Patents

Literature

21663results about How to "Not easy to damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

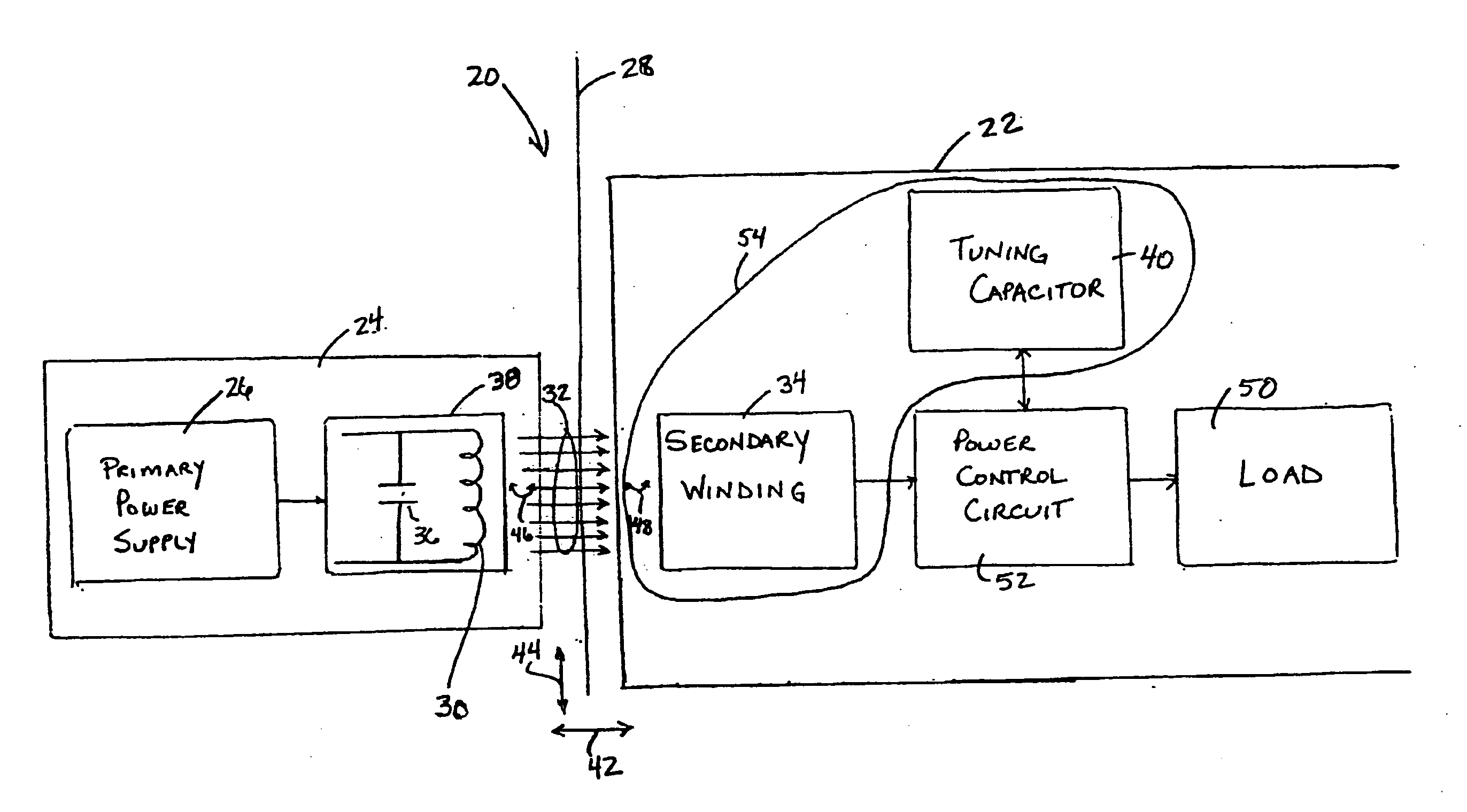

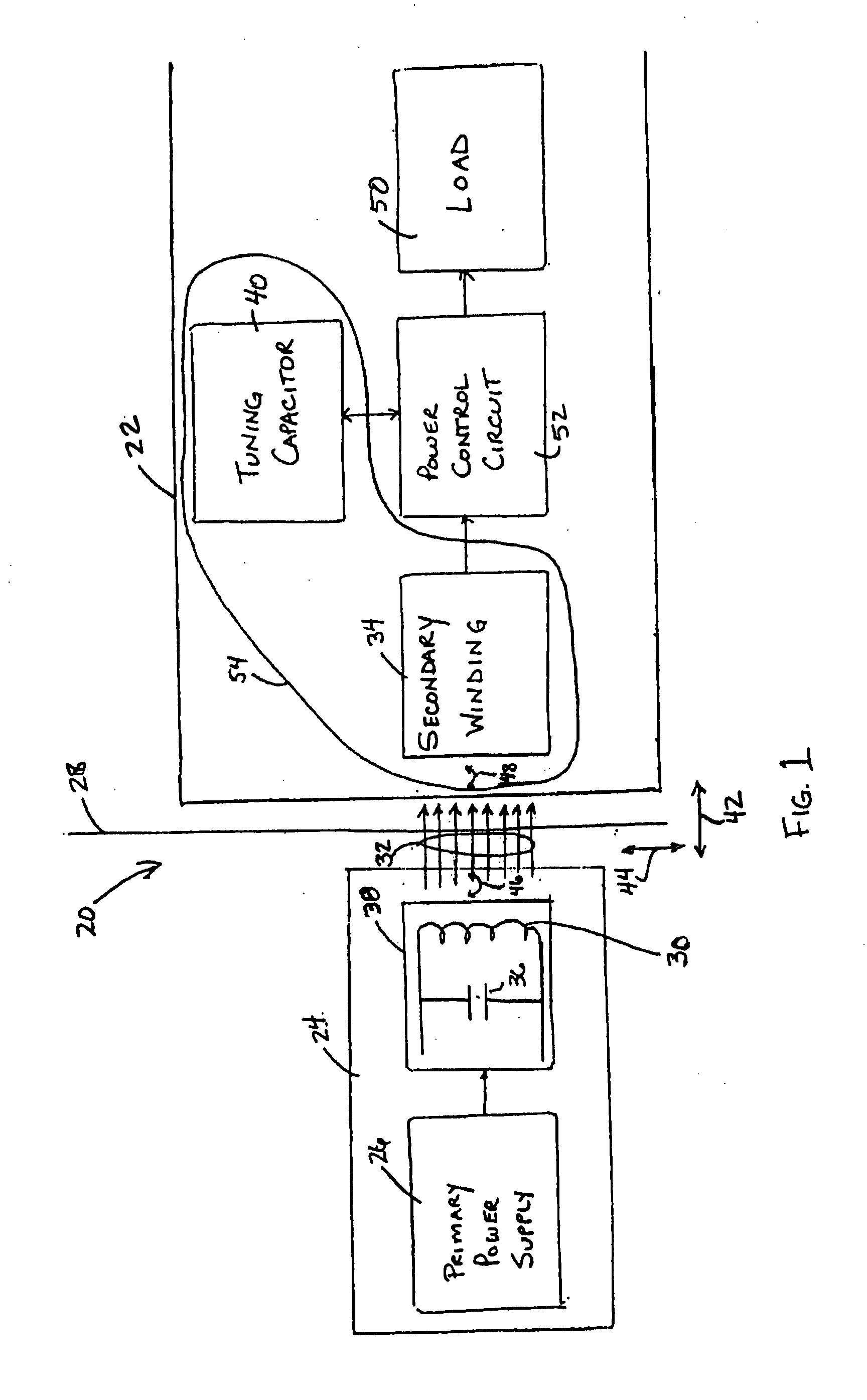

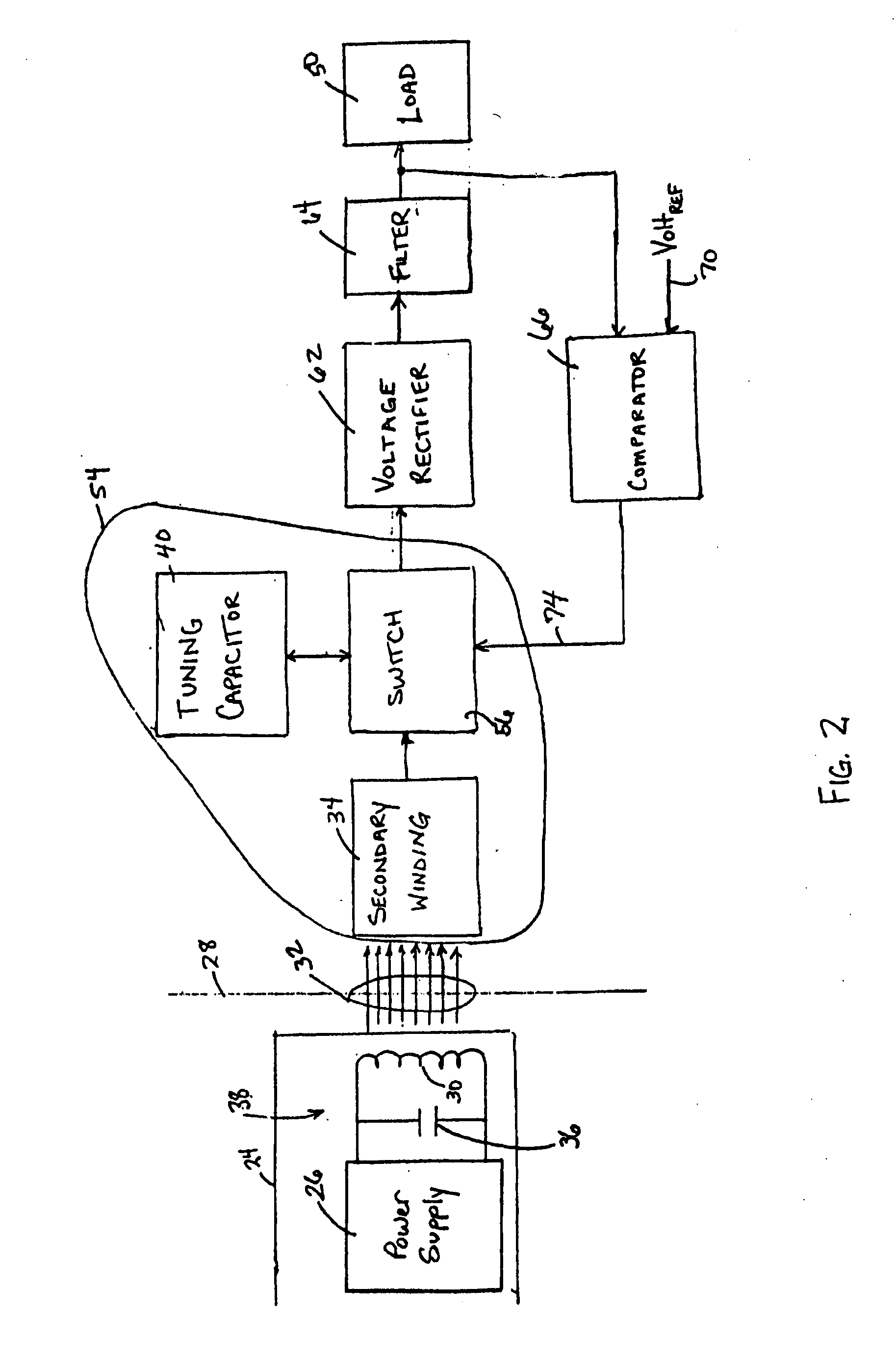

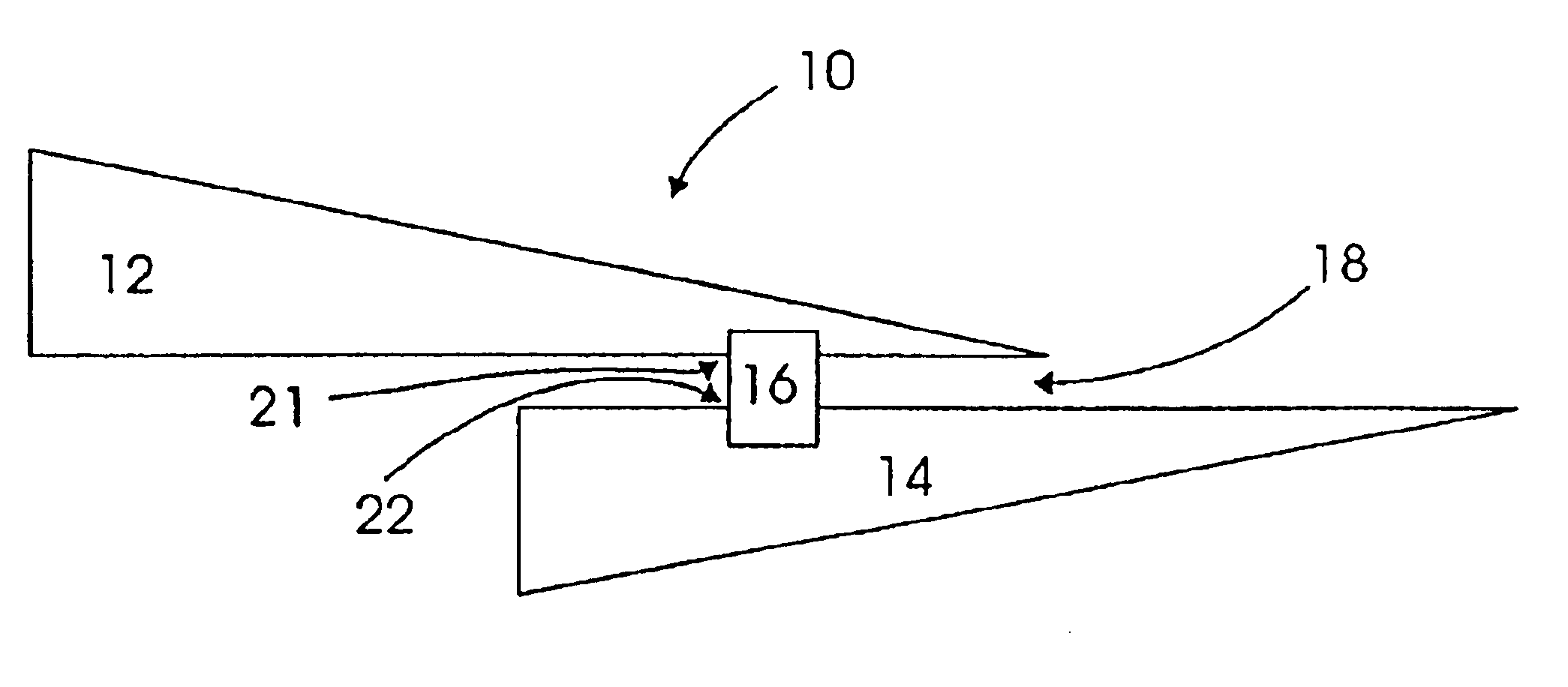

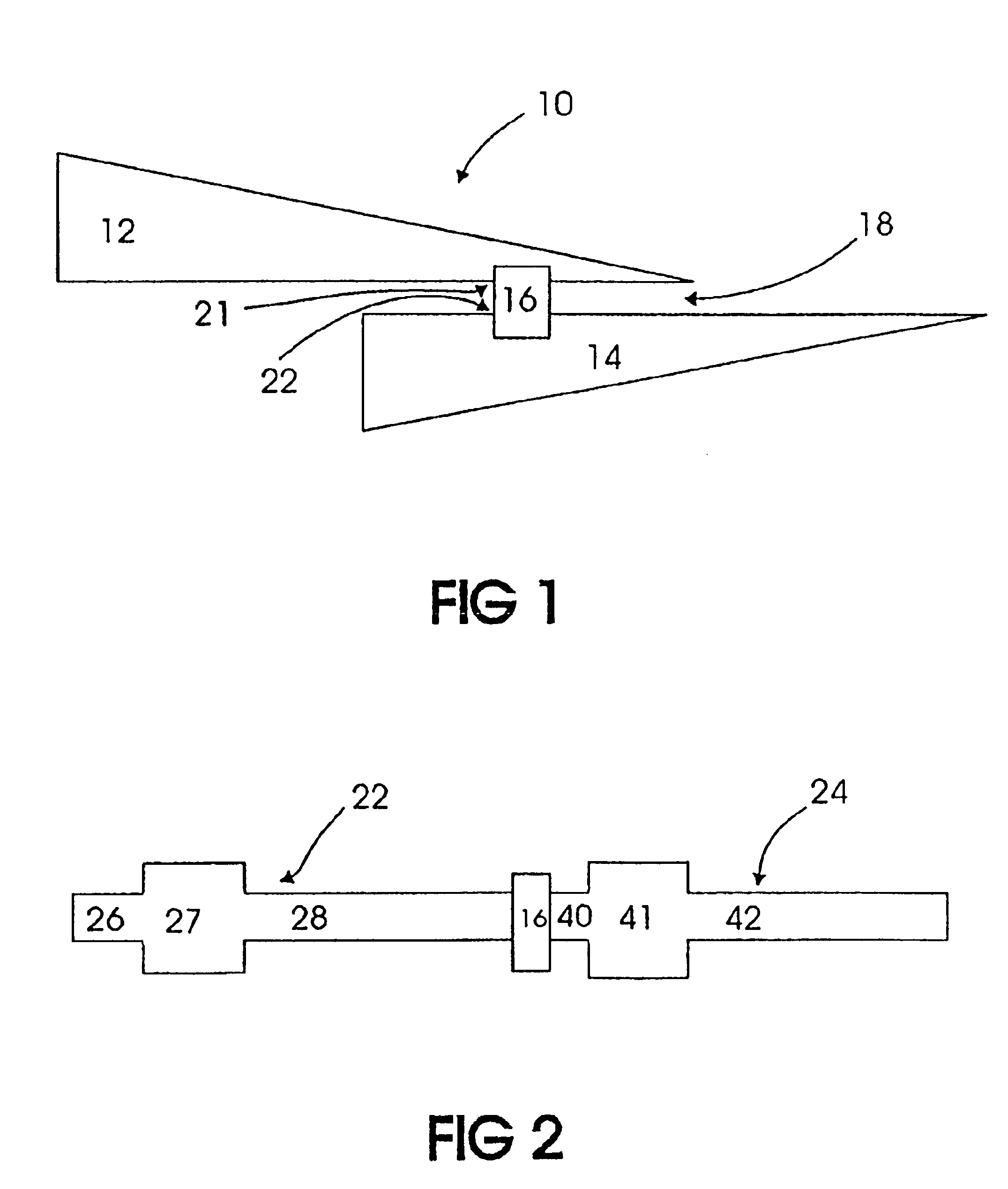

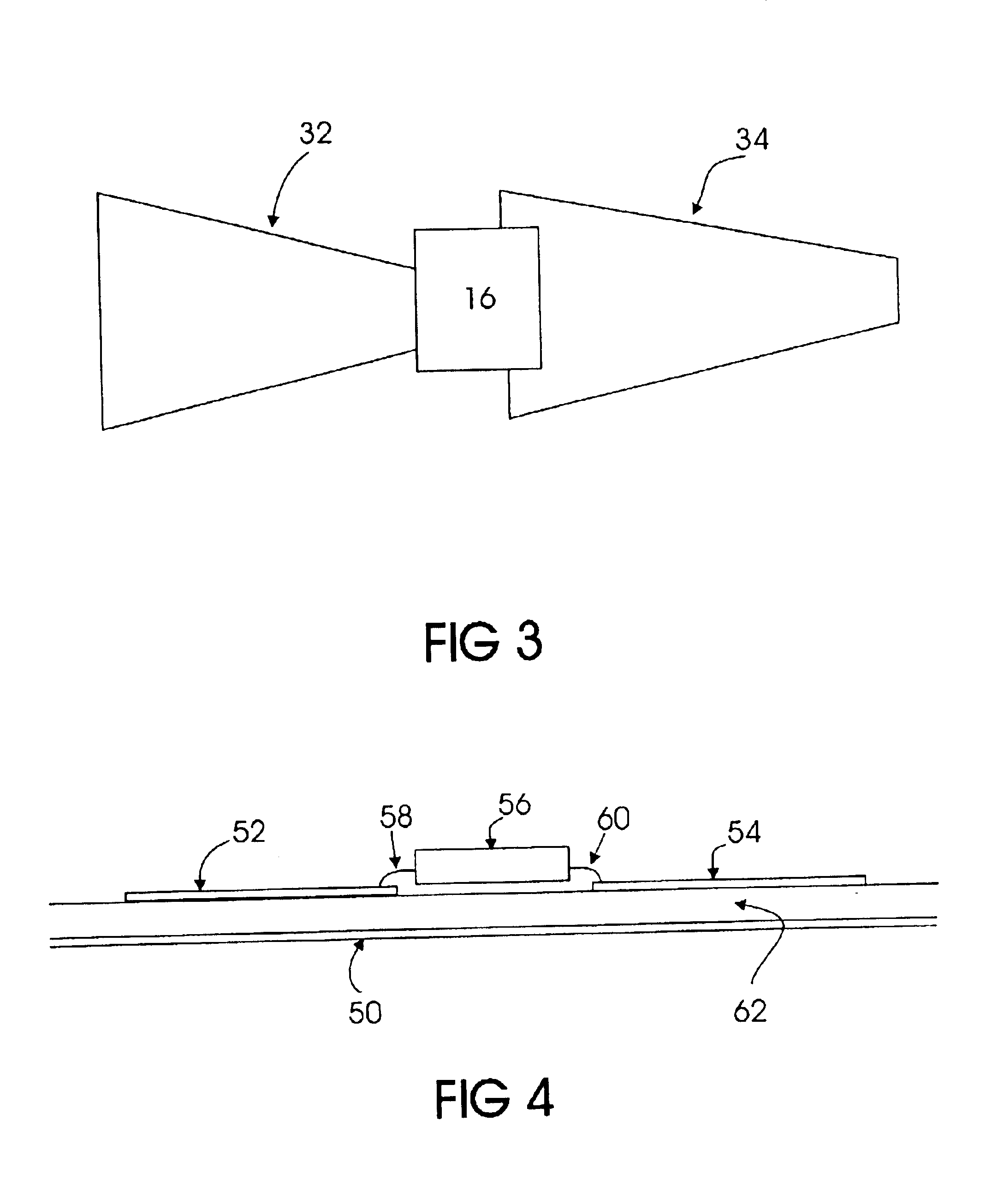

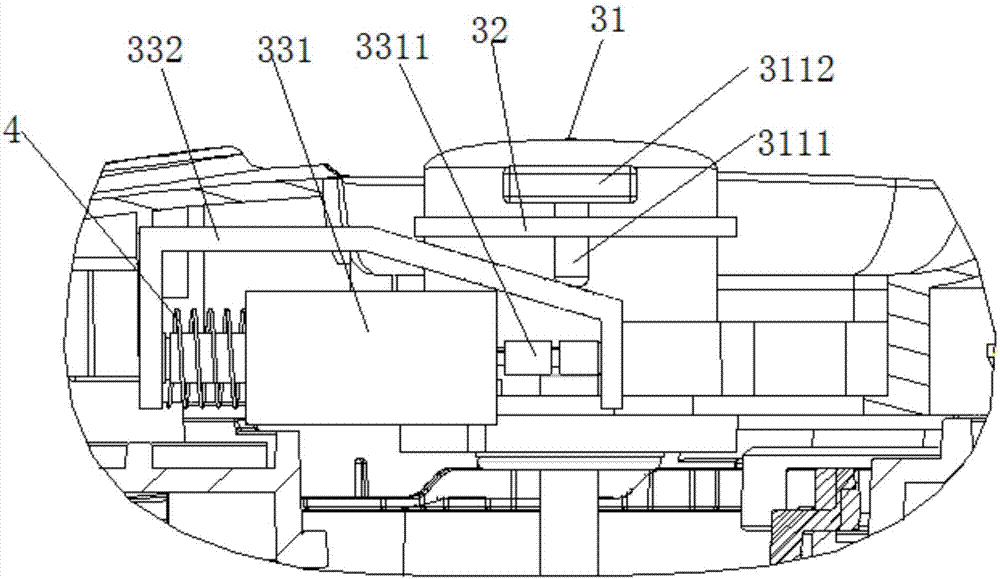

Medical implant having closed loop transcutaneous energy transfer (TET) power transfer regulation circuitry

InactiveUS20050288739A1Not easy to damageLess susceptible to inoperabilityElectrotherapyAnti-incontinence devicesElectrical batteryClosed loop

An implantable medical device, such as a bi-directional infuser device for hydraulically controlling an artificial sphincter (e.g., adjustable gastric band) benefits from being remotely powered by transcutaneous energy transfer (TET), obviating the need for batteries. In order for active components in the medical device to operate, a sinusoidal power signal received by a secondary coil is rectified and filtered. An amount of power transferred is modulated. In one version, a voltage comparison is made of a resulting power supply voltage as referenced to a threshold to control pulse width modulation (PWM) of the received sinusoidal power signal, achieving voltage regulation. Versions incorporate detuning or uncoupling of the secondary coil to achieve PWM control without causing excessive heating of the medical device.

Owner:ETHICON ENDO SURGERY INC

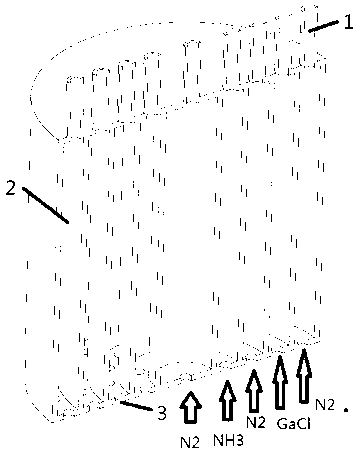

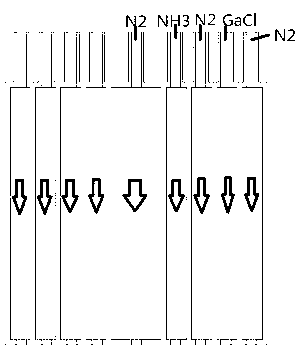

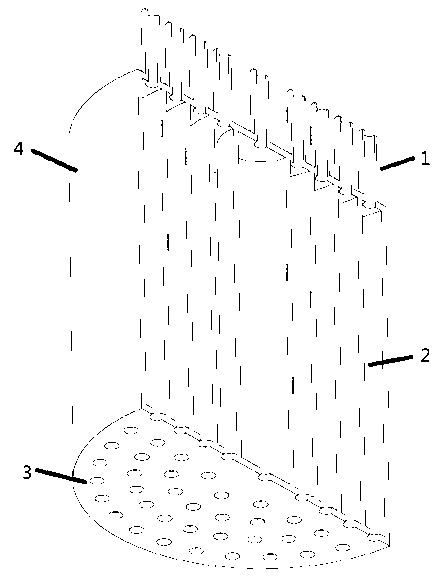

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

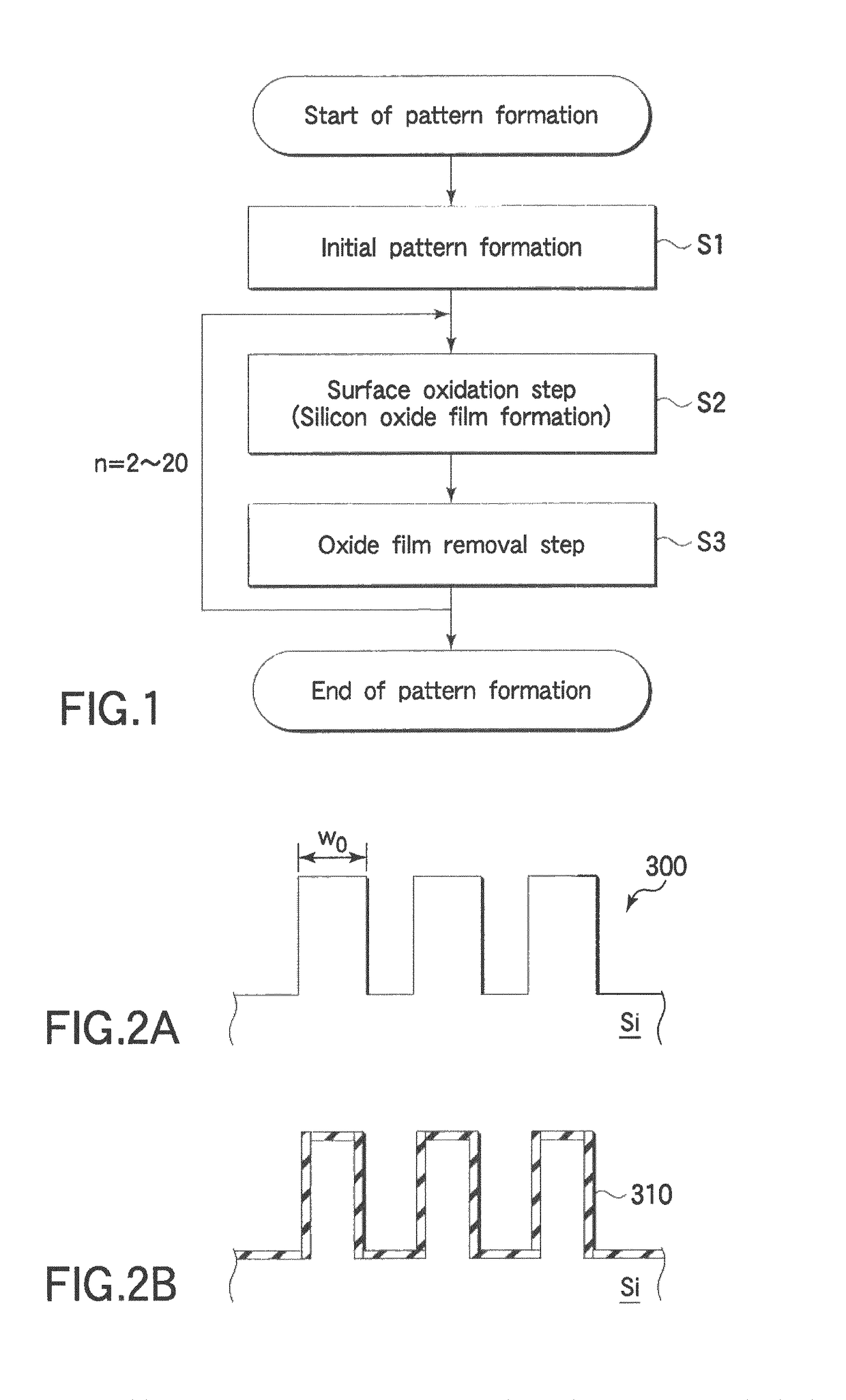

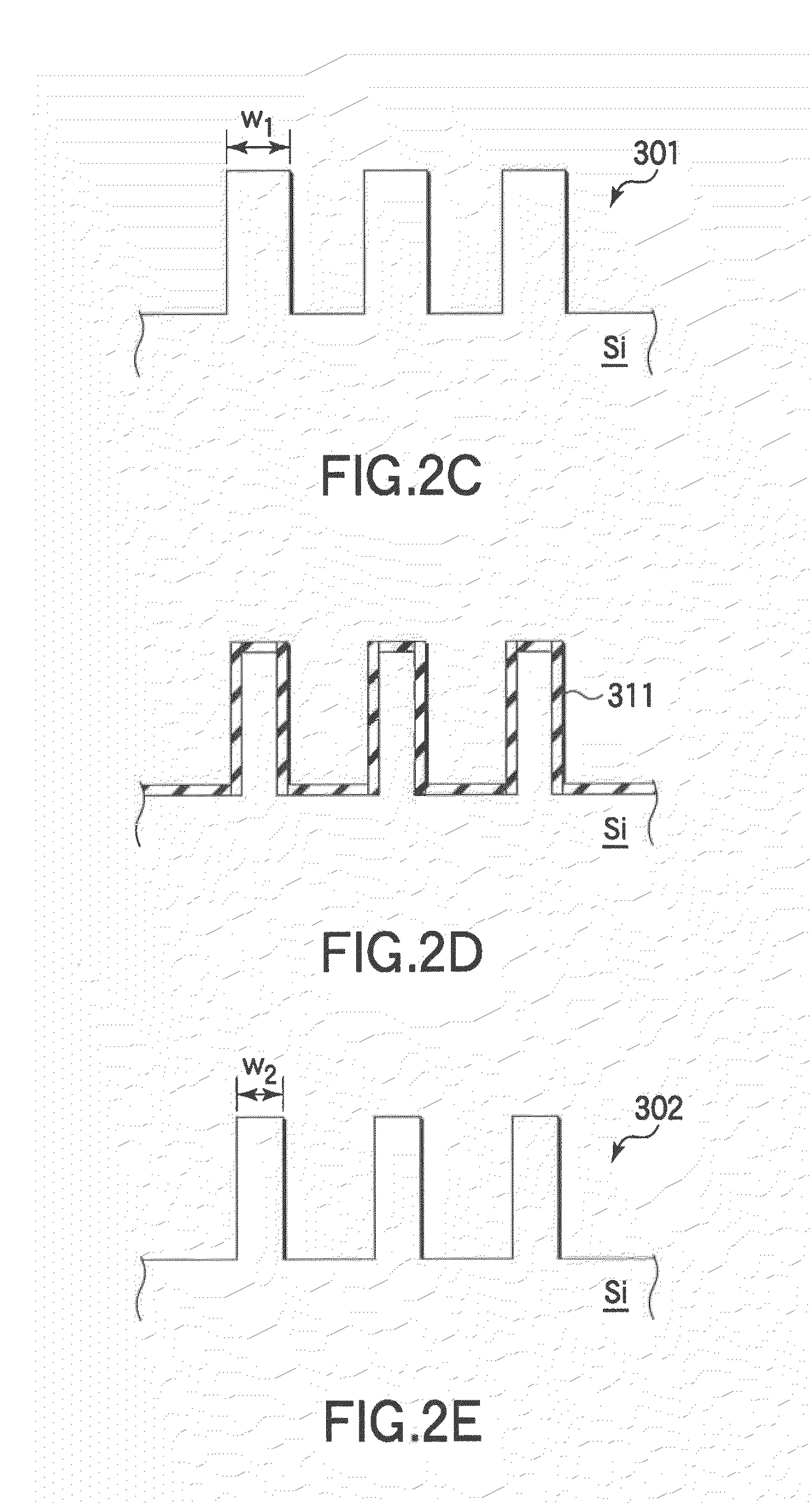

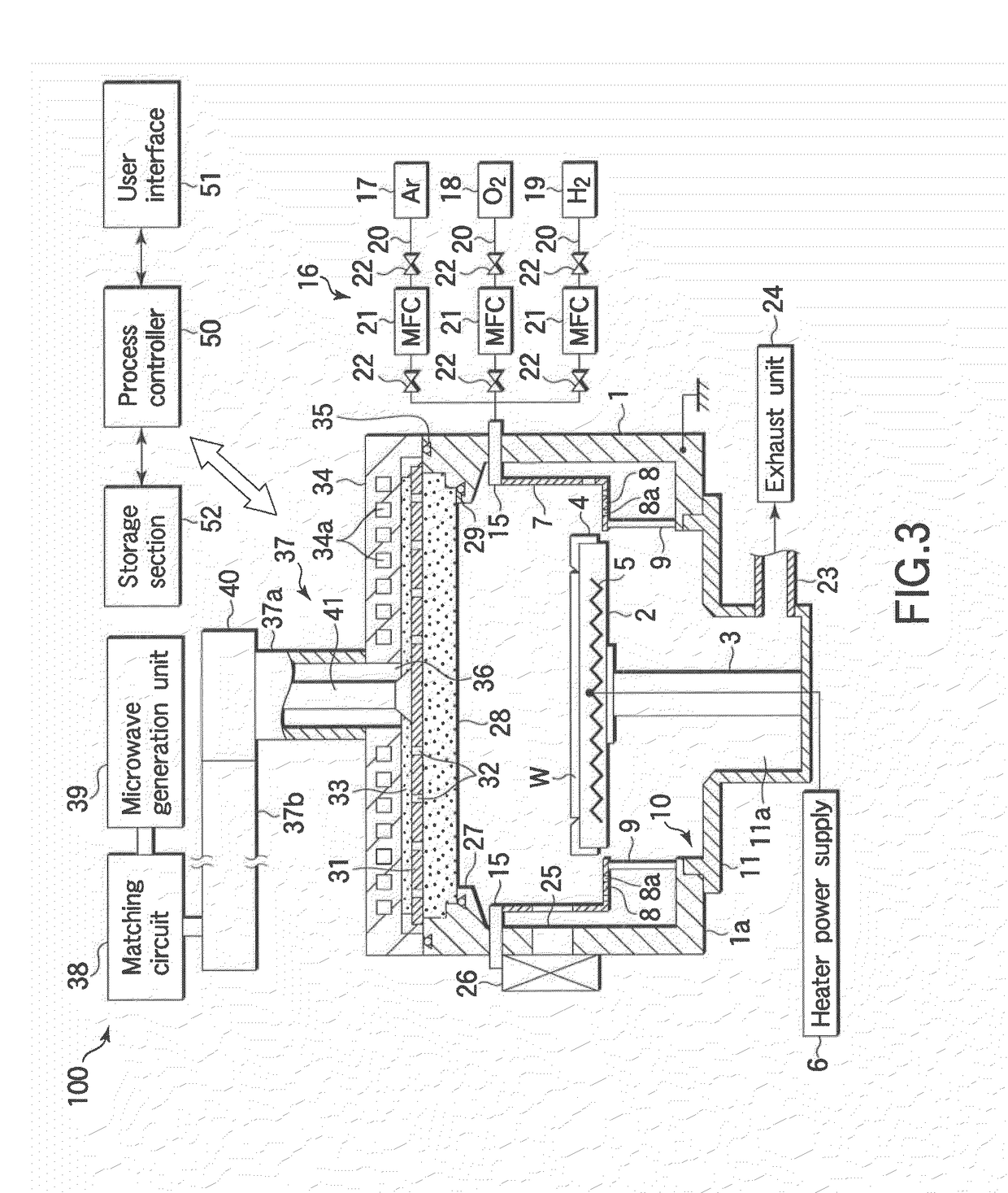

Pattern forming method and semiconductor device manufacturing method

ActiveUS8119530B2Not easy to damageImprove film qualitySemiconductor/solid-state device manufacturingSemiconductor devicesLine widthSilicon oxide

A pattern forming method includes preparing a target object including silicon with an initial pattern formed thereon and having a first line width; performing a plasma oxidation process on the silicon surface inside a process chamber of a plasma processing apparatus and thereby forming a silicon oxide film on a surface of the initial pattern; and removing the silicon oxide film. The pattern forming method is arranged to repeatedly perform formation of the silicon oxide film and removal of the silicon oxide film so as to form an objective pattern having a second line width finer than the first line width on the target object.

