Patents

Literature

14835 results about "Vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vulcanization (British: vulcanisation) is a chemical process, invented by Charles Goodyear, used to harden rubber. Vulcanization traditionally referred to the treatment of natural rubber with sulfur and this remains the most common example, however the term has also grown to include the hardening of other (synthetic) rubbers via various means. Examples include silicone rubber via room temperature vulcanizing and chloroprene rubber (neoprene) using metal oxides.

Tire and tread comprising a bis-alkoxysilane tetrasulfide as coupling agent

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

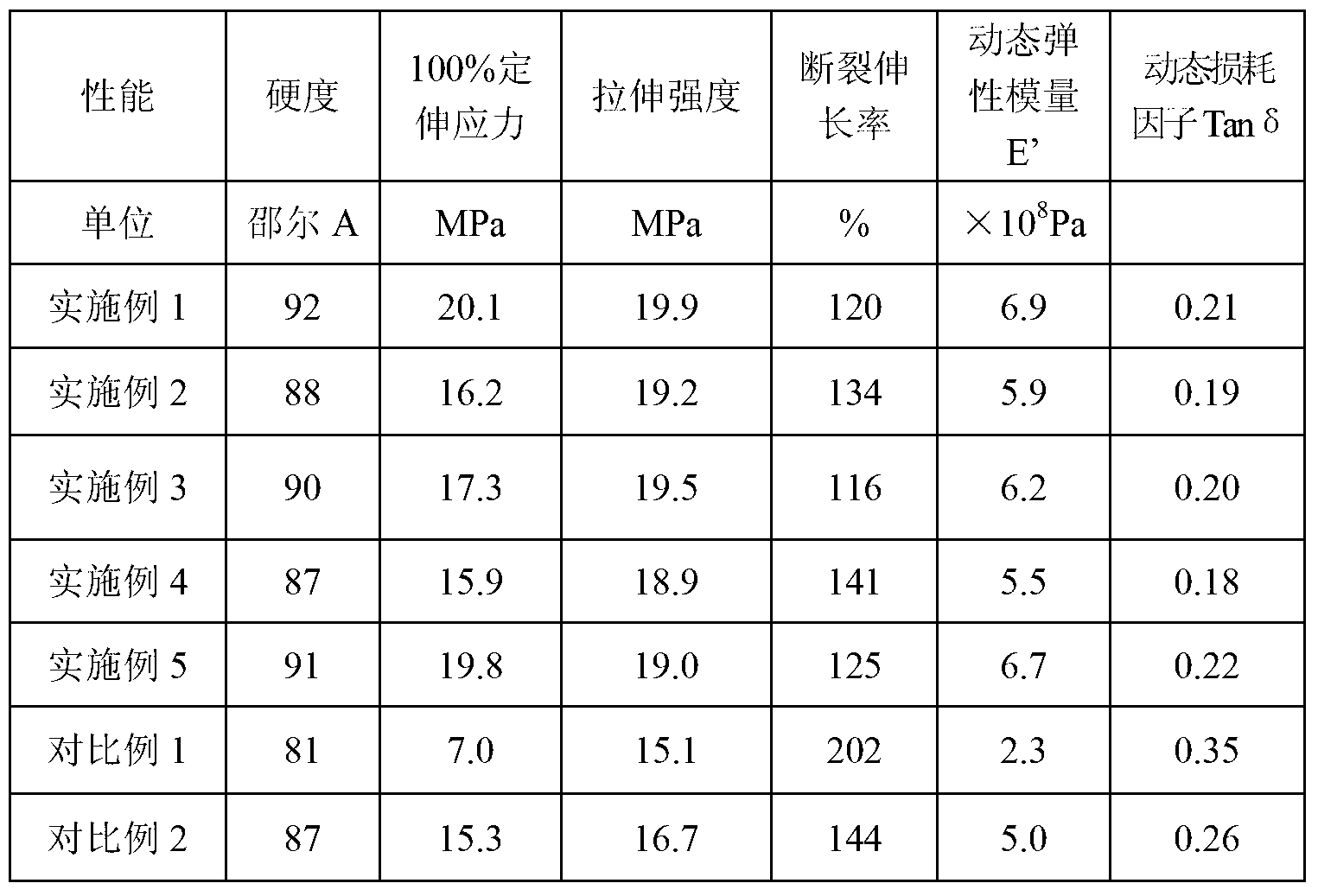

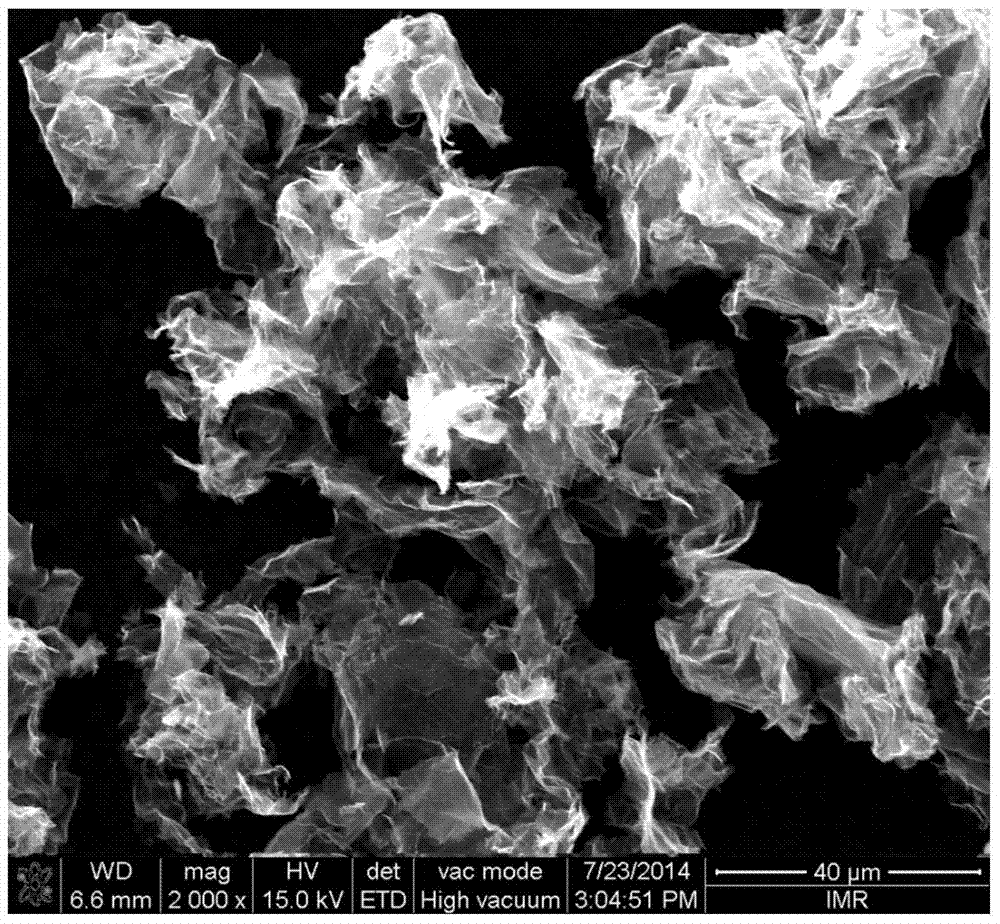

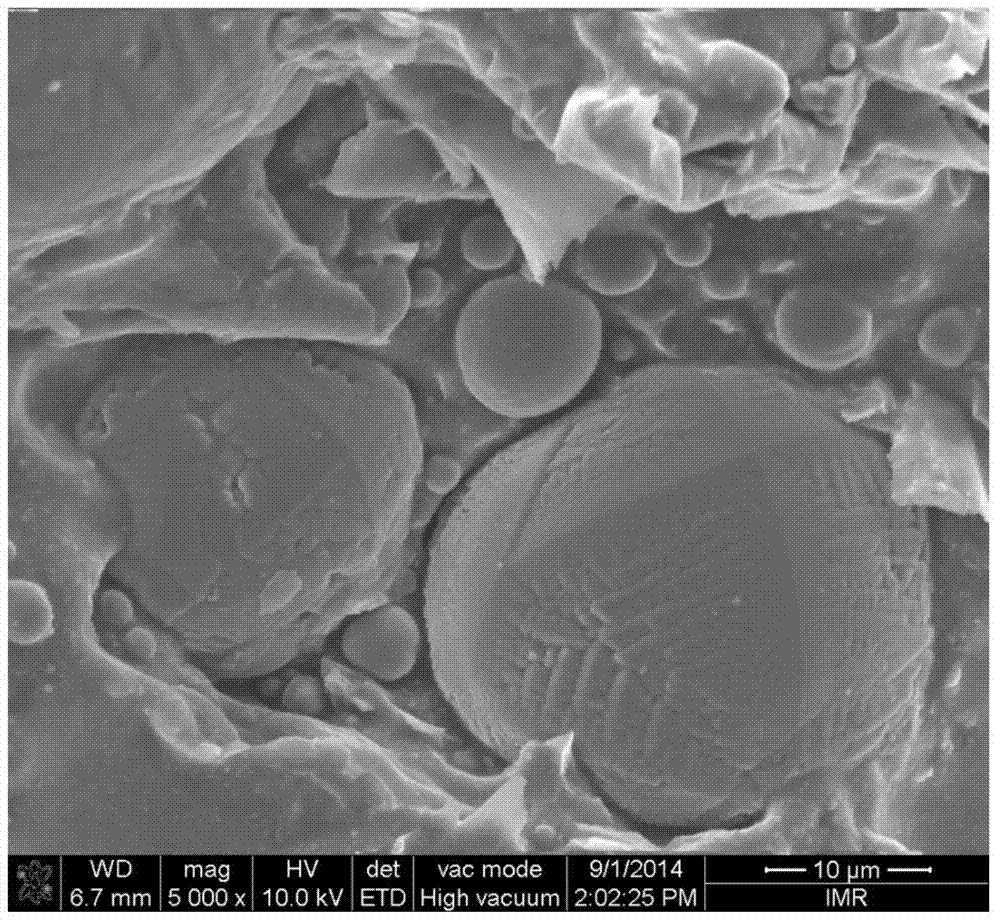

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

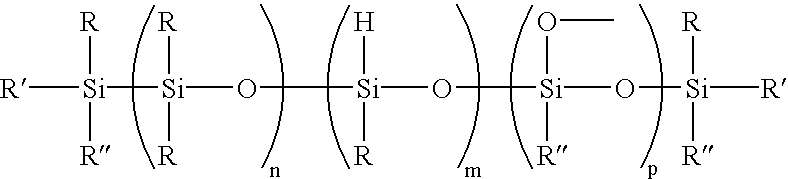

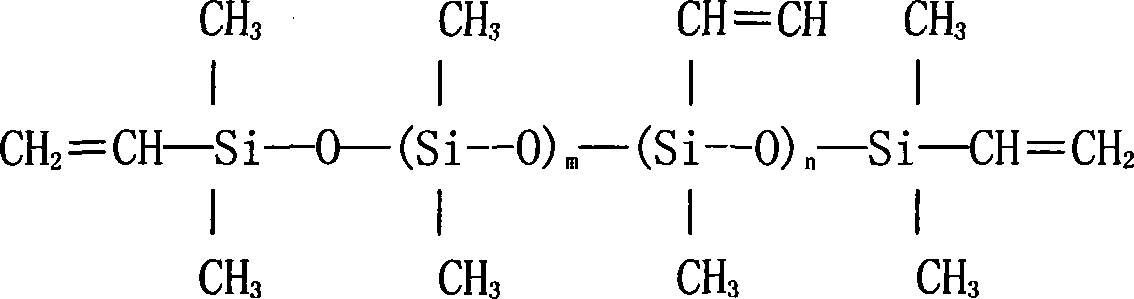

Hydrophilic polysiloxane compositions

The instant invention provides a method for improving the miscibility of the lower molecular weight unsaturated siloxane-polyether copolymers with the alpha , omega -divinylpolysiloxanes without loss of storage stability, or delay of cure at the vulcanization temperature, or loss of permanent hydrophilicity or other desirable features of the cured polysiloxane. The compositions of the present invention comprise one or more alpha , omega -divinylpolysiloxanes, unsaturated polysiloxane-polyether copolymers having from 2 to 5 silicon atoms per molecule which are preferably trisiloxanes, and a compatibilizing additive. The permanently hydrophilic, rapidly wettable polysiloxane compositions yield static water contact angles <50 DEG dynamic advancing contact angles of less than about 100.

