Patents

Literature

89results about How to "Concentrated hole distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Macropore alumina supporter and its preparation method

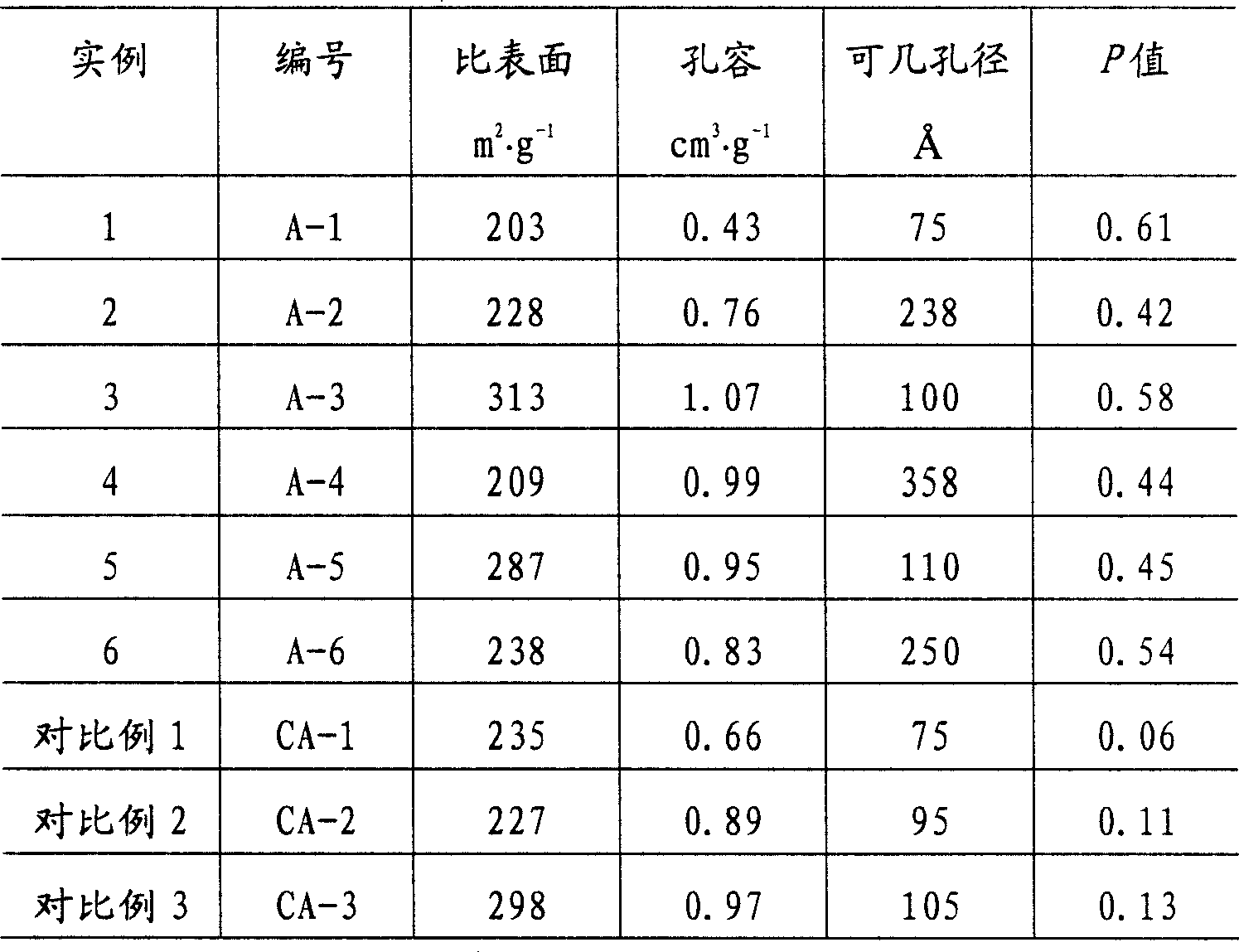

ActiveCN1765509ALarge apertureConcentrated hole distributionCatalyst carriersCatalyst activation/preparationPhosphorRoom temperature

The invention discloses a micro-porous alumina carrier and relative preparing method, which contains boric oxide and another agent selected from phosphor, silicon, zirconium, and titanium. The invention adds the boric acid into water or peptizate acid whose temperature is higher than room temperature, then adds the mixture of alumina leading material and physics expanding-hole agent to be molded, dried, and burnt to attain the final carrier. The inventive carrier contains a proper agent, with the characters of large aperture, centralized distribution hole and a certain acid. And its surface acid and aperture can be adjusted easily. Therefore, the invention can overcome the defects of present technique which can not have aforementioned characters at the same time. The inventive alumina carrier can be used in variable hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

