Patents

Literature

2978 results about "Horizontal wells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

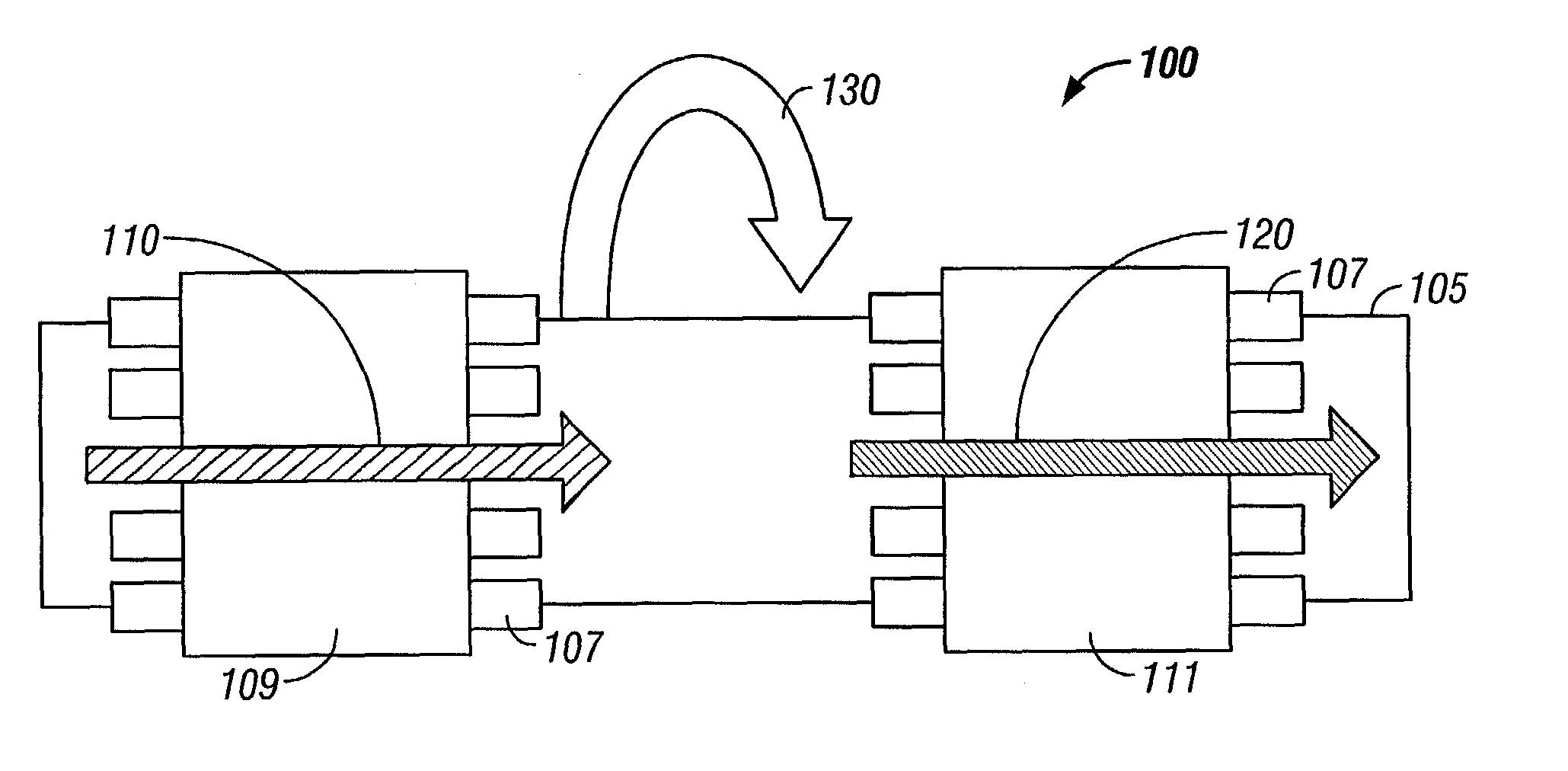

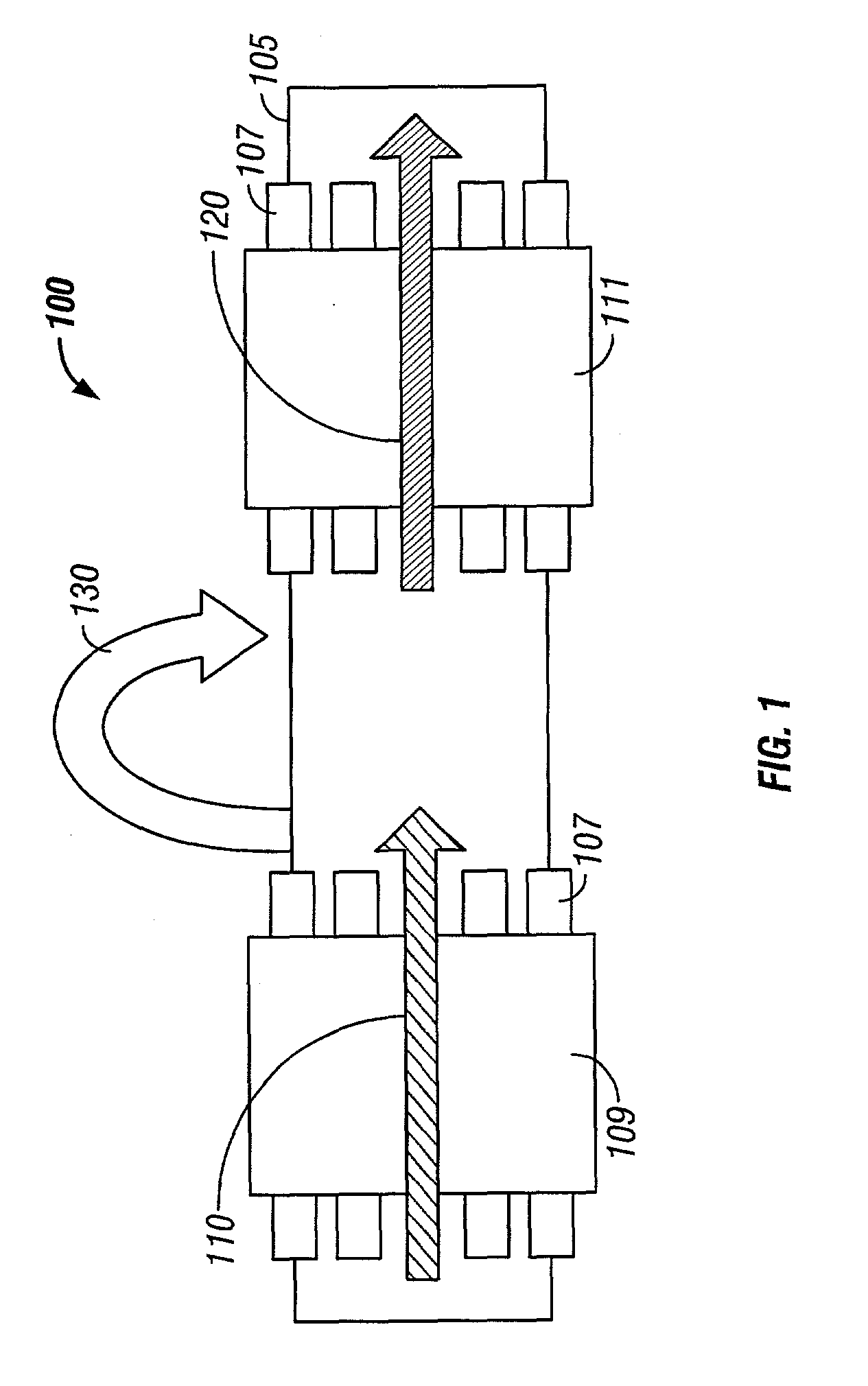

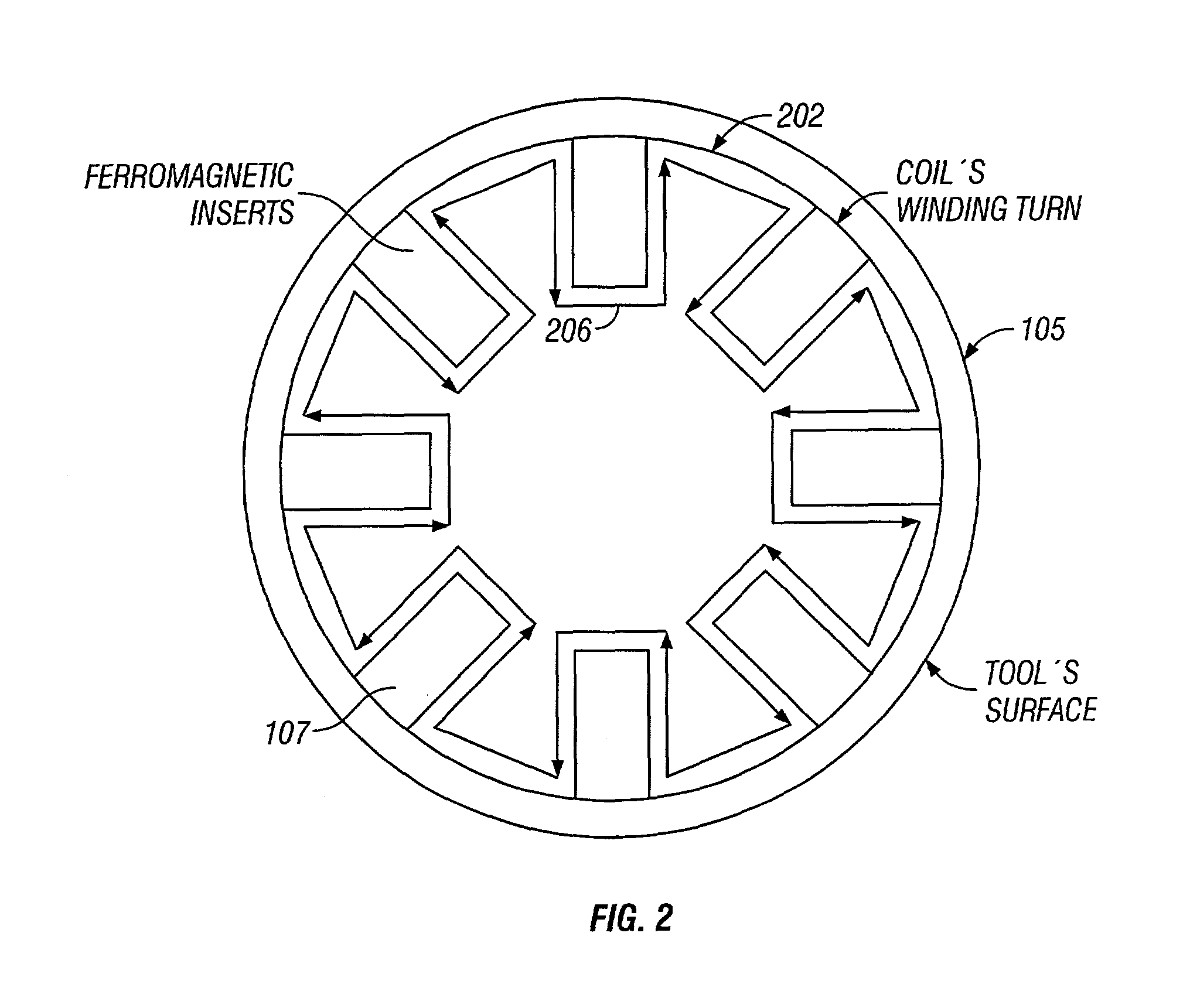

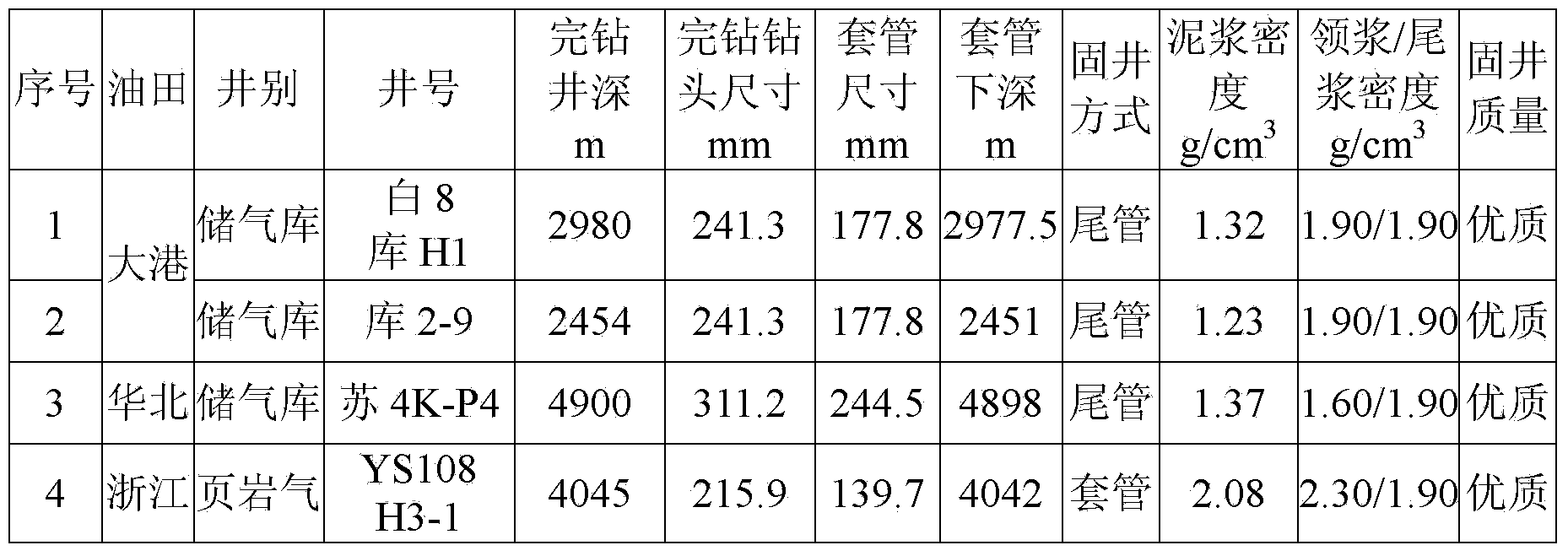

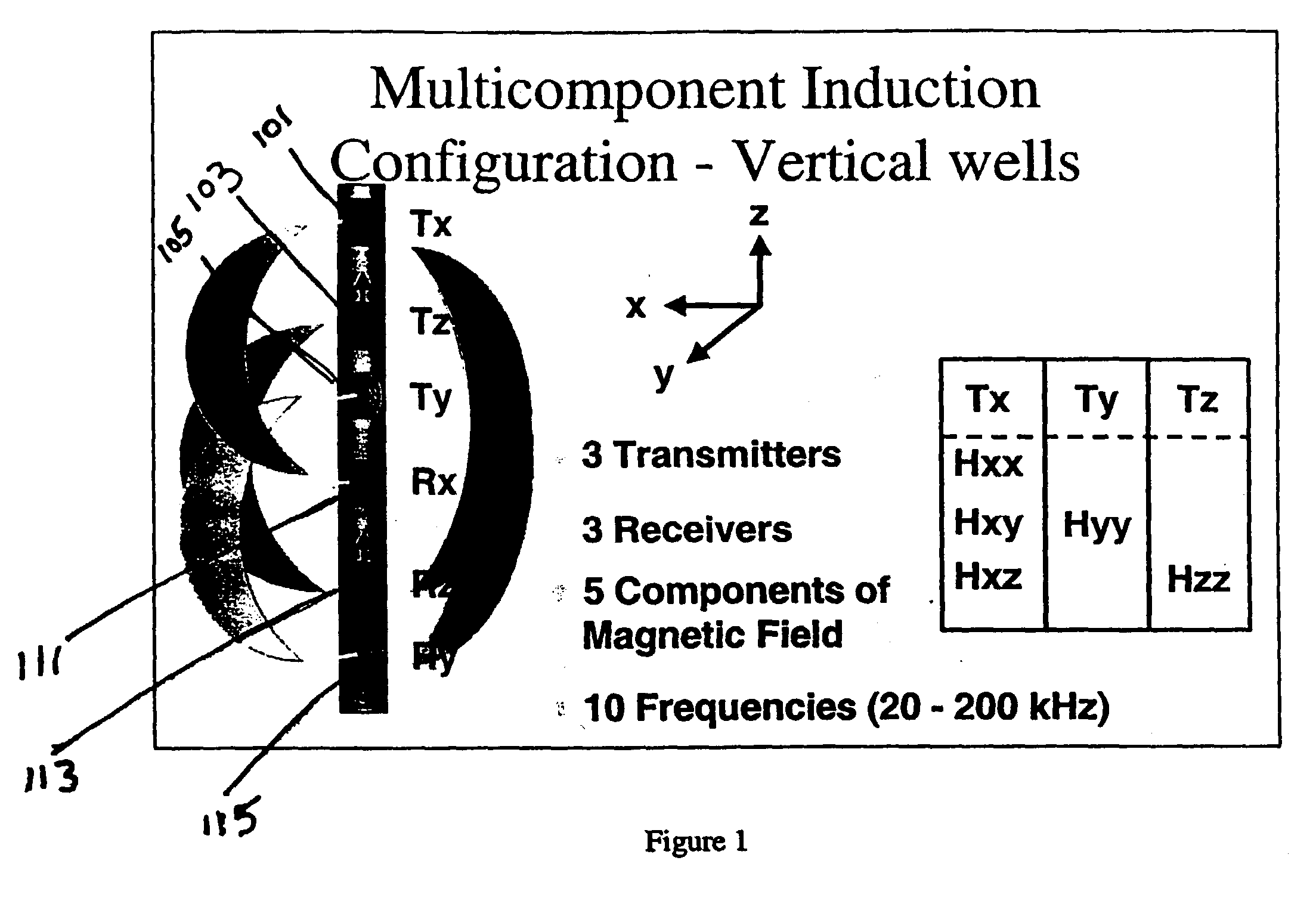

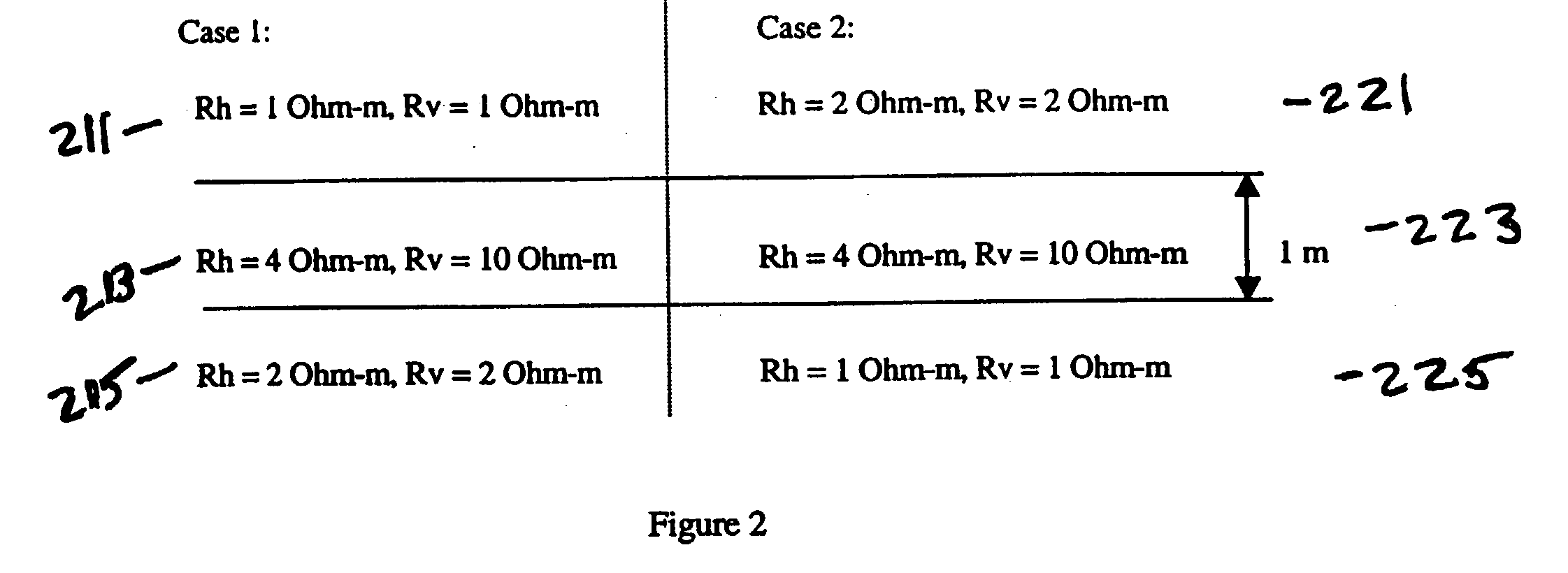

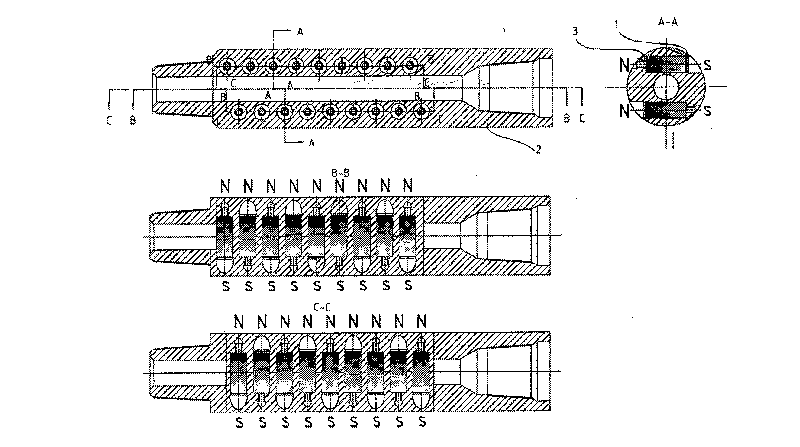

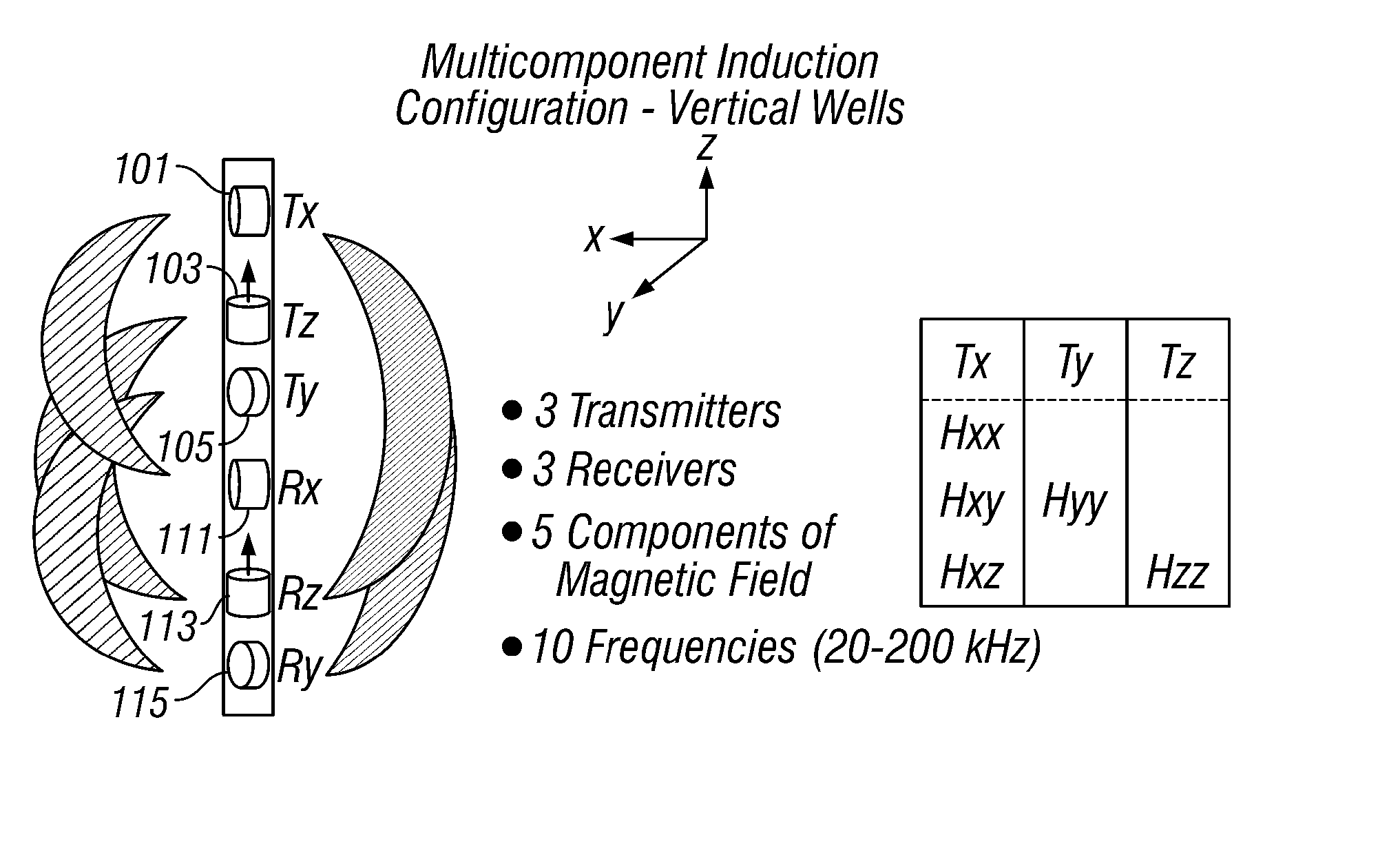

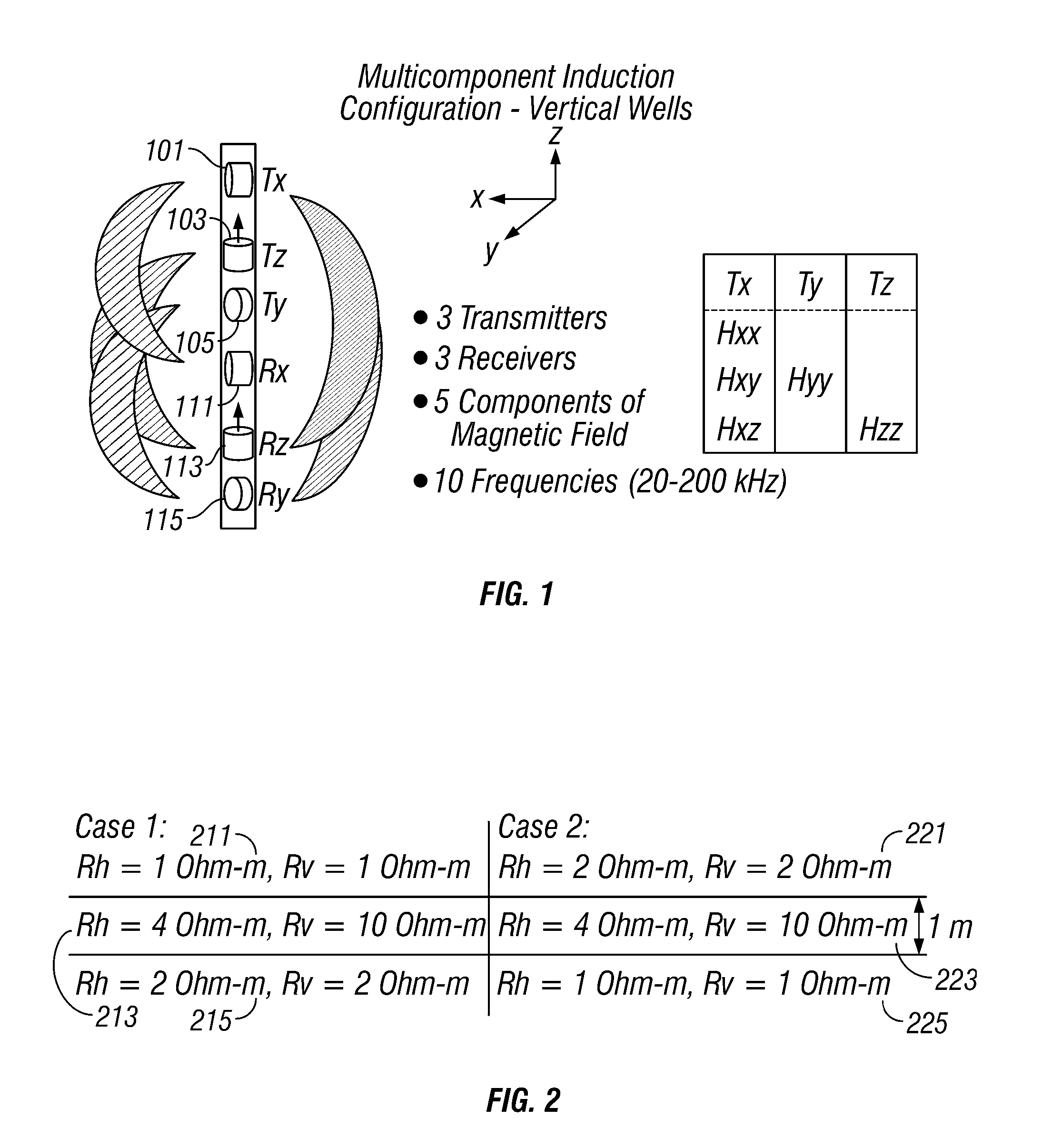

Method and apparatus for a multi-component induction instrument measuring system for geosteering and formation resistivity data interpretation in horizontal, vertical and deviated wells

