Patents

Literature

989 results about "Retort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a chemistry laboratory, a retort is a device used for distillation or dry distillation of substances. It consists of a spherical vessel with a long downward-pointing neck. The liquid to be distilled is placed in the vessel and heated. The neck acts as a condenser, allowing the vapors to condense and flow along the neck to a collection vessel placed underneath.

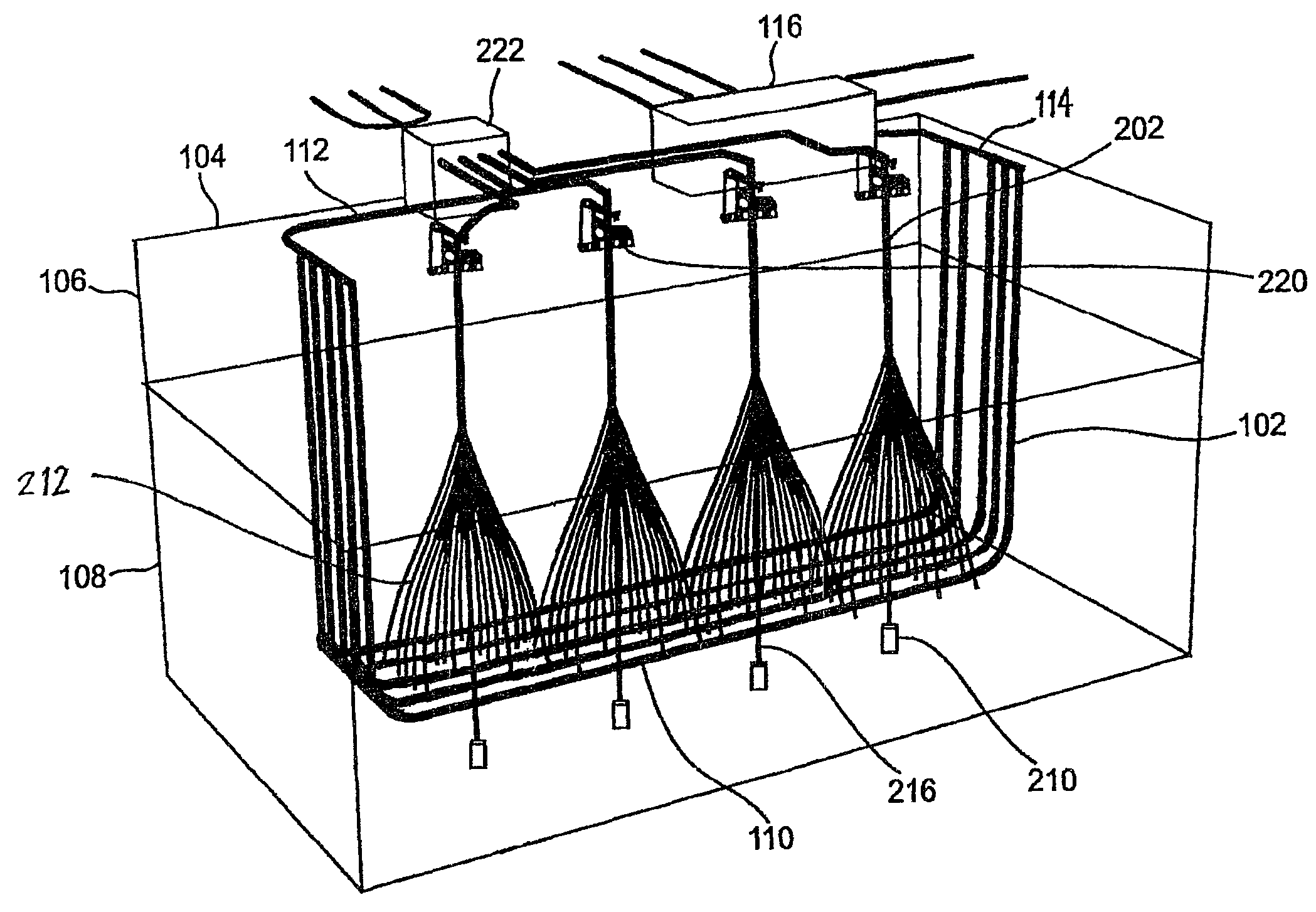

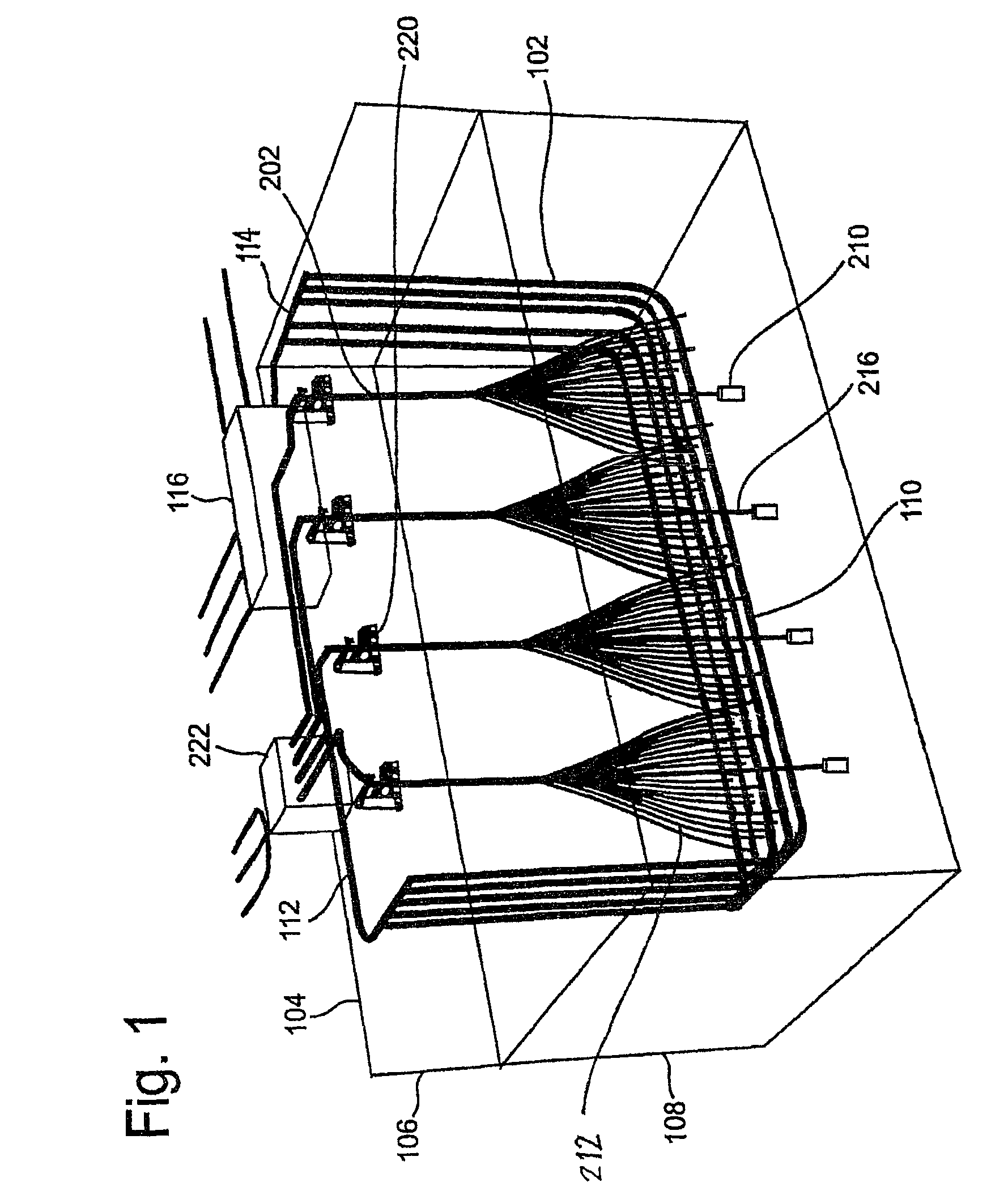

In situ method and system for extraction of oil from shale

ActiveUS20070193743A1Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

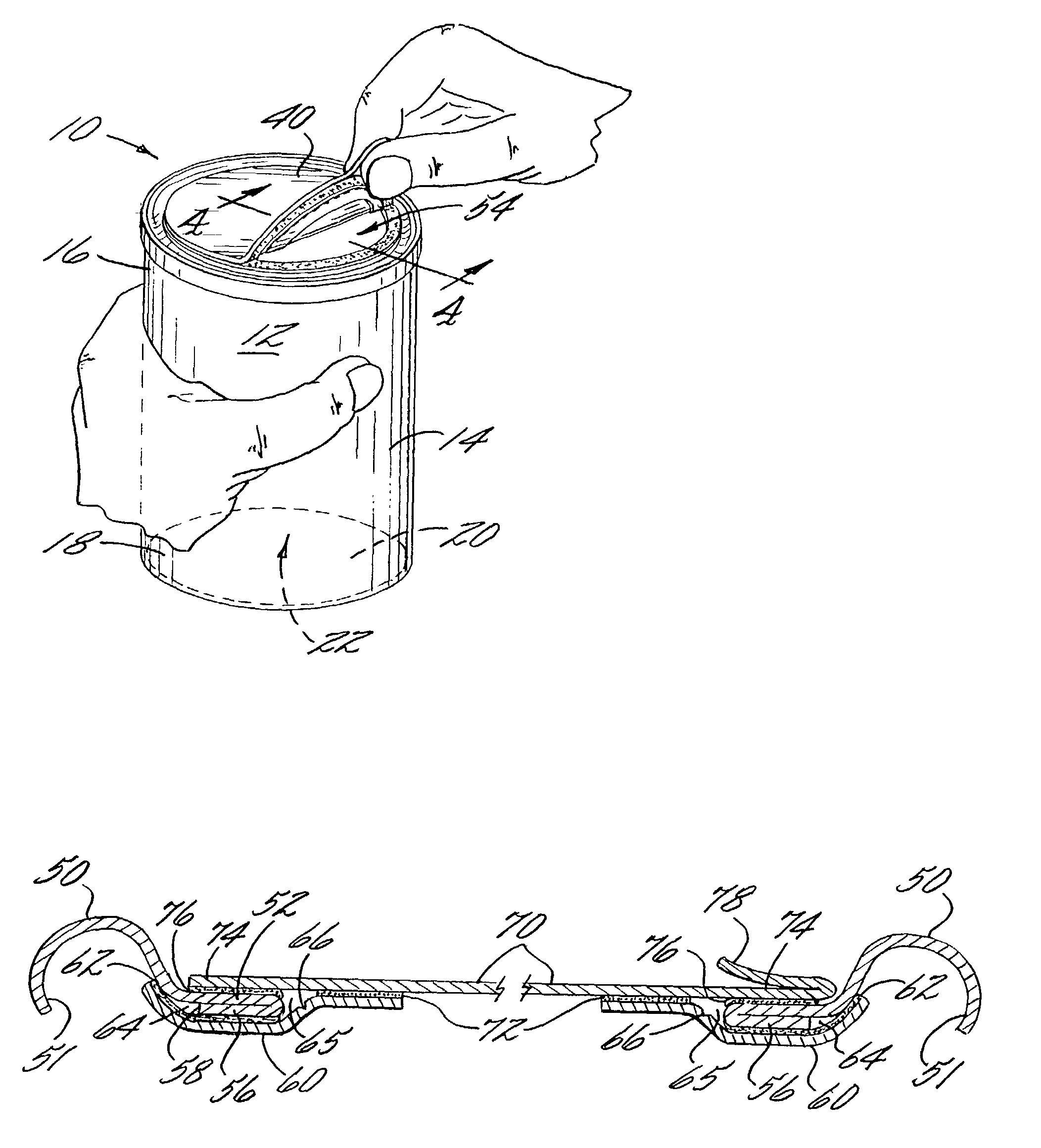

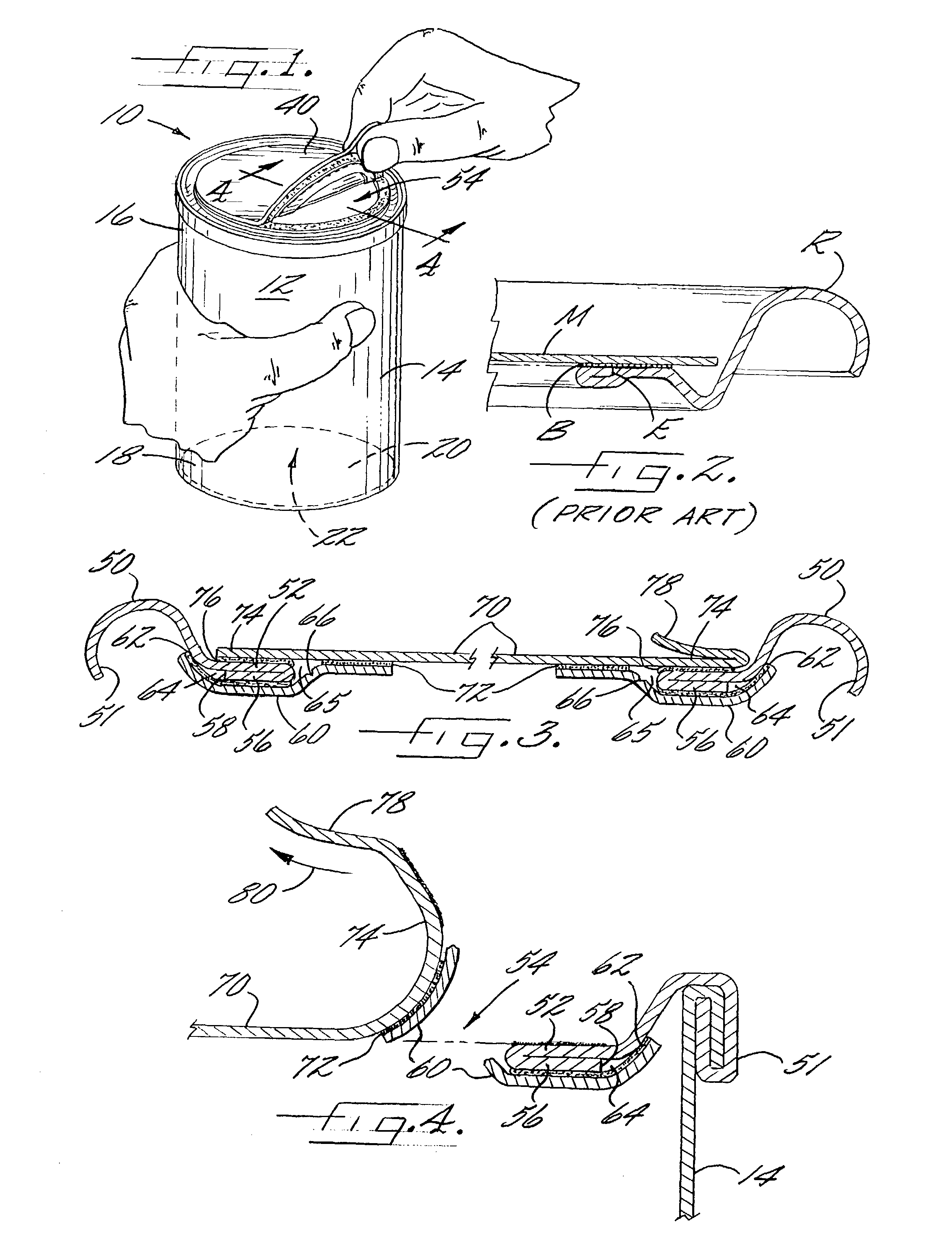

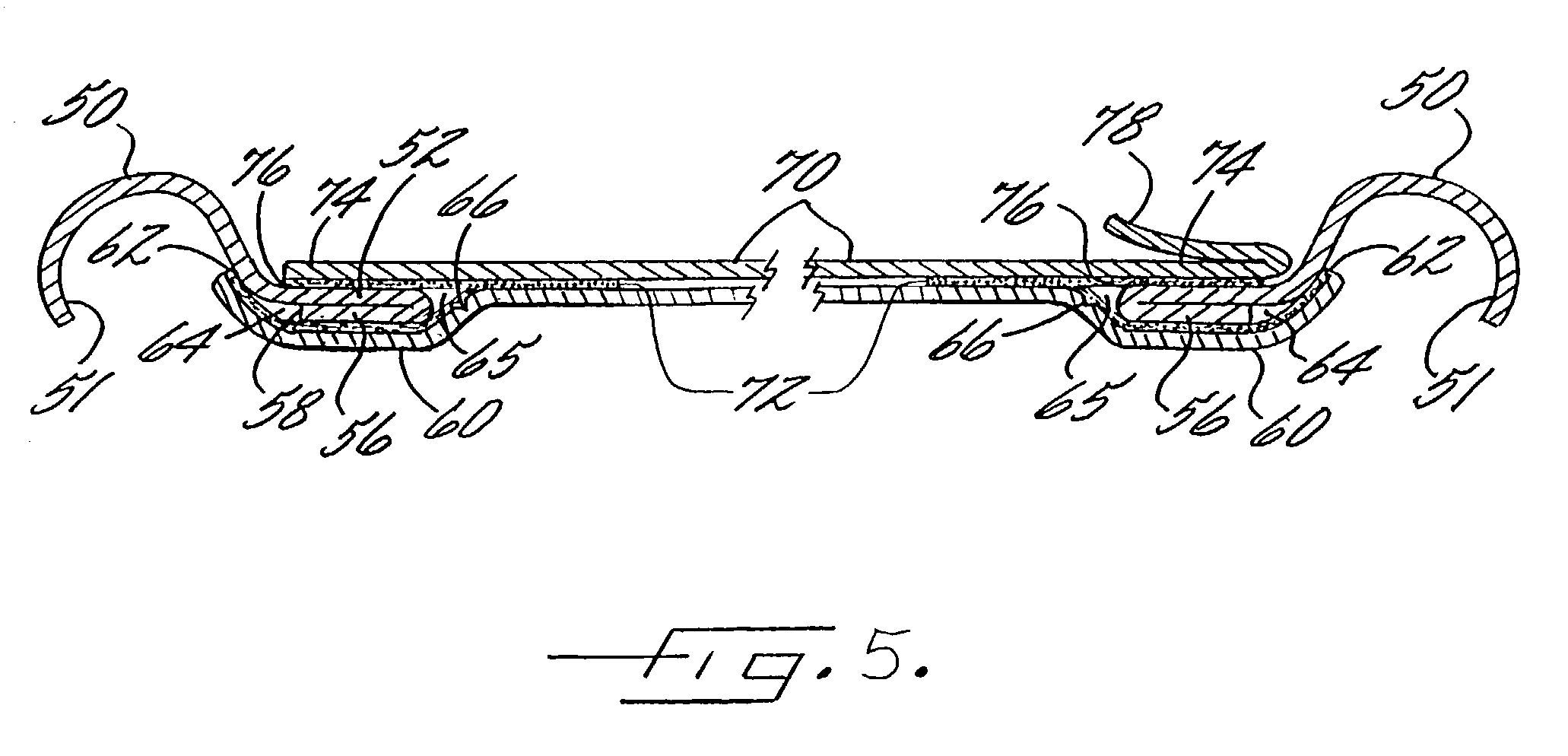

Easy-opening closure for retortable container

A retortable container and an easy-opening closure for hermetic sealing of an open end thereof. The closure includes a metal end ring adapted to be double seamed to an open end of the retortable container, an intermediate area extending radially inward and defining an opening to an interior of the container, and a folded area folded into the interior of the container. The folded area extends radially outward from the opening and substantially parallel to at least an adjacent portion of the intermediate area. A first membrane patch overlaps and is bonded to an under side of the intermediate area of the end ring such that the first membrane patch prevents contamination of contents of the container by the metal end. A second membrane patch covers the opening and is bonded to an upper side of the first membrane patch. The bonds have predetermined shear and tensile force strengths sufficient to withstand shear and tensile forces created during retort processing of the container, while allowing easy-opening of the container by peeling the second membrane patch.