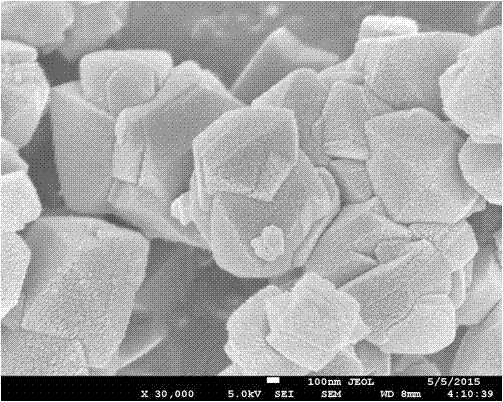

Pseudo thin allophane and its preparation method

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

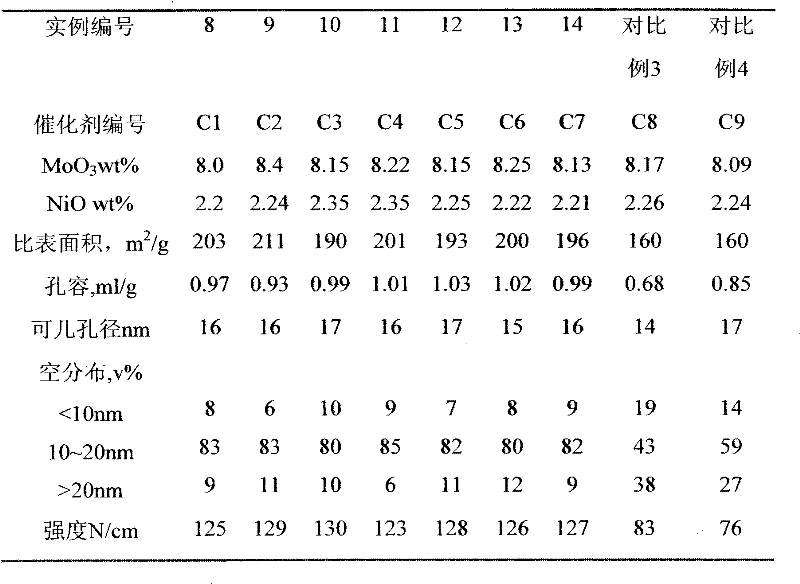

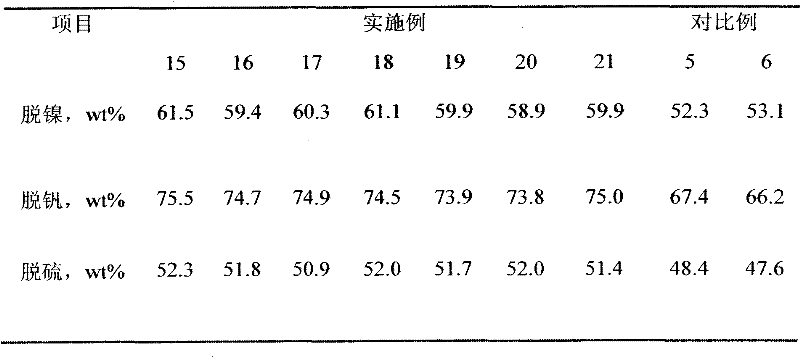

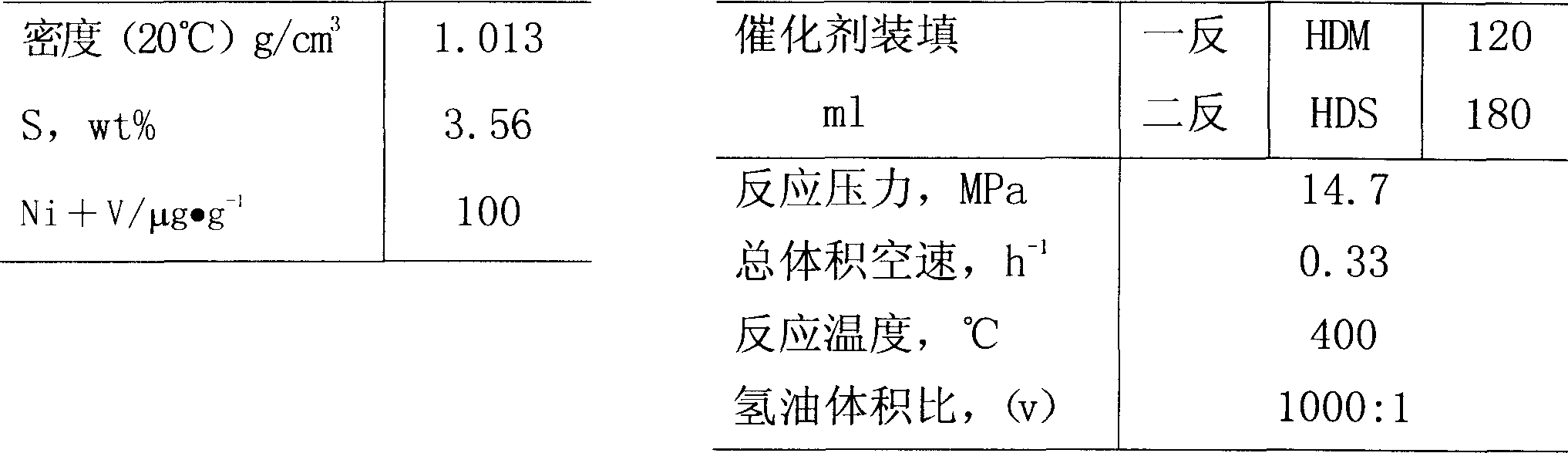

Method for preparing hydro-demetalization catalyst for heavy oil

ActiveCN102441368AConcentrated hole distributionControl product propertiesCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPore distributionChemistry

The invention discloses a method for preparing a hydro-demetalization catalyst for heavy oil. The method comprises the following steps of: firstly, preparing an alumina carrier, then, loading active metal components by using an immersion method, and obtaining the final hydro-demetalization catalyst after drying and roasting, wherein the process for preparing the alumina carrier comprises the following steps of: (1) evenly mixing pseudoboehmite dry colloidal powder with an extrusion aid, and then, adding an aqueous solution in which a physical pore-expanding agent and a chemical pore-expandingagent are dissolved, wherein the physical pore-expanding agent is a carbohydrate, and the chemical pore-expanding agent is phosphoric acid, phosphate or borate; (2) evenly mixing the materials prepared in the step (1), and then, forming; and (3) drying and roasting the materials prepared in the step (2) so as to prepare the alumina carrier. The hydro-demetalization catalyst for the heavy oil, prepared by the method disclosed by the invention, has the advantages of larger pore volume, larger pore diameter, concentrated pore distribution, good mechanical strength, and higher activity and higheractivity stability in the process of the hydro-demetalization for the heavy oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

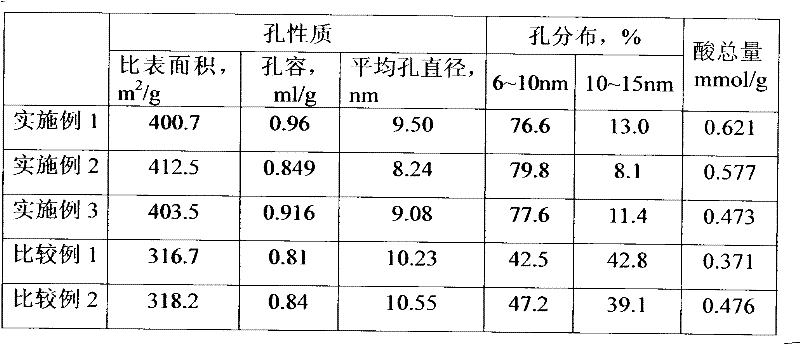

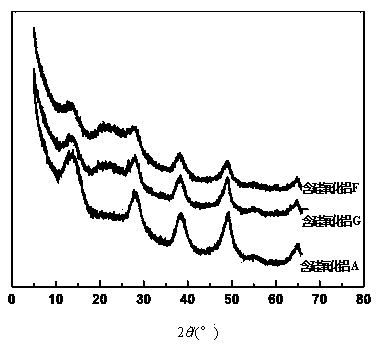

Amorphous silicon aluminium and preparation method thereof

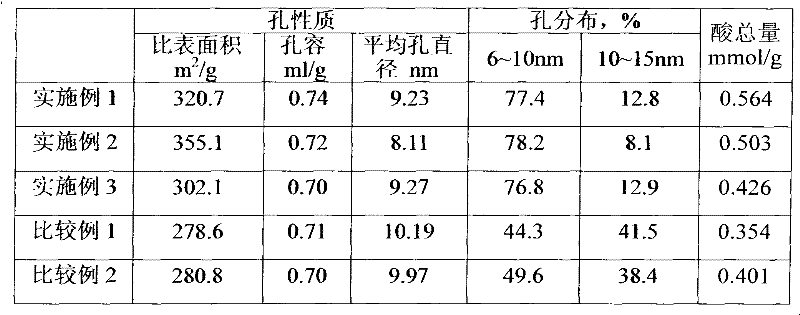

ActiveCN102039197ASimple processEasy to controlCatalyst carriersCatalytic crackingPore distributionStrong acids

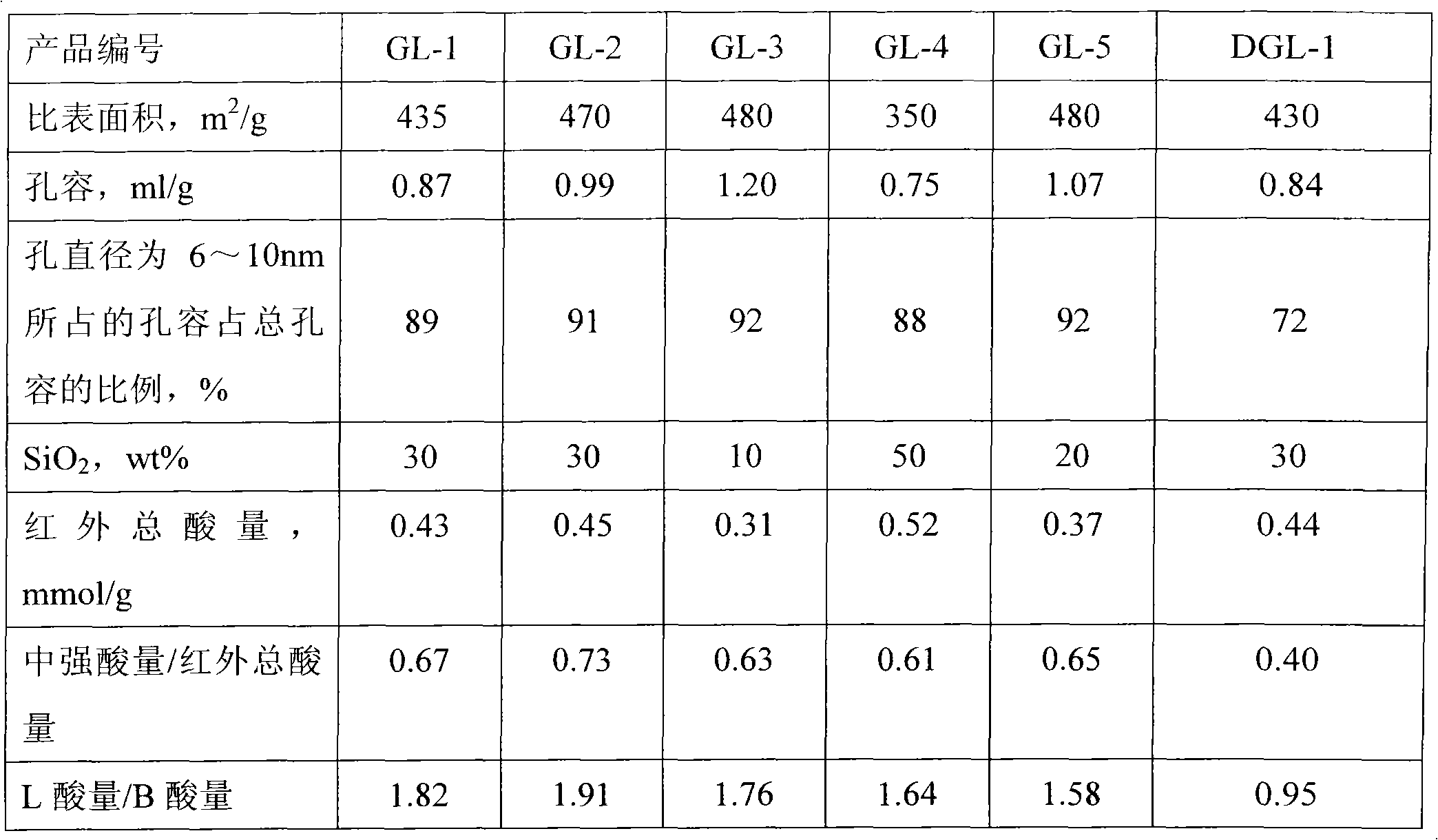

The invention discloses an amorphous silicon aluminium and a preparation method thereof. In the invention, hydro-thermal treatment is carried out on amorphous silicon aluminium obtained by a carbonization method, so that the amorphous silicon aluminium has higher specific surface area and bigger pore volume, the pore distribution is more intensive, and the pore volume the pore diameter of which is 6-10nm accounts for 80-95% of the total pore volume; meanwhile, the acid distribution of the amorphous silicon aluminium is improved; the amount of moderately strong acid and L acid is improved to effectively prevent raw material modules from excessively cracking, which is favourable for improving the selectivity of a target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

