Patents

Literature

8074 results about "Permanent magnet synchronous motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

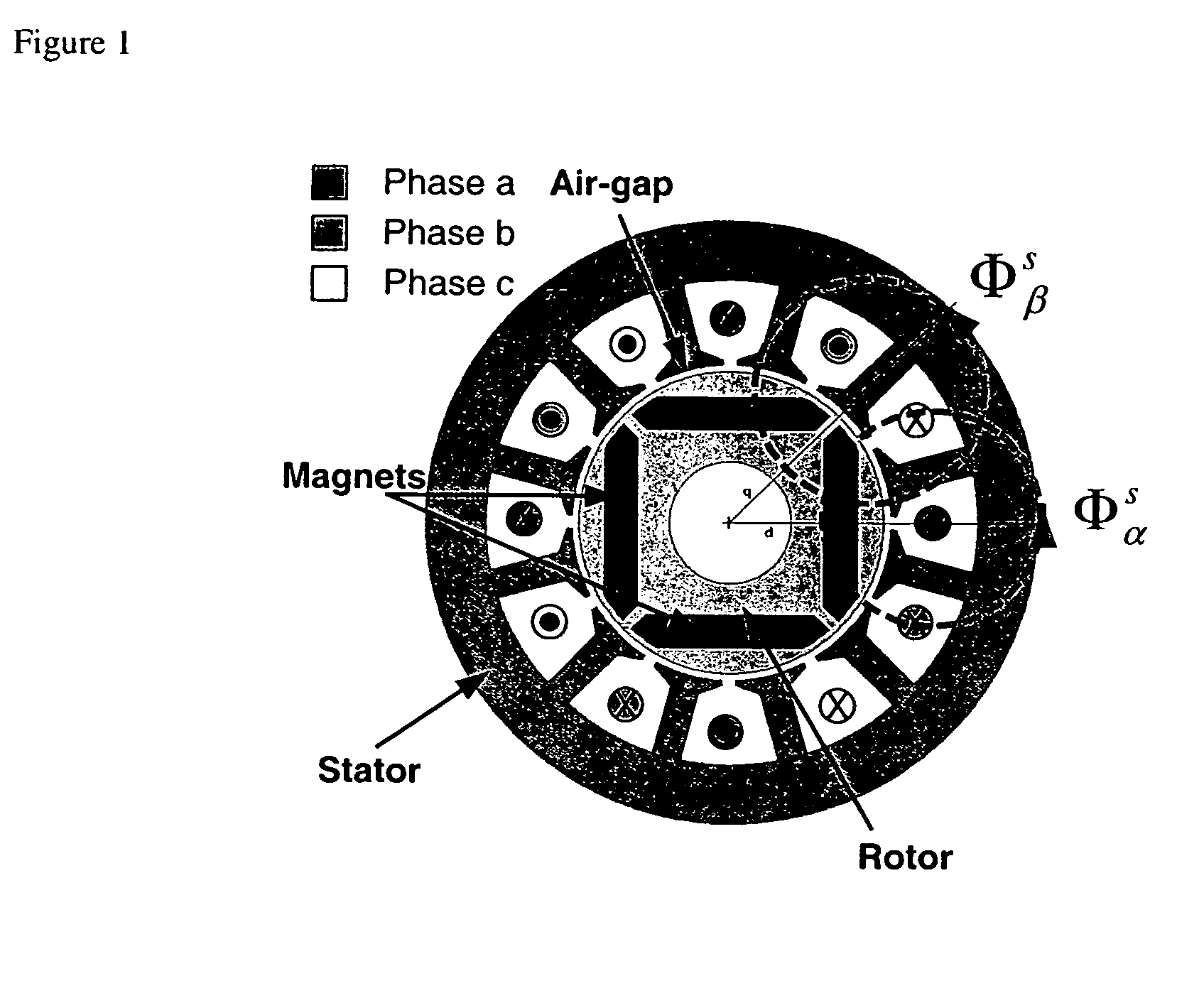

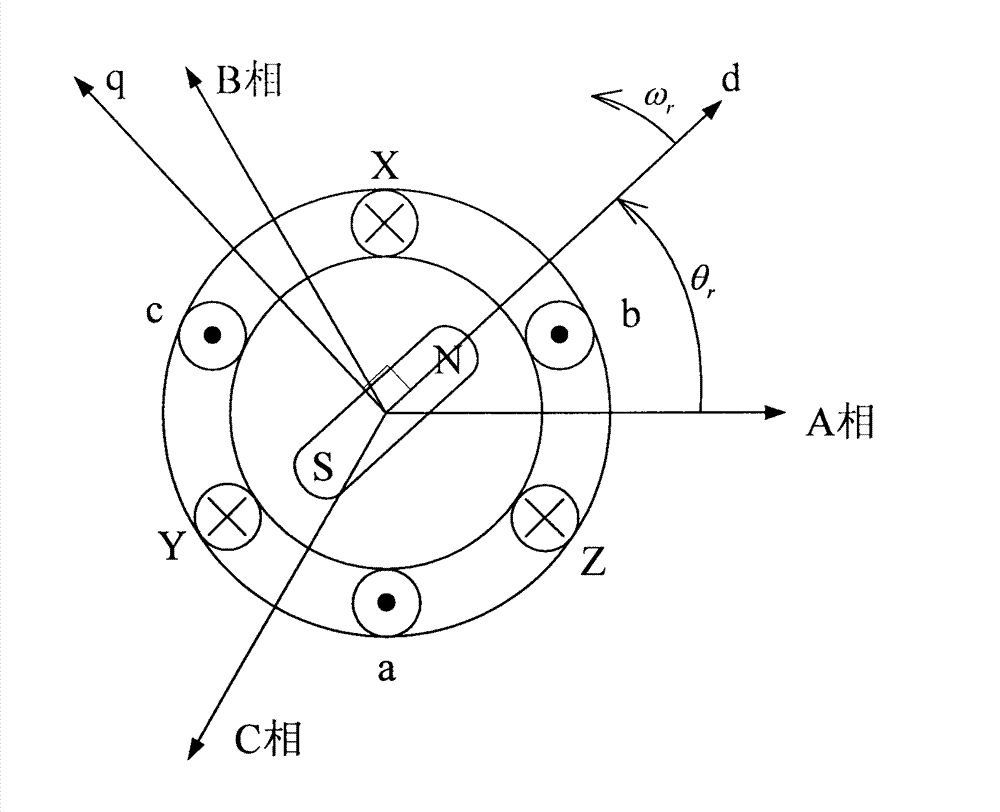

Permanent Magnet Synchronous Motor (PMSM) Overview. The Permanent Magnet Synchronous Motor (PMSM) is an AC synchronous motor whose field excitation is provided by permanent magnets, and has a sinusoidal Back EMF waveform.

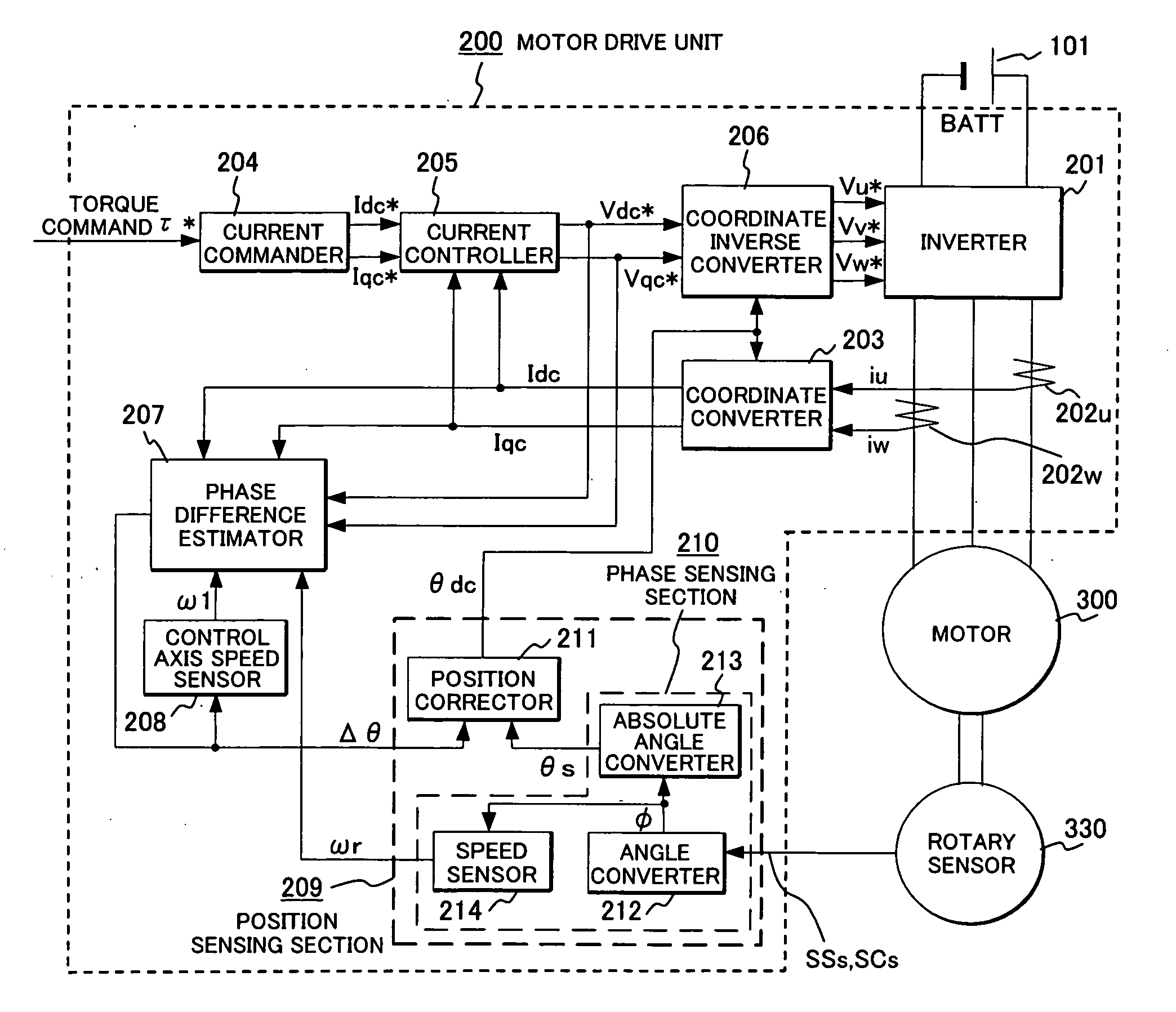

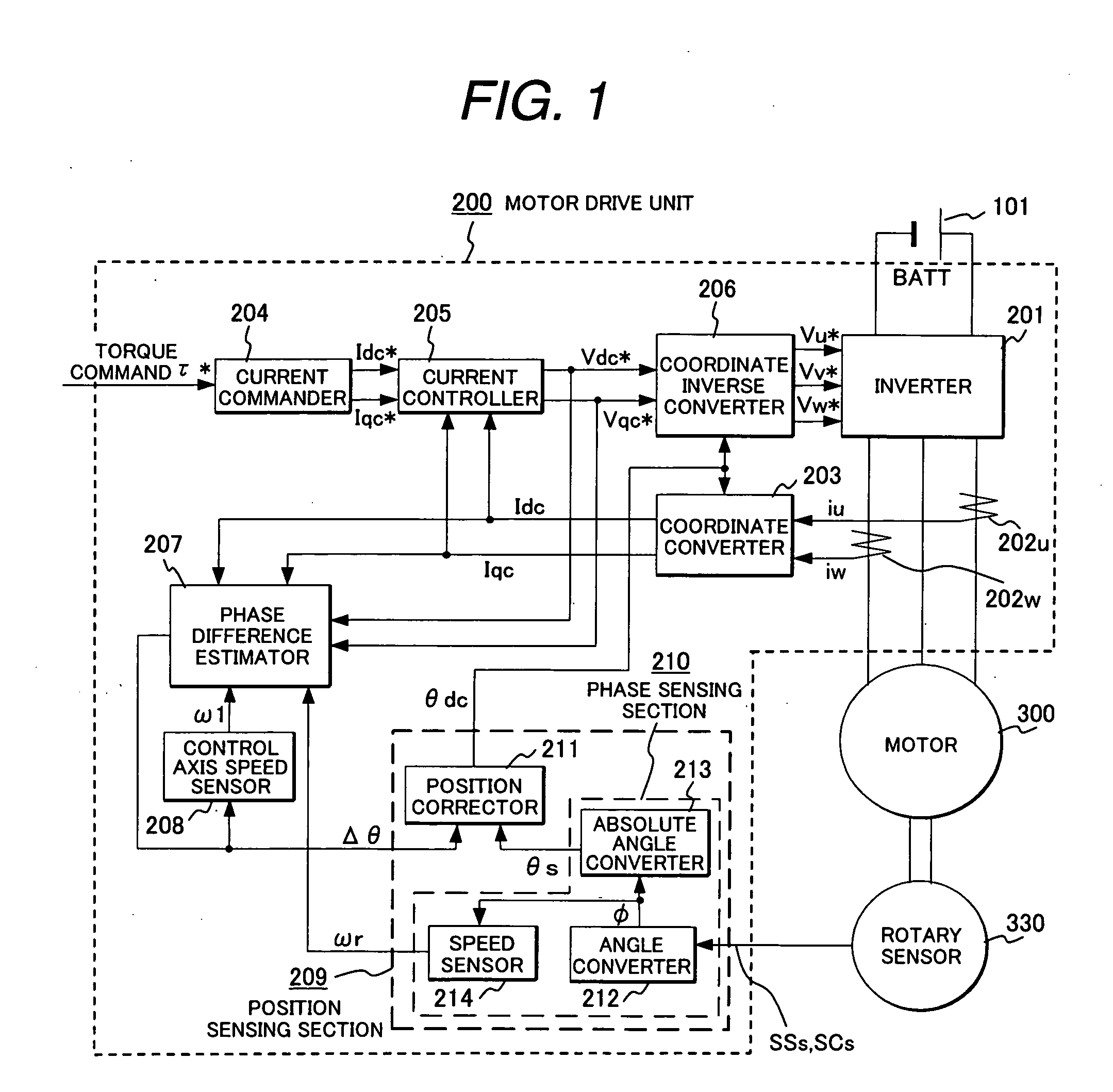

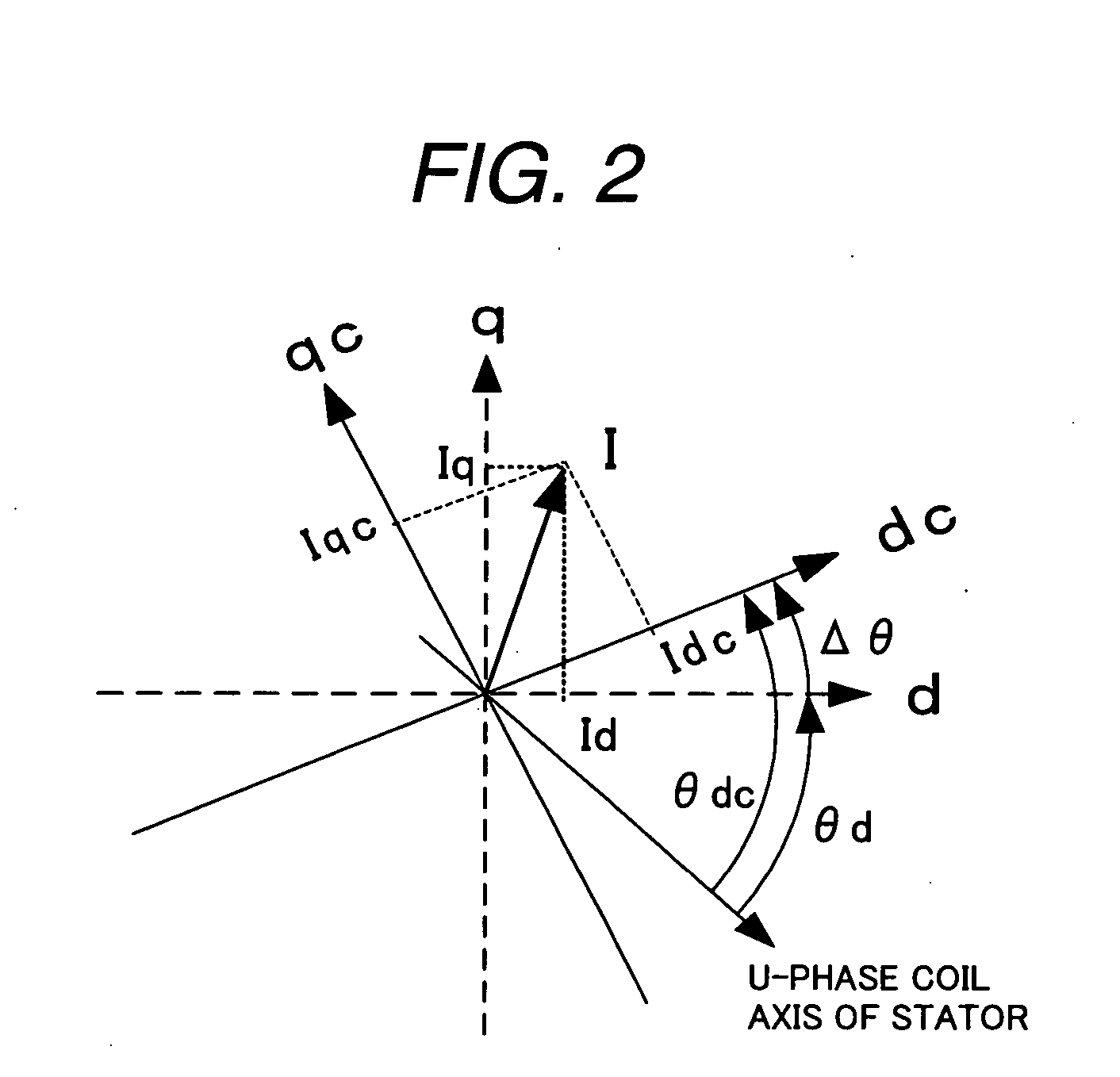

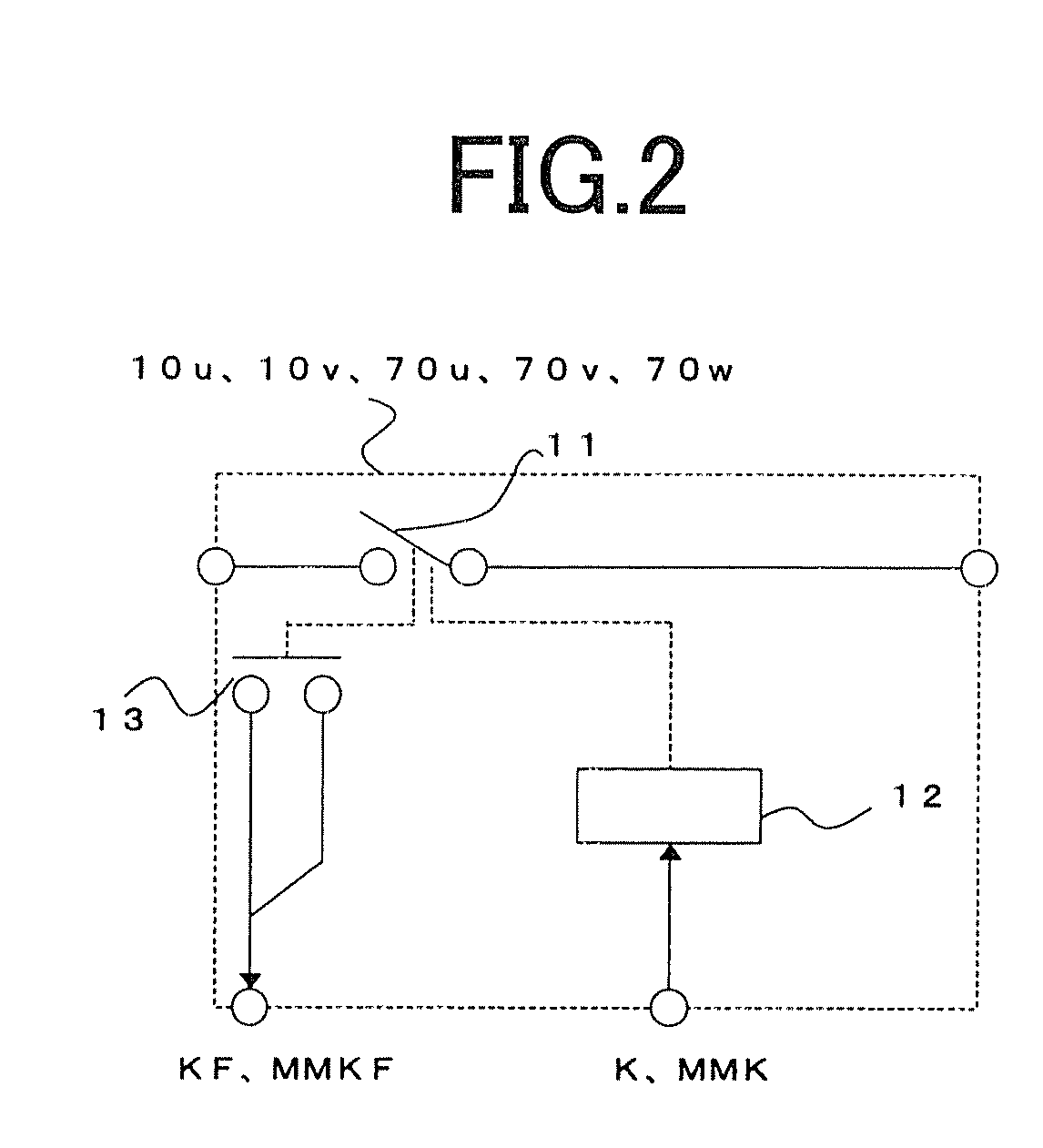

Synchronous motor drive unit and a driving method thereof

InactiveUS20060125439A1Efficient driveImprove maintainabilityAsynchronous induction motorsElectric energy vehiclesSynchronous motorPhase difference

