Patents

Literature

881 results about "Shale oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shale oil is an unconventional oil produced from oil shale rock fragments by pyrolysis, hydrogenation, or thermal dissolution. These processes convert the organic matter within the rock (kerogen) into synthetic oil and gas. The resulting oil can be used immediately as a fuel or upgraded to meet refinery feedstock specifications by adding hydrogen and removing impurities such as sulfur and nitrogen. The refined products can be used for the same purposes as those derived from crude oil.

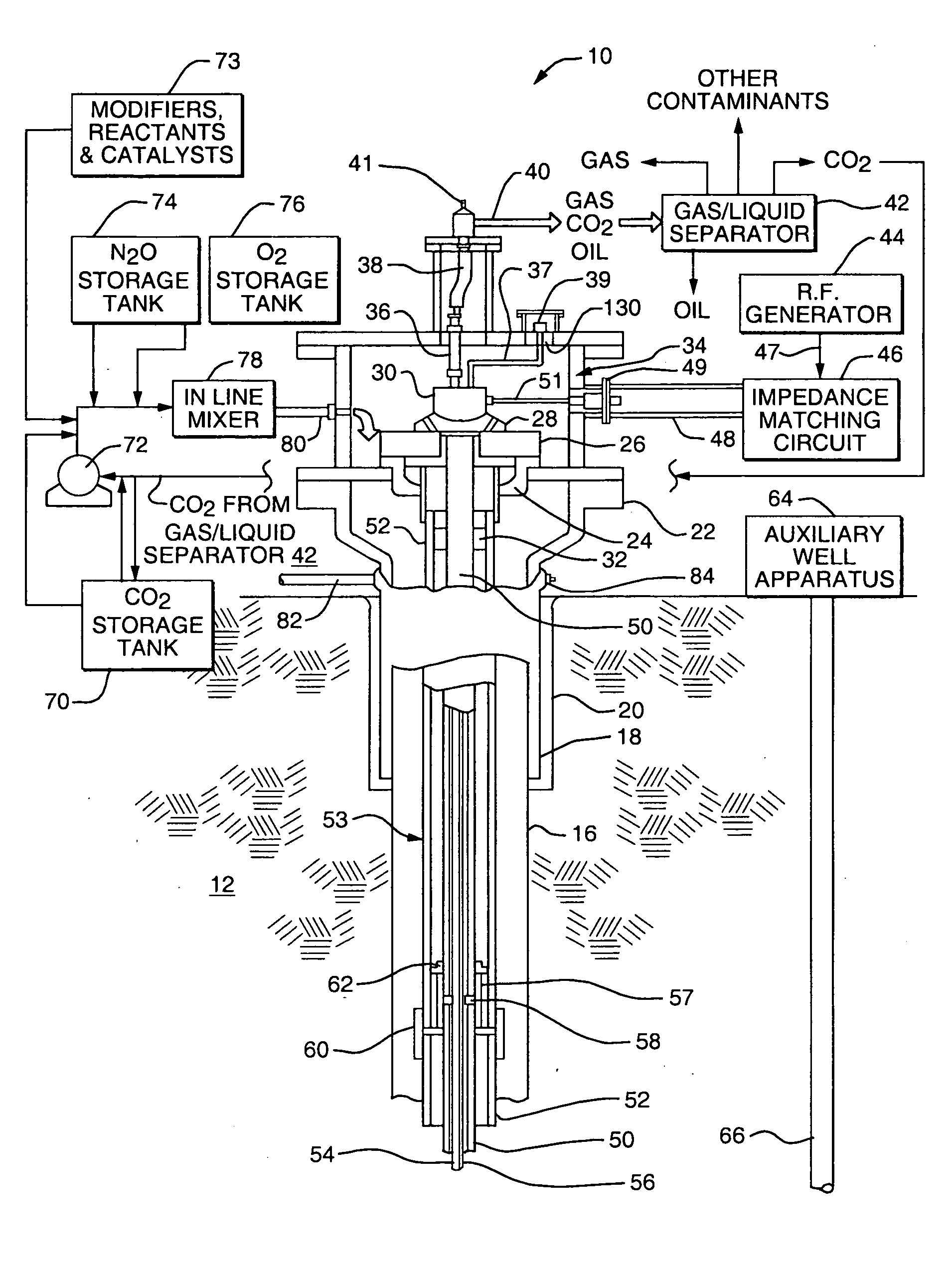

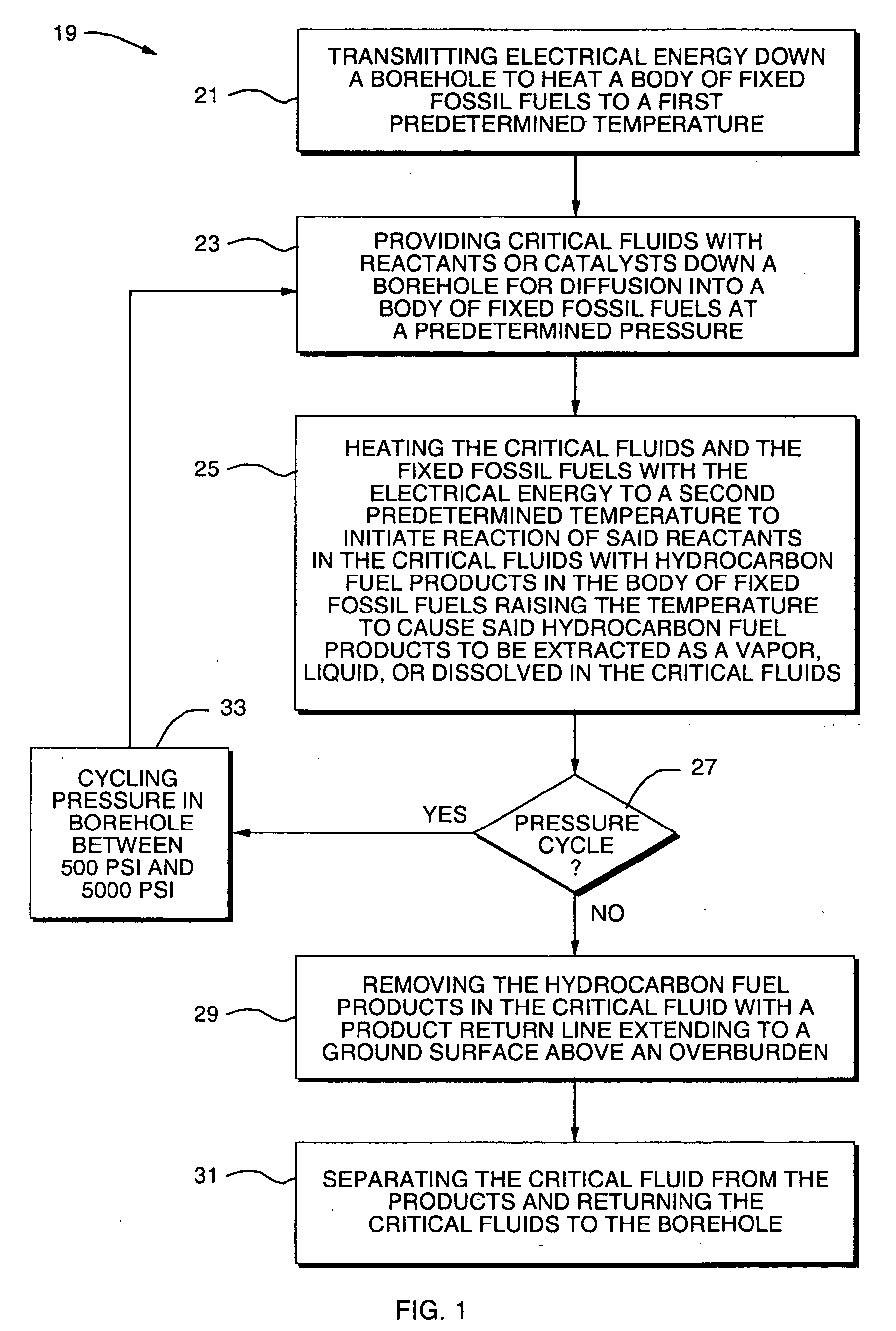

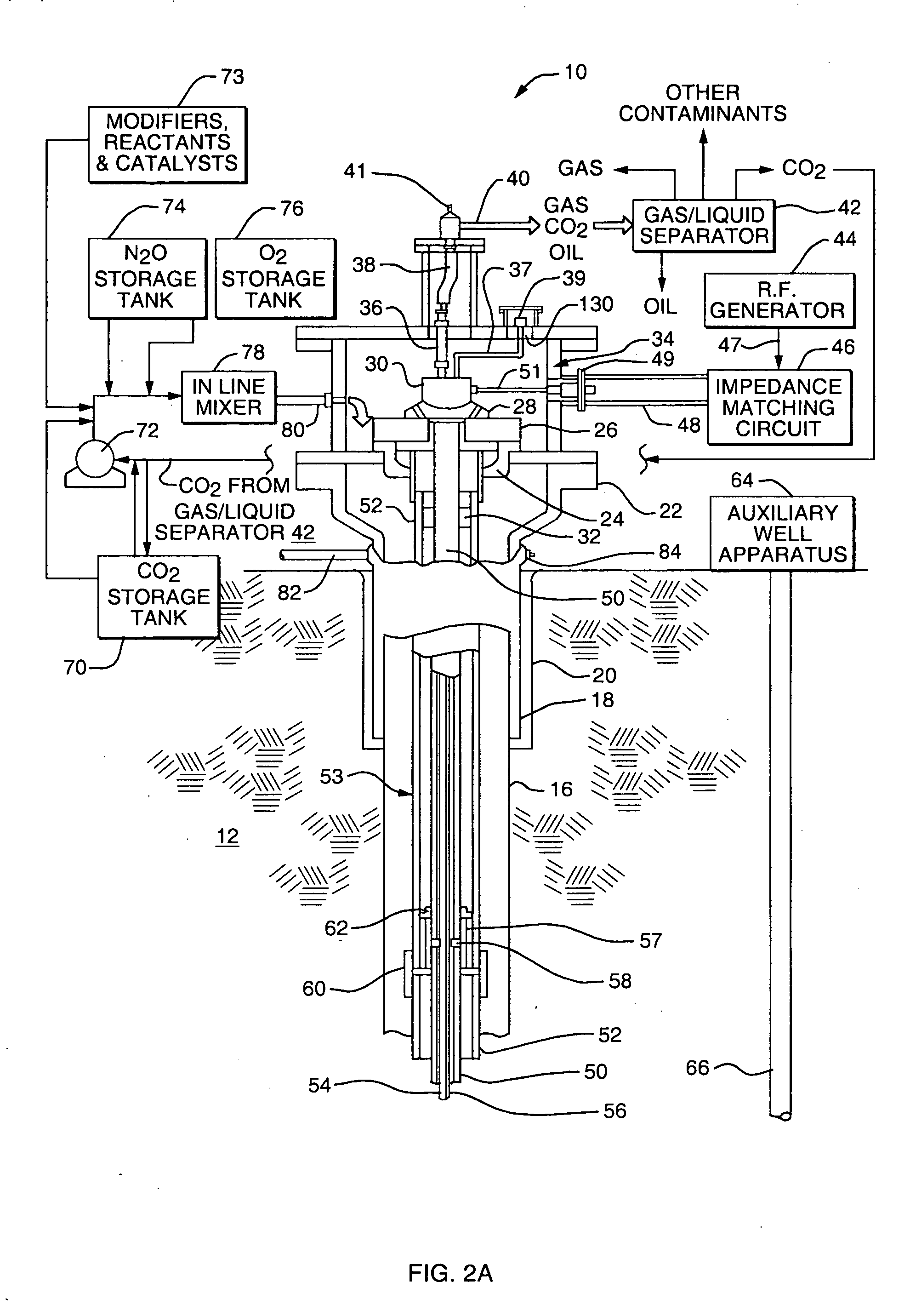

Method for extraction of hydrocarbon fuels or contaminants using electrical energy and critical fluids

ActiveUS20070137858A1Efficient heatingValid conversionSurveyHollow article cleaningVapor liquidHydrocotyle bowlesioides

The extraction of hydrocarbon fuel products such as kerogen oil and gas from a body of fixed fossil fuels such as oil shale is accomplished by applying a combination of electrical energy and critical fluids with reactants and / or catalysts down a borehole to initiate a reaction of reactants in the critical fluids with kerogen in the oil shale thereby raising the temperatures to cause kerogen oil and gas products to be extracted as a vapor, liquid or dissolved in the critical fluids. The hydrocarbon fuel products of kerogen oil or shale oil and hydrocarbon gas are removed to the ground surface by a product return line. An RF generator provides electromagnetic energy, and the critical fluids include a combination of carbon dioxide (CO2), with reactants of nitrous oxide (N2O) or oxygen (O2).

