Patents

Literature

1141416results about How to "Low cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

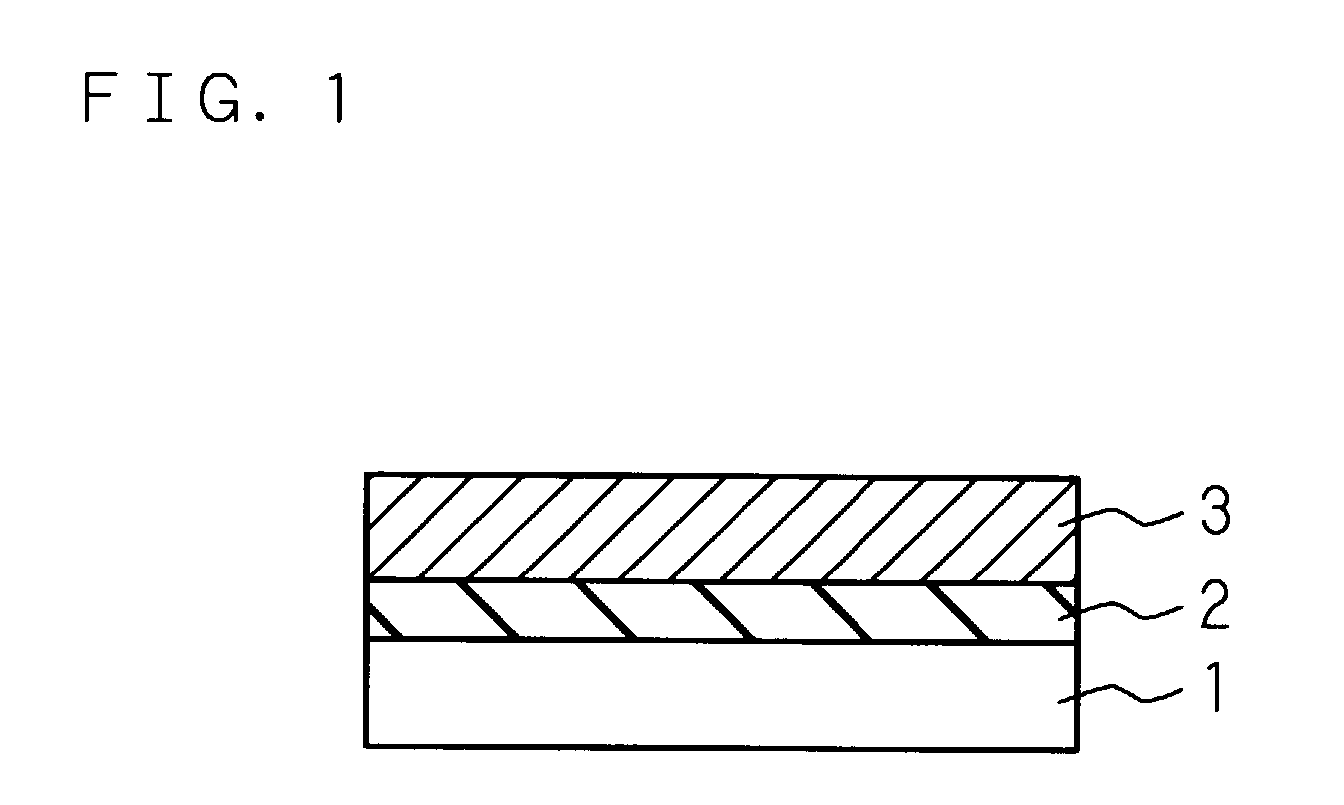

Semiconductor device, manufacturing method, and electronic device

ActiveUS20060244107A1Stabilize element propertyEasy to manufactureTransistorSemiconductor/solid-state device detailsSurface levelIntrinsic resistance

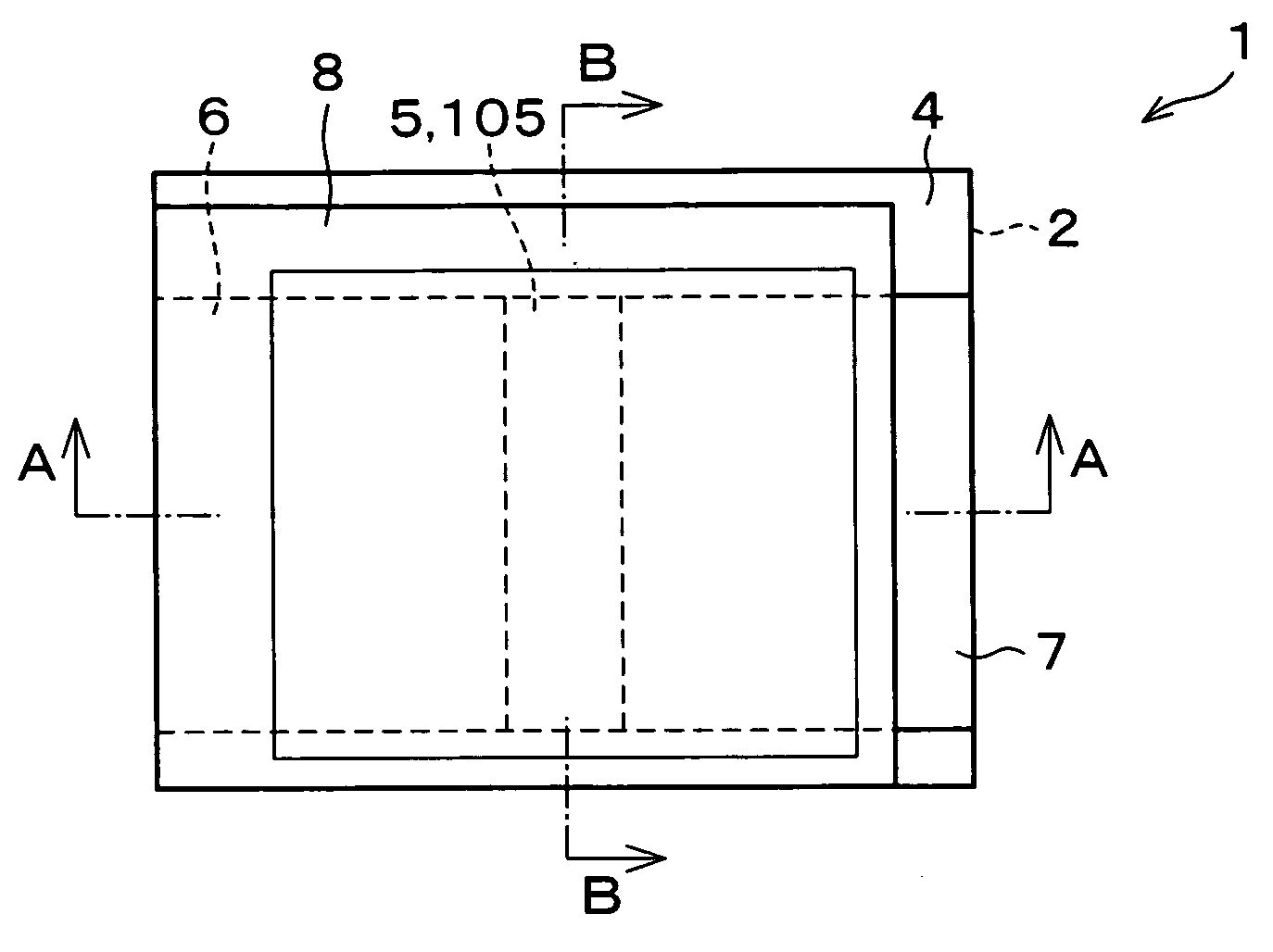

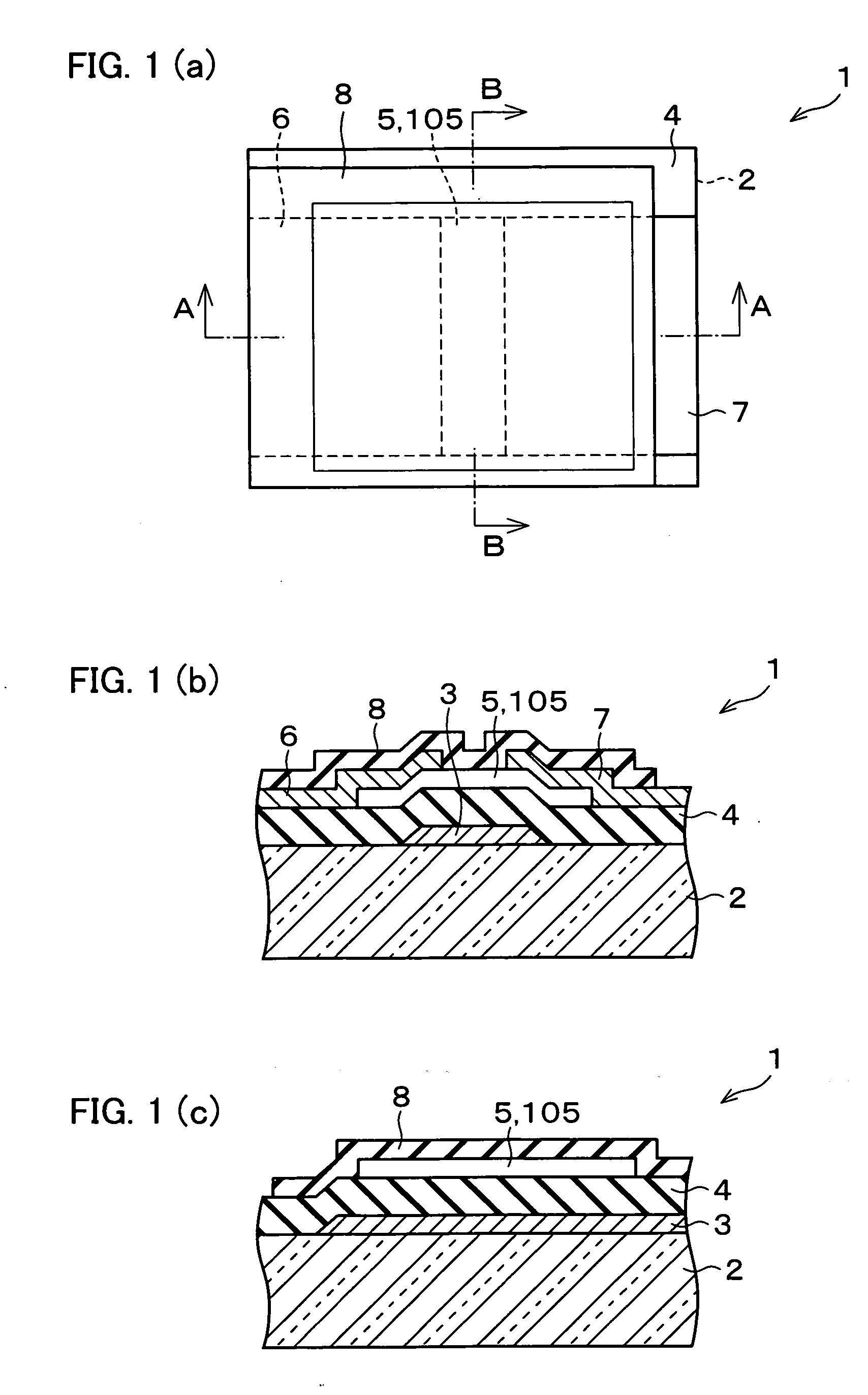

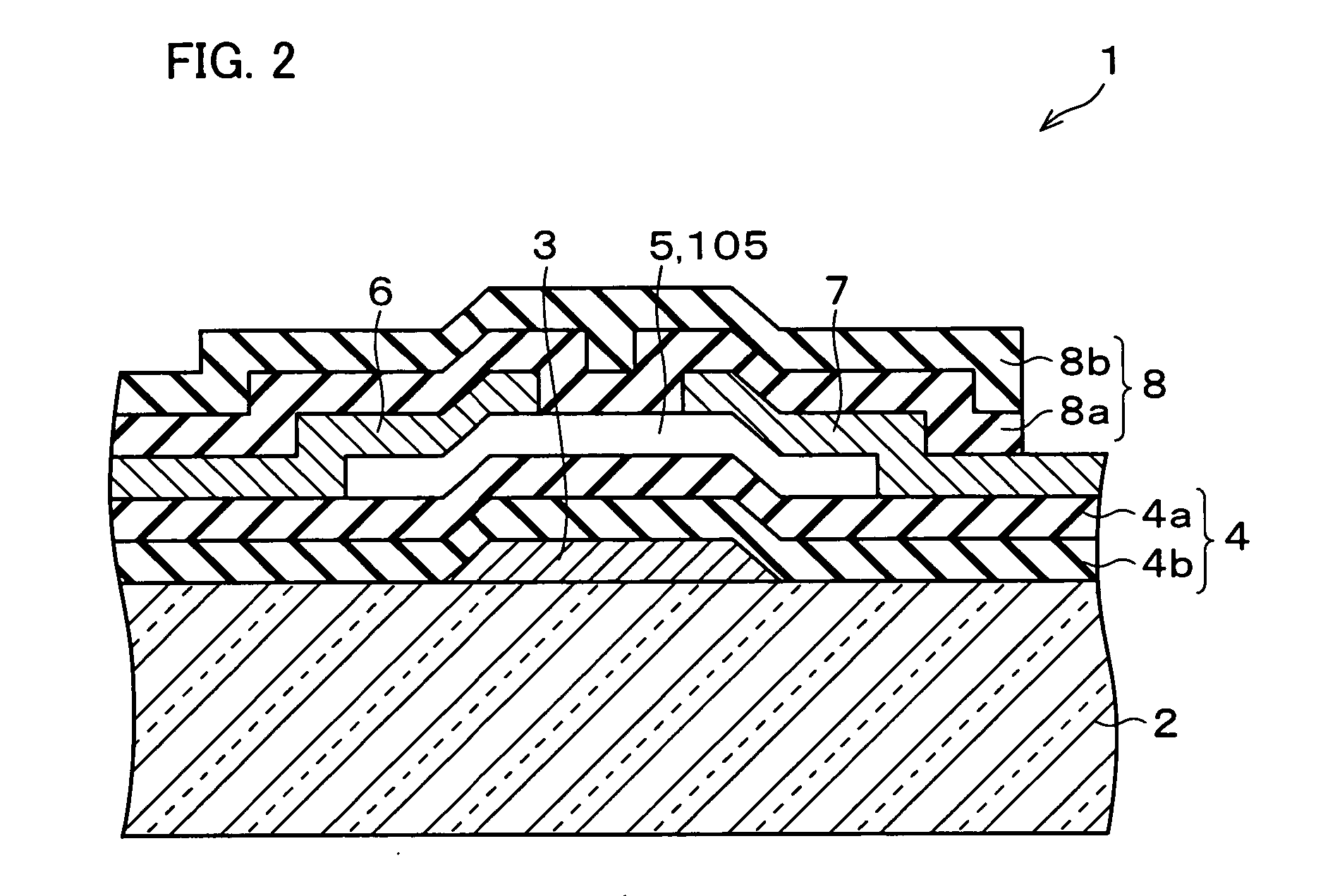

In a thin film transistor (1), a gate insulating layer (4) is formed on a gate electrode (3) formed on an insulating substrate (2). Formed on the gate insulating layer (4) is a semiconductor layer (5). Formed on the semiconductor layer (5) are a source electrode (6) and a drain electrode (7). A protective layer (8) covers them, so that the semiconductor layer (5) is blocked from an atmosphere. The semiconductor layer (5) (active layer) is made of, e.g., a semiconductor containing polycrystalline ZnO to which, e.g., a group V element is added. The protective layer (8) thus formed causes decrease of a surface level of the semiconductor layer (5). This eliminates a depletion layer spreading therewithin. Accordingly, the ZnO becomes an n-type semiconductor indicating an intrinsic resistance, with the result that too many free electrons are generated. However, the added element works on the ZnO as an accepter impurity, so that the free electrons are reduced. This decreases a gate voltage required for removal of the free electrons, so that the threshold voltage of the thin film transistor (1) becomes on the order of 0V. This allows practical use of a semiconductor device which has an active layer made of zinc oxide and which includes an protective layer for blocking the active layer from an atmosphere.

Owner:SHARP KK +2

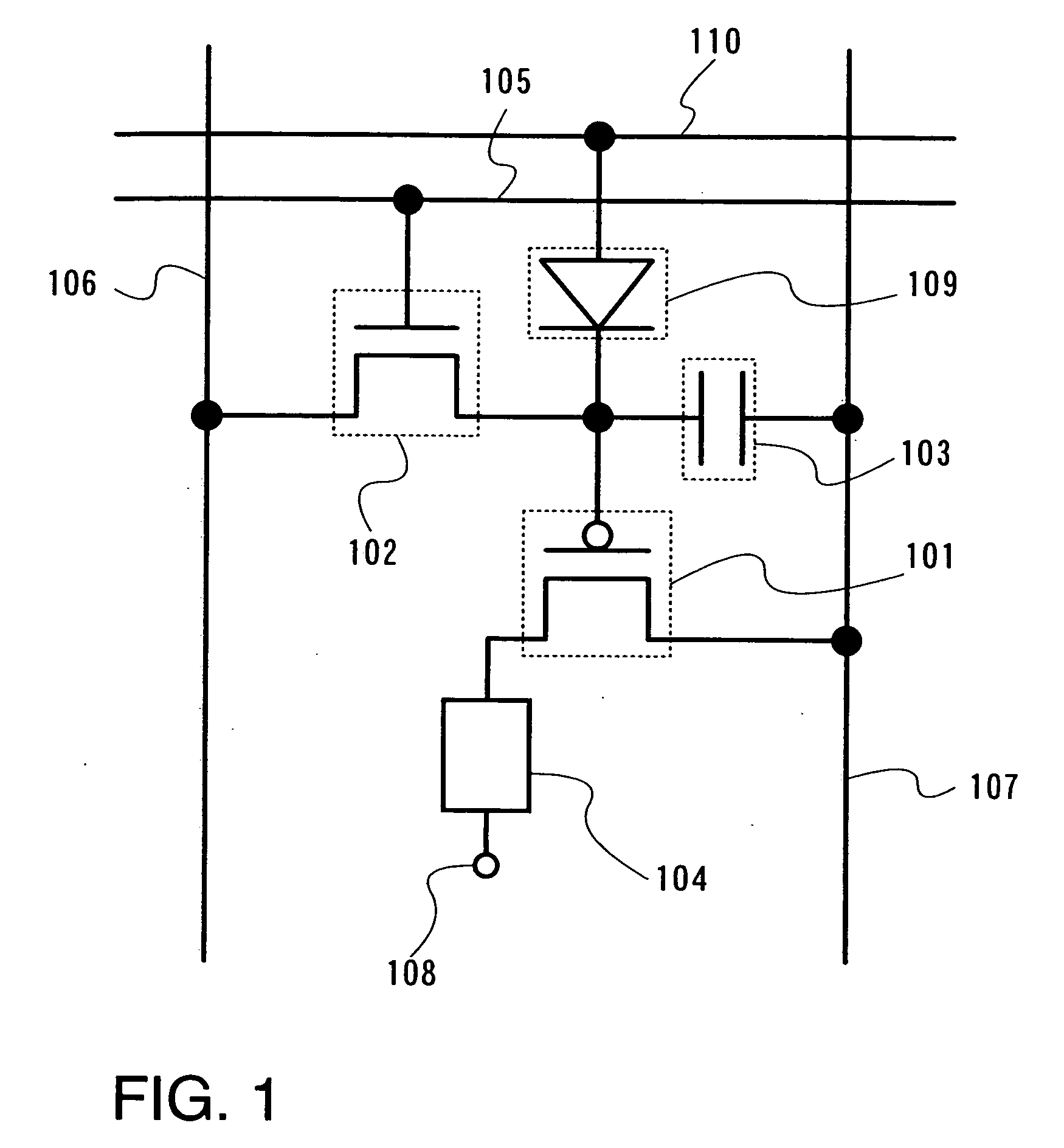

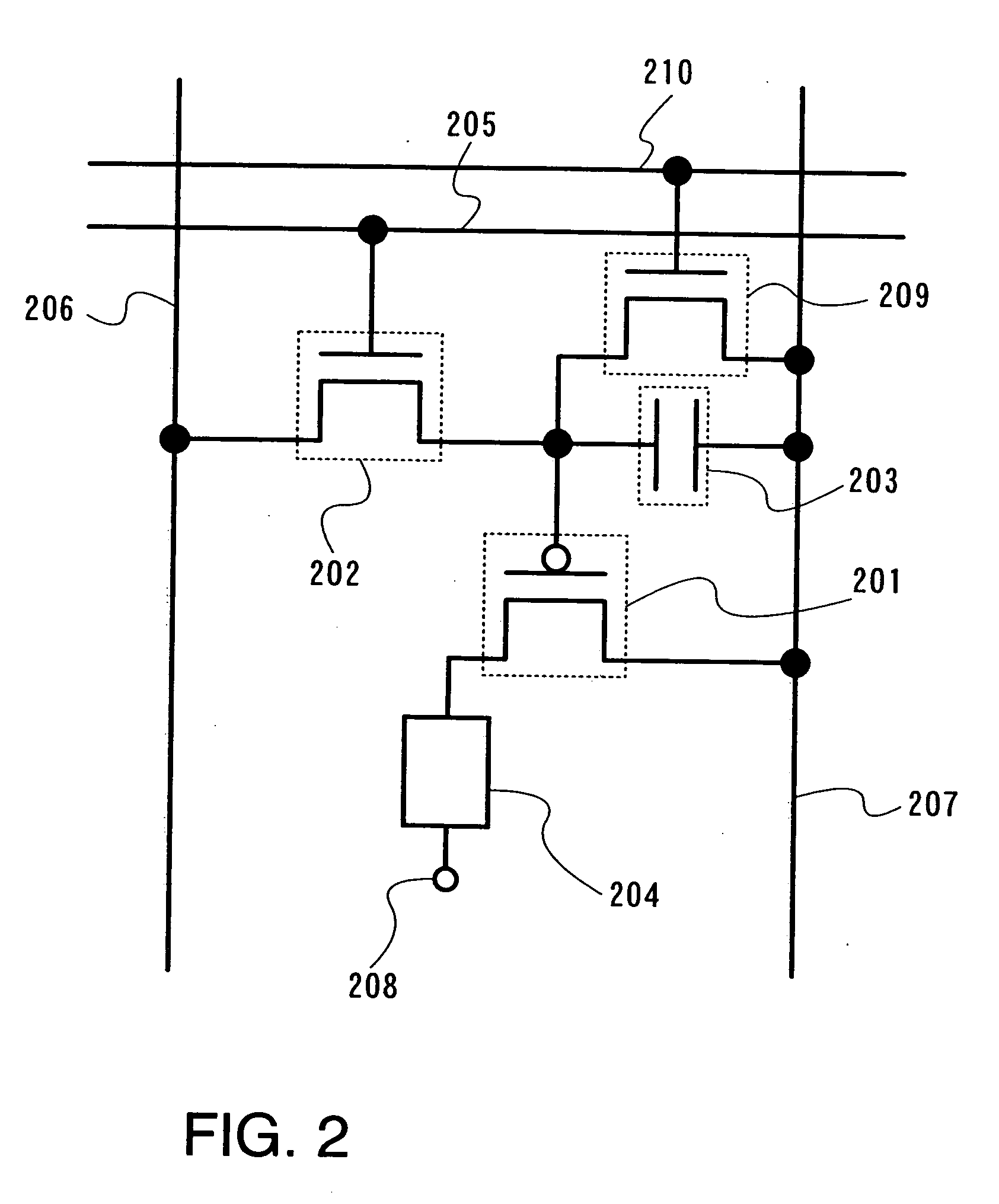

Semiconductor device and display device

InactiveUS20060238135A1Total current dropReduce trafficElectrical apparatusElectroluminescent light sourcesDevice materialScan line

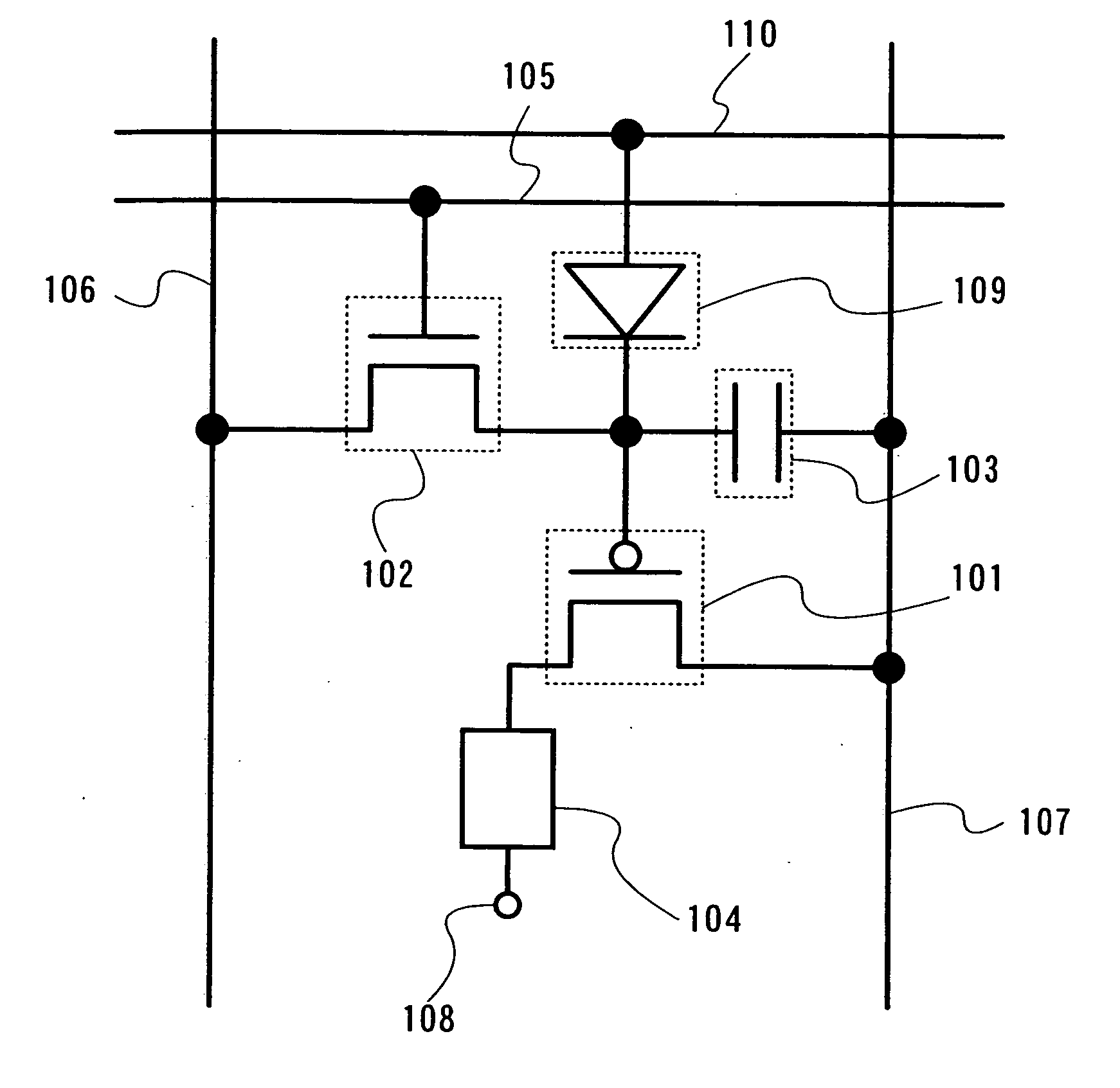

When a signal inputted to a pixel is erased by setting potentials of a gate terminal and a source terminal of a driving transistor to be equal, a current slightly flows through the driving transistor in some cases, which leads to occur a display defect. The invention provides a display device which improves the yield while suppressing the increase in manufacturing cost. When a potential of a scan line for erasure is raised, a potential of the gate terminal of the driving transistor is raised accordingly. For example, the scan line and the gate terminal of the driving transistor are connected through a rectifying element.

Owner:SEMICON ENERGY LAB CO LTD

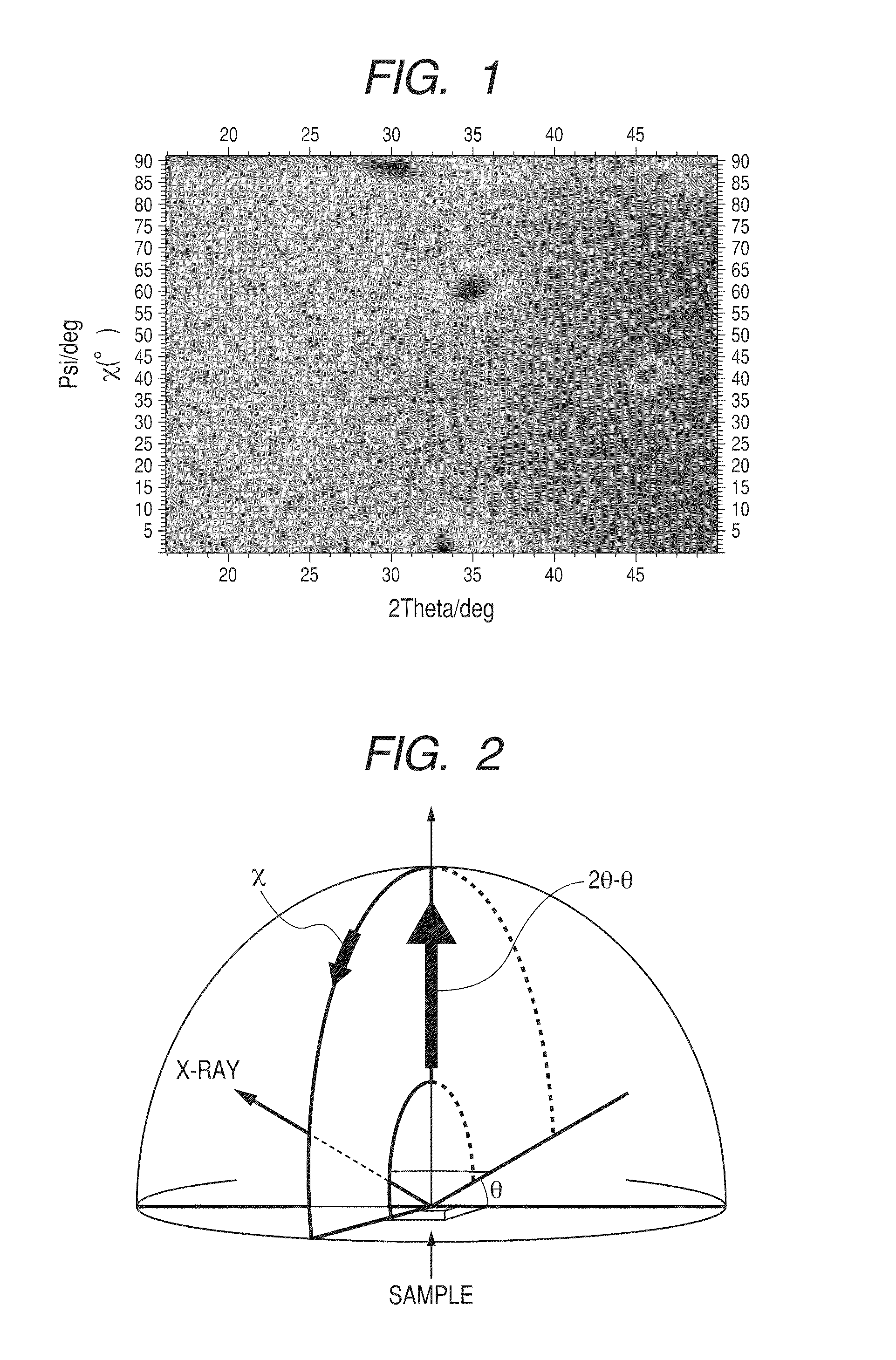

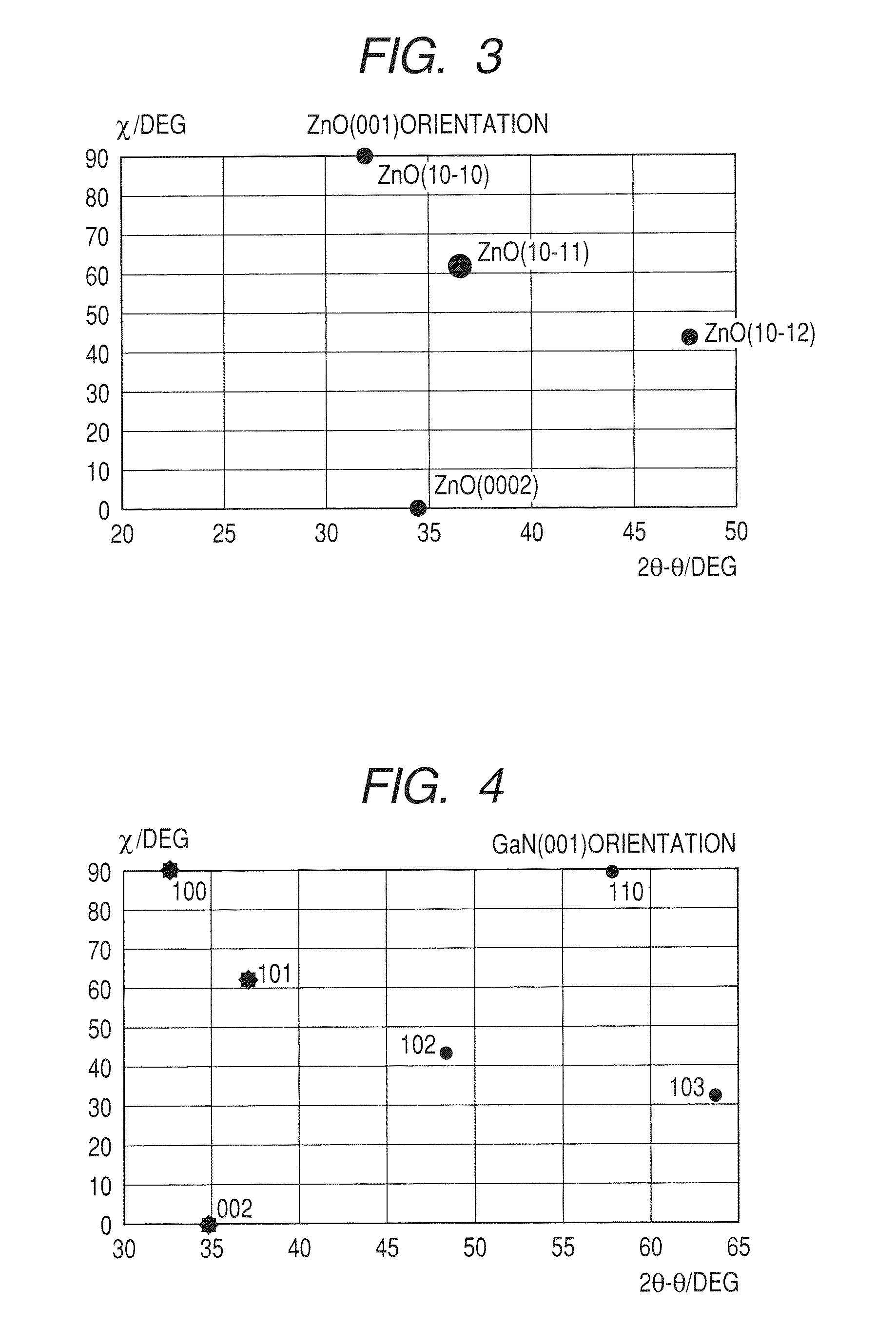

Method for forming ZnO film, method for forming ZnO semiconductor layer, method for fabricating semiconductor device, and semiconductor device

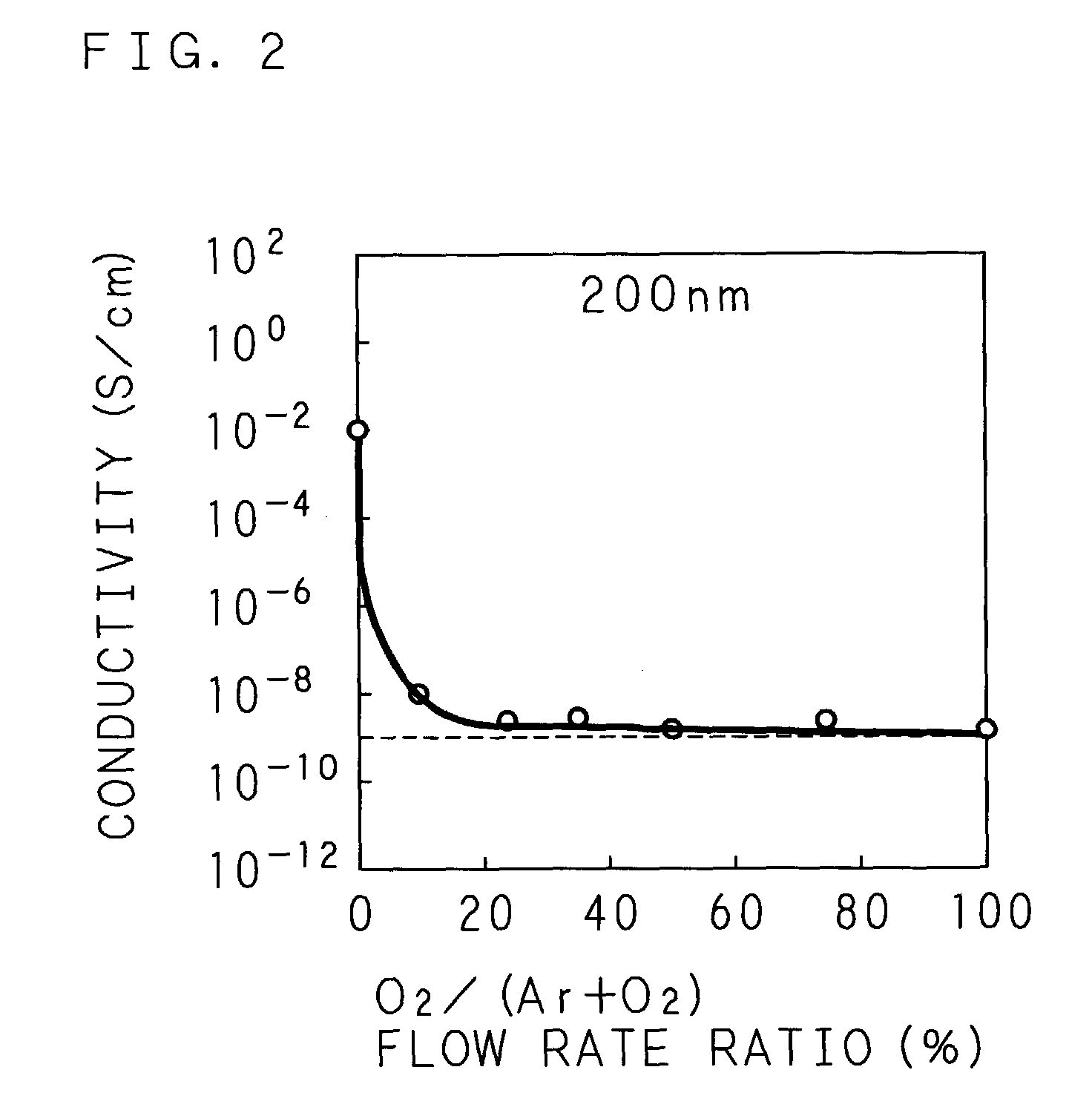

InactiveUS7049190B2High crystallinityLow costTransistorPolycrystalline material growthX-rayElectrical resistivity and conductivity

A ZnO buffer layer having an electric conductivity of 1×10−9 S / cm or lower or alternatively a ZnO buffer layer having a diffraction peak of a crystal face other than (002) and (004) in X-ray diffraction is formed on a substrate by sputtering. A ZnO semiconductor layer is formed on the ZnO buffer layer. The ZnO semiconductor layer is formed under the condition that the flow rate ratio of an oxygen gas in a sputtering gas is lower than that in the formation of the ZnO buffer layer.

