Patents

Literature

15706 results about "Mining engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mining engineering is an engineering discipline that applies science and technology to the extraction of minerals from the earth. Mining engineering is associated with many other disciplines, such as mineral processing, Exploration, Excavation, geology, and metallurgy, geotechnical engineering and surveying. A mining engineer may manage any phase of mining operations – from exploration and discovery of the mineral resource, through feasibility study, mine design, development of plans, production and operations to mine closure.

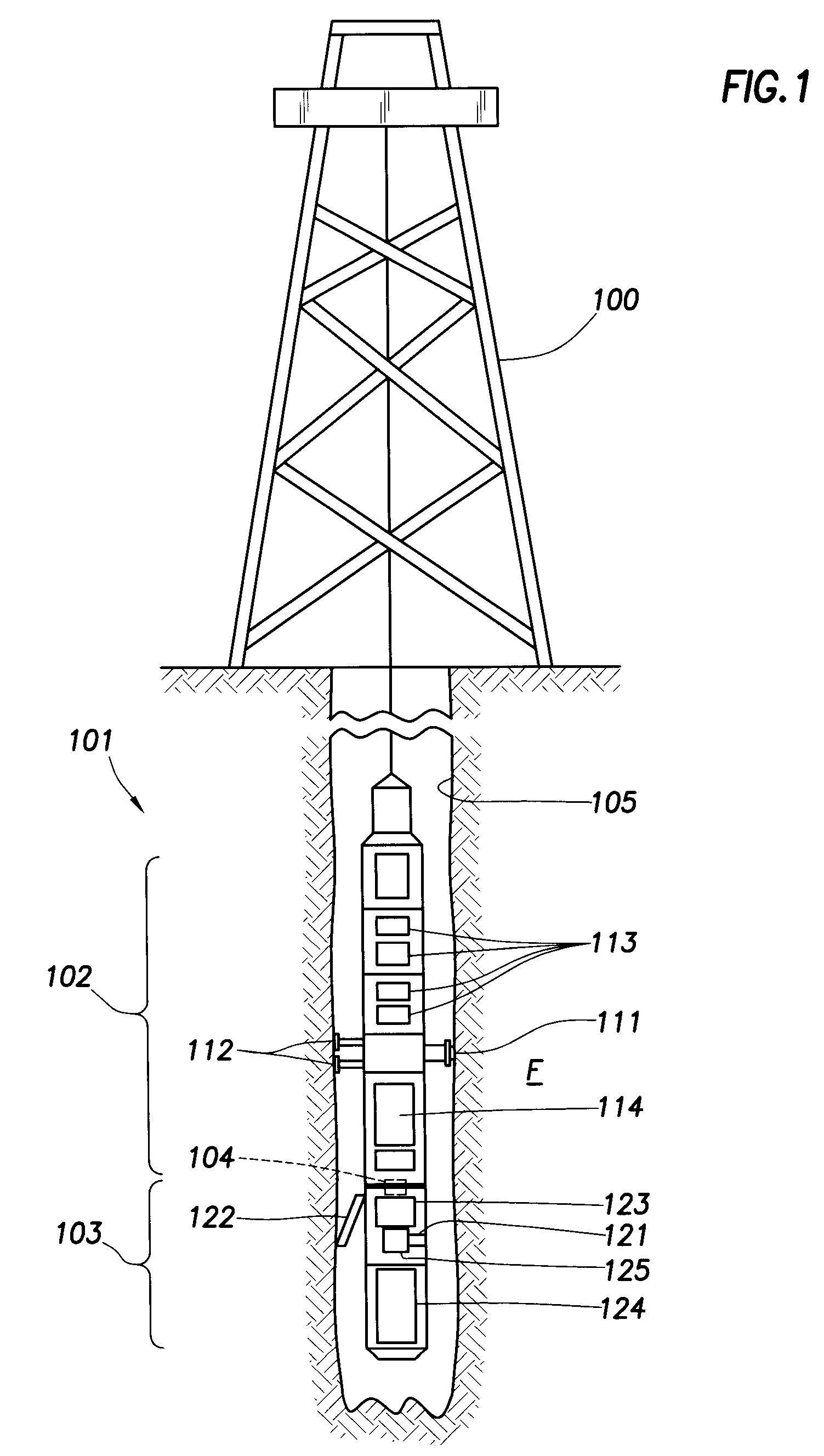

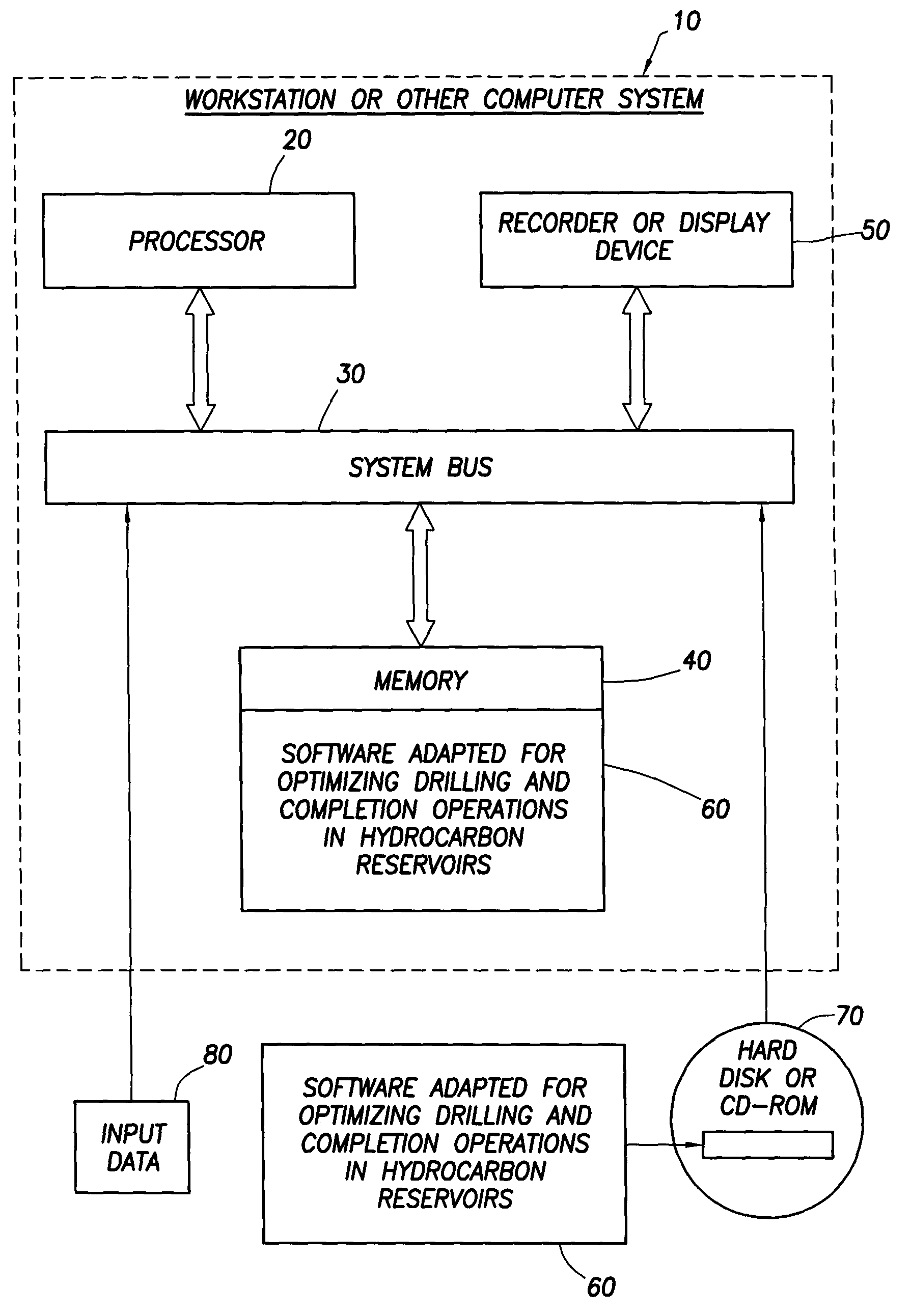

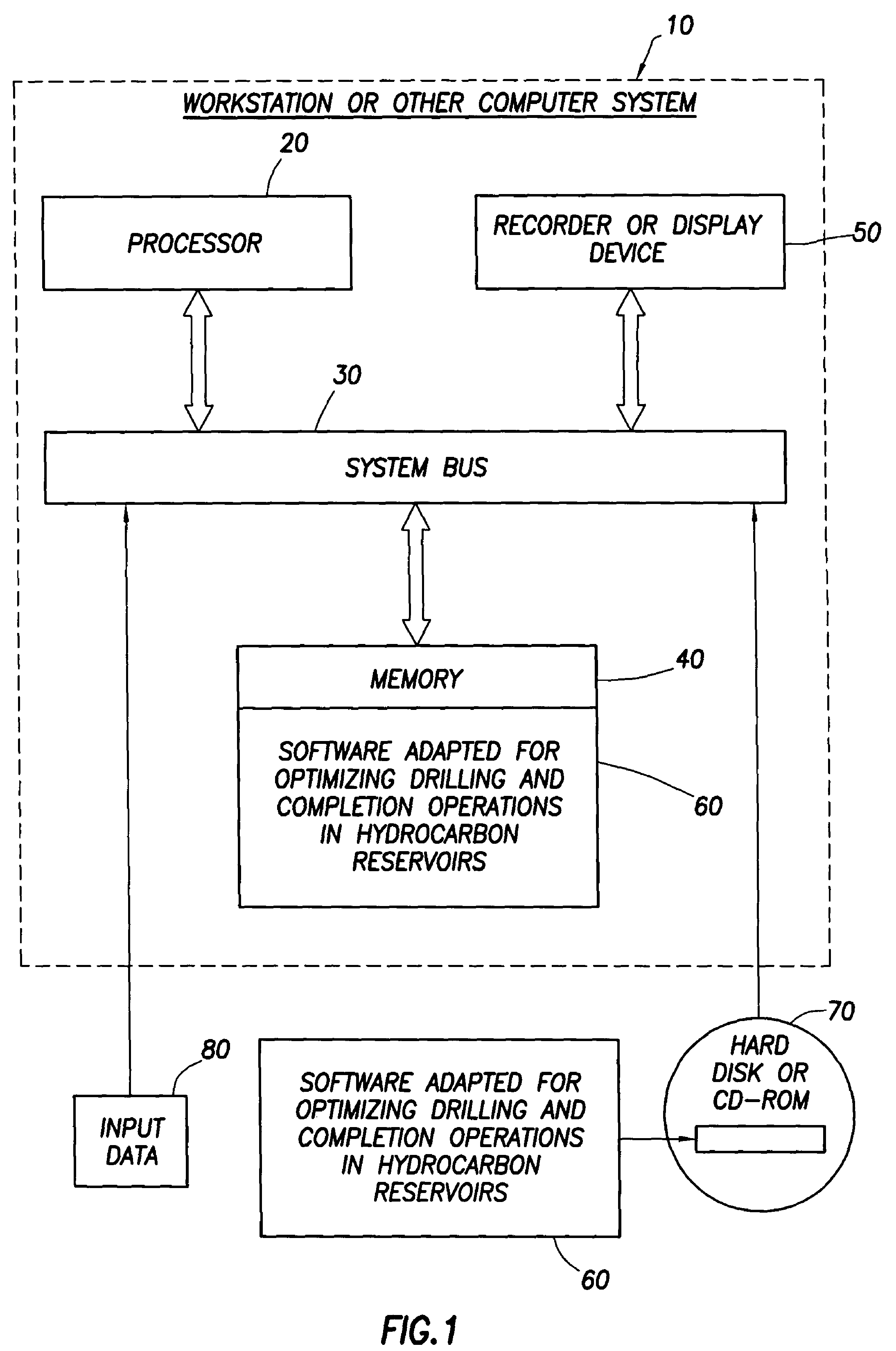

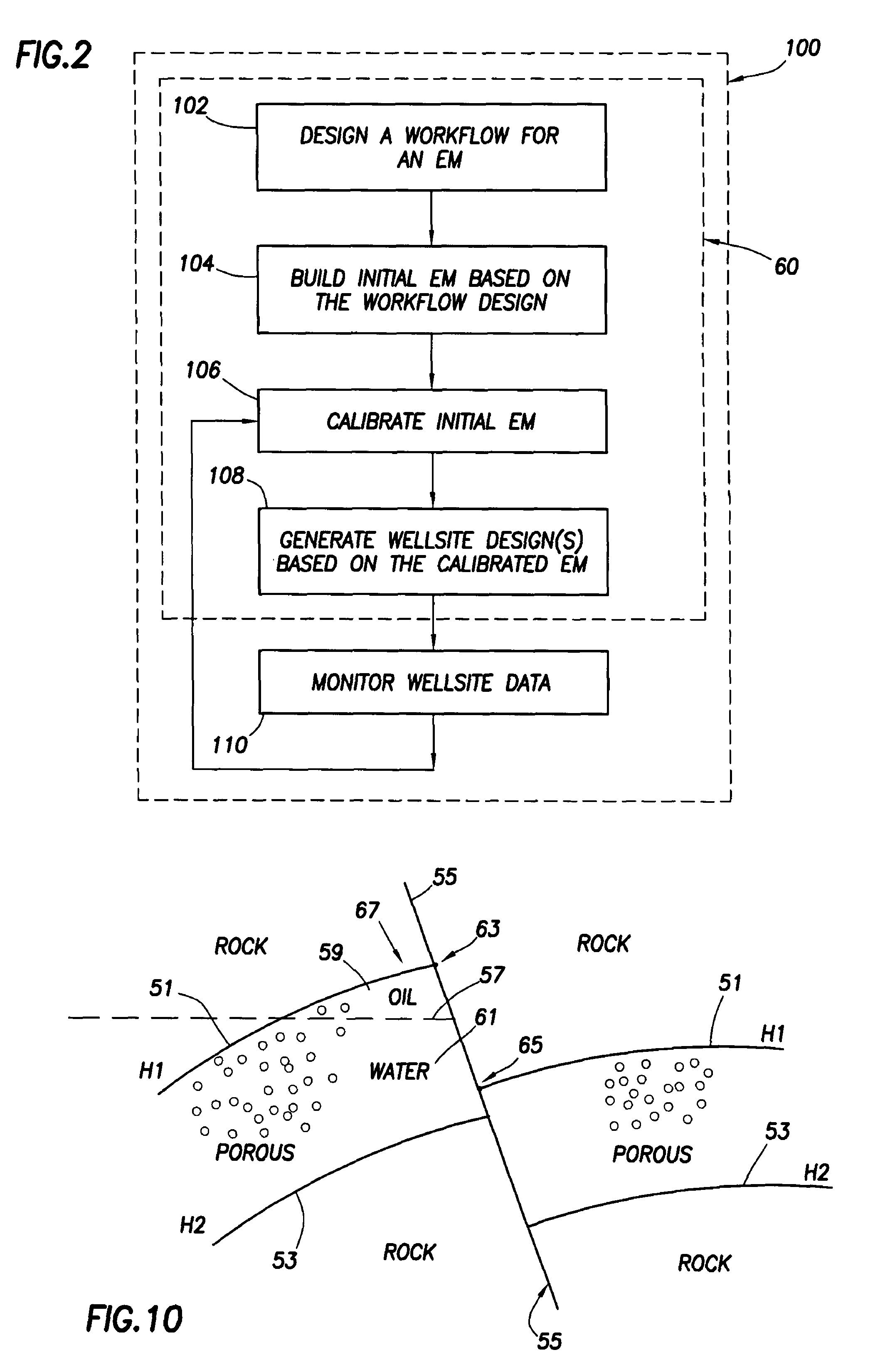

Method for designing and optimizing drilling and completion operations in hydrocarbon reservoirs

ActiveUS20070294034A1Speed maximizationMinimize damageGeometric CADElectric/magnetic detection for well-loggingWell drillingEarth model

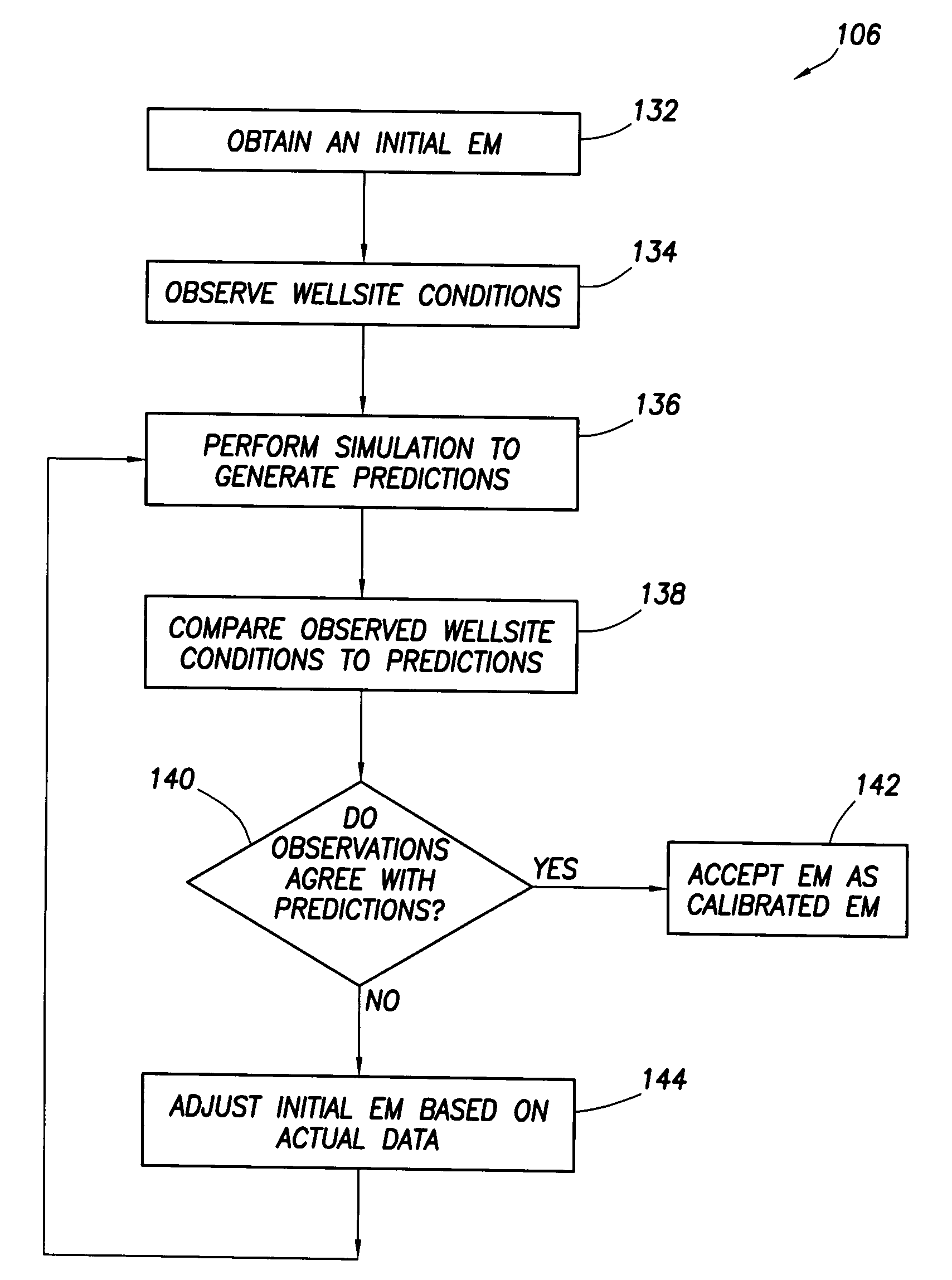

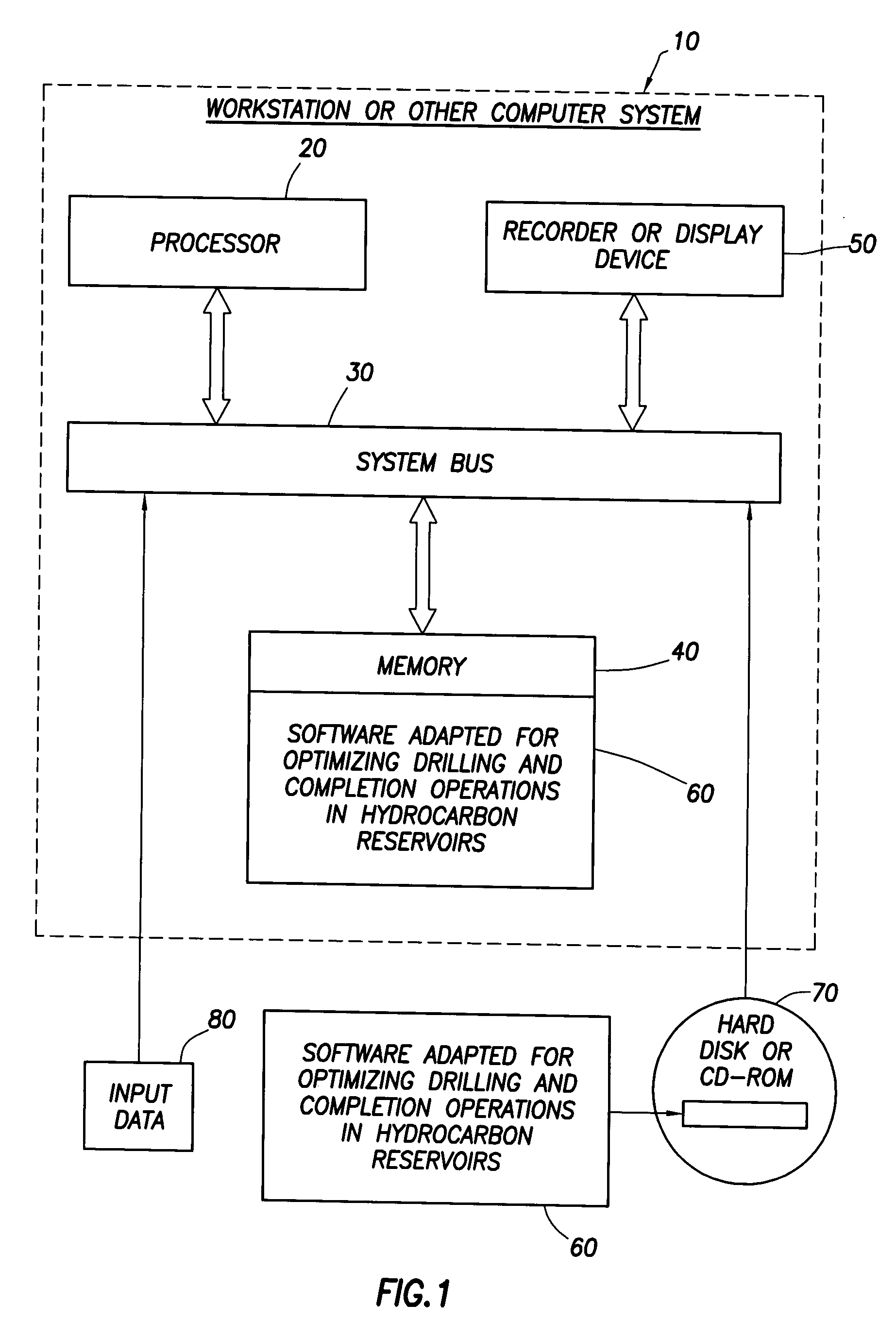

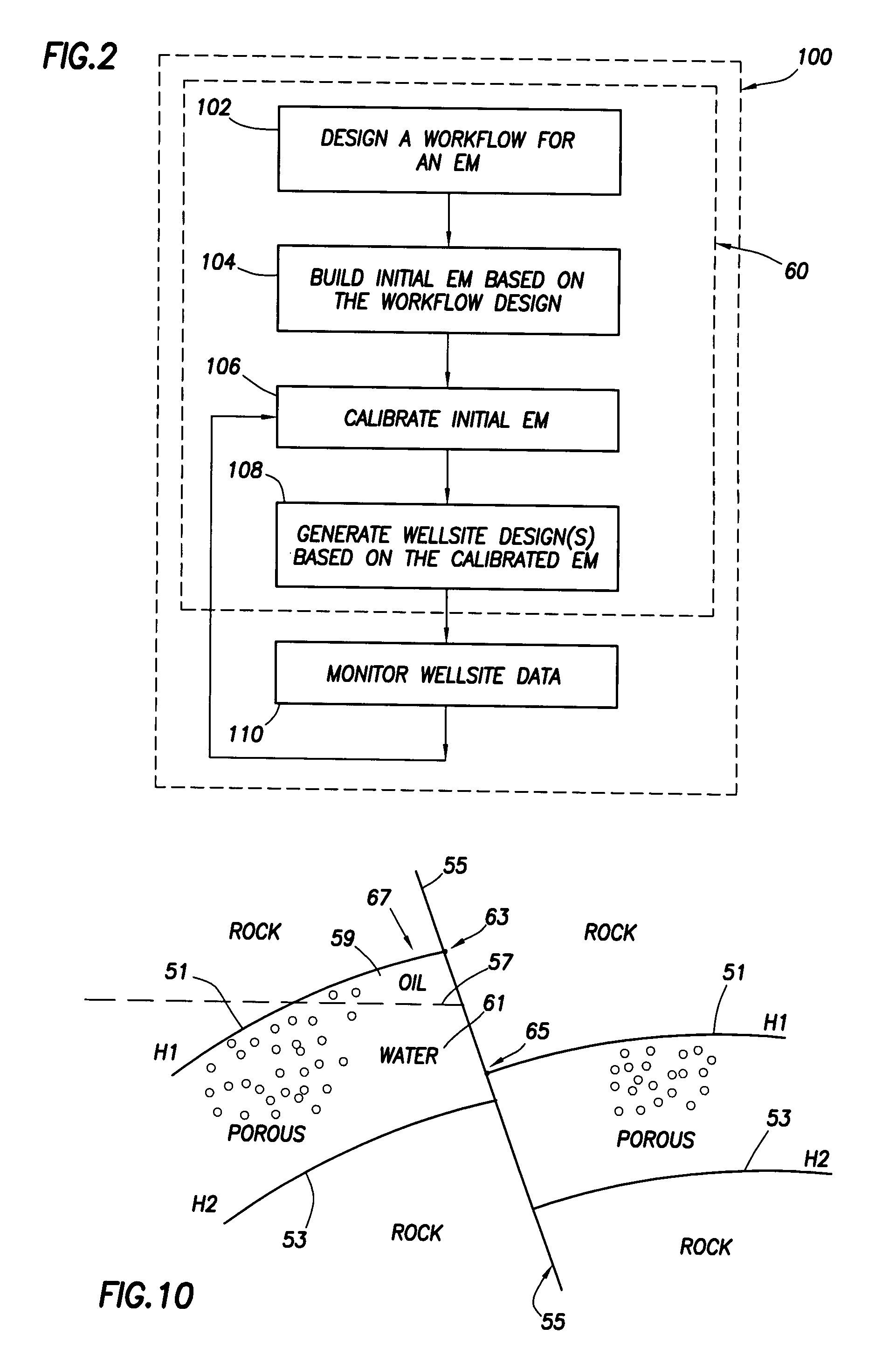

A method is disclosed for generating a wellsite design, comprising: designing a workflow for an Earth Model; building an initial Earth Model based on the workflow adapted for modeling drilling and completions operations in a hydrocarbon reservoir; calibrating the initial Earth Model thereby generating a calibrated Earth Model; and generating the wellsite design using the calibrated Earth Model.

