Patents

Literature

619 results about "Cement particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

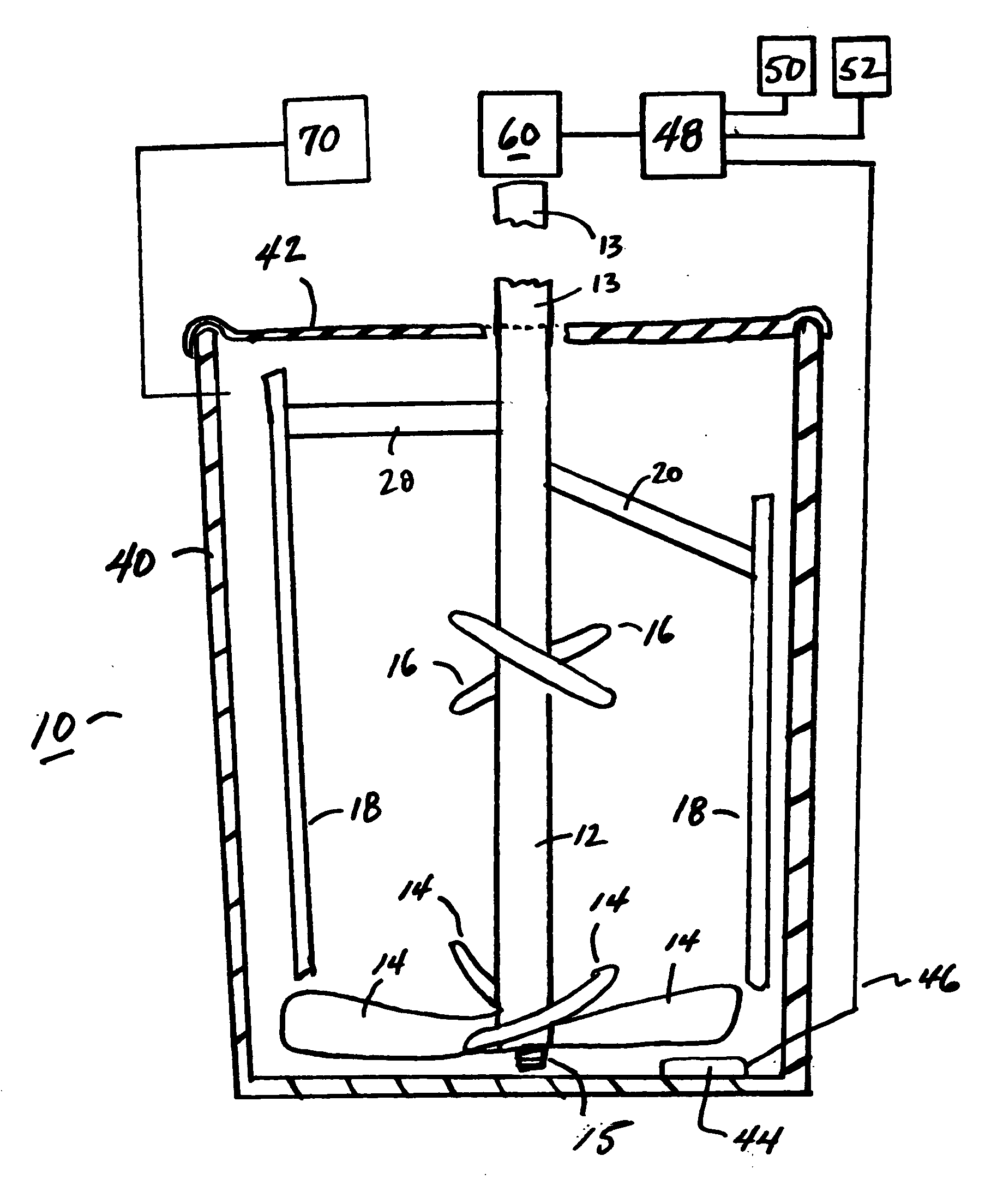

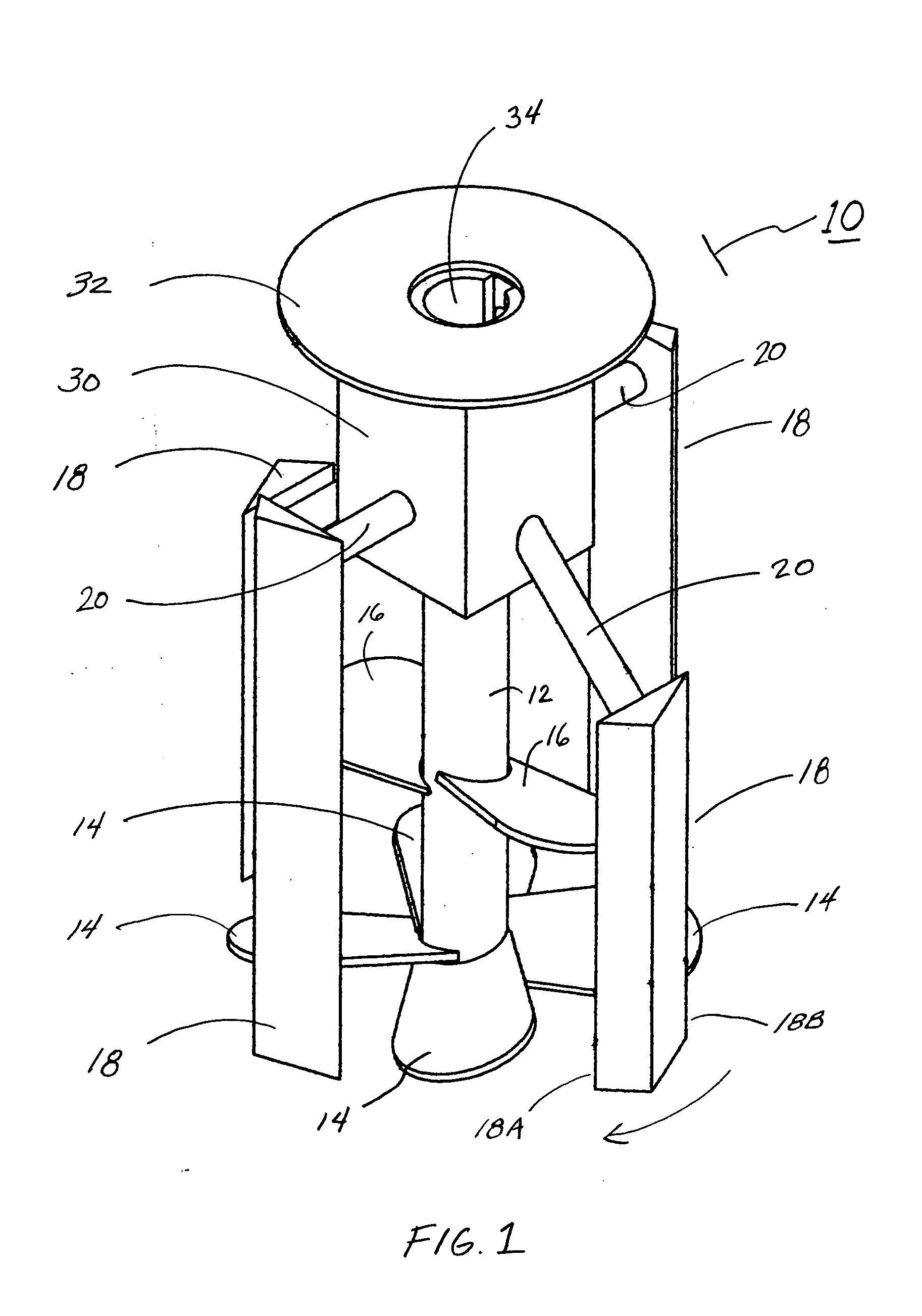

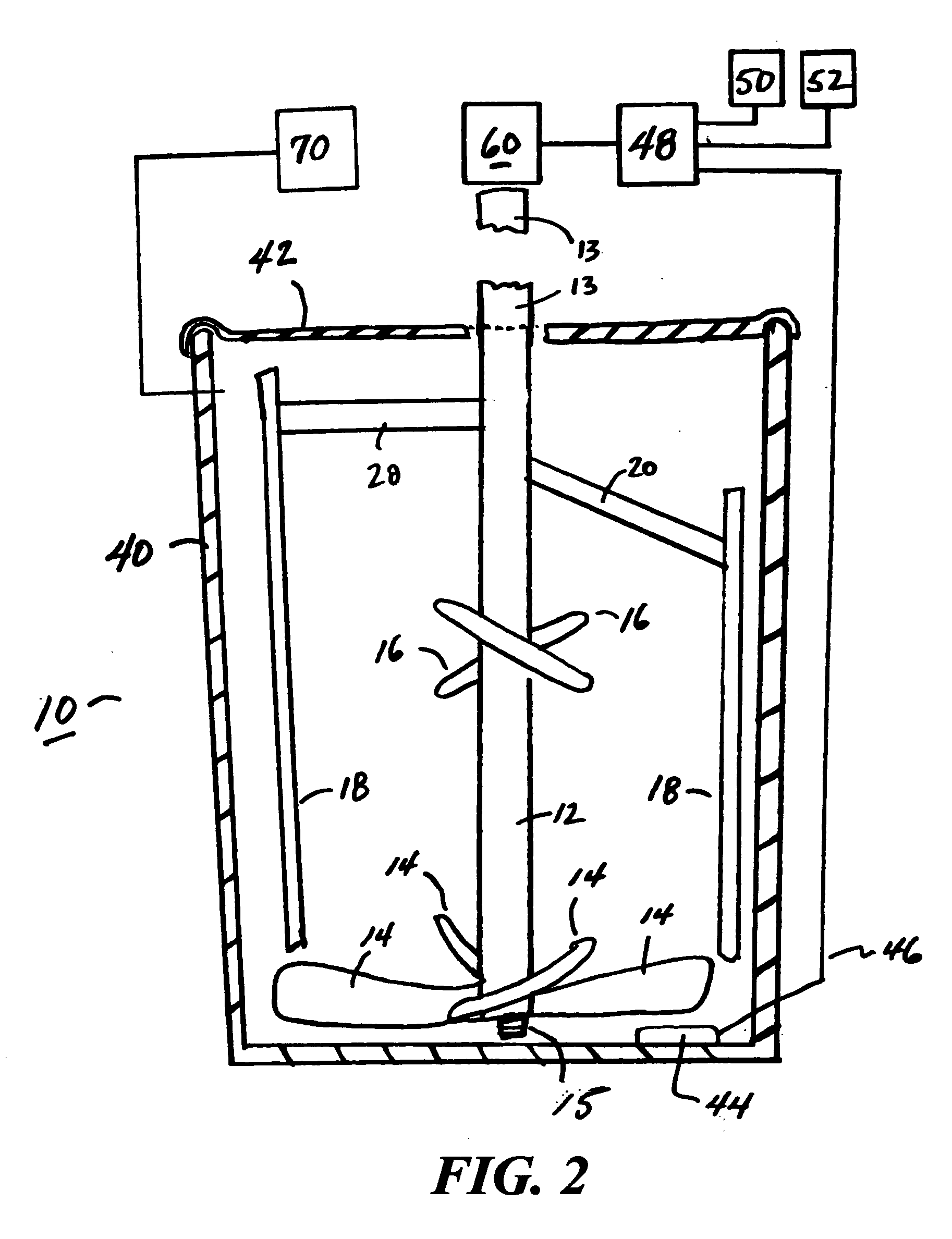

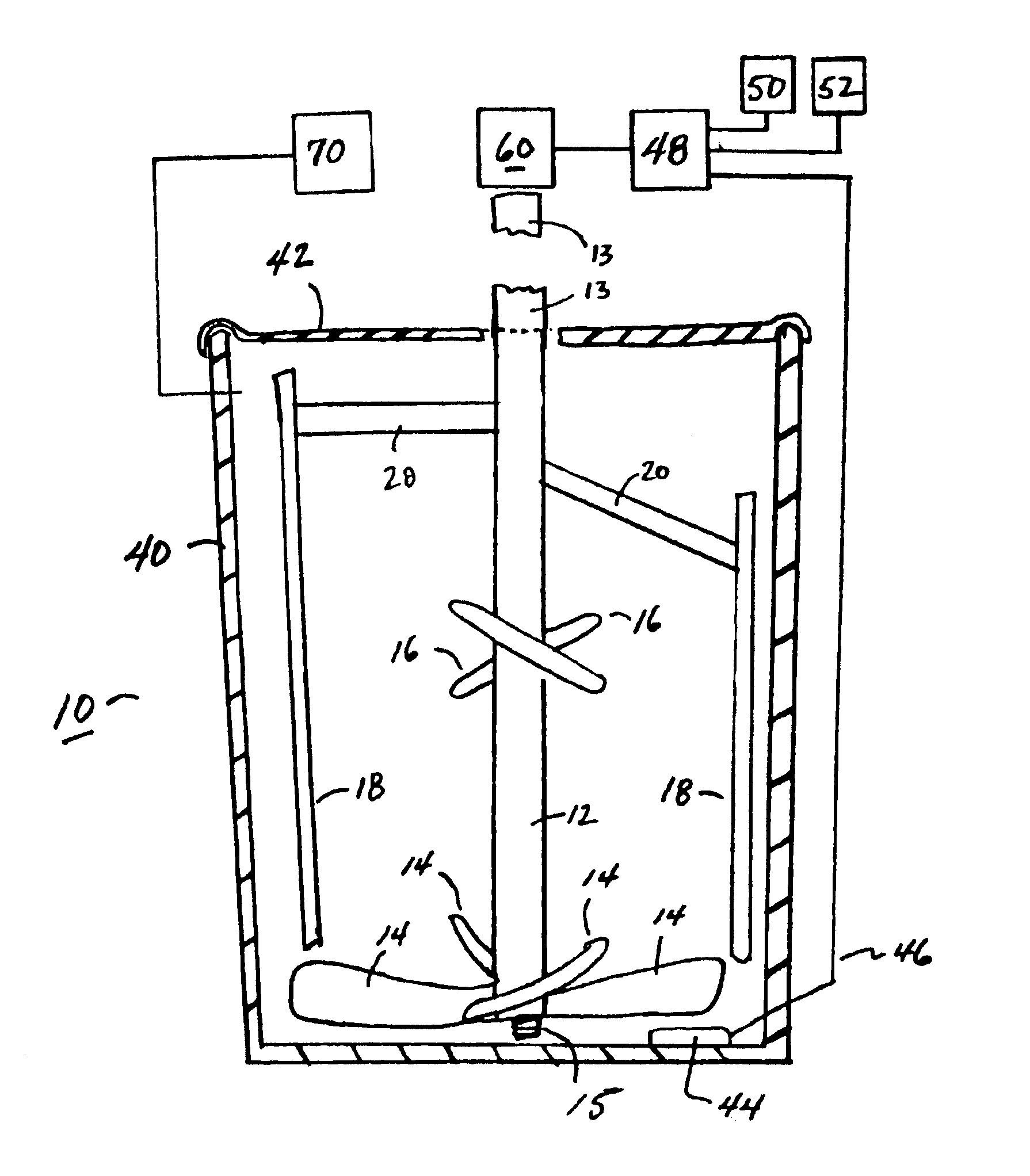

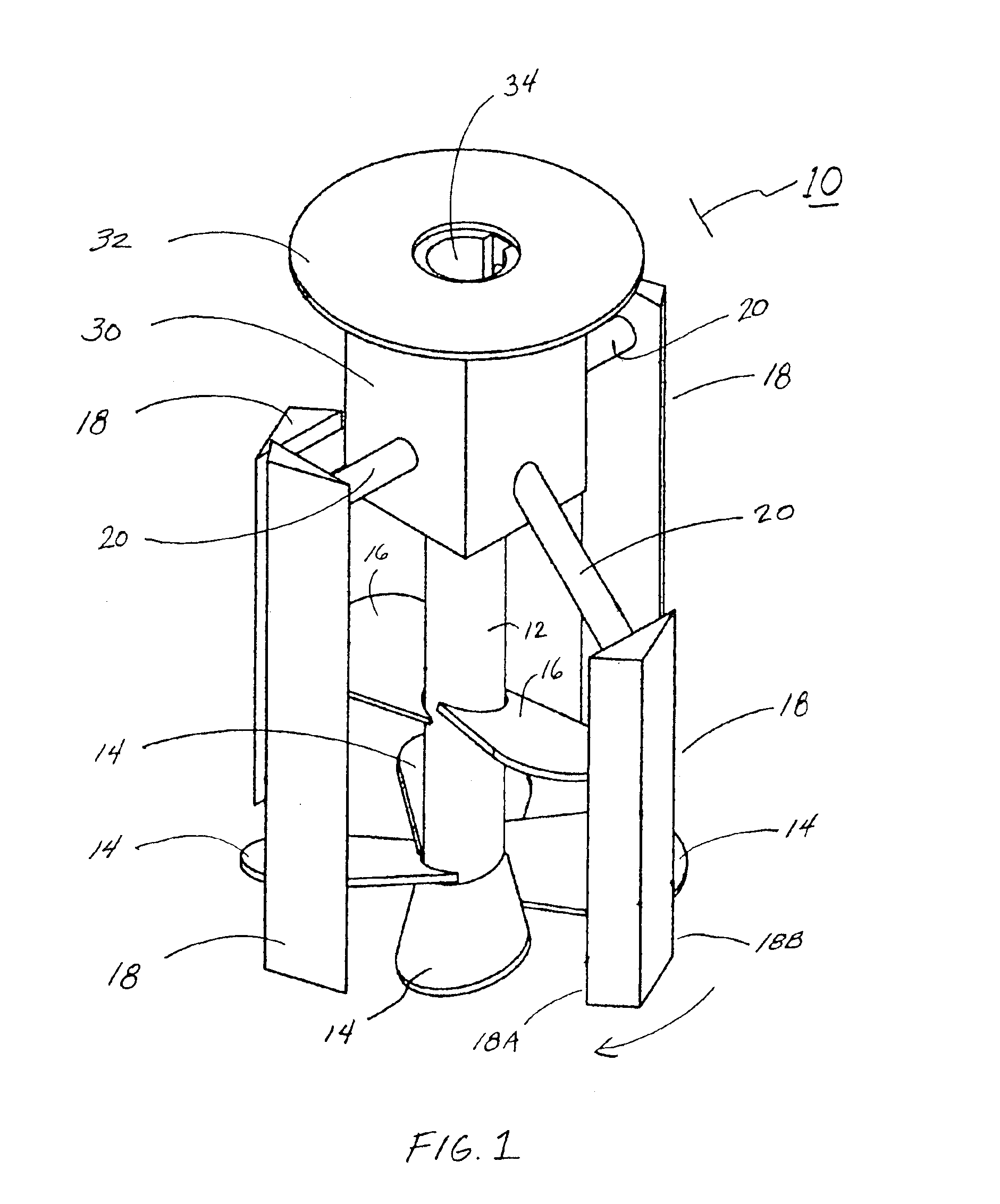

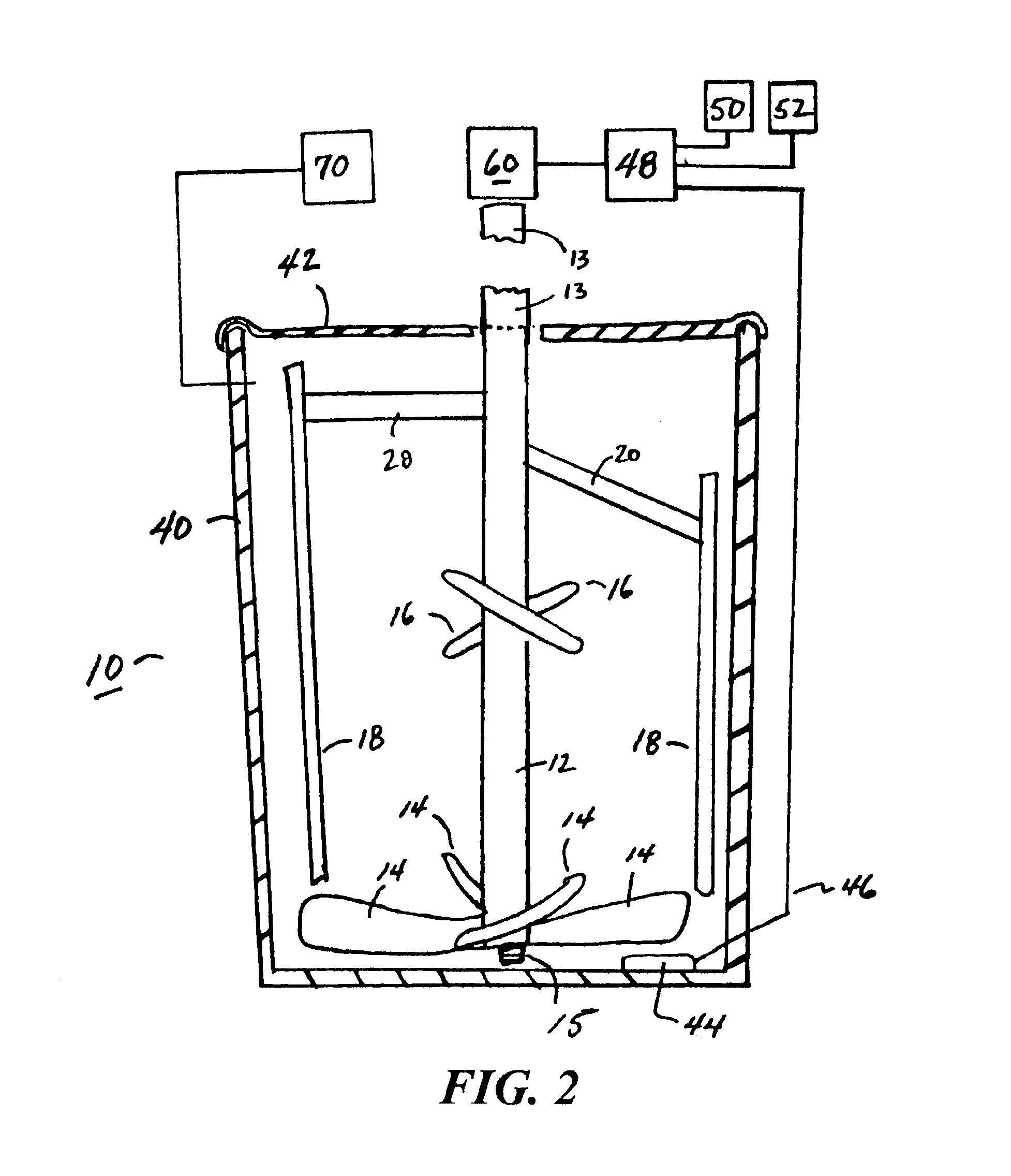

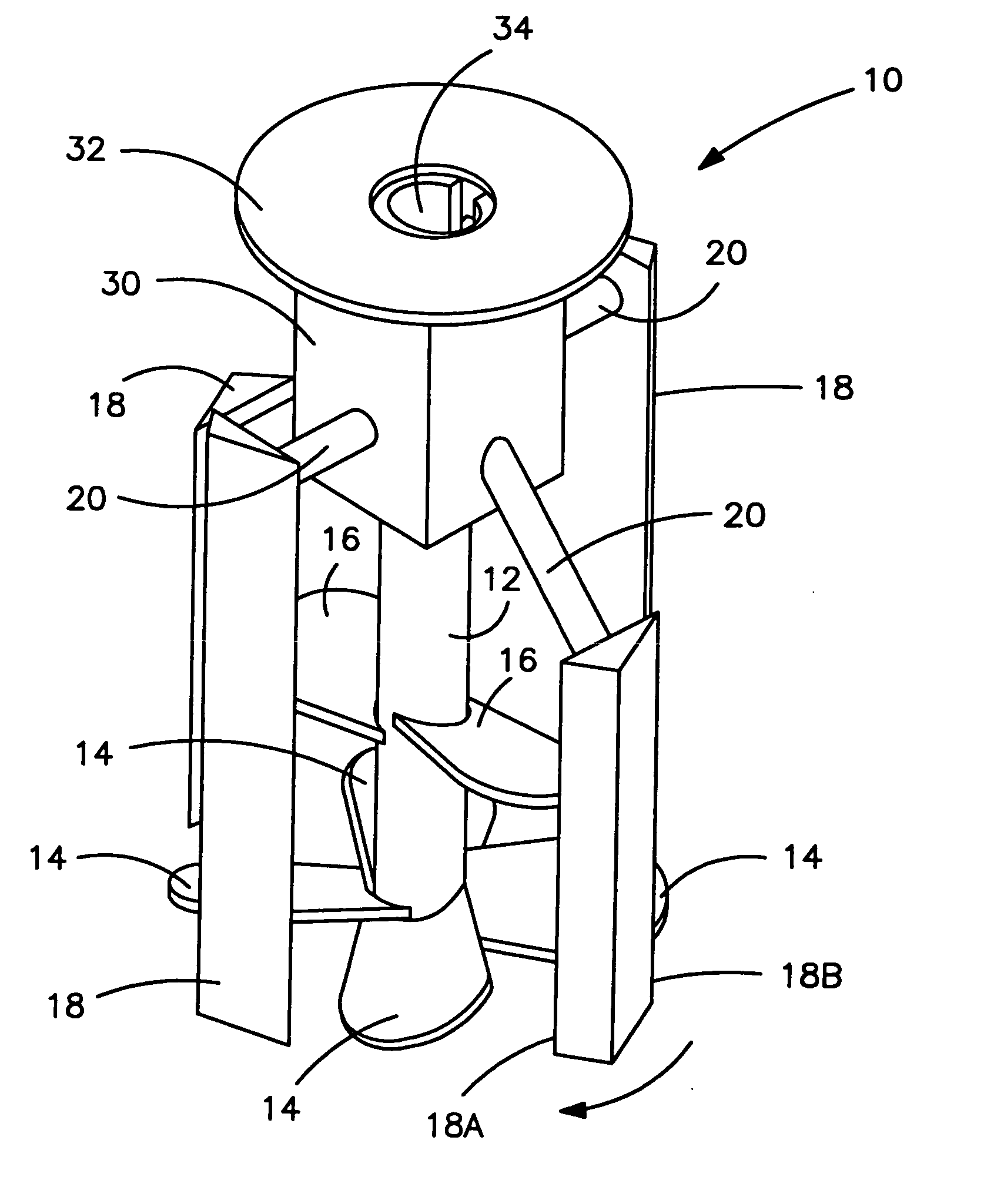

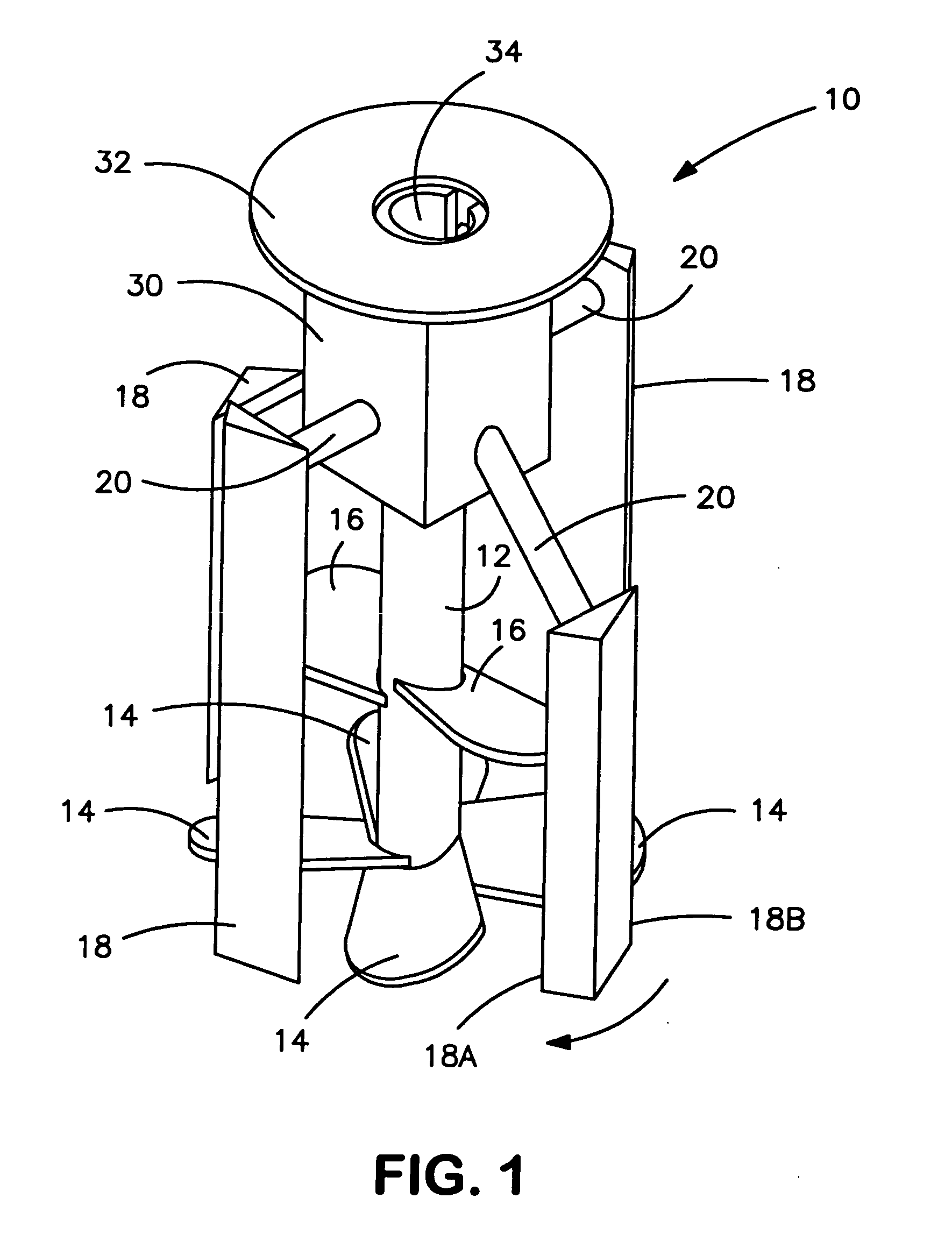

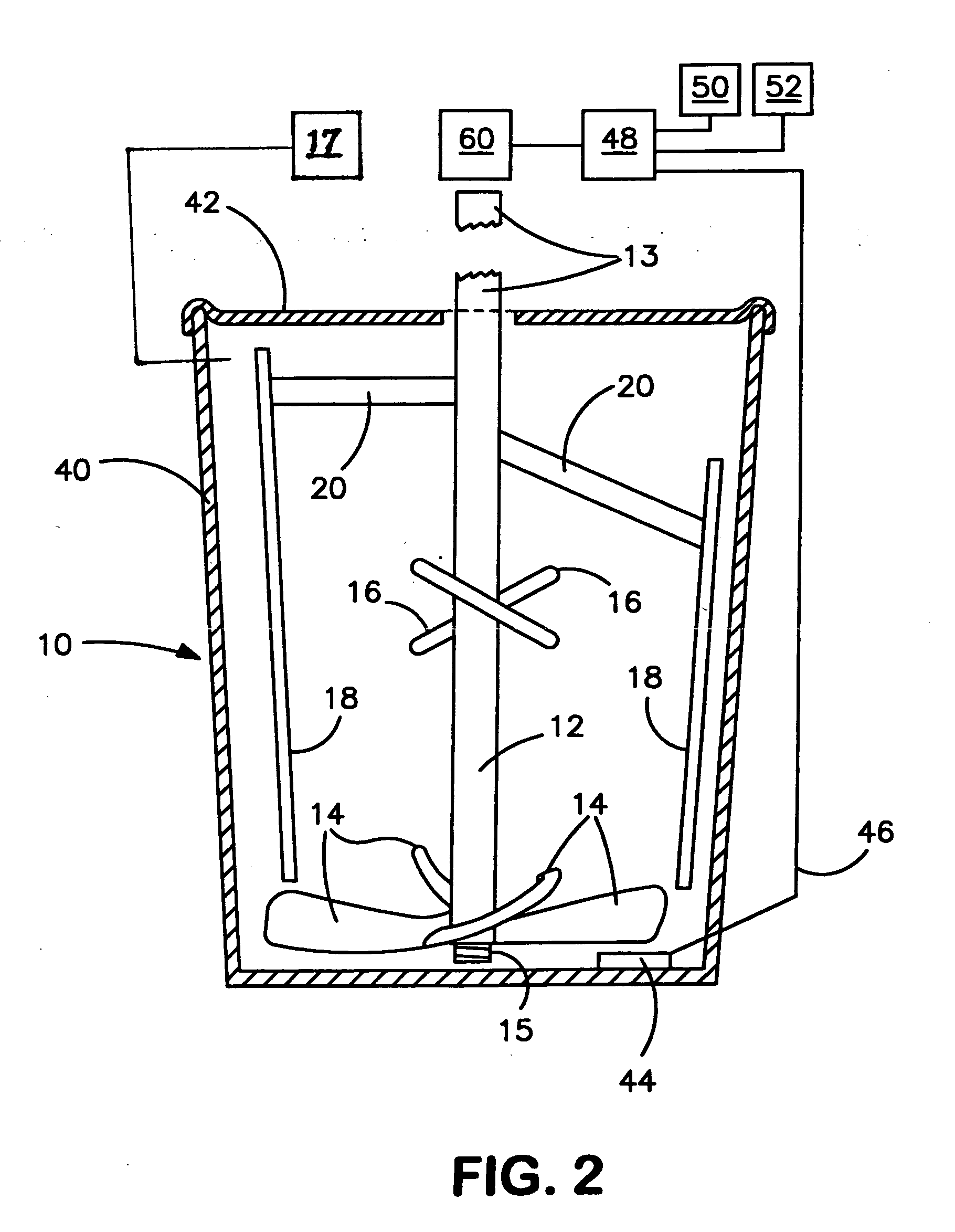

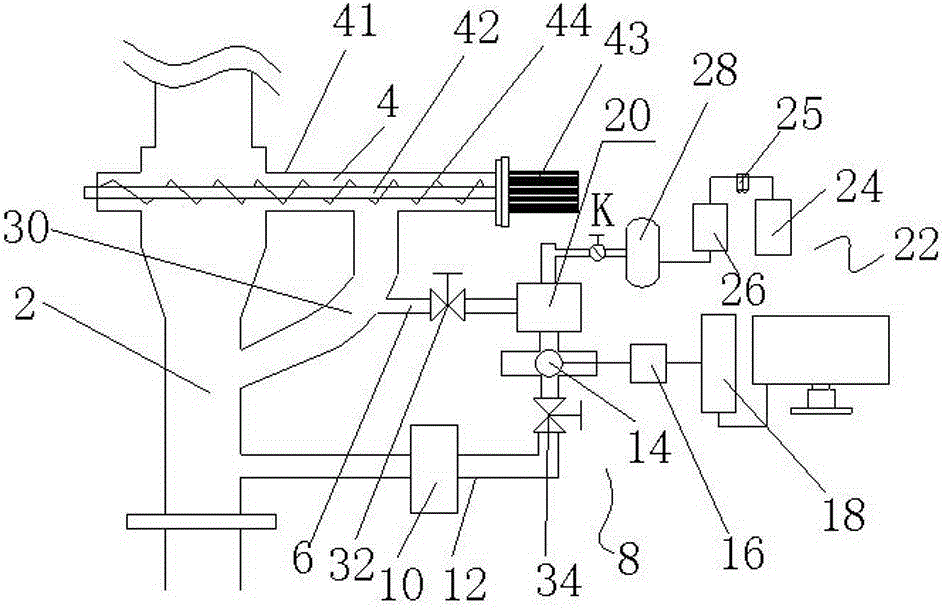

Rheomixer device

ActiveUS20050132782A1Minimize inaccuracyAccurate assessmentTransportation and packagingRotary stirring mixersCement particleEngineering

Device and methods for rotationally mixing and rheological testing of sample liquids, such as cement particle suspensions, employ mixing blades and shear-resistant members having substantially noncoincident orbital paths. Rheology is assessed by measuring the resistance of the liquid to rotation of the device. Both rheological and calorimetric testing can be performed during mixing, which ensures uniformity of rheology and hence the accuracy of results.

Owner:GCP APPL TECH INC

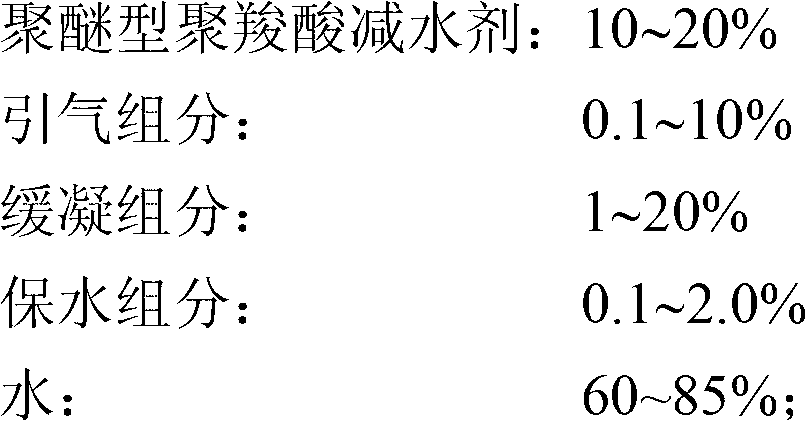

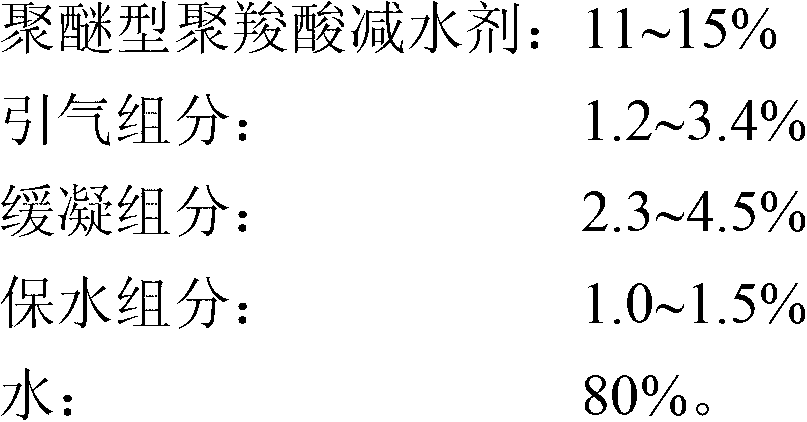

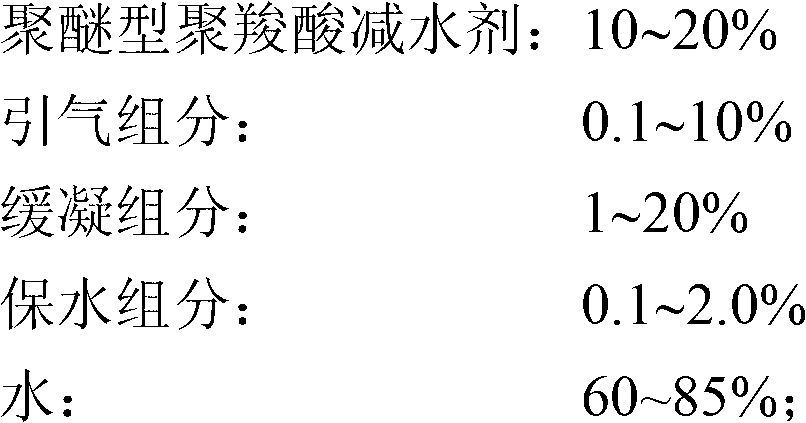

Water-based mortar modifier, its preparation method and application

The invention discloses a water-based mortar modifier, its preparation method and application. The modifier comprises the following preparation raw materials by mass: 10-20% of polyether polycarboxylic acid water reducing agent, 0.1-10% of air entraining components, 1-20% of coagulation retarding components, 0.1-2% of water retention components and 60-85% of water. The polyether polycarboxylic acid water reducing agent is prepared by the method of: dissolving an enol polyether macromonomer, acrylic acid, and maleic anhydride in water, conducting heating to raise the temperature to 60-70DEG C, then adding a persulfate water solution dropwisely, carrying out heat preservation under 60-65DEG C for 2-4h, then performing cooling to a temperature of 45DEG C, and adjusting the pH value of the system to 7-8, thus obtaining the polyether polycarboxylic acid water reducing agent. The modifier provided in the invention can form a protective film on a cement particle surface, and at the same time can produce uniform and tiny bubbles, as well as reduce the friction between the particles in the system, thus effectively improving the workability and plasticity of the mortar system. Furthermore, the mortar modifier provided in the invention is a water-based multifunctional building mortar modifier, and is convenient to use. Doping of the modifier can significantly improve the workability and vicidity of mortar, and can maintain the properties effectively for 8-16 hours.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Cement additive, cement composition and polycarboxylic acid polymer