Owner:SANYO ELECTRIC CO LTD

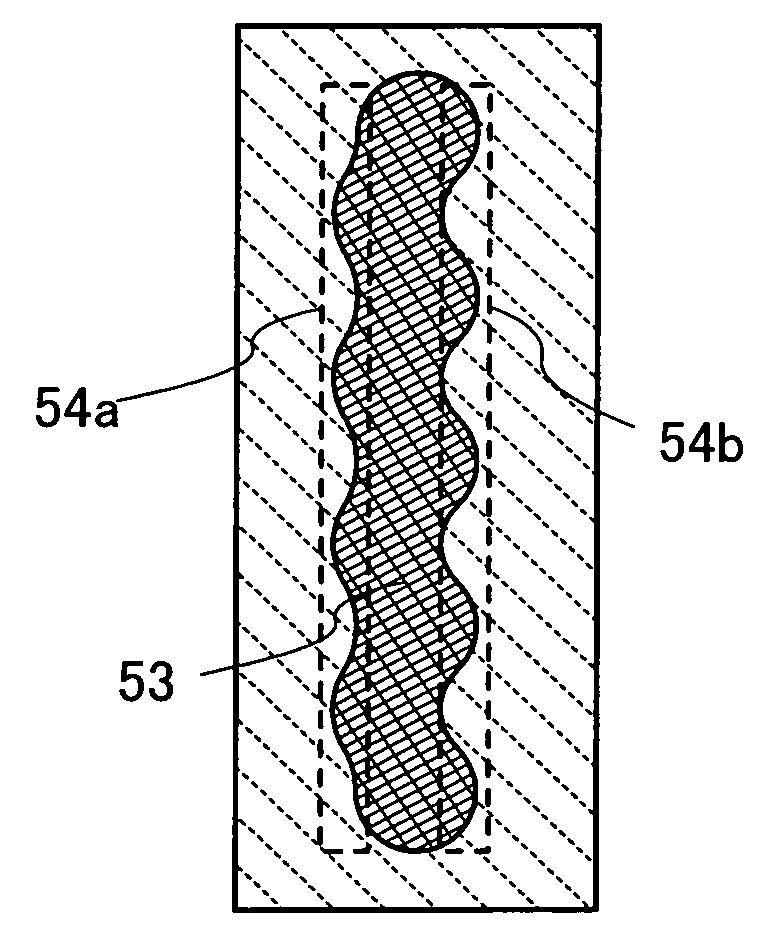

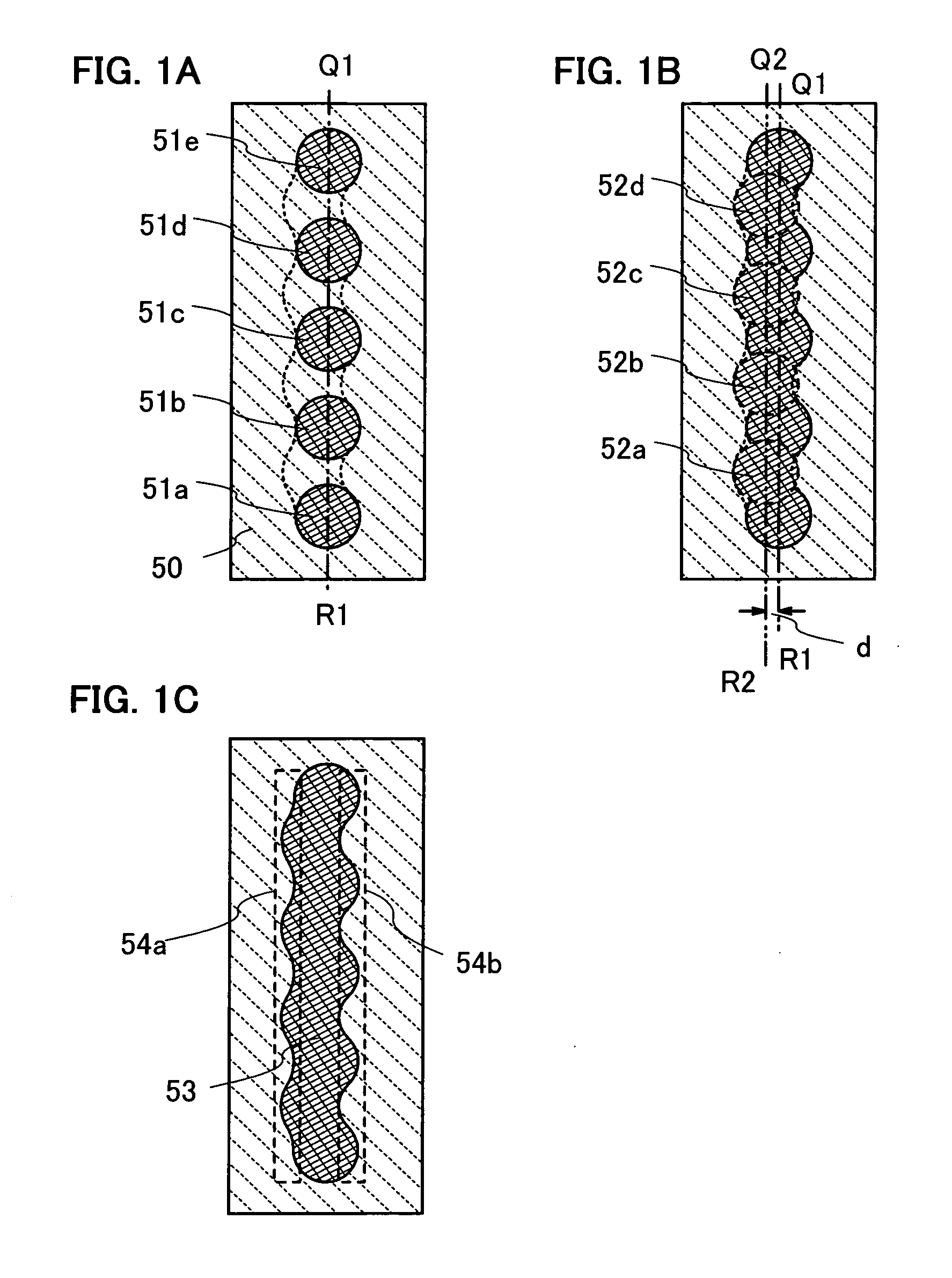

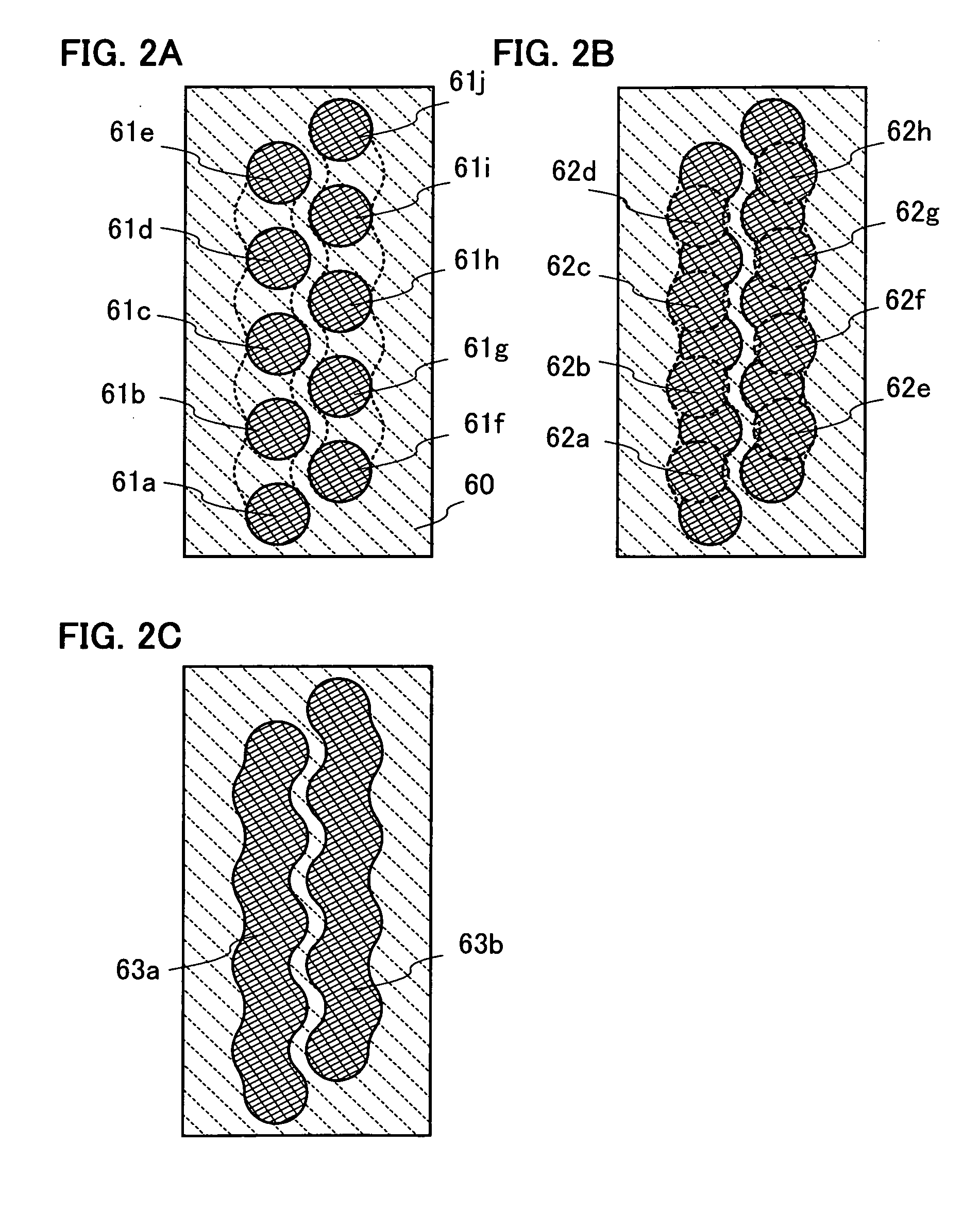

Semiconductor device, electronic device, and method of manufacturing semiconductor device

InactiveUS20060169973A1Stable formationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDisplay device

To provide a semiconductor device and a display device which can be manufactured through a simplified process and the manufacturing technique. Another object is to provide a technique by which a pattern of wirings or the like which is partially constitutes a semiconductor device or a display device can be formed with a desired shape with controllability.

Owner:SEMICON ENERGY LAB CO LTD

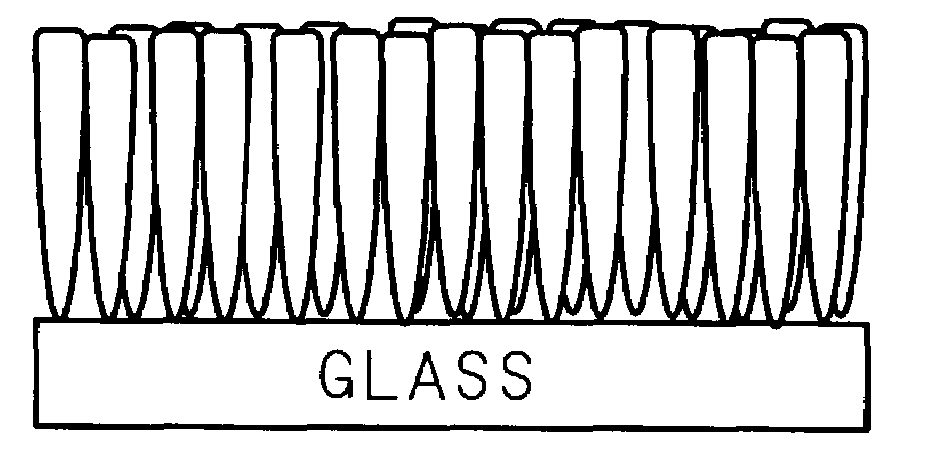

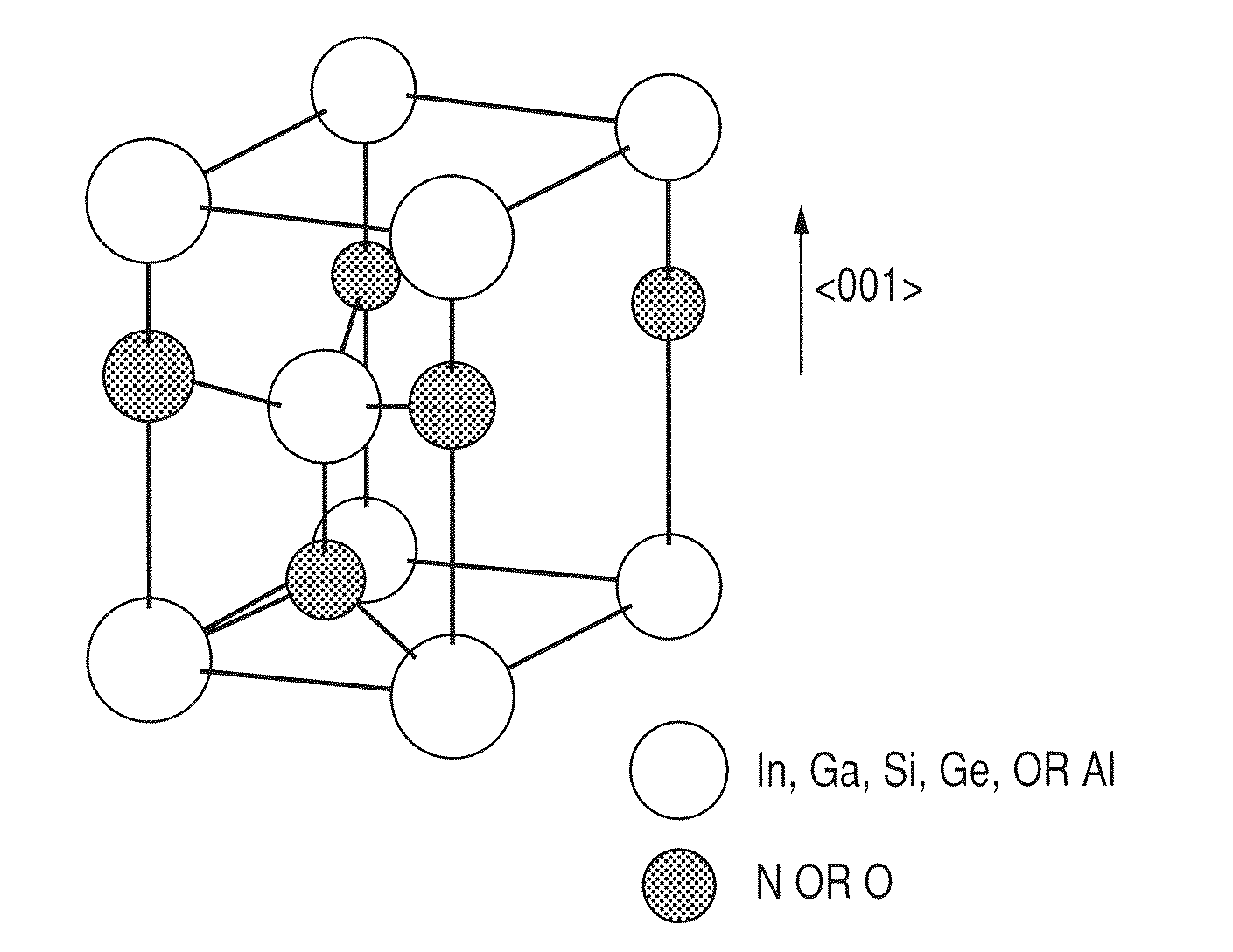

Substrate for growing wurtzite type crystal and method for manufacturing the same and semiconductor device

ActiveUS20100092800A1Low costHigh crystallinityPolycrystalline material growthVacuum evaporation coatingNitrideSemiconductor

A laminated structure comprises a first layer comprising a crystal with six-fold symmetry, and a second layer comprising a metal oxynitride crystal formed on the first layer, wherein the second layer comprises at least one element selected from the group consisting of In, Ga, Si, Ge and Al, N, O and Zn, as main elements, and wherein the second layer has in-plane orientation.

Owner:CANON KK

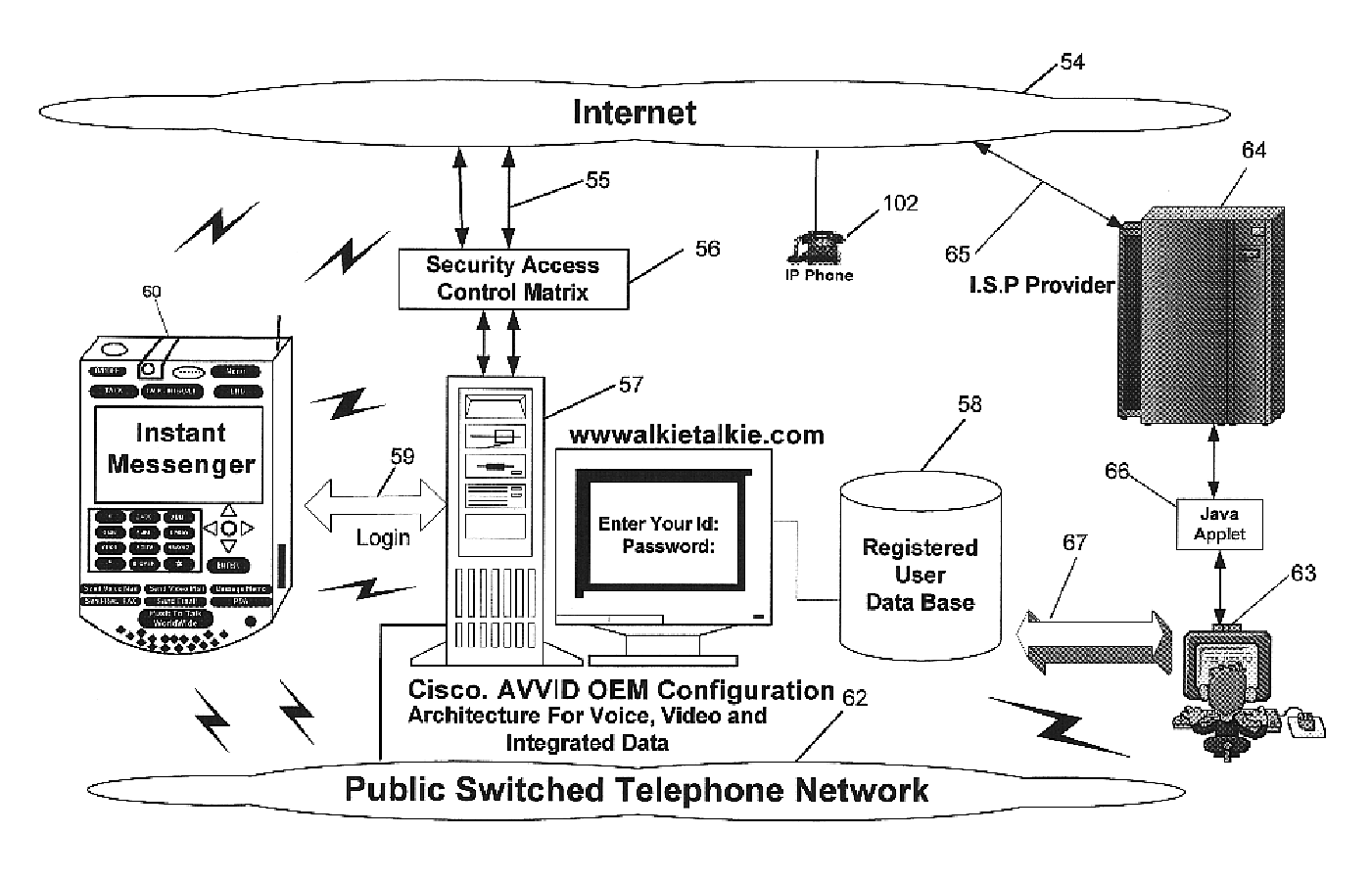

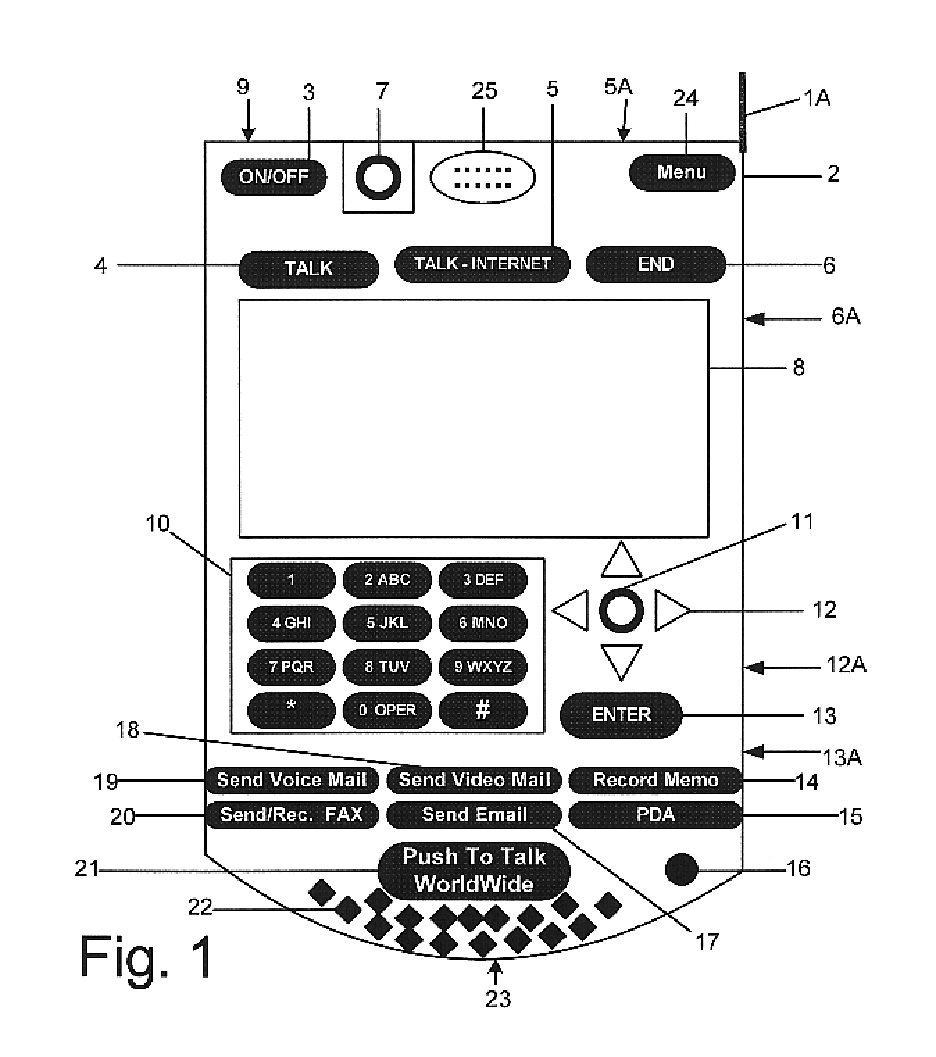

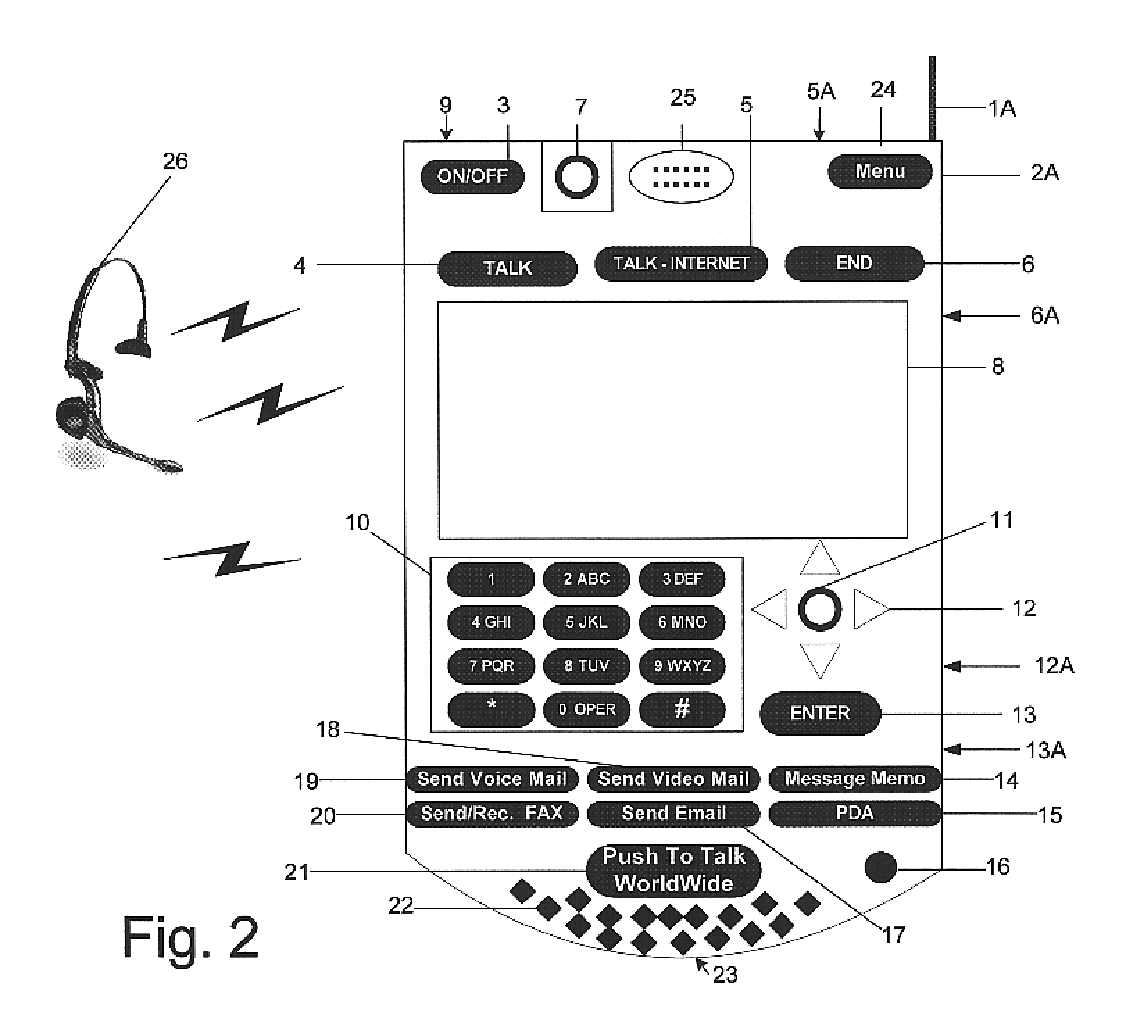

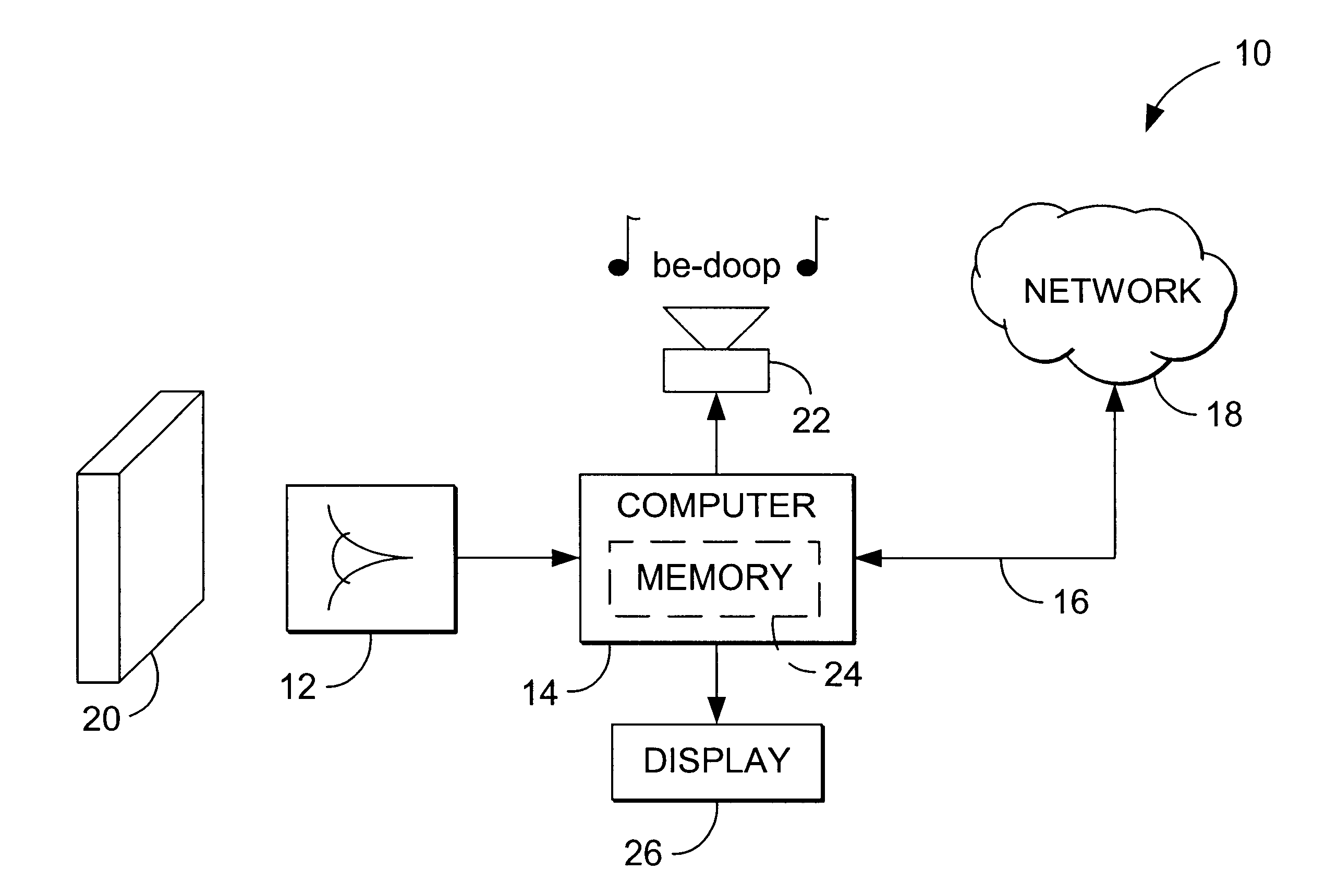

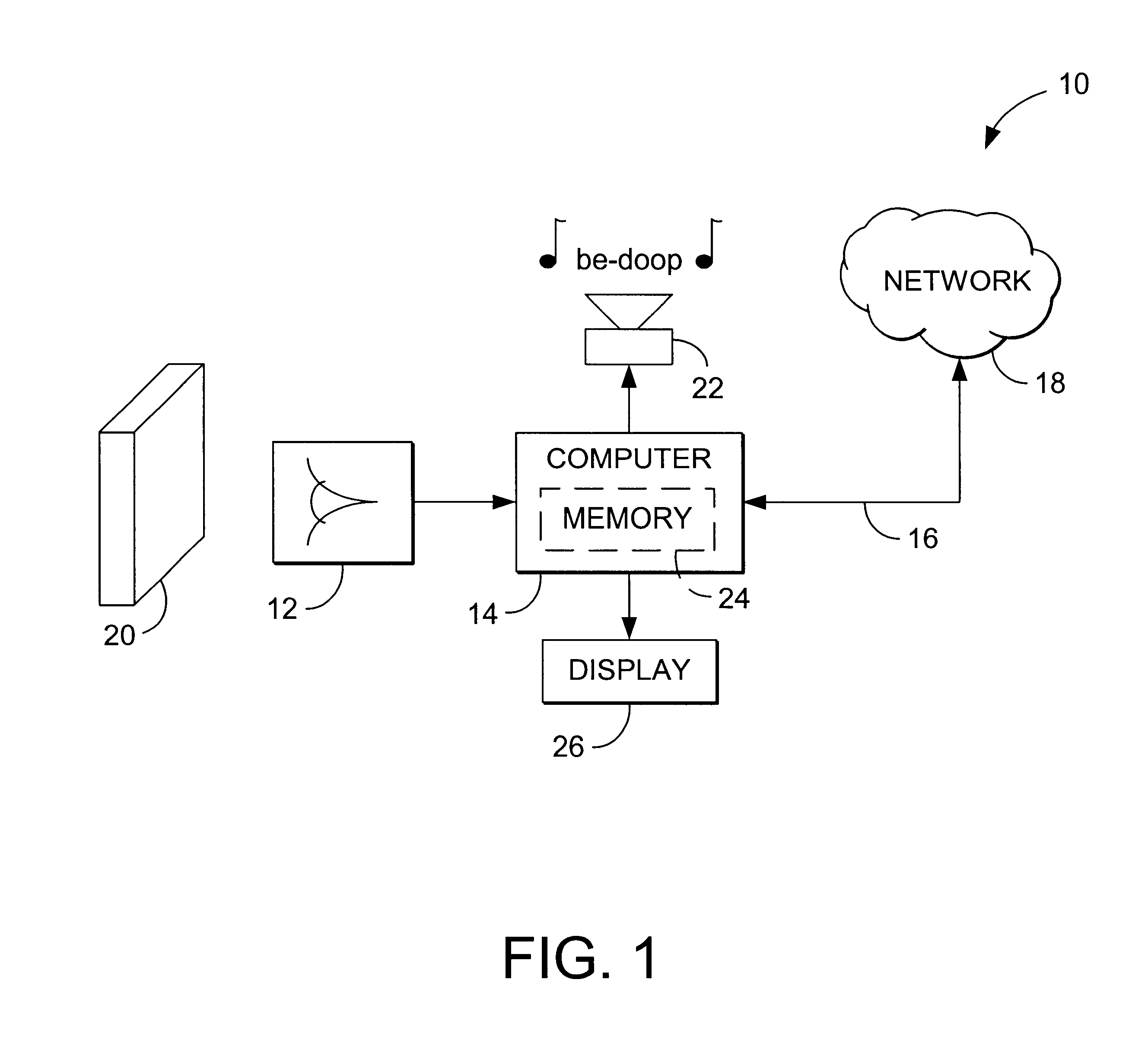

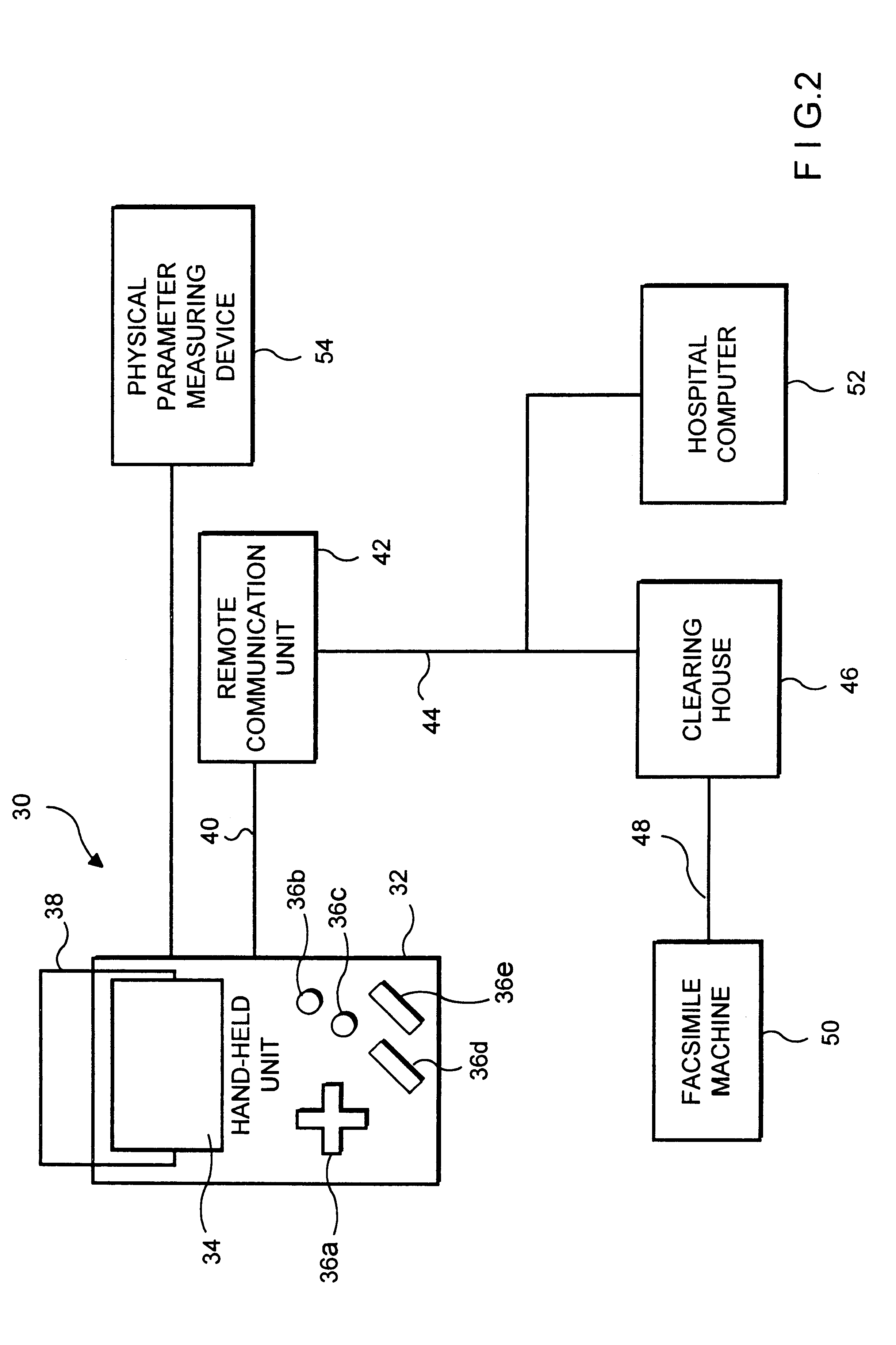

Multifunctional world wide walkie talkie, a tri-frequency cellular-satellite wireless instant messenger computer and network for establishing global wireless volp quality of service (QOS) communications, unified messaging, and video conferencing via the internet

InactiveUS6763226B1High quality voice and data communicationMinimal costCordless telephonesInterconnection arrangementsQuality of serviceMass storage

World-Wide-Walkie-Talkie, a high speed multifunction interstellar wireless computer / instant messenger communicator, Personal Digital Assistant (PDA), coupled with a resilient, robust, VoIP data network and internet server method, deploying multiple wireless networks and protocols such as Voice Over IP, GPRS, WAP, Bluetooth, PCS, I-Mode, comprising a high speed Intel Pentium 4 Mobile(TM) or compatible Processor, to formulate a internet gateway system (99) and network bridge (150) for establishing instant low cost, real time global communications to the Public Switched Telephone Network via the internet (54). A PUSH-TO-TALK-WORLDWIDE button (21) instantly initiates global bisynchronous communications, or videoconferencing sessions. Fax, VideoMail, and unified messaging services are immediately available. GPS and mass memory provides global navigational tracking and data storage. Internet users, telephones, and cellular / satellite phone users can intercommunicate with the invention via VoIP / IM services. The invention provides uniformed global wireless communications, eliminates traditional long distance costs, and operates anywhere on earth.