Owner:SONOCO DEV INC

In situ method and system for extraction of oil from shale

ActiveUS7743826B2Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

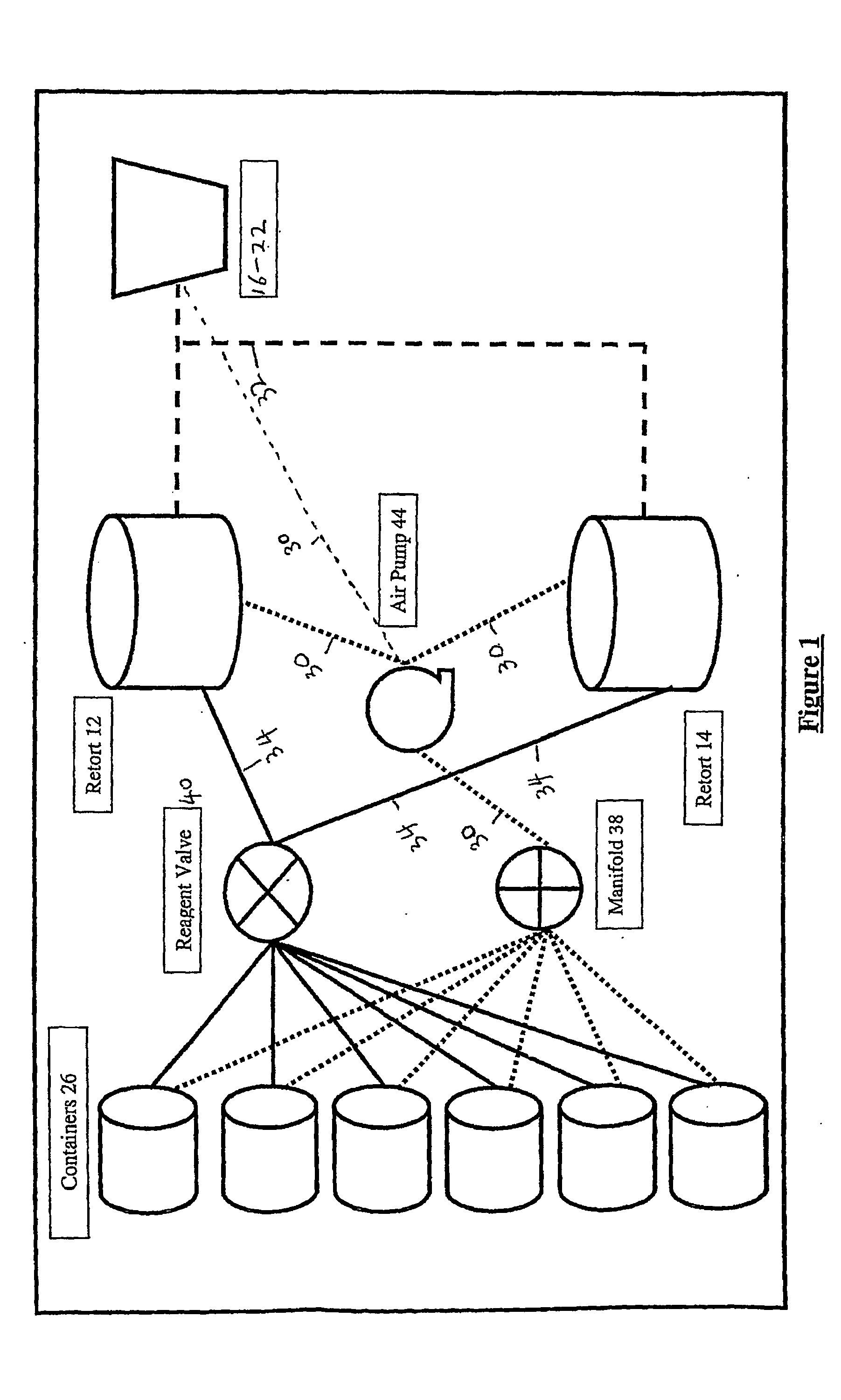

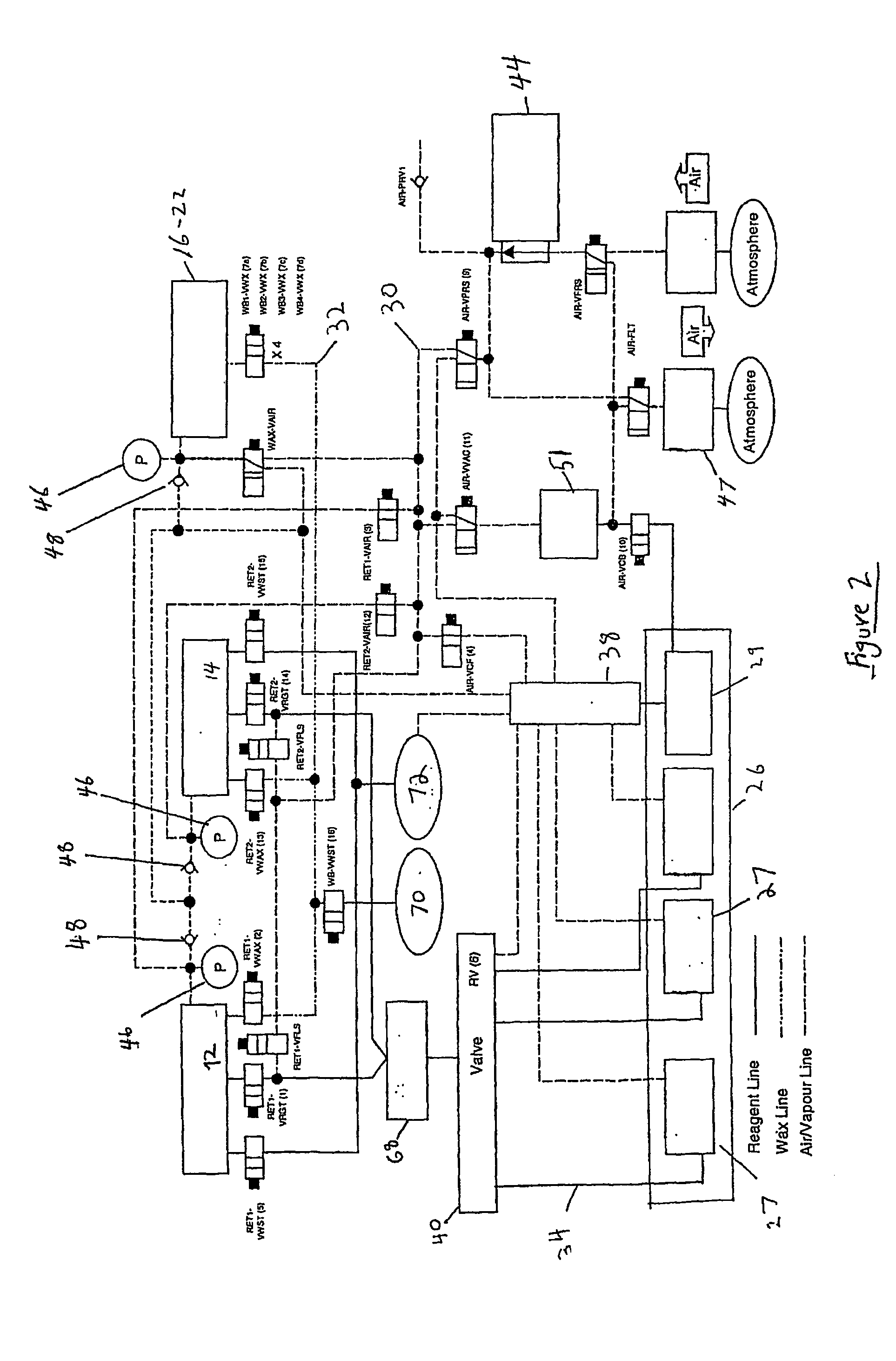

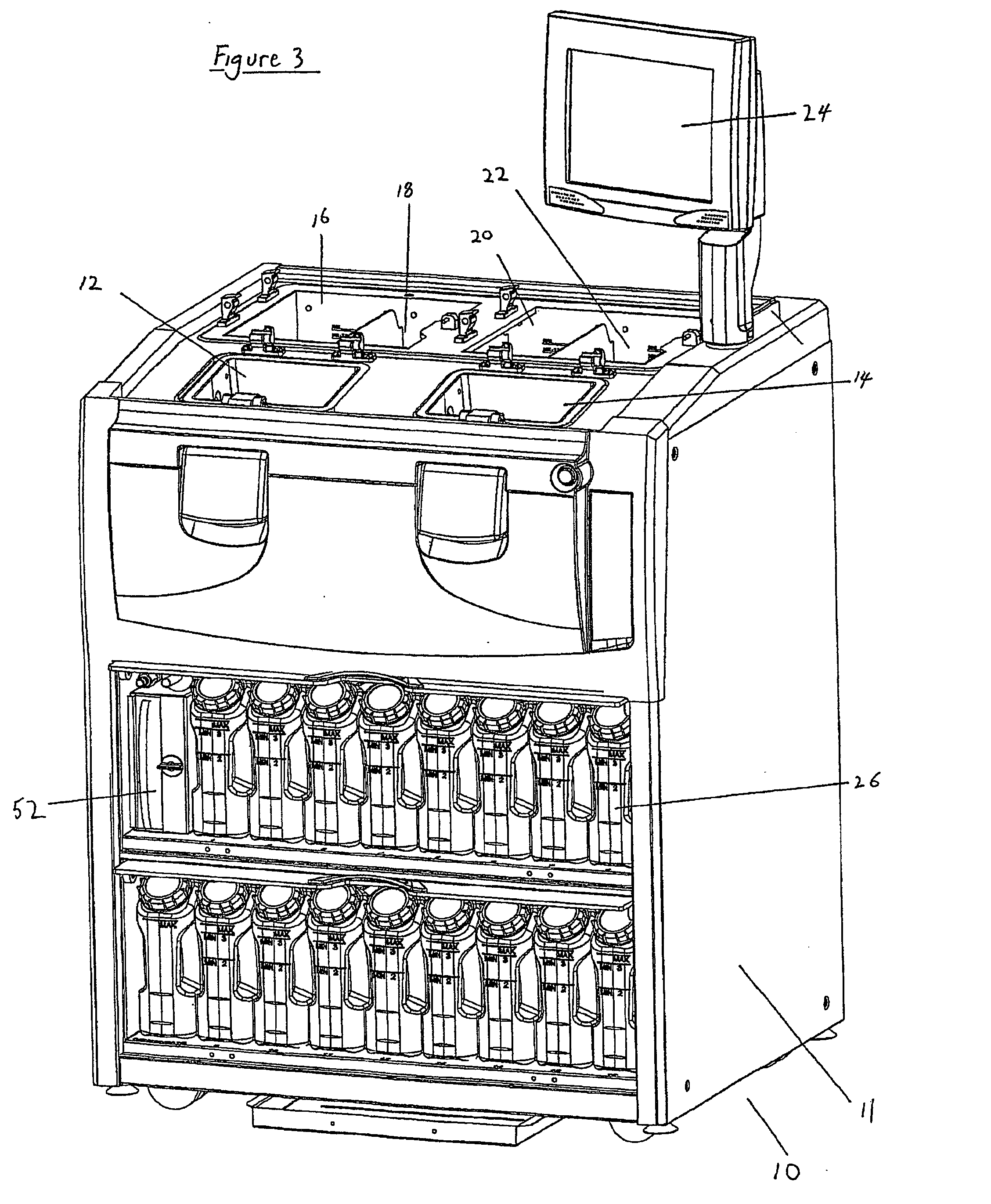

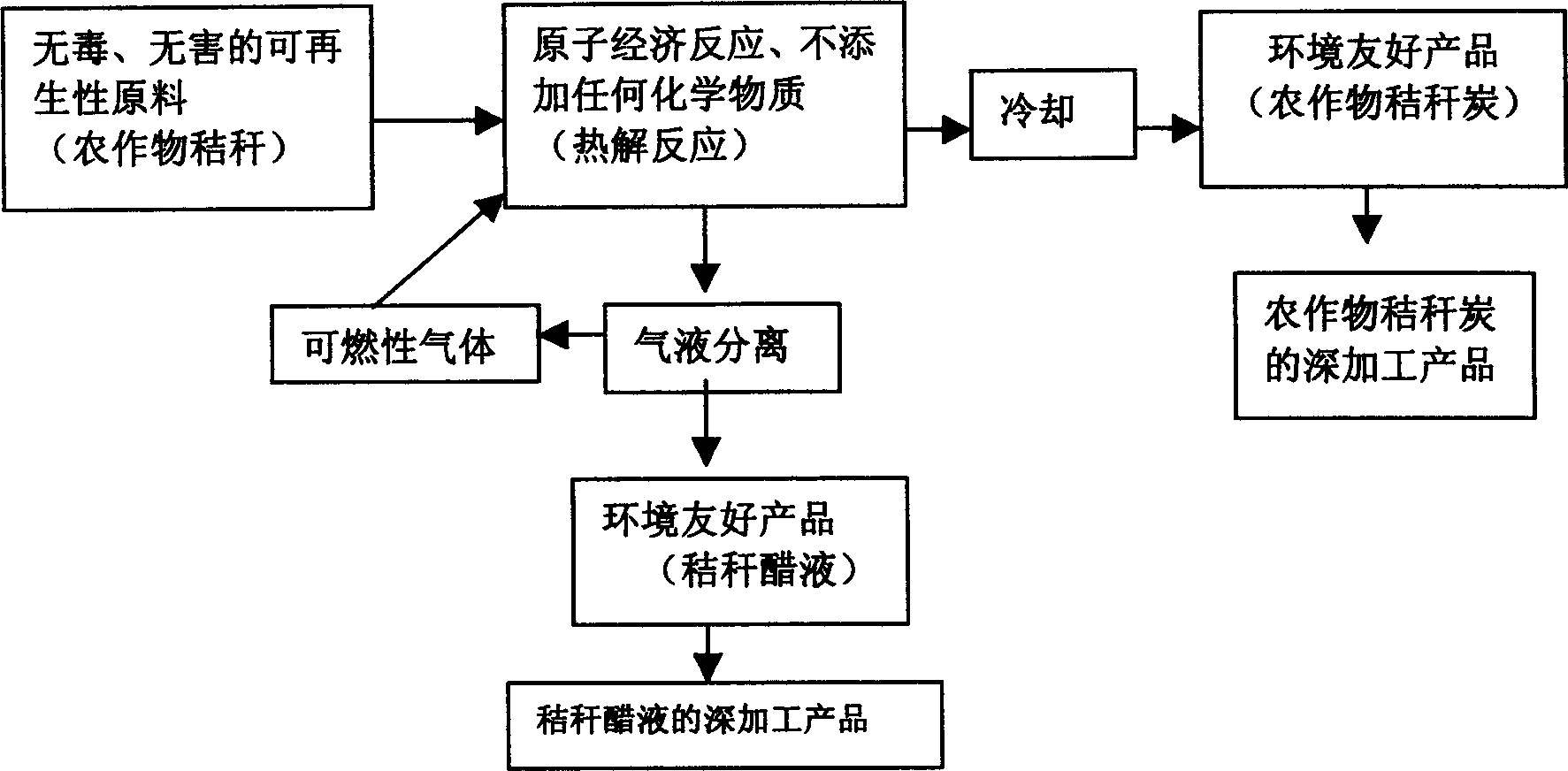

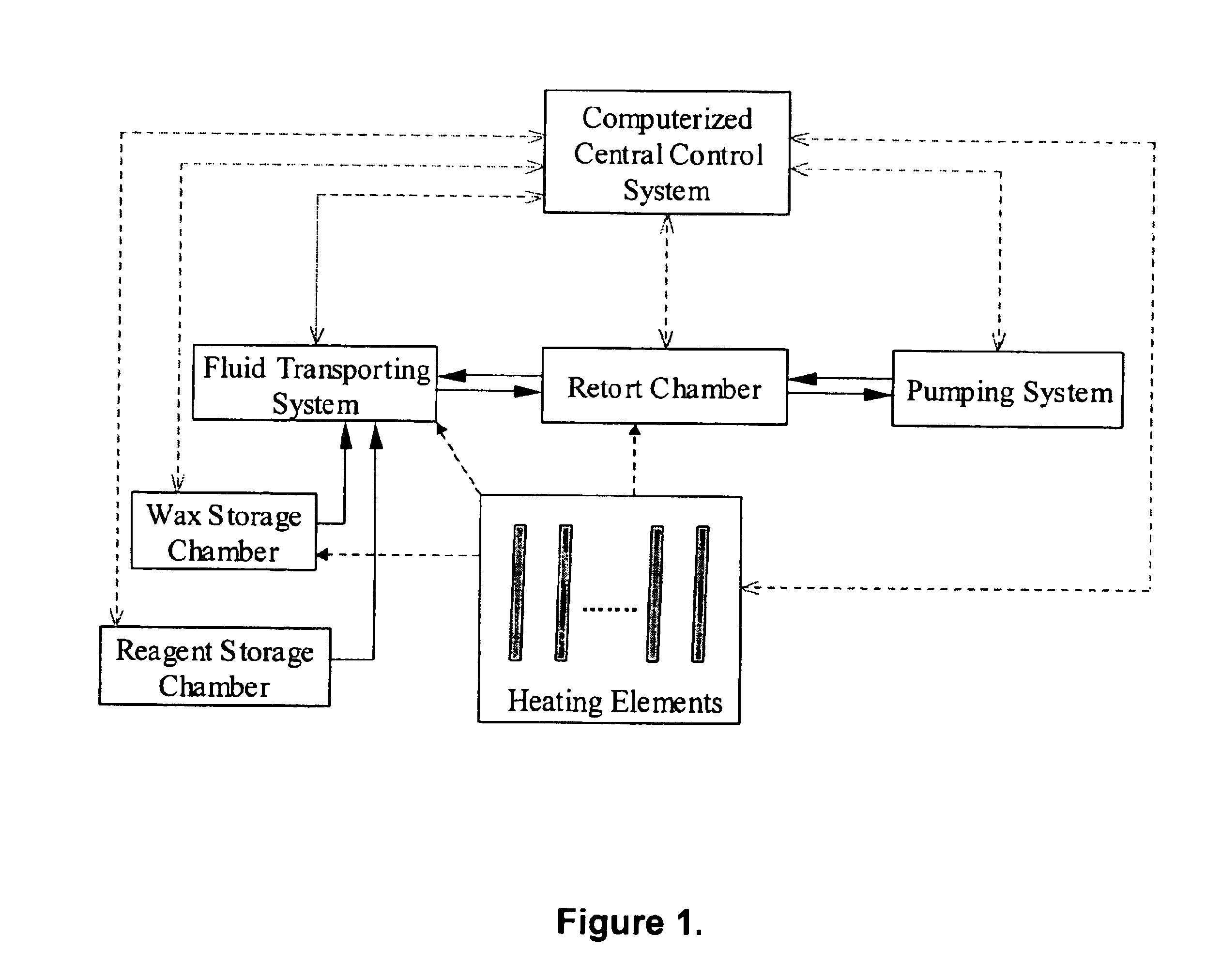

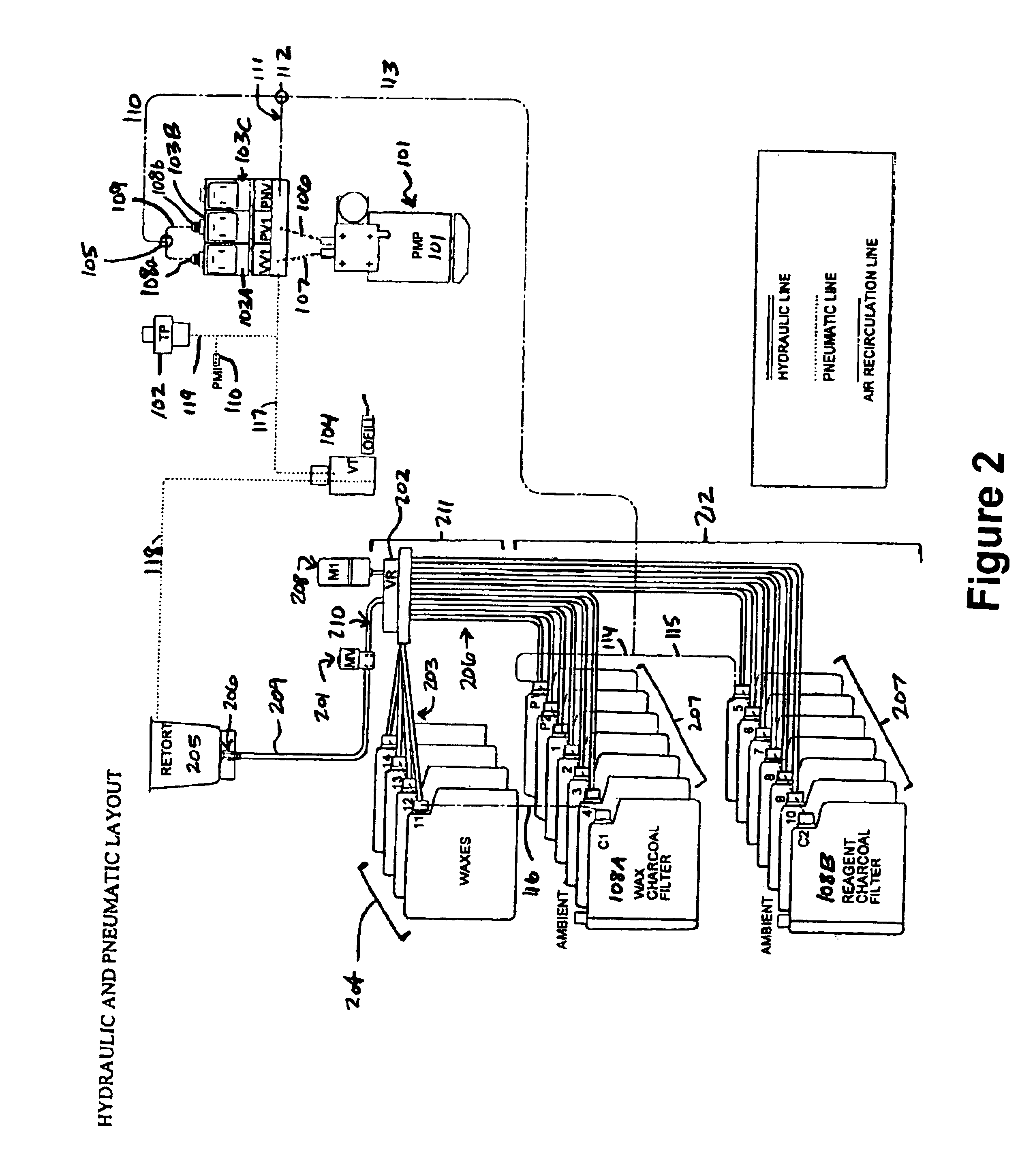

Histological tissue specimen treatment

InactiveUS20050124028A1Reduce pressureBoiling pointBioreactor/fermenter combinationsBiological substance pretreatmentsWaxAlcohol

A tissue processor for processing tissue samples for histological analysis. The processor comprises two retorts, wax baths, reagent containers, a pump and valve. The vale distributes the reagent from one container to either retort. Separate reagent lines connect the wax baths to the retorts. A method of infiltrating a sample containing a reagent such as a dehydrating reagent like an alcohol, where the infiltrating material is heated to a temperature at or above the boiling point of the reagent, to boil off the reagent when the tissue sample is contacted by the infiltrating material. The pressure in the retort may be reduced to lower the boiling point of the reagent.

Owner:LEICA BIOSYST MELBOURNE

Polyester film

ActiveUS20070009750A1Poor producibilityHigh production costFlexible coversWrappersPolyesterIngested food

[Problems] The present invention provides a-polyester-film superior in heat resistance, chemical resistance, insulation property and thermal dimensional stability, and suitable for application to fields associated with boiling or retort treatment, which require tenacity, pinhole resistance, bending resistance, bag breakage resistance on dropping, impact resistance and the like, fields requiring thermoforming or vacuum forming, and various uses such as packaging bags for water-containing food, pharmaceutical products and the like. [Solving Means] The polyester film characteristically shows an initial elastic modulus in at least one direction of 2.5-10 GPa, an impact strength of 40-10000 J / mm, a thermal shrinkage in at least one direction at 150° C. of −0.5% to 6%, a haze of 0.001% to 7%, and an absolute value of the difference in the thermal shrinkage between the longitudinal direction and the transverse direction of not more than 1.1%.

Owner:TOYO TOYOBO CO LTD

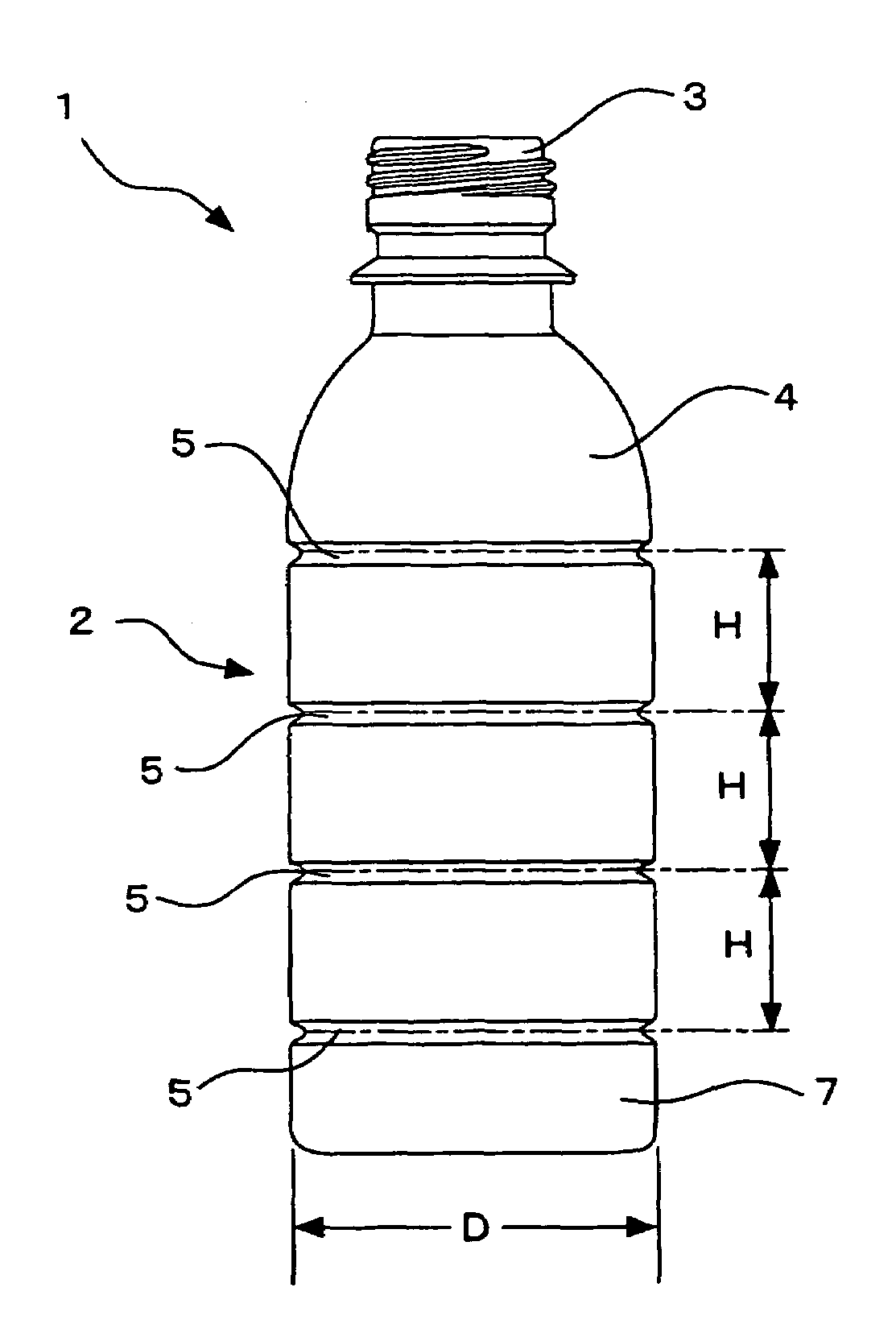

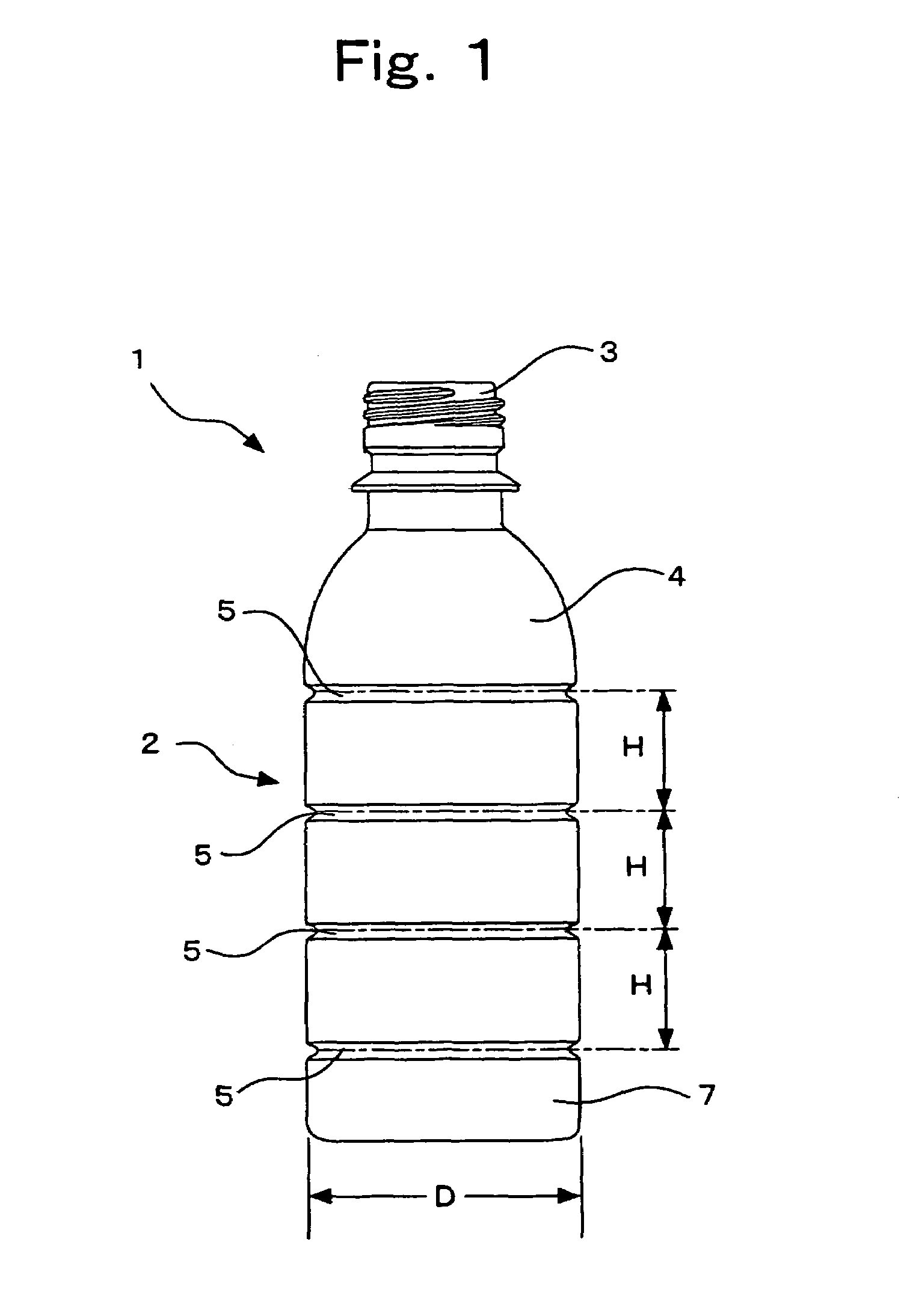

Synthetic resin bottle with circumferential ribs for increased surface rigidity

InactiveUS7051890B2Improve surface rigidityHigh surface hardnessBottlesLarge containersInternal pressureEngineering

The technical problem of this invention is to eliminate the need to use deformable panel walls and to find the body of a shape that no false deformation, such as dented deformation, takes place in a portion of the body due to the hot filling of the contents or the reduced pressure created by the treatment of retort-packed foods. The object of this invention is to obtain a bottle that can inhibit the deformation caused by reduced pressure, has a high buckling strength, and is good in outer appearance. As the solution, there is provided a biaxially drawn, blow-molded bottle made of a synthetic resin, in which the surface rigidity of the wall of body is set in such a manner that a part of the body wall cannot become dented inward under a reduced inner pressure of at least 350 mmHg (46.7 kPa).

Owner:YOSHINO KOGYOSHO CO LTD

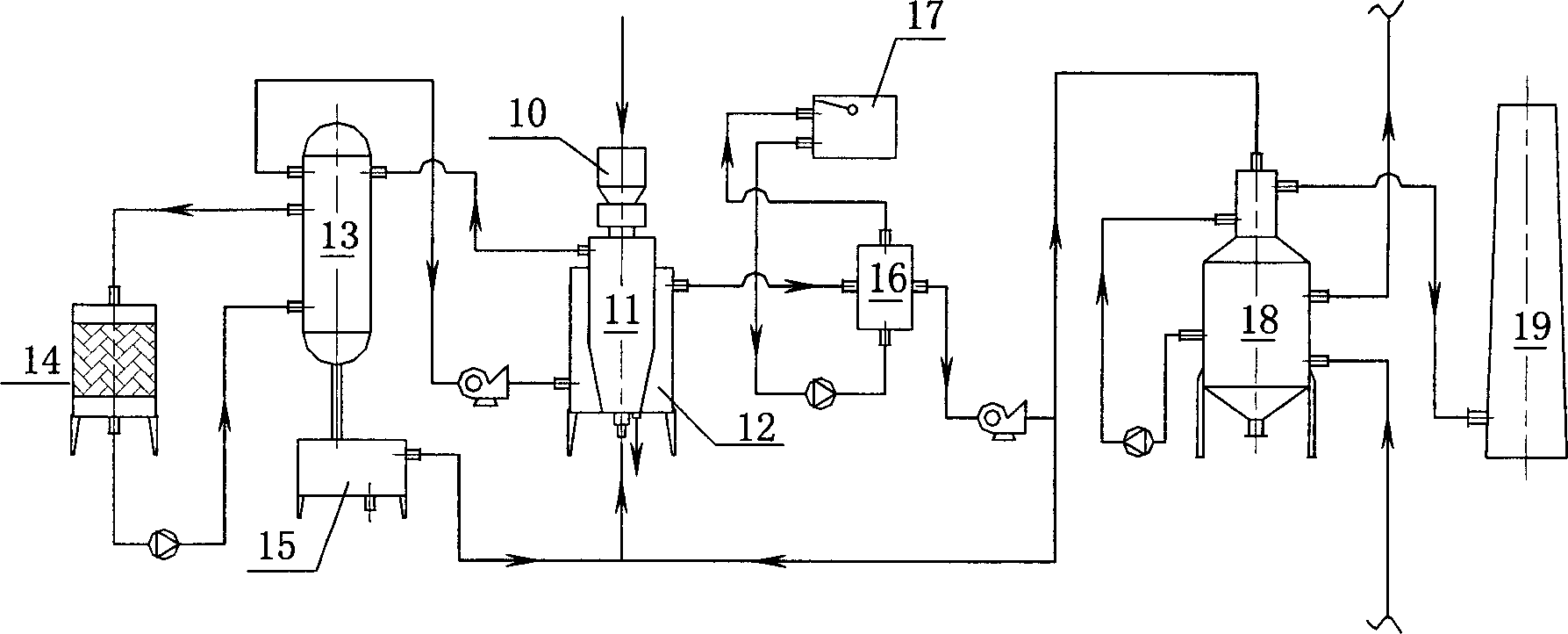

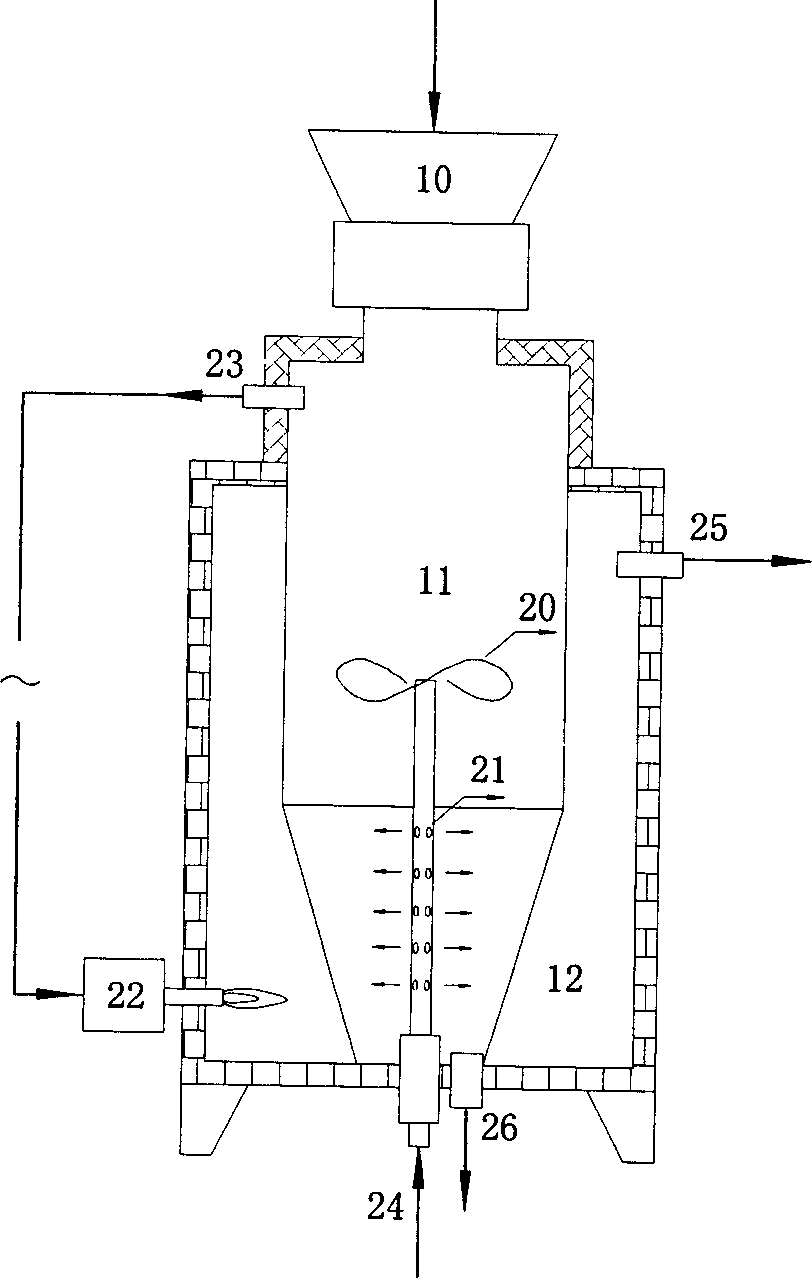

Device and method for suppressing refuse end gas injurant using pyrolysis and aerification technology

InactiveCN1769397ANo emissionsPrevent gasificationThermal non-catalytic crackingSolid waste disposalThermal dissociationVaporization

