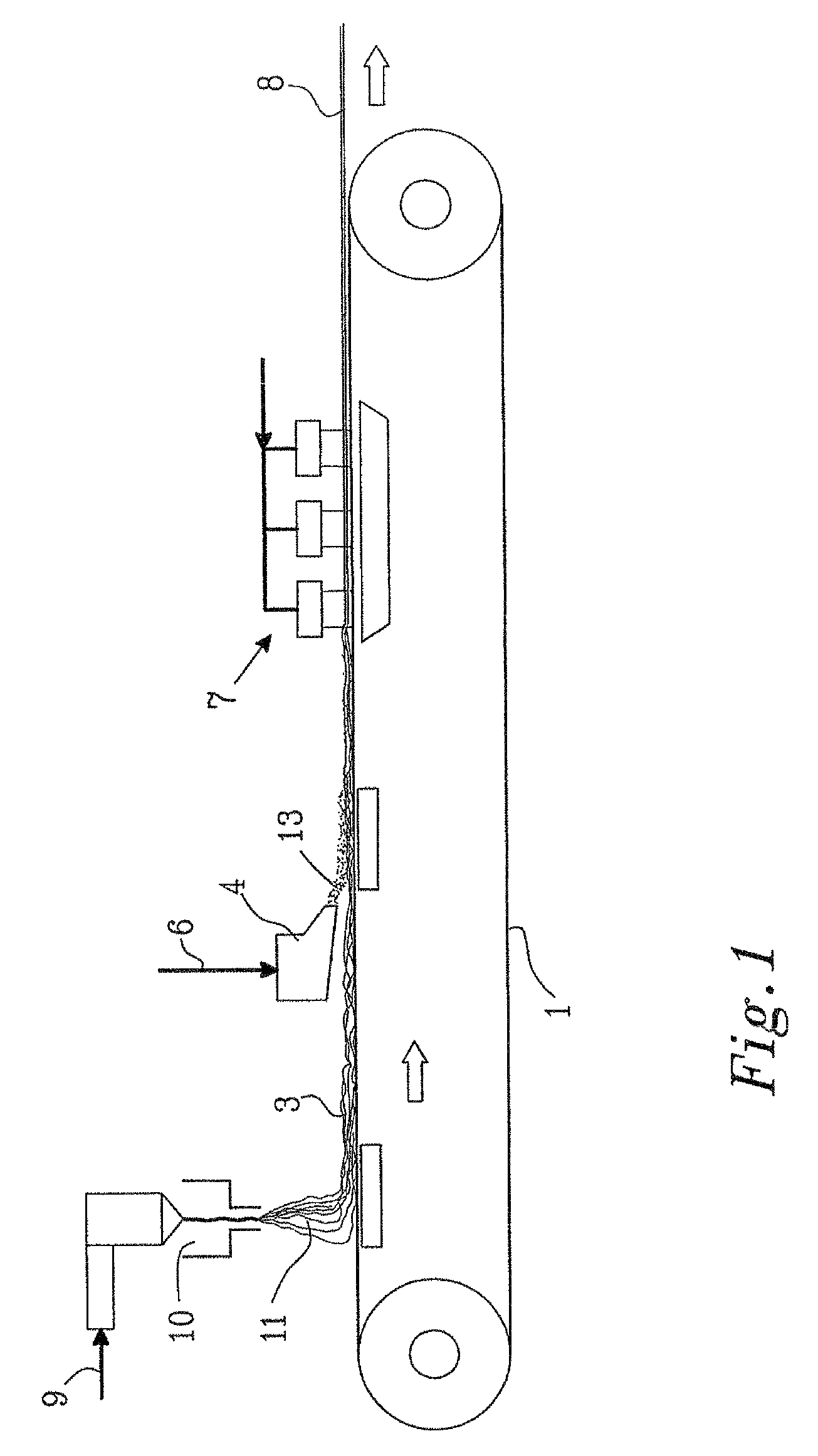

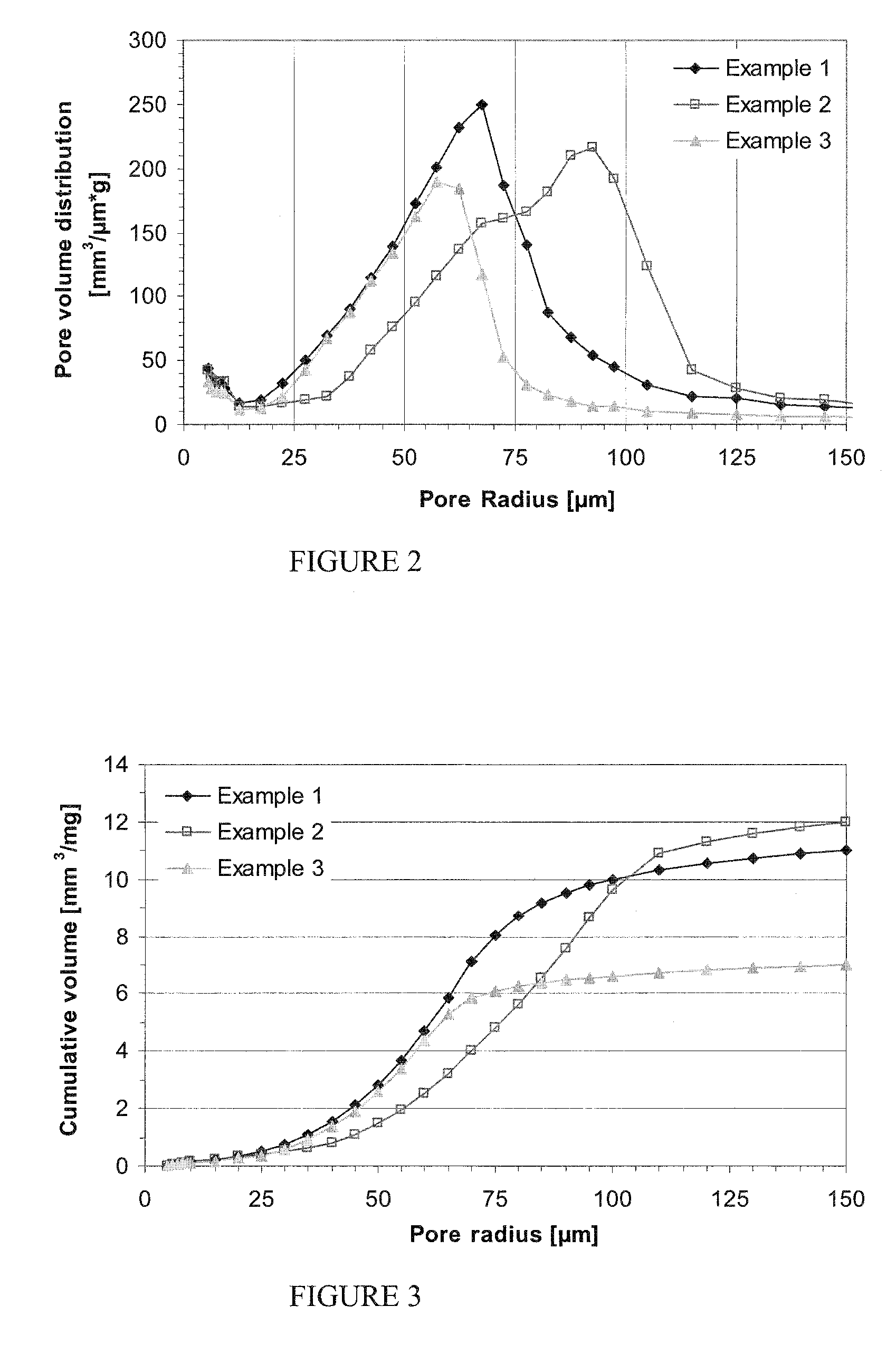

Hydroentangled integrated composite nonwoven material

InactiveUS20080050996A1Facilitated releaseLarge hole volumePattern makingLayered productsPolyesterPolymer science

An hydroentangled integrated composite nonwoven material, includes a mixture of randomized continuous filaments, and synthetic staple fibers, where there are no thermal bonding points between the continuous filaments. The nonwoven material exhibits a cumulative pore volume, measured by PVD in n-hexadecane, in the pore radius range 5-150 μm, where at least 70% of the cumulative pore volume is in the pores with a pore radius above 45 μm. The nonwoven material also exhibits a cumulative pore volume, which when the synthetic staple fibers are chosen from the group of polyethylene, polypropylene, polyester, polyamide, and polylactide staple fibers is at least 9 mm3 / mg, and when the synthetic staple fibers are lyocell staple fibers is at least 6 mm3 / mg.

