Patents

Literature

631 results about "Torque controller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Torque Control System is a plug and play, closed loop, CNC, measure and control system. The system is composed of an AC -Servomotor with integrated overload-protected torque transducer. This allows to link the NC-controlled rotary-motion with monitoring of the torque / angel of rotation process.

Torque controller in an electric motor

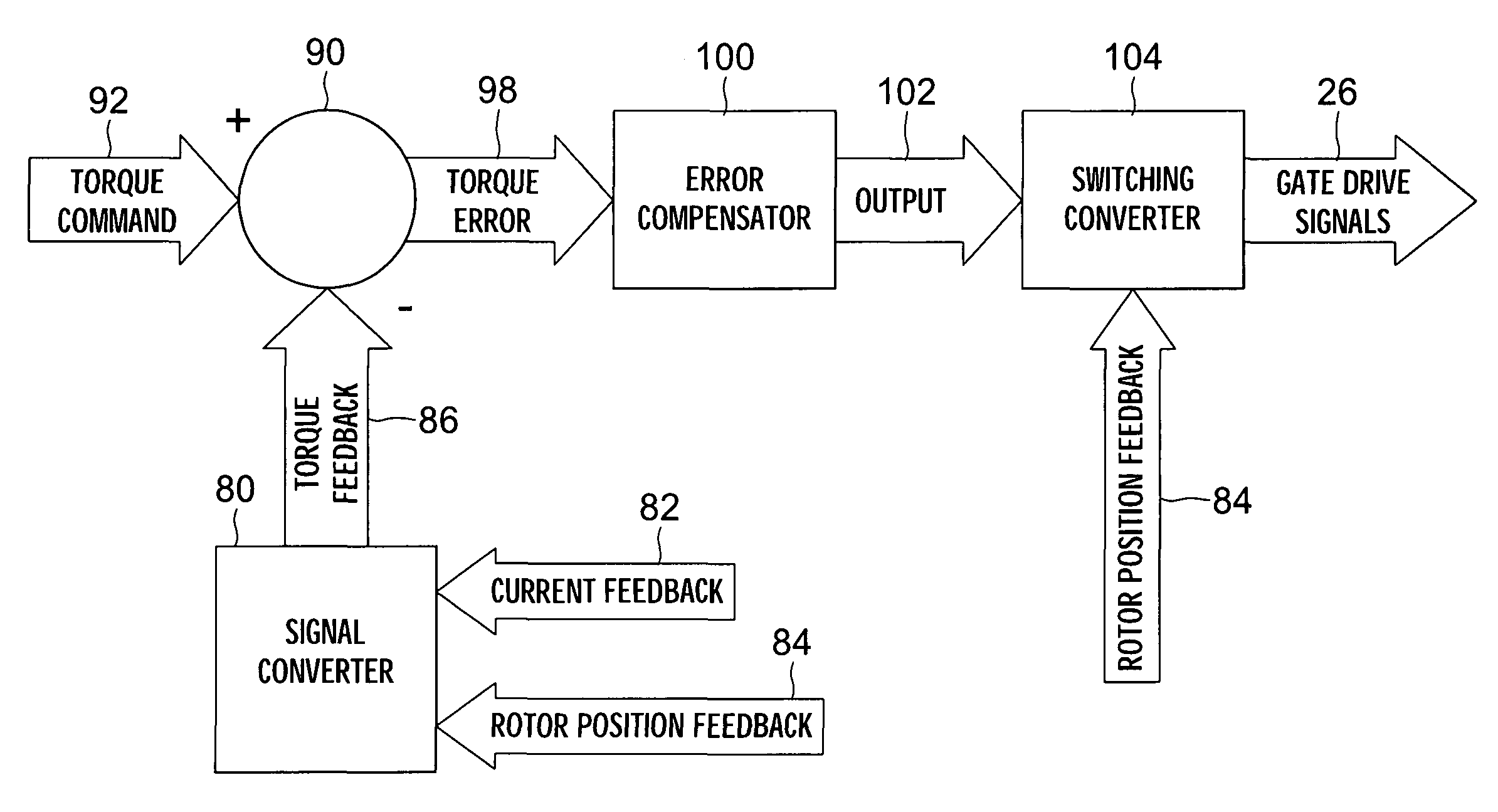

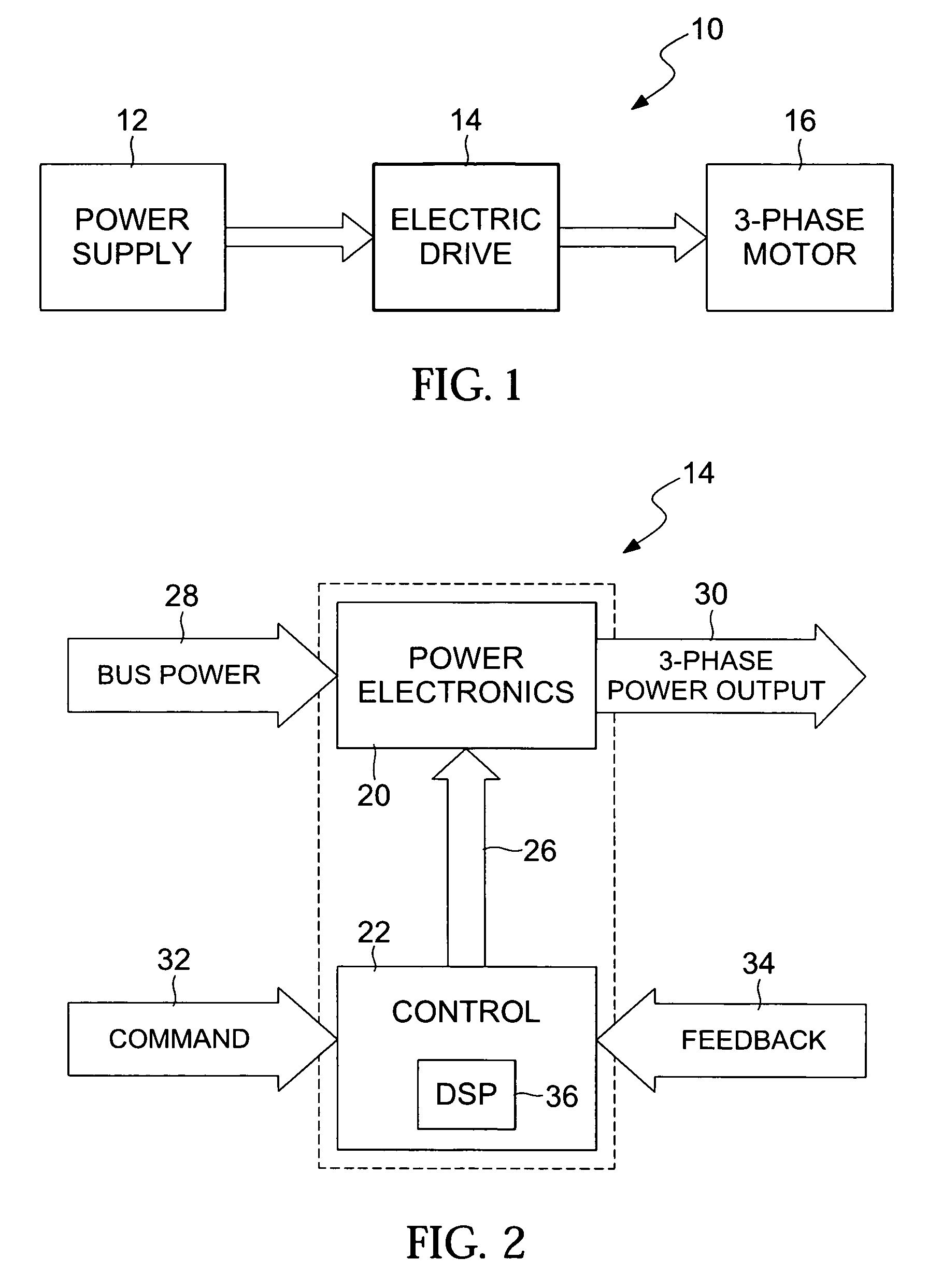

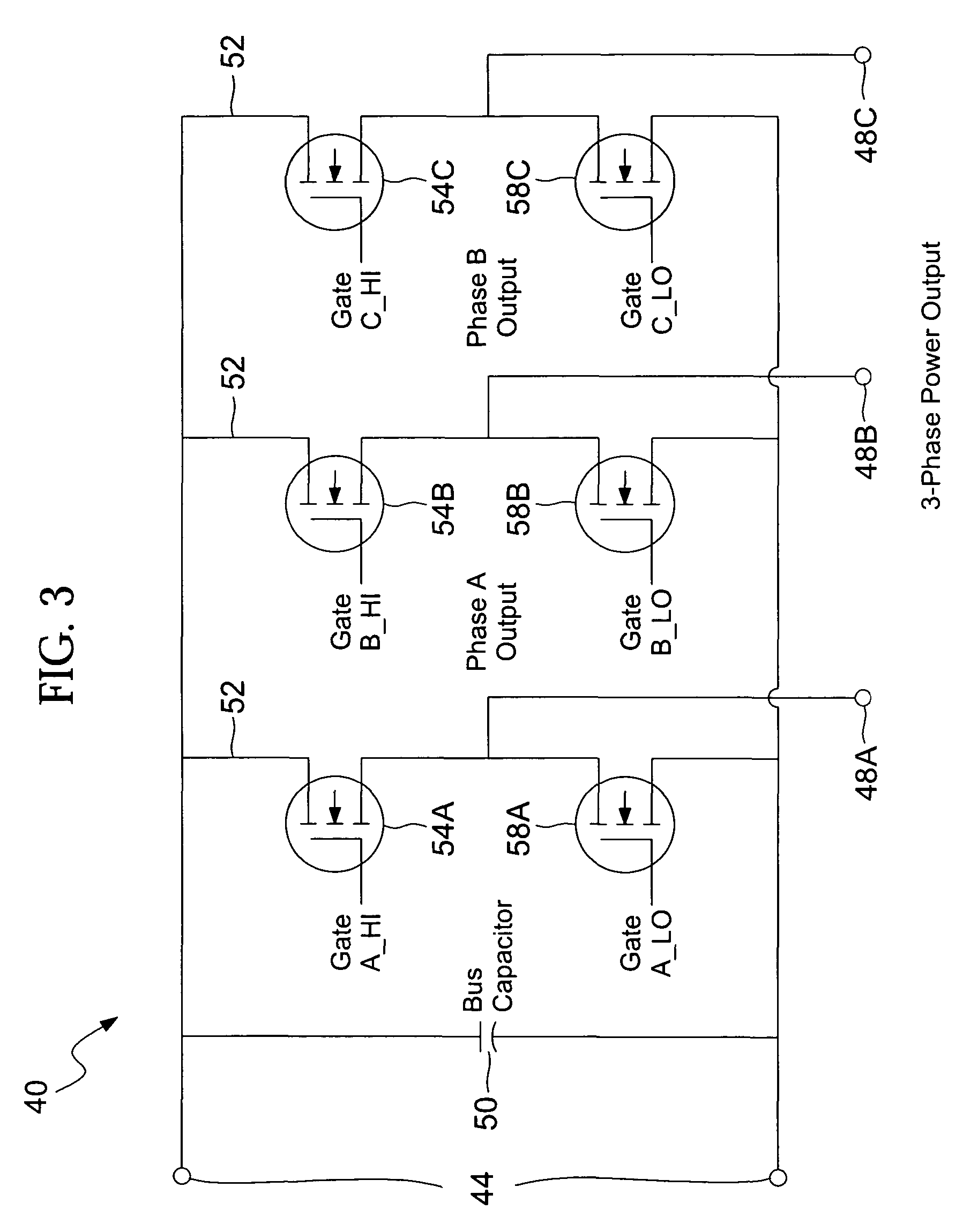

ActiveUS7898198B2Motor control for very low speedsDC motor speed/torque controlMaximum torqueSlow rotation

The torque of a motor operated by an inverter circuit is controlled to allow maximum torque in the motor when the motor is stalled or at low rotation speeds. Control is accomplished by providing a switching frequency to the motor at a first switching frequency, detecting a rotation speed of the motor, and switching the current to the motor to a second switching frequency when the rotation speed of the motor drops to a predetermined slow rotation speed. The second switching frequency is less than the first switching frequency.

Owner:DRS NETWORK & IMAGING SYST

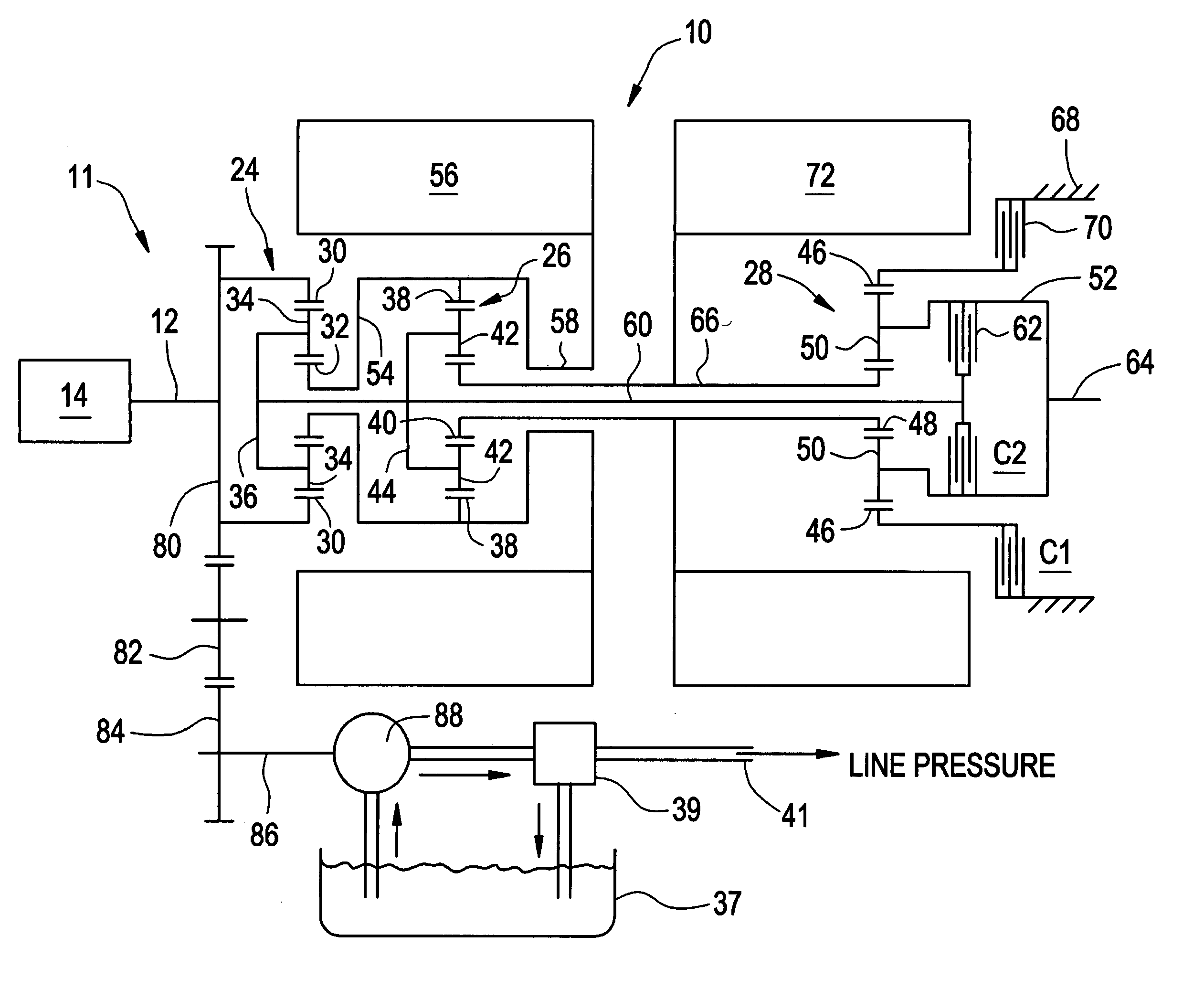

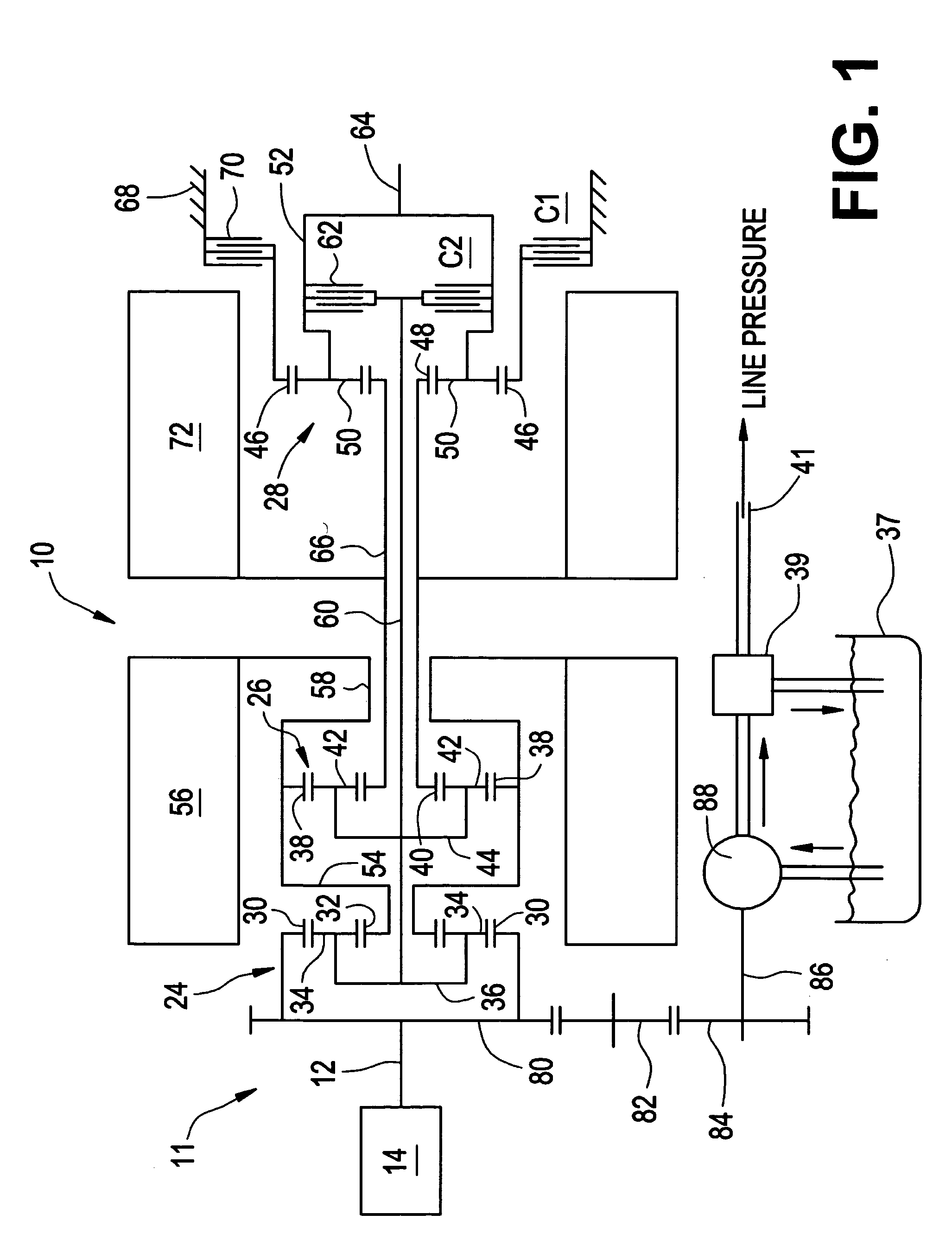

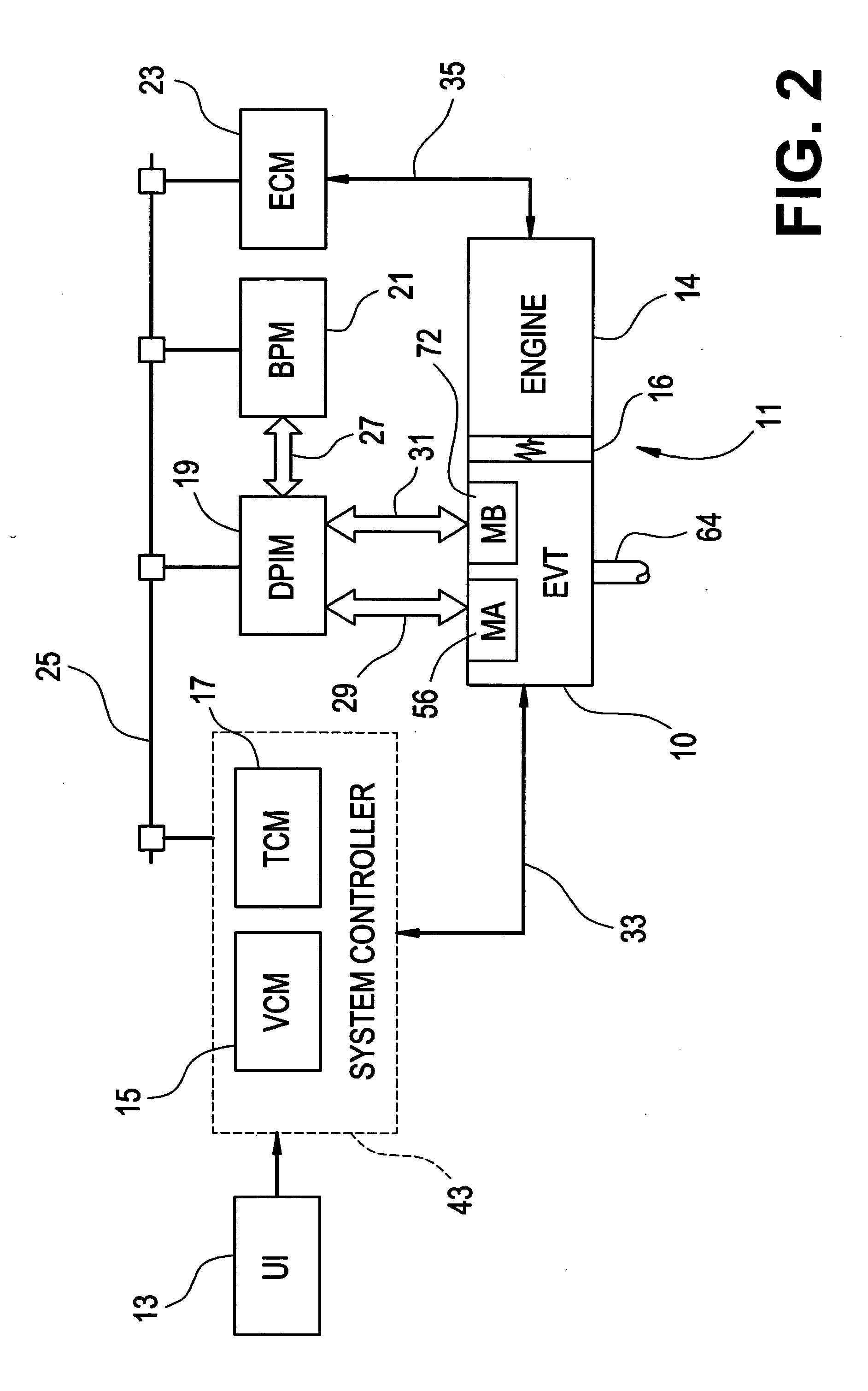

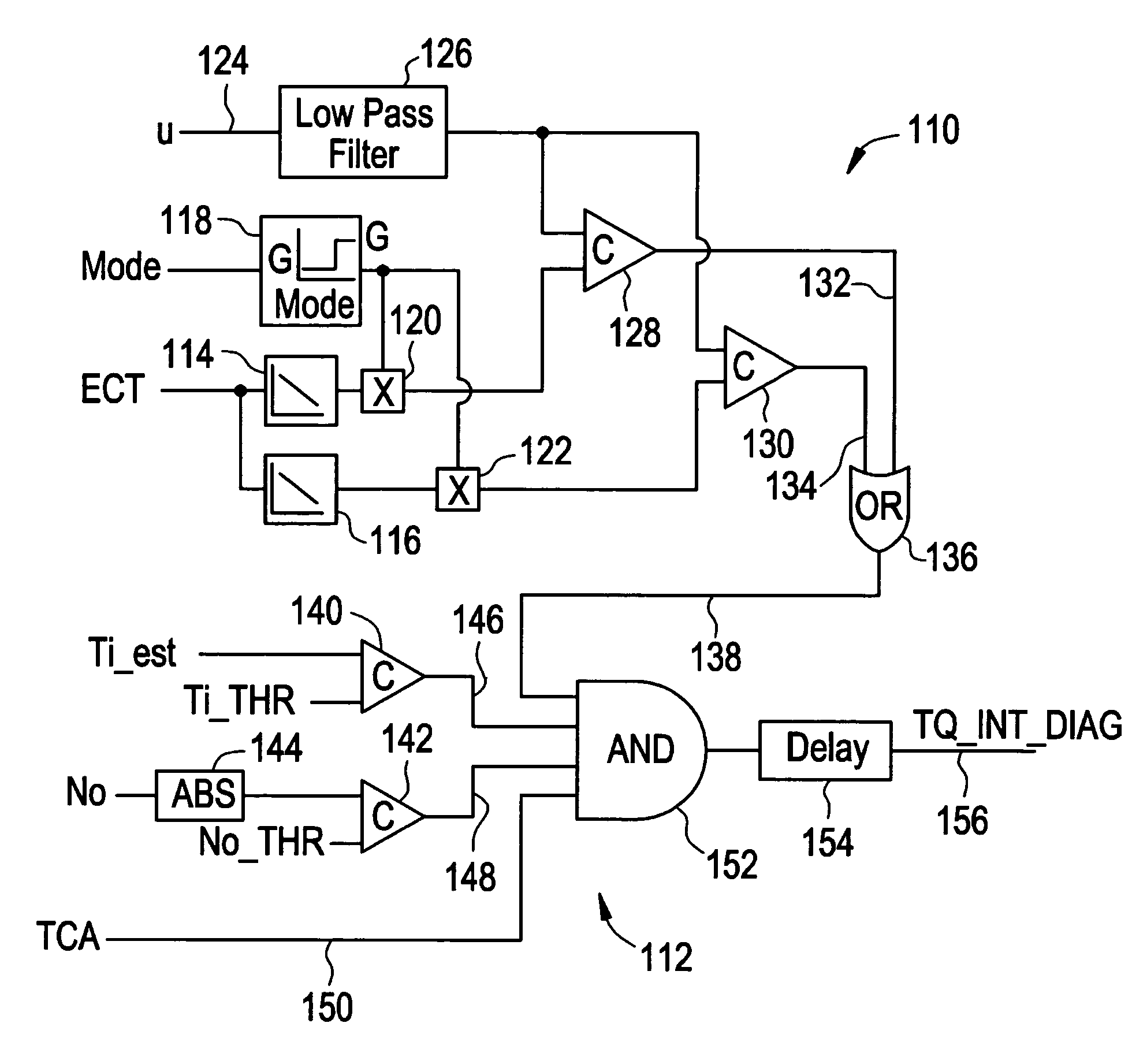

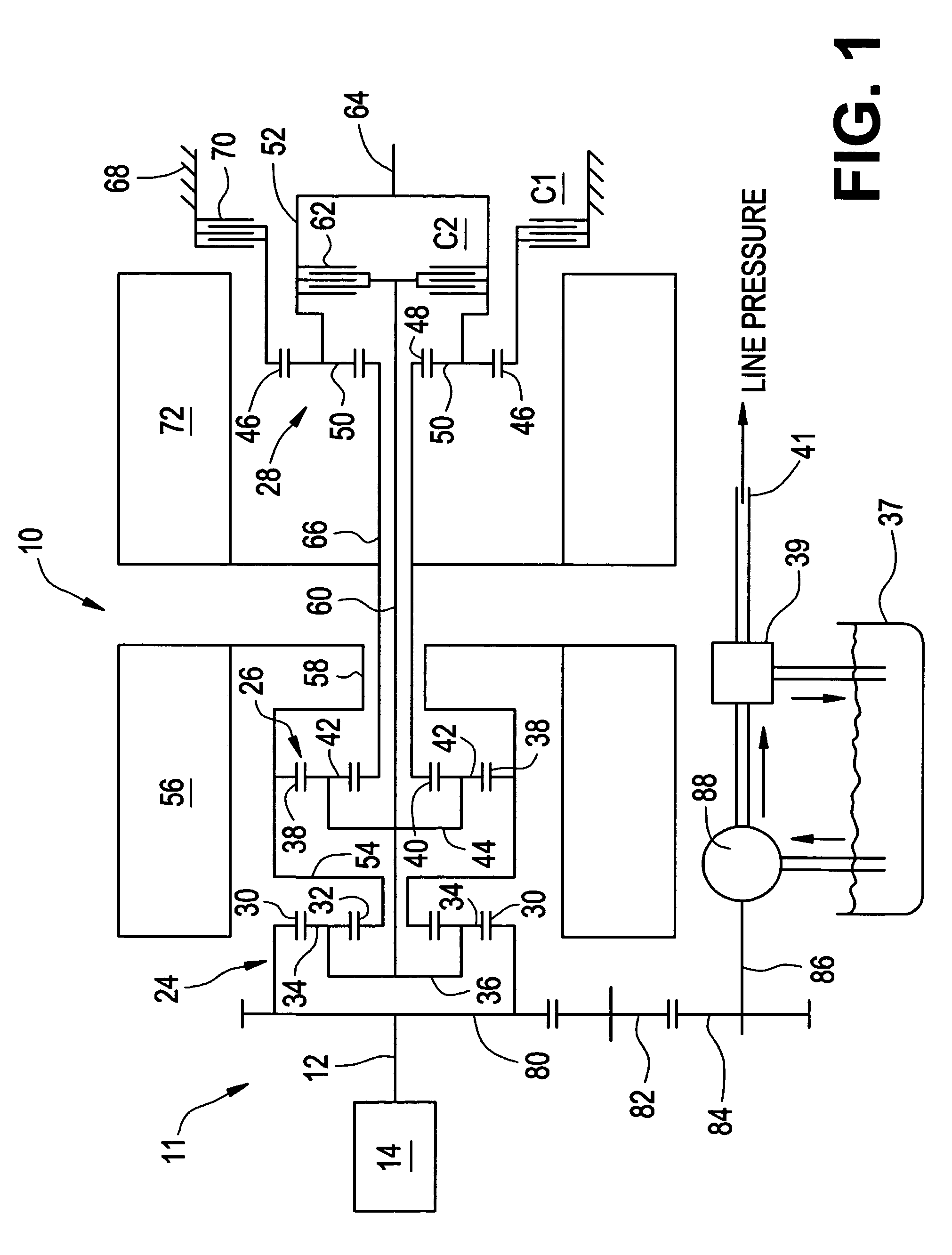

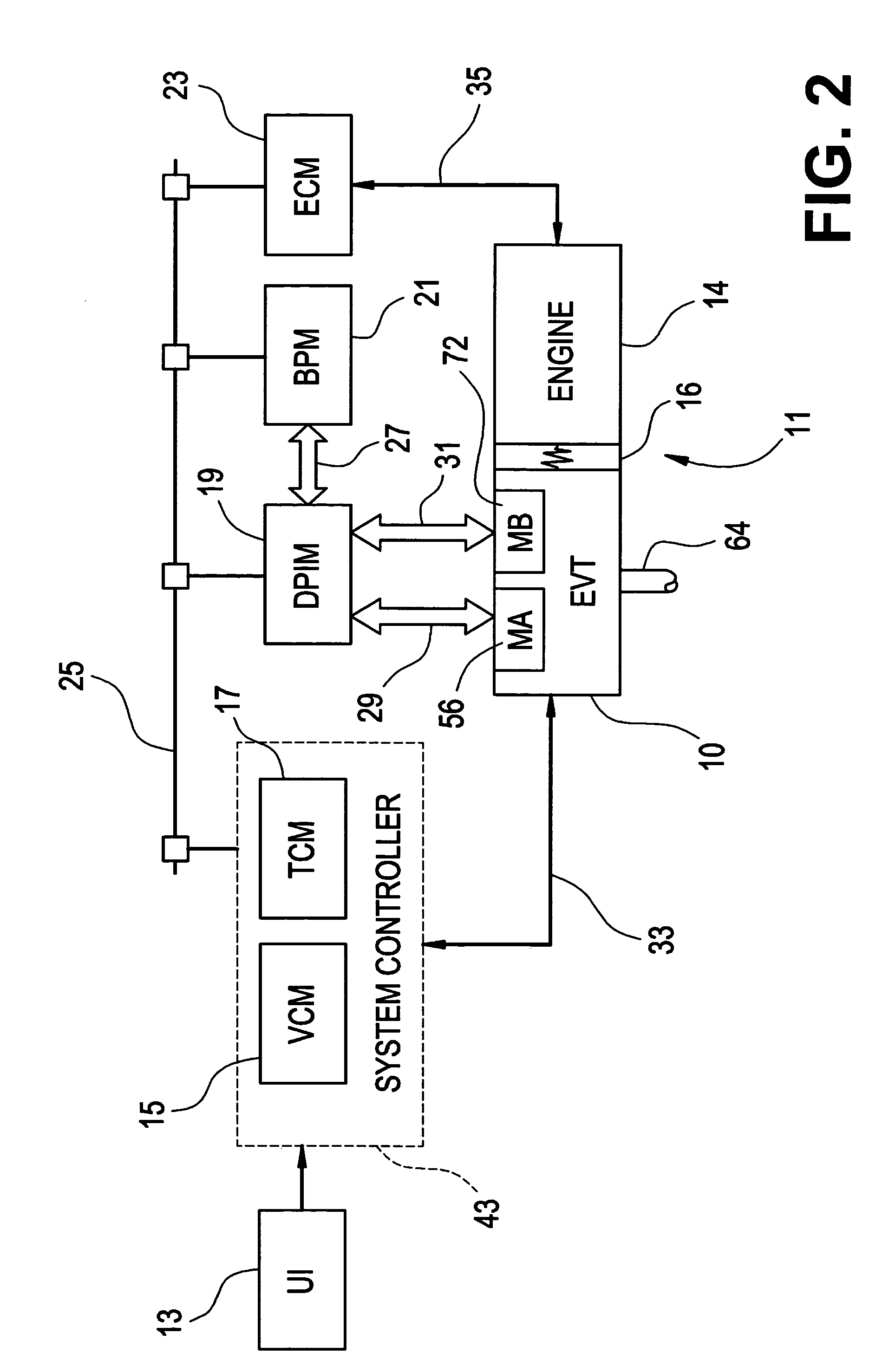

Diagnostic method for a torque control of an electrically variable transmission

ActiveUS20050252283A1Impaired speed controlImpaired torque controlVehicle testingRegistering/indicating working of vehiclesLoop controlLow speed

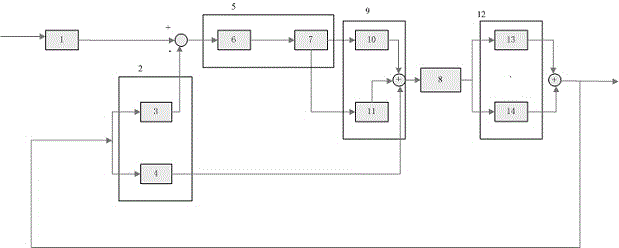

A condition of impaired speed and torque control of a parallel electrically variable transmission due to factors beyond nominal modeling and estimation errors is diagnosed under low speed operation. The transmission includes at least one electric machine and a motor torque controller for regulating the transmission input speed and output torque. The motor torque controller includes an open-loop control path based on predetermined torques and accelerations and a closed loop control path based on input speed error. The presence of a larger than expected closed-loop correction magnitude, combined with low output speed and one or more other conditions is used to diagnose a condition of potential torque error, in which case the transmission control is altered to prevent unwanted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