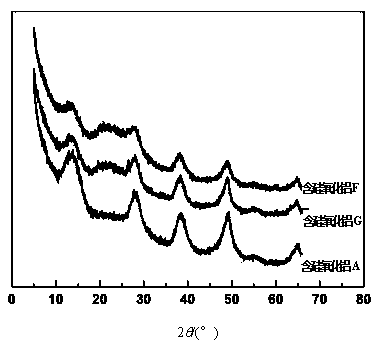

Hydrorefining catalyst and preparation method thereof

ActiveCN106179380AHigh active site densityEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsNitrogenAluminium oxide

The invention discloses a hydrorefining catalyst and a preparation method thereof. The catalyst is a bulk phase hydrorefining catalyst, and comprises alumina and hydrogenation active metal components W, Ni and Mo. The surface phase of the catalyst has the characteristics of high content of active metals, large density of active sites, uniform dispersion of the active metals, good coordination and cooperation among the active metals, and high utilization rate of the active metals, and the catalyst has the characteristics of reasonable pore structure, high mechanical strength and high hydrodesulfurization and hydrodenitrogenation reaction performances, and is especially suitable for being applied to ultra deep hydrodesulfurization and nitrogen removal reaction of diesel oil fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

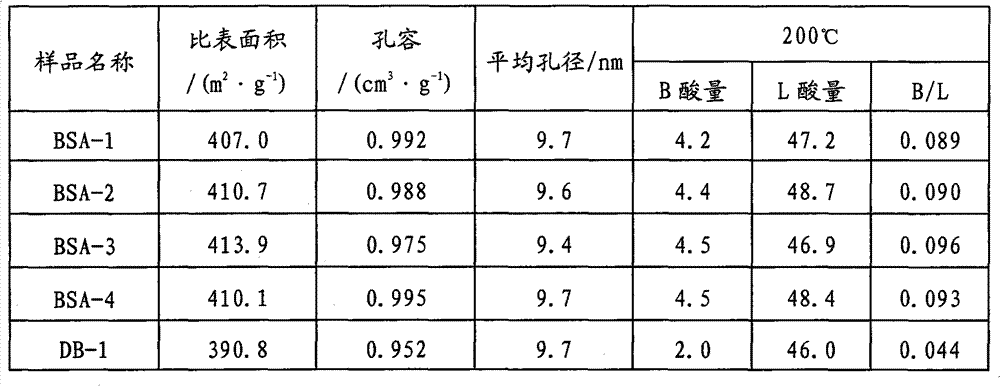

Acidic silicon-aluminium catalytic material

ActiveCN102949987APore characteristics are obviousHigh crystallinityCatalytic crackingHydrocarbon oil crackingCrystal structureCrystallinity

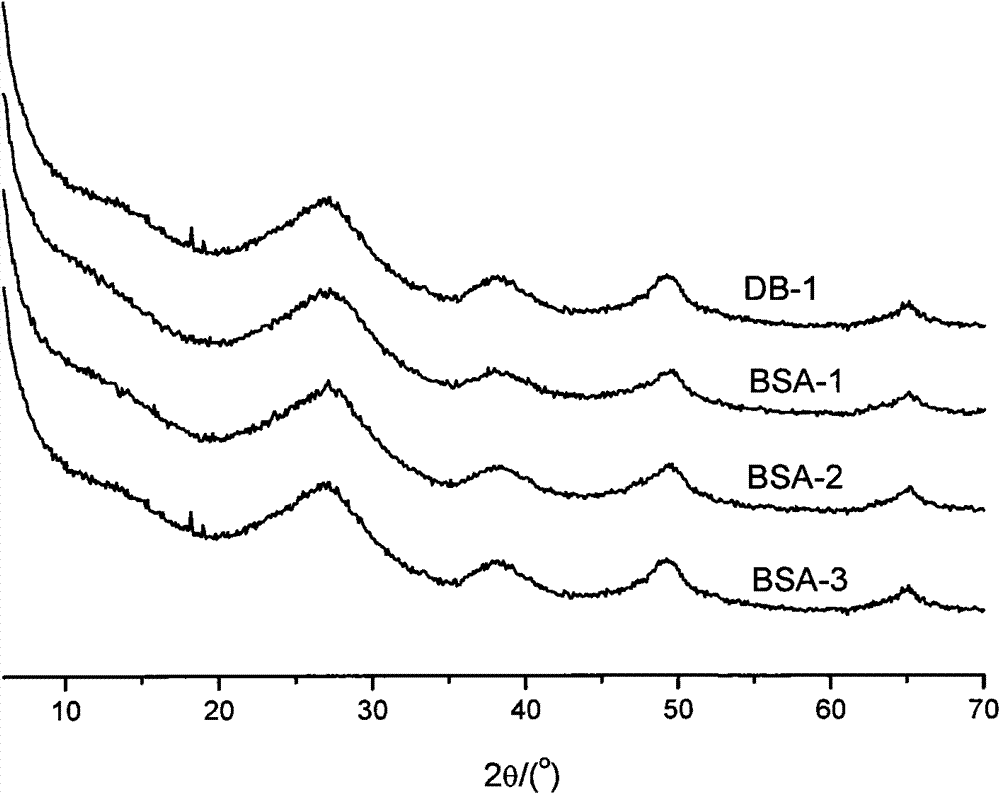

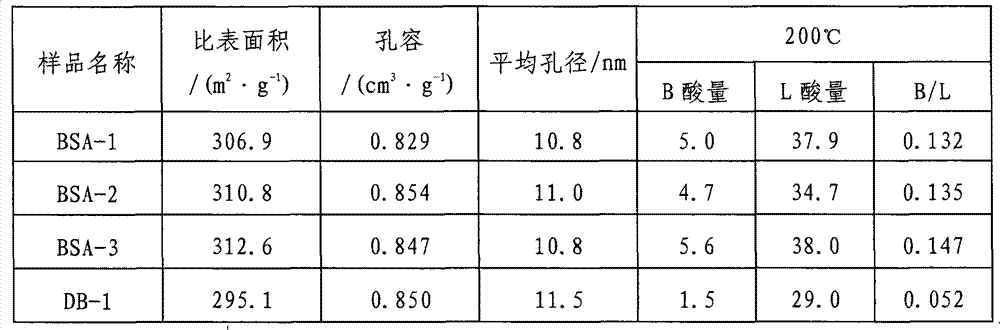

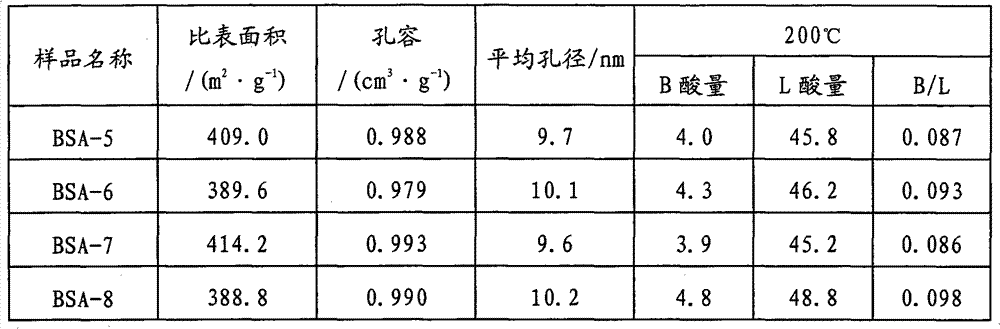

The invention provides an acidic silicon-aluminium catalytic material with a pseudo-boehmite crystal structure. By oxide weight, the anhydrous chemical formula of the catalytic material is (0-0.2)Na2O.(44-46)SiO2.(54-56)Al2O3, the specific surface area is 200-400m<2> / g, the pore volume is 0.5-1.0ml / g, and the mean pore size is 8-15nm. The catalytic material is characterized in that the ratio of pyridine infrared B acid to L acid, measured at 200 DEG C, in the catalytic material is 0.130-0.150. The silicon-aluminium catalytic material has the beneficial effects that the mesopore characteristic of the acidic silicon-aluminium catalytic material is obvious, the pores are distributed in a concentrated manner, meanwhile, the silicon-aluminium catalytic material contains B acid and L acid centers, the ratio of B acid to L acid is obviously increased and the material has better light oil micro-activity. Besides, the acidic silicon-aluminium catalytic material provided by the invention has higher degree of crystallinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