Owner:SCA HYGIENE PROD AB

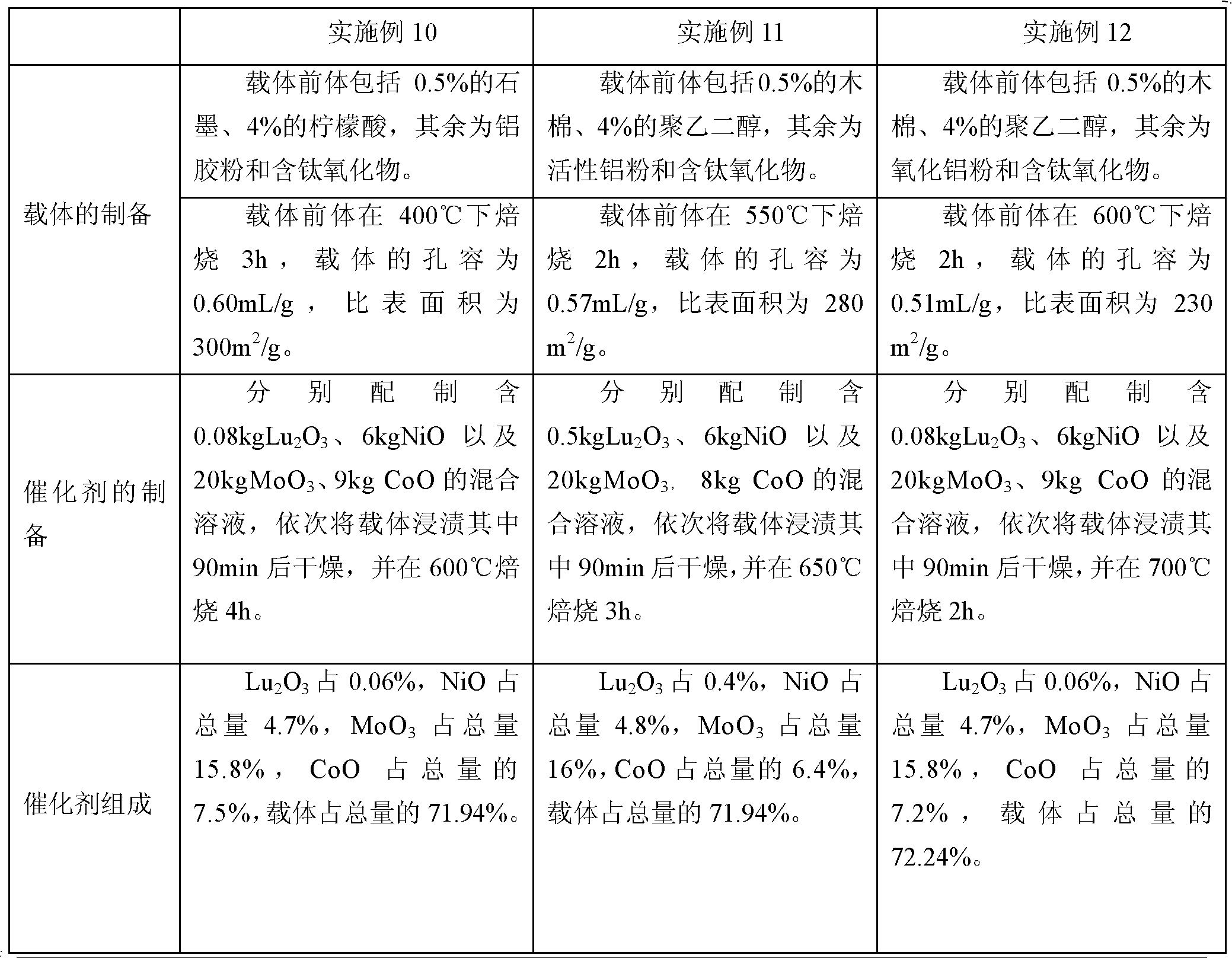

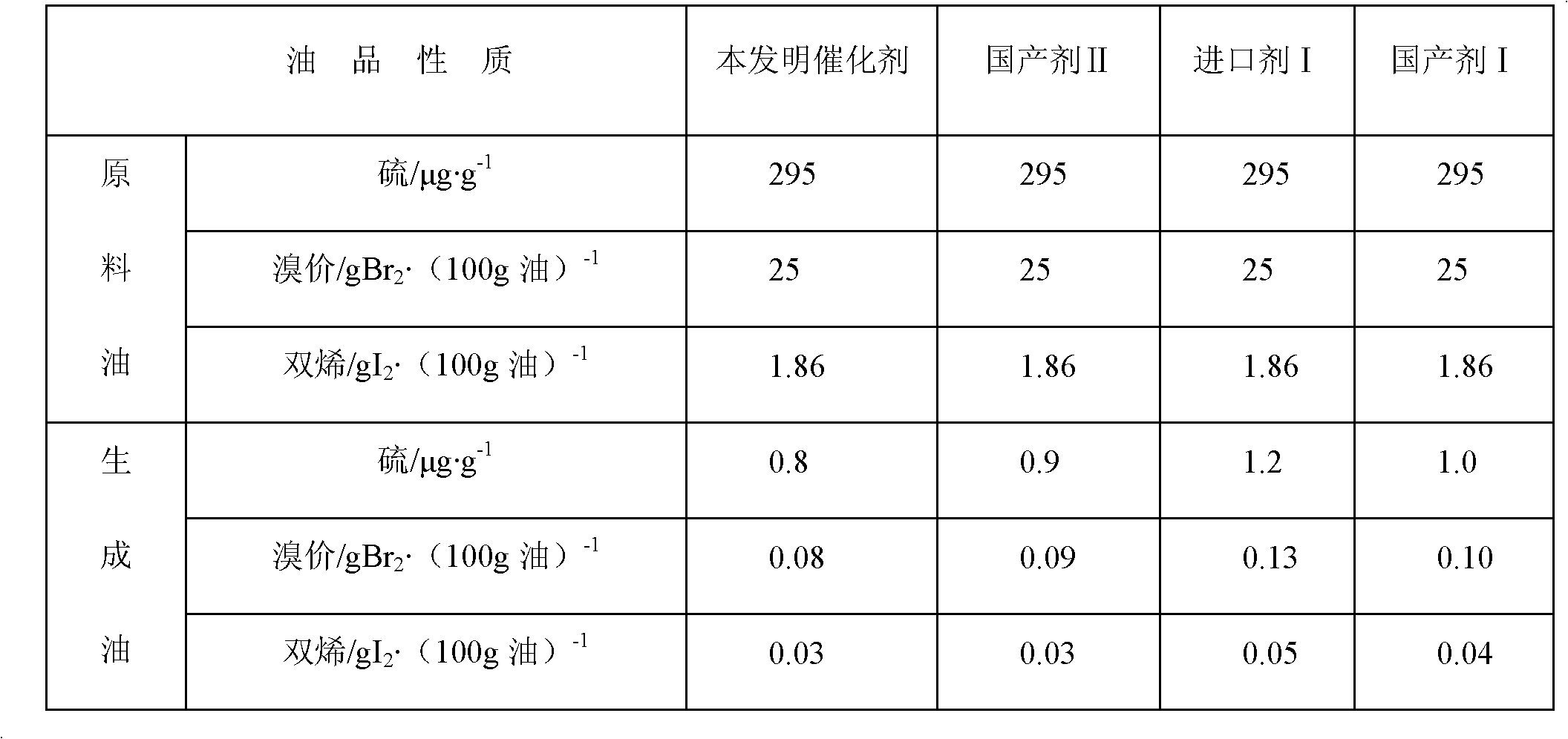

Hydrofining catalyst and preparation method thereof

ActiveCN102861593ALarge hole volumeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemical industryRare-earth element

The invention discloses a hydrofining catalyst and a preparation method thereof, belonging to the field of catalysts used in the petroleum-chemical industry. The hydrofining catalyst disclosed herein comprises a carrier, an active component and an auxiliary agent, wherein the carrier is Ti-modified gamma-alumina, the active component comprises oxides of Mo, Co and Ni, and the auxiliary agent comprises oxides of rare earth. The catalyst is characterized in that: based on 100% of the total weight of the catalyst, Co (measured in CaO) in the active component accounts for 2.0-7.5% of the total weight of the catalyst, Mo (measured in MoO3) in the active component accounts for 4.0-18.0% of the total weight of the catalyst, Ni (measured in NiO) in the active component accounts for 0.2-5.0% of the total weight of the catalyst, the auxiliary agent accounts for 0.05-1.0% of the total weight of the catalyst, and the balance consists of the carrier. According to the invention, the catalyst prepared by the formula and the method disclosed in the invention can carry out hydrogenation on saturated monoolefine while the catalyst is used for carrying out hydrodesulfurization on oils, can be suitable for technical requirements of heavy oriention, changeable sulphur content, and high air speed of hydrogenation liquid for pyrolysis gasoline two-stage hydrogenated raw materials, and simultaneously, the catalyst has the advantages of low activation temperature and low loss of aromatics in the hydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP

Modified carbon-coated alumina supporter with nucleocapsid structure and preparation method thereof

InactiveCN101327454ALarge specific surface areaLarge hole volumeCatalyst carriersCatalyst activation/preparationOil processingModified carbon

The present invention discloses a modified carbon-covered alumina support with a core-shell structure and a preparation method thereof. The modified carbon-covered alumina support of the present invention is a granule with the core-shell structure. A shell of the core-shell structure is alumina deposited with carbon, and an inner core of the core-shell structure is an industrial alumina support. The modified carbon-covered alumina support of the present invention has the advantages of high specific surface area, large pore volume, high mechanical strength, and the like; the aperture distribution is more concentrated; total acid quantity is increased obviously, and strong acid quantity is reduced; the modified carbon-covered alumina support can be directly used as a catalyst during certain processes and is more applicable to be used as a catalyst support, in particular as a hydrogenation treatment catalyst support during petroleum processing course.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water

ActiveCN101982237ASimple preparation stepsSuitable for industrial scale-upMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationParticulatesFerric hydroxide