InactiveUS20030076107A1Reduce the overall transmitter momentMinimize eddy currentElectric/magnetic detection for well-loggingSurveyGeosteeringWell logging

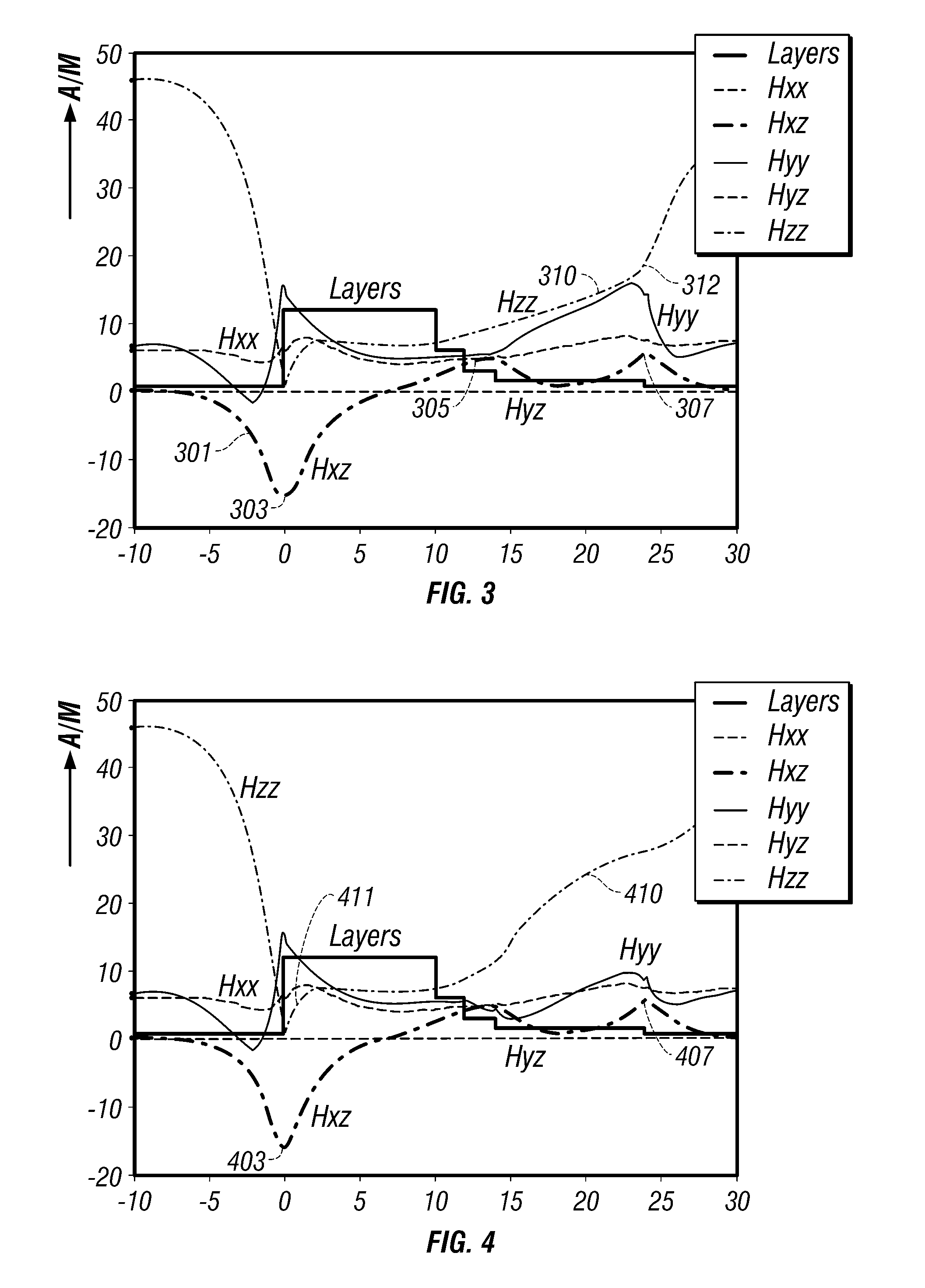

An improved induction tool for formation resistivity evaluations. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. Various transmitter receiver combinations are provided to select sensitivity to a desired reservoir formation properties, for example, different orientations xy, xz, yz, 20-40, 20-90, and combinations, such as, Symmetric-symmetric; Asymmetric-symmetric; and Asymmetric-asymmetric. Measurements made with a multi-component logging instrument when used in a substantially horizontal, vertical or deviated borehole in earth formations are diagnostic of the direction of resistive beds relative to the position of the borehole.

Owner:BAKER HUGHES INC

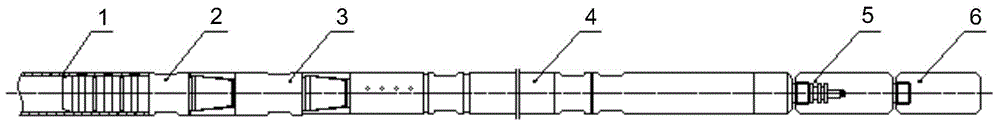

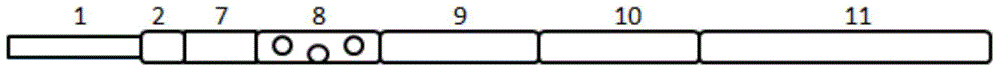

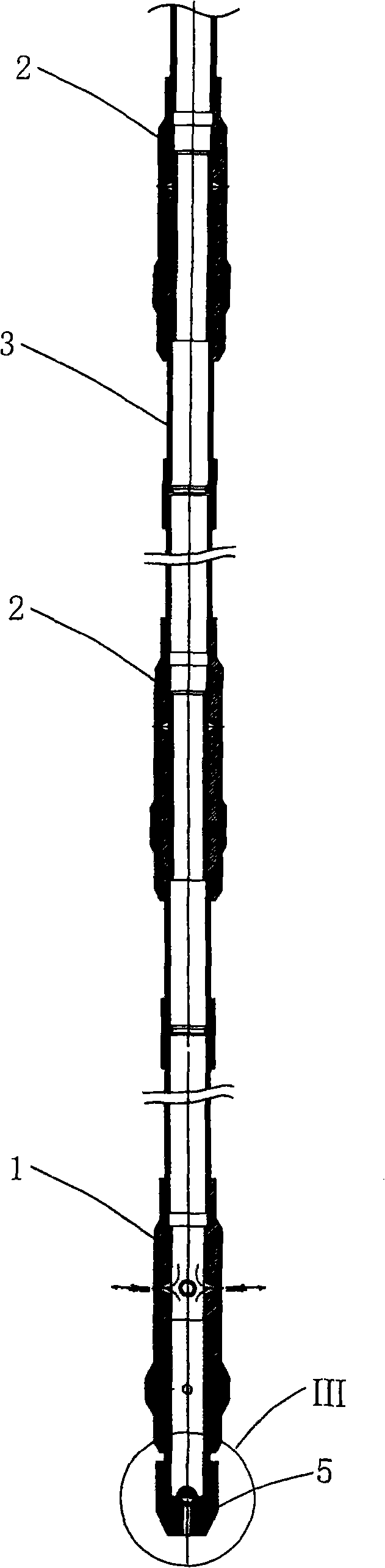

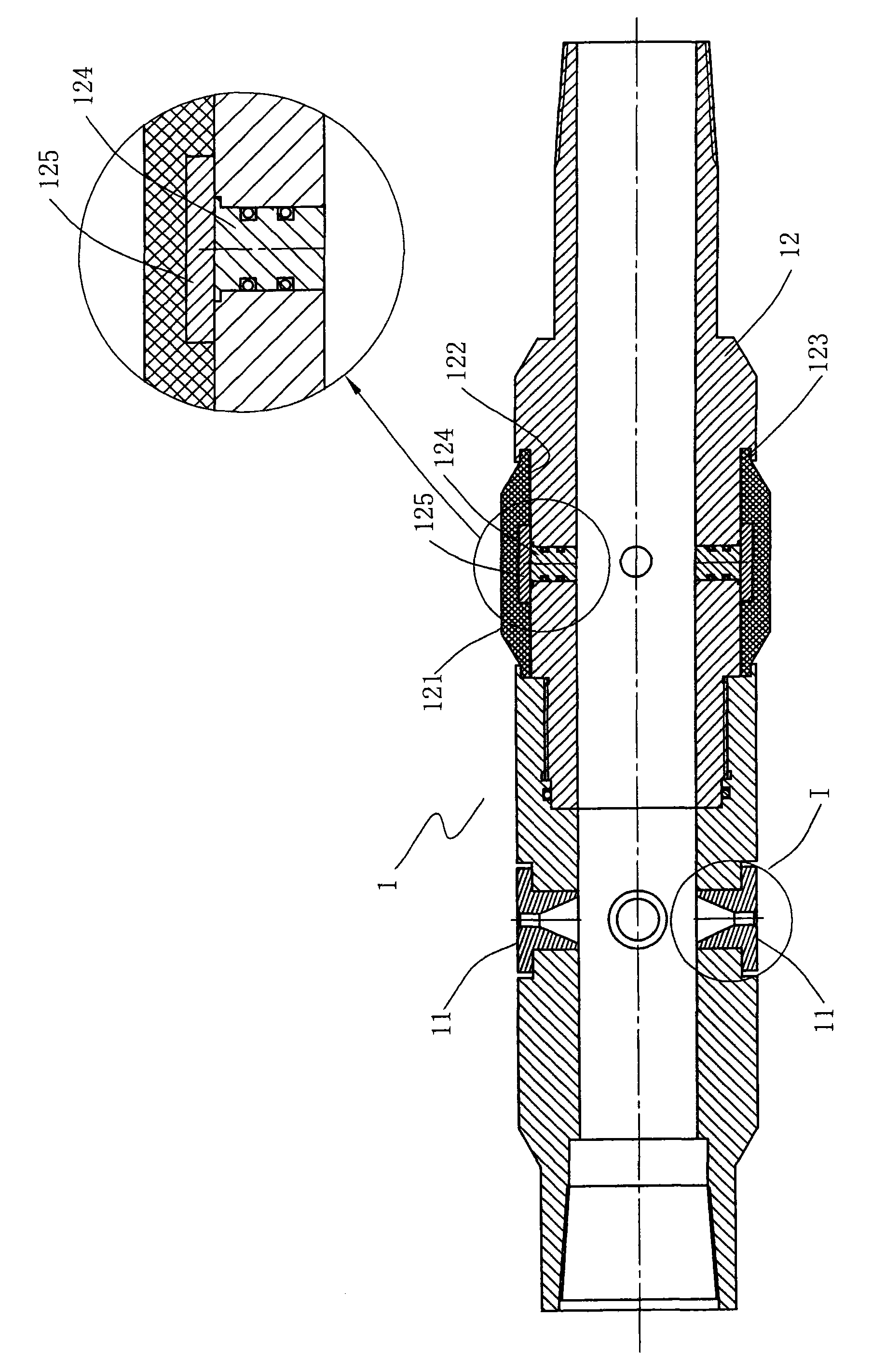

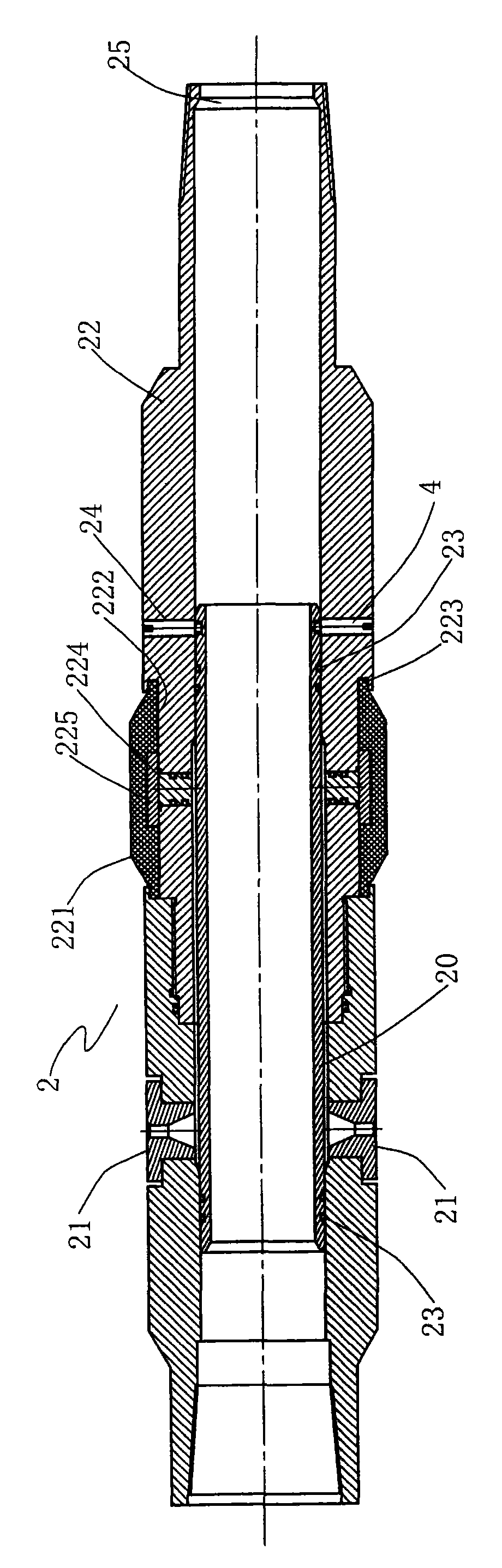

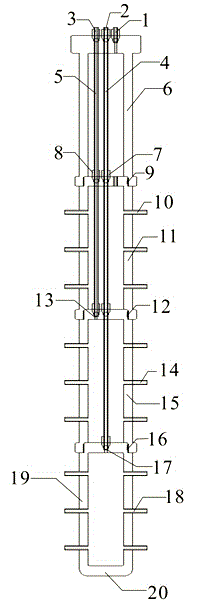

Coiled tubing tool set with cable perforations and technology

InactiveCN104533392AHigh strengthImprove toughnessSurveyFluid removalHorizontal wellsEconomic benefits

The invention discloses a coiled tubing tool set with cable perforations. The coiled tubing tool set comprises coiled tubing, a coiled tubing joint and a logging tool string or a perforation tool set. A cable is arranged in the coiled tubing. According to the coiled tubing tool set with the cable perforations, the structure of combining the coiled tubing and the logging tool string or the perforation tool set is adopted, and on the one hand, due to the characteristic that the coiled tubing is high in strength, toughness and loading capacity to work under pressure, the perforation requirements for highly-deviated wells and horizontal wells can be met, and the application range is wider; on the other hand, the coiled tubing can continuously work, work time is short, and efficiency is high. Meanwhile, due to production under pressure, a press does not need to be introduced, and the overall equipment occupied area is small. Therefore, through the coiled tubing, the cost of a work well is lowered, and economic benefits are improved. The invention further discloses a coiled tubing technology with cable perforations adopting the coiled tubing tool set with the cable perforations.

Owner:JEREH ENERGY SERVICES

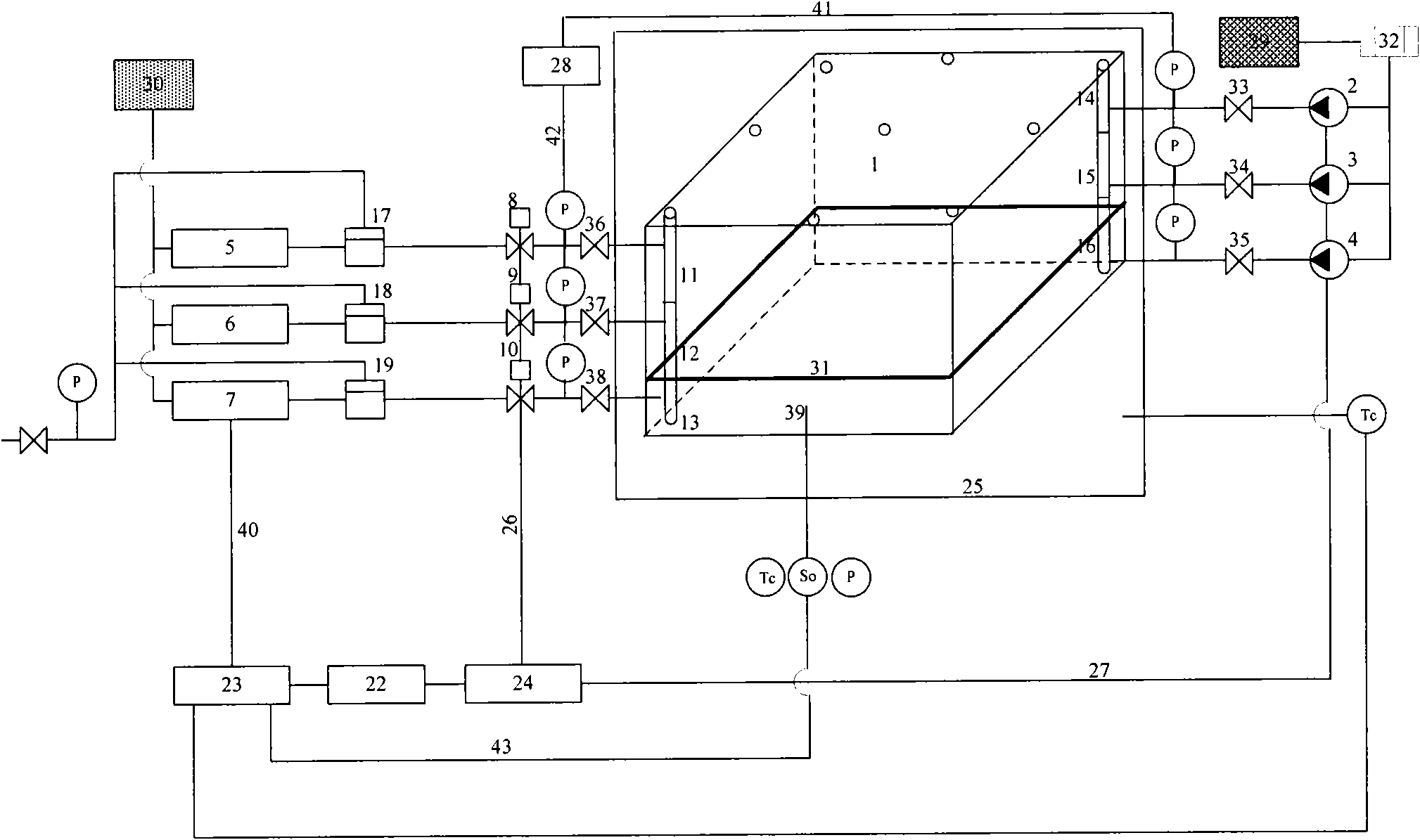

Intelligent oil well simulation experiment system and working method

InactiveCN102022112AEasy to operateFast and easy data collection and processingBorehole/well accessoriesTraffic volumeAutomatic control

The invention discloses an intelligent oil well simulation experiment system and a experiment method. The intelligent oil well simulation experiment system comprises a three-dimensional heterogenous reservoir simulating box, a wellbore hole simulator, a fluid injecting module, a fluid generating module, a data acquiring module, an automatic control module, a constant temperature module, a saturation probe, a pressure sensor and a temperature sensor. The wellbore hole simulator is arranged in the three-dimensional heterogenous reservoir simulating box, the automatic control modules realizes the real-time extraction and injection on the wellbore hole simulator through controlling the fluid injecting module and the fluid generating module; and the data acquiring module is used for monitoringinjected and extracted fluid, and monitoring the saturation, the temperature and the pressure in the simulating box in real time, and a computer is used for optimizing and analyzing the monitoring data, controlling the injection and extraction flow in real time through the automatic control module, simulating and realizing multilayer comingling production, sectional extraction of a horizontal well, extraction of a multi-branch well and control strategy of an injection and extracting well, and perfecting the researches of real-time optimization, real-time regulation and the like of the production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