A rotary sensor that outputs two analog signals, such as one sine wave and one cosine wave and has multiple periods within one period of the electrical angle of a motor is employed. The motor is energized at each position for a specified length of time upon its startup by using multiple electrical angles corresponding to the multiple candidate absolute angles obtained from the rotary sensor signal as the initial position of the motor, and the electrical angle at which the motor acceleration becomes maximum is determined as the absolute angle. While the motor drive is in operation, on the other hand, the phase difference Δθ between the phase of the motor at the counter electromotive voltage and the control phase is directly computed from the parameters of the motor, sensed current, voltage command and angle speed so as to correct the shifted position. A high-efficiency motor drive unit with improved maintainability of rotary sensor and improved accuracy of sensing the magnet pole position of a permanent magnet synchronous motor that accelerates and decelerates very quickly in a wide range of speed is realized.

Owner:HITACHI LTD

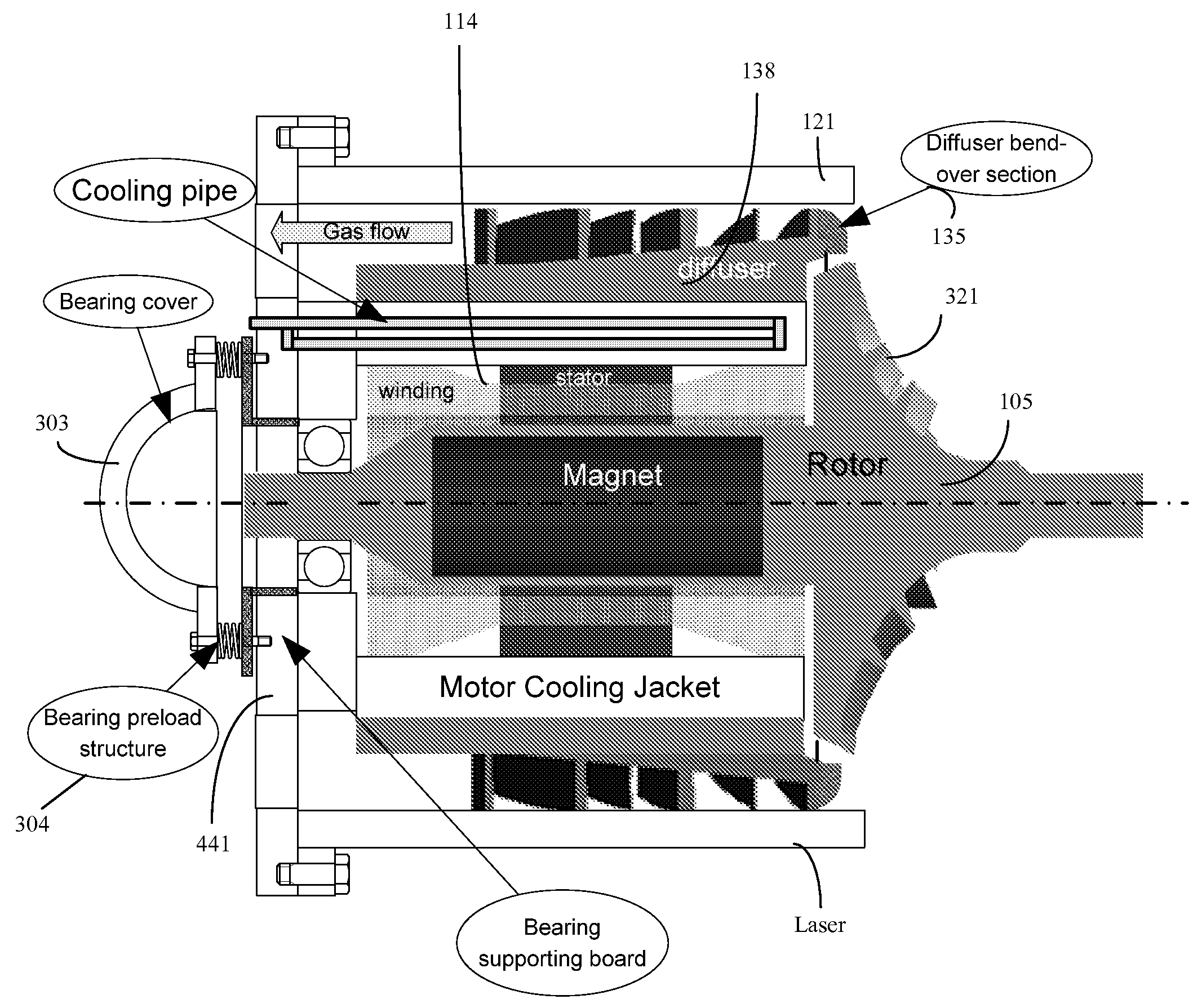

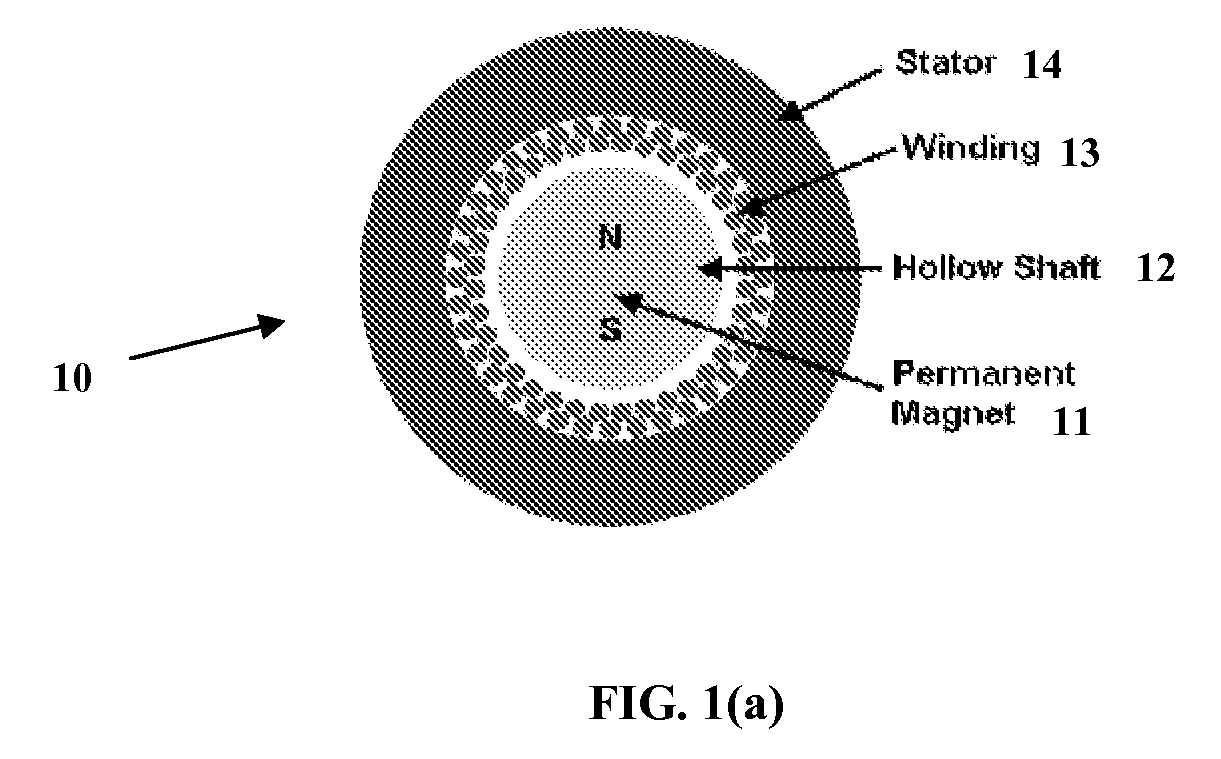

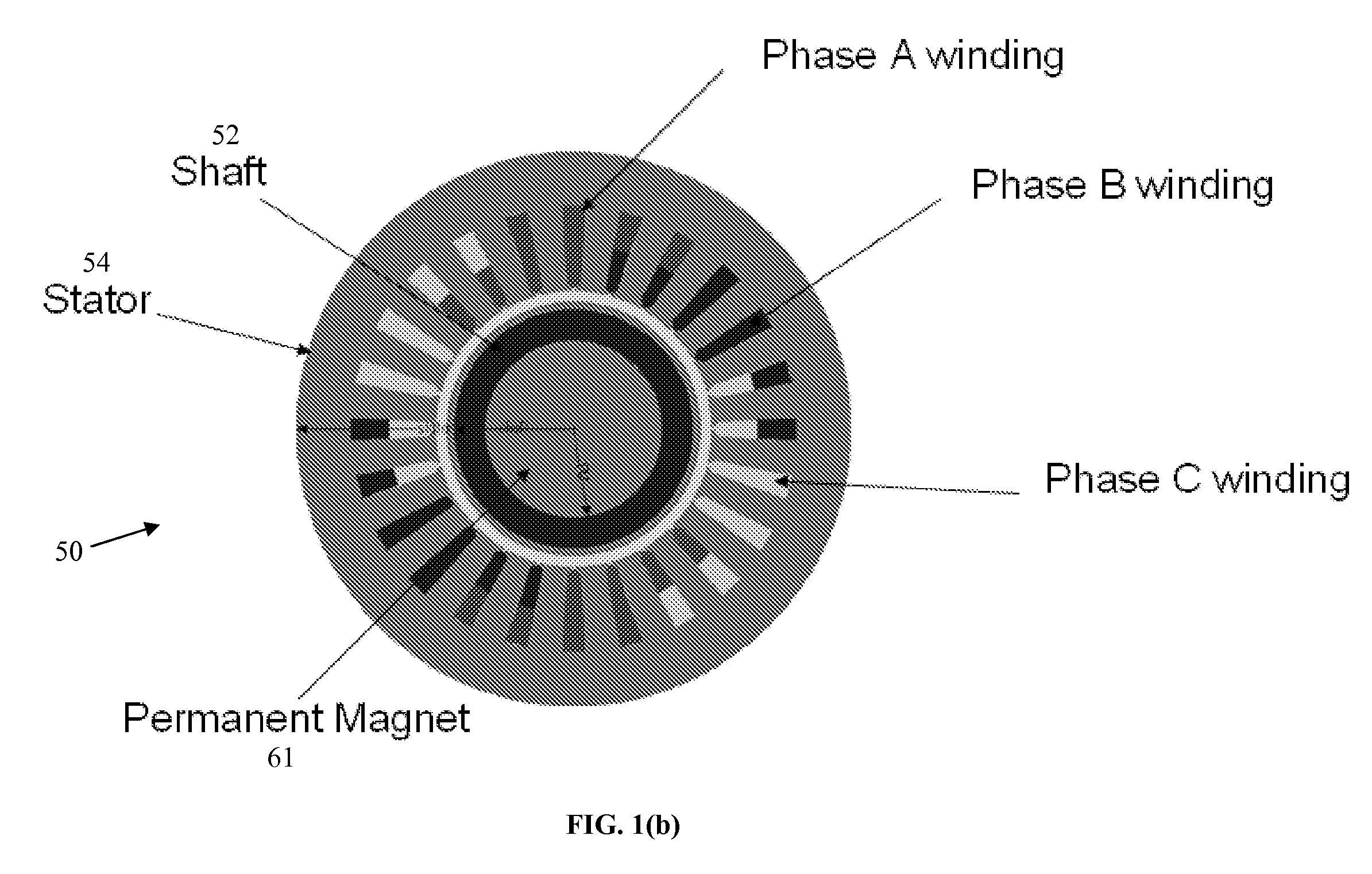

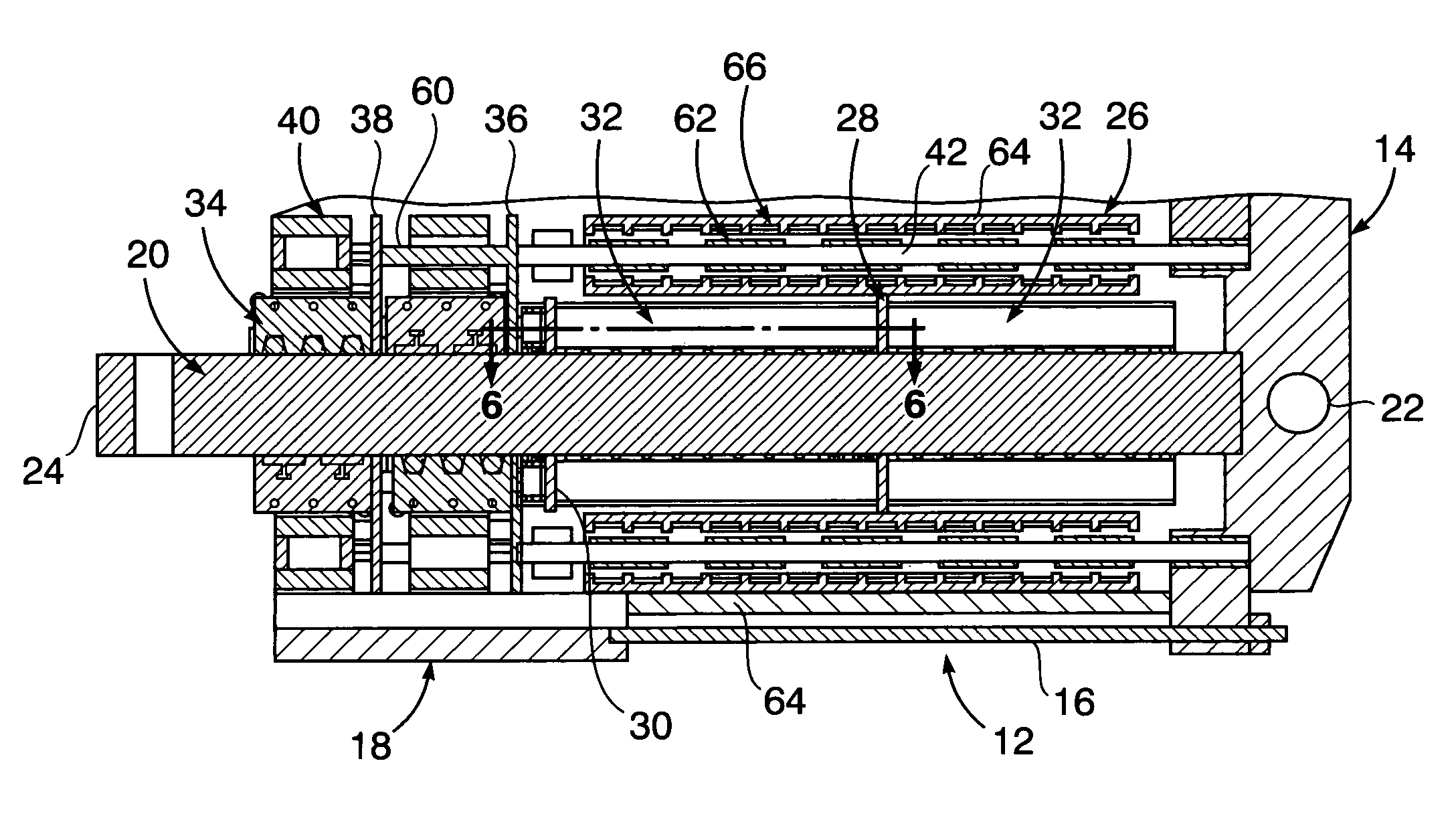

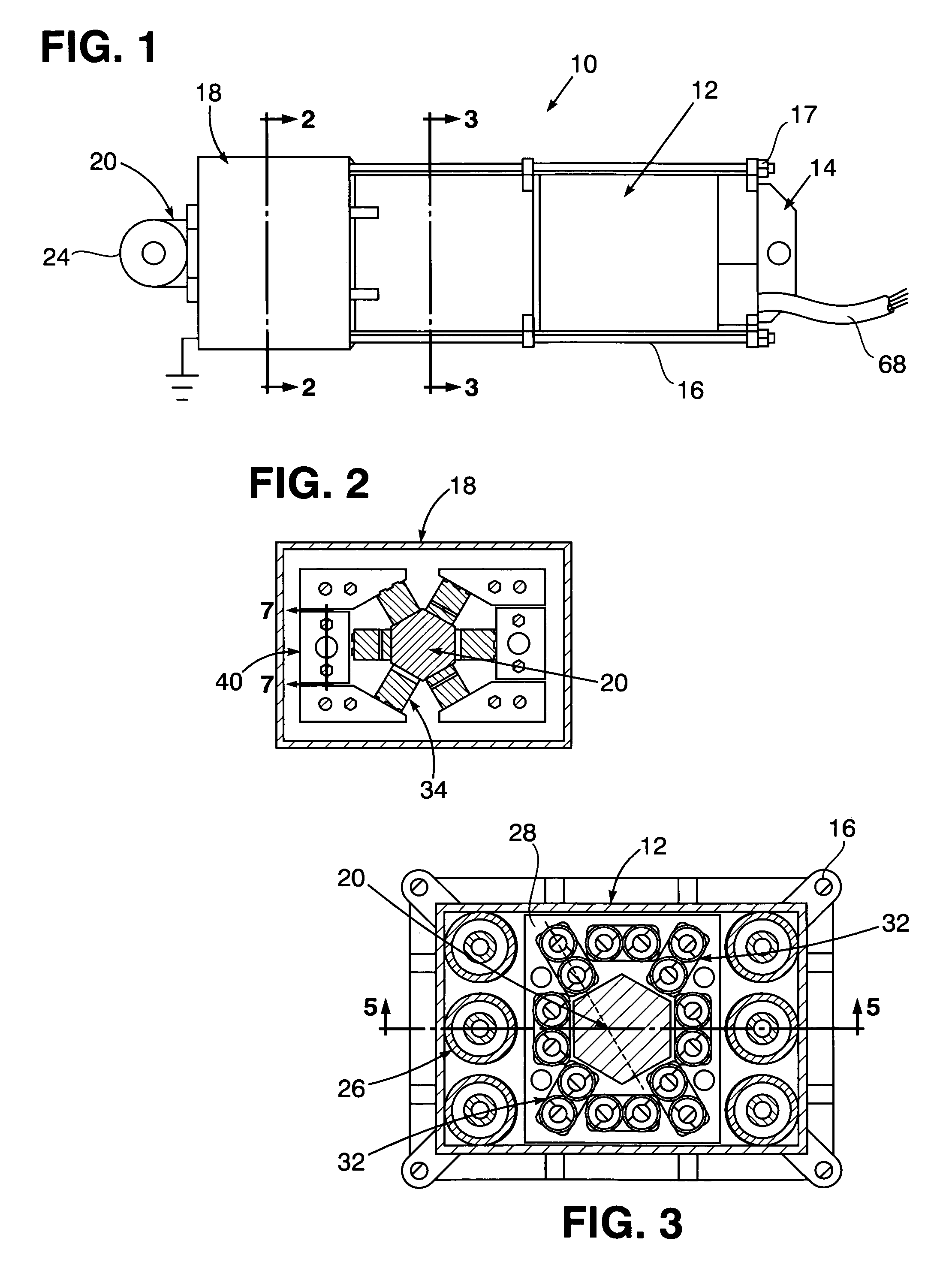

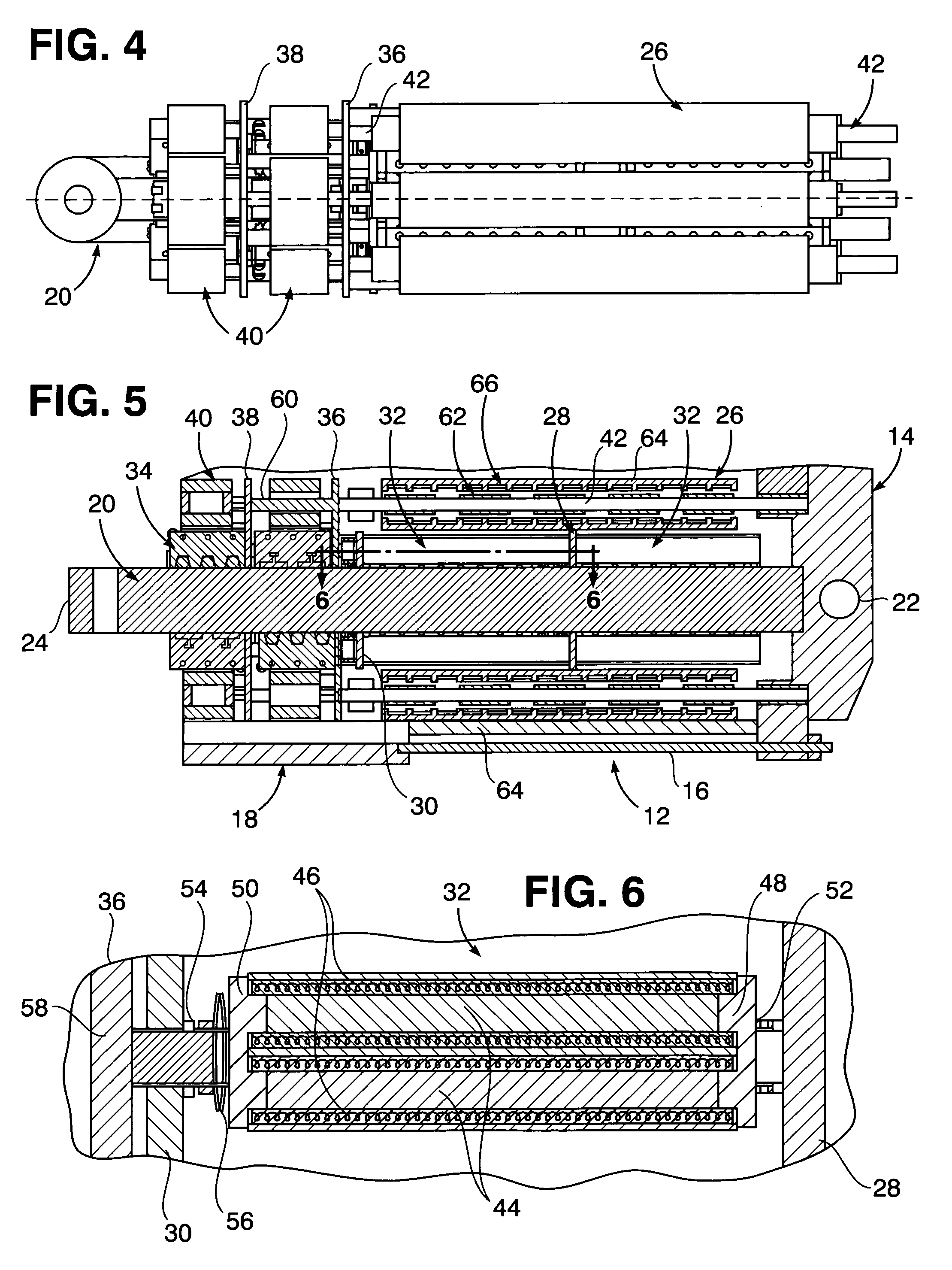

Miniature high speed compressor having embedded permanent magnet motor

InactiveUS20070269323A1Improve rigidityEasy to implementPositive displacement pump componentsEfficient regulation technologiesRigid rotorBall bearing