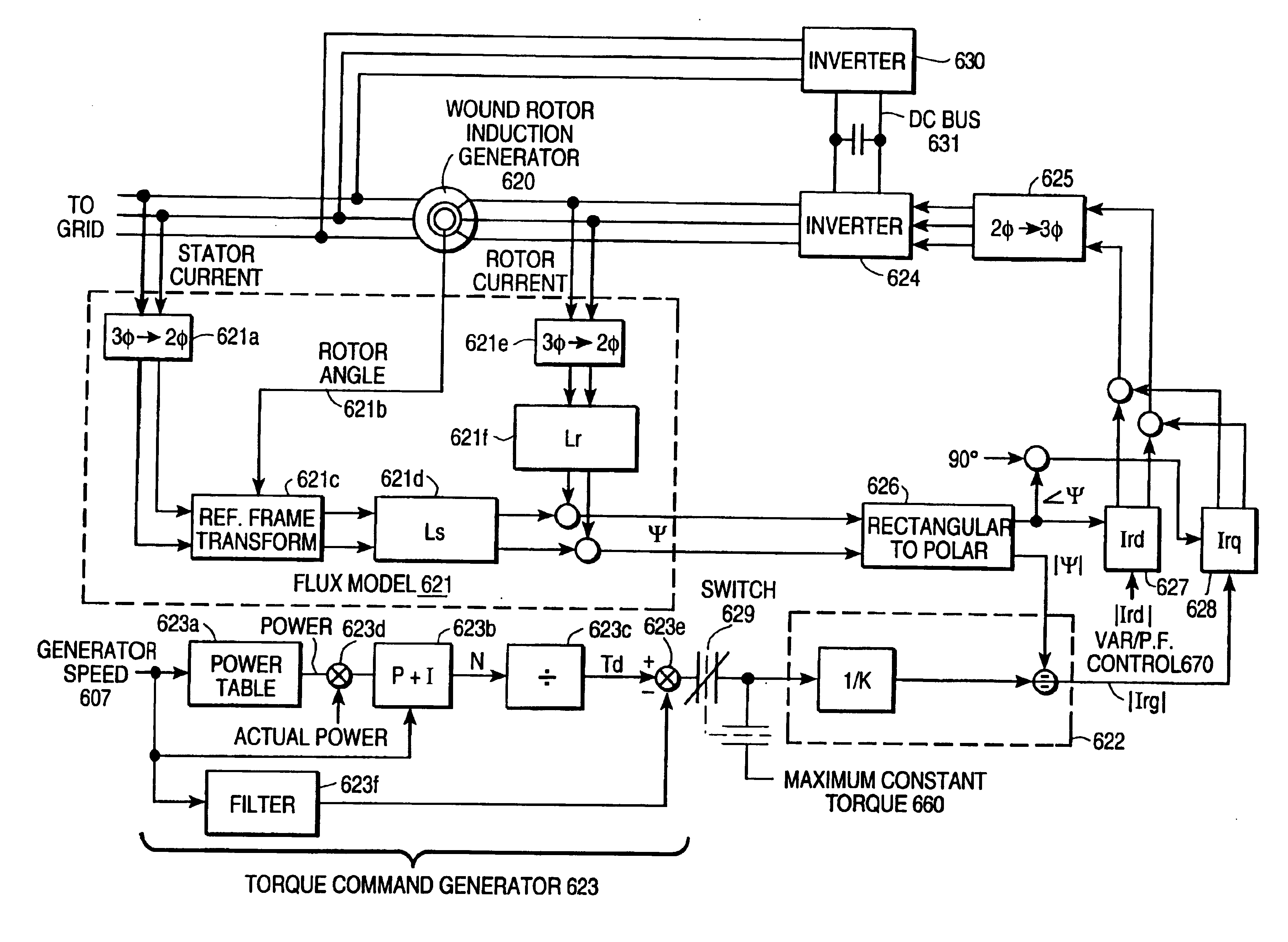

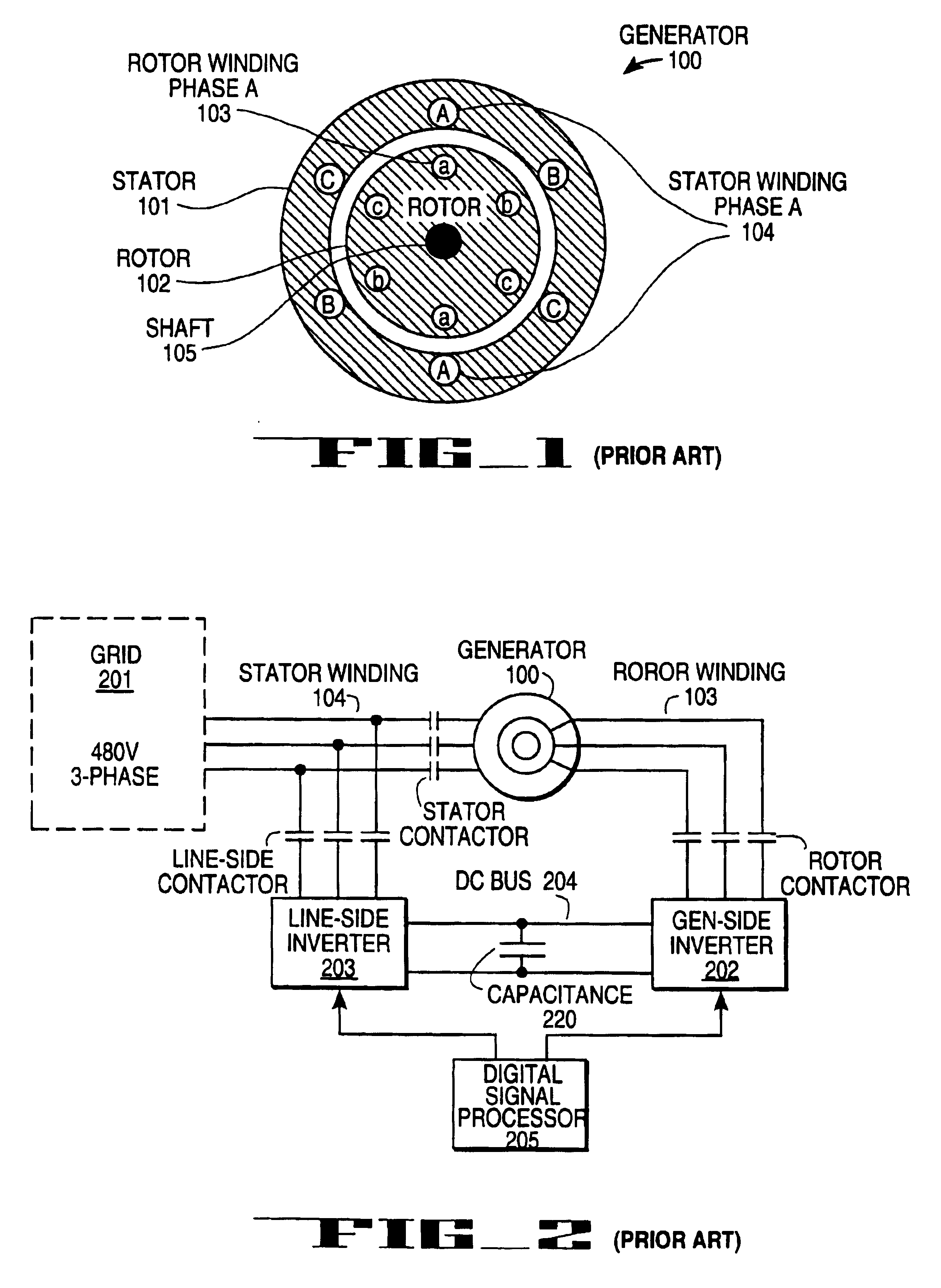

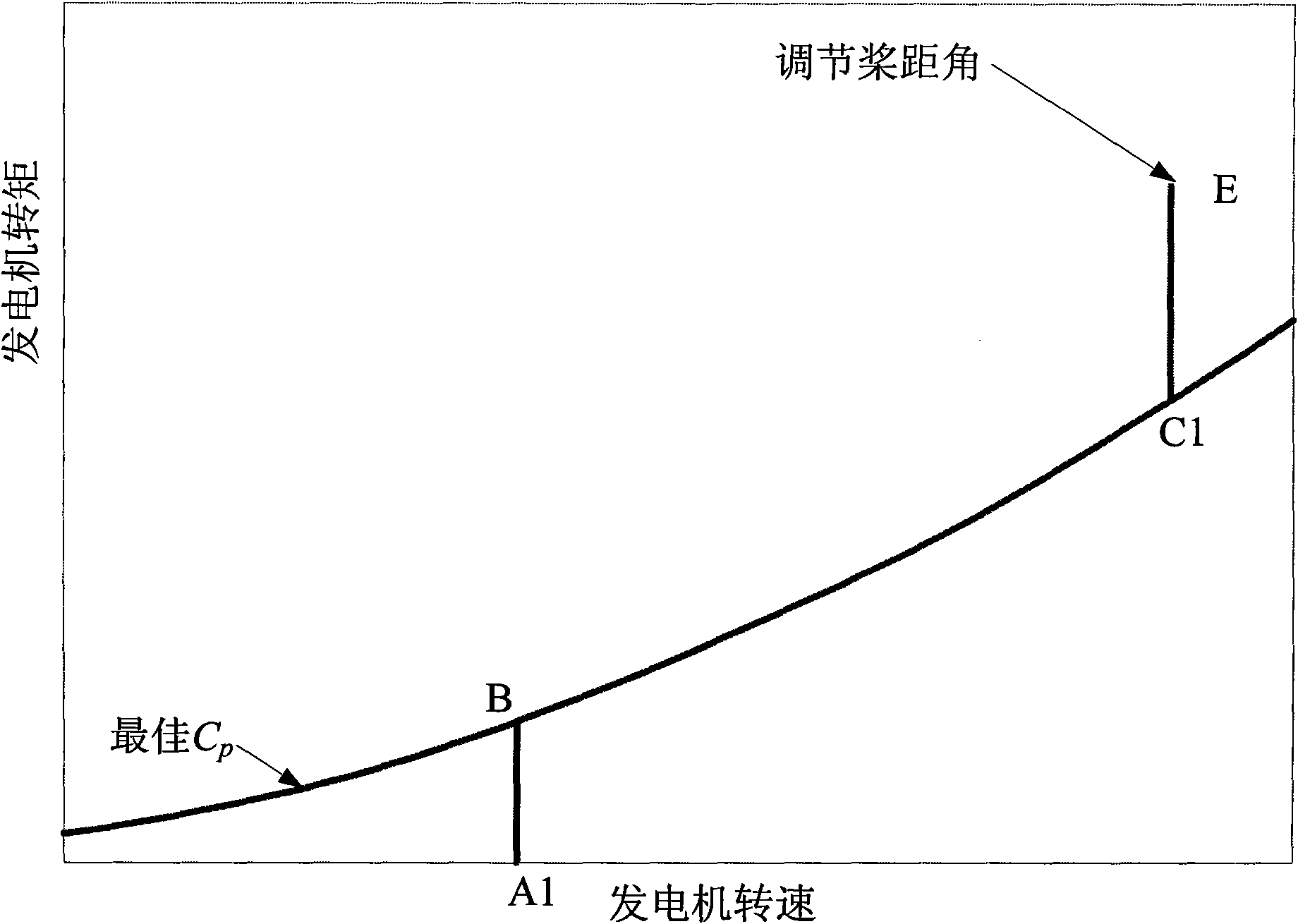

Variable speed wind turbine generator

InactiveUS6856039B2Generator control circuitsWind motor controlVariable speed wind turbineControl theory

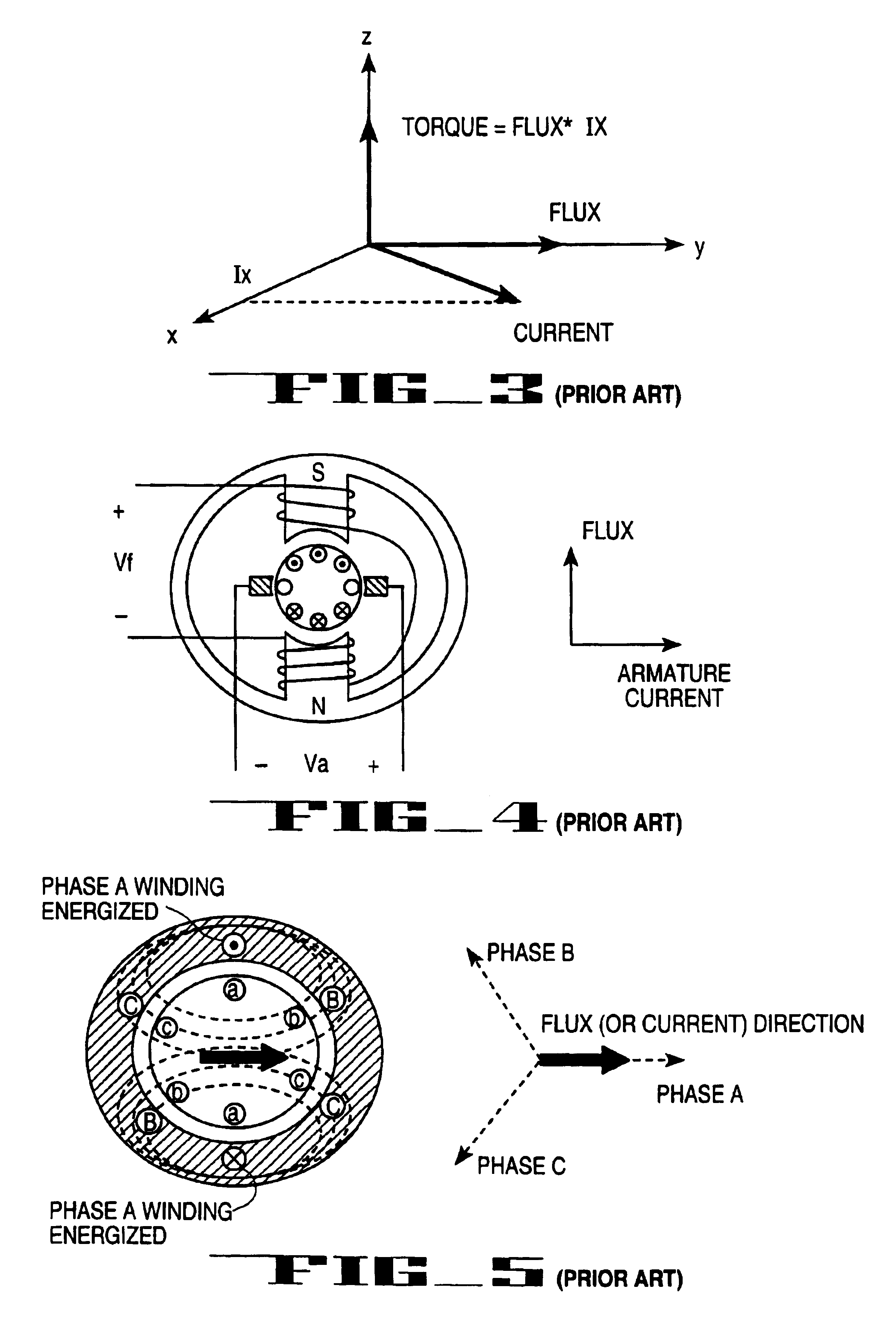

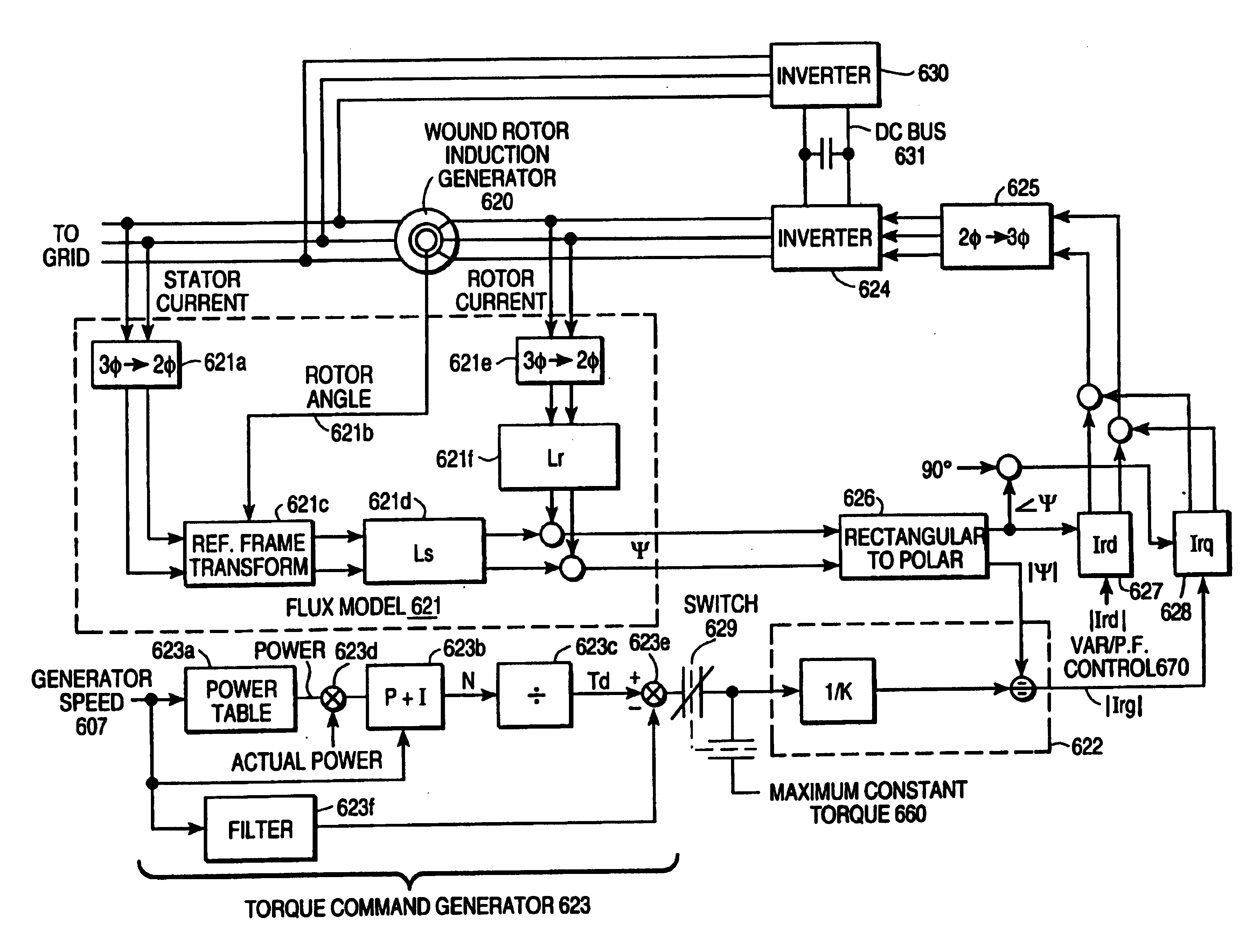

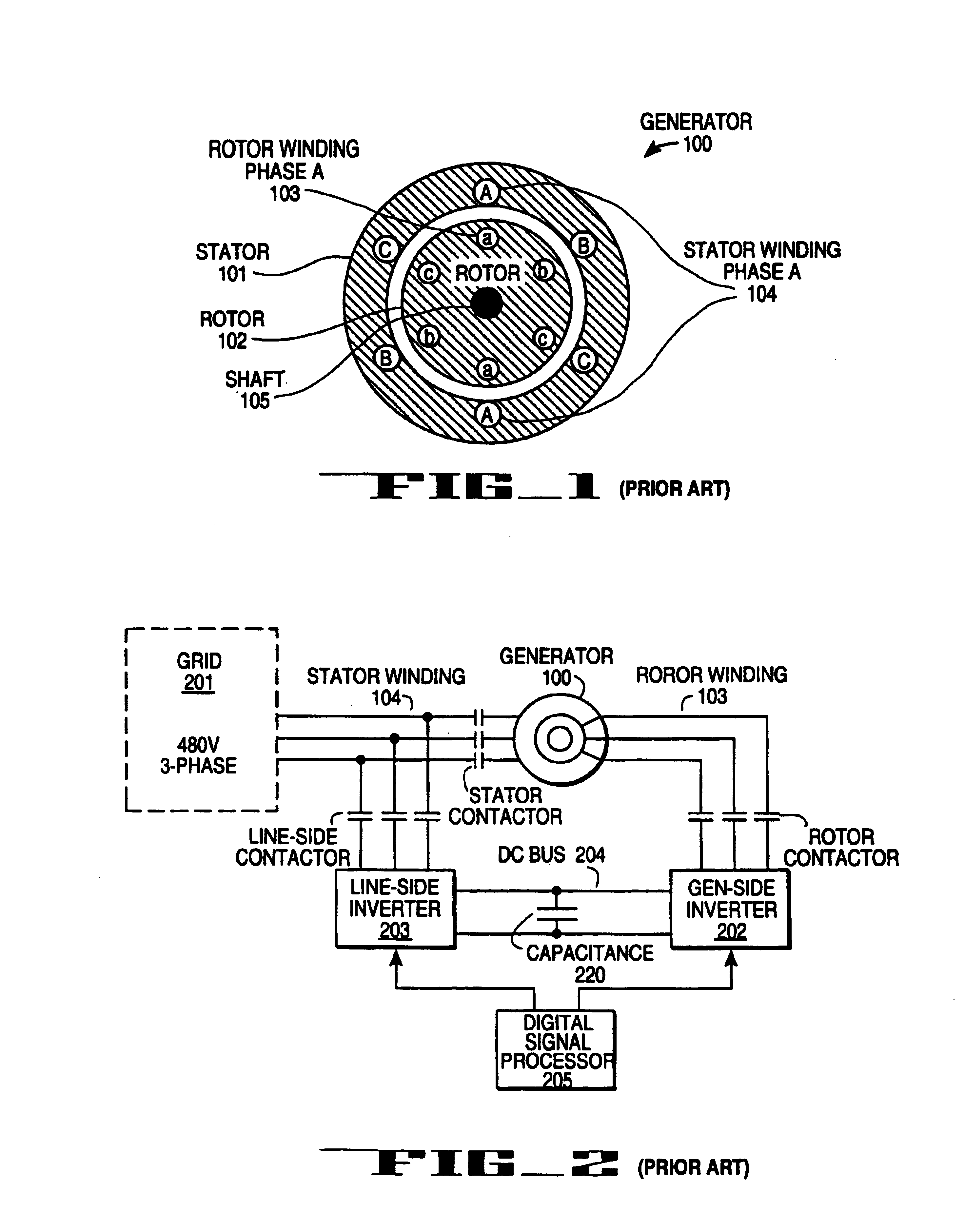

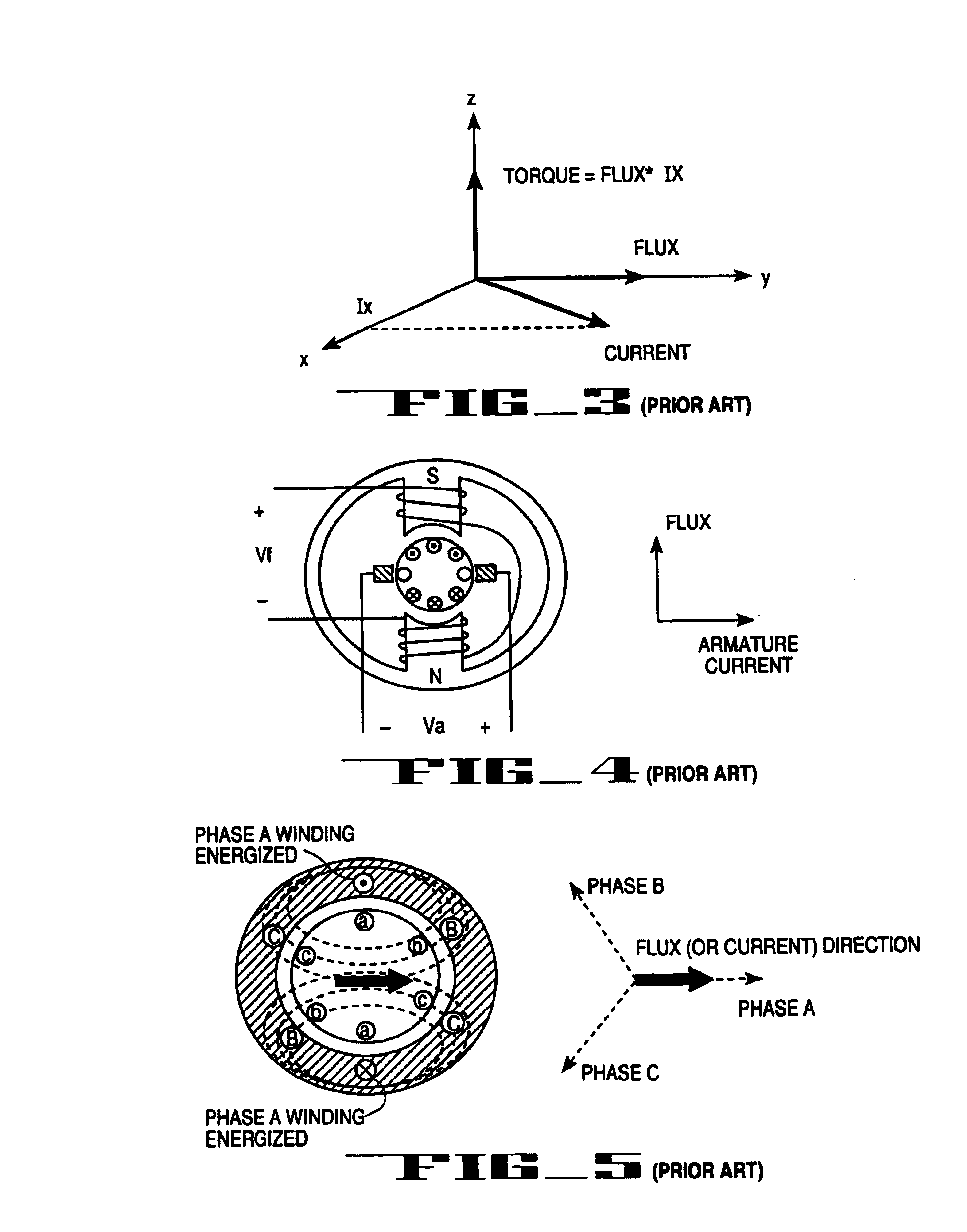

A variable speed system for use in systems, such as, for example, wind turbines, is described. The system comprises a wound rotor induction generator, a torque controller and a proportional, integral derivative (PID) pitch controller. The torque controller controls generator torque using field oriented control, and the PID controller performs pitch regulation based on generator rotor speed.

Owner:GENERAL ELECTRIC CO

Variable speed wind turbine generator

InactiveUS6847128B2Generator control circuitsWind motor controlVariable speed wind turbineControl theory

A variable speed system for use in systems, such as, for example, wind turbines, is described. The system comprises a wound rotor induction generator, a torque controller and a proportional integral derivative (PID) pitch controller. The torque controller controls generator torque using field oriented control, and the PID controller performs pitch regulation based on generator rotor speed.

Owner:GENERAL ELECTRIC CO

Sensorless ac motor controller

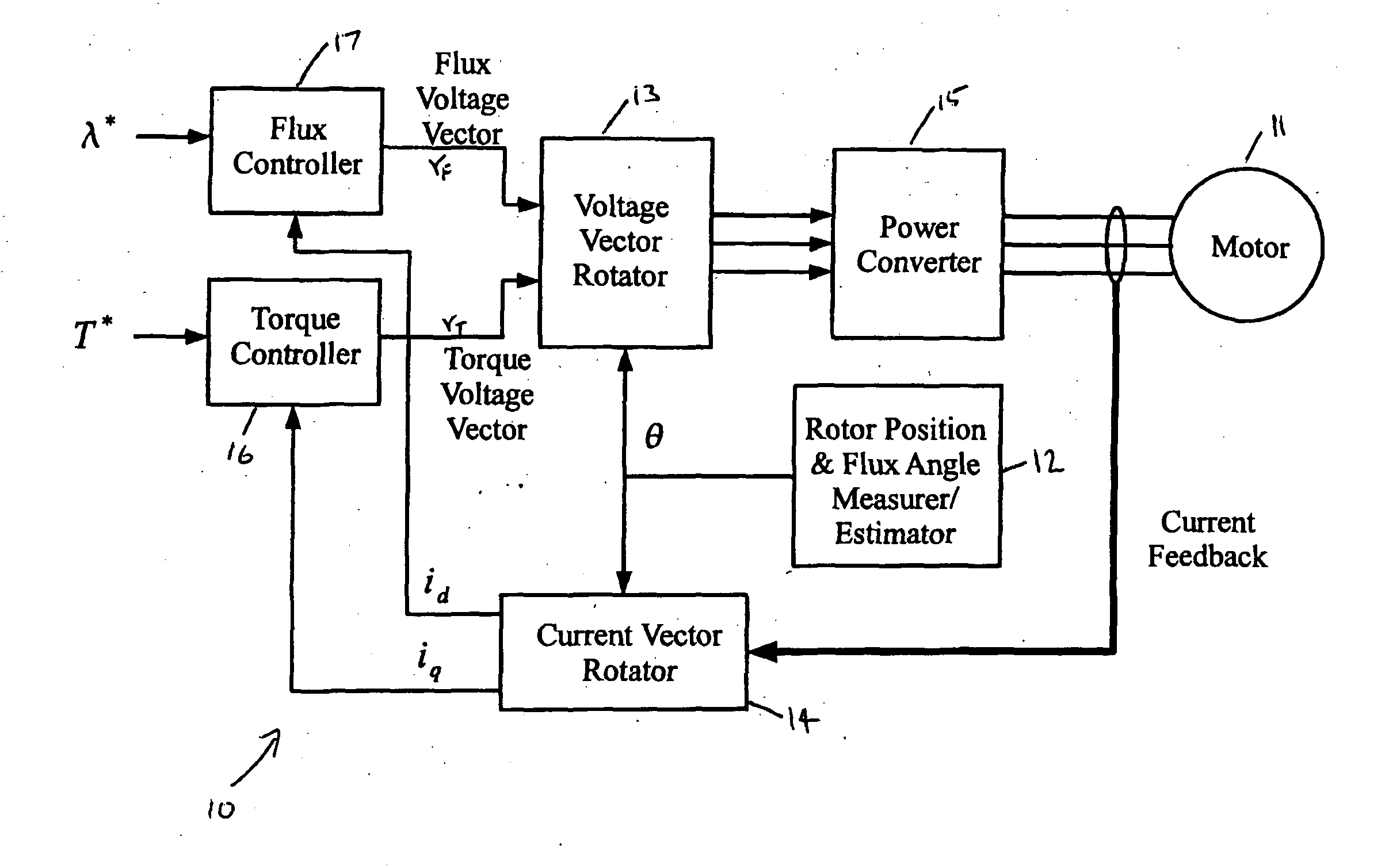

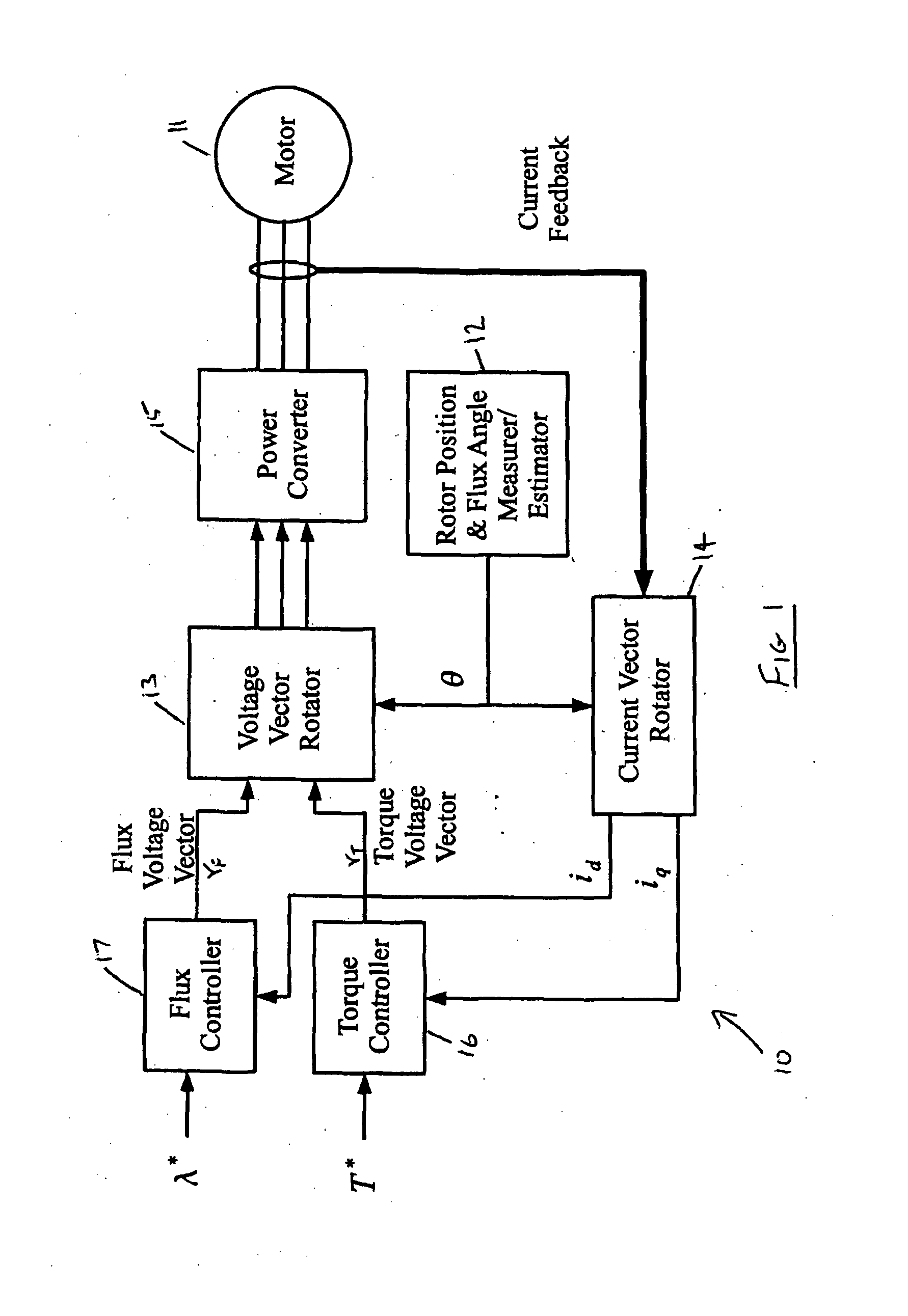

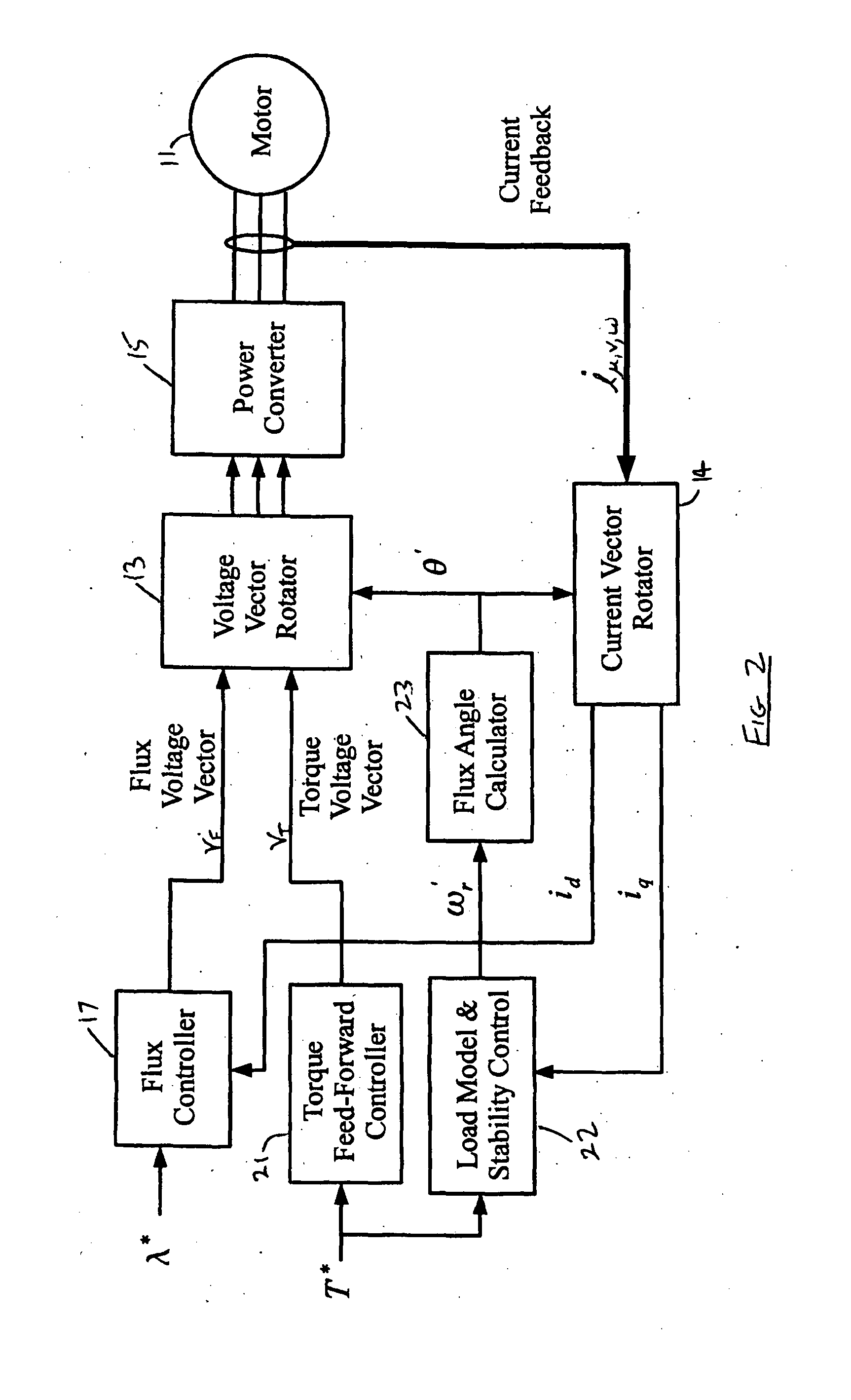

ActiveUS20130221885A1Control changesImprove stabilityCommutation monitoringMotor/generator/converter stoppersMotor speedVoltage vector

A controller for an AC electric motor, includes a Feed Forward Torque Controller and a load model. The Torque controller directly derives a torque related component of applied motor voltages from a signal representing a torque command input T* and at least one motor parameter. The load model derives a motor speed value including a model of motor speed behaviour of the AC electric motor to provide an output signal which represents the motor speed of the AC electric motor. This motor speed output signal is used in determining a frequency of rotation of an applied motor voltage vector. Where an input to the load model is the signal representing the torque command input T*, the load model uses the signal representing the torque command T*, at least over a part of an operating speed range of the AC motor which includes zero speed, to determine the motor speed output signal.

