Patents

Literature

1271 results about "Compression set" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The compression set (ASTM D395) of a material is the permanent deformation remaining after removal of a force that was applied to it. The term is normally applied to soft materials such as elastomers. Compression is normally measured in two ways: compression set A and compression set B.

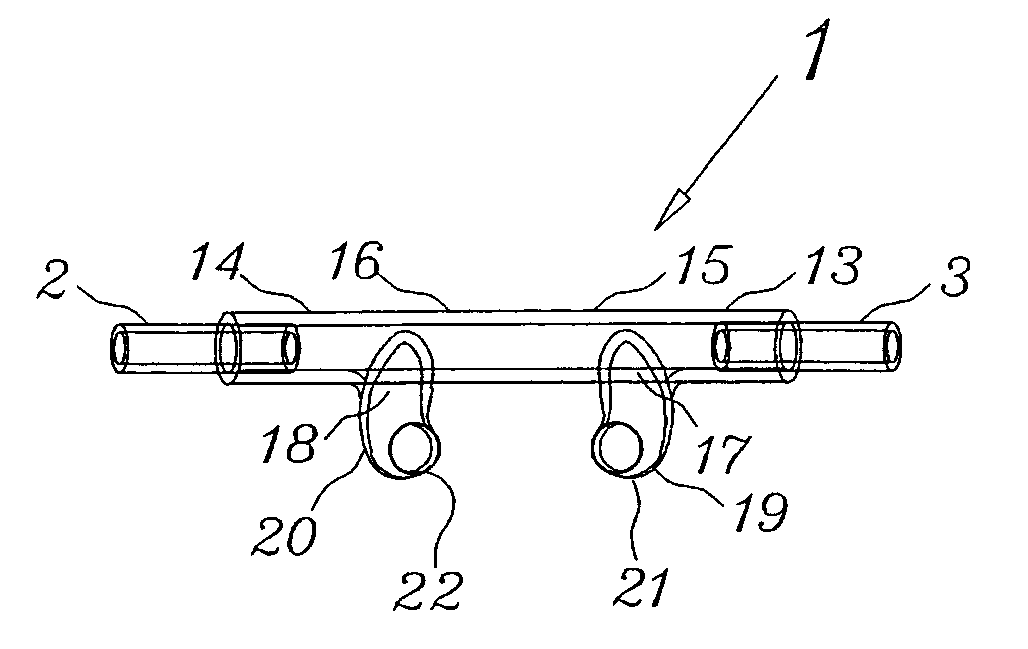

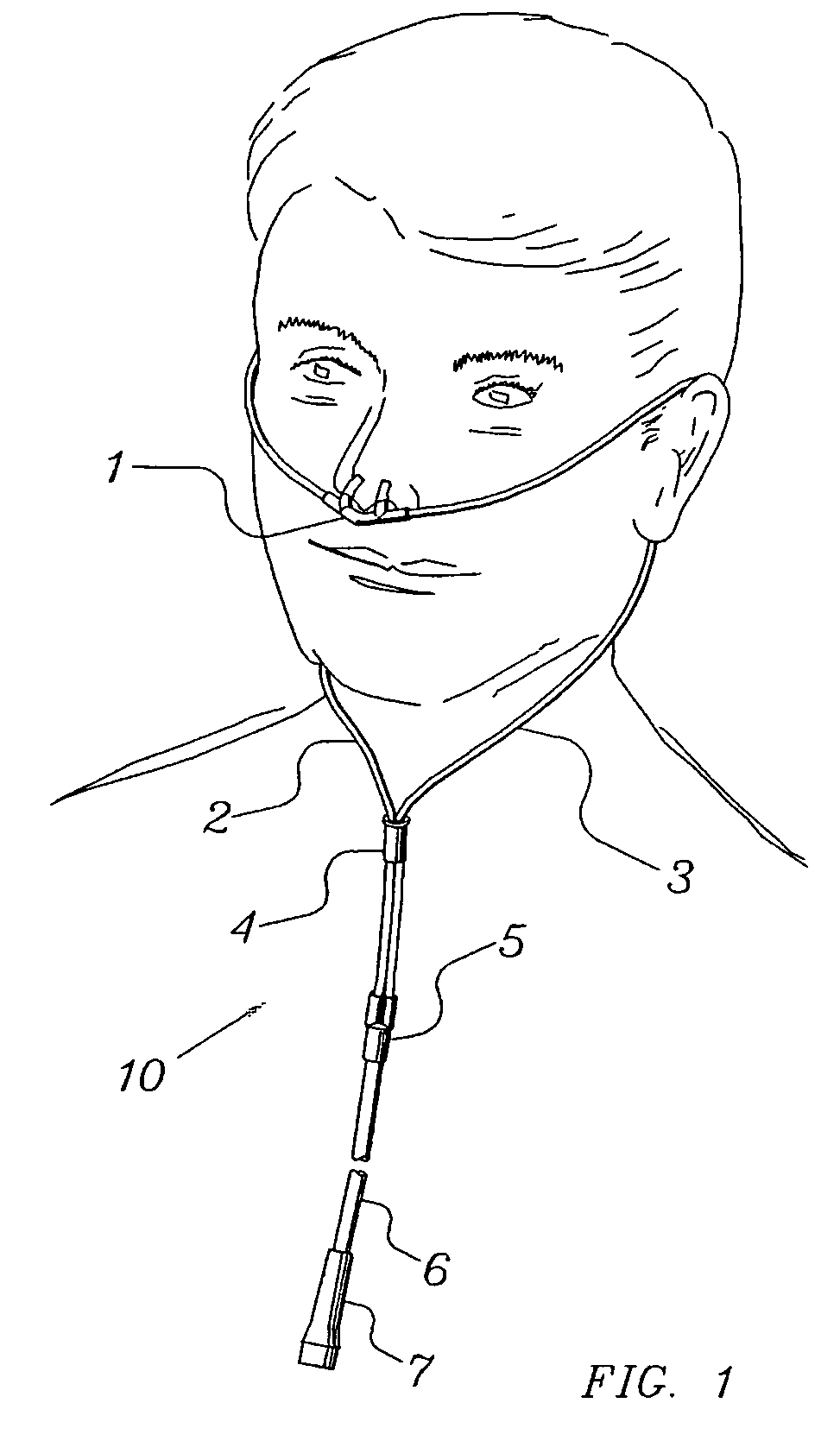

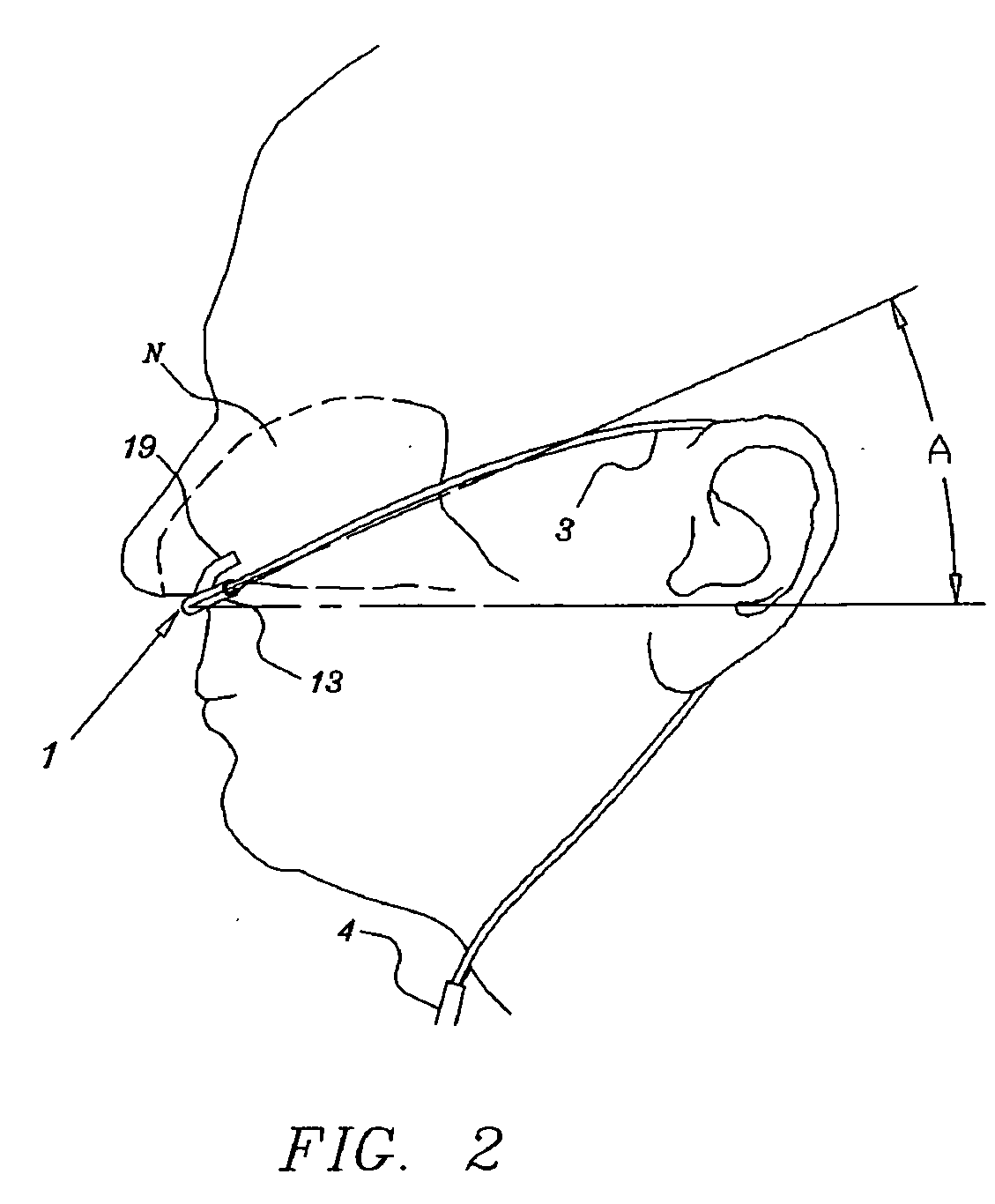

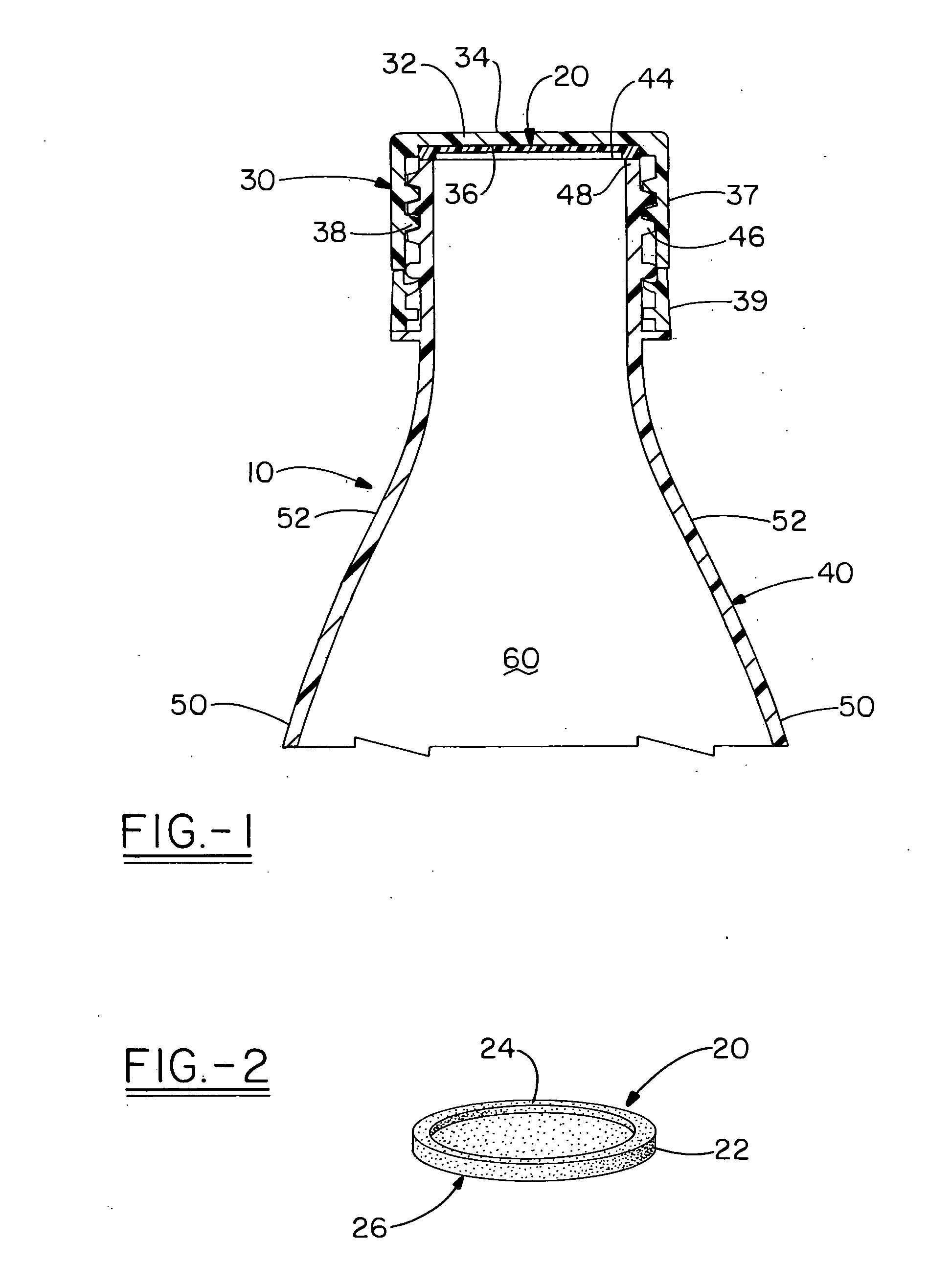

Nasal cannula assembly

A nasal cannula assembly designed for contact with the nasalabidial area of a patient's face comprising a nasal cannula, a pair of oxygen supply tubes connected to opposite ends of the nasal cannula and a main oxygen supply line. The nasal cannula is made of a flexible plastic material molded into a light-weight hollow tubular member having a main body portion formed at an acute angle in the center and having a pair of spaced exterior orifices projecting from the body at an angle and curved upwardly and inwardly for directing gas flow into a patient's nostrils. Attachment points for oxygen supply tubes are above center of gravity of the nasal cannula to make it self-righting thus eliminating need for stiff supply tubing to orient cannula. Oxygen supply tubes made from ultra-high molecular weight PVC possess superior flexibility and low compression set so that little tension on the tubing is required to hold cannula in proper position. A main oxygen supply line made from ultra-high molecular weight PVC resists the formation of twisted loops that tend to block oxygen flow.