A high speed centrifugal compressor for compressing fluids includes a permanent magnet synchronous motor (PMSM) having a hollow shaft, the being supported on its ends by ball bearing comprising supports. A permanent magnet core is embedded inside the shaft. A stator with a winding is located radially outward of the shaft. The PMSM includes a rotor including at least one impeller secured to the shaft or integrated with the shaft as a single piece. The rotor is a high rigidity rotor providing a bending mode speed of at least 100,000 RPM which advantageously permits implementation of relatively low-cost ball bearing comprising supports.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

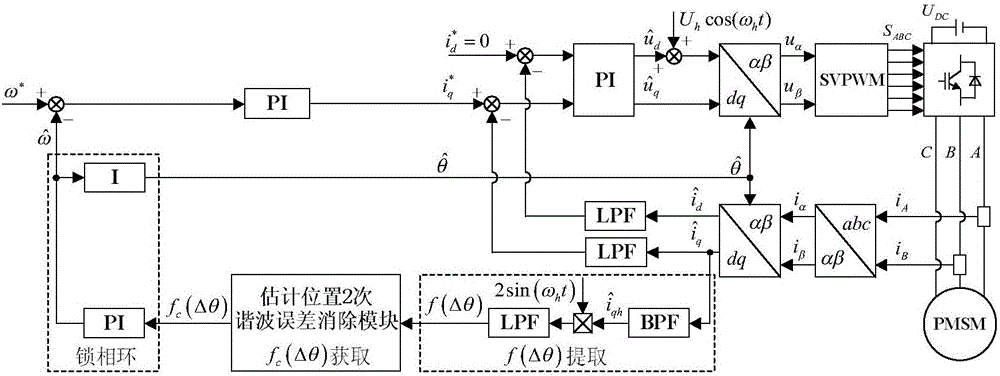

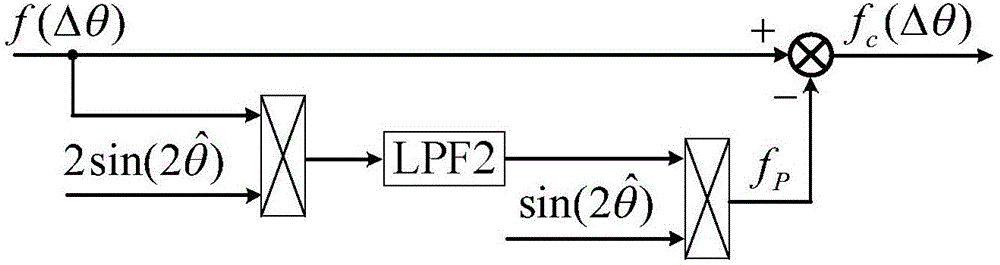

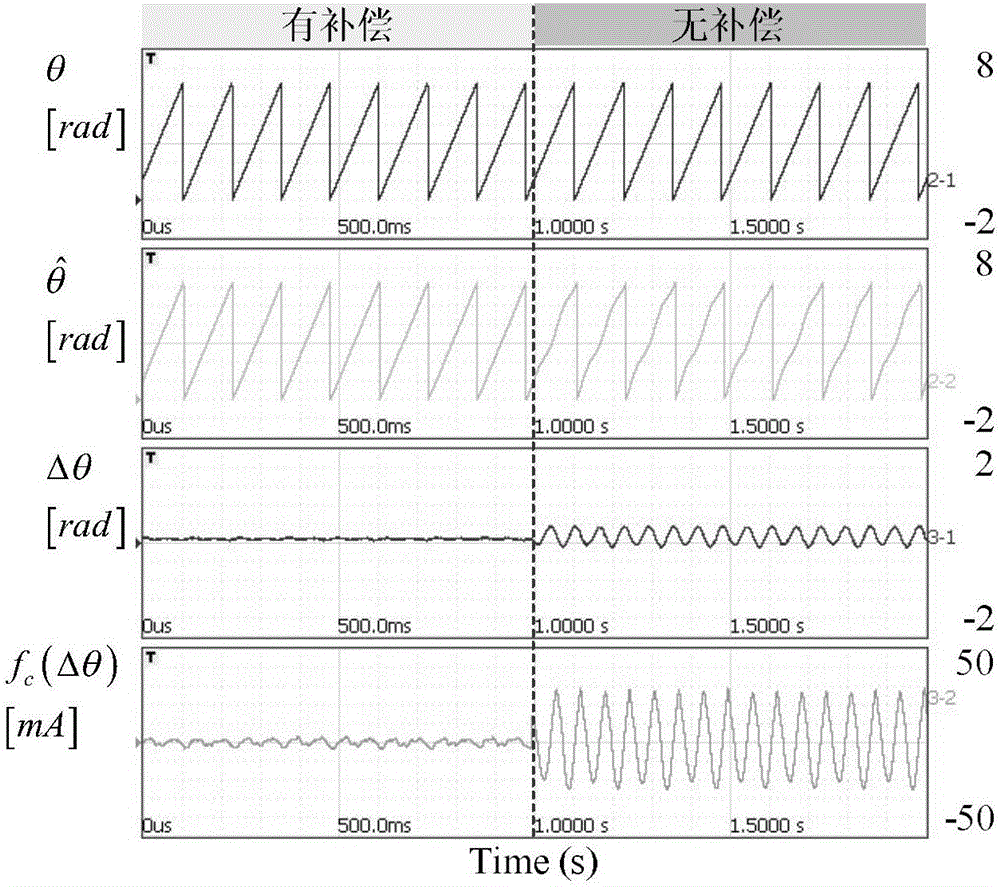

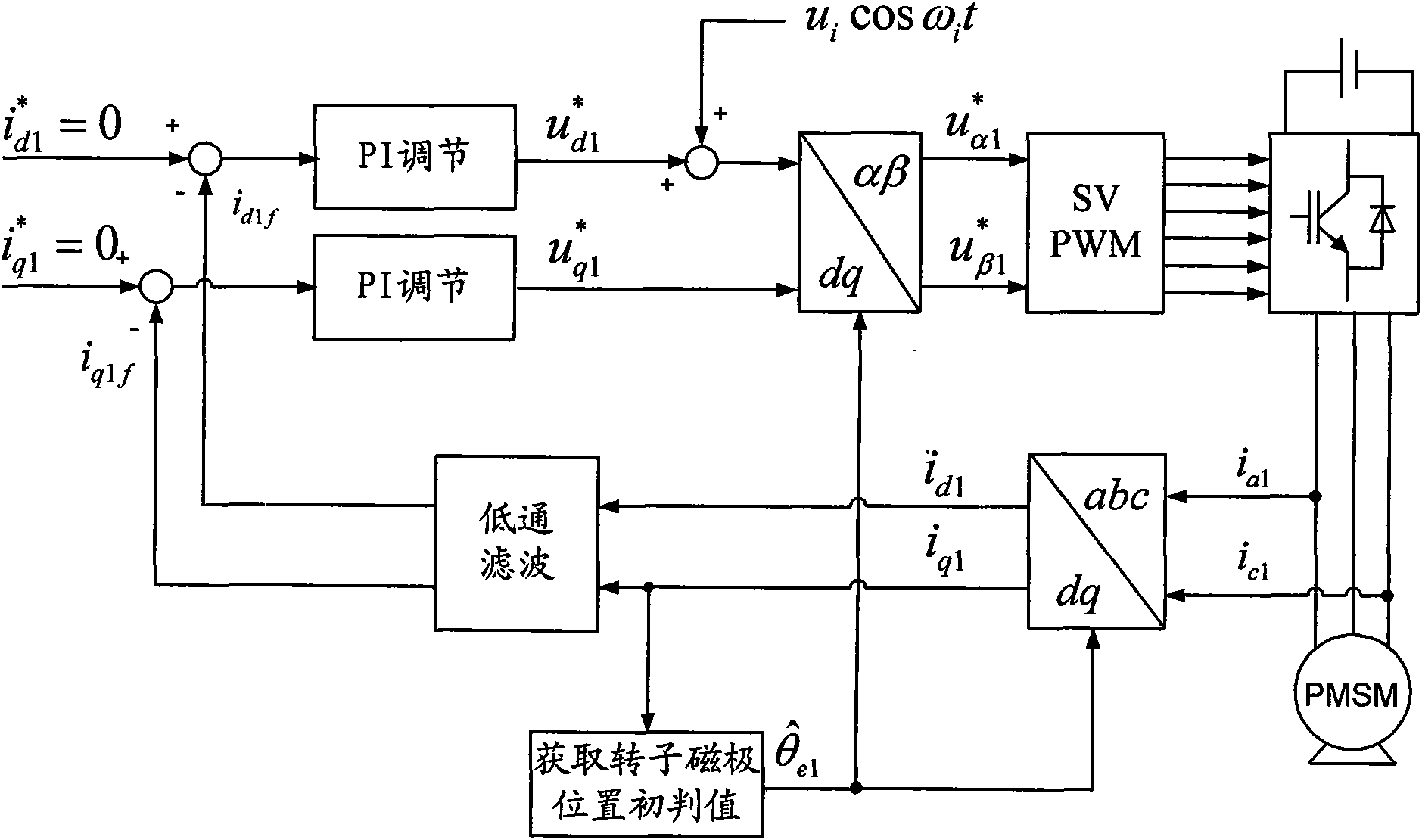

Method for improving estimation accuracy of rotor position of permanent magnet synchronous motor

ActiveCN106788071AEasy to implementReduce computing burdenElectronic commutation motor controlAC motor controlControl systemHarmonic

The invention discloses a method for improving the estimation accuracy of the rotor position of a permanent magnet synchronous motor. The method comprises the following steps: on the basis of realizing estimation of the rotor position of the permanent magnet synchronous motor by utilizing a pulse-shake high frequency voltage injection method, processing the extracted position estimation error function, eliminating a second harmonic component introduced due to asymmetric motor parameters, so as to obtain a processed position estimation error function, then establishing a phase-locked loop, and adjusting the phase-locked loop to be 0, thus obtaining estimated rotor speed and estimated rotor position. The method disclosed by the invention can effectively inhibit position estimation second harmonic error caused by the asymmetric motor parameters, and the performance of a control system without a position sensor can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

