Patents

Literature

115 results about "Silicone products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

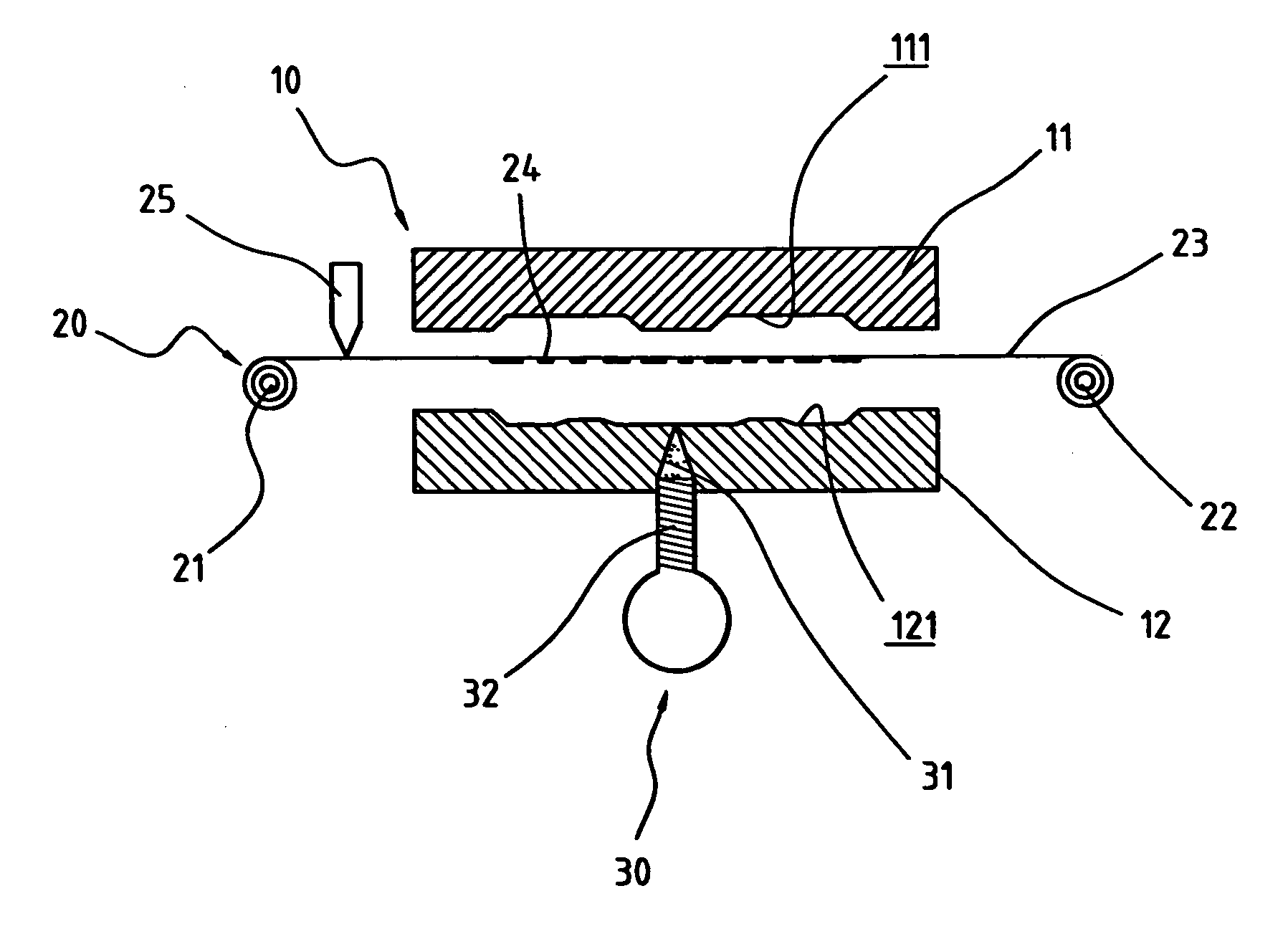

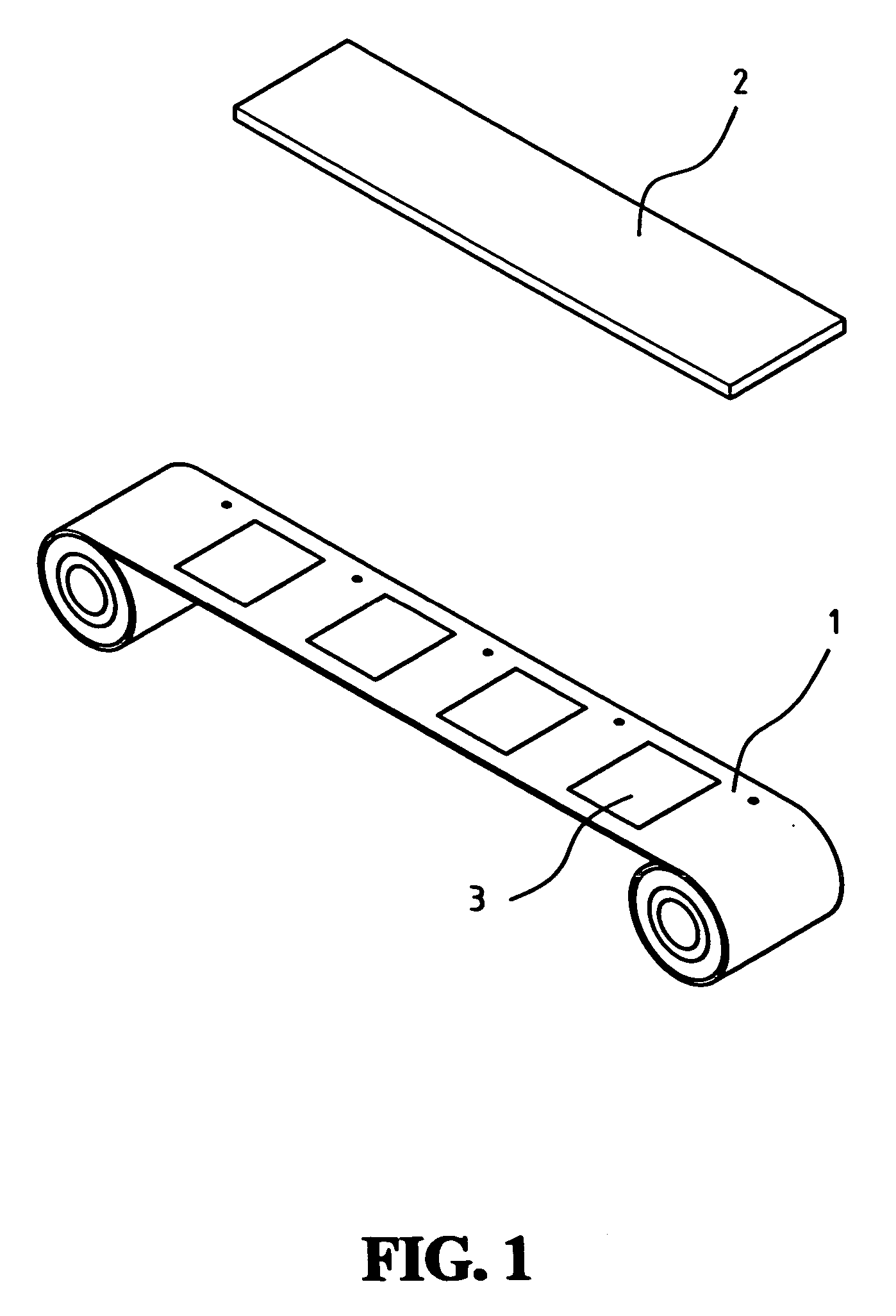

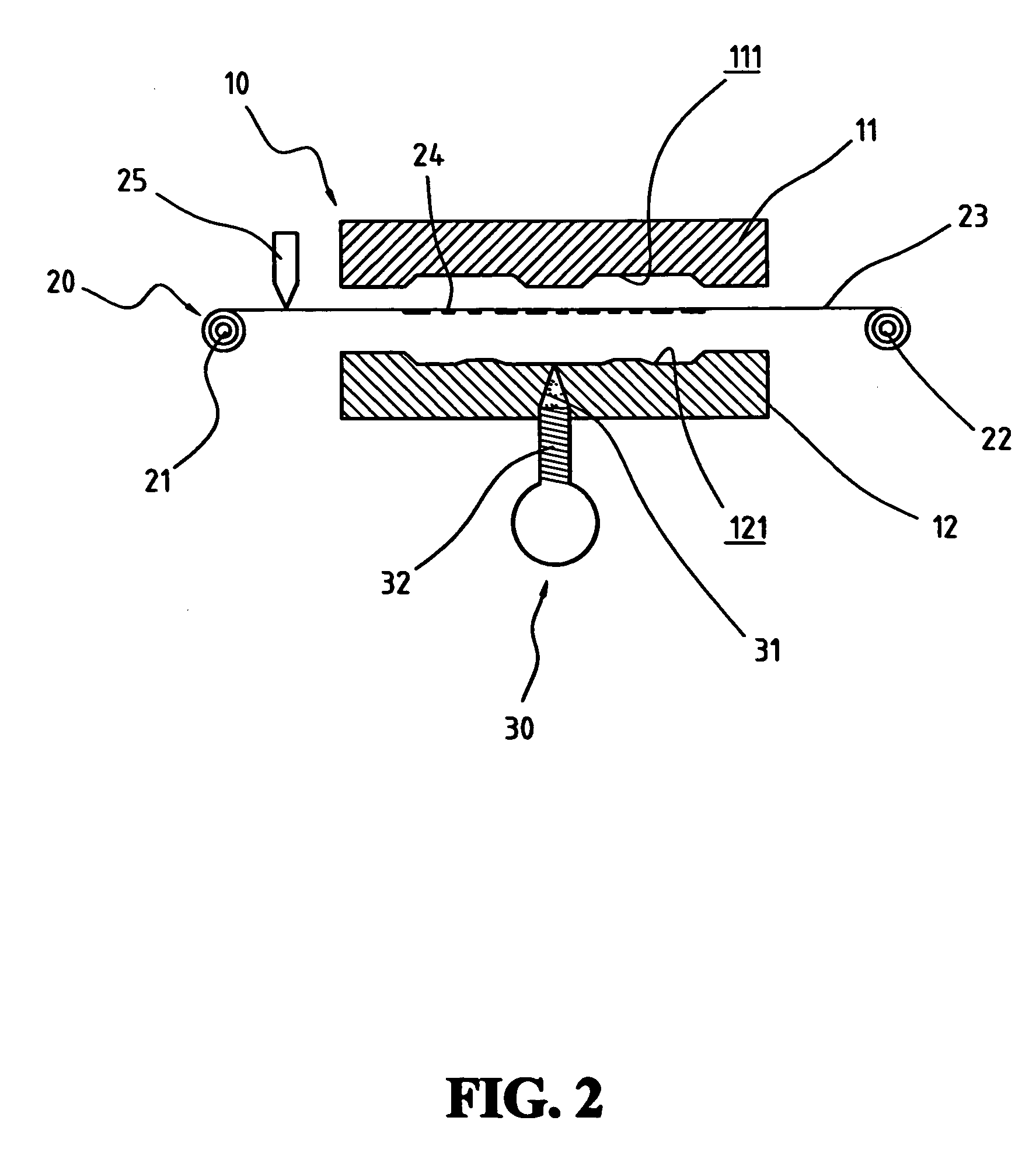

Stereo in mold transfer printing method of silicone

Disclosed is a stereo transfer printing method of in mold transfer printing concurs with injection molding of silicone. The stereo in mold transfer printing method of silicone includes the following steps: (a) providing ink mixed with silicone; (b) using the silicone containing ink to print text or graphic needed on the substrate film; (c) positioning the text or graphic on the substrate film between the mold dies; (d) closing and locking the mold; (e) injecting the silicone; and (f) opening the mold and getting the silicone product.

Owner:WANG CHING SHING

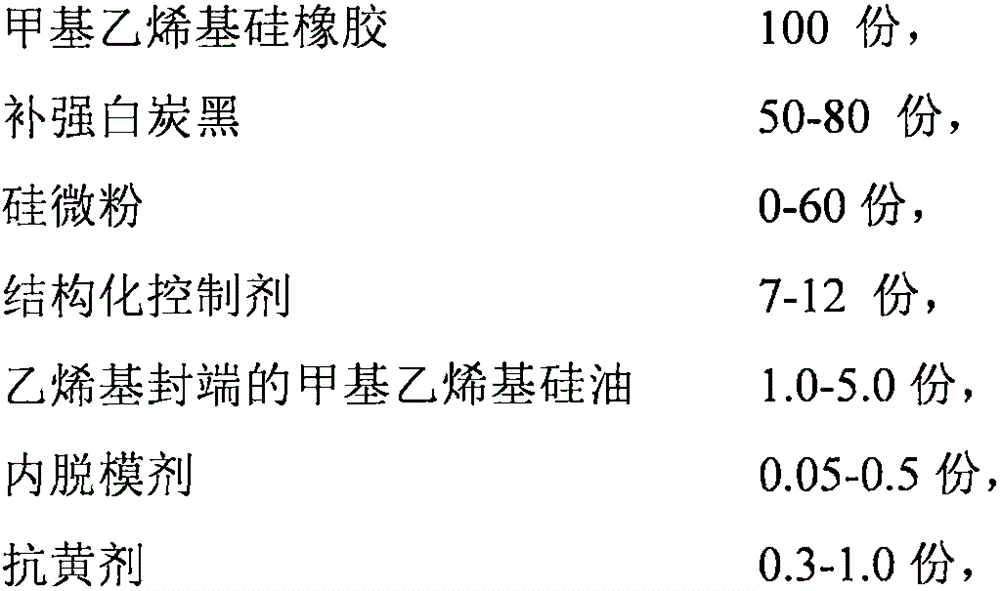

High-hardness extruded silicone rubber composition and preparation method thereof

The invention provides high-hardness extruded silicone rubber composition. The silicone rubber takes methyl vinyl siloxane with the average molecular weight of 0.55-0.75 million and the average vinyl molar content of 0.4-0.55% as rubber master batch, and reinforced white carbon black, silica powder, a structurized control agent, vinyl-terminated methyl vinyl silicone oil, an internal releasing agent, an anti-yellowing agent, magnesium oxide and cerium oxide are added. The prepared silicone rubber has high hardness, high resilience, relatively high elongation and high tear resistance after high temperature vulcanization and can be applicable to silicone products such as an industrial rubber-covered roller, a pressing wheel, a sealing ring and a sealing element.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Curable Silicone Composition

A curable silicone composition comprising: an alkenyl-containing organopolysiloxane (A) that contains: a dialkylpolysiloxane (A-1) having on average at least 2 alkenyl groups in one molecule having a 25° C. viscosity in the range of 5,000 to 35,000 mPa·s, and a alkenyl-containing organopolysiloxane resin (A-2) consisting of SiO4 / 2 units, R12R2SiO1 / 2 units, and R13SiO1 / 2 units (where R1 designates alkyl groups with 1 to 10 carbon atoms, and R2 designates alkenyl groups) with the content of alkenyl groups ranging from 3.5 to 5.0 mass %, and with the ratio of the sum of the mole numbers of the R12R2SiO1 / 2 units and R13SiO1 / 2 units to 1 mole of the SiO4 / 2 units in the range from 0.5 to 1.4; an organopolysiloxane (B), wherein silicon-bonded hydrogen atoms are in an amount of at least 0.7 mass %; and a hydrosilylation catalyst (C). The composition is capable of forming a flex-resistant highly transparent cured silicone product with non-tacky surface.

Owner:DOW TORAY CO LTD

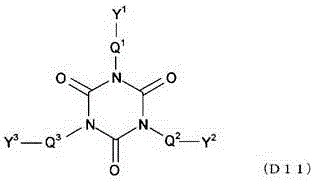

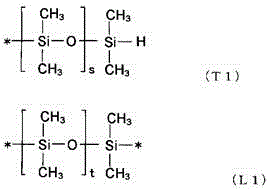

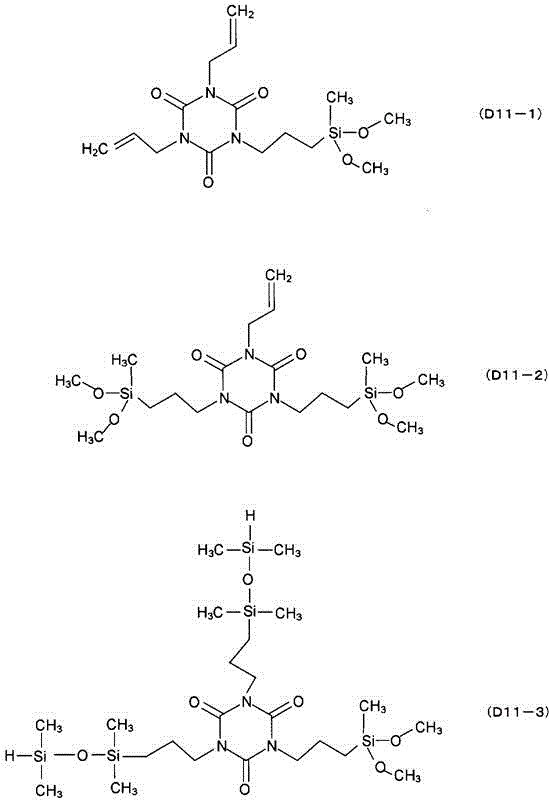

Addition-curable silicone composition

InactiveCN105814142AGood adhesionGood lookingSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceCarboxylic acid

Provided is an addition-curable silicone composition having little shrinkage or change in hardness due to heat, a cured silicone product of which obtained has excellent adhesiveness and appearance and makes it possible to protect metals, especially silver, from corrosion. An addition-curable silicone composition containing 100 parts by mass of polyorganosiloxane having an alkenyl group, polyorganohydrogensiloxane in an amount to make 0.9-3.0 mol of hydrogen atoms bonded to silicon atoms per 1 mol total amount of this alkenyl group, a catalytic amount of hydrosilylation catalyst, 0.01-10 parts by mass of adhesiveness-imparting agent, and 0.001-0.015 parts by mass, calculated in terms of metal atoms, of carboxylic acid metal salt indicated by (R<3>COO)kM (M indicates a metal atom selected from Ce, Fe, Cr, La, Nd, Pr, and Sm, k indicates a positive number of 2-4, and R<3> indicates a substituted or unsubstituted hydrocarbon group having 4-10 carbon atoms).

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

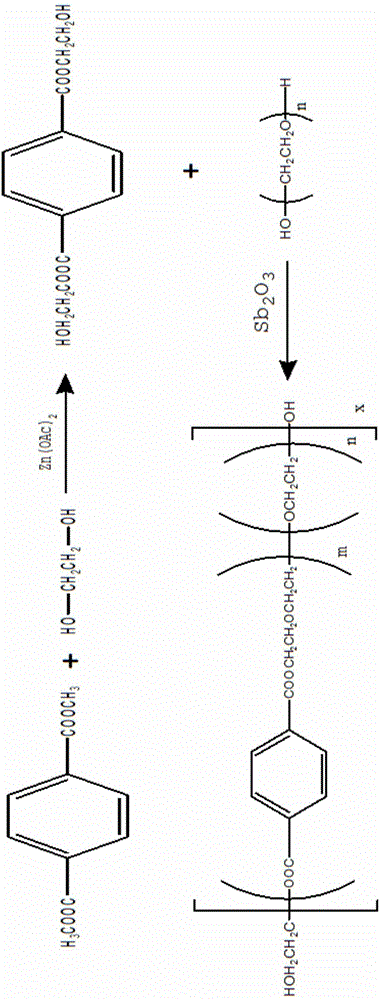

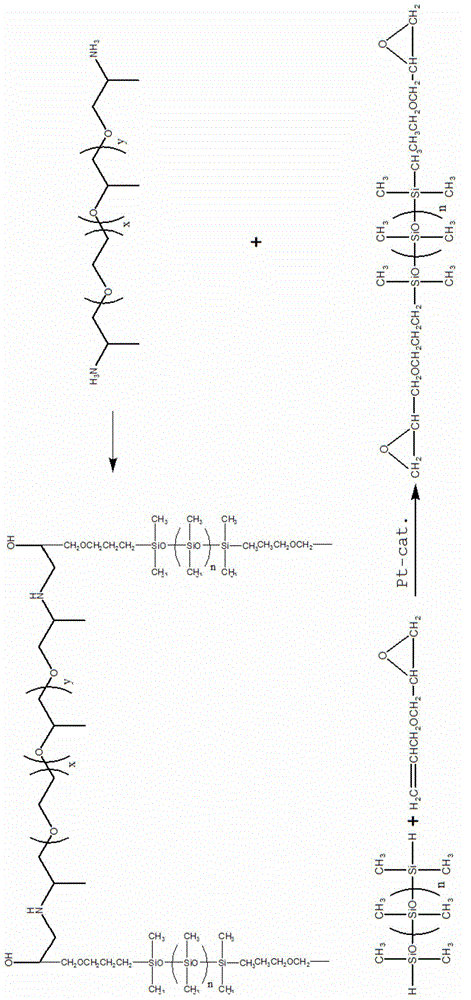

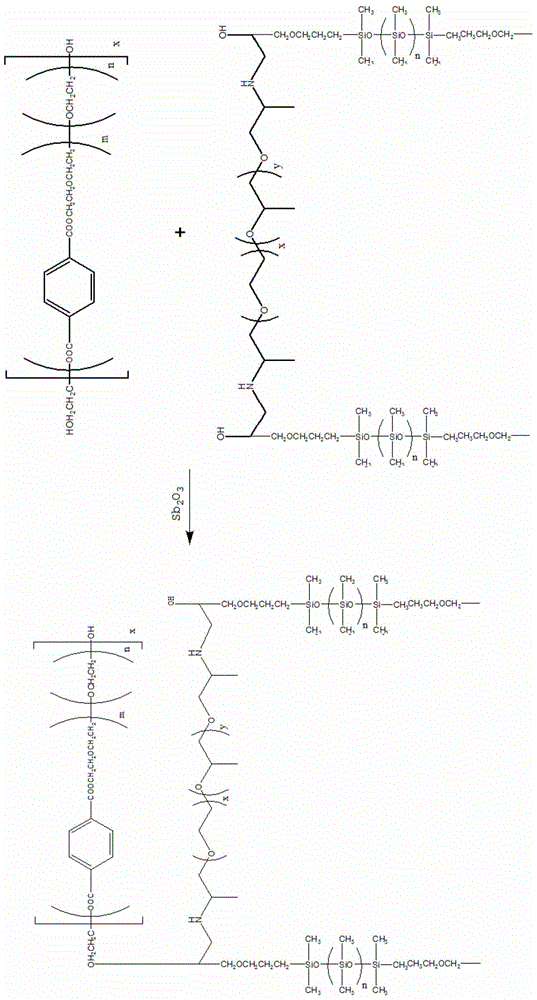

Preparation method of polyether polyester modified silicone oil

Belonging to the technical field of organic silicon products, the invention relates to a preparation method of polyether polyester modified silicone oil. Involving ester exchange reaction and condensation polymerization techniques, the method consists of: firstly adding dimethyl terephthalate, ethylene glycol and zinc acetate into a reaction container to undergo ester exchange reaction, adding ethylene terephthalate, antimony oxide and polyethylene oxide into a reaction container to undergo condensation polymerization so as to obtain a polyether polyester segmented copolymer; then terminal hydrogen-containing silicone oil, allyl glycidyl ether and a Pt catalyst are added into a reaction container to undergo heat preservation reaction, performing vacuum pumping to remove low-boiling-point substances; adding polyether amine and a solvent into terminal epoxy modified silicone oil to undergo reflux reaction, conducting pressure reduction to remove the solvent so as to obtain polyether amino modified silicone oil; and mixing the polyether polyester segmented copolymer and the polyether amino modified silicone oil evenly, and carrying out heat preservation reaction to obtain the polyether polyester modified silicone oil. The emulsion has good stability, is difficult to yellow and stick rolls. Also the use effect is better than that of compounding, and the tedious compounding procedure in the application process is omitted.