Owner:THOMPSON PAUL S

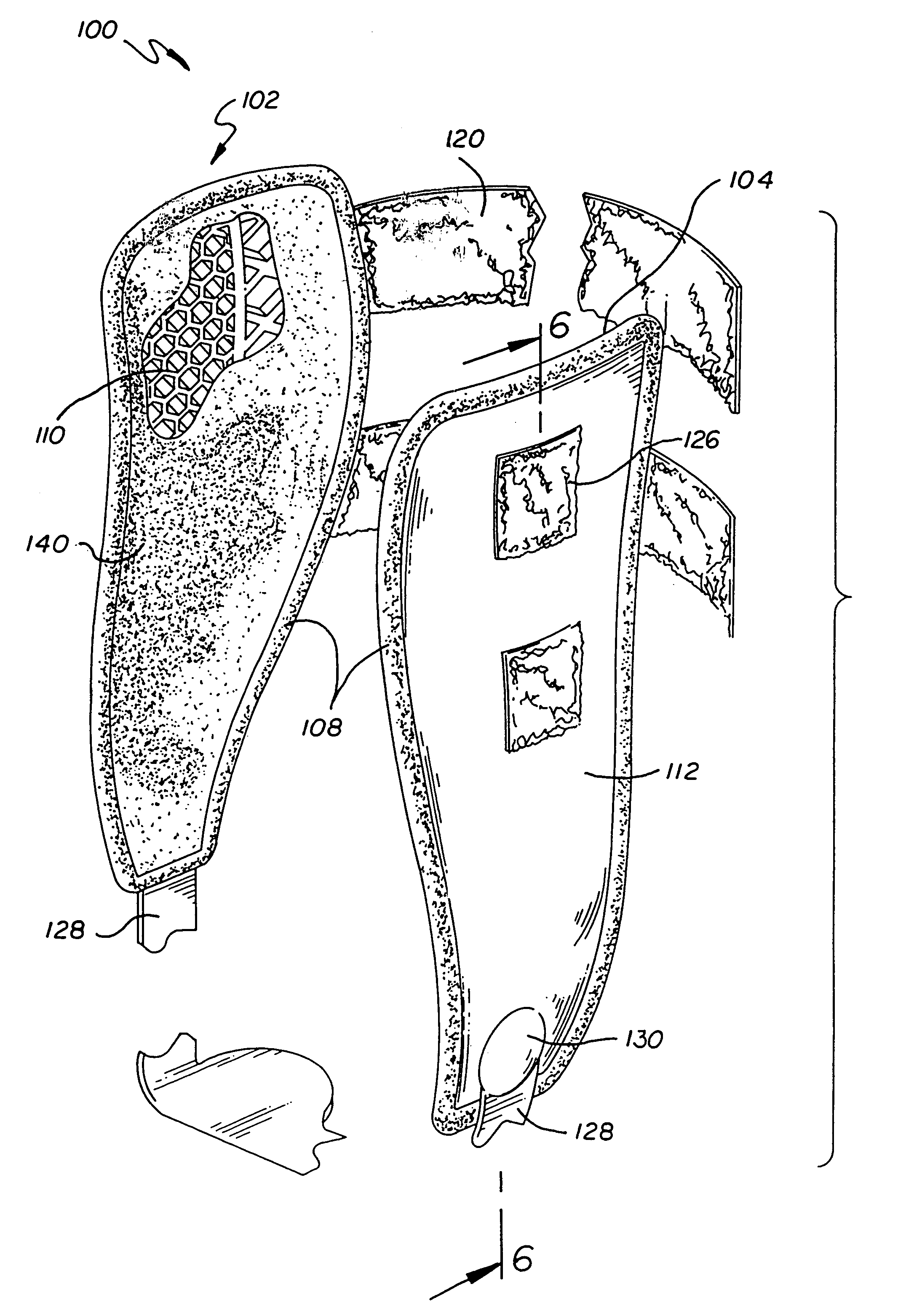

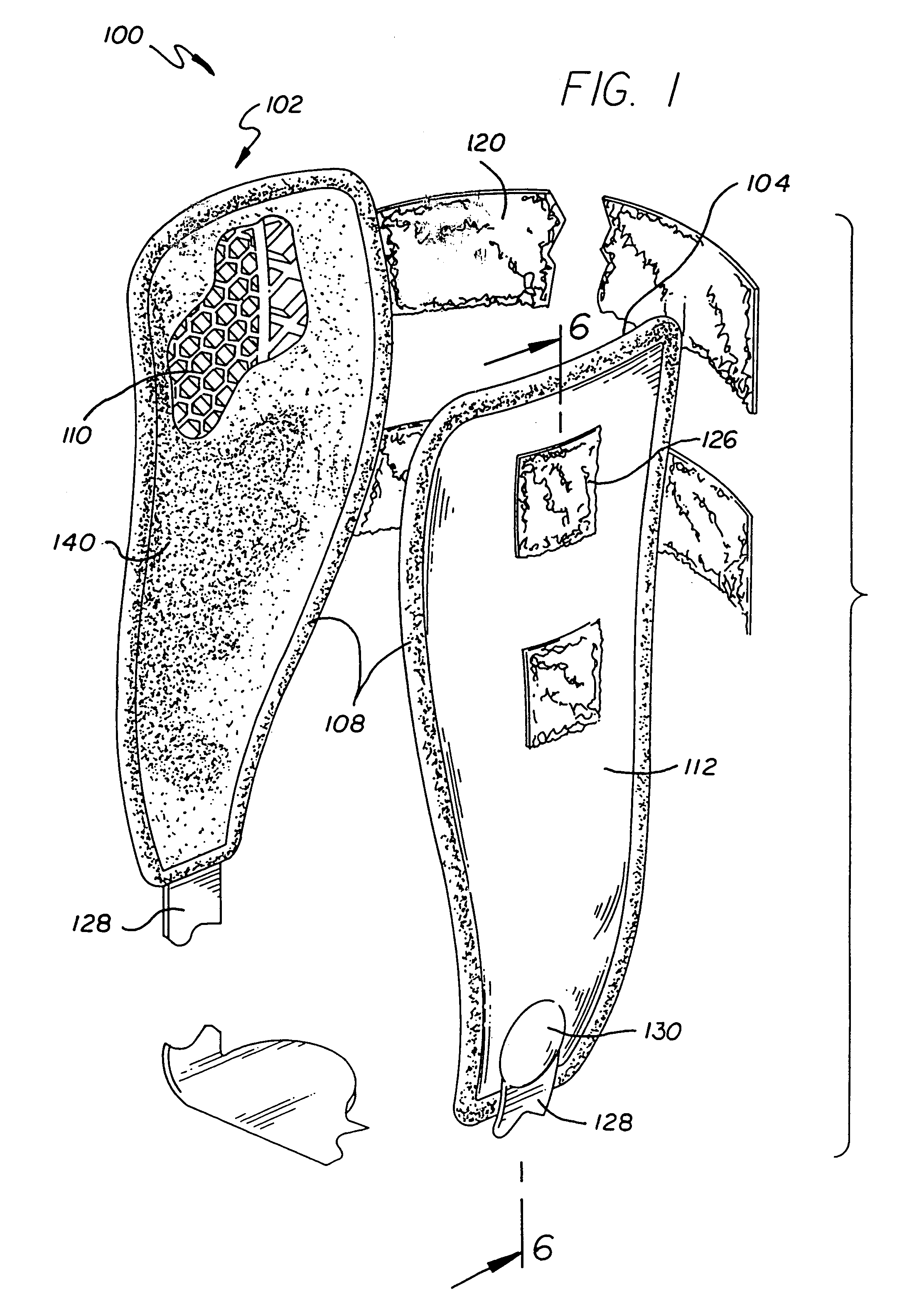

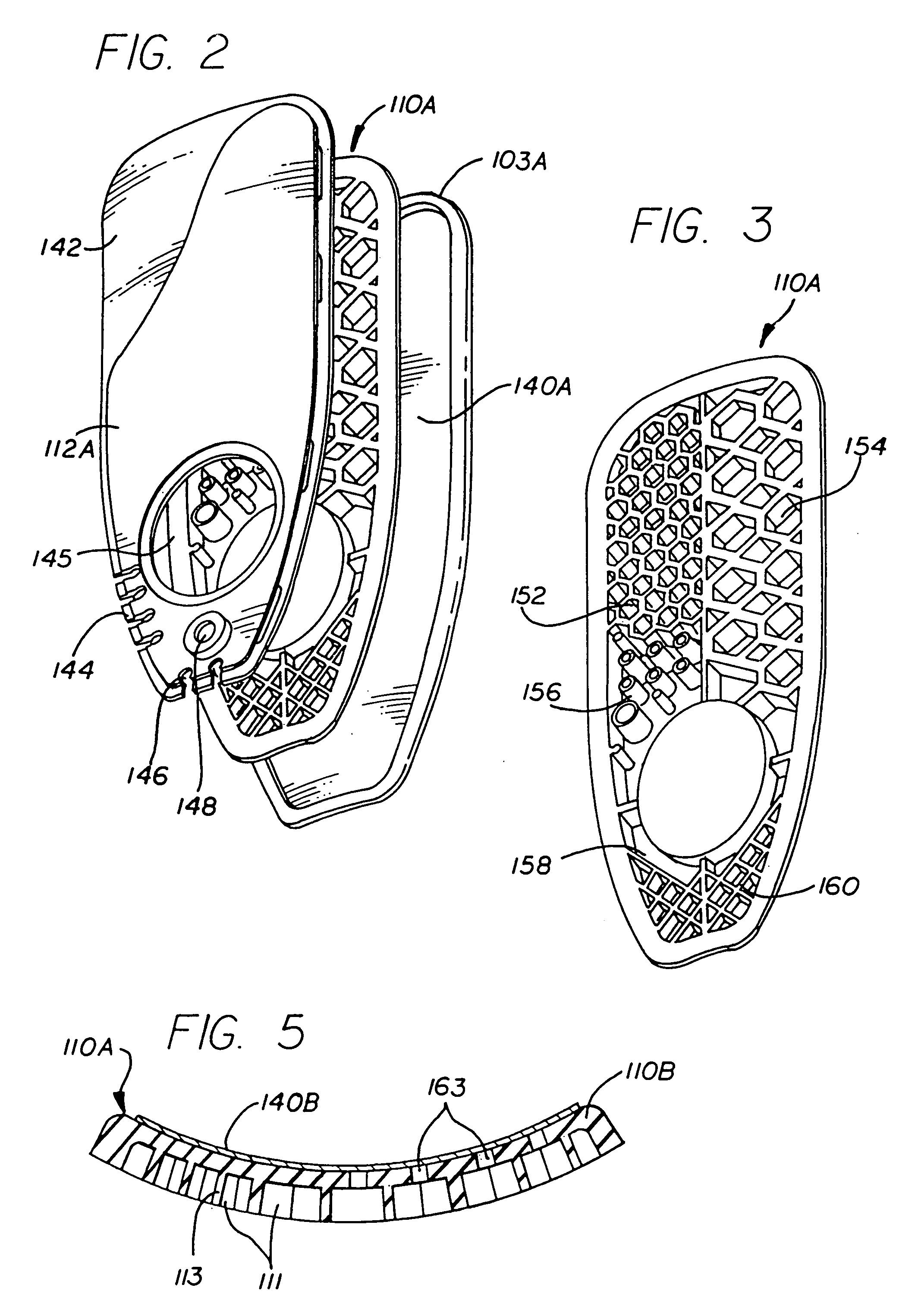

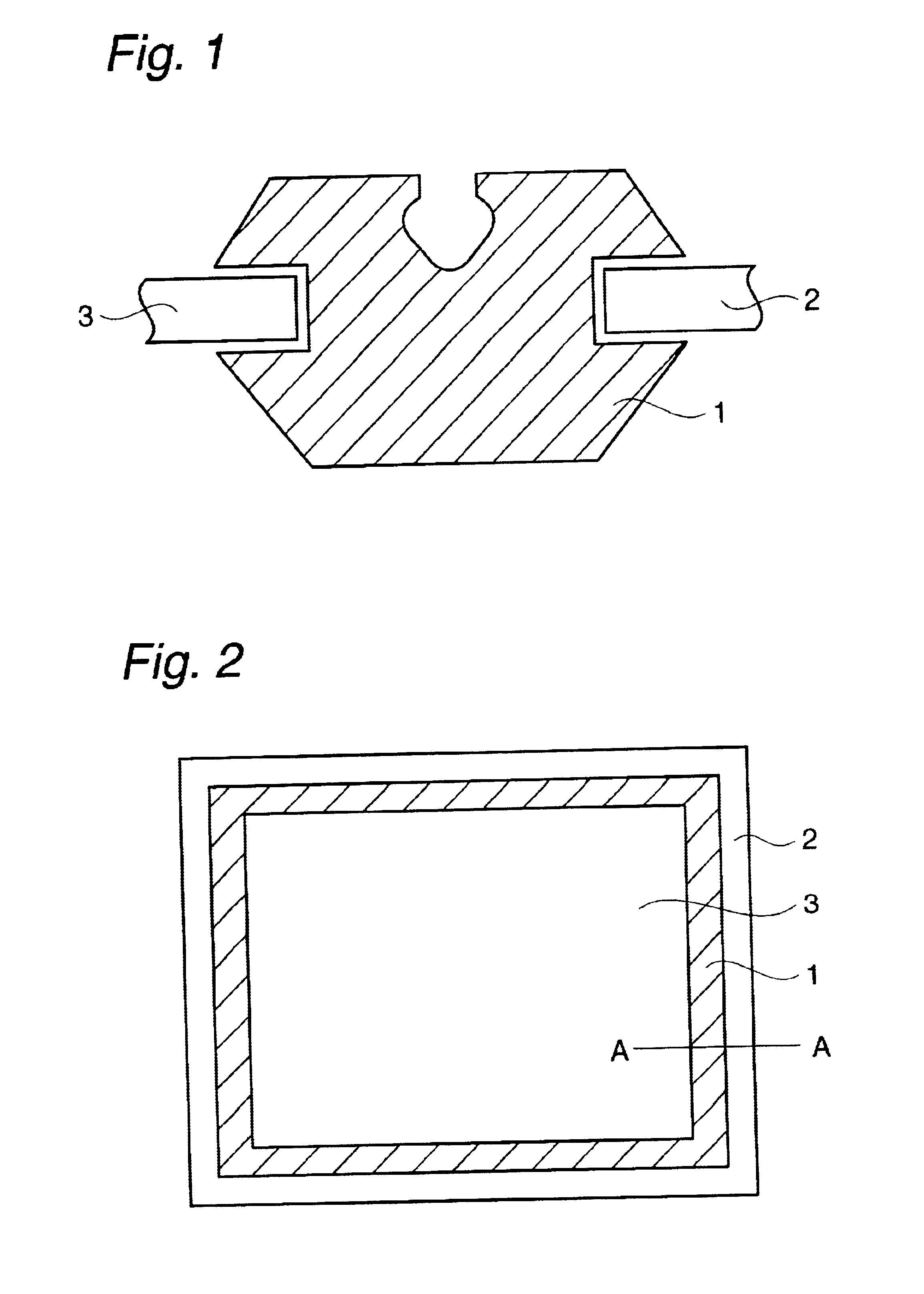

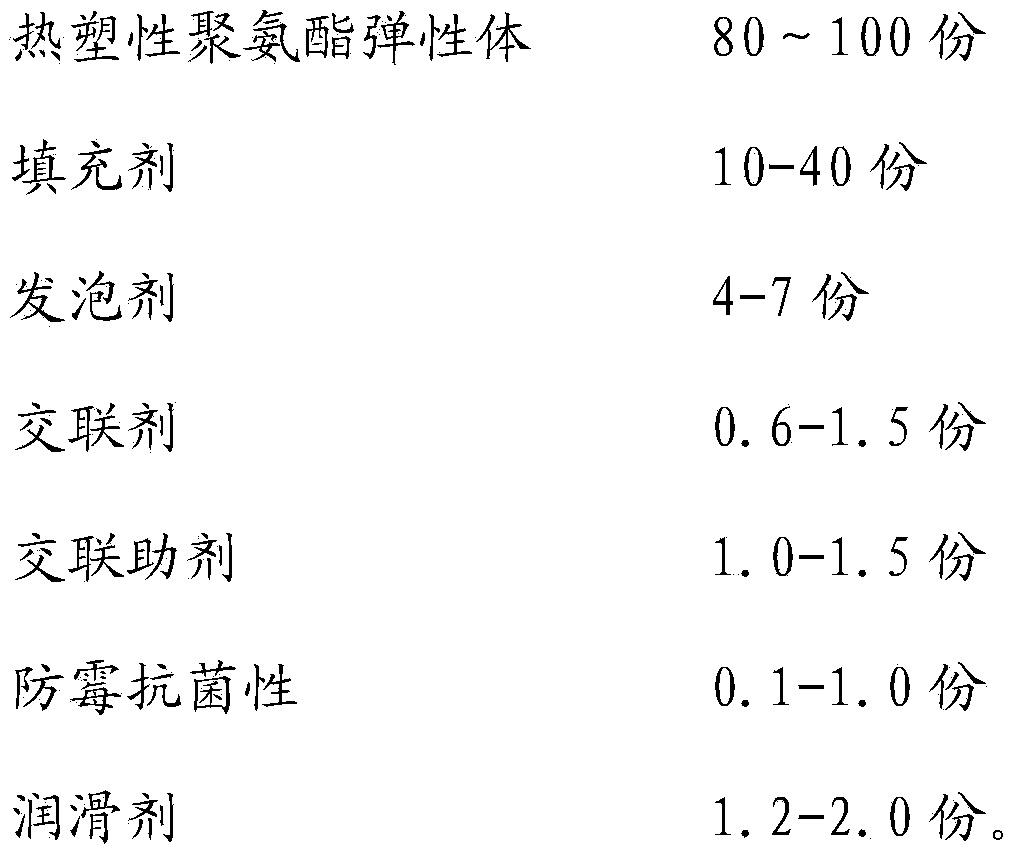

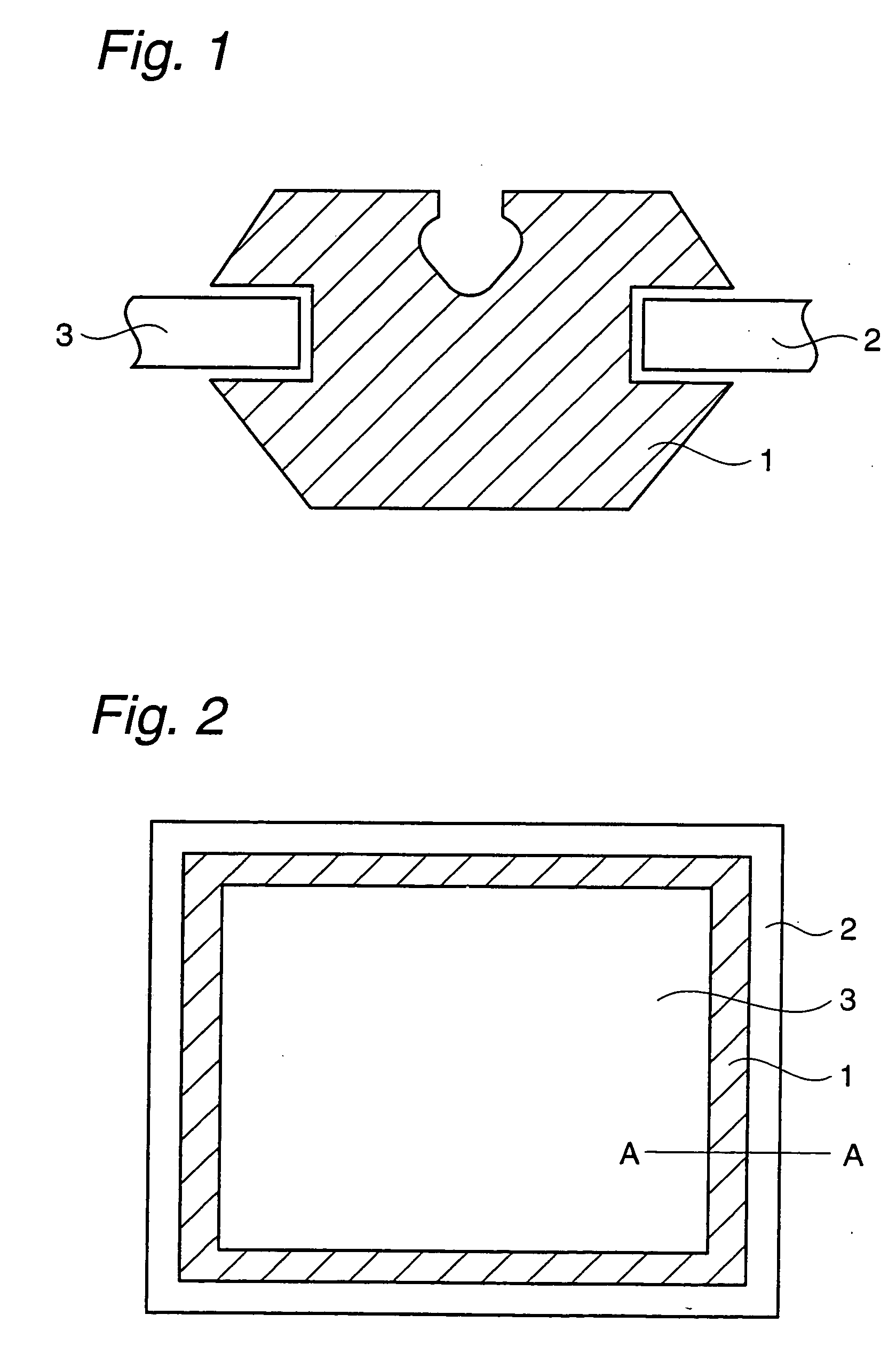

Comfortable orthopaedic support and the method of making the same

InactiveUS7018351B1Varying degreeHighly detailed designRestraining devicesNon-surgical orthopedic devicesThermoplastic elastomerCompression set

An ankle support (100) is constructed using a molded pad (110) and a rigid shell (112). The pad (110) and the shell (112) may be sealed together to form a bladder-pad cushion for comfort. The internal structure of the pad (110) is molded to include geometrically shaped cells of various size, shape and thickness to provide differing levels of localized comfort to the user of the ankle support (100). The pad may be made from a thermoplastic elastomer (TPE) which is spring-like and resists compression sets. The pad may include integrally-molded fingers extending to the shell. The fingers may have different lengths in one or more regions, in order to increase the cushioning effect in a particular region. The pad / shell combination may form a sealed bladder, and a pneumatic pump may be provided in conjunction with the shell so that the user can inflate the bladder.

Owner:OSSUR HF

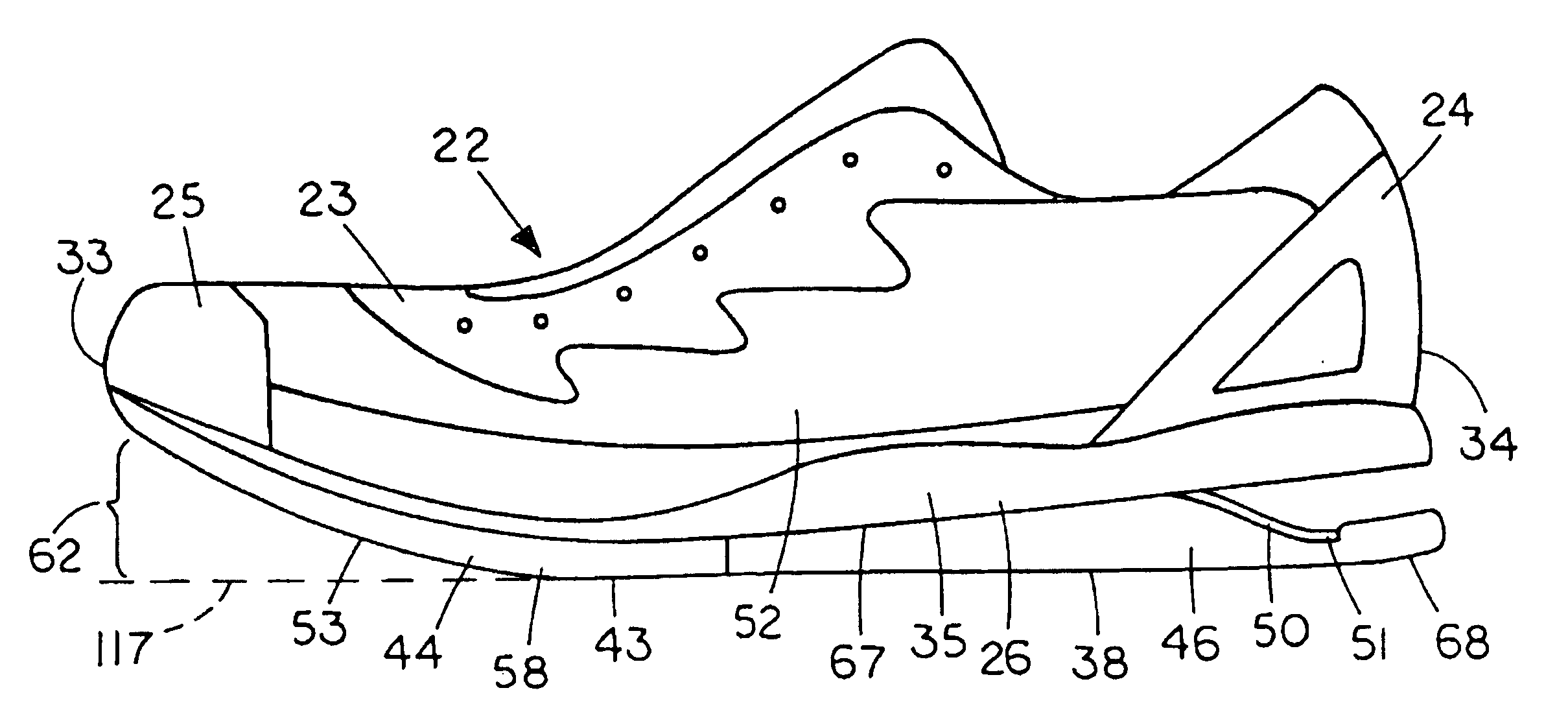

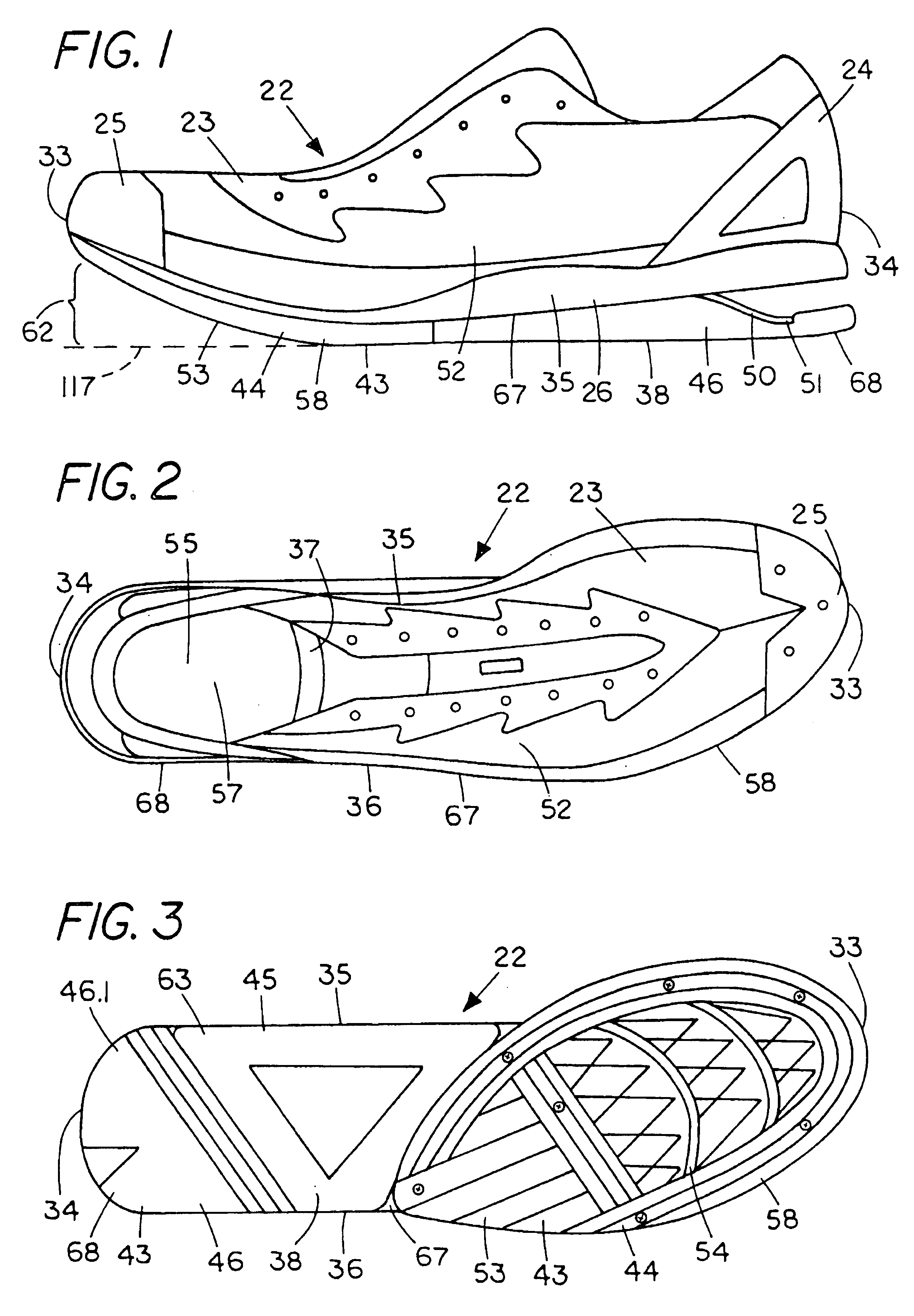

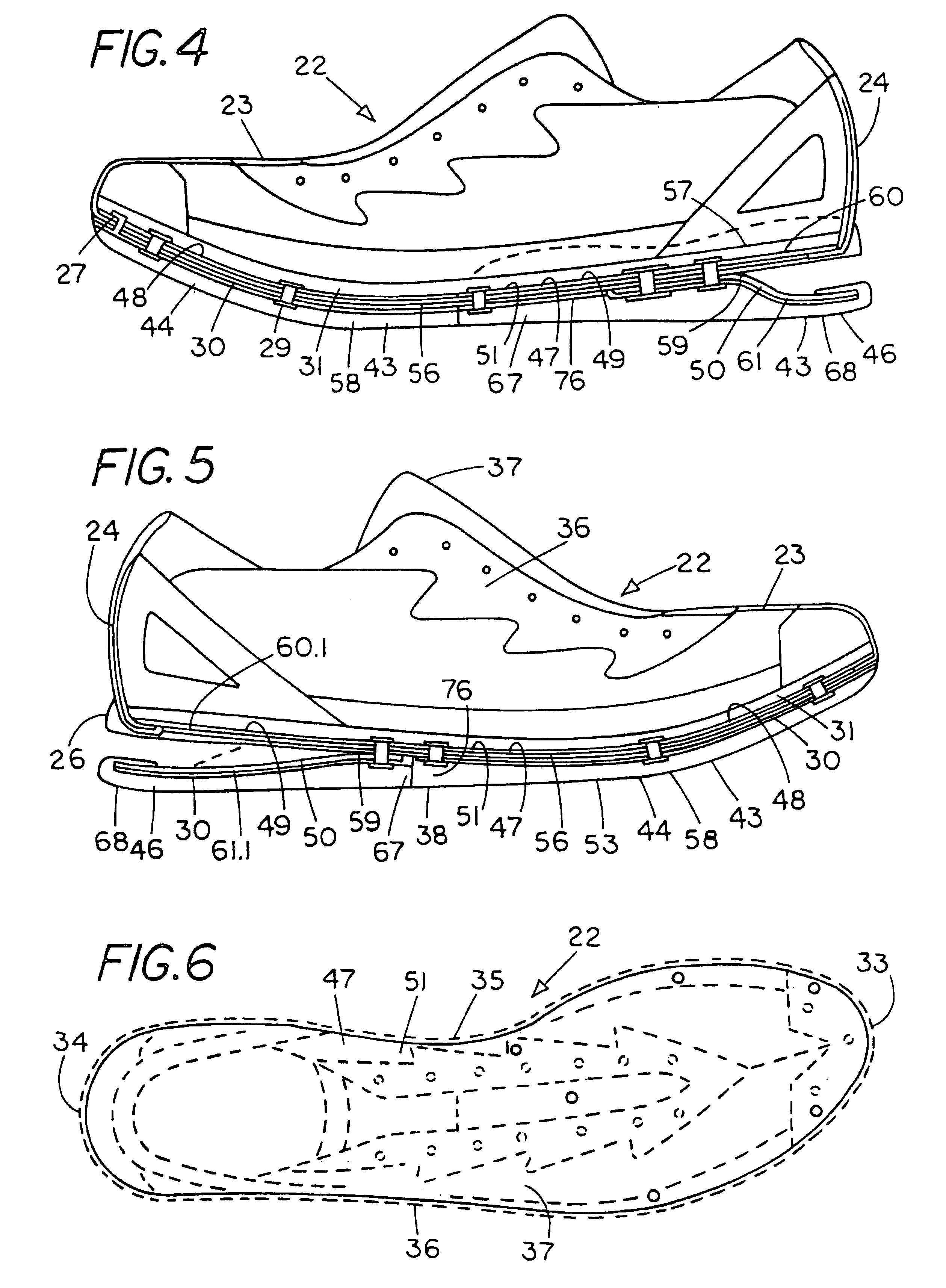

Method of conducting business including making and selling a custom article of footwear