Owner:SCHLUMBERGER TECH CORP

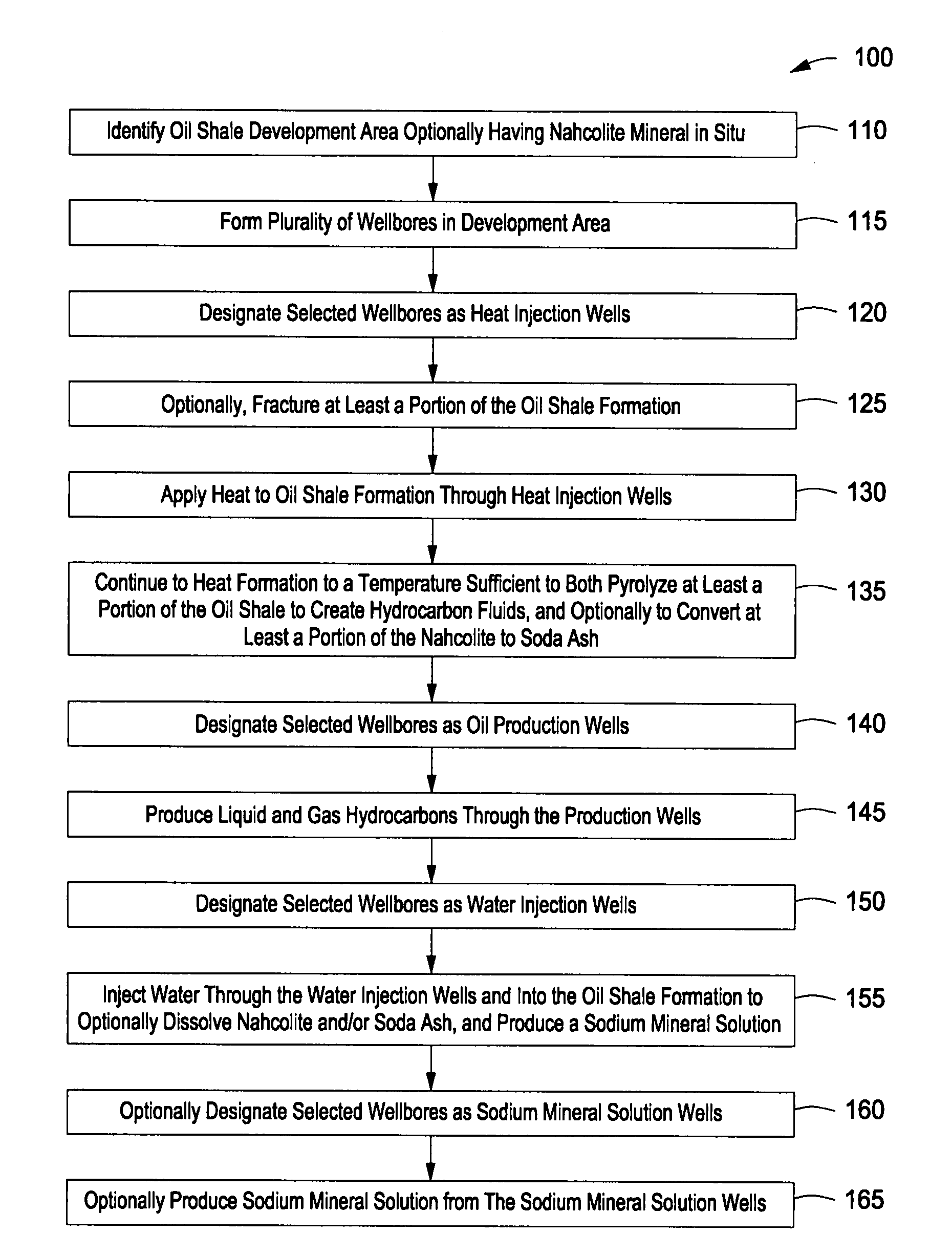

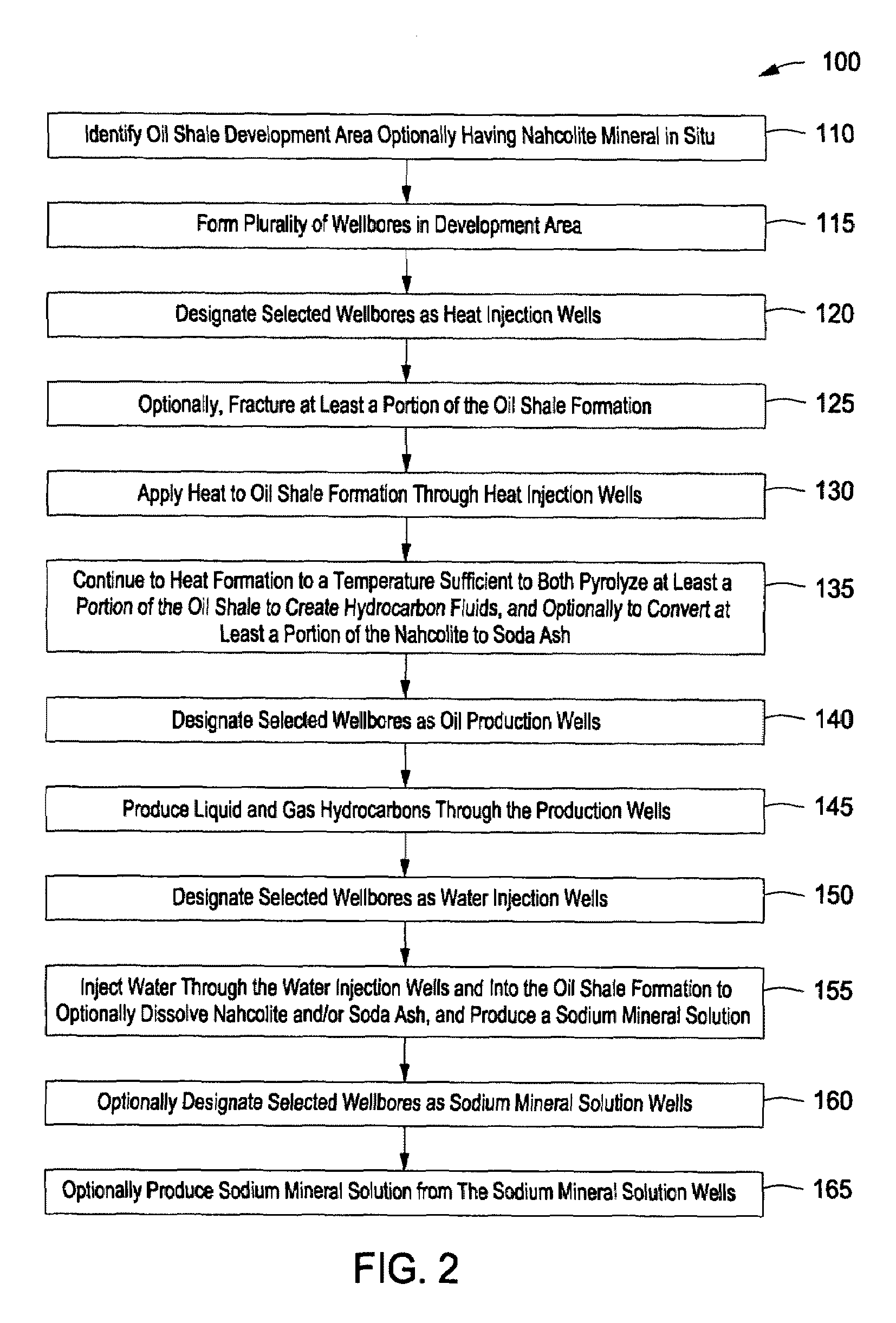

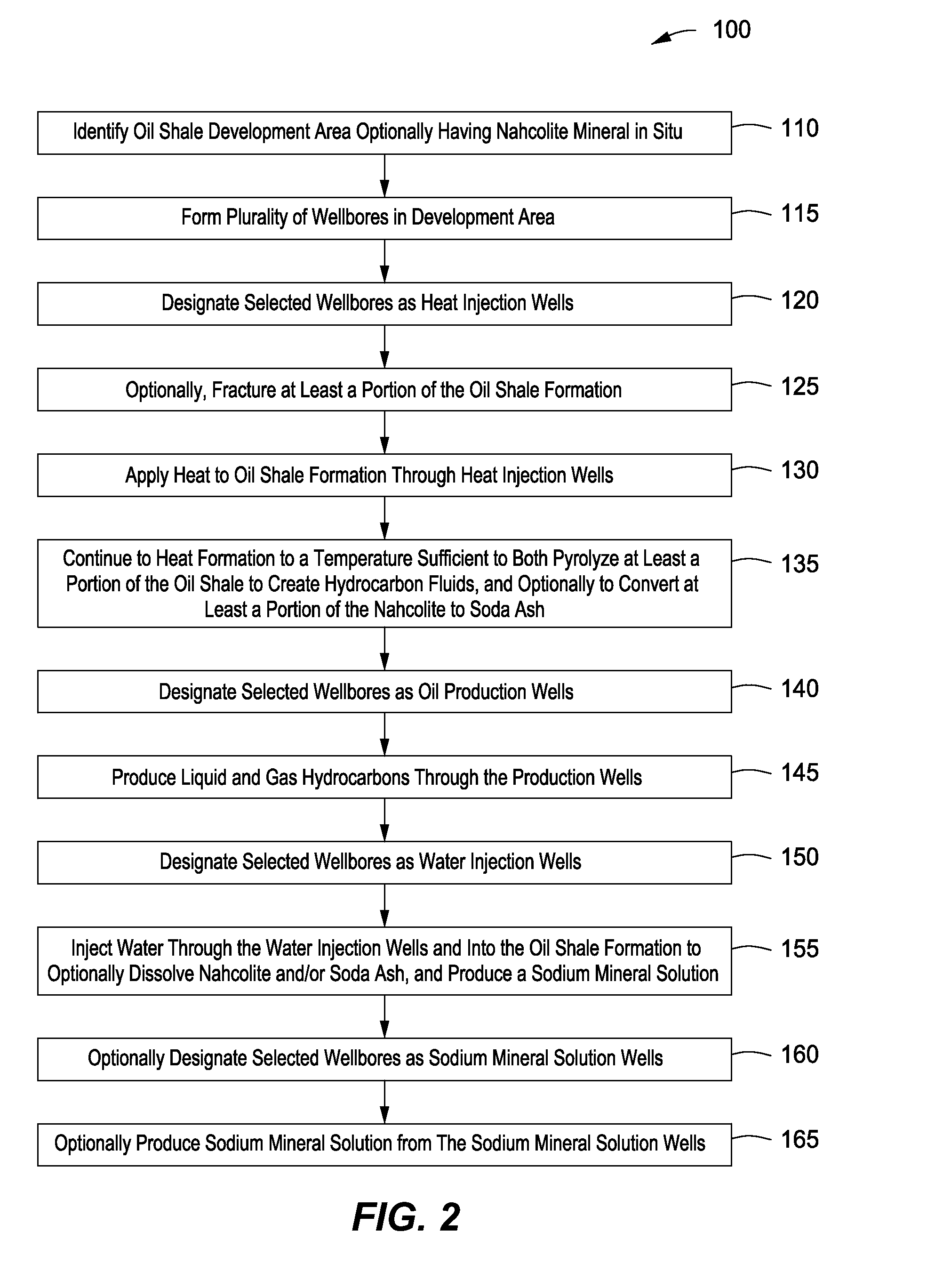

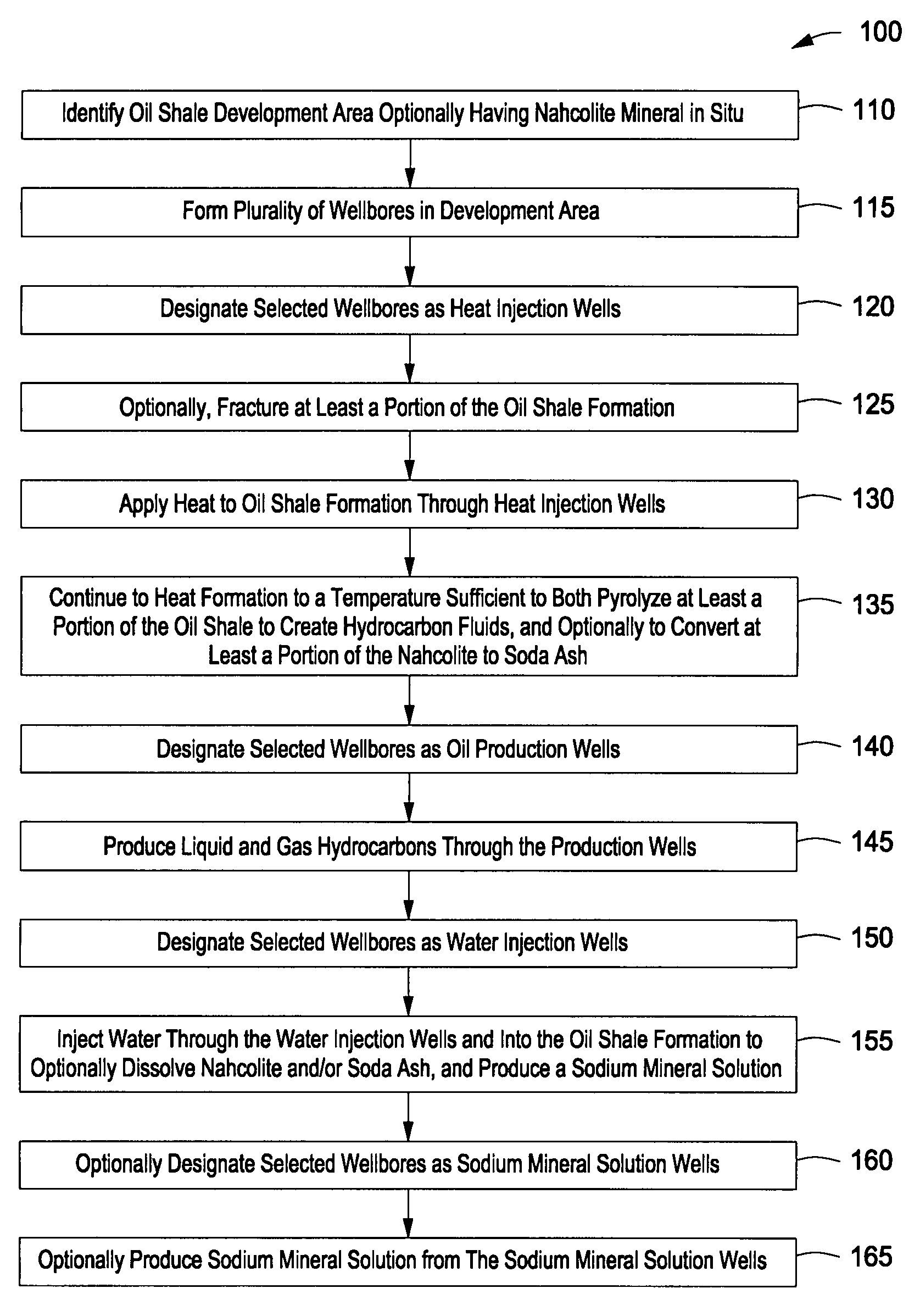

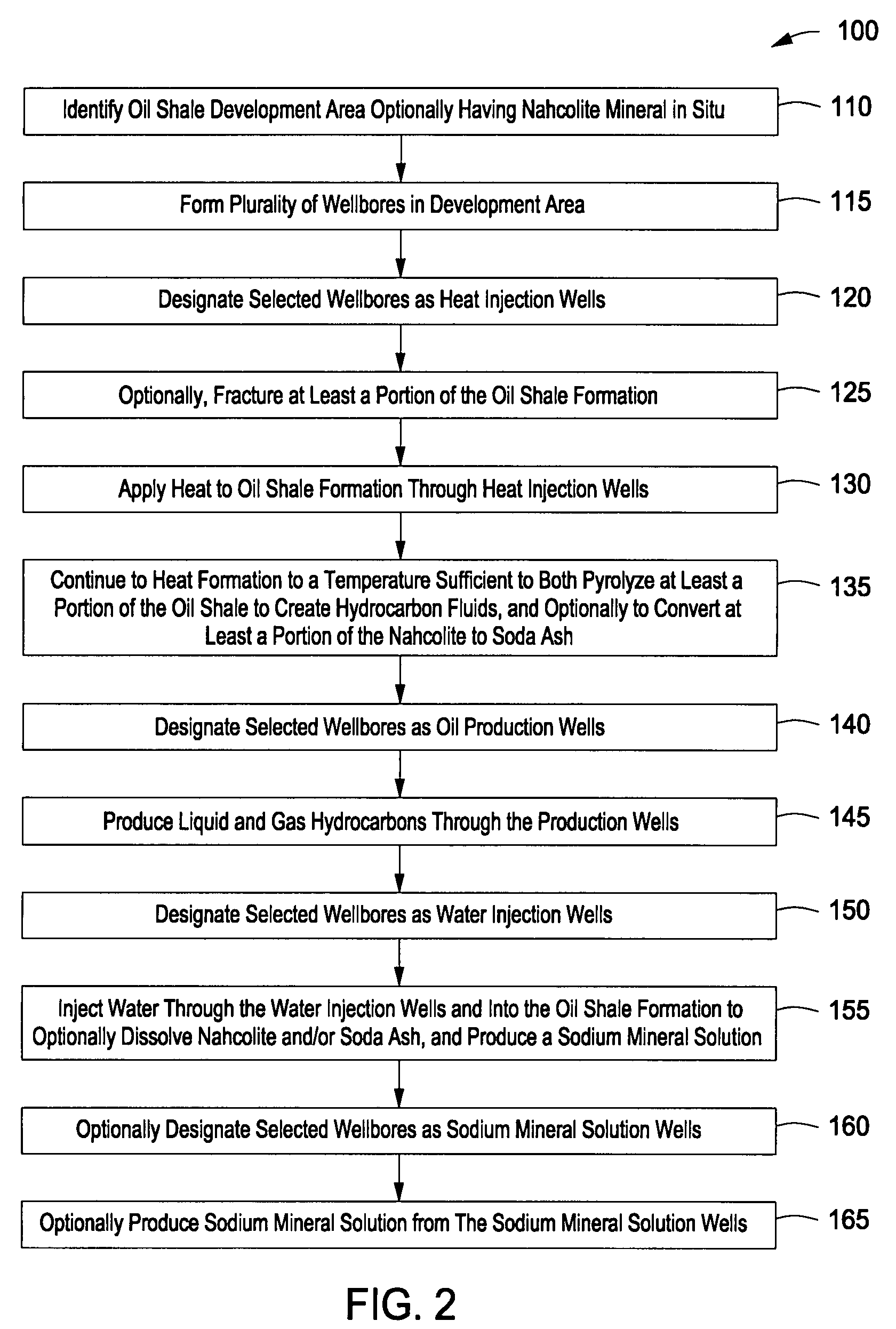

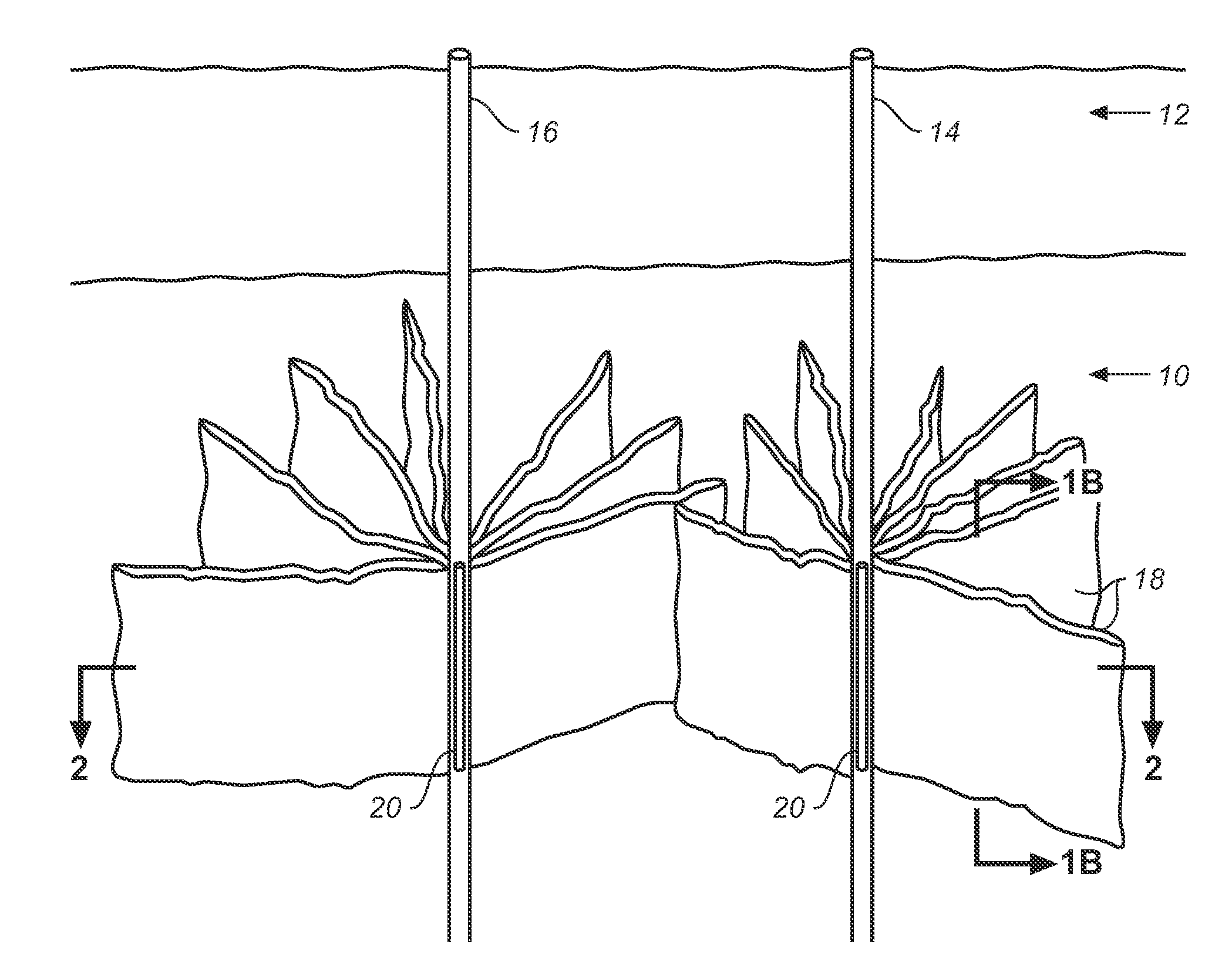

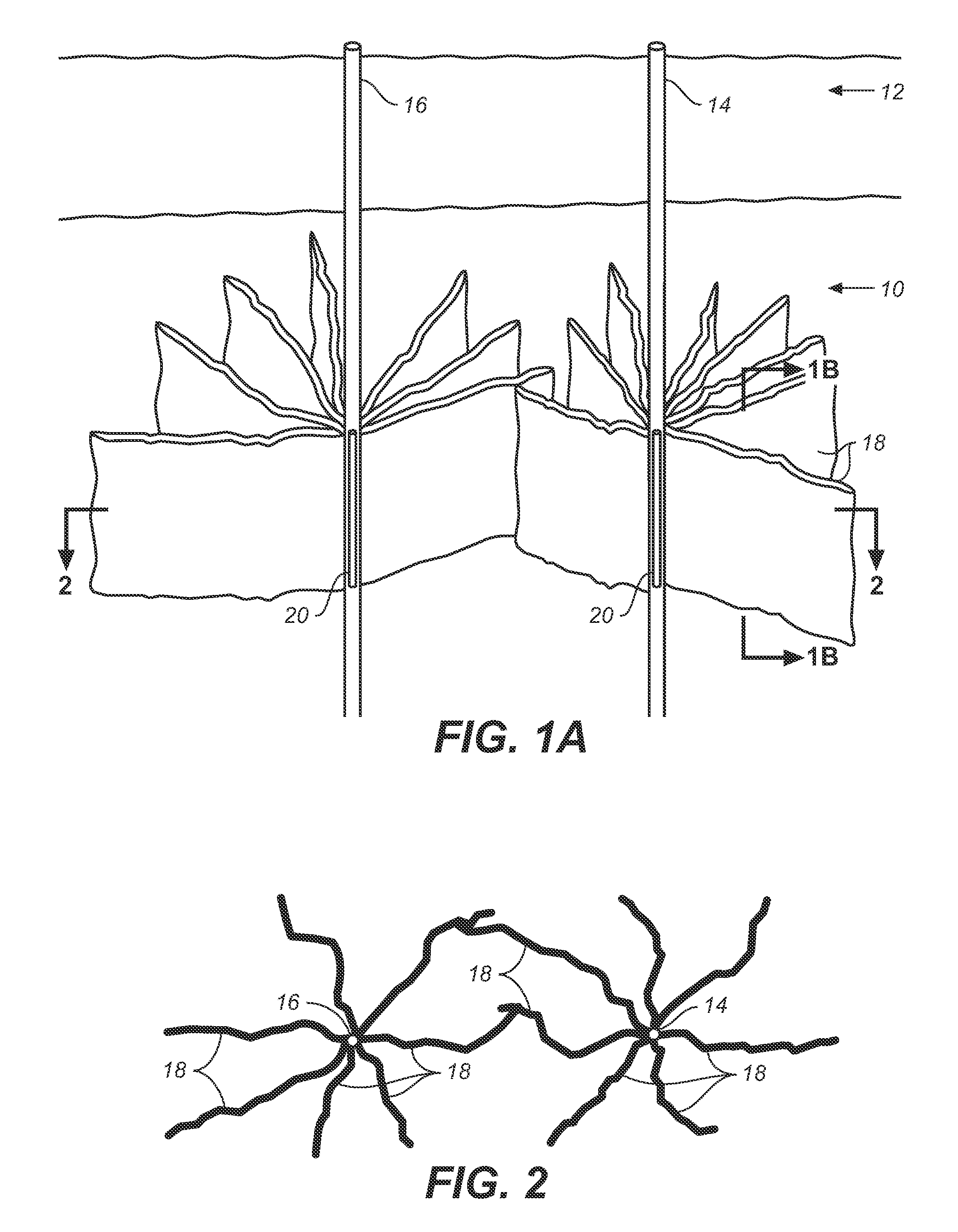

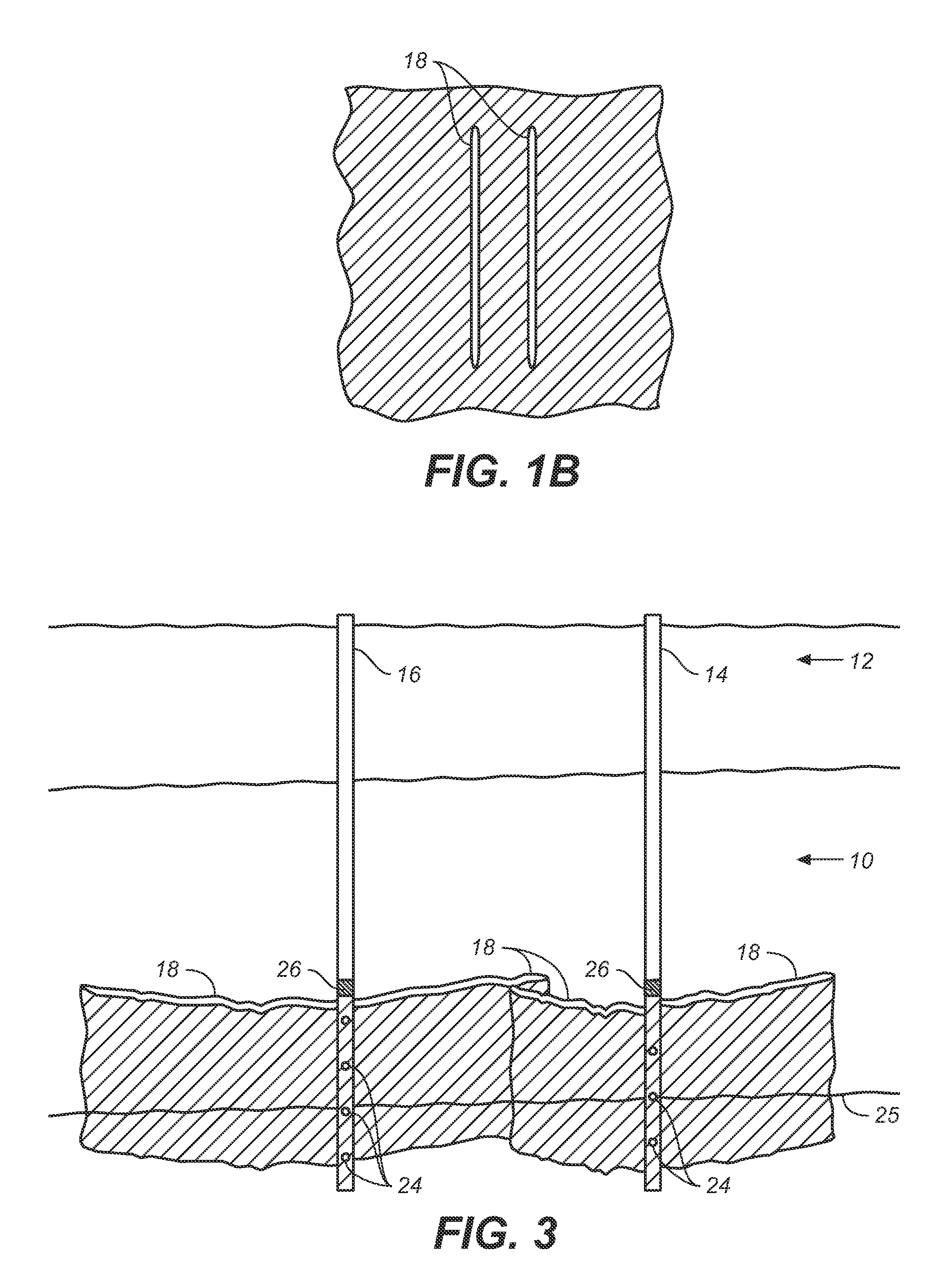

Enhanced shale oil production by in situ heating using hydraulically fractured producing wells

InactiveUS20080087428A1Extend the flow pathInsulationFluid removalHydraulic fracturingOil production

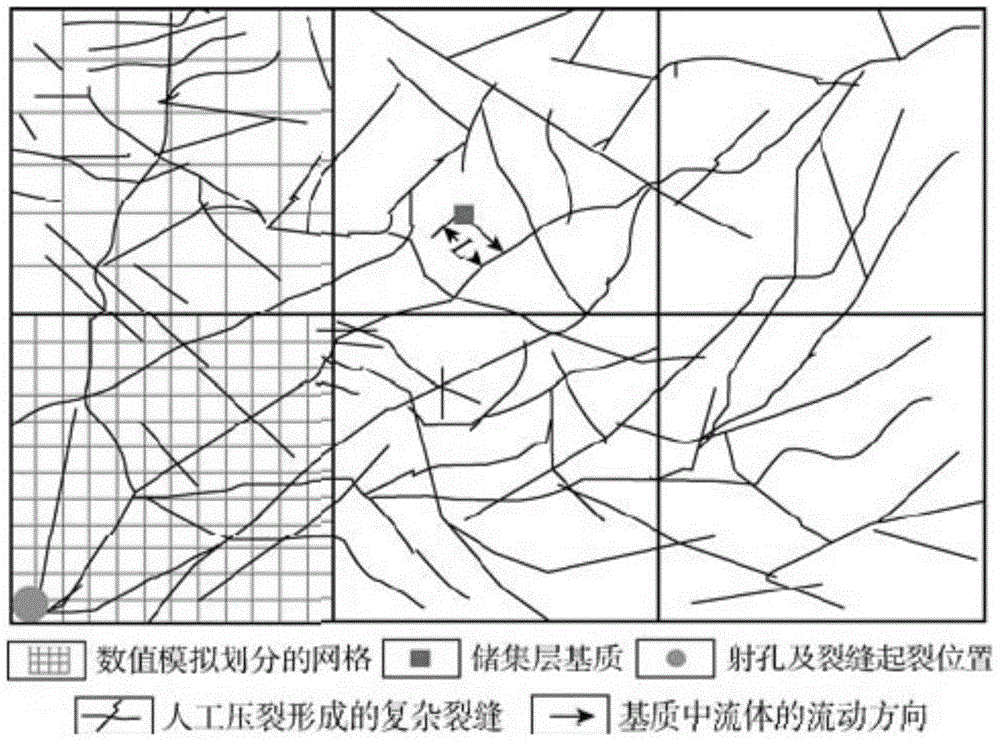

A method for enhanced production of hydrocarbon fluids from an organic-rich rock formation such as an oil shale formation is provided. The method generally includes completing at least one heater well in the organic-rich rock formation, and also completing a production well in the organic-rich rock formation. The method also includes the steps of hydraulically fracturing the organic-rich rock formation from the production well such that one or more artificial fractures are formed, and heating the organic-rich rock formation from the at least one heater well, thereby pyrolyzing at least a portion of the organic-rich rock into hydrocarbon fluids Pyrolyzing the organic-rich rock formation creates thermal fractures in the formation due to thermal stresses created by heating. The thermal fractures intersect the artificial fractures. As an additional step, hydrocarbon fluids may be produced from the production well. Preferably, the organic-rich rock formation is an oil shale formation.