Owner:TIANJIN UNIV

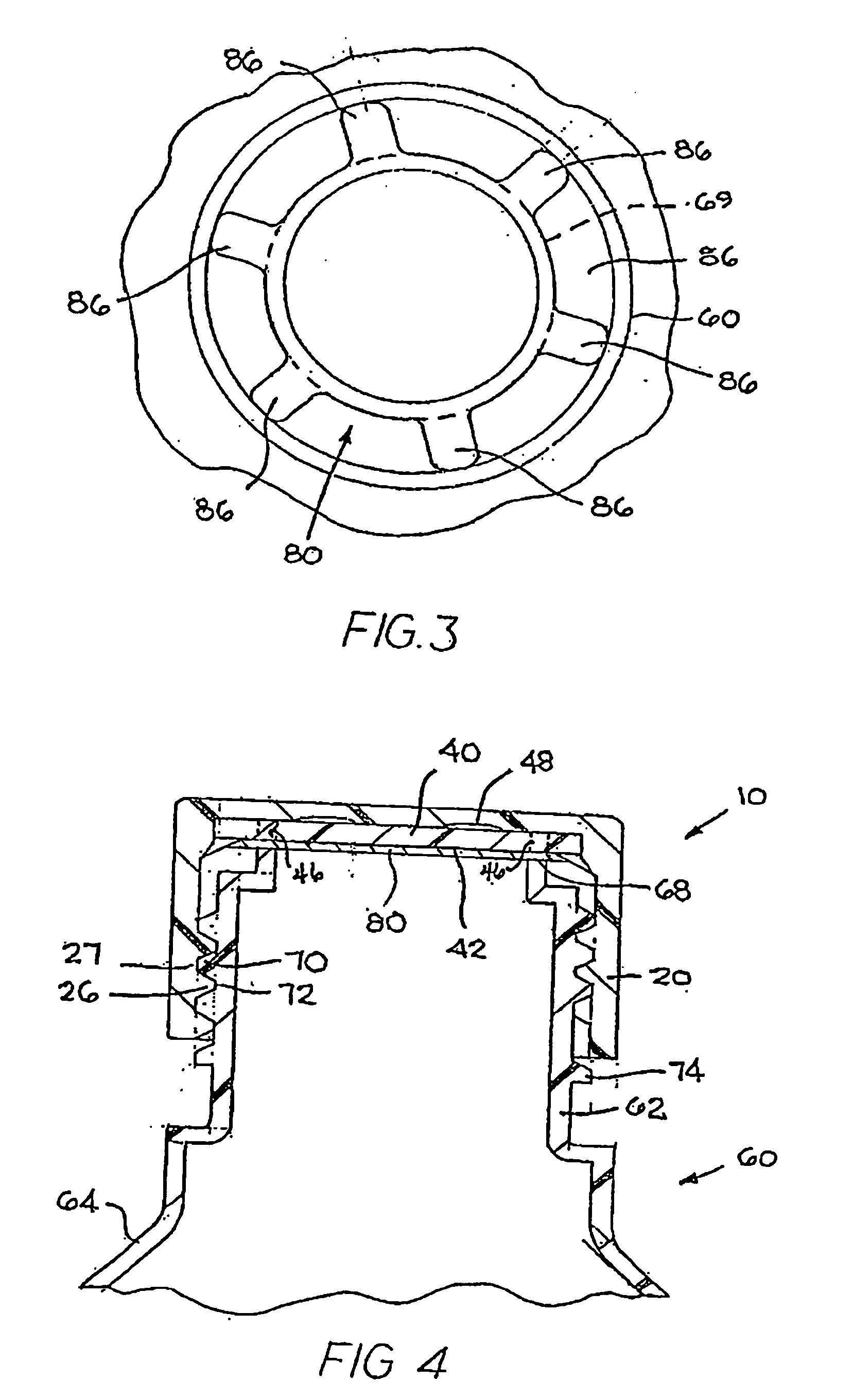

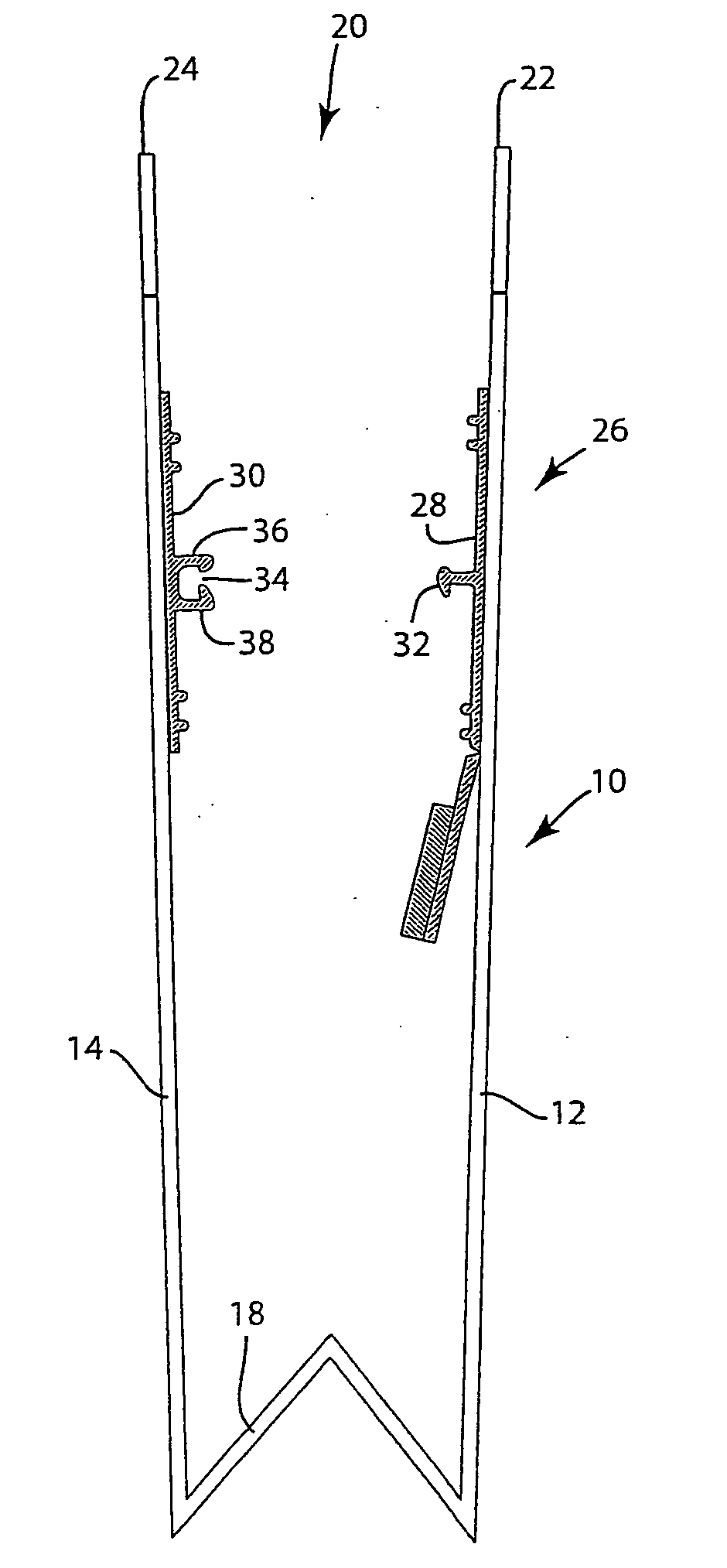

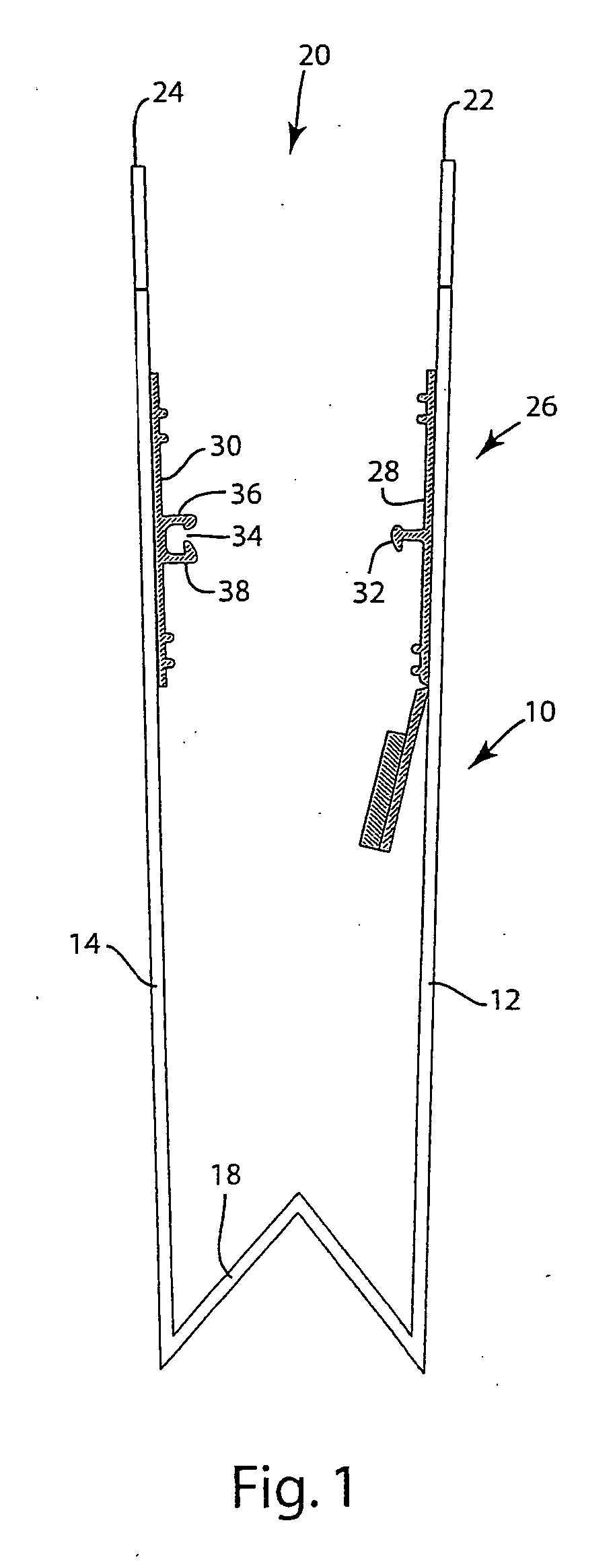

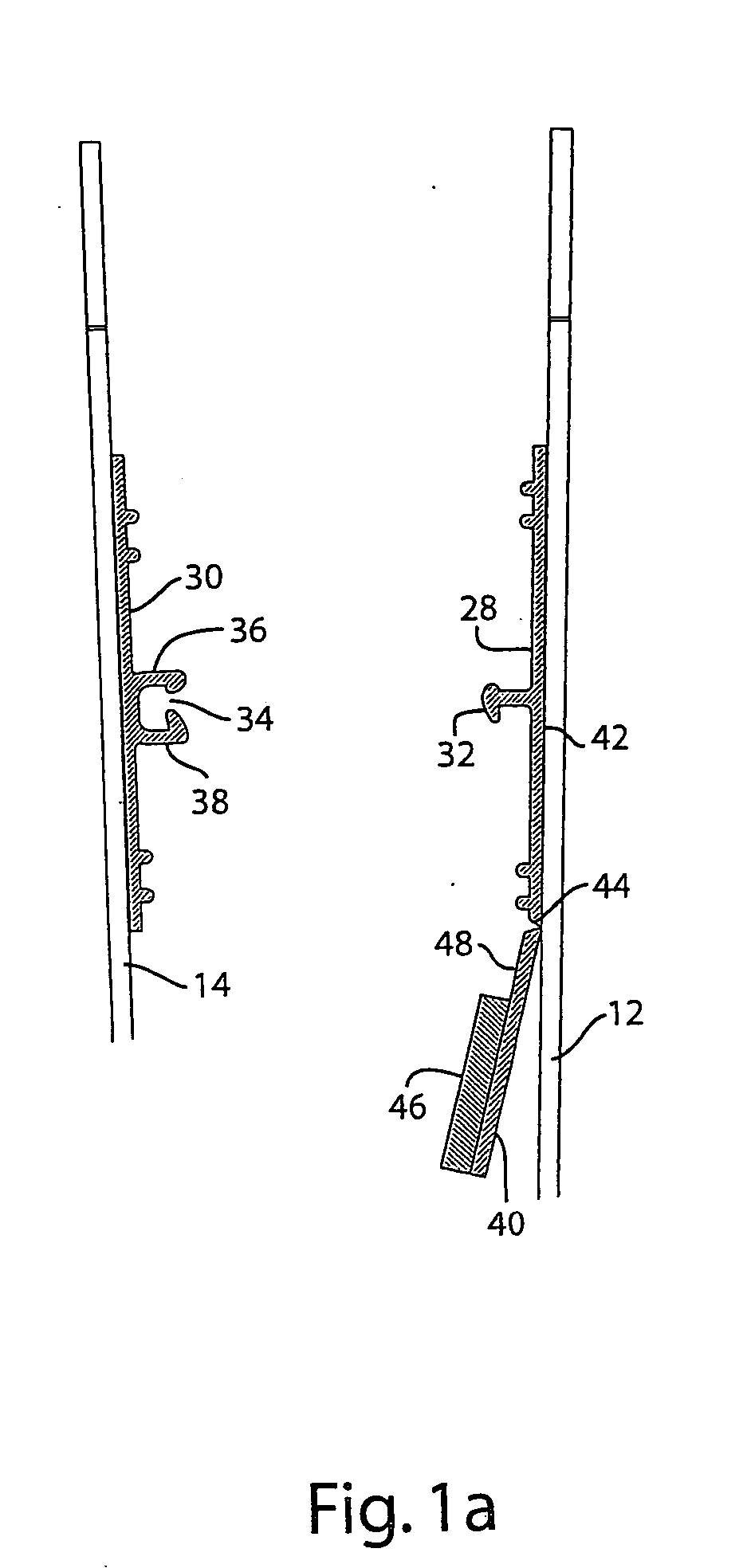

Closure for a Retort Processed Container Having a Peelable Seal

InactiveUS20070125785A1Effective pressurePrevent leakageCapsClosure using stoppersEngineeringMechanical engineering

A closure for maintaining pressure against a seal affixed to a container lip during a thermal sterilization process includes a top wall and an annular skirt depending from said top wall, at least one retaining structure extending from the annular skirt, a reseal structure rotatably disposed above said retaining structure and adjacent said top wall, an inner seal rotatably disposed above the retaining structure and beneath a lower surface of said reseal structure, wherein said inner seal and said reseal structure are both rotatable relative to said closure.

Owner:BERRY PLASTICS CORP

Equipment and method for extracting perfume plant essential oil by reduced pressure steam distillation

InactiveCN102250689AWide applicabilityEasy and flexible operationEssential-oils/perfumesWater vaporOil phase

The invention provides a piece of equipment and a method for extracting volatile essential oil from natural perfume plants by using the technology of reduced pressure steam distillation extraction. The equipment provided in the invention comprises a steam distillation system and a vacuum system, wherein the steam distillation system is composed of a steam generator, a material retort, a condenser, an oil-water separator and connecting pipelines, and the vacuum system comprises a vacuum unit or a suction pump, a pressure regulator valve, connecting pipelines and the like. The method comprises the following steps that: plant raw materials to be extracted for essential oil in the material retort is controlled to be at a certain temperature and under certain pressure so as to reduce changes of aroma components in perfume plants in the process of extraction as much as possible; extracted volatile components of essential oil is mixed with steam to form mixed steam of water and oil; the mixed steam enters into the condenser for condensation and then enters into the oil-water separator for separation; an oil phase is collected after separation and the oil phase is plant essential oil; the separated water phase is flower water. The essential oil and flower water obtained by the extraction method have pure aroma, suffer little loss for head volatile thereof, and are applicable to the industries of perfumes, essence, cosmetics, daily chemicals, etc.