Owner:COMP SCI CENT

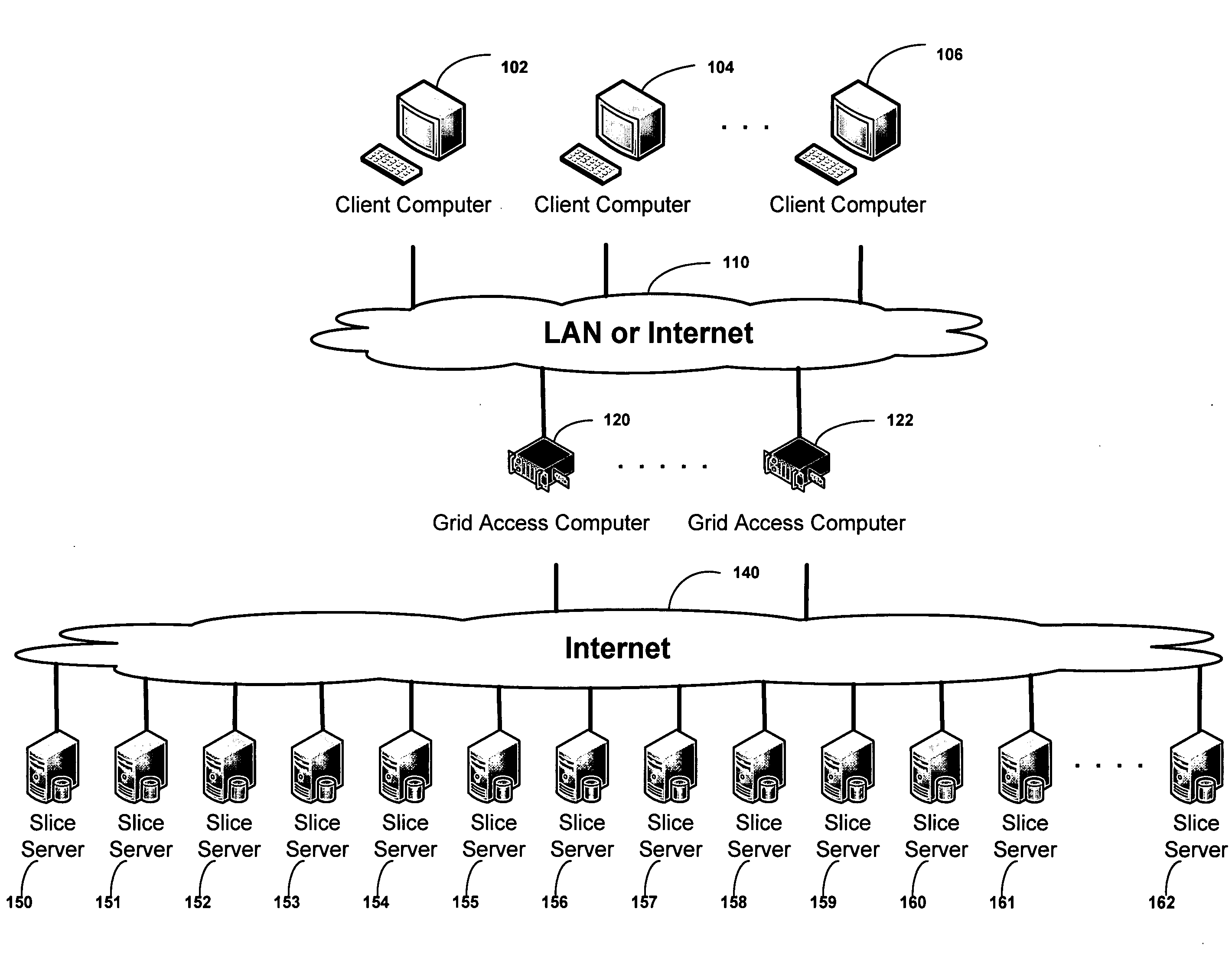

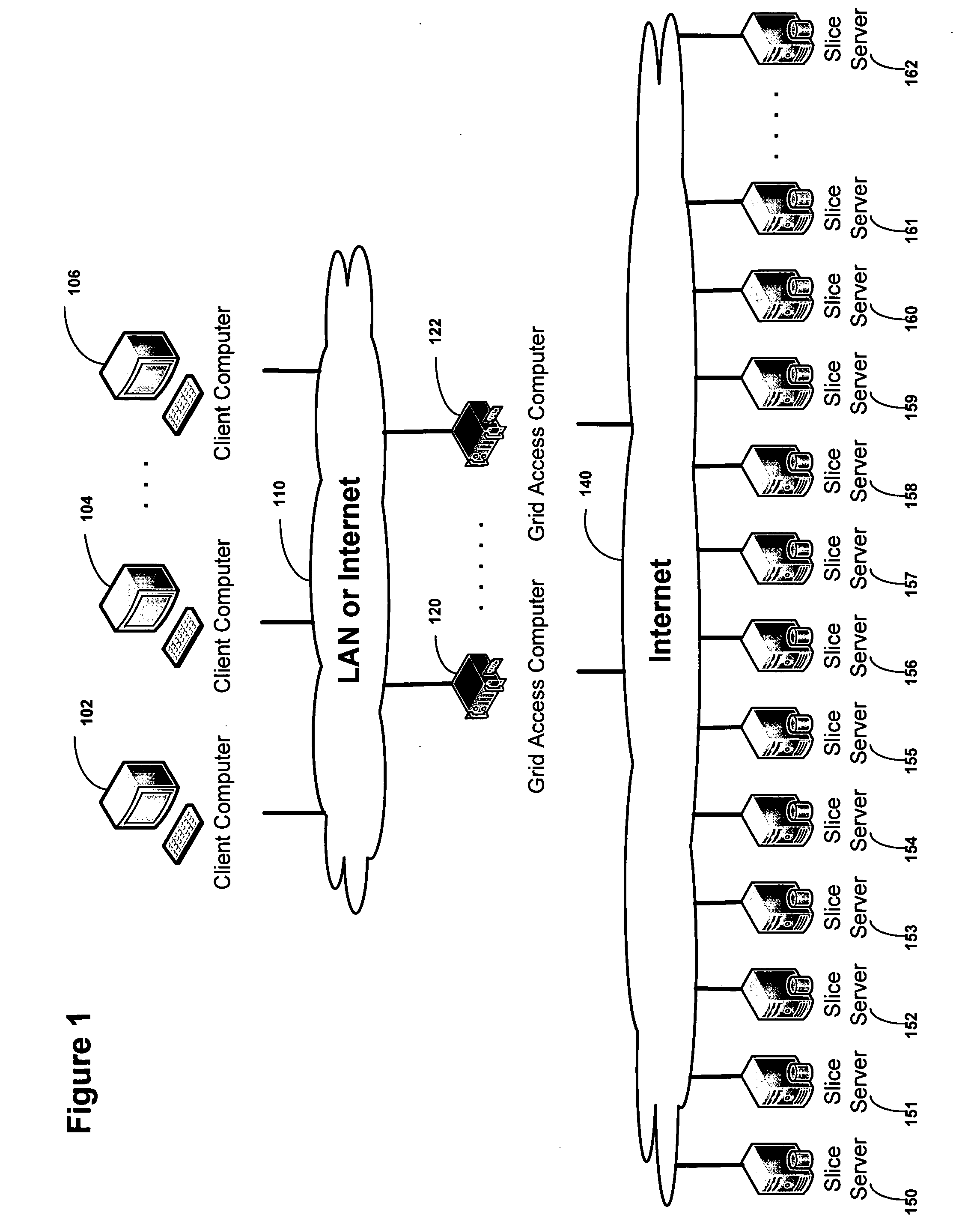

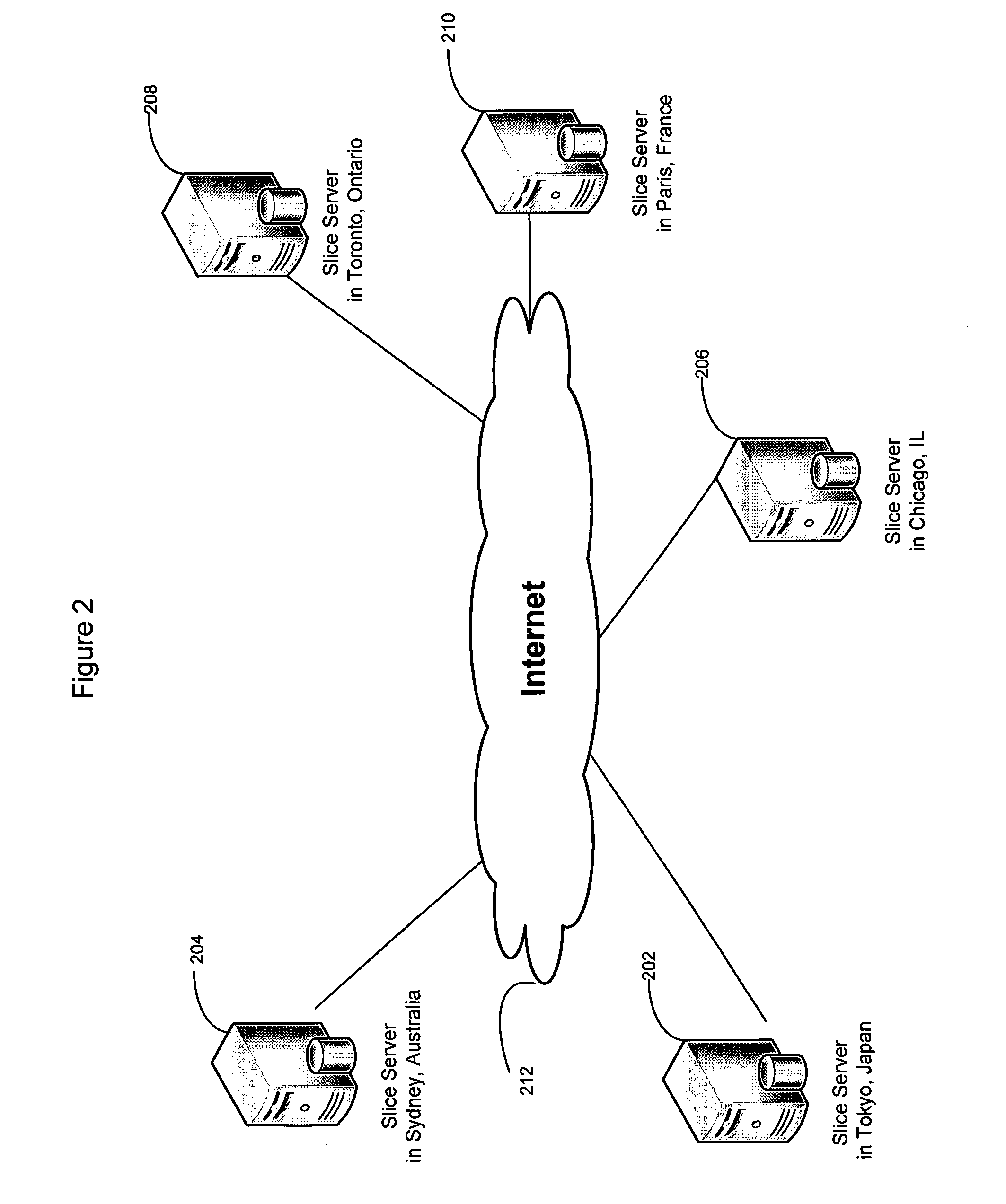

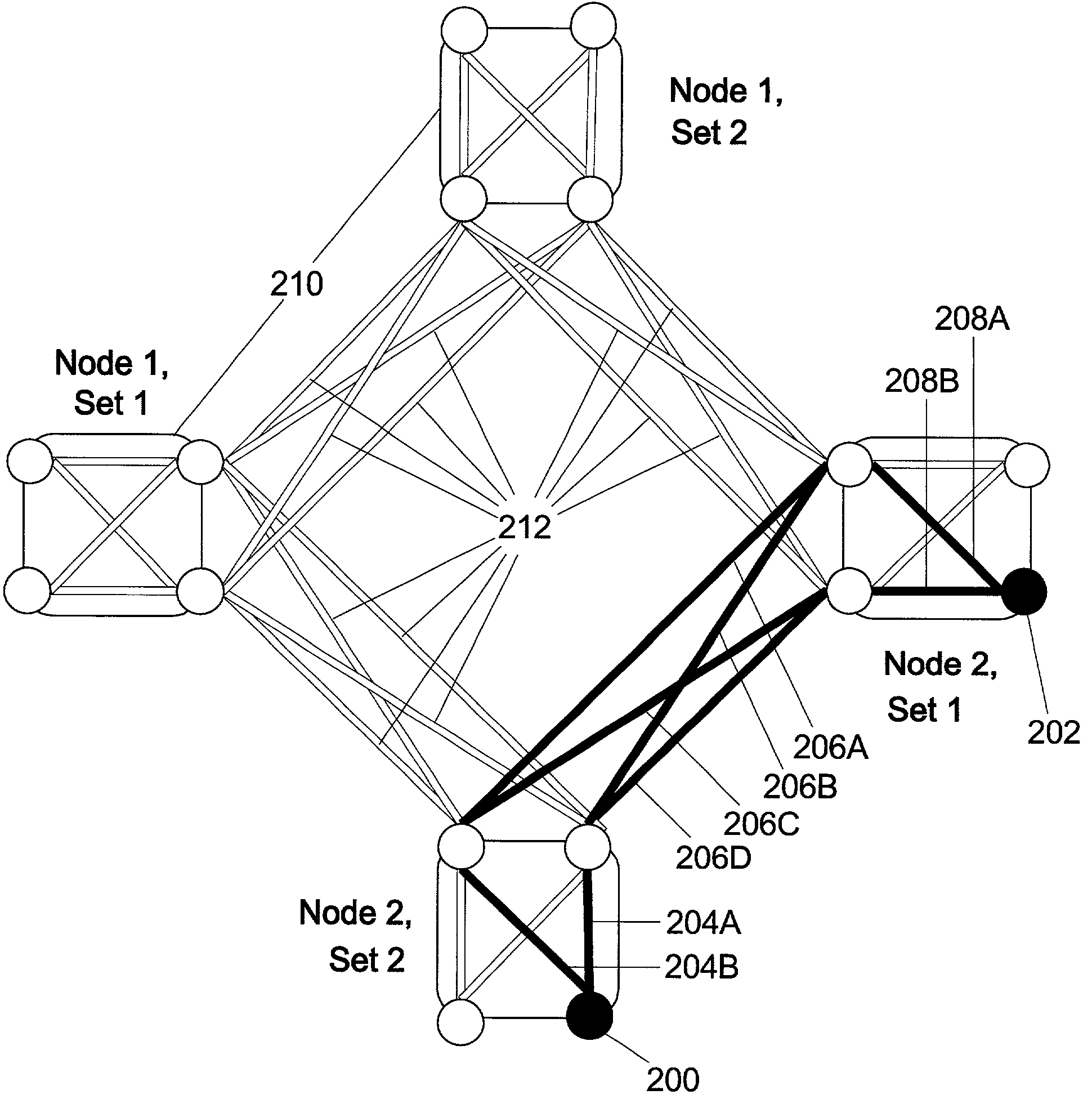

Smart access to a dispersed data storage network

ActiveUS20090094318A1Efficient accessImprove network performanceError preventionFrequency-division multiplex detailsData segmentRanking

An improved system for accessing data within a distributed data storage network (“DDSN”) is disclosed. In a system implementing the disclosed invention, traffic is routed to individual slice servers within the DDSN in accordance with objective criteria as well as user-defined policies. In accordance with one aspect of the disclosed invention, when a data segment is written to a DDSN, the segment is divided into multiple data slices, which are simultaneously transmitted to different slice servers. In accordance with another aspect of the disclosed invention, when a data segment is read from a DDSN, a list of slice servers, each containing a data slice that could be used to reconstruct the requested data segment, is assembled, and sorted in accordance with a preference rating assigned to each of the slice servers. Sufficient data slices to reconstruct the data segment are then read in accordance with the preference ranking of the slice servers.

Owner:PURE STORAGE

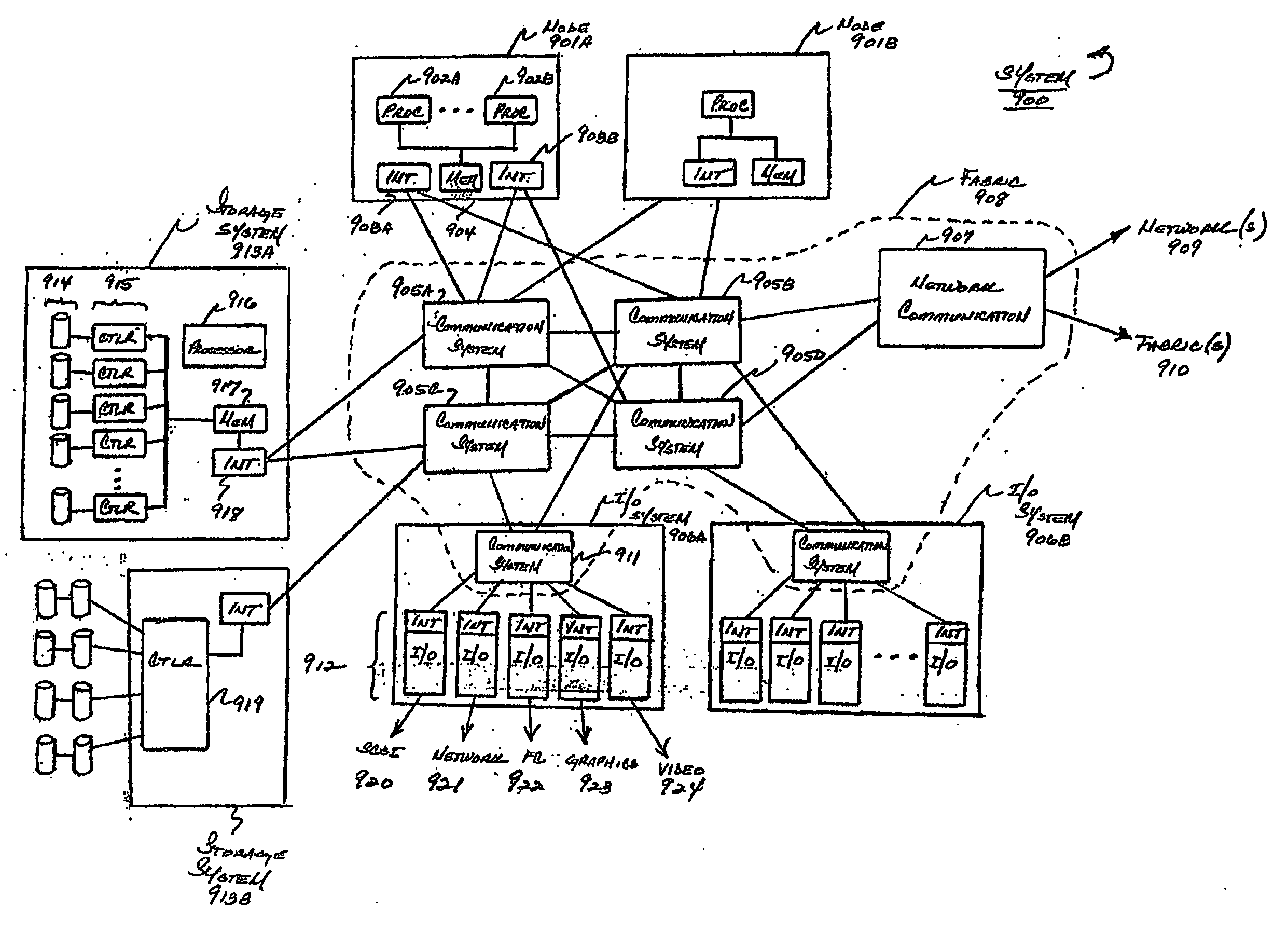

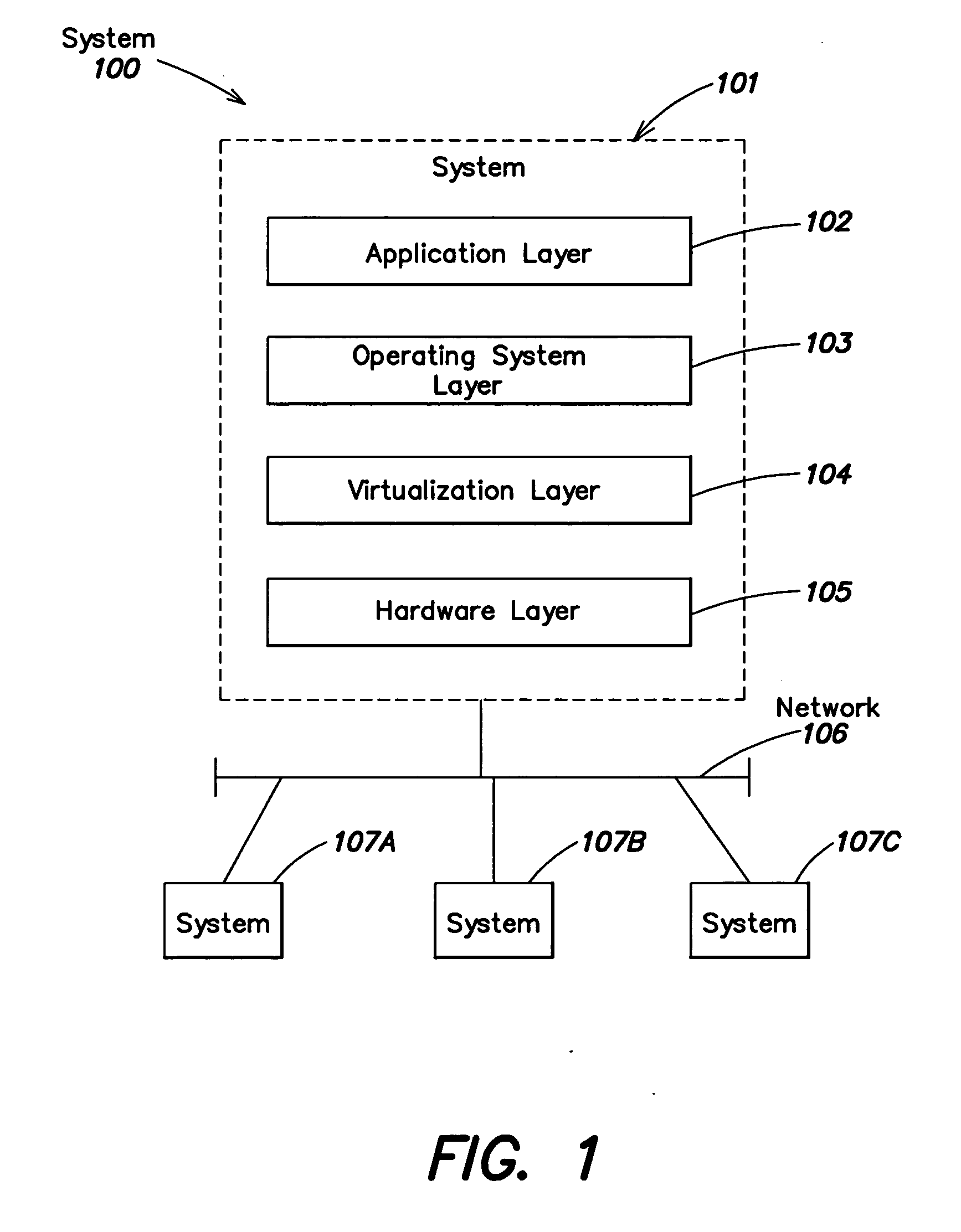

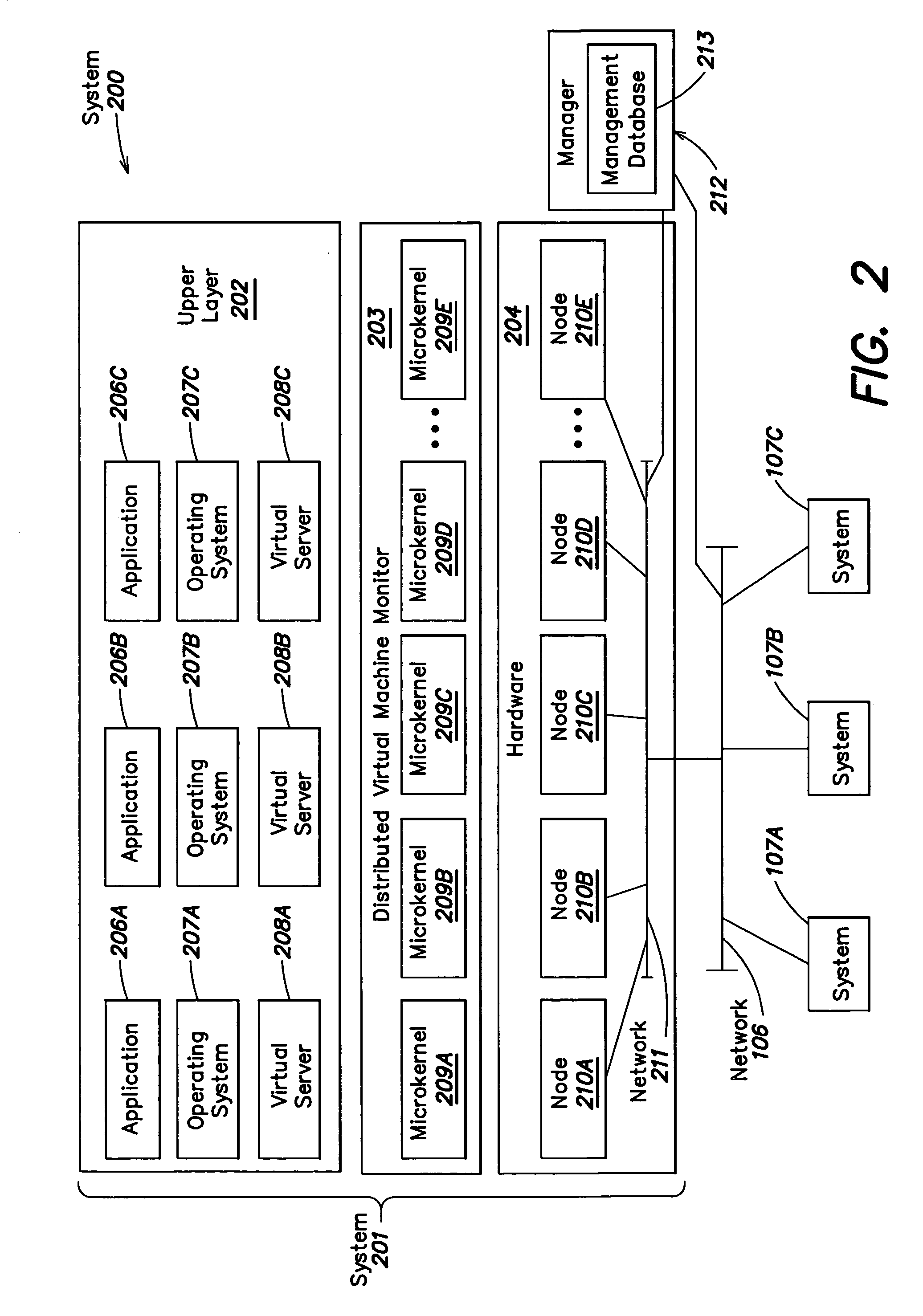

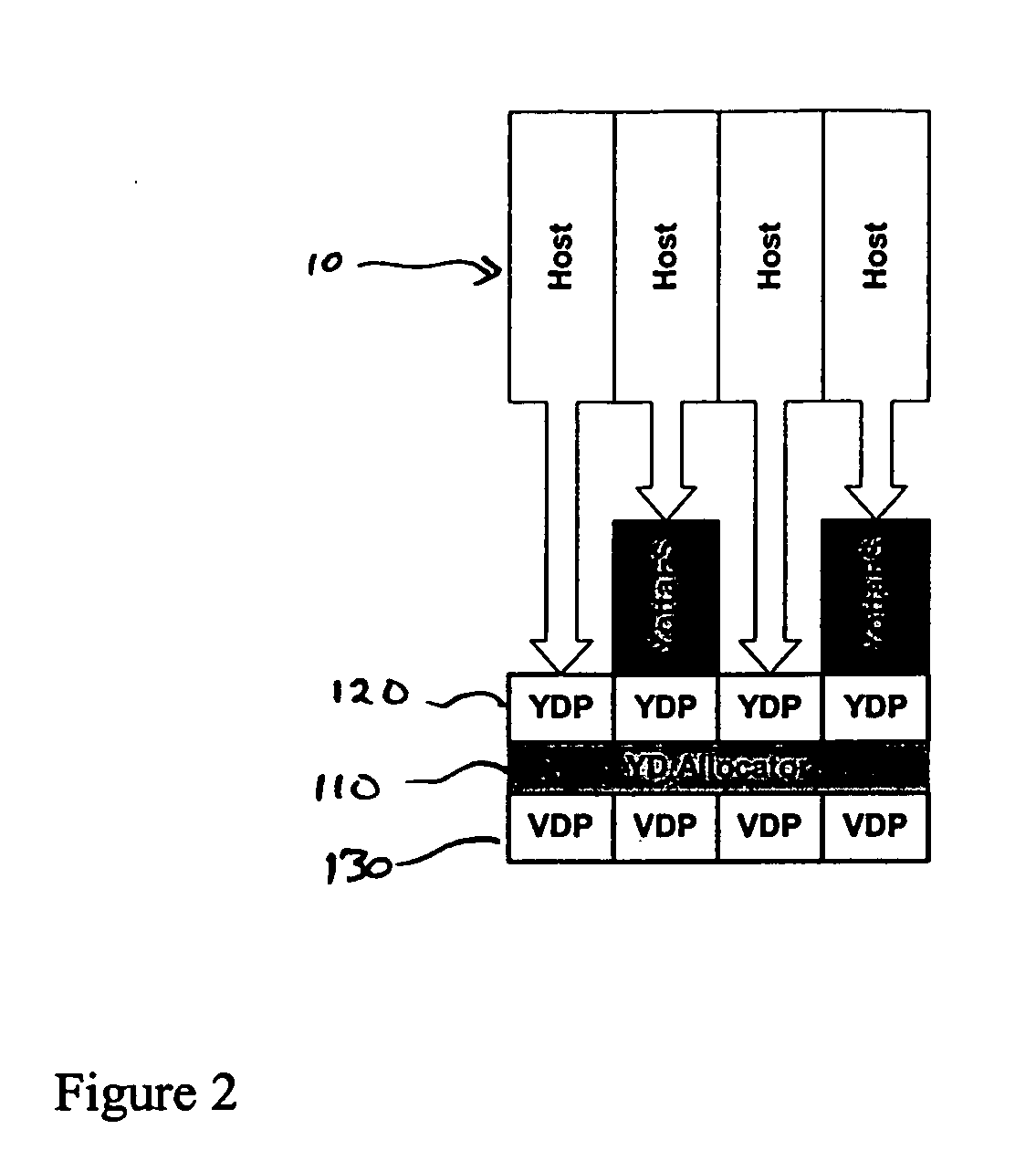

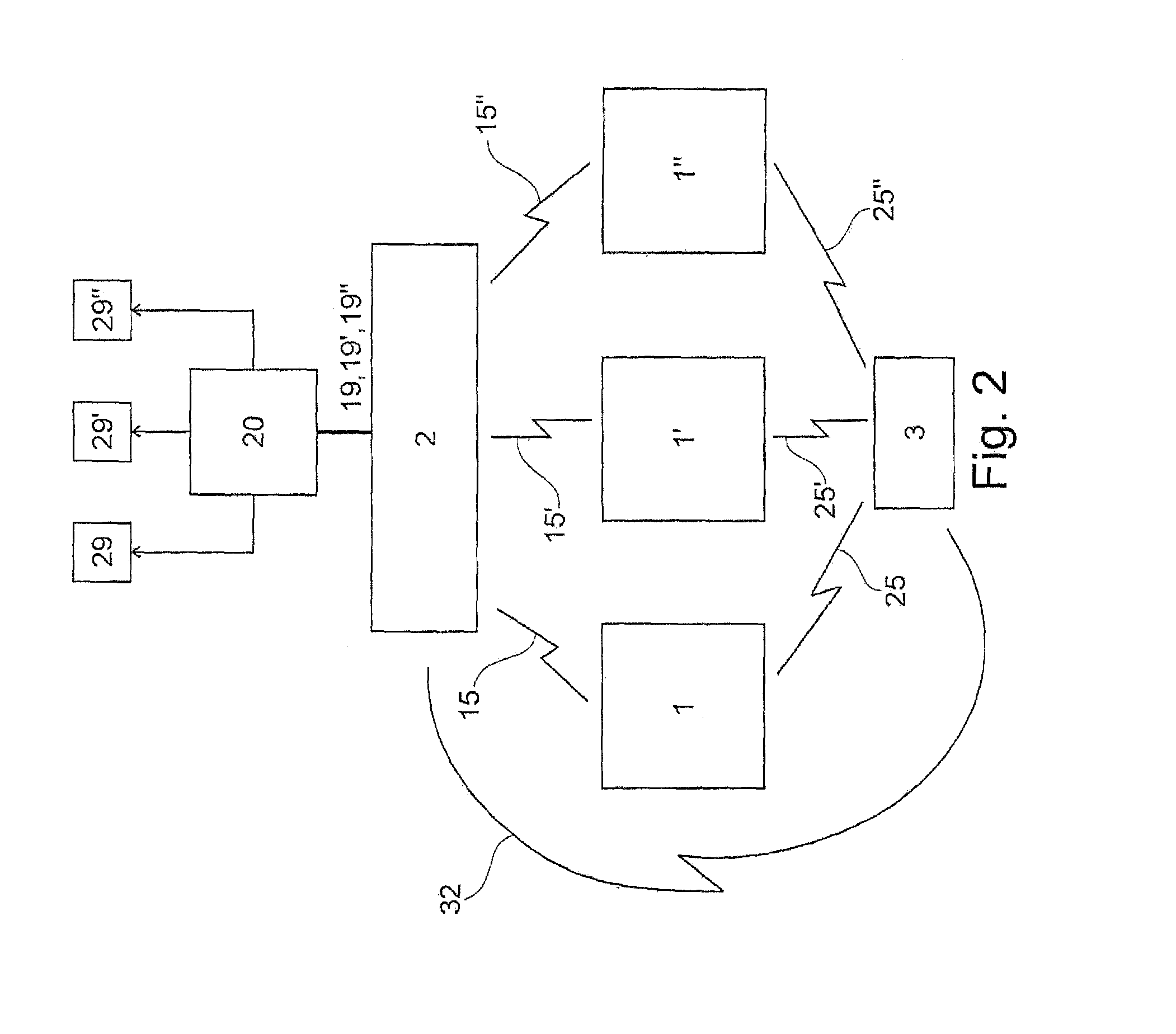

System and method for managing virtual servers

ActiveUS20050120160A1Grow and shrink capabilityMaximize useResource allocationMemory adressing/allocation/relocationOperational systemPrimitive state

A management capability is provided for a virtual computing platform. In one example, this platform allows interconnected physical resources such as processors, memory, network interfaces and storage interfaces to be abstracted and mapped to virtual resources (e.g., virtual mainframes, virtual partitions). Virtual resources contained in a virtual partition can be assembled into virtual servers that execute a guest operating system (e.g., Linux). In one example, the abstraction is unique in that any resource is available to any virtual server regardless of the physical boundaries that separate the resources. For example, any number of physical processors or any amount of physical memory can be used by a virtual server even if these resources span different nodes. A virtual computing platform is provided that allows for the creation, deletion, modification, control (e.g., start, stop, suspend, resume) and status (i.e., events) of the virtual servers which execute on the virtual computing platform and the management capability provides controls for these functions. In a particular example, such a platform allows the number and type of virtual resources consumed by a virtual server to be scaled up or down when the virtual server is running. For instance, an administrator may scale a virtual server manually or may define one or more policies that automatically scale a virtual server. Further, using the management API, a virtual server can monitor itself and can scale itself up or down depending on its need for processing, memory and I / O resources. For example, a virtual server may monitor its CPU utilization and invoke controls through the management API to allocate a new processor for itself when its utilization exceeds a specific threshold. Conversely, a virtual server may scale down its processor count when its utilization falls. Policies can be used to execute one or more management controls. More specifically, a management capability is provided that allows policies to be defined using management object's properties, events and / or method results. A management policy may also incorporate external data (e.g., an external event) in its definition. A policy may be triggered, causing the management server or other computing entity to execute an action. An action may utilize one or more management controls. In addition, an action may access external capabilities such as sending notification e-mail or sending a text message to a telephone paging system. Further, management capability controls may be executed using a discrete transaction referred to as a “job.” A series of management controls may be assembled into a job using one or management interfaces. Errors that occur when a job is executed may cause the job to be rolled back, allowing affected virtual servers to return to their original state.

Owner:ORACLE INT CORP

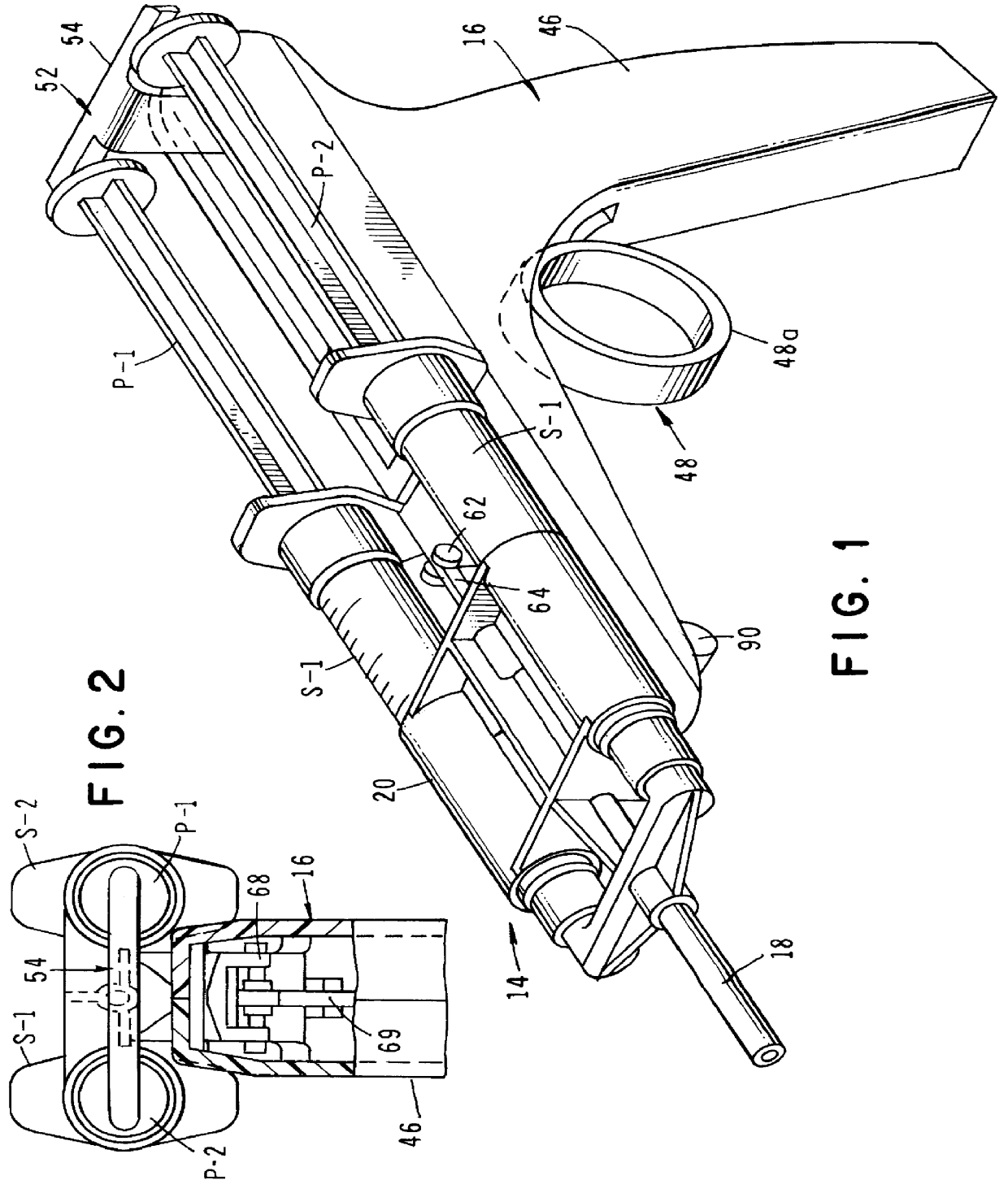

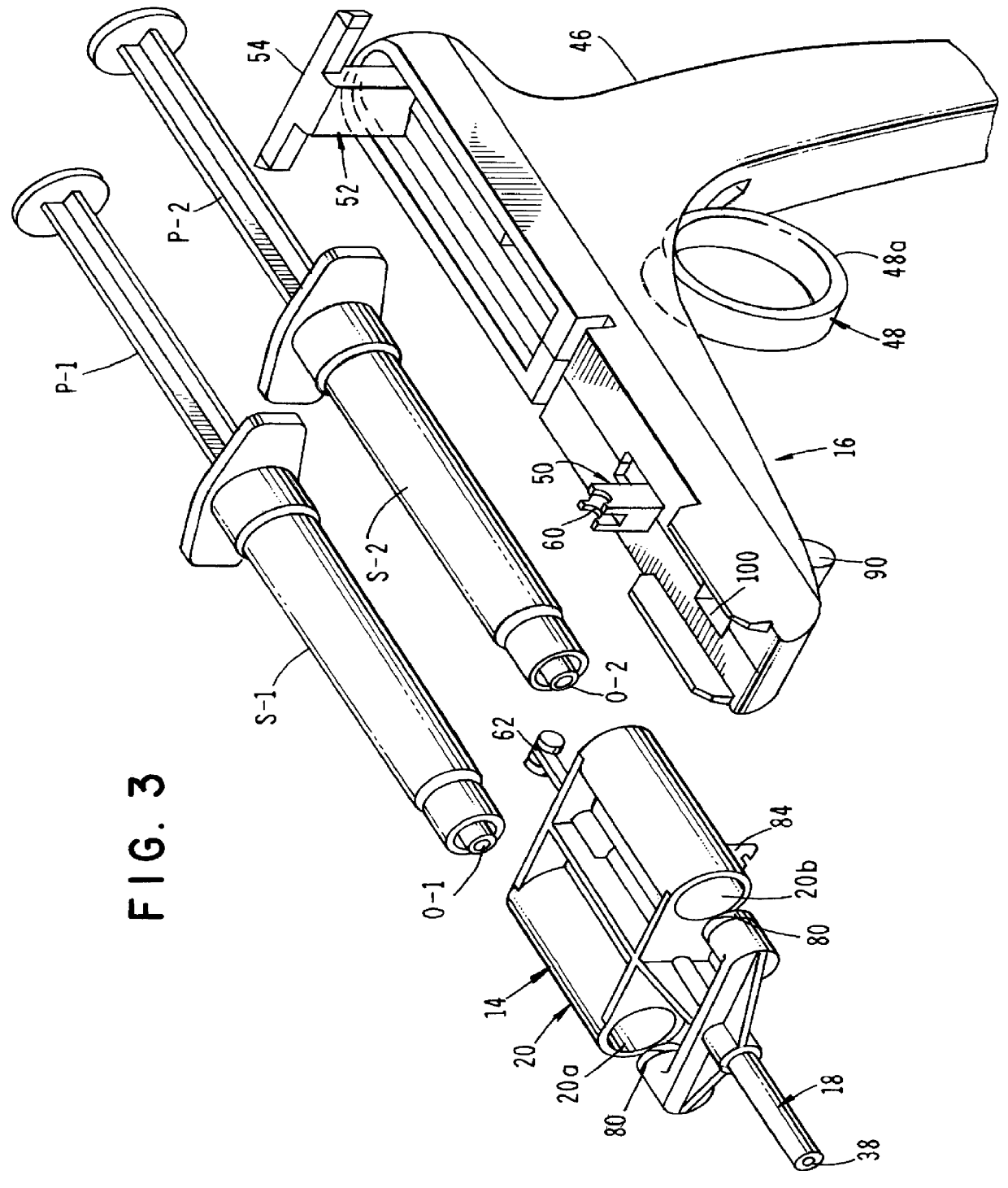

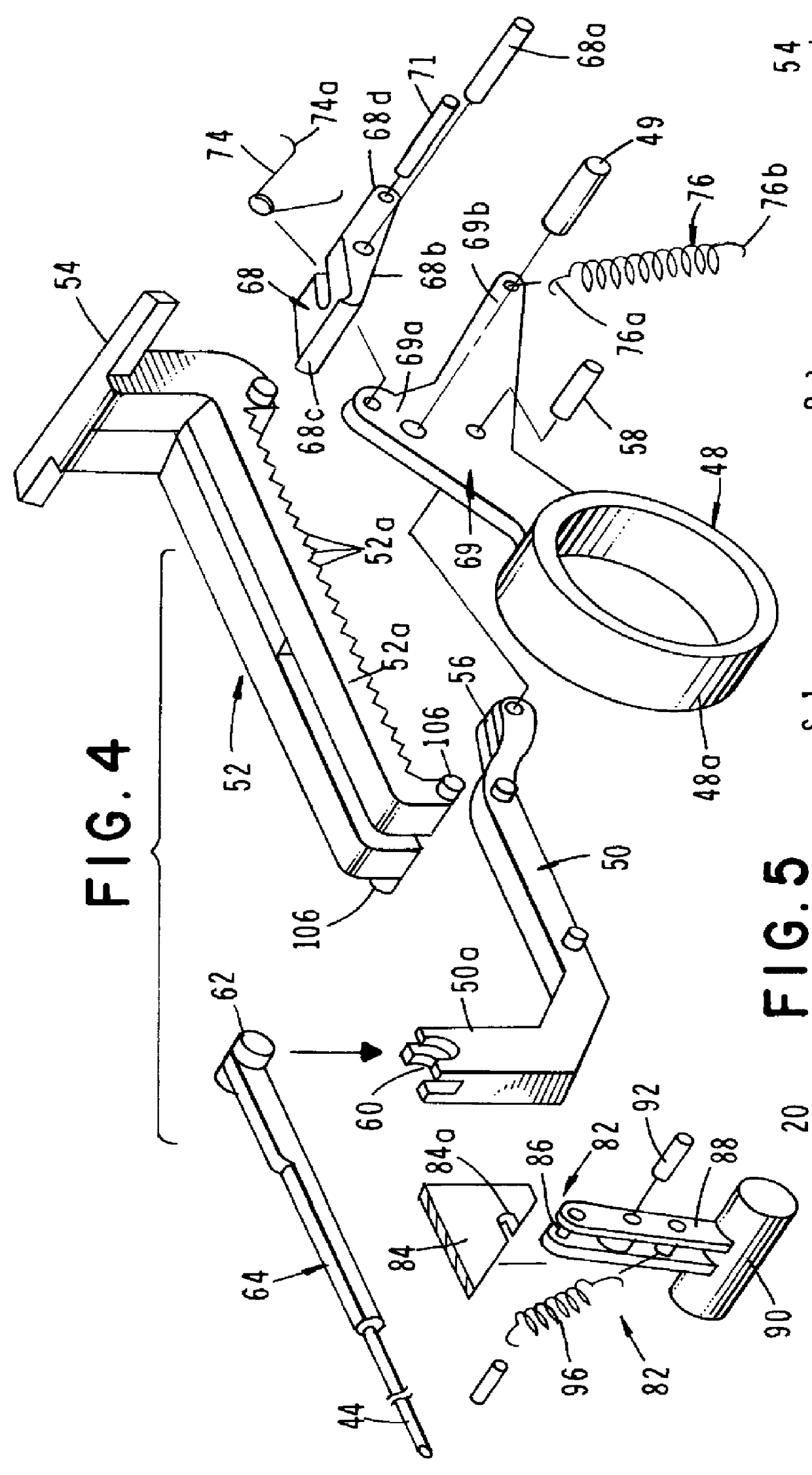

Two component fluid dispenser

InactiveUS6047861AEnhanced couplingSecurely holdLiquid surface applicatorsSurgeryEngineeringViscosity

A two-component fluid dispenser which can accurately mix two liquids of varying viscosity and then precisely deliver the mixture formed in discrete amounts. The mixture of the two components is delivered from a single delivery tube in a manner such that none of the mixture remains within the delivery tube at the completion of each mixing and delivery cycle. In one form of the apparatus, the single delivery tube of the apparatus is operably coupled with conventional hypodermic syringes of various sizes so that different fluids can be mixed in different ratios.