Owner:SCHLUMBERGER TECH CORP

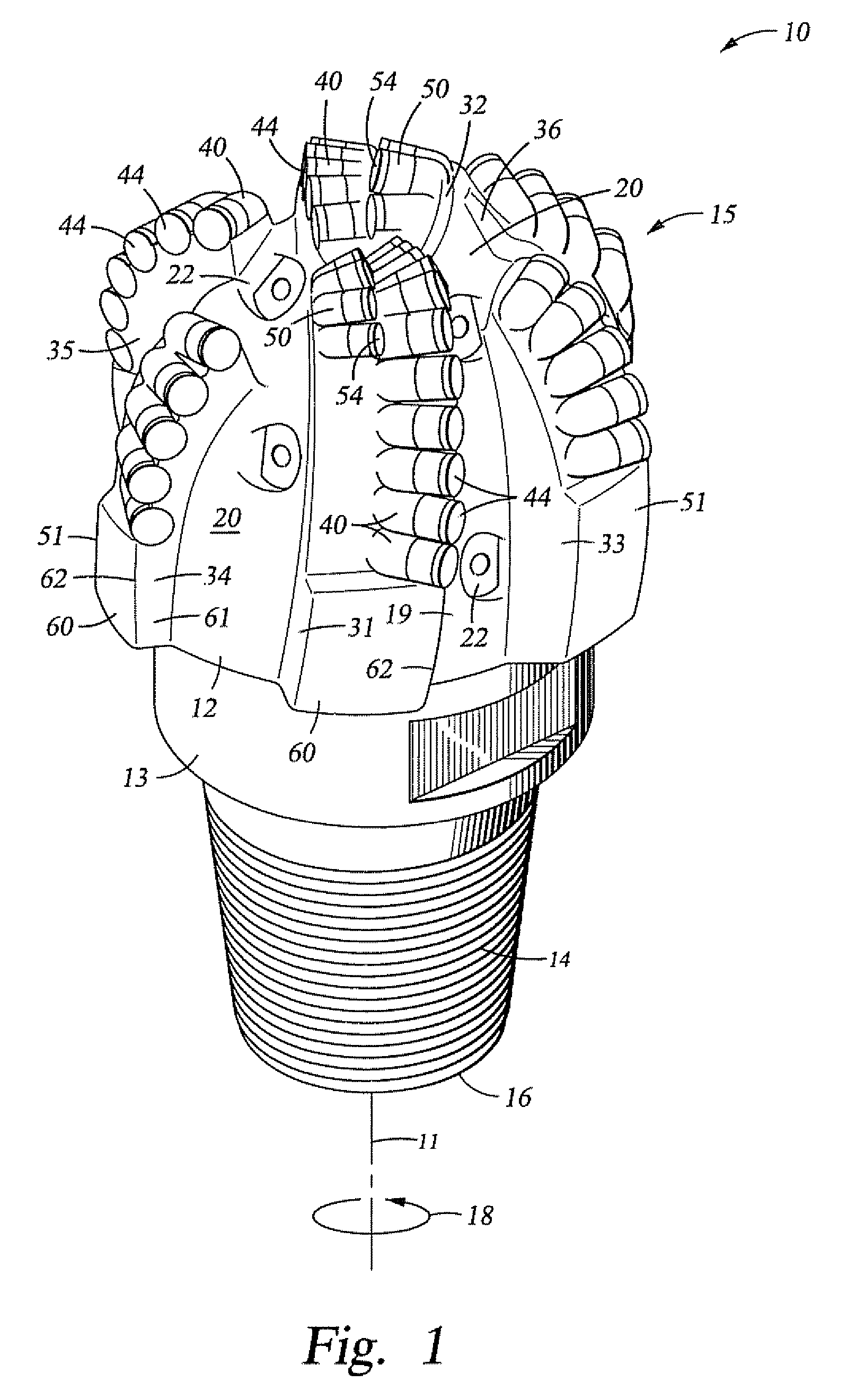

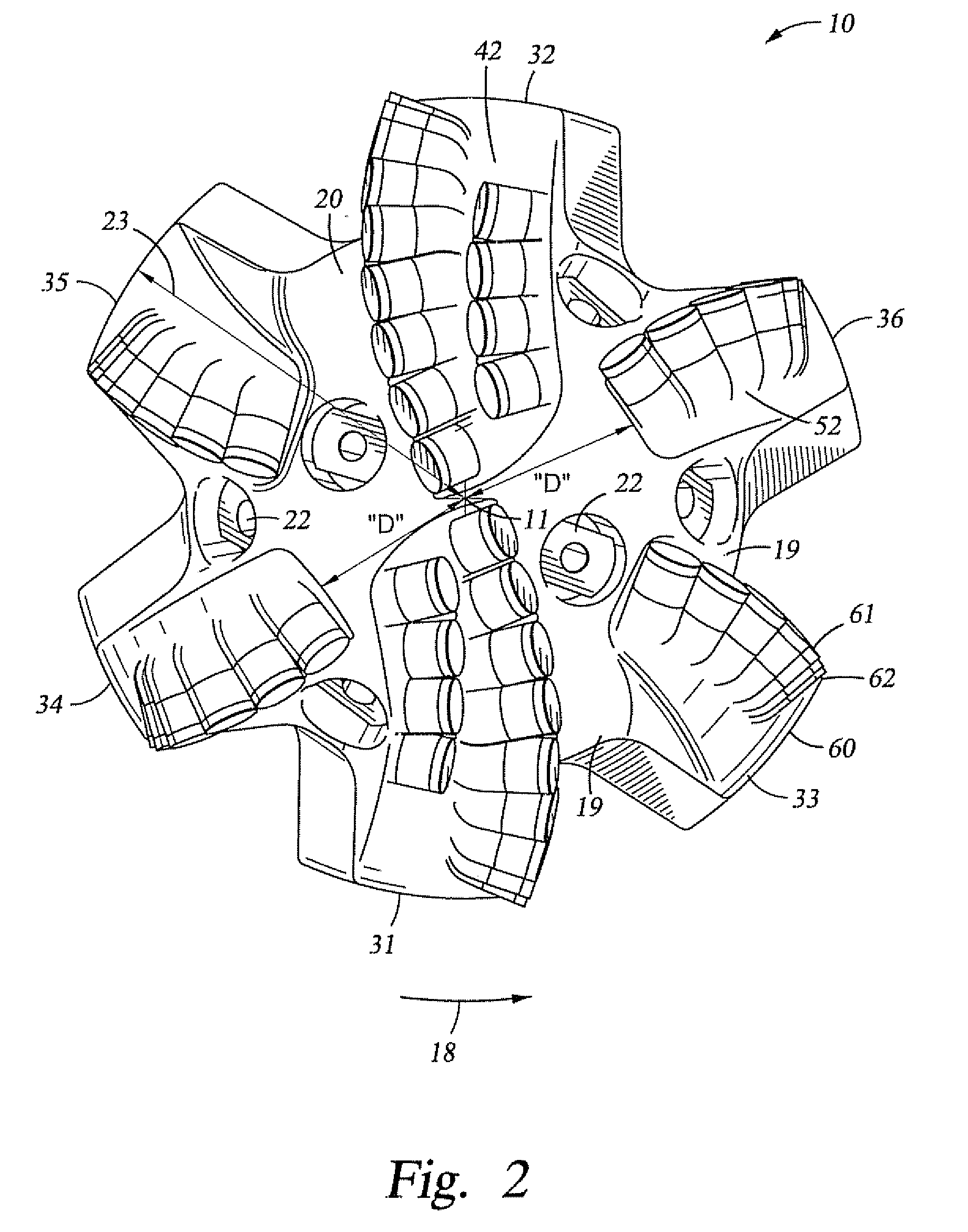

Fixed Cutter Bit With Centrally Positioned Backup Cutter Elements

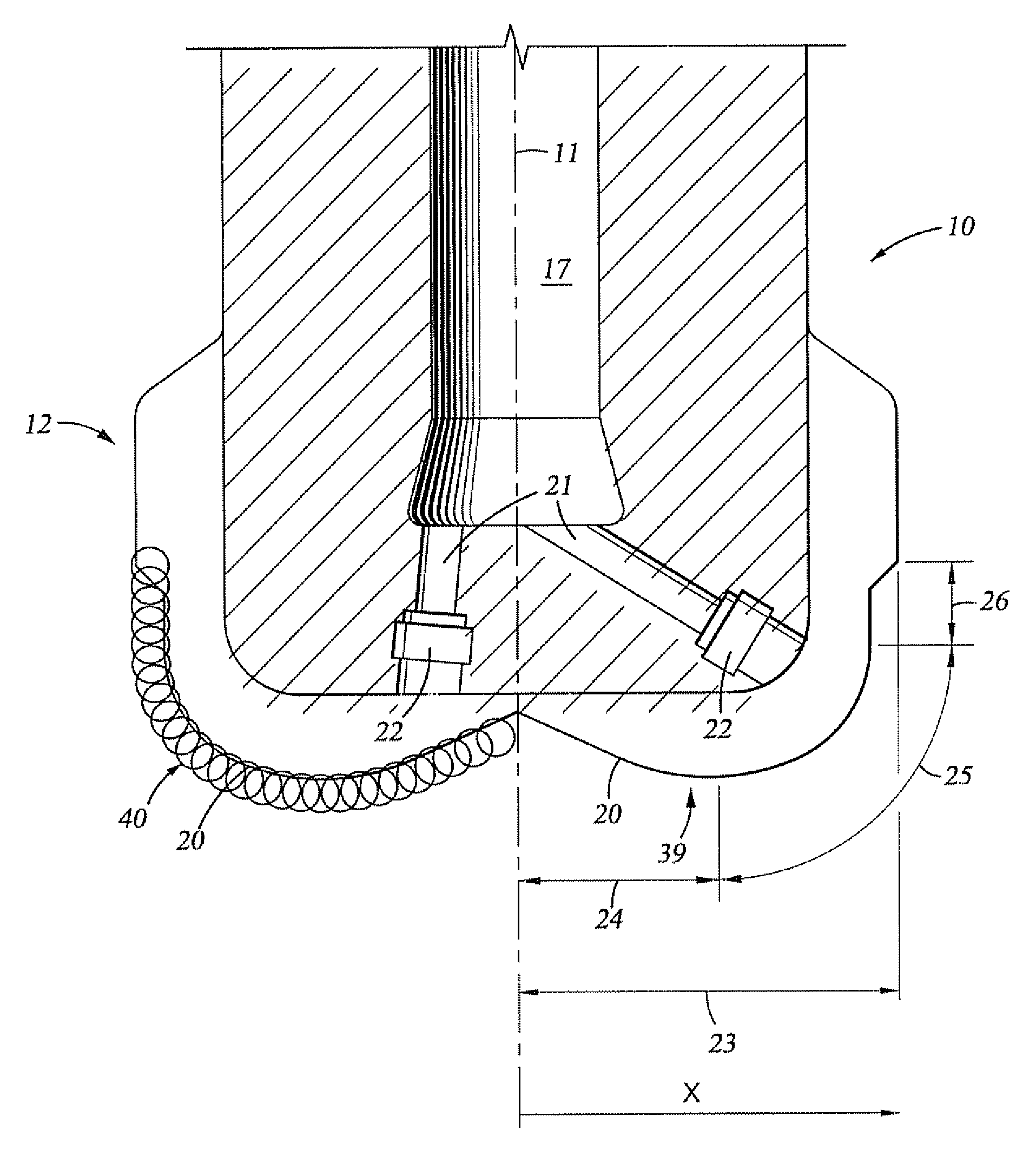

A drill bit for drilling a borehole in earthen formations. In an embodiment, the bit comprises a bit body having a bit face comprising a cone region, a shoulder region, and a gage region. In addition, the bit comprises at least one primary blade disposed on the bit face, wherein the at least one primary blade extends into the cone region. Further, the bit comprises a plurality of primary cutter elements mounted on the at least one primary blade in the cone region. Still further, the bit comprises a plurality of backup cutter elements mounted on the at least one primary blade in the cone region, wherein the at least one primary blade has a cone backup cutter density and a shoulder backup cutter density, and wherein the cone backup cutter density of the at least one primary blade is greater than the shoulder backup cutter density of the at least one primary blade.

Owner:SMITH INT INC

Coal gangue lightweight through-hole ceramsite

The invention discloses coal gangue lightweight through-hole ceramsite. The technical scheme has the essentials that the coal gangue lightweight through-hole ceramsite is composed of coal gangues, attapulgite clay, a powdery coal gangue foaming agent, active carclazyte waste dreg, hollow microspheres, lightweight magnesium oxide, expanded perlite, expanded vermiculite, ferrous sulfate and quick lime. The materials of the coal gangue lightweight through-hole ceramsite are stirred and mixed, extruded and granulated, dried, roasted, subjected to heat insulation, sieved, sealed and packaged to prepare the coal gangue lightweight through-hole ceramsite. The coal gangue lightweight through-hole ceramsite has the characteristics of large specific surface area, small bulk density, high water absorption rate, excellent ventilation performance, beautiful appearance and shape and no odors, no harmful bacteria, good lightweight strength, and consistent micro-pores and macro-pores. When the coal gangue lightweight through-hole ceramsite is used for culturing or planting various types of nursery stocks, flowers and vegetables, the roots of the plants can absorb nutrition constituents of water or a liquid fertilizer from the coal gangue lightweight through-hole ceramsite, so that good growth and development and the survival rate of the plants are ensured and the coal gangue lightweight through-hole ceramsite is suitable for preparing a soilless culture substrate and nutrient soil.

Owner:平凉华晨非金属应用科技有限公司

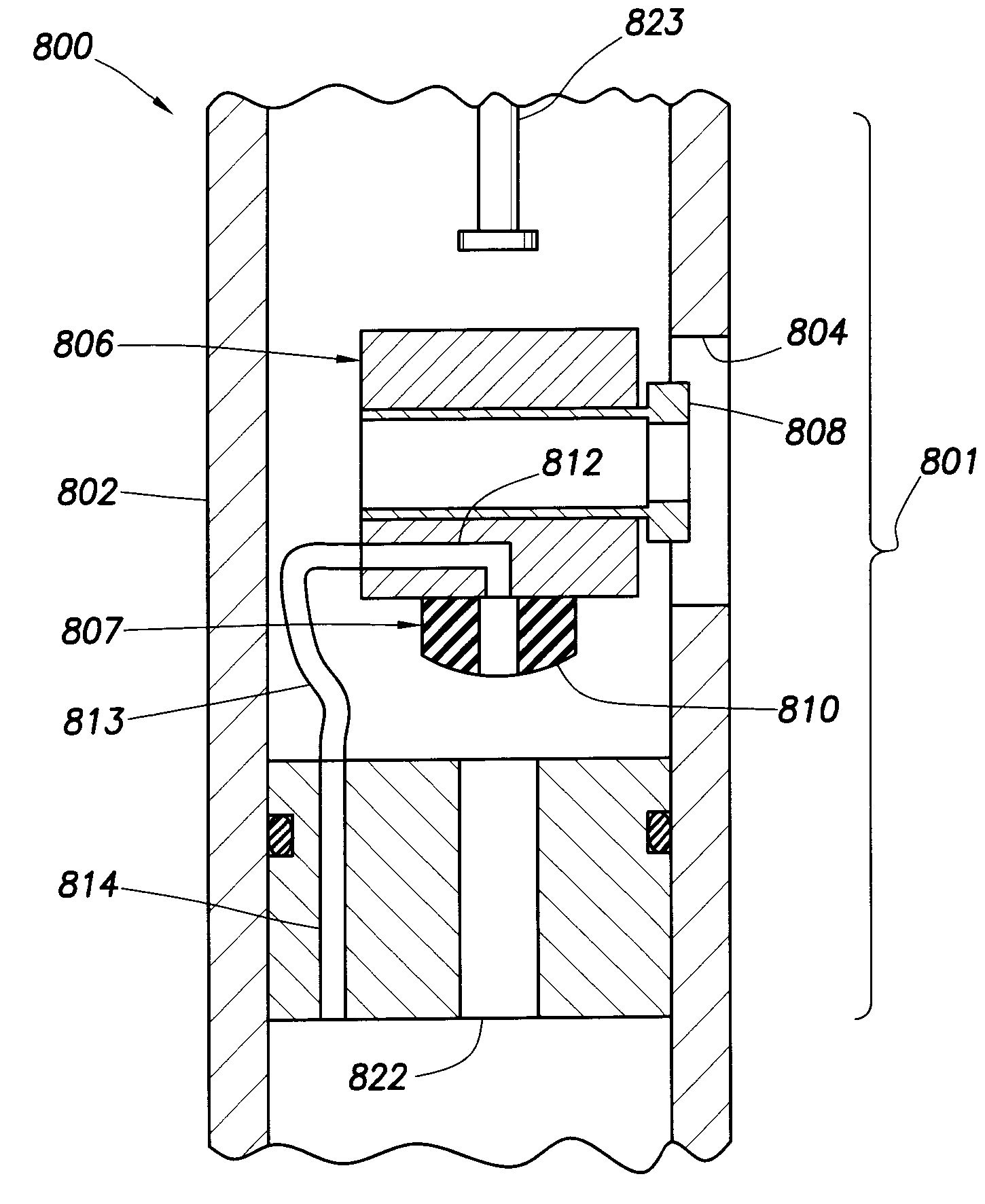

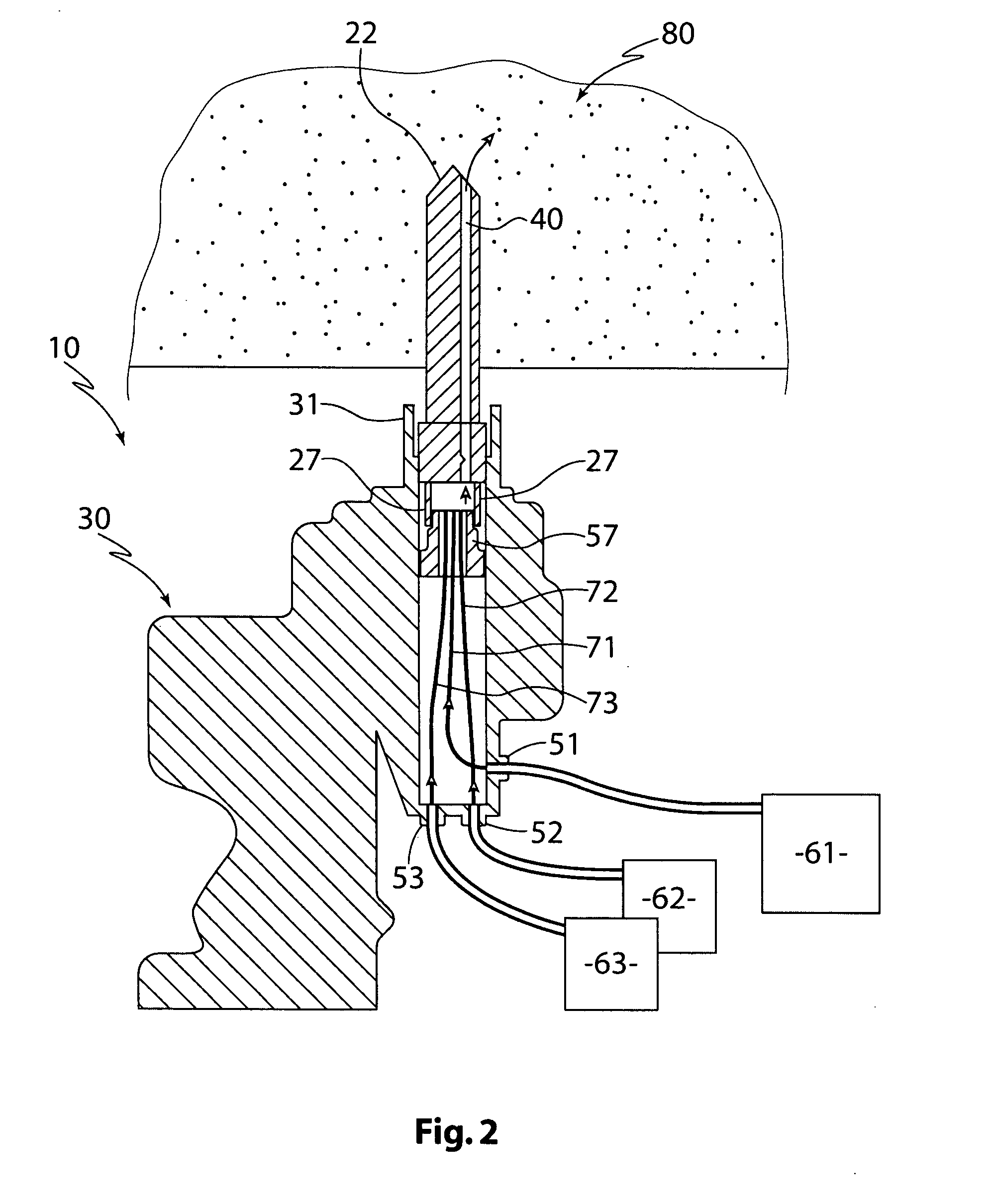

Downhole formation testing tool

Embodiments of the invention relate to a wireline assembly that includes a coring tool for taking coring samples of the formation and a formation testing tool for taking fluid samples from the formation, where the formation testing tool is operatively connected to the coring tool. In some embodiments, the wireline assembly includes a low-power coring tool. In other embodiments, the coring tool includes a flowline for formation testing.

Owner:SCHLUMBERGER TECH CORP

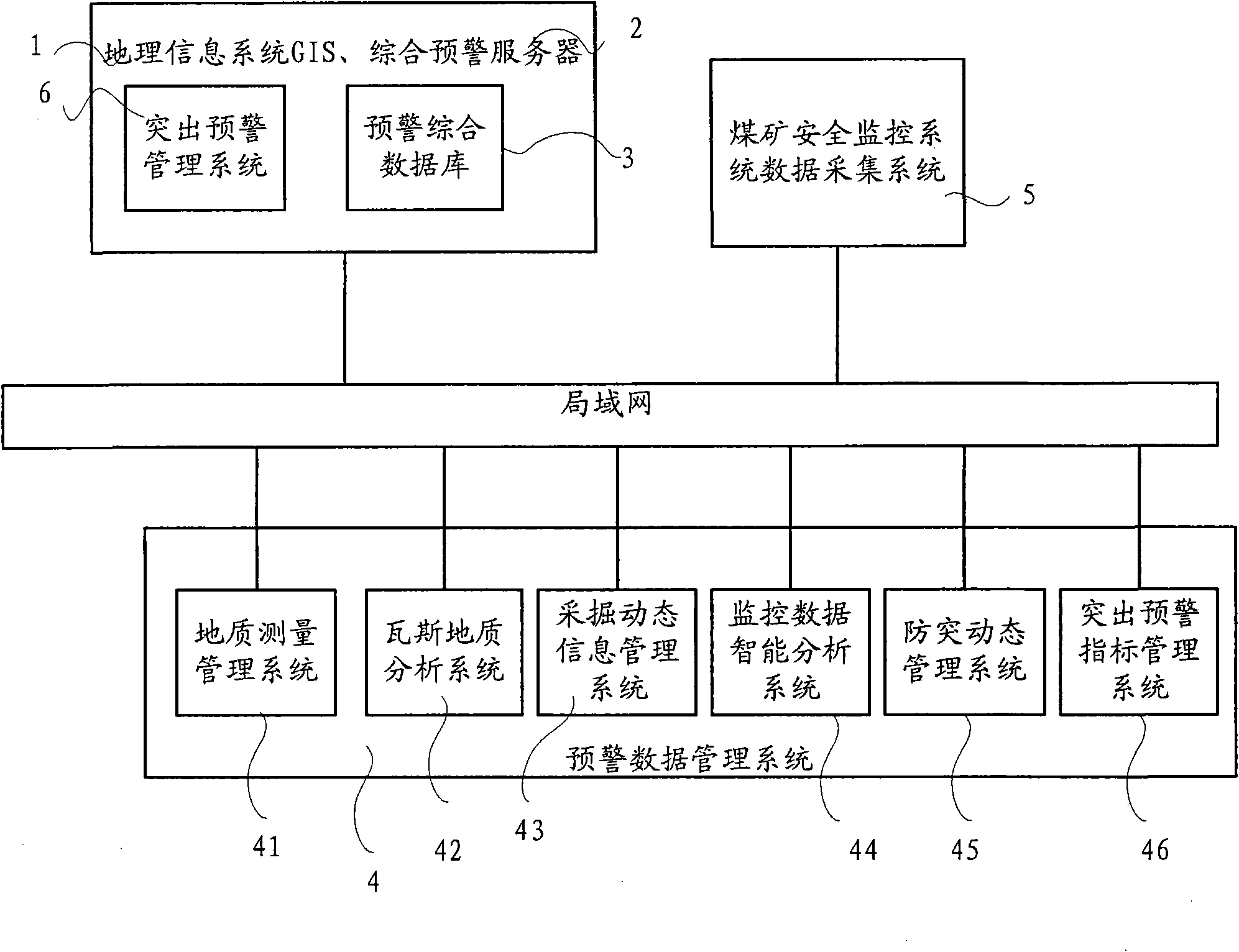

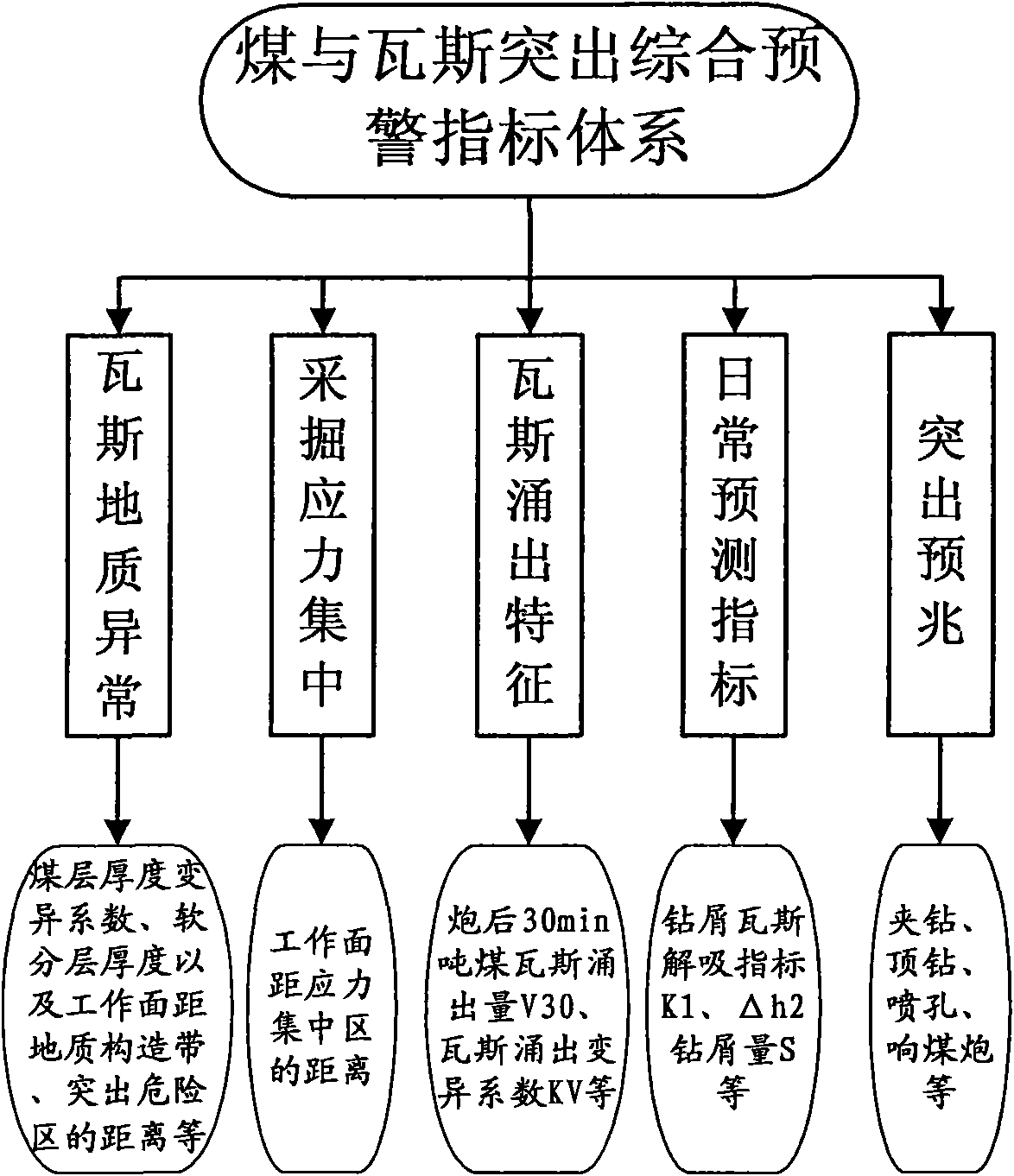

Coal and gas outburst hazard early warning system and early warning method

ActiveCN101550841APrevention of Outstanding DisastersReal-timeMining devicesDust removalForward lookingGeological structure

The invention relates to the field of coal mine safety technique, specifically to a down-hole coal and gas outburst hazard early warning system and early warning method. The coal and gas outburst synthesized early-warning system, uses the existing local area network to connect a synthesized early-warning data server, an early-warning data management system and the existing coal mine safety monitoring system; analyzes the coal and gas outburst early-warning data in the synthesized early-warning data server by an outburst early-warning module; and emits early-warning information based on the analyzed result. The inventive coal and gas outburst synthesized early warning system and early warning method can perform centralized management and comprehensive analysis of the geological structure, coal seam occurrence, gas occurrence, mining production, daily forecast indicators, outburst forecast, gas emission and other security information that originally scatter in various functional sections of coal mine on the geographical information system GIS platform, integrates the existing resources, improves the accuracy of early warning, so that the early warning is both real-time and forward-looking, and can effectively prevent the occurrence of coal and gas outburst in coal mine.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Gelatinization material gypsum-cement and producing method thereof

The invention relates to a gypsum-cement binding material and a production method thereof. The material contains gypsum binding material, active admixture, alkaline excitant, oagulation accelerator, lime, water-reducing agent, early-strength agent and gypsum hemihydrate. The weight proportions of the components are as follows: 40%-80% of gypsum binding material, 10%-45% of active admixture, 4%-15% of alkaline excitant, 0-6% of coagulation accelerator, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-5% of lime and 0-10% of gypsum hemihydrate. The production method comprises the following steps: weighing raw materials at the given ratio, mixing all raw materials, and packaging. The inventive gypsum-cement material has high strength, good water resistance and good volume stability; and can be used as masonry cement, cement mortar, gypsum plaster, jointing gypsum and heat-insulating mortar.

Owner:长沙归一新材料科技股份有限公司

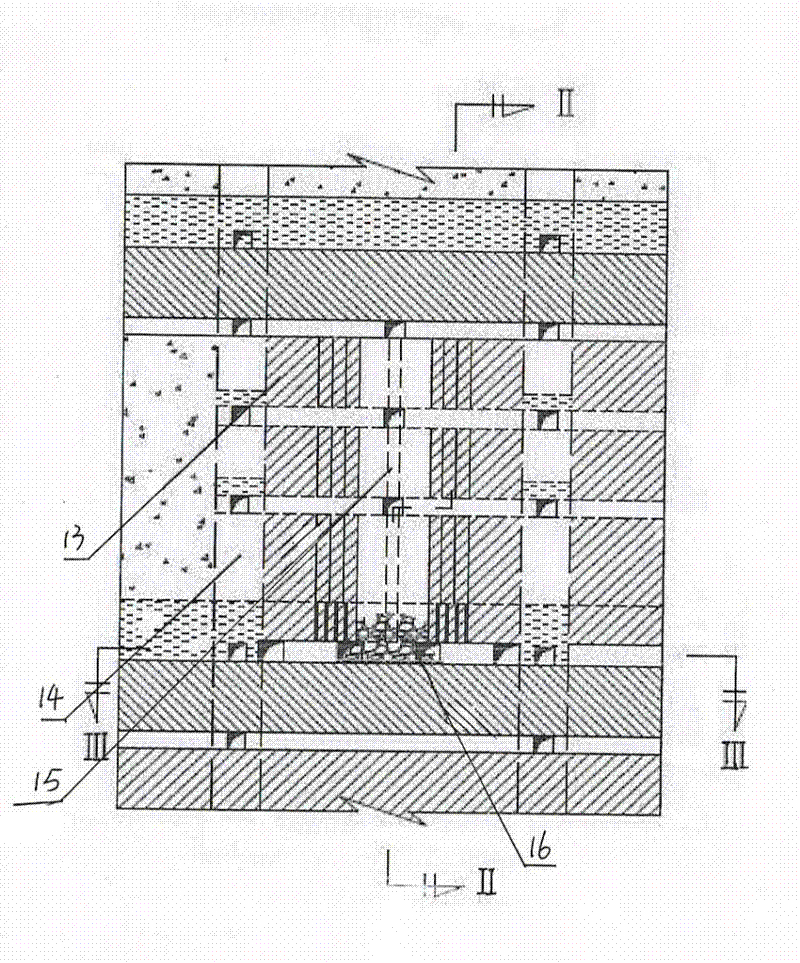

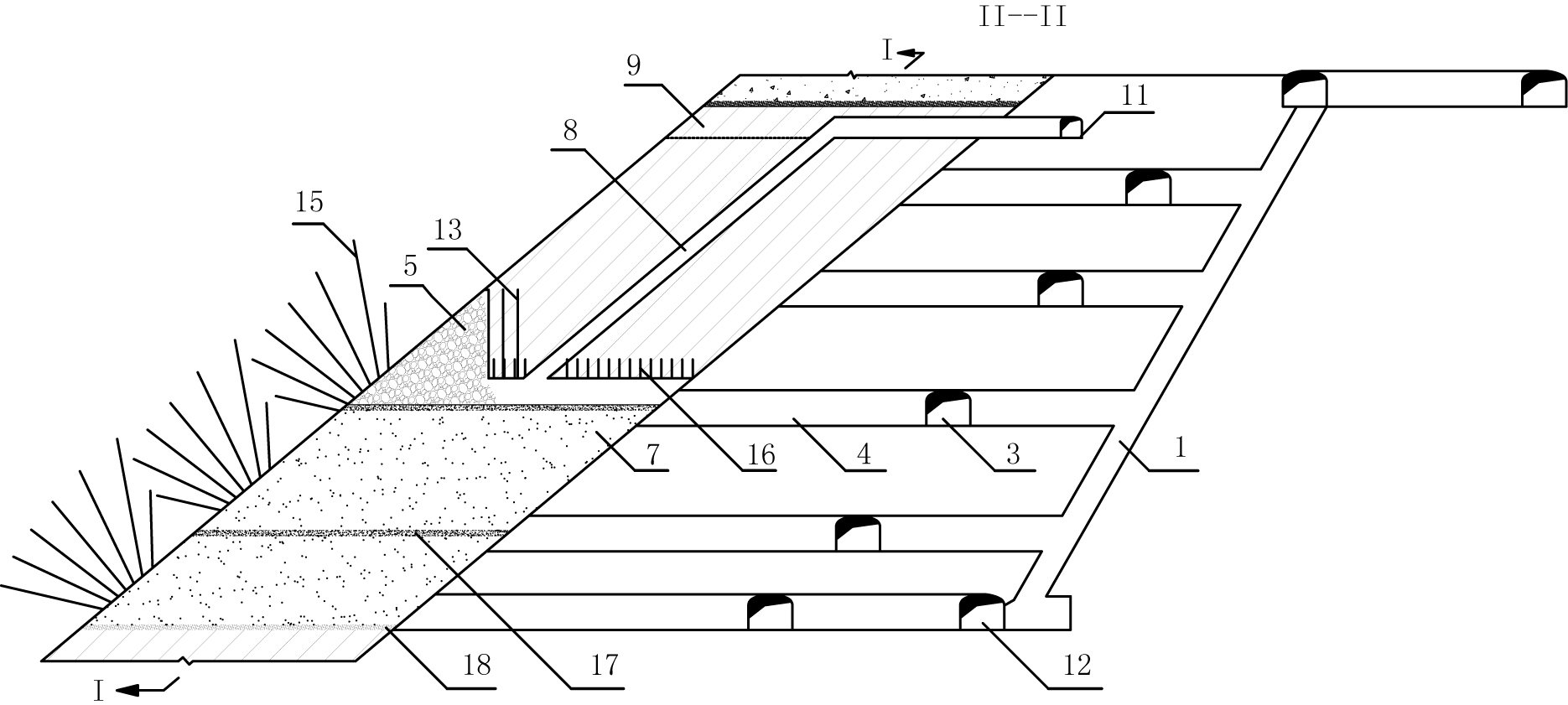

House pillar changeable panel upward demix filling mining method

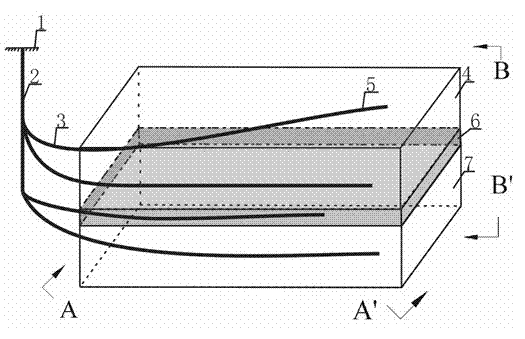

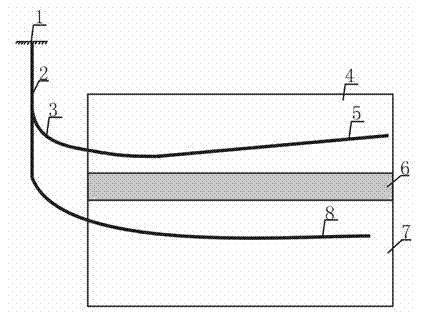

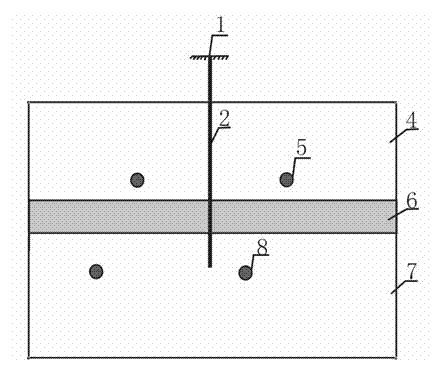

InactiveCN101858217AReduced suspension heightImprove integrityUnderground miningSurface miningRoom and pillar miningMineralogy

The invention discloses a house pillar changeable panel upward demix filling mining method. An ore body is divided into an ore house and an ore pillar arranged at intervals along the strike direction; a plurality of house pillars form a panel; a rock trackless preparation system is adopted and comprises a ramp, a rock slice drift, a demix ventilation connection and a rock concentrated ore removal winze; the mechanical upward demix filling mining method is adopted for mining, which mines a slice and fills the slice until the position required by the lower slice blasting compensation is reached. The backstopping order of the house pillars in the panel is the ore house first and then the ore pillar; all ore houses are subjected to upward backstopping at the same time; after a backstopping unit of the ore house is finished, the roof-contacted filling is carried out, and the mining of the ore house is temporarily stopped and the mining of the ore pillar is started; after two backstopping units of the ore pillar are finished, the roof-contacted filling is carried out, and the mining of the ore house is resumed; the abovementioned steps are repeated until the backstopping of the ore block is completed. The invention has the remarkable characteristics of improving the backstopping safety, reducing the resource dilution rate, lowering the support cost, increasing the enterprise profit, and the like.

