Patents

Literature

4120 results about "Rubber sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

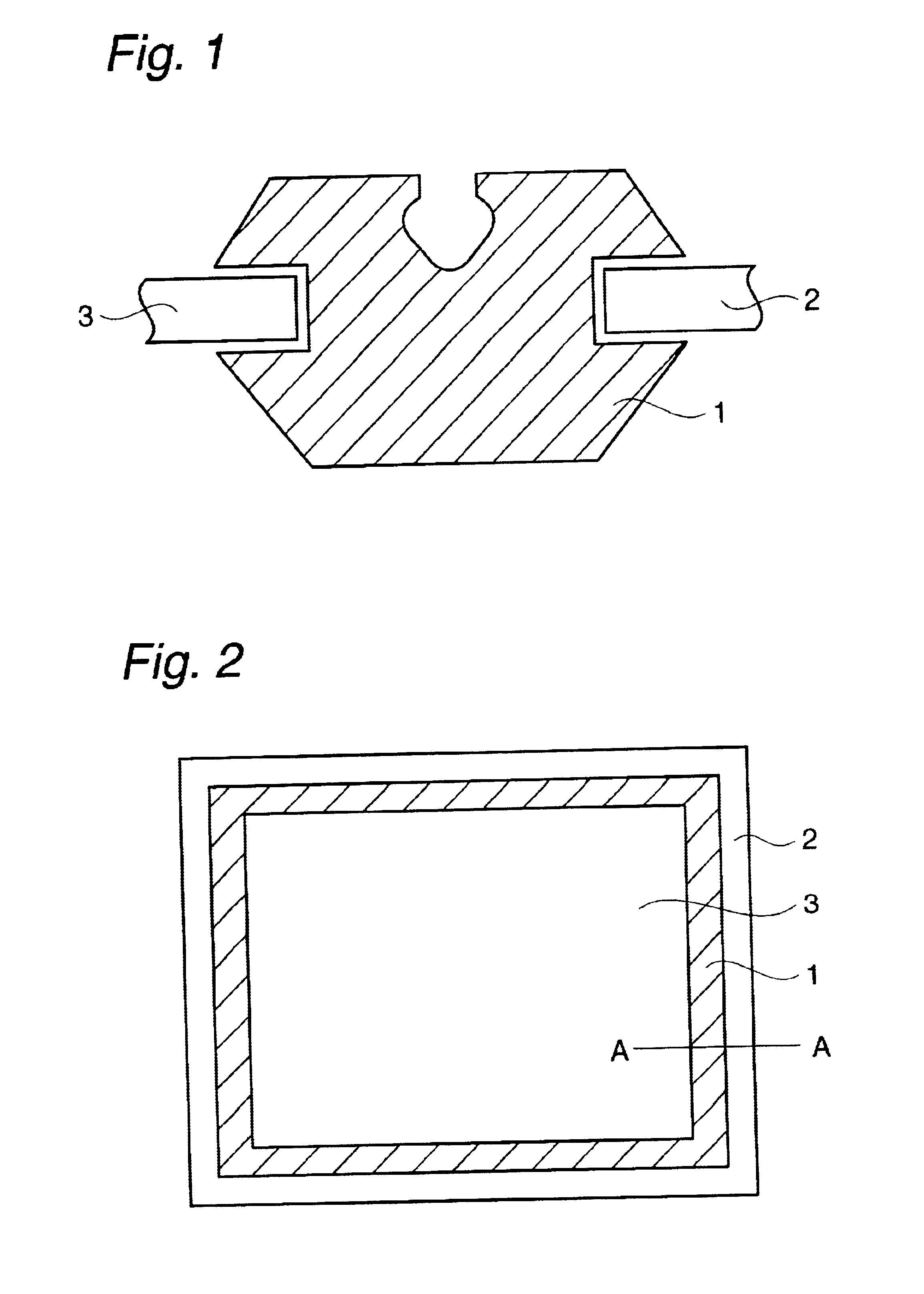

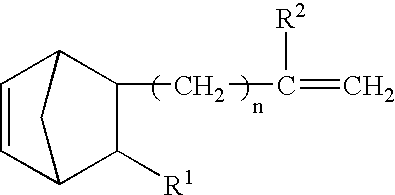

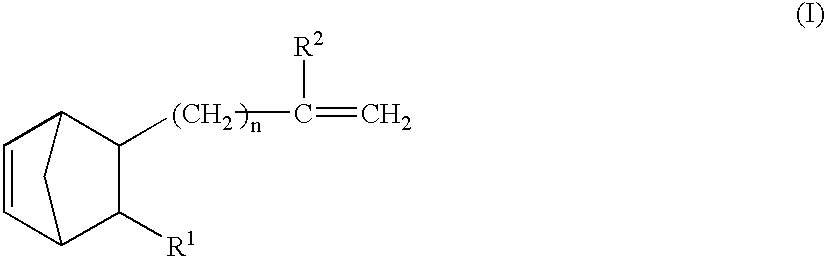

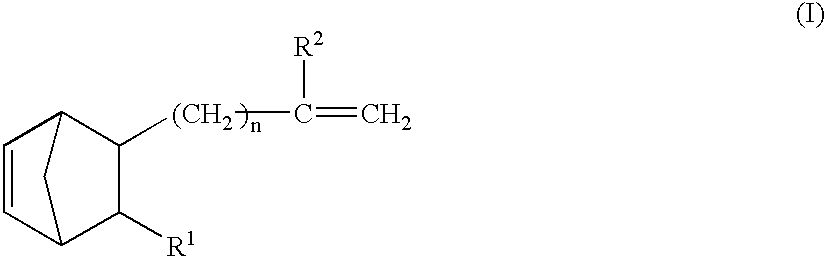

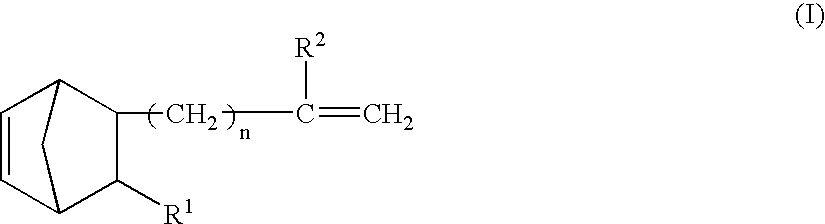

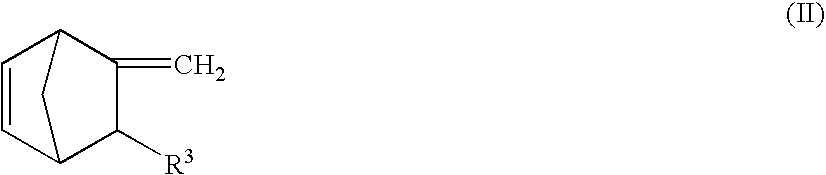

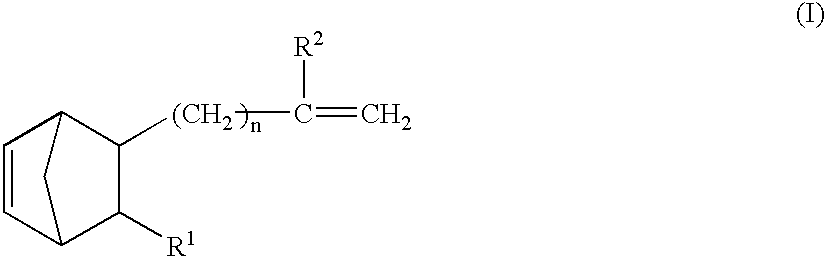

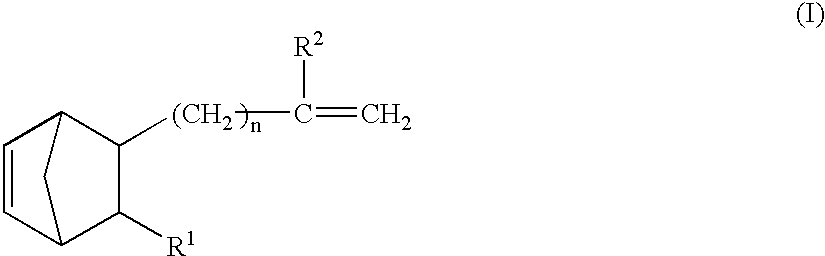

Crosslinkable rubber compositions and use thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC +1

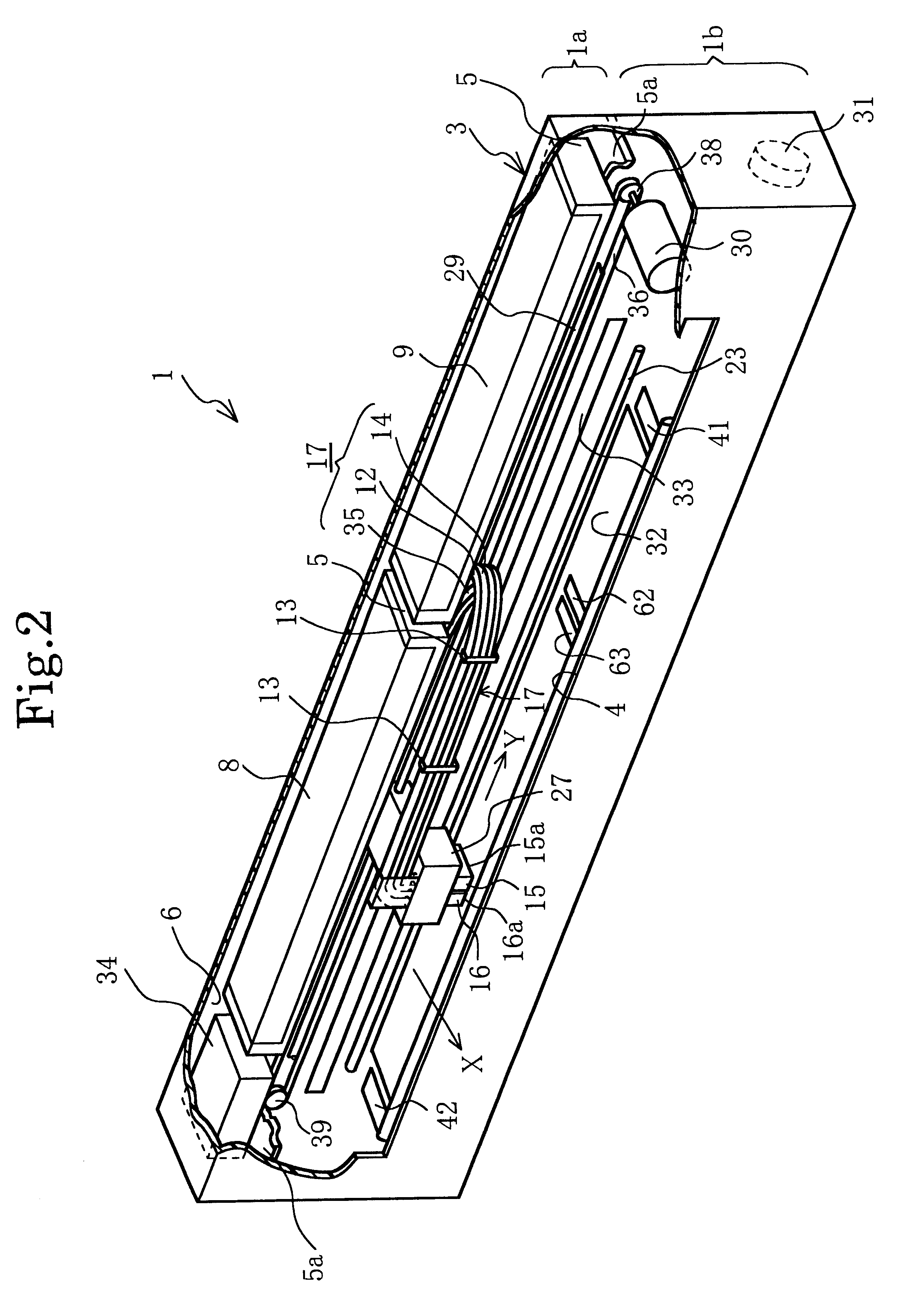

Hinge key switch

An apparatus for a hinged key switch is presented which operates around a hinged pivot point located external to the four points of the key cap, and which comprises a rubber spring providing a vertical bias and an arm with an extension which acts as a stopper when it abuts a raised portion of the mounting plate. The rubber spring is integrally formed from a rubber sheet which is supported on one side by the mounting plate and on the other by the back plate. The stopper extends vertically downward from the key cap and acts to limit the movement of the key in the vertical direction. A horizontal extension from a lower portion of the key cap further extends downward and through a slot in the mounting plate and has a hook which abuts an underside of the mounting plate, such extension from the key cap acting as the pivot point around which the key rotates.

Owner:LITE ON SINGAPORE PTE LTD

Ink cartridge

The invention provides a ink cartridge for supplying ink, including an ink pack formed from a flexible bag to seal liquid ink therein, a cartridge body having an ink pack housing therein, an extraction opening having a rubber plate into which a hollow ink extracting needle is inserted, an upper supporting spring movably supported with one end thereof by the cartridge body and affixed to the upper surface of the ink pack, and a lower supporting plate affixed to the lower surface of the ink pack and the lower surface of the cartridge body. A pair of the upper supporting spring and the lower supporting spring urges / pulls so that the volume of the bag of the ink pack is enlarged.