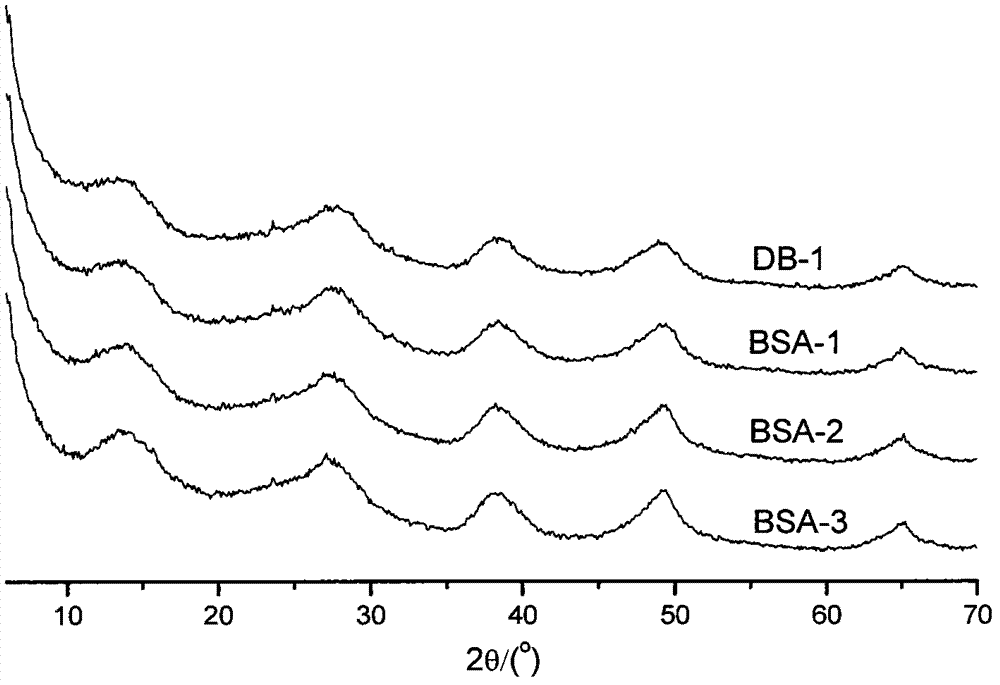

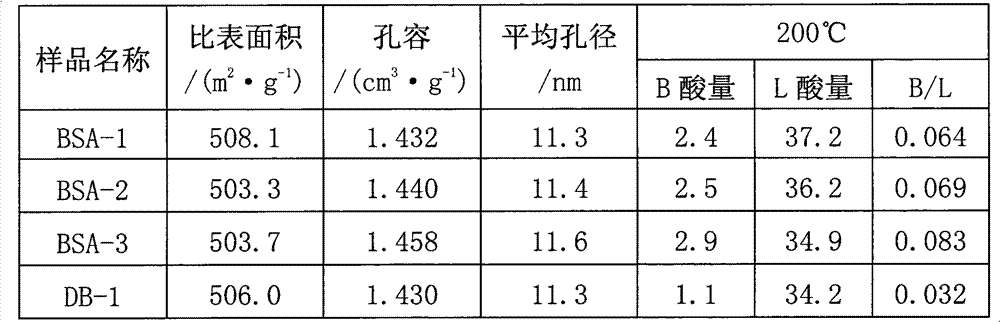

Mesoporous acid silicon-aluminum catalytic material

InactiveCN102949986APore characteristics are obviousHigh crystallinityCatalytic crackingHydrocarbon oil crackingPore distributionMesoporous silica

The invention discloses a mesoporous acid silicon-aluminum catalytic material which is of a pseudo boehmite crystalline phase structure. Based on the oxide weight, the anhydrous chemical expression of the material is (0-0.2)Na2O.(16-20)SiO2.(80-84)Al2O3, the specific surface area is 300-600m<2> / g, the pore volume is 1.0-2.0ml / g, the average pore size is 8-20nm, and the ratio of pyridine infrared B acid to L acid measured at 200 DEG C is 0.060-0.085. The material disclosed by the invention has obvious mesoporous characteristics and centralized pore distribution, and contains the centers of B acid and L acid at the same time; and moreover, the ratio of the B acid to the L acid is obviously increased, and the material obtains better light oil micro-activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pseudo thin allophane and its preparation method

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

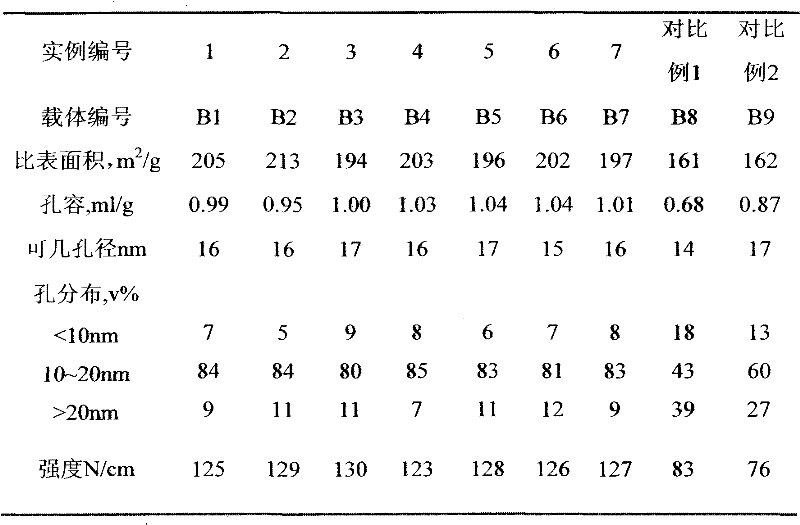

Aluminum oxide carrier and preparation method thereof

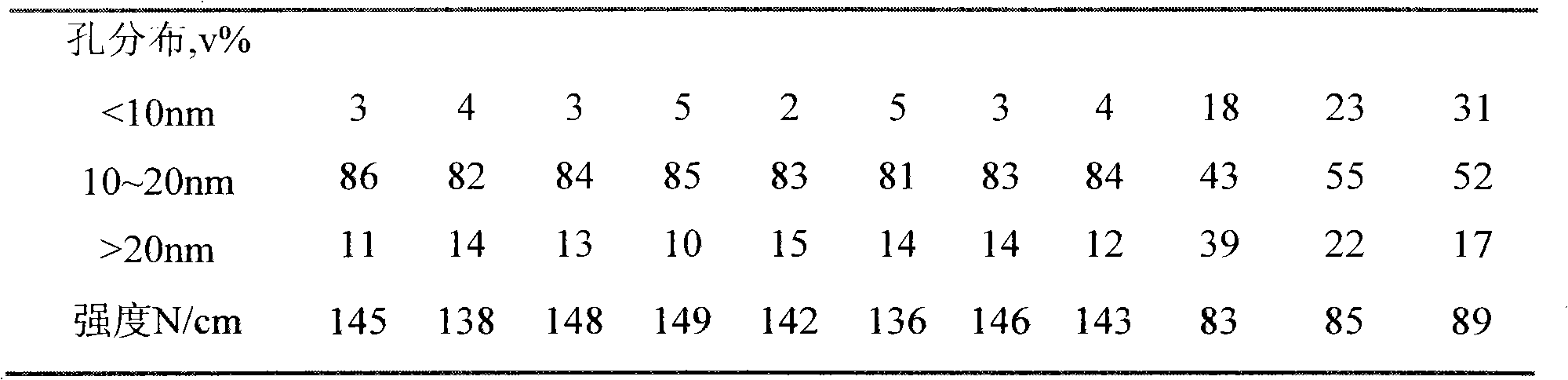

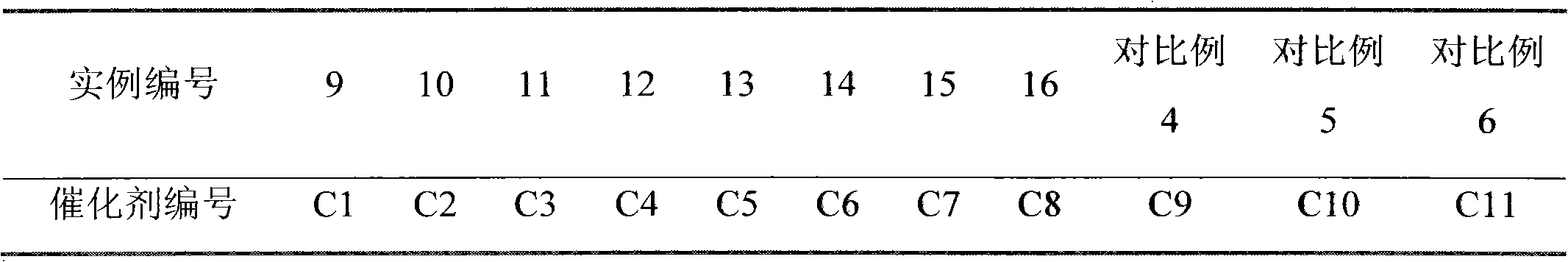

The invention discloses a preparation method of an aluminum oxide carrier. The preparation method comprises the following steps: firstly, performing neutralization reaction on an alkaline aqueous precipitator solution and an acidic aqueous aluminium salt solution to obtain precipitate slurry; secondly, adding water-soluble resin into the precipitate slurry, and performing aging treatment through microwave heating; finally, filtering, washing, drying and shaping the aged mixed material to obtain the final aluminum oxide carrier. The aluminum oxide carrier prepared by adopting the preparation method has a relatively large aperture and concentrated pore distribution, especially 10-20nm pores account for a large proportion of the total pore volume; the aluminum oxide carrier is suitable for being used as the carrier for a heavy oil hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