Owner:GENERAL ELECTRIC CO

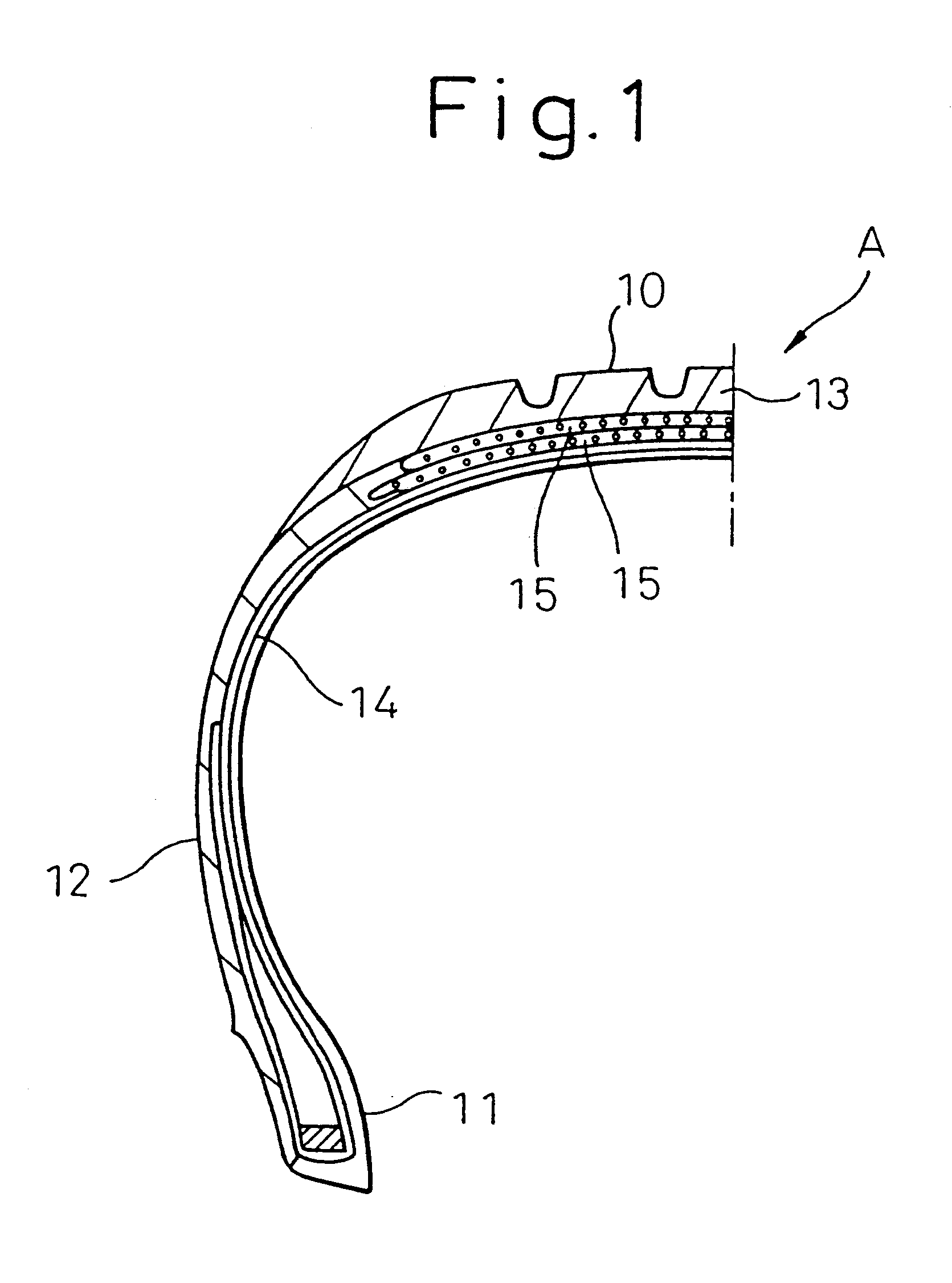

Thermoplastic elastomer composition, process for the preparation there of, hose made by using the composition, and process for the production thereof

InactiveUS6179008B1Improvement of hose flexibilityLow production costSynthetic resin layered productsFlexible pipesElastomerVulcanization

A thermoplastic elastomer composition which, when used for the inner tube and / or outer cover of a hose, can improve the hose flexibility at an ordinary temperature and low temperature, oil resistance, and cold resistance and can reduce the production costs since it does not require a vulcanization step and a hose having said properties using this elastomer composition for its inner tube and / or outer cover and a process and apparatus for the production thereof.

Owner:YOKOHAMA RUBBER CO LTD

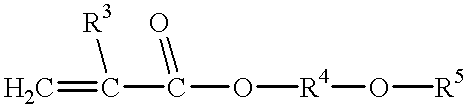

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

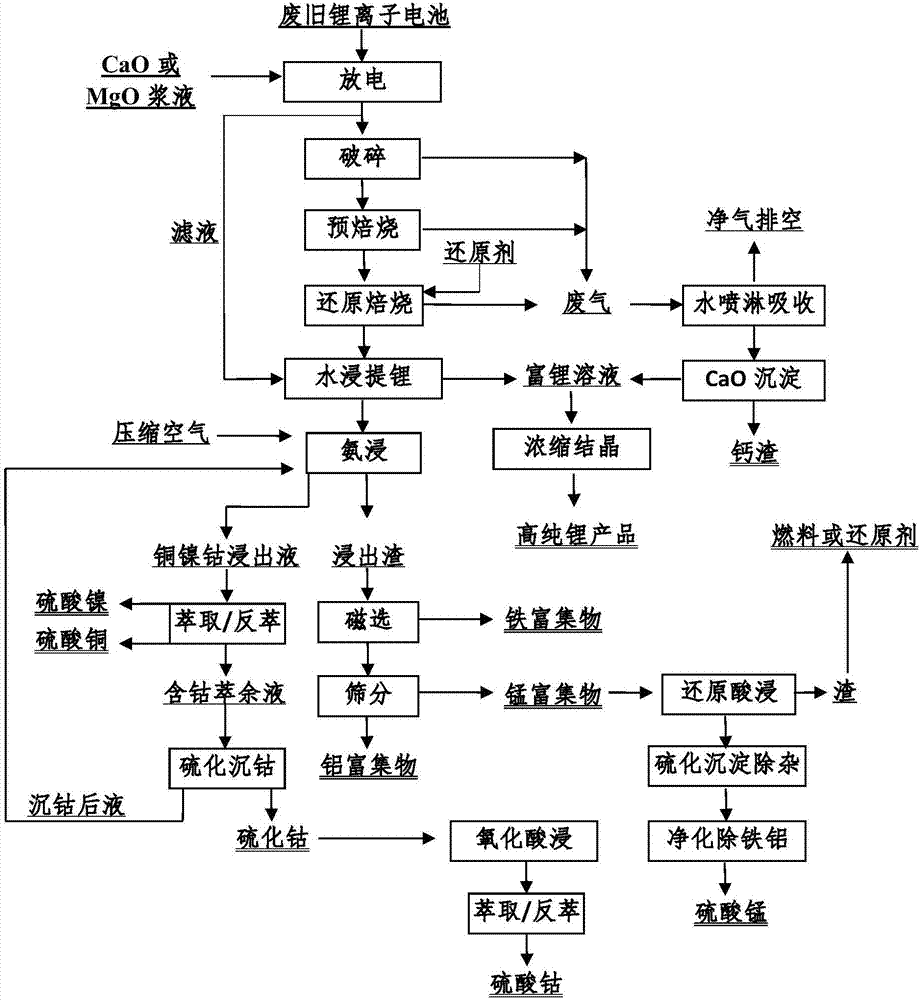

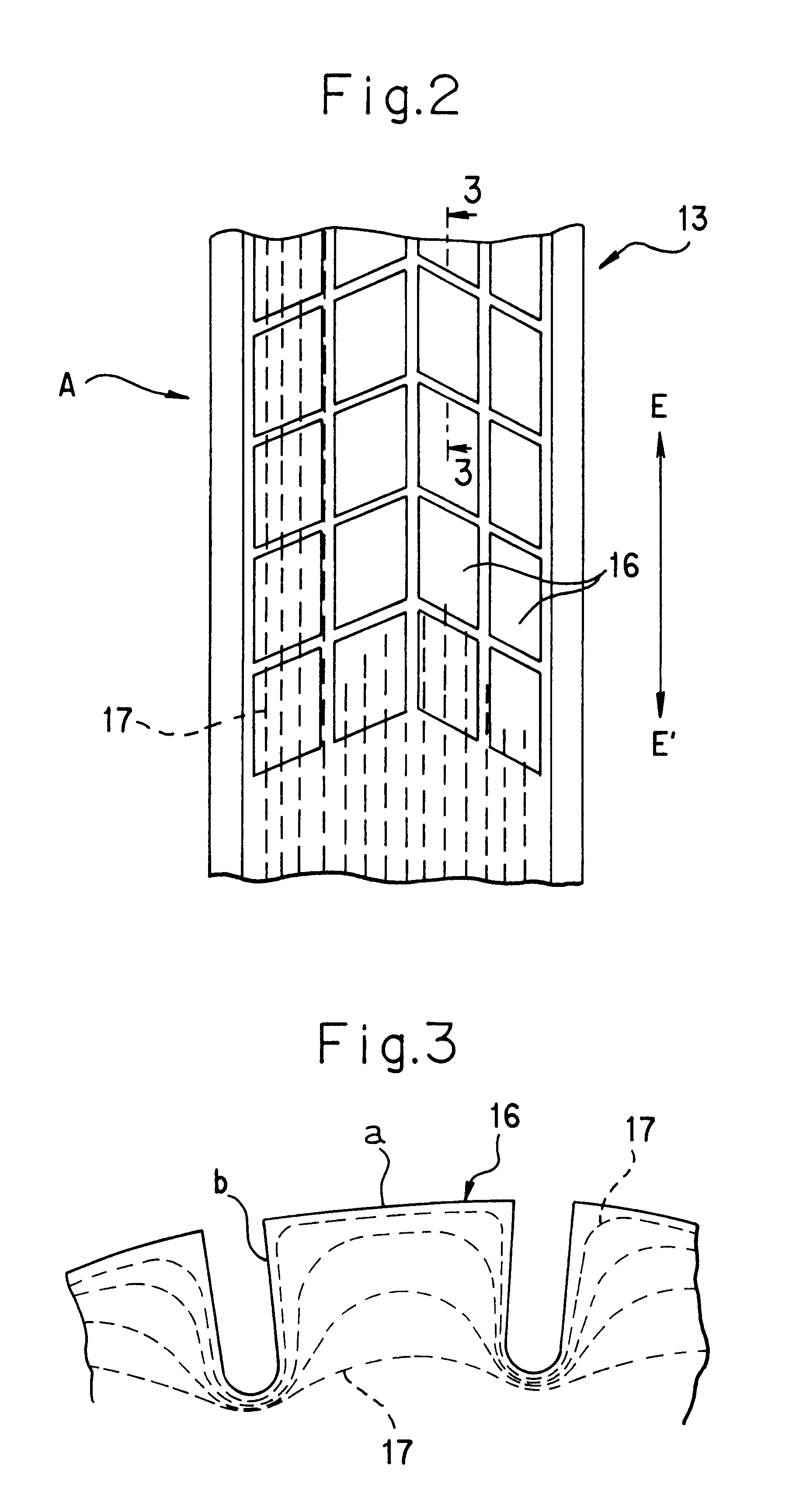

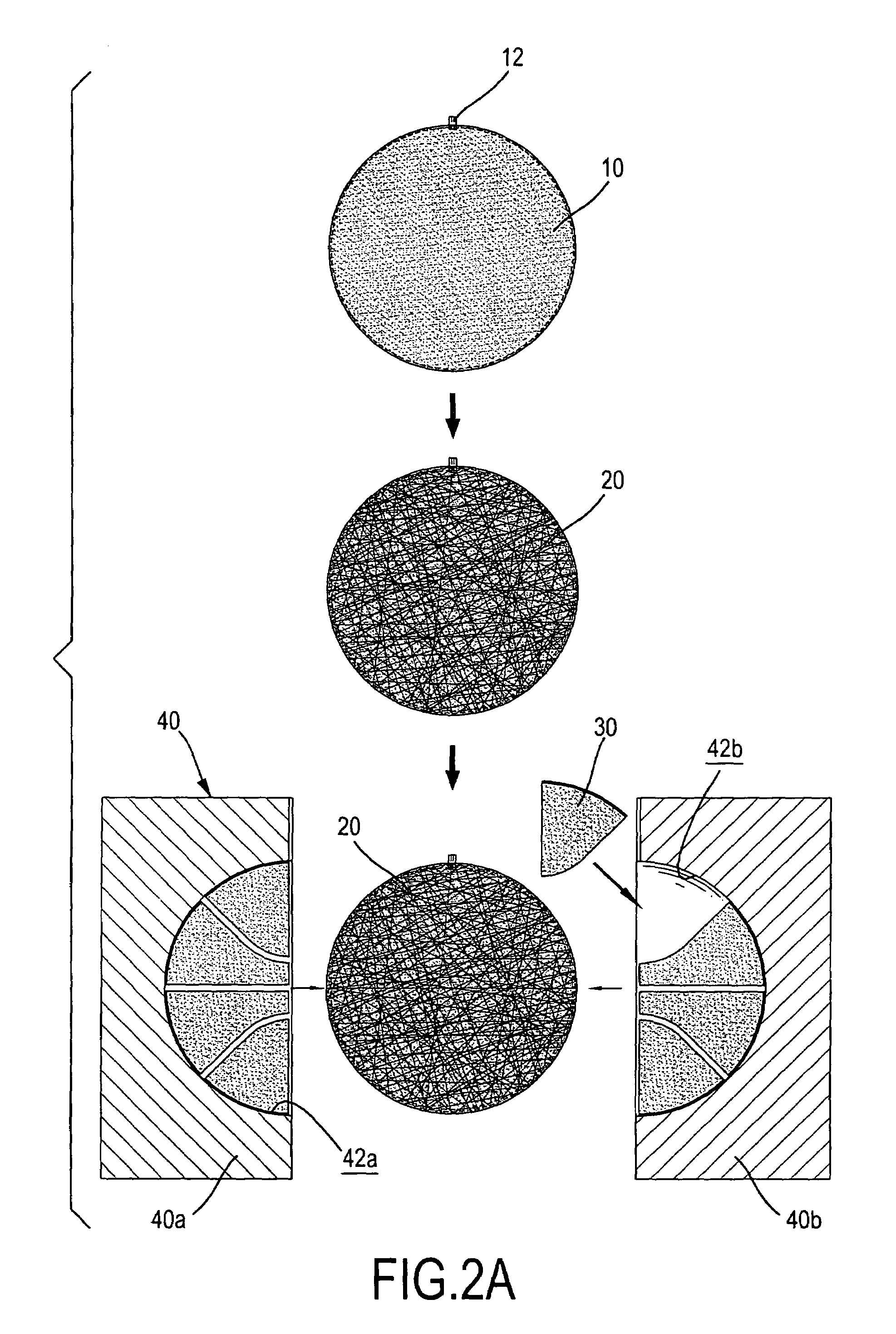

Solid golf ball

InactiveUS6919393B2Exceptional rebound characteristic and flight performanceExcellent shot feelingGolf ballsSolid ballsVulcanizationEngineering

The present invention provides a solid golf ball having exceptional rebound characteristics and flight performance, as well as good shot feel. The present invention relates to a solid golf ball comprising at least one layer of a core, and at least one layer of a cover formed on the core, wherein at least one layer including the inmost layer of the core is formed by vulcanizing a rubber composition comprising a base rubber, a co-crosslinking agent, a vulcanization initiator and a filler, the core has a center hardness in JIS-C hardness of 40 to 60, a surface hardness in JIS-C hardness of 80 to 95 and a hardness difference (B−A) between a hardness in JIS-C hardness at a distance of 5 mm from the center point of the core (B) and the center hardness (A) of not less than 1 to less than 10.