Owner:XINJIANG UNIVERSITY +2

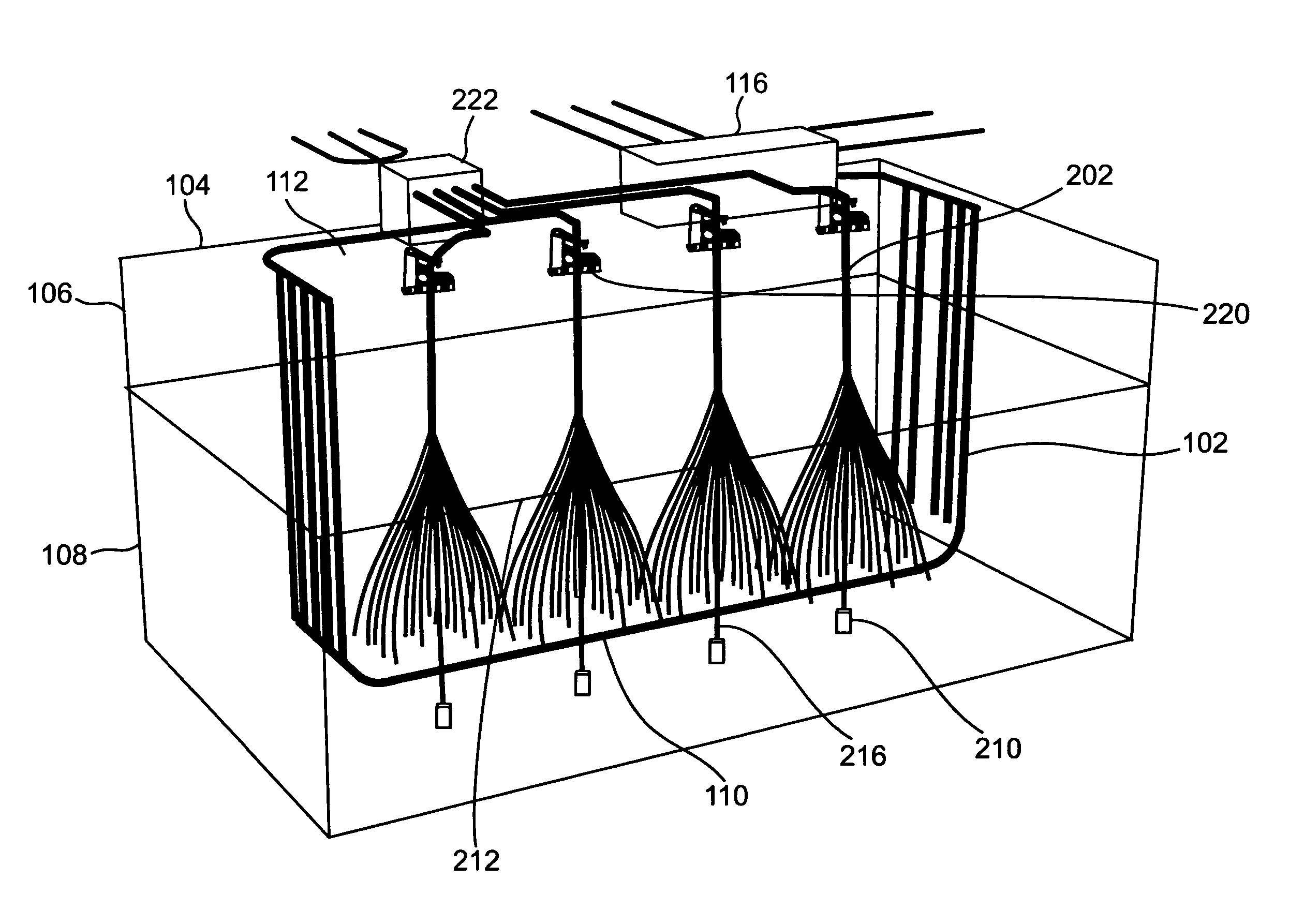

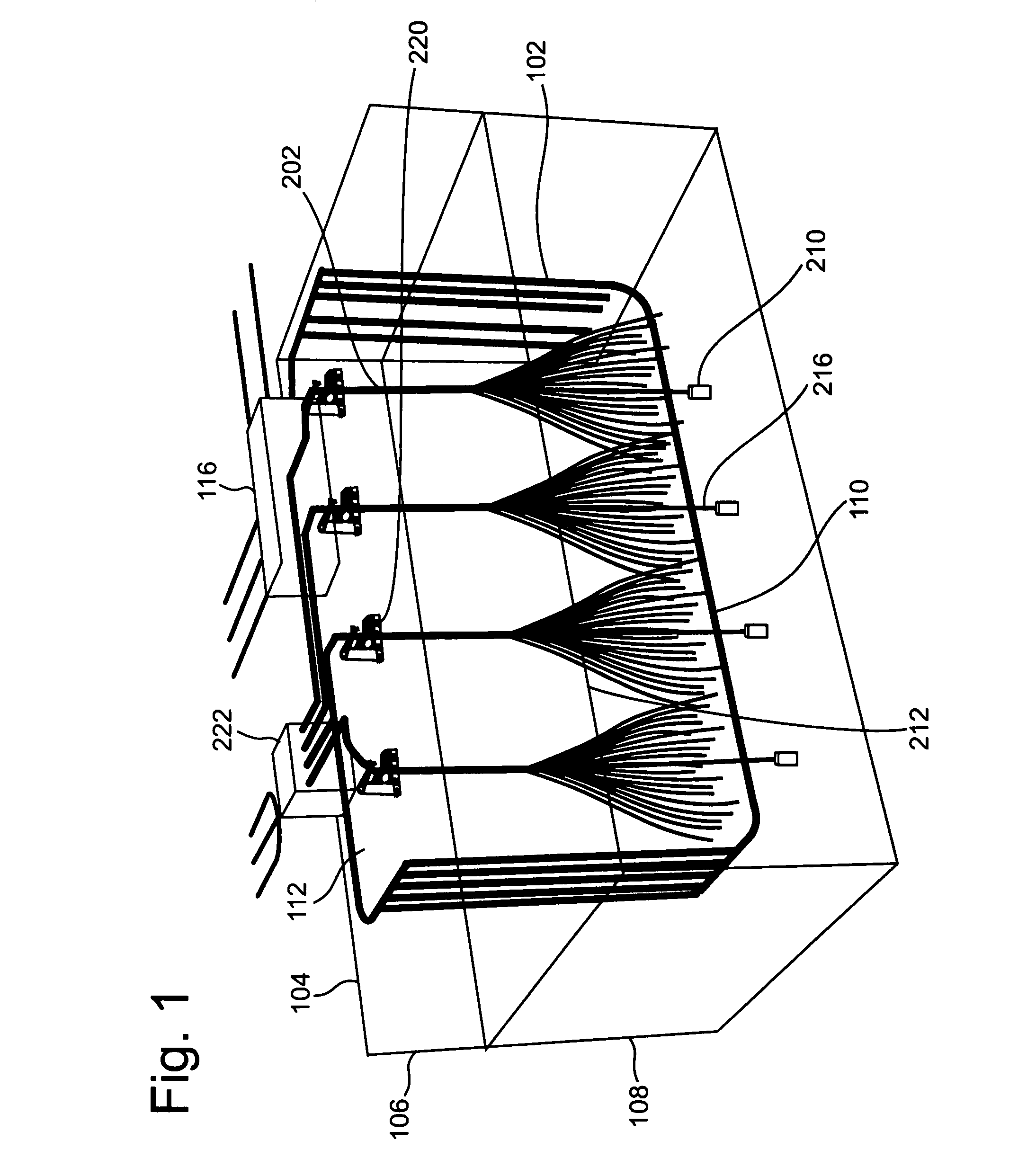

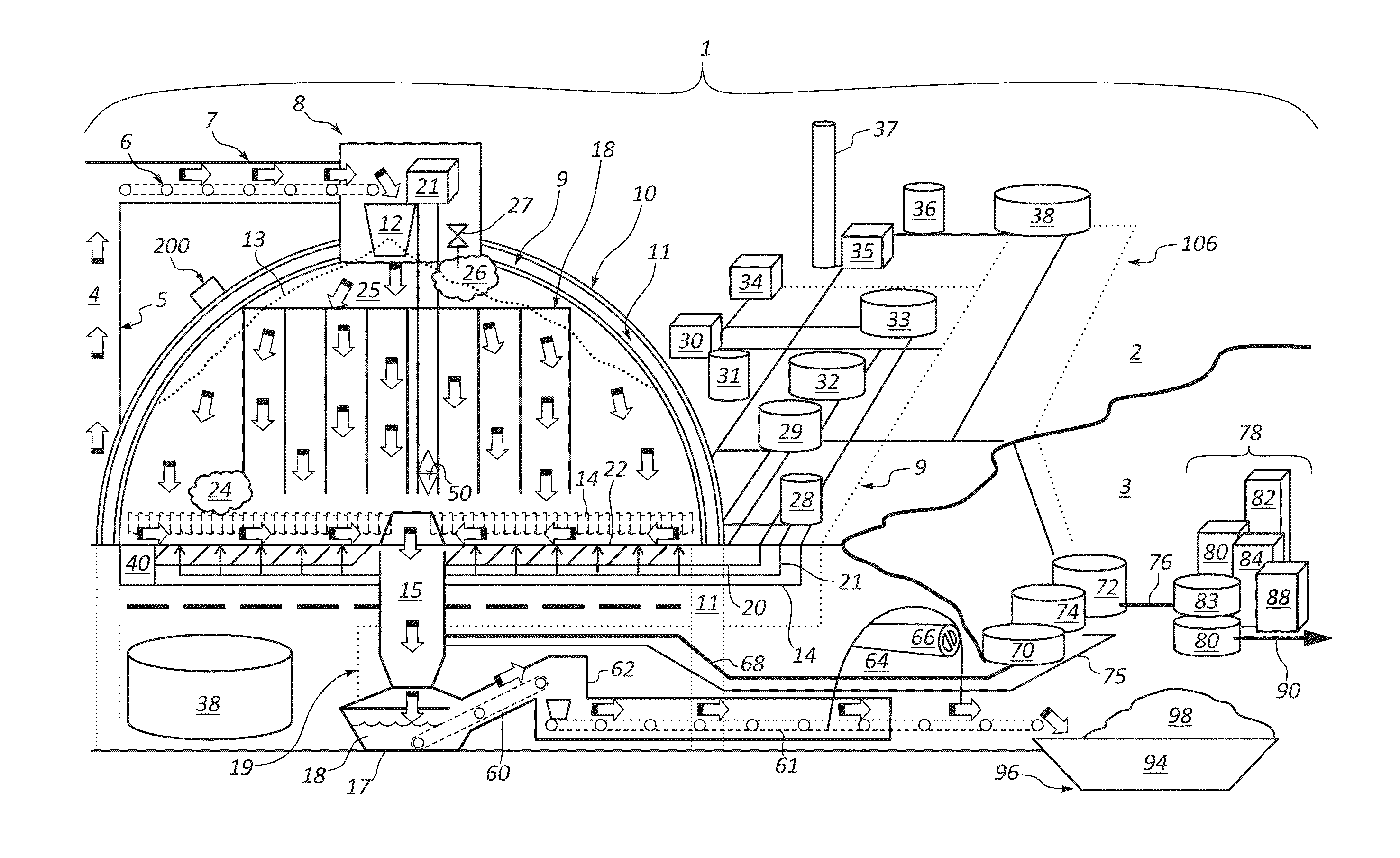

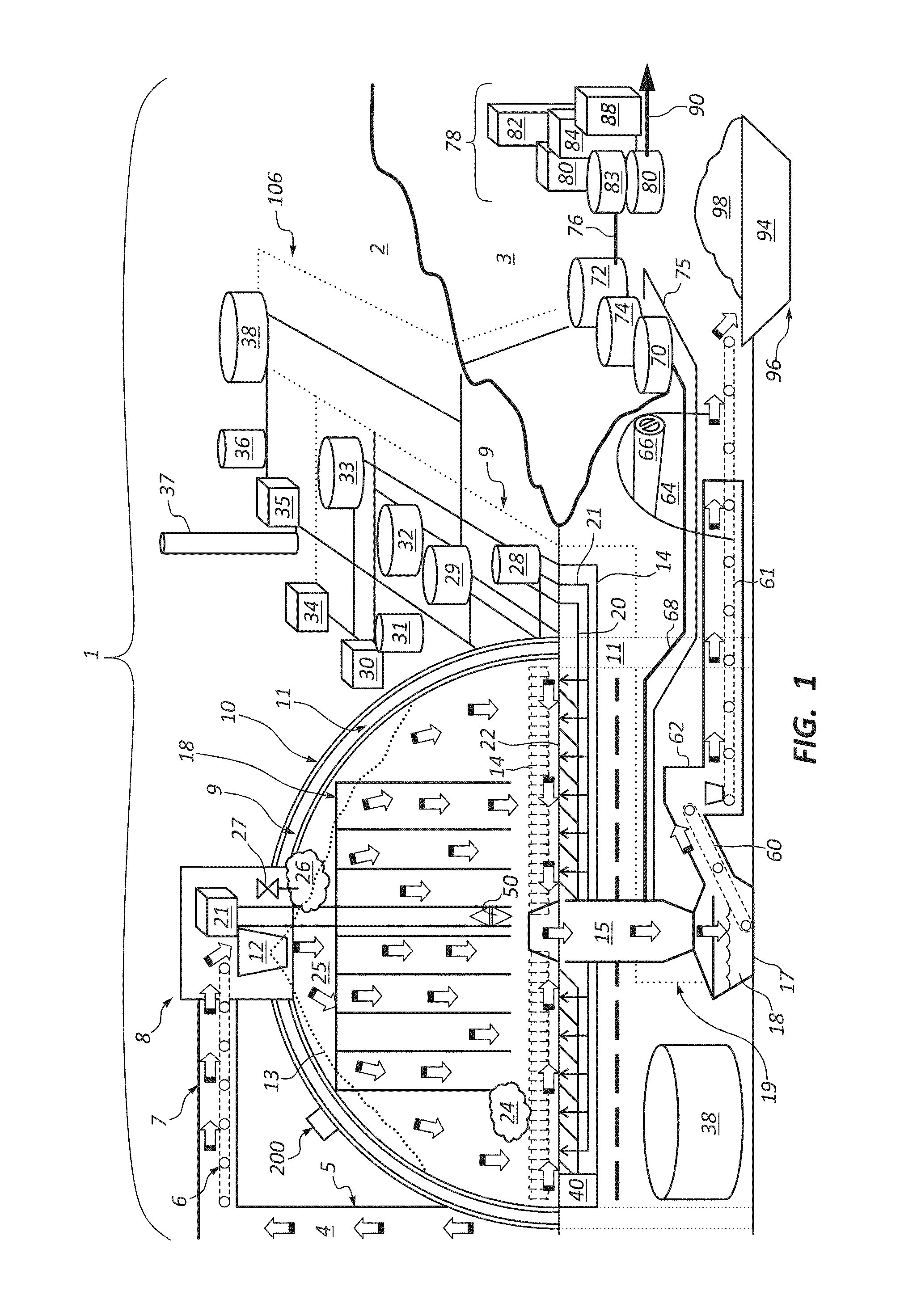

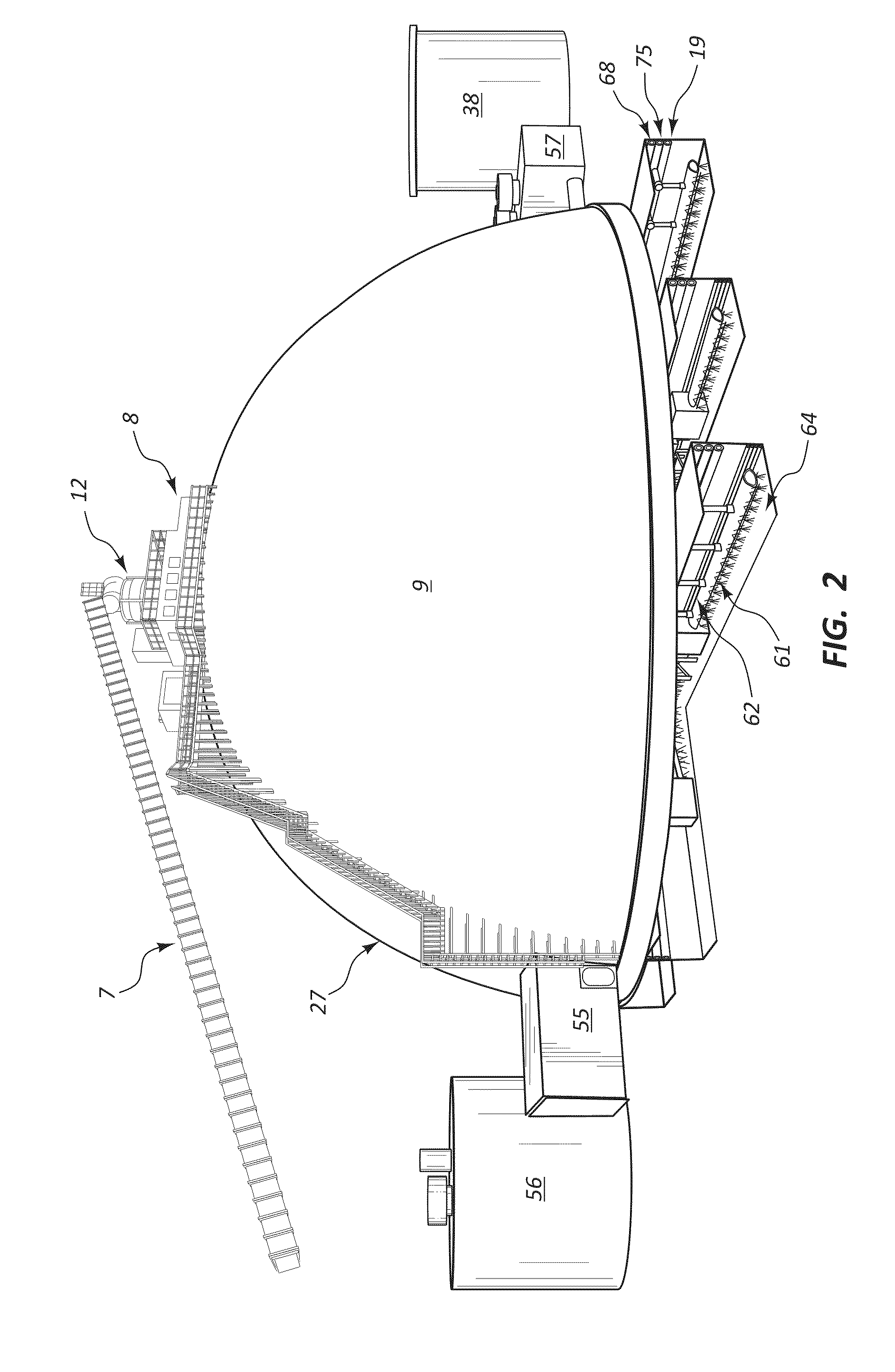

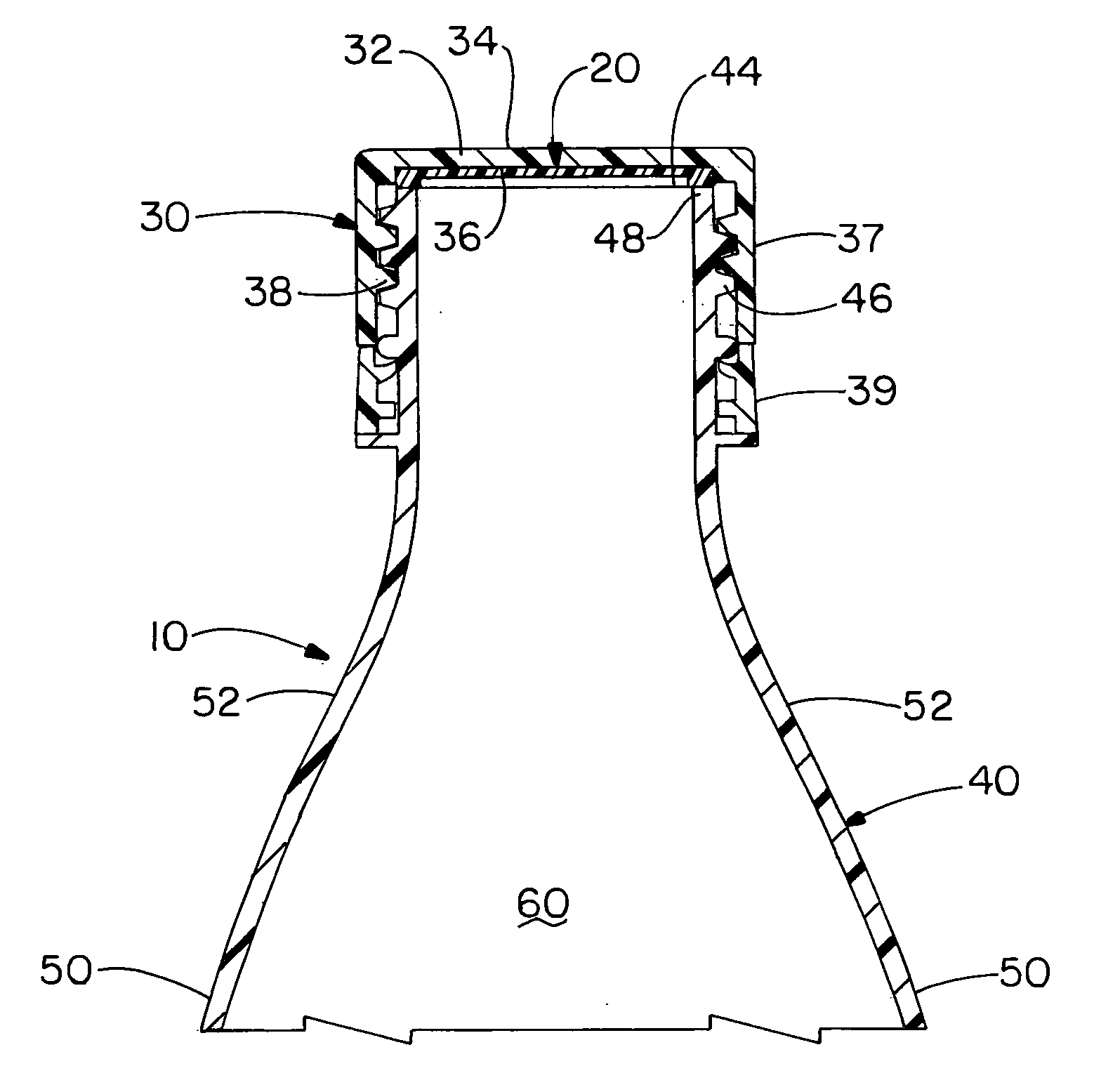

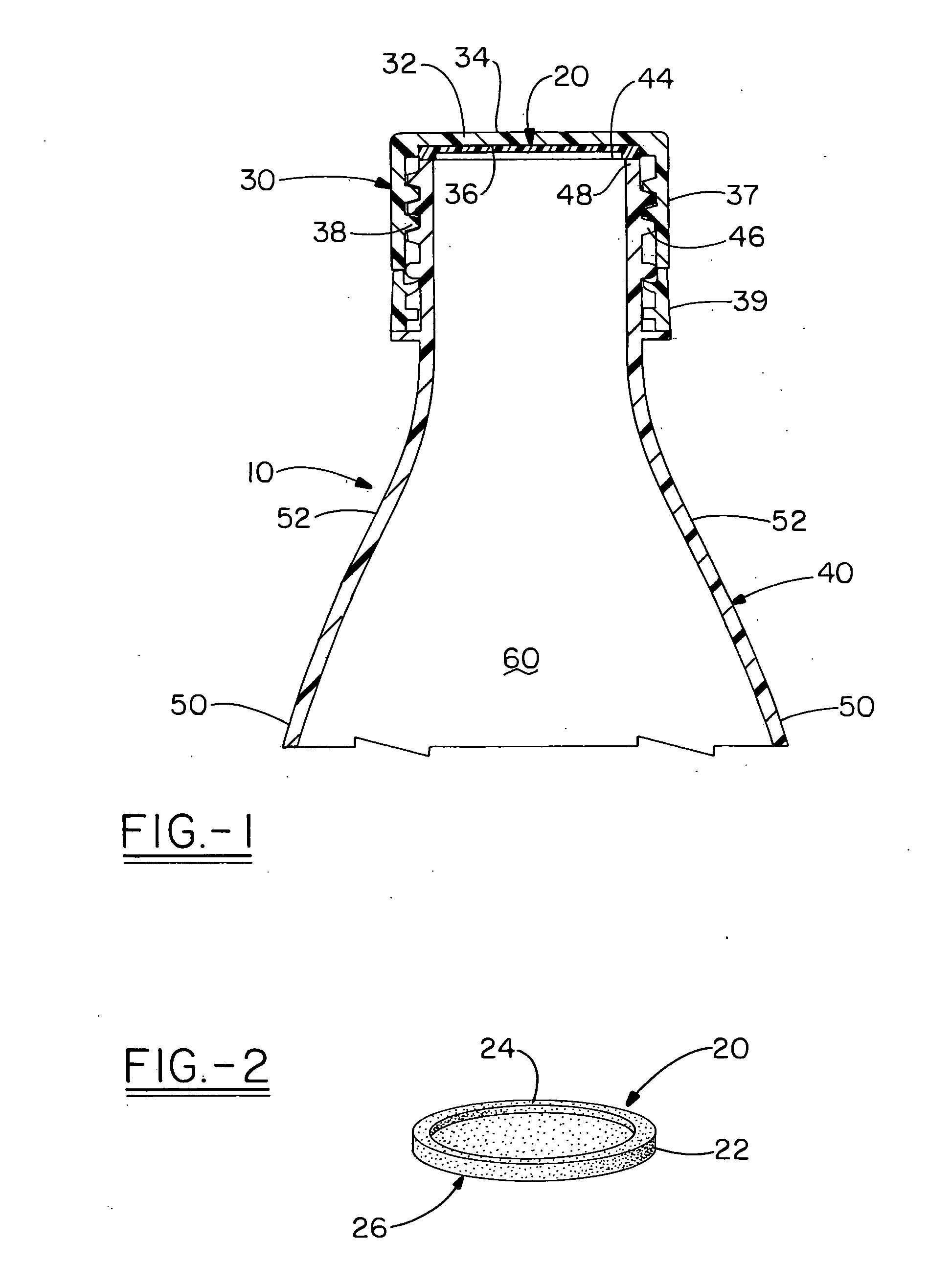

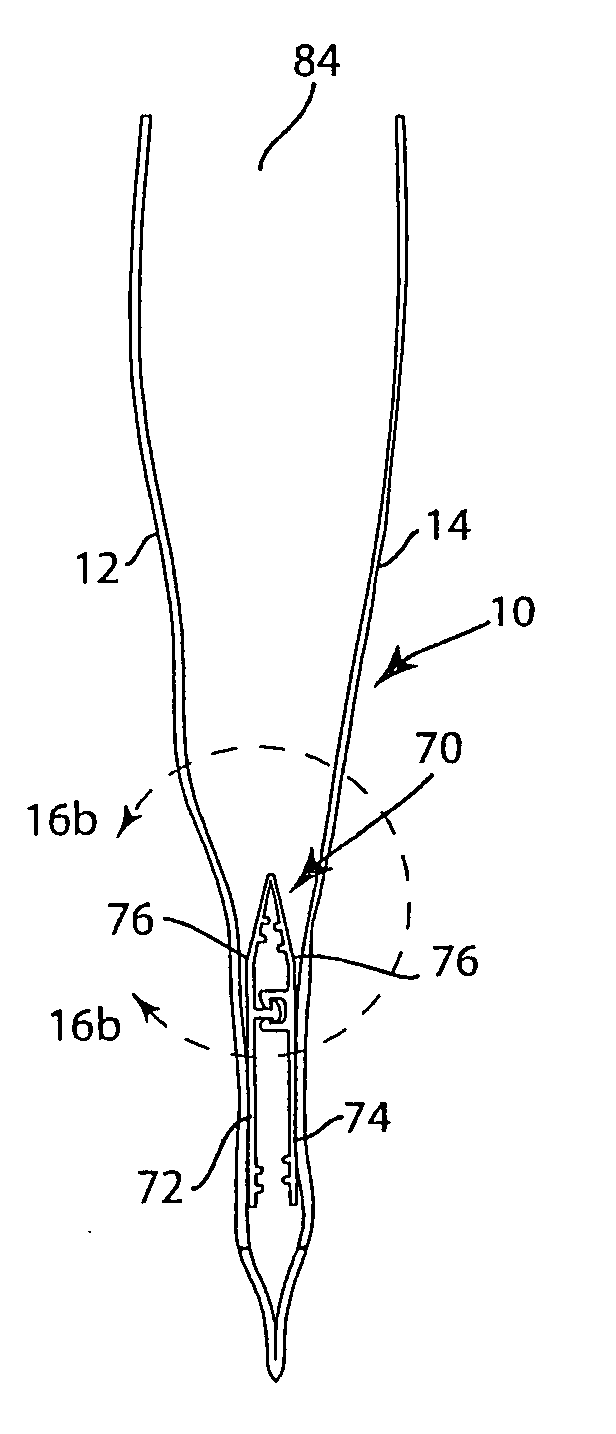

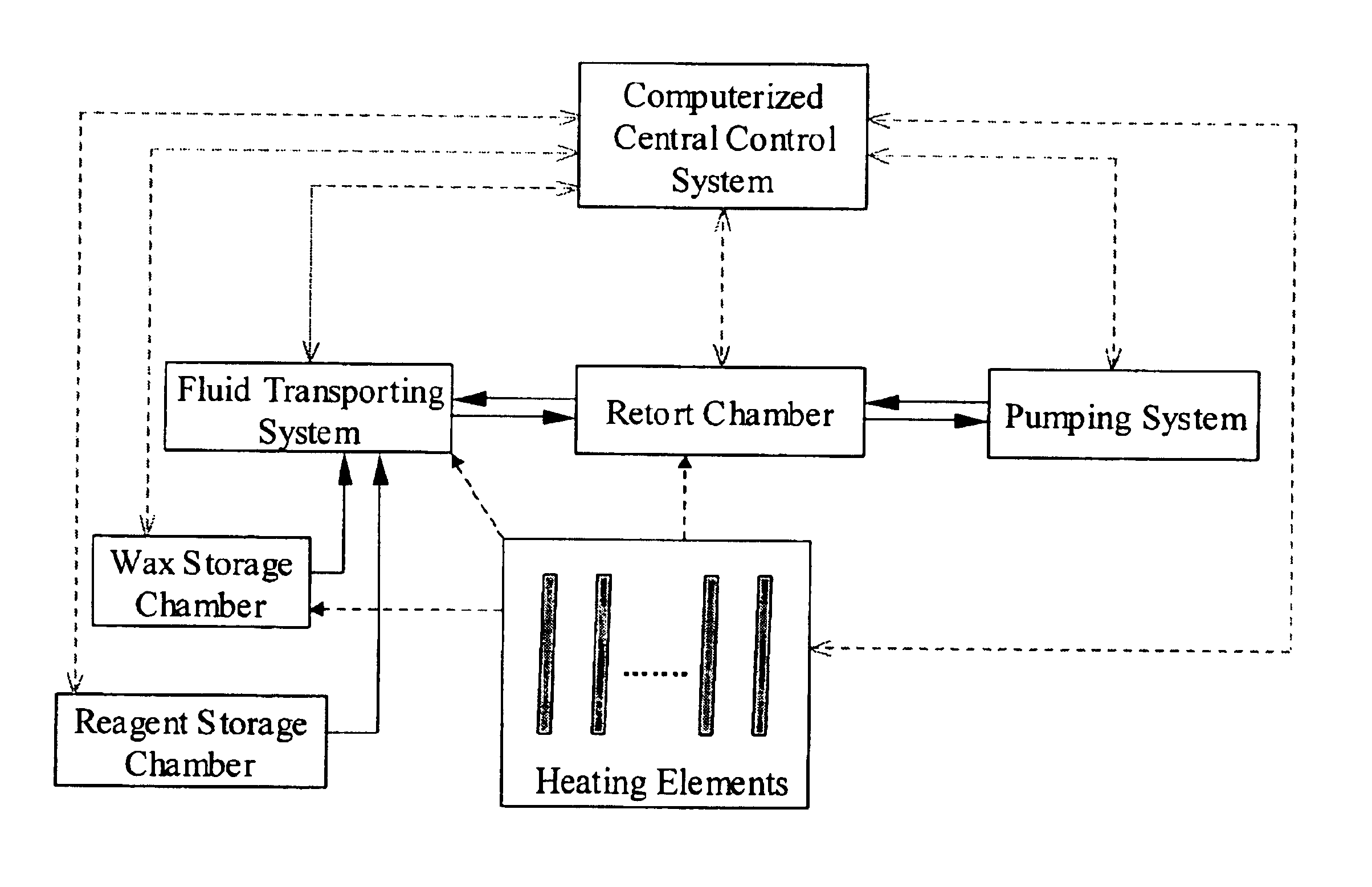

Systems, Apparatus and Methods of a Dome Retort

InactiveUS20110313218A1Increased material throughputLower cost of capitalPressurized chemical processDirect heating destructive distillationBasementControl system

A system, apparatus and method for hydrocarbon extraction from feedstock material that is or includes organic material, such as oil shale, coal, lignite, tar sands, animal waste and biomass. A retort system including at least one retort vessel may include a monolithic dome structure surrounded by a process isolation barrier, the dome structure being sealingly engaged with the process isolation barrier. The dome structure and the process isolation barrier define a retort chamber, at least a portion of which may comprise a subterranean chamber. A lower end of the dome retort structure provides an exit for collected hydrocarbons and spent feedstock material. Systems may include a plurality of such dome retort structures. A control system may be used for controlling one or more operating parameters of a retorting process performed within such a dome retort structure for extraction and collection of hydrocarbons.

Owner:DANA TODD C

Easily adhesive polyamide film

InactiveUS6352762B1High bonding strengthStrong adhesionLiquid surface applicatorsFilm/foil adhesivesWater basedPolyamide

An easily adhesive polyamide film has been created from unstretched or uniaxially stretched non-heated polyamide film coated with a water-base coating mixture, whose main constituents are (A) water polyurethane resin containing acetylene glycol in which each carbon atom immediately adjacent to the triple-bonded carbon atom is replaced with a hydroxyl group and a methyl group, and / or an ethylene oxide addition product of the acetylene glycol; (B) a water-soluble polyepoxy compound; and (C) particles with an average diameter between 0.001 and 1.0 mum, of which the solid-content weight ratio is 98-30 / 2-70 / 0.1-10, the coating amount after stretching is between 0.005 and 0.030 g / m2, and the film is stretched in at least one direction and then heated. This newly invented film possesses good blocking resistance and excellent adhesiveness with print ink, laminate, and other coating mixtures, and is especially suitable for boiling sterilization, retort sterilization, and packaging of liquids.

Owner:KOHJIN CO LTD

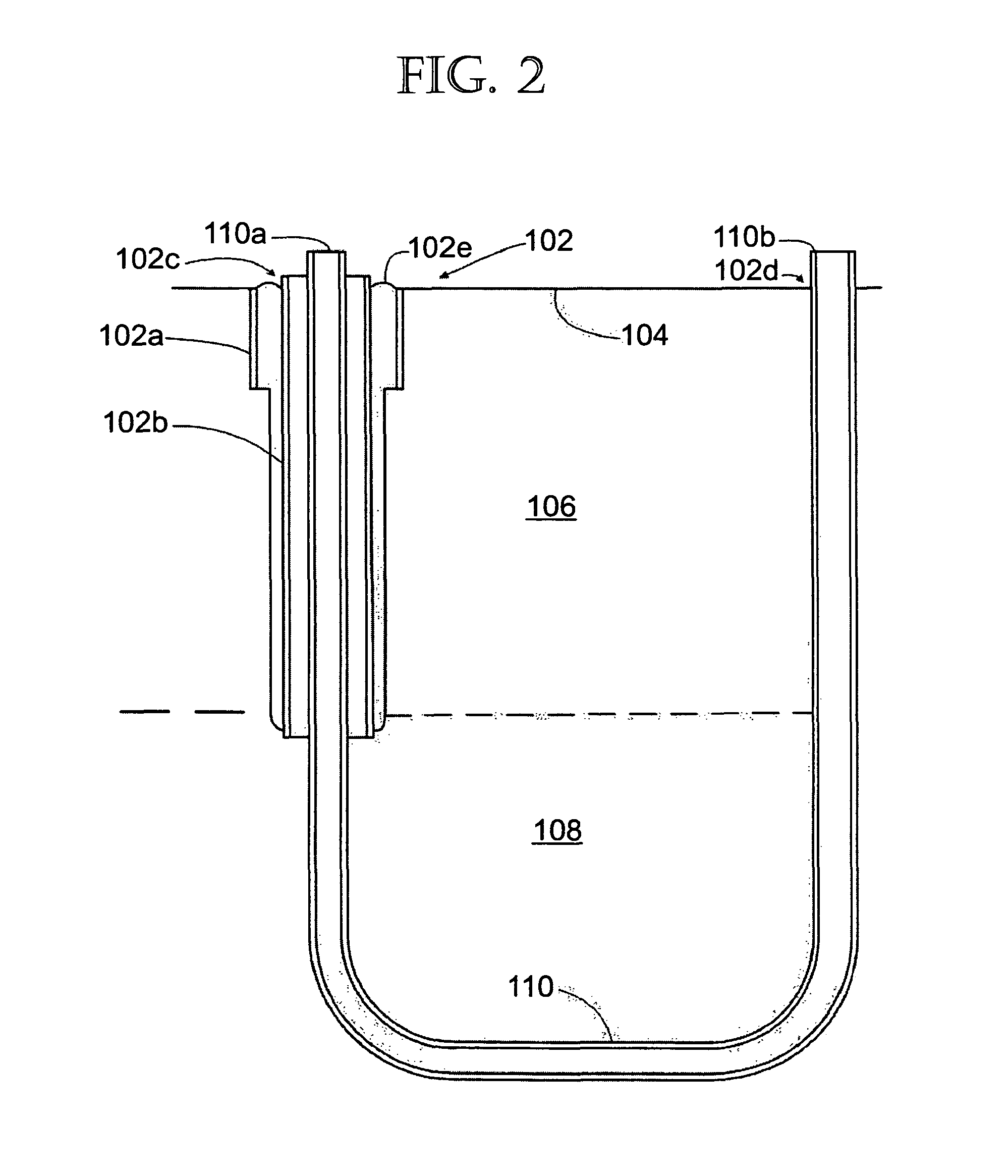

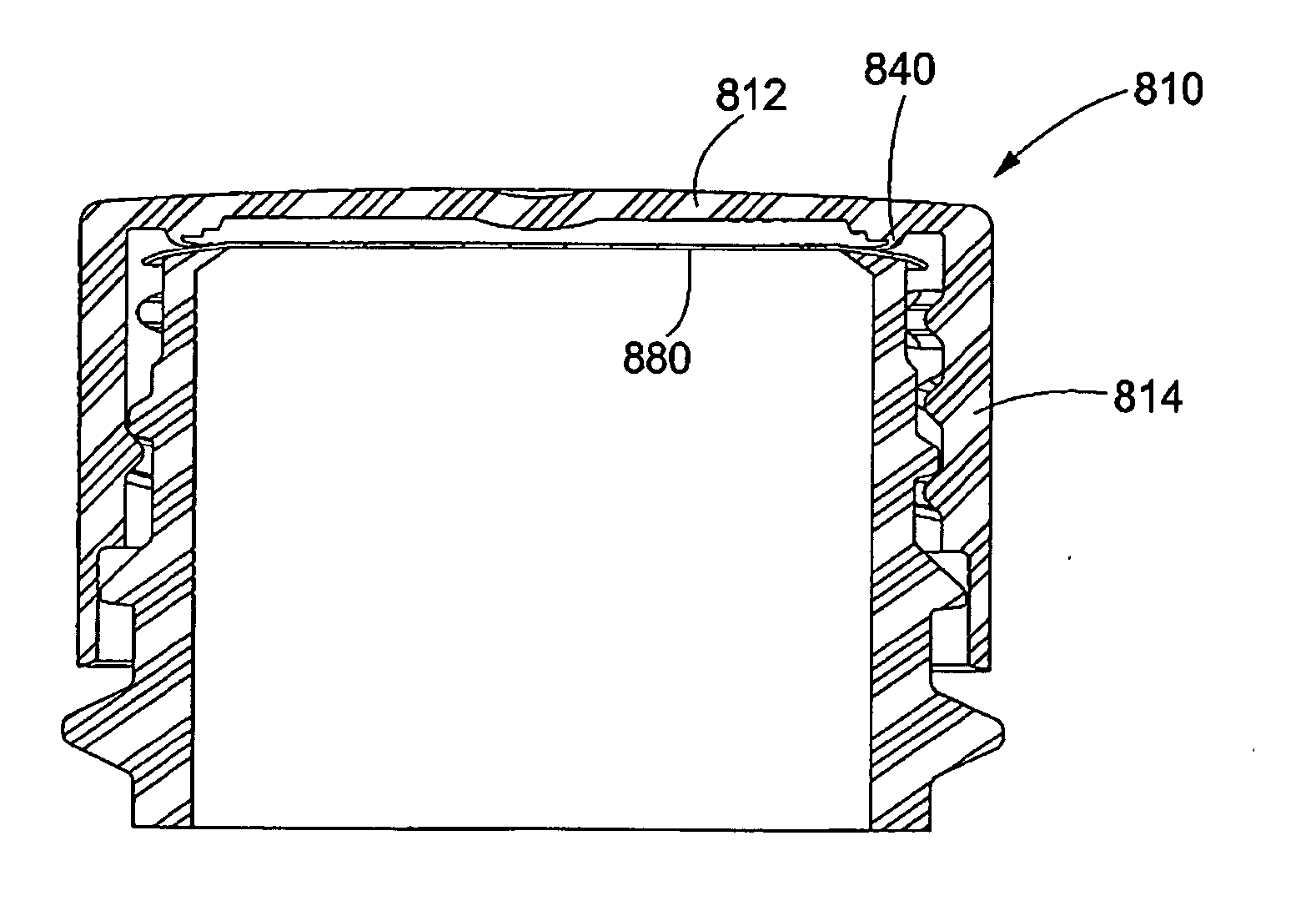

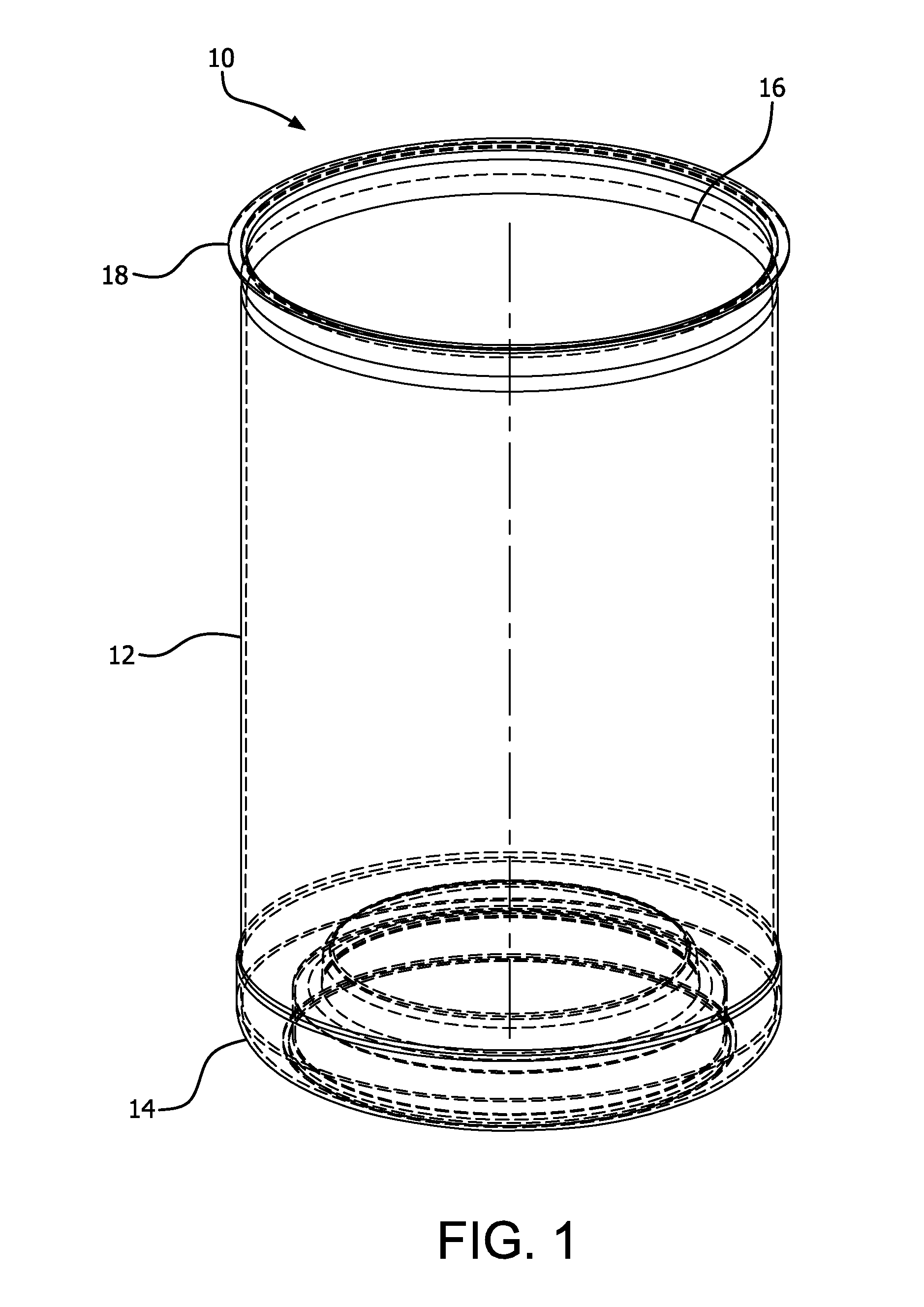

Retortable liners and containers

ActiveUS20100006532A1Improve sealingPrevent leakageSynthetic resin layered productsSealingPolyolefinPlastic packaging

Retort liners and containers including a container body such as a bottle or jar, a closure, and the retort liner, wherein the retort liners exhibit attractive properties such as low compression set under retort conditions, desirable adhesion to a polymeric closure such as a cap or lid, and beneficial oxygen barrier properties. In particular, the retort liners are thermoplastic elastomers formed from compositions including one or more styrenic block copolymers, one or more polyolefins and a softener. In a preferred embodiment, the retortable containers are all plastic packages, wherein the bottle or jar and the closure are thermoplastic compositions and the liner is a thermoplastic elastomer composition.