Owner:HUNTER GREGORY PETER

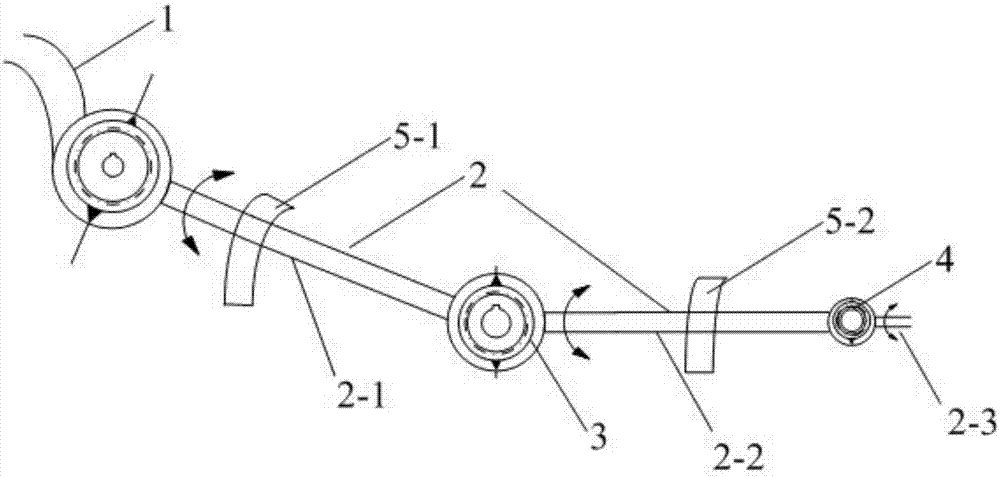

Upper limb exoskeleton rehabilitation robot control method based on radial basis neural network

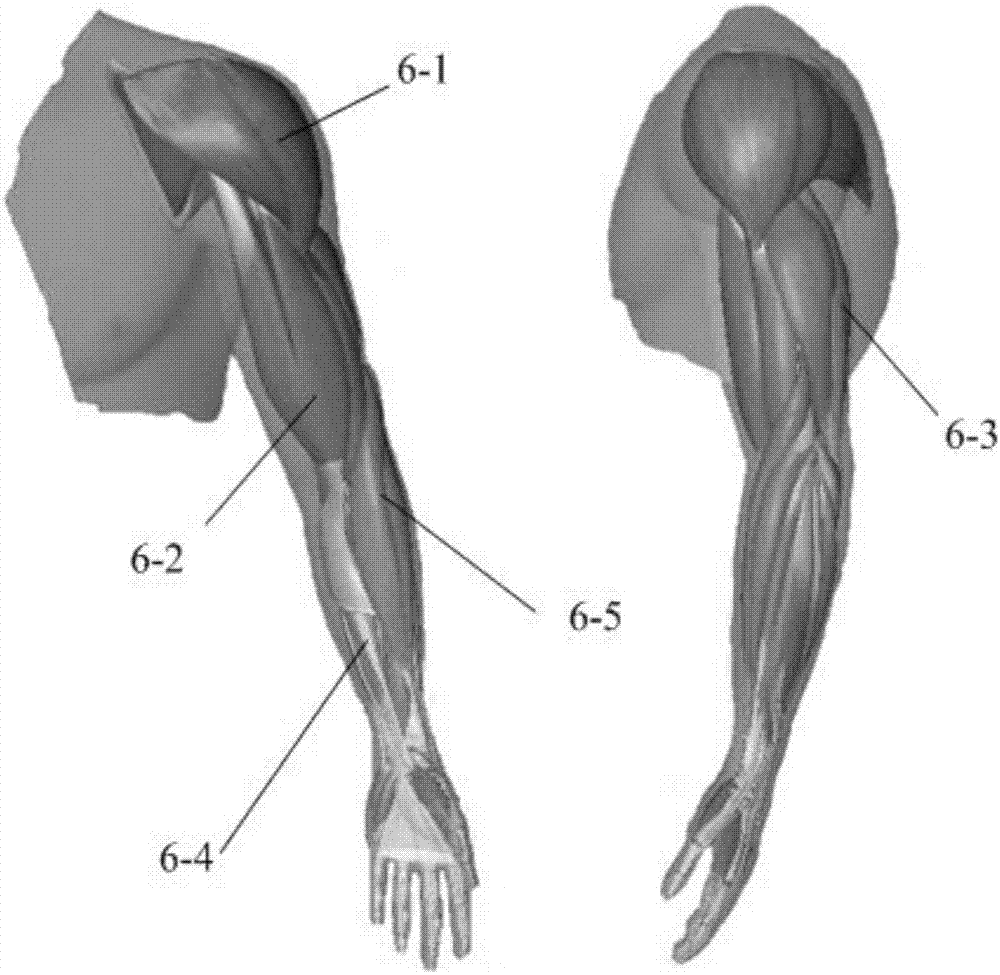

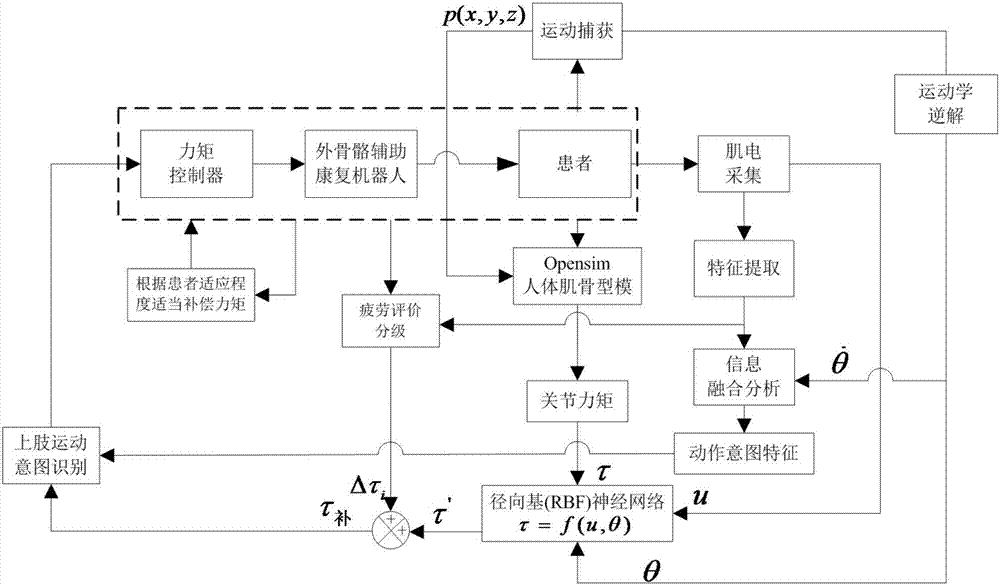

ActiveCN107397649ARealize interactive intelligent rehabilitationImprove rehabilitation effectChiropractic devicesDiagnostic recording/measuringUpper limb muscleNetwork model

The invention discloses an upper limb exoskeleton rehabilitation robot control method based on a radial basis neural network. The method includes the steps that a human body upper limb musculoskeletal model is established; upper limb muscle myoelectric signals and upper limb movement data are collected, the movement data are imported into the upper limb musculoskeletal model, upper limb joint torque is obtained, the radial basis neural network is established and a neural network model is given out; the patient movement intention is recognized, the joint angular speed is subjected to fusion analysis, the result is used for recognizing the training object joint stretching state, and the limb movement intention is determined; and myoelectric signals and joint angles in affected side rehabilitation training are collected in real time, affected side joint torque is obtained through the neural network, joint torque needing to be compensated by an exoskeleton mechanical arm is calculated, myoelectric signal fatigue characteristics are analyzed, the compensation torque magnitude can be adjusted by classifying the degree of fatigue, and a torque controller can be controlled to achieve the effect that an upper limb rehabilitation robot assists patients in rehabilitation training by combining the movement intention. By means of the upper limb exoskeleton rehabilitation robot control method, the rehabilitation training process is made to be more suitable for the patients, man-machine interaction is strengthened, and the rehabilitation effect is improved.

Owner:YANSHAN UNIV

Automatic regulating apparatus for controller parameters of servo driver of motor and method thereof

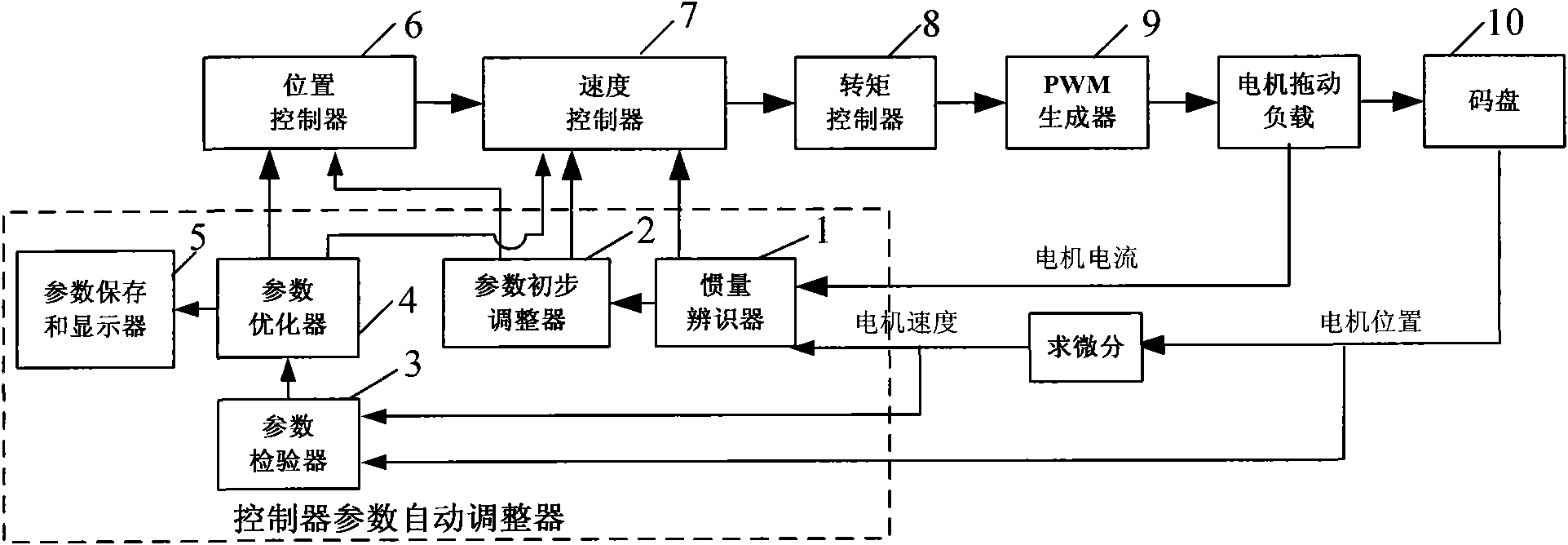

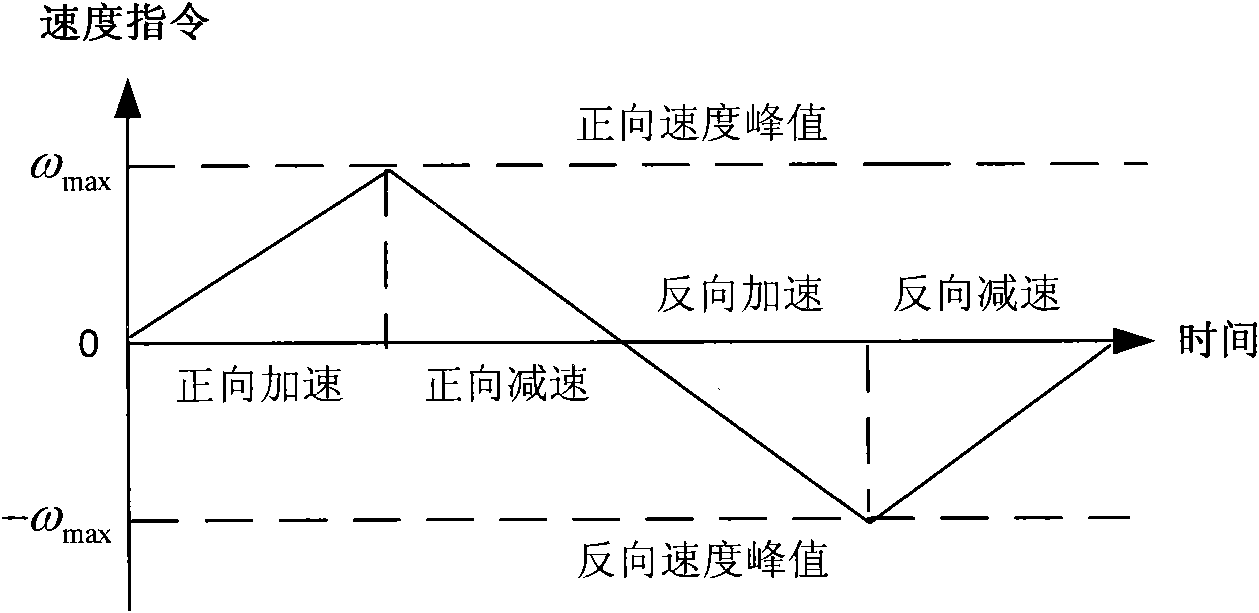

ActiveCN101895252AGood control effectAvoid misalignmentMotor parameters estimation/adaptationPermanent magnet synchronous motorDisplay device

The invention discloses an automatic regulating apparatus for controller parameters of a servo driver of a motor and a method thereof. The apparatus comprises an inertia identifier, a parameter initial regulator, a parameter checker, a parameter optimizer, a parameter saving and displaying device, a speed controller, a position controller, a torque controller, a PWM (Pulse-Width Modulation) generator and a coded disc. In the invention, the servo driver of an alternating current permanent magnet motor automatically configures the parameters of the position controller and the speed controller according to different rotary inertias of mechanic load, checks and further optimizes the automatically configured parameters through the parameter checker and the parameter optimizer so that the position response and the speed response of the servo driver are relatively optimal. The servo driver of the alternating current permanent magnet synchronous motor automatically regulates the control parameters according to work occasions and achieves ideal control effect. The whole process is manual participation free and completed fully by the servo motor of the alternating current permanent magnet synchronous motor.

Owner:上海新时达线缆科技有限公司 +2

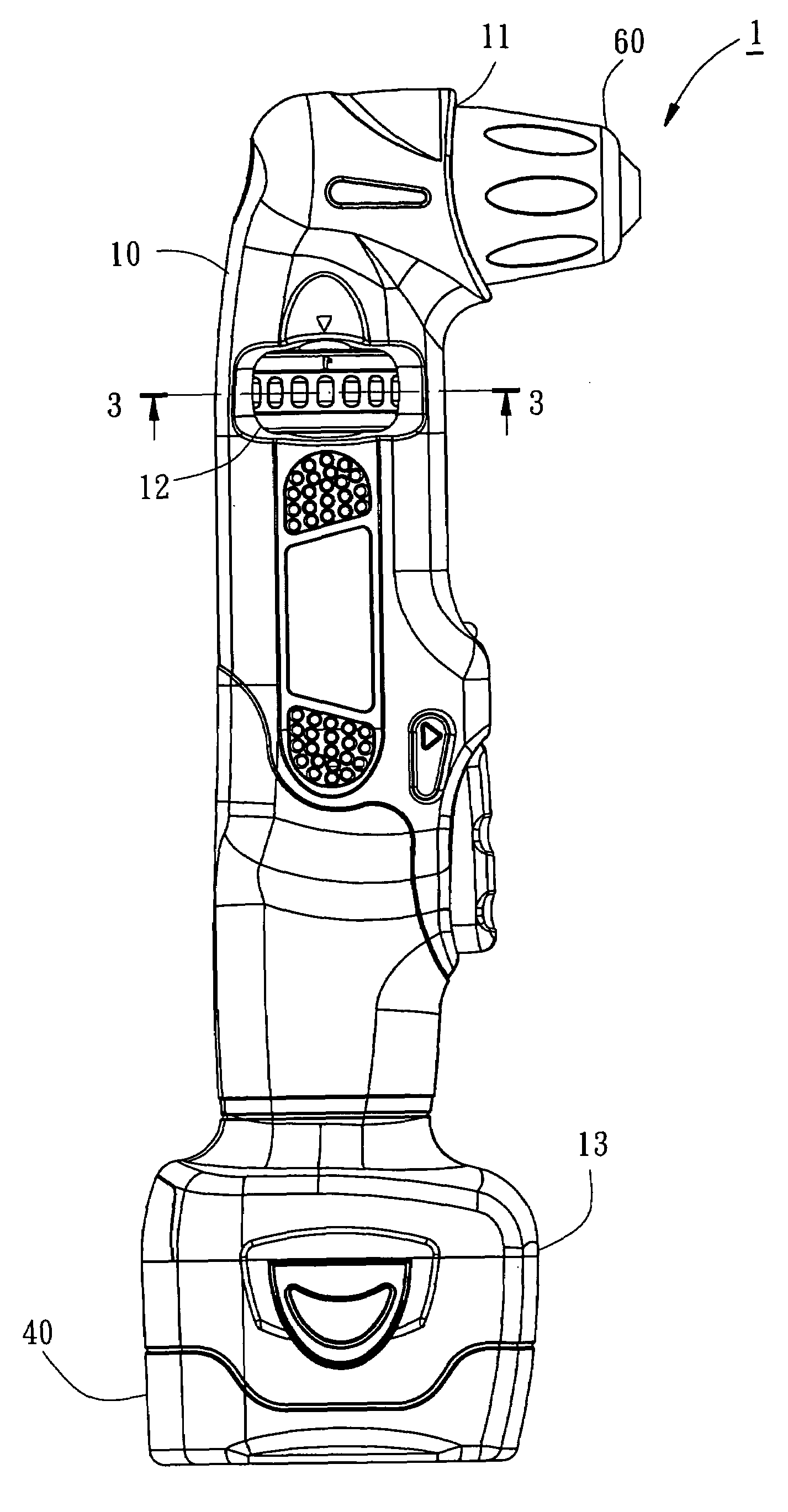

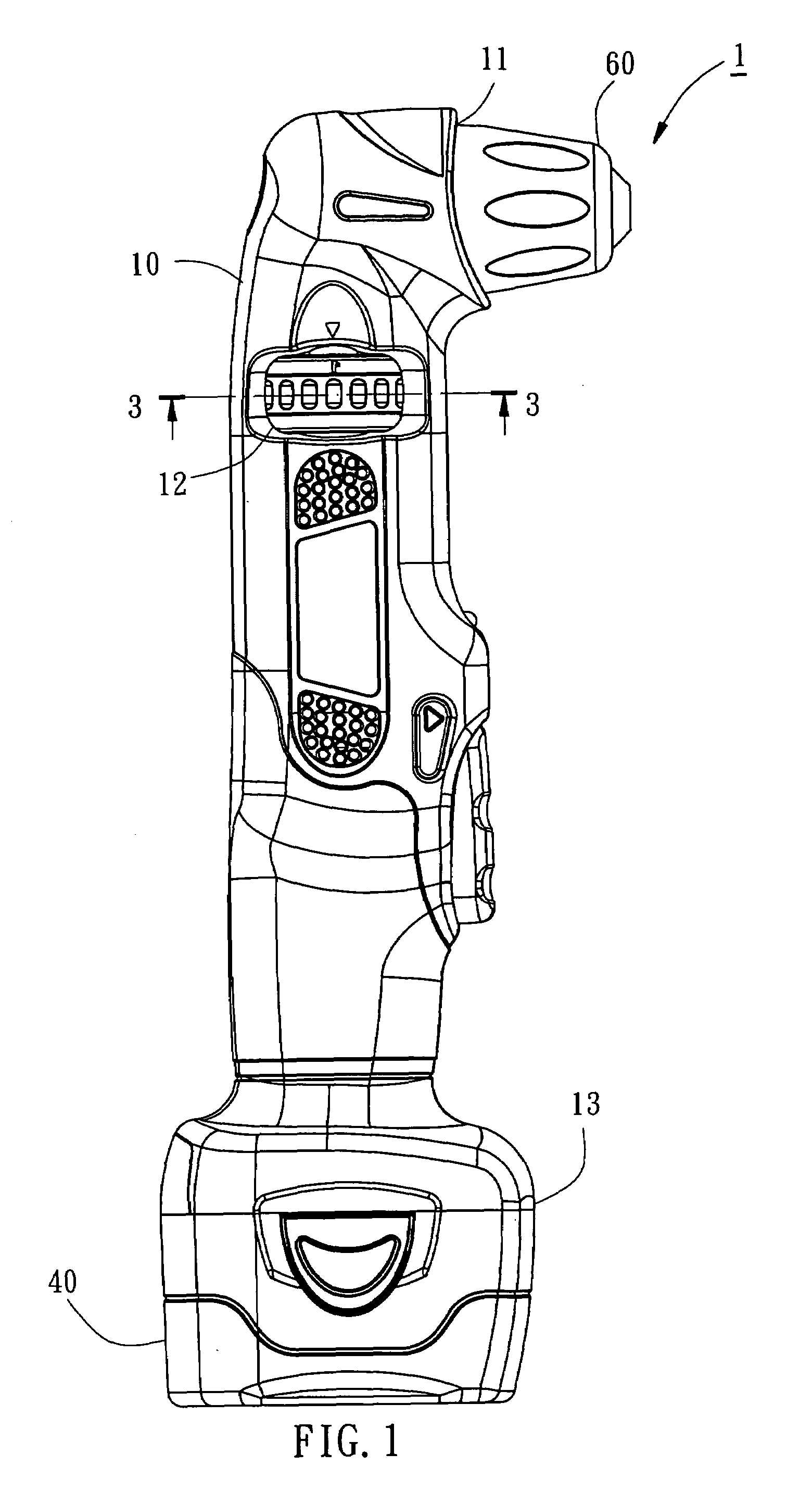

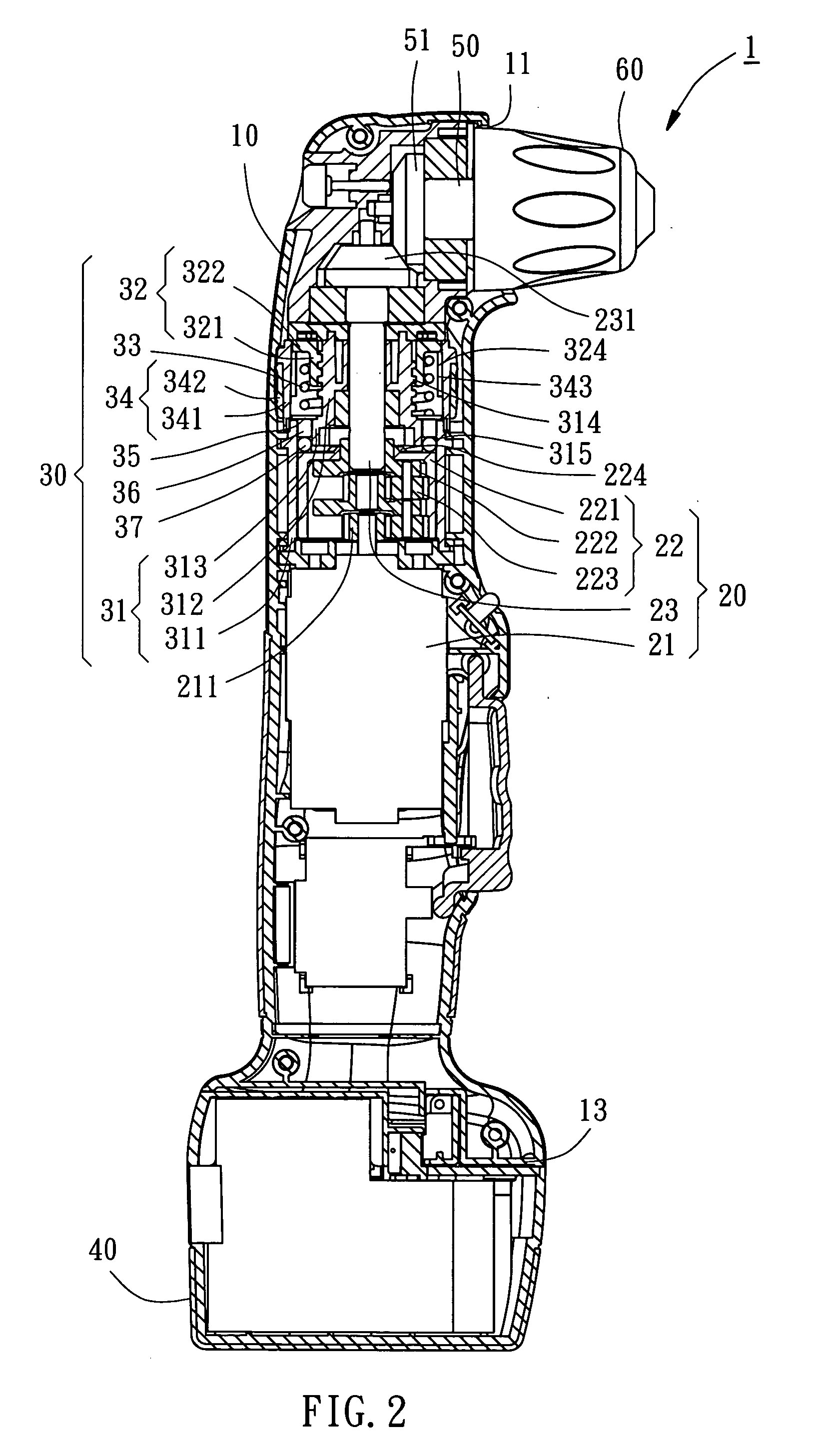

Elbow-type power hand tool

An elbow-type power hand tool including a housing, a motor, a planet gear set, a transmission shaft, and a torque controller mounted in the housing for controlling output torque of the transmission shaft. The power hand tool including a battery pack mounted in the housing that provides electricity to a power drive, an output shaft coupled to the transmission shaft that extends perpendicular to the transmission shaft, and a chuck assembly coupled to an end of the output shaft remote from the transmission shaft for holding a tool bit.

Owner:MOBILETRON ELECTRONICS

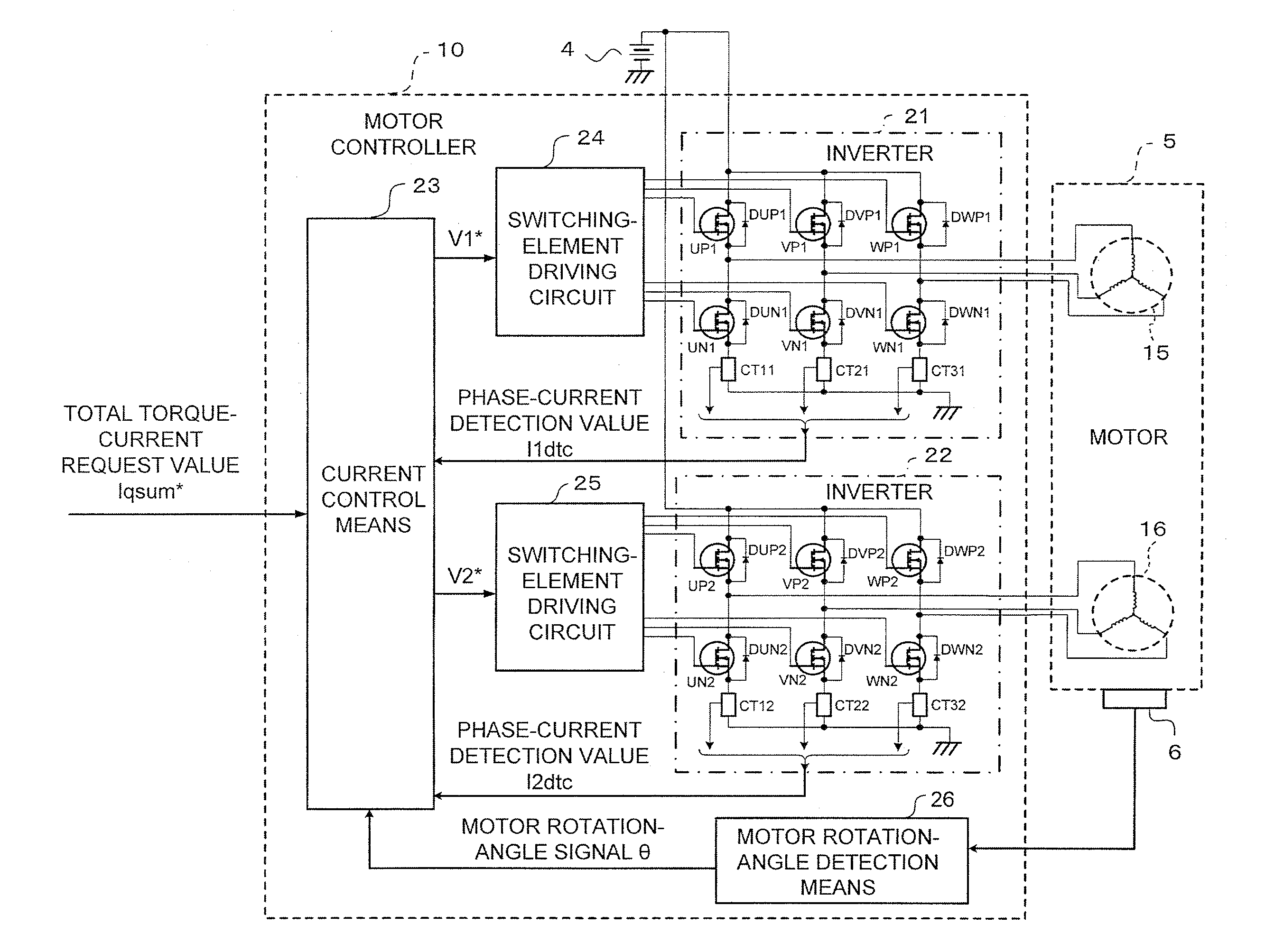

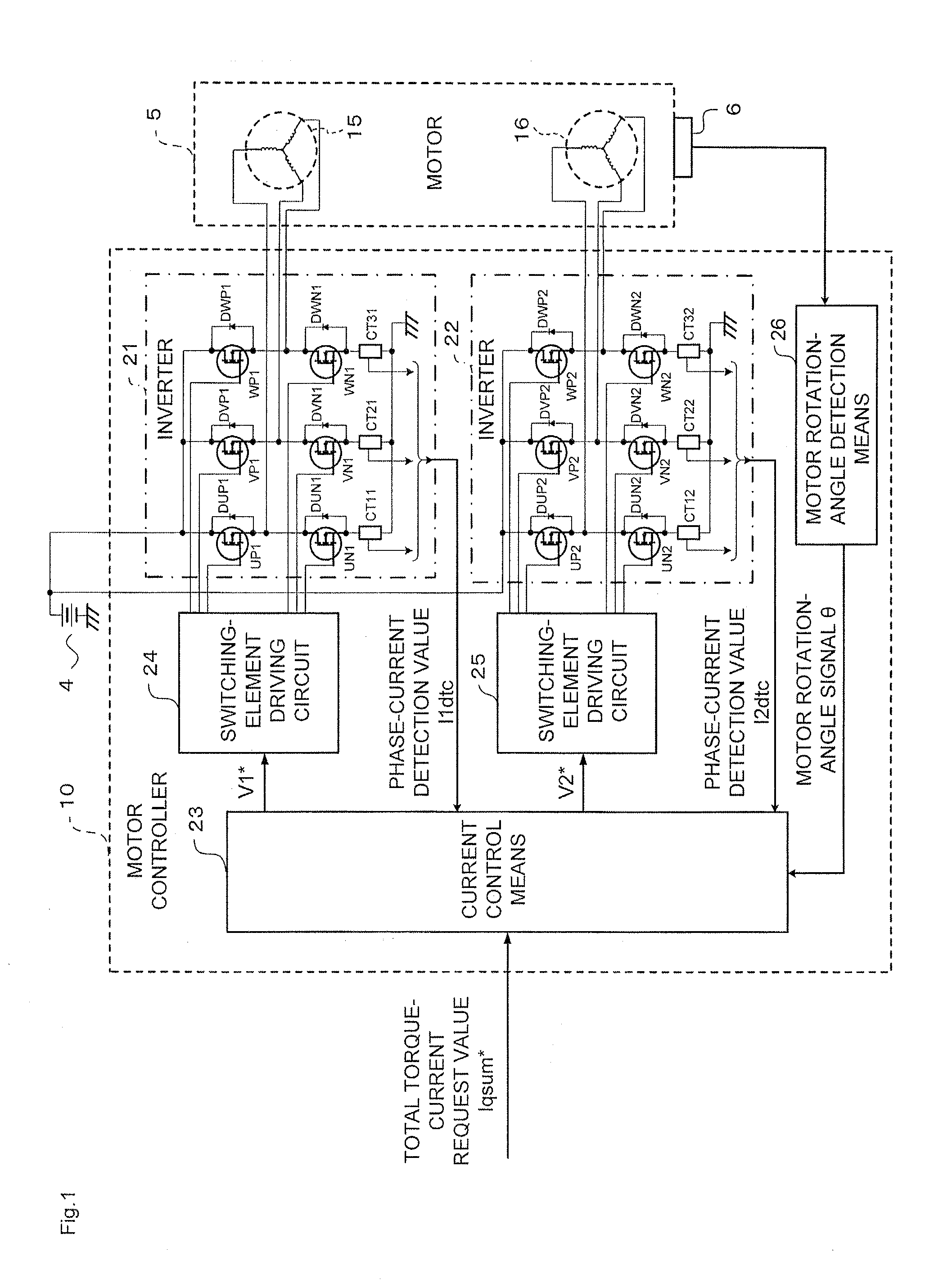

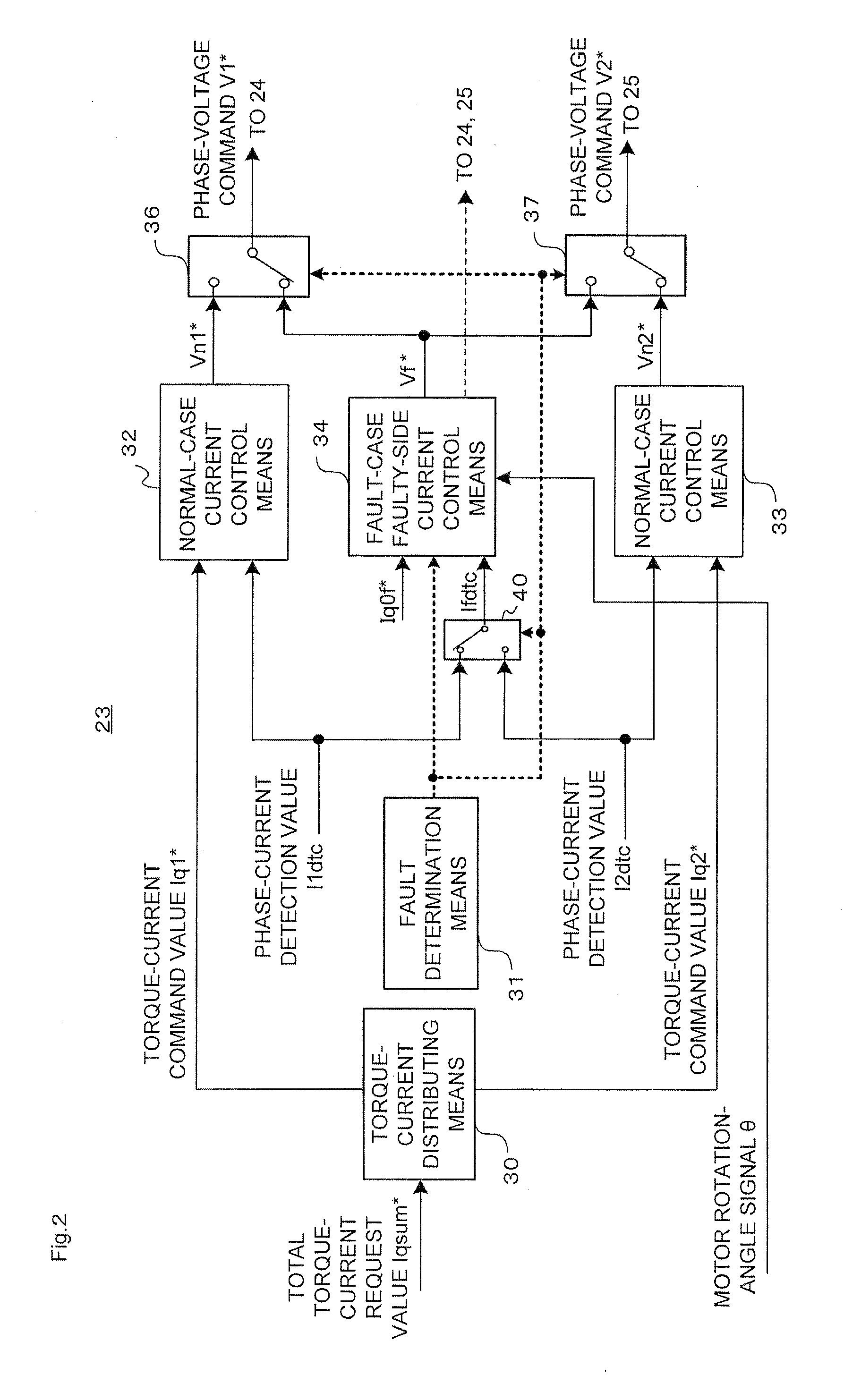

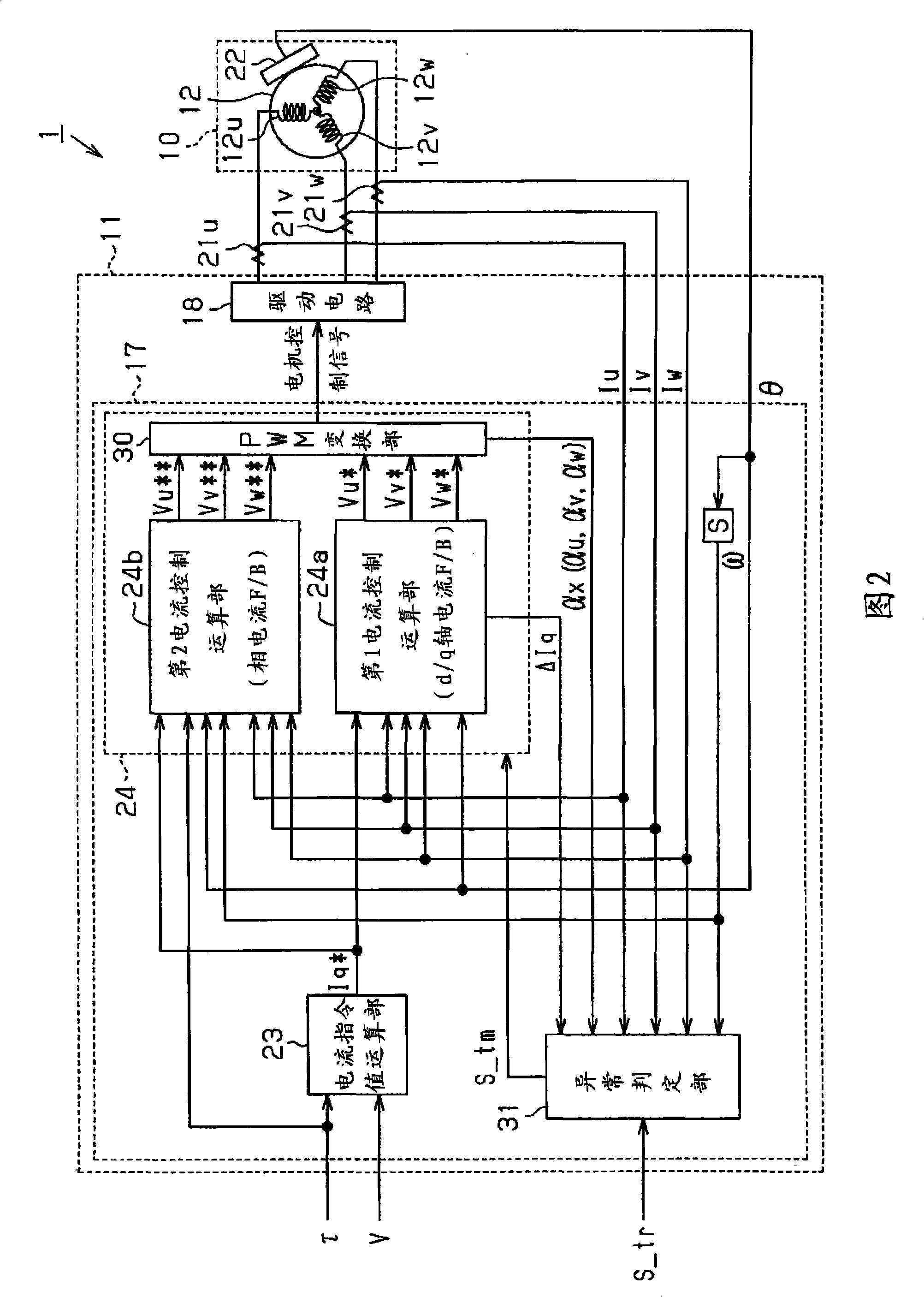

Motor controller and electric power steering device using the same

ActiveUS20130299271A1Low costSmall sizeCommutation monitoringMotor/generator/converter stoppersElectric power steeringMotor controller

Provided are a motor controller for suppressing a torque pulsation with a simple configuration and obtaining a sufficient output torque in the case of an open-type fault occurring in any one of windings of a motor and inverters, and an electric power steering device using the motor controller. In the motor controller for controlling a current supplied from and a voltage applied from a power source with respect to the motor including winding sets of a plurality of systems, when a fault determination unit (31) determines the occurrence of the open-type fault, the supply of the currents to the windings of one of the systems in which the fault has occurred is stopped by control performed on switching elements included in the inverter of the faulty system, whereas the supply of the currents to the windings of the normal system in which the fault has not occurred is continued.

