Patents

Literature

1557results about How to "High specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbent comprising activated carbon, process for making same and use thereof

InactiveUS20080207443A1High specific surface areaEfficiently remove mercuryGas treatmentDispersed particle separationFlueSyngas

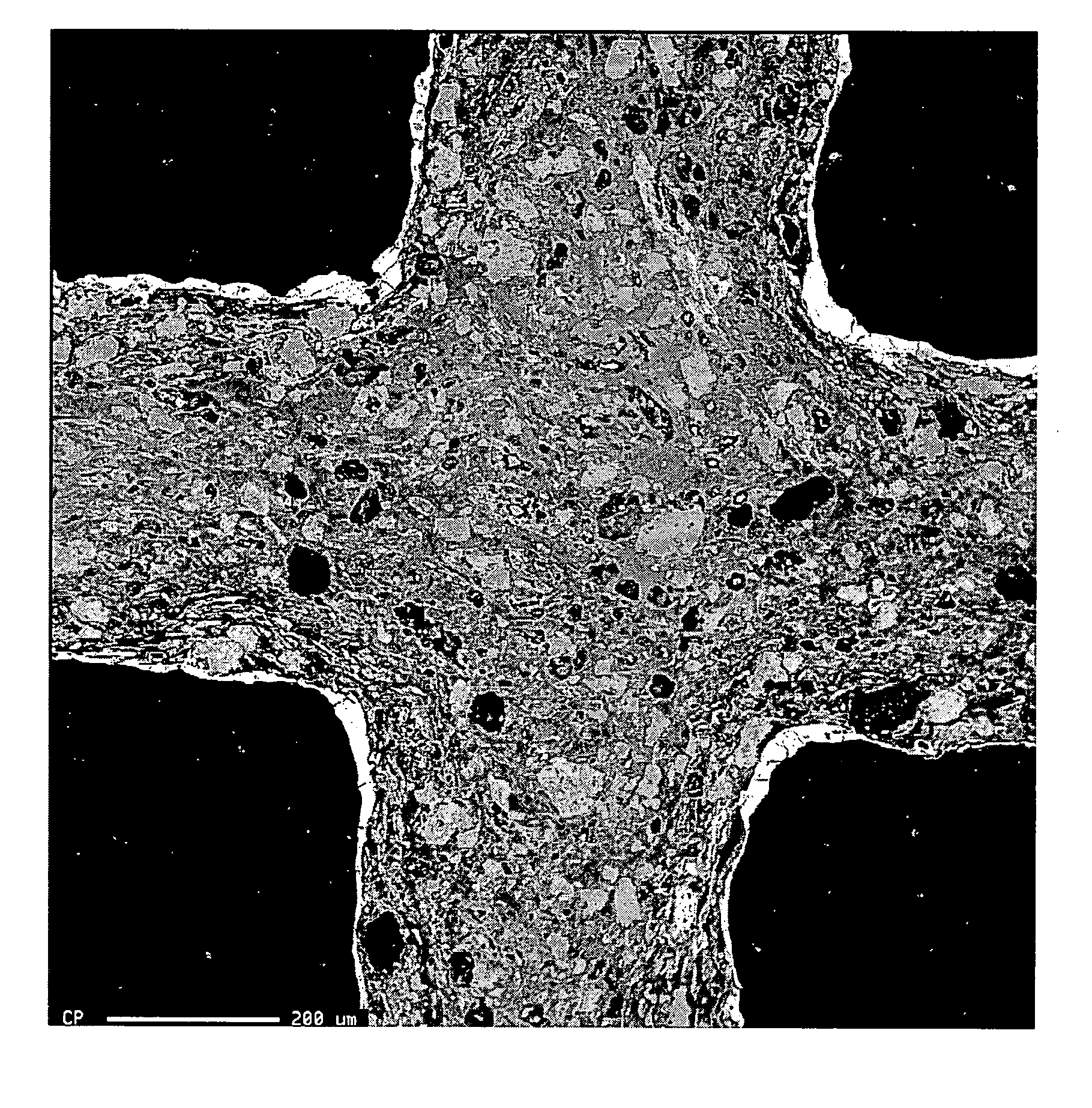

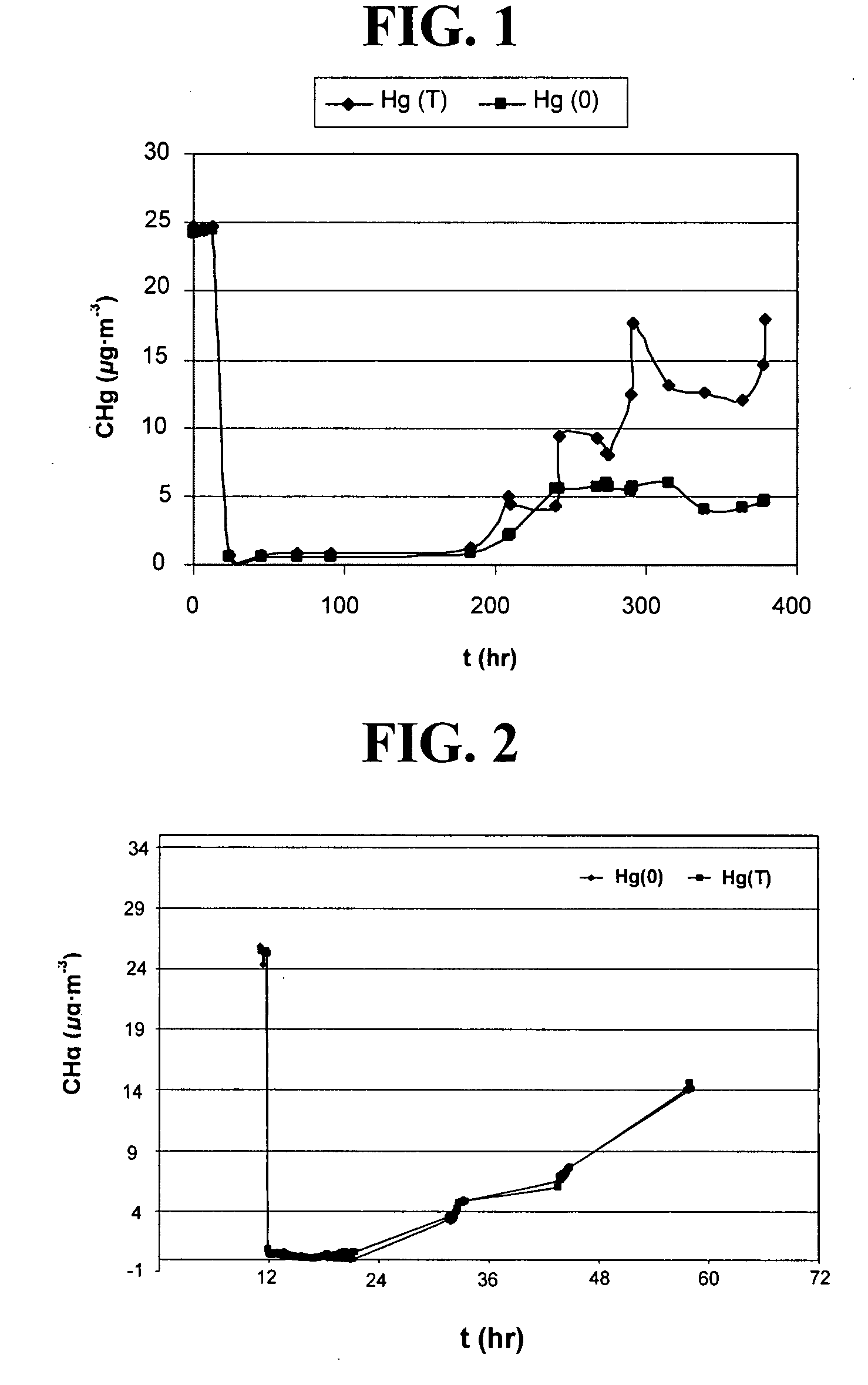

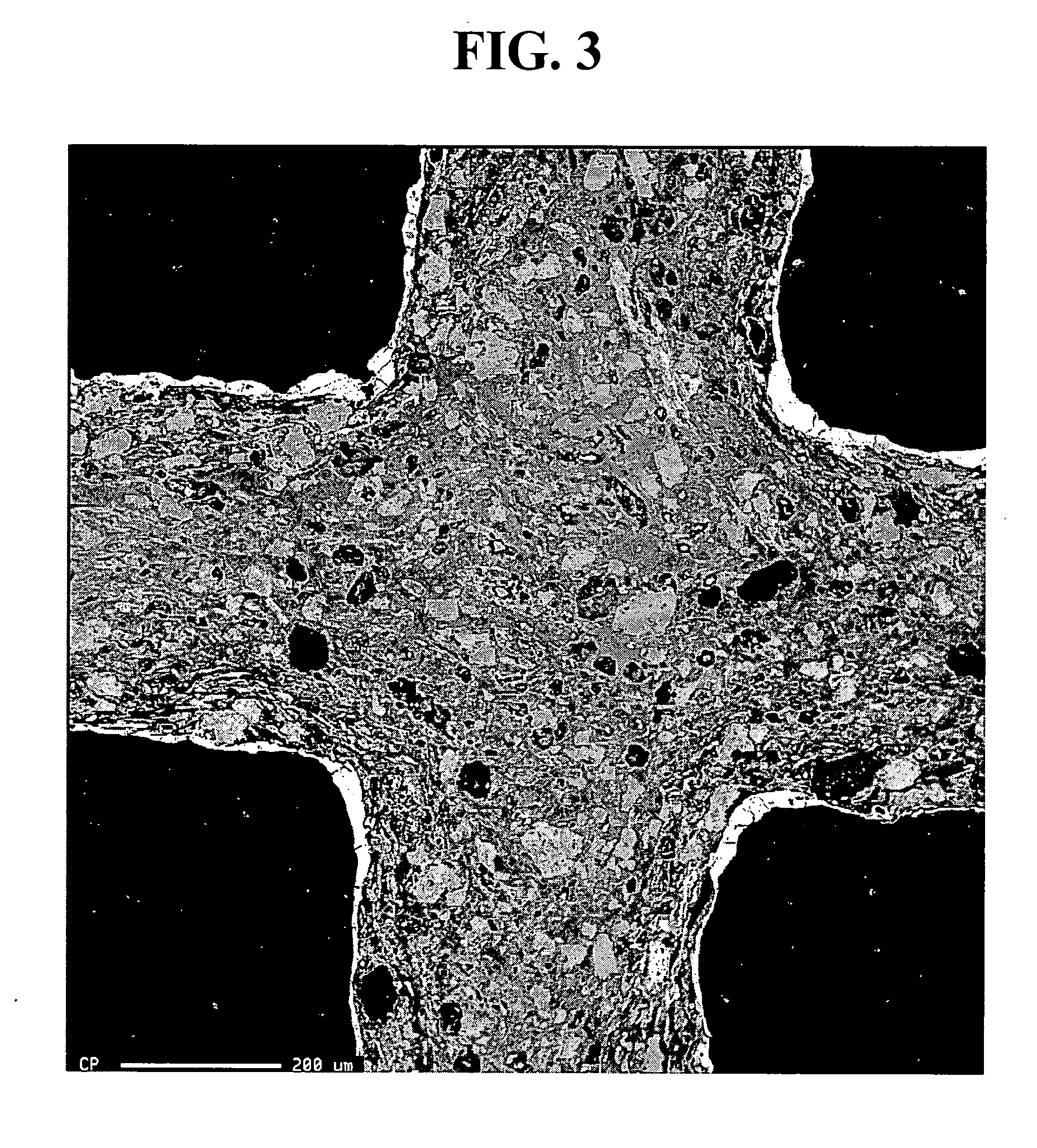

A sorbent body adapted for abating toxic elements from a fluid stream, such as a carbon combustion flue gas stream or a syngas stream produced in coal gasification process, and process for making such sorbent. The sorbent body comprises an activated carbon matrix defining a plurality of pores, sulfur and additive adapated for promoting the abatement of toxic elements from the fluid stream. The sorbent is useful for abatement of, e.g., arsenic, cadmium, mercury and selenium from gas streams.

Owner:CORNING INC

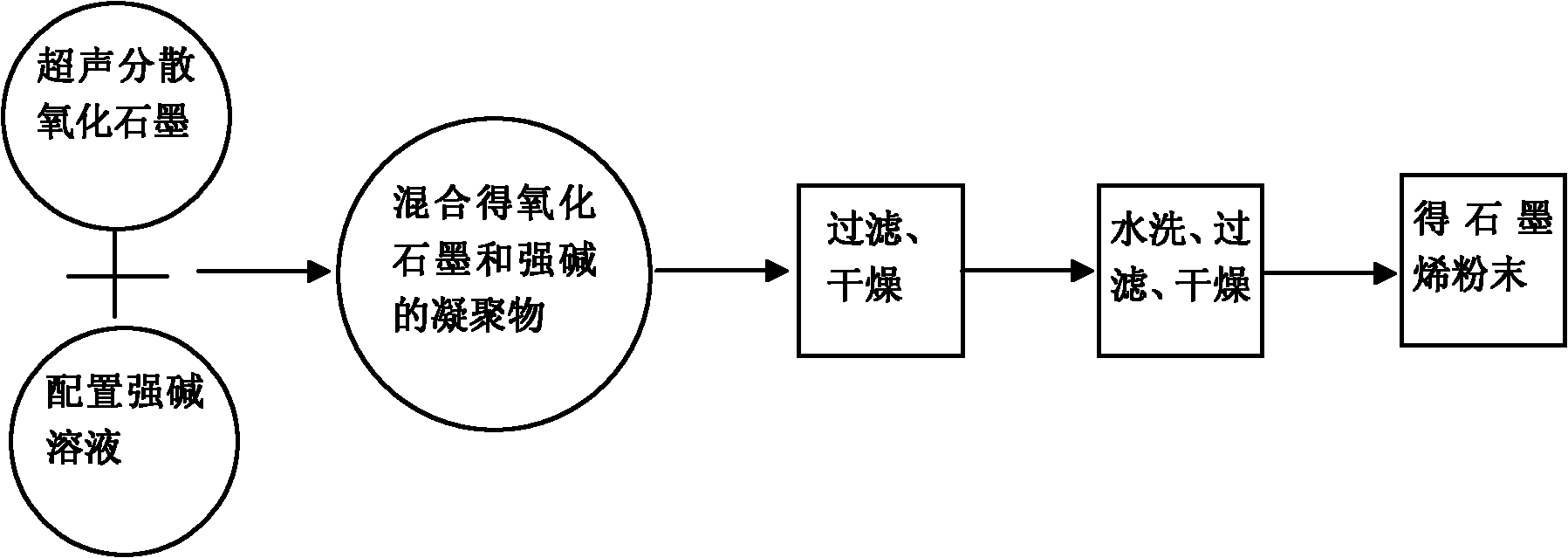

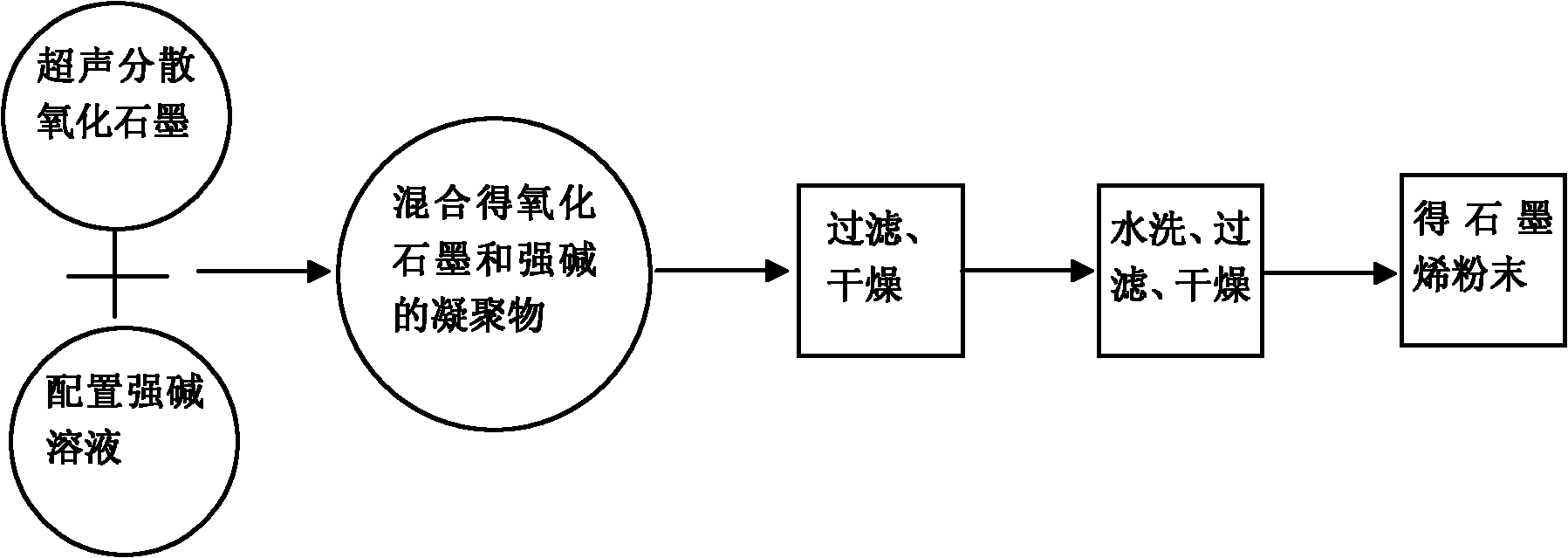

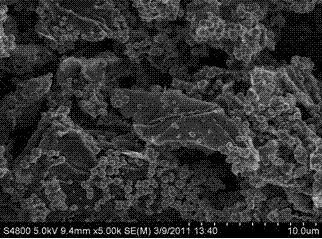

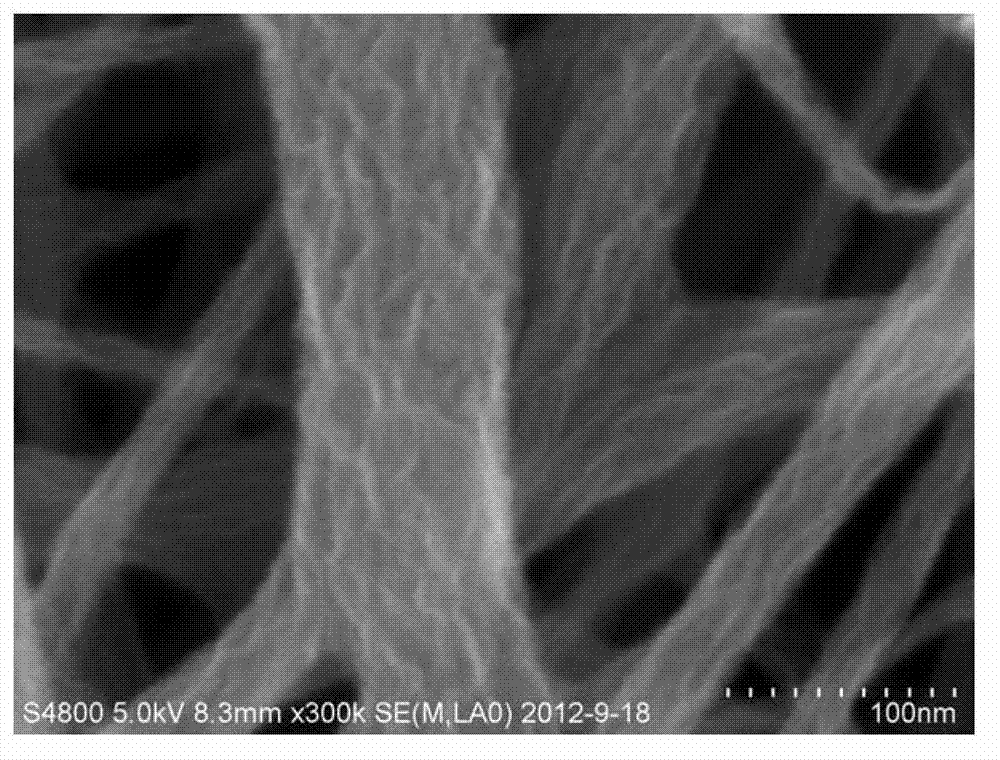

Method for preparing high-specific surface area graphene material by utilizing strong base chemical treatment

ActiveCN102070140AHigh specific surface areaHigh conductanceMaterial nanotechnologyGraphiteChemical treatmentCvd graphene

The invention relates to a method for preparing a high-specific surface area graphene material by utilizing strong base chemical treatment and belongs to the technical field of preparation of graphene materials. By reacting strong base with carbon at high temperature to further perform chemical treatment on graphene powder obtained through thermal treatment or microwave irradiation, nano-scale micropores are rapidly and massively corroded on the surface of graphene, and the specific surface area is greatly improved. Meanwhile, the graphene can be reduced through high-temperature treatment; therefore, high conductivity of the obtained material is guaranteed.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