The article of footwear taught in the present invention includes a spring element that can provide improved cushioning, stability, and running economy. Unlike the conventional foam materials presently being used by the footwear industry, a preferred spring element is not substantially subject to compression set degradation and can provide a relatively long service life. The components of the article of footwear including the upper, insole, spring element, and sole can be selected from a range of options, and can be easily removed and replaced, as desired. Moreover, the present invention teaches a method of making a customized article of footwear, and also a way of doing retail and Internet business.

Owner:ADIDAS

High-durability flexible polyurethane cold cure molded foam and process for producing the same

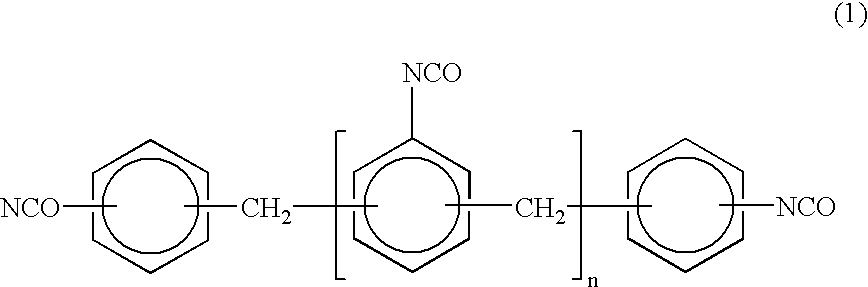

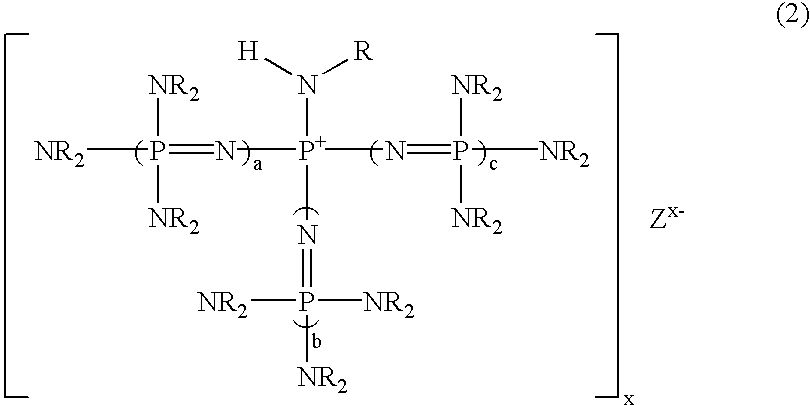

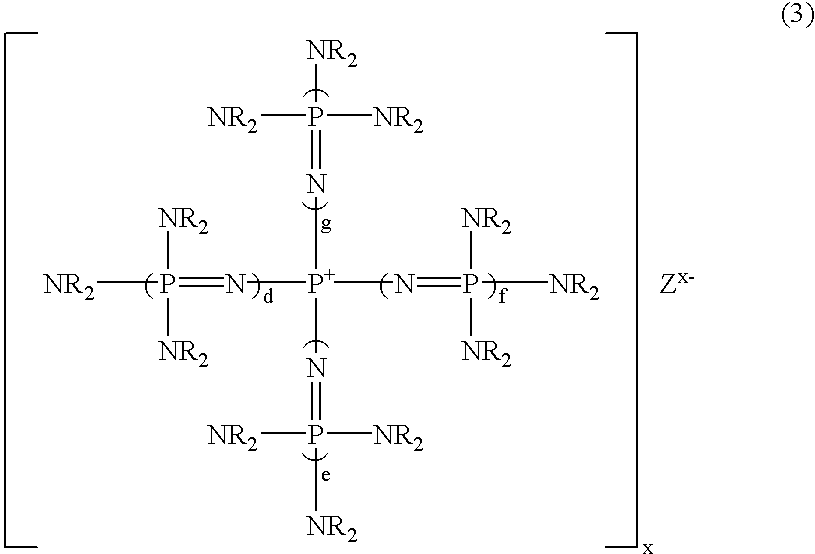

The high-durability flexible polyurethane cold cure molded foam of the invention has an overall density of not less than 35 kg / m3 and not more than 45 kg / m3 and a wet heat compression set of not more than 15%, and preferably has a hardness change ratio, as determined in a repeated compression test, of not more than 15%. This foam can be obtained by the process of the invention. The process of the invention is a process for producing a flexible polyurethane cold cure molded foam obtained from a polyol and / or a polymer polyol containing dispersed polymer microparticles obtained by radical polymerizing a compound having an unsaturated bond in the polyol, water, a catalyst and a polyisocyanate, wherein the polyol is a polyol synthesized by the use of a catalyst containing at least one compound selected from the group consisting of a compound having a nitrogen-phosphorus double bond, cesium hydroxide and rubidium hydroxide. The foam of the invention has a low density and is excellent in durability, particularly in hardness change ratio in a repeated compression test and wet heat compression set. According to the process of the invention, such a foam can be obtained.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

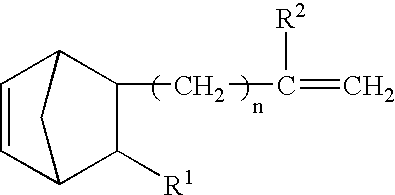

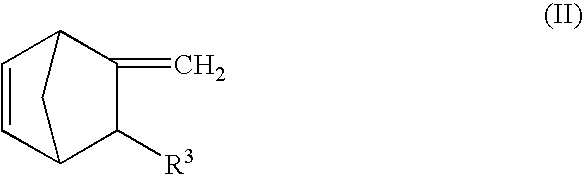

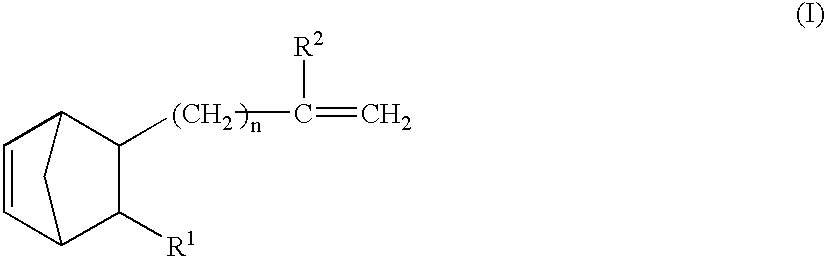

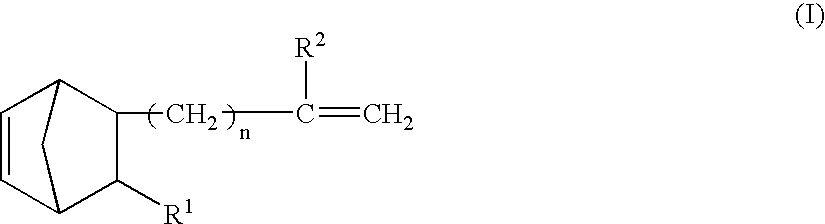

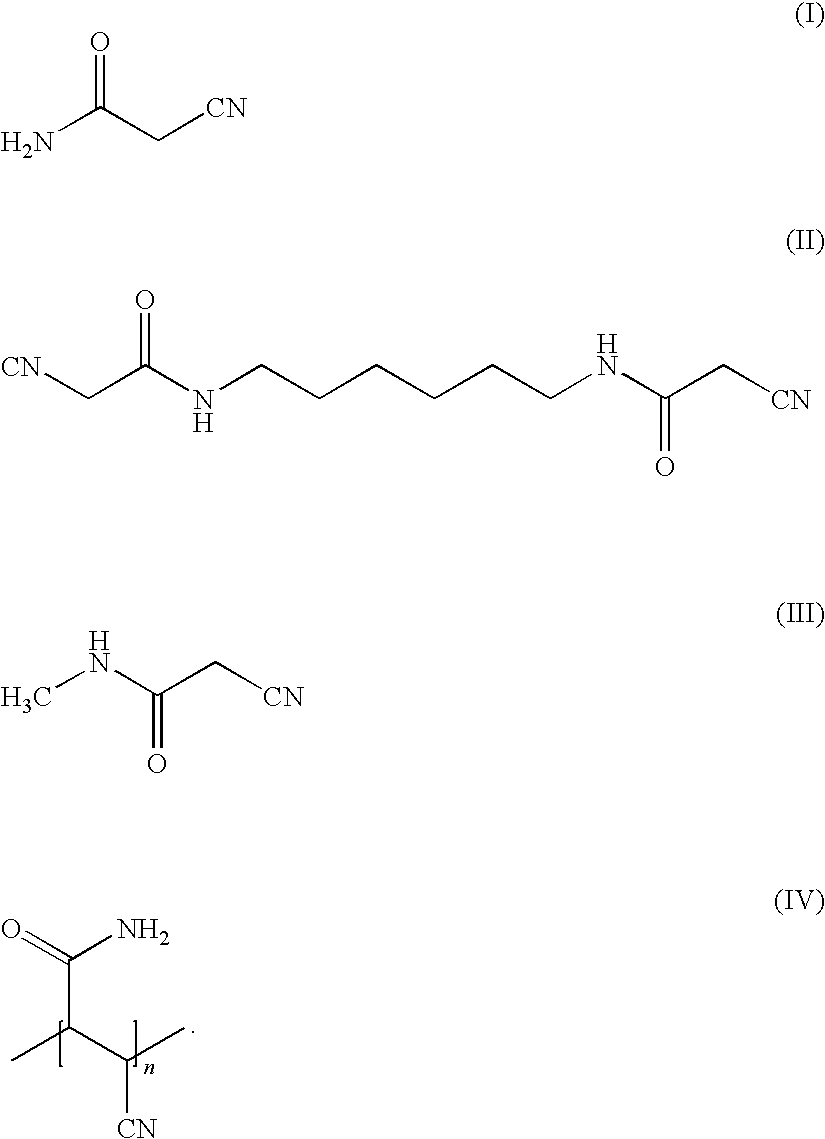

Crosslinkable rubber compositions and use thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC +1