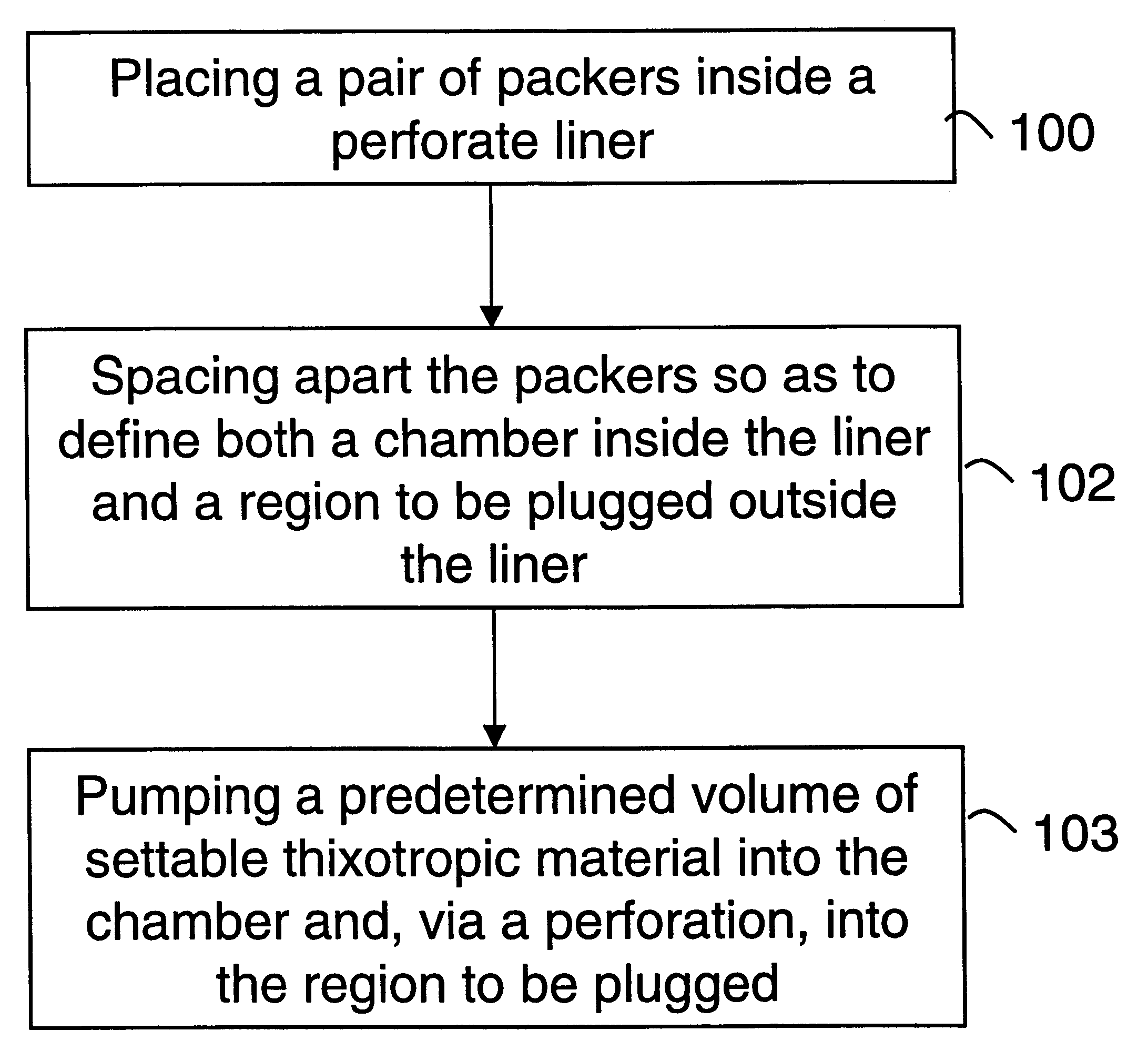

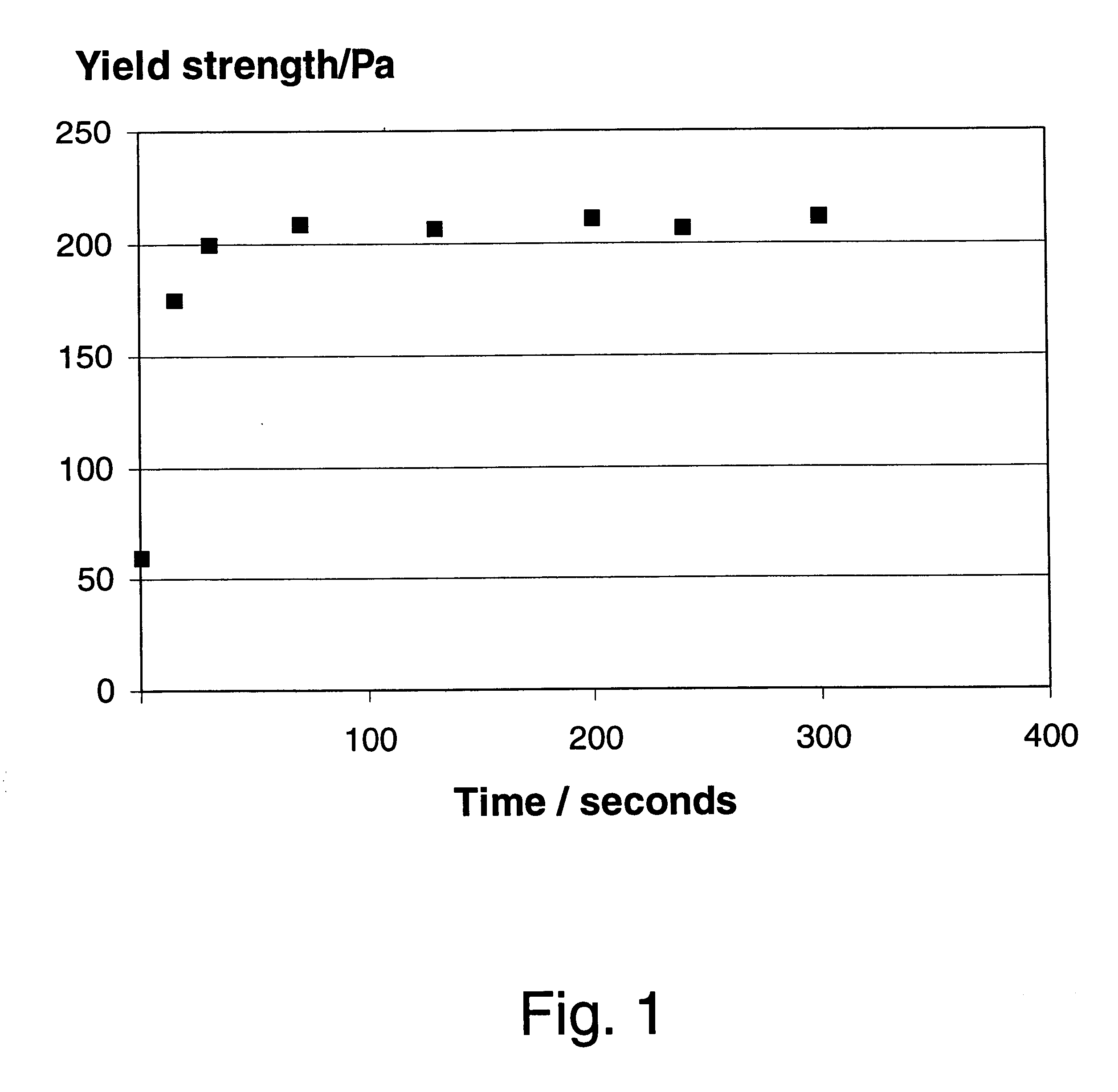

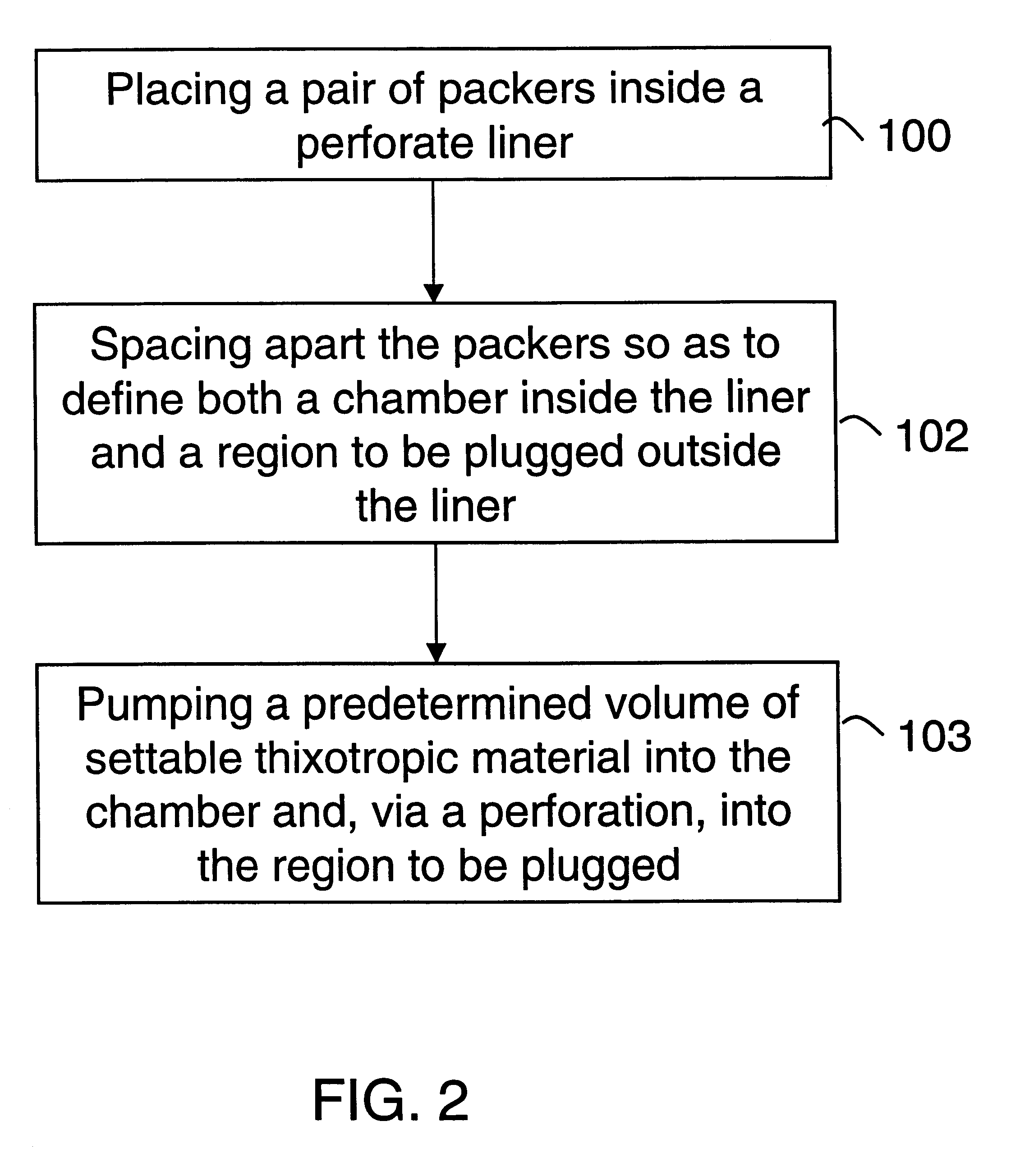

Thixotropic materials

A settable thixotropic material comprises a thixotrope and a settable substance, the material being capable of gelling reversibly in a gelling time of less than 60 seconds. The thixotrope conveniently comprises a fine grained clay, especially smectite clays, e.g. hectorites. It is preferred to use synthetic smectite type clay colloids, and goods results have been obtained with the synthetic clay known as Laponite RDS. The settable material conveniently comprises cement, particularly Portland cement. The thixotropic material finds use generally in oilwell applications, e.g. to plug lost circulation zones, to repair damaged or corroded casing, as grouts, and to limit annular gas migration. The material also finds particular application in techniques for completion of horizontal wells completed with slotted or pre-drilled liners.

Owner:SCHLUMBERGER TECH CORP

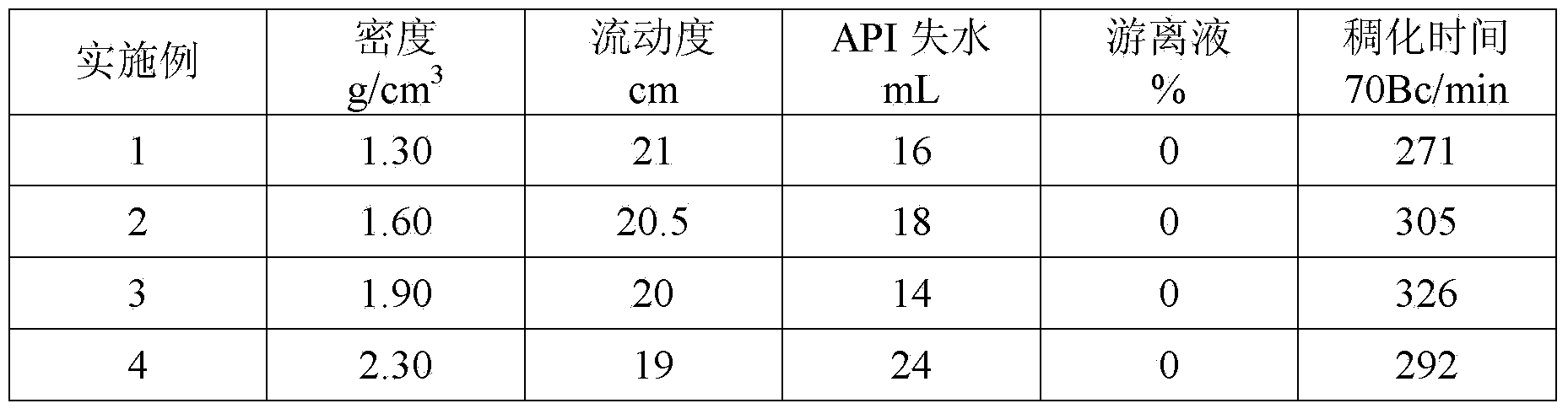

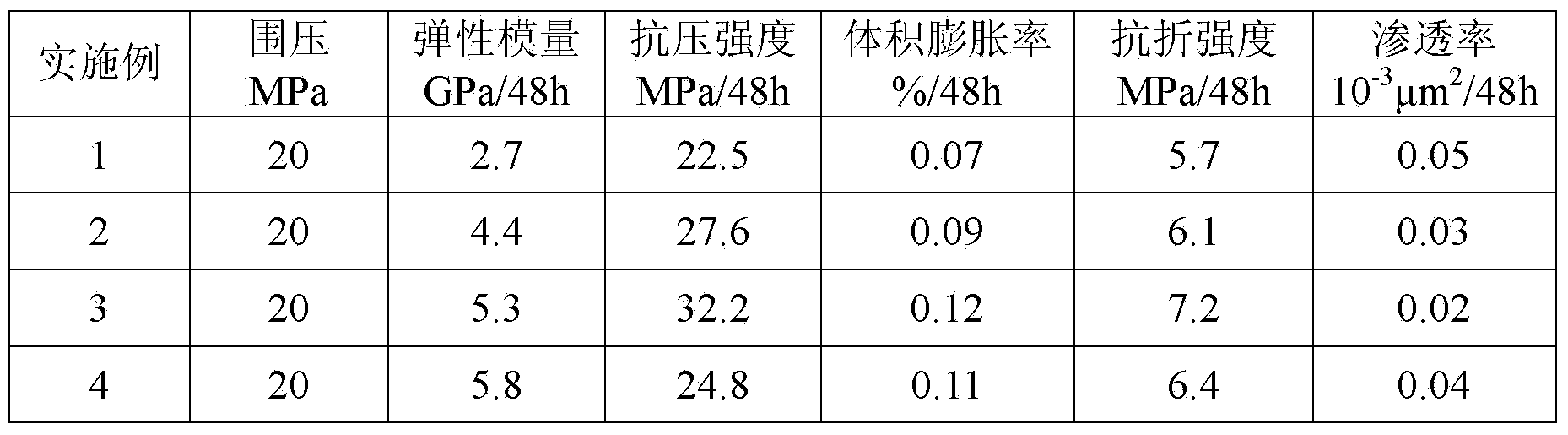

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method and apparatus for the use of multicomponent induction tool for geosteering and formation resistivity data interpretation in horizontal wells

InactiveUS20030229449A1Electric/magnetic detection for well-loggingSurveyGeosteeringHorizontal wells

Measurements made with a multicomponent logging instrument when used in a substantially horizontal borehole in earth formations are diagnostic of the direction of beds relative to the position of the borehole. When the logging instrument is conveyed on a drilling assembly, the drilling trajectory may be maintained to follow a predetermined trajectory or to maintain a desired distance from a boundary such as an oil-water contact.

Owner:BAKER HUGHES INC

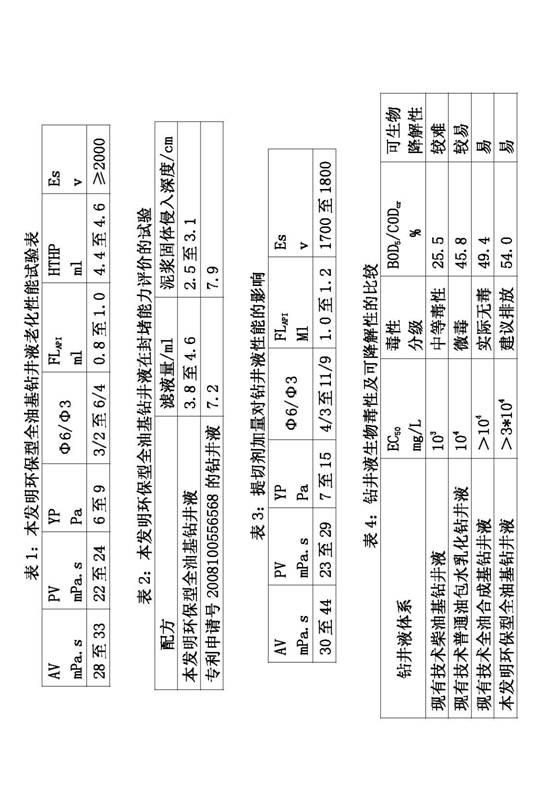

Environmental-friendly type oil-based drilling fluid and preparation method thereof

ActiveCN102304353AAvoid damageImprove the blocking effectDrilling compositionHorizontal wellsPetroleum

The invention relates to the technical field of an oil-based drilling fluid for petroleum drilling, in particular to an environmental-friendly type oil-based drilling fluid and a preparation method therefore. The environmental-friendly type oil-based drilling fluid is prepared from the following raw materials: base liquid white oil, calcium chloride water solution, an emulsifying agent, a wetting agent, organic oil for drilling fluid, a composite plugging agent, a shear strength improving agent, a basicity regulating agent and a fluid loss additive; and a weighting agent is added into a mixture of the raw materials. The oil-based drilling fluid has the following advantages of: good plugging property, high shear viscosity and strong rock carrying capability; the EC 50 (median effect concentration) of the drilling fluid is larger than 3*104mg / L; the drilling fluid has good environmental safety; the return permeability of the drilling fluid can reach 90%-98%; the drilling fluid has little damage to reservoirs; the preparation process of the drilling fluid is simple; the drilling fluid is mainly applied to a special construction technology such as underbalance, horizontal wells and the like, water sensitivity reservoirs and low-pressure low permeability gas wells.

Owner:克拉玛依市金鑫科技有限公司

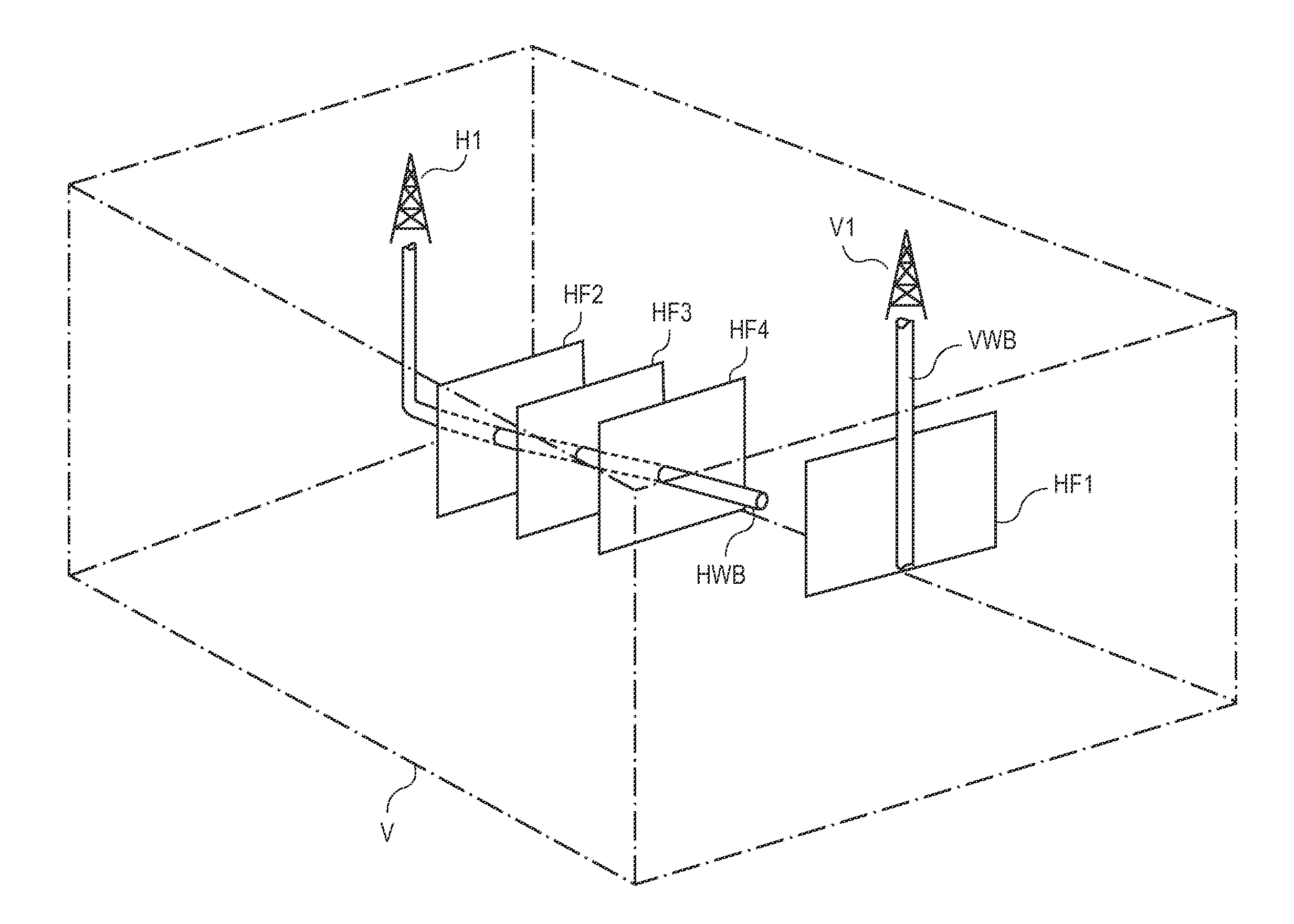

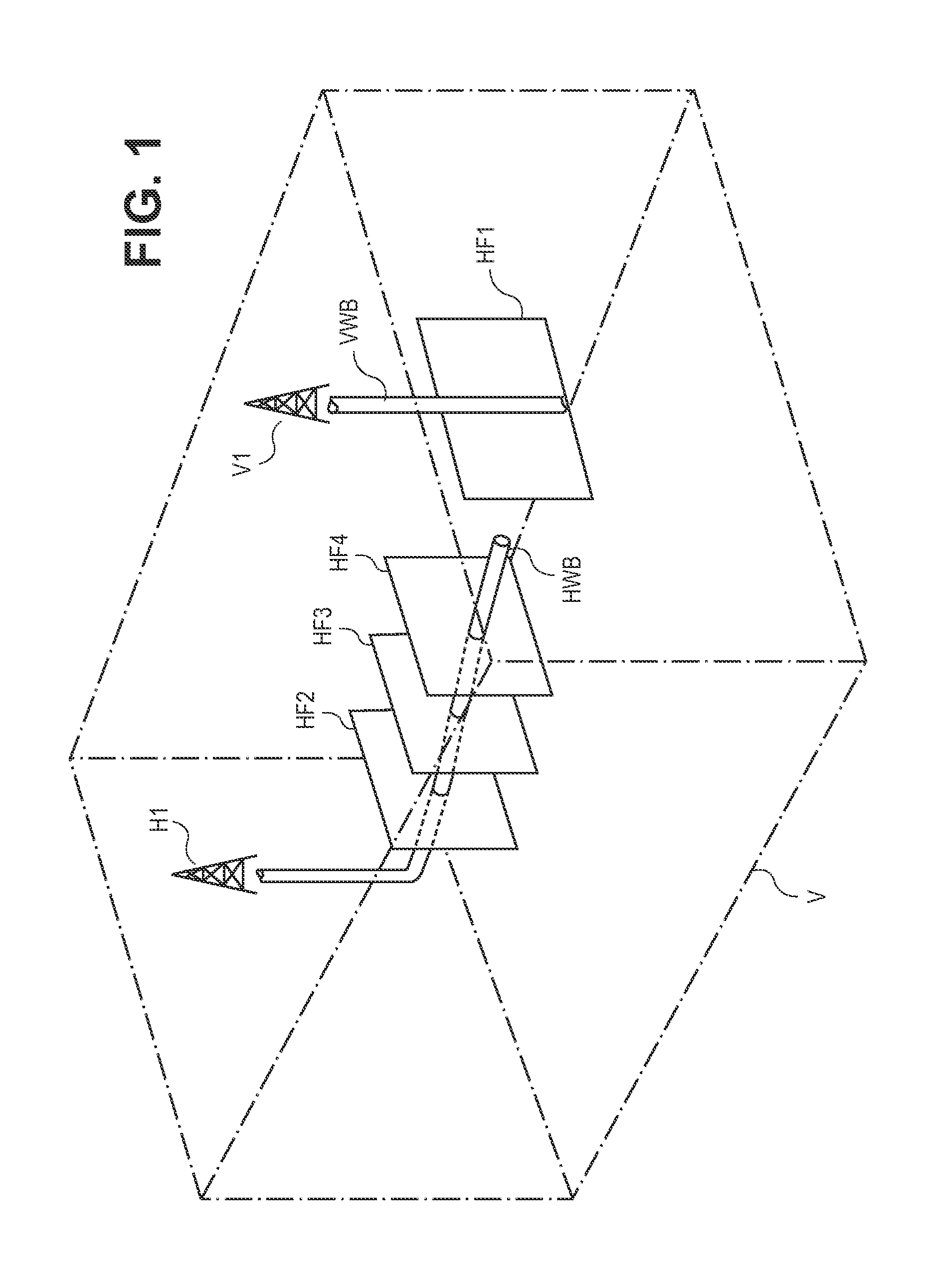

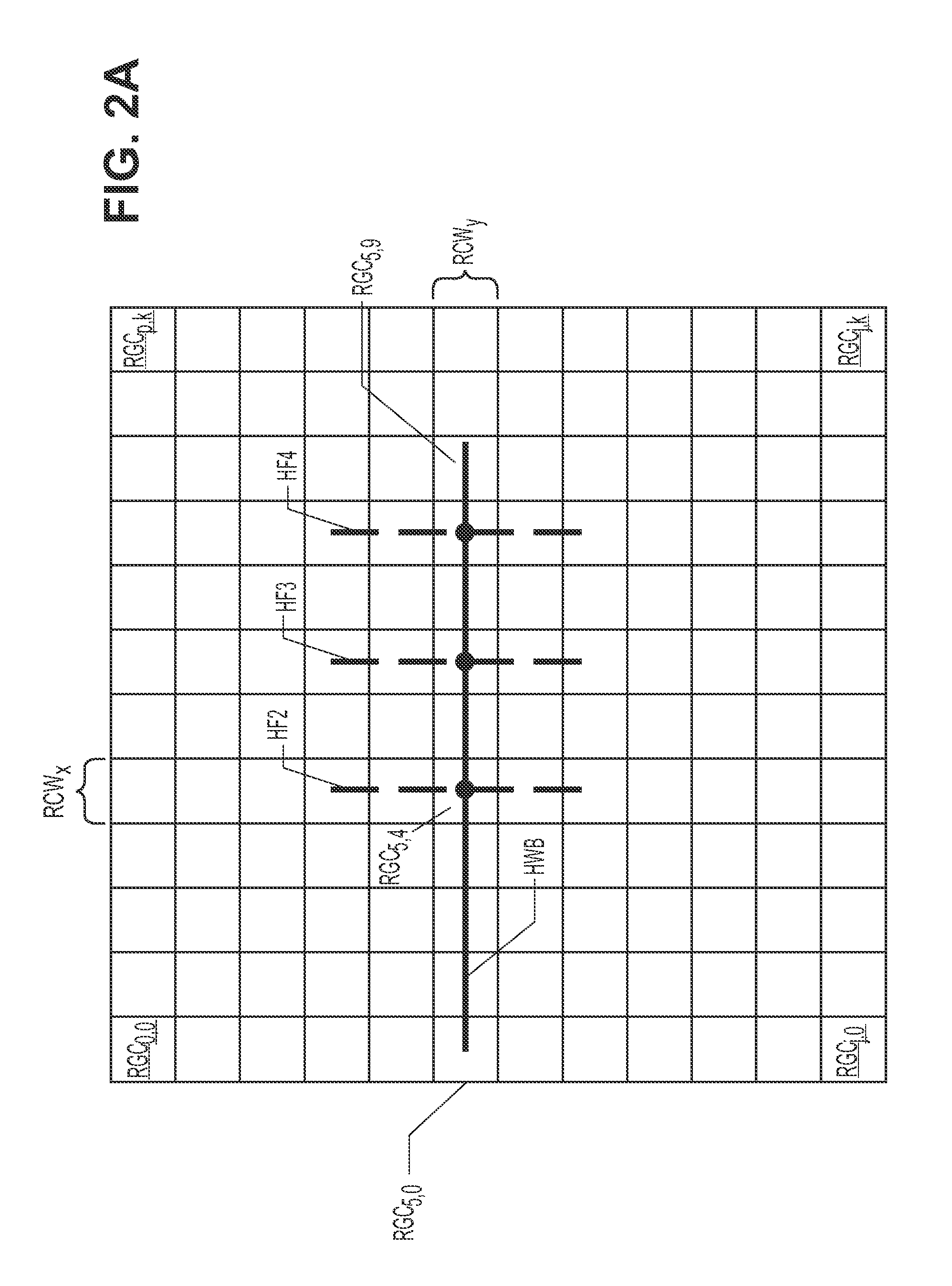

Automated generation of local grid refinement at hydraulic fractures for simulation of tight gas reservoirs

ActiveUS20130073268A1Reasonable computational complexityLow costComputation using non-denominational number representationDesign optimisation/simulationHorizontal wellsHydraulic fracturing

A computer system and method of automatically generating a Local Grid Refinement (LGR) gridded model of a gas reservoir. A geologic file includes information identifying the locations of one or more wells according to root grid cells within a volume of the earth to be modeled. User inputs specify the number of hydraulic fractures from each well, and such parameters as the fracture length, etc. User inputs also specify the number of “splits” of the root grid cells containing hydraulic fractures; those root grid cells are then split into finer resolution grid cells of increasing width within the root grid cells containing the fractures. For horizontal wells, user inputs indicate the number of splits of root grid cells containing the lateral portions of the wellbore. Non-orthogonal and complex fractures are processed by a“nested” LGR approach. Geologic properties are assigned to each grid cell, with a tensorial adjustment included for non-orthogonal fractures, and the resulting model is available for simulation.