Owner:CENT SOUTH UNIV +1

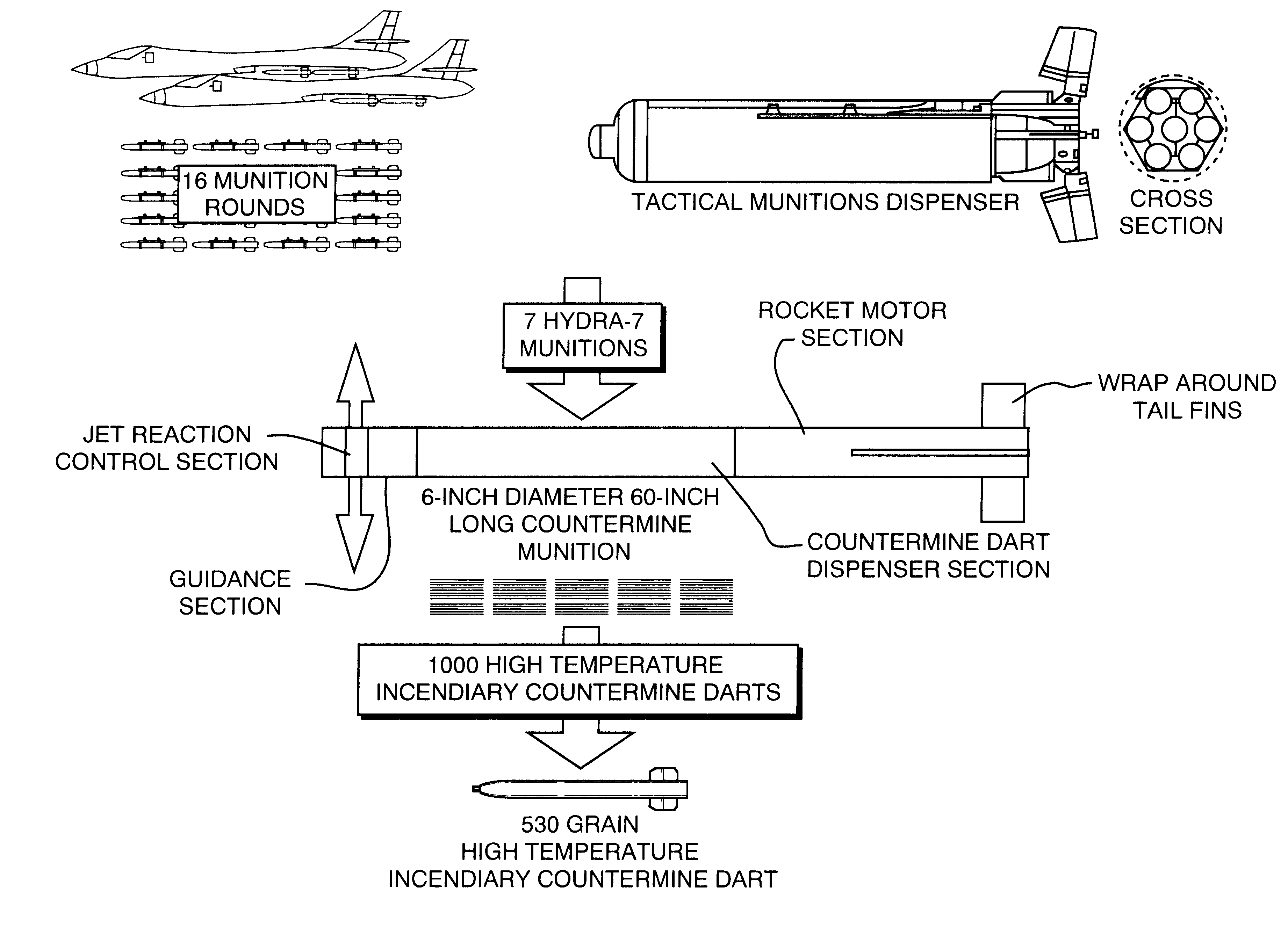

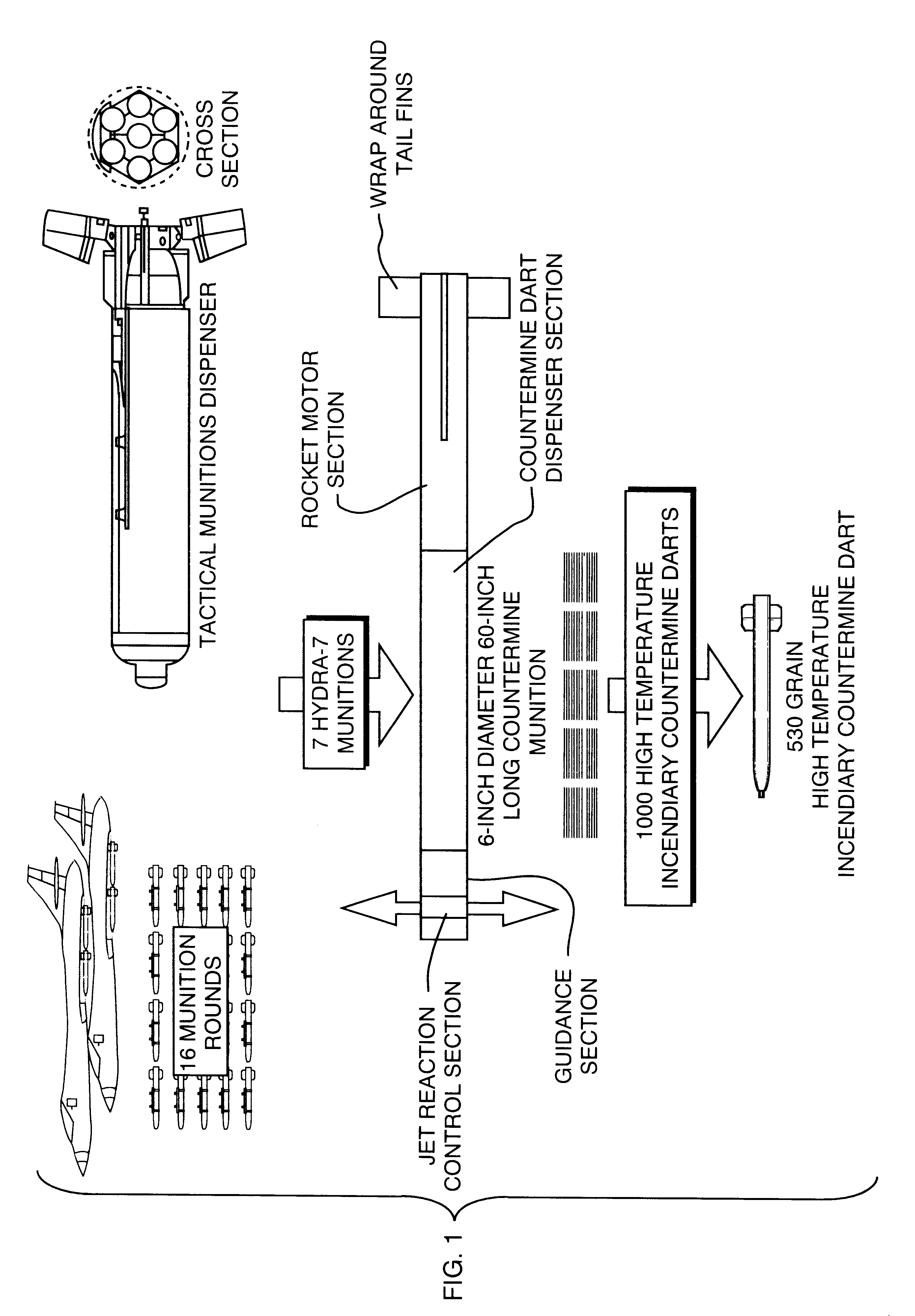

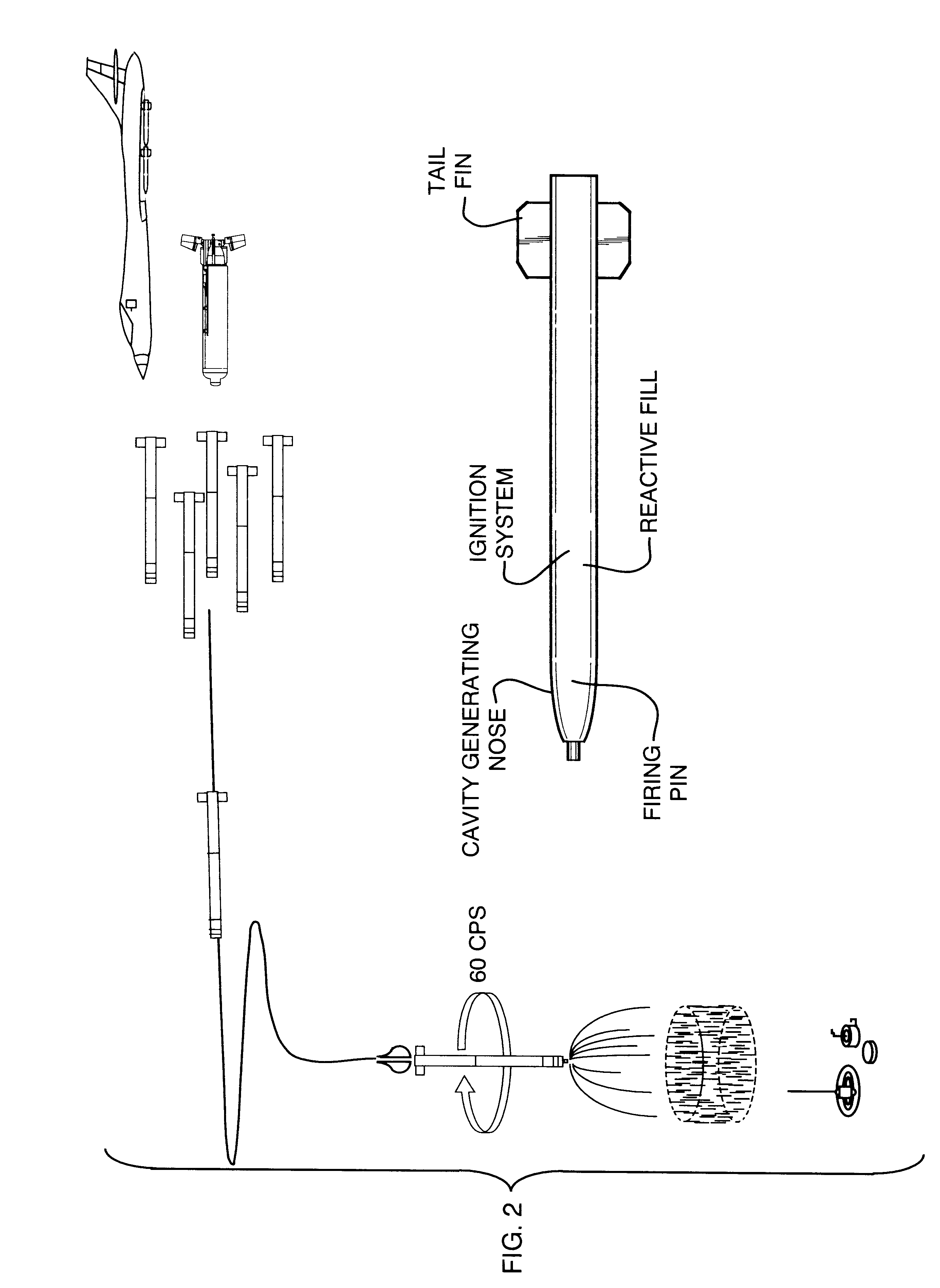

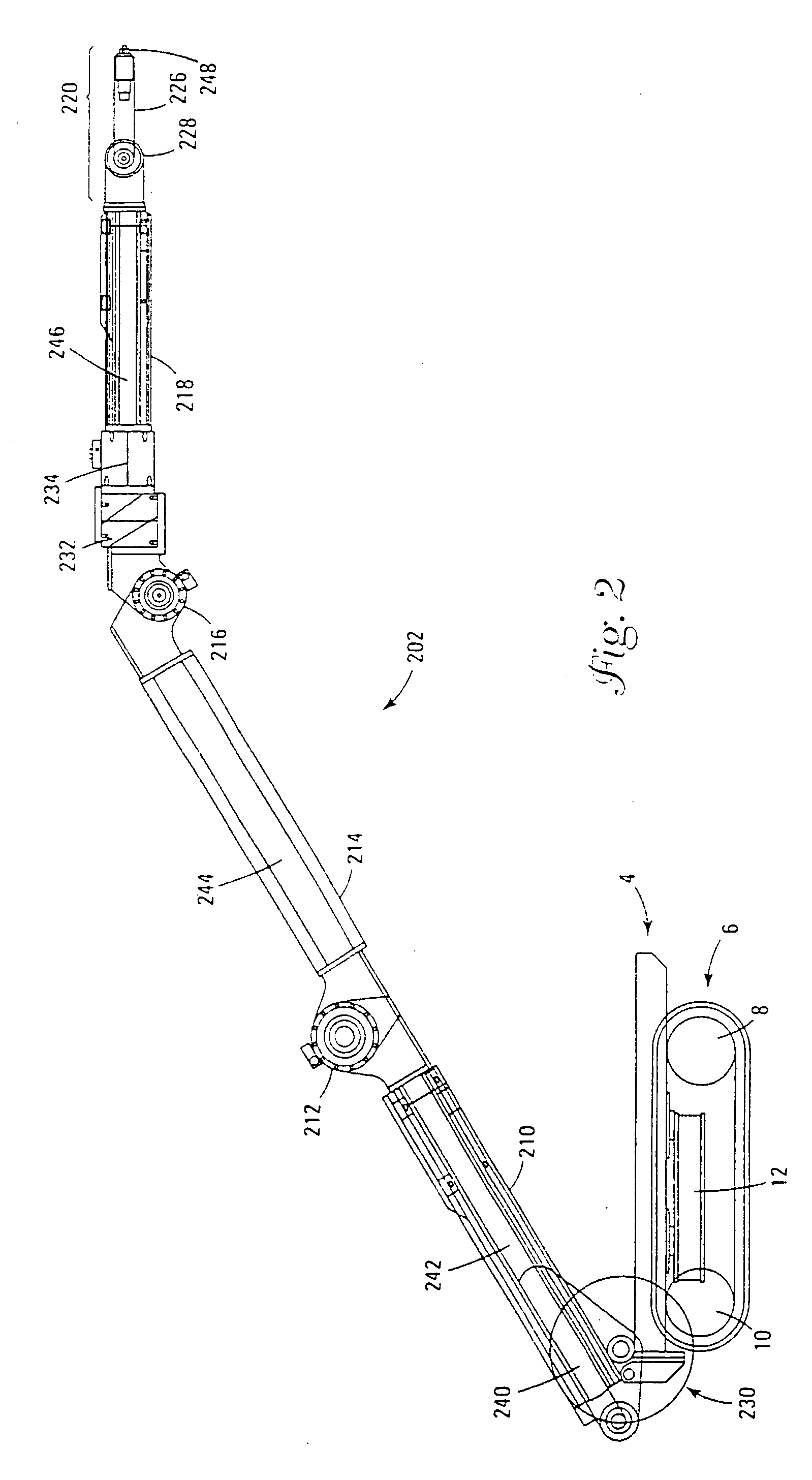

System for clearing buried and surface mines

Owner:LOCKHEED MARTIN ADVANCED PROJECTS

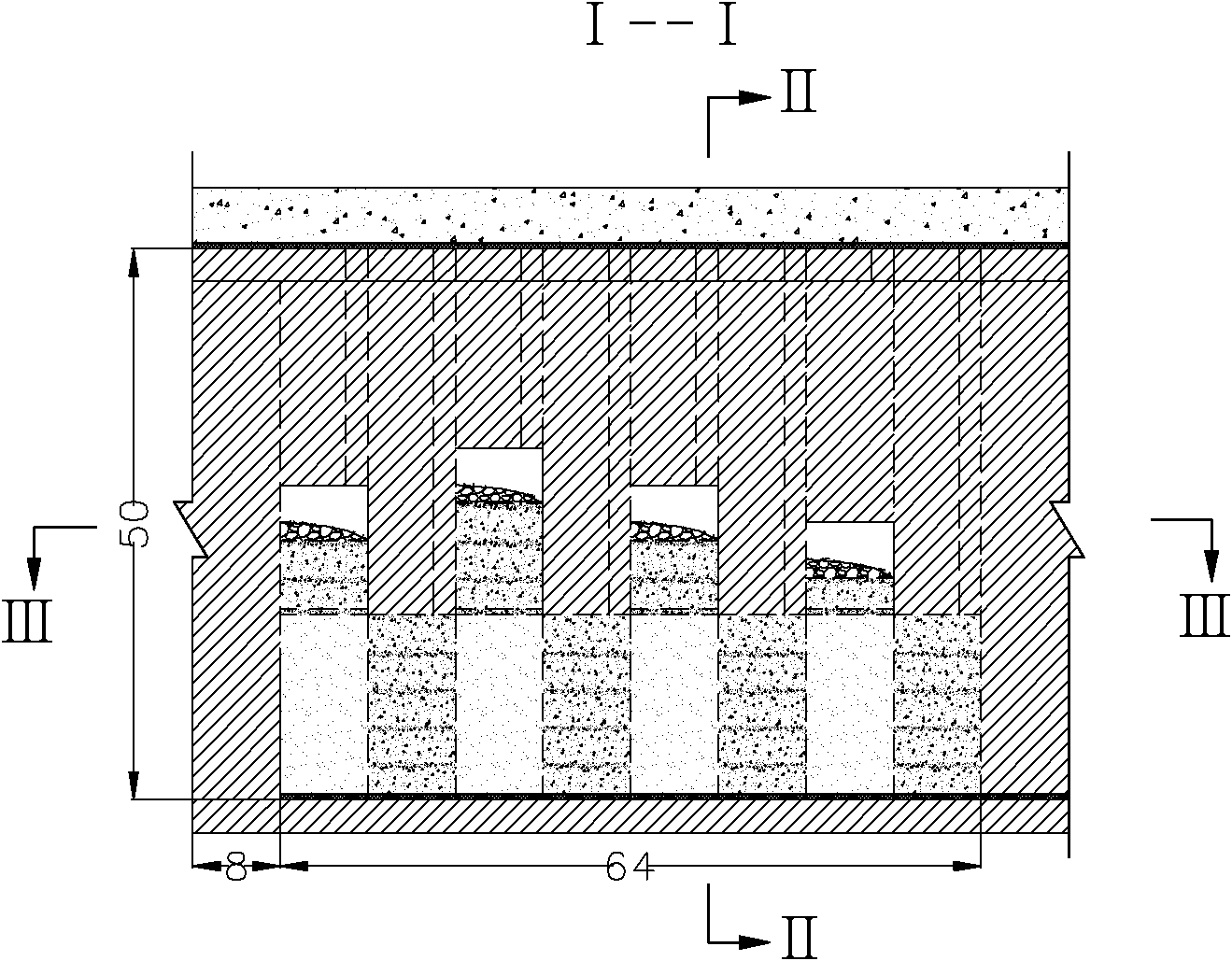

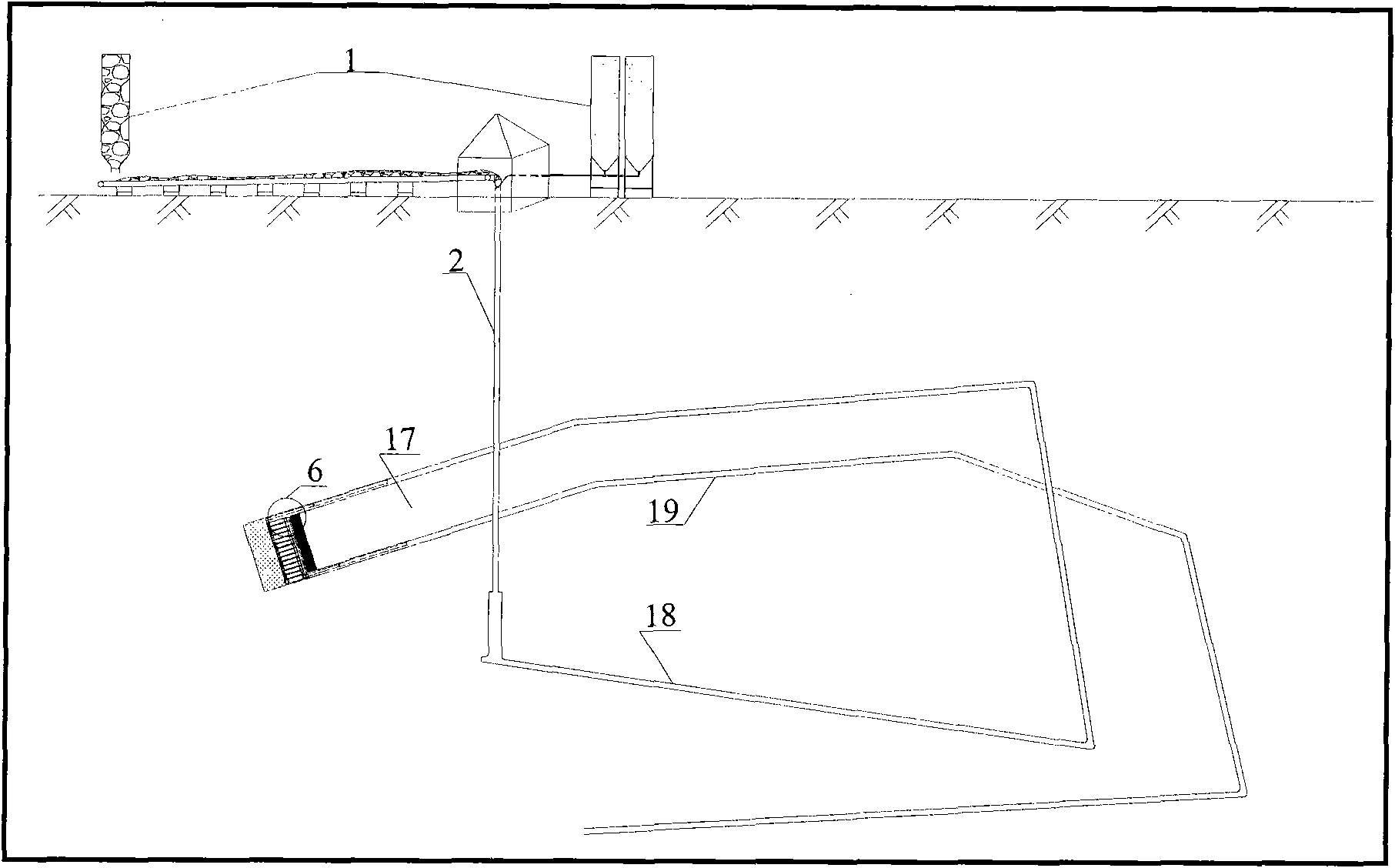

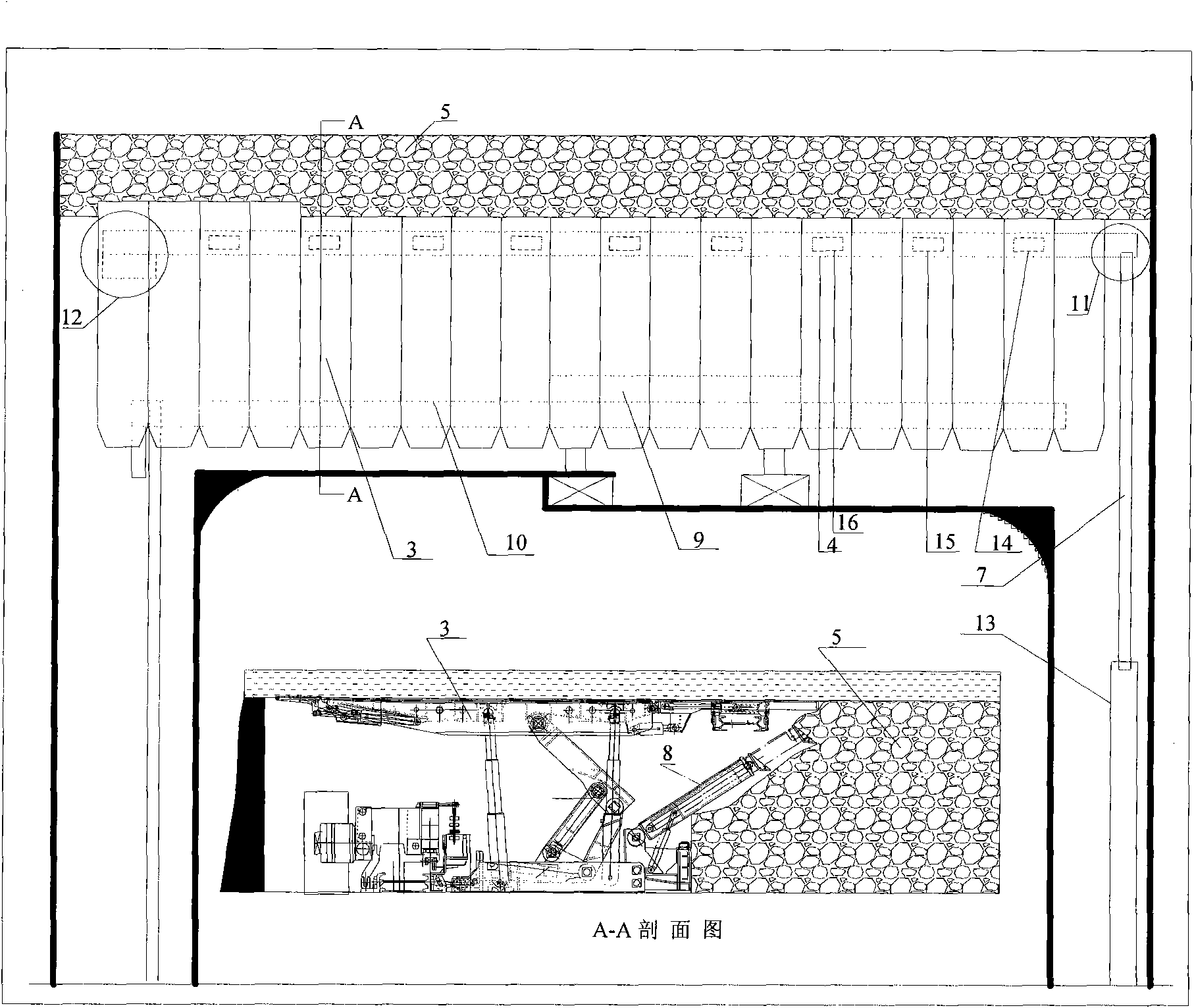

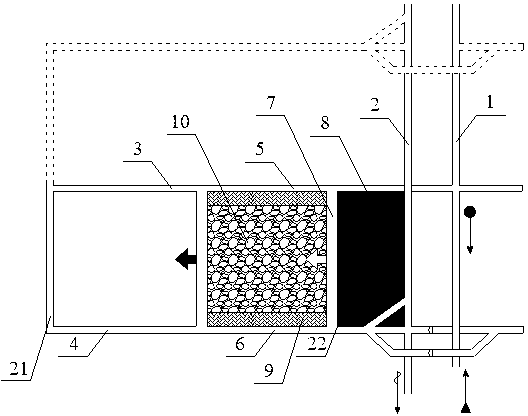

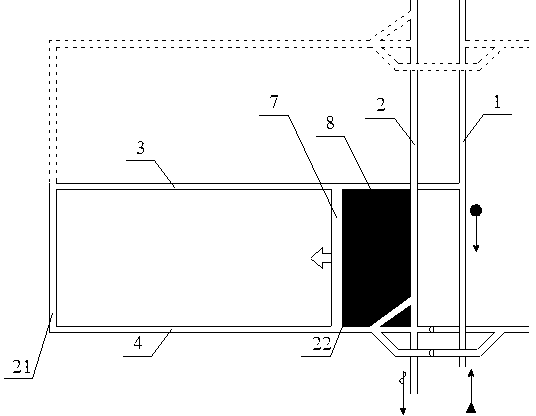

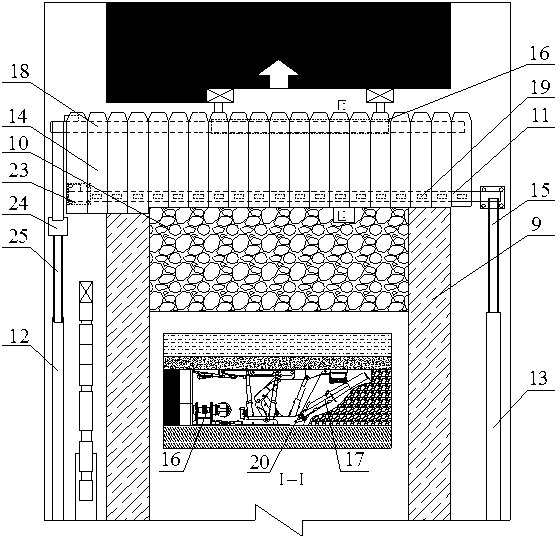

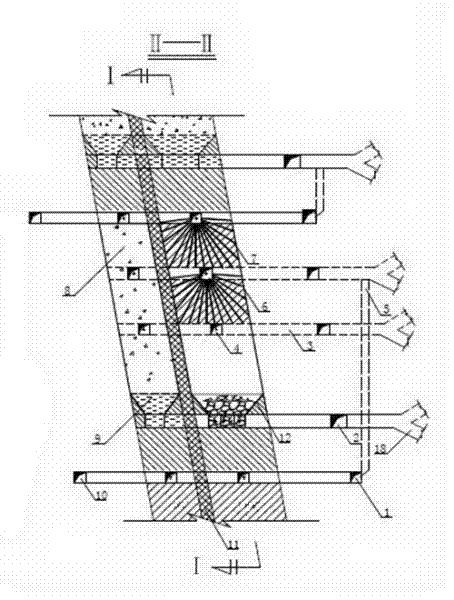

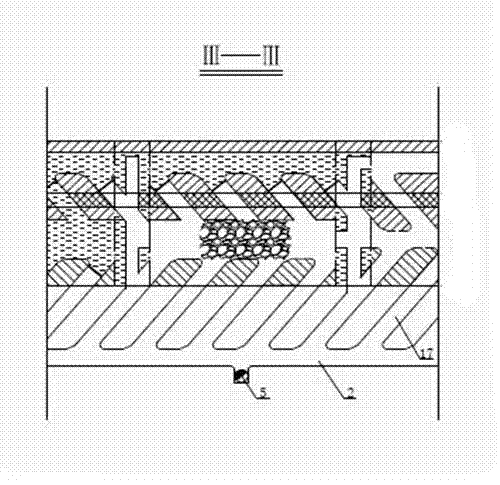

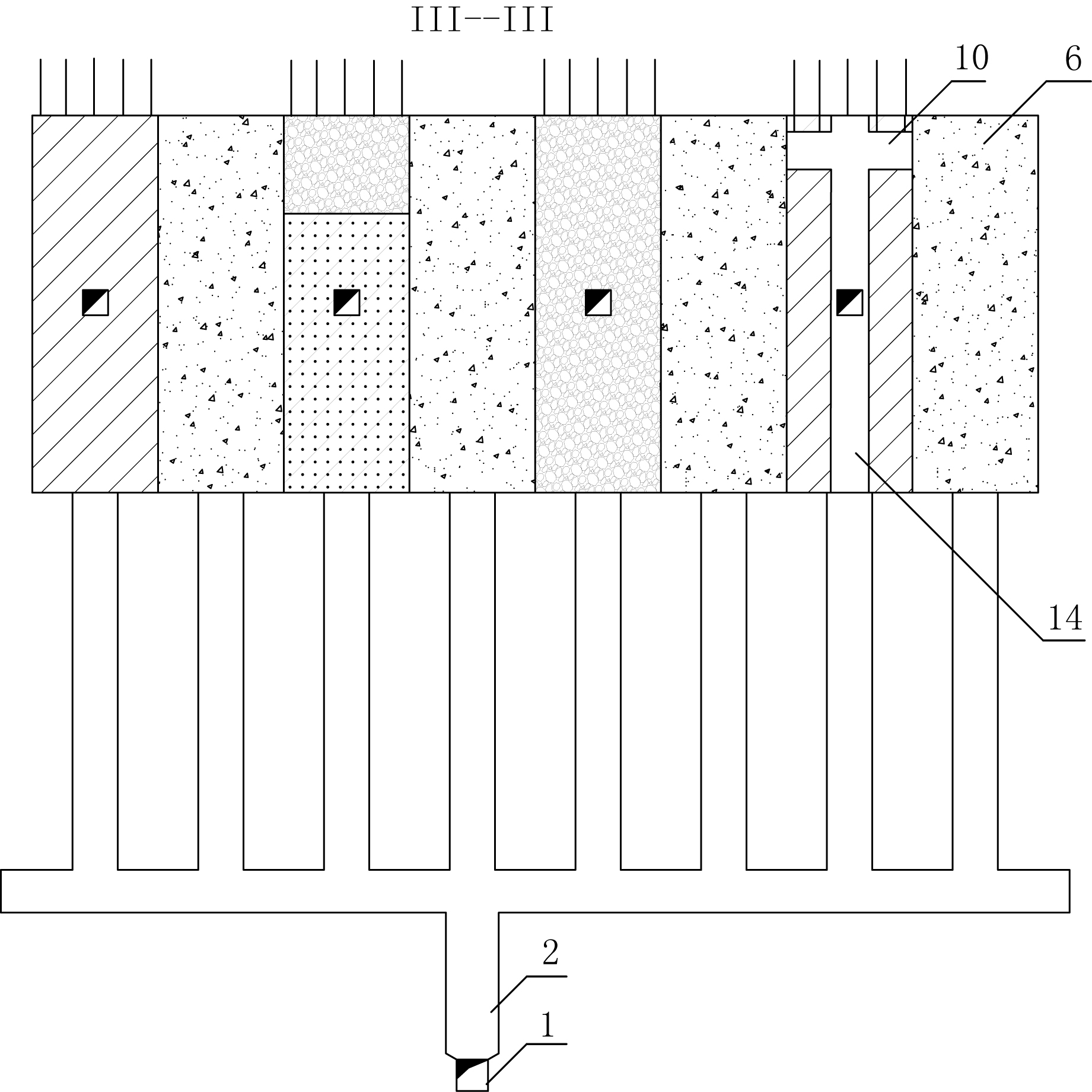

Coal mining solid filling method

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

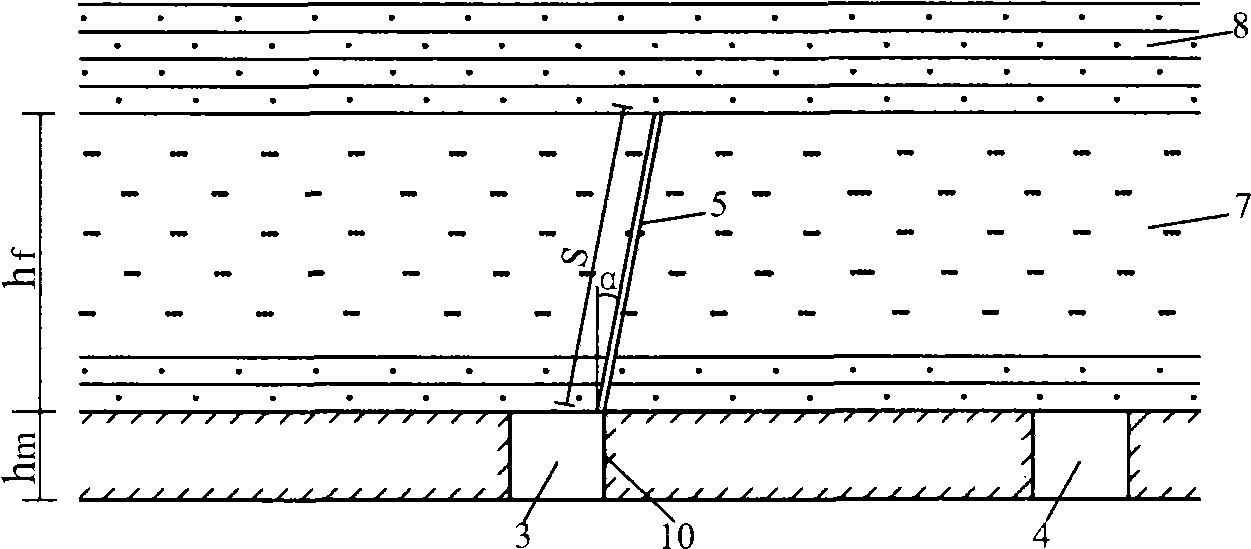

The roof caving and tunnel protecting method

InactiveCN101509395AHighlight substantiveReduce widthUnderground chambersMaterial fill-upMining engineeringFissure

The invention relates to a method for controlling caving and lane-guarding. The method is characterized in that in a working surface roadway, drilling, blasting or cracking are carried out on a roof of a coal seam of complete hard strata with large thickness of a hanging arch in a goaf; bursting or cutting off are carried out on a complete hard roof strata with large thickness to facilitate the hanging arch in the goaf to collapse at the back of a force piece; collapsed waste rock fills the goaf, supports superincumbent stratum in a fissure zone and releases high bearing stress passed into the coal body adjacent to the goaf from weight of the large-thickness complete hard strata of the hanging arch in the goaf and the superincumbent stratum in the fissure zone thereof, so that the bearing stress in the coal body adjacent to the goaf is reduced and laneways in the space are protected. The method of the invention fundamentally improves stability of surrounding rock of laneways adjacent to the goaf and increases coal mining rate of ends of thick coal seam caving coal working surface.

Owner:TAIYUAN UNIV OF TECH

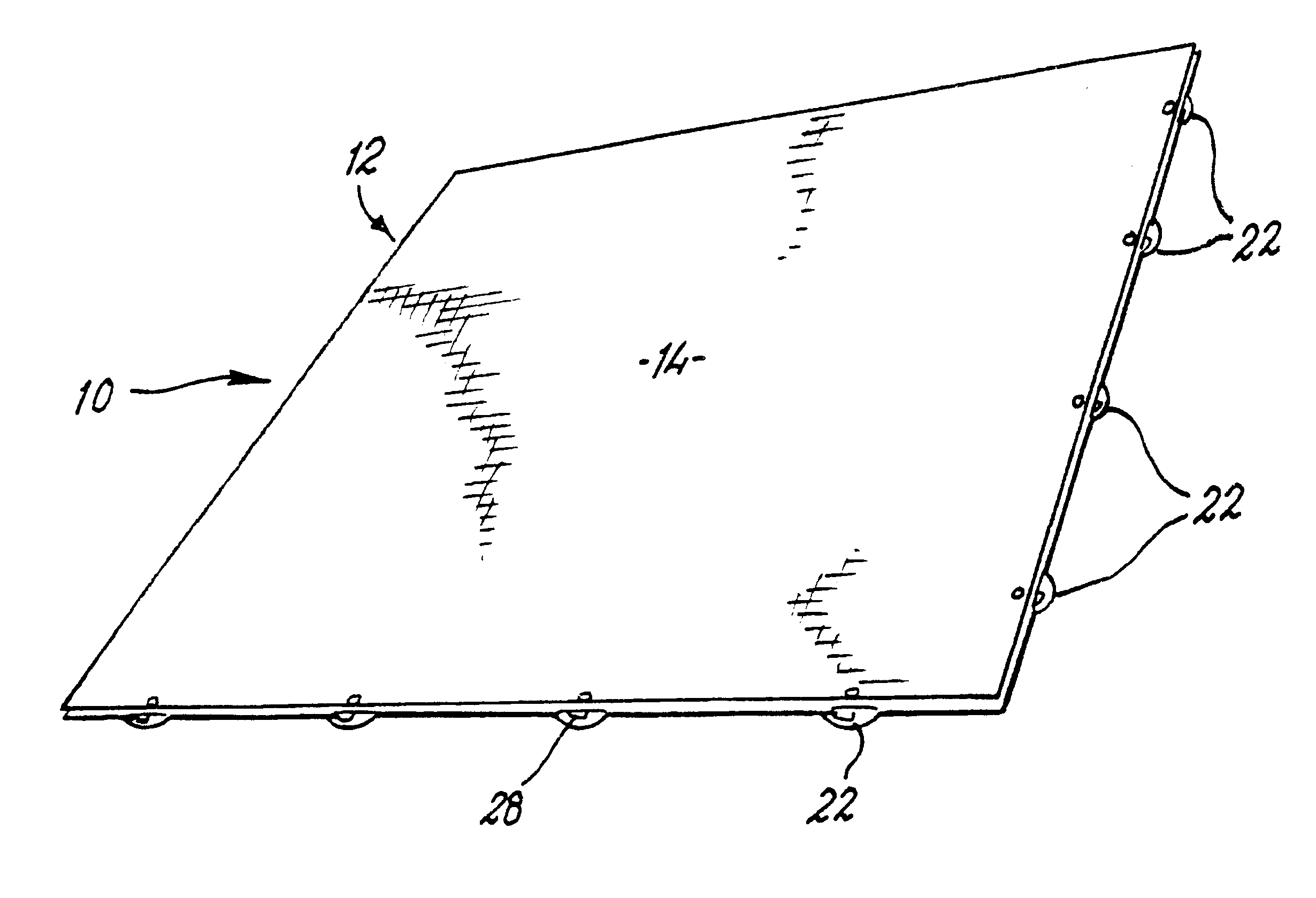

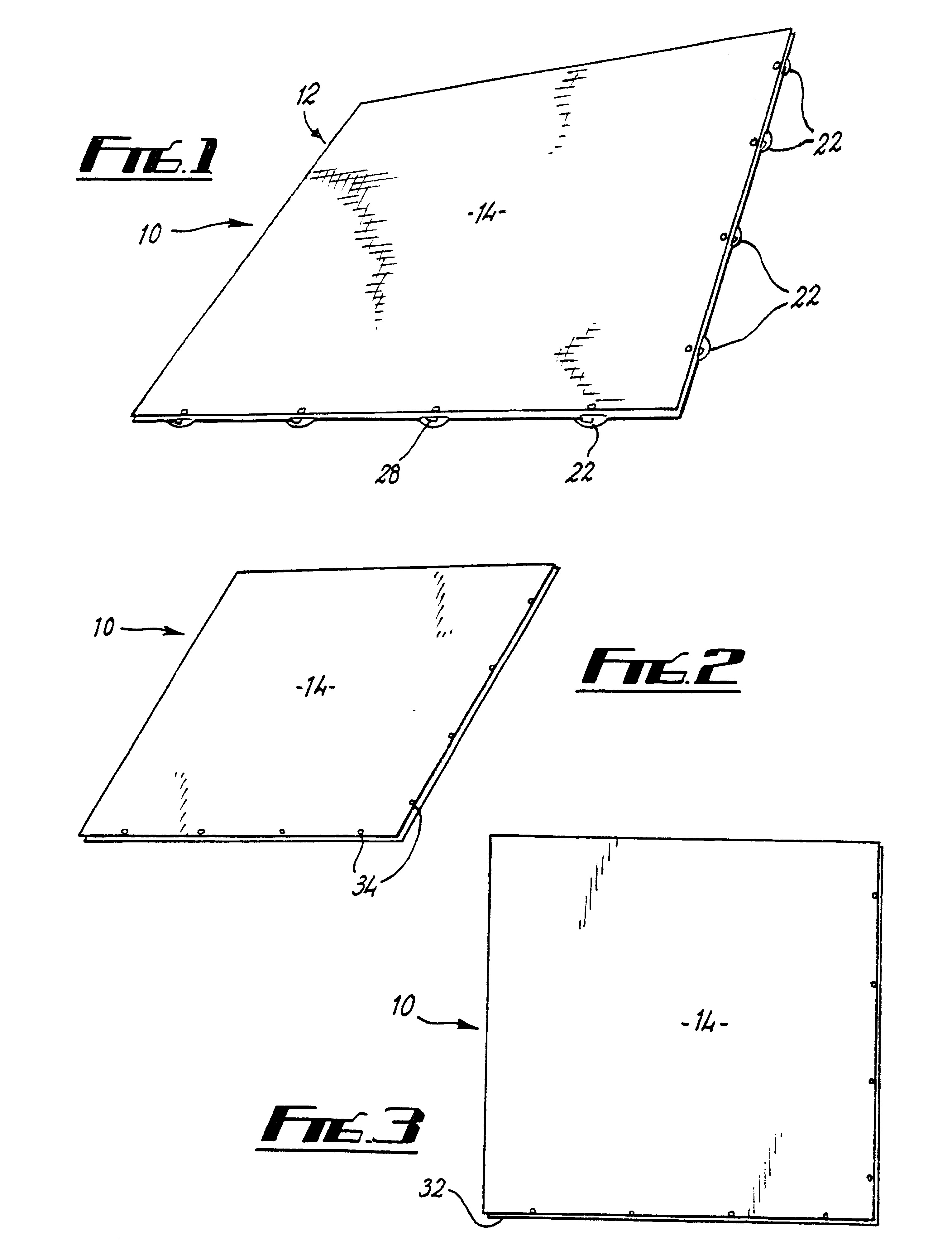

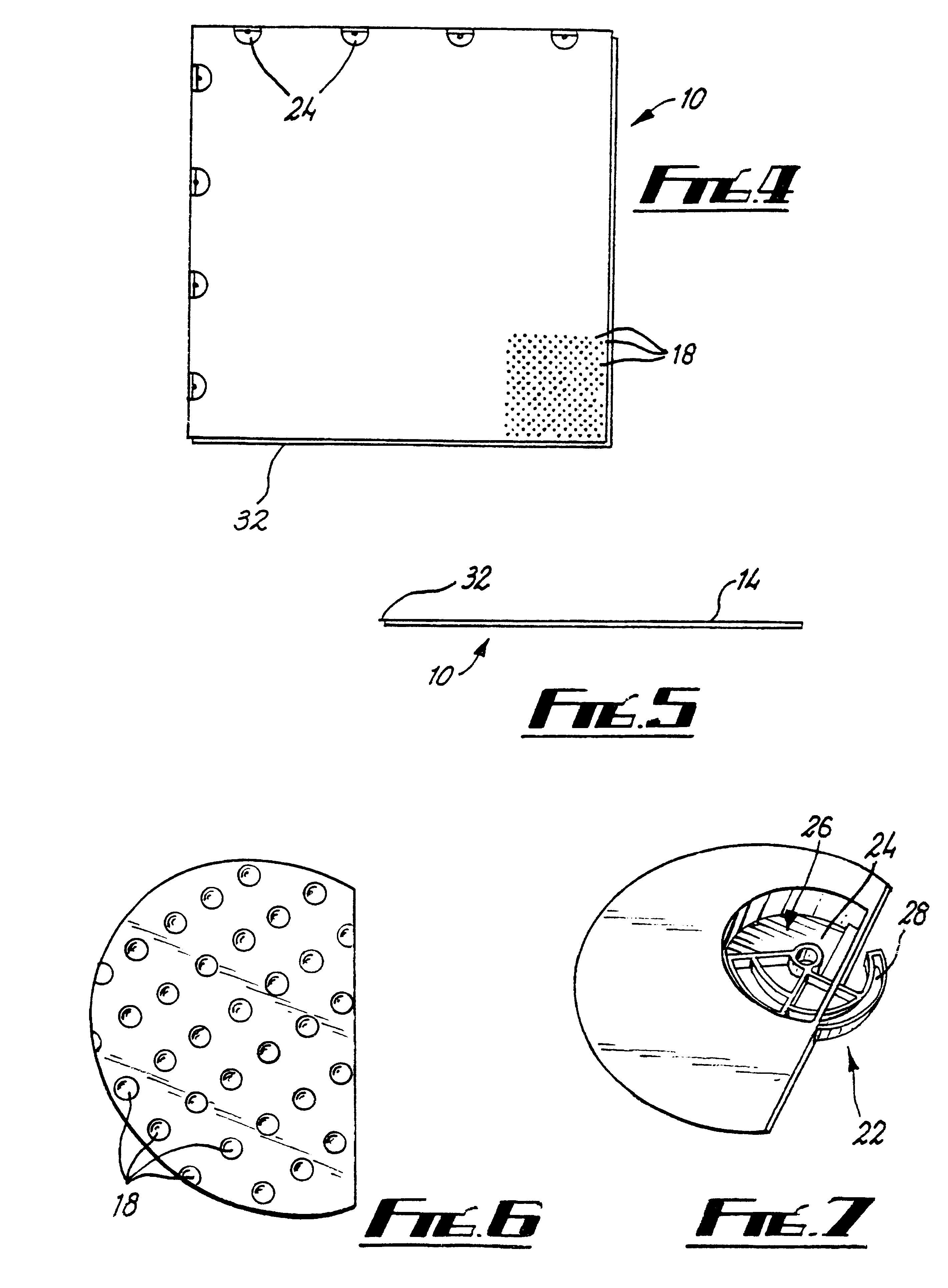

Cover assembly

A cover assembly for temporarily covering areas such as an ice rink, to support people or other items thereon. The assembly comprises a number of components (10) which can be engaged with other such components (10) placed adjacent thereto-on the surface to be covered. The components include upper and lower parts (12, 16) with a gap (20) being provided between such parts to provide insulation from the underlying area. Adjacent components (10) are retained together by locking means (22) which are provided on two adjacent sides of each component (10). and are selectively engageable in recesses (32) on adjacent components (10).

Owner:LINEBACKER UK

Gypsum board forming device

