Patents

Literature

6658 results about "Motor speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

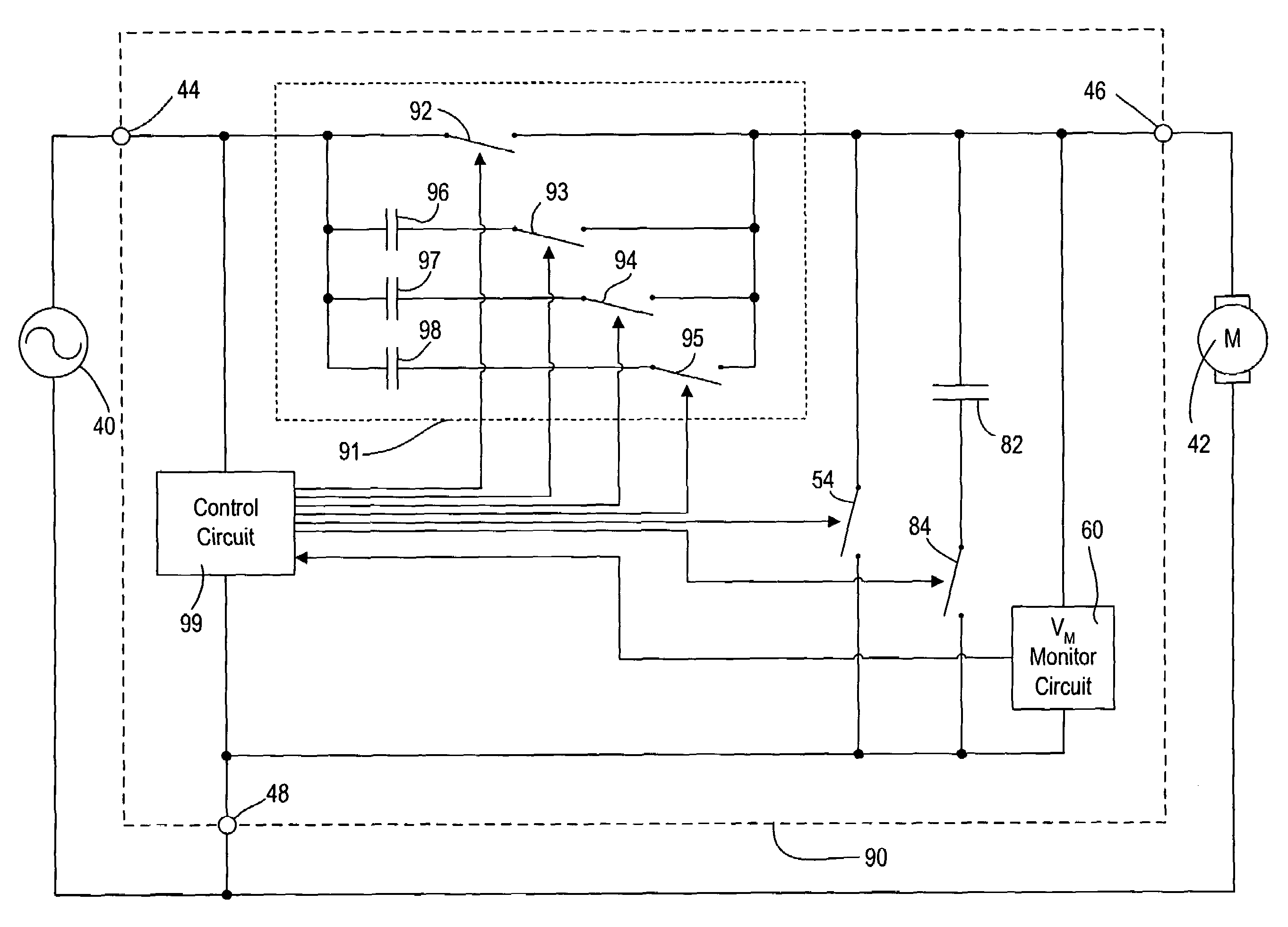

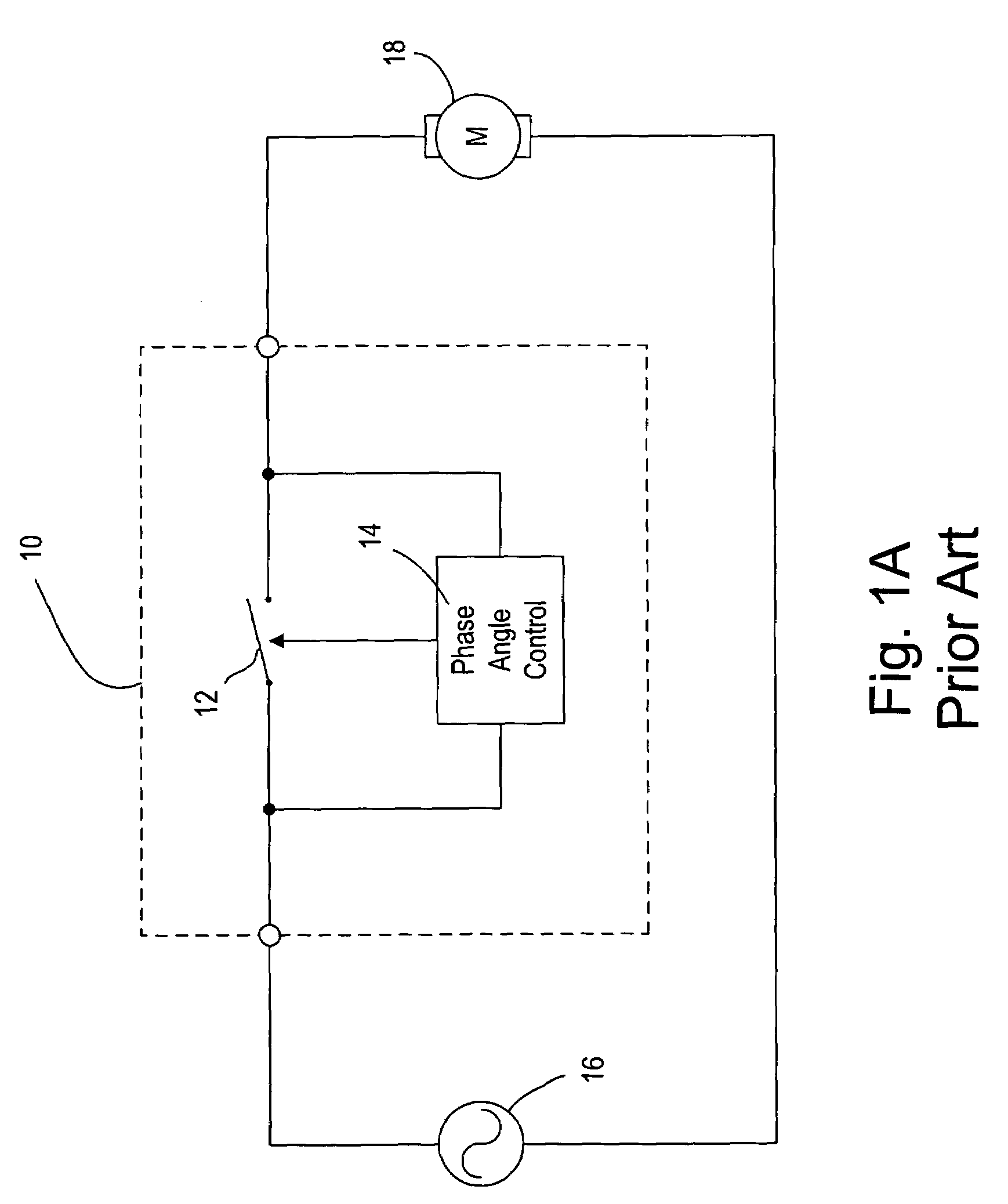

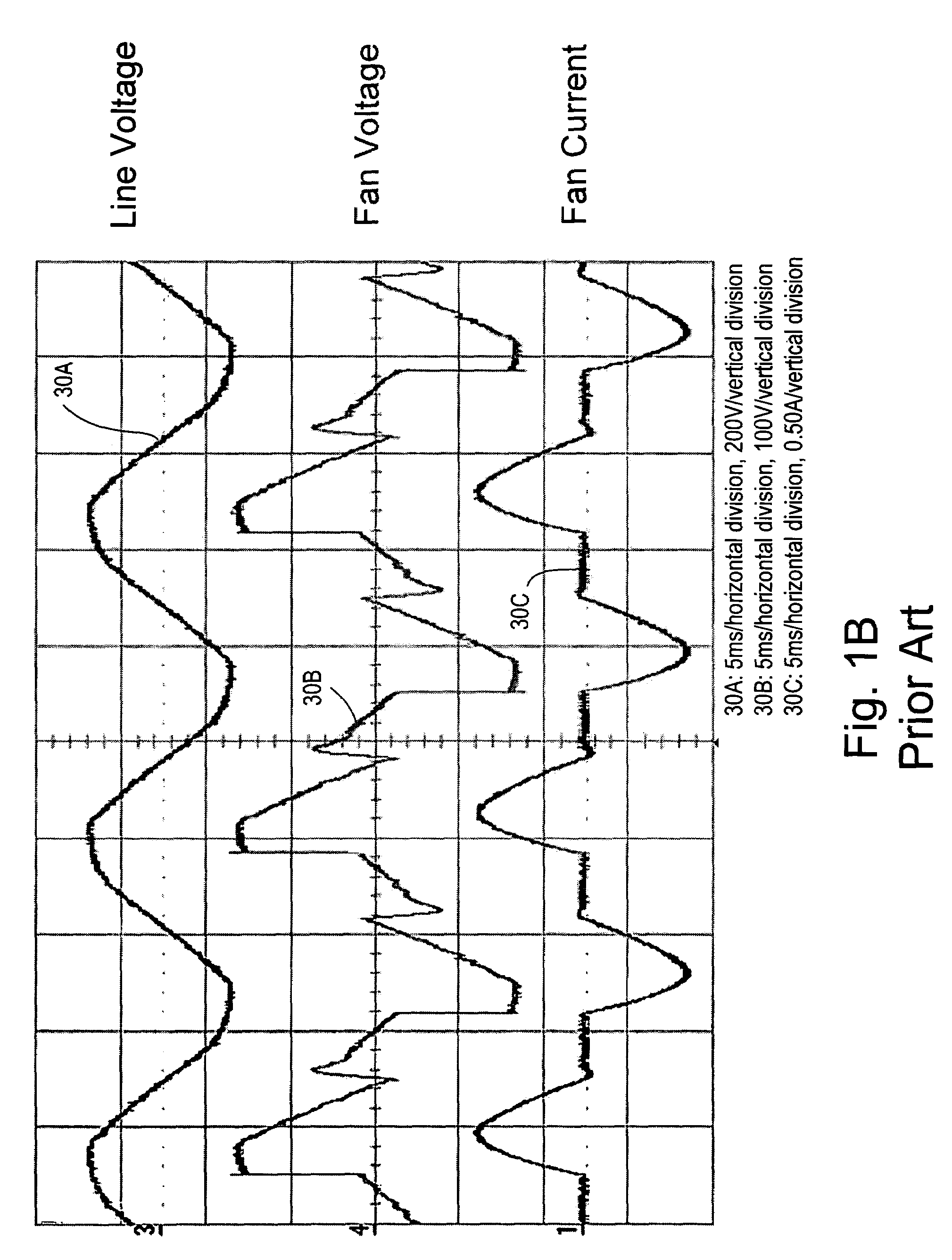

Method and apparatus for quiet variable motor speed control

ActiveUS7330004B2Single-phase induction motor startersMotor/generator/converter stoppersMotor speedEngineering

An apparatus for controlling the speed of an AC motor comprising a switch adapted to be coupled in parallel with power terminals for the AC motor; a capacitor coupled in series with the parallel combination of the switch and the motor; the capacitor adapted to provide an AC supply voltage from an AC source to the parallel circuit comprising the motor and the switch; and a control circuit for controlling the conduction time of the switch in order to vary the speed of the motor. The switch is preferably pulse-width modulated at a frequency twice the line frequency of the AC supply voltage, and the switch is turned on when the voltage across the AC motor is zero volts. The apparatus is operable to provide for continuously variable control of the motor speed while minimizing acoustic noise in the motor.

Owner:LUTRON TECH CO LLC

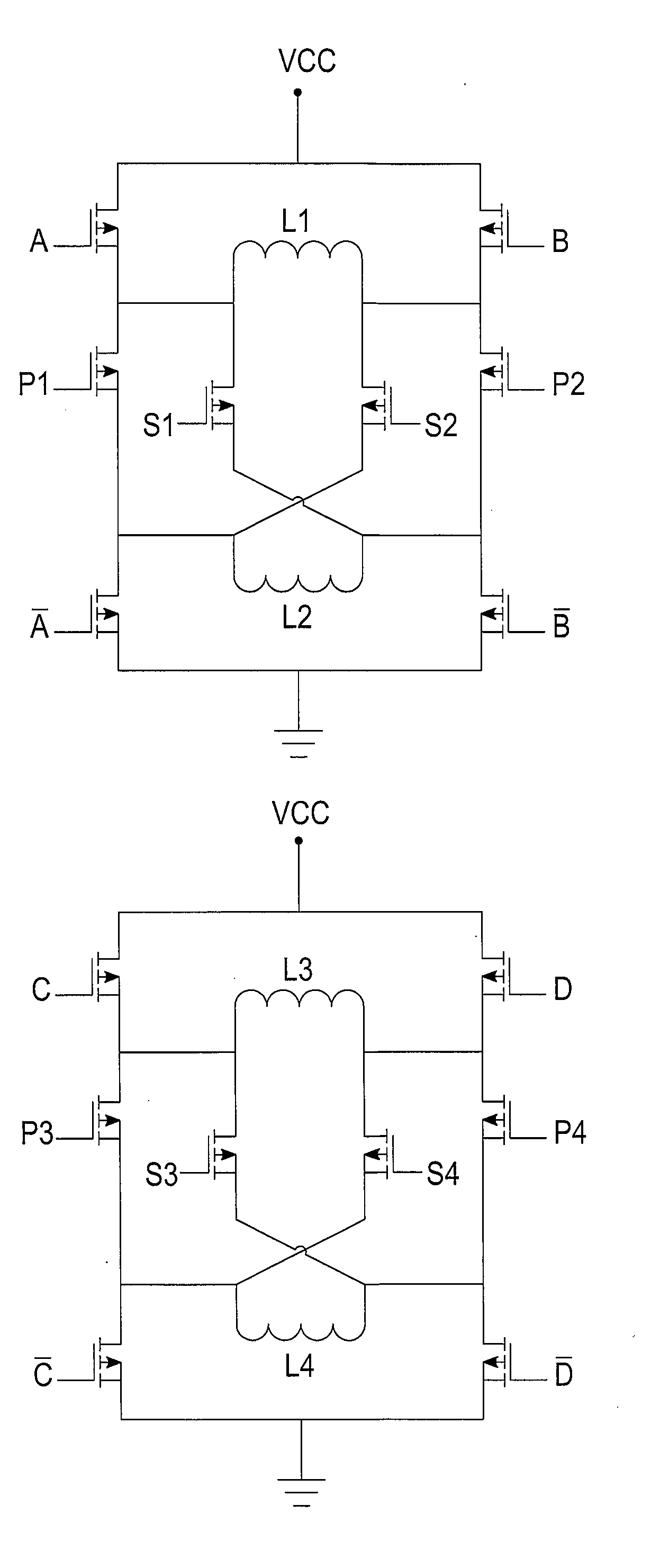

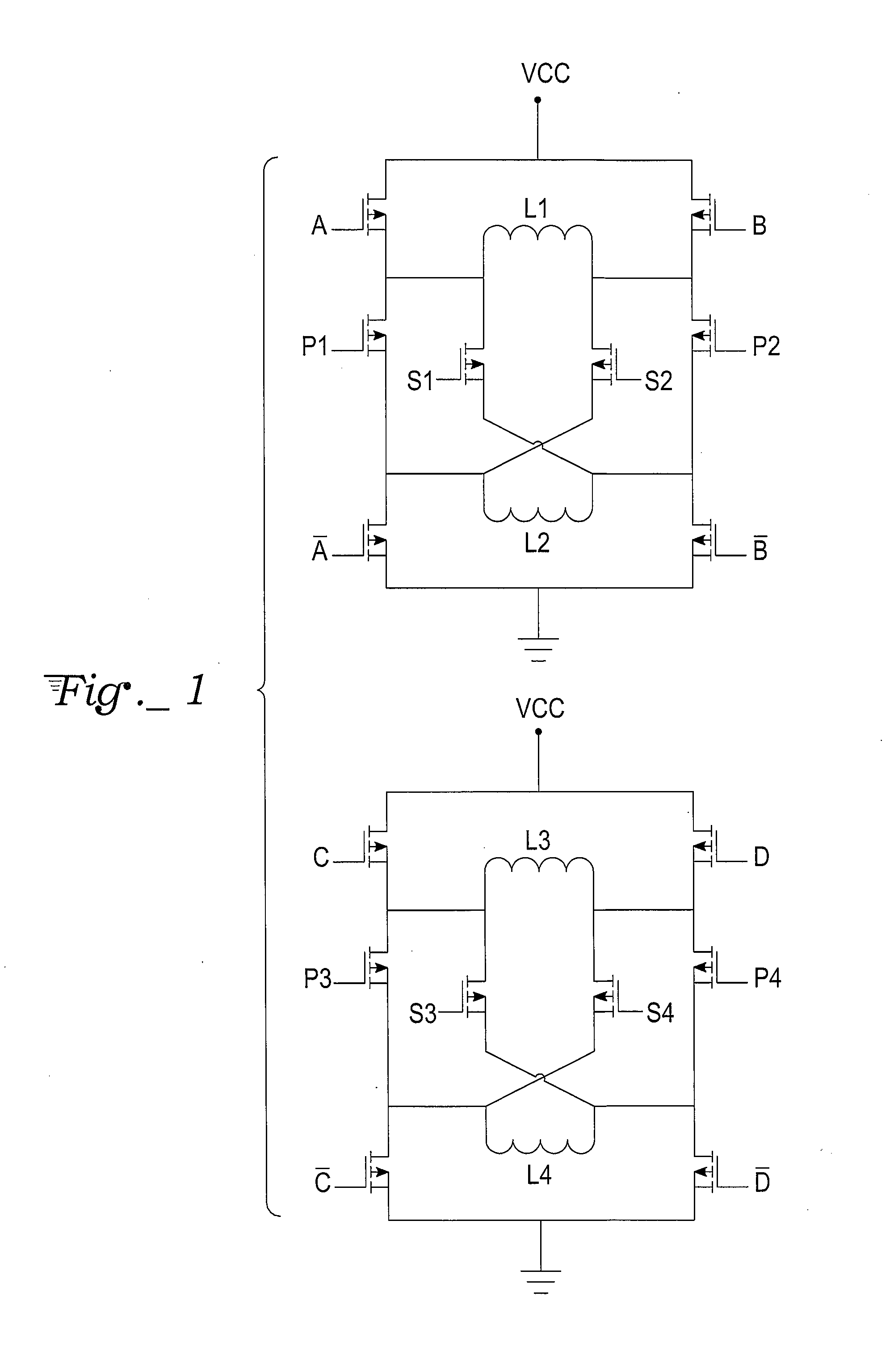

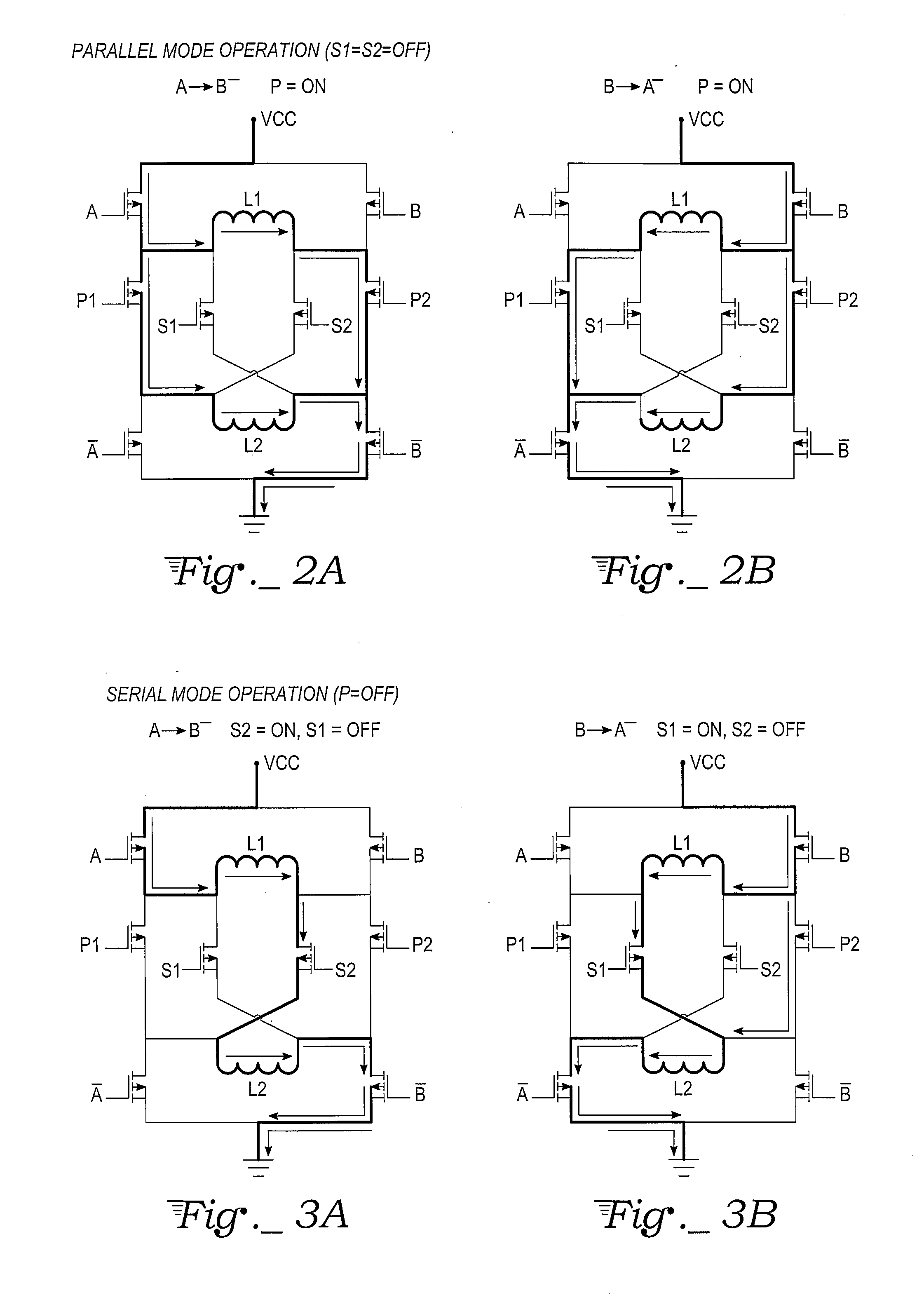

H-bridge drive circuit for step motor control

InactiveUS20110241597A1Improve stand-alone performanceEasy to implementDynamo-electric converter controlMotor speedDriving current

A drive circuit for step motors with bifilar windings is provided in which both parallel and series winding configurations for the stator coils are selectable by a motor controller based on the motor speed. For low speeds a series configuration is selected, while for higher speeds a parallel configuration is selected. Dynamic torque is optimized by the selection for more efficient motor operation with less drive current.

Owner:LIN ENG INC

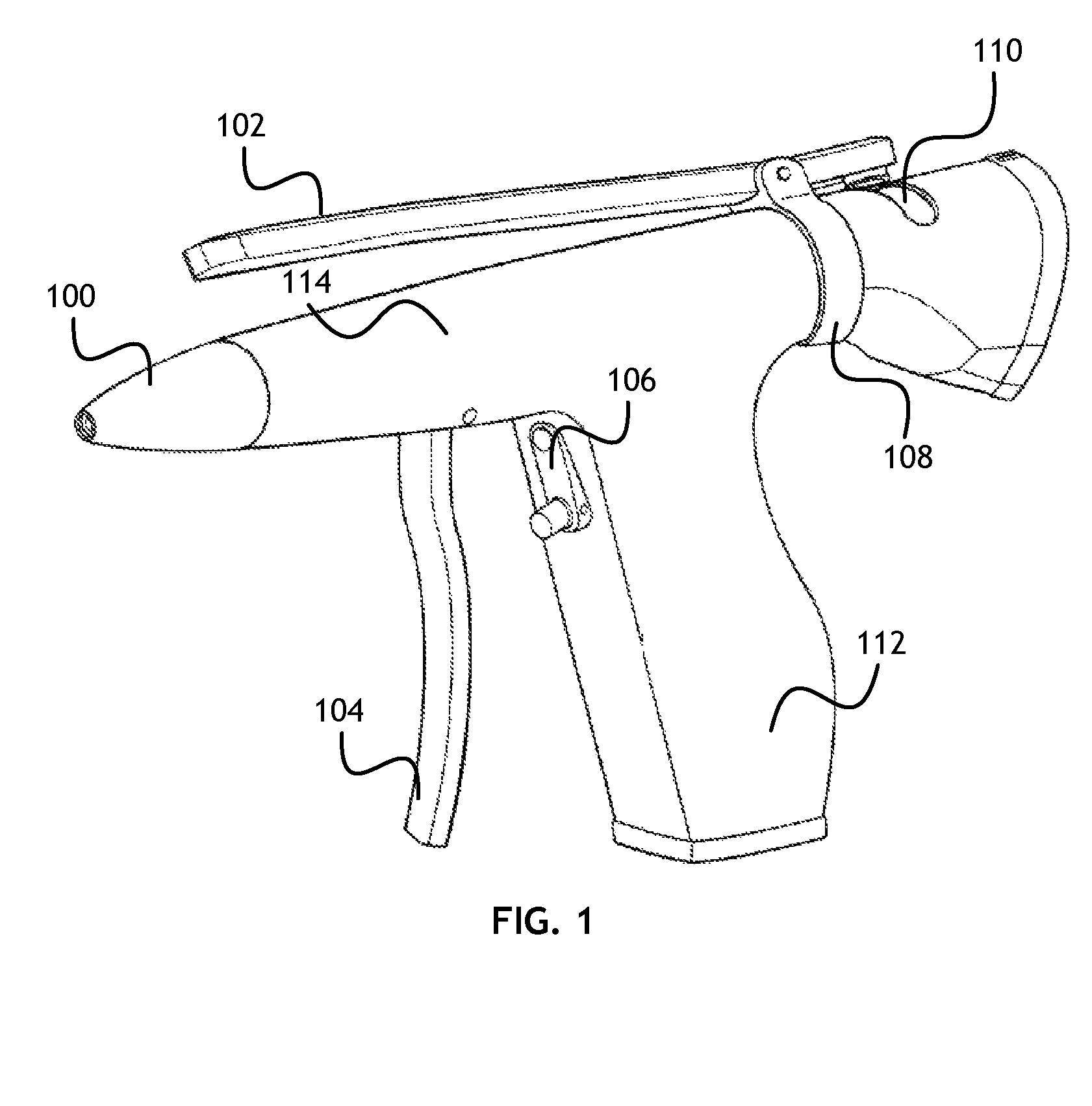

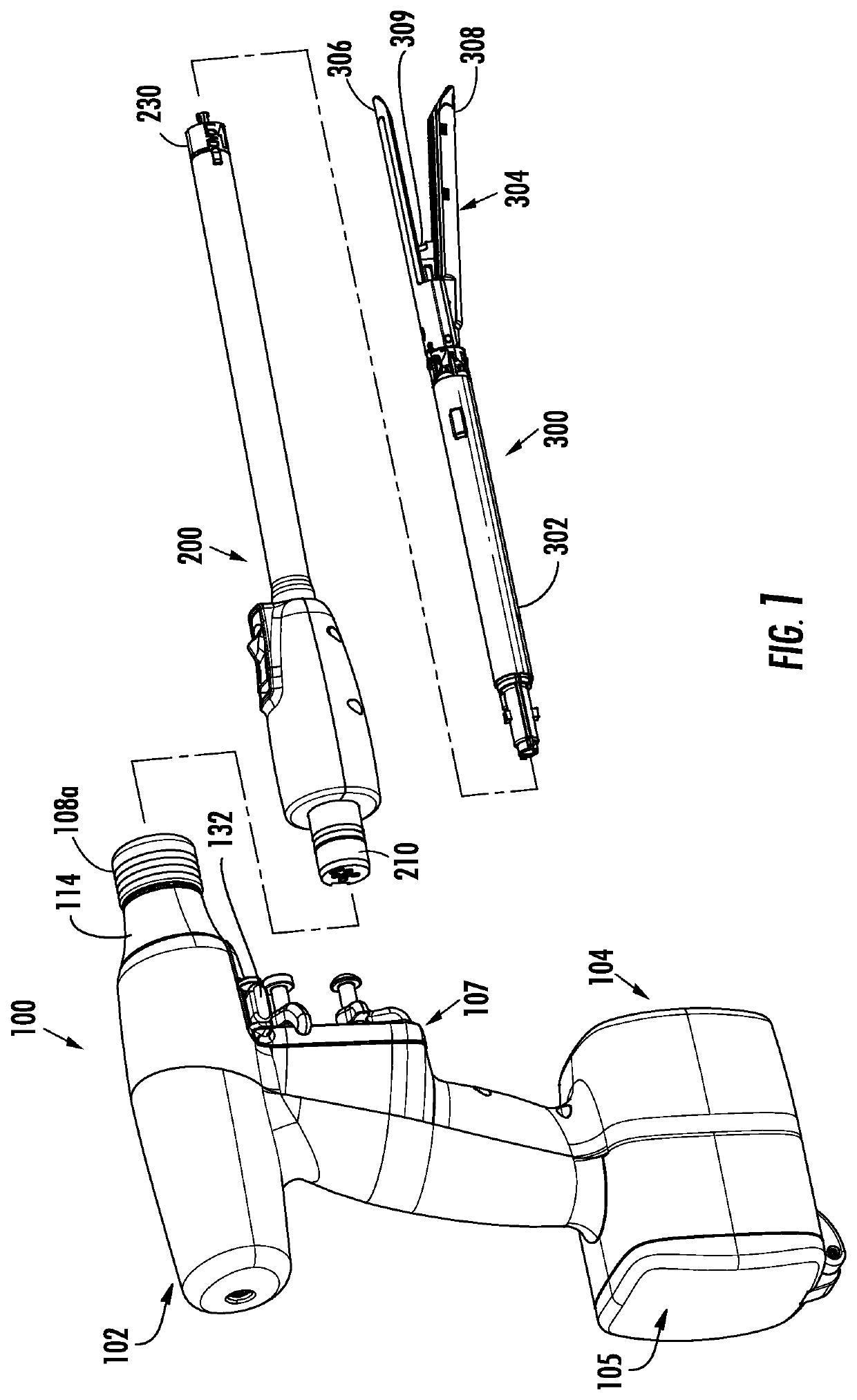

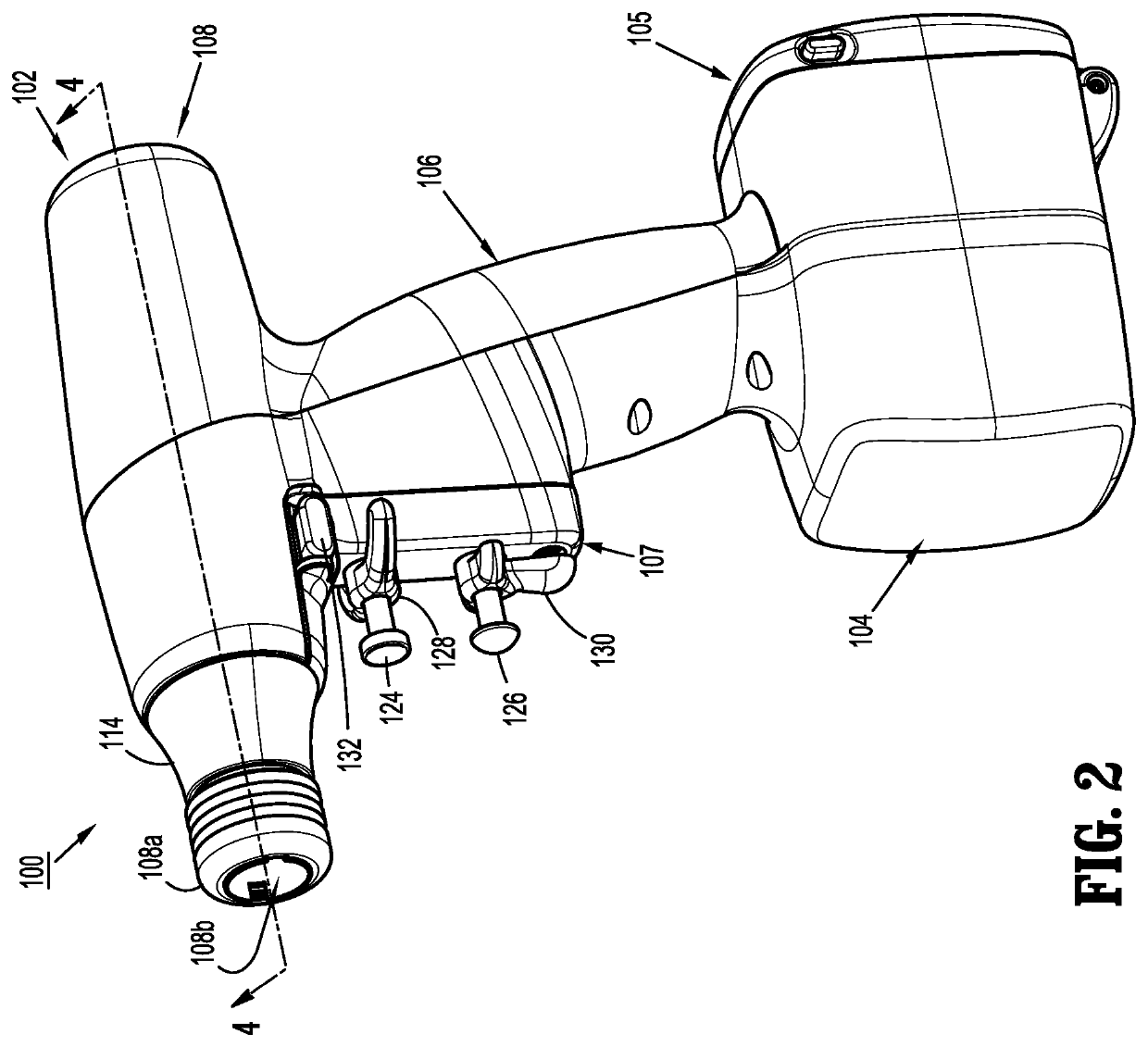

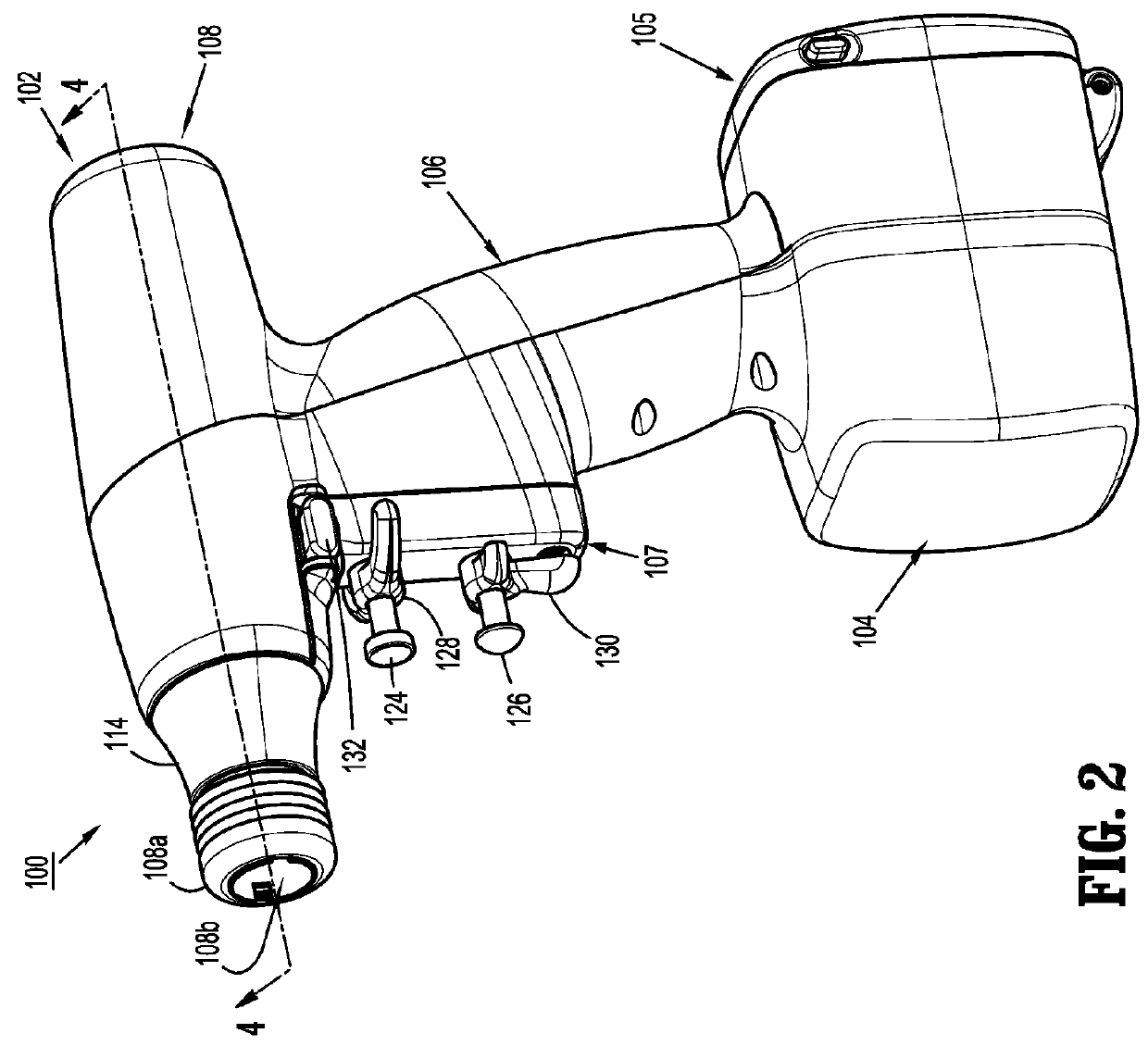

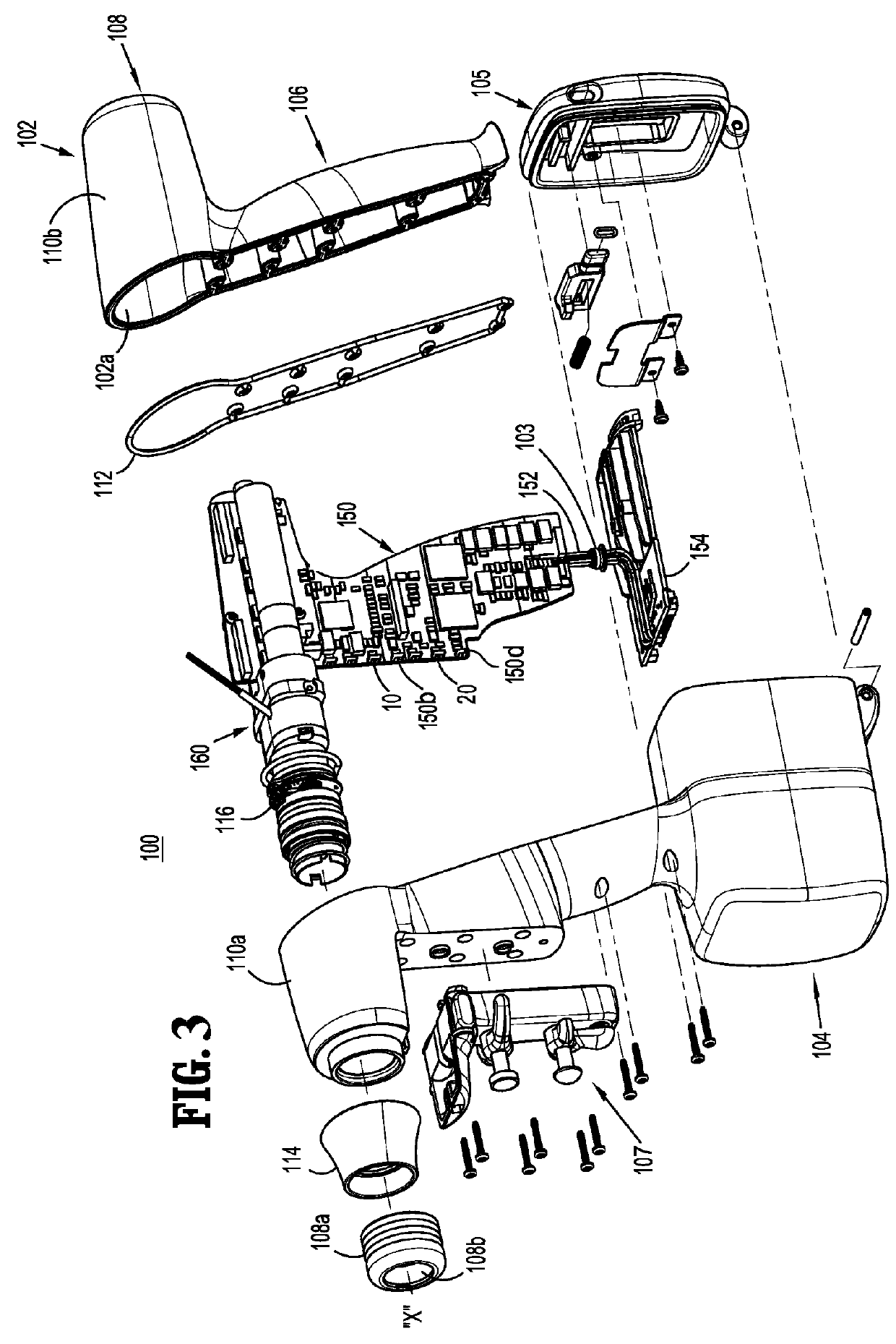

Method and device for ergonomically and ambidextrously operable surgical device

A handheld surgical device includes a multi-position throttle, rotatably attached to the body of the device, to allow for ambidextrous positioning of a motor speed control lever. The motor speed control lever may interact with a speed control sensor in the body of the device capable of detecting the actuation level of the motor speed control lever in any one of two or more positions.