Owner:BP CORP NORTH AMERICA INC

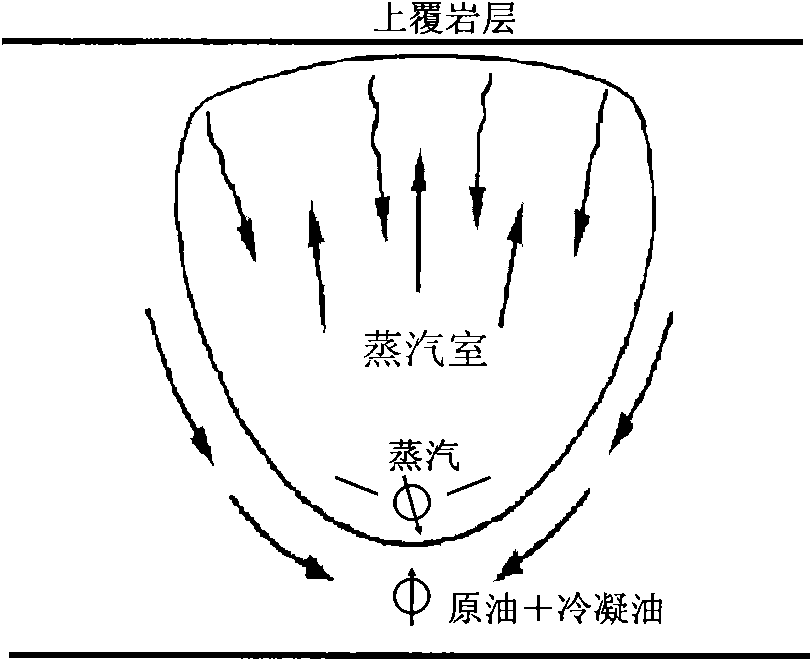

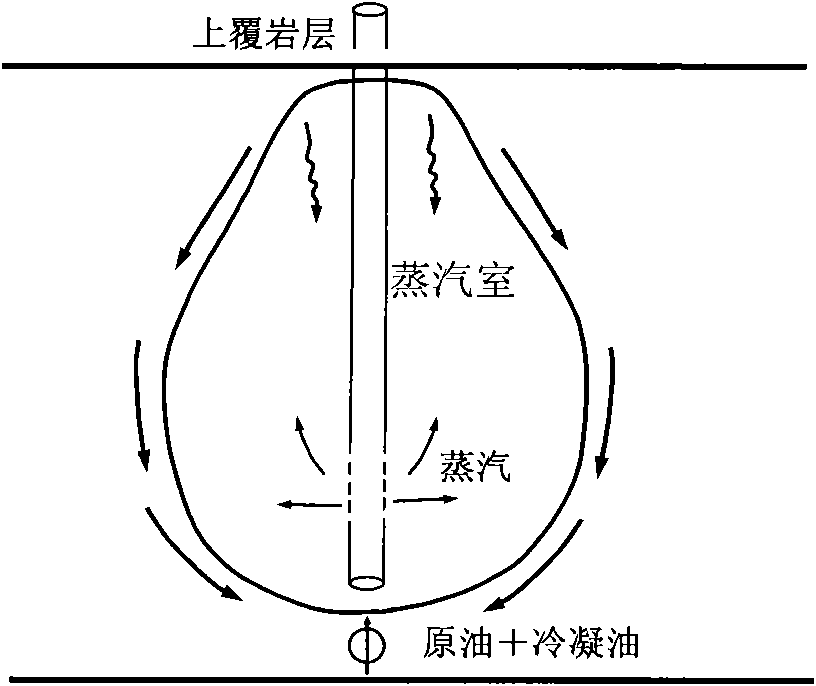

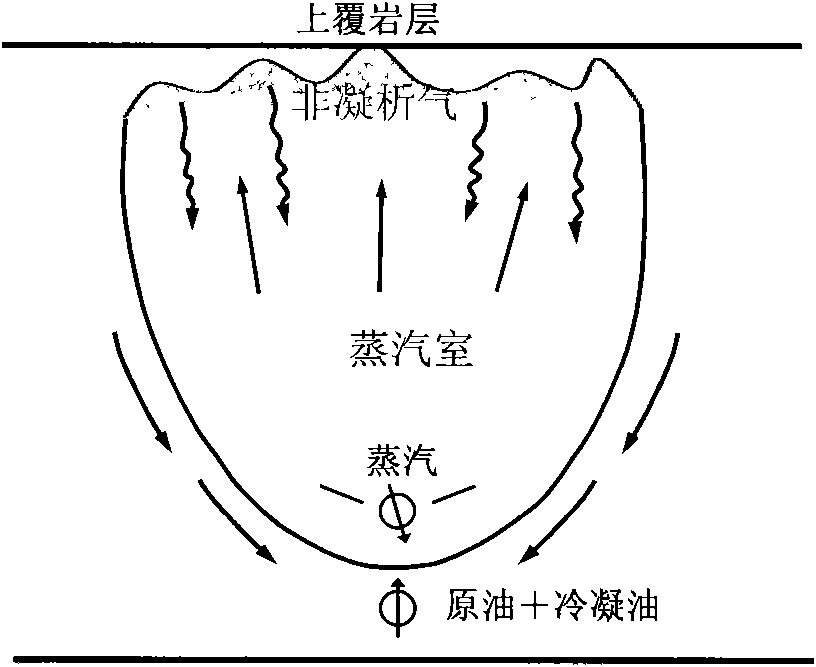

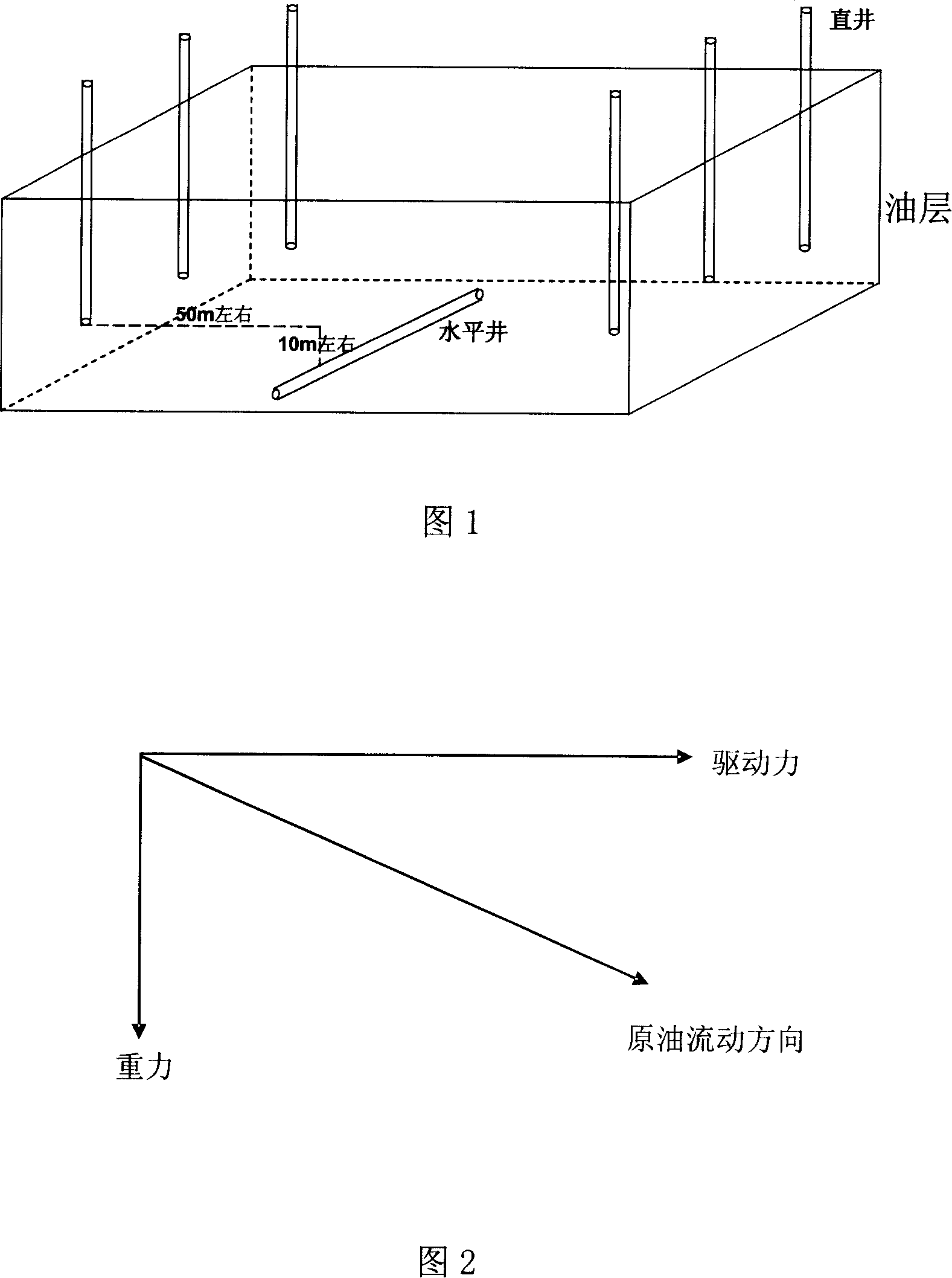

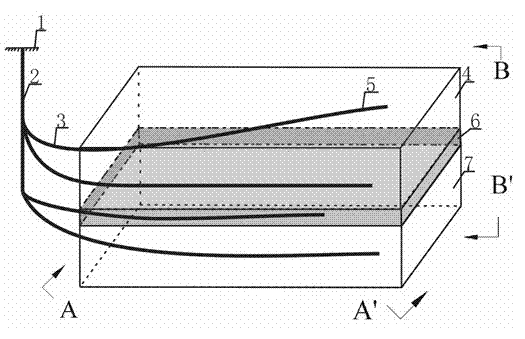

Gas-assisted SAGD method for exploiting super heavy oil

The invention relates to a gas-assisted SAGD method for exploiting super heavy oil; the selecting layer thickness is 530m, remaining oil saturation is more than 0.50, oil layer thickness is more than 10.0m, horizontal permeability is more than 250md, the ratio of the vertical permeability to the horizontal permeability is more than 0.1, the oil layer porosity is more than 0.20, continuous distributed impermeable clay and intercalated shale oil pools do not exist in the oil layer; a horizontal well is drilled between soaking vertical wells, the well spacing is 35m or a pair of horizontal wells are drilled at the bottom of the oil layer, the vertical distance is 6m; swallowing is carried out for 3 stages, when the hot communication is formed between the wells, the vertical wells is used to inject steam continuously, the production of horizontal wells is 3 years, then the vertical wells is used to inject nitrogen and steam until the underground volume ratio is 0.5 and the total injection rate of nitrogen is 0.10PV, then the steam is injected continuously, the steam injection rate is 1.4m / d.ha.m, the dryness of steam at the bottom of wells is 70%, the production-injection ratio is maintained at 1.2; the recovery percent is increased by 6.0-9.0% and the oil-steam ratio is improved by 0.02-0.05.

Owner:PETROCHINA CO LTD

Dual downhole pressure barrier with communication to verify

Owner:TEJAS RES & ENG

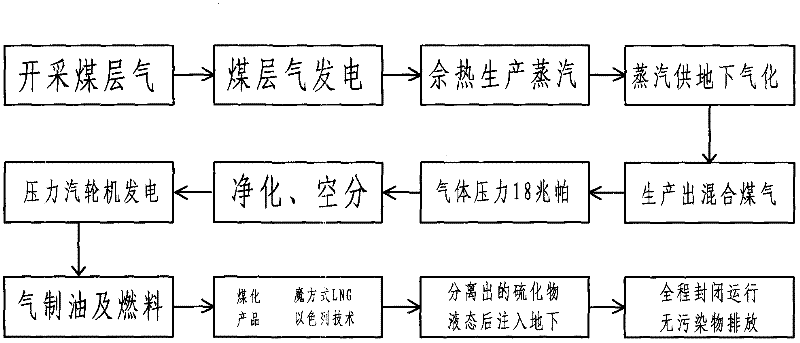

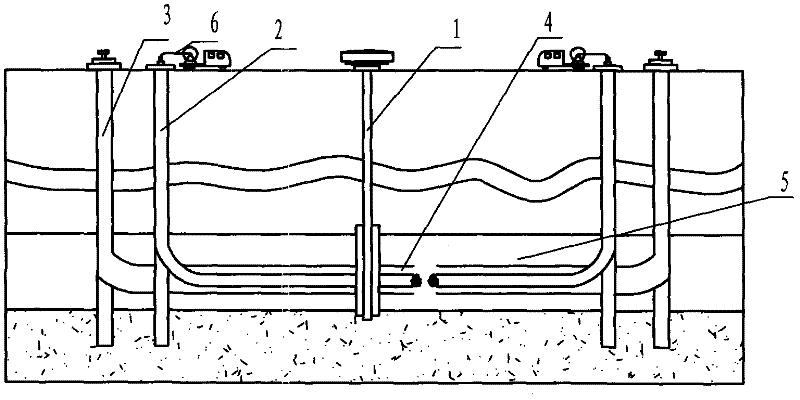

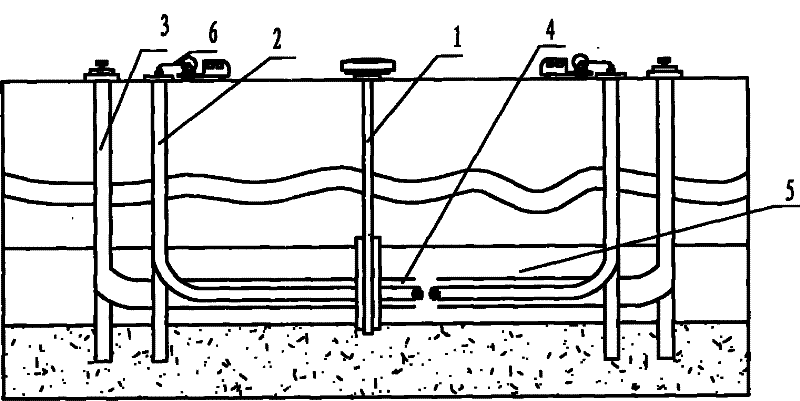

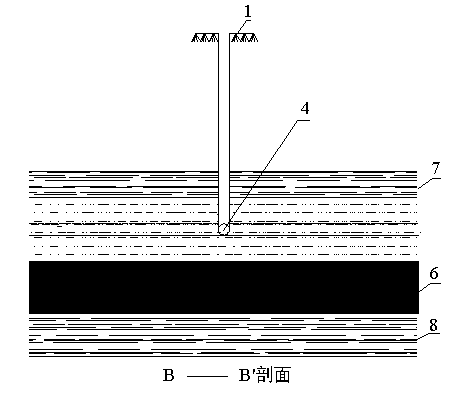

Deep coal and coal bed gas combined mining method

The invention relates to a deep coal resource mining method. When the buried depth of a coal bed is 800 to 3,000 meters, the thickness is more than 3 meters, an inclination angle is less than 10 degrees, and pressure is more than 10 Mpa, the most advanced well drilling and cementing, high-temperature resistant and high-pressure well completion technologies in oil industry, vertical shafts and vertical shafts and gas injection and gas production combined methods are adopted; the method is characterized by comprising the following steps of: drilling three vertical shafts first, wherein the distance between the wells is 500 meters; drilling a horizontal well which is more than 500 meters deep from a secondary well to a central well, combusting a long tunnel which is 1,000 meters long and 10 meters wide by a special combustion method, wherein the tunnel is a gasification tunnel special for gas production, observation, monitoring and the like, and drilling a plurality of overlong horizontal wells in the reverse direction according to the inclination gradient of the coal bed. The deep coal bed gas and the deep coal are gasified underground, and exploited in a combined way, so the problem of shortage in energy resources in China can be greatly improved, the method is a new environment-friendly, low-carbon, innovative new-energy development technology, and low in cost and has great economic value, and investment is reduced.

Owner:GUODING DALIAN INVESTMENT

Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

InactiveCN101539007AAvoid defects that require moving the downhole stringGood sealingFluid removalLiquid spraying apparatusHorizontal wellsOil field

The invention relates to an abrasive jetting device and a method for abrasive water jet perforation and multiple fracturing; wherein the abrasive jetting device has multistage jet guns which are connected in series; the jet guns are all hollow columns; the side walls thereof are respectively provided with at least two nozzles; the lower part of each stage of jet gun is provided with a packer; the side wall of the packer is provided with a sealing sleeve which can expand outward under the action of high-pressure liquid; the jet guns comprise a first stage bottom jet gun arranged at the lower part of the abrasive jetting device and multistage upper jet guns arranged above the bottom jet gun; wherein all the upper jet guns are respectively provided with a sliding sleeve which can seal the nozzle of the stage of jet gun and sealing sleeve; and the sliding sleeve can slide to the lower part of the sealing sleeve under the action of external force so as to open the nozzle and the sealing sleeve. The invention can be used for casing straight wells or horizontal wells, solves the problem of layered or staged fracturing in the straight wells or the horizontal wells in oil fields, and achieves the purposes of saving fracturing cost, improving fracturing effect and reducing the construction risk.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

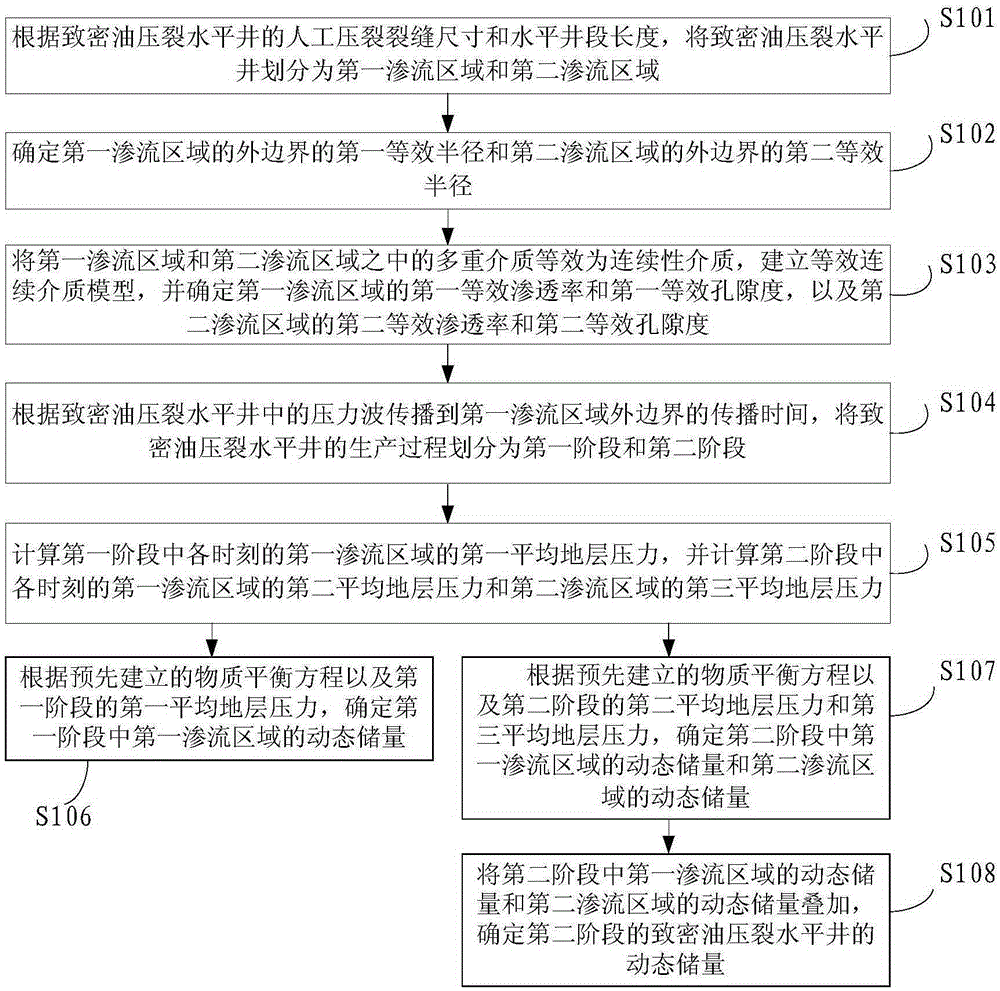

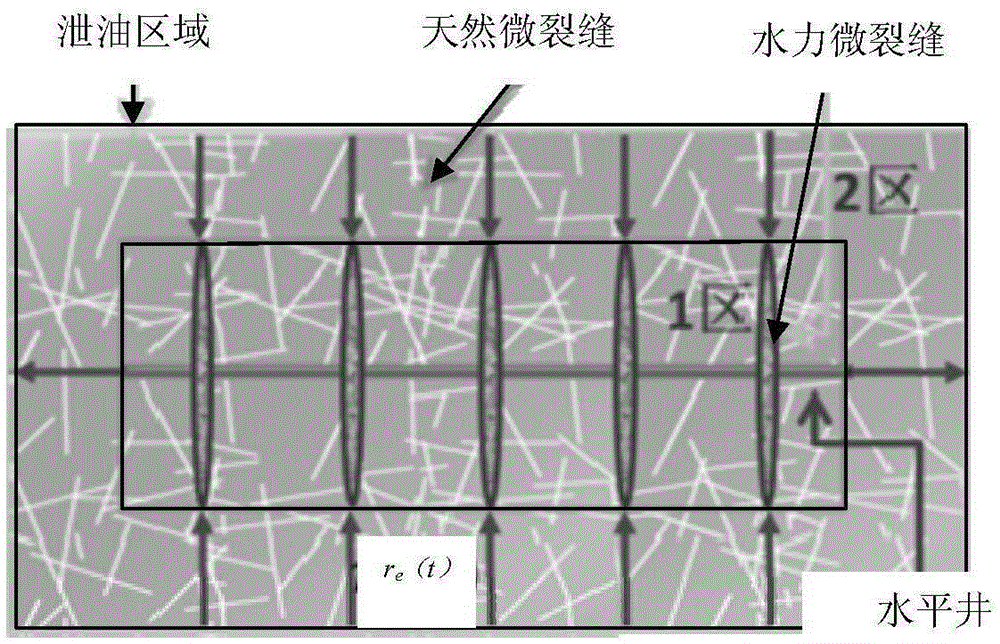

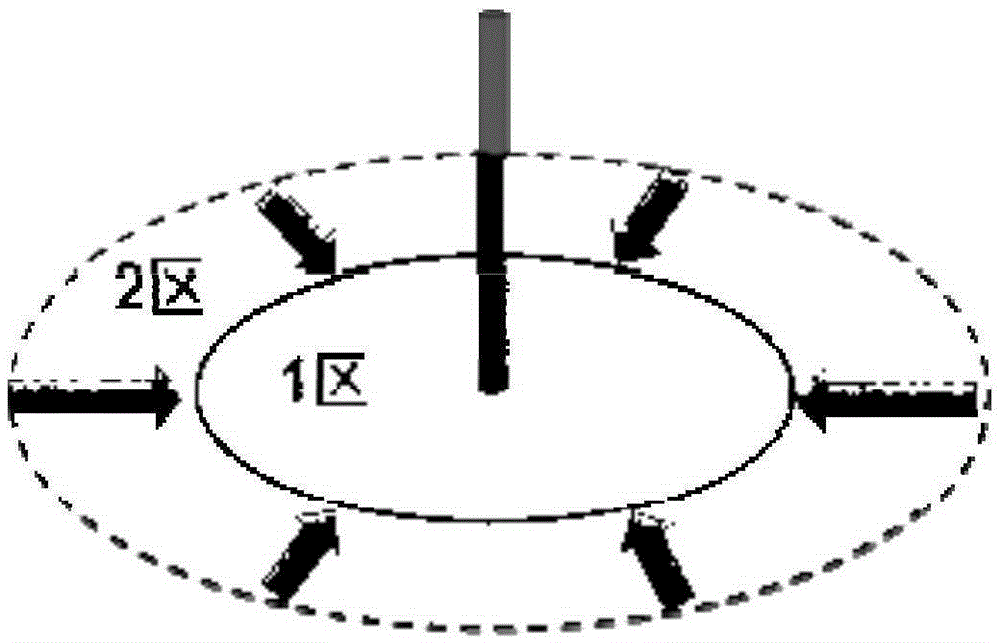

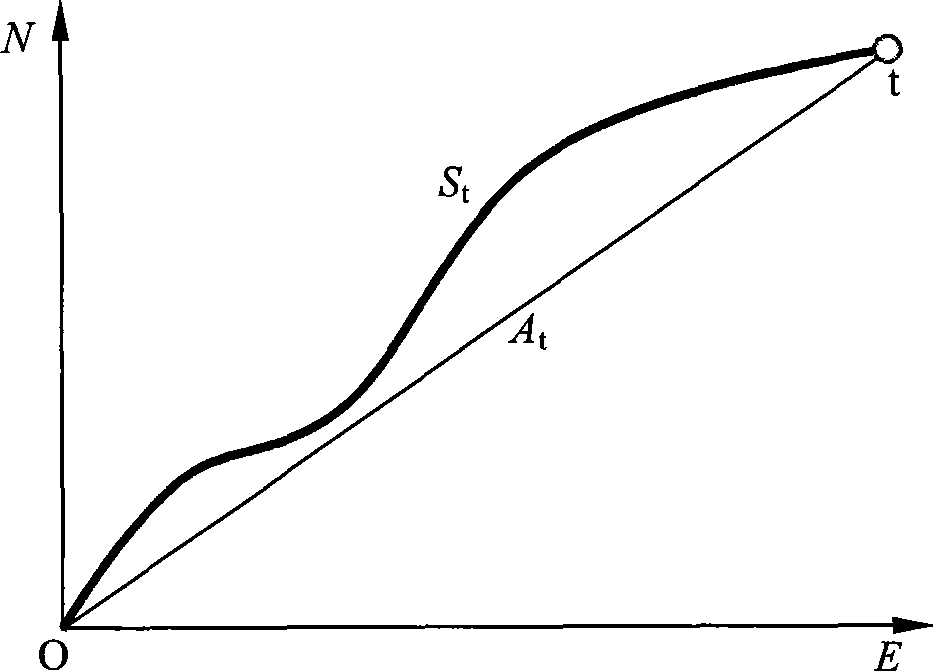

Method for calculating dynamic reserve of dense oil fractured horizontal well

ActiveCN105243182AAccurate predictionSpecial data processing applicationsMaterial balanceHorizontal wells

The present invention provides a method for calculating a dynamic reserve of a dense oil fractured horizontal well, and relates to the technical field of dense oil fractured horizontal wells. The method comprises: dividing a dense oil fractured horizontal well into a first percolation region and a second percolation region; dividing a production process of the dense oil fractured horizontal well into a first stage and a second stage; calculating a first average formation pressure of the first percolation at each time in the first stage, and calculating a second average formation pressure of the first percolation region and a third average formation pressure of the second percolation region at each time in the second stage; according to a pre-established mass balance equation, determining a dynamic reserve of the first percolation region in the first stage as a dynamic reserve of the dense oil fractured horizontal well of the first stage; and according to the pre-established mass balance equation, determining a dynamic reserve of the first percolation region and a dynamic reserve of the second percolation region in the second stage, and determining a sum of the dynamic reserve of the first percolation region and the dynamic reserve of the second percolation region to be a dynamic reserve of the dense oil fractured horizontal well in the second stage.