A gypsum board forming device having a gypsum forming station including two laterally disposed edger shoes, and at least one laterally disposed edger bar clamping element on the edger bar. In one embodiment a laterally extending forming plate extends over the top surface of the formed gypsum board, the forming plate including a plurality of micropore conduits through which pressurized water is supplied to provide a film of smoothing water over the top surface of the gypsum board. In another embodiment the edger shoes have a flapper mechanism for retaining unset slurry skimmed off the surface of the gypsum board by the edger bar.

Owner:BPB LTD

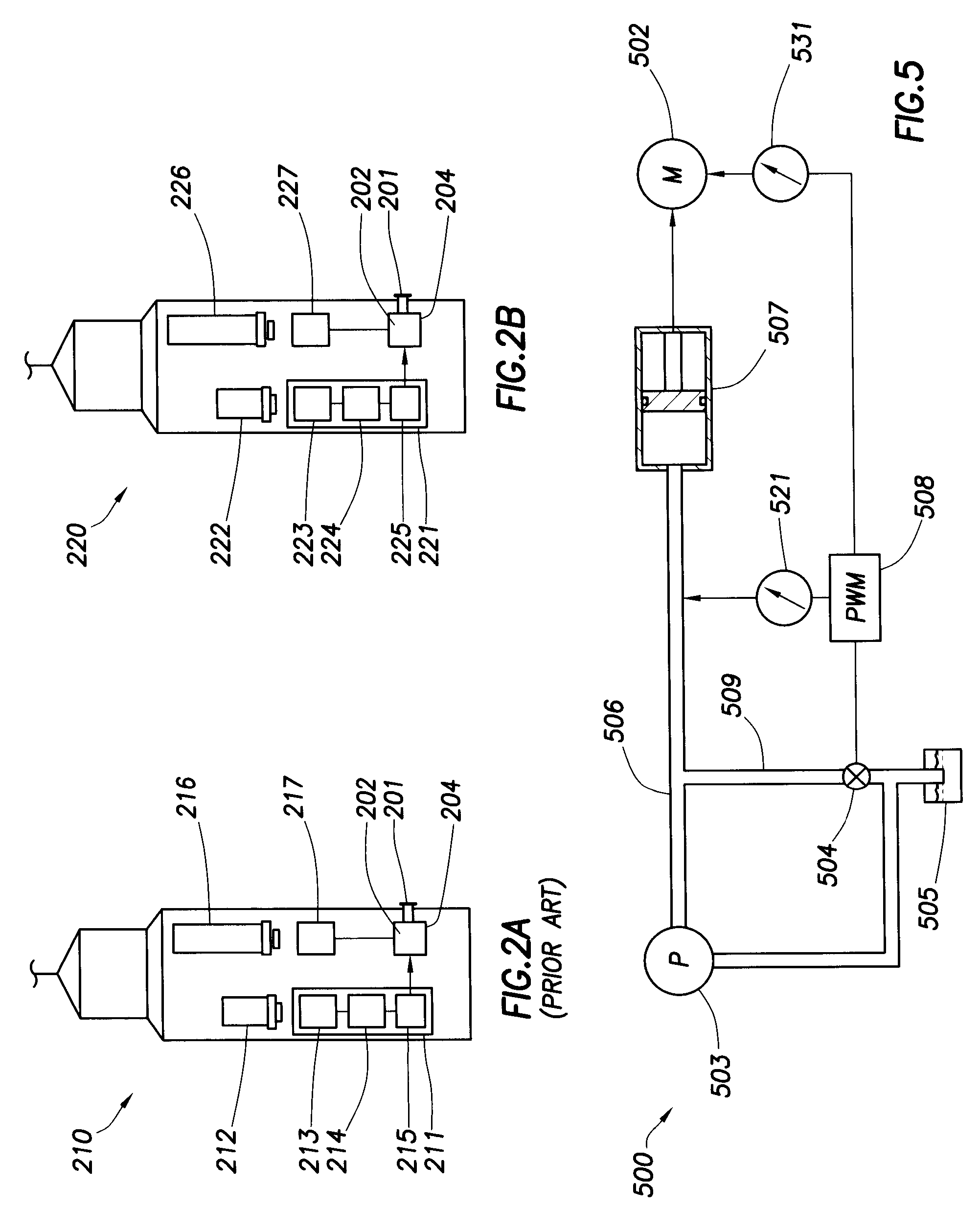

Methods of isolating hydrajet stimulated zones

ActiveUS20050211439A1Shorten cycle timeShorten operation timeFluid removalSealing/packingHigh pressureGeophysics

The present invention is directed to a method of isolating hydrajet stimulated zones from subsequent well operations. The method includes the step of drilling a wellbore into the subterranean formation of interest. Next, the wellbore may or may not be cased depending upon a number of factors including the nature and structure of the subterranean formation. Next, the casing, if one is installed, and wellbore are perforated using a high pressure fluid being ejected from a hydrajetting tool. A first zone of the subterranean formation is then fractured and stimulated. Next, the first zone is temporarily plugged or partially sealed by installing an isolation fluid into the wellbore adjacent to the one or more fractures and / or in the openings thereof, so that subsequent zones can be fractured and additional well operations can be performed.

Owner:HALLIBURTON ENERGY SERVICES INC

Solid-filling coal mining method with two pre-excavating tunnels for advancing

ActiveCN102996131ASolve the technical problems that cannot guarantee the filling effectEasy to useUnderground miningSurface miningFilling materialsMining engineering

The invention discloses a solid-filling coal mining method with two pre-excavating tunnels for advancing. A mining roadway adopts an arrangement mode that the pre-excavating tunnels are taken as air return and inlet roadways and a gob-side entry retaining roadway is taken as a roadway for transporting filling materials and coal; coal extraction and gob backfilling are carried out by a comprehensive mechanical solid-filling coal mining process; and according to the coal mining method, a mining sequence is propelled by making a filling coal mining work surface be back to the direction for transporting the coal to a mountain in a mining area. The pre-excavating tunnels are formed before the extraction of the work surface by tunneling, and the gob-side entry retaining roadway is formed by optimally designed filling bodies beside the roadway along with the implementation of advancing filling coal mining operation along the work surface. The coal mining method is simple in process and technically and completely realizes coal milling without pillars, and the resource extraction rate of the coal is high. The coal mining method can not only solve the technical problems that a draw-back-type down-mining and up-filling work surface cannot ensure a filling effect during a filling milling process of a mine with shortage of resources, but also materialize the comprehensive mechanical solid-filling coal mining of mines with limited geological conditions by virtue of an advancing up-milling and down-filling work surface.