Owner:NAGOYA UNIVERSITY +1

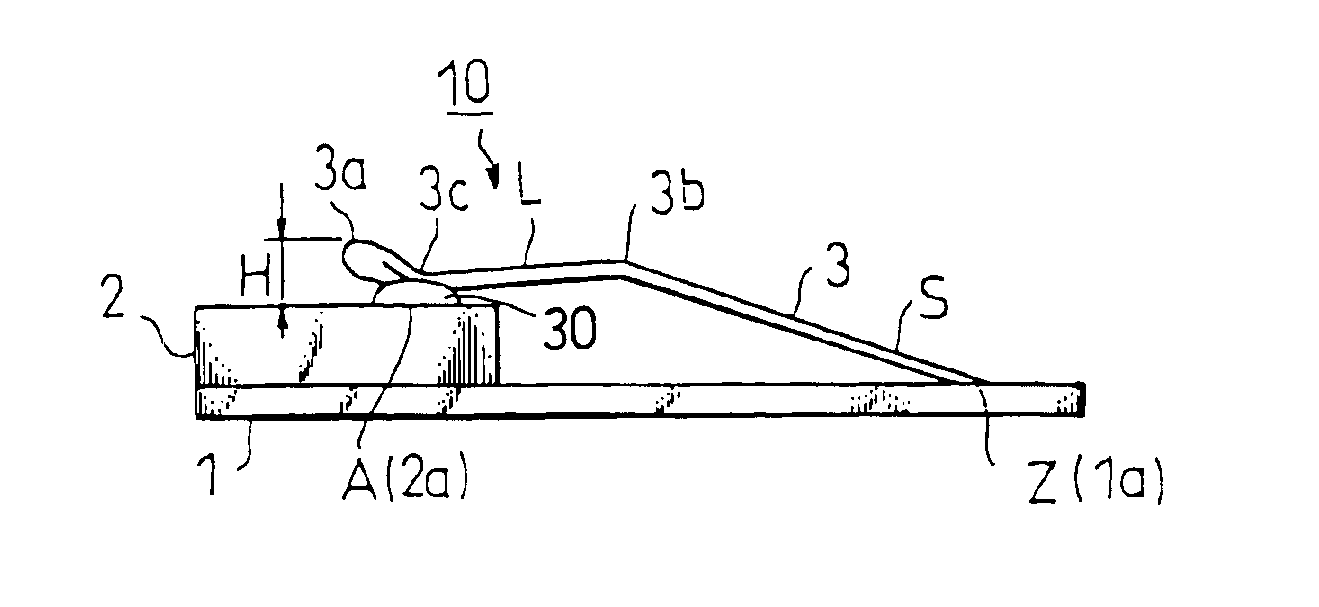

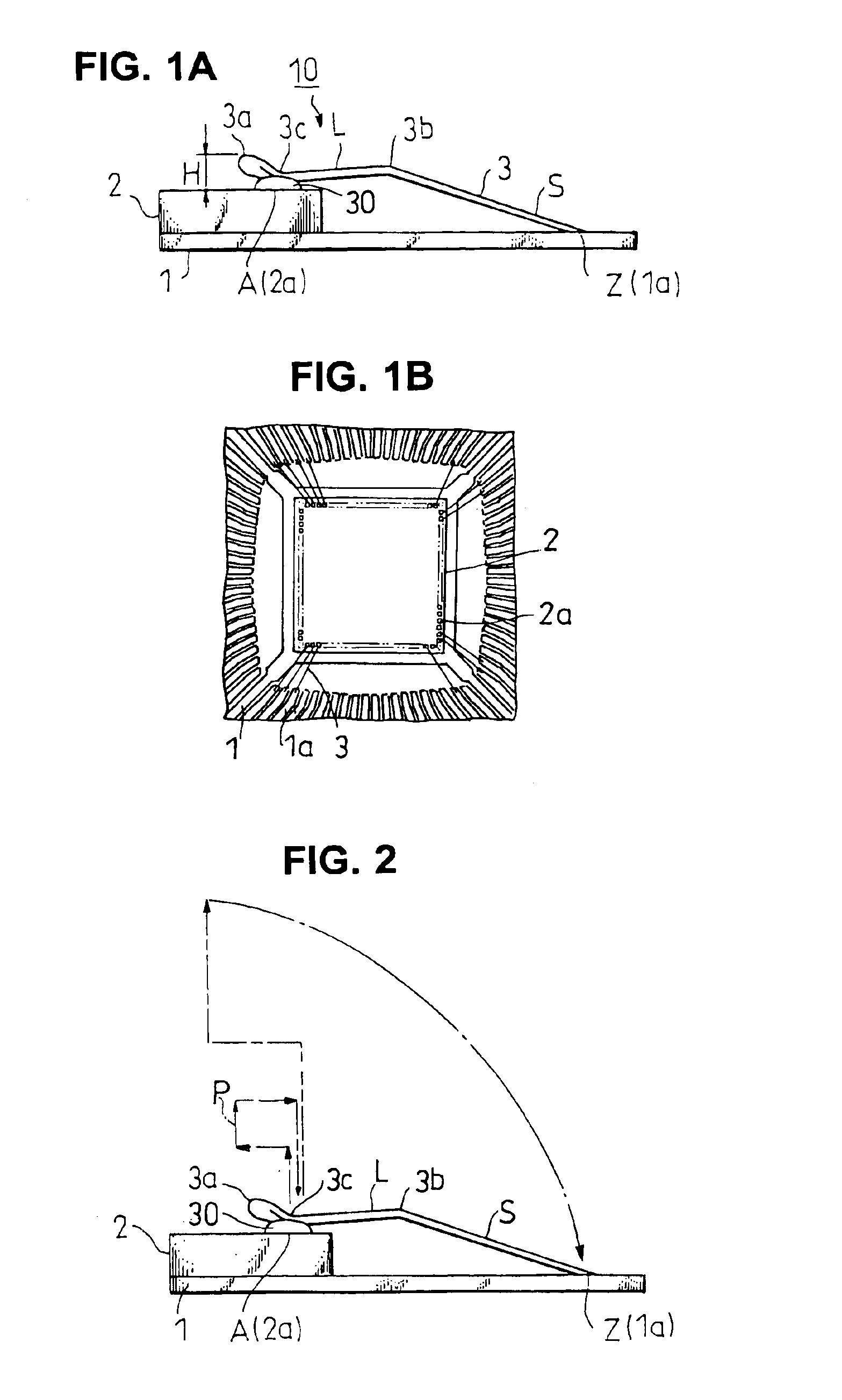

Wire loop, semiconductor device having same, wire bonding method and wire bonding apparatus

InactiveUS6933608B2Low profileNot easy to damageSemiconductor/solid-state device detailsSolid-state devicesWire rodLoop control

A wire loop comprises a wire connecting a first bonding point and a second bonding point therethrough, wherein the wire has a crushed part formed therein by crushing the part of the wire and a top of a ball bonded to the first bonding point with a capillary. The wire loop is formed by a wire bonding method which includes: bonding the wire to the first bonding point; moving the capillary horizontally and vertically while carrying out loop control; bonding the wire to the vicinity of the top of the ball bonded to the first bonding point; and thereafter, moving the capillary horizontally and vertically to the second bonding point while delivering the wire and carrying out loop control, and then bonding the wire to the second bonding point.

Owner:KAIJOO KK

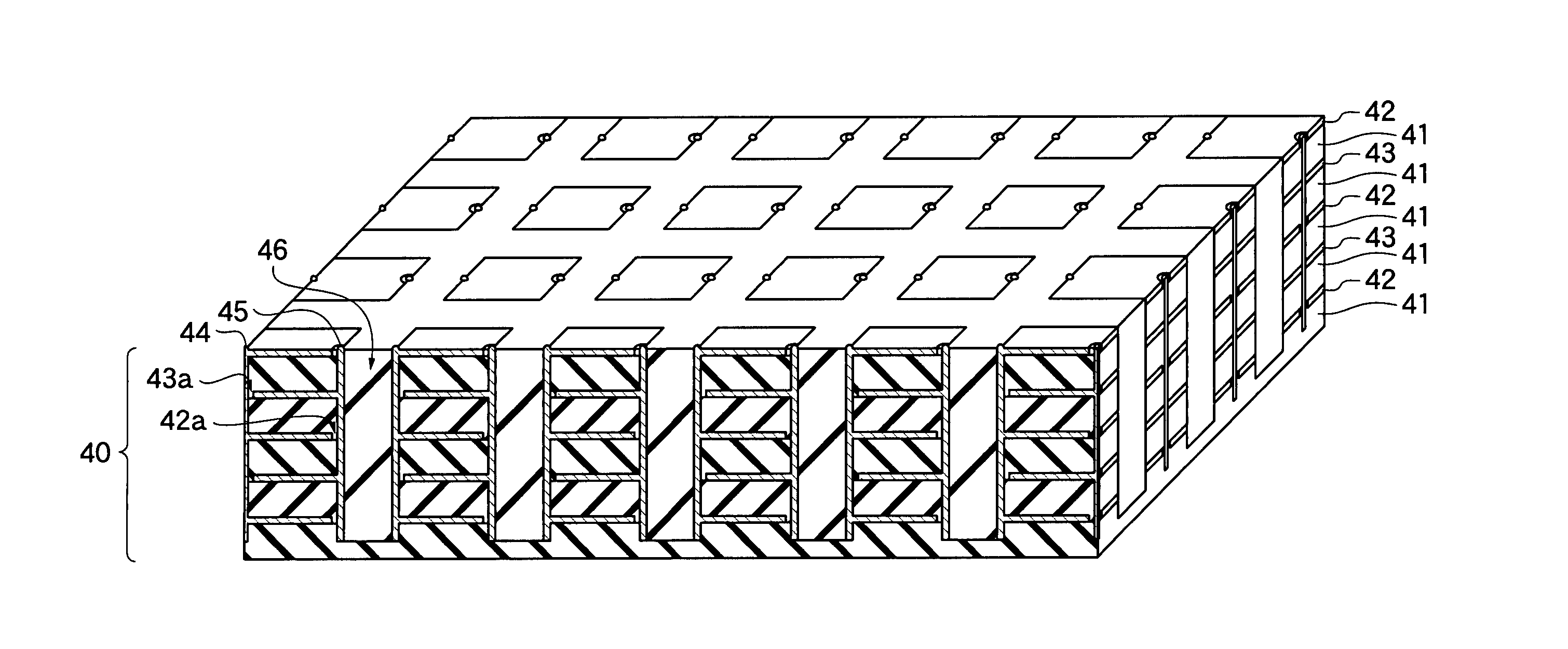

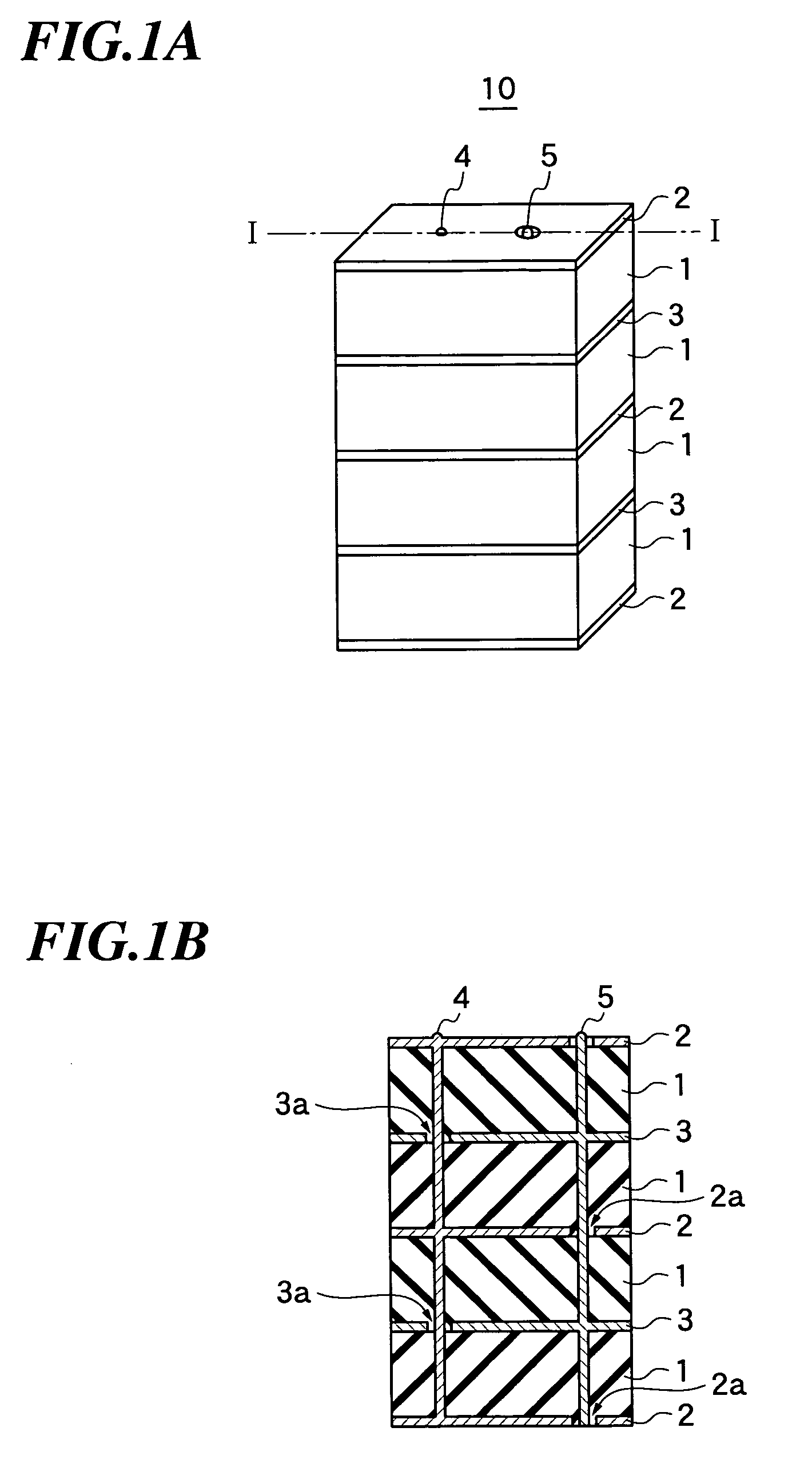

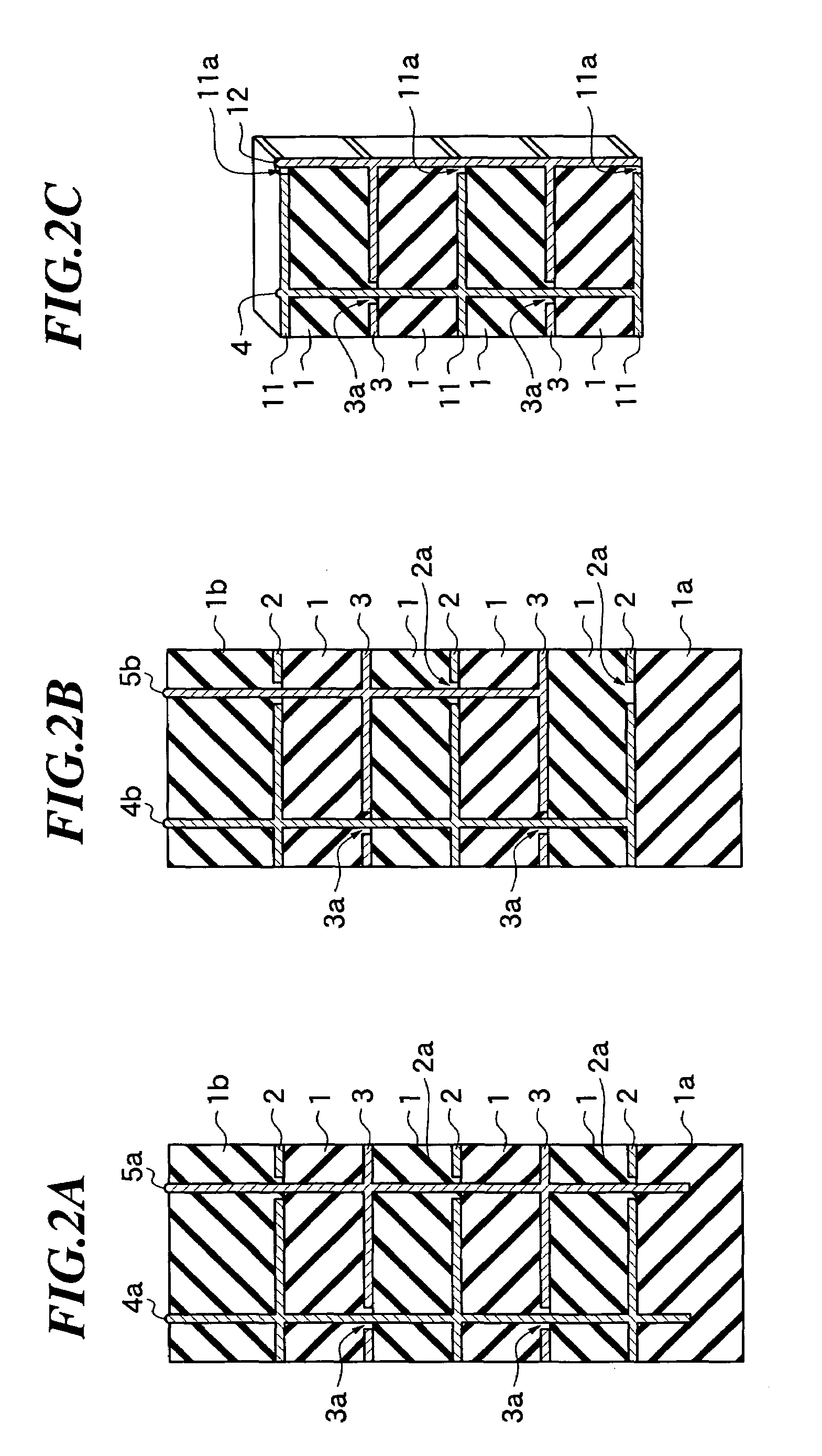

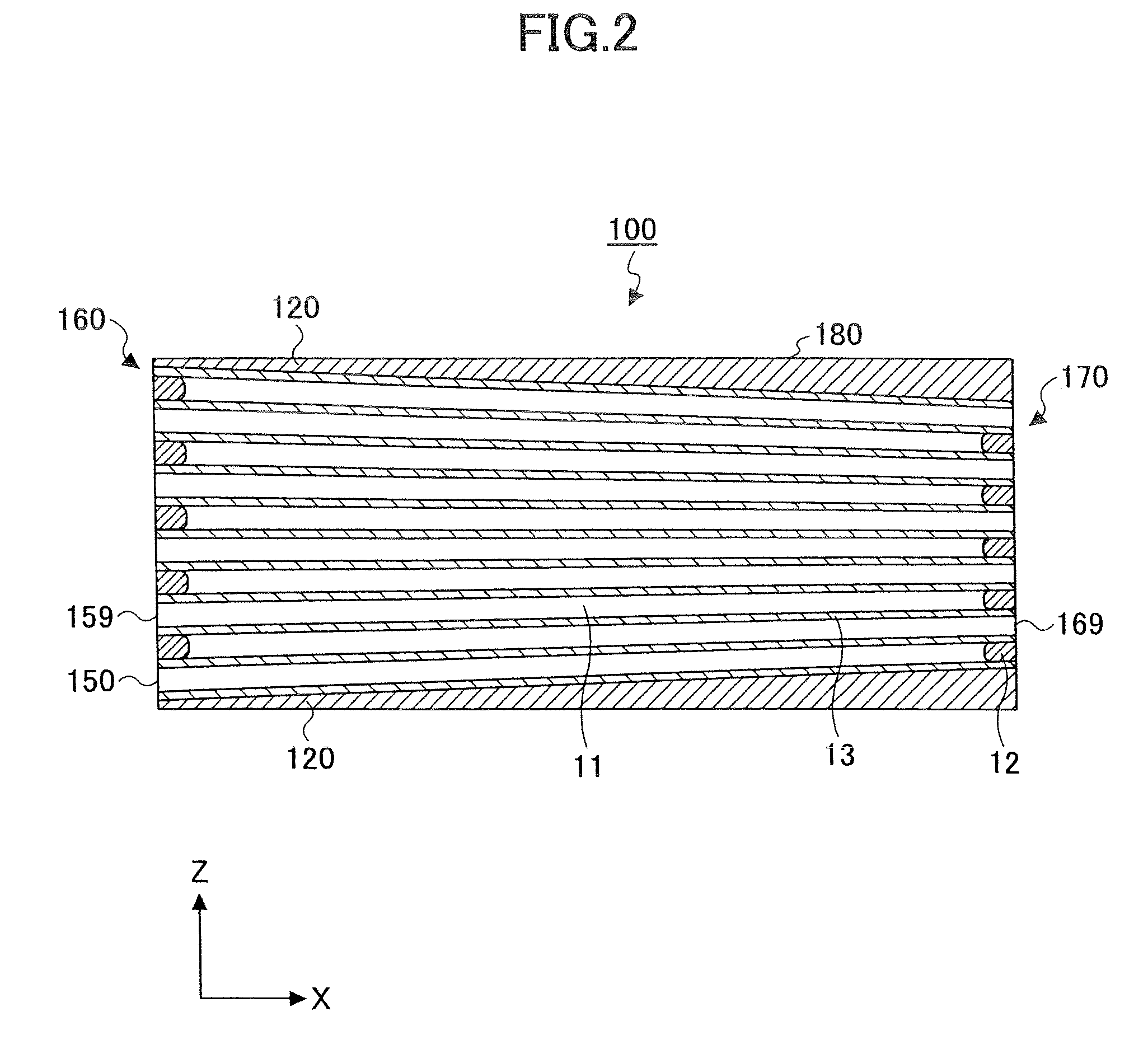

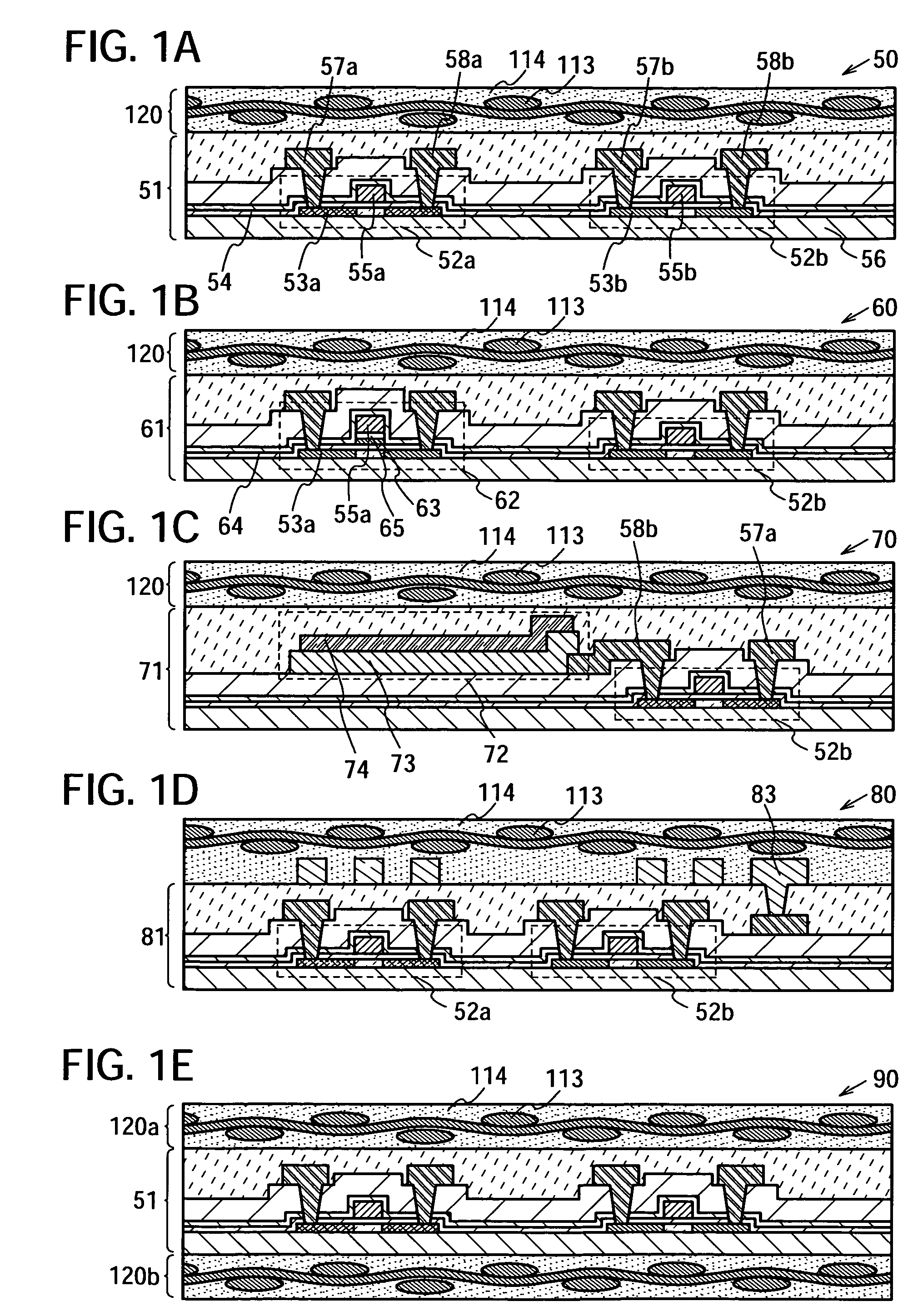

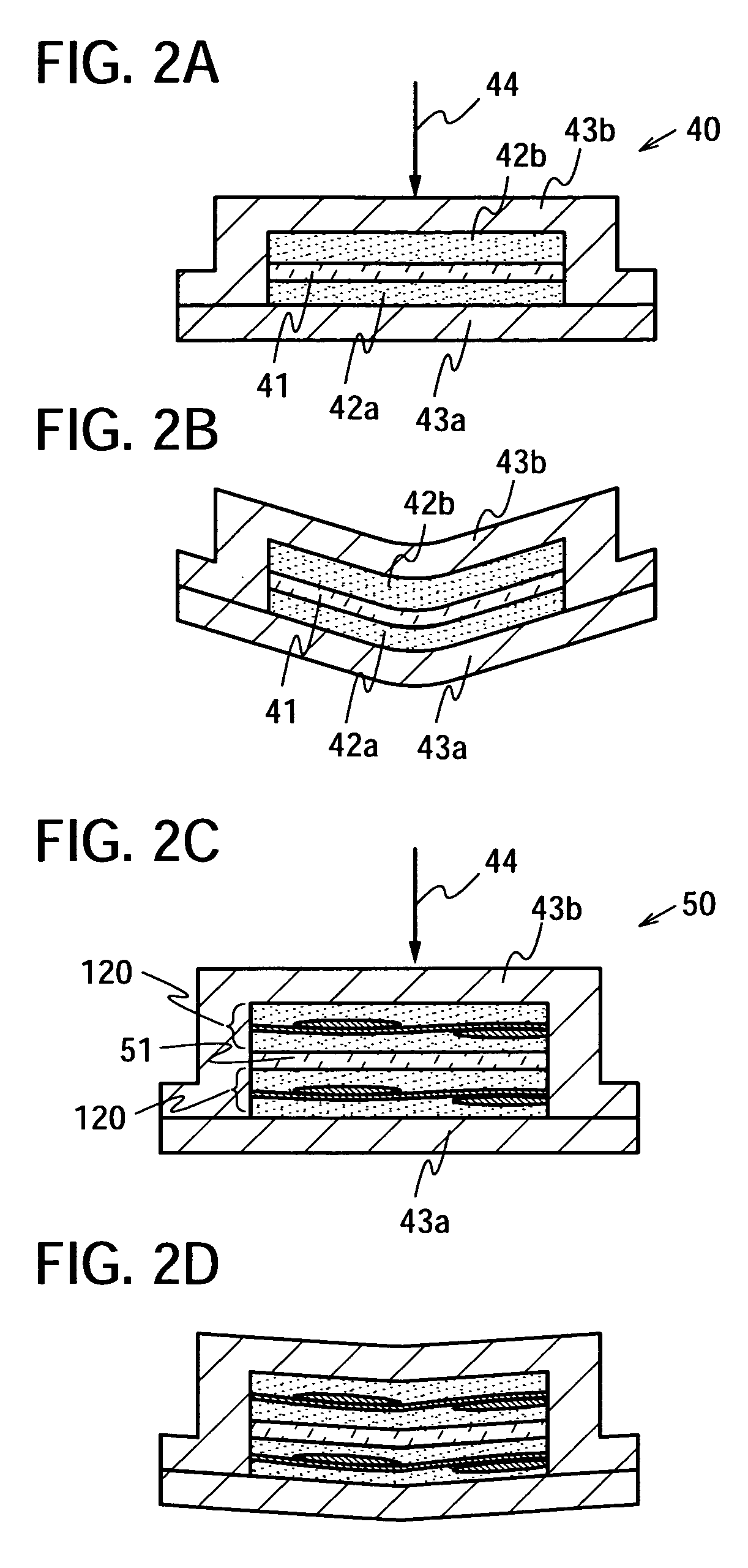

Laminated structure and method of manufacturing the same

InactiveUS7061166B2Not easy to damageWell formedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringInterconnection

A laminated structure in which interconnections can be easily formed for electrodes and in which the damage of an insulating layer attributed to stress is relieved. The laminated structure includes a laminated piece having a first electrode layer provided with a first insulating region, a piezoelectric material layer, and a second electrode layer provided with a second insulating region at a position different from that of the first insulating region, a first interconnection line electrically connected to the first electrode layer while passing through the second insulating region provided in the second electrode layer, and a second interconnection line electrically connected to the second electrode layer while passing through the first insulating region provided in the first electrode layer.