Owner:SUMITOMO RUBBER IND LTD

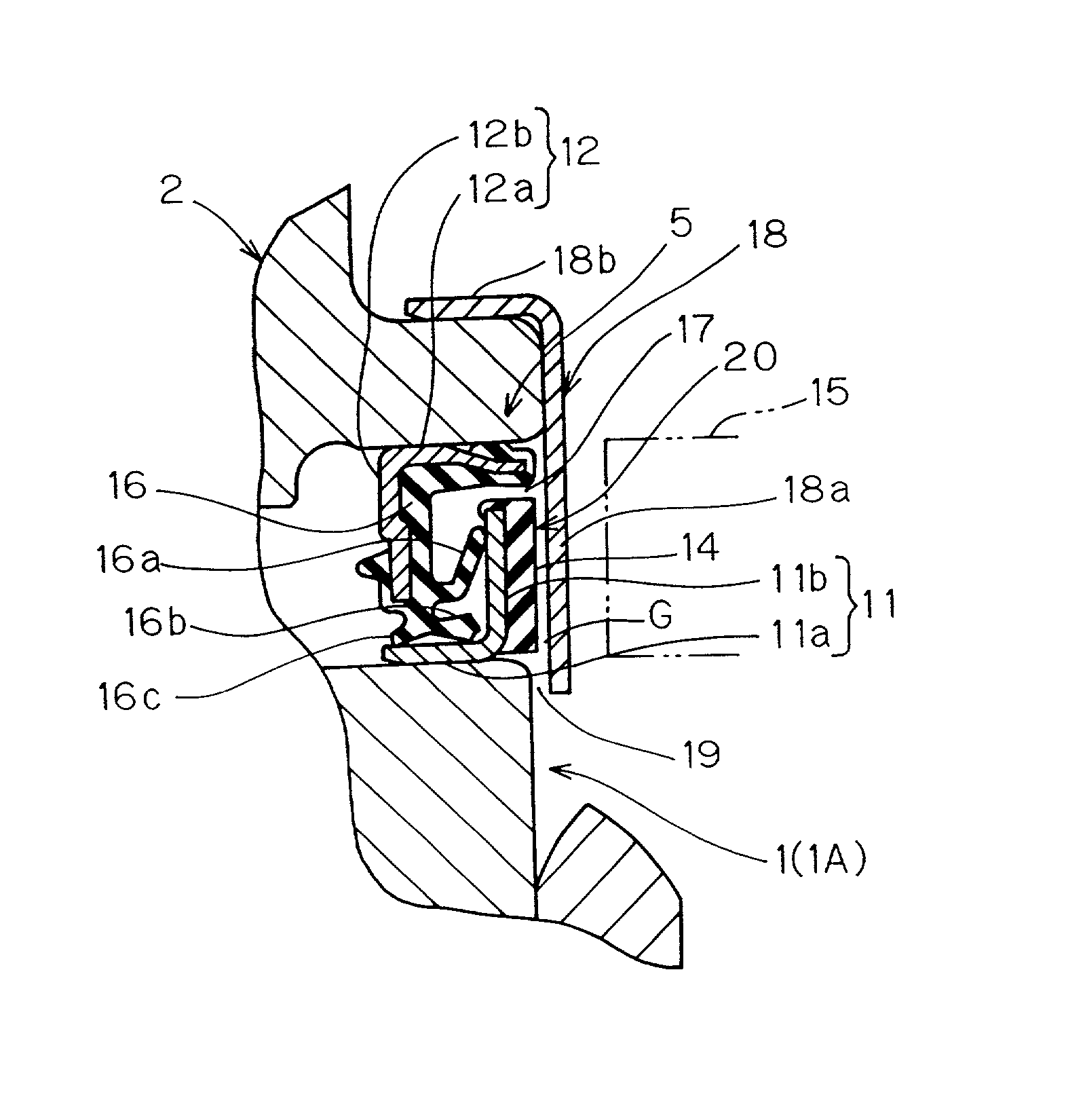

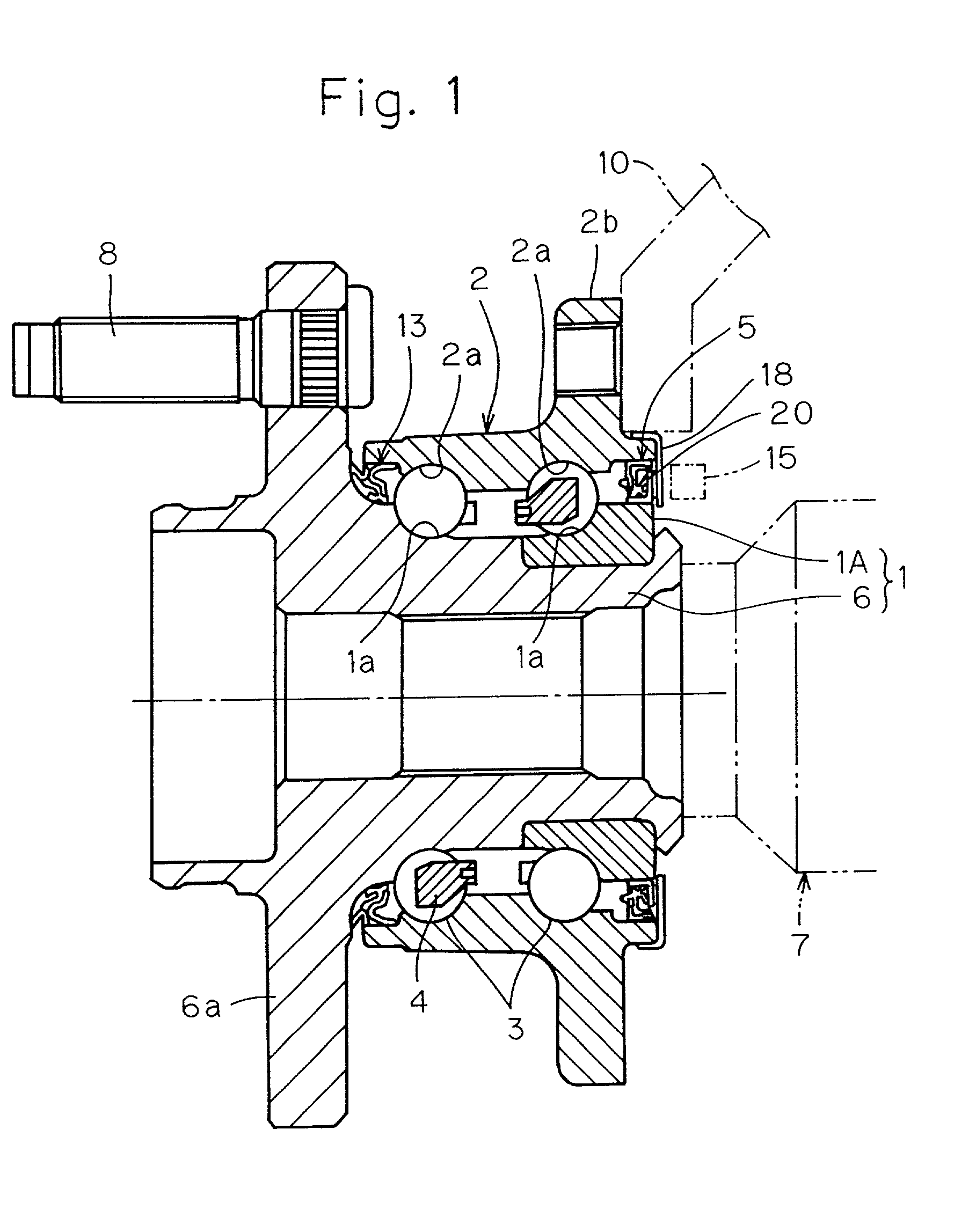

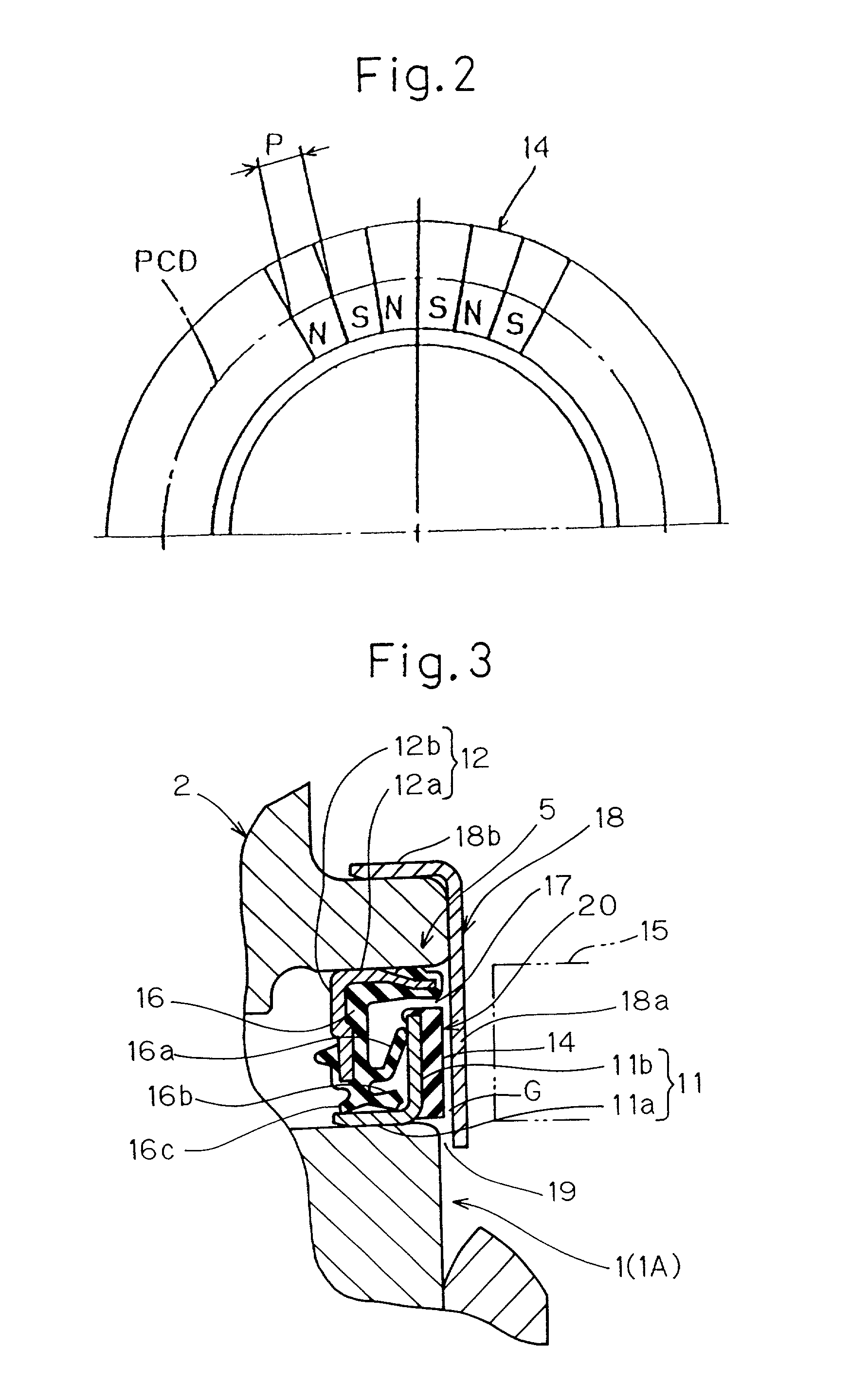

Wheel support bearing assembly

A wheel support bearing assembly includes inner and outer members (1 and 2) and at least one row of rolling elements (3) operatively interposed between the inner and outer members (1 and 2) and an annular sealing device (5) sealing an open end of an annular space defined between the inner and outer members (1 and 2). The sealing device (5) includes first and second annular sealing plates (11 and 12) fitted to different members out of the inner and outer members (1 and 2). Each of the first and second sealing plates (11 and 12) includes a generally cylindrical wall (11a or 12a) and a radial wall (11b or 12b) assembled together to represent a generally L-shaped section. The first sealing plate (11) is fitted to one of the inner and outer members (1 and 2) that serves as a rotating member. An elastic member (14) mixed with a powdered magnetic material is bonded by vulcanization to the radial wall (11b) of the first sealing plate (11). A protective cover (18) made of a non-magnetic material is positioned on one side adjacent an exterior of the multi-pole magnet (14) with a predetermined air gap left therebetween that the number of revolution can be detected through the protective cover (18).