Owner:CHINA UNIV OF MINING & TECH

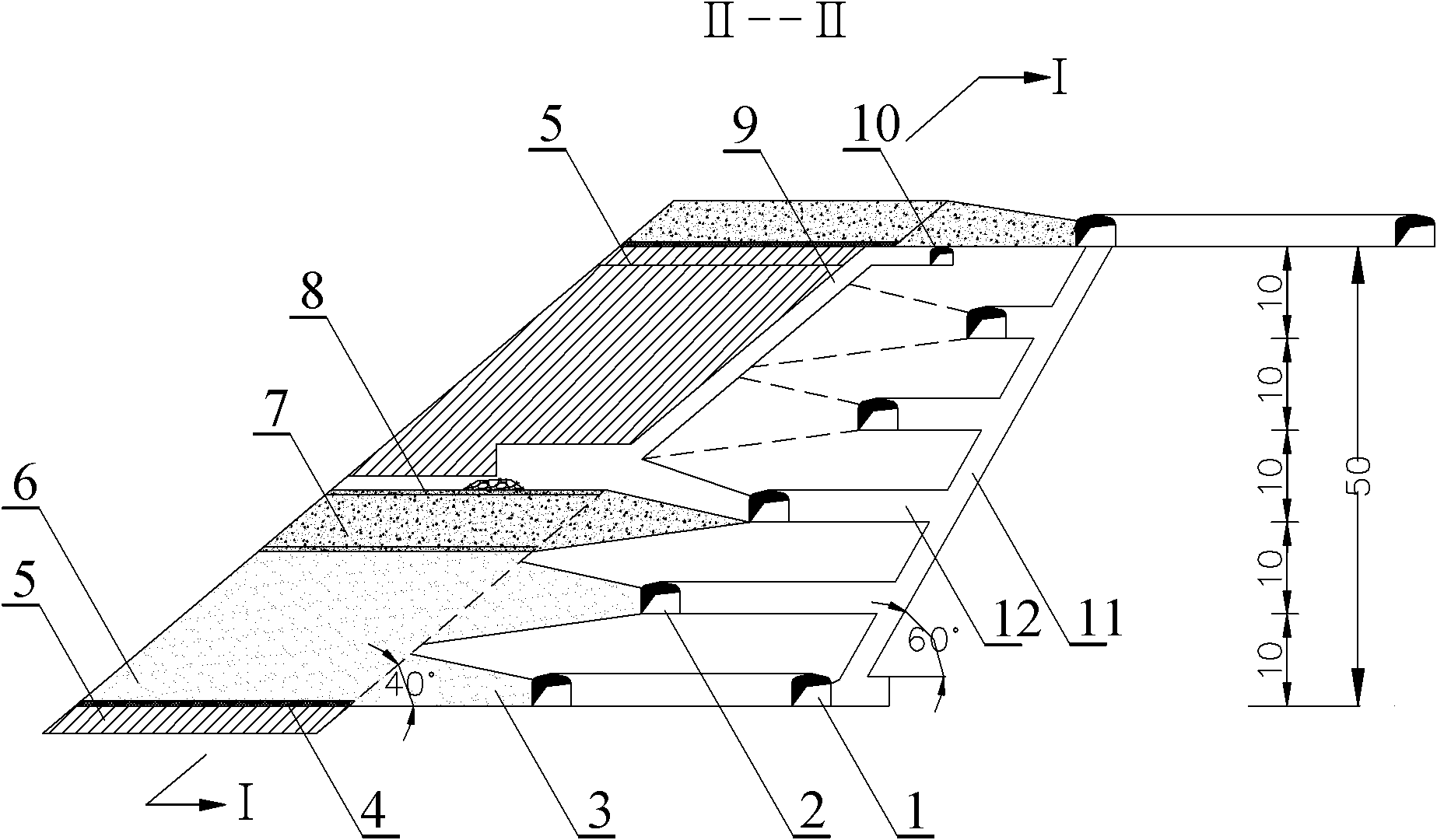

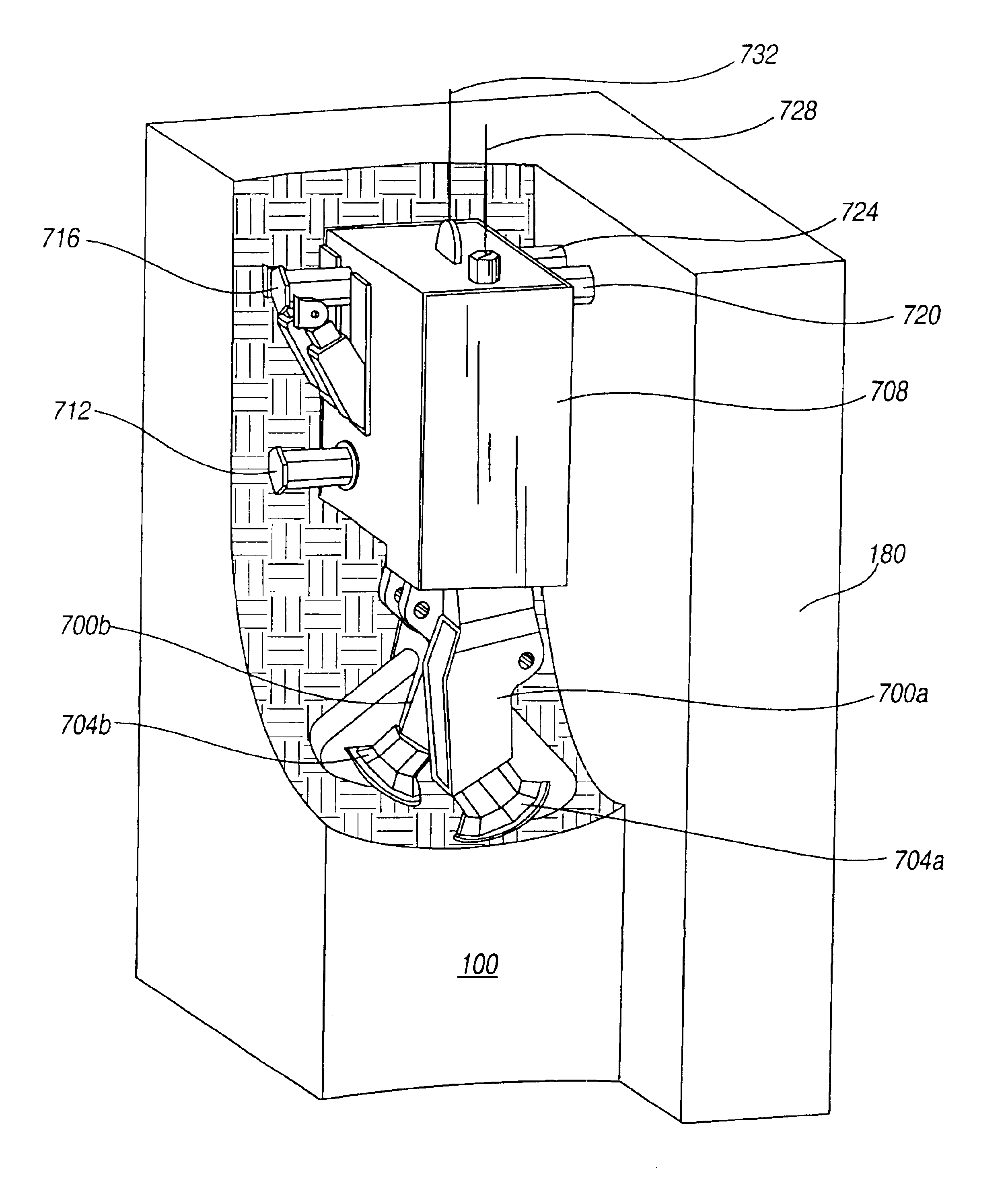

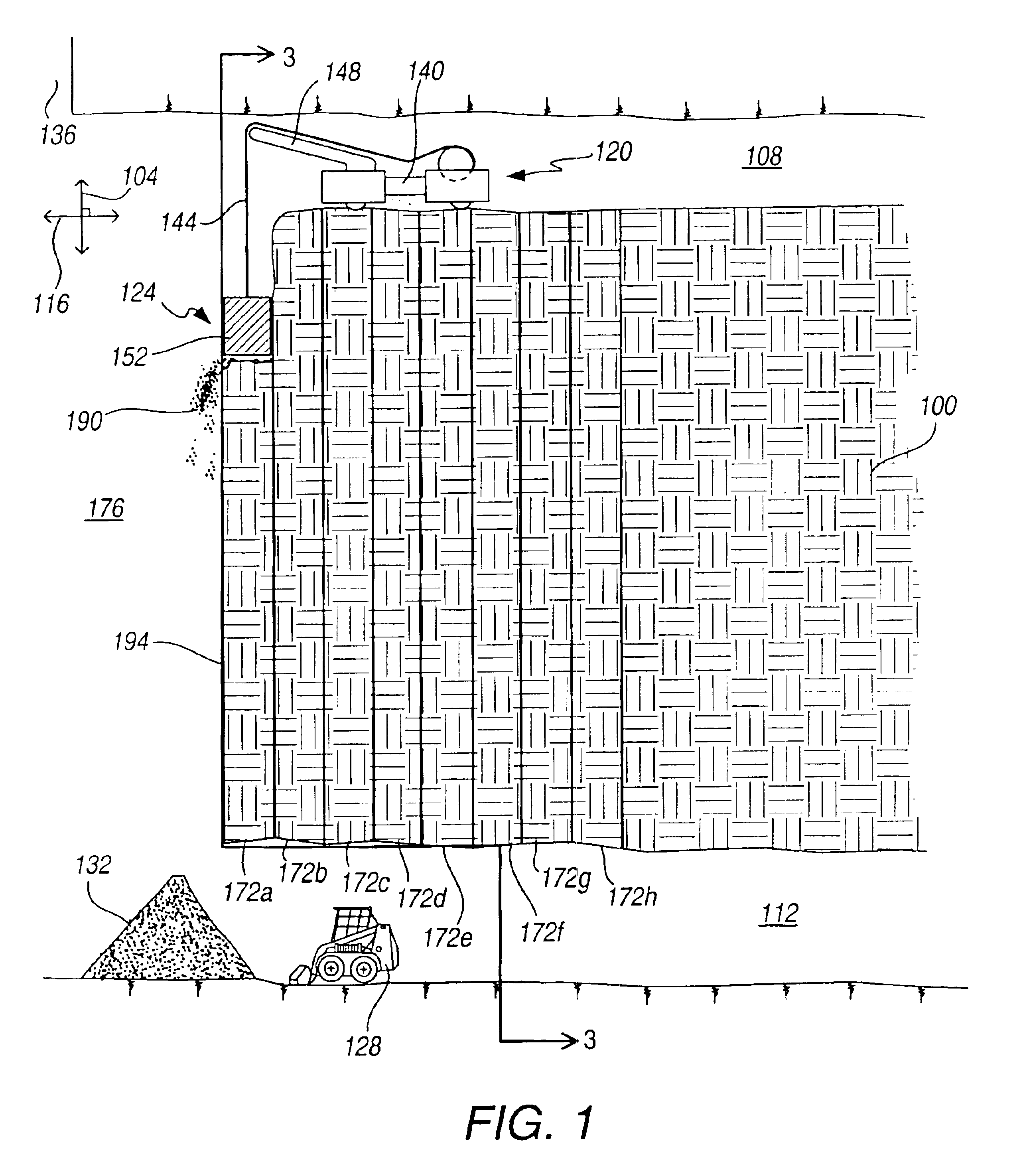

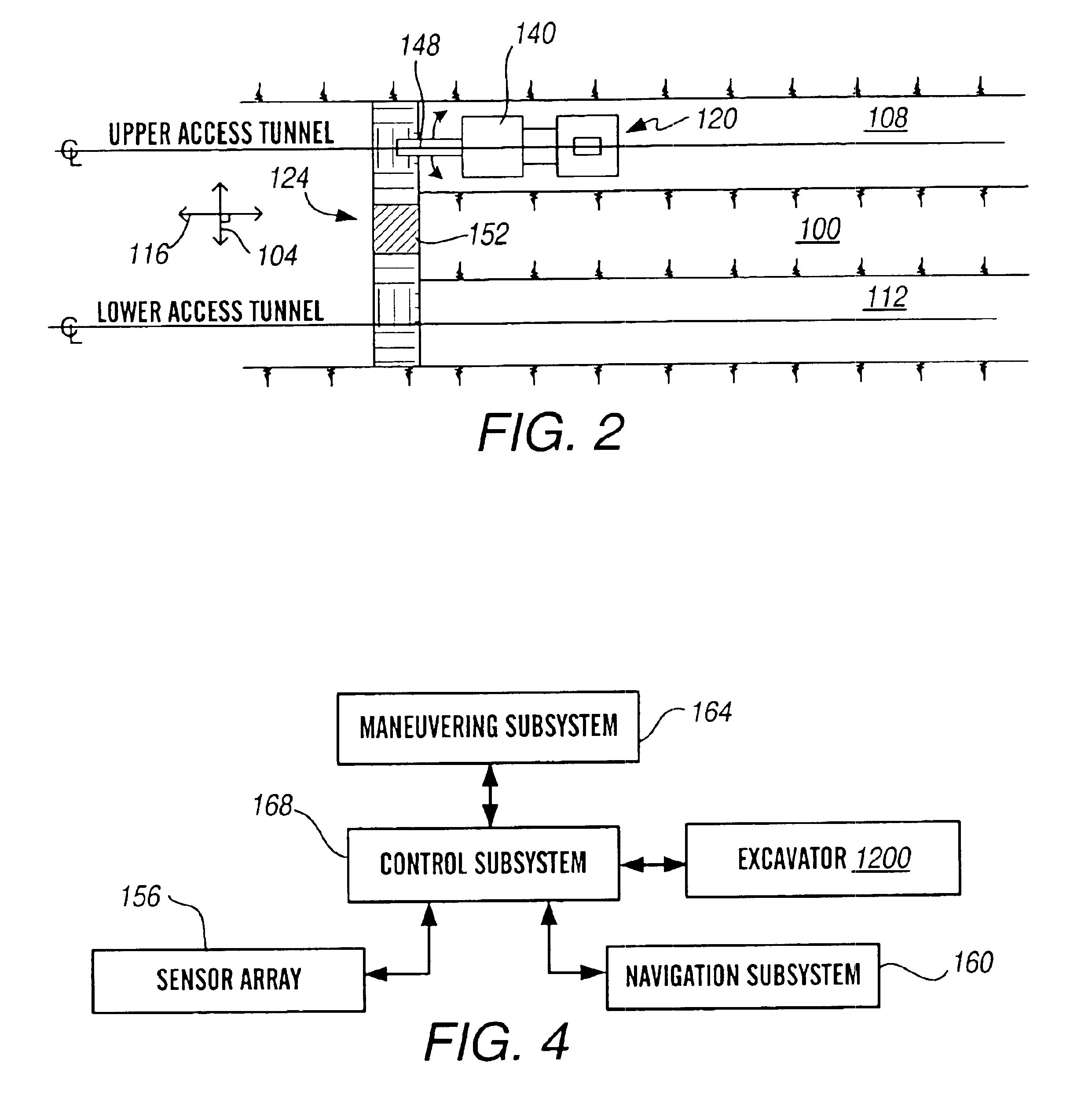

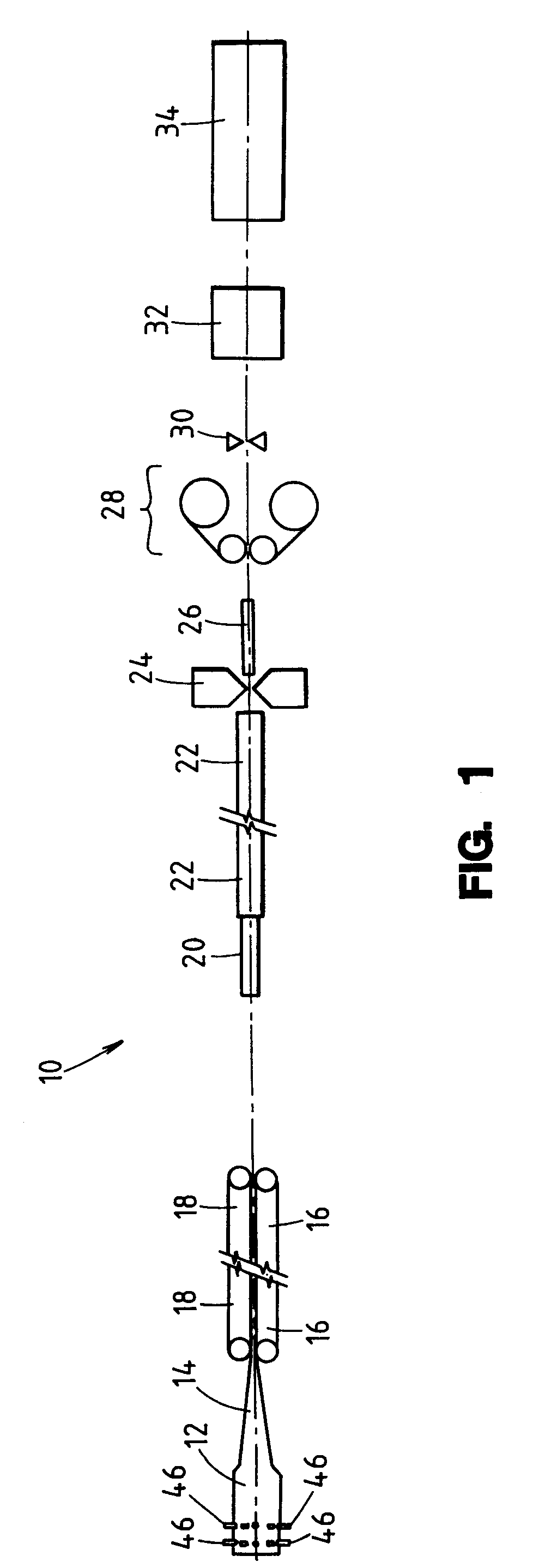

Mining method for steeply dipping ore bodies

InactiveUS6857706B2Efficiently and effectivelyAvoid a lotDisloding machinesUnderground miningEngineeringExcavator

The present invention is directed to a mining method for steeply dipping orebodies. In the method, an excavator 152 is tethered to a deployment system 120 by one or more cables / umbilicals 144. The excavator 152 excavates slices 172a-h of the orebody 100 by moving generally up-dip, down-dip or a combination thereof. The excavator can be automated.

Owner:MIN OF NATURAL RESOURCES CANADA

High-sublevel subdivision mining method of moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along strike

InactiveCN102418526AAvoid damageIncrease productivityUnderground miningSurface miningMining engineeringSlag

The invention discloses a high-sublevel subdivision mining method of a moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along a strike. The high-sublevel subdivision mining method comprises four steps of exploiting, mining preparation, cutting and recovery, wherein a footwall intermediate-section main roadway is respectively arranged on a high sublevel along a top plate and a bottom plate of the orebody, and the intermediate-section main roadways of the top plate and the bottom plate are connected through a communication channel at intervals of 100m, therefore reduced roadway cutting construction, small development rate and simple process are achieved; after overall blasting of a stope is finished, a large amount of concentrated ore drawing is carried out, and the production efficiency is high; tail sand is adhered and filled after space pillars are mined first, then rooms are evacuated, and the rooms are filled with waste rocks or tail sand in a non-adhering way, thus recovery rate is high; and the high-sublevel subdivision mining method has little damage to the environment and capabilities of changing oredressing tail sand and waste rocks generated in open-air production into valuables and reducing geological disaster from happening. Due to the adoption of the high-sublevel subdivision mining method disclosed by the invention, ore recovery rate can be increased, ore dilution rate and emission of mine wastes are reduced, capacity of slag disposal pit is relatively increased, expropriation of land is decreased, and mineral land harmony is promoted.

Owner:WENGFU (GRP) CO LTD

Method for designing and optimizing drilling and completion operations in hydrocarbon reservoirs