Owner:BROTHER KOGYO KK

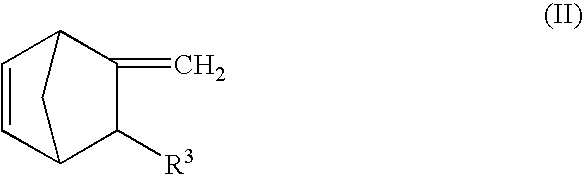

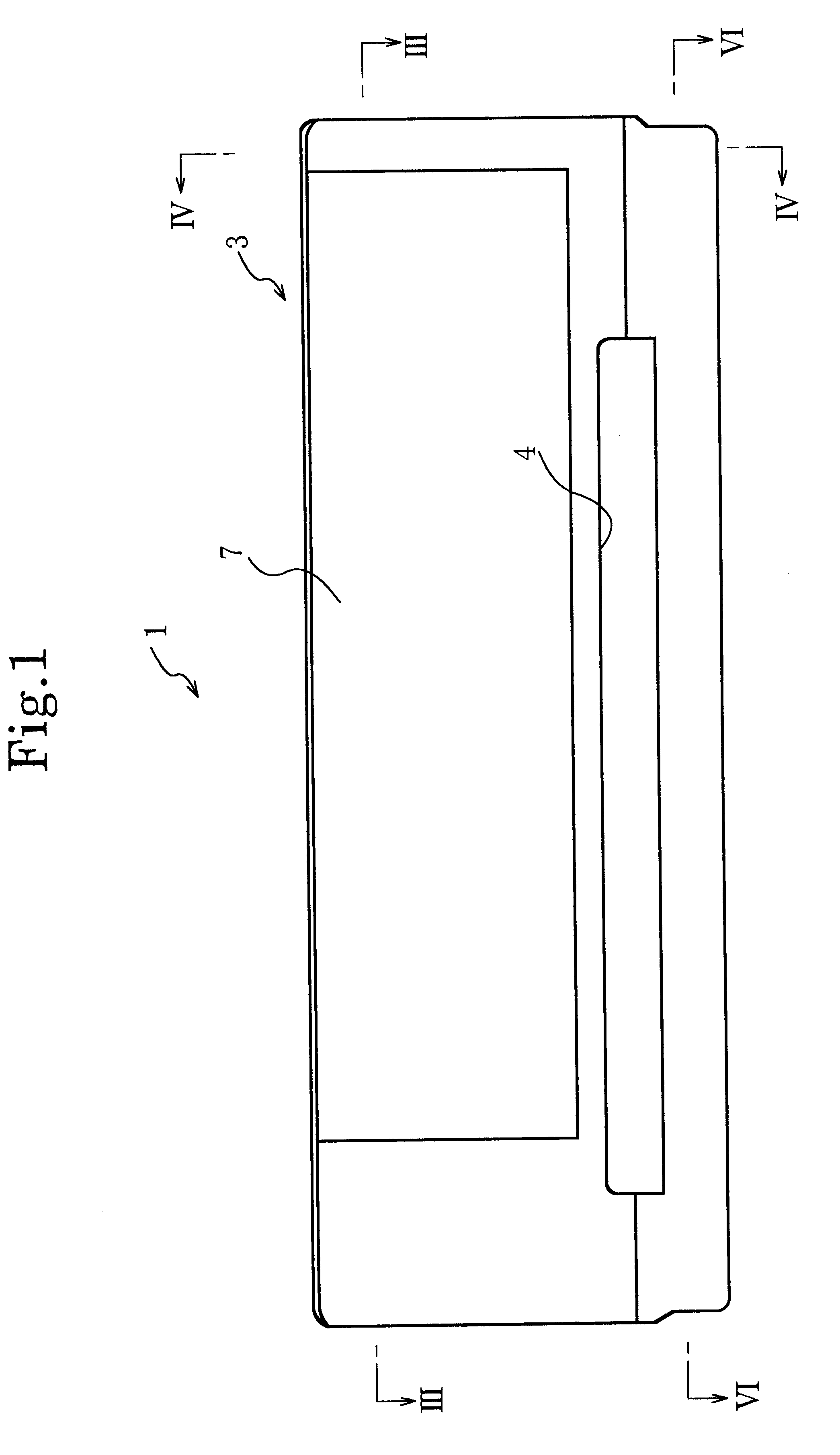

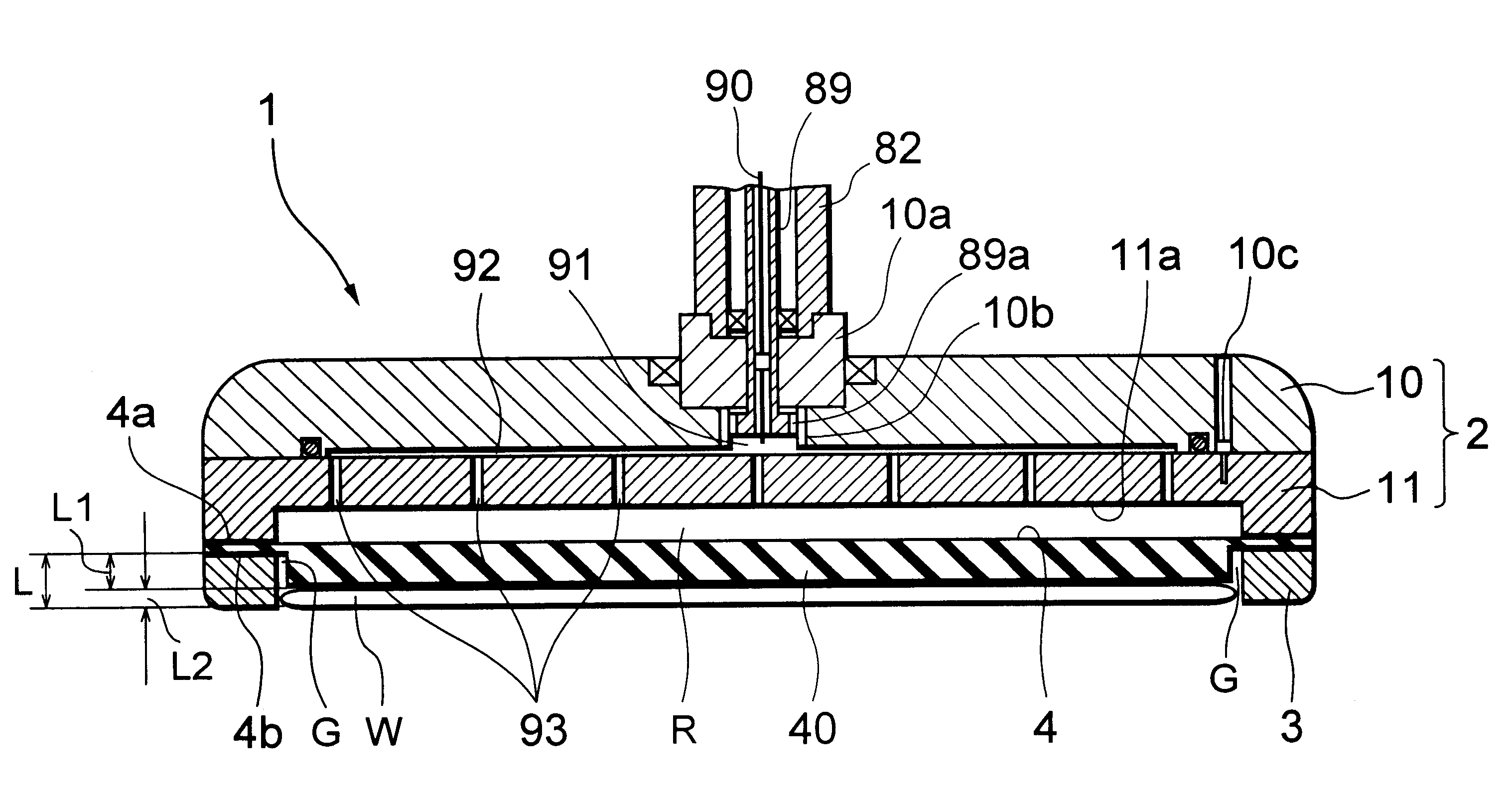

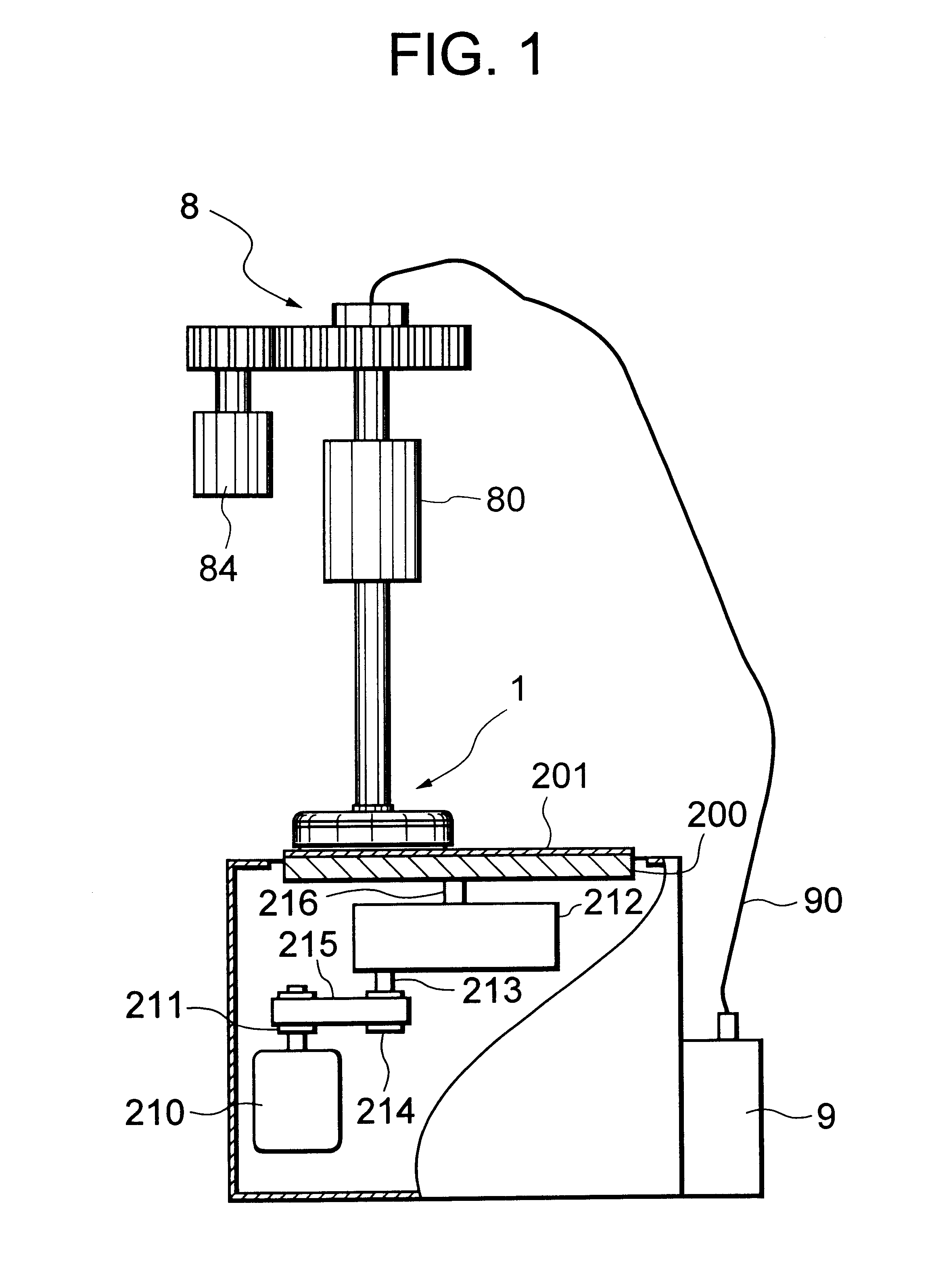

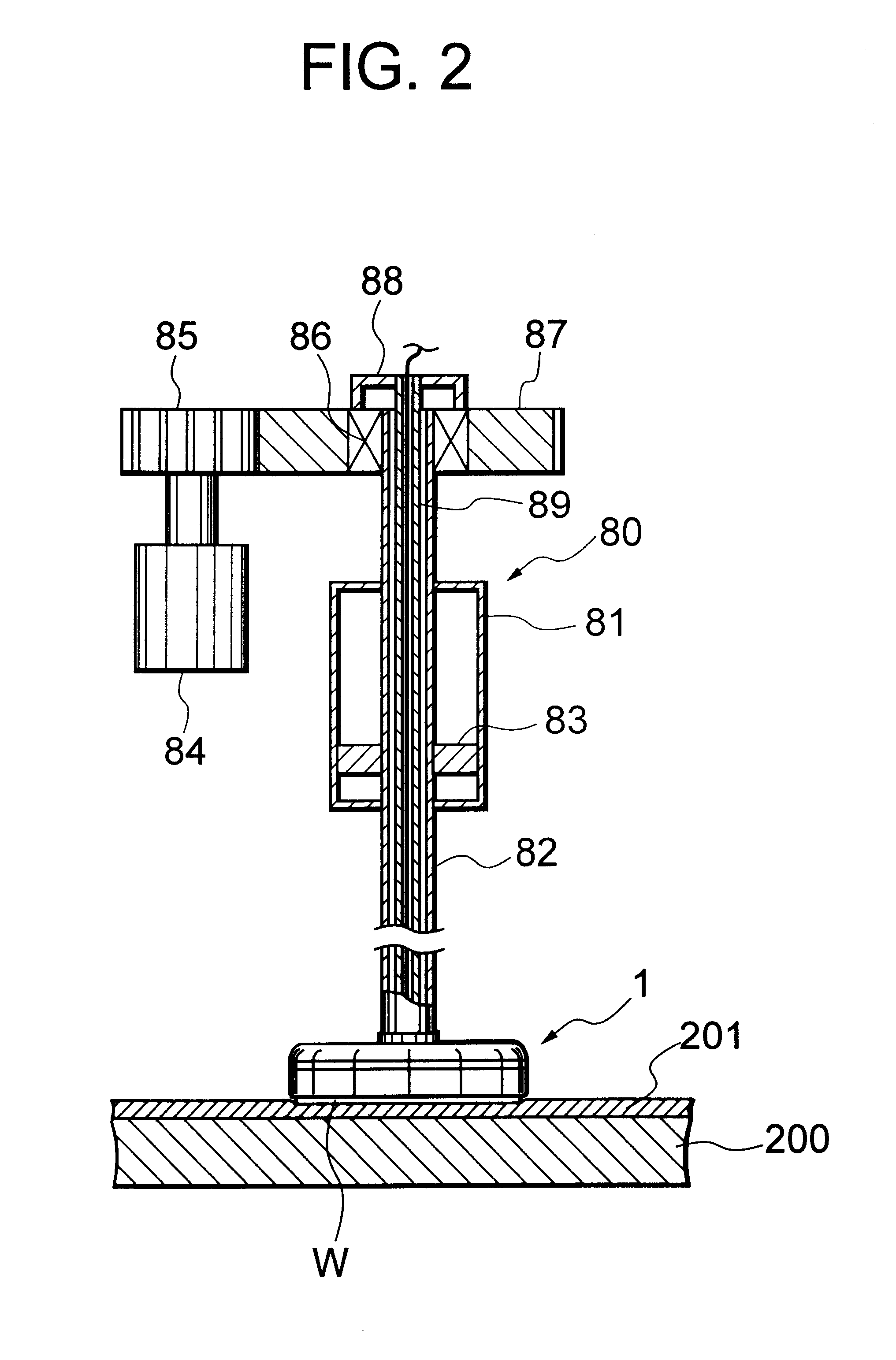

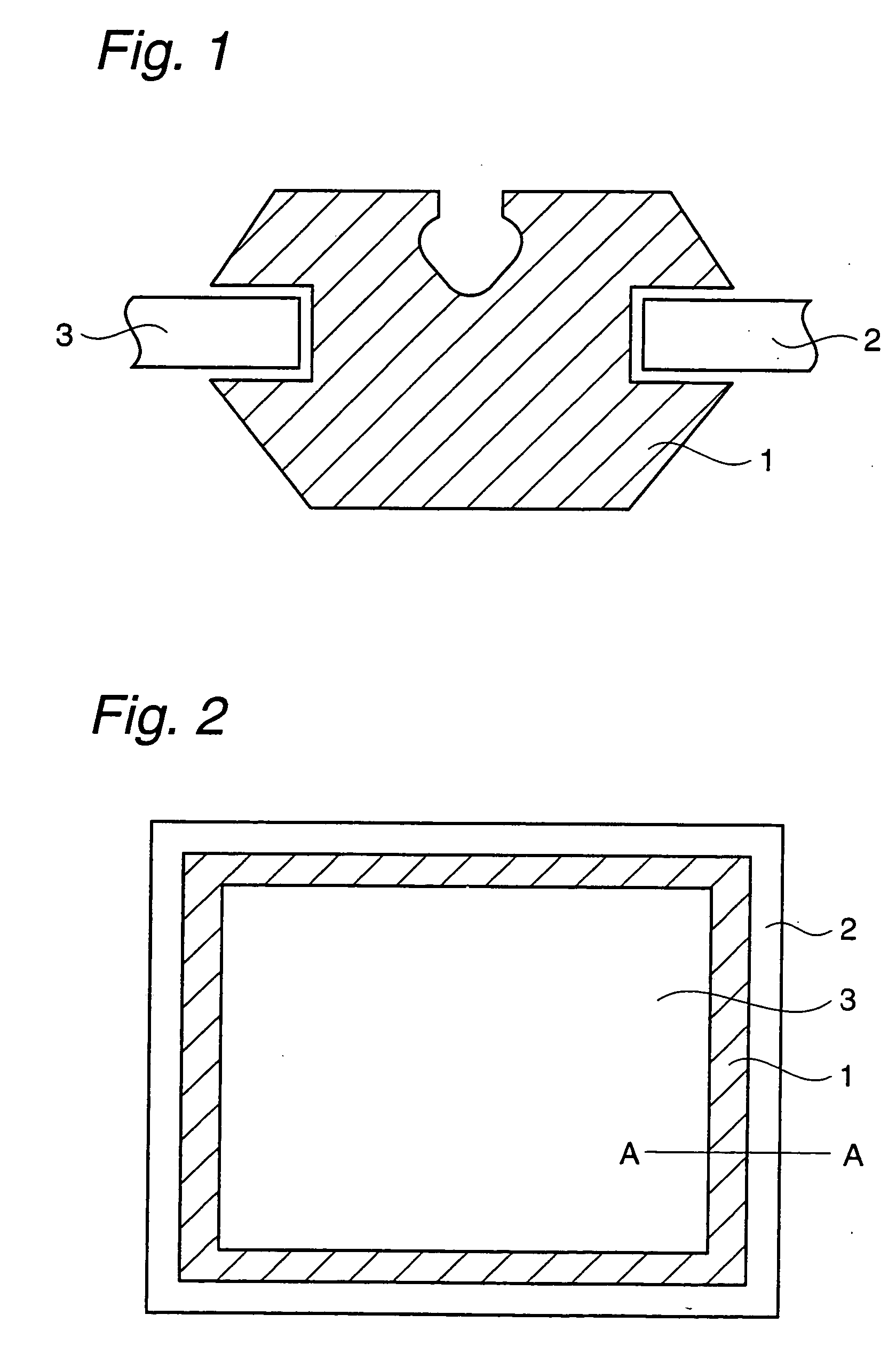

Carriers and polishing apparatus

A carrier and a polishing apparatus are designed to improve the mass producibility of wafers while using a retainer ring formed by a soft material. A rubber sheet 4 is bonded to the bottom surface of a carrier body 2 of the carrier 1 to define a pressure chamber R, a retainer ring 13 formed by a soft material such as EG is bonded to the bottom surface of the sheet 4. A margin block 40 is provided projecting out from the bottom side of the sheet 4, and the thickness of the retainer ring 13 is set to be substantially equal to the sum of the thickness L1 of the margin block 40 and the thickness L2 of the wafer W.

Owner:SPEEDFAM CO LTD

Tearproof antiwear conveying belt

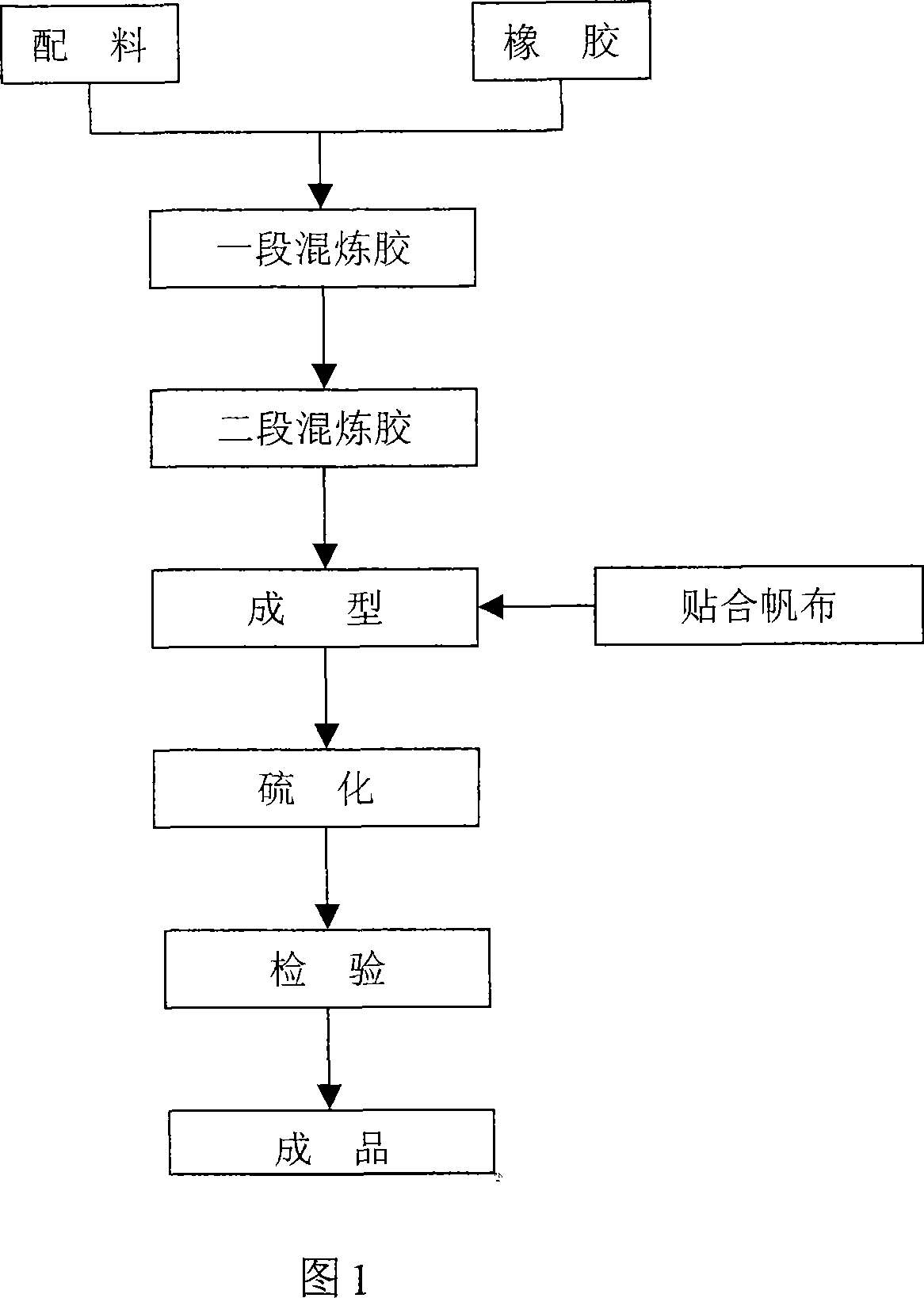

The present invention relates to one kind of tearproof antiwear conveying belt, and belongs to the field of rubber product technology. The tearproof antiwear conveying belt is produced through pre-pressing and mixing natural rubber, styrene butadiene rubber and cis-butadiene rubber inside a Banbury mixer; adding promoter, activator, leveler and antiaging agent before further mixing; adding reinforcing agent, softening agent and aramid fiber before further mixing to obtain mixed rubber; mixing for the second time and adding cross-linking agent inside a Banbury mixer after being set for some time; discharging batch to obtain mixed rubber; rolling to form rubber sheet; combining rubber sheet with tension element belt blank, rolling up and sulfurizing; and trimming to obtain the product. The tearproof antiwear conveying belt has excellent tearproof performance, excellent antiwear performance and long service life, and is suitable for use in mines.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

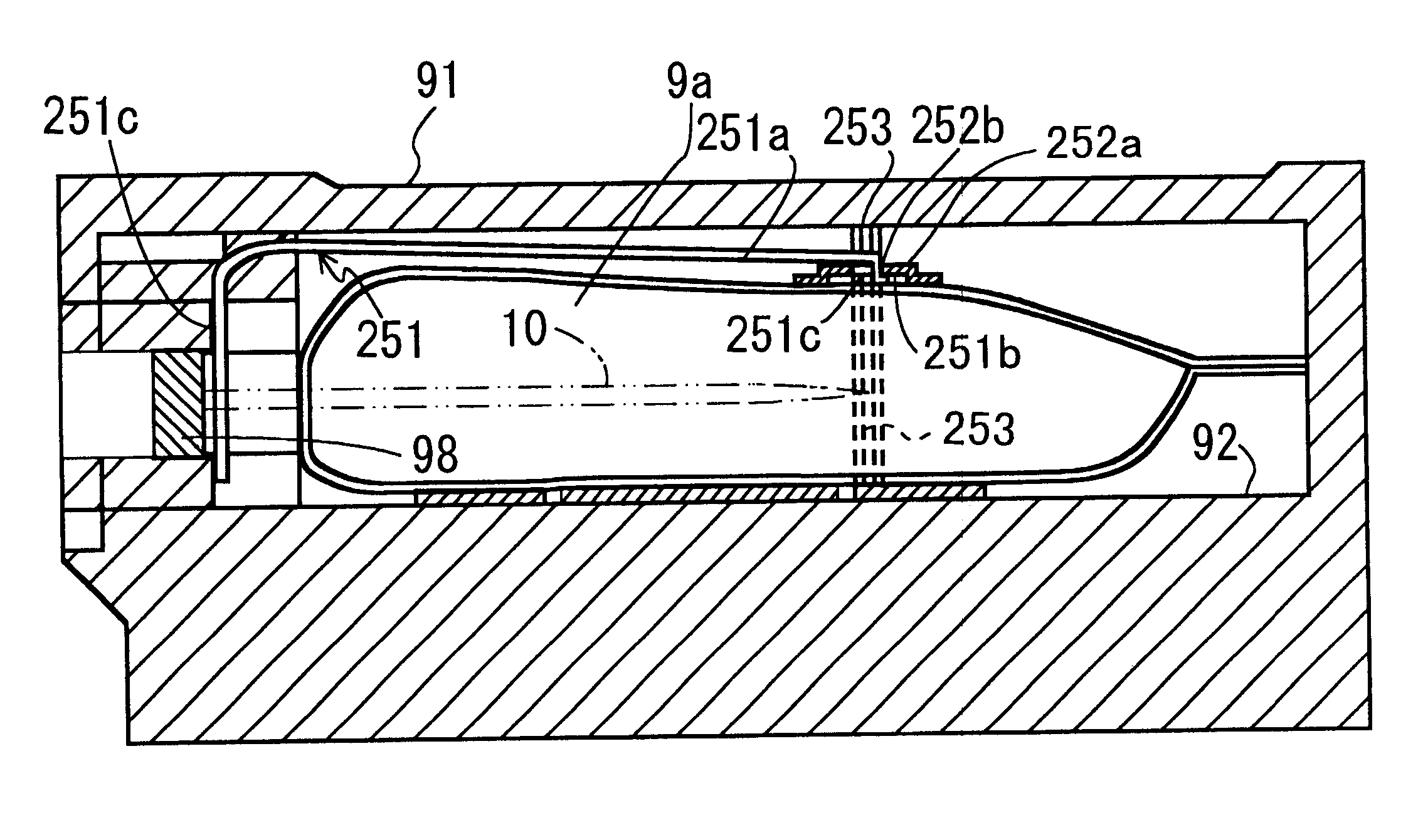

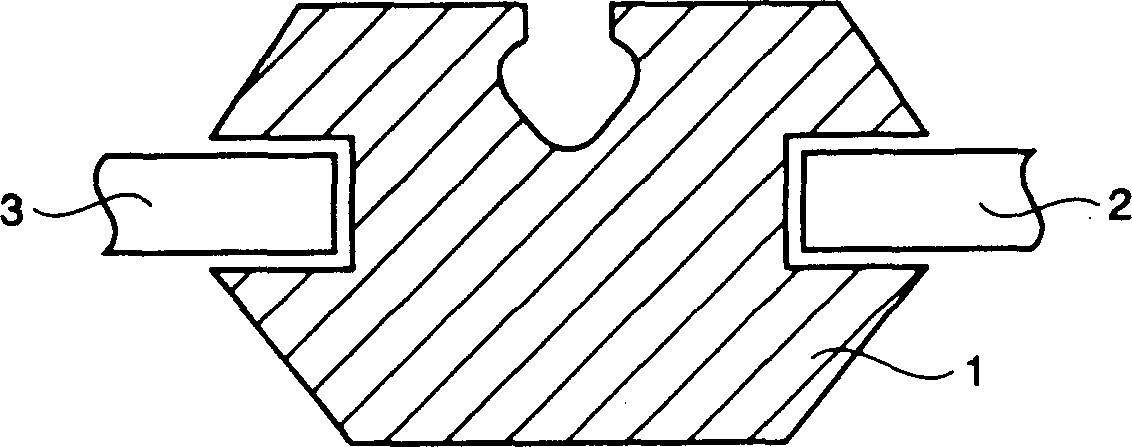

Pharmaceutical syringe piston

InactiveUS7547297B2Simply and cost-effectively producedImprove sealingMedical devicesScrew-threads articlesEngineeringRubber sheet