The present invention has for its object to provide an economical cement additive capable of reducing the amount of water to be added to cement compositions and still capable of providing cement compositions with high fluidity, good processability, and a proper level of air-entraining ability resulting from sufficient foaming prevention, at low addition levels, a cement composition in which the above cement additive is used, and a polycarboxylic acid polymer excellent in dispersing effects on cement particles or inorganic powders or pigments and capable of being used with advantage as a cement additive or a dispersant for various uses.The invention provides, among others, a cement additive comprising, as main component, a polycarboxylic acid polymer (X) which has; repeating units (A), (B), (C) and (D), wherein none of the proportion of occurrence S1 of repeating unit (A) the proportion of occurrence T1 of repeating unit (B) and the proportion of occurrence E1 of repeating unit (C) is not equal to zero, the average number n of moles of an oxyalkylene group as added in repeating unit (B) is not less than 110, and that the weight average molecular weight of said polycarboxylic acid polymer is not less than 10000.

Owner:NIPPON SHOKUBAI CO LTD

Rheomixer device

ActiveUS6997045B2Minimize inaccuracyStudy of effectFlow propertiesRotary stirring mixersRheometryEngineering

Owner:GCP APPL TECH INC

Use of a salt of a poly-acid to delay setting in cement slurry

A spray-dryable cement composition comprises unreacted cement particles and a salt of a poly-acid. The composition can be used in a method for solid free-form fabrication of a three-dimensional object, in which a slurry comprising unreacted cement particles and a poly acid in a liquid carrier is spray-dried so as to substantially remove the carrier and form dry cement particles, the cement particles are deposited in a defined region and a liquid binder is applied to a predetermined area within the defined region such that upon contact of the liquid binder with the cement particles a hydrated cement forms in the predetermined area, and the steps of depositing the cement and applying the binder are repeated so as to form a three dimensional object.