The invention relates to a preparation method of ozone catalytic oxidation catalyst used for treating oil refining waste water. Amorphous aluminium oxide powder and ferric hydroxide powder are mixed by dry basis weight ratio of 100: 1-30, and rolling pelleting, maintaining, drying and roasting are carried out, thus obtaining the finished product catalyst. The method includes the following steps: (a) amorphous aluminium oxide and ferric hydroxide powder are mixed to be uniform; (b) the mixture is placed into a rotary pelleting machine, binder is sprayed, and rolling pelleting is carried out, the binder is sprayed in solution or colloid form in an atomizing way, and the amount of binder sprayed into the pelleting machine is 2-50% of total mass of amorphous aluminium oxide; and diameter of pelleting is controlled to be 1-8mm; (c) particle matter is maintained for 3-24 hours under the condition that temperature of water vapour is 100-110 DEG C; (d) catalyst is dried, drying temperature is 50-180 DEG C, drying time is 2-10 hours, and then roasting is carried out; and roasting temperature of catalyst is 400-600 DEG C, roasting time is 2-8 hours, and finished product catalyst is obtained.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Dechlorinating agent used for removing HCl from gas by dry method and preparation method thereof

InactiveCN101773768AImprove dechlorination activityHigh activityOther chemical processesAluminium silicatesPorosityCross-link

The invention relates to a dechlorinating agent used for removing HCl from a gas by using a dry method and a preparation method thereof. The dechlorinating agent is prepared from Na2CO3, CaCO3, CaO and MaO as active constituents, crosslinked bentonite as a porous auxiliary agent, and methyl cellulose as a foaming agent and an auxiliary extrusion agent through extrusion forming, drying and roasting. The cross-linked bentonite is prepared by exchanging large-size poly aluminum cation with small-size simple cation, so that the crosslinked bentonite has great porosity factor and large specific surface. The specific surface and the pore volume of the crosslinked bentonite are larger than those of non-crosslinked bentonite. By using the crosslinked bentonite as the porous auxiliary agent, the specific surface of the dechlorinating agent is enlarged, and the dechlorinating activity and the chlorosity of the dechlorinating agent are increased. The dechlorinating agent prepared by using the crosslinked bentonite has a pore volume of 0.3-0.4 mL / g, a specific surface of 70-90 m<2> / g and a crushing strength of 60-80 N / cm, not only has lower price than pseudo-boehmite and a molecular sieve, but also has simple preparation process, high dechlorinating activity and great low-temperature penetration chlorosity.

Owner:长春惠工净化工业有限公司

Dual-pore distribution silica synthesis method

ActiveCN101767790ALarge specific surface areaLarge hole volumeSilicaPore distributionSynthesis methods

A dual-pore distribution silica synthesis method includes that water, silicon source and template agent are mixed, and the pH value of the mixture is regulated to 4-12, the mixture is aged for 0.5-4 days at the temperature of 40-120 DEG C, and then the mixture is filtered, rinsed, dried and roasted; the template agent is the mixture of sugar and surfactant, the weight ratio of sugar and surfactant of the template agent is 0.5-2, the molar ratio of silicon and water is 1:30-1:200, the molar ratio of silicon and template agent is 1:0.005-2. The portable pore diameter of the pore with smaller pore diameter of the dual-pore distribution silicon-aluminum material is 2-10 nm, the portable pore diameter of the pore with larger pore diameter is 10-25nm, the specific area is 400-750 m2 / g, and the pore volume is 0.8-1.5cm3 / g. The dual-pore distribution silicon-aluminum material can be used as absorbent and catalyst, or used as the carriers of absorbent and catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of macroporous aluminum oxide with diplopore distribution

InactiveCN101214454AStrong combinationOvercoming low mechanical strengthCatalyst carriersCarbon blackPetroleum

A preparation method of a large-pore aluminum oxide with double-pore spread structure. First, aluminum oxide, a poreforming agent and solid silica are mixed, and receive ball-milling treatment in a ball milling machine; the mixture after treatment is kneaded into a plastic body by aqueous solution with cationic surfactant, extrusion aid, peptizator, etc. dissolved in, and put into the water vapor atmosphere to be treated; and the prepared mould is dried and baked, to obtain the final aluminum oxide carrier. The poreforming agent is one or the mixture of carbon black, cellulose and starch, and the loading is 3.0 to 15w percent of the weight of the aluminum oxide; the solid silica is silica aerogel, and the loading is 1.0 to 10w percent of the weight of the aluminum oxide; in the ball milling machine, the ball-material ratio is 15:1 to 10:1, and the ball milling time is 0.5 to 3.0h; the treatment temperature of the water vapor is 120 DEG C to 180 DEG C, and the treatment time is 0.5 to 6.0h. The aluminum oxide prepared by the invention has double-peak channel structure and high strength, and is applicable in fields of petrochemical, petroleum processing, environmental protection, etc.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