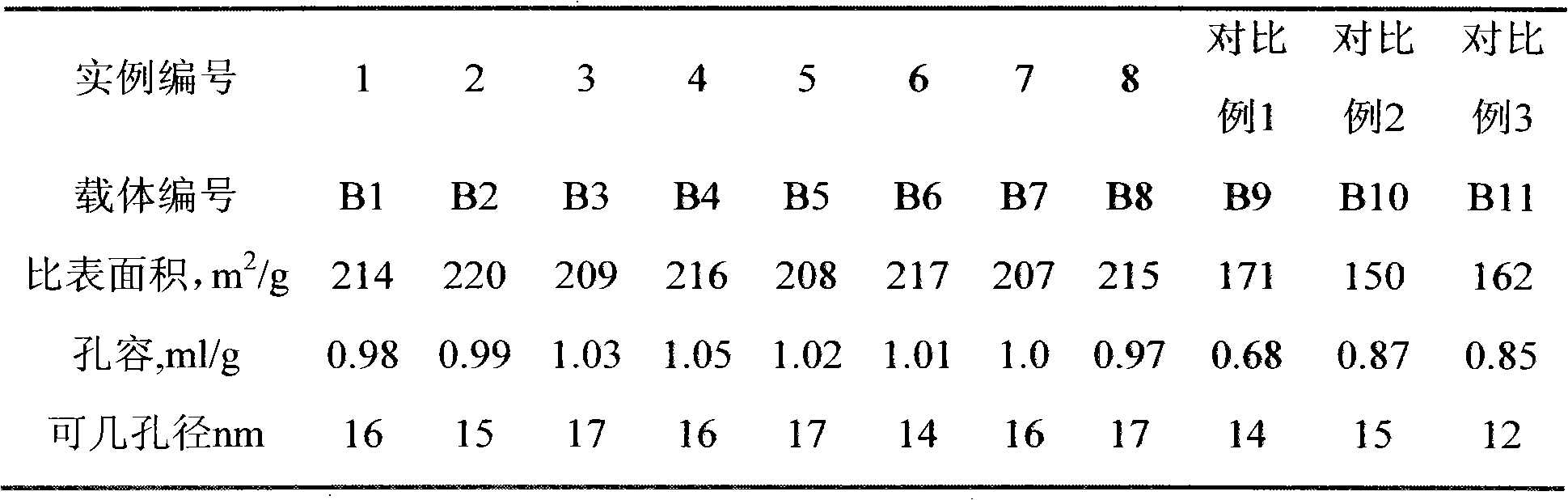

Preparation method for alumina carrier

ActiveCN102310000AReduce dosageExtensive sources of raw materialsCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryPore distribution

The invention discloses a preparation method for an alumina carrier. The preparation method comprises the following steps of: (1) performing pressing hydrothermal treatment on pseudo-boehmite dry colloid powder; (2) kneading the pseudo-boehmite dry colloid powder obtained in the step (1) into plastic; and (3) performing forming on the plastic obtained in the step (2), drying and roasting the formed substance, and thus obtaining the final alumina carrier. The alumina (Al2O3) carrier with large aperture, centralized pore distribution and good strength is prepared by the method; and meanwhile, the method is simple in process, low in reaming agent consumption and low in raw material cost. The prepared alumina carrier can be applied in the fields of petroleum processing, chemical industry, environment friendliness and the like, and is particularly suitable for preparing heavy oil and residuum hydro-treating catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

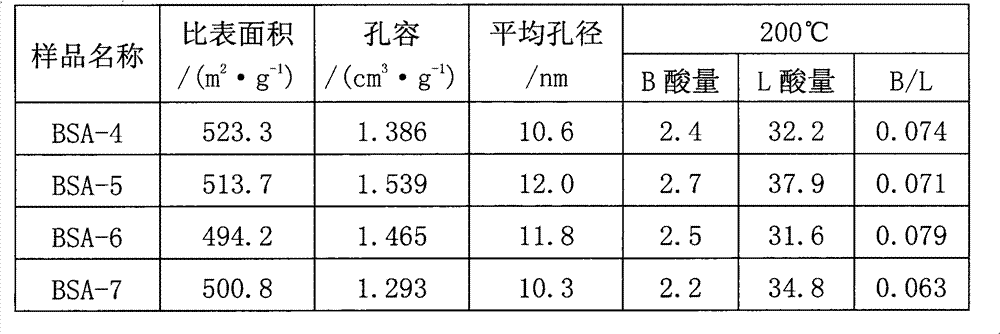

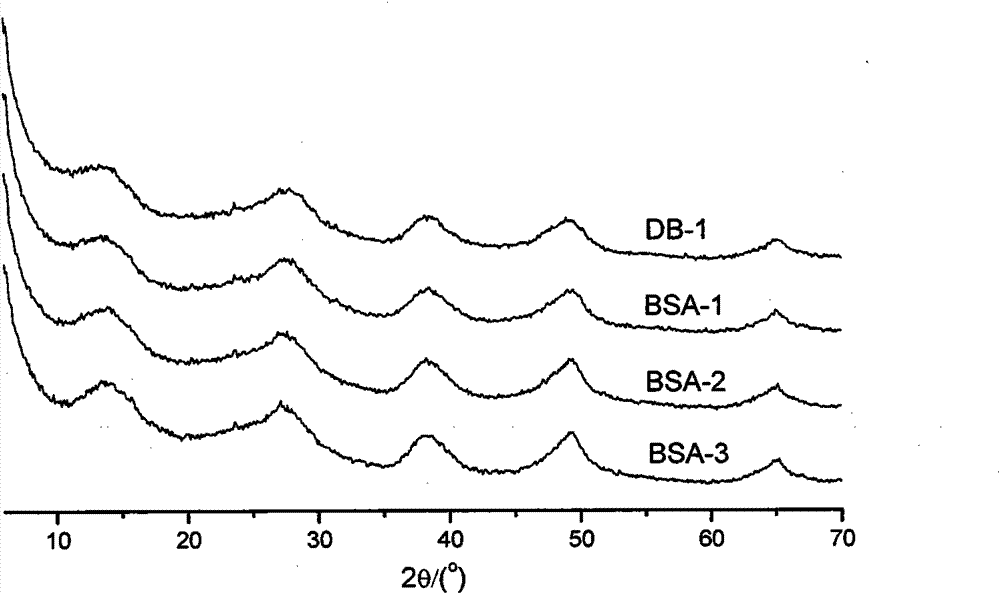

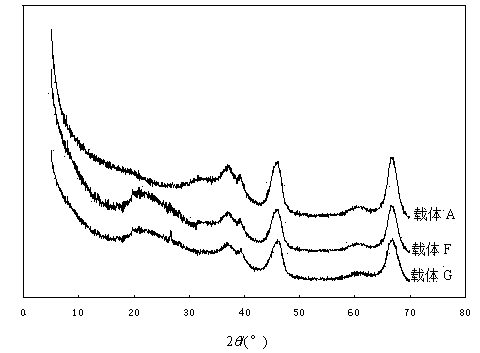

Silicon-aluminium catalytic material with pseudo-boehmite crystal structure

ActiveCN102949989APore characteristics are obviousHigh crystallinityCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsCrystal structureCrystallinity

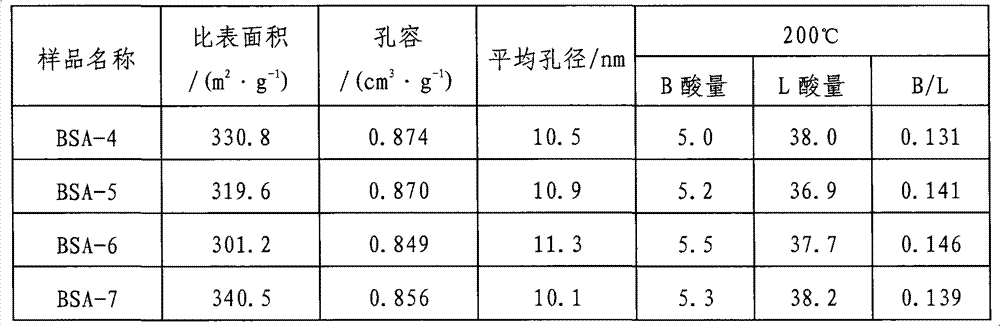

The invention provides a silicon-aluminium catalytic material with a pseudo-boehmite crystal structure. By oxide weight, the anhydrous chemical formula of the catalytic material is (0-0.2)Na2O.(30-33)SiO2.(67-70)Al2O3, the specific surface area is 300-500m<2> / g, the pore volume is 0.5-1.5ml / g, and the mean pore size is 8-15nm. The catalytic material is characterized in that the ratio of pyridine infrared B acid to L acid, measured at 200 DEG C, in the catalytic material is 0.085-0.100. The silicon-aluminium catalytic material has the beneficial effects that the mesopore characteristic of the acidic silicon-aluminium catalytic material is obvious, the pores are distributed in a concentrated manner, meanwhile, the silicon-aluminium catalytic material contains B acid and L acid centers, the ratio of B acid to L acid is obviously increased and the material has better light oil micro-activity. Besides, the acidic silicon-aluminium catalytic material provided by the invention has higher degree of crystallinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A reactor and a method of preparing pseudoboehmite by the reactor