Owner:MICROAIRE SURGICAL INSTR

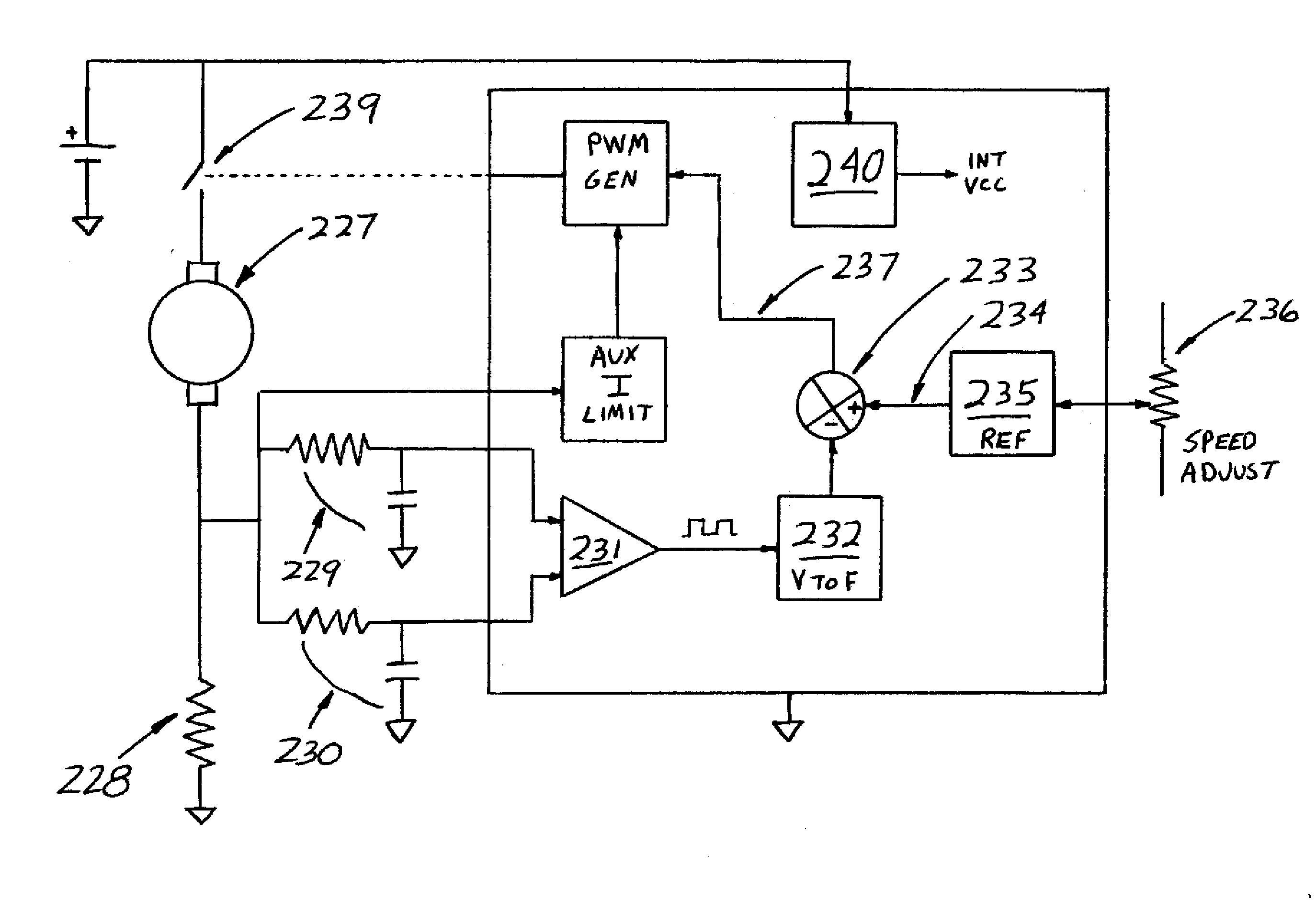

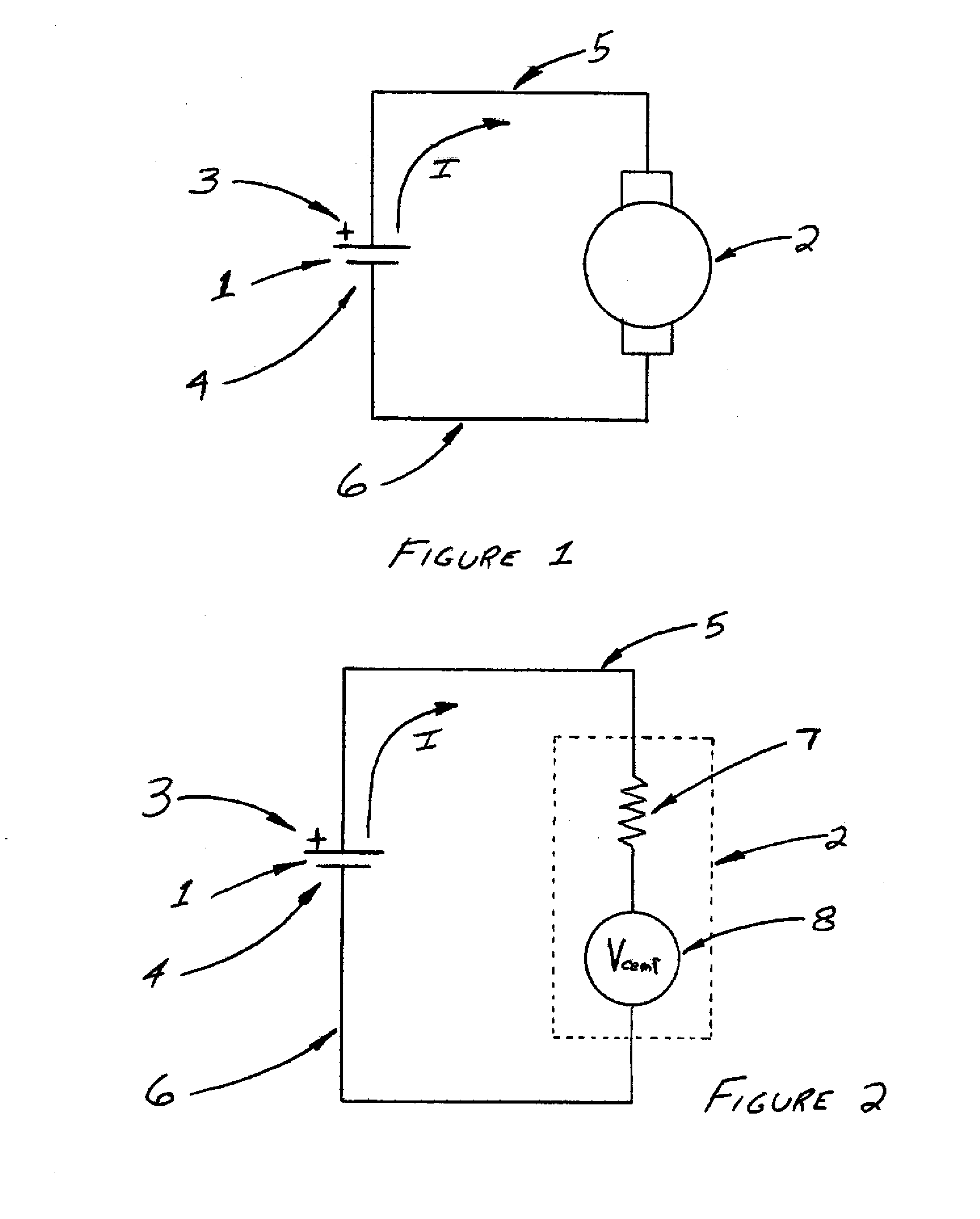

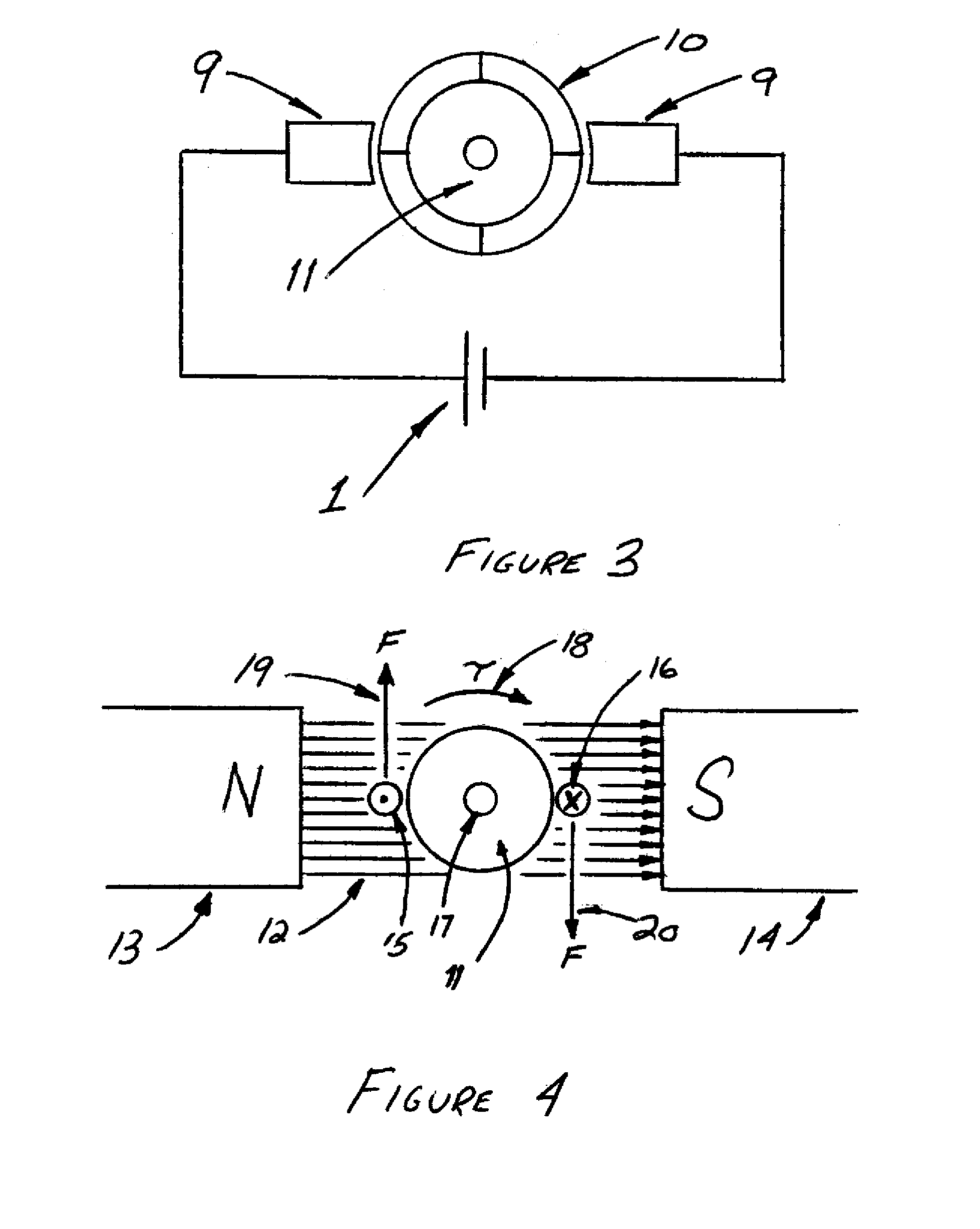

Method of Sensing Speed of Electric Motors and Generators

InactiveUS20080298784A1Simple and inexpensiveLow costMotor/generator/converter stoppersField or armature current controlMotor speedMotor control

A method and circuit for determining the speed and / or counting the revolutions of brush and commutator motors is described. The method and circuitry detects signals present on the windings of the motor due to commutation that occurs at the brushes and commutator of the motor. This method can be used to simply monitor & indicate the motor speed and revolutions or to form the basis of a motor control.

Owner:KASTNER MARK ALLEN

Powered surgical instrument with pressure sensitive motor speed control

A surgical instrument includes a drive shaft, a motor for rotating the drive shaft, and a motor speed control. The motor speed control includes a first switch and a second switch which are in communication with the motor. The first switch is disposed over and in registration with the second switch. The first switch has an activated state such that the first switch sends a first signal to the motor. The motor rotates the drive shaft in response to the first signal. The second switch sends a second signal to the motor that varies the speed that the motor rotates the drive shaft in response to a force applied to the second switch by the first switch.

Owner:TYCO HEALTHCARE GRP LP

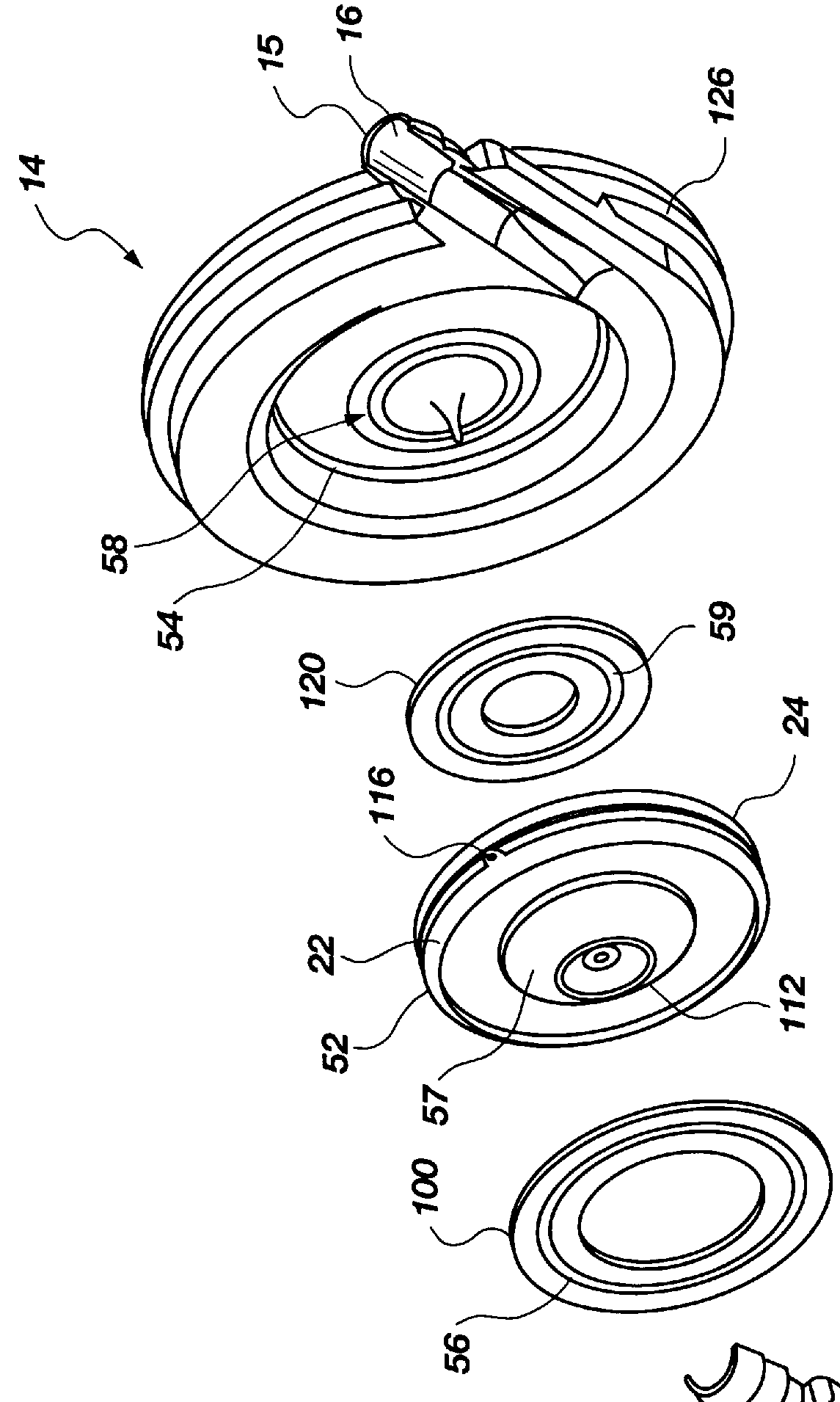

Multiple stage blowers and volutes therefor

ActiveUS20050103339A1Faster pressure rise timeImprove reliabilityPump componentsMedical devicesImpellerMotor speed

A multiple stage variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the multiple stage blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