Owner:SCHLUMBERGER TECH CORP

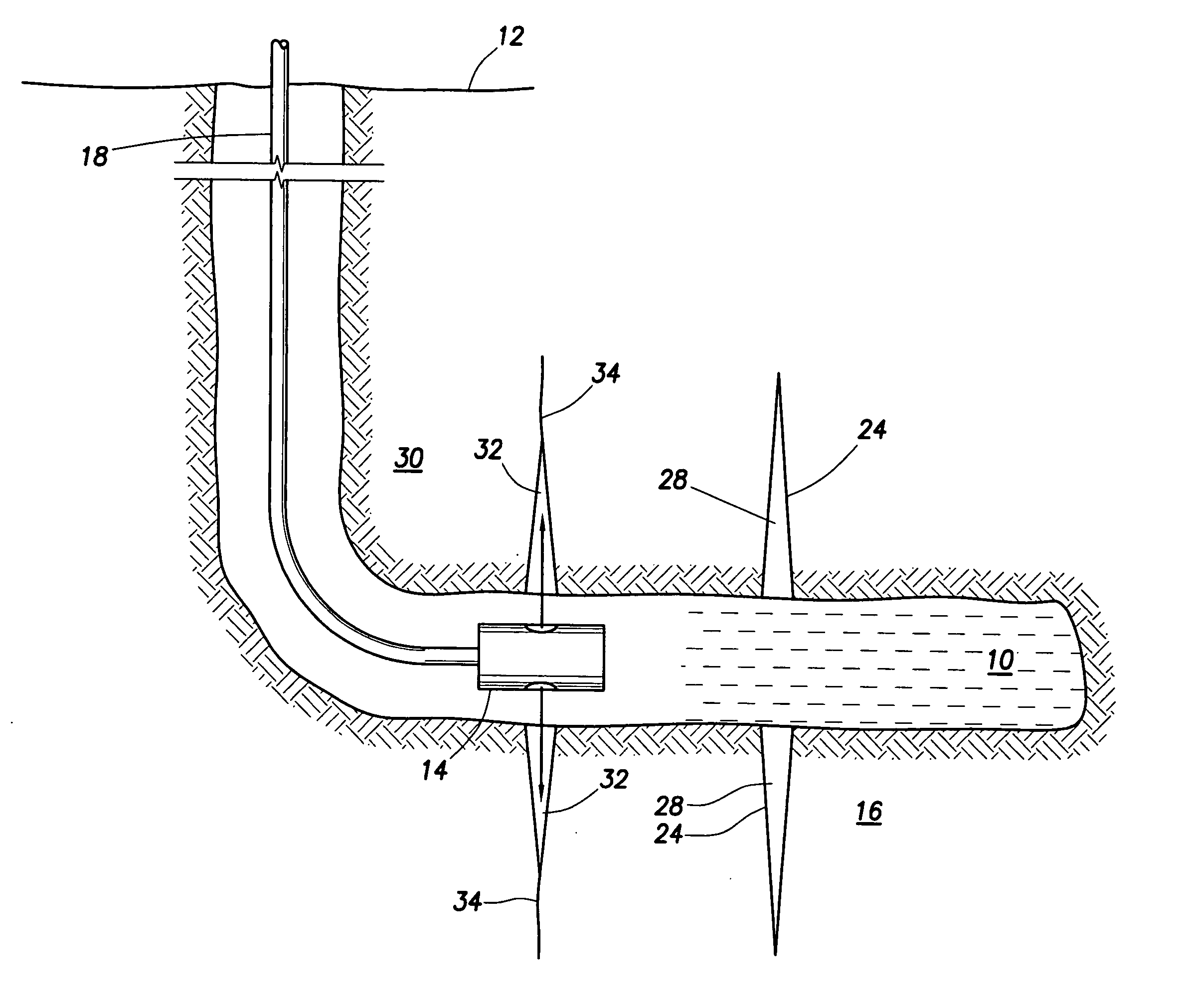

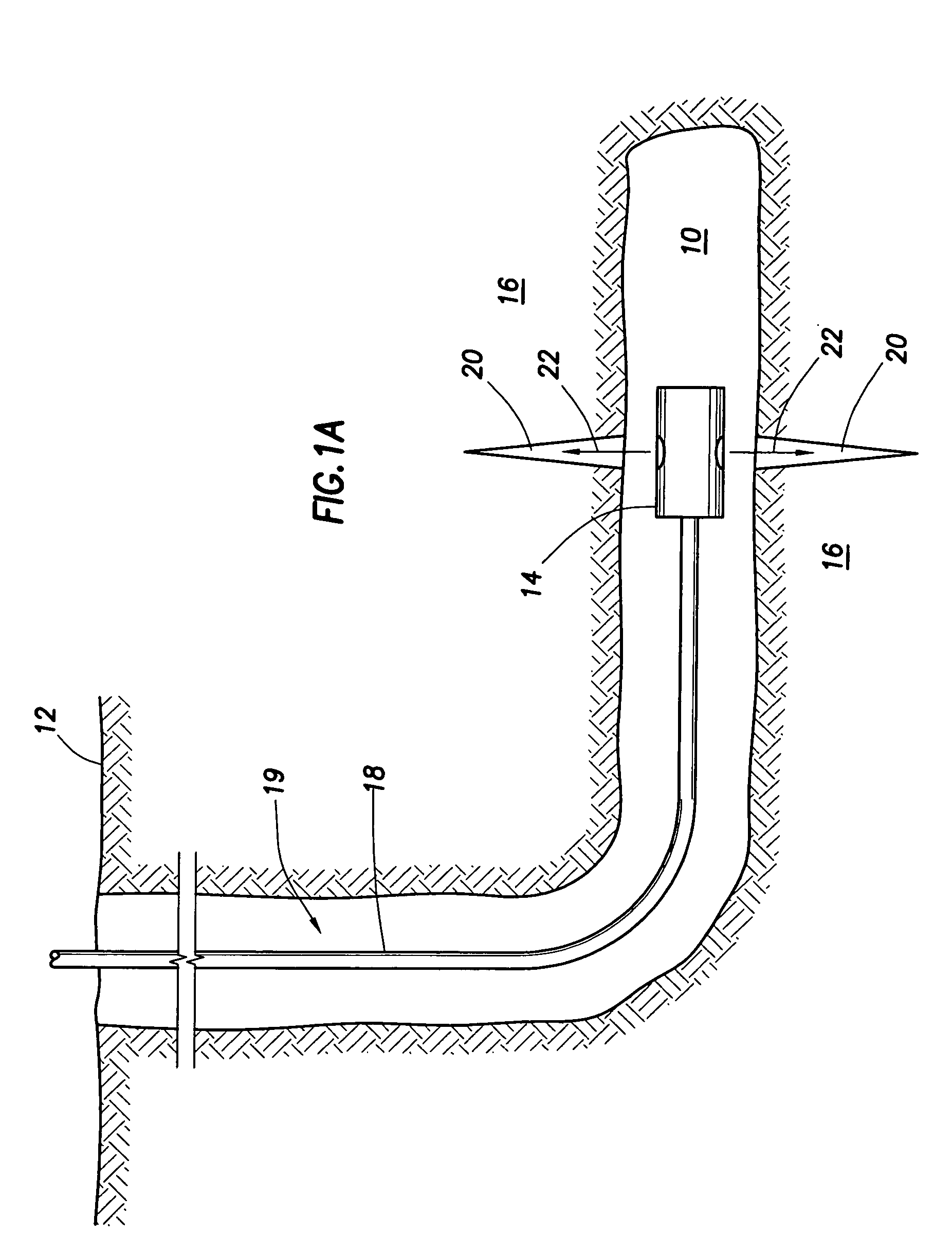

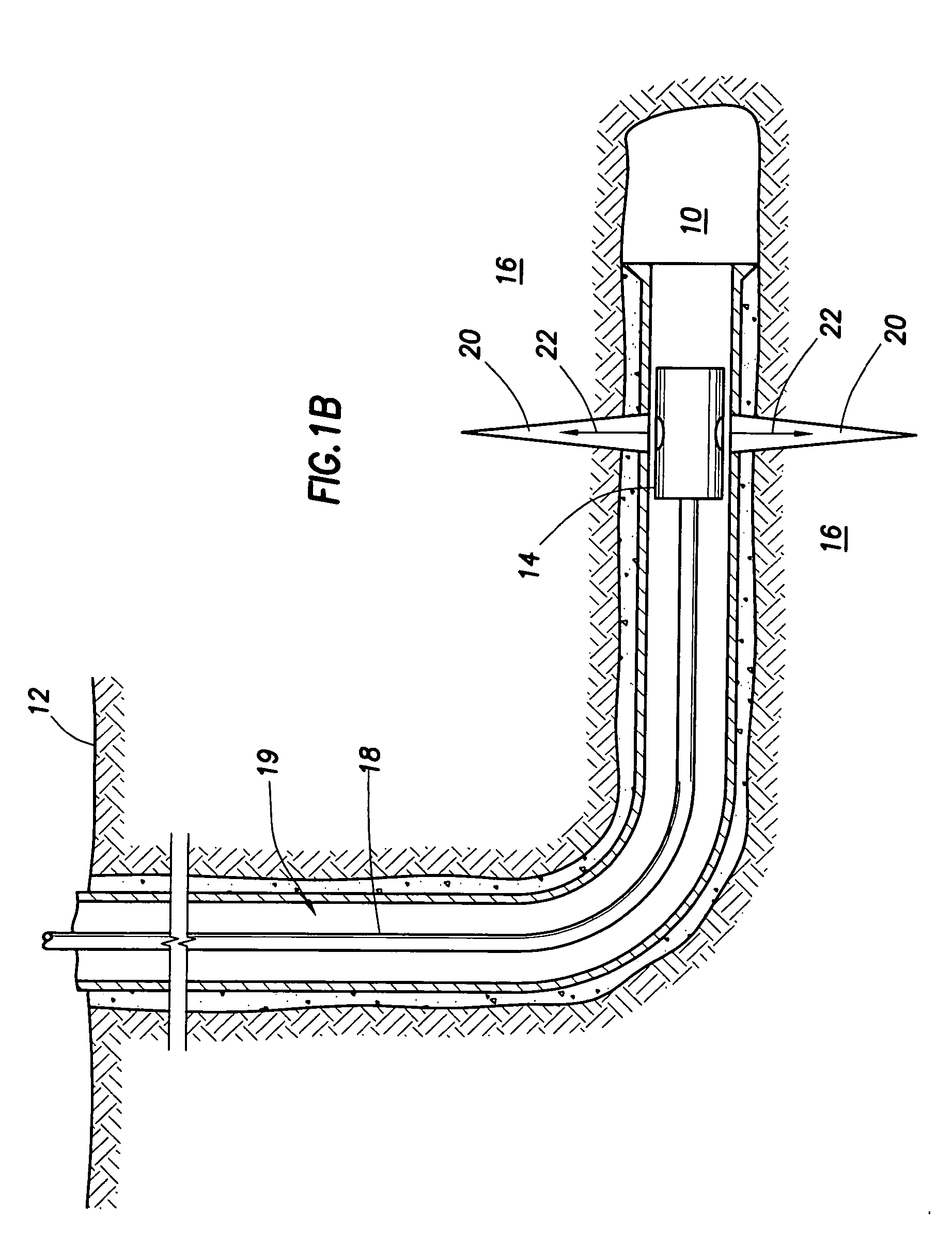

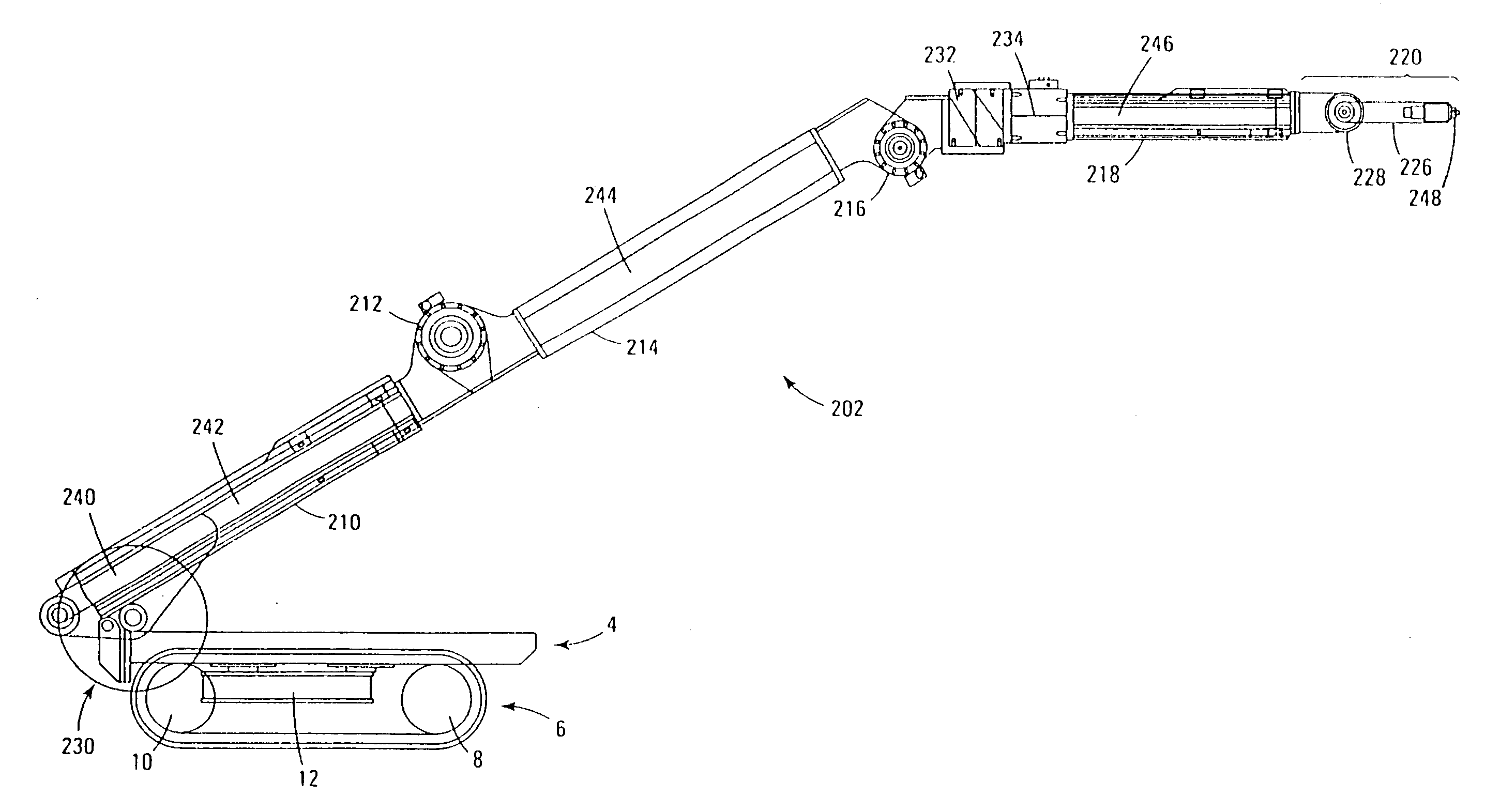

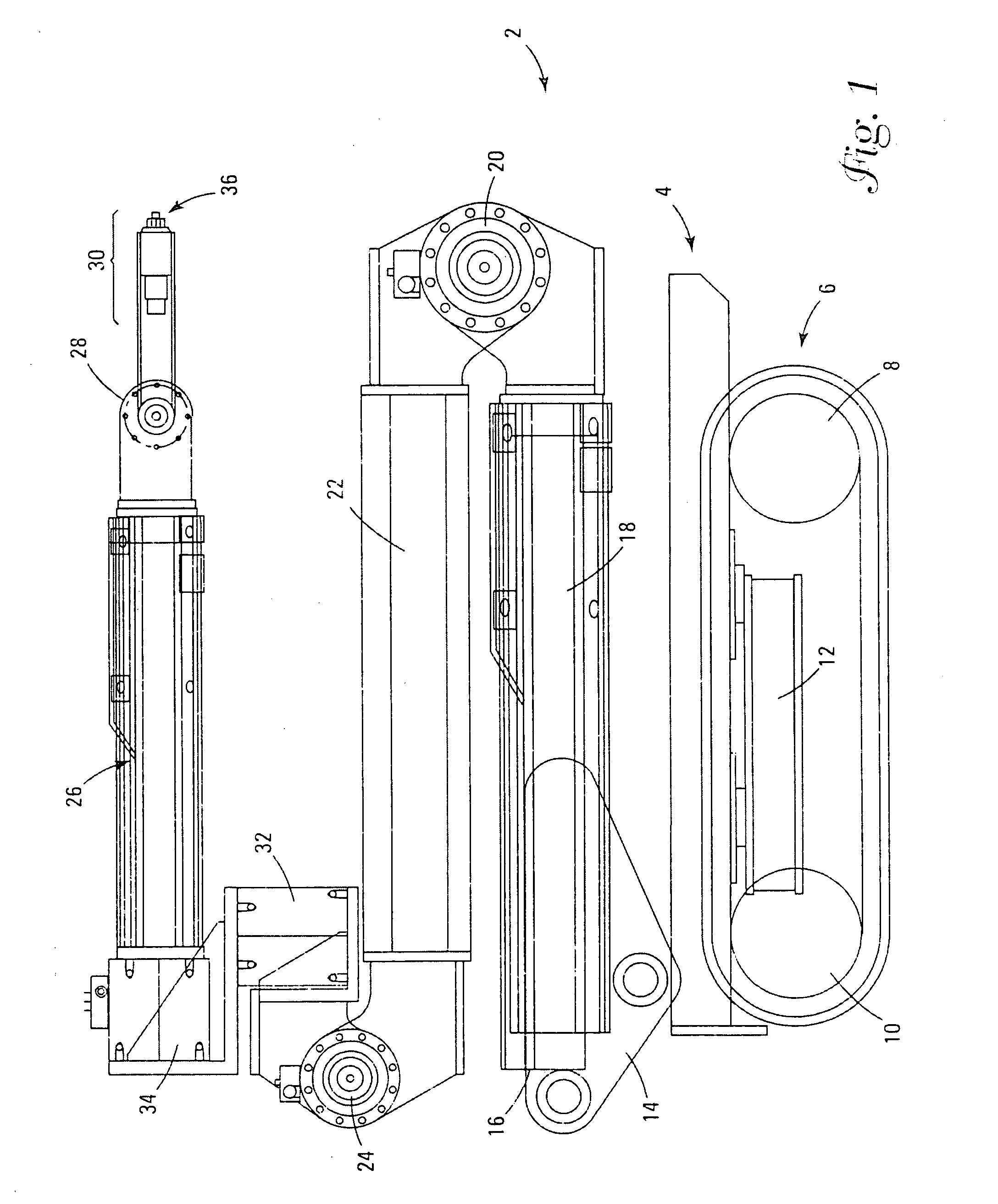

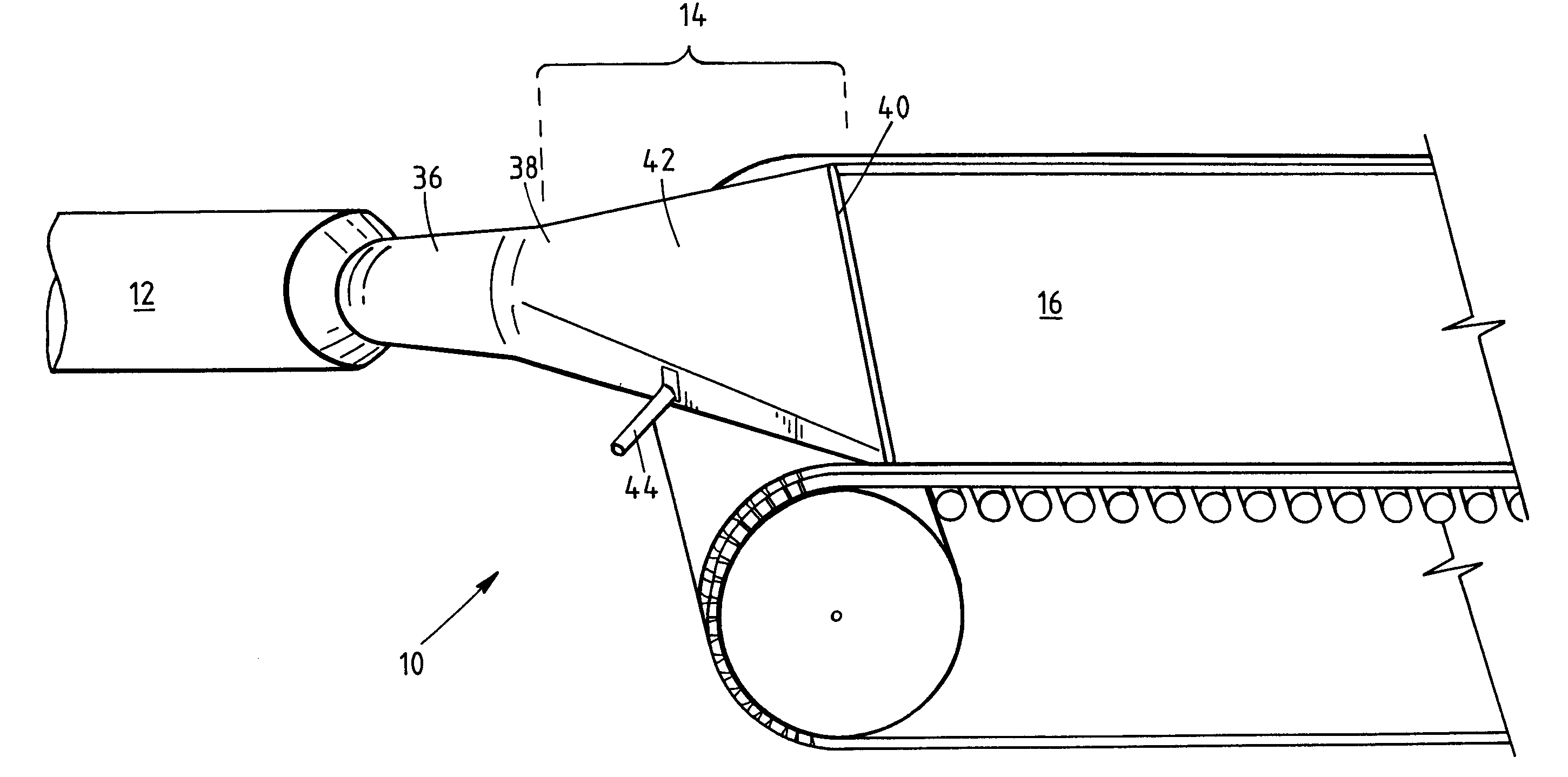

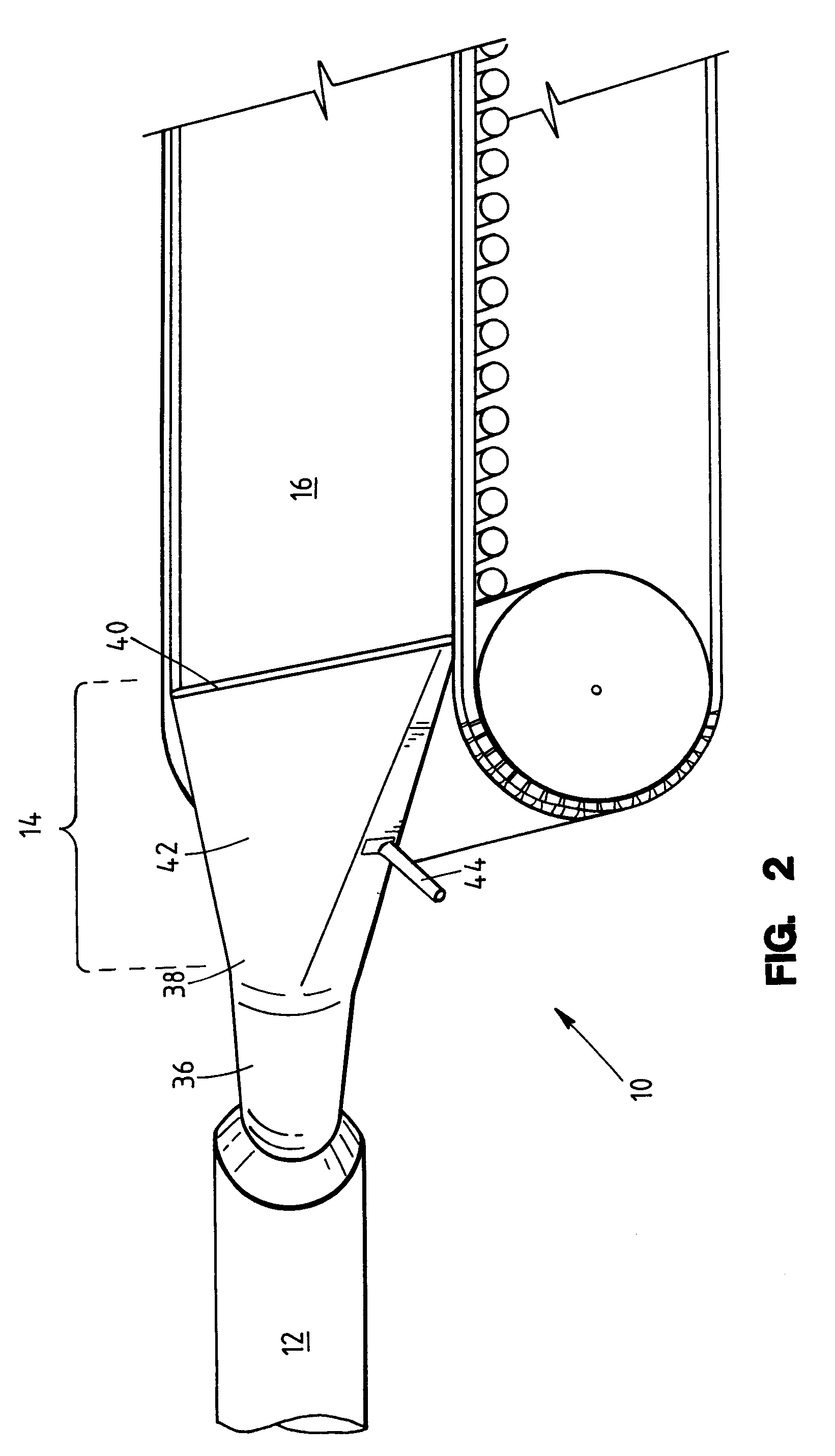

On-site land mine removal system

InactiveUS20090223355A1Reduced effectivenessReduce eliminateDefensive equipmentDefence devicesLiquid jetDetonation

A method of deactivating land mines buried in ground comprises projecting high-pressure water jets into ground, cutting through ground with the high-pressure water jets, and making at least one cut through a land mine or cutting through at least one land mine that had been under the ground, the cutting of the land mine reducing the performance of the land mine. The method may reduce the performance of the land mine by rendering the land mine inactive to normal detonation procedures for the land mine. To reach as many surface areas on the buried landmines, it is preferable that at least two high-pressure water jets are spaced apart are used to cut through the ground. The method may be practiced with the high-pressure water jet being carried on a vehicle and cutting is done in a line that is formed at least in part by movement of the vehicle over the ground while the high-pressure water jet is cutting ground. An apparatus for the reduction in effectiveness of land mines buried in ground may comprise a self-contained push-cart unit or a unit attached or attachable to a vehicle. A complete system could comprise a vehicle having a source of liquid, a high-pressure pump to move the liquid under high pressure, a nozzle directing a liquid jet path for the liquid, a support for the nozzle, abrasive delivery system, and nozzle being controllable to direct the liquid towards the ground while the nozzle is fixed relative to the vehicle.

Owner:MANDERS STEPHEN M

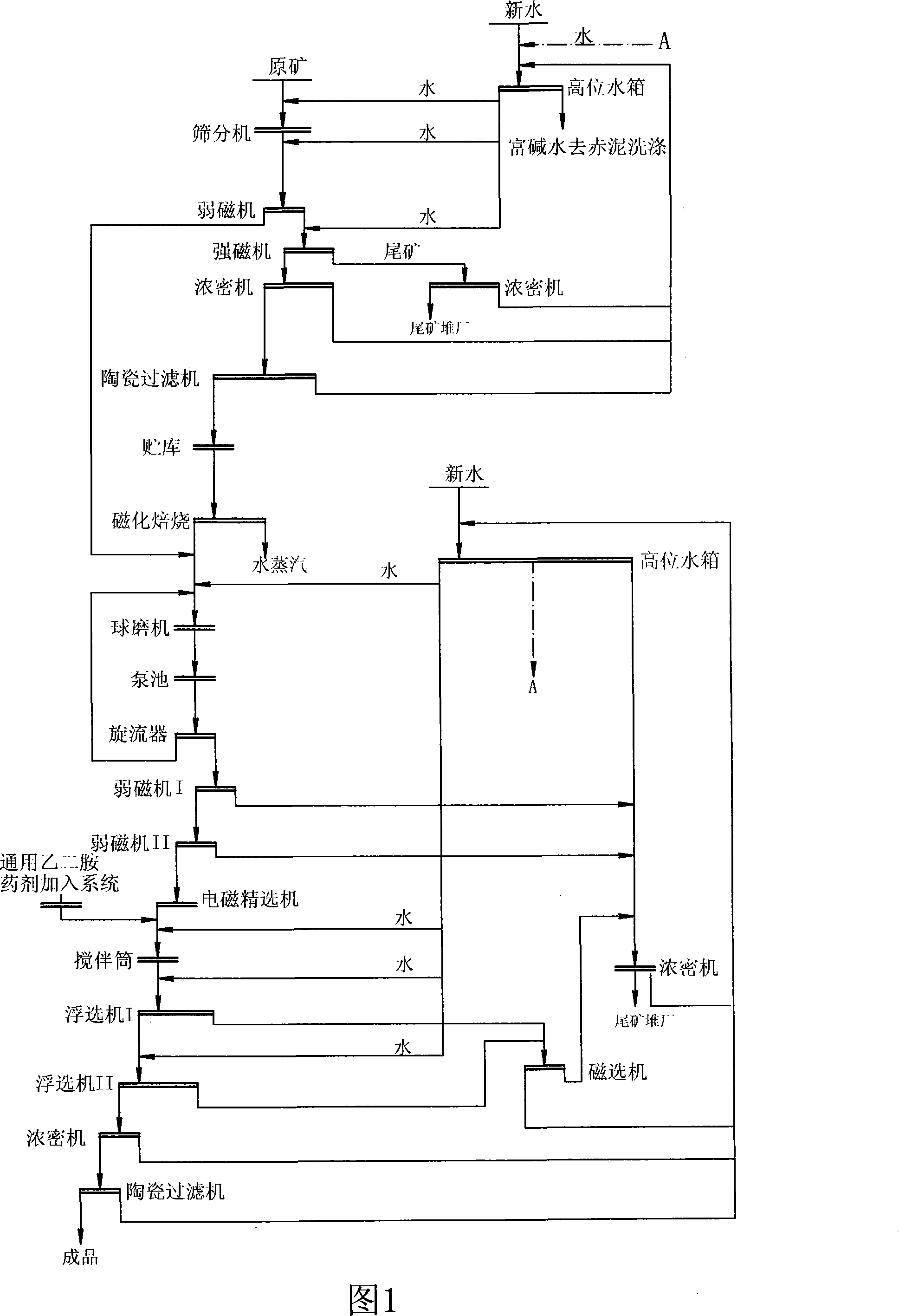

Method of refining iron ore from alkaline red mud and making gangue neutral

The invention relates to a method to select refined iron ore from alkaline red mud and neutralize mine tailings. The method consists of red mud pretreatment and technological process of preparing refined iron ore. The red mud pretreatment is that water is added into the red mud slurry discharged from aluminum factory; the red mud slurry is diluted to the solid concentration of 30 to 40 percent and then is screened and put into a low intensity magnetic separator for selecting ferromagnetic substance. The ferromagnetic substance is dehydrated and directly selected as the product. The remaining red mud is watered down to 30 percent solid concentration and put into a high intensity magnetic separator for magnetic separation and desliming. The obtained coarse ore is washed to a coarse ore settling tank or a thickener to be concentrated while the undercurrent is sent into a vacuum ceramic filter and a filter cake is roasted in a suspended magnetic roasting furnace. The roasted materials are crushed into a ball mill and then are milled. The water is overflown until 95 percent of the solid material granularities are less than 75m and then is treated by the third stage magnetic separation and the second flotation. The undercurrent is filtered by the ceramic filter, and then the refined iron ore with a purity of 58 to 65 percent is obtained. The refined iron ore is recycled from the red mud by the invention so as to fully employ aluminum ore, save resources and energy consumption and neutralize the whole red mud. The invention reduces environmental pollution and has good economic and social benefits.

Owner:SHENYANG XINBO IND TECH

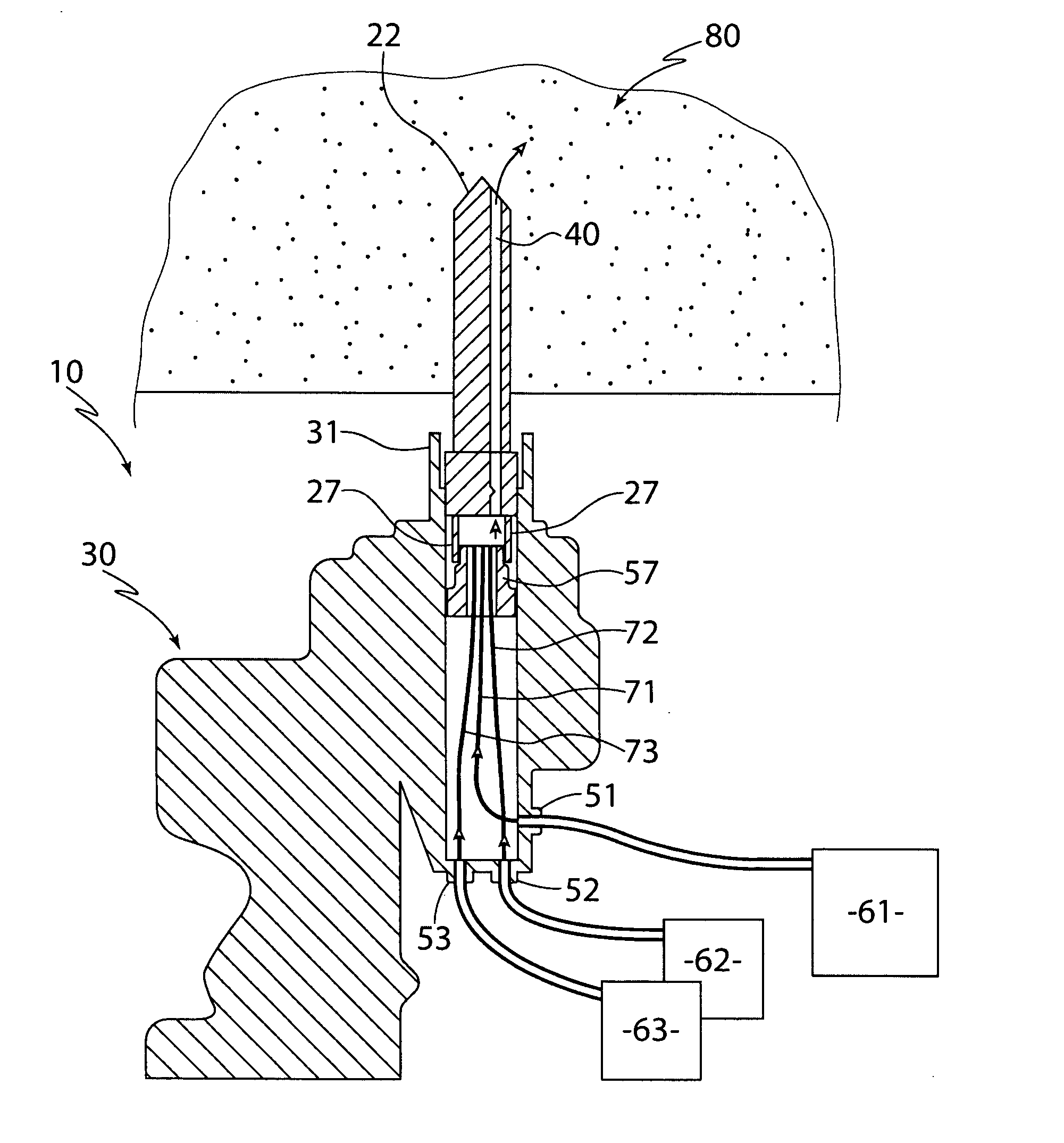

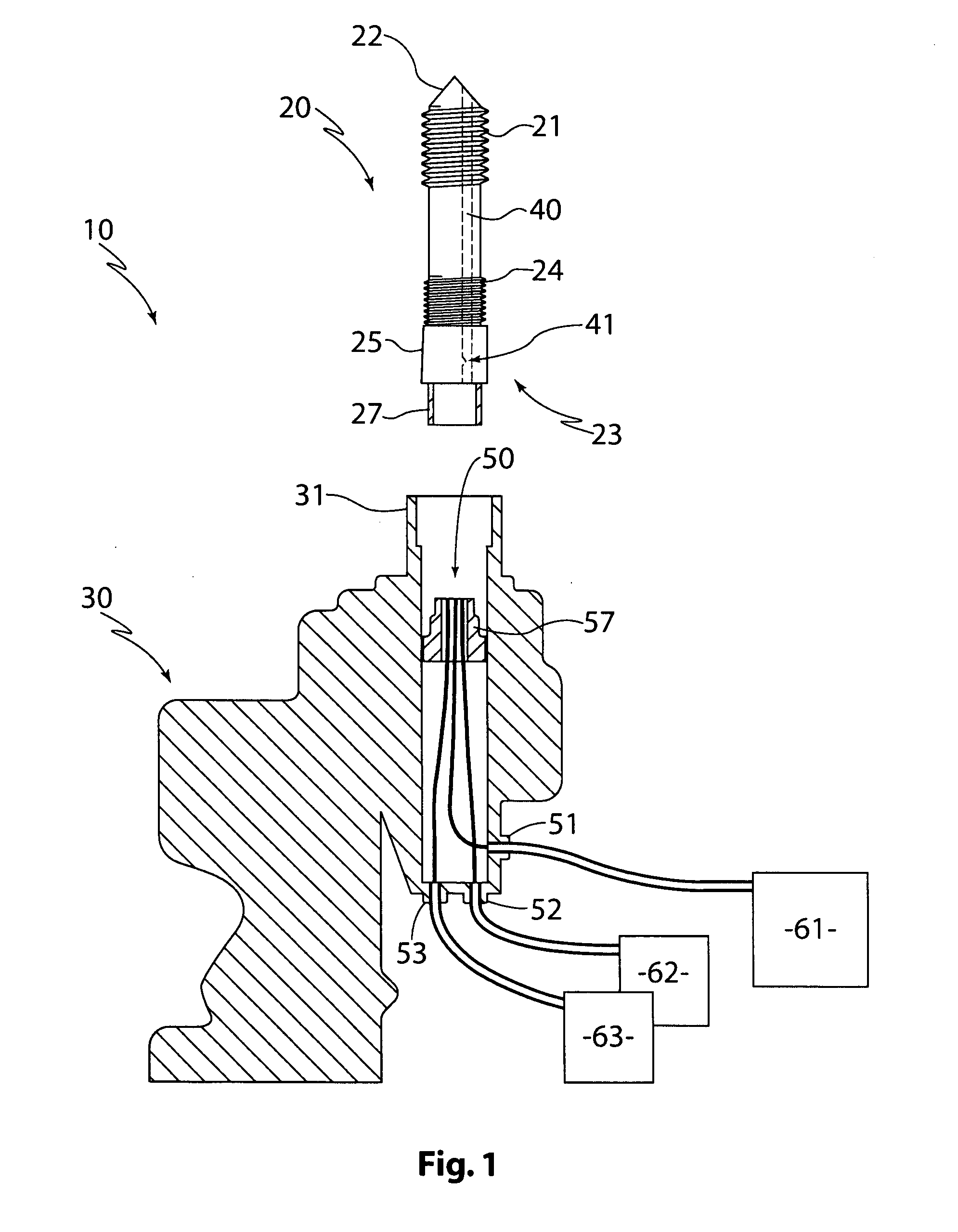

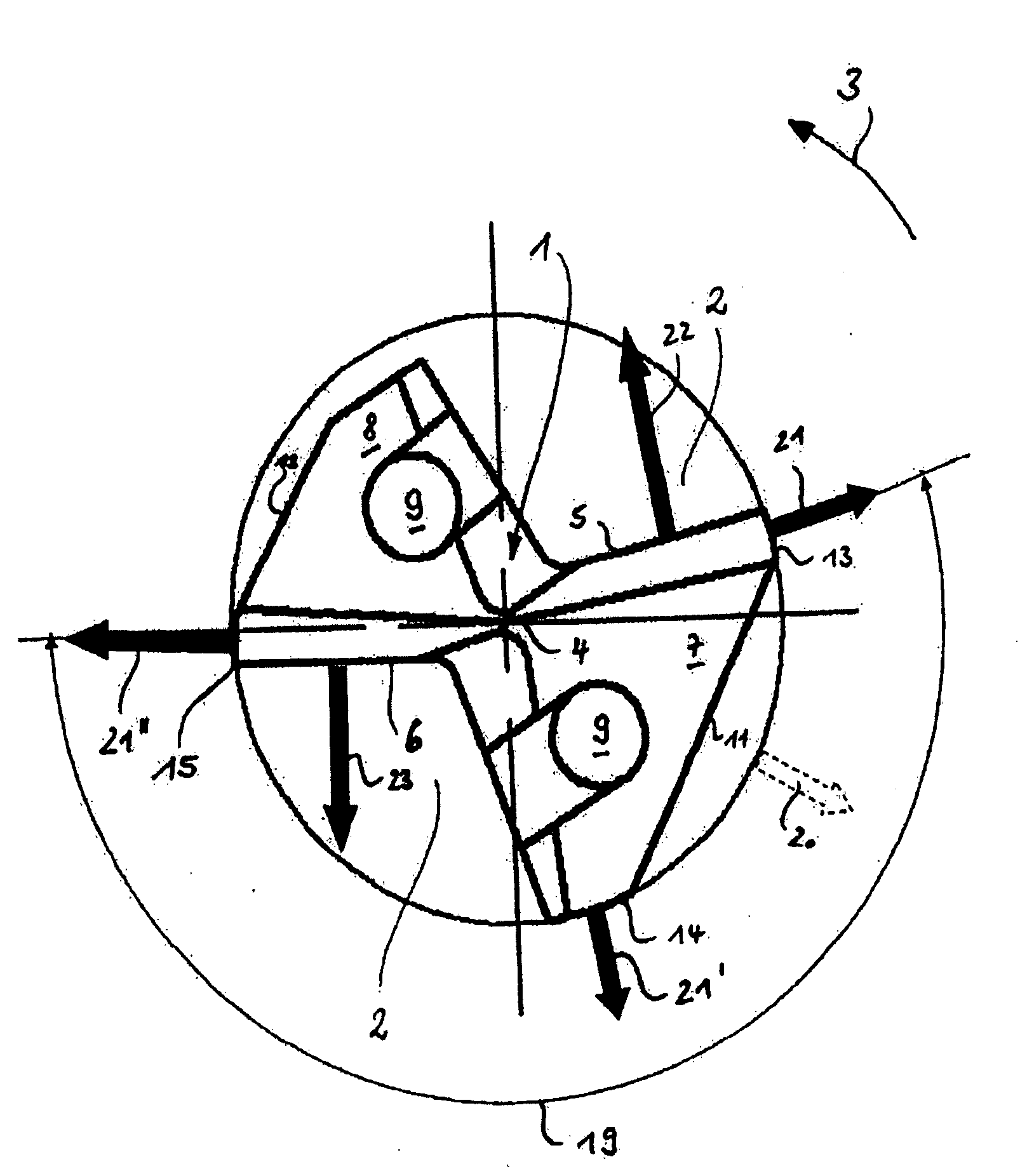

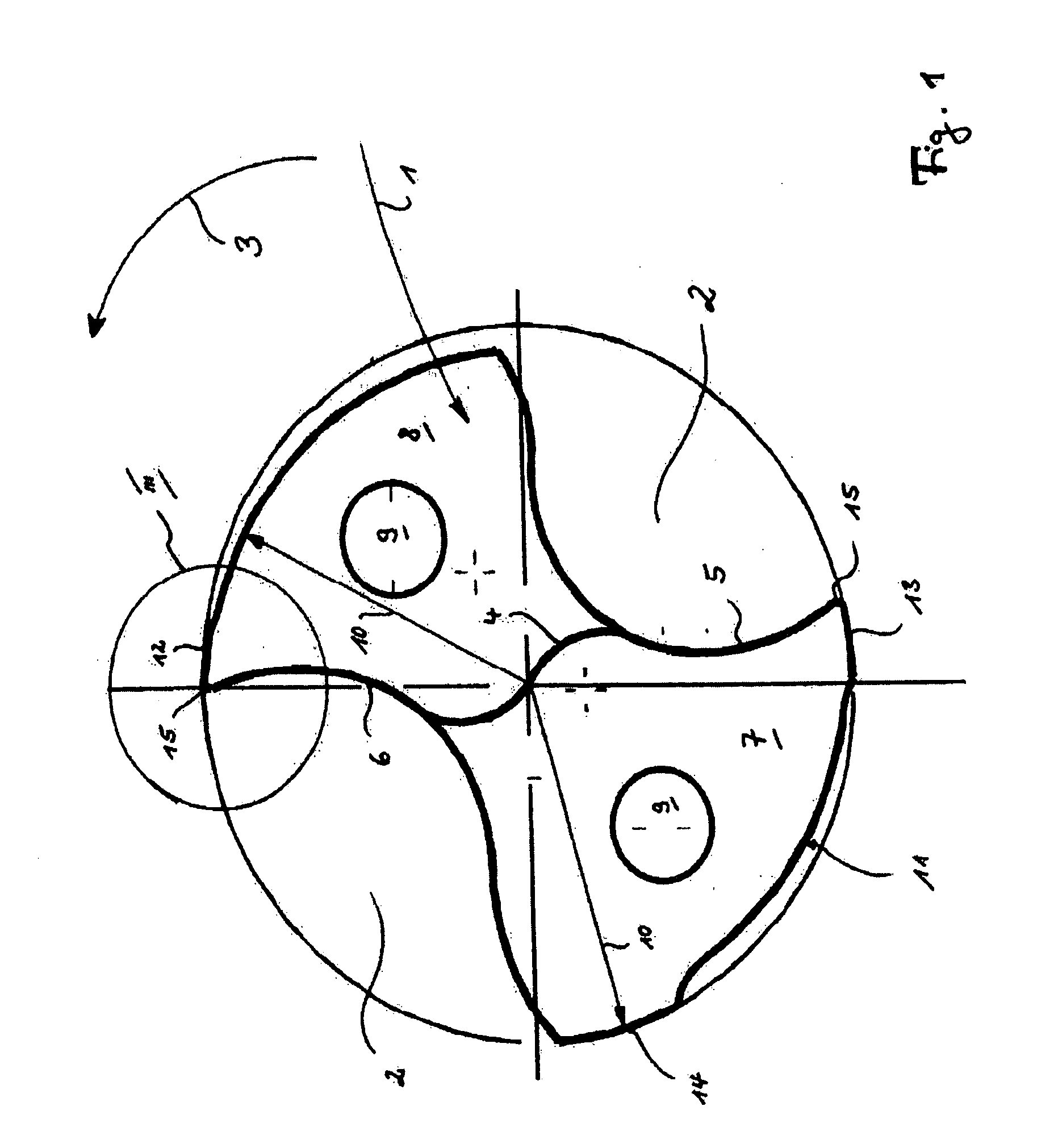

Self drilling rock bolting

The present invention relates to self drilling rock bolting. In particular, the invention concerns both a drilling apparatus for rock bolting, and a rock bolt for use with the drilling apparatus. The drilling apparatus comprises within it a fluid injector having an upper part that mates with a self-drilling rock bolt for boring a hole. The injector includes three fluid inlets, three fluid outlets in the upper part, and three fluid conduits extending from respective inlets to respective outlets. The self drilling rock bolt comprises an elongate body having a leading end with a cutting tip, and around the tip a thread with a coarse pitch. The bolt also has a trailing end with an integral collar for fluid connection to a channel that extends axially through the body of the rock bolt to the leading end. Above the collar is a thread with a fine pitch. In other aspects the invention concerns a system comprising the drilling apparatus in combination with a rock bolt and a method for rock bolting using the system. The invention has application, but not exclusively, to rock bolting to stabilise the roof and walls of underground coal mines.