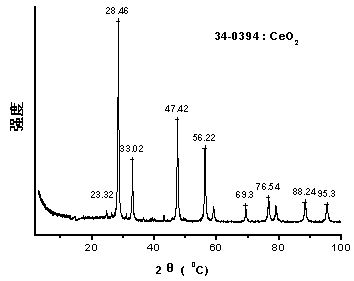

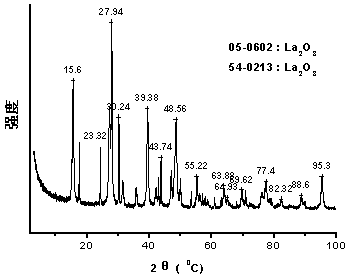

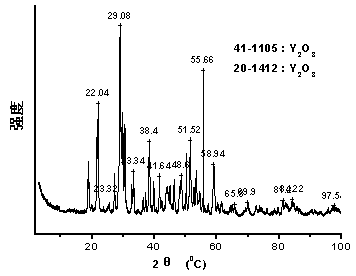

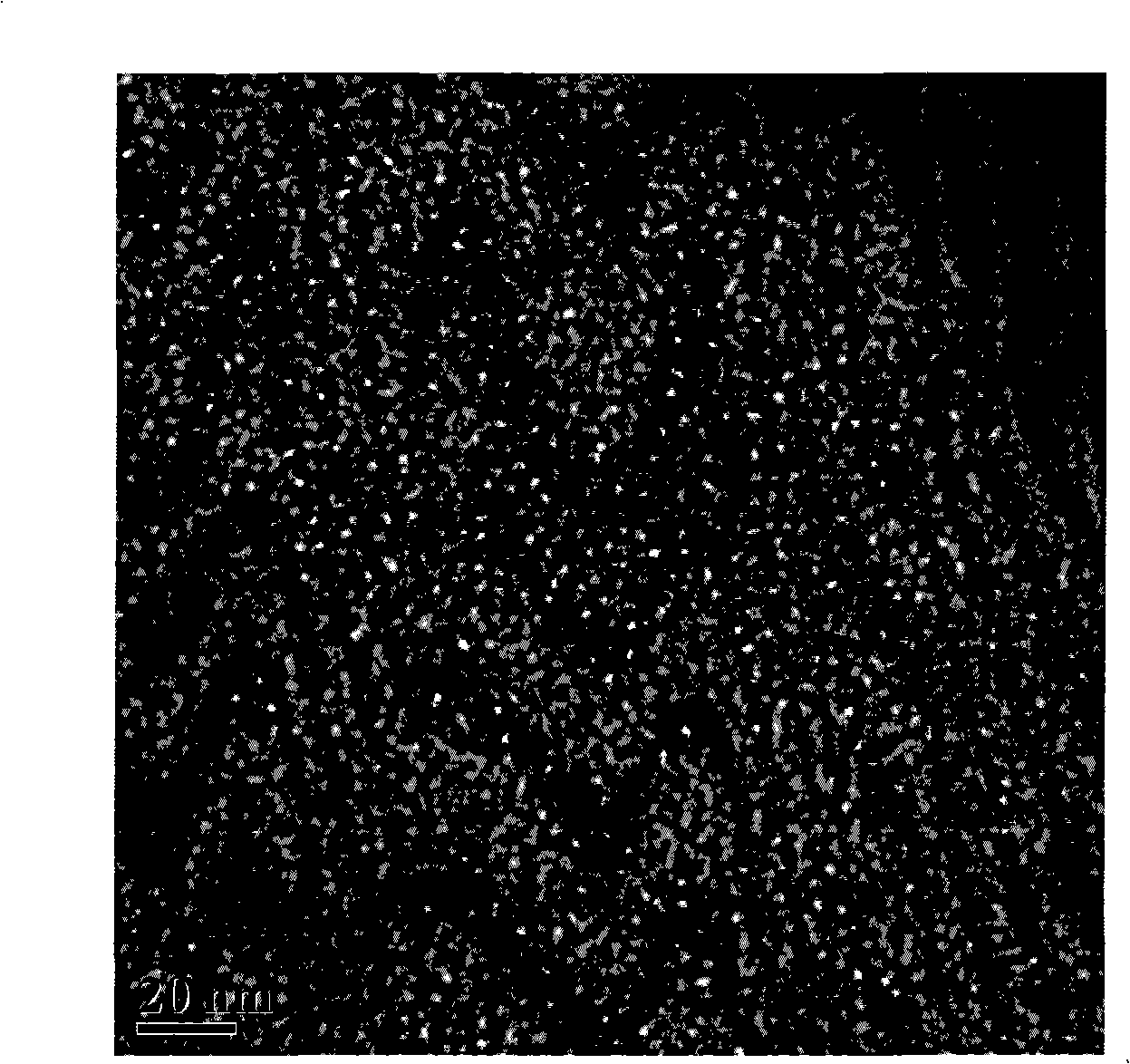

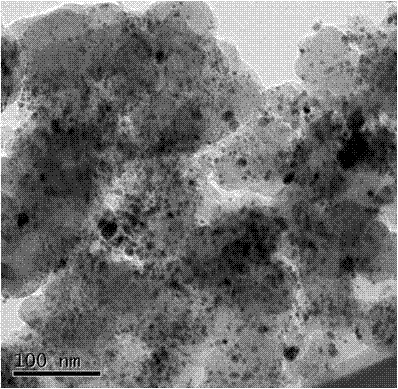

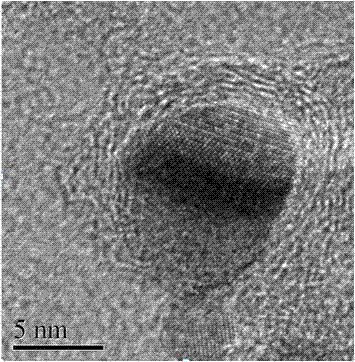

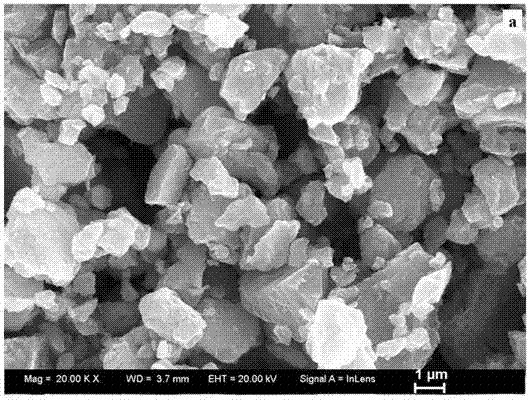

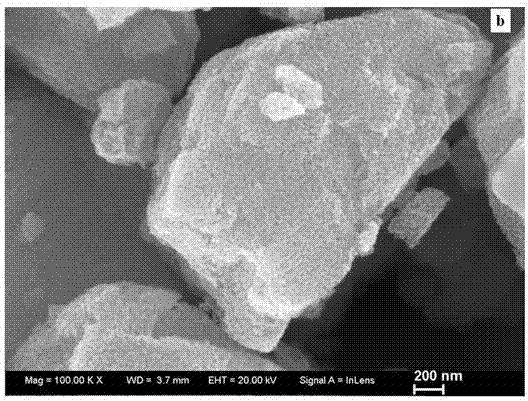

Grapheme/rare earth oxide nanometer composite material and preparation method and application thereof

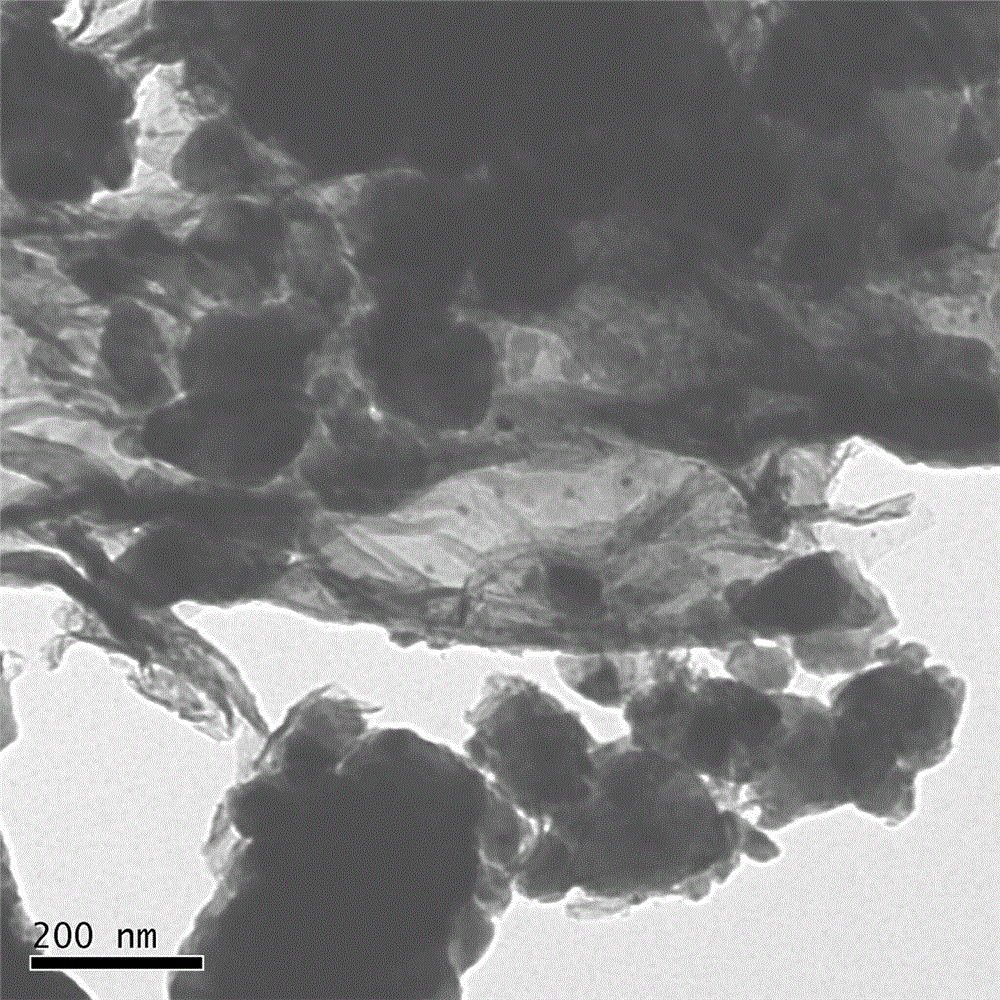

InactiveCN103066292ANot easy to reuniteHigh specific surface areaMaterial nanotechnologyCell electrodesLithium-ion batteryNanocomposite

The invention relates to a graphene / rare earth oxide nanometer composite material and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing oxidized graphene dispersion liquid and a soluble rare earth compound at the weight ratio of (1:1)-(1:10), regulating a pH value to alkalescence, and carrying out hydrothermal reaction to obtain the graphene-rare earth oxide nanometer composite material; and uniformly mixing the oxidized graphene dispersion liquid and the soluble rare earth compound at the weight ratio of (1:1)-(1:10), adding a reducer, and carrying out reflux reaction at certain temperature to obtain the graphene-rare earth oxide nanometer composite material. According to the invention, rare earth oxides are successfully loaded to the surface of graphene, the rare earth oxides can be connected in a physical loading or chemical bonding way because of the electrostatic action of the surface of the oxidized graphene and uniformly dispersed to the surface of a nanometer graphene sheet by being formed into nanometer level particles, the particle size is 5-50 nanometers, and the sheet thickness is 1-5 layers, so that the agglomeration phenomena of the graphene is obviously improved, and the electrochemical property of the graphene nanometer composite material as a cathode material and the circulation stability of the graphene nanometer composite material in the charge-discharge process are effectively enhanced and superior to those the cathode of the traditional commercial lithium ion battery. The preparation method disclosed by the invention has the advantages of simple process, low cost, short period, and the like.

Owner:TONGJI UNIV

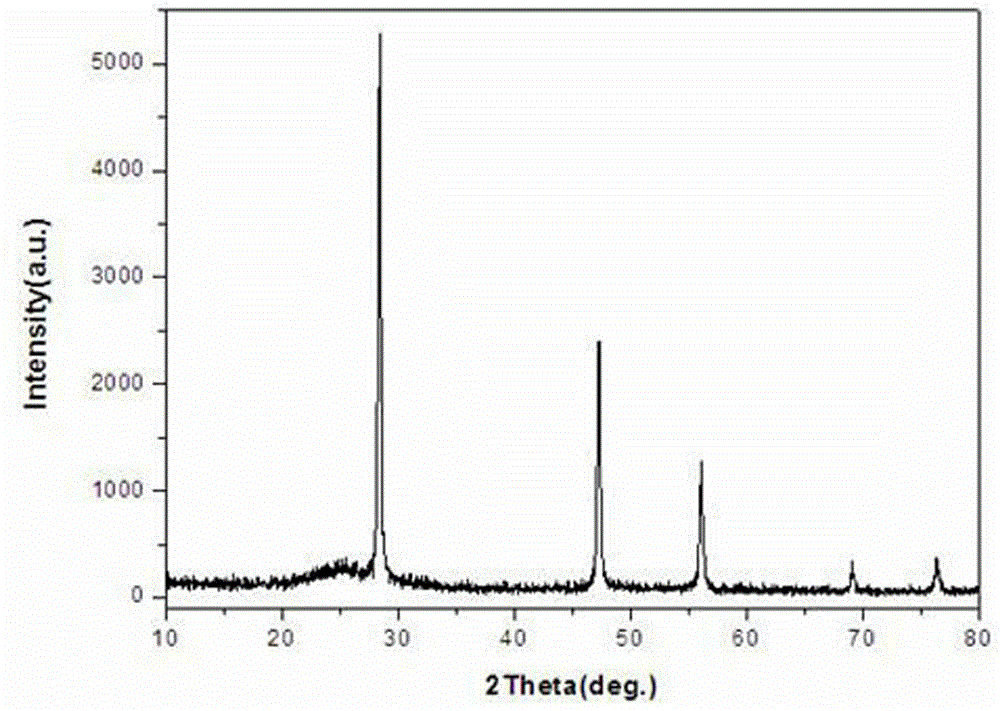

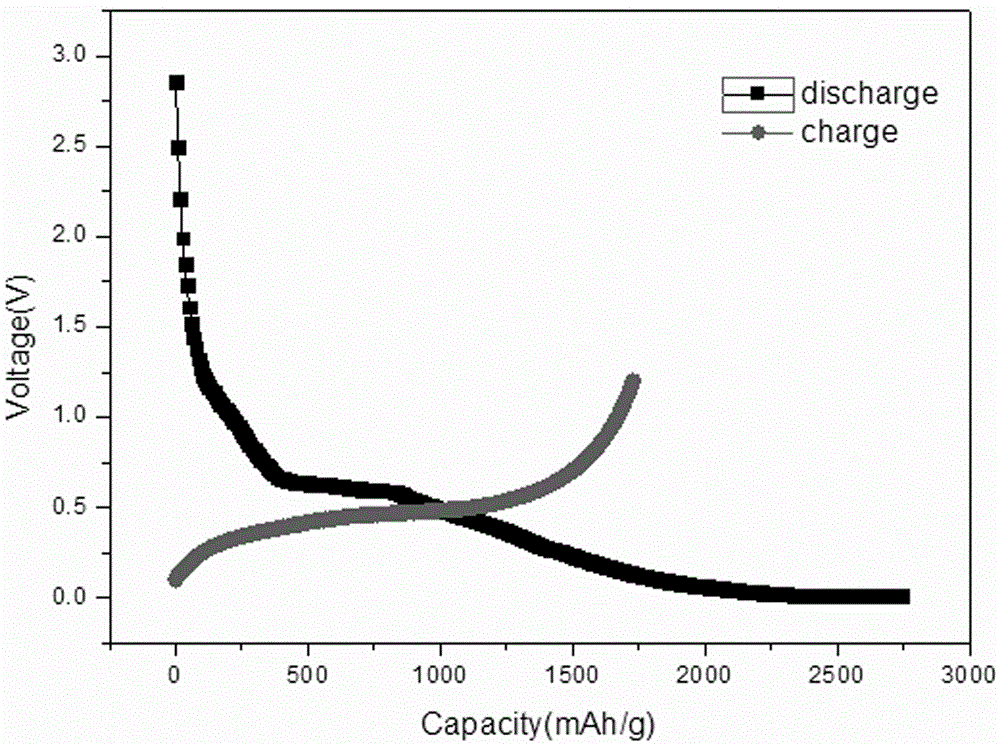

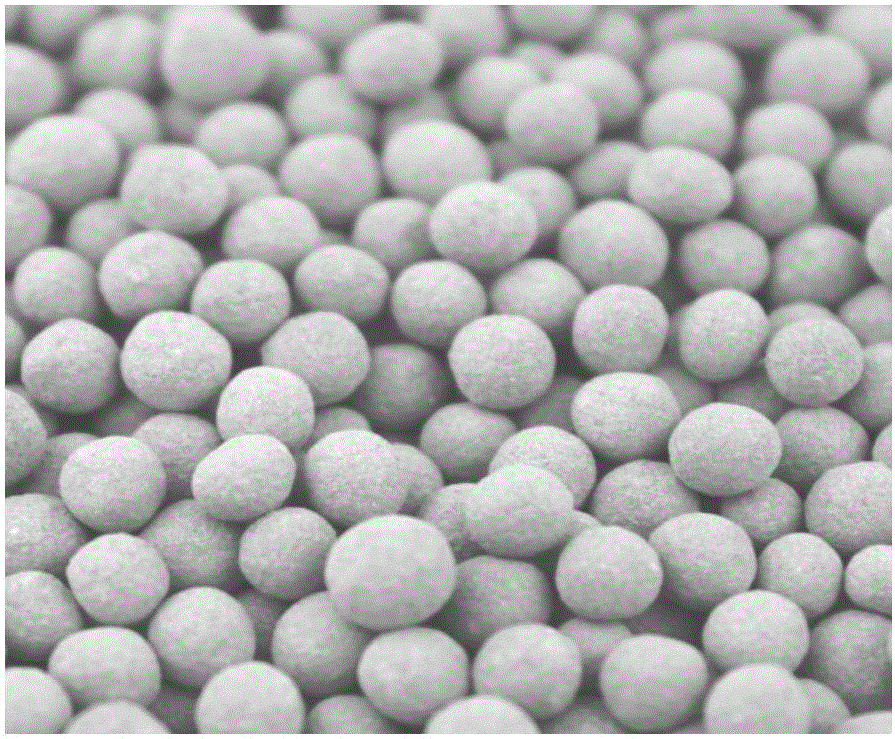

Silicon cathode material coated with graphene and preparation method thereof

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

Preparation method of high-yield biochar

ActiveCN104371748AHigh specific surface areaImprove pore structureProductsReagentsPorosityCarbonization

The invention discloses a preparation method of high-yield biochar, which mainly comprises the following steps: (1) putting a collected biomass raw material into a catalyst solution, stirring and impregnating at normal temperature, and filtering to obtain the biomass raw material containing moisture and catalyst, the moisture weight percentage is 50-150%, and the catalyst weight content is 0.5-5%; and (2) heating the biomass raw material containing moisture and catalyst in an oxygen-free or limited-oxygen atmosphere to 100-180 DEG C at the rate of 0.5-2 DEG C / minute, keeping the temperature for 1-2 hours, heating to 240-300 DEG C at the rate of 0.5-3 DEG C / minute, keeping the temperature for 1-3 hours, heating to 500-900 DEG C at the rate of 10-50 DEG C / minute, keeping the temperature for 1-4 hours, and cooling to obtain the biochar, wherein the yield of the biochar is greater than 40 wt% of the biomass raw material. The method does not need drying in the biochar preparation process; the biomass raw material containing moisture and catalyst and the multi-step carbonization technique are utilized to achieve the goal of enhancing the biochar yield; and the biochar has the characteristics of energy saving, large specific area and high porosity, and can be widely used in the fields of water treatment, functional textiles and the like.

Owner:DONGHUA UNIV

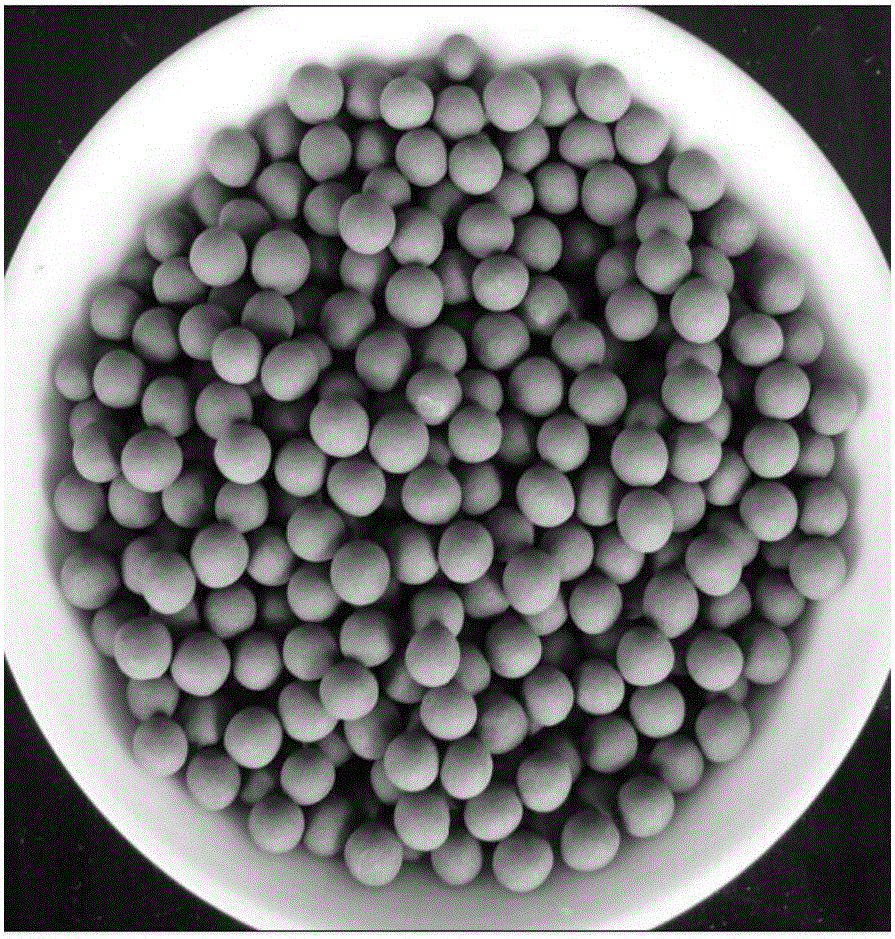

Ceramal material for manufacturing hydrogen-enriched water and preparing method and application thereof

The invention belongs to the technical field of new environment-friendly materials, and particularly relates to a ceramal material for manufacturing hydrogen-enriched water and the preparing method and application thereof. The ceramal material is prepared from, by weight, 30-85 parts of base material component, 20-60 parts of hydrogen-enriched component, 2-25 parts of anti-microbial component, and 3-30 parts of binder. The base material component is prepared from tourmaline, serpeggiante, silicon oxide, calcium oxide and zeolite. The hydrogen-enriched component is prepared from magnesium metal powder, magnesia powder and KDF alloy powder. The anti-microbial component is prepared from zinc oxide, titanium oxide and cerium oxide. The binder is prepared from one or more of high-purity distilled water, carboxypropyl cellulose and bentonite. The ceramal material can be used for manufacturing alkalescent water, negative-potential water and hydrogen-enriched water and also has an anti-microbial function and a water activating function. The invention further provides the preparing method and application of the ceramal material. The technology is simple and easy to realize. The ceramal material can be applied to products including water purifiers, water purifying kettles and cups.