Owner:PETROCHINA CO LTD

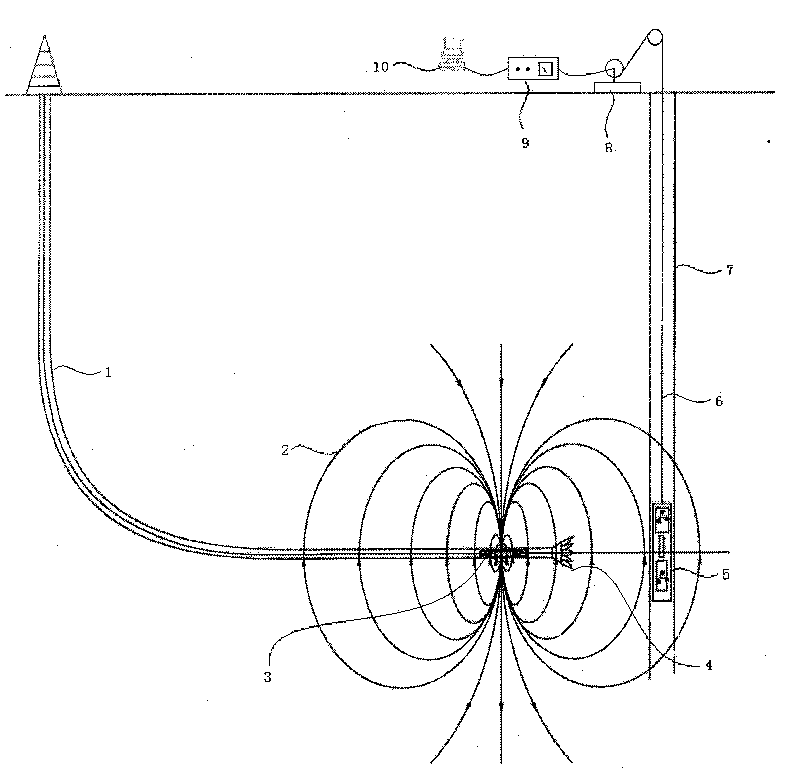

Electromagnetic system for detecting distance between adjacent wells while drilling

ActiveCN101713286ASimple structureEasy to useElectric/magnetic detection for well-loggingSurveyMeasuring instrumentRs 232 interface

The invention provides an electromagnetic system for detecting a distance between adjacent wells while drilling, which is capable of providing accurate guide measurement and calculation for the control of well tracks of wells with complex structures, such as a cross well, a U-shaped communicated well, a dual-horizontal well, an accident rescue well and the like. The electromagnetic system for detecting the distance between adjacent wells while drilling mainly comprises a magnetic pipe nipple, an electromagnetic measuring instrument and a method for calculating the distance between adjacent wells, wherein the magnetic pipe nipple is a hollow cylinder with API standard ports at the two ends consisting of a non-magnetic drill collar and a plurality of permanent magnets, and is used as a signal source for an electromagnetic guide system; the measuring instrument mainly comprises an underground searching tube and a ground system, and is mainly used for detecting a magnetic vector signal ofthe magnetic pipe nipple and for sending data to a computer through an RS-232 interface; and the computer processes and analyzes measured information by using the method for calculating the distance between adjacent wells so as to convert the measured information of a drill position into readable data for engineers. The electromagnetic system for detecting the distance between adjacent wells while drilling has a simple structure and convenient use, and provides an effective high and new technological measure for the detection and control of the distance between adjacent wells with complex structures.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Gravity-assisted steam flooding exploitation method for heavy laver common heavy oil reservoir

The invention relates to a gravity-assisted steam flooding mining method for exploiting thick-bed ordinary heavy oil reservoirs. In the thick-bed ordinary heavy oil reservoirs, the methods of steam injection in vertical wells and production in horizontal wells or steam injection in horizontal wells and production in horizontal wells are adopted . For the oil reservoir blocks that have been developed by vertical wells, the combination of vertical wells and horizontal wells can be used to drill horizontal production wells along the lower part of the oil layer in the known oil reservoir blocks, so that the vertical steam injection wells are obliquely above the horizontal wells, and the production wells and injection wells Simultaneous huff and puff of steam wells for 2-4 cycles or thermal communication between steam injection wells and production wells or formation of reservoir pressure down to 3-4MPa, transfer to steam injection wells and steam injection production wells for production and production; or steam injection wells and production wells have formed thermal communication , After the newly drilled horizontal production well huffs and puffs for one cycle and removes the pollution near the wellbore, the steam injection production well is transferred to the steam injection well for production and production. The invention can exert the sweeping effect of the displacement fluid in both vertical and horizontal directions, increase the sweeping range of the driving fluid, and increase the crude oil recovery rate of the thick common heavy oil reservoir.

Owner:PETROCHINA CO LTD

Permeability improvement technology for coal bed gas reservoir cap by using three-dimensional fracture network modification

InactiveCN102392677AImprove permeabilityIncrease contact areaFluid removalGas removalMining engineeringHorizontal wells

The invention relates to a permeability improvement technology for a coal bed gas reservoir cap by using three-dimensional fracture network modification. The technology is as follows: building a bedding horizontal well from ground to top and bottom plates of the coal bed of an area not mined; building bedding, three-dimensional cross-type or multi-branch long boreholes on the top and bottom plates of the coal bed of the area not mined through perforation and segmented fracturing or existing sinking and driving engineering, and then carrying out hydraulic fracturing; modifying the coal bed gas reservoir cap into a crisscross fracture network system to form a modified volume; building various types of drainage boreholes in the modified volume; and carrying out negative pressure extraction together with a fractured well, so that coal bed gas can be continuously desorbed and dispersed and then extracted out in large scale through the modified volume. According to the invention, the crisscross fracture network system is formed in the coal bed gas reservoir cap, so that the coal bed gas can be continuously desorbed and dispersed at negative pressure and then extracted out in large scale through the modified volume, thus the content of coal bed gas in the modified bed can be quickly reduced to be below the safety standard in the outburst prevention formulation, and safe and high-efficiency production of mines can be realized on the basis of forming scale coal bed gas development.

Owner:HENAN COAL CHEM IND GROUP INST

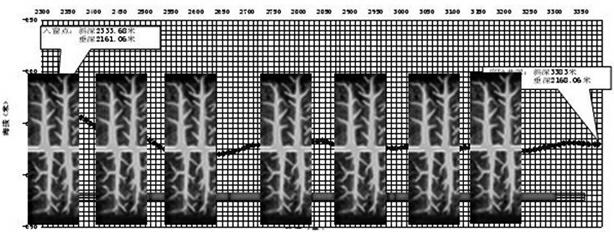

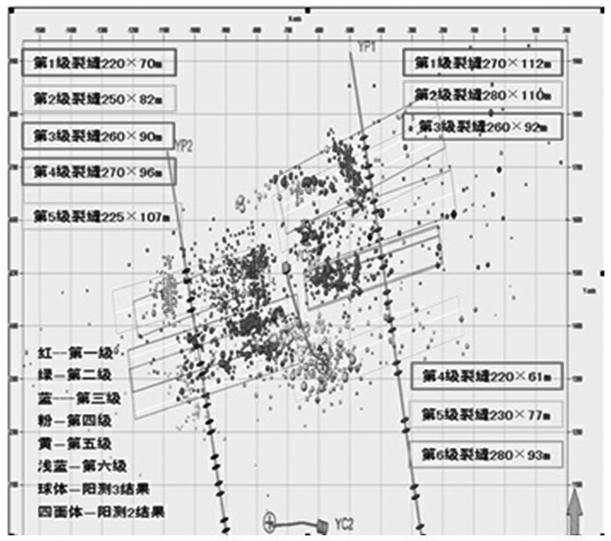

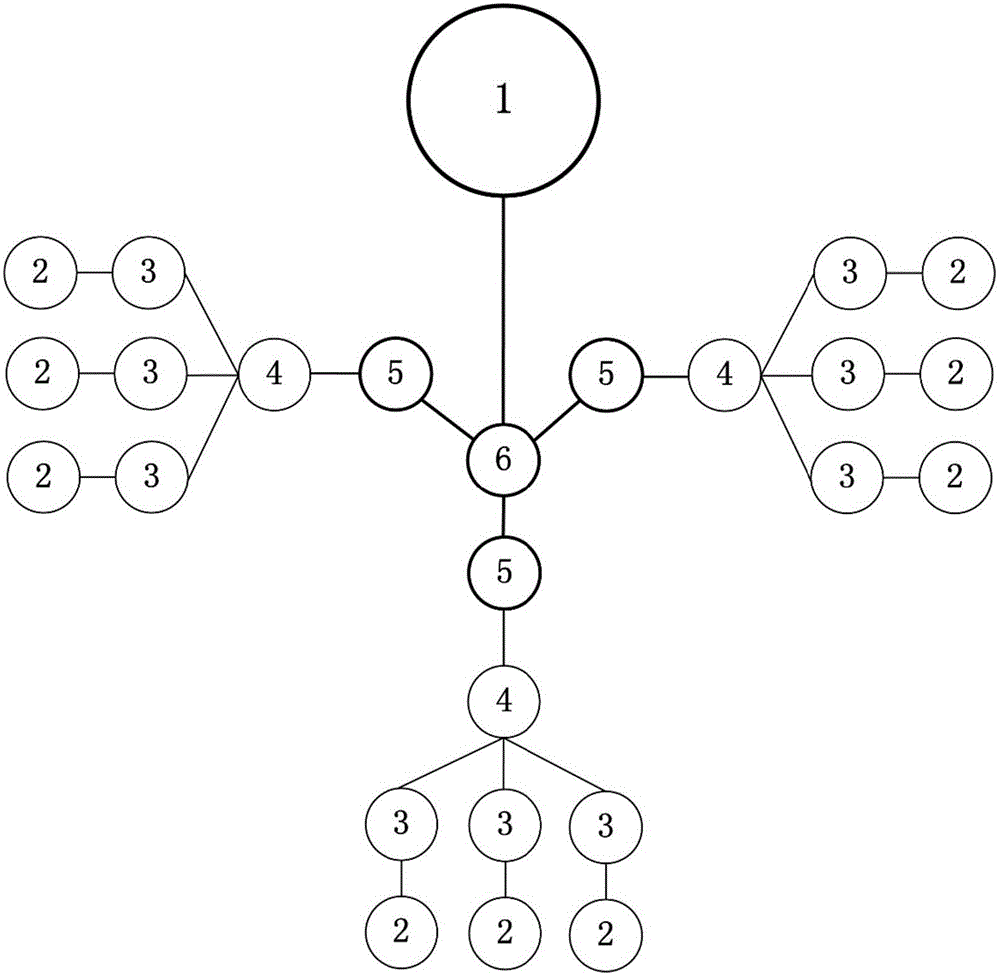

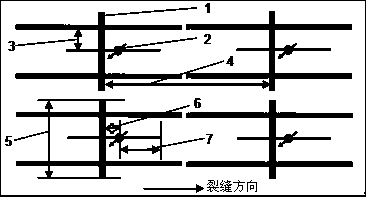

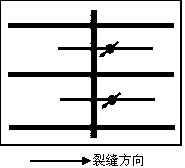

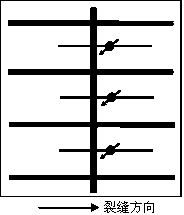

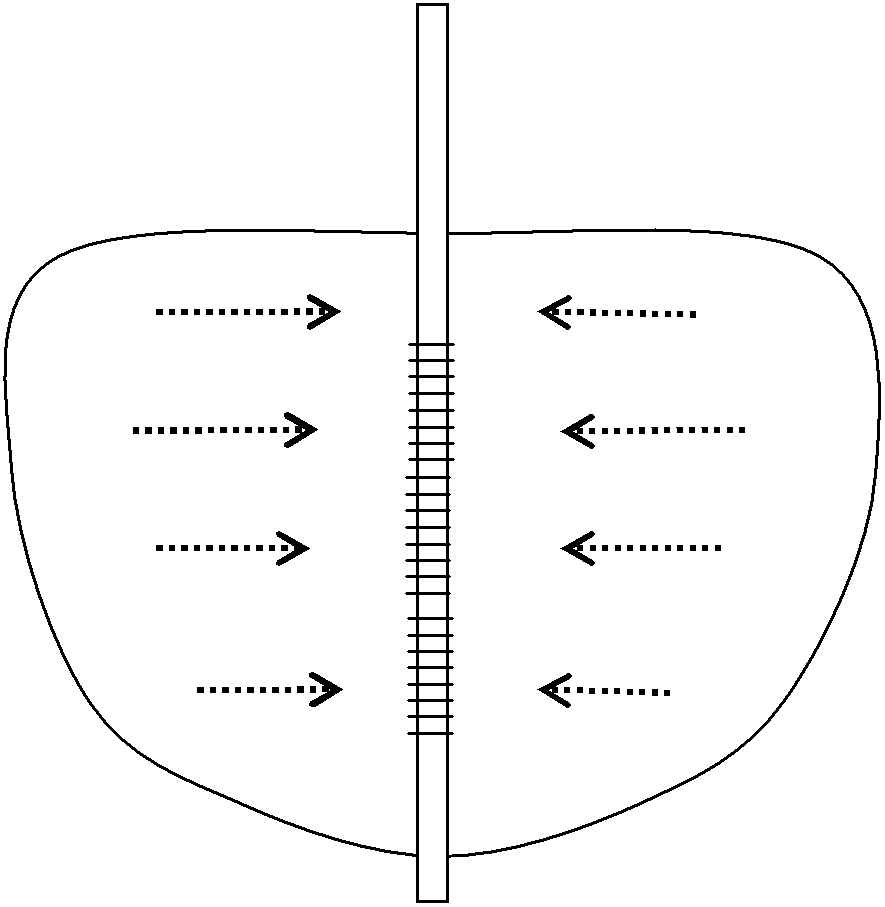

Sectioned multi-cluster synchronous volume fracturing technology for double horizontal wells

ActiveCN102606124AThe average air penetration rate is smallGood oilinessFluid removalMulti clusterHorizontal wells

The invention belongs to the field of oil and gas field exploration, discloses novel technology for volume fracturing of a compact oil reservoir, and particularly relates to a sectioned multi-cluster synchronous volume fracturing technology for double horizontal wells. The technology is characterized by including the steps of synchronous fracturing selection, synchronous fracturing well selection, multi-section and multi-cluster perforation position determination, synchronous fracturing construction and synchronous fracturing effect evaluation. In the technology, cracks are impelled to turn by means of interference among the cracks, thereby realizing complicated netted cracks and effectively modifying the compact oil reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method and Apparatus for the Use of Multicomponent Induction Tool for Geosteering and Formation Resistivity Data Interpretation in Horizontal Wells

InactiveUS20070236221A1Electric/magnetic detection for well-loggingSurveyGeosteeringHorizontal wells

Owner:BAKER HUGHES INC

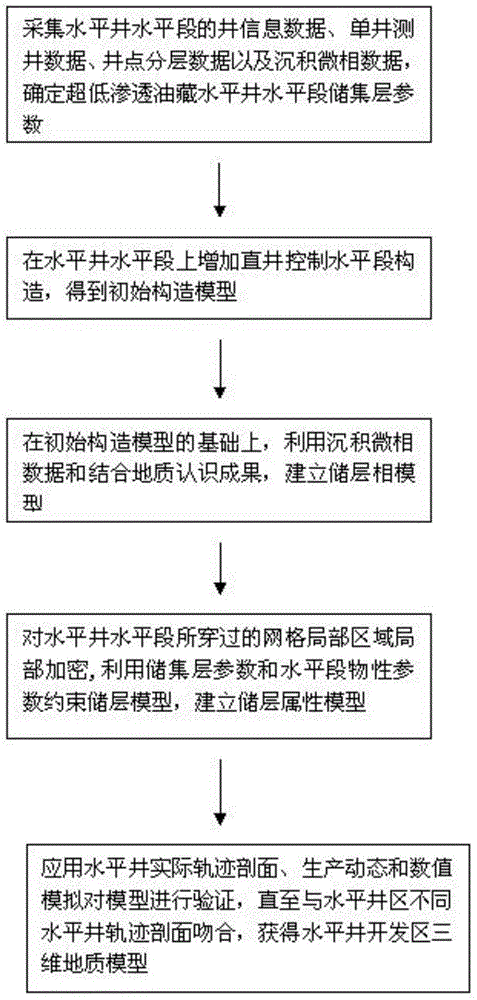

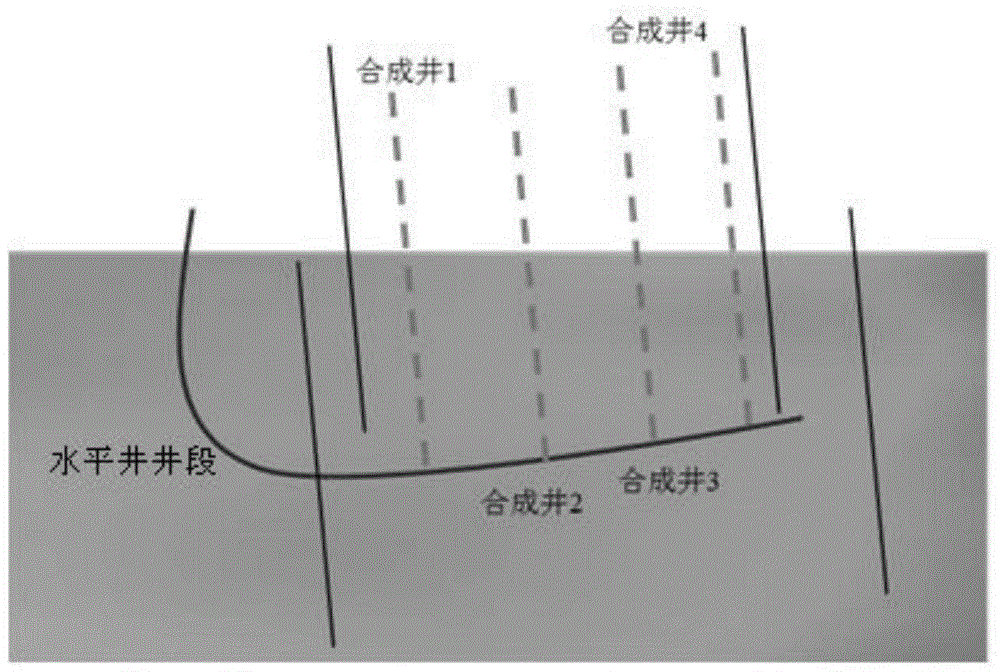

Geological modeling method for horizontal wells in ultra-low permeability tight reservoirs

ActiveCN104809277ASolve the sonic time differenceSolve the problem of high resistivitySpecial data processing applications3D modellingGeomorphologyWell logging

The invention provides a geological modeling method for horizontal wells in ultra-low permeability tight reservoirs, which includes the following steps: (1) the well information data, single-well logging data, well point layer data and sedimentary microfacies data of the horizontal section of a horizontal well are acquired, and the reservoir stratum parameters of the horizontal section of the horizontal well are determined; (2) vertical wells are added on the horizontal section of the horizontal well to control the horizontal section structure, so that an initial structure model is obtained; (3) a reservoir facies model is created by utilizing the sedimentary microfacies data and in combination with geological knowledge and achievements; (4) the reservoir stratum parameters of the horizontal section of the horizontal well are utilized for analysis, and a reservoir property model is created; (5) the actual locus profiles, production performance and numerical simulation of the horizontal well are applied to verify the geological models, so that a three-dimensional geological model of an exploitation area of the horizontal well is obtained. The method provides a data source for the research on the characteristics of the planar distribution of sand, accurately describes the planar distribution trend and vertical facies distribution trend of a reservoir stratum, increases the precision of the prediction model, and lays a foundation for the optimization of an ultra-low permeability oil reservoir exploitation technology policy and fine injection and production adjustment.

Owner:PETROCHINA CO LTD

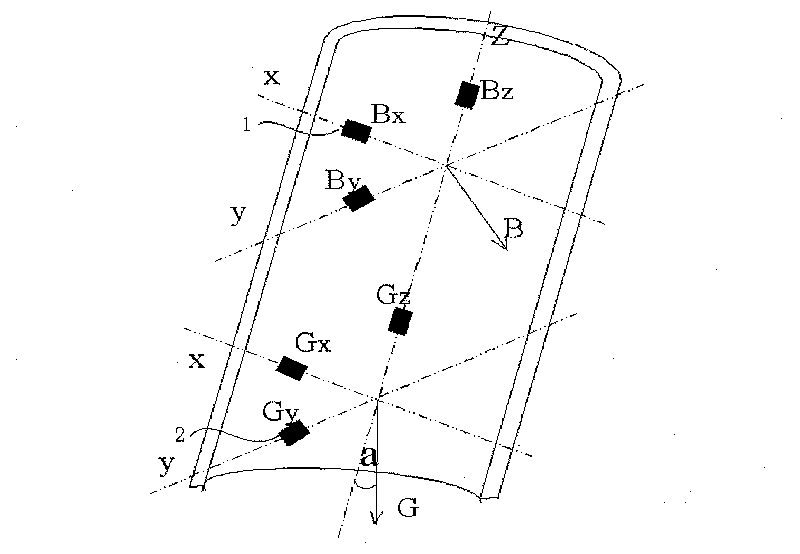

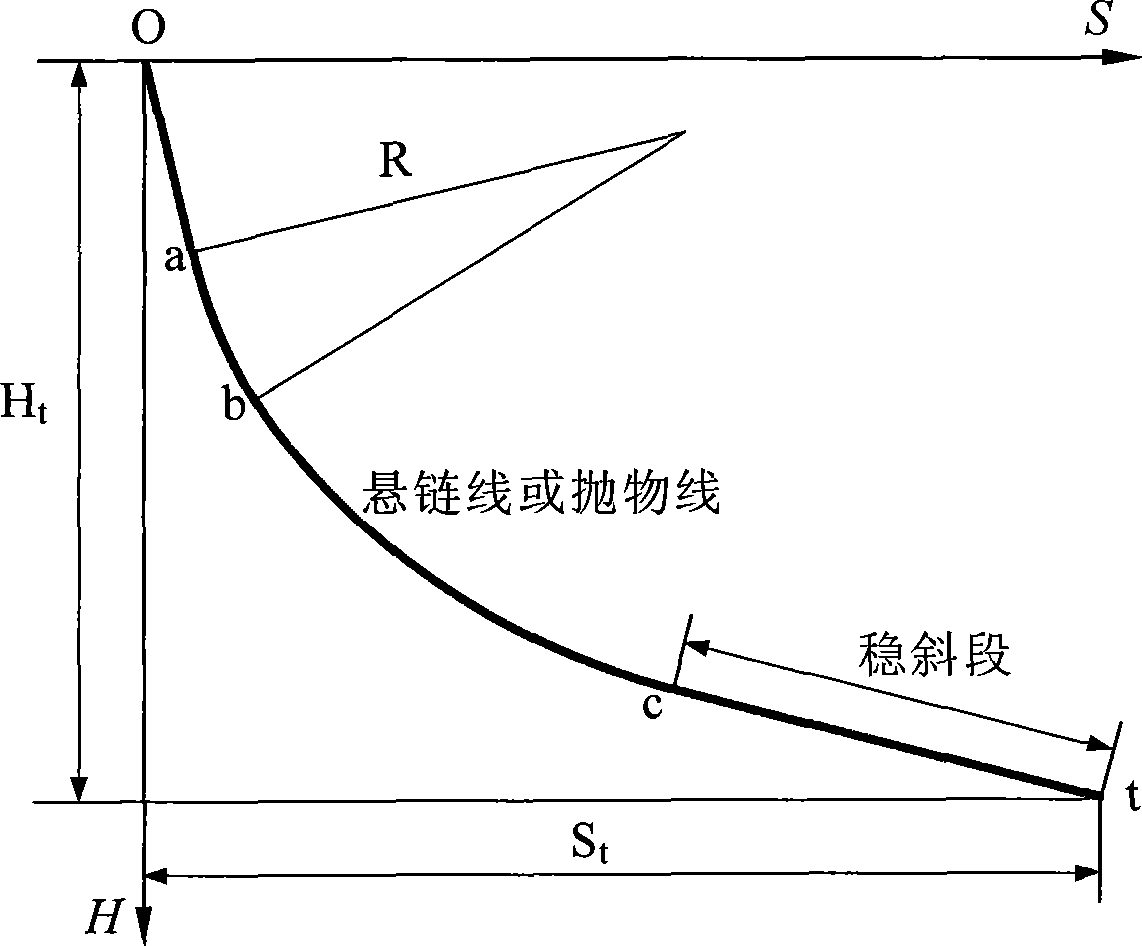

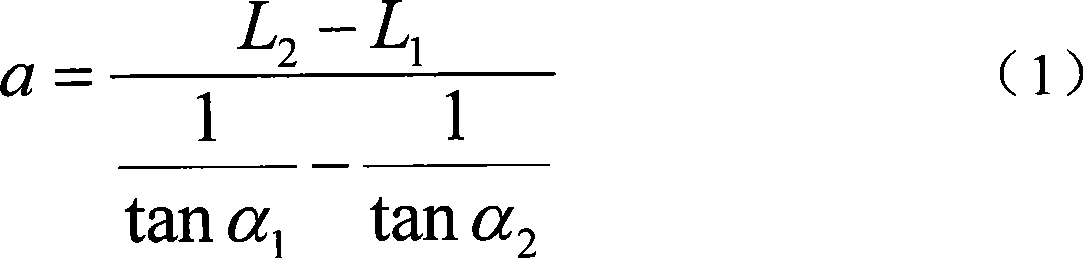

Monitoring method for drilled wellbore trajectories

InactiveCN101387198AIn line with the actual situationImprove monitoring accuracySurveyTracking modelHorizontal wells