Thermoplastic resin composition and elastomer composition

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

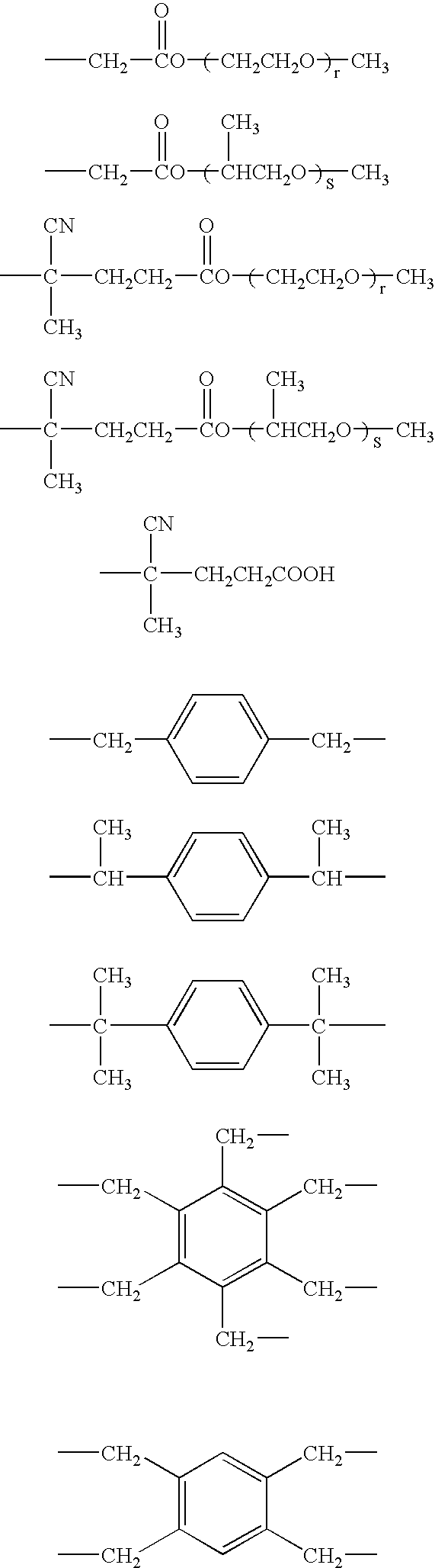

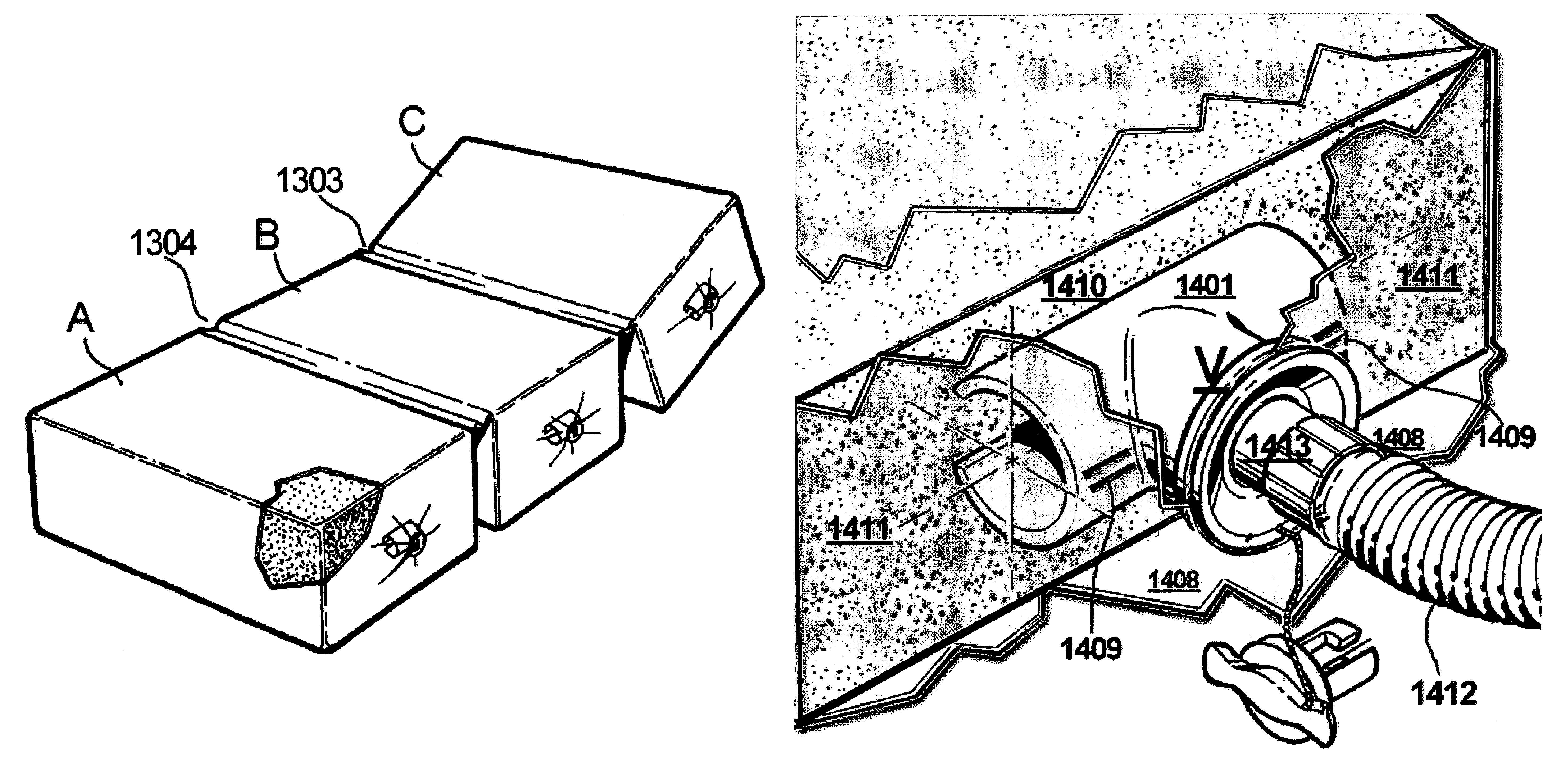

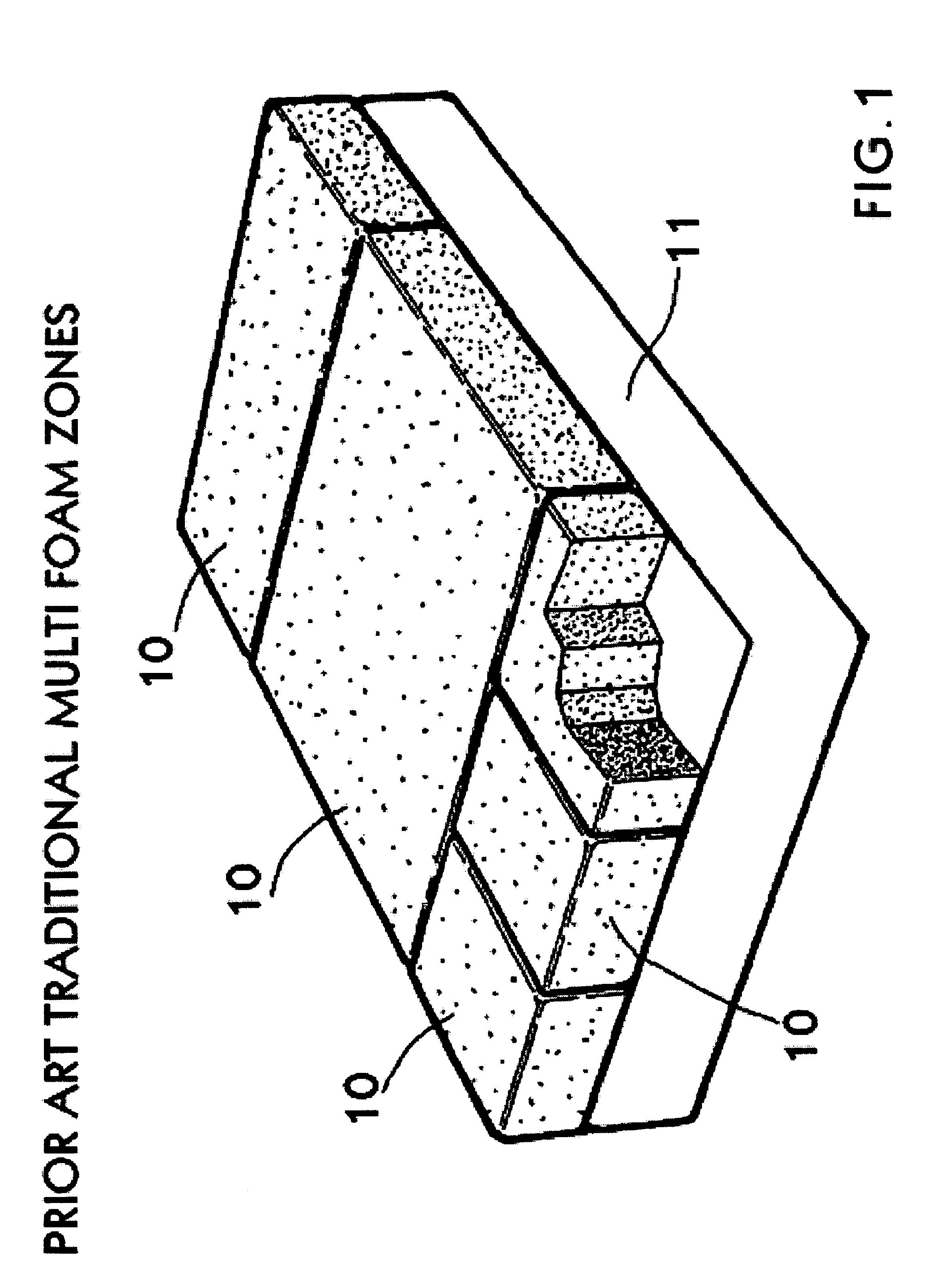

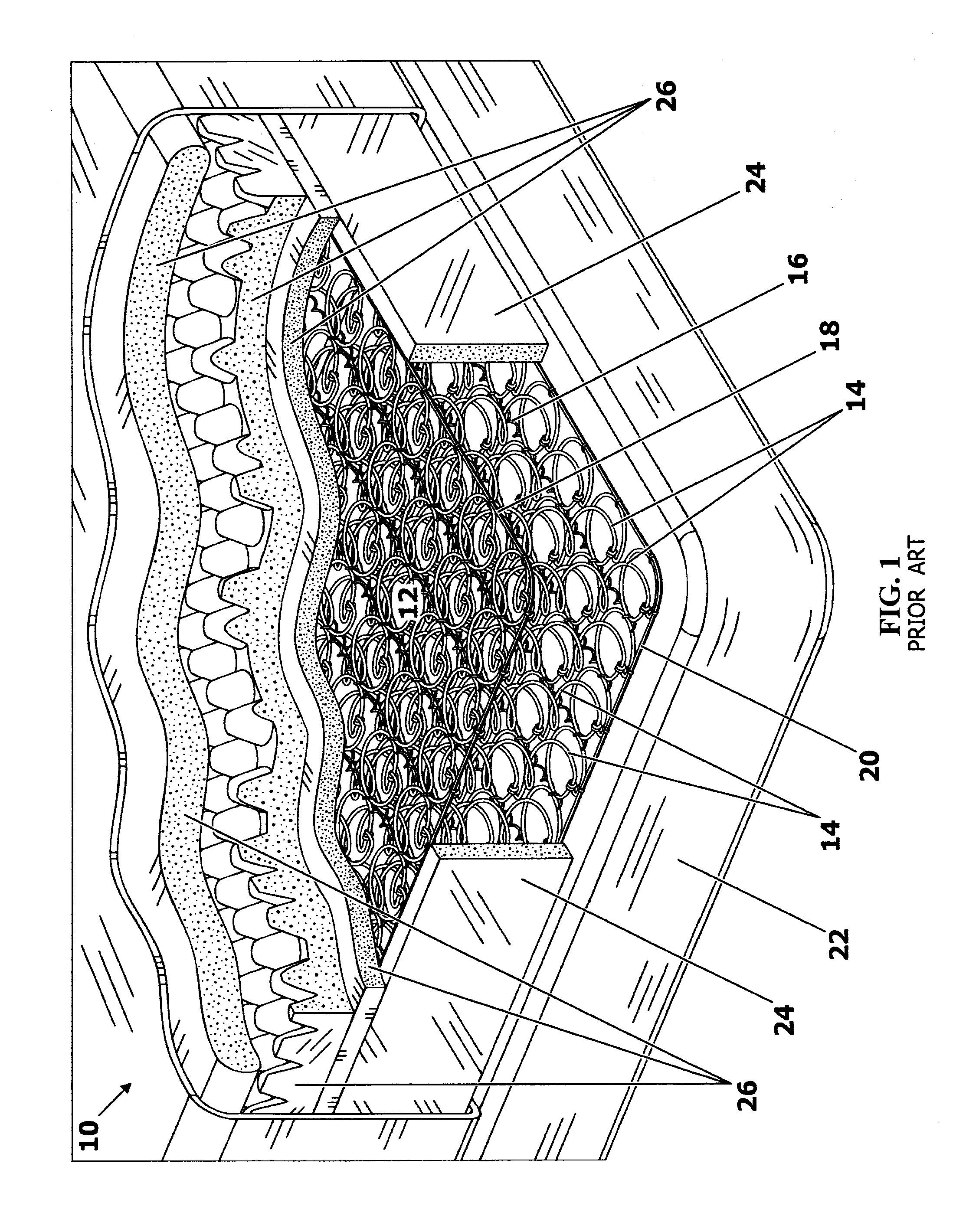

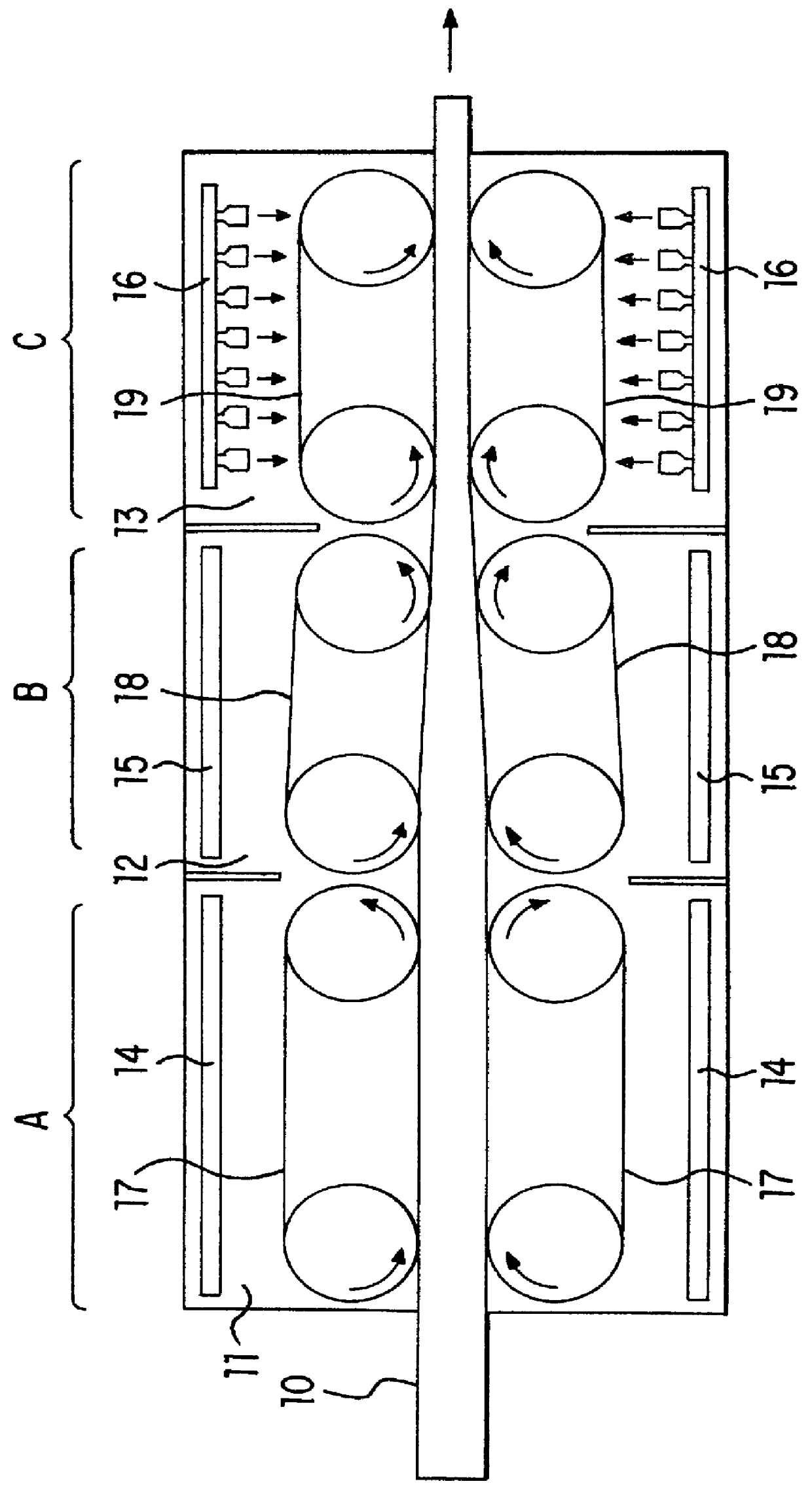

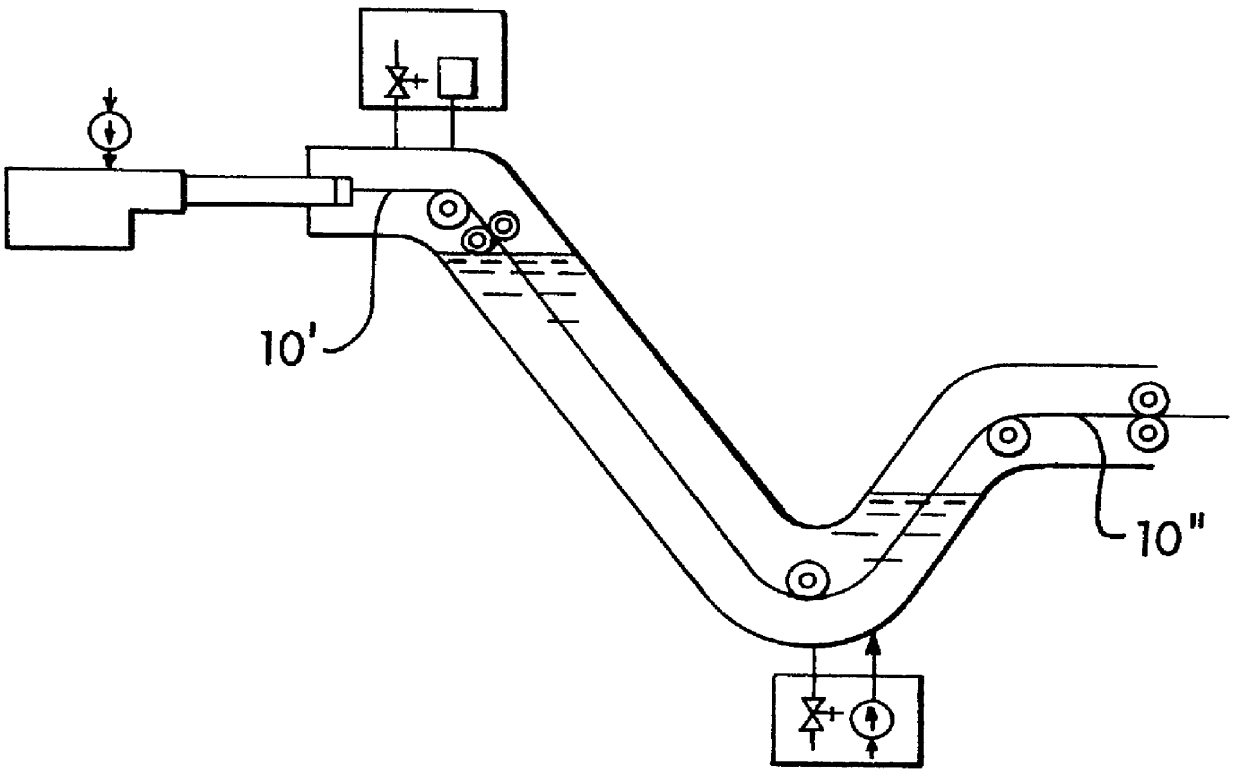

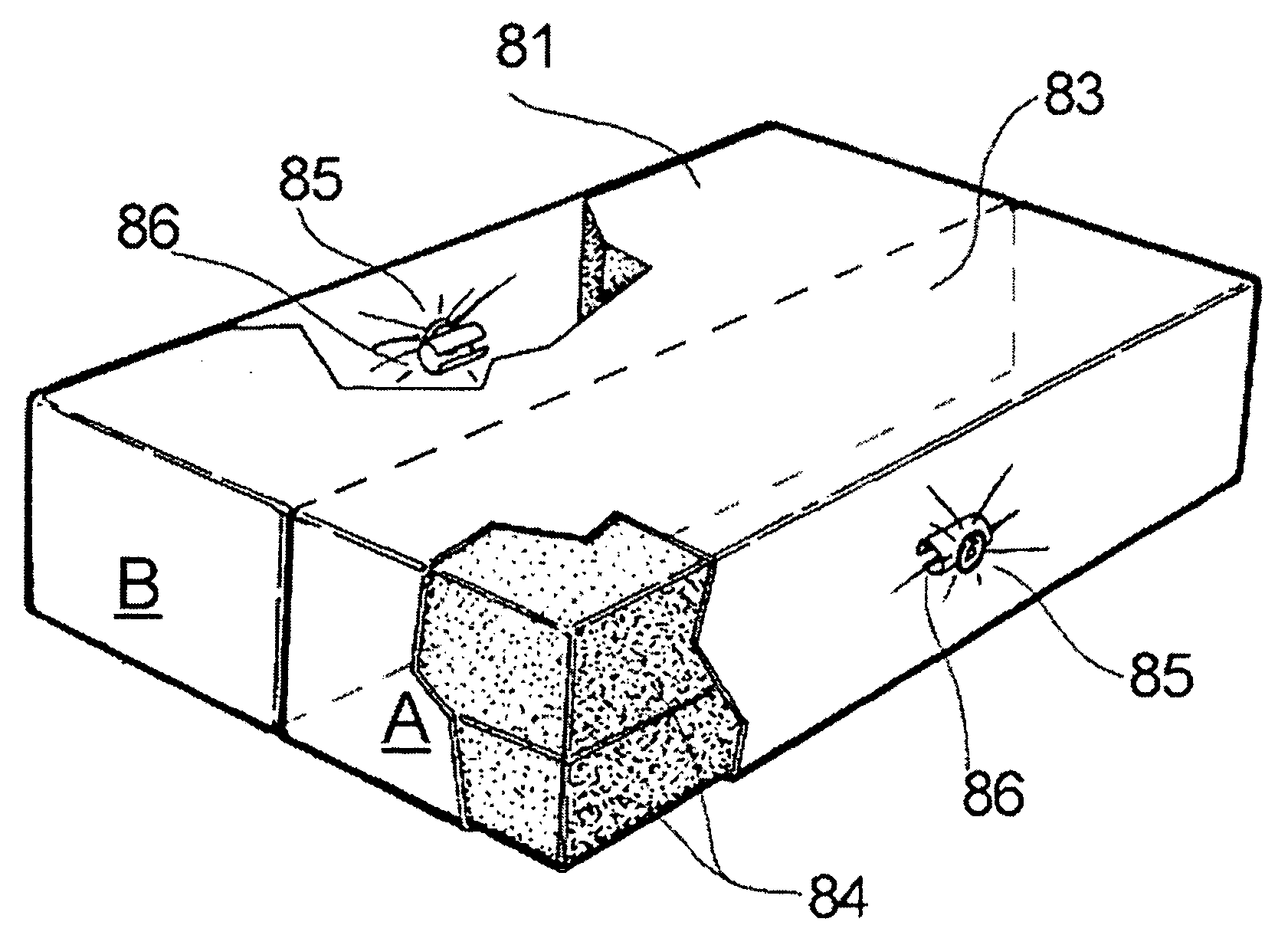

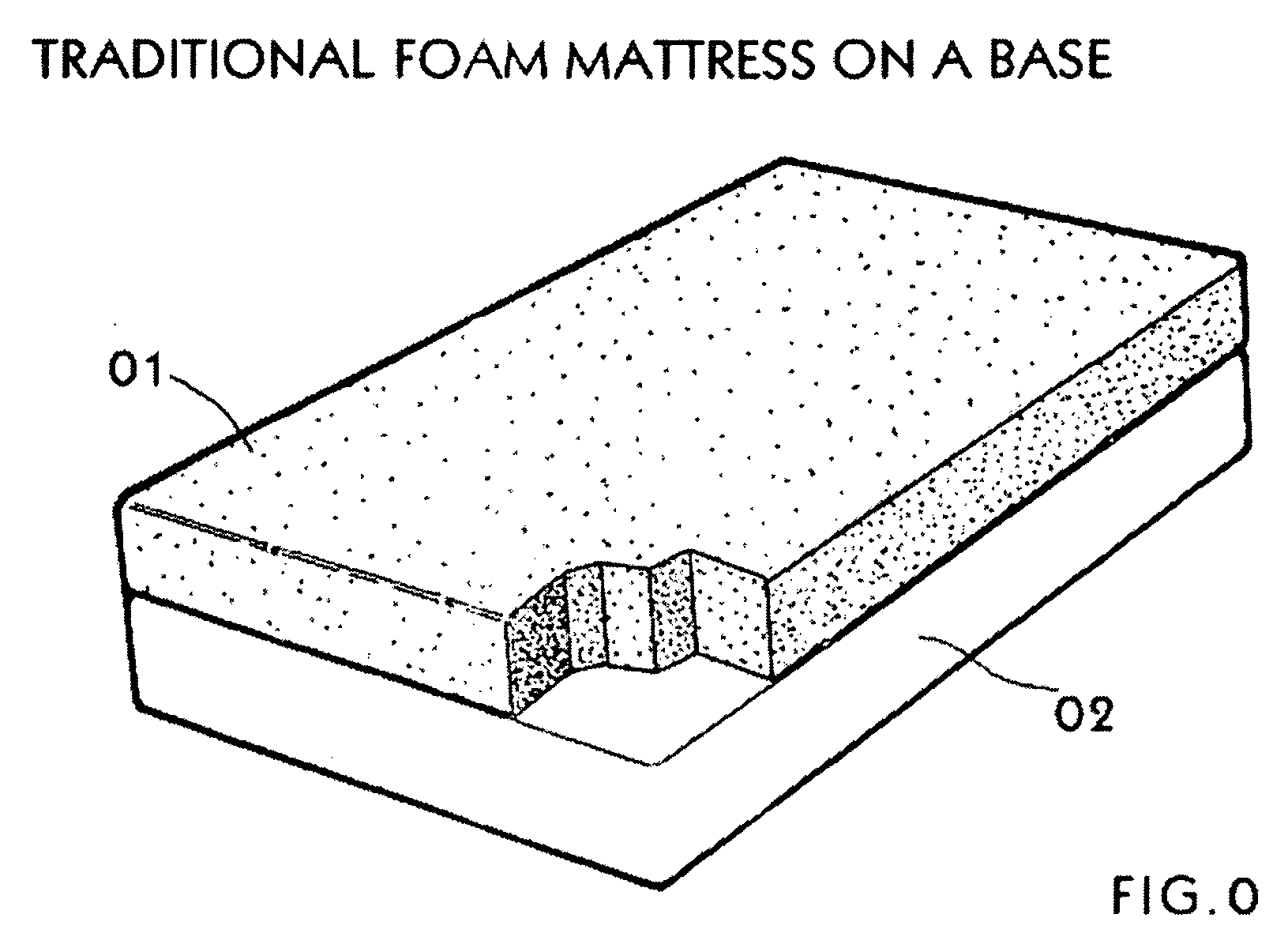

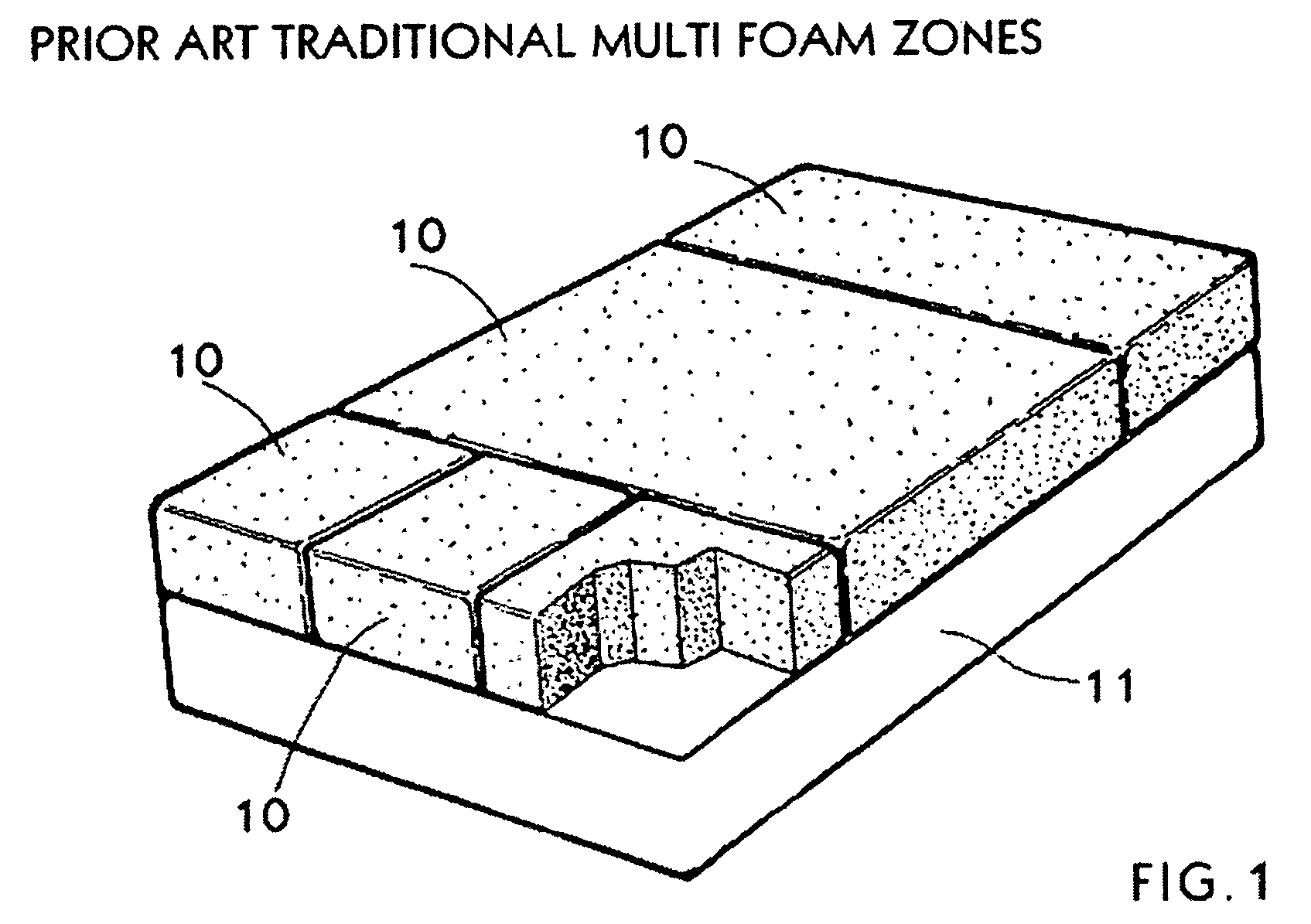

Adjustable foam mattress

InactiveUS6922863B2Improve comfortLower comparable costStuffed mattressesSpring mattressesAir volumeCoil spring

The invention modulates the air volume in foam cores of cushioning support devices and any other support apparatus using foam or similar materials. The foam core can be incrementally modulated to realize an infinite number of comfort levels as to softness and support firmness. The core consists of self-inflating open-cell flexible polyurethane foam and is completely sealed within an enclosure fitted over it, with one or more valves installed in the side walls which communicate with the outside air. Through the valves air is selectively withdrawn from the foam core, allowing the foam's density to increase. The invention uses relatively inexpensive foam, but through air volume modulation achieves a tactile feel of supreme softness for the user, without giving up the necessary firmness to support the body, as happens with very soft foam (bottoming-out or hammock-effect). When air is extracted from a self-inflating foam core, the surface of the core will soften uniformly while maintaining its support firmness. Contrary to this, when pressure is exerted on, for example, traditional coil spring core mattresses, their surface will harden. Integral part of the invention is a device using balanced springs in valve assemblies to avoid compression set, an irreversibly solid state of totally air-depleted foam.