Owner:安徽科光新材料有限公司

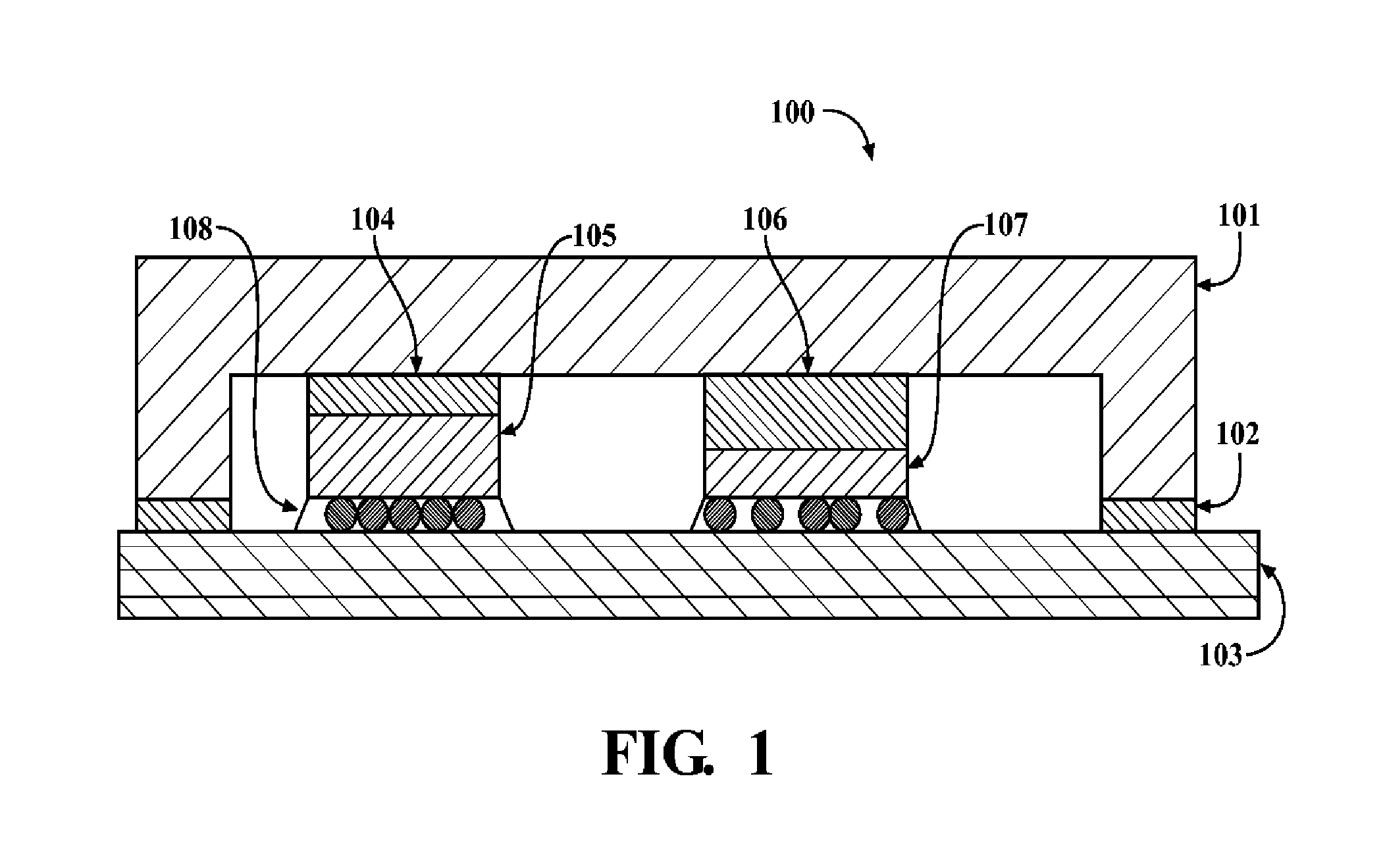

Method of Fabricating an Electronic Device

InactiveUS20160197025A1Avoid heat dissipationEfficient heat transferSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceElectric devices

A silicone composition contains I) a shrink additive and II) a curable polyorganosiloxane composition. A method for fabricating an electronic device includes the steps of: 1) interposing the silicone composition between an IHS and a substrate, 2) curing the curable polyorganosiloxane composition to form a cured silicone product, and 3) removing the shrink additive during and / or after step 2), thereby compressing the IHS to the substrate. Compressing occurs as thickness of the cured silicone product decreases, as compared to thickness of the silicone composition interposed in step 1).

Owner:DOW CORNING CORP

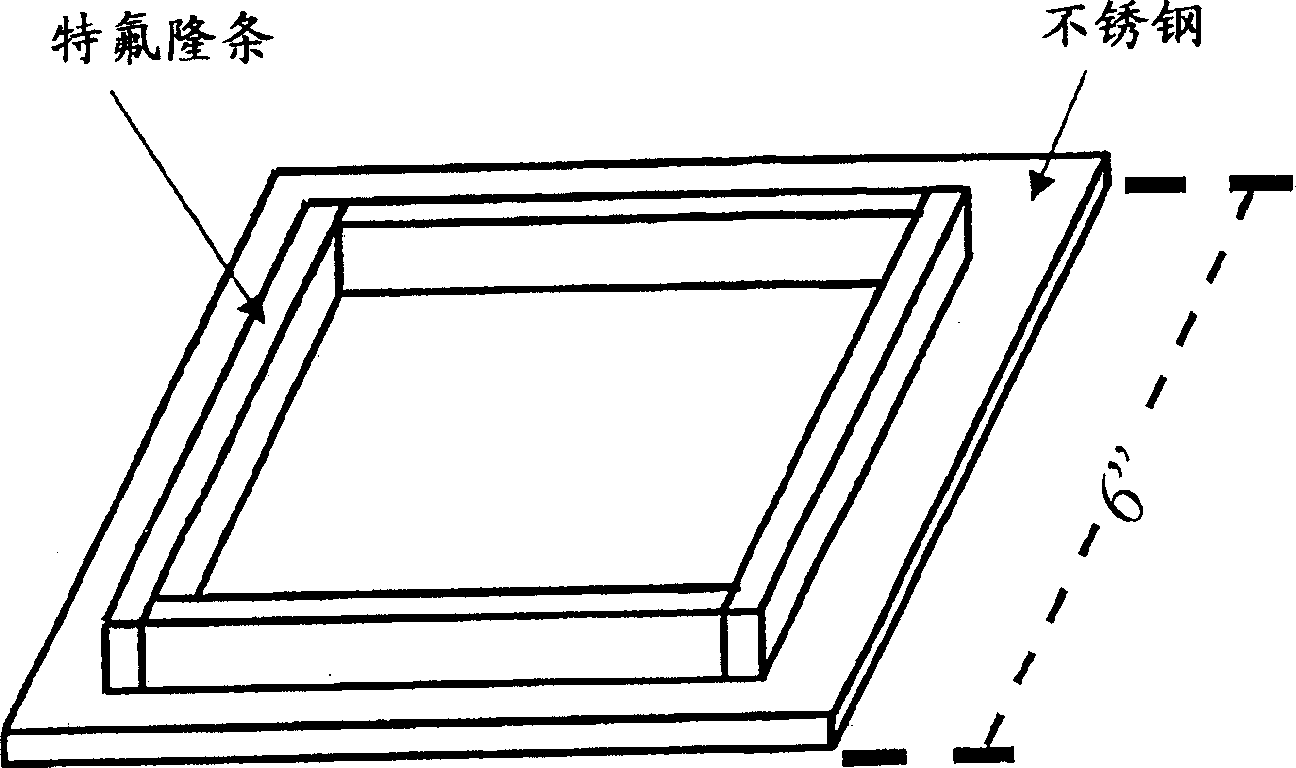

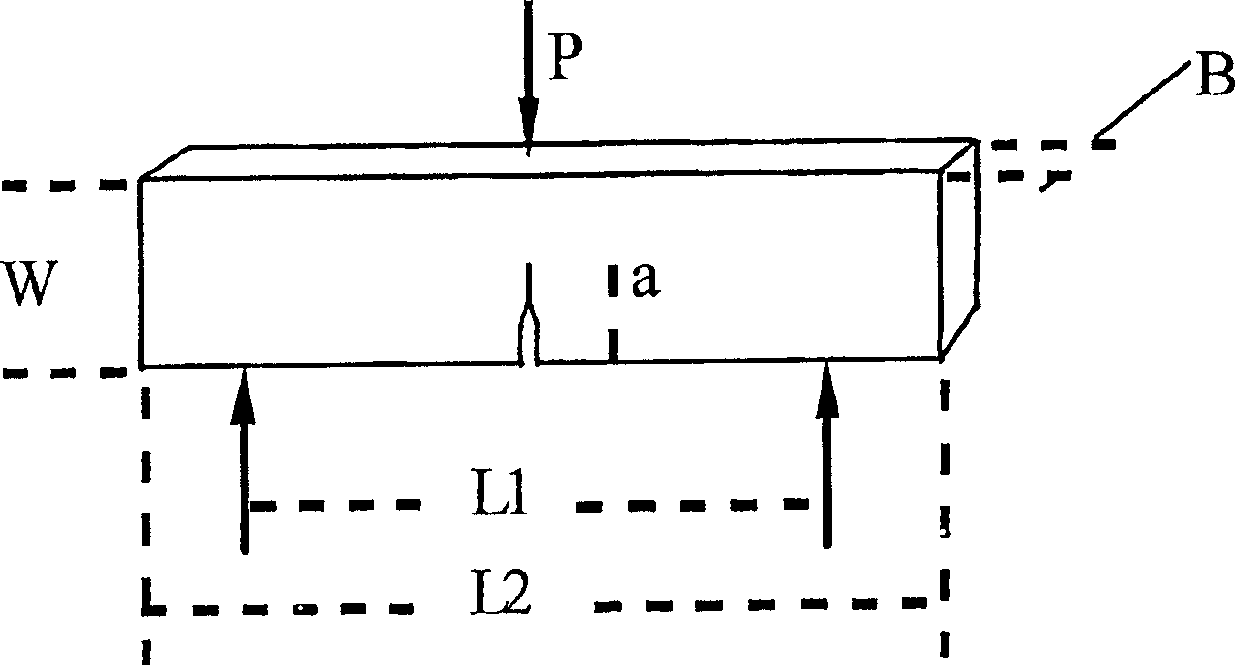

Curable silicone composition for vibration-isolating laminate

InactiveUS6075112ANon-rotating vibration suppressionProtective foundationPolymer sciencePtru catalyst

A curable silicone composition for a vibration-isolating laminate comprising (A) 100 parts by weight of an organopolysiloxane having at least two alkenyl groups per molecule and a viscosity of 10-100,000 mPa.s at 25 DEG C.; (B) an organopolysiloxane having at least two silicon atom-bonded hydrogen atoms per molecule and a viscosity of 1-100,000 mPa.s at 25 DEG C. in an amount such that this component contains 0.2-5 mol of silicon atom-bonded hydrogen atoms per mole of alkenyl groups in component (A); (C) 1-300 parts by weight of an inorganic filler; and (D) a hydrosilylation catalyst in an amount sufficient to cure the composition, designed for forming a cured silicone product for a vibration-isolating laminate by laminating a metal layer and a cured silicone layer having a loss factor of 0.4 or greater and a storage modulus of 1.0x105 dyne / cm2 or greater at 25 DEG C. and a shear frequency of 0.2 Hz.

Owner:DOW CORNING TORAY SILICONE CO LTD

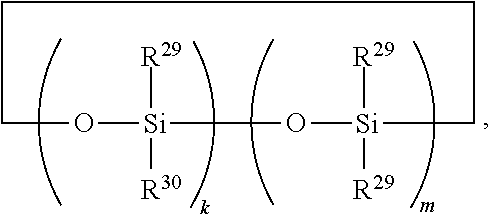

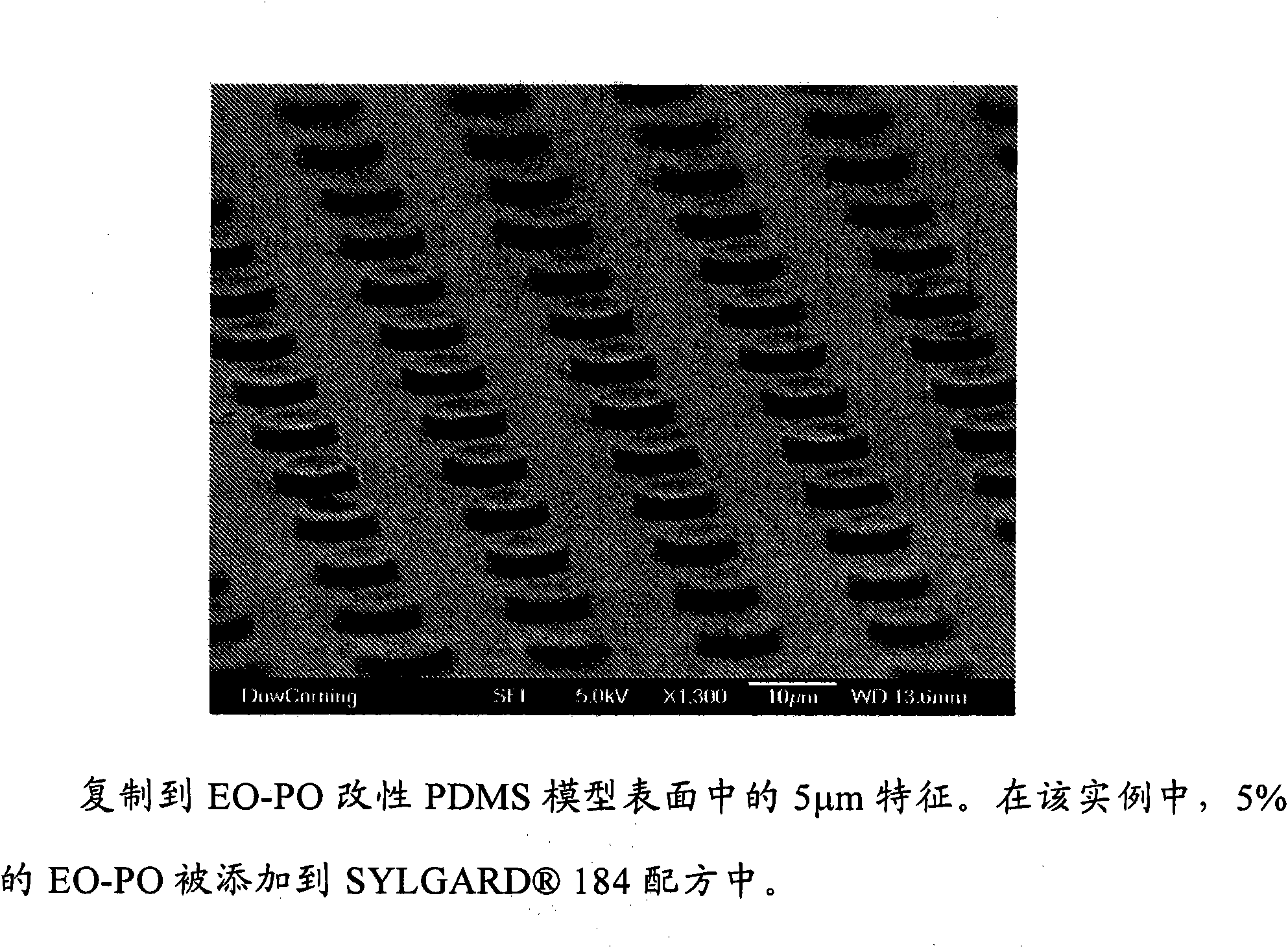

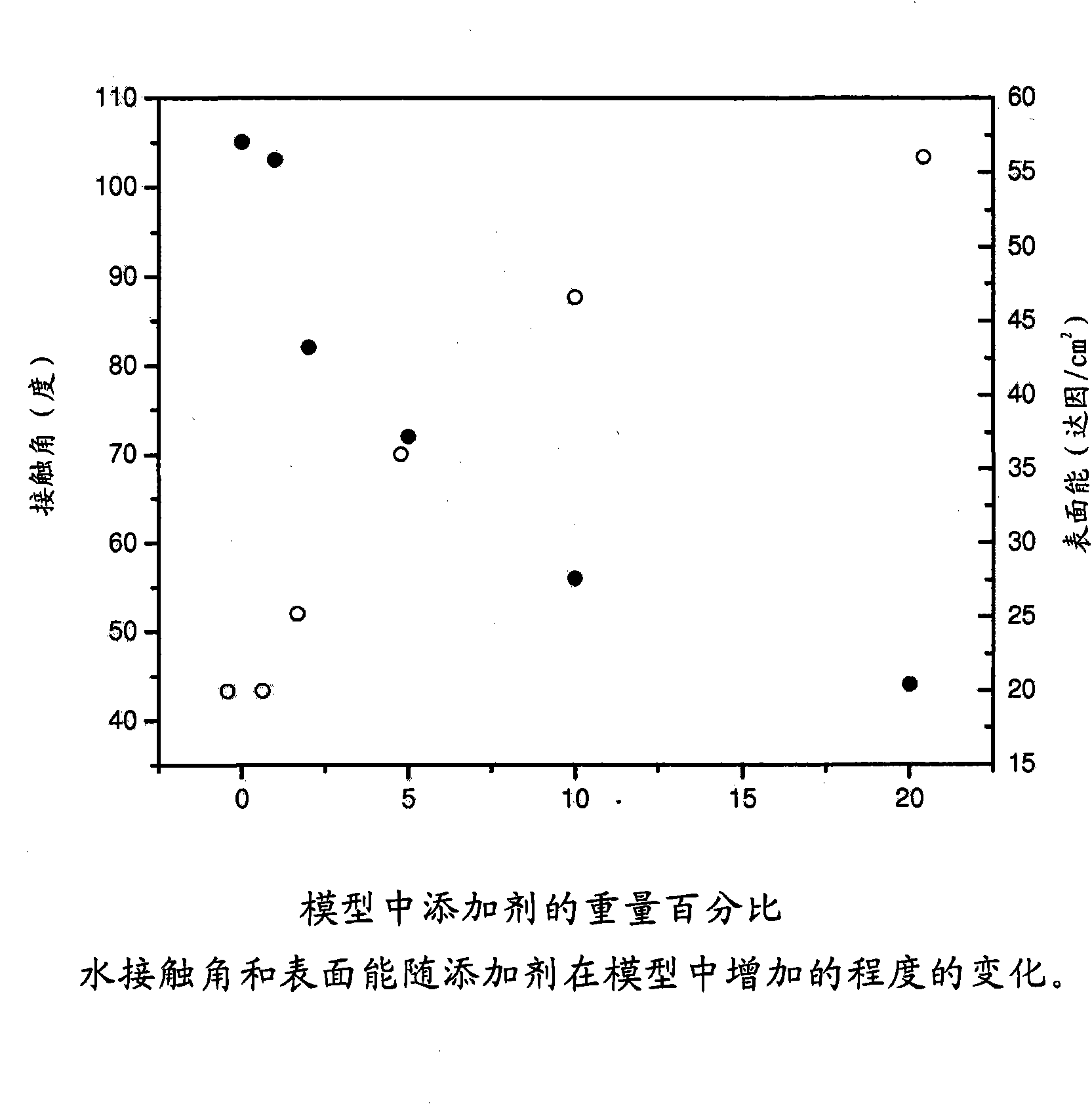

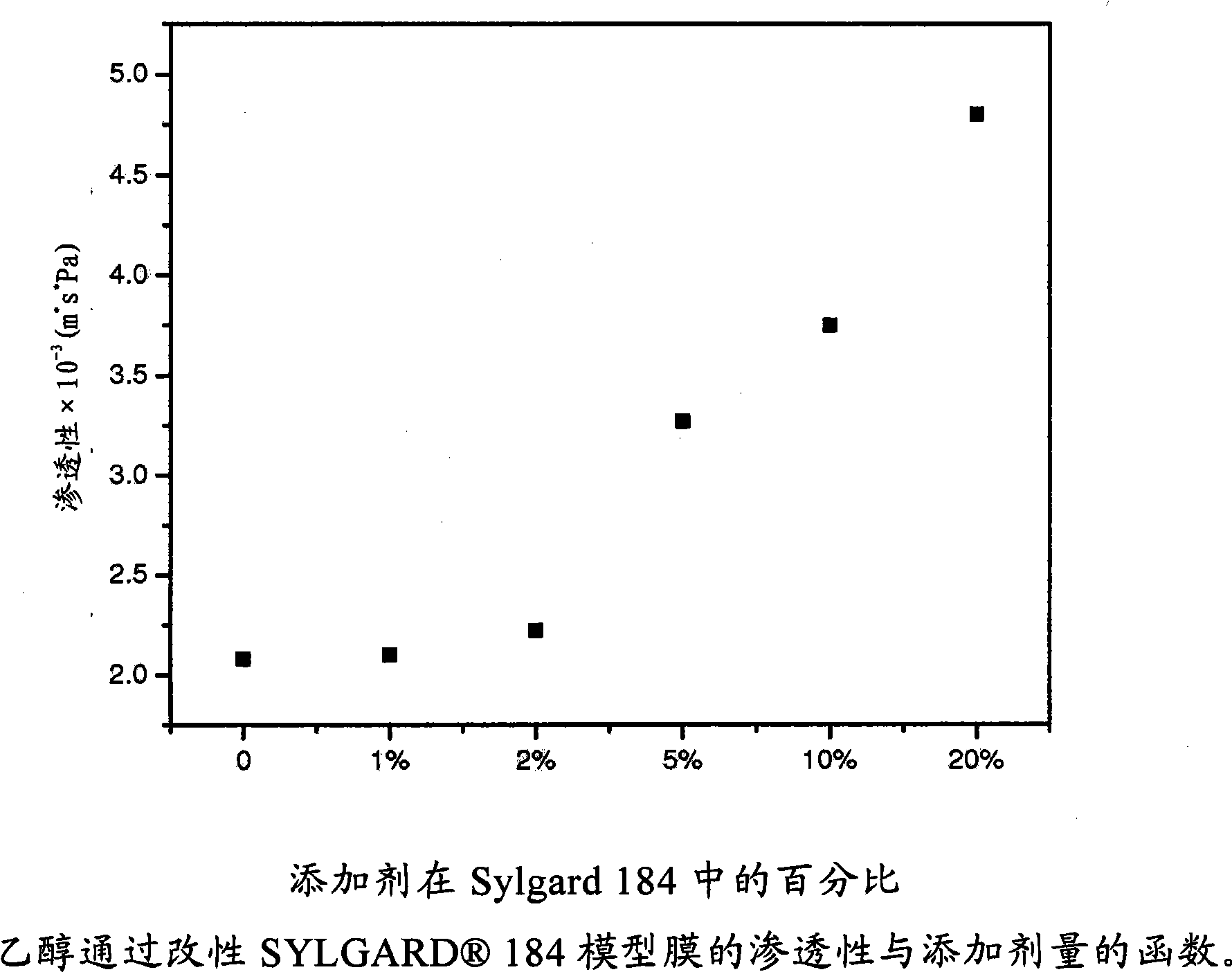

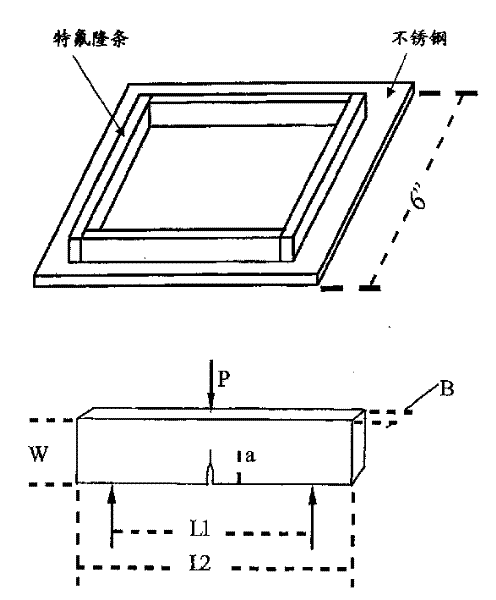

Polar polydimethylsiloxane molds, methods of making the molds, and methods of using the molds for pattern transfer

A method includes the steps of (I) fabricating a cured silicone product and (II) using the cured silicone product in a patterning technique. The cured silicone product is a reaction product of (A) a silicone cure package and (B) is a polar additive having a polyalkylene oxide functionality and a reactive functionality. The method is useful in soft lithography applications.