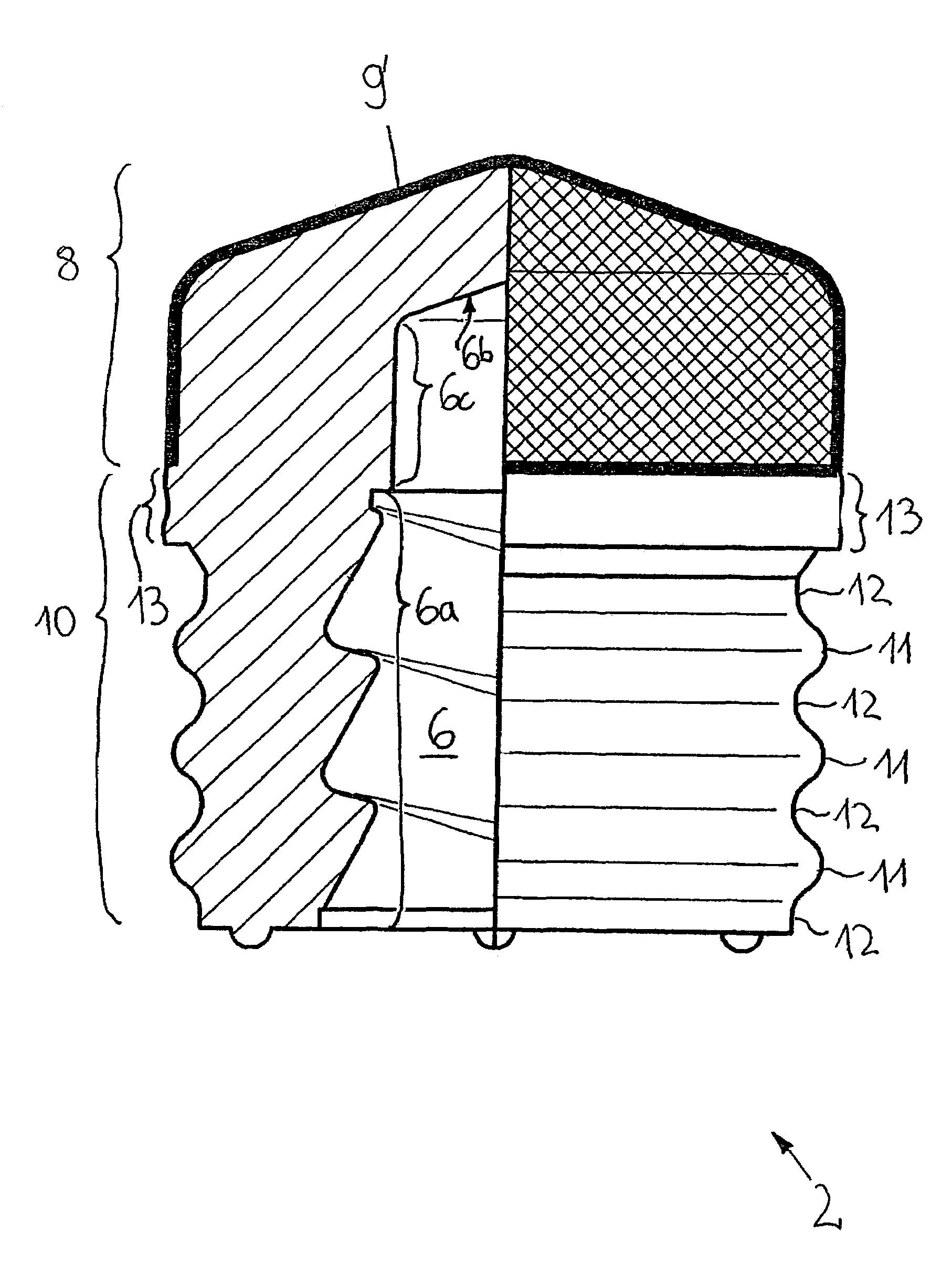

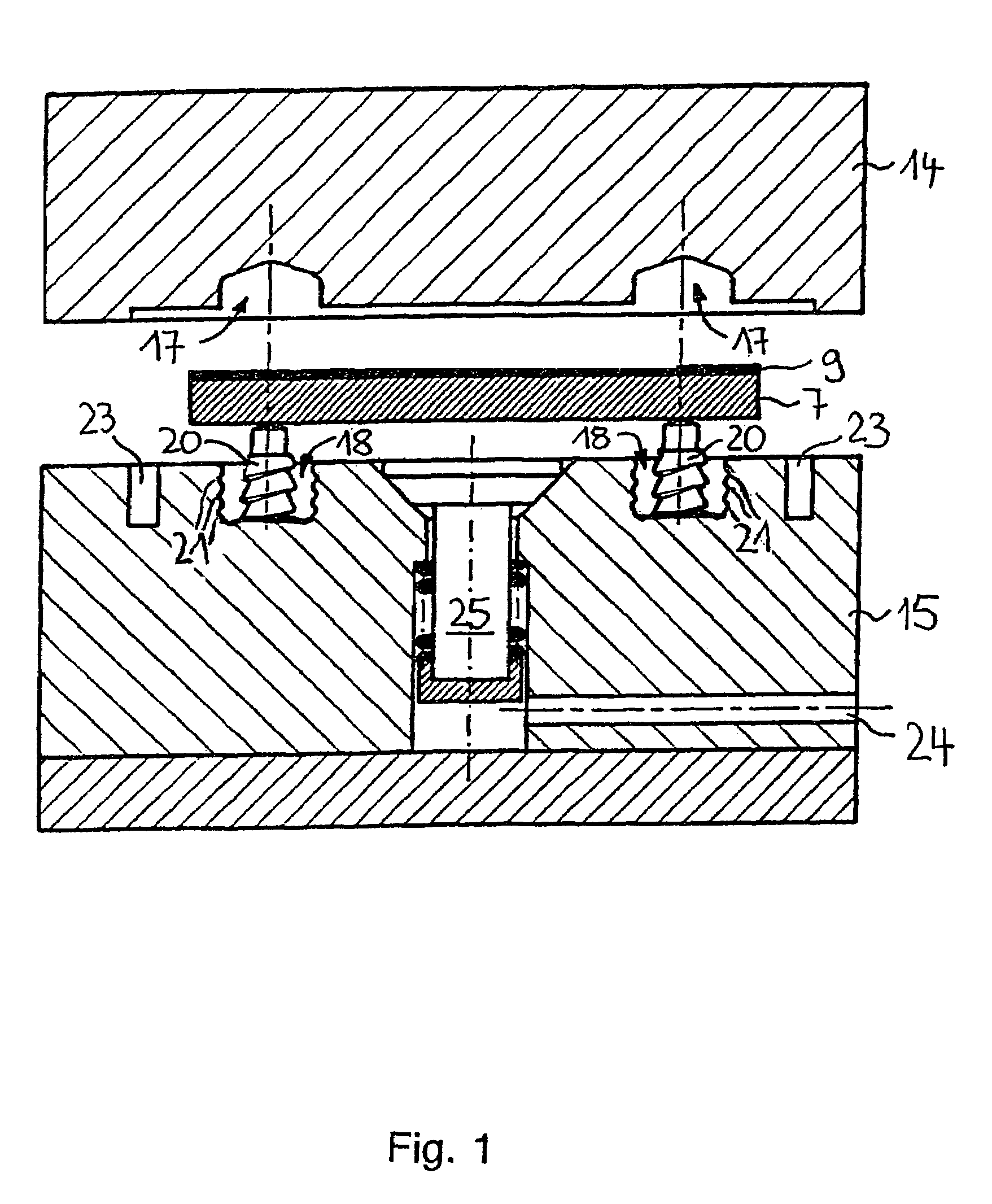

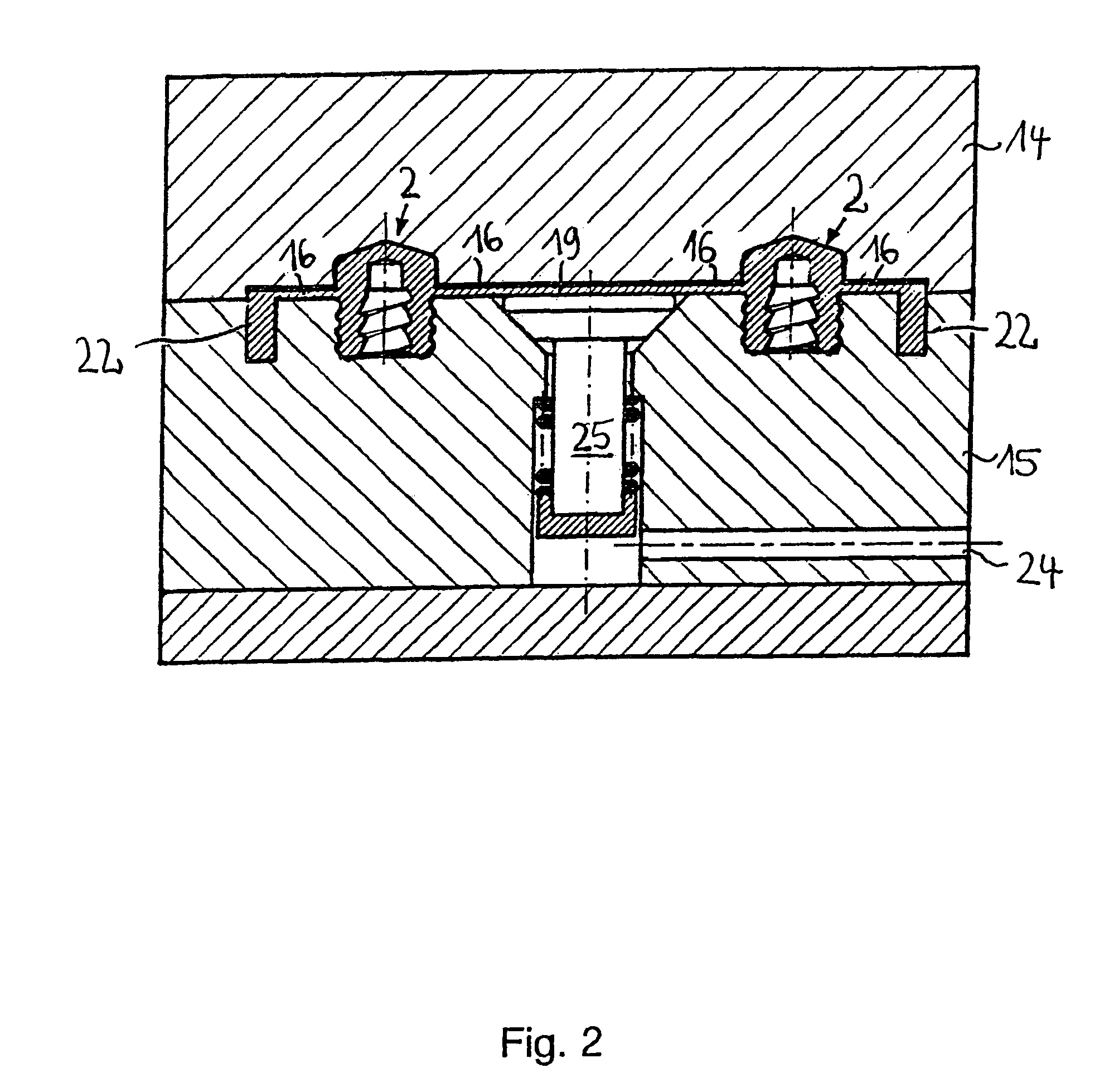

A piston stopper (2) made substantially of rubber has a piston section (8) enclosed in cap-like manner by an inert film (9′) facing the contents of a syringe or carpule cylinder (1), the inert film (9′) being located adjacent to the syringe or carpule cylinder (1). Adjacent to the piston section (8), the piston stopper (2) has a non-coated sealing section (10). According to a device and method for producing one such piston stopper (2), a non-vulcanized rubber sheet (7) is inserted into a form tool, together with an inert film (9). Under the effect of pressure and heat, an entire piston stopper contour is formed from the layered arrangement, extending to a flange (16) which protrudes laterally beyond the piston stopper (2) in the region of the separating plane of the form tool. A receiving cavity (6) for a piston rod is created in the piston section (8). The wall area of the sealing section (10) surrounding the receiving cavity (6) is forced into the receiving cavity (6). The piston stopper (2) is subsequently separated from the flange (16) in a blanking process, whereby a peripheral sealing area (13), directly adjacent to the edge of the inert film (9′) enclosing the piston section (8), is formed in the sealing section (10).