Owner:山东木齐健康科技有限公司

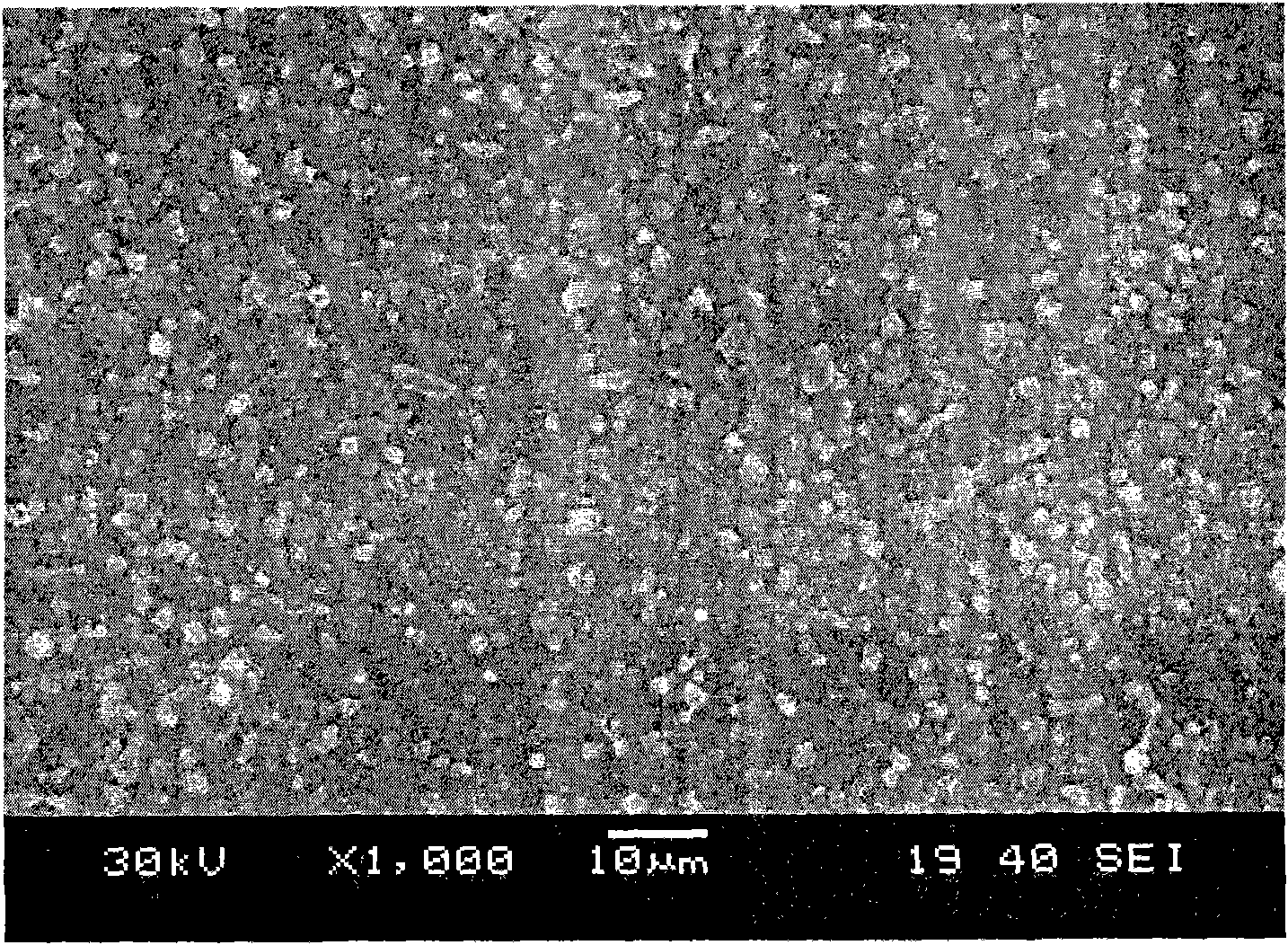

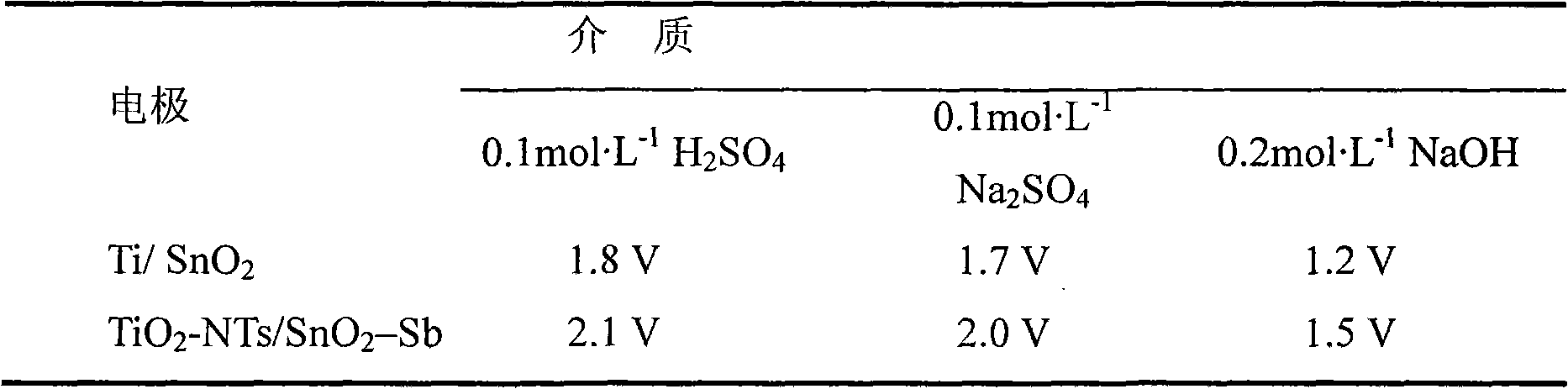

Preparation method of titanium-based titanium dioxide nanotube stannic oxide electrode

ActiveCN101857288AOrderly rowsHigh specific surface areaWater/sewage treatmentAnodic oxidationTin dioxide

The invention relates to a preparation method of a titanium-based titanium dioxide nanotube stannic oxide electrode, belonging to the technical field of electro-catalysis electrode preparation. The method comprises the following steps: firstly adopting an anodic oxidation method to prepare a titanium dioxide nanotube on a titanium matrix, thus improving the specific surface area of the titanium matrix; and depositing stibium and tin in the titanium dioxide nanotube by an electro-deposition method successively, and performing thermal oxidation to lead the stibium doped stannic oxide to be bonded firmly with the titanium dioxide nanotubes directly connected with the titanium matrix. The stannic oxide crystal particles prepared by the electro-deposition method are dispersed evenly, and the electrode surface is compact and has no crack. The method overcomes the defect that crack is generated on the surface of the electrode prepared by the traditional brush coating thermal decomposition method. The electrode prepared by the invention has high potential for oxygen evolution, high electric catalytic activity and long service life and the like; the preparation process is easily controlled, has low cost and lower equipment requirements; and the prepared electrode can effectively treat pollutants that are poorly biodegradable.

Owner:NANJING UNIV OF SCI & TECH

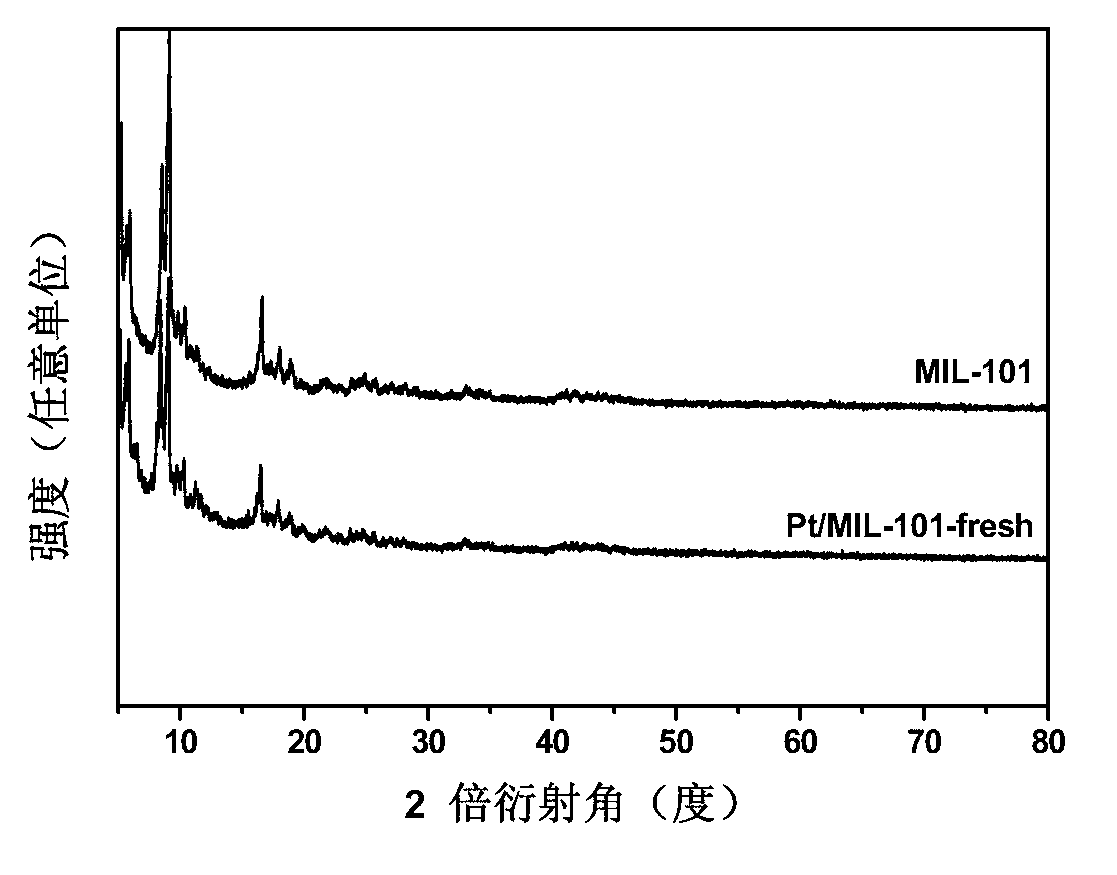

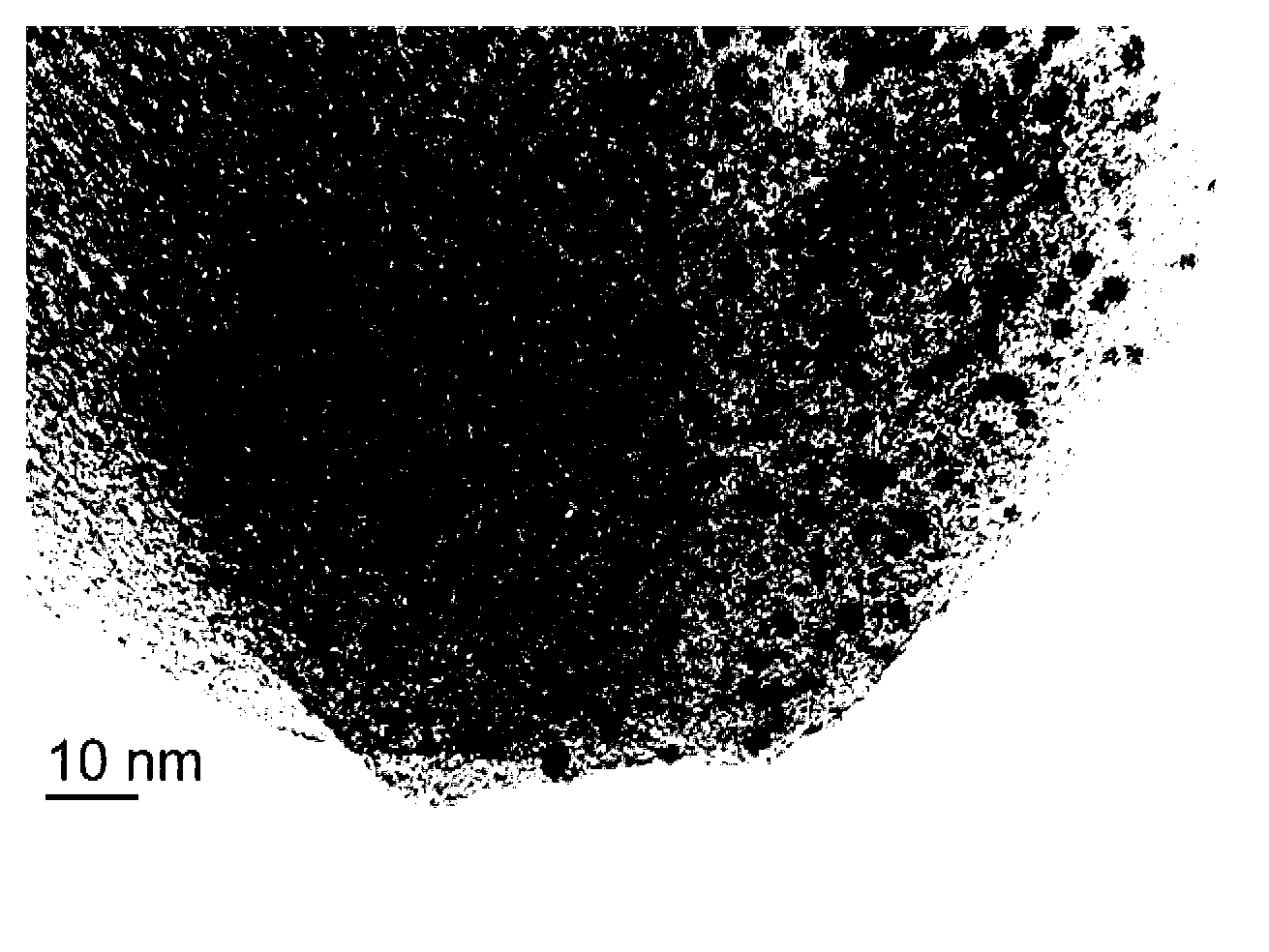

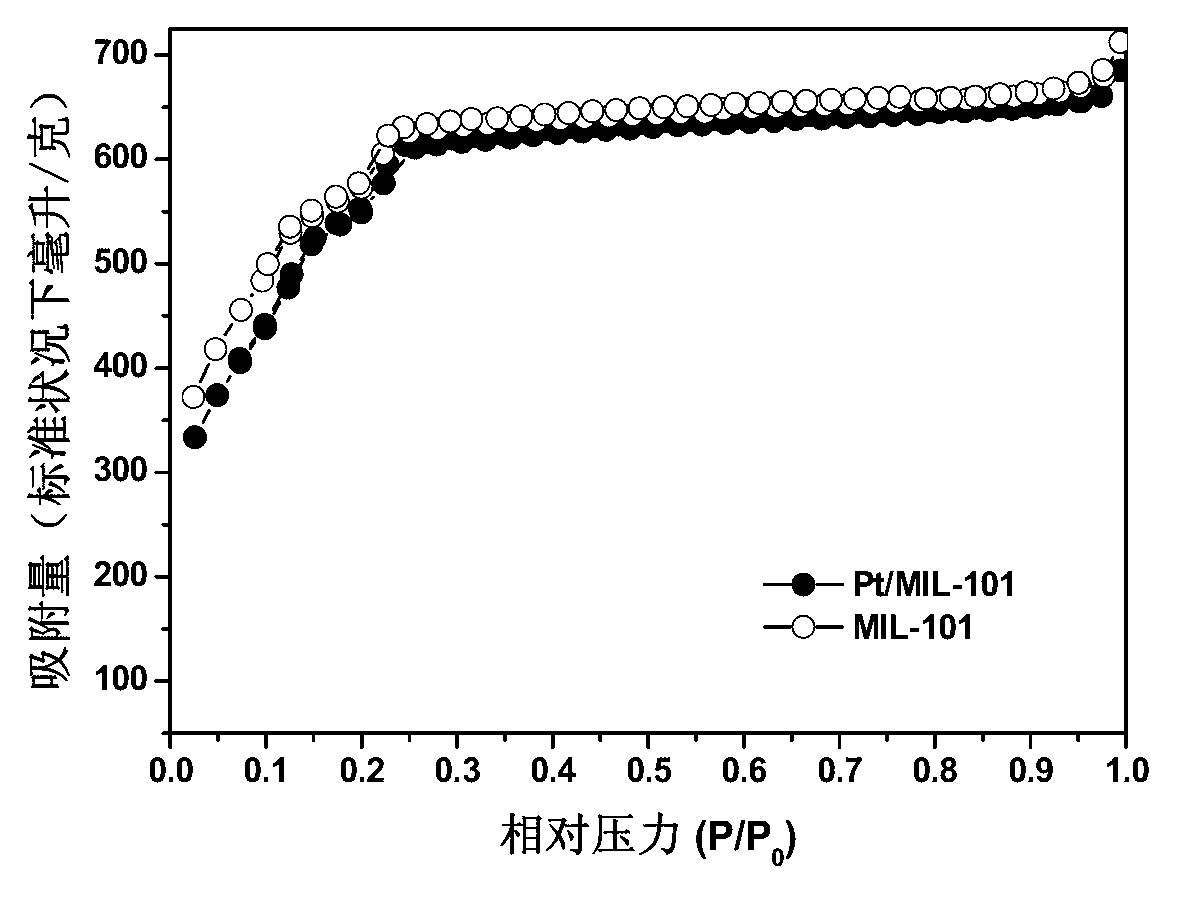

Metal organic skeleton structure material load platinum catalyst, as well as preparation method and application thereof

InactiveCN103008012AHigh specific surface areaImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEnvironmentally friendlyCatalytic hydrogenation

The invention discloses a metal organic skeleton structure material load platinum catalyst. The metal organic skeleton structure material load platinum catalyst comprises a carrier and an active component loaded on the carrier, wherein the carrier is a metal organic skeleton structure material MIL-101, and the active component is platinum. The invention also discloses a preparation method of the metal organic skeleton structure material load platinum catalyst and a catalytic hydrogenation application thereof. The catalyst provided by the invention has a higher specific surface area and a larger porthole structure, the catalyst is suitable for application in a catalytic hydrogenation reaction, the catalyst is environmentally-friendly, the reaction conditions are gentle, and the catalyst is high in efficiency and good in stability.