Owner:HEWLETT PACKARD DEV CO LP

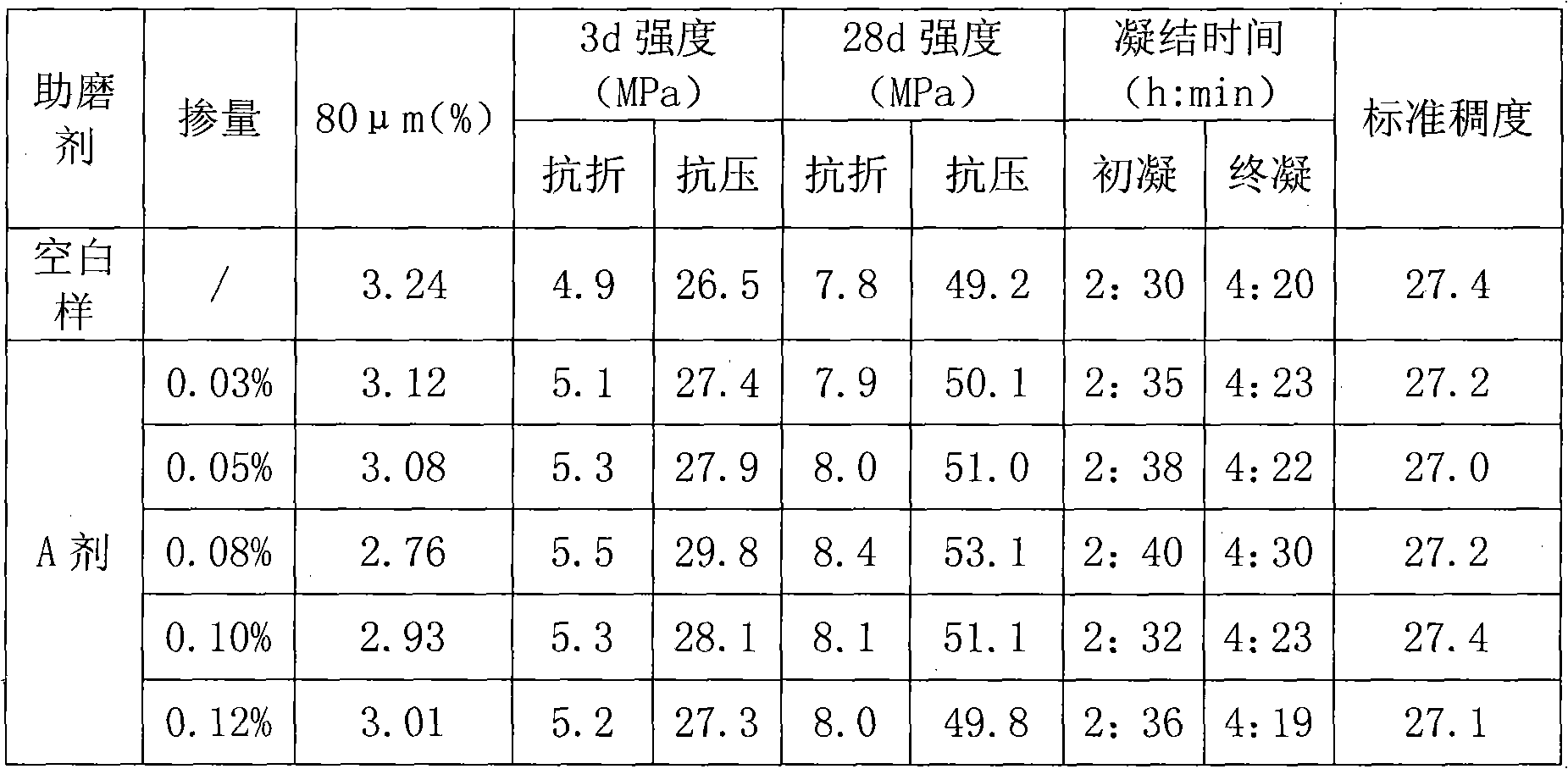

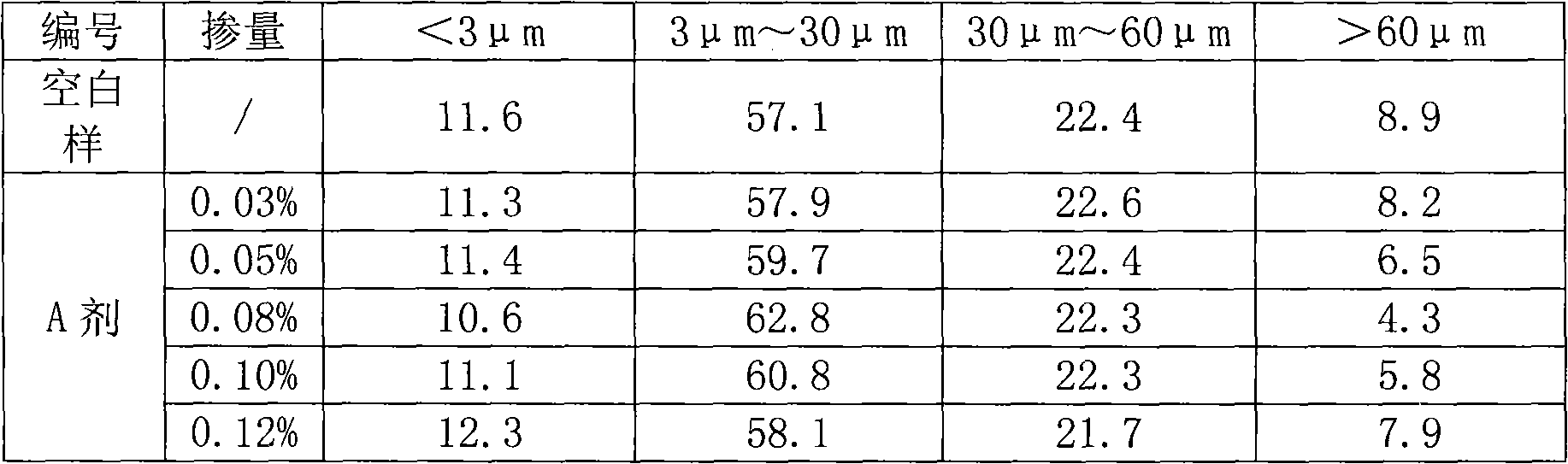

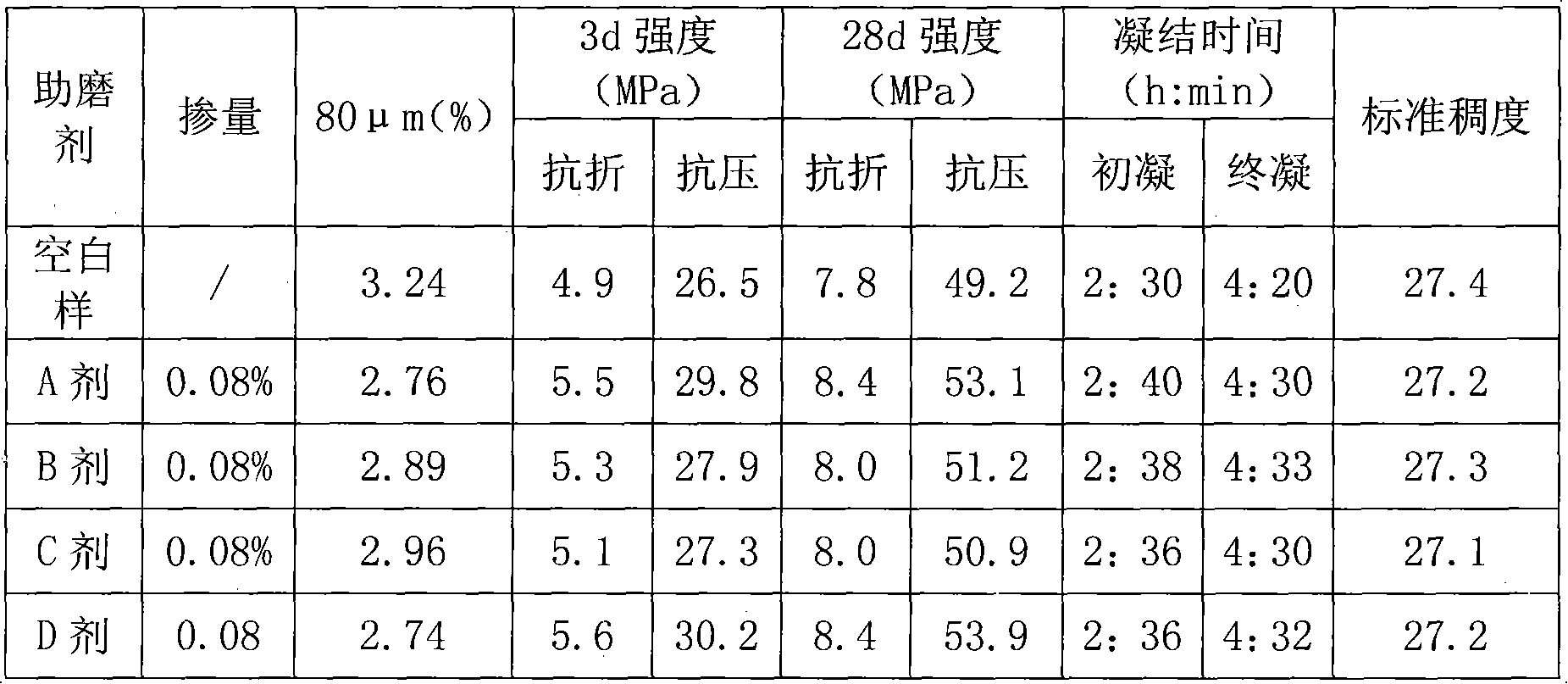

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

Rheological and calorimetric testing method

InactiveUS20050138991A1Minimize inaccuracyStudy of effectTransportation and packagingFlow propertiesRheometryMaterials science

Device and methods for rotationally mixing and rheological testing of sample liquids, such as cement particle suspensions, employ mixing blades and shear-resistant members having substantially noncoincident orbital paths. Rheology is assessed by measuring the resistance of the liquid to rotation of the device. Both rheological and calorimetric testing can be performed during mixing, which ensures uniformity of rheology and hence the accuracy of results.

Owner:GCP APPL TECH INC

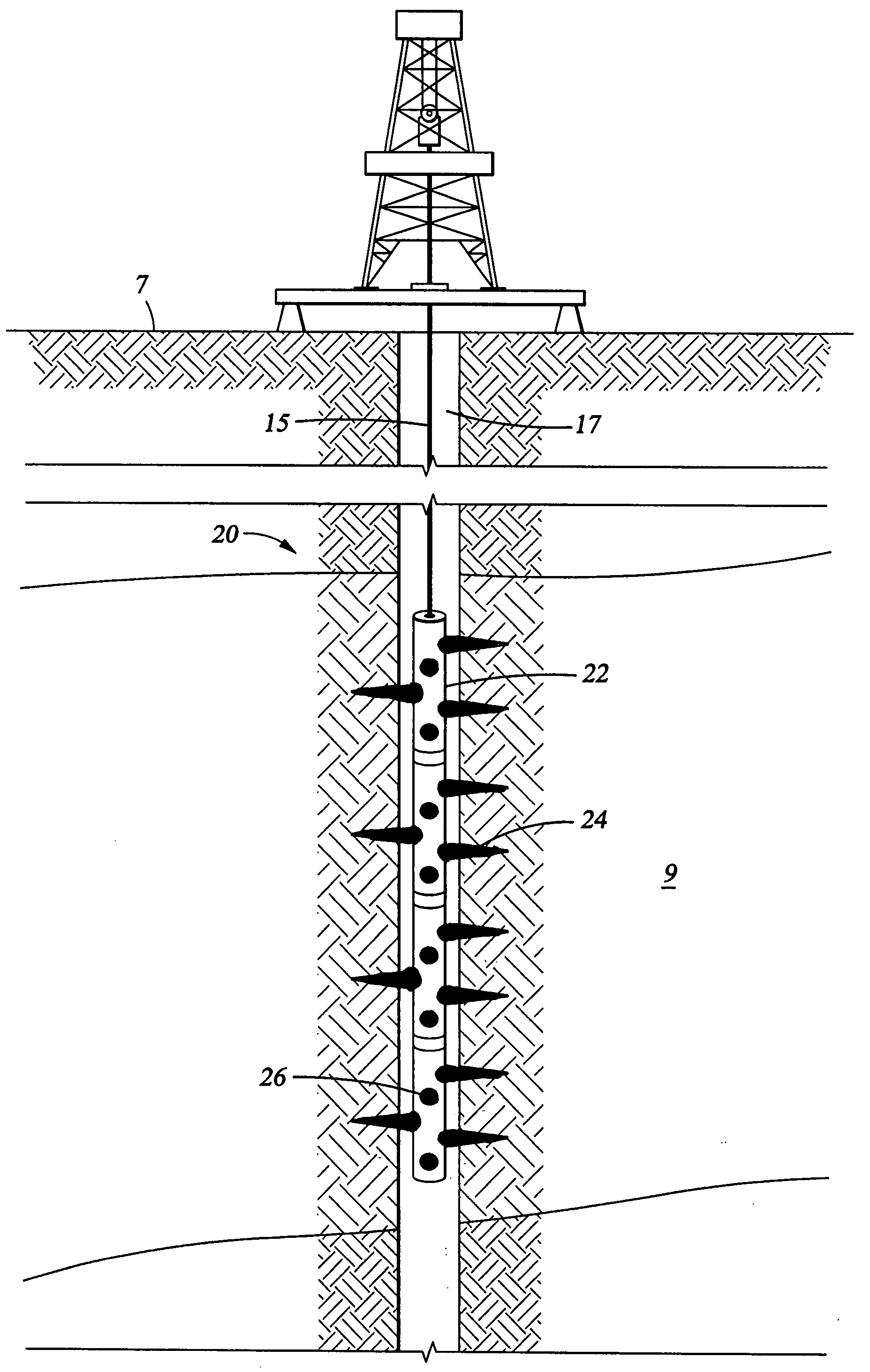

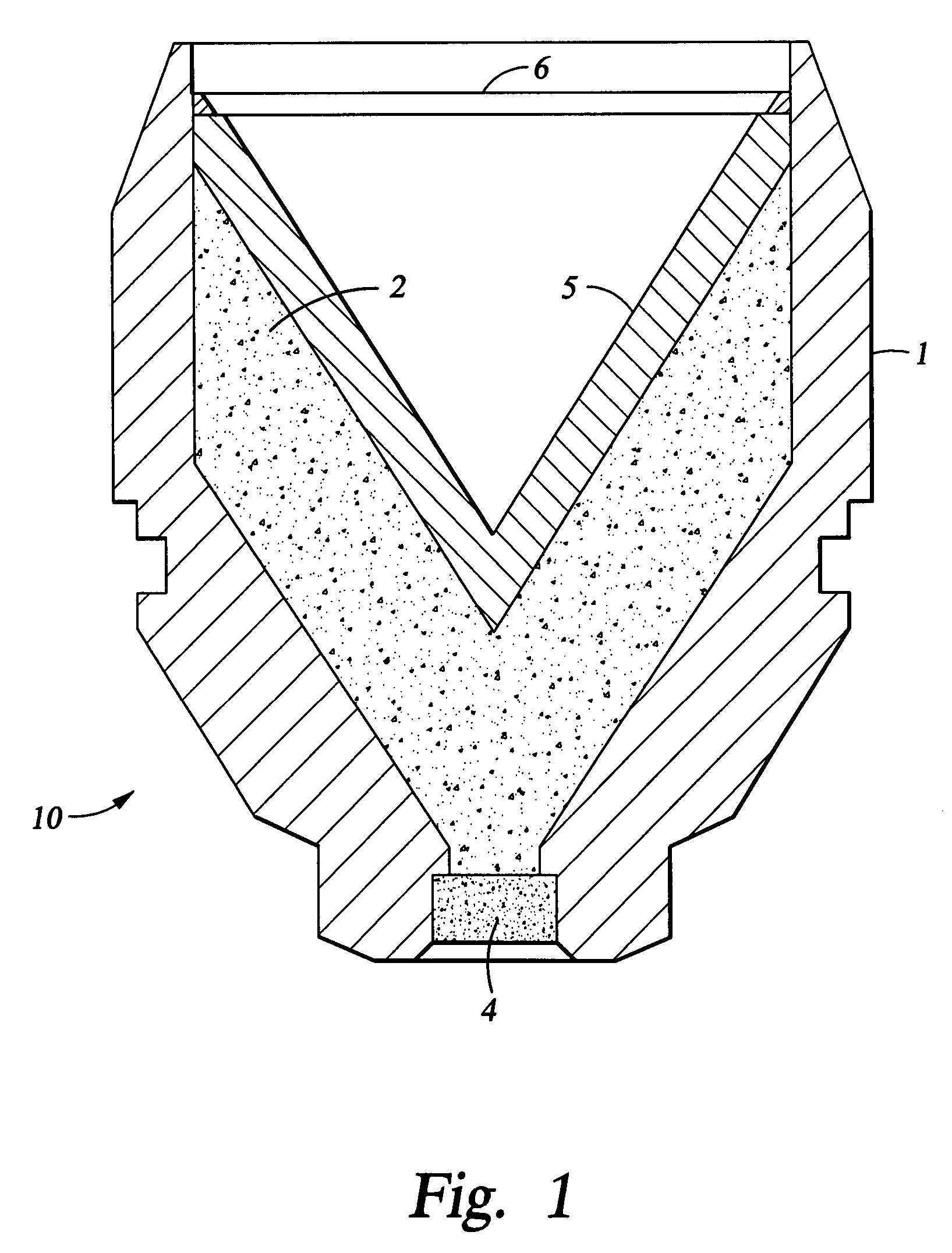

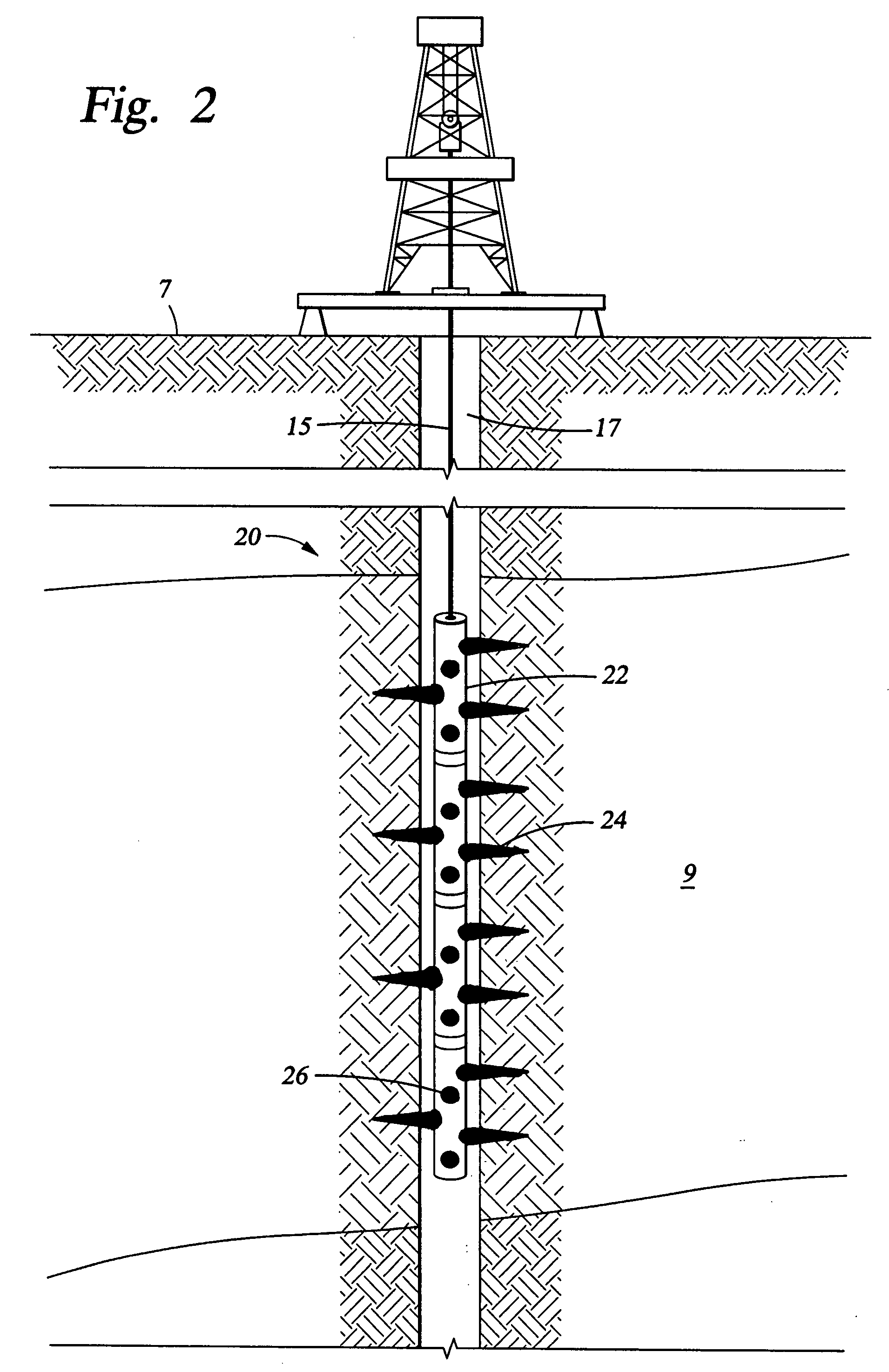

Perforating system comprising an energetic material

A perforating system, including a shaped charge assembly comprising a charge case, a liner, and a main body of explosive. The material of the perforating system components, including the gun body, the charge case and the liner may be comprised of an energetic material that conflagrates upon detonation of the shaped charge. The material may be an oxidizer, tungsten, cement particles, rubber compounds, compound fibers, KEVLAR®, steel, steel alloys, zinc, and combinations thereof.

Owner:BAKER HUGHES INC

Composite method of isopentenol polyoxyethylene ether

InactiveCN101928392AStrong dispersion retention abilitySimple processEther preparation from oxiranesPolymer scienceEthylene oxide

The invention discloses a preparation method of isopentenol polyoxyethylene ether. Isopentenol and ethylene oxide are served as raw materials; in the presence of catalyst, the raw materials react for 5-40 hours to obtain the isopentenol polyoxyethylene ether at the reaction temperature of 70-160 DEG C. The isopentenol polyoxyethylene ether has the molecular weight of 200-6000 and the iodine value of 3.9-123; the mass ratio of isopentenol to ethylene oxide in the raw materials is 1:0.0143-0.754; and the mass of the catalyst is 0.03-0.5% of total mass of the raw materials of isopentenol and ethylene oxide. The invention has simple and reasonable technology. Because the invention has the structural particularity of branched chain methyl, molecular space steric hindrance is increased, and the composite polycarboxylic acid high-efficiency water reducer has strong cement particle dispersibility holding capacity. Thus, the product has the advantages of low dosage, high water-reducing ratio, good strengthening effects, good durability and the like, does not erode reinforcing steel bars and protects environment.

Owner:ZHEJIANG HUANGMA TECH

Cement grinding aid

InactiveCN101898878AIncrease productionReduce power consumptionCement productionCalcium formateGlycerol

The invention discloses a cement grinding aid, comprising calcium formate solution, compound glycerol distilled residue solution, triethanolamine, diols and molasses. While the product reutilizes the industrial wastes, the components of the product synergistically act to optimize the efficacy of the grinding process and the product modifies the cement particles, thus improving the quality and performance of the cement while improving the cement yield and saving electricity, and the product does not only have grinding function.