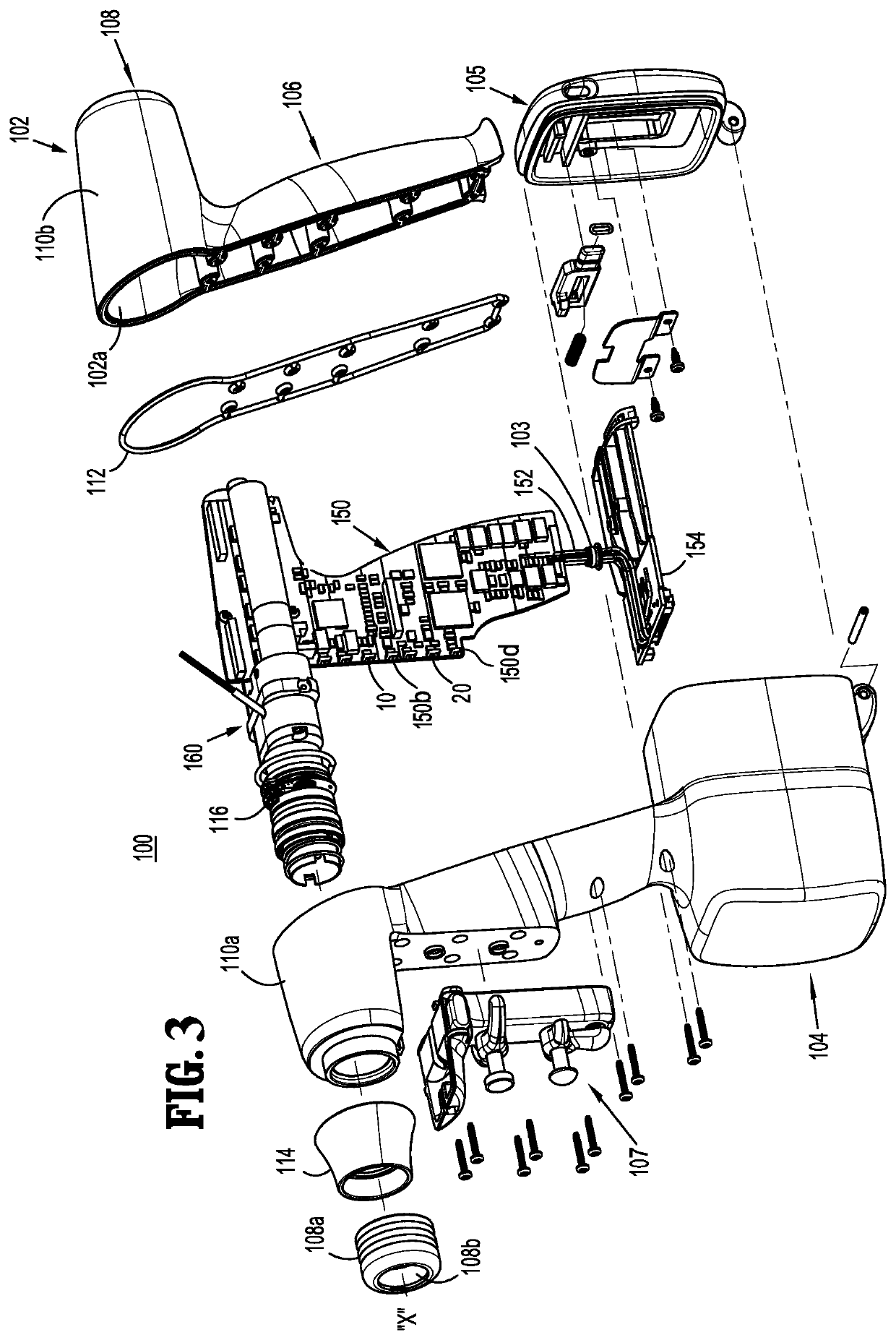

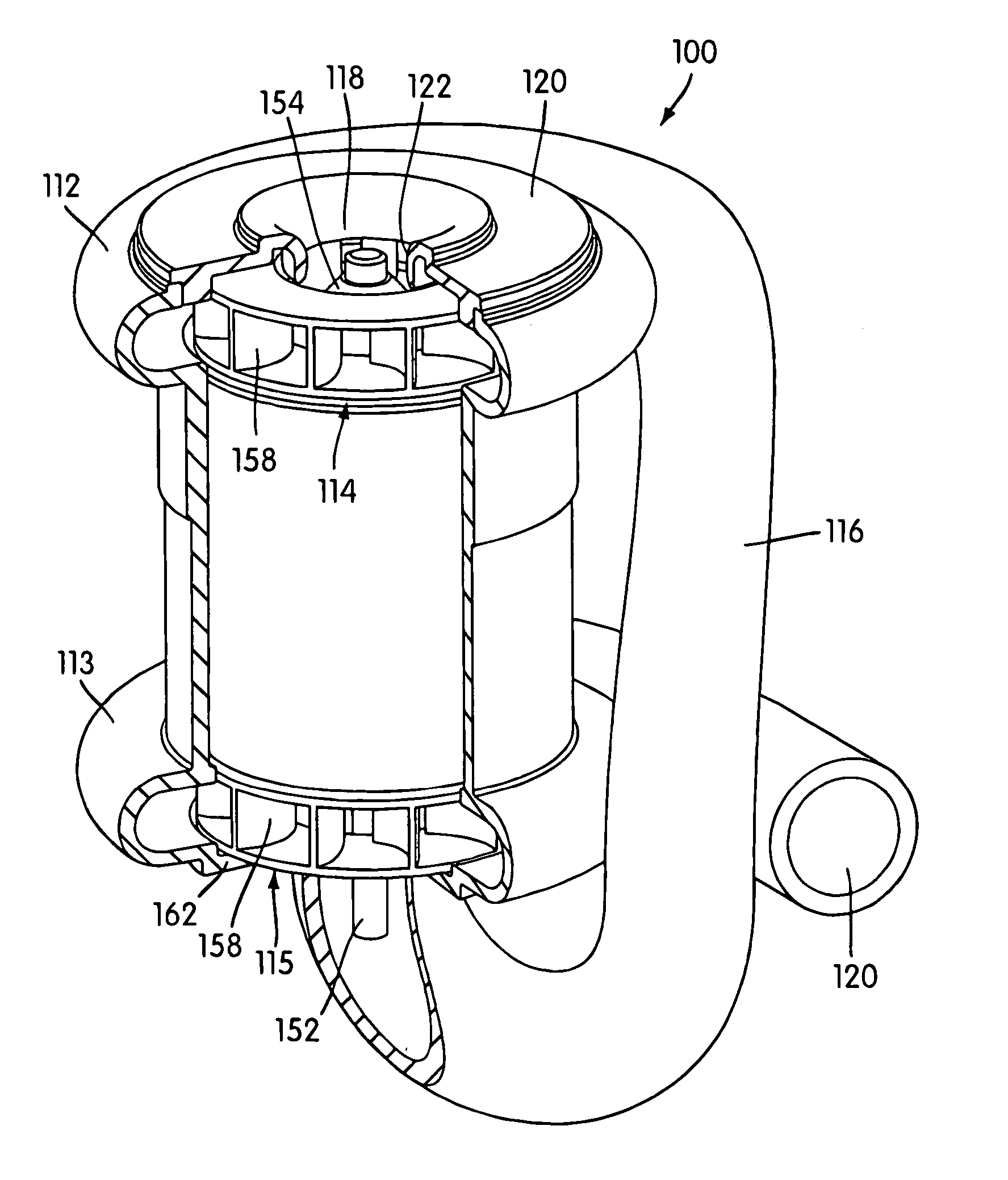

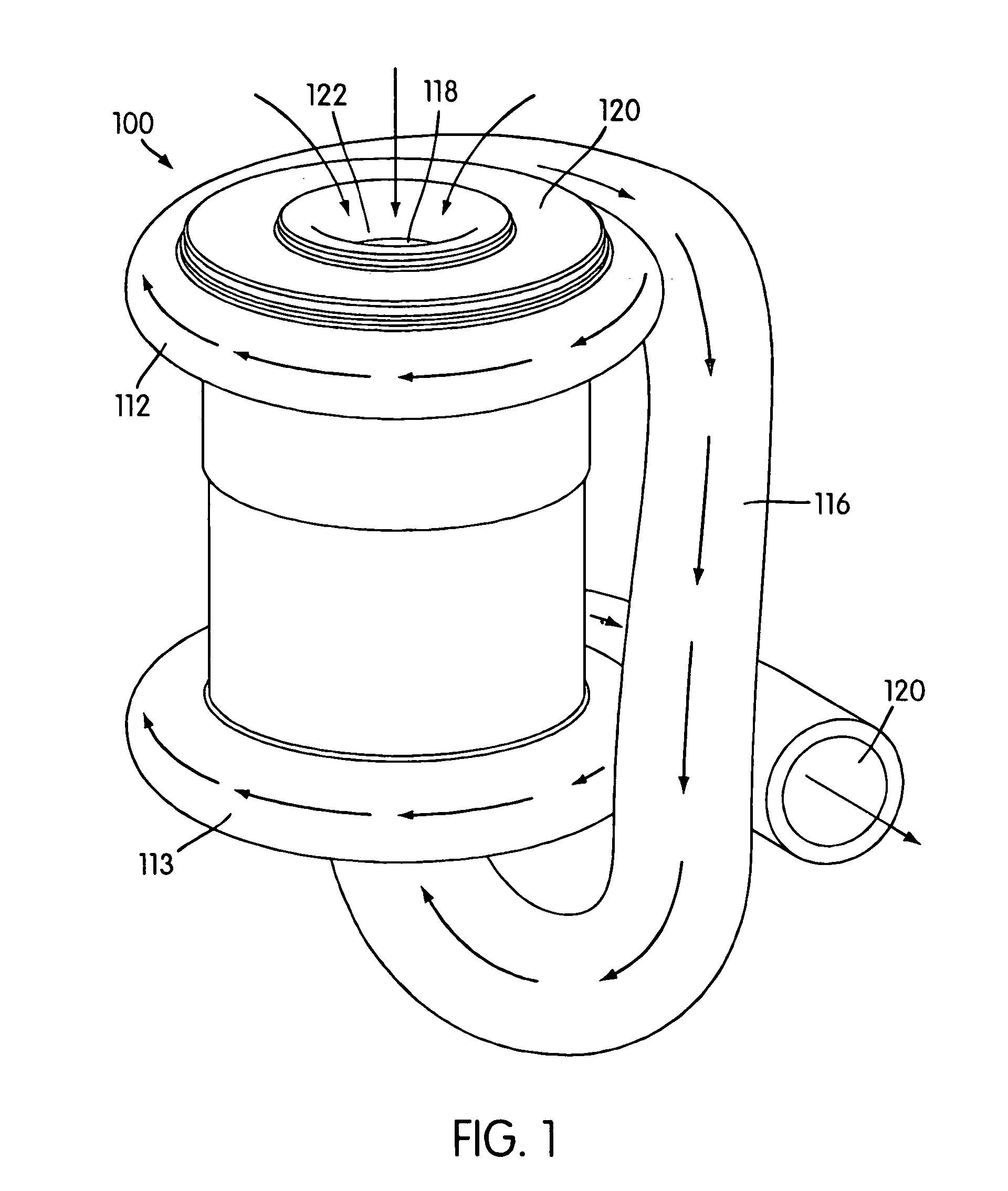

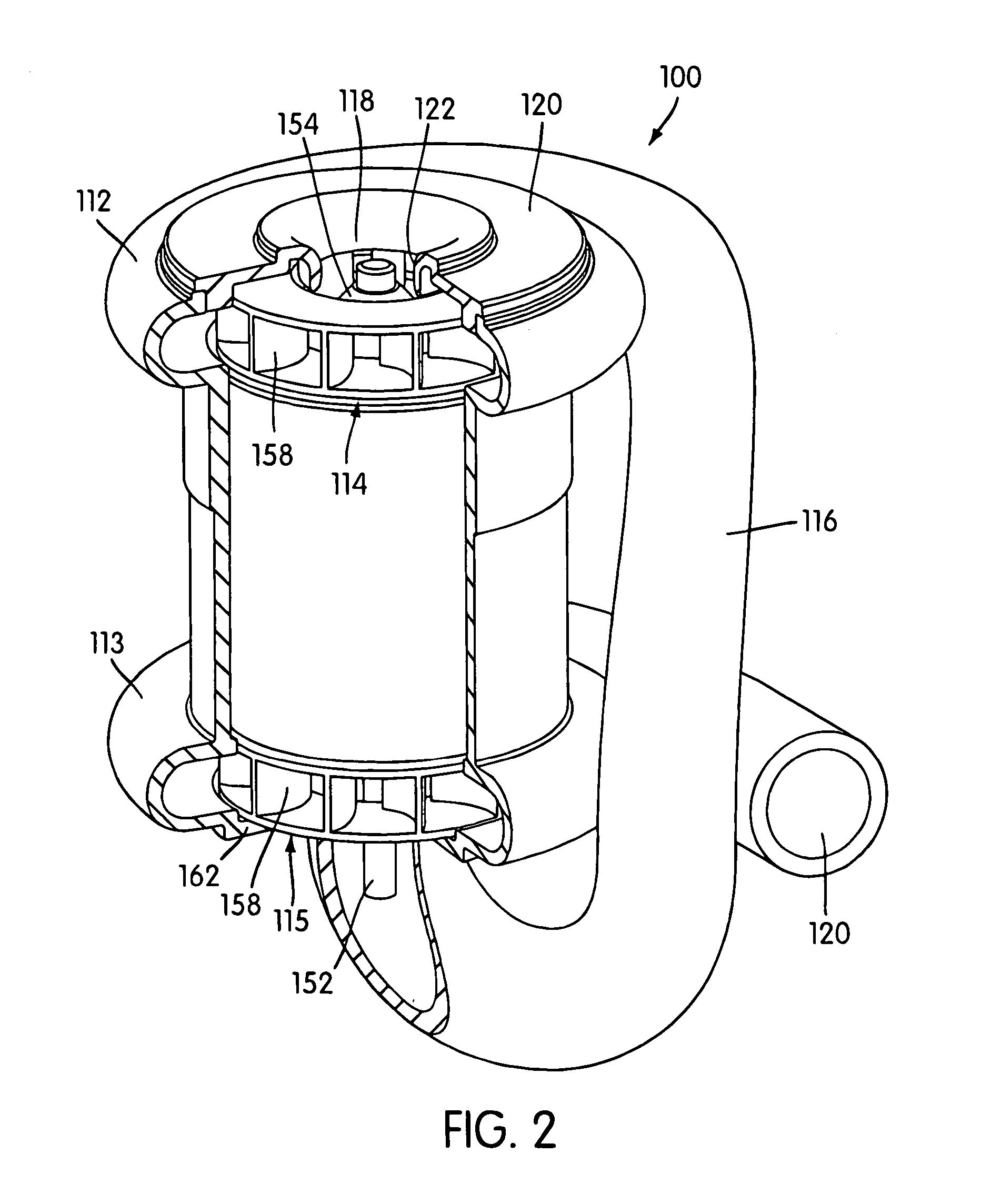

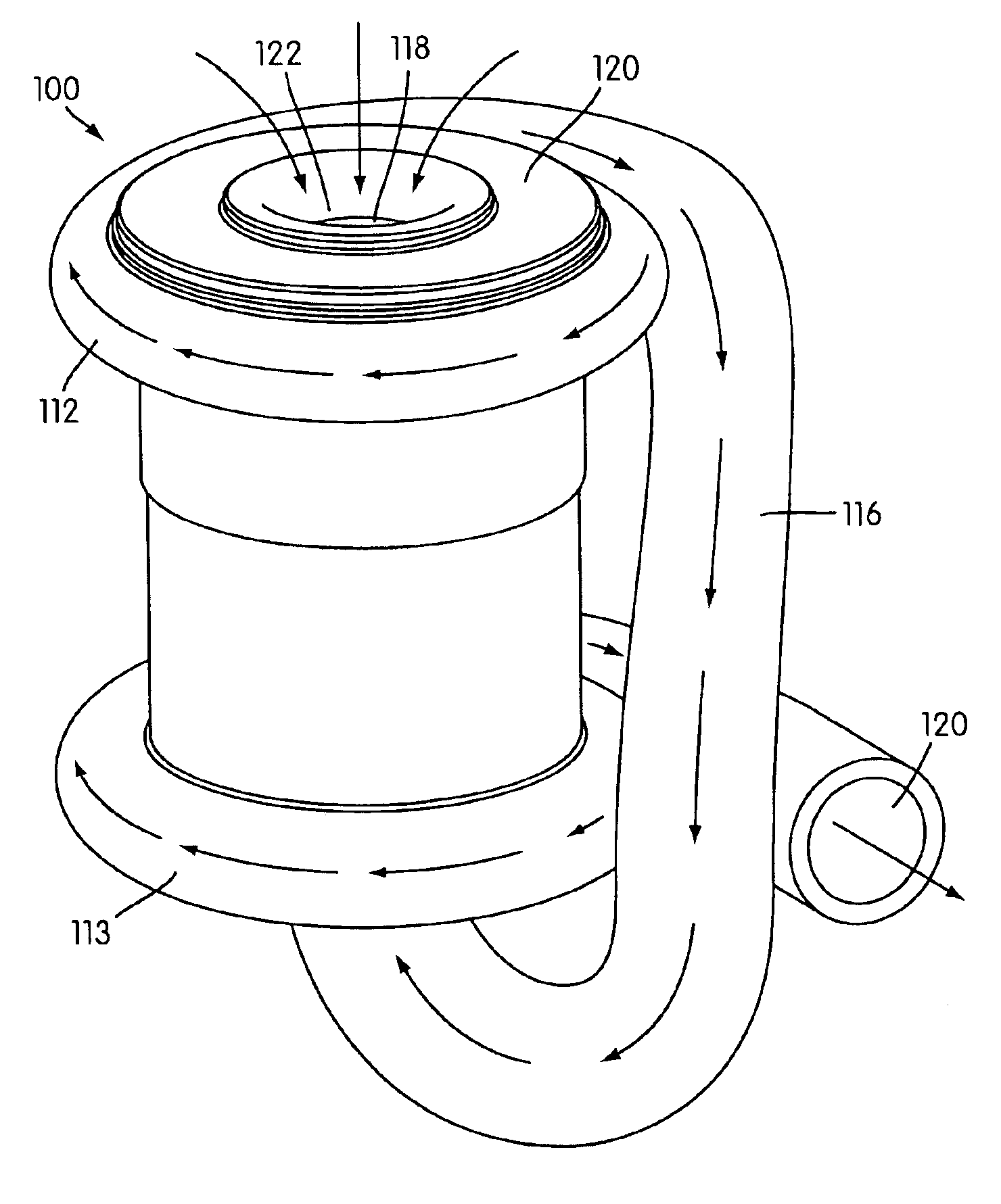

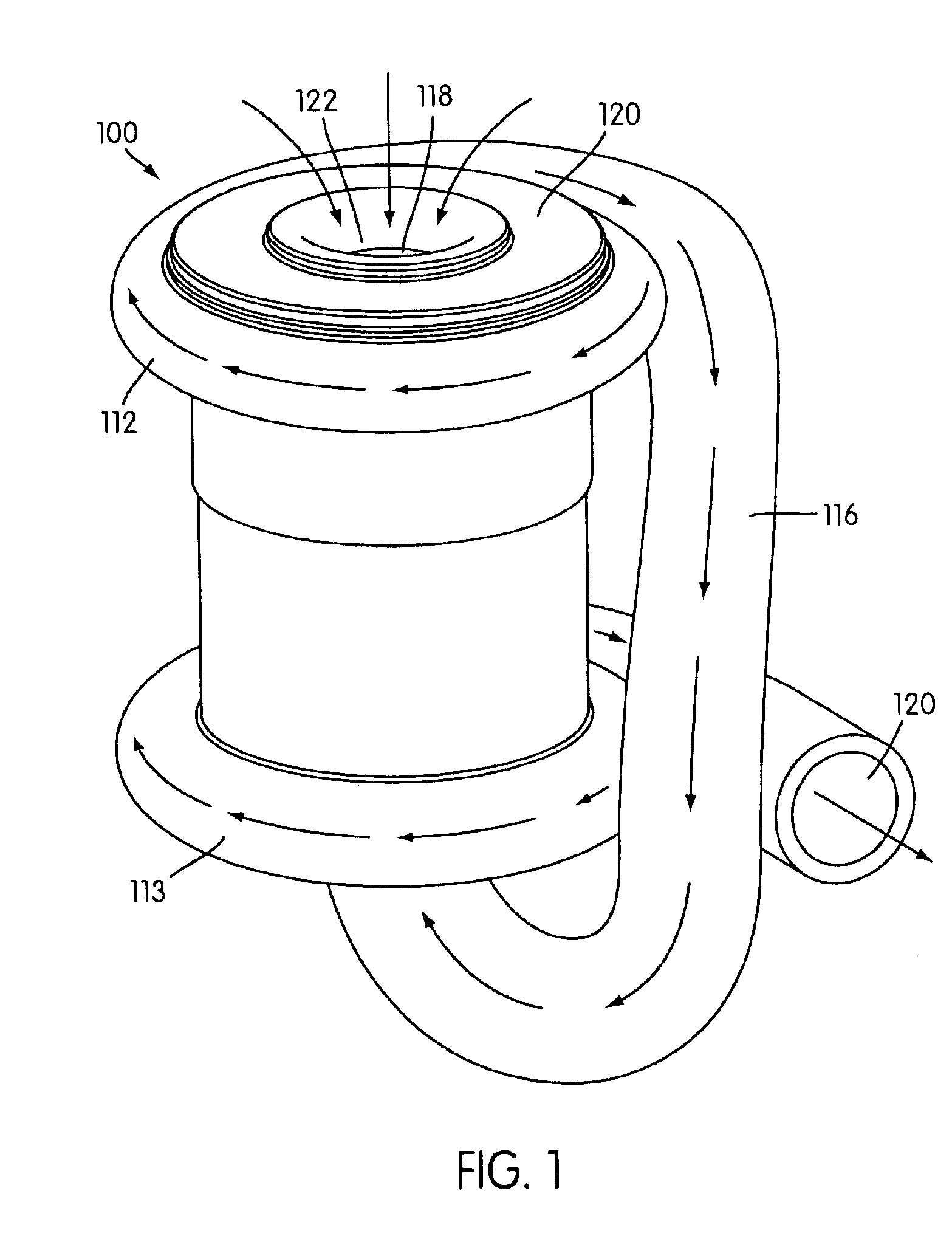

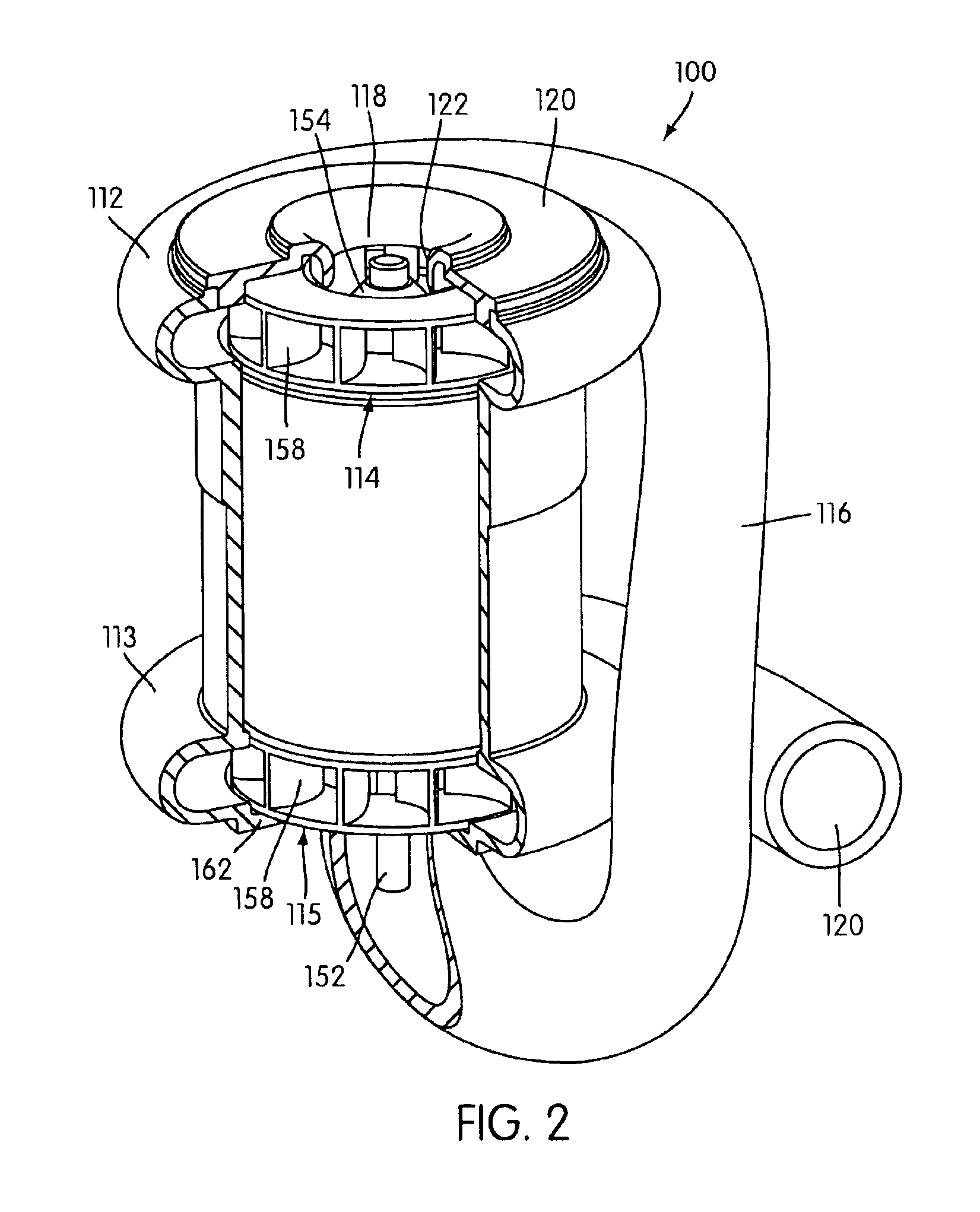

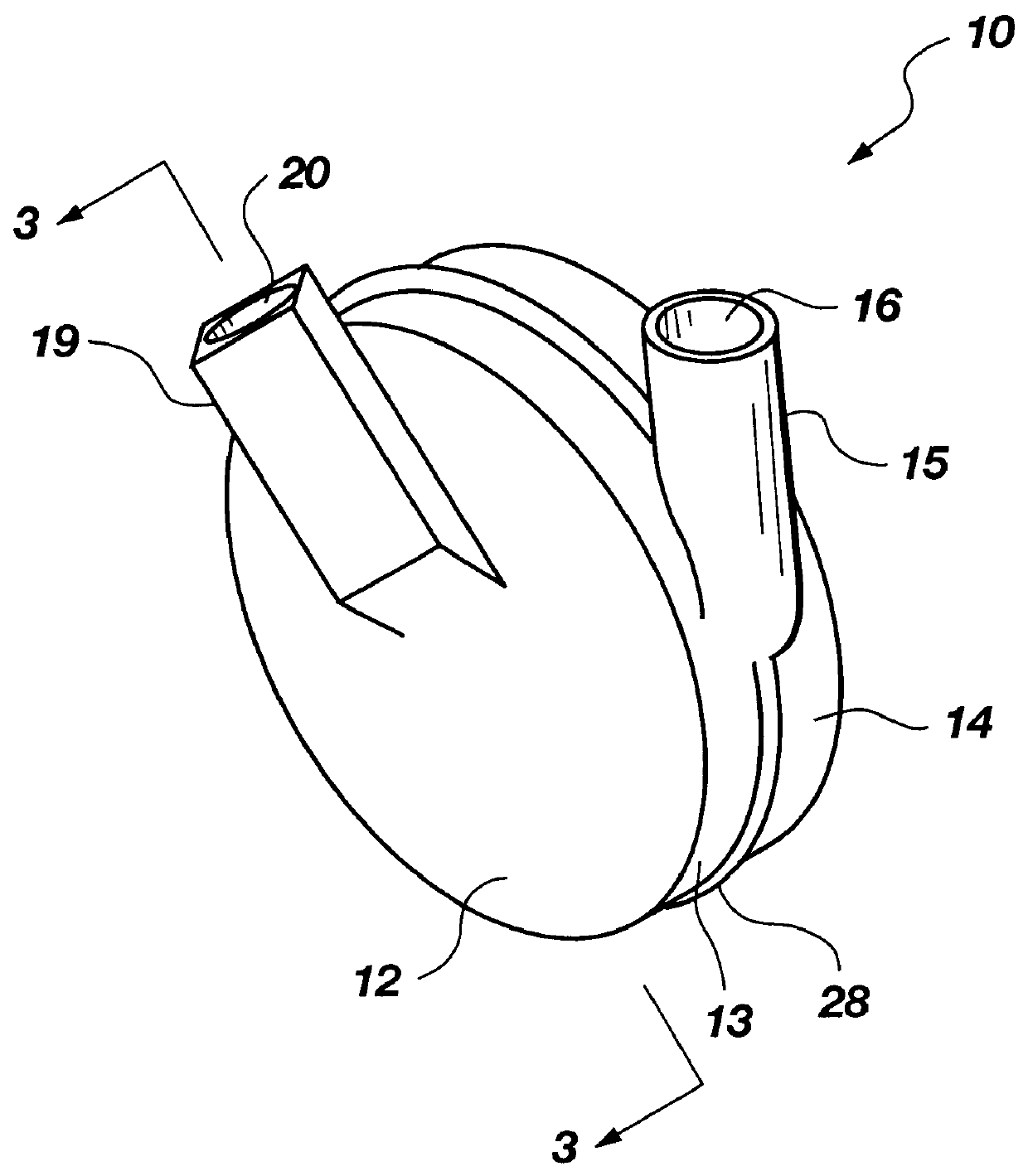

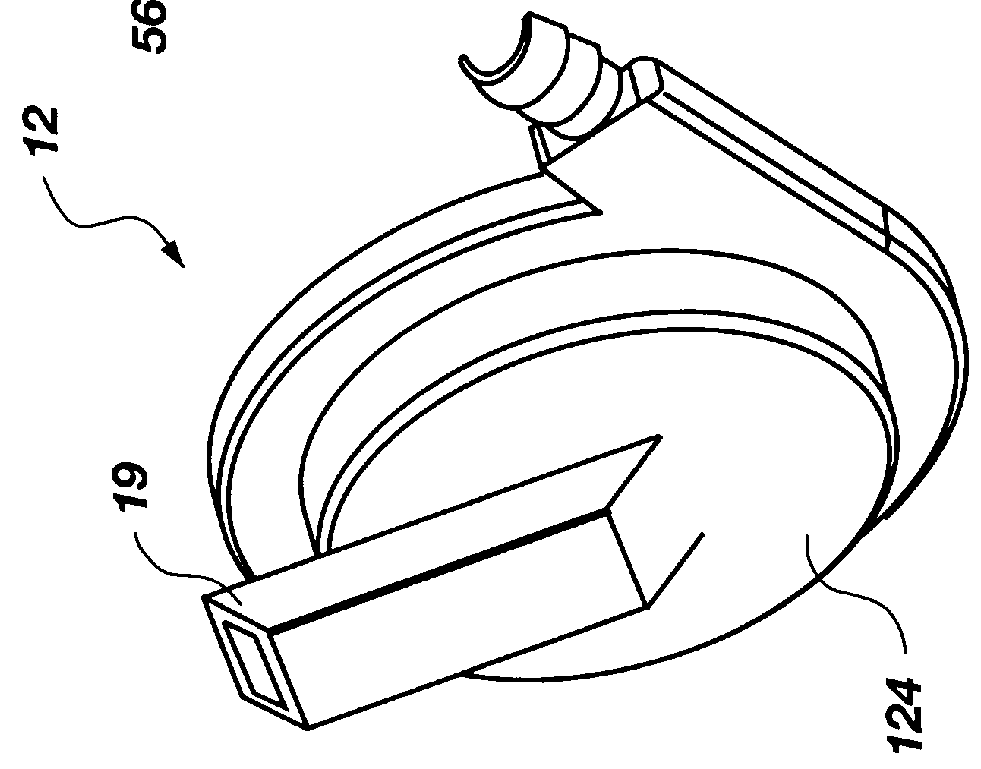

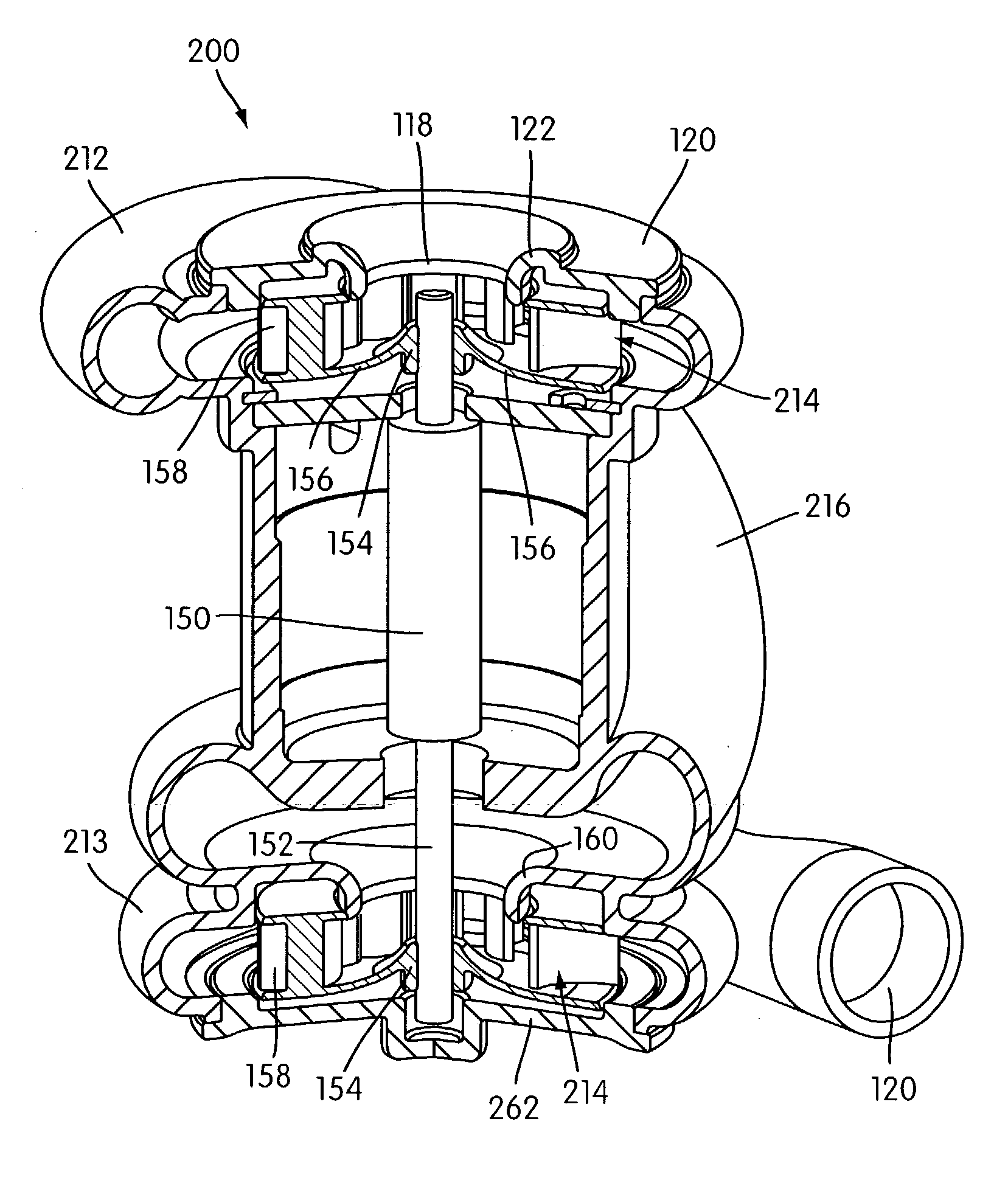

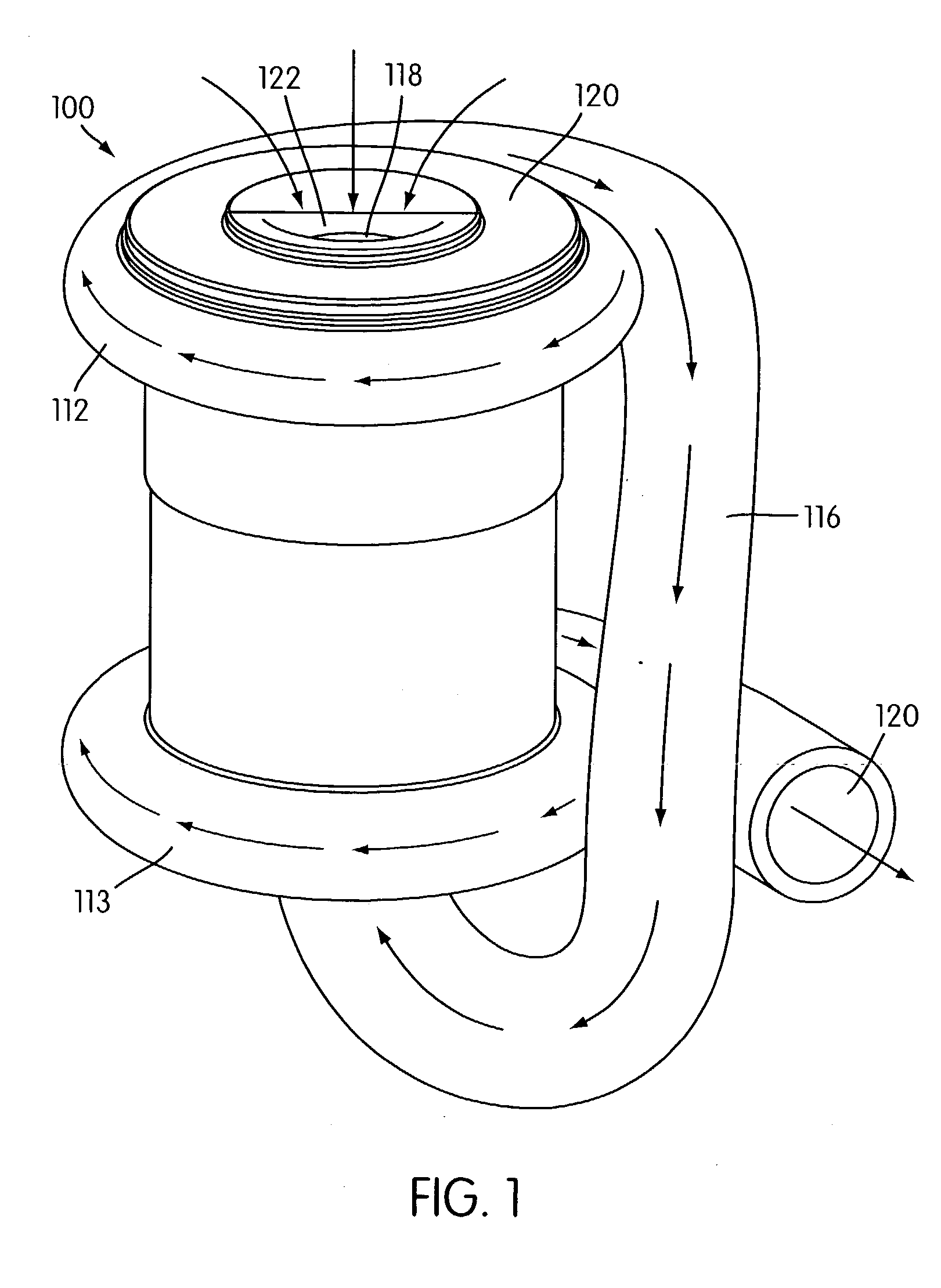

Double-ended blower and volutes therefor

InactiveUS6910483B2Faster pressure rise timeImprove reliabilityPropellersElement comparisonMotor speedImpeller

A double-ended variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the double-ended blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

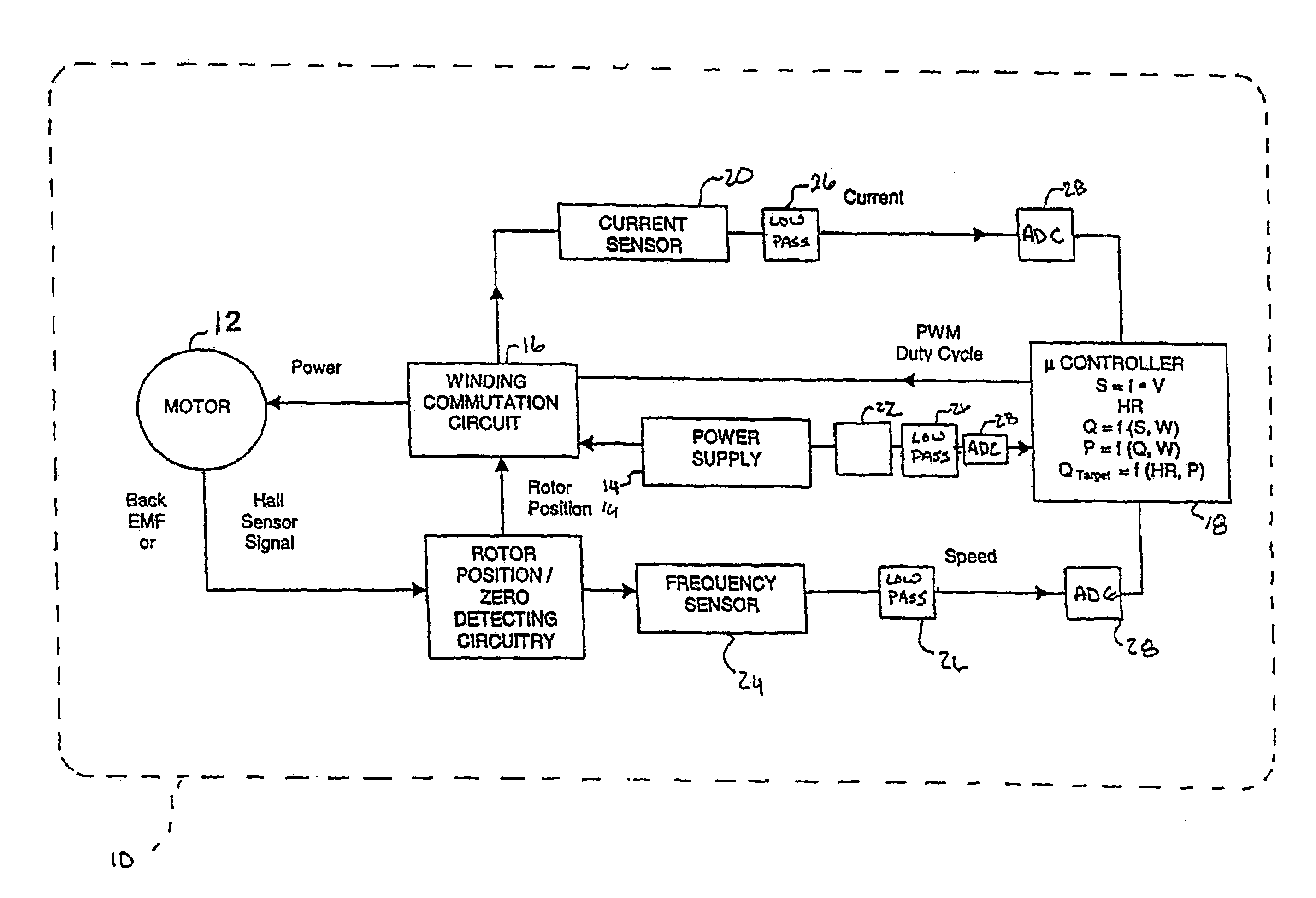

Chronic performance control system for rotodynamic blood pumps

InactiveUS7645225B2Simple control circuitIncrease control flexibilityDC motor speed/torque controlAC motor controlMicrocontrollerMotor speed

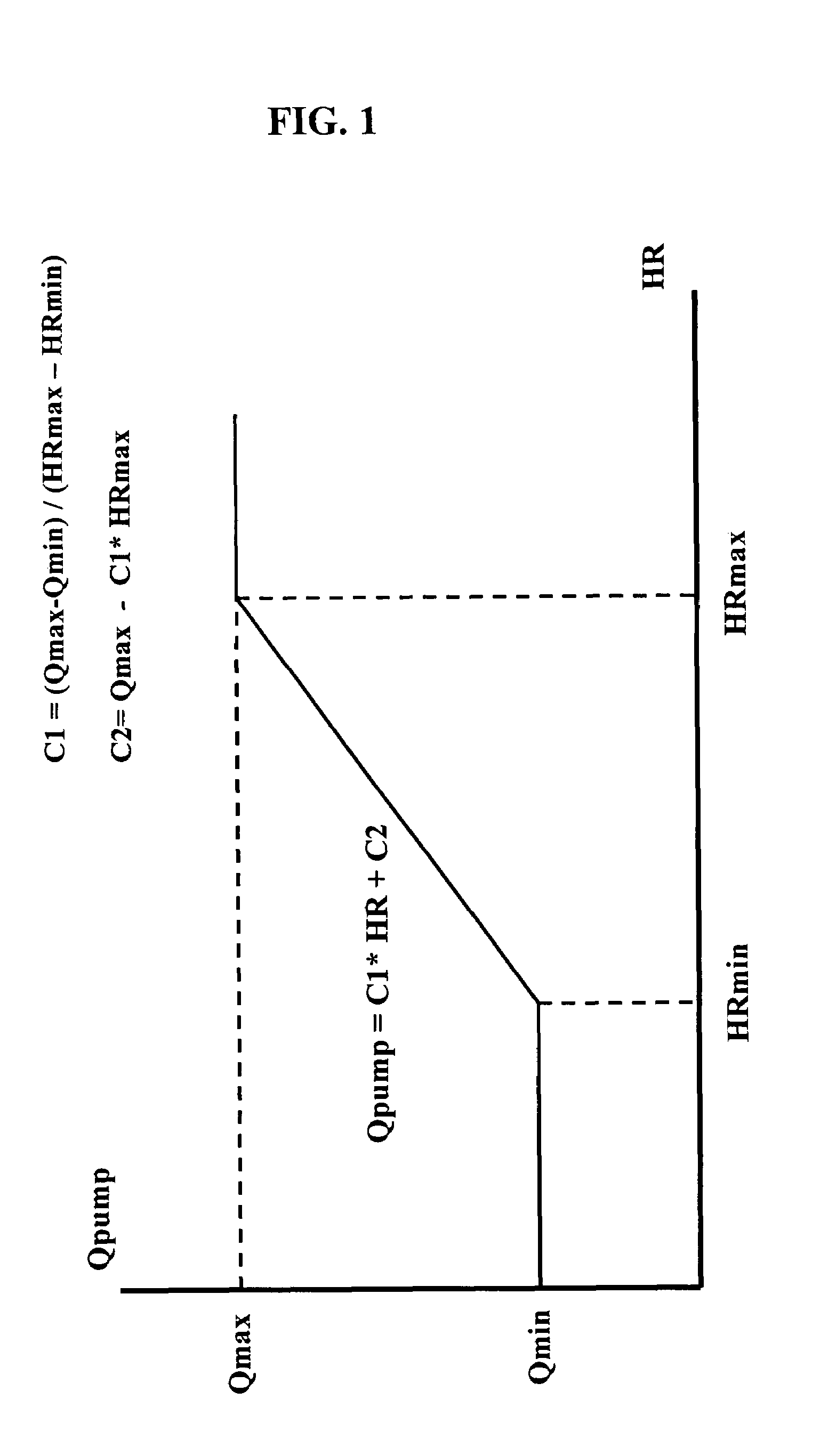

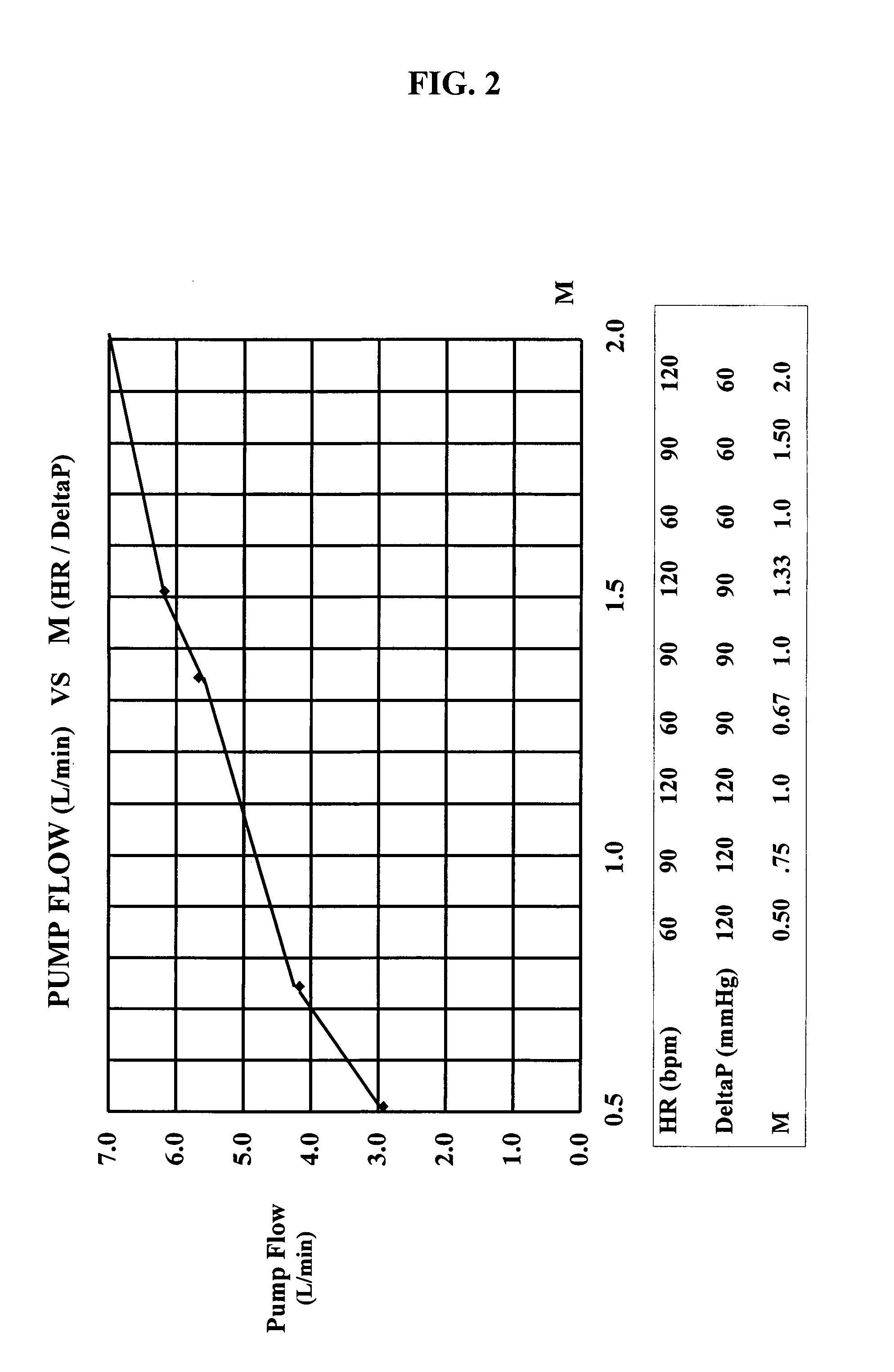

In a left ventricular assist device (LVAD) a rotodynamic blood pump (10) is powered by a brushless DC motor (12). A power supply (14) supplies power to the motor (12). Three feedback channels, one for each of voltage, current, and motor speed lead to a microcontroller or microprocessor (18). The three feedback waveforms are analyzed, and from these waveforms, motor input power, patient heart rate, current pump flow rate, and systemic pressure are determined. The microprocessor (18) then calculates a desired flow rate proportional to the patient heart rate. The microprocessor communicates a new power output to a commutation circuit (16), which regulates power to the motor (12). The pump (10) also includes safety checks that are prioritized over desired pump flow. These include prevention of ventricular suction, low pulsatility, minimum and maximum pump speed, minimum speed-relative pump flow, minimum absolute pump flow, minimum and maximum motor input power.