Owner:NTN CORP

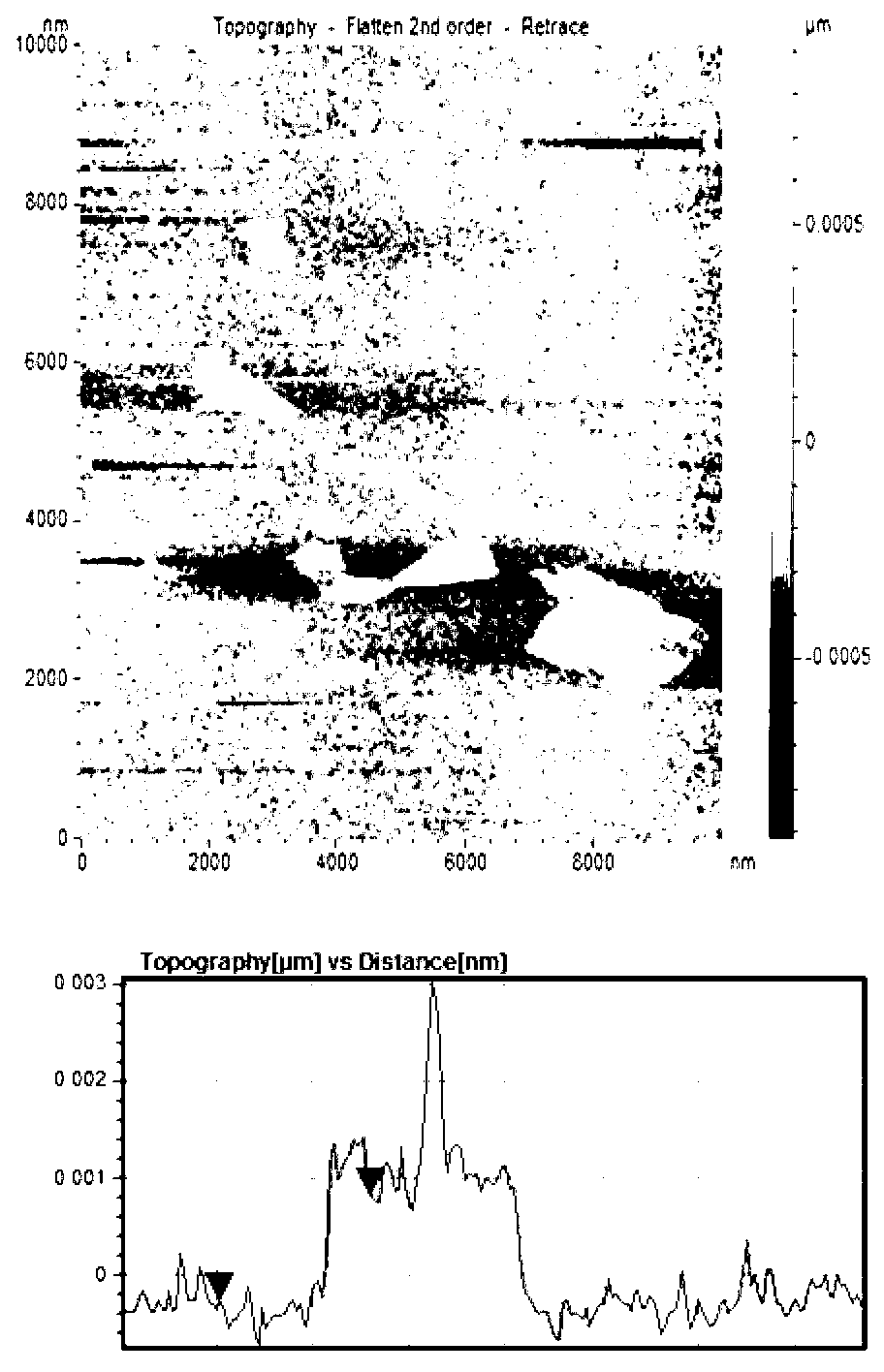

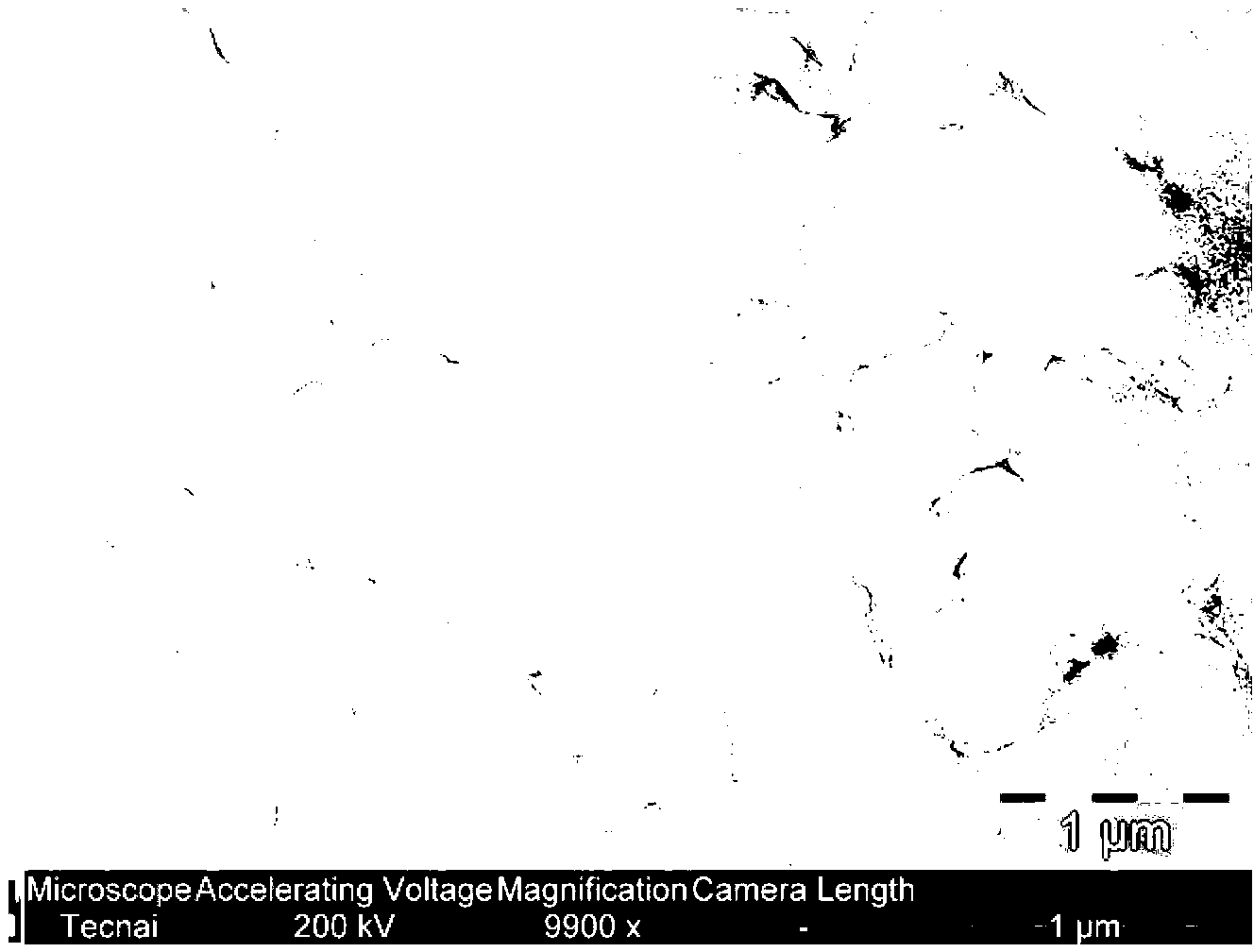

Oxidized grapheme/carbon black rubber nanocomposite and preparation method thereof

The invention provides an oxidized grapheme / carbon black rubber nanocomposite and preparation method thereof, which belongs to the field of rubber nanocomposite technology. The nanocomposite comprises the following basic compositions by mass: 100 parts of diene series rubber matrix, 0.5-5 parts of oxidized grapheme, 30-70 parts of hard carbon black of average particle size 11-30nm, 1-10 parts of plasticizer, 6-10 parts of activator, 0.5-4 parts of anti-aging agent, 1-4 parts of sulfuration promoter and 1-6 parts of insoluble sulphur; oxidized grapheme modifier. The oxidized grapheme powder is dispersed in deionized water for ultrasound, and a natural rubber emulsion is added, and masterbatch after flocculation, washing and drying is mixed uniformly with other additives, after sulfuration, the product is obtained. The oxidized grapheme / carbon black rubber nanocomposite has the advantages of excellent processing performance and obviously reduced dynamic themogenesis, thereby improving the usage life of tyre.

Owner:BEIJING UNIV OF CHEM TECH

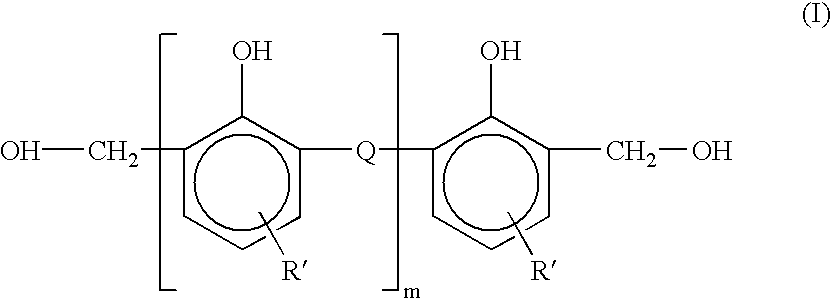

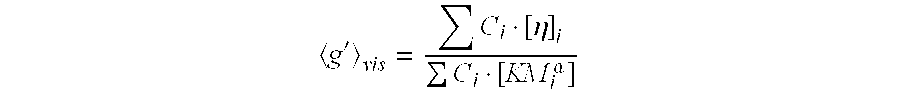

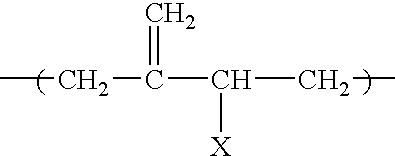

Thermoplastic elastomers having improved set foams made therefrom

A thermoplastic vulcanizate prepared by a process comprising the steps of dynamically vulcanizing a vulcanizable rubber within a mixture that includes from about 15 to about 90 percent by weight of the rubber and from about 10 to about 85 percent by weight of a long-chain branched thermoplastic resin, where the long-chain branched thermoplastic resin is (i) an alpha-olefin polymer, (ii) a copolymer of an alpha-olefin and an alpha-omega-olefin diene, or (iii) a mixture thereof, where the long-chain branched thermoplastic resin is characterized by a weight average molecular weight from about 100,000 to about 600,000, a number average molecular weight from about 40,000 to about 200,000, a z-average molecular weight from about 400,000 to about 2,000,000, a <g'>vis from about 0.2 to about 0.95, and a melt flow rate from about 0.3 to about 30 dg / min.

Owner:CELANESE INT CORP

Solid golf ball

InactiveUS6121357AImprove controllabilityImprove flight performanceAnti-corrosive paintsGolf ballsVulcanizationHardness

Owner:SUMITOMO RUBBER IND LTD

High-heat-conductivity rubber composite material and preparation method thereof

InactiveCN102504358AImprove thermal conductivitySimple preparation processRubber materialVulcanization

The invention discloses a high-heat-conductivity rubber composite material and a preparation method of the high-heat-conductivity rubber composite material. The high-heat-conductivity rubber composite material consists of the following ingredients in parts by mass: 100 of rubber, 4 to 6 of zinc oxide, 1 to 3 of stearic acid, 1 to 2 of anti-aging agents, 40 to 60 of carbon black, 1 to 1.5 of promoters, 1 to 3 of sulphur and 50 to 170 of heat conducting agents. The manufacture method comprises the following process steps that: the rubber is added into an open mill, the zinc oxide, the stearic acid, the anti-aging agents, the promoters, the carbon black and the heat conducting agents are sequentially added after the roll recovering, and finally, the sulphur is added. After rubber materials are uniformly mixed, the thin conduction is carried out, triangle bag packing and rolling are respectively carried out for five times, and the roll distance is regulated to 1.5mm for sheet output. The material sheets are placed into a mold, the vulcanization is carried out on a flat plate vulcanization machine, the vulcanization time is 15 to 20 minutes, the vulcanization temperature is 160 to 165 DEG C, and the vulcanization pressure is 10 to 12MPa. The material disclosed by the invention has an excellent physical and mechanical property and a high heat conduction factor.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

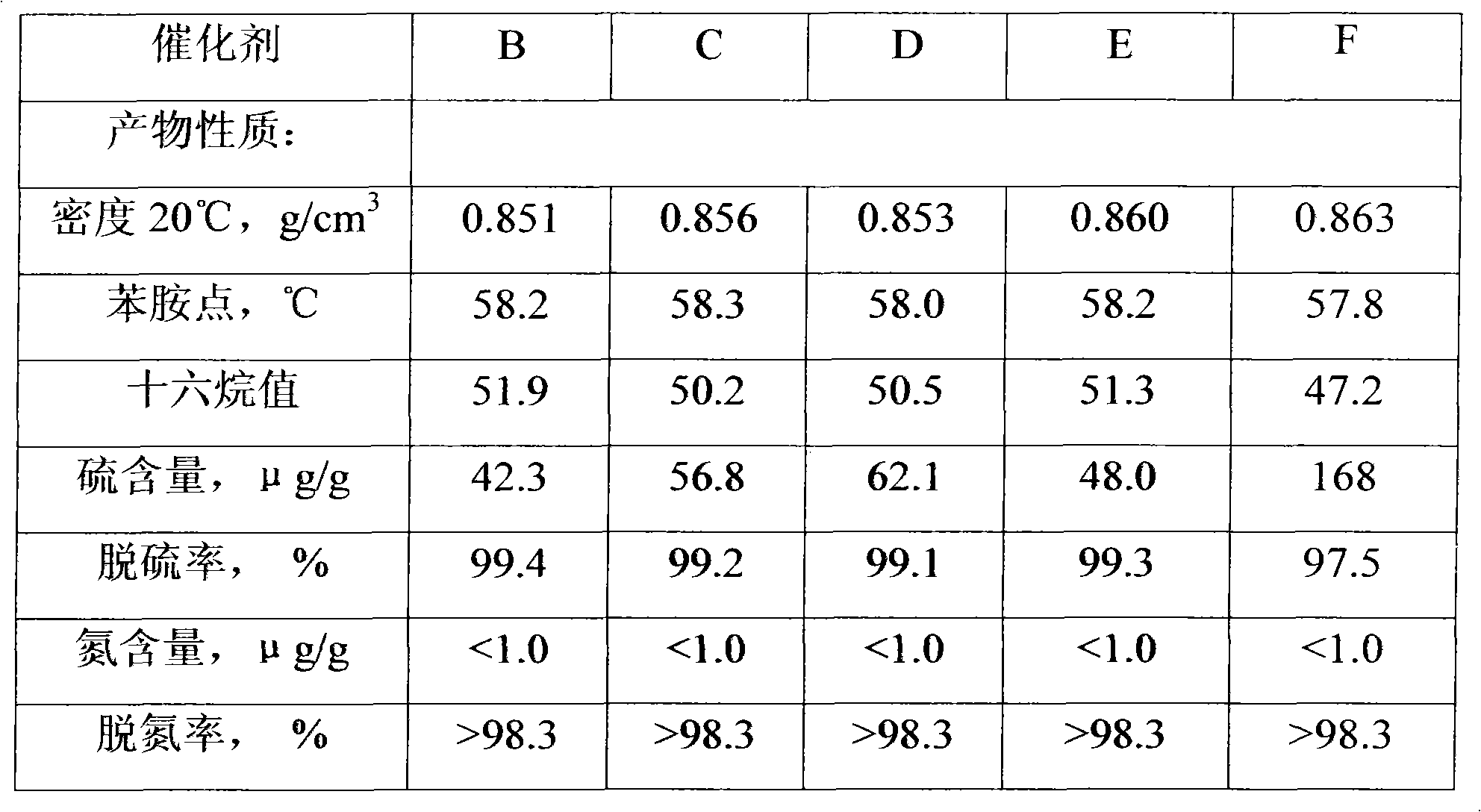

Preparation method of hydrogenation catalyst

ActiveCN101491766AImprove stabilityGood dispersionOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsVulcanizationActive component

The invention provides a method for preparing a hydrogenation catalyst. Active components are introduced by a two-stage method; previously introduced metal components have strong action with a carrier through a roasting step, and subsequently introduced active components have no roasting step and have weak action with the carrier; and during vulcanization and usage of the catalyst, the active metal components having strong action with the carrier can inhibit migration and concentration of the active metals having weak action with the carrier, so the catalyst keeps ideal activity and stability. The catalyst prepared by the method can be used in a hydrotreating process of various distillate oils.