Owner:宜兴市宏伟科技有限公司

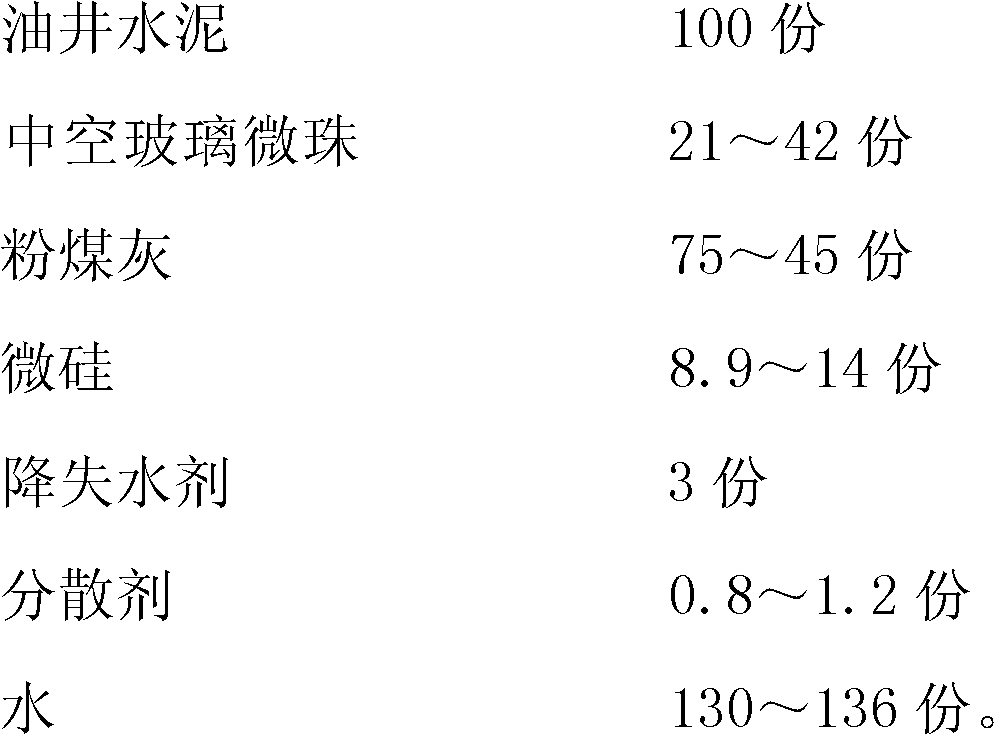

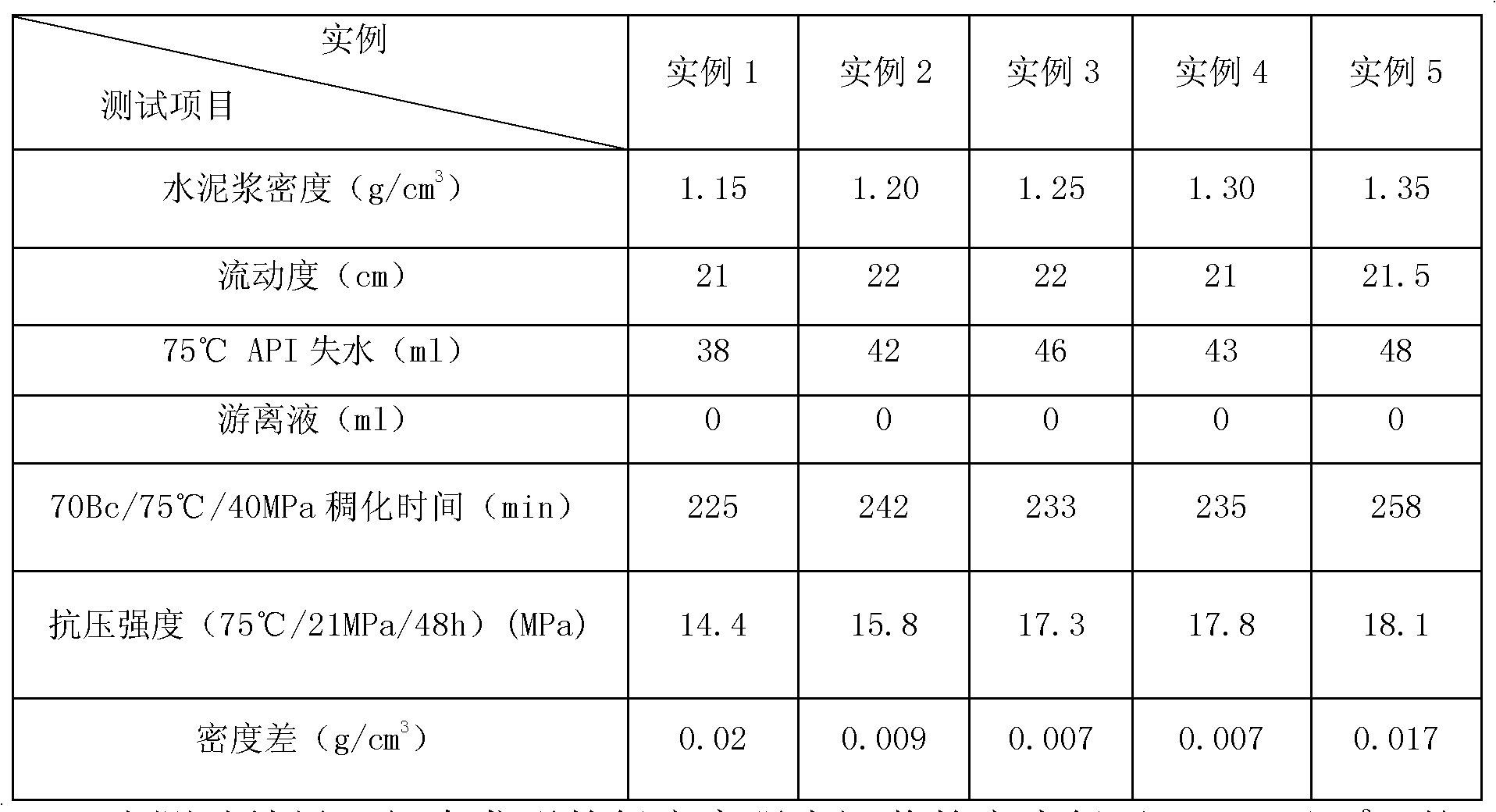

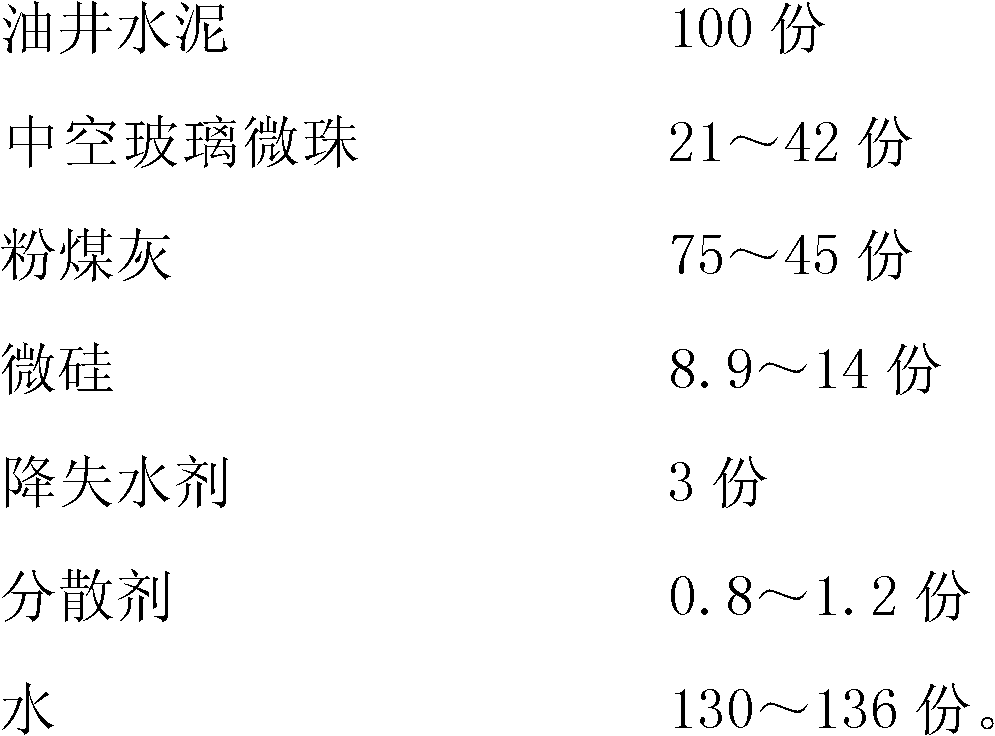

Low-density and high-strength cement paste

ActiveCN102516964AIncrease percentageIncreased percentage of solid phase particlesDrilling compositionFiltrationVolumetric Mass Density

The invention discloses low-density and high-strength cement paste, which is applied to cementing of wells tending to leak under a low pressure. The cement paste is prepared from the following components in parts by weight: 100 parts of oil well cement, 21-42 parts of hollow glass microbeads, 75-45 parts of coal ash, 8.9-14 parts of micro silicon, 3 parts of a filtration-reducing agent, 0.8-1.2 parts of a dispersing agent and 130-136 parts of water. In the cement paste, glass microbeads are taken as main lightening materials, so that the density of low-density cement paste is lowered to 1.15-1.35 g / cm<3>, and the application arrange of the low-density cement paste is widened; by compactly piling cement particles, coal ash particles, glass microbead particles and micro silicon particles, the percentage of solid-phase particles is increased, and cement stone is dense, has high strength, high penetration resistance, high sedimentation stability and contribution to preventing of rush, and is free from concentration; and the cement paste does not contains any early strength admixture, the strength is enhanced by fully depending on compact piling of particles, the cement paste can be mixed with any fluid loss agent without damaging the fluid loss effect, and pollution on stratum is low.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

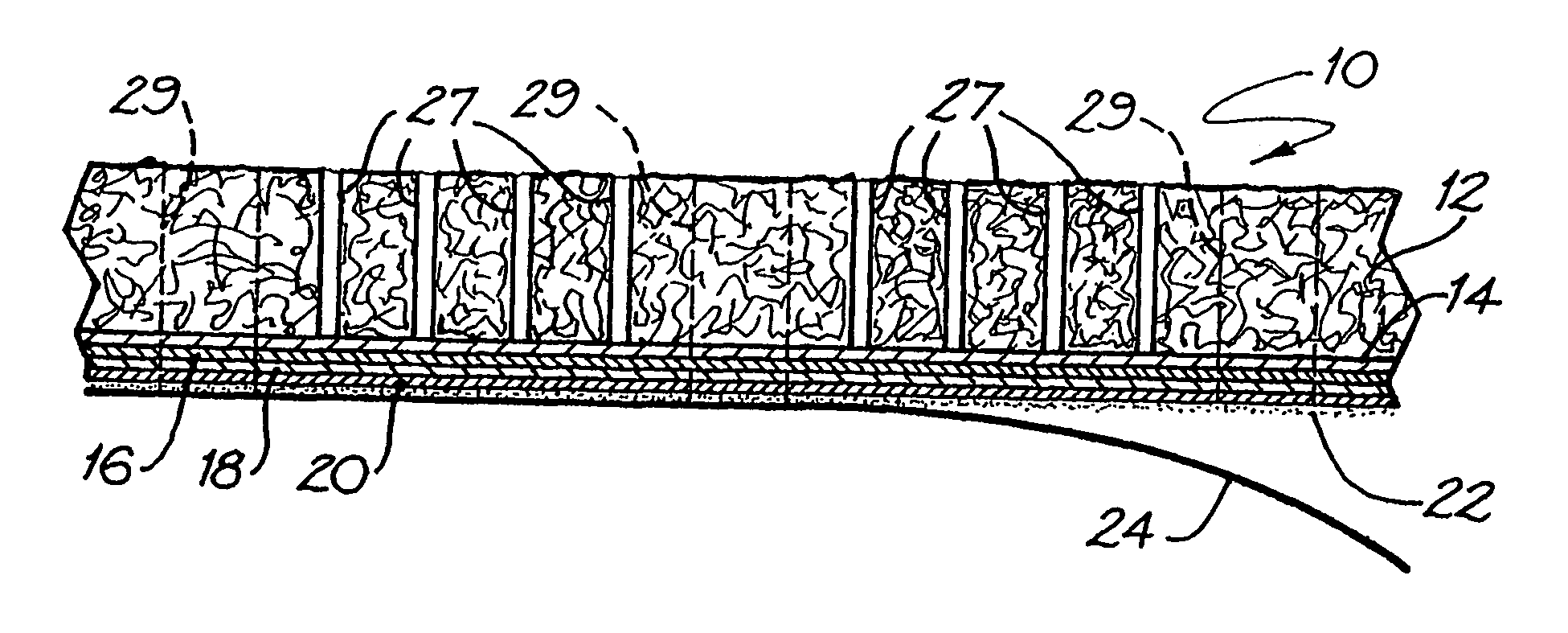

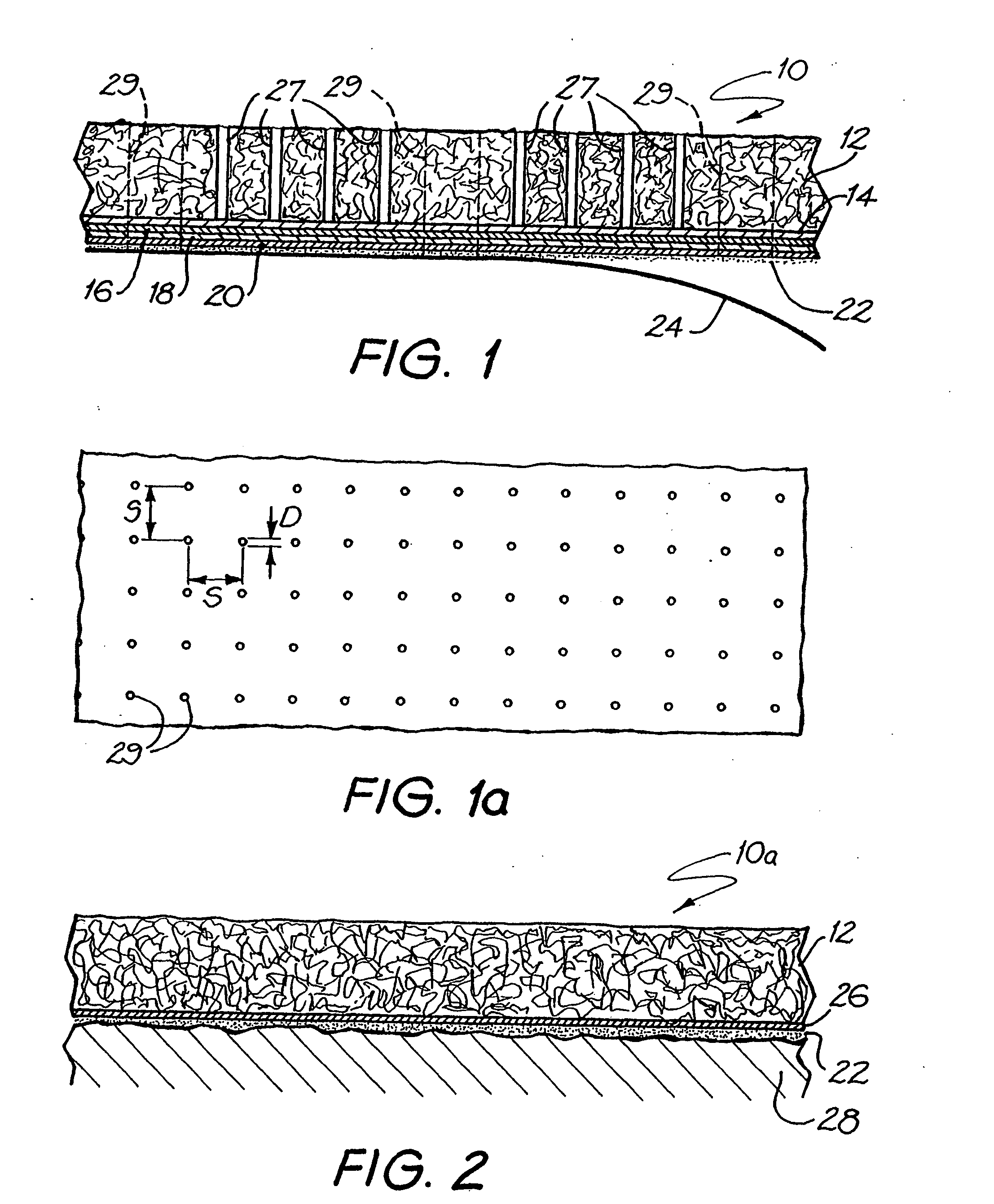

Multi-layer covering

InactiveUS20060174585A1Efficient use ofSame degree of flexibilityCeilingsCovering/liningsFiberAdhesive

A multi-layer covering includes a flexible fabric layer. The fabric layer may be a fluffy blanket or a mesh. Where the fabric layer is a blanket it has a thickness of 2 mm to 5 mm, and is in the form of a batt or weave or spun bonded layer, and defining gaps between the strands of in the blanket. Where the fabric layer is a mesh the spacing between adjacent strands of the mesh is 3 mm to 20 mm. The multi-layer covering further includes a metallic reflective foil (or paper) support layer, and a layer of adhesive protected by a peel-off backing layer for ease of applying the covering to a surface. When covering a wall, the covering is stuck to the wall and one or more protective coatings of paint render such as acrylic are applied to the blanket with a brush or roller or spray. Acrylic render paints typically includes a relatively thick mixture of cement, sand and acrylic polymer. The coarse sand and cement particles penetrate into the gaps between the fibres of the blanket or the holes in the batt as far as the face of the wall and saturate the blanket with acrylic render paint. The blanket provides an even surface when coated with render paint and avoids the need for extensive preparation of the wall. The covering may also be applied to floors, ceilings and roofs and covered with differing coatings, including acrylic render, plaster, paint, glue, and other surface treatments. The covering may be used to cover cracks and undulations in buildings and other structures.

Owner:BARR OWEN DEREK

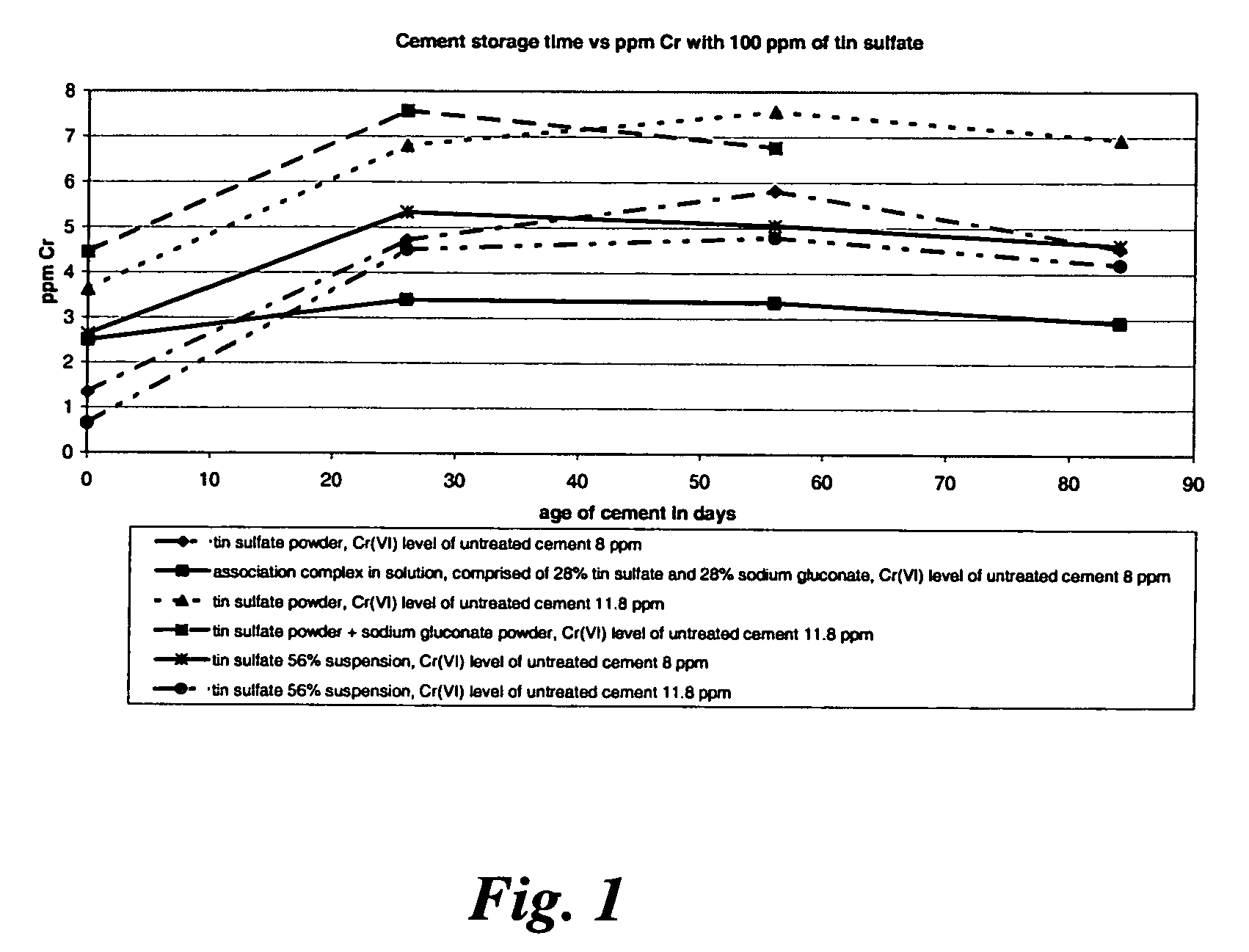

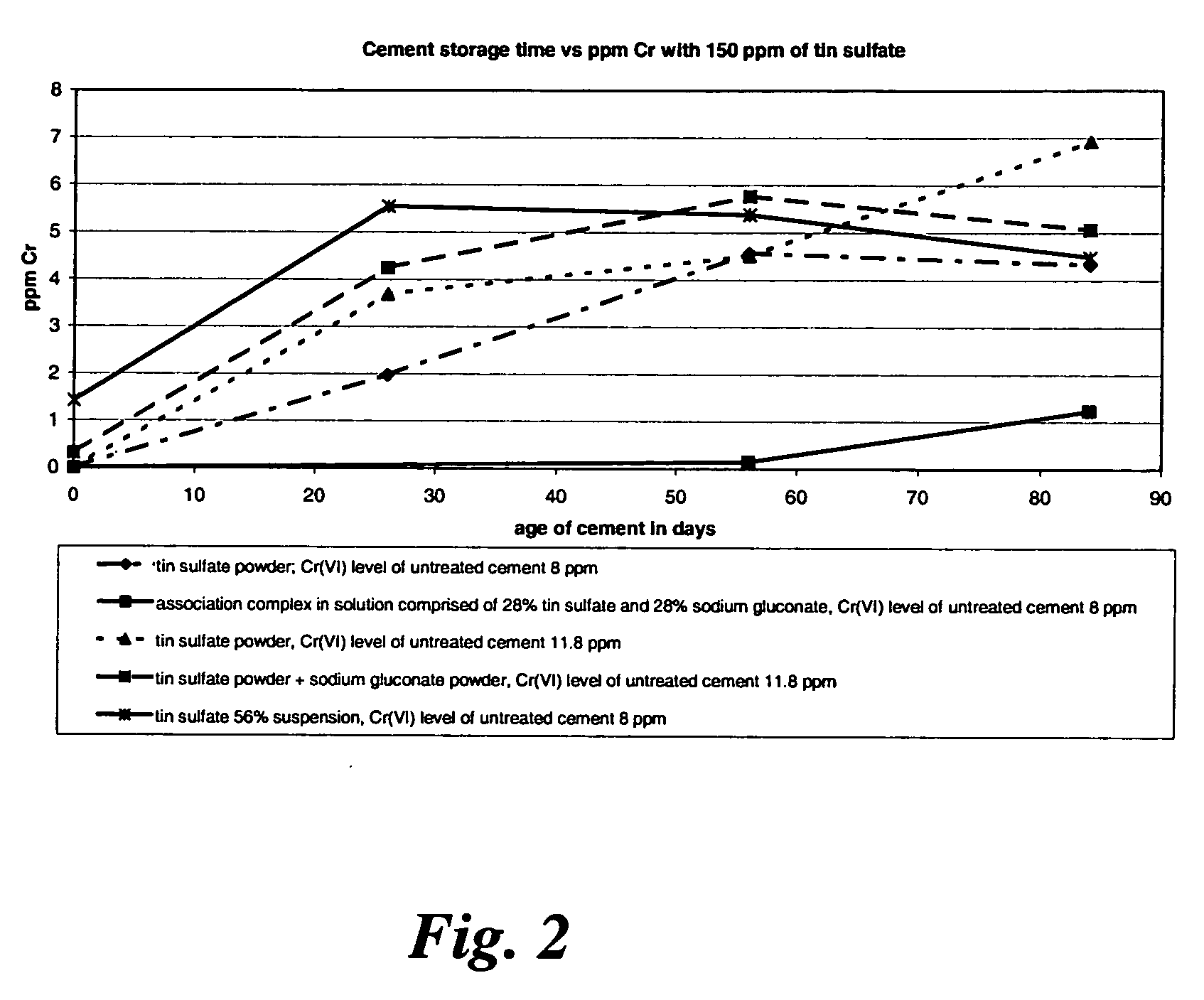

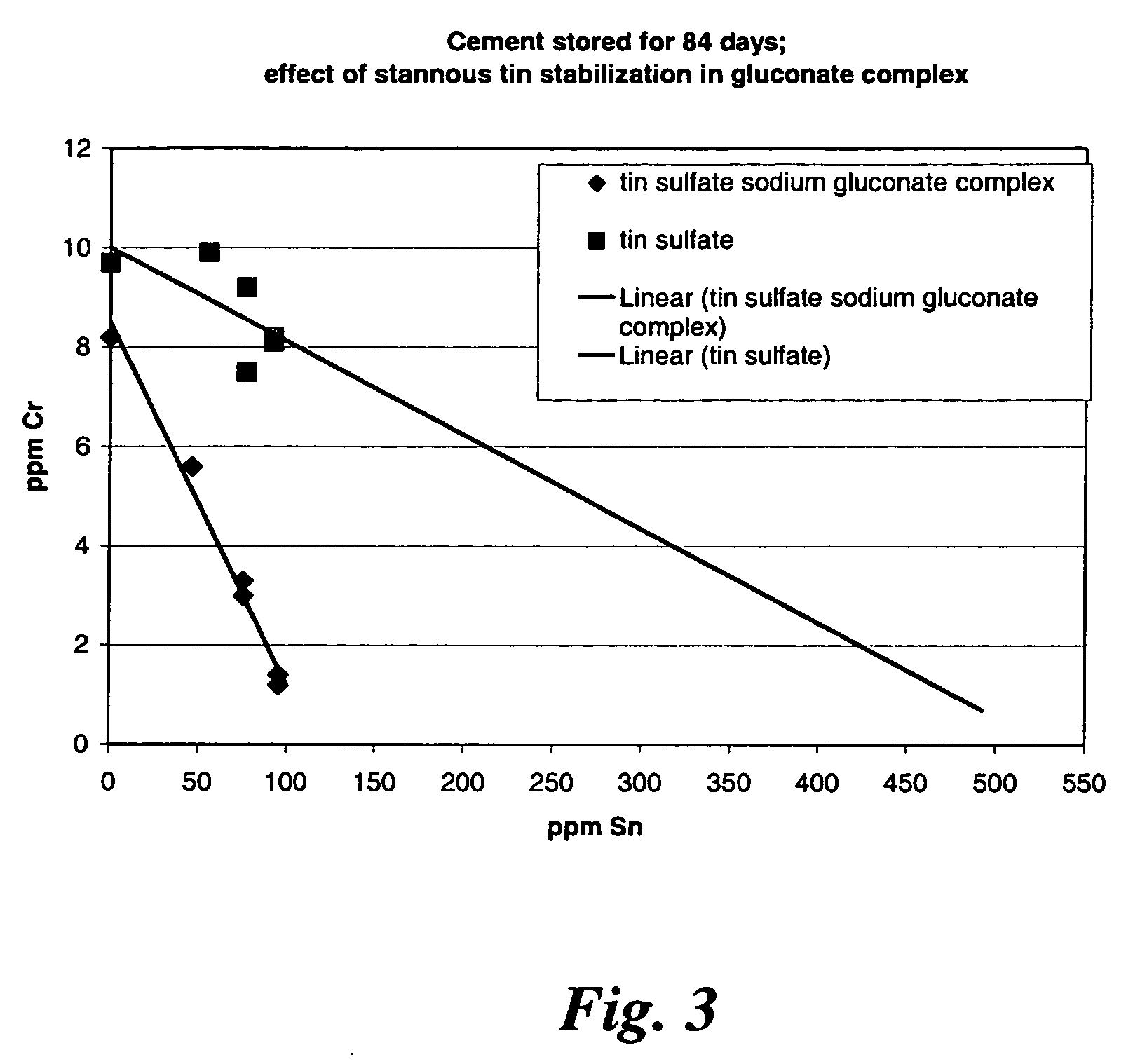

Dosage efficient, storage stable compositions for reducing chromium (VI) in cement