Owner:DOW CORNING CORP

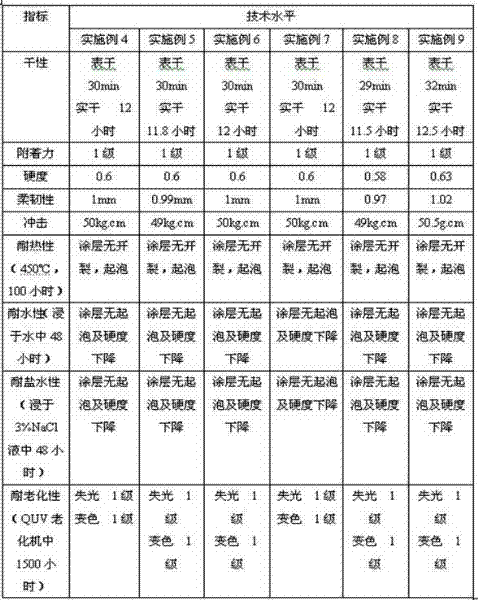

Self-crosslinking organosilicone heat-resistant coating

ActiveCN102226057AImprove heat resistanceGood physical and chemical propertiesCoatingsTalcDimethyl benzene

The invention relates to a self-crosslinking organosilicone heat-resistant coating capable of reaching good drying properties and excellent physical and chemical properties through a self-crosslinking reaction. The self-crosslinking organosilicone heat-resistant coating is characterized in that the coating is prepared from the following raw materials in parts by weight: 50-60 parts of modified organosilicone resins with a concentration not less than 60%, 0.3 part of dispersant BYK, 0.4 part of organic bentonite, 10-15 parts of pigment, 5-10 parts of mica powder with a particle size of 350-450meshes, 5-10 parts of precipitate barium sulfate with a particle size of 350-450 meshes, 5-10 parts of talc powder with a particle size of 350-450 meshes and 10-20 parts of xylene; and the coating can achieve good drying properties and excellent physical and chemical properties through a self-crosslinking reaction in a 25 DEG C environment. Through the coating, the shortcomings of the existing one-component organosilicone products are solved, the coating has good heat resistance, and simultaneously the coating layer formed by the coating has excellent mechanical strength and protective properties. The coating provided by the invention is adaptable to the decorative protection of large-sized heat-resistant components, the components coated by the coating can withstand the temperature of 450 DEG C for a long term and can withstand long-term UV (ultraviolet) exposure, and the coating layer is not damaged.

Owner:西安经建油漆有限责任公司

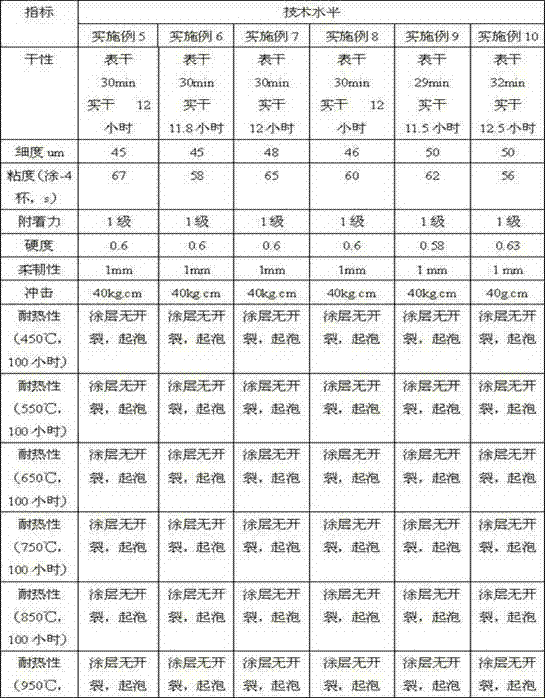

Gradient organic silicon heat-resisting coating

ActiveCN103113826AExcellent heat resistance temperatureSolve the problem of narrow heat-resistant temperature rangeCoatingsEpoxySolvent

The invention relates to a gradient organic silicon heat-resisting coating which is characterized by being prepared from the following raw materials in parts by weight: 40-50 parts of no less than 65wt% epoxy modified organic silicon resin solution, 0.5 parts of dispersing agent BYK-110, 0.6 parts of organobentonite, 10-15 parts of dye, 3-5 parts of mica powder with the granularity of 350-450 meshes, 5-10 parts of precipitated barium sulphate with the granularity of 350-450 meshes, 5-10 parts of M-1 glass material, 5-8 parts of B-11 glass material, 5-10 parts of B-12 glass material and 5-10 parts of mixing solvent (the ratio of dimethylbenzene to butanol is 7:3), wherein the epoxy modified organic silicon resin solution is prepared from the following raw materials in parts by weight: 30-40 parts of E-20 epoxy resin, 50-60 parts of 65-70wt% organic silicon middle body, and 5-10 parts of dimethylbenzene. The coating can be used for solving the defects that the conventional organic silicon product is low in thermal resistance when being compared with an inorganic coating, and the coating has good thermal-resistance. The coating provided by the invention is applicable to decoration and protection of a large-sized thermal-resisting component, and the coated component can endure high temperature of 400-1,000 DEG C for long term.

Owner:西安经建油漆有限责任公司

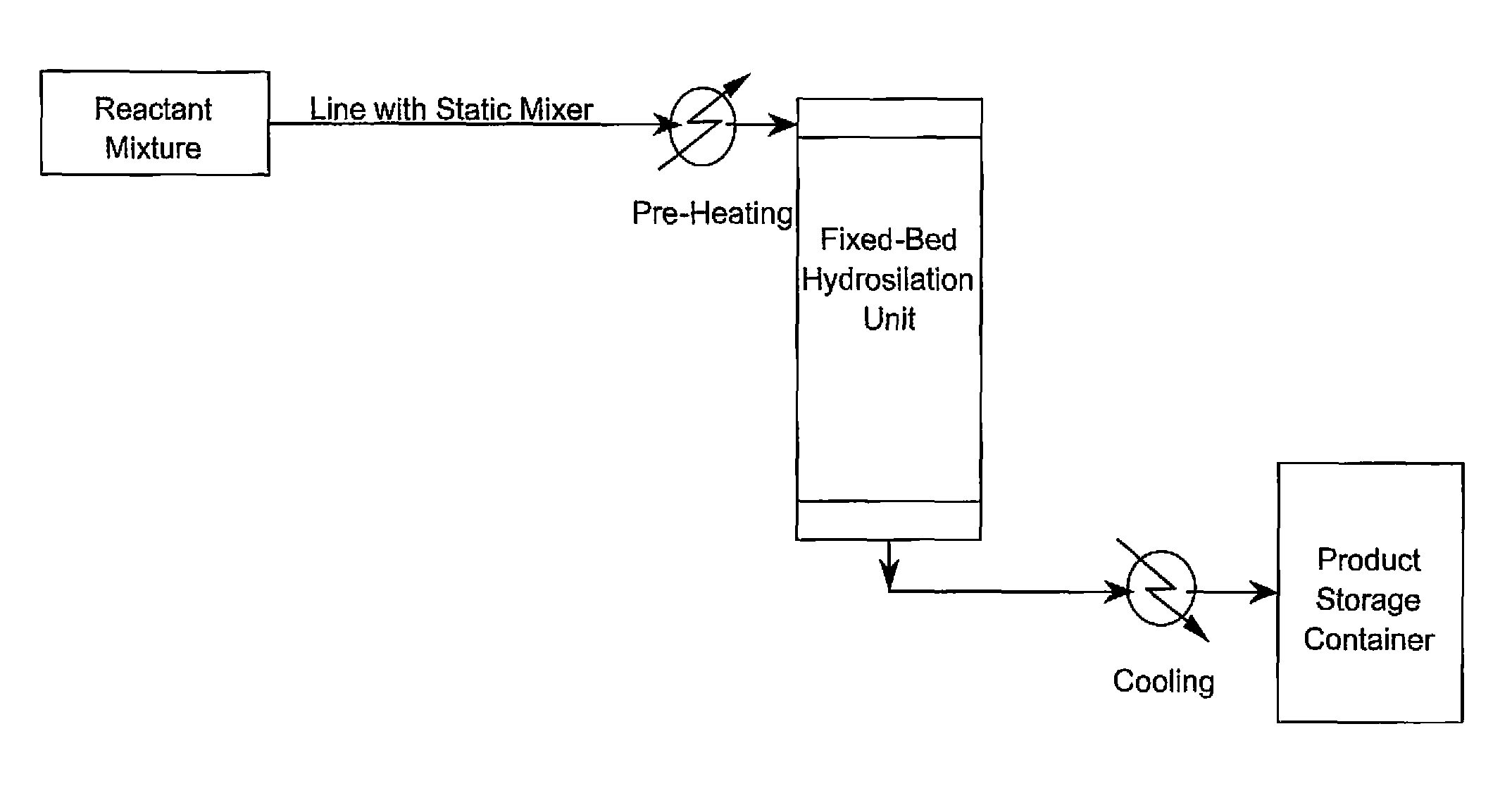

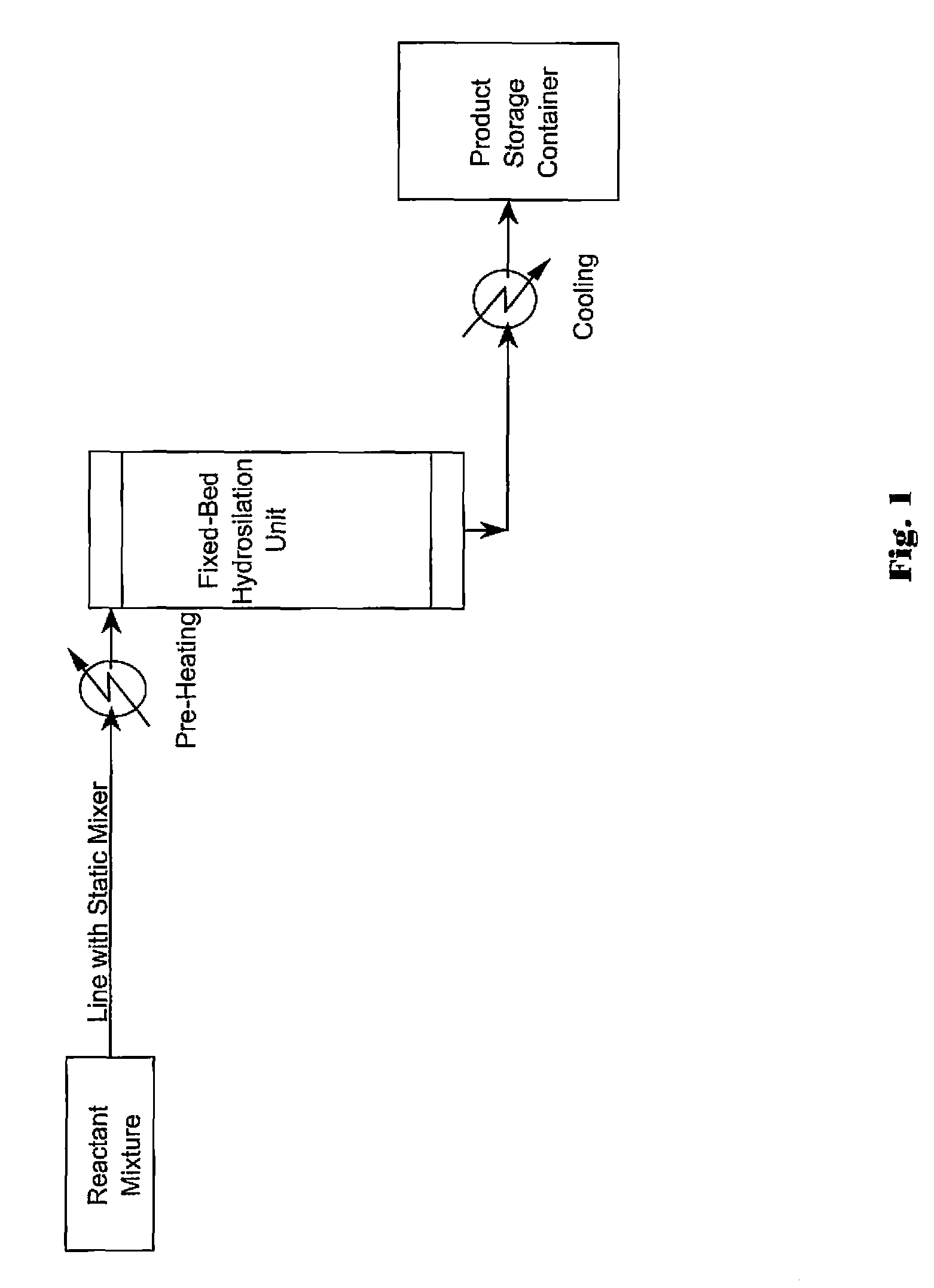

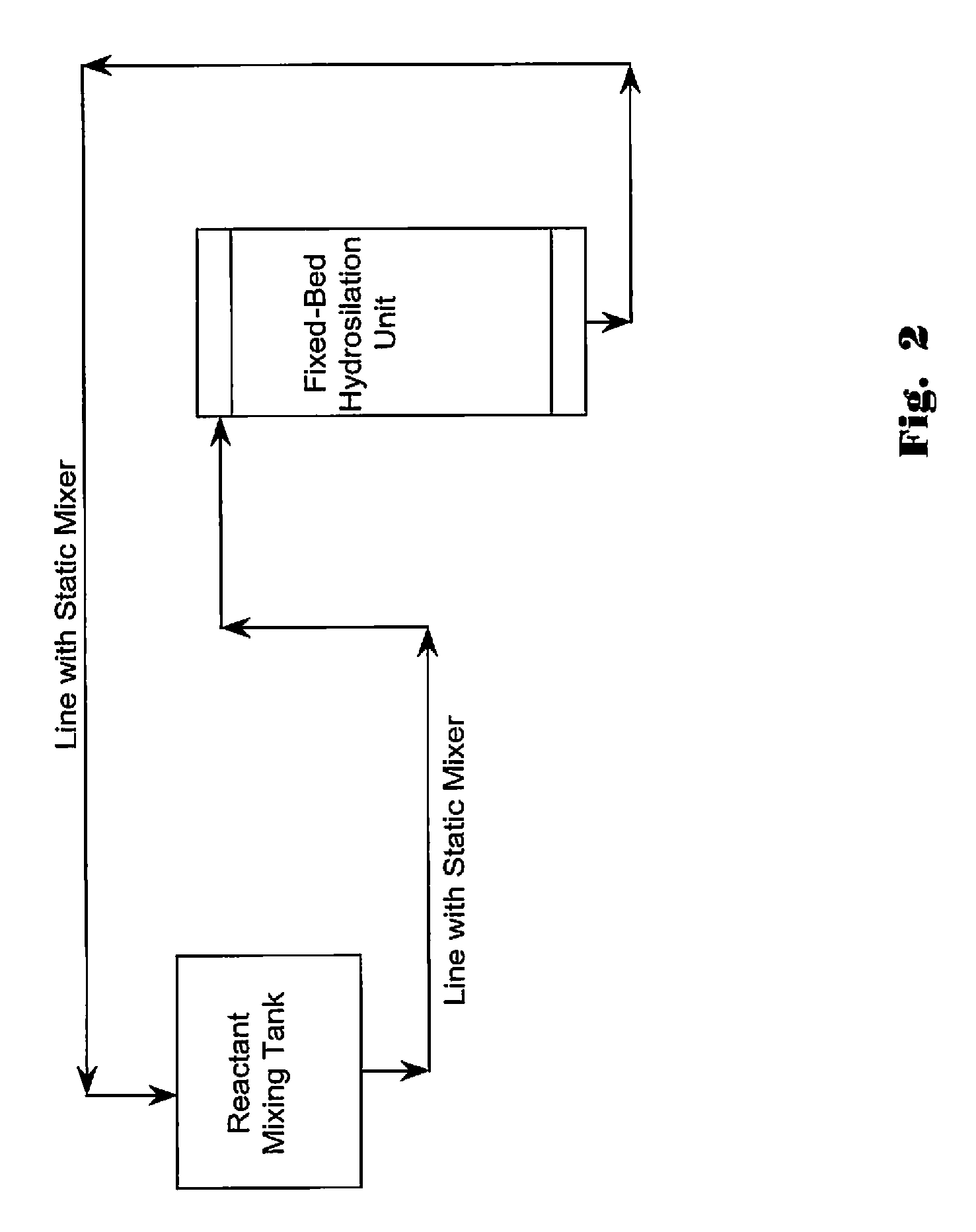

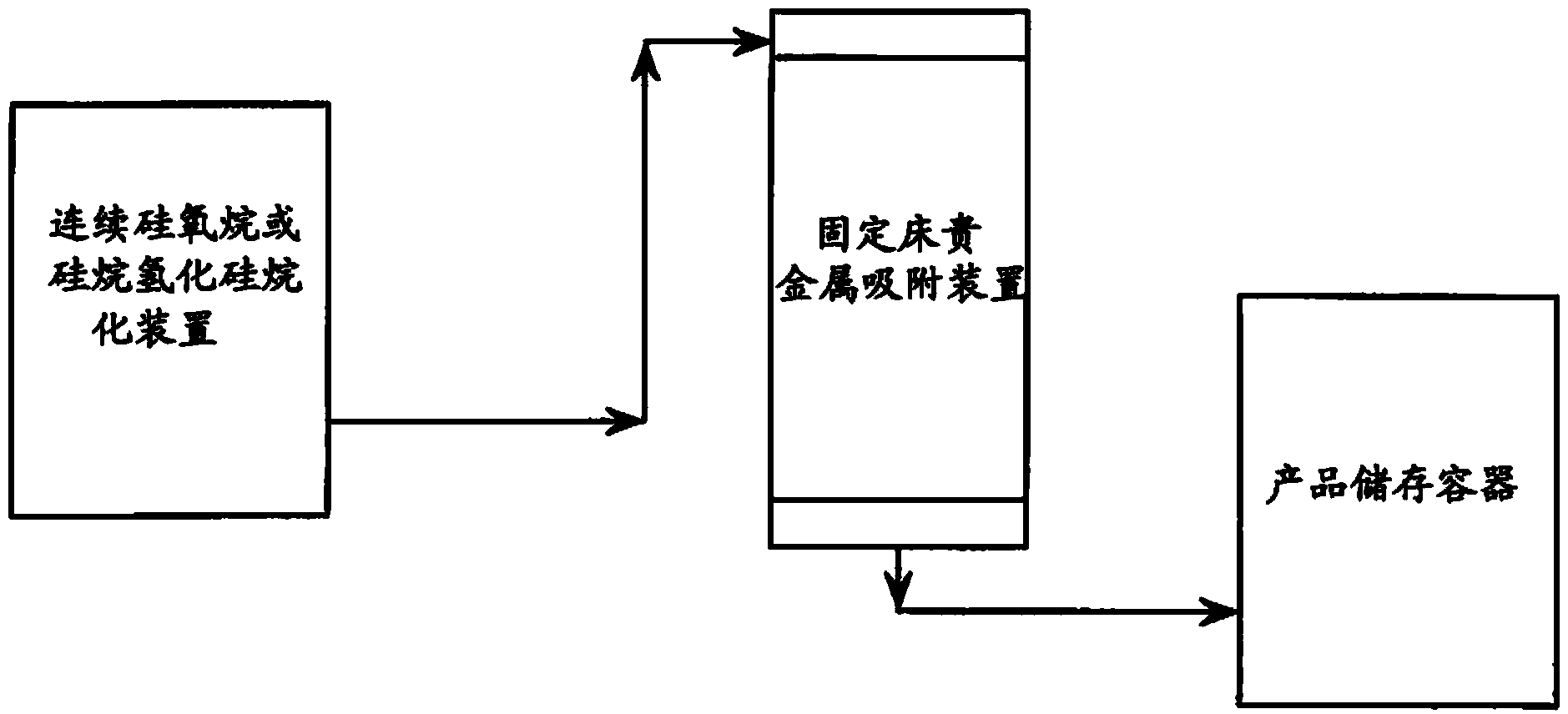

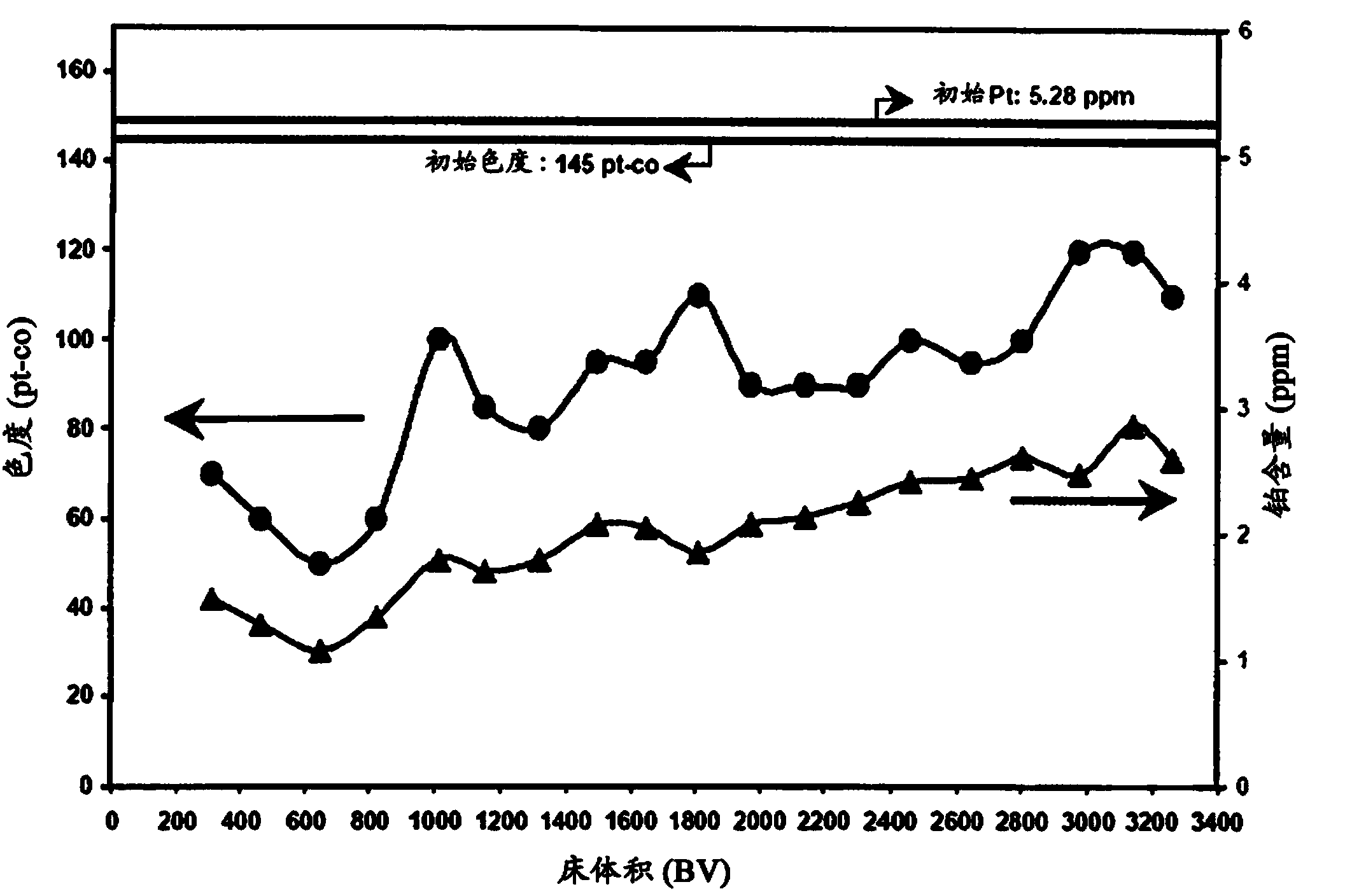

Process of manufacturing organosilicon products with improved quality using heterogeneous precious metal catalysts