Owner:EXXONMOBIL UPSTREAM RES CO

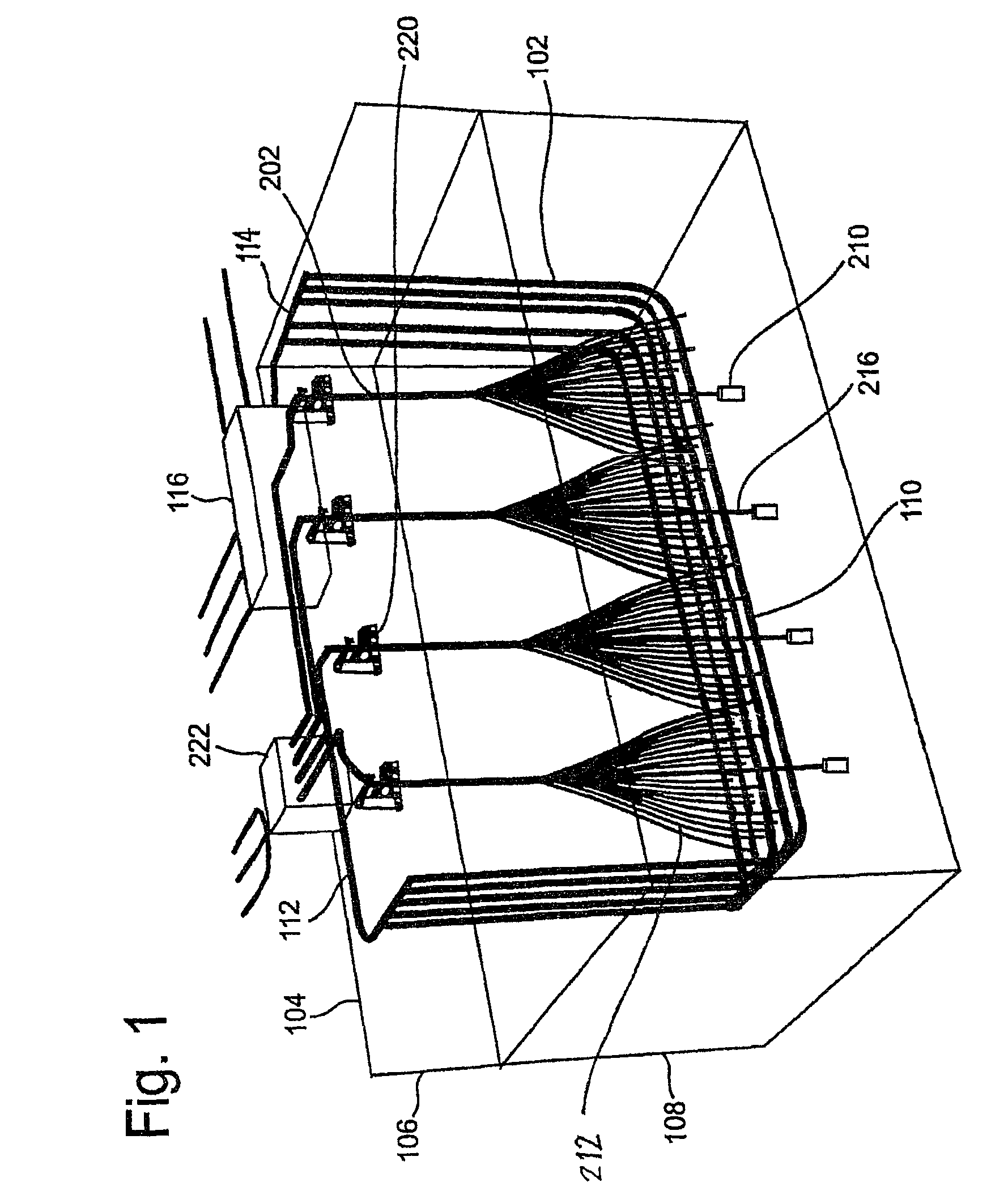

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

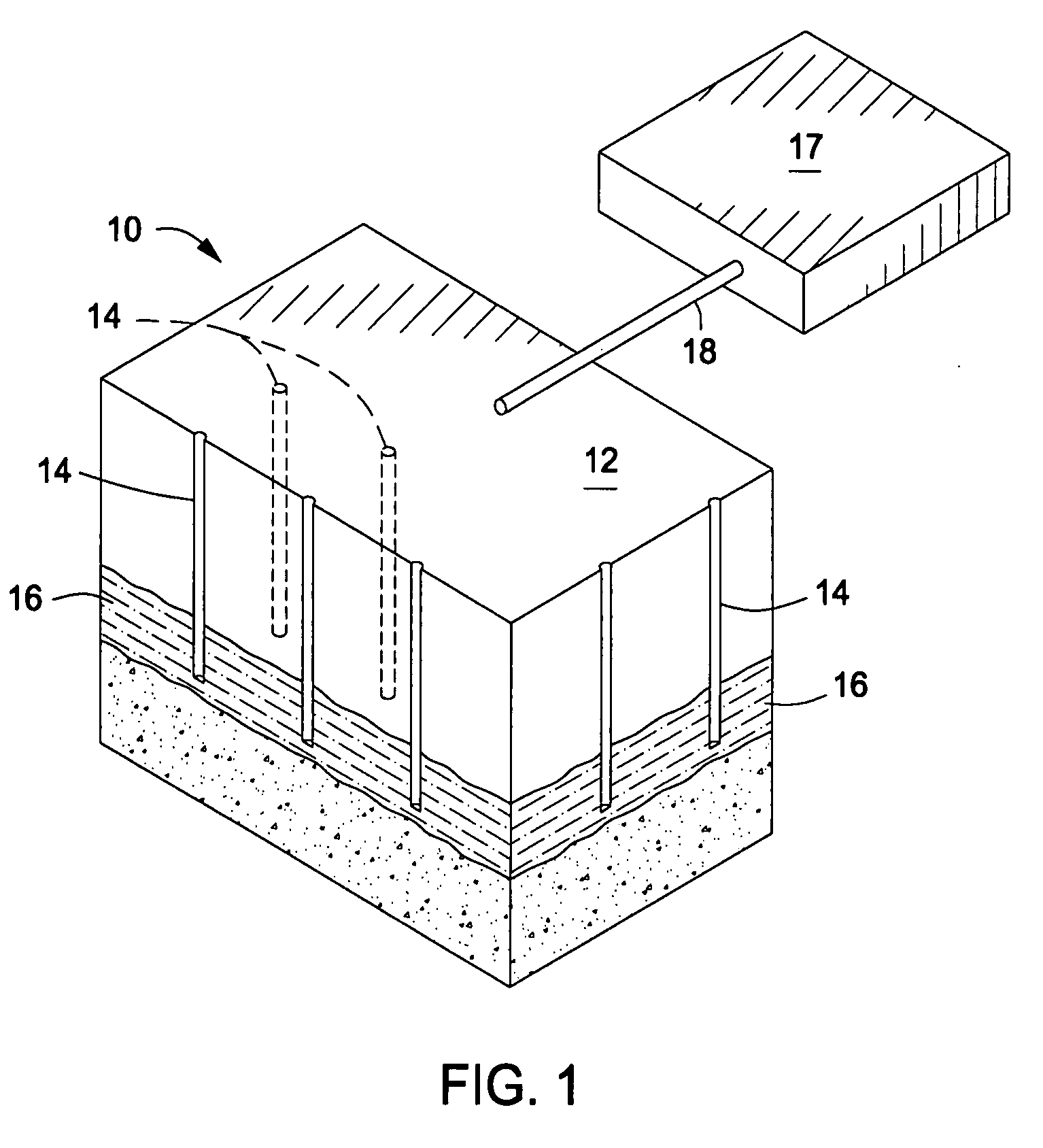

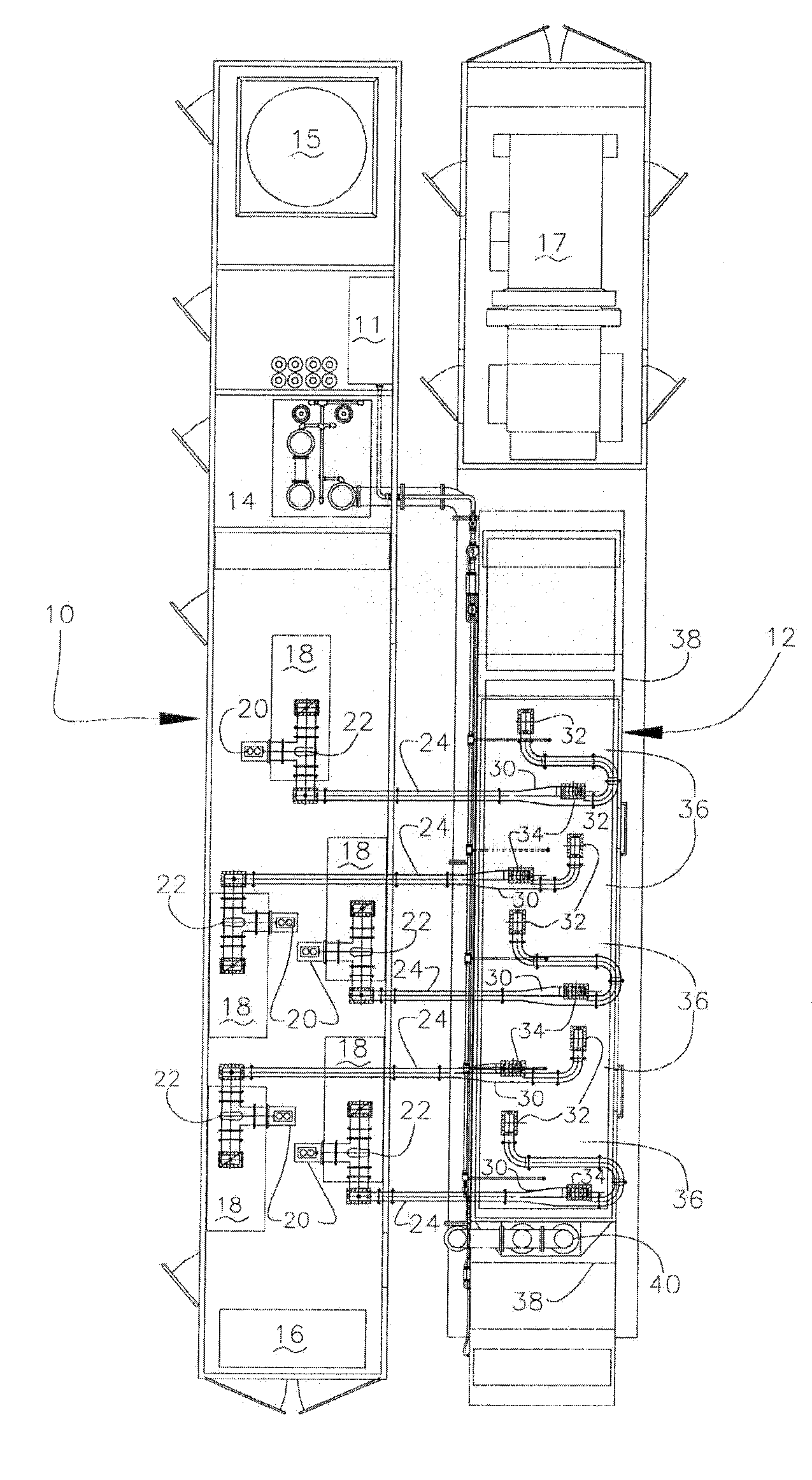

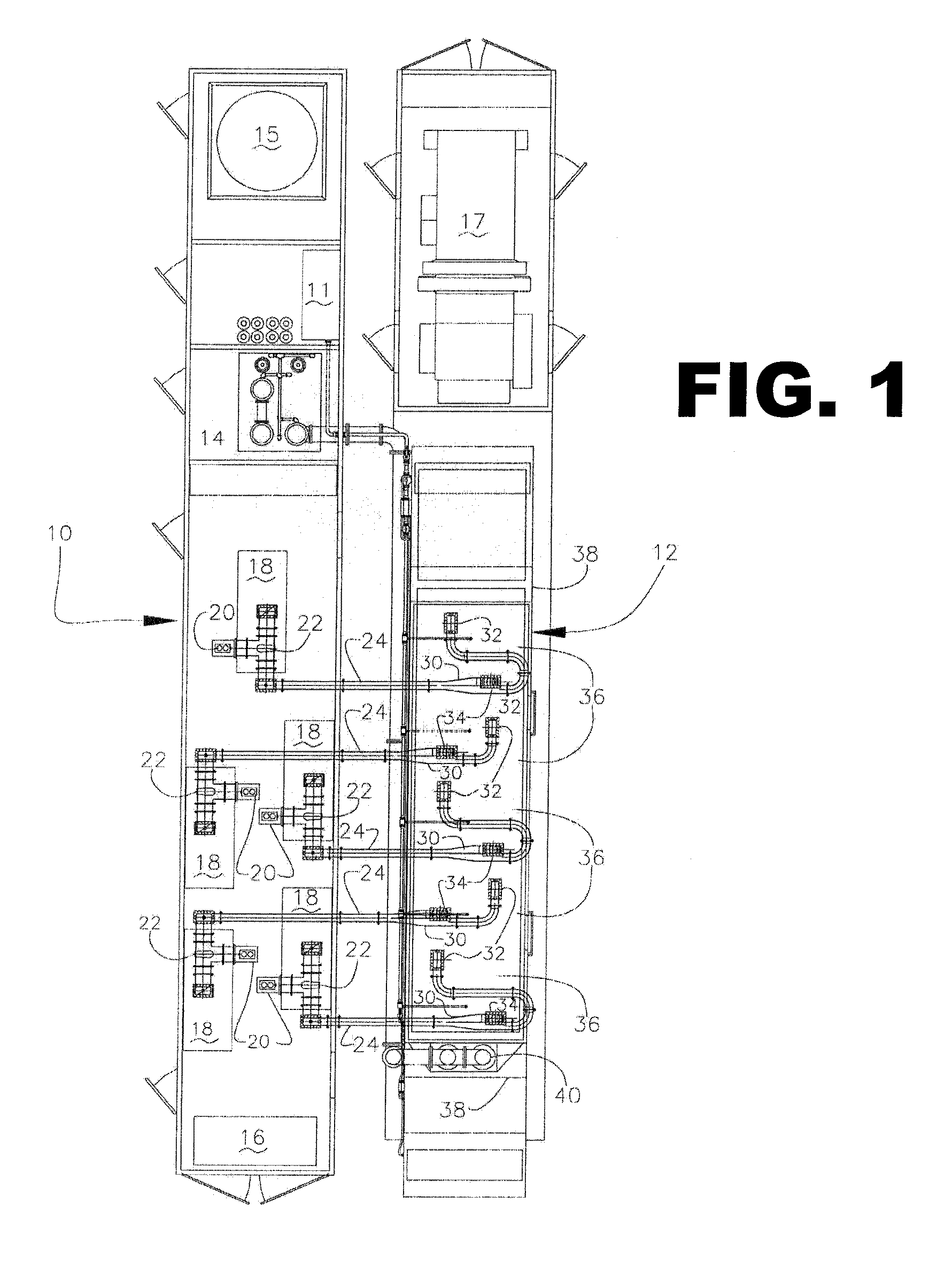

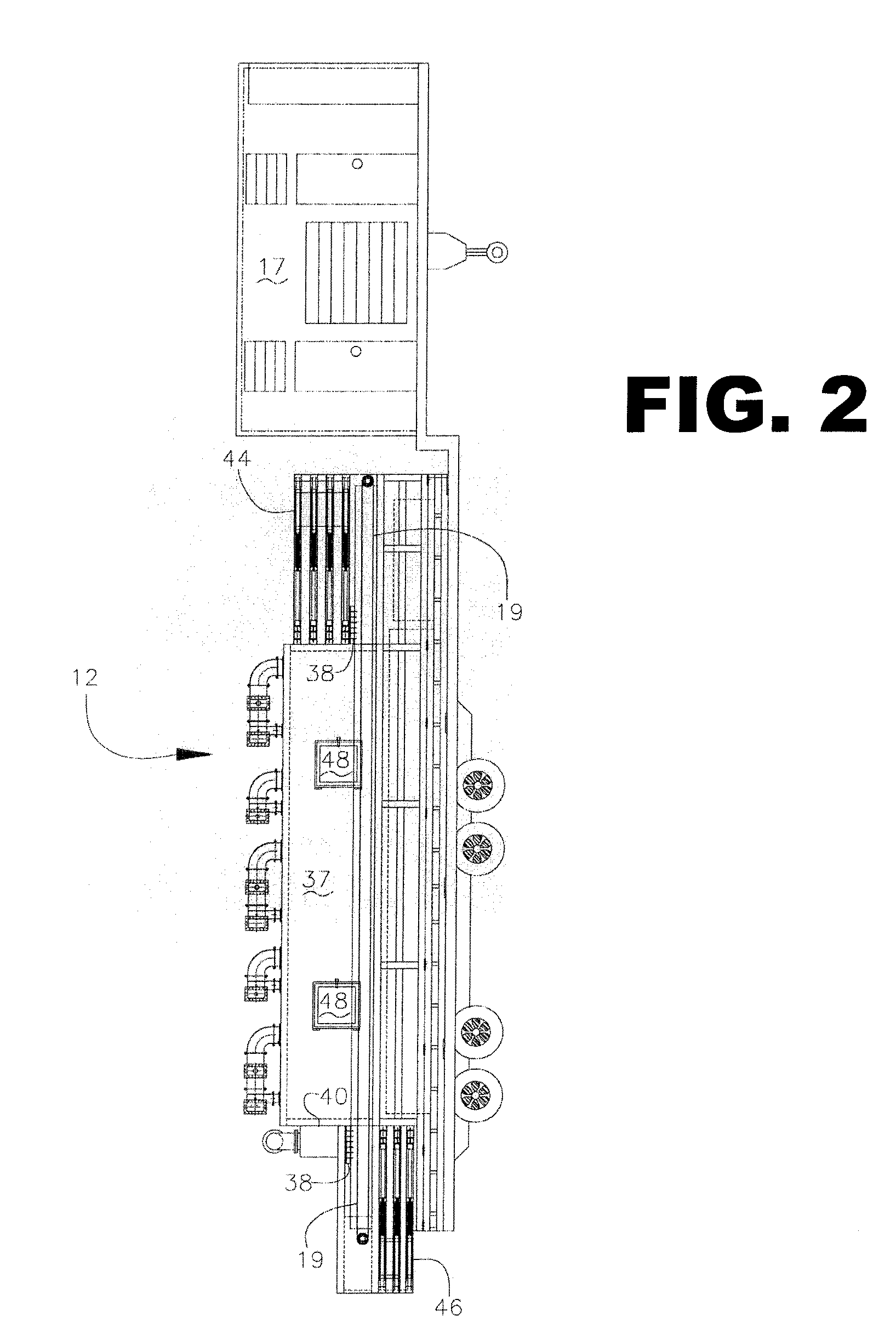

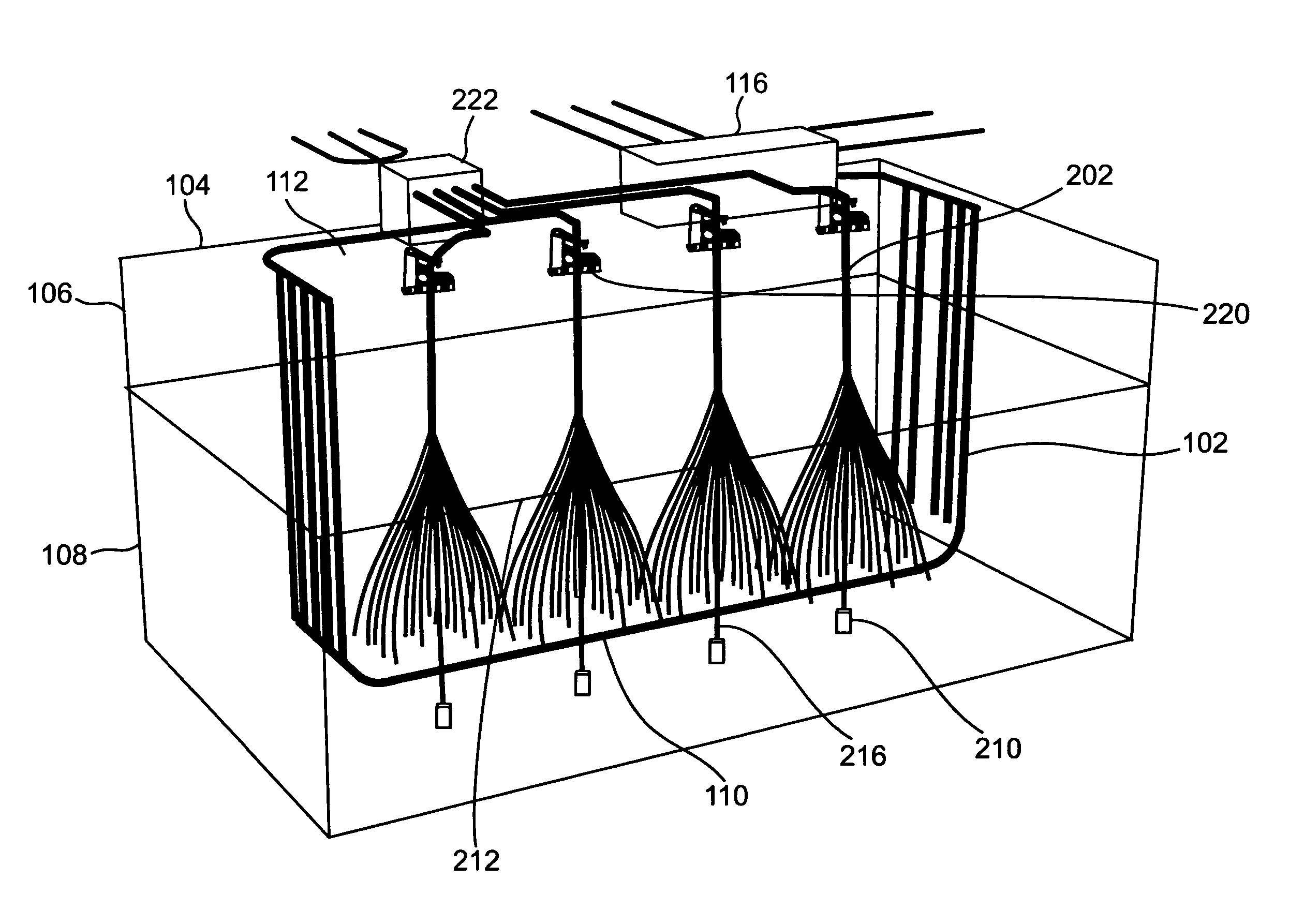

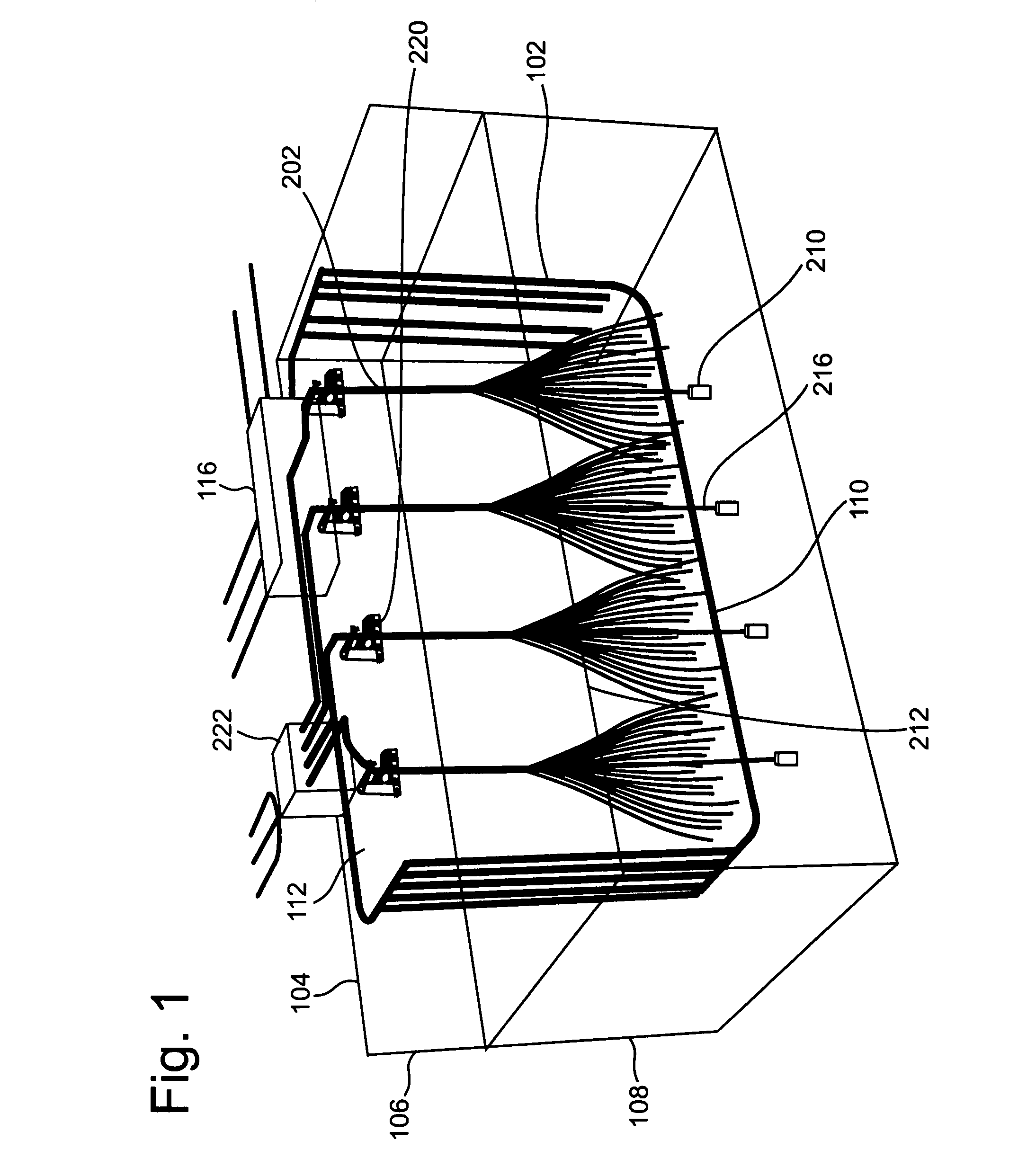

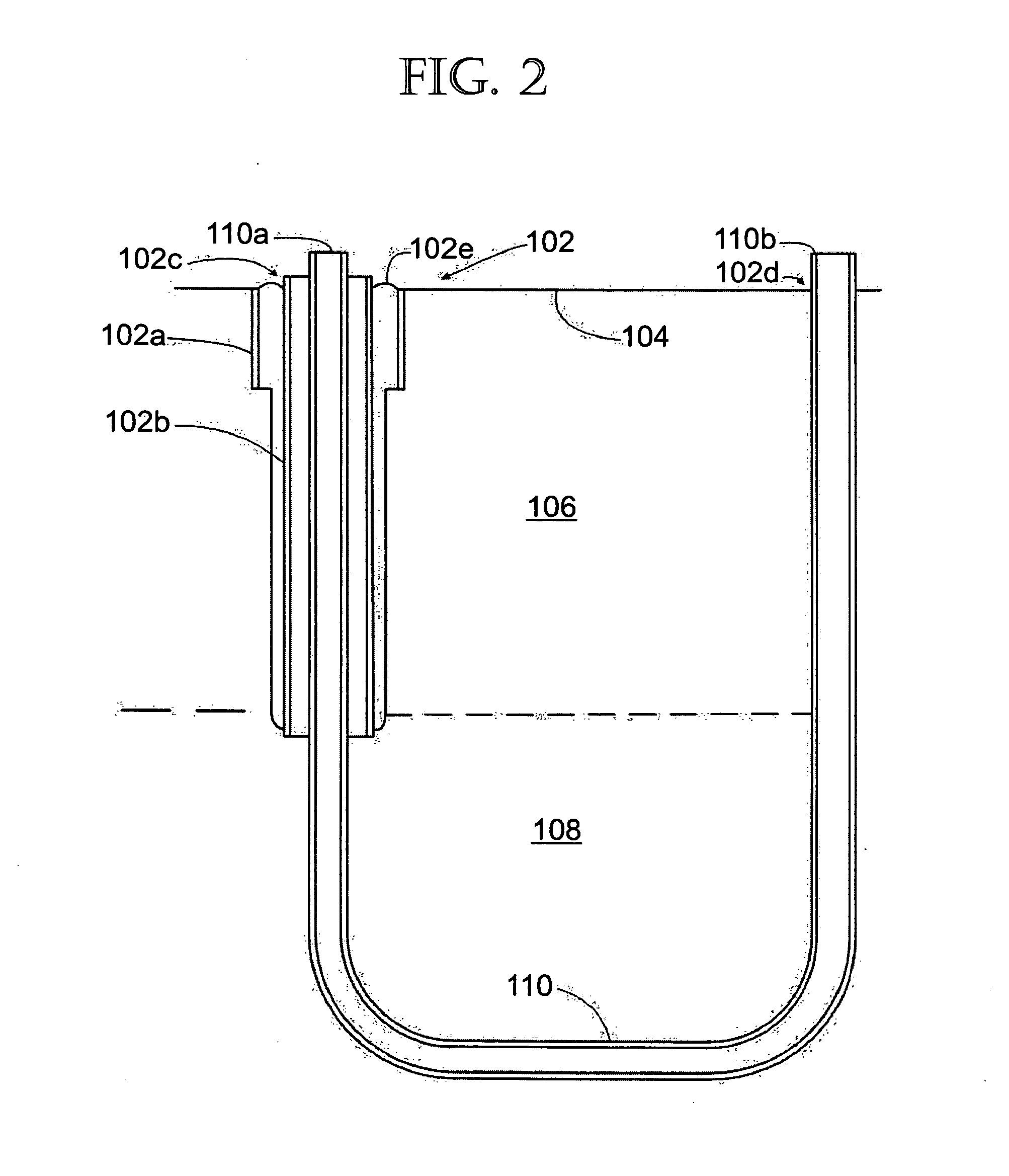

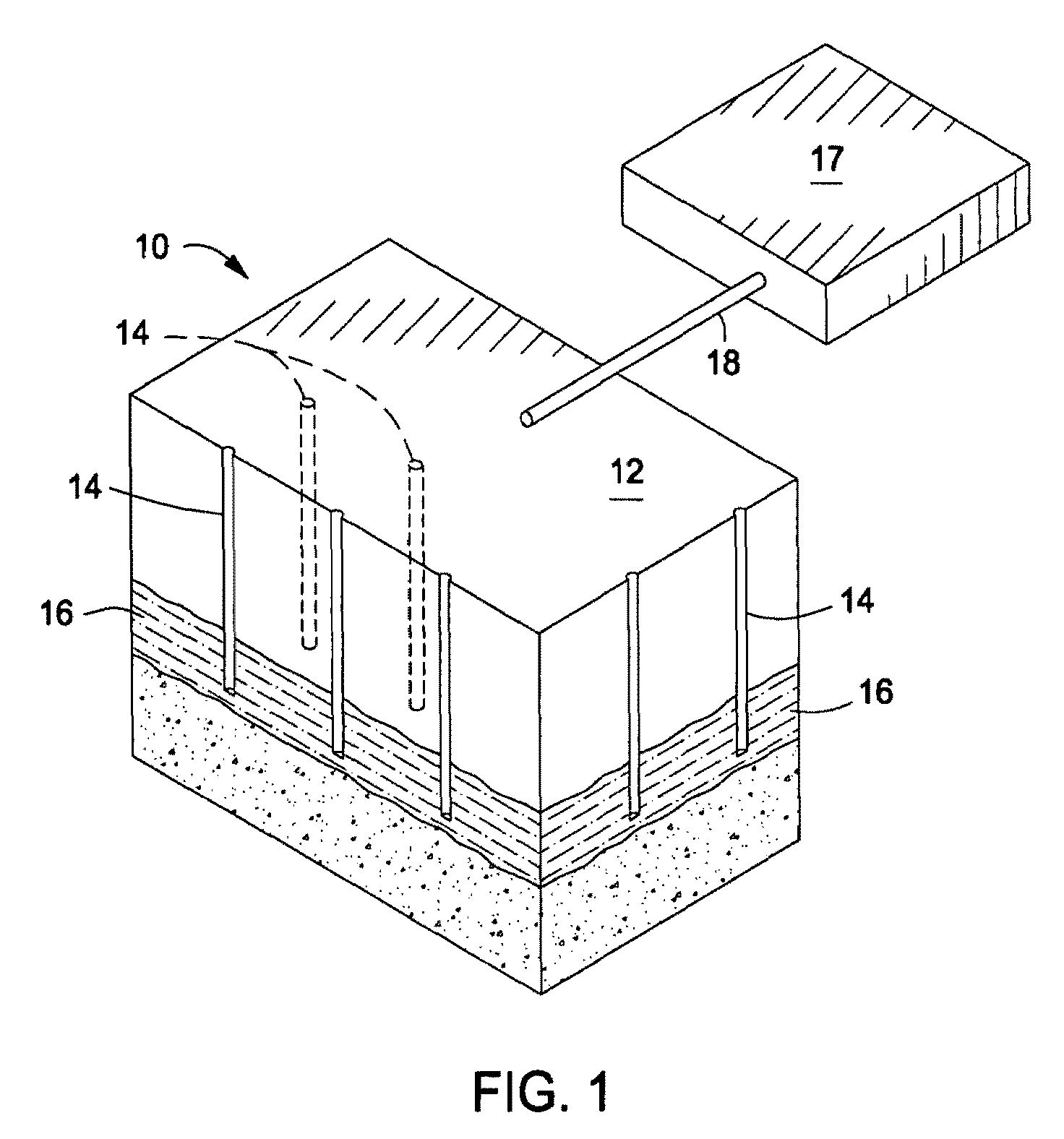

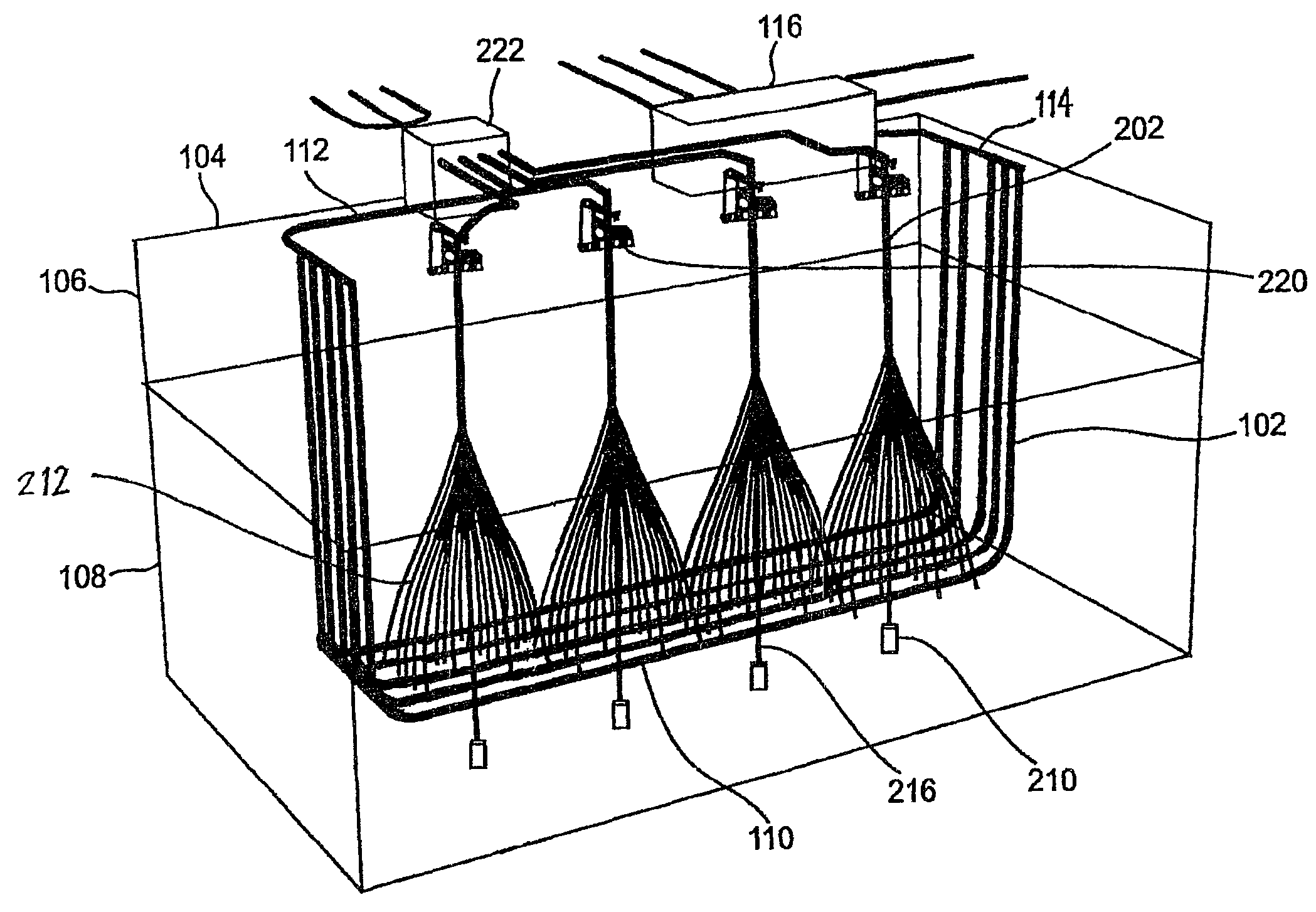

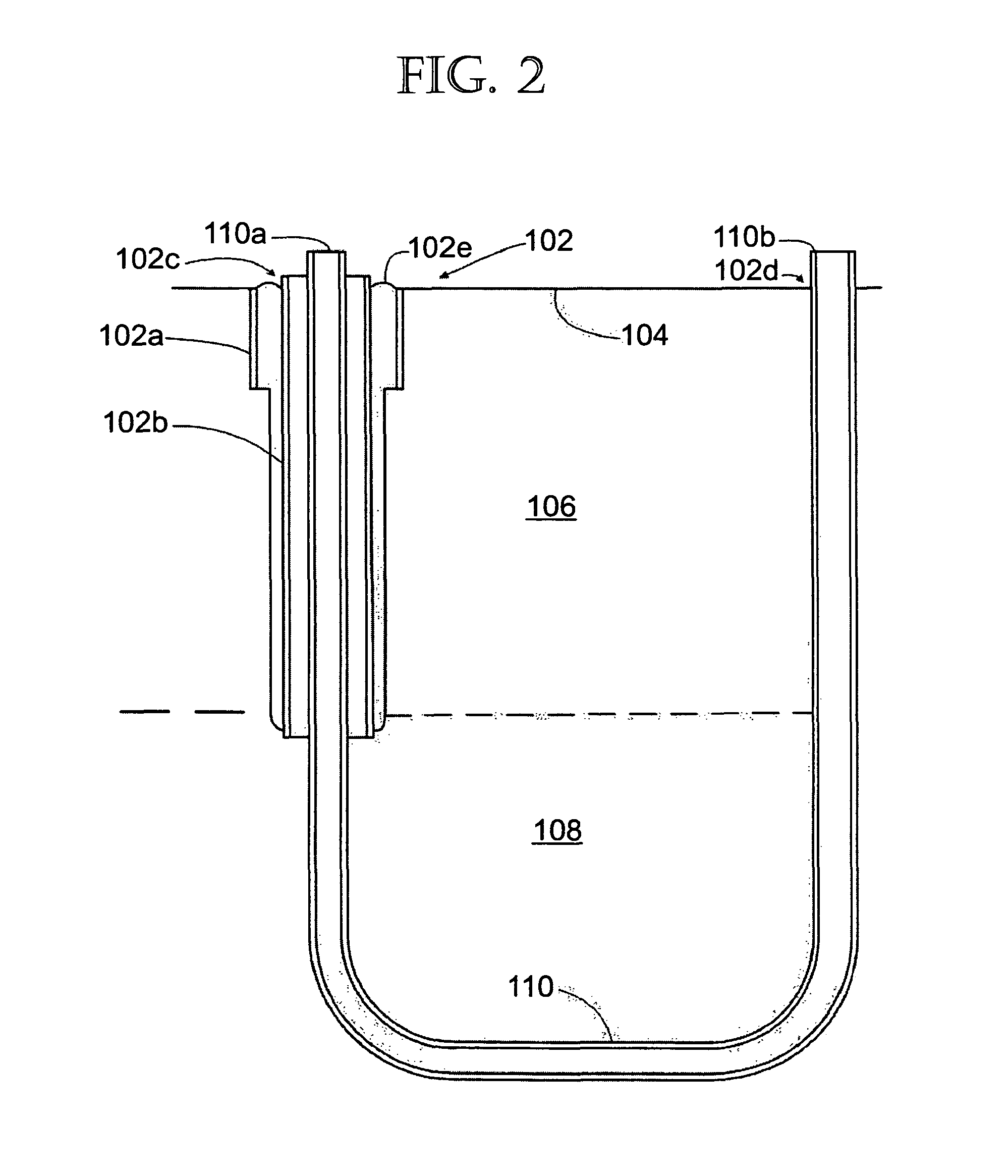

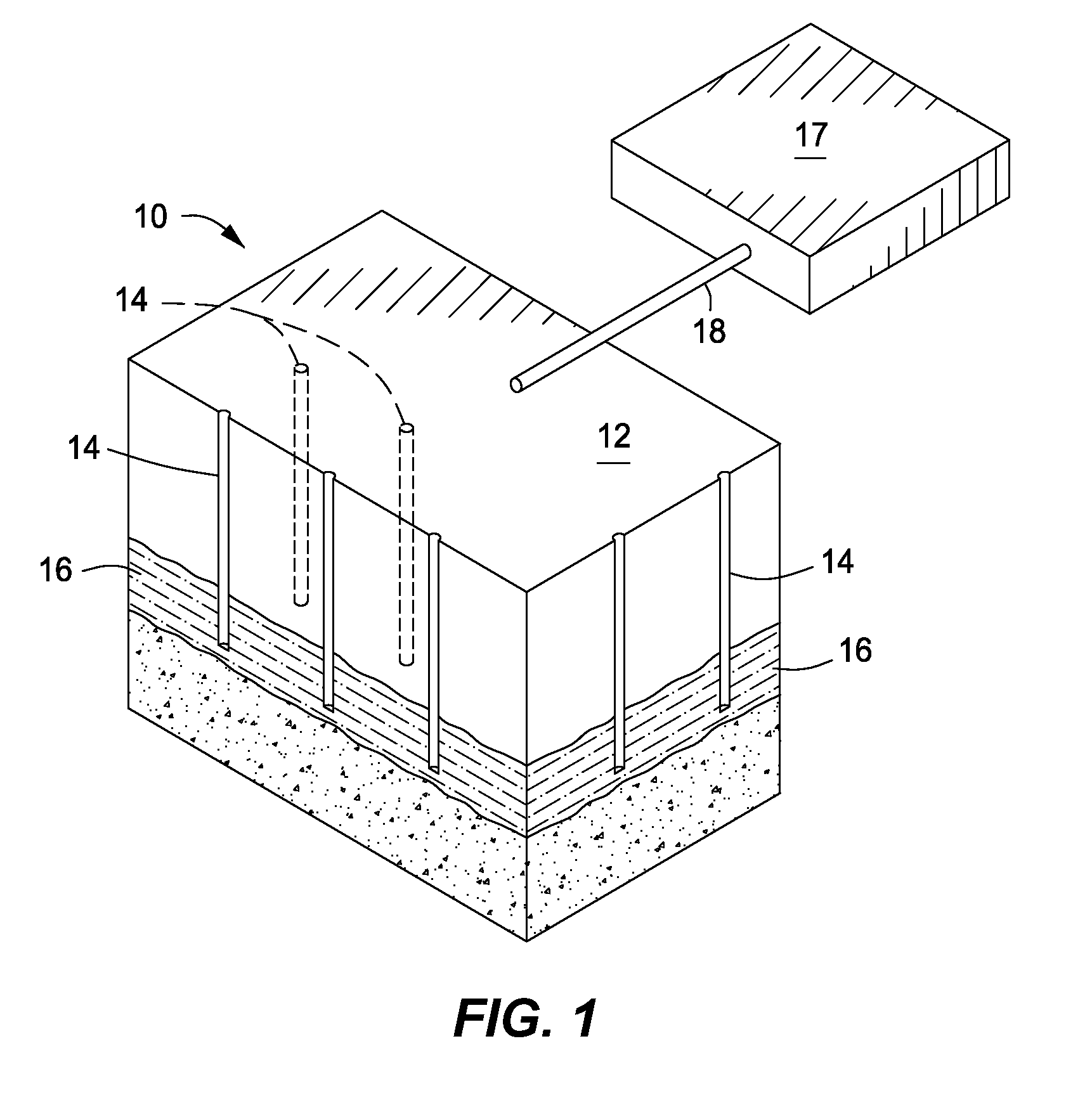

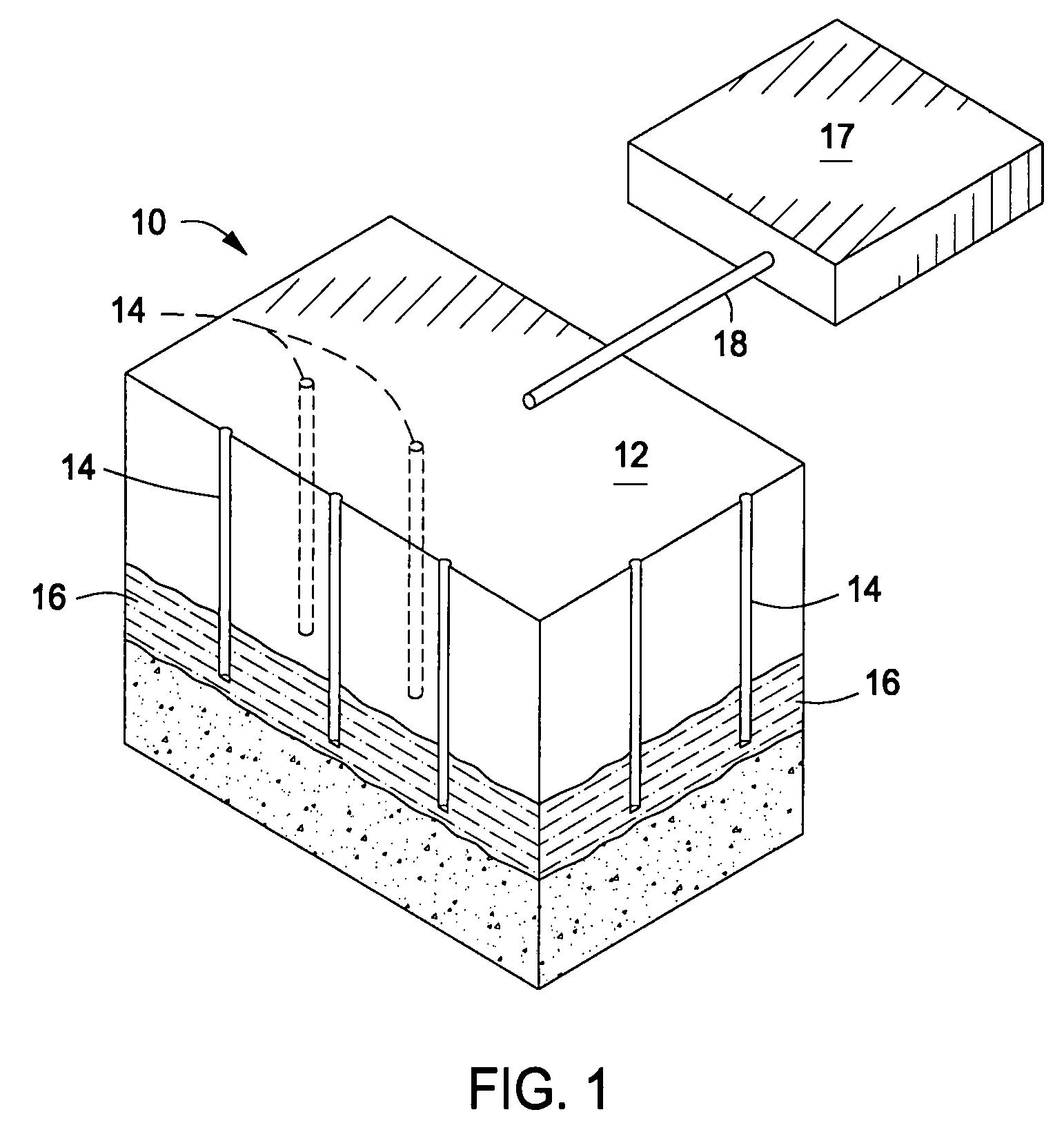

In situ method and system for extraction of oil from shale

ActiveUS20070193743A1Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

Enhanced shale oil production by in situ heating using hydraulically fractured producing wells

Owner:EXXONMOBIL UPSTREAM RES CO

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN1903994AReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

In situ method and system for extraction of oil from shale

ActiveUS7743826B2Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

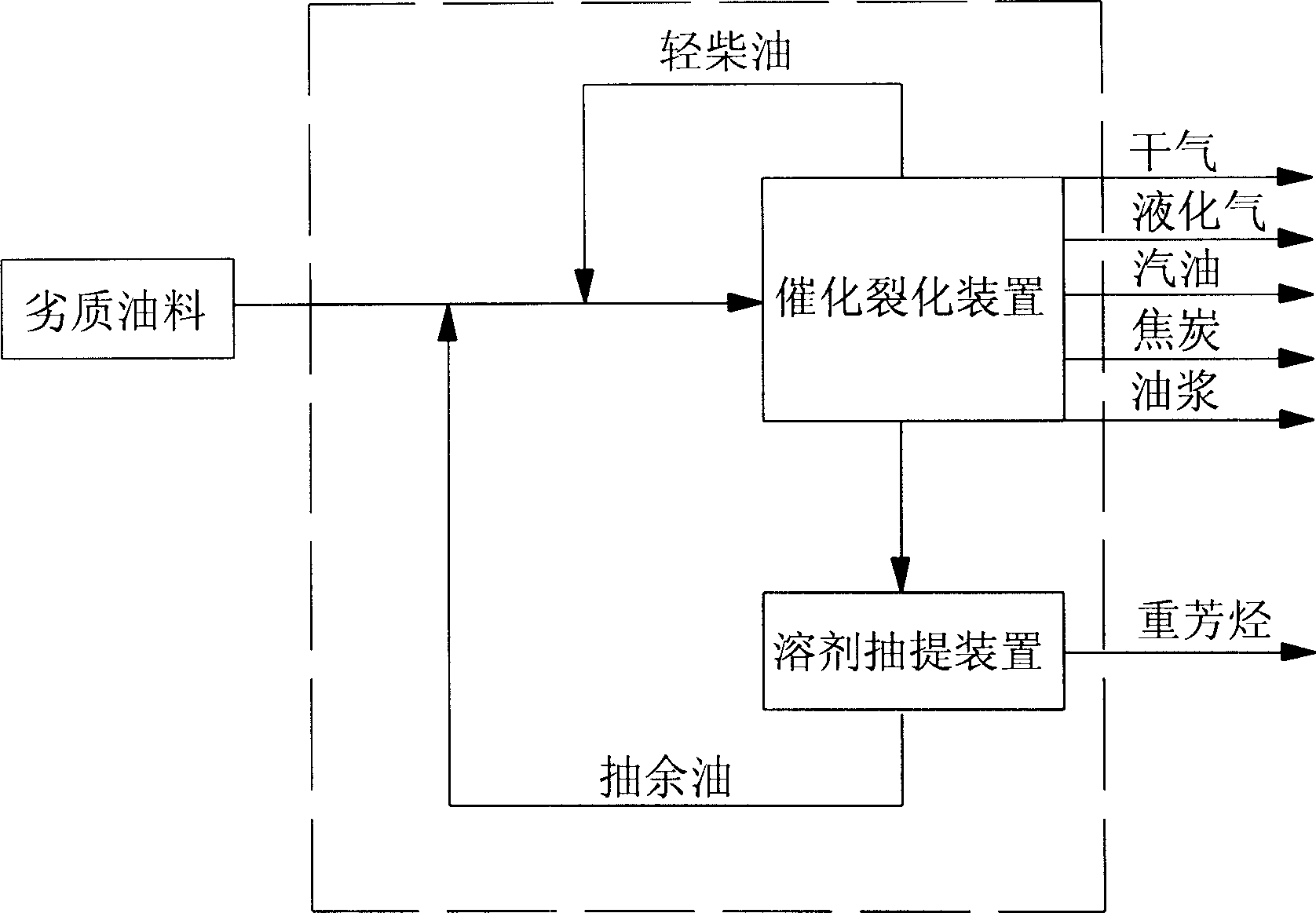

Catalyzing and cracking process of inferior oil

InactiveCN1746265AHigh yieldReduce unit consumptionCatalytic crackingHydrocarbon oils refiningResidual oilSolvent

A catalytic and cracking process of inferior oil is characterized by catalytic cracking the inferior oil to obtain light diesel fuel cut fraction, returning it to catalytic cracker to recycle, extracting the obtained heavy diesel fuel cut fraction from solvent, extracting residual oil and returning to catalytic cracker to recycle. It has higher recovery rate, better quality and more yield of product. It can be used for various inferior fuel heavy oils, catalytic raw materials, shale oil and coal tar.

Owner:邓先樑 +4

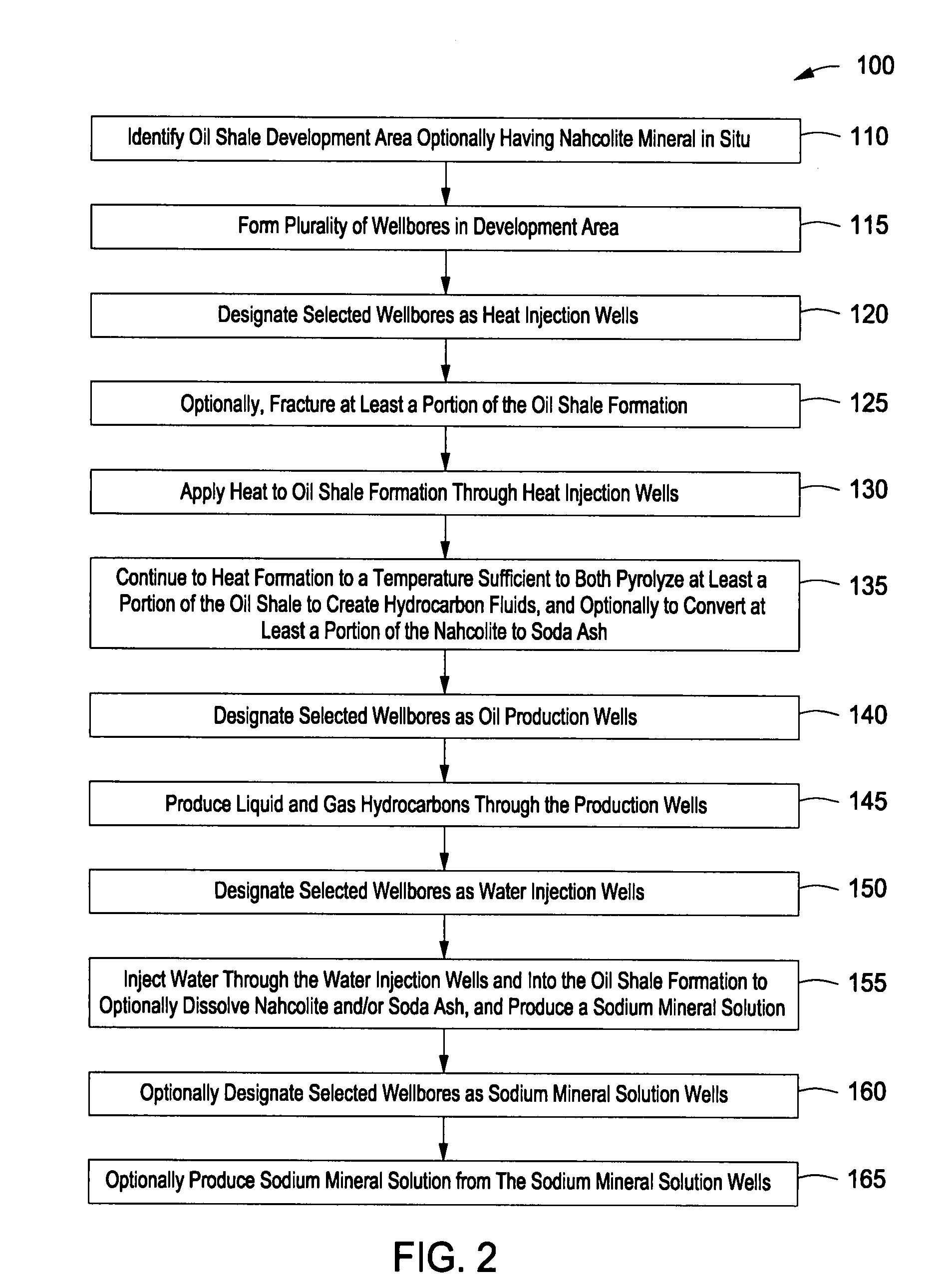

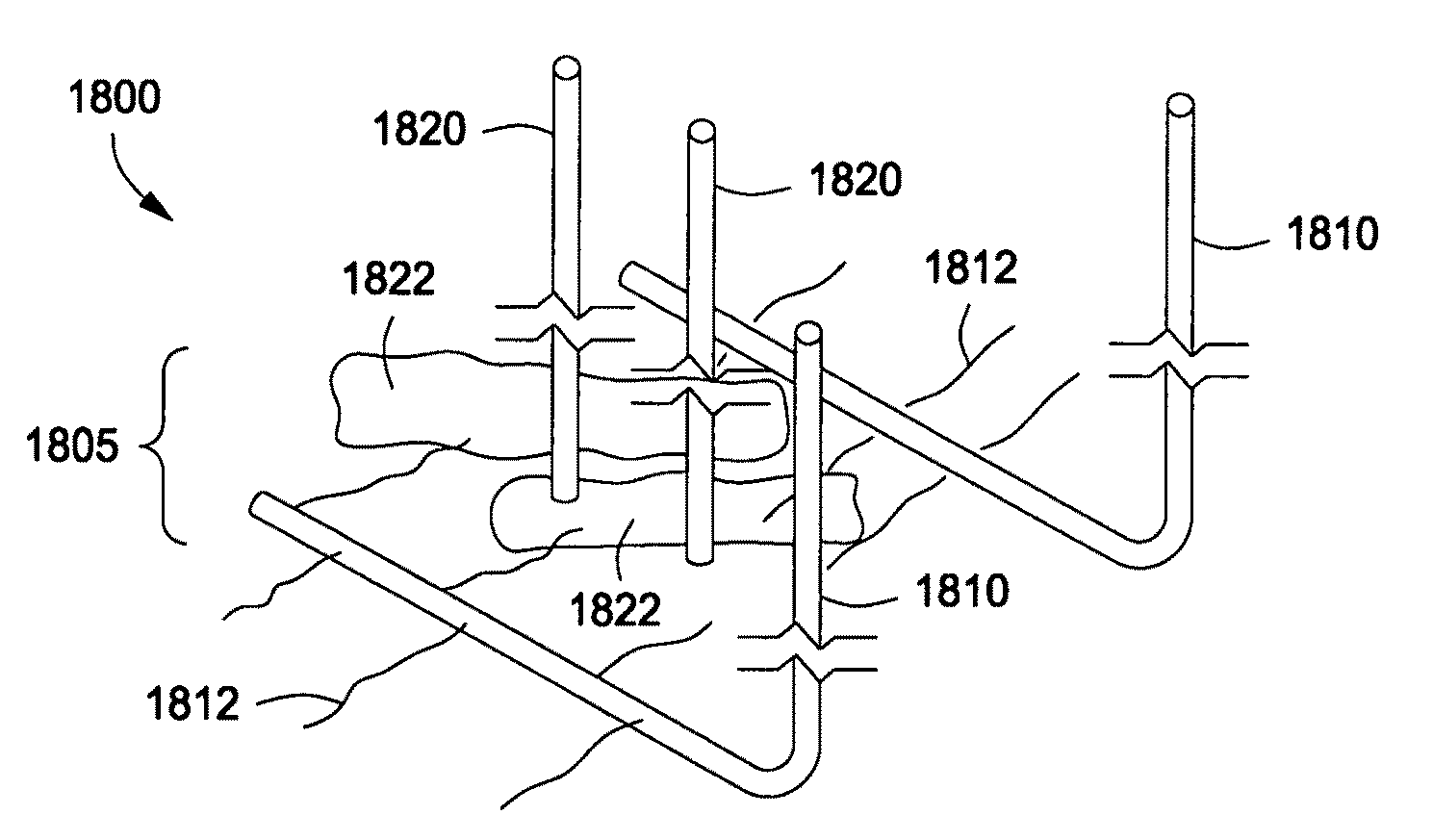

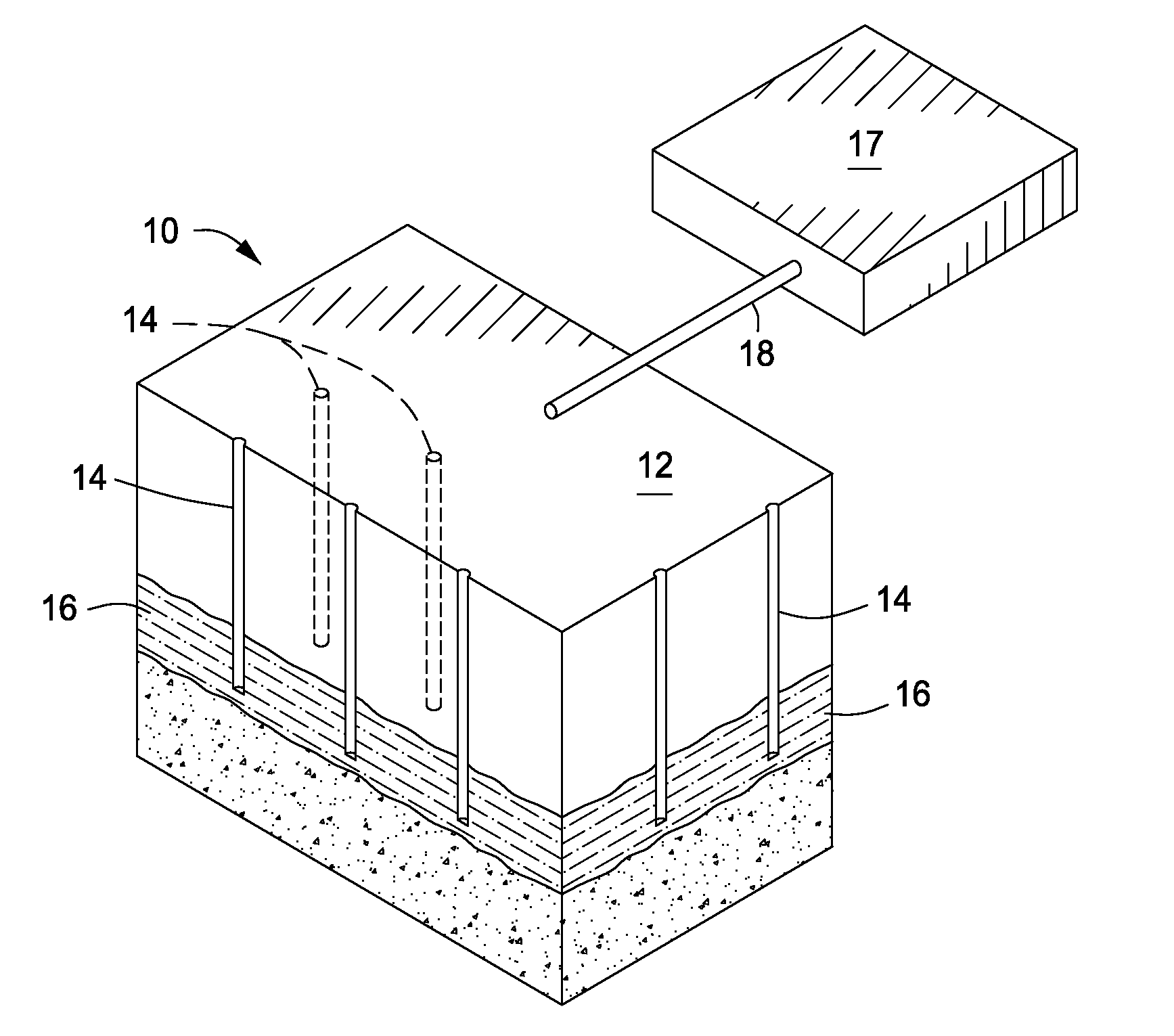

Optimized Well Spacing For In Situ Shale Oil Development

InactiveUS20110132600A1Minimize secondary crackingTravel efficientlySurveyInsulationThermal energyKerogen

A method for spacing heater wells for an in situ conversion process includes the steps of determining a direction along which thermal energy will travel most efficiently through a subsurface formation, and completing a plurality of heater wells in the subsurface formation, with the heater wells being spaced farther apart in the determined direction than in a direction transverse to the determined direction. In one aspect, the step of determining a direction along which thermal energy will travel most efficiently is performed based upon a review of geological data pertaining to the subsurface formation. The geological data may comprise the direction of least horizontal principal stress in the subsurface formation. Alternatively, the geological data may comprise the direction of bedding in the subsurface formation, the tilt of the subsurface formation relative to the surface topography, the organic carbon content of the kerogen, the initial formation permeability, and other factors.