High-silicon amorphous silica aluminum and preparation method thereof

ActiveCN101491774AHigh ratio of silicon to aluminumLarge specific surface area and pore volumeCatalyst carriersLarge poreCoprecipitation

The invention discloses high-silicon amorphous silica alumina and a preparation method thereof. The amorphous silica alumina product has the properties of a specific surface area of 400 to 650m / g, a pore volume of 1.0 to 2.0cm / g, a silicon oxide content of 20 to 80wt percent, a infrared acid content of 0.3 to 0.8 mmol / g and evenly distributed acidic centers. Moreover, the amorphous silica alumina is prepared by a method comprising first coprecipitation of silicon oxide and alumina and then modification of organic silicon. Compared with the prior art, the amorphous silica alumina has larger pore volume and specific surface area, evenly distributed acidic centers and excellent service performance; moreover, the preparation method is simple, free from special environmental protection problem and low in production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroentangled integrated composite nonwoven material

InactiveUS7998889B2Facilitated releaseMaximum effectivePattern makingLayered productsPolyesterPolymer science

An hydroentangled integrated composite nonwoven material, includes a mixture of randomized continuous filaments, and synthetic staple fibers, where there are no thermal bonding points between the continuous filaments. The nonwoven material exhibits a cumulative pore volume, measured by PVD in n-hexadecane, in the pore radius range 5-150 μm, where at least 70% of the cumulative pore volume is in the pores with a pore radius above 45 μm. The nonwoven material also exhibits a cumulative pore volume, which when the synthetic staple fibers are chosen from the group of polyethylene, polypropylene, polyester, polyamide, and polylactide staple fibers is at least 9 mm3 / mg, and when the synthetic staple fibers are lyocell staple fibers is at least 6 mm3 / mg.

Owner:SCA HYGIENE PROD AB

Preparation method of hydrocracking catalyst

ActiveCN103100400AIncrease the apertureIncrease contentMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises: first selecting a solution containing a hydrogenation active metal and an organic reagent to dip mixed powder of a molecular sieve and alumina, conducting drying, then subjecting the obtained material and a peptizing agent or a binder together to rolling, molding, drying and roasting, thus obtaining the catalyst. Only through one time high temperature roasting can the catalyst product be obtained. The preparation method is simple, and the preparation cost is obviously reduced. In addition, the hydrogenation activity center and the cracking activity center of the catalyst coordinate, so that the catalyst has very high catalytic activity. Also with a large specific surface area and pore volume, the hydrocracking catalyst is more suitable for a catalytic process of treating high dry point inferior vacuum distillate oil by hydrocracking for high production of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Amorphous silica-alumina, a carrier combination and a hydrocracking catalyst containing the same, and processes for the preparation thereof

InactiveUS20020160906A1Increase surface areaLarge hole volumeMolecular sieve catalystsAluminium silicatesPtru catalystPhysical chemistry

Owner:CHINA PETROCHEMICAL CORP +1

Supported polyethylene catalyst ingredient and preparation method thereof, and supported polyethylene catalyst and application thereof

ActiveCN105330768ALarge specific surface areaLarge hole volumeBulk chemical productionMolecular sieveMagnesium salt

The invention discloses a supported polyethylene catalyst ingredient and a preparation method thereof, and a supported polyethylene catalyst and an application thereof. The supported polyethylene catalyst ingredient comprises a spherical composite carrier, and magnesium salt and titanium salt supported on the spherical composite carrier, wherein the spherical composite carrier contains a molecular sieve material having a one-dimensional hexagonal tunnel structure, the molecular sieve material having a two-dimensionl hexagonal tunnel structure and silica gel, an average particle size of the spherical composite carrier is 30-60 micrometers, a specific surface area is 150-600 square meter / g, a pore volume is 0.5-1.5milliliters / g, apertures present three-peak distribution, three peaks can be respectively corresponded to a first most probable aperture, a second most probable aperture and a third most probable aperture, the first most probable aperture is 2-4 nanometers, the second most probable aperture is 5-15 nanometers, and the third most probable aperture is 10-40 nanometers. The provided supported polyethylene catalyst has high catalysis efficiency during an ethene catalysis / polymerization process.