Owner:FUJIFILM HLDG CORP +1

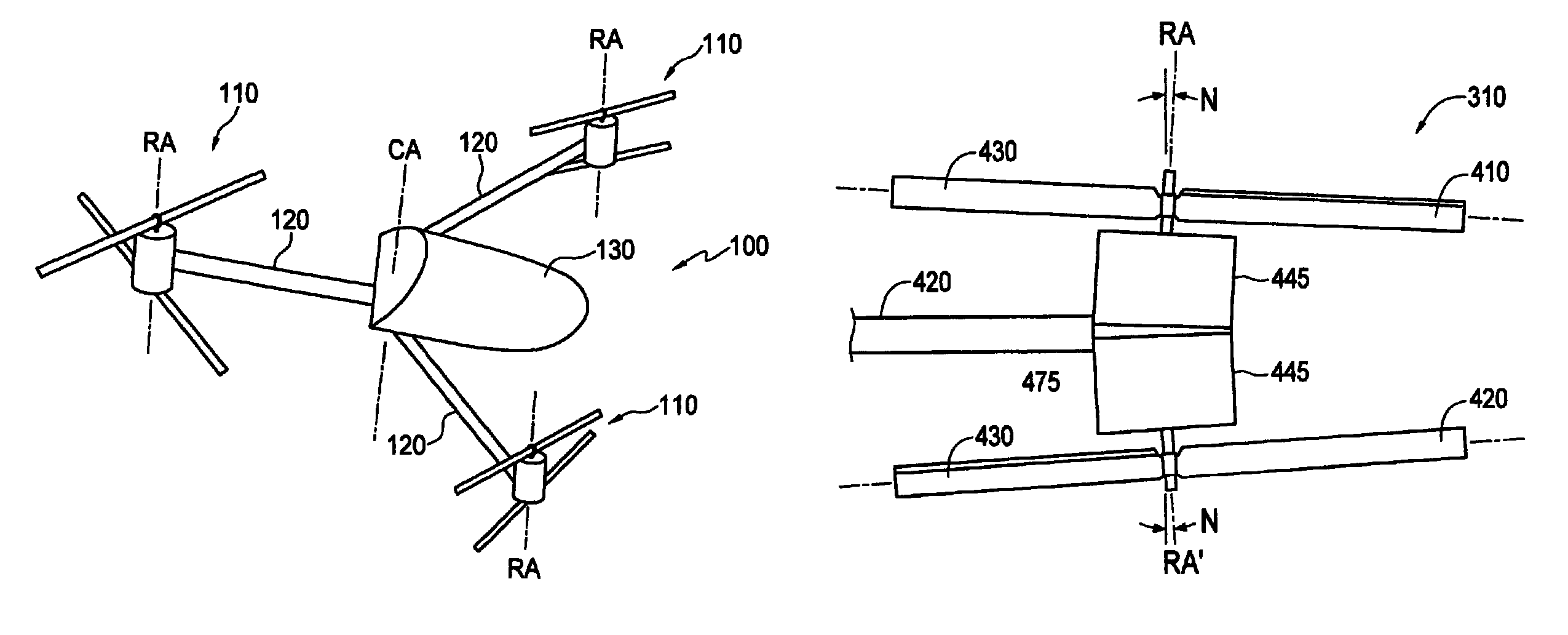

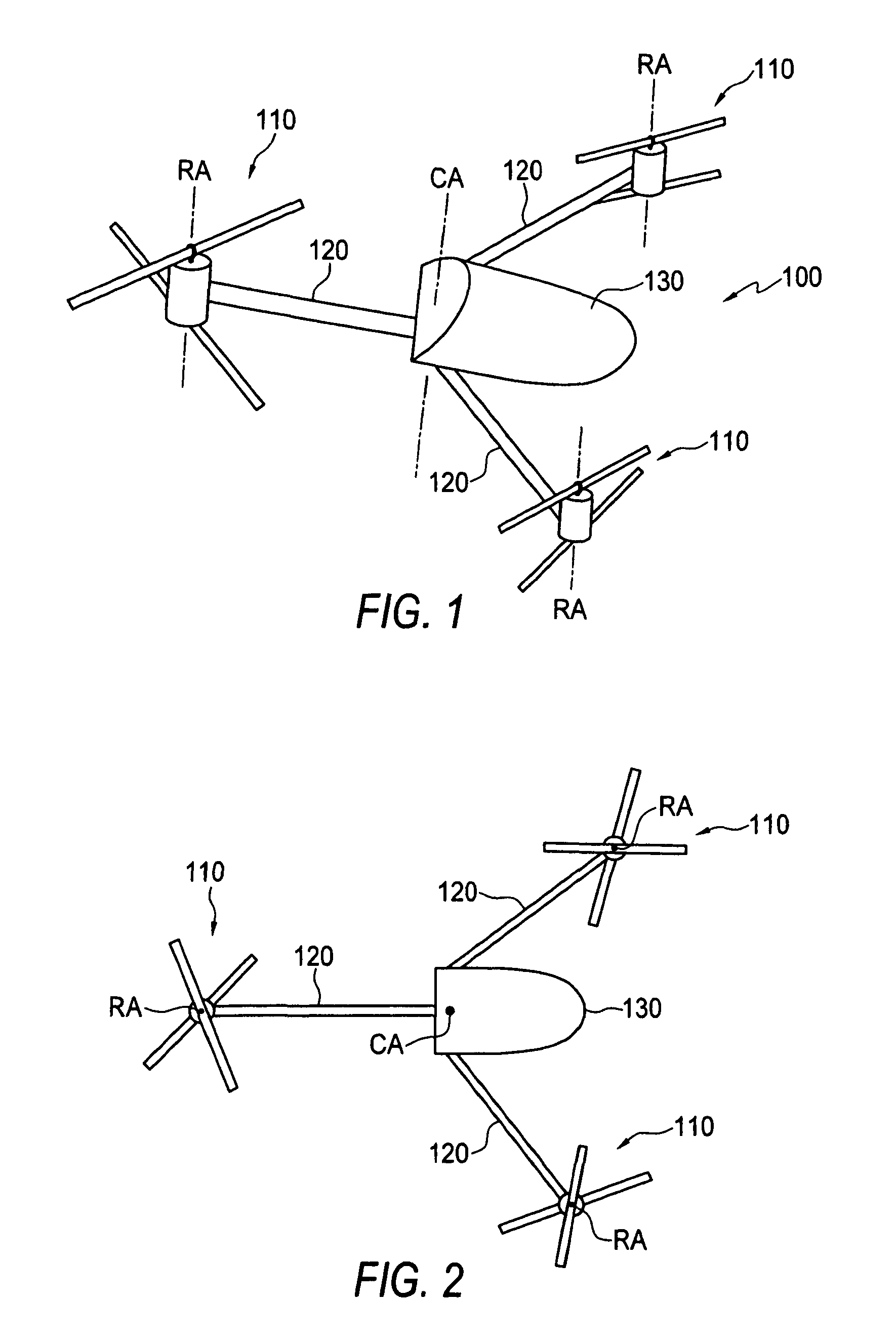

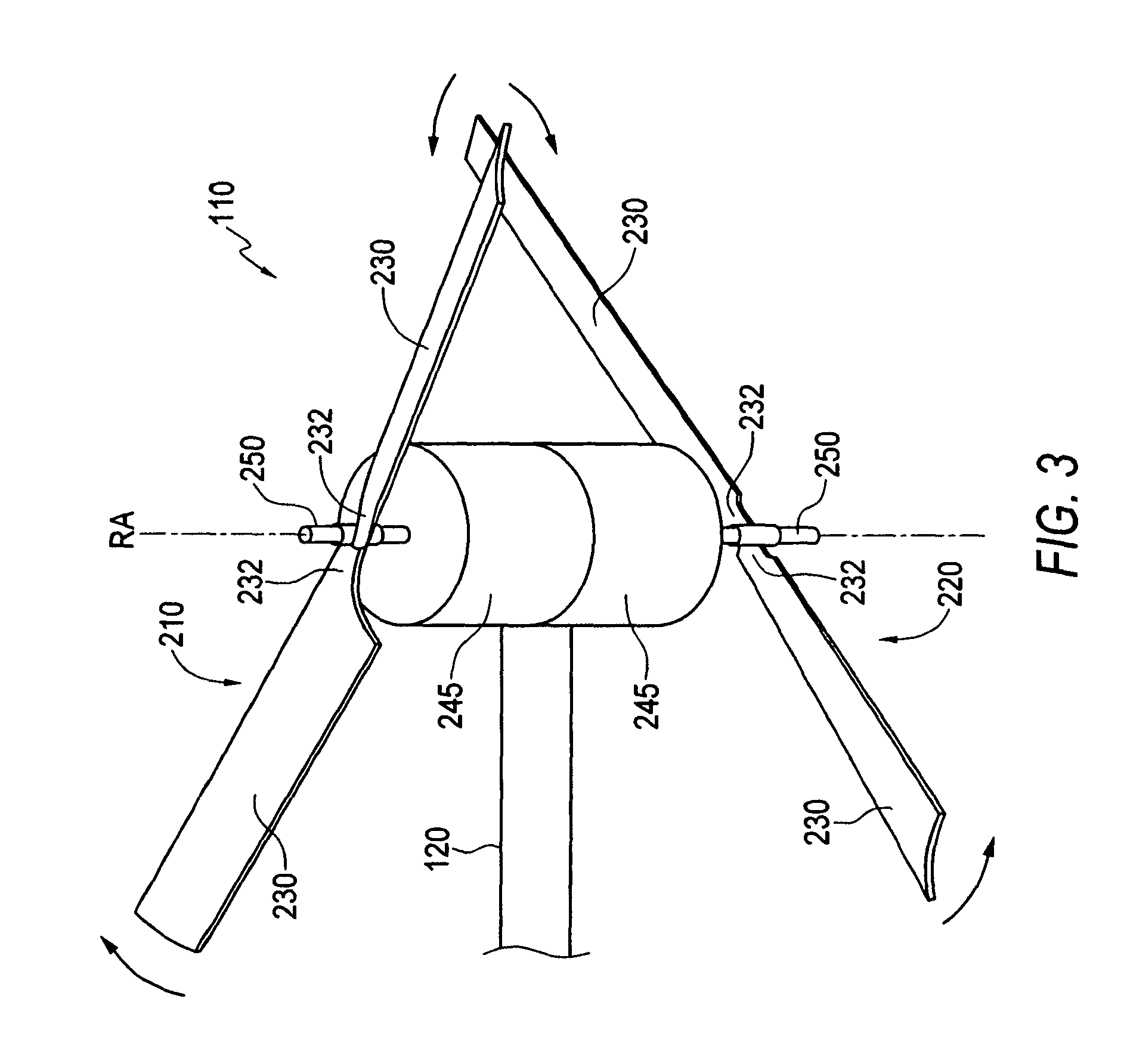

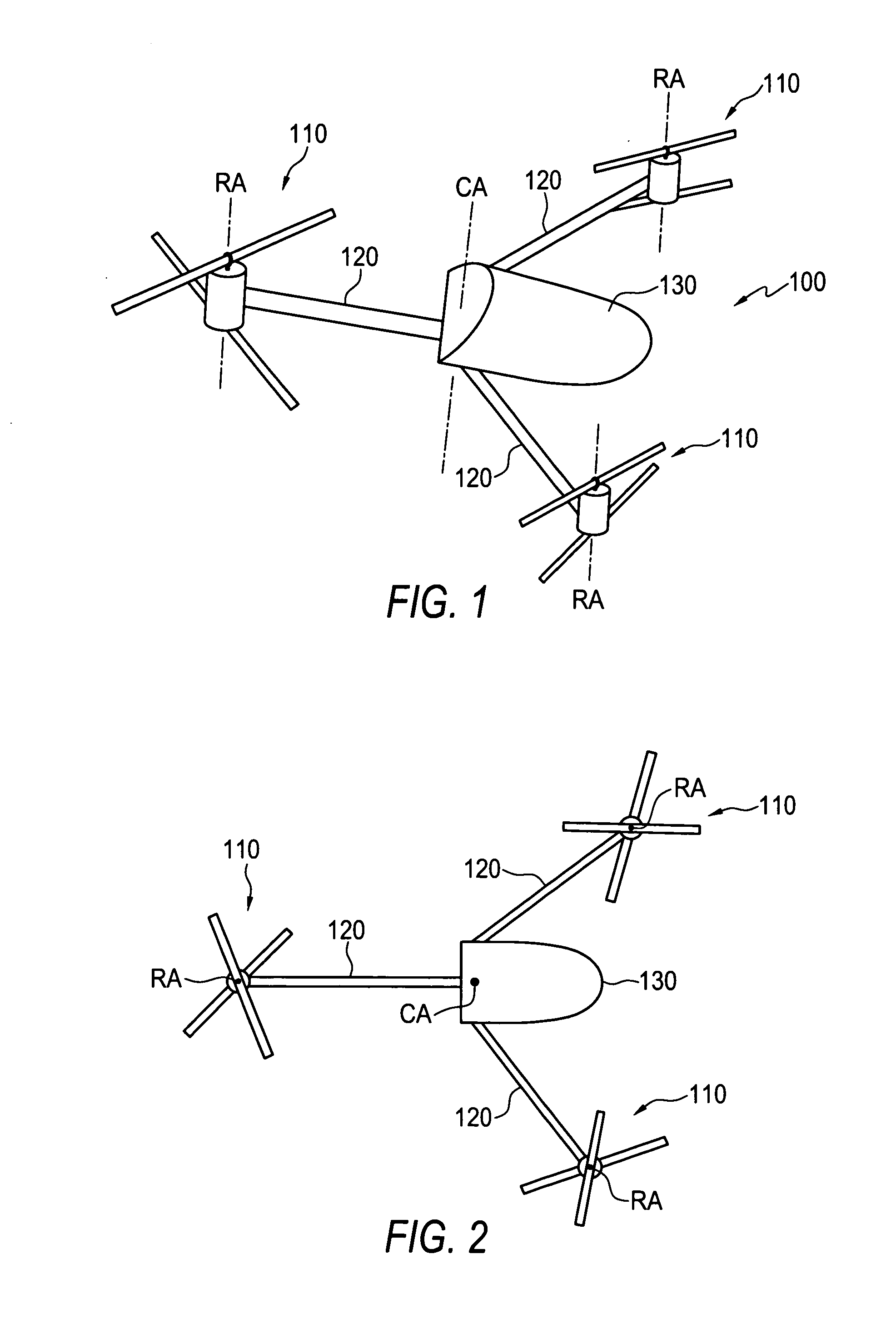

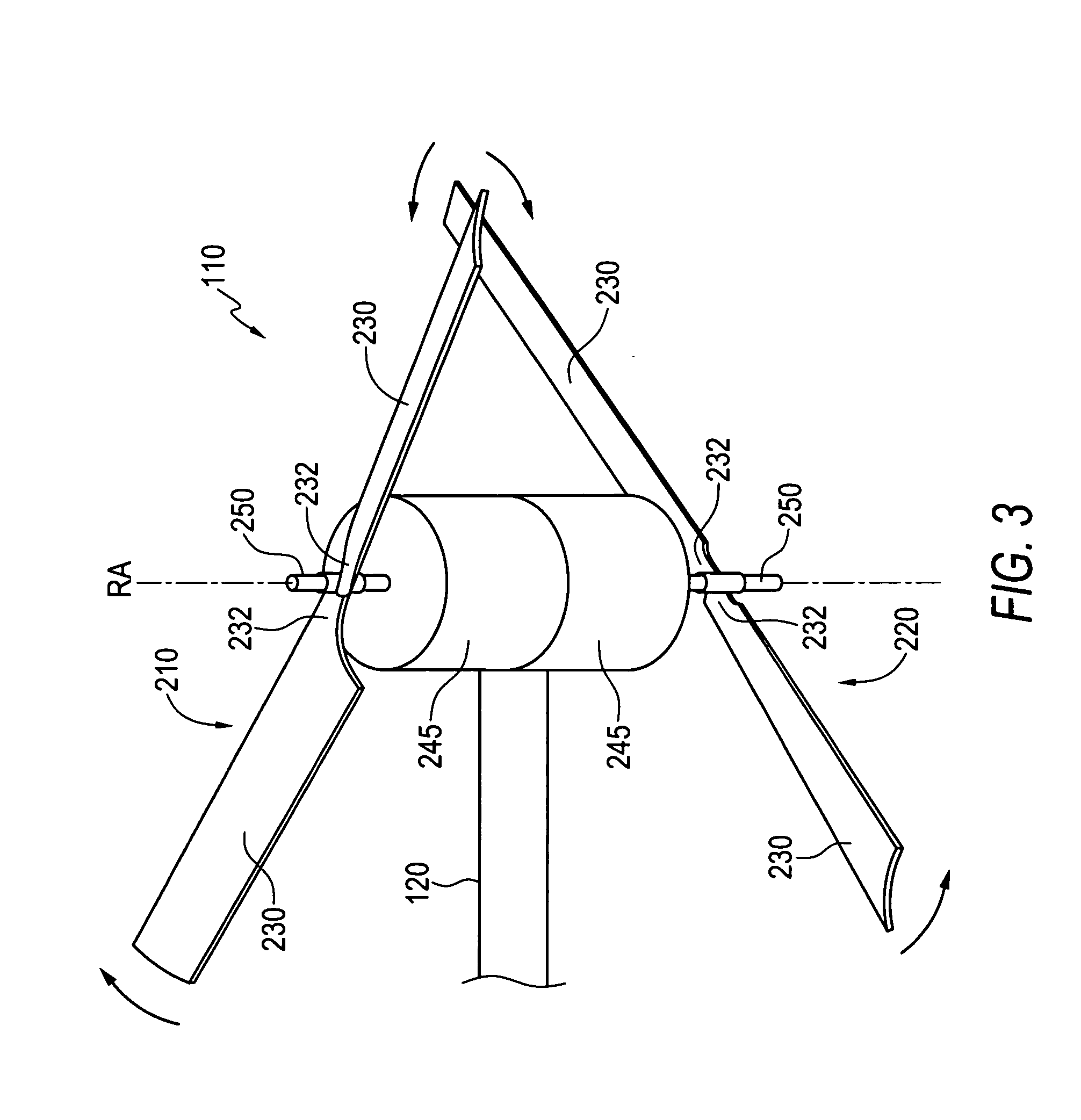

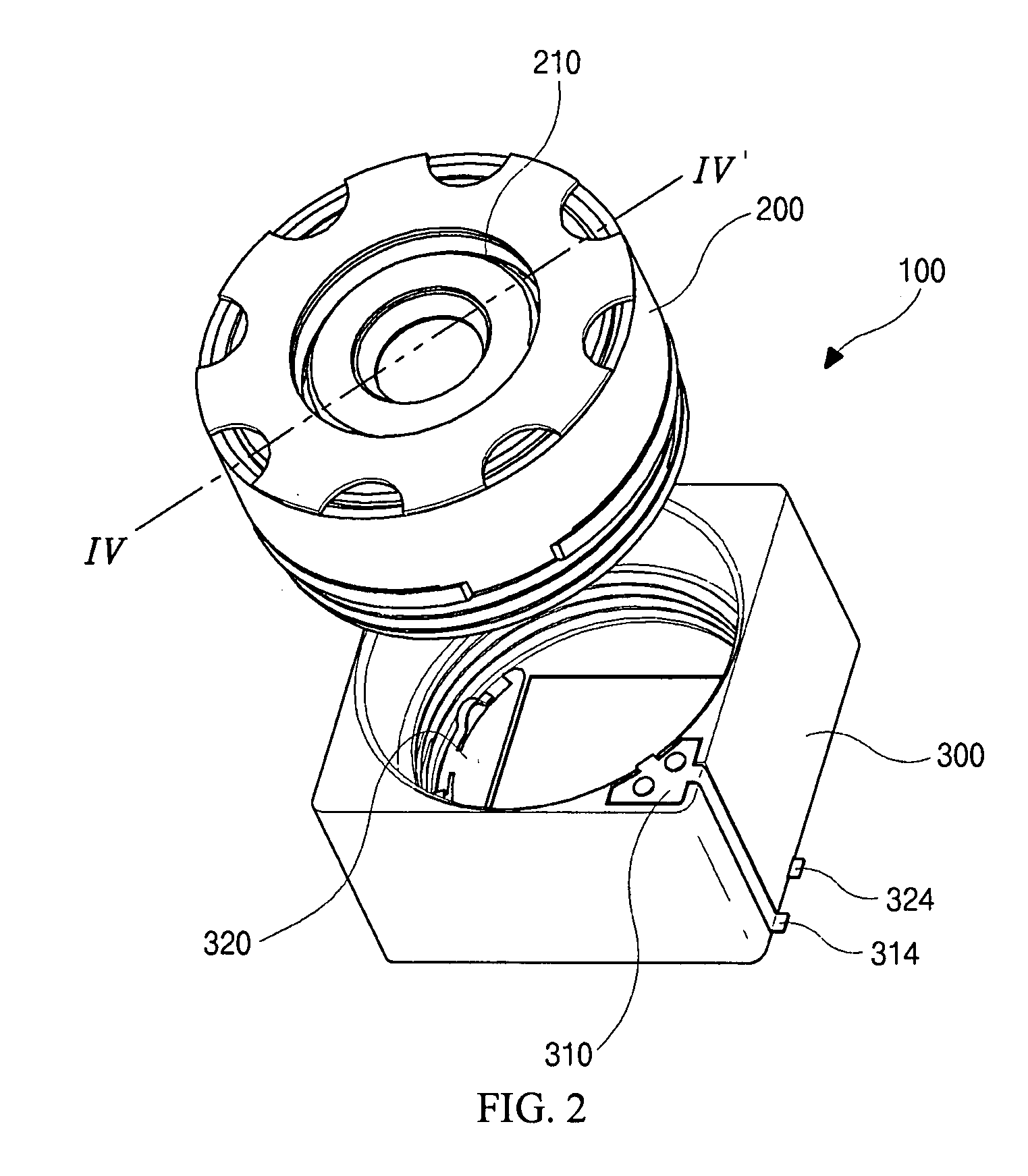

Dual rotor helicopter with tilted rotational axes

ActiveUS8052081B2Reduce riskIncrease distanceUnmanned aerial vehiclesRemote controlled aircraftRotational axisRotary wing

A rotary wing aircraft apparatus includes a body and a rotor pair connected to the body by an arm. The rotor pair has an upper rotor driven by an upper motor and rotating about an upper rotor axis and a lower rotor driven by a lower motor and rotating about a lower rotor axis. The upper and lower rotor axes are tilted with respect to each other. Tilting the axes away from the arm increases the distance from the rotor blades to the arm, and decreases the risk of the blades of the rotor contacting the arm. In an aircraft with a plurality of arms extending from the body, and a rotor assembly connected to each arm, the arms can be pivoted from a flying position, where the arms extend laterally outward to a folded position where the arms are positioned substantially parallel and adjacent to each other.

Owner:ZENON DRAGAN

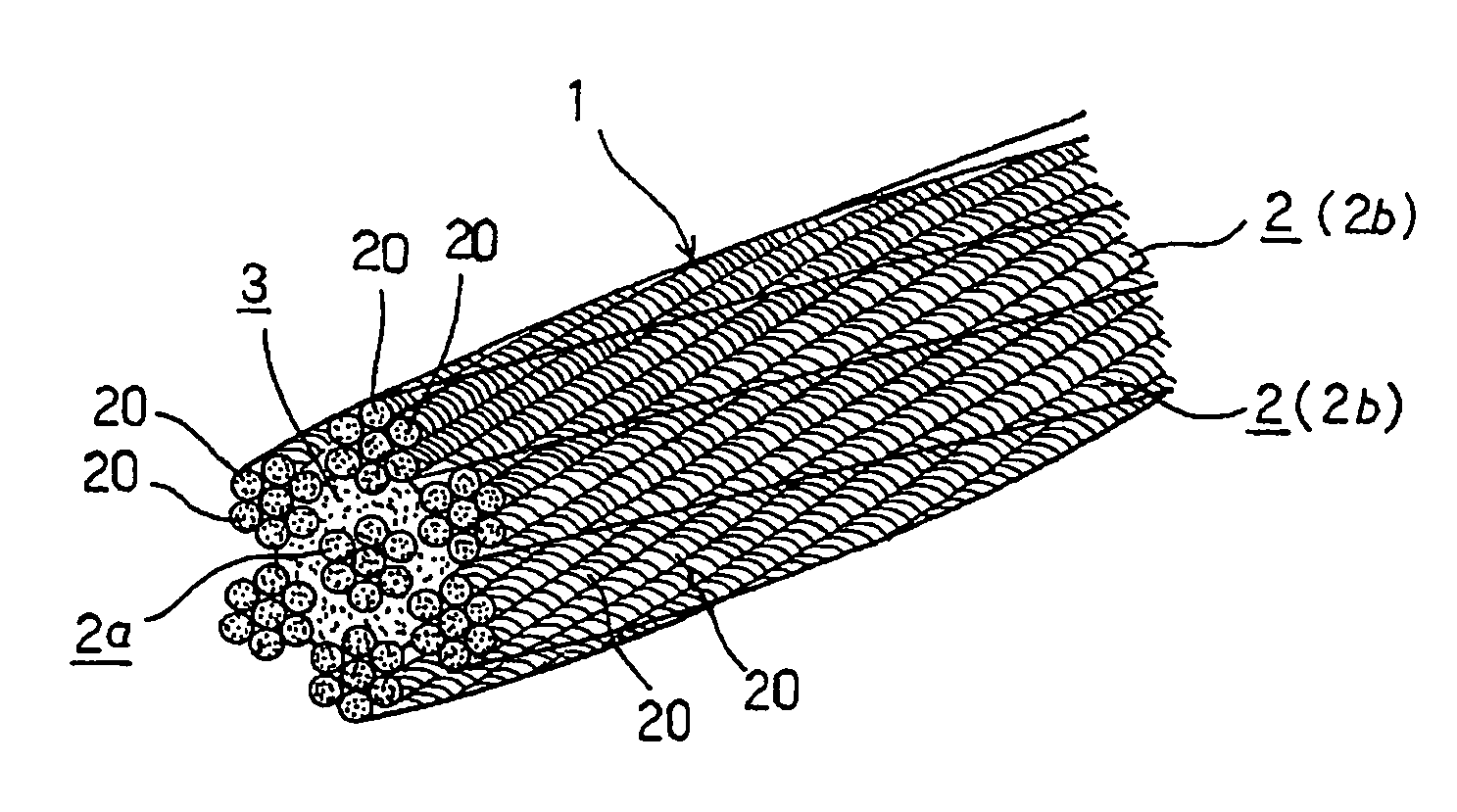

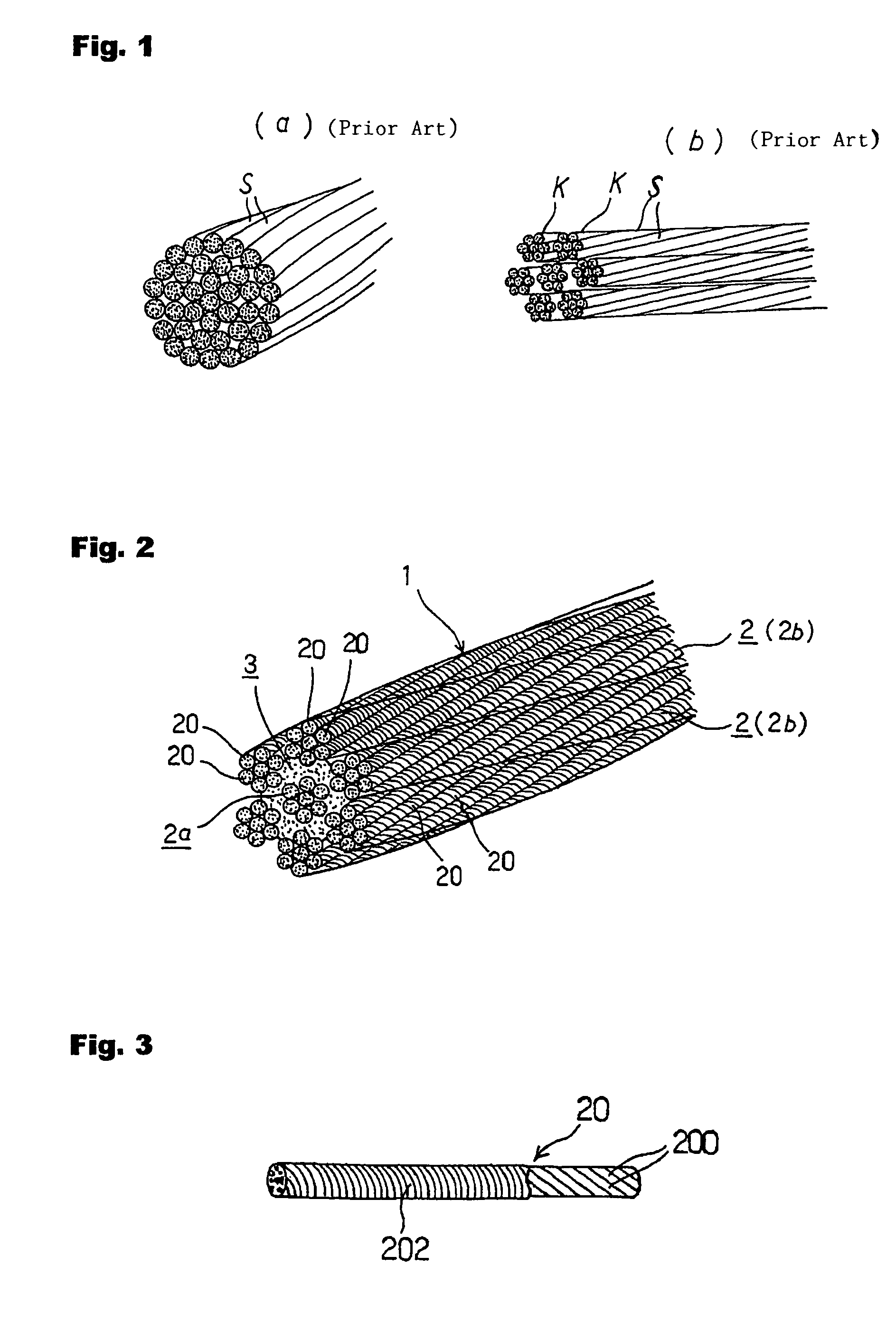

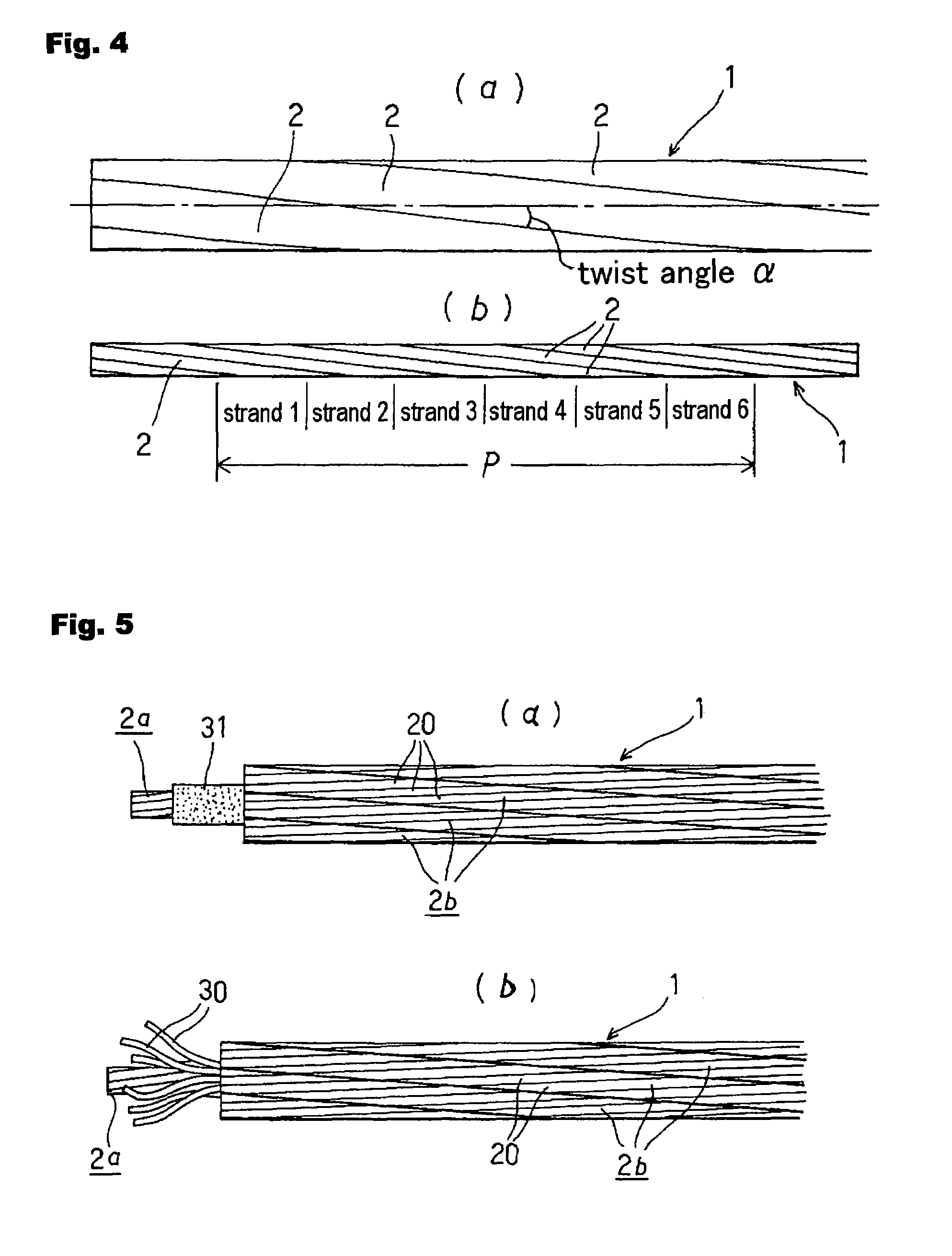

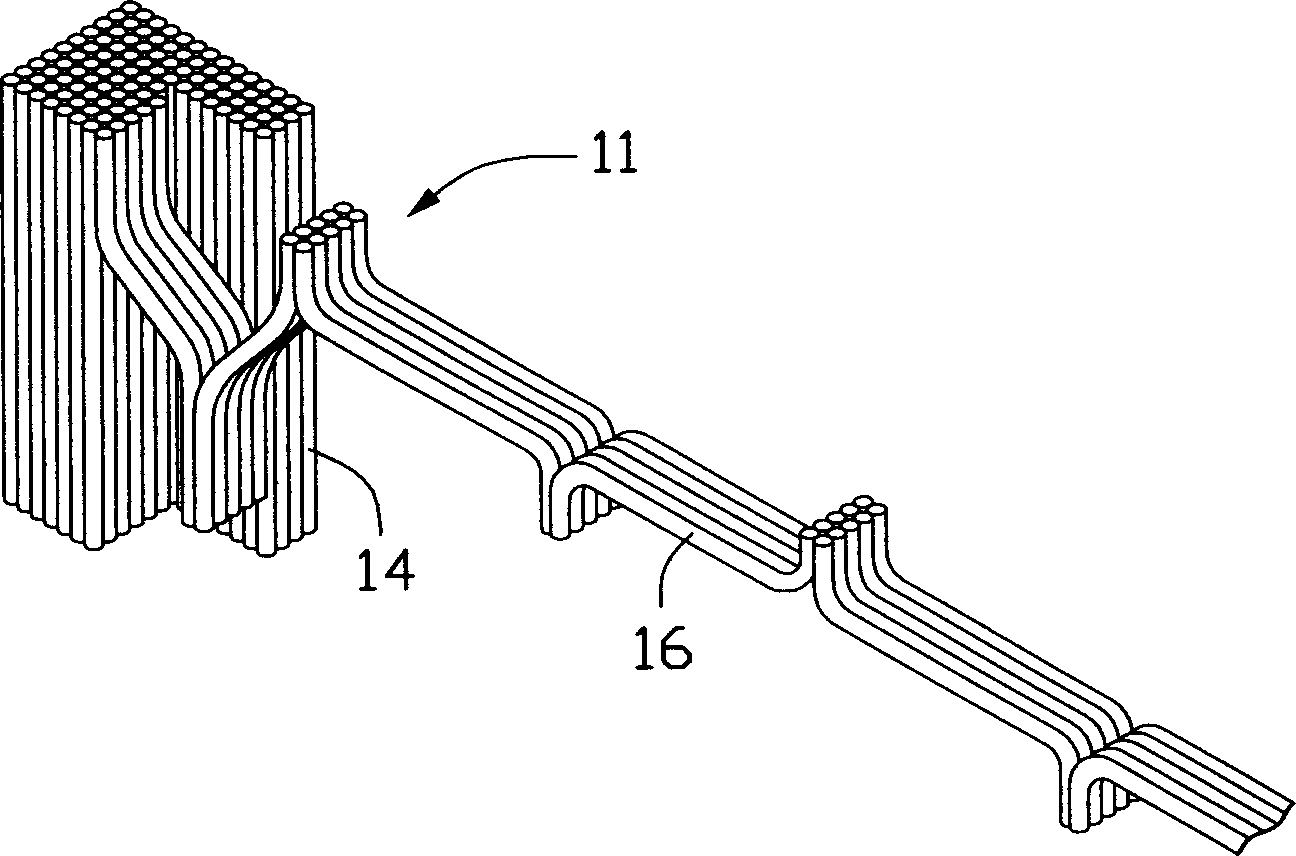

Cable made of high strength fiber composite material

A practical cable made of a high strength fiber composite material is provided, which has high and stable strength, in addition, has even axial tension against bending and thus has a stable shape, and can be wound on a reel without shape deformation, and is hardly buckled when it is inserted into a hole or cylinder. The cable is formed by singly twisting a plurality of high strength fiber composite materials is used as a strand, and a plurality of the strands are twisted together at a twist angle of 2 to 12 degrees in a direction opposite to a twist direction of the strands, so that a double twist structure is made.

Owner:TOKYO ROPE MFG

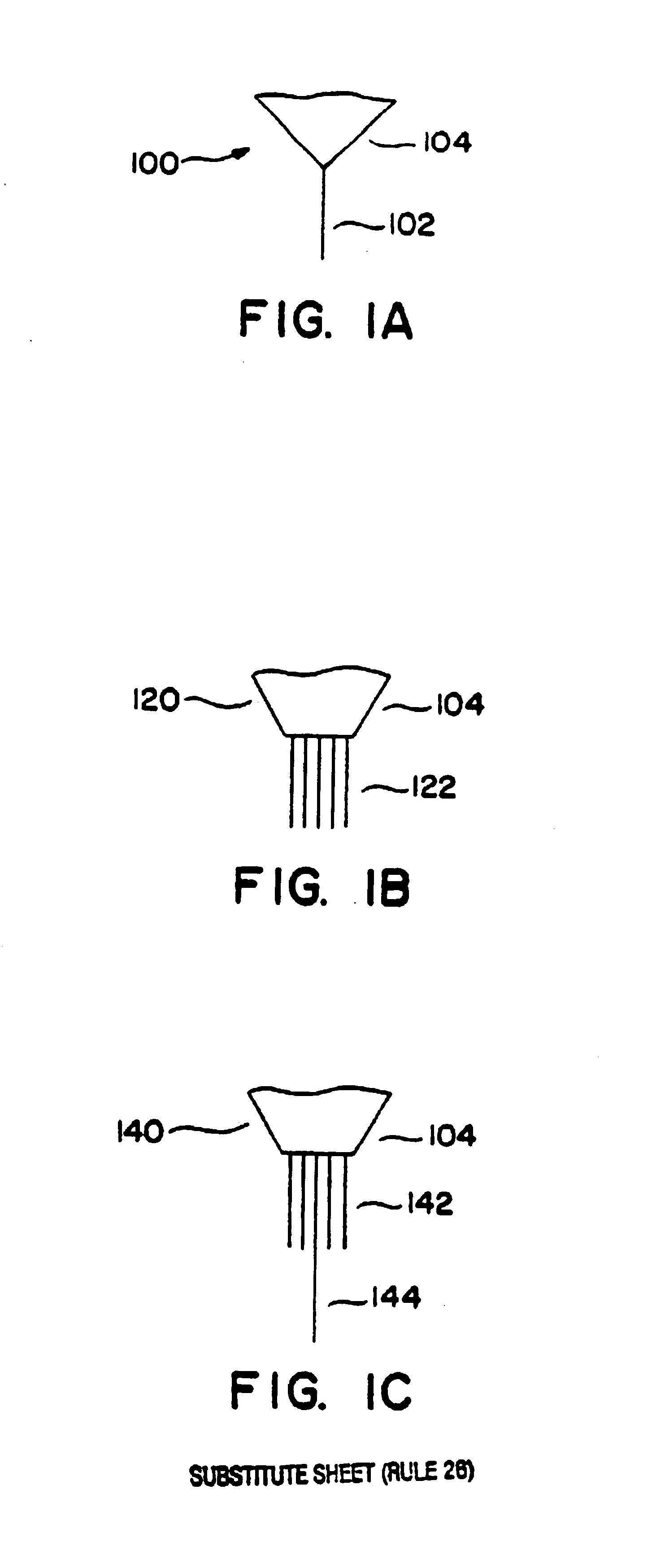

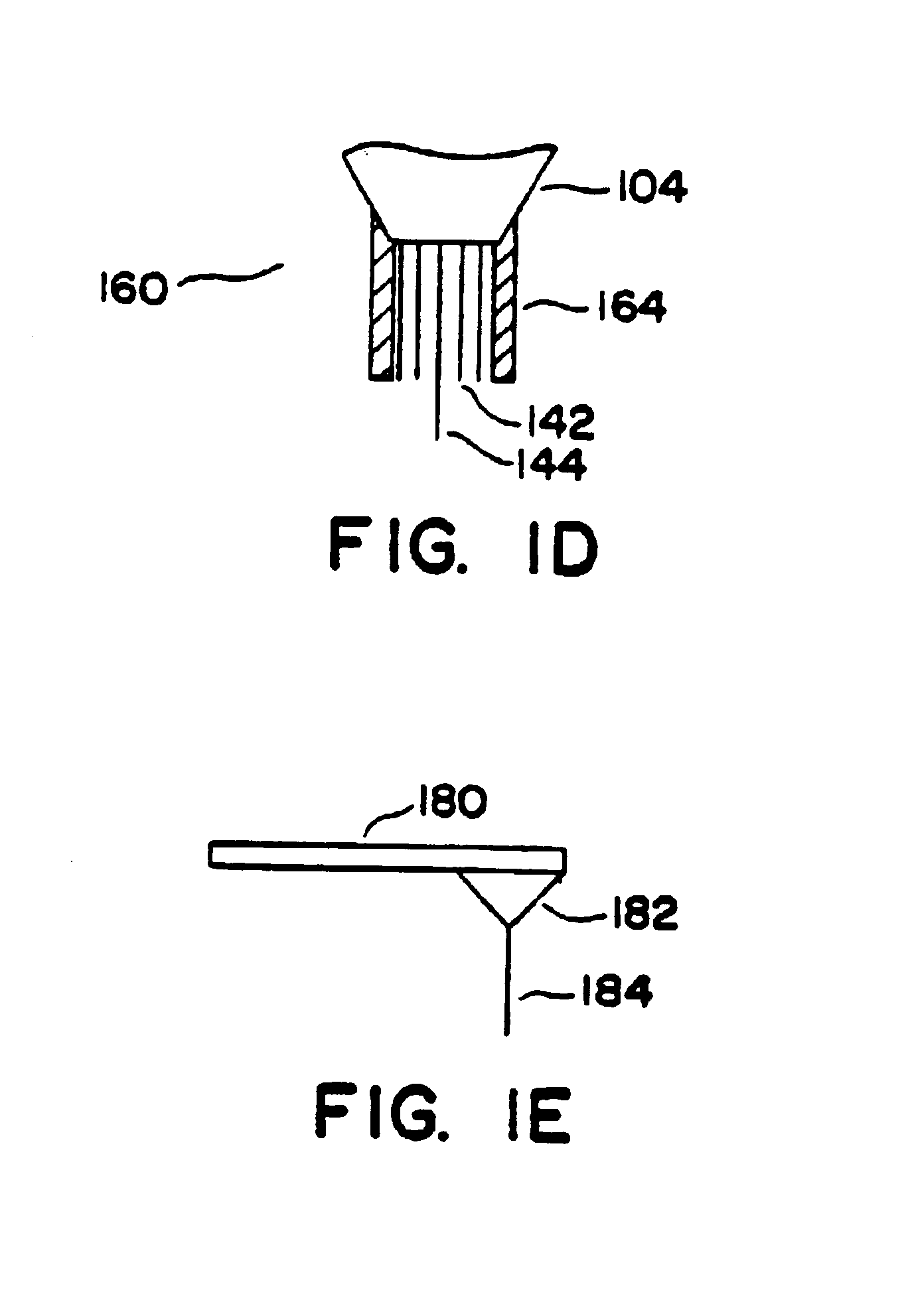

RFID tag using a surface insensitive antenna structure

InactiveUS6914562B2Efficient executionEasy to manufactureSimultaneous aerial operationsAntenna supports/mountingsRadio frequency energyCommunication device

An antenna system that is insensitive to the surface on which it is mounted for use with a RFID tag having a wireless communication device, including a plurality of conductive tabs coupled to the wireless communication device for receiving and radiating radio frequency energy. At least two of the tabs are substantially identical in shape and coupled to the wireless communication device at feedpoint differing in location on each of the two tabs wherein the width of said at least two of said plurality of tabs taken transverse to the longitudinal centerline axis of each tab varies with distance along the longitudinal centerline axis of each of said tabs from its feedpoint. Alternatively, the wireless communication device is coupled to the tab at a feedpoint selected at a location differing on each of the tabs where the conducting area per unit length of the longitudinal centerline axis of each tab varies with distance along the longitudinal centerline axis of each of said tabs from its feedpoint. A radio frequency reflecting structure is coupled to the conductive tabs for reflecting radio frequency energy radiated therefrom. A dielectric material is located intermediate the conductive tabs and the radio frequency reflecting means.