InactiveUS20070034118A1Maintain curative effectMaintaining the efficacy of chromium reducers in cement over timeHydration reactionSulfonate

An association complex formed in a liquid environment from a metal-based chromium (VI) reducer and a non-lignosulfonate-based complexing agent is introduced into cement clinker or hydratable cement particles. In preferred embodiments, the formation of the association complex provides storage stability to the chromium reducer within the cement, such that the level of chromium (VI) after water is added to the cement remains less than 2 ppm for certain duration after mixing with water and without the necessity for further additions of chromium reducer during said duration (e.g., 26-84 or more days after addition). Compositions having the association complex are also described.

Owner:WR GRACE & CO CONN

Concrete gel reducing agent

ActiveCN104119014ARefined particlesImprove initial flow propertiesThree-dimensional spaceUltimate tensile strength

The invention relates to a concrete gel reducing agent which comprises the following formula components in percentage by weight: 1%-3% of phosphonic acid ramifications A, 2%-5% of hydroxy aromatic compounds B, 8%-13% of alkylamine C and the balance of water, wherein the total amount of the phosphonic acid ramifications A, the hydroxy aromatic compounds B and the alkylamine C is 15%. A part of organic substances contained in the concrete gel reducing agent used as a novel concrete additive have molecular structures with three-dimensional spaces and have higher micro dispersion property on cement. If the gel reducing agent is doped into concrete, cement particles are sufficiently refined under the condition that the usage amount of the cement is reduced, the initial flowing property of the concrete is improved, and the hydration degree of a cement mineral is enhanced by promoting the hydration of ferrite which is more difficult to hydrate, so that the early strength is enhanced, the later strength of the cement is effectively excited and the compactness of the concrete is enhanced.

Owner:浙江五龙新材股份有限公司

Construction Product

InactiveUS20090085253A1Less expensiveReduce weightConstruction materialSolid waste managementEtherSurface plate

The invention relates to a construction element which has advantages over regular concrete elements by being much lighter, stronger and less expensive. The element comprises at least 15% by weight of cement, particulate filler material, ethylene-vinylacetate copolymer binder and optionally cellulose ether and PYA binder. The filler material may be selected from particulate wood, particulate elastomeric material, fiyash, crushed rock, cellulosic materials or sand. The invention also relates to a slurry mixture for producing the construction element. The said element may have a variety of shapes, such as sheets, bricks, beams, blocks, panels and boards.

Owner:KRUSS LEON

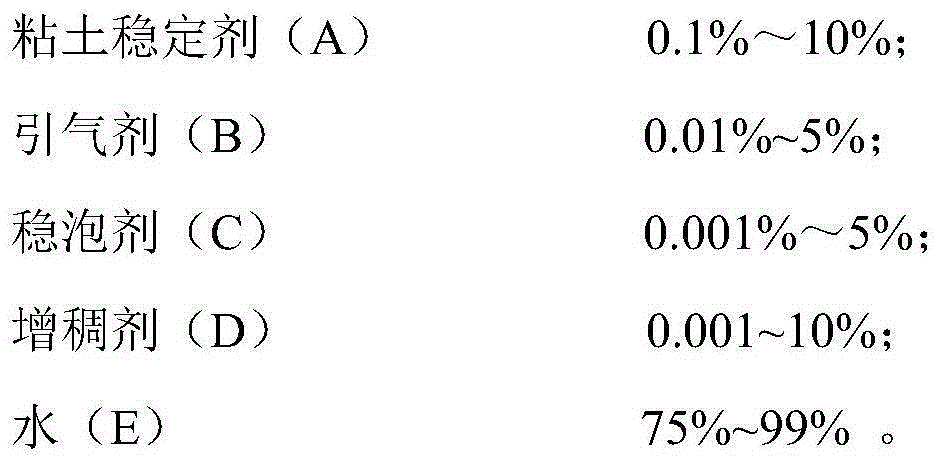

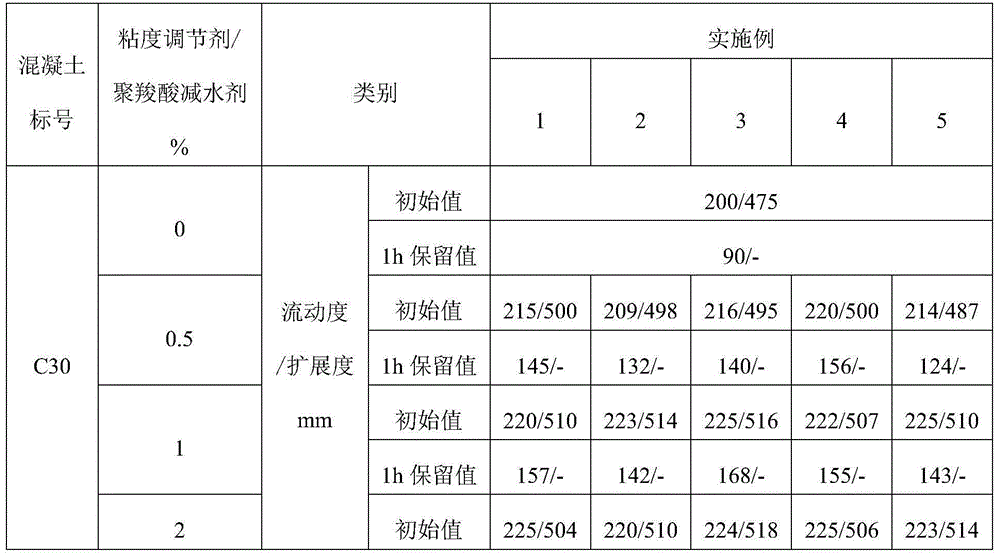

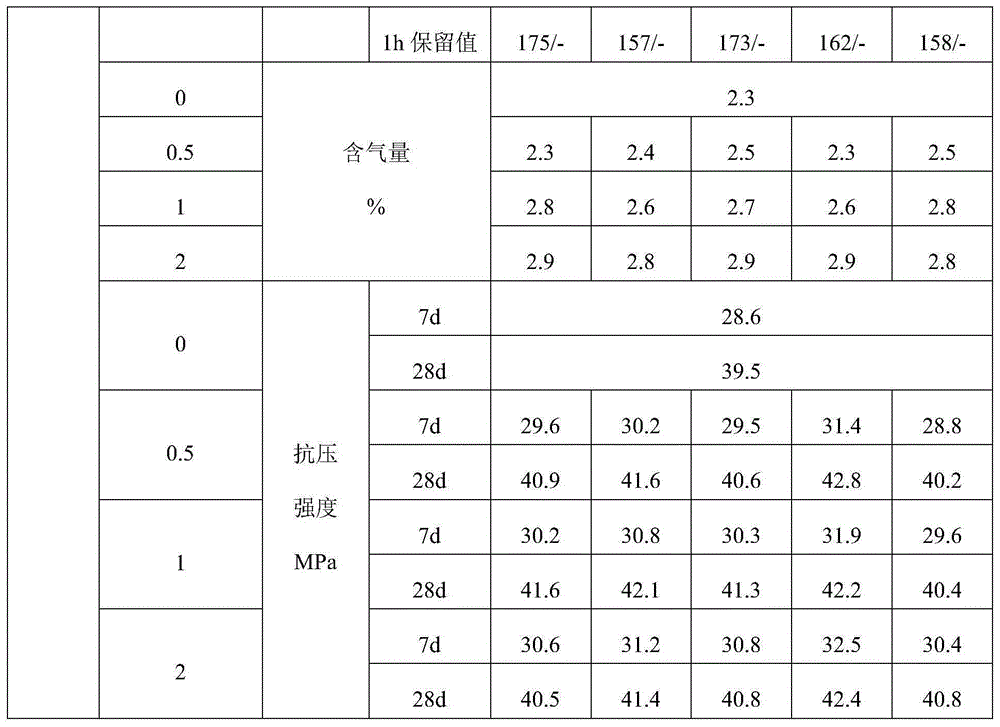

Concrete viscosity regulator suitable for compatible use with polycarboxylic acid water reducer and preparation method thereof

The invention discloses a concrete viscosity regulator suitable for compatible use with a polycarboxylic acid water reducer and a preparation method thereof; the concrete viscosity regulator comprises the components by the weight percentage: 0.1%-10% of a clay stabilizer, 0.01%-5% of an air-entraining agent, 0.001%-5% of a foam stabilizer, 0.001-10% of a thickener, and 75%-99% of water. The preparation method comprises the steps: firstly, adding water to a stirrer, fully mixing evenly other components, starting up the stirrer, after running smoothly, slowly adding the materials, and thus obtaining the concrete viscosity regulator when the materials are fully dissolved and stirred evenly. With cooperative use of the prepared viscosity regulator with the polycarboxylic acid water reducer, the polycarboxylic acid water reducer can be promoted to be adsorbed on cement particle surfaces to form a water film lubrication layer, a cement slurry steric-hinerance effect and rheological properties (the cement slurry has low plastic viscosity and higher yield stress) are effectively increased, wrapping performance on aggregates is increased while the viscosity of the concrete slurry is reduced, and thus the concrete construction performance is improved.

Owner:NANJING HYDRAULIC RES INST

Synthetic method for maleic polycarboxylic water reducer

The invention discloses a synthetic method for maleic polycarboxylic water reducer. The method is characterized in that: maleic anhydride (MA) and polyethylene glycol (PEG) / methoxy polyethylene glycol (MPEG) are used as the raw materials to synthesize polyethylene glycol maleate monoester (PEG-MA) / methoxy polyethylene glycol maleate monoester (MPEG-MA); and PEG-MA / MPEG-MA, AA / AANa and methoxy polyethylene glycol metacrylic acid ester (MPEG-MAA) are used as the raw materials to synthesize a maleic polycarboxylic water reducer containing carboxyl and a polyoxyethylene (PEO) side chain structure. According to the invention, the molecular structure of the polycarboxylic water reducer introduces carboxyl and PEO with a long side chain, which enables electrostatic repulsion among cement particles to be increased, dispersibility, i.e. retentivity of dispersion of cement to be improved, and steric hindrance among cement particles is realized, thereby realizing low slump loss. Simultaneously, the preparation method provided in the invention has the advantages of a simple process, mild reaction and wide sources of cheap raw materials.

Owner:赵争艳

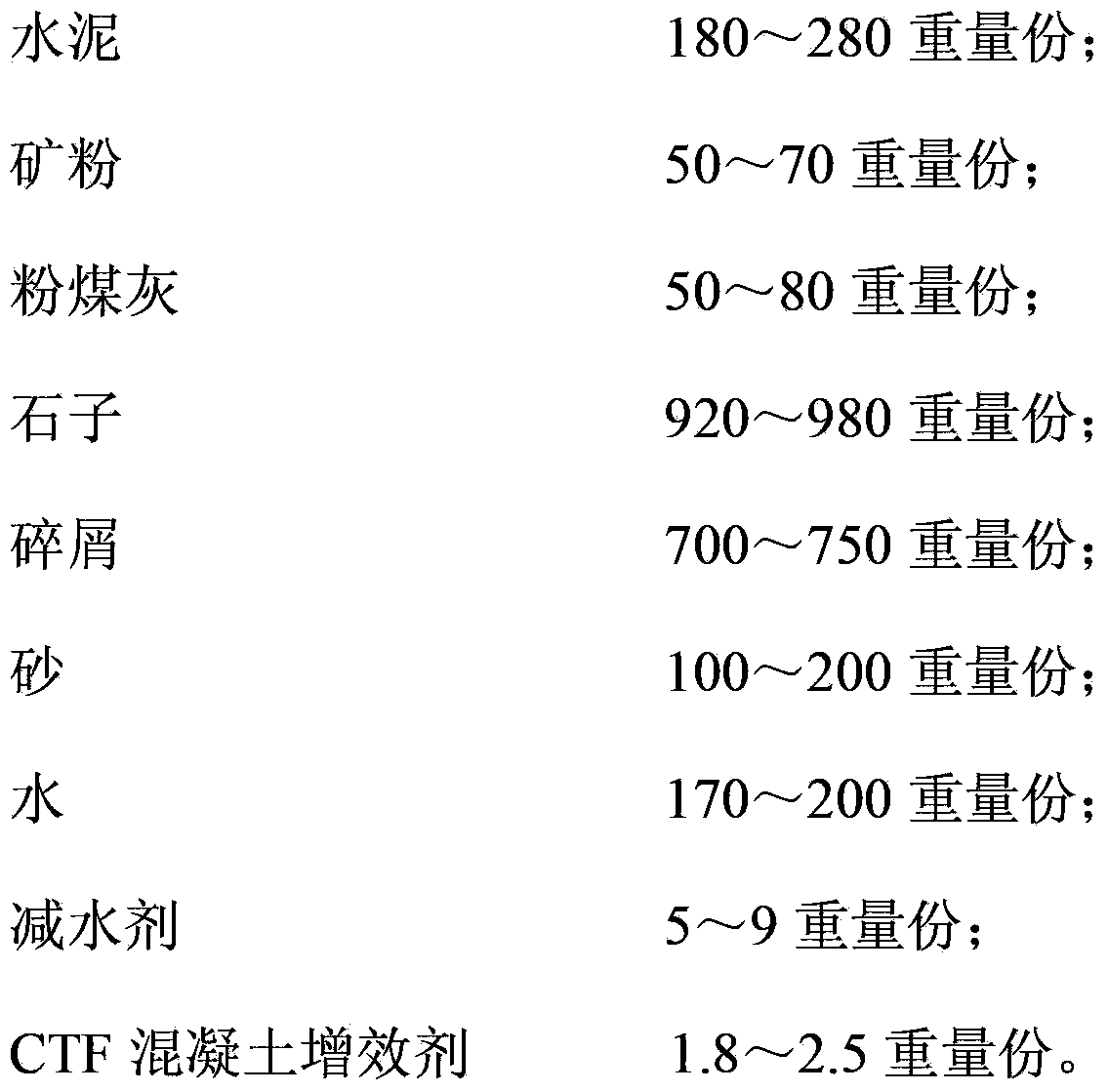

Concrete

ActiveCN103467014AImprove water retentionGuaranteed durabilitySolid waste managementMining engineeringUltimate tensile strength

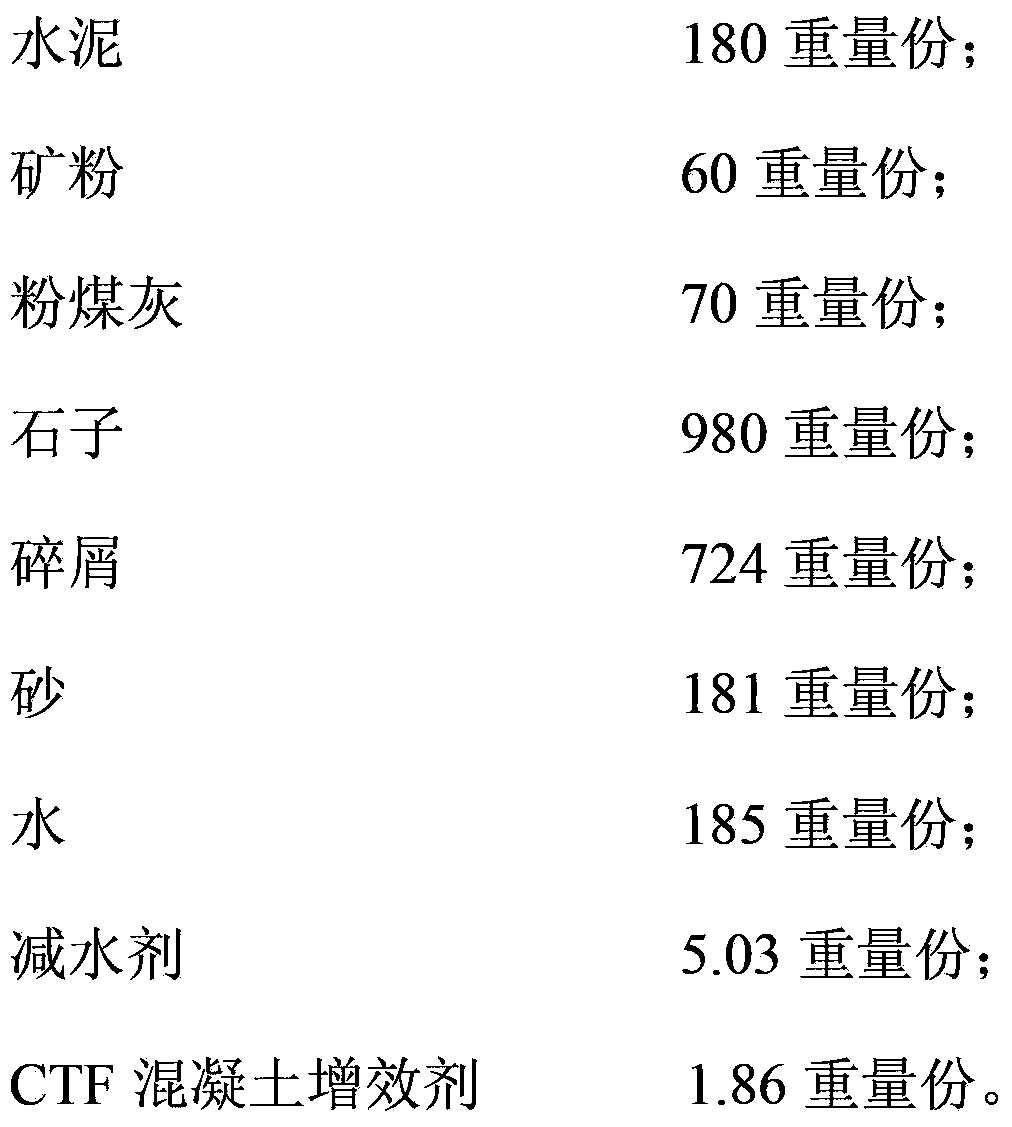

The invention discloses concrete which comprises the following ingredients in parts by weight: 180-280 parts of cement, 50-70 parts of mineral powder, 50-80 parts of coal ash, 920-980 parts of stone, 700-750 parts of fragment, 100-200 parts of sand, 170-200 parts of water, 5-9 parts of water reducer and 1.8-2.5 parts of CTF concrete synergist. According to the concrete, the fragment replaces the most sand and a part of the stone, and an action of the CTF concrete synergist is fully exerted to improve the dispersity of cement particles and an effect of the water reducer, so that the concrete solves the problems that due to poor gradation of the stone and the sand, the fresh concrete is poor in cohesiveness and water retention, and easy to isolate and bleed, the workability and flowability are reduced, the strength and durability of the concrete are reduced, the early contraction is aggravated, a water ripple phenomenon on the surface of the hardened concrete is severe, and the sensory quality of a concrete structure is influenced.