Owner:EXXONMOBIL UPSTREAM RES CO

Optimized well spacing for in situ shale oil development

InactiveUS20080087420A1Minimize secondary crackingTravel efficientlyFluid removalCarbon-dioxide storageKerogenThermal energy

A method for spacing heater wells for an in situ conversion process is provided. The method includes the steps of determining a direction along which thermal energy will travel most efficiently through a subsurface formation, and completing a plurality of heater wells in the subsurface formation, with the heater wells being spaced farther apart in the determined direction than in a direction transverse to the determined direction. In one aspect, the step of determining a direction along which thermal energy will travel most efficiently is performed based upon a review of geological data pertaining to the subsurface formation. The geological data may comprise the direction of least horizontal principal stress in the subsurface formation. Alternatively, the geological data may comprise the direction of bedding in the subsurface formation, the tilt of the subsurface formation relative to the surface topography, the organic carbon content of the kerogen, the initial formation permeability, and other factors.

Owner:KAMINSKY ROBERT D +1

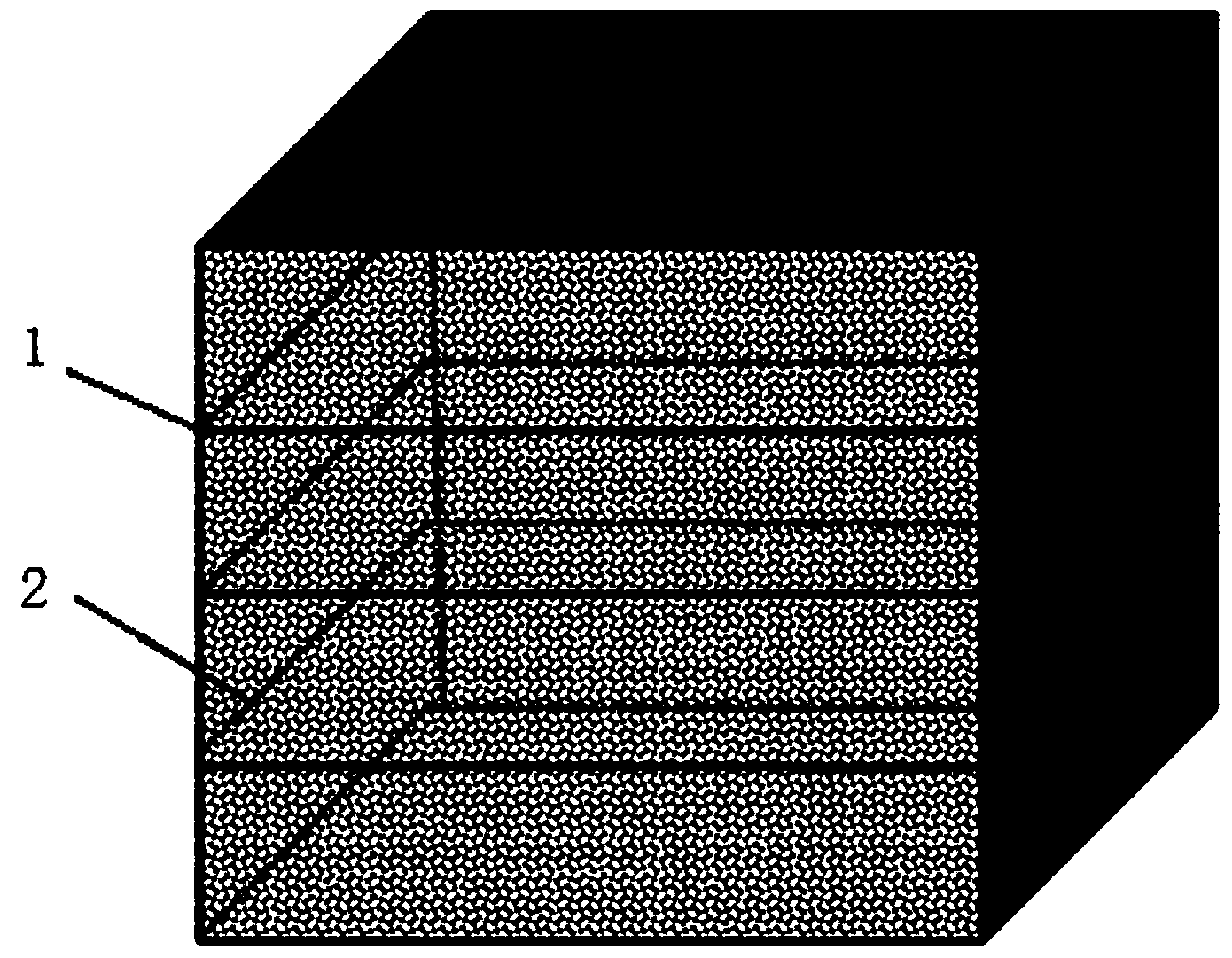

Preparation method of artificial rock core of jointing shale

ActiveCN104034563AEfficient developmentSimple materialPreparing sample for investigationRock coreTest sample

The invention belongs to the technical field of artificial rock core preparation, and in particular relates to a preparation method of an artificial rock core of jointing shale. The method comprises the following steps: mixing and stirring cement, quartz sand, clay and gypsum powder; adding a small amount of cereal and scraps of paper into the mixture, adding water into the mixture and stirring uniformly; casting the mixture in a layered manner to form a cement test sample; and coating lubricating oil between every two layers, and drying the cement test sample for molding, thereby obtaining the artificial rock core of the jointing shale. By the preparation method, the cement test sample with certain fracture development, bedding development and brittleness can be obtained, and the mechanical properties of a bedding plane (1), a natural fracture (2), a hydraulic fracture (3) and the like of the jointing shale rock can be simulated relatively accurately, so that shale oil and gas can be developed effectively. According to the preparation method, the used materials are simple, the cost is low, and the operation is simple and convenient.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