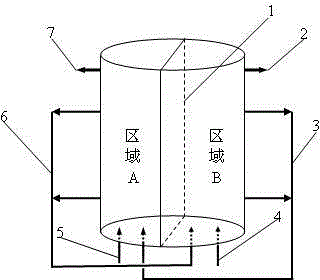

ActiveCN104667841AIncrease profitUniform natureLiquid-liquid reaction processesAluminium oxides/hydroxidesPseudoboehmitePore distribution

A reactor and a method of preparing pseudoboehmite by the reactor are disclosed. The reactor comprises a reactor cylinder. A separating plate is disposed in the reactor cylinder to divide the inner cavity of the reactor into two zones along the axial direction. At least two material circulating pipelines are disposed outside the reactor cylinder. A circulated material outlet and a circulated material inlet in each material circulating pipeline are disposed in different zones. The circulated material outlets are at the upper part of the reactor cylinder and the circulated material inlets are at the bottom of the reactor cylinder. In each of the zones, the corresponding lower part of the reactor cylinder is provided with a material feeding port, and the corresponding upper part of the reactor cylinder is provided with an overflow port higher than the corresponding circulated material outlet. Continuous gel forming can be achieved by the reactor. Pseudoboehmite particles prepared by adopting the reactor are uniform in particle size, so that prepared aluminum oxide is large in pore volume, large in pore diameter and centralized in pore distribution, and the prepared aluminum oxide is uniform and constant in properties, and is not influenced by batch production scales.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydro-treatment catalyst

ActiveCN103769122AUniform particlesEasy to shapeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPore distributionHydrodesulfurization

The invention discloses a method for preparing a hydro-treatment catalyst. The preparation method comprises the following steps: burning clay at a high temperature, grinding, sieving, separately adding the clay burned at a high temperature into an aluminum-containing alkaline solution and an aluminum-containing acidic solution, then carrying out a parallel-flow gel-forming treatment under a proper condition, filtering, water washing, and drying so as to obtain silicon-containing alumina dry gel, then forming, drying, and burning so as to obtain a catalyst carrier, and finally loading a hydrogenation active metal component onto the catalyst carrier through an impregnation method or a kneading method so as to obtain the hydro-treatment catalyst. The preparation method can organically combine clay and the generated alumina particles, and adjusts the pore structure and acidity of the catalyst. The obtained catalyst has the advantages of uniform particle size and concentrated pore distribution. The catalyst is suitable for hydro-demetalization, hydro-desulfurization, or hydro-conversion of heavy oil or residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrorefining catalyst preparation method

ActiveCN106179386AEvenly dispersedIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHeat treatedMineralogy

The present invention discloses a hydrorefining catalyst preparation method. According to the method, a nickel aluminum precipitate is prepared through a positive adding method, a tungsten, molybdenum and aluminum precipitate is prepared through a parallel flow method, an organic amine is added during any one or two above gelatinization processes, the two precipitates are mixed, aging is performed, a hydrothermal treatment is performed while urea is added, and molding and the like are performed to prepare the catalyst. According to the present invention, the prepared catalyst is particularly suitable for super deep hydrodesulfurization and denitrification reaction of diesel oil distillates, and has high hydrodesulfurization and hydrodenitrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

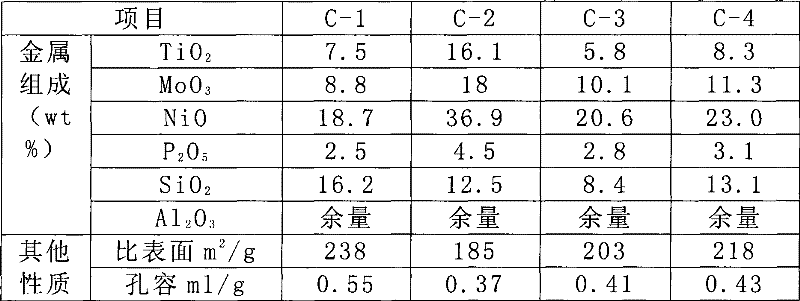

Refined hydrogenation catalyst and its preparation method

ActiveCN1769379ALarger than surfaceConcentrated hole distributionRefining to eliminate hetero atomsHydrogenation processSolvent

Owner:CHINA PETROLEUM & CHEM CORP +1

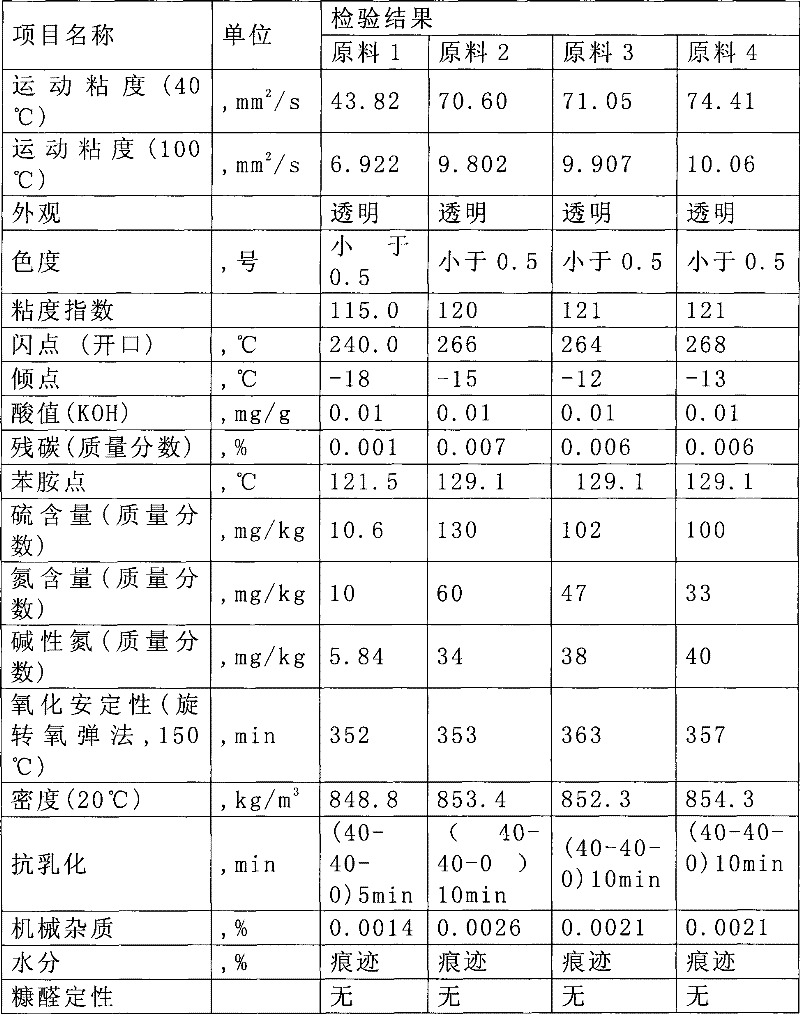

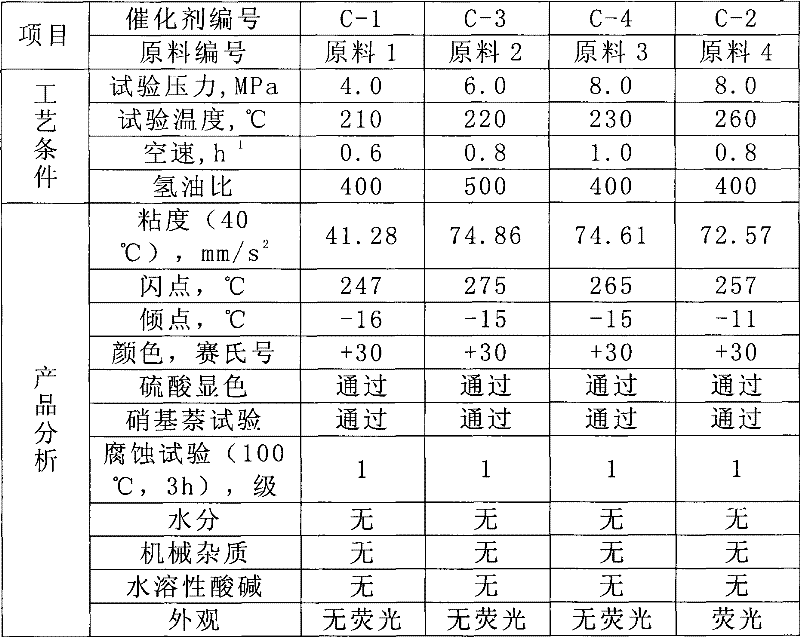

Process for preparing high-viscosity technical white oil

ActiveCN101343558BLarger than surfaceConcentrated hole distributionRefining to eliminate hetero atomsActive componentSulfur