Owner:WEST PHARMA SERVICES DEUT GMBH & CO KG

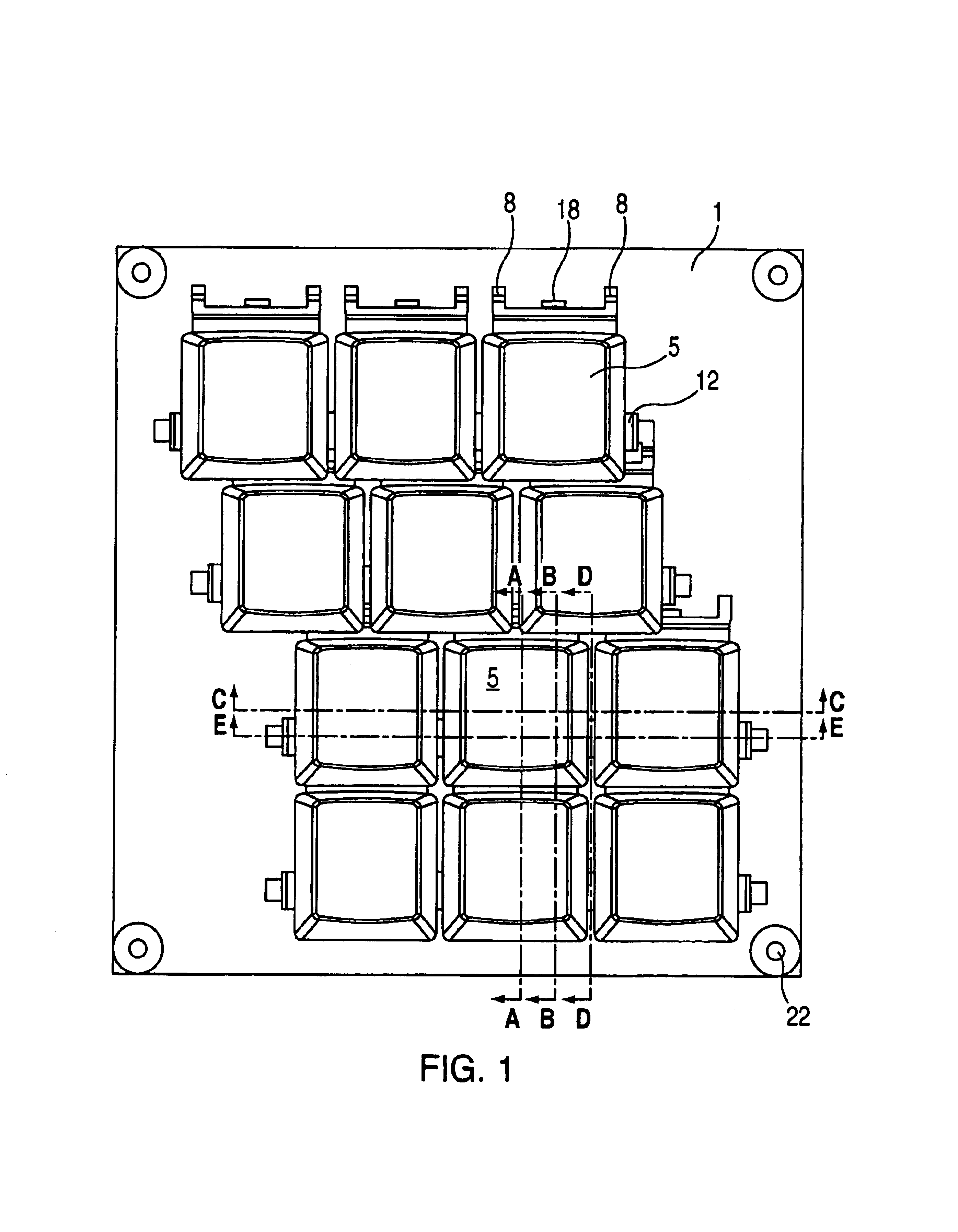

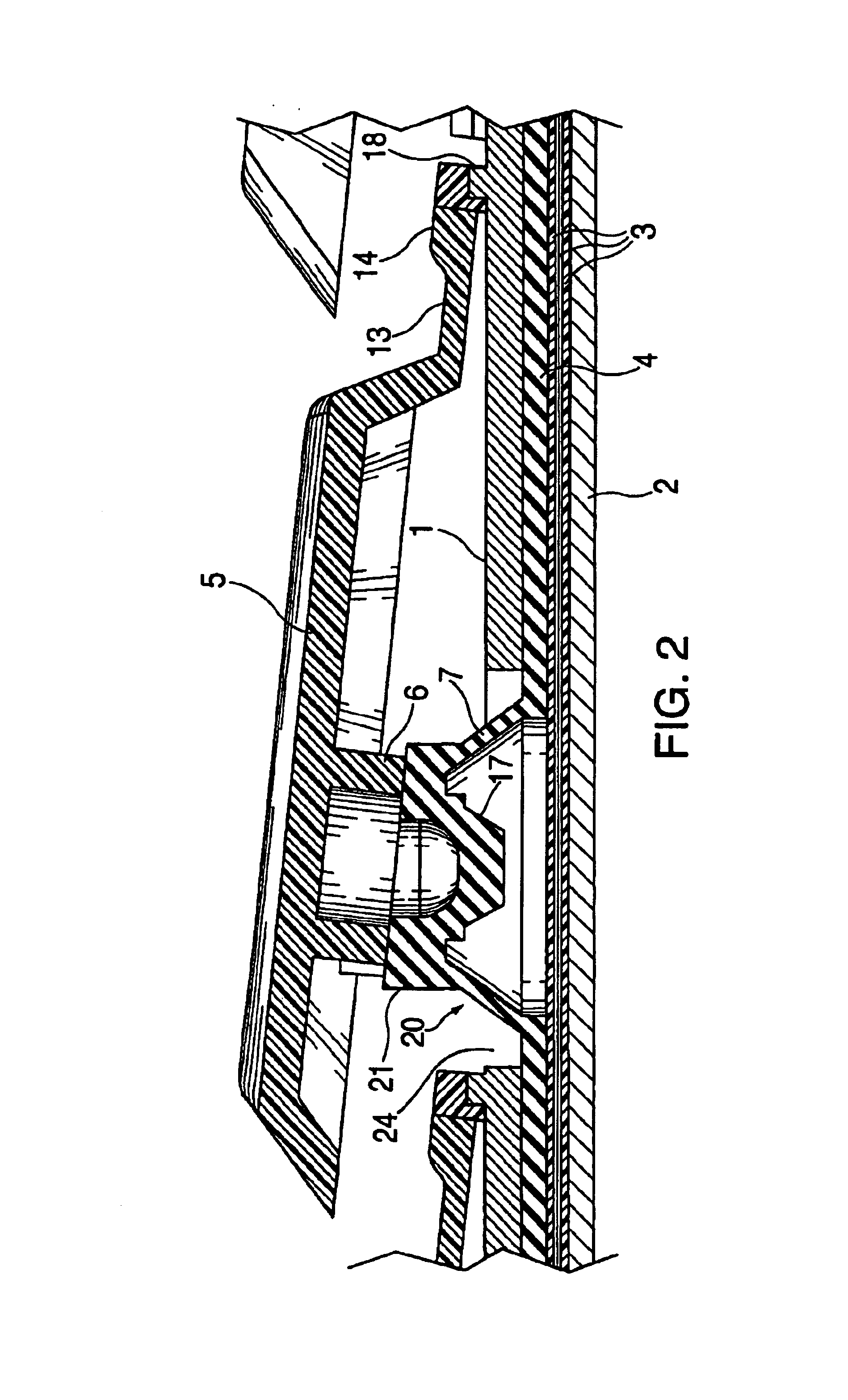

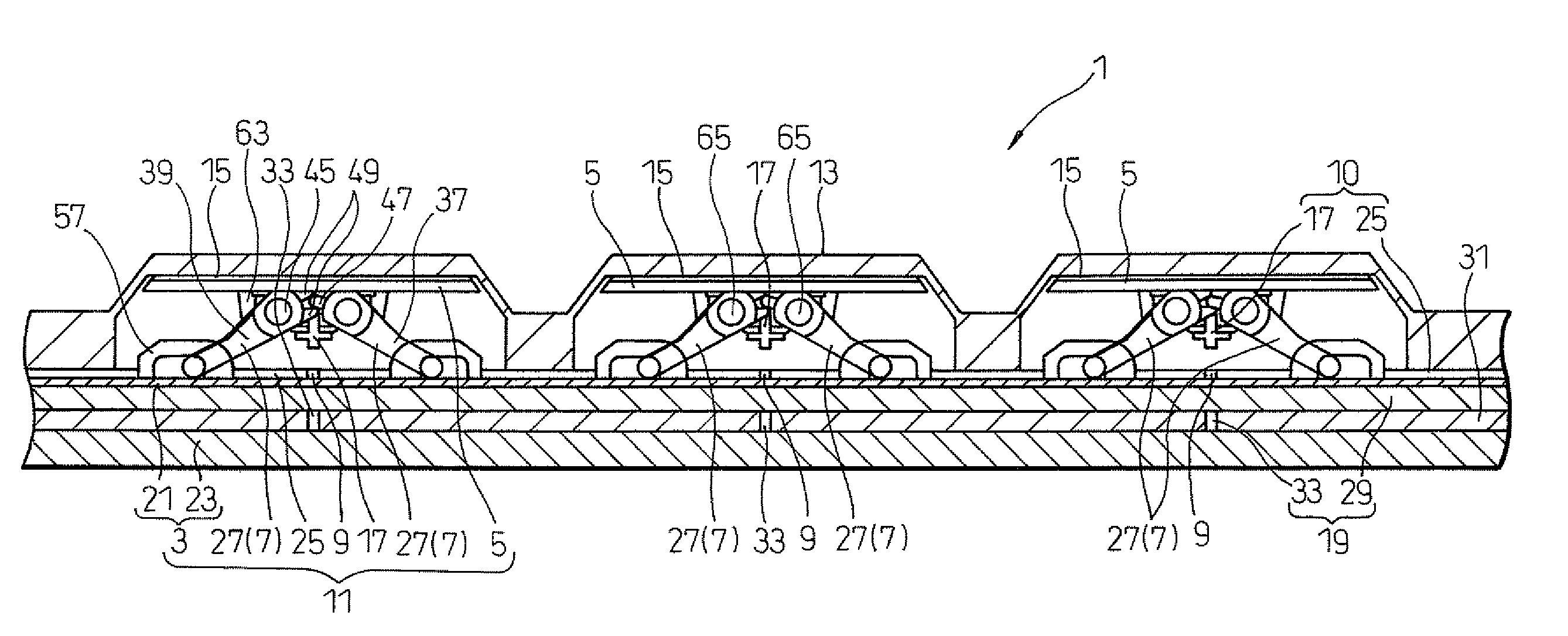

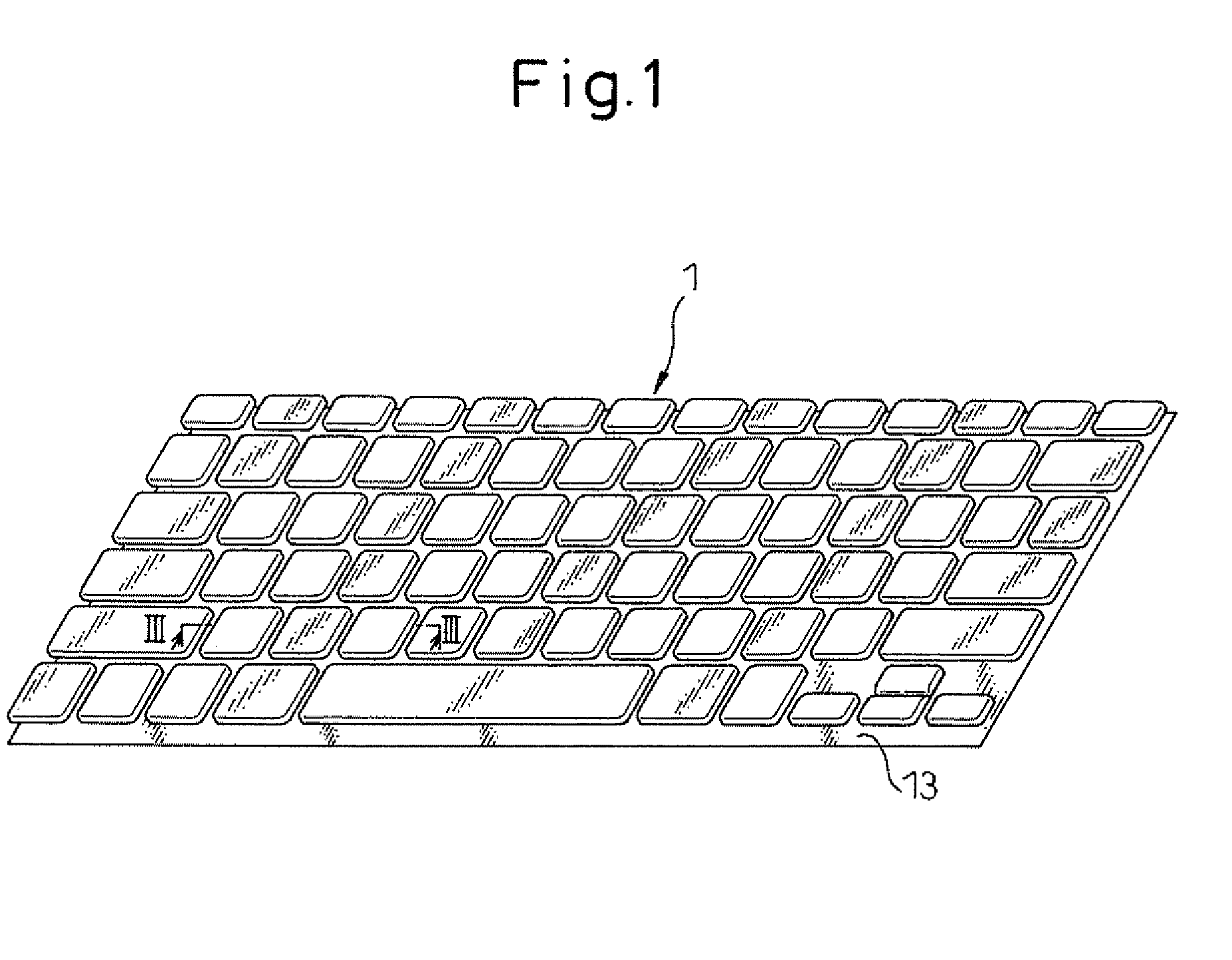

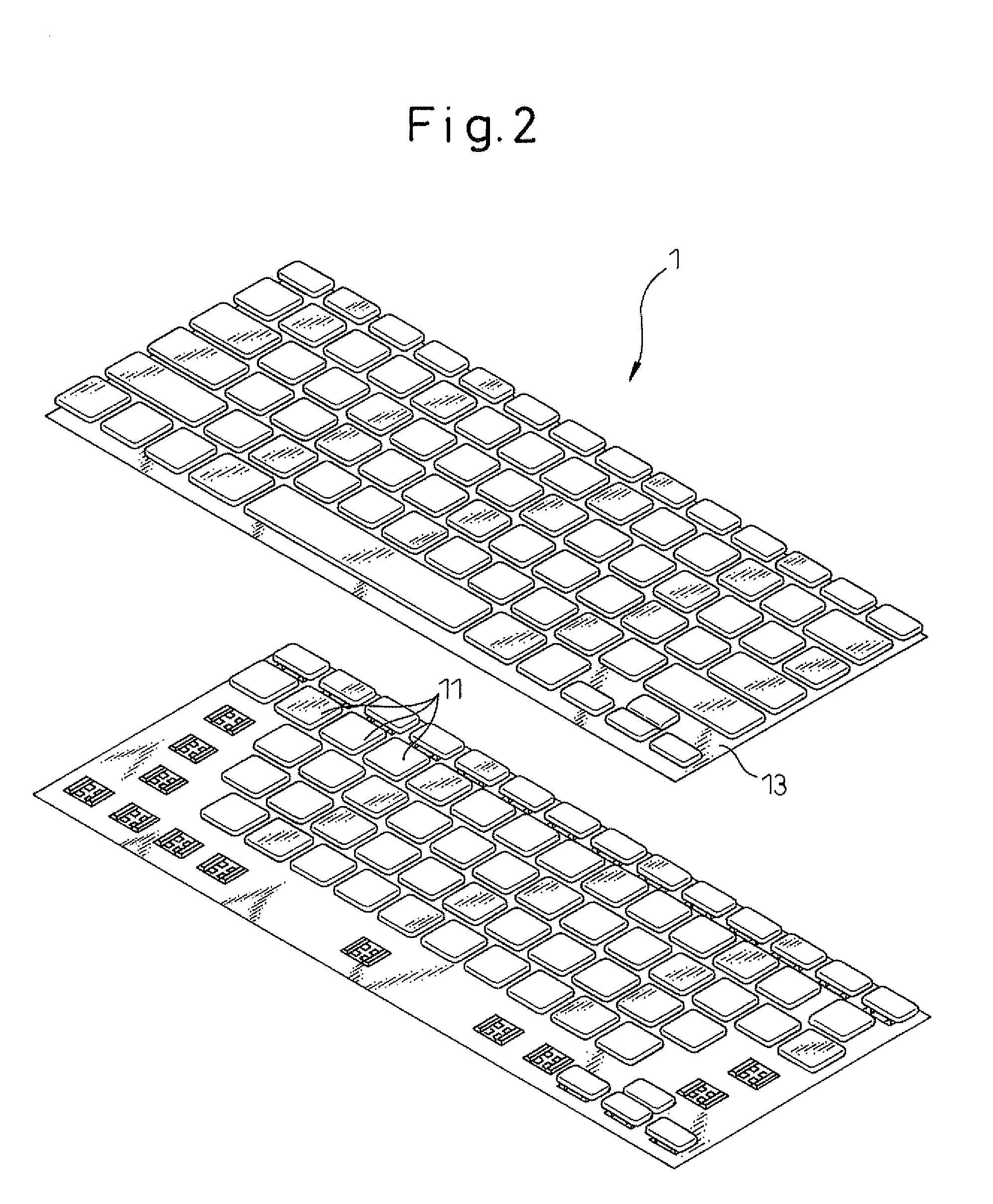

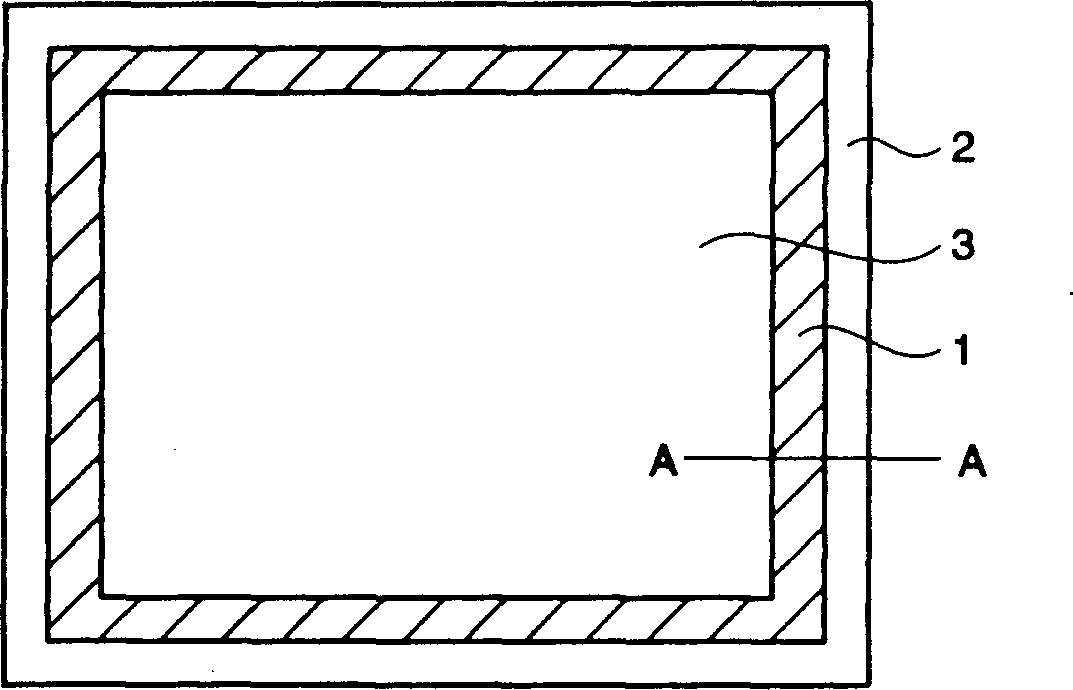

Keyboard

InactiveUS8436265B2Low costAccurate pressingEmergency actuatorsEmergency casingsEngineeringRubber sheet

The keyboard includes a rubber sheet fixed on key tops of a set of key-switch devices. The rubber sheet elastically urges the key tops upward so that they are borne away from the base of the key-switch devices. The rubber sheet is arranged so as to cover the key-switch devices from outside. According to the invention, the cost of a keyboard covered with a dustproof and watertight rubber sheet can be reduced.

Owner:FUJITSU COMPONENENT LTD

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition. The rubber composition has a high crosslinking rate at room temperature and excellent productivity, and can prepare crosslinked rubber molded products (including foamed products) having excellent weathering resistance, ozone resistance, heat aging resistance and compression set at low cost. Further, it is suitable for use of electric and electronic parts, transportation machines, civil engineering and construction materials, medical appliances and goods for leisure activities.

Owner:MITSUI CHEM INC

Addition curing silicone rubber composition and pressure-sensitive adhesive rubber sheet

An addition curing silicone rubber composition comprising (A) an alkenyl-containing organopolysiloxane, (B) a resinous copolymer composed mainly of R3SiO1 / 2 units and SiO2 units in a molar ratio between 0.5 / 1 and 1.5 / 1 wherein R stands for a monovalent hydrocarbon group and is substantially free of alkenyl groups, (C) a resinous copolymer composed mainly of R'3SiO1 / 2 units and SiO2 units in a molar ratio between 0.5 / 1 and 1.5 / 1 wherein R' stands for a monovalent hydrocarbon group and includes an alkenyl group, and the total content of alkenyl groups is at least 0.0001 mol / g, (D) an organohydrogenpolysiloxane, and (E) an addition reaction catalyst cures into a silicone rubber sheet that has a satisfactory rubber strength and surface adhesive property.

Owner:SHIN ETSU CHEM IND CO LTD

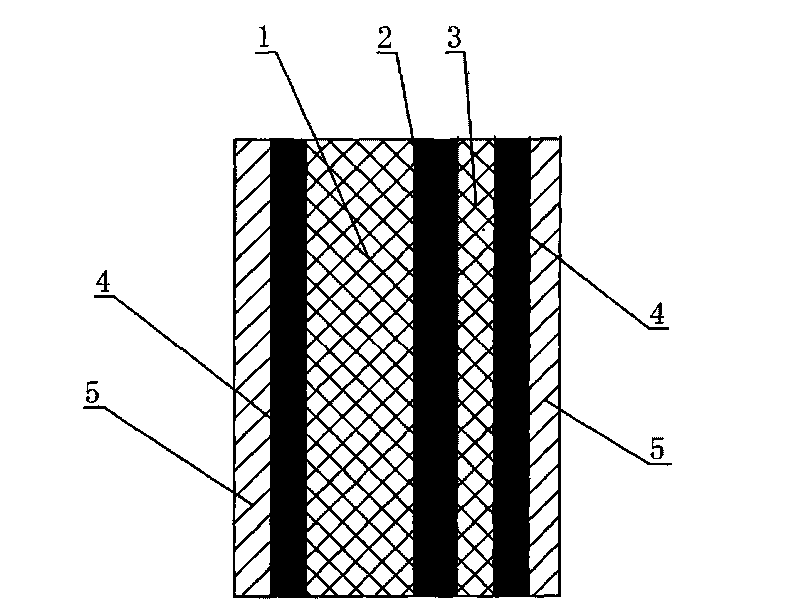

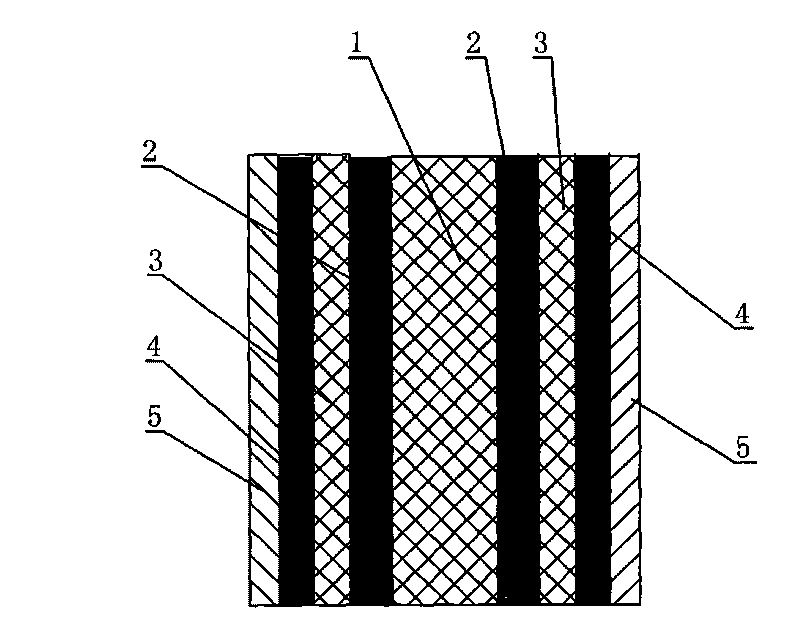

Electrostatic-resisting rubber board and its production

ActiveCN101074301AWill not polluteWon't change colorOther chemical processesEngineeringPolymer science

An anti-electrostatic rubber plate (desk pad and floor mattress) and its production are disclosed. The anti-electrostatic rubber plate consists of anti-electrostatic layer and conducting layer. It is prepared by preparing anti-electrostatic layer, preparing conducting layer film and vulcanizing to obtain final product.

Owner:浙江一远静电科技有限公司

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC

Ink warping for normalization and beautification / ink beautification

InactiveUS20070003142A1Improve legibilityEasy to classifyCharacter and pattern recognitionInput/output processes for data processingHandwritingRubber sheet

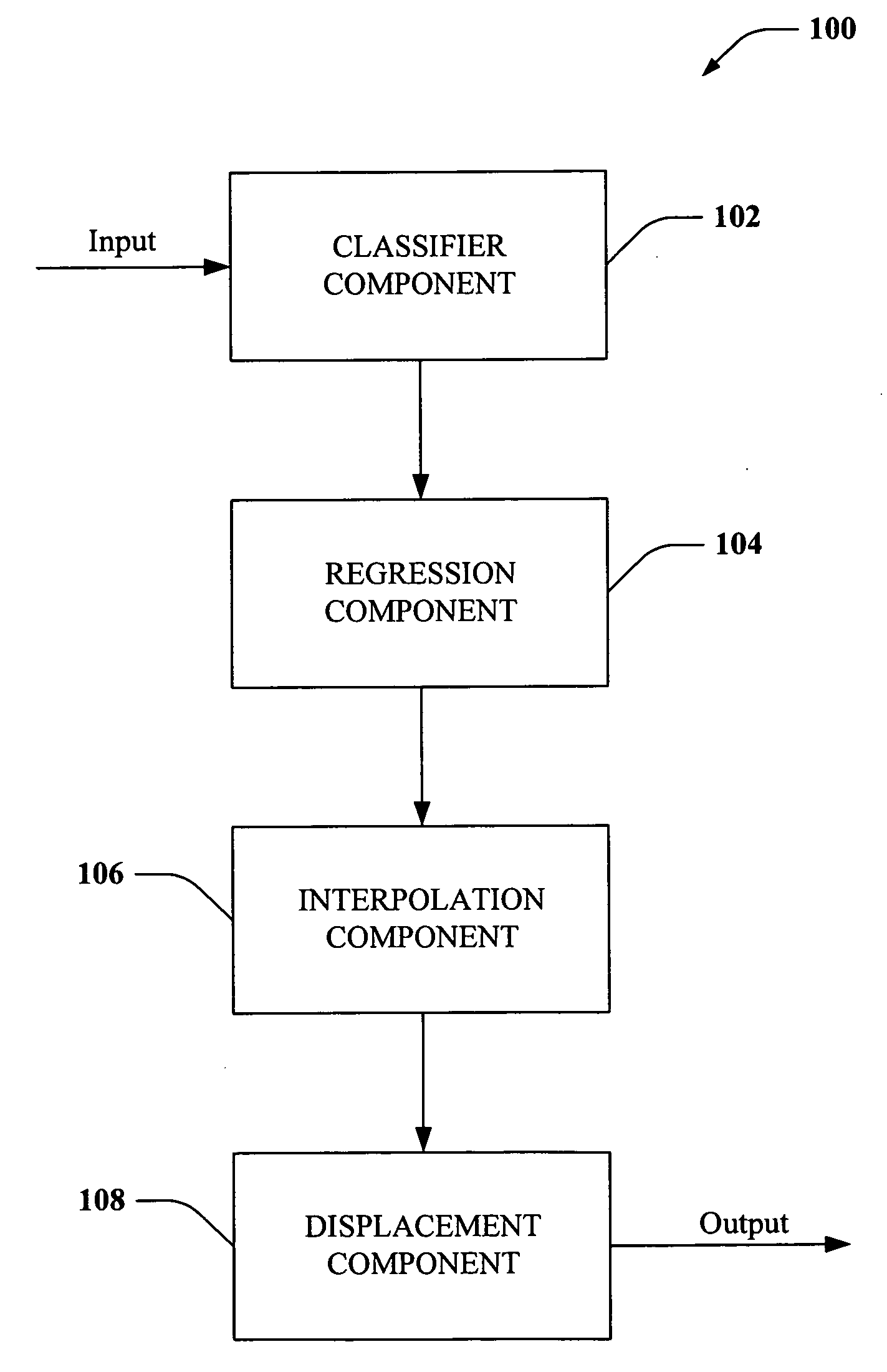

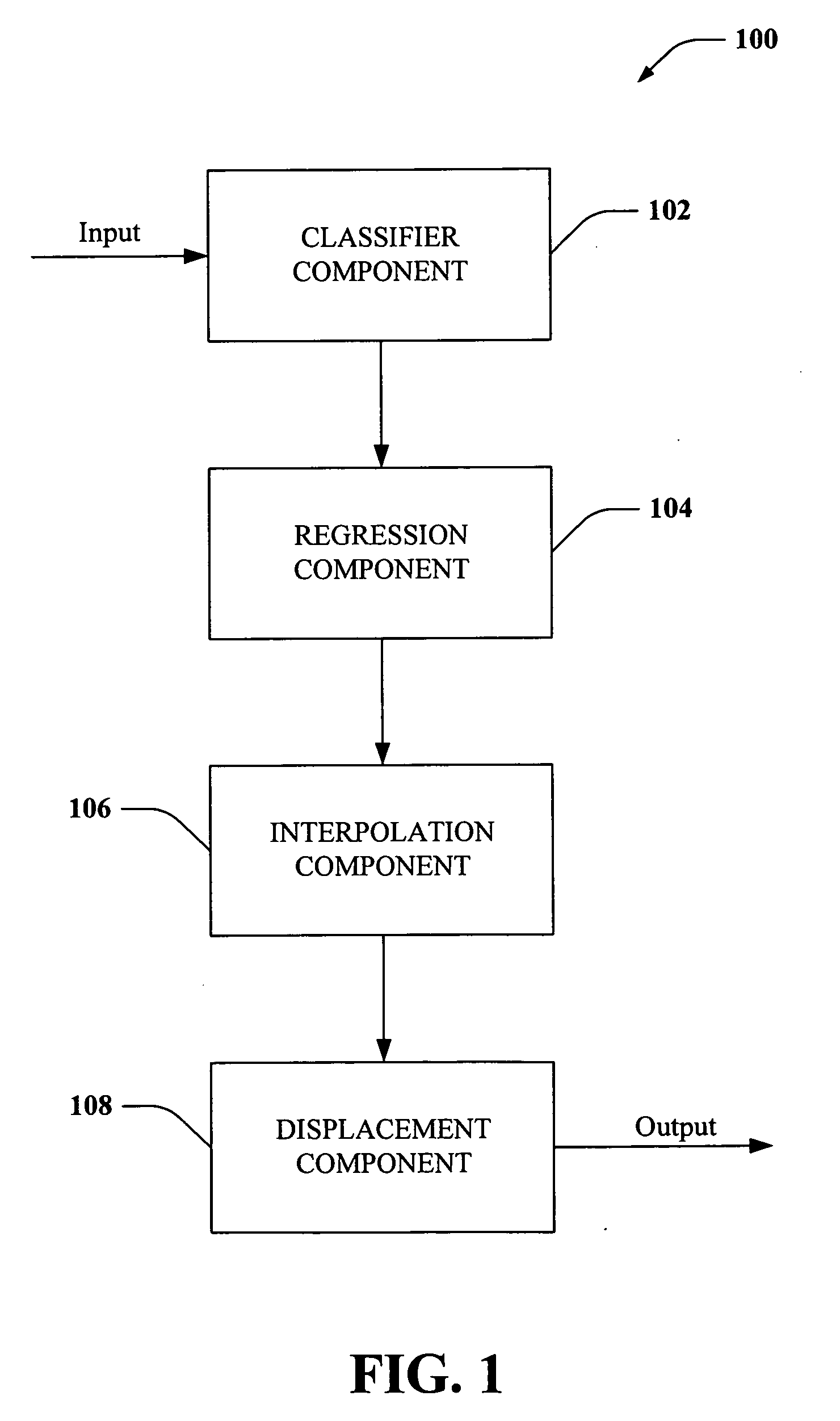

Systems and methods are disclosed that facilitate normalizing and beautifying digitally generated handwriting, such as can be generated on a tablet PC or via scanning a handwritten document. A classifier can identify extrema in the digital handwriting and label such extrema according to predefined categories (e.g., bottom, baseline, midline, top, other, . . . ). Multi-linear regression, polynomial regression, etc., can be performed to align labeled extrema to respective and corresponding desired points as indicated by the labels. Additionally, displacement techniques can be applied to the regressed handwriting to optimize legibility for reading by a human viewer and / or for character recognition by a handwriting recognition application. The displacement techniques can comprise a “rubber sheet” displacement algorithm in conjunction with a “rubber rod” displacement algorithm, which can collectively preserve spatial features of the handwriting during warping thereof.

Owner:MICROSOFT TECH LICENSING LLC

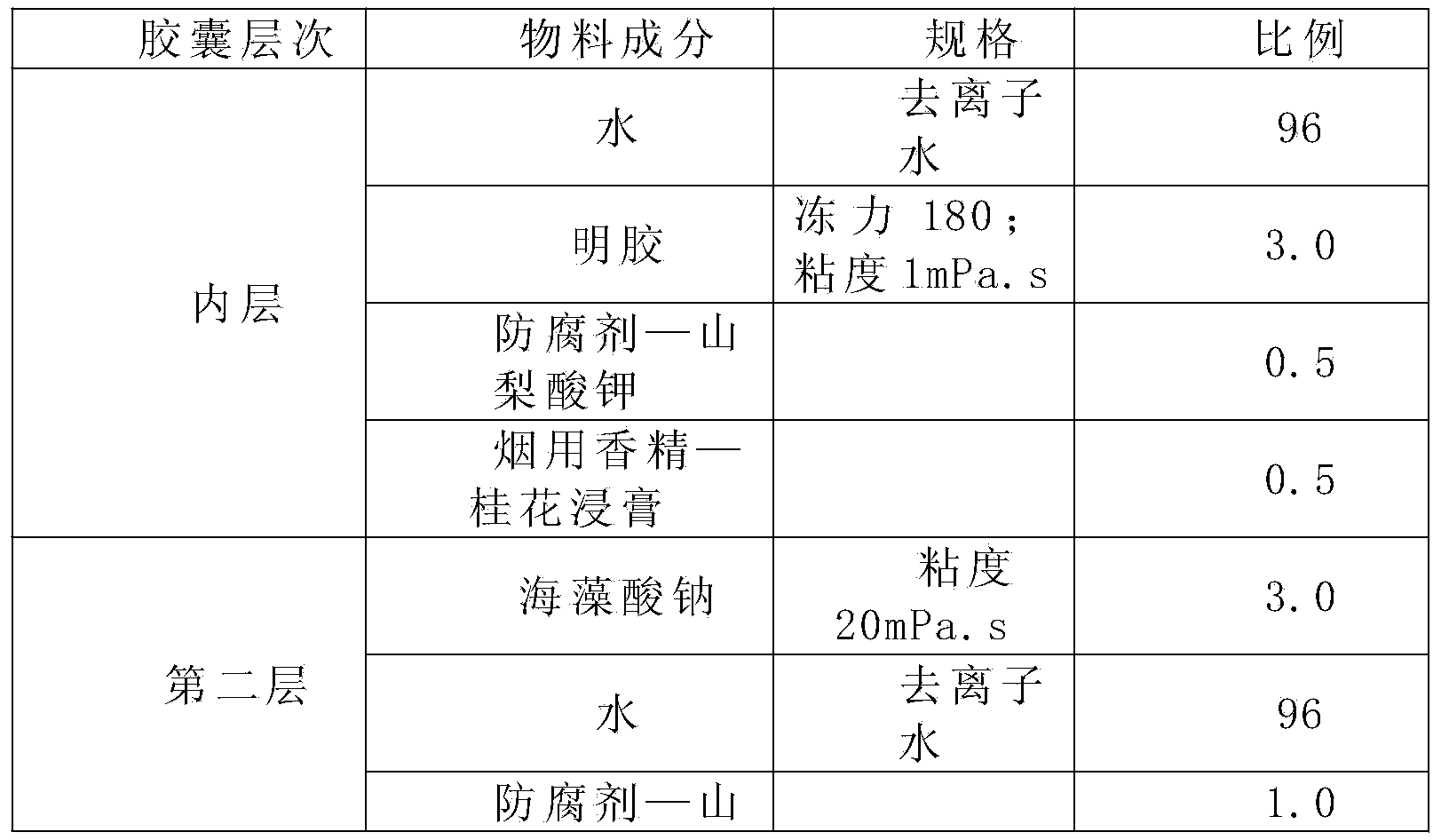

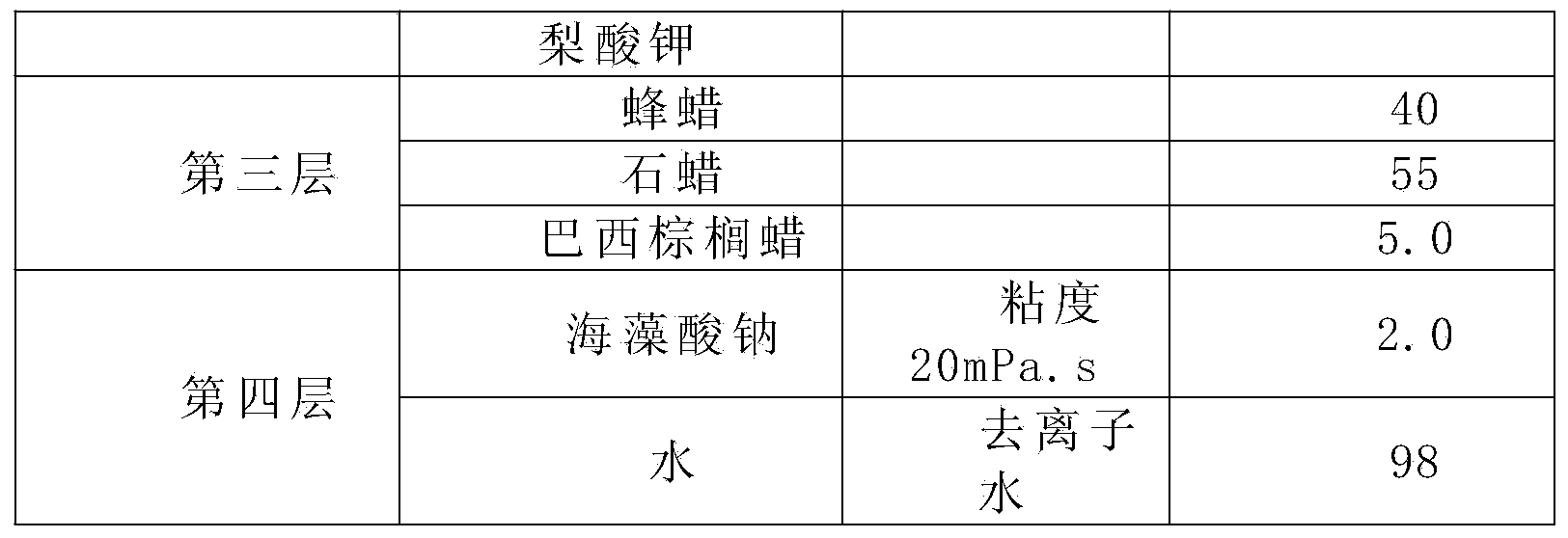

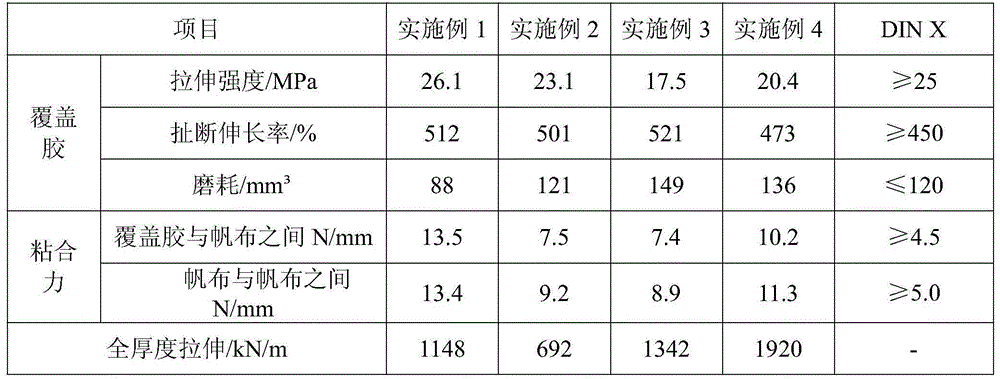

Four-layer water capsule used for cigarettes and manufacturing method of four-layer water capsule

ActiveCN103815542AImproved scrollabilityImprove pressure resistanceTobacco preparationTobacco treatmentWater solubleSolvent

The invention discloses a four-layer water capsule used for cigarettes and a manufacturing method of the four-layer water capsule. According to the four-layer water capsule used for cigarettes, water-soluble essence serves as an inner layer in the capsule, water serves as a solvent to dilute the essence, sodium alga acid complex compounds serve as the middle layer to wrap the water and the essence, waxy material serves as the third layer to prevent possible permeation of the water in the capsule, and sodium alga acid also serves as raw materials for the outermost layer to form a protection film so that cracking of the waxy layer can be reduced and the efficiency of adding the capsule to cigarettes can be improved. The manufacturing method of the four-layer water capsule includes the steps of wrapping a cigarette additive in a special rubber sheet and manufacturing the capsule through a dropping method. Dropping pills of the cigarette additive are manufactured through a dropping mechanism, used for filter tips and wrapped in tobacco bundles, and the additive or the essence is exposed when the four-layer water capsule is used and pinched broken by hand. The method is simple and practicable in process, simple in device, capable of being directly used for cigarette machining and convenient to popularize and apply. Raw materials are wide in source and low in cost.