Owner:CHINA PETROLEUM & CHEM CORP +1

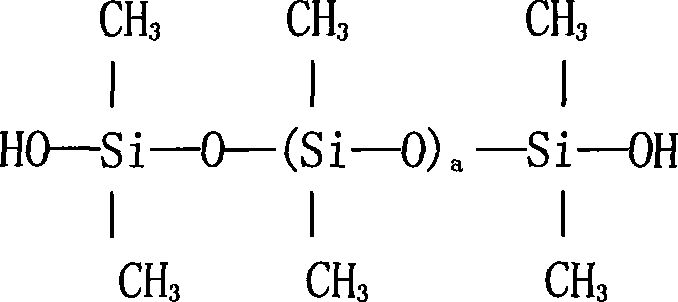

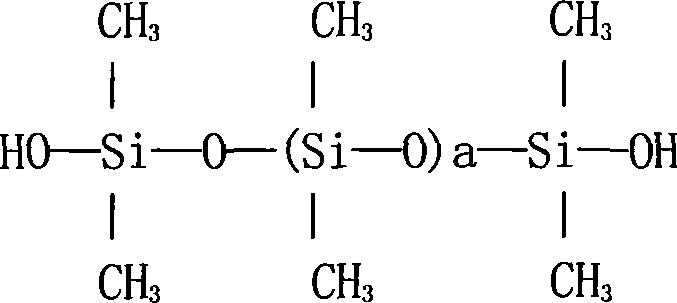

Highly ripping-resistant high temperature sulfidation silicon rubber and method for making same

The invention relates to a high anti-tearing and high temperature vulcanized silicon rubber, which is made through mixing and vulcanization of peroxide vulcanization agent and a combination which uses methylvinyl silicone rubber as base adhesive. The combination, according to weight proportion, comprises 100 of methylvinyl silicone rubber with low vinyl content, 1 to 30 of hydroxyl silicone oil, 0.1 to 3 of inner mold release agent, 15 to 80 of reinforcement agent, 1 to 10 of methylvinyl silicone rubber with high vinyl content and 1 to 10 of hydrogen-containing silicone oil; wherein, the vinyl molar content of the low vinyl-content methyvinyl silicone rubber is 0.01 percent to 0.15 percent; the vinyl molar content of the high vinyl-content methylvinyl silicone rubber is 1 percent to 10 percent. The invention has the advantages that the high vinyl-content methylvinyl silicon rubber is added into the methylvinyl silicone rubber, leading unsymmetrical concentration-crosslinking or one place multiple crosslinking to be formed during sulfuration period and the silicone rubber to generate so large resistance at the place that the rubber is difficult to be torn. In addition, the broken and tensile strength of vulcanized silicon rubber products is up to 8.5 MPa, and the tear strength is up to 45 N / mm.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

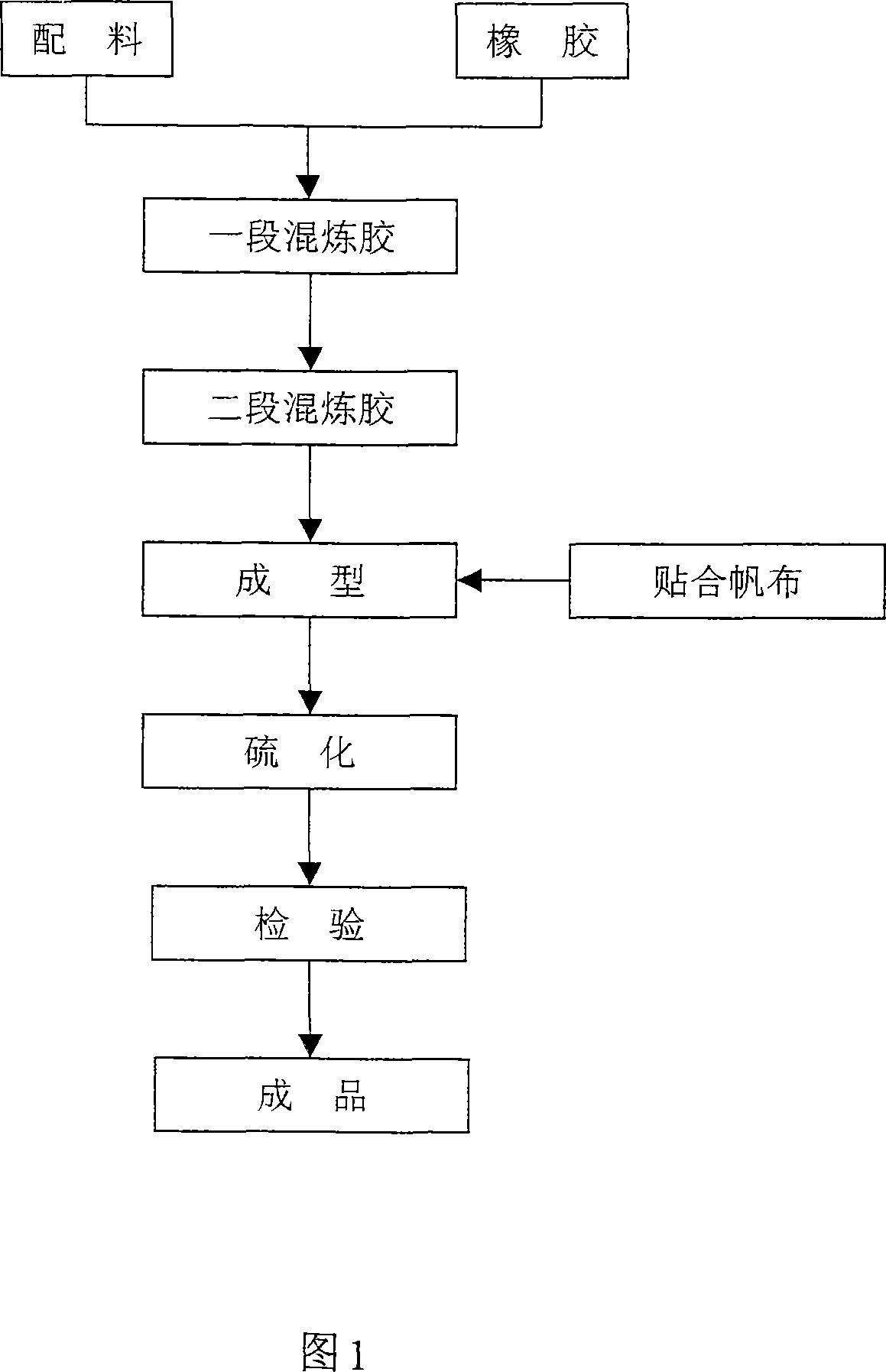

High-temperature-resisting conveyer belt

ActiveCN101028888AImprove heat resistanceExtended service lifeConveyorsBeltsCross-linkPolymer science

A refractory conveying belt is prepared from the dibasic ethylene propylene rubber, or dibasic ethylene propylene rubber and ternary ethylene propylene rubber through pre-pugging, adding heat conducting agent and anti-ageing agent, pugging, adding reinforcing agent, softening agent and short aramid fibers, pugging, adding cross-linking agent and cross-linking aid, heating, calendering to become sheet, attaching it onto tension-resistant canvas, rolling and sulfurizing.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Solid golf ball

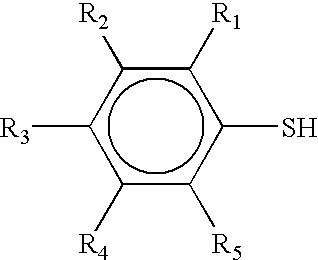

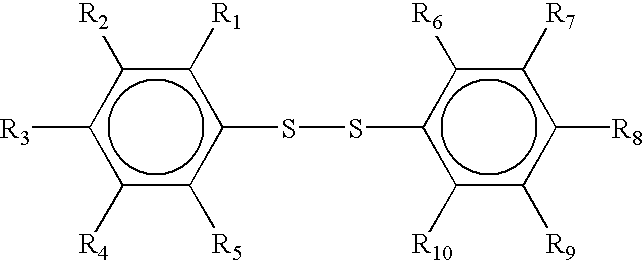

InactiveUS6583229B2Exceptional rebound characteristic and flight performanceExcellent shot feelingLayered productsGolf ballsSulfurEngineering

The present invention provides a solid golf ball having exceptional rebound characteristics and flight performance, as well as good shot feel. The present invention relates to a solid golf ball comprising at least one layer of a core, and at least one layer of a cover formed on the core, wherein at least one of the layers of the core is formed by vulcanizing and press-molding a rubber composition comprising a base rubber, co-crosslinking agent, organic peroxide, filler and specific organic sulfur compound which contains substituent groups having a substituent constant of not less than 1.42.

Owner:SUMITOMO RUBBER IND LTD

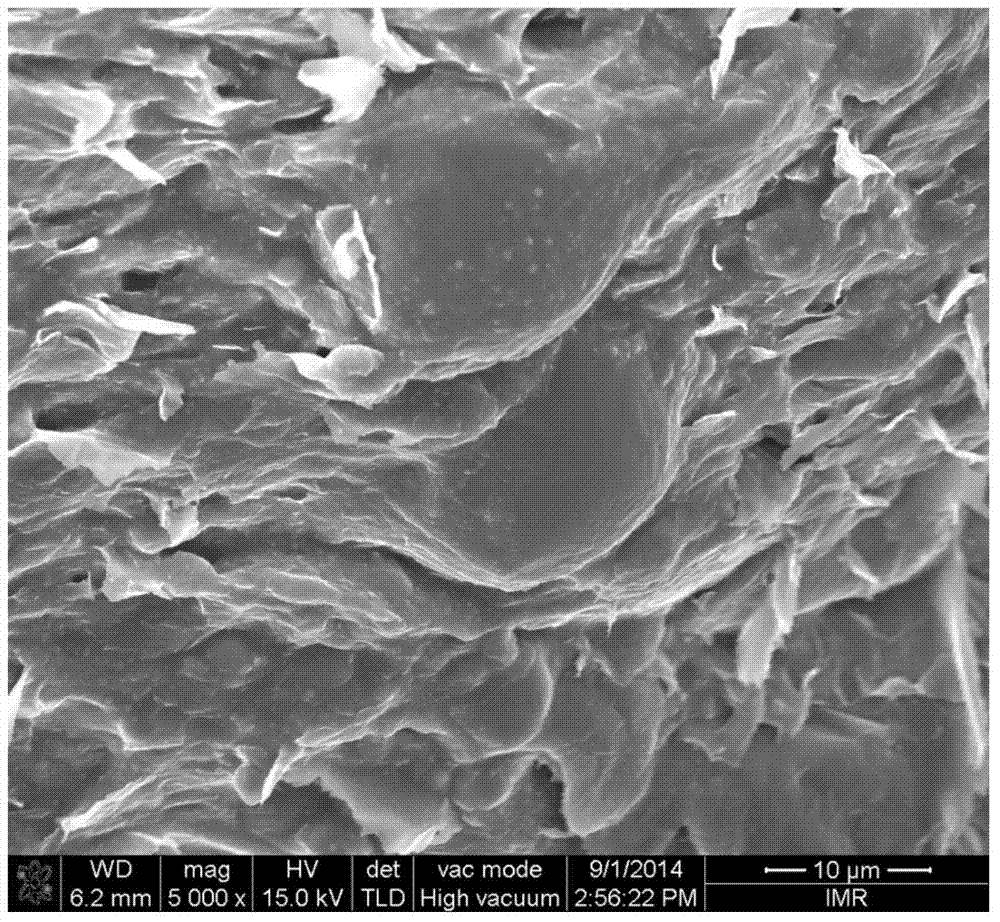

Graphene-containing silicon rubber heat-conducting composite material and preparation method thereof

The invention relates to the field of heat-conducting high-polymer composite materials, particularly a graphene-containing silicon rubber heat-conducting composite material and a preparation method thereof. The heat-conducting composite material is mainly composed of graphene, an inorganic heat-conducting filler and a silicon rubber matrix, wherein the graphene accounts for 0.1-10 wt% of the silicon rubber heat-conducting composite material, and the graphene constitutes a heat-conducting network in the heat-conducting composite material. The method comprises the following steps: uniformly compounding the inorganic heat-conducting filler, graphene, crosslinking agent and other assistants and silicon rubber on a double-roll open mill to obtain a heat-conducting silicon rubber prepolymer; and carrying out primary vulcanization on the prepolymer on a flat vulcanizing machine, and carrying out secondary vulcanization in a drying oven to finally obtain the composite heat-conducting silicon rubber. Since the two-dimensional graphene has large thickness-diameter ratio and can easily constitute an effective heat-conducting network in the silicon rubber, a small amount of two-dimensional graphene can obviously enhance the heat-conducting property of the silicon rubber (the heat conductivity coefficient at 40 DEG C is 4.98 W / m.K). The silicon rubber composite heat-conducting material can be widely used in the field of heat dissipation of electronic products.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Rubber composition for tire tread having high performance on ice and pneumatic tire using the same

InactiveUS6550508B1Good physical propertiesReduce hardnessNon-inflatable tyresSpecial tyresFiberVulcanization

Owner:YOKOHAMA RUBBER CO LTD

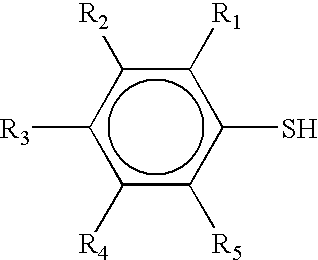

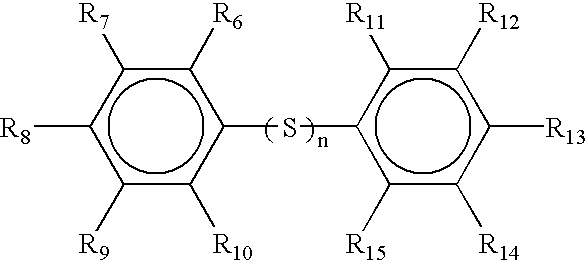

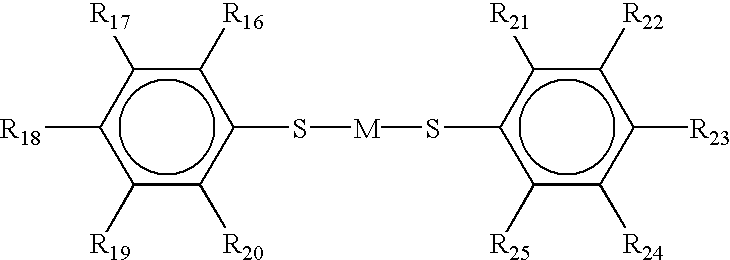

Silica-reinforced rubber compounded with blocked mercaptosilanes and alkyl alkoxysilanes

The invention provides a sulfur vulcanizable silica-reinforced elastomeric compound having improved tensile mechanical and dynamic viscoelastic properties. The compounds are formed by mixing an elastomer optionally having an alkoxysilane terminal group, with silica in the presence of an alkyl alkoxysilane and a blocked mercaptosilane. In particular, the mercaptosilane moiety of the blocked mercaptosilane and the alkyl alkoxysilane are present in a weight ratio of about 0.001:1 to about 0.20:1. Preferably, the blocked mercaptosilane and the alkyl alkoxysilane are compounded with the elastomer and the silica at high temperature to facilitate the silica-silane reaction. A deblocking agent is added at any desired mixing stage, optionally with the cure package, to allow binding of the mercaptosilane to the polymer.