The invention relates to a drilling engineering technology in petroleum engineering, in particular to a method for monitoring the track of an actually drilled wellbore. The method comprises the following steps: acquisition of inclination survey data and naturalization treatment; determination of characteristic parameters of a wellbore track model; determination of a hole inclination equation and an azimuth equation; calculation of coordinate increment; calculation of surveying point coordinates; and so on. As for large-displacement wells containing catenary or parabola tracks and various directional wells and horizontal wells, the method can accurately monitor the coordinates of various surveying points, so as to make the monitoring result accord with the practice of the drilling engineering, thereby effectively improving the construction precision and the reliability of catenary drilling and parabola drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

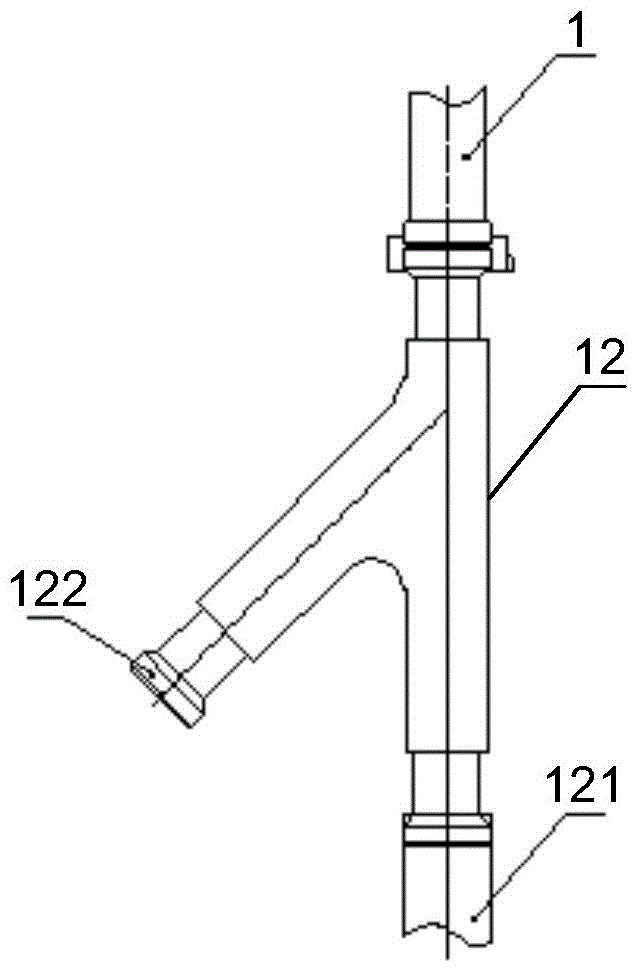

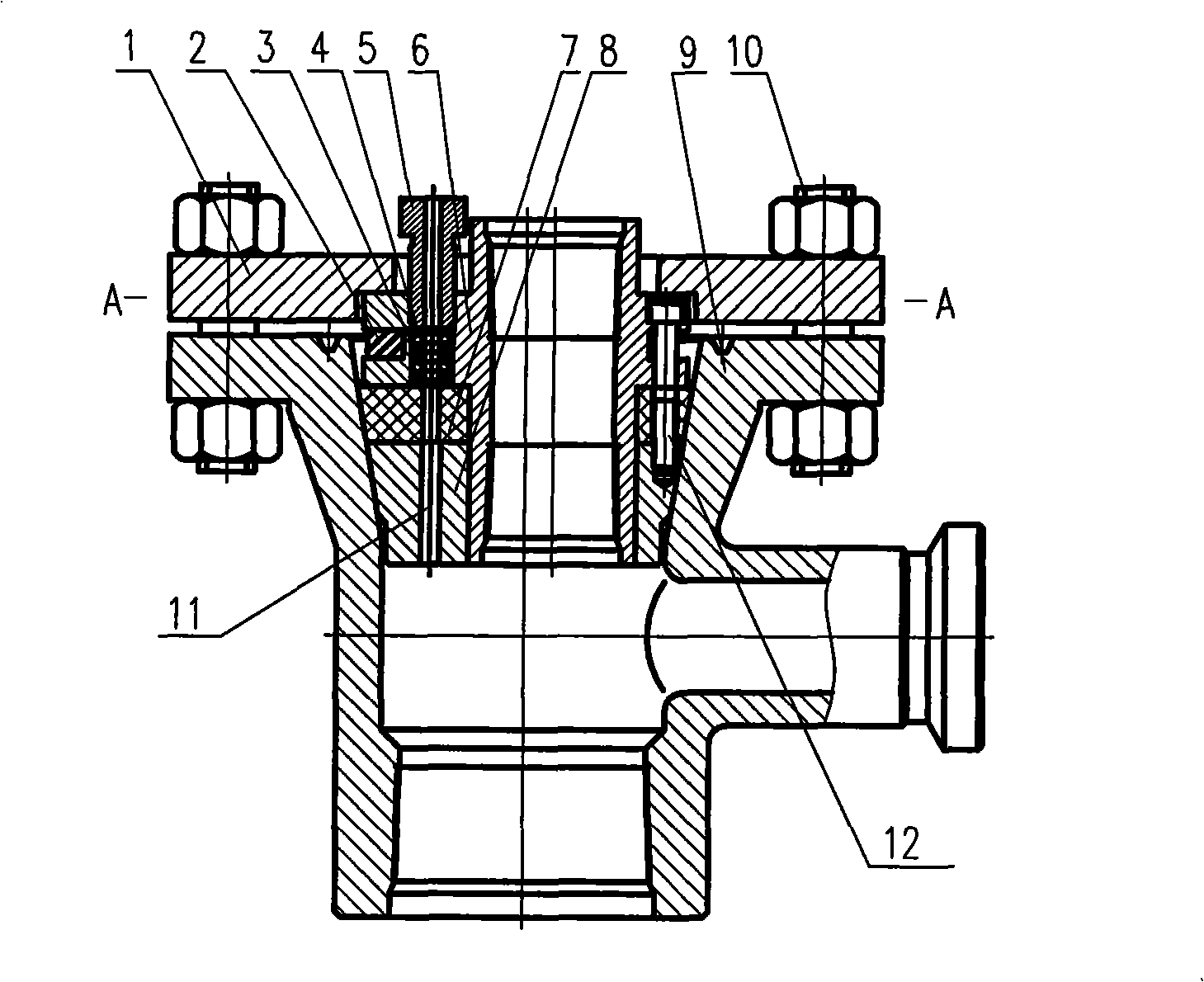

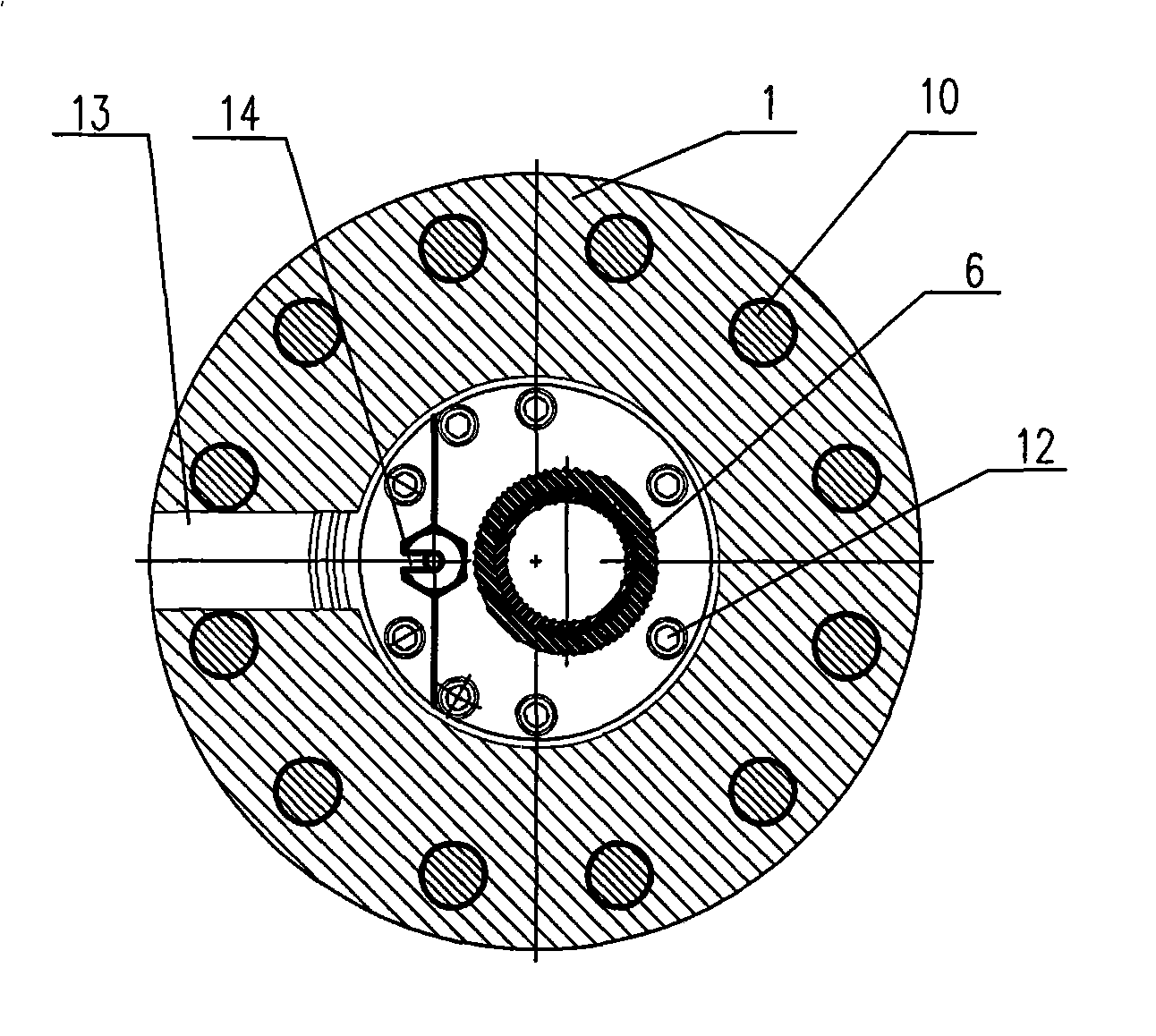

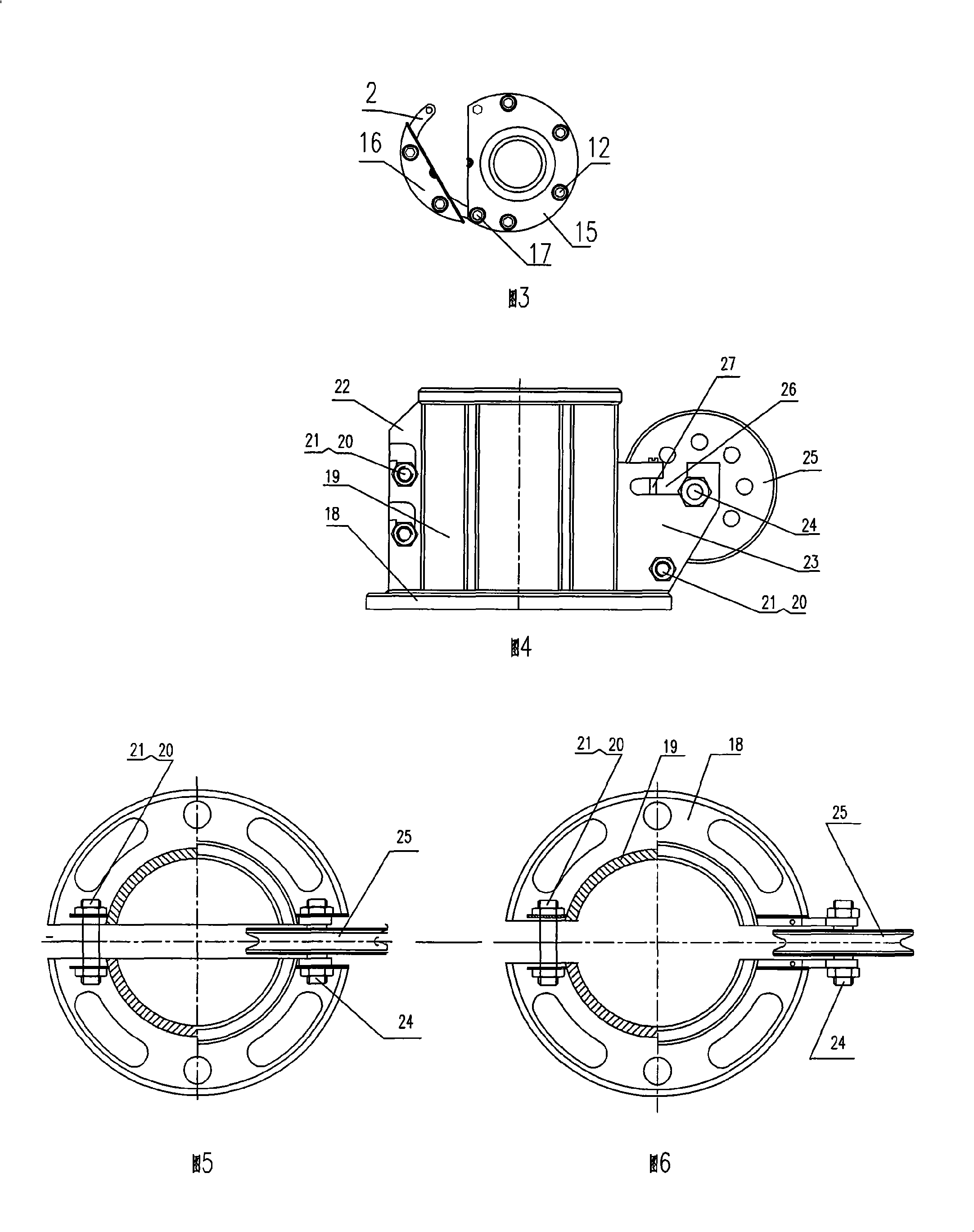

Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

ActiveCN101403291AEasy to get up and downSo as not to damageSurveySealing/packingSection planeTubing hanger

The invention relates to a mechanical recovery horizontal well preset produced fluid profile testing method and a special wellhead testing device thereof, mainly aiming at solving the problem of the downhole testing of a mechanical recovery horizontal well. The invention is characterized in that: the special wellhead testing device comprises an eccentric type tubing hanger body connected with a tubing string, wherein, the side wall of the tubing hanger body is divided into a body and splits which are completely matched with each other, and the splits are fixed on a locking arm which is fixed on the body though bolts; and a corresponding matched cable penetrating a channel is arranged at the splitting seam of the body and the splits, the channel is internally provided with a cable gasket, a spacer and a pressing cap. By being matched with a special wellhead support, under the condition that a testing cable and a tester are pre-arranged in the horizontal well to test a target layer, an oil pipe does not touch the cable during the up and down process of the oil pipe. The method and the special wellhead testing device can realize the produced fluid profile testing of the mechanical recovery horizontal well, and ensure the accuracy of normal testing and data of the mechanical recovery horizontal well with simple and reliable operation method.

Owner:DAQING OILFIELD CO LTD +1

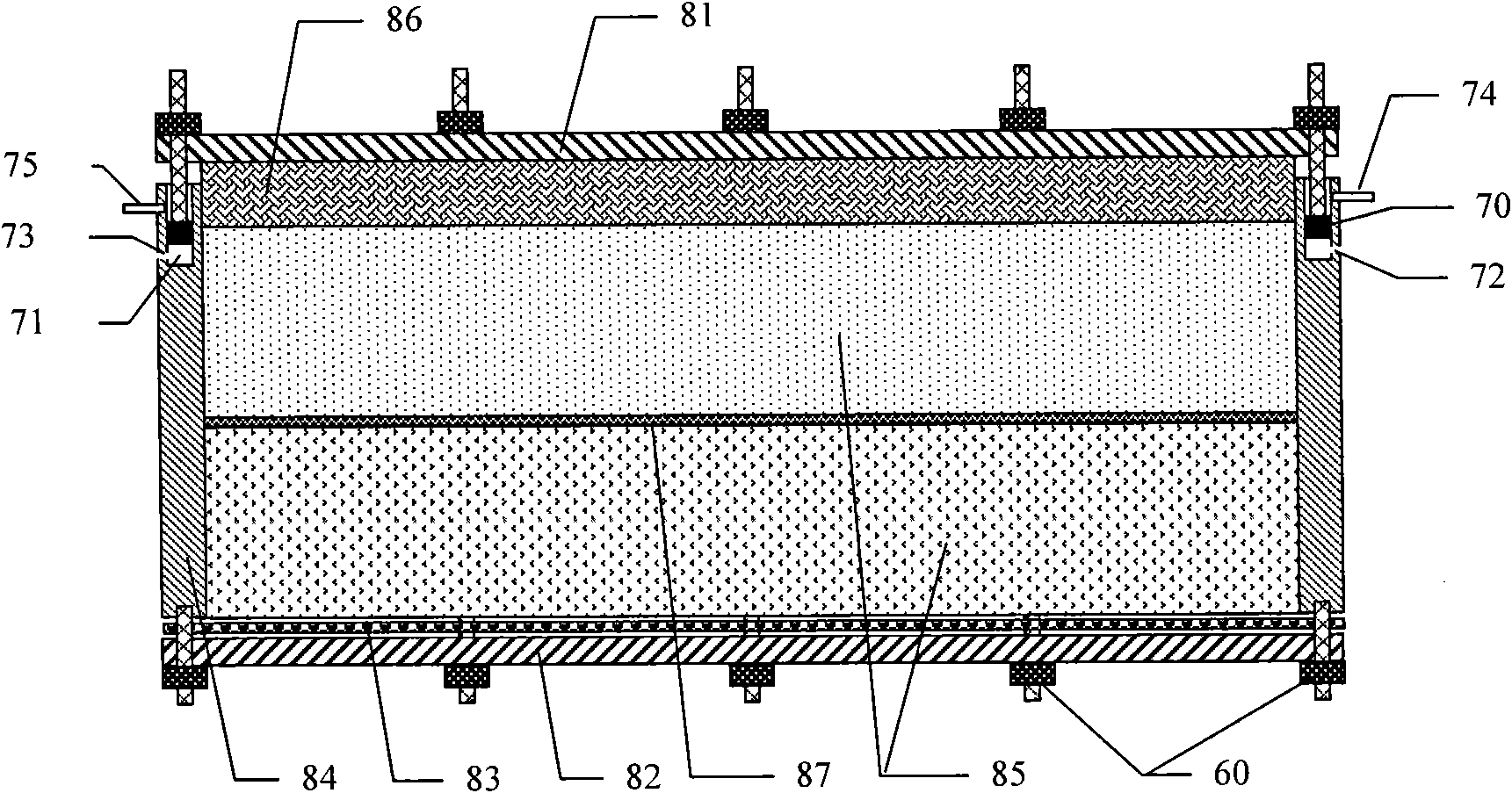

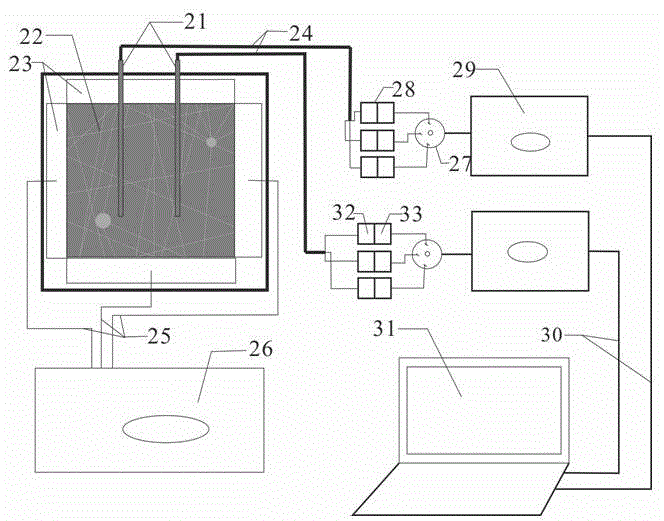

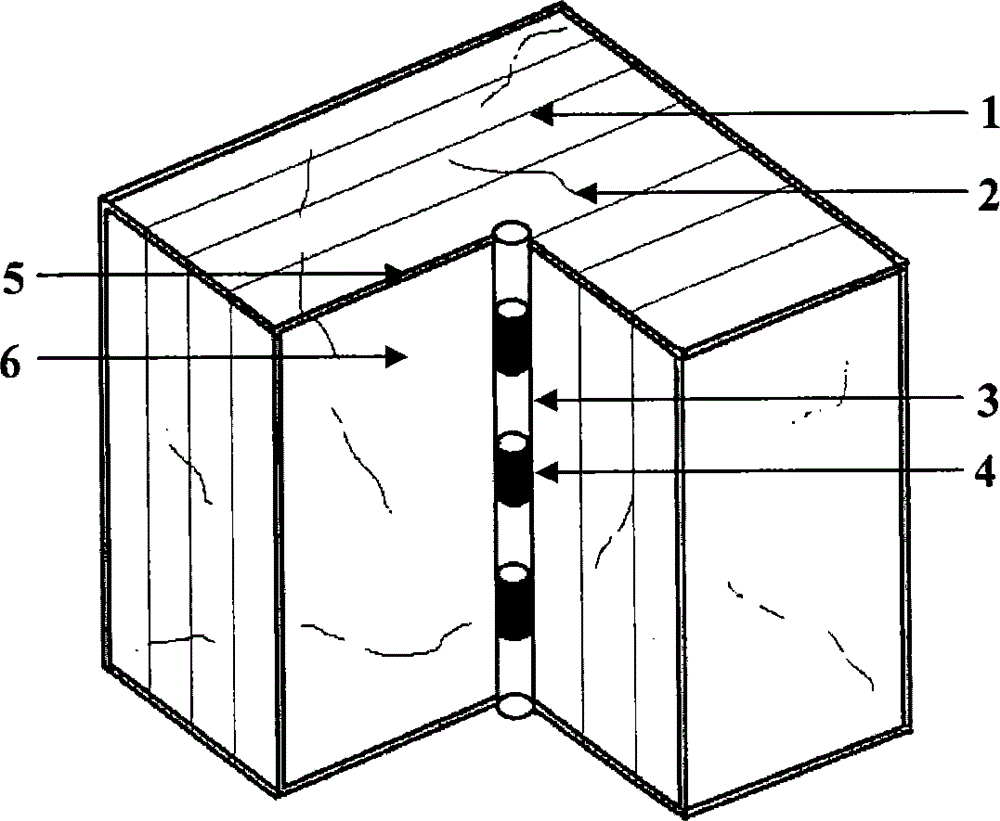

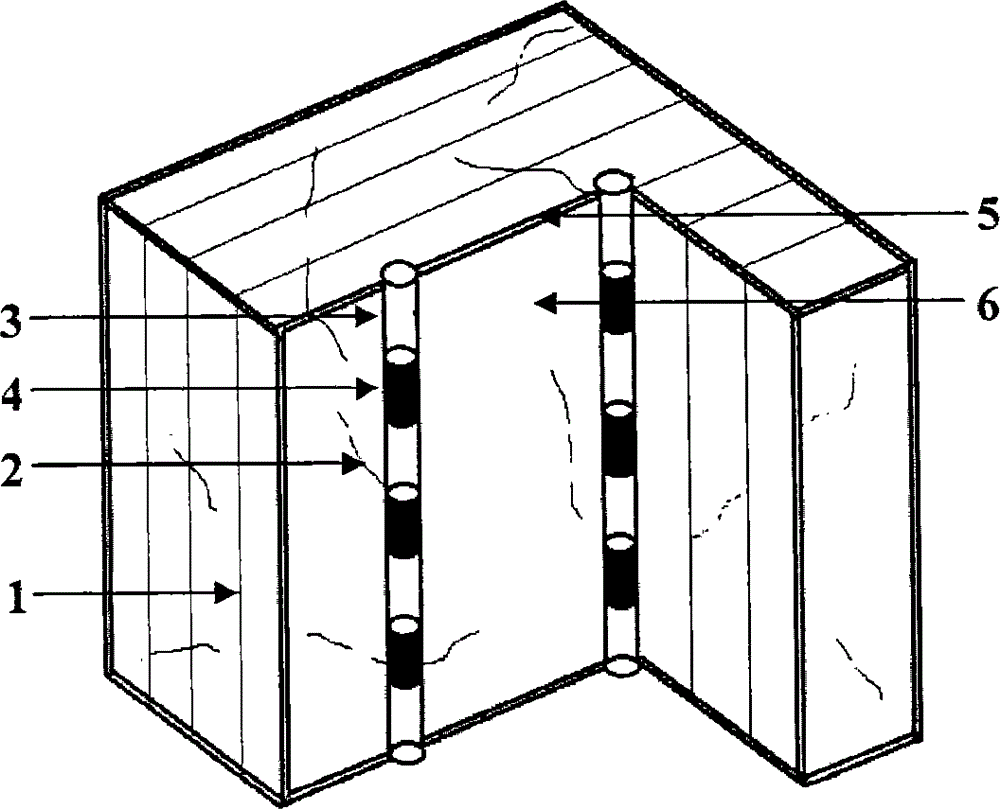

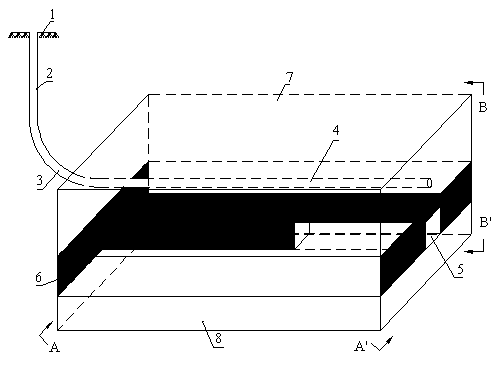

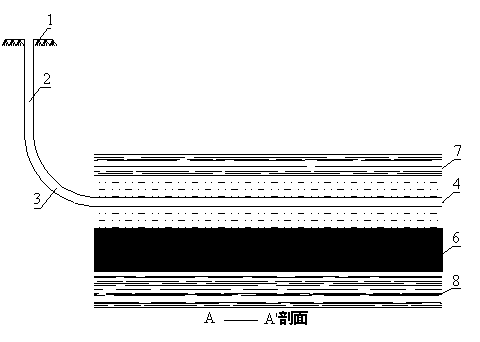

Indoor experiment shaft device and method for synchronous or asynchronous multistage clustering fracturing of two horizontal wells