Owner:HUBEI CHINA TOBACCO IND +1

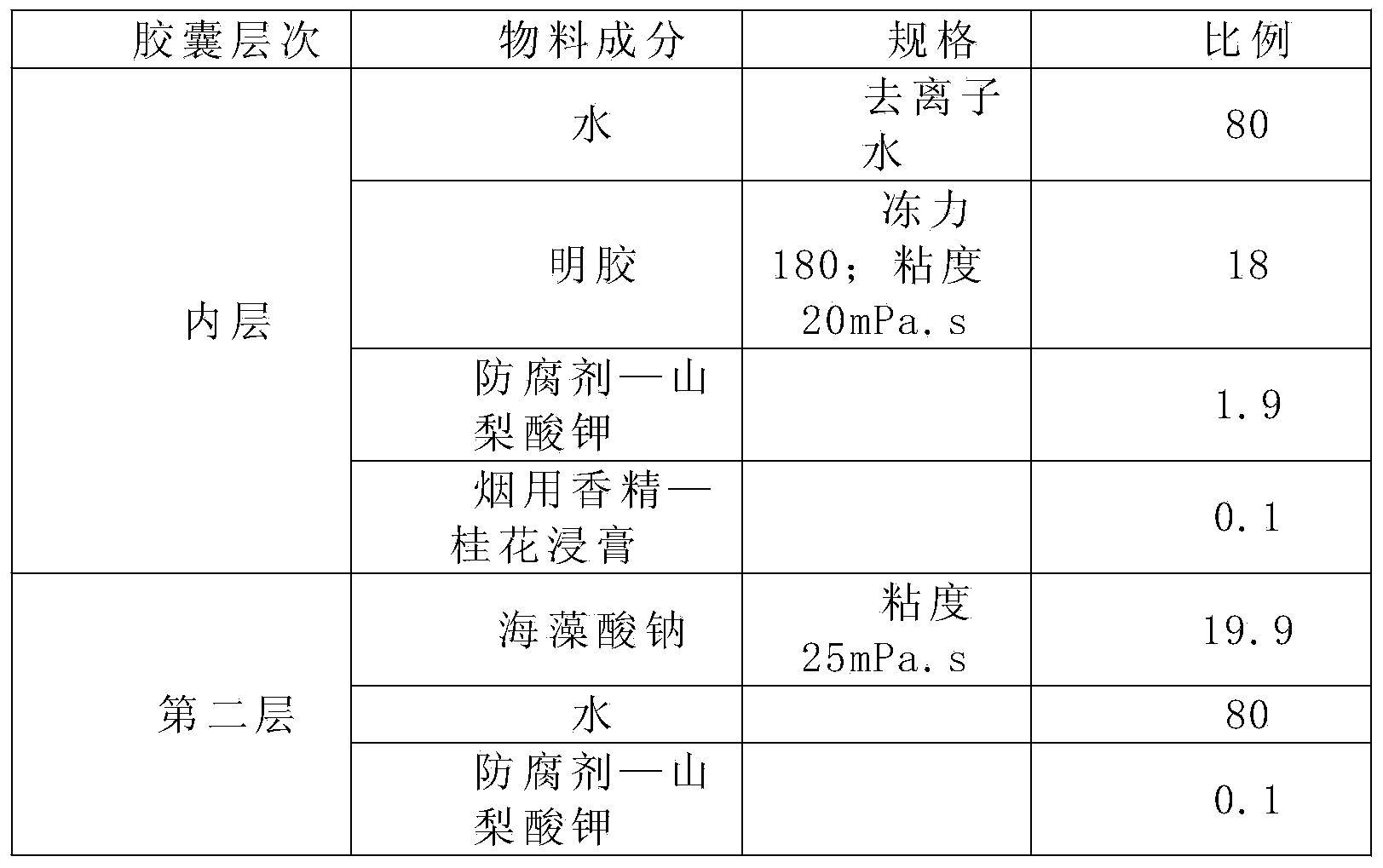

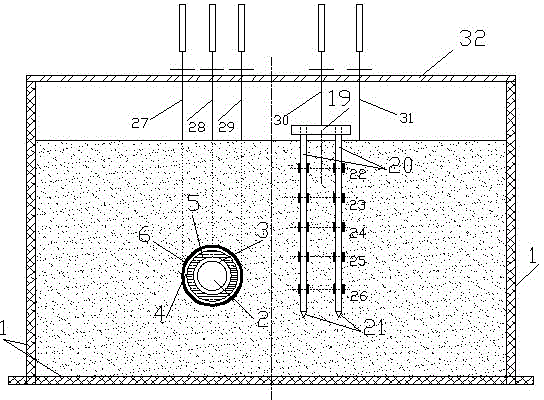

Preparation method for basalt fiber conveying belt

ActiveCN104692027AReduce weightReduce energy consumptionNatural rubber adhesivesConveyorsPolymer scienceAdhesive

The invention relates to a preparation method for a basalt fiber conveying belt, and belongs to the technical field of rubber products. The preparation method comprises the following steps: performing hydrochloric acid treatment, coupling agent treatment and plasma grafting and impregnation treatment on basalt fiber cloth; mixing natural rubber, synthesized rubber, an activating agent, an anti-aging agent, a reinforcement agent and a plasticizer to obtain a first section of mixed rubber; adding a promoter and a vulcanizer for mixing to obtain a second section of mixed rubber, and extruding the second section of mixed rubber to obtain a coverage rubber sheet; mixing the natural rubber, the synthesized rubber, the activating agent, the anti-aging agent, an adhesive, the reinforcement agent and the plasticizer to obtain a first section of mixed rubber; then adding the promoter, the vulcanizer and an adhesive RA for mixing to obtain a second section of mixed rubber, freshening after the second section of mixed rubber is stewed, and attaching the second section of mixed rubber and the basalt fiber cloth to obtain rubberized canvas; attaching the basalt fiber rubberized canvas layer by layer to obtain a framework, attaching the coverage rubber sheets to the upper surface and the lower surface of the framework to obtain a belt blank, and vulcanizing the belt blank to obtain the basalt fiber conveying belt. The conveying belt prepared by the preparation method is low in cost, light in mass, high in intensity, fatigue-resistant and long in service life; the conveying energy consumption can be greatly reduced.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition.

Owner:MITSUI CHEM INC

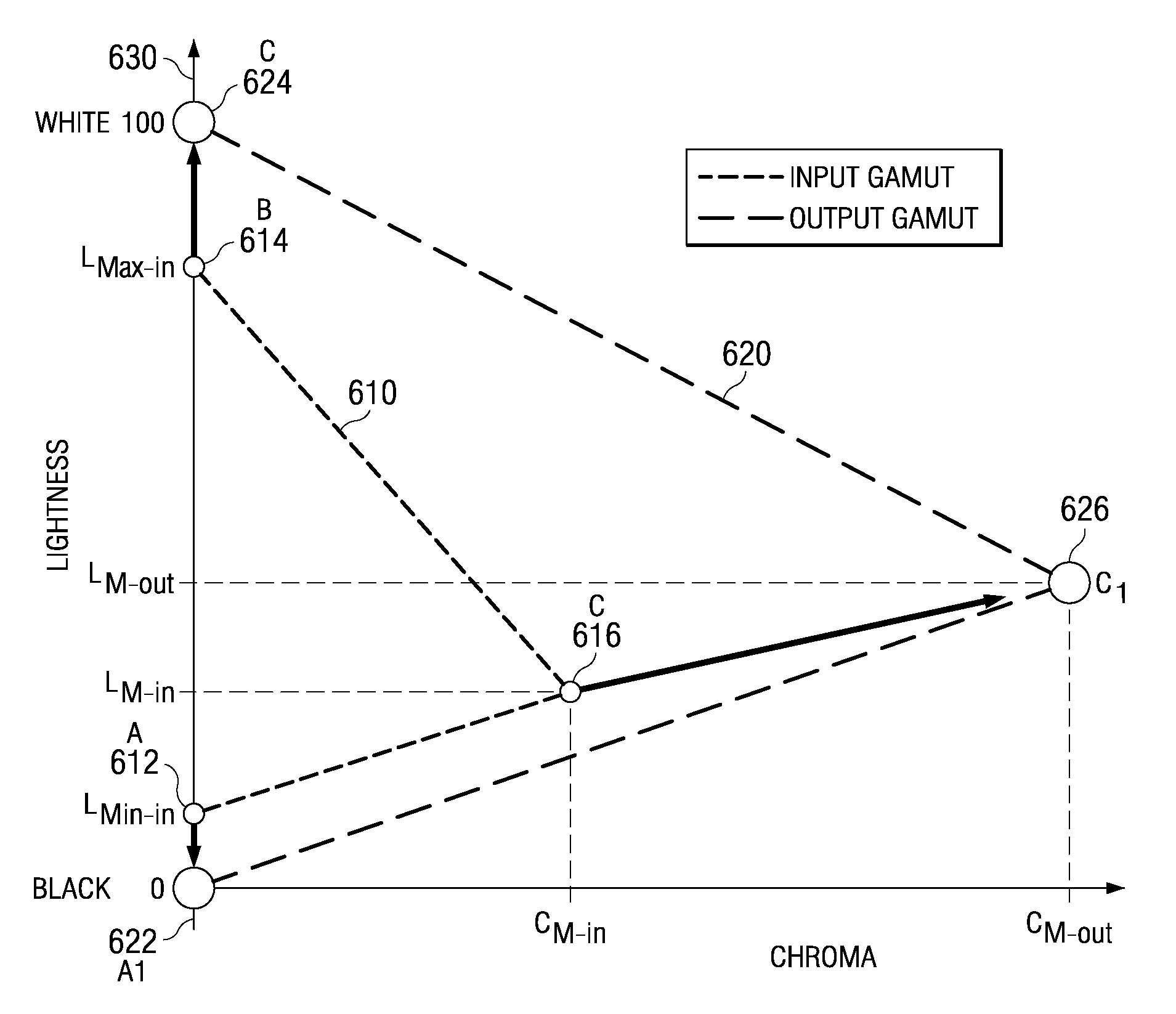

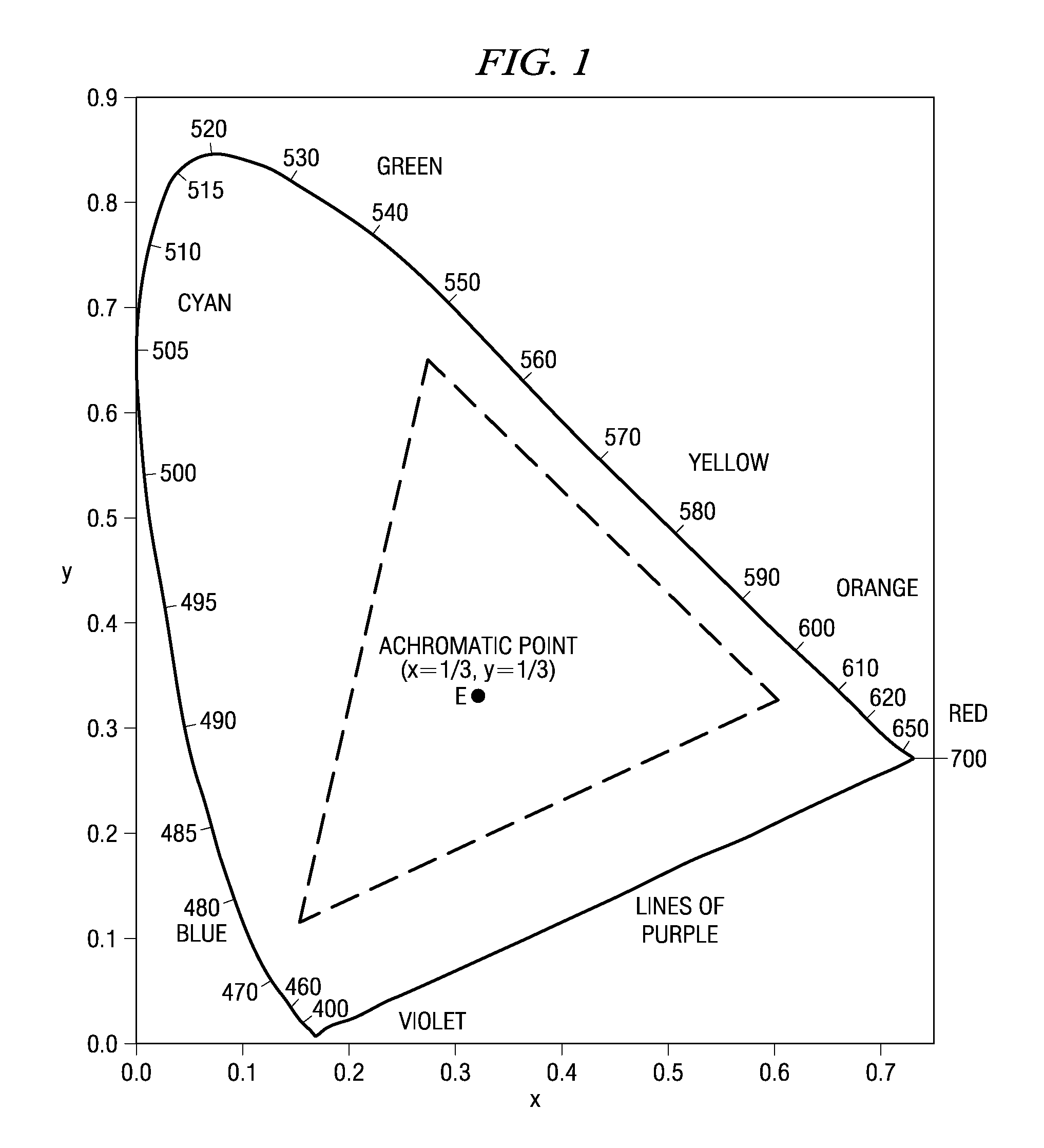

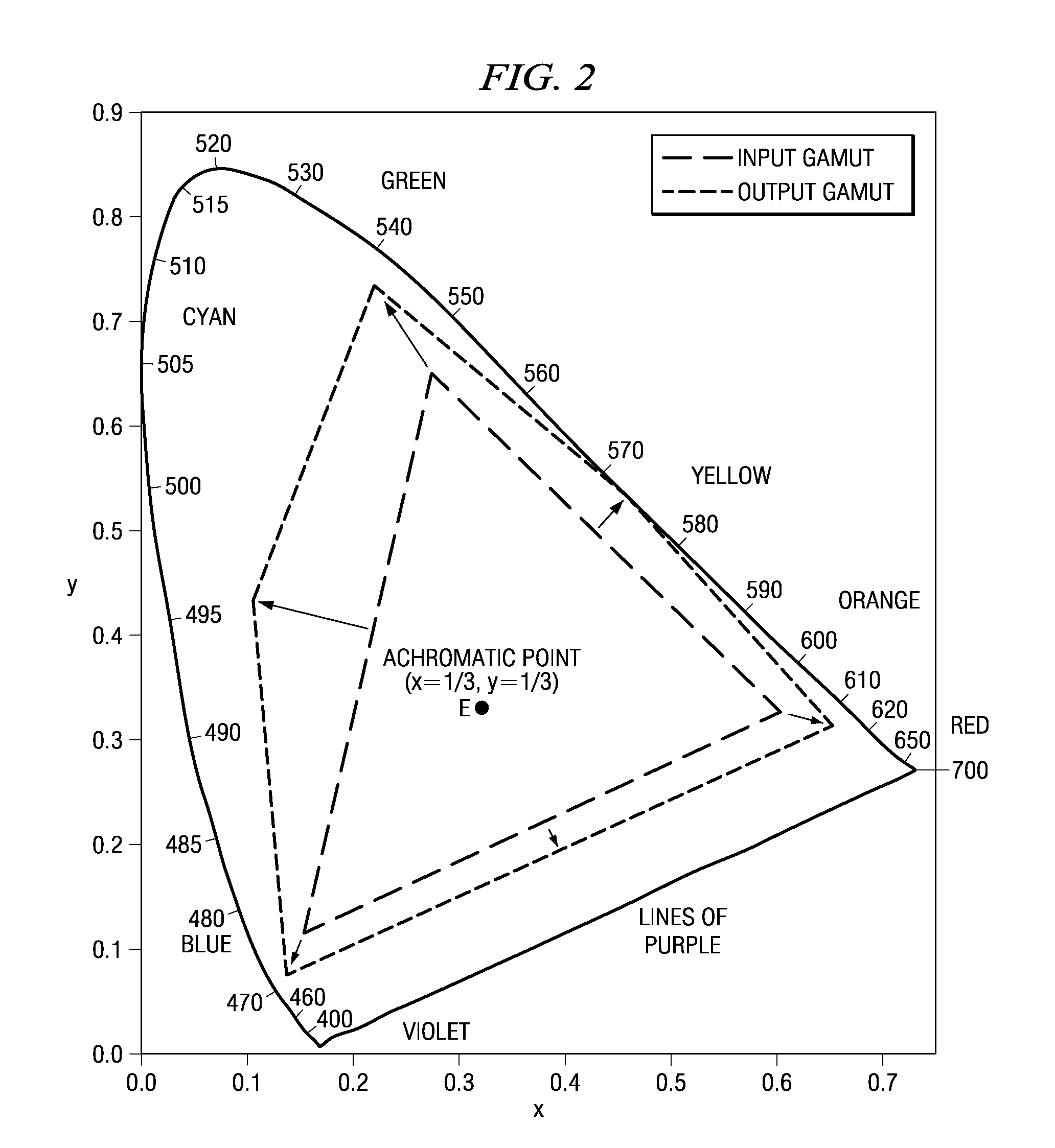

Color mapping techniques for color imaging devices

ActiveUS20080043260A1Smooth outEffective coloringDigitally marking record carriersTexturing/coloringGamutColor mapping

Disclosed embodiments relate to techniques for color gamut mapping when an input signal transmitting color visual images has a different color gamut than does the output display device. Polynomial rubber-sheet mapping may be used to translate the input color gamut to the output color gamut on a hue-by-hue basis within a three-dimensional perceptual color space. Also, a memory color look-up table may be used to preserve memory colors in the input gamut which are capable of reproduction within the output gamut. By using such techniques alone or in combination, it may be possible to more effectively map an input color gamut to a different output color gamut with improved calorimetric accuracy.