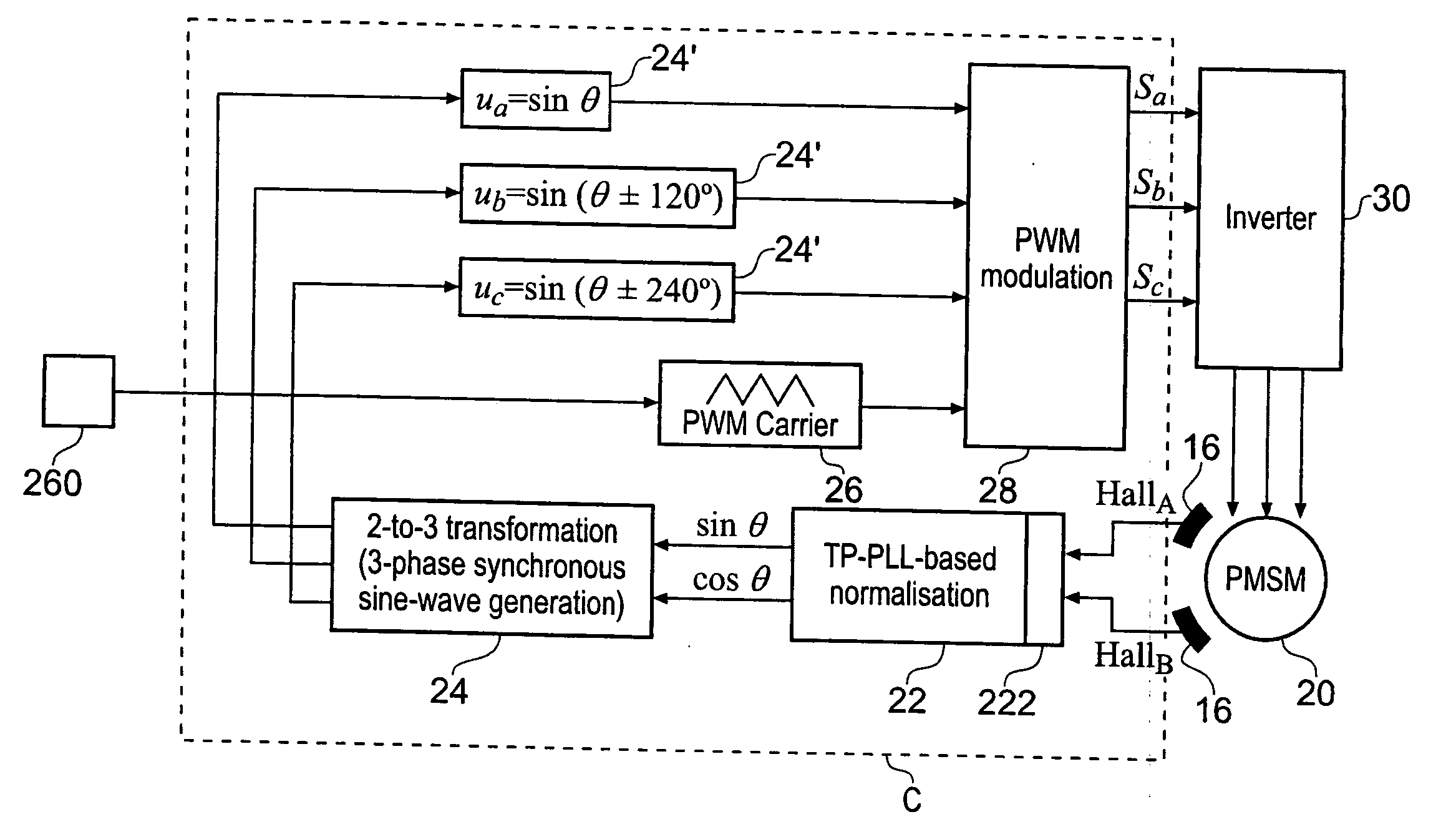

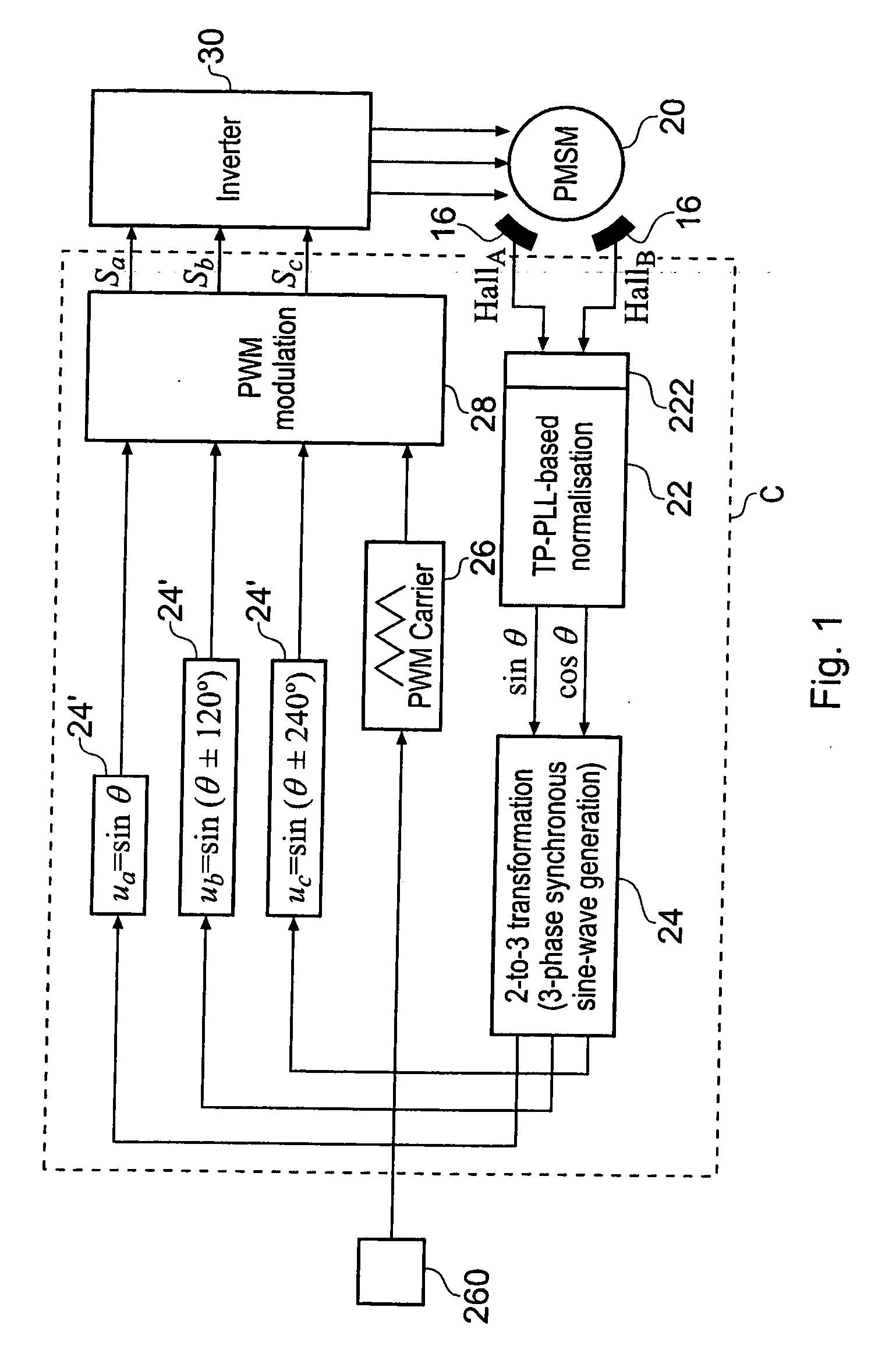

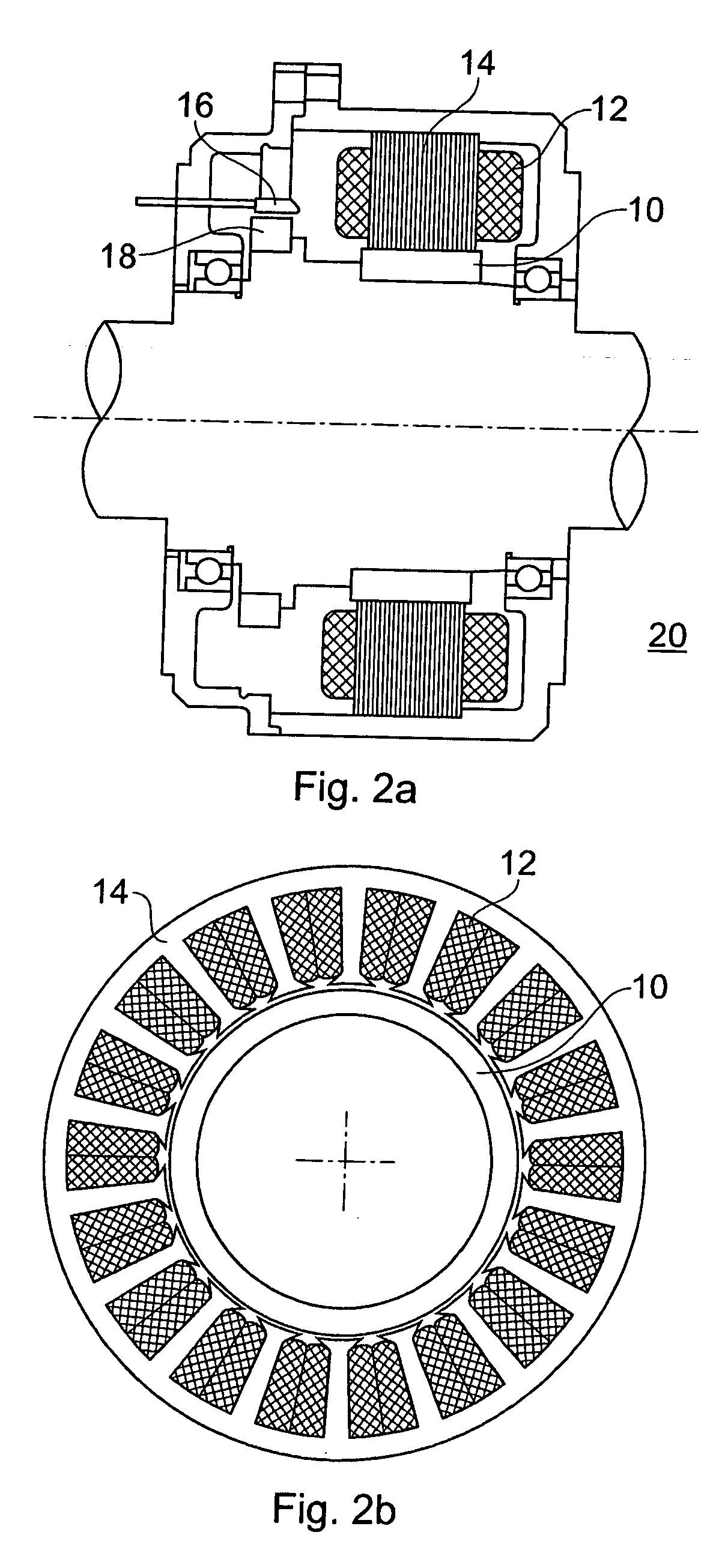

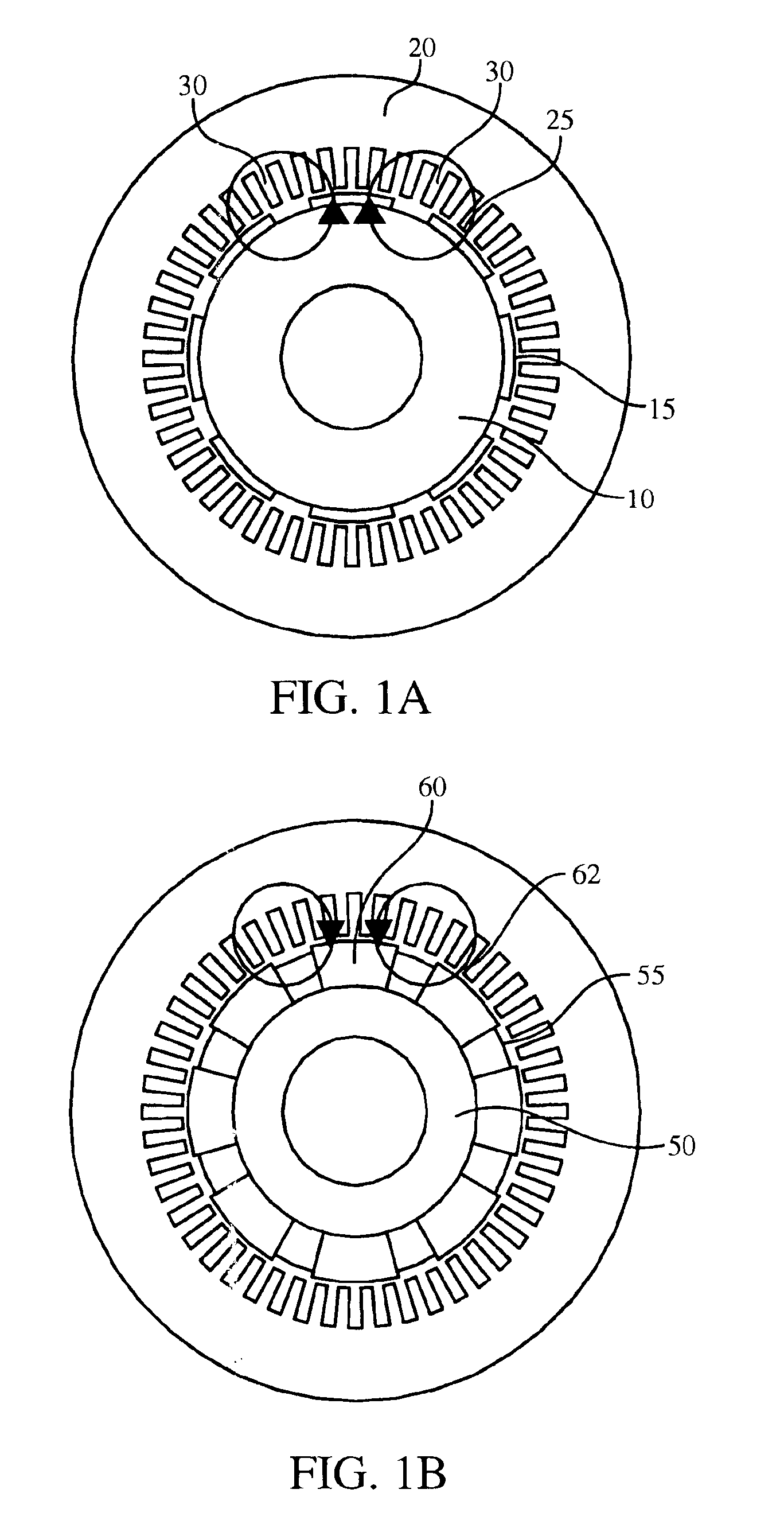

Permanent magnet synchronous motor and controller therefor

InactiveUS20050248306A1Low costReduce impactTorque ripple controlMotor/generator/converter stoppersPhase currentsLoop control

A low-cost sine-wave drive for a 3-phase permanent magnet synchronous AC machines (PMSM) in open-loop control is based on the measurements of two linear Hall sensors. The two Hall sensors are excited by a magnetic ring with the same pole number as the PMSM rotor magnet and sinusoidal flux distributions. The output signals of the Hall sensors are unified through a two-phase-type phase-lock-loop in order to reduce the impact of the sensor mounting non-uniformity during mass production. The peak torque and speed of motor is simply controlled by adjusting the amplitude of pulse-width-modulation carrier. Smooth torque control is achieved due to sinusoidal 3-phase currents. Such a simple sine-wave drive can be achieved with or without the assistance of a micro-controller unit (MCU). No current sensor is required for the motor phase current detection. This motor can be used in industrial applications where there is no strict requirement on torque response and constant speed control of PMSM machines.