Owner:BAXTER INT INC

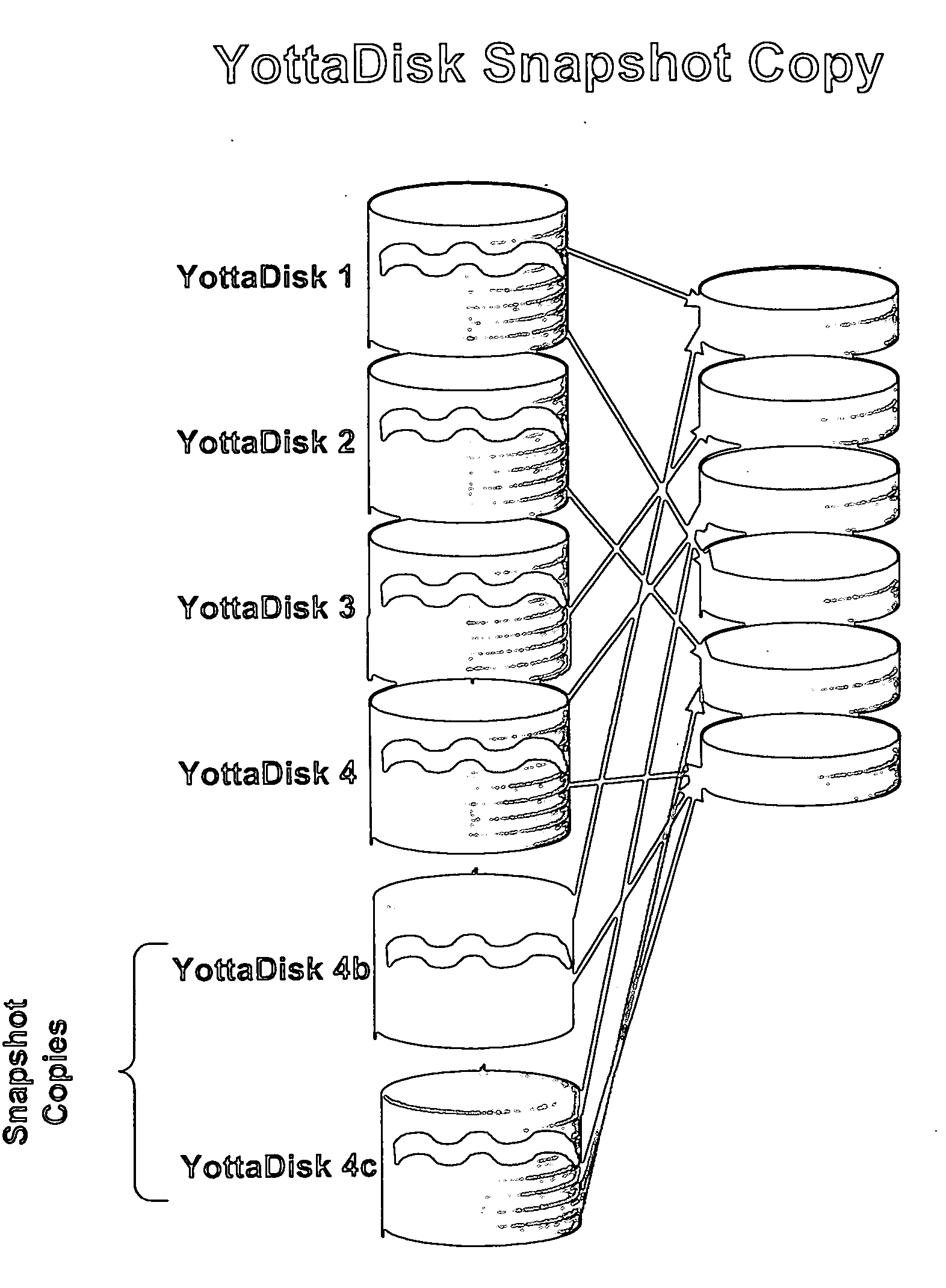

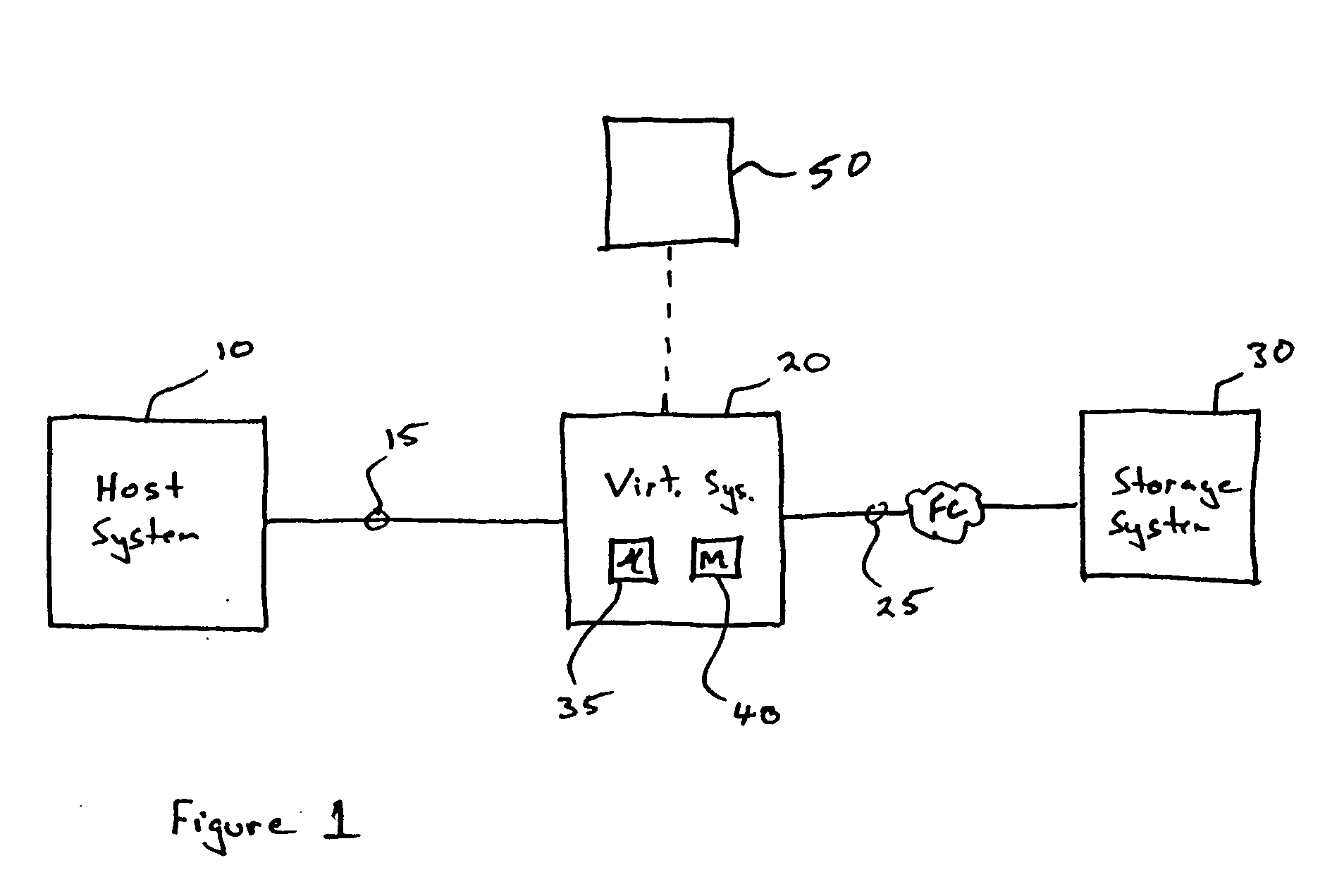

Storage virtualization system and methods

InactiveUS20050125593A1Reduce consumptionWithout impactInput/output to record carriersMemory adressing/allocation/relocationRAIDIslanding

Storage virtualization systems and methods that allow customers to manage storage as a utility rather than as islands of storage which are independent of each other. A demand mapped virtual disk image of up to an arbitrarily large size is presented to a host system. The virtualization system allocates physical storage from a storage pool dynamically in response to host I / O requests, e.g., SCSI I / O requests, allowing for the amortization of storage resources-through a disk subsystem while maintaining coherency amongst I / O RAID traffic. In one embodiment, the virtualization functionality is implemented in a controller device, such as a controller card residing in a switch device or other network device, coupled to a storage system on a storage area network (SAN). The resulting virtual disk image that is observed by the host computer is larger than the amount of physical storage actually consumed.

Owner:EMC IP HLDG CO LLC

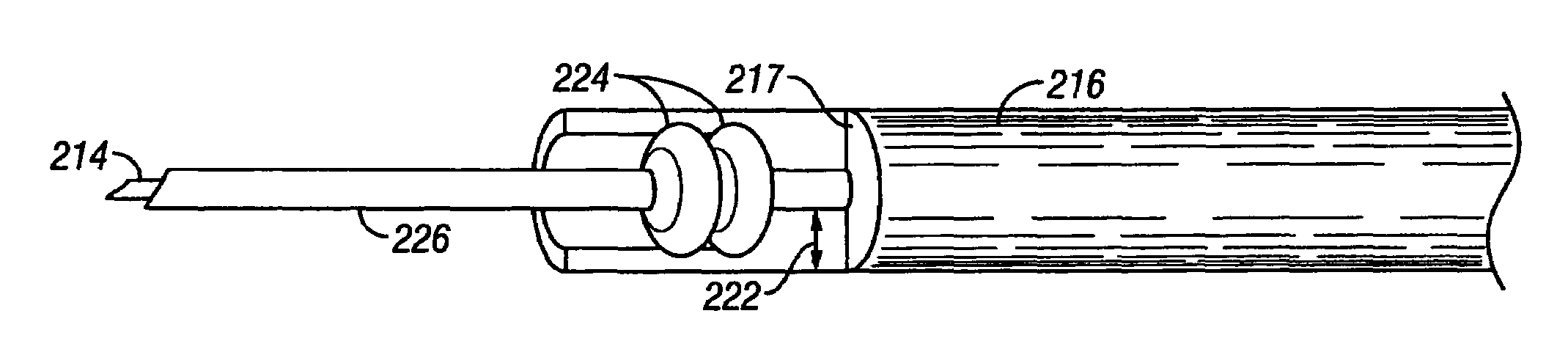

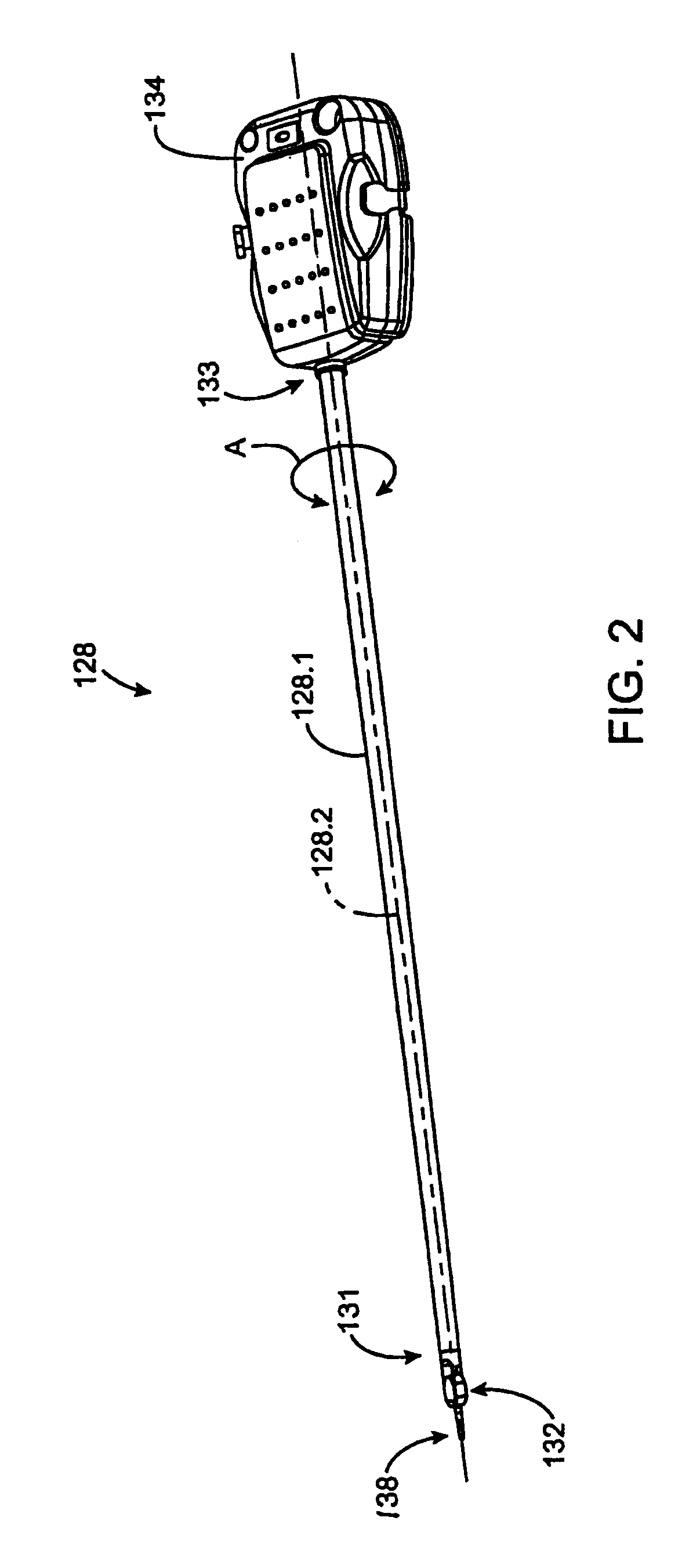

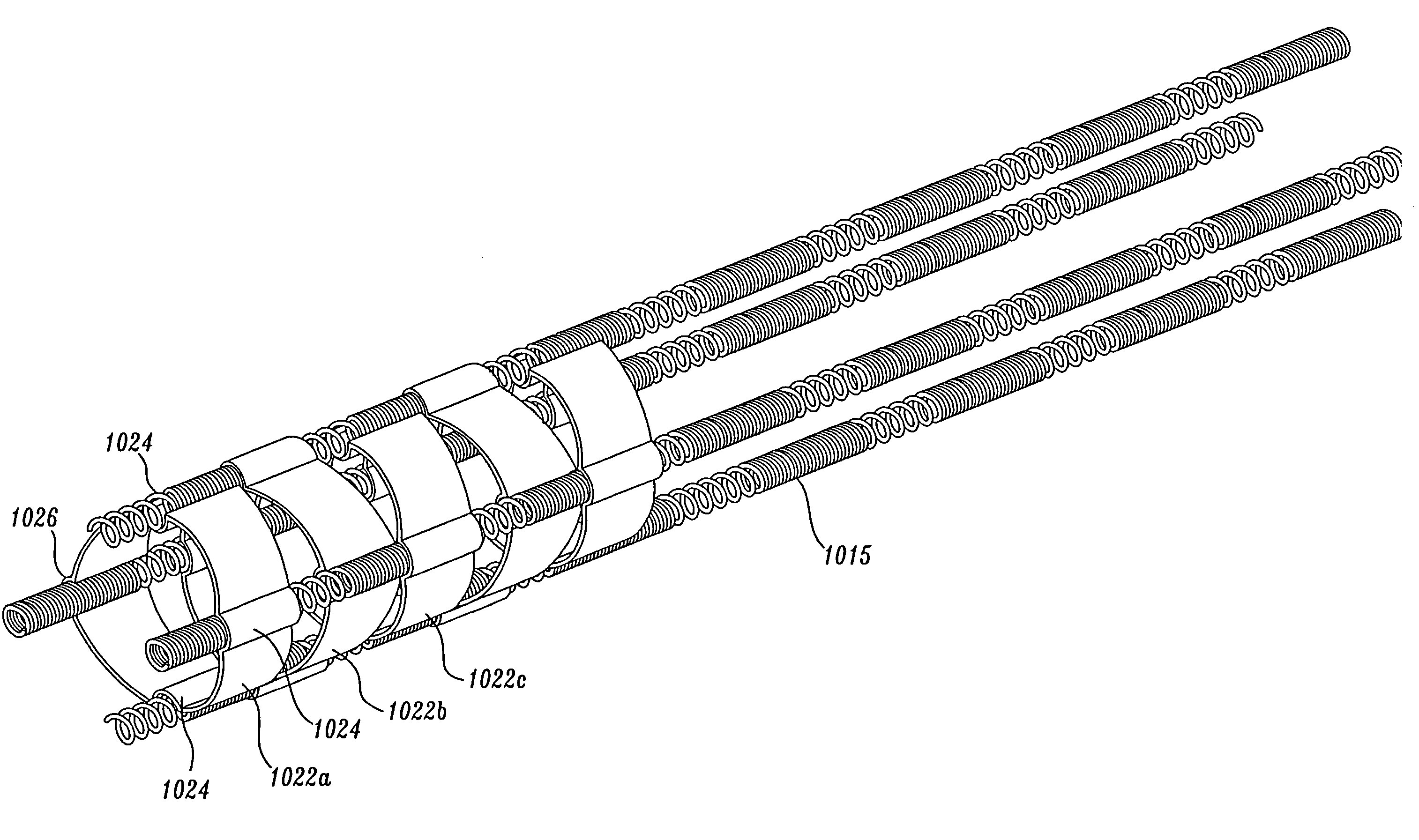

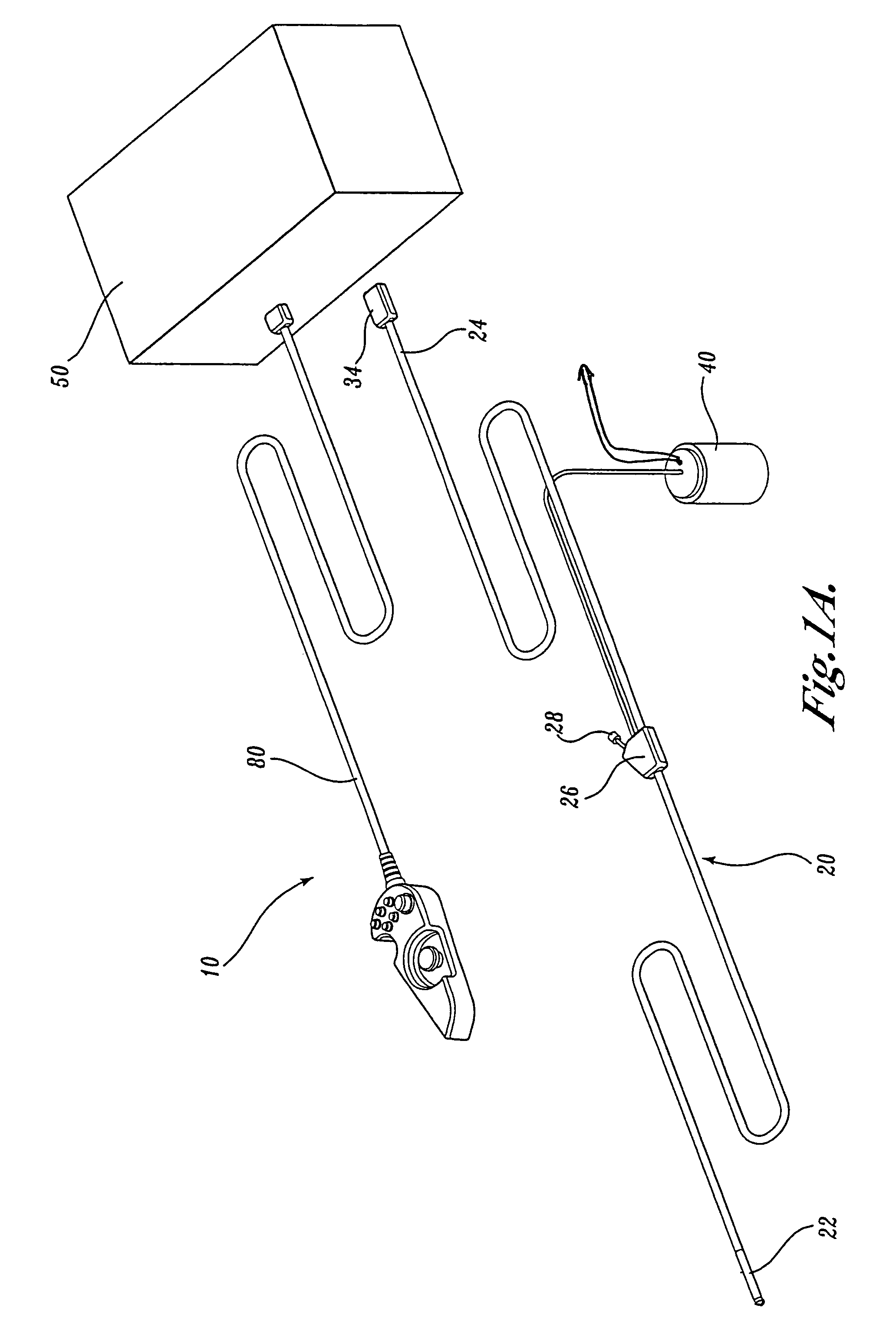

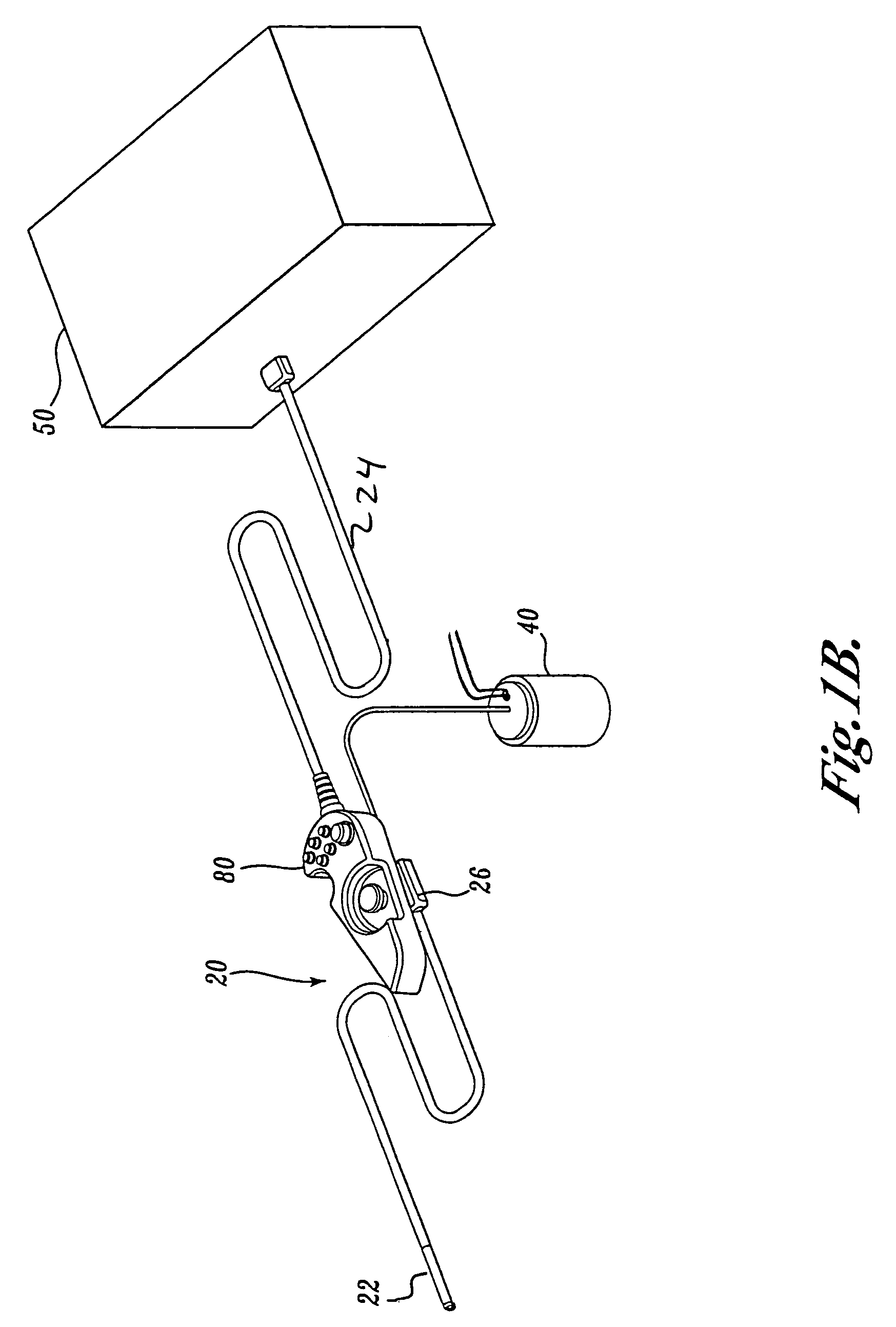

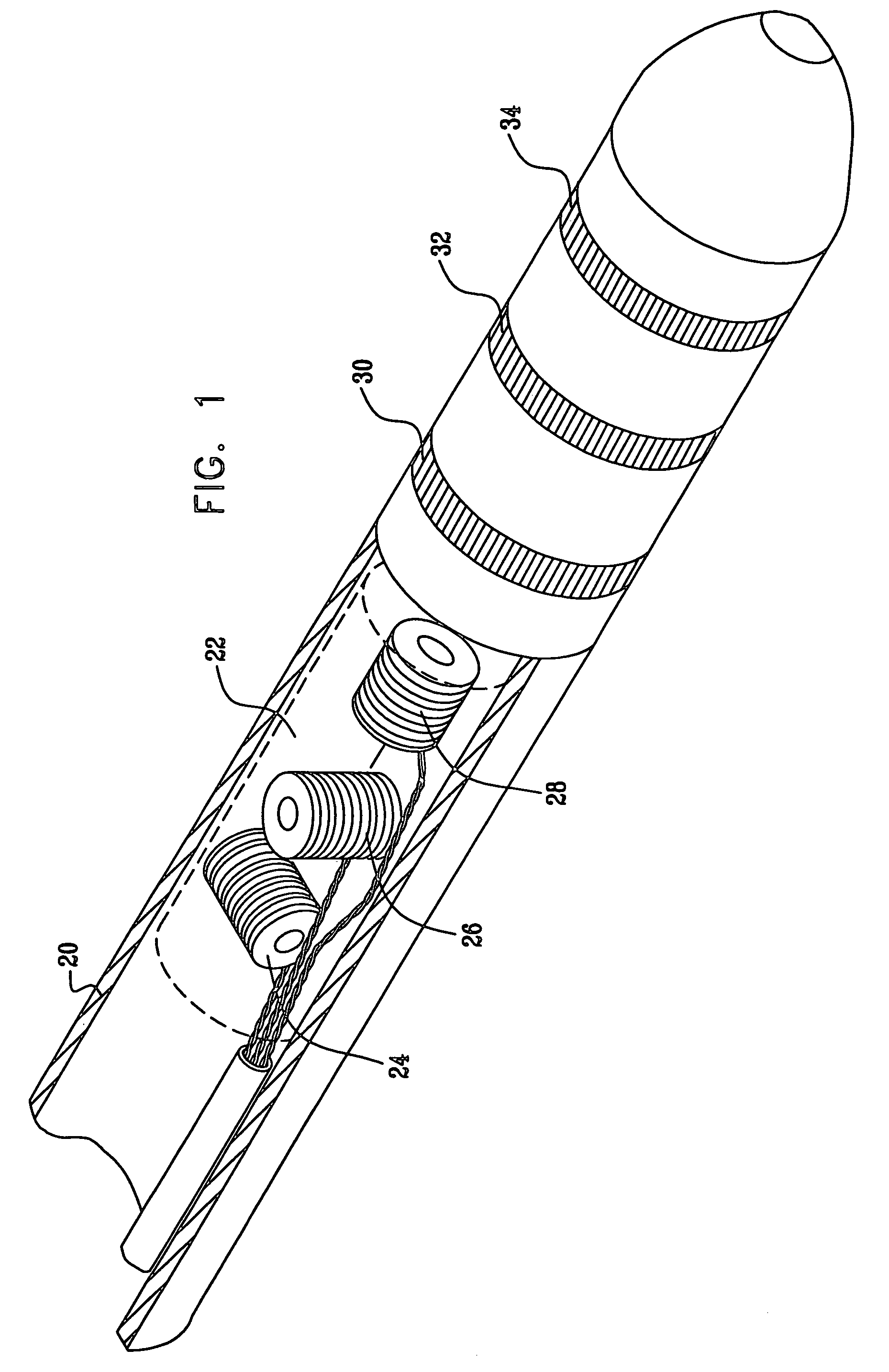

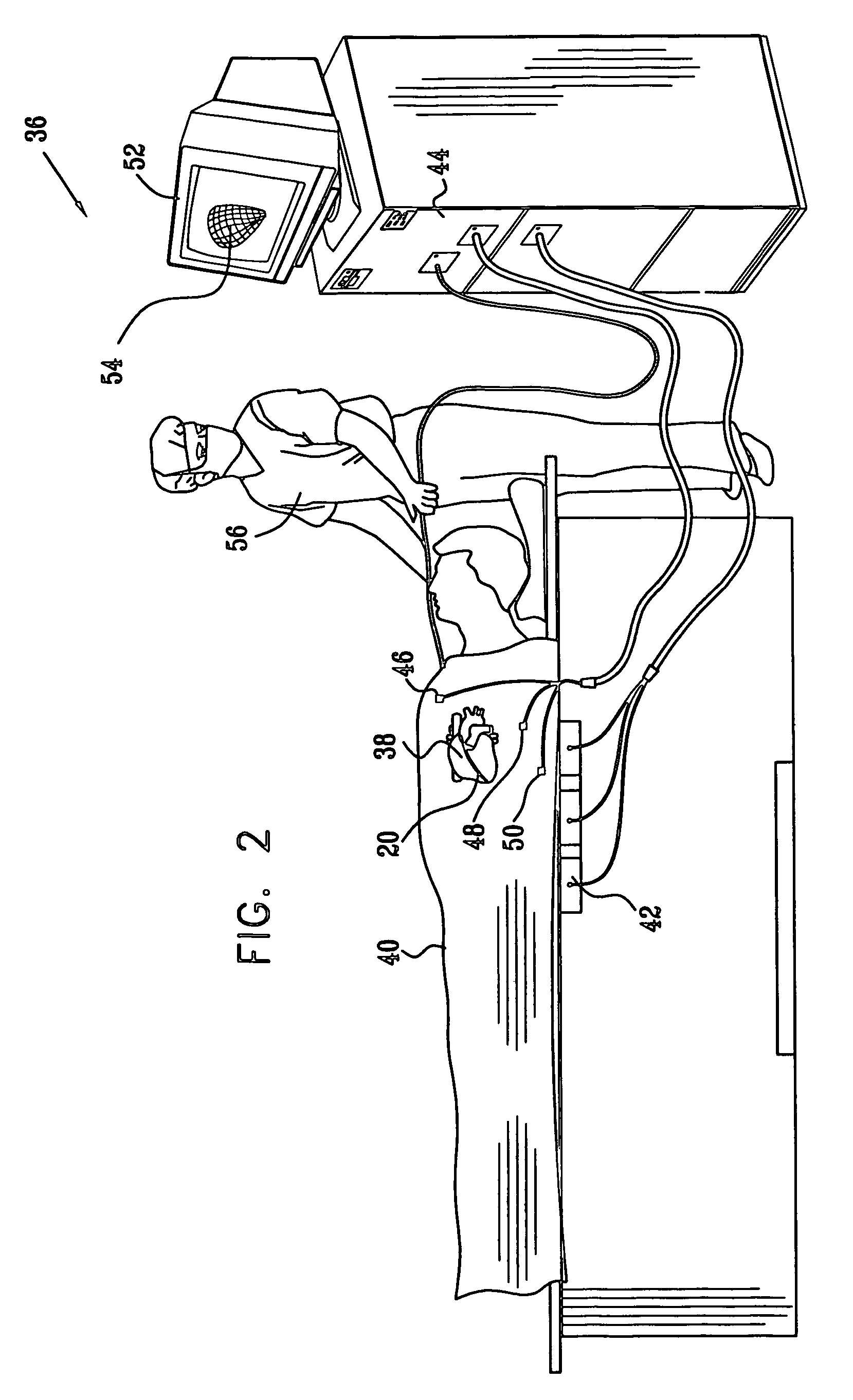

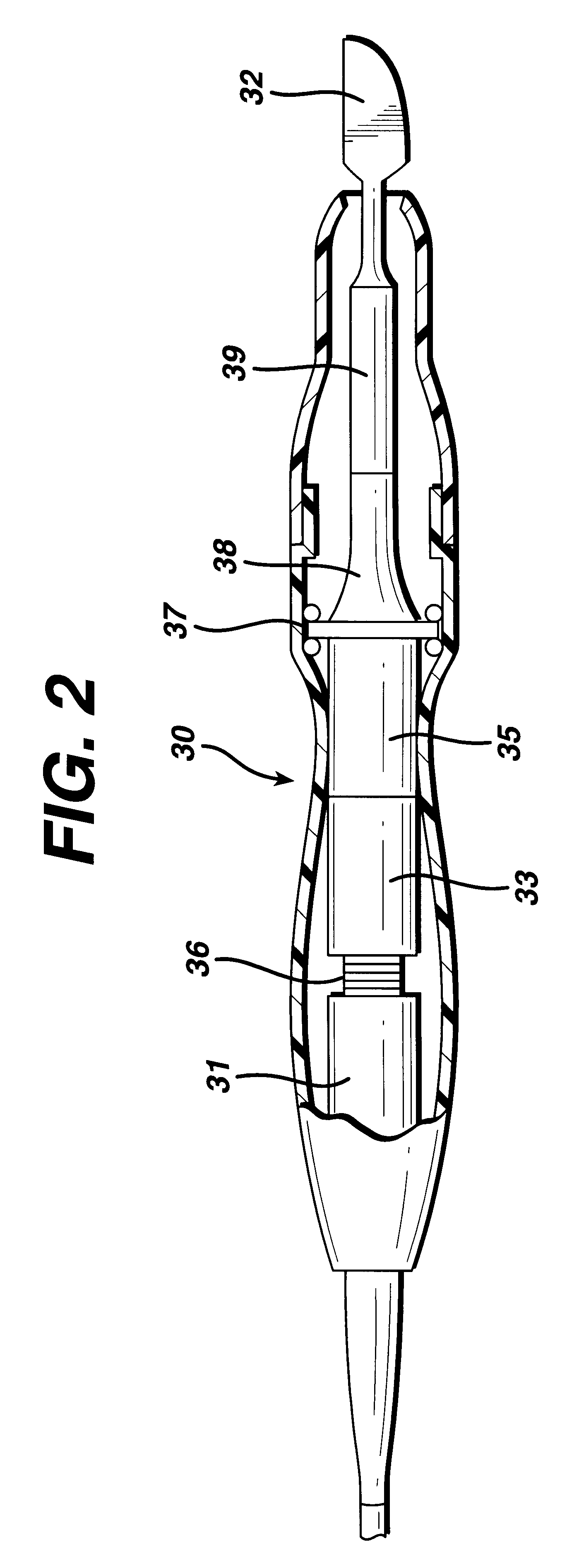

Surgical tool having electrocautery energy supply conductor with inhibited current leakage