Owner:TEKNOR APEX

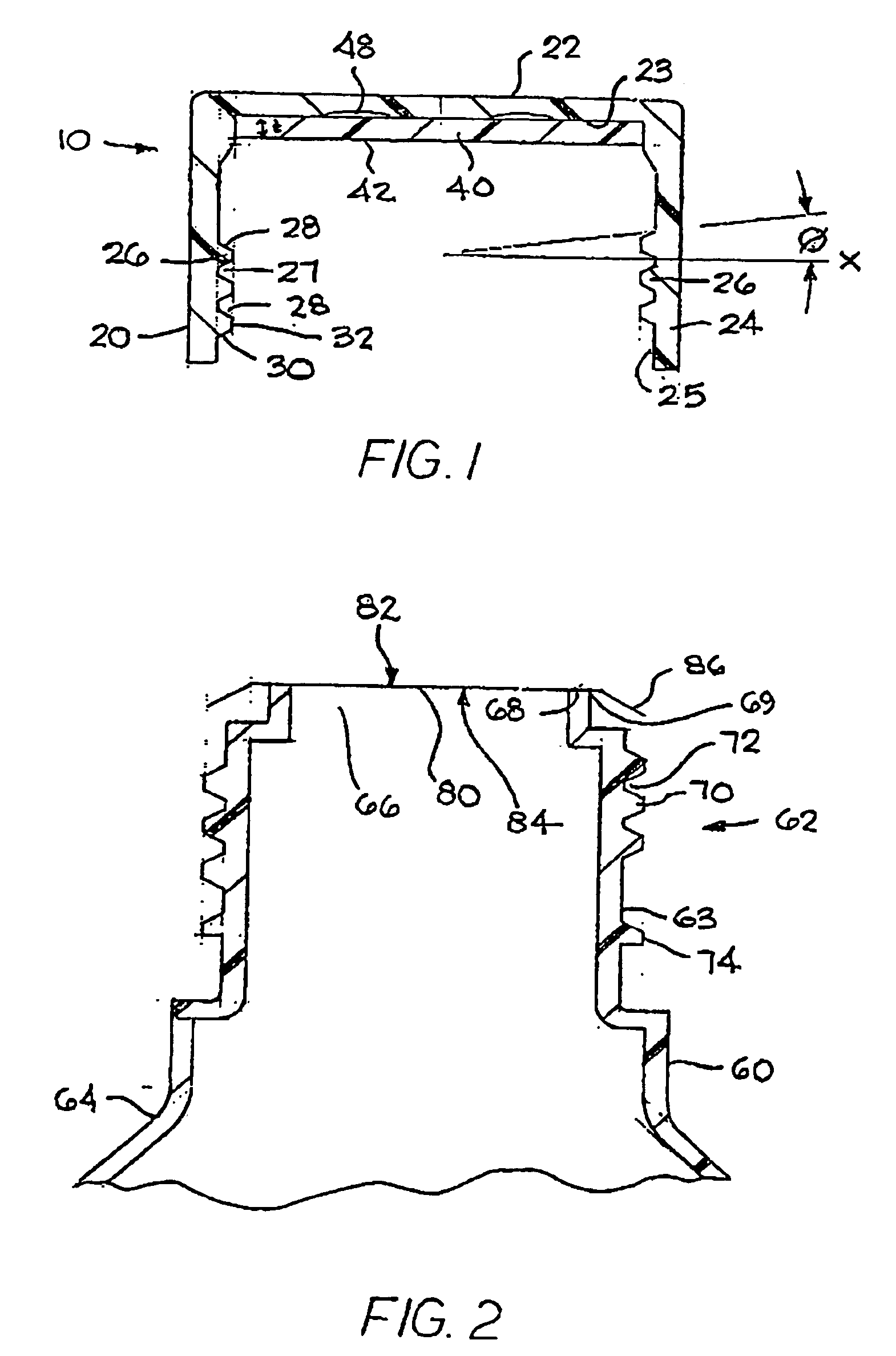

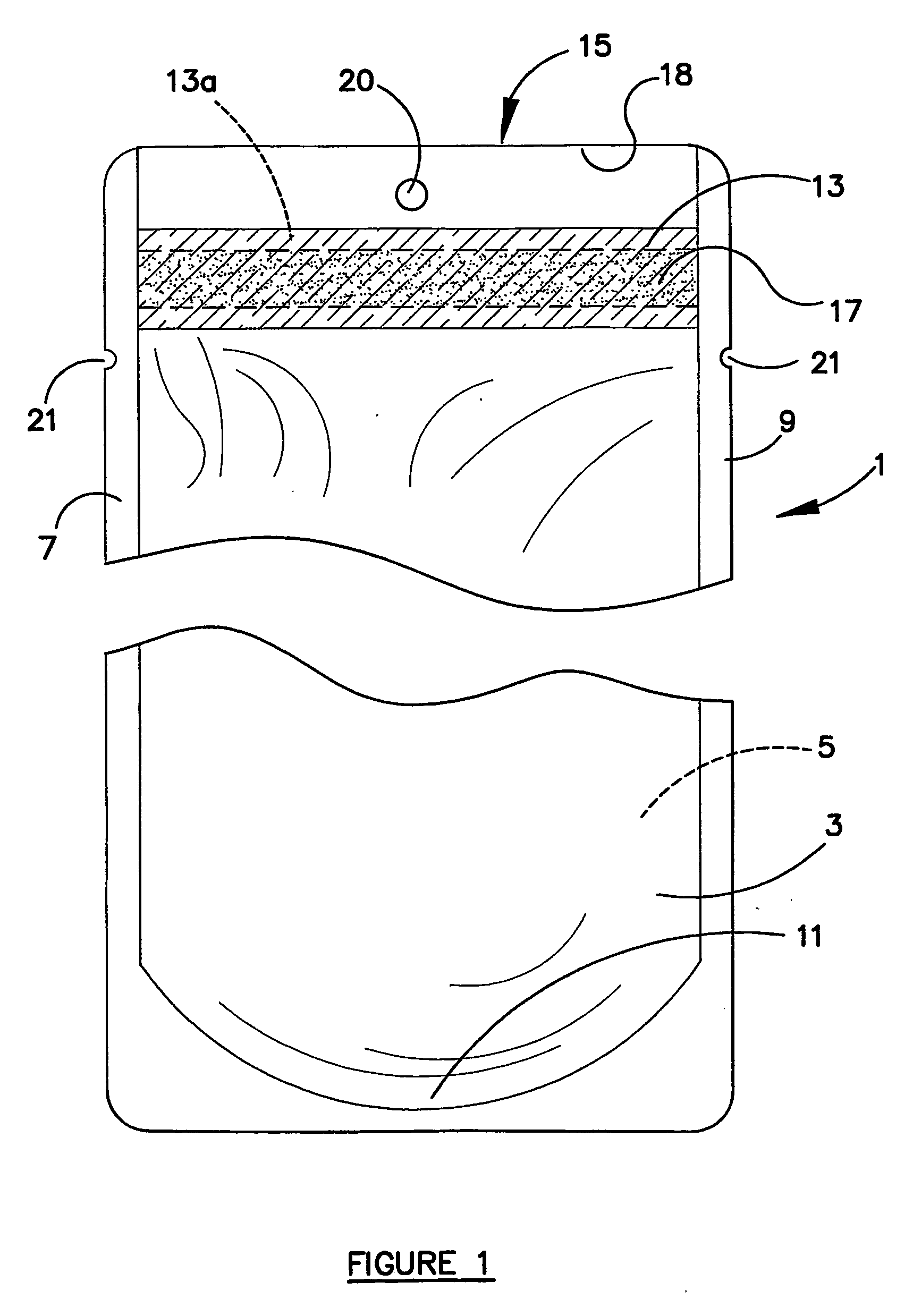

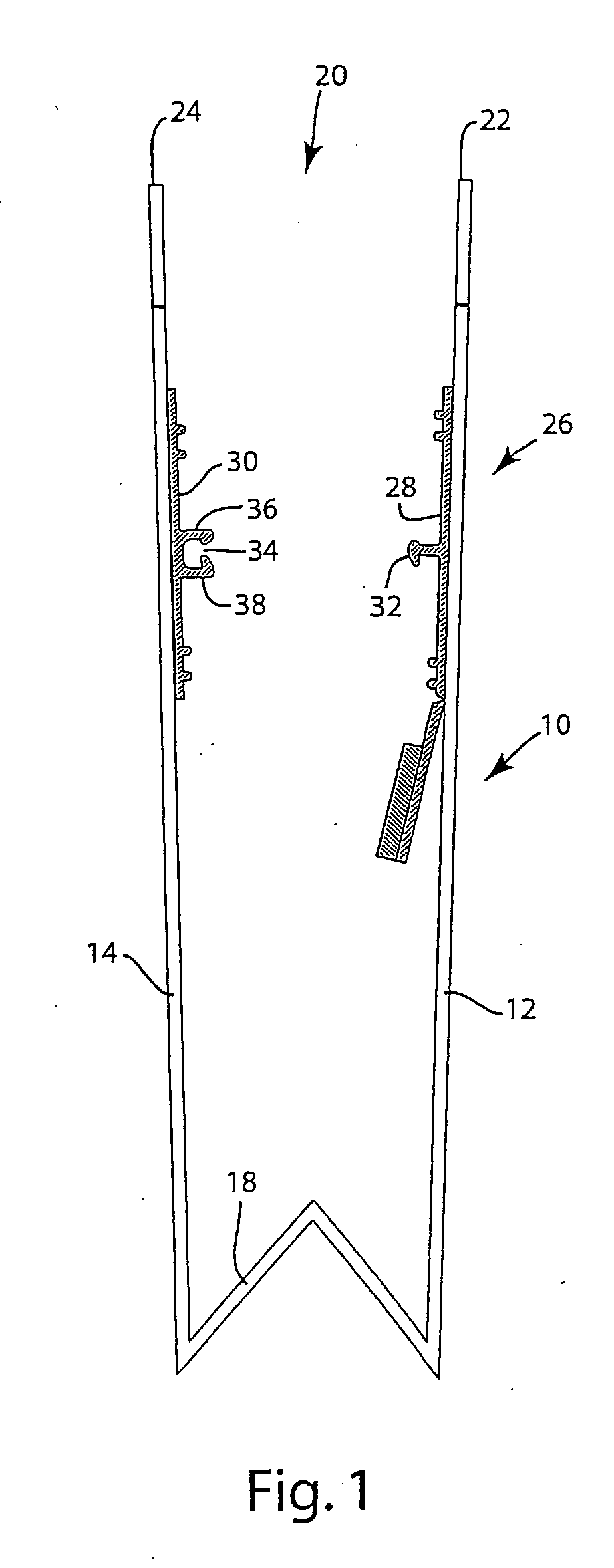

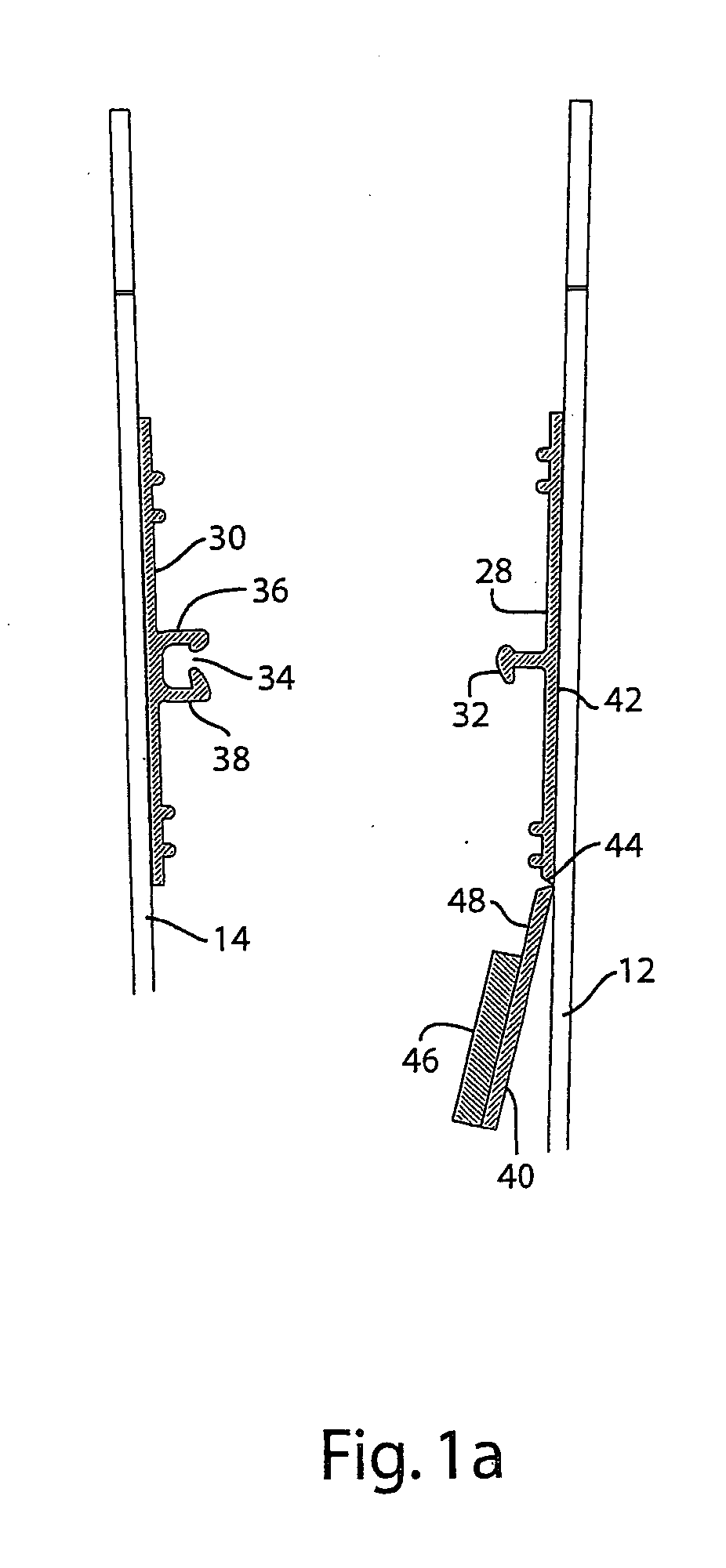

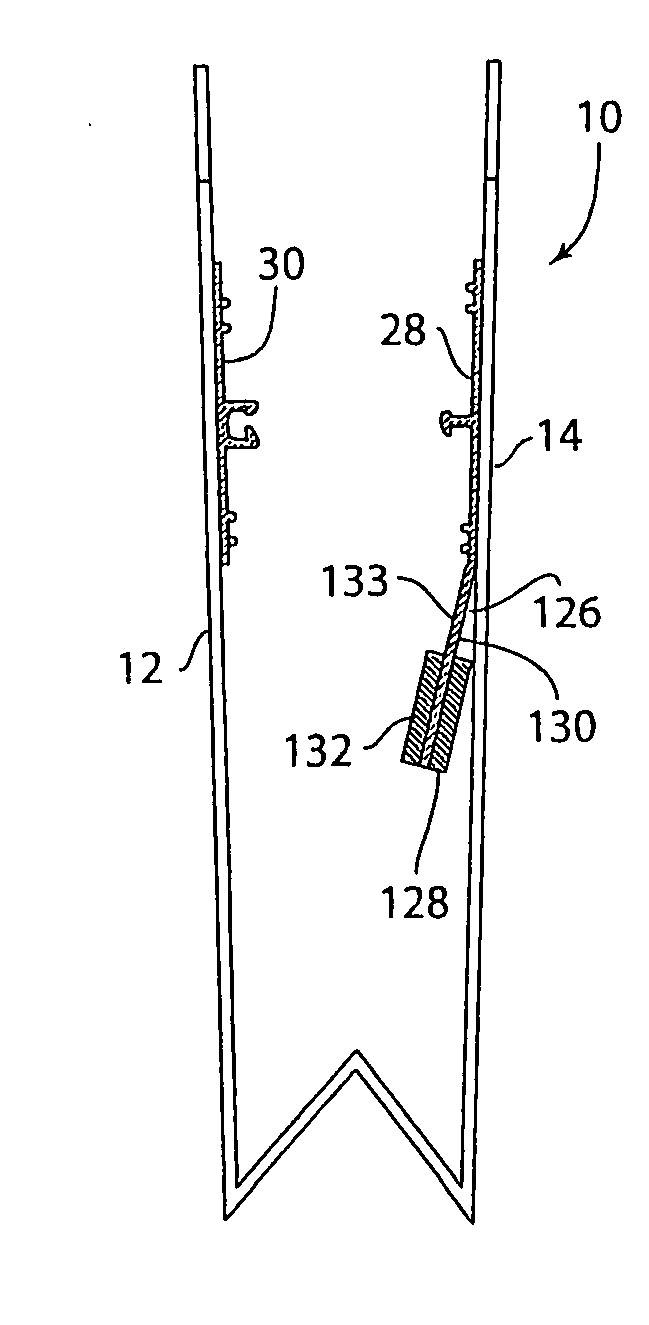

Autoclavable reclosable package

A reclosable package that seals an enclosed product and allows the product to be subjected to a retort procedure to cook the product while the product is in the package. The reclosable package is formed from a polypropylene film and includes a zipper closure including a pair of mating closure profiles both formed from a polypropylene material. One of the male or female closure profiles includes a sealing flange having a layer of sealant such that the sealing flange provides a seal for the package below the interaction between the closure profiles. This seal prevents the product from migrating through the profile member during the retort procedure and prior to the package being opened for the first time.

Owner:REYNOLDS CONSUMER PROD INC

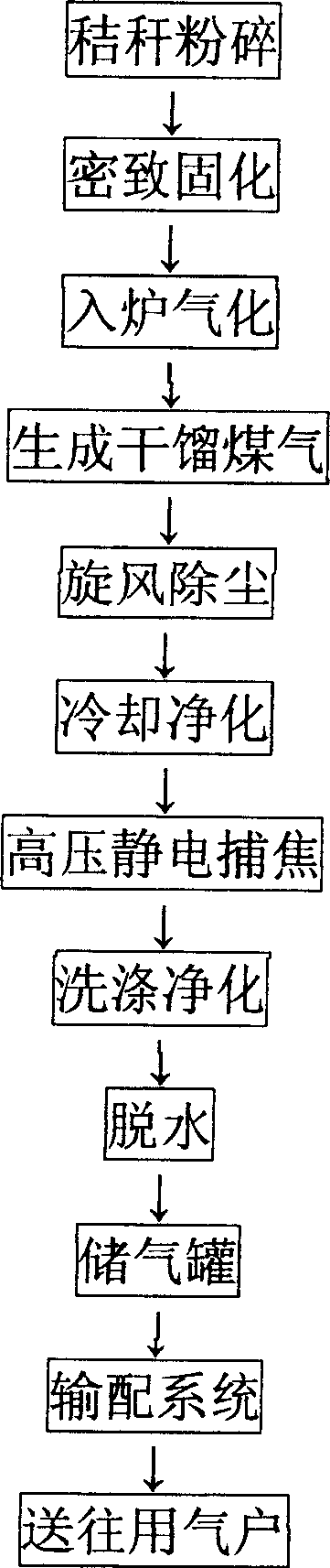

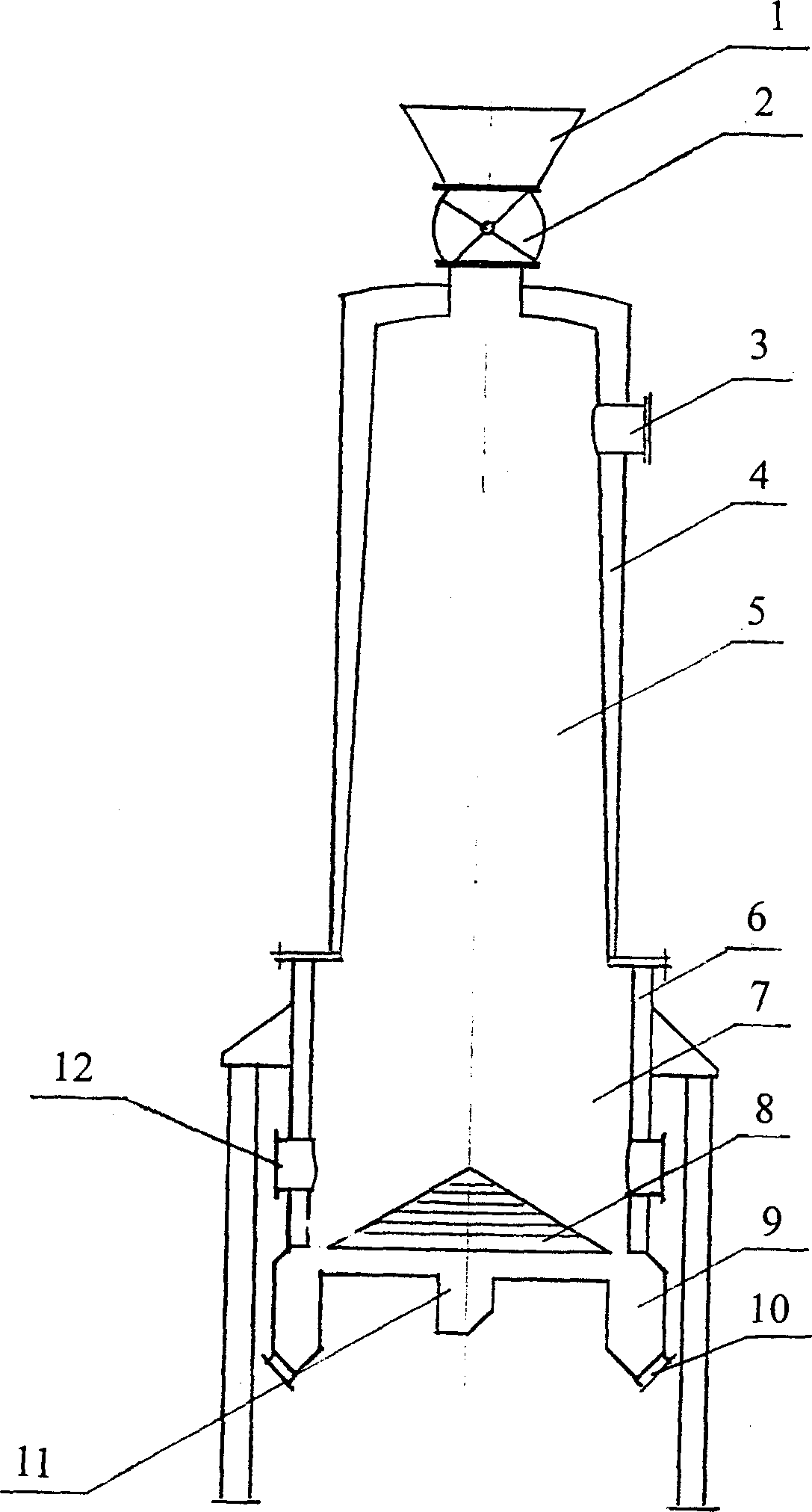

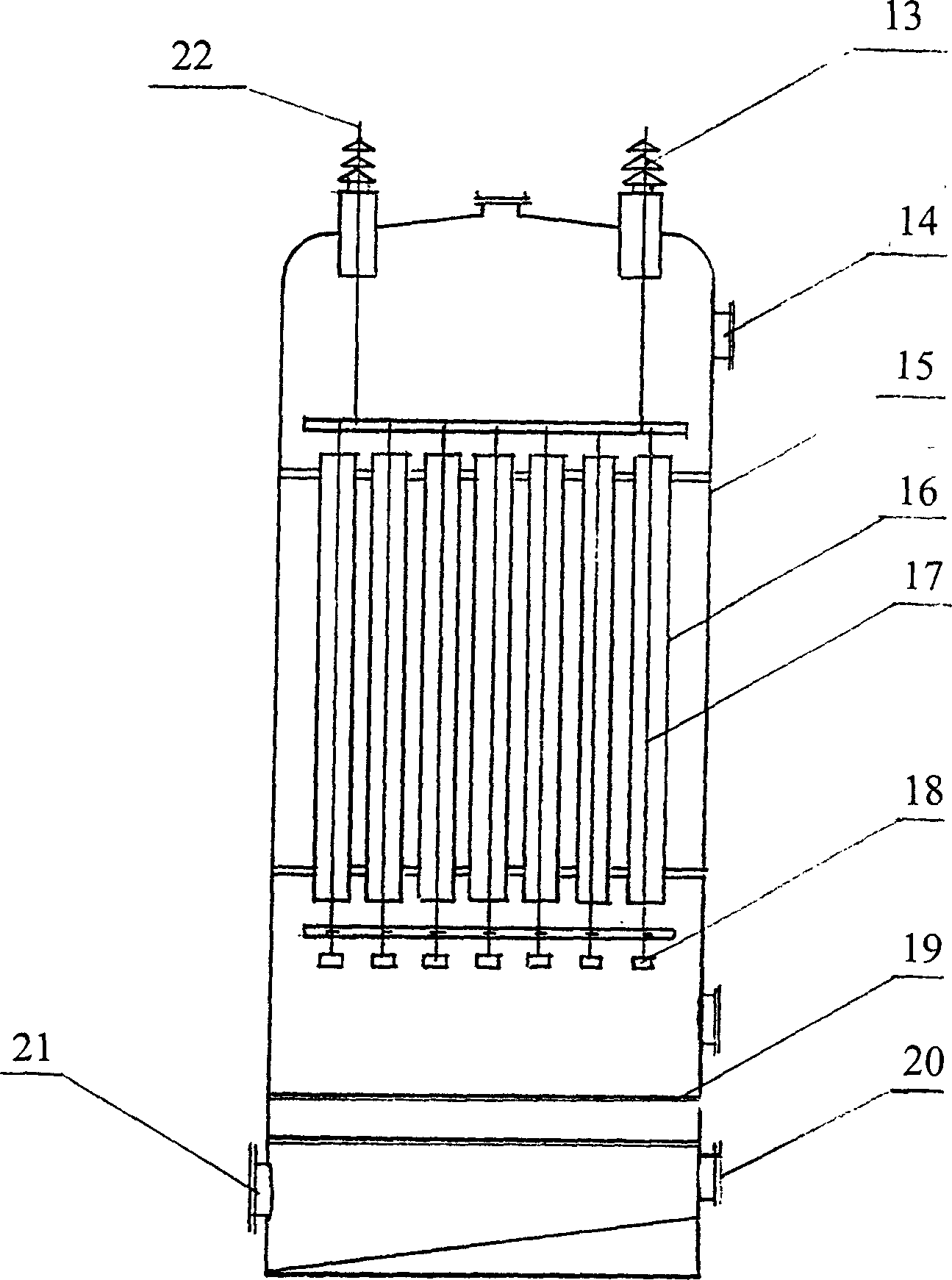

Biomass pyrogenation gasification and purification method

InactiveCN1730609AHigh calorific valueHigh hydrogen contentBiofuelsCombustible gas purificationCyclonePurification methods

The invention provides a biological mass thermal decomposition, gasification and purification method which comprises, disintegrating the biological mass, gasifying in a furnace, obtaining retort gas, cyclone dedusting, cooling down and purifying, high voltage static coke trapping, making the coke tar bubbles and dust in the coal gas deposit onto the coke collection poles, thus purifying the coal gas, finally washing and dewatering.

Owner:MIANYANG TONGMEI ENERGY SCI & TECH CO LTD

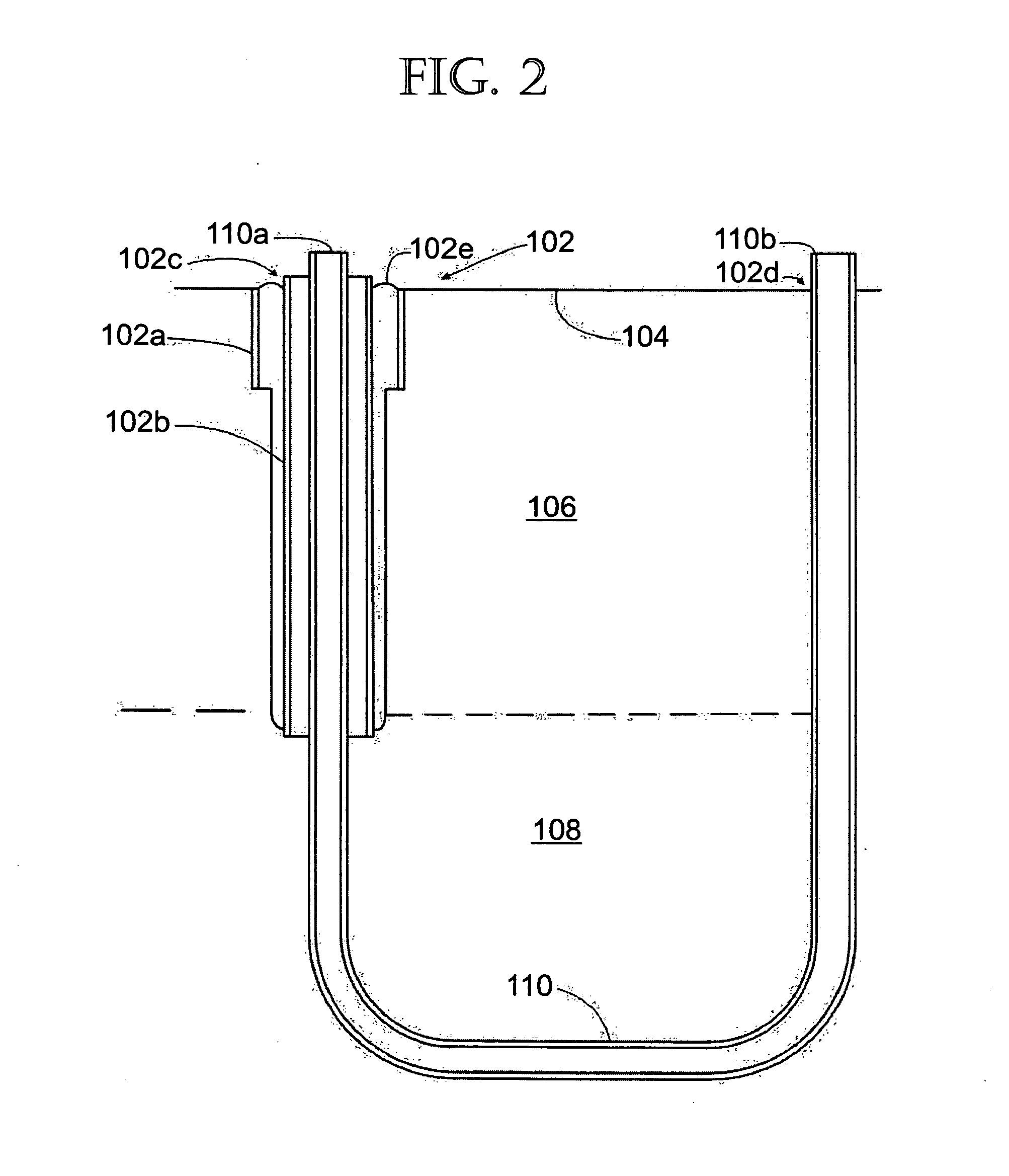

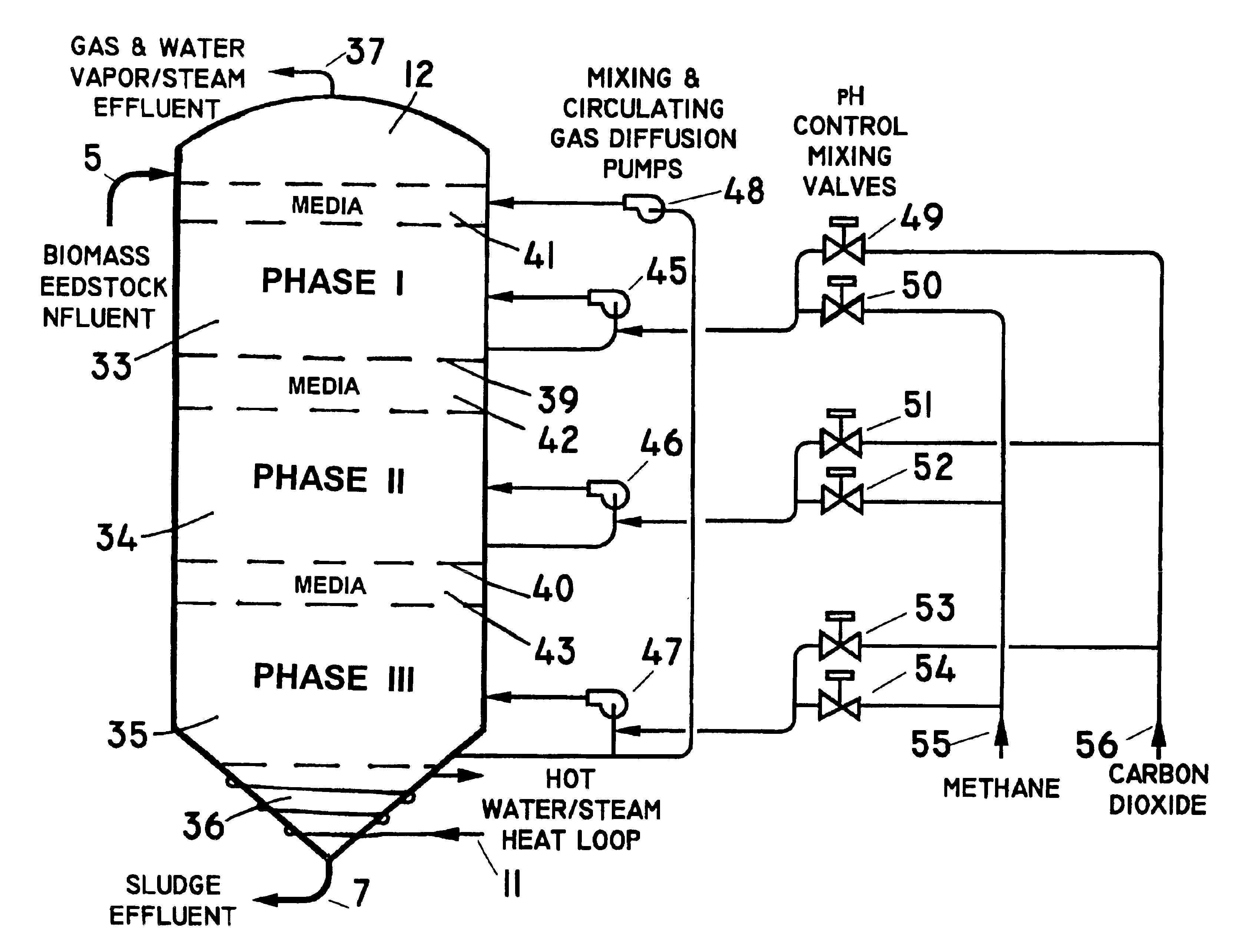

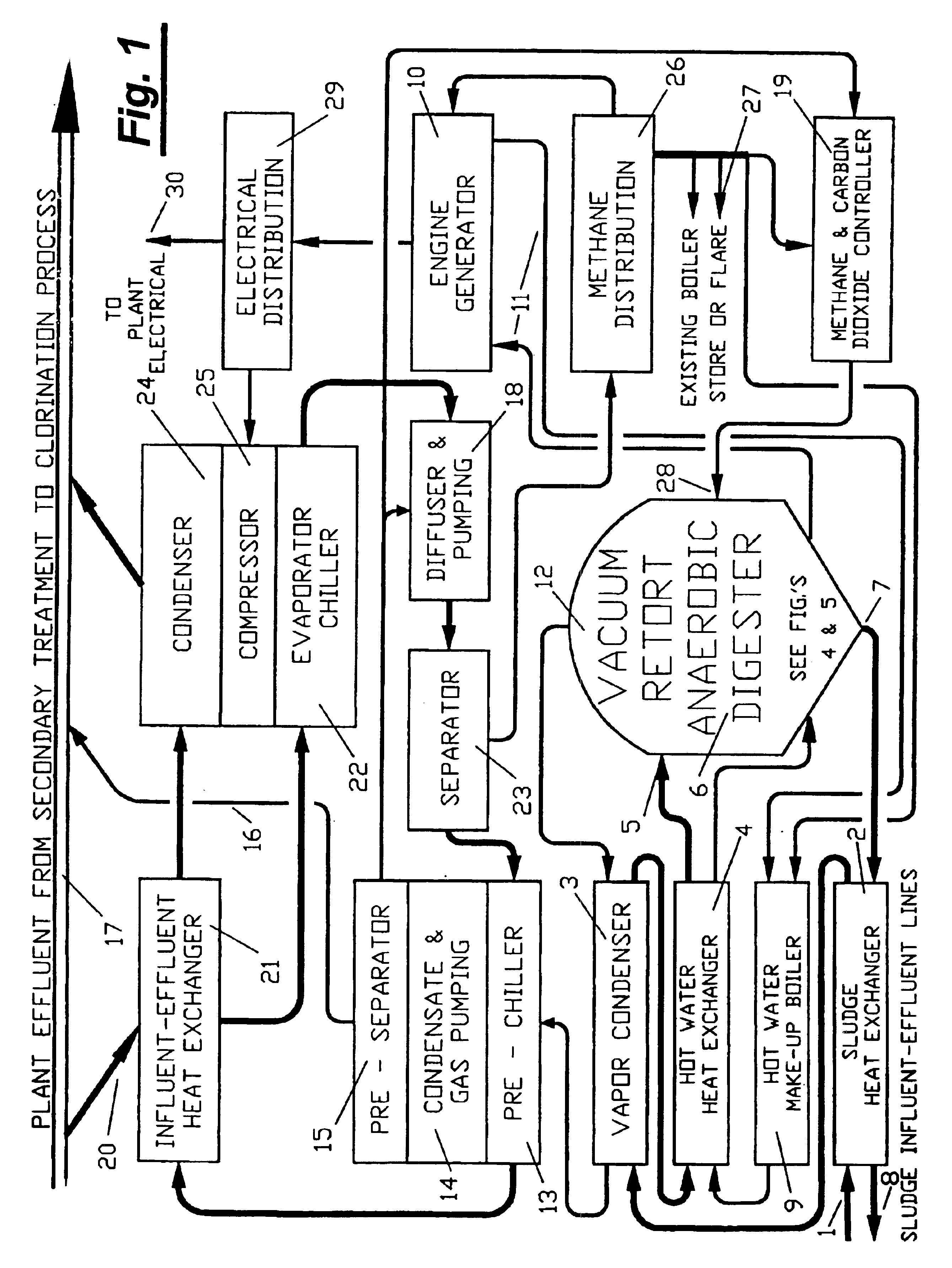

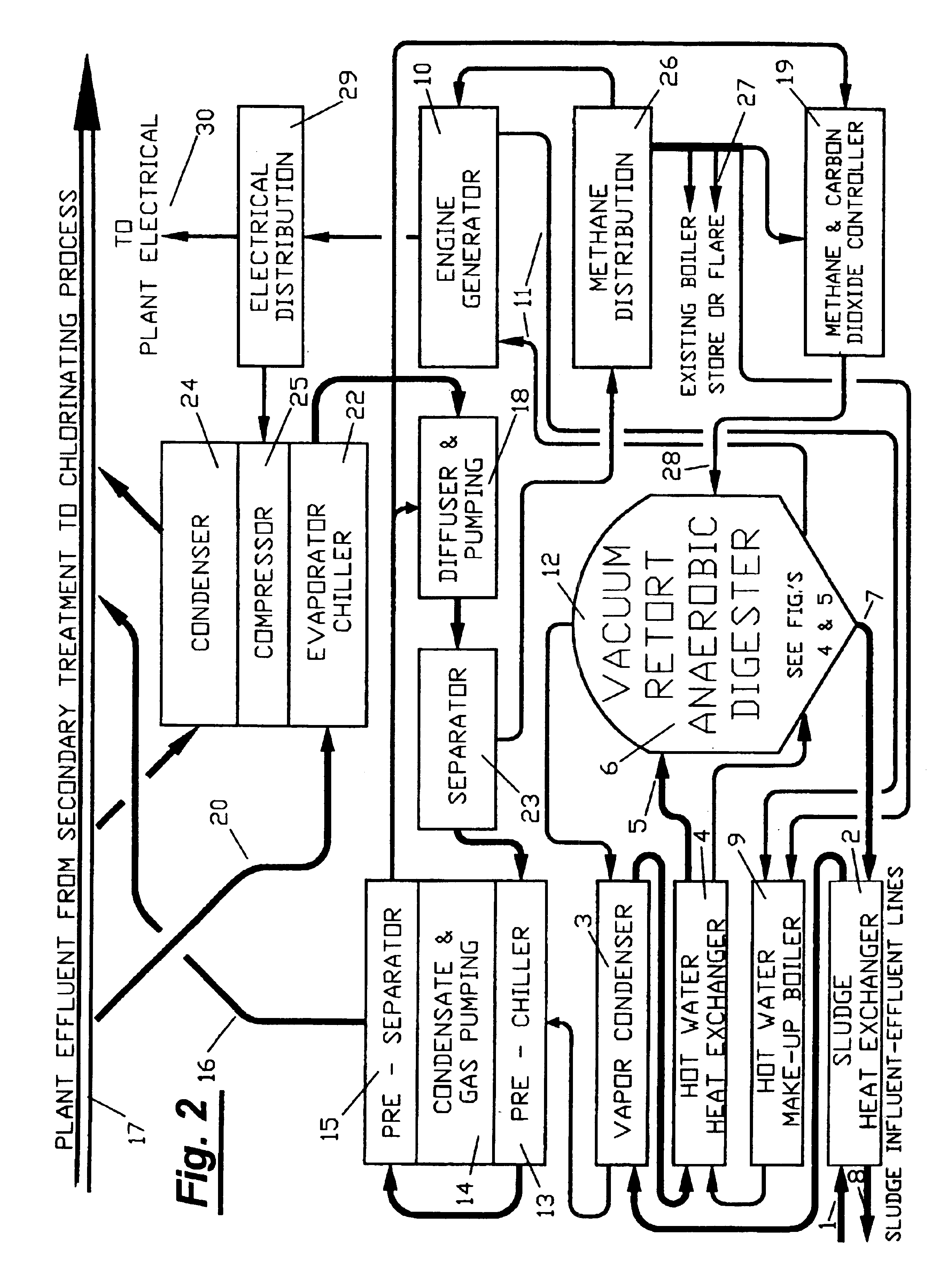

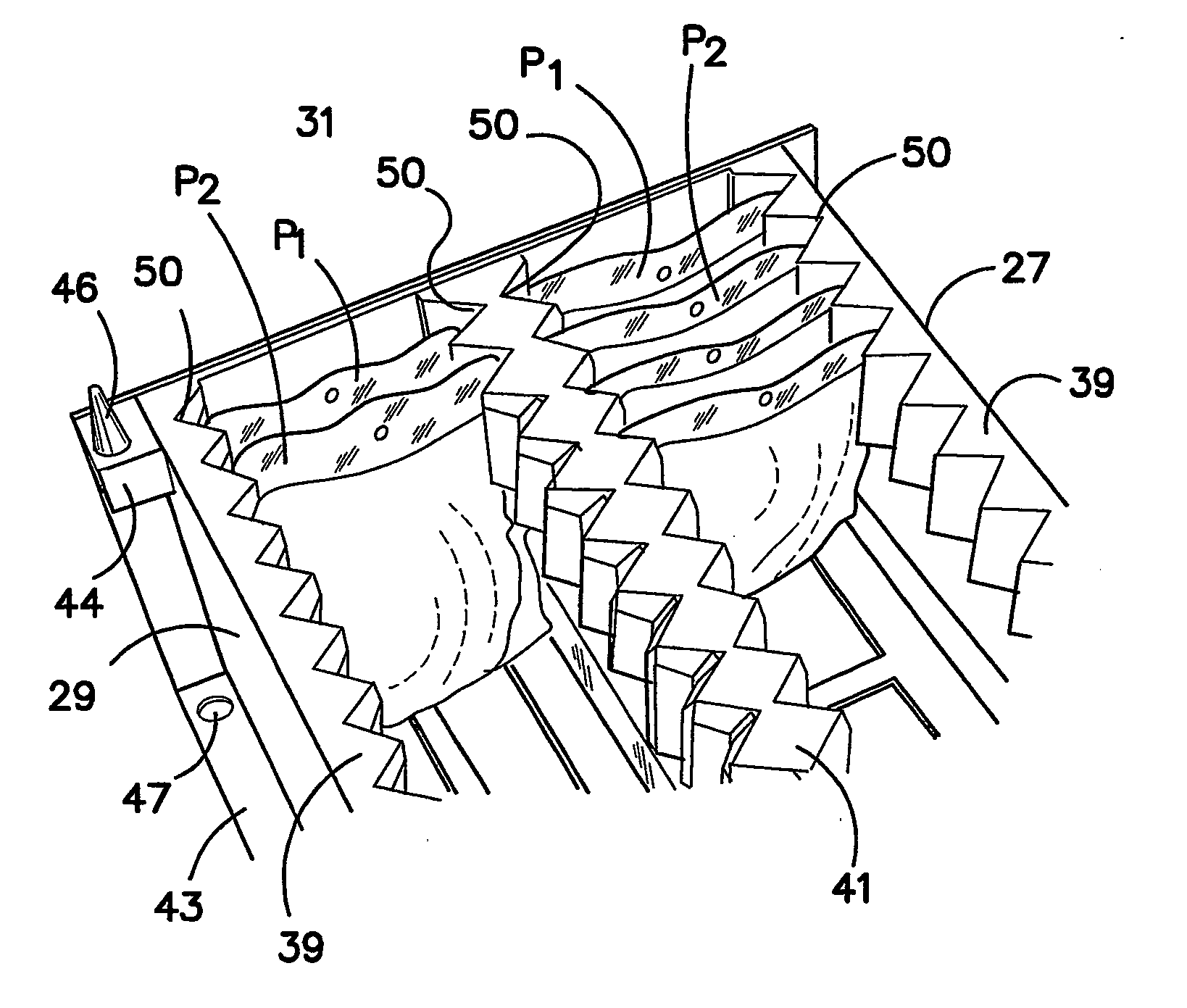

Vacuum retort anaerobic digestion system and process

InactiveUS6942798B2Environmental pollutionWaste based fuelTreatment with anaerobic digestion processesVacuum pressurePulp and paper industry

Anaerobic digestion system and process in which a liquor containing a digestible biomass is processed a retort vessel at a thermophilic temperature and with a vacuum pressure at the surface of the liquor. A pressurized feedstock is introduced into the vessel so that the feedstock impacts upon the surface of the liquor in a manner which serves to break up any scum on the surface and produce a mixing of the liquor.