Owner:平湖南方混凝土制品有限公司

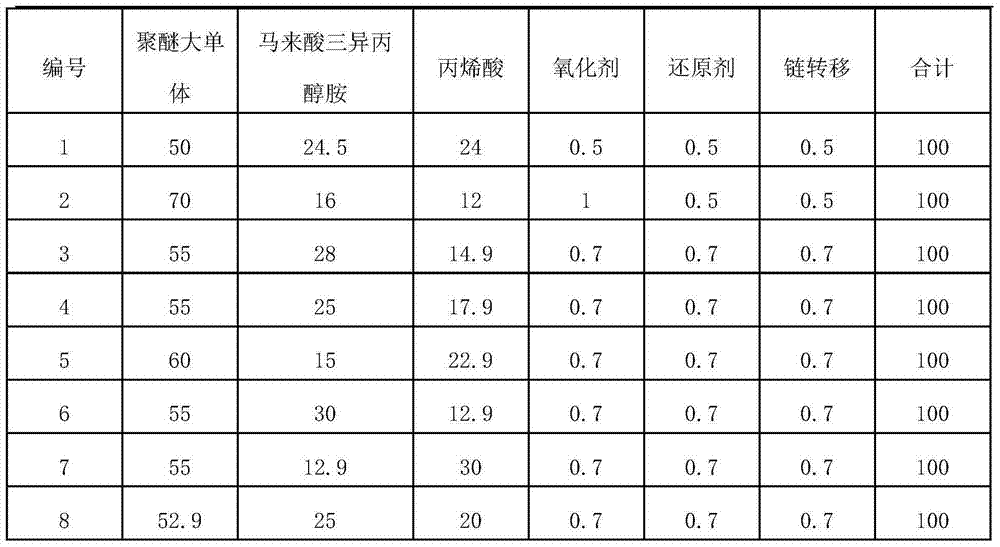

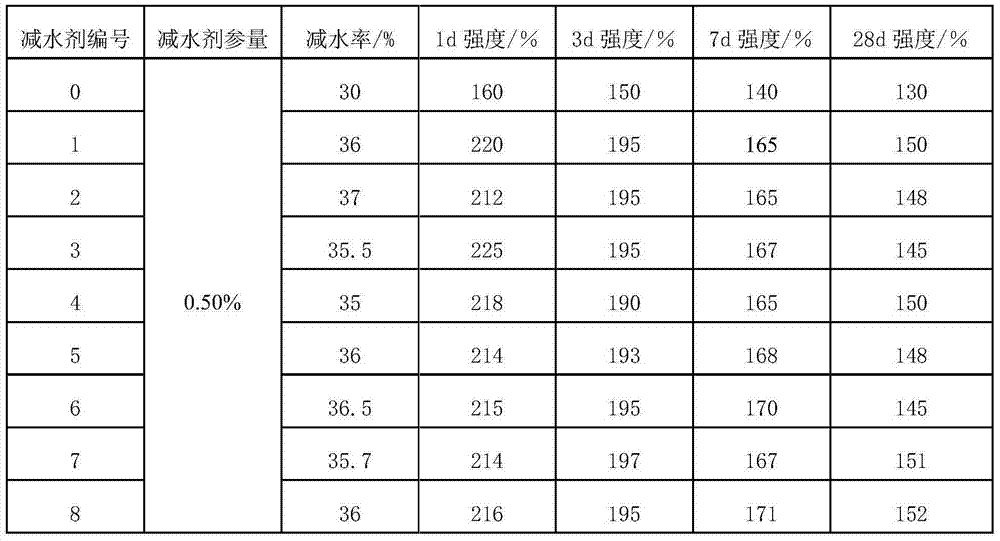

Preparation method of triisopropanolamine modified early strength polycarboxylate superplasticizer

InactiveCN103936934AImprove early strengthHigh water reduction rateOrganic compound preparationAmino-hyroxy compound preparationPolyesterSuperplasticizer

The invention relates to a preparation method of a triisopropanolamine modified early strength polycarboxylate superplasticizer. The preparation method comprises the following steps of (1) selecting raw materials; (2) dissolving polyester macromonomer, acrylic acid and maleic acid triisopropanolamine ester while stirring to obtain a uniform solution, then, adding an oxidizing agent, and stirring to obtain a uniform solution; (3) adding a reducing agent and chain transfer agent mixture into the uniform solution obtained in the step (2) at one step, continuing to stir, and adding a proper amount of deionized water to obtain the early strength polycarboxylate superplasticizer. The preparation method has the following main advantages that 1, the water reducing ratio is high, cement particles can be effectively dispersed, and the early stage hydration is promoted; 2, triisopropanolamine can be slowly released in an alkaline environment for cement hydration, so that the hydration is further promoted, the early strength is improved, but the initial flowability of slurry is not affected; 3, a one-step method and a one-step feeding way are adopted in the preparation method, and the preparation method is simple in process and short in reaction period.

Owner:WUHAN UNIV OF TECH

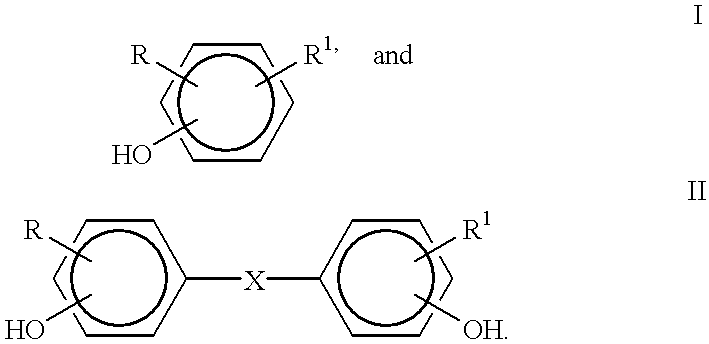

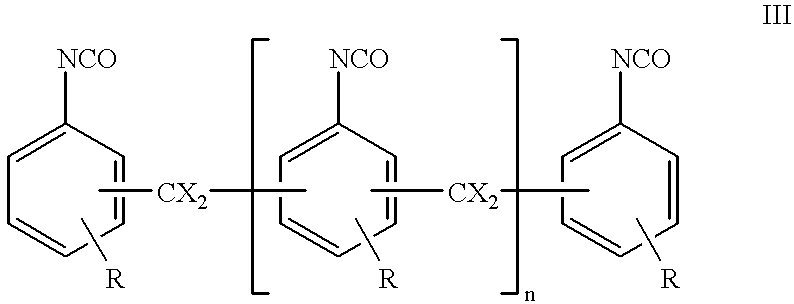

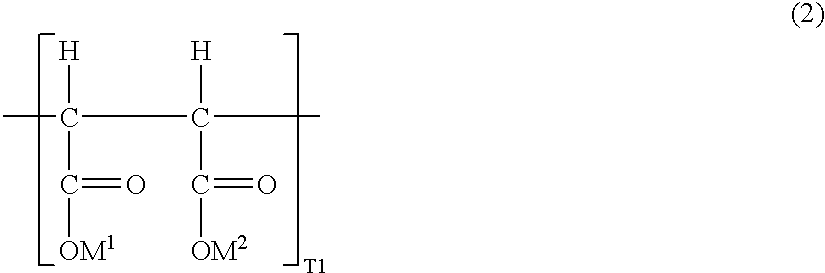

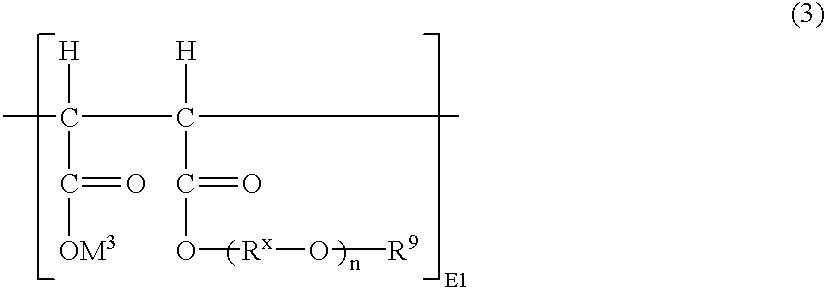

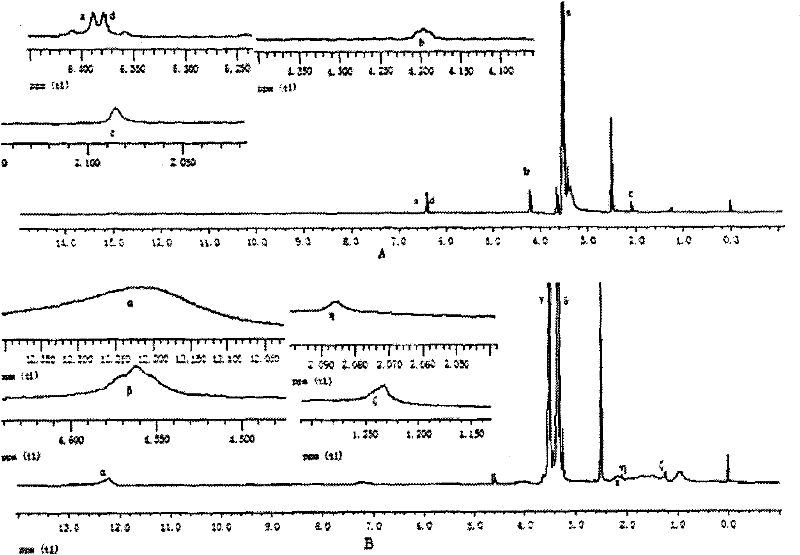

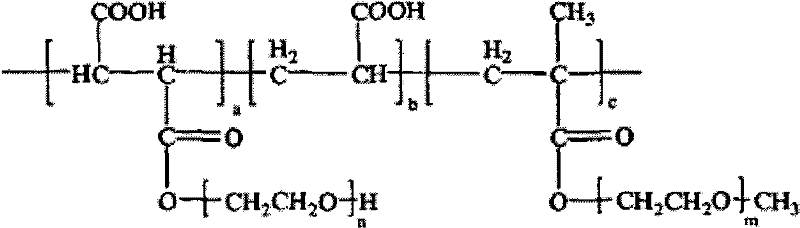

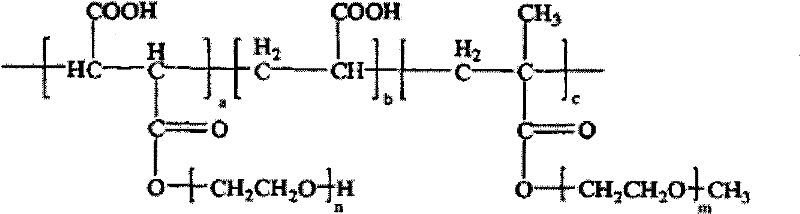

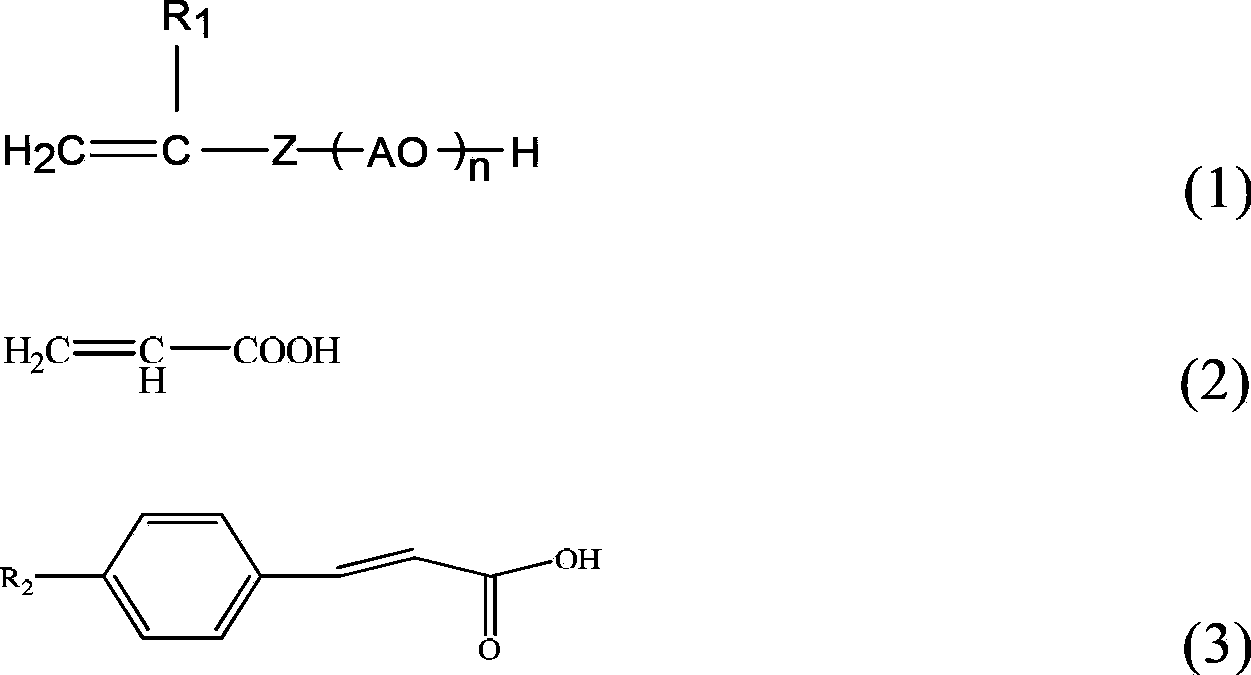

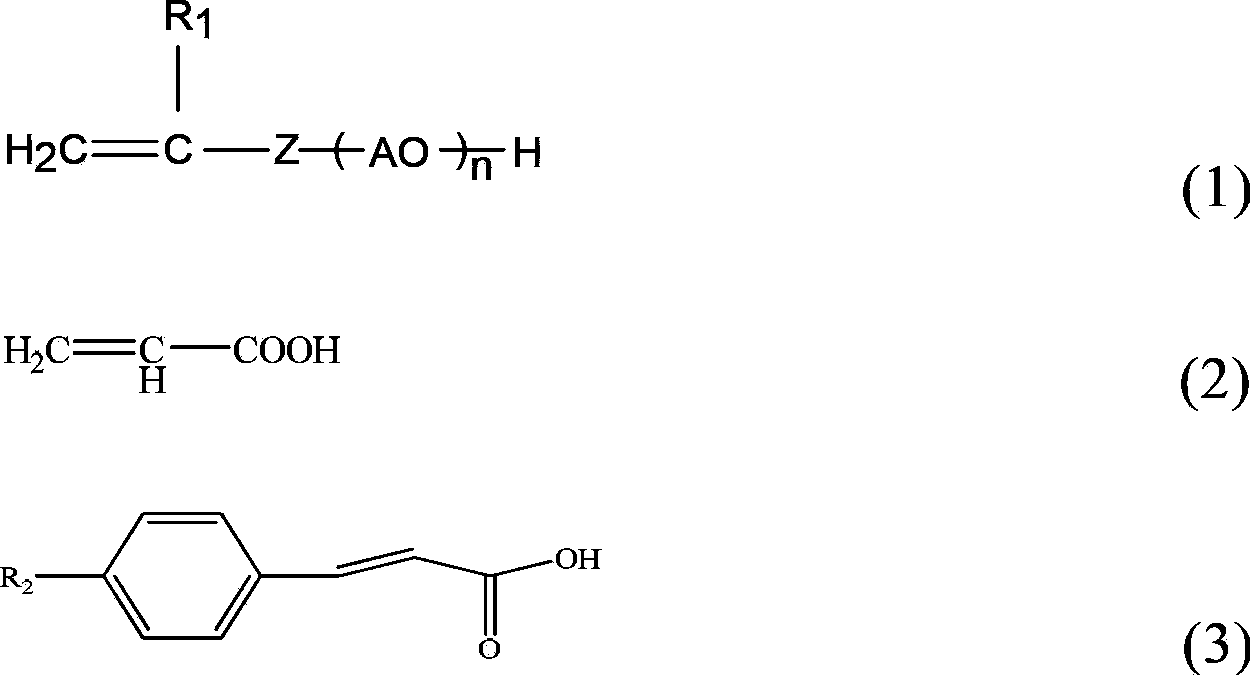

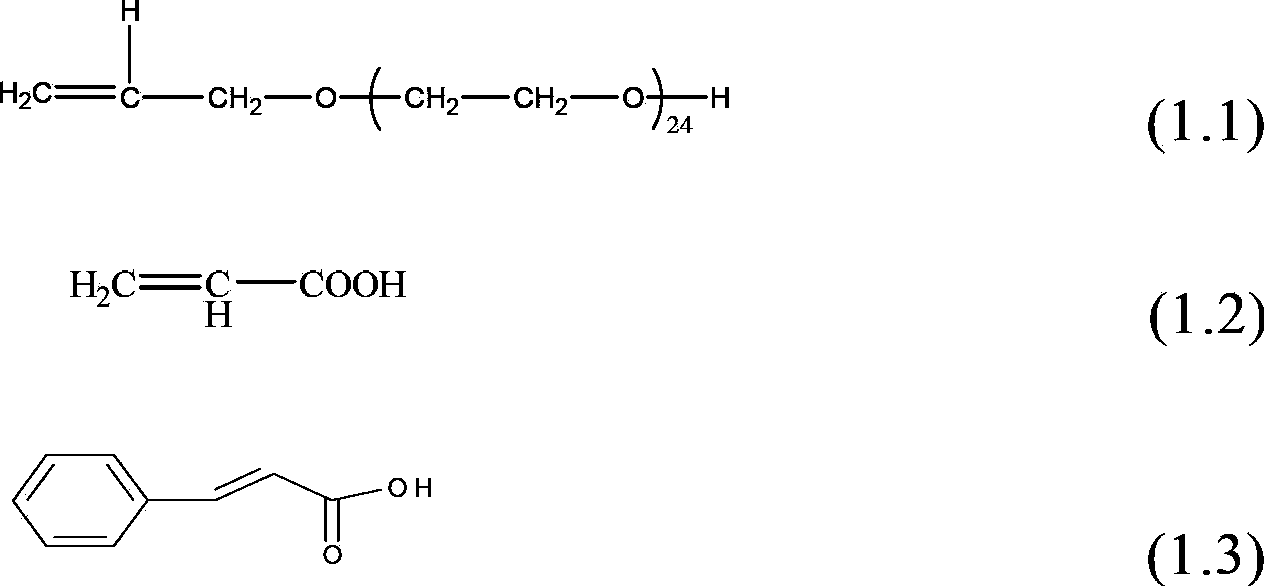

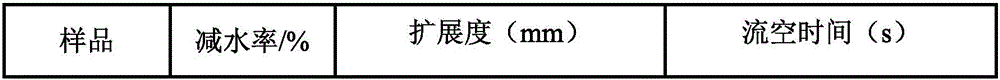

Polycarboxylate superplasticizer with high dispersion and high slump protection and preparation method of polycarboxylate superplasticizer

The invention discloses a polycarboxylate superplasticizer. The superplasticizer is prepared from monomers A, B and C as shown in the formulae (1), (2) and (3) by virtue of random copolymerization, and the molar ratio of A to B to C is 2.5:(7.5-10):1, wherein the symbols in the formulae are as definitions in the specification. The invention also discloses a method for preparing the polycarboxylate superplasticizer, which comprises the following steps: (1) dissolving the alkenyl-terminated polyoxyethylene ether serving as the monomer A in deionized water in a reaction container, heating to 60-65 DEG C under stirring; (2) adding a hydrogen peroxide aqueous solution, and stirring for about 3-5 minutes; (3) simultaneously dripping crylic acid serving as the monomer B and an aqueous solution serving as the monomer C to substitute crylic acid, and an aqueous solution for ascorbic acid and chain transfer agent; and (4) stirring and insulating for about 1-2 hours after the dripping is finished, cooling, and neutralizing with sodium hydroxide to obtain the polycarboxylate superplasticizer. According to the polycarboxylate superplasticizer, the contact among cement particles can be reduced due to the steric hindrance of a benzene ring in the structure of the polycarboxylate superplasticizer, so that the dispersion and slump protection of concrete can be improved.

Owner:LIAONING OXIRANCHEM INC

Preparation method of ester type viscosity reduction type polycarboxylate superplasticizer

ActiveCN106380554AImprove adsorption capacityIncrease electrostatic repulsionFunctional monomerSludge

The invention discloses a preparation method of an ester type viscosity reduction type polycarboxylate superplasticizer. The method comprises the following steps: (1) preparing an esterified monomer; (2) conducting the copolymerization reaction; (3) conducting the neutralization reaction. According to the technical scheme of the preparation method, methyl methacrylate and dimethylaminoethanol, remaining after the preparation of the esterified monomer, are subjected to ester exchange in the same condition of preparing the esterified monomer so as to obtain dimethylaminoethyl methacrylate as a functional monomer. Therefore, the preparation method is cost-saving and simple in operation. In addition, the functional monomer is directly introduced into the copolymerization reaction to react with other cationic monomers. During the polymerization process, anions, cations and tertiary amine groups are attached to polycarboxylic acid molecular chains, so that the surface adsorbability of cement particles can be improved. The electrostatic repulsion effect between cement particles is improved. Not only the ester type viscosity reduction type polycarboxylate superplasticizer is good in anti-sludge effect for sand and gravel materials high in cement content, but also the ester type viscosity reduction type polycarboxylate superplasticizer is good in dispersibility and viscosity-reducing effect.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Enhanced polycarboxylate superplasticizer and preparation method thereof

The invention belongs to the field of water reducing agents and particularly discloses an enhanced polycarboxylate superplasticizer and a preparation method thereof. The method includes: (1) subjecting, by weight, 50-150 parts of methacrylic acid, 50-250 parts of an alcohol amine compound, 1-5 parts of a catalyst and 0.1-3 parts of a polymerization inhibitor to esterification reaction at 110-130 DEG C for 3-5h, cooling to 35-50 DEG C, and adding alkali to obtain a reaction product containing an esterified functional monomer; (2) subjecting, by weight, 100-200 parts of methyl allyl polyoxyethylene ether, 10-20 parts of unsaturated carboxylic acid and 5-20 parts of the reaction product containing the esterified functional monomer and obtained in the step (1) to polymerization reaction in existence of, by weight, 0.5-1.5 parts of a chain initiator and 0.4-0.8 part of a chain transfer agent to obtain mother liquor of the enhanced polycarboxylate superplasticizer. The enhanced polycarboxylate superplasticizer is capable of promoting hydration reaction of cement, enabling complete hydration of large cement particles, promoting hydration product growth, improving a porous structure and aninterface structure and improving concrete structural compactness and is high in adaptability and stability.

