Polar polydimethylsiloxane molds, methods of making the molds, and methods of using the molds for pattern transfer

A model, transfer medium technology, applied in the direction of nanotechnology for information processing, printing plate copying, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0167] These examples are included to illustrate the present invention, and those skilled in the art will appreciate that, in light of the above disclosure, many changes may be made to the disclosed embodiments and still obtain a similar result. All amounts, ratios and percentages are expressed by weight unless otherwise specified. The following components were used in these examples.

[0168] Base Polymer A is 68% dimethylvinylsiloxy end-terminated polydimethylsiloxane, 31% dimethylvinylated and trimethylated silica, and 1% tetra( Trimethylsiloxy)silane mixtures.

[0169] Base Polymer B is 67% dimethylvinylsiloxy end-terminated polydimethylsiloxane, 31% dimethylvinylated and trimethylated silica, 1% tetra( A mixture of trimethylsiloxy)silane and 1% of impurities.

[0170] Base polymer C is a dimethylvinylsiloxy end-terminated polydimethylsiloxane.

[0171] Base polymer D is a dimethylvinylsiloxy end-terminated polydimethylsiloxane.

[0172] Base polymer E is 71% dimethy...

example 1

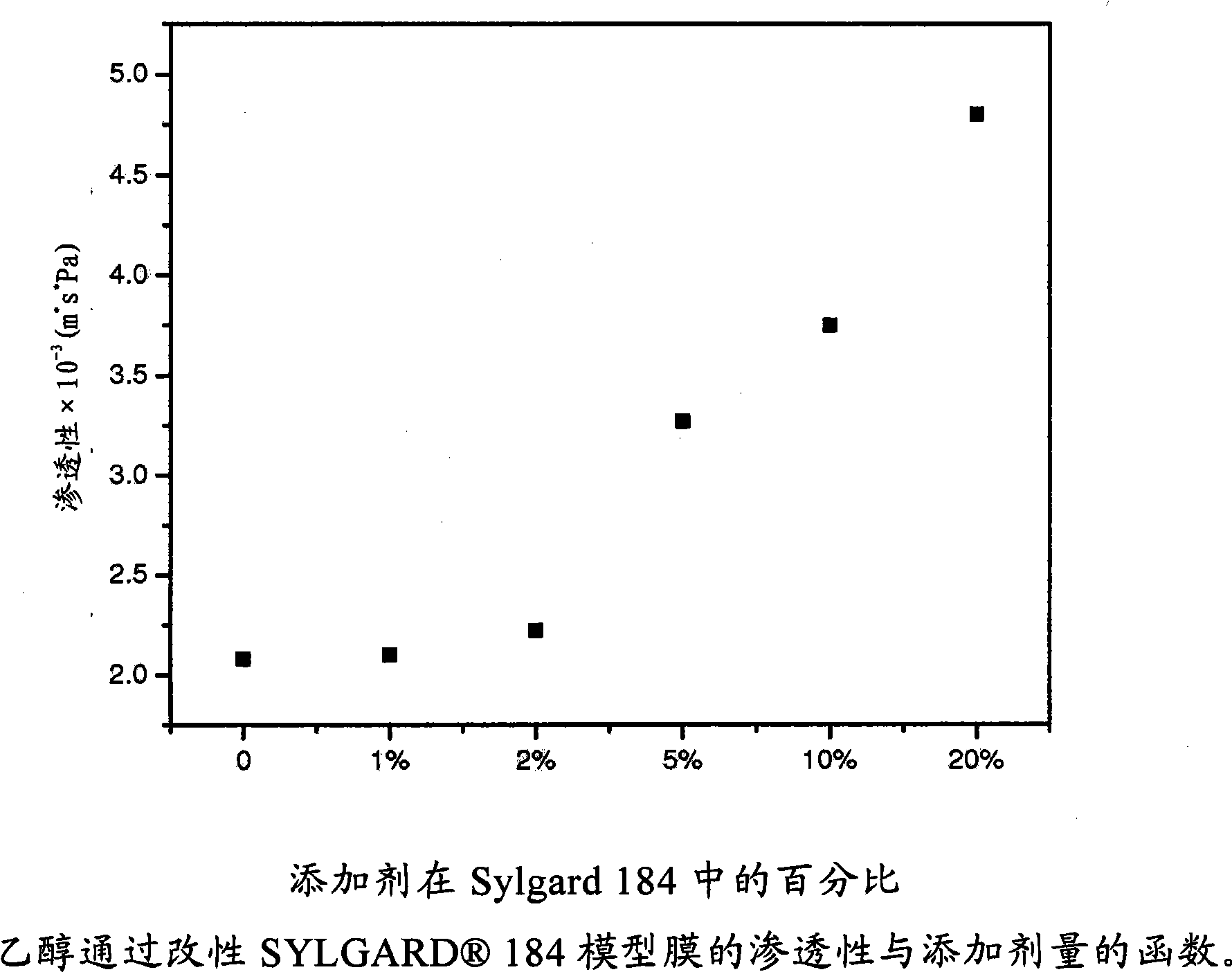

[0184] A polar additive (i.e., XUS13461 ethylene oxide propylene oxide (EO-PO) from Dow Chemical Company, Midland, Michigan, USA) was added to DOW 184 recipes. The amount of EO-PO is in the range of 1 to 20 weight percent. In these examples, it can be found that when the amount of EO-PO is Above 20 wt% in 184, the resulting pattern becomes too viscous to be used in some soft lithography processes.

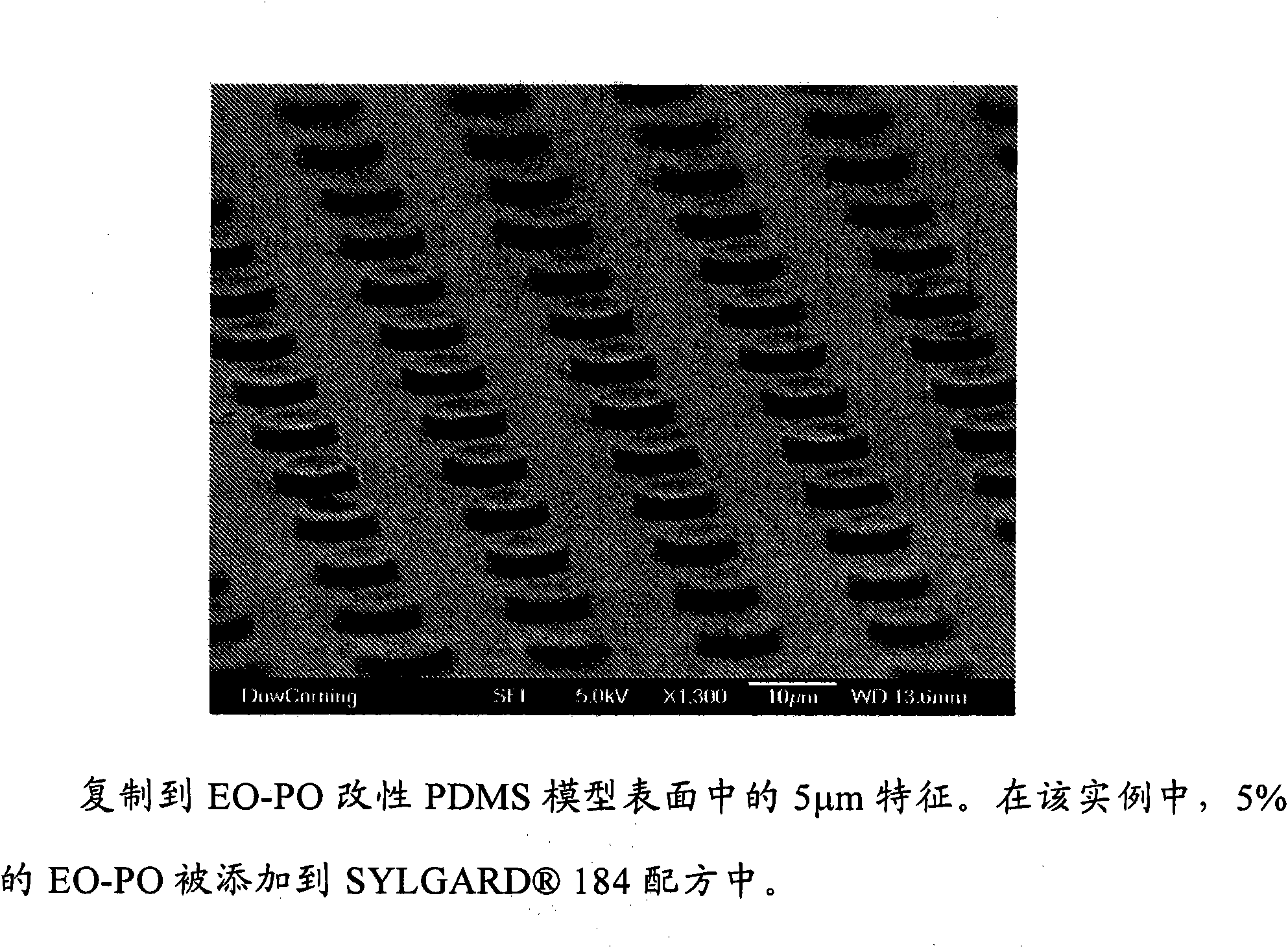

[0185] After mixing EO-PO, the resulting composition was much better than that without EO-PO 184 is more viscous. A thermocompression curing method was used to fabricate models with microscale features. The pressure curing method forces the viscous composition into the master model to create high precision patterns in the polar model. After curing, as figure 1 As shown, in the modified PDMS model surface, the negative image of the patterned features from the original model was replicated.