Owner:GIORI GUALTIERO G +1

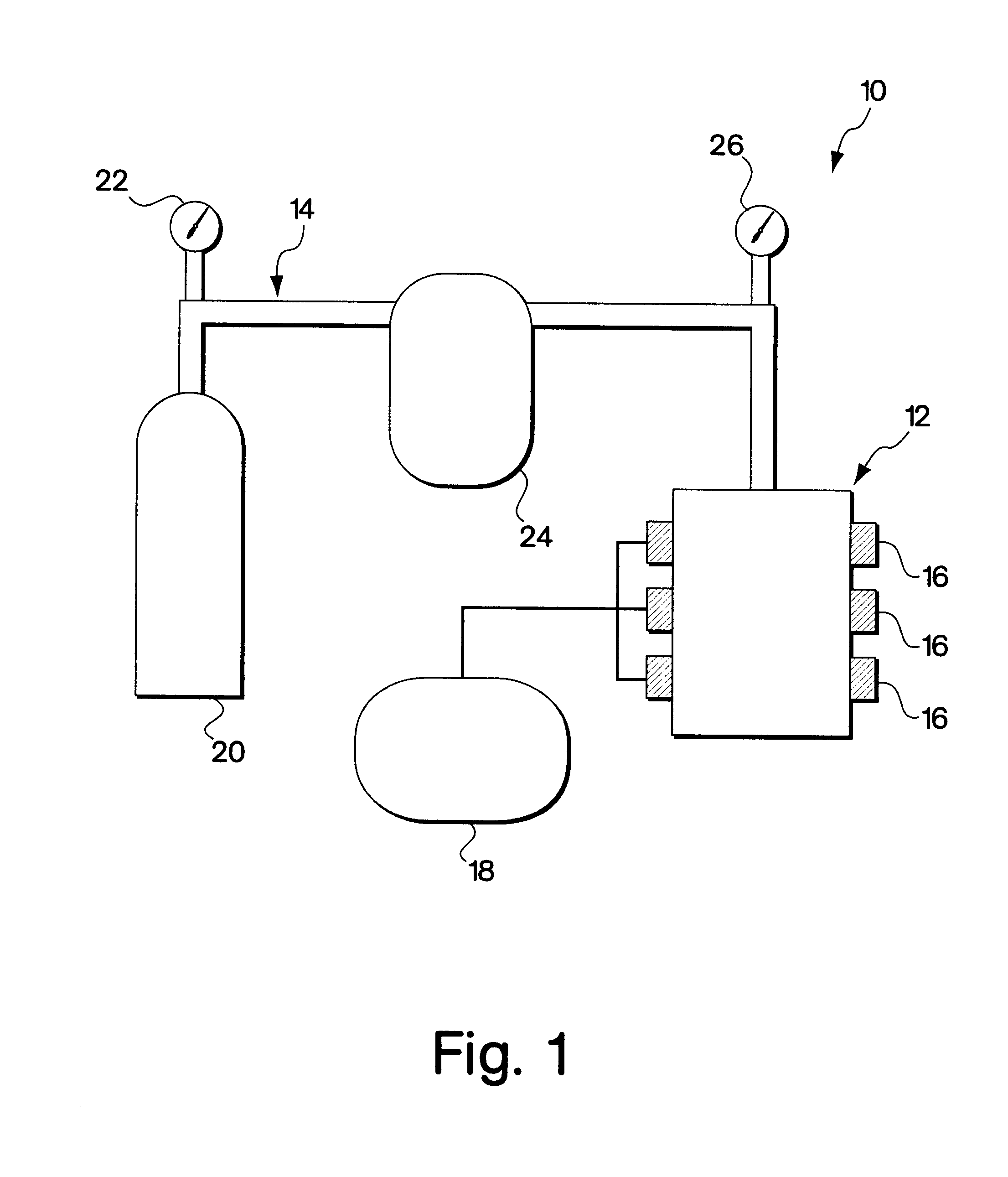

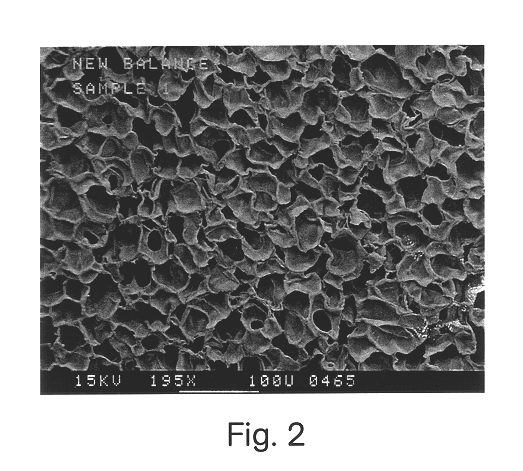

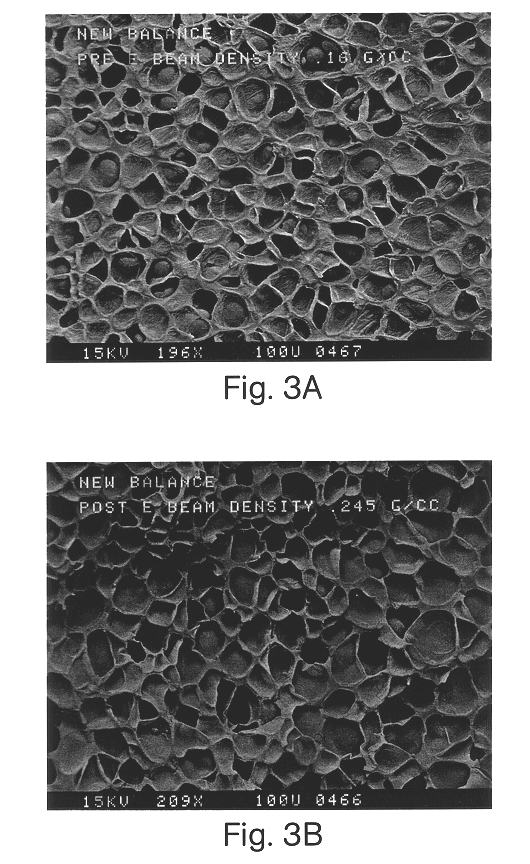

Microcellular thermoplastic elastomeric structures

Microcellular thermoplastic elastomeric polymeric structures are provided. The articles have an average cell size of less than 100 mum and a compression set ranging from less than about 30% to less than about 5%, and a rebound value of at least 50%. The articles may be formed from a thermoplastic elastomeric olefin, preferably metallocene-catalyzed polyethylene. The density of the articles ranges from less than 0.5 gm / cm3 to less than 0.3 gm / cm3.

Owner:TREXEL

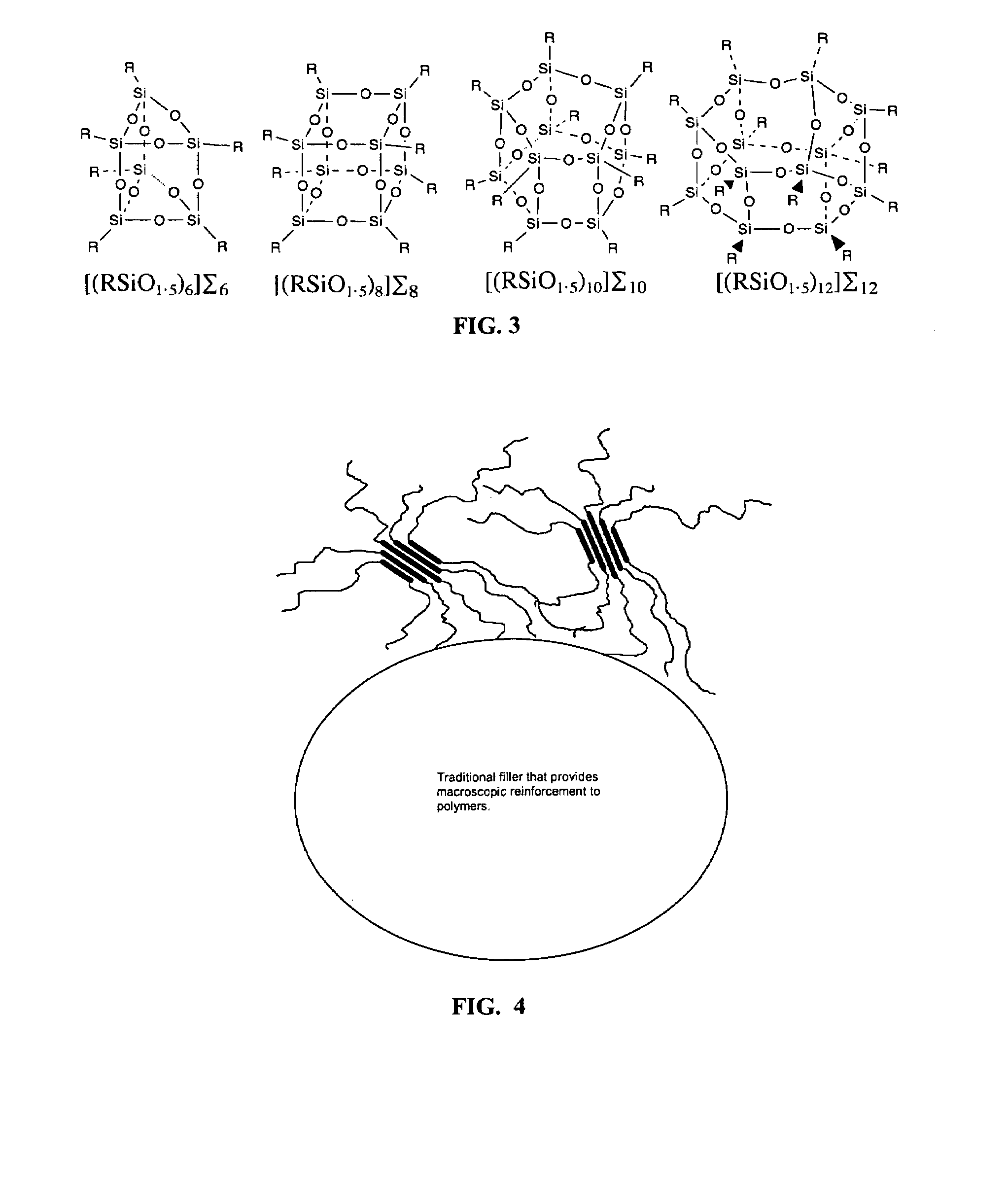

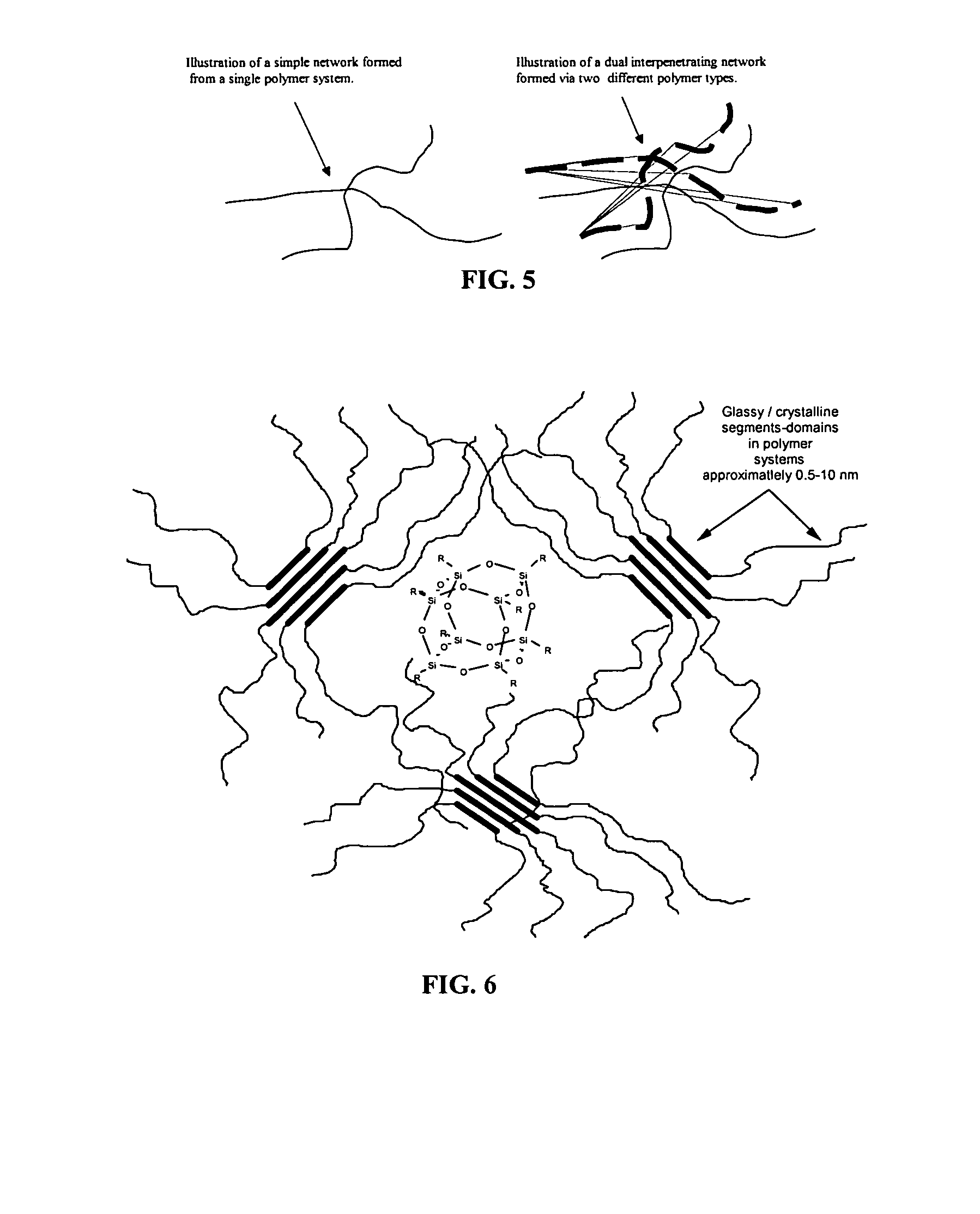

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Polyurethane foam, process for producing the same, and foam forming composition

InactiveUS6455606B1Improve mechanical propertiesLow compression setPeptide preparation methodsCushioningFoaming agent

A polyurethane foam which is obtained by reacting an addition-polymerizable active hydrogen component comprising a compound having a group containing active hydrogen and an addition-polymerizable functional group or comprising both this compound and a compound containing at least 2.5 groups (on the average) containing active hydrogen and not containing addition-polymerizable functional groups with an organic polyisocyanate in the presence or absence of at least one auxiliary selected from the group consisting of foaming agents and additives to polymerize the addition-polymerizable functional group and simultaneously form a polyurethane, and which has a structure in which the chains formed by the addition polymerization have been cross-linked to the polyurethane chains. The polyurethane foam is useful as a rigid polyurethane foam excellent in hardness, dimensional stability, etc. and usable as a heat insulator, shock-absorbing material, synthetic wood, etc., or is useful as a soft polyurethane foam reduced in compression set and usable as a cushioning material, shock-absorbing material, sound insulating / absorbing material, etc.

Owner:SANYO CHEM IND LTD

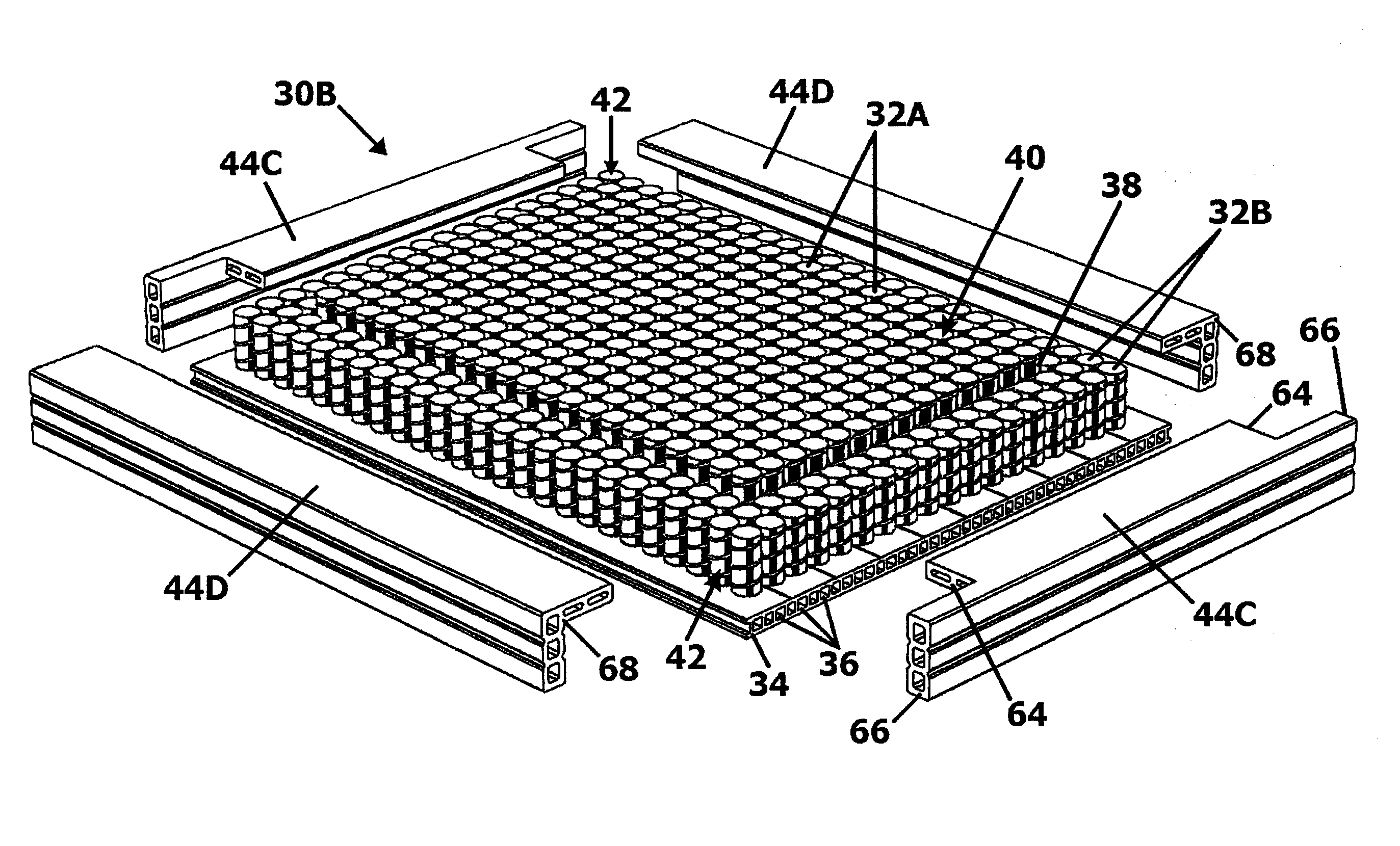

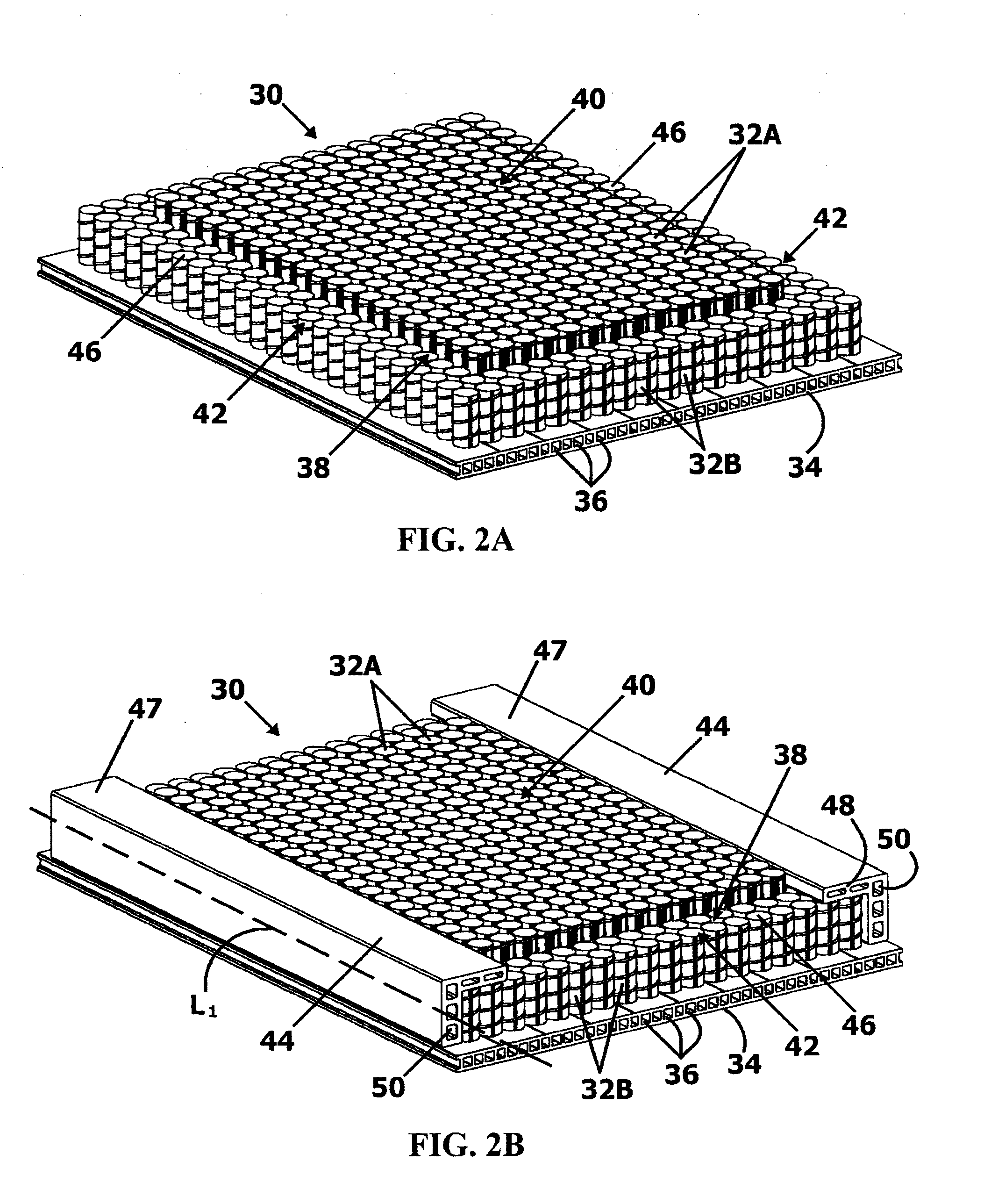

Stepped-edge and side-support members, assemblies, systems, and related methods, particularly for bedding and seating

InactiveUS20100319137A1Low costReduce the amount requiredUpholstery manufactureStuffed mattressesCompression setMechanical engineering

Stepped-edge and side-support members, systems, assemblies, and related methods for an innerspring assembly or other core are disclosed. In one embodiment, an innerspring assembly or core is provided having an interior area of a first height surrounded by one or more exterior, perimeter area(s) of shorter height(s) to provide a stepped-edge innerspring assembly or core. At least a portion of side-support members are placed onto at least a portion of the top surface of the perimeter area to provide edge-support for the innerspring assembly or core. In this manner, a greater portion of the side-support members can be disposed in the sleeping area of the innerspring assembly or core since the underlying perimeter area provides spring support to the side-support members. Further, this support can assist in retention and / or recovery of the shape of the side-support members to further prevent or reduce compression set of the side-support members.