The invention relates to a high viscosity industrial white oil production method, which takes the catalytic cracking mesoplasm lube base oil as the raw material, anti-sulfur catalyst is adopted, the industrial white oil is generated through the first stage hydrogenation, the reaction temperature is 200 DEG C to 320 DEG C, the reaction hydrogen partial pressure is 4.0 MPa to 8.0 MPa, the liquid volume space velocity is 0.3 to 1.5 h-1, and the hydrogen oil volume rate is 200 to 1000; the catalyst carrier is SiO2-Al2O3 modified by TiO2, an active component takes the catalyst weight as the datum, the NiO content is 10 wt percent to 40 wt percent, the MoO3 content is 15 wt percent to 20 wt percent, the TiO2 content is 3 wt percent to 8 wt percent, the surplus is a SiO2-Al2O3 carrier, the catalyst active component content is low, the sulfur-resistant and nitrogen poisoning ability is high, the method is suitable for the impurities, such as sulfur, nitrogen and the like, and the mesoplasm lube base oil with a higher aromatics content, and the superior grade high viscosity industrial white oil is generated by adopting the first stage hydrogenation technology.

Owner:PETROCHINA CO LTD

Prepn process of hydroprocessing catalyst

ActiveCN101088610AHigh pore volumeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsPlastic materialsActive component

The present invention relates to preparation process of hydrocarbon hydroprocessing catalyst, which has gamma-Al2O3 as carrier, VIB and VIII metal as the active component, and Ti, etc as the active assistant, with the assistant Ti being introduced in the pH swinging carbonization process for producing aluminum hydroxide. The process of preparing the catalyst is one complete mixing and kneading process including the steps of introducing Ti to aluminum hydroxide powder via adding Ti salt solution, adding Mo and / or W containing alkaline solution, mixing and kneading until the aluminum hydroxide powder is wetted completely by the alkaline solution, adding Co and / or Ni containing acid solution, mixing and kneading to obtain plastic material, extruding, drying, and roasting to obtain the catalyst. The catalyst has homogeneously distributed Ti component and obviously raised performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing zirconia-alumina composite oxide carrier

ActiveCN102451764AMaintain skeleton structureIncrease profitCatalyst carriersRefining to eliminate hetero atomsAluminium hydroxideZirconia alumina

The invention discloses a method for preparing a zirconia-alumina composite oxide carrier. An aluminum hydroxide sol and a zirconium-containing sol are prepared firstly, and then are mixed, aged, washed, filtrated and dried to obtain a composite oxide xerogel, accordingly, most of zirconia is distributed on the surface of alumina, the impact on a pore structure of the alumina is weakened, the co-catalysis of the zirconia is improved, the advantages of the alumina and the zirconia are fully utilized, and the obtained composite oxide carrier has the characteristics of large pore volume, high specific surface area, concentrated pore size distribution and controllable acidity, and is suitable for being used as a hydrogenation catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

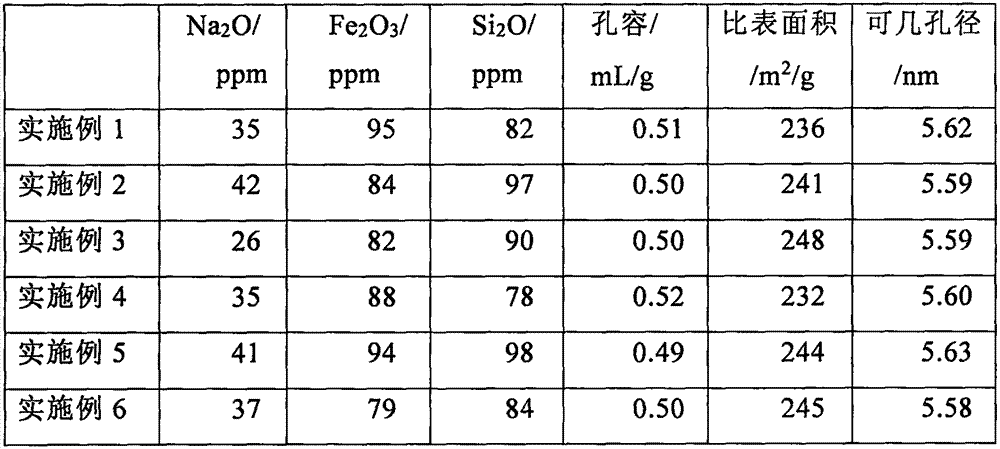

Preparation method of highly pure pseudoboehmite

ActiveCN106938851ALow impurity contentConcentrated hole distributionCatalyst carriersAluminium oxide/hydroxide preparationCatalytic reformingPseudoboehmite

The invention provides a preparation method of highly pure pseudoboehmite. The method comprises the following steps: 1, alkoxylaluminum preparation; 2, filtering; 3, a hydrolysis reaction; 3, alcohol separation; 4, ageing and alcohol distillation; and 6, filtering, and drying for preparing the highly pure pseudoboehmite. The pseudoboehmite product prepared in the invention has the advantages of low impurity content, concentrated pore distribution and good stability. The preparation method has the advantages of environmental protection, no discharge of three wastes, and realization of recycling of the recovered alcohol and solvent after treatment, and the obtained product can be widely applied to catalytic reforming and catalytic hydrogenating carriers.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

Preparation method of alumina dry glue containing silicon

ActiveCN103769069ARegulate acidityUniform particlesCatalyst carriersRefining to eliminate hetero atomsPtru catalystDry glue

The invention discloses a preparation method of an alumina dry glue containing silicon. The preparation method comprises the following steps: burning clay at a high temperature, then grinding the clay, sieving, adding an alkaline solution containing aluminum and an acidic solution containing aluminum into the clay which has been burned at a high temperature, carrying out a glue-forming treatment by adopting a parallel-flow method under proper conditions, filtering, washing, and drying so as to obtain the alumina dry glue containing silicon. The preparation method can organically combine clay and the generated alumina particles, adjusts the pore structure and acidity of the alumina containing silicon, and can further obtain silicon-containing alumina which has the advantages of uniform particle size and concentrated pore distribution. The alumina dry glue containing silicon is suitable for being used as a carrier component of a catalyst, which is applied to hydrogenation demetalization, hydrogenation desulfurization, or hydrogenation conversion of heavy oil or residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

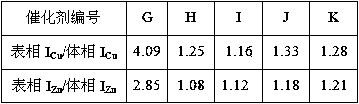

Preparation method of copper-zinc catalyst

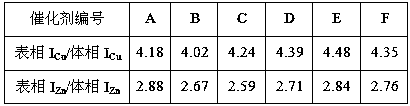

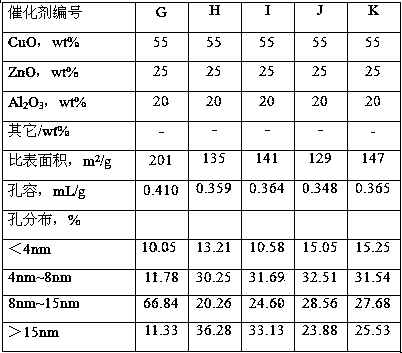

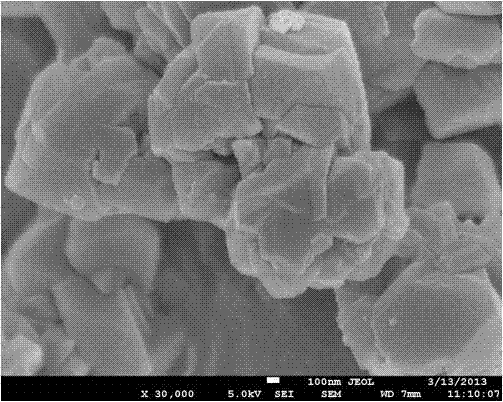

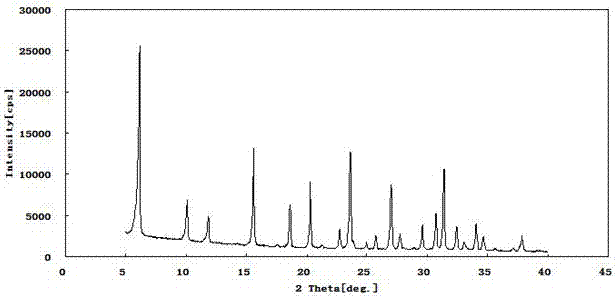

ActiveCN107790137AHigh densityEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsCatalyst activation/preparationHeat stabilityCopper oxide