ActiveCN104832169AGuaranteed reliabilityObservation distributionFluid removalComputational scienceExperimental research

The invention provides an indoor experiment shaft device for synchronous or asynchronous multistage clustering fracturing of two horizontal wells and a simulation method. The device and simulation method are used for indoor experiment simulation of synchronous or asynchronous multistage clustering fracturing of two shale horizontal wells. A designed multistage clustering fracturing experiment shaft can simulate influences of the number of horizontal well fracturing segments, number of perforation clusters, perforation parameters and the like on synchronous or asynchronous fracturing fracture shapes. The experiment scheme comprises the six steps of making of an experiment scheme, machining of a special experiment shaft, machining of a test piece, preparation of fracturing fluid, an extended experiment of fracturing fractures, and CT scanning of an experiment result. The novel fracturing experiment shaft and method are provided for shale reservoir fracturing research, can simulate the joint network fracturing fracture distribution of a reservoir in multistage clustering synchronous fracturing of two horizontal wells or multistage clustering asynchronous fracturing of two wells front and back, and can provide theoretical support for shale reservoir fracturing experiment research and fracturing construction.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

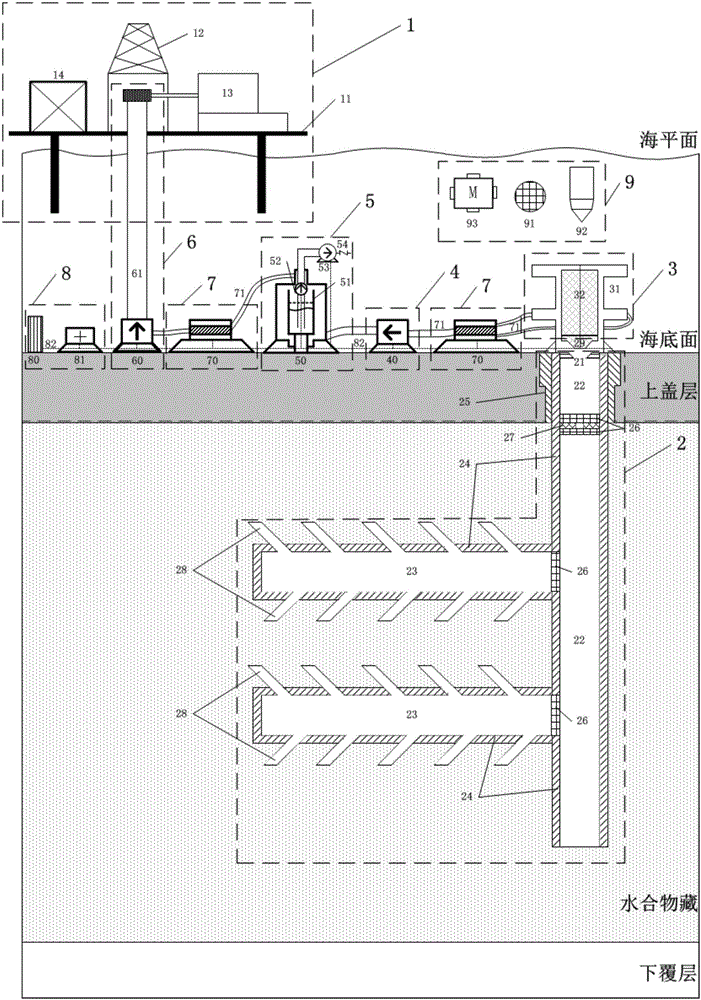

Decompression marine natural gas hydrate mining method and submarine mining system

The invention relates to a decompression marine natural gas hydrate mining method and a submarine mining system. The submarine mining system comprises a semi-submersible offshore platform, a mining well with multiple shower holes, a wellhead gas and water acquisition tree, a gas and water mixed delivery system, a submarine gas and water separating device, a gas delivery system, a pipeline system, a power and communication system and an auxiliary device. The decompression marine natural gas hydrate mining method and the submarine mining system have the advantages that submarine natural gas hydrate reservoirs can be safely, efficiently and economically mined; the submarine mining system is complete, and various portions of the submarine mining system are high in modularization, low in manufacturing cost and short in manufacturing cycle and can be reused; most devices are positioned in submarine environments and are controlled via the offshore platform, only natural gas is delivered offshore, and accordingly the submarine mining system is low in extra energy consumption; owing to a technology for forming the multiple shower holes in the mining well, missed mining regions can be effectively reduced, and the gas yield can be effectively increased owing to multiple horizontal wells; the submarine mining system has functions of well blocking prevention, well blowout prevention, hydrate secondary generation and the like, and accordingly safety production can be guaranteed; various main devices can flexibly move and are used with one another, and accordingly movable regional production operation can be implemented.

Owner:DALIAN UNIV OF TECH

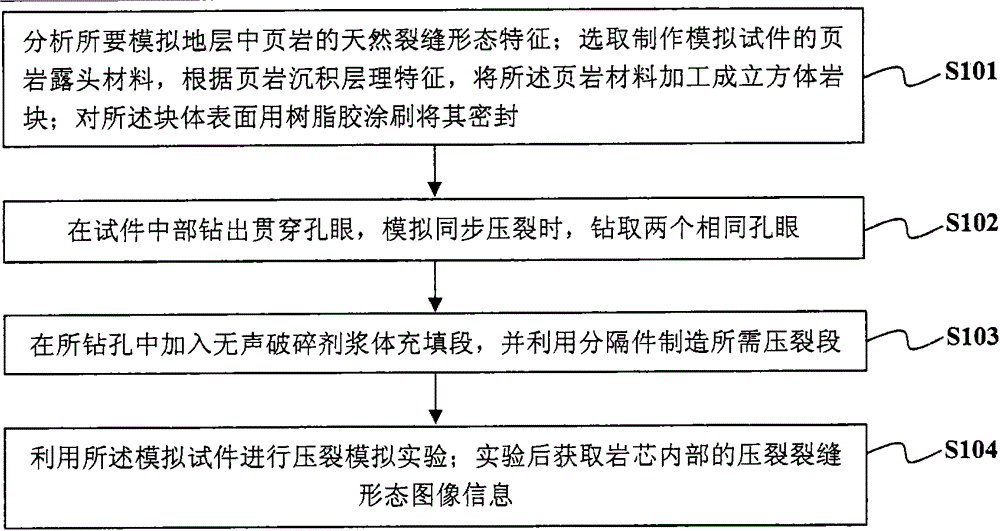

Staged fracturing or synchronous fracturing simulation experiment method for shale horizontal well

InactiveCN104563993AQuality improvementAccurate observationFluid removalNatural fractureNondestructive testing

The invention provides a staged fracturing or synchronous fracturing simulation experiment method for a shale horizontal well. The method comprises the following steps: (a) the natural fracture morphological characteristics of shale in a stratum to be simulated are analyzed; a shale outcrop material for producing a simulation test piece is selected, and the shale material is machined to a cube rock mass according to the shale settled layer characteristics; and the surface of the mass is brushed with resin adhesive for sealing; (b) a through hole is drilled in the middle of the test piece; and when the synchronous fracturing of the horizontal well is simulated, two equal holes are drilled; (c) silent crushing agent slurry filling sections are added in the drill holes; and the needed number of fracturing sections is produced by partition pieces; and (d) the simulation fracturing experiment is performed by using the simulation test piece; and fracture morphology image information in a rock core is obtained after the experiment. For brittle shale with natural fracture development, the method is easy to realize the experimental simulation of staged fracturing or synchronous fracturing of the horizontal well. Meanwhile, the high-energy CT scanning is performed for the test piece through a linear accelerator nondestructive testing system to realize precise observation of a shale fracturing net. The experiment method can be applied to the research on propagation rules of the shale fracturing net under the effect of matrix pressure transfer.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

Composite blocking remover and method for removing blockage of compact sandstone reservoir pressing crack commissioning horizontal well in composite manner

ActiveCN103740353AGood retarding performanceDecontamination of reservoirCleaning apparatusDrilling compositionSolid phasesOrganic acid

The invention discloses a composite blocking remover and a method for removing blockage of a compact sandstone reservoir pressing crack commissioning horizontal well in a composite manner. The composite blocking remover comprises a preposition liquid, a main treating fluid, an active blocking remover and a subsequent fluid. The preposition liquid is composed of organic acid, inorganic acid, a stabilizer, an oxidizing agent, a chelating agent, a corrosion inhibitor, polyol ether and water. The main treating fluid is composed of organic acid, inorganic acid, the stabilizer, the oxidizing agent, a fluorine carbon surfactant and water. The active blocking remover is composed of a zwitterionic surfactant, the stabilizer and water. The subsequent fluid is water. The composite blocking remover can remove the blockage of routine colloid, asphalt mass and inorganic solid phase particles, and can remove the damage of water blocking and crude oil emulsification by pertinency, and has the advantages of good slow performance, effectively preventing secondary deposition pollution such as the iron ion deposition and acid sludge generation, the horizontal well near-well and deep reservoir pollution can be effectively released, the oil well production power is recovered, and the recovery efficiency can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Placing method of self-simulating lateral-displacement horizontal well of super-low permeability tight reservoir

ActiveCN105239990AAvoid re-openingReduce water injection pressureFluid removalOffset distanceWater flooding

The invention provides a placing method of a self-simulating lateral-displacement horizontal well of a super-low permeability tight reservoir. The placing method comprises the following specific steps: determining a main force construction layer section; determining the positions of horizontal wells, water injection wells and artificial fractures; determining a well row direction of the horizontal wells; determining a well spacing between the horizontal wells; determining a distance between the rows of the horizontal wells; determining the length of each horizontal well; determining an offset distance of each water injection well; determining a length of each artificial fracture of each water injection well; and injecting water; scattered water injection in the past is changed into linear water injection, and in case of the same water injection amount, a water injection pressure is reduced so that secondary opening of a natural fracture generated in the water injection process can be avoided and a risk of fractured water flooding can be reduced; elastic solution gas drive in a region between the artificial fractures is converted to water drive and a fracture dominant direction of a local region is kept consistent so that early-phase water breakthrough can be avoided and an energy supplementing level can be increased. Row water injection displacement is formed through appropriate fracturing of the directional water injection wells, leading to the advantages that layered water injection can be realized and maximum draw-on in a longitudinal direction can be realized, compared with taking the horizontal wells as the water injection wells.