Owner:MITSUBISHI ELECTRIC CORP

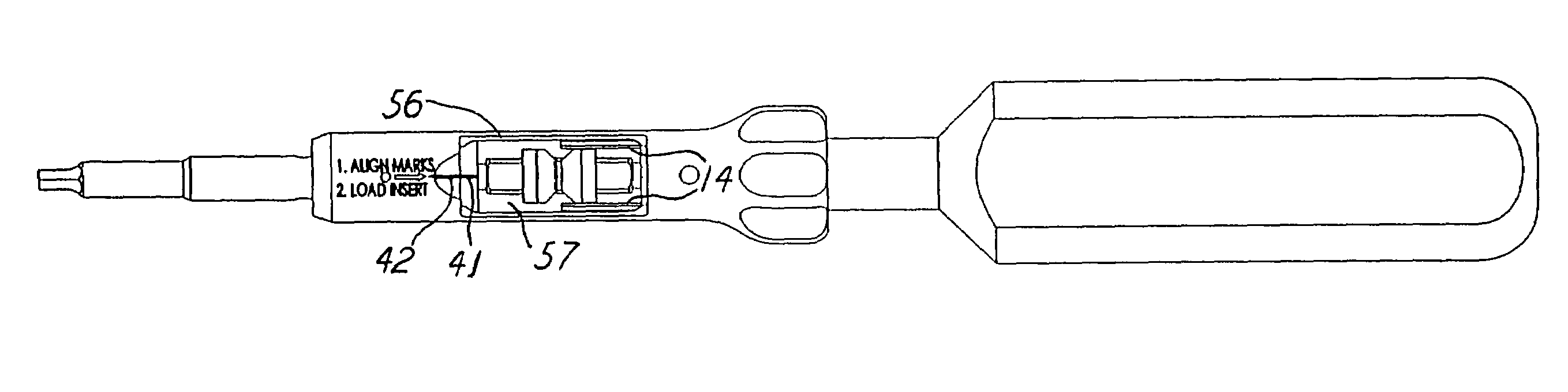

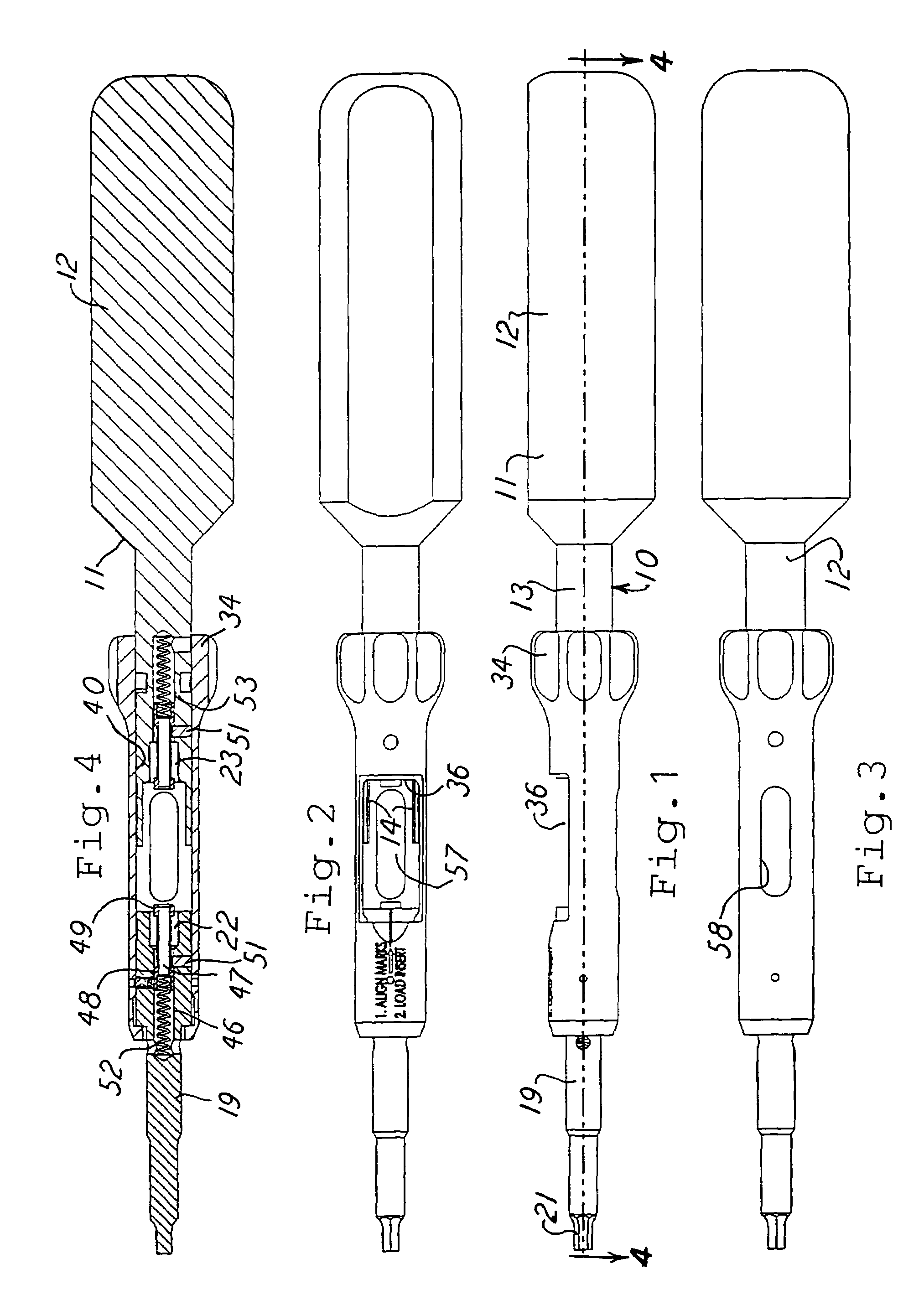

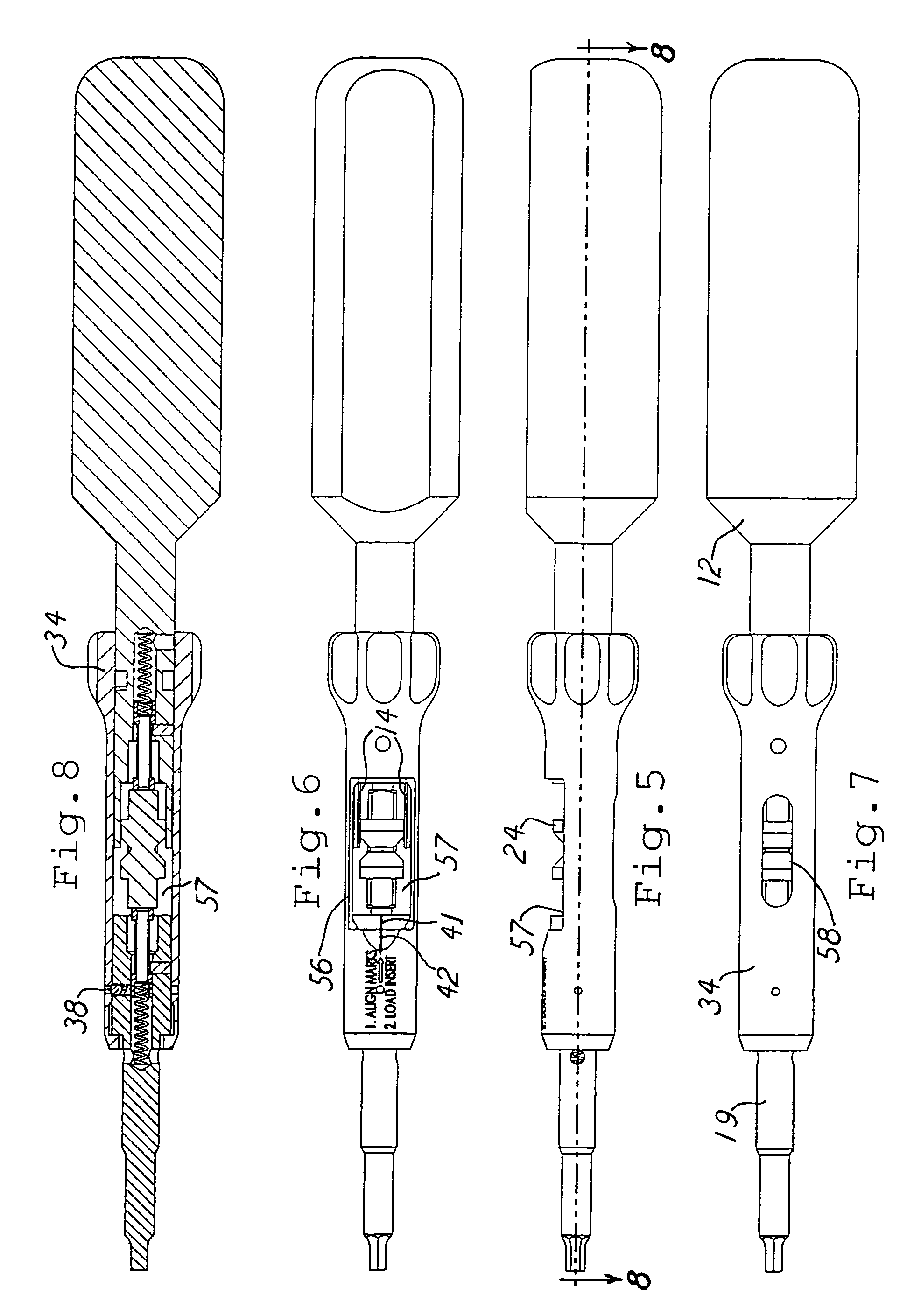

Rotatable hand tool with a torque controller and method

A hand tool rotatable about an axis and having a handle and a bit in alignment along the axis. A plurality of inserts are available for individual placement between the handle and the bit for controlling torque transmitted by the tool. The insert can provide for limited or unlimited torque, in accord with the construction of the individual insert. The insert is replaceable relative to the tool.

Owner:TECMET

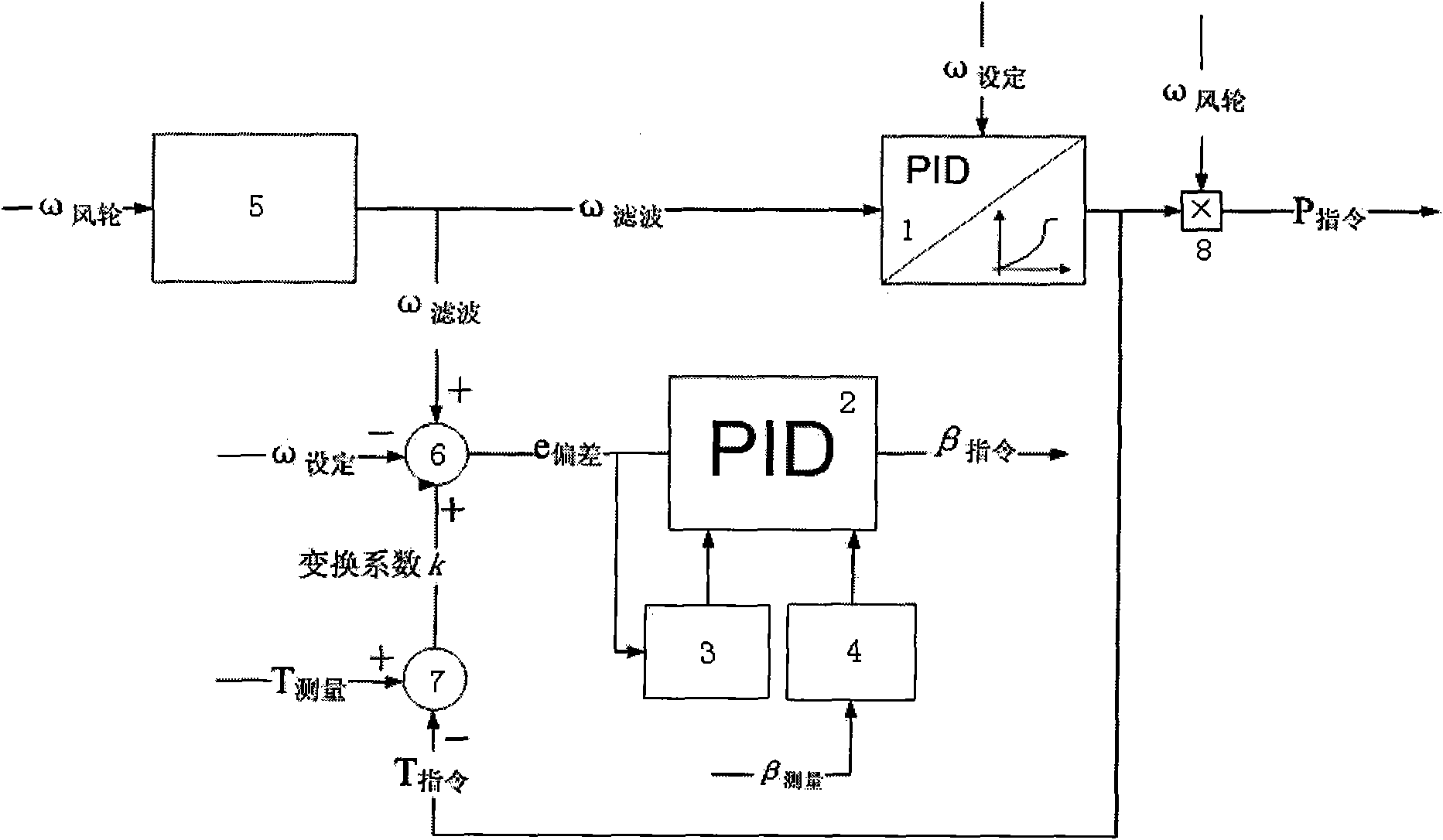

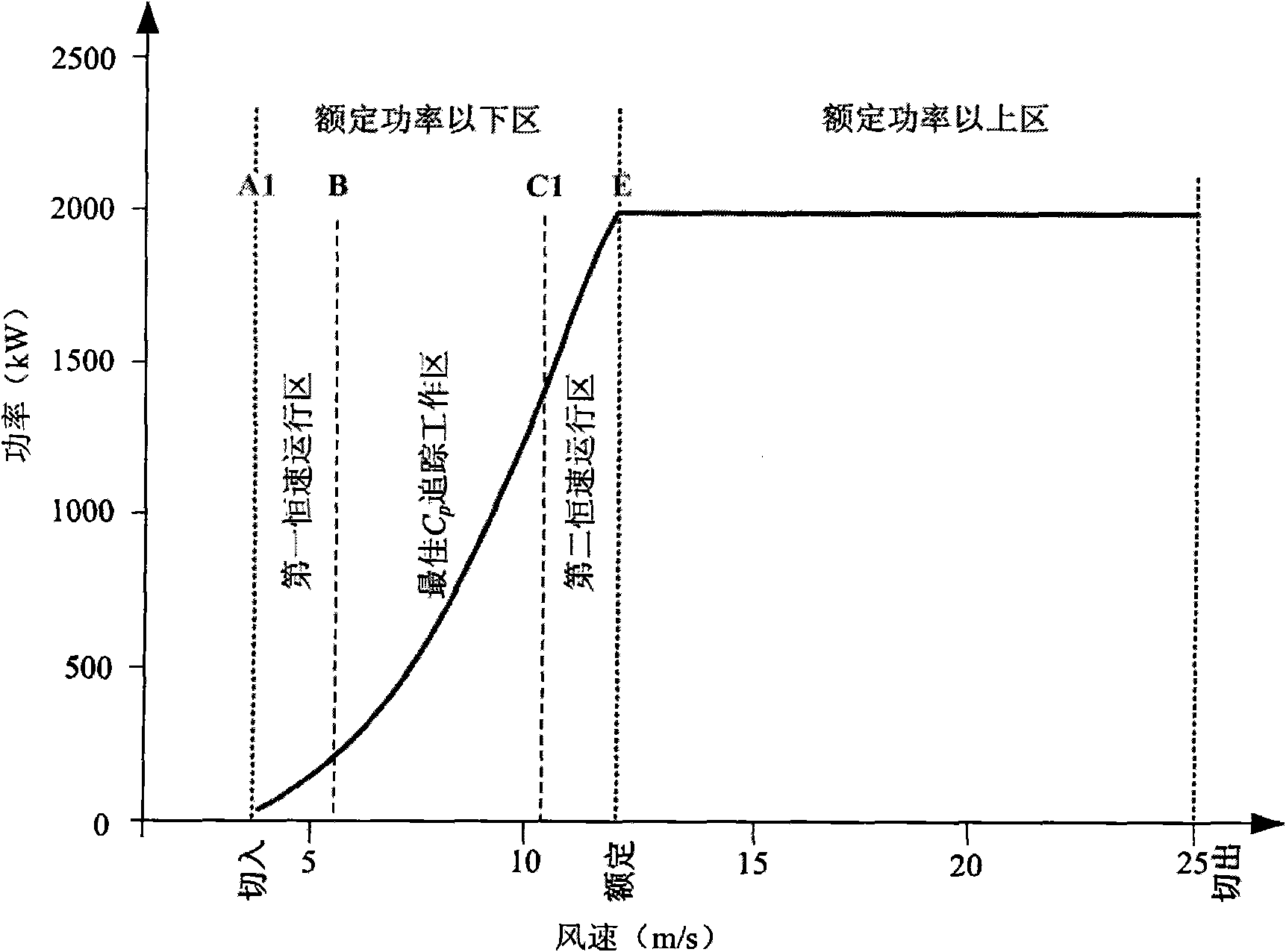

Megawatt wind generating set combination control policy

InactiveCN101660489AAvoid mutual interferenceSwitching is smooth and responsiveWind motor controlMachines/enginesPower qualityControl theory

The invention relates to a megawatt wind generating set combination control policy. When the wind speed of a wind generator fluctuates at rated wind speed, a torque control policy and feather control policy simultaneously remain in operation state, so as to realize undisturbed switching between a feather PID controller and a torque PID controller. The invention makes the best of the integral saturation characteristic of PID algorithm, so that switching between the torque PID controller and the feather PID controller is smooth and sensitive, mutual interference between the feather controller and the torque controller in the previous switch mode switching process while only one controller is ensured to operate at the same time, drastic fluctuation of wind generator power when the wind speedfluctuates at the rated wind speed is avoided, further load impact is reduced, electric energy quality is improved, reliability of the wind generating set is improved, and operation performance of the wind generating set is improved.

Owner:南京智昊置业有限公司

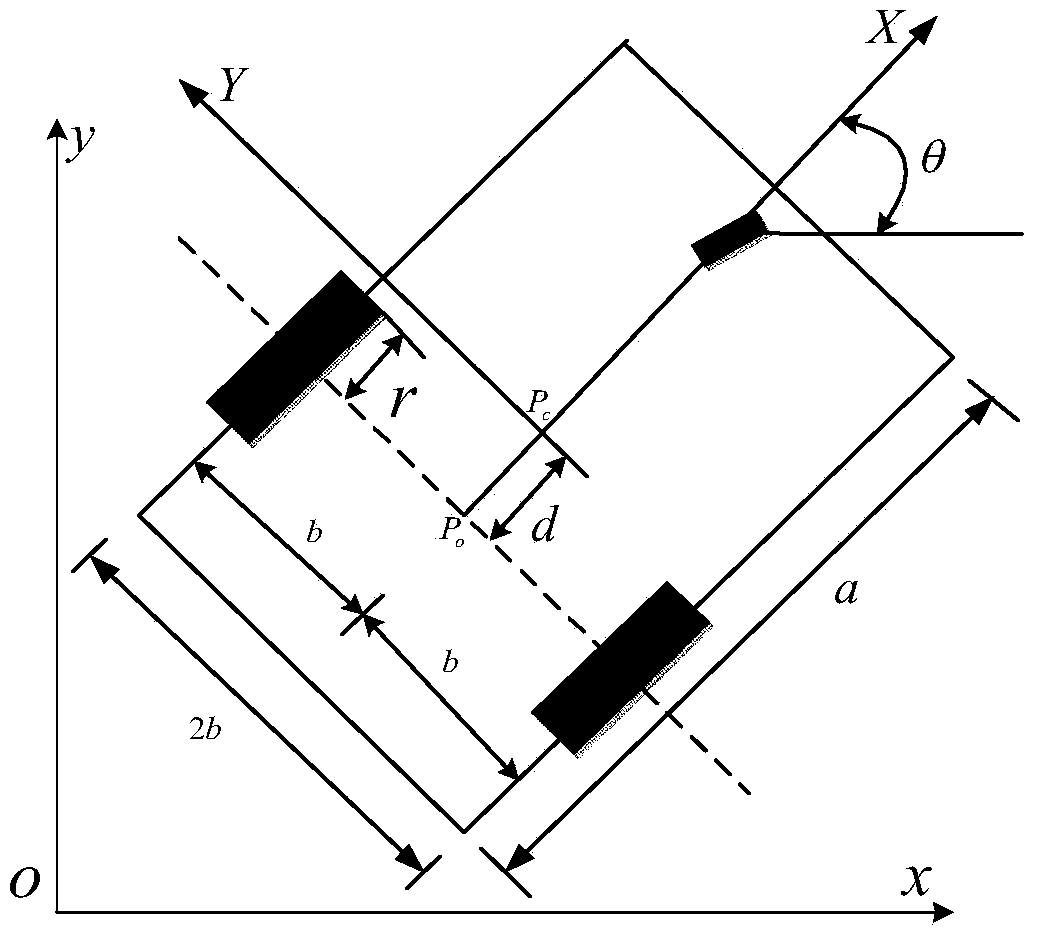

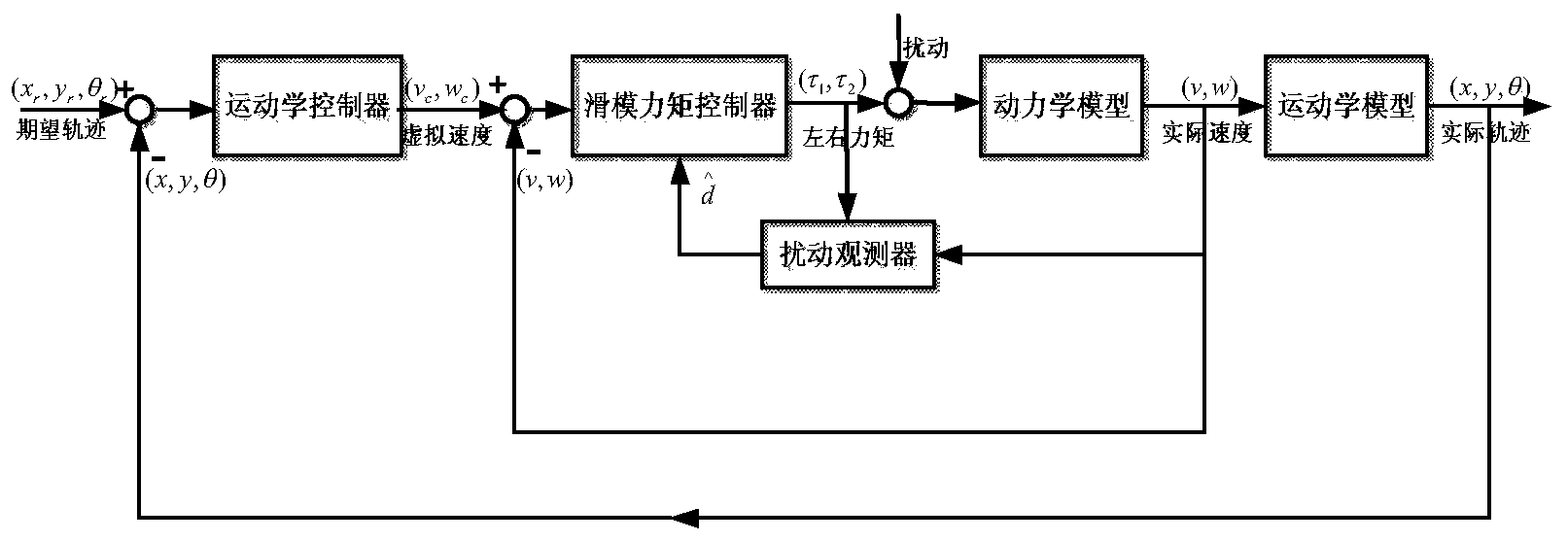

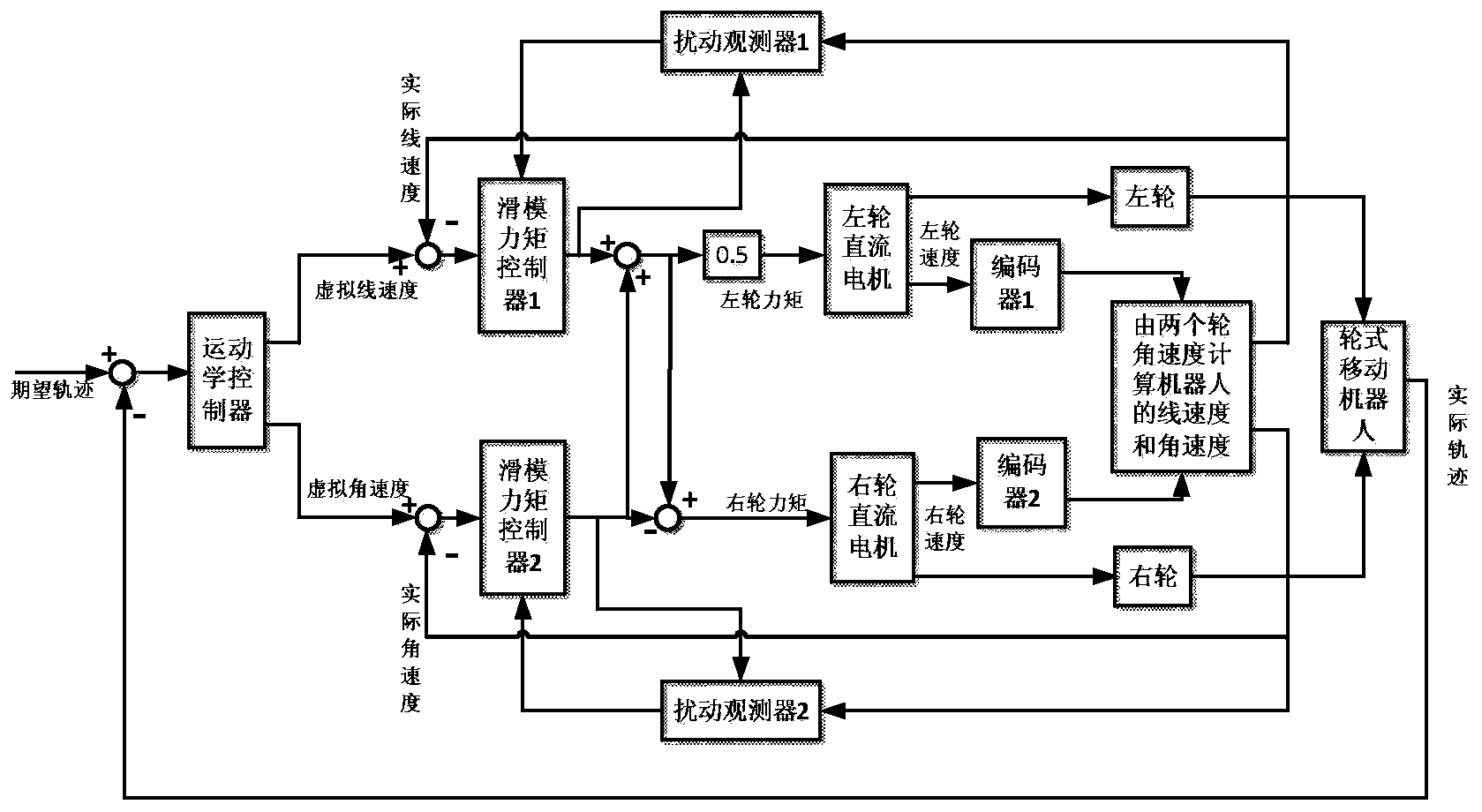

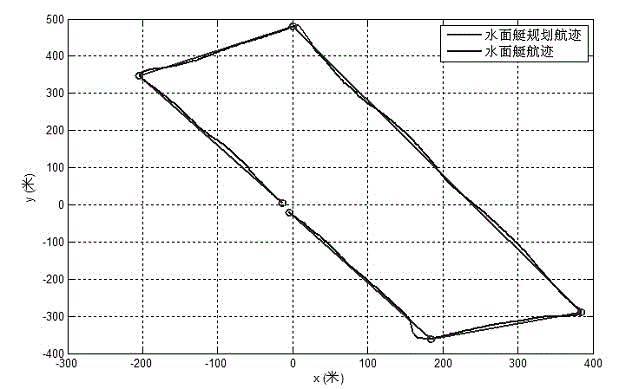

Mixed control method based on trace tracking of wheeled mobile robot

ActiveCN104317299AReduce the amount of controlGuaranteed stabilityPosition/course control in two dimensionsKinematicsAngular velocity

The invention discloses a mixed control method based on trace tracking of a wheeled mobile robot. A kinematic virtual velocity controller, a sliding mode torque controller and a disturbance observer are involved in the mixed control method, wherein the sliding mode torque controller and the disturbance observer are based on dynamics. The virtual velocity controller is used for designing the linear velocity and the angular velocity of the robot; the sliding mode torque controller is used for designing a sliding mode face and a sliding mode control law, and the disturbance observer is used for observation of the external disturbance of a system to reduce the control quantity of the sliding mode controller and is introduced as a feedforward term. By means of the mixed control method, control over the trace tracking of the robot is achieved by the system under the condition that external change and external disturbance happen to a parameter. It is shown upon simulation experiments that by means of the mixed control method, chatter output by sliding mode control and output of the control quantity can be effectively reduced, and good robustness is achieved.

Owner:SOUTHEAST UNIV

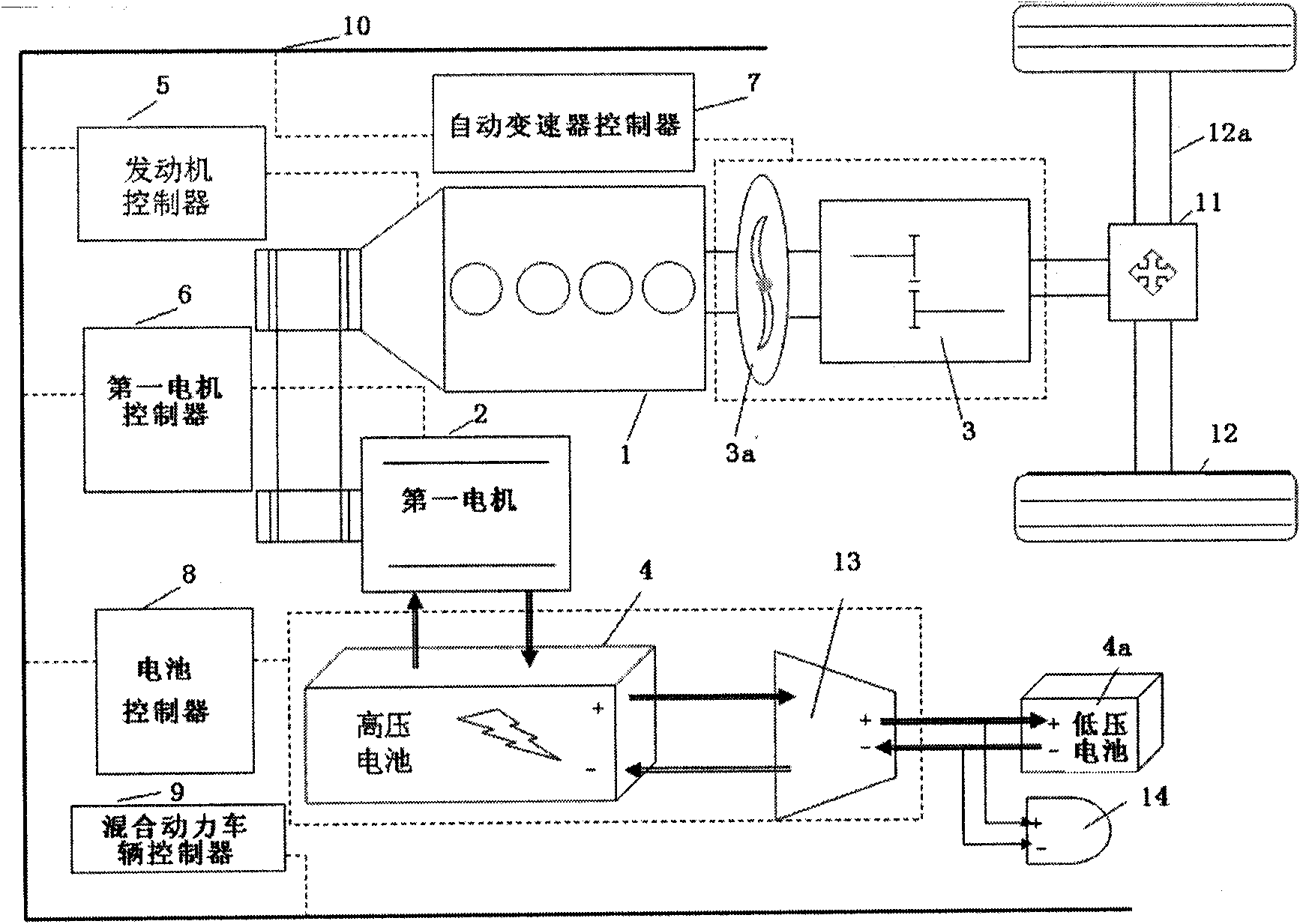

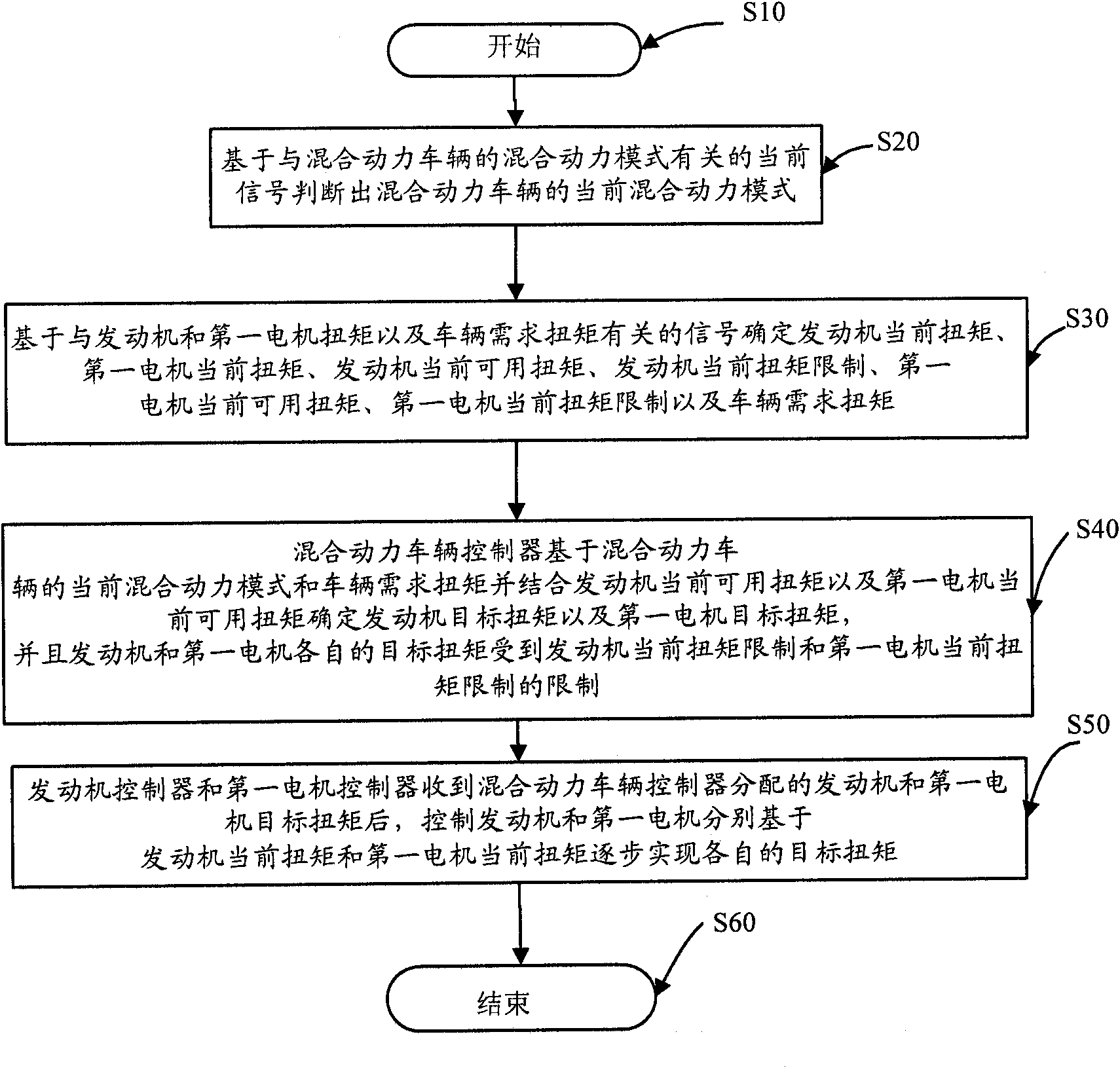

Torque control method for hybrid power vehicle

The invention discloses a torque control method for a hybrid power vehicle. A hybrid power vehicle controller is coupled with an engine controller, a speed changer controller, a motor controller, a battery controller, a brake antilock controller and a vehicle body controller through a vehicle local area network bus in a communication way so as to realize the torque control method. The torque control method comprises the following steps: judging current hybrid power mode of the hybrid power vehicle; determining a vehicle required torque and current torques related with an engine and a motor; determining target torques of the engine and the motor according to the current hybrid power mode, the vehicle required torque and the current torques related with the engine and the motor; and after the engine controller and the motor controller receive the target torques of the engine and the motor distributed by the hybrid power vehicle controller, controlling the engine and the motor to gradually achieve the respective target torques. The method has the advantages of low cost, better control accuracy, better fuel economy and easier matching with the vehicle.