Owner:EAST CHINA NORMAL UNIVERSITY

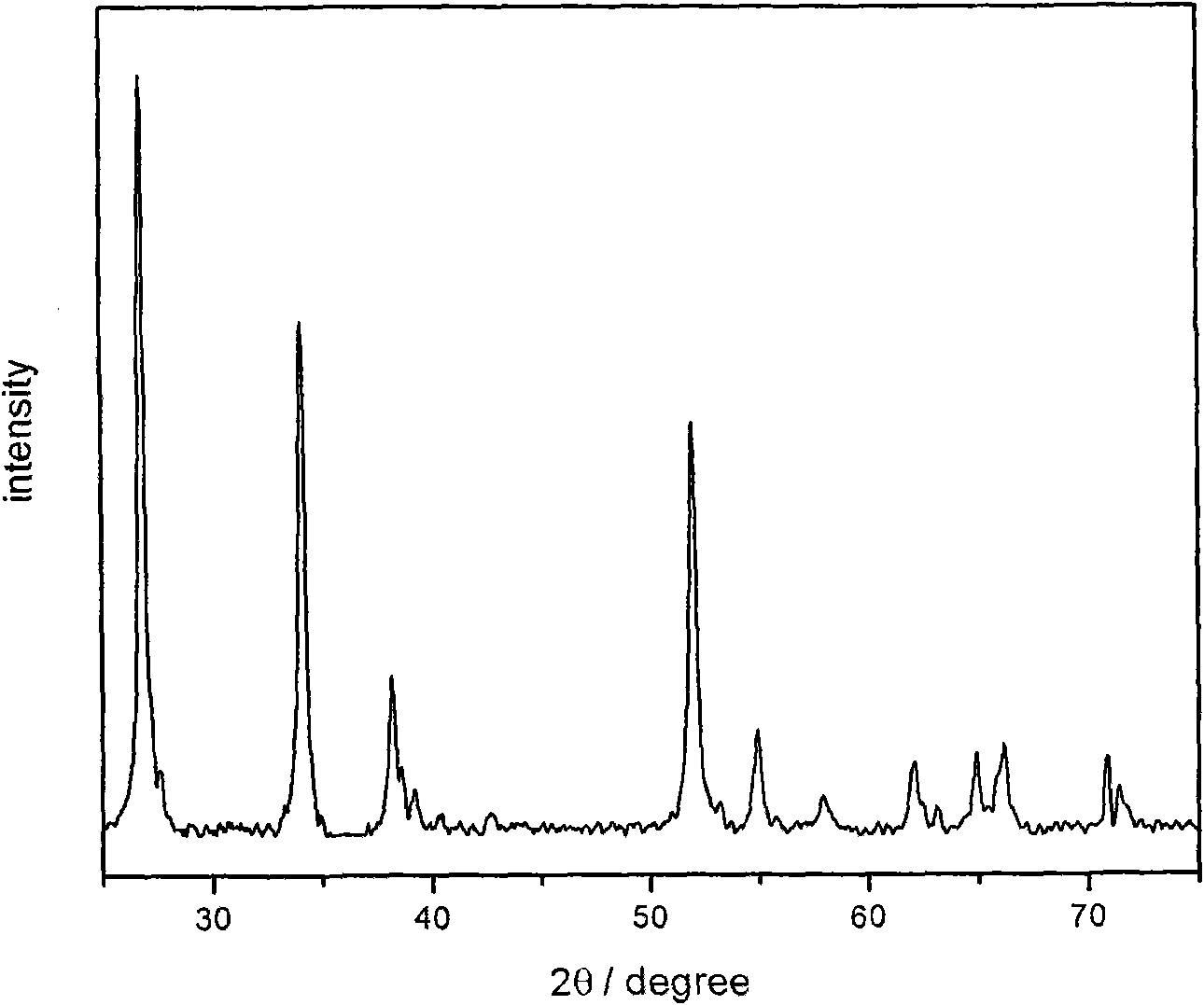

Super-stable Y zeolite, preparation method and application thereof

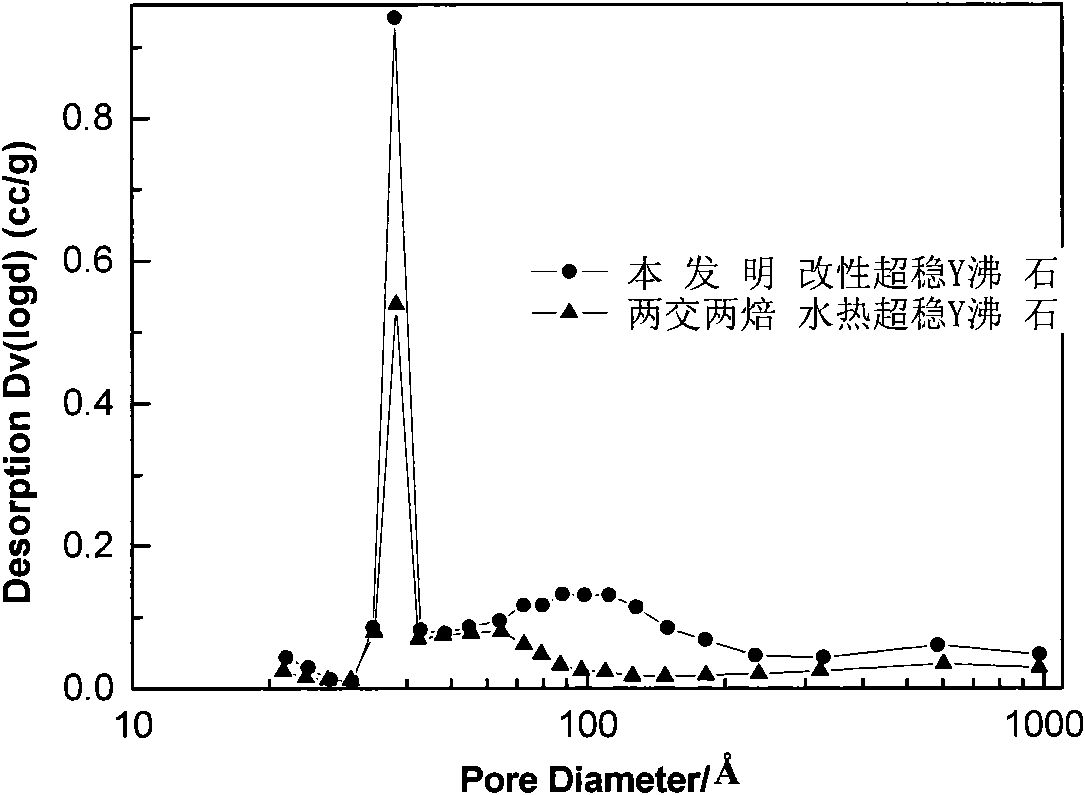

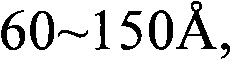

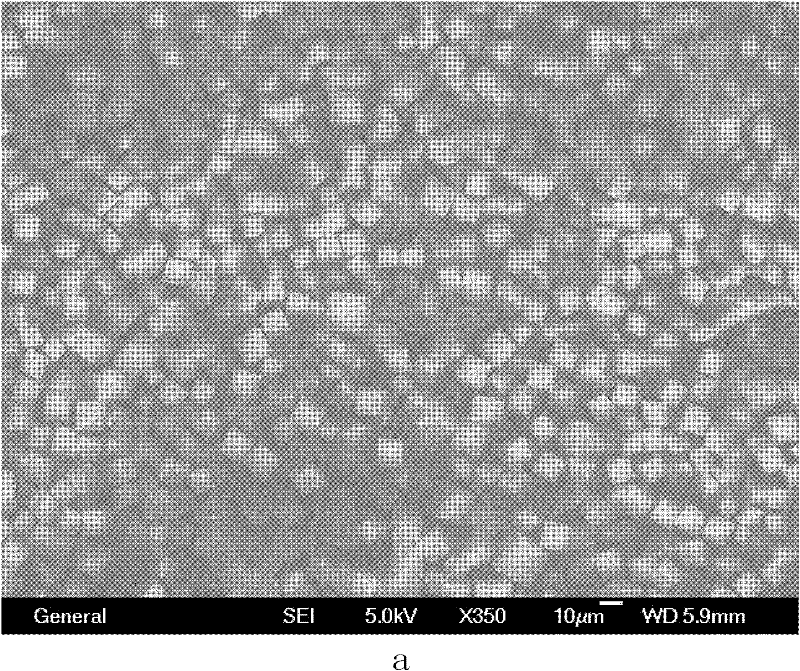

ActiveCN102020289AHigh crystallinityIncrease the areaCatalytic crackingMolecular sieve catalystsOrganic acidGasoline

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing phosphorus-silicate-aluminum molecular sieve with metal-amine-complex as template

ActiveCN102259892AHigh specific surface areaHigh reactivityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesIonMolecular sieve

The invention relates to a synthesis of a molecular sieve and aims to provide a method for synthesizing a silicoaluminophosphate molecular sieve by the use of a metal-amine-complex as a template agent. The method provided by the invention comprises the following steps of: adding boehmite or aluminium hydroxide into deionized water, adding dropwisely phosphoric acid with stirring, and adding amorphous silica; successively adding a divalent metal salt and organic amine after uniformly mixing to make the PH value of a gel to reach 7-9, stirring at room temperature for 12 hours, placing into a reaction vessel for a crystallization reaction, washing a solid crystal product to a neutral one, and drying to obtain a molecular sieve powder. According to the invention, different metal ions can be introduced so as to adjust the acidity of the SAPO-34 molecular sieve; And the metal ions in the obtained molecular sieve can be dispersed uniformly and the metal ions can be introduced in larger amounts; in addition, the molecular sieve has higher specific surface area and has a high reaction activity in a catalytic reaction. The synthesis method provided by the invention requires a simple template agent and low cost, the crystallization temperature is controlled from 150 DEG C to 200 DEG C, and a method for removing the template agent is simple and easy to operate.

Owner:ZHEJIANG UNIV

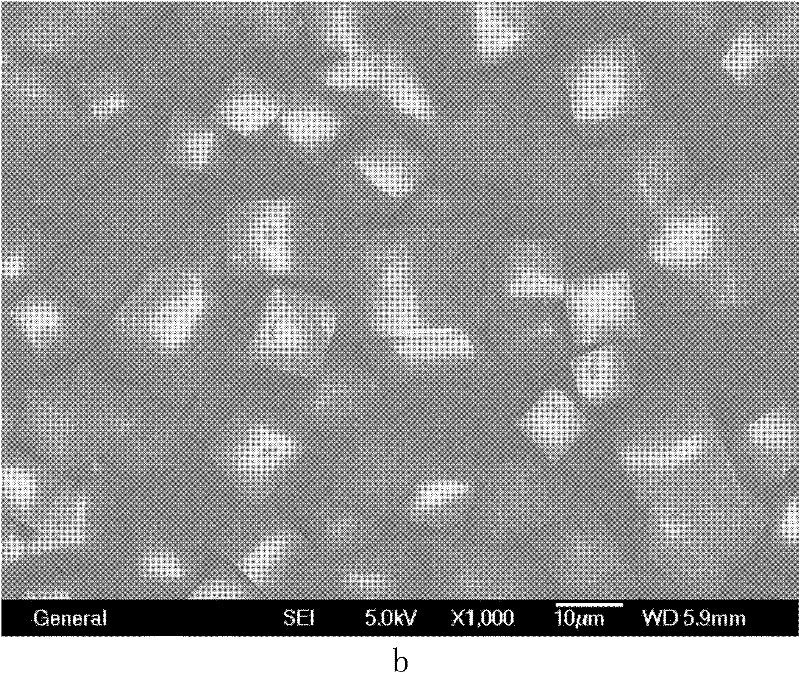

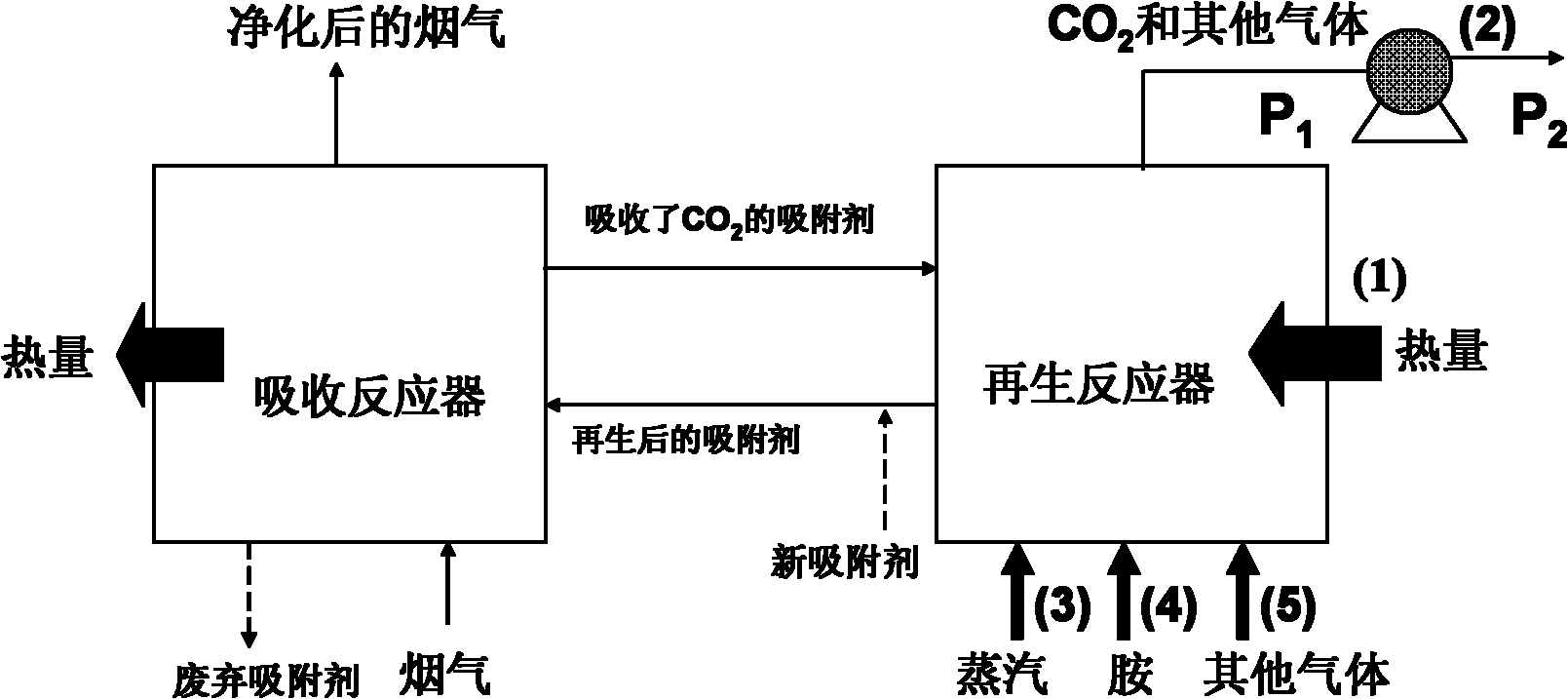

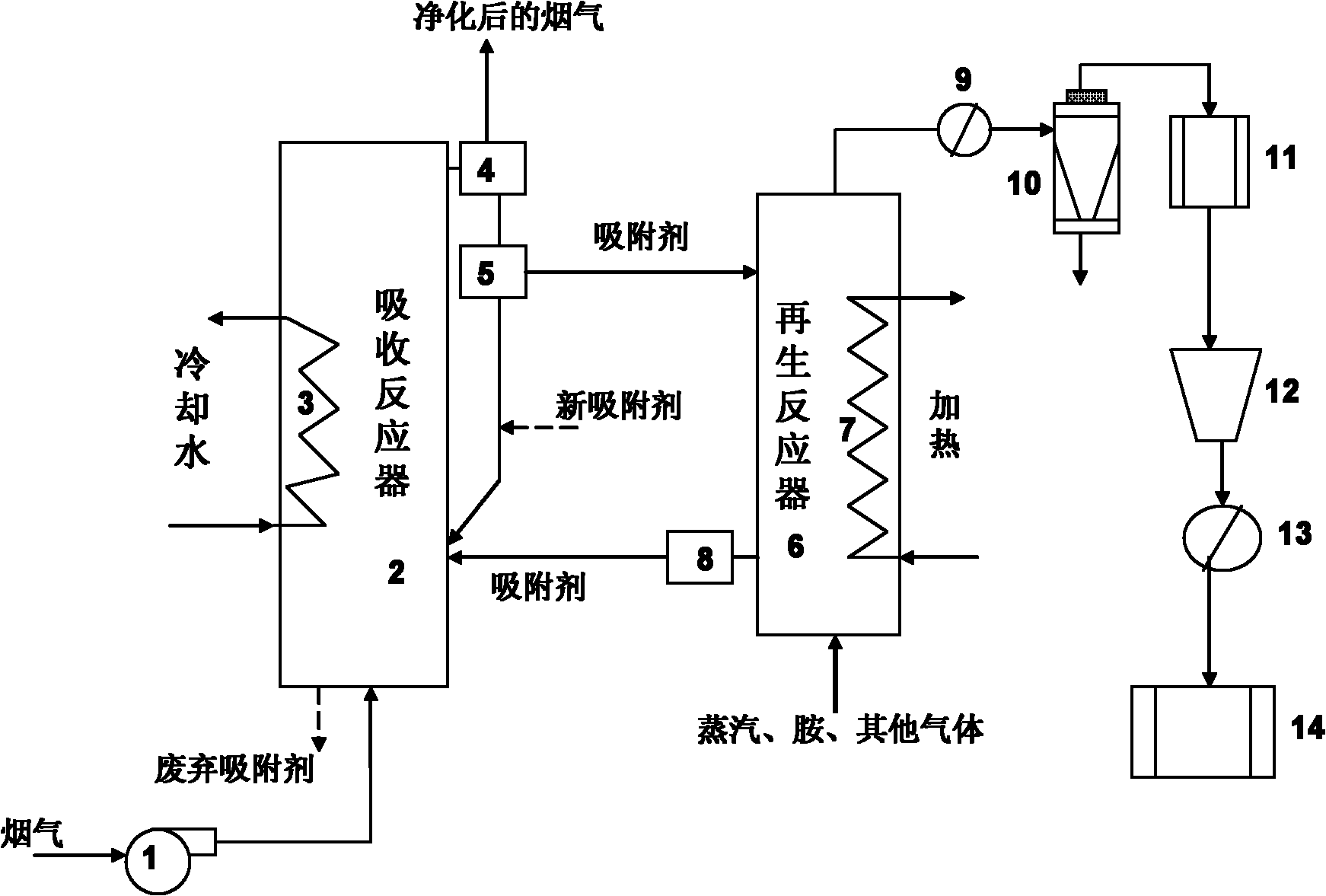

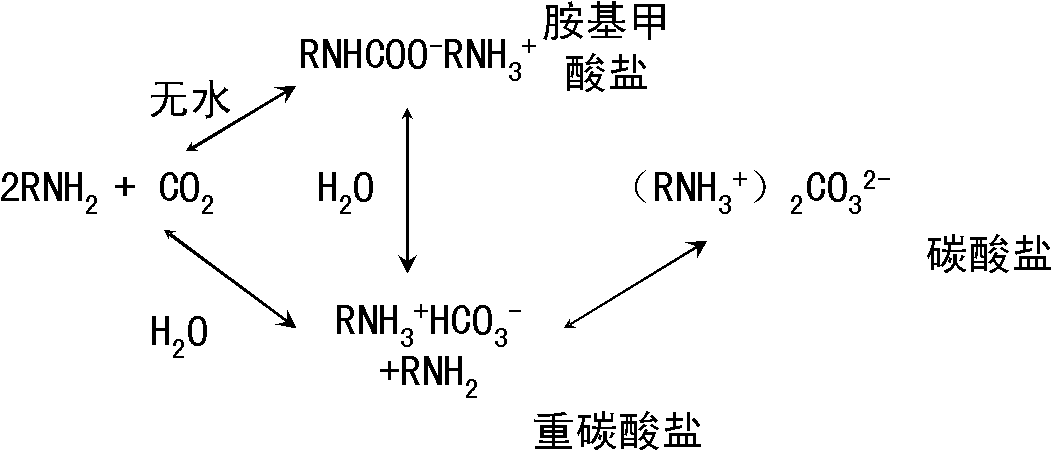

Process and equipment for removing CO2 in flue gas by utilizing amine solid adsorbent

InactiveCN102198360AHigh specific surface areaHigh porosityProductsMethane captureChemistryProduct gas

The invention belongs to the technical field of separation of CO2 in flue gas discharged during s combustion process, and in particular relates to a process and equipment for removing CO2 in flue gas by utilizing an amine solid adsorbent. In the process, the CO2 gas in the flue gas is fully contacted with the amine solid adsorbent so that CO2 gas molecules are rapidly diffused into pores of the solid adsorbent to react with amine liquids in the pores and then the CO2 is rapidly adsorbed by the adsorbent, and meanwhile the amine solid adsorbent adsorbed with the CO2 is regenerated by utilizing one or more regeneration methods such as thermal regeneration, vacuum regeneration, steam regeneration, amine steam regeneration and gas introduction regeneration. The adopted main equipment consists of a CO2 absorption reactor using the amine solid adsorbent, a regeneration reactor, a gas-solid separator, a gas-liquid separator and the like. The process and equipment provided by the invention have the advantages of simple and compact overall design, low investment and operating cost, stable and reliable operating performance and capability of efficiently separating the CO2 in the flue gas with low cost.

Owner:TSINGHUA UNIV

Multifunction carbon rod filter cartridge and manufacturing method thereof

InactiveCN102580405AHigh specific surface areaHigh activityWater/sewage treatment using germicide/oligodynamic-processFiltration separationResidual chlorineActivated carbon

The invention relates to a carbon rod filter cartridge, in particular to a multifunction carbon rod filter cartridge and a manufacturing method thereof. The multifunction carbon rod filter cartridge is capable of effectively removing residual chlorine and heavy metal in tap water and has good effects of killing and restraining bacteria. The multifunction carbon rod filter cartridge comprises, by mass percentage, 50%-98% of activated carbon, 1%-30% of modified cellular material powder and 1%-20% of adhesive. The preparation method includes mixing the activated carbon, the modified cellular material powder and the adhesive, drying, pouring dried mixing materials into a charging port of a screw extruder, heating the screw extruder, extruding the hollow column-shaped formed carbon rod filter cartridge, and cutting the carbon rod filter cartridge according to required lengths.