Owner:MILLER III HERMAN P

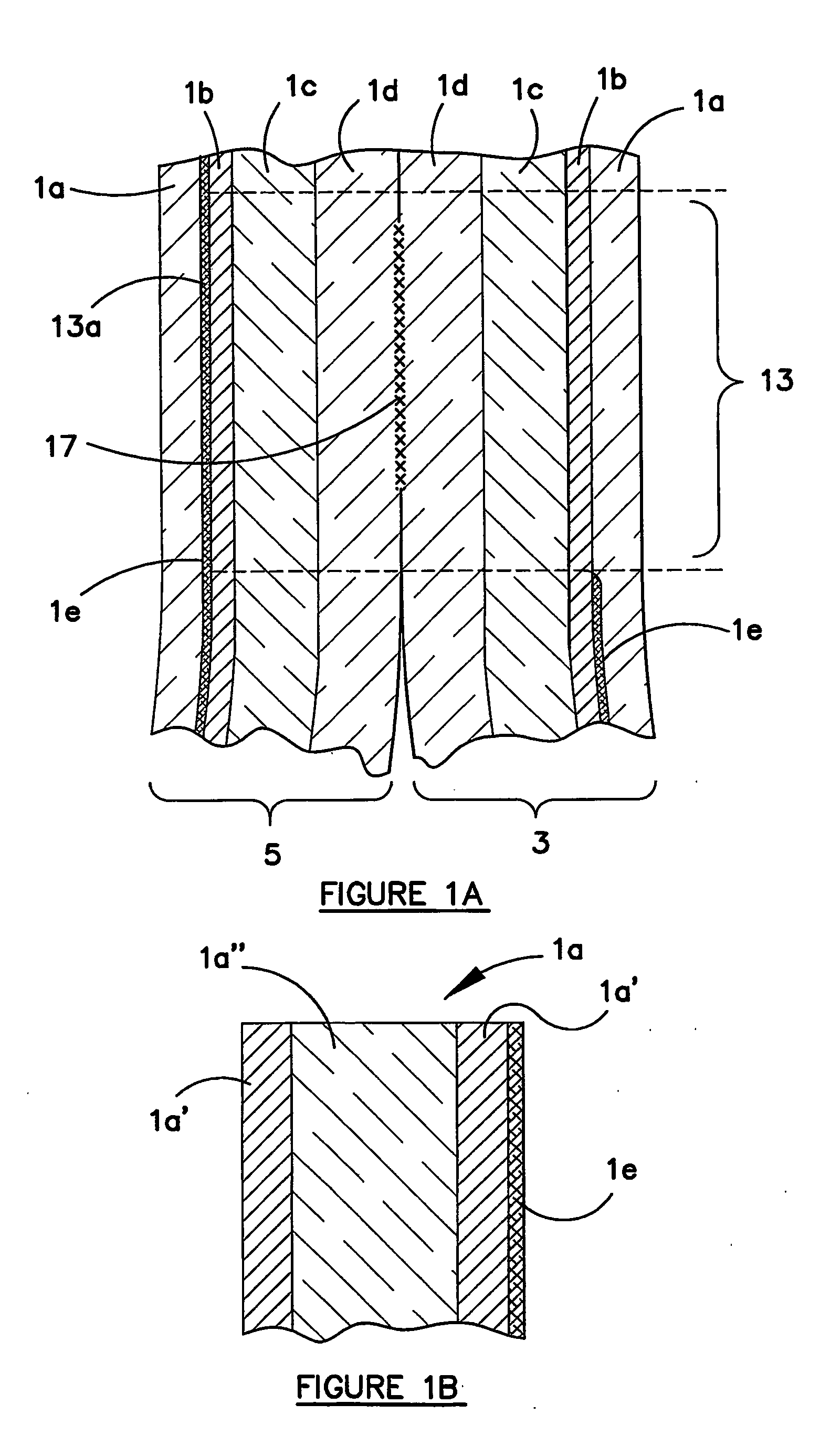

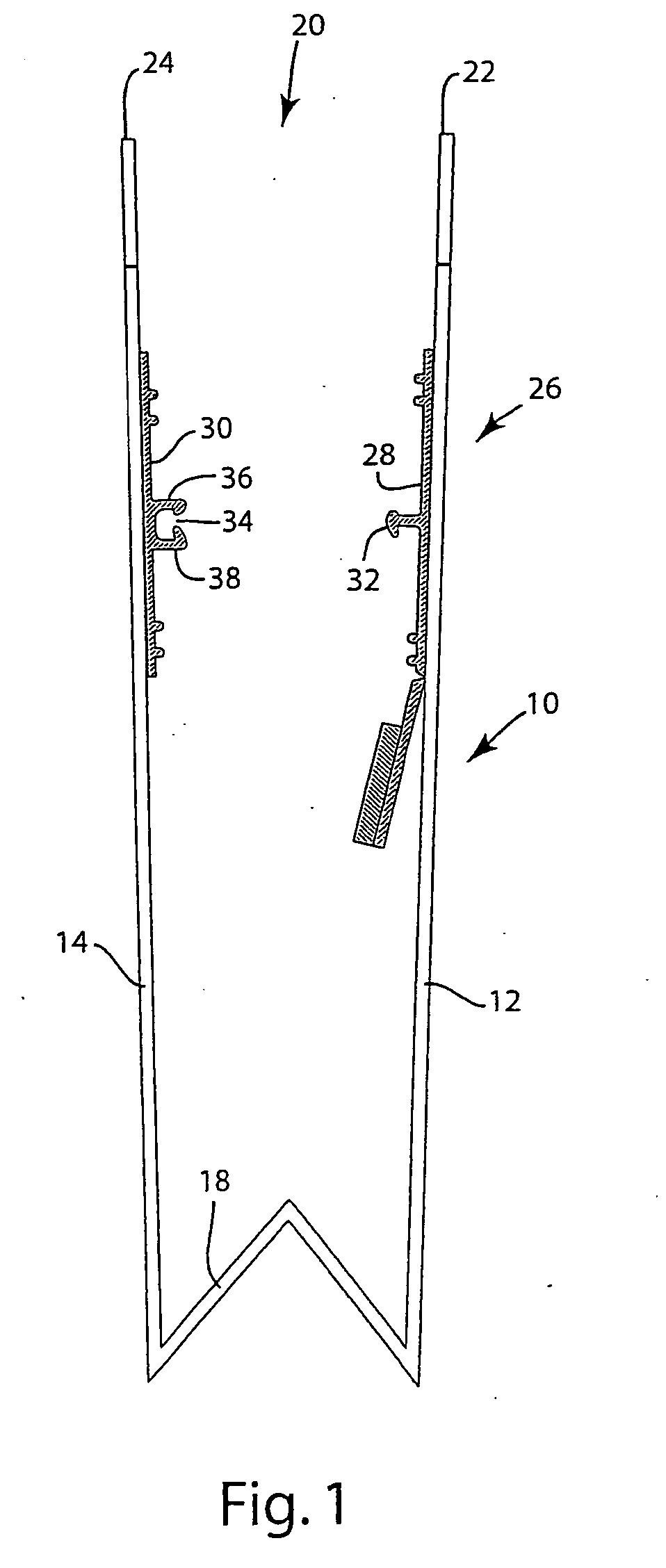

Flexible pouch filling and heat sealing line for flexible pouches and containers for supporting and moving the flexible pouches

InactiveUS20060048486A1Good light transmissionImprove sealingSolid materialPackaging foodstuffsUltraviolet lightsEngineering

A flexible pouch is provided which has panels (3, 5). A transparent strip (13) is provided on one of the panels and a translucent filter (13a) on the other. The panels are heat sealed together to close the pouch and the integrity of the heat seal is determined by shining ultraviolet light through the clear strip and inspecting the translucent filter (13a) so that imperfections in the seal can be identified. Pouches are packaged into containers (25) which include slots (50) and the full containers are stacked for transport through the plant for further processing in a retort, cooler or the like. This enables a large number of pouches to be easily transported through the plant for further processing after they have been filled and heat sealed. The heat sealing line may include a vision system, or the vision system may be a stand-alone item for inspecting the seal to determine the integrity of the seal. The vision system includes a UV light source for directing UV light through the transparent strip and a camera for inspecting the translucent filter (13a) to obtain an image of the filter (13a). The image is processed to identify dark regions which enable the integrity of the seal to be determined.

Owner:PAK TECH GROUP

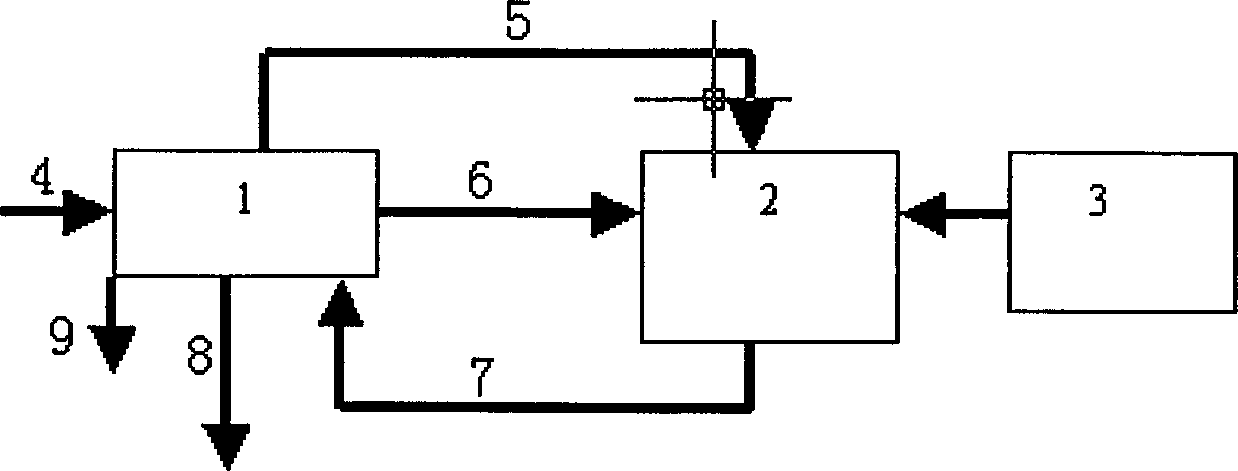

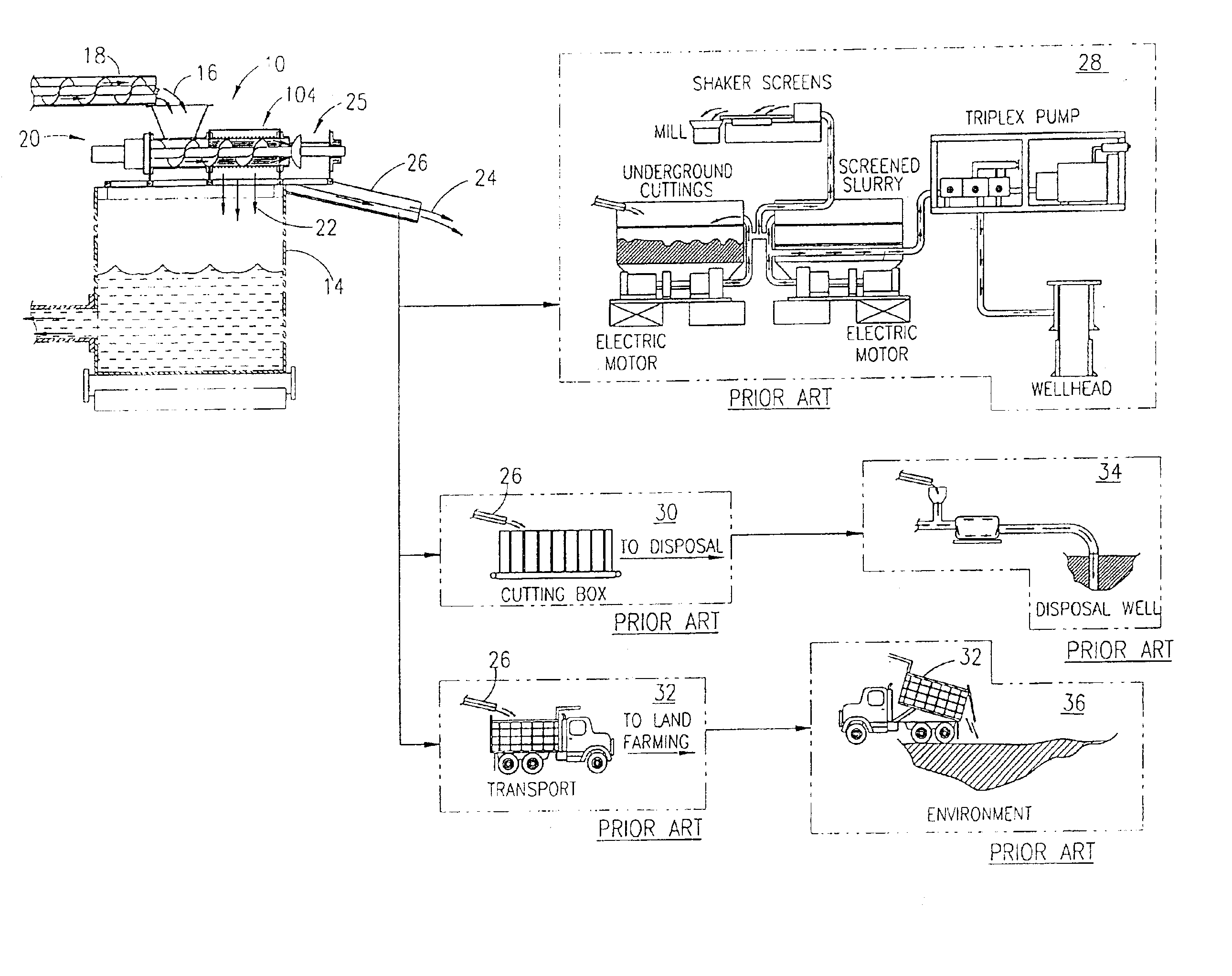

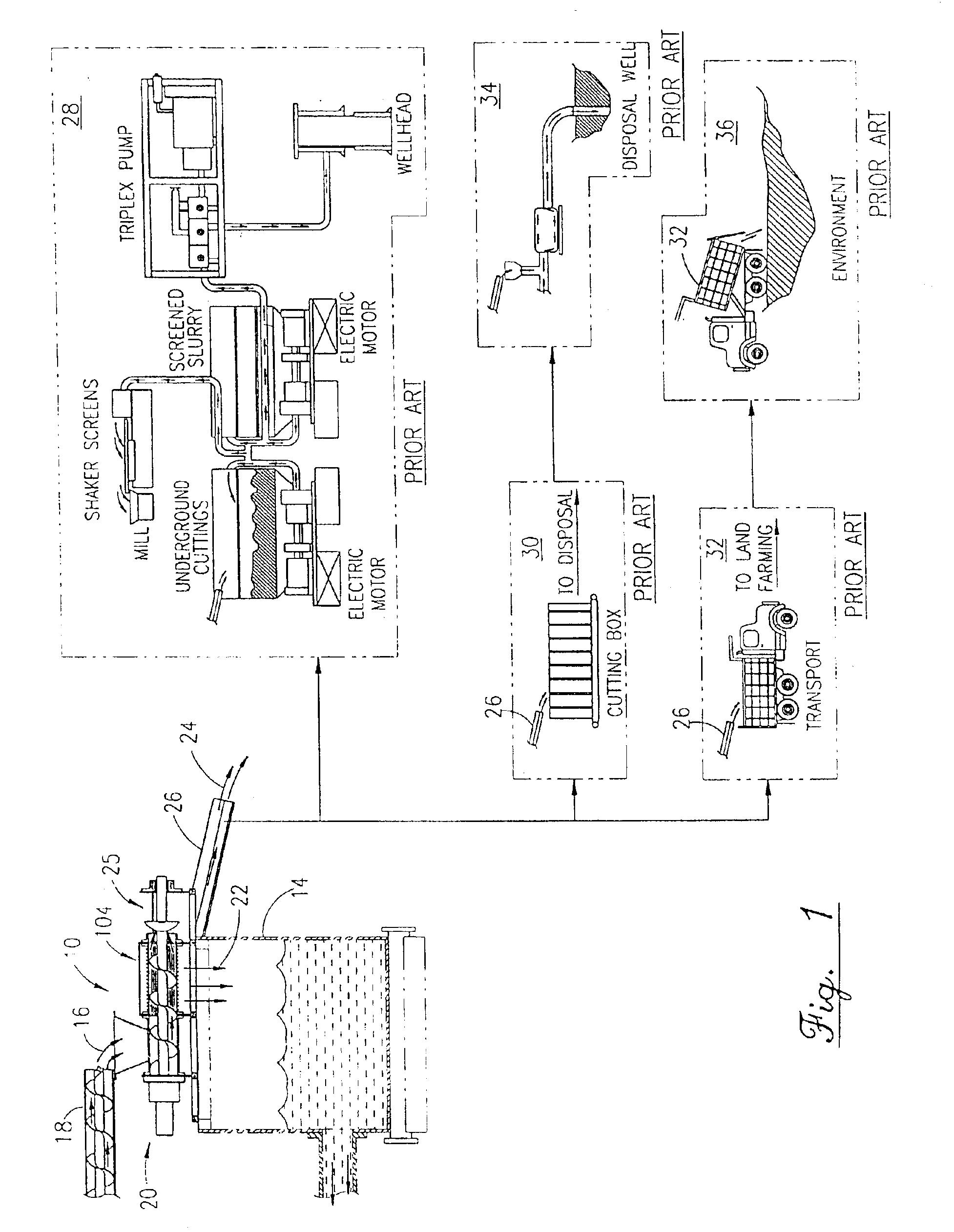

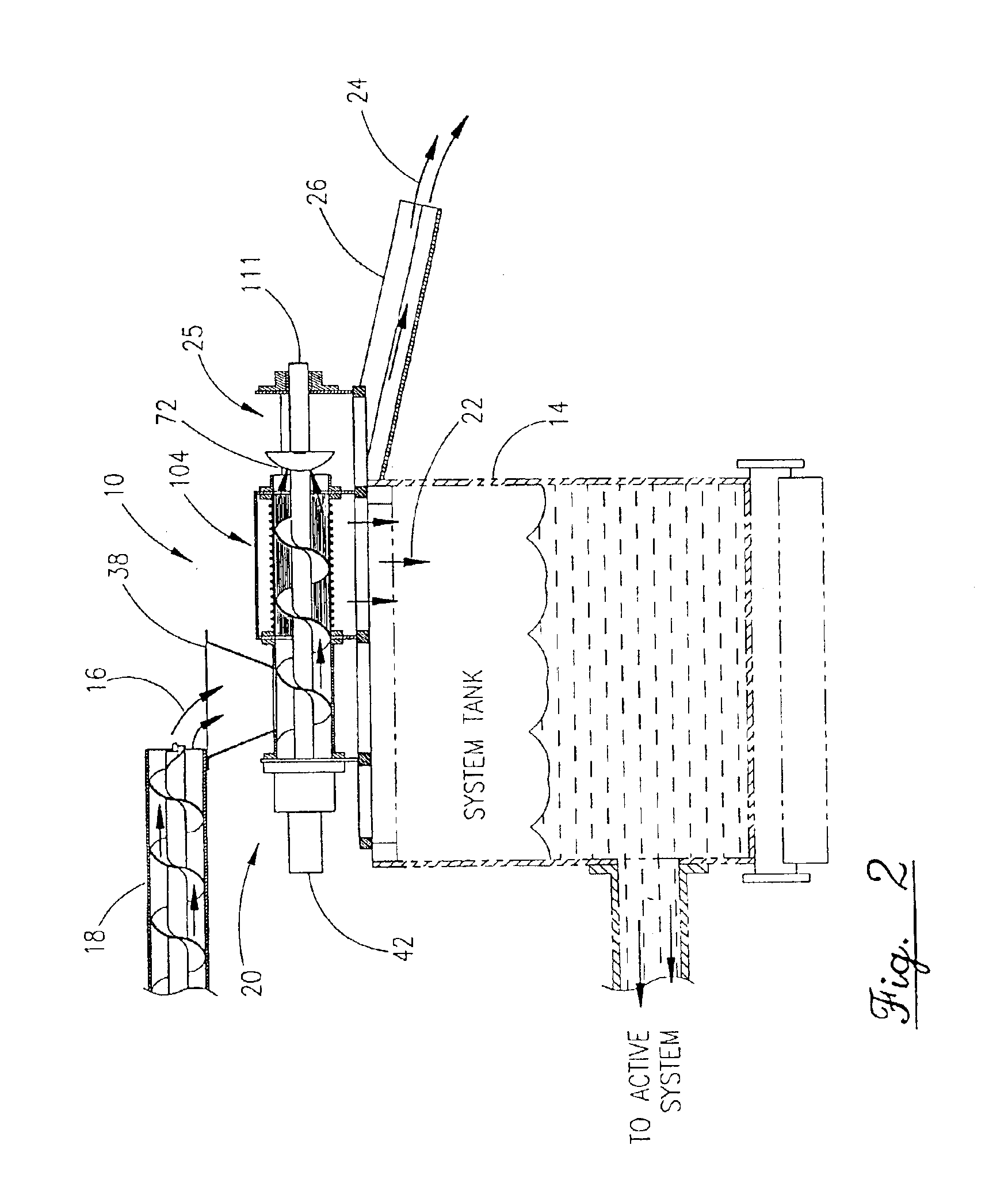

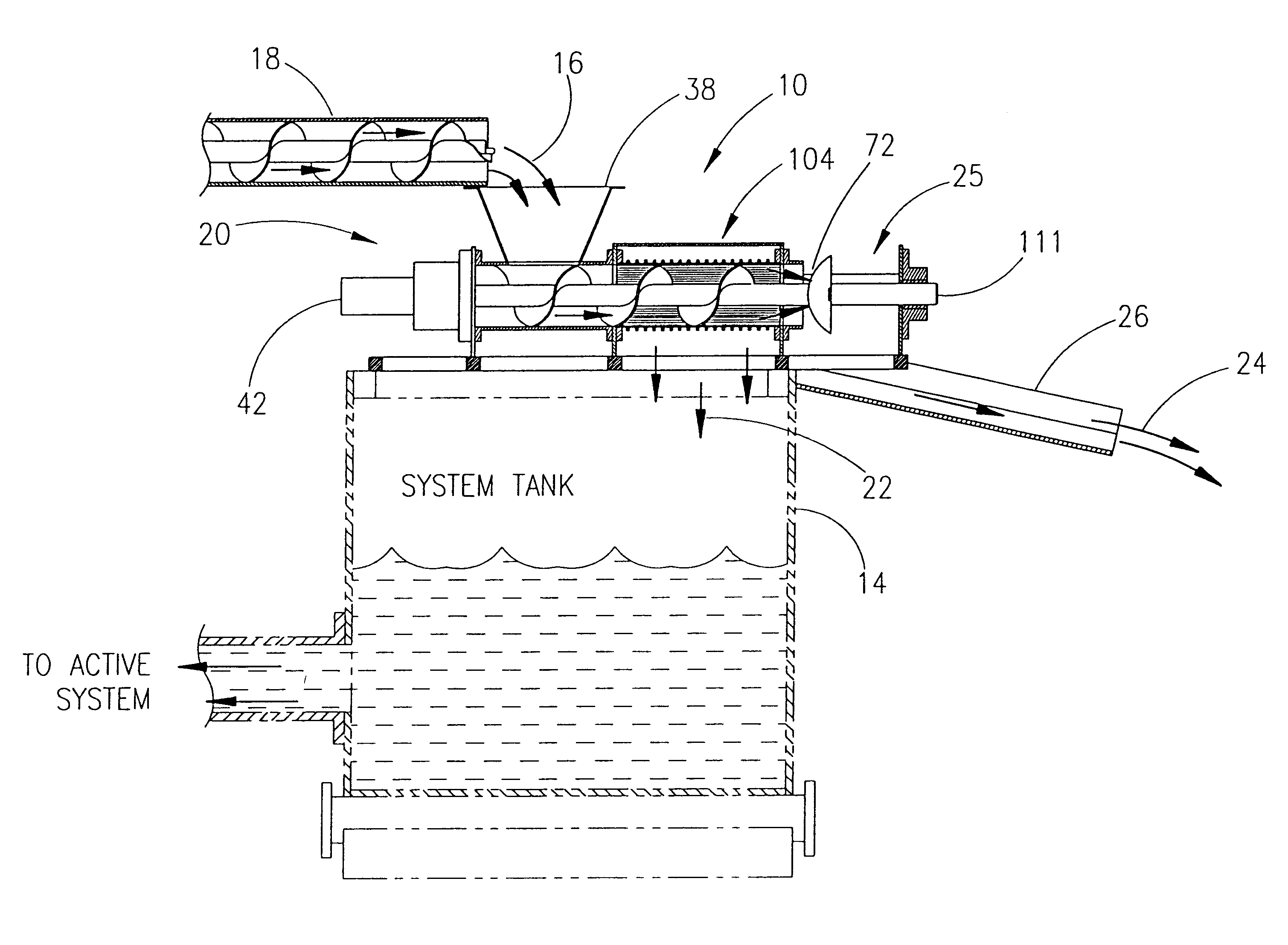

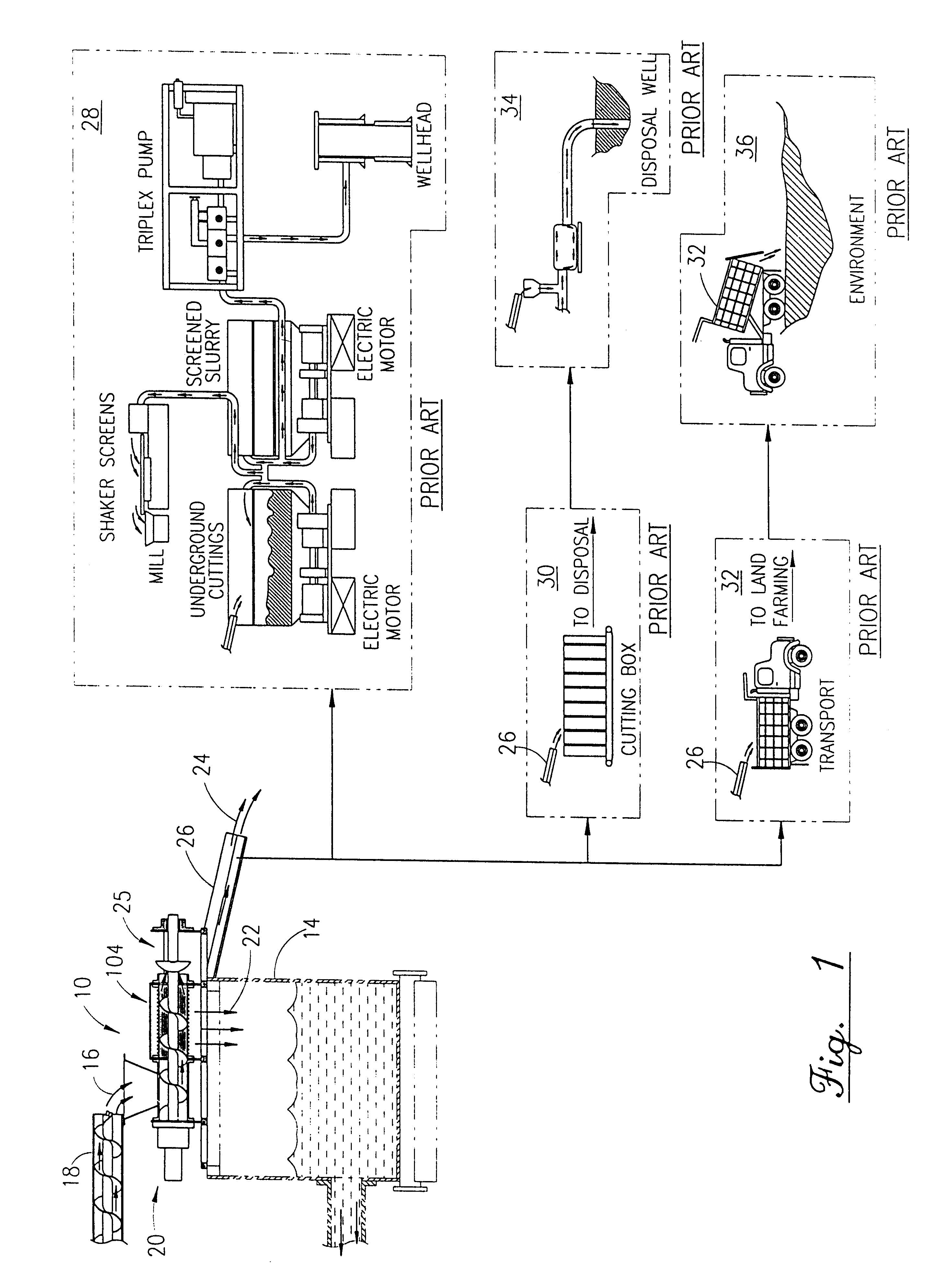

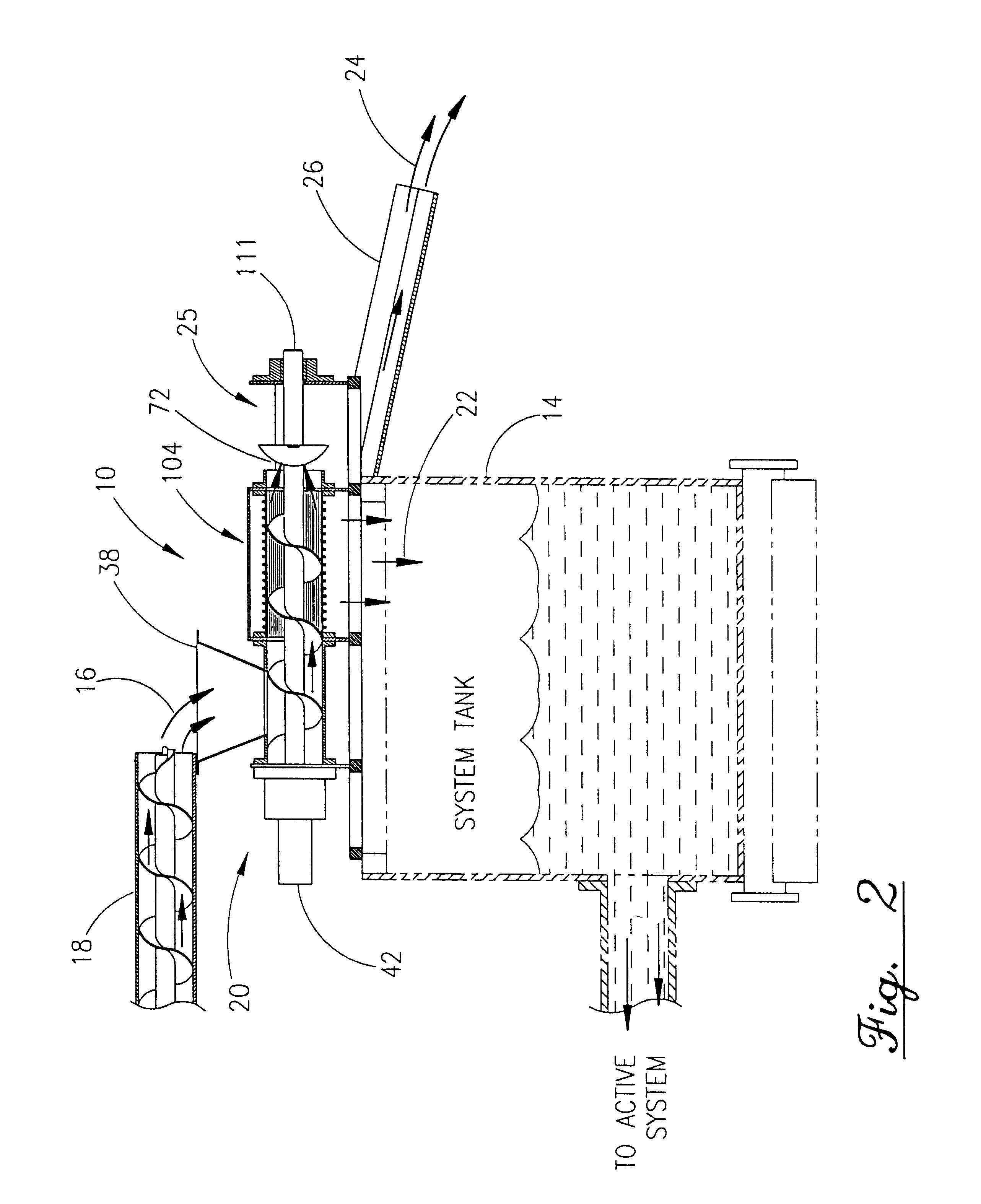

Drilling fluid recovery and cuttings processing system

InactiveUS6910411B2Reduce liquid contentDischarge volume reductionFlushingDrilling compositionProcess systemsDistillation

A drill cuttings slurry process system is disclosed for defluidizing earth drill cuttings, thereby extracting valuable drilling additives and returning them to the drilling system while producing a dense, drier material which may be discharged directly in the environment at or near the well being drilled or chemically treated for distillation and / or better dissolution into the environment, thereby reducing, cost in transportation and environmental treatment chemicals thus reducing environmental contamination. The system comprising a cuttings press having solids / fluids separation a dryer and / or a retort for flashing off any residual petroleum residue and moisture, a fines grinder and a chemical injection system. The retort including an analyzer system for weighing and determining rate of throughput and analyzing the cuttings for residual petroleum residue content prior to discharge to environment or further refinement prior to reinjection into the well or transport to environmental depository sites.