Owner:PETROCHINA CO LTD

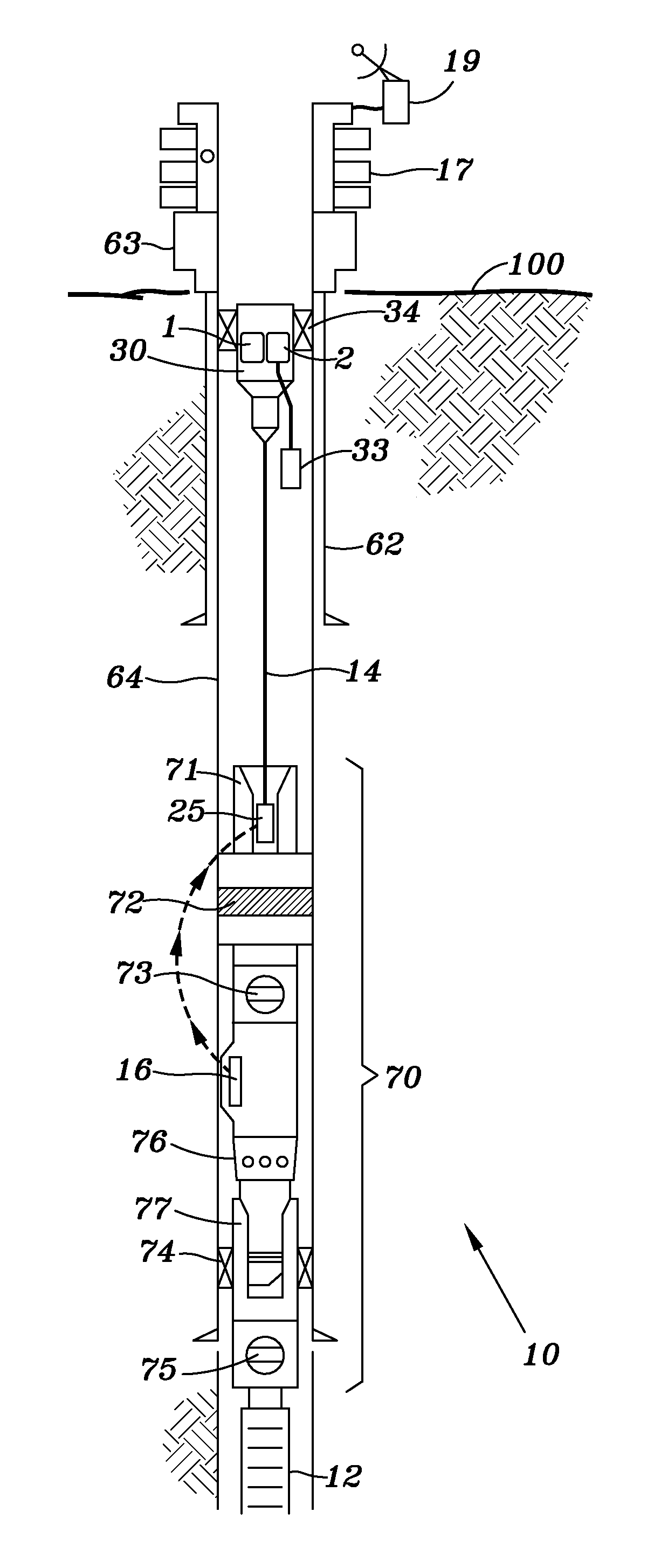

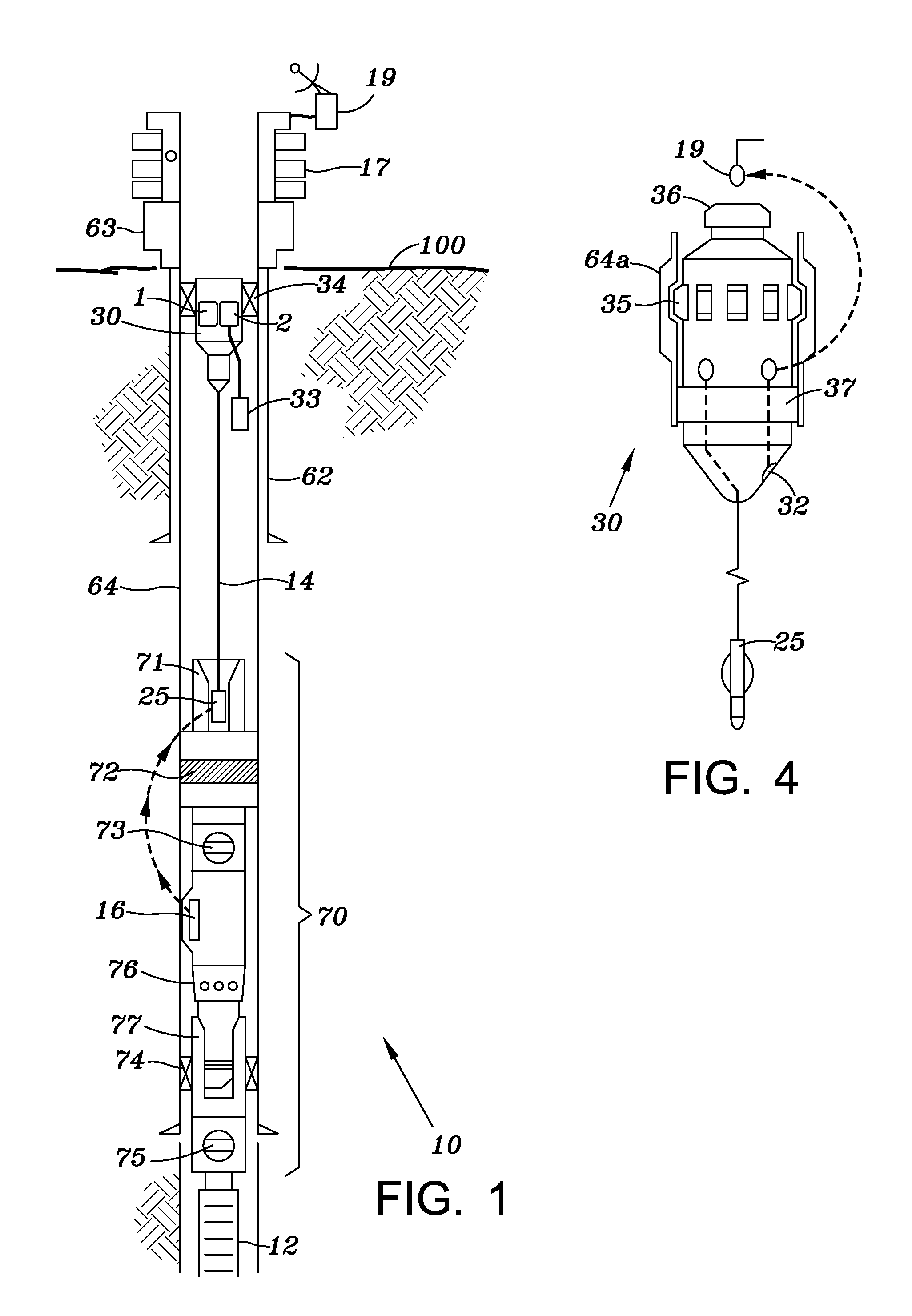

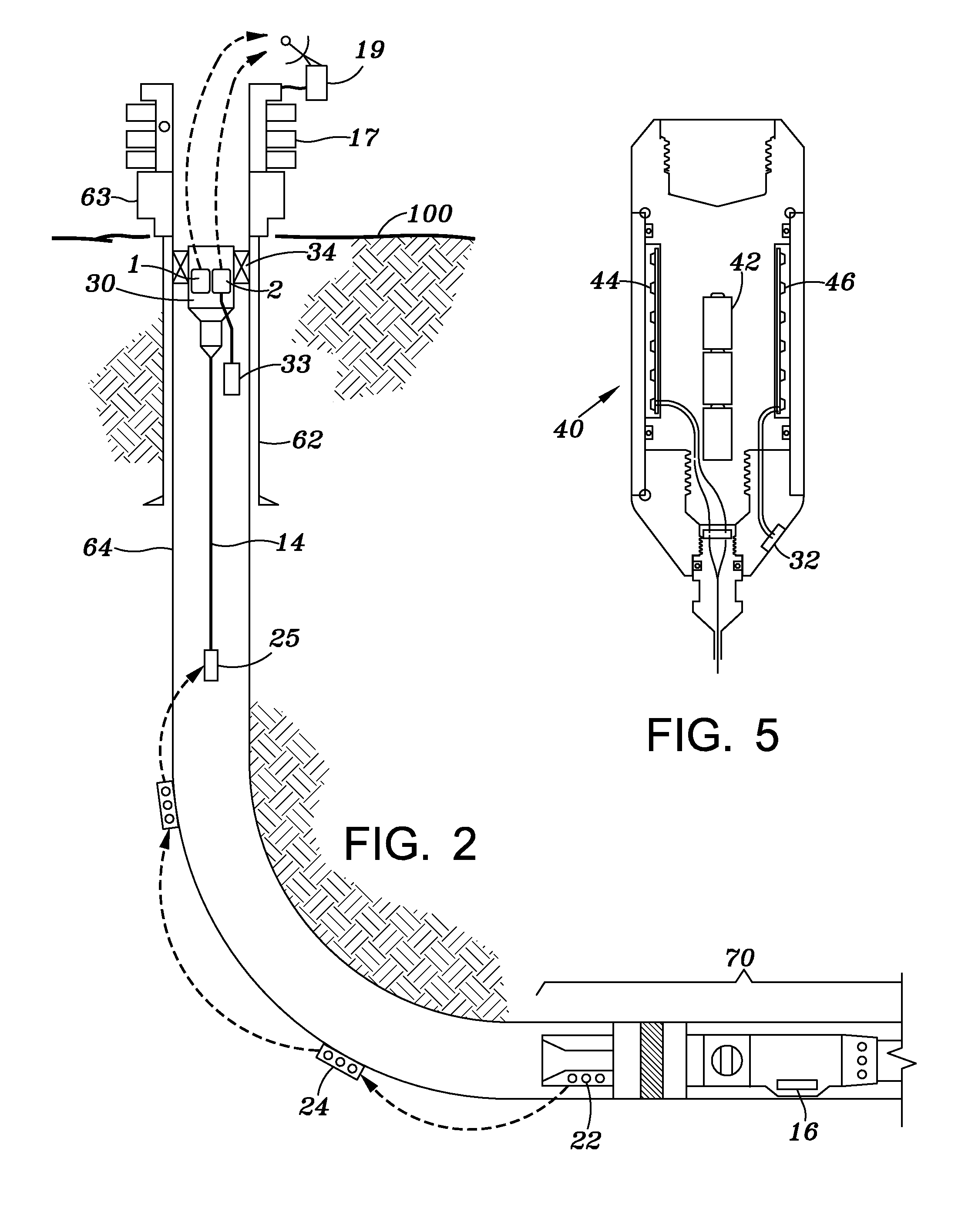

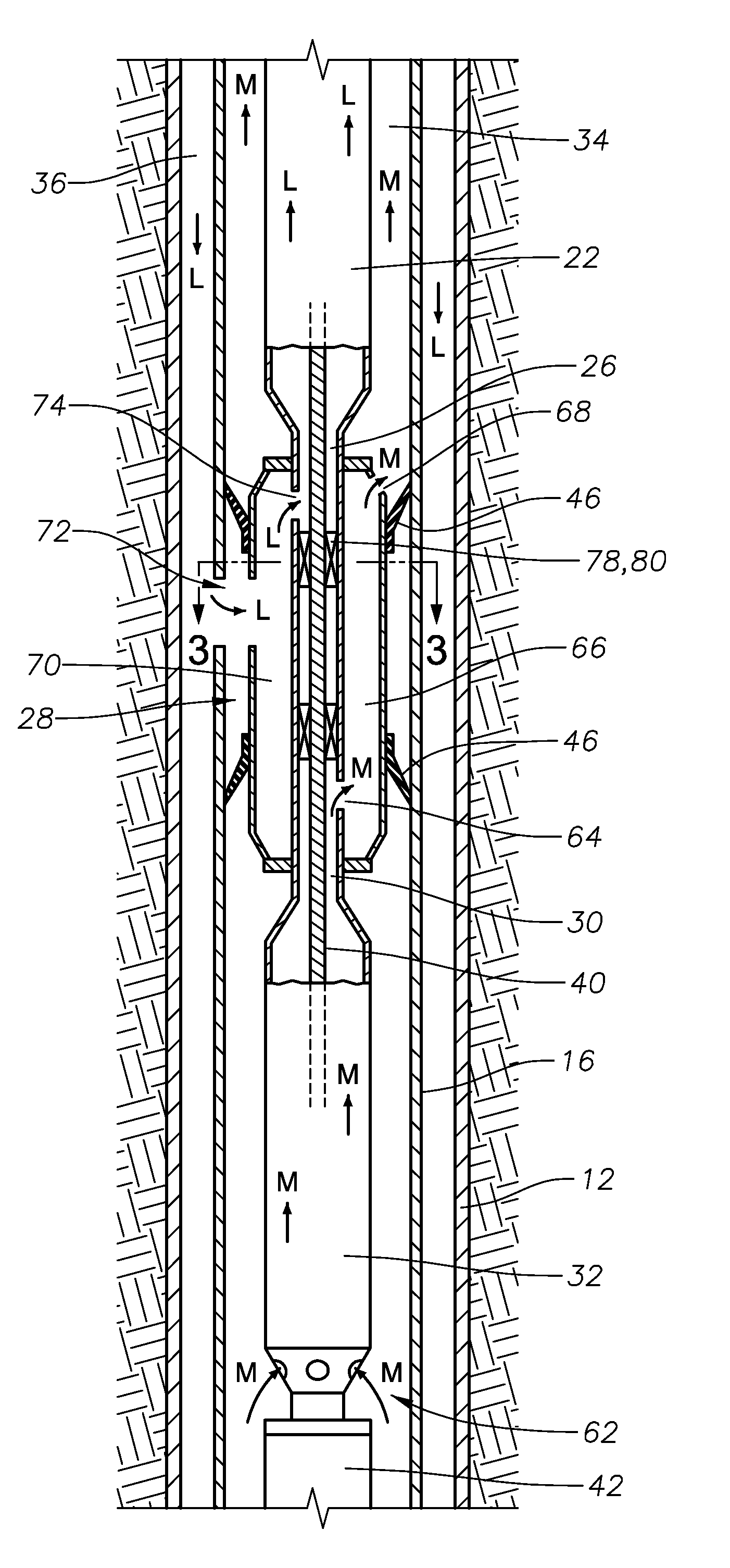

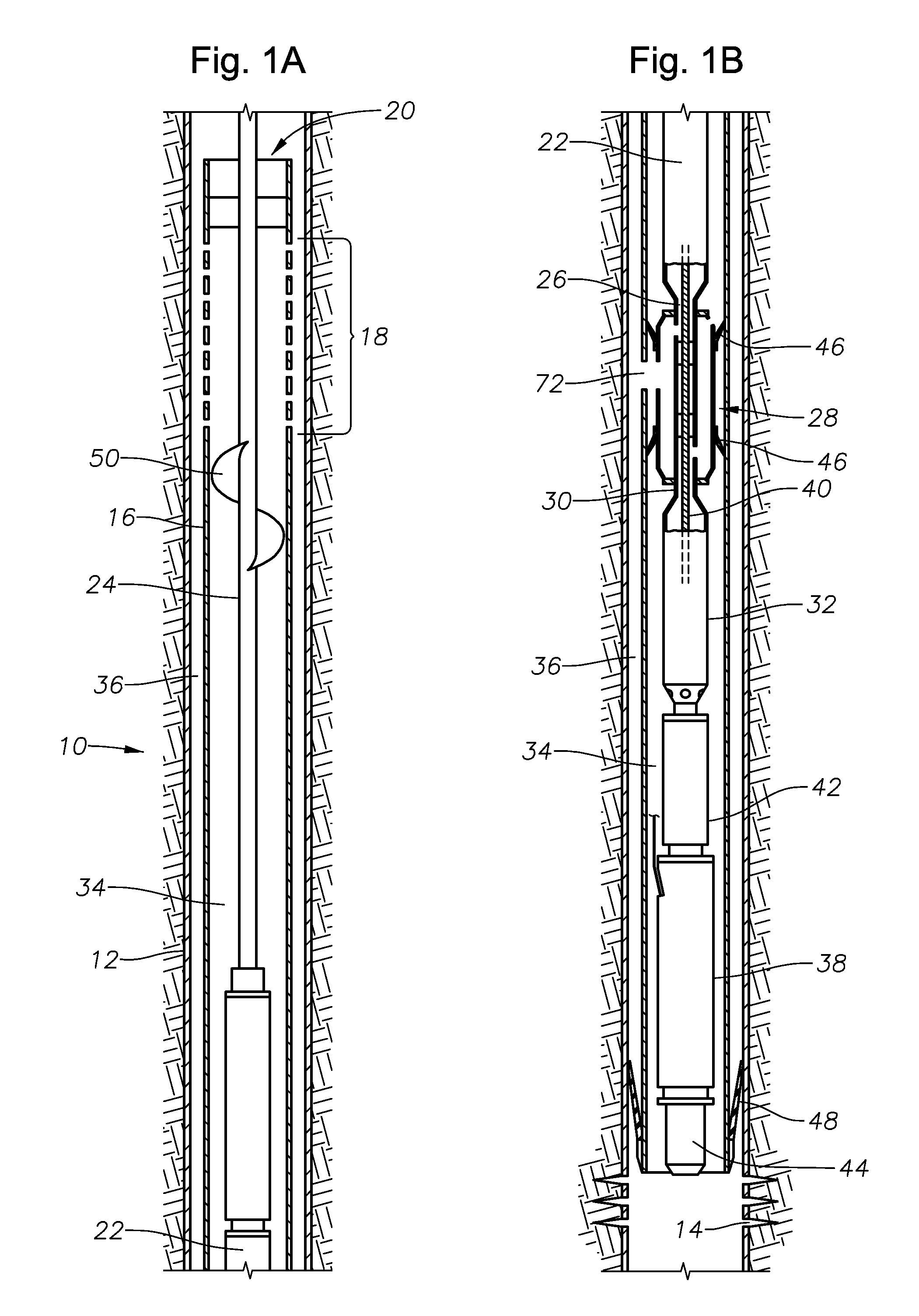

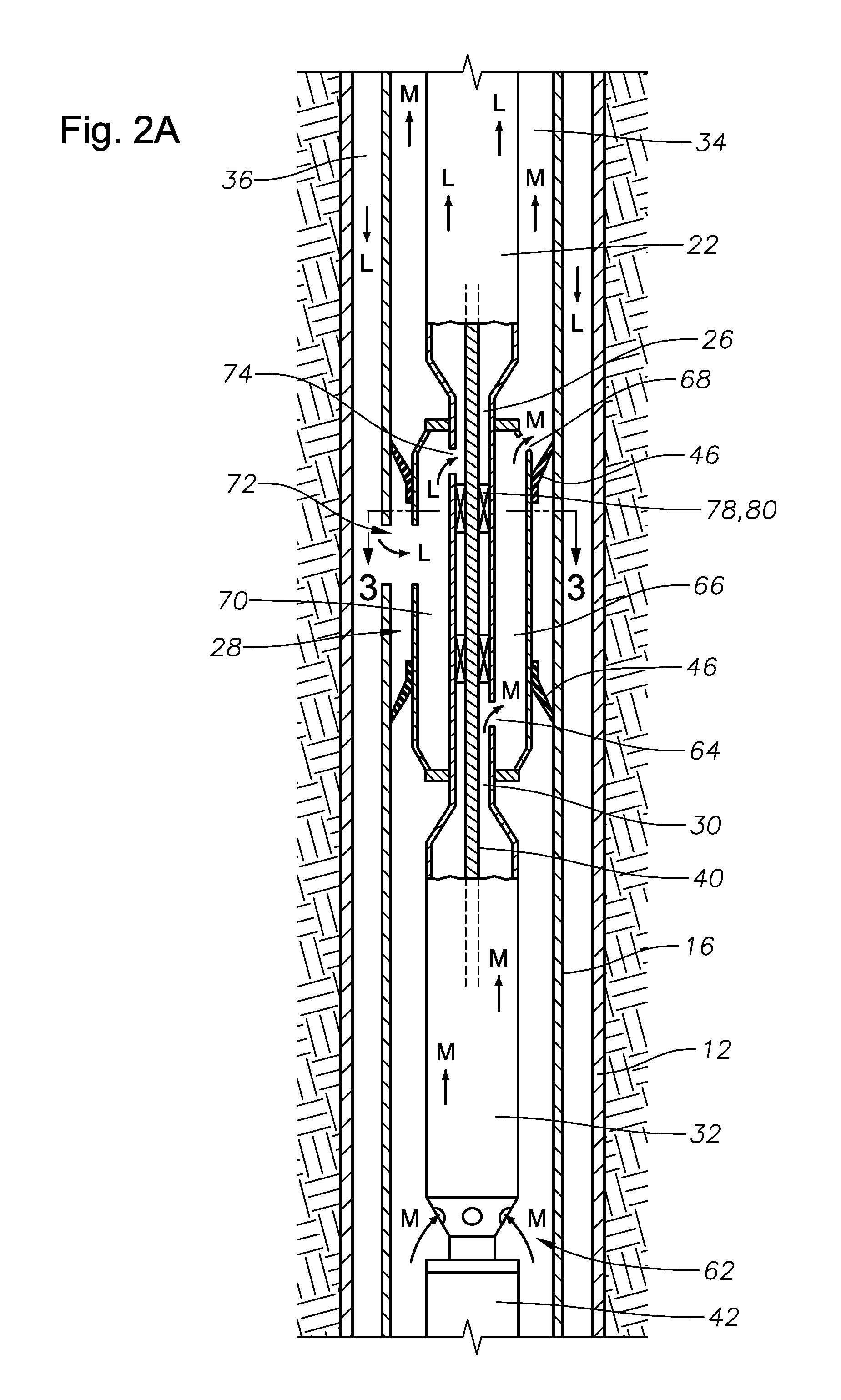

Gas boost pump and crossover in inverted shroud

ActiveUS20110162832A1Enhanced gas separationIncrease gas handling capacityFluid removalSealing/packingVapor–liquid separatorMixed flow

An above-motor mixed flow booster pump combined with a fluid crossover that directs up into the inside of an inverted shroud to allow enhanced gas separation. A gas and liquid separator is used to enhance separation. The system is simple and provides increased gas handling capability for high flow or low flow gas well dewatering applications, including vertical wells, horizontal wells, slant wells. The boost pump allows the moving of a mixed flow upwards to the top of an inverted shroud in wells lacking the required pressure.

Owner:BAKER HUGHES INC

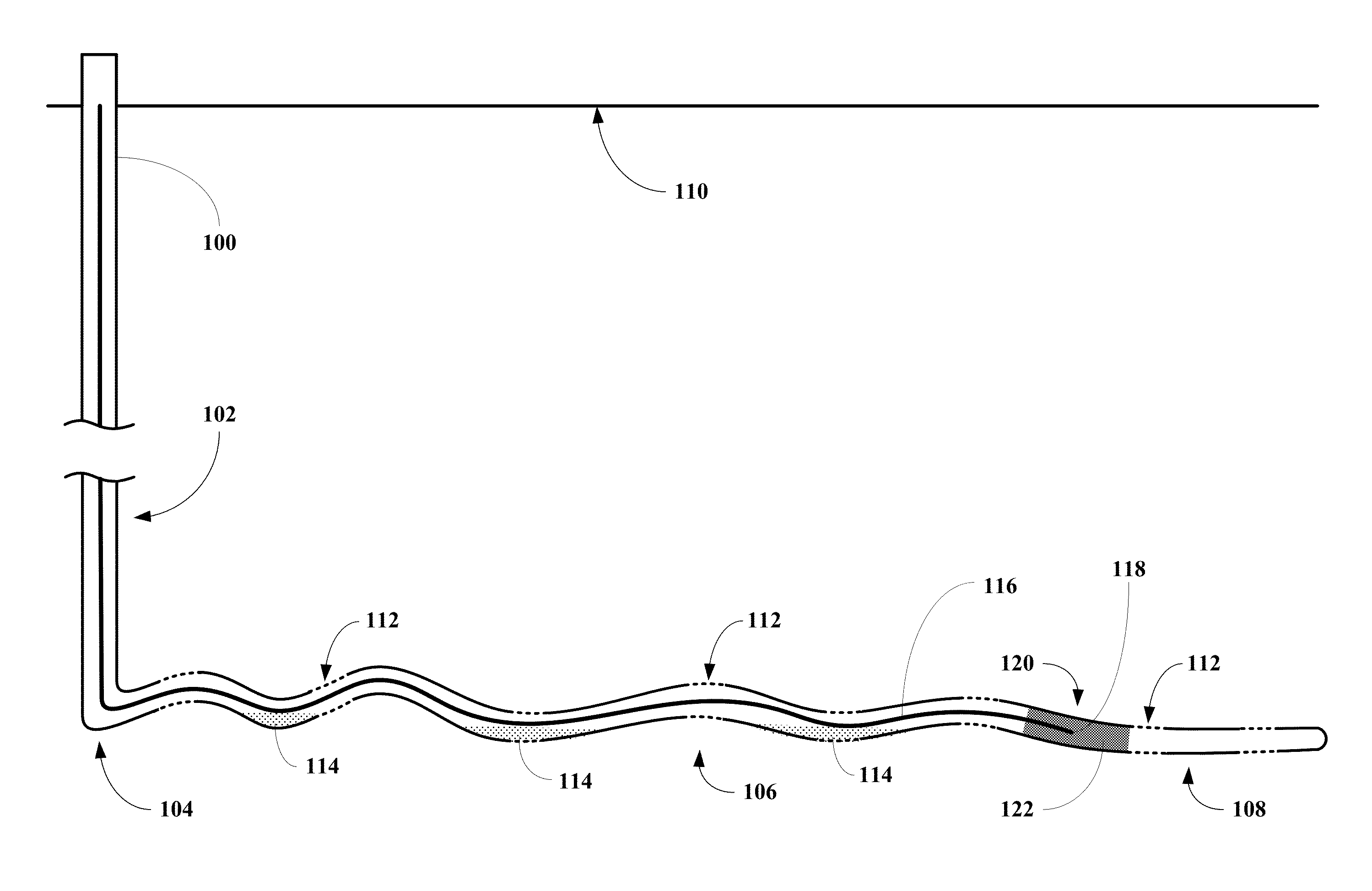

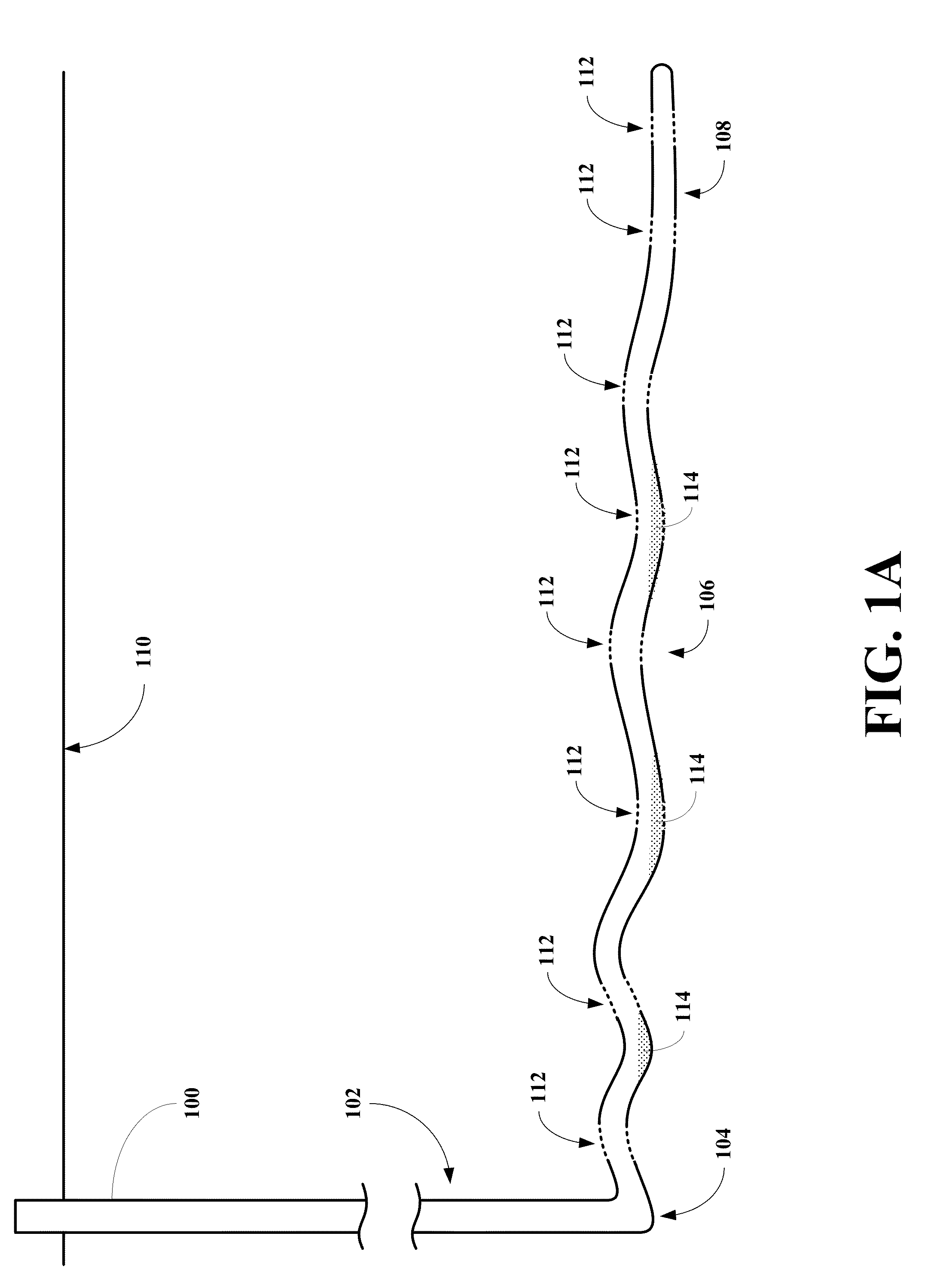

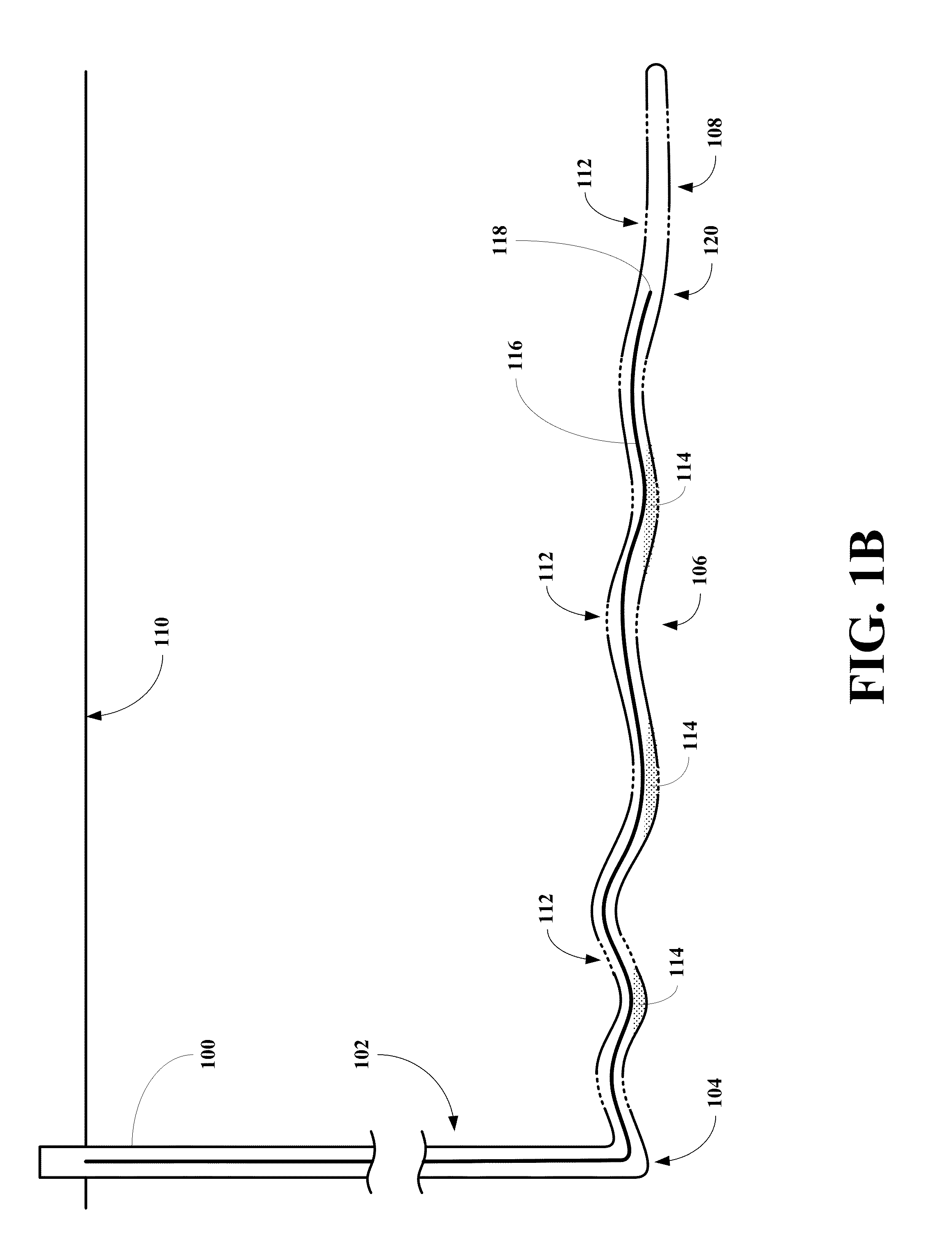

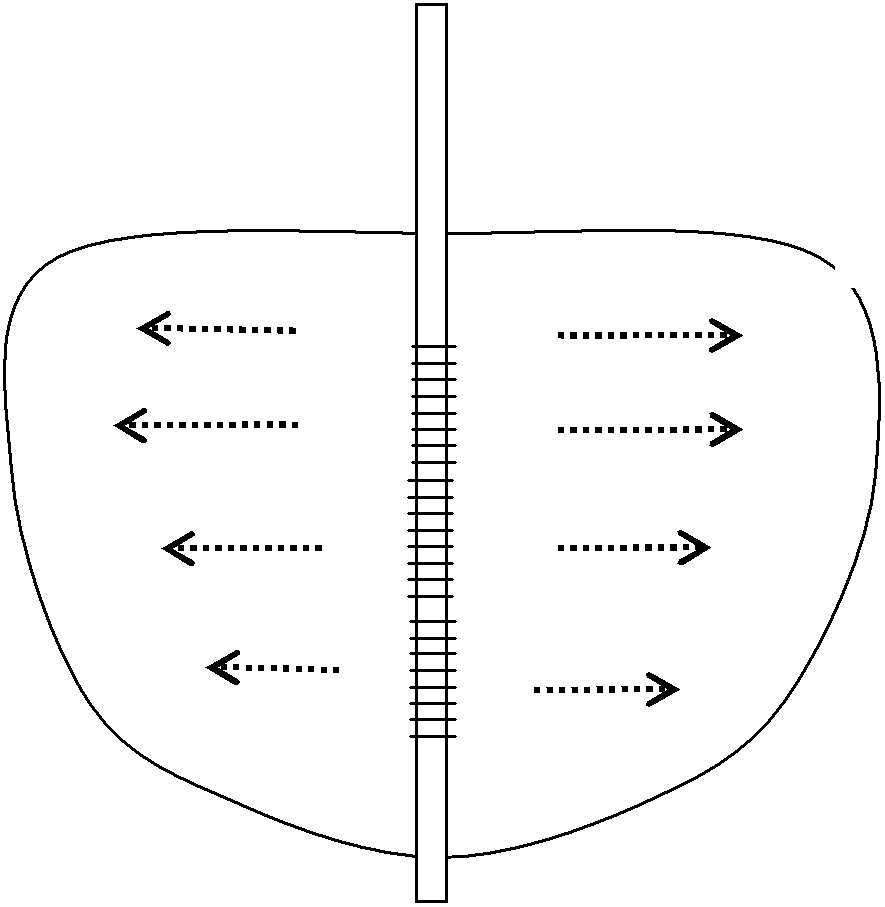

Apparatuses, systems, and methods for forming in-situ gel pills to lift liquids from horizontal wells

InactiveUS20130312977A1Low viscosityIncrease gas productionDrilling rodsCleaning apparatusHorizontal wellsEngineering

Methods include the injection of a gelled, gelling or gellable composition into a horizontal section of a well at a location, where produced well gases or a combination of well gases and injected gases are sufficient to move the pill through the horizontal section into heal section, sweeping the horizontal section of accumulated liquids. Once in the heal section, the pill and the accumulated liquids are uplifted to the surface resulting in a cleaned well.

Owner:CLEARWATER INT LLC

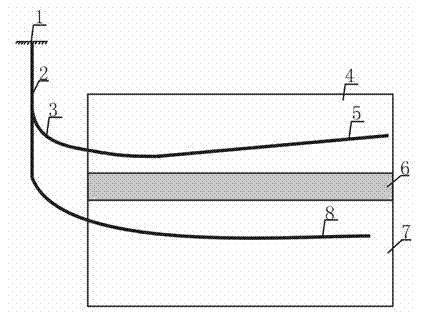

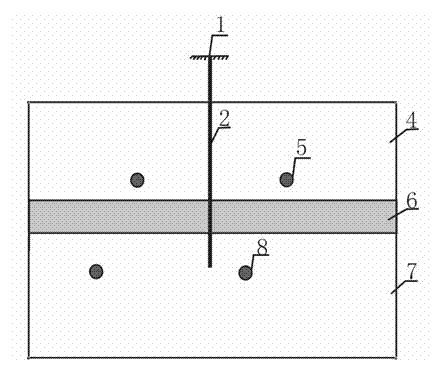

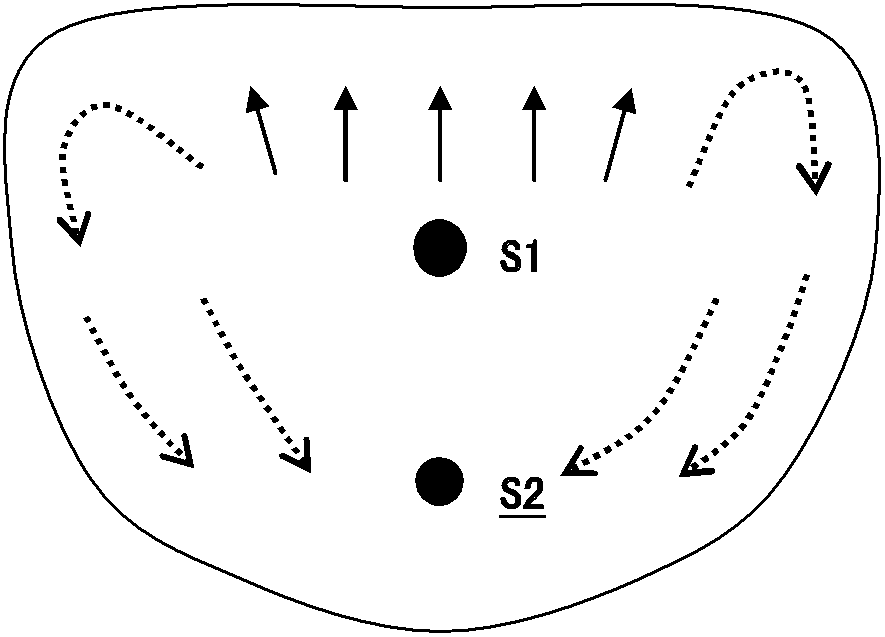

A method of gravity drainage assisted steam flooding to enhance the recovery of deep ultra-heavy oil reservoirs

The invention relates to a method for improving the oil deposit recovery ratio of deep massive extremely-viscous oil in an extraction mode of gravity drainage assisted steam flooding. In the method, superposition horizontal wells are arranged among wells by combining results of researches on the fine contrast of small geological strata of massive oil deposit, the distribution rule of interlayer, the distribution rule of remaining oil and the like and a fine research on numerical simulation; an upper superposition horizontal well is used for injecting steam, a peripheral vertical shaft is used for production, and a lower superposition horizontal well is used for discharging liquid (crude oil between condensate water and the horizontal wells); and thus, a production-injection ratio of high-speed steam injection of deep oil deposit is improved, the dryness of steam on the well bottom is improved, the pressure of an oil layer is reduced, a steam cavity is easy to expand, the swept volume is improved, a development effect is improved, and the aim of improving the recovery ratio finally is fulfilled.

Owner:PETROCHINA CO LTD

Method for pre-pumping coal roadway stripe gas of single soft protruded coal seam of unexploited area

InactiveCN102852546AAvoid investmentIncrease the lead timeFluid removalDrainageMining engineeringHorizontal wells

The invention provides a method for pre-pumping coal roadway stripe gas of a single soft protruded coal seam of an unexploited area and relates to the technical field of gas pumping. Through the method, outburst removal of the area with a single soft hypotonic protruded coal seam coal roadway stripe can be achieved. The method for pre-pumping the coal roadway stripe gas of the single soft protruded coal seam of the unexploited area comprises building a concordant layer horizontal well which is 3-6m away from the coal seam from the ground to a top plate and a base plate of the single soft protruded coal seam of the unexploited area, performing segmented fracturing after oriented perforating, enabling top plate and base plate rock terrane where coal seam gas is sealed and stored originally to be transformed into a pumping liberation layer with developed fracture networks, enabling the pumping liberation layer to be communicated with the coal seam in a large-area mode through the fracture networks, performing decompression and aerogenesis by dewatering, determining whether to perform negative pressure pumping according to water production conditions, enabling the coal seam gas to be desorbed and diffused continuously, and pumping the gas massively by pumping a horizontal well opening in the liberation layer. By pumping the gas massively, the outburst prevention index in the coal roadway stripe can be reduced to below the safety standard in the outburst prevention rules, and safe and speedy drivage is achieved.

Owner:HENAN COAL CHEM IND GROUP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com