Owner:XIAMEN RUNNER IND CORP

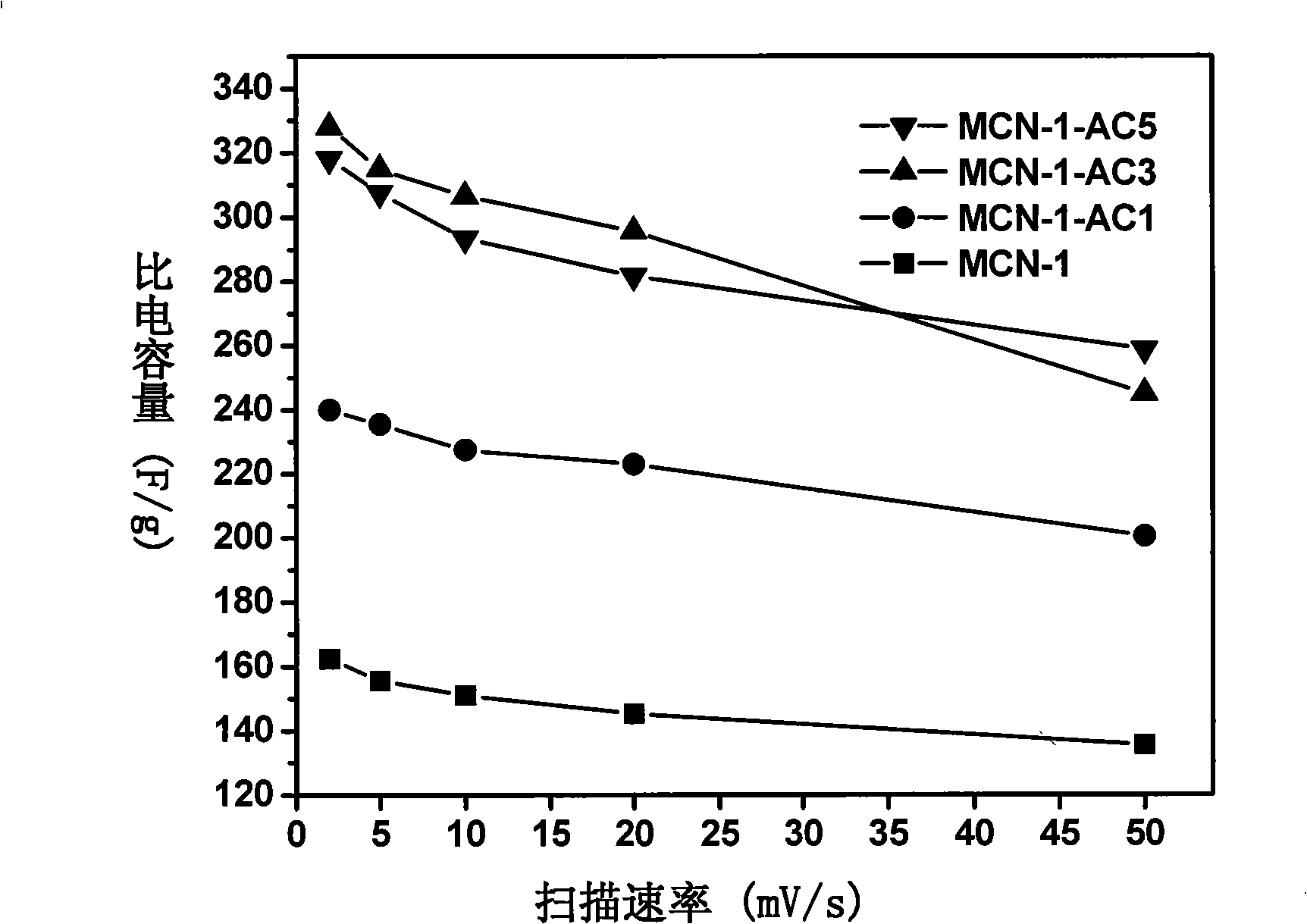

Method for preparing nitrogen-doped porous carbon material

InactiveCN101306807AHigh specific surface areaLarge pore volumeDouble-layer capacitanceAqueous electrolyte

The invention relates to a method of preparing a nitrogen-doped porous carbon material, and belongs to the field of inorganic nanometer materials and electrochemistry. The inventive method comprises the steps of: preparing mesoporous carbon nitrogen compound with mesoporous silicon oxide powder and ethylene diamine as precursors, and activating with an activator potassium hydroxide at high temperature while controlling the mass ratio of the potassium hydroxide and the mesoporous carbon nitrogen material to obtain a nitrogenous material with high specific surface area and pore volume. The specific electric double layer capacitance of the inventive nitrogen-doped porous carbon material in alkaline aqueous electrolyte under potential scanning speed of 2mV / s is 328F / g and 318F / g, respectively, which are much higher than that of the reported porous carbon materials. The inventive nitrogen-doped porous carbon material has good application prospect as a high-power super capacitor active material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

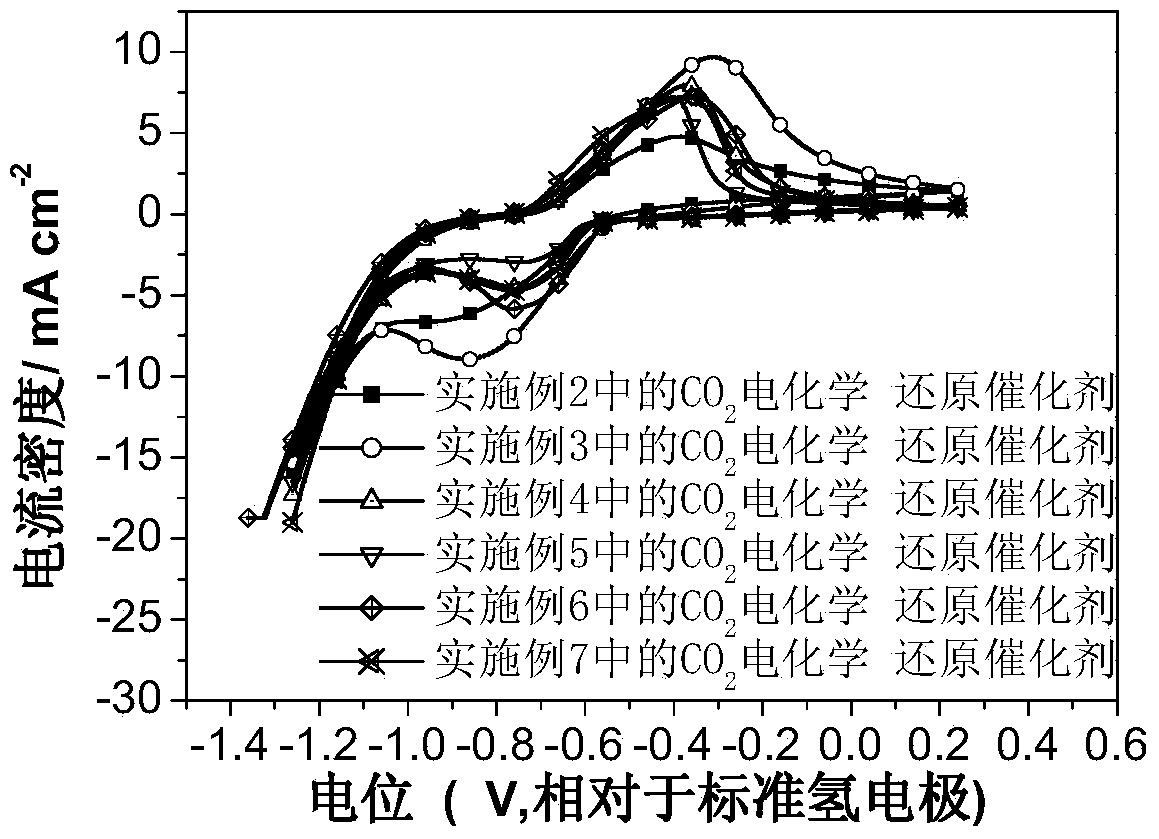

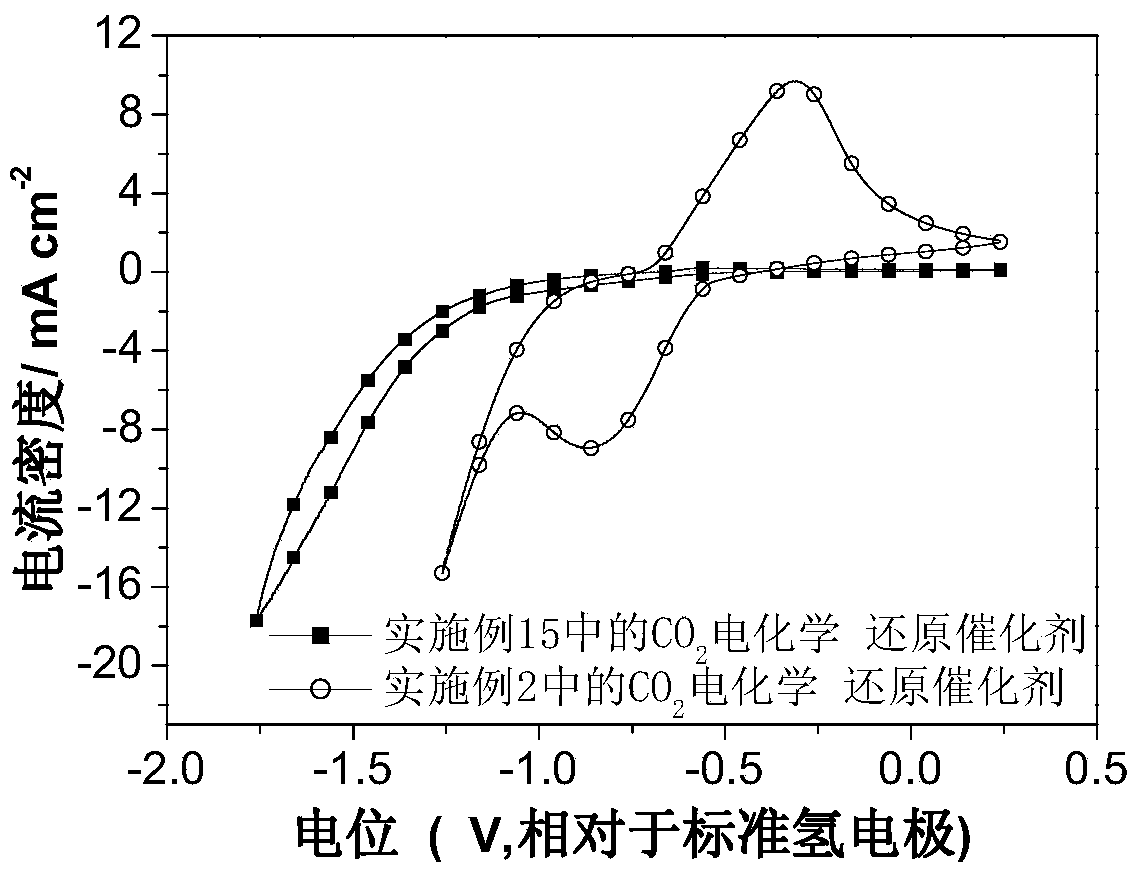

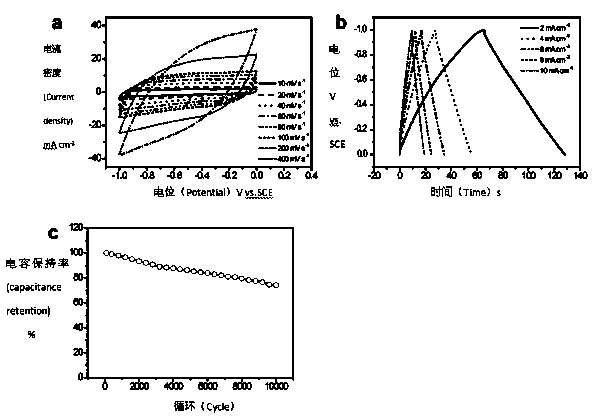

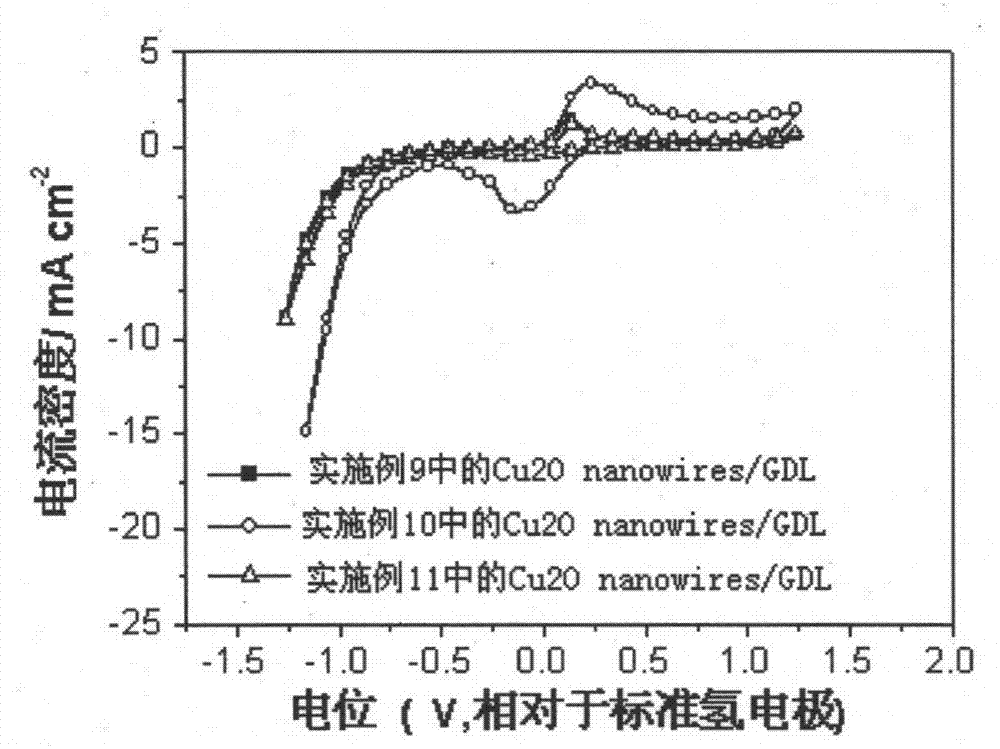

Carbon dioxide electrochemical reduction catalyst as well as preparation method and application thereof

InactiveCN103715436AIncrease the number of active sitesThe synthesis method is simpleMaterial nanotechnologyCell electrodesTin dioxideTrisodium citrate

The invention relates to a carbon dioxide electrochemical reduction catalyst as well as a preparation method and an application thereof. The carbon dioxide electrochemical reduction catalyst comprises tin dioxide nanoflower, wherein the tin dioxide nanoflower is synthesized through hydrothermal reaction and comprises the synthesis raw materials including 0.1-0.5M of tin dioxide, 1-5M of trisodium citrate mixed solution and 0.1-0.5M of sodium hydroxide. The carbon dioxide electrochemical reduction catalyst is applied to a carbon dioxide electrochemical reduction catalyst gas diffusion electrode. The carbon dioxide electrochemical reduction catalyst has the advantages that the specific surface area of the catalyst is enlarged, the electrochemical reduction catalytic activity of the catalyst for carbon dioxide reduction is improved, the hydrogen evolution reaction is effectively inhibited, and the selectivity of formic acid in a product is improved.

Owner:DONGHUA UNIV +1

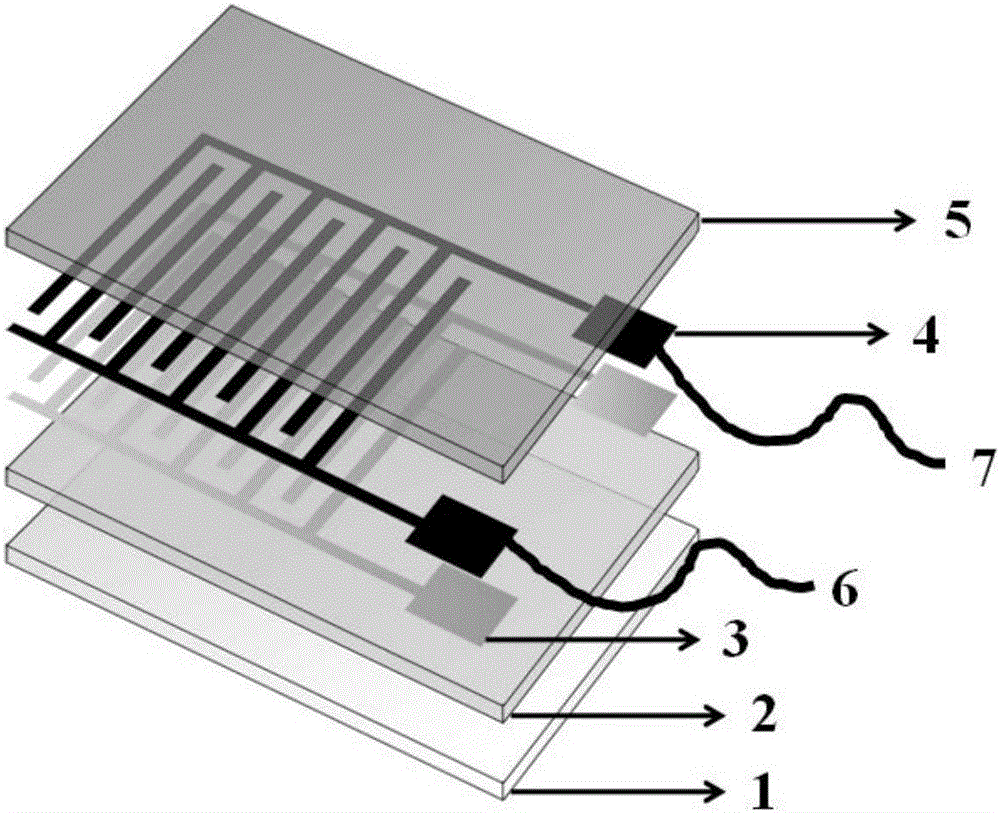

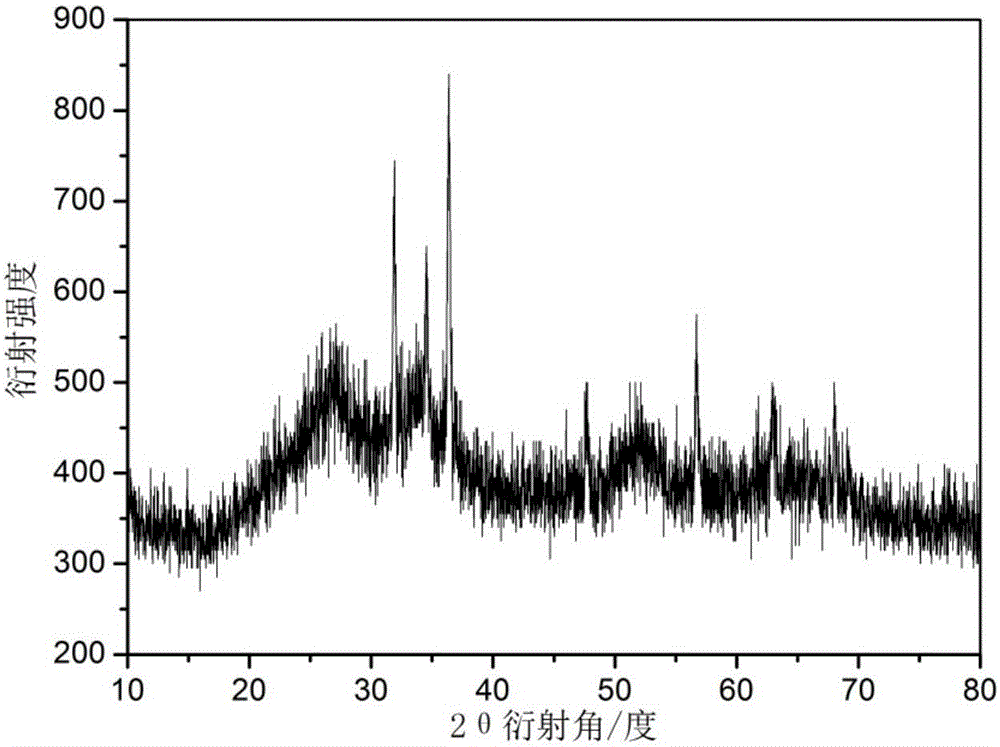

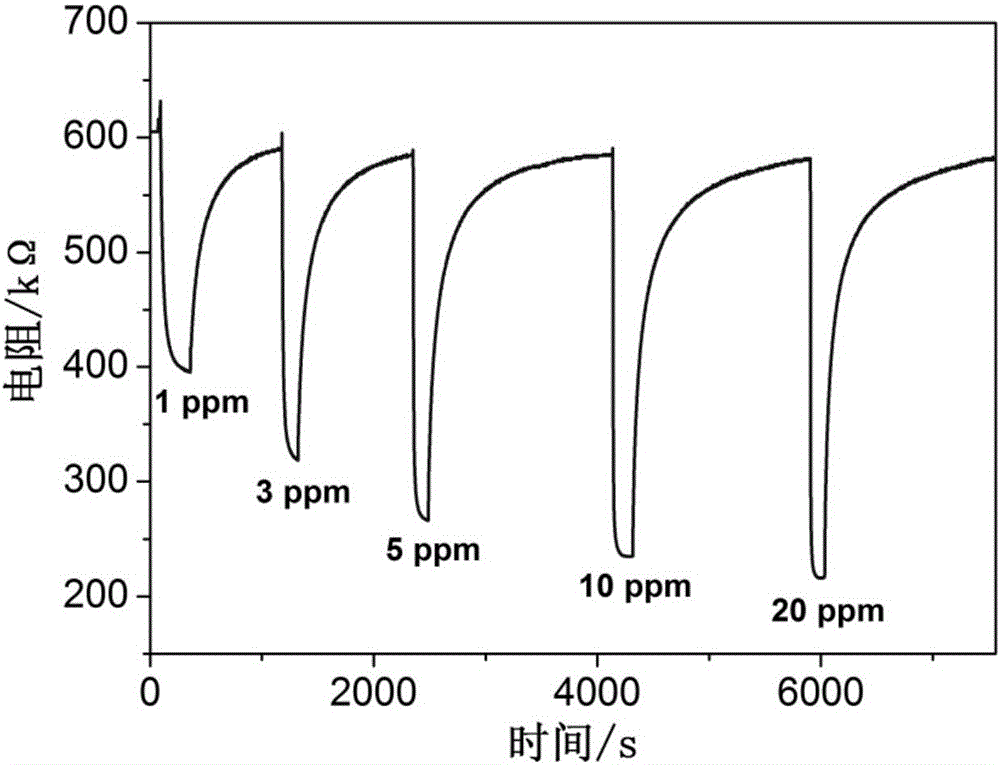

Resistance-type gas sensor based on graphene, stannic oxide and zinc oxide composite, preparation method and application thereof

InactiveCN105891271AImprove adhesionImprove stabilityMaterial nanotechnologyMaterial resistanceResponse sensitivityOxide composite

The invention relates to a resistance-type gas sensor based on a graphene, stannic oxide and zinc oxide composite, a preparation method and application thereof, and belongs to the technical field of gas sensors. The gas sensor is composed of a monocrystalline silicon substrate, a silicon dioxide layer, a titanium adhesion layer, interdigital platinum electrodes and a gas sensitive film covering the silicon dioxide layer and the surfaces of the interdigital platinum electrodes in sequence; the structure of the titanium adhesion layer is the same as that of the interdigital platinum electrodes, and the gas sensitive film is the graphene, stannic oxide and zinc oxide ternary composite; the ternary composite is prepared by mixing graphene, stannic oxide and zinc oxide and is of a three-dimensional porous structure. Before and after the gas sensitive film makes contact with gas to be tested, the resistance of the gas sensitive film can change, and the sensitivity of the sensor can be obtained by measuring resistance changes between the interdigital platinum electrodes. The sensor has high response sensitivity, rapid response recovery rate and good response reversibility at room temperature, and the problem that the a stannic oxide and zinc oxide gas sensor can work only at high temperature is solved.