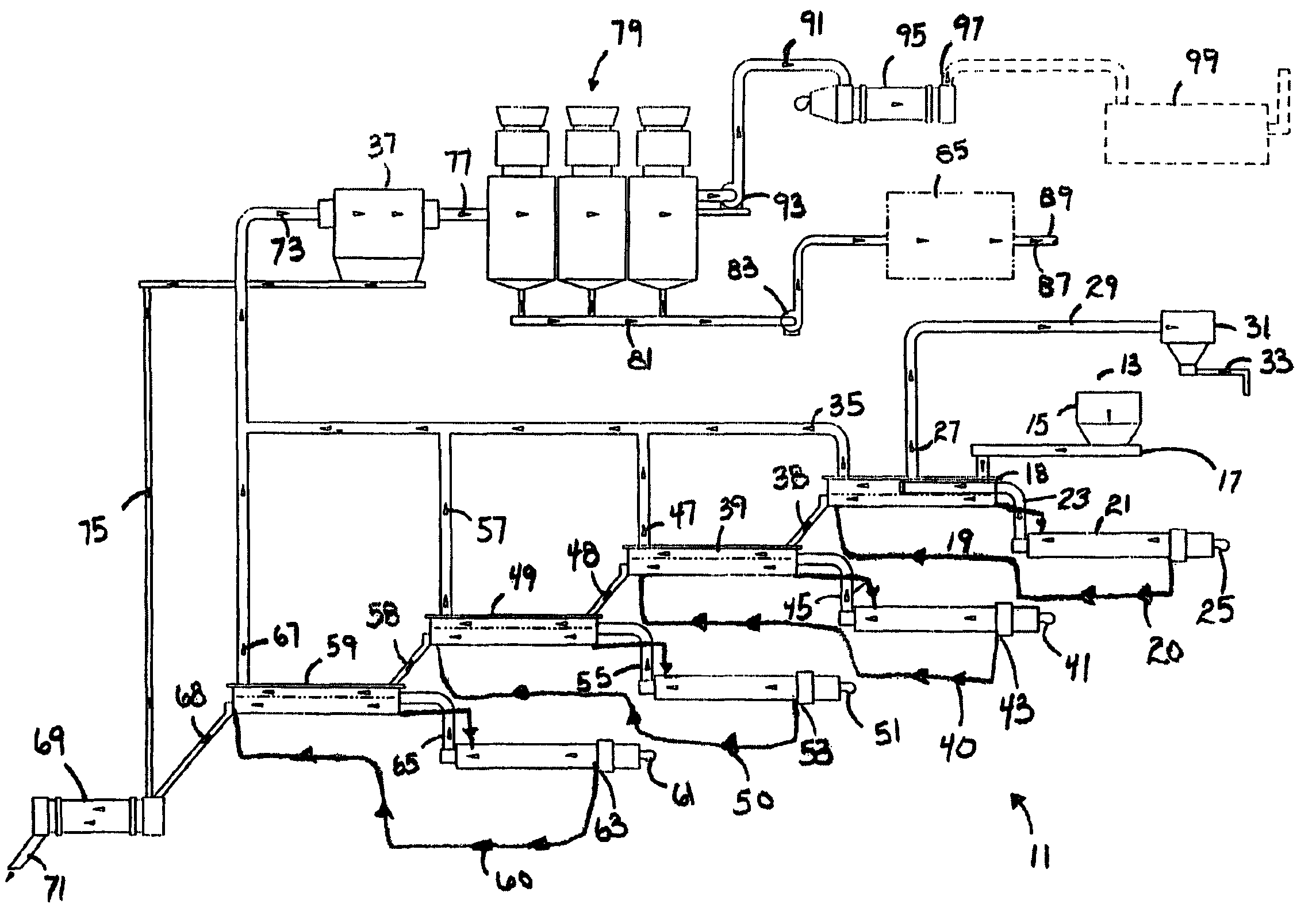

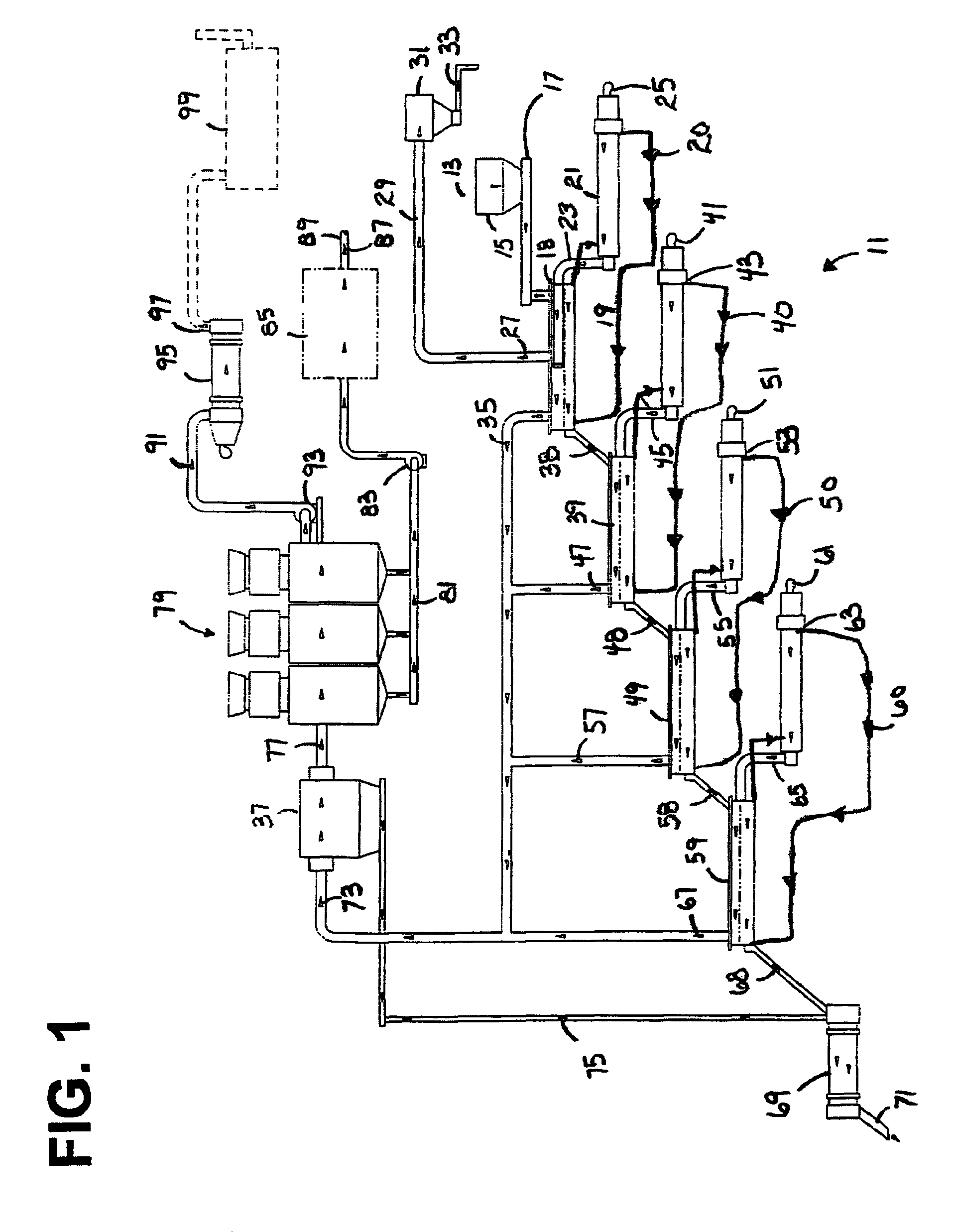

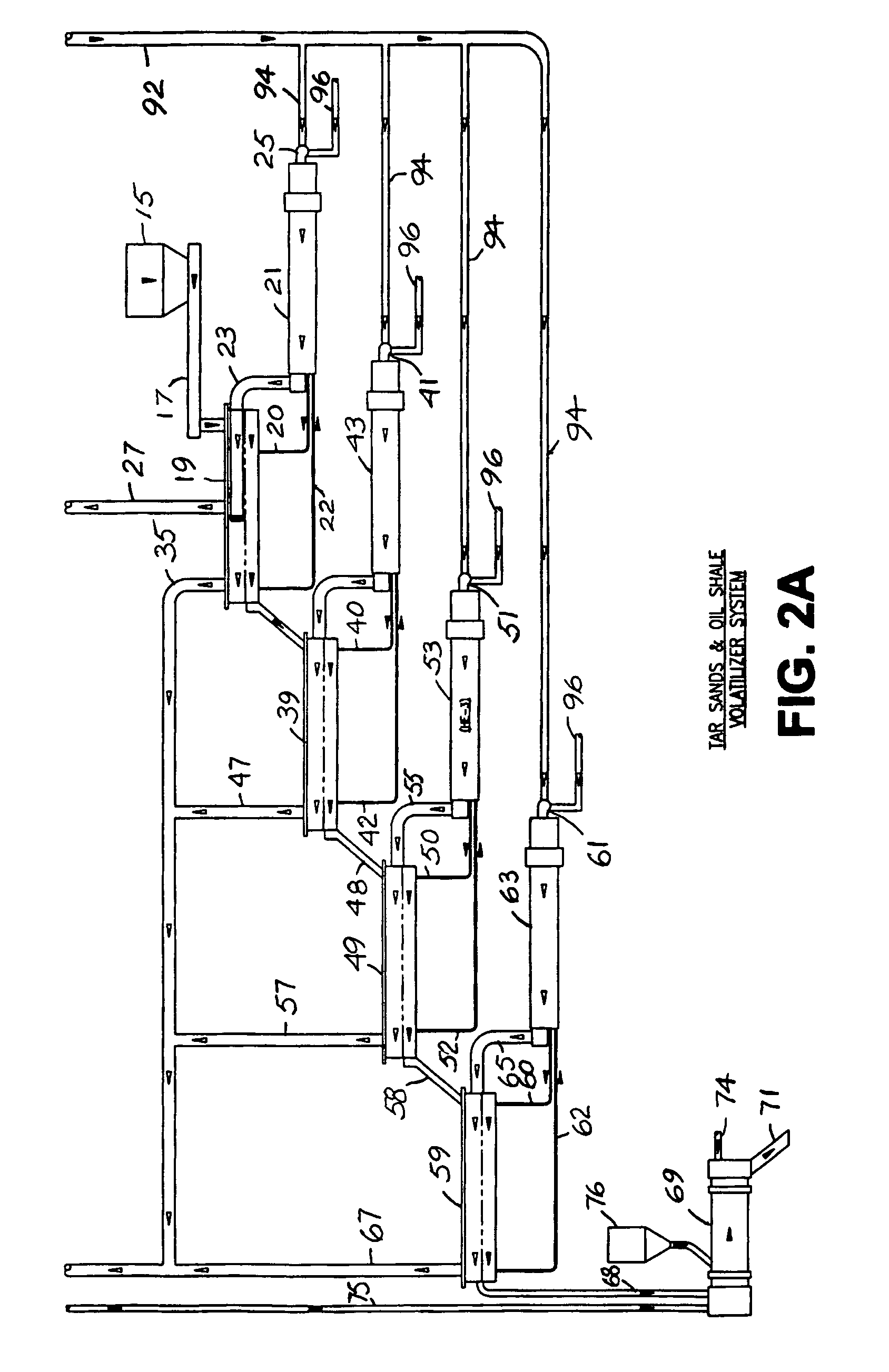

Thermal recovery of petroleum crude oil from tar sands and oil shale deposits

InactiveUS7807048B2Rule out the possibilityEliminate needHydrocarbon oil cracking processIndirect heating destructive distillationParticulatesFuel oil

A tar sand volatilizer system thermally removes petroleum crude oil from tar sands or shale oil. A series of heated augers or thermal screws are used to elevate material temperature gradually using conductive heat transfer. The thermal screws blades and auger case receive a heated fluid. The screws are driven by variable speed drive systems. The unit is sized for any throughput rate desired. Hot clean material discharges into a rotary cooler and re-hydrator unit. The exhaust gases are pulled through a high temperature filter collector for particulate removal. The particulate free petroleum vapor laden hot gas exits the filter house into a multi stage condenser system with water chillers where the vapor temperature is gradually cooled. A microwave upgrader system processes crude oil using catalyst injected microwave technology to produce a diesel like fuel oil in a continuous process stream.

Owner:COLLETTE JERRY R

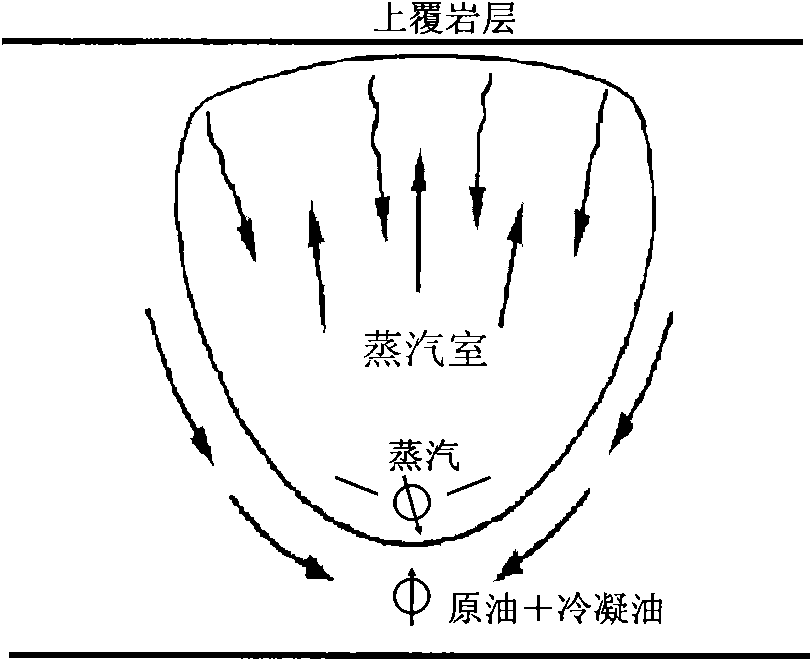

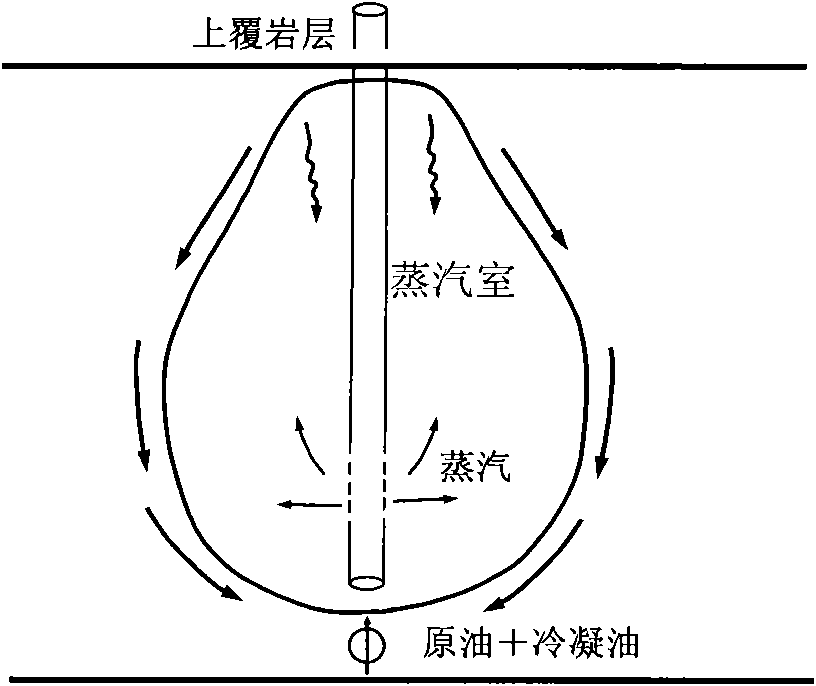

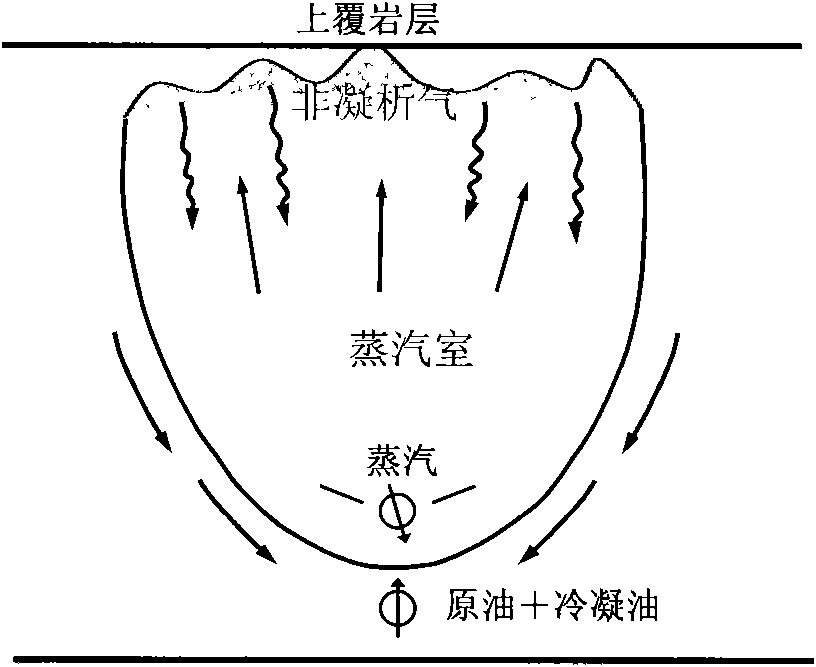

Gas-assisted SAGD method for exploiting super heavy oil

The invention relates to a gas-assisted SAGD method for exploiting super heavy oil; the selecting layer thickness is 530m, remaining oil saturation is more than 0.50, oil layer thickness is more than 10.0m, horizontal permeability is more than 250md, the ratio of the vertical permeability to the horizontal permeability is more than 0.1, the oil layer porosity is more than 0.20, continuous distributed impermeable clay and intercalated shale oil pools do not exist in the oil layer; a horizontal well is drilled between soaking vertical wells, the well spacing is 35m or a pair of horizontal wells are drilled at the bottom of the oil layer, the vertical distance is 6m; swallowing is carried out for 3 stages, when the hot communication is formed between the wells, the vertical wells is used to inject steam continuously, the production of horizontal wells is 3 years, then the vertical wells is used to inject nitrogen and steam until the underground volume ratio is 0.5 and the total injection rate of nitrogen is 0.10PV, then the steam is injected continuously, the steam injection rate is 1.4m / d.ha.m, the dryness of steam at the bottom of wells is 70%, the production-injection ratio is maintained at 1.2; the recovery percent is increased by 6.0-9.0% and the oil-steam ratio is improved by 0.02-0.05.

Owner:PETROCHINA CO LTD

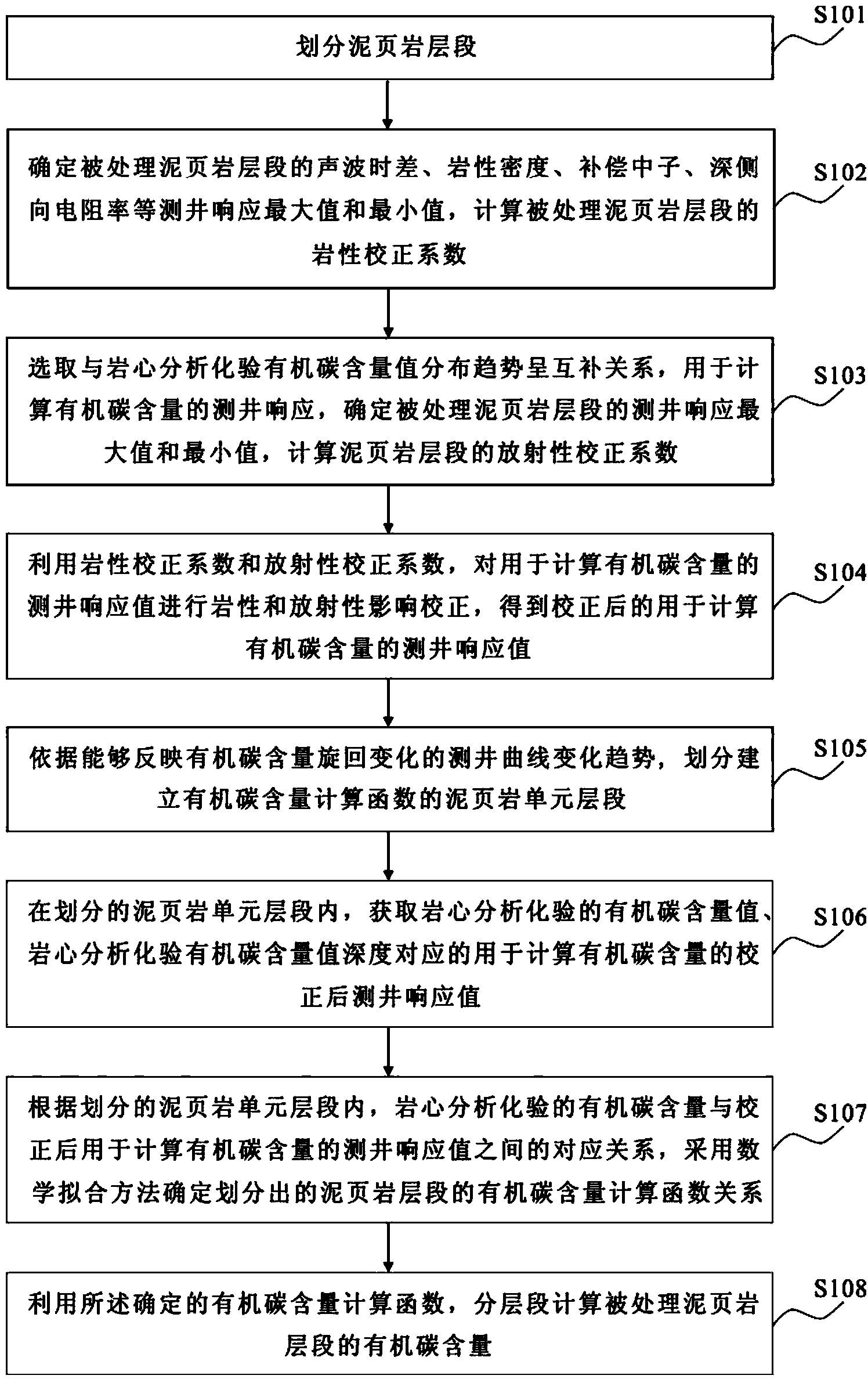

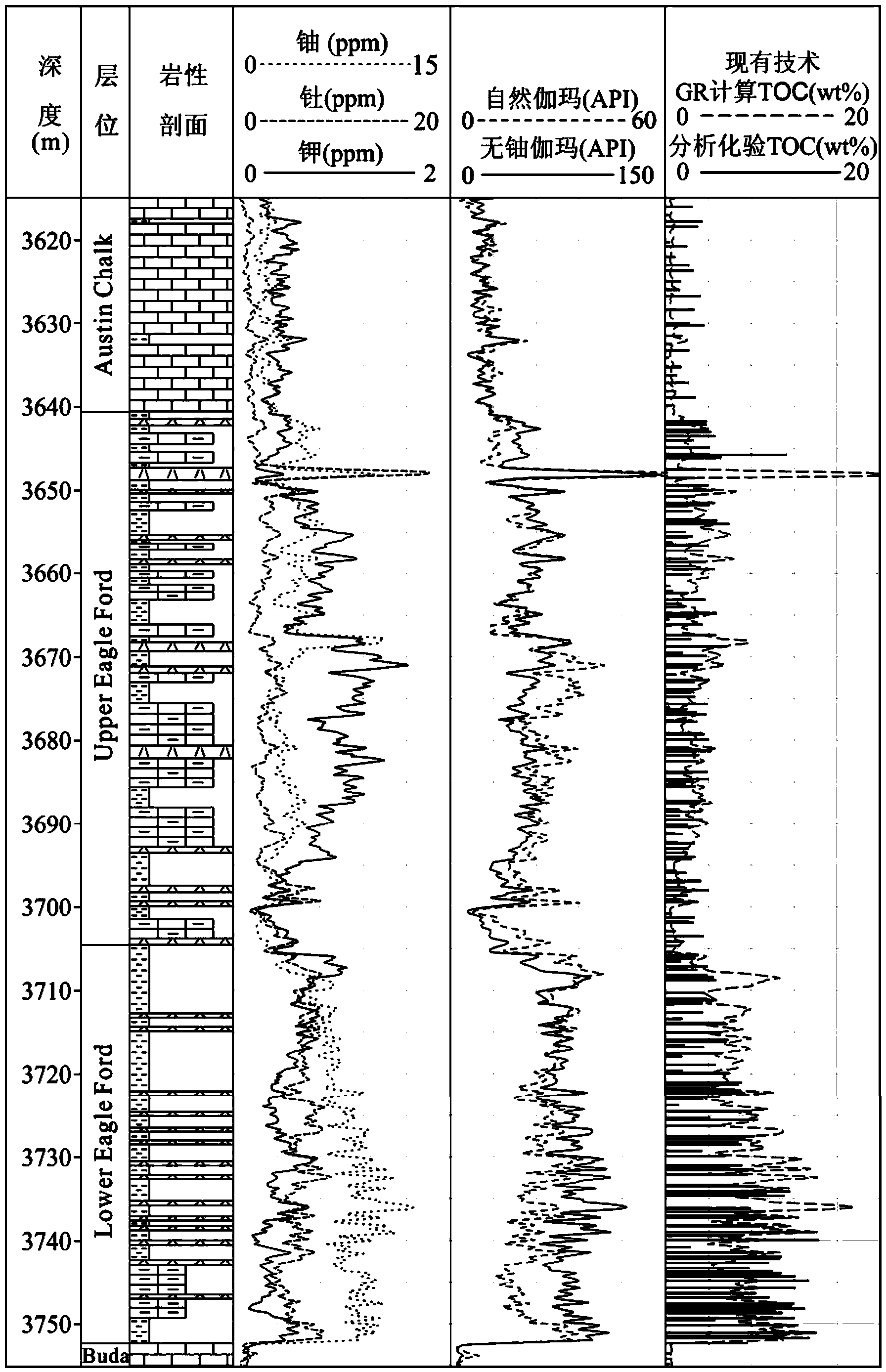

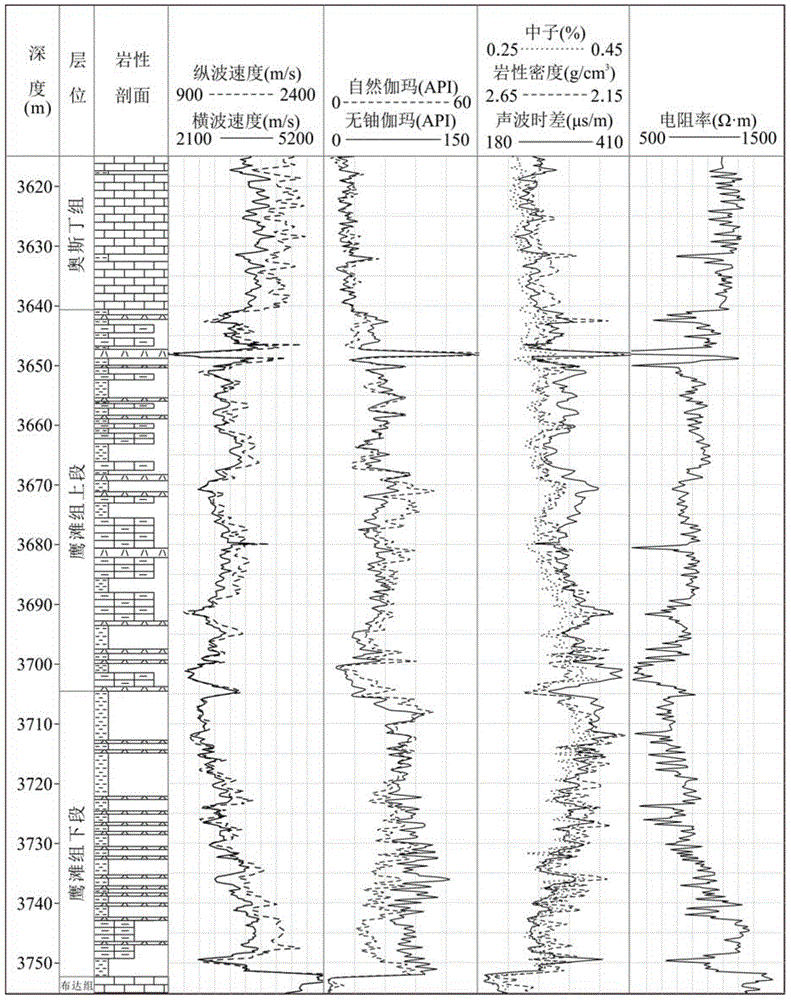

Method for evaluating organic carbon content of shale

ActiveCN103670388AEliminate errorsEliminate calculation errorsBorehole/well accessoriesLithologyComputer science

The invention relates to a method for evaluating the organic carbon content of shale. The method comprises the steps that logging information is obtained and layer sections of the shale are obtained through division; lithology correction coefficients and radioactivity correction coefficients are obtained and corrected log response characteristic values are obtained; organic carbon content calculation functions of shale unit layer sections are established and the calculation function of the organic carbon content of each shale unit layer section is obtained; according to the determined organic carbon content calculation function, the organic carbon content of each shale unit layer section is calculated. According to the method for evaluating the organic carbon content of the shale, the defect that an organic carbon content result in the prior art is large in error is overcome, the organic carbon content in a stratum can be accurately and reliably evaluated, and therefore effective technical supports are provided for exploration and development of shale oil gas.