Owner:AVERY DENNISON CORP

Organic solar cells including group IV nanocrystals and method of manufacture

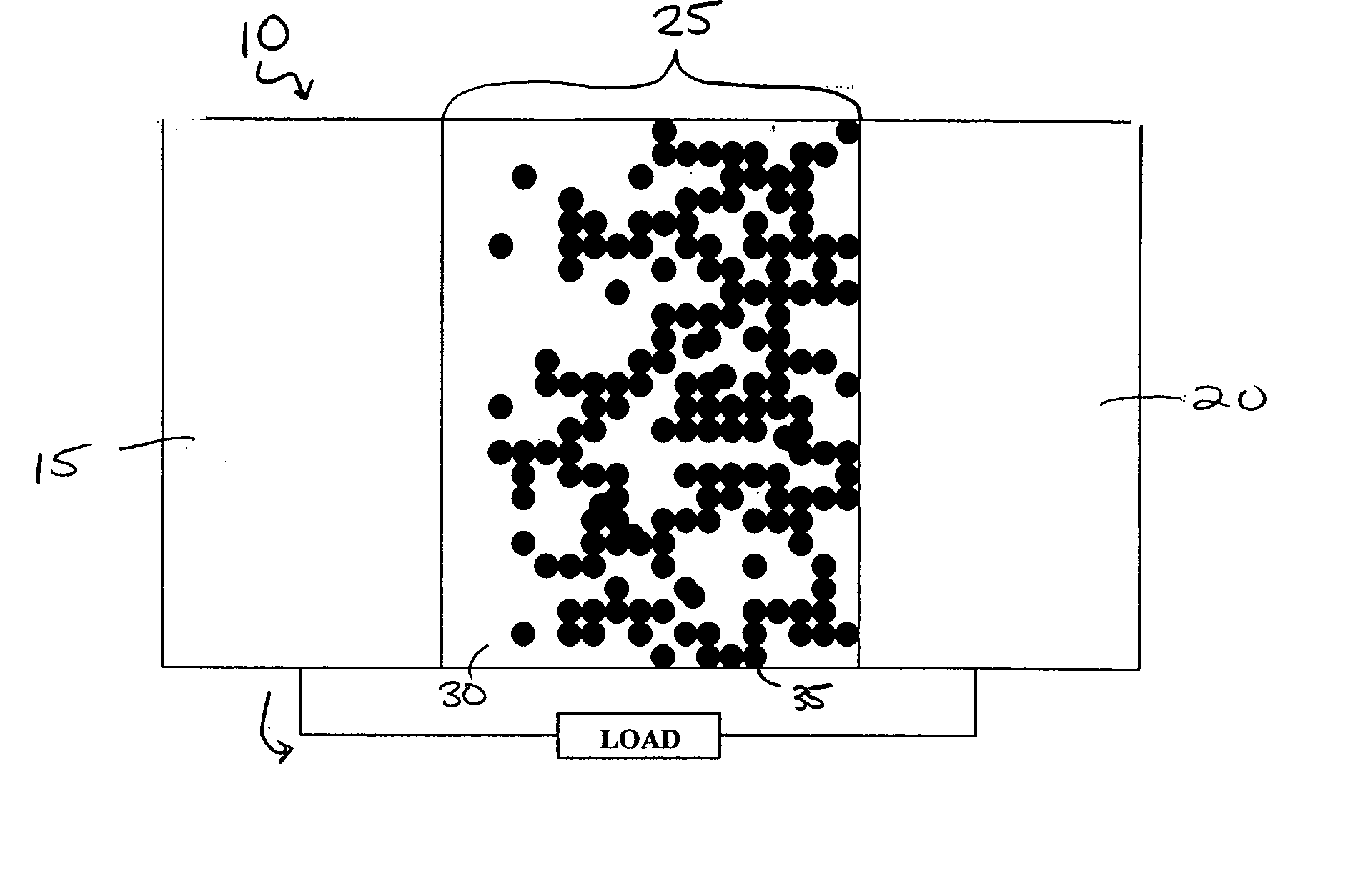

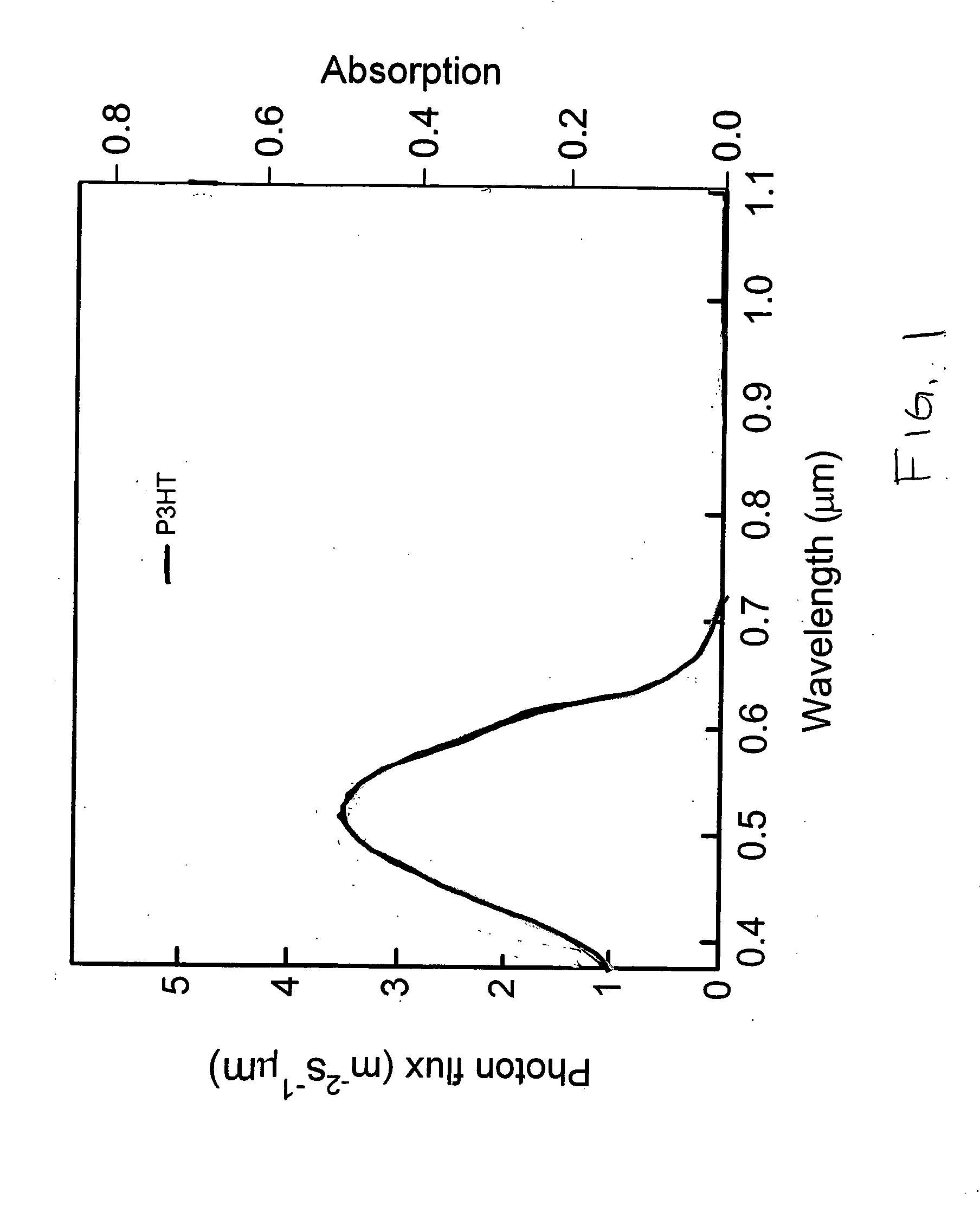

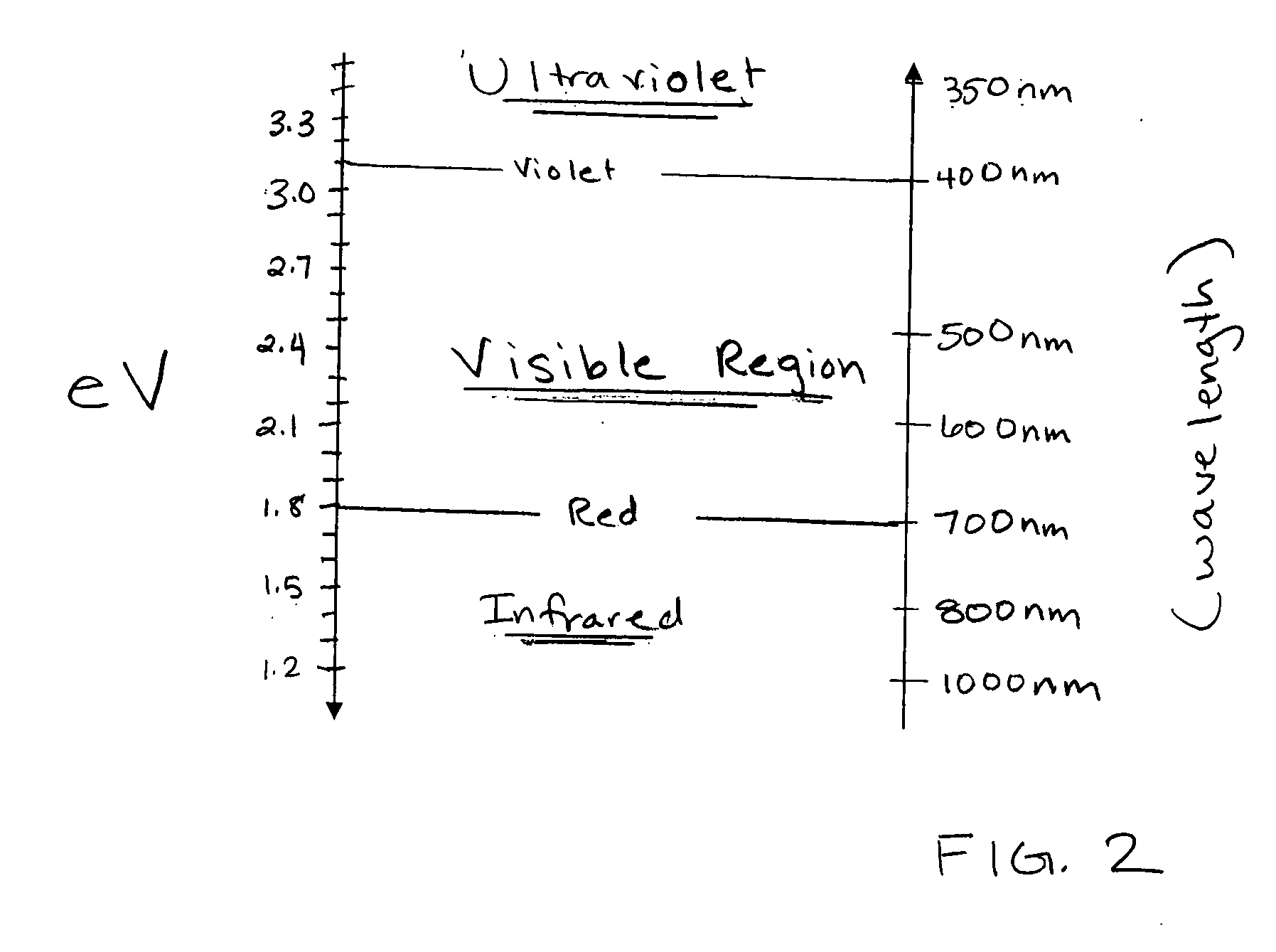

InactiveUS20050061363A1Promote absorptionEasy to manufactureMaterial nanotechnologyFinal product manufactureHeterojunctionOrganic solar cell

An improved organic solar cell converts light into electricity. The organic solar cell includes a cathode, an anode, and a bulk heterojunction material disposed therebetween. The bulk heterojunction material includes a plurality of group IV nanocrystals (e.g., silicon nanocrystals) disposed within an organic absorber (e.g., an organic polymer).

Owner:EVERGREEN SOLAR

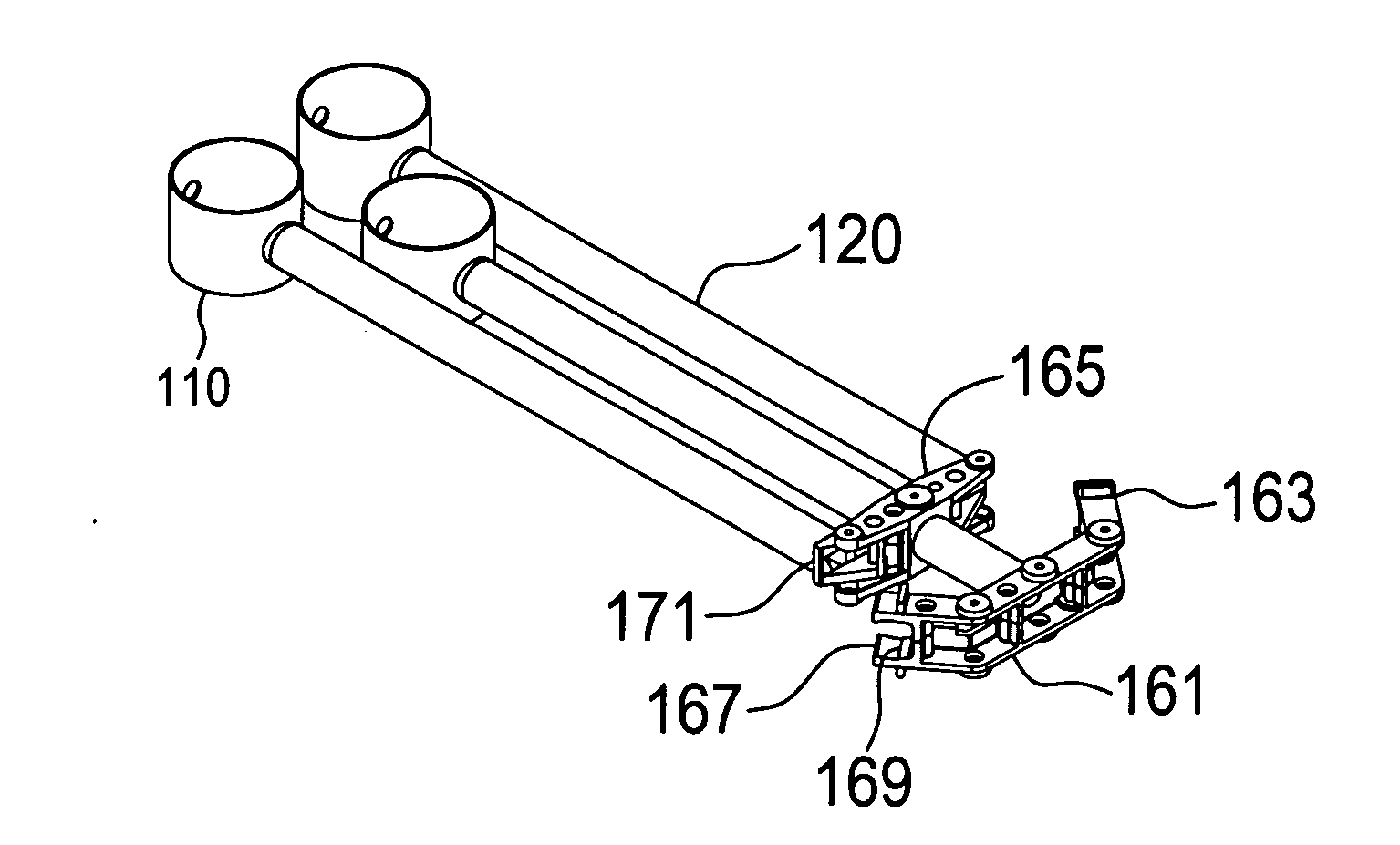

Helicopter with folding rotor arms

ActiveUS20120138732A1Reduce riskIncrease distanceUnmanned aerial vehiclesRemote controlled aircraftAerospace engineering

A rotary wing aircraft apparatus includes a body and a rotor pair connected to the body by an arm. The rotor pair has an upper rotor driven by an upper motor and rotating about an upper rotor axis and a lower rotor driven by a lower motor and rotating about a lower rotor axis. The upper and lower rotor axes are tilted with respect to each other. Tilting the axes away from the arm increases the distance from the rotor blades to the arm, and decreases the risk of the blades of the rotor contacting the arm. In an aircraft with a plurality of arms extending from the body, and a rotor assembly connected to each arm, the arms can be pivoted from a flying position, where the arms extend laterally outward to a folded position where the arms are positioned substantially parallel and adjacent to each other.

Owner:DRAGANFLY INNOVATIONS

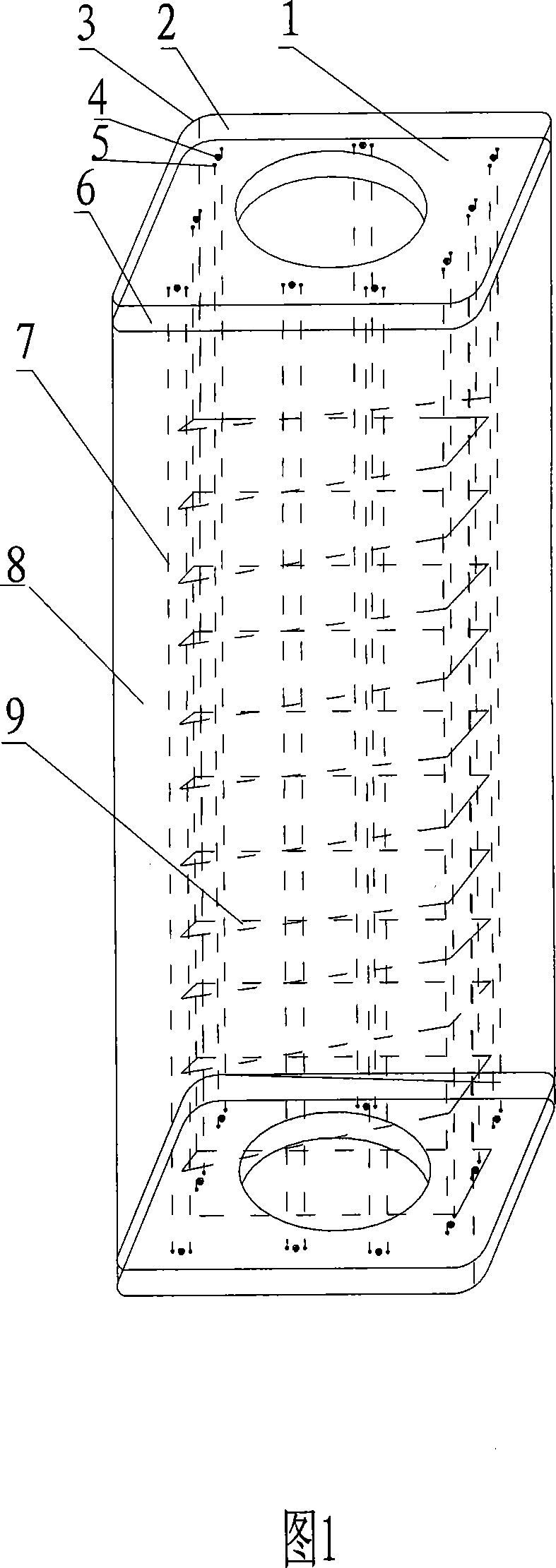

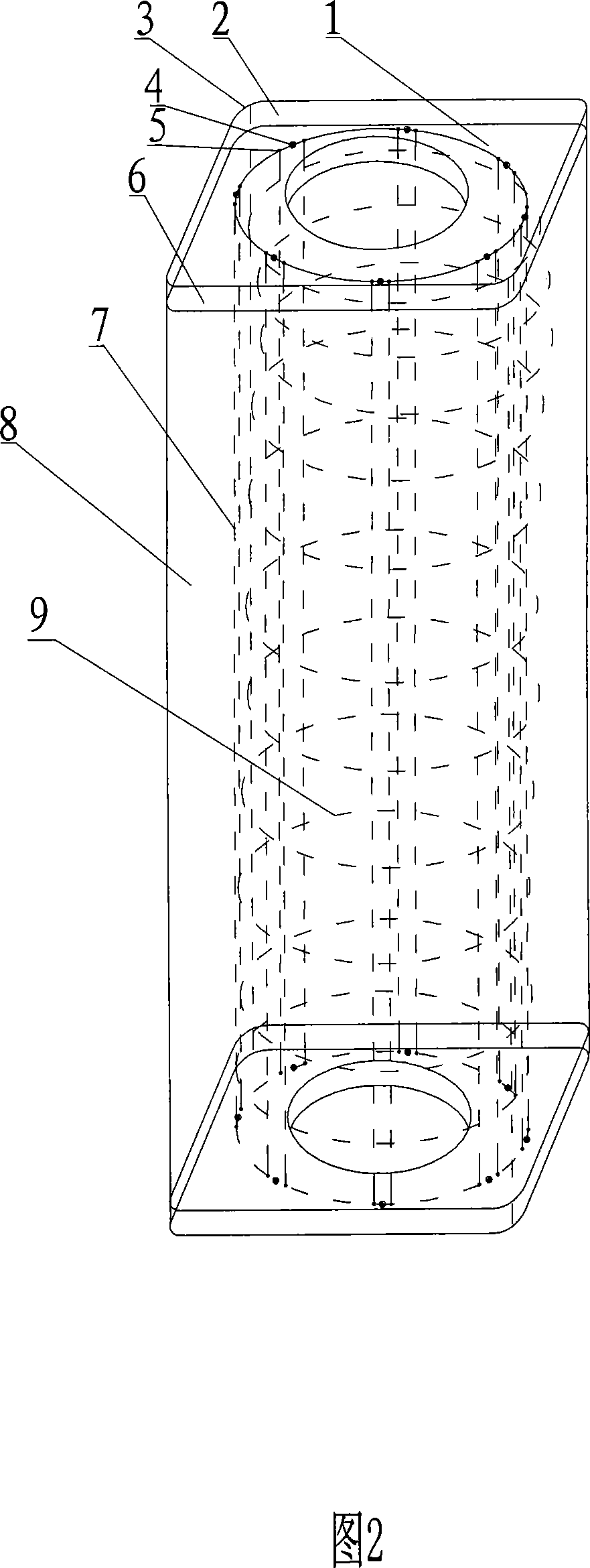

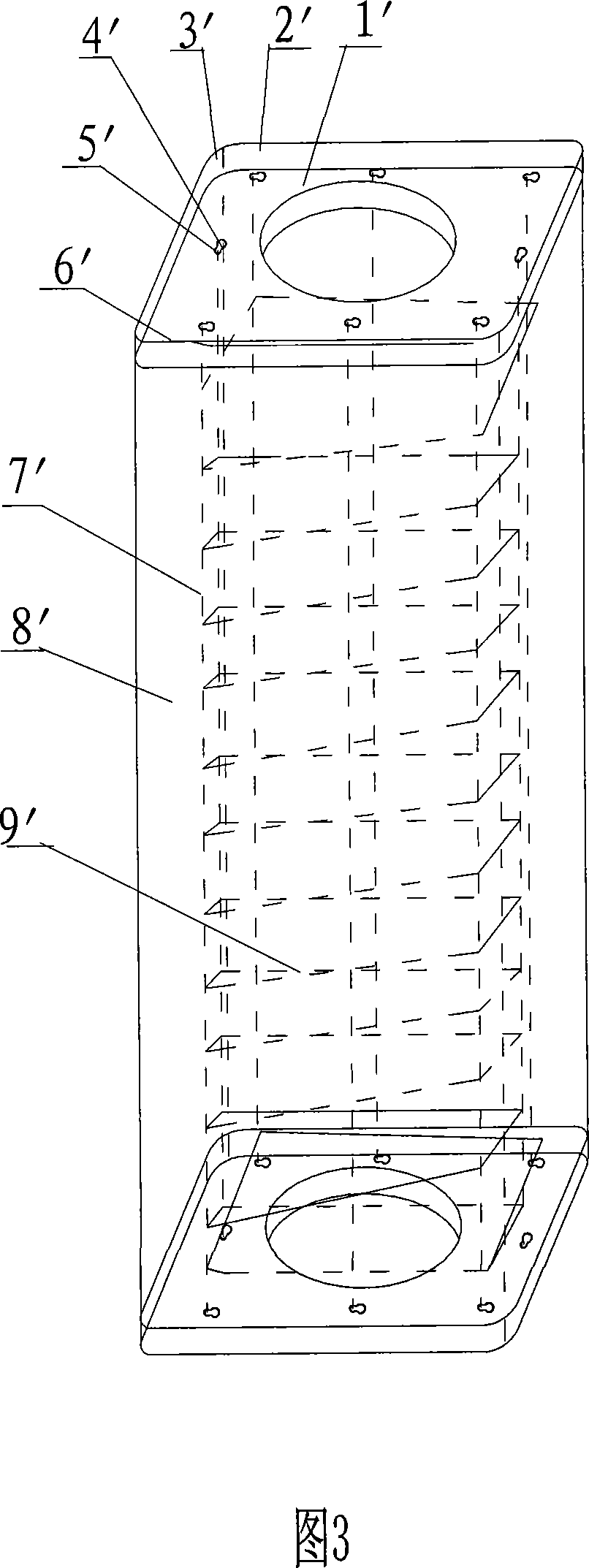

Prestress high intensity concrete square pile and its production method and moulding die

InactiveCN101054800AHigh pile rateIncrease profitCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention belongs to the architecture field, which relates to an improvement with the foundation pile shape and the structure and the manufacturing method of the foundation pile and the foundation pile shaper in the architecture field, in particular the invention is a prestressing force high strength concrete square pile and the manufacturing method thereof and the shaping device. In the invention a square terminal plate is disposed on the two ends of the square pile, and the four sides of the terminal plate is provided with a groove, while the center is equipped with a circular hole, and between the circular hole and the four sides, a strain hole and a threading hole are arranged symmetrically; a stirrp of a reinforcement cage in a twist is welded on the principal reinforcement continuously, wherein the principal reinforcement is the steel strand or the steel bar; the concrete square pile and the four-side corners of the terminal plate are in a stress elimination arc, and the pile core is a columnar mid level outlet having the same diameter with the terminal plate central circular hole. The manufacturing method is characterized in that, the principal reinforcement has the fix ed length and blanking, and the stirrp of the reinforcement cage is welded in the seam welder with the high degree of mechanisation; the principal reinforcement is stretched in a group of a whole pile fixed value, wherein the stretching performance is good and the balance is consistent; the disposable high pressure has short shaping time, low energy consumption, high product grade; the die design meets with the shaping requirement of the shape, which is convenient to use.

Owner:SHANGHAI ZHONGJI PILE IND

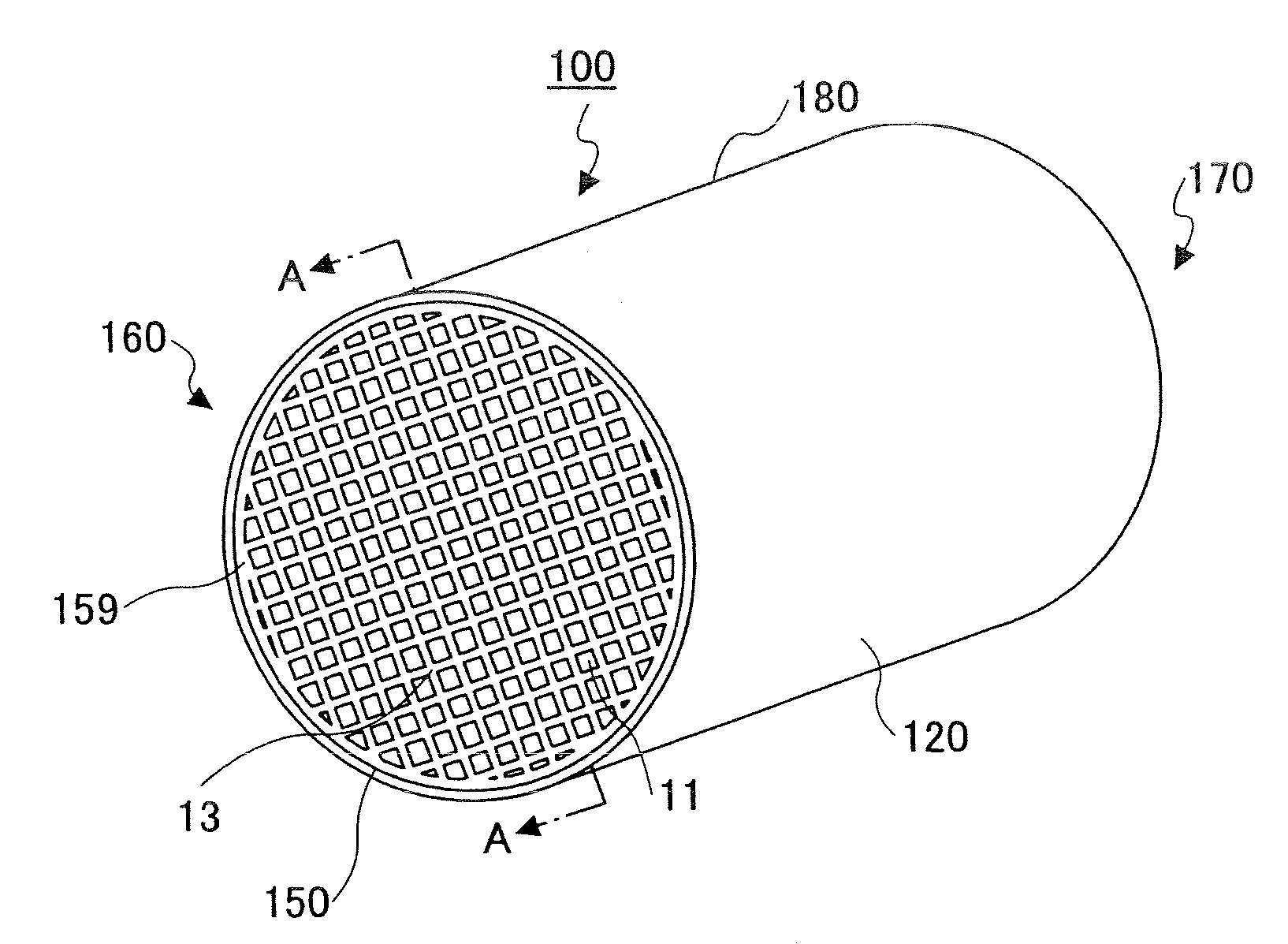

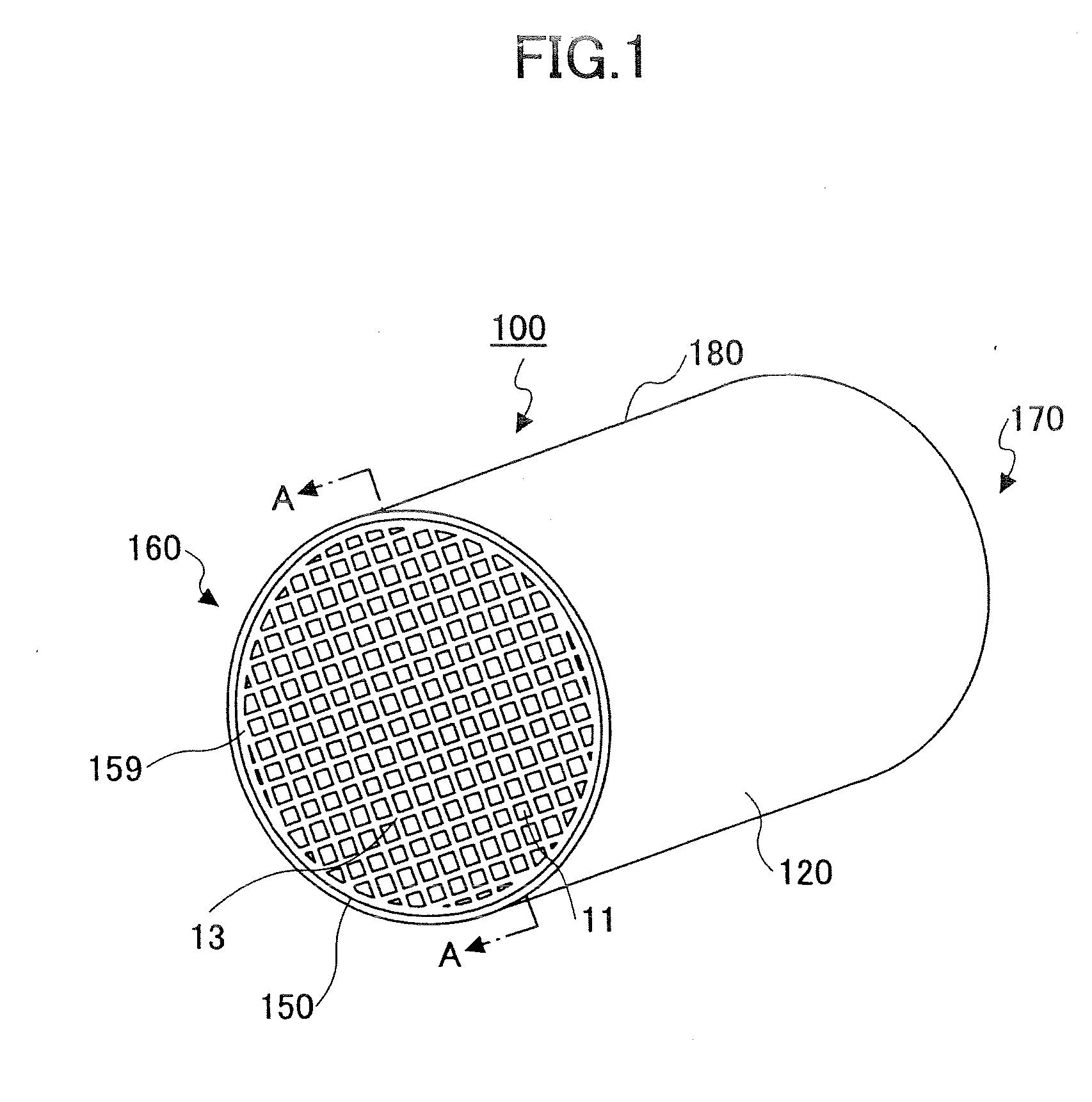

Honeycomb structure and exhaust gas treatment device

ActiveUS20080190081A1Not easy to damageCombination devicesInternal combustion piston enginesExhaust fumesHoneycomb structure

A honeycomb structure includes a first end face and a second end face substantially parallel to each other, a peripheral face interconnecting the first end face and the second end face, a ceramic block including plural through cells with partition walls inbetween, the cells extending from the first end face to the second end face, and a coating layer forming the peripheral face of the honeycomb structure. The thickness of the coating layer at the second end face is greater than at the first end face.