Owner:BAKER HUGHES INC

Drilling fluid recovery and cuttings processing system

InactiveUS6553901B2Reduce liquid contentDischarge volume reductionFlushingDrilling compositionProcess systemsDistillation

A drill cuttings slurry process system is disclosed for defluidizing earth drill cuttings, thereby extracting valuable drilling additives and returning them to the drilling system while producing a dense, drier material which may be discharged directly in the environment at or near the well being drilled or chemically treated for distillation and / or better dissolution into the environment, thereby reducing, cost in transportation and environmental treatment chemicals thus reducing environmental contamination. The system comprising a cuttings press having solids / fluids separation a dryer and / or a retort for flashing off any residual petroleum residue and moisture, a fines grinder and a chemical injection system. The retort including an analyzer system for weighing and determining rate of throughput and analyzing the cuttings for residual petroleum residue content prior to discharge to environment or further refinement prior to reinjection into the well or transport to environmental depository sites.

Owner:BAKER HUGHES INC +1

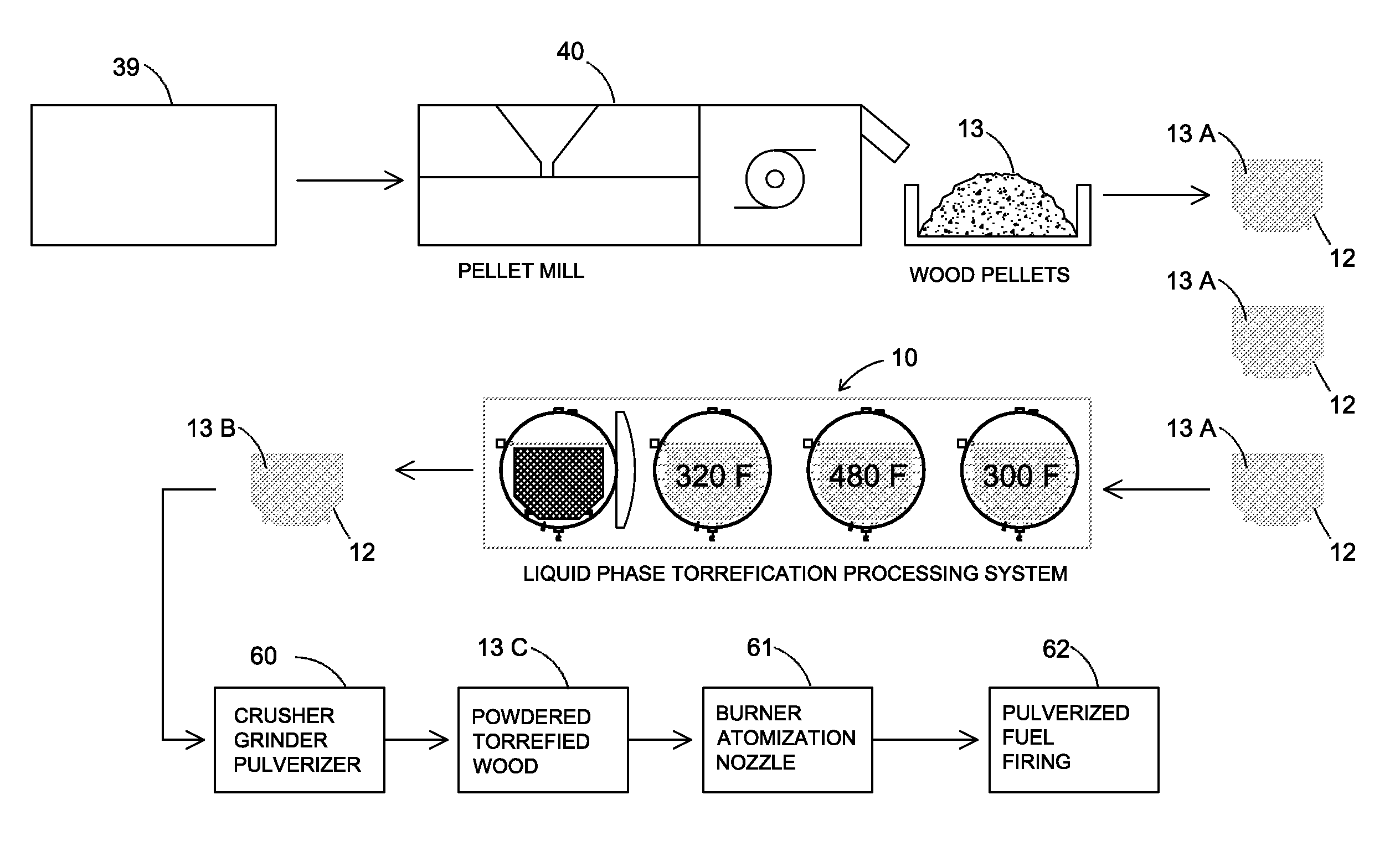

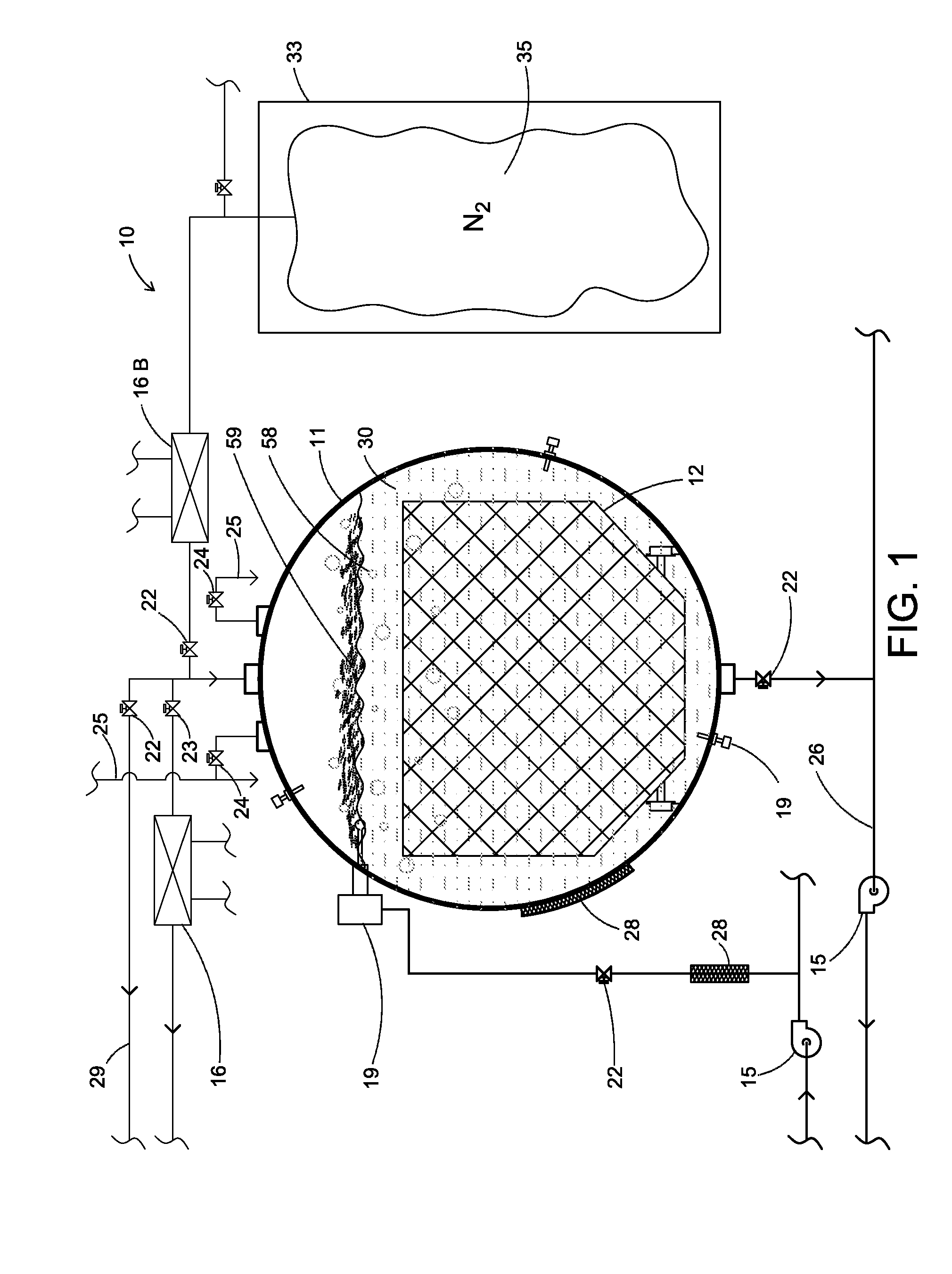

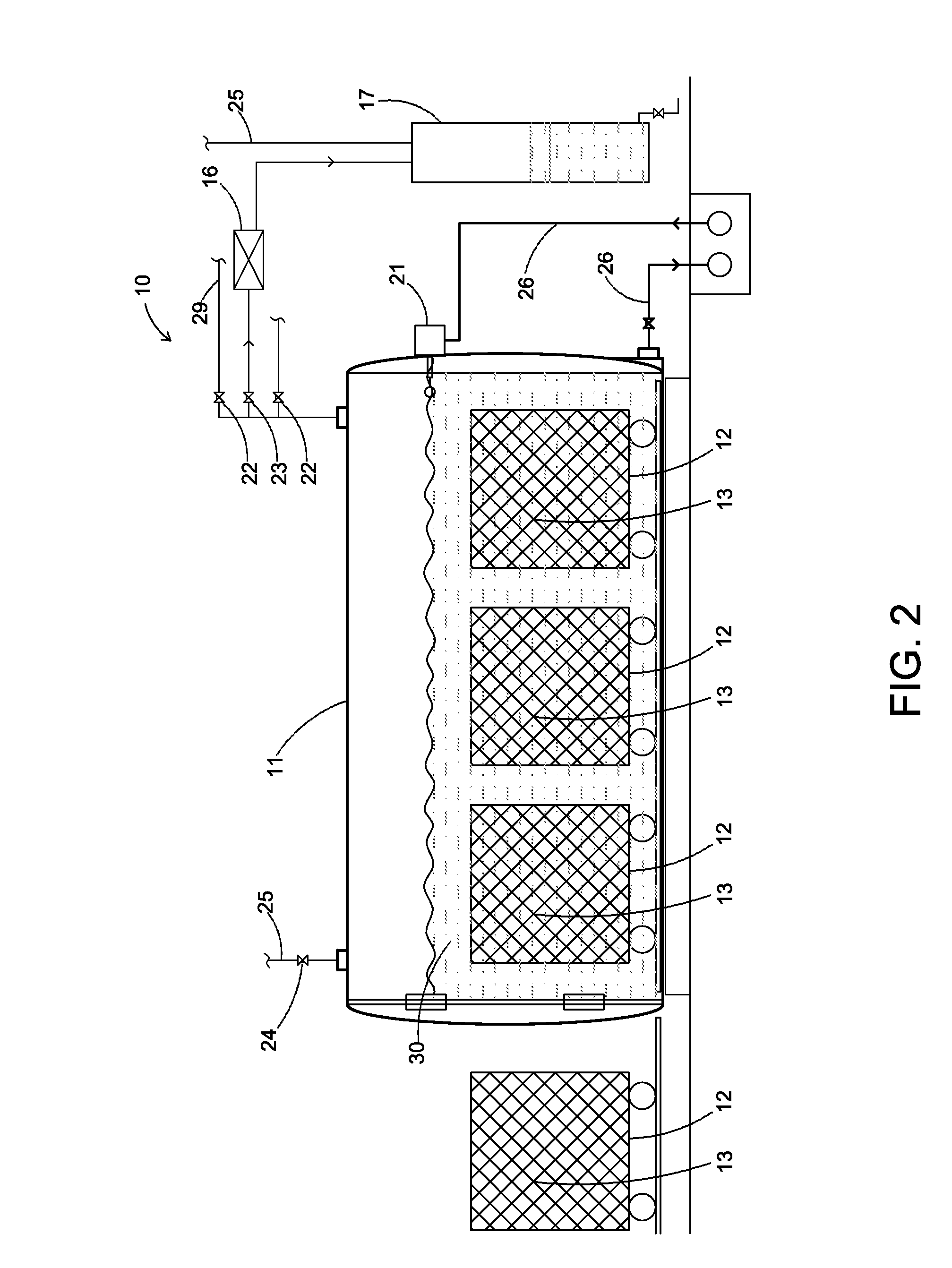

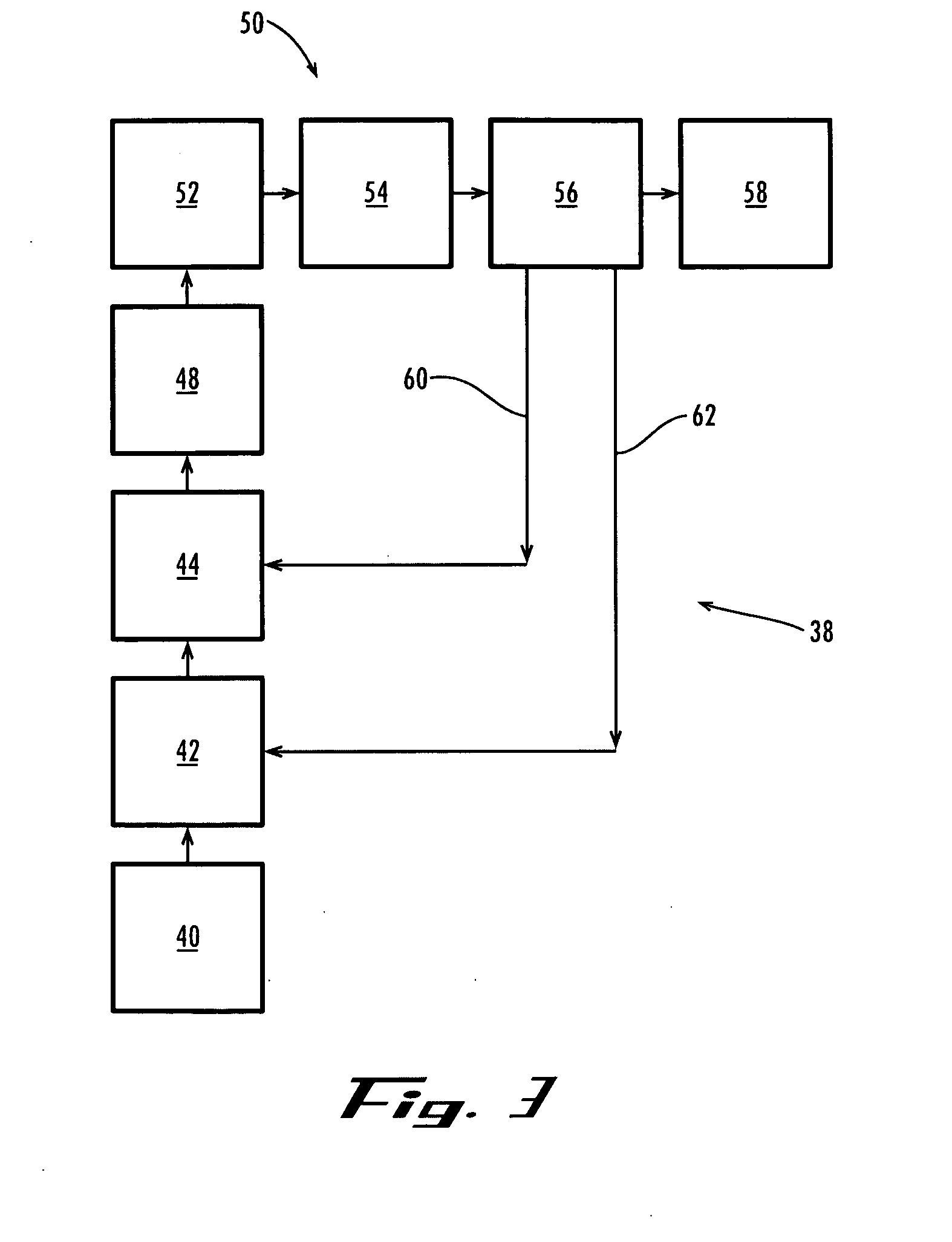

Sequencing retort liquid phase torrefication processing apparatus and method

ActiveUS20100251616A1Combustible gas coke oven heatingSolid waste disposalPositive pressureProduct gas

A method and related apparatus for torrefaction of associated biomass which includes providing an enclosed chamber having a body and a door having an open position allowing passage into and out of the enclosed chamber and a closed position in which the door is disposed in sealing engagement with the body, providing the enclosed chamber with walls capable of sustaining both a negative pressure and a positive pressure within the enclosed chamber; moving the door to an open position; depositing a liquid heat transfer fluid within the enclosed chamber at a temperature sufficient to achieve torrefication of the biomass and a first quantity of biomass material in the enclosed chamber that is substantially totally immersed in the liquid heat transfer fluid whereby heat transfer occurs between the liquid heat transfer fluid and the biomass immersed therein; moving the door to a closed position in sealing engagement with the body; and allowing the pressure within the enclosed chamber to rise to a pressure above the vapor pressure of the heat transfer fluid as a result of the expansion of liquids and gases entrained within the biomass.

Owner:PAOLUCCIO JOHN A +1

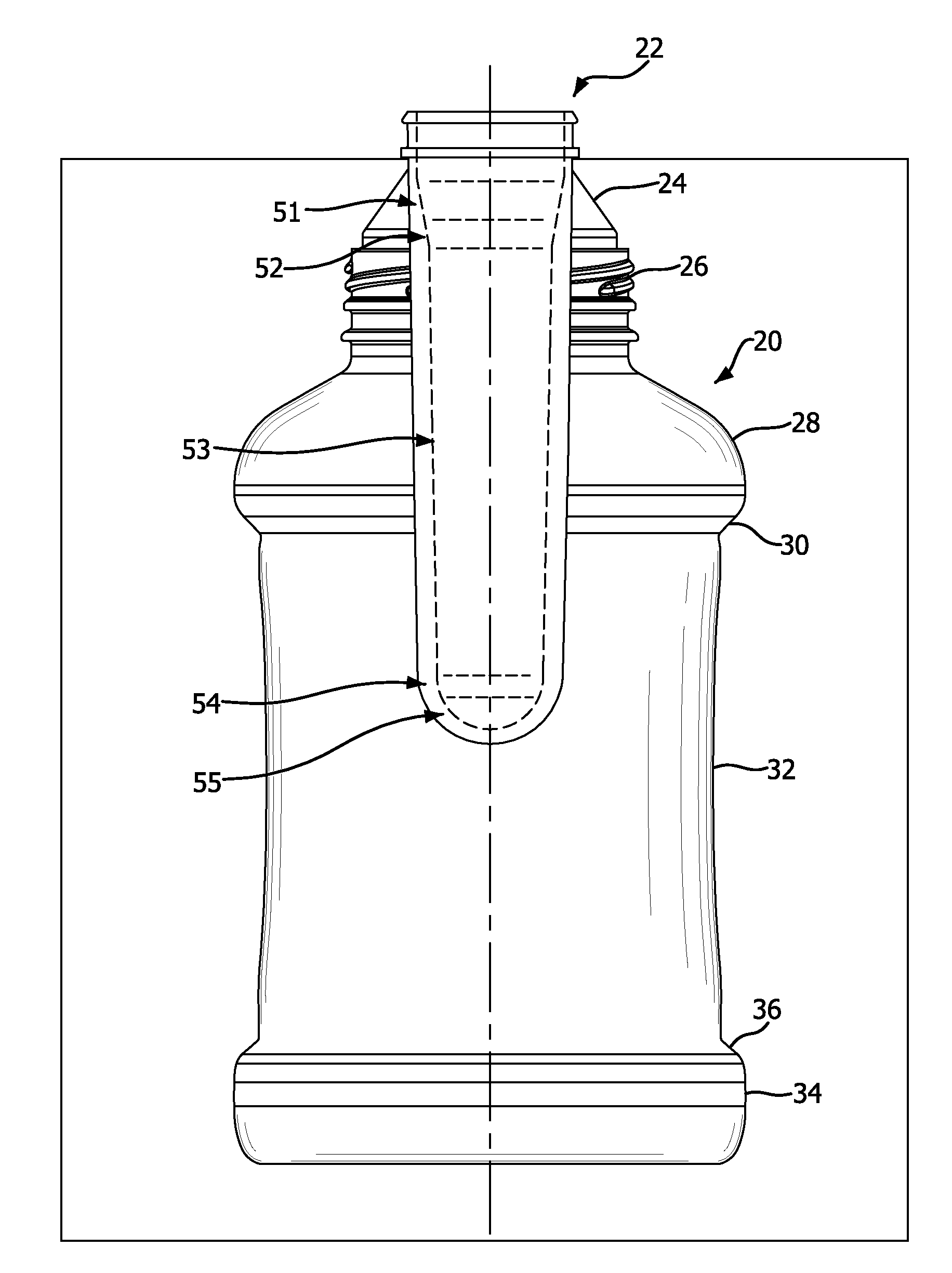

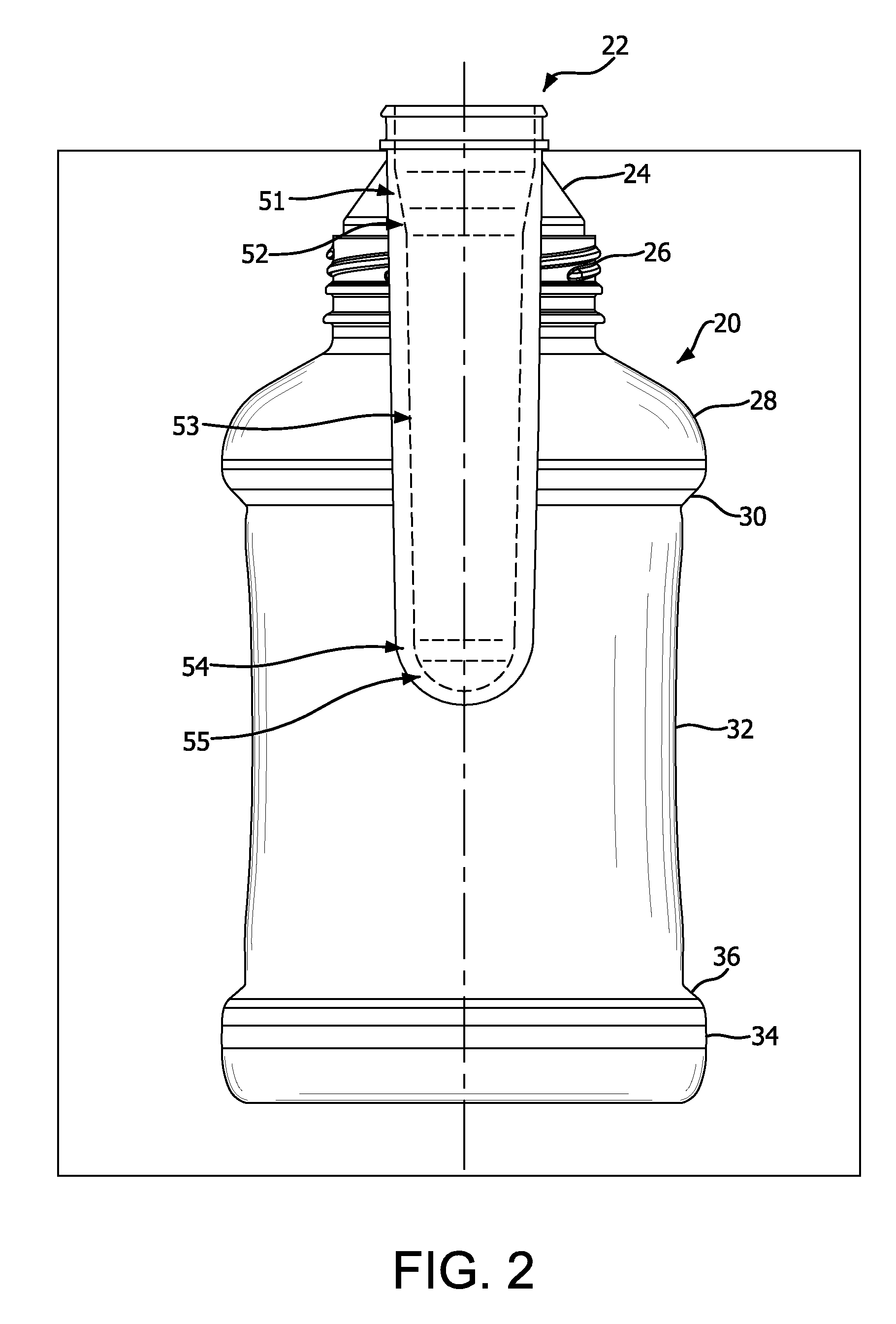

Pet containers with enhanced thermal properties and process for making same

ActiveUS20120076965A1Improve thermal performanceHigh transparencyLayered productsBottlesPasteurizationVolumetric Mass Density

A blow-molded PET container comprising a wall having a density of between about 1.370 g / cc and 1.385 g / cc, a heat-induced crystallinity of from about 18% to about 25%, and a strain-induced crystalinity of from about 55% to about 75%, wherein the PET container, when filled with a liquid having a temperature of from about 100° C. to about 132° C. or when subjected to a pasteurization or retort process, will not experience a change in volume of greater than 3%.

Owner:GRAHAM PACKAGING PET TECH

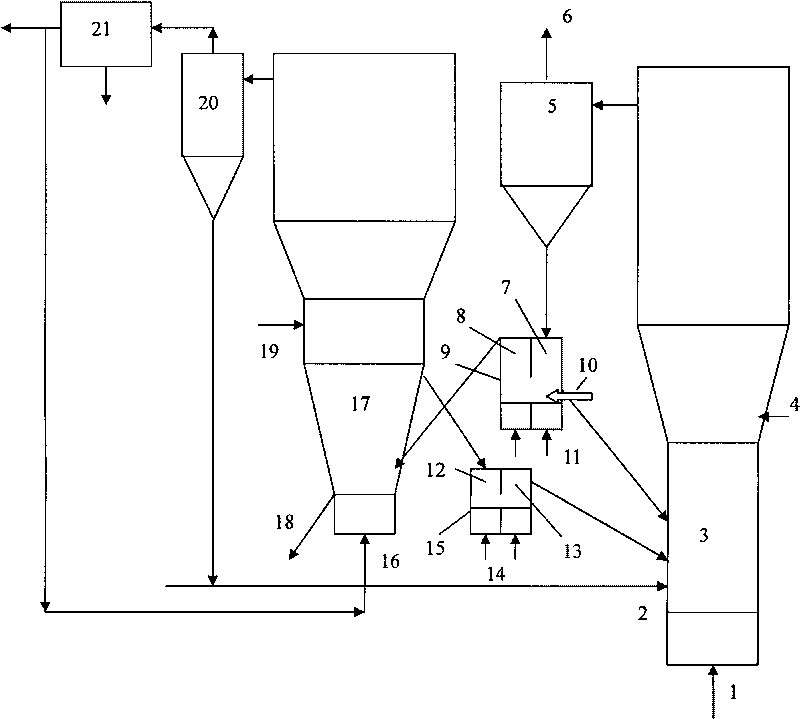

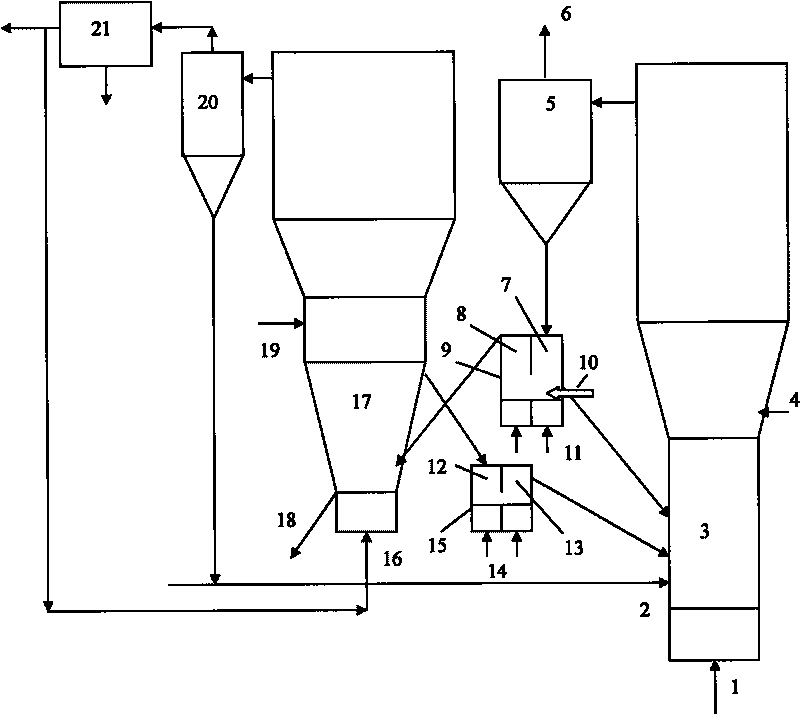

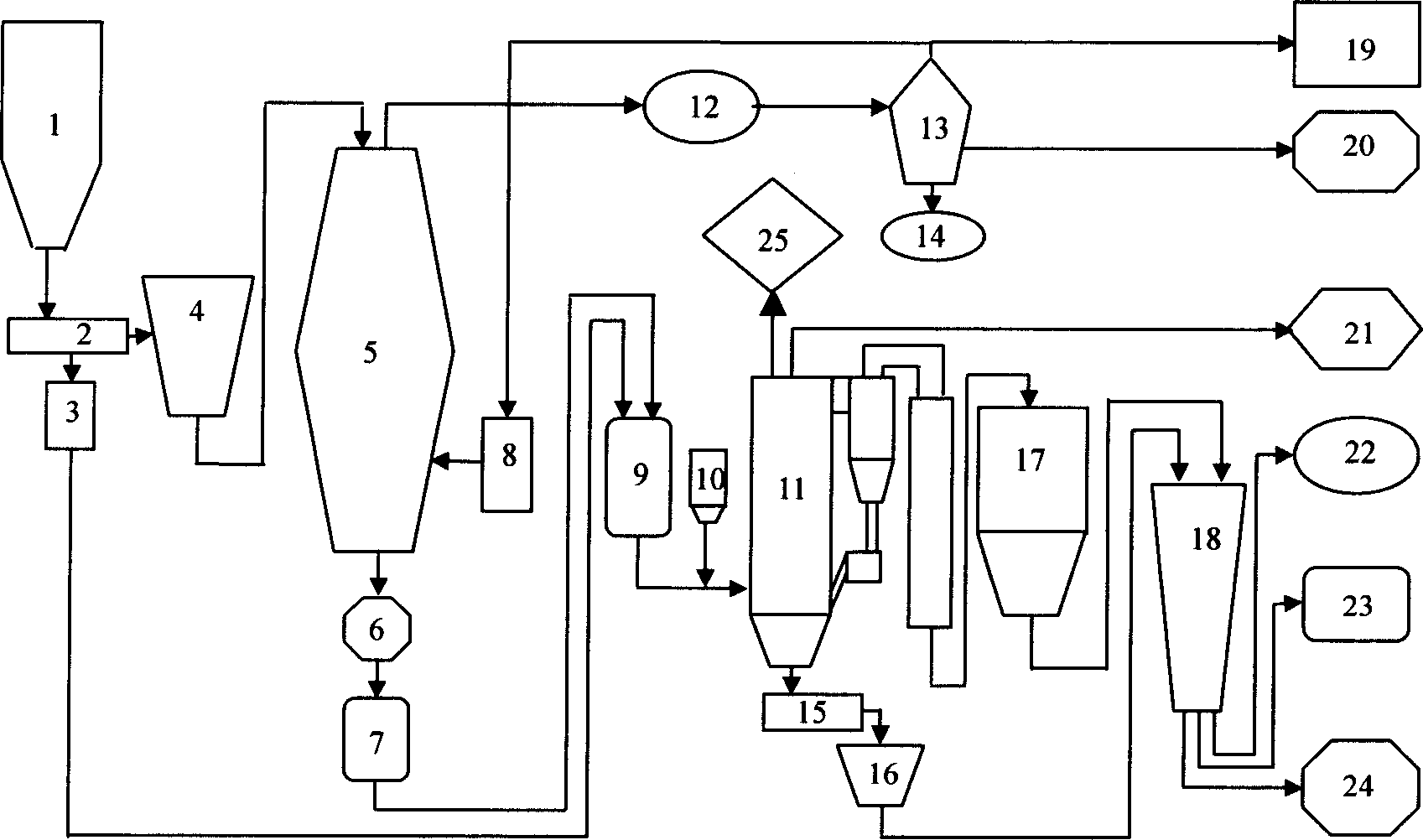

Coal-grading conversion poly-generation device and method for producing coal gas, tar and carbocoal on circulating fluid bed

ActiveCN101691501ARealize joint productionReasonable useSpecial form destructive distillationCombustible gas productionTarProcess engineering

The invention discloses a coal-grading conversion poly-generation device and a method for producing coal gas, tar and carbocoal on a circulating fluid bed. The device combines a circulating fluid bed gasification-furnace with a fluid bed gas retort. The gas retort is a normal-pressure fluid bed and uses circulating coal gas as the fluidizing medium; fuel is firstly heated and cracked in the gas retort to precipitate high-heating-value fugitive constituents comprising coal gas and tar; the heat absorbed by the gas retort is provided by a high-temperature thermal-circulation material in the circulating fluid bed gasification-furnace; the carbocoal part obtained after the coal is retorted is cooled and discharged through the bottom of the gas retort, and part of the carbocoal is conveyed to the circulating fluid bed gasification-furnace along with the circulating material to heat the circulating material; and the medium-temperature coal gas from the gas retort is processed in a dust removal way and cooled by a coal gas purification system, the tar is recycled, and the purified coal gas is output for industrial and civil use, thereby realizing the poly-generation of coal gas, tar and carbocoal in one set of device and realizing the grading conversion and the high-efficiency comprehensive utilization of coal.