Owner:MEDVEDEV ALEXANDER +2

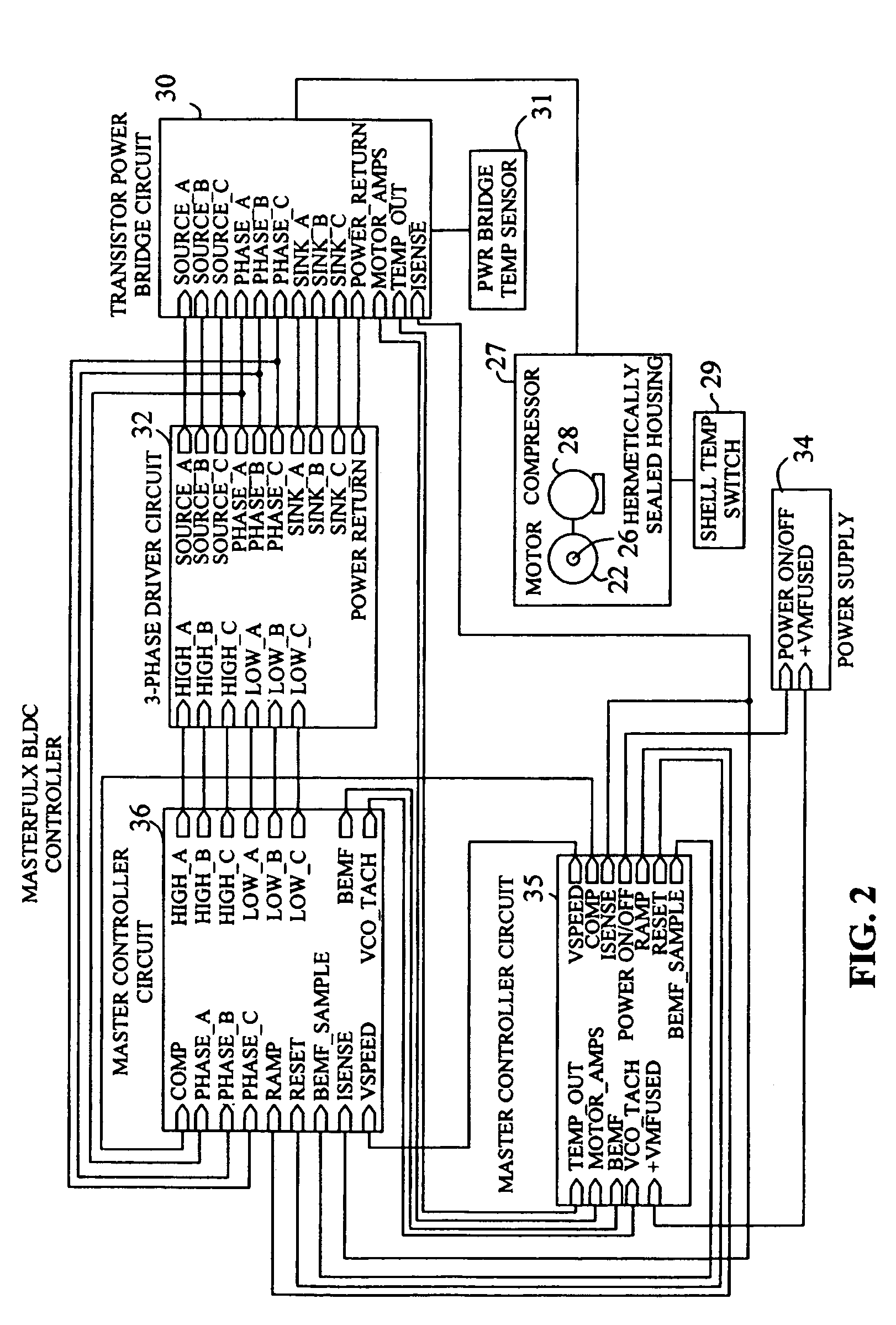

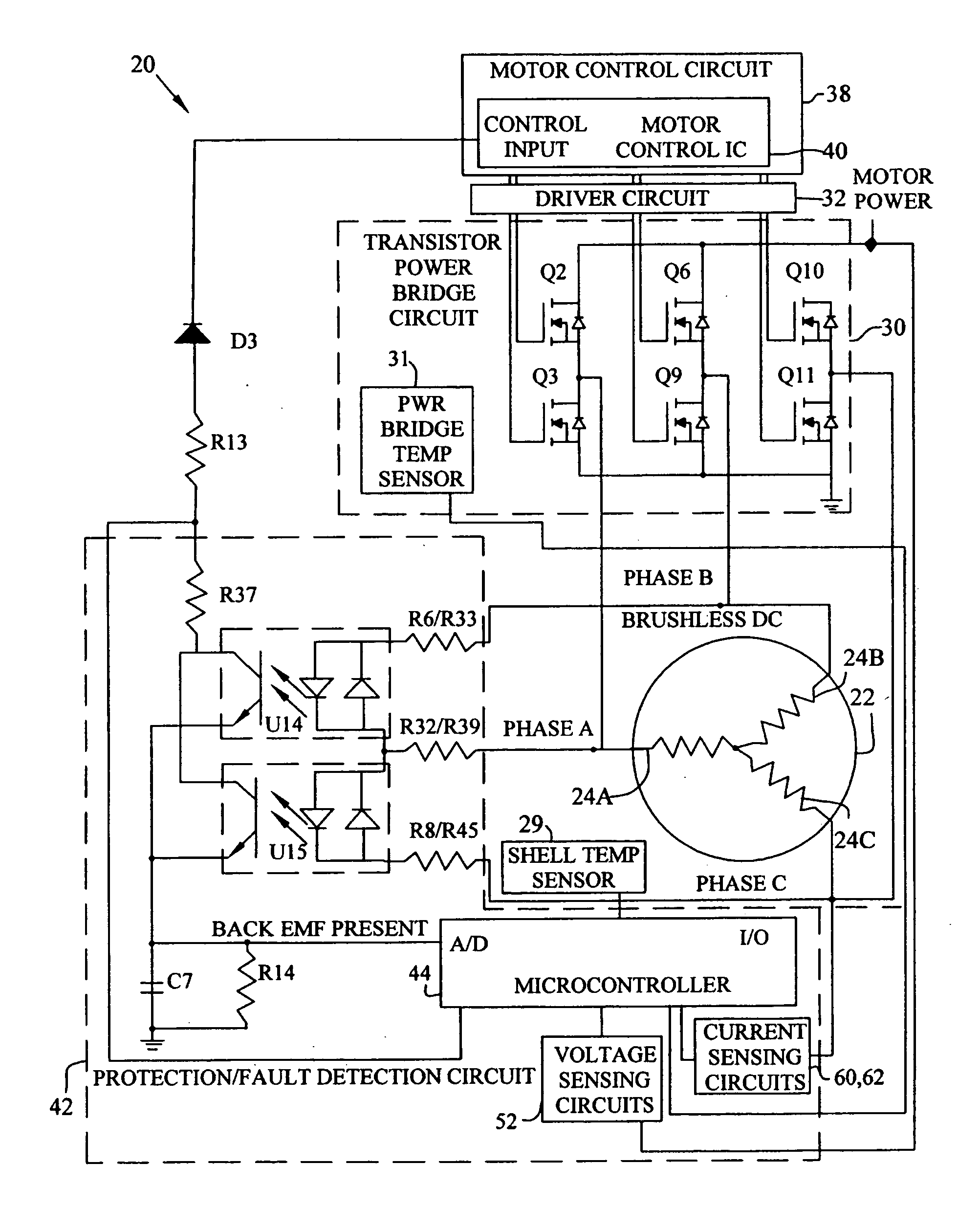

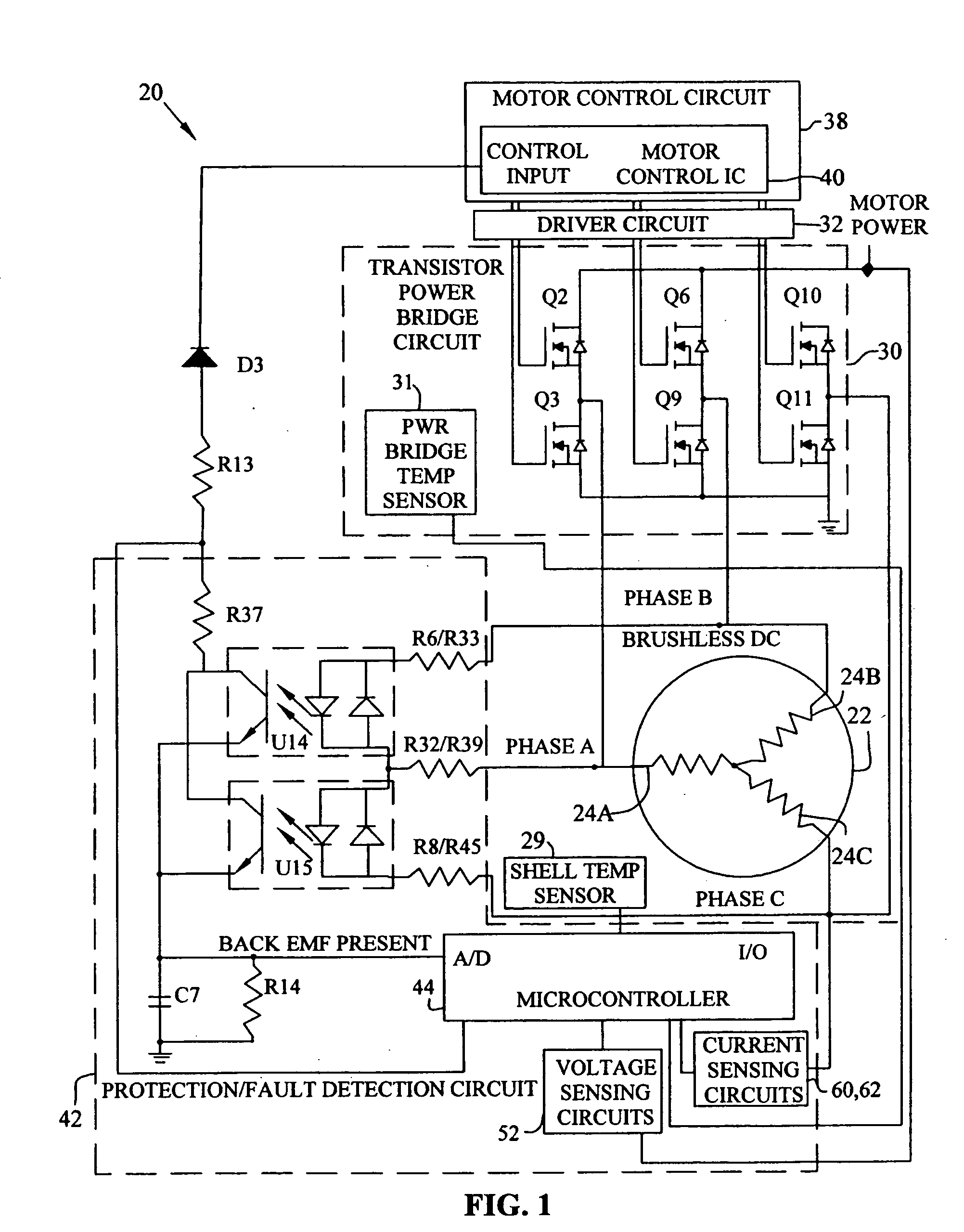

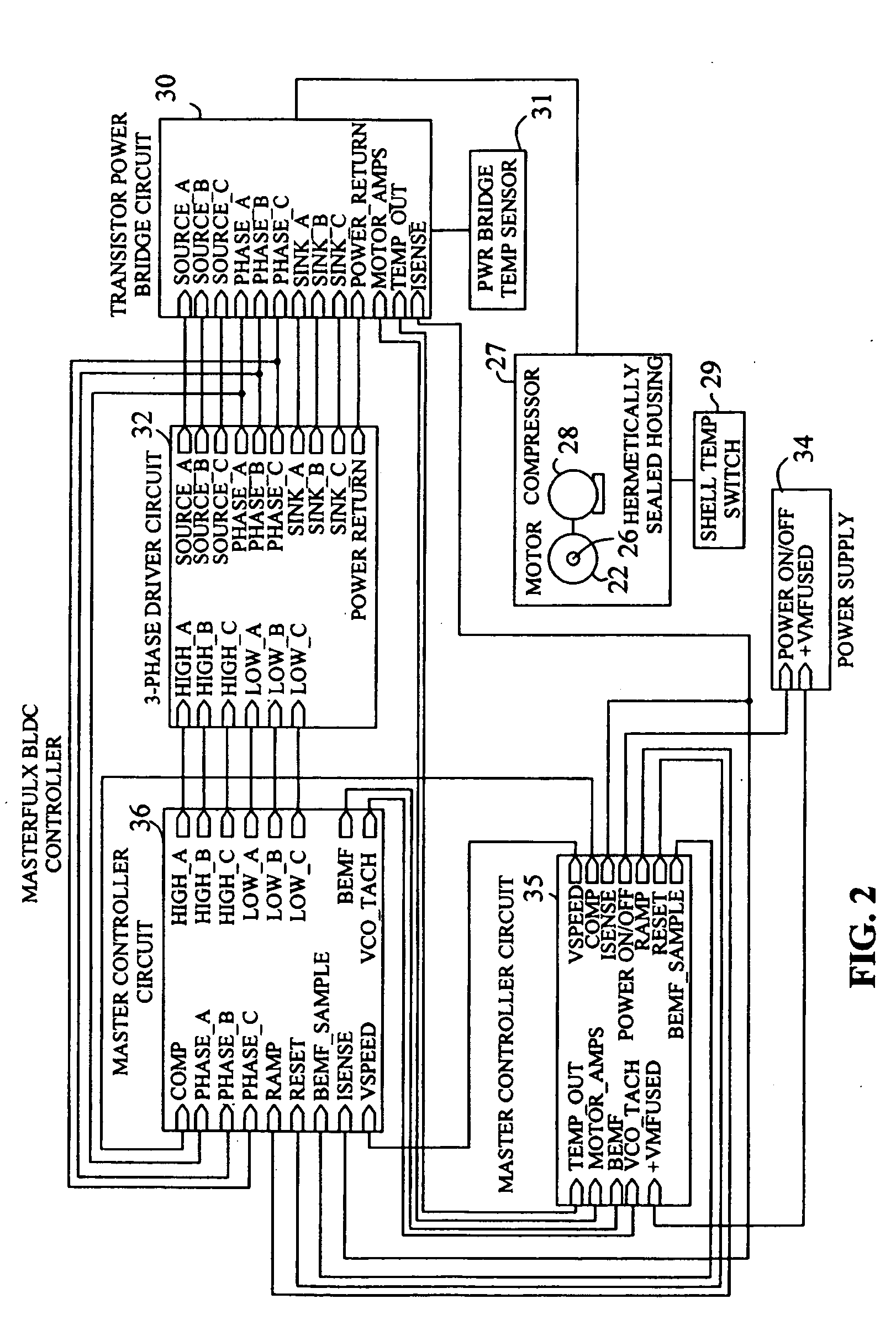

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS7042180B2Simple control methodEasily interfaceCommutation monitoringAC motor controlMotor speedDc motor control

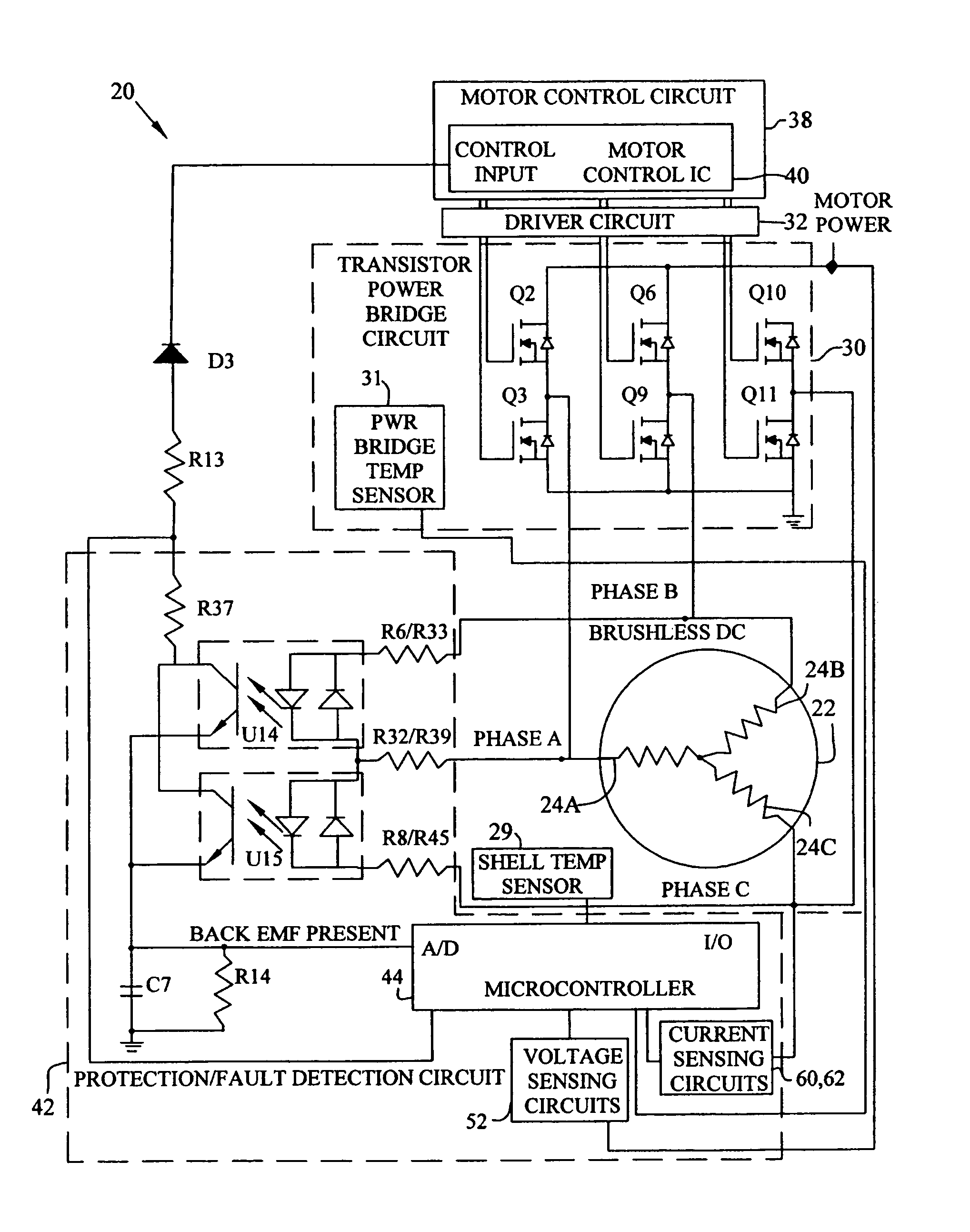

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

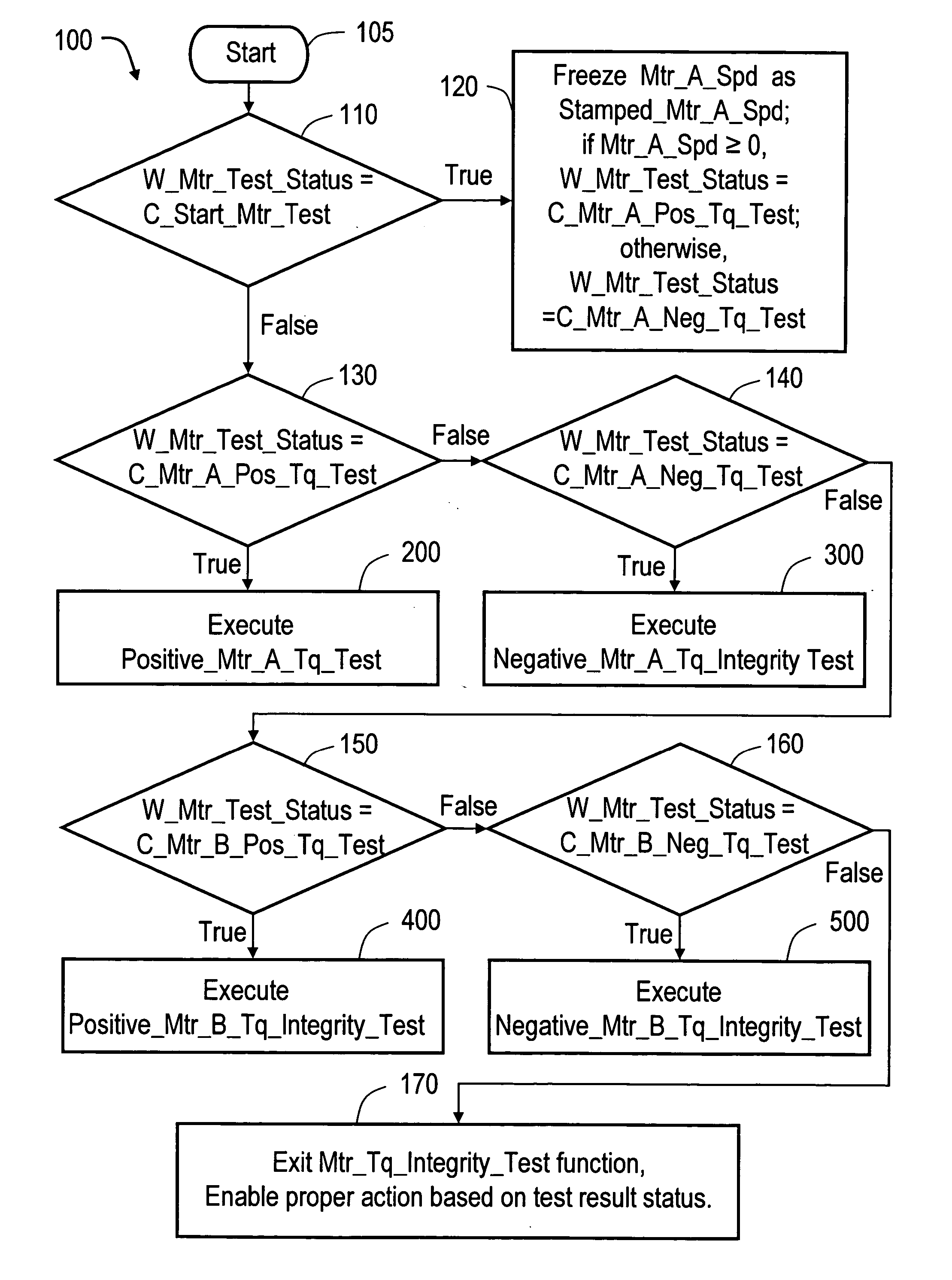

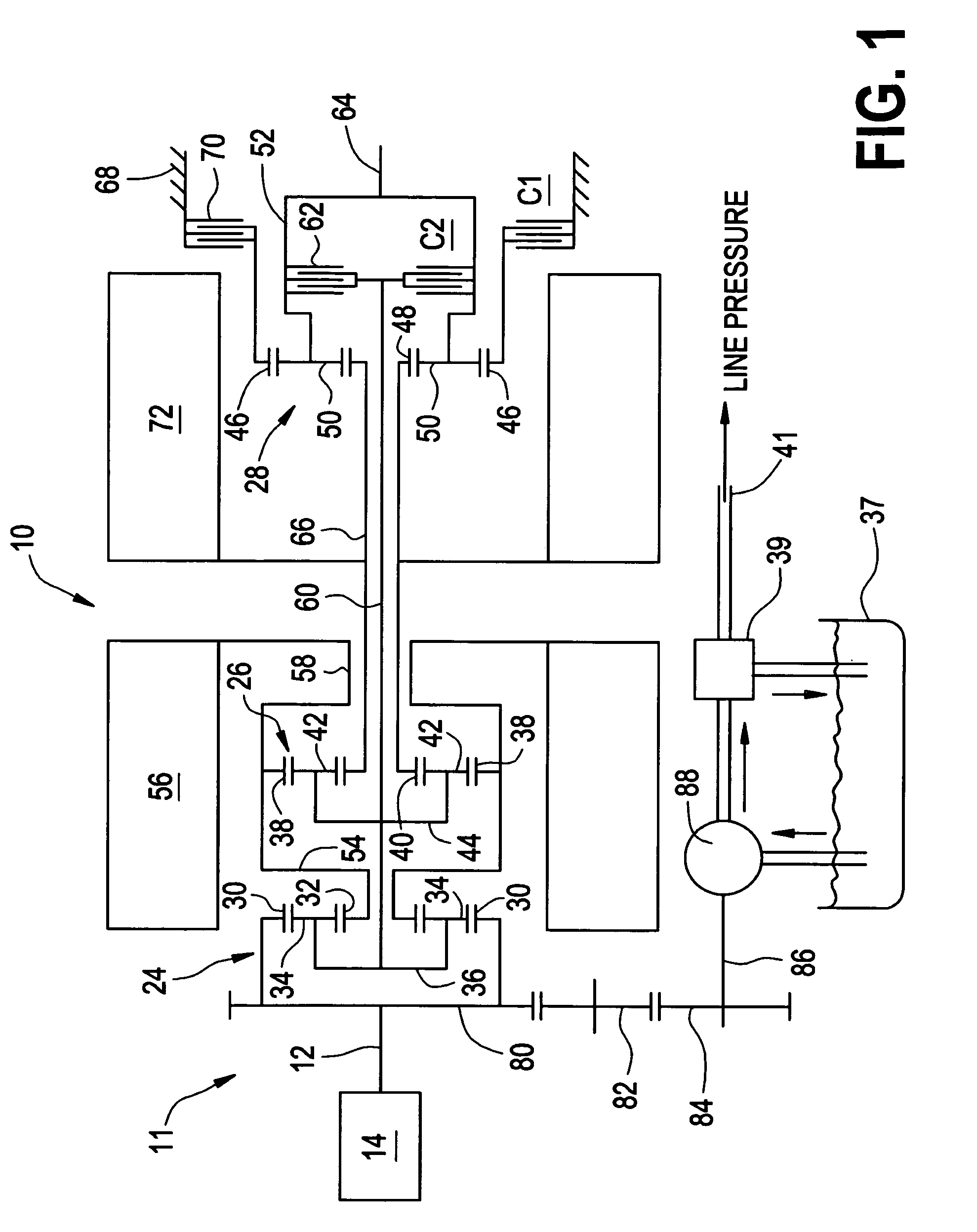

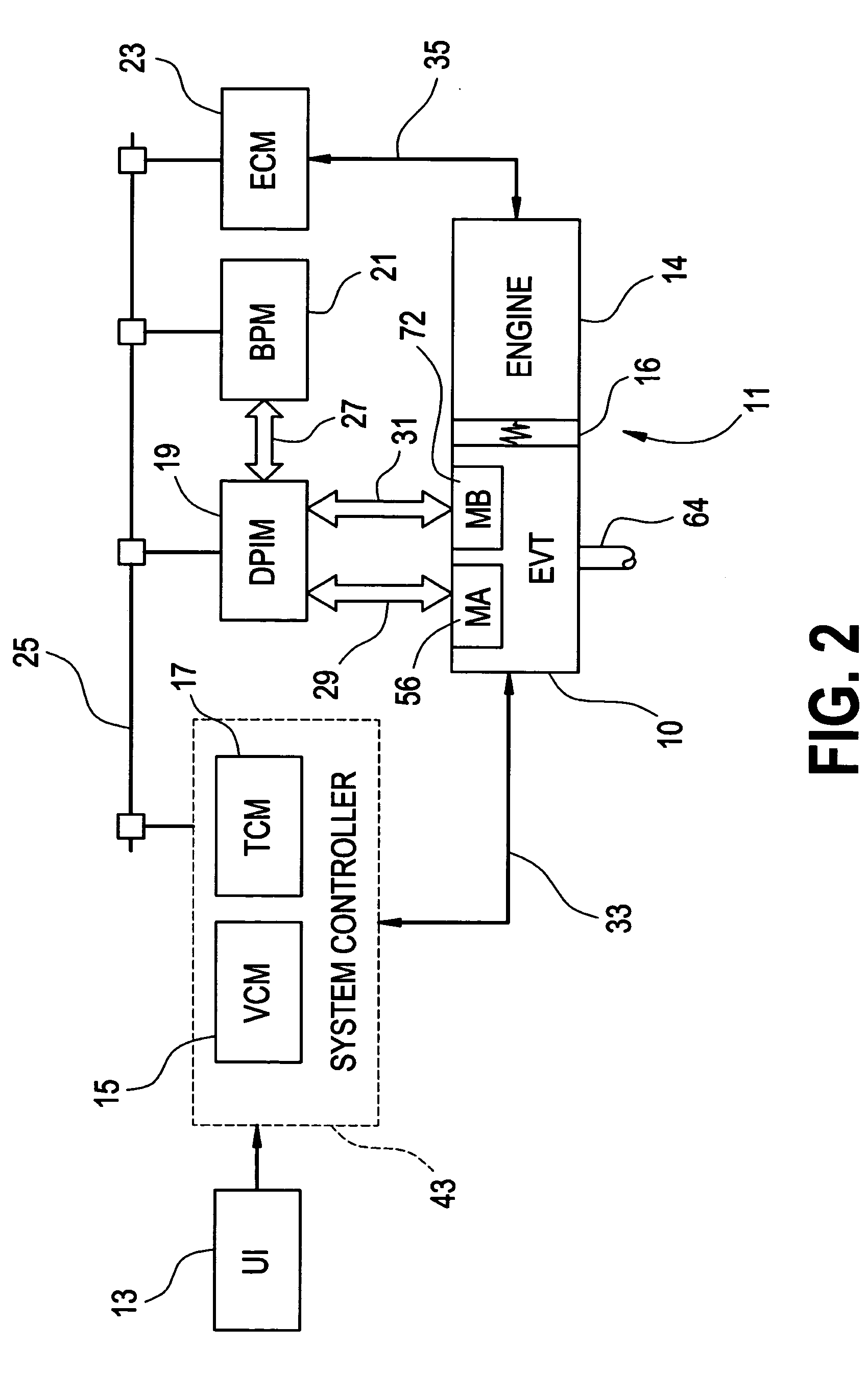

Method of testing motor torque integrity in a hybrid electric vehicle

InactiveUS20050256618A1DC motor speed/torque controlDigital data processing detailsMotor speedEngineering

A method of testing an electric motor that is adapted to provide a desired electric motor output torque to a vehicle powertrain system comprising an engine and the electric motor which are operatively and selectively coupled to a transmission. The method includes the steps of determining an initial motor speed of the electric motor, determining a motor torque command as a function of the initial motor speed, applying the motor torque command to the electric motor to produce an output torque from the electric motor, measuring a resultant motor speed of the electric motor and establishing a motor status as a function of the resultant motor speed. The method may be implemented as a computer control and diagnostic algorithm.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hybrid magnetically suspended and rotated centrifugal pumping apparatus and method

InactiveUS6074180AAvoid displacementEfficient startSpecific fluid pumpsPump componentsMotor speedRotary pump

An apparatus and method for a centrifugal fluid pump for pumping sensitive biological fluids, which includes (i) an integral impeller and rotor which is entirely supported by an integral combination of permanent magnets and electromagnetic bearings and rotated by an integral motor, (ii) a pump housing and arcuate passages for fluid flow and containment, (iii) a brushless driving motor embedded and integral with the pump housing, (iv) a power supply, and (v) specific electronic sensing of impeller position, velocity or acceleration using a self-sensing method and physiological control algorithm for motor speed and pump performance based upon input from the electromagnetic bearing currents and motor back emf-all fitly joined together to provide efficient, durable and low maintenance pump operation. A specially designed impeller and pump housing provide the mechanism for transport and delivery of fluid through the pump to a pump output port with reduced fluid turbulence.

Owner:WORLD HEART +2

Brushless and sensorless DC motor control system with locked and stopped rotor detection

ActiveUS20050029976A1Easy to modifyEasily interfaceCommutation monitoringDC motor speed/torque controlMotor speedDc motor control

A motor control system for a brushless and sensorless DC motor for driving a compressor, pump or other application, includes a protection and fault detection circuit for detecting a locked rotor and a rotor which has stopped because of lost rotor phase lock. The motor control system also includes an off-the-shelf motor control integrated circuit having an input for disabling power outputs to the motor phase coils. The protection and fault detection circuit uses a back EMF sampling circuit coupled to the motor phase coils and momentarily disables power to the motor phase coils, via the motor control integrated circuit input, to determine if the motor rotor is rotating. The system also monitors supply voltage, supply current, temperature, and motor speed limits to detect faults and protect system components.

Owner:REGAL BELOIT AMERICA

Double ended blower and volutes therefor

InactiveUS20030168064A1Faster pressure rise timeImprove reliabilityPropellersElement comparisonMotor speedImpeller

A double-ended variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the double-ended blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

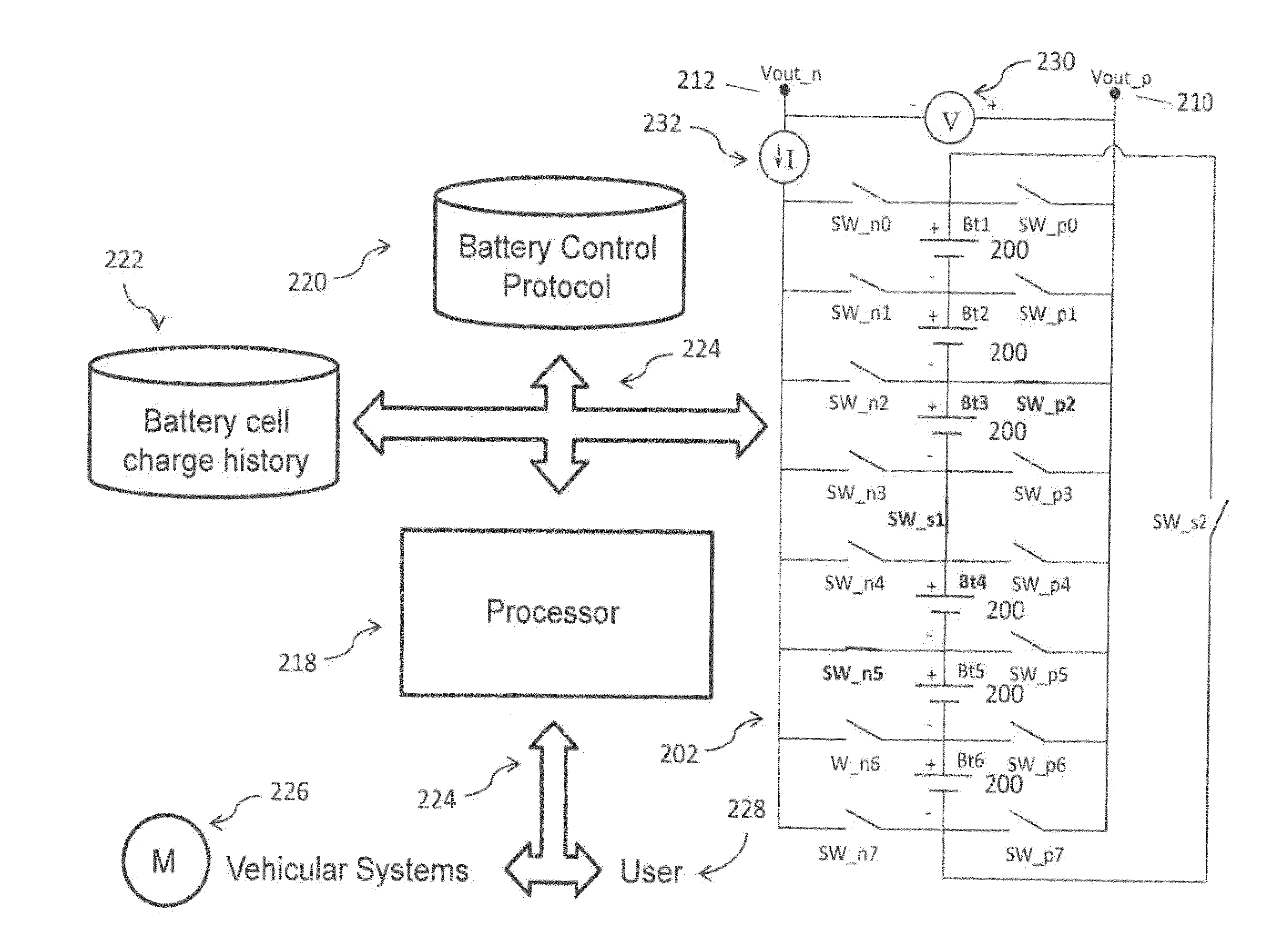

Multi-port reconfigurable battery

A multi-port reconfigurable battery has at least one bank of statically joined series connected battery cells, each including a positive and negative pole connected through switches to respective output connections on at least one port. Processor controlled switches reconfigure the cells to provide power for electrical loads on one or more ports and simultaneously provide charging on one or more other ports. An alternative configuration divides groups of series connected cells into separate battery banks that permit other configurations. Ports are configurable to share one electrically common connection with other ports providing a simplified configuration (multi-tap reconfigurable battery). Applications include selectable motor speed control and battery regeneration schemes matched to motor output, and single or multiphase AC power output at selectable frequencies for use as an Uninterruptible Power Supply. The battery is also described as a power source for a forced-air induction system (e.g. electric supercharger) for a combustion engine.