Owner:IBIDEN CO LTD

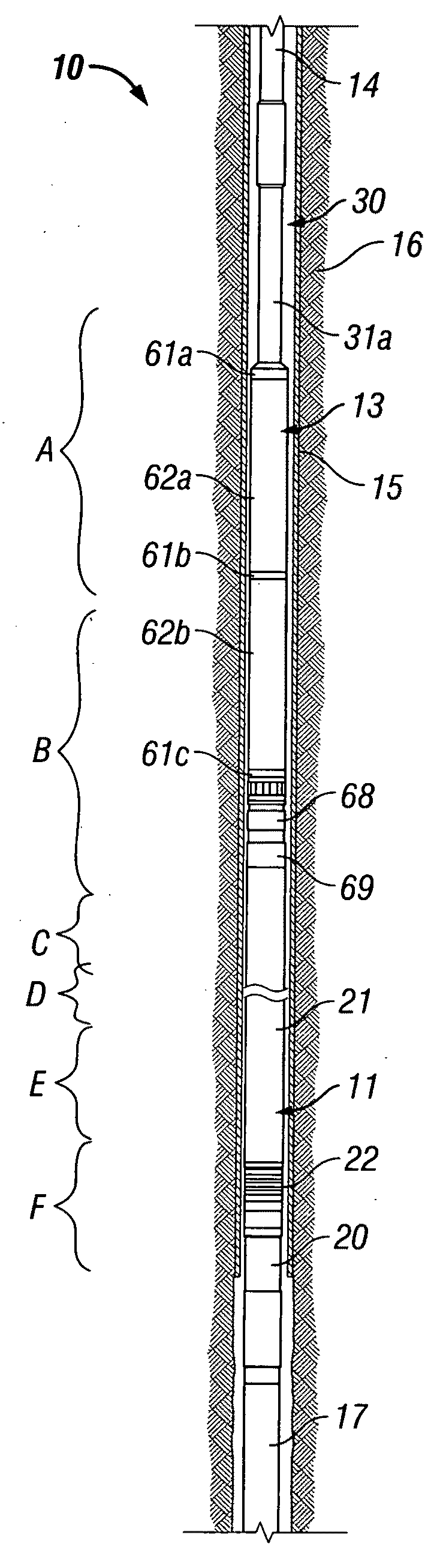

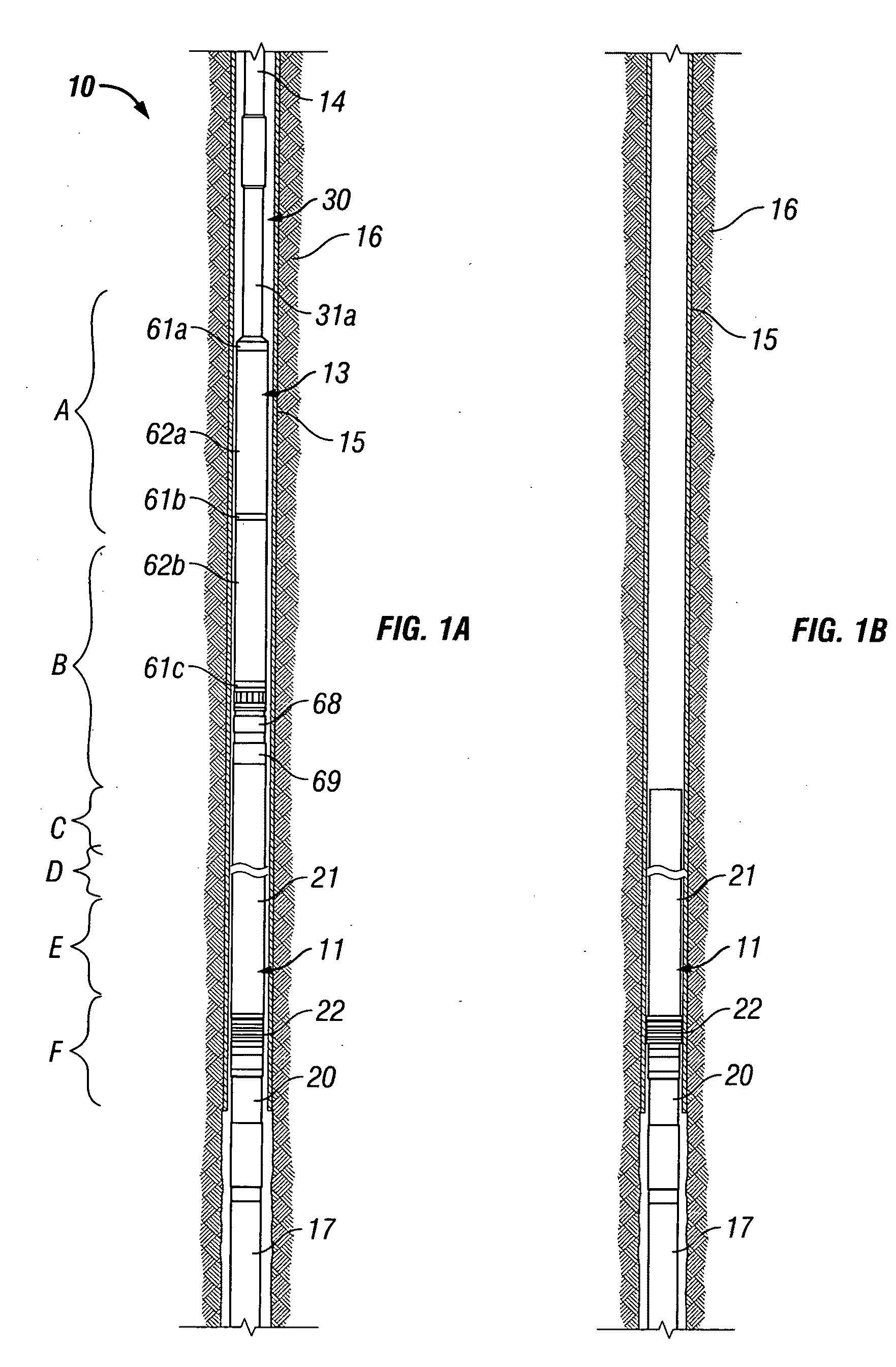

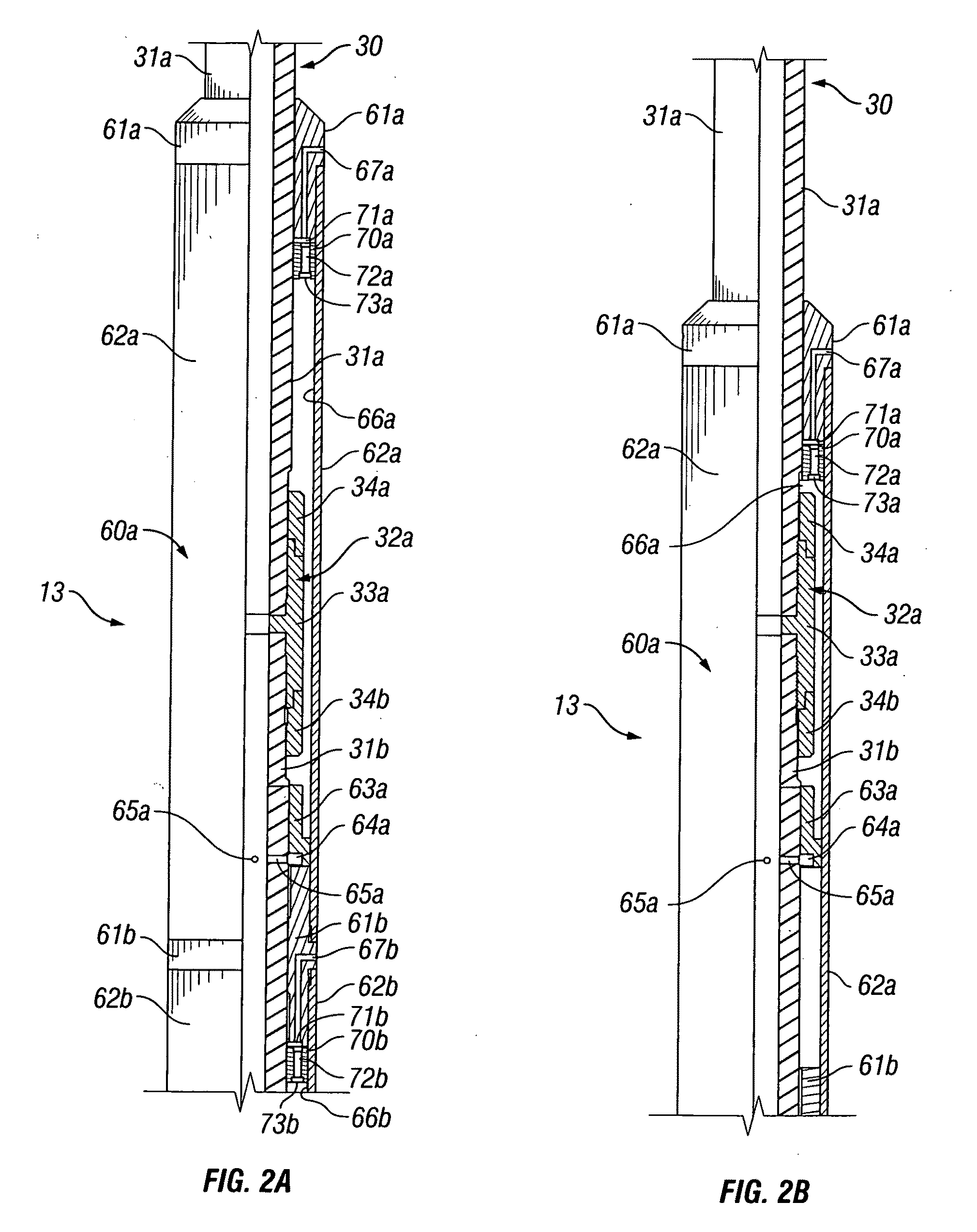

Hydraulic setting assembly

ActiveUS20100252252A1Increase load capacityReduce amountFluid removalSealing/packingHydraulic cylinderHydrostatic pressure

Novel hydraulic actuators and hydraulic setting assemblies are provided for use in downhole, oil and gas well tools. The novel hydraulic actuators include a cylindrical mandrel and an annular stationary' sealing member connected to the mandrel. A hydraulic cylinder is slidably supported on the mandrel and stationary sealing member and is releasably fixed in position on the mandrel. The stationary sealing member divides the interior of the cylinder into a bottom hydraulic chamber and a top hydraulic chamber. An inlet port provides fluid communication into the bottom hydraulic chamber, and an outlet port provides fluid communication into the top hydraulic chamber. A balance piston is slidably supported within the top hydraulic chamber of the actuator. The piston includes an axially extending passageway. Fluid communication through the piston and between its upper and lower sides is controlled by a normally shut valve in the passageway. In the absence of relative movement between the mandrel and cylinder, the balance piston is able to slide in response to a difference in hydrostatic pressure between the outlet port, is which is on one side of the piston, and the portion of the top hydraulic chamber that is on the bottom side of the piston.

Owner:SCHLUMBERGER TECH CORP

Semiconductor device and manufacturing method thereof

InactiveUS20080224941A1Avoid partialAvoid destructionSemiconductor/solid-state device detailsSolid-state devicesFiberInorganic compound

The present invention provides a semiconductor device which is not easily damaged by external local pressure. The present invention further provides a method for manufacturing a highly-reliable semiconductor device, which is not destructed by external local pressure, with a high yield. A structure body, in which high-strength fiber of an organic compound or an inorganic compound is impregnated with an organic resin, is provided over an element layer having a semiconductor element formed using a non-single crystal semiconductor layer, and heating and pressure bonding are performed, whereby a semiconductor device is manufactured, to which the element layer and the structure body in which the high-strength fiber of an organic compound or an inorganic compound is impregnated with the organic resin are firmly fixed together.

Owner:SEMICON ENERGY LAB CO LTD

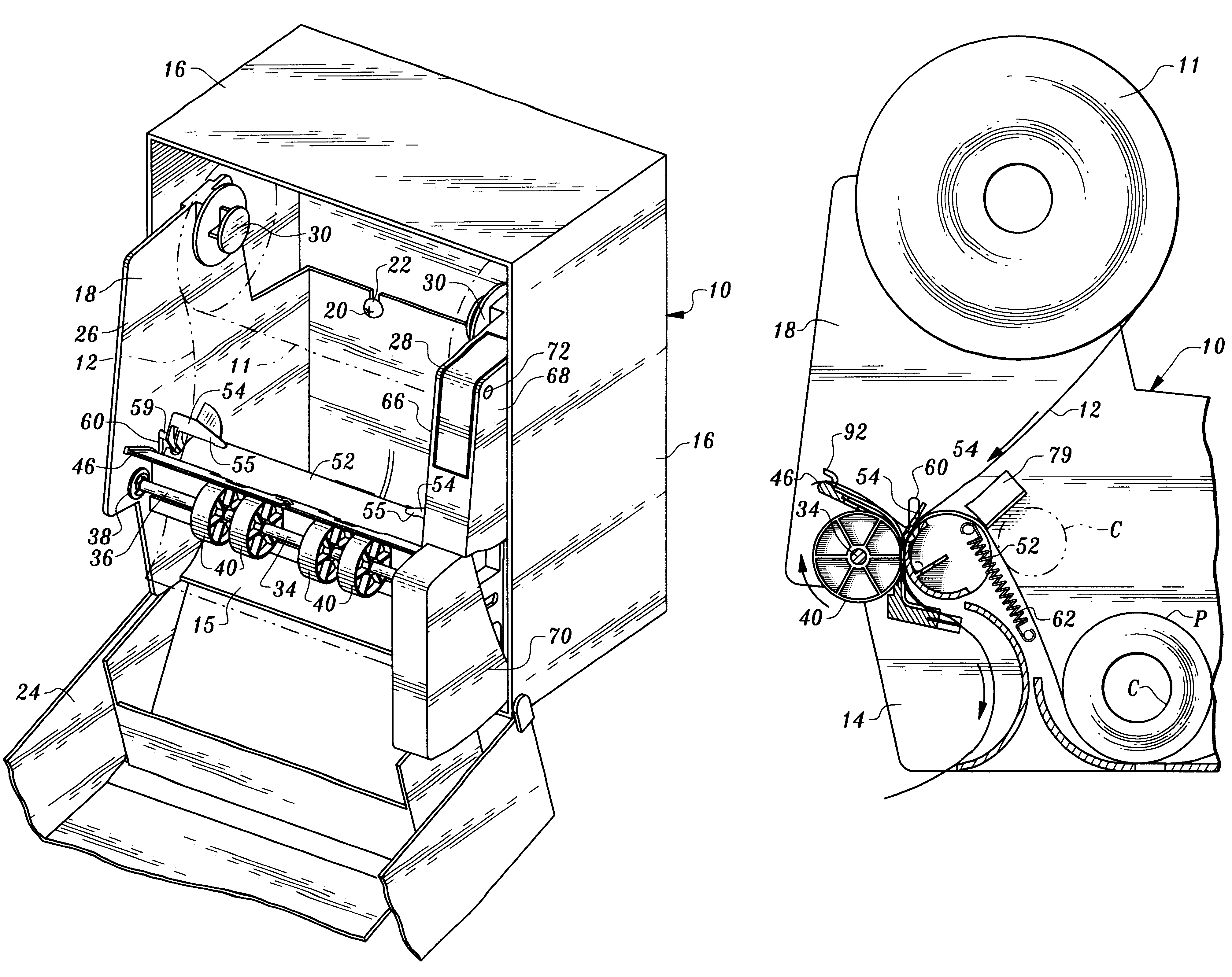

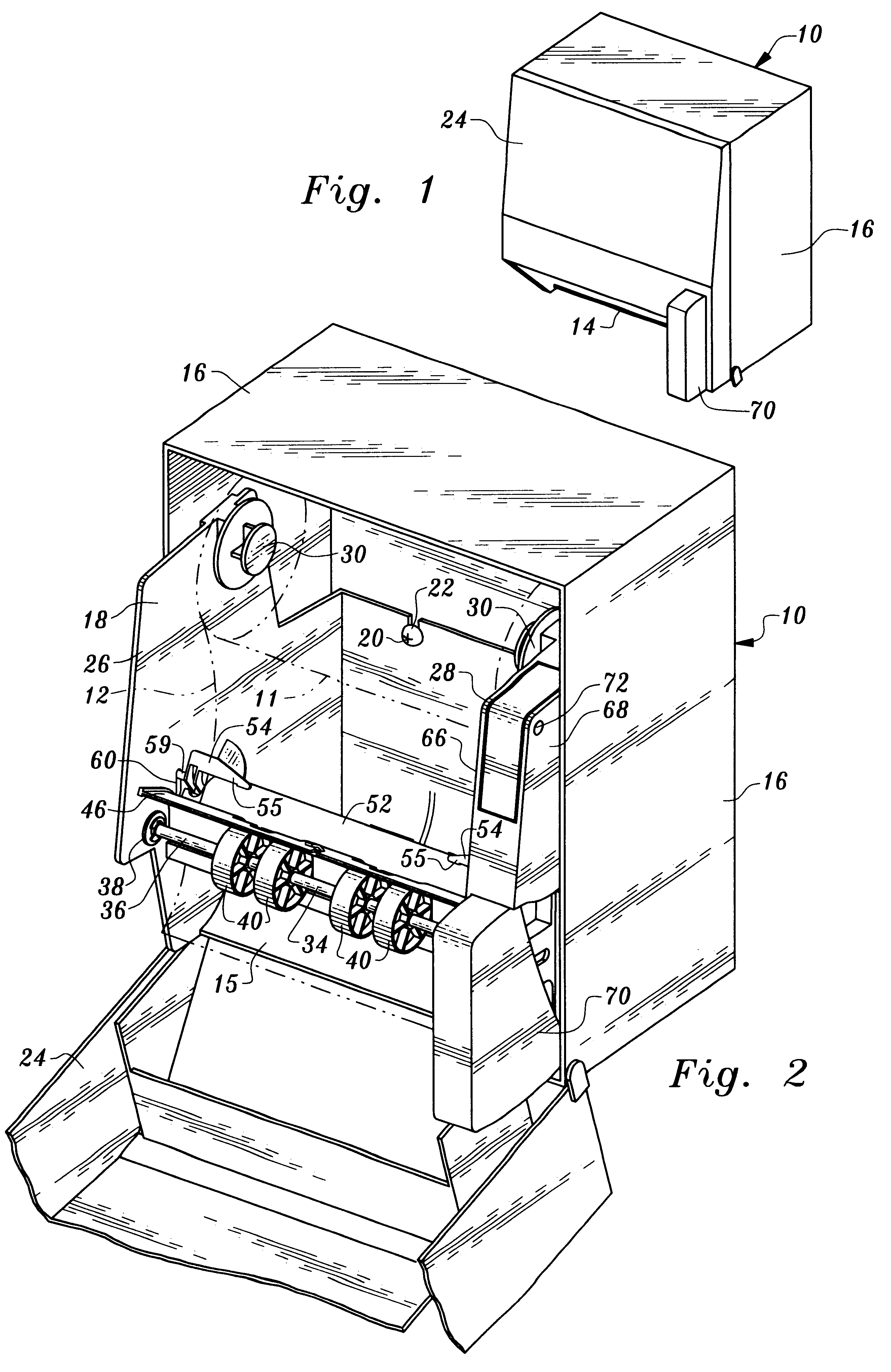

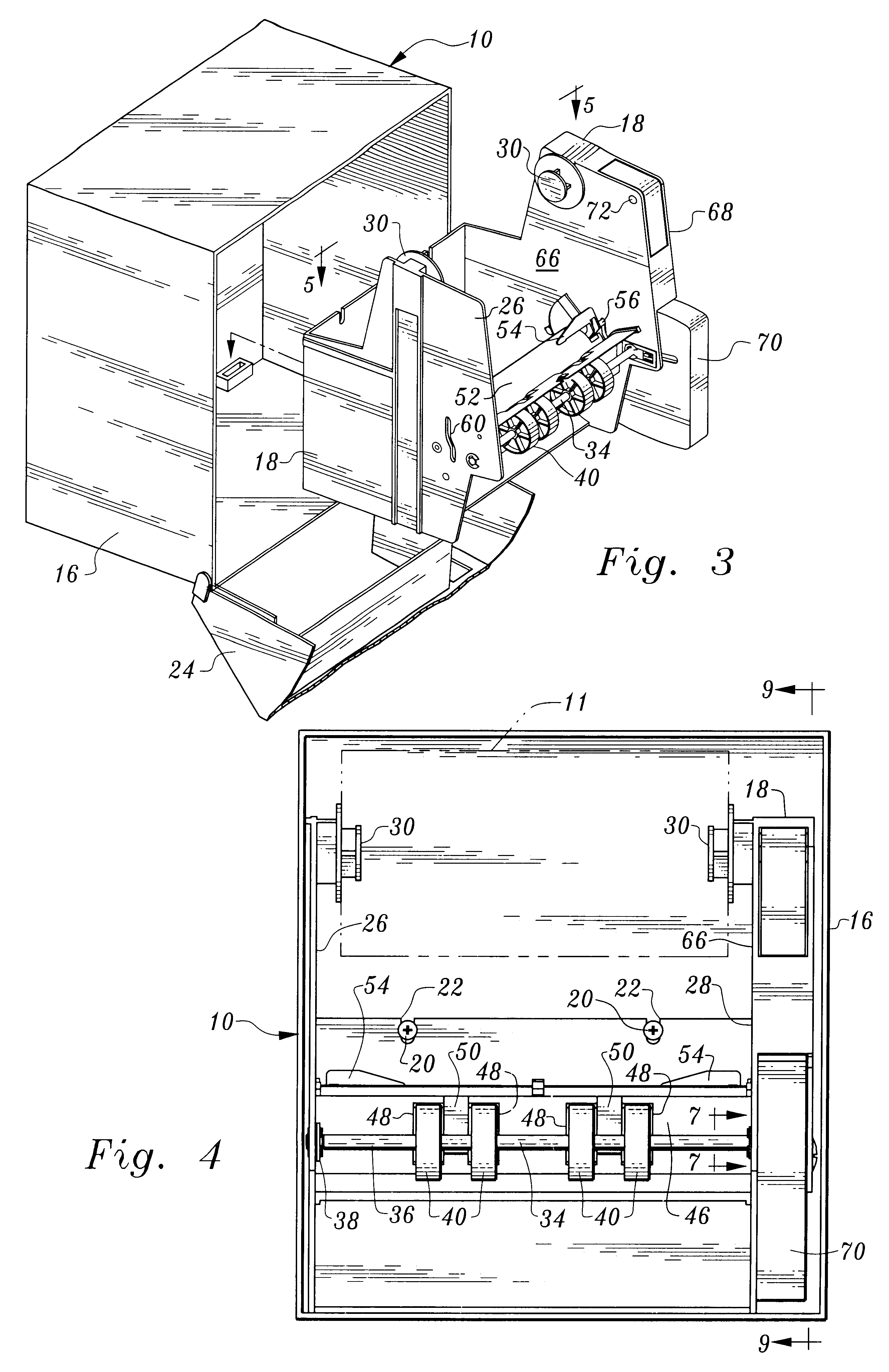

Paper towel transfer apparatus

InactiveUS6237871B1Easy to installLow costFilament handlingDomestic applicationsPaper towelEngineering

Apparatus for dispensing sheet material from a roll of sheet material includes a rotatable sheet material engagement member having an outer surface for engaging the sheet material. A pivoted shaft is mounted adjacent to the sheet material engagement member having a feed roller mounted thereon. The shaft and feed roller are pivotally moved toward the sheet material engagement member and the feed roller is rotated to transport the sheet material over the outer surface of the sheet material engagement member. Spaced tucker members are connected to the sheet material engagement member and simultaneously rotate and pivot upon depletion of a primary roll of sheet material to position the lead end of a reserve roll between the sheet material engagement member and the feed roller.

Owner:DISPENSING DYNAMICS INT

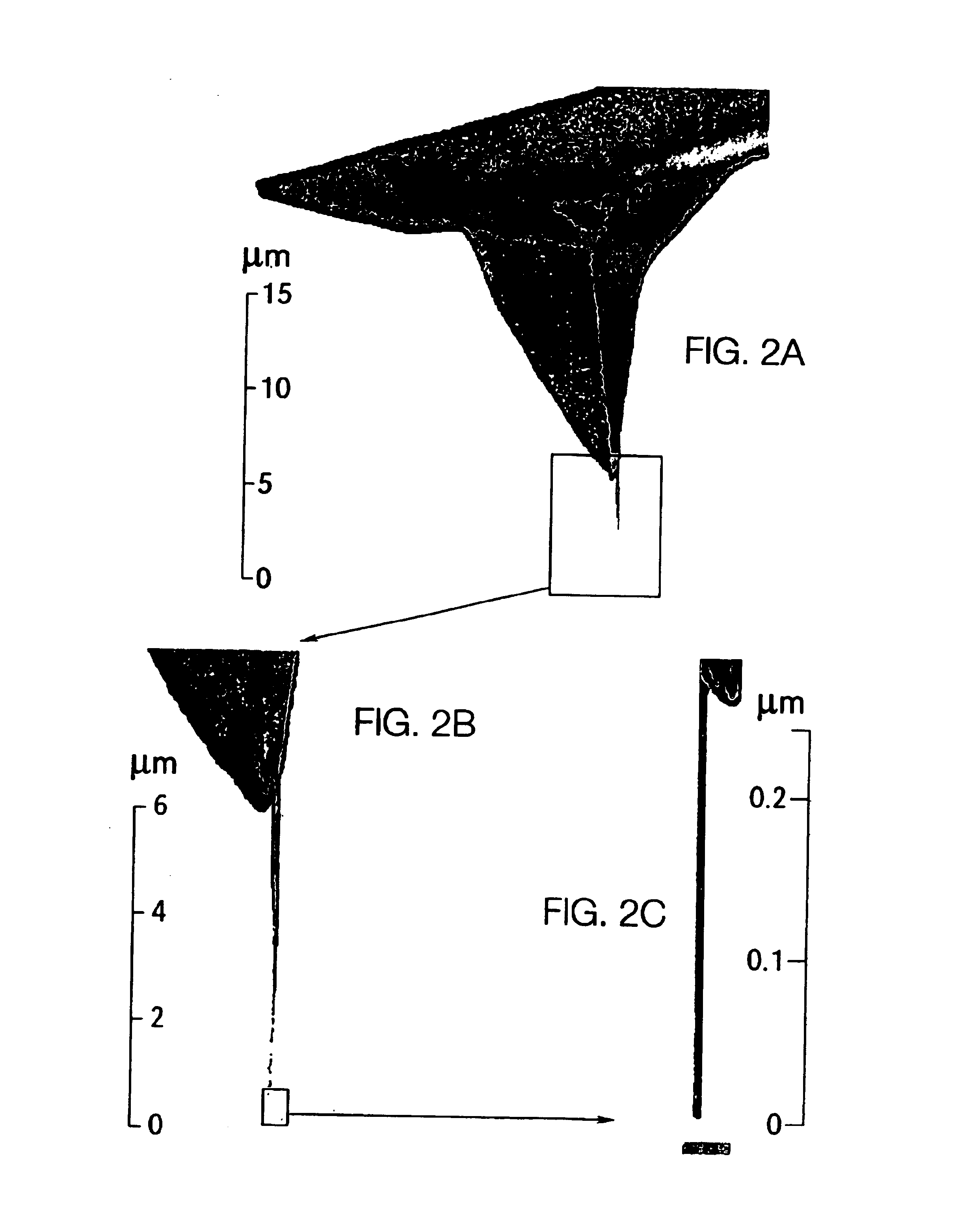

Method of forming composite arrays of single-wall carbon nanotubes and compositions thereof

InactiveUS6939525B2Hard to damageUniform diameterMaterial nanotechnologyCarbon compoundsMolecular arrayCarbon nanotube

This invention relates generally to forming arrays of single-wall carbon nanotubes (SWNT) and compositions thereof. In one embodiment, the present invention involves forming an array from more than one separately prepared molecular arrays or templates to prepare a composite structure. The multiple arrays can be the same or different with respect to the SWNT type or geometric arrangement in the array.