ActiveUS8497338B2Easy to separateProduct quality issues caused by precious metal presence can be eliminatedSilicon organic compoundsChemical recyclingReaction zoneHydrosilylation

A process for manufacturing an organosilicon product having a stabilized low color and no formation of black particles during storage includes (a) reacting an unsaturated compound with a silicon compound having a reactive Si—H bond under hydrosilylation conditions in a reaction zone in the presence of a heterogeneous precious metal catalyst to provide an organosilicon product having a color of less than 40 pt / co; (b) separating the heterogeneous precious metal catalyst from the organosilicon product; and (c) recovering the heterogeneous precious metal catalyst.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

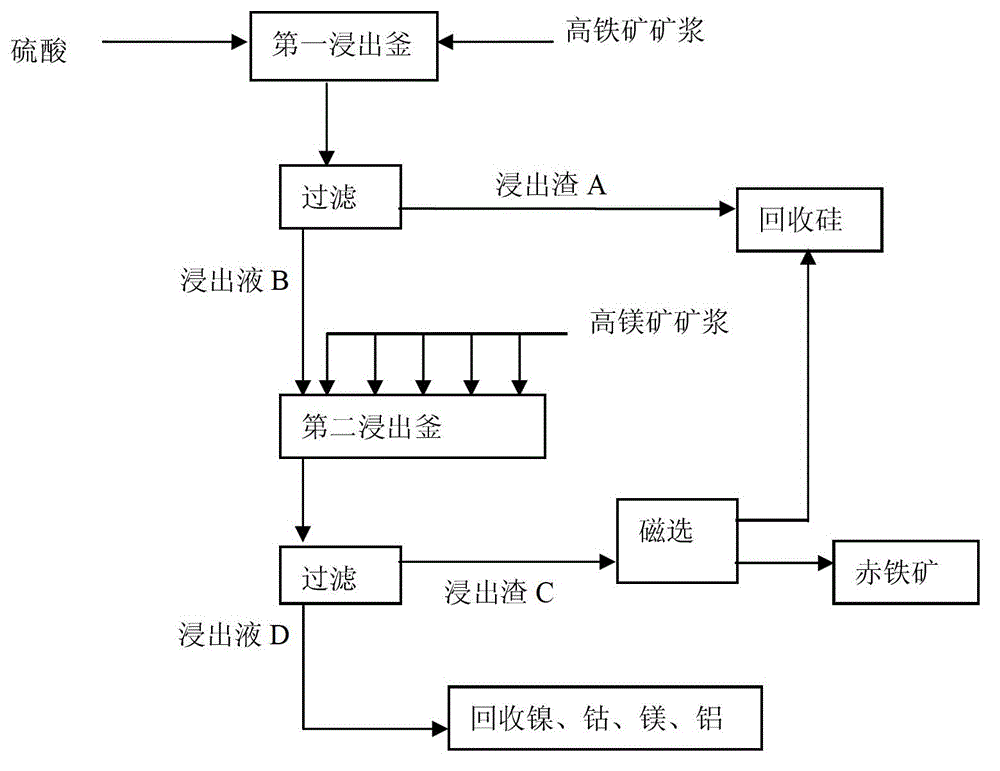

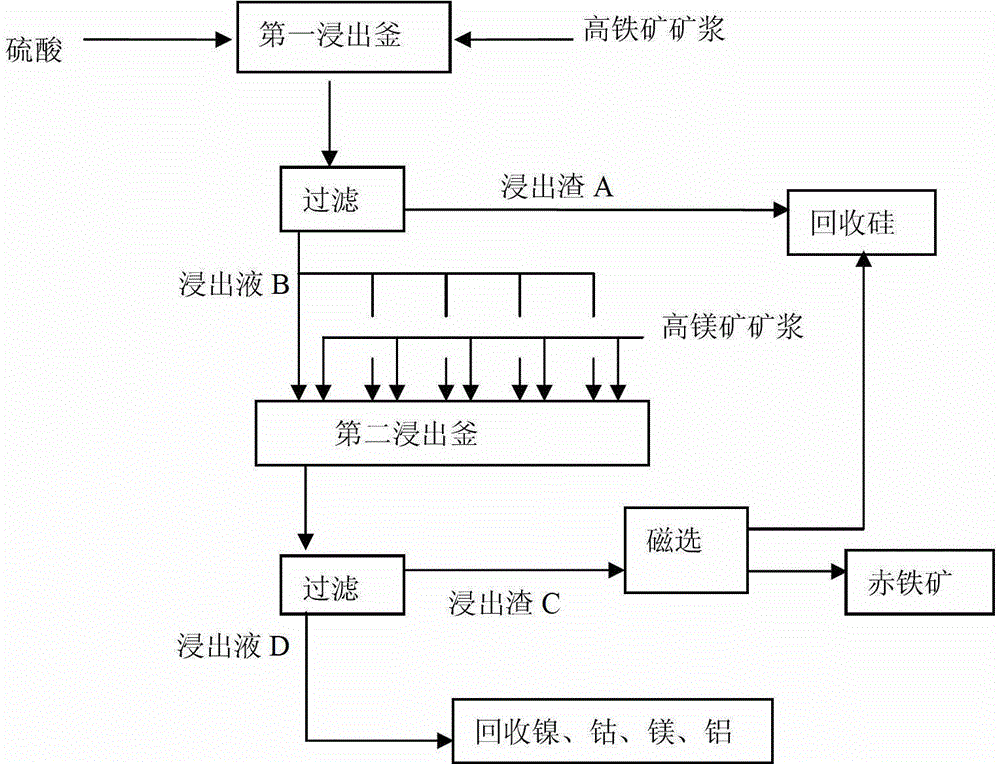

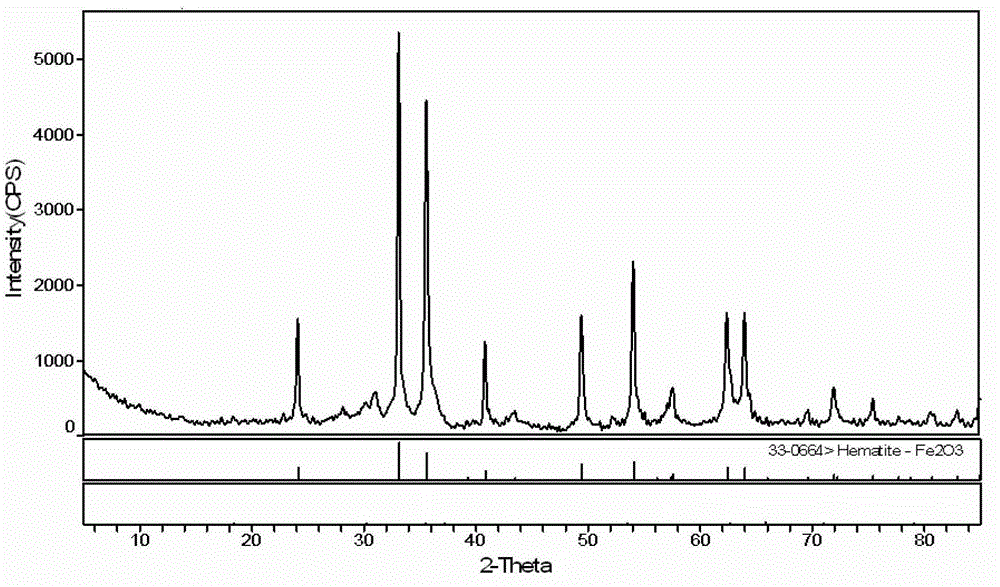

Improved method for processing high-iron and high-magnesium laterite and obtaining hematite product

The invention discloses an improved method for processing high-iron and high-magnesium a laterite and obtaining a hematite product. The method comprises the following steps of: dividing laterite ores into high-iron ores and high-magnesium ores; leaching the high-iron ore at a normal pressure and filtering to obtain leaching slag A for later use, putting leaching liquor B in a second leaching kettle; determining the addition of the high-magnesium ore, inputting water-based ore pulp in the second leaching kettle in batch, leaching at 120-180 DEG C; filtering the ore pulp discharged from the second leaching kettle, magnetically separating the obtained leaching slag C, wherein the magnetic part solid is collected as the hematite product, and the non-magnetic part solid and the leaching slag A are combined to be used for recycling silicone products; and sending the obtained leaching liquor D into a recovery process of nickel, cobalt, aluminum and magnesium. By the method, a high nickel-cobalt leaching rate is obtained, efficient separation of nickel-cobalt, iron and silicone is realized, and the hematite product is obtained; and moreover, acid consumption, energy consumption and equipment investment cost in a production process are low.

Owner:GUANGXI NORMAL UNIV

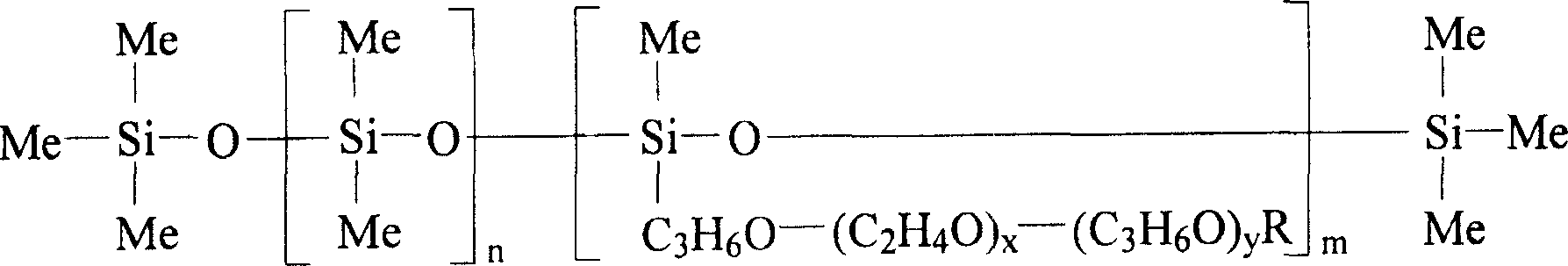

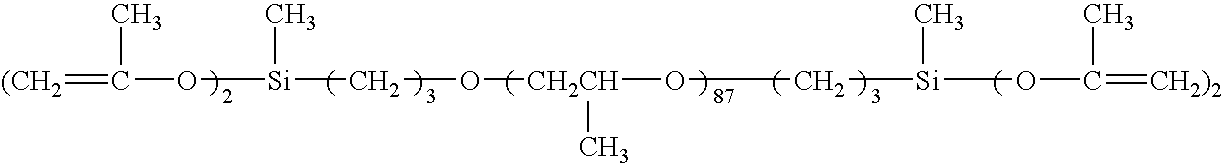

Oriented silicon steel insulation coating capable of improving punched piece performance

ActiveCN1978569AGood water solubilityIncrease the number of punchesCoatingsColloidal silicaSolubility

This invention discloses an oriented silicon steel insulation coating, which can be used to improve the performance of the laminated sheet . It has the composition weight percentage as follows: polyether-modified silicon oil, the water solution with 1% weight proportion, accounts for 0.01%-2.0%, of which the radio of hydrophilic chains to hydrophobic chains ranges from 20 / 80 to 100 / 0; aluminium dihydrogen phosphate 3%-24%, colloidal silica 4%~16%, chromic anhydride 0.15%~4.50% and the rest is water. After coated in the oriented electrical steel, the said insulation coating can remarkably enhance the laminated sheet times by the intrinsic lubricity of silicone during the machining of oriented silicon steel, and hence greatly enhance the production efficiency. Besides, due to the favorable water-solubility of the polyether-modified silicon oil and the common heat-resistance of the silicone products, the said coating is easily prepared, uniformly coated, and has good dispersibility. The coated surface is in good quality, able to endure sintering with high temperature without thermal degradation.