Owner:SAIC MOTOR

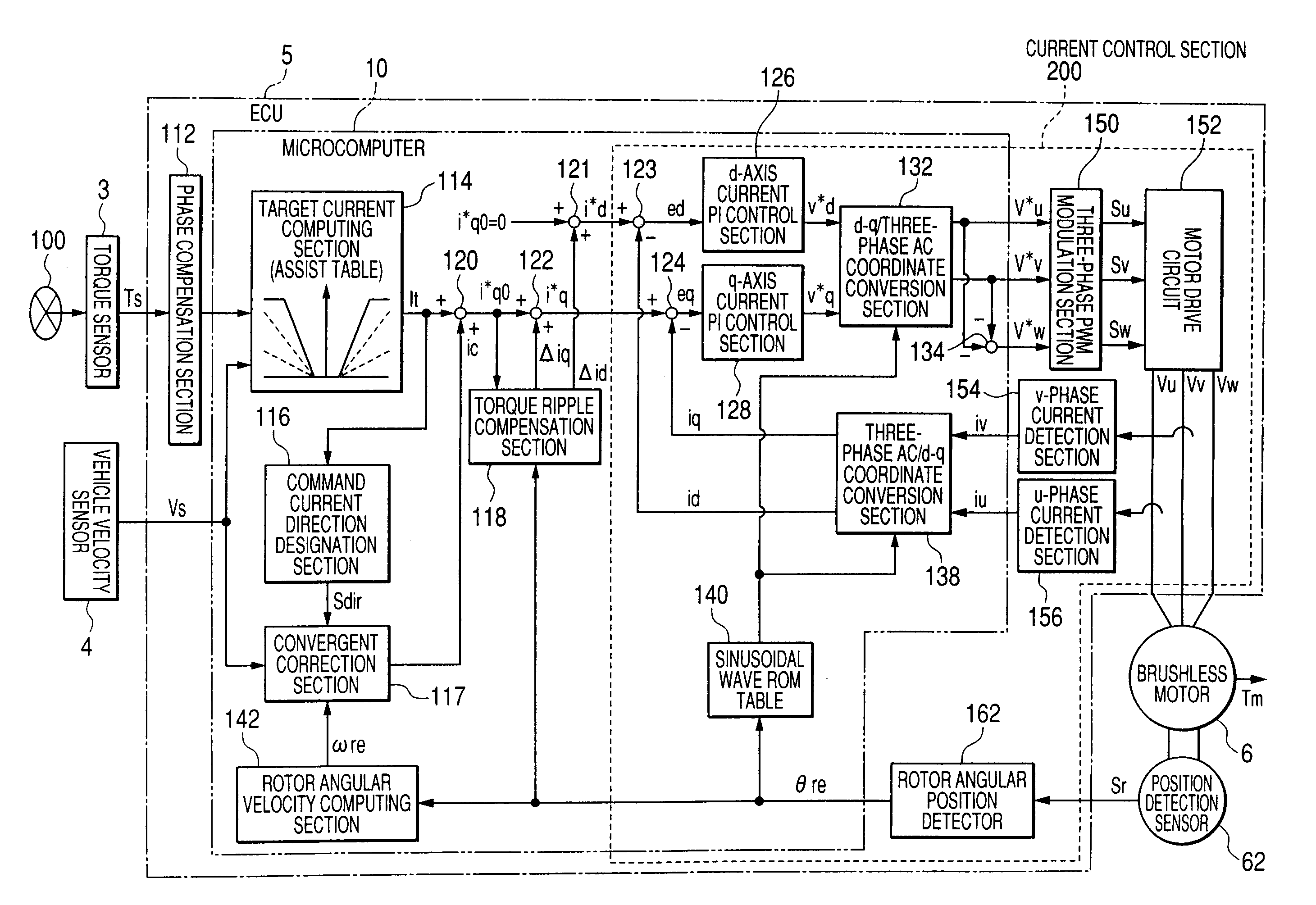

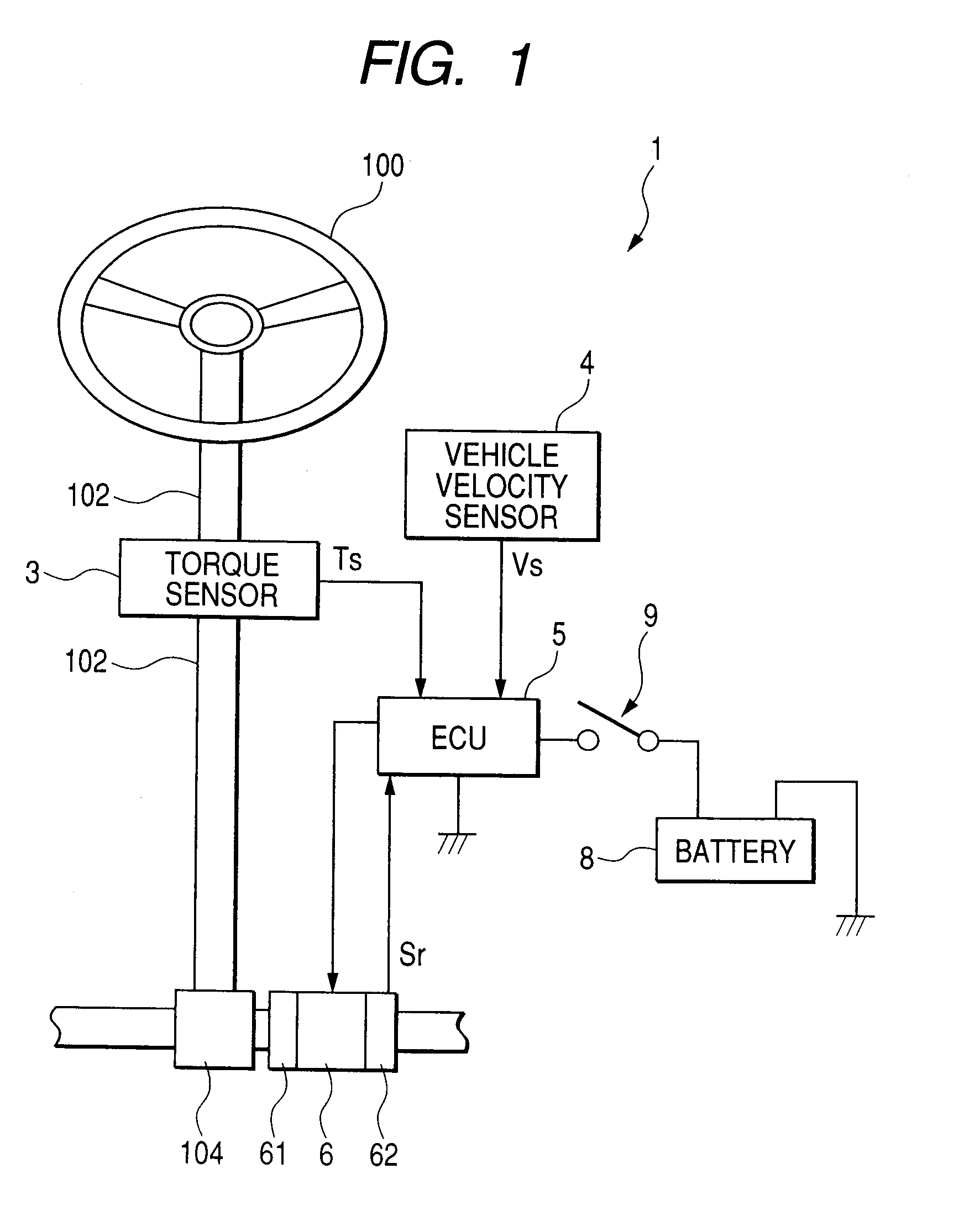

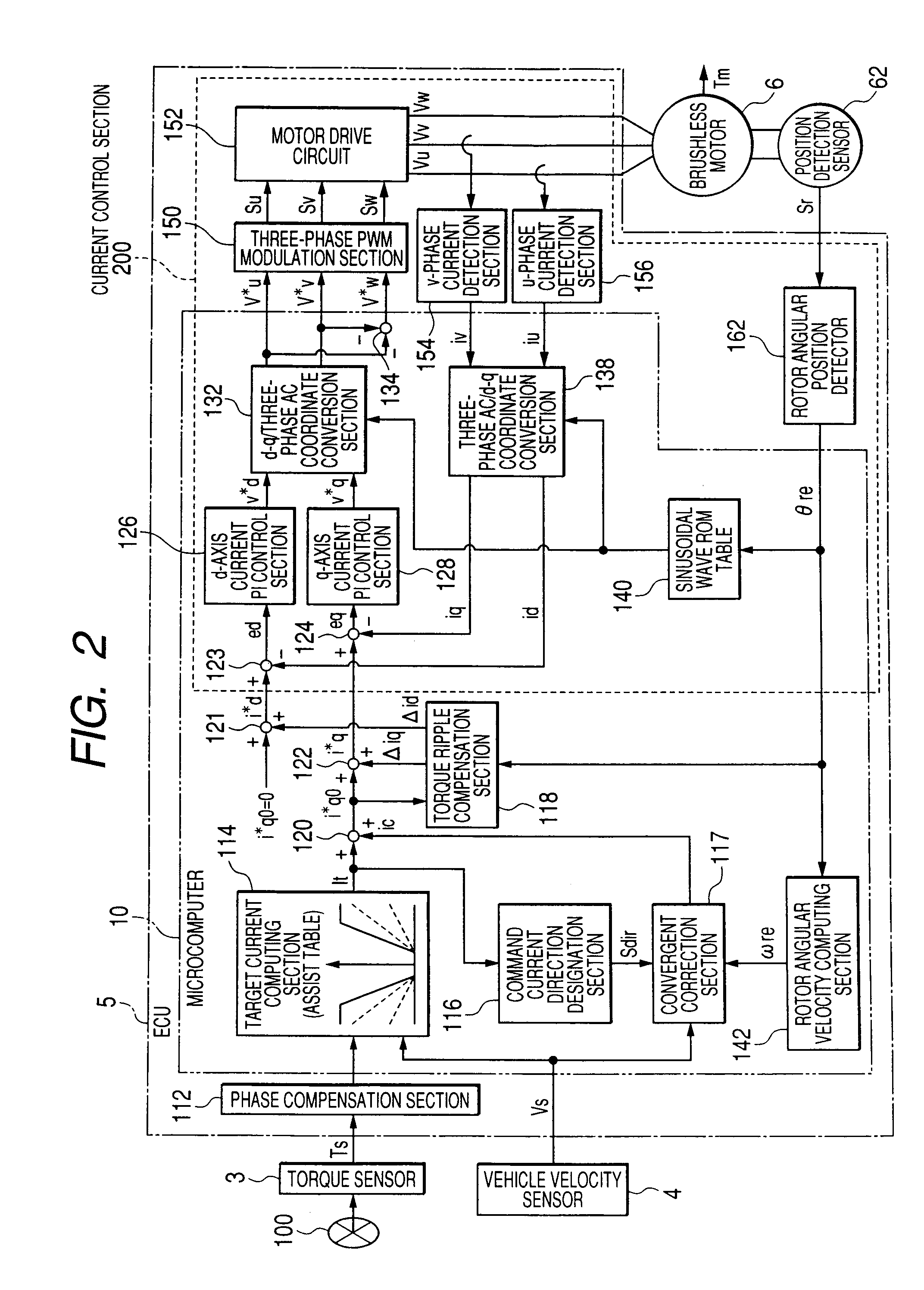

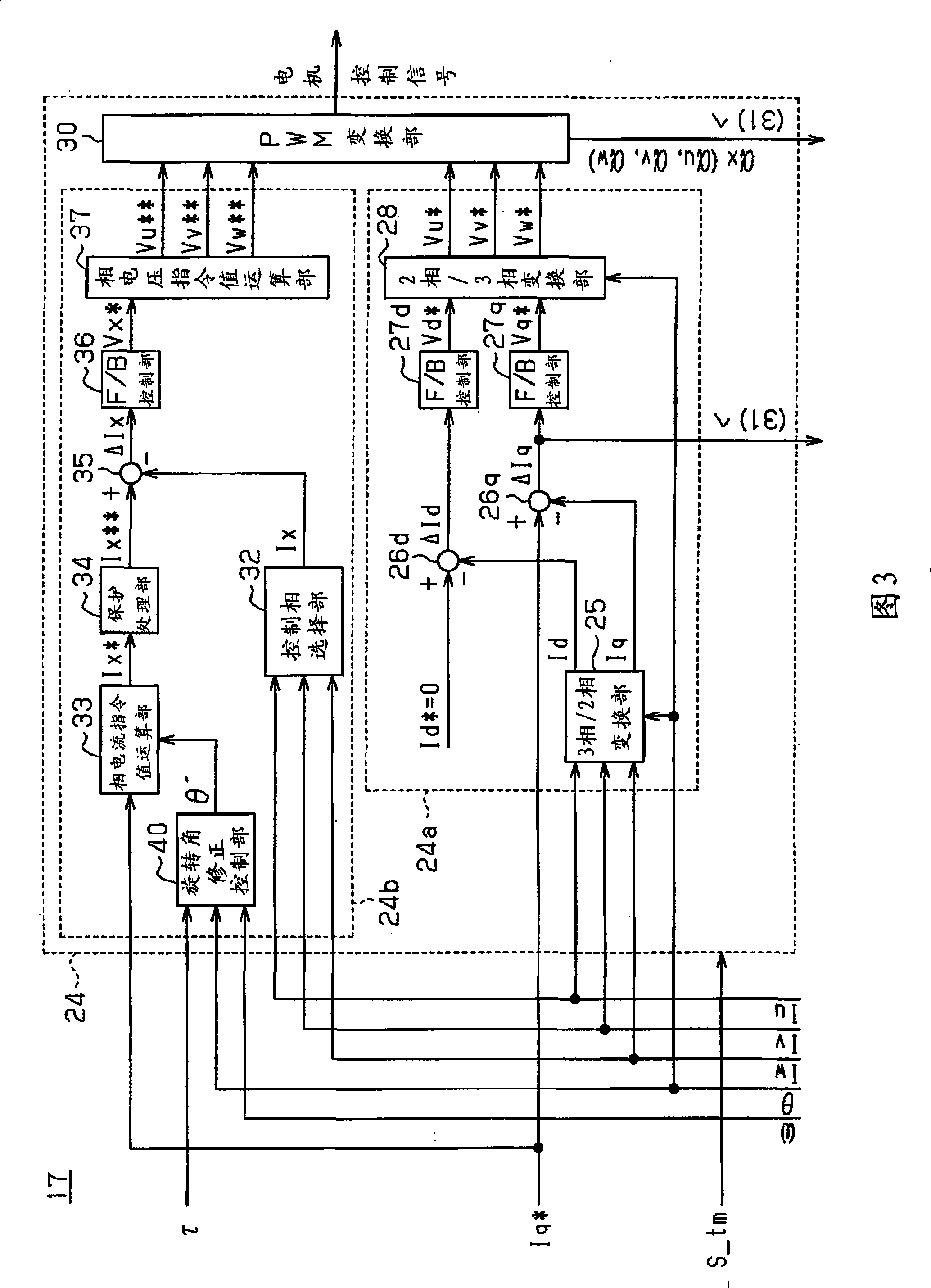

Motor controller and electric power steering system

InactiveUS20080167779A1Reduce torque rippleReduce a torque rippleTorque ripple controlSingle motor speed/torque controlElectric power steeringMicrocomputer

In a case where a computing period of a torque ripple compensation section which computes current compensation values Δid and Δiq to be caused to flow into a motor in order to prevent occurrence of a torque ripple in the motor differs from a control period of a current control section which controls a feedback to the motor in such a way that current command values i*d and i*q additionally provided with the current compensation values Δid and Δiq flow into the motor, the microcomputer sets the current compensation values Δid and Δiq to zero when a rotor angular velocity ωre of the motor is equal to or greater than a first threshold value ω1.

Owner:JTEKT CORP

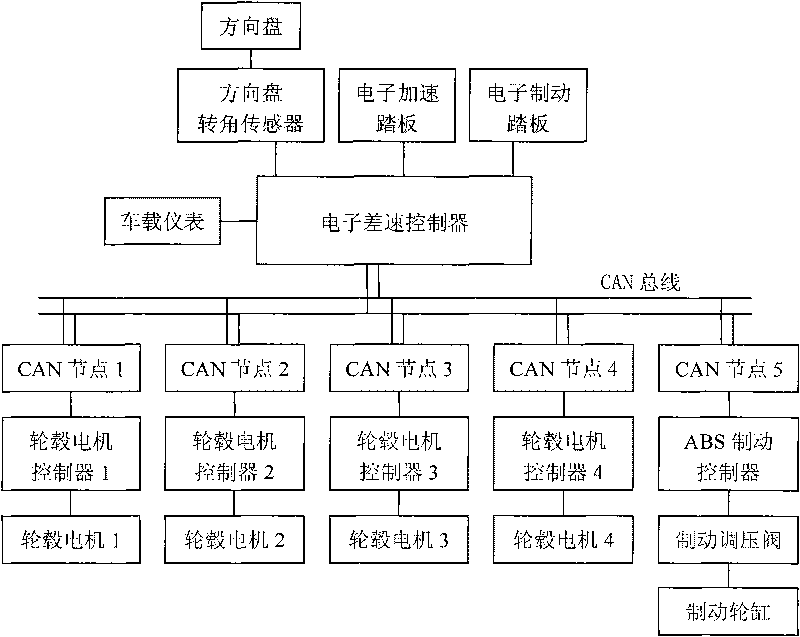

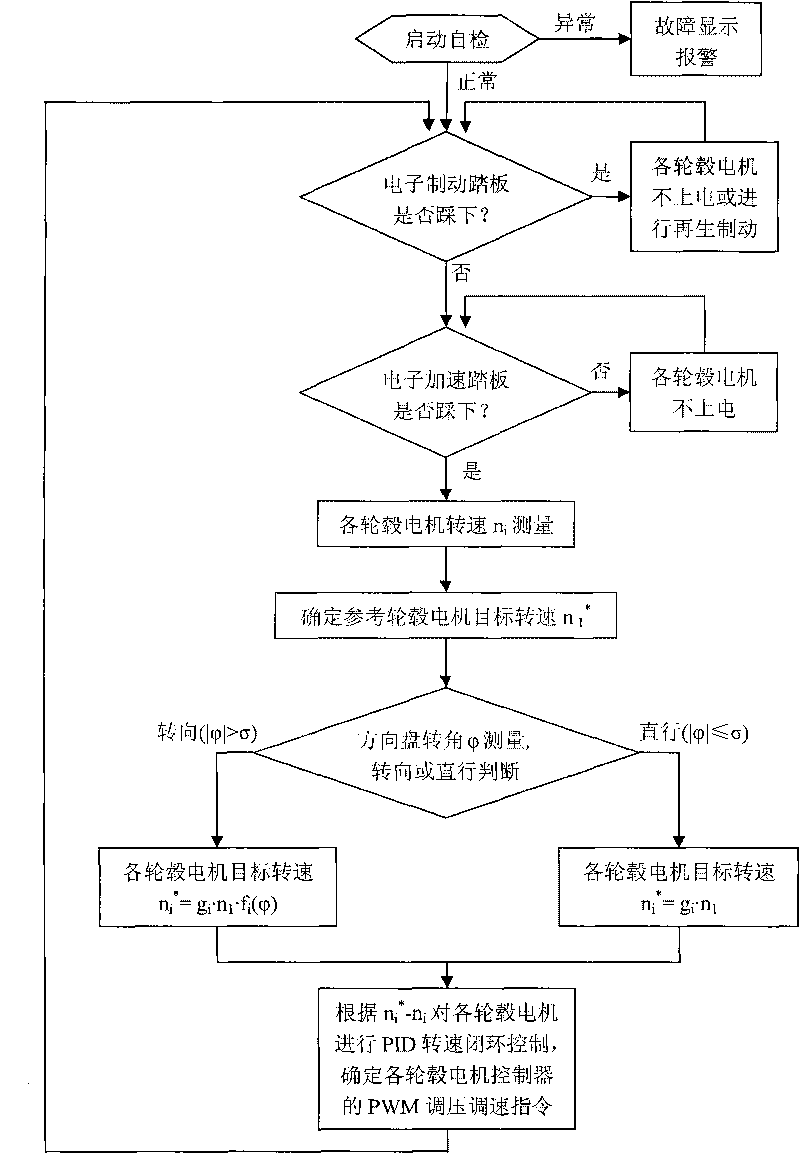

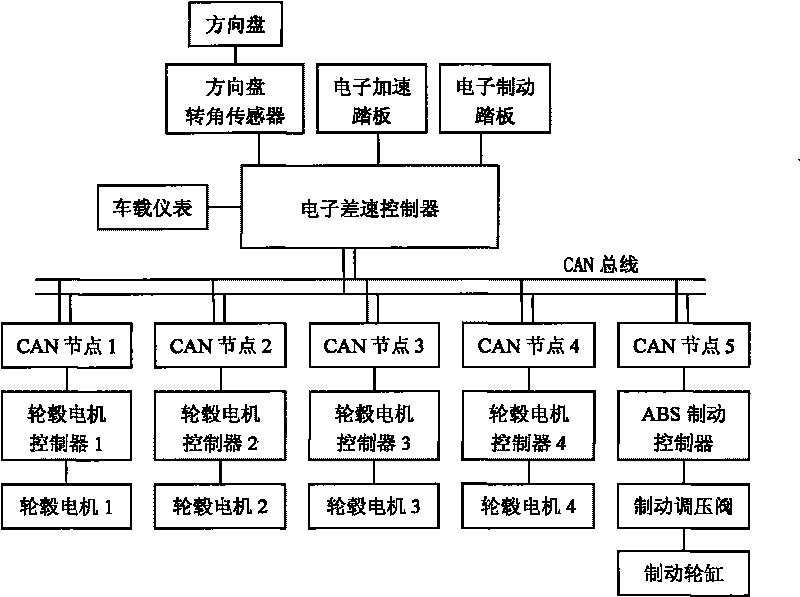

Electronic speed differential control system of an electric wheel drive vehicle

ActiveCN101758854AReasonable differential controlMeet differential requirementsSpeed controllerSteering linkagesElectronic differentialControl system

The invention relates to an electronic speed differential control system of an electric wheel drive vehicle, which comprises a controller, a motor controller of each hub motor, a rotation angle sensor, an electronic accelerating pedal and a rotation speed sensor, wherein the rotation angle sensor is used for measuring the rotation angles of a steering wheel; the electronic accelerating pedal can output opening values; and the rotation speed sensor is used for measuring the actual rotation speed of the hub motor. The signal output ends of the electronic accelerating pedal, the rotation speed sensor and the rotation angle sensor are respectively connected with the signal input ends of the controllers. The controller is communicated and connected with the controller of each hub motor. Each controller comprises a first-stage following control module and a second-stage following control module. The invention can be used for reasonably controlling the electronic differential speed of each driving motor.

Owner:武汉经开科创运营有限公司

Method and apparatus for controlling an electric motor

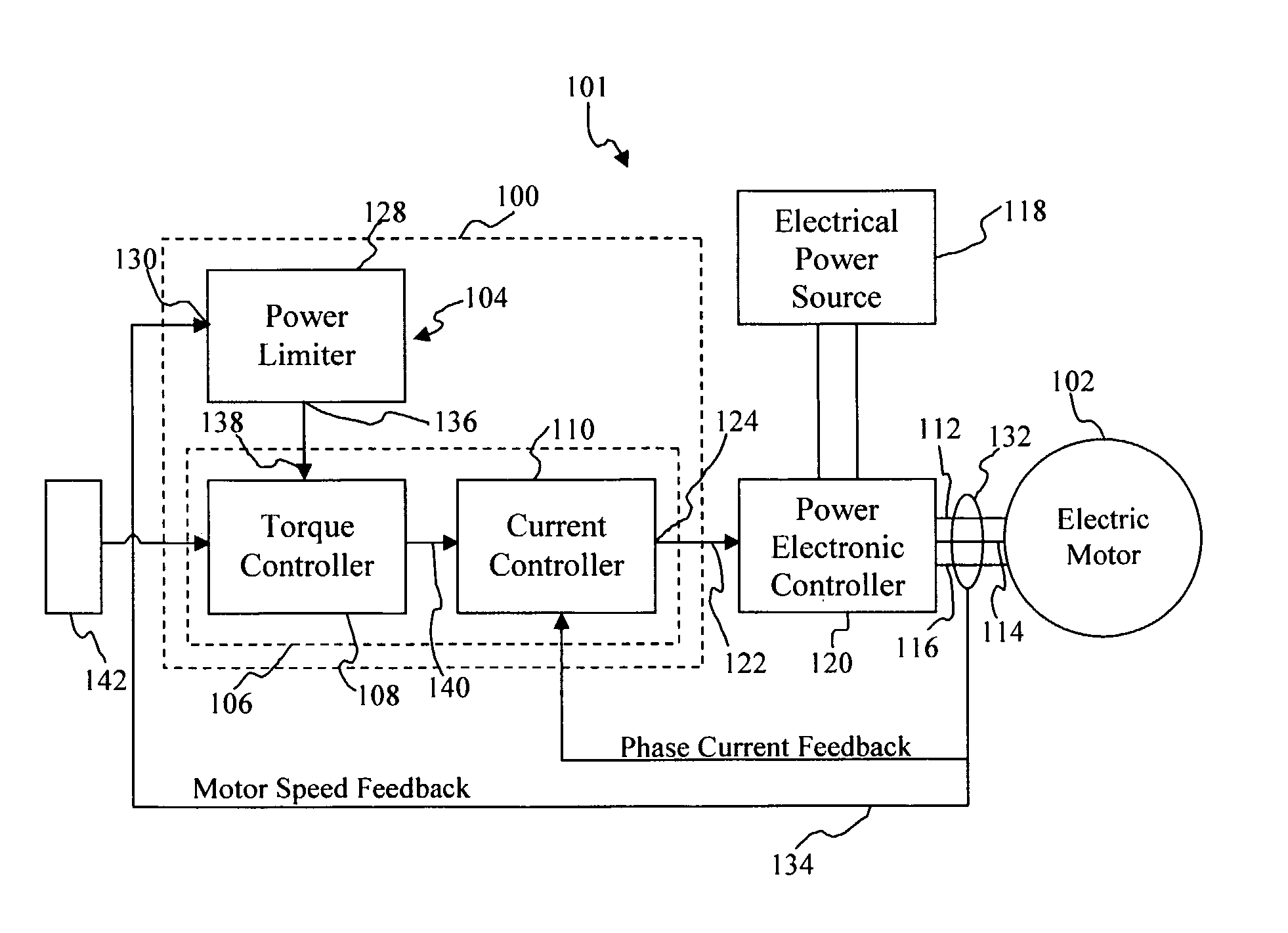

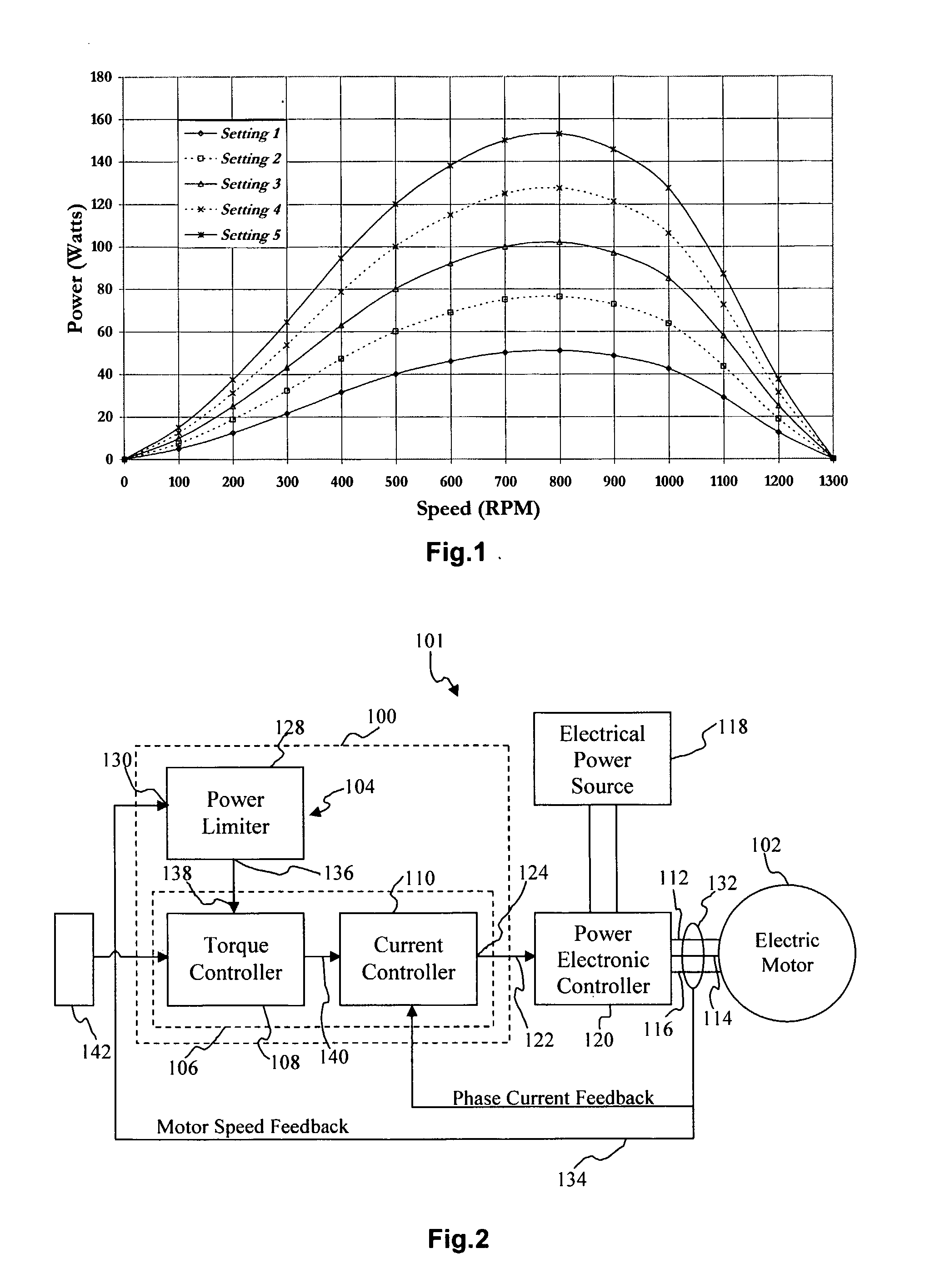

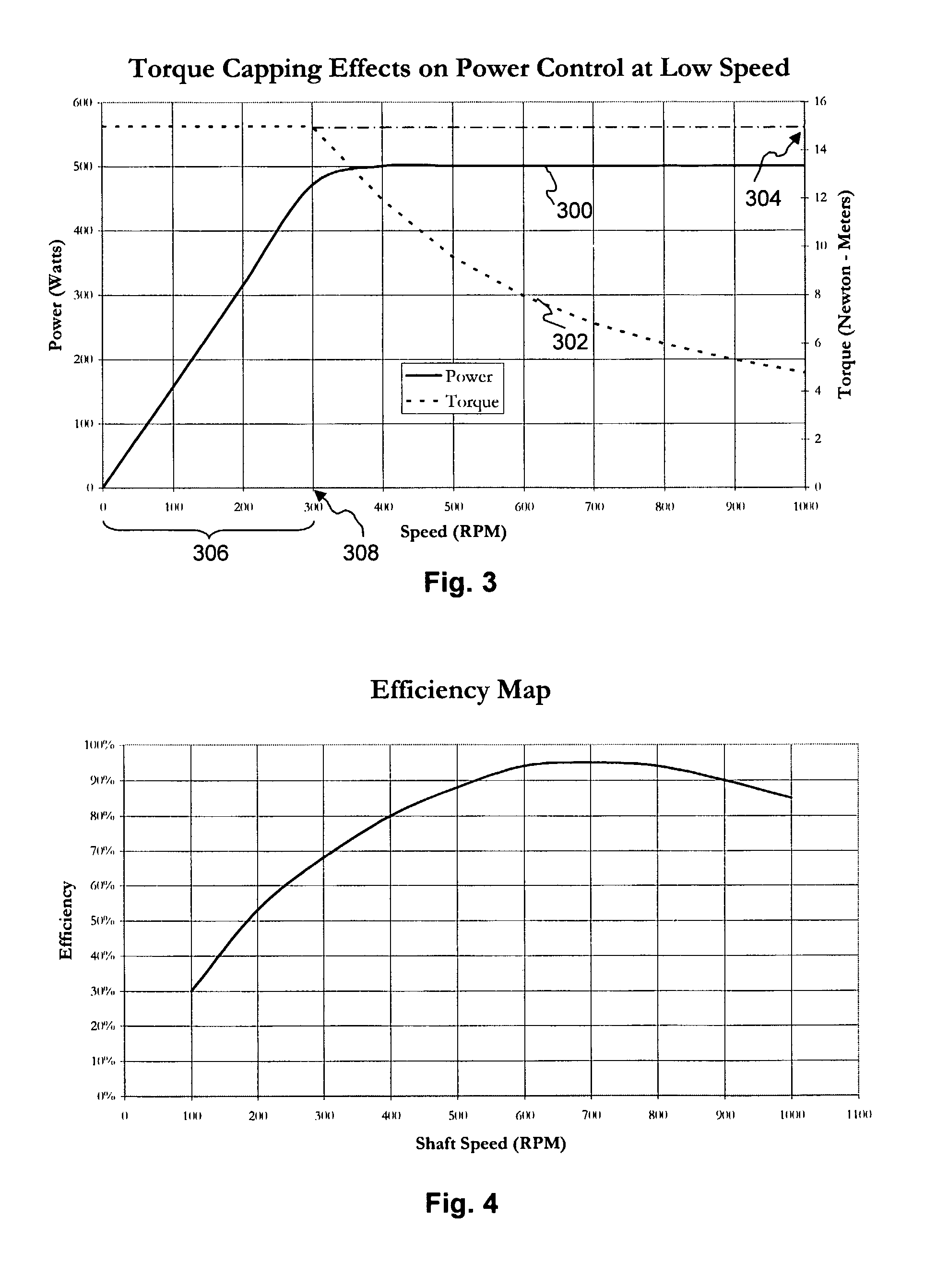

InactiveUS20070182350A1Control output powerConstant output power valueElectronic commutation motor controlSpeed controllerMotor speedPhase currents

The present invention provides a method for controlling the output power of a permanent magnet electric motor (102) using a control means (106). The control means (106) includes a means (134) for measuring motor speed (134) and motor phase current (134), and a means for controlling motor phase current (110) to a desired level. A known relationship between motor phase current and motor torque is then employed by a torque controller so that motor shaft torque can be controlled. A power limiting means (128) then limits the output mechanical power of the motor by dividing a limit value of power by the motor speed to produce a maximum allowable torque setting for that speed.