Owner:福建路桥翔通建材科技有限公司

Polycarboxylic super plasticizer

The invention discloses a polycarboxylic super plasticizer which is formed by copolymerizing alkyl unsaturated polyether A which accounts for 60-95% of the total weight of a monomer, an unsaturated carboxylic monomer which accounts for 5-30% of the total weight of the monomer, N-vinyl pyrrolidone which accounts for 0.5-5.0% of the total weight of the monomer and a polymerizable monomer C which accounts for 0-20% of the total weight of the monomer in an aqueous liquid at 40-100 DEG C in the presence of an initiator and a chain transfer agent. According to the polycarboxylic super plasticizer disclosed by the invention, in the presence of pyrrolidone lactam ring, the contact among cement particles is reduced, so that good dispersibility and dispersing stability are provided for concrete.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

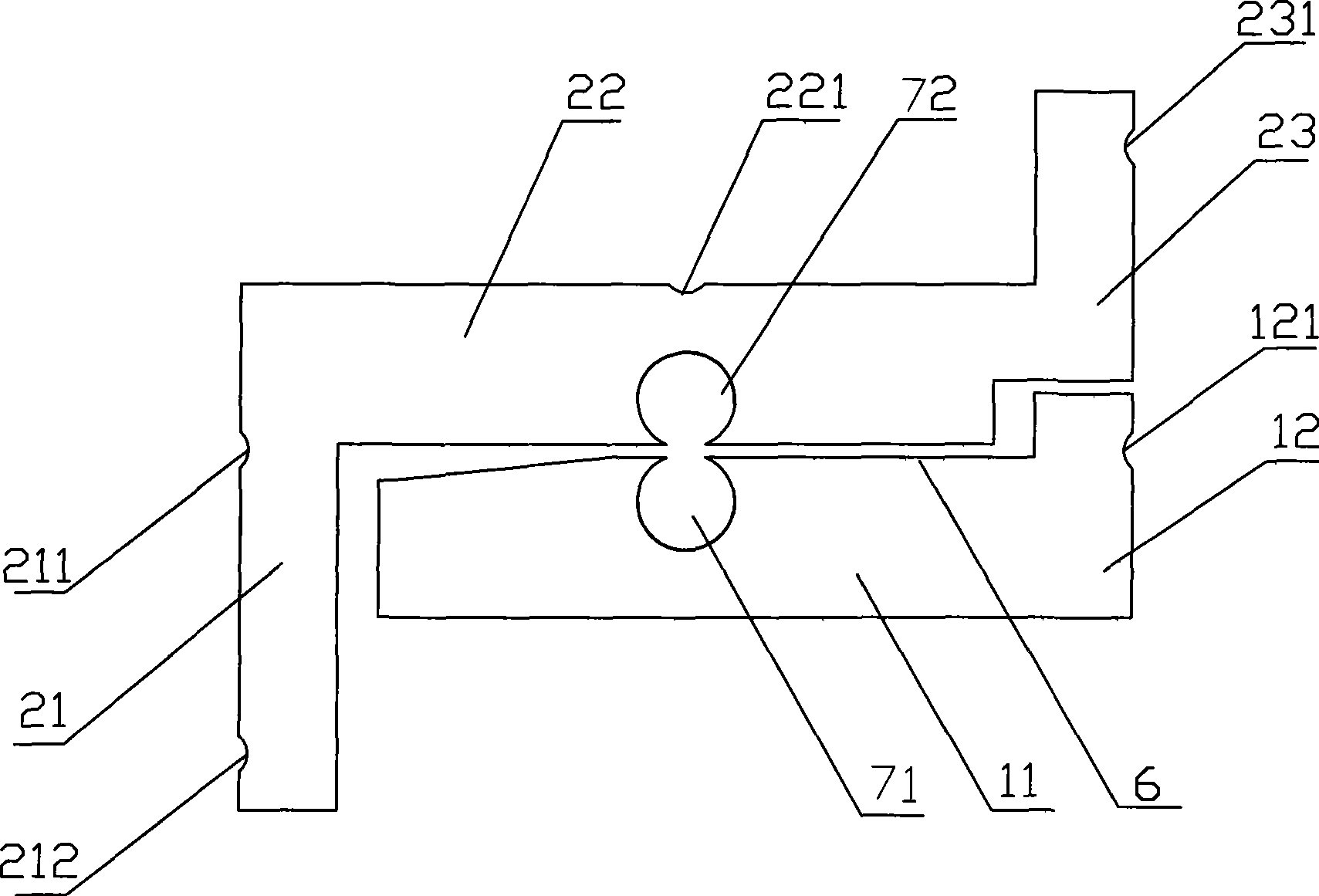

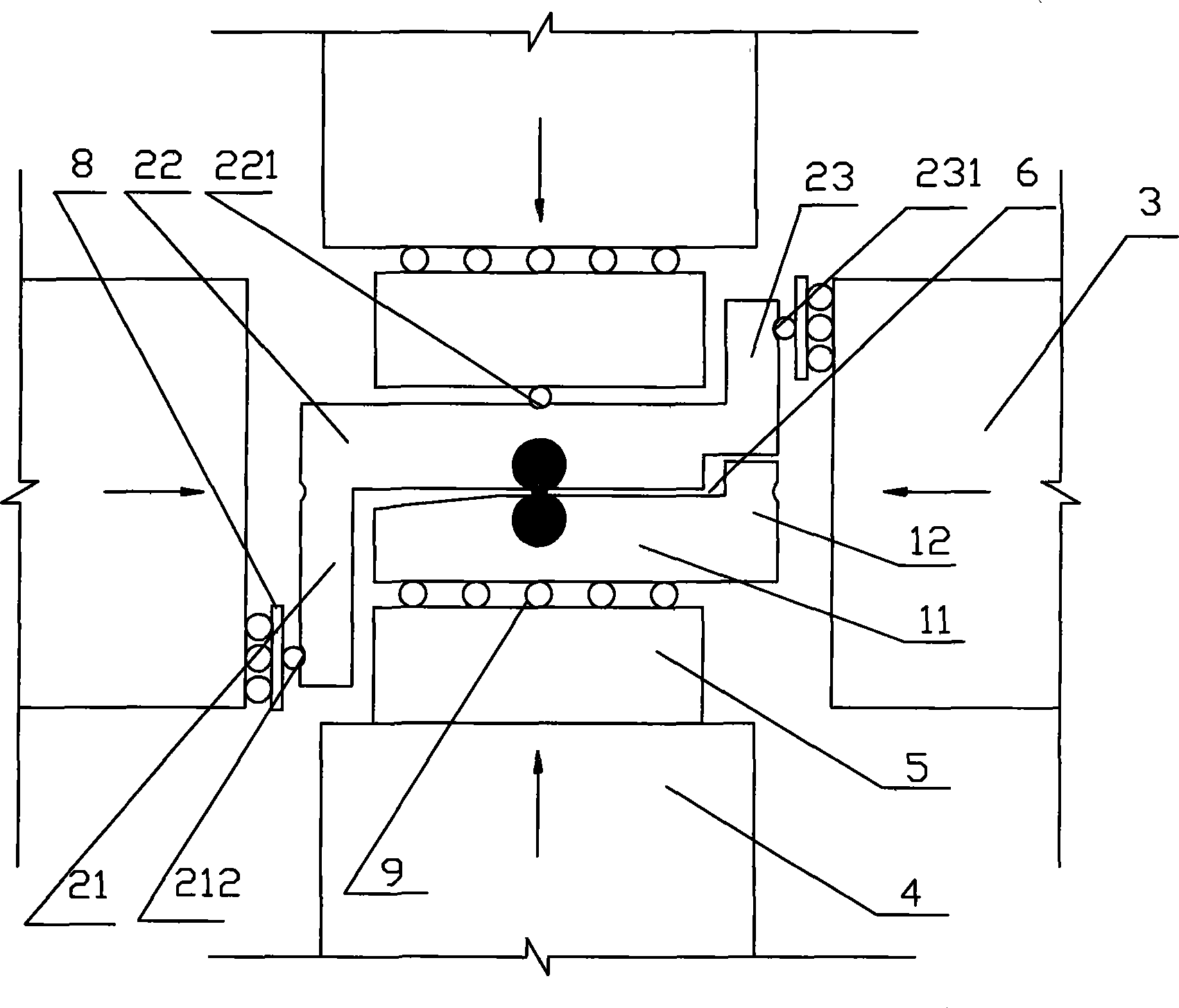

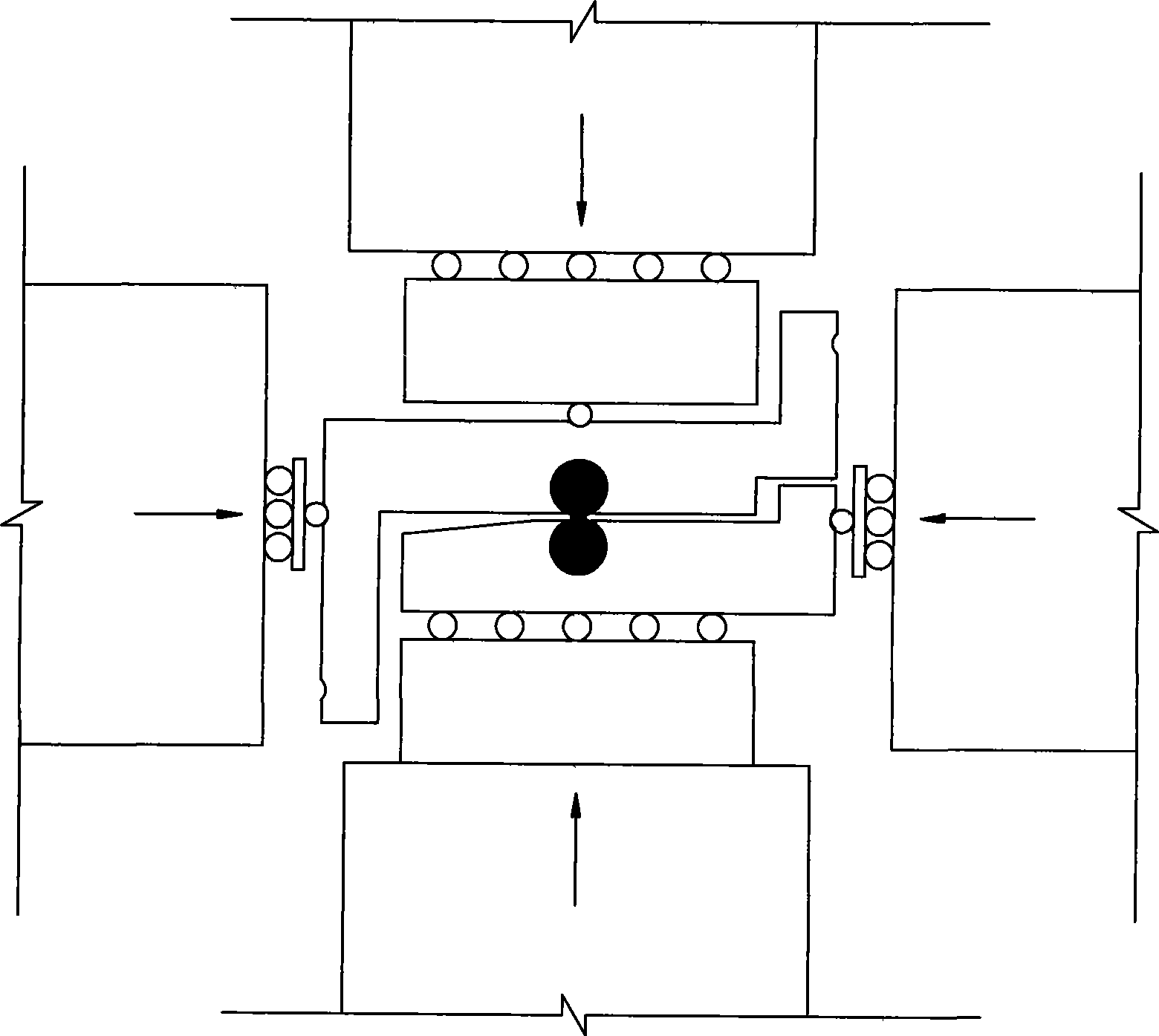

Cementing granule contact anti-shearing and torsion resistant test device

The invention discloses a device for a contact shear resistant and torsion resistant test of cement particles, which comprises an L-shaped part one and a Z-shaped part two, wherein the part one consists of a horizontal part (11) and a vertical part (12), the part two consists of a first vertical part (21), a first horizontal part (22) and a second vertical part (23), opposite surfaces (6) of the first horizontal part (22) of the part two and the horizontal part (11) of the part one is positioned in the horizontal direction, the opposite surfaces (6) of the part two and the part one are respectively provided with fixing devices (71, 72) which can fix the cement particles, and the central connecting line of the opposite surfaces (6) is in the vertical direction. With the structure, the shearing and torsion mechanical characteristics of contact points of the cement particles at different normal pressures can be measured precisely.

Owner:TONGJI UNIV

Cement flakeboard and production process thereof

InactiveCN101117005AEasy to useLow costSolid waste managementCeramic shaping apparatusWood shavingsChloride

The present invention provides a cement particle board and the manufacturing method thereof; the cement particle board comprises the weight percentage compositions of raw materials: 15 to 35 percent of wood wool (absolute dry wood wool), 15 to 45 percent of high-calcium fly ash, 30 to 55 percent of cement, 1 to 3 percent of sodium silicate, 0.3 to 1.8 percent of calcium chloride and 0.1 to 2 percent of addition agent. The method of the present invention uses high-calcium fly ash of industrial wastes, frutex or lops wood shavings for manufacture of hard board, thereby reaching the 'Cement Xylolite Slab (JC / T411-1991)' standard and saving production cost, reducing environmental pollution, expanding, at the same time, the range of wood raw materials for particle board production and creating higher economic value.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