Owner:BRIDGESTONE CORP

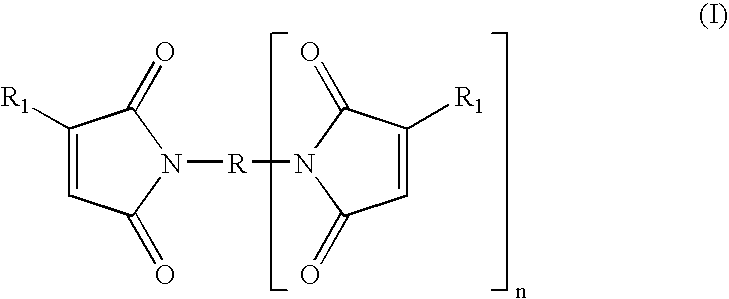

Tack free surface cures of polymers by organic peroxides in the presence of air

Compositions are disclosed which comprise mixtures of at least one compound selected from silicone elastomers, bis-, tri- or higher polymaleimides and / or bis-, tri- or higher polycitraconimides, and at least one compound selected from p-phenylene-diamine based antiozonants, sulfur compounds capable of accelerating sulfur vulcanization of polymers capable of being crosslinked by sulfur and polysulfide polymers which when compounded into polymers curable by free radical initiators in the presence of free radical initiators permit substantially tack free surface cure of the polymers by decomposition of the free radical initiator in the presence of molecular oxygen. Compositions containing the above ingredients and at least one free radical initiator, curable compositions containing the combination and processes for making and using the compositions are also disclosed.

Owner:ARKEMA INC

Low permeability thermoplastic elastomer composition

InactiveUS8021730B2Reducing complex viscosityComplex viscosityClosuresWithout separate inflatable insertsElastomerPolymer science

Owner:EXXONMOBIL CHEM PAT INC +1

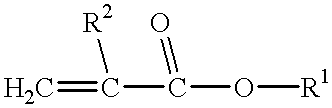

Carboxylic acid-modified nitrile copolymer latex and latex composition for dip forming comprising the same

ActiveUS20100152365A1Good oil resistanceHigh mechanical strengthGroup 4/14 element organic compoundsSpecial tyresVulcanizationSulfur

A carboxylic acid-modified nitrile copolymer latex is provided. The copolymer latex comprises a carboxylic acid-modified nitrile copolymer of an unsaturated monomer having at least one crosslinkable functional group selected from vinyl and epoxy groups. The use of the copolymer latex enables the production of a molded article that does not undergo long stirring and maturation, causes no allergic reactions due to the absence of sulfur and a vulcanization accelerator, has good oil resistance and high mechanical strength, and produces a soft feeling. Further provided is a latex composition for dip forming comprising the copolymer latex, and an article produced from the latex composition by dip forming.

Owner:LG CHEM LTD

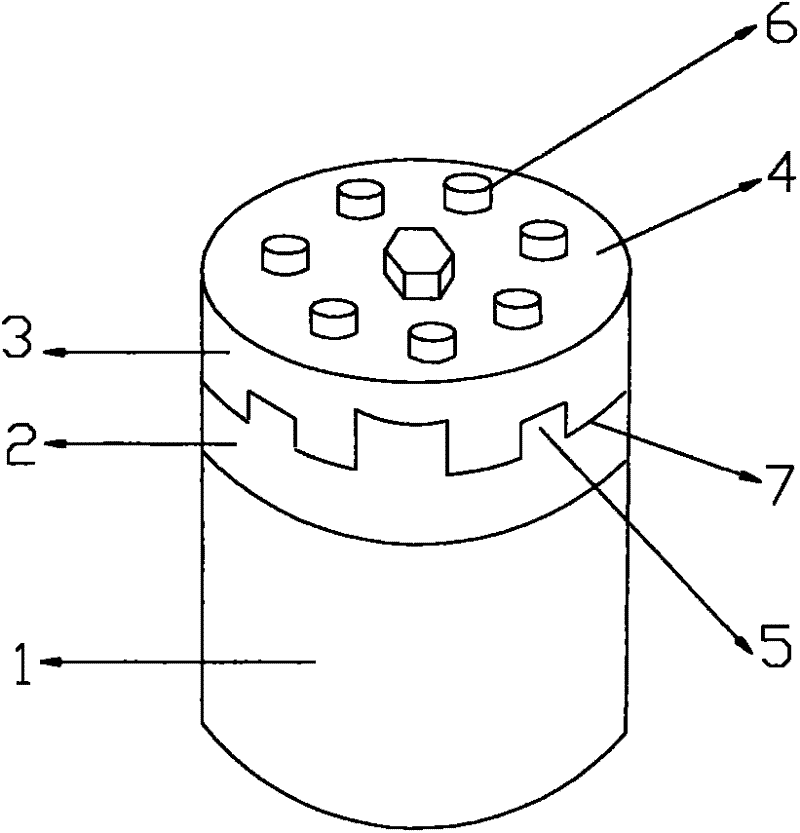

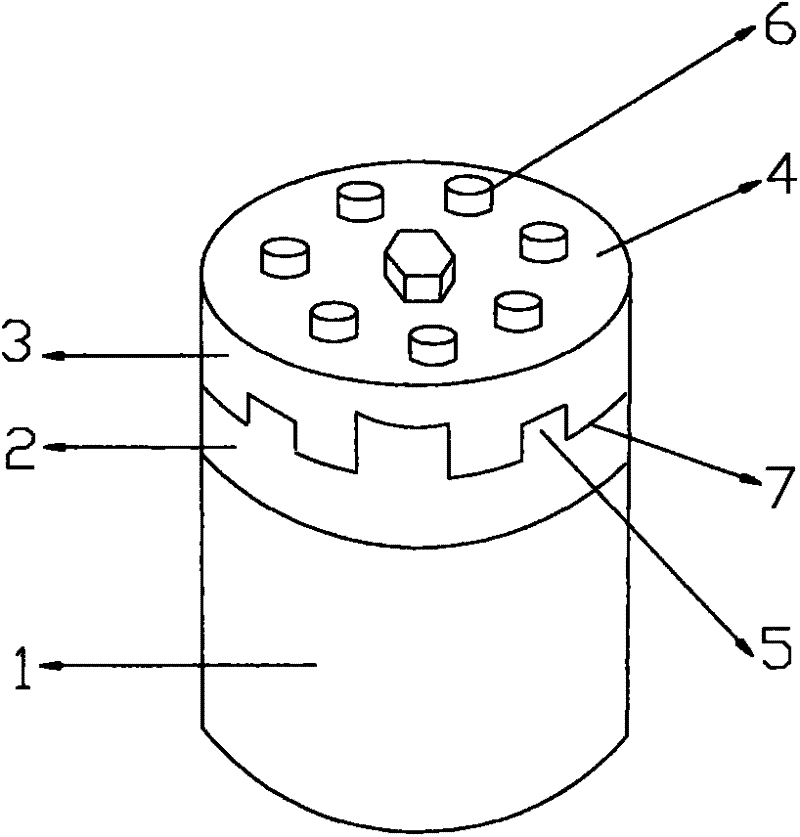

Pitted-surface metal and rubber composite conductive particle

The invention provides a pitted-surface metal and rubber composite conductive particle, which is formed by adhering a metal surface layer to a rubber basic body or slitting after adhesion, wherein the metal surface layer is a pitted surface and has pits or bumps or both the pits and the bumps; the pits or the bumps are formed on an external surface of the metal surface layer or an internal surface or both the external surface and the internal surface; the depths of the pits are smaller than the thickness of the metal surface layer; the heights of the bumps are greater than or equal to one tenth of the thickness of the metal surface layer; the metal surface layer is made of metal or alloy; gold, silver, copper or nickel can be coated on the external surface of the metal surface layer; the rubber basic body is made of silicon rubber or polyurethane rubber; an adhesion layer can be arranged between the metal surface layer and the rubber basic body; the adhesion layer is made of a heat vulcanization adhesive, a prime coating agent or a material which is the same as that of the rubber basic body; and aids such as a coupling agent can be coated on the internal surface of the metal surface layer. The metal surface layer is high in strength, stable in conductivity, high in strength of the adhesion layer and high in elasticity of the rubber basic body; and the pitted-surface metal and rubber composite conductive particles can serve as conductive parts of various kinds of keys of a mobile phone, an automobile and the like, and the cost can be controlled.

