Highly ripping-resistant high temperature sulfidation silicon rubber and method for making same

A technology of high temperature vulcanization and silicone rubber, applied in the field of high tear resistance high temperature vulcanized silicone rubber and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

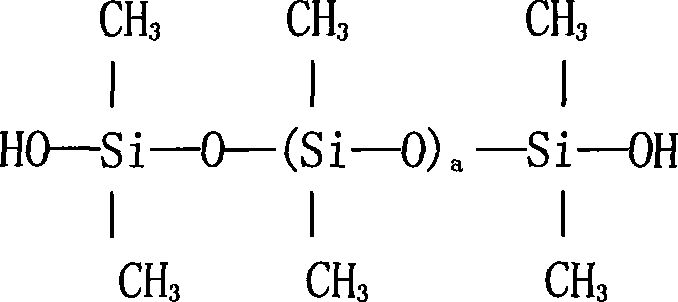

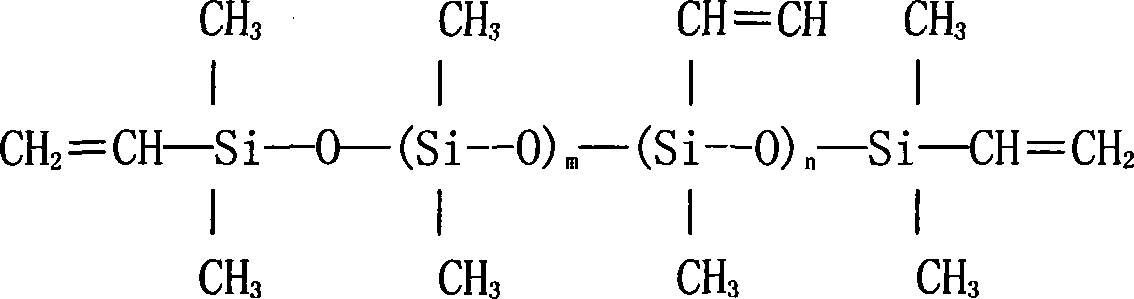

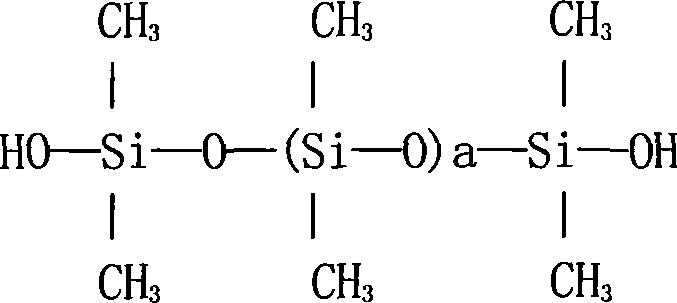

Method used

Image

Examples

Embodiment 1

[0043] The preparation process of the high-tear-resistant high-temperature vulcanized silicone rubber of the present invention is as follows:

[0044] The first step: 100 parts by weight of low vinyl content methyl vinyl silicone rubber with a molecular weight of 600,000 and a vinyl molar content of 0.06%, 0.2 parts by weight of an internal release agent zinc stearate, a viscosity of 20 cps at 25°C, and a hydroxyl content of 8.0% 9.6 parts by weight of the structured control agent hydroxy silicone oil, put into the kneader and kneaded for 10 minutes;

[0045] The second step: put 48 parts by weight of T-40 white carbon black into the kneader for 5 times for kneading, the temperature is controlled below 80°C until the kneading is uniform and complete;

[0046] Step 3: transfer the mixture of step 2 to an internal mixer at 150-180°C for heat treatment for 3 hours;

[0047] Step 4: Park the rubber obtained in Step 3 for 1 to 2 hours, cool it down to below 120°C, and carry out th...

Embodiment 2

[0052] The T-40 silica in Example 1 was changed to N20 silica, the added hydroxy silicone oil was changed to 7.2 parts by weight, and the rest were the same as in Example 1 to obtain the silicone rubber composition (II).

Embodiment 3

[0054] The T-40 silica in Example 1 was changed to V-15 silica, the added hydroxy silicone oil was changed to 6.2 parts by weight, and the rest were the same as in Example 1 to obtain the silicone rubber composition (III).

[0055] See Table 1 for a comparison of their performance parameters.

[0056] Table 1

[0057]

[0058] Tensile strength (Mpa)

[0059] It can be seen from Table 1 that the larger the specific surface area of the fumed silica used, the greater the tear strength and tensile stress, and the correspondingly higher hardness of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com