Owner:PETROCHINA CO LTD

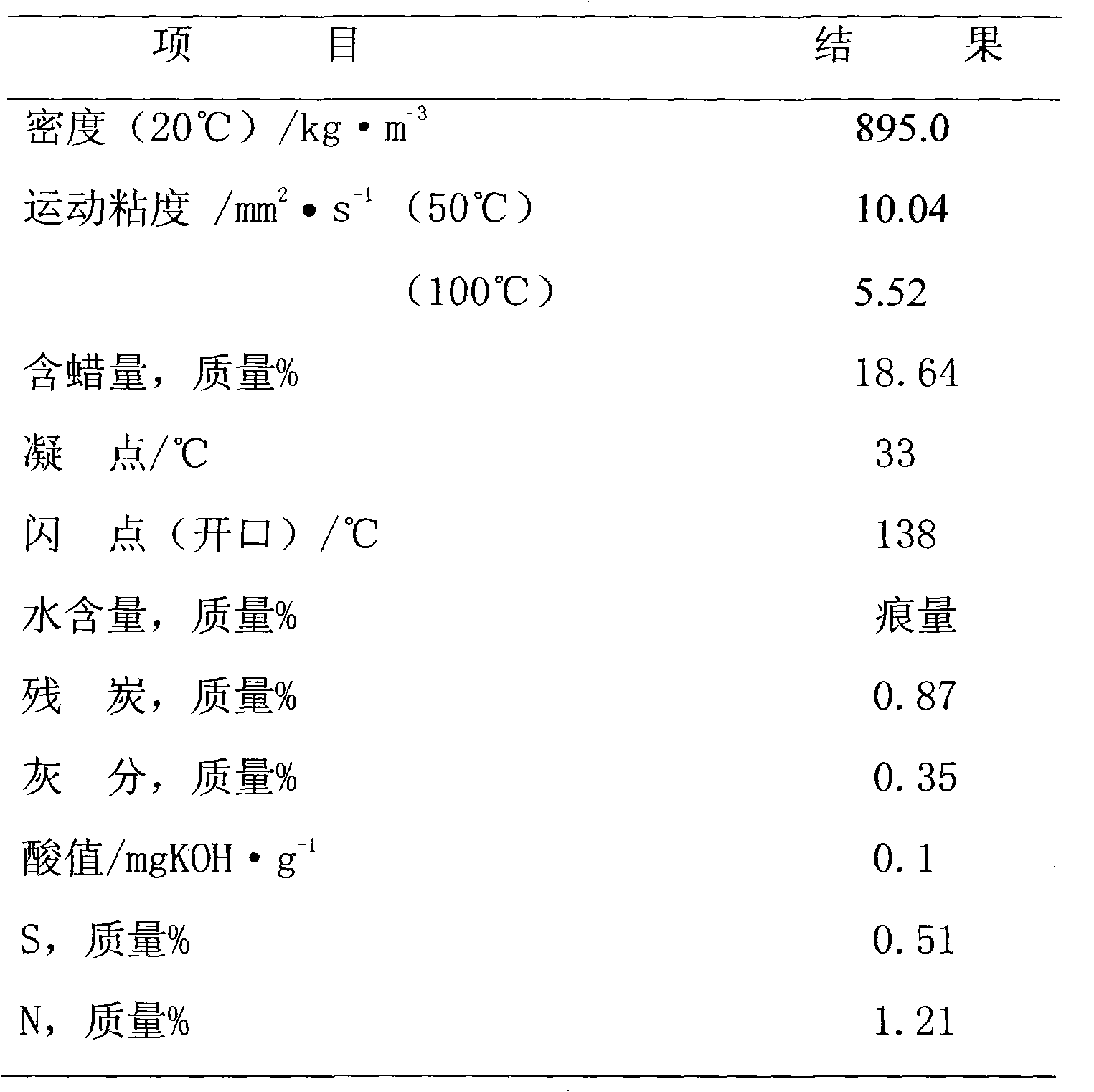

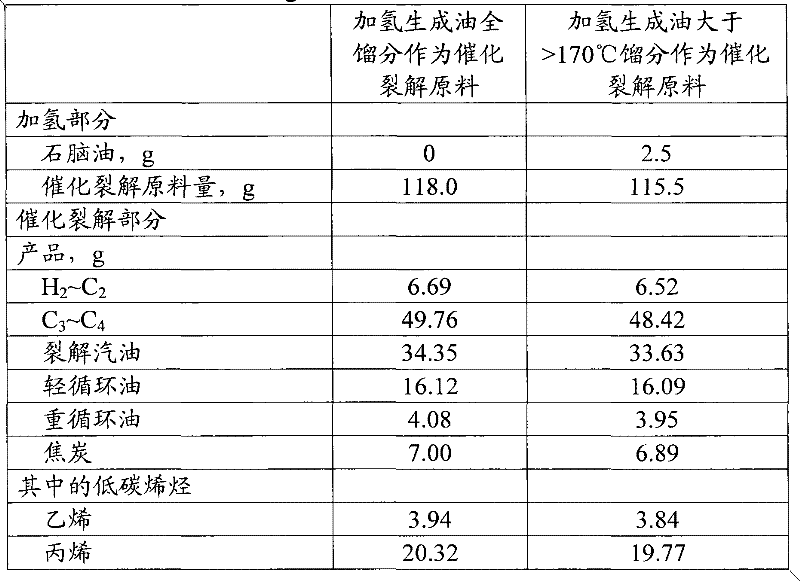

Shale oil producing process

The present invention relates to shale oil processing procedure, which includes the steps of hydrogenating shale oil to obtain hydrogenated shale oil; separating into heavy hydrogenated shale oil and light product; catalytically converting the heavy hydrogenated shale oil to obtain dry gas, liquefied gas, gasoline, diesel oil and catalytic heavy oil; and returning the diesel oil to the hydrogenating step. The shale oil processing procedure has the advantages of high light product yield and high product quality.

Owner:黄玉豹 +4

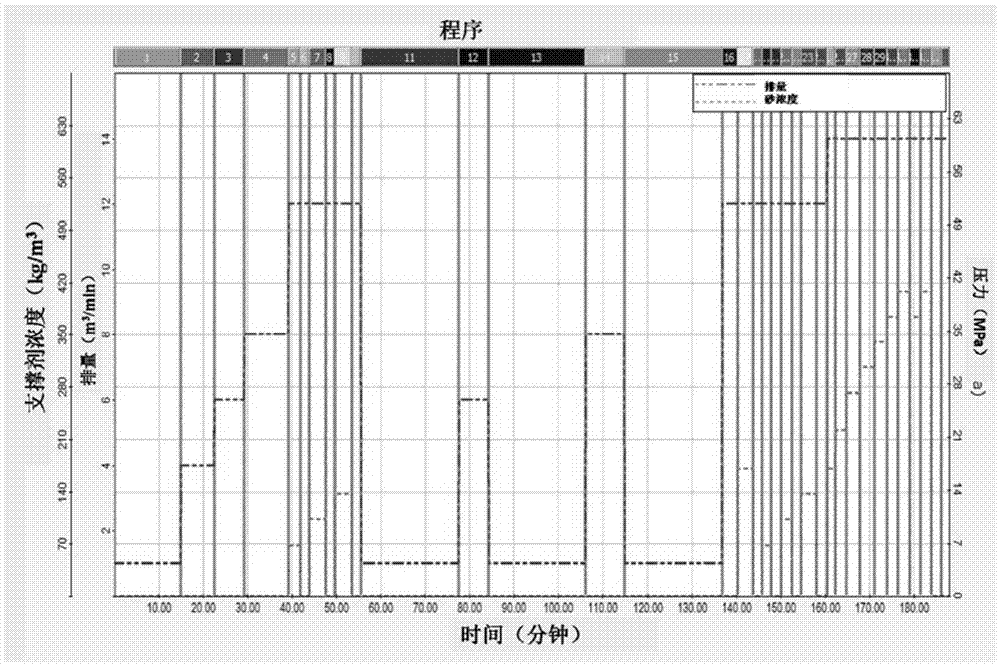

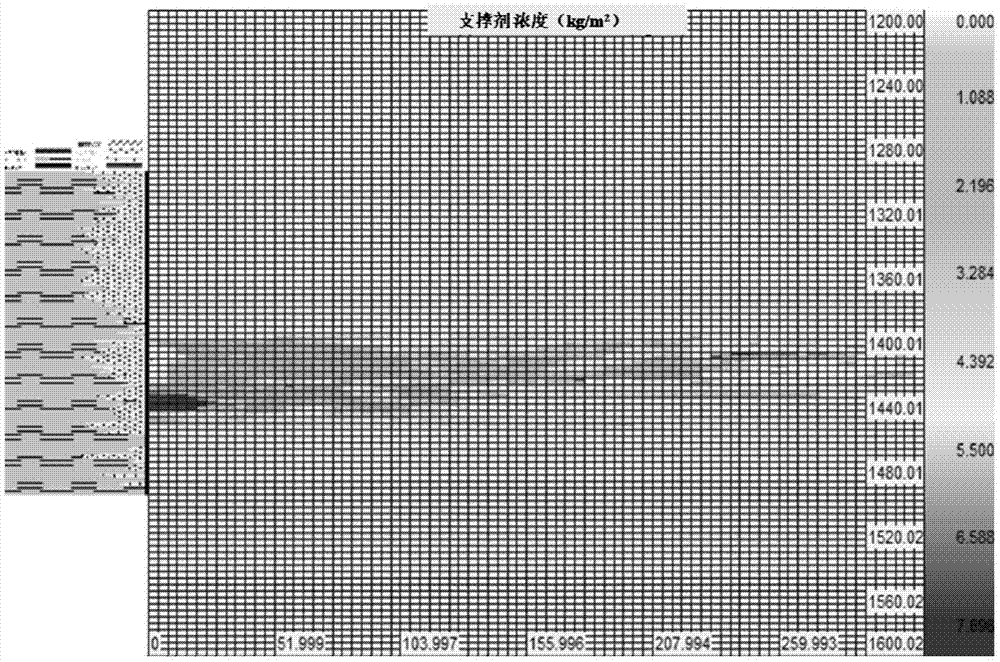

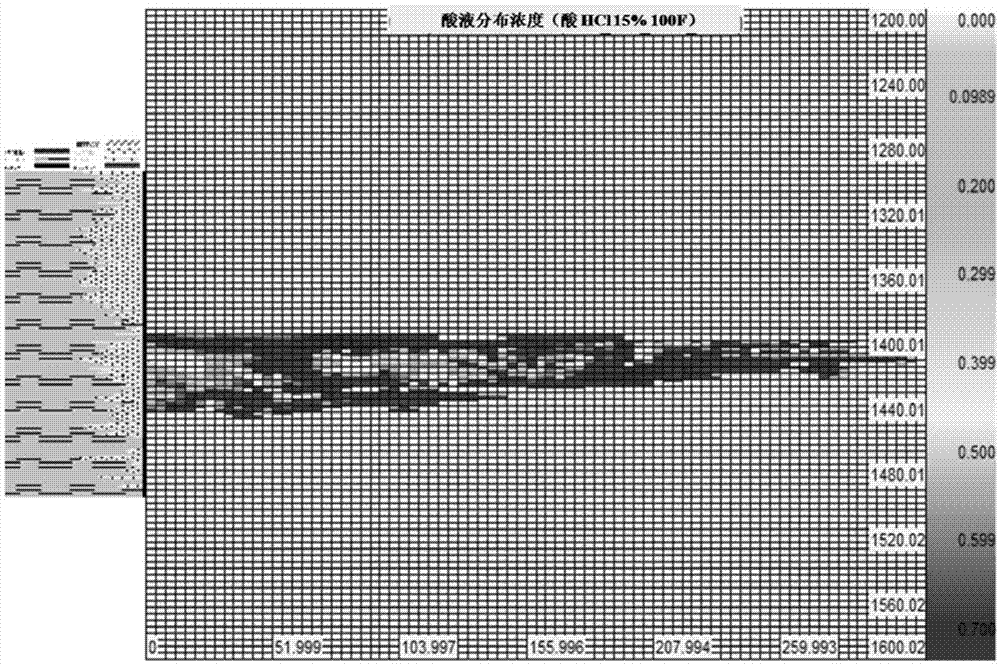

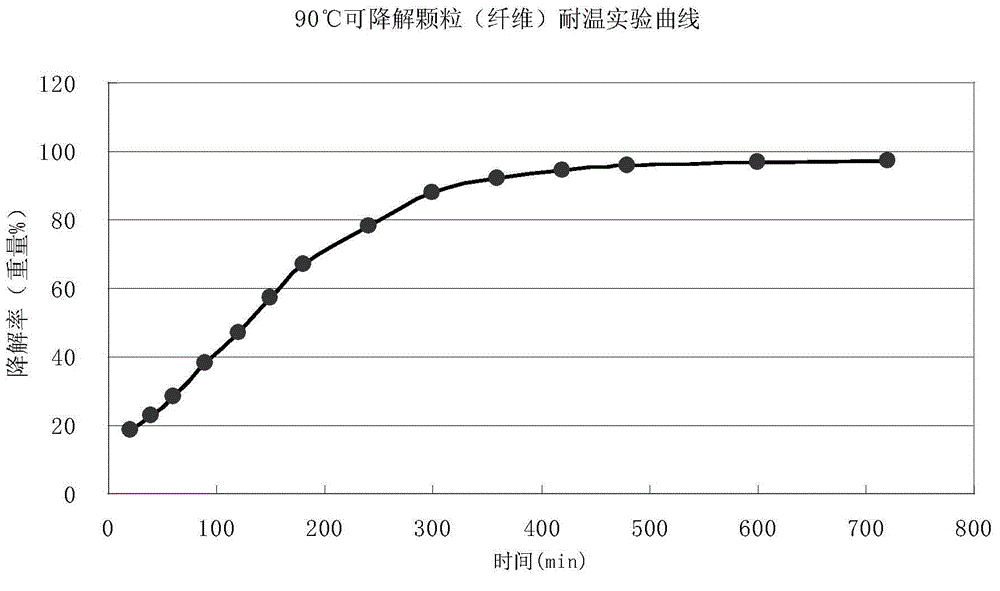

Method suitable for effective flow guide for fractures in fracturing of shale oil pool reservoir

ActiveCN106907137AImprove diversion capacityIncrease "retrofit volumeFluid removalMicro fractureFracturing fluid

The invention relates to the technical field of hydraulic fracturing capacity increasing revamping of oil and gas reservoirs, in particular to a method suitable for effective flow guide for fractures in fracturing of a shale oil pool reservoir. The method includes the following steps that A, the reservoir is pretreated through acid liquor; B, the main fracture is constructed through low-viscosity fracturing fluid; C, the micro fractures and the branch fractures are opened by injecting low-viscosity slickwater; D, slugging is conducted by injecting low-viscosity acid liquor and low-viscosity slickwater alternately; E, low-viscosity slickwater carrying a proppant and low-viscosity fracturing fluid carrying a proppant are injected in sequence so as to support a micro fracture system and a branch fracture system, and the first proppant is different from the second proppant; F, intermediate-viscosity fracturing fluid carrying proppants is injected so as to support a main fracture system; and G, the fourth proppant in a shaft is completely displaced to the openings of the fractures by means of the low-viscosity slickwater.

Owner:CHINA PETROLEUM & CHEM CORP +1

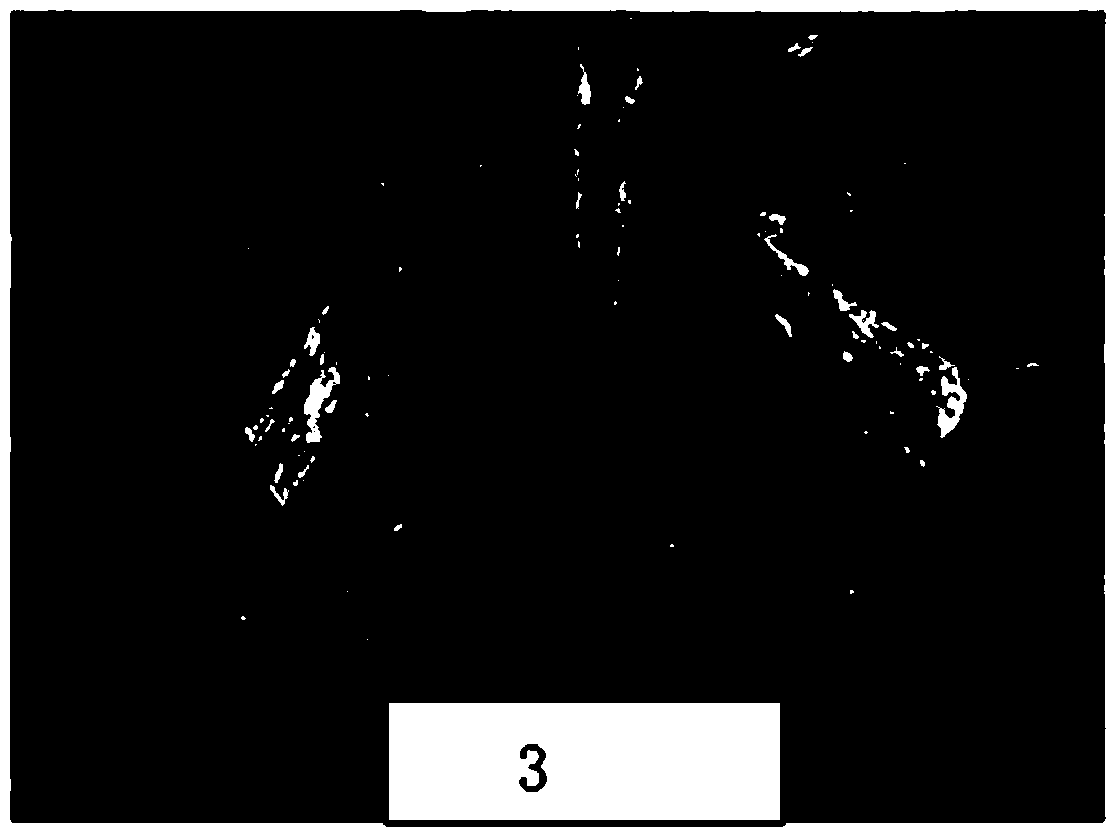

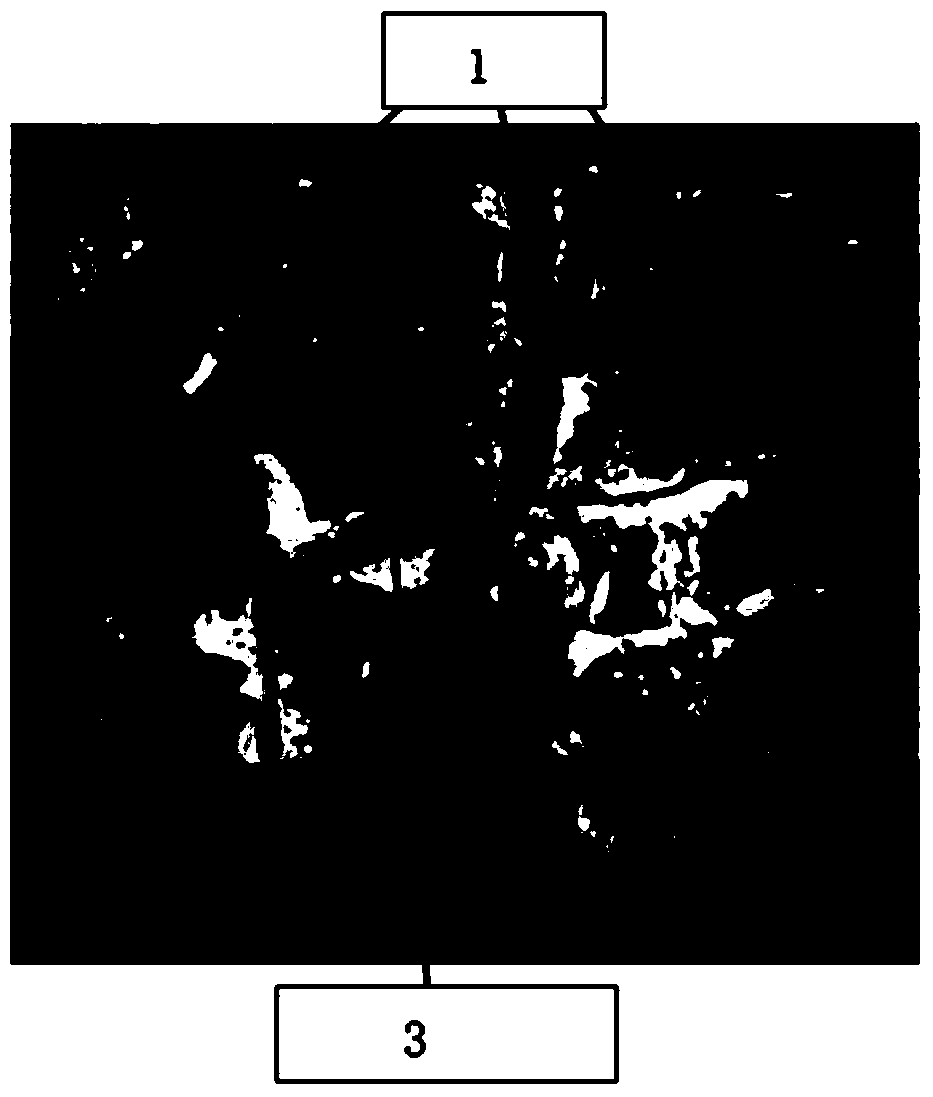

Process for two-step fracturing of oil shale formations for production of shale oil

A process for in situ production of shale oil comprises fracturing the target zone 10 of an shale oil formation using a two step approach. First, an initial set of fractures 18 is developed in the formation by using high pressure gas pulses. Second, a secondary set of fractures 28 extending and further fracturing the initial set of fractures 18 is created using a modified ANFO mix 22 wherein rubber particles acting as solid fuel are blended in with ammonium nitrate and fuel oil. The solid fuel enhances the fracturing characteristics of ANFO while minimizing its crushing and compacting tendencies. Hot high pour point oil is then injected into the formation and forced into the receptor well 16 where it is pumped to the surface. By circulating oil in the formation at carefully controlled temperatures, kerogen can be decomposed at the optimum rate to maximize the amount of oil recovered and yield high quality shale oil. High pour point oil reaching cooler extremities of the fractured formation will solidify creating an impermeable perimeter barrier 34 around the target zone 10.

Owner:YOUNG MICHAEL ROY

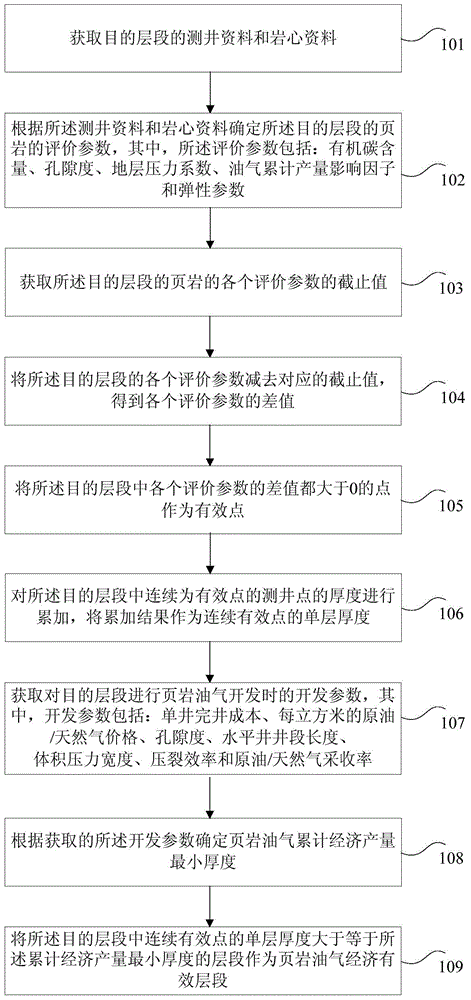

Shale oil-gas economical and effective layer section evaluation method

ActiveCN104453873AImprove development efficiencyEliminate defects with large evaluation errorsBorehole/well accessoriesPorositySlice thickness

The invention provides a shale oil-gas economical and effective layer section evaluation method. The method comprises the steps of determining evaluation parameters of shale of target layer sections according to obtained logging data and core data, wherein the evaluation parameters include the organic carbon content, the porosity, the formation pressure coefficient, the oil-gas accumulative output impact factor and elastic parameters; subtracting a corresponding cut-off value from each evaluation parameter to obtain a difference value of each evaluation parameter; using points with the difference values, larger than 0, of the evaluation parameters as efficient points; adding the thicknesses of logging points which are continuous efficient points in the target layer sections, and using the added result as the single-layer thickness of the continuous efficient points; determining the shale oil-gas accumulated economical yield minimum thickness; using the layer section with the single-layer thickness of the continuous efficient points larger than or equal to the accumulated economical yield minimum thickness in the target layer section as the shale oil-gas economical and effective layer section. According to the shale oil-gas economical and effective layer section evaluation method, the shale oil-gas economical and effective layer section can be accurately and effectively determined, and therefore the shale oil-gas development benefits are improved.

Owner:PETROCHINA CO LTD

Pretreatment method of coal tar

ActiveCN101012385ARetain light and heavy componentsIncrease profitWorking-up tarPretreatment methodPre treatment