Owner:BAOSHAN IRON & STEEL CO LTD

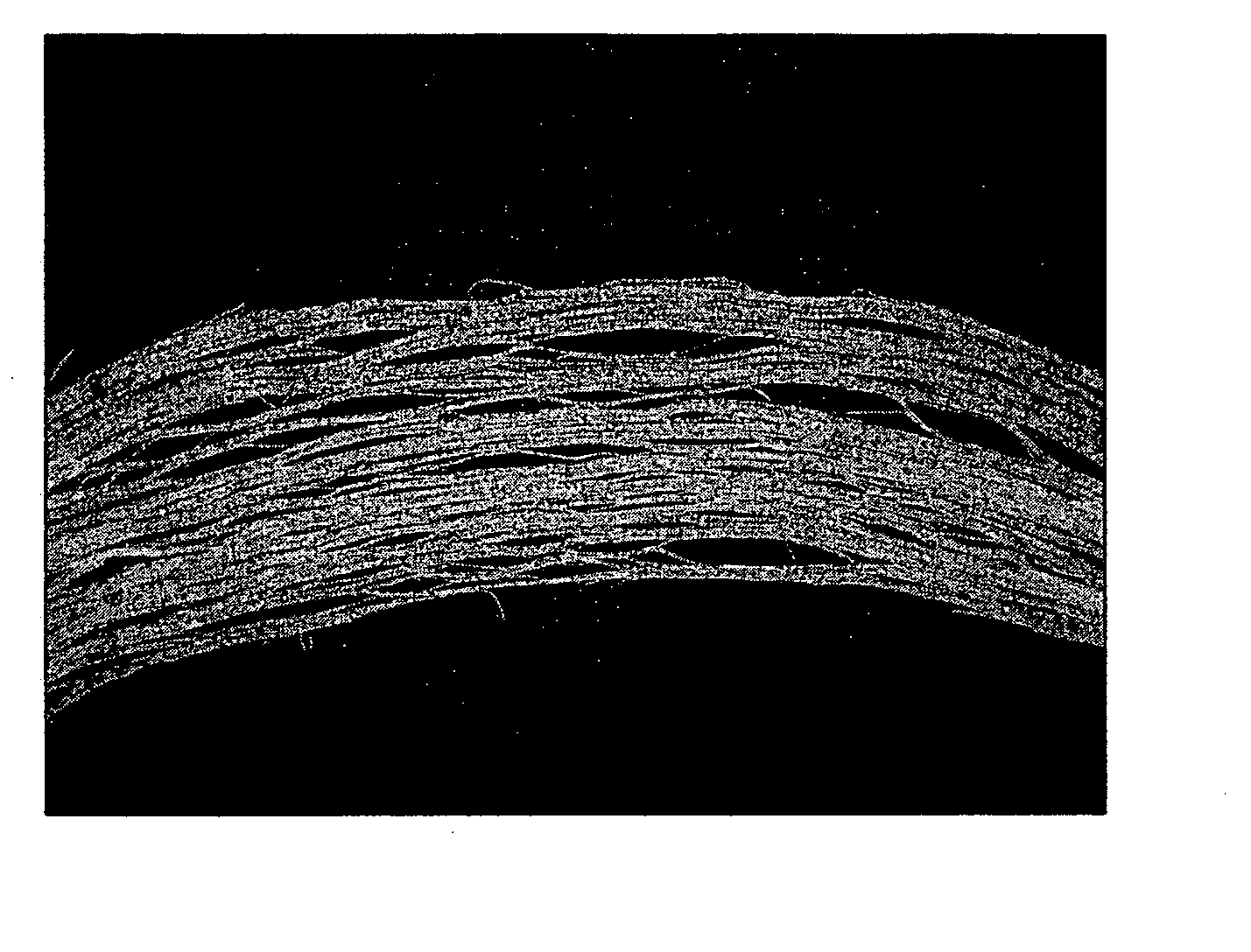

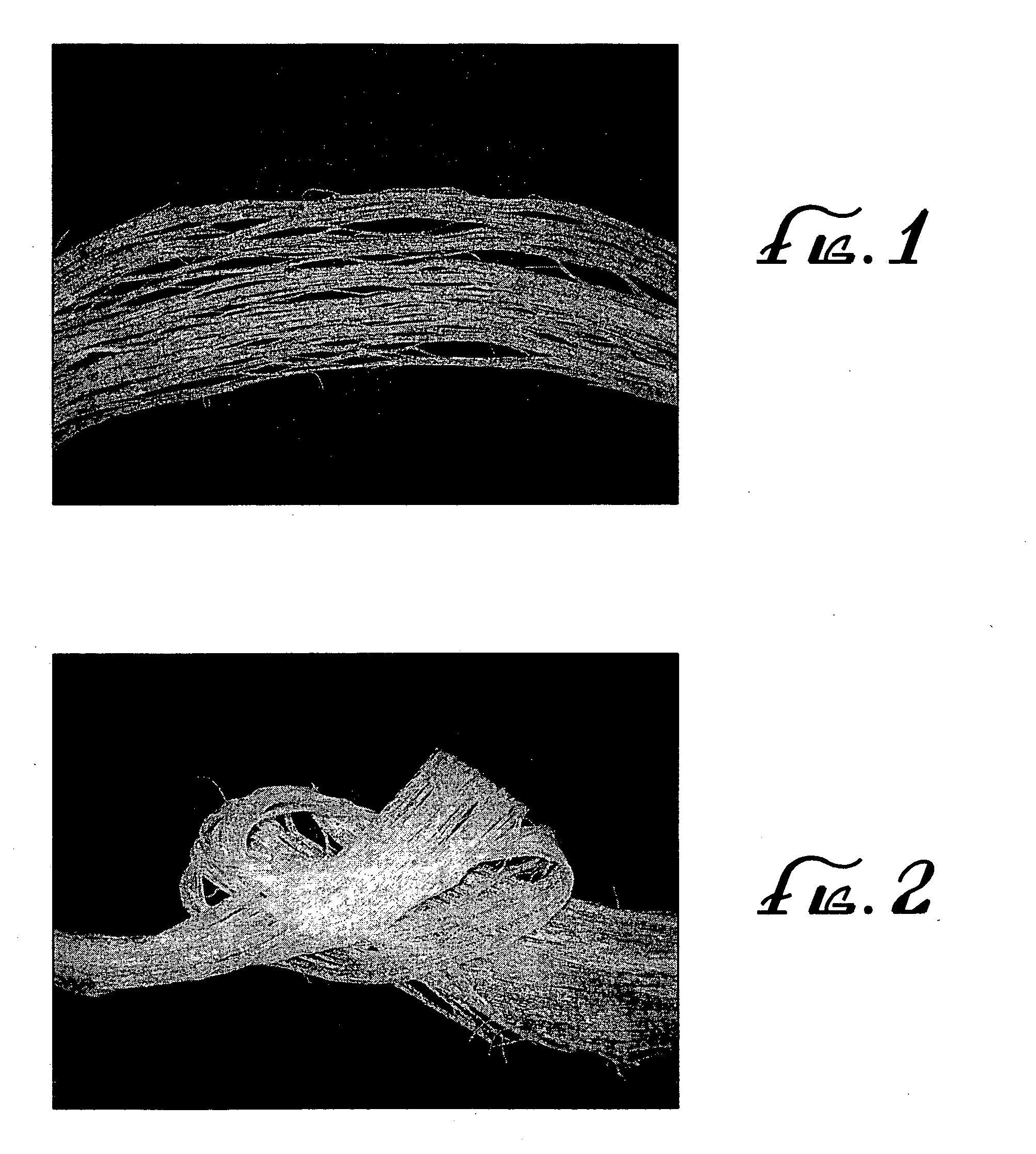

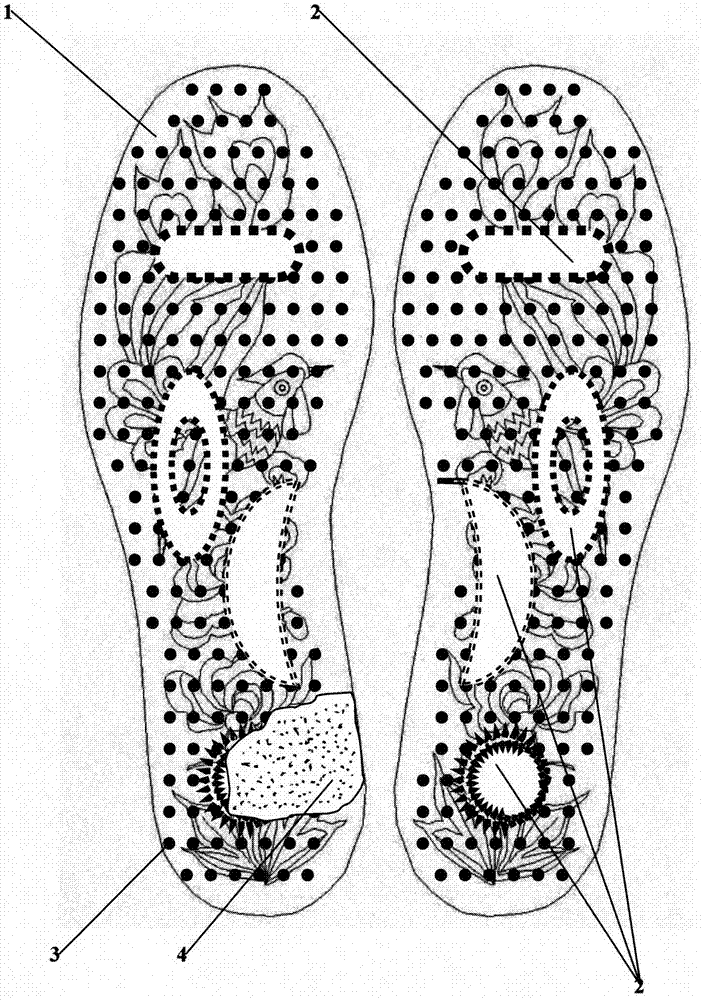

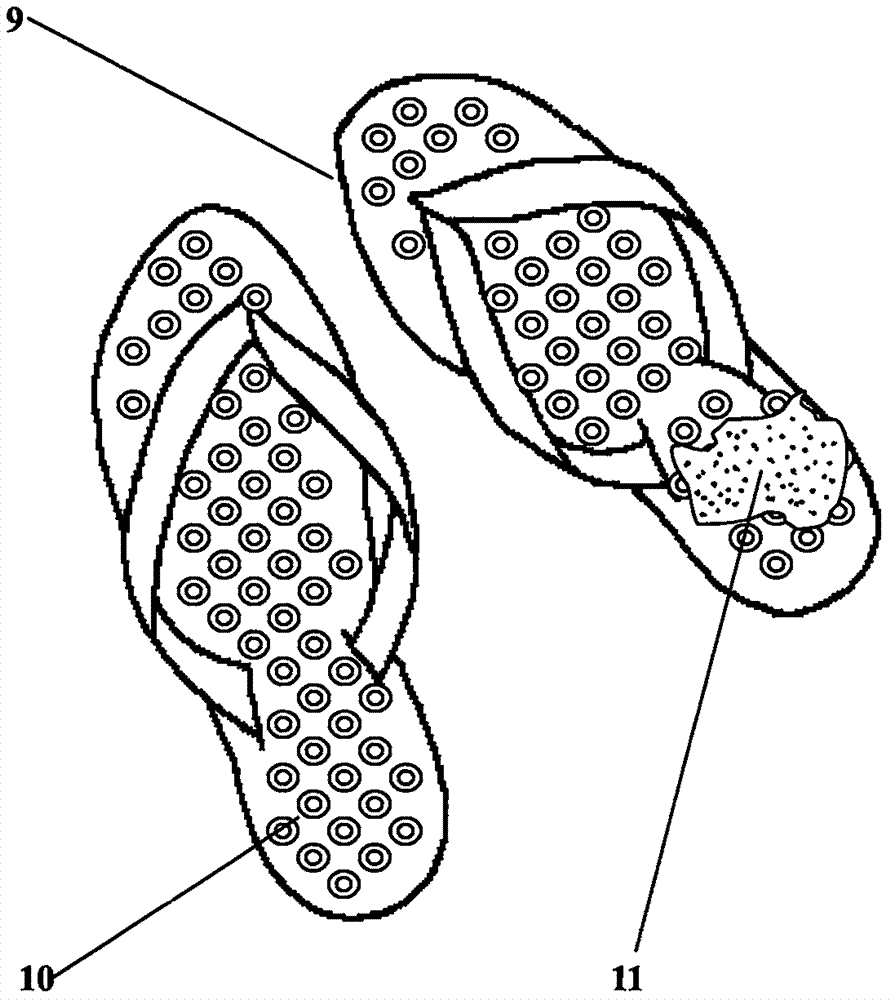

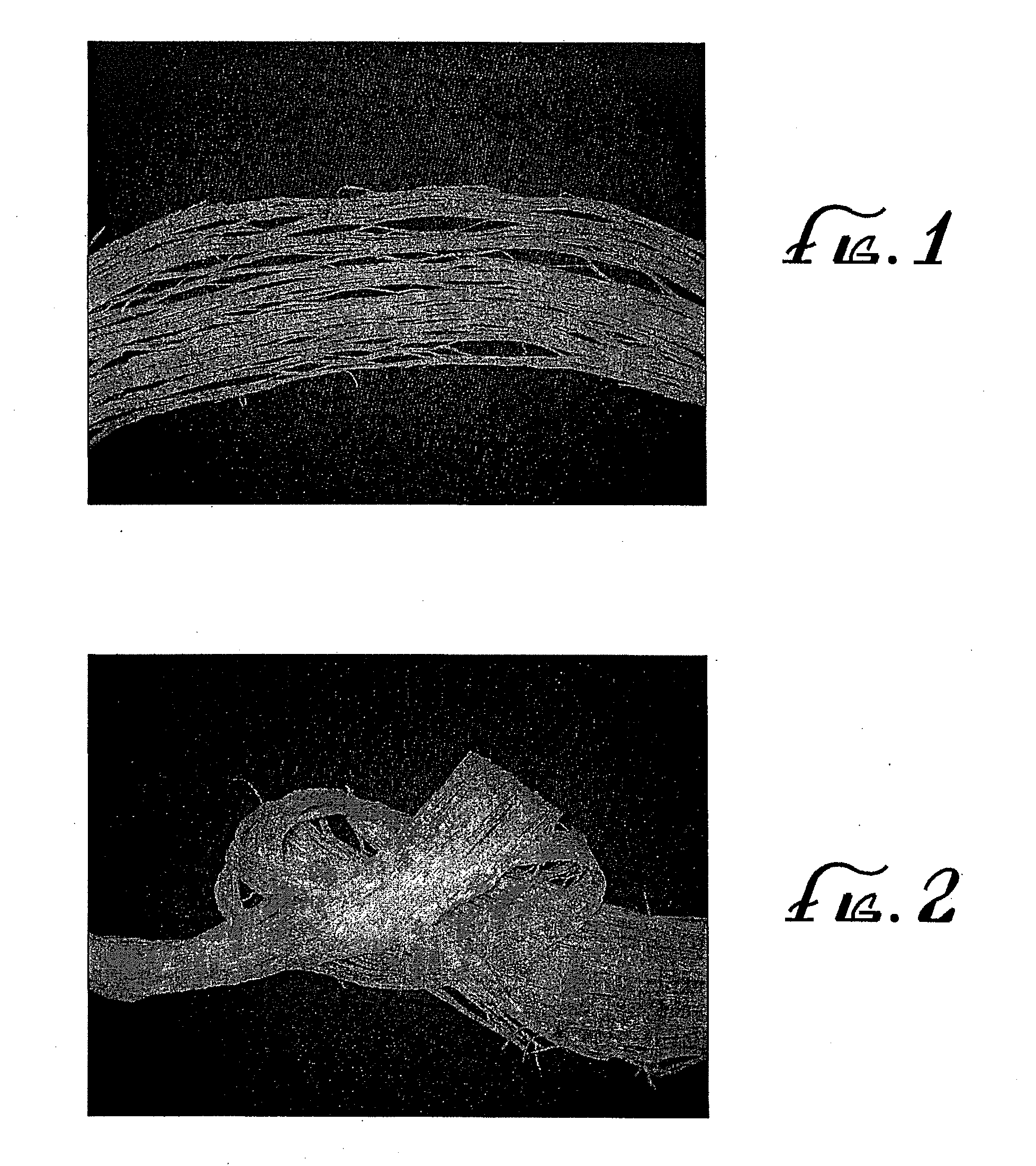

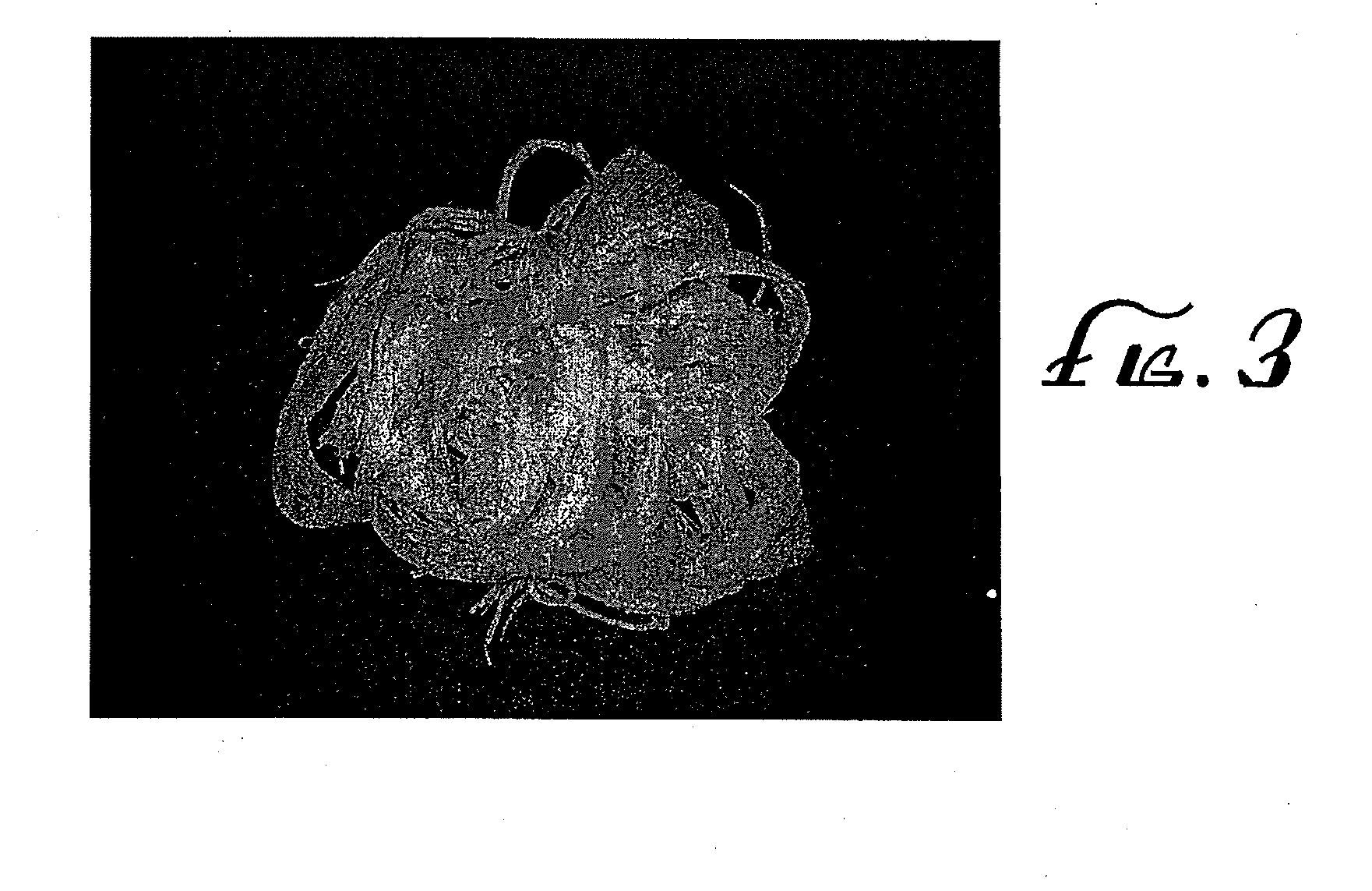

Novel enhanced filamentous silicone products & processes

InactiveUS20070003759A1Increase packing densityPredetermined timeLayered productsFibre chemical featuresFiberUltimate tensile strength

Filamentous bodies which are longitudinally extended and other film-like constructions are made by combining liquid siliceous precursors with air and extruding them. Distinct types or grades of fibers, strands, and other film-like constructions are produced which have a multiplicity of useful applications and indications for use owing to their inherent memory, compactability, tensile strength and density. Processes for making the novel enhanced filamentous bodies and products by the same can be optimized for uses ranging from safe and effective (“leak-free”) prosthetics to cushions, inserts, membranes, in a plurality of fields from consumer electronics to medical devices, and athletic or orthopedic shoe inserts.