Owner:NOMACO

Form-in-place gasket for electronic applications

A non-silicone, form-in-place gasket produced using automated placement followed by curing of a pattern of an extrudable thixotropic material comprising a liquid polyolefin oligomer a reactive diluent a thixotropic filler and a curative. The form-in-place gasket, after curing, has a compression set of about 7% to about 20%, a level of outgassing components of about 10 mug / g to about 45 mug / g and a Shore A hardness from about 45 to about 65.

Owner:3M INNOVATIVE PROPERTIES CO

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition. The rubber composition has a high crosslinking rate at room temperature and excellent productivity, and can prepare crosslinked rubber molded products (including foamed products) having excellent weathering resistance, ozone resistance, heat aging resistance and compression set at low cost. Further, it is suitable for use of electric and electronic parts, transportation machines, civil engineering and construction materials, medical appliances and goods for leisure activities.

Owner:MITSUI CHEM INC

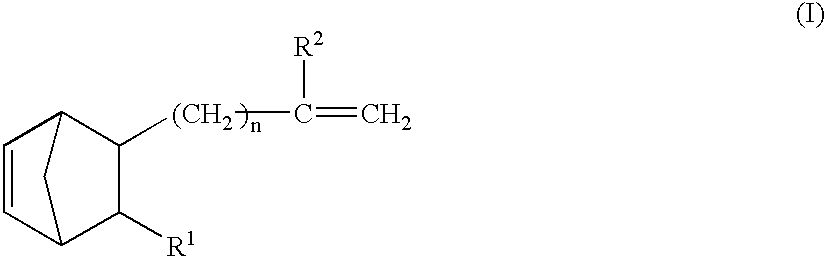

Thermoplastic polyurethane elastomer foam material and preparation method thereof

The invention discloses a thermoplastic polyurethane elastomer foam material, which is prepared from the following raw materials by weight: 80-100 parts of a thermoplastic polyurethane elastomer, 10-40 parts of a filler, 4-7 parts of a foaming agent, 0.6-1.5 parts of a cross-linking agent, 1.0-1.5 parts of a cross-linking assistant, 0.1-1.0 part of a mildew proof antibacterial agent and 1.2-2.0 parts of a lubricant. Adopting the above technical scheme, the invention has the beneficial effects of improving the foam expansion of the thermoplastic polyurethane foam material, expanding the scope of usage of the polyurethane foam material, and realizing compression deformation of a finished product produced from the thermoplastic polyurethane foam at no more than 35%, which is unmatched by an EVA foam material with equivalent foam expansion and similar elasticity. In addition, the foam material improves the performance of existing traditional foam materials, and solves the defects that polyester-type thermoplastic polyurethane elastomer has short service life, easily goes moldy on the product surface and generates mechanical performance loss in the field and damp and hot environment.

Owner:泉州三盛橡塑发泡鞋材有限公司

Retortable liners and containers

ActiveUS20100006532A1Improve sealingPrevent leakageSynthetic resin layered productsSealingPolyolefinPlastic packaging

Retort liners and containers including a container body such as a bottle or jar, a closure, and the retort liner, wherein the retort liners exhibit attractive properties such as low compression set under retort conditions, desirable adhesion to a polymeric closure such as a cap or lid, and beneficial oxygen barrier properties. In particular, the retort liners are thermoplastic elastomers formed from compositions including one or more styrenic block copolymers, one or more polyolefins and a softener. In a preferred embodiment, the retortable containers are all plastic packages, wherein the bottle or jar and the closure are thermoplastic compositions and the liner is a thermoplastic elastomer composition.

Owner:TEKNOR APEX

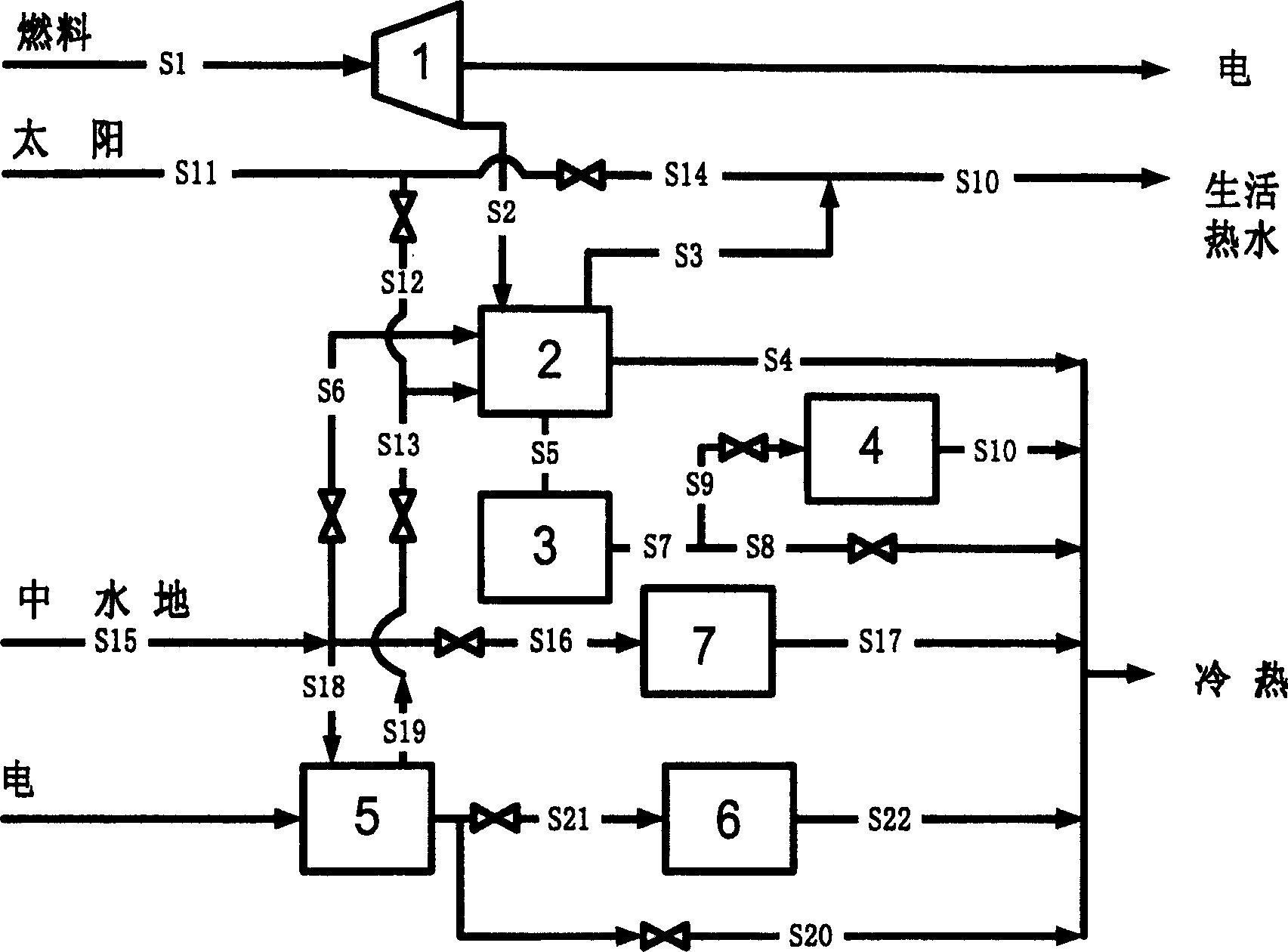

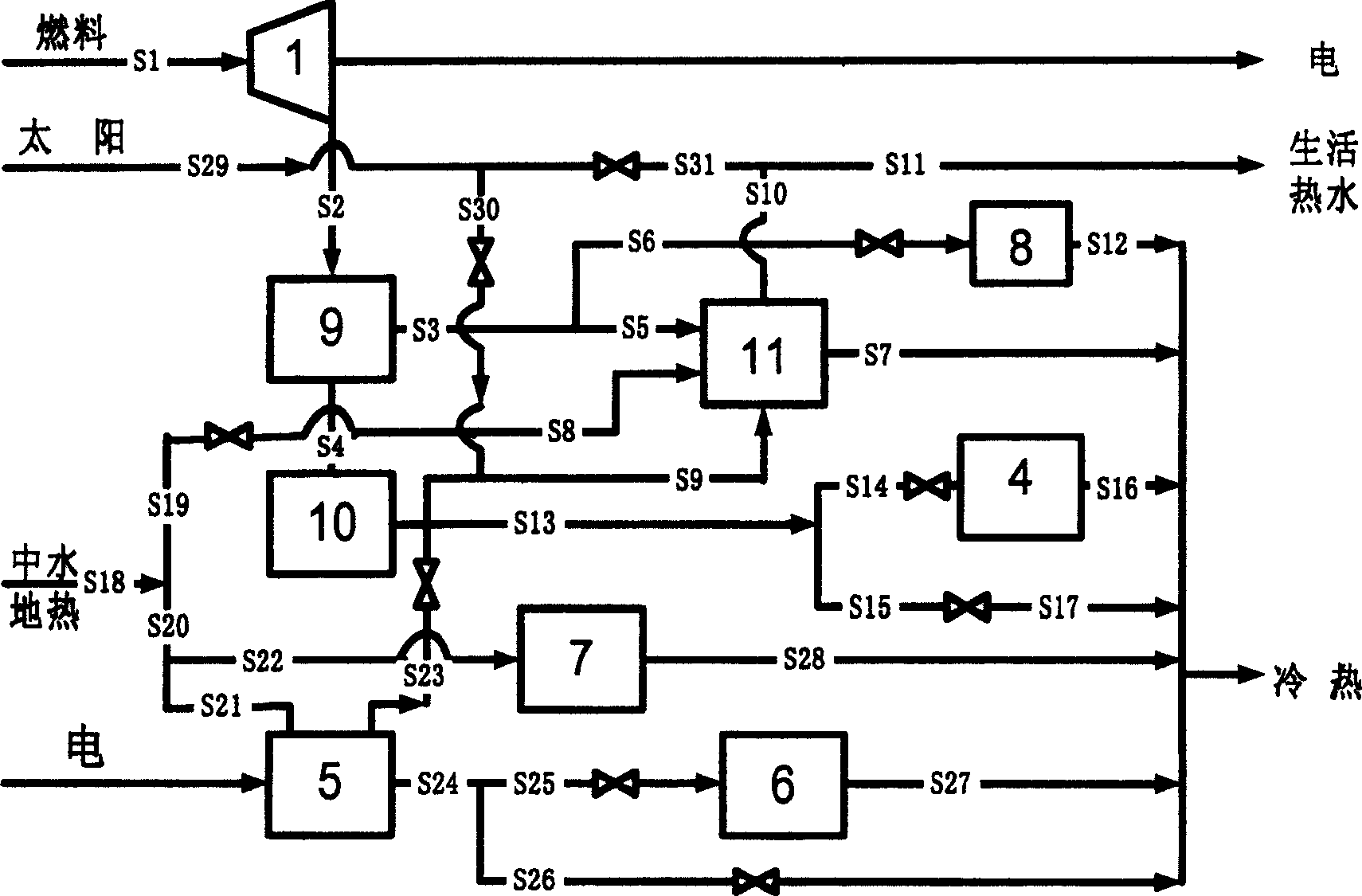

Multifunctional distributed refrigeration, heat and electricity production system and method

ActiveCN1629463AImprove the level of comprehensive utilizationImprove performanceOther heat production devicesGeothermal energy generationCogenerationCompression set

This invention relates to energy technique field and especially to a multi-function distribution heat and electricity co-production system and method, which comprises the following: gas turbine, dual-purpose lithium brominate absorptive-type set, exhaust-heat boiler, heat exchanger, absorptive dehumidification device, cold storage device, heat storage device and compression set. The system comprehensively uses the multiple energies and resources to become a new system with input and output of multiple energies.

Owner:中科科林节能环保科技有限公司

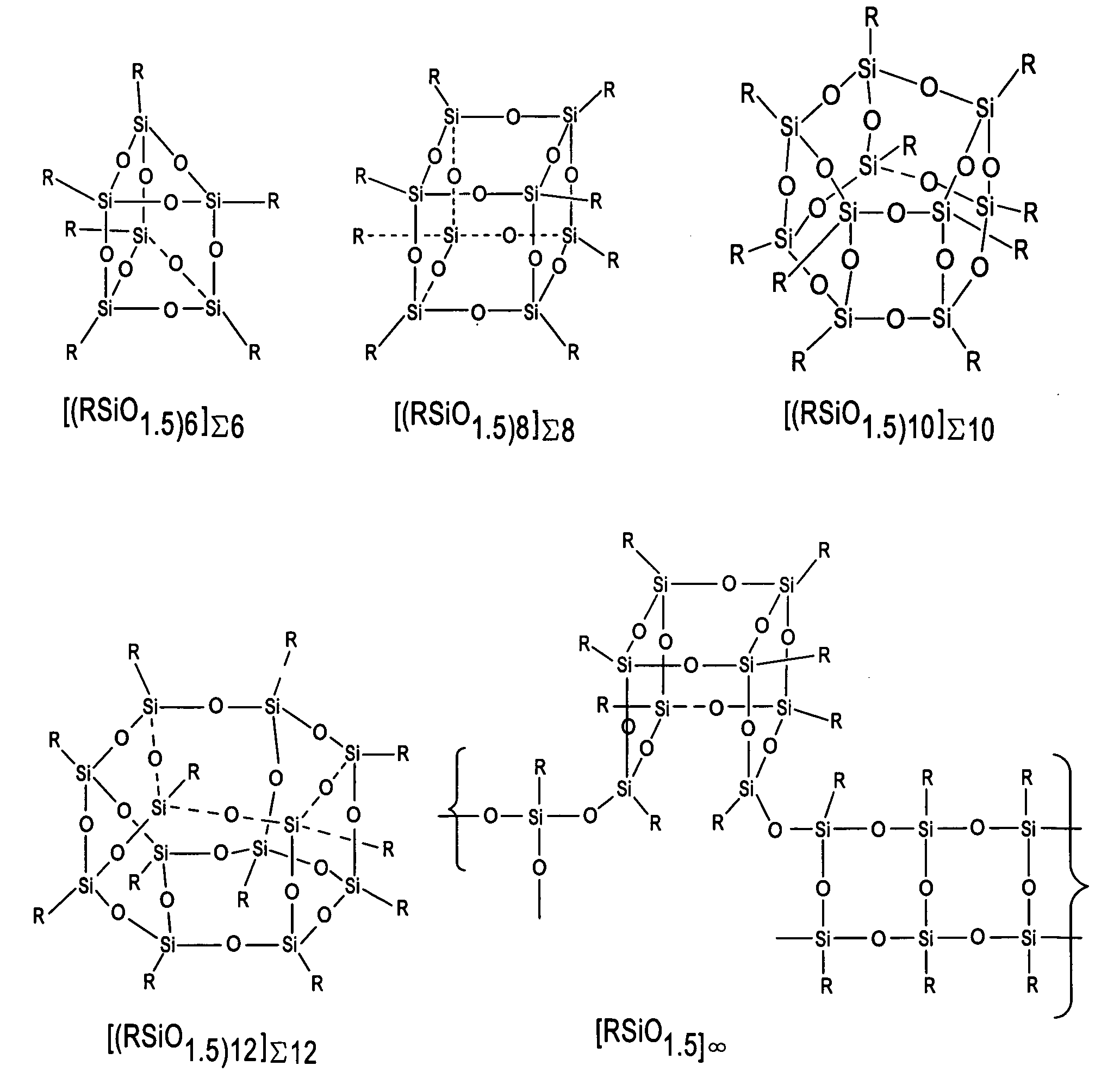

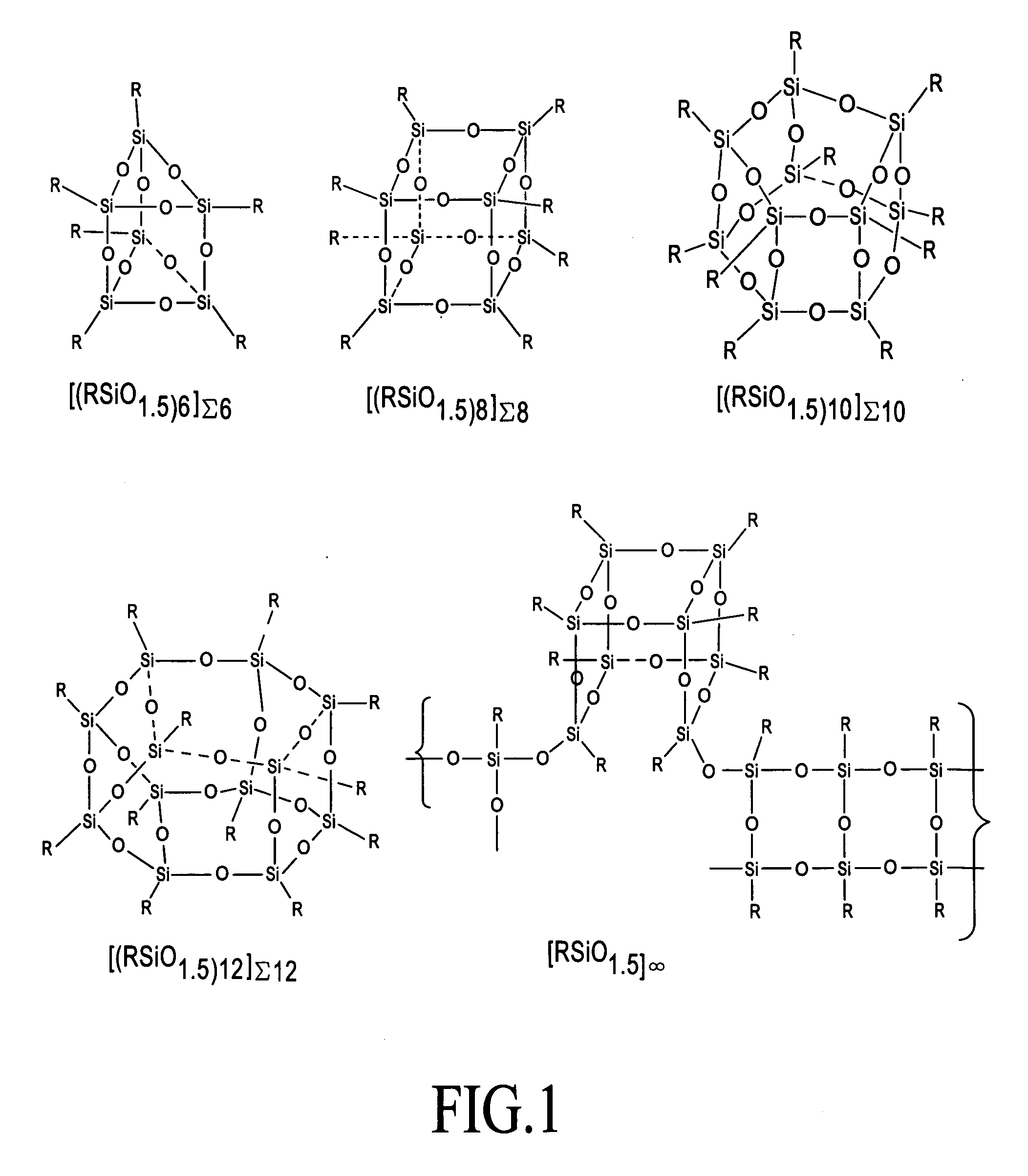

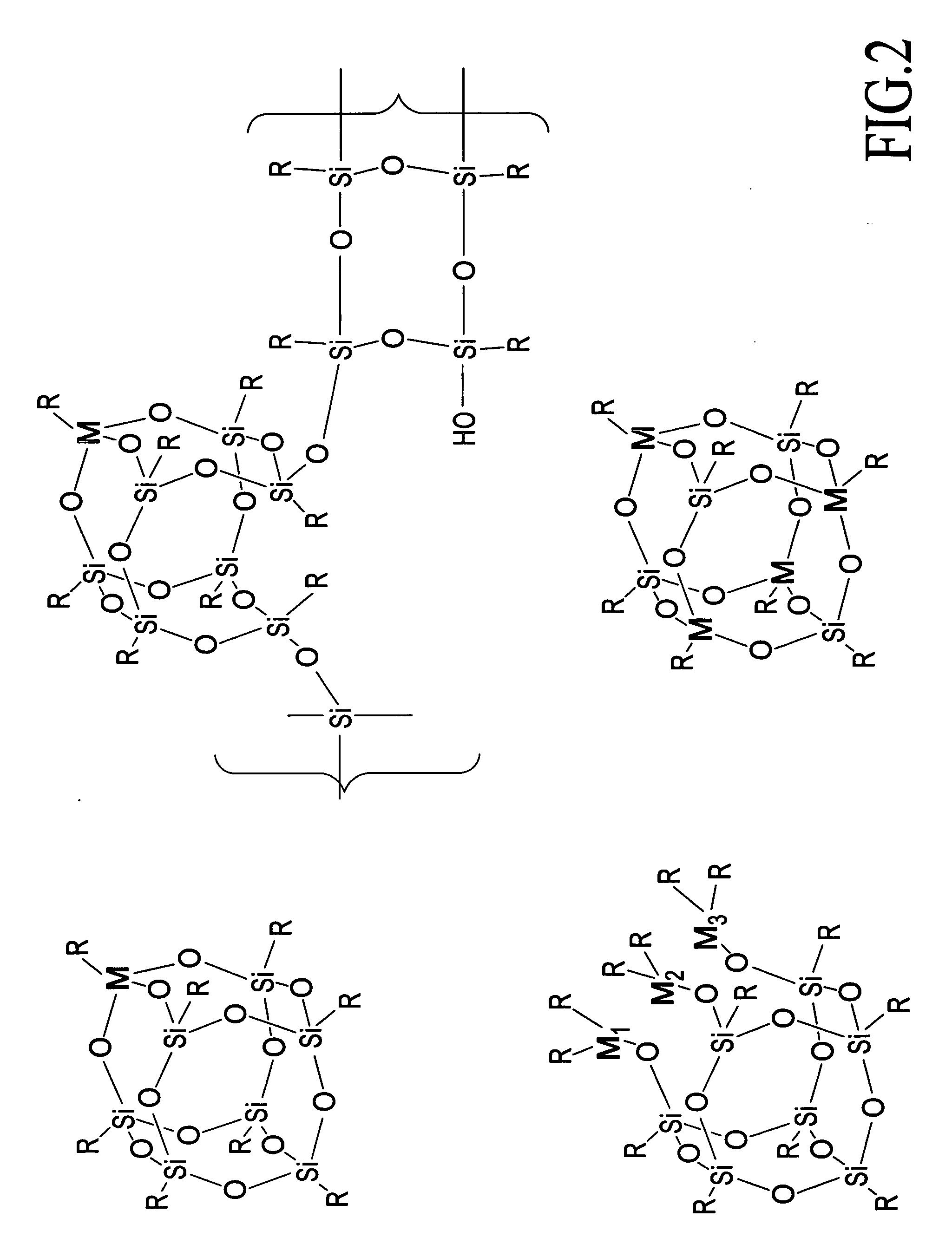

Polyhedral oligomeric silsesquioxanes and metallized polyhedral oligomeric silsesquioxanes as coatings, composites and additives

InactiveUS20050192364A1Improve electrical performanceGood printabilityTin organic compoundsSemiconductor/solid-state device detailsCompression setBiological materials

A method of using metallized and nonmetallized nanoscopic silicon containing agents for physical property control, radiation absorption, and in situ formation of nanoscopic glass layers on material surfaces. Because of their tailorable compatibility with polymers, metals, composites, ceramics, glasses and biological materials, nanoscopic silicon containing agents can be readily and selectively incorporated into materials at the nanometer level by direct mixing processes. Properties improved include gas and liquid barrier, stain resistance, resistance to environmental degradation, radiation absorption, adhesion, printability, time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance, electrical and thermal conductivity, and fire resistance. The materials are useful in a number of applications, including beverage and food packaging, space-survivable materials, microelectronic packaging, and radiation absorptive paints and coatings.