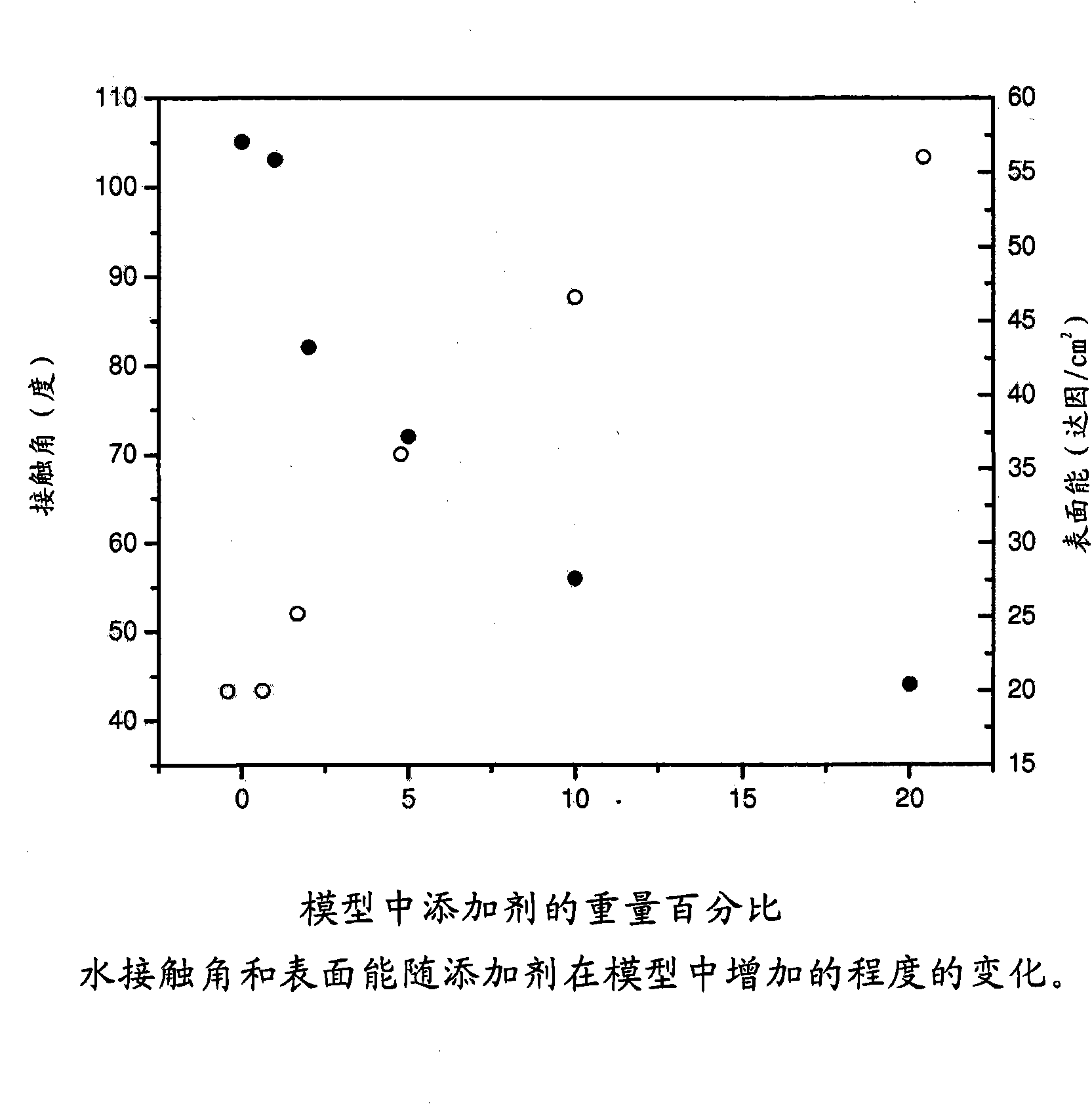

[0186] After fabricating the modified PDMS phantom, surface energy measurements ...

example 3

[0193] Two-part samples were prepared by mixing the components in the amounts shown in Table 2 to form Parts A and B. Parts A and B were mixed in a 1:1 ratio. The molar SiH / Vi ratio of the mixture was 1.6. The resin / polymer ratio of the mixture was 0.45. The amount of resin in the mixture was 28%.

[0194] Table 2

[0195]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com