Owner:SOLSONA ENTERPRISE LLC

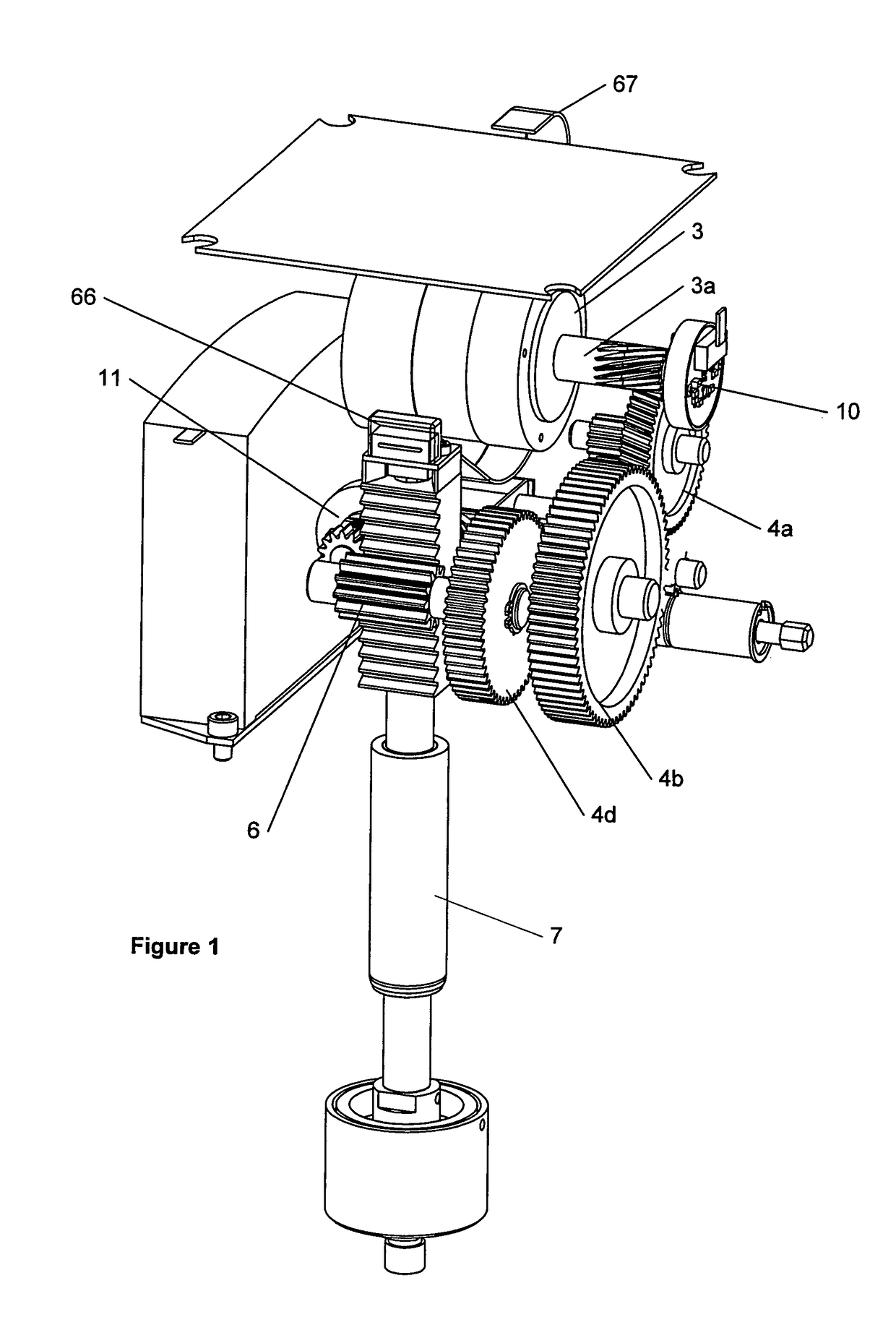

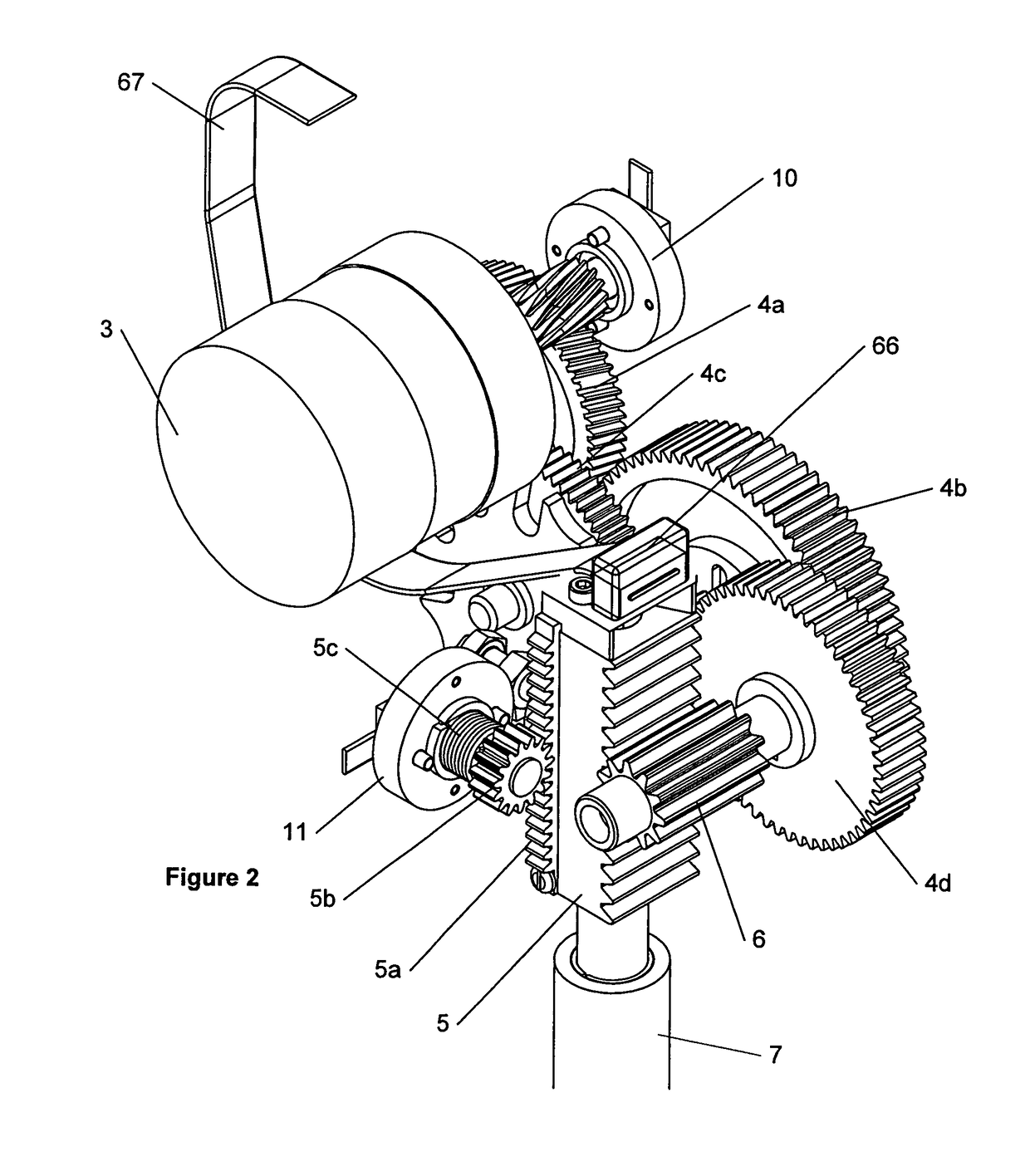

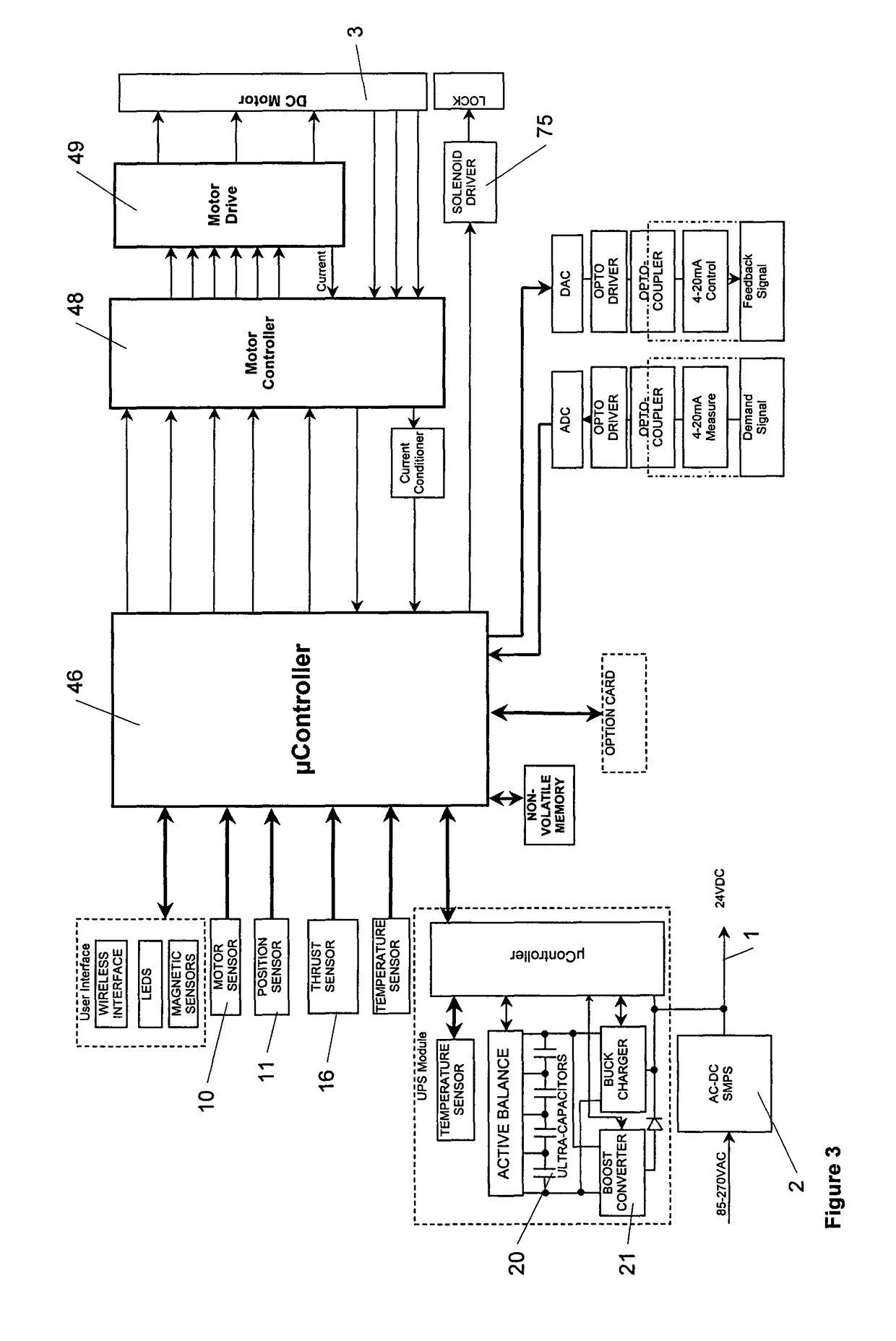

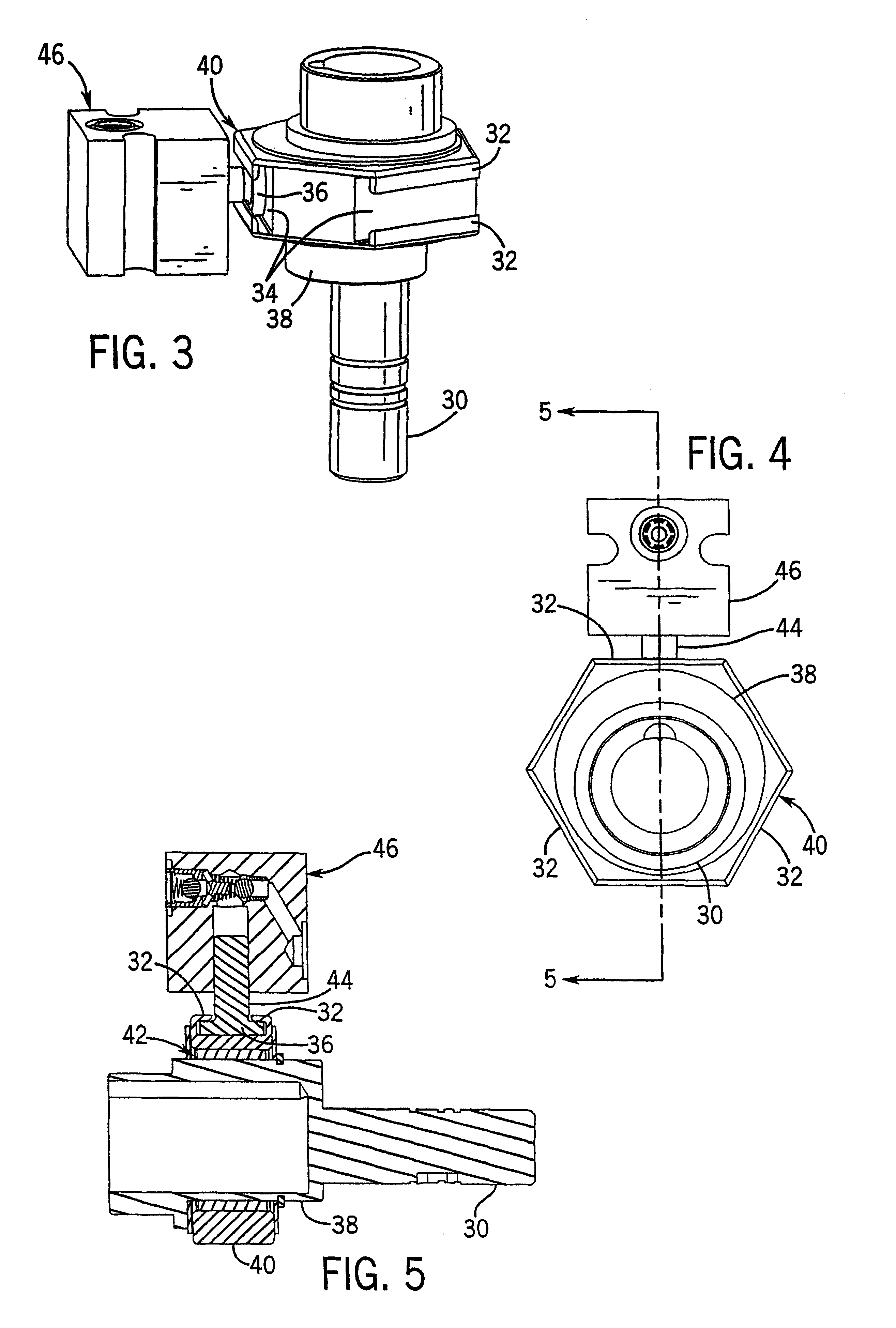

Valve actuators

ActiveUS8118276B2Low costImprove accuracySafety arrangmentsOperating means/releasing devices for valvesMotor speedValve actuator

A valve actuator having an electric drive motor with a motor shaft and having an output shaft linked to the motor shaft to drive movement of a valve, the actuator further having a control system arranged to provide a first closed loop control of the actuator output shaft and including a controller coupled to a first position sensor to sense the position of the actuator output shaft, and to a second position sensor to sense the position of the motor shaft and to enable determination of the speed of the motor shaft, the control system being configured to respond to sensed signals from the first and second sensors and adjust the motor speed / position accordingly.

Owner:ROTORK CONTROLS LTD

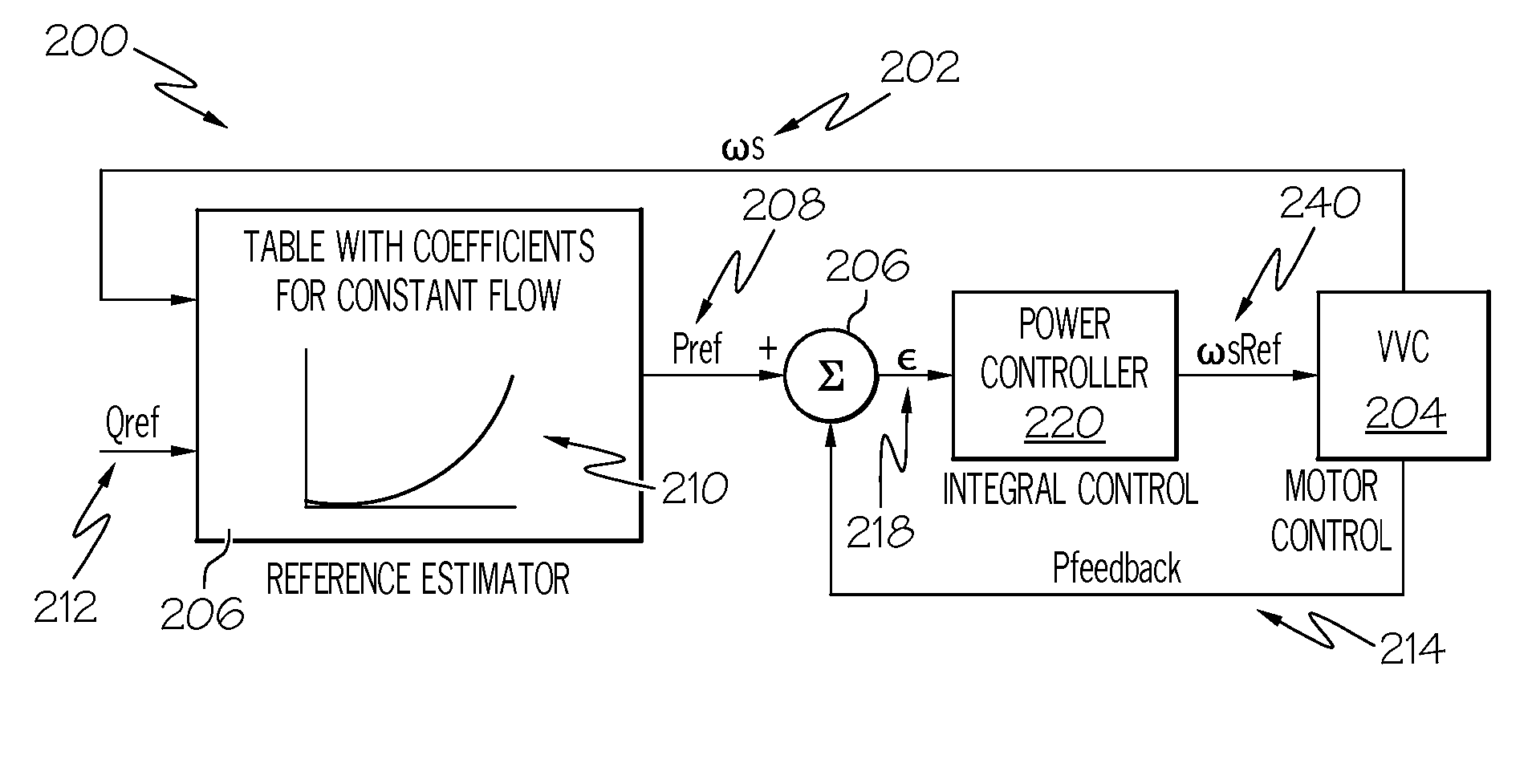

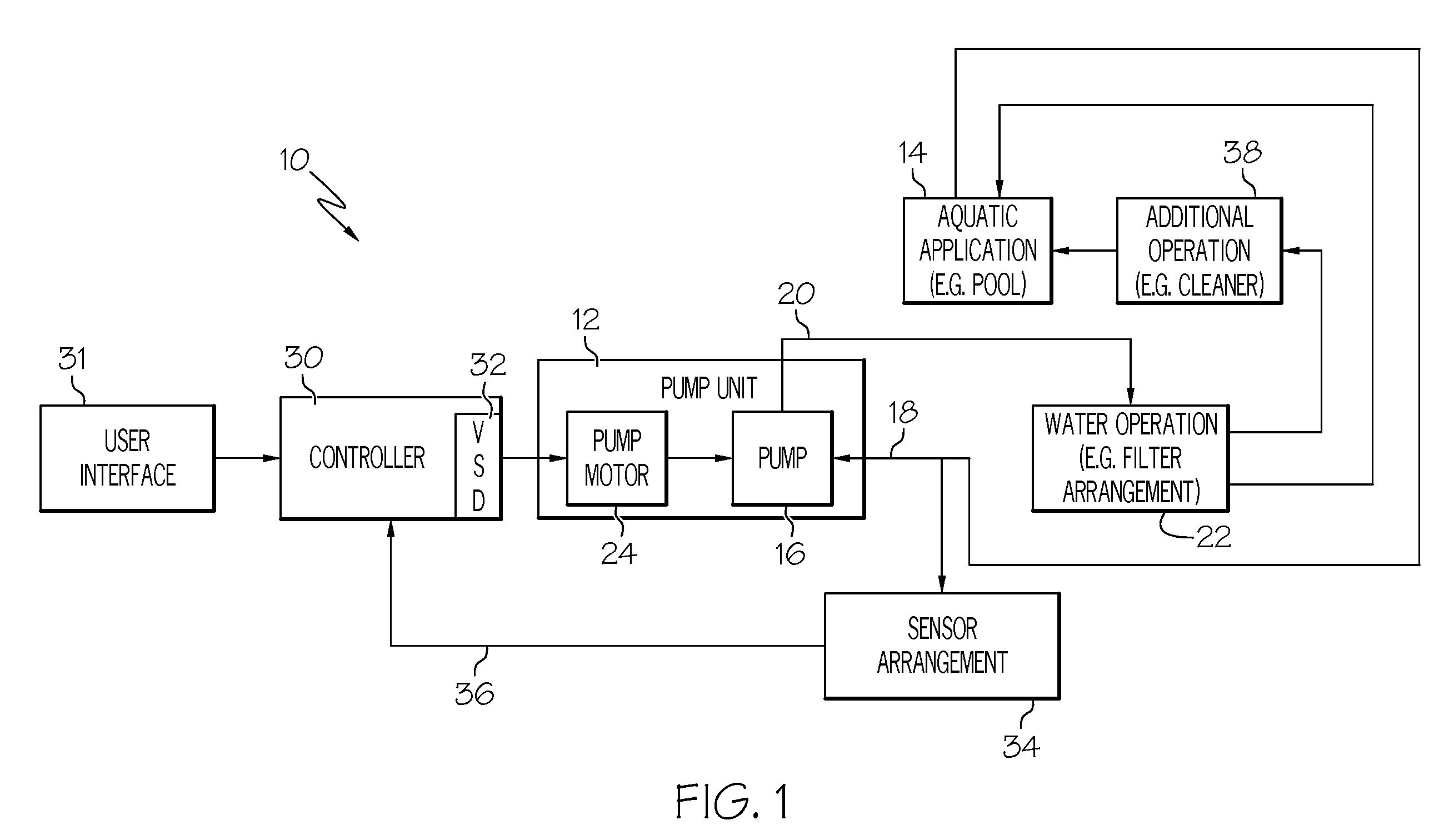

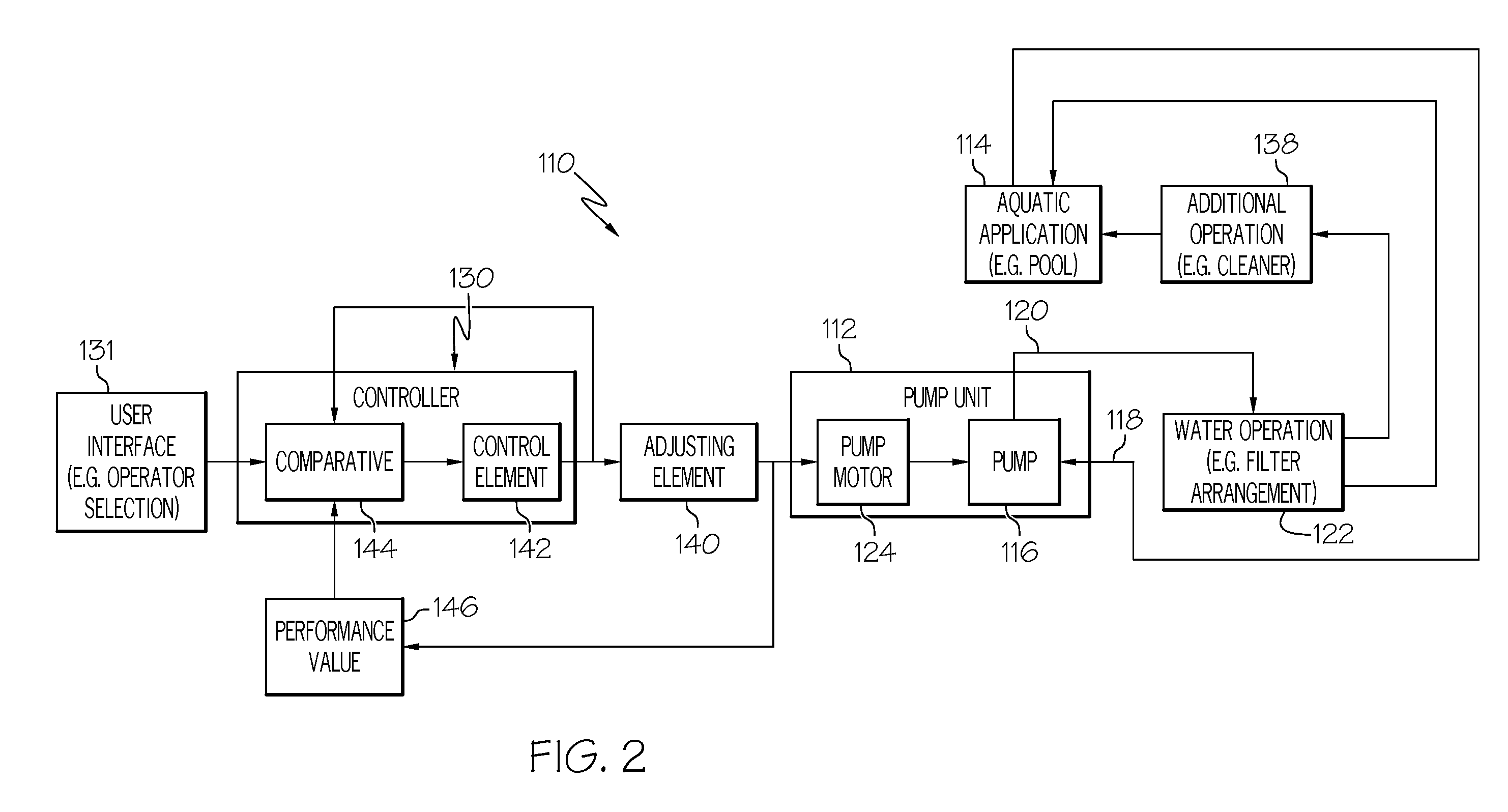

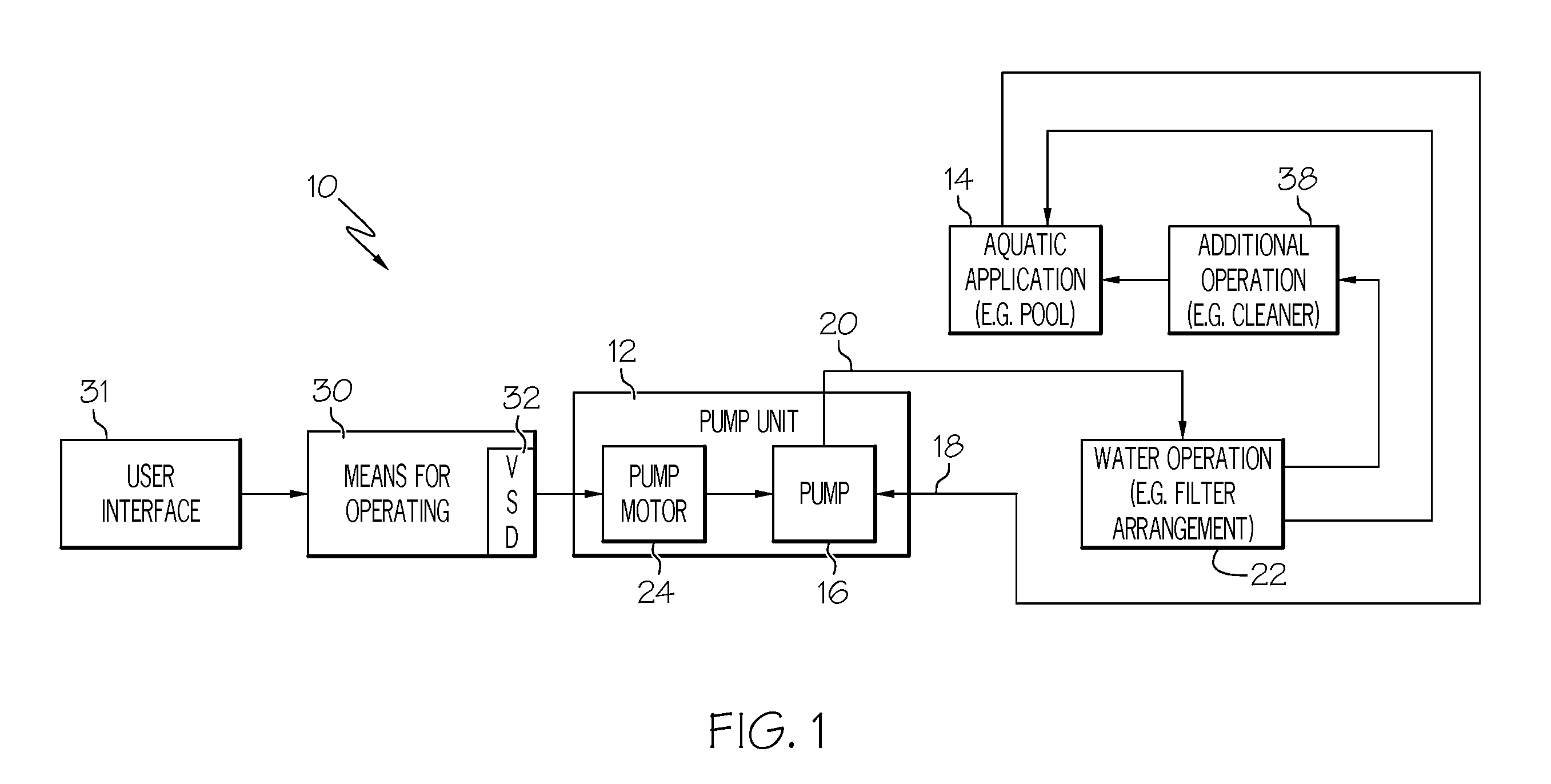

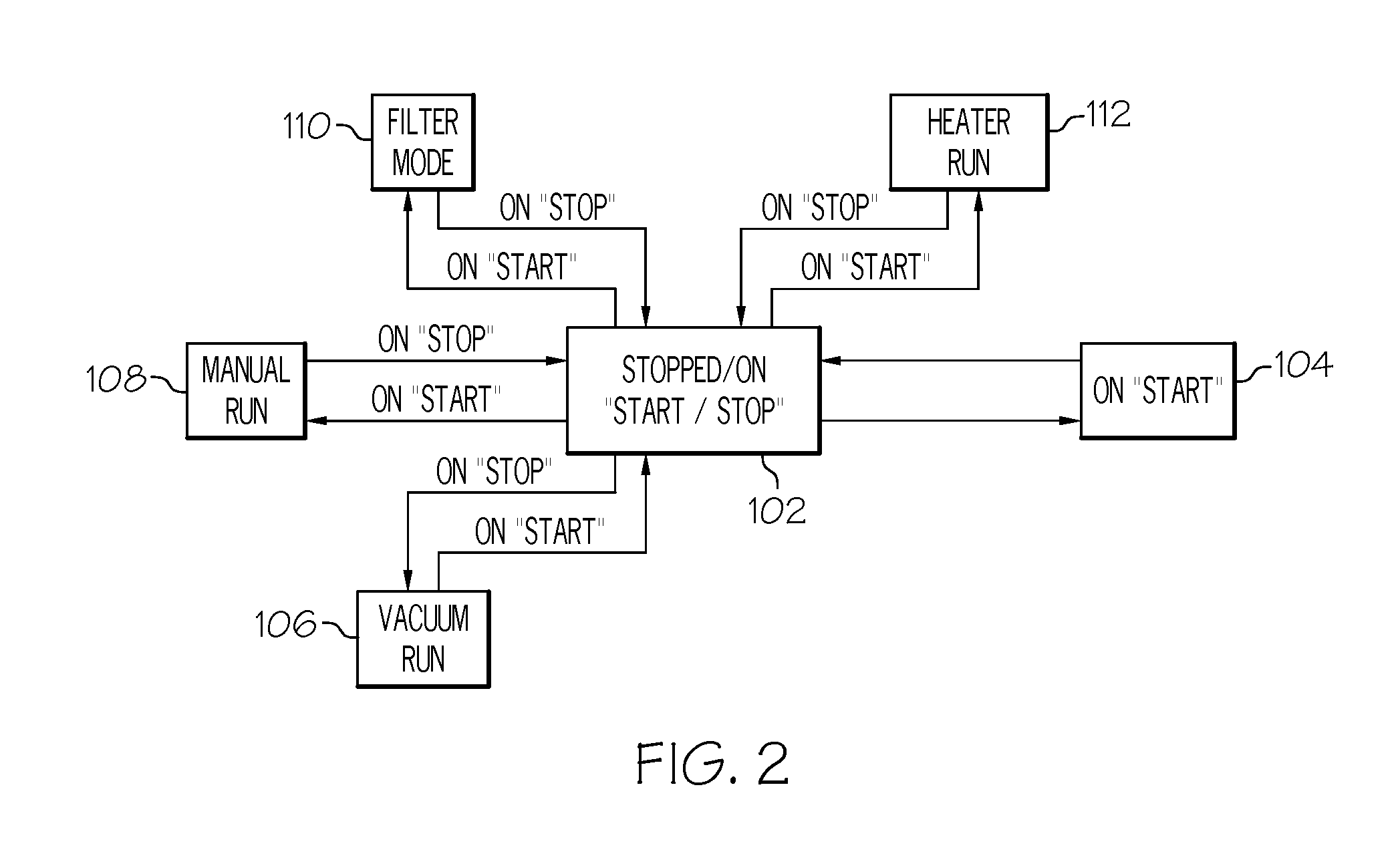

Flow control

A pumping system for moving water of a swimming pool includes a water pump and a variable speed motor. The pumping system further includes means for determining a first motor speed of the motor, means for determining first and second performance values of the pumping system, and means for comparing the first and second performance values. The pumping system further includes means for determining an adjustment value based upon the comparison, means for determining a second motor speed based upon the adjustment value, and means for controlling the motor in response to the second motor speed. In one example, the pumping system includes means for determining a value indicative of a flow rate of water moved by the pump. In addition or alternatively, the pumping system includes a filter arrangement. A method of controlling the pumping system for moving the water of the swimming pool is also disclosed.

Owner:DANFOSS POWER ELECTRONICS AS +1

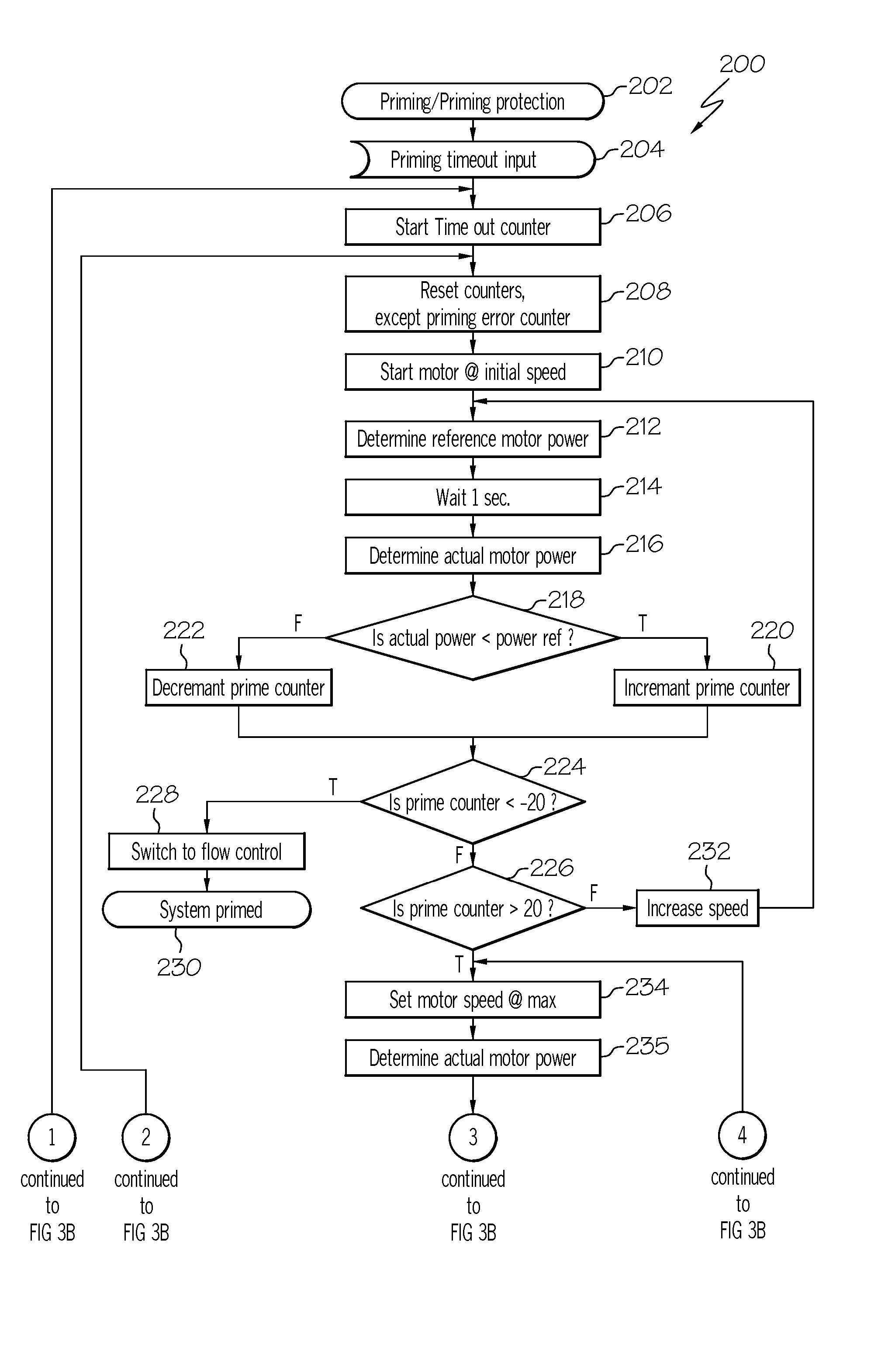

Priming protection

A method and apparatus are provided for determining a priming status of a pumping system. The pumping system includes a water pump and a variable speed motor. The method includes the steps of determining a reference power consumption of the motor, determining an actual power consumption of the motor, comparing the reference and actual power consumptions, and determining a priming status of the pumping system based upon the comparison. In addition or alternatively, the method includes operating the motor at a motor speed and altering control of the motor based upon the priming status. In addition or alternatively, the pumping system includes means for determining a reference power consumption of the motor, means for determining an actual power consumption of the motor, means for determining a priming status of the pumping system, and means for altering control of the motor based upon the priming status.

Owner:PENTAIR WATER POOL & SPA INC +1

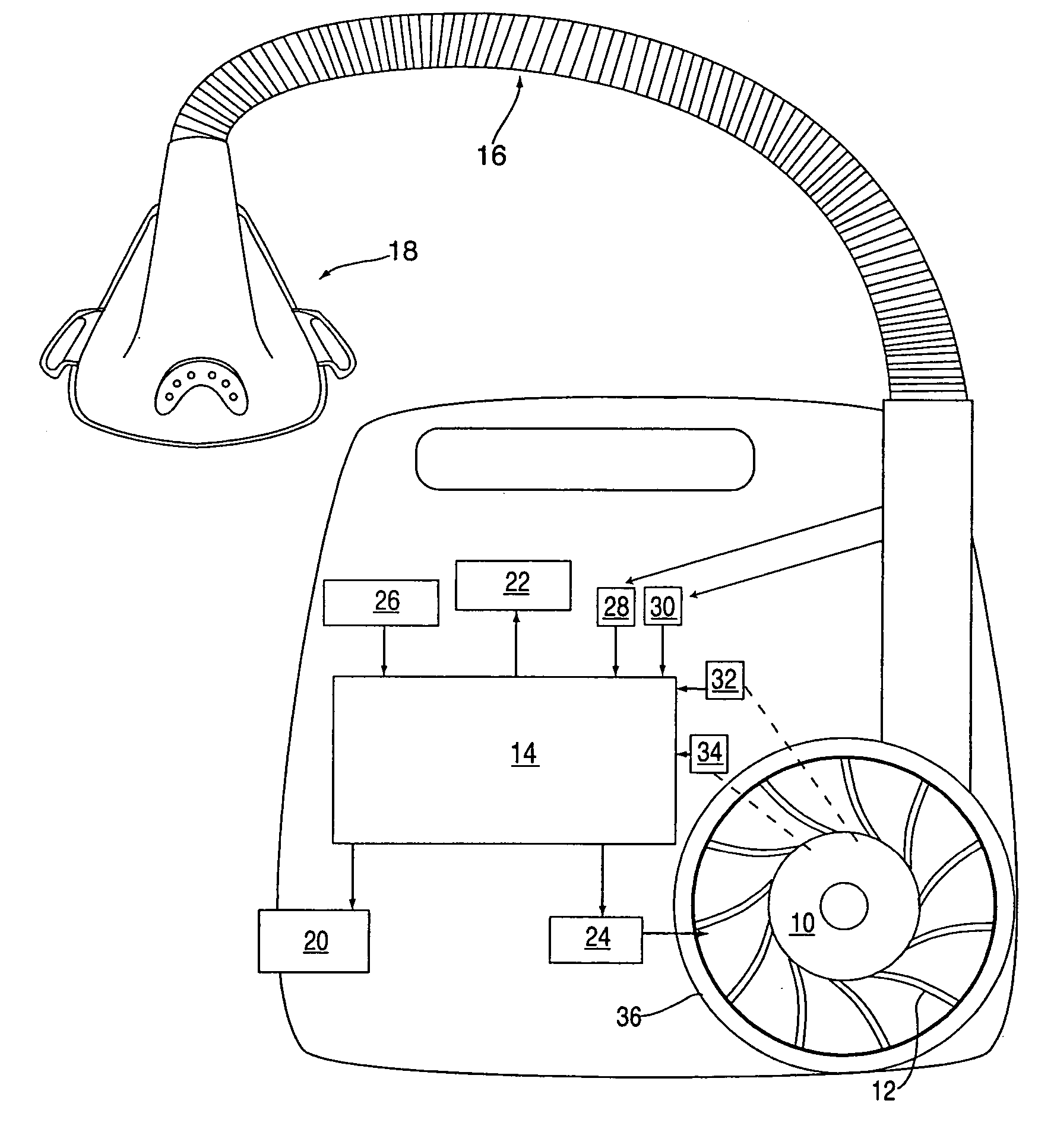

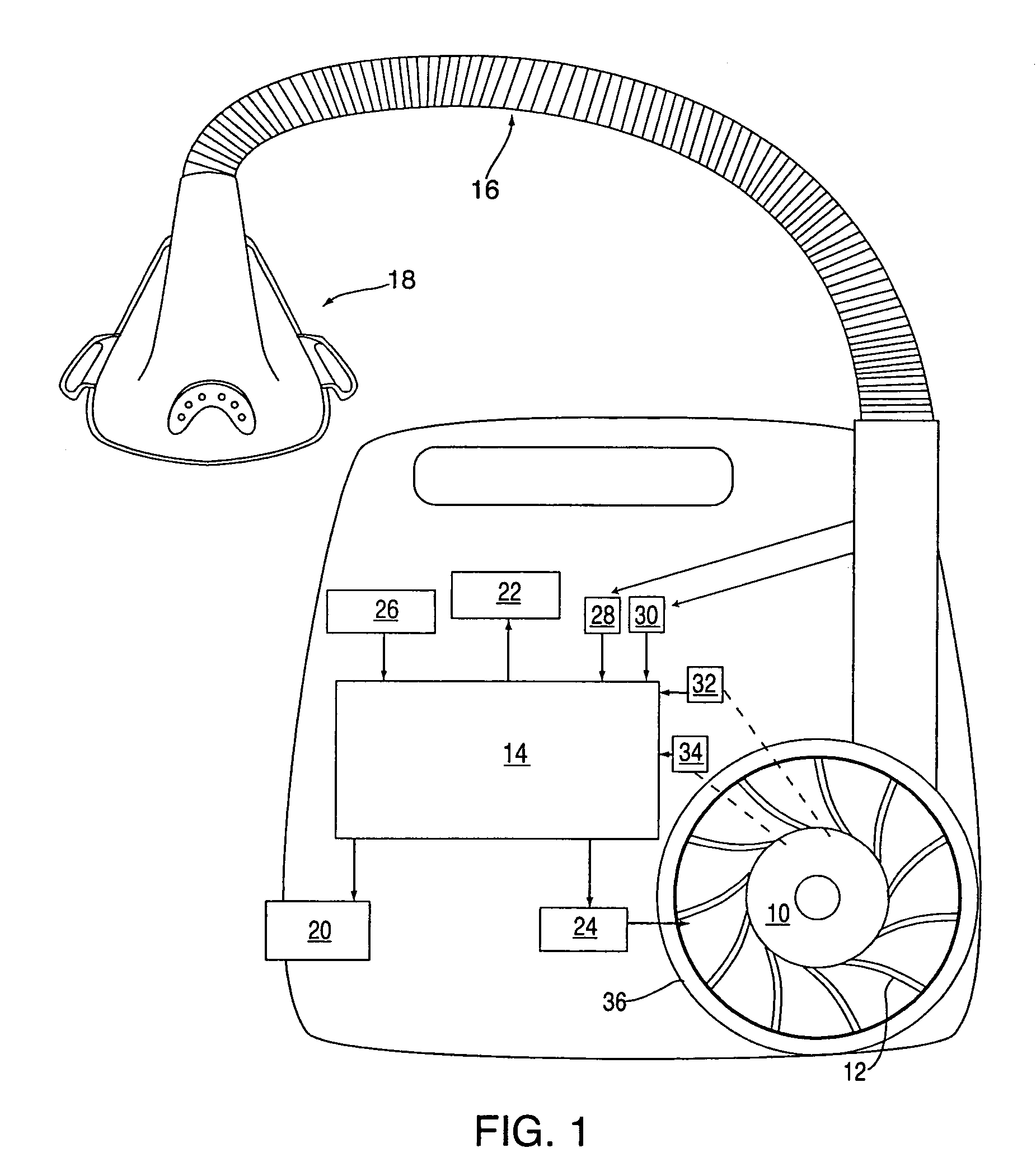

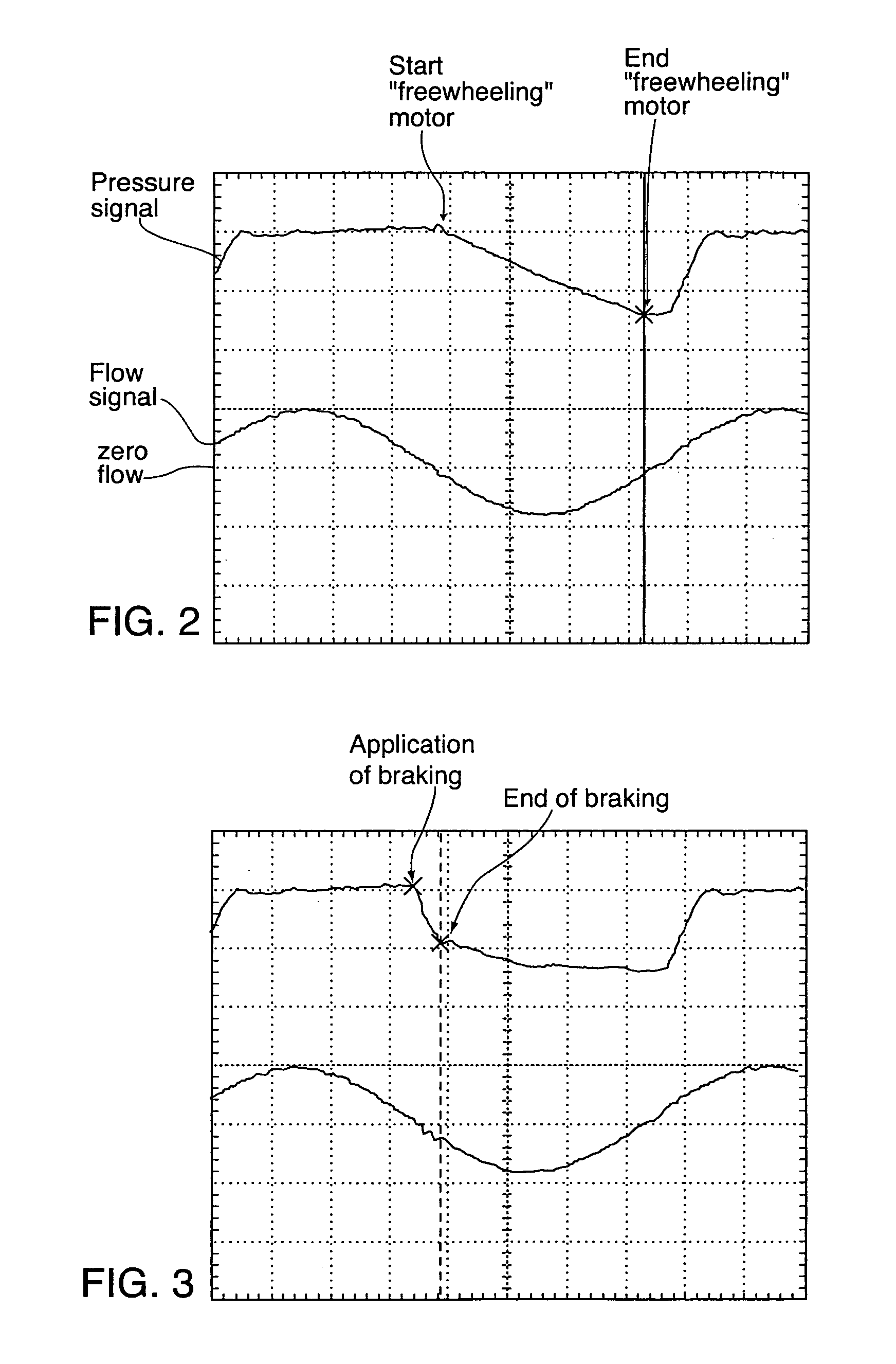

Method and apparatus for improving the comfort of CPAP

ActiveUS7128069B2Comfortable waveformReduce air pressureOperating means/releasing devices for valvesPhysical therapyMotor speedInhalation

A low-cost CPAP apparatus in which, upon detection of the transition from inhalation to exhalation, the blower motor is de-energized to allow it to freewheel. When the pressure in the patient mask (or whatever interface is utilized) reaches a minimum pressure level during exhalation, the motor is re-energized and its speed is controlled so to maintain the pressure at a level suitable for exhalation. Upon detection of the transition from exhalation to inhalation, the motor speed is increased to provide higher pressures in the patient mask suitable for inhalation.