Owner:ZHEJIANG UNIV

Autoclavable reclosable package

InactiveUS20050286810A1Inhibit migrationAvoid contactFlexible coversWrappersEngineeringHigh pressure

A reclosable package that seals an enclosed product and allows the product to be subjected to a retort procedure to cook the product while the product is in the package. The reclosable package is formed from a polypropylene film and includes a zipper closure including a pair of mating closure profiles both formed from a polypropylene material. One of the male or female closure profiles includes a sealing flange having a layer of sealant such that the sealing flange provides a seal for the package below the interaction between the closure profiles. This seal prevents the product from migrating through the profile member during the retort procedure and prior to the package being opened for the first time.

Owner:REYNOLDS CONSUMER PROD INC

Autoclavable reclosable package

A reclosable package that seals an enclosed product and allows the product to be subjected to a retort procedure to cook the product while the product is in the package. The reclosable package is formed from a polypropylene film and includes a zipper closure including a pair of mating closure profiles both formed from a polypropylene material. One of the male or female closure profiles includes a sealing flange having a layer of sealant such that the sealing flange provides a seal for the package below the interaction between the closure profiles. This seal prevents the product from migrating through the profile member during the retort procedure and prior to the package being opened for the first time.

Owner:REYNOLDS CONSUMER PROD INC

Container for retort packaging, resin composition, and gas-barrier film prepared therefrom

InactiveUS6022913AExcellent oxygen barrier propertiesExcellent not in resistanceCosmetic preparationsWrappersCross-linkChemical structure

PCT No. PCT / JP97 / 03131 Sec. 371 Date Mar. 19, 1998 Sec. 102(e) Date Mar. 19, 1998 PCT Filed Sep. 5, 1997 PCT Pub. No. WO98 / 09813 PCT Pub. Date Mar. 12, 1998The present invention provides a container for retort packaging comprising a laminated film having an outermost layer comprising a layer formed of a cross-linked structure containing ester bonds between poly(meth)acrylic acid (A) and polyalcoholic polymer (B); a resin composition having at least the chemical structures (X) [poly(meth)acrylic acid (A) residue], (Y) [poly(meth)acrylic acid (A)-polyalcoholic polymer (B) residue] and (Z) [metal cross-linked ionic residues], wherein the degree of esterification defined by the equation: degree of esterification=c / (b+c+d) is from 0.01 to 0.5 and the degree of ionization defined by the equation: degree of ionization=c / (b+c+d) is from 0.01 to 0.9 (wherein b, c and d represent the molar ratios of the carbon-oxygen double bond in the chemical structure of the resin composition; and a gas barrier film comprising the same.

Owner:TOPPAN PRINTING CO LTD

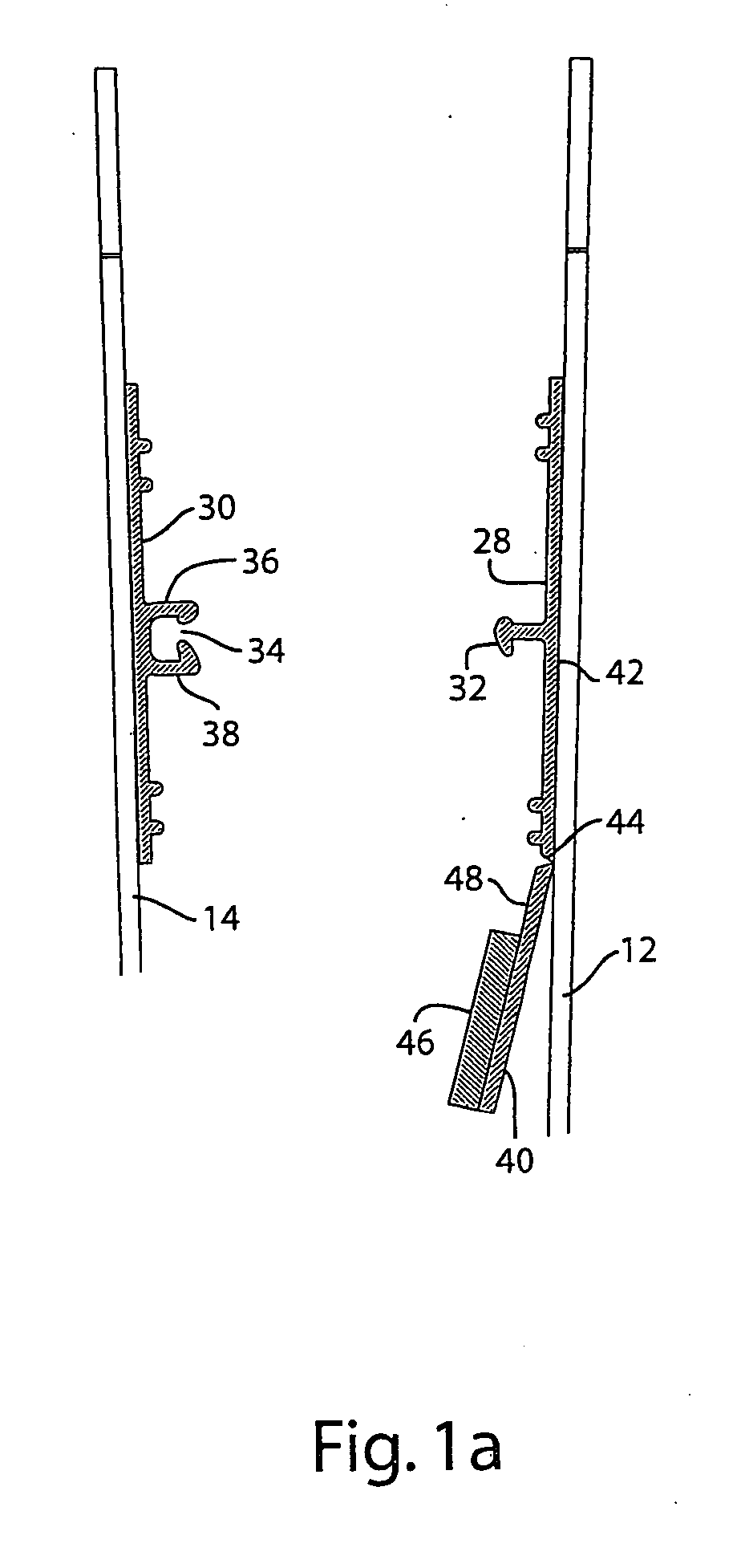

Method for preparing stalk charcoal and stalk vinegar liquid form stalks of cropper

InactiveCN1563277AImprove fertilizer efficiencyImprove compactionBiofuelsPyroligneous acid productionCombustion chamberProduct gas

A method for preparing straw charcoal and straw vinegar liquid includes placing agricultural straw into retort for pyrolytic reaction of 4-12 h. at 300-600 deg.C under condition of oxygen being isolated or being provided with limitation; obtaining straw charcoal from solids through drying, precharring, charring and calcining; obtaining straw vinegar liquid and combustible gas by arrying out gas-liquid separation of pyrolysis gas and sending combustible gas back to combustion chamber as heating source.

Owner:NANJING FORESTRY UNIV

Tissue processor

Owner:GENERAL DATA

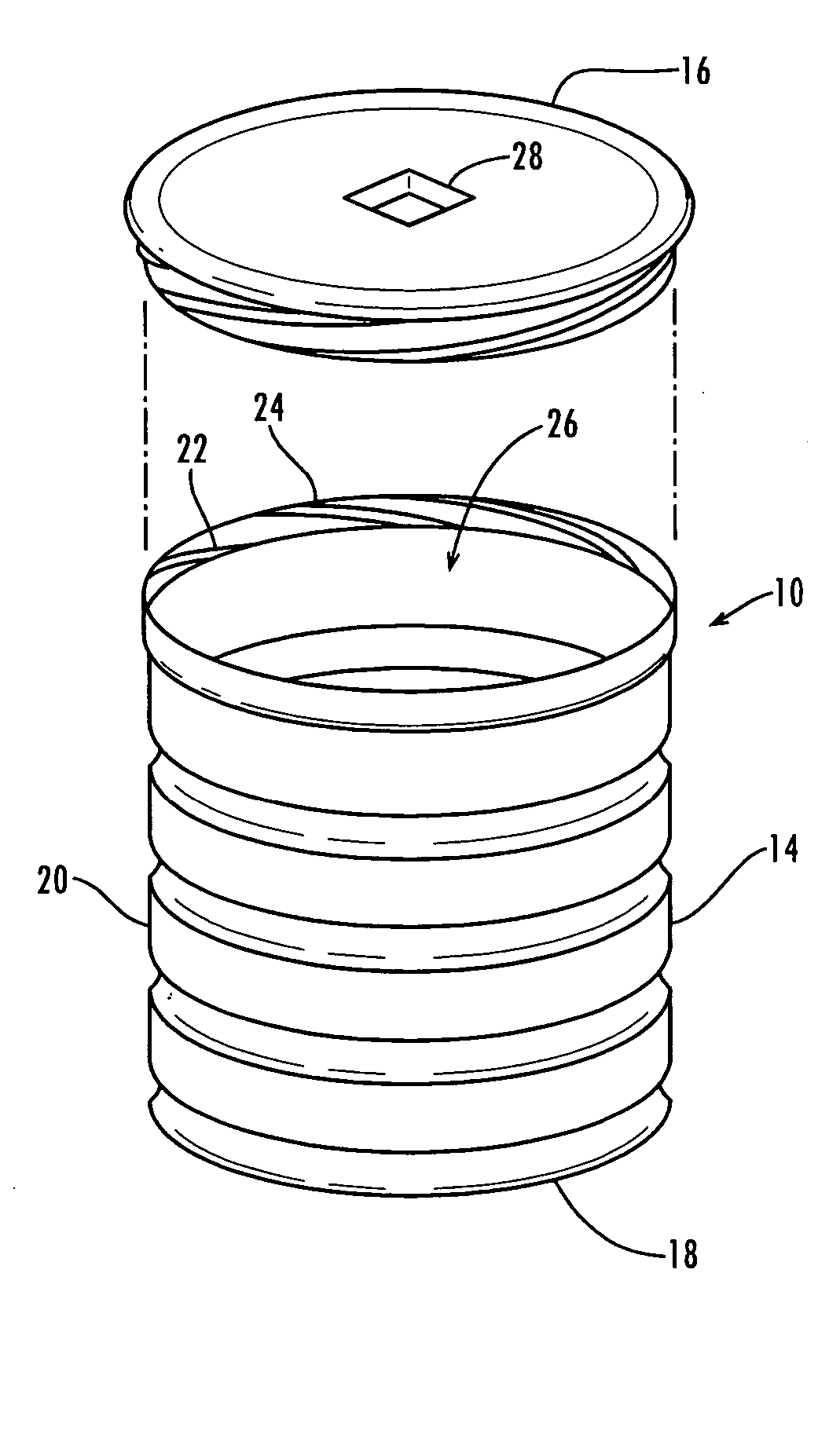

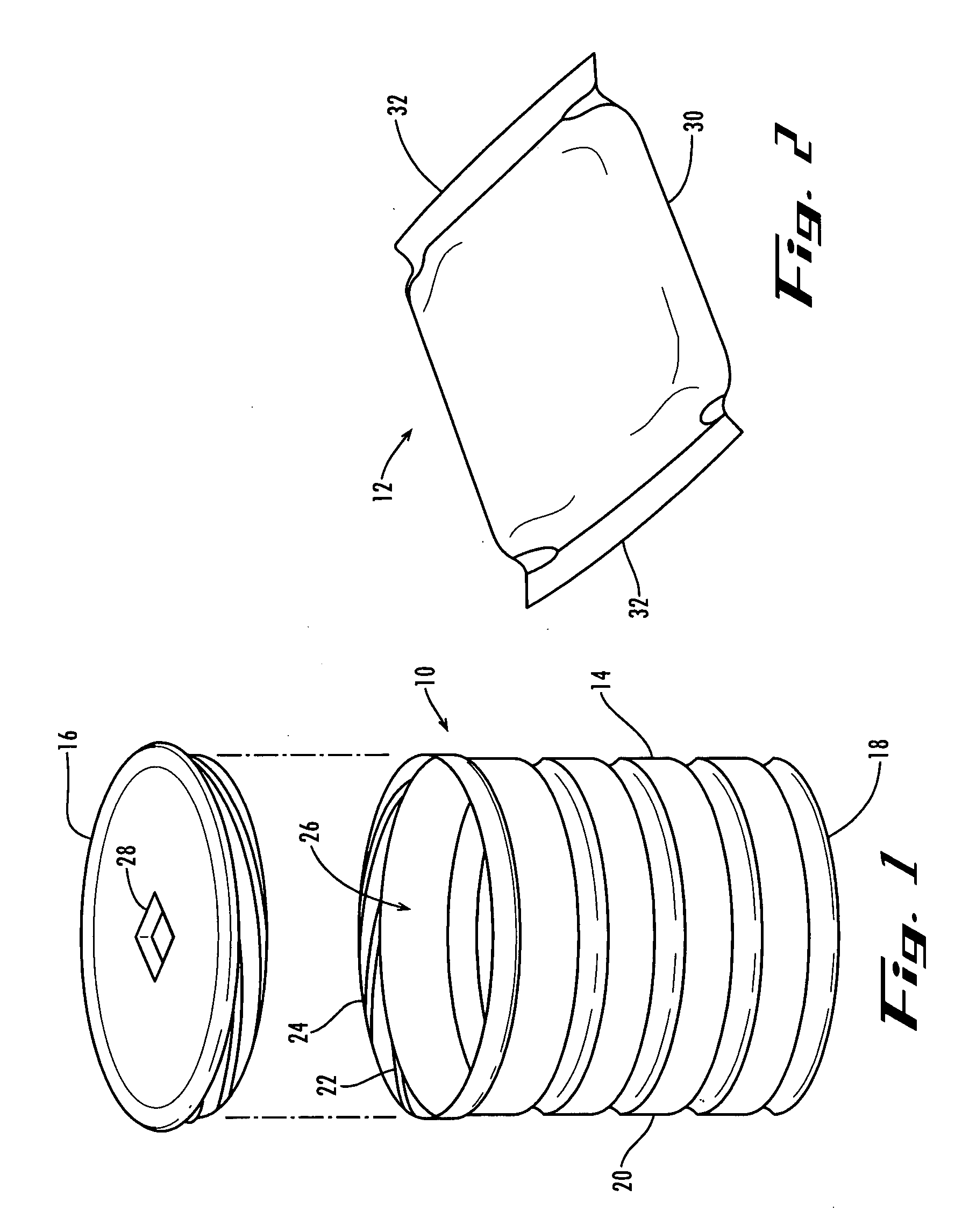

Reusable Container and Method for Retorting Flexible Packages Containing Foodstuff

InactiveUS20070082096A1Heat thoroughlyReduce packaging costsPackage sterilisationHops treatmentMechanical engineeringFood item

Method for retorting flexible packages containing foodstuff comprising retorting the flexible packages containing foodstuff in reusable, hermetically resealable, rigid retort containers. A retort container comprises a body portion including a base and outer side walls extending from the base to a mouth portion defining an opening and a resealable lid for selectively hermetically sealing the opening in the container and alternatively opening the container for removal of the flexible packages containing foodstuff.

Owner:PRINTPACK ILLINOIS

Method for complex optimum using oil shale

InactiveCN1683472AAchieve optimal utilizationIncrease profitLiquid hydrocarbon mixture productionSpecial form destructive distillationFluidized bedOil shale gas

The comprehensive optimized oil shale utilizing method includes crushing and sieving oil shale ore, dry distilling the 8-80 mm size component in retort furnace to produce shale oil and fuel gas, crushing the semicoke waste into 8 mm below size, mixing the crushed semicoke waste and 8 mm below size waste grain from oil refining to form mixed fuel for the circulating fluidized bed boiler, using the produced steam partially for externally supplying and partially to drive turbine generator, and using the cinder in producing cement, haydite and building block. The present invention provides one new way for comprehensive utilization of giant oil shale resource.

Owner:SHANGHAI JIAO TONG UNIV

Method for producing nutritionally balanced food compositions

InactiveUS20050003054A1High activityExtended shelf lifeFruit and vegetables preservationMilk preservationEmulsionSoya bean

This invention relates to a process for manufacturing nutritionally balanced food compositions suitable for retort sterilization which have a low pH, extended shelf life, high antimicrobial activity, and which include protein in a stable emulsion. The primary protein source for the food composition is caseinates or milk protein concentrates and isolates comprised mostly of casein. Alternately, milk protein concentrates, milk protein isolates, milk protein hydrolystates, soy protein isolates or soy protein concentrates may also be used. The process includes two homogenization steps.

Owner:ENTRA SAFE

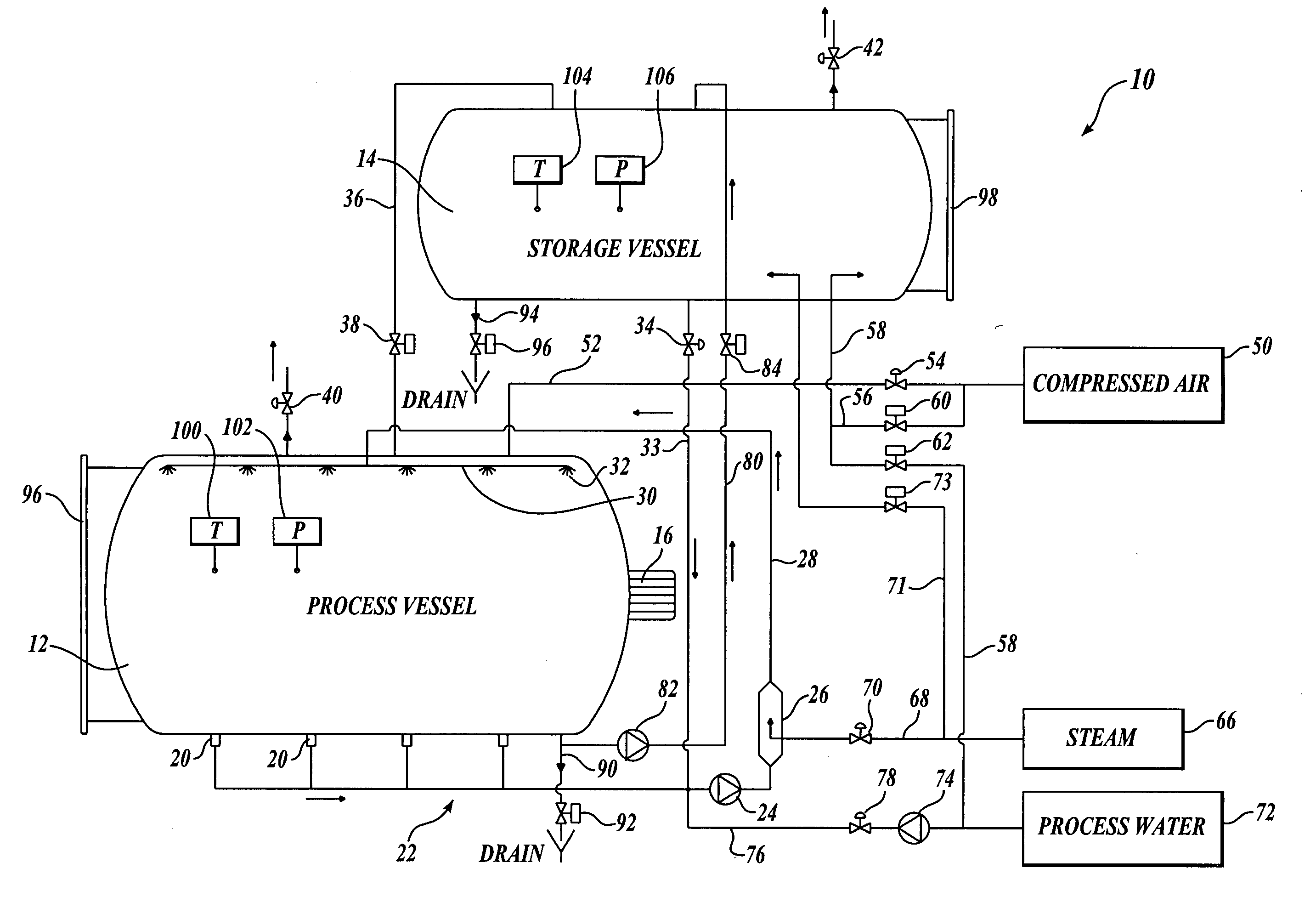

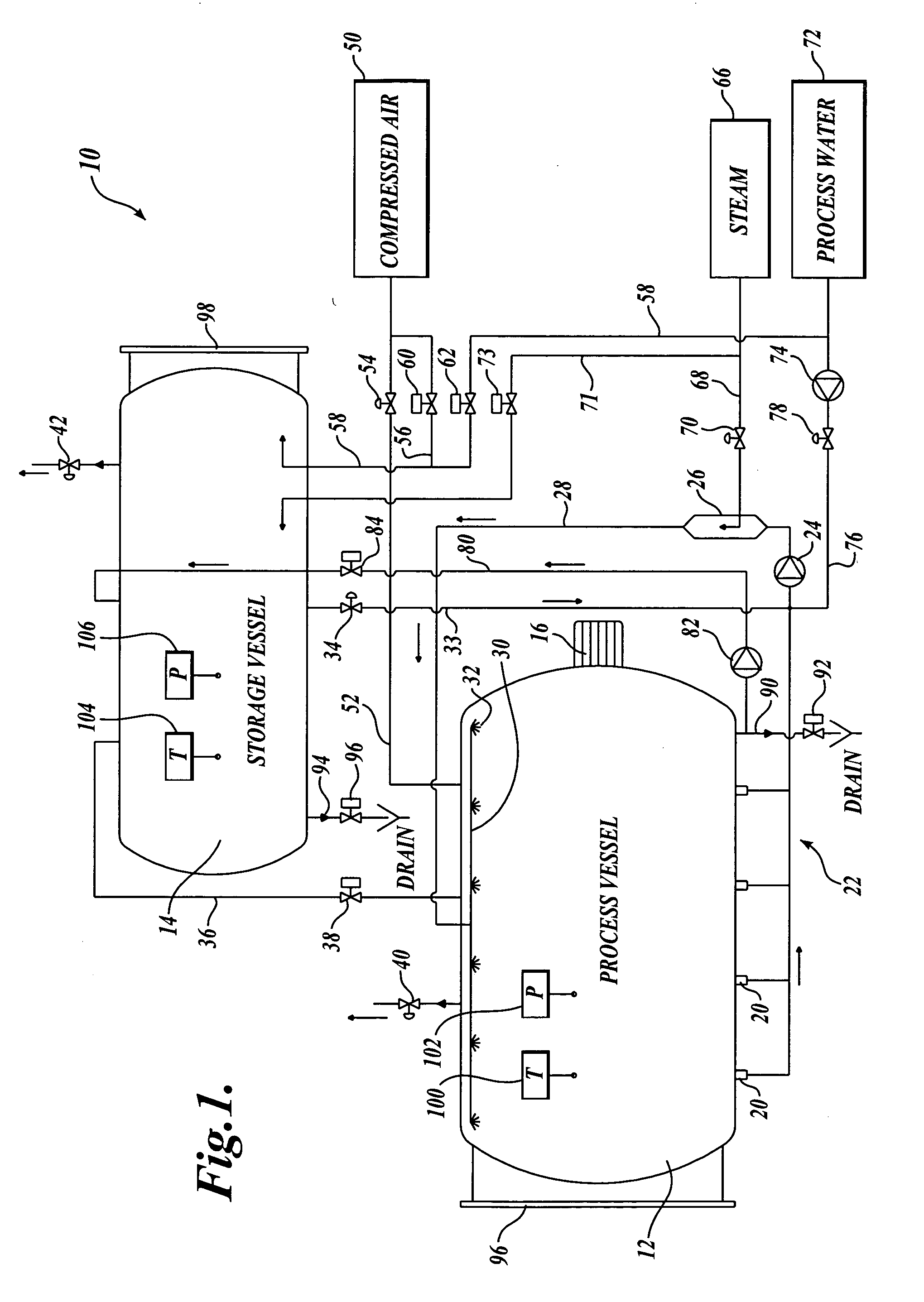

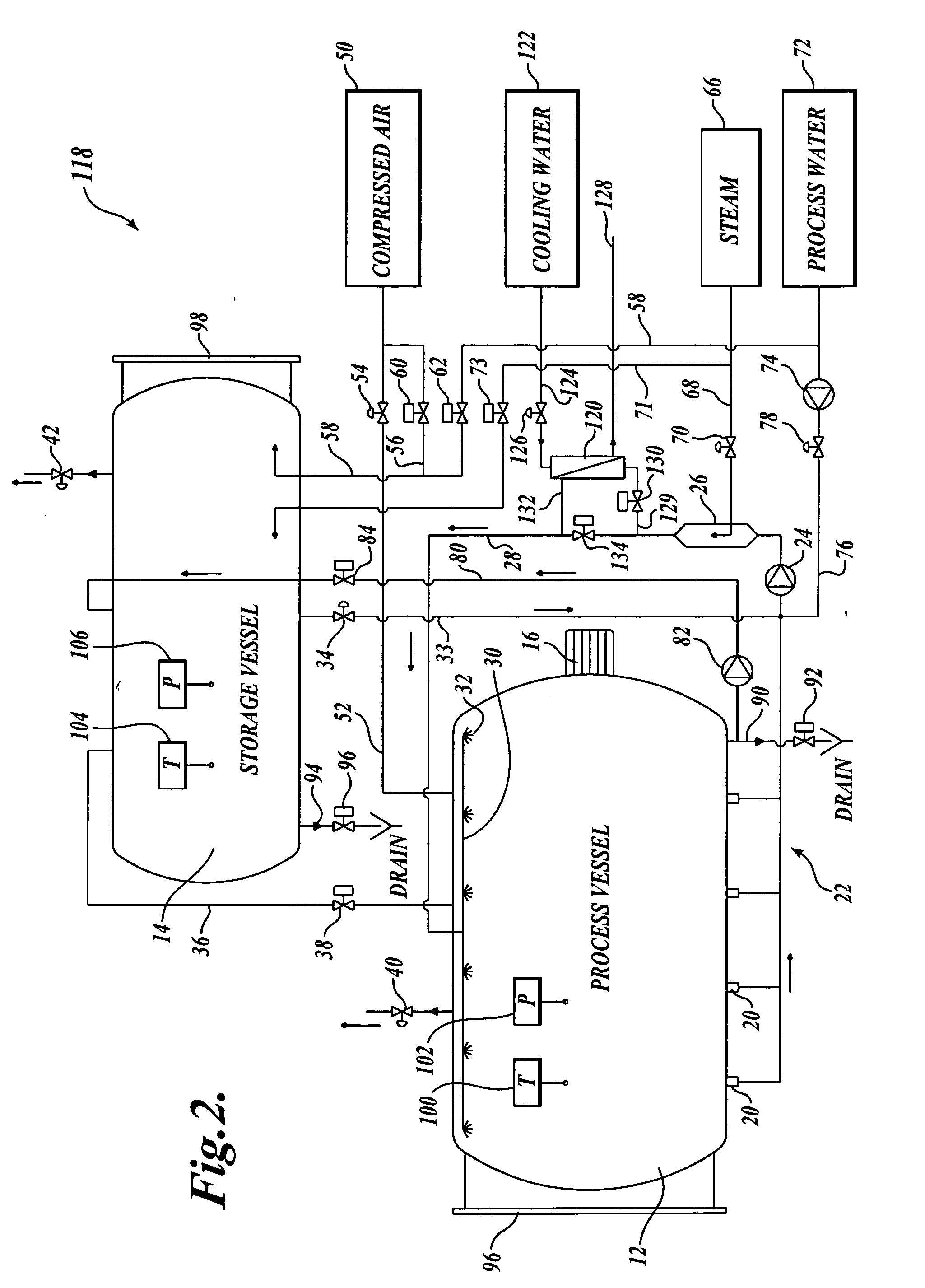

Immersion retort

InactiveUS20050249650A1Control pressureMilk preservationFood preservationProcess engineeringCooking process

An overpressure retort system includes a process vessel in fluid flow communication with a storage vessel. Heated process fluid from the storage vessel is transferred to the process vessel, including through spraying outlets or nozzles to direct heated process fluid onto the nutrient product containers. After the cooking process has been completed, the heated process fluid is returned to the storage vessel and then cool process fluid is used to cool the nutrient products in the process vessel, including by spraying the cooled process fluid onto the nutrient product containers. During the cooking and cooling processes, the process fluid from the process vessel is recirculated, and the overpressure within the process vessel is controlled by supplying compressed gas at a controlled pressure to the headspace of the process vessel. The headspace of the process vessel and the headspace of the storage vessel are in fluid flow communication. In the cooling process, process fluid may be withdrawn from the process vessel, then cooled in a heat exchanger, then reintroduced to the process vessel.

Owner:FMC TECH INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com