Owner:ALMINCO

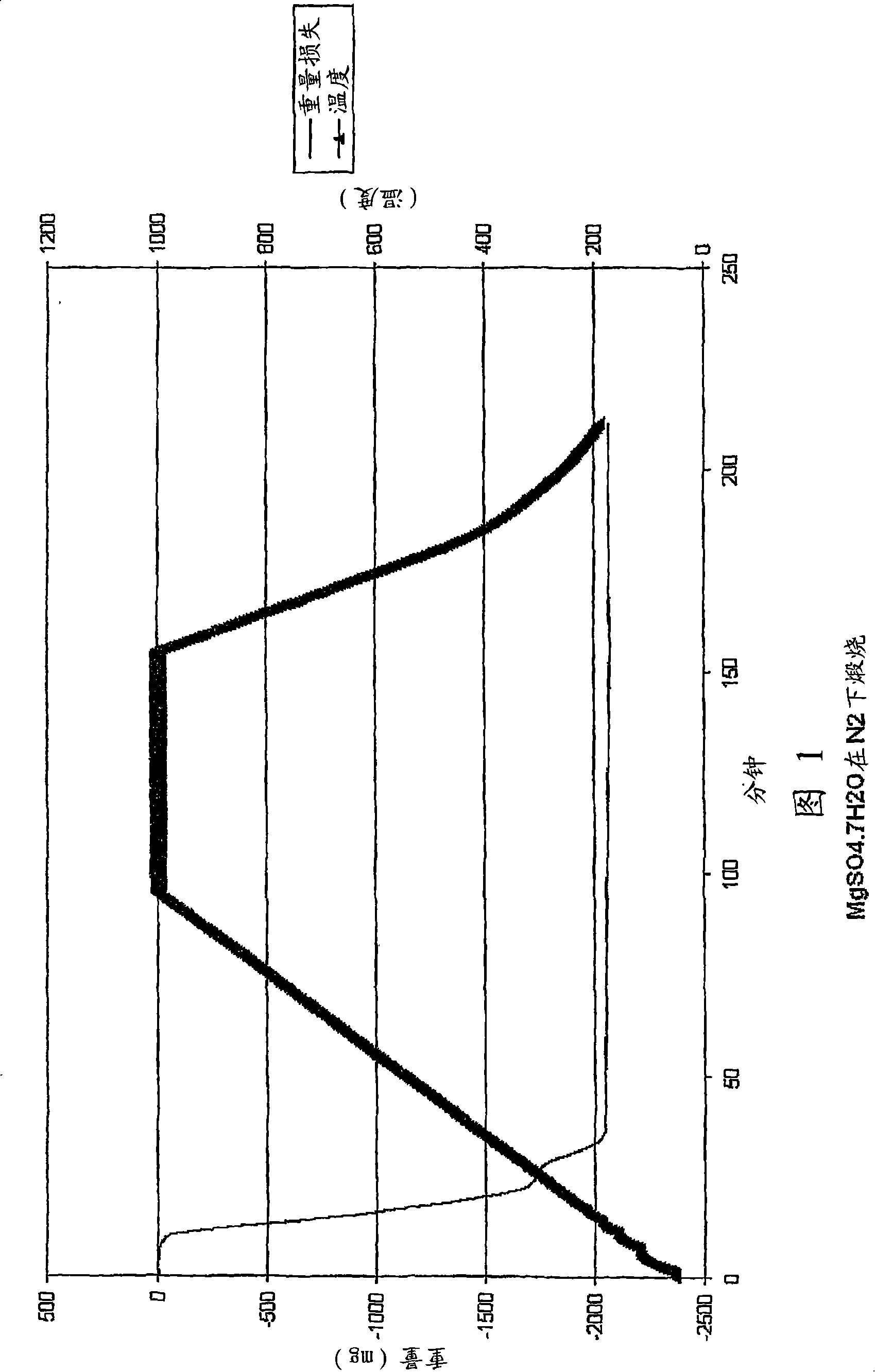

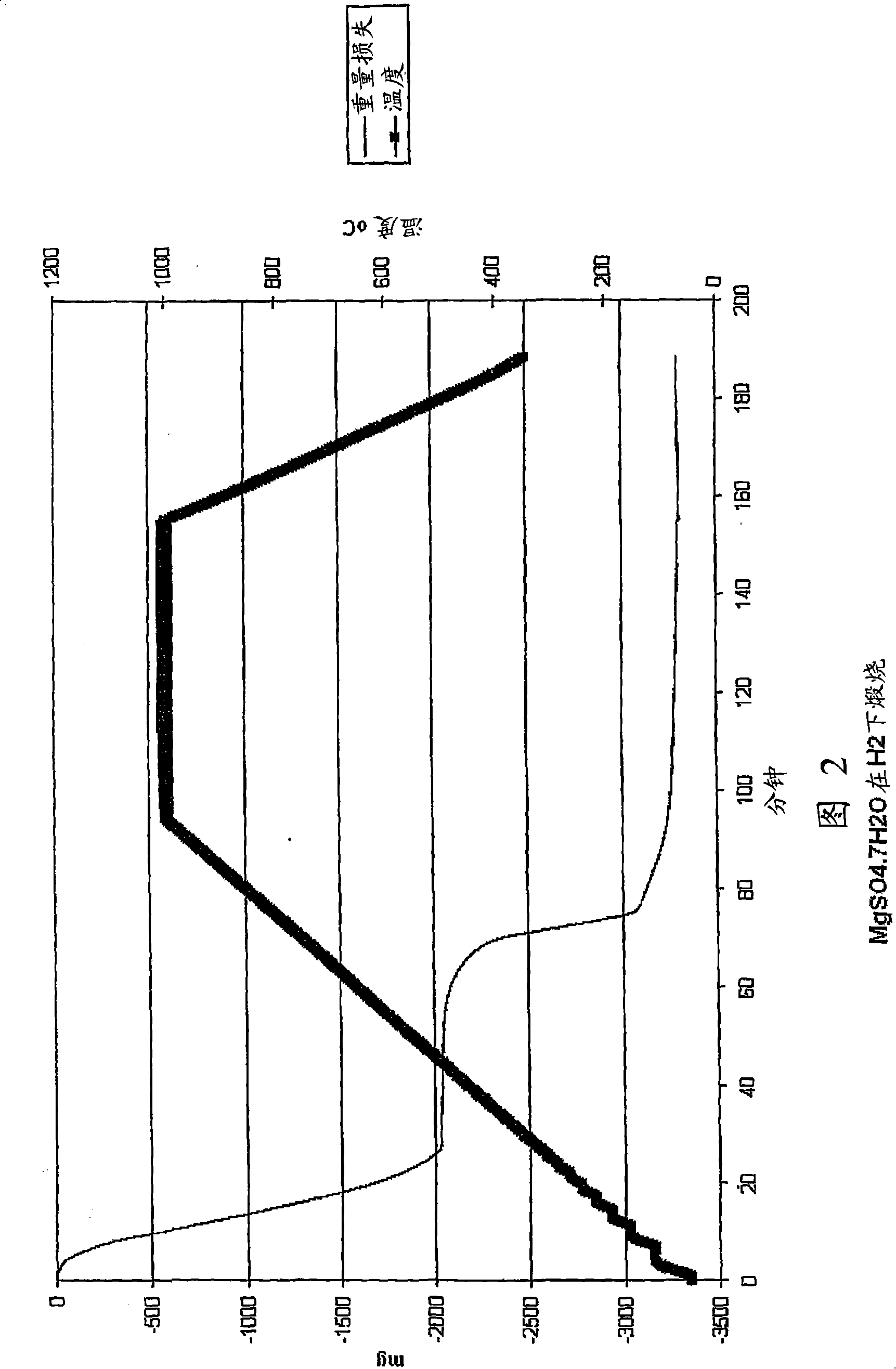

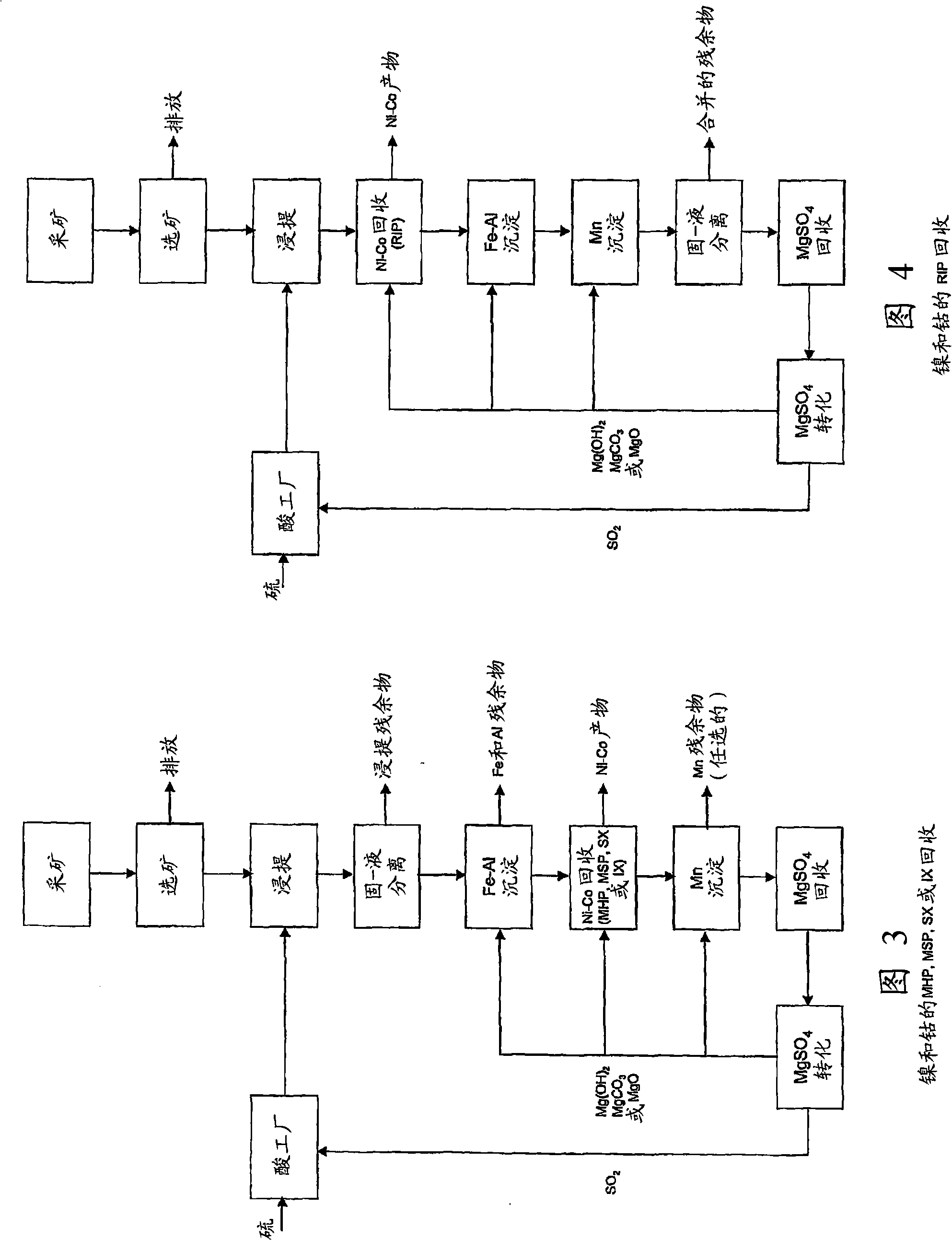

Method for atmospheric digestion of laterite ore

InactiveCN101273146AAvoid it happening againLow costProcess efficiency improvementHigh magnesiumDigestion

An atmospheric leaching process in the recovery of nickel and cobalt from a lateritic ore, said lateritic ore including a low magnesium ore fraction and a high magnesium ore fraction, said process including the steps of: (a) forming an aqueous pulp of said lateritic ore, (b) leaching said aqueous pulp with a concentrated mineral acid at atmospheric pressure to produce a slurry containing a pregnant leach liquor and a leach residue, (c) treating the pregnant leach liquor either separately or as part of said slurry to recover dissolved nickel and cobalt therefrom, leaving a magnesium containing barren solution, (d) treating said magnesium containing solution to recover a magnesium containing salt therefrom.

Owner:BHP比利通创新有限公司

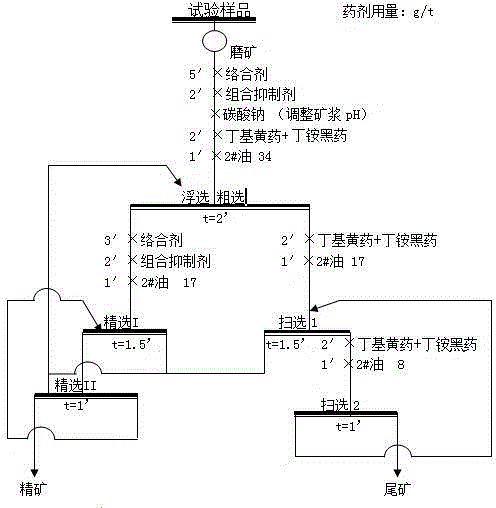

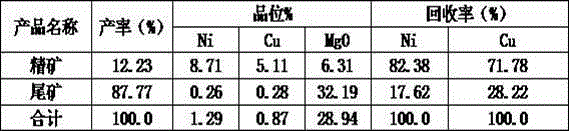

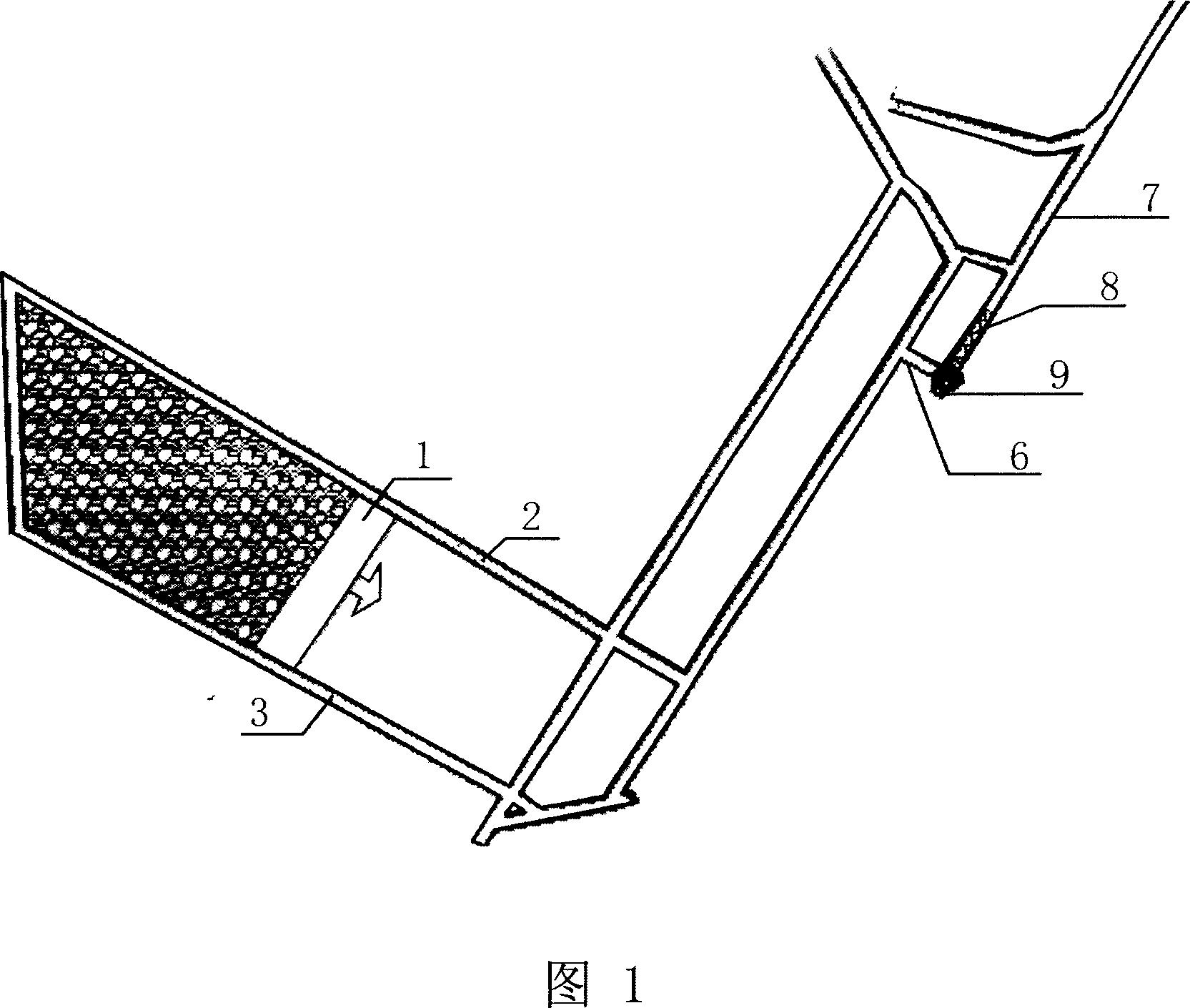

Method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation

The invention relates to a method for reducing concentrate magnesium oxide content in copper-nickel sulfide ore flotation. The method includes steps of firstly adding complexing agent oxalic acid, citric acid, tartaric acid, quadrol and EDTA (ethylene diamine tetraacetic acid), cleaning active ions of copper and nickel on the surface of magnesium-contained gangue mineral such as serpentine, removing flotation activity of sulfide ore collector such as xanthogenate, and adding composition agent to suppress gangue mineral. Ore pulp is treated by complexing agent, the flotation environment is improved, and floatability difference between copper-nickel sulfide mineral and magnesium-contained gangue mineral is increased. By combined inhibitor, serpentine and talc gangue mineral are suppressed, and magnesium-reducing effect is better; nickel recovery rate is increased to some extent as compared with that of actual production. Meanwhile, content of magnesium oxide in concentrate is reduced, and melting cost is lowered.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

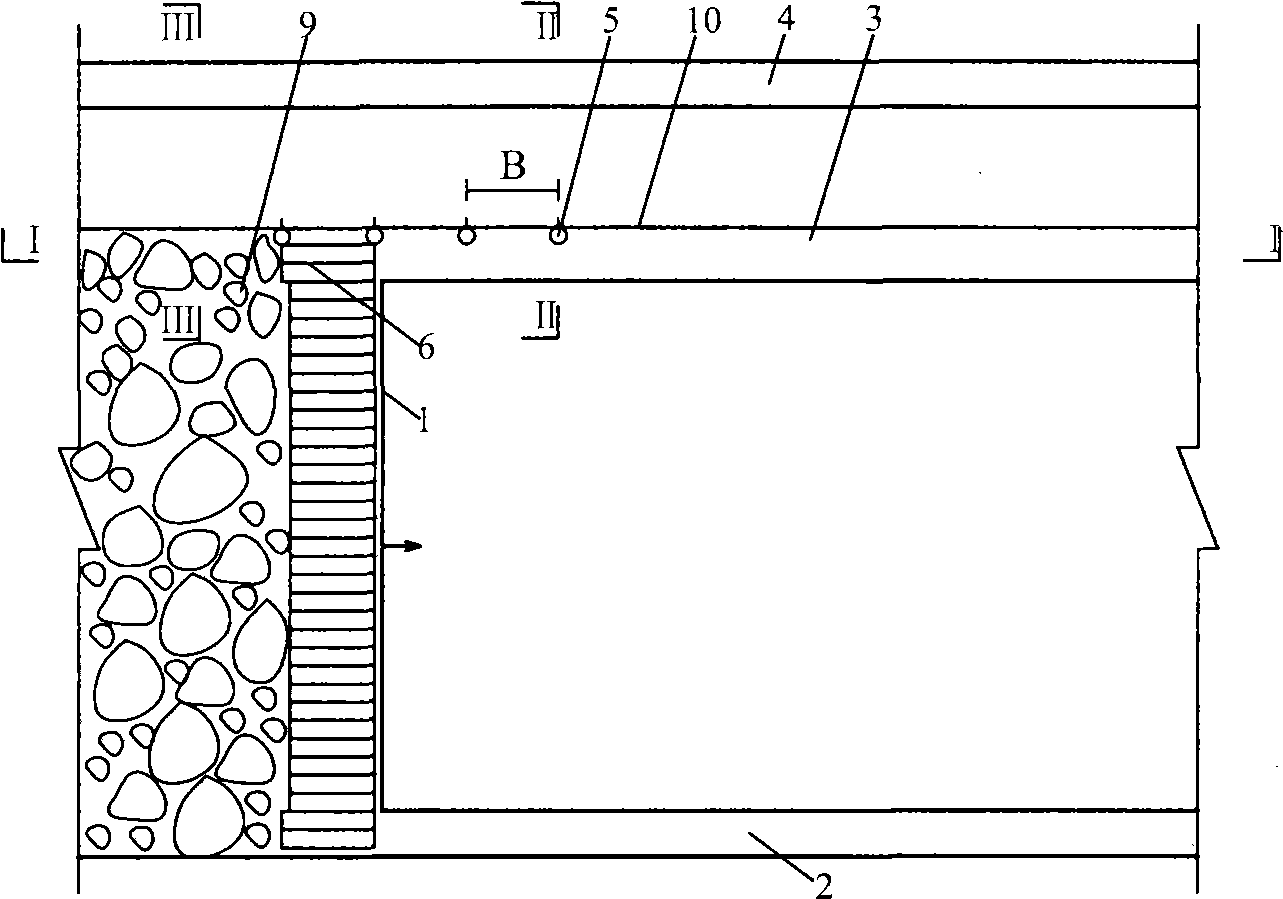

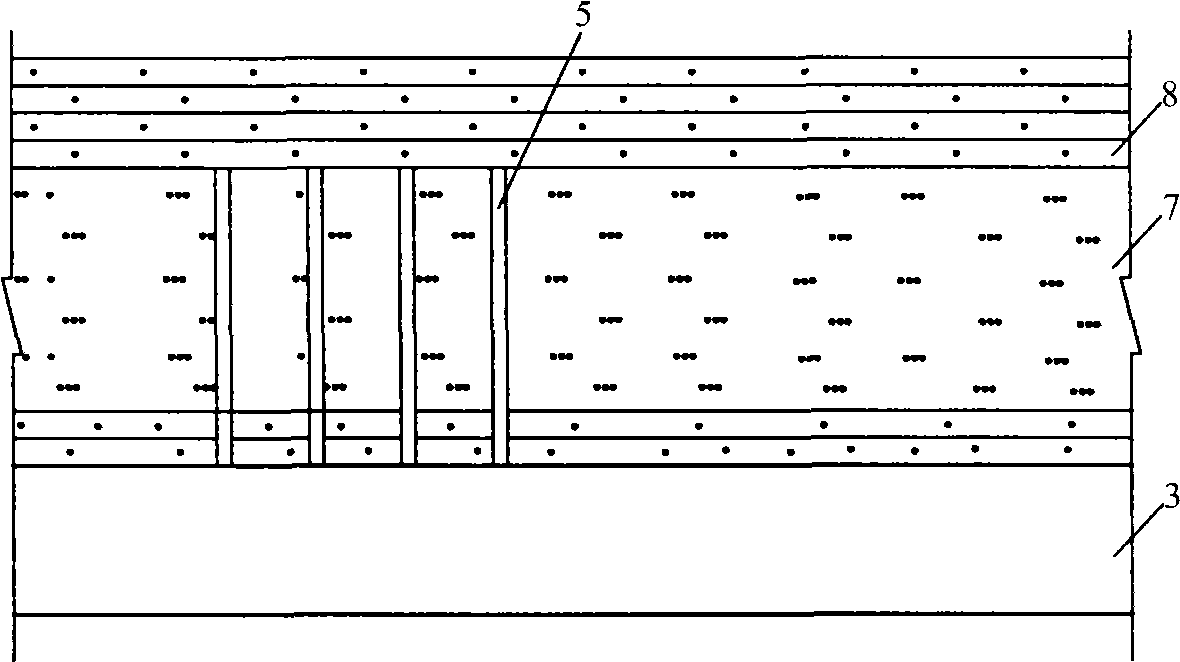

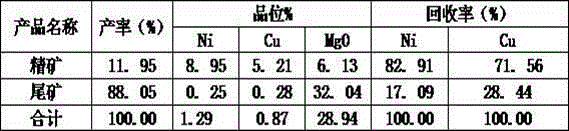

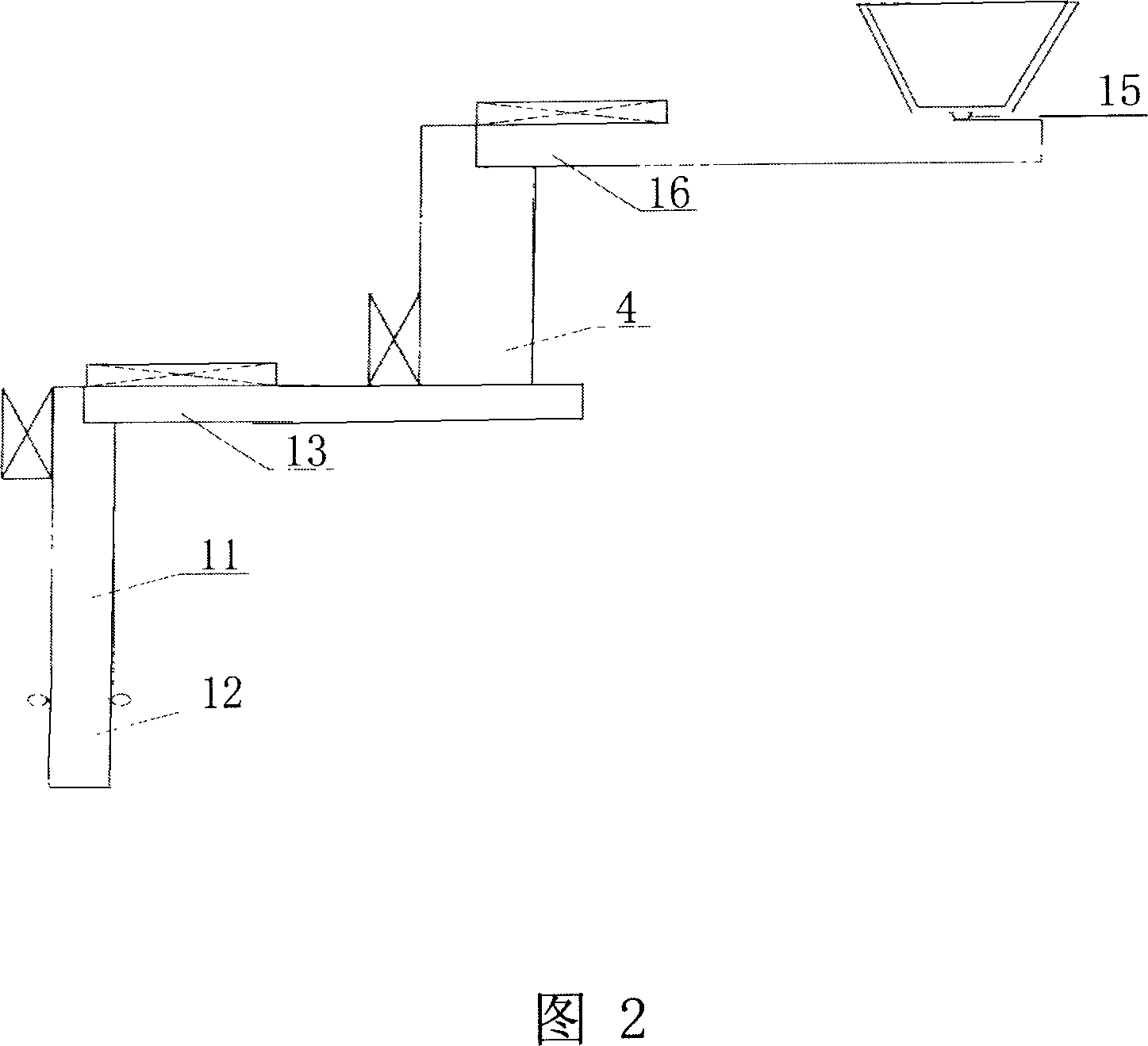

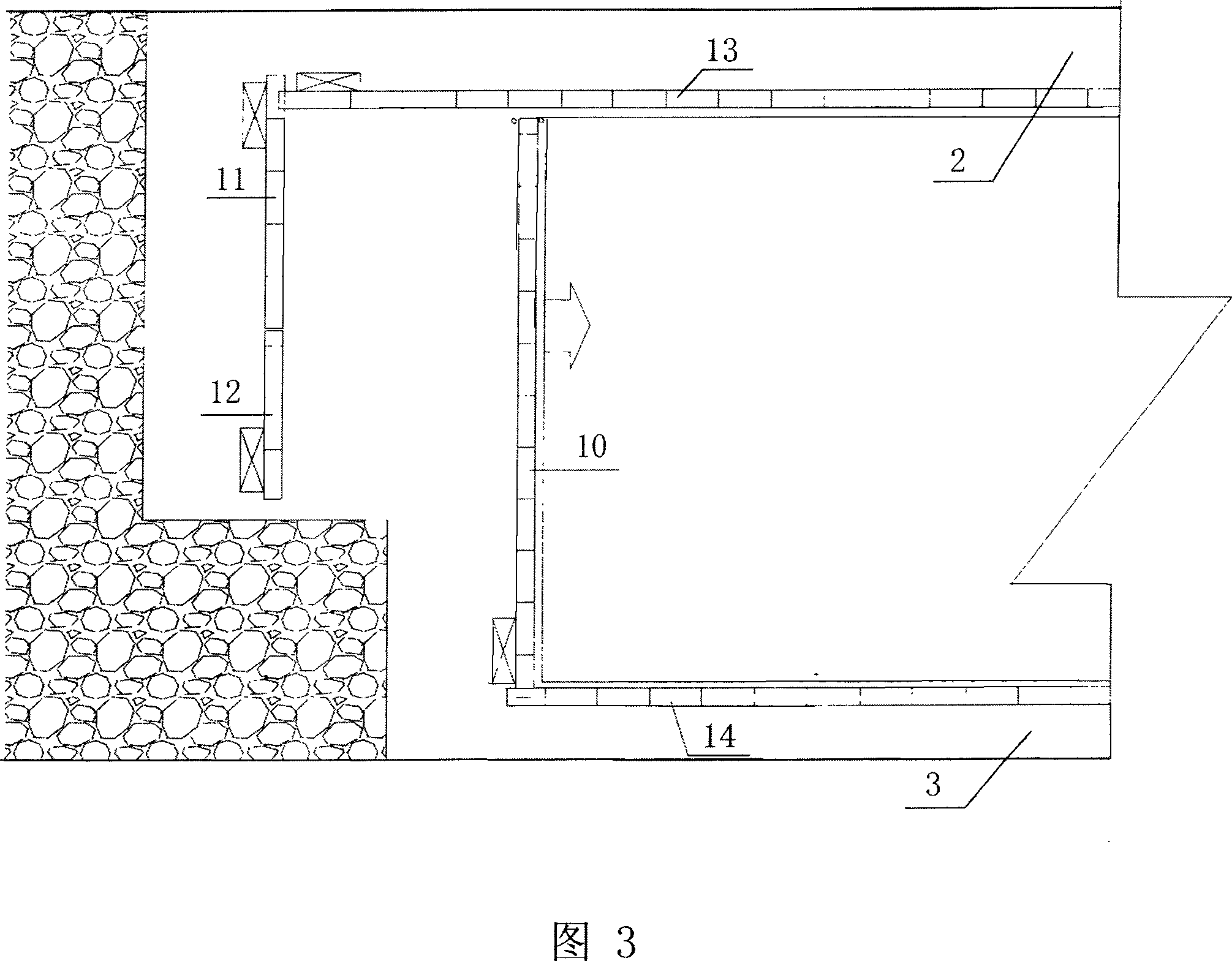

Method for filling coal-steam-free extraction working surface goaf by coal mine waste rock

InactiveCN1936271ARealize no MasuiImprove the environmentUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to a method to filling non-coal column face workplace by gangue. It includes the following steps: directly transferring the gangue to gangue storehouse, discharging to the slat conveyer through hopper gate, transferring the gangue to face through gangue transferring belt, face slat conveyer, and high speed gangue throwing belt. It needs not to smash the gangue and could realize zero stacking of gangue to improve coal mine environment. The invention supplies a new coal mining method for realizing environment protecting exploitation.

Owner:SHANDONG SHENGQUAN MINING

Drilling tool

ActiveUS20080199268A1Trend downReduce riskWood turning toolsTransportation and packagingTrademarkEngineering

A drilling tool. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

Process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt

InactiveCN103436720ASolve the problem of ammonia nitrogen pollutionRealize green miningProcess efficiency improvementAmmoniacal nitrogenCalcium hydroxide

The invention relates to a process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt. The process comprises the step of replacing ammonium salt by taking a mixture of calcium, magnesium and sodium salts as a leaching agent and taking non-ammonium salts, such as calcium hydroxide, magnesium hydrate or sodium hydroxide as a precipitator. According to the process disclosed by the invention, the ammonia nitrogen pollution problem in exploitation of ion-adsorption type rare earth is radically solved; environmental-friendly exploitation of the ion-adsorption type rare earth can be realized; the process disclosed by the invention has higher economic benefit and social benefit.