Owner:LEIDIEZ INC +1

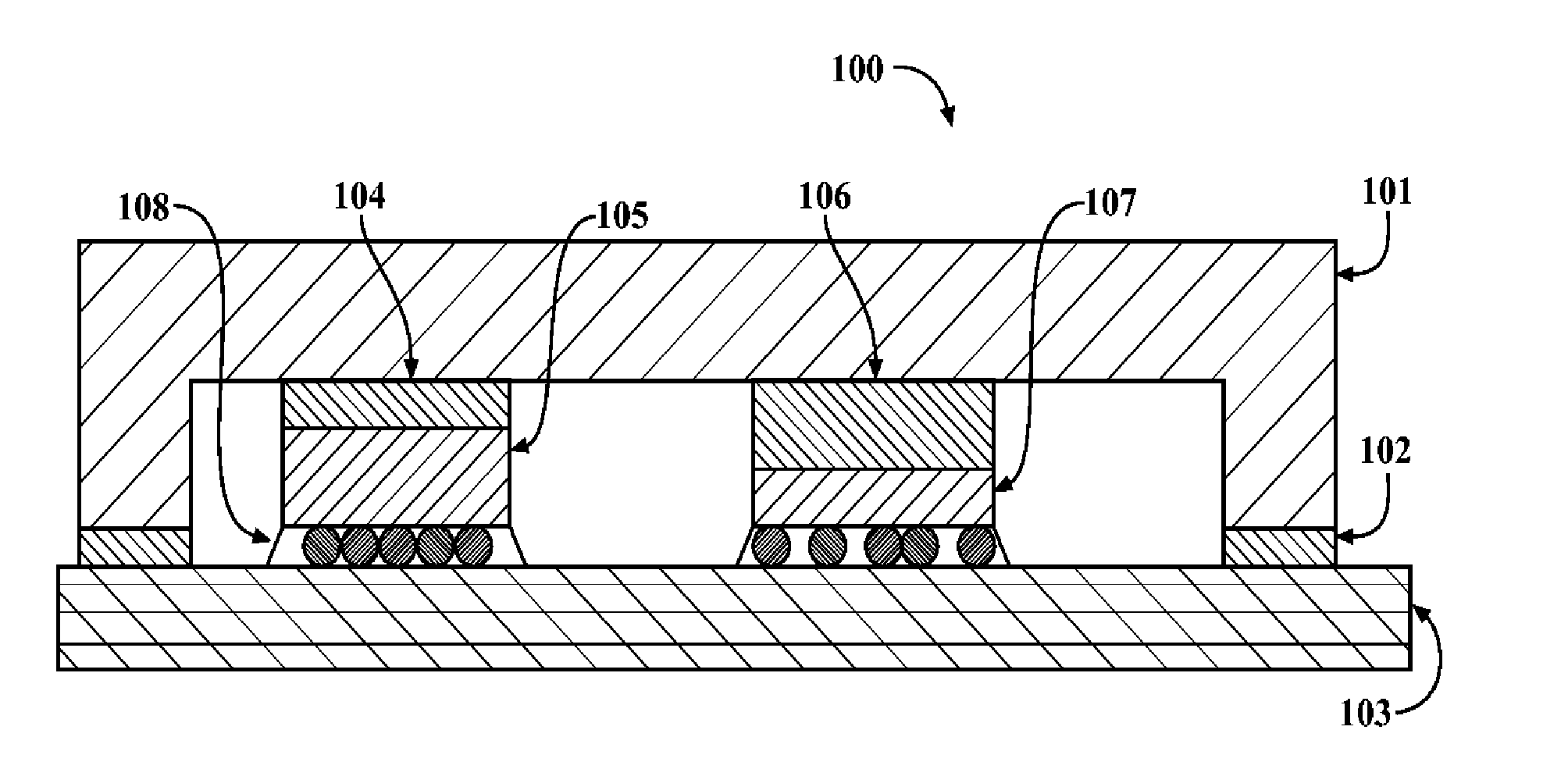

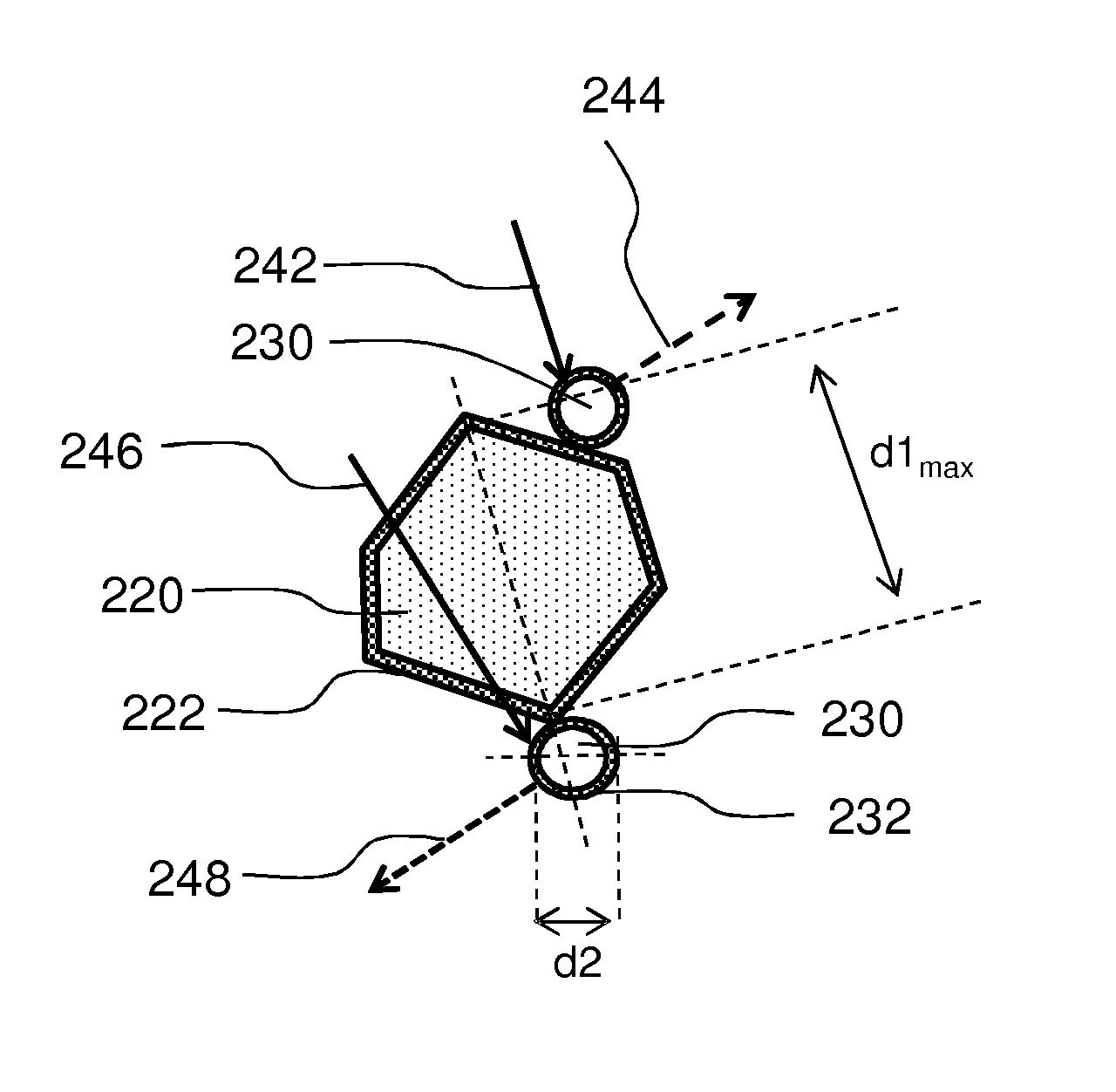

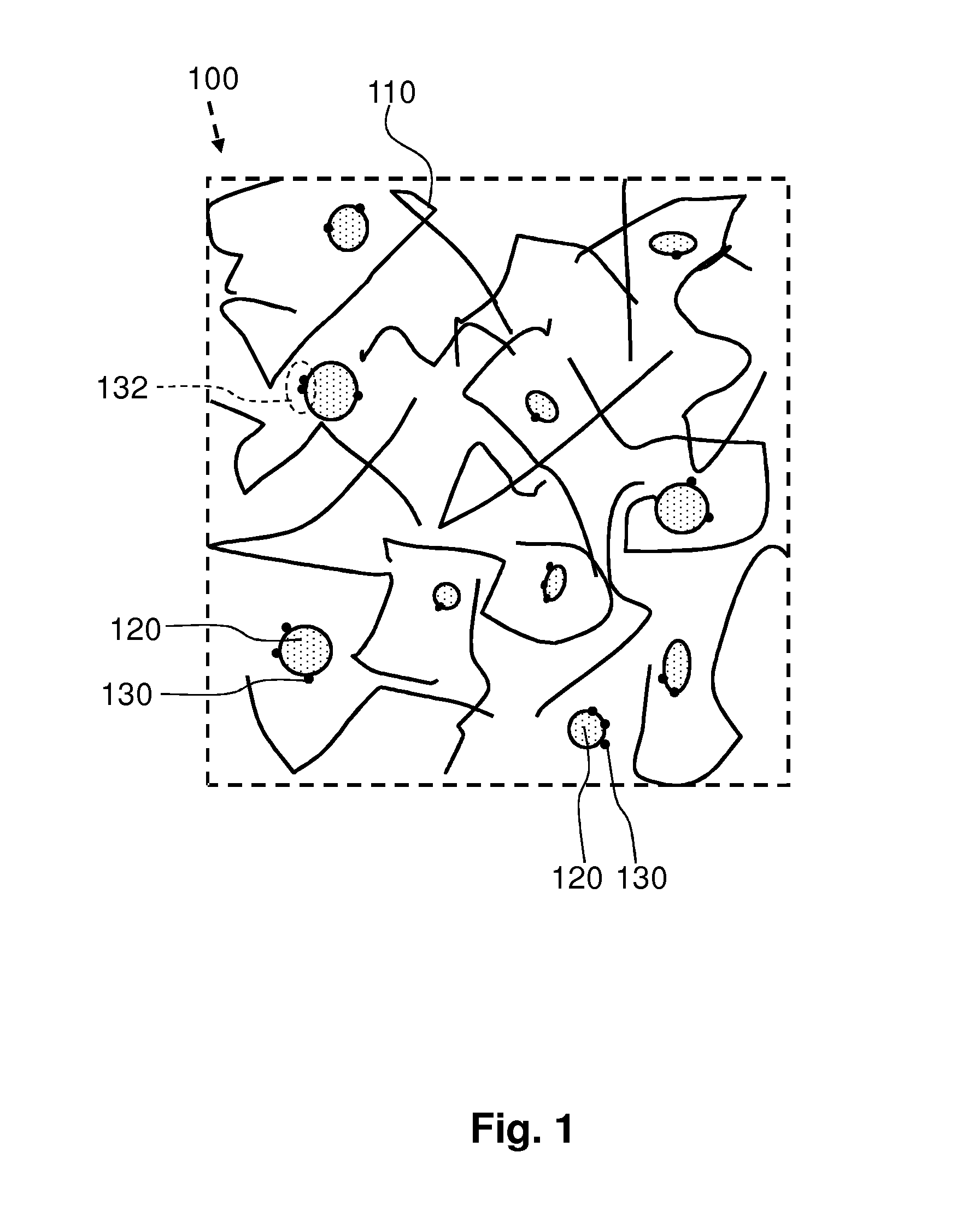

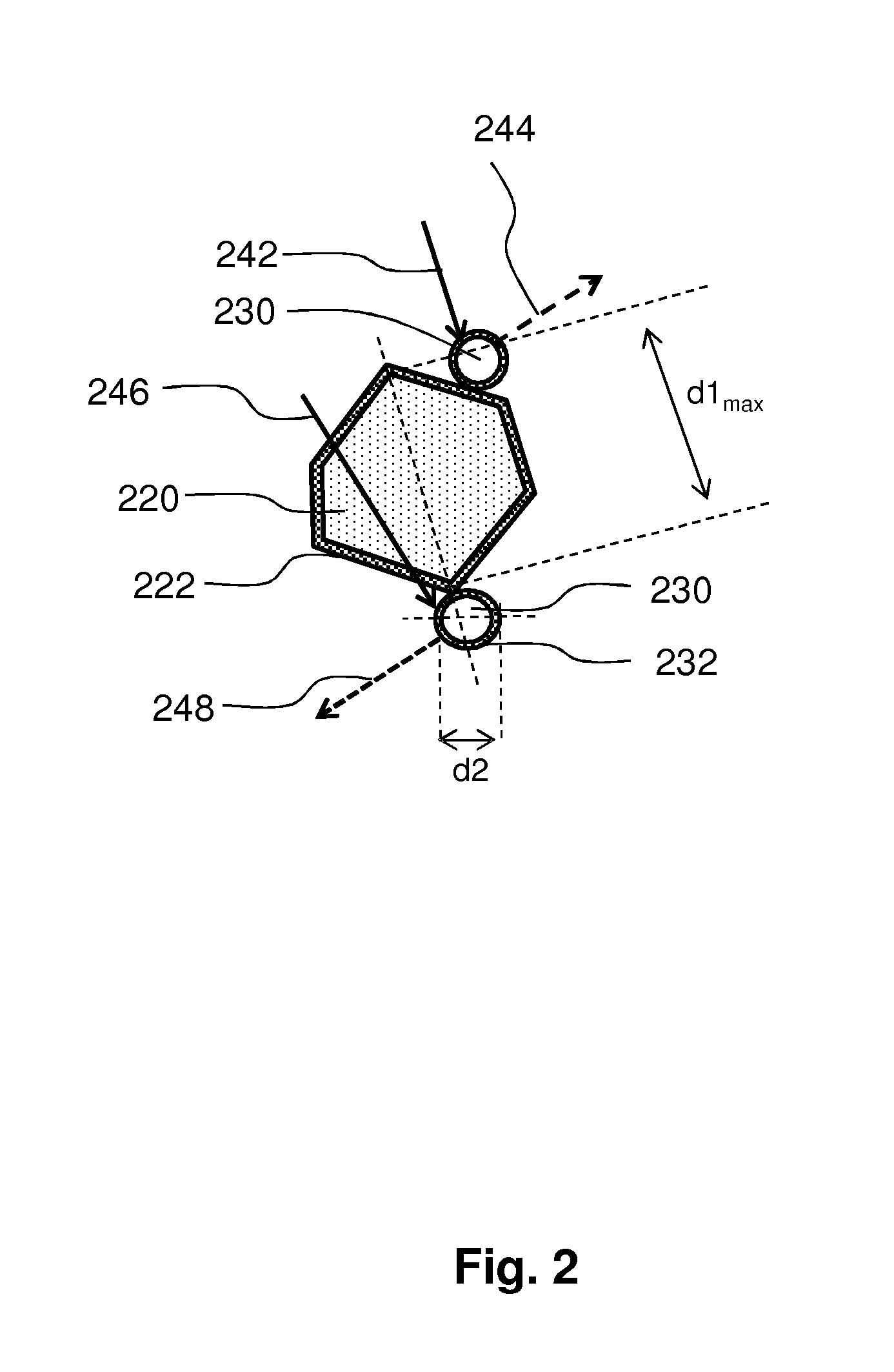

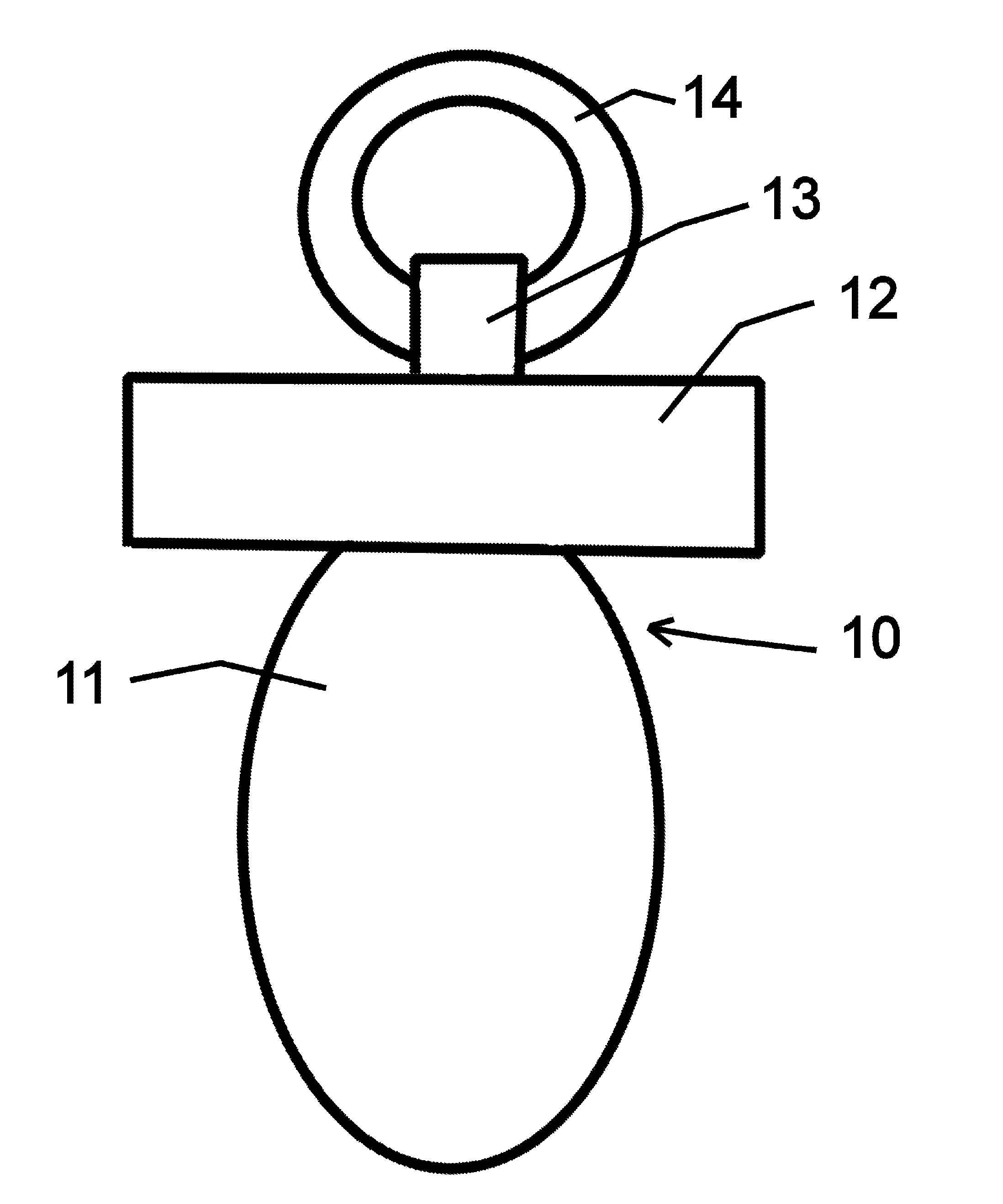

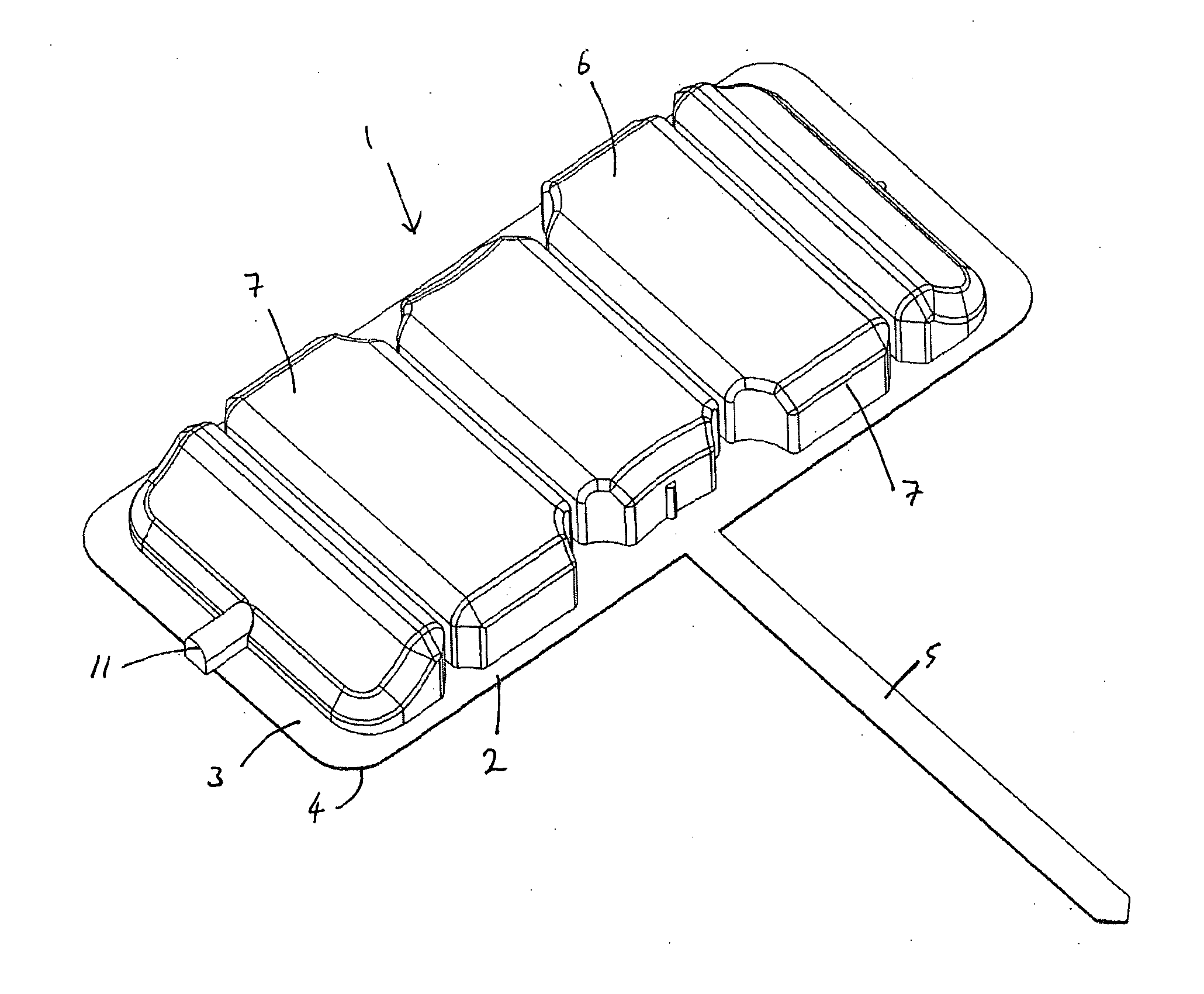

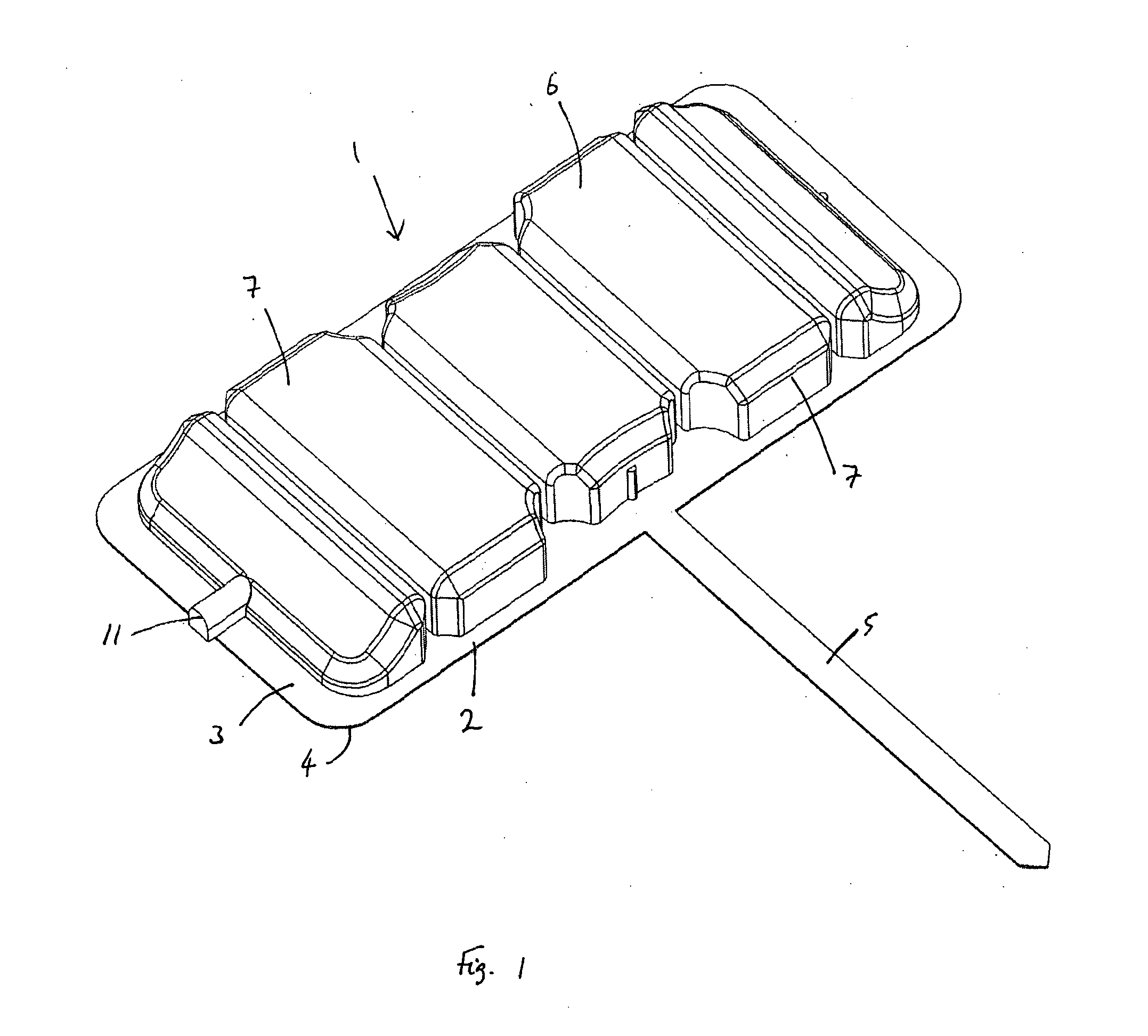

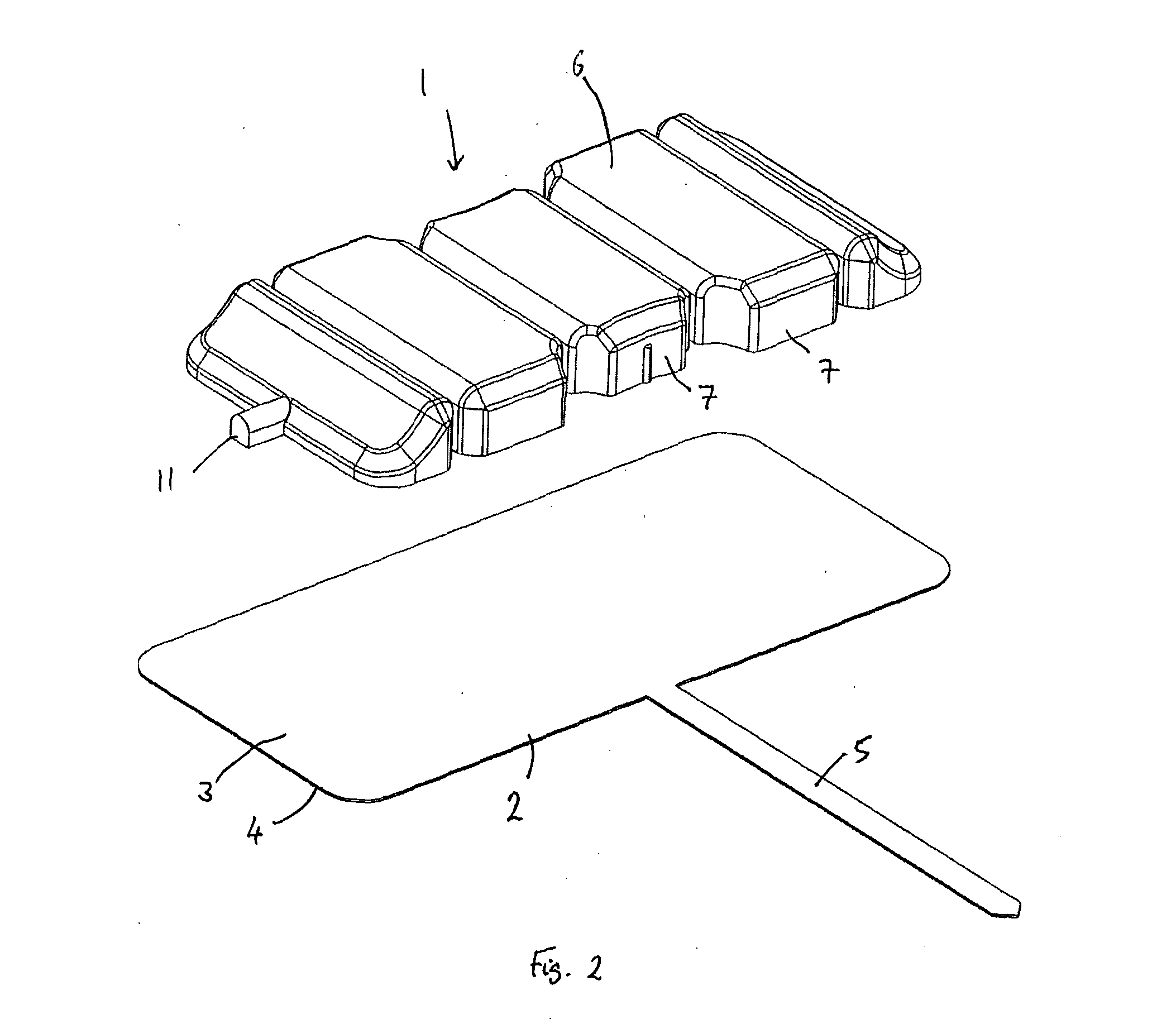

Silicone product, a lighting unit comprising the silicone product and method of manufacturing a silicone product

ActiveUS20150152323A1Reduced stabilityDischarge tube luminescnet screensLamp detailsNanometrePolymer chemistry

A silicone product 100, a lighting unit comprising the silicone product and a method of manufacturing a silicone product are provided. The silicone product 100 comprises polymeric material 110, luminescent material 130 and filler particles 120. The polymeric material 110 comprises a material of the group of polysiloxanes. The polymeric material 110 being light transmitting. The luminescent material 130 comprises particles which have at least in one dimension a size in the nanometer range. The luminescent material 130 is configured to absorb light of a first spectral range and to convert a portion of the absorbed light into light of a second spectral range. The filler particles 120 are of a light transmitting inert material. The filler particles 120 are miscible with the luminescent material 130. The filler particles 120 are provided in the polymeric material 110. The particles of luminescent material 130 are distributed along a surface of the filler particles 120.