Owner:AISIN SEIKI KK

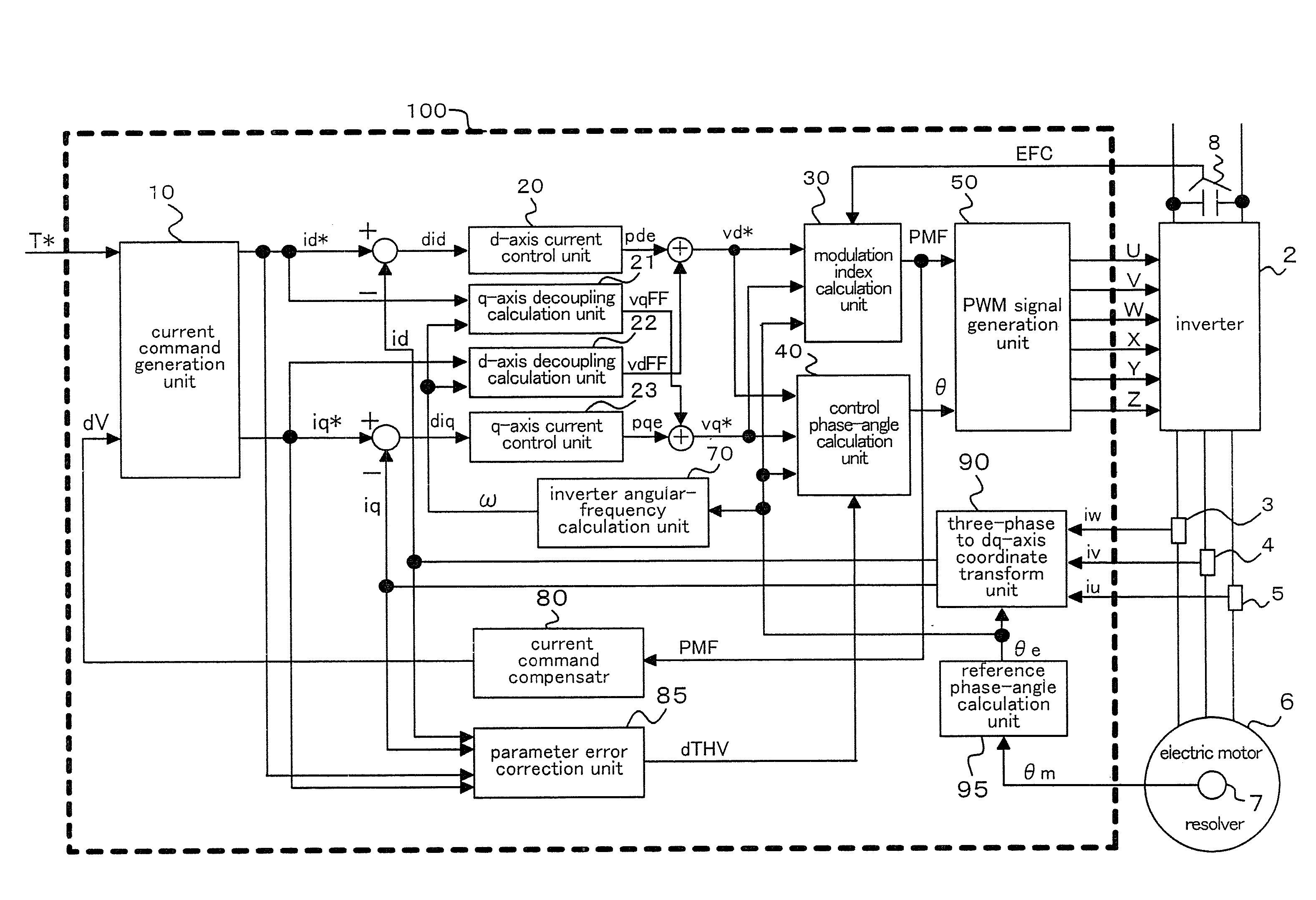

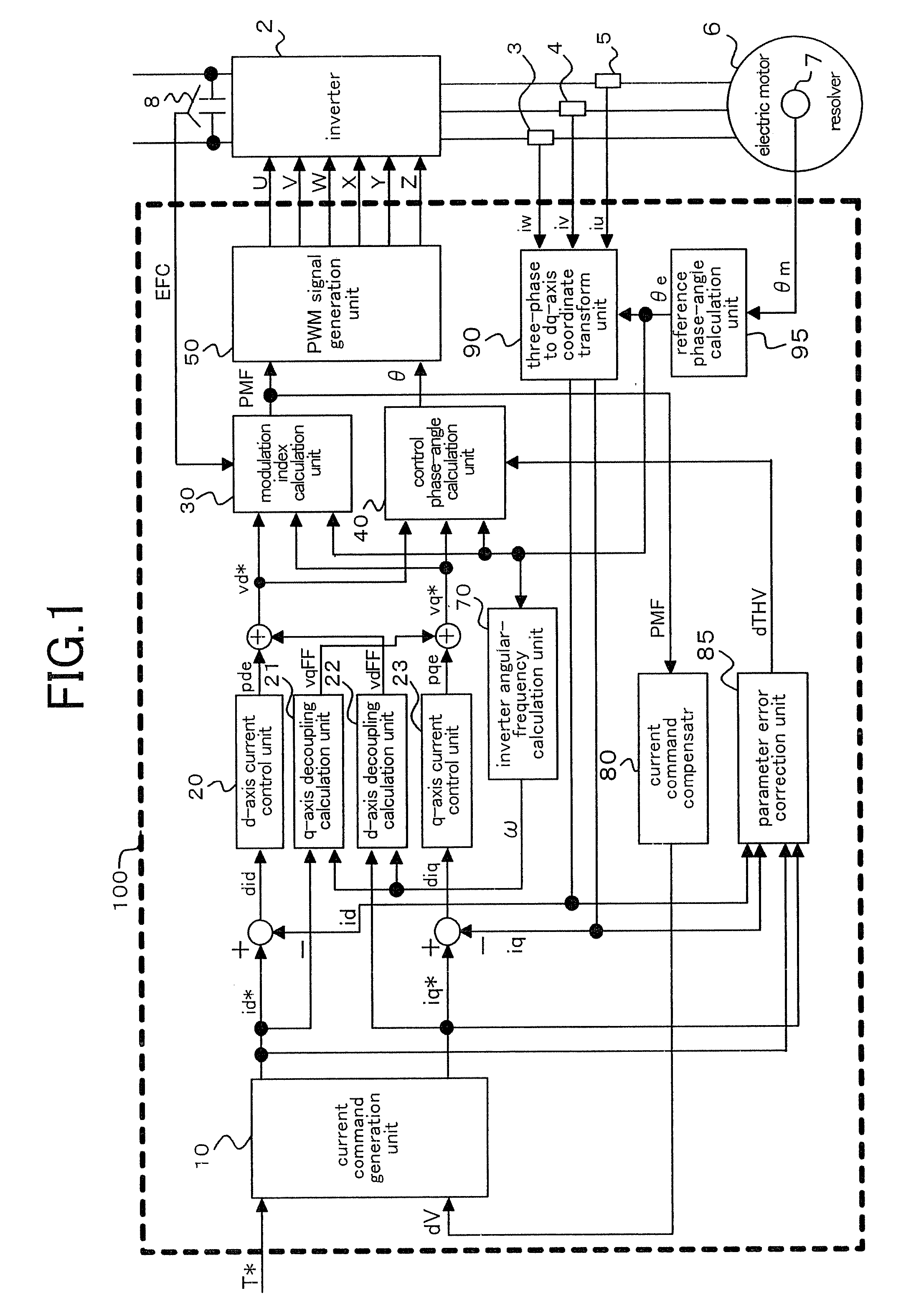

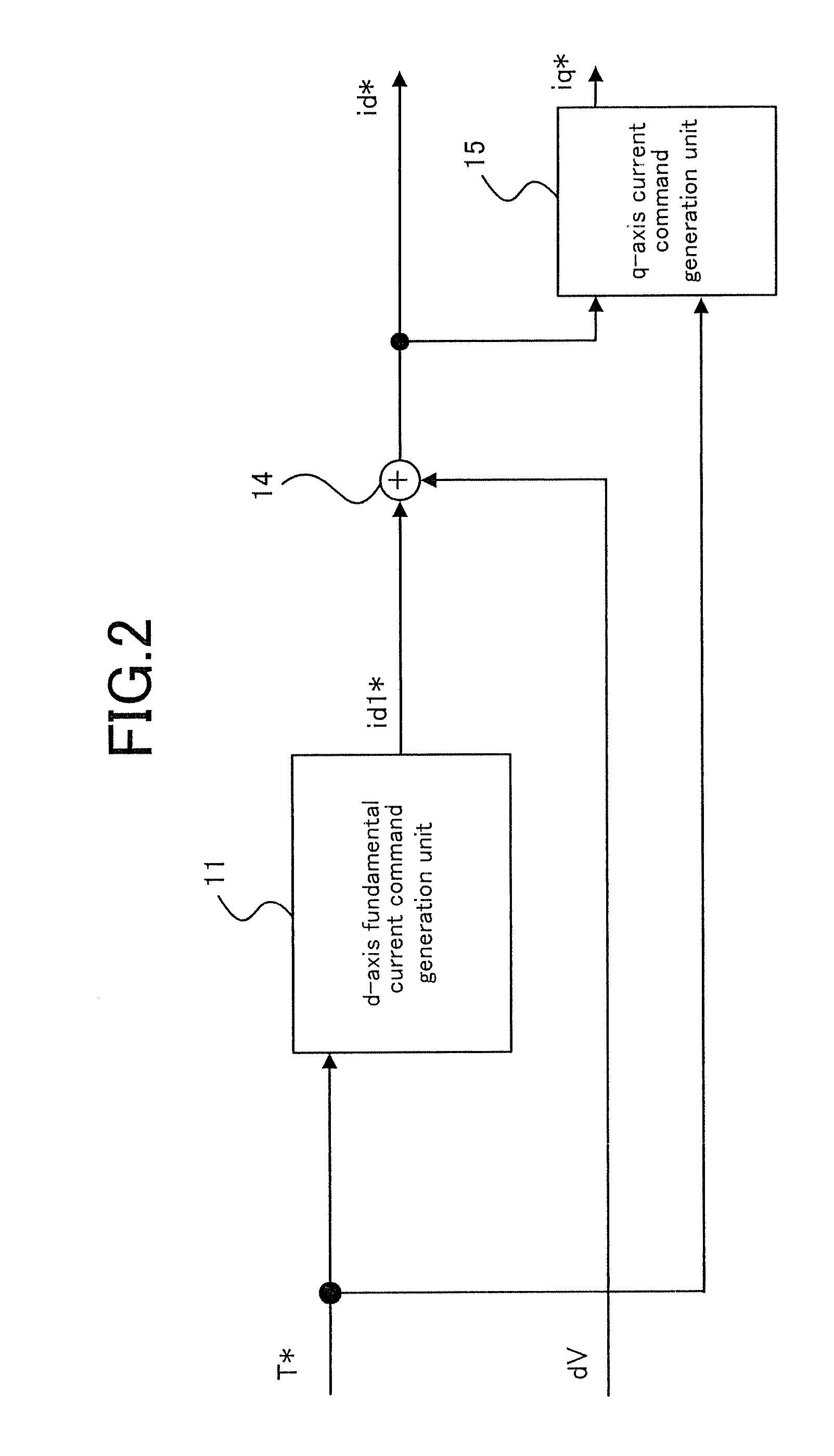

Vector controller for permanent-magnet synchronous electric motor

InactiveUS20100066283A1High speed rangeIncrease rangeDC motor speed/torque controlAC motor controlPermanent magnet synchronous motorPulsed mode

A method of controlling a current command by comparing voltage with a set value needs to vary the set value depending on voltage fluctuation, which involves taking a complicated control. A vector controller for a permanent-magnet synchronous electric motor, according to the present invention, can realize with a simplified configuration a field-weakening operation in a one-pulse mode in a high speed range by providing a current command compensator that corrects a current command by a corrected current command calculated based on a modulation index.

Owner:MITSUBISHI ELECTRIC CORP

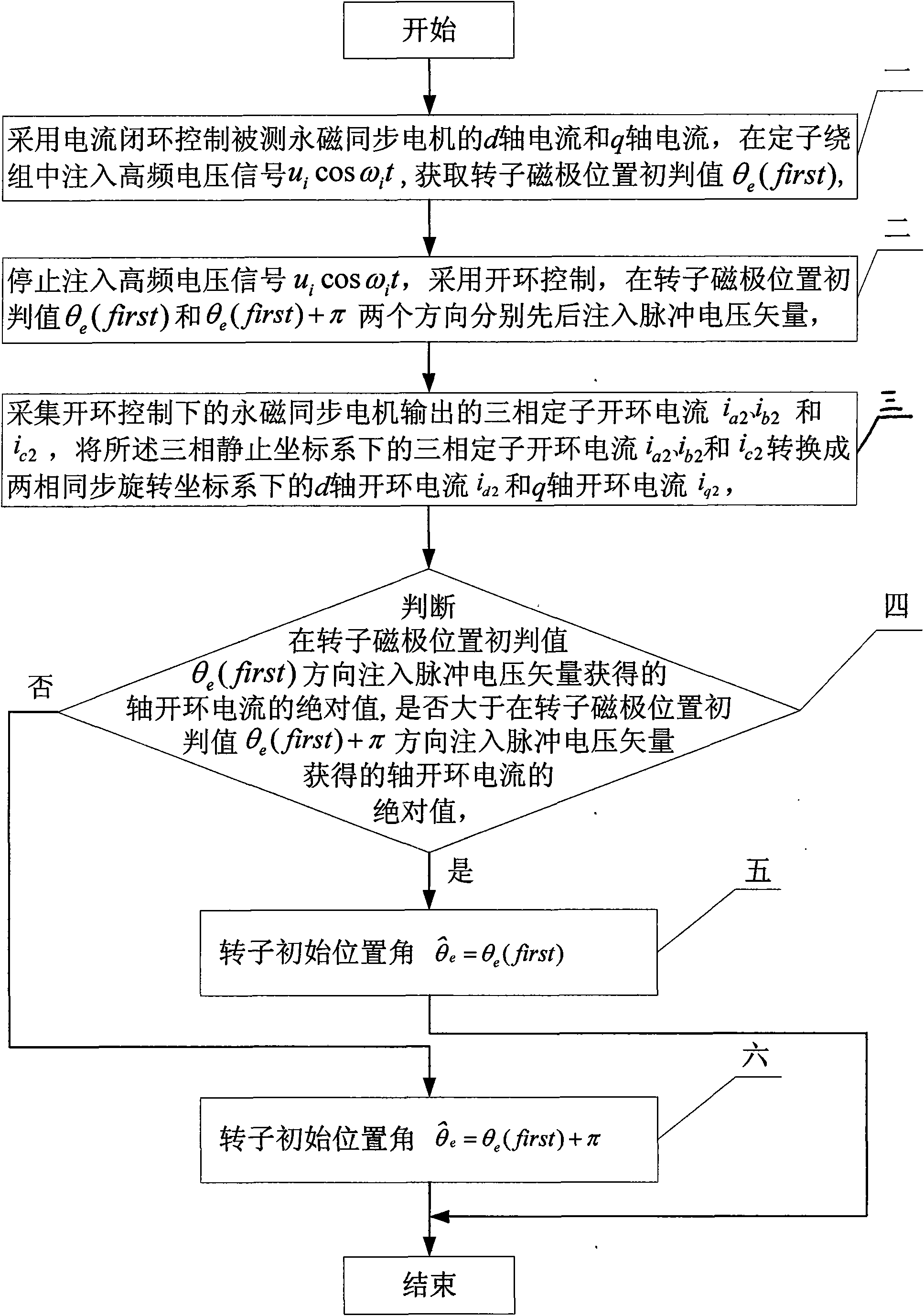

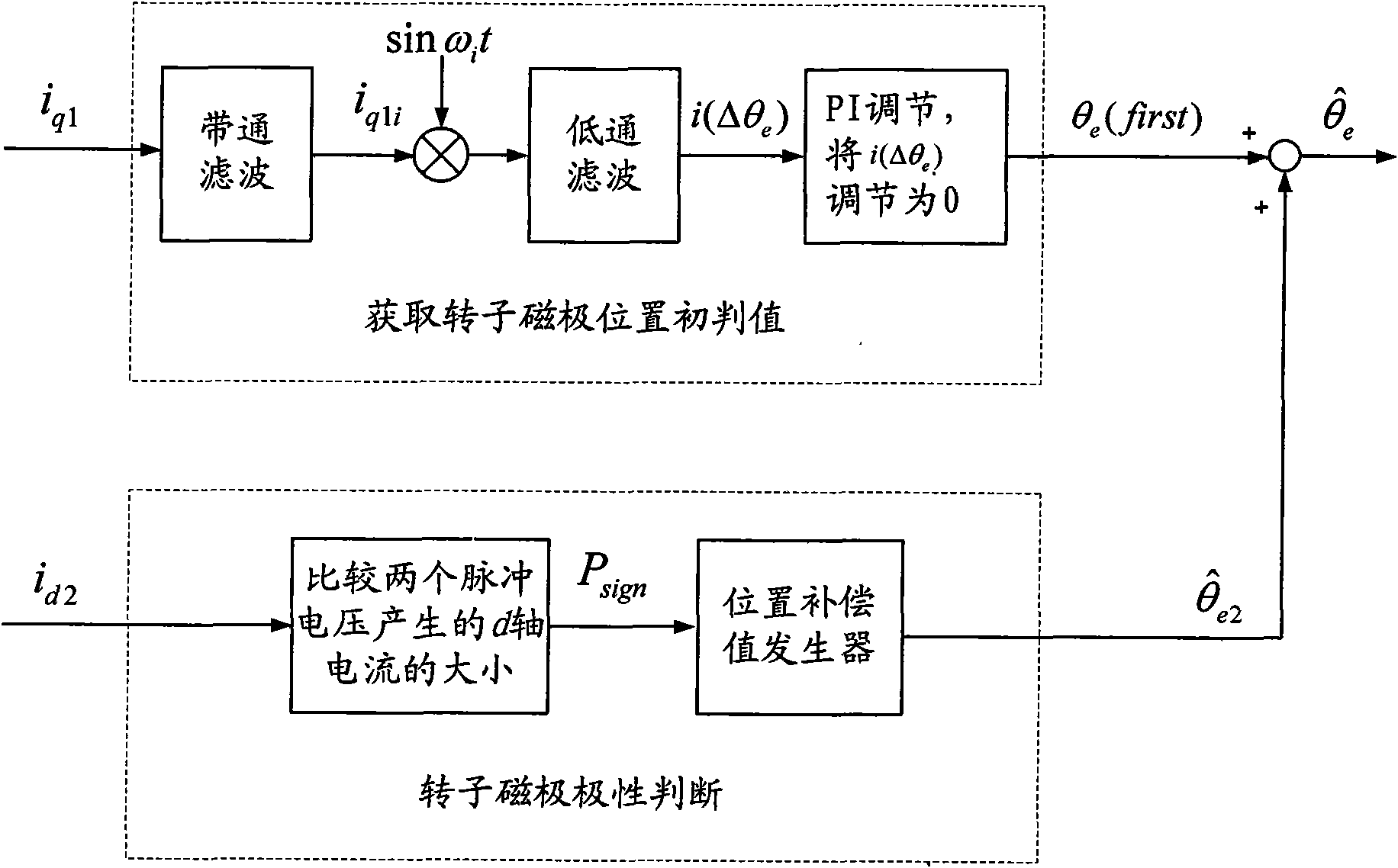

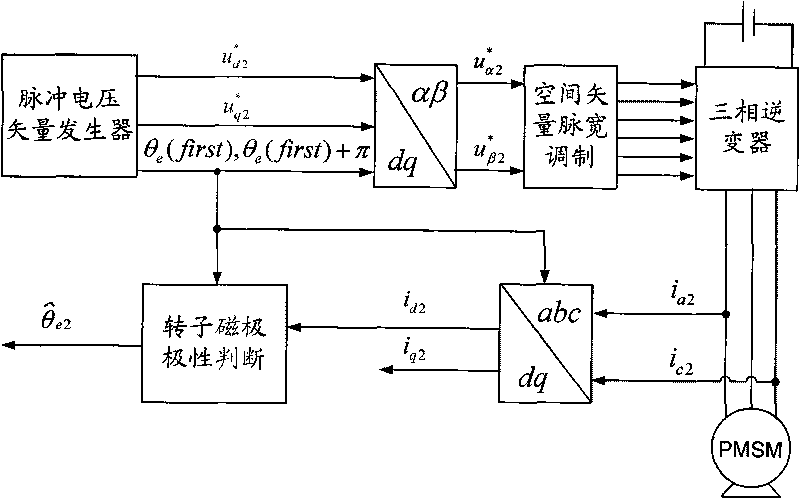

Method for identifying initial position of rotor of permanent magnet synchronous motor of non-position sensor

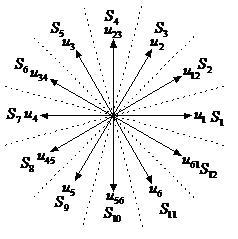

InactiveCN101630938AEfficient identificationSatisfied with the initial position identification accuracyAC motor controlVector control systemsVoltage vectorPosition angle

A method for identifying an initial position of a rotor of a permanent magnet synchronous motor of a non-position sensor belongs to the motor control field, and aims at solving the problems of the traditional method for identifying the initial position of magnetic poles of the rotor such as position change of the rotor, low identification precision or complex algorithm. The method comprises the following steps: maintaining the rotor under a static state during the identification process of the initial position of the rotor, injecting a high-frequency voltage signal to a stator winding, carrying out rotational coordinate conversion on three-phase stator current, and acquiring position information of the magnetic poles of the rotor by current components at q axis to obtain an initial judgment value of the magnetic pole position of the rotor; and then injecting two impulse voltage vectors in opposite directions to the stator winding, judging the polarity of the magnetic poles by comparing size of current components at d axis, and correcting the initial judgment value of the magnetic pole position obtained formerly by the judged polarity information of the magnetic poles to finally obtain an initial position angle of the rotor.

Owner:HARBIN INST OF TECH

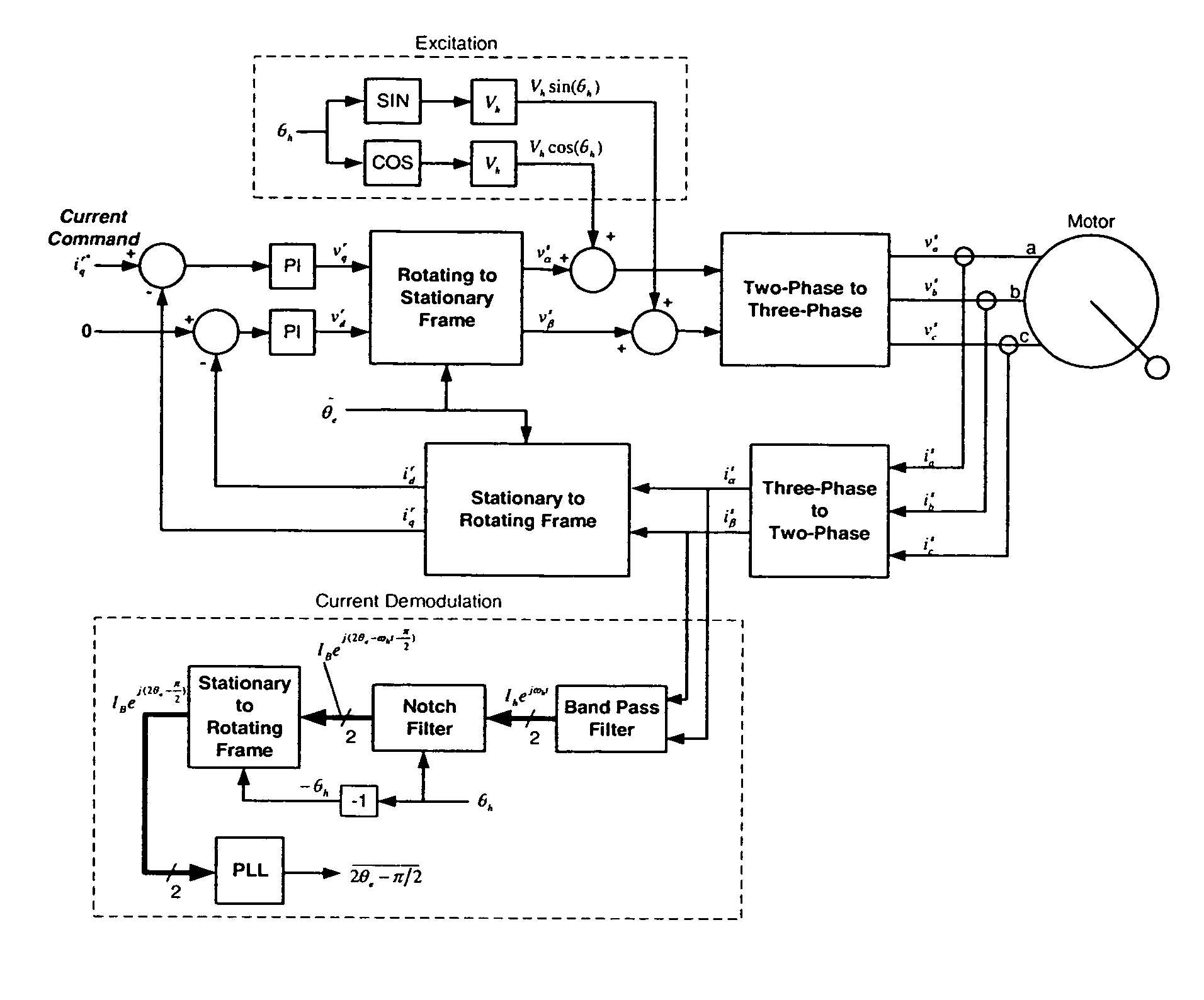

Position sensorless drive for permanent magnet synchronous motors

ActiveUS20050151502A1AC motor controlSynchronous motors startersLow speedPermanent magnet synchronous motor

A sensorless motor control algorithm that single-handedly permits operation over the entire speed range from low speed to high speed. This “fusion” algorithm seamlessly fuses the position data generated respectively by high speed and low speed sensorless algorithms. The resulting sensorless drive permits effective position sensorless operation over the entire speed range of a PM motor.