Owner:JILIN UNIV

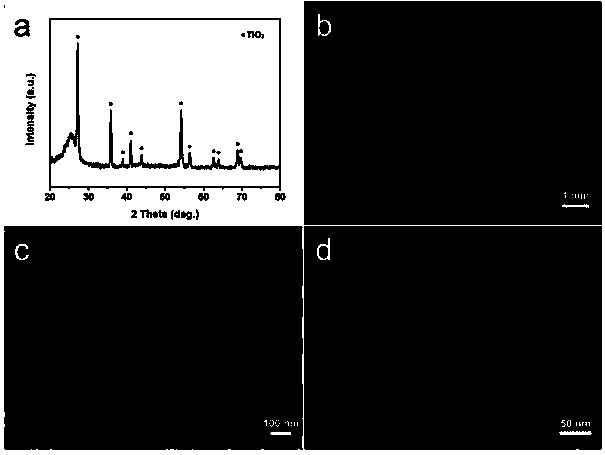

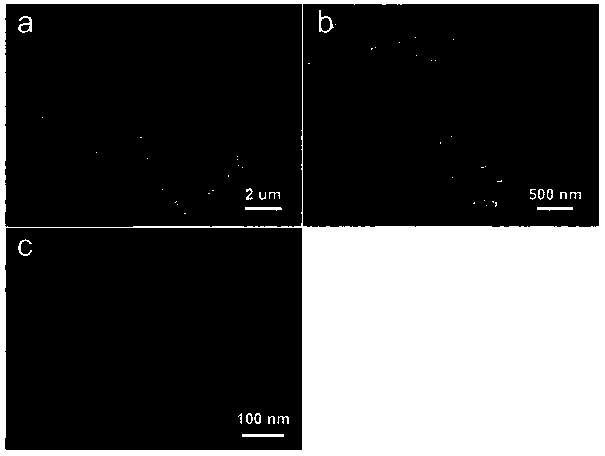

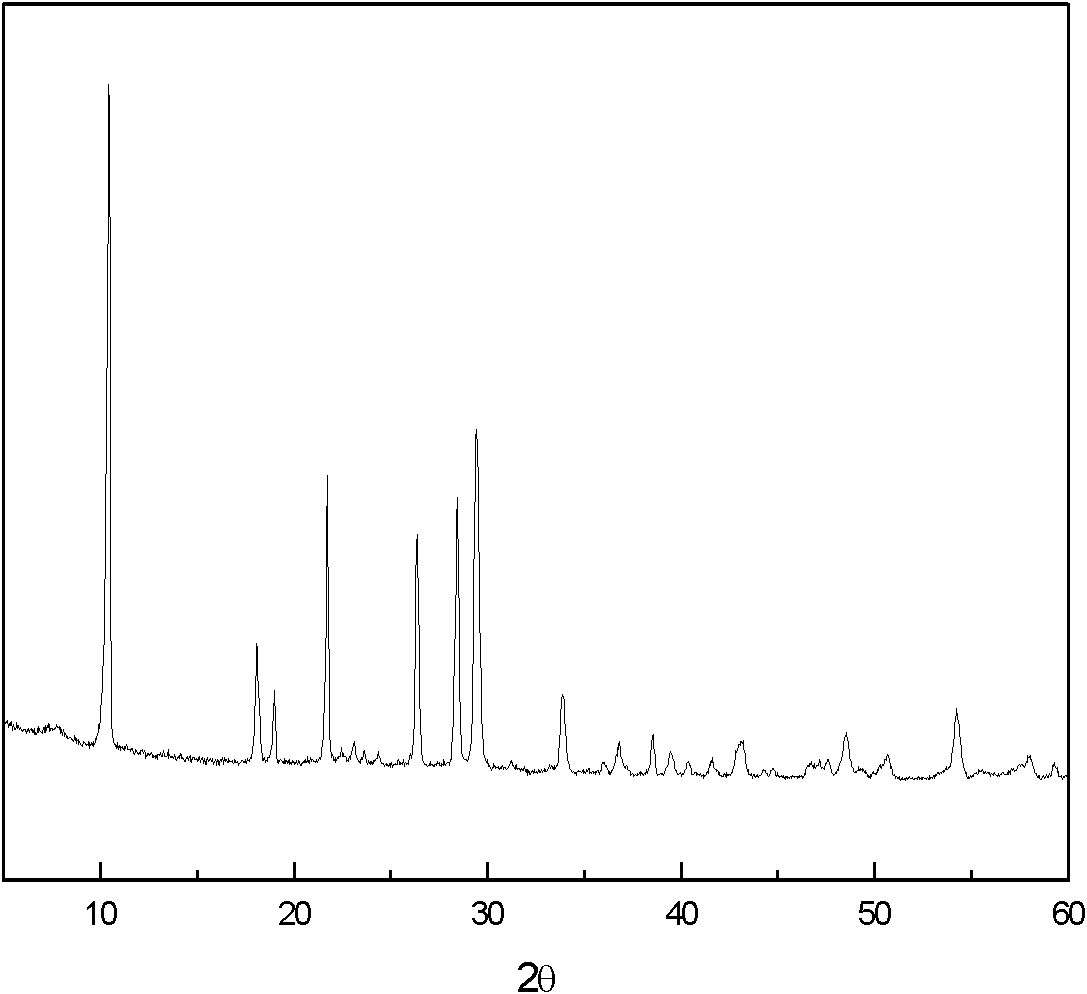

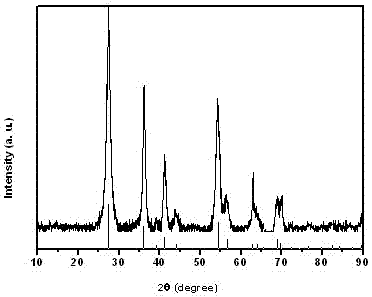

MOS2 (molybdenum disulfide) and TiO2 (titanium dioxide) nanocomposites and production method thereof

ActiveCN103426648AIncrease capacitanceIncrease the active siteHybrid capacitor electrodesNanocompositeMolybdenum disulfide

The invention relates to the energy storage field and discloses MOS2 (molybdenum disulfide) and TiO2 (titanium dioxide) nanocomposites and a production method thereof. The MOS2 and TiO2 nanocomposites are composite materials of nano molybdenum disulfide and titanium dioxide, namely the MOS2 and TiO2. The MOS2 and TiO2 nanocomposites are obtained through the two-step hydrothermal method which comprises, to be specific, growing titanium dioxide nanorods on a seed layer through the auxiliary hydrothermal method and coating a layer of molybdenum disulfide on the outer layer of the titanium dioxide nanorods through the direct hydrothermal method. According to the obtained MOS2 and TiO2 nanocomposites through production, the energy can be effectively stored and a good method is provided for the existing energy storage problem due to the high specific surface area of the titanium dioxide one-dimensional nanorods and the excellent super capacitance performance of the molybdenum disulfide. According to the production method, the energy consumption is low, the condition is simple, the large-scale production is easy and the like.

Owner:SUN YAT SEN UNIV

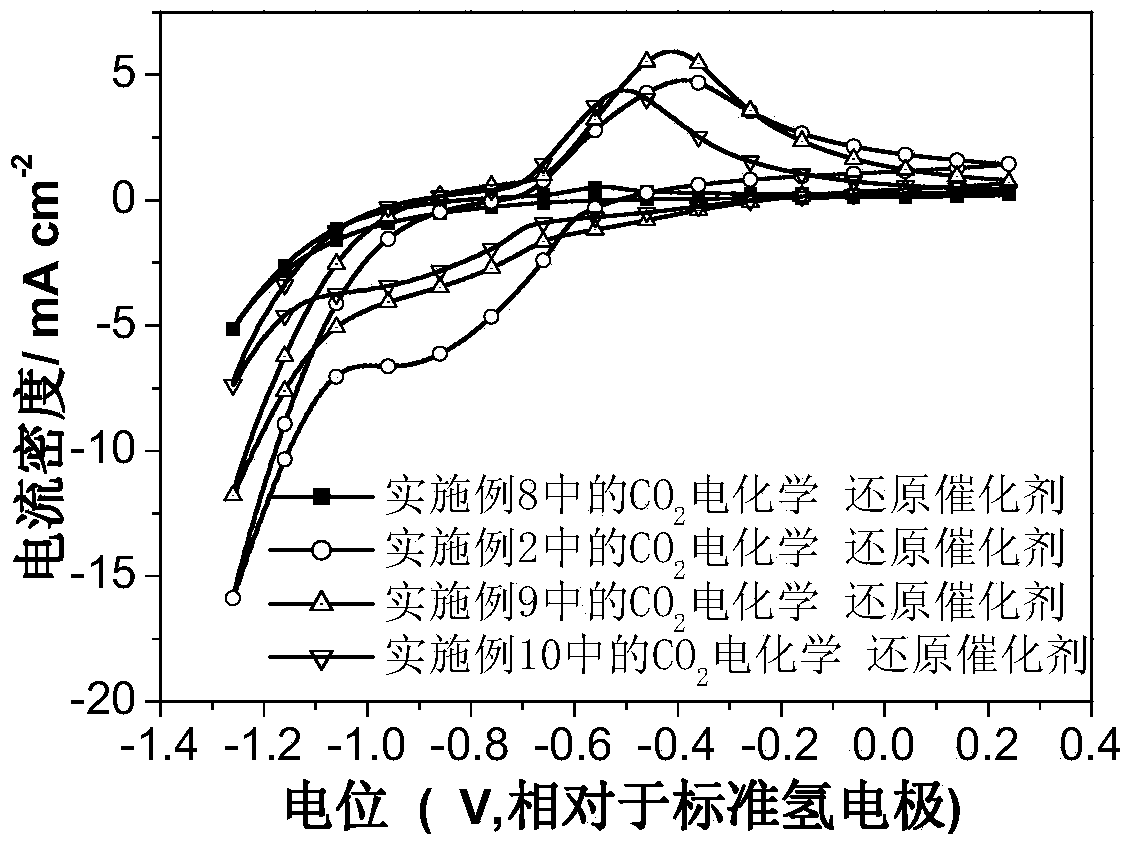

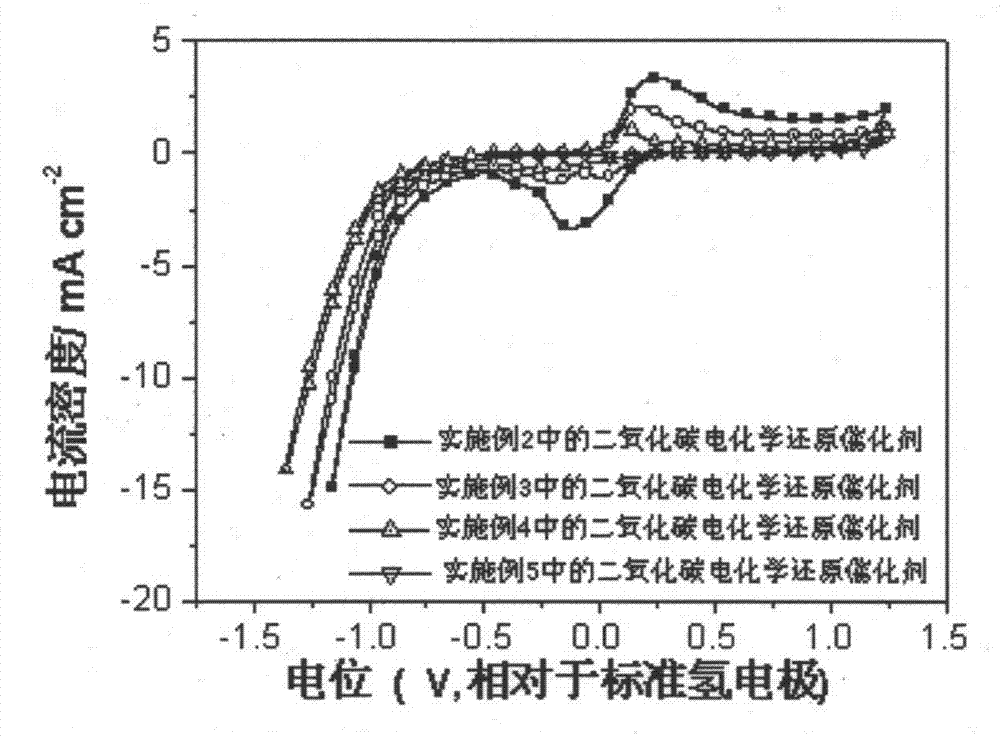

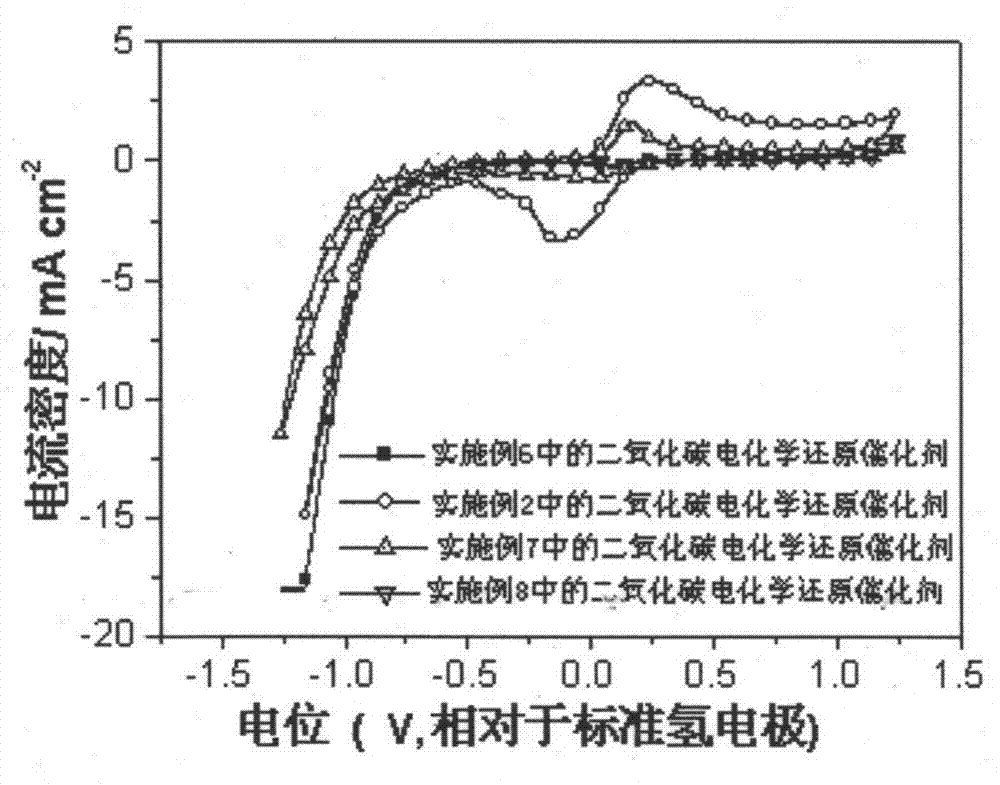

Carbon dioxide electrochemical-reduction catalyst, and preparation and application thereof

InactiveCN103566934AHigh specific surface areaIncrease contact areaMetal/metal-oxides/metal-hydroxide catalystsElectrodesM-AnisidineHydrogen

The invention provides a carbon dioxide electrochemical-reduction catalyst, and preparation and application thereof. The carbon dioxide electrochemical-reduction catalyst is characterized by comprising cuprous oxide nanowires, wherein the cuprous oxide nanowires are synthesized by hydrothermal reaction from 0.01-0.05M copper acetate and 0.01-0.05M anisidine at a volume ratio of 0.9:0.1 to 0.1:0.9. According to the carbon dioxide electrochemical-reduction catalyst, and the preparation and application thereof, the specific surface area of the catalyst is remarkably enlarged, the electrochemical reduction catalysis activity of the catalyst for the reduction of carbon dioxide is improved, and hydrogen evolution reaction is effectively inhibited.

Owner:DONGHUA UNIV

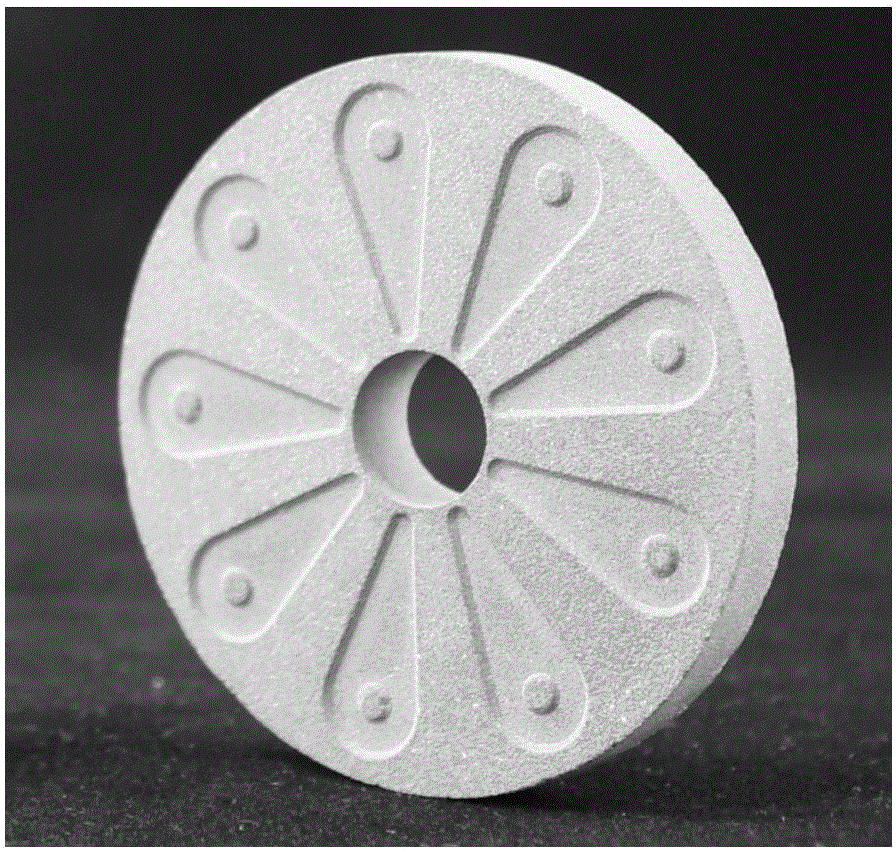

Preparation method of porous ceramic-metal composite film material

ActiveCN102836642AHigh specific surface areaIncrease contact areaSemi-permeable membranesCeramic coatingPorous metal

The invention provides a preparation method of a porous ceramic-metal composite film material. The method comprises steps of: using ceramic as a rigid outer mold; preparing a ceramic coating in the inner surface of the rigid outer mold; adding a metal powder into a hollow cavity between the rigid outer mold and an elastic inner mold; sealing; forming by cold isostatic pressure; sintering a formed porous ceramic-metal composite film blank together with the rigid outer mold; and separating a sintering body from the rigid outer mold. Through improvement on the preparation process, the ceramic coating and the metal powder subjected to isostatic pressure forming are sintered under high temperature condition, so that a porous metal substrate and the ceramic film layer expand synchronously under effect of compressive stress of the rigid outer mold during the sintering. The prepared porous ceramic composite film material has strong adhesion, high strength, smooth, flat and flawless film layer, and improved practicability.