Owner:LUMILEDS

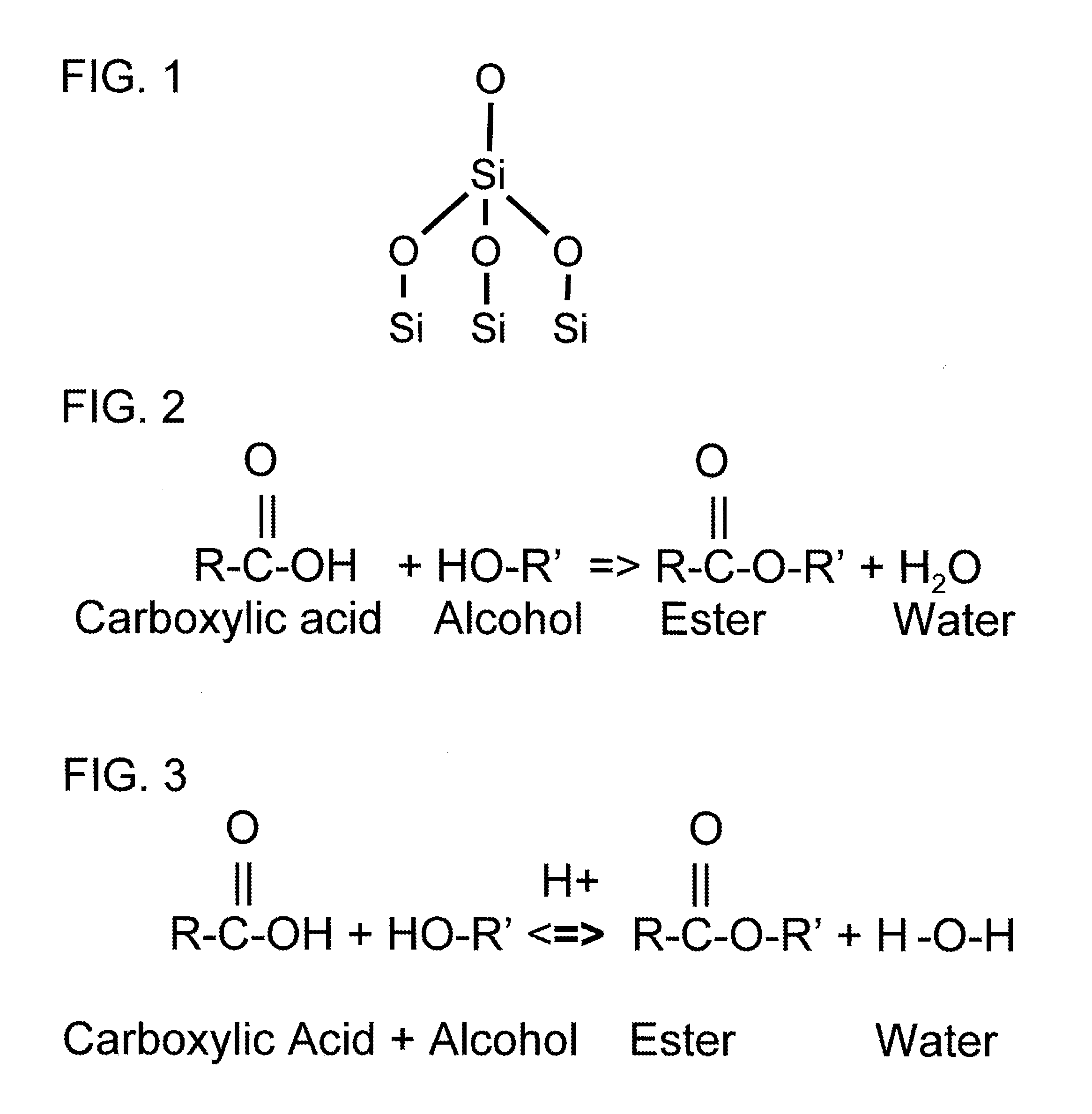

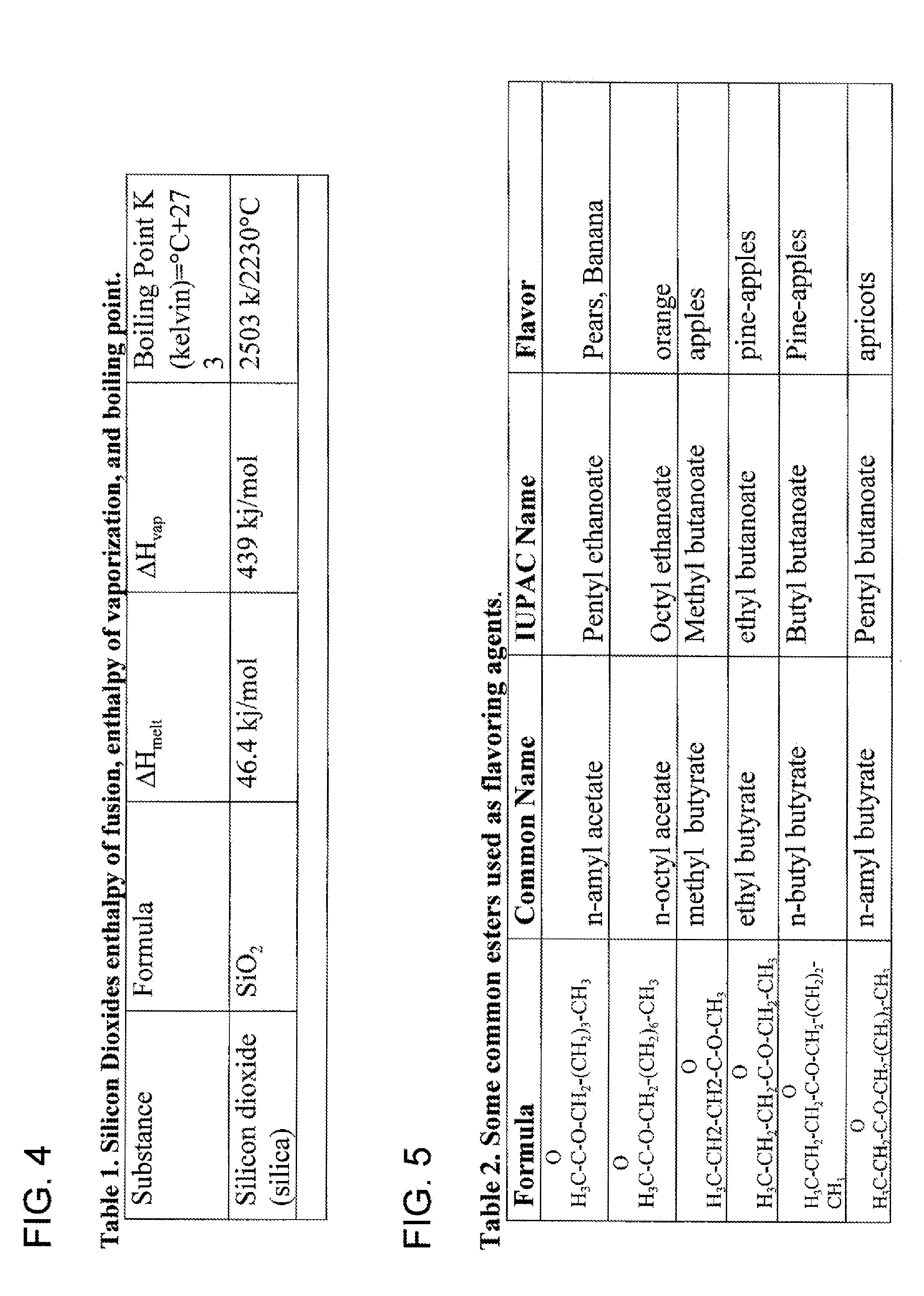

Flavored silicone products

A system for flavoring silicone products, such as baby bottle nipples and baby pacifiers, and a system for forming the flavored silicone products. Flavors, in the form of esters, are bond to Silicon (IV) Oxide, the resulting flavored intermediate is mixed into silicone, and the mixture is formed into a flavored product.

Owner:MAHONEY CASSANDRA ANN

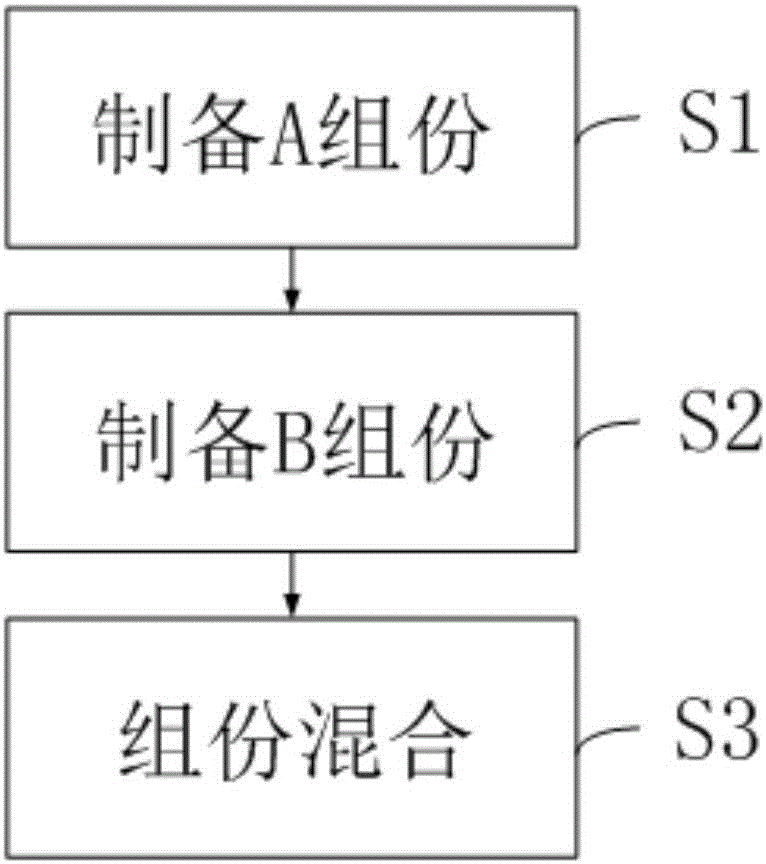

Double-component low-hardness silicone rubber and preparation method thereof

The invention relates to a double-component low-hardness silicone rubber and a preparation method thereof. The double-component low-hardness liquid silicone rubber comprises two components A and B, the mass ratio of A to B is 1:1, wherein the component A comprises 50-70 parts of vinyl-terminated organopolysiloxane with the viscosity of 5000-15000 mPa.s, 20-45 parts of fumed silica powder with the specific area of 200-380 m<2> / g, and 0.01-0.5 part of platinum catalyst; the component B comprises 50-70 parts of vinyl-terminated organopolysiloxane with the viscosity of 5000-15000 mPa.s, 20-45 parts of fumed silica powder with the specific area of 200-380 m<2> / g, 5-10 parts of polysiloxane with low hydrogen content of 0.05-0.2%, and 0.01-0.03 part of inhibitor. The prepared double-component low-hardness silicone rubber forms a soft elastic material after being vulcanized, is environmentally friendly, non-toxic, and good in simulation performance, and can be used to make flexible silicone products like the human body, insoles, non-slip mats and the like, in addition, the double-component low-hardness silicone rubber is high in tensile strength and tearing strength, and is suitable or the fields of electronics, automobiles, aviation and the like having requirements on complicated shape or high precision.

Owner:镇江高美新材料有限公司

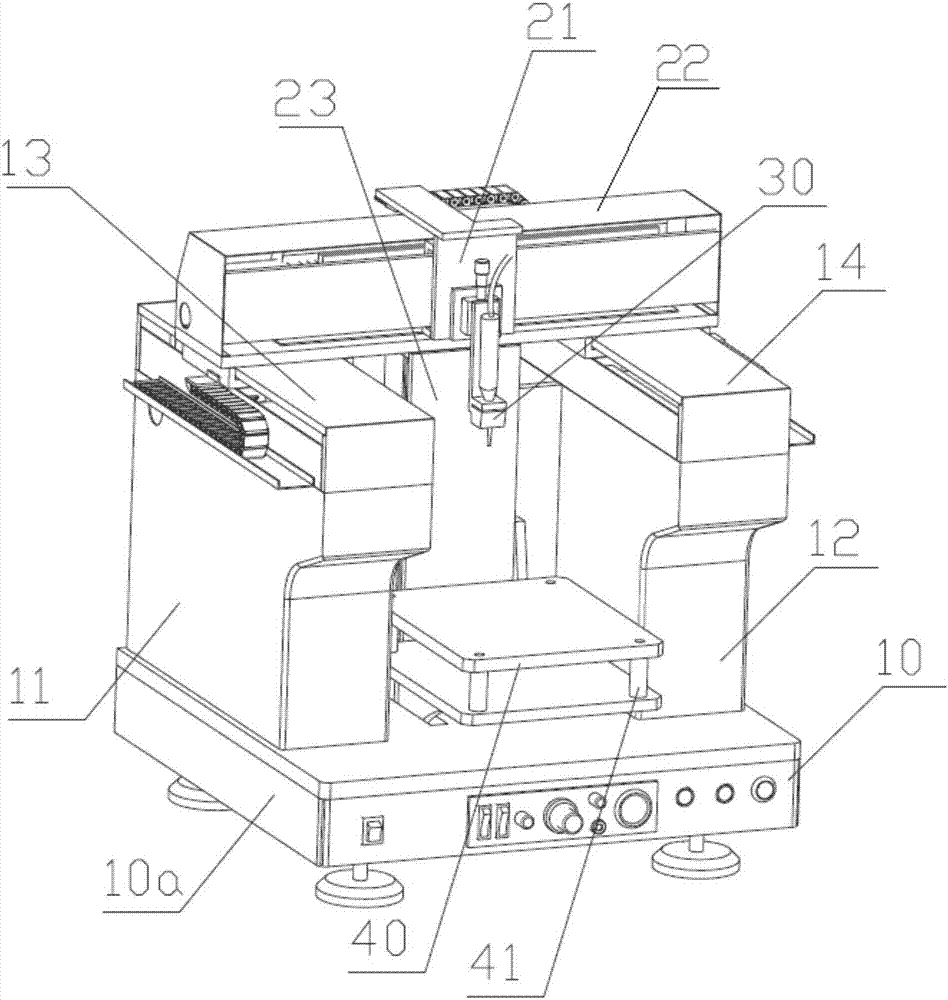

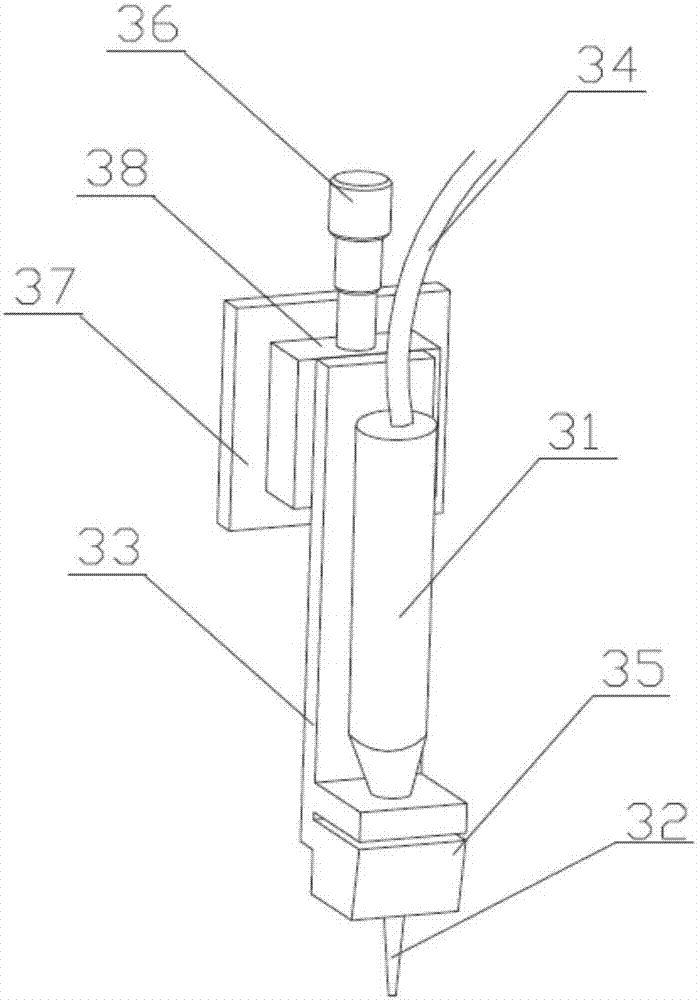

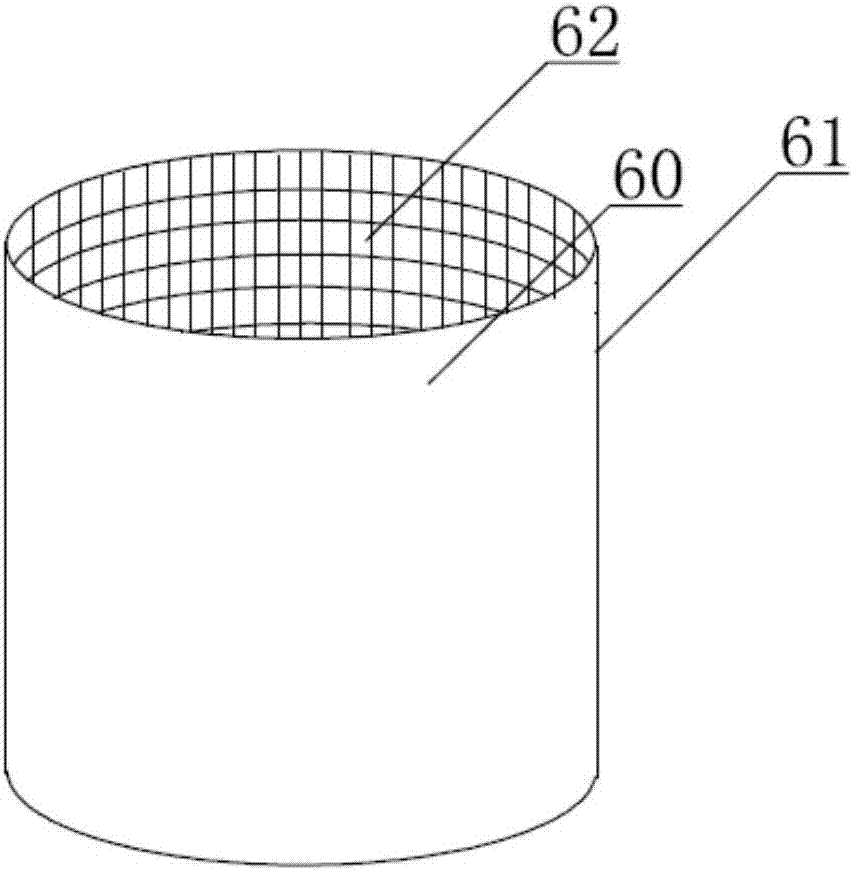

Silicone 3D printer and printing method of silicone products

ActiveCN105643939BHigh precisionPrecise output controlManufacturing driving meansManufacturing heating elementsData informationComputer module

The invention provides a silica gel 3D printer and a silica gel product printing method. The silica gel printer comprises a frame, an X-axle slide module, a Y-axle slide module, a Z-axle slide module, a silica gel printing head and an air pressure adjusting module. A main control module is used for controlling the Z-axle slide module to drive a forming platform to change the position along a Z axle according to model data information of a silica gel product to be printed, controlling the X-axle slide module and the Y-axle slide module to drive the silica gel printing head to move along a predetermined path at a first predetermined speed, and controlling the air pressure adjusting module to adjust air pressure in the silica gel printing head so as to control the silica gel printing head to extrude out silica gel at a second predetermined speed. The silica gel printer has the beneficial effects of simple structure, low energy consumption and simple technological flow.

Owner:SHENZHEN ADVENTURE TECH CO LTD

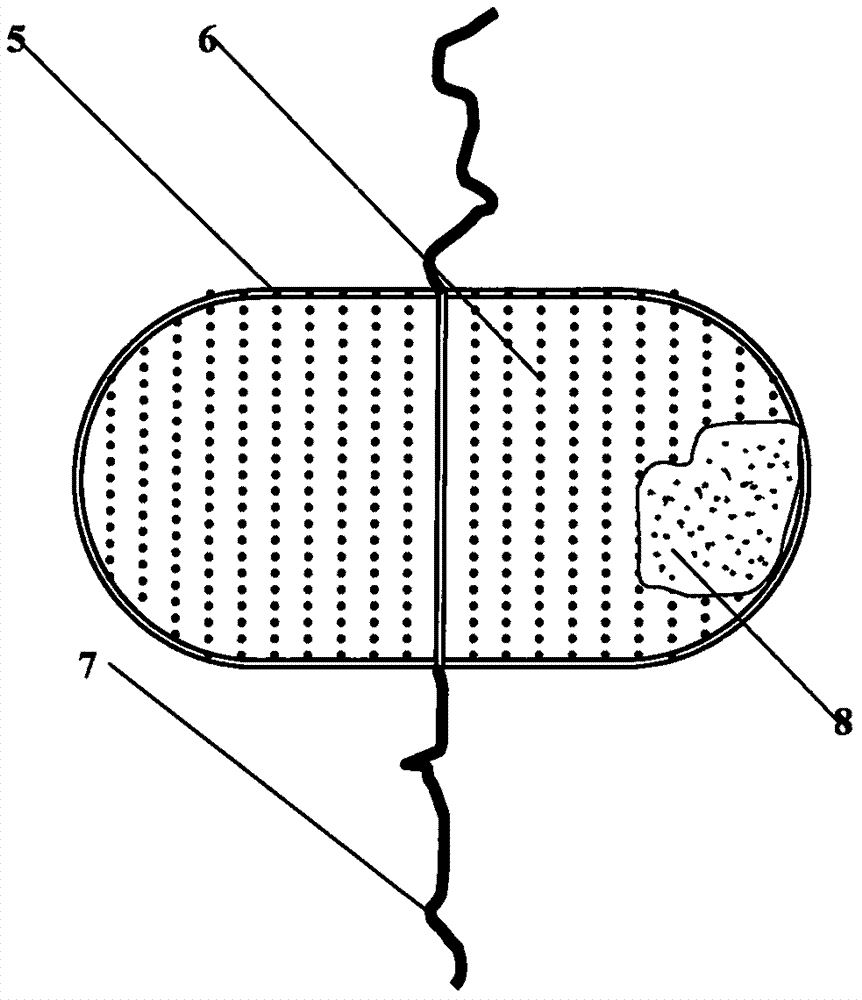

Silicone product supported with graphene titanium dioxide nano-silver tourmaline magnetic powder

The invention relates to a silicone product supported with graphene titanium dioxide nano-silver tourmaline magnetic powder, belonging to the technical field of health care products. In the technicalscheme, 33 silicone products are provided. The technical scheme is as follows: the silicone product is characterized in that at least one functional material of graphene, titanium dioxide, nano-silver, tourmaline and magnetic powder is added into the 33 silicone products on line in the production process. The silicone products have effects of releasing far infrared rays, releasing negative oxygenions and resisting bacteria. The silicone product disclosed by the invention has the beneficial effects that the functional silicone product has an antibacterial function, a water purification function, an air purification function and electric heating and formaldehyde removing functions, brings convenience to people's life and brings health to the body of people. The silicone product disclosed bythe invention is low in production cost, high in practicality and convenient for large-scale popularization and has wide market prospects.

Owner:张迎秋

High stability conductive elastomer for electromagnetic shielding and preparation method thereof

The invention relates to a high stability conductive elastomer for electromagnetic shielding. The high stability conductive elastomer comprises the following components: 100 parts by mass of siliconerubber, 100-400 parts by mass of conductive filler, 0-10 parts by mass of silicone oil, 0-10 parts by mass of graphene, 1-5 parts by mass of a silane coupling agent, 0.5-5 parts by mass of an internalreleasing agent, and 0.5-10 parts by mass of a crosslinking agent. The conductive elastomer prepared from the components has the advantages of high tensile strength, high elongation at break, low compressive deformation, low product cost and good shielding effectiveness, the tensile strength and elongation at break enable difficult pull-apart of the product in the assembly process and reusabilityof the product during reworking, the compressive deformation is low, and relative to pure electrically conductive silicone products, the product provided by the invention has low compressive deformation amount, so that the whole installation shell has good sealing performance and good shielding effectiveness, and the product cost is low. In addition, the invention also provides a preparation method of the high stability conductive elastomer for electromagnetic shielding.

Owner:PINGHU ALLIED IND

Silicone composition and cured silicone product

A silicone resin composition, comprising (A) 100 parts by weight of an organopolysiloxane resin containing an average of greater than two alkenyl groups per molecule and having less than 1.5 mole percent of silicon-bonded hydroxy groups, (B) an organohydrogensilane in an amount sufficient to cure the composition, (C) an effective amount of an inorganic filler; and (D) a catalytic amount of a hydrosilylation catalyst. The present invention is further directed to a cured silicone product comprising a reaction product of the above-described composition. A cured silicone product comprising a reaction product of the silicone resin composition and a multi-part silicone composition comprising components (A) through (D) in two or more parts, provided components (A), (B), and (D) are not present in the same part.

Owner:DOW CORNING CORP

Hydrophilic polyorganosiloxane composition

InactiveUS7456246B2Improve curing effectImprove stabilityImpression capsDental impression compositionsElastomerPolymer chemistry

A hydrophilic polyorganosiloxane composition comprising (A) a curable organopolysiloxane containing at least 5 mol % of diphenylsiloxane units or at least 10 mol % of methylphenylsiloxane units, (B) a curing agent, and (C) a specific polyether cures into an elastomeric or gel-like silicone product having excellent hydrophilic properties and prevents separation of the polyether over time.