Owner:RICE UNIV

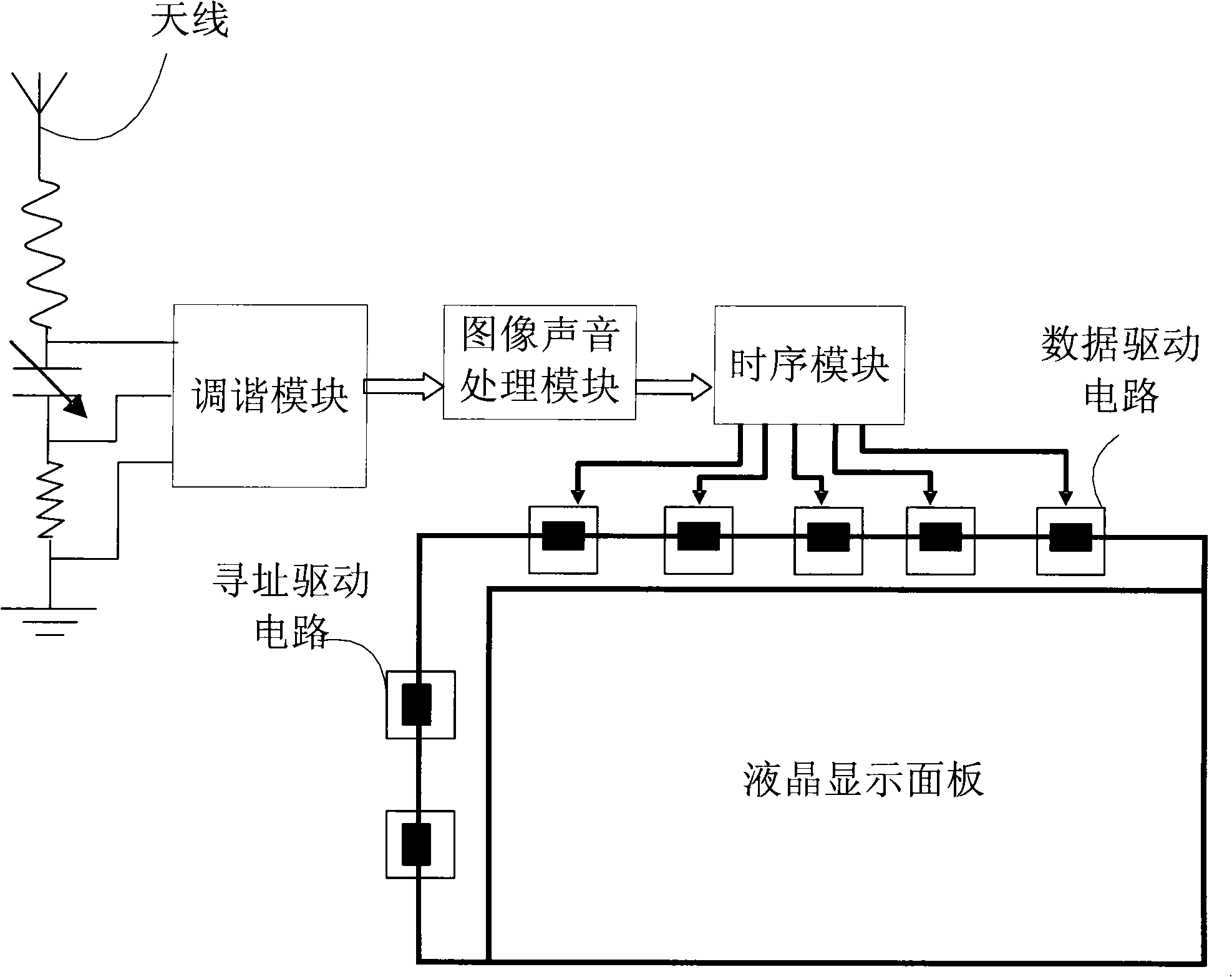

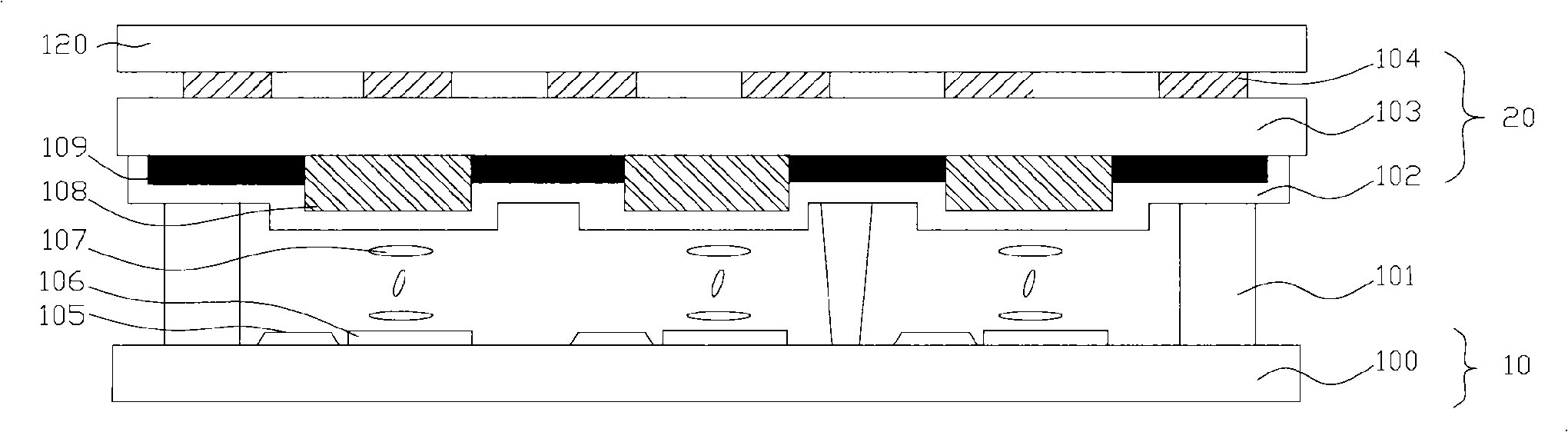

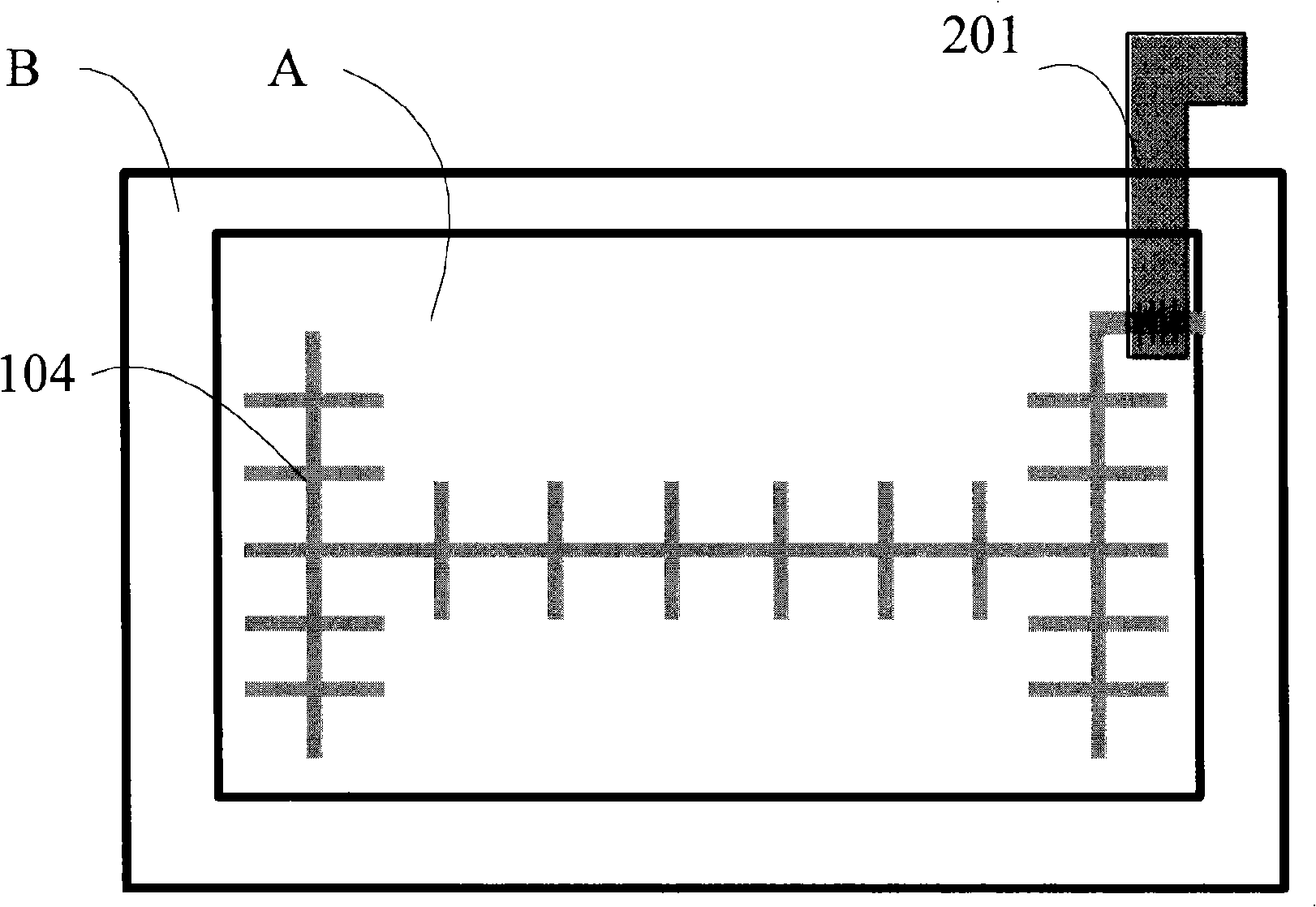

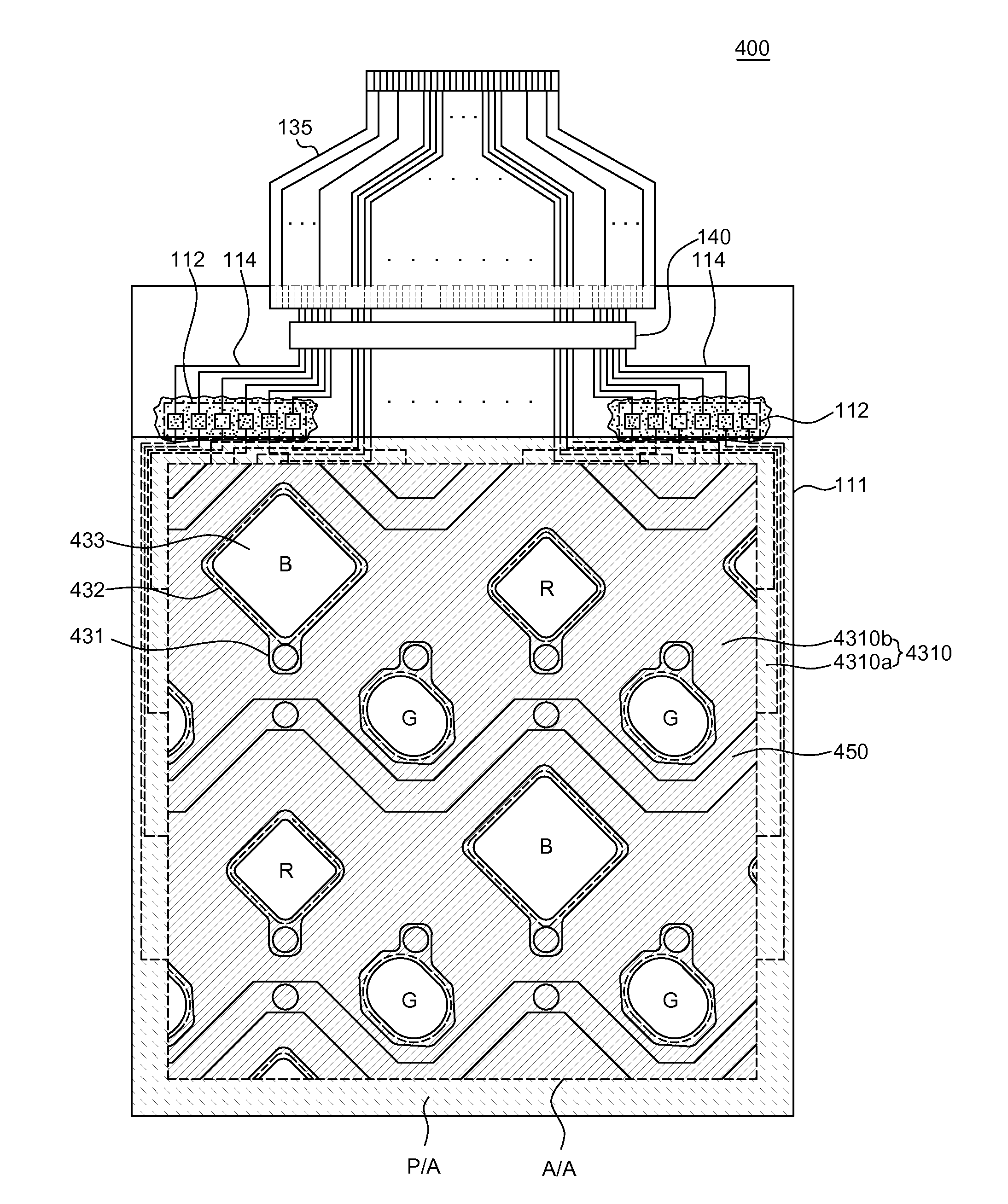

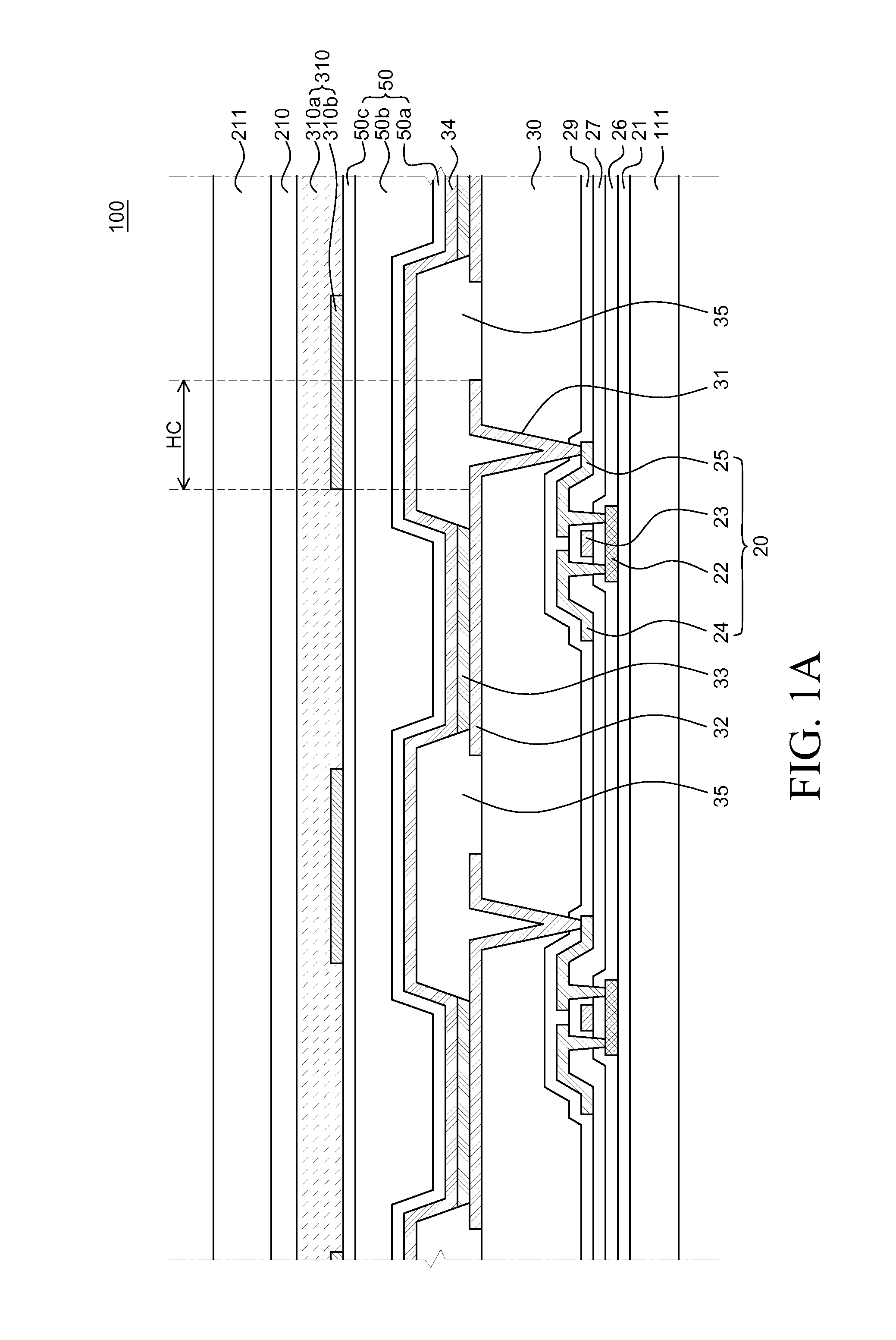

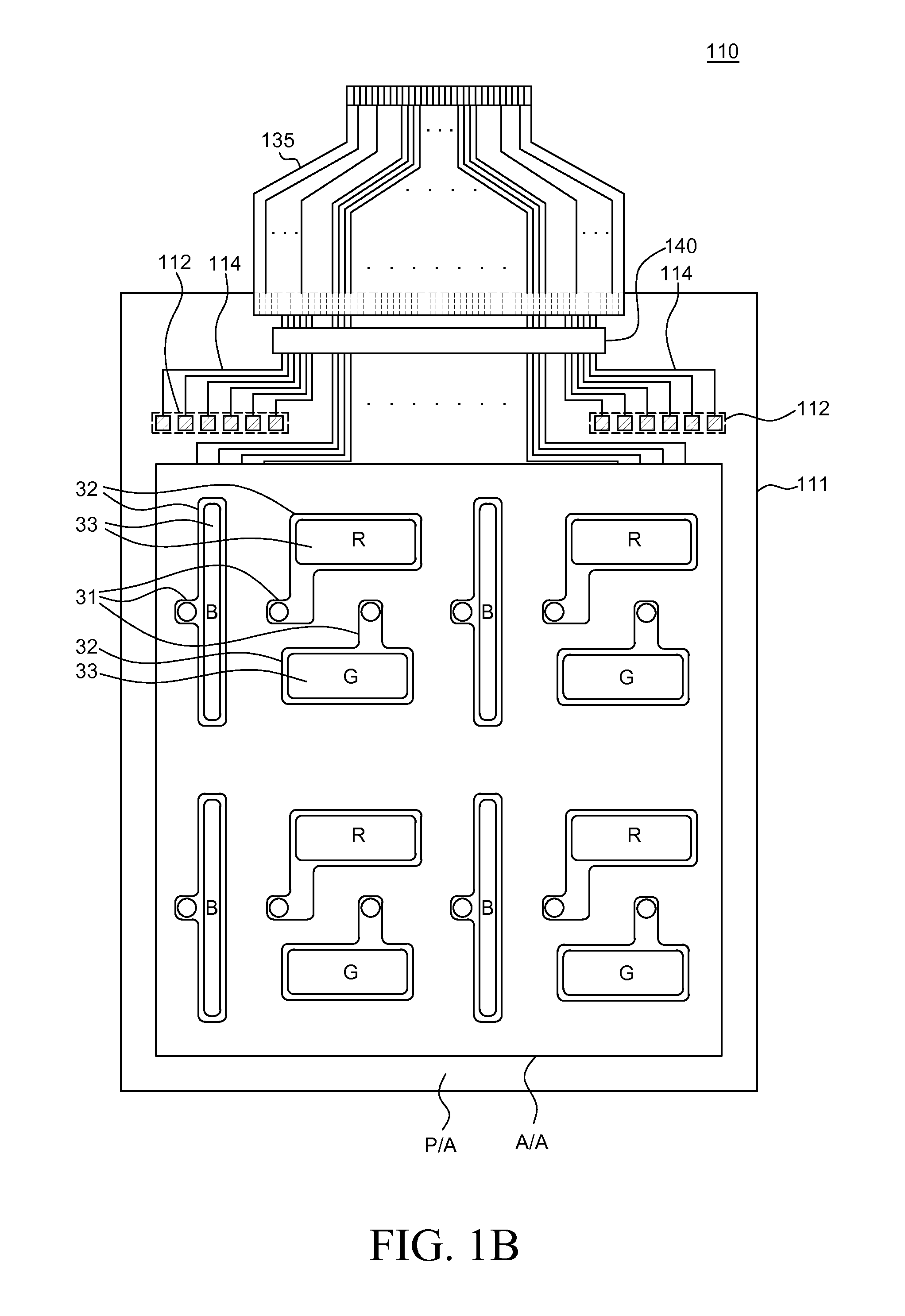

Liquid crystal display panel, LCD device and electronic equipment

ActiveCN101308266ANot easy to damageLow costStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel comprising: an upper base plate and a lower base plate relatively arranged, a liquid crystal layer between the upper and lower base plates, and a first polarizer on one face of the upper base plate backing the liquid crystal layer; the upper base plate at least includes a first base plate; the lower base plate at least includes a second base plate and a pixel electrode layer and a thin-film transistor array positioned on the second base plate; and the liquid crystal display panel is provided with an antenna composed of graphics of a conductive film. Correspondingly, the invention also provides a liquid crystal display device and an electronic device. The liquid crystal display panel is provided with the antenna for receiving or transmitting signals, the antenna does not occupy space independently, and will not be broken easily by external factors, in addition, the processes of additional design and making the complementary antenna are also saved, and the whole costs can be reduced.

Owner:KUSN INFOVISION OPTOELECTRONICS

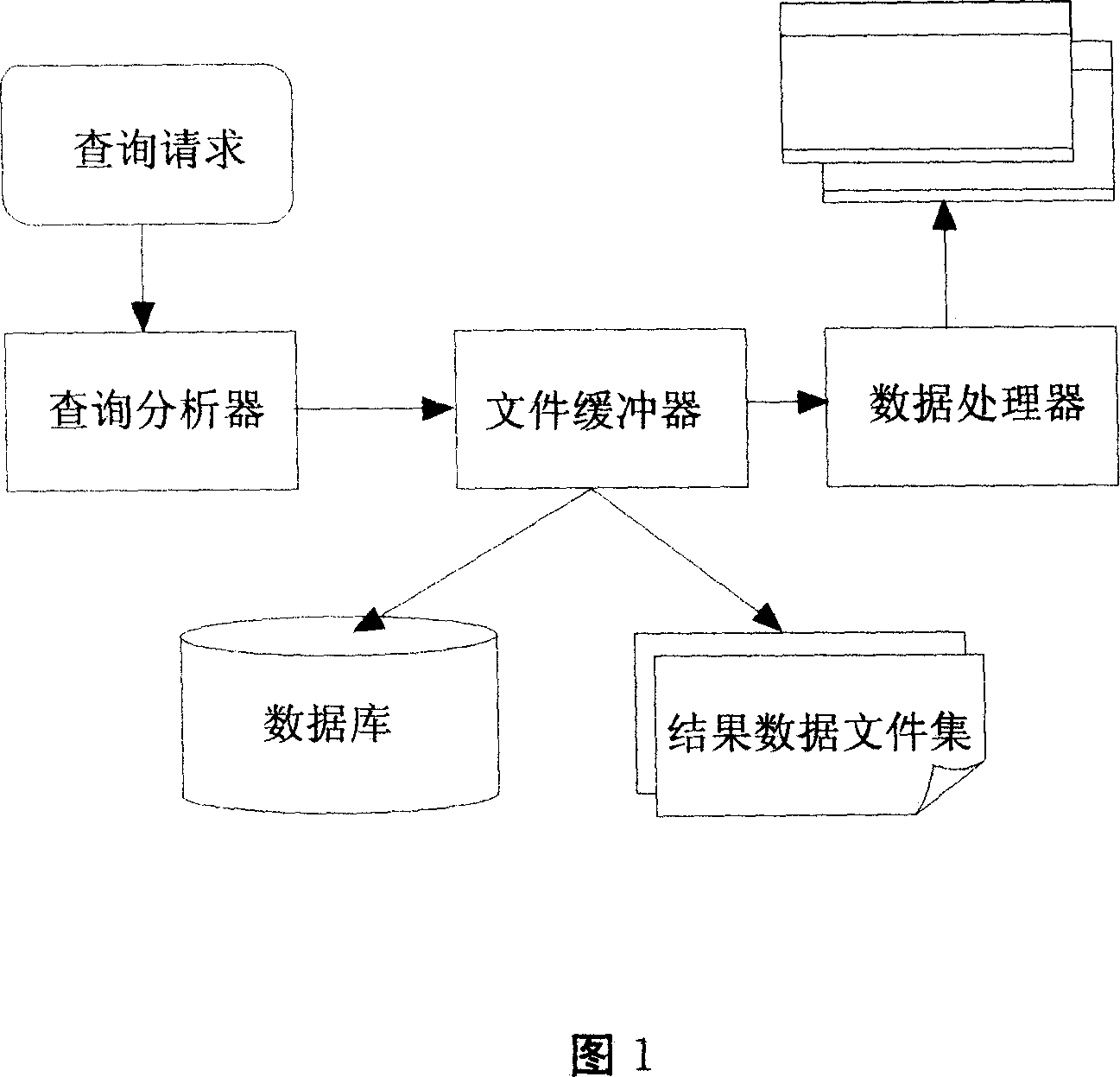

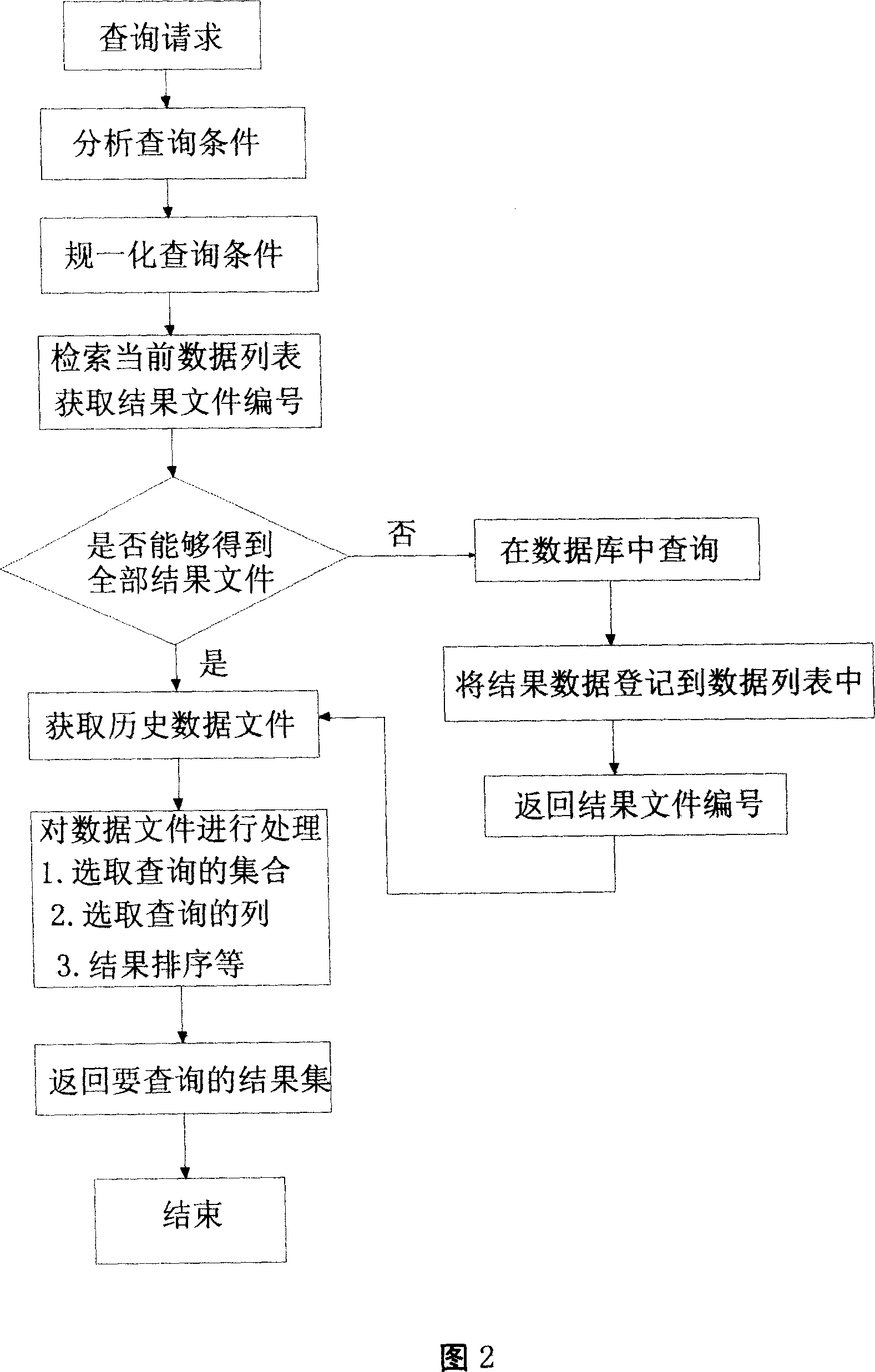

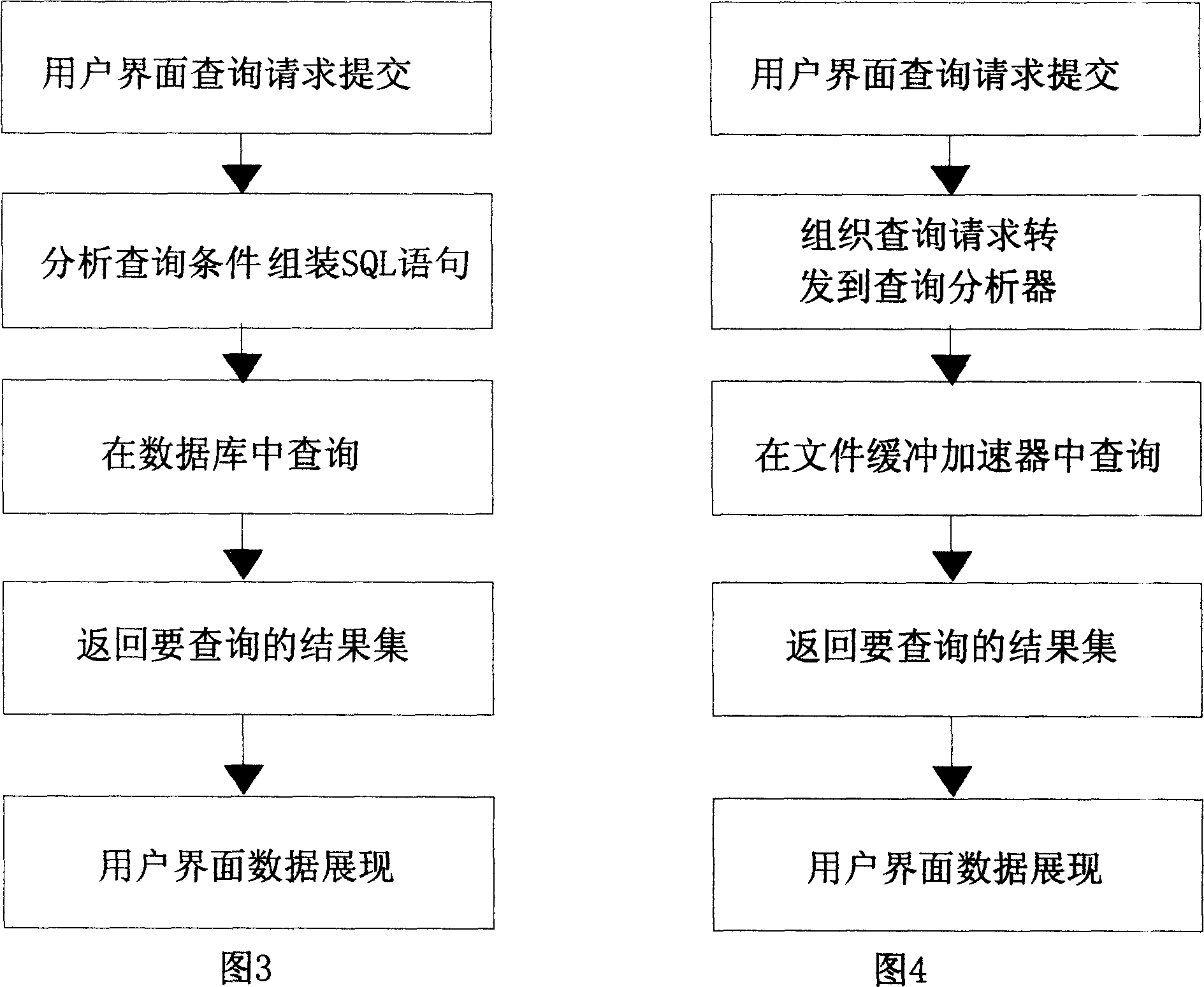

Data speedup query method based on file system caching

InactiveCN101110074AImprove hit rateIncrease in inquiriesSpecial data processing applicationsQuery analysisFile system

The invention relates to an accelerated data query method in a query system, which provides an accelerated data query method based on a cache of document system according to the features of unchanged saved historical data and frequent query of same data. The invention saves the historical query data and takes it as the cache data for query, so as to accelerate the query. Upon receiving the query quest from user, the system will first of all turn to the query analyzer; the principal function of the query analyzer is to analyze and plan the query condition; then, after passing through a document buffer, the system analyzes whether the data document in the result satisfies the present query need; if not, the query will be carried out in the database and the final result will be fed back to a data processor; then, the data processor will filter and sort the data according to the final query demand and finally feed back the result document to a super stratum application system. Therefore, without increasing the investment on hardware, this query method is able to greatly reduce the occupation of database and system resource, so as to improve the query speed.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

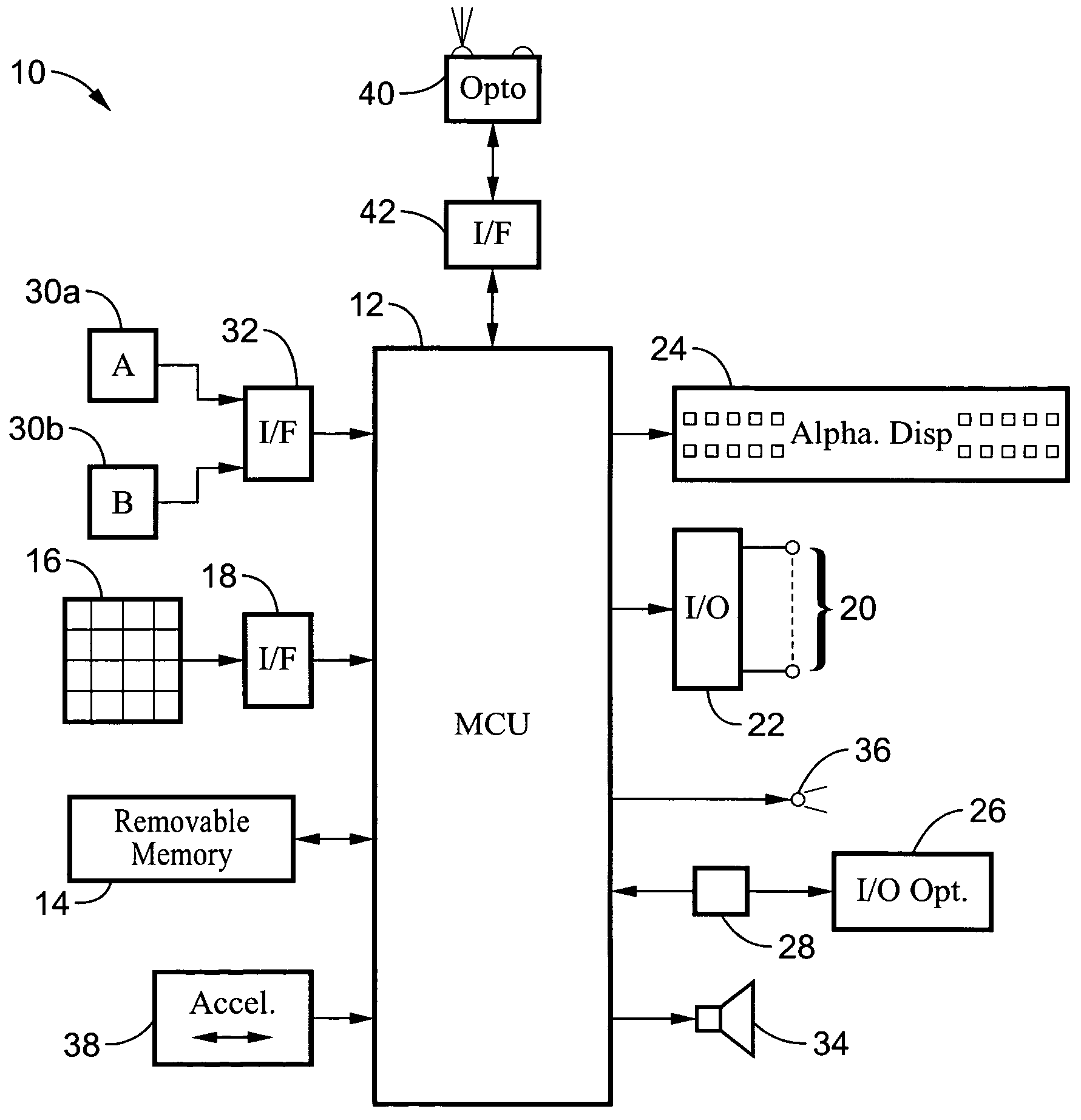

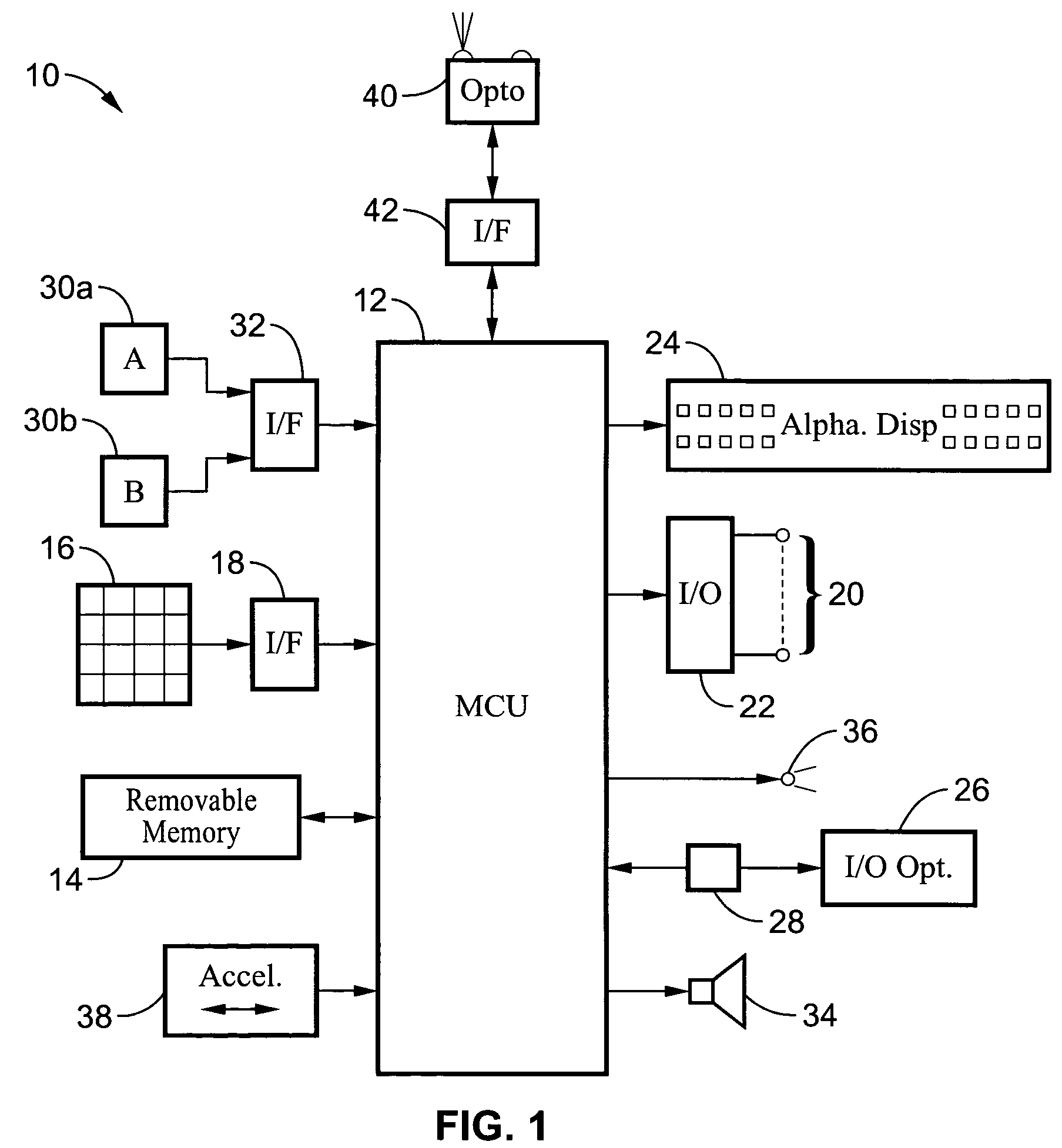

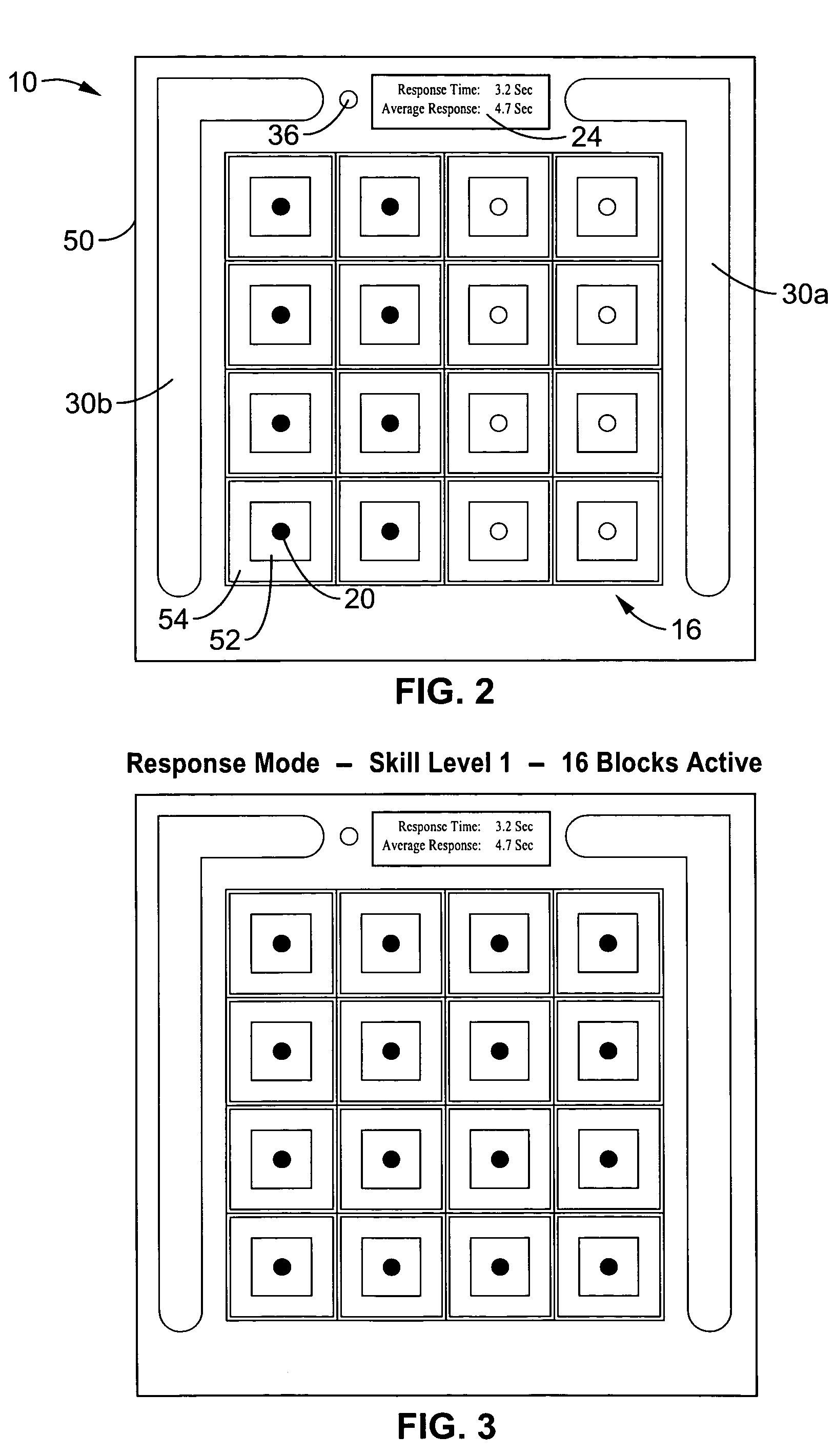

Interactive neural training device

InactiveUS7452336B2Easy to useNot easy to damageElectrotherapyPerson identificationTouch PerceptionHand movements

Owner:INTERACTIVE NEURO TECH

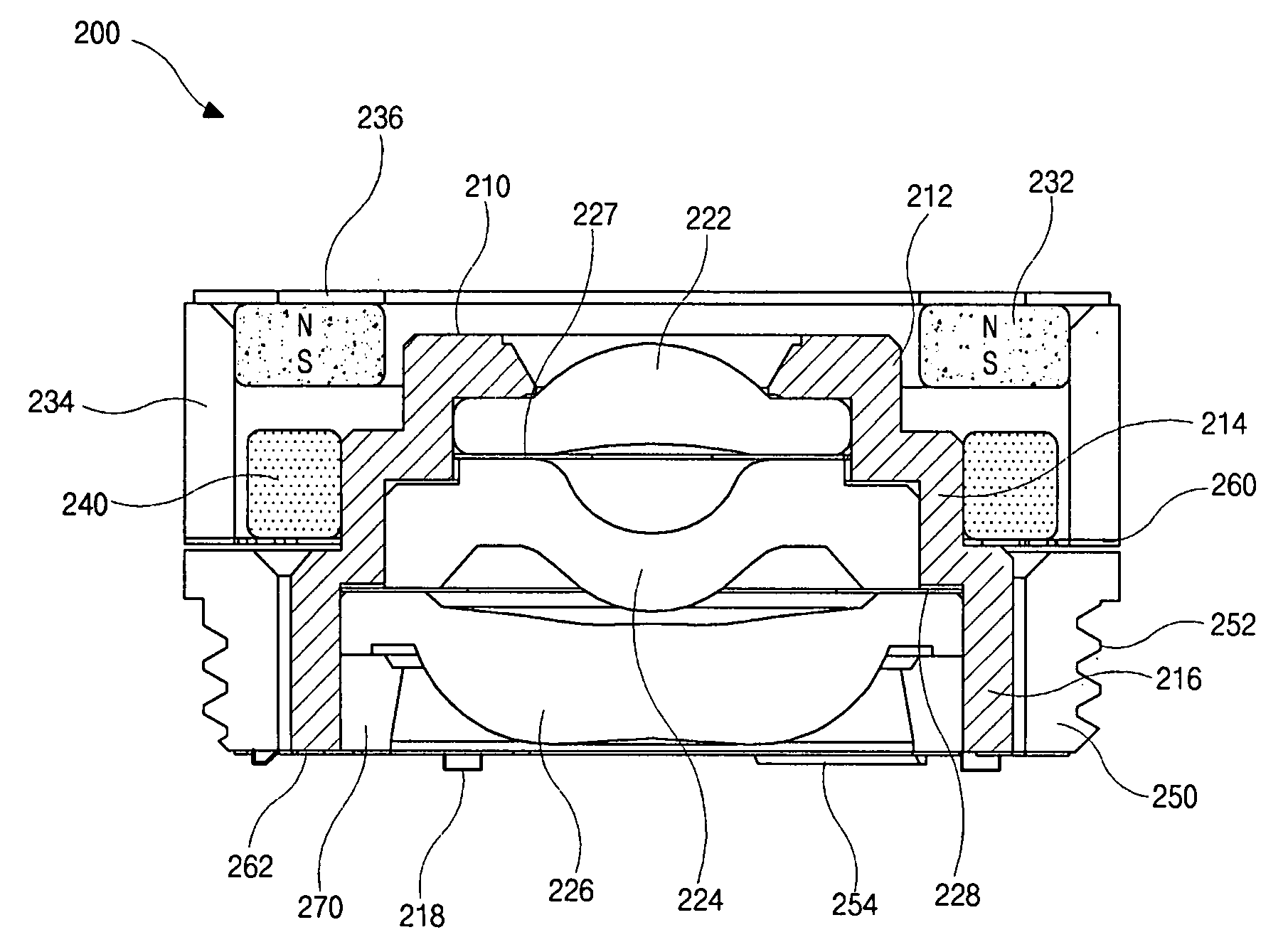

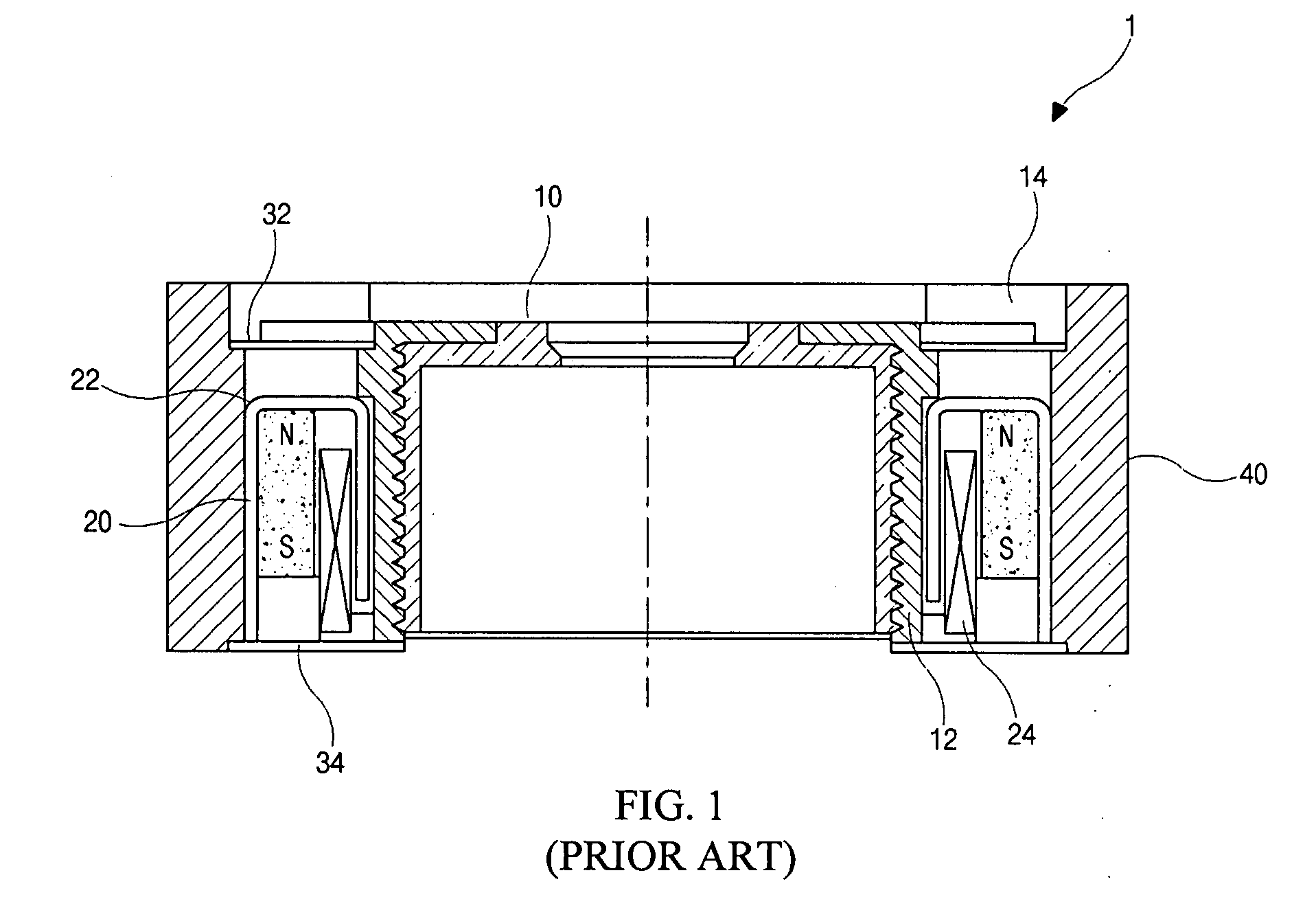

Lens assembly with actuating means and auto-focus controlling apparatus having the same

InactiveUS20080037143A1Avoid excessive currentSmall sizeMountingsFocusing aidsSmall lensCamera module

A lens assembly has a driving actuator which includes a magnet, a yoke and a coil and is formed along a lens barrel that accommodates a lens unit for focusing and an auto-focus controlling apparatus comprises the lens assembly for camera module. The magnet or the coil has an internal diameter smaller than a maximal diameter of the lens barrel. Therefore, it is possible to manufacture much smaller lens assembly according to the present invention compared to the conventional ones and to reduce the possibility of component damages in the lens assembly in operating the camera module.