Owner:CHINA PETROLEUM & CHEM CORP +1

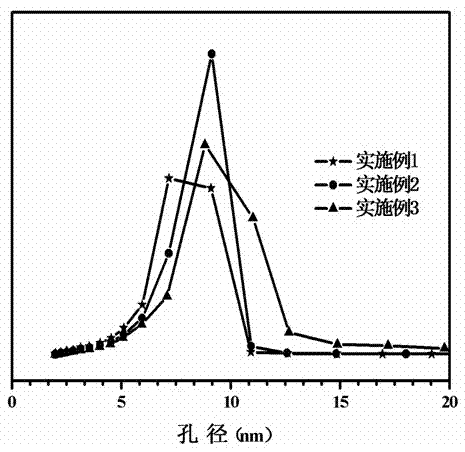

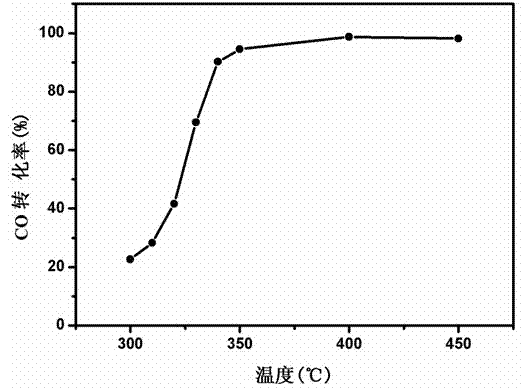

Carbon monoxide methanating catalyst and preparation method thereof

InactiveCN103480375ARaw materials are readily availableLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationFiltration

The invention discloses a carbon monoxide methanating catalyst with high hydrothermal stability and a preparation method thereof, and belongs to the technical field of preparation of catalysts. The carbon monoxide methanating catalyst is prepared mainly by a co-precipitation method according to the following steps: taking alumina (Al2O3) as a carrier and metal nickel as an active component, adding Zr and transition metals as additives, uniformly mixing salt solutions, precipitating, aging, performing suction filtration, washing, drying and calcining the mixture. The preparation method is simple; raw materials are easily available; the cost is low; and the prepared catalyst has the characteristics of high specific surface area, large pore volume and concentrated pore size distribution, is applicable to hydrogenation reactions, in particular to methanation reaction of high-concentration carbon monoxide, and has the advantages of wide using temperature range, high catalytic activity, high hydrothermal stability and the like.