The invention discloses a preparation method of a copper-zinc catalyst, wherein the preparation method includes the following contents: (1) dissolving Cu and Al soluble salts in water to prepare a solution A, and preparing a sodium carbonate solution B; (2) merging the solution A and the solution B and adding into a reaction tank, gelatinizing, then aging in a stirring condition, and adding nano zinc oxide in the gelatinizing and / or aging process; (3) filtering the slurry obtained in the step (2), and carrying out hydrothermal treatment on the obtained material with water steam, wherein urea is added during hydrothermal treatment; and (4) washing, filtering, drying, roasting and molding the material obtained in the step (3), and thus obtaining the copper-zinc catalyst. The copper-zinc catalyst prepared by the method has large active component copper oxide density in an epiphase, the utilization rate of active metal copper is high, the copper and zinc distribution is more uniform, the cooperation effect of the active metal copper and the auxiliary agent zinc is enhanced, a pore structure of the catalyst is reasonable, the activity, selectivity, heat stability of the catalyst for methanol synthesis are improved and the service life of the catalyst for methanol synthesis is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method

ActiveCN107345155AThe skeleton structure is stable and perfectElimination of non-skeletal structuresMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking method which comprises the following steps that a straight-run diesel oil raw material is in contact with a hydrocracking catalyst to carry out hydrocracking reaction, and an obtained hydrocracking product is separated to obtain heavy naphtha, diesel oil, a jet fuel and hydrogenation tail oil, wherein the used hydrocracking catalyst adopts a modified Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide as carriers, and the modified Y-shaped molecular sieve is an Y-shaped molecular sieve which is rich in meso pores and is concentrated in effective pore size distribution. The hydrocracking method is particularly suitable for a hydrocracking technology for carrying out hydro-conversion on straight-run diesel oil to produce the jet fuel, and has very high catalytic activity and aviation fuel product yield and the quality of a product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydroprocessing catalyst

ActiveCN106179388AImprove distributionEvenly distributedMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSimple Organic CompoundsHydrodesulfurization

The invention discloses a preparation method of a hydroprocessing catalyst. The catalyst is a bulk phase catalyst and comprises Ni<x>W<y>O<z>, MoO3 and aluminum oxide components. The preparation method comprises the following steps of enabling W, Ni and Al components to react with a precipitant to form colloid so as to obtain tungsten, nickel and aluminum precipitate pulp, after performing ageing, performing hydrothermal treatment with steam, adding urea, performing pulping with MoO3, then performing uniform mixing, performing soaking in a solution containing an organic compound, performing shaping and the like so as to prepare the hydroprocessing catalyst. The catalyst is particularly suitable for being used for ultra-deep hydrodesulfurization and denitrification reactions of diesel fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bulk phase hydrotreating catalyst preparation method

ActiveCN106179382AEvenly dispersedIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationWater vapor

The invention discloses a preparation method of a bulk phase hydrogenation treatment catalyst. The composition of the catalyst includes hydrogenation active metal components W, Ni and Mo, alumina, and its preparation method is to prepare nickel and aluminum precipitate slurry I by acid precipitation method; adopt co-current precipitation method to prepare tungsten and aluminum precipitate slurry II, mix the two, after aging, hydrothermal treatment with water vapor and add urea, then combine with MoO 3 After beating and mixing evenly, soaking in the solution containing organic compounds, and then forming and other steps to prepare the hydrogenation treatment catalyst. The catalyst is particularly suitable for application in ultra-deep hydrodesulfurization and denitrogenation reactions of diesel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrofining catalyst composition

ActiveCN106179377AEvenly dispersedImprove coordinationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsDistillationPrecipitation

The invention discloses a preparation method of a hydrofining catalyst composition. The catalyst composition is a bulk phase hydrofining catalyst composition, and comprises hydrogenation active metal components W, Ni and MO, and alumina. The preparation method of the catalyst composition comprises the following steps: preparing a nickel and aluminum mixed precipitate through an ammonia distillation and precipitation technology in the presence of an organic compound, preparing a tungsten, molybdenum and aluminum mixed precipitate through a parallel flow precipitation technology, mixing the nickel and aluminum mixed precipitate with the tungsten, molybdenum and aluminum mixed precipitate, ageing the obtained mixture, carrying out hydrothermal treatment and adding urea, and molding the finally obtained mixture to prepare the catalyst composition. The catalyst composition prepared through the method is especially suitable for being applied to ultra deep hydrodesulfurization and nitrogen removal reactions of diesel oil fractions, and has high hydrodesulfurization and hydrodenitrogenation reaction performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Titanium-containing aluminium hydroxide preparation method

ActiveCN1951818AHigh crystal purityIncrease contentCatalyst activation/preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideTitanium

The invention discloses a making method of titanium aluminium hydroxide, which is characterized by the following: introducing adjuvant titanium in the gelling course of aluminium hydroxide through shaking pH value reciprocally; dispersing titanium evenly on the surface of aluminium hydroxide; enlarging the most probable aperture of titanium aluminium hydroxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrofining catalyst

ActiveCN106179385AHigh density of surface active sitesEvenly dispersedMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsUreaChemistry

The invention discloses a preparation method of a hydrofining catalyst. The method comprises the following steps of in the presence of an organic compound, preparing nickel and aluminum precipitates by a normal precipitation method, preparing tungsten, molybdenum and aluminum precipitates by a parallel flow precipitation method, mixing the nickel and aluminum precipitates with the tungsten, molybdenum and aluminum precipitates, performing ageing, adding urea while performing hydrothermal treatment, then performing shaping and the like so as to prepare the catalyst. The catalyst prepared by the method is high in content of surface phase active metal, and high in active site density, the active metal is uniformly dispersed, the active metal is well coordinated and matched, the utilization rate of the active metal is high, and the pore structure of the catalyst is reasonable. The catalyst is high in mechanical strength, has higher hydrodesulfurization and hydrodenitrogenation reaction properties, and is particularly suitable for being used in ultra-deep hydrodesulfurization and denitrification reactions of diesel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of macroporous alumina support

ActiveCN103055949AHigh specific surface areaConcentrated hole distributionCatalyst carriersAluminium saltsSaw dust

The invention discloses a preparation method of a macroporous alumina support. The method is characterized by taking sawdust produced in the wood processing industry as a pore-enlarging agent, enabling the sawdust to adsorb an inorganic aluminium salt solution after carbonizing treatment, and kneading, forming, drying and roasting the sawdust and an alumina precursor after drying the sawdust, thus obtaining the macroporous alumina support. The alumina support obtained by the method is larger in specific surface area, more concentrated in pore size distribution and high in mechanical strength, also contains part of macropores with sizes more than 100nm, is suitable for preparing heavy / residual oil hydrogenation catalysts, and is favorable for removing macromolecular impurities in heavy / residual oil and delaying the increase of diffusion resistance in heavy / residual oil hydrogenation, thus being favorable for maintaining the activities of the hydrogenation catalysts and lengthening the running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing silicon-containing alumina dry gel

ActiveCN103769229AContent adjustment is simpleHigh pore volumeCatalyst carriersPtru catalystAluminium oxides

The invention discloses a method for preparing silicon-containing alumina dry gel. The preparation method comprises the following steps: mixing original clay with a weak acid and a dispersant, then carrying out a hydrothermal treatment, grinding, sieving so as to obtain modified clay with a particle size larger than 160 meshes; then separately adding the modified clay into an aluminum-containing alkaline solution and an aluminum-containing acidic solution, carrying out a parallel-flow gel-forming treatment under a proper condition, filtering, water washing and drying so as to obtain the silicon-containing alumina dry gel. The preparation method can organically combine clay and the generated alumina particles, and adjusts the pore structure and acidity of the silicon-containing alumina so as to further obtain silicon-containing alumina which has the advantages of uniform particle size and concentrated pore distribution. The obtained silicon-containing alumina dry gel is suitable for being used as a carrier component of a catalyst for hydro-demetallization, hydro-desulfurization, or hydro-conversion of heavy oil or residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrofining catalyst composition and preparation method thereof

ActiveCN106179480AEvenly dispersedImprove coordinationMolecular sieve catalystsHydrocarbon oils refiningSurface phaseMolecular sieve

The invention discloses a hydrofining catalyst composition and a preparation method thereof. The catalyst composition is a bulk phase hydrofining catalyst and comprises hydrogenation active metal components W, Ni and Mo, an SAPO-11 molecular sieve and aluminum oxide, the content of surface phase active metal is high, the active site density is high, active metal is uniformly dispersed, the active metal is well coordinated and matched, the utilization rate of the active metal is high, and the pore structure of the catalyst is reasonable. The catalyst composition is high in mechanical strength, has high hydrodesulfurization and hydrodenitrogenation reactive properties, and is particularly suitable for being used in ultra-deep hydrodesulfurization and denitrification reactions of diesel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com