InactiveUS7083615B2Low costEasy to manufactureDiagnosticsSurgical instruments for heatingCapacitanceElectrical conductor

The present invention provides improved electrosurgical instruments and systems having electrocautery energy supply conductors that provide inhibited current leakage and methods of performing a robotically controlled minimally invasive surgical procedure while preventing unintended capacitive coupling. A surgical instrument generally comprises an elongate shaft having a proximal end and a distal end and defining an internal longitudinally extending passage. An electrocautery end effector is coupled to or disposed at the distal end of the shaft. An interface or tool base is coupled to or disposed at the proximal end of the shaft and removably connectable to the robotic surgical system. Typically, an independent electrical conductor extends from the interface to the end effector to transmit electrical energy to tissue engaged by the end effector. A sealed insulation tube extends within the passage and over the conductor. A separation is maintained between the sealed insulation tube and the conductor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

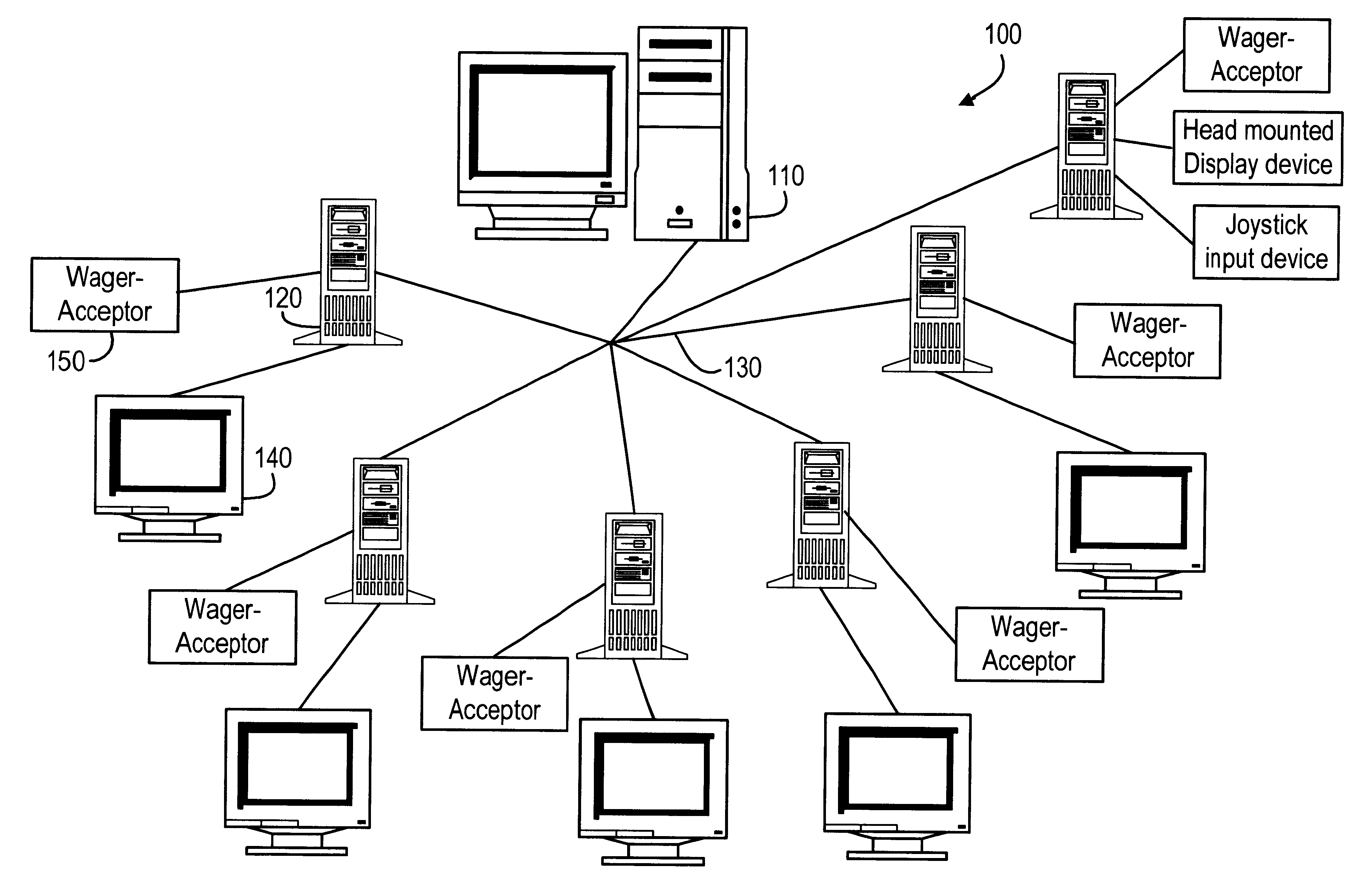

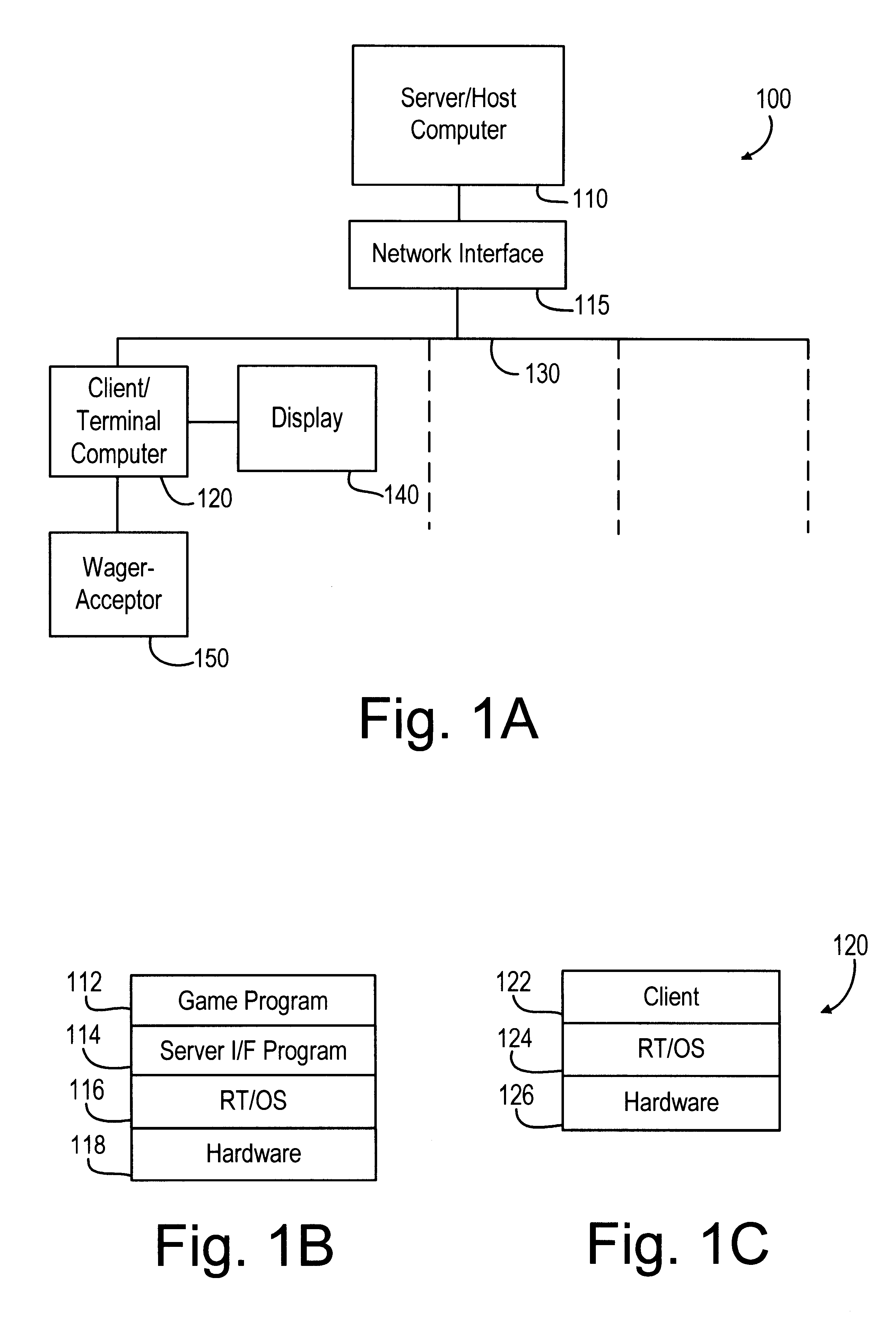

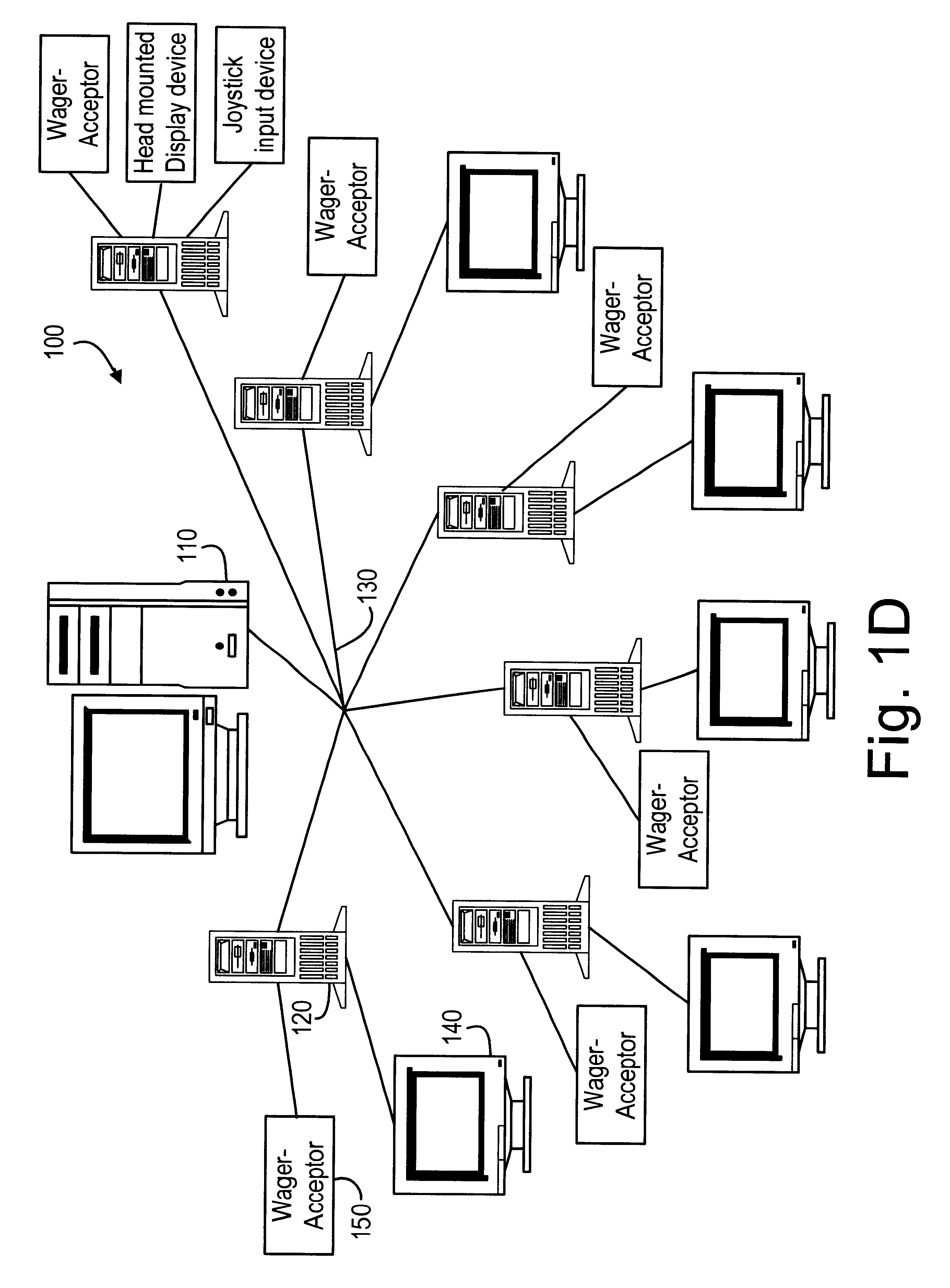

Slim terminal gaming system

InactiveUS6409602B1Minimizing unavailabilityReduce hardware and software costsData processing applicationsBoard gamesClient-sideUpgrade

A computer gaming system and method of operation thereof are provided that both drastically reduce the cost of gaming stations and allow contemporaneous access to multiple game programs from a single gaming station. The computer gaming system of the present invention allows for transparent modifications and upgrades to the gaming programs by executing gaming programs on a server / host computer connected to a plurality of client / terminal computers via communication pathways. Each client / terminal computer comprises a client / terminal program that allows input and output streams of the gaming program executed on the server / host computer to be separated and redirected to the client / terminal computers. Since the gaming programs are executed entirely on the server / host computer, with only wagering input and display output operations being executed on the client / terminal computers, the cost of the hardware and software required for each client / terminal computer is greatly reduced. A patron of a client / terminal computer can access any of the gaming programs executed on the server / host computer. Modifications and upgrades of the gaming programs only need to be performed on the server / host computer. By using a stereo head-mounted display together with a joystick input device and wireless communication pathways, the present invention allows a patron to participate in a mobile gaming environment.

Owner:NEW MILLENIUM GAMING

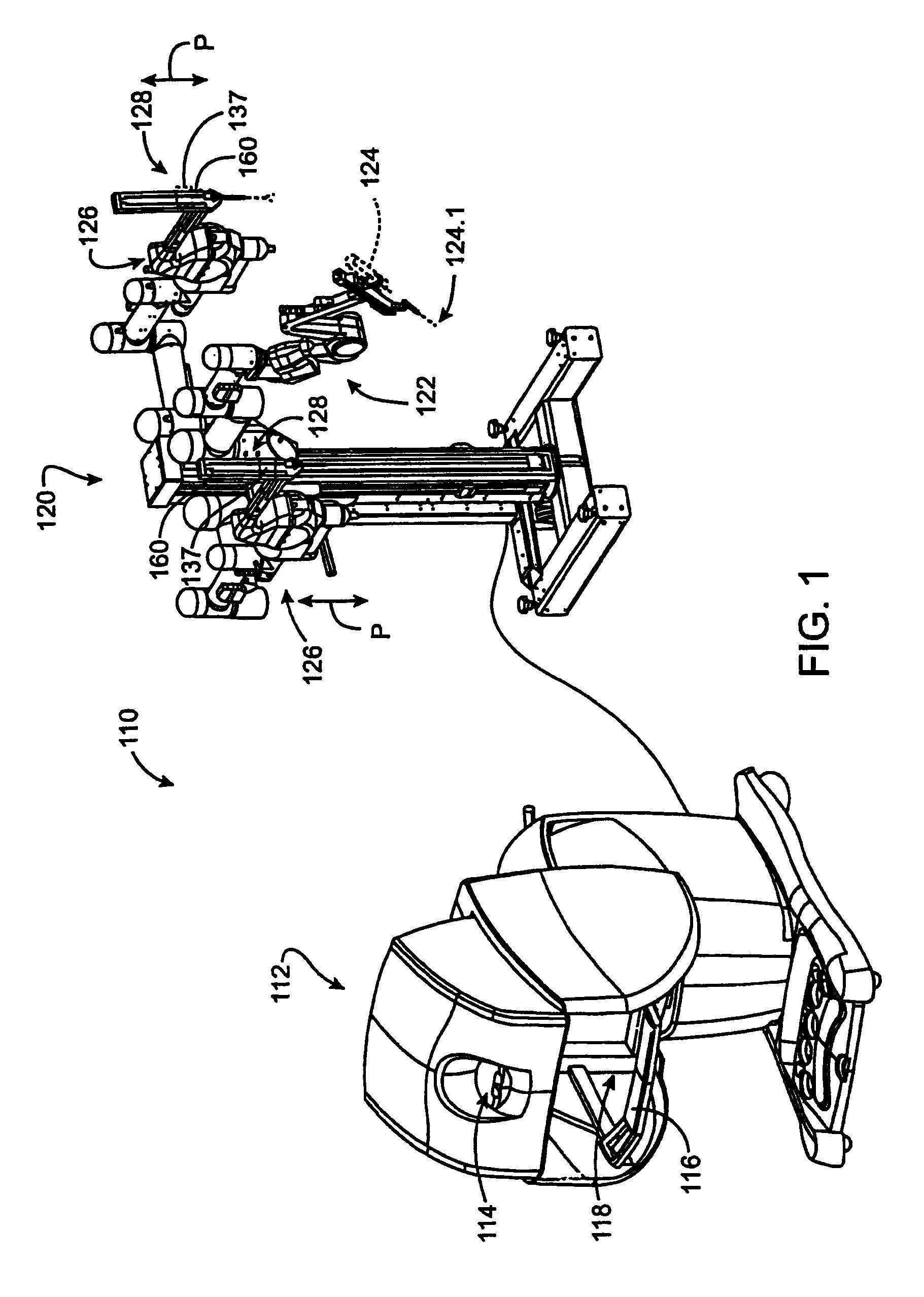

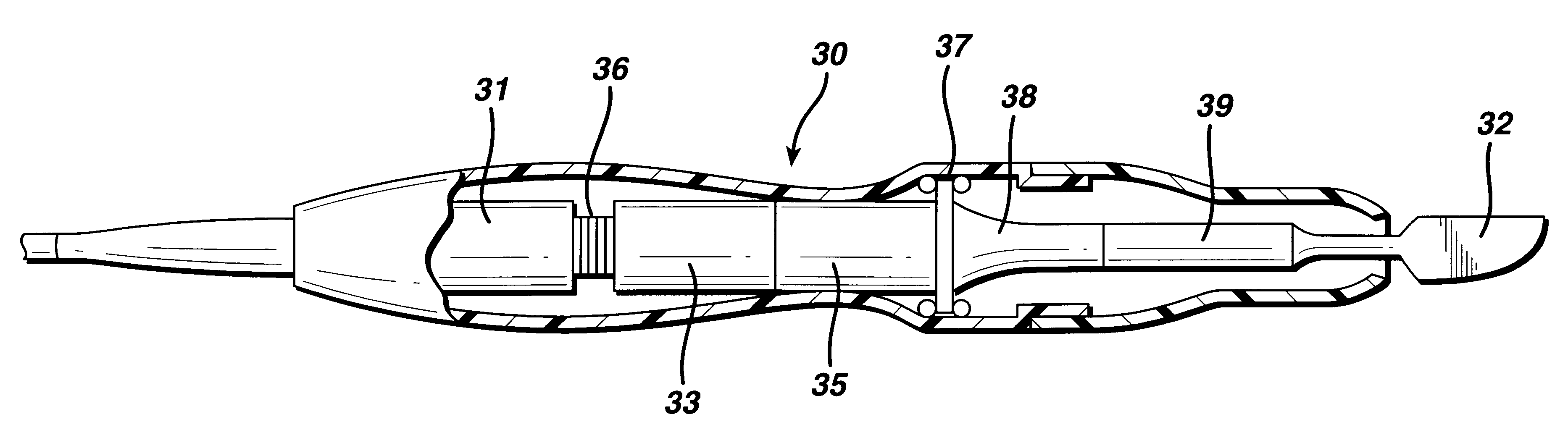

Articulation joint for video endoscope

A video endoscope system includes a reusable control cabinet and an endoscope that is connectable thereto. The endoscope may be used with a single patient and then disposed. The endoscope includes an illumination mechanism, an image sensor, and an elongate shaft having one or more lumens located therein. An articulation joint at the distal end of the endoscope allows the distal end to be oriented by the actuators in the control cabinet or actuators in a control handle of the endoscope. Fluidics, electrical, navigation, image, display and data entry controls are integrated into the system along with other accessories.

Owner:BOSTON SCI SCIMED INC

Linking of computers based on optical sensing of digital data

InactiveUS6311214B1Reduce businessLow costCoin-freed apparatusRecord information storageDigital dataBusiness card

A printed object, such as an item of postal mail, a book, printed advertising, a business card, product packaging, etc., is steganographically encoded with plural-bit data. When such an object is presented to an optical sensor, the plural-bit data is decoded and used to establish a link to an internet address corresponding to that object.

Owner:DIGIMARC CORP (FORMERLY DMRC CORP) +1

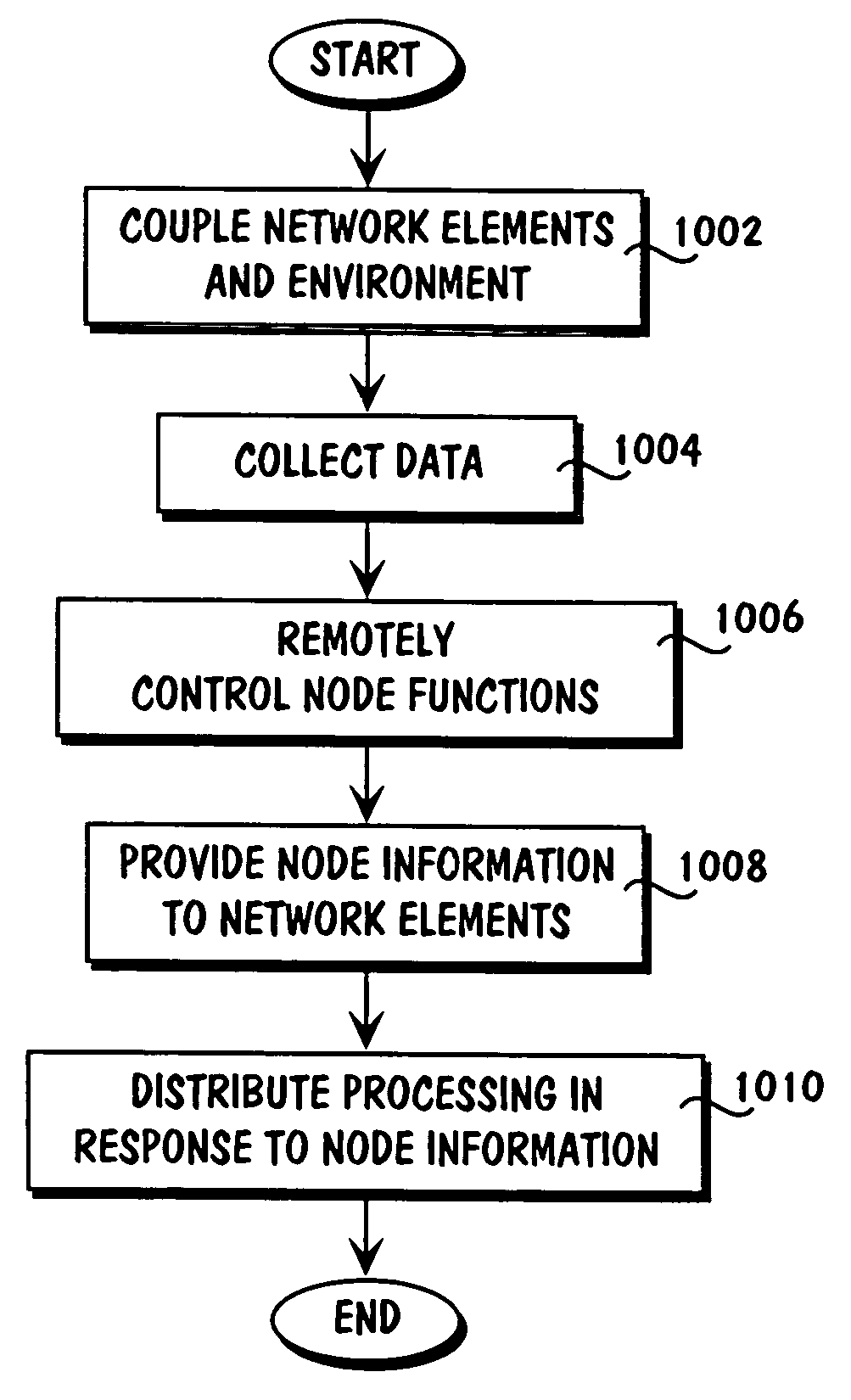

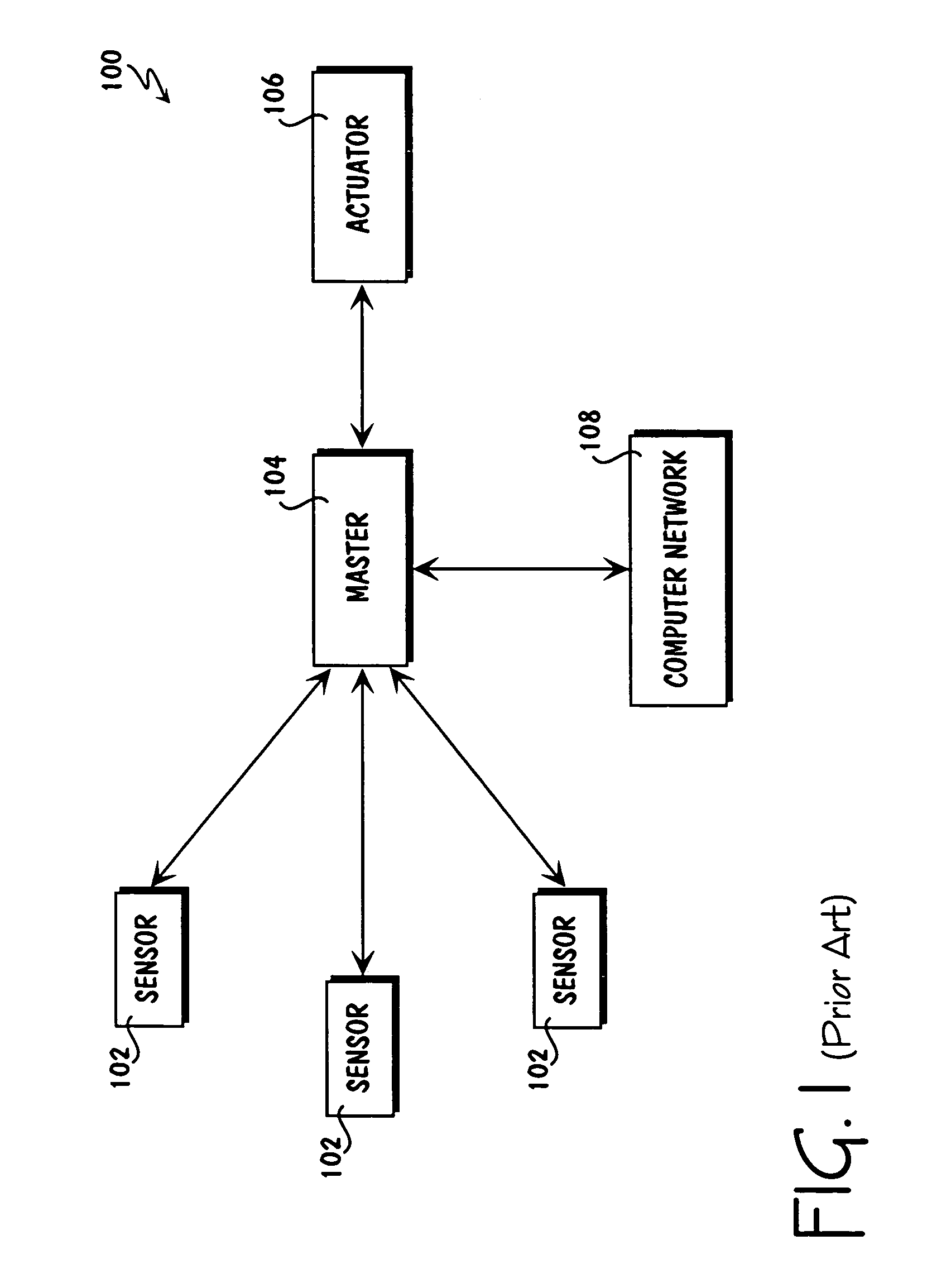

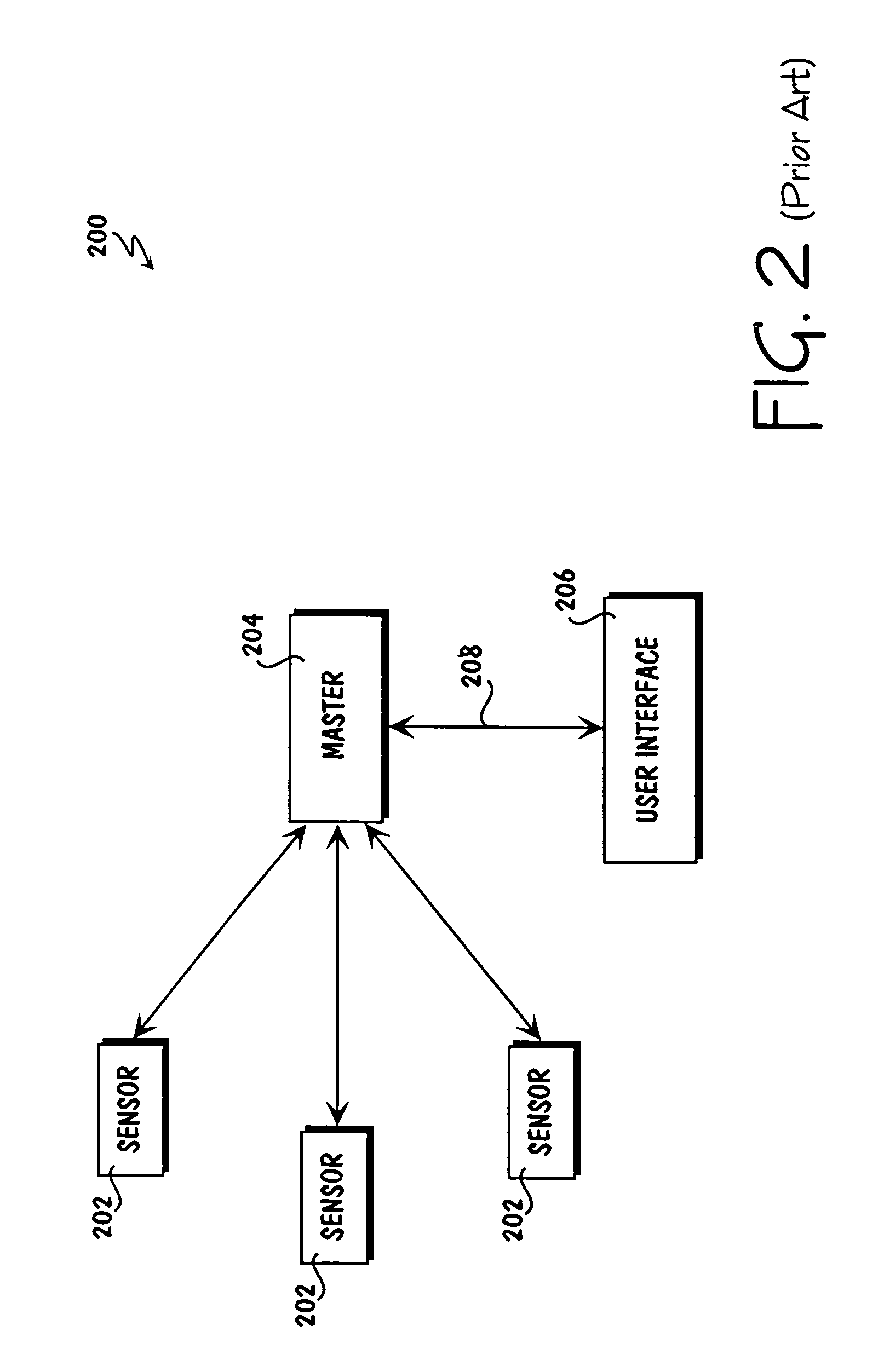

Method for collecting and processing data using internetworked wireless integrated network sensors (WINS)

InactiveUS7020701B1High reliability accessEasy to operateEnergy efficient ICTPower managementReconfigurabilityMonitoring and control

The Wireless Integrated Network Sensor Next Generation (WINS NG) nodes provide distributed network and Internet access to sensors, controls, and processors that are deeply embedded in equipment, facilities, and the environment. The WINS NG network is a new monitoring and control capability for applications in transportation, manufacturing, health care, environmental monitoring, and safety and security. The WINS NG nodes combine microsensor technology, low power distributed signal processing, low power computation, and low power, low cost wireless and / or wired networking capability in a compact system. The WINS NG networks provide sensing, local control, remote reconfigurability, and embedded intelligent systems in structures, materials, and environments.

Owner:INTELLECTUAL VENTURES I LLC

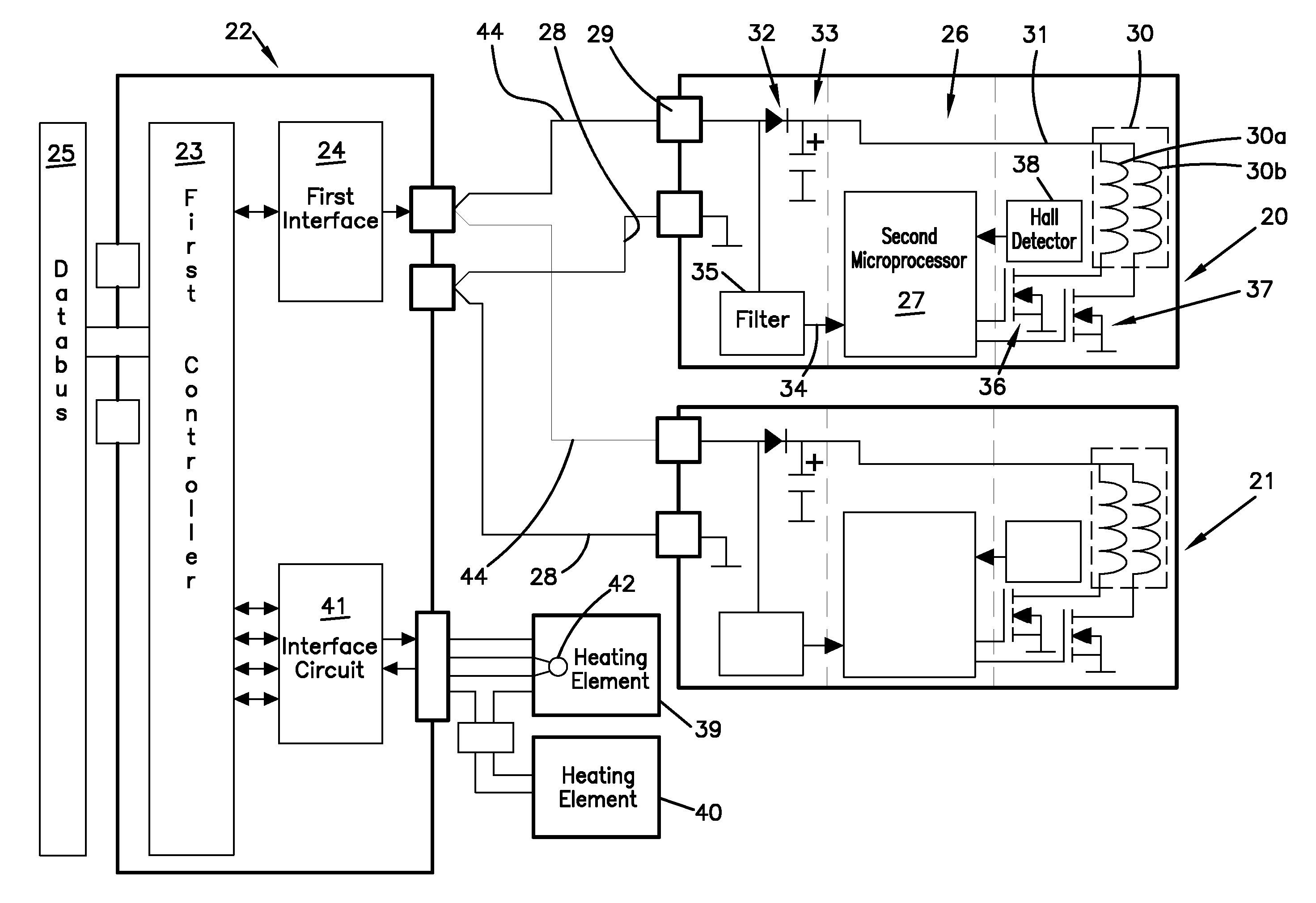

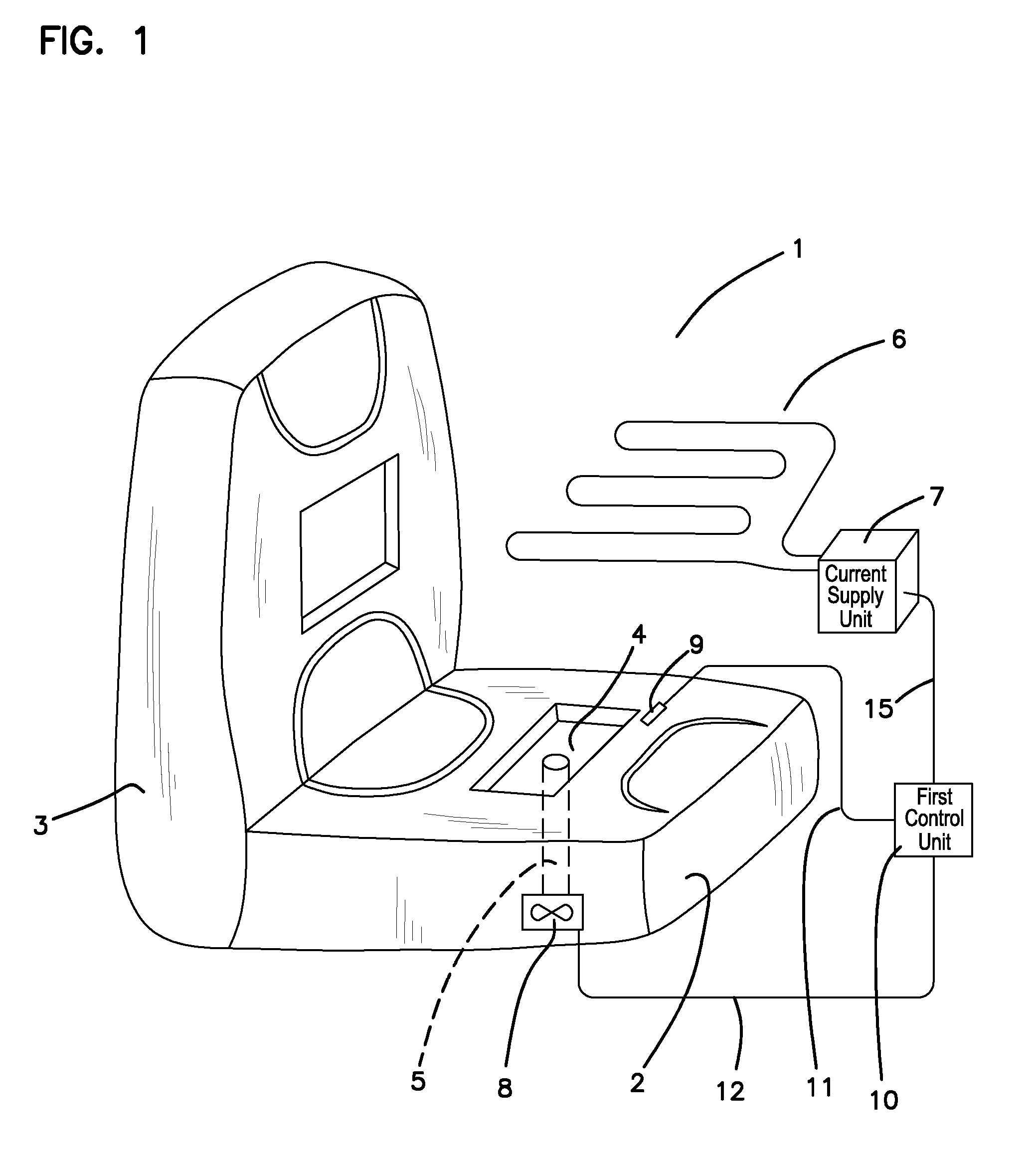

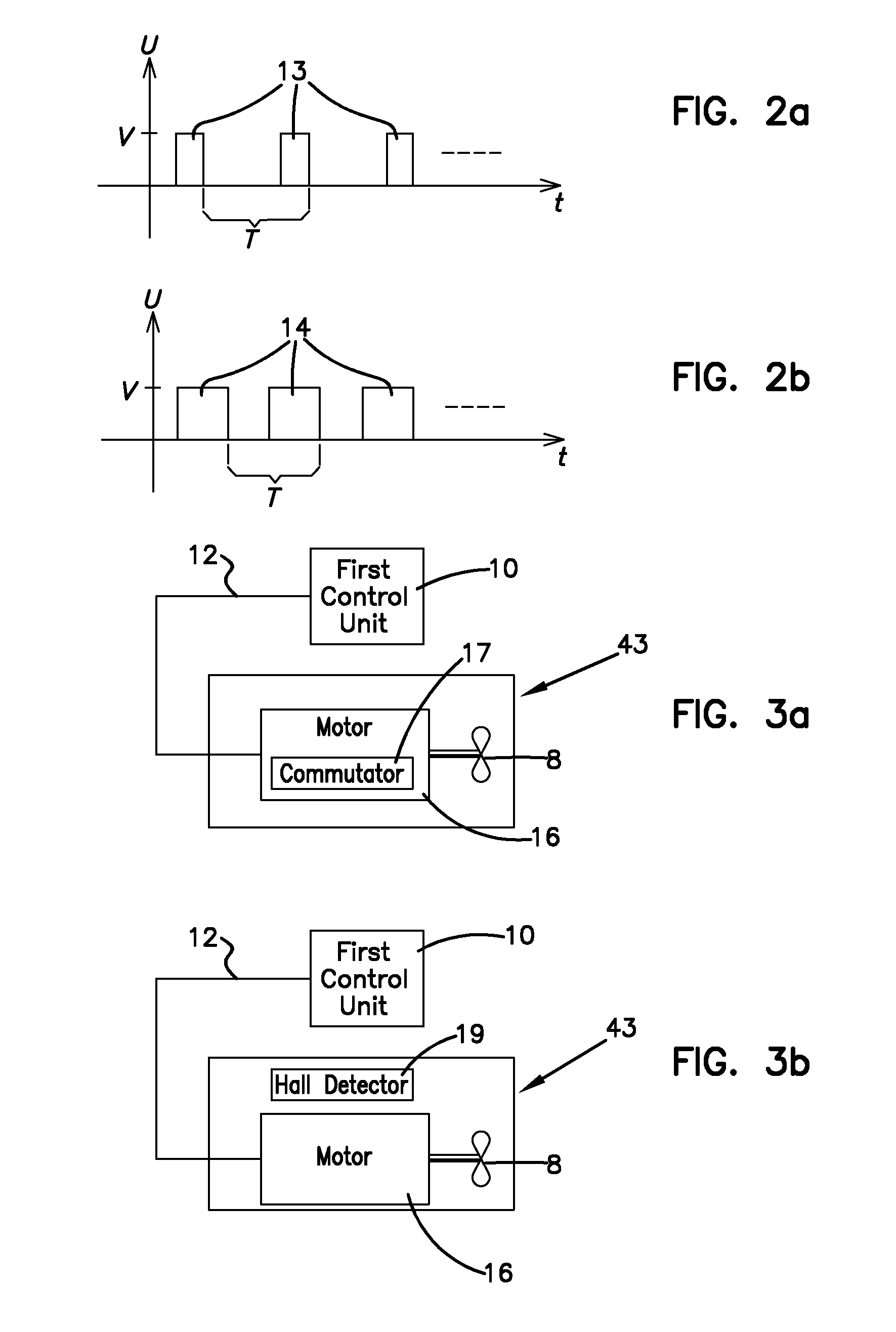

Method and arrangement for control of direct current motor

InactiveUS7567045B2Efficient coordinationLow costVehicle seatsMultiple motor speed/torque controlTelecommunications linkControl signal