Owner:FUZHOU UNIV

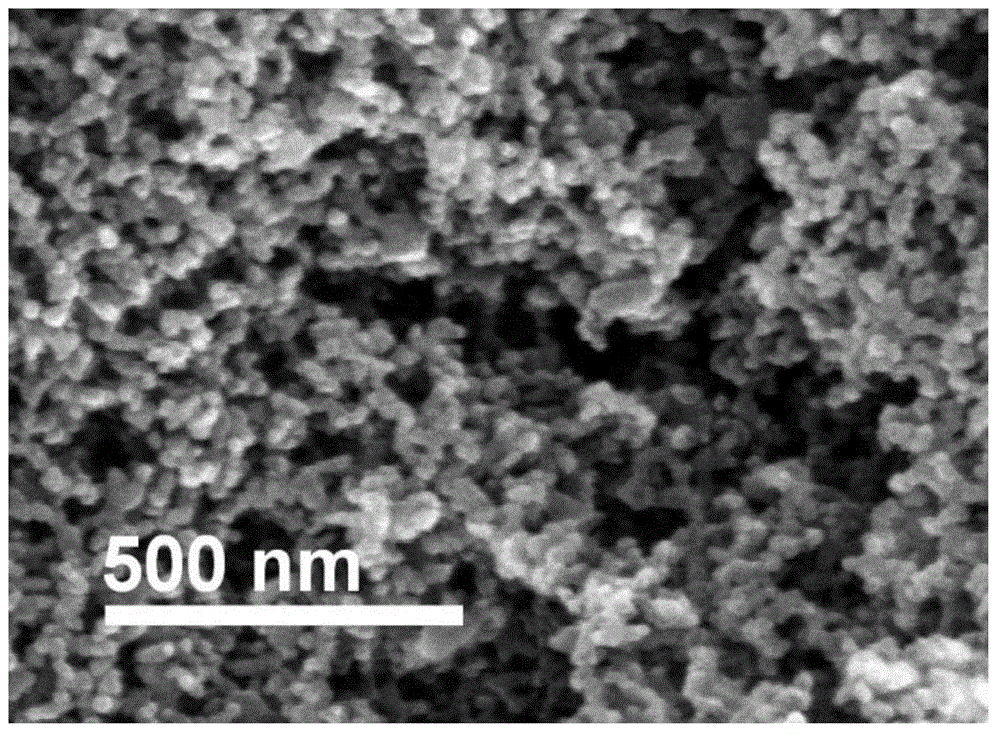

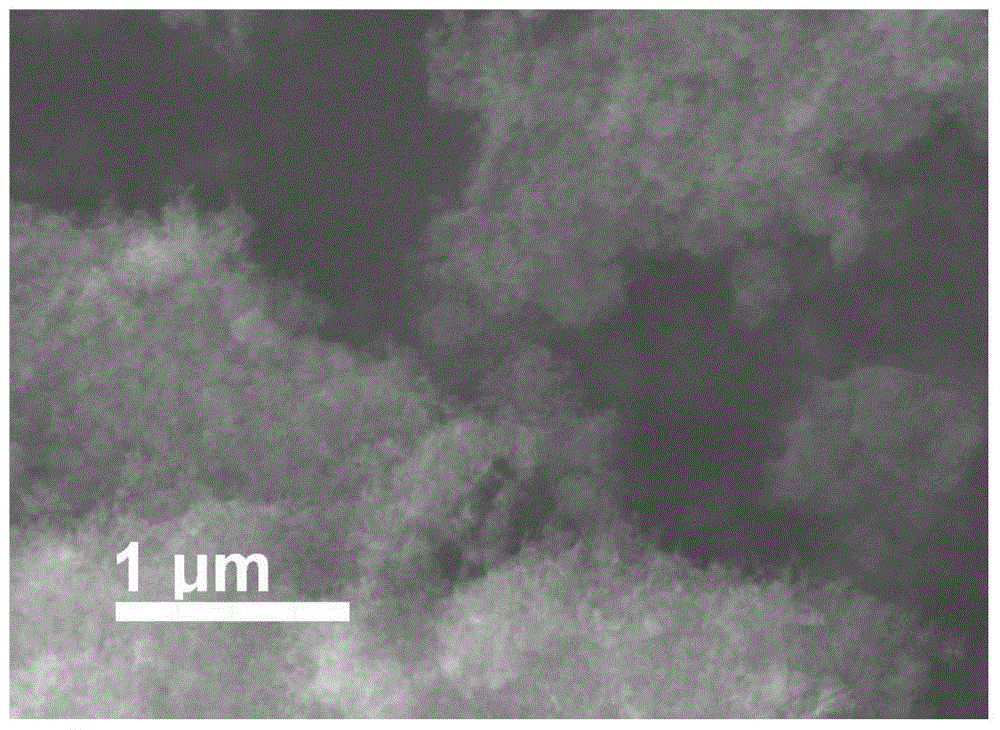

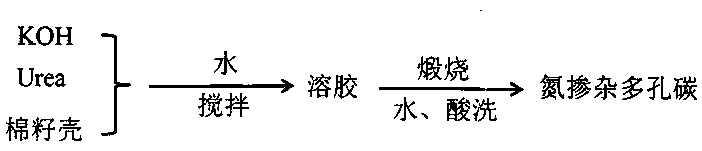

Method for preparing nitrogen-doped porous carbon by taking cottonseed hull as raw material and application

InactiveCN108455597AWide range of resource sourcesLow costCarbon preparation/purificationCapacitancePorous carbon

The invention discloses a method for preparing nitrogen-doped porous carbon by taking cottonseed hull as a raw material and application. The method is characterized in that the nitrogen-doped porous carbon material is prepared by taking the cottonseed hull as a raw material and urea as a nitrogen source, stirring and uniformly mixing the substances with a sodium hydroxide solution, and then carrying out high-temperature carbonization and activation. An electron microscope photo shows that the prepared nitrogen-doped porous carbon material is of a three-dimensional inner cross-linking network structure. XPS and elemental analysis show that the nitrogen element is successively and uniformly doped in a carbon matrix; the XPS analysis shows that the nitrogen content is 1.84 to 7.35%; the elemental analysis shows that the nitrogen content is 2.07 to 6.52 % and the specific surface area is 1010 to 2500m<2> / g. The super-capacitor experiment shows that the prepared nitrogen-doped porous carbonmaterial has good electrochemical properties and the specific capacitance can reach 320 to 340F / g (current density is 0.5A / g). The method has the advantages of simplicity in preparation, wide range of renewable resources as raw materials, low price, low cost, easiness in large-scale industrialization application and capability of being applied to the field of energy storage.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Preparation method of catalyst for hydrogenation desulfurization and denitrification of light-weight oil

InactiveCN102247864AGood dispersionIncrease profitCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideTitanium oxide

The invention discloses a preparation method of a catalyst for hydrogenation desulfurization and denitrification of light-weight oil and is characterized in that the composition of the catalyst comprises a carrier, an auxiliary agent and active metals, wherein the carrier contains aluminum oxide, titanium oxide and silicon oxide; the auxiliary agent is phosphorus; the active metals are oxides of nickel, molybdenum and tungsten; and on the basis of the catalyst, the contents of all components in percentage by weight are as follows: 1 to 4 percent of cobalt oxide, 3 to 10 percent of nickel oxide, 2 to 12 percent of molybdenum oxide, 18 to 30 percent of tungsten oxide, 2 to 5 percent of phosphorus pentoxide, 2 to 15 percent of titanium oxide, 2 to 20 percent of silicon oxide, and the balance of aluminum oxide. The catalyst is obtained by the steps of carrier preparation, co-immersion, calcination and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com