Owner:LICHTENHAN JOSEPH D +2

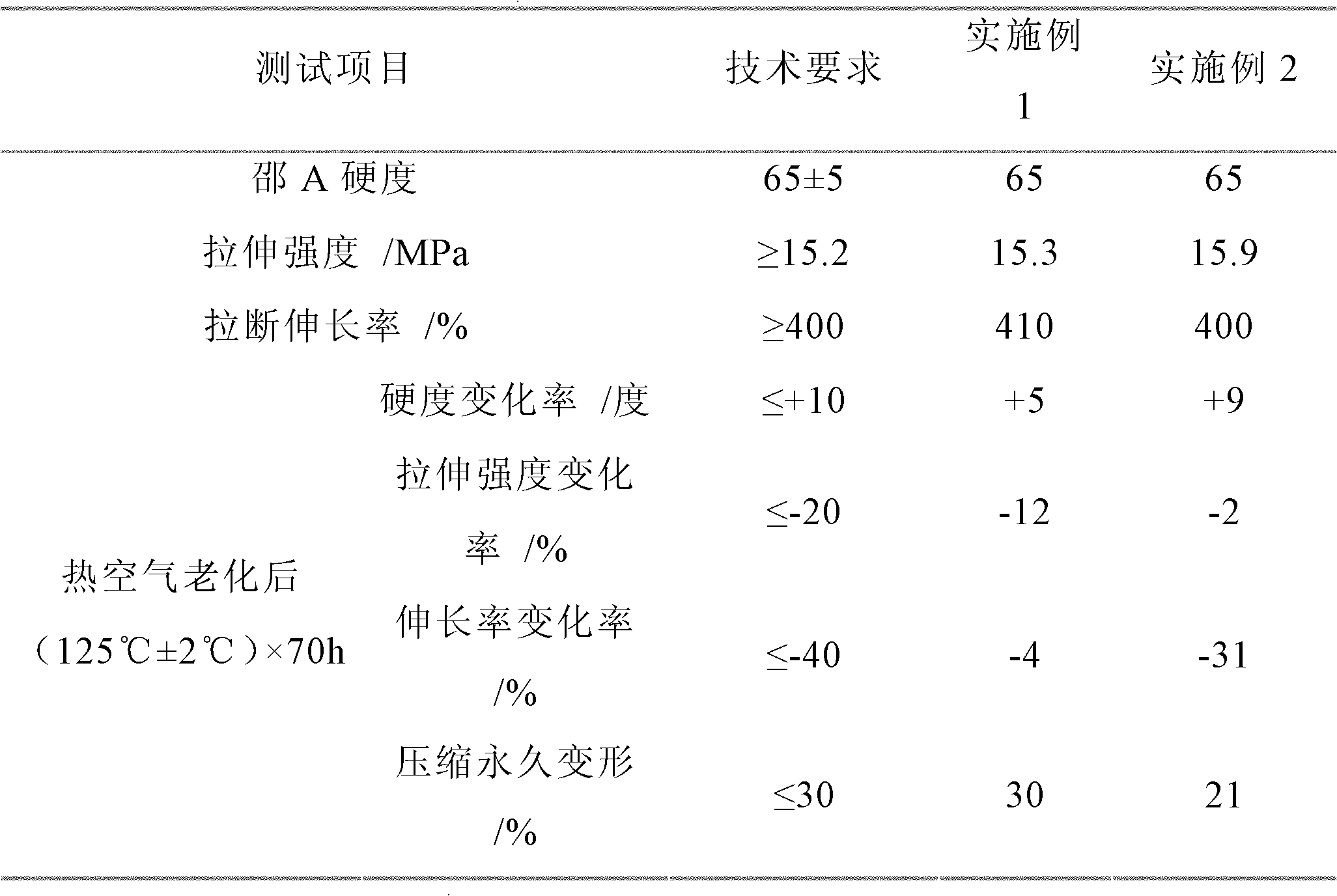

Ethylene propylene diene rubber composition and preparation method

The invention discloses an ethylene propylene diene rubber composition and a preparation method. The preparation method comprises the following steps of: firstly, performing after plastication on ethylene propylene diene rubber; then, adding zinc oxide, stearic acid, anti-aging agent, carbon black, plasticizers, accelerant, vulcanizer and the like in sequence; evenly mixing and then extruding a sheet; and preparing the sheet into the ethylene propylene diene rubber / carbon black nanometer composite material by adopting the after vulcanization process. Through adding various plasticizers and adopting special process treatment, the tensile strength of the ethylene propylene diene rubber composition disclosed by the invention is at least 15.2MPa, the elongation at break is at least 400 percent, and the compression set is lower than 30 percent under the condition of 125 DEG C*70h. The composite material can be used as a sealing article of rubber, especially a rubber sealing washer applied to a groove-type pipeline joint part of an automatic water spray fire extinguishing system, and thereby, a long-term sealing effect is ensured.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Permanent gas blown microcellular polyurethane elastomers

Microcellular polyurethane elastomers having sharply reduced or virtually no urea linkages may be prepared without resort to organic physical blowing agents by frothing a frothable mixture containing isocyanate reactive polyols and chain extenders, and a frothable isocyanate component. The isocyanate component is derived by reacting a stoichiometric excess of a di- or polyisocyanate with a polyol component containing an ultra-low unsaturation polyol. The froth-produced elastomers surprisingly exhibit greatly improved tear strengths, compression set, and other physical properties as compared to all water-blown microcellular elastomers of the same density.

Owner:ARCO CHEM TECH INC

Thermoplastic elastomer and thermoplastic elastomer composition

A thermoplastic elastomer exhibiting high recyclability and oil resistance as well as excellent mechanical strength, and in particular, excellent resistance to compression set is provided. The thermoplastic elastomer is comprising an elastomeric polymer having epoxide, hydroxy group, and a nitrogen-containing heterocycle, wherein the nitrogen-containing heterocycle is bonded to backbone of the elastomeric polymer through nitrogen atom or oxygen atom.

Owner:YOKOHAMA RUBBER CO LTD

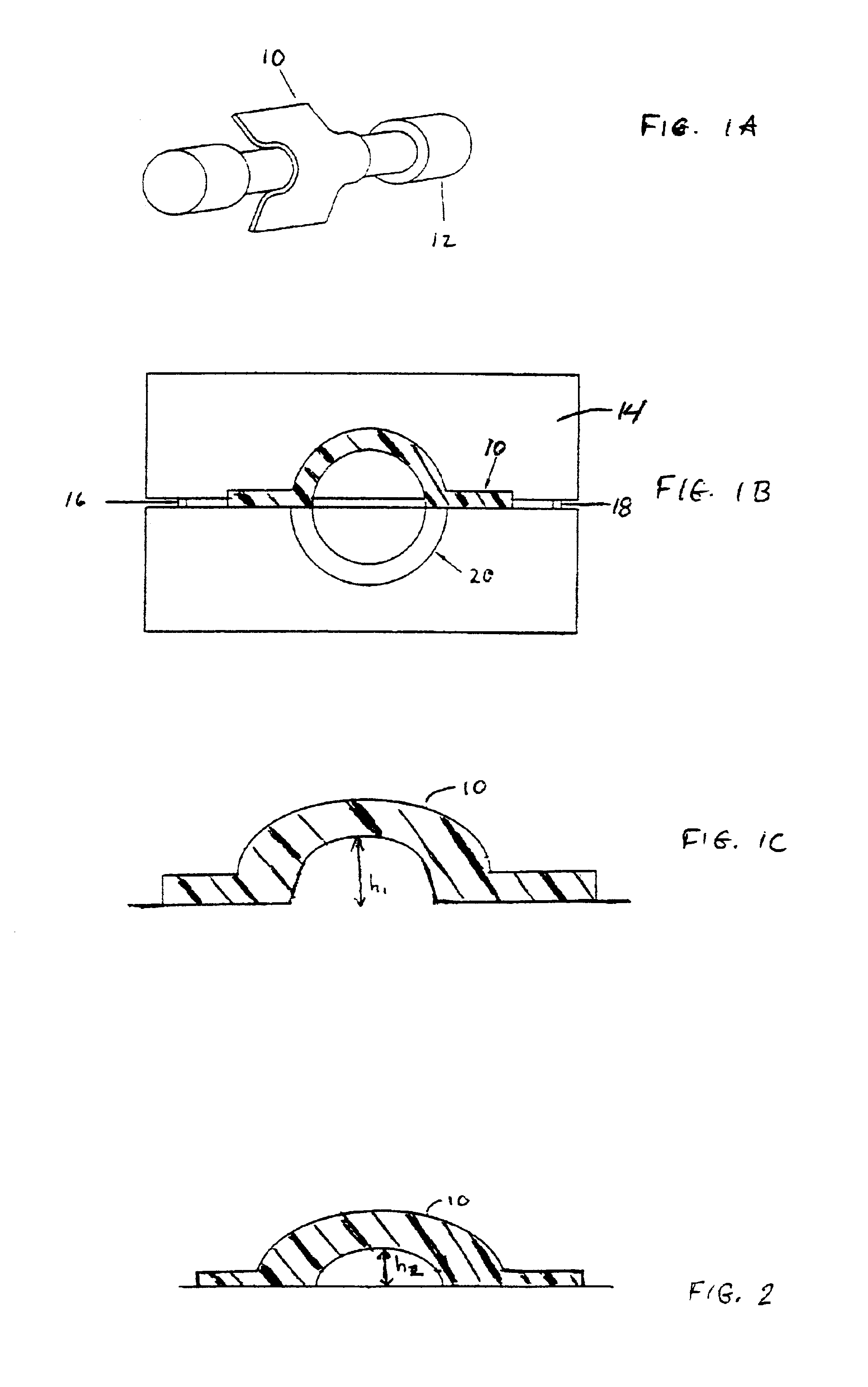

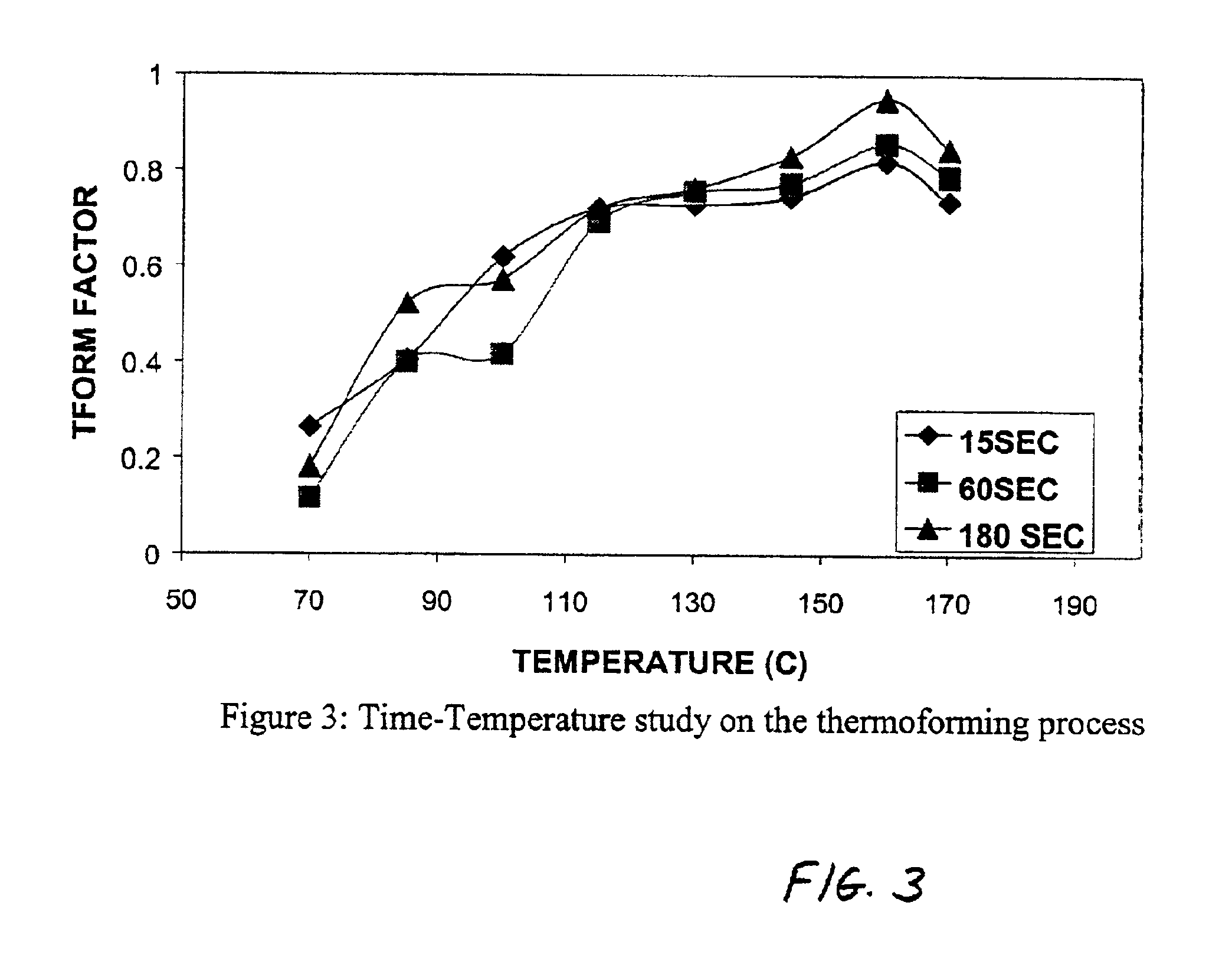

Polyurethane foams and method of manufacture thereof

InactiveUS6872758B2Excellent low temperature compression set resistanceFacilitate phase separationSynthetic resin layered productsThin material handlingCompression setChemistry

A thermoformable polyurethane foam having excellent compression set resistance, and a thermoformable polyurethane foam having excellent compression set resistance and shape retention under load. In another embodiment, at least one additional layer of a polyurethane foam is integrally bonded to the thermoformable foam. A moisture management system for polyurethane foams is also described. The foams have particular utility as shoe sole inserts.

Owner:WORLD PROPERTIES

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC

Low permanent compression deformation thermoplastic polyurethane elastomer

The invention discloses a low permanent compression deformation thermoplastic polyurethane elastomer, which is characterized in that: a certain amount of short-chain alcohol with the molar mass of 100-600g and the functionality of more than 2 is added into a chain extender; and due to the crosslinking of the short-chain alcohol, the elasticity, strength and permanent compression deformation resistance of a product are improved.

Owner:烟台美瑞化学材料有限公司

Crosslinked olefin elastomer foam and elastomer composition therefor

A crosslinked olefin elastomer foam has a specific gravity of 0.05 to 0.2, an expansion ratio of 8 to 15, a compression set of 30 to 60% and a tear strength of 1.5 to 2.5 kg / cm. The crosslinked foam is obtained by heating an elastomer composition comprising a specific ethylene / alpha-olefin copolymer, an organic peroxide, a crosslinking auxiliary and a foaming agent. The crosslinked foam has a high expansion ratio, is free from surface roughening attributed to defoaming, realizes a soft touch, exhibits a low compression set and is excellent in mechanical strength (particularly tear strength) and heat resistance.

Owner:MITSUI CHEM INC

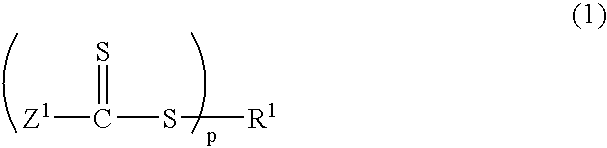

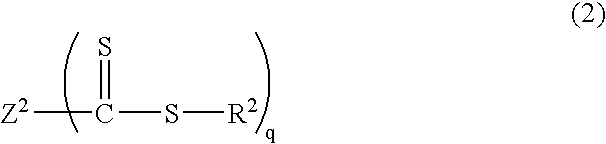

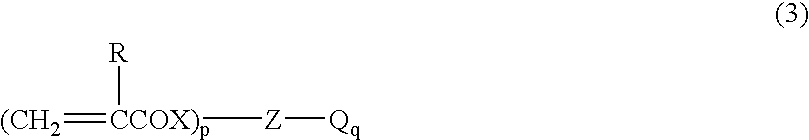

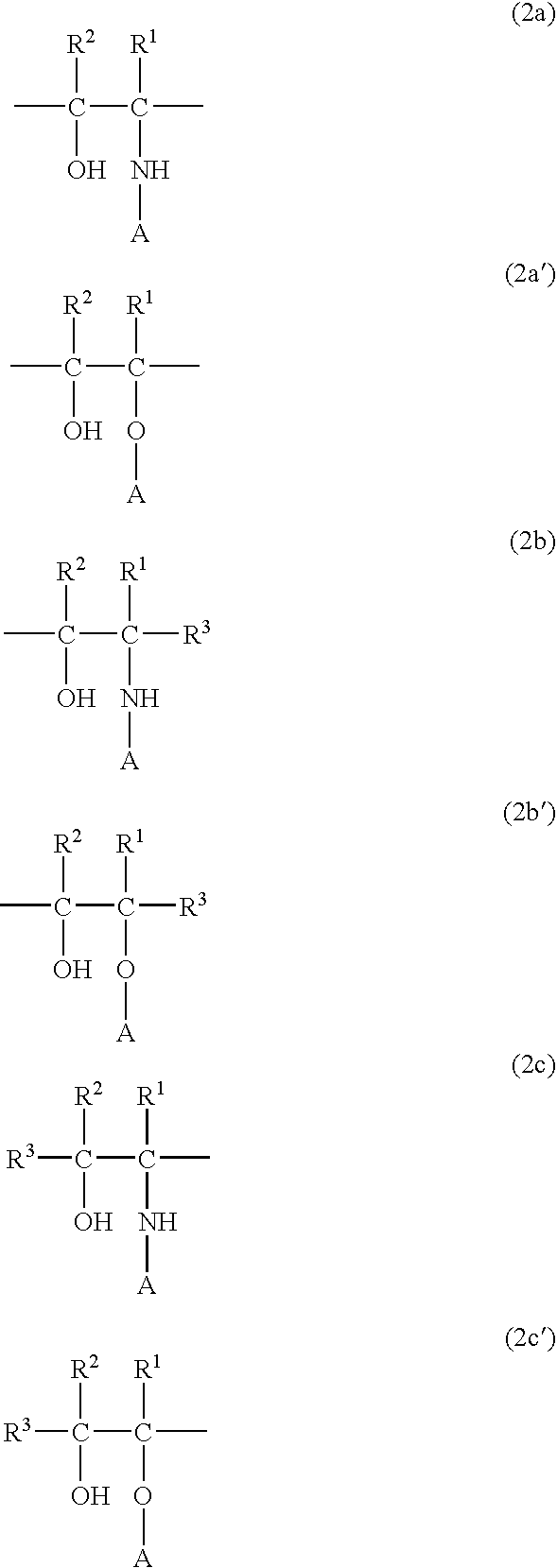

Block copolymer

InactiveUS20050085592A1Excellent in thermal decomposition resistanceImprove the heating effectThin material handlingPolymer scienceMeth-

The present invention relates to a block copolymer (A) including a (meth)acrylic polymer block (a) and an acrylic polymer block (b). The (meth)acrylic polymer block (a) is preferably copolymerized with a monomer having a functional group having high cohesive force, such as a carboxyl group, so that the 5%-weight-loss temperature is 300° C. or more or the tensile strength is 3 MPa or more, and the hardness measured by a type A durometer according to JIS K6253 is 50 or less, and a compression set measured after 22 hours at 70° C. is 45% or less. The block copolymer (A) exhibits excellent thermal decomposition resistance and low compression set at high temperatures. The block copolymer (A) can be used as a soft material for automobile, and has low hardness, high adhesion, high oil resistance, high weather resistance, high heat resistance, high recycling property, high tensile properties, and high wax remover resistance.