Owner:KONGSBERG AUTOMOTIVE AB (SE)

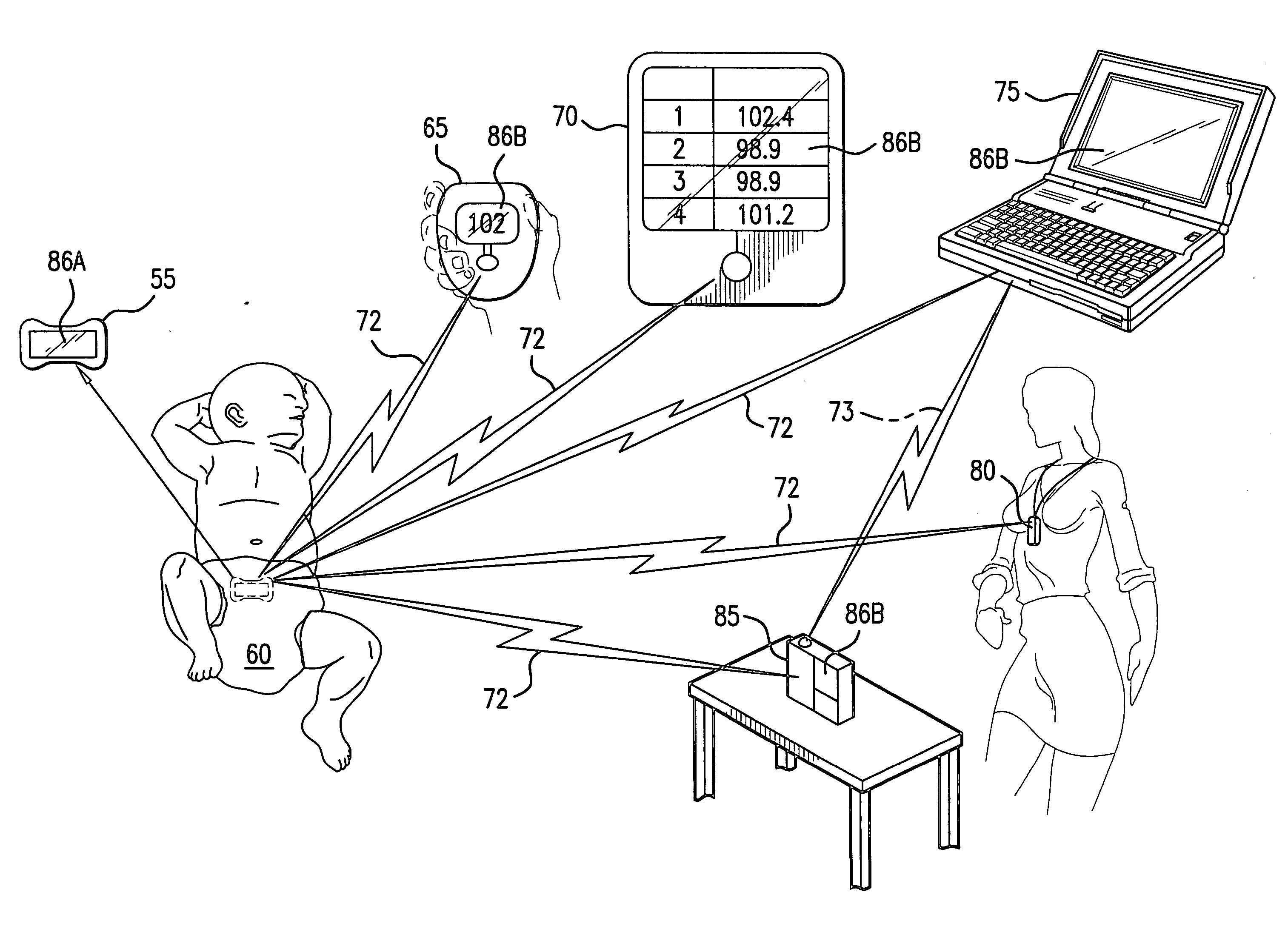

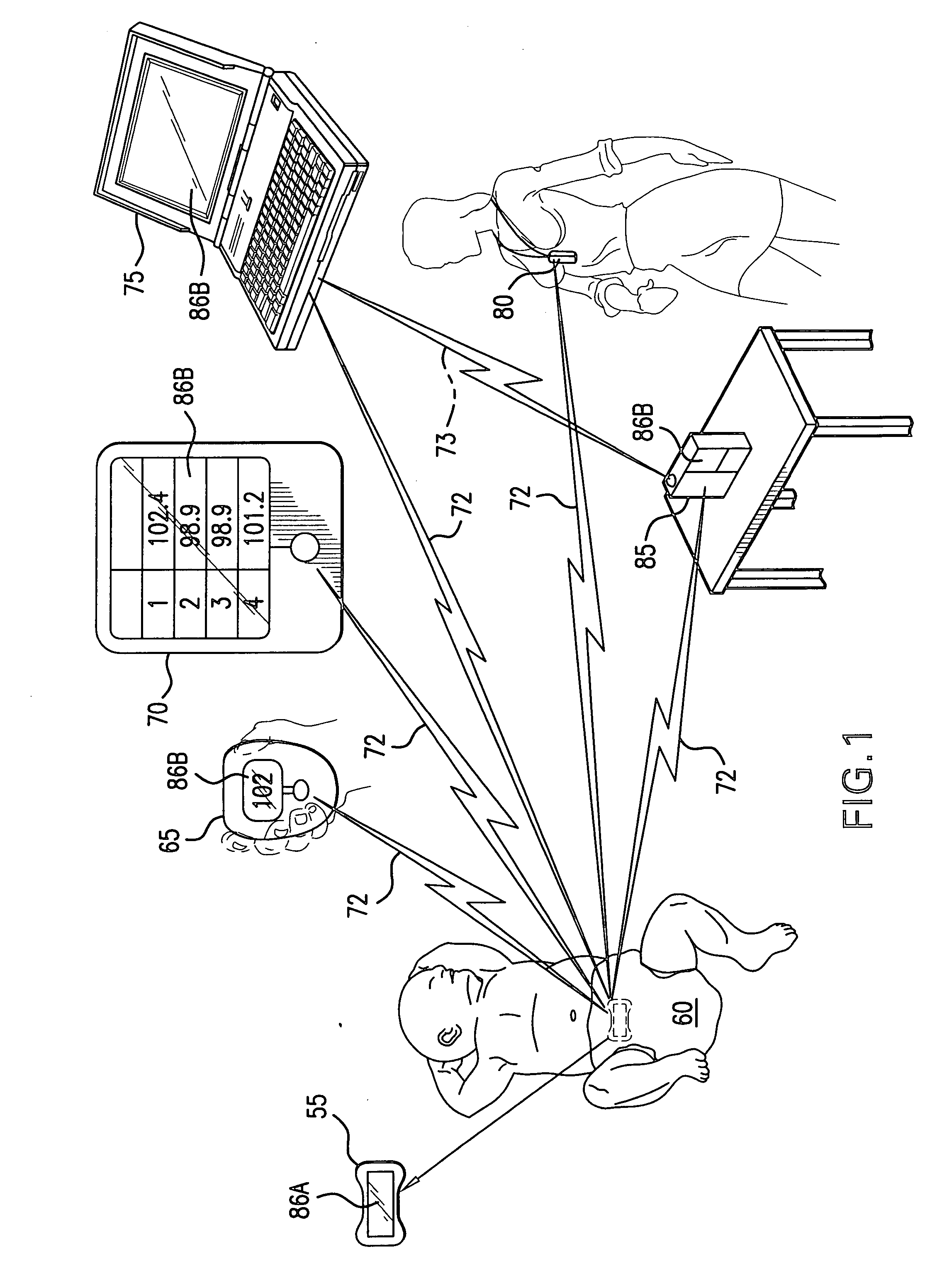

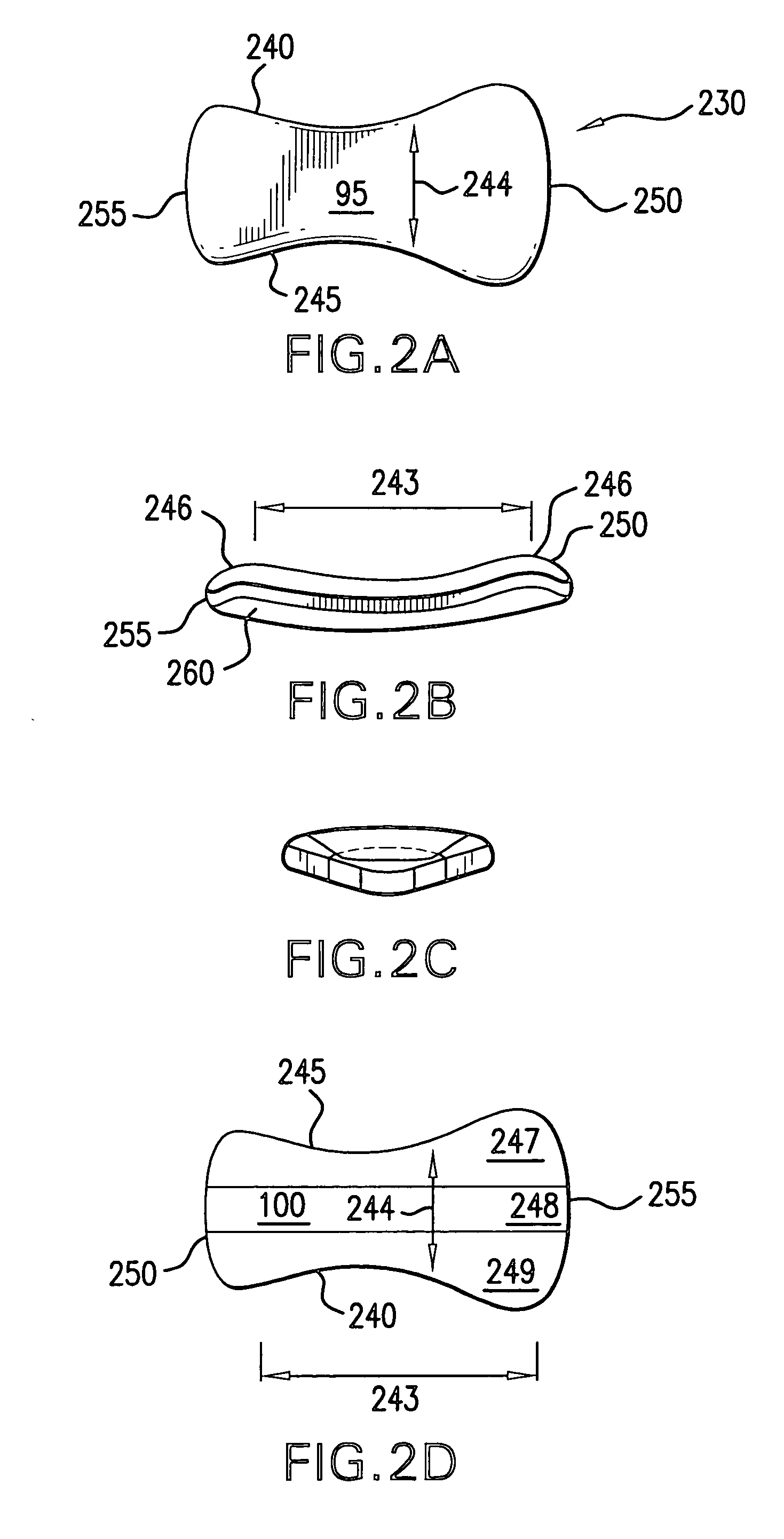

Non-invasive temperature monitoring device

InactiveUS20050245839A1Short-term useLow costThermometer detailsElectrocardiographyMonitoring systemEngineering

A monitoring system comprises a module having at least one sensor and preferably skin and ambient temperature sensors within a housing. The device may be durable or disposable. The housing may be provided with certain surface features and shapes to facilitate mounting on and interface with the skin of the wearer for more accurate temperature measurement. A receiver may be provided to obtain and display data from the module. The module may also display the output data. The output data comprises both detected and derived data relating to physiological and contextual parameters of the wearer and may be transmitted directly to a local recipient or remotely over a communications network. The system is capable of deriving and predicting the occurrence of a number of physiological and conditional states and events and reporting the same as output data.

Owner:J FITNESS LLC

Using internet content as a means to establish live social networks by linking internet users to each other who are simultaneously engaged in the same and/or similar content

ActiveUS20080222295A1Low costReduced flexibilityMultiple digital computer combinationsOffice automationPush and pullInternet content

A system and method that uses internet content and / or content metadata as a means to establish social networks. Examples include linking internet users, searchers, viewers and / or listeners of the same and / or similar internet content to each other via a platform that enables any of the following in n-dimensional environments: social networking, communications, sharing, e-commerce, advertising, search, hosting and registry services, push and pull applications, anonymous communications, and rich presence.

Owner:NEONEKT LLC

Wireless communication

ActiveUS8102278B2Low costReduce power consumptionProgramme controlElectric signal transmission systemsComputer hardwareConverters

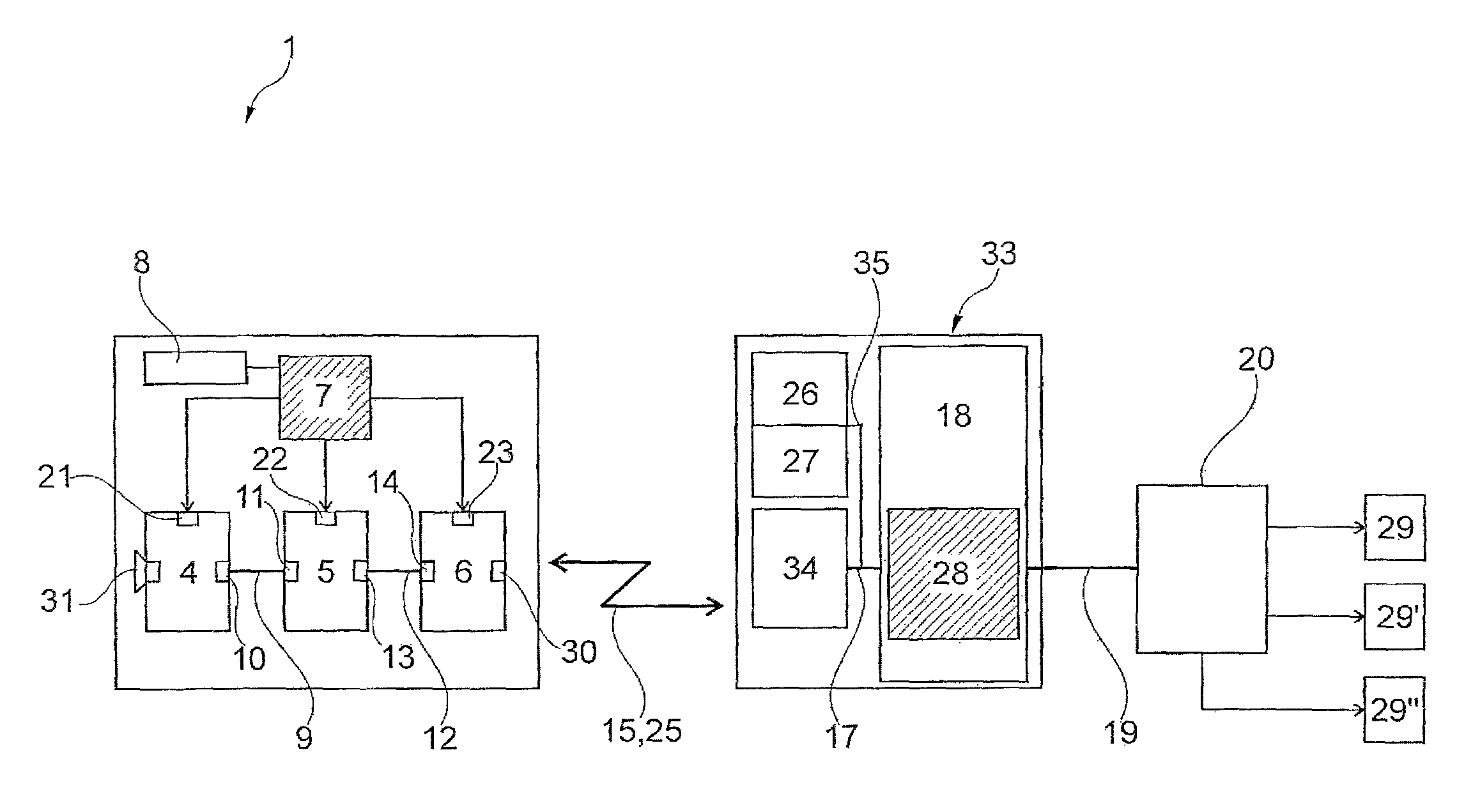

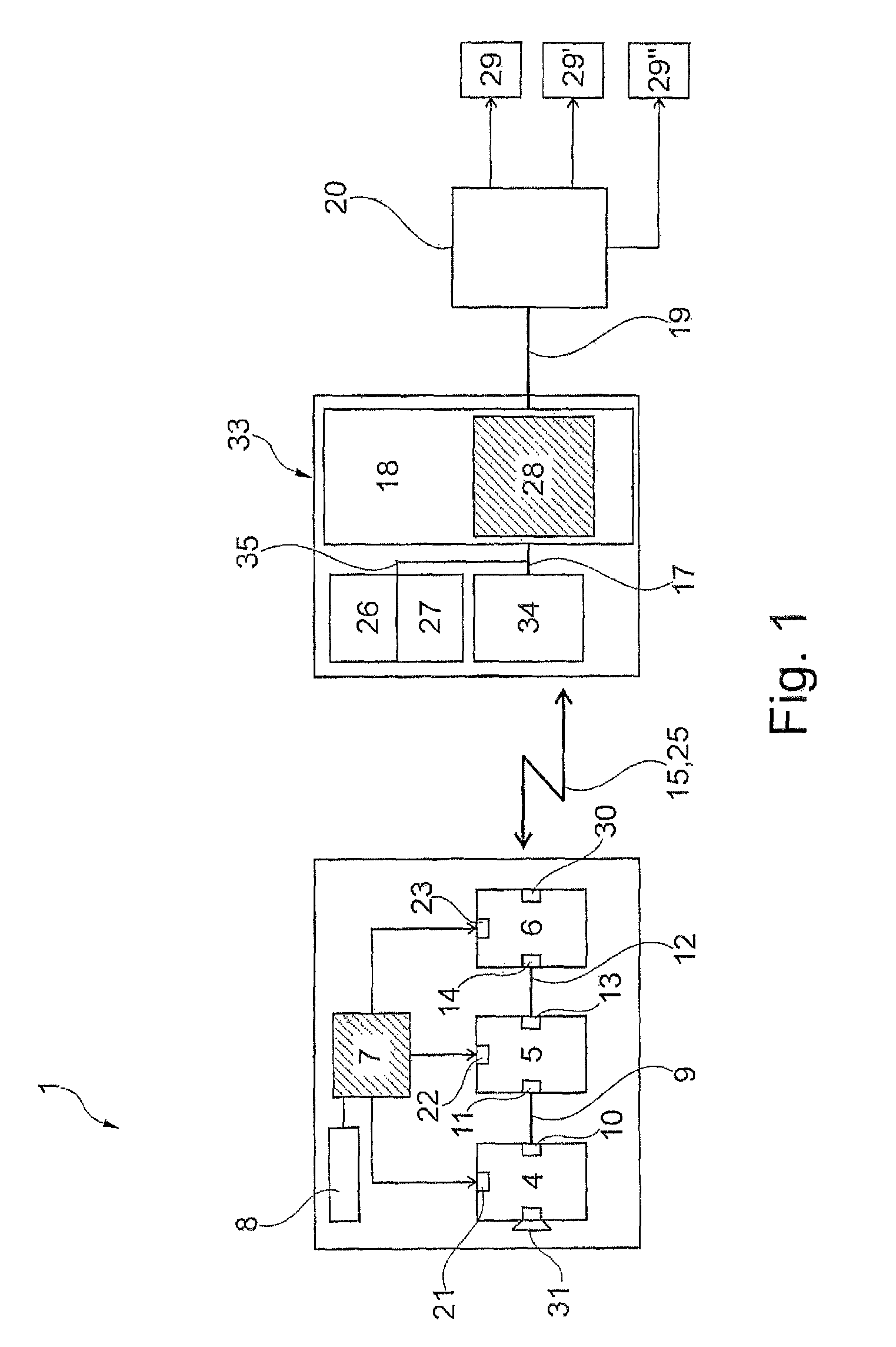

Described is a sensor unit having a measured signal receiver, which registers a measured signal, an A / D converter for digitizing the measured signal, a transceiver device for wireless data communication to an environmental device, and a processor. The processor is a control processor for activating the measured signal receiver, the A / D converter, and the transceiver device. The digitized measured signal is transmitted directly via the transceiver device to the environmental device, without the complex and performance-intensive and therefore costly analysis occurring in the sensor unit.

Owner:VEGA GRIESHABER GMBH & CO

Method and apparatus for optimization of wireless multipoint electromagnetic communication networks

InactiveUS20040095907A1Improve signal qualityReduce interference energyPower managementSpatial transmit diversityGlobal optimizationDiversity scheme

Exploiting the substantive reciprocity of internode channel responses through dynamic, adaptive modification of receive and transmit weights, enables locally enabled global optimization of a multipoint, wireless electromagnetic communications network of communication nodes. Each diversity-channel-capable node uses computationally efficient exploitation of pilot tone data and diversity-adaptive signal processing of the weightings and the signal to further convey optimization and channel information which promote local and thereby network-global efficiency. The preferred embodiment performs complex digital signal manipulation that includes a linear combining and linear distribution of the transmit and receive weights, the generation of piloting signals containing origination and destination node information, as well as interference-avoiding pseudorandom delay timing, and both symbol and multitione encoding, to gain the benefit of substantive orthogonality at the physical level without requiring actual substantive orthogonality at the physical level.

Owner:COMCAST CABLE COMM LLC

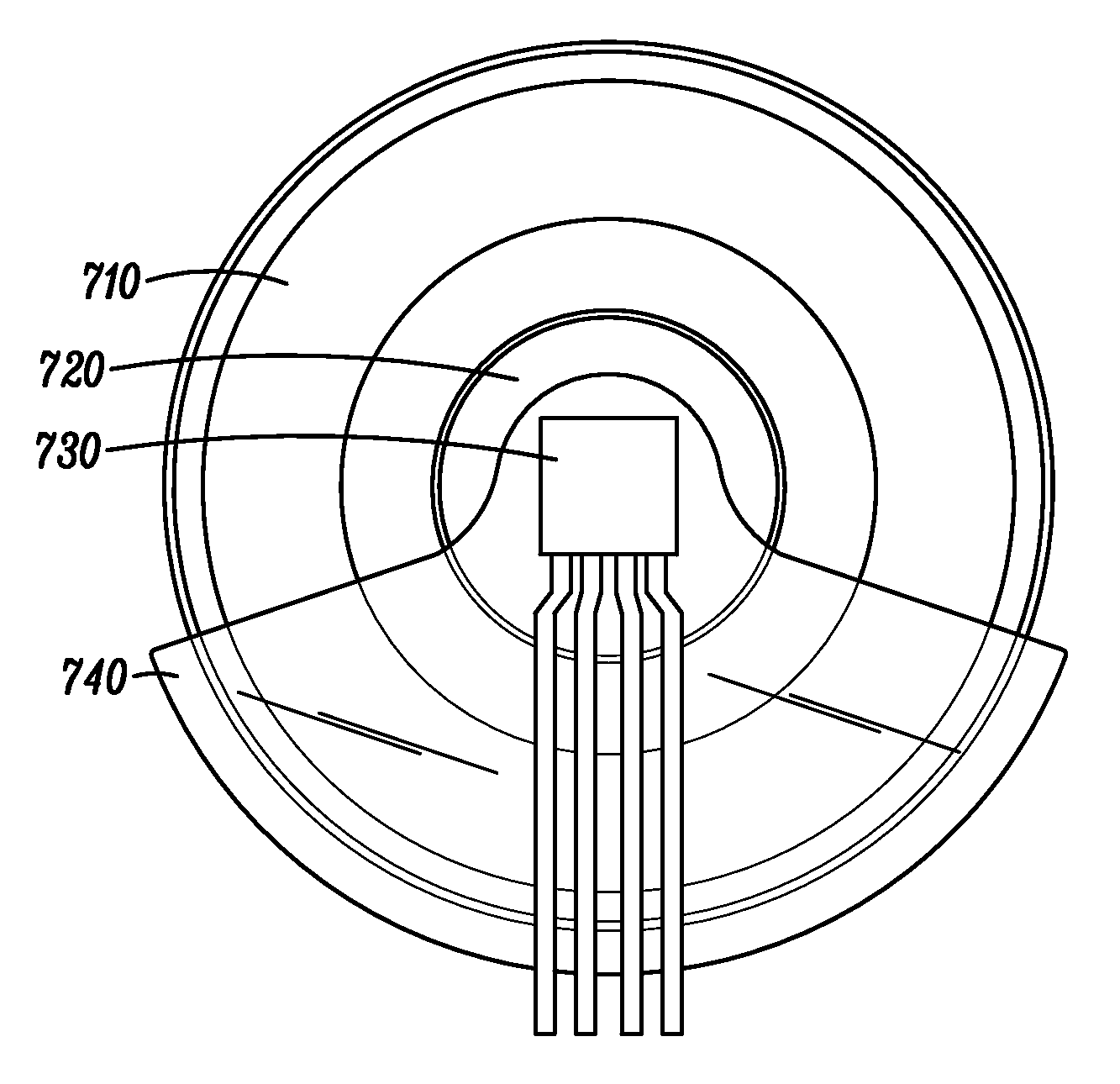

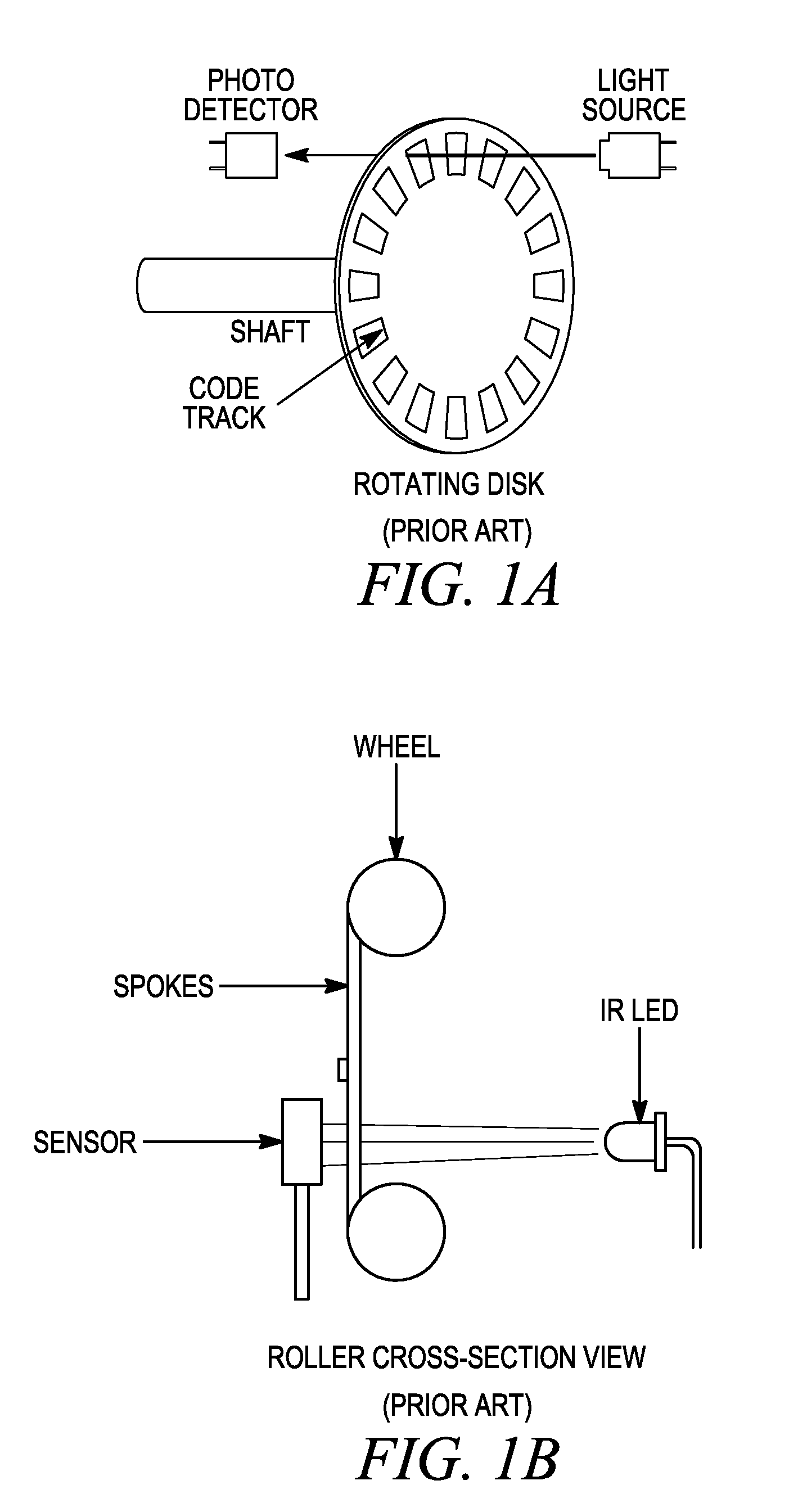

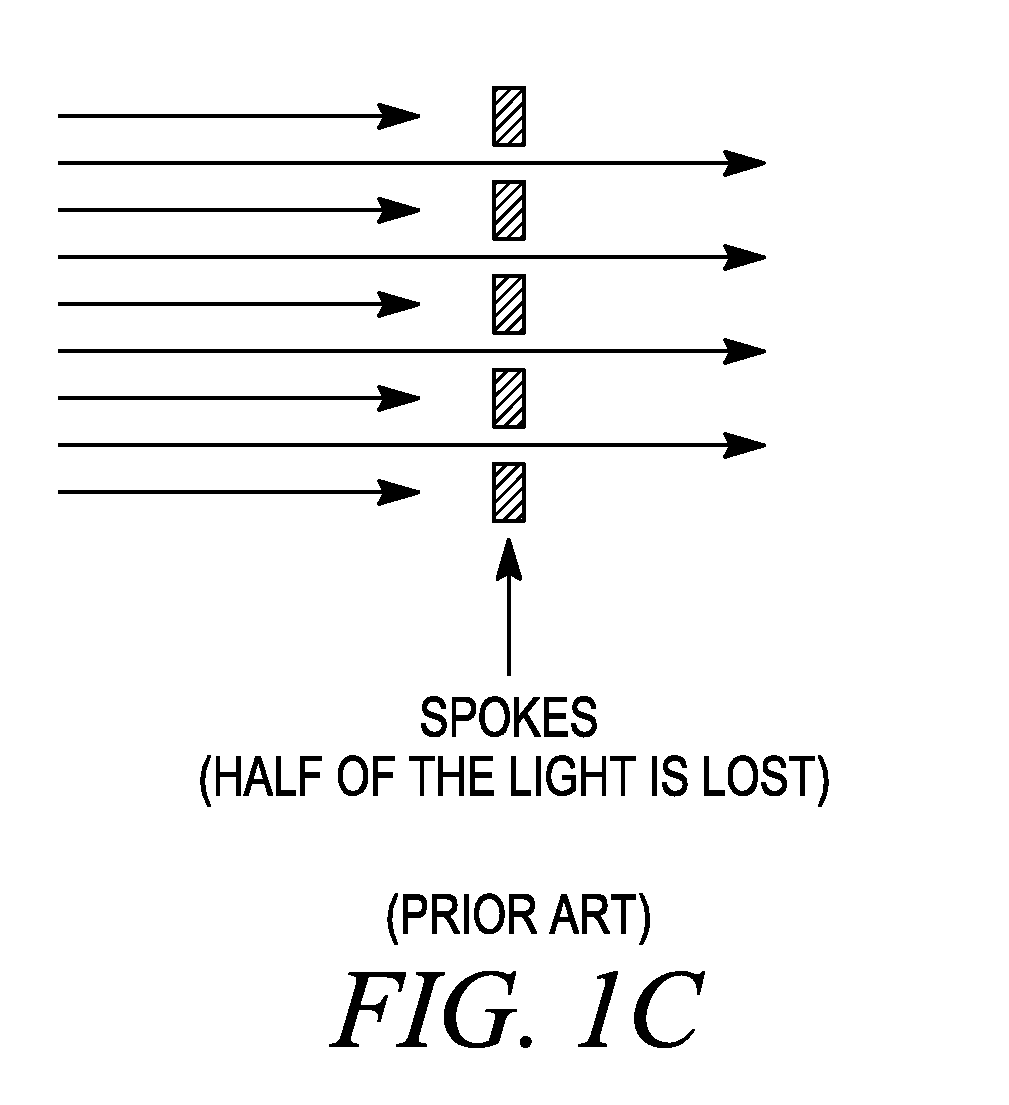

Magnetic rotary system for input devices

InactiveUS20110025311A1Easy to manufactureMagnetization is simpleDigital data processing detailsUsing electrical meansMagnetizationEngineering

Embodiments of the present invention include a roller for an input device, where the roller's absolute angular position is measured by a magnetic encoder. A magnet is attached to the roller, possibly inside the roller so as to make the embodiment more compact. In one embodiment, the magnetization is simple and low cost. Further, tight tolerances are not required, and such a system is easy to manufacture. In one embodiment, the sensor is covered by any non-ferromagnetic material, to protect it from foreign particles, and to reduce ESD. In one embodiment, the wheel consumes much less power than conventional wheels in input devices. In one embodiment, the tilting of the wheel is measured using the same sensor that is used for measuring the rotation of the wheel. In one embodiment, a ratcheting feel provided to the user when rotating the wheel is synchronized with the rotation signal.