Owner:TEXAS INSTR INC

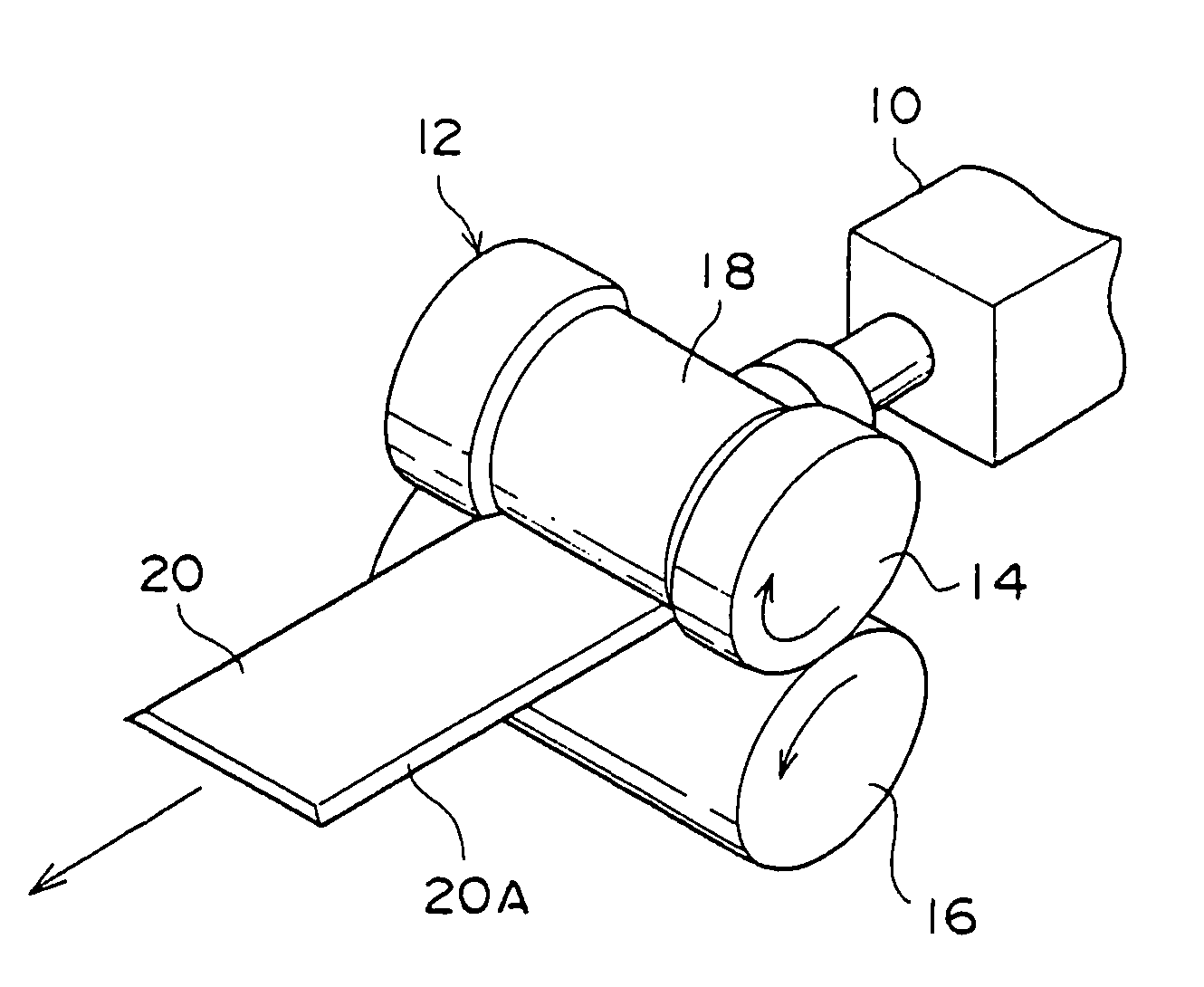

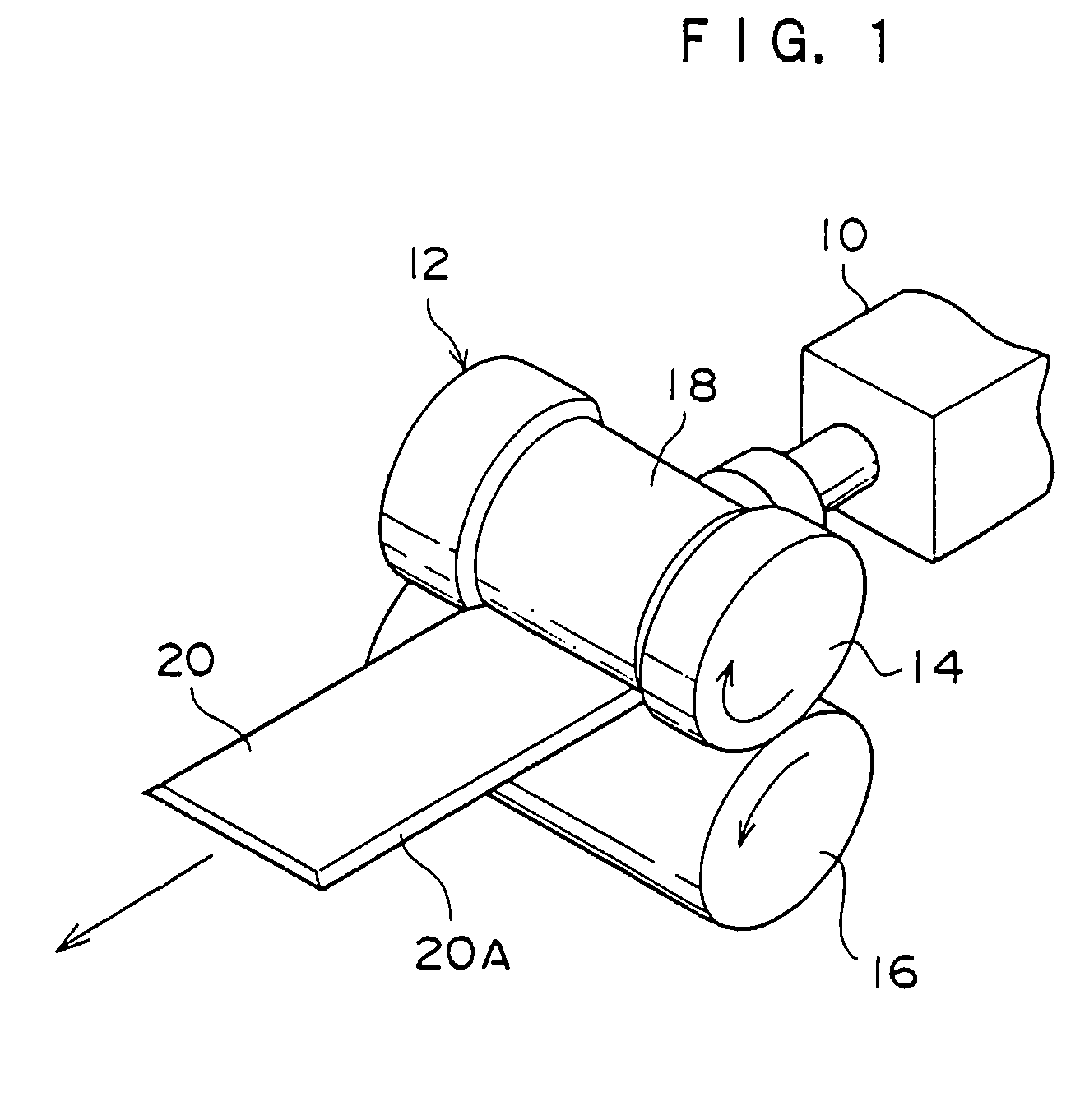

Thin rubber member producing method, rubber rolling device and rubber rolling method

InactiveUS20050116374A1Improve accuracyImprove stabilityConfectioneryPress rollersEngineeringRubber sheet

To provide a method of manufacturing a thin rubber member capable of accommodating various-size and manufacturing a thin rubber member having a constant thickness. In the first step, a long rectangular rubber strip having taper portions formed at both end portions in a transverse direction of the long rectangular rubber strip is cut to a predetermined length to thereby form a plurality of segmented rubber strips 36. In the second step, taper portions 36B at both end portions in a transverse direction of the rubber strip 36 are overlapped with one another, and a plurality of the segmented rubber strips 36 is connected to each other in the transverse direction, whereby a rubber sheet 38, the end portions of which are tapered and which has a large area, can be formed. Further, the rubber sheet 38 that can accommodate various sizes can be obtained by changing the length of the segmented rubber strip 36 and the number of connections thereof.

Owner:BRIDGESTONE CORP

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Preparation process of ethylene propylene diene rubber foaming materials

InactiveCN101824189AUniform Radiation VulcanizationIncreased Radiation Processing EnergyCross-linkVulcanization

The invention discloses a preparation process of ethylene propylene diene rubber foaming materials. A rubber compounding recipe of the invention consists of ingredients of rubber base materials, an anti-aging system, a filling system, a plasticizing agent, a vulcanizing system, a foaming system and a radiation cross linking sensitizing agent. The ethylene propylene diene rubber foaming materials are prepared through vulcanization foaming and demolding after the pretreatment of compounding, sheet cutting and electronic beam radiation pretreatment. The rubber sheets of the invention after radiation pretreatment have a certain pre-cross-linking degree before the heating vulcanization foaming, the fit of the vulcanization speed and the foaming velocity can be realized, the integral performance of products can be improved, the pre-vulcanization time can be shortened, energy sources can be saved, and the production efficiency can be improved.

Owner:BEIJING RADIATION APPL RES CENT

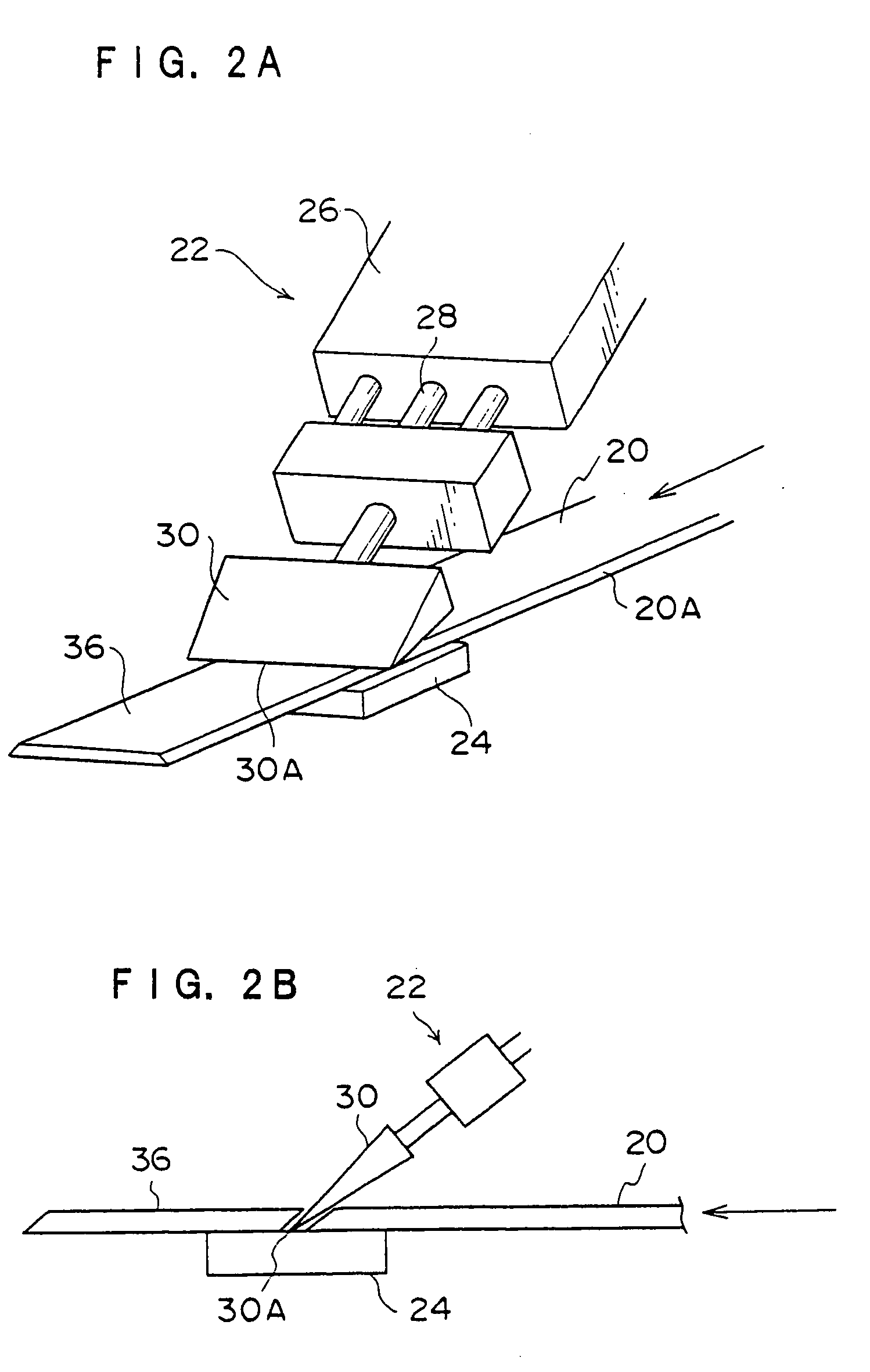

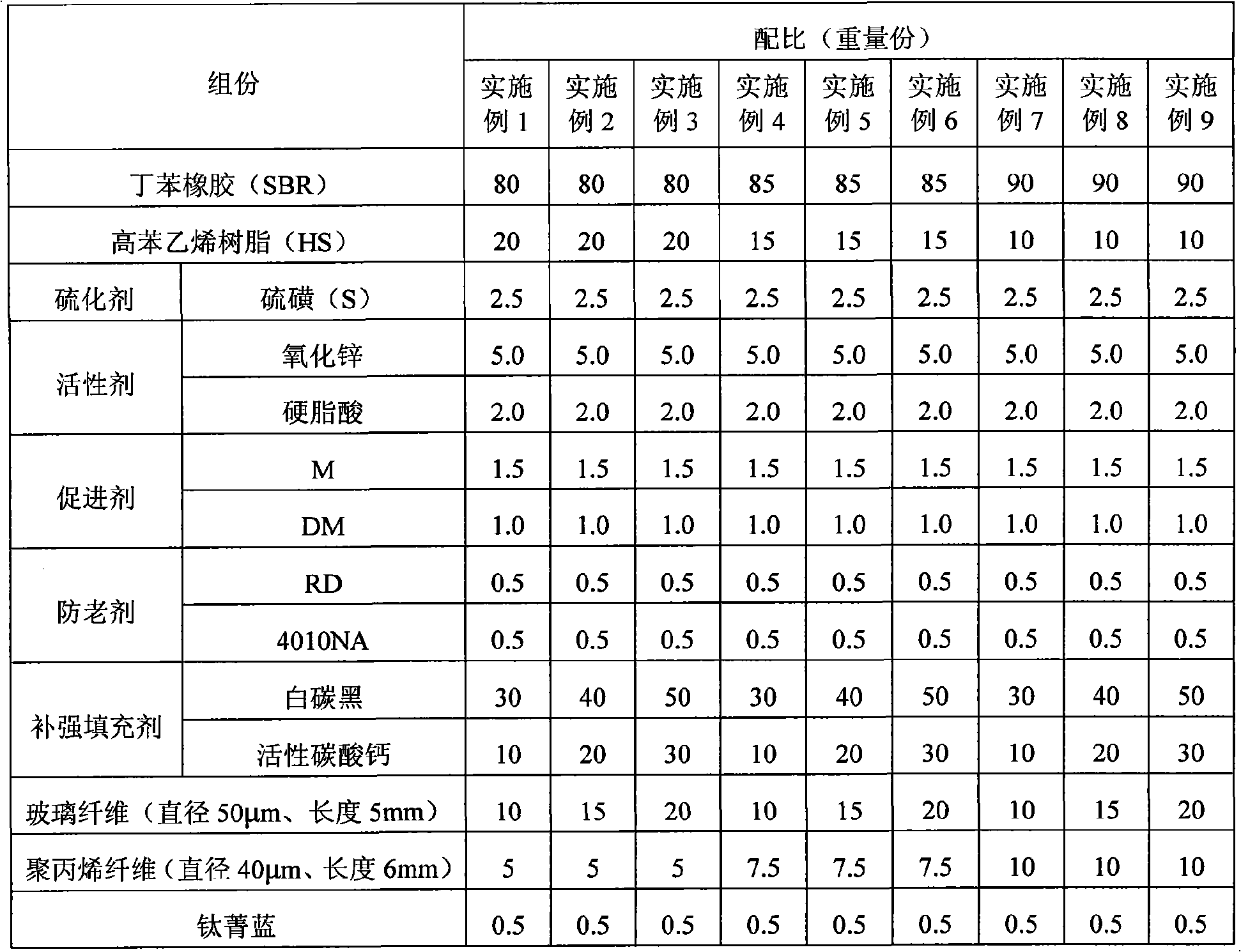

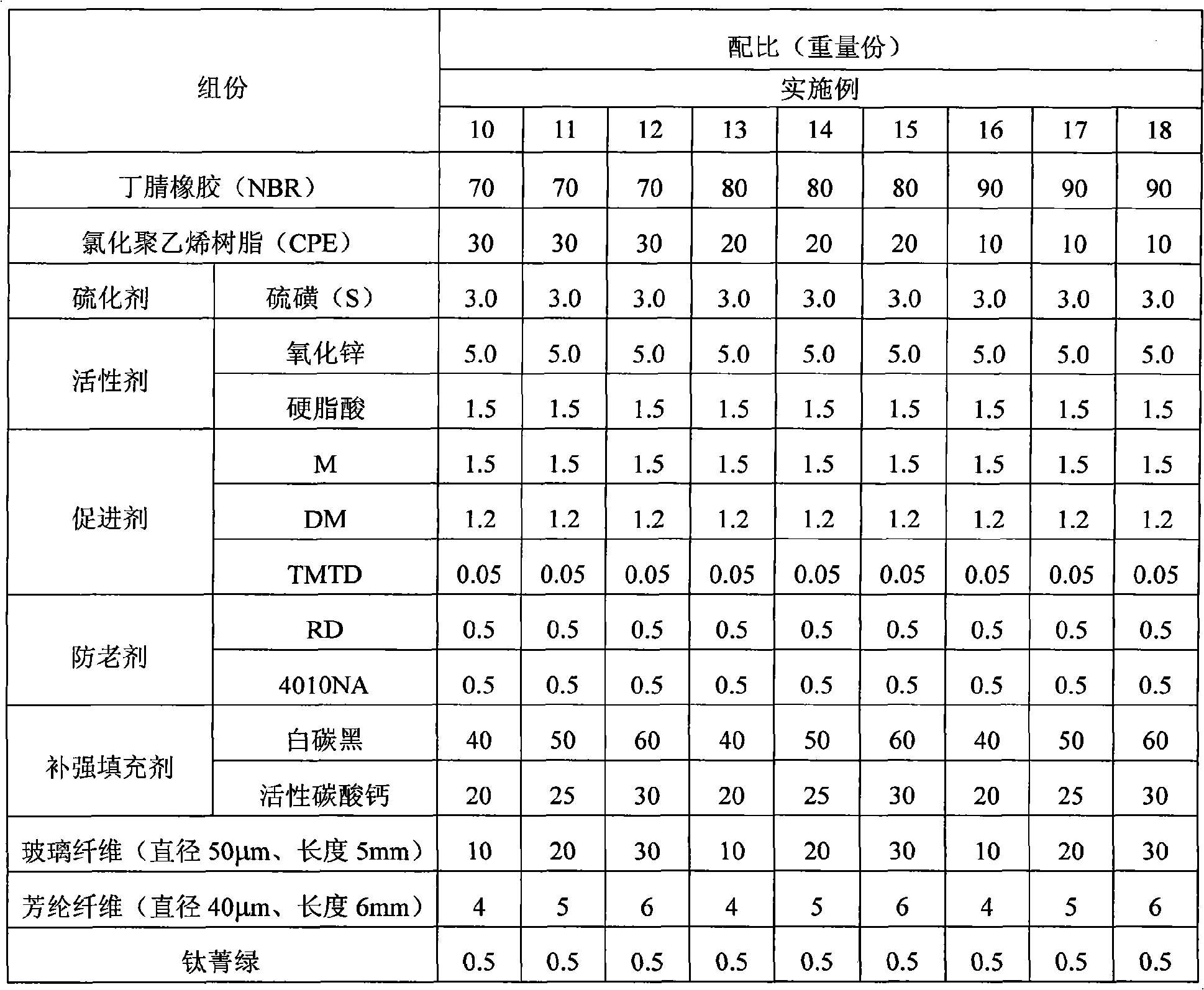

Fiber reinforced rubber

The invention relates to a fiber reinforced rubber, for which the strength can be remarkably improved, the permanent compression set can be reduced and the anti-tear performance of rubber sheet can be enhanced. A method for preparing the fiber reinforced rubber comprises the following steps: a. mastication of rubber; b. reinforcing filler, fiber and accessory ingredient are added into the rubber for mixing; wherein, the fiber and the reinforcing filler is evenly mixed to prepare pre-dispersoid, and the pre-dispersoid is added into the rubber. As a preferred proposal, the method adopts styrene-butadiene rubber, nitrile rubber and neoprene which have the good properties of wearing resistance, pressure resistance, oil and water resistance and air tightness resistance as the rubber. The rubber sheet produced by the method can work under ultra-high temperature and pressure in various media for a long time with the maximum working temperature being 300 DEG C, and maintains good elasticity, less compressive deformation and excellent physical and mechanical properties which are reduced by not more than 20% compared with those at the normal temperature.