Owner:南京髙谦功能材料科技有限公司

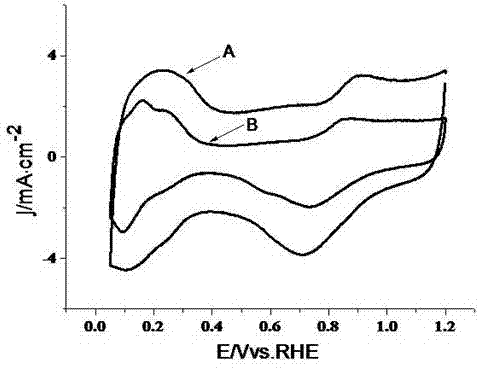

Nitrogen-doped graphene-ferronickel hydrotalcite difunctional oxygen catalyst and preparation method and application thereof

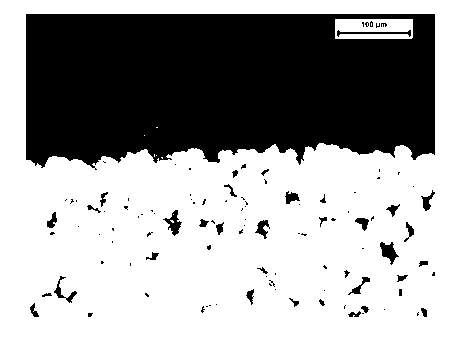

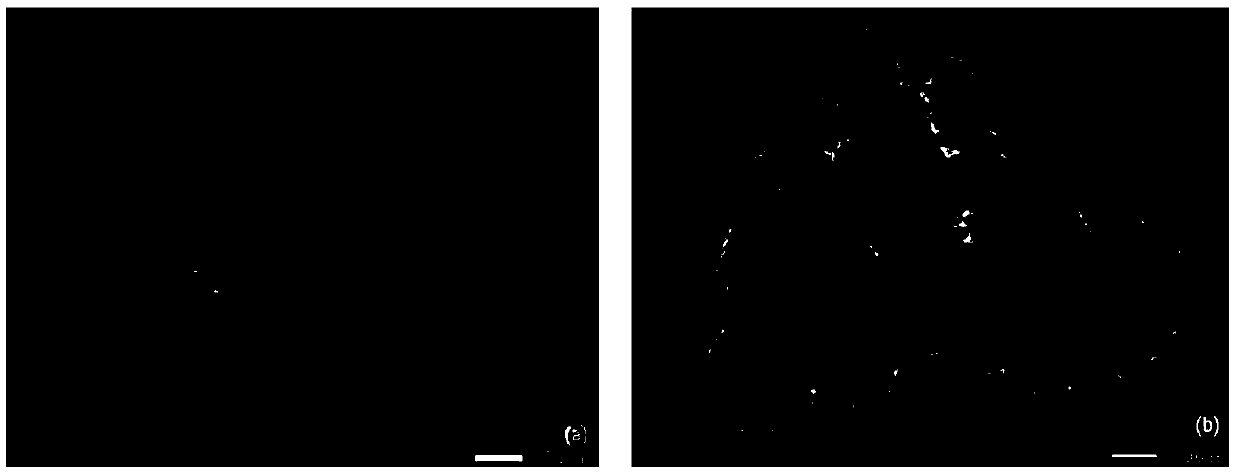

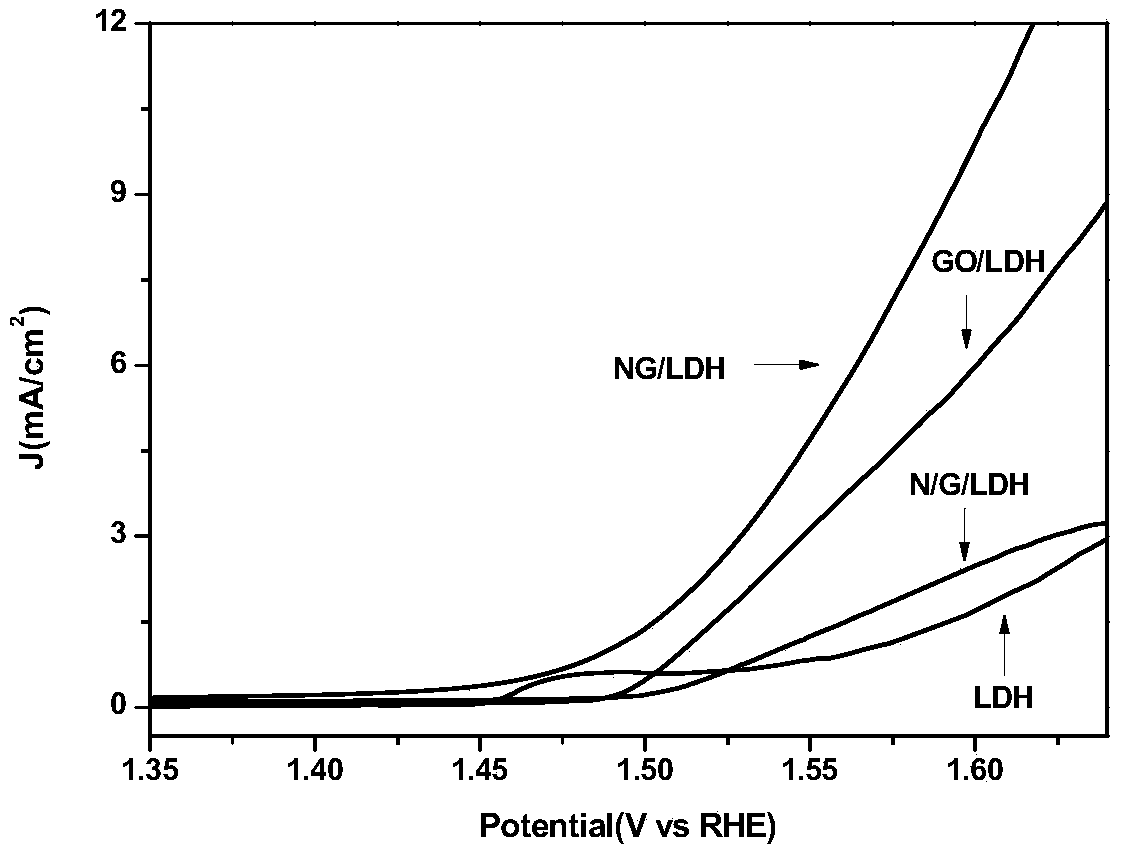

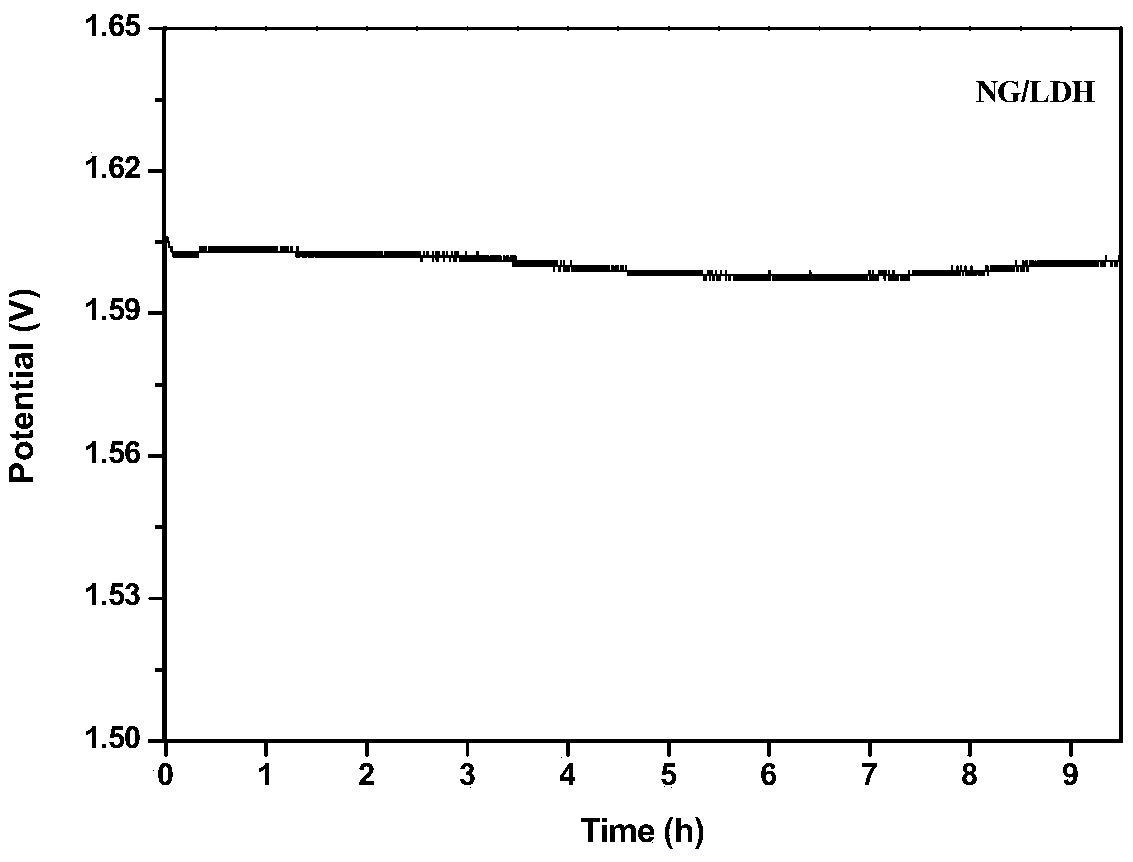

ActiveCN105514450AImprove conductivityHigh specific surface areaPhysical/chemical process catalystsCell electrodesCvd grapheneHydrotalcite

The invention relates to a nitrogen-doped graphene-ferronickel hydrotalcite non-noble metal difunctional oxygen catalyst and a preparation method thereof and electrocatalysis application of the oxygen catalyst in an alkaline medium to an oxygen evolution reaction and an oxygen reduction reaction. According to the catalyst, a micelle is taken as a template, ferronickel hydrotalcite is assembled on graphene oxide under the hydrothermal condition to form a spherical porous compound, the graphene oxide is reduced and doped with a nitrogen carbide nanosheet simultaneously under the hydrothermal condition, and then the nitrogen-doped graphene-ferronickel hydrotalcite oxygen catalyst is obtained. The method comprises the steps that the graphene oxide and metal salt are firstly dispersed into the micelle, the graphene oxide-ferronickel hydrotalcite compound is obtained through hydro-thermal synthesis under the alkaline condition, the product is doped with the nitrogen carbide nanosheet under the hydrothermal condition, and then the oxygen catalyst is obtained. The oxygen catalyst has the catalytic activity both on oxygen evolution and oxygen reduction under the alkaline condition and is high in stability and methyl alcohol tolerance, low in used raw material cost, simple in preparation method and convenient for scale production.

Owner:湛江市菱霸润滑油有限公司

Method for preparing efficient stable fuel cell catalyst

ActiveCN103495432AHigh specific surface areaHigh catalytic activityPhysical/chemical process catalystsCell electrodesNano catalystDoped carbon

The invention provides a method for preparing an efficient stable fuel cell catalyst and aims to solve the defect that an existing fuel cell catalyst is low in property and poor in stability. The method provided by the invention is characterized in that polyaniline covers the surface of a Pt / C catalyst through using an in-situ chemical oxidation polymerization method, and further an N-doped carbon layer is formed under transition metal salt catalysis through high-temperature pyrolysis; on one hand, the formed N-doped carbon layer is utilized as a second active centre and can strengthen the catalytic activity with Pt synergism, on the other hand, the migration and birdnesting growth of Pt nano particles on the surface of a carbon support are effectively blocked, and the stability of a catalyst is improved; in addition, the nanometer limited range action of the polyaniline can effectively restrain the sintering growth of the Pt nano particles on the surface of the carbon support in the high-temperature processing process, and the high activity specific surface area of a final catalyst is guaranteed; the oxygen reduction activity and the stability of the prepared Pt / C catalyst modified by the N-doped carbon layer are remarkably better than those of a commercialization Pt / C catalyst.

Owner:重庆铈坦新材料技术研究院有限公司

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

Preparation method of non-supported high-activity hydrogenation catalyst

ActiveCN103861609AHigh specific surface areaLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentAluminiumFixed bed

The invention relates to a preparation method of a non-supported high-activity hydrogenation catalyst. The preparation method of the non-supported high-activity hydrogenation catalyst is characterized by comprising the following steps: preparing an acid solution A containing at least one group VIII metal compound and at least one group VIB metal compound, and an alkali solution B containing at least one silicon source or aluminium source, slowly mixing the two solutions into a sedimentation reactor, carrying out co-precipitation reaction to obtain slurry under the conditions that temperature is 20-120 DEG C and pH value is 7-12, and carrying out ageing, suction filtration, washing, drying, moulding and roasting on the slurry, so that a catalyst with high catalytic performance for hydrogenation reaction of a fixed bed is obtained. The prepared non-supported hydrogenation catalyst has large specific surface area, high pore volume and high hydrogenation activity; meanwhile, the preparation method of the non-supported high-activity hydrogenation catalyst is simple, reaction conditions are mild, and operation is easy and stable, so that the preparation method of the non-supported high-activity hydrogenation catalyst is applicable to industrial batch-type production.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

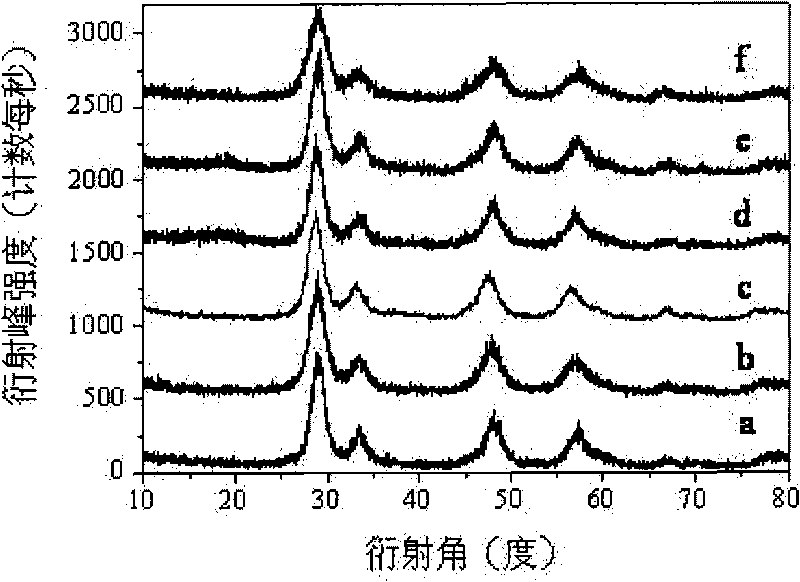

Cerium zirconium aluminum based multiple oxide material and preparing method thereof

ActiveCN101745375AImprove anti-aging propertiesHigh specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCe element

The present invention provides cerium zirconium aluminum based multiple oxide material and a preparing method thereof, wherein on the basis of the total amount of the cerium zirconium aluminum based multiple oxide material, the cerium zirconium aluminum based multiple oxide material is composed of the following components by weight: 25 to 70 shares of aluminum oxide, 20 to 60 shares of cerium oxide, 5 to 25 shares of zirconium oxide, 2 to 4.9 shares of lanthanum oxide and 2 to 15 shares of stable addition agent which is one or more oxides selected from Y, Eu, Gd and Sm. The cerium zirconium aluminum based multiple oxide material has high specific surface area. After the cerium zirconium aluminum based multiple oxide material is roasted in 450 DEG C to 550 DEG C for two to four hours, the specific surface area is all larger than 100m2 / g; after the cerium zirconium aluminum based multiple oxide material is roasted in 1000 DEG C for ten hours, the specific surface area at least can reach60 m2 / g; after the cerium zirconium aluminum based multiple oxide material is roasted in 1100 DEG C for five hours, the specific surface area at least can reach 40m2 / g. thus, the cerium zirconium aluminum based multiple oxide material is superior to the anti-aging performance of multiple oxide material of the prior art, and can be used as an addition agent or carrier for vehicle tail gas purifying three-way catalyst.

Owner:苏州相城埭辰科技产业发展有限公司

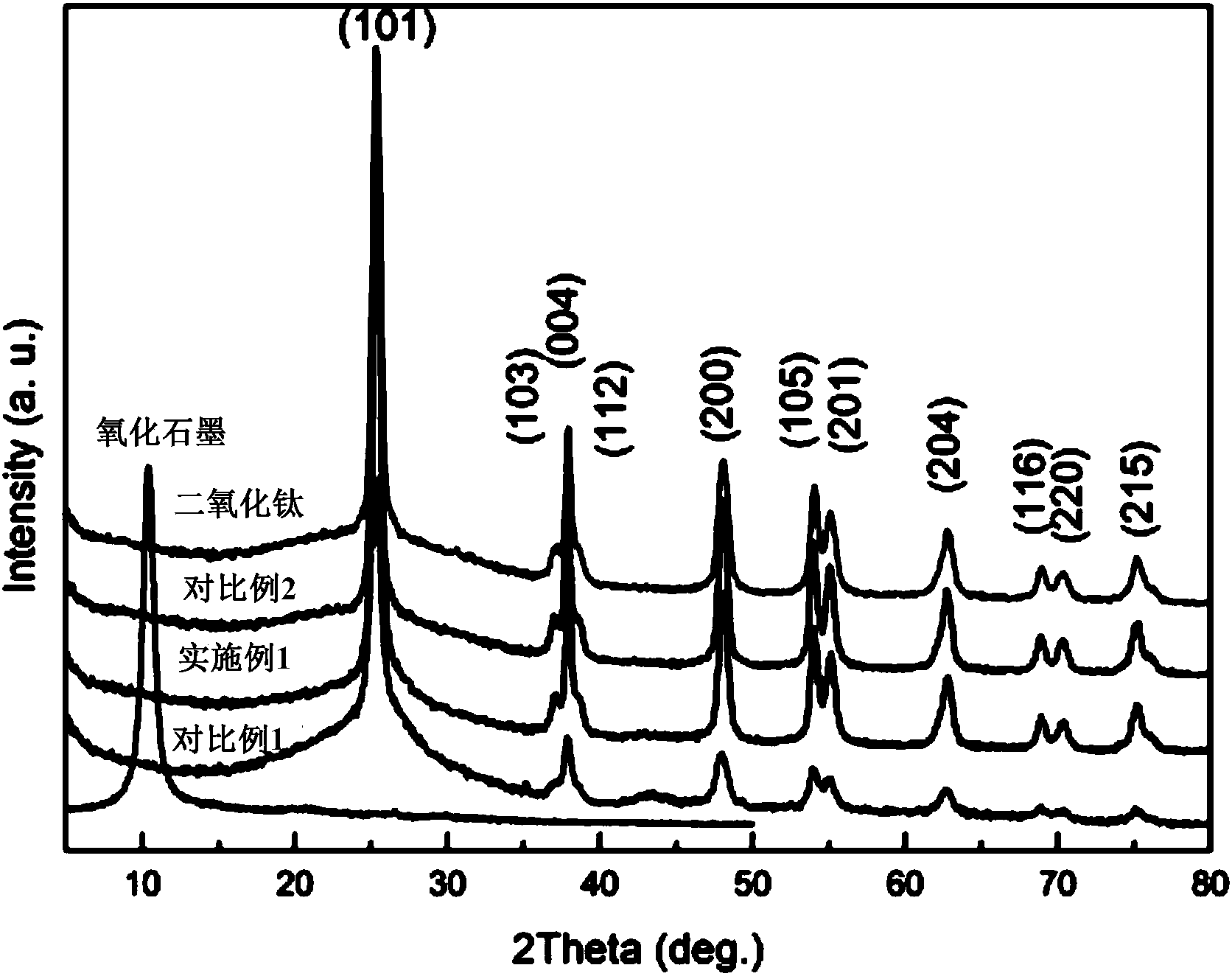

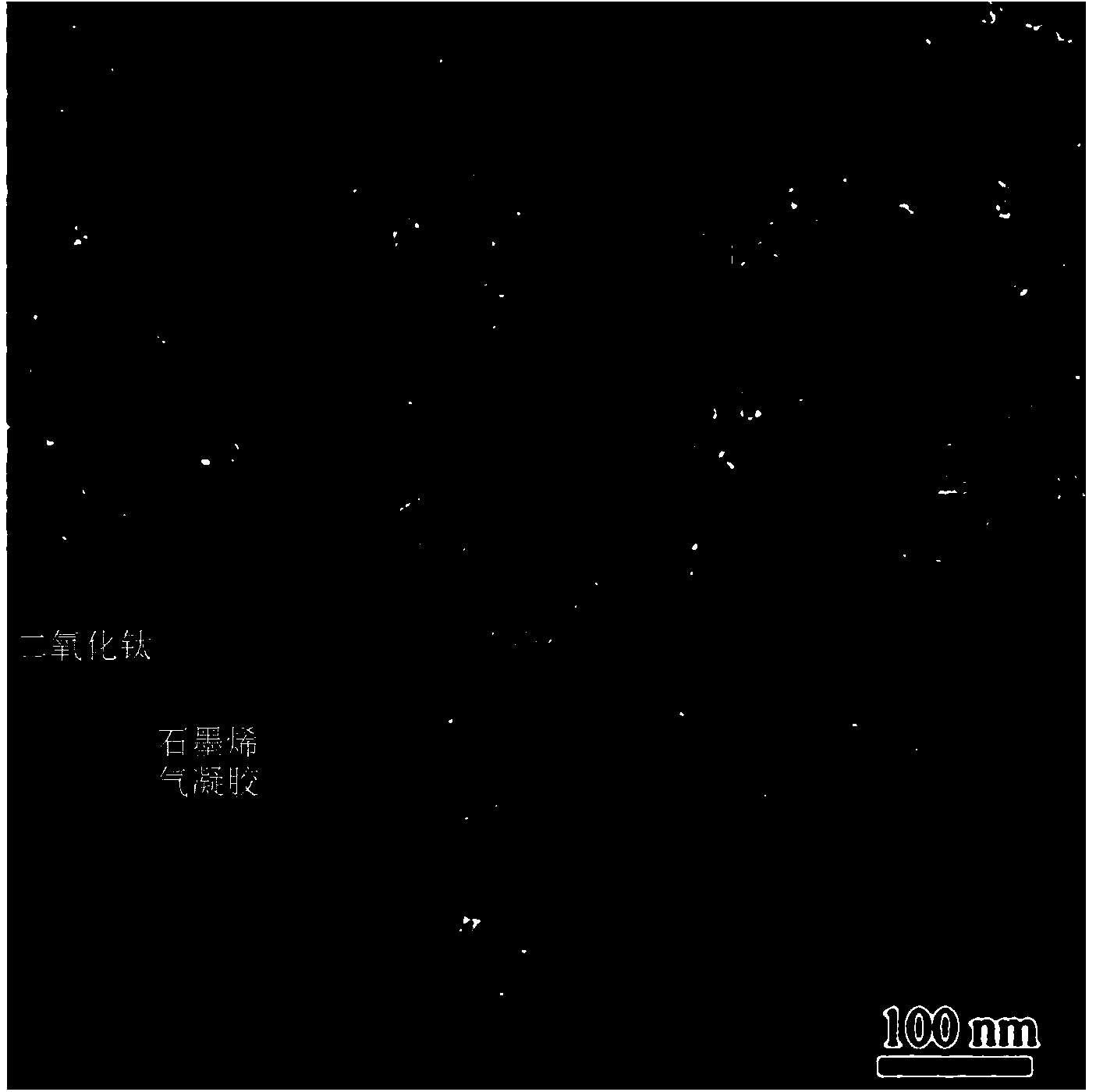

Grading three-dimensional porous graphene/titanium dioxide photocatalyst and preparation method thereof

InactiveCN104069844AHigh specific surface areaImprove adsorption capacityPhysical/chemical process catalystsPorous grapheneMicrosphere

The invention provides a grading three-dimensional porous graphene / titanium dioxide photocatalyst and preparation method thereof. The photocatalyst is composed by a three-dimensional grapheme framework and nano titanium dioxide particles; the grahene is provided with a macroporous structure; titanium dioxide is mesoporous titanium dioxide; the macropores and the mesopores are communicated; the nano titanium dioxide particles are scattered on a grapheme nano sheet; the surfaces of nano titanium dioxide microspheres are wrapped with graphene nano sheets; the macropores of the graphene are filled with the nano titanium dioxide microspheres. The photocatalyst with a three-dimensional structure can not only prevent the graphene sheet layers from stacking, but also scatter titanium dioxide particles excellently, and is high in specific surface area; besides, samples can be used for photocatalysis degradation of methylene blue, and the methylene blue can be fully degraded in 25 minutes. The preparation method provides a new thought for preparation of the photocatalyst, and has a potential application value in the fields of energy sources and environment.