Owner:LOGITECH EURO SA

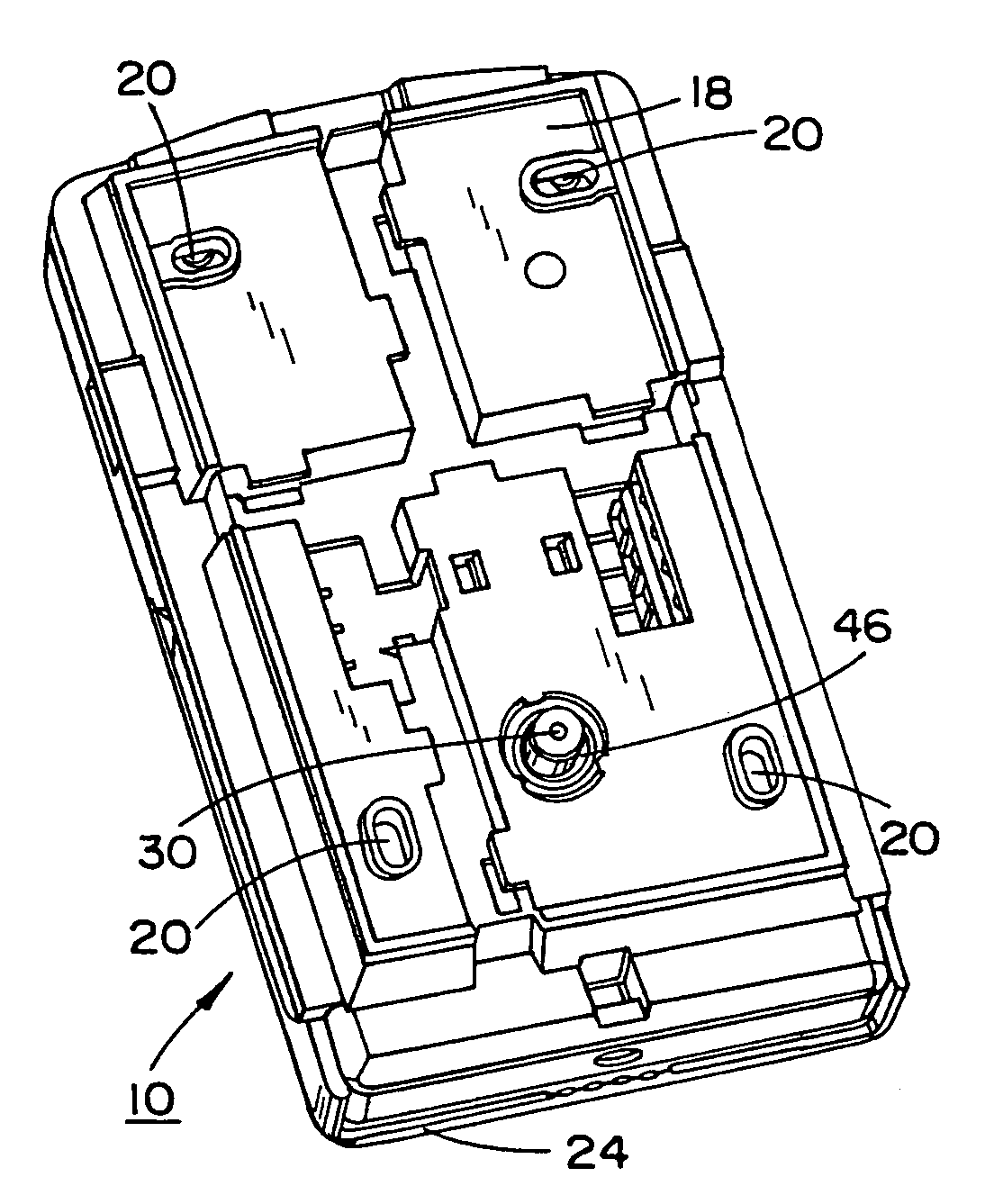

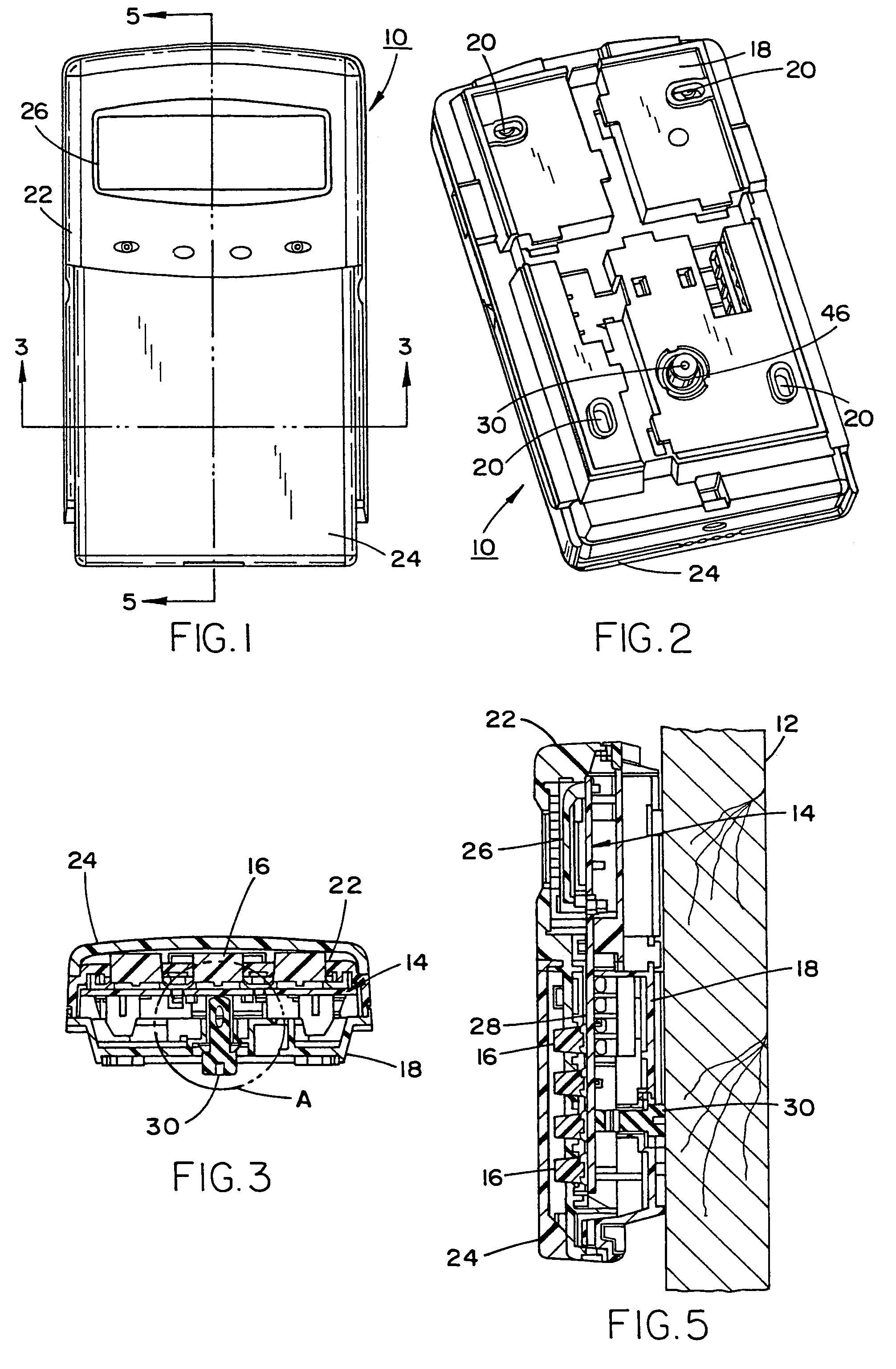

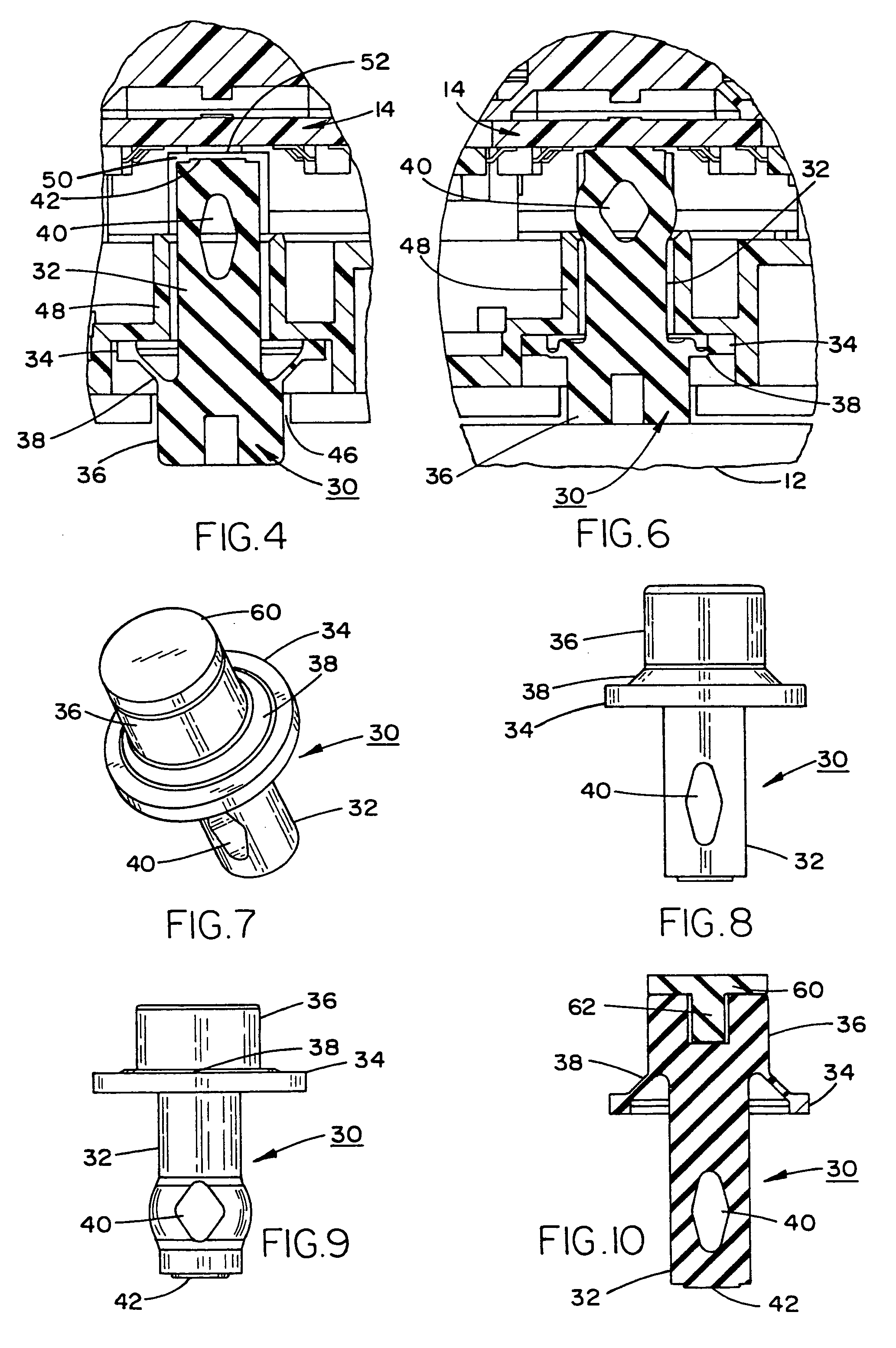

Conductive tamper switch for security devices

InactiveUS7388484B2Highly efficient and reliable in operationCost-effectively mountedInternal/peripheral component protectionRadio/inductive link selection arrangementsMonitoring siteFire alarm system

A tamper switch mechanism utilized in security interface devices such as keypad installations to render them tamper-resistant, wherein the devices are generally connected to burglar alarm and fire alarm systems. More particularly, provided is a conductive tamper switch which is installed in a security interface device, such as a keypad, which upon an unauthorized attempt to dislodge the device or keypad from a wall or surface on which it is mounted, will trigger an alarm or generate a warning signal at a monitoring site indicative that an effort at tampering with the device has been effected. Also disclosed is a method of providing the tamper switch mechanism in a security interface device, such as a keypad installation.

Owner:HONEYWELL INT INC

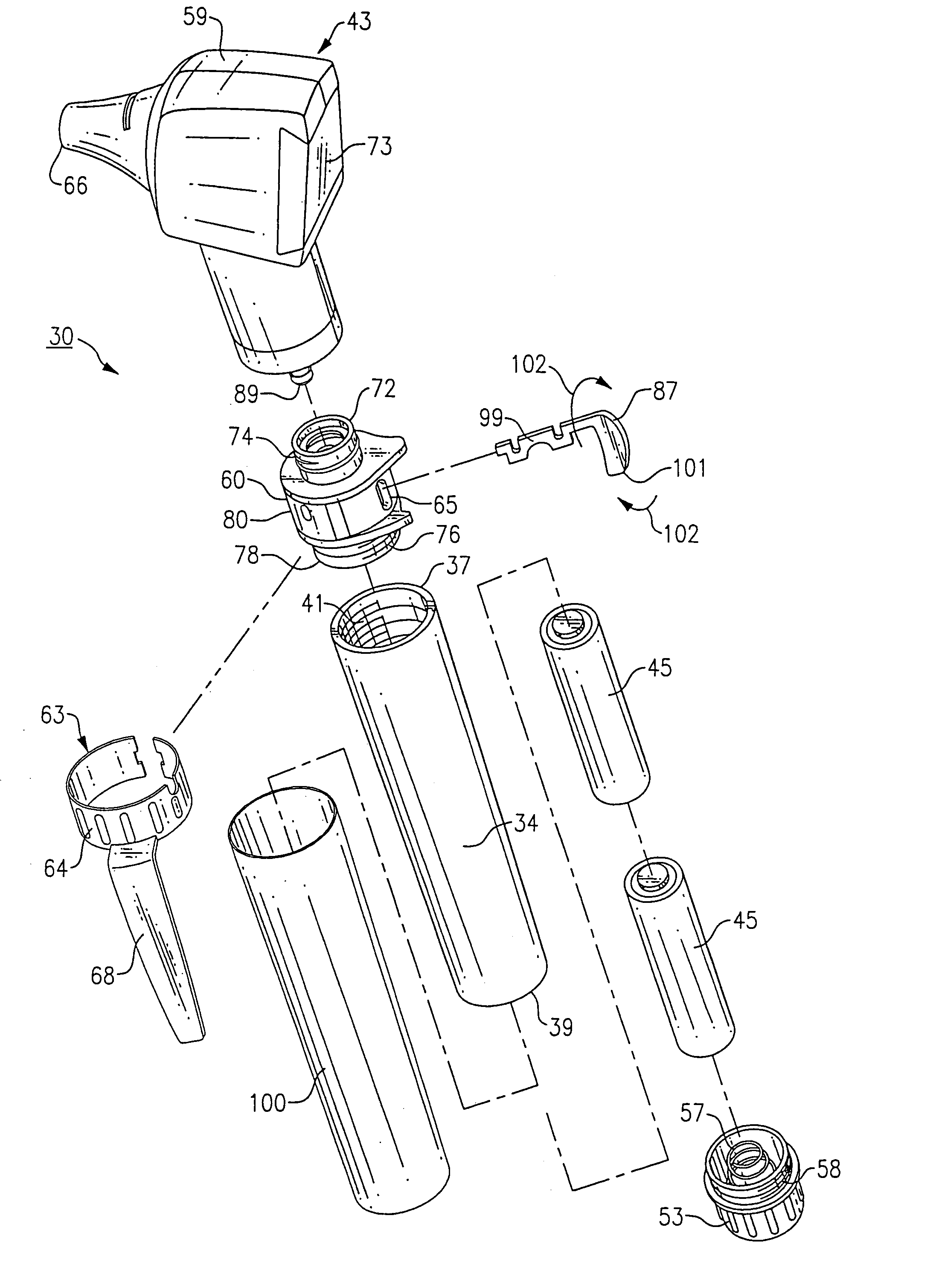

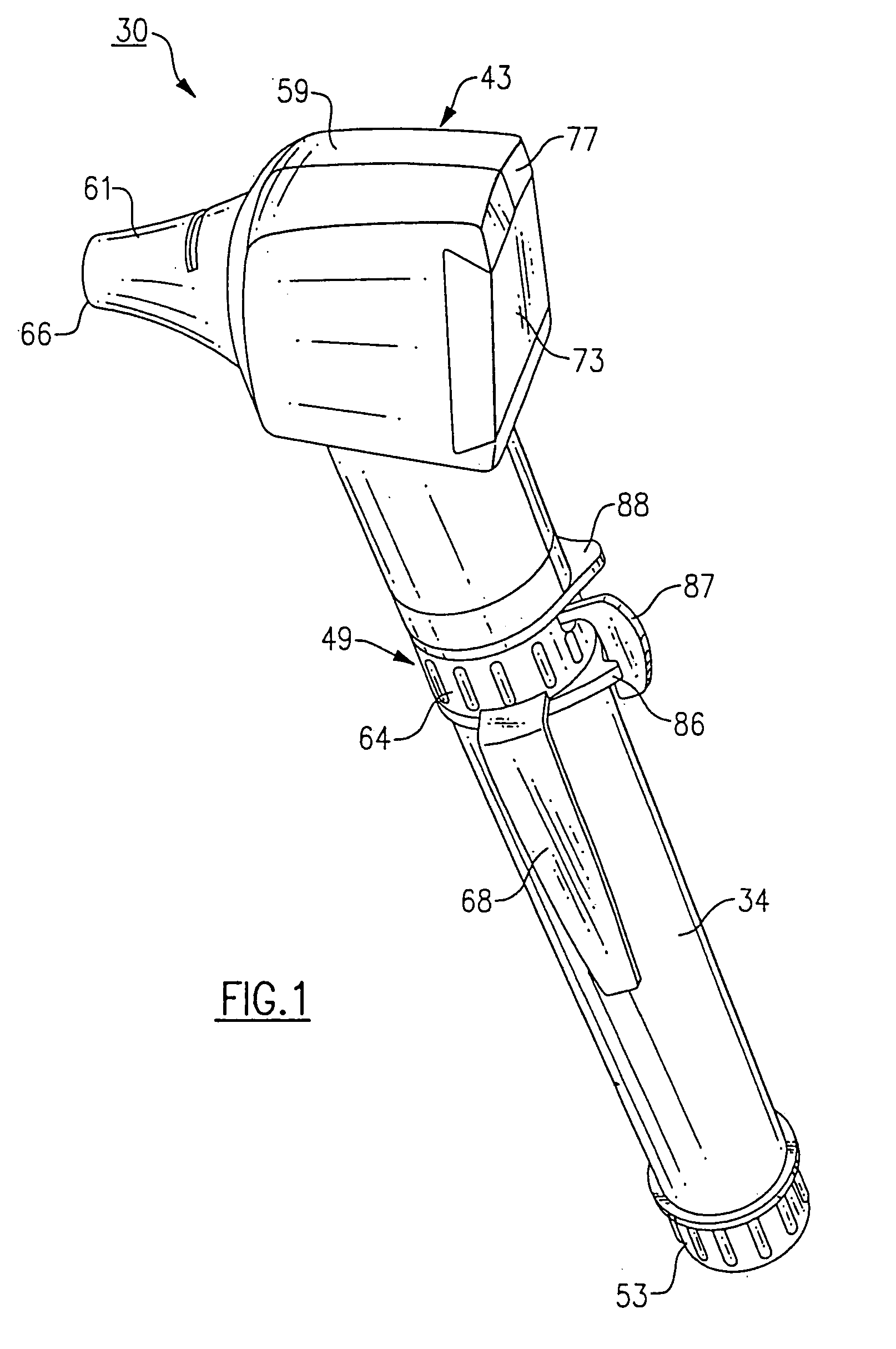

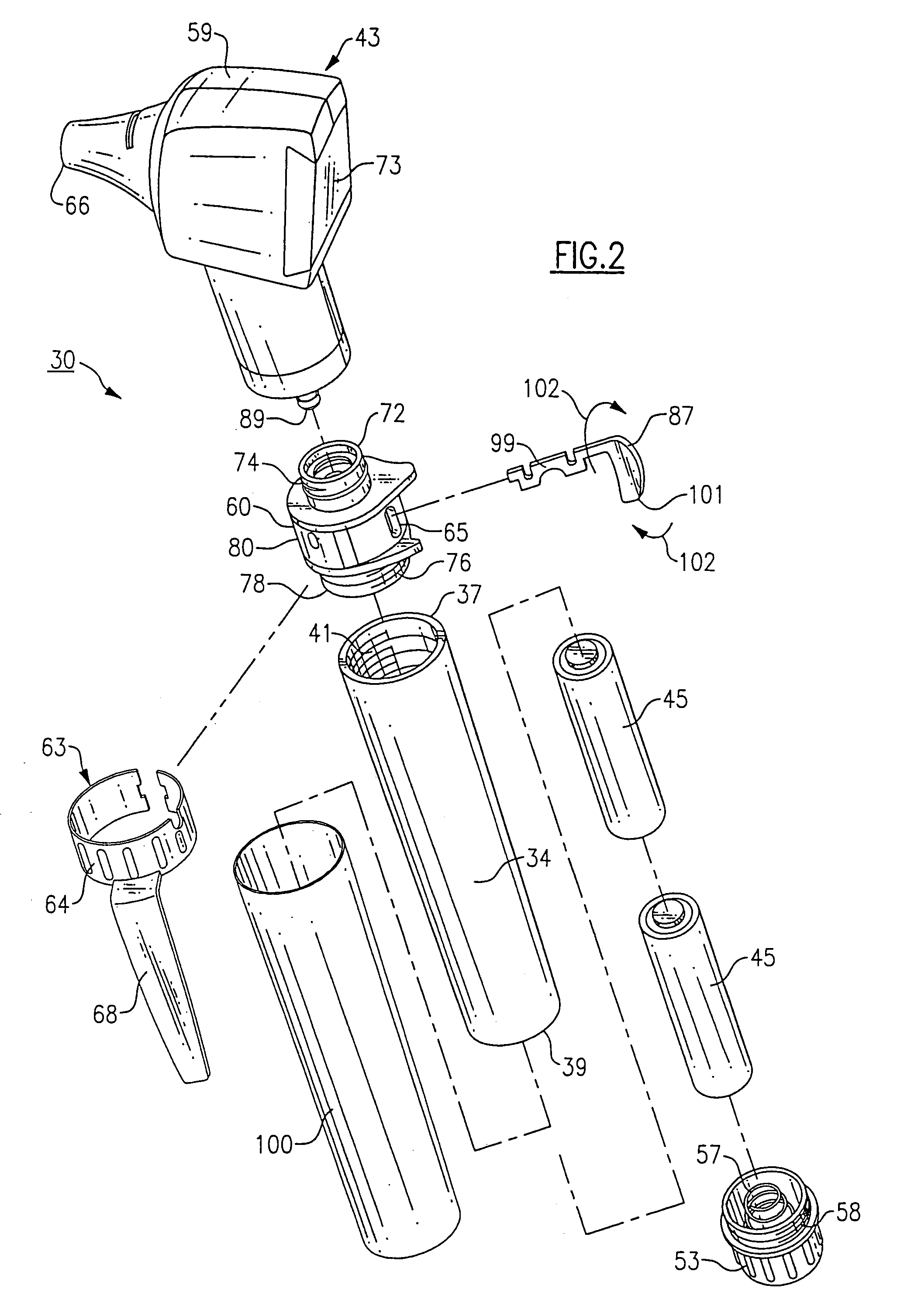

Medical diagnostic instrument

InactiveUS7029439B2Easy to manufactureImprove versatilityBronchoscopesLaryngoscopesElectricityElectrical connection

A medical diagnostic instrument includes a housing containing at least one battery and a light source, such as a lamp, for illuminating a medical target. A switch includes a movable member that selectively moves at least one of the battery and the lamp into and out of electrical connection with the other. The instrument is preferably fabricated from a diecast or an extrusion process wherein a thin plastic sleeve member having text and / or graphic materials can be shrink fitted onto an extruded handle.

Owner:WELCH ALLYN INC

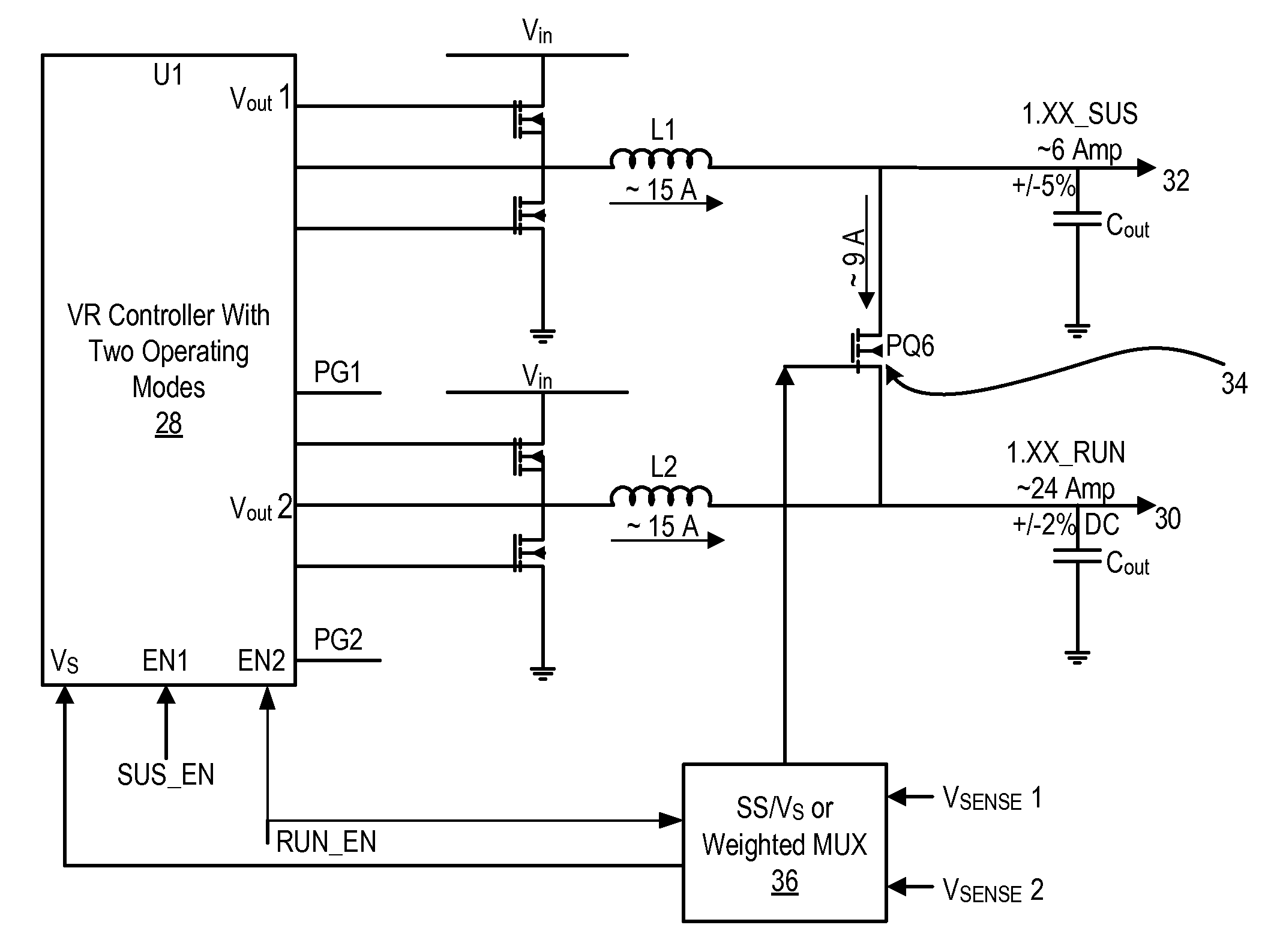

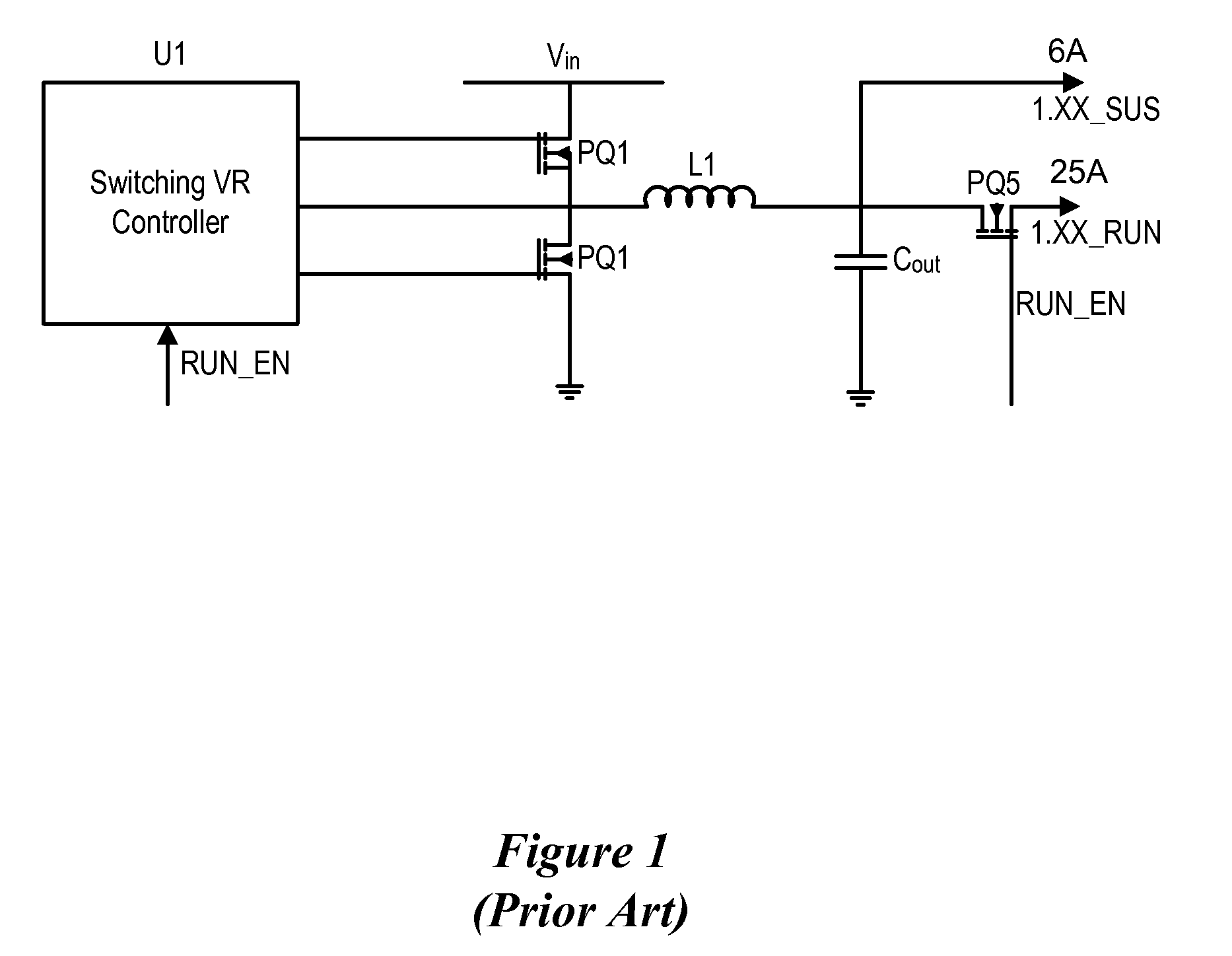

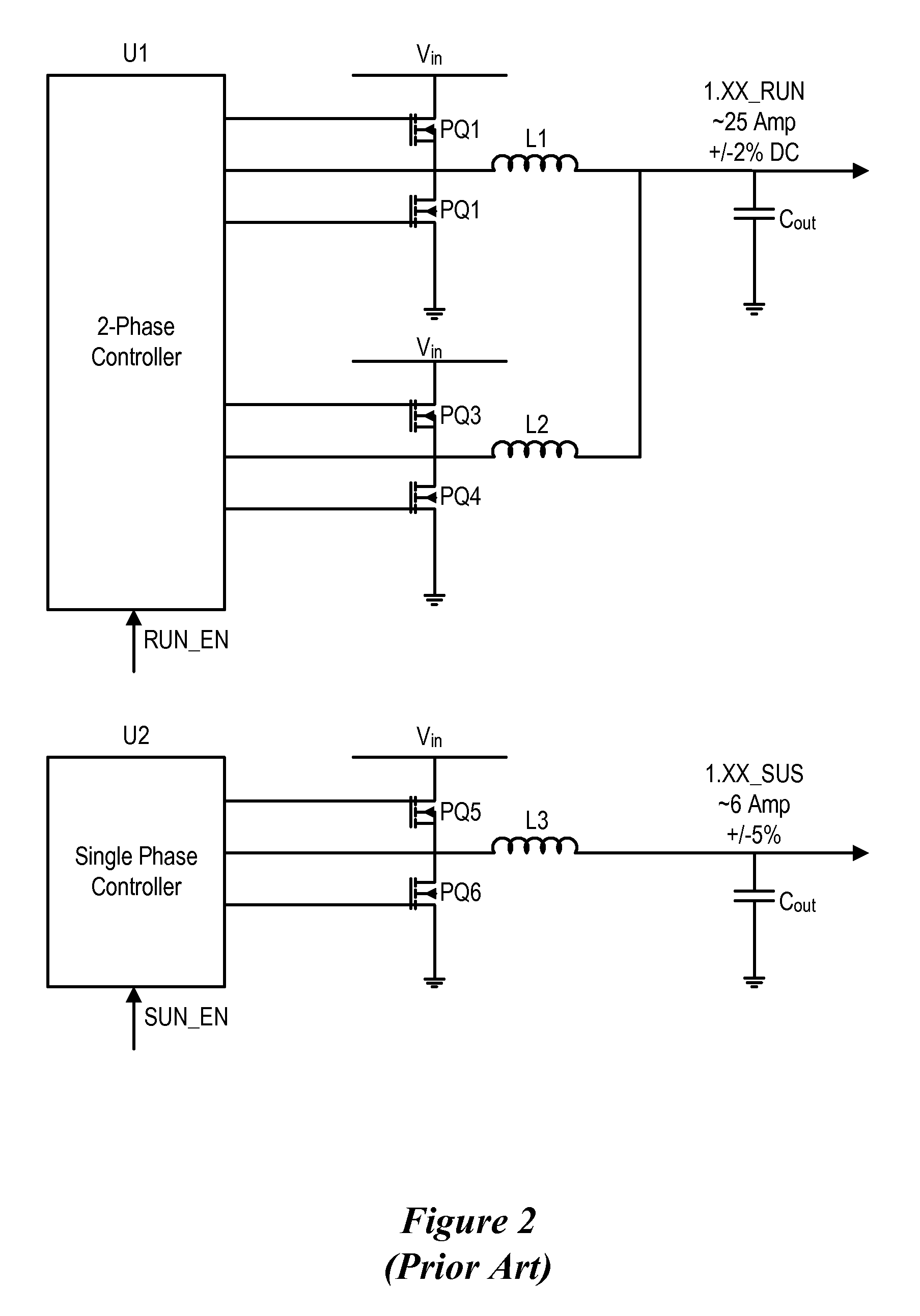

System and method for powering an information handling system in multiple power states

ActiveUS8063619B2Reduce disadvantagesReduce problemsElectric signal transmission systemsDc network circuit arrangementsMOSFETVoltage regulation

Power is supplied to an information handling system chipset with a single voltage regulator having dual phases. A first phase of the voltage regulator provides power to a low power state power rail in an independent mode to support a low power state, such as a suspend or hibernate state. A second phase of the voltage regulator provides power to a run power state power rail in combination with the first phase by activation of a switch, such as a MOSFET load switch, that connects the low power state power rail and the run power state power rail. Voltage sensed from both power rails is applied to control voltage output so that the run power state power rail is maintained within more precise constraints than the low power state power rail.

Owner:DELL PROD LP

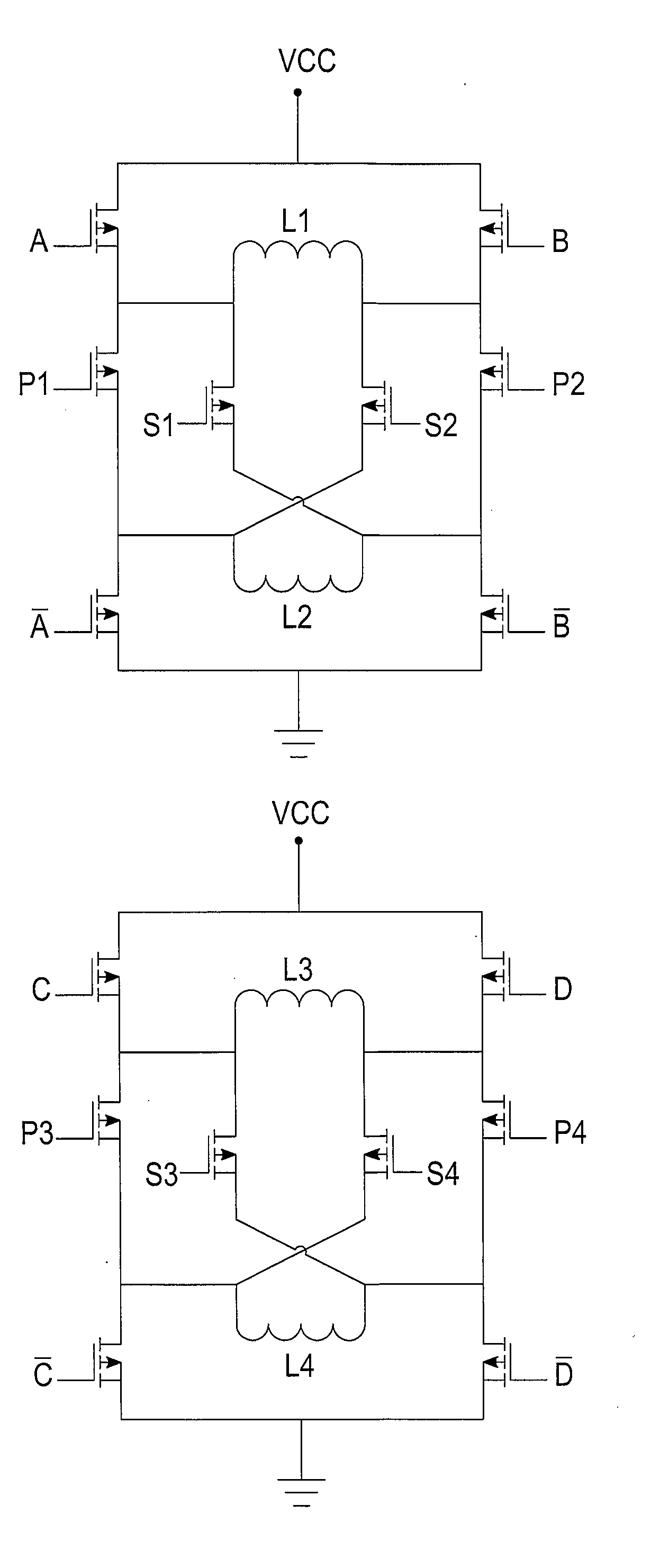

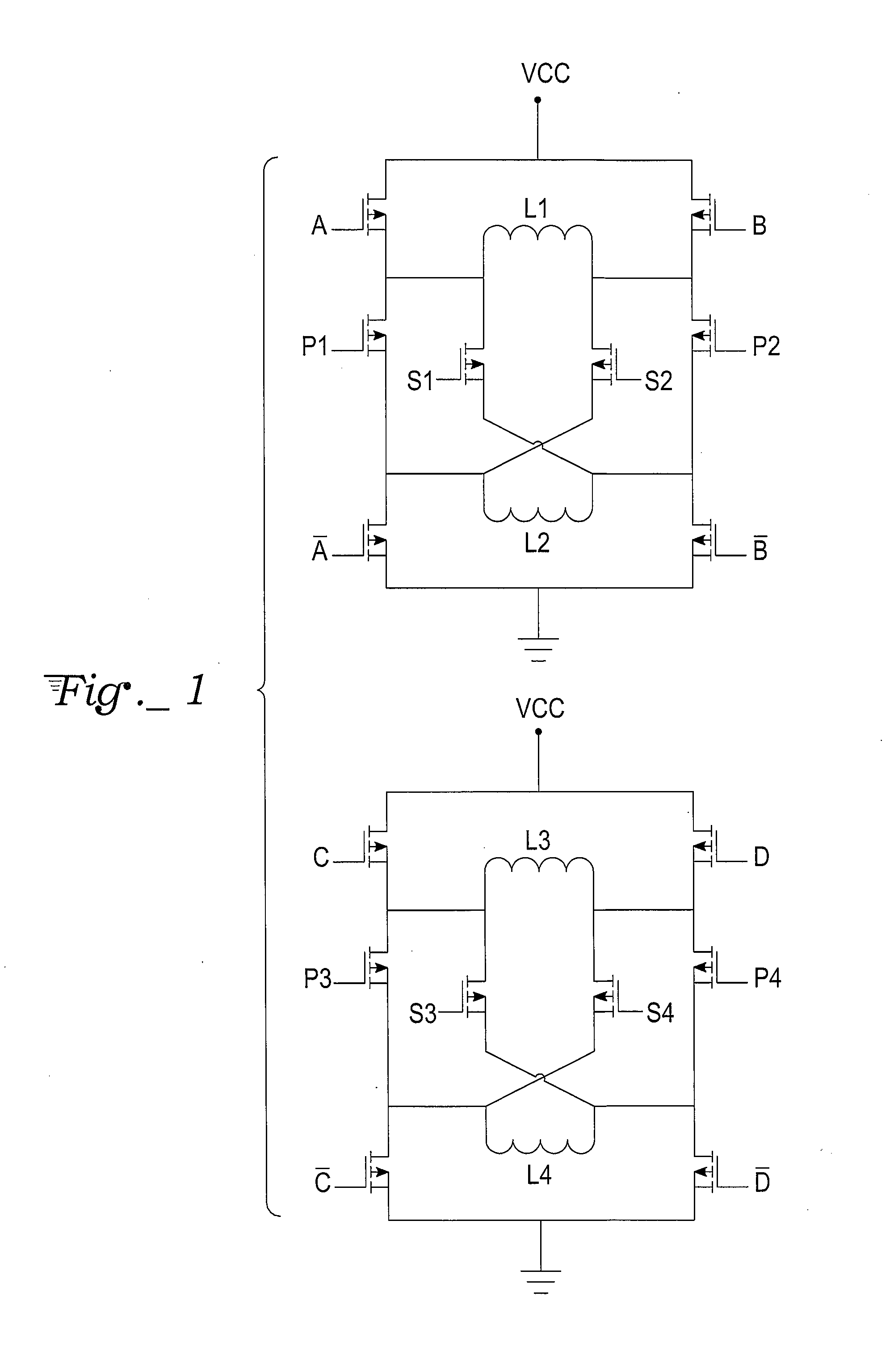

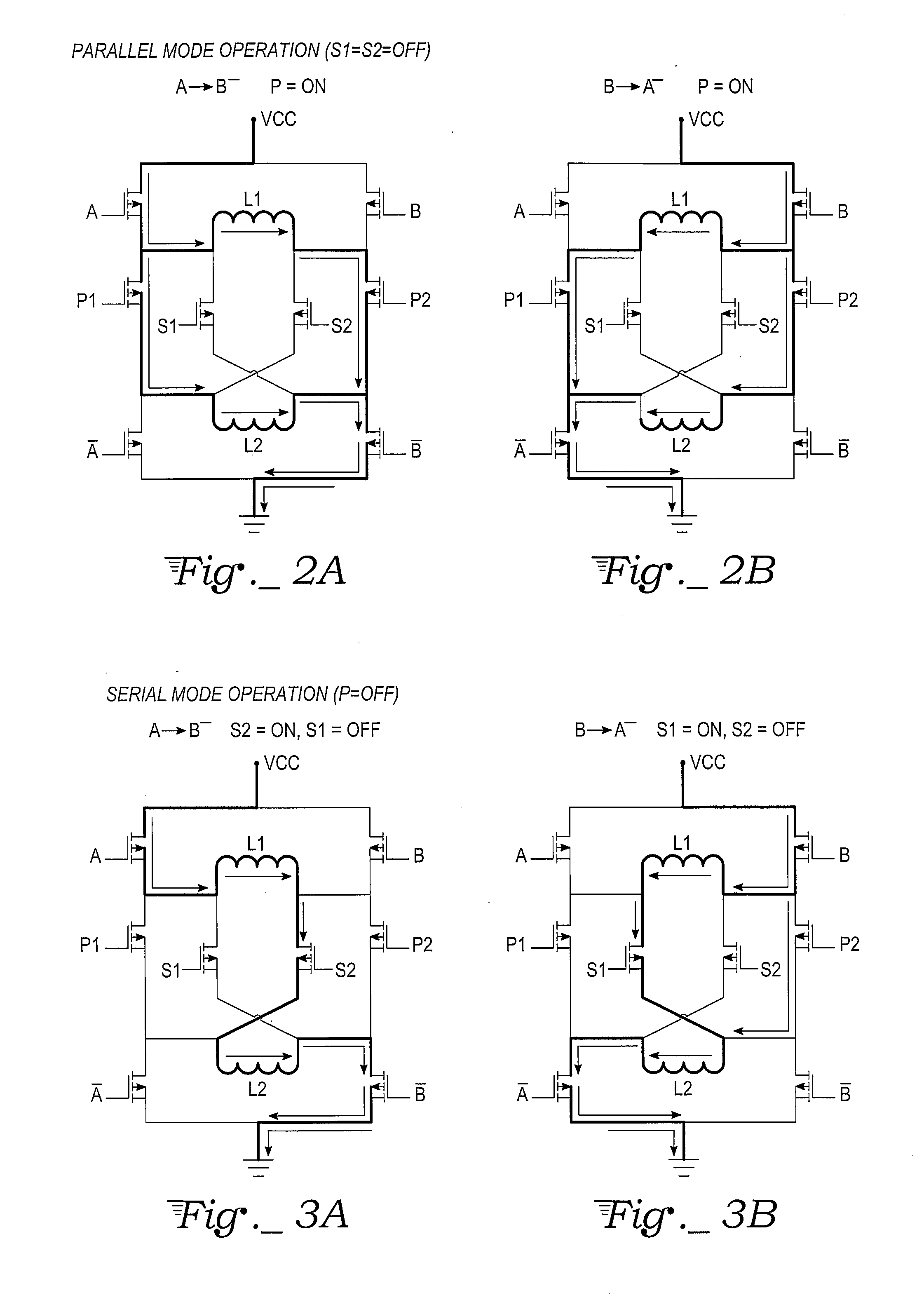

H-bridge drive circuit for step motor control

InactiveUS20110241597A1Improve stand-alone performanceEasy to implementDynamo-electric converter controlMotor speedDriving current

A drive circuit for step motors with bifilar windings is provided in which both parallel and series winding configurations for the stator coils are selectable by a motor controller based on the motor speed. For low speeds a series configuration is selected, while for higher speeds a parallel configuration is selected. Dynamic torque is optimized by the selection for more efficient motor operation with less drive current.