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

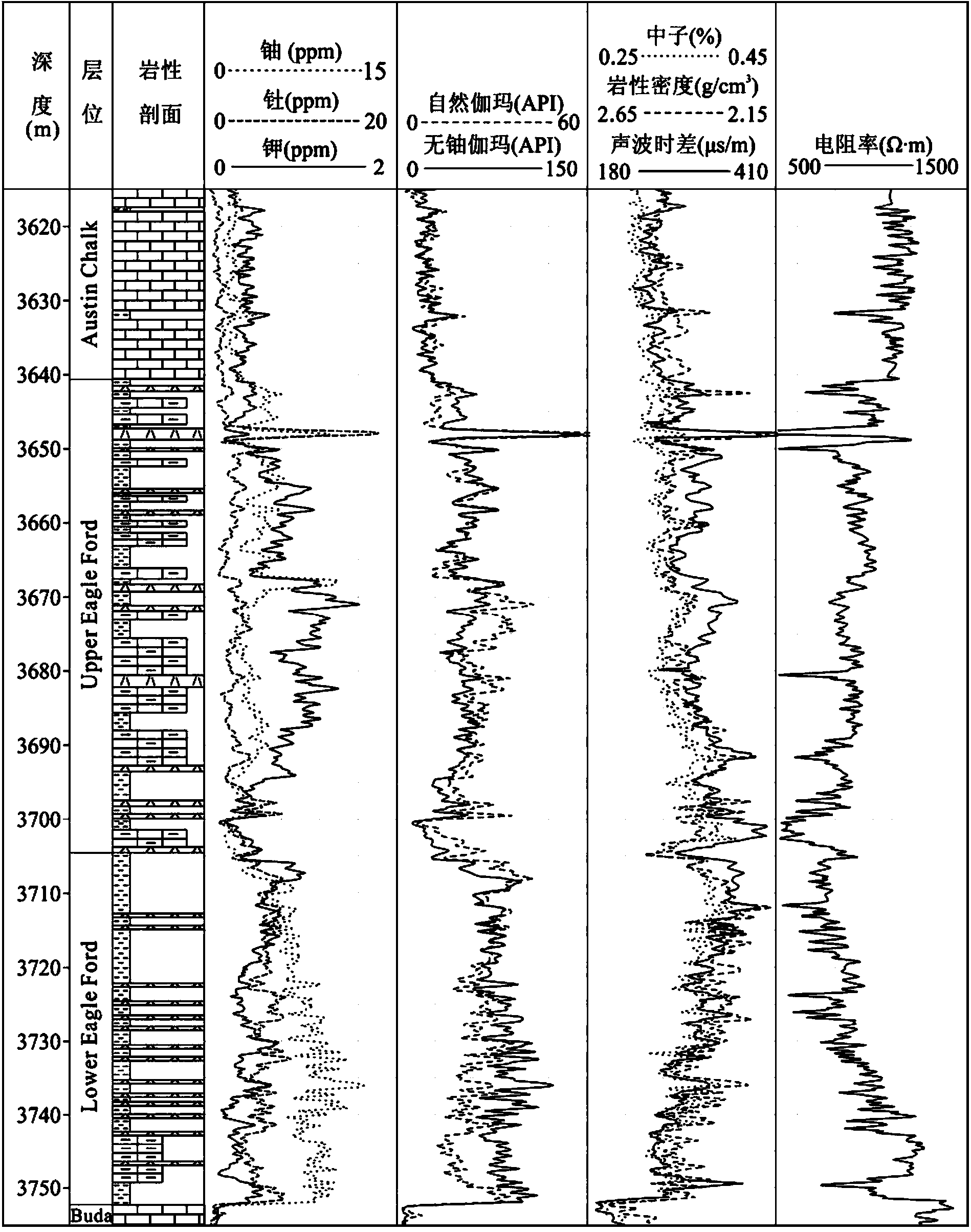

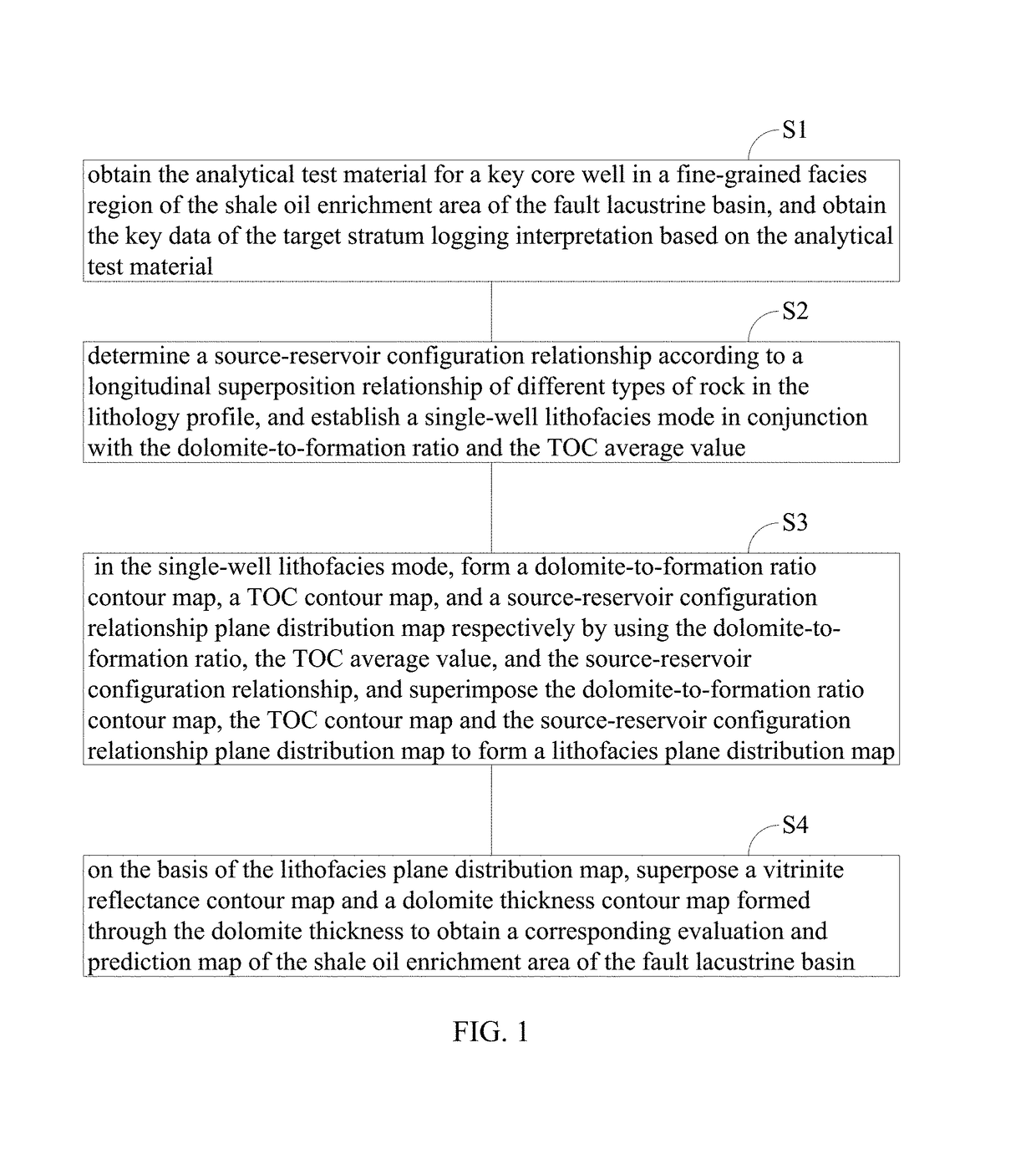

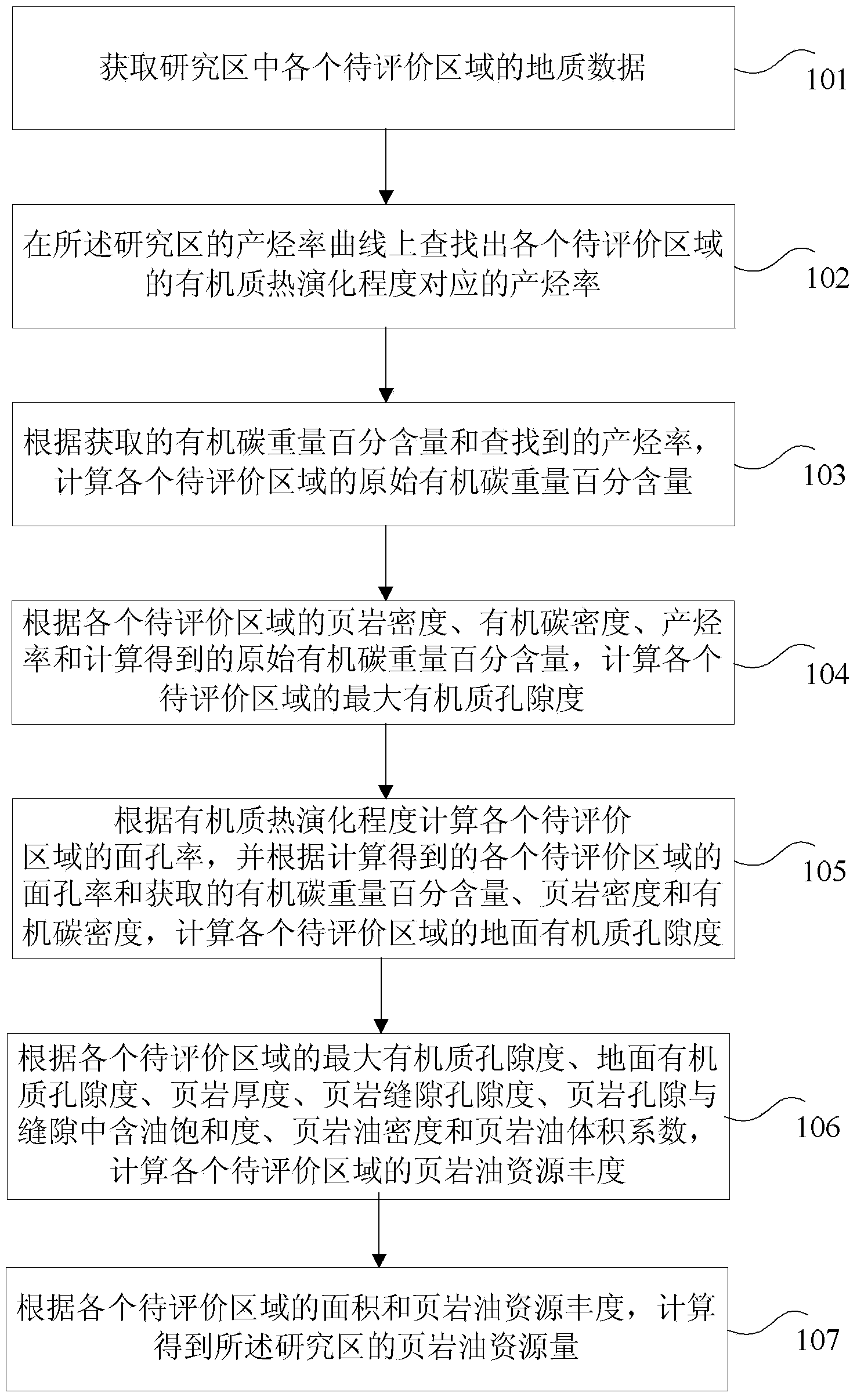

Method and device for evaluating and predicting a shale oil enrichment areas of fault lacustrine basins

ActiveUS10190998B1Reduce economic costsEasy to operateMaterial analysis using wave/particle radiationEarth material testingLithologyDolomite

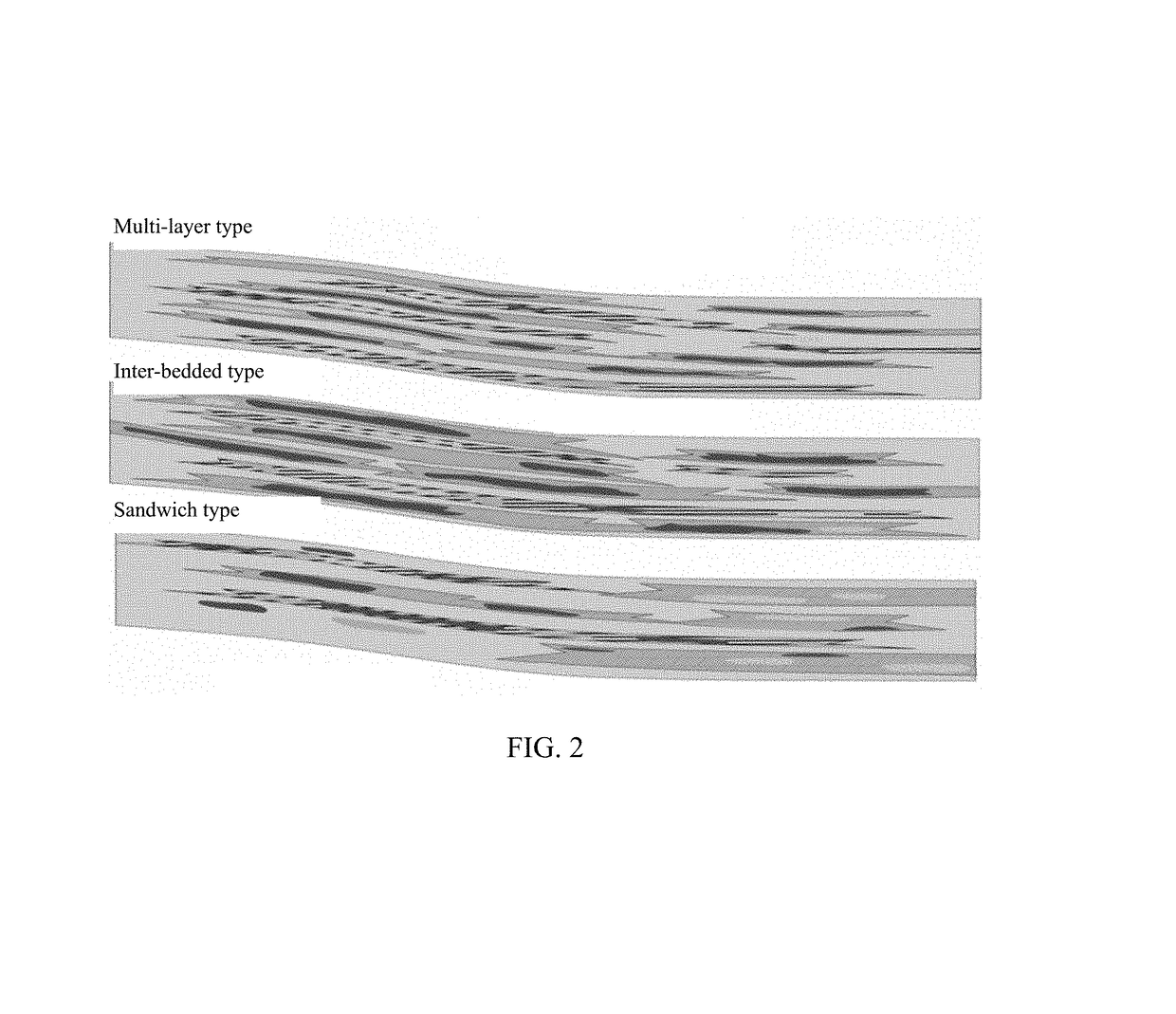

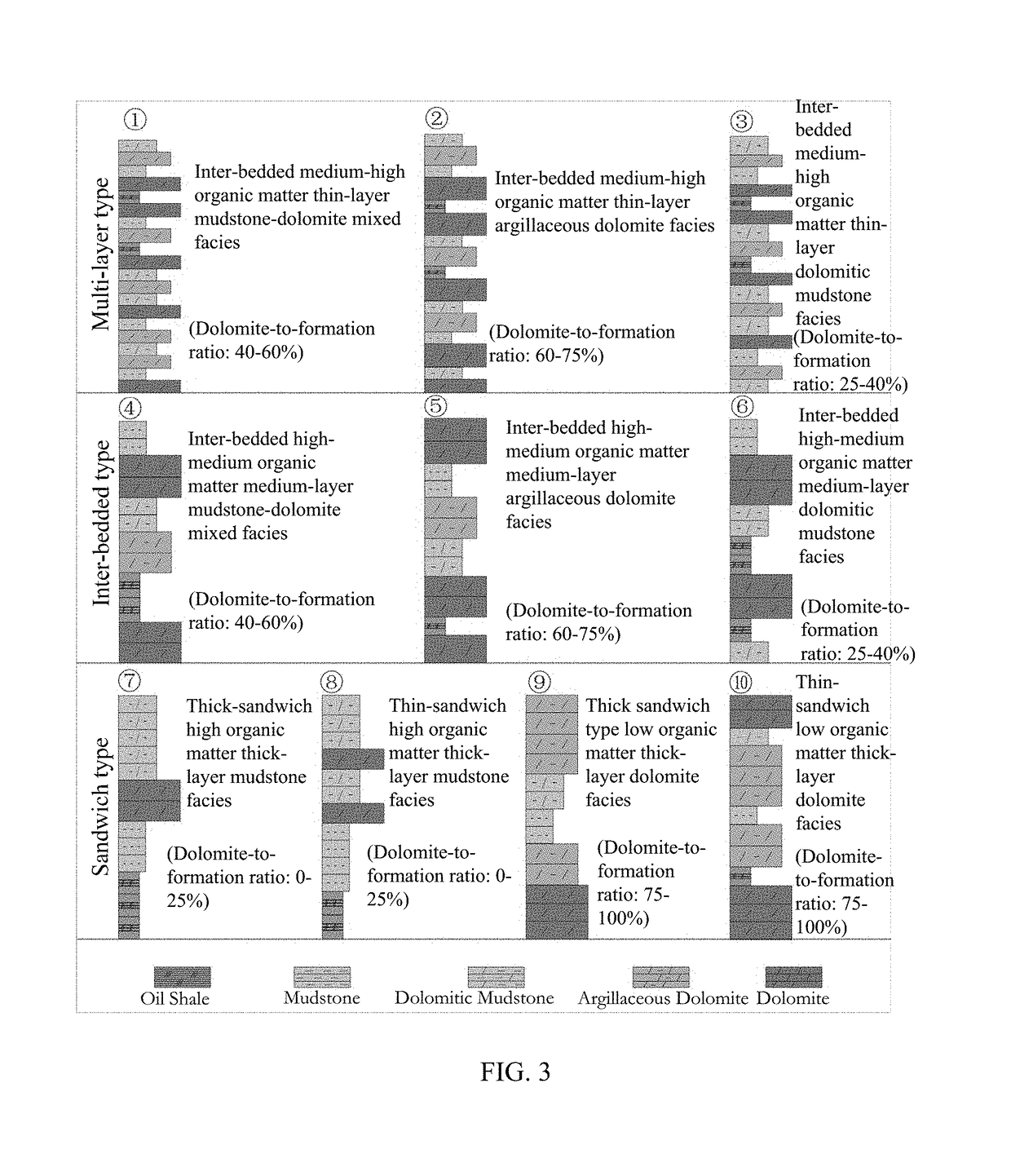

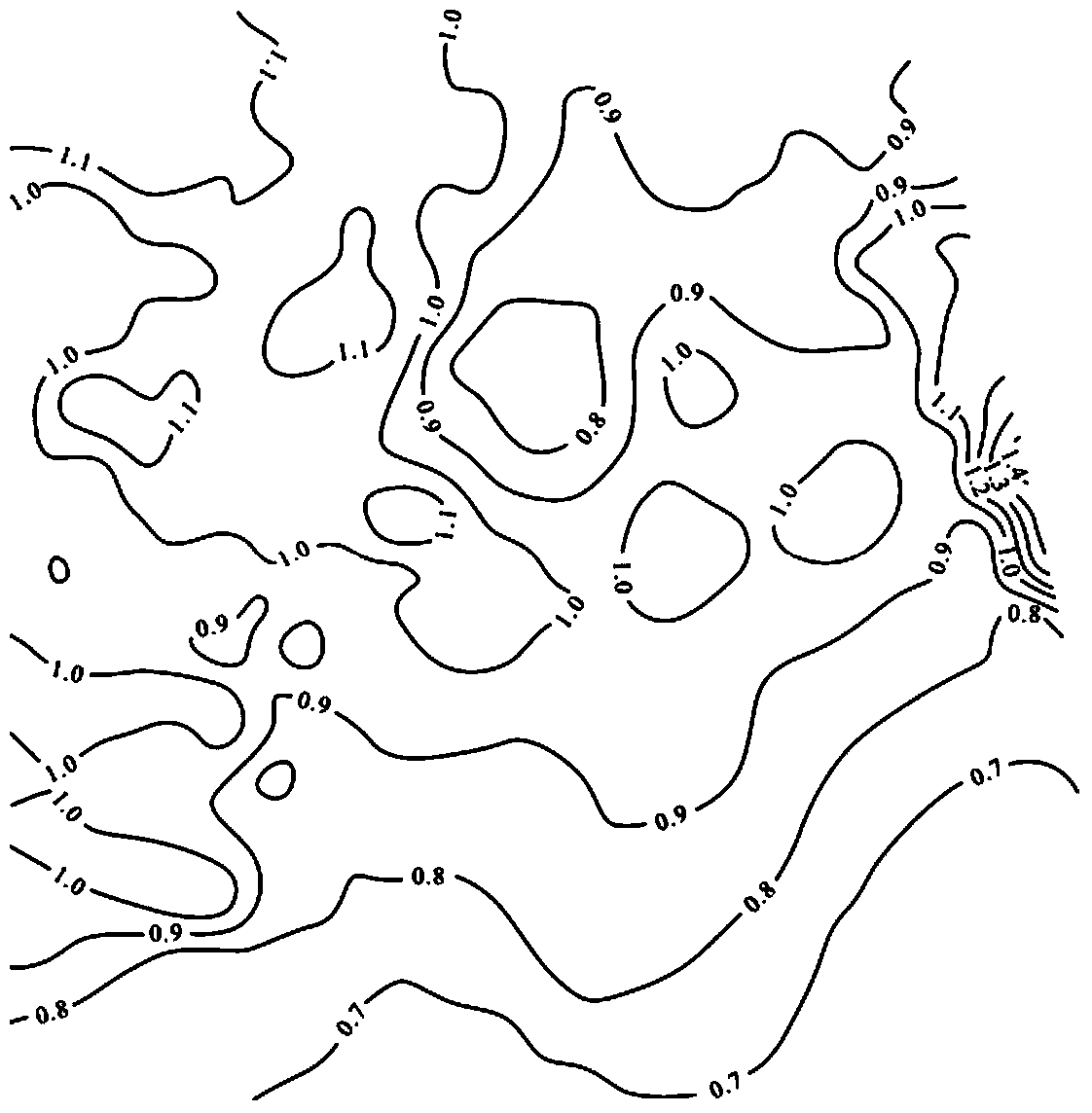

A method is disclosed for evaluating and predicting a shale oil enrichment area of a fault lacustrine basin, comprising: obtaining materials and key data; determining a source-reservoir configuration relationship according to a longitudinal superposition relationship of different types of rock in a lithology profile and establishing a single-well lithofacies model; in the single-well lithofacies model, using a dolomite-to-formation ratio and a TOC average value to form a dolomite-to-formation ratio contour map and a TOC contour map, and superposing the dolomite-to-formation ratio contour map, the TOC contour map and a source-reservoir configuration relationship plane distribution map to form a lithofacies plane distribution map; on the basis of the lithofacies plane distribution map, superposing a vitrinite reflectance contour map and a dolomite thickness contour map to obtain a corresponding evaluation and prediction map of the shale oil enrichment area of the fault lacustrine basin.

Owner:RES INST OF GASOLINEEUM EXPLORATION & DEV DAGANG OIL FIELD OF CNPC

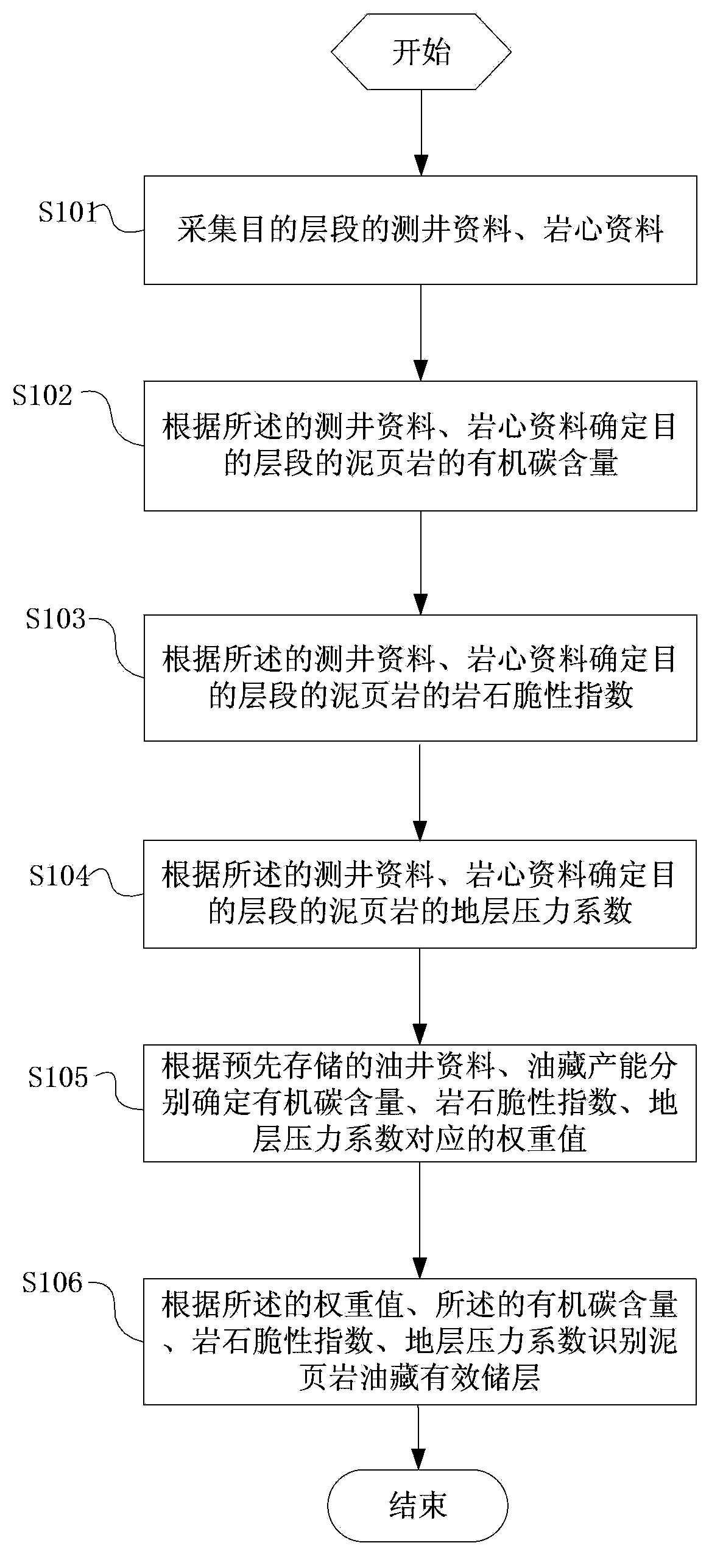

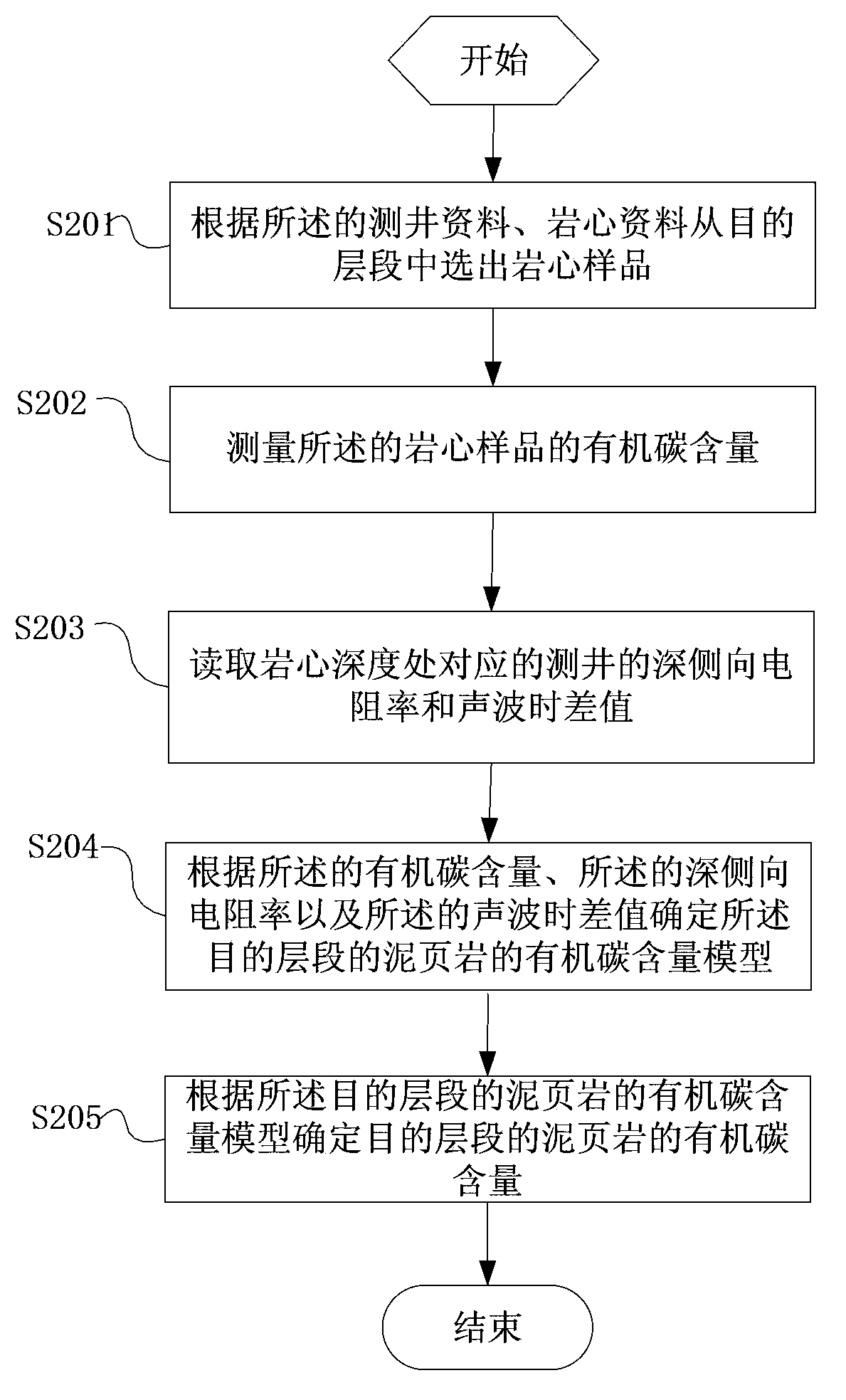

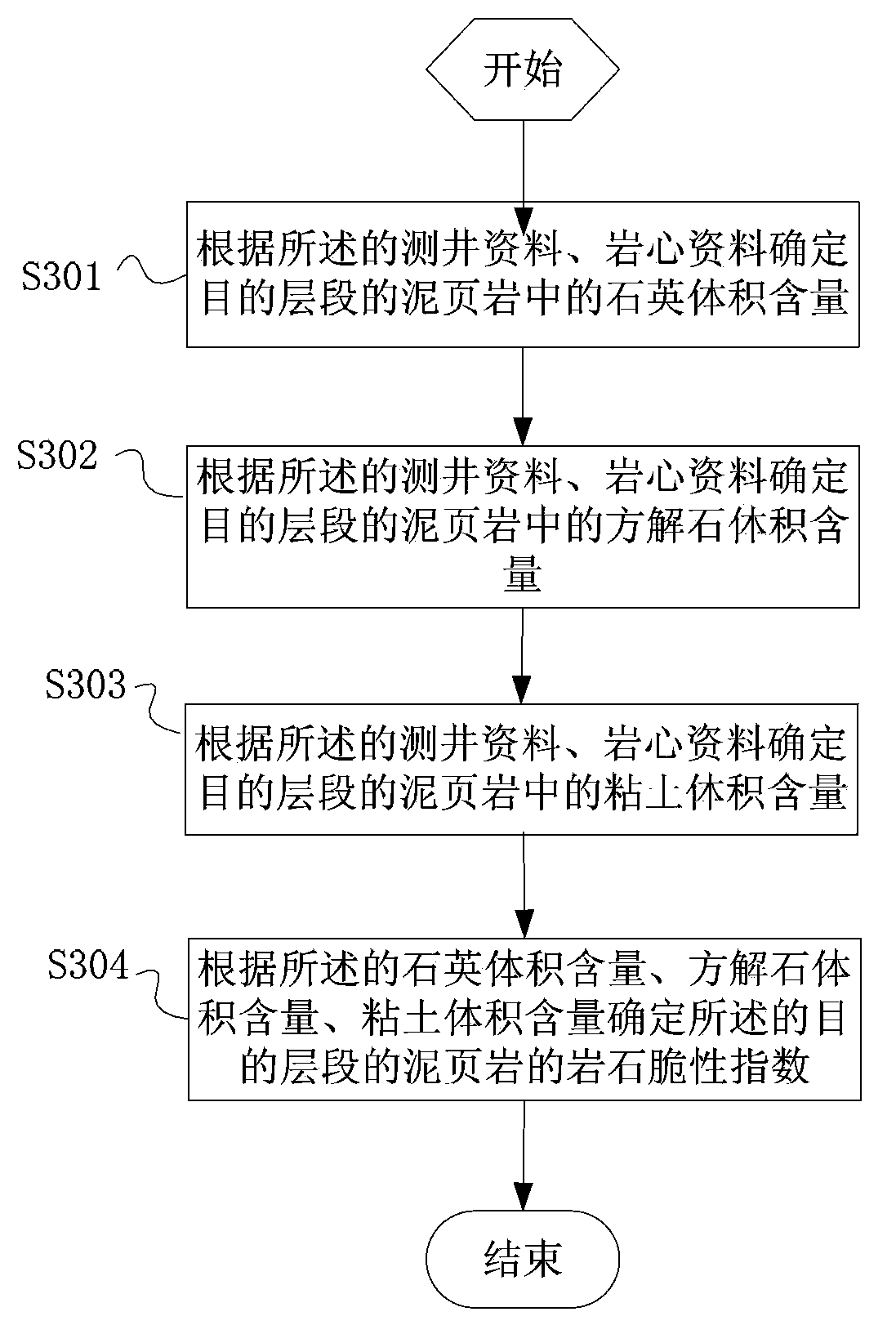

Method and device for identifying shale oil deposit effective reservoir

The invention provides a method and a device for identifying a shale oil deposit effective reservoir. The method comprises the following steps: collecting logging data and core data of an interest interval; determining a content of organic carbon of shale of the interest interval according to the logging data and the core data; determining a rock brittleness index of the shale of the interest interval according to the logging data and the core data; determining a formation pressure coefficient of the shale of the interest interval according to the logging data and the core data; determining weighted values corresponding to the content of the organic carbon, the rock brittleness index and the formation pressure coefficient according to oil well data and oil deposit capacity which are stored in advance; and identifying the shale oil deposit effective reservoir according to the weighted values, the content of the organic carbon, the rock brittleness index and the formation pressure coefficient. Through the method and the device, actual production requirement of fracturing effective intervals in exploration and development of the shale oil deposit effective reservoir are met.

Owner:PETROCHINA CO LTD

Low-density oil fracturing propping agent and preparation method thereof

InactiveCN102786921AIncrease productionQuality improvementFluid removalVolumetric Mass DensityOil and natural gas

The invention discloses a low-density oil fracturing propping agent. The low-density oil fracturing propping agent comprises the following components in parts by weight: 40 to 90 parts of bauxite, 5 to 30 parts of clay and 1 to 30 parts of auxiliary additive, wherein the mass percentage of Al2O3 in the bauxite is 30 to 75 percent. The oil fracturing propping agent is prepared by blending the bauxite, the clay and the auxiliary additive in special proportion, and performing a pulverizing process, a pelletizing process and a sintering process on the mixture. Detection on the propping agent shows that the propping agent has the characteristics of wide raw material resource, low production cost and the like; the yield and mass of powder are improved, and the production cost is reduced; and the problems of large fracturing and propping volume density and visual density, large abrasion of fracturing to equipment, high construction cost and the like in exploitation of shale oil and shale gas, and shallow shaft fracturing construction of an oil well and a natural gas well in the prior art are solved. A preparation method of the low-density oil fracturing propping agent is simple in process, easy to operate and very suitable for industrial production.