Owner:RESMED LTD

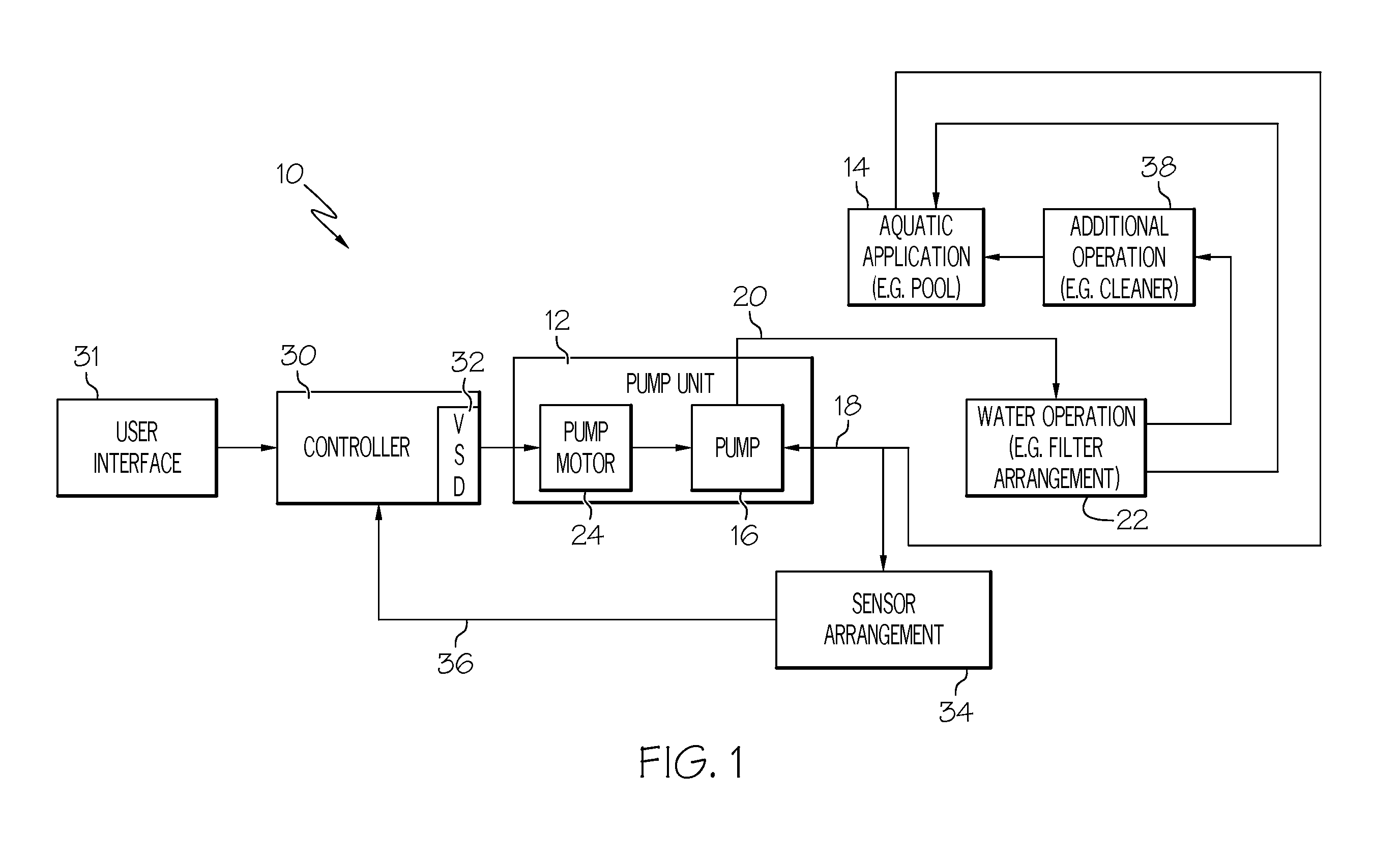

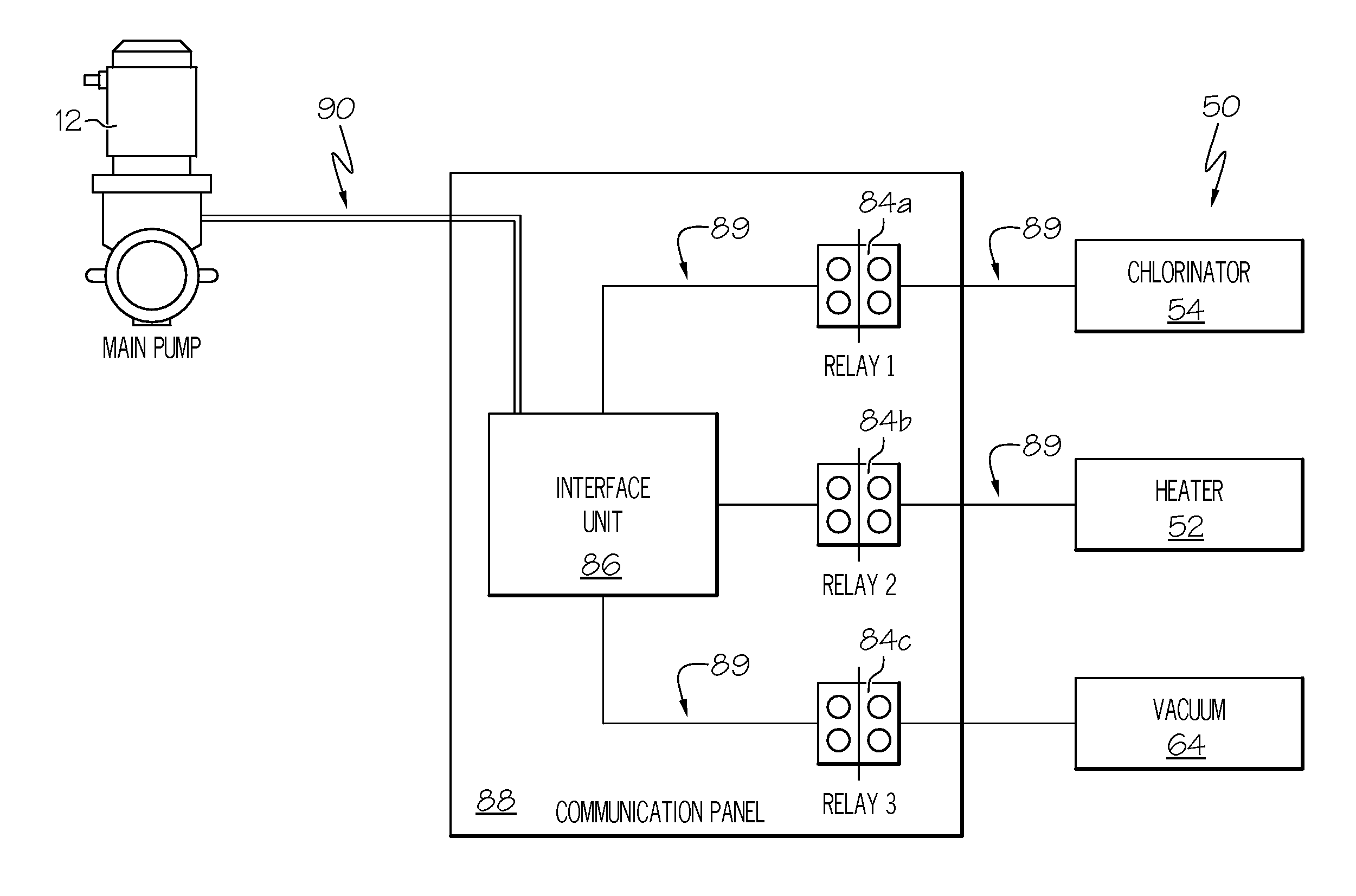

Speed control

A pumping system for moving water of a swimming pool includes a water pump, an infinitely variable speed motor, and an arrangement for operating the motor. In one example, the pumping system includes a memory configured to store a plurality of retained speed values, an arrangement for providing a plurality of retained speed values to the memory, and an arrangement for reading a selected one of the plurality of retained speed values from the memory. In addition or alternatively, the pumping system includes a storage medium for digitally storing a plurality of pre-established motor speed values and an arrangement for receiving input from a user to select one of the pre-established motor speeds. In addition or alternatively, the pumping system further includes an arrangement for restarting operation of the motor at a previously selected speed value when power supplied to the motor is interrupted during operation of the motor. A method for controlling the pumping system is also provided.

Owner:DANFOSS POWER ELECTRONICS AS +1

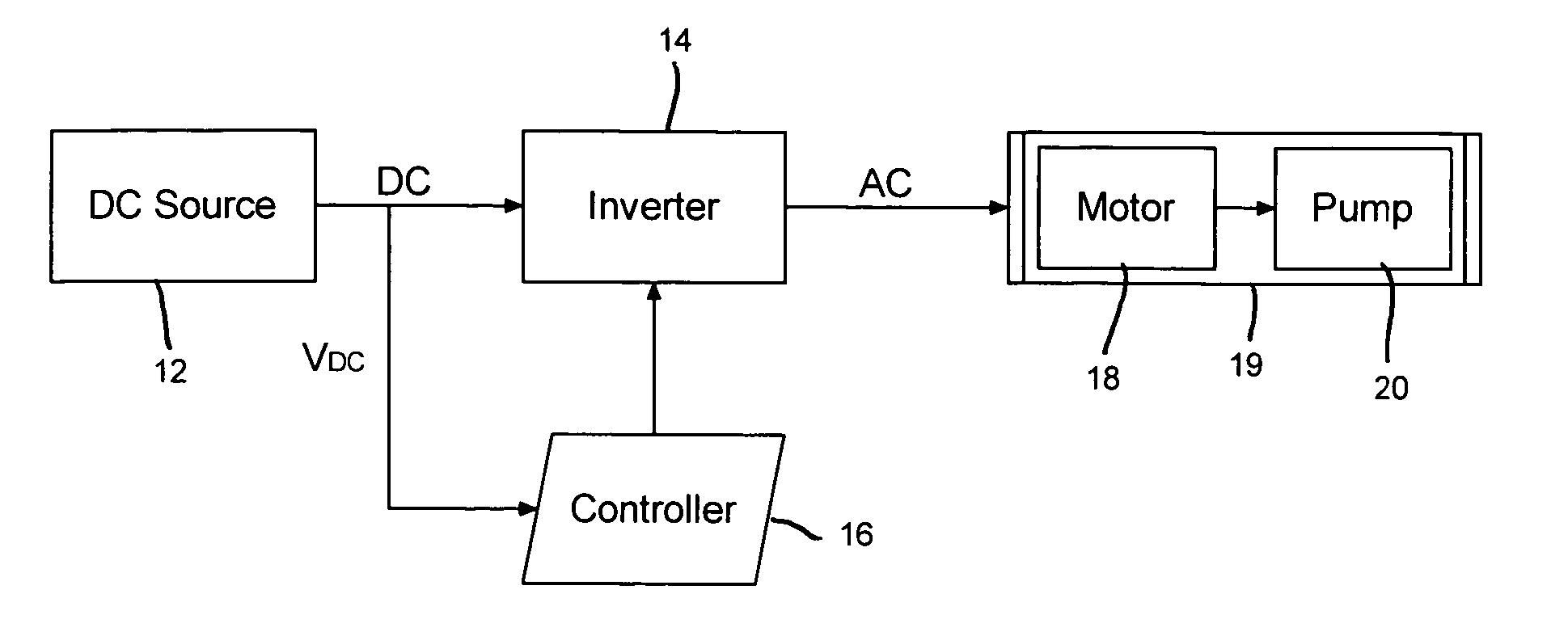

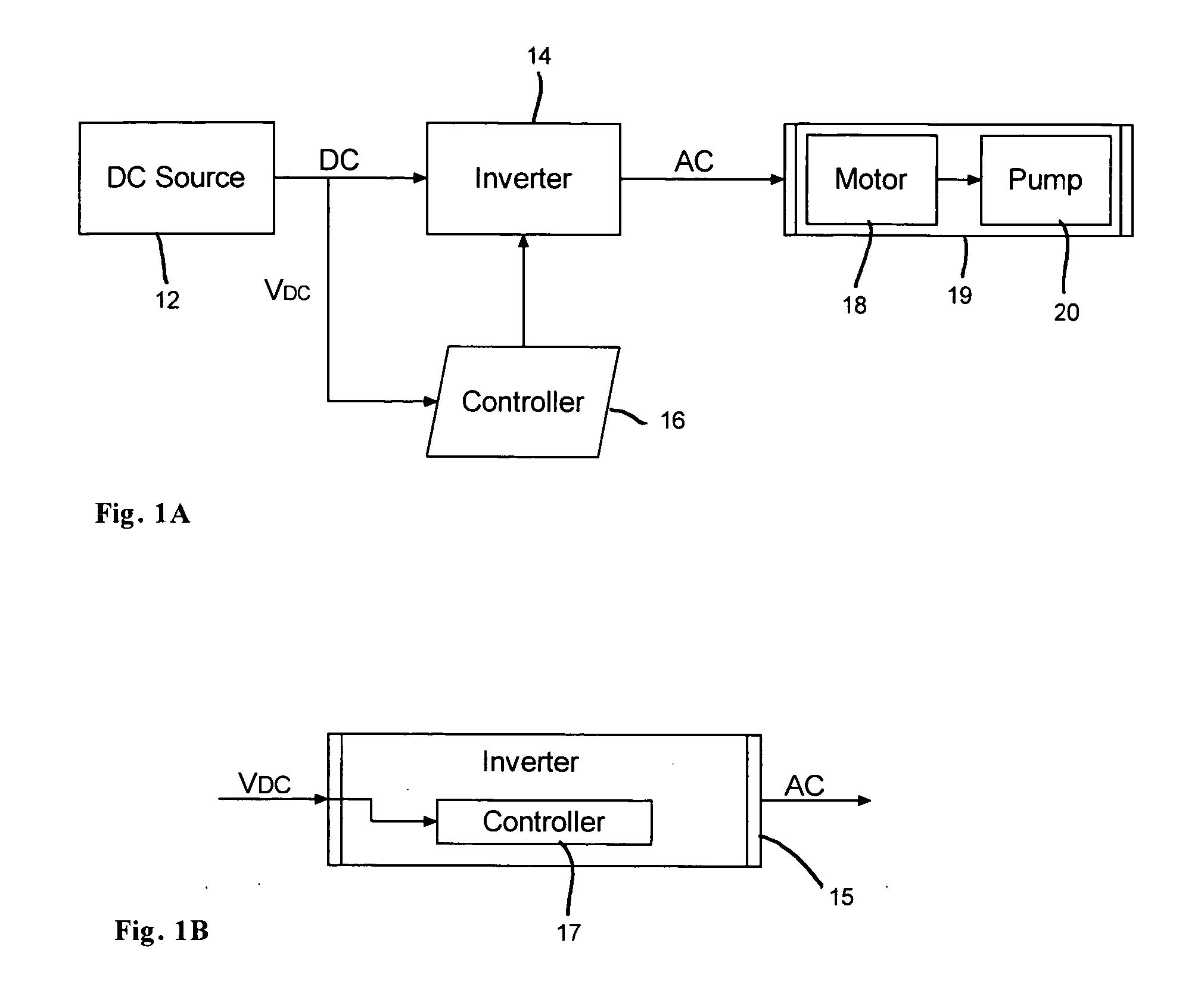

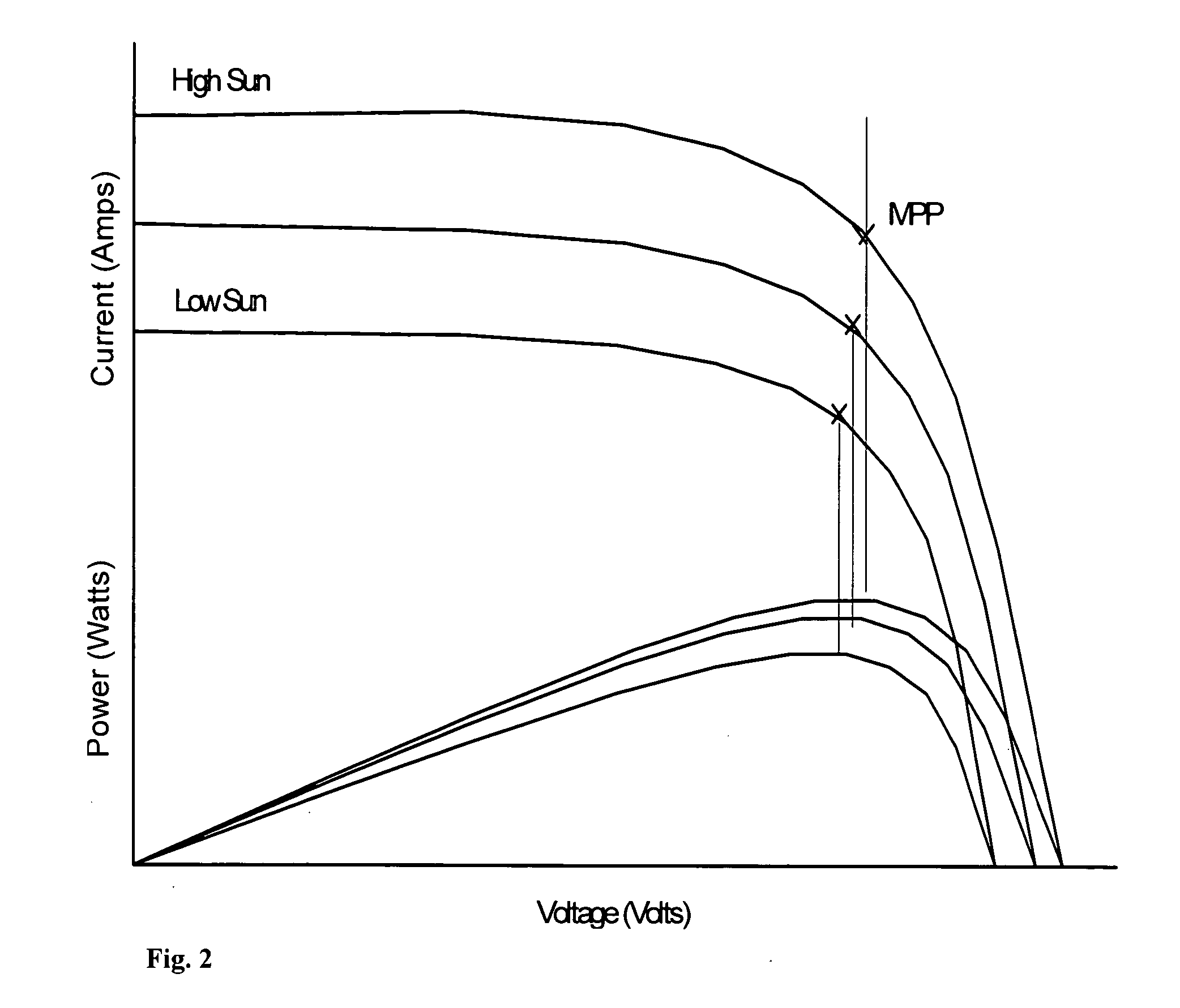

Maximum power point motor control

InactiveUS20060290317A1Batteries circuit arrangementsDC motor speed/torque controlMotor speedMotor drive

A method and apparatus are implemented in software to control motor speed as a function of available power in a DC source—inverter—AC motor system, i.e. to perform maximum power tracking of motor speed. An inverter or motor drive converts DC power from a DC source, such as a solar panel, to AC power, to power the motor. The inverter or motor drive is controlled by software, implemented either by programmable features built directly into the inverter or drive or by a separate programmable device connected to the inverter or drive, to track motor power as a function of source power. The software-controlled inverter or drive sets motor speed as a function of source power by sensing only a single parameter, the DC source voltage. The software-controlled inverter or drive samples the source voltage at preset intervals, and changes the frequency of the AC output of the inverter or drive to match or track the available power so that the motor operates at or near its optimum for any source voltage.

Owner:WORLDWATER & SOLAR TECH

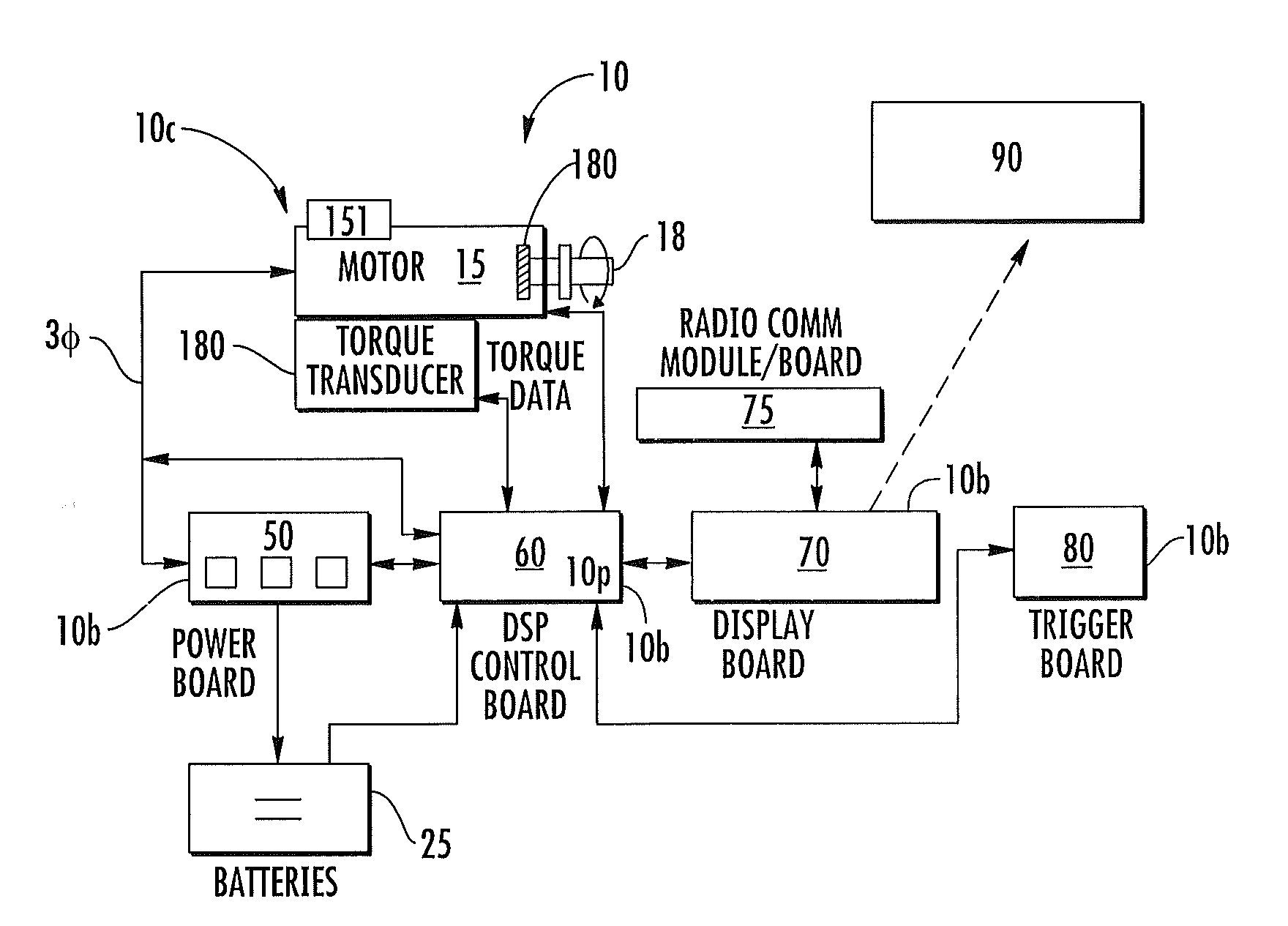

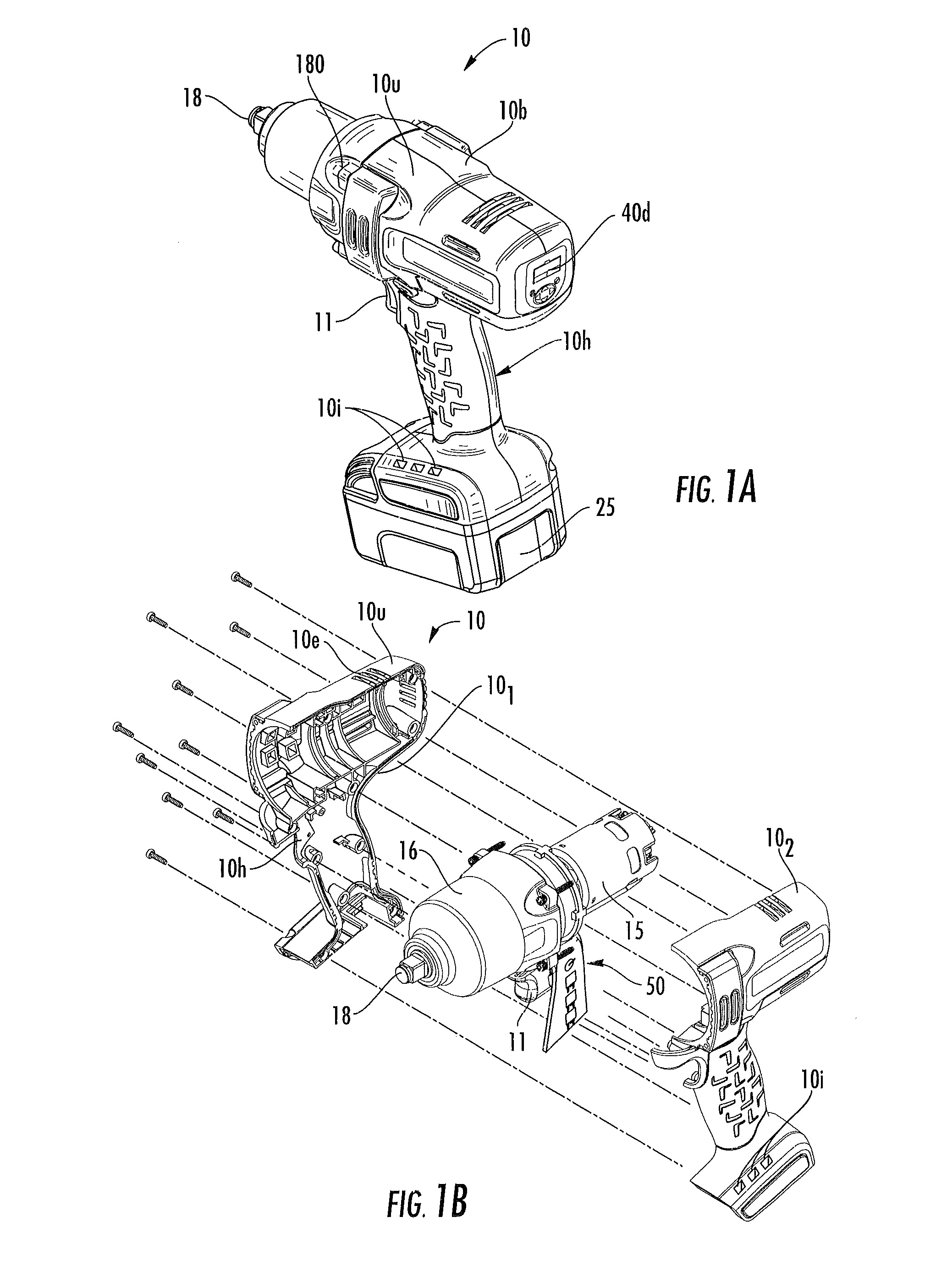

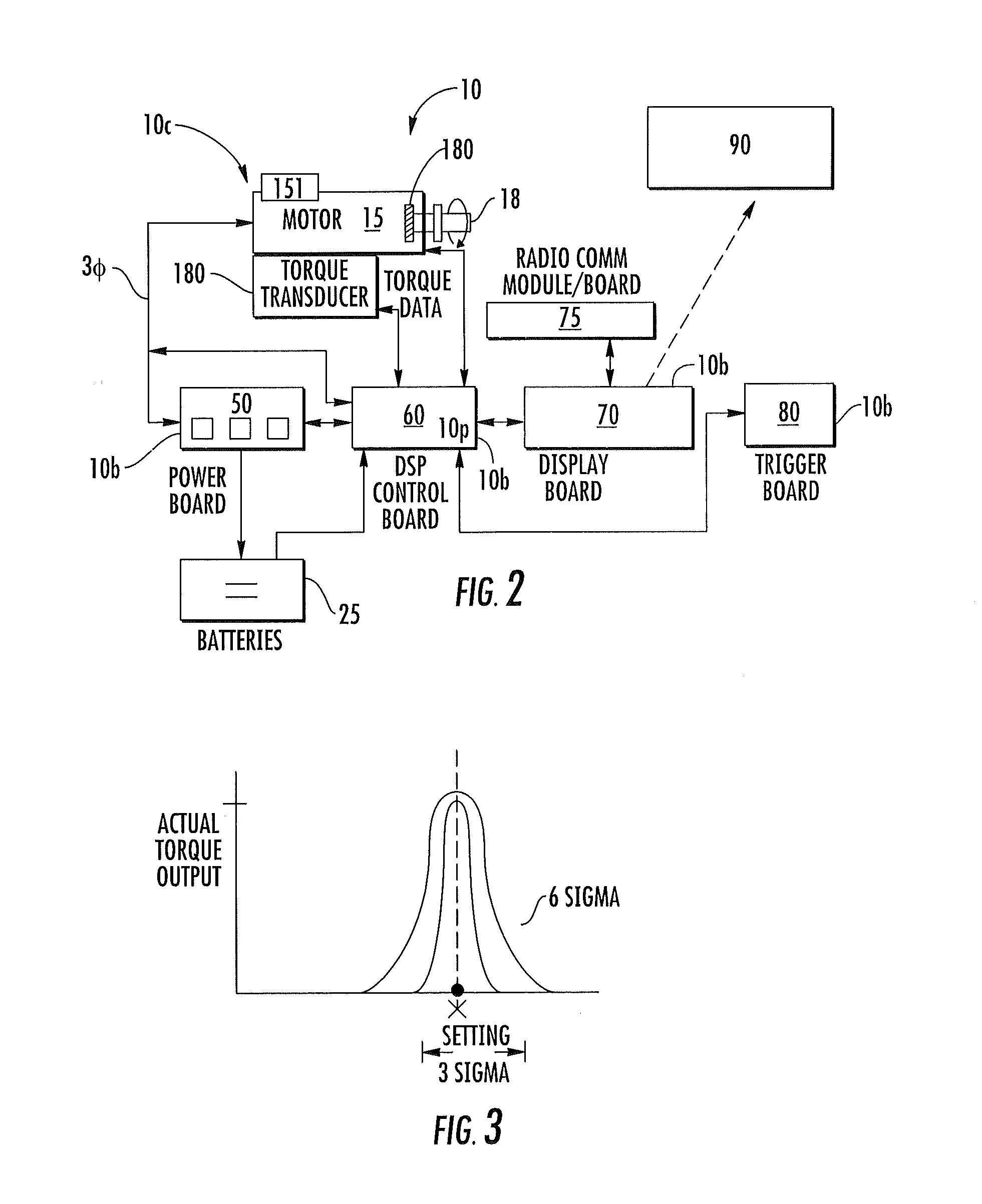

Precision-fastening handheld cordless power tools

ActiveUS20130193891A1Total current dropMotor/generator/converter stoppersSingle motor speed/torque controlMotor speedOn board

Cordless power tools include a pistol housing having an upper portion that merges into a downwardly extending handle, a DC motor residing in the upper portion of the housing, the DC motor having a rotor that drives an output shaft; a torque transducer on board the tool in communication with the output shaft; and a dynamic motor control circuit residing in the housing in communication with the motor and torque transducer. The dynamic motor control circuit includes a Kelvin resistor in communication with the motor for measuring motor current and digital hall switches in communication with the motor for measuring motor speed. The motor current can vary by at least 100 A during operation.