Owner:KANEKA CORP

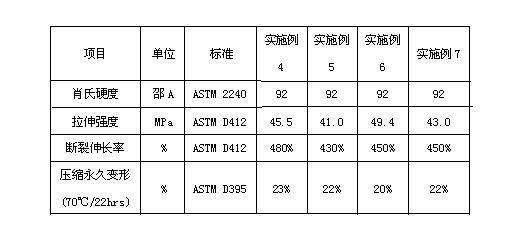

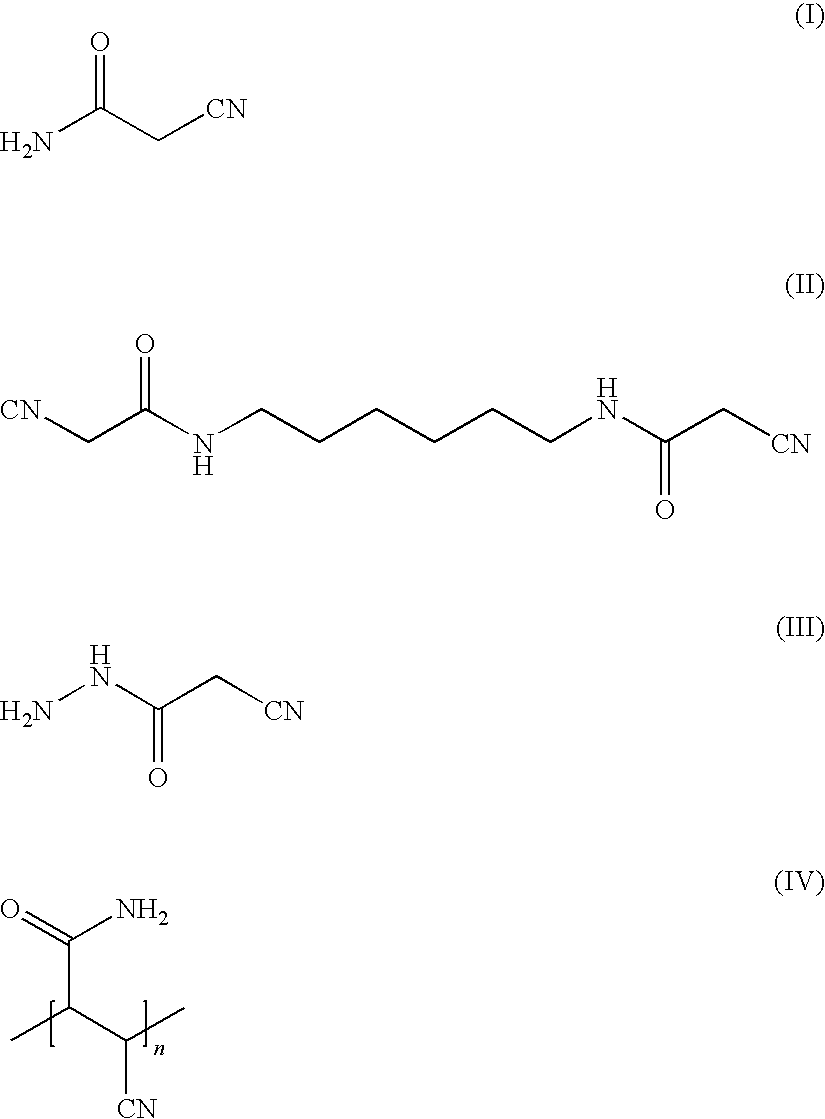

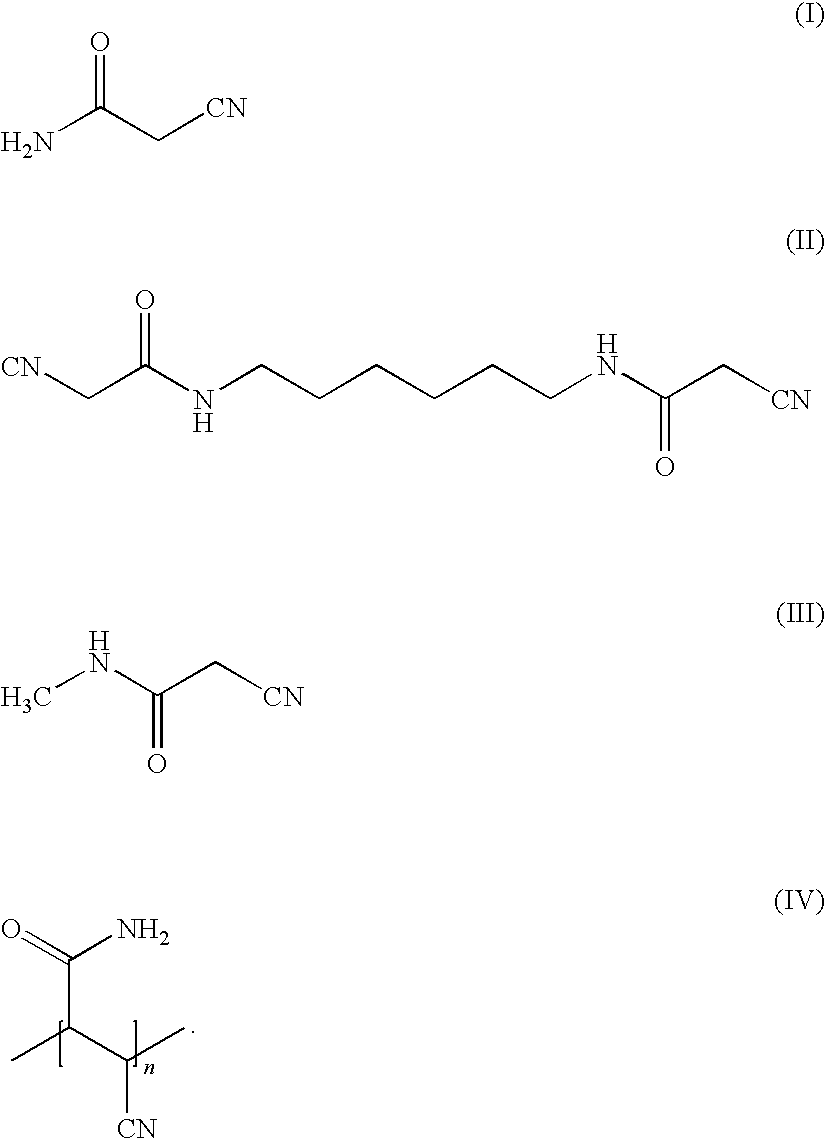

Process for lowering emissions of a polyurethane foam

The present invention provides a process for producing polyurethane foams from (A1) compounds with a molecular weight of 400-15,000 exhibiting hydrogen atoms that are reactive towards isocyanates, (A2) optionally, compounds with a molecular weight of 62-399 exhibiting hydrogen atoms that are reactive towards isocyanates, (A3) water and / or physical blowing agents, (A4) optionally, auxiliary substances and additives, (A5) compounds with at least one carbonamide group and one nitrile group, and (B) diisocyanates or polyisocyanates, which results in polyurethane foams with lowered emission of formaldehyde and wherein the activity of the raw-material mixture is not significantly influenced and wherein the mechanical properties of the resulting foam (in particular, compression set and ageing behaviour under humid conditions) are not influenced negatively.

Owner:BAYER MATERIALSCIENCE AG

Shape-recoverable resin foamed product

InactiveUS6090479AImprove comprehensive applicabilityMaintain good propertiesOther chemical processesSynthetic resin layered productsEngineeringCompression set

A resin foamed product is formed of a resin, and closed cells dispersed in the resin. The resin with the closed cells therein has a shape-recoverable property at an ambient temperature, a closed cell rate higher than 30% and a compression permanent set lower than 10%. Thus, when contraction takes place in the resin with the closed cells, after a predetermined time has passed without providing an outer stimulation to the resin, a shape of the resin foamed product formed of the resin with the closed cells is automatically recovered at least in one direction without equally expanding in all directions.

Owner:SEKISUI CHEM CO LTD

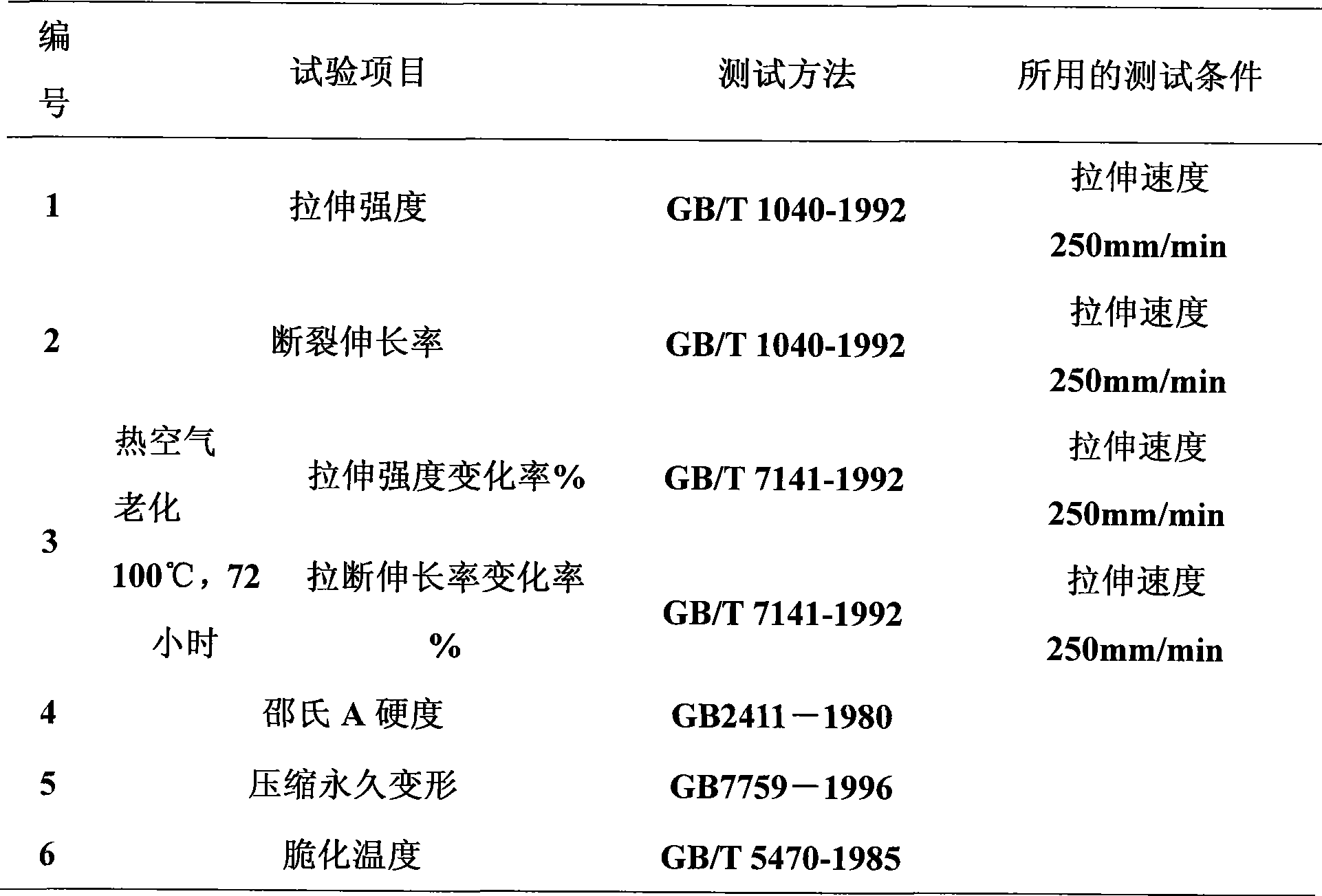

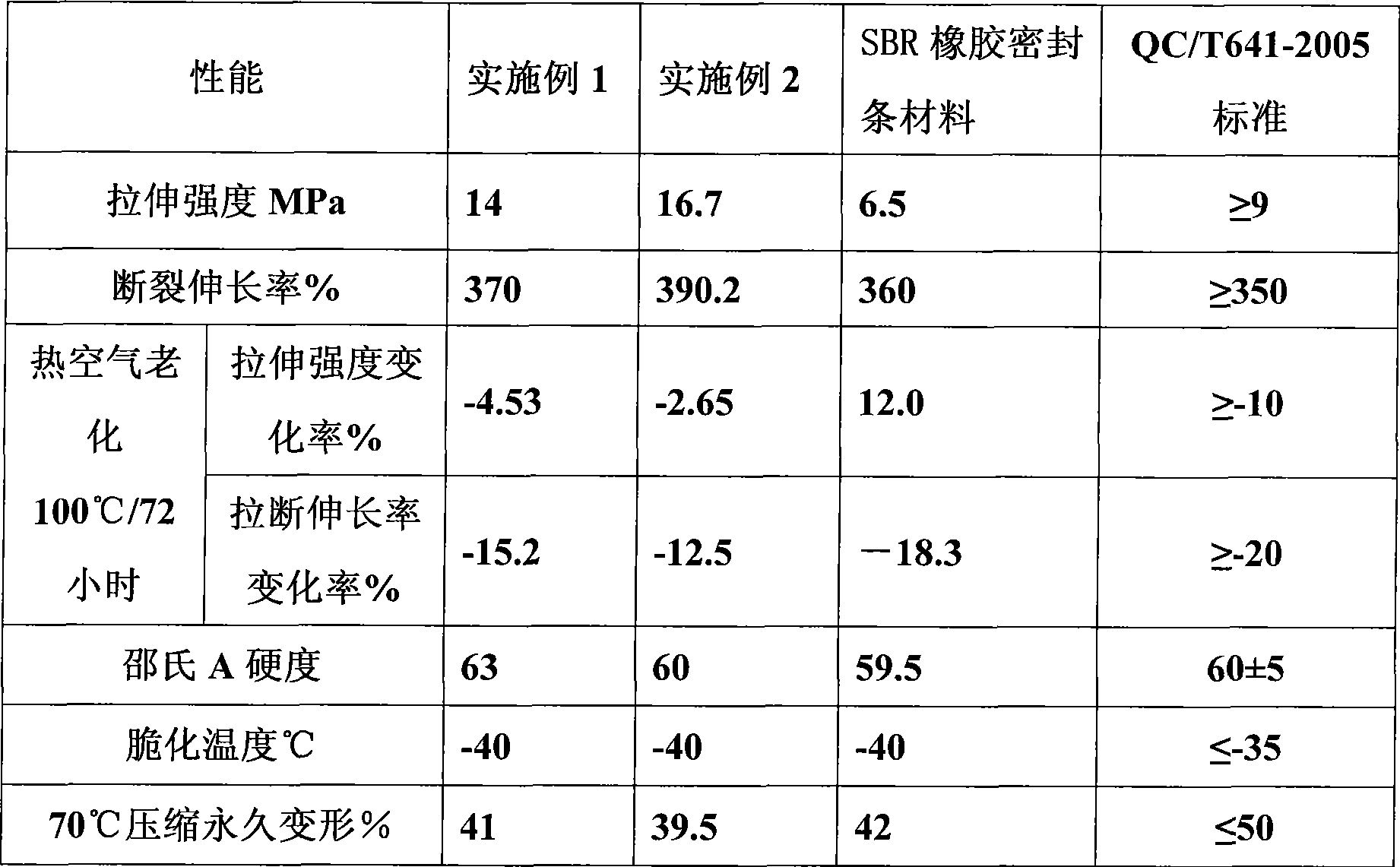

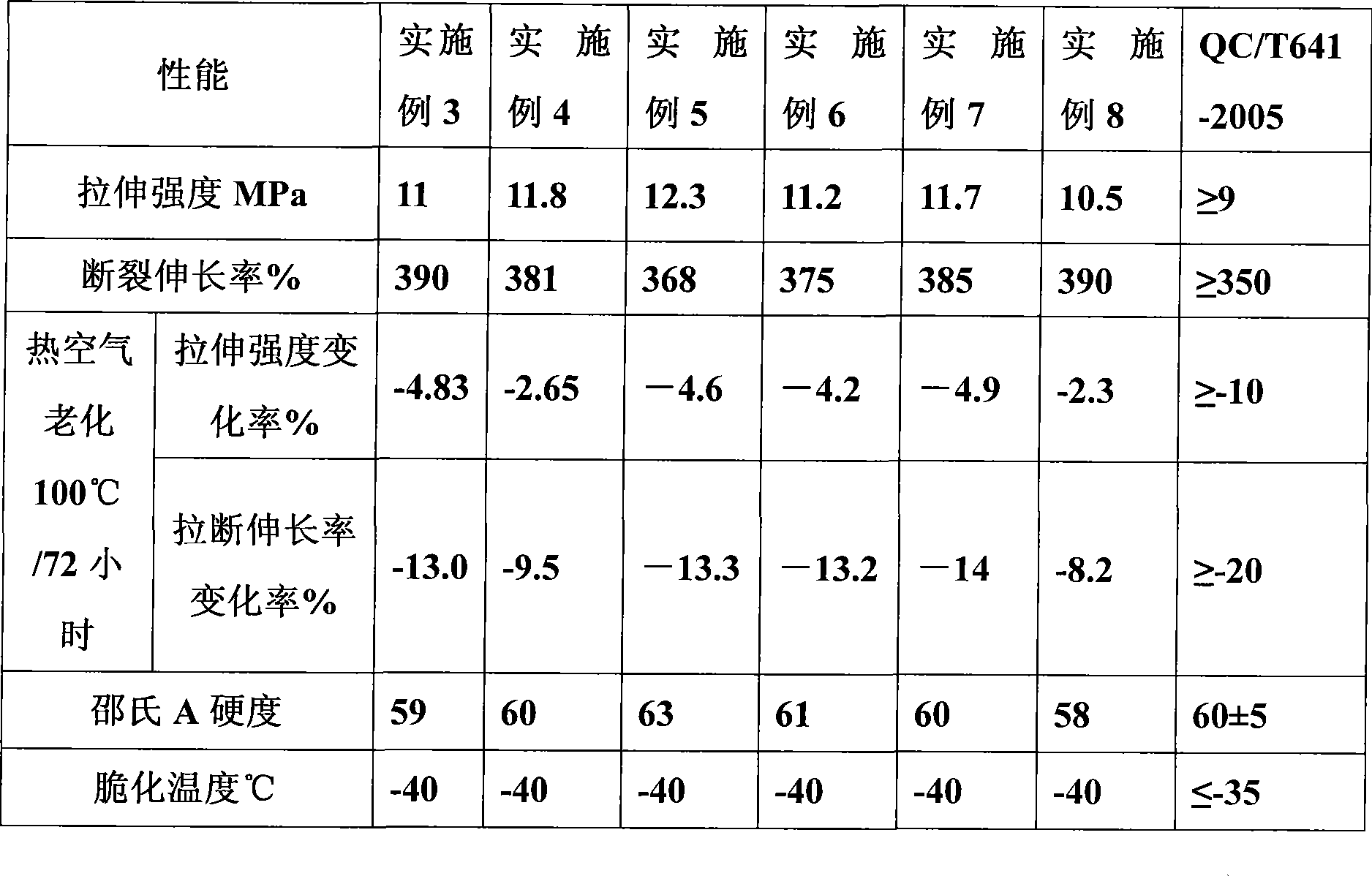

Special material for automotive seal strip and preparation method thereof

ActiveCN101519578AExcellent tear strengthIncrease elasticityEngine sealsOther chemical processesRubber materialVulcanization

A material for automotive seal strip comprises PVC with a certain amount of powdered nitrile rubber, plasticizer, heat stabilizer, lubricant, inorganic filler, coloring agent, curing agent and vulcanization aid; and squeezing granulation is carried out by a screw extruder. The invention utilizes the PVC thermoplastic elastomer to replace part of the rubber material and has the features possessed by the rubber material, thus significantly reducing the cost of raw materials and having the characteristics of simple processing technology, easy recycling of materials and the like, and improving shortcomings in the prior art that the materials can not be recycled after rubber vulcanization. Compared with other thermoplastic elastomers, the PVC thermoplastic elastomer seal strip provided by the invention has excellent compression set resistance reaching below 40%, low temperature resistance reaching minus 40 DEG C, and excellent chemicals resistance. The material has flexibility, and soundproofing, dustproofing, watertight and shock-absorbing functions, and can meet performance requirement of rubber automotive sealing strips.

Owner:CHINA PETROLEUM & CHEM CORP

Polyurethane foam, process for producing the same, and foam forming composition

InactiveUS20020052425A1Improve mechanical propertiesLow compression setPeptide preparation methodsCushioningHydrogen

A polyurethane foam which is obtained by reacting an addition-polymerizable active hydrogen component comprising a compound having a group containing active hydrogen and an addition-polymerizable functional group or comprising both this compound and a compound containing at least 2.5 groups (on the average) containing active hydrogen and not containing addition-polymerizable functional groups with an organic polyisocyanate in the presence or absence of at least one auxiliary selected from the group consisting of foaming agents and additives to polymerize the addition-polymerizable functional group and simultaneously form a polyurethane, and which has a structure in which the chains formed by the addition polymerization have been cross-linked to the polyurethane chains. The polyurethane foam is useful as a rigid polyurethane foam excellent in hardness, dimensional stability, etc. and usable as a heat insulator, shock-absorbing material, synthetic wood, etc., or is useful as a soft polyurethane foam reduced in compression set and usable as a cushioning material, shock-absorbing material, sound insulating / absorbing material, etc.

Owner:SANYO CHEM IND LTD

Adjustable foam mattress

InactiveUS20060075569A1Improve comfortLower comparable costStuffed mattressesSpring mattressesAir volumeEngineering

The invention modulates the air volume in foam cores of cushioning support devices and any other support apparatus using foam or similar materials. The foam core can be incrementally modulated to realize an infinite number of comfort levels as to softness and support firmness. The core consists of self-inflating open-cell flexible polyurethane foam and is completely sealed within an enclosure fitted over it, with one or more valves installed in the side walls which communicate with the outside air. Through the valves air is selectively withdrawn from the foam core, allowing the foam's density to increase. The invention uses relatively inexpensive foam, but through air volume modulation achieves a tactile feel of supreme softness for the user, without giving up the necessary firmness to support the body, as happens with very soft foam (bottoming-out or hammock-effect). When air is extracted from a self-inflating foam core, the surface of the core will soften uniformly while maintaining its support firmness. Contrary to this, when pressure is exerted on, for example, traditional coil spring core mattresses, their surface will harden. Integral part of the invention is a device using balanced springs in valve assemblies to avoid compression set, an irreversibly solid state of totally air-depleted foam.

Owner:GIORI GINO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com