Owner:LIN ENG INC

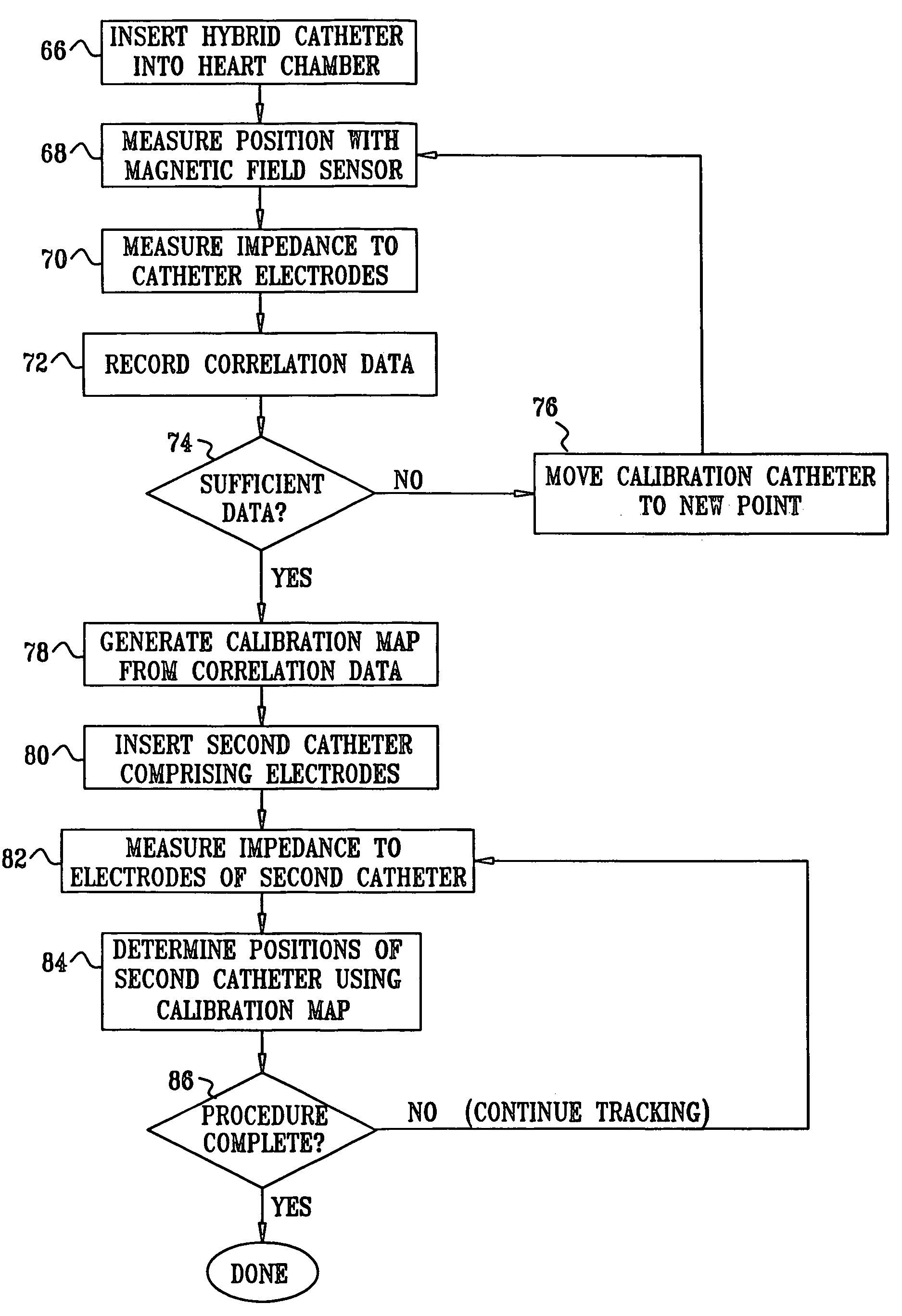

Hybrid magnetic-based and impedance-based position sensing

ActiveUS7536218B2Improve accuracyLow costCatheterDiagnostic recording/measuringTransducerBody surface

Owner:BIOSENSE WEBSTER INC

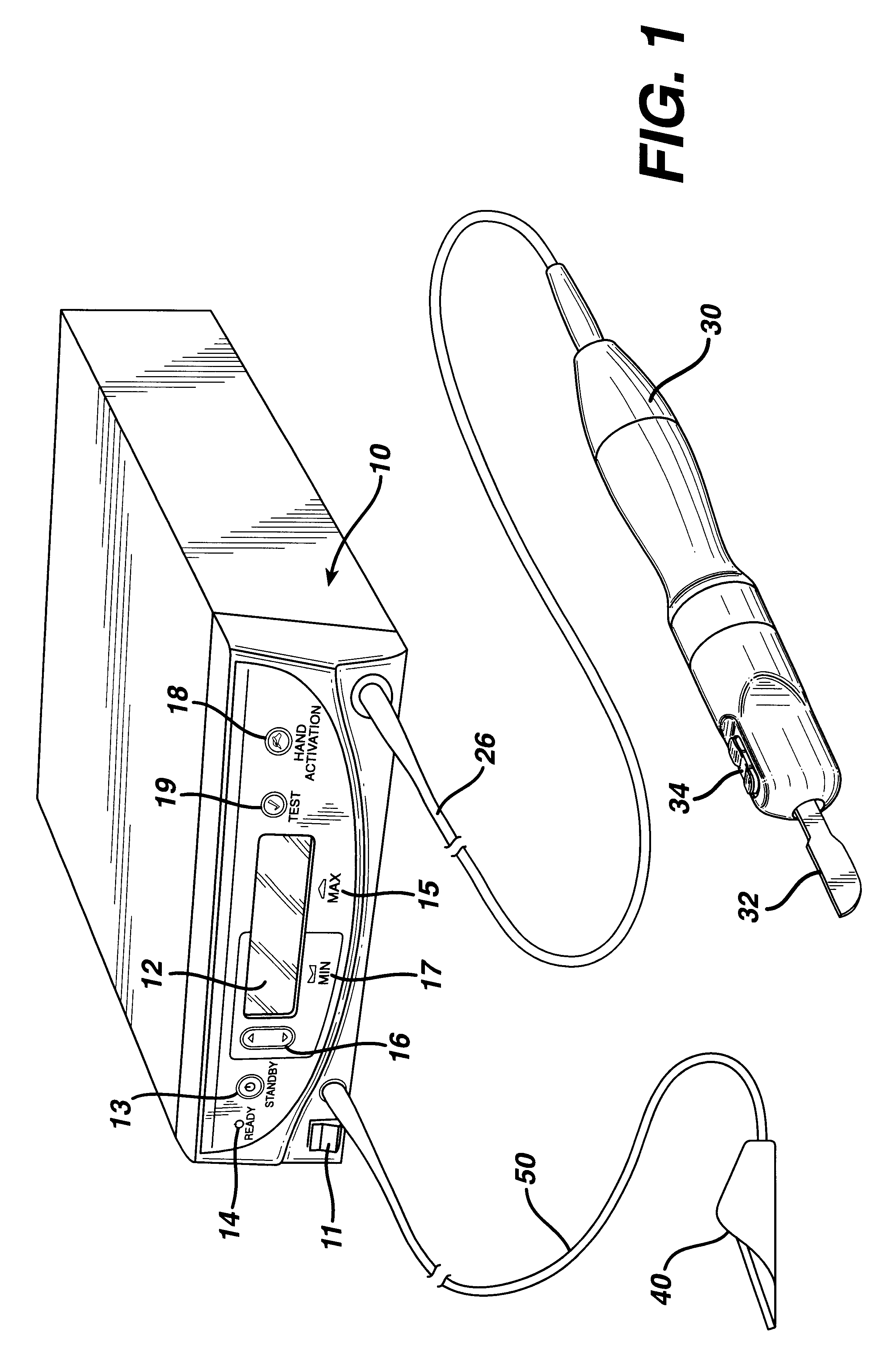

Method for detecting transverse mode vibrations in an ultrasonic hand piece/blade

InactiveUS6588277B2Low costRecuperation increasedVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesResonanceEngineering

A method for detecting transverse mode vibrations in an ultrasonic hand piece / blade for determining the existence of unwanted vibration in the hand piece / blade. A tracking filter centered at the drive frequency of the generator, is used to monitor the drive frequency of the ultrasonic generator and attenuate the drive signal when it exceeds a predetermined level. The tracking filter has a wide pass band. Alternatively, a tracking filter having a pass band which is divided into several regions is used to avoid other longitudinal resonances, such as a resonance at a second harmonic, or other spectral features that would otherwise detract from the tracking accuracy of the filter.

Owner:ETHICON ENDO SURGERY INC

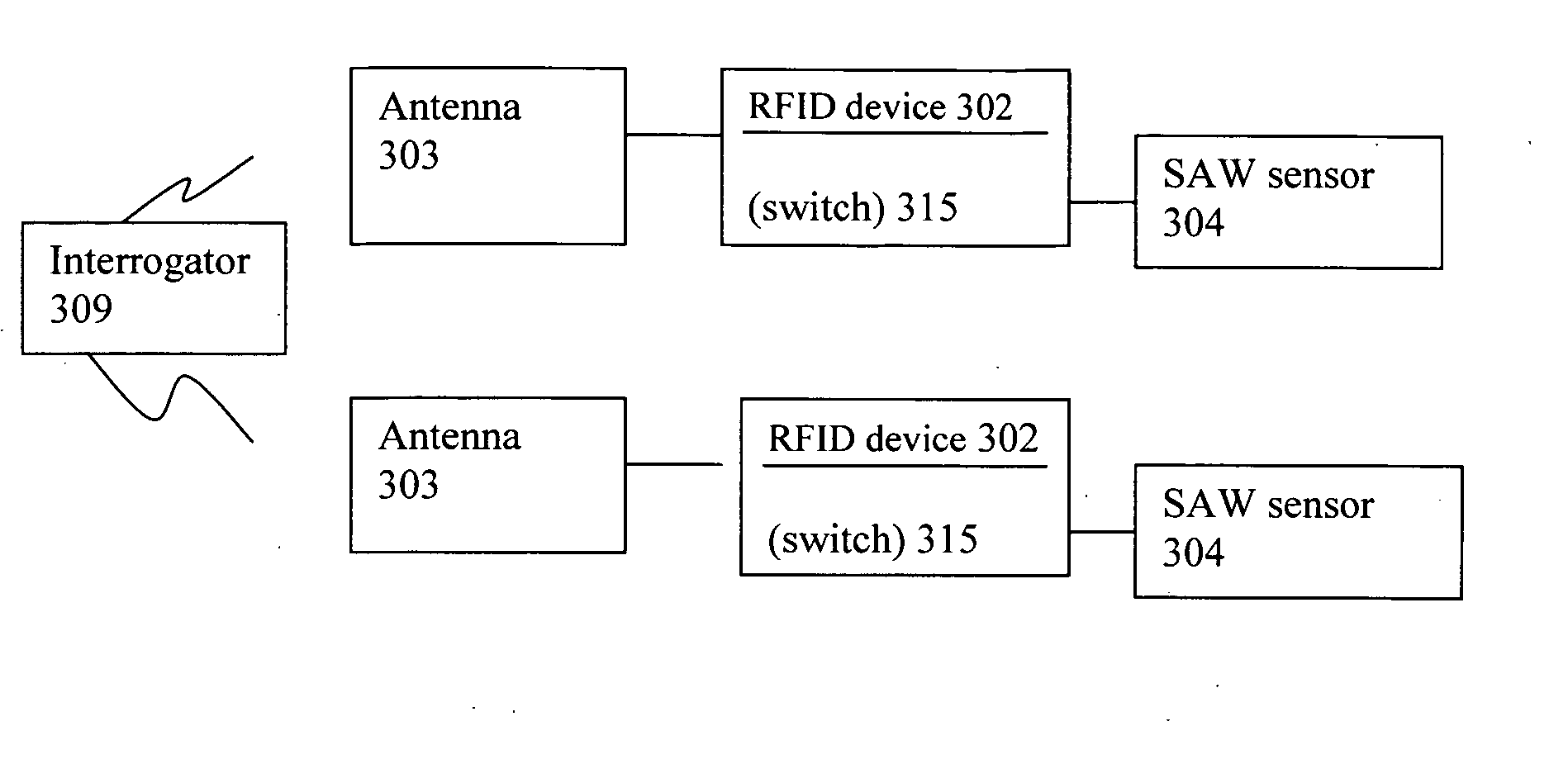

Sensor assemblies

InactiveUS20060025897A1Low costPrecise positioningVehicle testingRegistering/indicating working of vehiclesRadio frequency signalPhysical quantity

Sensor assembly capable of obtaining and providing a measurement of a physical quantity, e.g., measurement of temperature and / or pressure of a vehicular tire, includes an antenna capable of receiving a radio frequency signal, a radio frequency identification (RFID) device coupled to the antenna, a sensor coupled to the RFID device arranged to generate a measurement of the physical quantity or quantities, and a switch coupled to the RFID device and arranged to connect or disconnect the sensor from a circuit with the antenna dependent on whether the antenna receives a particular signal associated with the RFID device. When the antenna receives the particular signal associated with the RFID device, the RFID device causes the switch to close and connect the sensor in the circuit with the antenna to enable the measurement generated by the sensor to be directed to and transmitted by the antenna.

Owner:AMERICAN VEHICULAR SCI

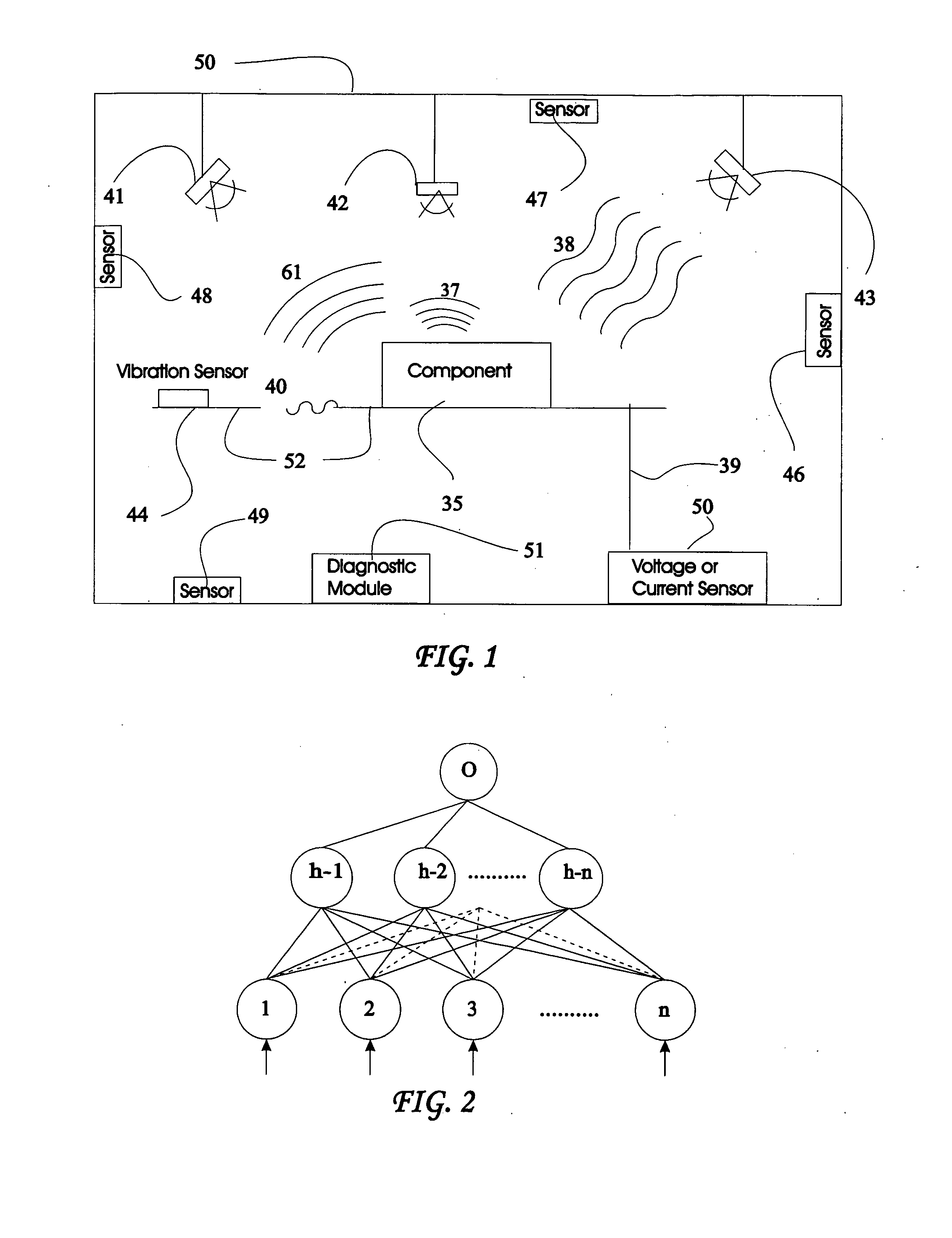

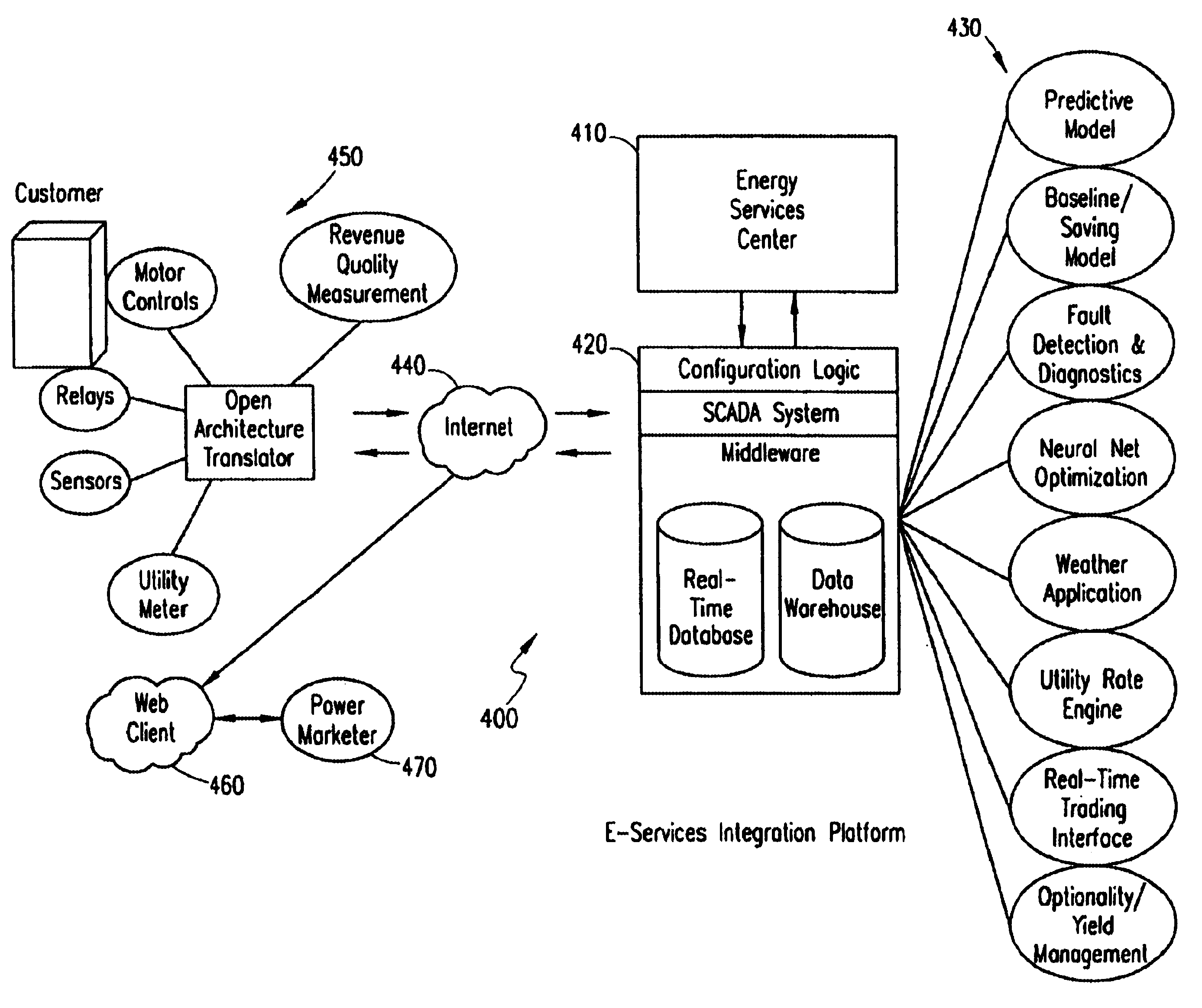

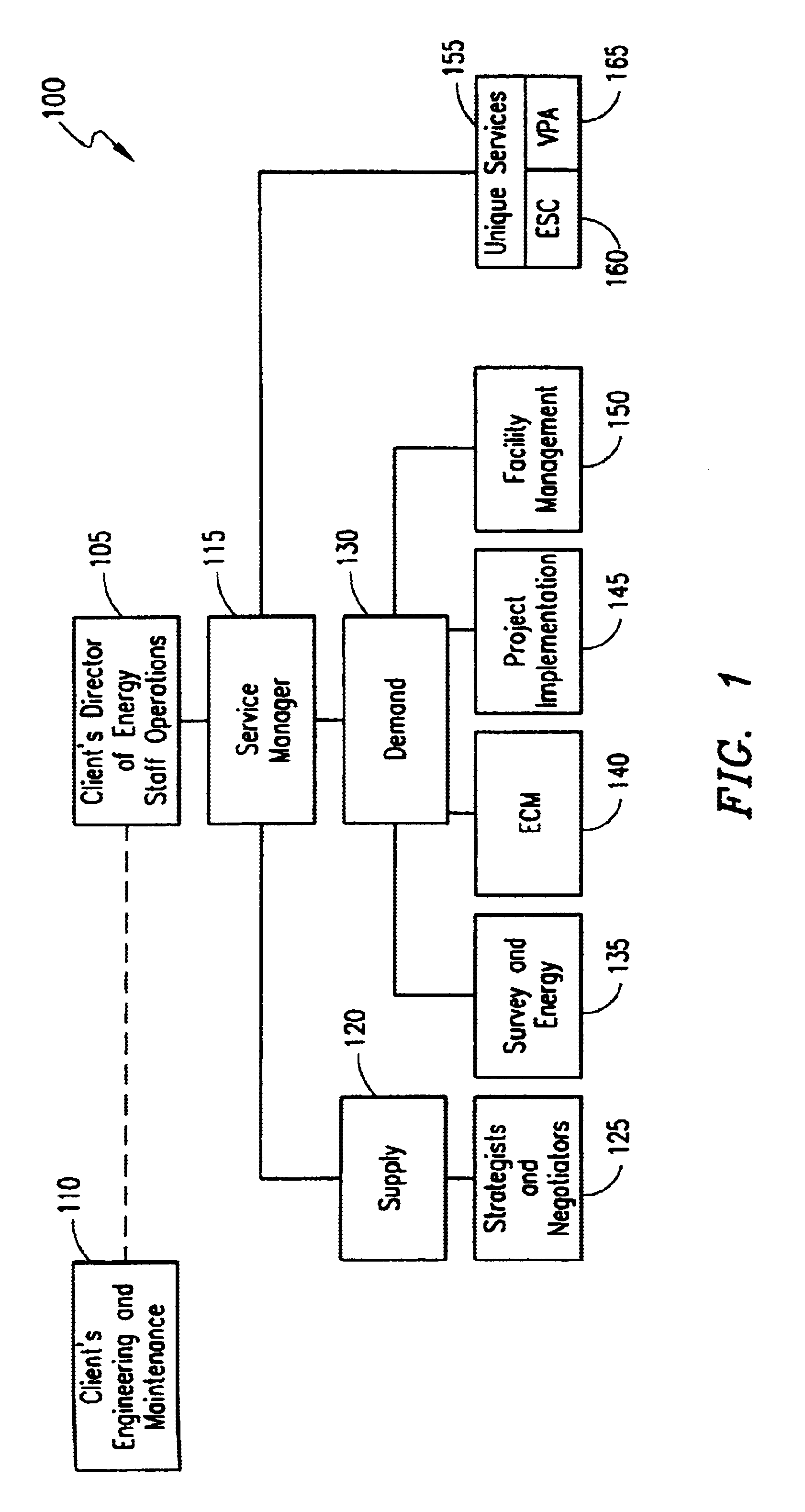

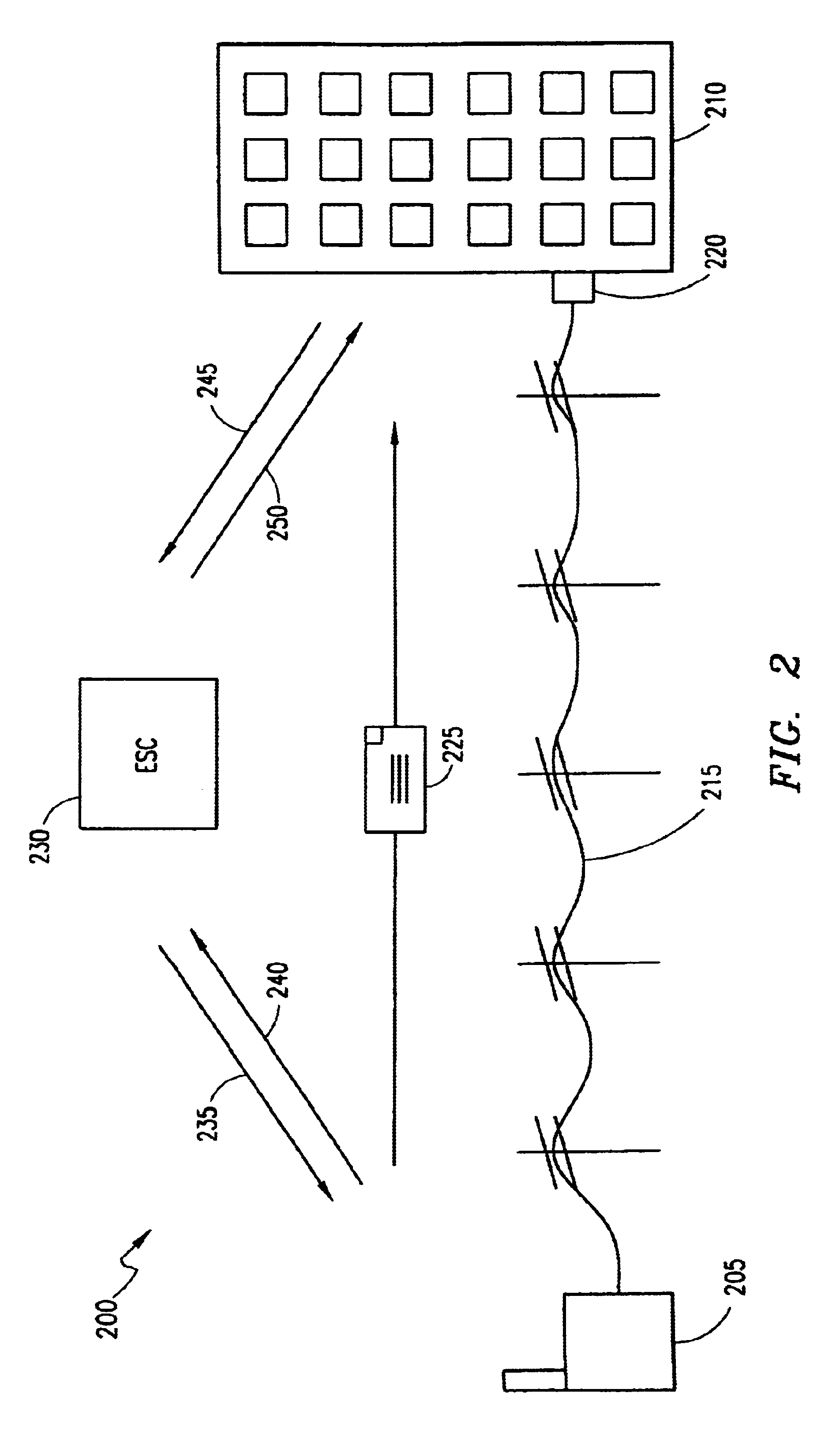

System and method for energy management

InactiveUS6785592B1Economic savingsImprove economyLevel controlSpecial tariff metersConservation energyProcess engineering

A business methodology for optimizing energy procurement energy demand (usage) and energy supply for a facility or complex. After ascertaining a baseline model, energy consumption is monitored and adjusted to reflect dynamic economic factors of operations. With the accumulation of data, contract negotiations with energy suppliers may provide further energy savings. Over time and patterns of usage determined further savings and optimization in energy, equipment, staffing and other operational areas are obtained. Remote access provides efficient monitoring of established systems.

Owner:PEROT SYSTEMS

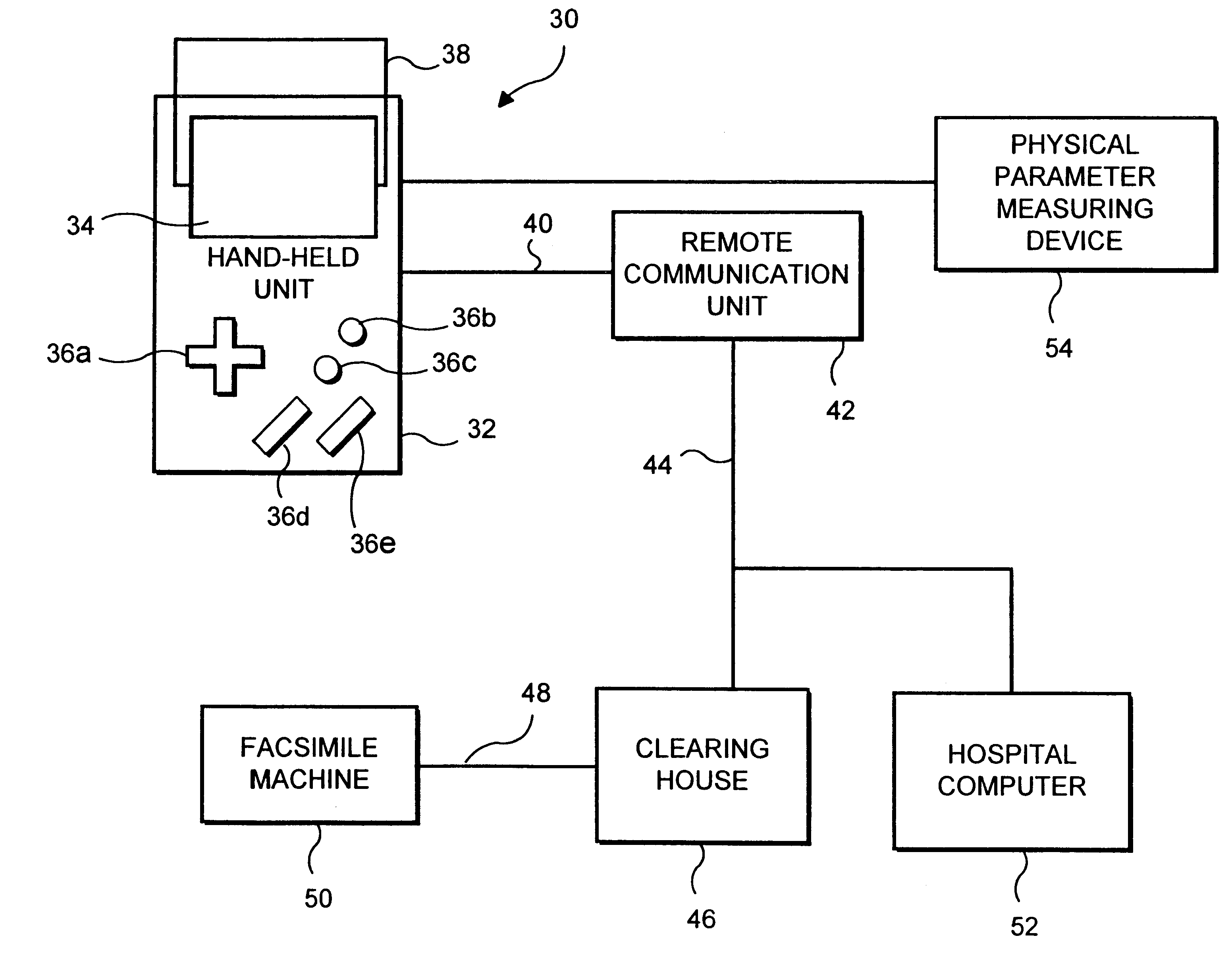

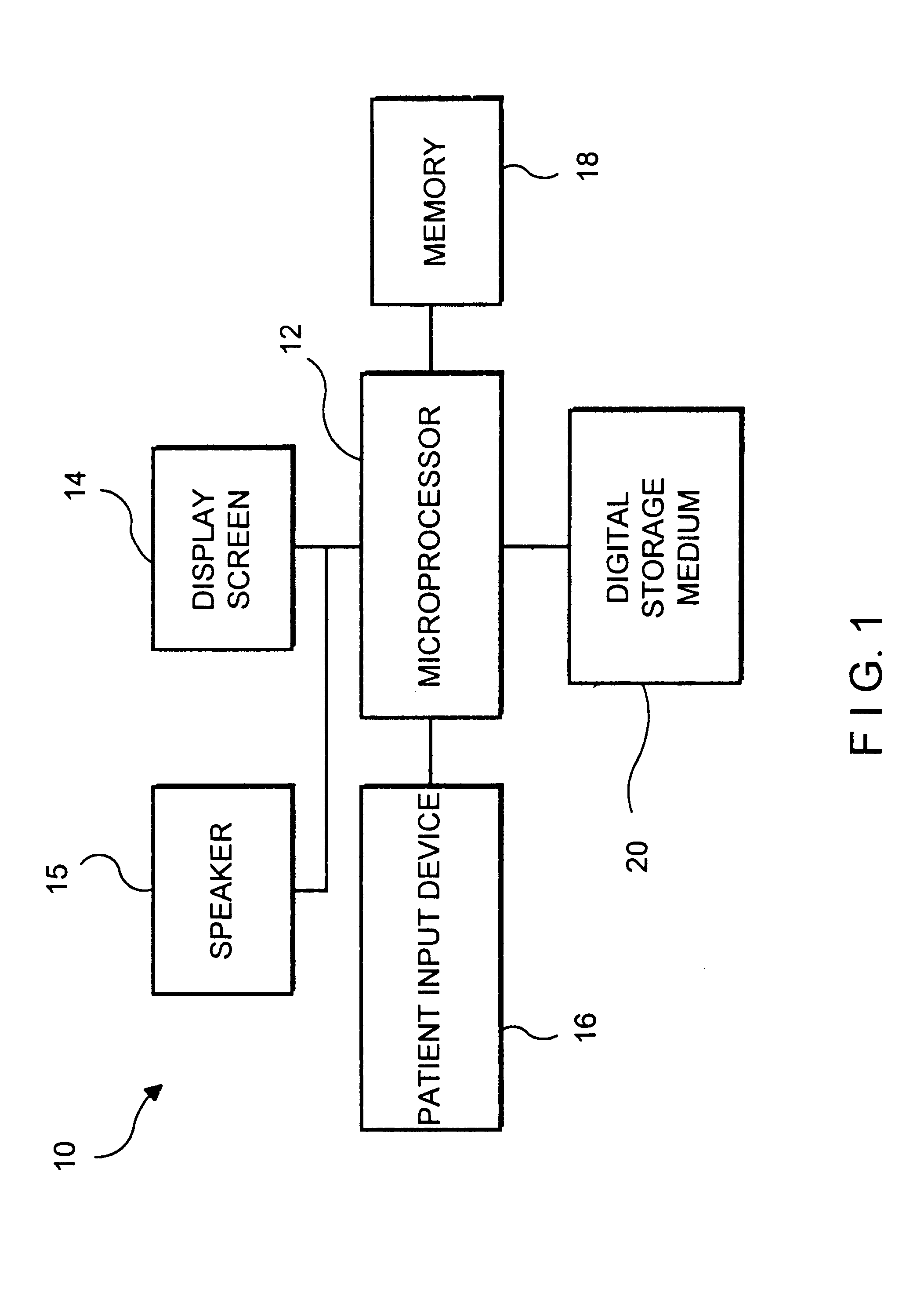

Method for diagnosis and treatment of psychological and emotional conditions using a microprocessor-based virtual reality simulator

Methods and systems for monitoring, diagnosing and / or treating psychological conditions and / or disorders in patients with the aid of computer-based virtual reality simulations. Pursuant to one preferred embodiment, a computer program product is used to control a computer. The program product includes a computer-readable medium, and a controlling mechanism that directs the computer to generate an output signal for controlling a video display device. The video display device is equipped to display representations of three-dimensional images, and the output signal represents a virtual reality simulation directed to diagnosis and / or treatment of a psychological condition and / or disorder.

Owner:HEALTH HERO NETWORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com