Owner:INFINEON TECH AMERICAS CORP

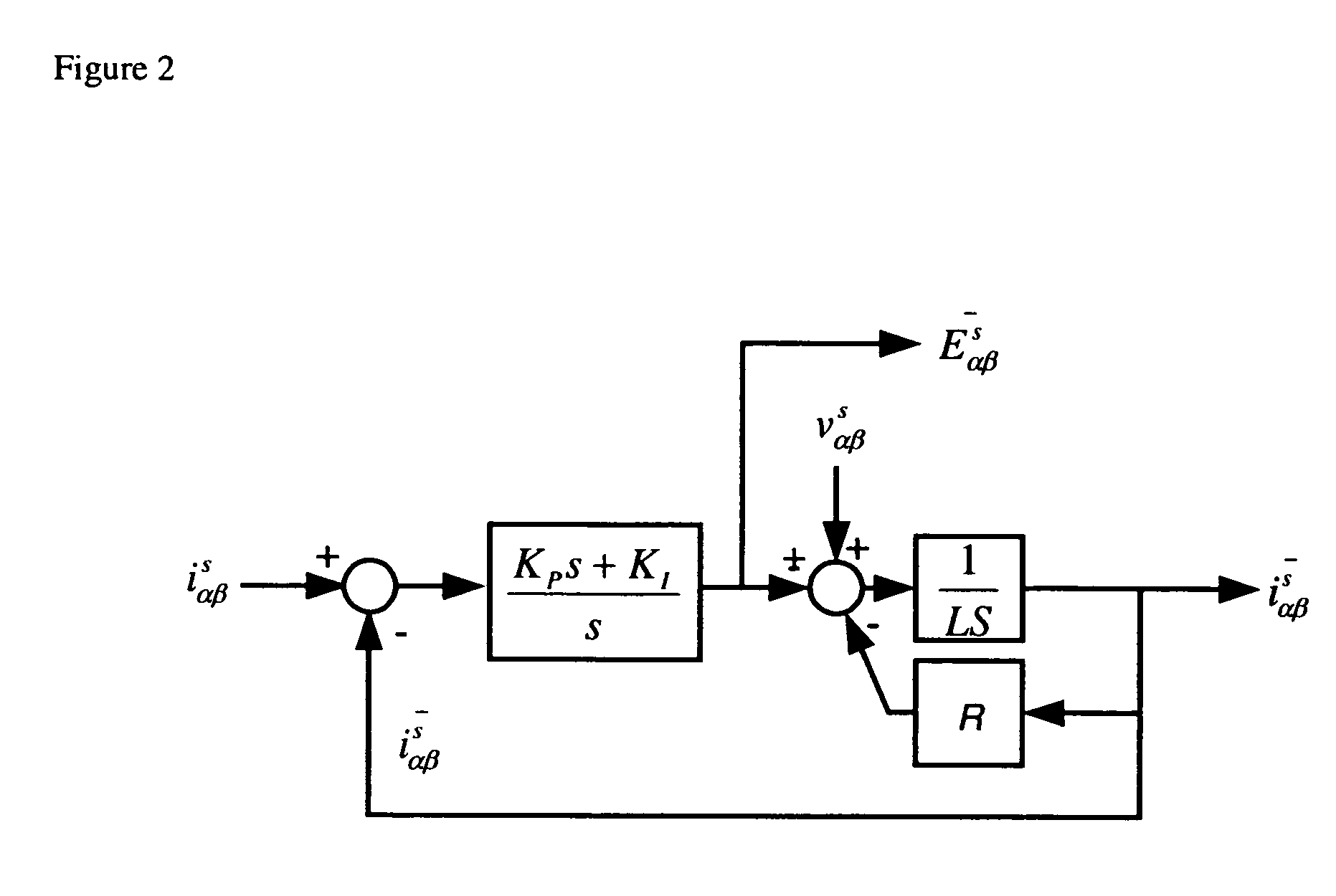

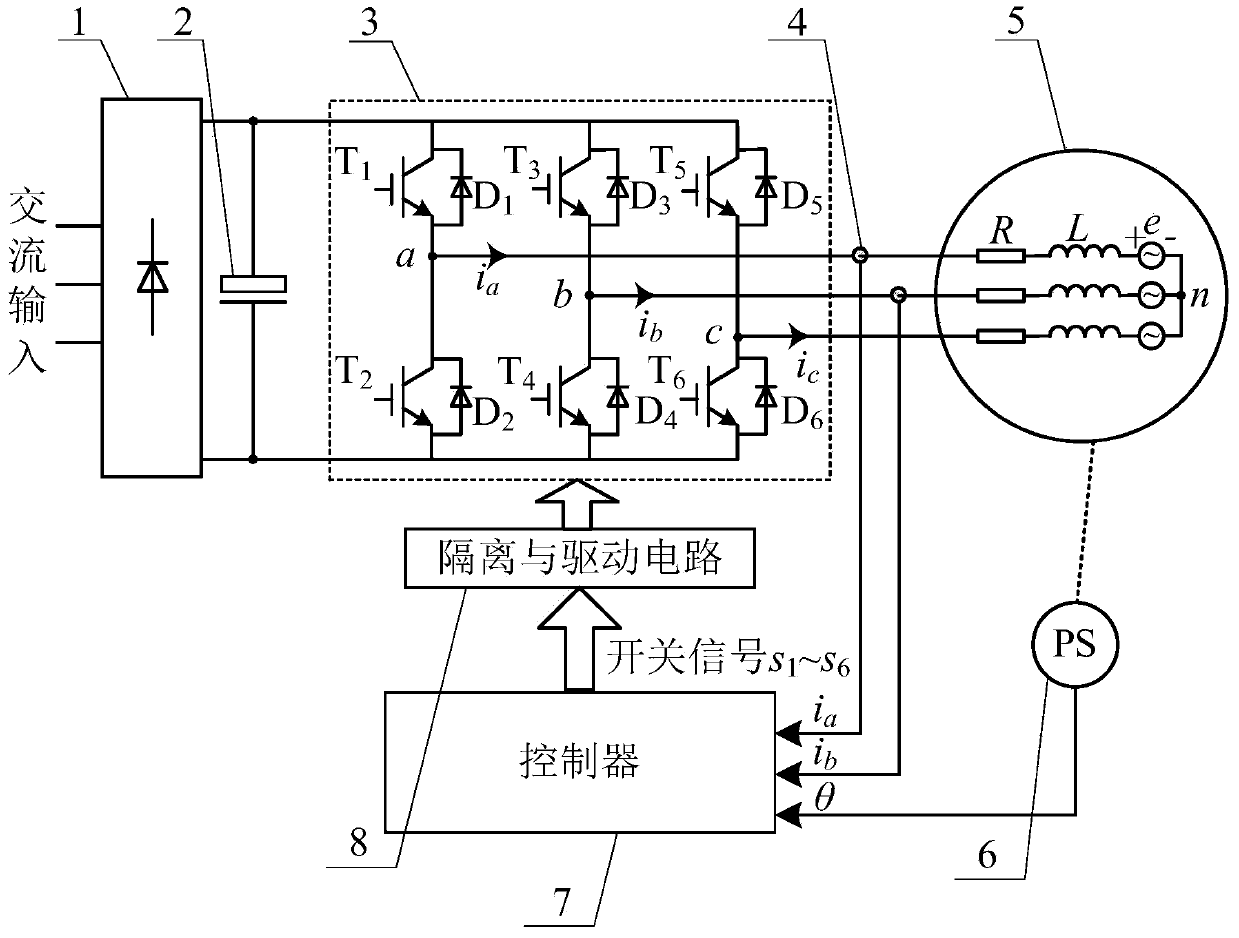

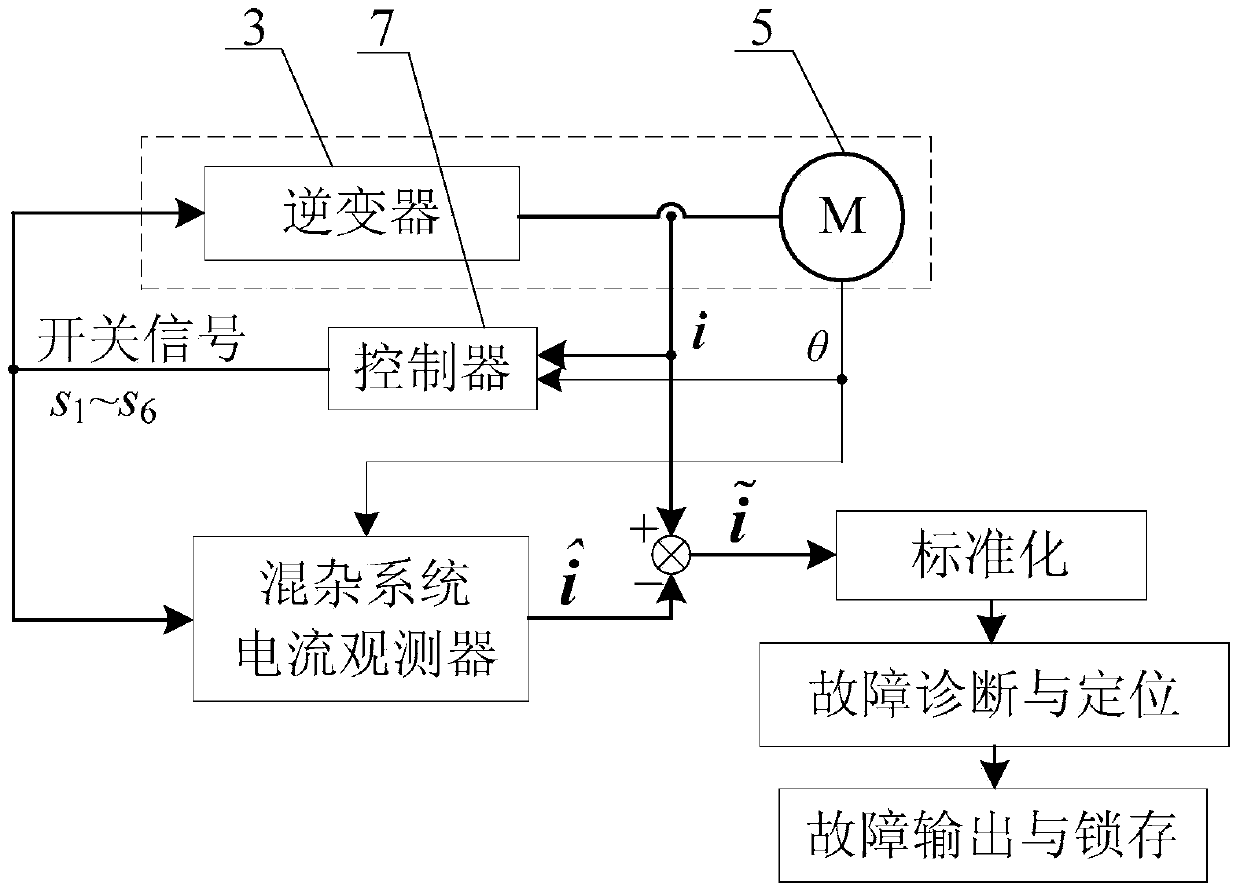

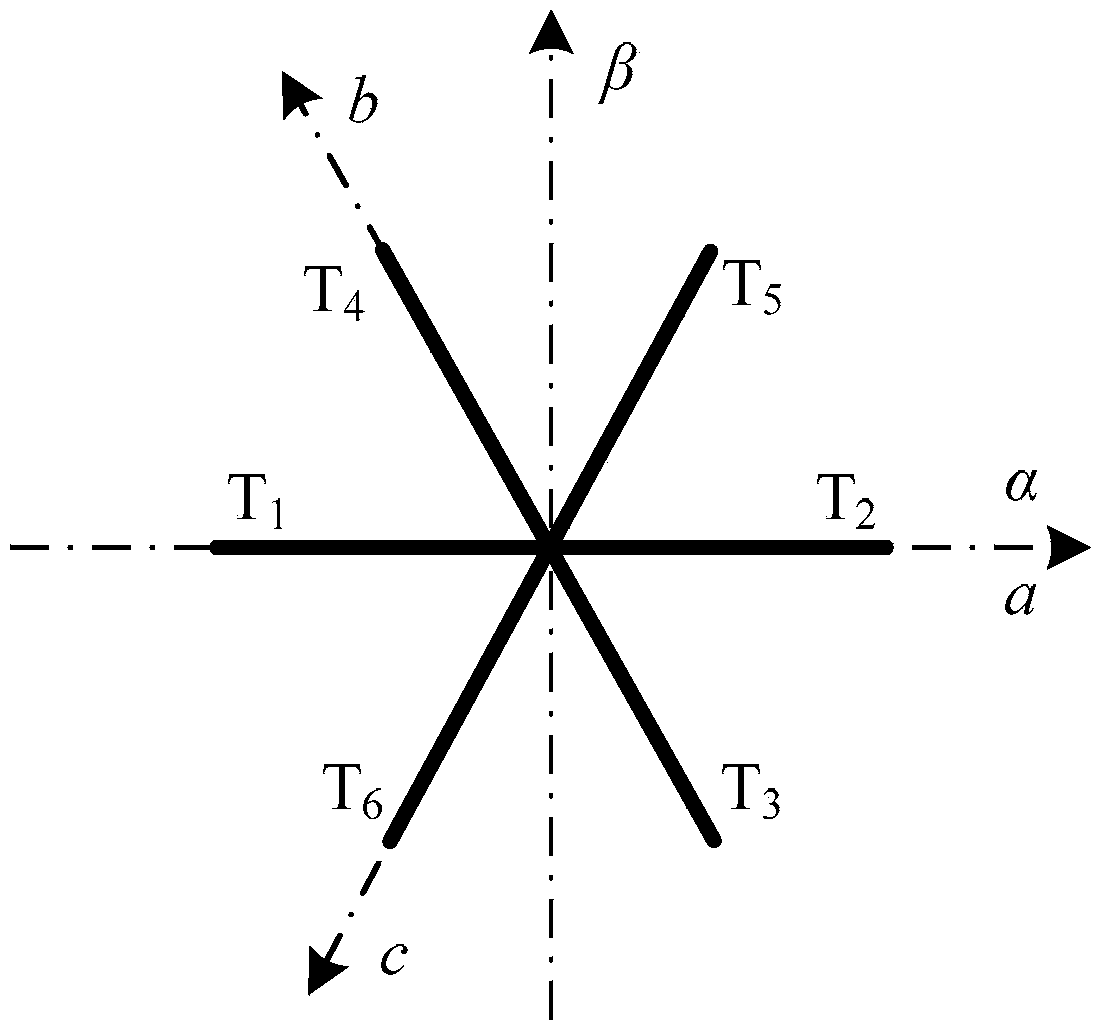

Current-magnitude-based open-circuit failure online-diagnosis method for power tube of inverter

InactiveCN103701394AImprove robustnessElectronic commutation motor controlVector control systemsObservational errorLoop control

The invention discloses a current-magnitude-based open-circuit failure online-diagnosis method for a power tube of an inverter, belongs to the field of motor control, and aims to solve the problem of poor robustness of a current-magnitude-based open-circuit failure diagnosis technology for the power tube of the inverter. The method comprises the following steps of establishing a current observer model of a permanent magnet synchronous motor driving system in a failure-free state, comparing an observed current value with detection current to obtain a three-phase current residual, converting the three-phase current residual to a two-phase coordinate system in a coordinate conversion way to obtain a current residual vector, standardizing the current residual vector, and diagnosing and positioning an open-circuit failure of the power tube of the inverter according to the amplitude and the phase of the standardized current residual vector. The current-magnitude-based open-circuit failure online-diagnosis method for the power tube of the inverter is free of influence of a system closed-loop control algorithm and insensitive to loads, and has higher robustness to parameter errors, measurement errors, system disturbance and the like.

Owner:HARBIN INST OF TECH

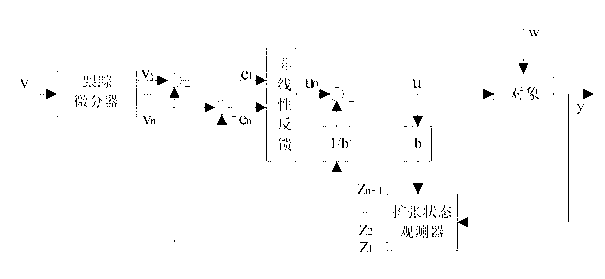

Permanent magnet synchronous motor (PMSM) servo system control method based on fuzzy and active disturbance rejection control

InactiveCN103401501AWide speed rangeImprove robustnessElectronic commutation motor controlAC motor controlDifferential coefficientFriction torque

The invention relates to a PMSM servo system control method based on fuzzy and active disturbance rejection control. A position signal is given by a differential tracker to arrange a transition process so that the contradiction between rapidness and overshoot of a system is solved, and uncertainty, friction torques and external disturbance due to modeling errors of the system are observed via an expansion state observer; according to the error between the differentials generated by the differential tracker and state variation generated by the expansion state observer, a fuzzy inference rule is obtained with application of experimental experience of technical staff, so that a fuzzy rule control table of an error proportion coefficient, a differential coefficient and an integration coefficient is established; accurate control amount is obtained after de-fuzzification, so that parameter self-adaptive adjustment of a nonlinear error feedback control law is realized; and compensation amounts of the nonlinear error feedback control law and the expansion state observer to the total disturbance forms the control amount, thereby realizing optimal control for an controlled object. The method of the invention improves both tracking precision and disturbance rejection capability of the system.