Owner:DIOSTECH

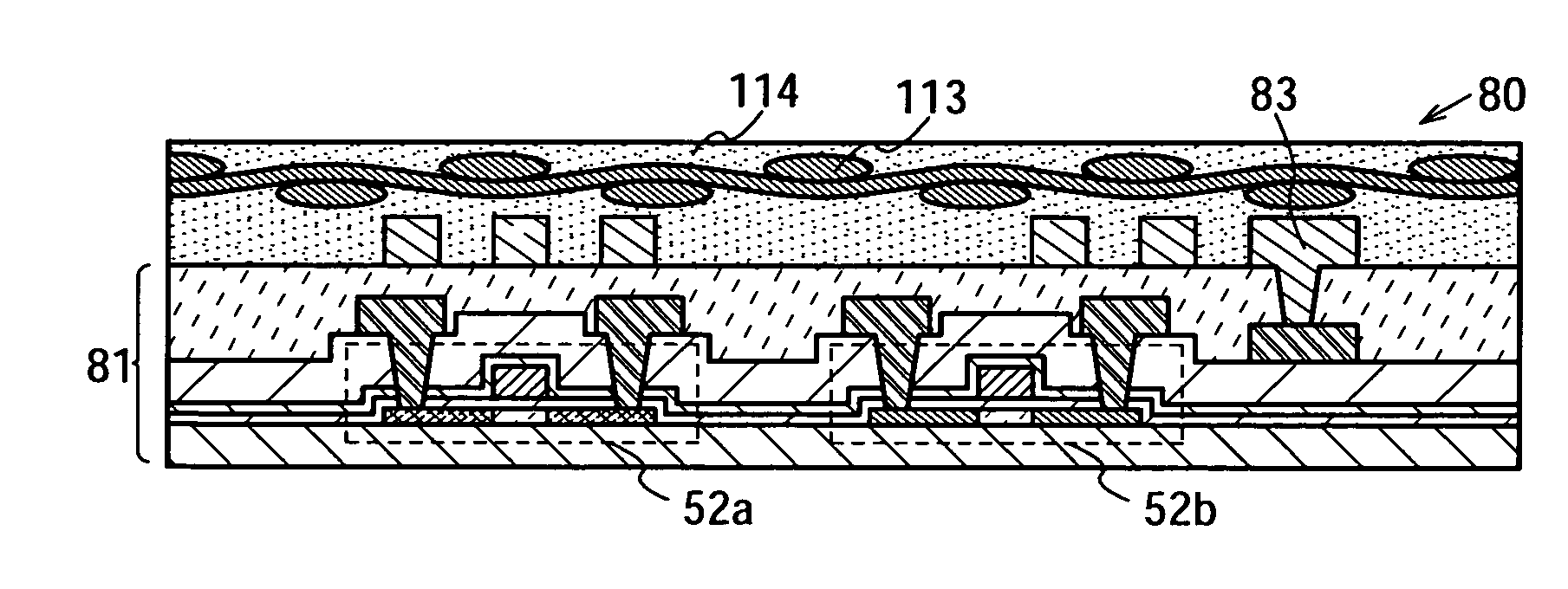

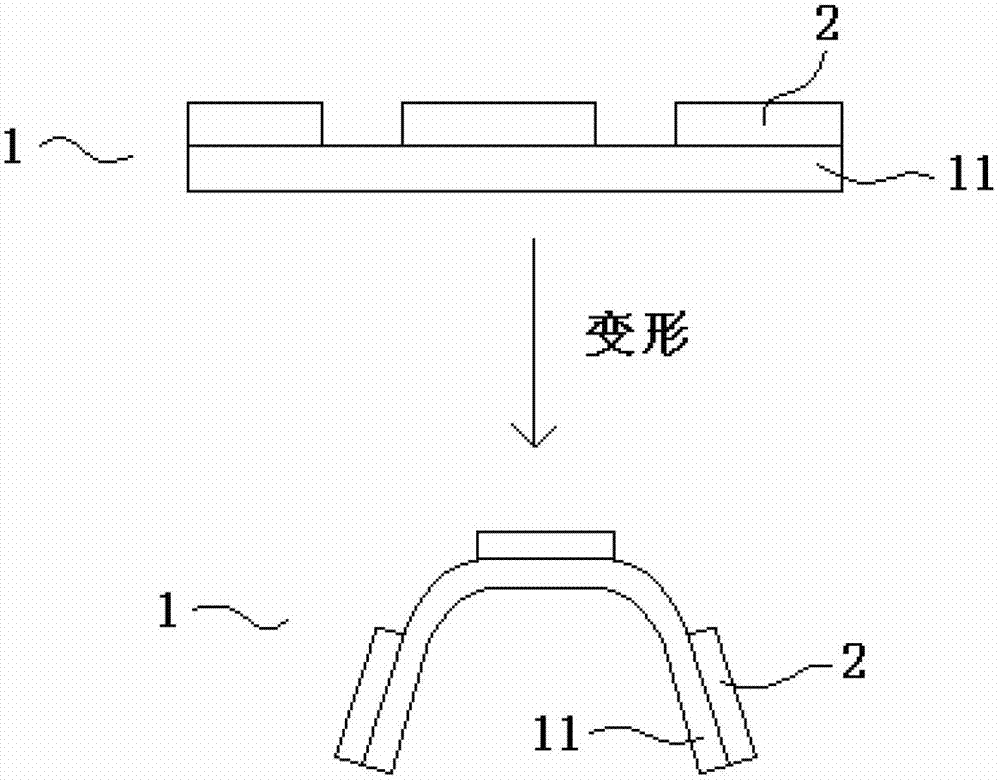

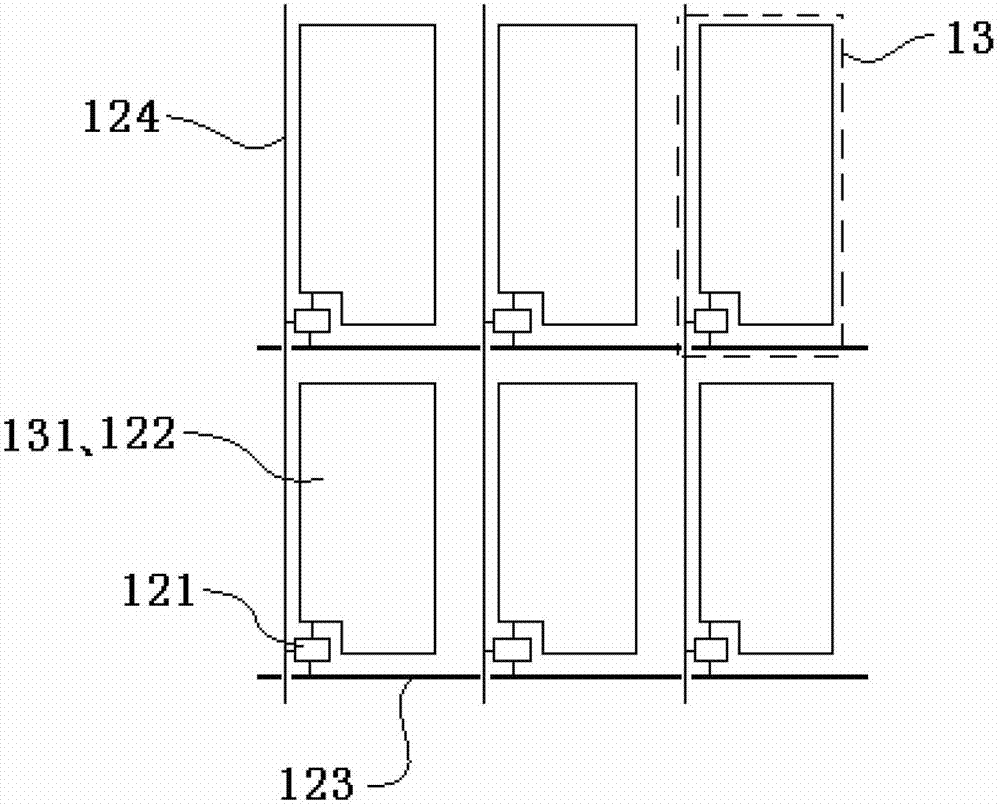

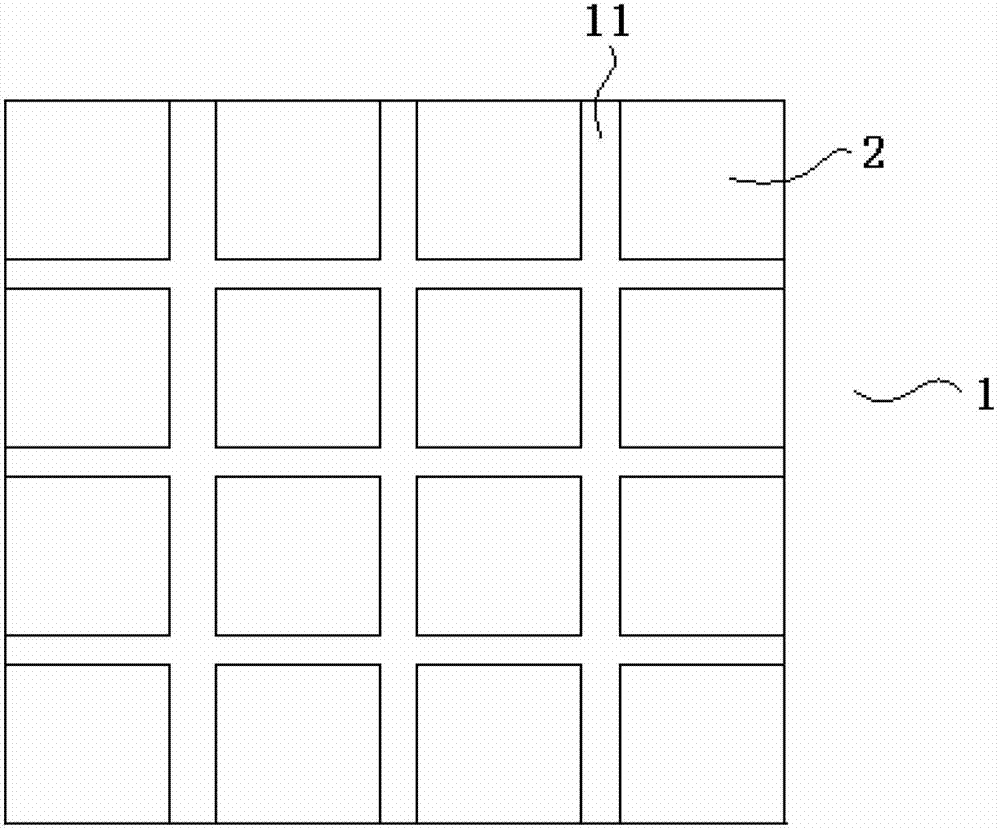

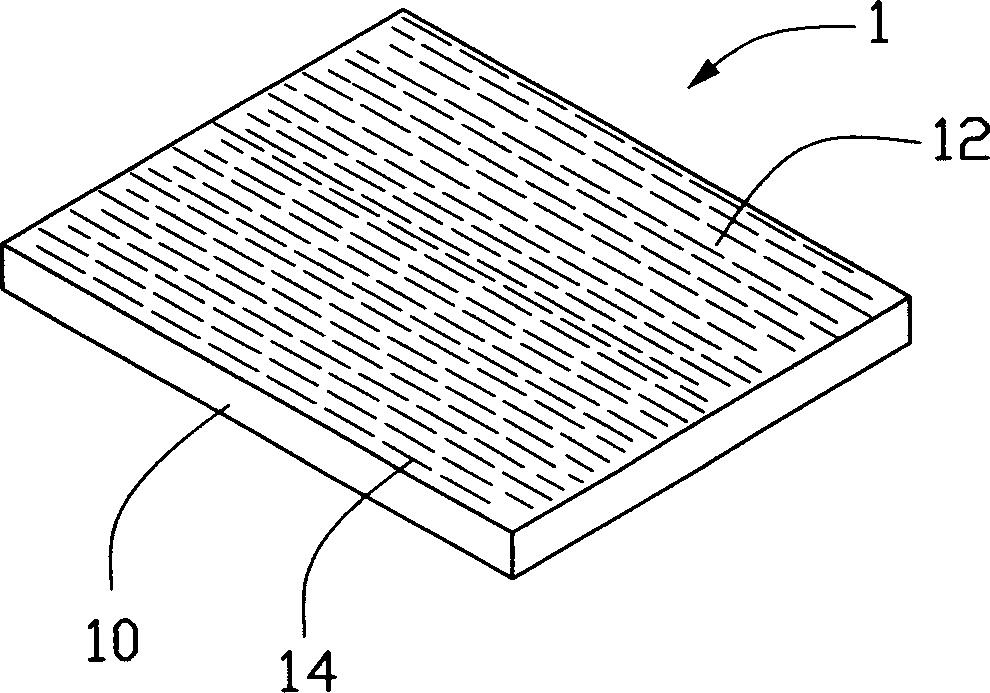

Flexible display substrate and preparation method thereof as well as flexible display device

ActiveCN102969320ANot easy to damageSmall amount of deformationFinal product manufactureSolid-state devicesLiquid-crystal displayOrganic electroluminescence

The invention provides a flexible display substrate and a preparation method thereof as well as a flexible display device, belongs to the technical field of flexible display, and can solve the problem that the conventional flexible display substrate is easily damaged during deformation, small in deformation quantity, low in display performance, high in cost, or difficult in preparation. The flexible display substrate comprises a hard material layer which is arranged at a vulnerable position of the flexible display substrate. The preparation method of the flexible display substrate comprises a step of forming a graph of the hard material layer. The flexible display device comprises the flexible display substrate. The flexible display substrate can be used in the flexible display devices such as an organic electroluminescent display device, a flexible electrophoretic display device and a flexible liquid crystal display device.

Owner:BOE TECH GRP CO LTD

Method for making coal fine into form coke by microwave energy

InactiveCN101497835AReduce manufacturing costIncrease productivitySolid fuelsMicrowave heatingMicrowaveWork in process

The invention relates to a method for producing formed coke, in particular to a method for preparing coal powder into the formed coke by microwave. The method adopts coal powder as raw material and comprises the following steps: sieving the coal powder for preparing fine coal powder, sending the fine coal powder into a first microwave heating device for dehydration until the water content of the heated fine coal powder is below 1 percent, and sending the heated fine coal powder into a second microwave heating device by a conveying device for dry distillation; performing the dry distillation to the fine coal powder by the second microwave heating device to analyze other materials in the coal powder, preparing carbocoal after the dry distillation, sending the carbocoal into a mixer by the conveying device to prepare the mixture after adding bonding material; sending the mixture to a forming machine by a conveyer for forming so as to prepare a formed coke semi-finished product; sending the reformed coke semi-finished product into a third microwave heating device for being heated and carbonized to prepare red coke, and sending the carbonized red coke into a coke car to prepare a formed coke product. The invention has low production cost, high production efficiency, cleanness and environment protection because coke powder and waste are not produced during the production.

Owner:唐山金强恒业压力型焦有限公司

Polarized element and method for manufacturing same

InactiveCN1482472AExtended service lifeNot easy to damagePolarising elementsNanoopticsCarbon nanotubeAtmospheric pressure

The invention discloses an optical polarized light element and method for manufacturing the same, wherein the method comprises, providing a silicon base having a smooth surface, depositing iron catalyst onto the silicon base surface, feeding the silicon base into a reaction furnace, heating the reaction furnace and feeding in the mixture gas of acetylene and argon, controlling the flow capacity of the mixture gas, controlling the mixture ratio of acetylene and argon gas, gripping and pulling a bundle of carbon nanometer tubes using a clamp, arranging the carbon nanometer tubes rope compactly and parallelly onto a transparent base sheet.

Owner:BEIJING FUNATE INNOVATION TECH +1

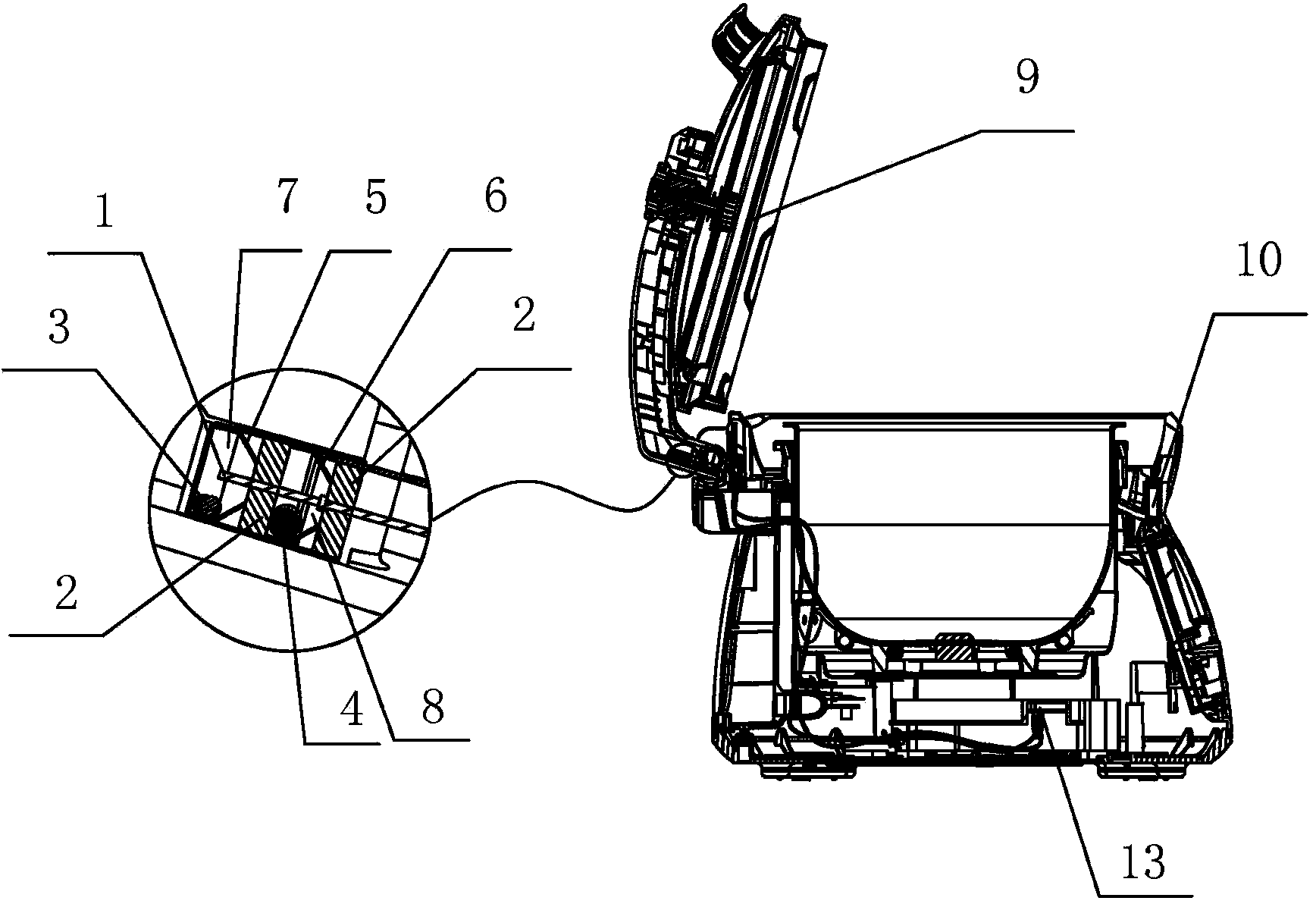

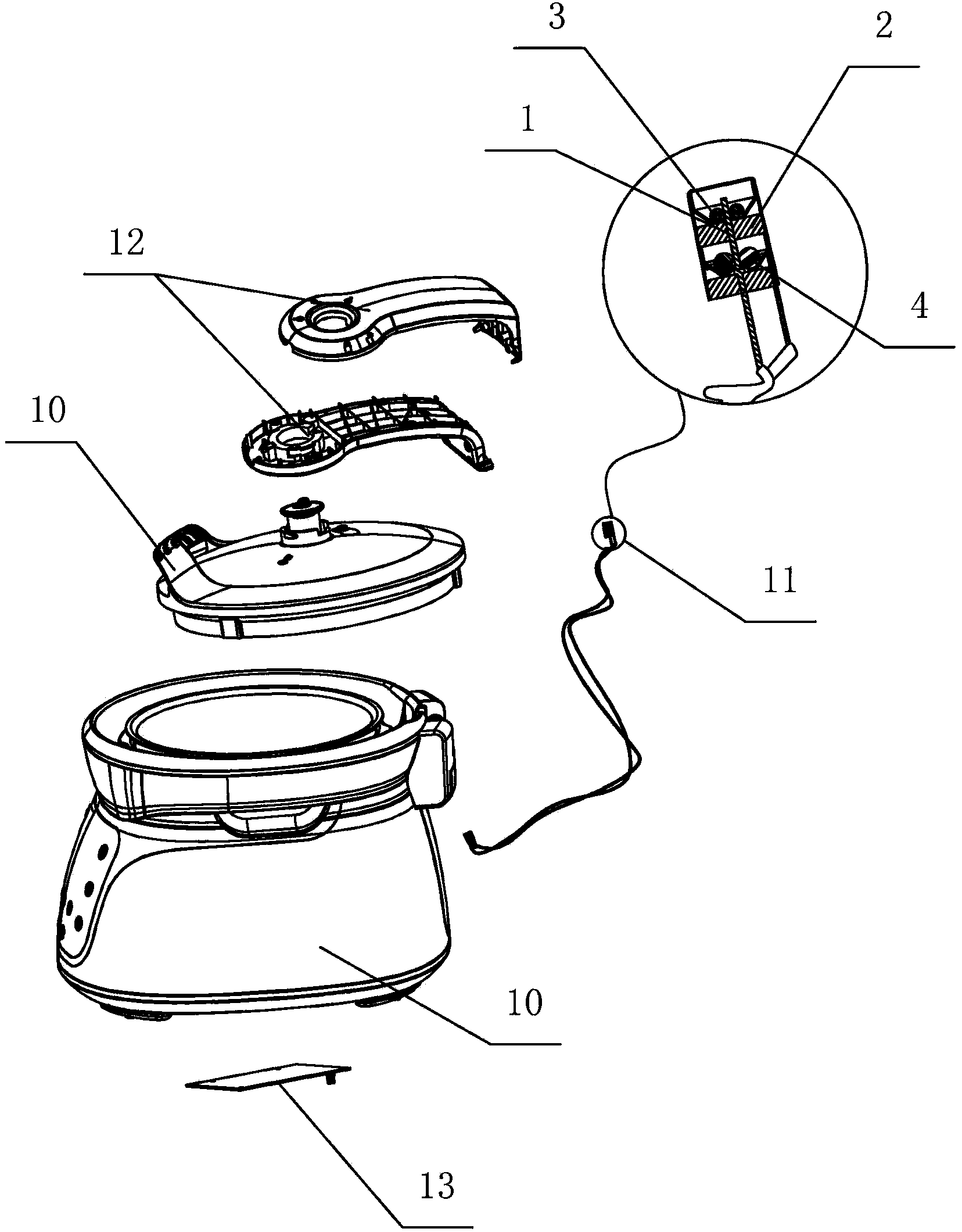

Electric pressure cooker cover opening and closing signal feedback device

The invention discloses an electric pressure cooker cover opening and closing signal feedback device. When a cover body of the electric pressure cooker is in a closed position, a conductive ball is in a switched-on position, and a first conductor and a second conductor are switched on by the conductive ball; when the cover body of the electric pressure cooker is in an opened position, the conductive ball is in a switched-off position, the first conductor and the second conductor are switched off. According to the electric pressure cooker cover opening and closing signal feedback device, an electronic switch in the prior art is replaced by a mechanical switch; the structure is simple; the electric pressure cooker cover opening and closing signal feedback does not need to rely on the switching on and off of electric, magnetic and optical control switches; the position of the conductive ball is changed by means of the self gravity of the conductive ball by only changing the position of the cover body; the switching on or off of the first conductor and the second conductor is used as a signal for controlling the heating of the electric pressure cooker; when the position of the cover body is changed, the opening and closing of the cover body are directly related to the heating; the reliability is higher; the control switch is unlikely to damage even when the control switch is used in the high-temperature and high-humidity environment for a long time; the use safety can be ensured; the manufacture and maintenance costs are low.

Owner:GUANGDONG LUBY ELECTRONICS

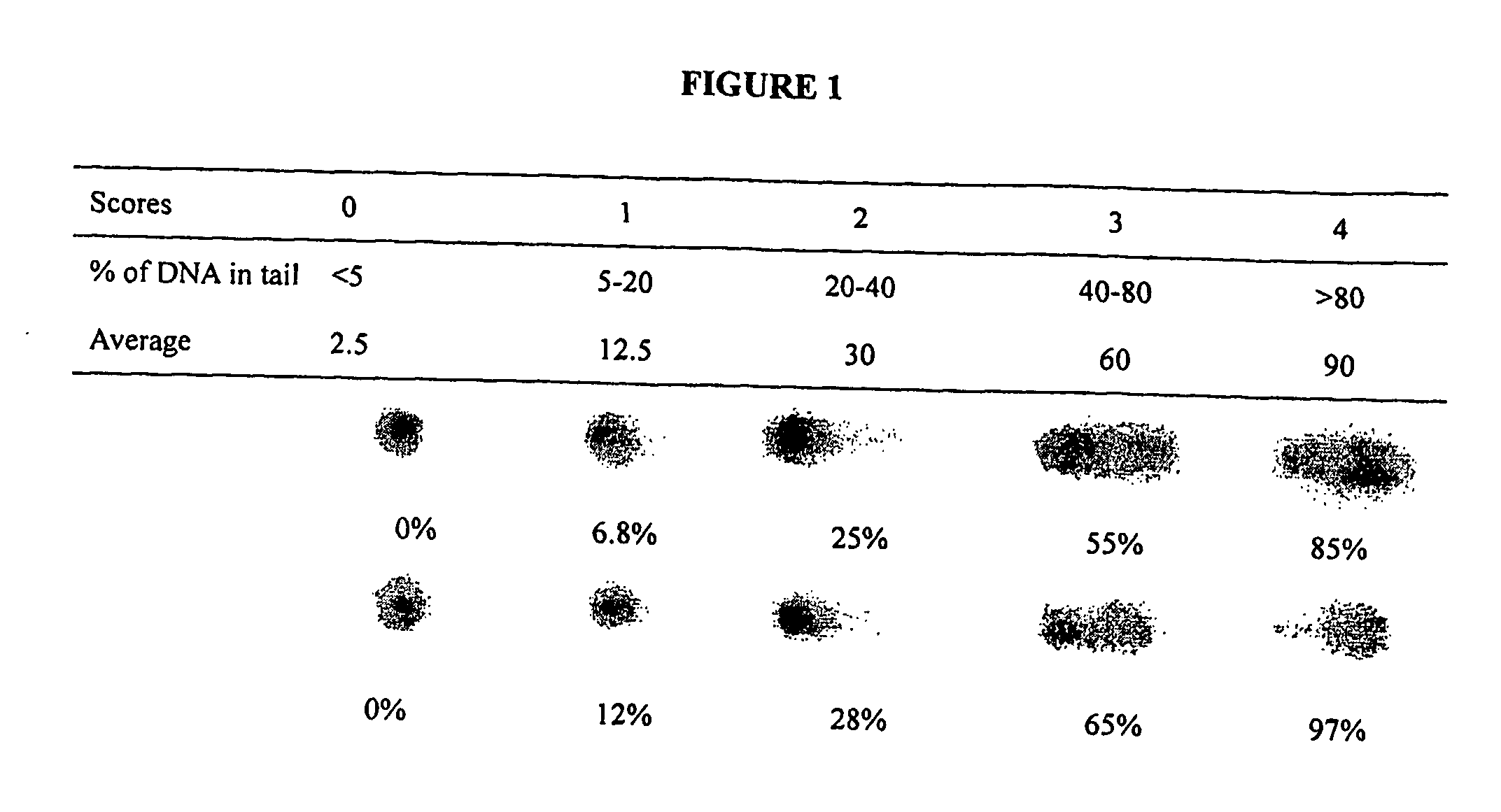

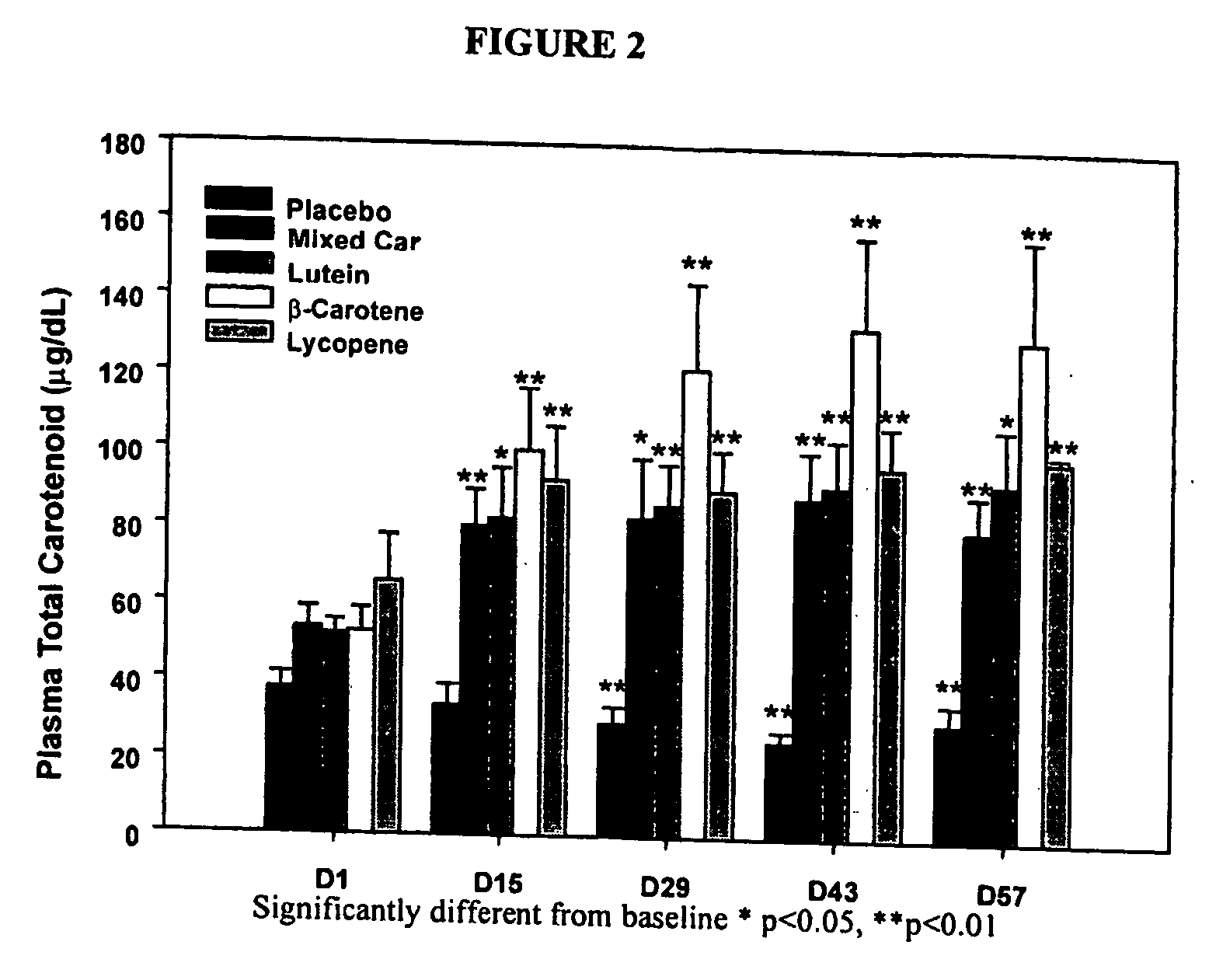

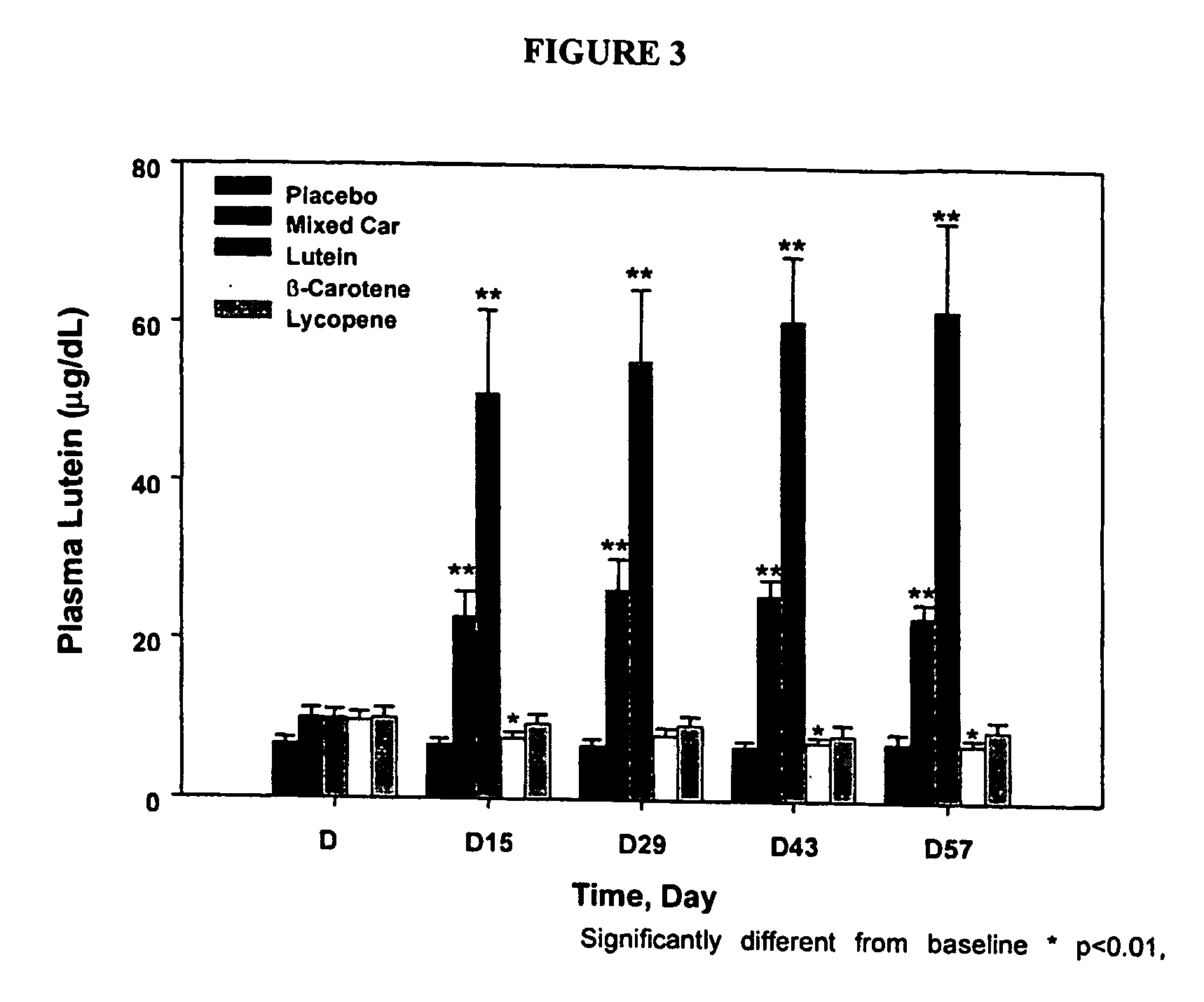

Synergistic effect of compositions comprising carotenoids selected from lutein, beta-carotene and lycopene