Owner:贵州林海陶粒制造有限公司

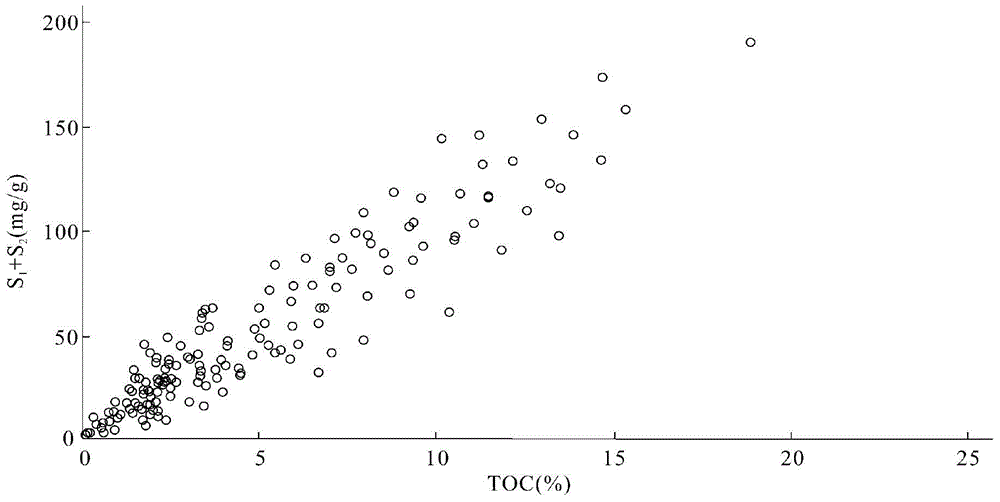

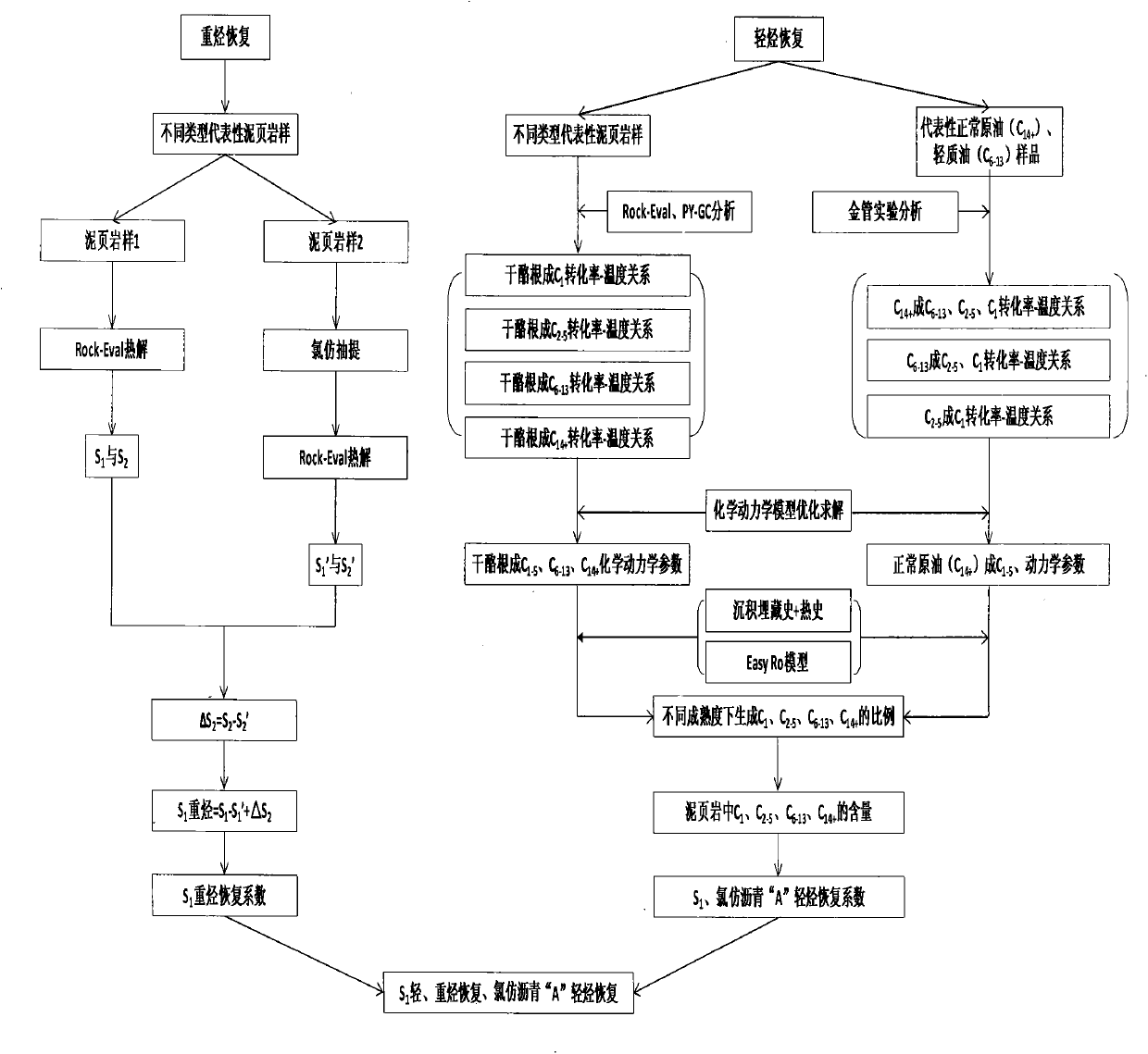

Correction method of light and heavy hydrocarbon of free hydrocarbon/residual hydrocarbon S1 in pyrolysis rock

Provided is a correction method of light and heavy hydrocarbon of free hydrocarbon / residual hydrocarbon S1 in a pyrolysis rock, and the light and heavy hydrocarbon of the free hydrocarbon / residual hydrocarbon S1 in the pyrolysis rock is a key parameter for evaluating the resources potential of shale oil. The correction method of the light and heavy hydrocarbon of the free hydrocarbon / residual hydrocarbon S1 in the pyrolysis rock solves the problem of loss of the light and heavy hydrocarbon when the shale oil resources are evaluated. The correction method of the parameter is established based on experiments, the free hydrocarbon / residual hydrocarbon S1 in existing data of an oil field is corrected in a compensation mode, and therefore the quantity of resource of the shale oil is corrected in an evaluation mode through the correction method of S1.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

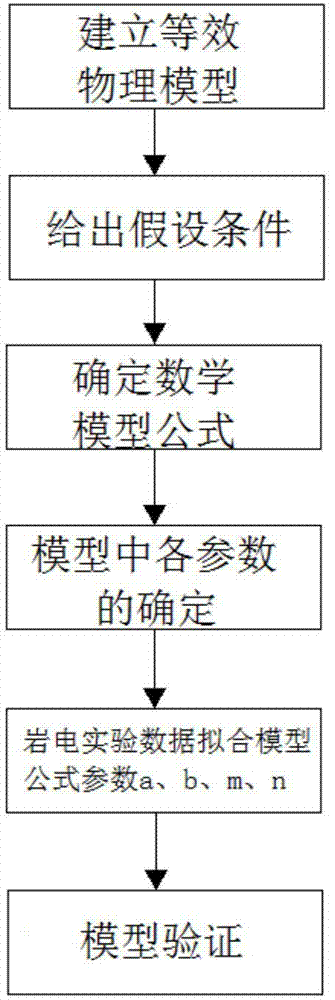

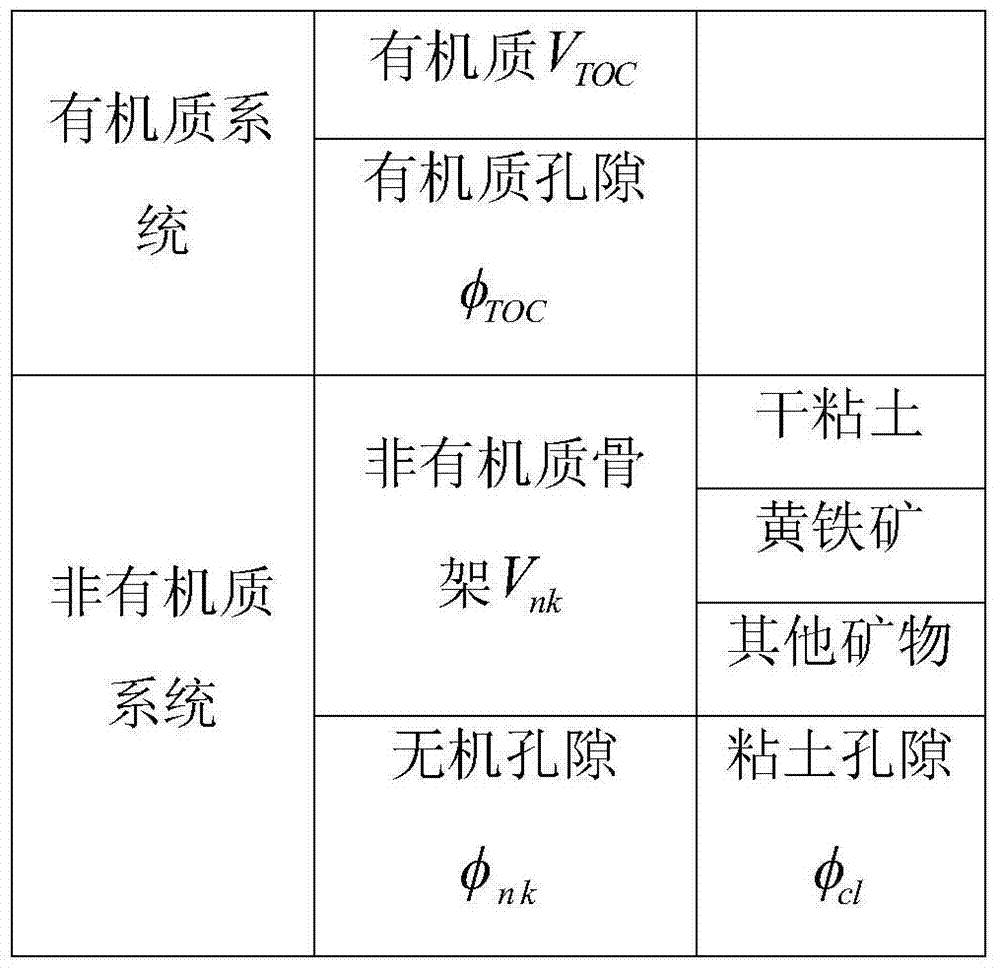

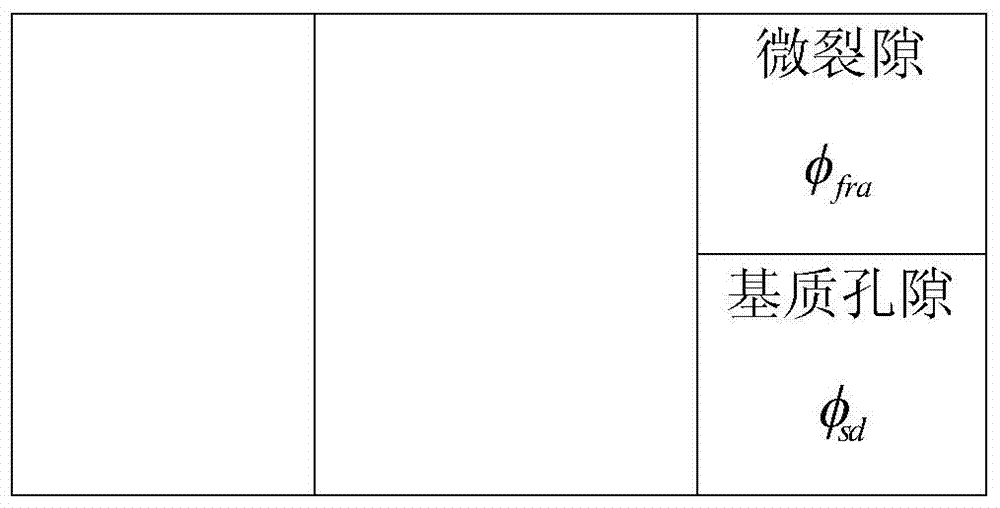

Computing model of mud shale oil gas saturability

ActiveCN104712329AAddressing Non-Archie PhenomenaImprove applicabilityInformaticsSpecial data processing applicationsMathematical modelPhysical model

The invention discloses a computing model of mud shale oil gas saturability. The computing model comprises the steps that A. an equivalent physical model is established; B. an assumed condition is given out; C. a mathematical model formula is determined; D. various parameters in the model are determined; E. rock electric experimental data formula parameter a, b, m and n fitting is carried out; and F. model verification is carried out. The non-Archie phenomenon of a mud shale oil storage layer caused by the problems that framework minerals are complex, a pore structure is complex, and pore wettability is complex can be avoided, the oil gas saturability of the mud shale storage layer is accurately computed, help is provided for a logging evaluation storage layer and oil field development, the unparalleled advantages which other saturability models do not have are achieved on mud shale water saturability computing are achieved, practical application effect is obvious, and accordingly great promotion value is achieved. In current public-published literatures and commercial application software, similar method providing and application do not exist.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

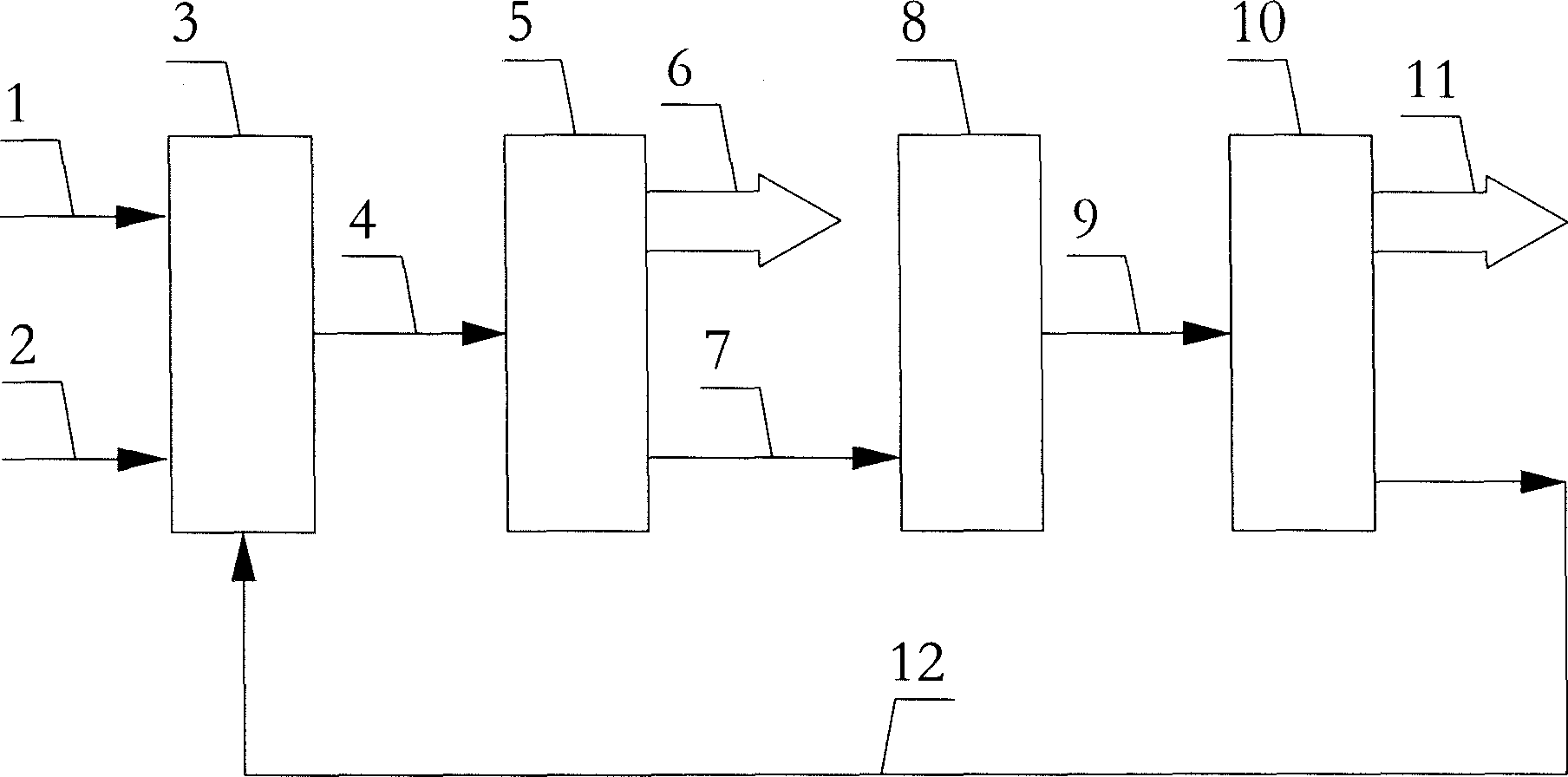

Shale oil single-stage serial hydrocracking technology method

ActiveCN101942333AHigh yieldConducive to smooth operationHydrocarbon oil crackingTreatment with hydrotreatment processesSingle stageHydrogen

The invention discloses a shale oil single-stage serial hydrocracking technology method. A shale oil raw material and hydrogen are in cocurrent flow to feed a hydrofining reactor from the upper part; in the presence of hydrofining catalyst, hydrofining reaction is carried out; hydrofining reaction outflows feed to the upper part of a hydrocracking reactor; the upper part of the hydrocracking reactor is subject to gas-liquid separation; gas phase is discharged from the top of the hydrocracking reactor; liquid phase carries out hydrocracking reaction with reverse flow of the hydrogen which enters the hydrocracking reactor from the bottom of the hydrocracking reactor on hydrocracking catalyst; after hydrocracking reaction ends, the liquid phase product is discharged out of from the bottom ofthe hydrocracking reactor; and the gas phase and the gas phase separated from the hydrofining reaction outflows are jointly discharged from the top of the hydrocracking reactor. The method of the invention solves the deficiencies of low yield and the like of hydrocracking light products because nitrogen content is high in the shale oil in the prior art; meanwhile, the method can improve product quality and has simple processes and stable operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reusable slippery water fracturing fluid for shale oil and gas reservoir

ActiveCN103275691ALow viscosityRapid Dispersion DissolutionDrilling compositionUniform systemWater quality

The invention discloses reusable slippery water fracturing fluid for a shale oil and gas reservoir. The reusable slippery water fracturing fluid for the shale oil and gas reservoir comprises the following components in percentage by weight: 0.02 to 0.08 percent of a resistance reducing agent, 0.7 to 1.5 percent of a discharge aid, 8 to 12 percent of an auxiliary discharge aid, 5 to 10 percent of an interfacial tension-reducing synergist, 0.05 to 0.1 percent of a clay stabilizer, 0.007 to 0.01 percent of a sterilizing agent, 0.04 to 0.06 percent of a scale inhibitor and the balance of water. The reusable slippery water fracturing fluid for the shale oil and gas reservoir has the beneficial effects that (1) the resistance reducing agent can be dispersed and dissolved quickly to form a uniform system, so the problem of difficulty in large-scale intermediate liquid preparation in a shale fracturing process is solved; (2) the slippery water fracturing fluid can be reused, so the treatment cost of return liquid is reduced; (3) the resistance reducing ratio of the slippery water is more than 75 percent, so large-displacement construction is realized, the requirement on pump injecting equipment is reduced, and the frictional resistance of the slippery water in a pipeline in a large-displacement fracturing construction process can be effectively reduced; and (4) the slippery water fracturing fluid has a wide application range, strong temperature adaptability and temperature adaptability, and low requirement on water quality.

Owner:PETRO KING OILFIELD TECH

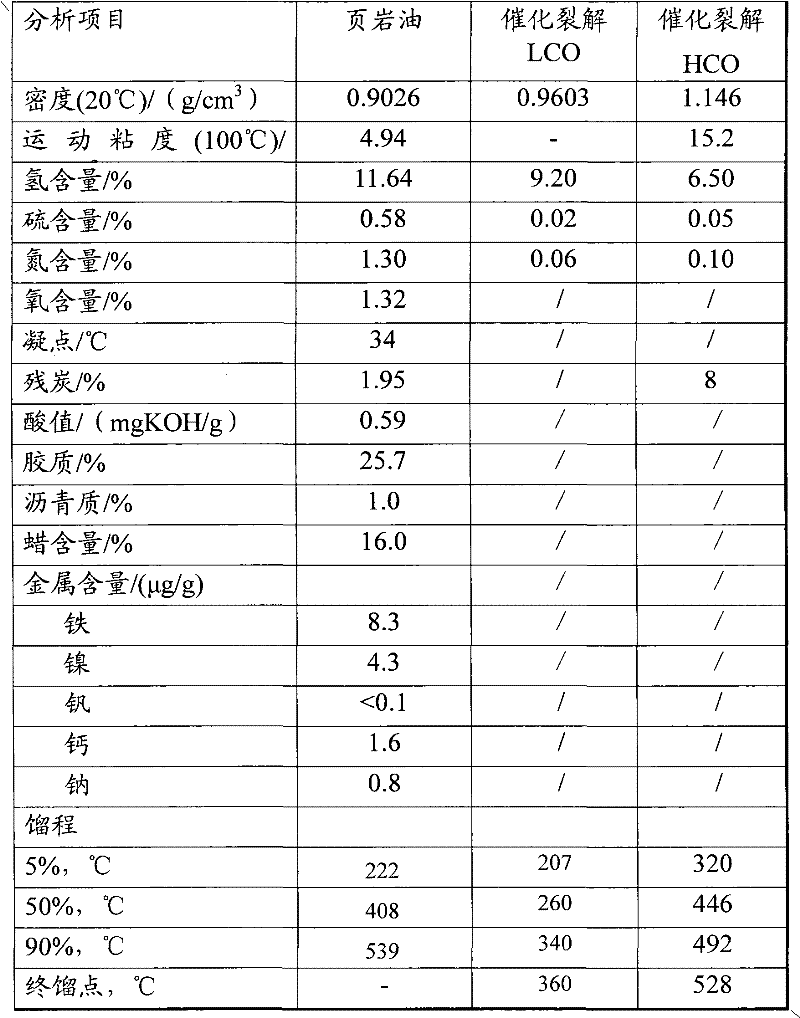

Deep processing method for shale oil

ActiveCN102453546ASave resourcesOvercome expensiveTreatment with hydrotreatment processesHydrogen treatmentLiquid gas

The invention relates to a deep processing method for shale oil, which comprises the following steps: placing shale oil, catalytic cracking light cycle oil and catalytic cracking heavy cycle oil into a shale oil hydrotreatment apparatus; placing the obtained hydrogenation generation oil and optional vacuum gas oil in a catalytic cracking apparatus, separating the reacted product to obtain ethane-containing dry gas, propylene and butylene-containing liquefied gas, monocyclic aromatics-rich catalytic cracking gasoline, catalytic cracking light cycle stock oil, catalytic cracking heavy cycle oil and catalytic cracking oil slurry; circulating catalytic cracking light cycle stock oil and catalytic cracking heavy cycle oil to the shale oil hydrotreatment apparatus. The deep processing method of shale oil is used for high value substances like ethane, propylene, butylene, benzene, toluene, xylene and the like, so that added value of the product can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

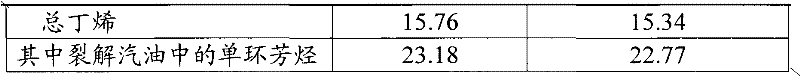

Shale oil resource evaluating method and device

The invention provides a shale oil resource evaluating method and device. The method comprises the steps that geological data of each region to be evaluated in a research region are obtained; a hydrocarbon production rate curve of the research region is searched for the hydrocarbon production rate corresponding to the organic matter thermal evolution degree of each region to be evaluated; the original organic carbon weight percentage composition of each region to be evaluated is calculated; the maximum organic matter porosity of each region to be evaluated is calculated; the ground organic matter porosity of each region to be evaluated is calculated; the shale oil resource abundance of each region to be evaluated is calculated; according to the area and the shale oil resource abundance of each region to be evaluated in the research region, the shale oil resource quantity of the research region is obtained through calculation. According to the shale oil resource evaluating method and device, the problem that when shale oil is evaluated in the prior art, only organic matter porosity is considered, factors such as non-movable oil are not removed, and therefore the determined shale oil resource quantity is inaccurate is solved, and the evaluating result accuracy is improved.

Owner:PETROCHINA CO LTD

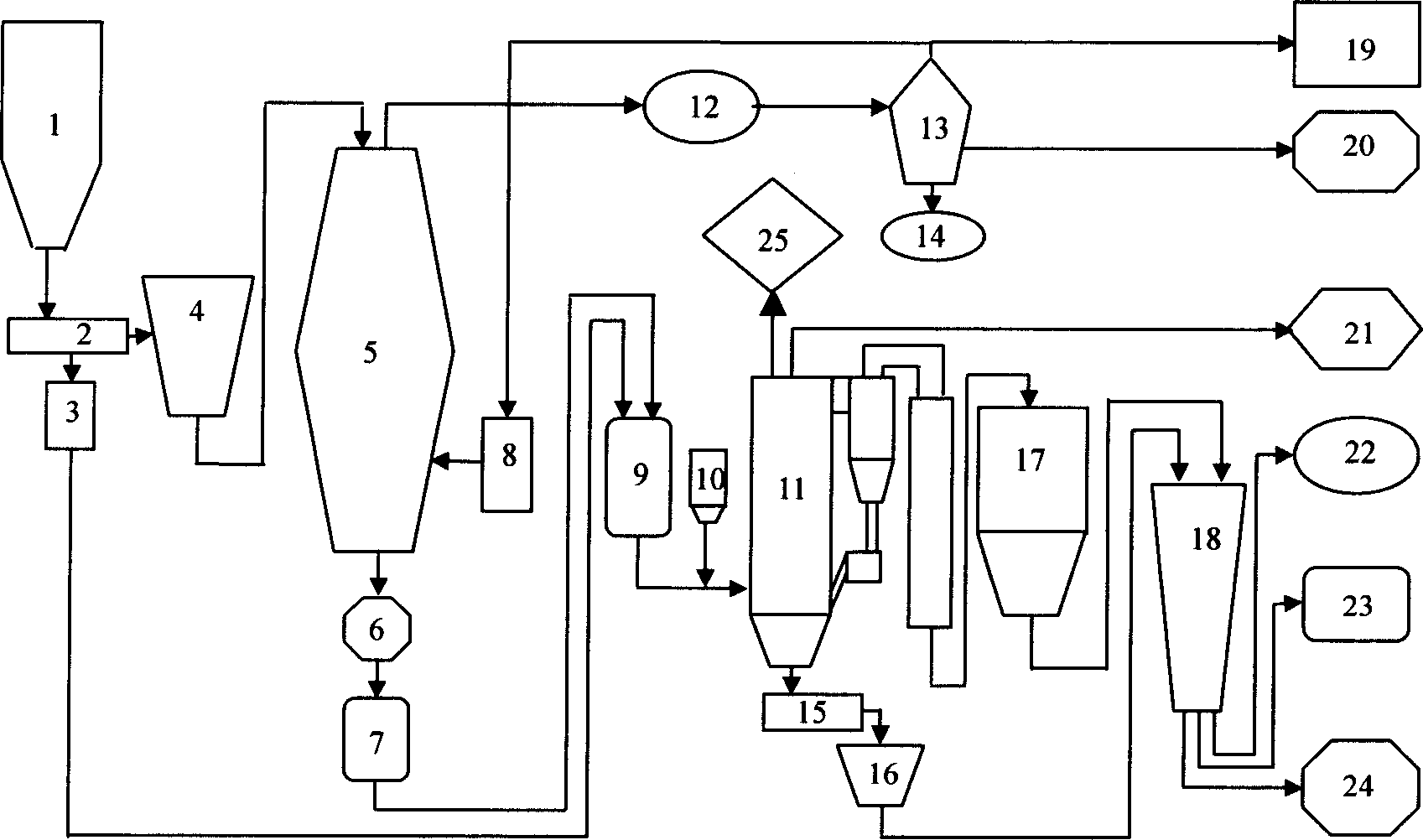

Method for complex optimum using oil shale

InactiveCN1683472AAchieve optimal utilizationIncrease profitLiquid hydrocarbon mixture productionSpecial form destructive distillationFluidized bedOil shale gas

The comprehensive optimized oil shale utilizing method includes crushing and sieving oil shale ore, dry distilling the 8-80 mm size component in retort furnace to produce shale oil and fuel gas, crushing the semicoke waste into 8 mm below size, mixing the crushed semicoke waste and 8 mm below size waste grain from oil refining to form mixed fuel for the circulating fluidized bed boiler, using the produced steam partially for externally supplying and partially to drive turbine generator, and using the cinder in producing cement, haydite and building block. The present invention provides one new way for comprehensive utilization of giant oil shale resource.

Owner:SHANGHAI JIAO TONG UNIV

Reservoir modifying method through forming crack network by temporary plugging turning in cracks

ActiveCN105089603AReduce seepage distanceImprove seepage capacityFluid removalDrilling compositionTight oilEngineering

The invention provides a reservoir modifying method through forming a crack network by temporary plugging turning in cracks. The method comprises the following steps: injecting a temporary plugging turning material liquid into a reservoir man-made crack and forming a bridge plug in the deep part of the crack, forcing the crack to turn and form a plurality of cracks, using an active fluid or an acid fluid to activate reservoir micro-cracks, and forming the crack network. The method can form the man-made crack network in unconventional oil-gas reservoirs such as low-permeability, ultra low permeability oil-gas reservoirs, tight oil reservoirs and shale oil-gas reservoirs, so as to increase the contact area to the reservoirs and greatly shorten the seepage distance and the seepage resistance of the oil and gas in the reservoirs towards the cracks in the arbitrary directions, and furthermore the single well yield and the final recovery efficiency are increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com