Owner:INGERSOLL RAND IND U S INC

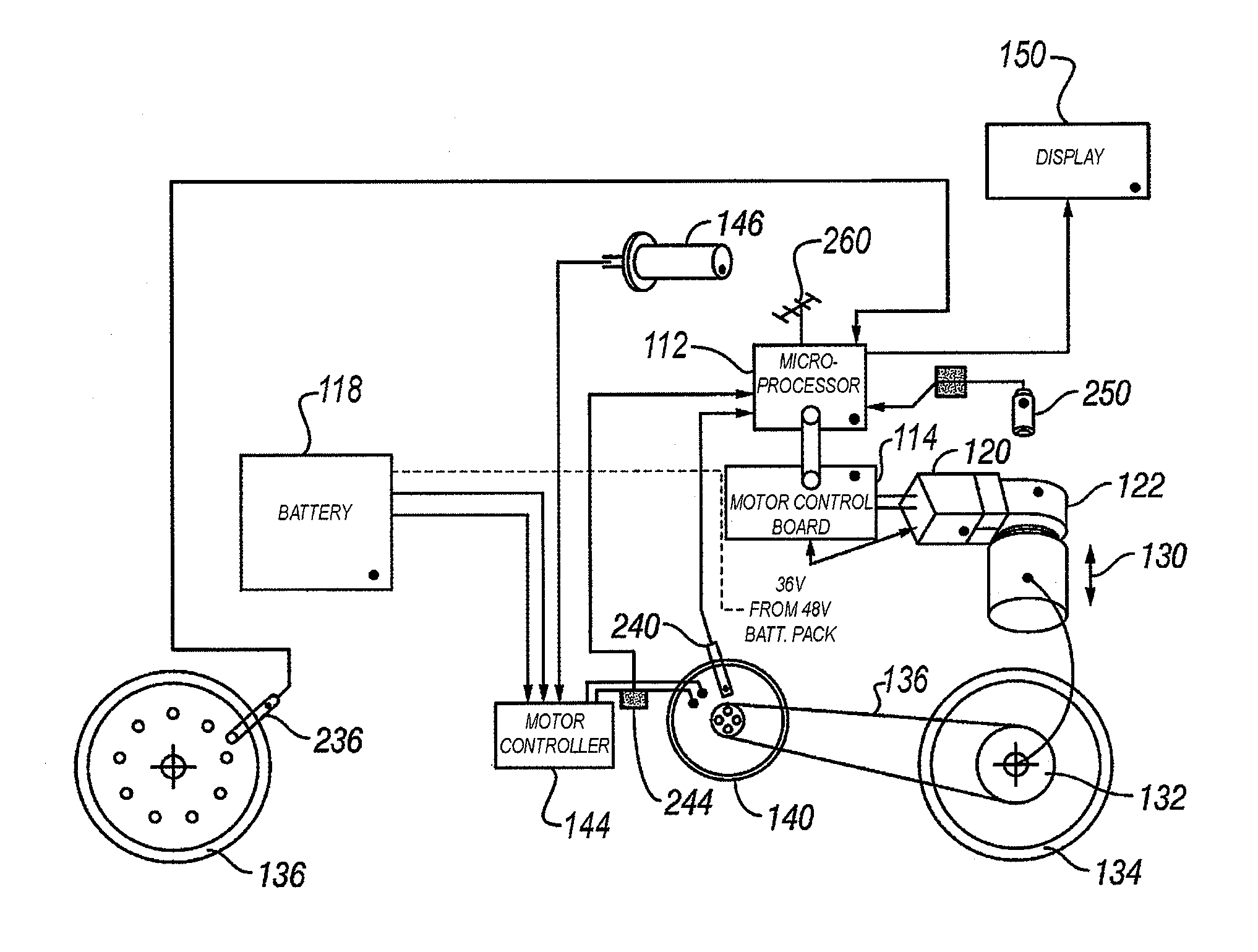

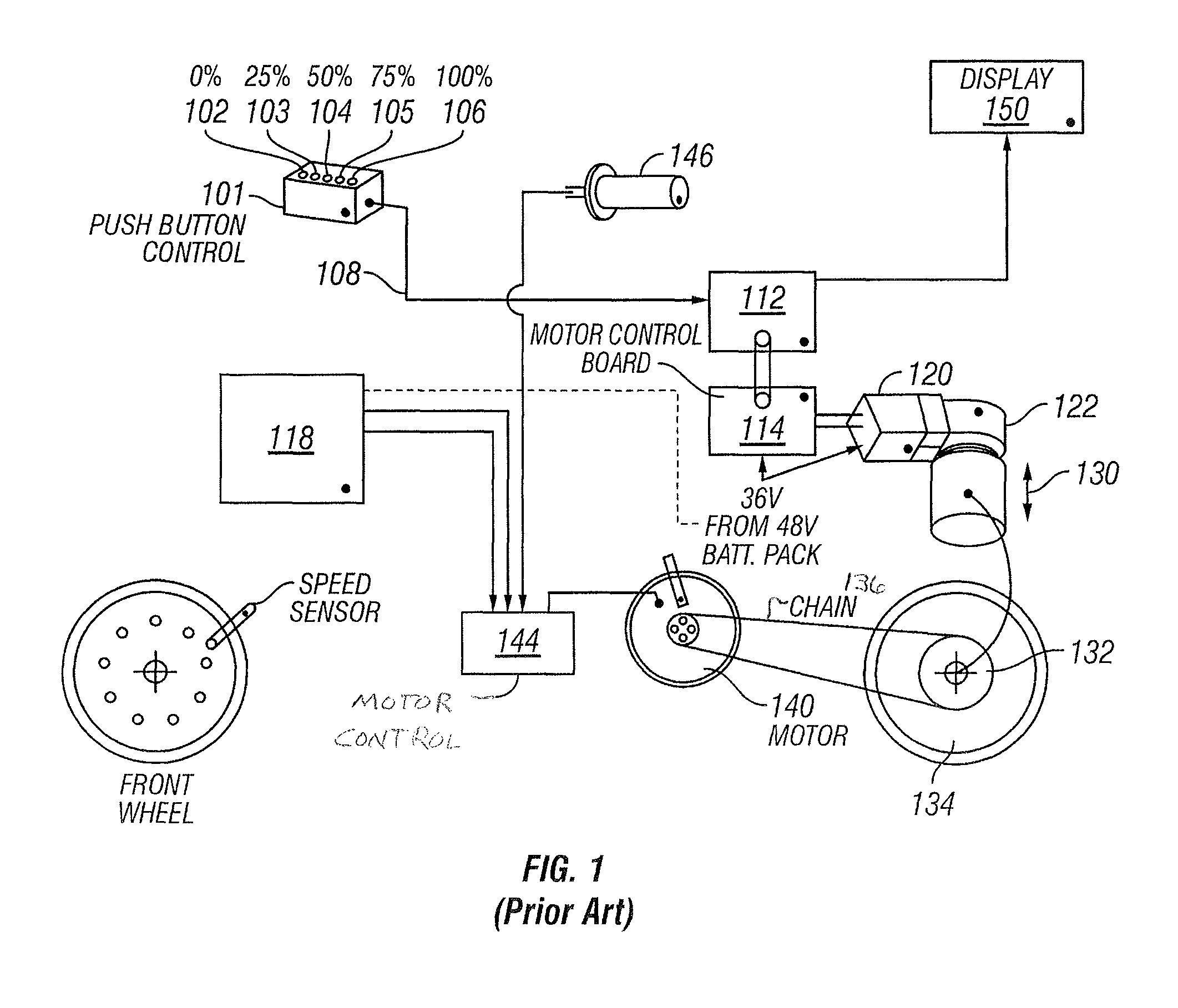

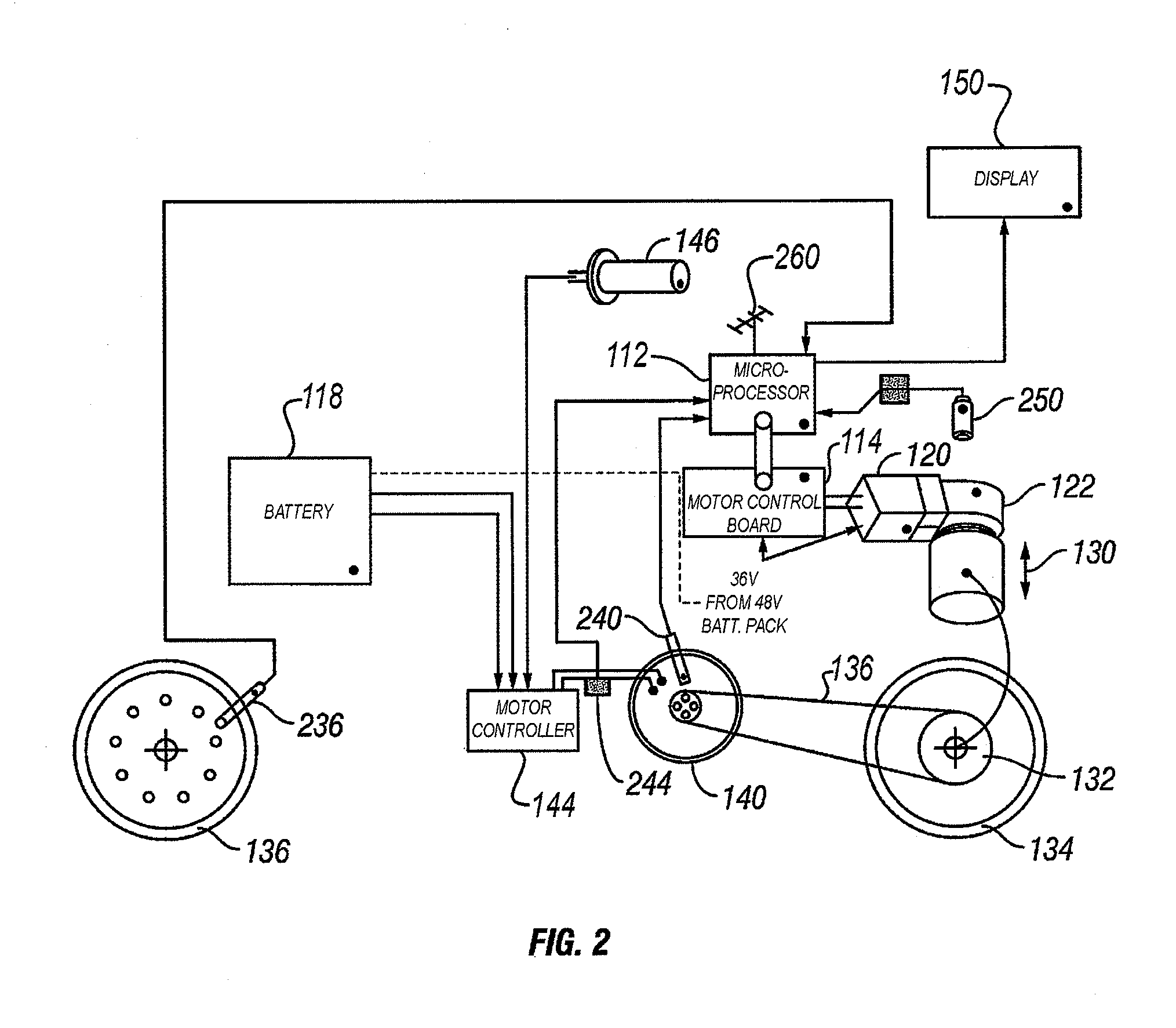

Scooter shifter

The present invention provides a system and method for automatically adjusting a continuously variable transmission (CVT) in a motorized vehicle. A microprocessor processor in the vehicle receives data about the operating status of the vehicle from a plurality. Examples of vehicle data include vehicle speed, motor speed, throttle position, current draw from a battery, and battery level. A servo motor is in mechanical communication with the CVT and provides an axial force to adjust the CVT. The microprocessor uses lookup tables of optimal set points for vehicle data to instruct the servo motor to adjust the transmission ratio of the CVT according to the vehicle data provided by the sensors.

Owner:FALLBROOK INTPROP COMPANY

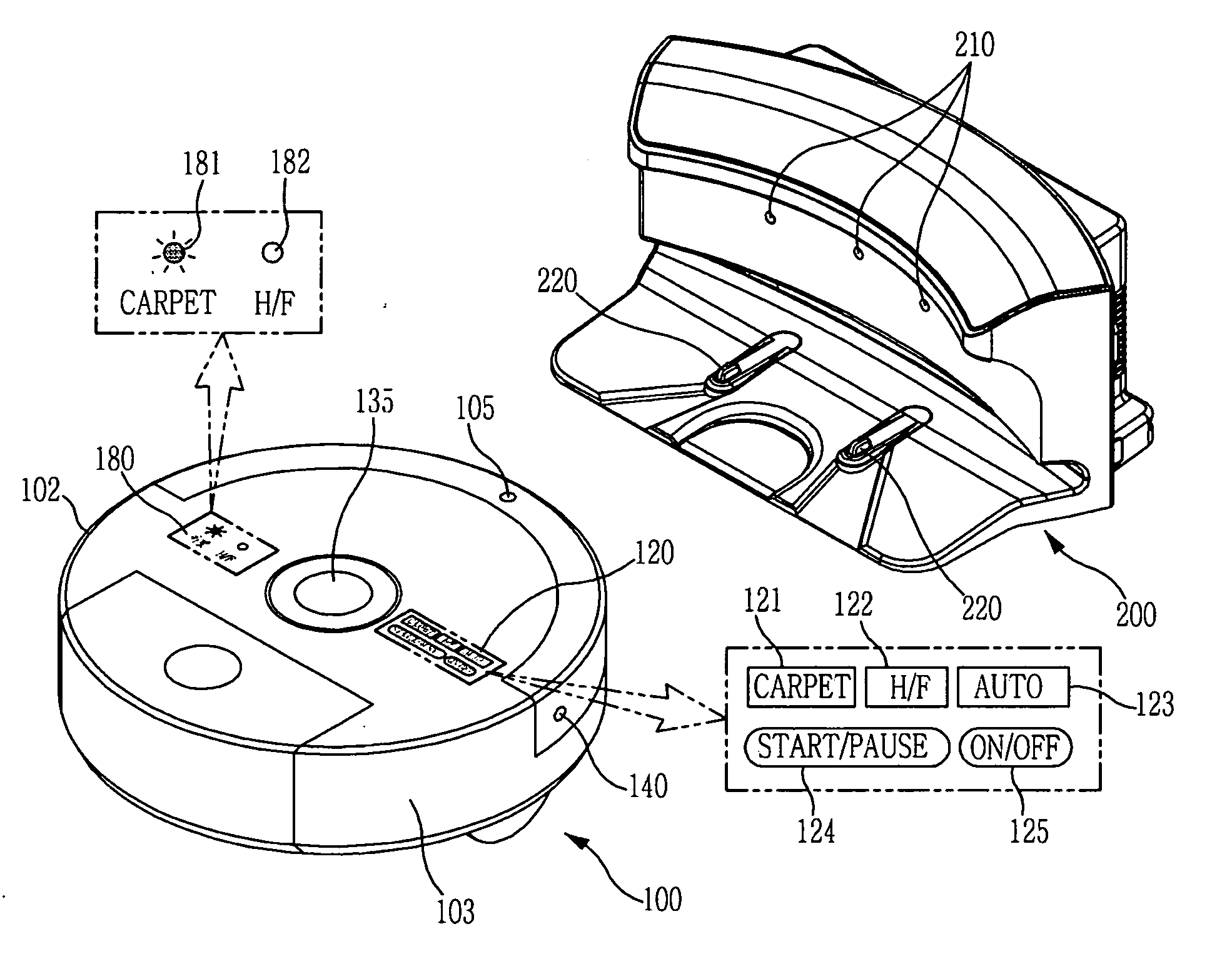

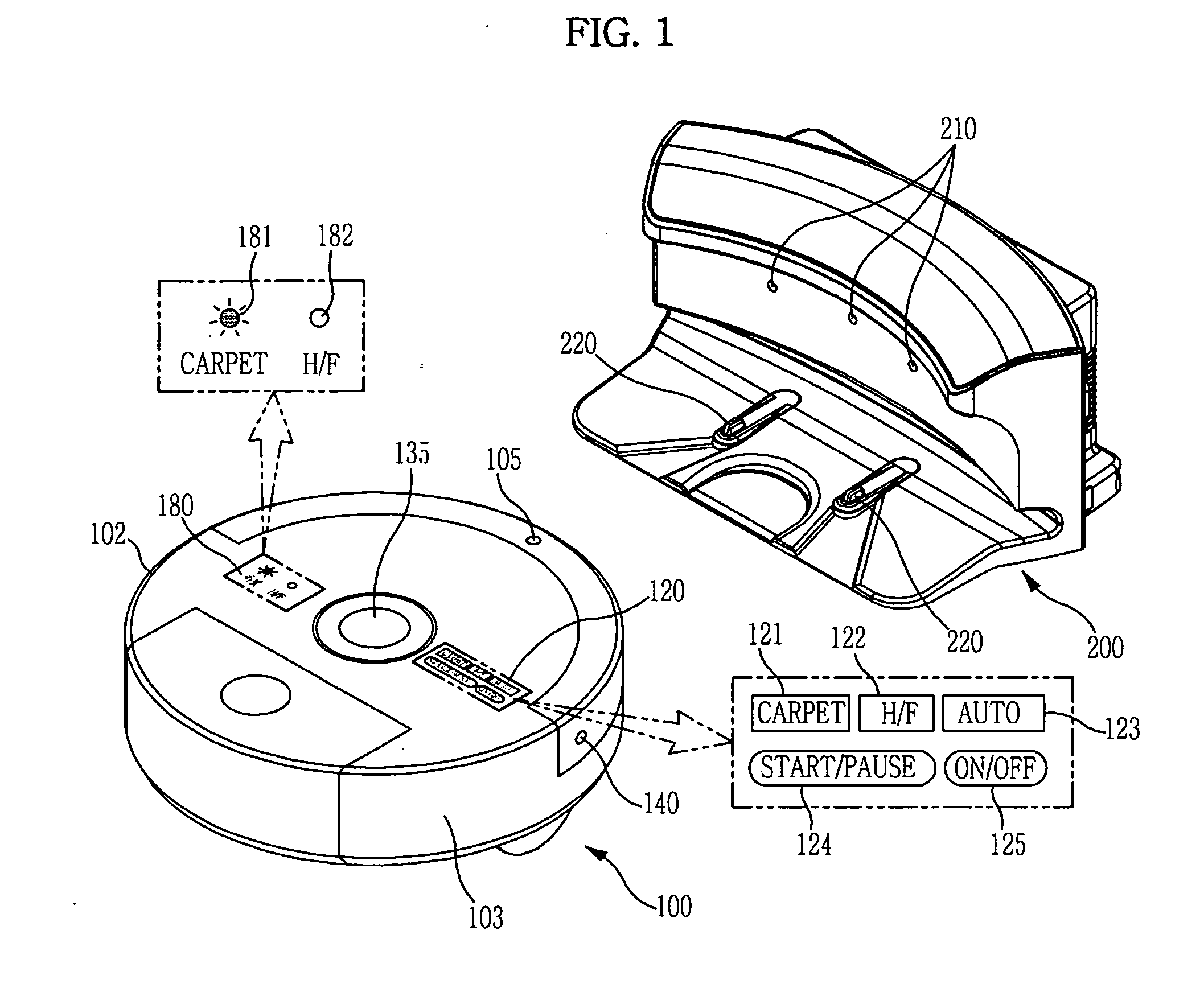

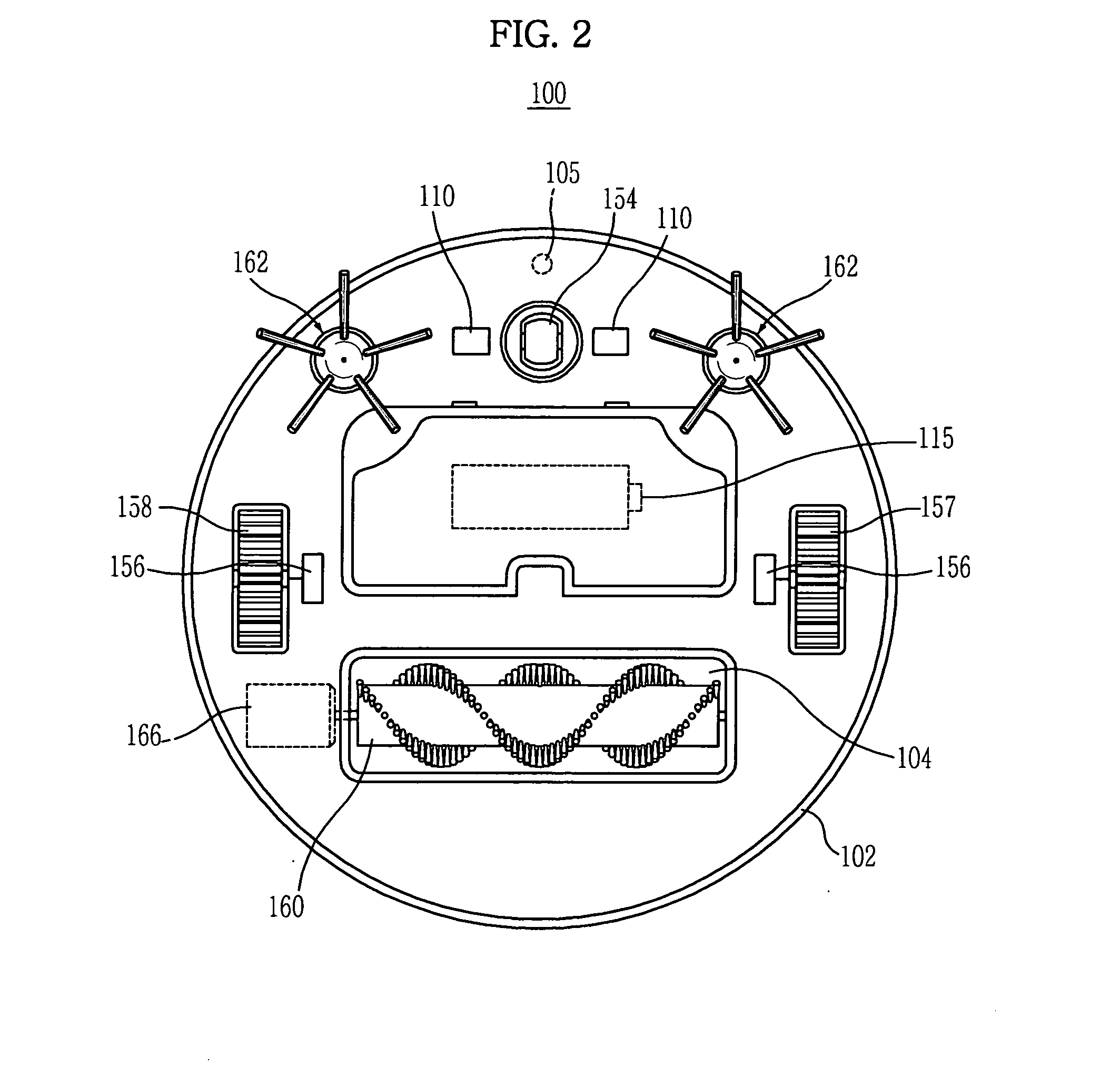

Robot cleaner and control method thereof

InactiveUS20120125363A1Avoid areaOperation is completedAutomatic obstacle detectionTravelling automatic controlMotor speedEngineering

A robot cleaner includes a main brush to sweep or scatter dust off a floor, a main brush motor to rotate the main brush, a Revolution Per Minute (RPM) detector to detect an RPM of the main brush motor, and a control unit to determine a type of floor according to the RPM of the main brush motor acquired by the RPM detector and control an operation of the robot cleaner based on the determined type of floor. A carpet mode to clean only a carpet area and a hard floor mode to clean a hard floor area excluding the carpet area are given based on detected information relating to the material of a floor, which enables partial cleaning with respect to a cleaning area selected by a user and adjustment in the number of cleaning operations or the intensity of cleaning according to the material of the floor.

Owner:SAMSUNG ELECTRONICS CO LTD

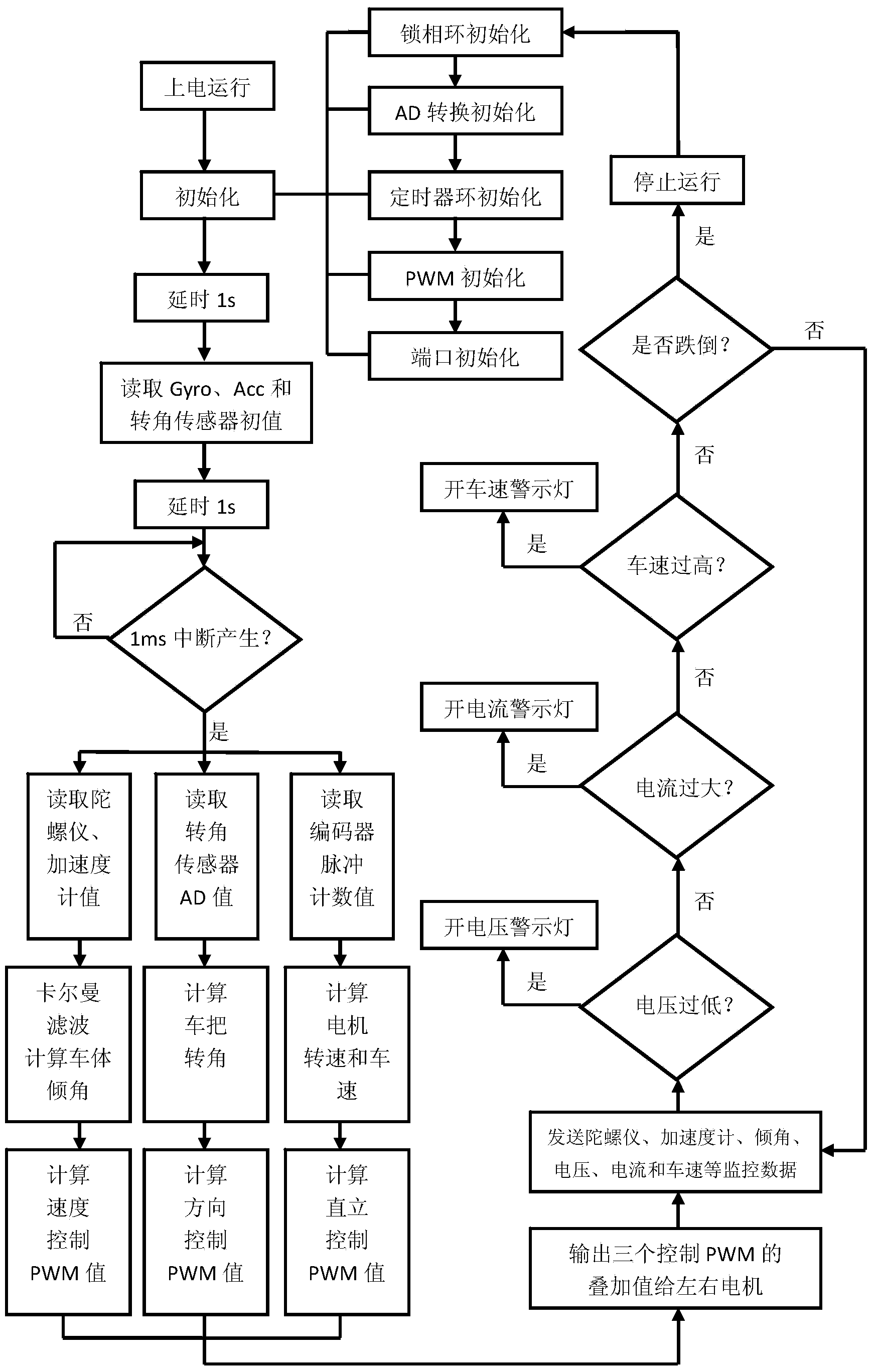

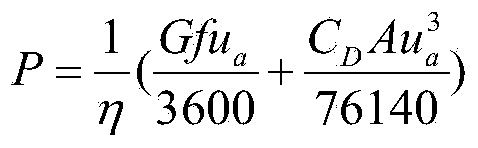

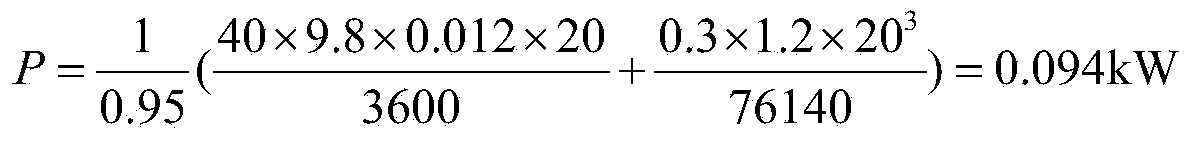

Control method of two-wheeled self-balance vehicle

InactiveCN103529850AShort correction timeShorten the timeAttitude controlMotorcyclesMotor speedAccelerometer

A control method of a two-wheeled self-balance vehicle comprises the steps as follows: (1), performing initialization: (2), reading values of a gyroscope, an accelerometer and a rotation angle sensor as well as the pulse number of an encoder respectively; (3), obtaining a vehicle body inclination, a handlebar turning angle, motor speeds and a vehicle speed; (4), then calculating PWM (pulse width modulation) values of vertical control, direction control and speed control respectively through a PID (proportion integration differentiation) control algorithm; (5), superposing the three PWM values together and outputting the three PWM values to left and right motors; (6), then sending data of the gyroscope, the accelerometer, the vehicle body inclination, a battery voltage, motor currents and the vehicle speed to an upper computer so as to monitor the operating status of the whole vehicle; (7), when the battery voltage is monitored to be smaller than a preset value, and the motor currents or the vehicle speed is monitored to be larger than the preset value through monitoring, turning on corresponding LED warning lights; and (8), when the vehicle body inclination is larger than a preset angle through monitoring when the vehicle body inclination is monitored to be larger than a preset angle, determining that the vehicle body falls down, stopping the operation and returning to an initializer. According to the control method, a more accurate operational method is adopted.

Owner:GUANGZHOU COLLEGE OF SOUTH CHINA UNIV OF TECH

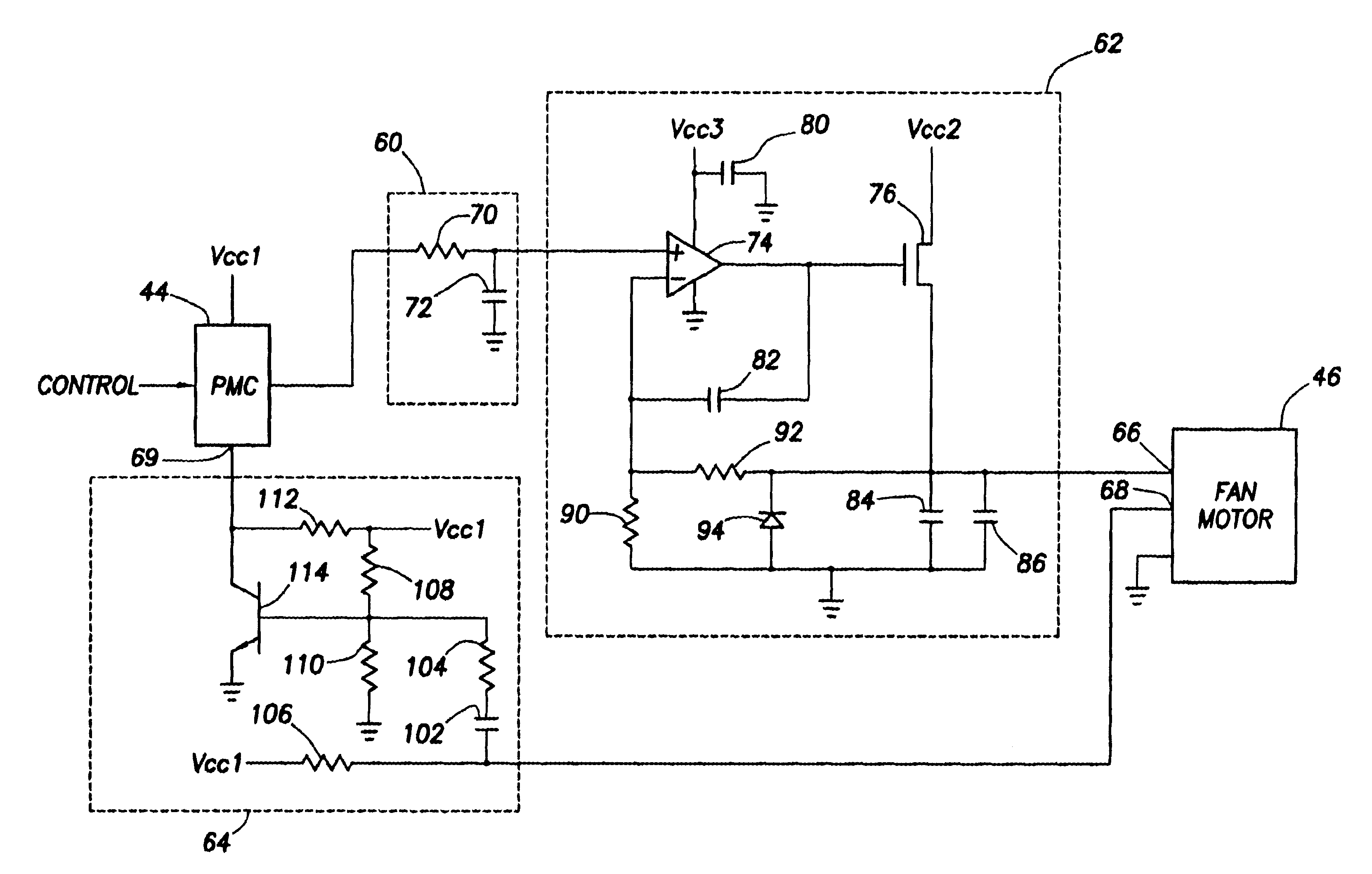

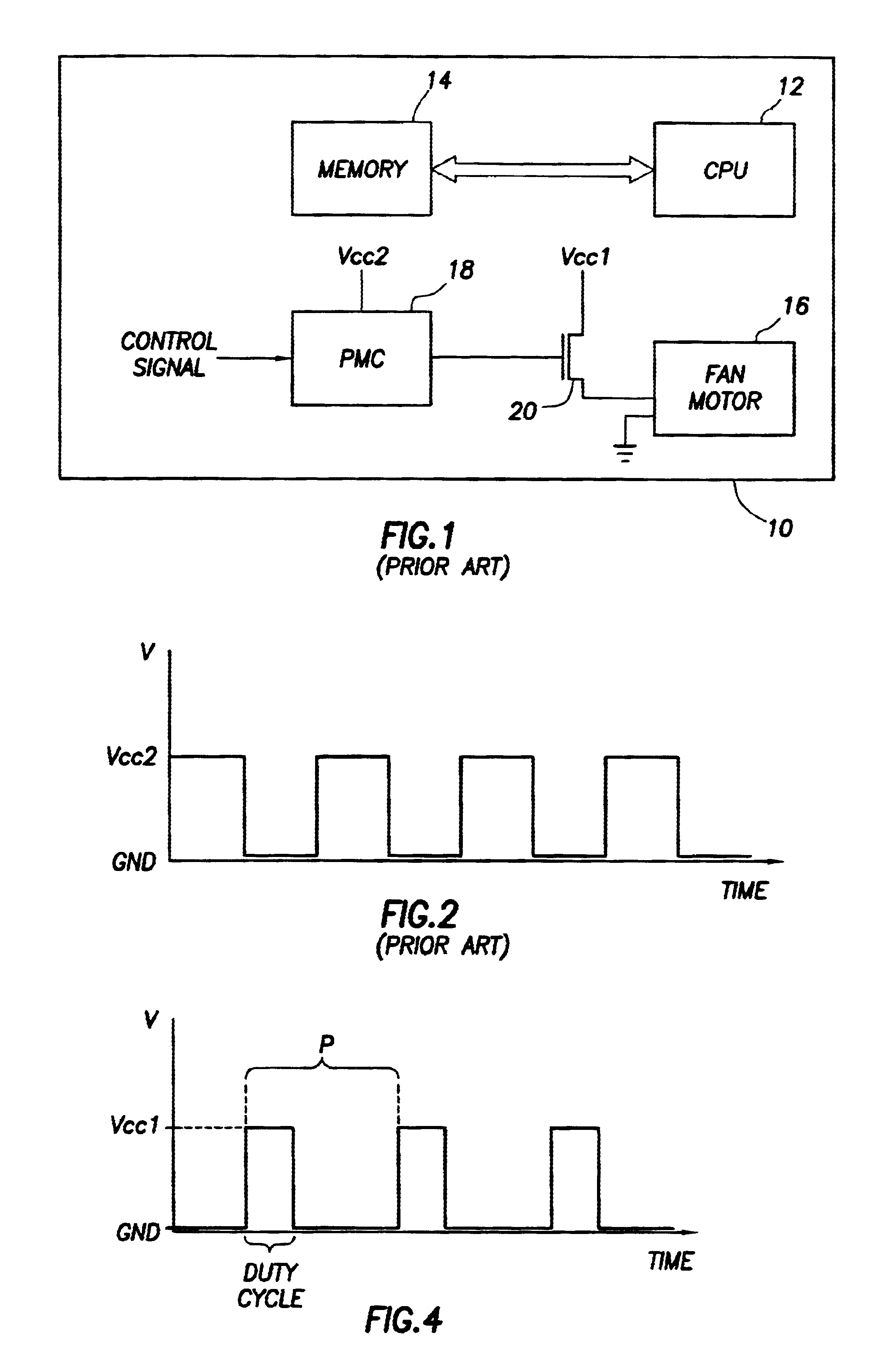

Fan speed controller with conditioned tachometer signal

The speed of a fan motor is controlled by varying a DC voltage to the fan motor. A series pass transistor is used to vary the DC voltage to the fan motor. A power management controller sets the fan motor speed by outputting pulses to a pulse-to-DC voltage converter that changes the pulses to a proportional DC control voltage for controlling the series pass transistor. A tachometer output amplifier circuit is used to remove DC components and amplify to useful logic levels a low level tachometer output signal from the fan motor. The amplified tachometer signal is used by the power management controller in controlling the rotational speed of the fan motor.