Owner:NANTONG MEMTECH TECH

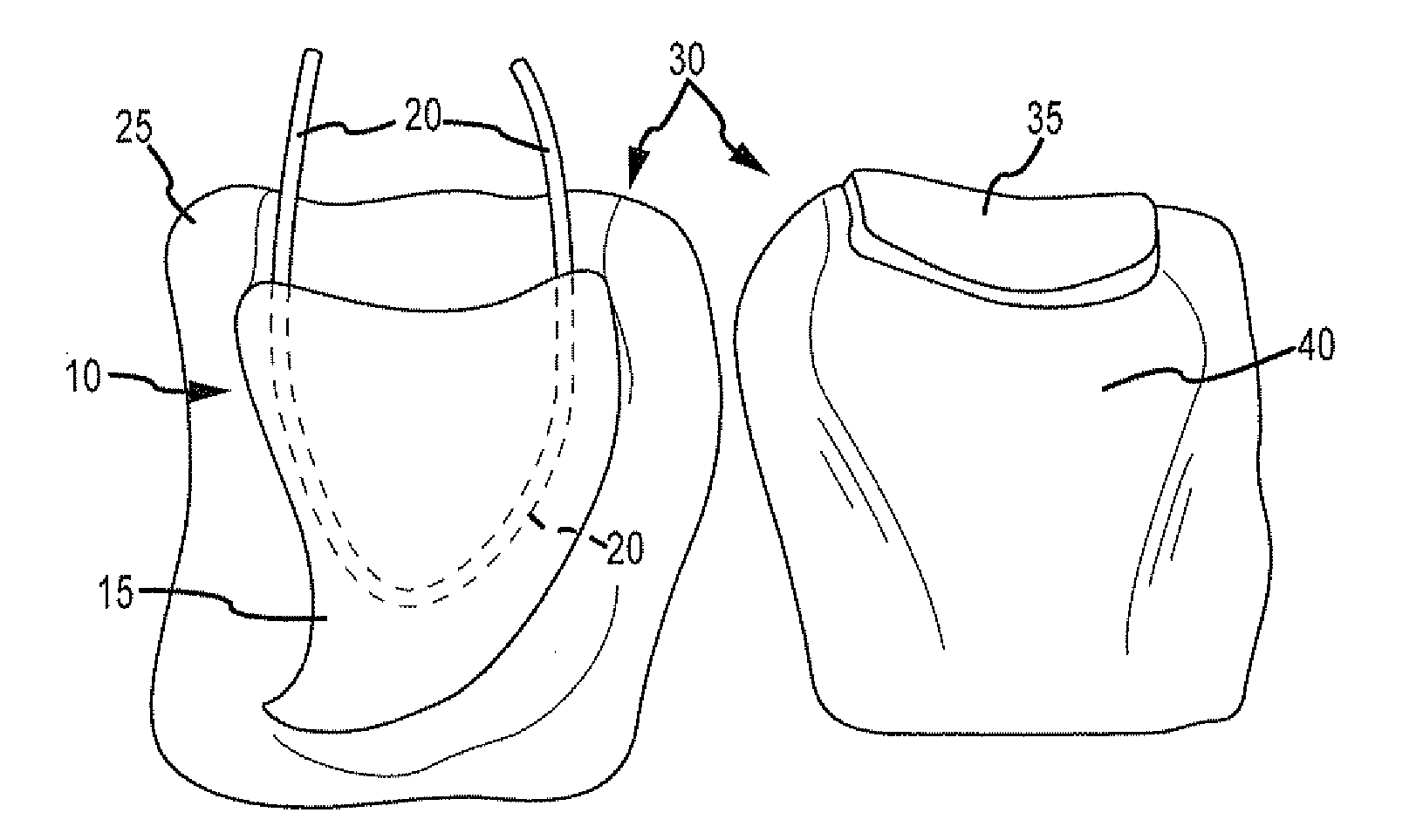

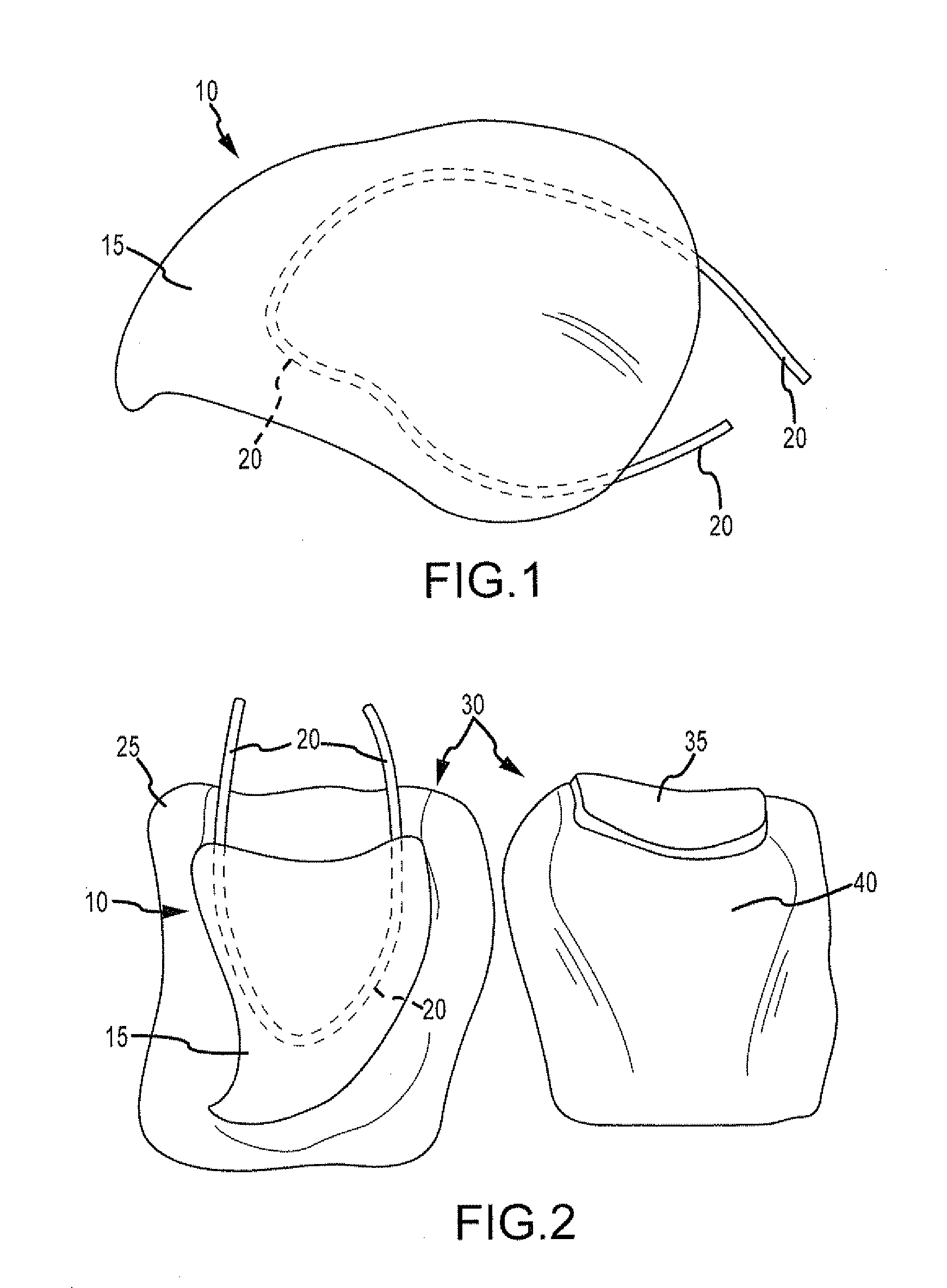

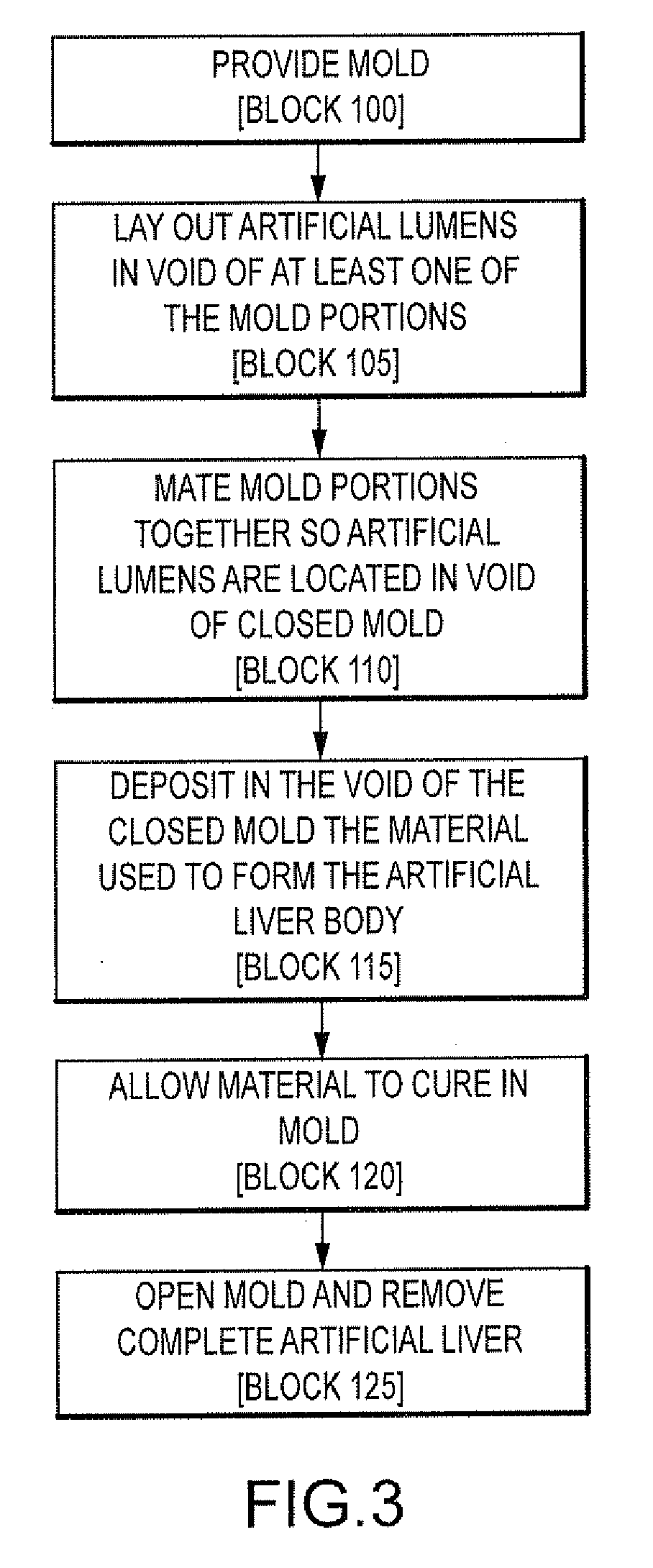

Surgical simulator, simulated organs and method of making same

A surgical simulator is disclosed herein. The surgical simulator includes an artificial organ and an enclosure substantially enclosing the artificial organ. The artificial organ is substantially formed of platinum cured room temperature vulcanization silicone rubber (“PCRTVS”).

Owner:COLORADO STATE UNIVERSITY

Sneaker sole material with high wear resistance and low hardness and preparation method thereof

The invention discloses a sneaker sole material with high wear resistance and low hardness and a preparation method thereof, particularly a method for preparing a sneaker sole material which is suitable for middle and high-grade sneaker soles with higher requirements on wear resistance and comfort. The sneaker sole material comprises the following components: butadiene rubber (BR), natural rubber (NR), styrene butadiene rubber (SBR), softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizer, a vulcanization accelerator, a tackifier and an anti-aging agent. A series of sole material with high wear resistance (DIN abrasion is less than or equal to 40mm<3>, and the length of grinding marks is 3.0 to 4.0mm) and low hardness (ShoreA 60-66) is prepared by screening the proportion of rubber composition, the coupling agent, the accelerator, and the activating agent and reasonably controlling a process on the basis of the rubber, the softening oil and the reinforcing agent. The material has the advantages that: (1) the total weight of a sneaker sole is expected to be reduced, namely the thickness of a rubber outer sole of a sneaker can be reduced under the condition that the material has the wearing life which is the same as that of the conventional sneaker sole, so that the total weight of the sole is reduced; (2) the humidity and slip resistance is improved, namely the hardness of the sole is lower and the sole is easy to distort under the condition of stress, so that the contact area of the sole and the ground is increased, and the aim of improving the humidity and slip resistance of the sole is fulfilled; and (3) the comfort is improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