Owner:HUNAN UNIV

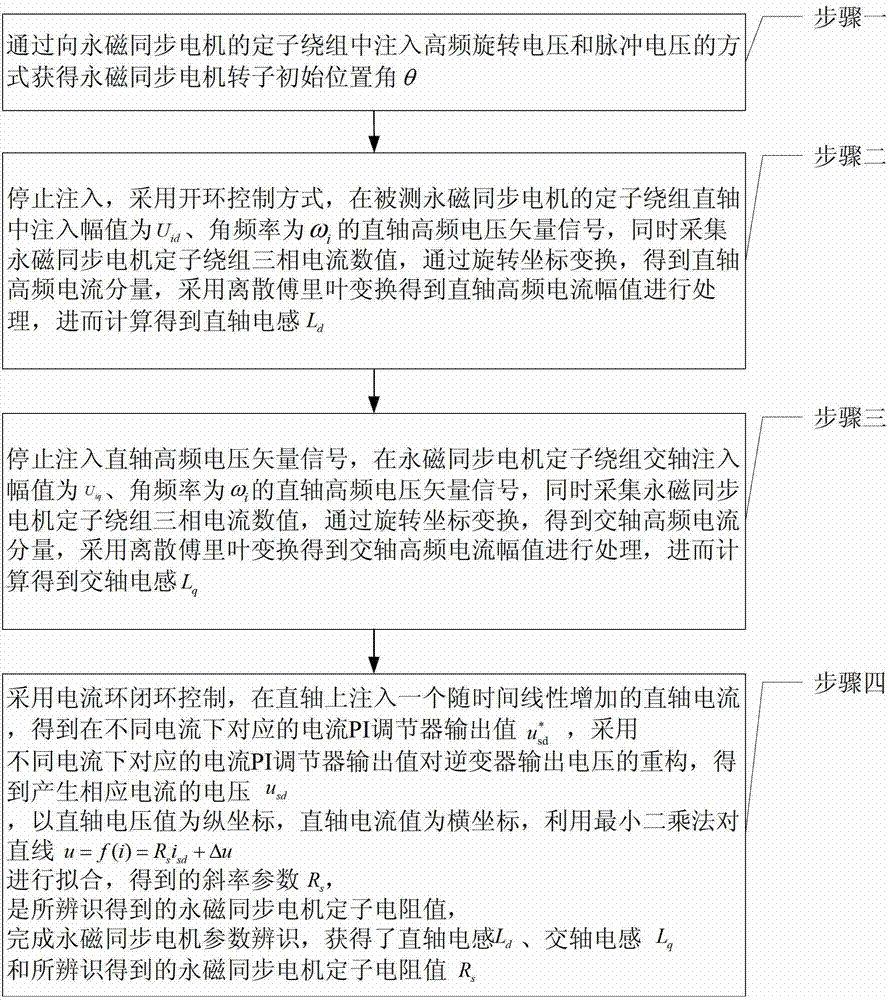

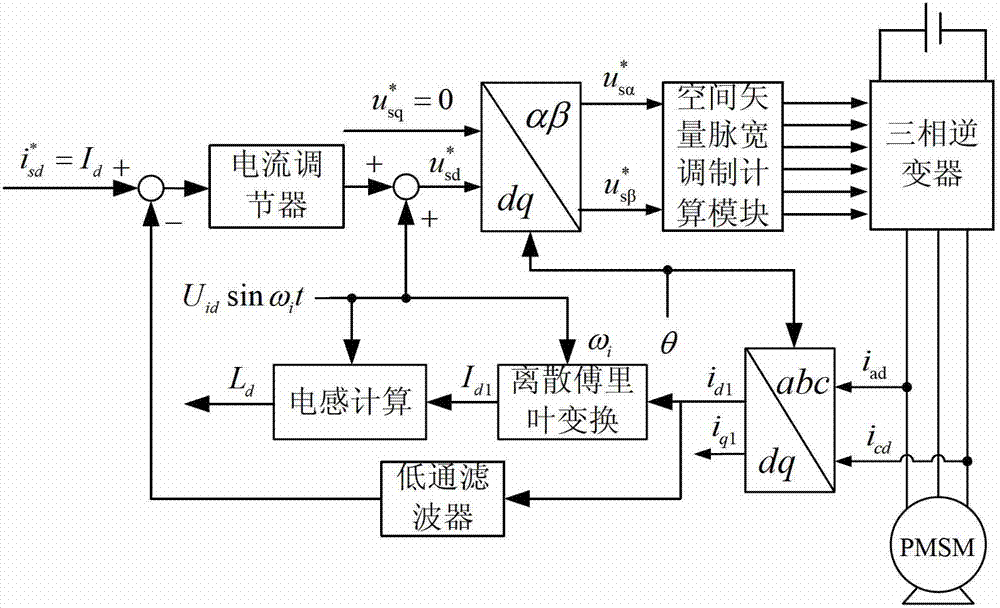

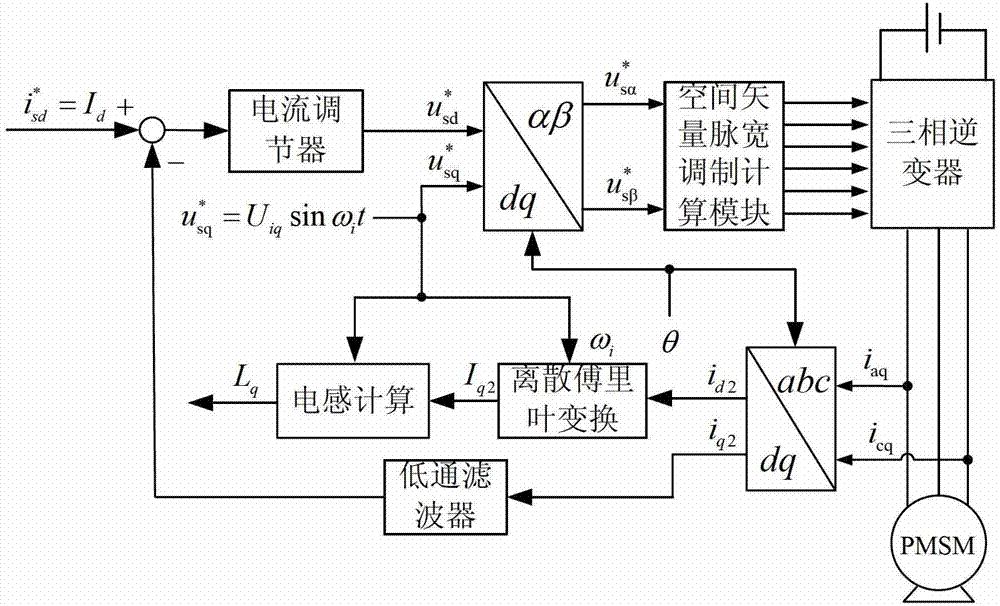

Parameter offline identification method for permanent magnet synchronous motor under condition of rest

InactiveCN103178769AImprove consistencyEliminate the effects ofElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a parameter offline identification method for a permanent magnet synchronous motor under the condition of rest, belonging to the field of motor control and solving the problems of rotor external locking, overlong identification time, poor result consistency, poor practicability and the like of the existing parameter offline identification method for the permanent magnet synchronous motor under the condition of rest. The parameter offline identification method comprises the steps of: always keeping a rotor in a rest state, injecting a high-frequency voltage signal in a straight axis of a rotor winding, detecting a three-phase stator current and transforming into two-phase rotational coordinates, carrying out discrete Fourier transform on the current to obtain a straight axis high-frequency current amplitude so as to obtain a straight-axis inductance value through calculation; then injecting a high-frequency voltage signal in a quadrature axis of the stator winding, obtaining a quadrature axis inductance value by using the same method; and then introducing a linearly increasing current into the straight axis of the stator winding so as to obtain a voltage generating a corresponding current through reconstruction of a voltage of an inverter, calculating and fitting a straight slope by using a least square method by using a straight axis voltage value as a longitudinal coordinate and a straight axis current value as a transverse coordinate, and finally obtaining a slope value, wherein the slope value is a stator resistance value.

Owner:HARBIN INST OF TECH

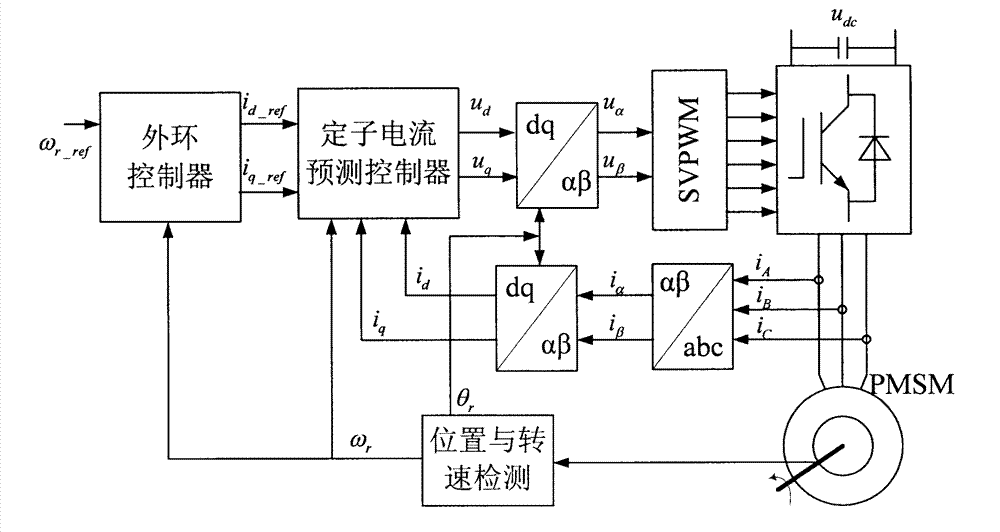

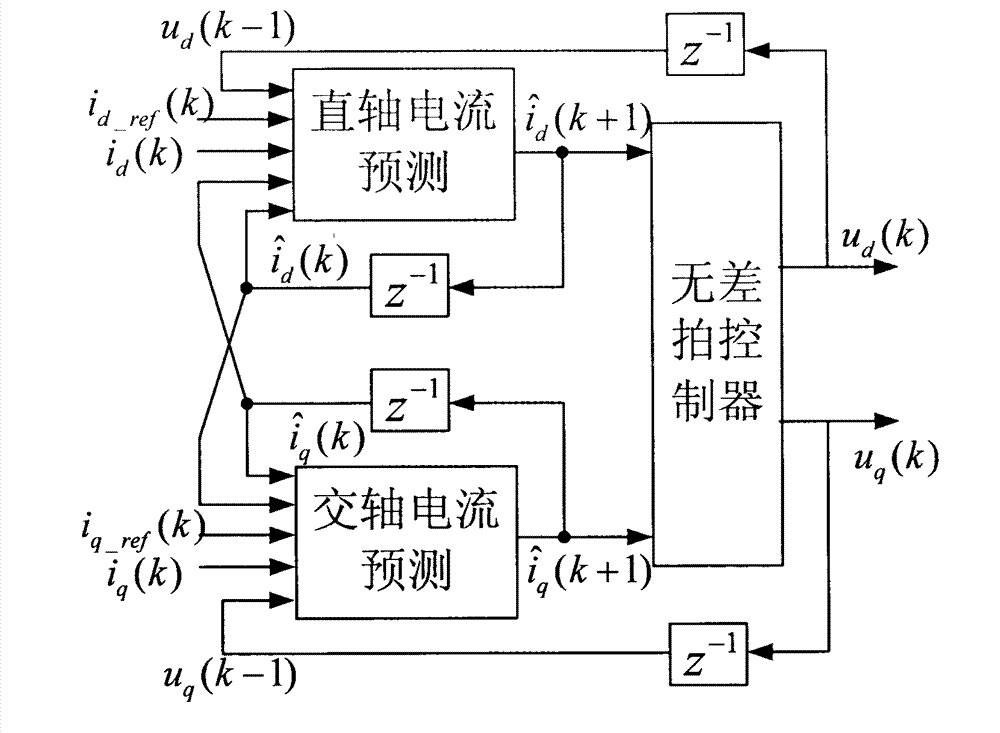

Current predictive control method of permanent magnet synchronous motor

InactiveCN102904520AFast startShorten the timeElectronic commutation motor controlAC motor controlStator voltageControl signal

The invention relates to a current predictive control method of a permanent magnet synchronous motor, which belongs to the electric control field. The dynamic response speed and the control accuracy for the stator current control of the permanent magnet synchronous motor are improved through stator current prediction and deadbeat control, and the system delaying is compensated, so that the noise and the torque ripple of the motor in operation are reduced. The method comprises the steps as follows: obtaining a three phase stator current signal, and the electrical angle and the electrical angular speed of the motor rotor through the technologies of sensor sampling and a photoelectric coded disc or position sensorless detection; carrying out Clarke transformation and Park transformation on the stator current signal to obtain the stator current in a synchronous revolution dq coordinate system; substituting the obtained stator current signal in the dq coordinate system into a control equation of a current predictive controller of the permanent magnet synchronous motor, carrying out deadbeat control according to the given value of the obtained stator current in the dq coordinate system in an outer ring controller to obtain a stator voltage vector in the dq coordinate system; carrying out Park inverse transformation on the obtained stator voltage vector in the dq coordinate system, to obtain a pulse-width modulation (PWM) control signal of an inverter by a space vector pulse width modulation (SVPWM) method, controlling the stator current through the inverter, and then implementing the current predictive control over the permanent magnet synchronous motor.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

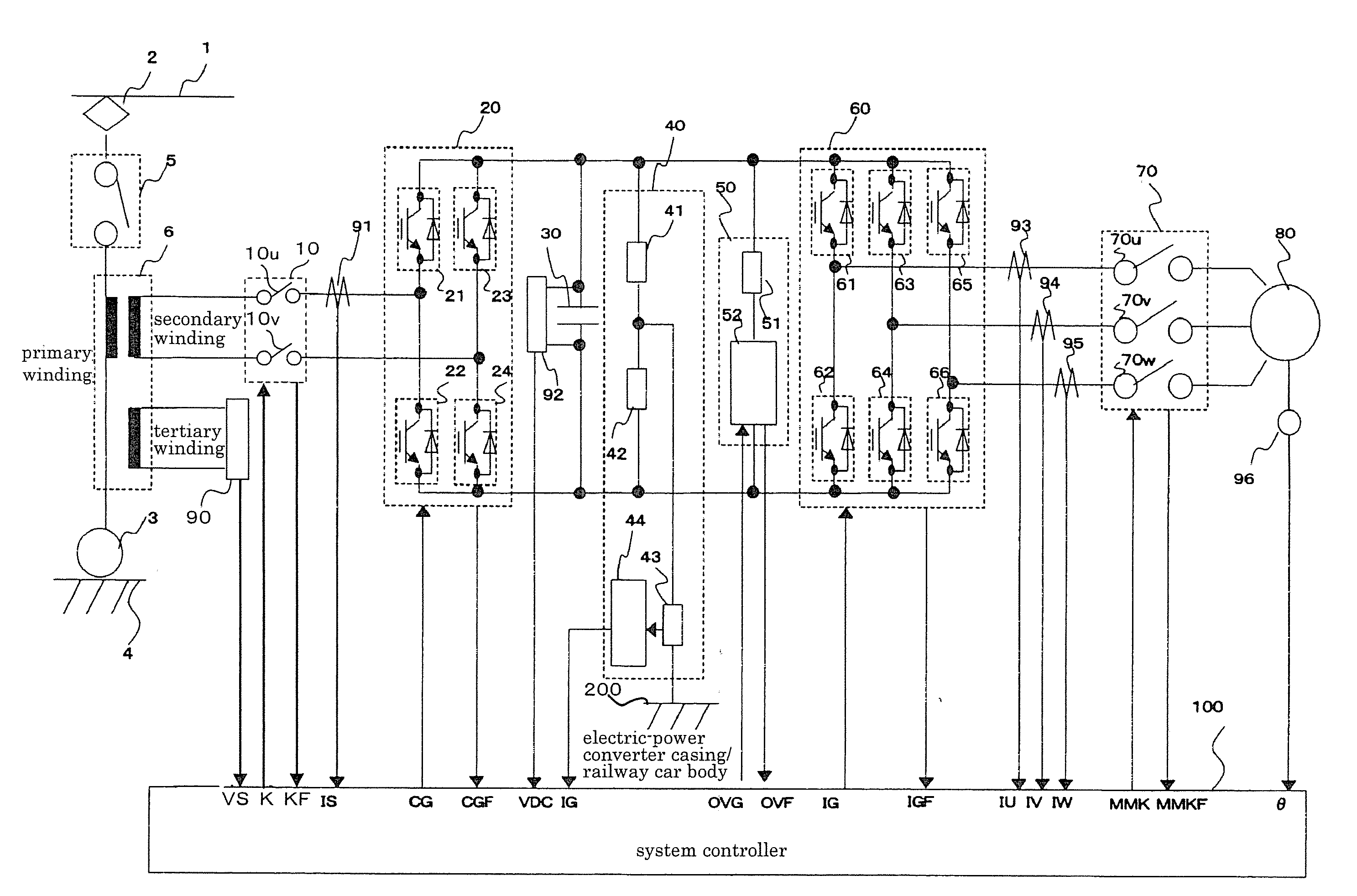

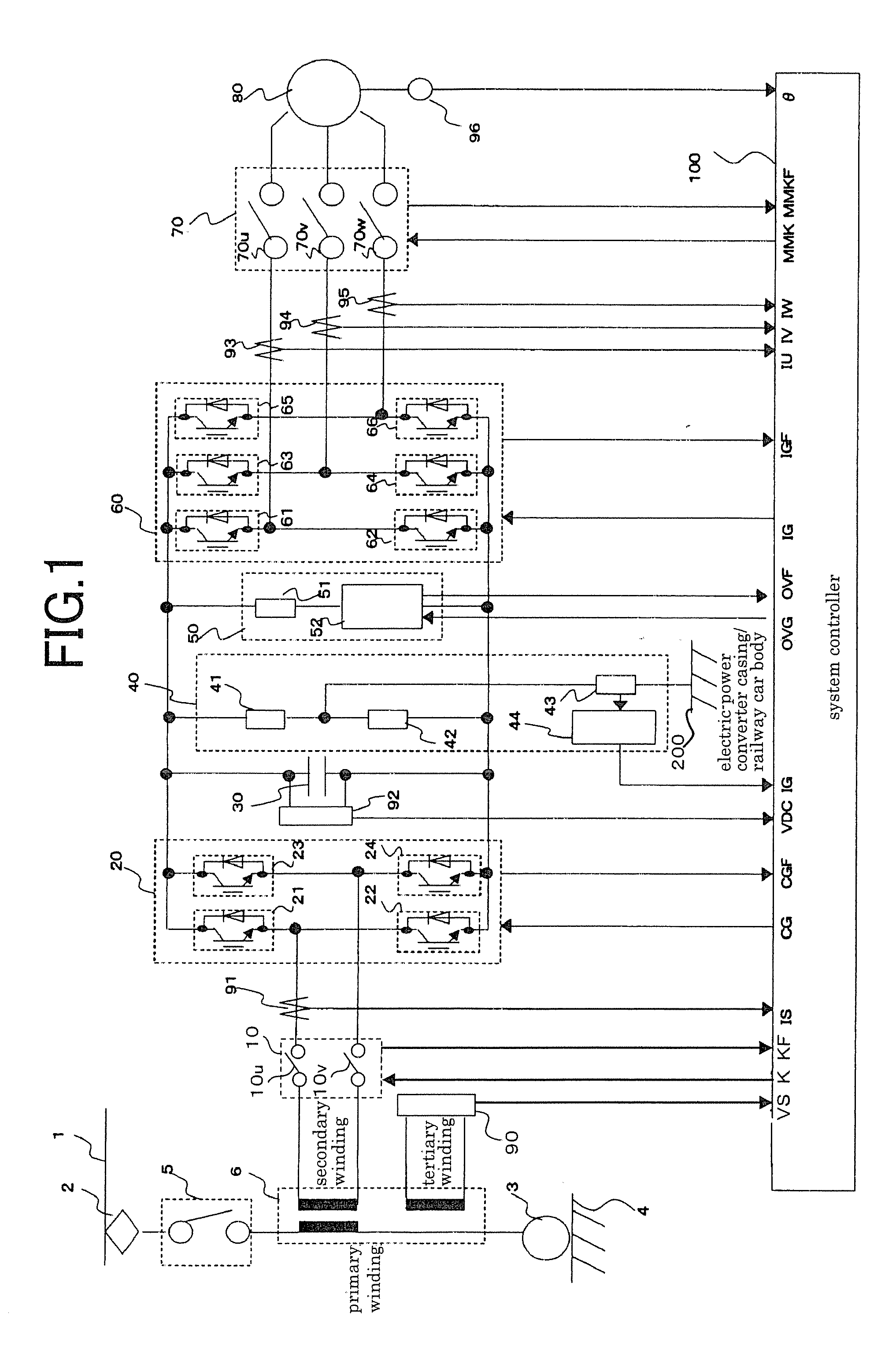

Electric power converter

InactiveUS20100079093A1Reliable protective operationGuaranteed uptimeAC motor controlSynchronous motors startersSynchronous motorPermanent magnet synchronous motor

Specific anomalies and details of failures as well as measures thereagainst are described that might possibly occur in electric power converters that drive and control permanent-magnet synchronous motors. An electric power converter capable of stable operation has a protective function of taking proper measures against such failures that might possibly occur.