Owner:INMOTION TECH CO LTD

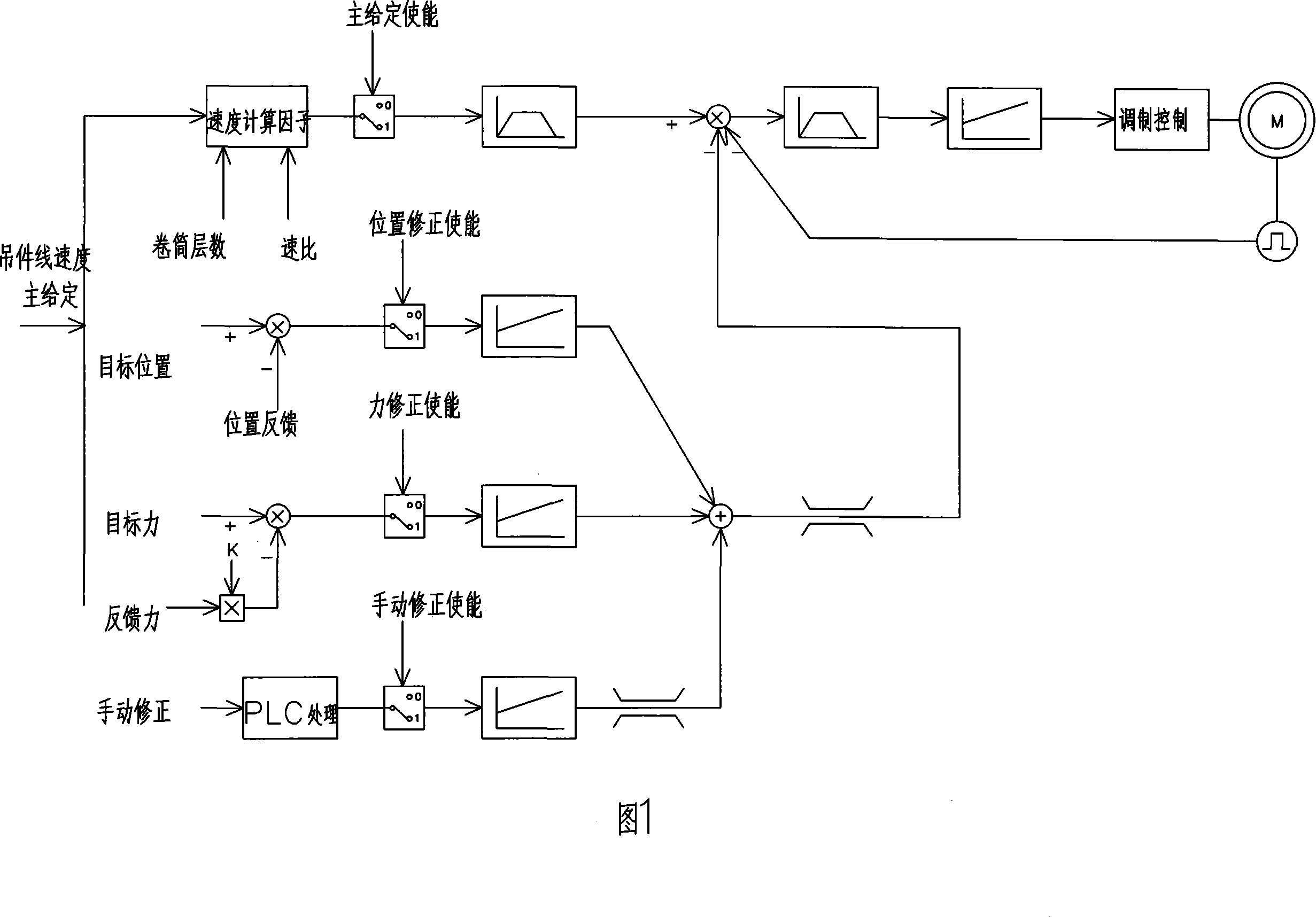

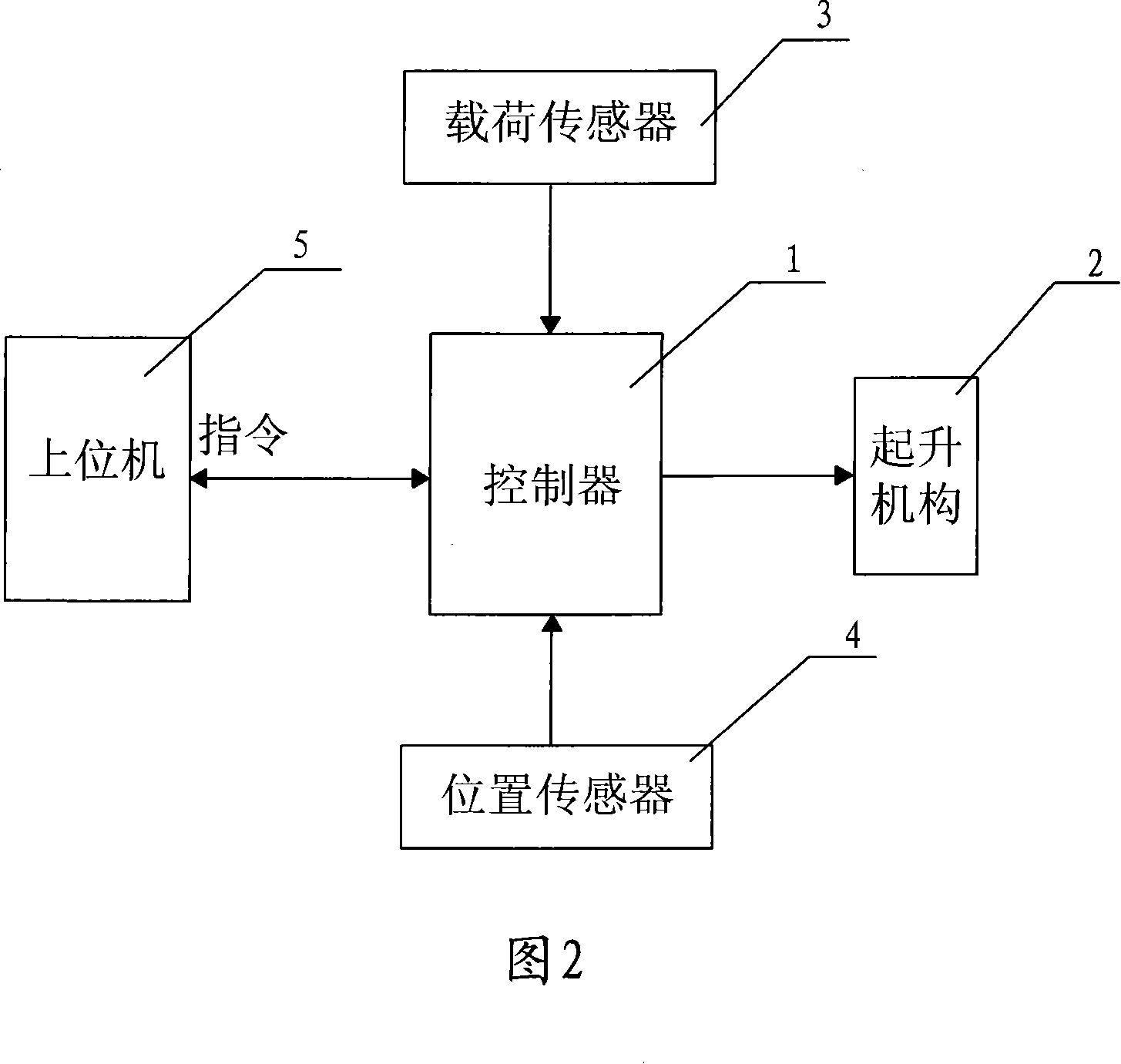

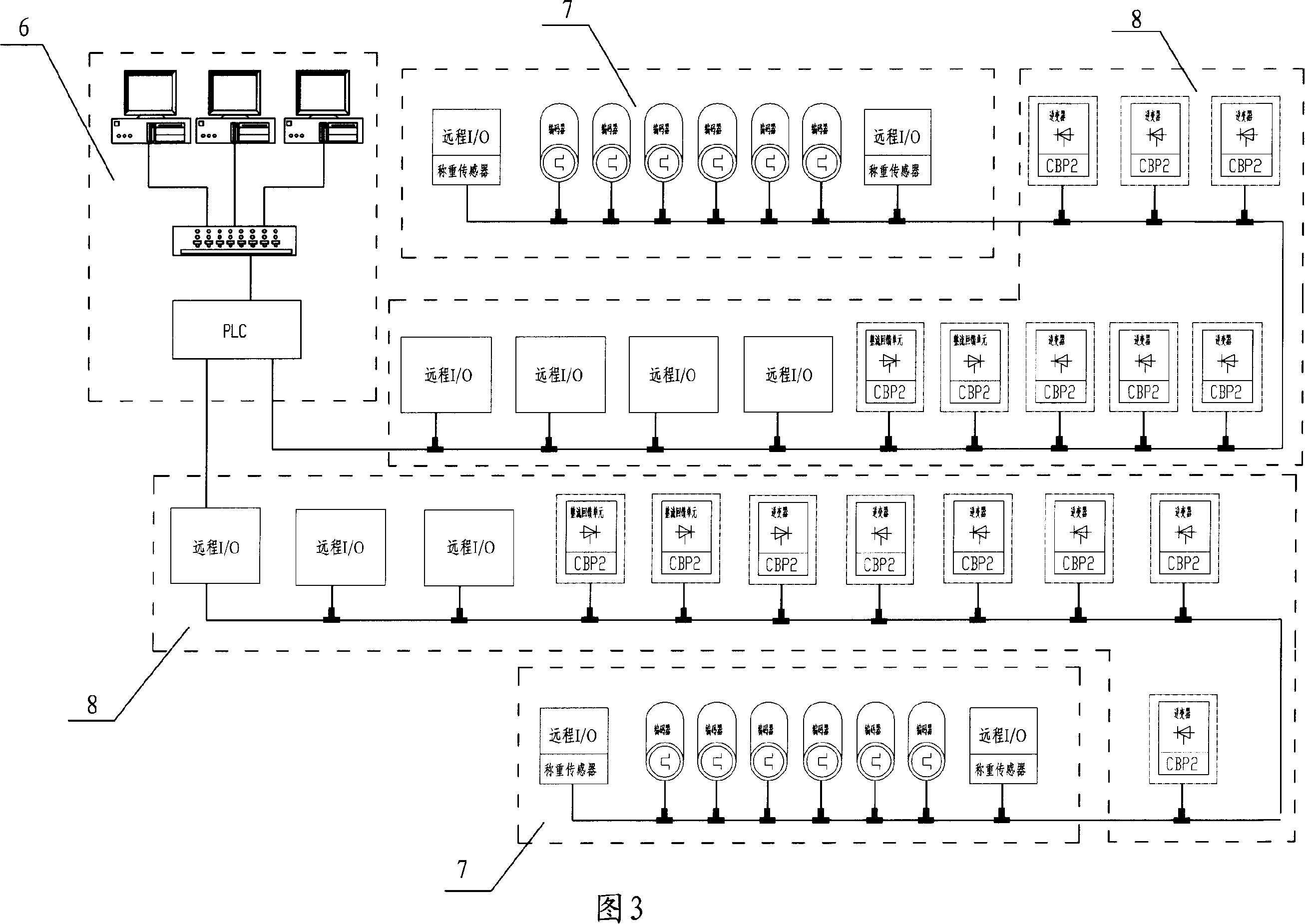

Multiple hanging points crane electric control method

InactiveCN101139069ATroubleshoot Synchronous Control IssuesMeet the requirements of special hoisting processLoad-engaging elementsSynchronous motorLow voltage

The present invention discloses an electrical control method and a device for a multi-suspension-point crane. The control method comprises the following steps: a. preparation mode: a high and low voltage distribution system, a main driving system and a control system, etc can be detected to check whether fault is existed; b. steel wire rope pre-tensioning mode: each lifting motor adopts torque control and gives out torque given valve, and then a weighing sensor can check whether the steel wire rope is tightened; c. hovering mode: each lifting motor adopts speed control, the controller sets motor torque limiting valve, load hoist can be underwent and centroid position of loaded object can be calculated; d. joint lifting mode: each lifting motor adopts speed control, the torque limiting value of the motor is the same as that in hovering mode, and constantly monitoring and correction can ensure smooth lifting of hanging piece. The electrical control method improves control level of automatic operation and operation efficiency and reduces error of manual operation. The technology can be used for various cranes with the need of synchronous control and has broad application prospect.

Owner:DALIAN HUARUI CO LTD

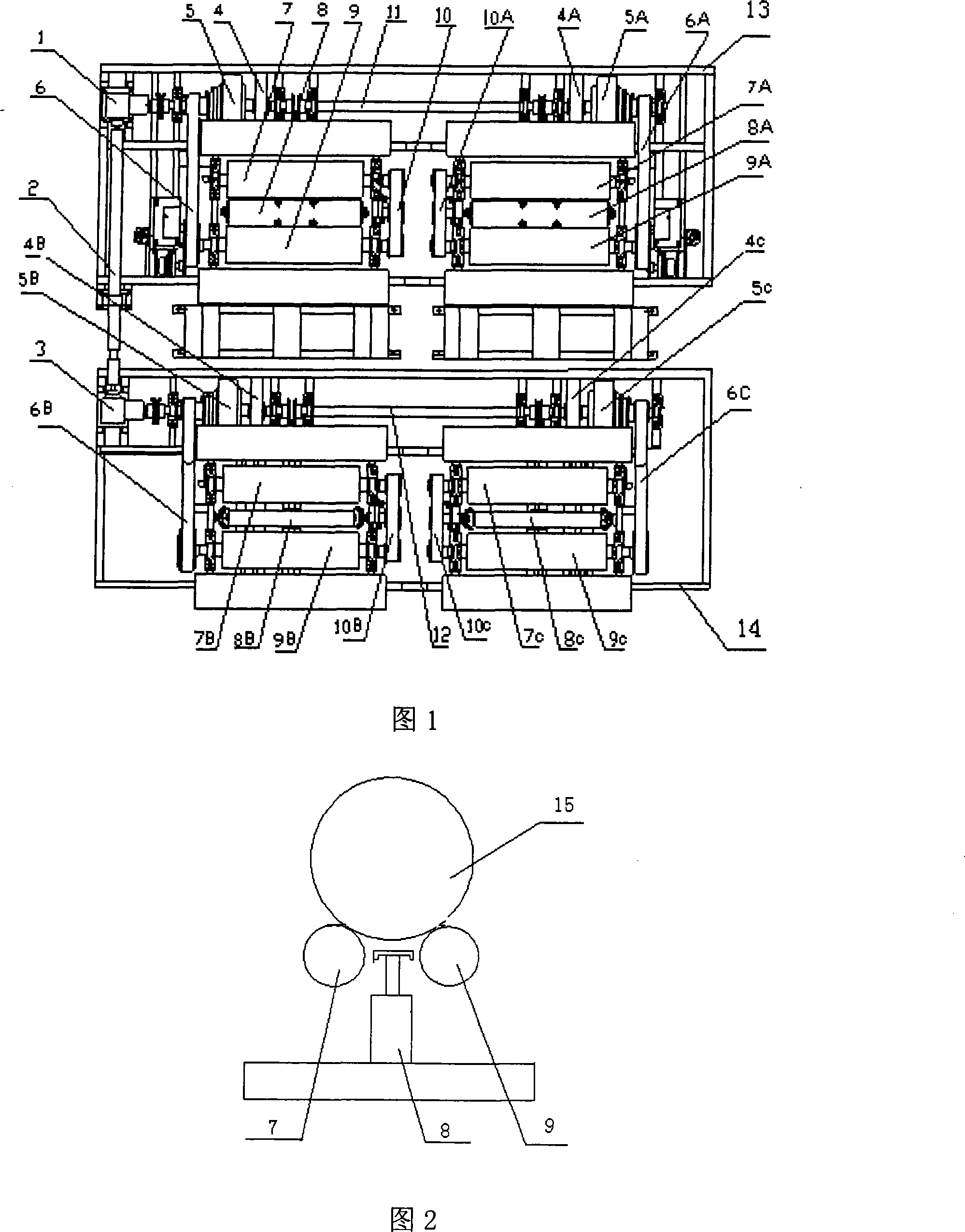

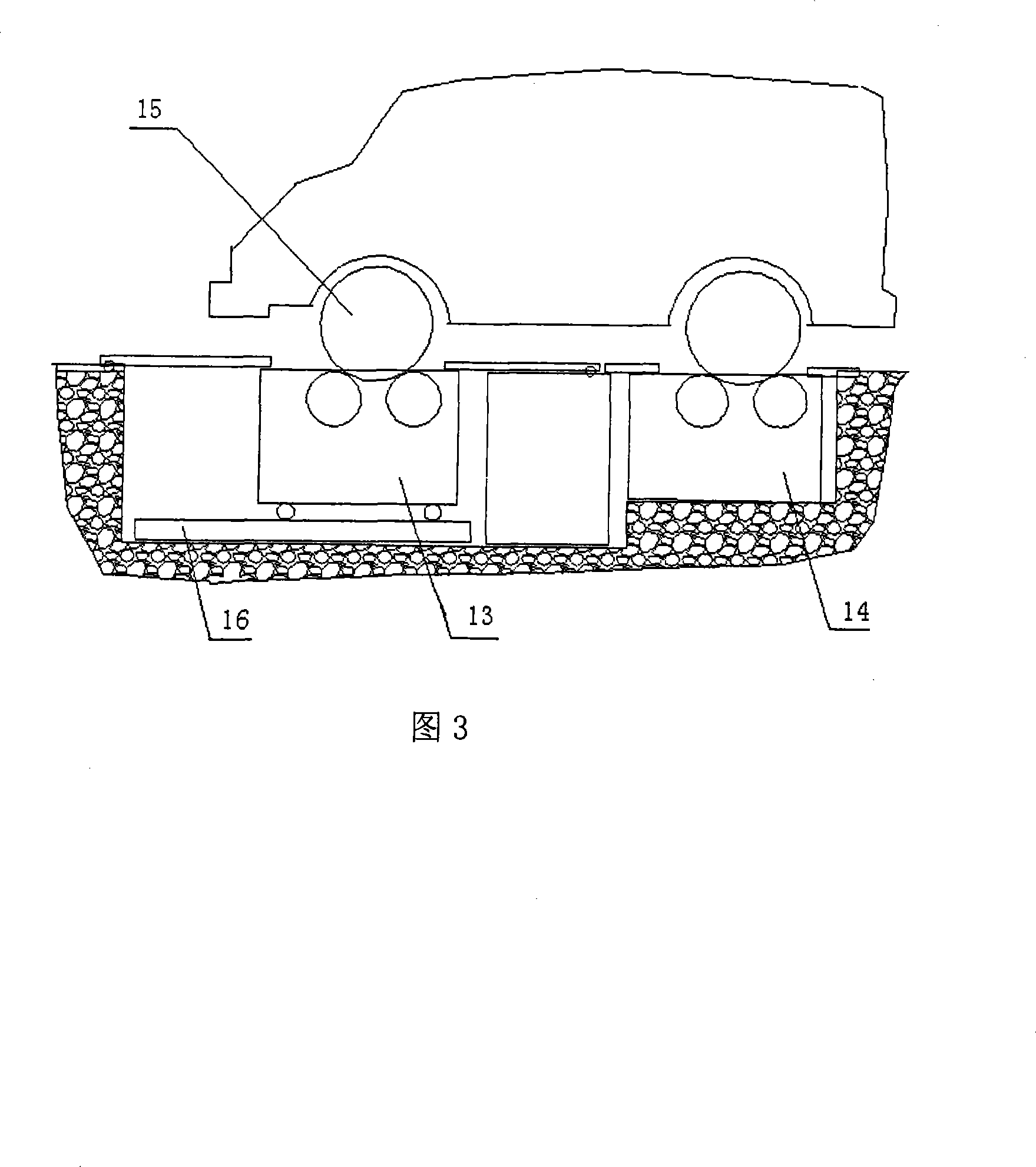

Indoor vehicle ABS test-bed with variable adhesion coefficient

InactiveCN101183046AEasy to detectAvoid lostVehicle testingApparatus for force/torque/work measurementAdhesion coefficientIn vehicle

The invention discloses a vehicle ABS test bed with changeable attachment coefficient and comprises a front and a back shaft frames, a front and a back fly wheel shafts, a transmission box and a telescopic transmission shaft; the front and the back shaft frames are respectively and symmetrically provided with a front left wheel, a front right wheel, a back left wheel and a back right wheel roller group and the front left wheel, the front right wheel, the back left wheel and the back right wheel roller group are totally uniform; each roller group is respectively connected with the output end of a torque controller through a transmission belt in correspondence and the input end of the torque controller is respectively and rigidly connected with the front and the back fly wheel shafts; the front and the back fly wheel shafts are connected with the telescopic transmission shaft through the transmission box to realize mutual synchronization; each fly wheel shaft is rigidly and symmetrically provided with two fly wheels with same turning inertia; the braking force of the wheel of the measured vehicle can be changed by controlling magnetizing current of the torque controller when the wheel is in lock braking and then the attachment coefficient of the road can be simulated. The invention can be widely applied in vehicle examination, ABS research and development, vehicle maintenance and service industry.

Owner:CHANGAN UNIV

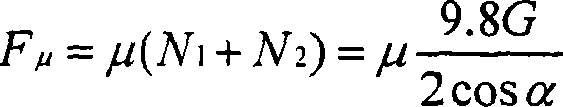

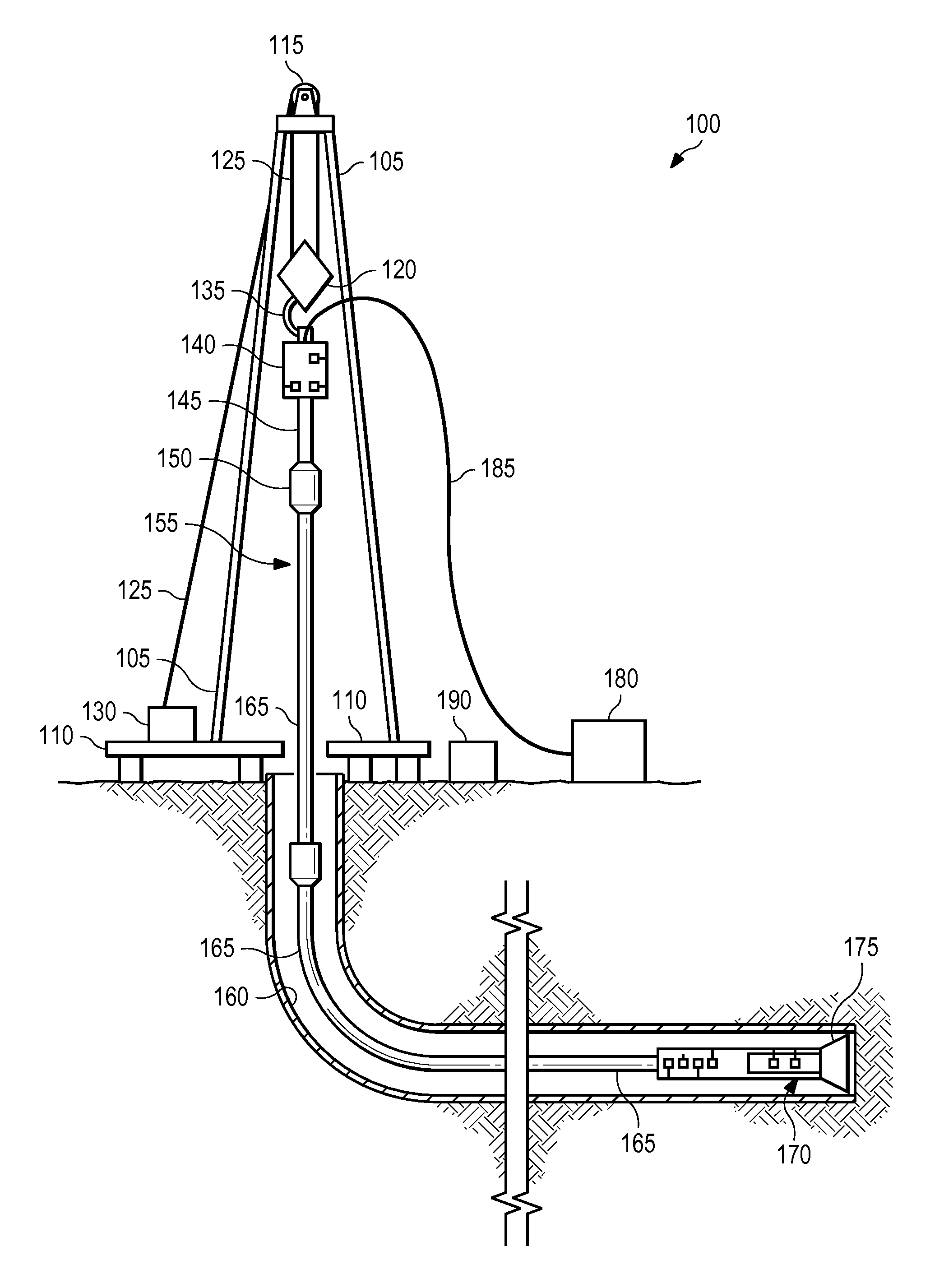

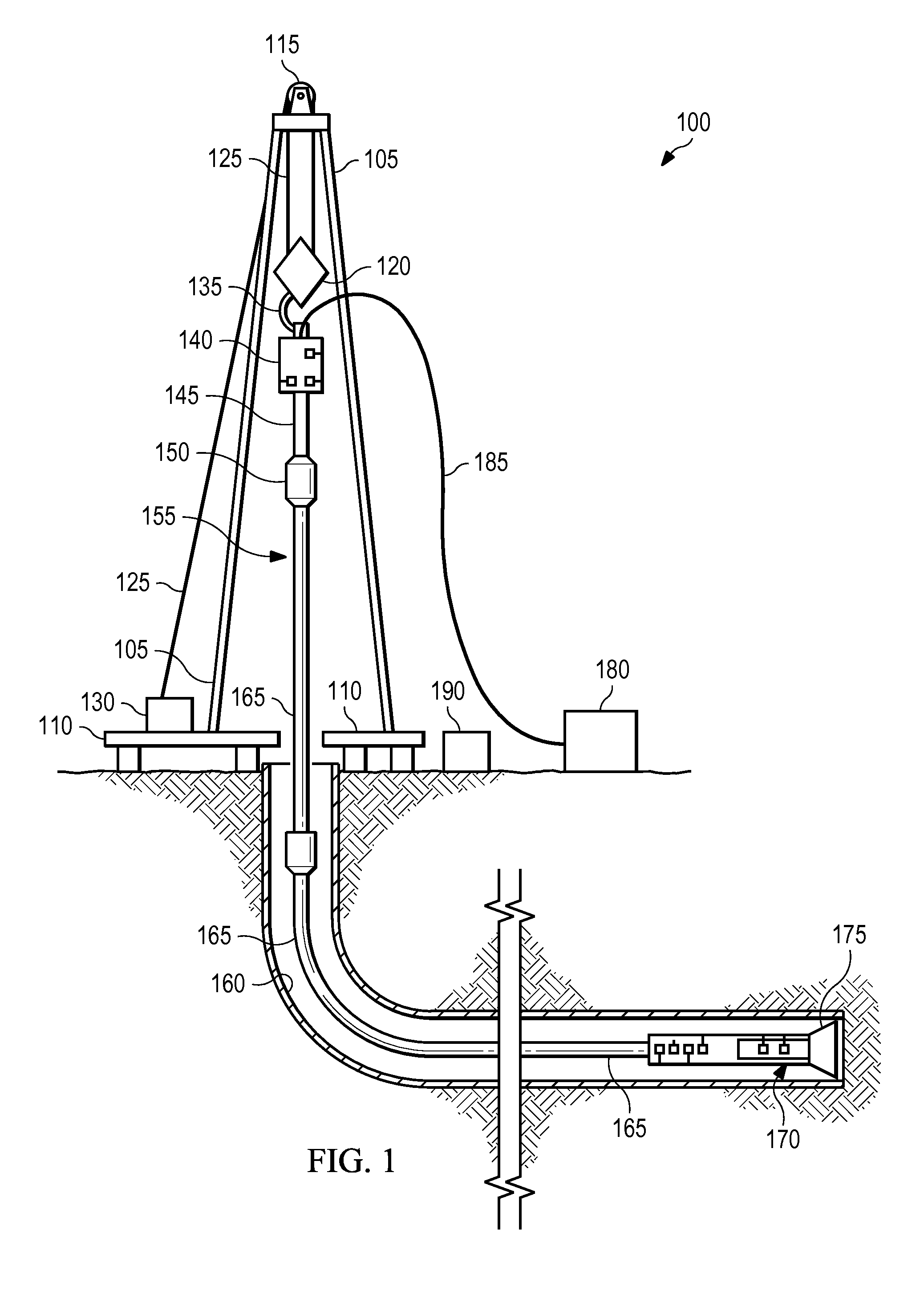

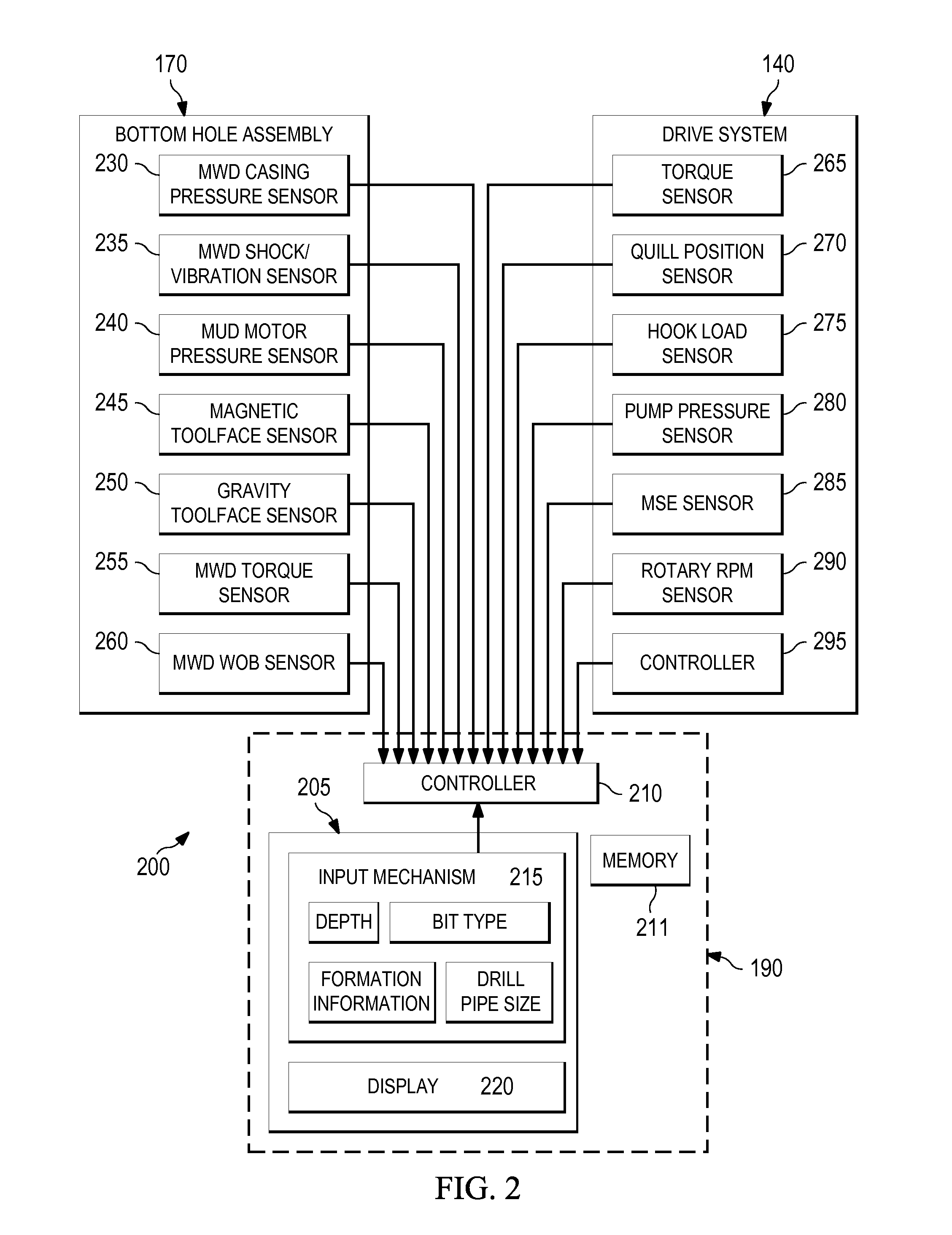

Drill Pipe Oscillation Regime and Torque Controller for Slide Drilling

Apparatuses, methods, and systems are described which assist in controlling toolface orientation of a bottom hole assembly. A controller instructs a top drive to oscillate a drill string an oscillation revolution amount to reduce friction of the drill string in a wellbore during a slide drilling procedure. A torque sensor detects torque at an interface between the drill string and the top drive, and the controller determines properties of a torsional wave from the detected torque that is propagating along the drill string during the slide drilling procedure. The controller determines a modification to the oscillation revolution amount and / or rotations per minute in order to control the toolface orientation in a desired manner. The top drive implements the determined modification and thereby assists in controlling the toolface orientation during the slide drilling procedure.

Owner:NABORS DRILLING TECH USA INC

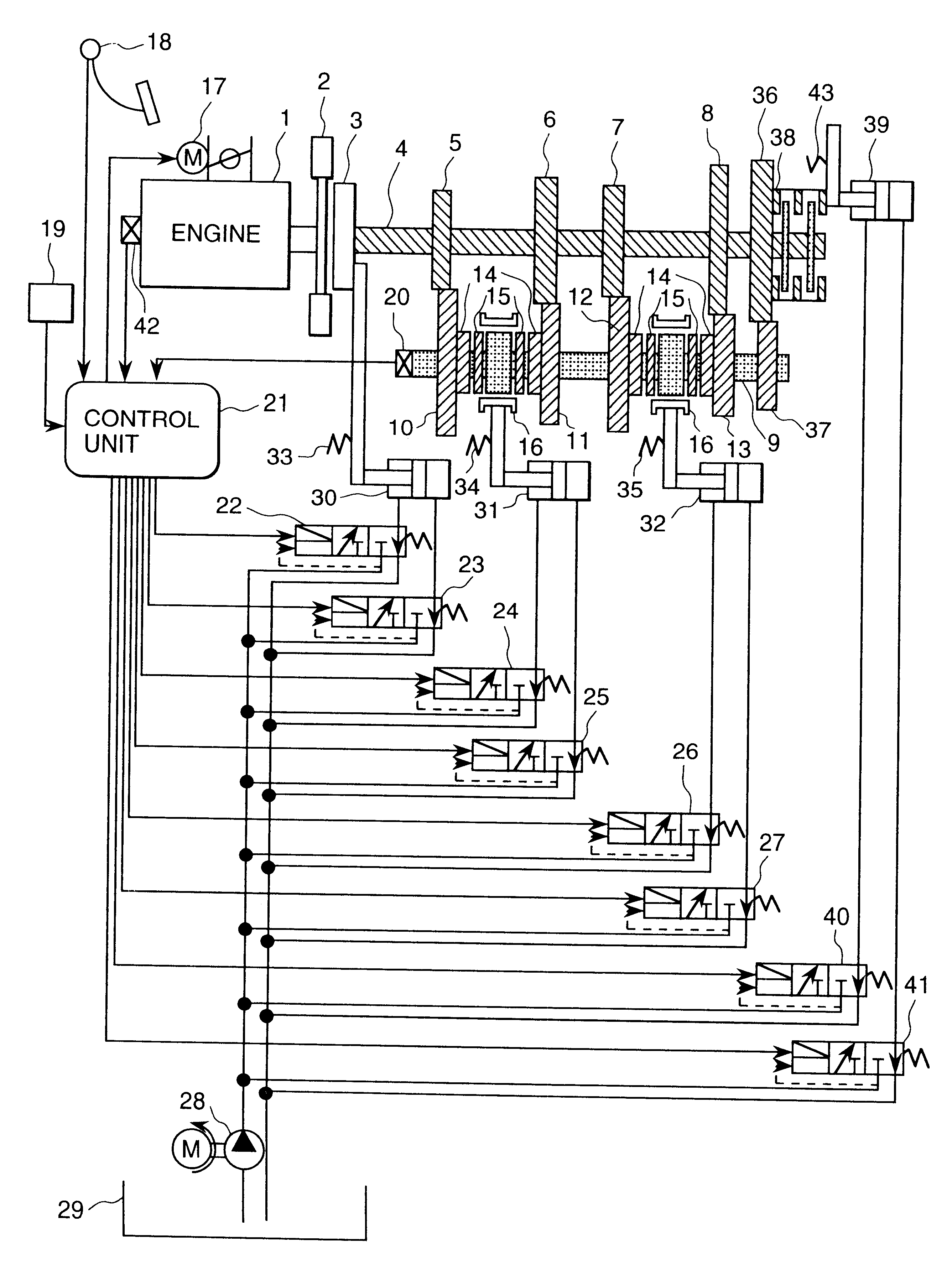

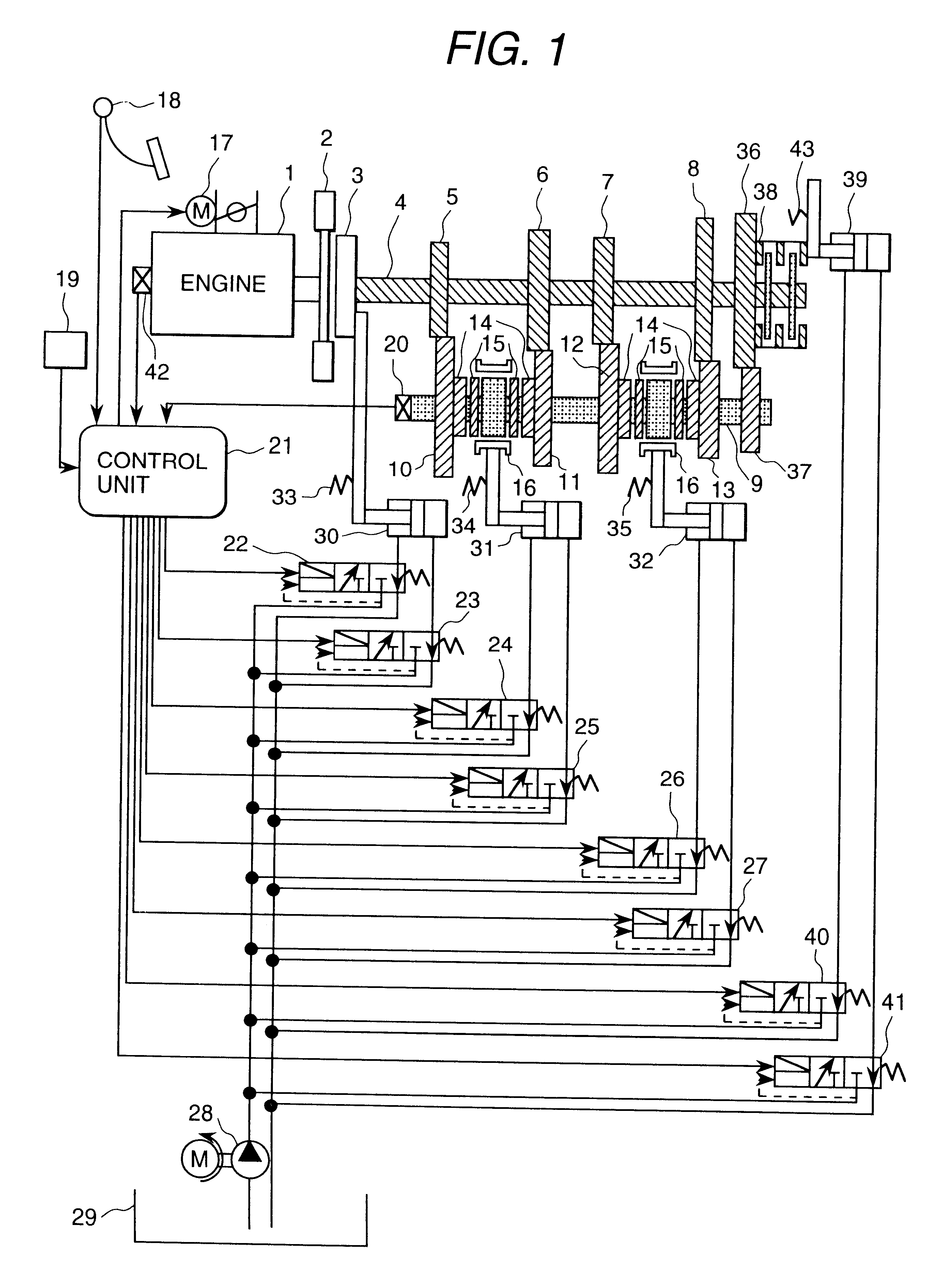

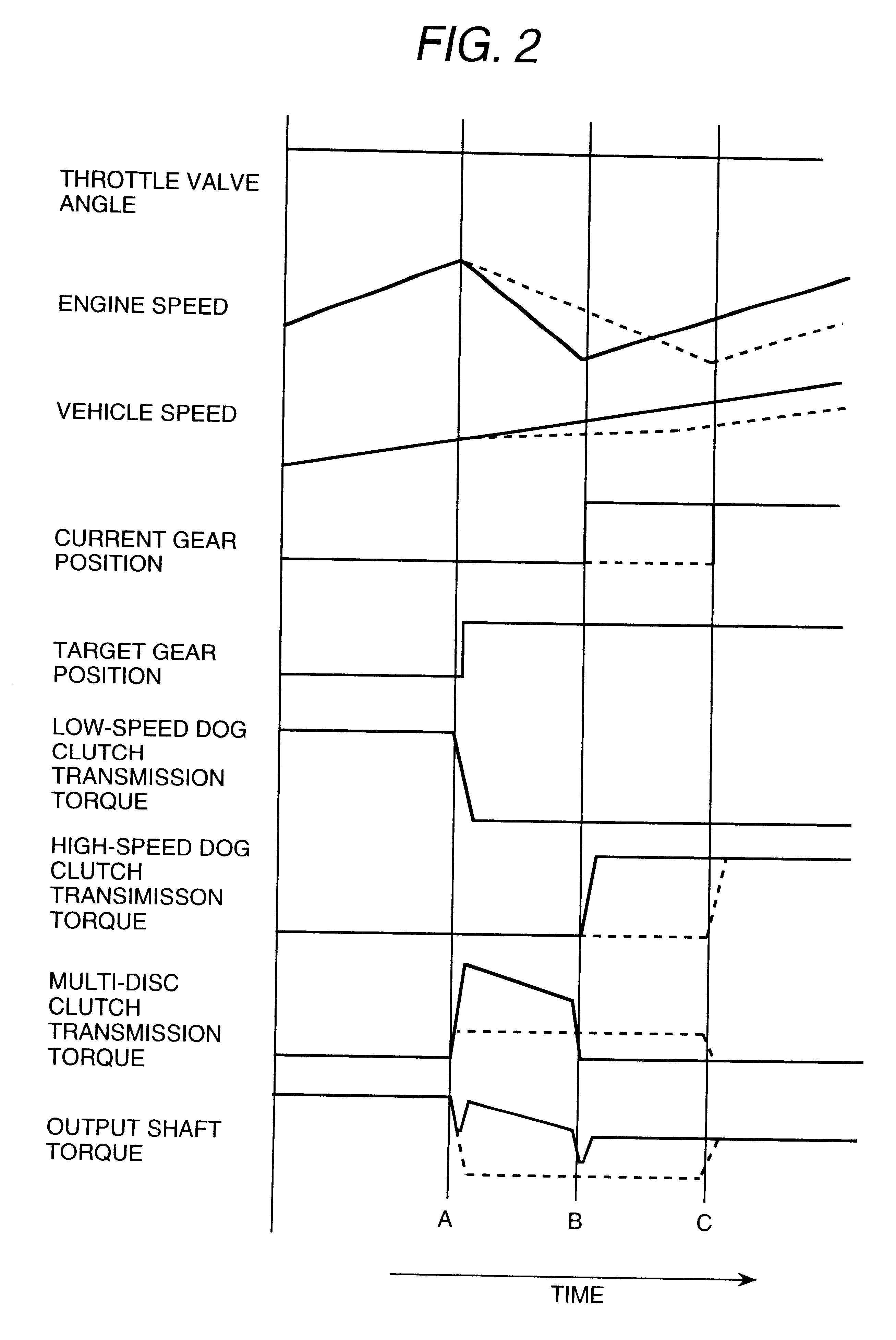

Gear-type automatic transmission and car using the gear type automatic transmission

A vehicle transmission system has a gear-type transmission with a plurality of gears and a plurality of claw clutches which transmits a torque between an input shaft of said gear-type transmission and an output shaft of said gear-type transmission. The transmission changes transmission courses by engaging with and / or disengaging from the gears and the claw clutches, and forms another transmission course via a torque controller between the input shaft of the gear-type transmission and the output shaft of said gear-type transmission during a period between a first transmission course and a second transmission course formed by the gears and the claw clutches. A torque capacity of the torque controller is greater than the maximum output shaft torque of the transmission.