Owner:南京固柏橡塑制品有限公司

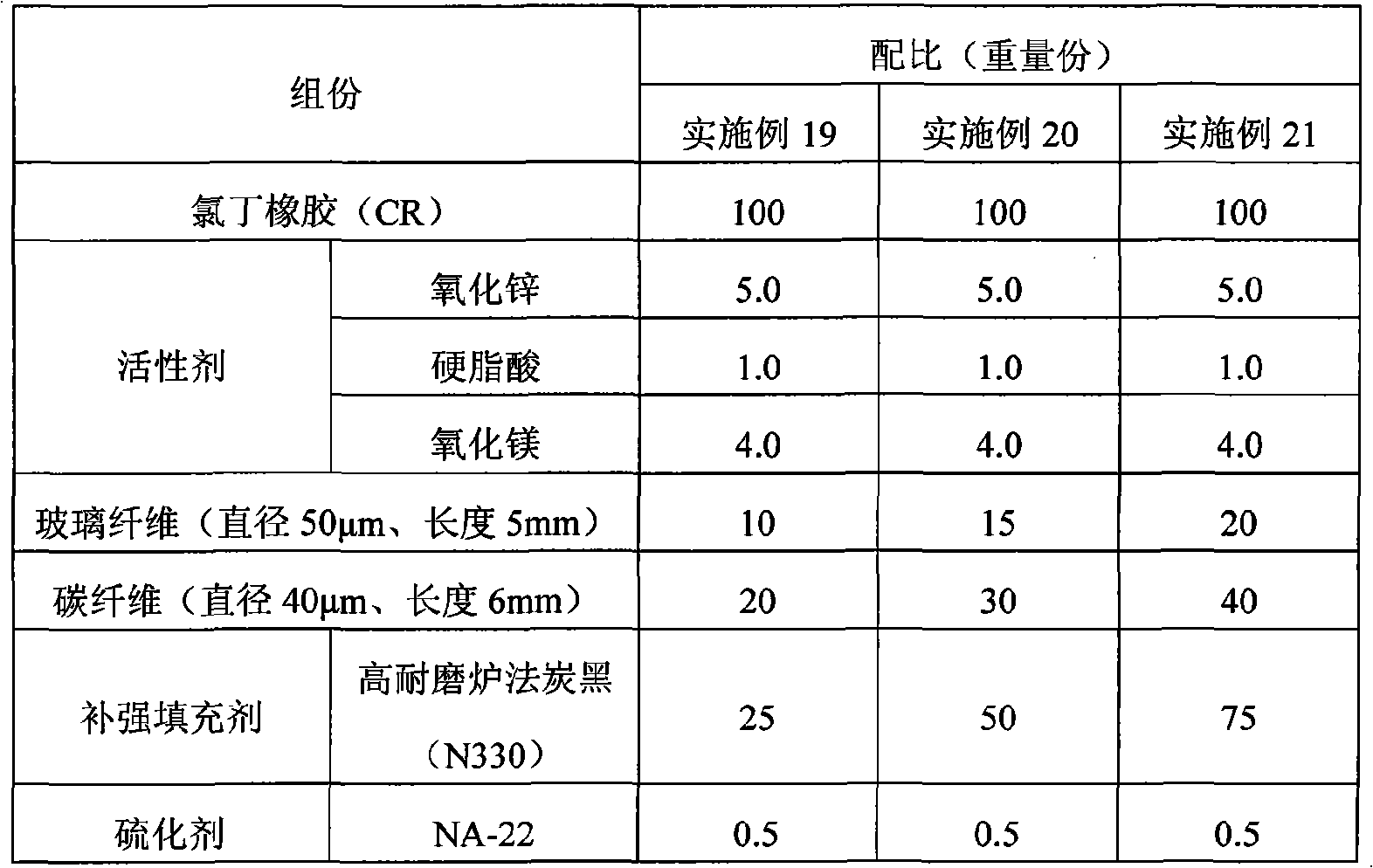

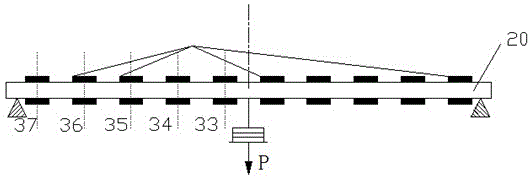

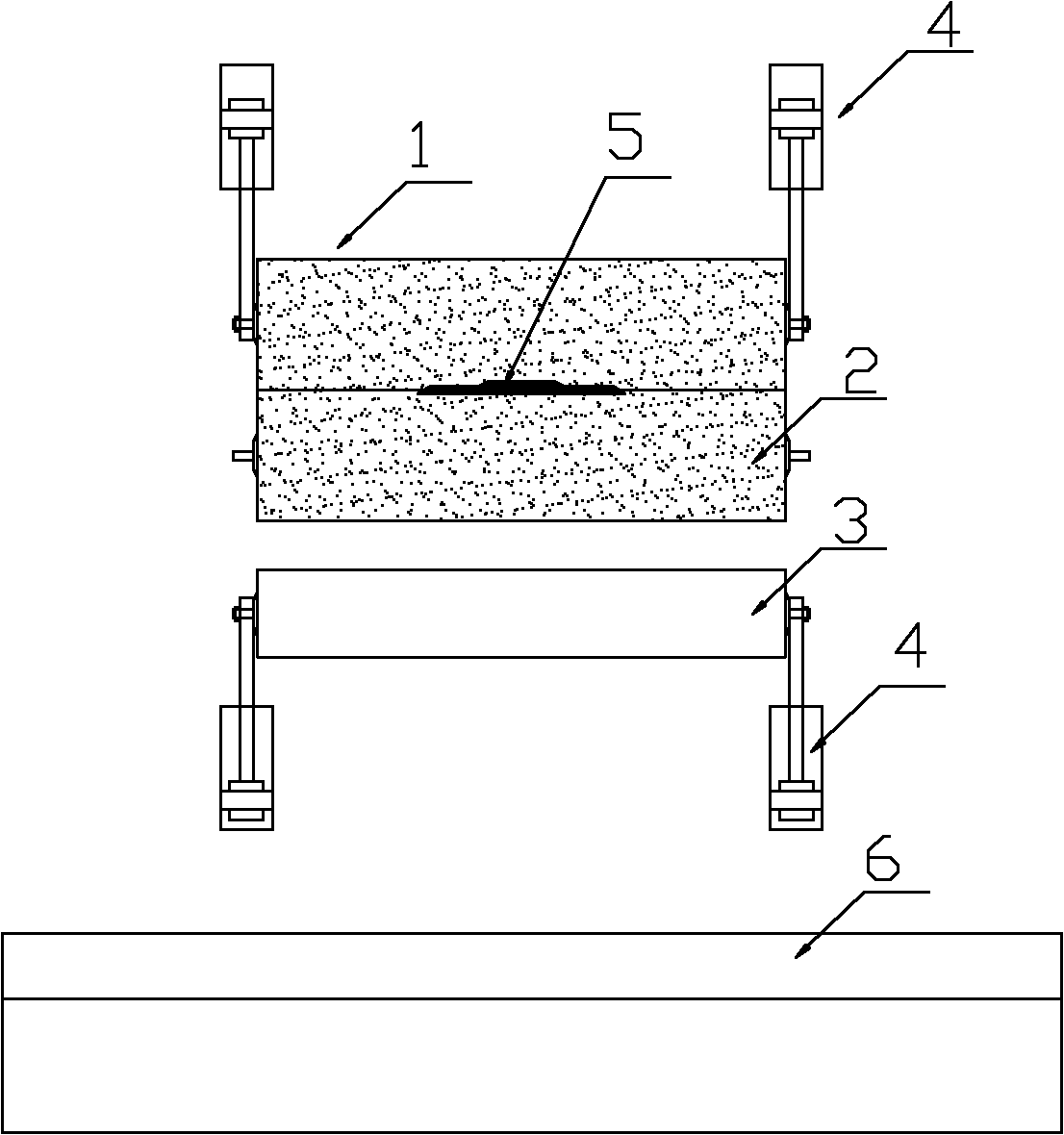

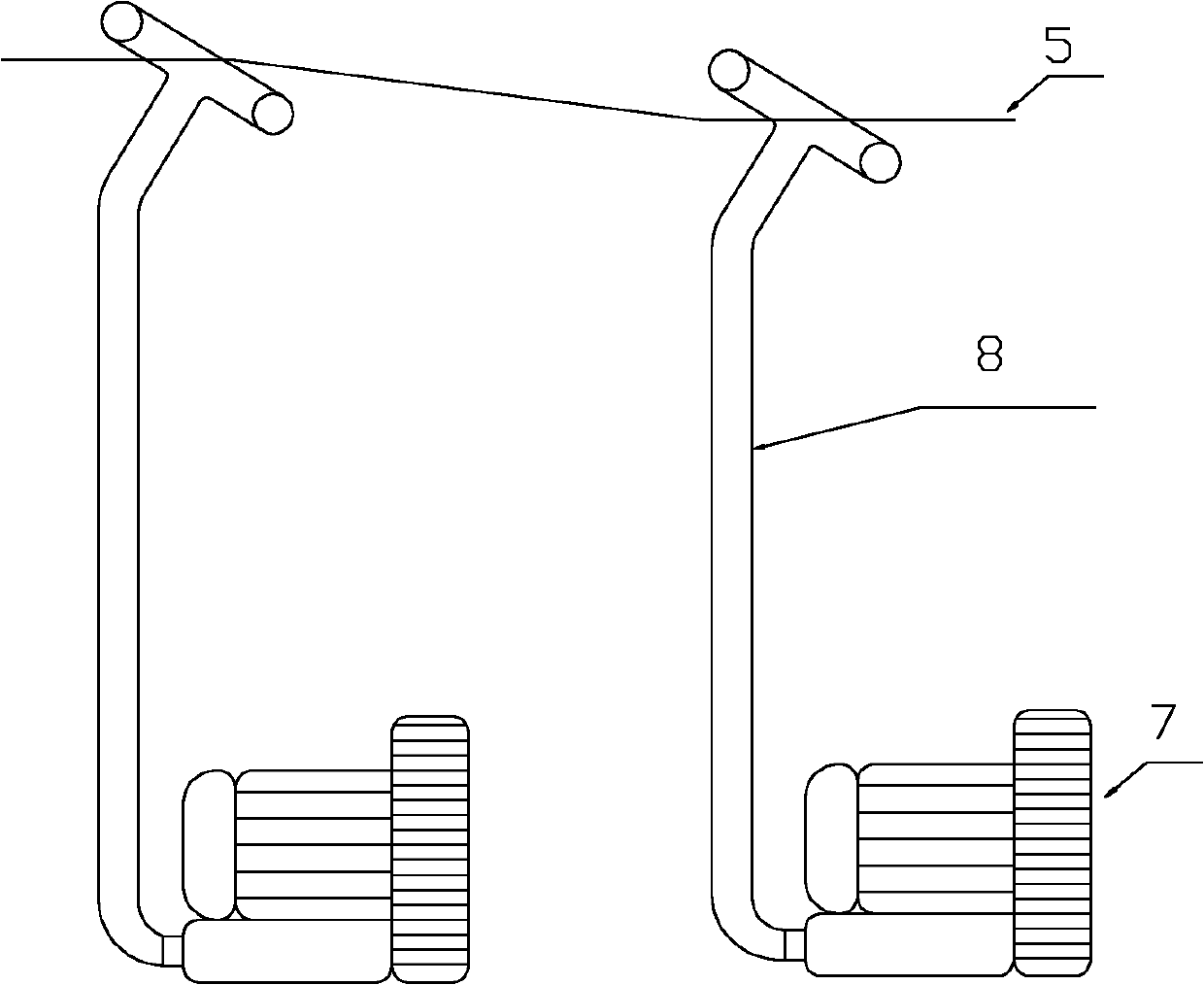

Indoor model testing apparatus for analyzing influences of shield tunnel grouting construction on adjacent pile foundations

InactiveCN103558044AImprove scalabilityAccurate measurementStructural/machines measurementSolenoid valveSlurry

The invention relates to an indoor model testing apparatus for analyzing influences of shield tunnel grouting construction on adjacent pile foundations. The indoor model testing apparatus comprises a model box, a tunnel grouting construction simulator, a tunnel lining model and a pile foundation model. The model box is filled with sandy soil mass, the tunnel lining model comprises longitudinally-segmented aluminum alloy hollow pipes and is placed in the left half part of the model box, and lining segments are separated by annular thin rubber plates; the pile foundation model is placed in the right half part of the model box and vertical to the tunnel lining model; a displacement meter support is fixed to the top surface of the model box; multiple displacement meters are respectively fixed to the corresponding sandy soil mass and the surfaces of piled raft foundations of the pile foundation model through the displacement meter support; the tunnel grouting construction simulator comprises a latex film surrounding the periphery of the tunnel lining model and an annular liquid cavity formed between the tunnel model and the latex film, the annular liquid cavity is filled with grouting liquid, one end of the annular liquid cavity is connected with a liquid injection guide pipe provided with a liquid injection solenoid valve, and a liquid discharge guide pipe provided with a liquid discharge solenoid valve is arranged at the other end of the annular liquid cavity in the horizontal direction.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

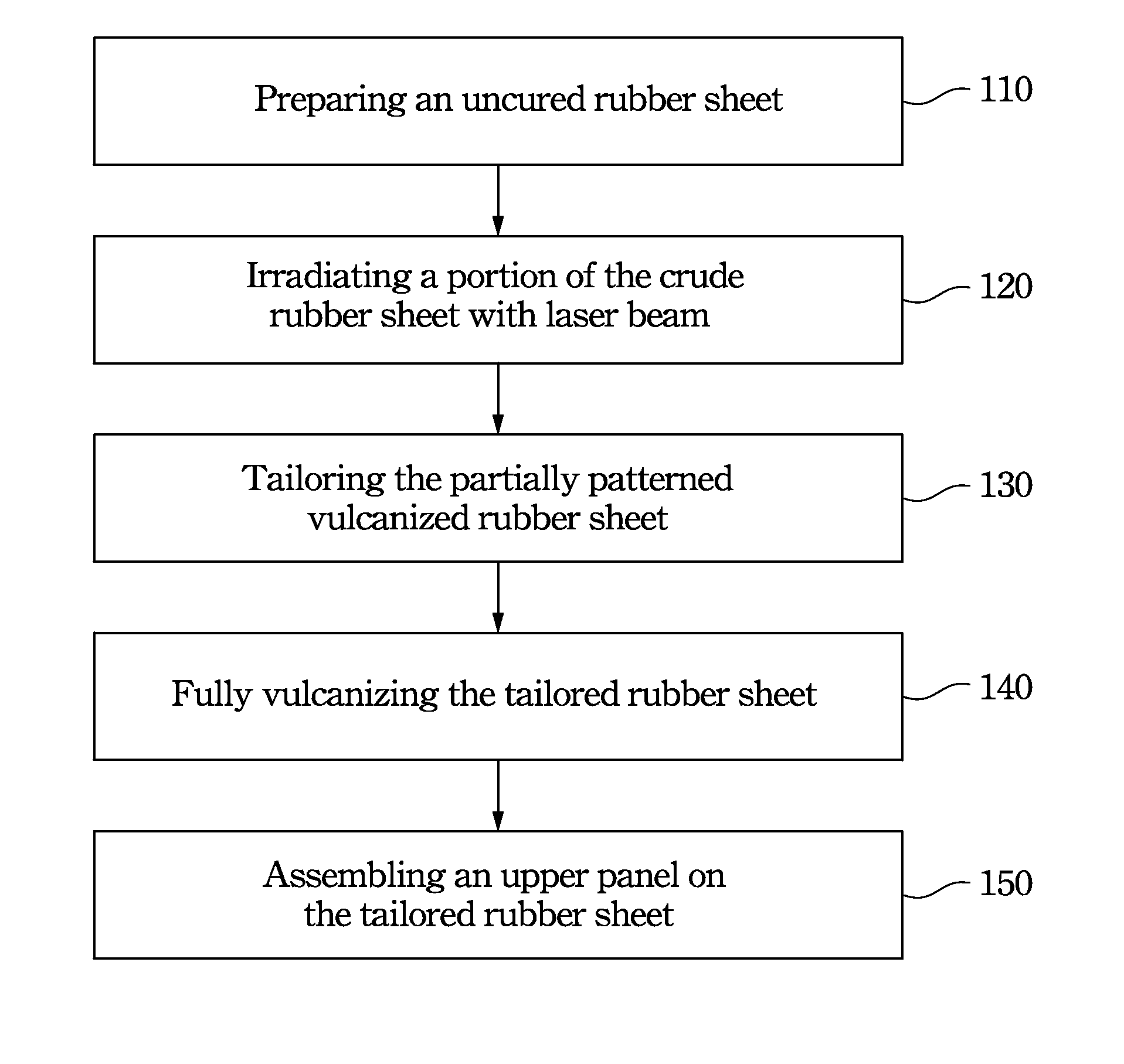

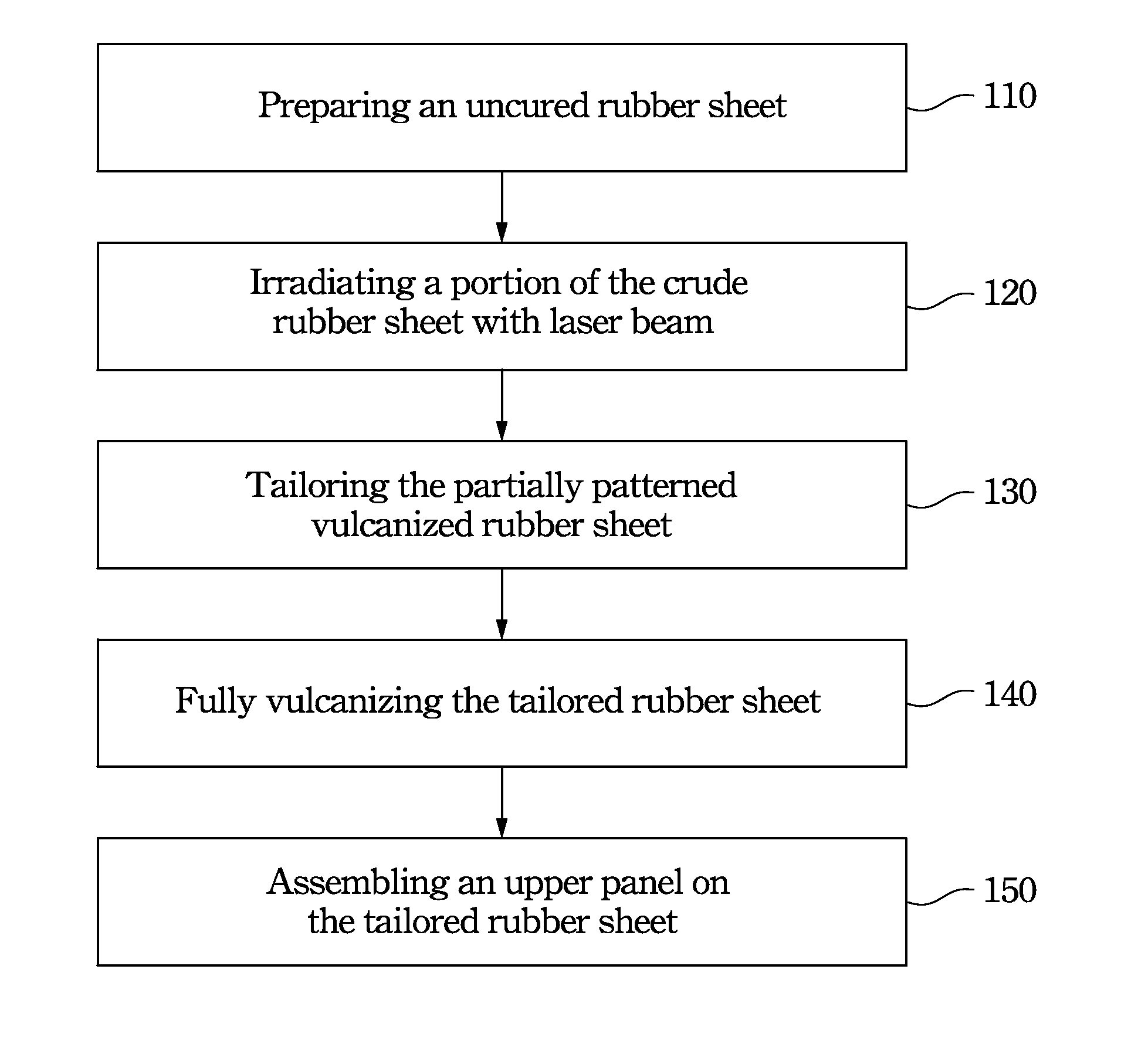

Method of preparing a rubber shoe sole

ActiveUS8689381B2Increase variabilityTime and cost-effectiveShoemaking devicesSolesEngineeringRubber sheet

Disclosed herein is a novel method of preparing shoe sole. The method of preparing shoe sole includes irradiating an uncured rubber sheet by laser beam to pattern and vulcanize a portion of the uncured rubber, tailoring the partially patterned vulcanized rubber into a shoe shape, and afterward fully vulcanizing the partially patterned vulcanized rubber sheet to form a shoe sole. An additional step of assembling the upper panel of shoe sole on the partially vulcanized rubber sheet is also performed.

Owner:SHEI CHUNG HSIN IND

Method for preparing rice hull ash-natural rubber composite material

The invention provides a method for preparing a rice husk ash-natural rubber composite material. The method is characterized in that epoxidized natural rubber is taken as compatilizer of rice husk ash and natural rubber; the excellent compatibility of the epoxidized natural rubber and the natural rubber, as well as the chemical reaction of the epoxidized natural rubber and the rice husk ash are utilized to improve the dispersion effect of the rice husk ash in the natural rubber, and strengthen the interaction between the rice husk ash and the natural rubber, so as to prepare the rice husk ash-natural rubber composite material with high performance; the tensile strength of a vulcanized rubber sheet of the composite material is between 19 and 23 MPa; the tensile failure elongation of the vulcanized rubber sheet is between 750 and 900 percent; and the 300-percent stress at definite elongation of the vulcanized rubber sheet is between 4.0 and 6.0 MPa.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Crosslinkable rubber composition and use thereof

A rubber composition which is crosslinkable with hot air or a hot press and gives a hot-air-crosslinked rubber sheet which receives no scratch on the surface in an HB pencil hardness test and has a compression set of 70% or lower through 22-hour heat treatment at 150 DEG C. The composition comprises: an ethylene / alpha -olefin / unconjugated polyene random copolymer rubber wherein the unconjugated polyene is a specific norbornene compound terminated by a vinyl group; and a compound having two or more SiH groups per molecule. It may optionally contain an addition reaction catalyst comprising a platinum-group metal and a reaction inhibitor.