Owner:DELL PROD LP

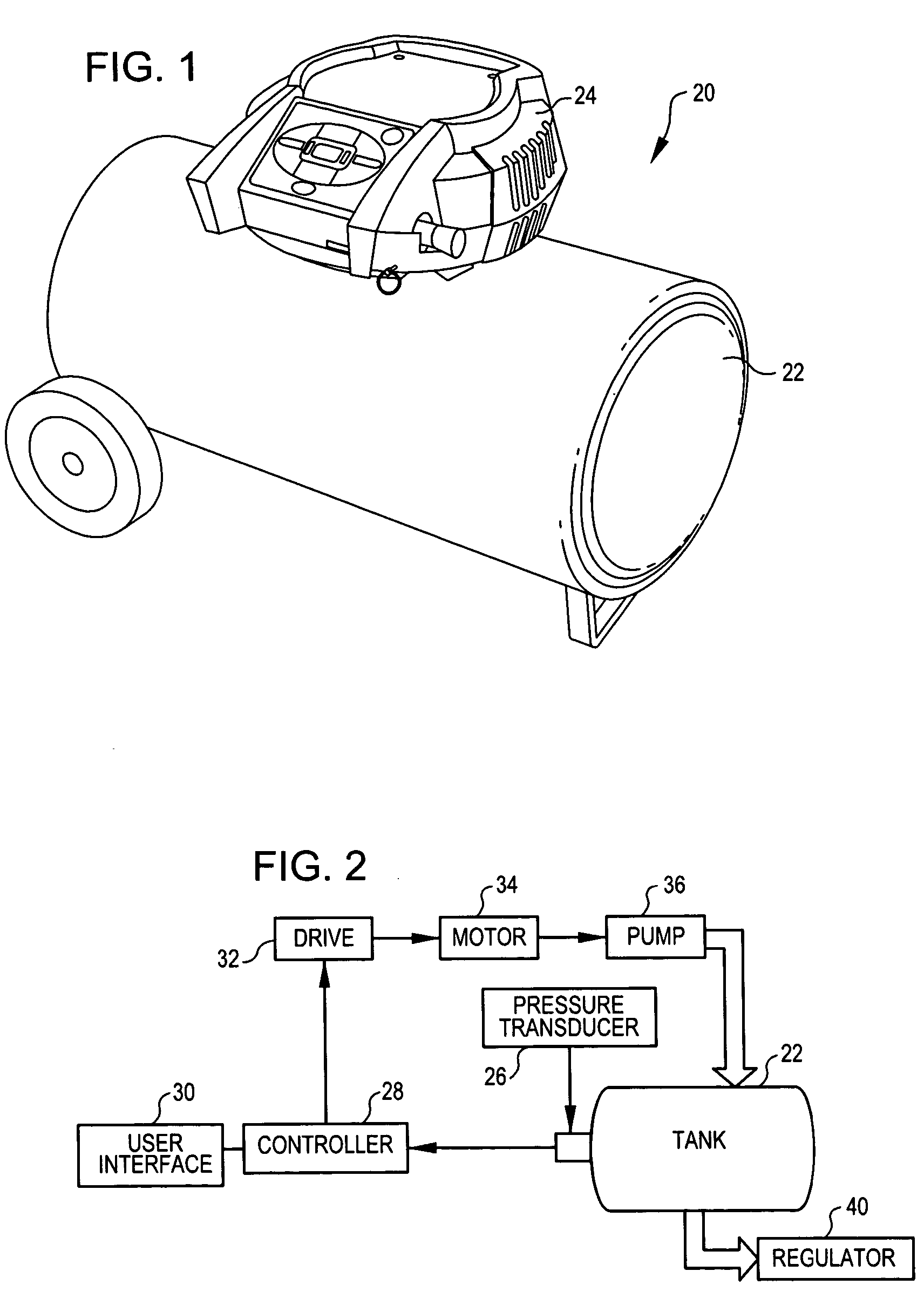

Air compressor with variable speed motor

InactiveUS20060045751A1Resistance may varyEliminate confusionMotor parameterPump controlMotor speedControl system

An air compressor utilizing an electronic control system. A pneumatically controlled regulator is provided for controlling output pressure for an air compressor. Digital gauges are provided on the air compressor to replace conventional mechanical gauges. A variable speed motor is used, which in turn varies the speed of the pump. Tools are provided for an air compressor that are capable of transmitting a signal to the air compressor indicating a desired pressure and / or motor speed at which the air compressor is to operate.

Owner:DEVILBISS AIR POWER COMPANY

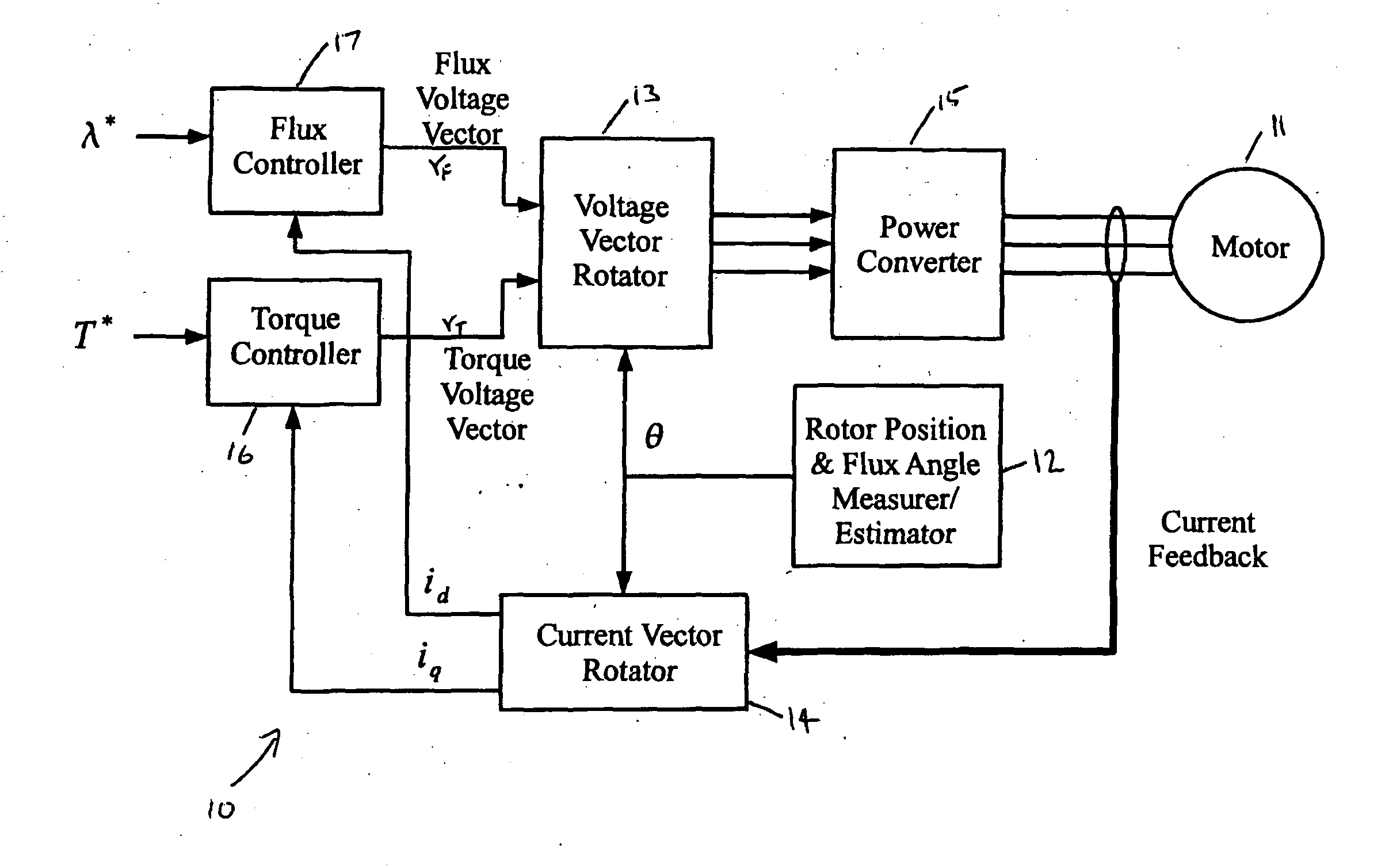

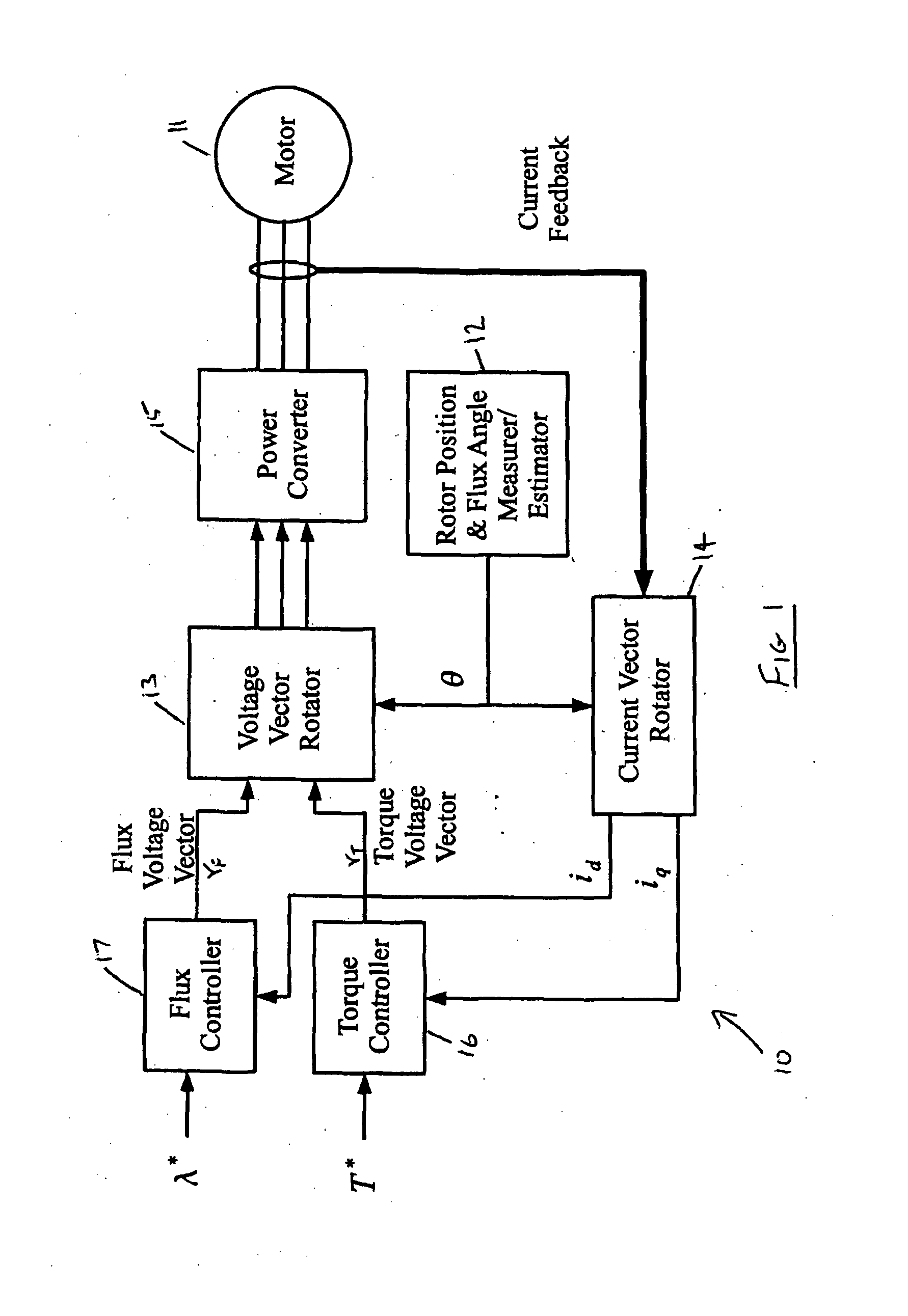

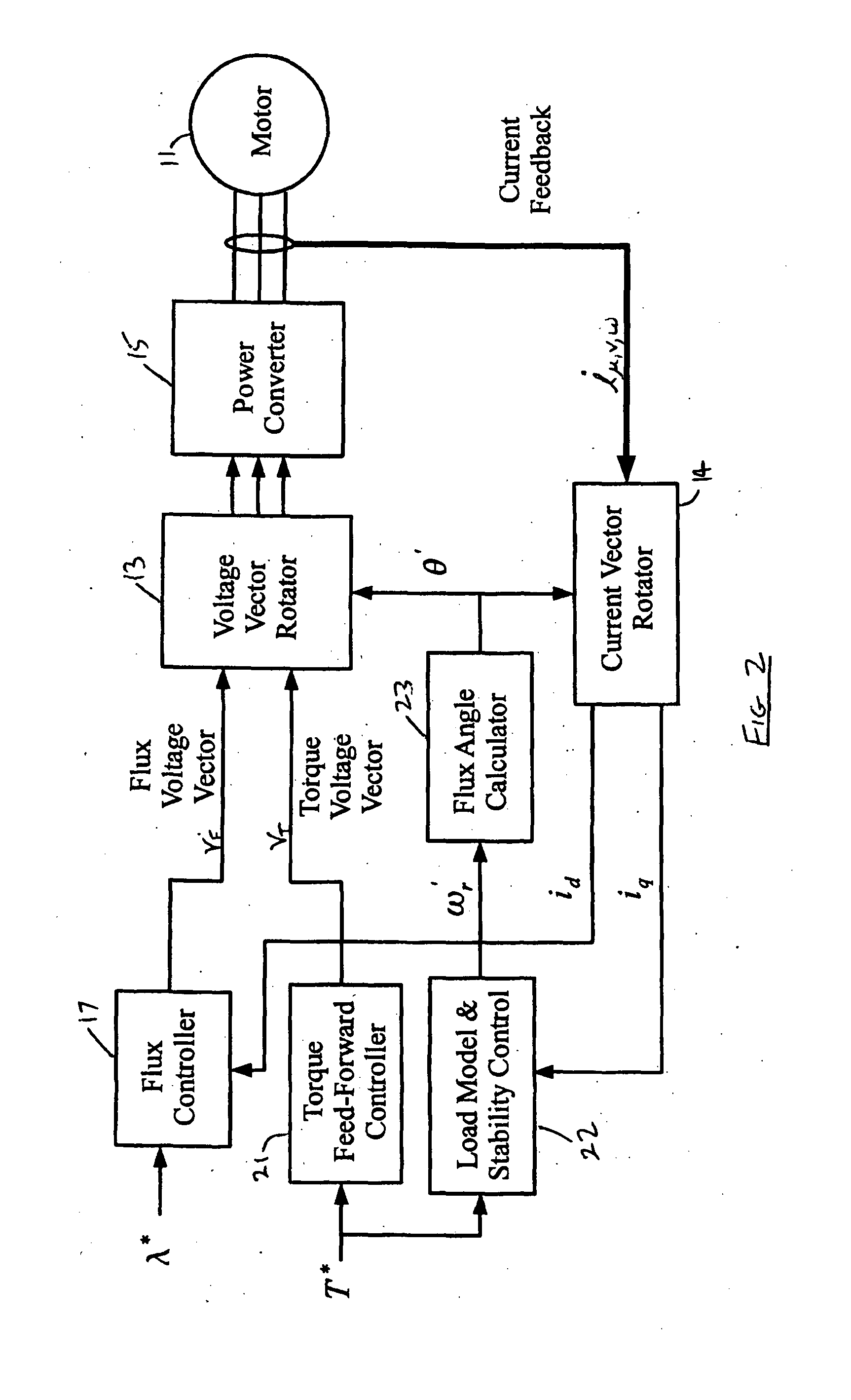

Sensorless ac motor controller

ActiveUS20130221885A1Control changesImprove stabilityCommutation monitoringMotor/generator/converter stoppersMotor speedVoltage vector

A controller for an AC electric motor, includes a Feed Forward Torque Controller and a load model. The Torque controller directly derives a torque related component of applied motor voltages from a signal representing a torque command input T* and at least one motor parameter. The load model derives a motor speed value including a model of motor speed behaviour of the AC electric motor to provide an output signal which represents the motor speed of the AC electric motor. This motor speed output signal is used in determining a frequency of rotation of an applied motor voltage vector. Where an input to the load model is the signal representing the torque command input T*, the load model uses the signal representing the torque command T*, at least over a part of an operating speed range of the AC motor which includes zero speed, to determine the motor speed output signal.

Owner:HUNTER GREGORY PETER

Powered surgical instrument with pressure sensitive motor speed control

A surgical instrument includes a drive shaft, a motor for rotating the drive shaft, and a motor speed control. The motor speed control includes a first switch and a second switch which are in communication with the motor. The first switch is disposed over and in registration with the second switch. The first switch has an activated state such that the first switch sends a first signal to the motor. The motor rotates the drive shaft in response to the first signal. The second switch sends a second signal to the motor that varies the speed that the motor rotates the drive shaft in response to a force applied to the second switch by the first switch.

Owner:TYCO HEALTHCARE GRP LP

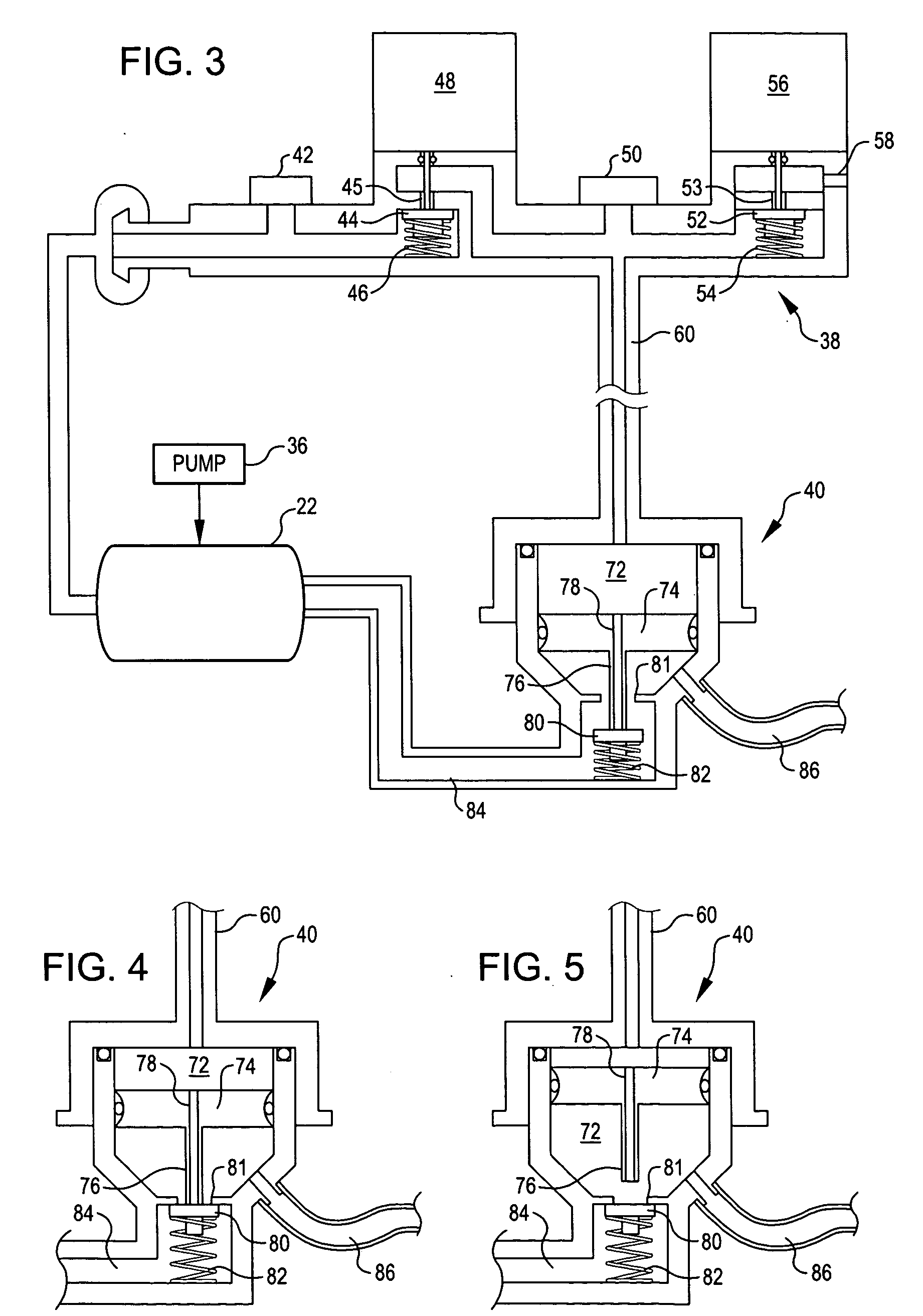

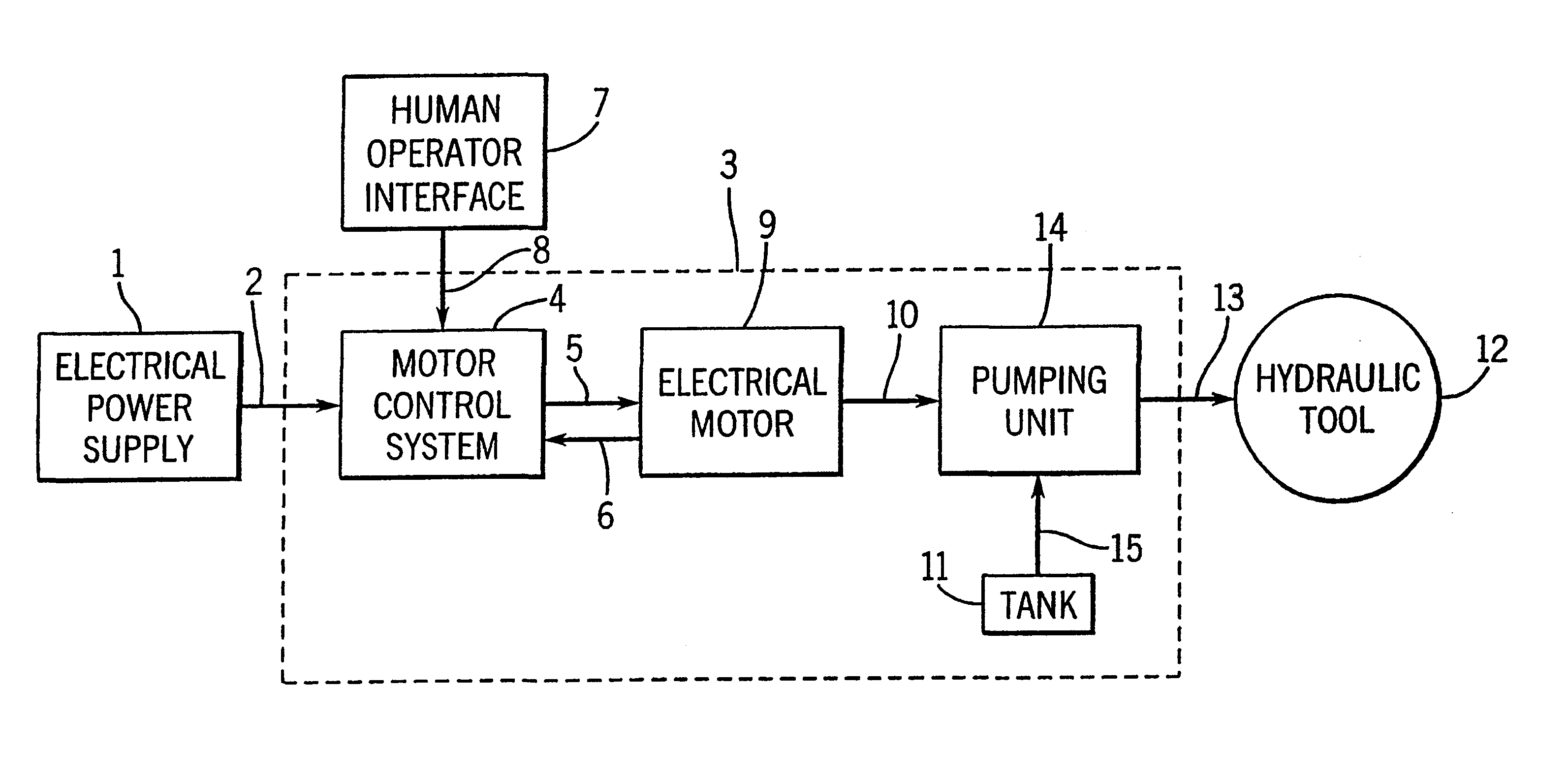

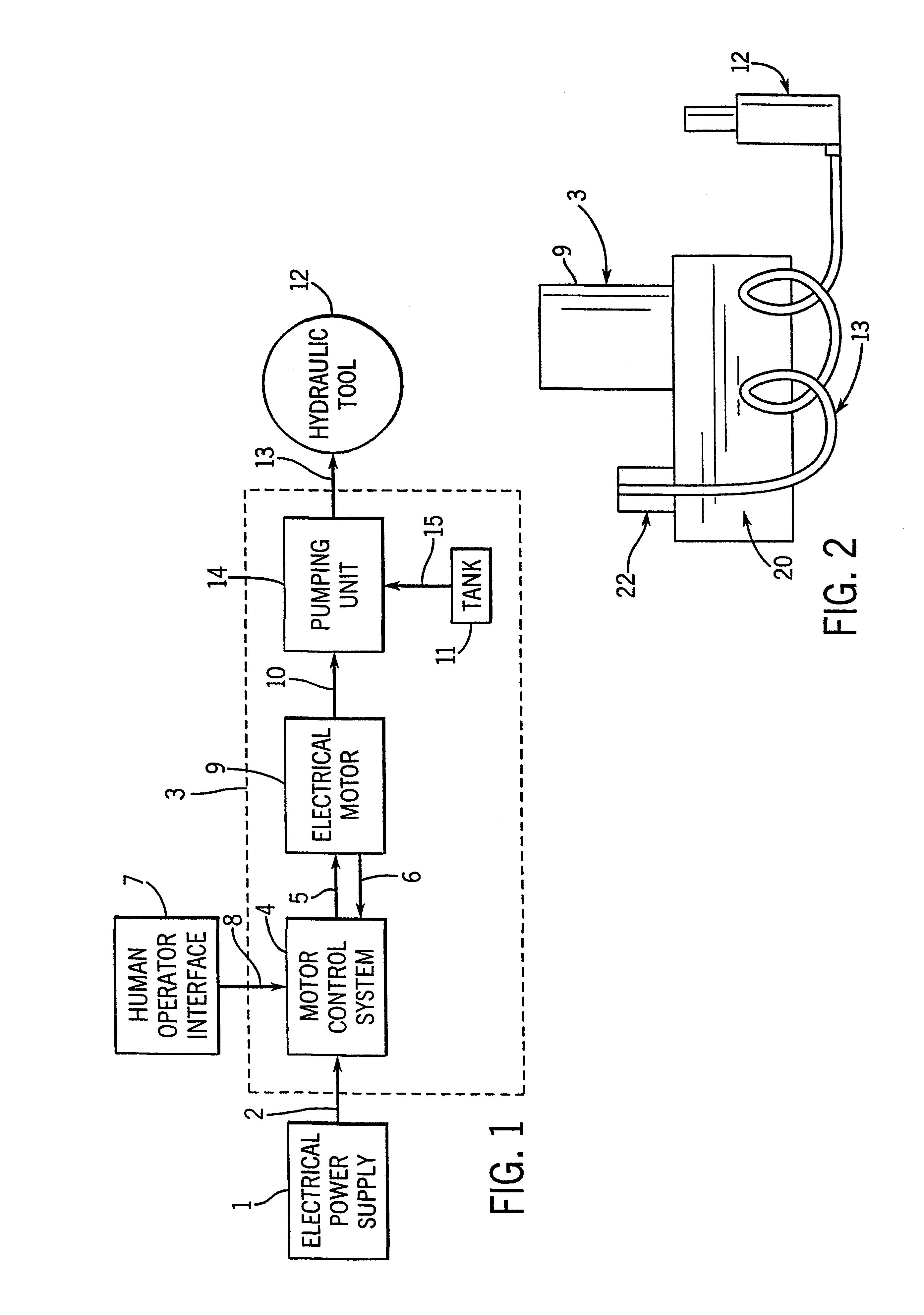

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

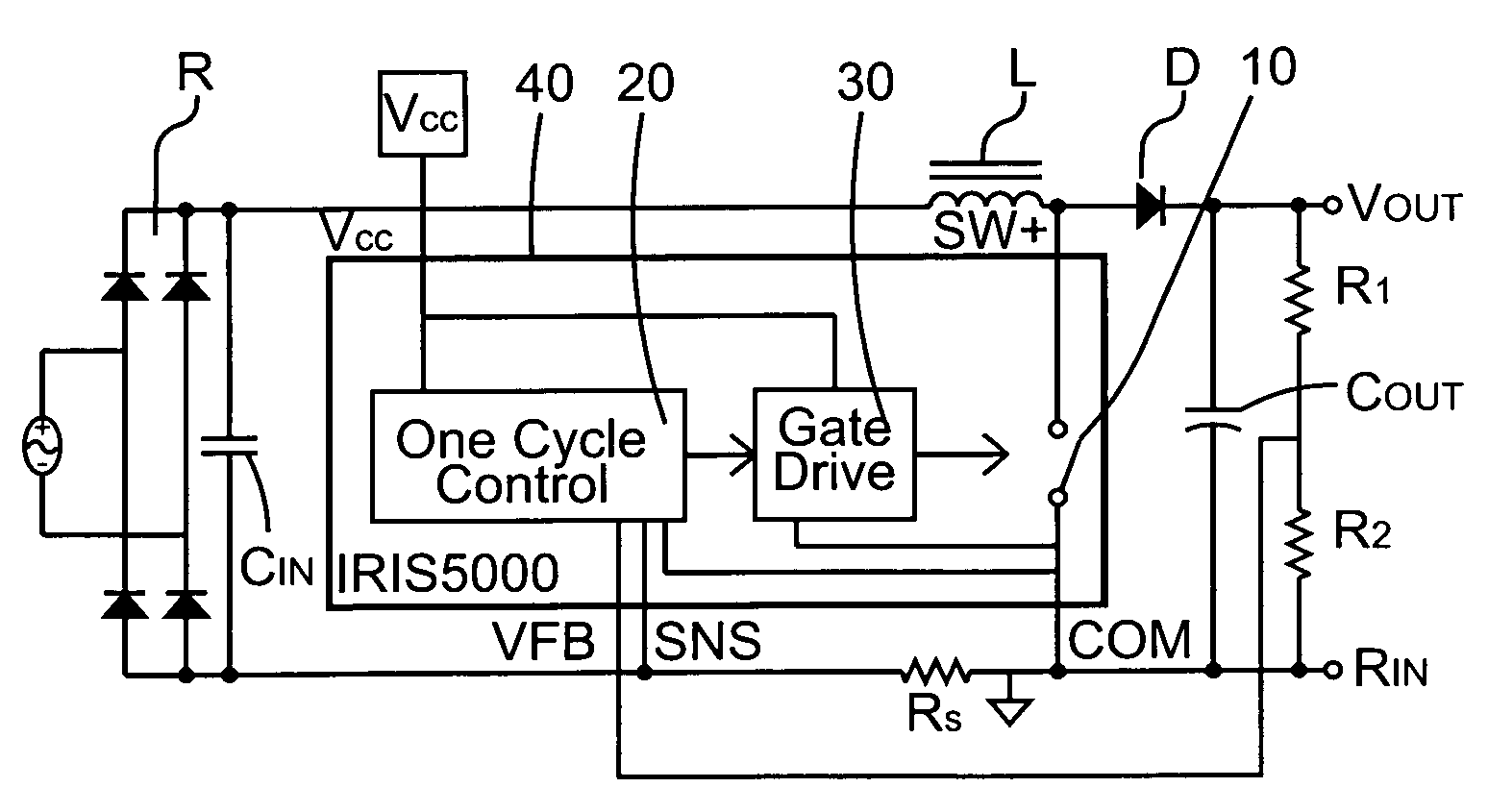

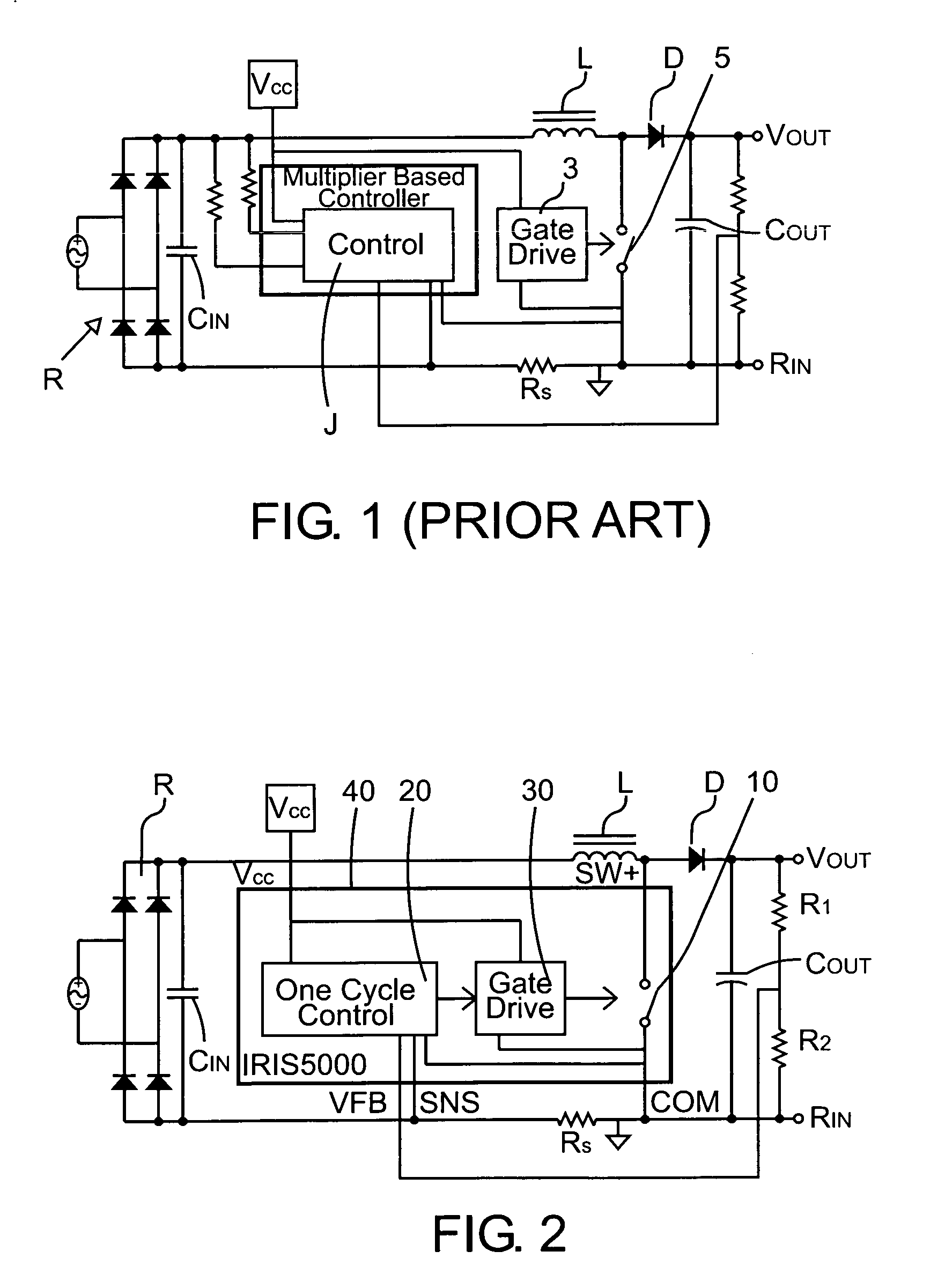

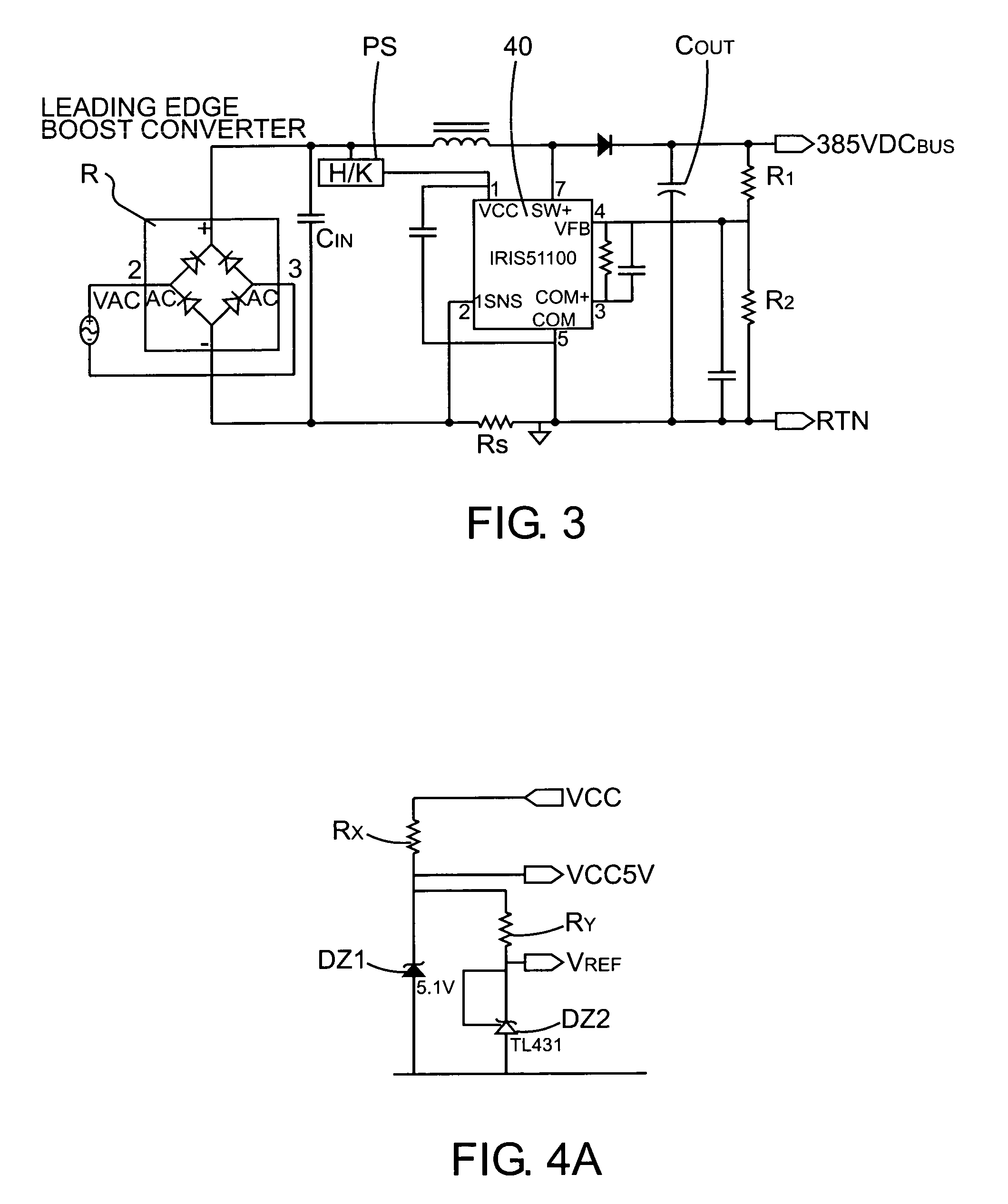

One cycle control PFC boost converter integrated circuit with inrush current limiting, fan motor speed control and housekeeping power supply controller

ActiveUS7068016B2Eliminating redundant switching circuitsSimplifies inclusionBatteries circuit arrangementsEfficient power electronics conversionMotor speedCycle control

A power factor corrected boost converter circuit includes a rectifier connectable to an ac input and having a rectified dc output provided across a dc bus, an inductor having first and second terminals connected in one leg of the dc bus, an integrated circuit comprising a control circuit for controlling a switch, the integrated circuit including a housing enclosing the control circuit, the integrated circuit having a power terminal, a ground terminal, a first control input terminal coupled to an output of the converter circuit, and a second control input terminal coupled to a sensor for sensing current in the dc bus and further having an output terminal connected to the switch, a boost rectifier diode having a first terminal, the diode coupled to the inductor, and a storage capacitor connected to the diode. The control circuit comprises a one cycle control circuit having an integrator reset by a clock signal for each cycle of the clock signal. The circuit further includes any or all of an inrush current limiting circuit for limiting the current through the inductor to a value below a predetermined level, a fan motor speed controller and a housekeeping power supply controller.

Owner:INFINEON TECH AMERICAS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com