Owner:HITACHI LTD

Unmanned surface vehicle trajectory tracking control device and method based on nonlinear control theory

ActiveCN103955218AGuaranteed uptimeReduce consumption costPosition/course control in two dimensionsState variablePath generation

The invention provides an under-actuated unmanned surface vehicle self-adaptive trajectory tracking control device and method. The device comprises a reference path generator, a state sensor, a differential converter, a parameter estimator, a virtual controller and a longitudinal thrust and bow steering torque controller. According to the unmanned surface vehicle actual position and course angle collected by the state sensor (2) and the reference position and reference course angle information generated by the reference path generator (1), the new state variable is obtained through the differential converter (5), the new state variable and the speed and angle speed information collected by a sensor (4) are transmitted to the parameter estimator (8) and the longitudinal thrust and bow steering torque controller (12), a control instruction is obtained through calculation to drive an execution mechanism, and the longitudinal thrust and bow steering torque of an unmanned surface vehicle are adjusted. According to the device and method, the unmanned surface vehicle can reach the specific position within specific time at specific speed. Due to the under-actuated unmanned surface vehicle, energy consumption and manufacturing cost of a system can be lowered, and the weight of the system is reduced.

Owner:精海智能装备有限公司

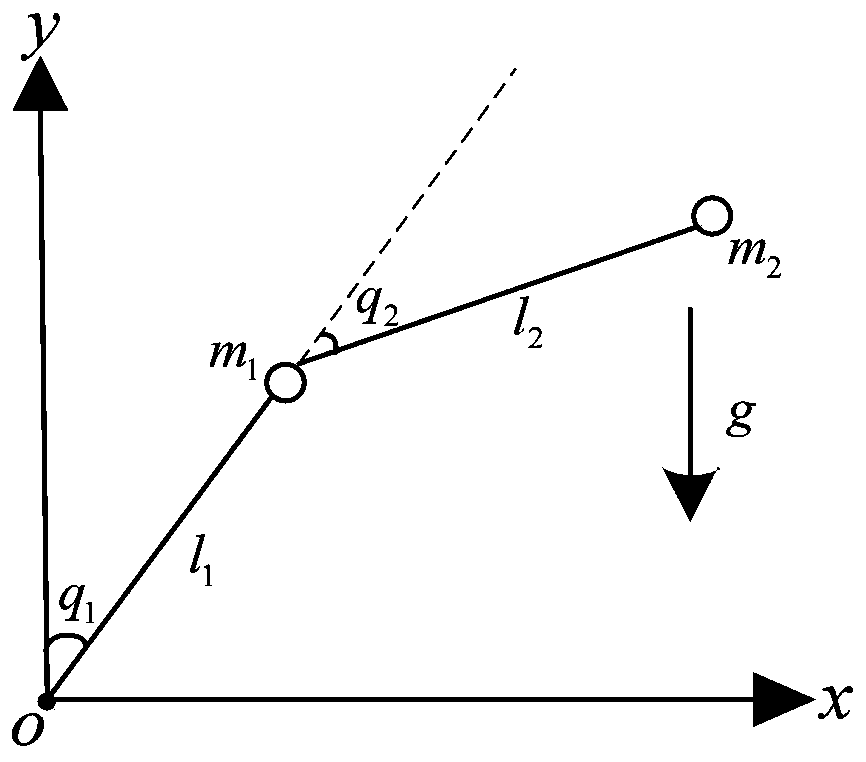

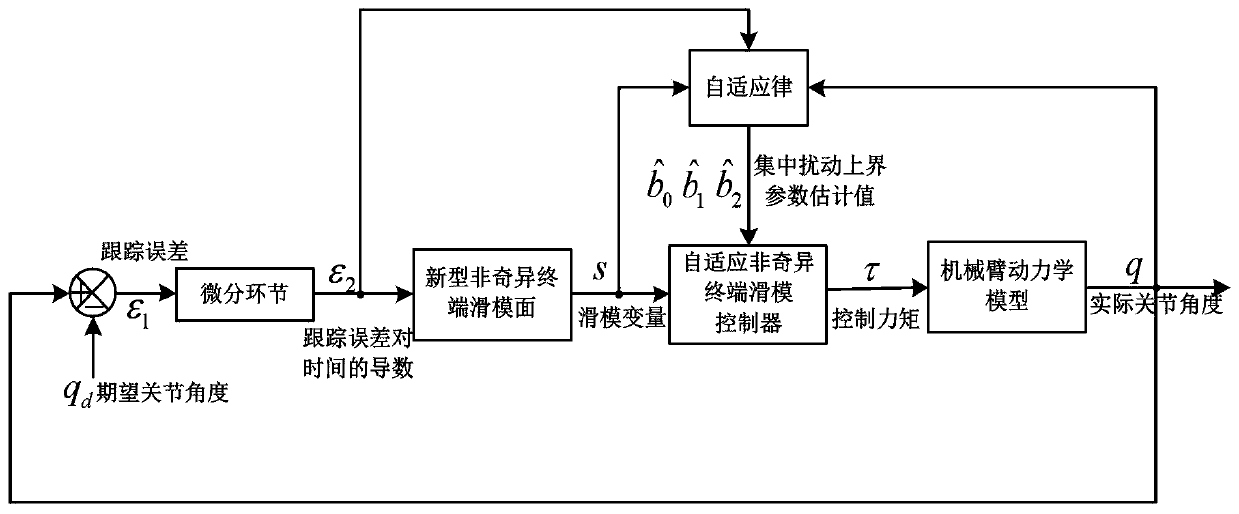

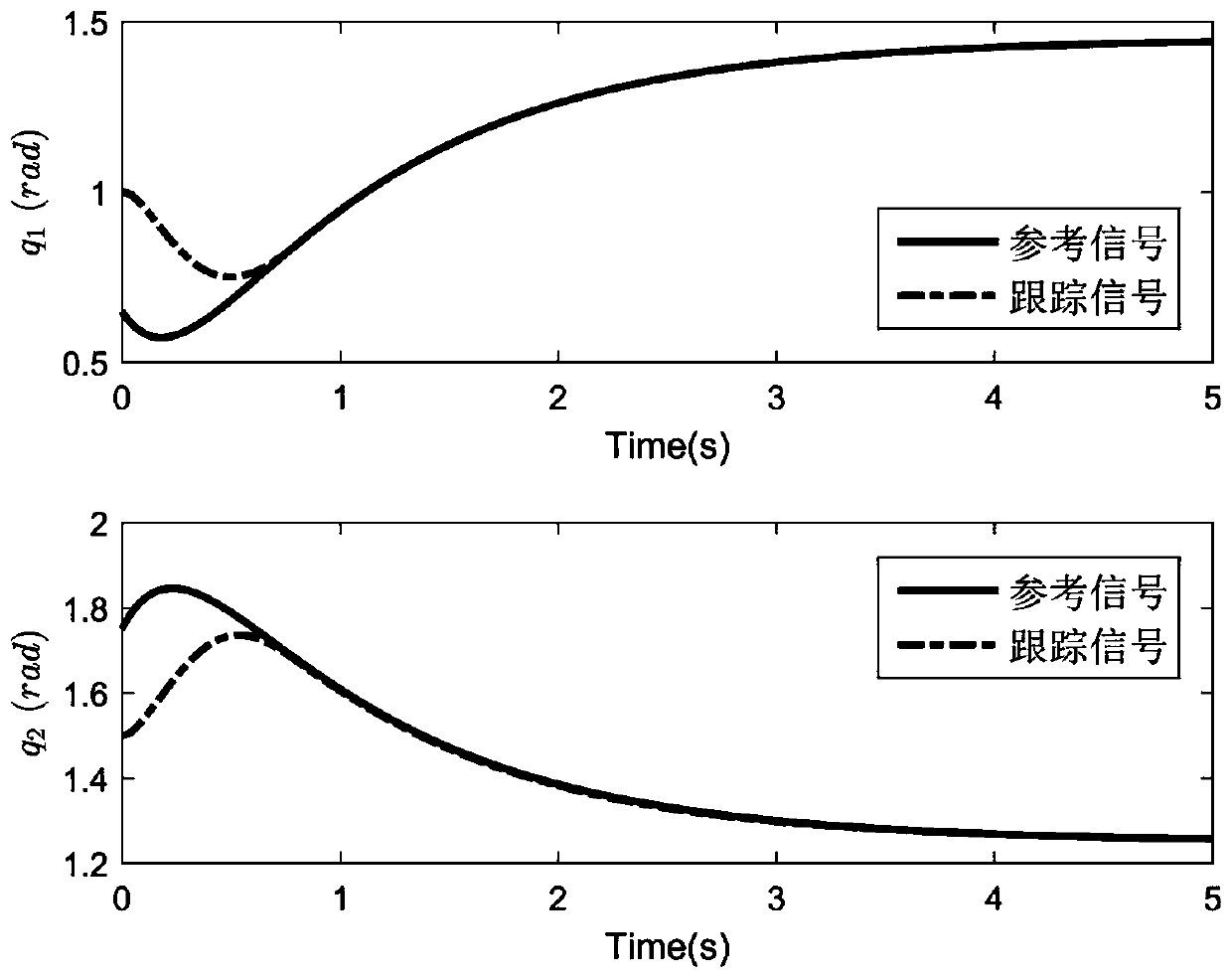

Adaptive terminal sliding-mode controller based mechanical arm trajectory tracking control method

The invention discloses an adaptive terminal sliding-mode controller based mechanical arm trajectory tracking control method. The method includes the following steps: 1, establishing a rigid mechanical arm system dynamics model having n degrees of freedom rotating joints; 2, obtaining the measuring information of each joint angle q and angular velocity which is shown in the description of a mechanical arm through a photoelectric encoder, setting the expected angle q<d> and expected angular velocity which is shown in the description tracked by each joint, and calculating mechanical arm trajectory tracking errors [epsilon]1 = q - q<d> and the first derivative shown in the description of trajectory tracking error versus time; 3, establishing a novel non-singular terminal sliding-mode surface s according to the [epsilon]1 and [epsilon]2; and 4, designing the controlling moment tau of the driving motor of each joint of the mechanical arm according to the sliding-mode surface s, and establishing an adaptive rate which can adjust control gain to dynamically estimate system lumped disturbance upper bound. Under the circumstance that internal and external interference such as parameter perturbation and torque disturbance existing in the mechanical arm system, the method can perform real-time feedback so as to realize the accurate controlling of mechanical arm trajectory tracking based on the measuring information of each joint angle and angular velocity, and the controlling on the robustness of the whole course can be guaranteed.

Owner:SOUTHEAST UNIV

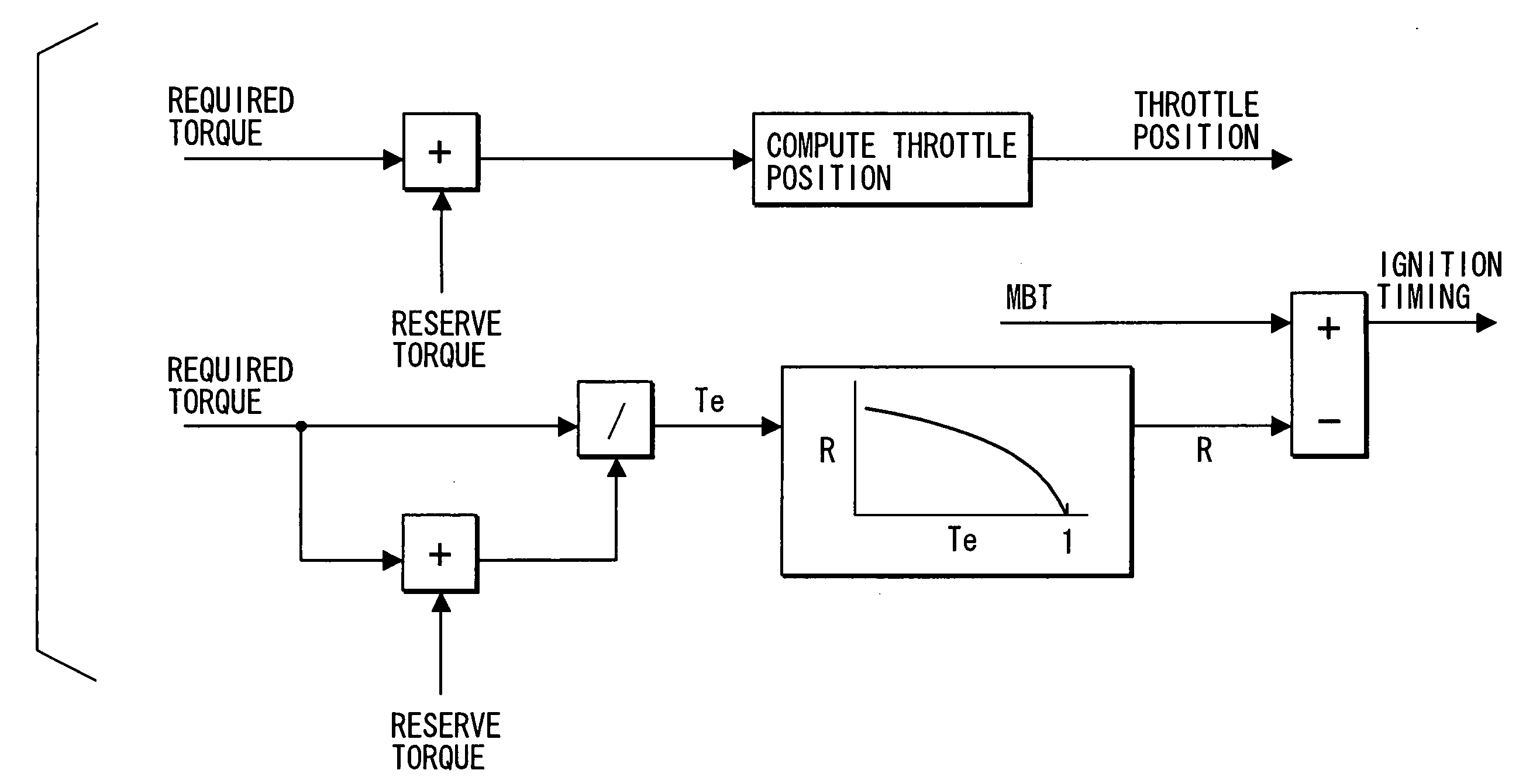

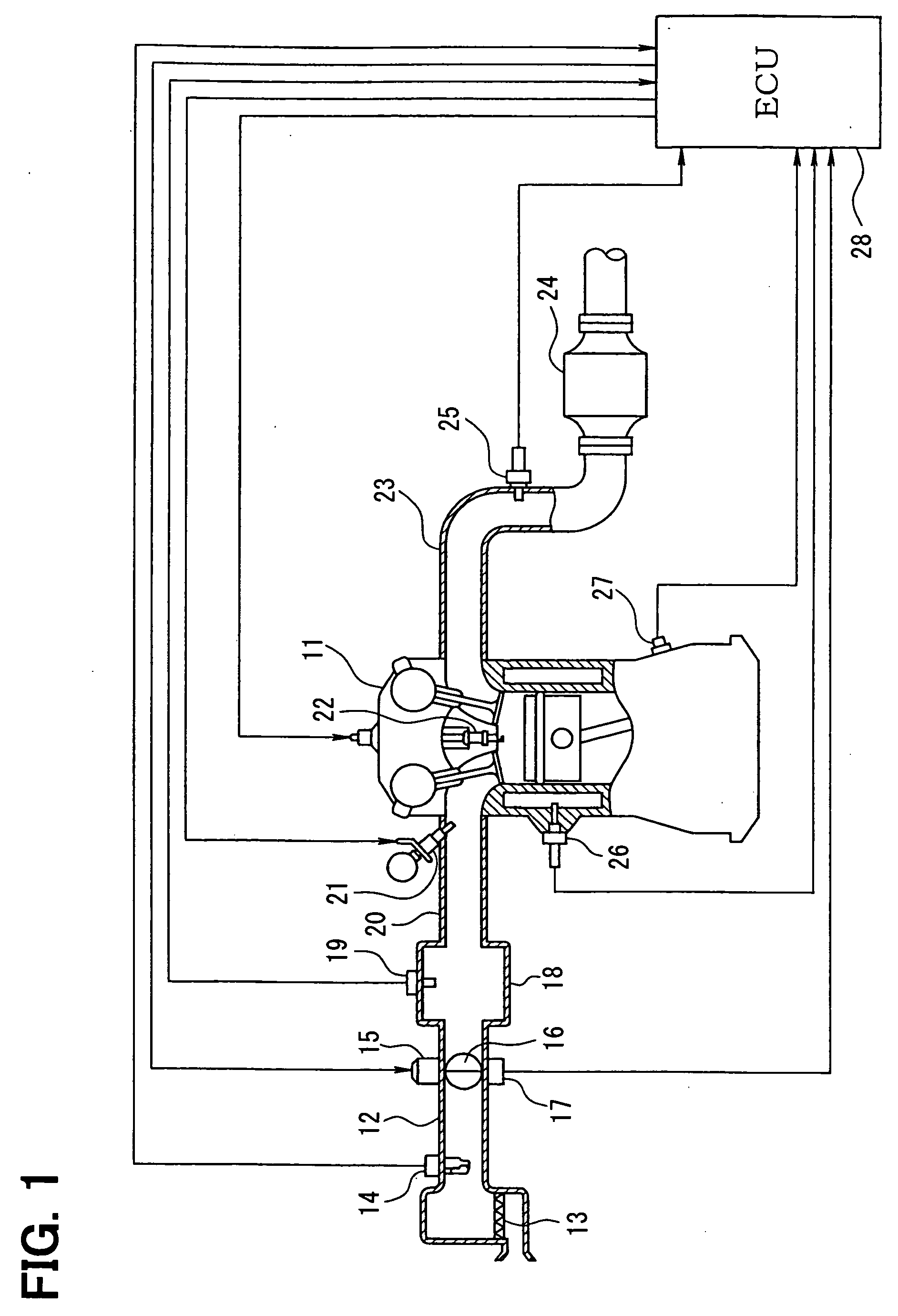

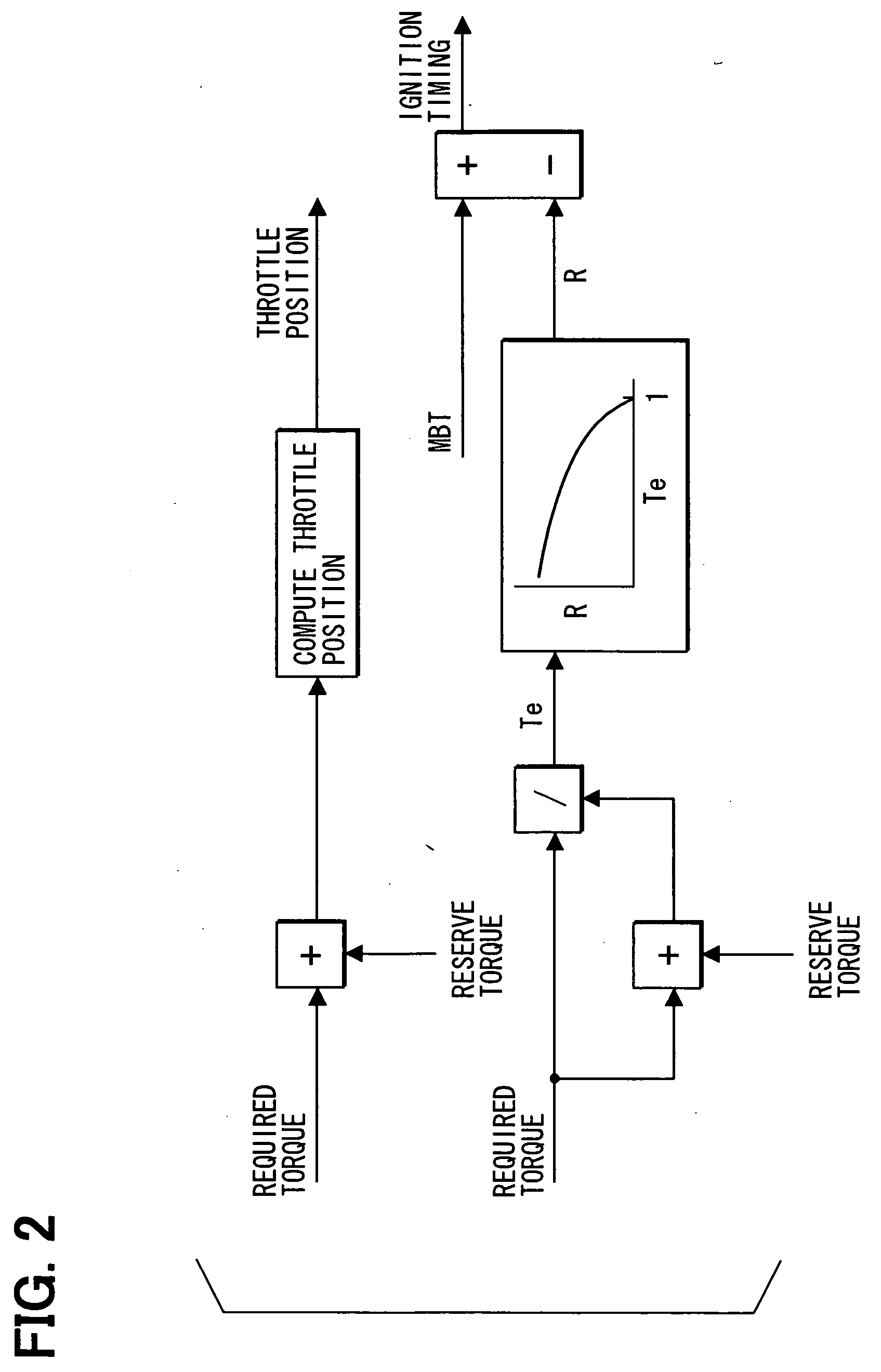

Torque controller for internal combustion engine

InactiveUS20060102143A1Increment of exhaust gas temperature can be restrictedElectrical controlIdling devicesIgnition delayIgnition timing

A throttle position corresponding to a R-R torque representing a torque in which a reserve torque is added to a required torque at MBT is computed. The throttle position is offset by an amount of a reserve torque in a torque increasing direction. An ignition retard amount for obtaining the required torque is computed based on a ration between the required torque and the R-R torque to cancel an increment in torque due to the offset of the throttle position. Because the offset amount of the ignition timing in the retard direction can be computed without an estimated torque which is determined based on the intake air flow rate including the leak air, it is restricted that the ignition retard amount becomes too large even if the large amount of leak air is generated at the throttle valve.

Owner:DENSO CORP

Diagnostic method for a torque control of an electrically variable transmission

ActiveUS6976388B2Easy to controlVehicle testingRegistering/indicating working of vehiclesLoop controlLow speed

A condition of impaired speed and torque control of a parallel electrically variable transmission due to factors beyond nominal modeling and estimation errors is diagnosed under low speed operation. The transmission includes at least one electric machine and a motor torque controller for regulating the transmission input speed and output torque. The motor torque controller includes an open-loop control path based on predetermined torques and accelerations and a closed loop control path based on input speed error. The presence of a larger than expected closed-loop correction magnitude, combined with low output speed and one or more other conditions is used to diagnose a condition of potential torque error, in which case the transmission control is altered to prevent unwanted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

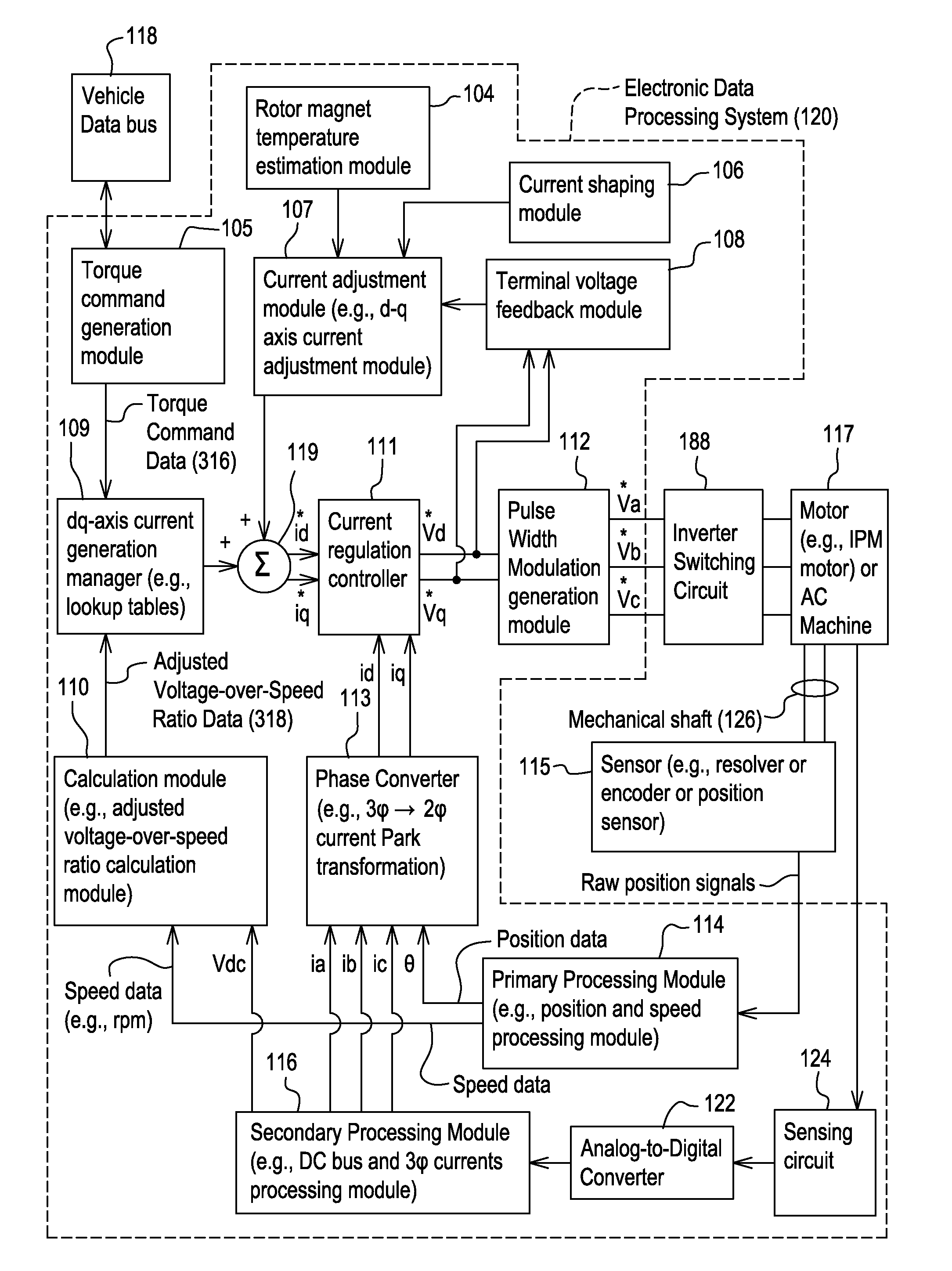

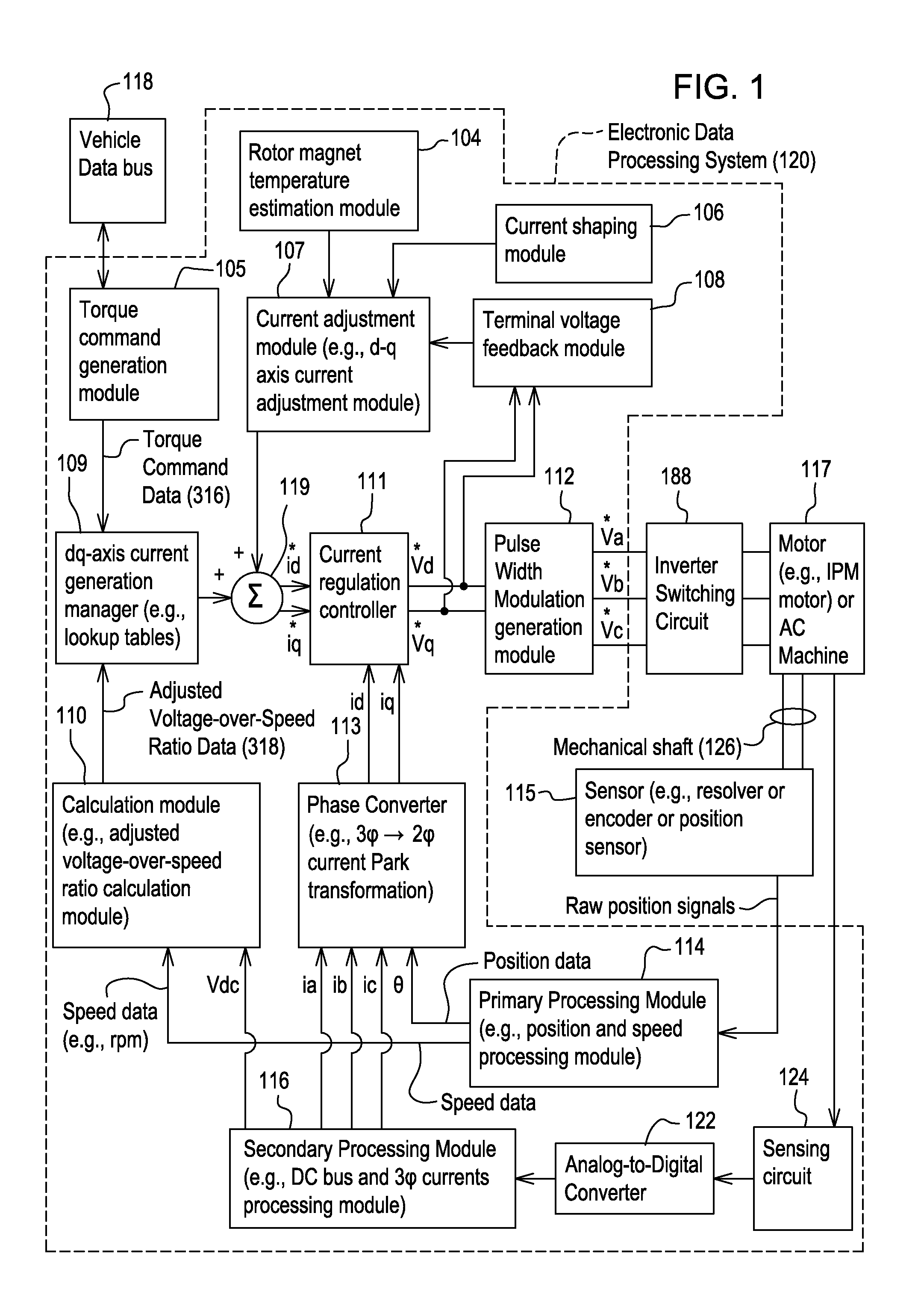

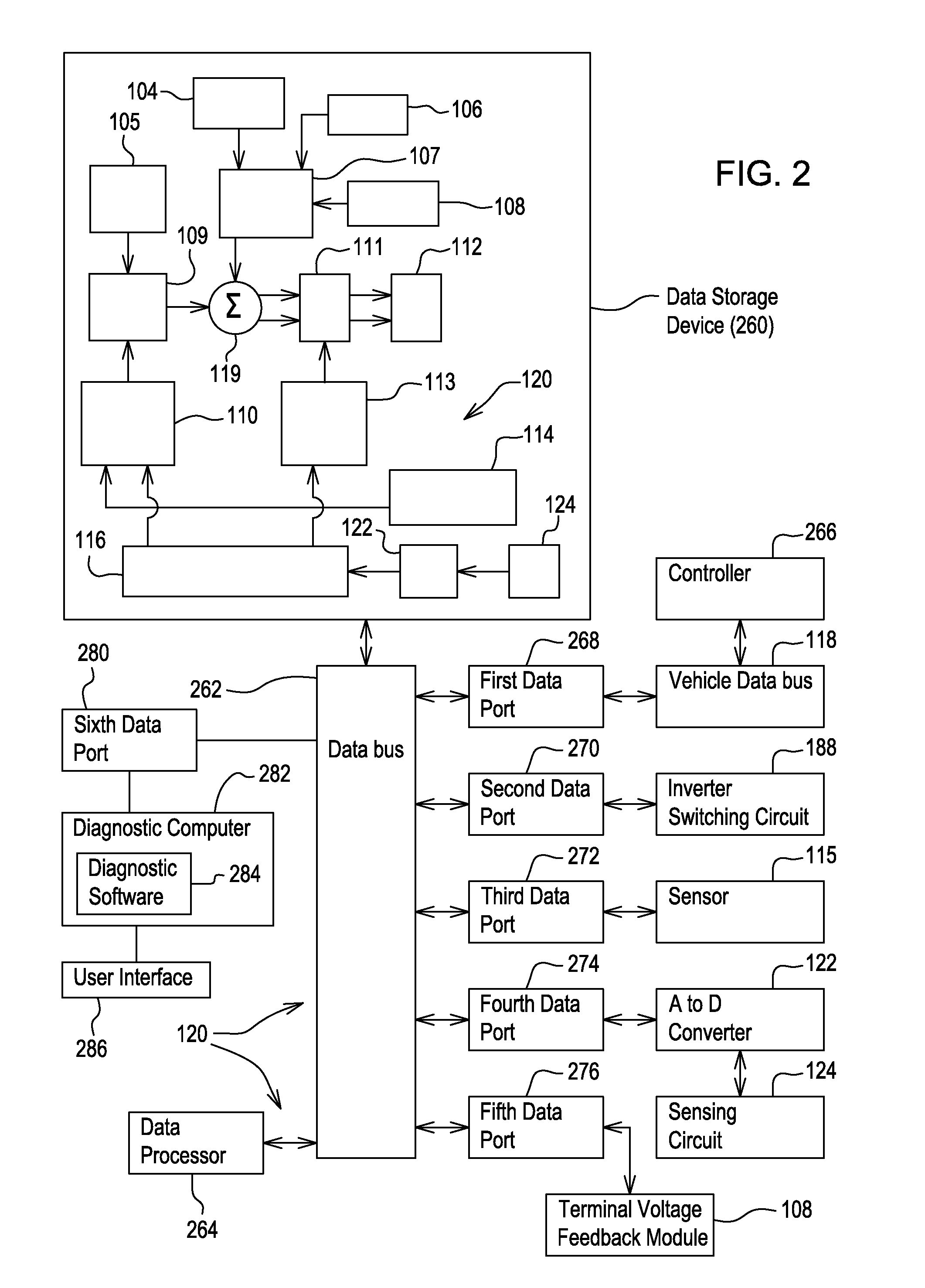

Method and system for evaluating electrical connections between an motor controller and motor

ActiveUS20120217921A1Accurate connectionMotor/generator/converter stoppersElectric motor controlElectricityElectrical conductor

A pair of direct d-q-axis voltage commands is associated with a monotonically varying test sequence of test rotor angular positions to determine a correct rotational direction of a rotor of the motor in response to application of the pair of direct d-q-axis voltage commands to the motor. The rotor of the motor rotates (e.g., self spins in a diagnostic mode) in response to the applied direct d-q-axis voltage commands and applied monotonically varying test sequence of test rotor angular positions. The primary positioning module or data processor determines that conductor connections between the inverter (e.g., motor controller) and the motor are correct if the calculated shaft speed sign is positive with respect to an applied monotonically varying test sequence of rotor angular positions that monotonically increases.