InactiveUS20070082044A1Improve antioxidant capacitySlow effectCosmetic preparationsBiocideDiseaseAntioxidant capacity

The methods of the invention can be used to protect against lymphocyte DNA damage and free-radical associated disorders in a subject. The methods of the present invention can be used to increase the antioxidant capacity in both the aqueous and lipid compartments, decrease DNA oxidation, decrease lipid peroxidation, and increase antioxidant nutrient levels in the circulation. The protective effect of the physiologic dose of the mixed carotenoid supplement is rapid, consistent and cumulative.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Methods of performing medical procedures which promote bone growth, compositions which promote bone growth, and methods of making such compositions

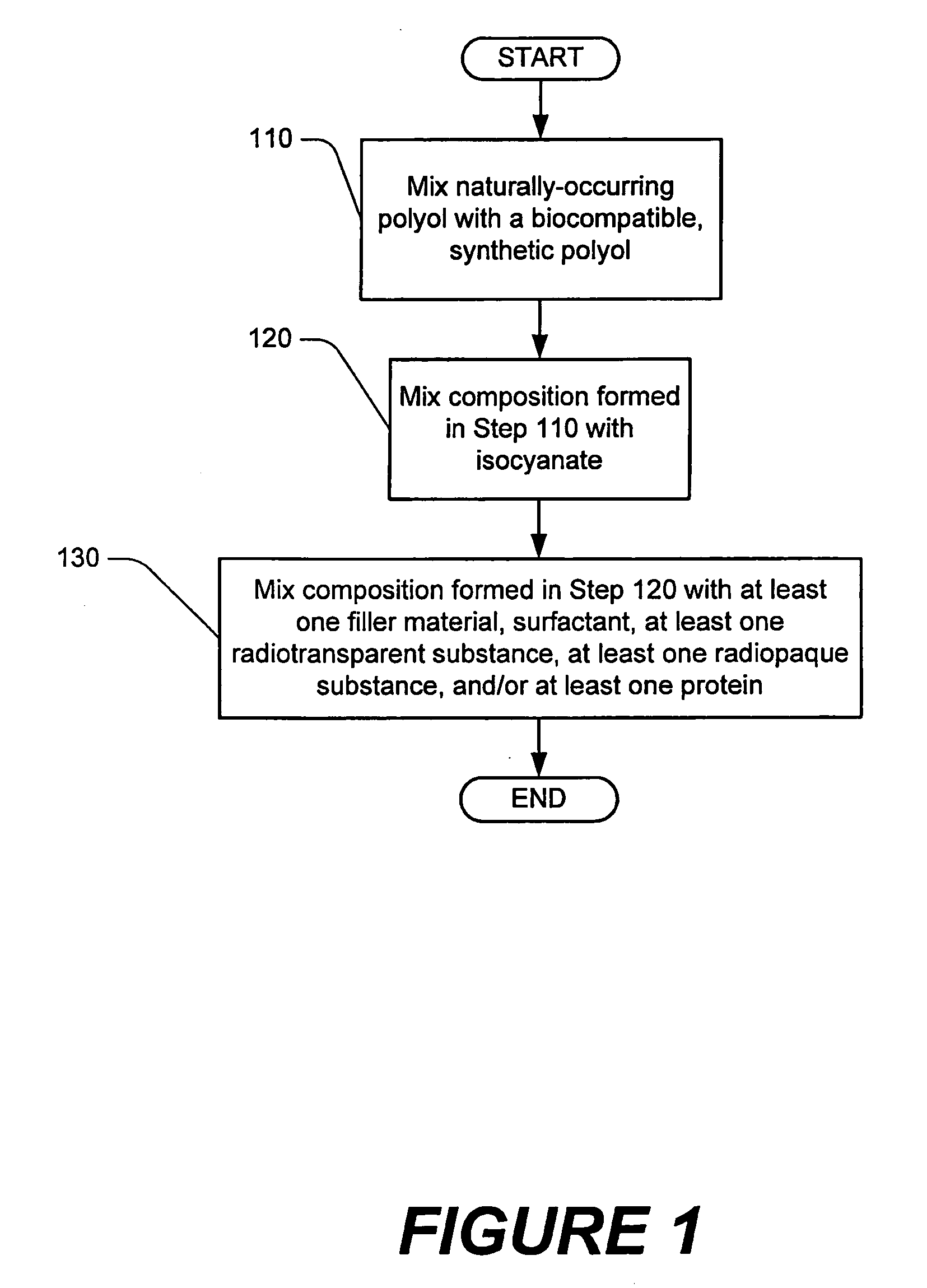

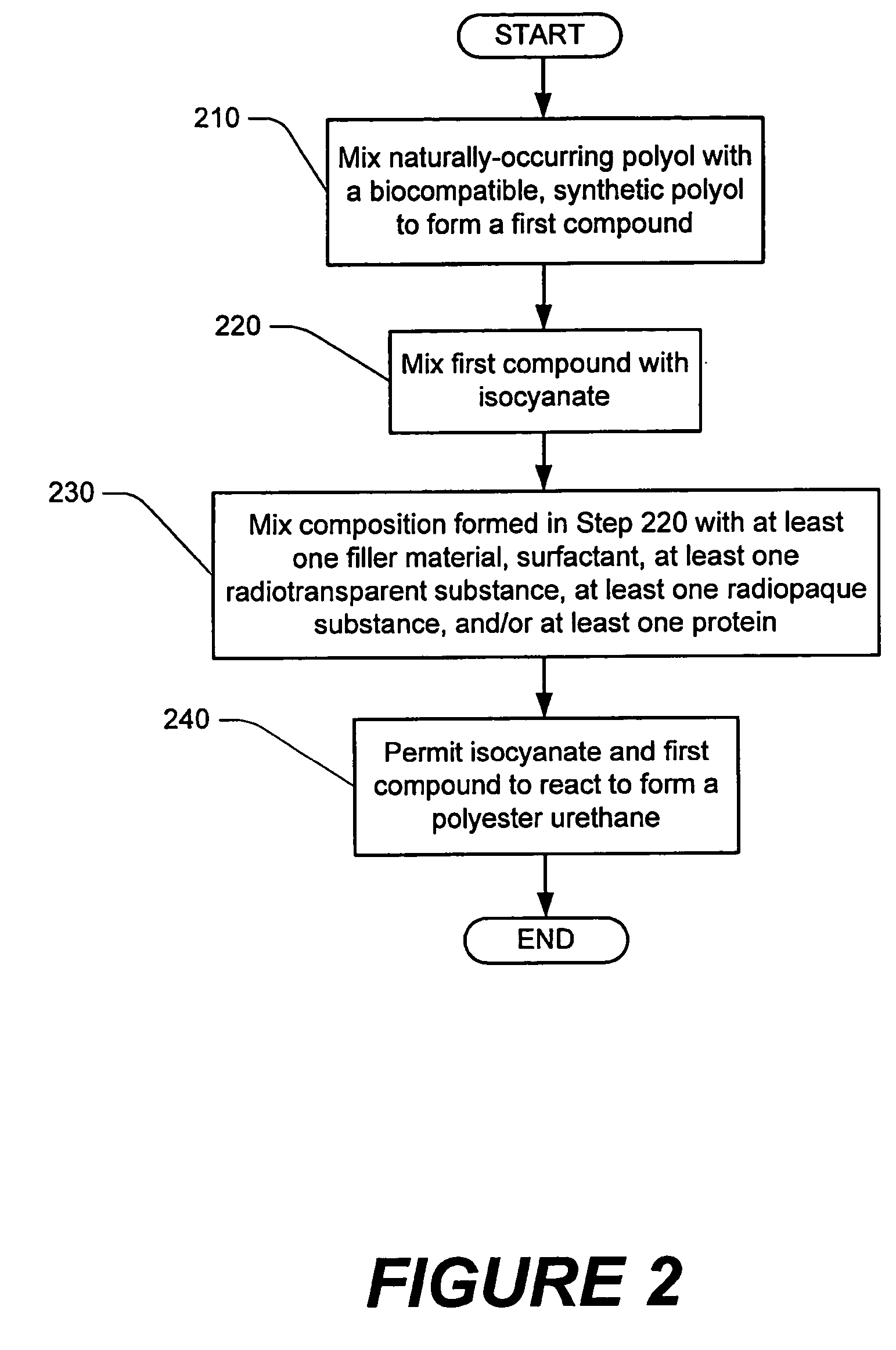

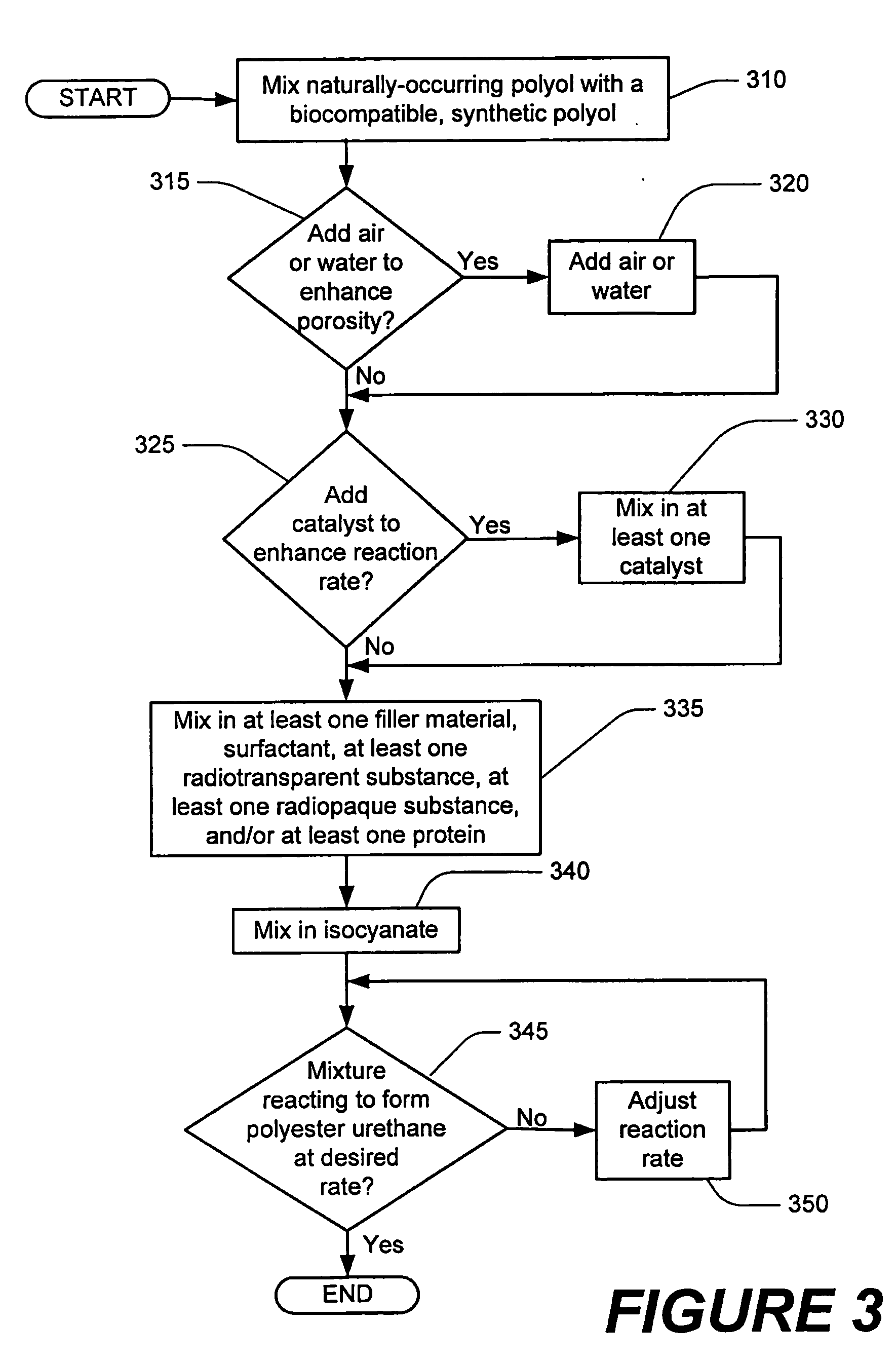

InactiveUS20050031578A1Promote growthReduce or eliminate damageTissue culturePharmaceutical non-active ingredientsBiomedical engineeringMedical treatment

The present invention provides compositions that may be useful, inter alia, in medical procedures, methods for making such compositions, and methods of performing medical procedures using such compositions. The present invention further provides a kit that includes a first container comprising a dispensing means and a first compound; and a second container comprising a dispensing means and a second compound, wherein the first compound may include, inter alia, a naturally occurring polyol, a biocompatible synthetic polyol, and mixtures thereof, and wherein the second compound may include, inter alia, isocyanate.

Owner:DOCTORS RES GROUP

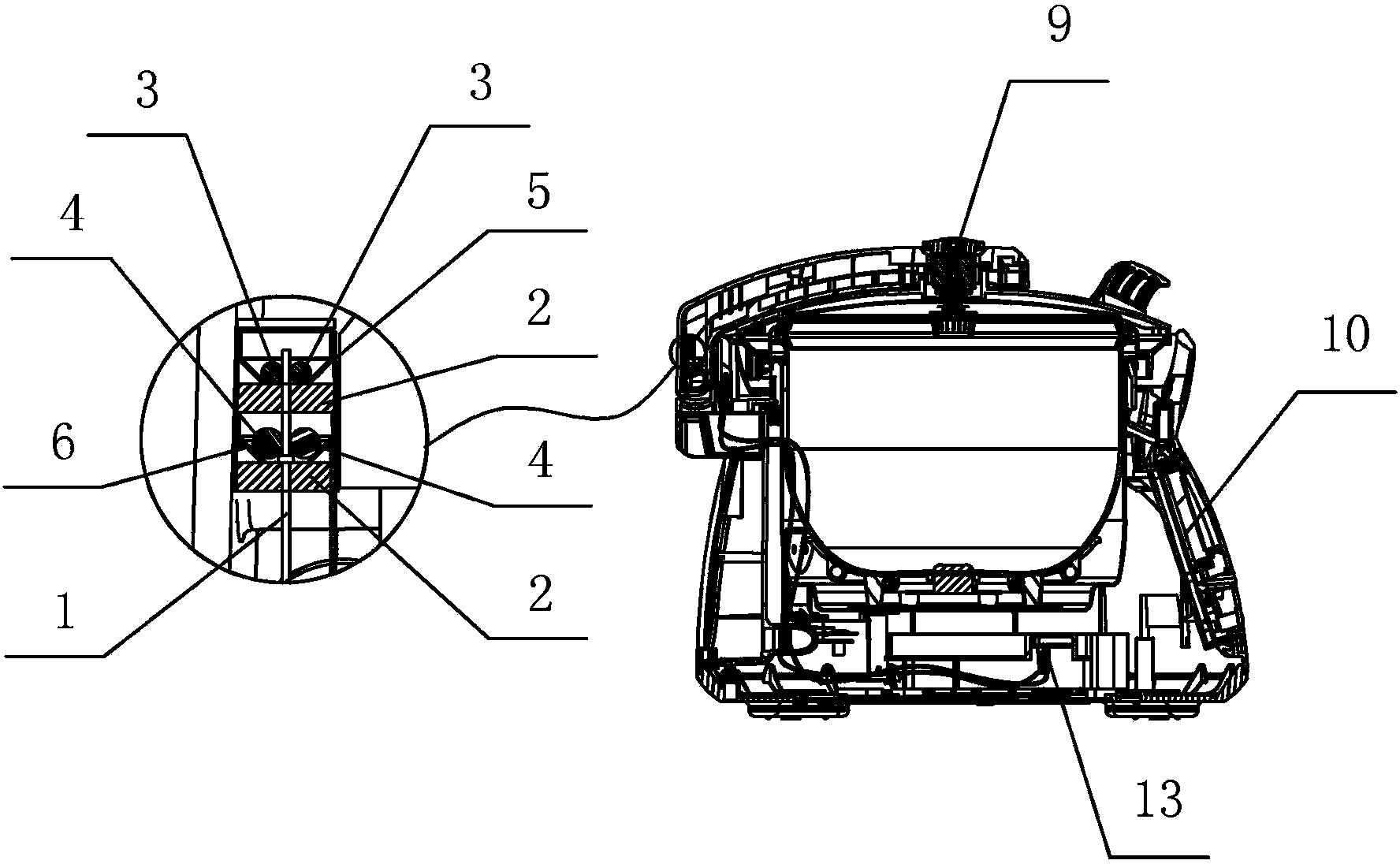

Venting structure of pressure cooker and pressure cooker with the same

The invention relates to a cooking device, in particular to a venting structure of a pressure cooker and the pressure cooker with the same. The venting structure of the pressure cooker includes a pressure limiting valve, a limiting part and a driving component, wherein the pressure limiting valve is arranged on a venting pipe and fixedly provided with a pushing component; the limiting part is fixed to a cooker cover; the driving component drives the pushing component; the movement of the pressure limiting valve is limited to an axis of the venting pipe in a vertical direction by the limiting part, and the driving component drives the pushing component to move vertically along the axis of the venting pipe. The venting structure of the pressure cooker and the pressure cooker with the same aim at solving the technical problems that when the pressure limiting valve of the pressure cooker is switched on, a plurality of components need to cooperate with one another, and a stud is likely to be broken to influence the service life of the pressure cooker; therefore, the venting structure of the pressure cooker with a longer service life and the pressure cooker with the same are provided.

Owner:GREE ELECTRIC APPLIANCES INC

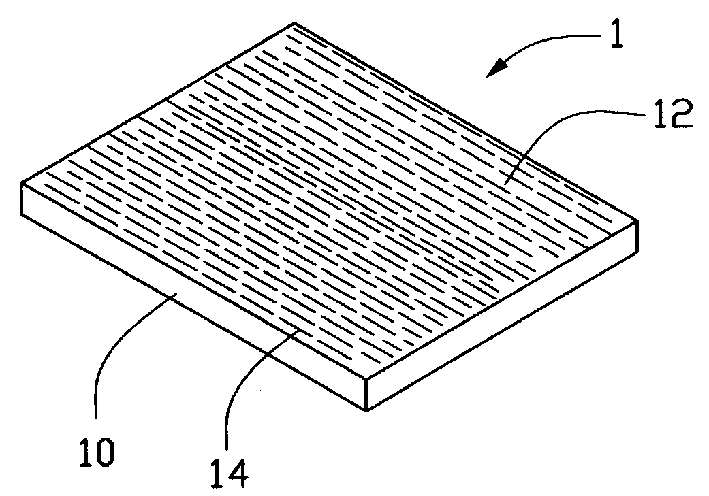

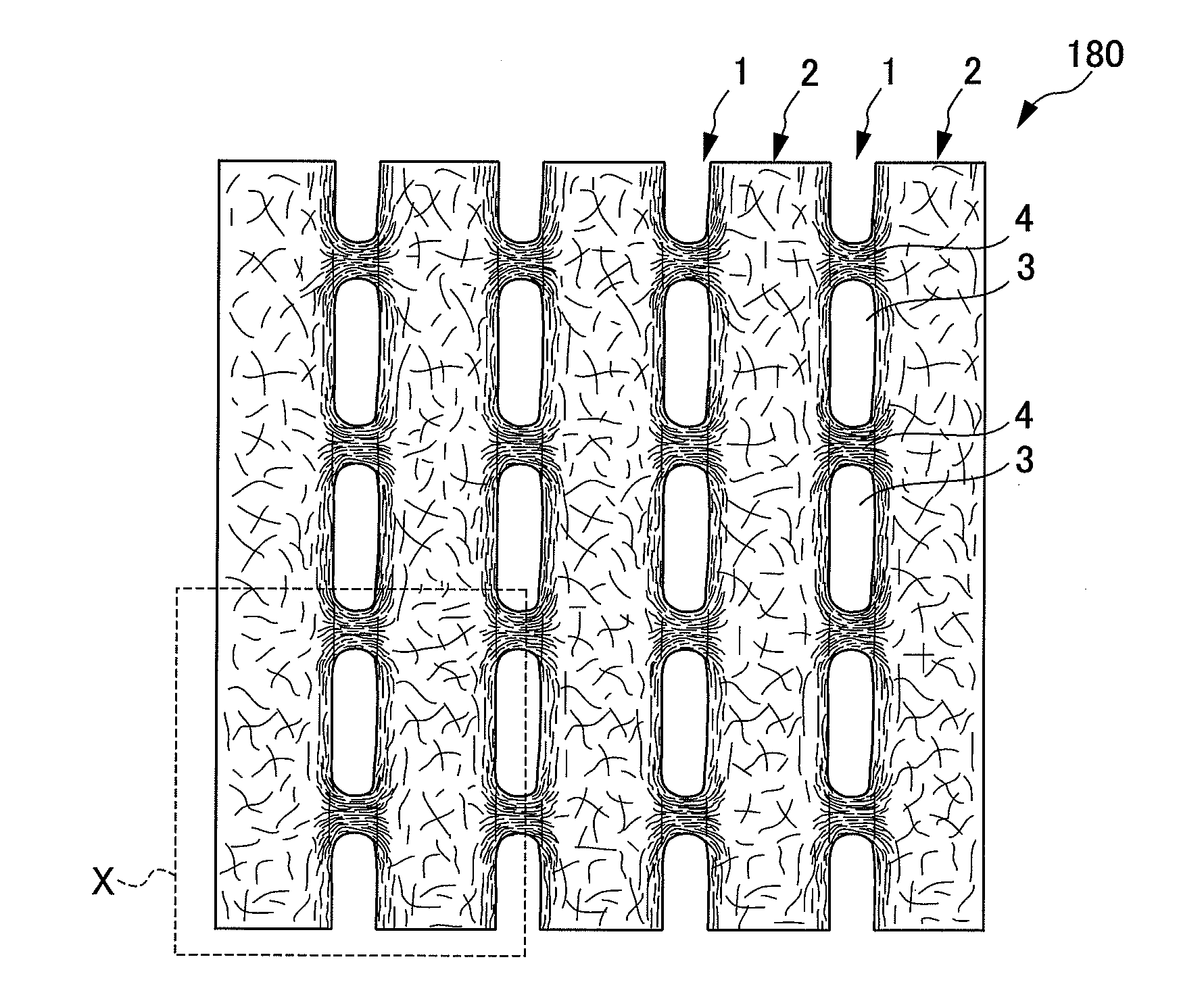

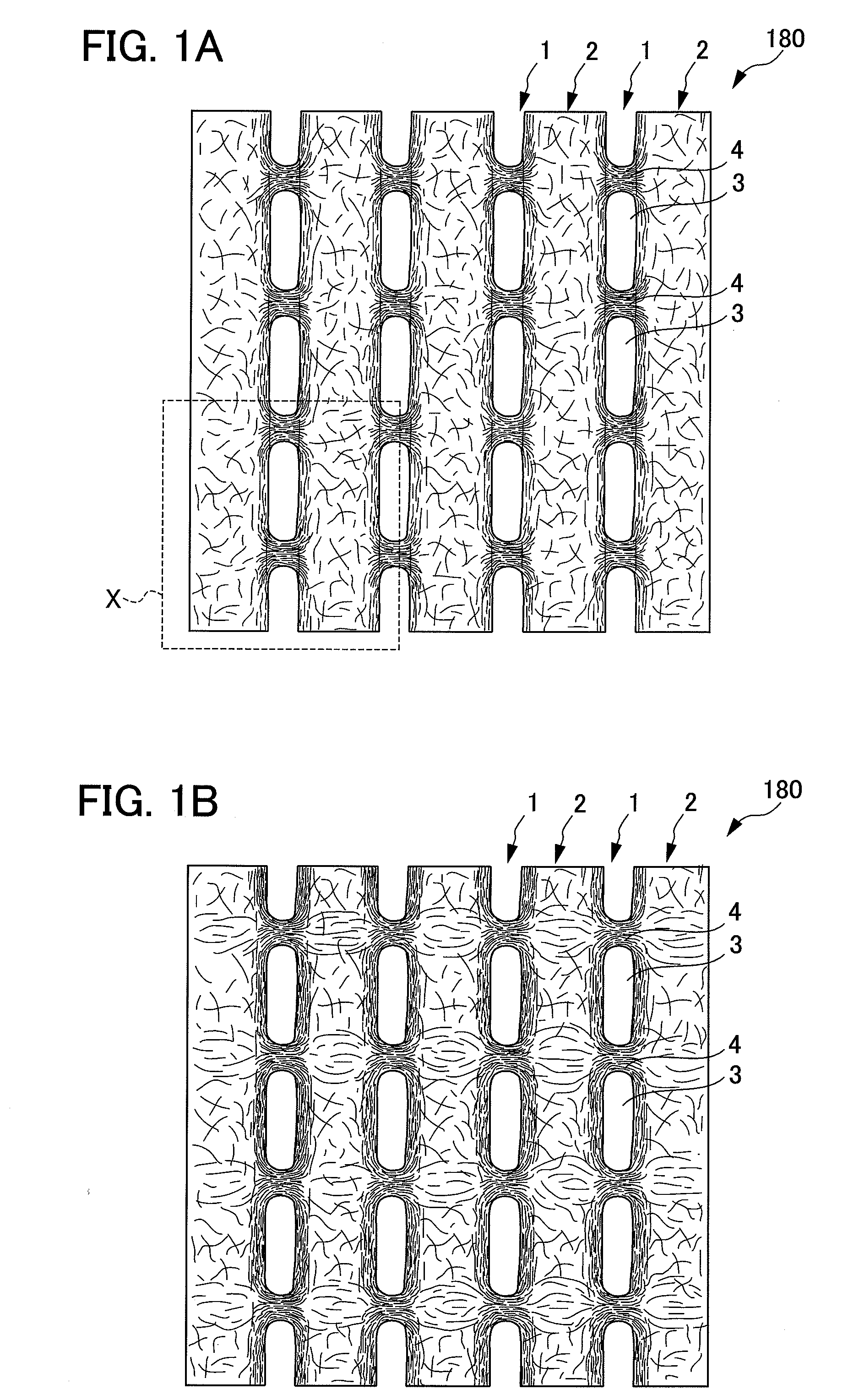

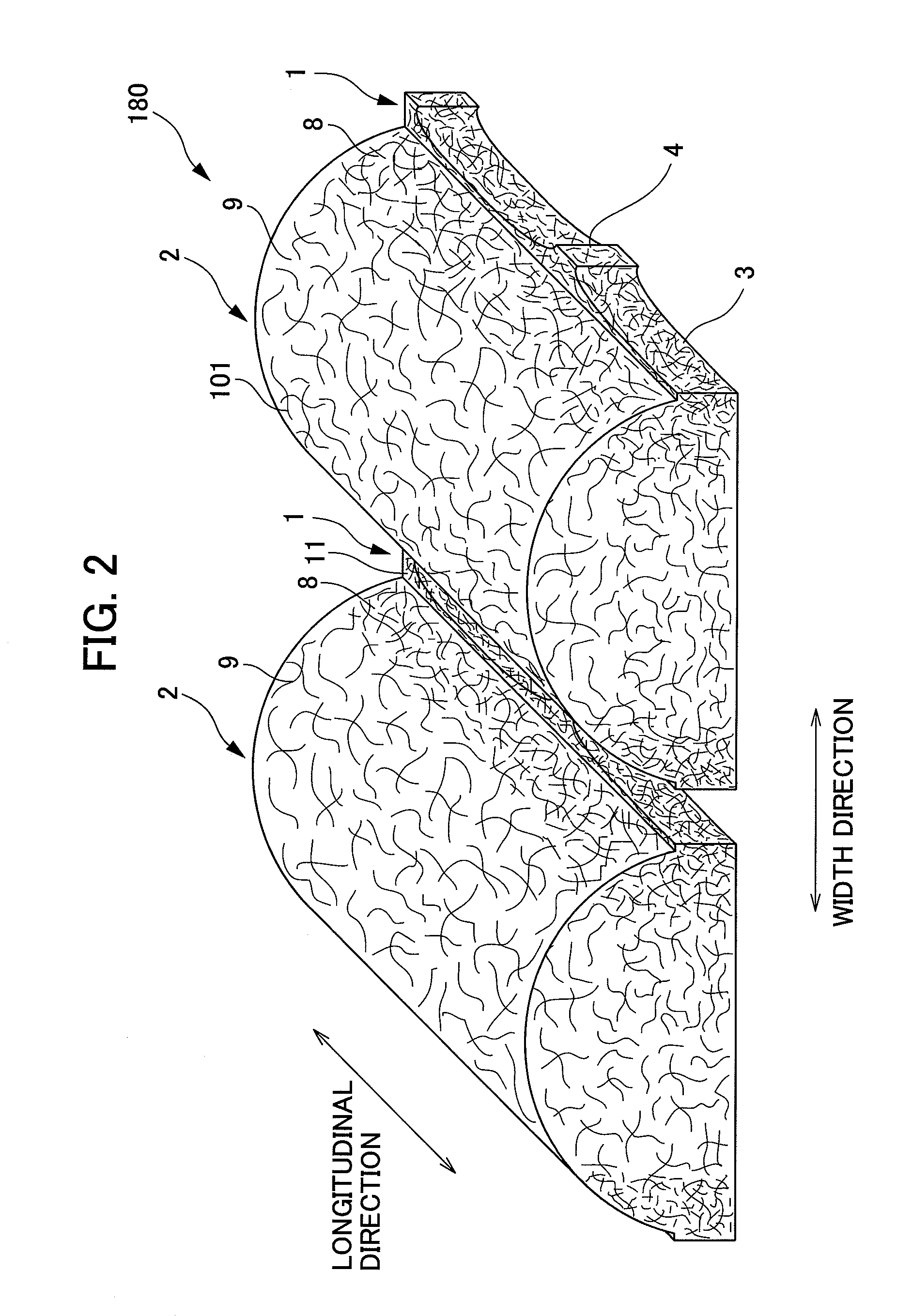

Nonwoven fabric

ActiveUS20070298213A1Not easy to damageResist damageLayered productsAbsorbent padsNonwoven fabricLower face

A nonwoven fabric that is not easily damaged during use is provided. A fiber web supported by a predetermined supporting member from the lower face side is blown with fluid, mainly composed of gas, from the upper face side of the fiber web to move fibers that constitute the fiber web, thereby forming at least a plurality of open areas. The nonwoven fabric includes a plurality of open areas continuously formed along a predetermined direction with a predetermined interval and a plurality of joining portions, each of which are formed between the open areas adjacent to each other in a predetermined direction.

Owner:UNI CHARM CORP

Organic light emitting display device and method for manufacturing the same

ActiveUS20160124557A1Keep displayNot easy to damageDigital data processing detailsInput/output processes for data processingDisplay deviceTouch panel

Disclosed is a touch panel integrated organic light emitting display apparatus. The apparatus includes a substrate, a thin film transistor disposed on the substrate, an organic light emitting unit including an anode, an organic emission layer and a cathode, an anode contact unit connected to the thin film transistor and extending from the anode, an encapsulation unit configured to cover the organic light emitting unit, a low-reflective adhesive member disposed on the encapsulation unit, the low-reflective adhesive member comprising an adhesive layer and a low-reflective pattern disposed on a lower surface of the adhesive layer, and a touch panel disposed on the low-reflective adhesive member, wherein the low-reflective pattern has a visible light absorption property.

Owner:LG DISPLAY CO LTD

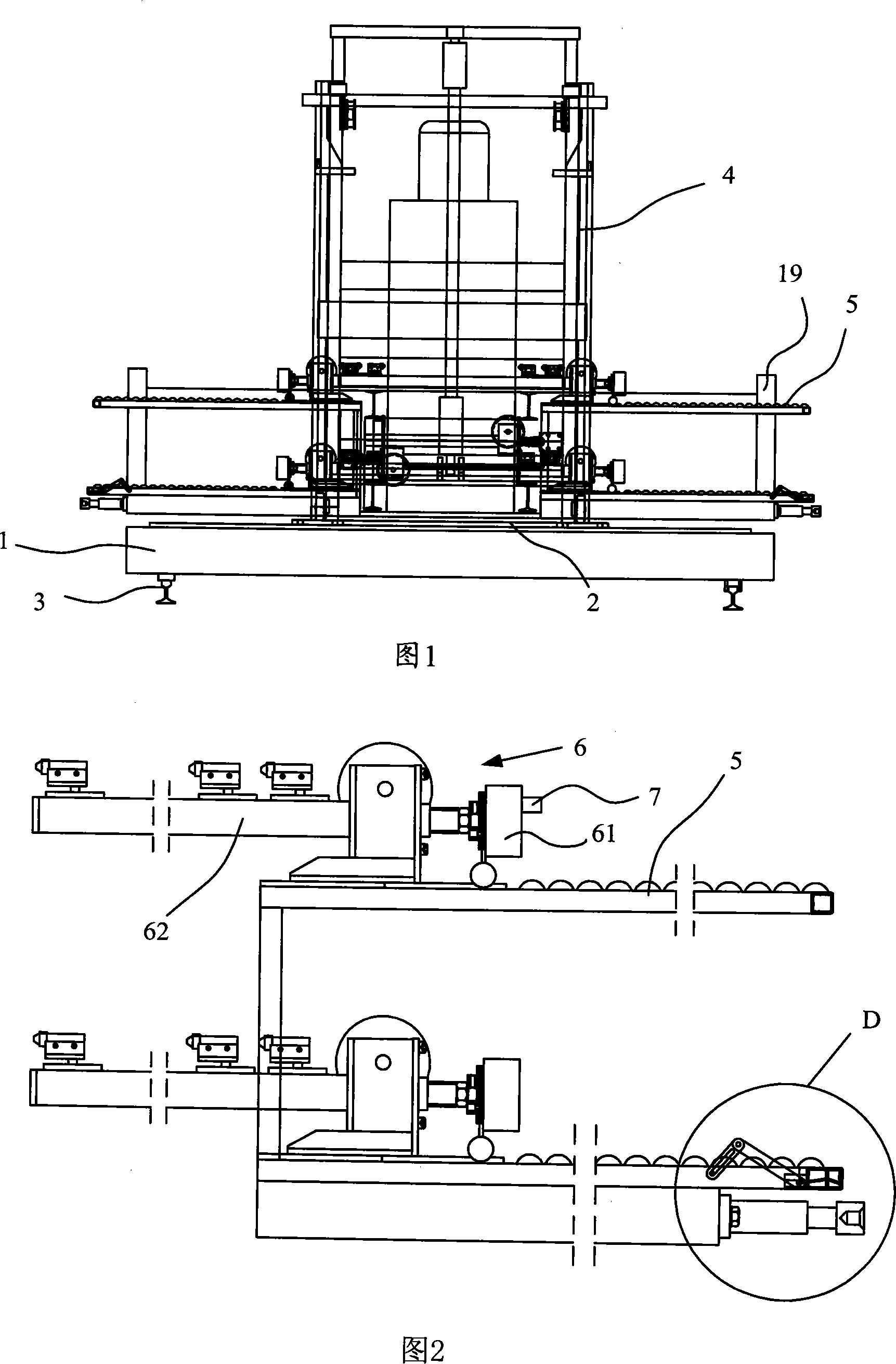

Vehicle mounted dynamic battery changing system

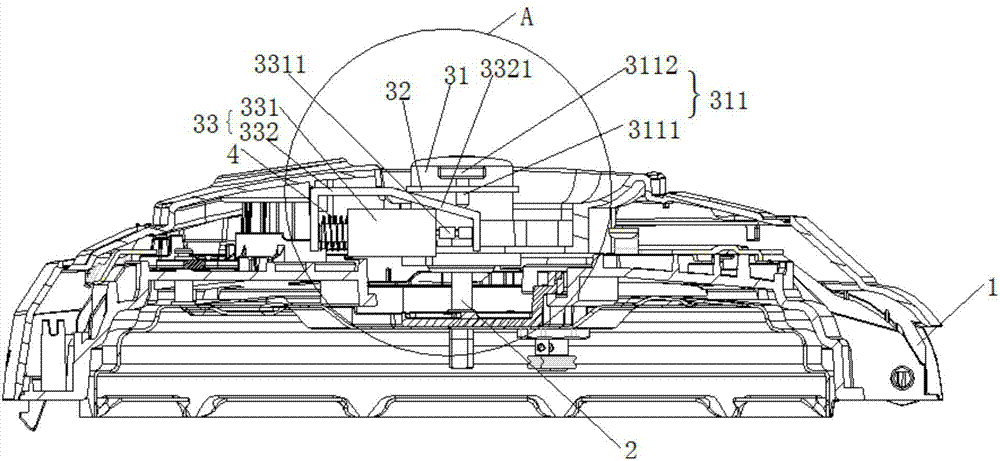

InactiveCN101214814ANot easy to damageAccurate placementElectric propulsion mountingElectric/fluid circuitPower batteryEngineering

The invention discloses a battery replacement system for power battery loaded on a vehicle. The system comprises a parallel mobile platform, a rotating platform, a track, a vertical lifting device and a battery tray. The parallel mobile platform is positioned on the track and moves along the track. The rotating platform is positioned on the parallel mobile platform. The battery tray is positioned on the rotating platform via the vertical lifting device. The battery tray is equipped with an electromagnetic suction device for drawing the battery box. The invention has the advantages of more convenient unloading of the battery box, more accurate positioning, and realizing the single loading and unloading of the battery box to be controlled within 3 minutes.

Owner:BEIJING DIANBA TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com