Owner:LONGNAN COUNTY NANYU RARE EARTH RESOURCES COMPREHENSIVE UTILIZATION CO LTD

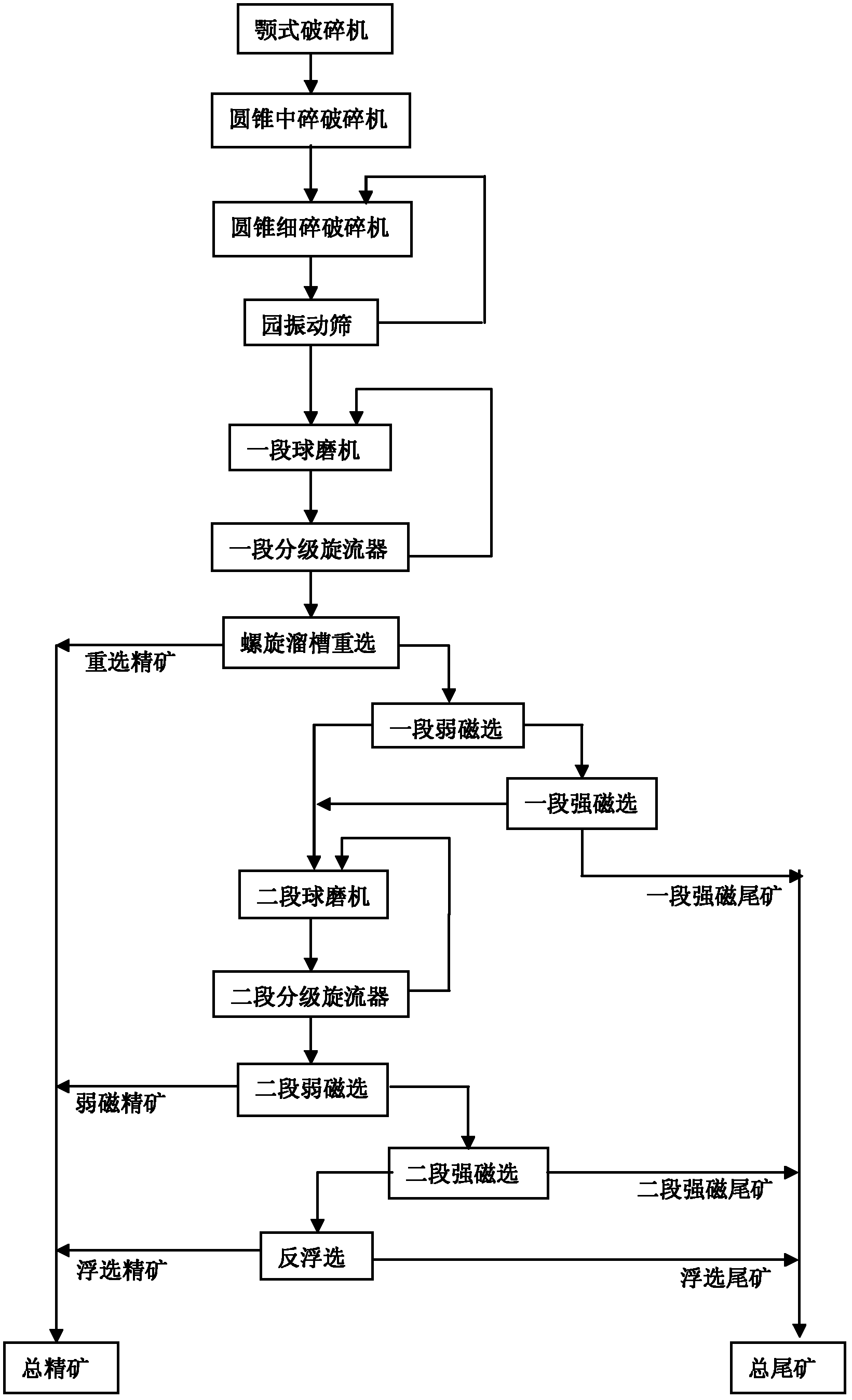

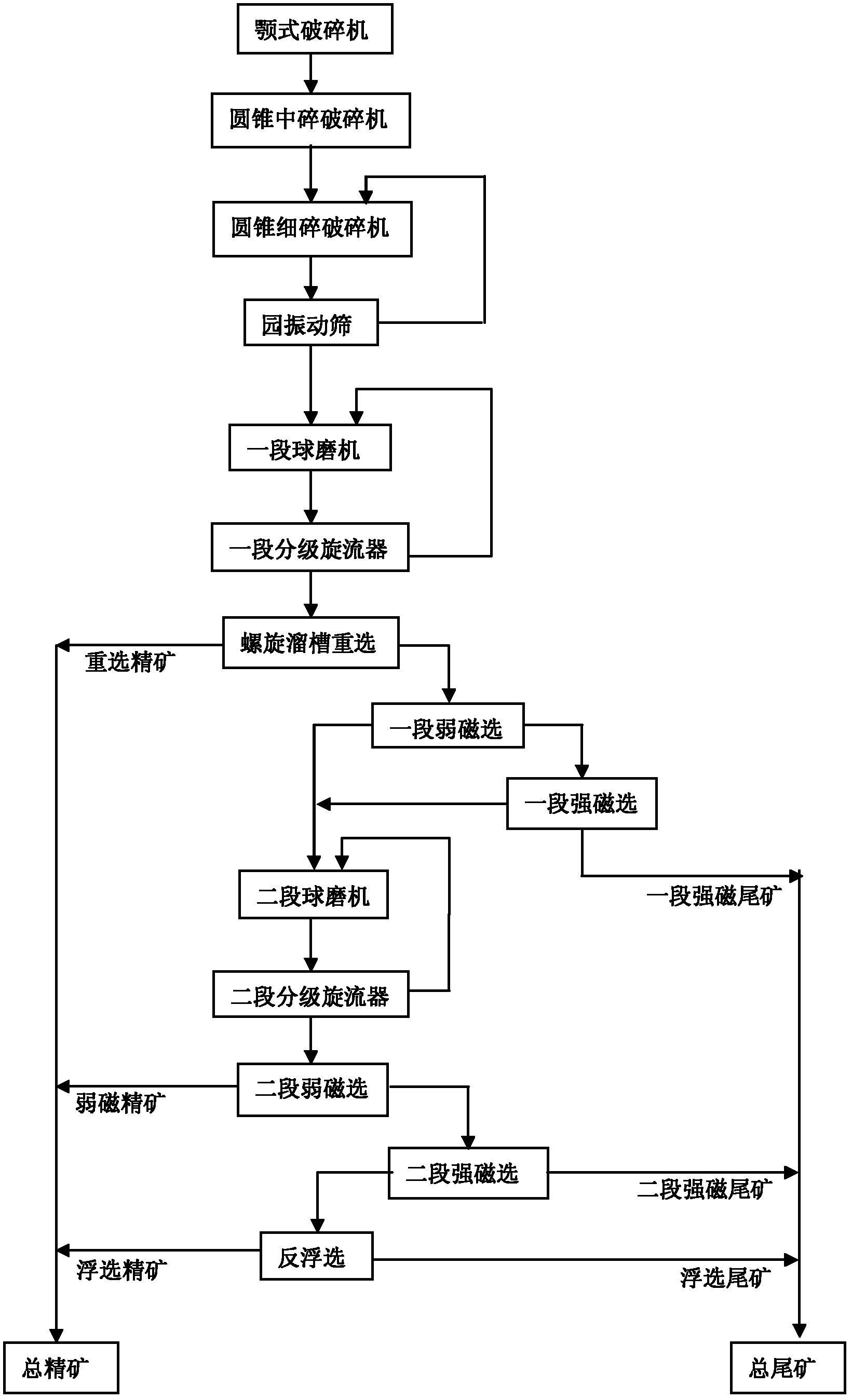

Beneficiation process of low-grade magnetite and specularite mixed ore

ActiveCN102205273AReduce loadReduce energy consumptionMagnetic separationMining engineeringMagnetite

The invention relates to the technical field of black metal ore exploitation and beneficiation, in particular to a beneficiation process of low-grade magnetite and specularite mixed ore, which is especially suitable for associated magnetite and specularite mixed ore of Zhouyoufang iron ore. The novel beneficiation process is realized according to an operation procedure and the process proceduressuch as ore crushing, one-stage grinding and grading, reselecting, one-stage weak magnetic separation, one-stage strong magnetic separation, two-stage grinding and grading (crude concentrate re-grinding), two-stage weak magnetic separation, two-stage strong magnetic separation, reverse floating and the like. The iron ore is comprehensively recycled, and a high-quality iron concentrate product is produced. The process has the characteristics of energy saving, high beneficiation efficiency and low beneficiation cost.

Owner:ANHUI JINRISHENG MINING

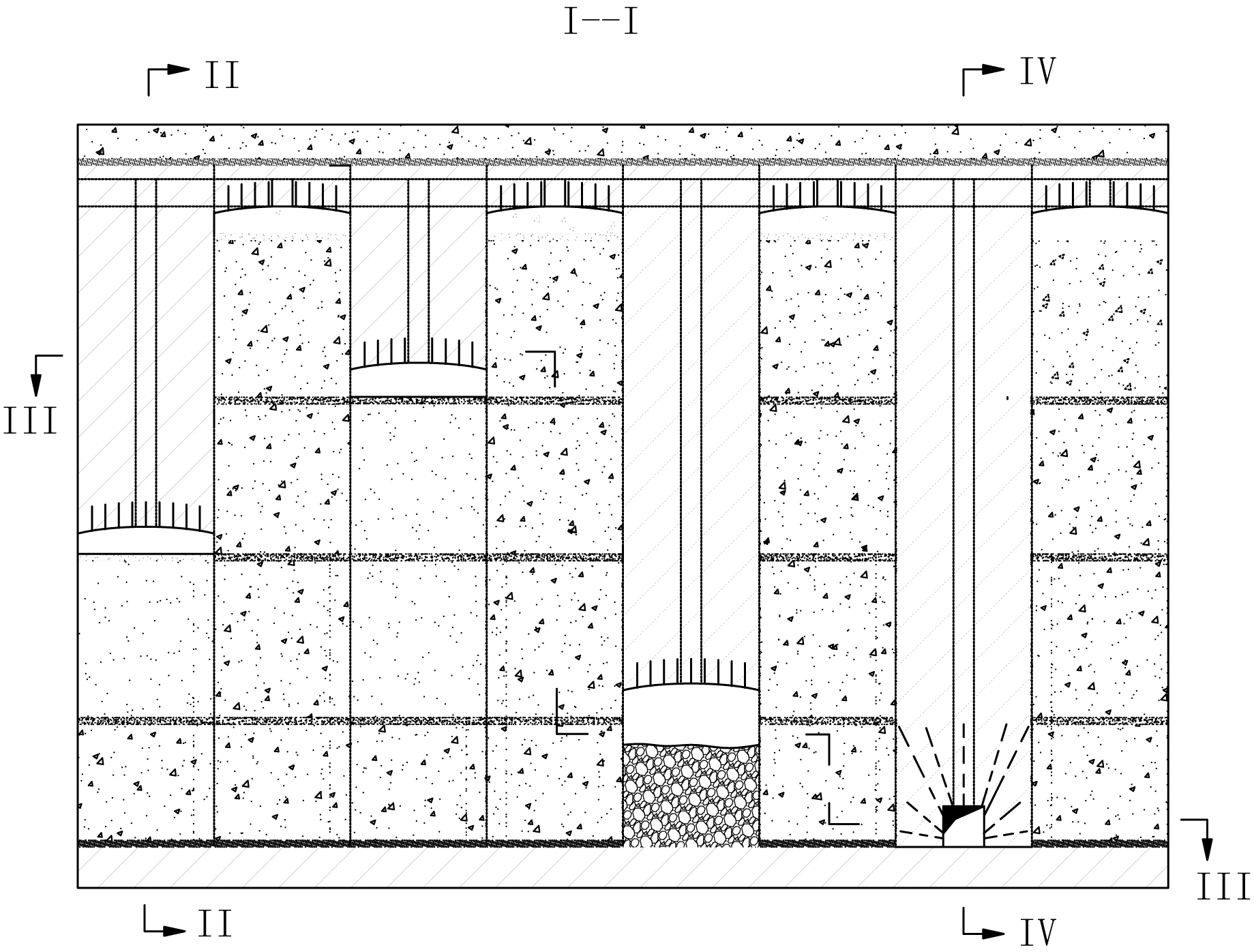

Layered top-controlling filling mining method for residual ores in deep hole in diskless area

ActiveCN102678121AImprove mining safetyReduce unit consumptionUnderground miningSurface miningMineralogyDeep hole

The invention discloses a layered top-controlling filling mining method for residual ores in a deep hole in a diskless area. An ore body is divided into ore room ore columns which are arranged at intervals along the travelling direction, and production is preformed by taking 6 to 8 ore room ore columns as a unit; a mountain outer oblique slope, a mountain outer sectional stulm, a sectional contact way and a mountain outer middle-section orepass form a mountain outer rail-free mining preparation system; after bursting and ore falling in medium and deep holes are performed in the ore room ore columns, a part of ores is shoveled out, and the other ores are temporarily left in a stope to form an ore pile of which the top is provided with a hollow top space with the diameter of 1.5 to 2m; a layer of mine body with the thickness of 2.0 to 2.5m is exploited from the ore pile, a 1 / 4 three-center arc top plate is formed by a control burst method, the out ores are pressed and exploited on the ore pile, and surrounding rocks are crushed on an anchoring rod or an anchoring net supporting and protecting top plate and a long anchoring rope supporting and protecting upper disc; the ores are taken out in a concentrating way after the top is protected, and cement and tailings are glued and filled to a 3.5-4m position; and the steps are repeated until ore blocks are completely stoped and the top is connected and filled. The method has the characteristics of safety, high efficiency, low barren loss, low cost and the like.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU +1

Apparatus for preparing a gypsum wallboard core

A gypsum wallboard core, and methods and apparatus for making the same are disclosed. Methods of making a gypsum wallboard core include extruding a gypsum slurry containing water, gypsum, slip agents, water-reducing agents, surfactants and, optional additives, through a die and onto a substantially flat, smooth, moving surface. The die has provisions at its outer sides for the introduction of slip agents into the slurry, and provisions at its lateral outer edges for the introduction of a strength-enhancing agent. Once extruded onto the conveyor belt, the slurry is chemically-activated to set and form a hardened board core which then may be easily removed from the conveyor belt and dried.

Owner:GOLD BOND BUILDING PROD LLC

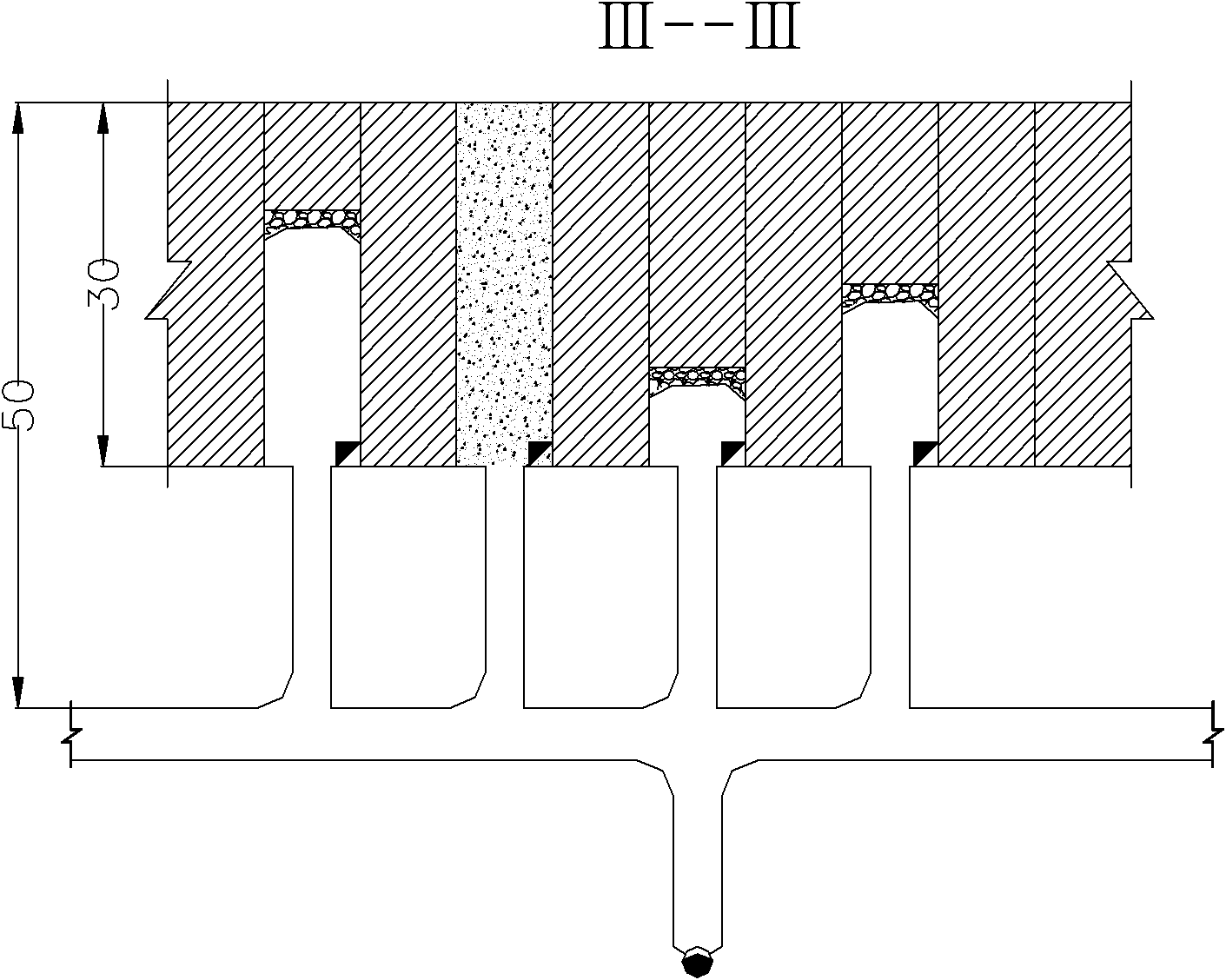

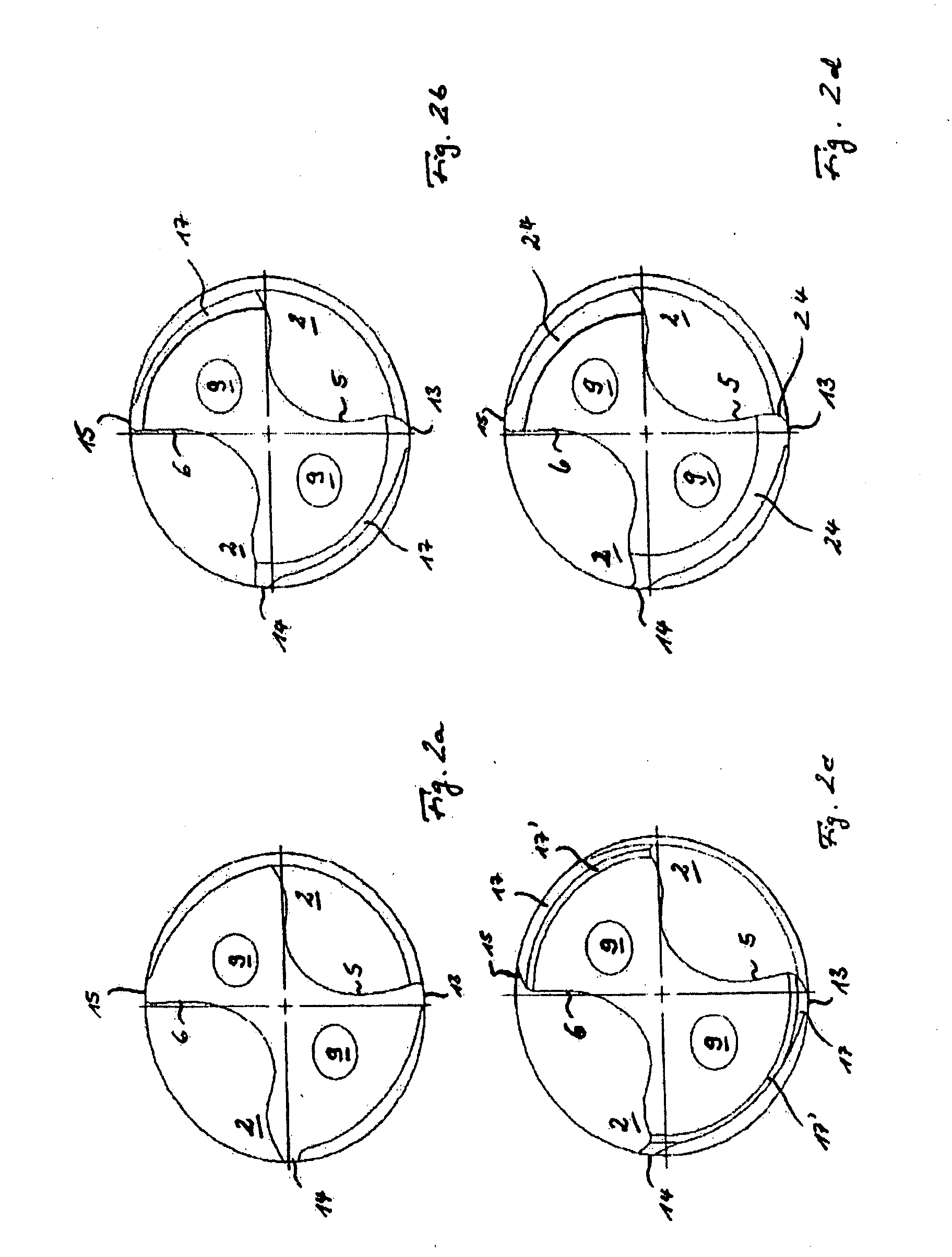

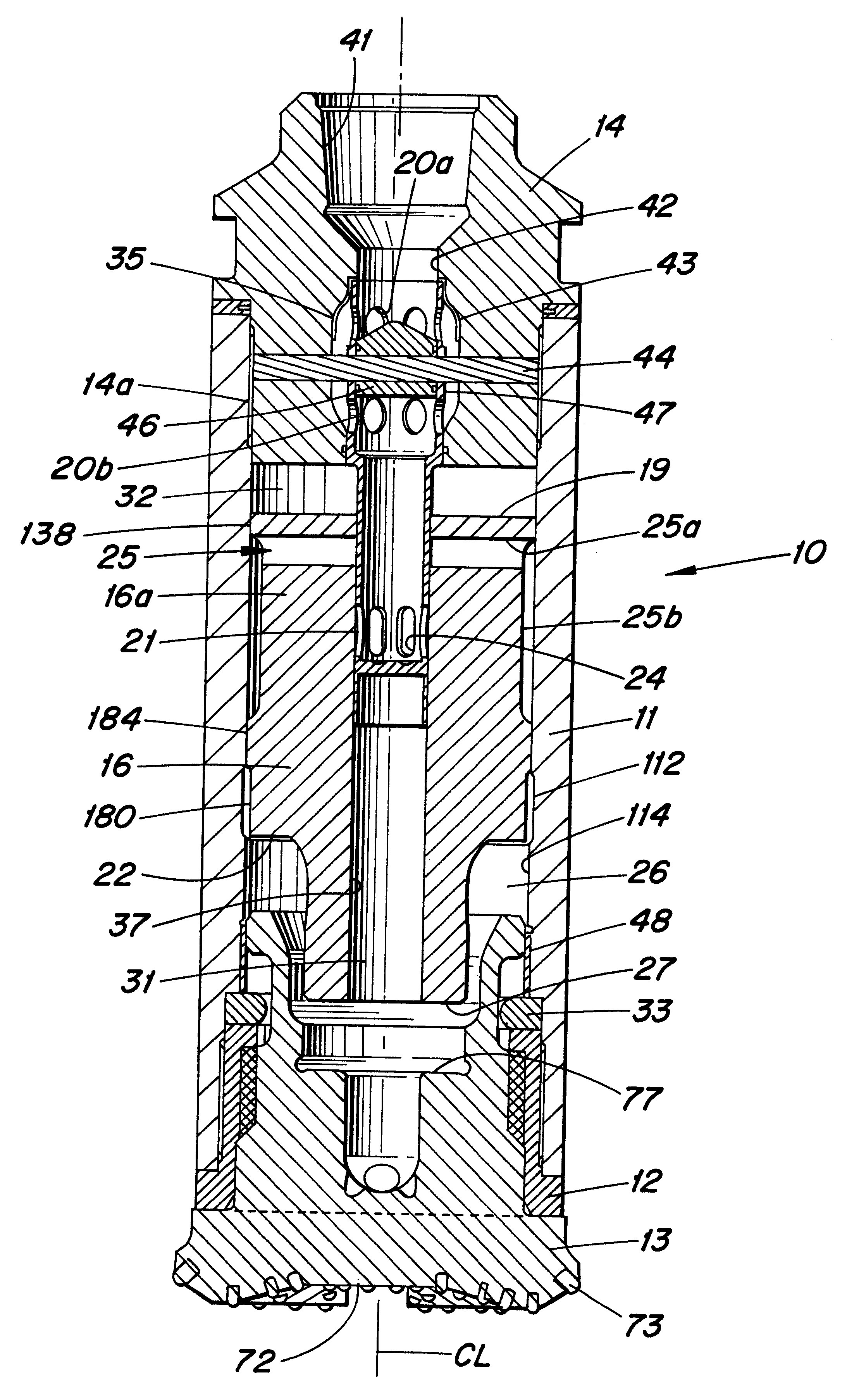

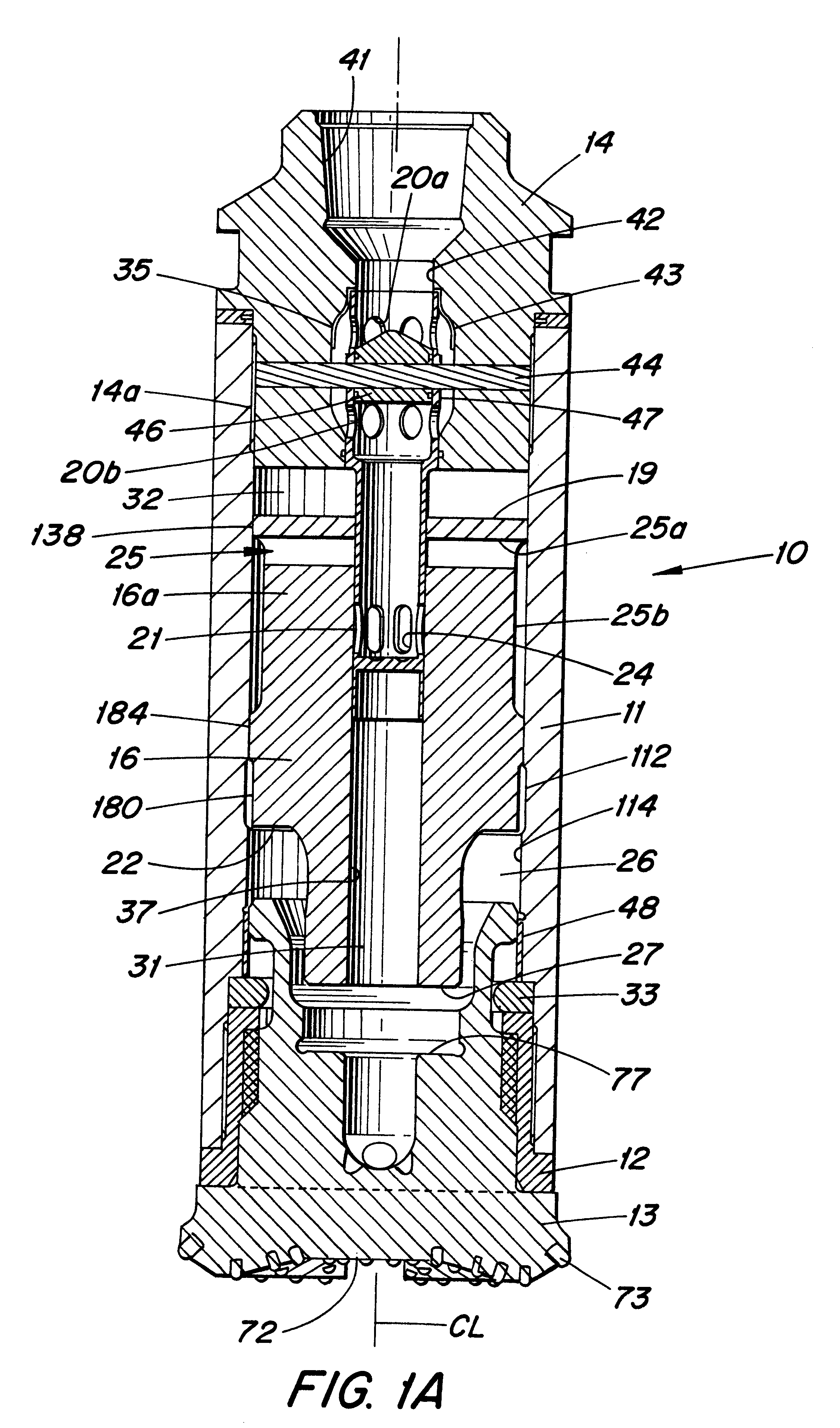

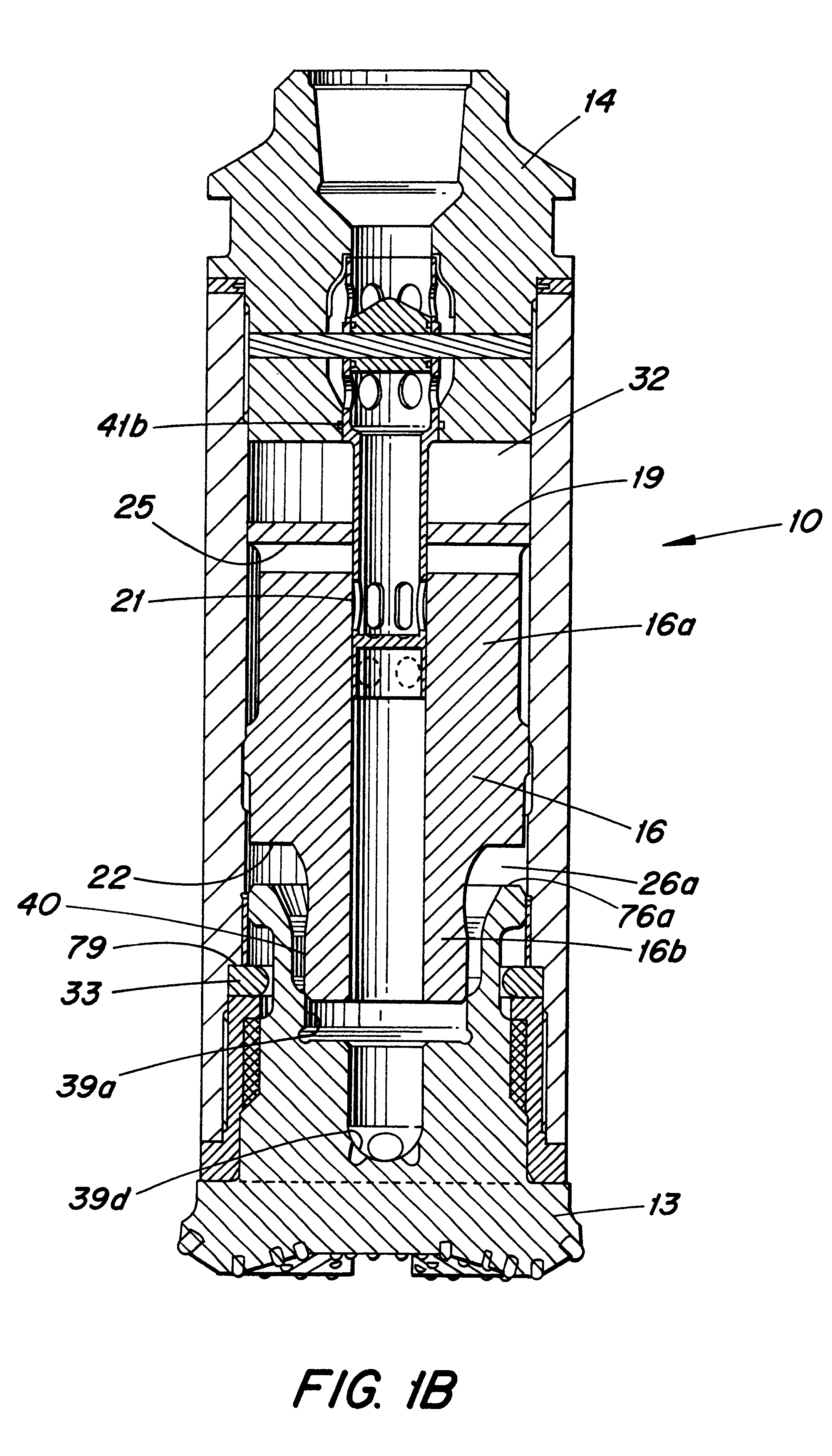

Percussive down-the-hole hammer for rock drilling, and a drill bit used therein

InactiveUS6502650B1Easy to manufactureLow production costDrill bitsBorehole drivesPortion sizeReciprocating motion

A down-the-hole percussive hammer for rock drilling includes a cylindrical casing and a drill bit disposed at a front end of the casing. The drill bit includes a forwardly facing cutting surface and a center longitudinal passage extending forwardly through a rearwardly facing rearwardmost end surface of the drill bit. The passage includes a rearwardly facing impact surface. A piston is mounted in the casing longitudinally behind the drill bit for reciprocation in a longitudinal direction. The piston includes a front portion sized to enter the center passage of the drill bit and strike the impact surface of the drill bit during each forward stroke of the piston. The impact surface of the drill bit is spaced forwardly from the rearwardmost end surface of the drill bit by a distance of at least ten percent of a total longitudinal length of the drill bit.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Permeability improvement technology for coal bed gas reservoir cap by using three-dimensional fracture network modification

InactiveCN102392677AImprove permeabilityIncrease contact areaFluid removalGas removalMining engineeringHorizontal wells

The invention relates to a permeability improvement technology for a coal bed gas reservoir cap by using three-dimensional fracture network modification. The technology is as follows: building a bedding horizontal well from ground to top and bottom plates of the coal bed of an area not mined; building bedding, three-dimensional cross-type or multi-branch long boreholes on the top and bottom plates of the coal bed of the area not mined through perforation and segmented fracturing or existing sinking and driving engineering, and then carrying out hydraulic fracturing; modifying the coal bed gas reservoir cap into a crisscross fracture network system to form a modified volume; building various types of drainage boreholes in the modified volume; and carrying out negative pressure extraction together with a fractured well, so that coal bed gas can be continuously desorbed and dispersed and then extracted out in large scale through the modified volume. According to the invention, the crisscross fracture network system is formed in the coal bed gas reservoir cap, so that the coal bed gas can be continuously desorbed and dispersed at negative pressure and then extracted out in large scale through the modified volume, thus the content of coal bed gas in the modified bed can be quickly reduced to be below the safety standard in the outburst prevention formulation, and safe and high-efficiency production of mines can be realized on the basis of forming scale coal bed gas development.

Owner:HENAN COAL CHEM IND GROUP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com