Owner:MITSUI CHEM INC +1

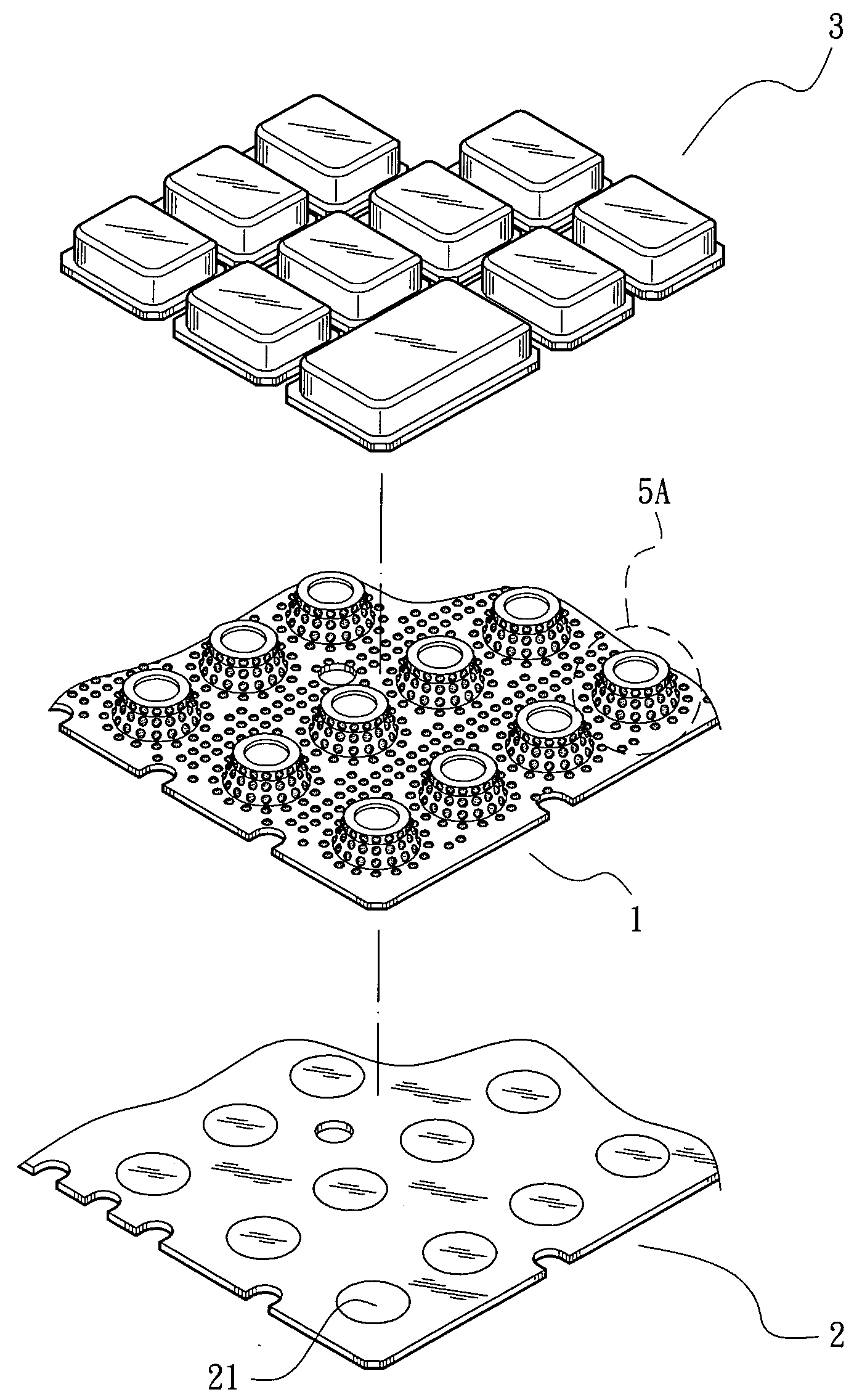

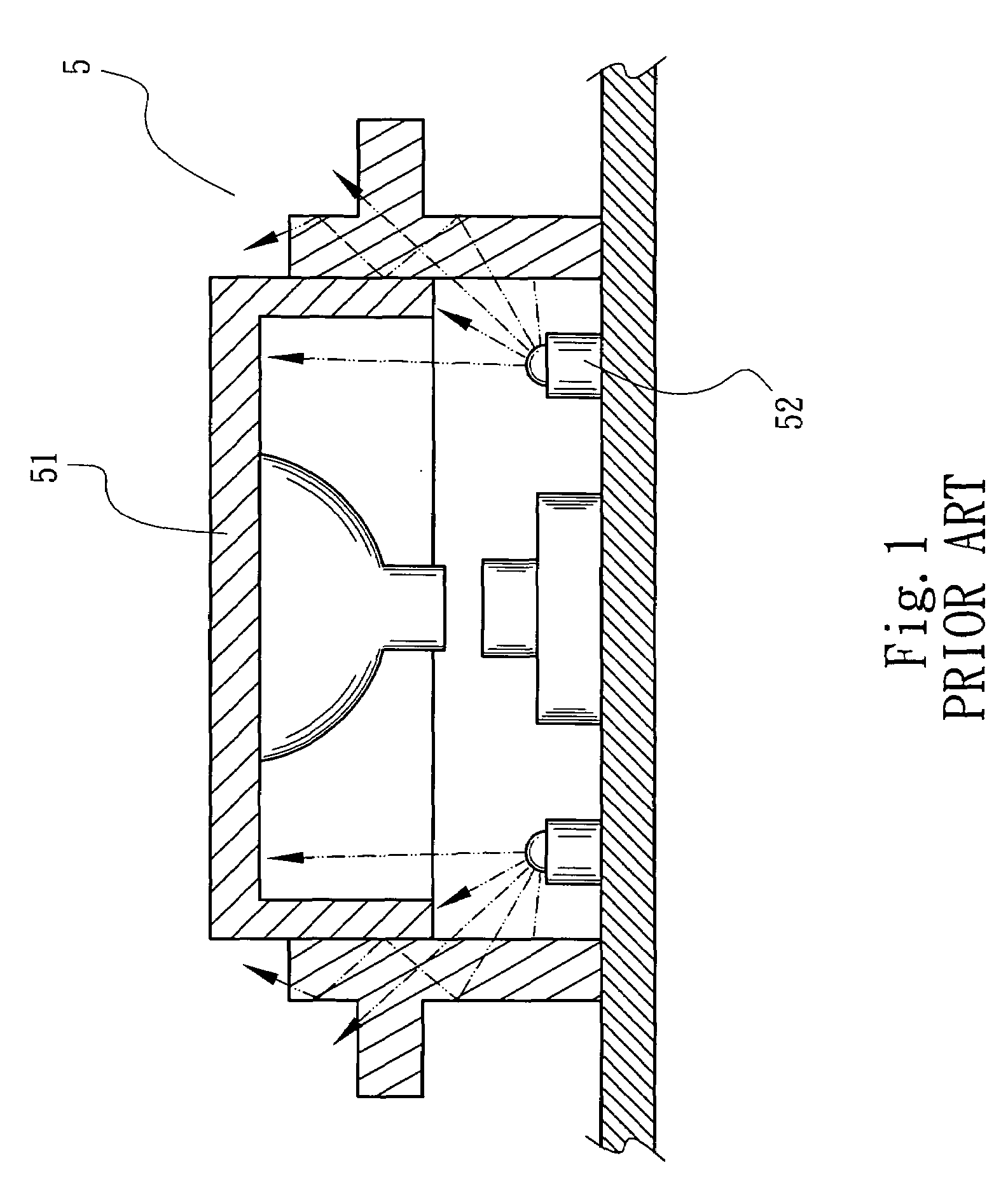

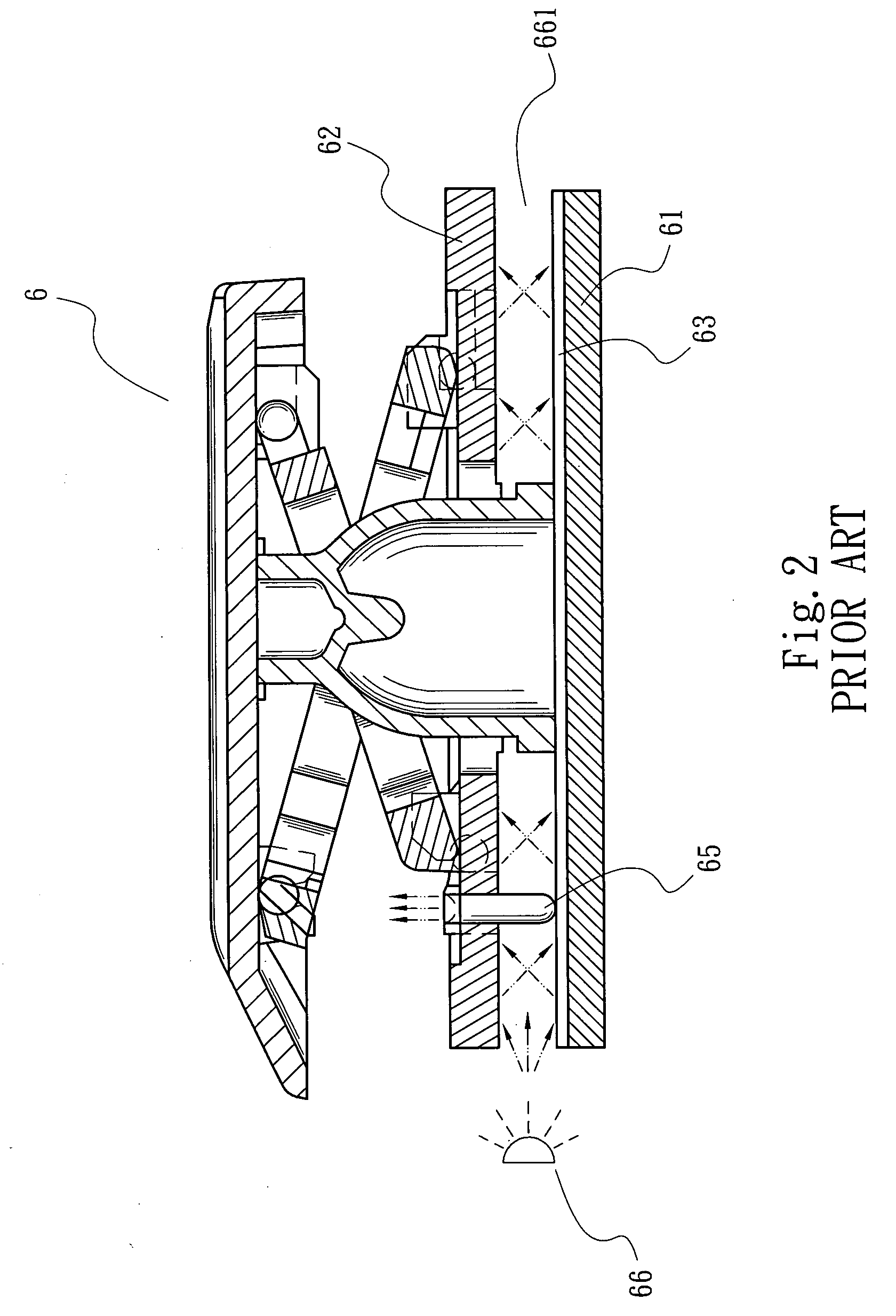

Light guide structure for a keyboard

InactiveUS20100148996A1Enhance uniform backlight illuminationAvoid shadowsLegendsElectronic switchingLight guideLight reflection

A light guide structure for a keyboard. The light guide structure includes a transparent rubber sheet. Multiple resilient support sections are formed on the rubber sheet in alignment with press keys of the keyboard respectively. Multiple diffusive reflection units are disposed on a surface of the rubber sheet and circumferences of the resilient support sections. The diffusive reflection units are boss sections protruding from the surface of the rubber sheet or recessed sections formed on the surface of the rubber sheet. Each diffusive reflection unit has a surface coated with a light reflection layer for reflecting light. When the light is reflected by external components back to the surface of the rubber sheet, the light reflection layers of the diffusive reflection units that are boss sections or recessed sections will again effectively reflect the light to enhance backlight brightness of the press keys and peripheries thereof.

Owner:KINPO ELECTRONICS

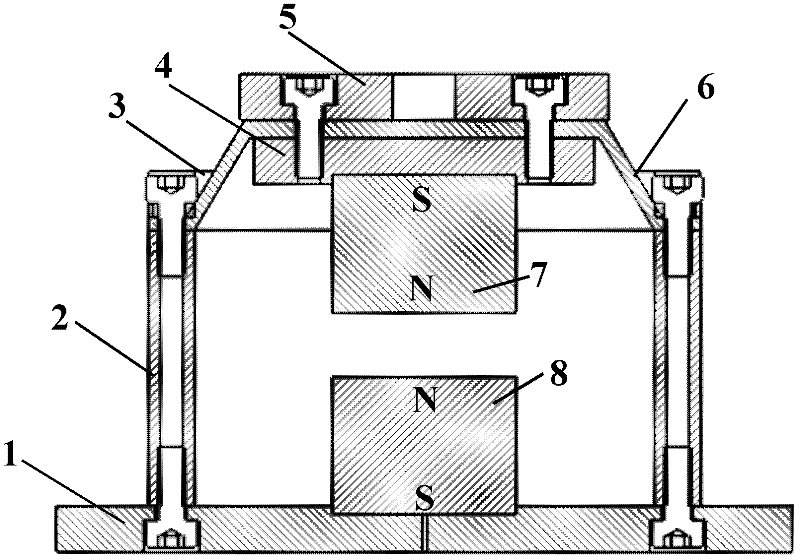

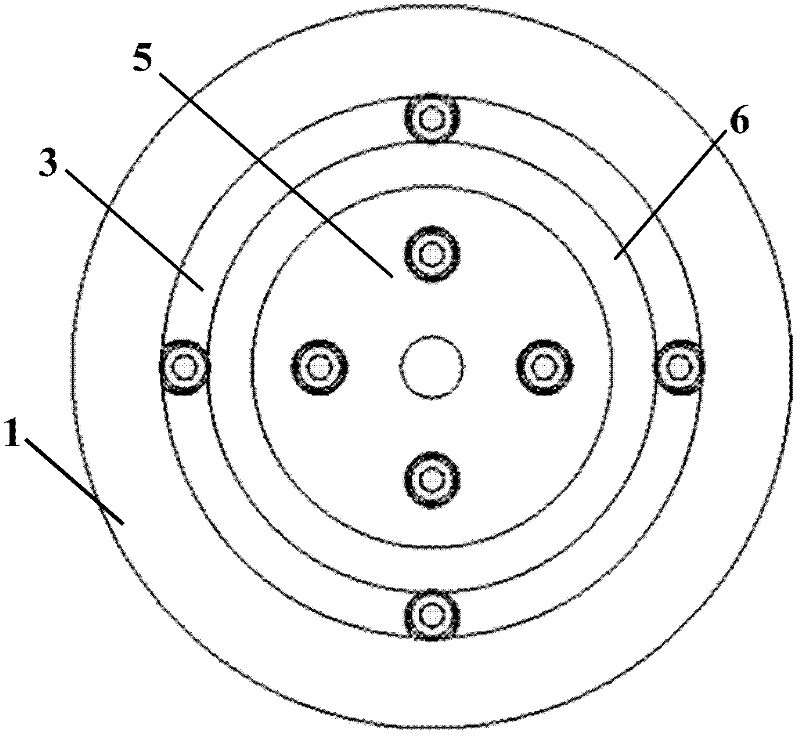

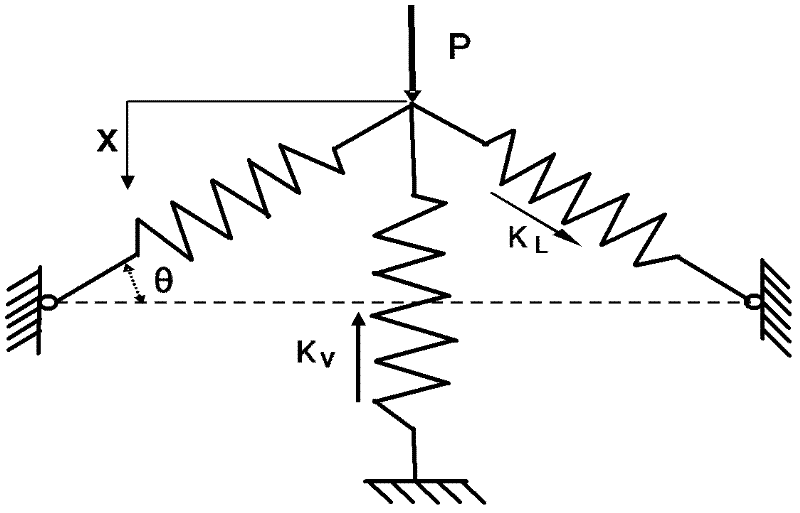

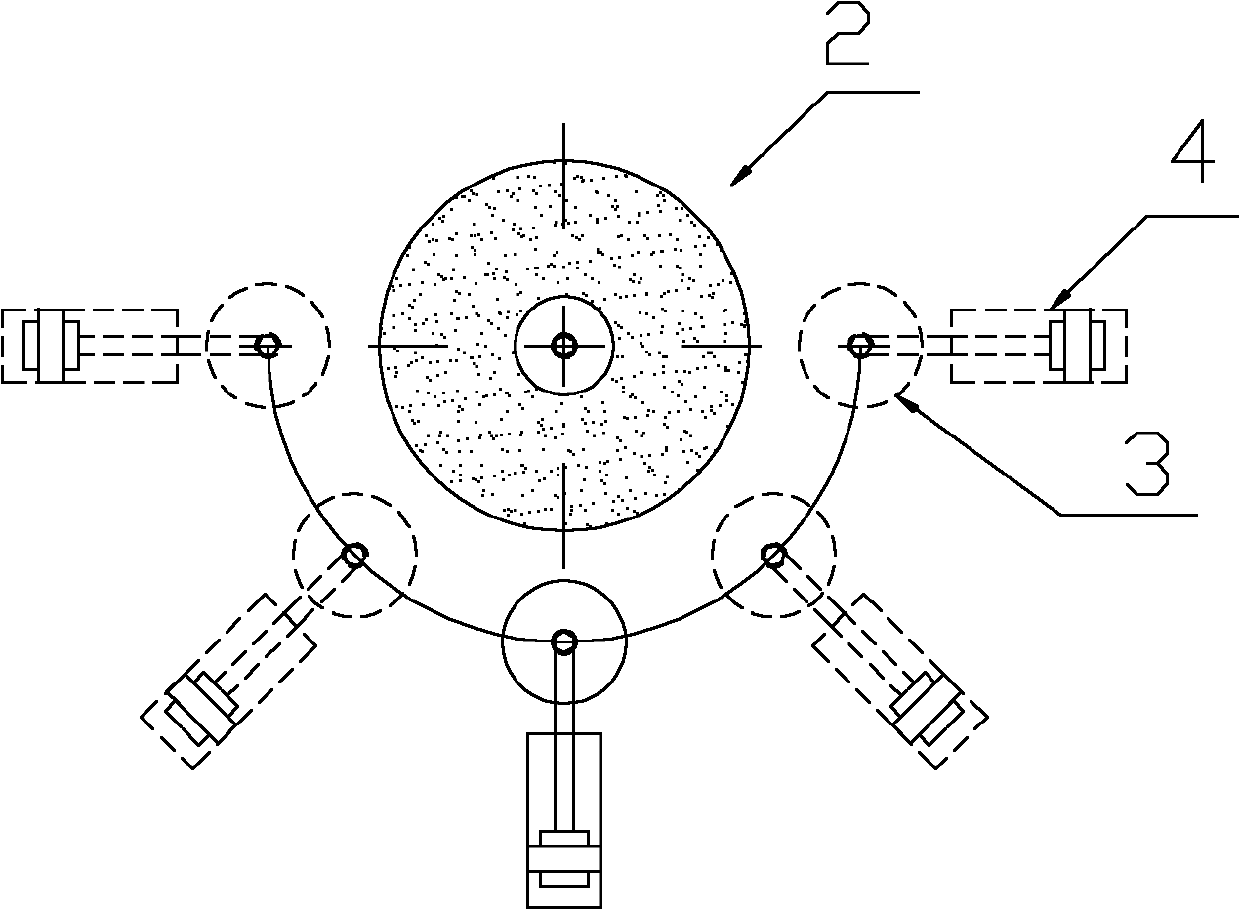

Permanent magnet low-frequency multidegree of freedom vibration isolation mechanism based on negative stiffness principle

InactiveCN102410337ASimple structureLow costNon-rotating vibration suppressionMagnetic springsExternal energyThree degrees of freedom

A permanent magnet low-frequency multidegree of freedom vibration isolation mechanism based on the negative stiffness principle comprises a lower permanent magnet, an upper permanent magnet, a rubber sheet, a lower permanent magnet fixing plate, a rubber fixing seat, an upper permanent magnet fixing plate, a rubber pressure block and a rubber sheet edge fixing pressure ring, wherein the permanent magnets are magnetized in the vertical direction and opposite for same poles. A positive stiffness system is formed by the permanent magnets under the action of repulsive force, the rubber sheet is stretched to a negative stiffness system under the action of repulsive force of the permanent magnets, two systems are combined to form a low-frequency vibration isolation mechanism, the single vibration isolation mechanism can realize three degrees of freedom low-frequency vibration isolation, and three or four systems are combined in parallel to realize the six degrees of freedom low-frequency vibration isolation. The vibration isolation mechanism can be used in vacuum without the input of external energy. The vibration isolation mechanism has the characteristics of simple structure, low cost and easy processing, and can be used in the fields like optics, acoustics, biology, advanced manufacturing equipment, semiconductor manufacturing and precision measurement, etc.

Owner:TSINGHUA UNIV

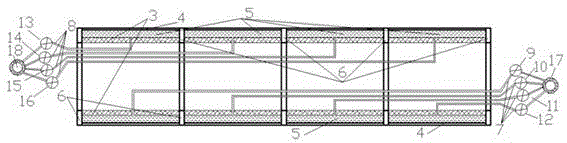

Fire retardant cushion rubber of fire retardant canvas laminated core conveyer belt and preparation method thereof

InactiveCN101580607AImprove flame retardant performanceEasy to prepareConveyorsAluminium hydroxideWear resistant

The invention relates to a preparation method for fire retardant cushion rubber of a fire retardant canvas laminated core conveyer belt, which is characterized by comprising the following steps: firstly plasticating nitrile rubber; then respectively putting plasticize nitrile rubber, stearic acid, petroleum softener, meta resol thickening agent, semi-strengthening carbon black, high wear-resistant carbon black, white carbon black, pot clay, polyvinyl chloride plastic paste, zinc oxide, magnesium oxide, aluminium hydroxide and the like for banburying; and then adding an accelerating agent for overturning milling, hot milling and sheeting, arranging layer cloth on rolled rubber sheets, and rolling the rubber sheets for forming the conveyor belt. The cushion rubber of the fire retardant laminated core conveyer belt in underground coal mines is used to make the fire retardant laminated core conveyer belt in the underground coal mines inherit the prior mechanical property of a common canvas laminated core conveyer belt and maintain the good fire retardance of a whole woven core conveyer belt; and the preparation method is simple and has easy operation.

Owner:WUXI BOTON TECH CO LTD

Rubber sheet dewatering device

InactiveCN101947843AReduce usageSimple processDrying machines with progressive movementsRubber sheetMechanical engineering

The invention discloses a rubber sheet dewatering device which comprises an upper water-absorbing press roll, a lower water-absorbing press roll, a squeeze roll and an air cylinder, wherein the axial lines of the upper water-absorbing press roll and the lower water-absorbing press roll are on the same plane, the axial line of the squeeze roll and the axial line of the lower water-absorbing press roll are on the same plane, a lower water-absorbing press roll shaft is fixed on a support frame, an upper water-absorbing press roll shaft is connected with the air cylinder and can be subject to height adjustment, a squeeze roll shaft is connected with the air cylinder, can be subject to height adjustment and is positioned below or at the side face of the lower water-absorbing press roll, and the device can be also provided with a water-collecting tank. The invention is the dewatering device of rubber cooling equipment for rubber processing, and achieves the advantages of simple process and convenient maintenance by using sponges, foam and other water-absorbing materials to absorb water and using the squeeze roll to continuously or intermittently squeeze water, thereby avoiding the use of a high-power motor and realizing energy saving.

Owner:SICHUAN YUANXING RUBBER

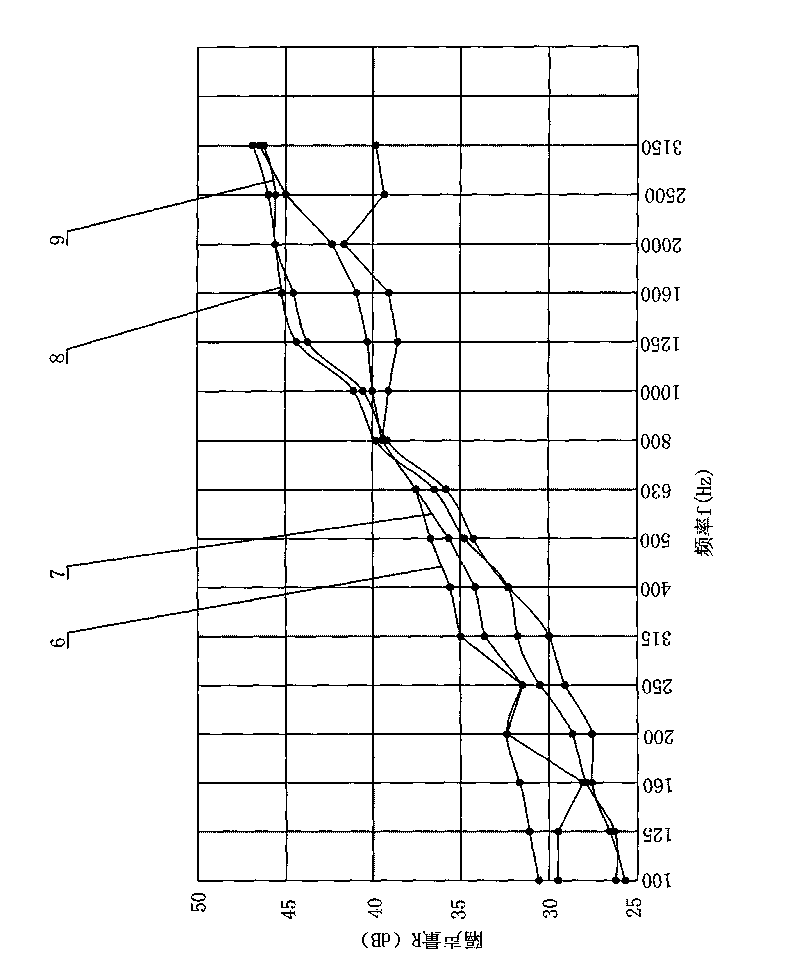

High speed train damping sound insulation sheet material and manufacturing method thereof

InactiveCN101691119AHigh sound insulation coefficientImprove sound insulationFilm/foil adhesivesLayered productsRubber materialAdhesive

The invention relates to a high speed train damping sound insulation sheet material and a manufacturing method thereof. The sheet material consists of a sound insulation main body damping basal layer, a damping seam gum layer and a resin fiber layer. The manufacturing method comprises the following steps: firstly, mixing raw material components of the sound insulation damping basal layer in percentage by weight, putting the mixture into an internal mixer to perform mixing operations, and discharging the materials; secondly, transferring the discharged rubber materials into a mixing mill to perform hot mixing; thirdly, sending the rubber materials after the hot mixing into a calender to perform calendering operations to manufacture rubber sheets; fourthly, coating a damping adhesive on the rubber sheets, and adhering resin fibers to the damping adhesive; and finally, transferring the rubber sheets coated with the damping adhesive and the resin fibers into a coating and drying compound machine to coat a binding agent, and simultaneously packaging release paper outside the binding agent. The manufacturing method can obtain a damping sound insulation material which obviously reduces vibrations and noise radiations of sheet material structures and other components on a carriage of a high speed train.

Owner:广州市延昌新型塑胶制品有限公司

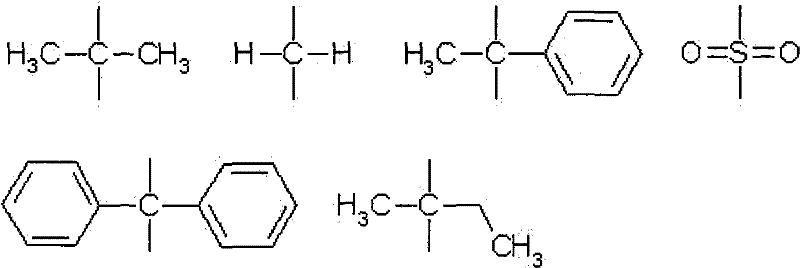

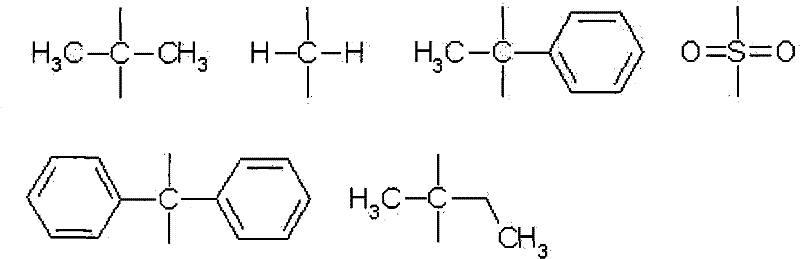

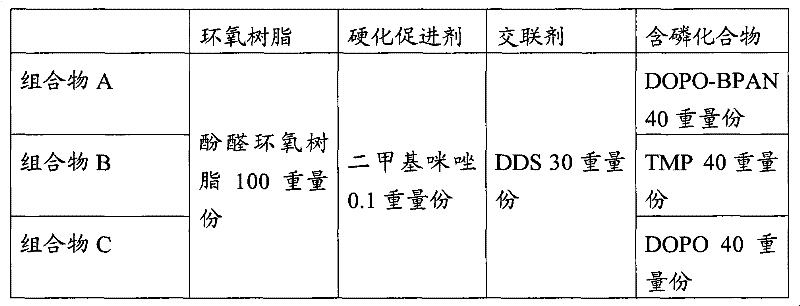

Resin composition as well as semi-solidified rubber sheet, laminating board and circuit board containing same

ActiveCN102206397AImprove flame retardant performanceImprove heat stabilitySynthetic resin layered productsGlass/slag layered productsCross-linkSheet film

The invention relates to a resin composition which mainly comprises epoxy resin, a hardening accelerator, a cross-linking agent and phosphorus-containing resin, wherein the phosphorus-containing resin is bisphenol phenolic resin or phenolic resin substituted by a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide or derivatives thereof. The resin composition can be applied to semi-solidified rubber sheets or insulating layers of circuit boards. In addition, the invention relates to a semi-solidified rubber sheet, a laminating board and a circuit board containing the resin composition.

Owner:ELITE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com