Polarized element and method for manufacturing same

A polarizing element and polarizing film technology, applied in polarizing elements, optical elements, optics, etc., can solve the problems of loss of polarizing effect of polarizing elements, humidity requirements of polarizing elements, etc., and achieve the effects of not easy damage, high degree of polarization, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

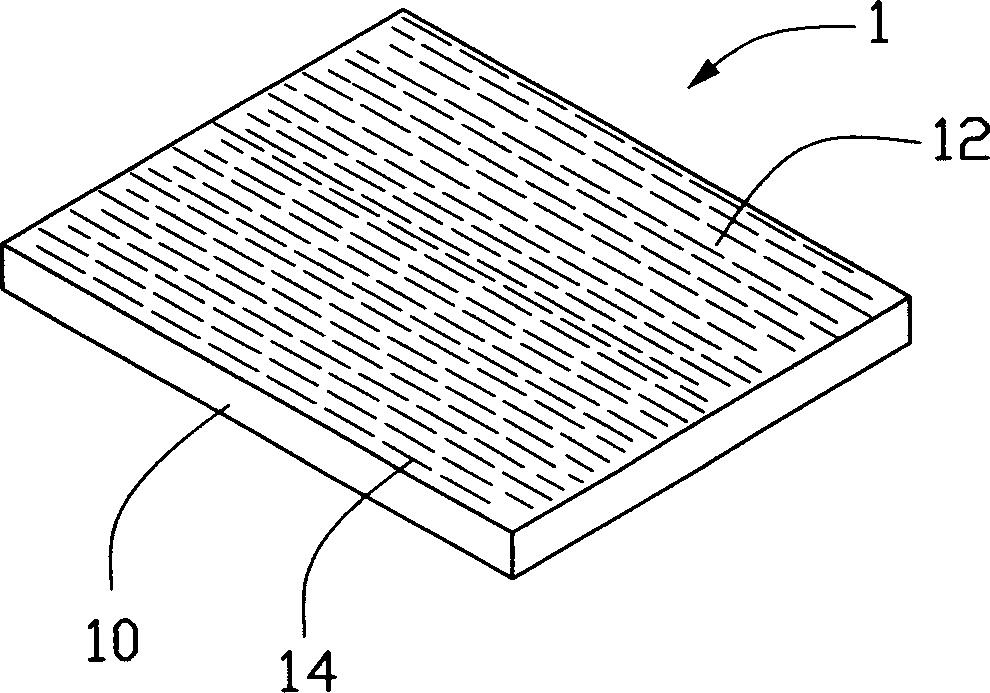

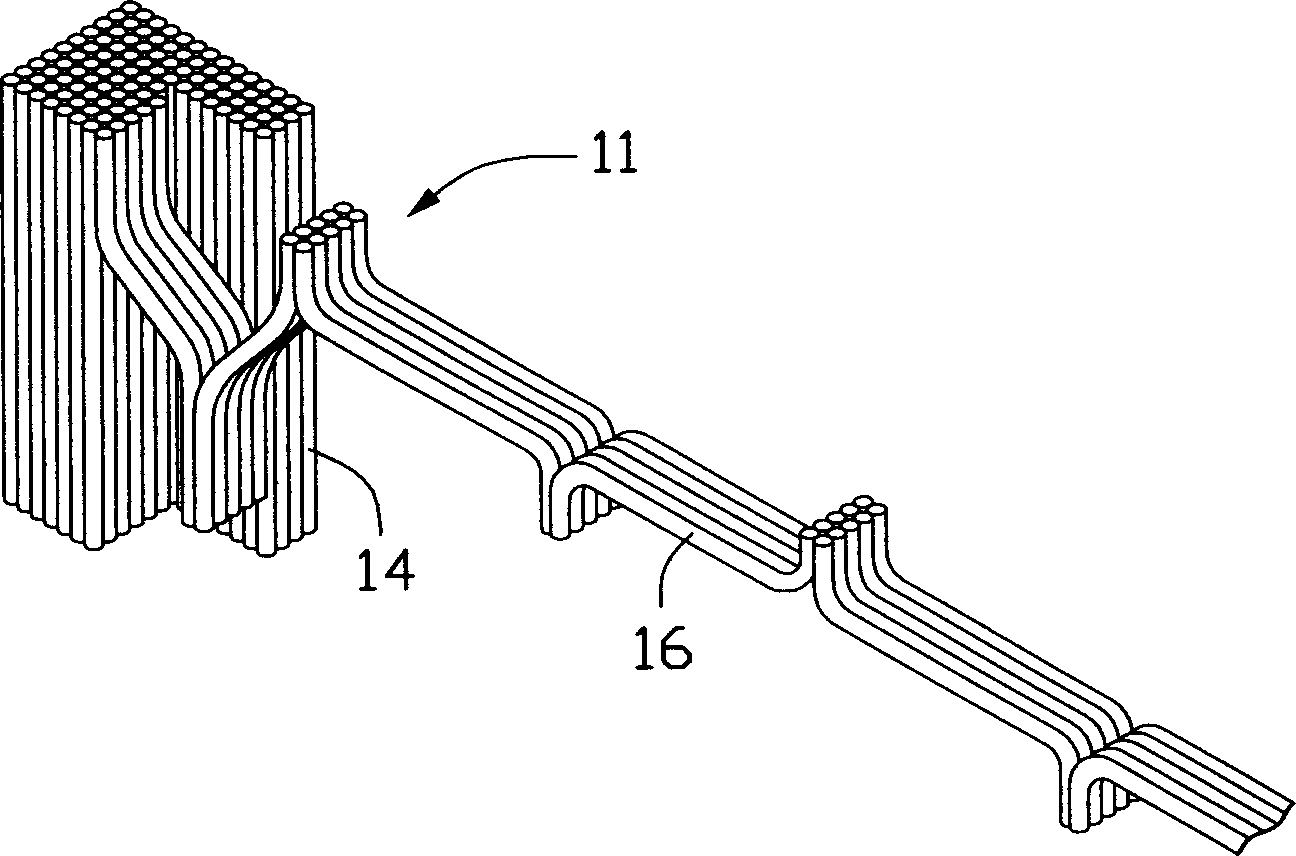

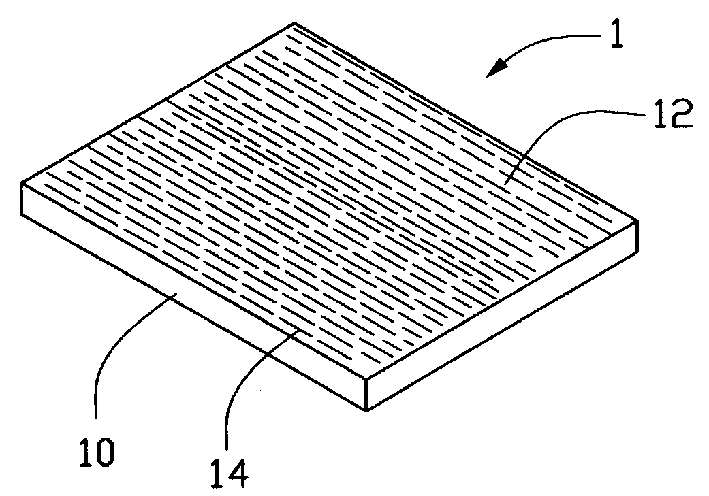

[0022] see figure 1 , the polarizing element 1 of the present invention includes a transparent substrate 10 and a polarizing film 12 distributed on the substrate, and the polarizing film includes a series of carbon nanotubes 14 closely arranged in parallel. Since the carbon nanotubes 14 arranged in parallel have a diameter of 0.4-30 nm, the polarizing element 1 can polarize ultraviolet light and light with a wavelength longer than ultraviolet, and its polarization degree for light in the ultraviolet range can reach 0.92. When the light wave is incident, the light whose vibration direction is parallel to the length direction of the carbon nanotube 14 is absorbed, and the light perpendicular to the length direction of the carbon nanotube 14 can be transmitted, so the transmitted light becomes linearly polarized light.

[0023] To manufacture the above polarizing element 1, the present invention provides the following method:

[0024] Firstly, a carbon nanotube array is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com