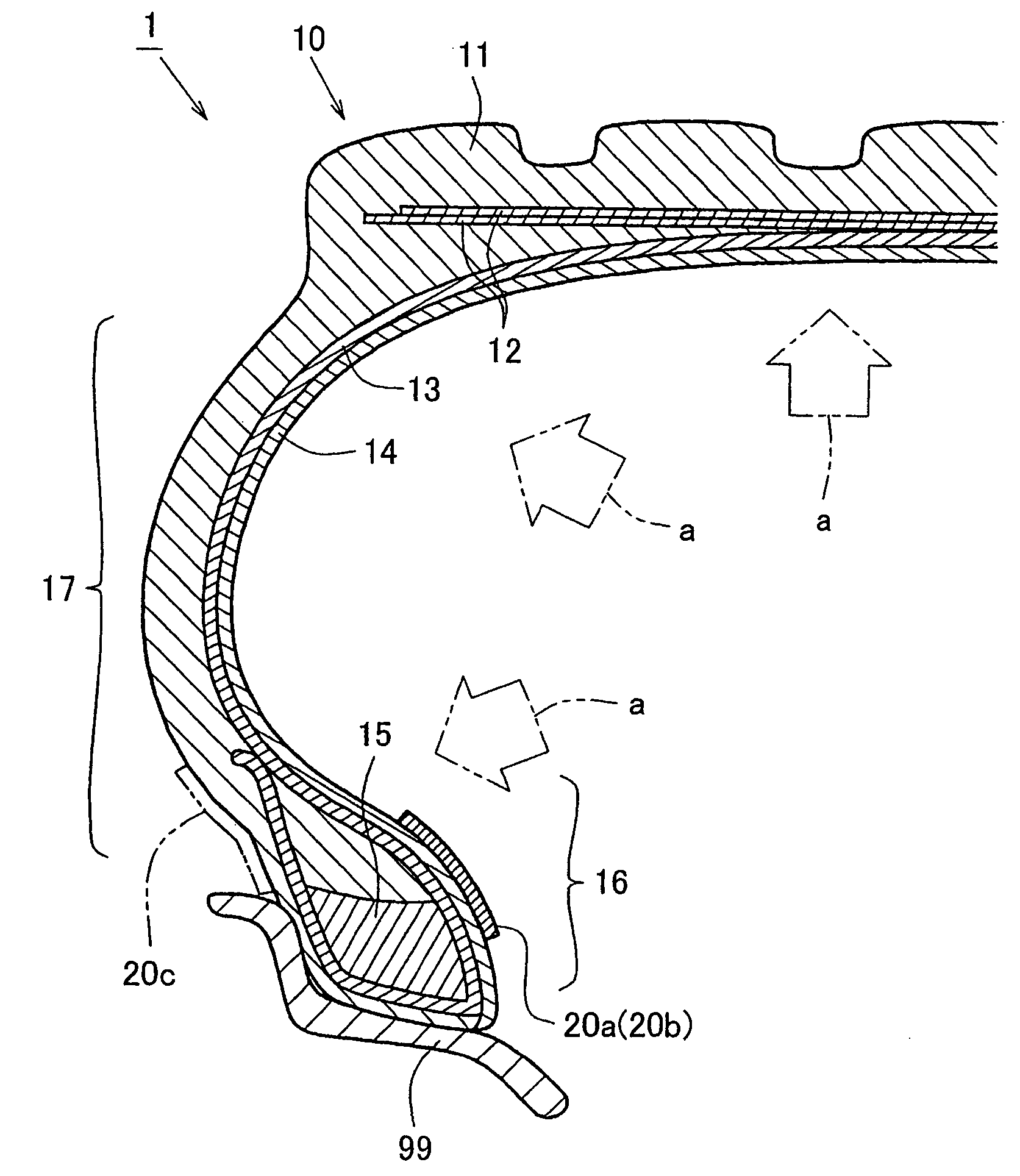

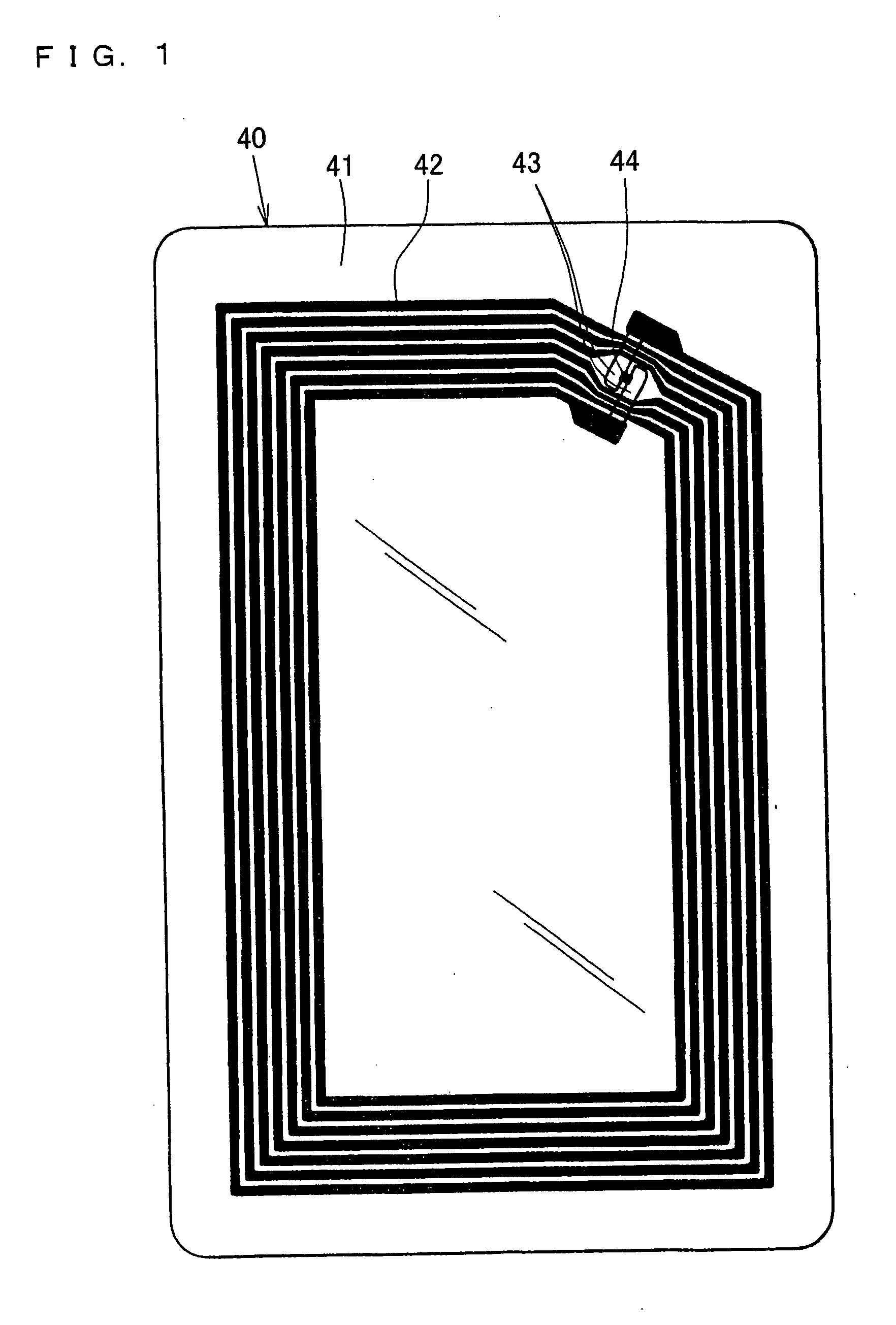

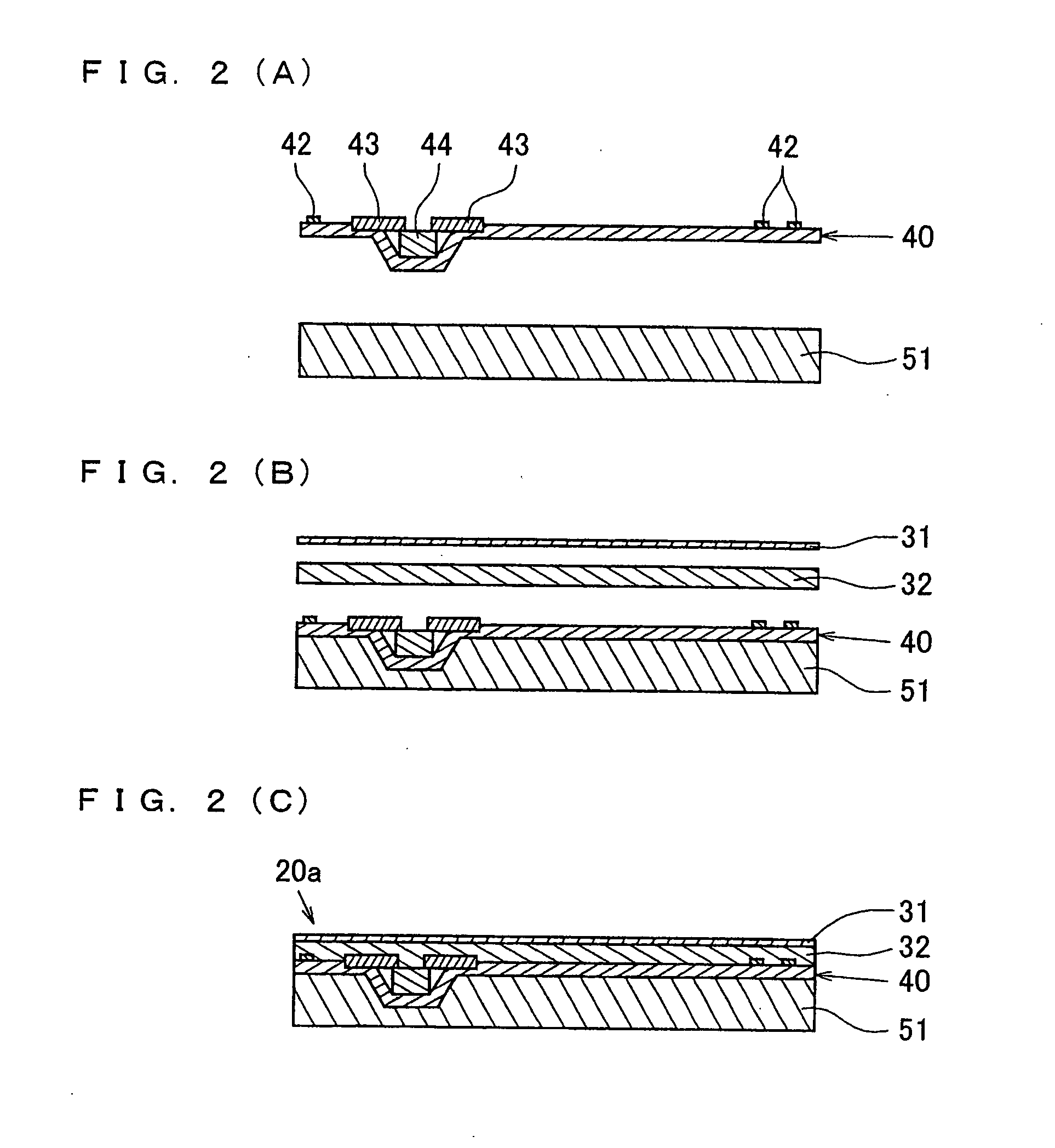

Wireless ic tag joining method, wireless ic tag-carrying article, and vehicle

InactiveUS20060164250A1Even by forceStress resistantTyresTyre measurementsVulcanizationData transmission

A flat IC tag contains memory means capable of data storage and transmission means capable of data transmission. The IC tag has on a surface thereof an unvulcanized rubber having identical properties to the unvulcanized rubber used for an article to which the IC tag is mounted. The opposite surface of the IC tag is mounted to the article before vulcanization. The article is vulcanized in this state to mount the IC tag to the article. Hence, the IC tag is not damaged if attached to tires and other articles in harsh operating environment.

Owner:ORMON CORP

Thermoplastic elastomers with improved coring properties

Thermoplastic vulcanizates having improved coring properties, comprising a blend of thermoplastic polypropylene resin, vulcanized butyl rubber, a SEPS block copolymer and a polybutene oil plasticizer.

Owner:ADVANCED ELASTOMER SYST LP

Preparation method of vulcanization type hydrogenation catalyst

ActiveCN101491765AAvoid low loadLoad type high activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsVulcanizationSulfur

The invention relates to a method for preparing a vulcanized hydrogenation catalyst. A catalyst carrier adopts an impregnation method to load hydrogenation metal components; before, after or simultaneously loading the hydrogenation metal components, a vulcanizing agent is introduced, and the use level of the vulcanizing agent is 85 to 150 percent of theoretic sulfur demand of the hydrogenation metal components; and during loading the hydrogenation metal components and introducing the vulcanizing agent, the method comprises at least one step of low-temperature thermal treatment but does not comprise a roasting step. The method overcomes the defects that the conventional oxidation catalyst has high preparation cost, long vulcanizing time and high operating cost. The catalyst prepared by the method is suitable for a hydrogenation process of petroleum fractions, and the hydrogenation activity of the catalyst prepared by the method can reach or exceeds the effect of the conventional catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

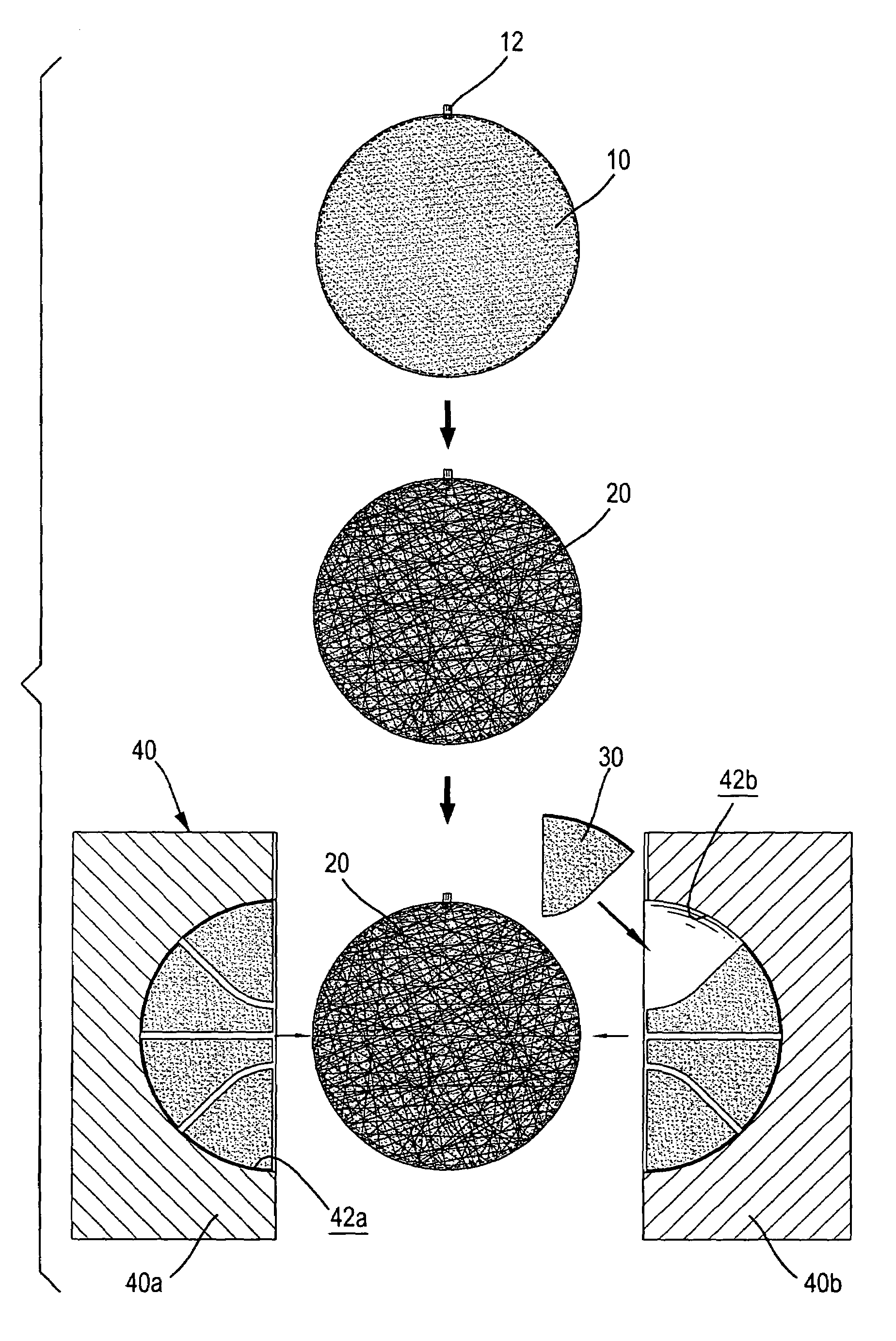

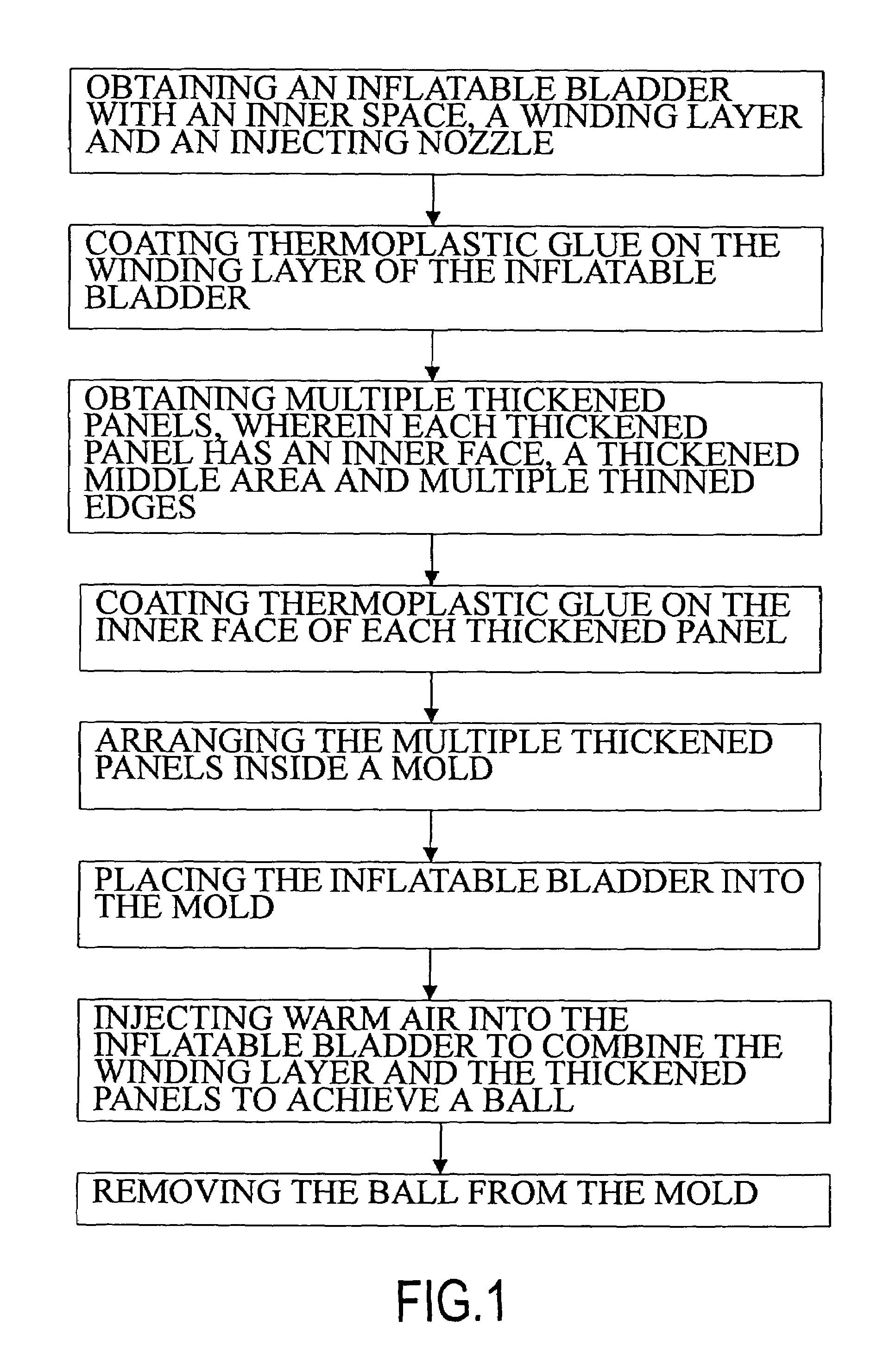

Method for manufacturing an inflatable ball and a ball made with the method

InactiveUS7066853B2Quick and simplified procedureGood appearanceHollow inflatable ballsHollow non-inflatable ballsVulcanizationThermal deformation

A method for manufacturing an inflatable ball has the following acts of: obtaining an inflatable bladder with a winding layer; coating thermoplastic glue on the winding layer; obtaining multiple thickened panels; coating thermoplastic glue on the thickened panels; arranging the thickened panels and the inflatable bladder inside a mold; and injecting thermal air into the inflatable bladder to make the winding layer combine with the multiple thickened panels. Wherein, each thickened panel is made of a leather layer and an optional filling layer and has a thickened middle area and multiple thinned edges around the thickened middle area. By eliminating the rubber layer in the prior arts, vulcanization is avoided. Moreover, heating the inflatable ball from inside of the mold avoids thermal deformation of outer pebbled patterns of the panels.

Owner:CHANG YEN LI

Giant engineering tire tread rubber and giant engineering tyre using the same

InactiveCN101440176ASolve wear resistanceSolve heat resistanceSpecial tyresHeat resistanceTear resistance

The invention discloses tread rubber for a large project tire and the large project tire using the tread rubber. The tread rubber for the large project tire consists of (A) tread cap rubber, (B) tread center rubber and (C) tread base rubber. On one hand, the invention adopts rubber matrixes with three different formulas to well solve the problem that an outer layer is easy to overcure if the tread rubber for the large project tire is thick; and on the other hand, the tread rubber prepared by the three formulas of the rubber matrixes can obtain superior equilibrium between abrasion resistance, heat resistance, tear resistance, low heat generation and curing speed.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Pneumatic tire having built-in sealant layer and preparation thereof

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G′ (80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G′ (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com