Owner:WUHAN UNIV OF TECH

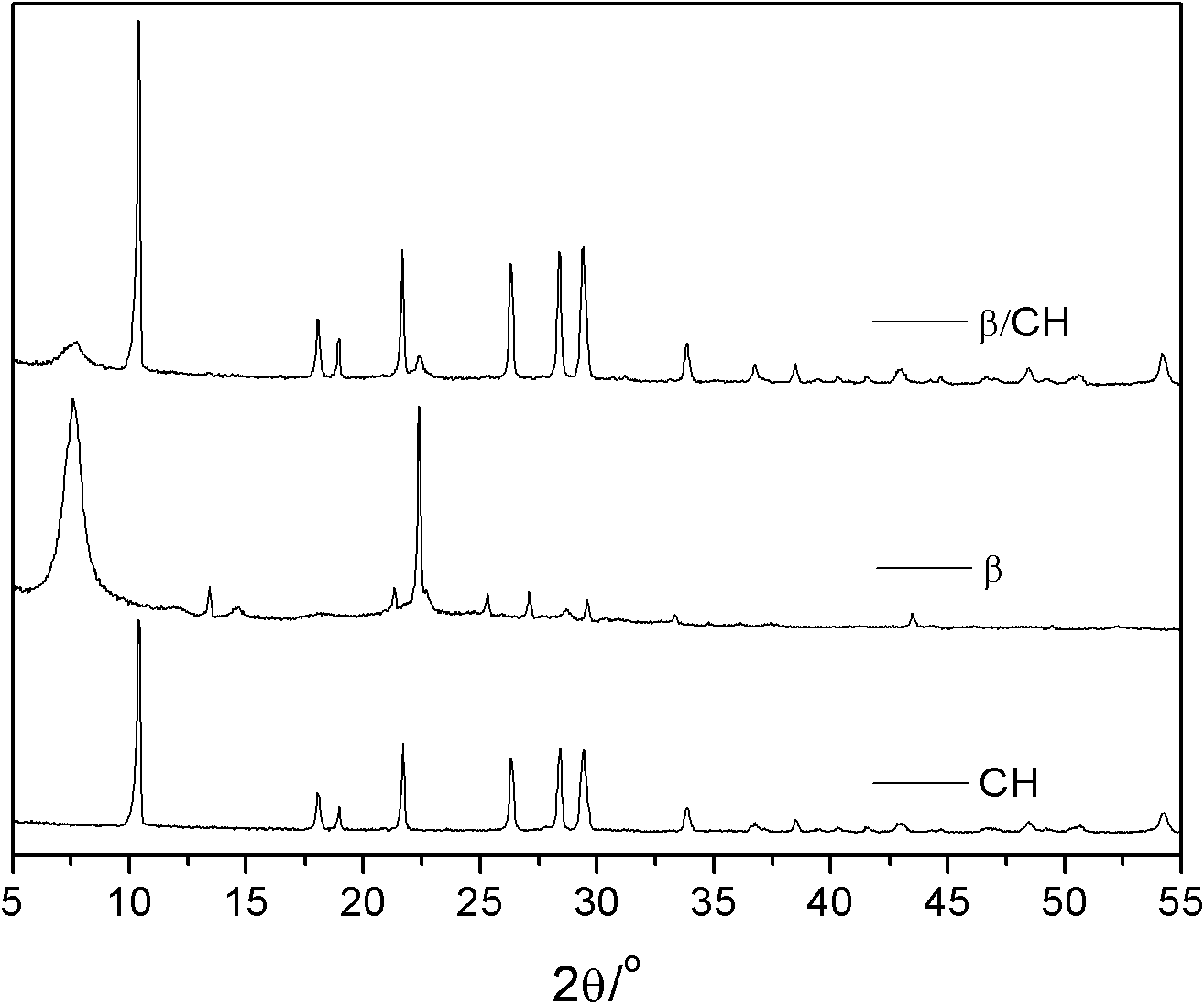

Honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof

InactiveCN102133537AIncrease roughnessPromote nucleationMolecular sieve catalystsDispersed particle separationMass ratioCordierite

The invention discloses a honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof. The monolithic catalyst takes honeycomb ceramic as a carrier, a Beta molecular sieve is coated on the surface of the honeycomb ceramic and taken as a coating layer, and then active component, namely precious metal, is loaded on the surface of Beta molecular sieve; the active component of the precious metal is one or two selected from palladium or platinum; in the honeycomb-ceramic-type monolithic catalyst, the mass ratio of the coating layer of the Beta molecular sieve to the honeycomb ceramic is 0.02-0.2:1, the mass ratio of the precious metal to the coating layer of the Beta molecular sieve is 0.02-0.2:1, the honeycomb ceramic is cordierite honeycomb ceramic; and in the invention, the high-silicon or full-silicon Beta molecular sieve is taken as the coating layer of the monolithic catalyst, and has the characteristics of good water resistance, high heat stability andthe like, and the monolithic burning catalyst taking the Beta molecular sieve as the coating layer can keep better activity and stability under high temperature, and suitable for being taken as catalytic combustion catalyst for application.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

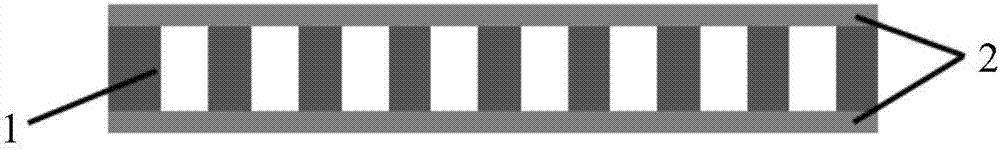

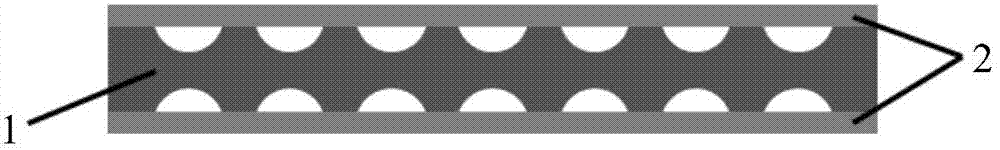

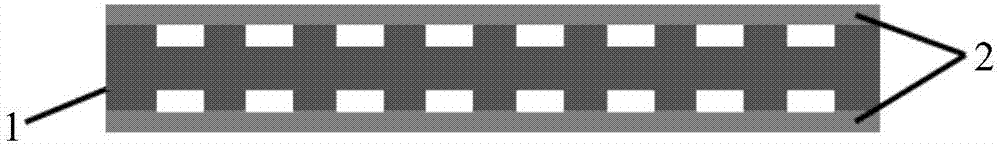

Negative plate, preparation method thereof and lithium battery

InactiveCN107482224AHigh specific surface areaIncrease energy densityElectrode carriers/collectorsSecondary cellsElectrical batteryNickel–lithium battery

The invention provides a negative plate, a preparation method thereof and a lithium battery. The negative plate comprises a current collector, wherein the current collector is copper with a hole structure, and a protective layer is arranged on the surface of the current collector. Copper with the hole structure is taken as the current collector of the negative plate, so that inside space of the current collector can serve as lithium storage space for storing lithium precipitated in a battery charging process, meanwhile, lithium metal precipitates between the copper current collector and the protective layer by means of the inorganic protective film on the surface of the current collector, and production of lithium dendrites is inhibited. Compared with a common lithium ion battery with a graphite cathode, a lithium secondary battery provided with the lithium-free negative plate has the advantage that the energy density of the lithium battery can be improved substantially under the precondition that higher safety performance and better cycle performance are guaranteed.

Owner:ZHUHAI COSMX BATTERY CO LTD

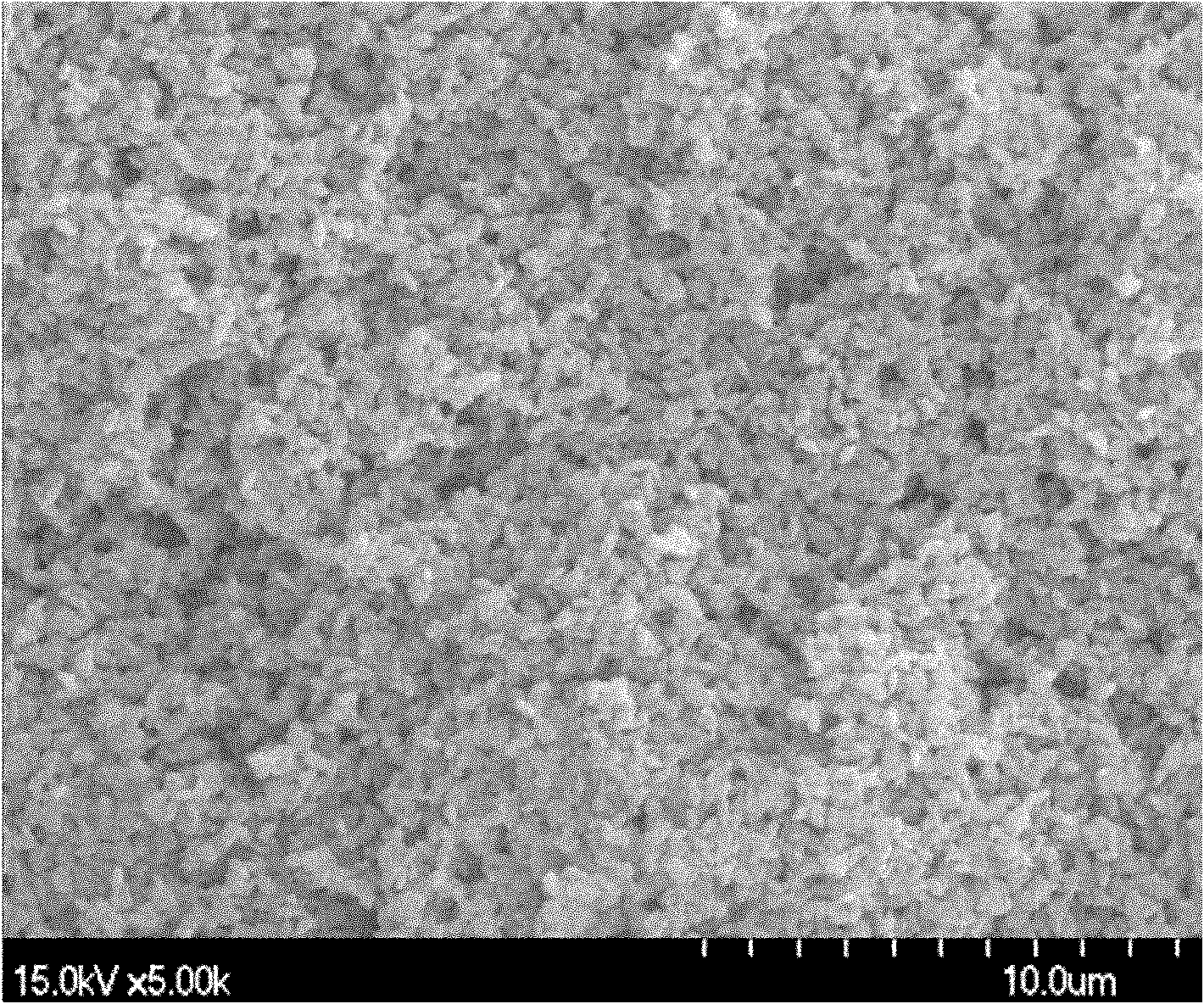

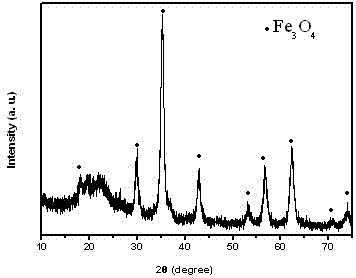

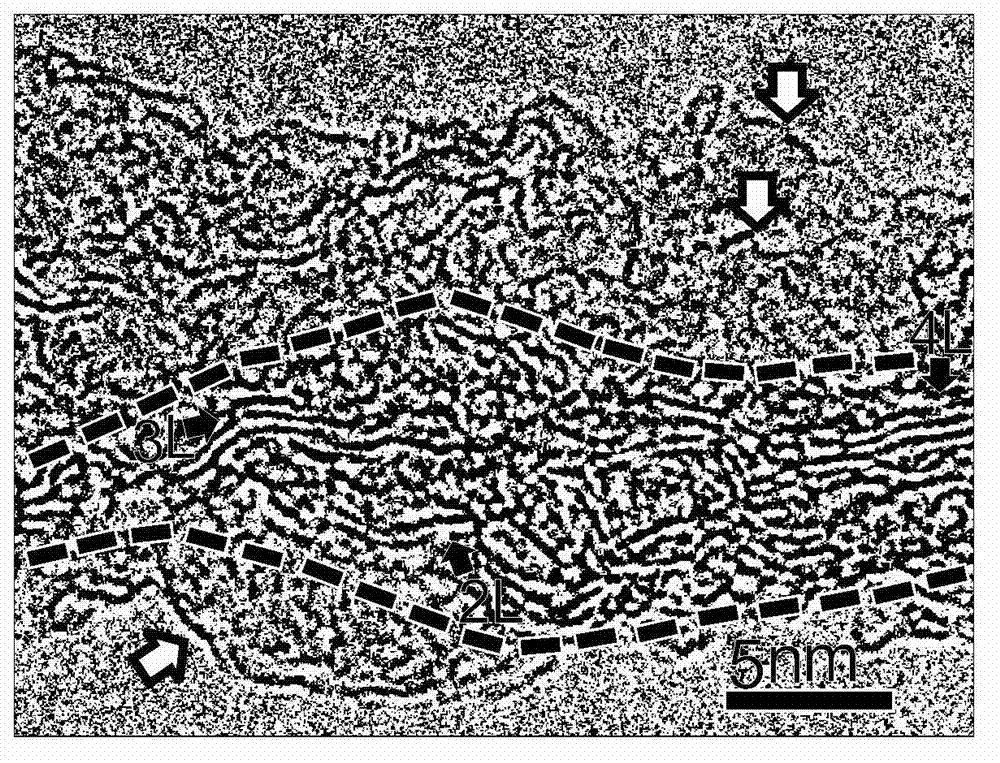

Graphene composite titanium dioxide photocatalyst capable of magnetic separation and recovery, and preparation method thereof

ActiveCN102489284AHigh specific surface areaGood electrical conductivityWater/sewage treatment by irradiationCatalyst activation/preparationTitanium dioxide nanoparticlesGraphene

The present invention relates to a graphene composite titanium dioxide photocatalyst capable of magnetic separation and recovery, and a preparation method thereof. The photocatalyst is synthesized by a two-step hydrothermal method, wherein graphene and magnetic particles are compounded to prepare magnetic graphene, the magnetic graphene is compounded with titanium dioxide nanoparticles synthesized by a hydrothermal method to prepare the three-element composite photocatalyst. The photocatalyst comprises three parts of the graphene, the titanium dioxide, and the magnetic nanoparticles, wherein the magnetic nanoparticles are loaded on the graphene lamellas to form the magnetic graphene having large specific surface area and magnetism, the rutile type titanium dioxide has a three-dimensional ordered nanostructure, and is loaded on the magnetic graphene lamellas to form the graphene composite rutile type titanium dioxide photocatalyst with the characteristic of magnetic separation, whereinthe photocatalyst has the large specific surface area, the nanoparticles have the magnetism, the photocatalyst can be separated and recovered, and has the efficient catalytic performance.

Owner:ZHEJIANG UNIV

Method for preparing tobacco activated carbon based on low temperature plasma modification

ActiveCN105060293AImprove qualityHigh specific surface areaCarbon compoundsActivated carbonCarbonization

The invention discloses a method for preparing tobacco activated carbon based on low temperature plasma modification. The method is characterized by comprising the steps of: firstly drying and crushing waste and inferior tobacco into fine particles, and performing high temperature carbonization on the fine particles under nitrogen protection so as to obtain tobacco scorching samples; then putting the tobacco scorching samples into an inorganic acid solution for treatment, then cleaning the treated tobacco scorching samples until the cleaned tobacco scorching samples are neutral, putting the neutral scorching samples into an activator solution, macerating the neutral scorching samples in the activator solution, filtering the macerated scorching samples, and drying the filtered scorching samples; and finally, treating the scorching samples with low temperature plasma under activated gas atmosphere so as to obtain the tobacco activated carbon. According to the method disclosed by the invention, the waste and inferior tobacco in cigarette plants is directly prepared into the high-quality activated carbon, so that the cost of raw materials is low, and the purpose of locally transforming and utilizing the waste and inferior tobacco is realized. In addition, through the treatment of the low temperature plasma and under the joint action of fitting modification conditions, an activator and activated gas, the specific surface area of the tobacco activated carbon is enlarged, and the surface chemistry characteristics of the tobacco activated carbon are enriched.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

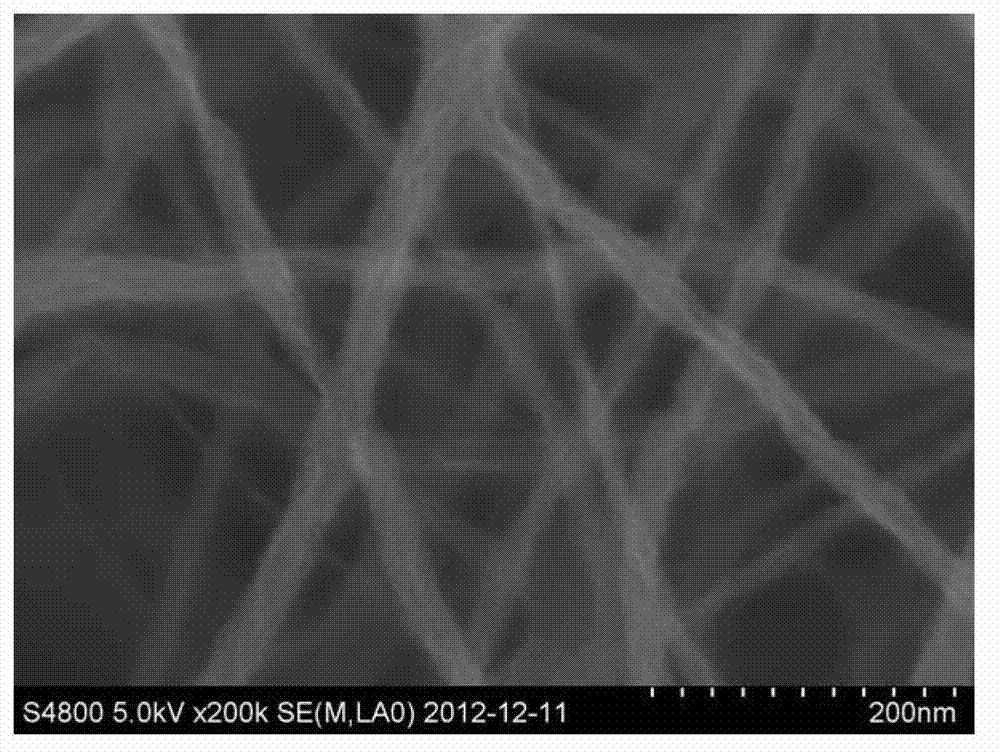

Preparation method of graphene nano-fiber and super-capacitor application thereof

ActiveCN103198931AEasy to fixNo reunionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a preparation method of a graphene nano-fiber and super-capacitor application of the preparation method of the graphene nano-fiber. The preparation method of the graphene nano-fiber includes the following steps: (1) an electrostatic spinning method is utilized to prepare a polymer fiber; (2) the polymer fiber obtained by the method is conducted with stabilizing treatment in appropriate temperature and in an oxygen-bearing atmosphere; (3) the fiber after the stabilizing treatment is conducted with carbonization thermal treatment in an NH3-bearing atmosphere and in appropriate temperature. The surface of the prepared graphene nano-fiber is provided with a graphene sheet which grows along the radial direction, and the thickness of the graphene sheet is 1 to 10 atomic layers. The graphene nano-fiber integrates the advantages of graphene and carbon nanofibers, solves the problems of graphene agglomeration and recrystallization, is high in surface activity and has various application values. The graphene nano-fiber is utilized to serve as a super-capacitor of electrode material preparation. Therefore, compared with the prior art, the preparation method of the graphene nano-fiber and the super-capacitor application of the preparation method of the graphene nano-fiber have good performance. The working voltage reaches 1.8-2.2 volts; the energy density reaches 41.3 watt hour / kilogram; and the specific capacitance in acid can reach 300 F / g.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Method for preparing nanometer porous copper powder

The invention discloses a method for preparing nanometer porous copper powder. The method comprises the following steps of: weighing pure copper powder and pure aluminum powder in a ratio of Al-Cu alloy ingredients; adding the pure copper powder, pure aluminum powder and grinding balls into a ball-milling tank, adding a grinding aid, and performing mechanical alloying treatment in a ball-milling machine to obtain Al-Cu alloy powder; and performing dealloying on the obtained Al-Cu alloy powder in alkaline solution, and washing a sample until the sample is neutral to obtain the nanometer porouscopper powder. Precursor alloy is prepared by a mechanical alloying method, and a process is simple; precursor alloy powder has small sizes, so the corrosion time is shortened greatly (within 1 hour generally), and the production efficiency is improved greatly; and the hole size of the prepared nanometer porous copper is only between 15 and 80 nanometers and is reduced greatly, the porous copper is the powdery sample, and a specific surface area is improved greatly.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com