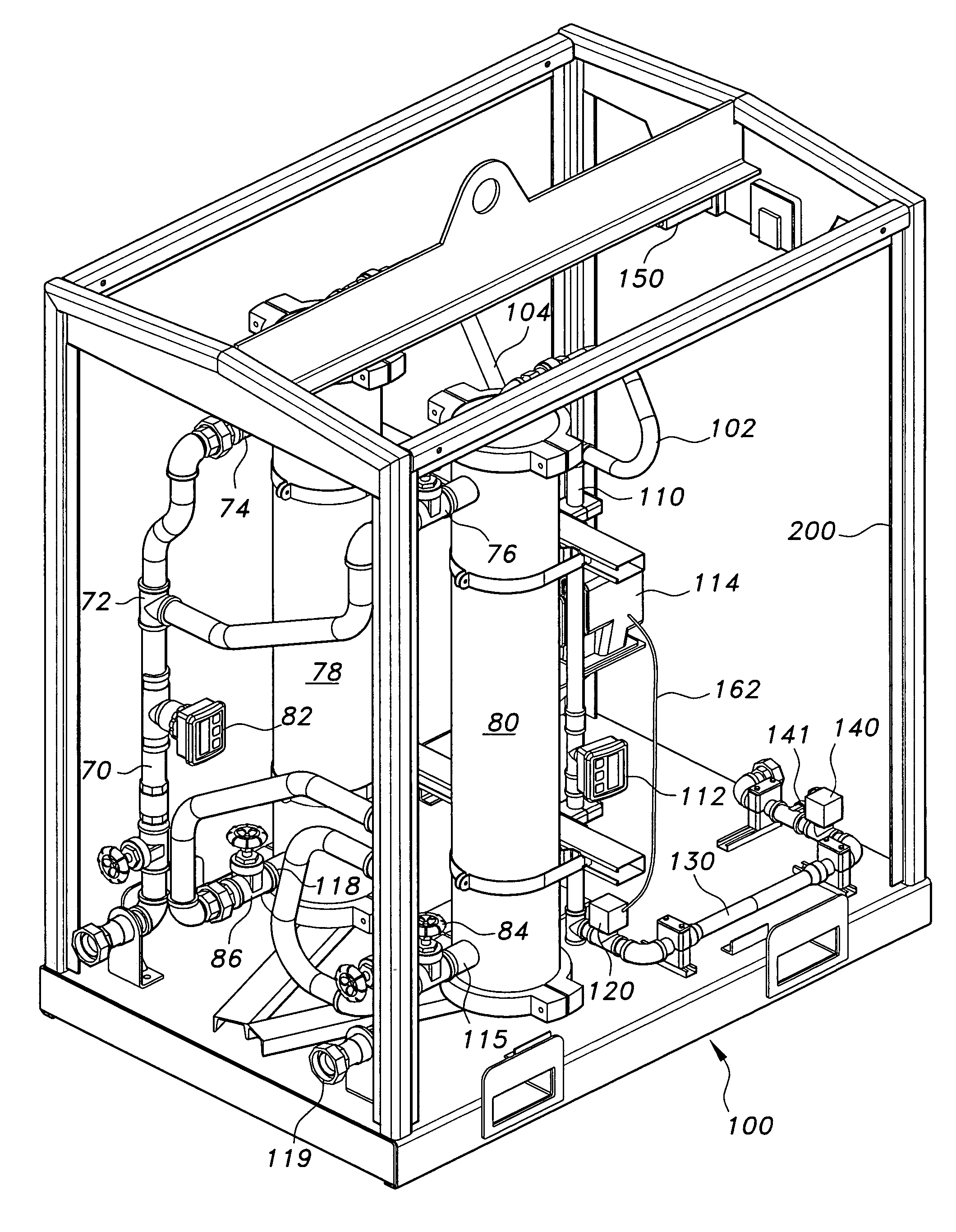

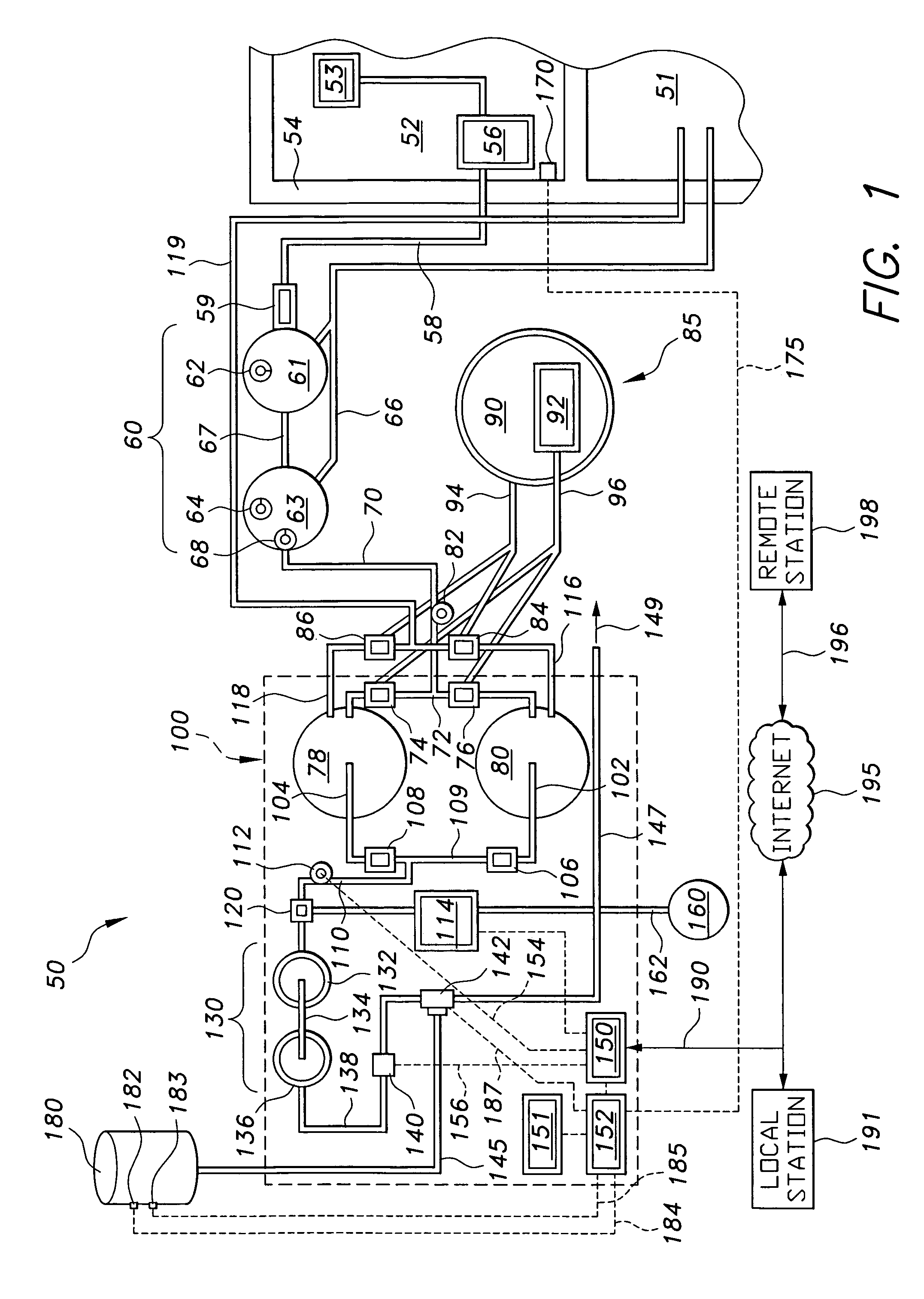

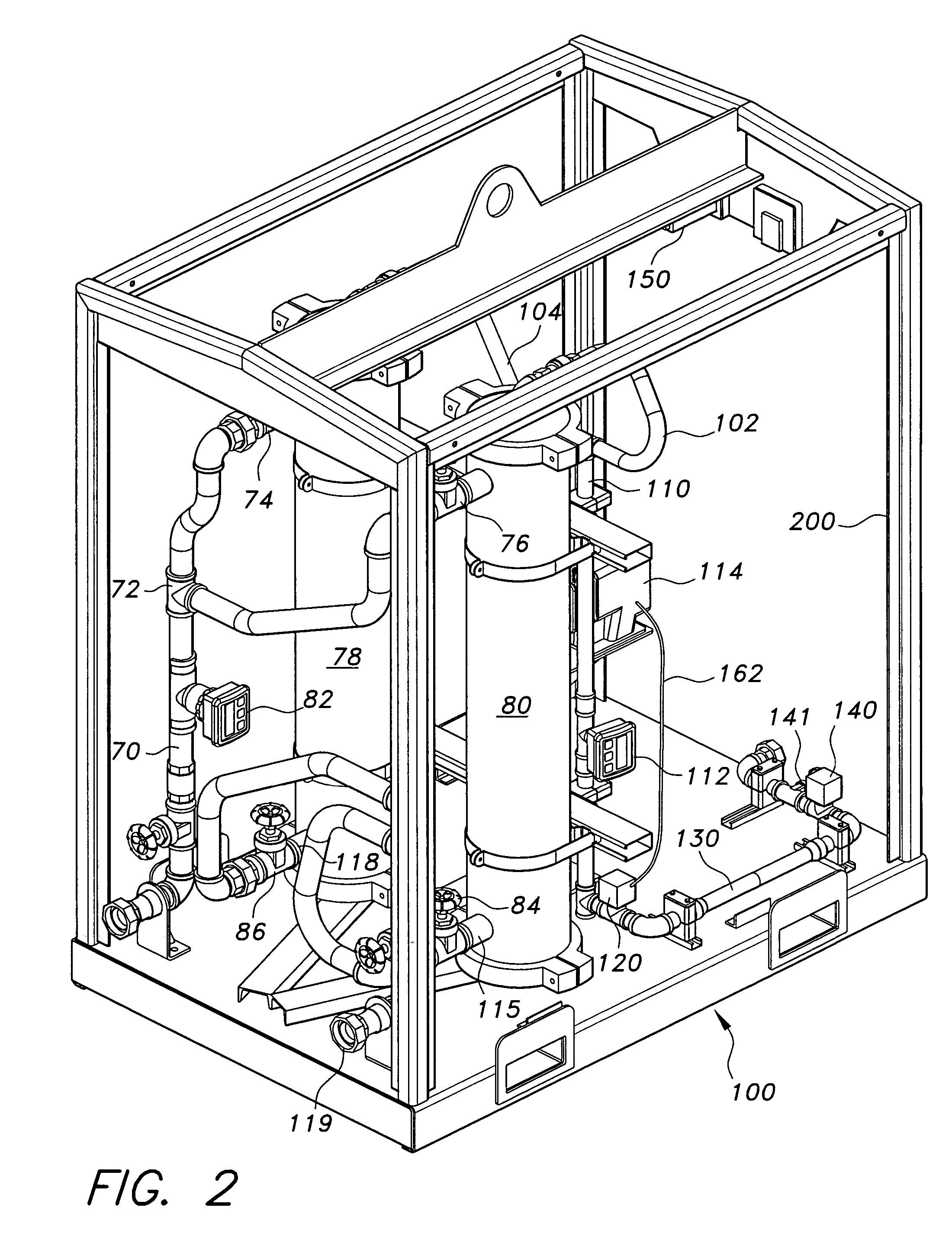

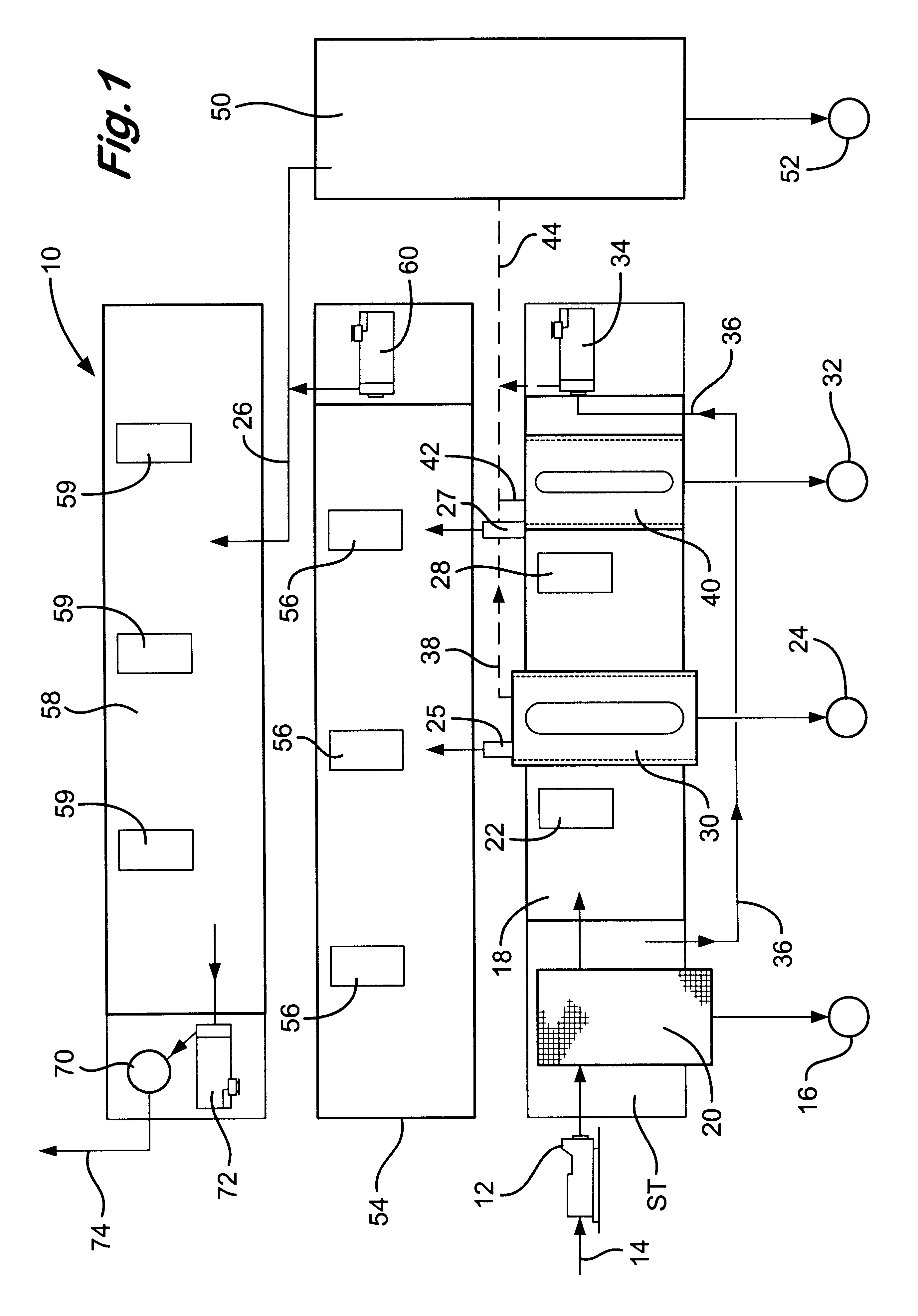

Water treatment system

InactiveUS7404926B2Waste water treatment from ceramic industriesUltrafiltrationWater treatment systemFilter media

A method and system for treating a fluid containing entrained cementitious particles involves drawing the fluid from a storage location, pre-filtering the fluid, dividing the pre-filtered fluid into a flow of permeate and a flow of bypass by passing said pre-filtered fluid through a tangential flow filter. The permeate flow is fluid that has passed through a polymeric membrane filter media disposed in the tangential flow filter, while the bypass flow is flow exiting said tangential flow filter without passing through said membrane filter media. The system and method also includes a pH probe for testing the pH of the filtrate, and a metering pump operated by a controller which injects a neutralizing agent into the filtrate to reduce the alkalinity of the filtrate before discharge.

Owner:RHOADES FR G

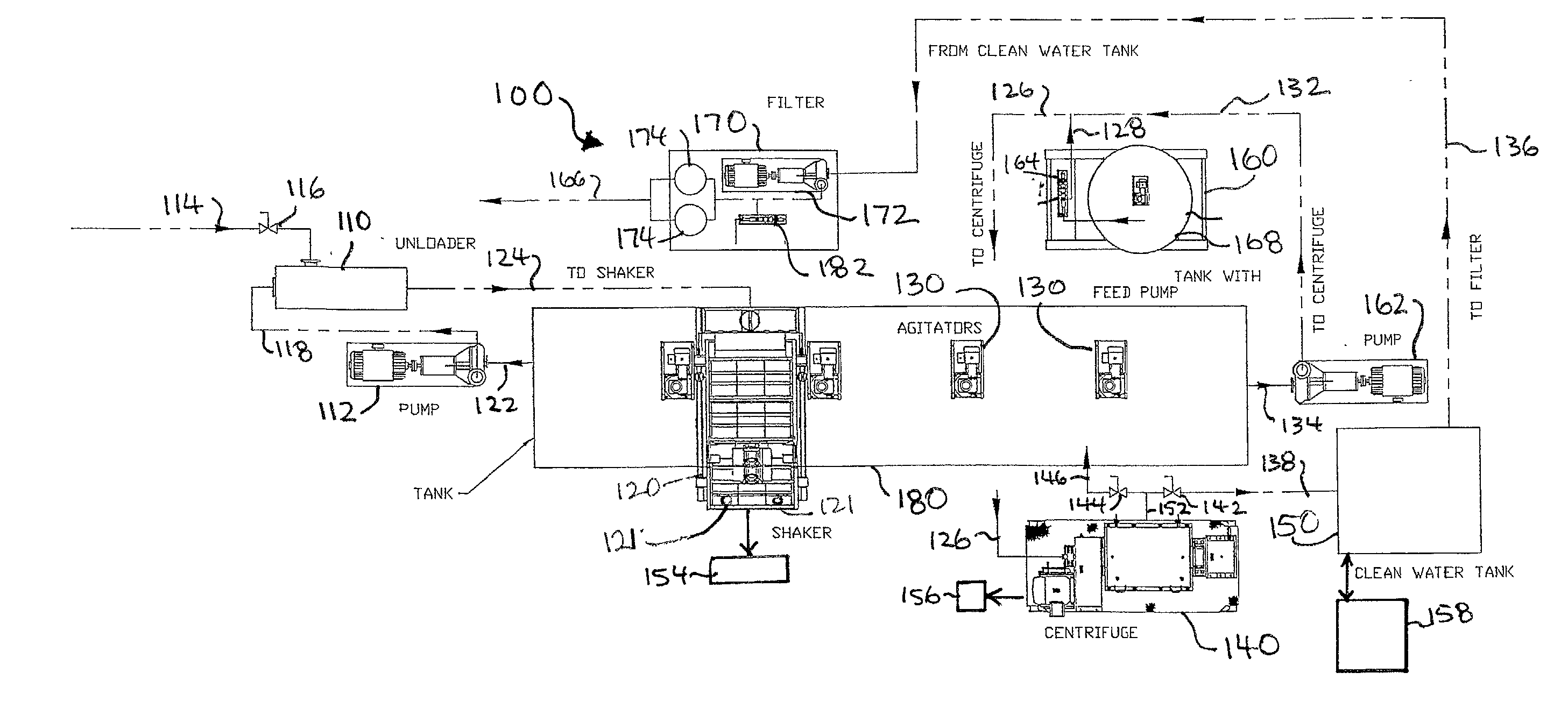

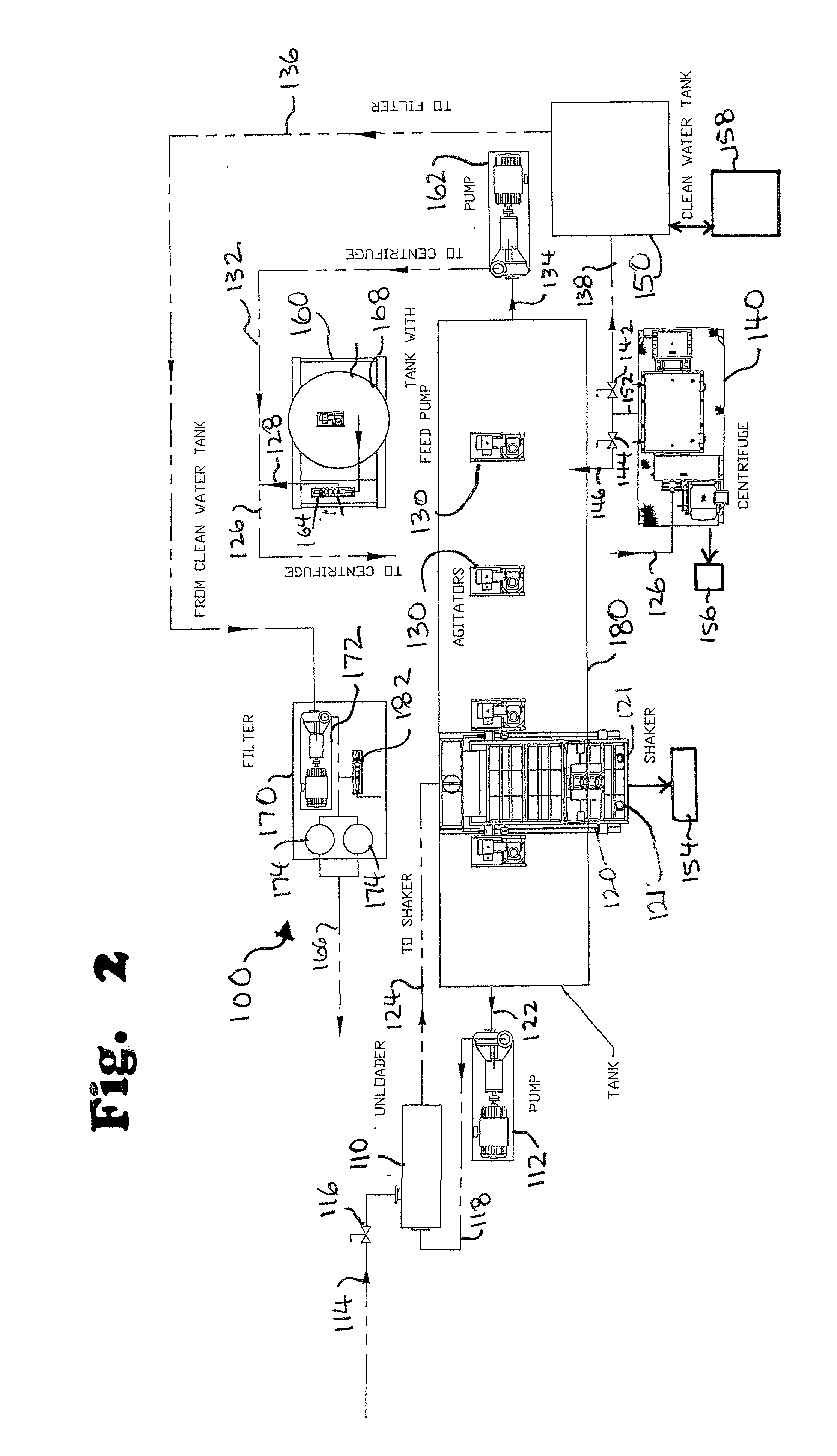

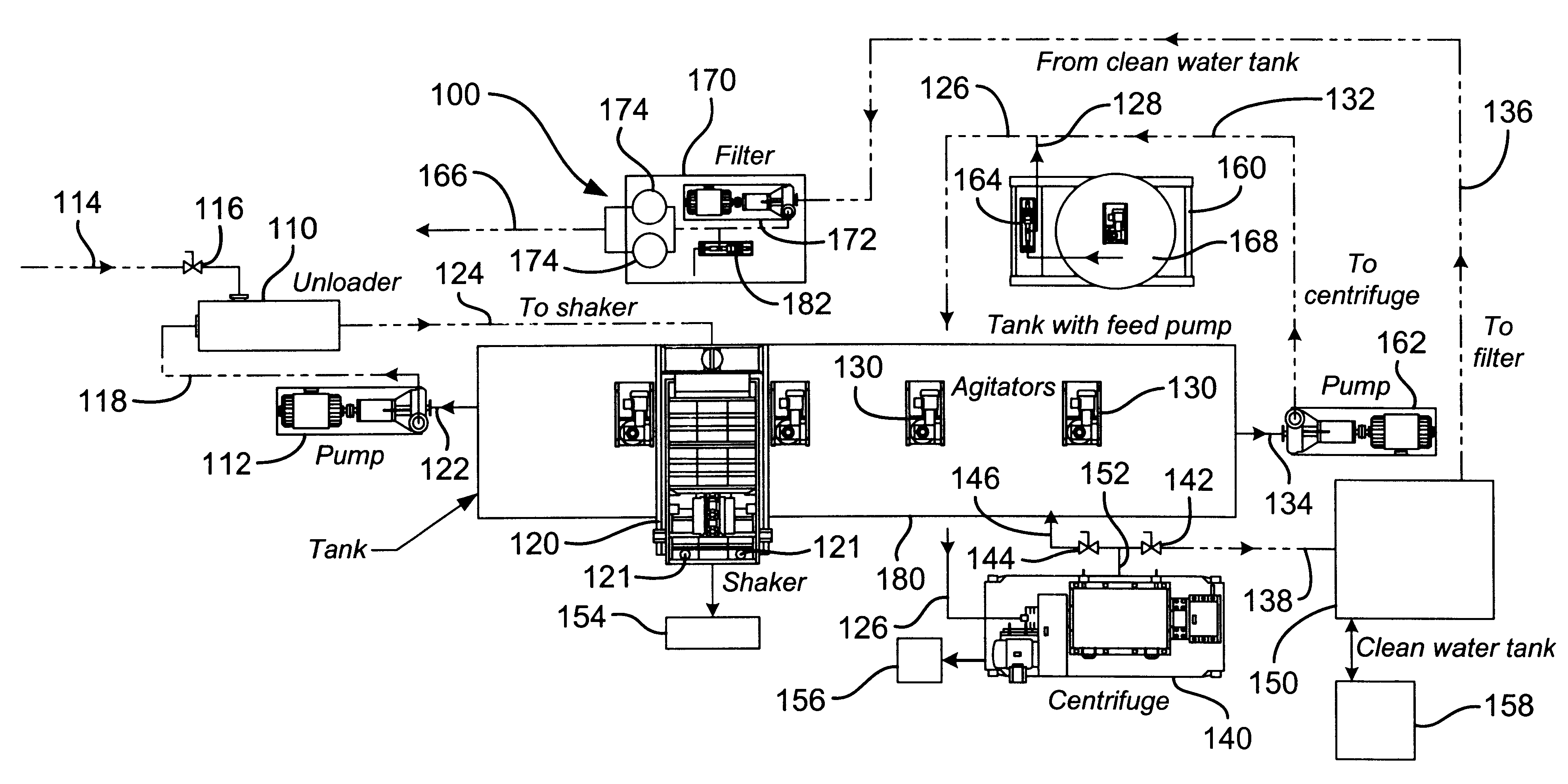

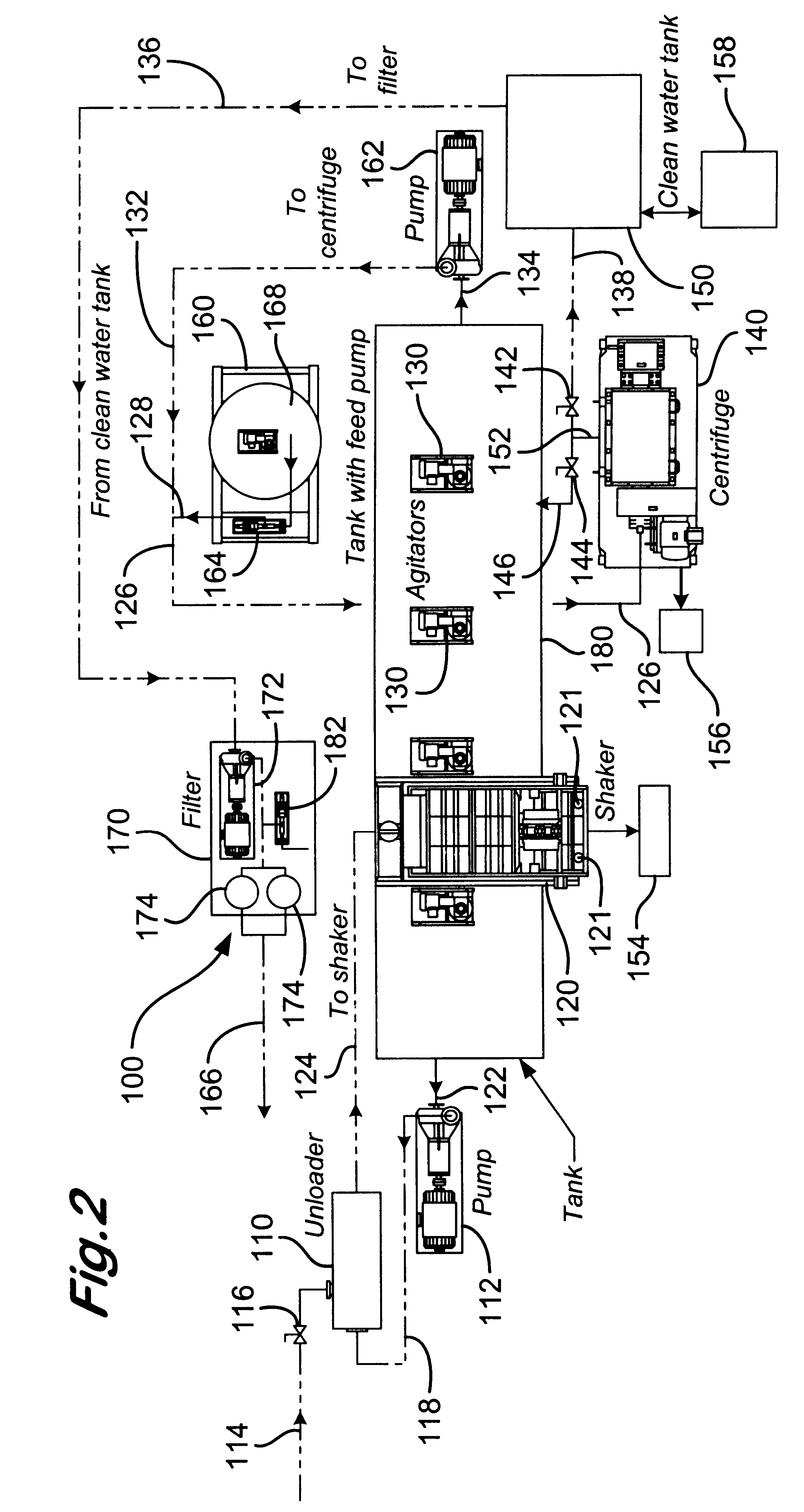

Concrete grindings reclamation system

InactiveUS20030006194A1Water/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningWater flowSlurry

A method for treating a fluid slurry with concrete grindings to separate constituents thereof, the constituents including water, sand and cement particles, the method including removing solids (e.g. large concrete fragments, rock, etc.) from fluid slurry with vibratory separation apparatus, the vibratory separation apparatus having screen apparatus for separating materials, the vibratory separation apparatus producing wet solids flowing off the top of the screen apparatus and a fluid stream containing water and cement particles, the fluid stream discharged beneath the screen apparatus, feeding at least a portion of the fluid stream to centrifuge apparatus, and separating cement particles from the fluid stream with the centrifuge apparatus and producing a stream of water with the centrifuge apparatus; and re-usable cement particles recovered using such a method.

Owner:VARCO I P INC

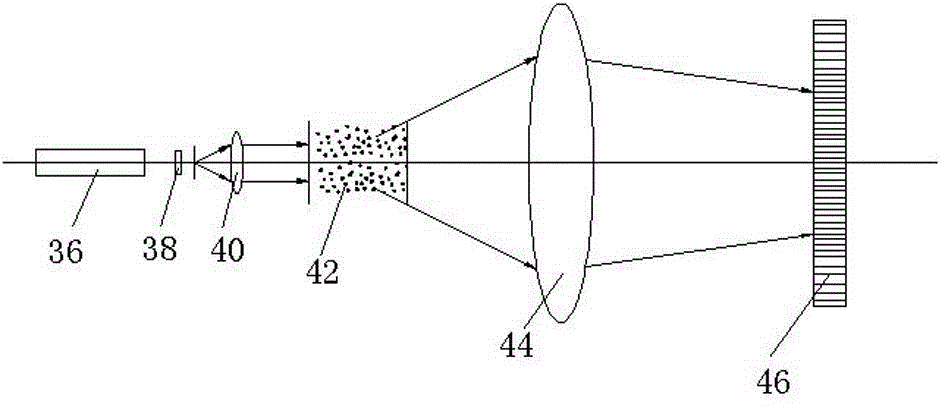

On-line cement particle size detection method and one-line cement particle size device

InactiveCN104614293AQuality improvementImprove stabilityParticle size analysisElectrical connectionLaser beams

The invention provides an on-line cement particle size detection method. The on-line cement particle size detection method is characterized in that a laser particle size analyzer is arranged in a material conveying chute of a cement grinding powder selector, a signal control box and a analyzer host are arranged to be in electrical connection with the laser particle size analyzer, cement samples in the shape of single particles are blown into a detection window of the laser particle size analyzer, when laser beams emitted by the laser particle size analyzer encounter cement particles in a propagation process, a part of light deviates from an original propagation direction and is scattered to form a scattering angle, a signal representing the size of the scattering angle and the intensity of scattered light which is output by the laser particle size analyzer is converted into an electrical signal by the signal control box and the electric signal is output to the analyzer host, and the particle size and size distribution of cement can be seen in the analyzer host. The on-line cement particle size detection method provided by the invention has the characteristics of rapid and accurate detection, and wide range; and a device provided by the invention can be used for improving the quality and particle size stability of cement after being used, and reducing the waste of energy consumption caused by quality fluctuation.

Owner:XIANGSHUI ZHONGLIAN CEMENT CO LTD

Concrete grindings reclamation system

InactiveUS6582610B2Water/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningWater flowSlurry

A method for treating a fluid slurry with concrete grindings to separate constituents thereof, the constituents including water, sand and cement particles, the method including removing solids (e.g. large concrete fragments, rock, etc.) from fluid slurry with vibratory separation apparatus, the vibratory separation apparatus having screen apparatus for separating materials, the vibratory separation apparatus producing wet solids flowing off the top of the screen apparatus and a fluid stream containing water and cement particles, the fluid stream discharged beneath the screen apparatus, feeding at least a portion of the fluid stream to centrifuge apparatus, and separating cement particles from the fluid stream with the centrifuge apparatus and producing a stream of water with the centrifuge apparatus; and re-usable cement particles recovered using such a method.

Owner:VARCO I P INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com