Owner:DEERE & CO

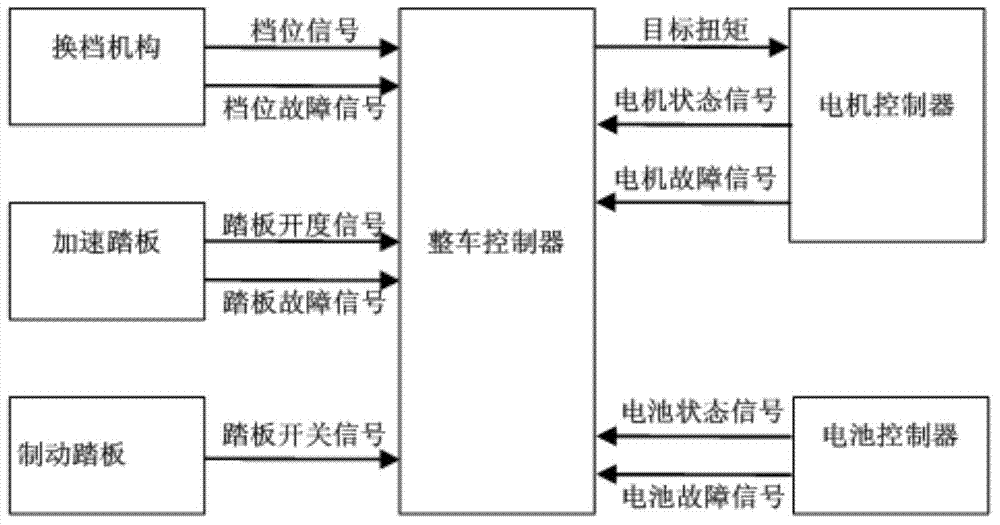

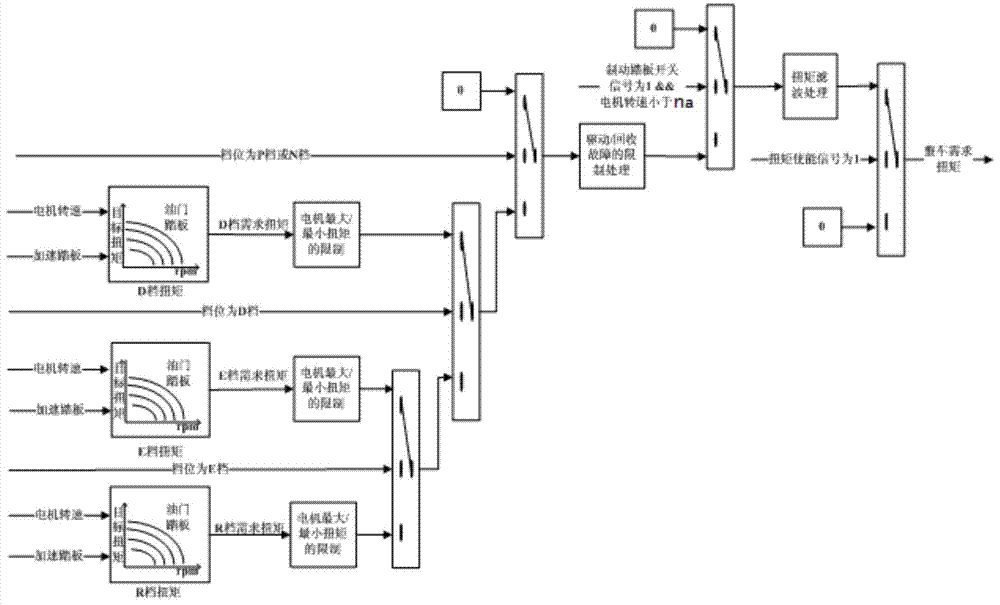

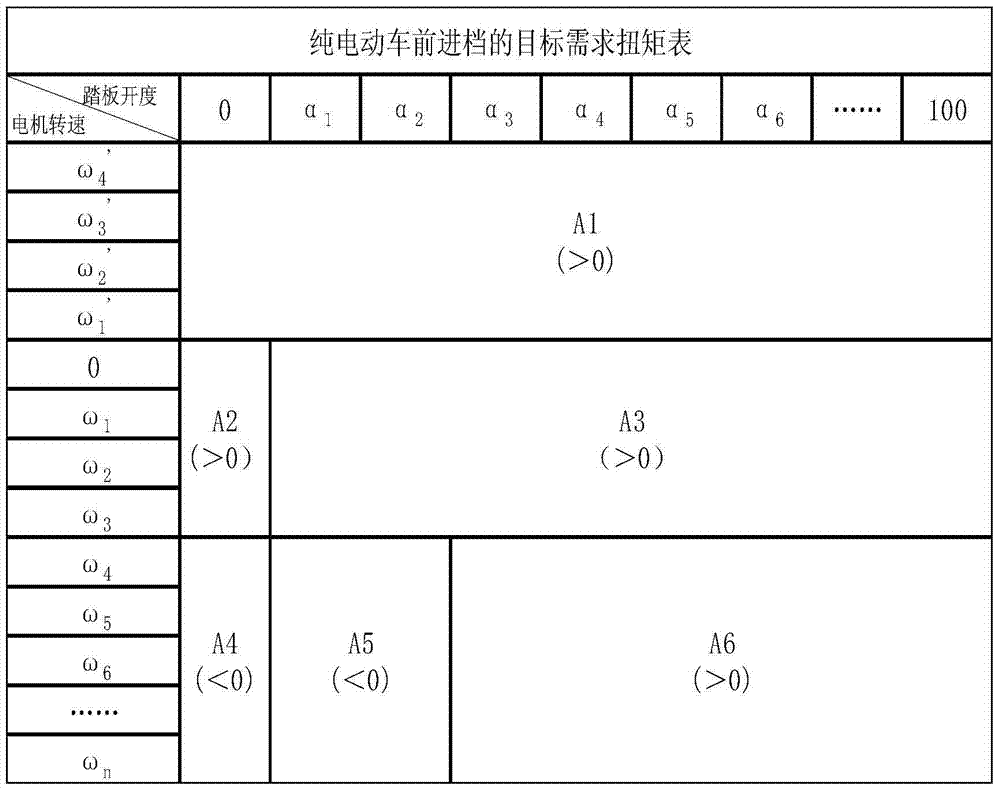

Torque management control method of battery electric vehicle

ActiveCN103692987AImprove economyIncrease mileageElectric/fluid circuitElectrical batteryElectric machinery

The invention discloses a torque management control method of a battery electric vehicle. Due to the fact that a vehicle control unit receives all status signals transmitted by a gear shifting mechanism, an accelerator pedal, a brake pedal, a motor controller and a battery controller, target demand torque of a vehicle is determined, a series of processing is performed on the target demand torque, the target demand torque subjected to the processing is output to the motor controller to control operation of a motor, and accordingly, the battery electric vehicle can meet all travel requirements.

Owner:深蓝汽车科技有限公司

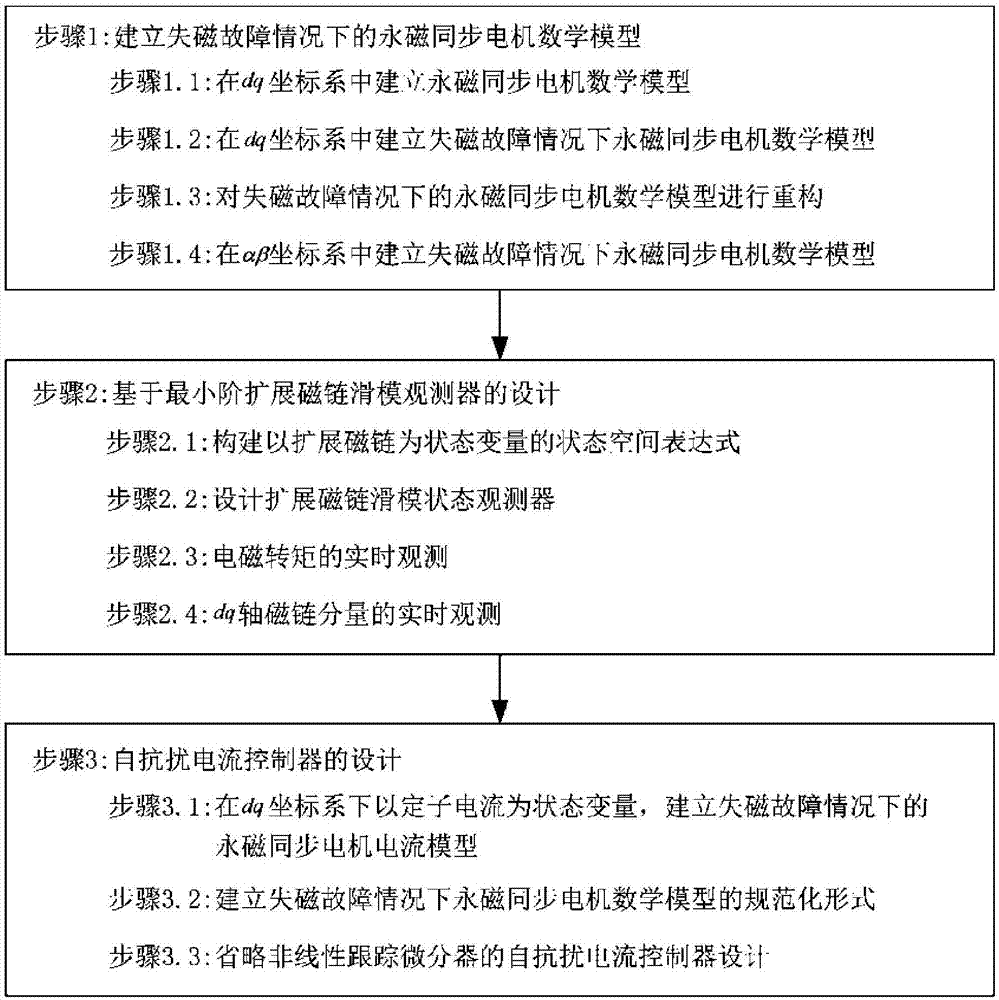

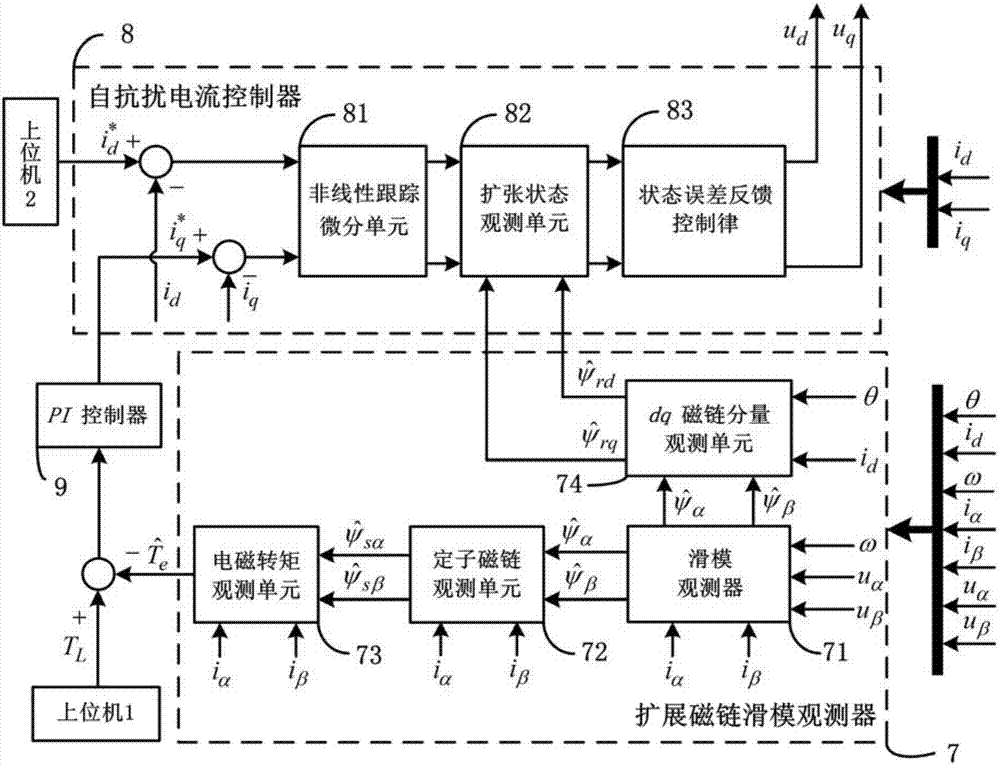

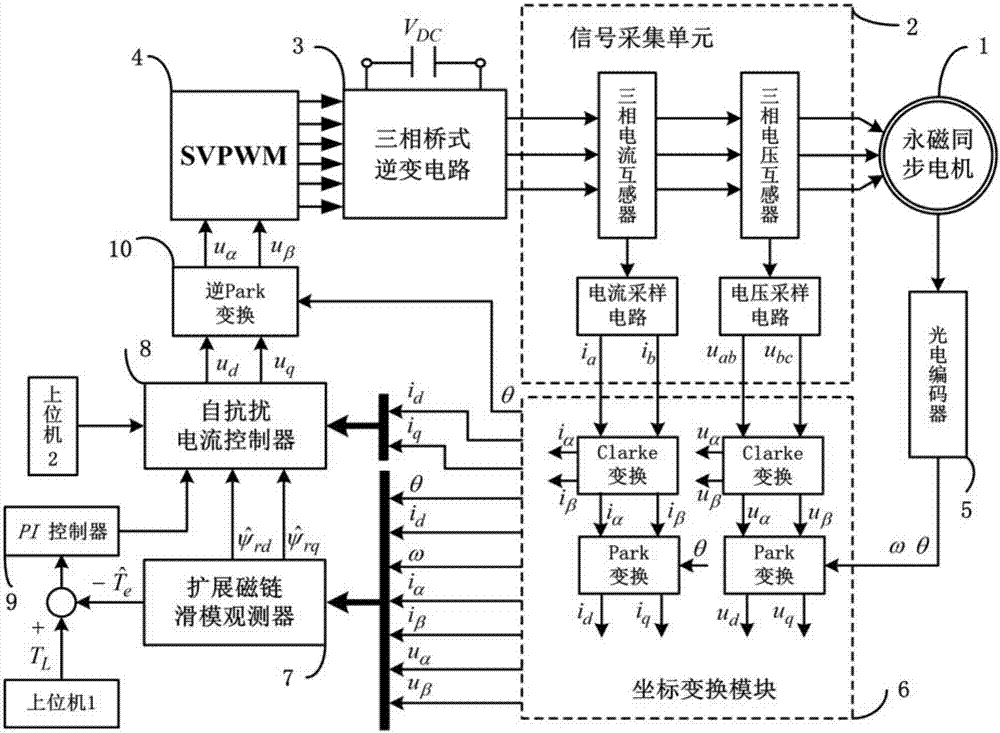

Permanent-magnet synchronous motor torque control system and method based on a sliding-mode observer and auto-disturbance rejection control

PendingCN107359837AFast dynamic responseImprove reliabilityElectronic commutation motor controlElectric motor controlControl systemClosed loop

The invention discloses a permanent-magnet synchronous motor torque control system and method based on sliding-mode observer and auto-disturbance rejection control, so that the torque of the permanent-magnet synchronous motor is controlled rapidly and precisely. A minimal-order extended flux-linkage sliding-mode observer is designed; an auto-disturbance rejection current controller is designed; difference processing is carried out on an electromagnetic torque outputted by an observer and a given torque signal outputted by an upper computer and the difference is inputted into a PI controller; a q-axis current signal outputted by the PI controller and dq-axis flux-linkage component outputted by the observer are inputted into the auto-disturbance rejection current controller to form a torque closed loop. According to the permanent-magnet synchronous motor torque control system and method, the dynamic response of the output torque of the motor is accelerated and no overshoot phenomenon is avoided. Moreover, on the basis of combination of the sliding-mode observer and the auto-disturbance rejection controller, the reliability and robustness of the torque control of the permanent-magnet synchronous motor are enhanced. The permanent-magnet synchronous motor torque control system and method are applied to occasions with the permanent-magnet synchronous motor as a driving system.

Owner:HUNAN UNIV OF TECH

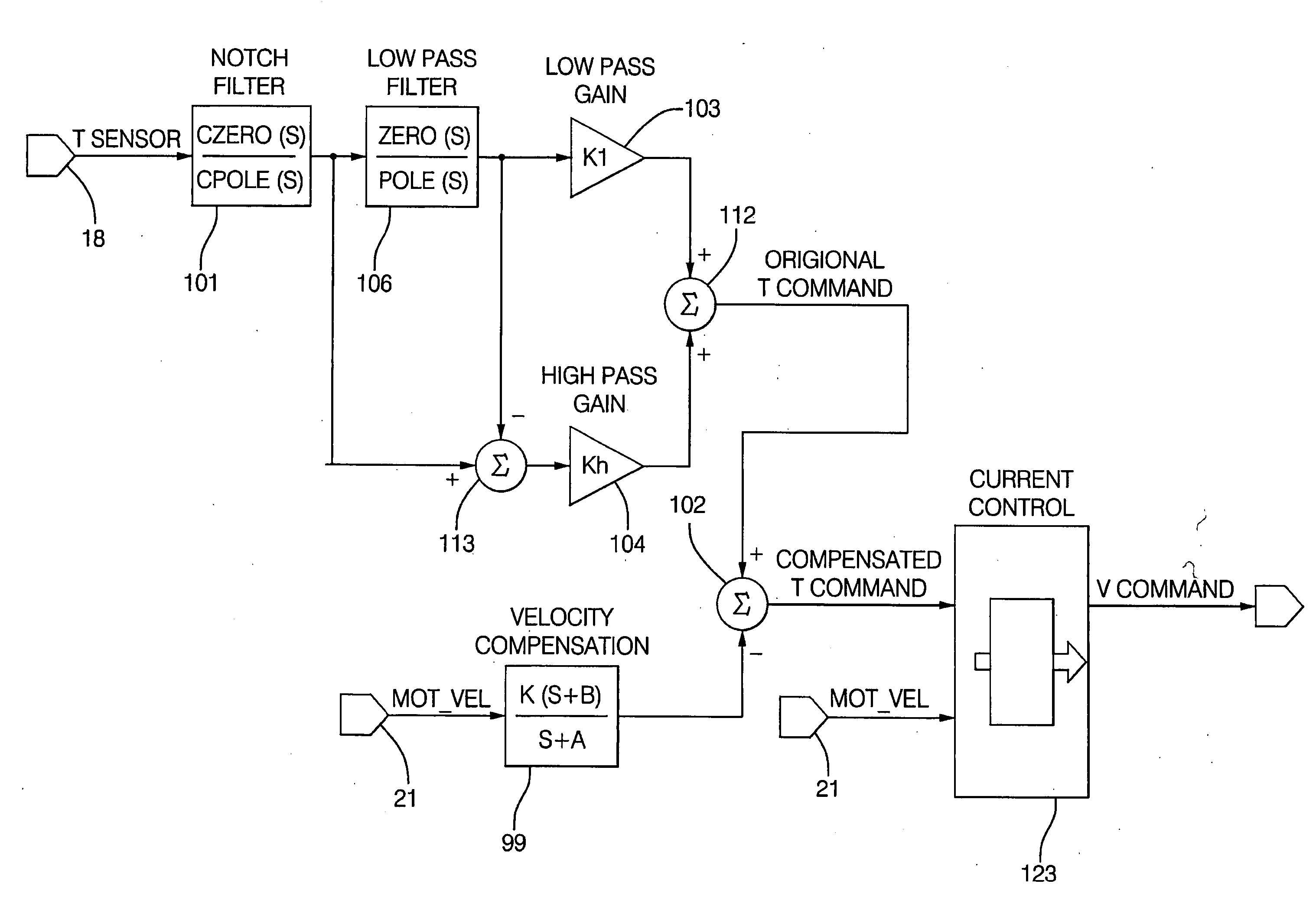

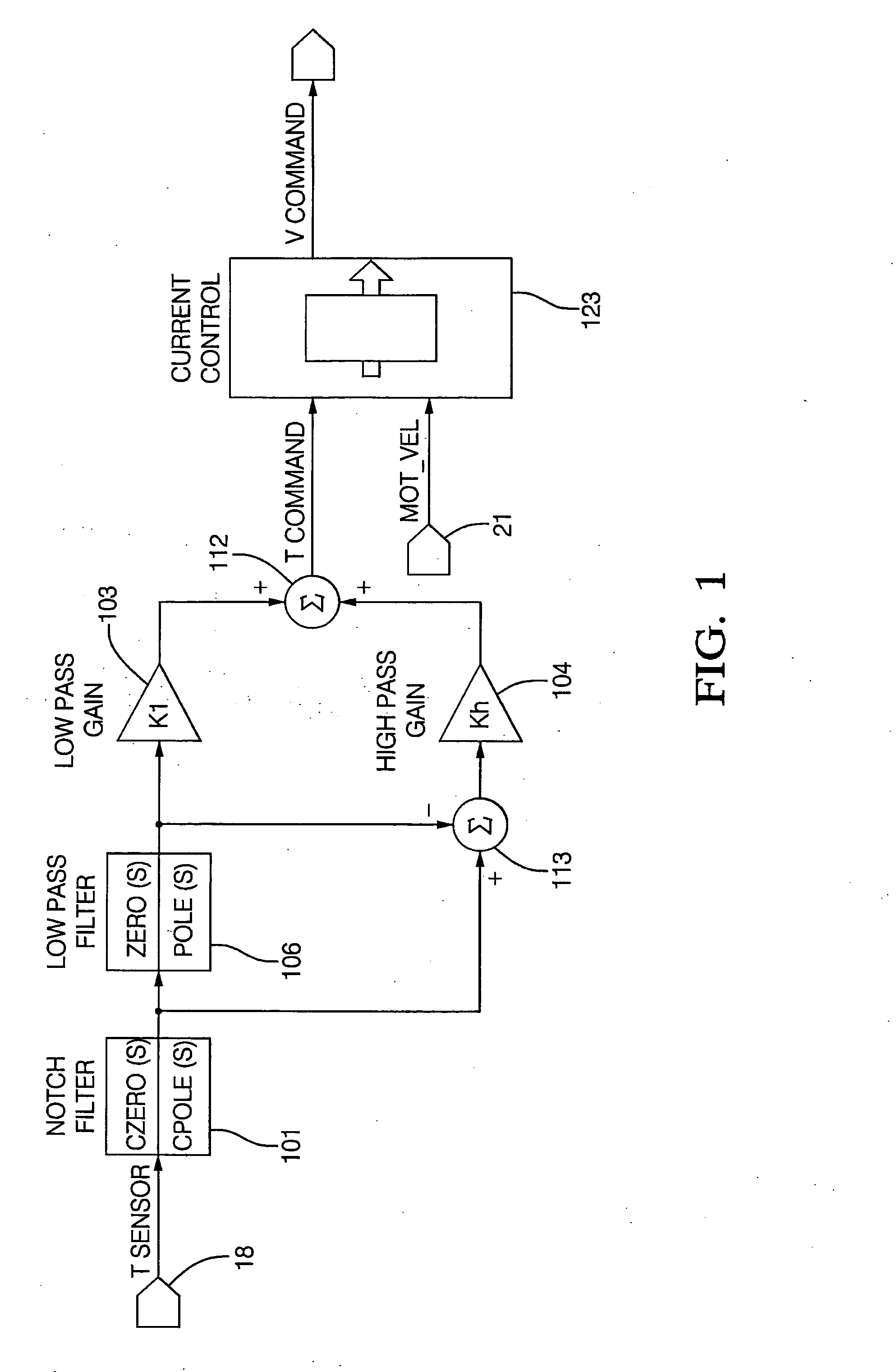

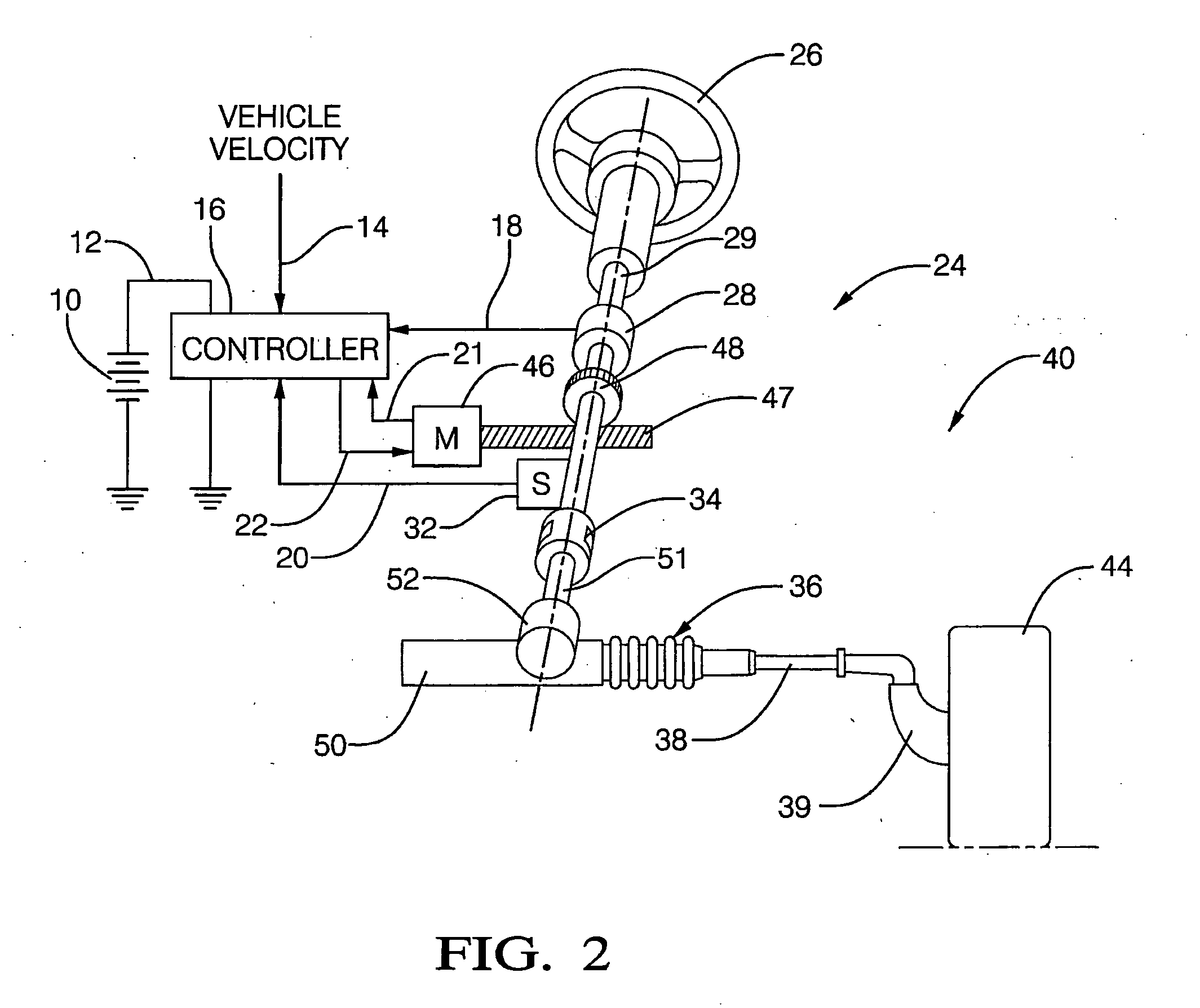

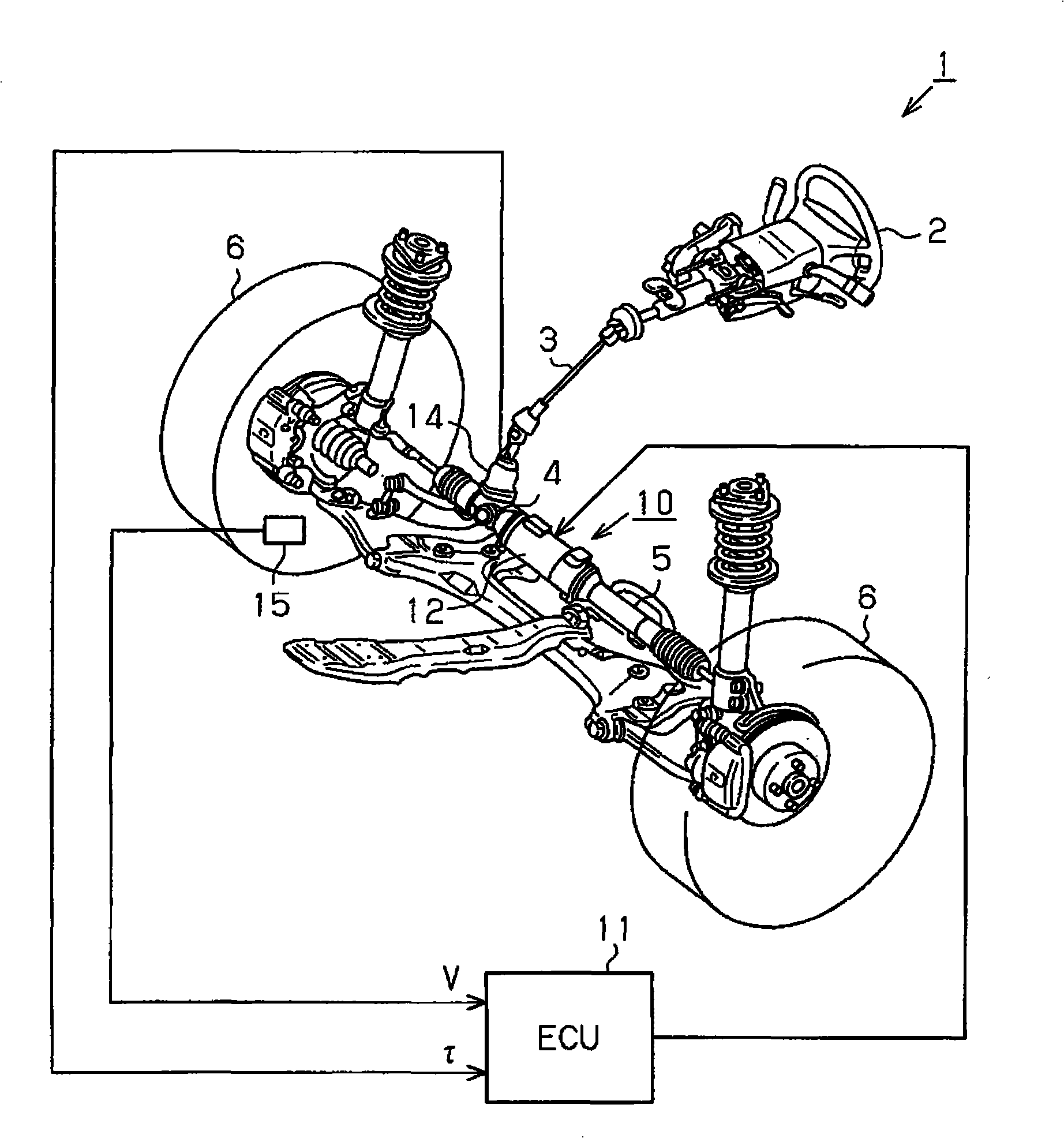

Velocity compensation control for electric steering systems

InactiveUS20040162655A1Digital data processing detailsSteering initiationsElectric power steeringSteering wheel

Disclosed herein is a method as well as a system for controlling an electric power steering system. The method includes: receiving a torque signal from a torque sensor responsive to a torque applied to a steering wheel; obtaining a motor velocity signal, the motor velocity signal indicative of a speed of an electric motor which applies torque to a steerable wheel; and generating a command for said electric motor with a controller coupled to the torque sensor, and the electric motor. The command includes torque control and motor velocity compensation, responsive to at least one of the torque signal, and a motor velocity signal. Also disclosed herein is a storage medium encoded with a computer program code for controlling an electric power steering system, the storage medium includes instructions for causing controller to implement the disclosed method. Further disclosed is a computer data signal for controlling an electric power steering system, the data signal comprising code configured to cause a controller to implement the disclosed method. Additionally, a method for optimizing controlling torque in an electric power steering system is disclosed. The method including: receiving a torque signal responsive to a torque applied to a steering wheel; obtaining a motor velocity; generating a command with a controller for the electric motor, where the command includes a torque control and motor velocity compensation, responsive to the torque signal, and the motor velocity. The performance of the torque control is responsive to a torque compensator, a high pass low pass structure, and motor velocity compensation.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Motor controller and electric power steering apparatus

ActiveCN101330269ASmooth rotationImprove output performanceCommutation monitoringAC motor controlPhase currentsElectric power steering

The present invention provides a motor control device and an electric power steering device. Under any one phase generating the current-carrying failure, a micro computer 17 selects other two phases as electrifying phases except the phase generating the current-carrying failure, in order to generate phase current changing like a secant curve or a cosecant curve at making a predetermined rotational angle according to the phase generated the current-carrying failure as an asymptote at the generation of the current-carrying failure and continue an output of a motor control signal to execute a current control. In addition, the micro computer 17 comprises a rotational angle correcting section 40 correcting (offsetting) an input rotational angle (theta). Furthermore, when the two phases as electrifying phases of diphasic drive except the phase generating the current-carrying failure in order to compensating a phase offset between a phase current command value Ix* as a current command value and an actual phase current value Ix as an actual current value in the current control, and correct the rotational angle (theta) becoming the basis of the current control.

Owner:JTEKT CORP

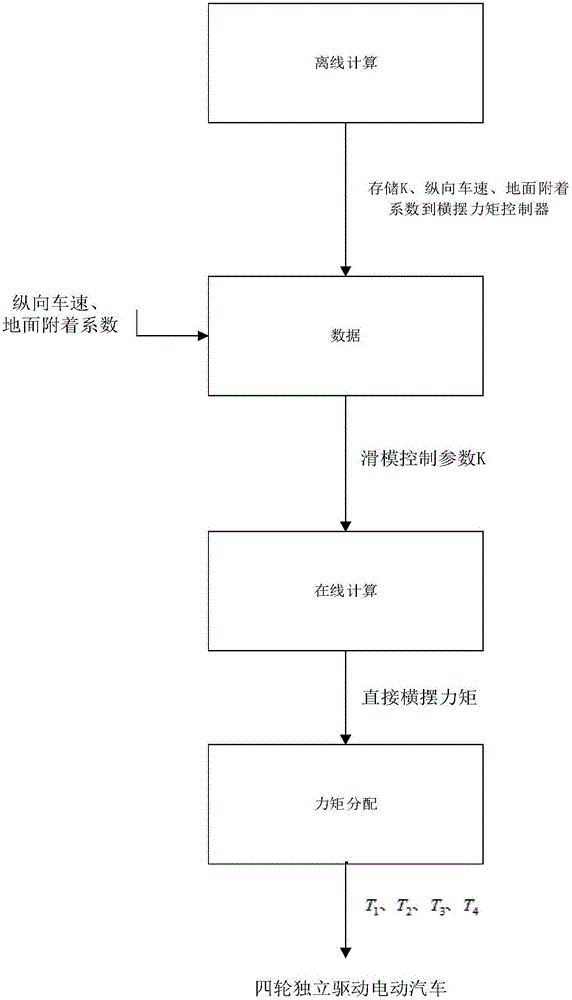

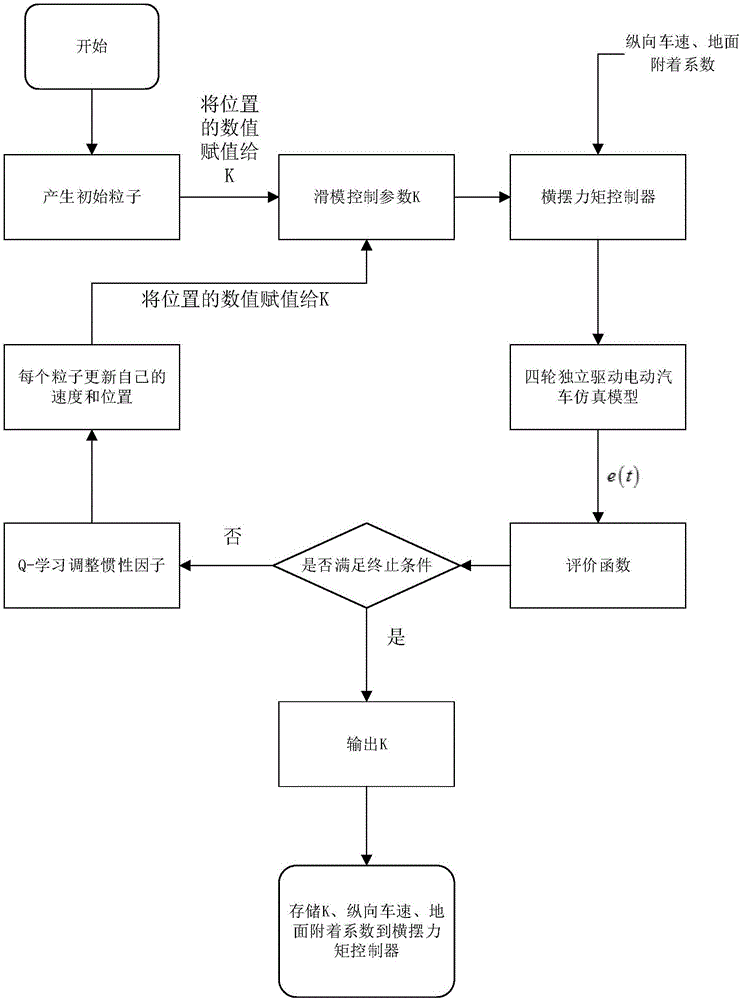

Stability control method for four-wheel independent driving electric automobile based on Q-learning

InactiveCN106218633AReduce computing timeImprove real-time performanceSpeed controllerElectric devicesControl systemOptimal control

The invention discloses a stability control method for a four-wheel independent driving electric automobile based on Q-learning. The control method comprises the following steps of selecting corresponding optimal control parameters based on actual external conditions, and calculating and obtaining an ideal control torque by utilizing the parameters; calculating slip form control parameters K of a yaw torque controller under different external conditions, and storing different external conditions and the slip form control parameters K which are in the yaw torque controller and correspond to the different external conditions, to a stability control system; and reasonably distributing the calculated ideal control torque to four wheels. According to the stability control method disclosed by the invention, the control parameters required by online calculation are found by the Q-learning manner, and stored to the yaw torque controller, so that during working, the yaw torque controller of the four-wheel independent driving electric automobile can directly call the control parameters in a manner of table look-up, the calculating time is greatly shortened, and the real-time capability, the robust ability and the practicability of the stability control system of the four-wheel independent driving electric automobile are improved.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com