Owner:GC CORP +1

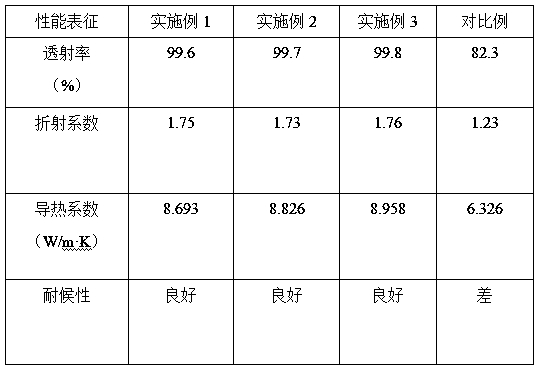

Preparation method of anti-aging silicone material for LED packaging

InactiveCN110016319AImprove aging resistanceHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceHydrosilylation

The invention relates to a preparation method of an anti-aging silicone material for LED packaging, and belongs to the technical field of silicone products. Polyurethane is adopted to modify siliconerubber so as to obtain a raw material, and through combination with vinyl-terminated methylsilicone oil and a platinum catalyst, a rubber matrix is obtained through hydrosilylation; and the hydrogen-containing methylsilicone oil is adopted as a cross-linking agent, and vulcanization is performed so as to obtain the LED packaging anti-aging silicone material. The anti-aging silicone material has agood refractive index, aging resistance and good mechanical properties, and polyurethane has the advantages of high hardness, high strength, high elasticity, high wear resistance, tear resistance, aging resistance, ozone resistance, radiation resistance, good electrical conductivity and the like, and silicone rubber has excellent heat resistance, cold resistance, dielectric properties, ozone resistance, atmosphere aging resistance and other properties, so that after the silicone rubber is modified by using polyurethane, the tensile strength and tear strength of the modified silicone rubber areimproved, and the aging resistance is also improved.

Owner:宁波市海曙果壹电子科技有限公司

Curable silicone composition

Owner:DOW TORAY CO LTD

Method for electrolytic synthesis of siloxane

InactiveCN103952716ALow priceSimple structureElectrolysis componentsElectrolytic organic productionElectrolytic agentOrganosolv

The invention relates to a method for electrolytic synthesis of siloxane, belonging to the technical field of organosilicon chemistry. The method disclosed by the invention comprises the following steps of carrying out an electrolysis reaction on minerals containing SiO2 and an alkylating agent as raw materials at room temperature and normal pressure in an electrolyte solution comprising an aprotic polar organic solvent and an electrolyte by an electrolytic cell or an electrolytic bath with a cathode and an anode and synthesizing to obtain the silicone-containing materials, and finally the separating siloxane in the silicone-containing materials to obtain siloxane products. According to the method for electrolytic synthesis of siloxane, production costs and energy consumptions are greatly reduced, the production efficiency is improved; no pollution to the environment is generated and the synthesis process is environment friendly; a plurality of silicone products are obtained by flexibly choosing alkylating agents. The method disclosed by the invention has the advantages of high converted rate and product quality.

Owner:罗凯

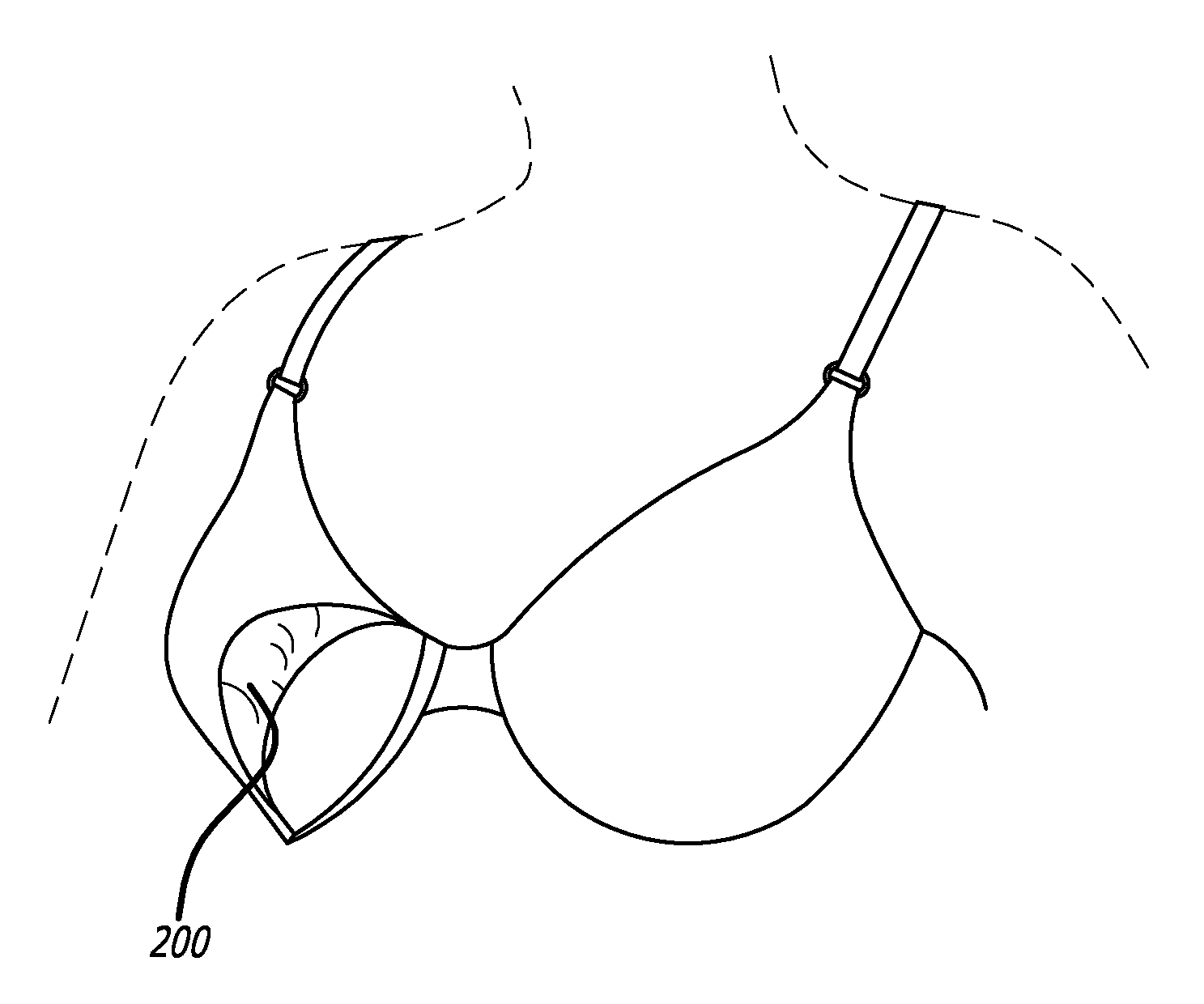

Novel enhanced filamentous silicone products and processes

Filamentous bodies which are longitudinally extended and other film-like constructions are made by combining liquid siliceous precursors with air and extruding them. Distinct types or grades of fibers, strands, and other film-like constructions are produced which have a multiplicity of useful applications and indications for use owing to their inherent memory, compactability, tensile strength and density. A prosthetic device for a mastectomy bra is constructed with filamentous bodies. It can be sewn permanently into the bra cup. The device can be refilled to counteract volume loss.

Owner:LEIDIEZ

Coupling an Ultrasound Probe to the Skin

ActiveUS20150018686A1Improve adhesionEfficient preparationUltrasonic/sonic/infrasonic diagnosticsFilm/foil adhesivesSilicone GelsMedicine

A tape for securing an ultrasound probe to the skin may include a sonolucent silicone gel for transmitting ultrasound from an ultrasound transducer to the body. A method of manufacturing an adhesive silicone product may include a step of treating the adhesive composition or components of the composition to remove air or prevent the formation of air bubbles, in order to provide a sonolucent adhesive product.

Owner:RESPINOR

Efficient purifying and oil stain resistant diatom ooze paint

ActiveCN106280998AHigh water vaporHigh air permeabilityAntifouling/underwater paintsPaints with biocidesHazardous substanceContamination

The invention provides diatom ooze paint which can be used for efficiently purifying indoor air and has a good oil stain resistant effect. The paint is prepared from the following components in parts by weight: 15 to 20 parts of kieselguhr, 10 to 30 parts of fluorine modified organosilicone, 5 to 10 parts of acrylic emulsion, 1 to 5 parts of photocatalyst materials, 20 to 55 parts of fillers, 1 to 3 parts of thickeners, 0.3 to 0.5 part of defoamers, 0.3 to 0.7 part of wetting dispersant, 0.2 to 0.5 part of anti-mildew bactericide and 15 to 35 parts of water, wherein the fluorine modified organosilicone is a silicone product which is produced by German Wacker Chemical Co., Ltd., and the brand of the fluorine modified organosilicone is WACKER BS-38; the photocatalyst materials are photocatalyst which is produced by Guangdong Longhu Science and Technology Co., Ltd., and the brand of the photocatalyst materials is CLAUVIS P-10; the thickeners include hydroxyethyl cellulose, polyurethane thickeners and alkali swelling thickeners. The diatom ooze paint has the advantages of good decorative effect, low contamination and oil resistance, indoor toxic and harmful substances can be efficiently absorbed, and the excellent characteristics of the diatom ooze paint can be achieved to the maximum.

Owner:广东龙湖科技股份有限公司

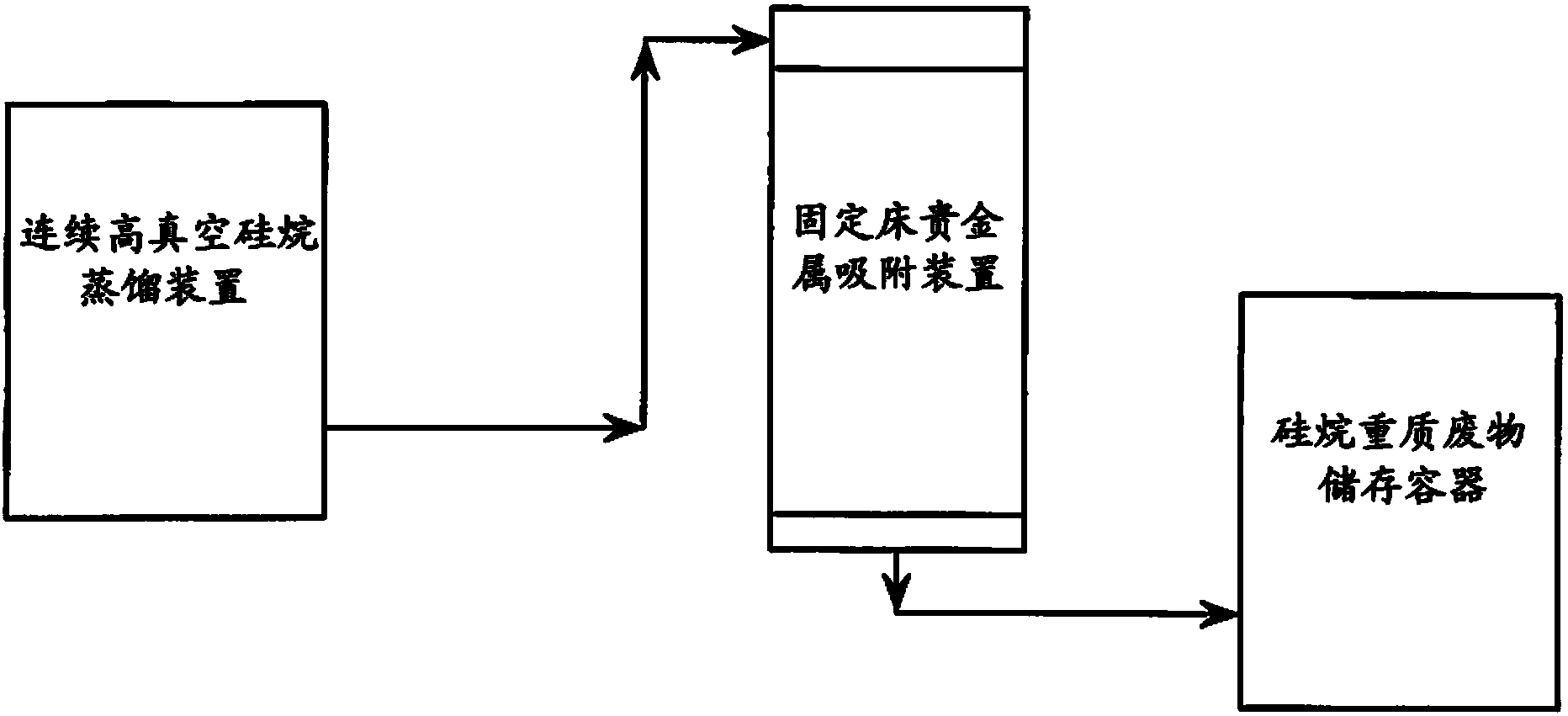

Process of precious metal recovery and color removal from an organosilicon product-containing liquid reaction medium

InactiveCN103619431AOther chemical processesRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPhysical chemistrySilicone products

The present invention relates to a process for recovery of a precious metal catalyst from an organosilicon product-containing liquid reaction medium containing precious metal catalyst.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

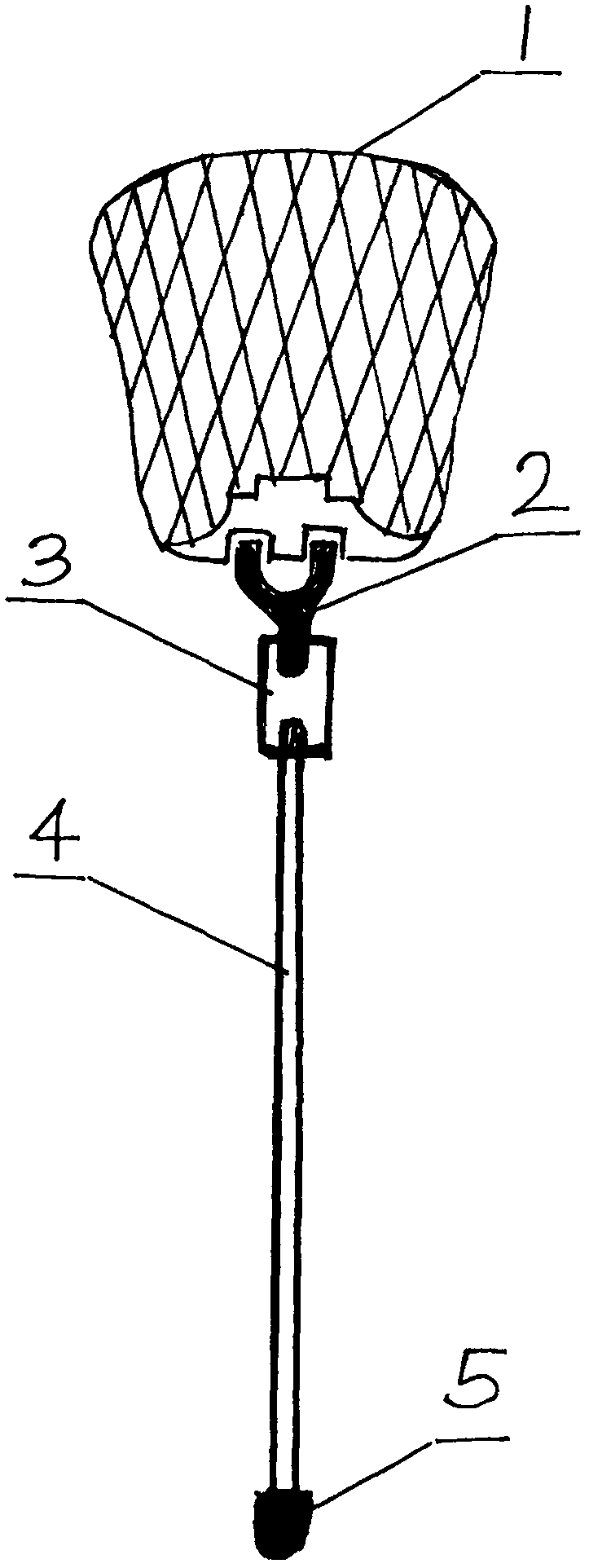

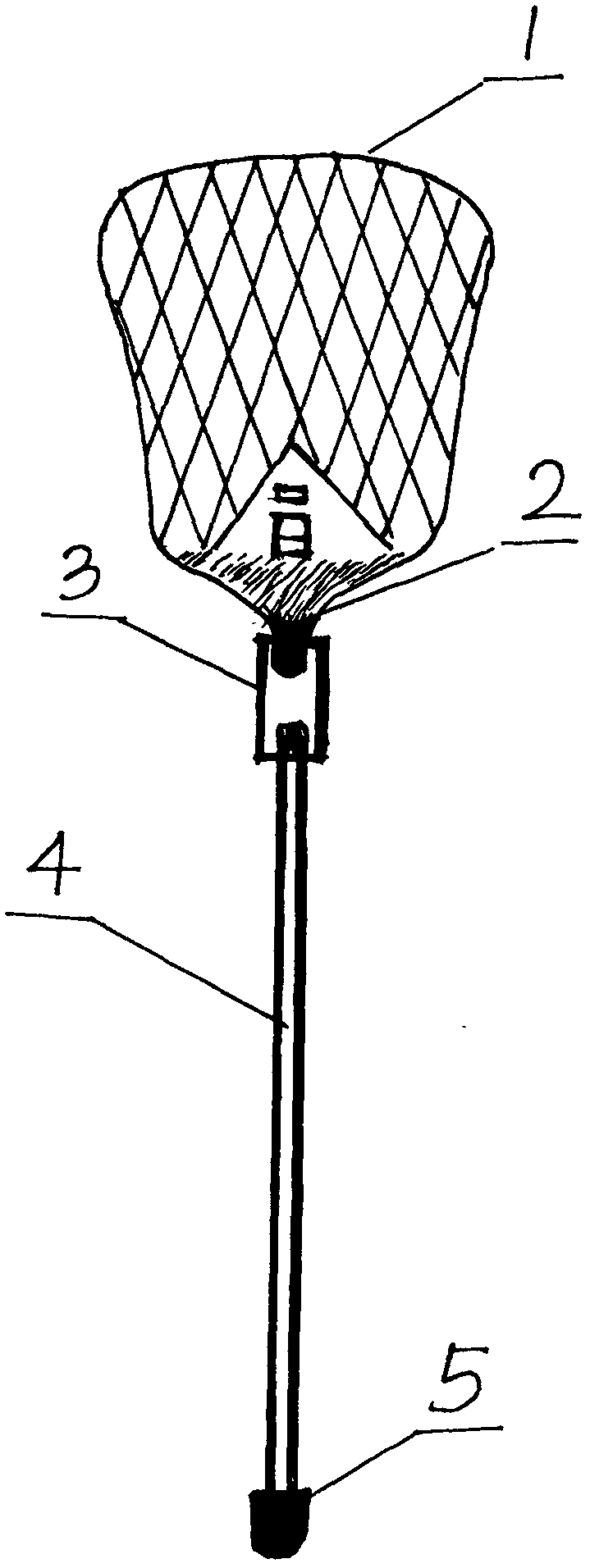

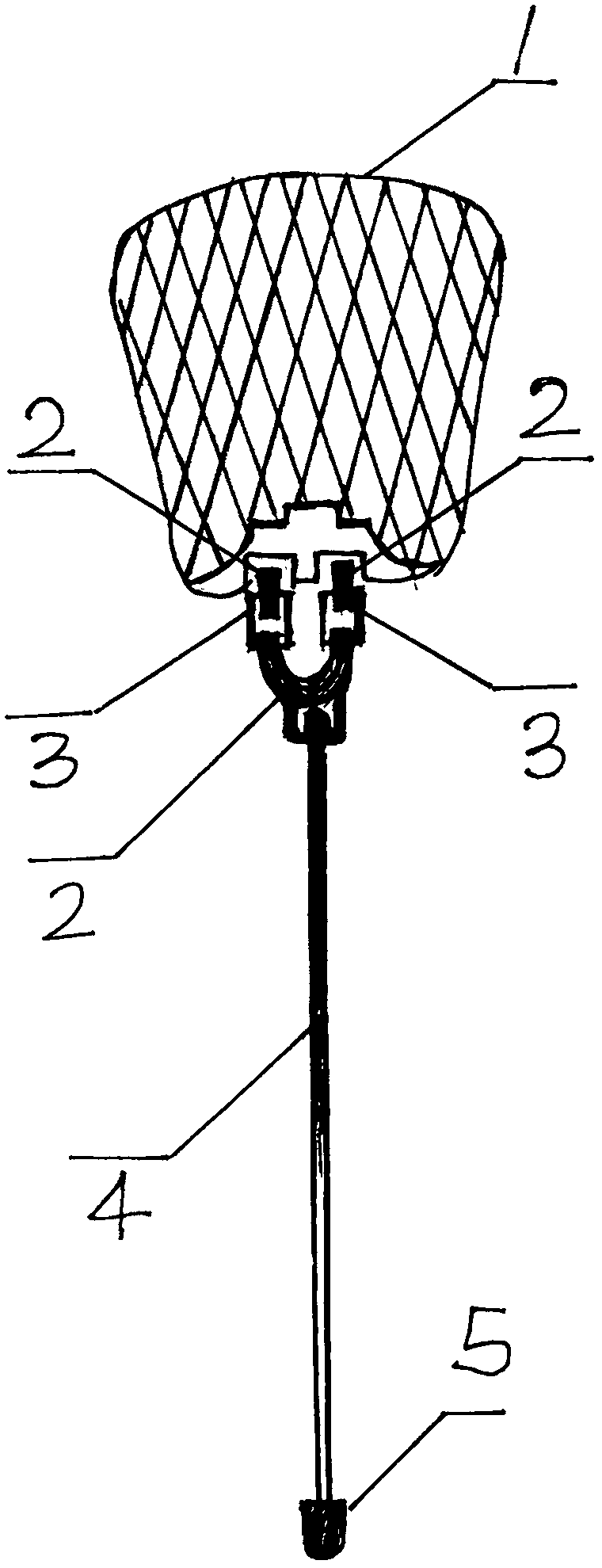

Soft elastic buffering manual flyswatter

InactiveCN110999889AReduce breakageExtended service lifeInsect catchers and killersLatex rubberMechanical engineering

The invention discloses a soft elastic buffering manual flyswatter. The soft elastic buffering manual flyswatter is composed of a plastic flyswatter 1, a flyswatter plug 2, a soft elastic buffering connection sleeve 3, a bamboo cane handle 4, a handle sheath 5 and the like, and is characterized in that the plug 2, on the plastic flyswatter 1, and the bamboo cane handle 4 are connected into a wholethrough the soft elastic buffering connection sleeve 3, the soft elastic buffering connection sleeve 3 is made of a soft elastic material of a silicone product soft, a rubber product, a latex product, a plastic product or the like, and the soft elastic buffering connection sleeve 3 can also be produced from a dichotomanthes tube, a silicone tube, a rubber tube, a latex tube, a plastic tube, a resin tube, a metal spring or the like. The soft elastic buffering manual flyswatter has the biggest advantage that under the action of the soft elastic buffering connection sleeve 3, the plastic flyswatter 1 can be bent from side to side at 180 degrees without being broken, after being let go, the plastic flyswatter 1 fast returns to an original position, and the plastic flyswatter 1 rarely breaks under the protective action of the soft elastic buffering connection sleeve 3, so that the service life of the plastic flyswatter 1 is prolonged; and the soft elastic buffering manual flyswatter has the advantages of being energy-saving, environmentally friendly, economic, practical, simple in production technology and the like.

Owner:王清林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com