Owner:MITSUBISHI ELECTRIC CORP

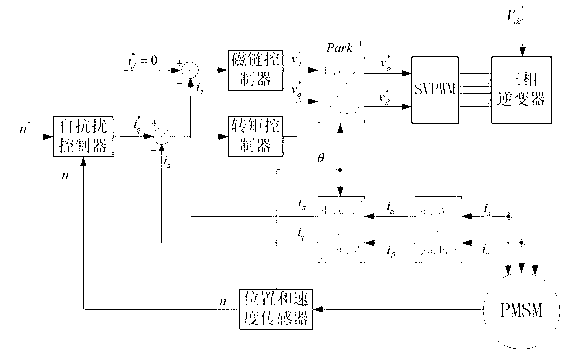

Method and device for controlling speed of permanent-magnet synchronous motor

ActiveCN103312255ASpeed control without overshootImprove anti-disturbance abilityElectronic commutation motor controlAC motor controlSynchronous motorDifferentiator

The invention discloses a method and a device for controlling speed of a permanent-magnet synchronous motor. The method includes that an active-disturbance-rejection control technology is adopted for a speed ring, speed setting and a speed detection value are taken as input of a first-order active-disturbance-rejection controller, a tracking differentiator reasonably arranges a transition process, an extended state observer observes an actual value of rotating speed of the motor, estimates total disturbance of a system and acquires output of the speed ring through a nonlinear state error feedback control ratio, a load torque observer is designed through detection values of a current and the speed, and observed load torque through output of a feedforward controller and the active-disturbance-rejection controller is taken as reference input of a quadrature-axis current. The method carries forward characteristics of overshoot freeness, high disturbance rejection capacity, good robustness and the like of the permanent-magnet synchronous motor in speed control in the active-disturbance-rejection control technology, and compensation is performed on the problem of load disturbance, so that the problem of fluctuation of the rotating speed under the circumstance of load disturbance is improved.

Owner:SHANDONG UNIV

Sine DC variable frequency air conditioner controller and its control method

ActiveCN101464032AGuaranteed uptimeImprove efficiencyAC motor controlVector control systemsLow noisePermanent magnet synchronous motor

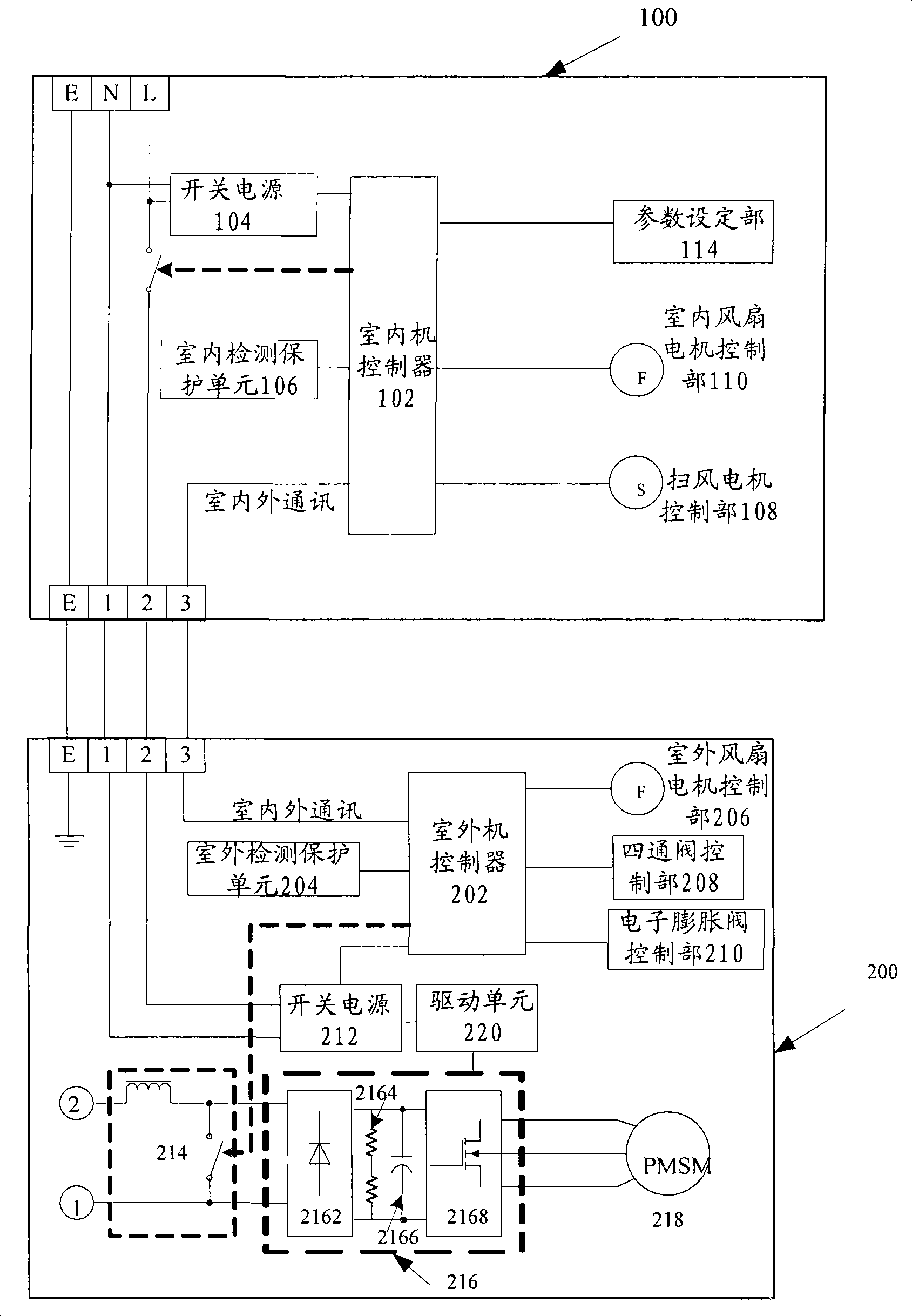

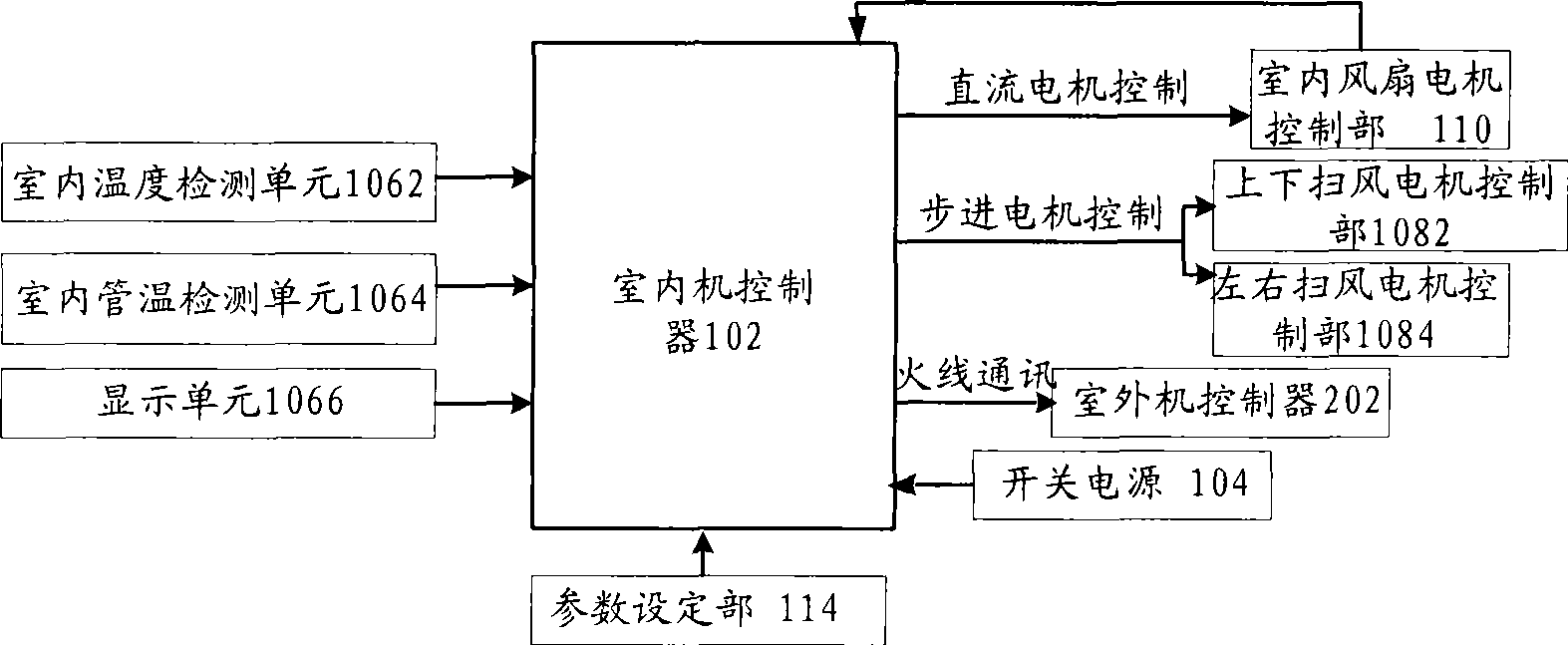

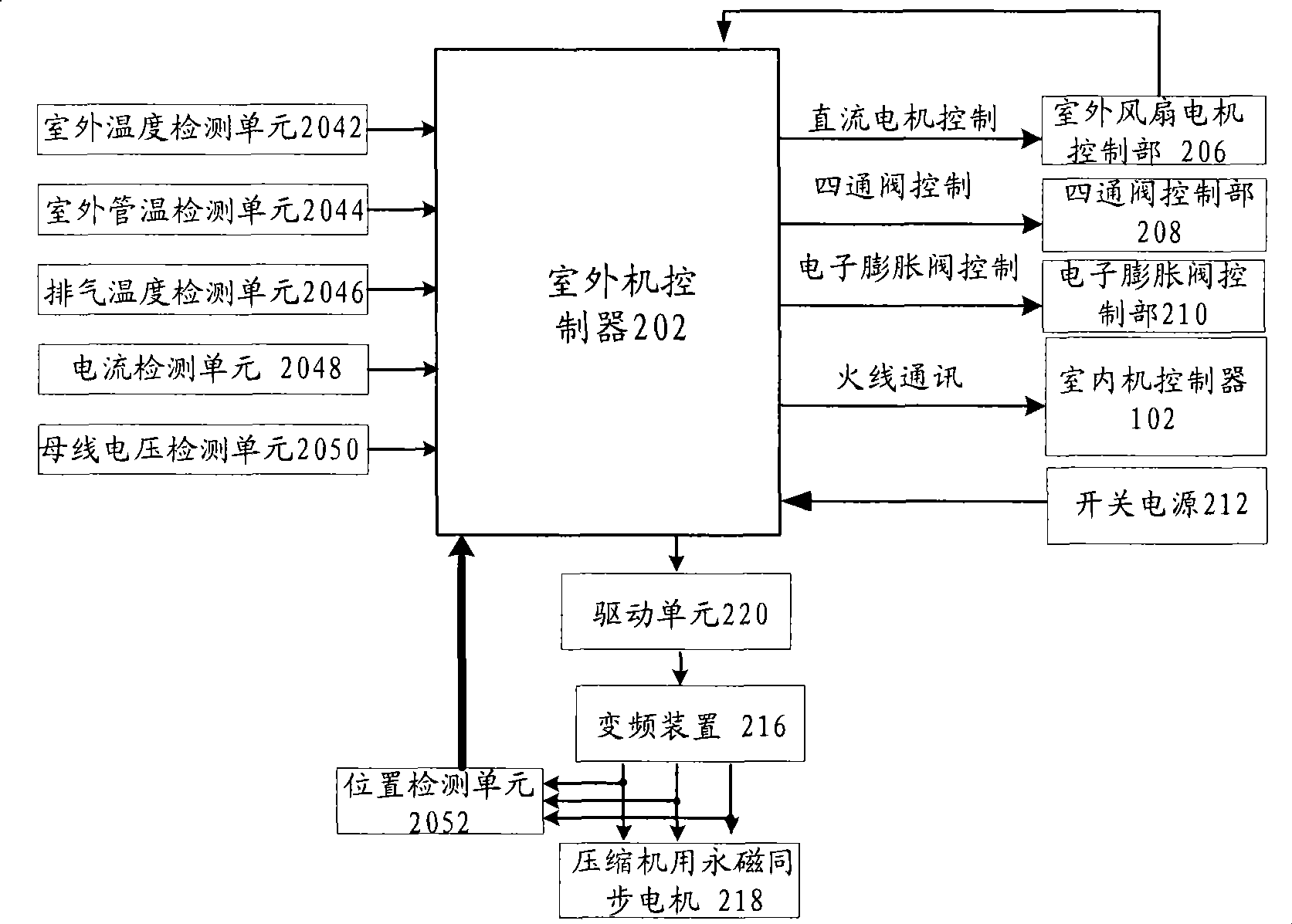

The invention provides a controller of a DC inverter air conditioner. The controller comprises a controller part 100 of an indoor unit and the controller part 200 of an outdoor unit. The controller part 100 of the indoor unit comprises an indoor unit controller 102 which comprises a single-chip microcomputer circuit, a parameter setting part 114 and an indoor detection and protection unit 106. The controller part 200 of the outdoor unit comprises an outdoor unit controller 202 which is connected with the indoor unit controller 102 through a live wire communication circuit, an outdoor detection and protection unit 204, a PFC device 214, a switch power supply 212, a drive unit 220 and an inverter 216 of a permanent magnet synchronous motor 218 for driving a compressor. The invention also provides a method for utilizing the controller of the air conditioner to control the operation of the compressor. The rapid refrigeration / heating ability of an air-conditioning system can be realized through the technical scheme, thereby having the advantages of low temperature fluctuation, energy conservation and low noise.

Owner:GREE ELECTRIC APPLIANCES INC

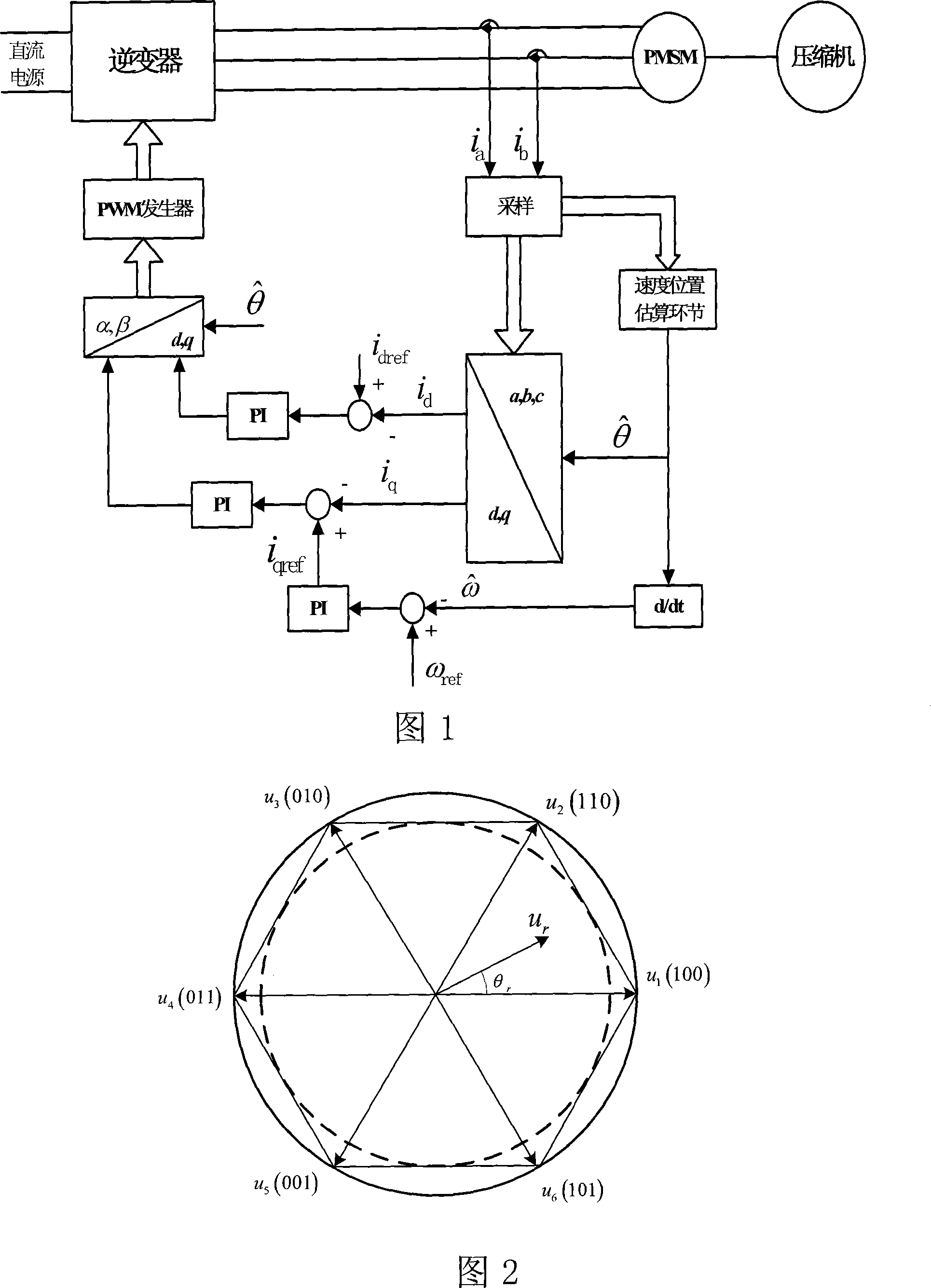

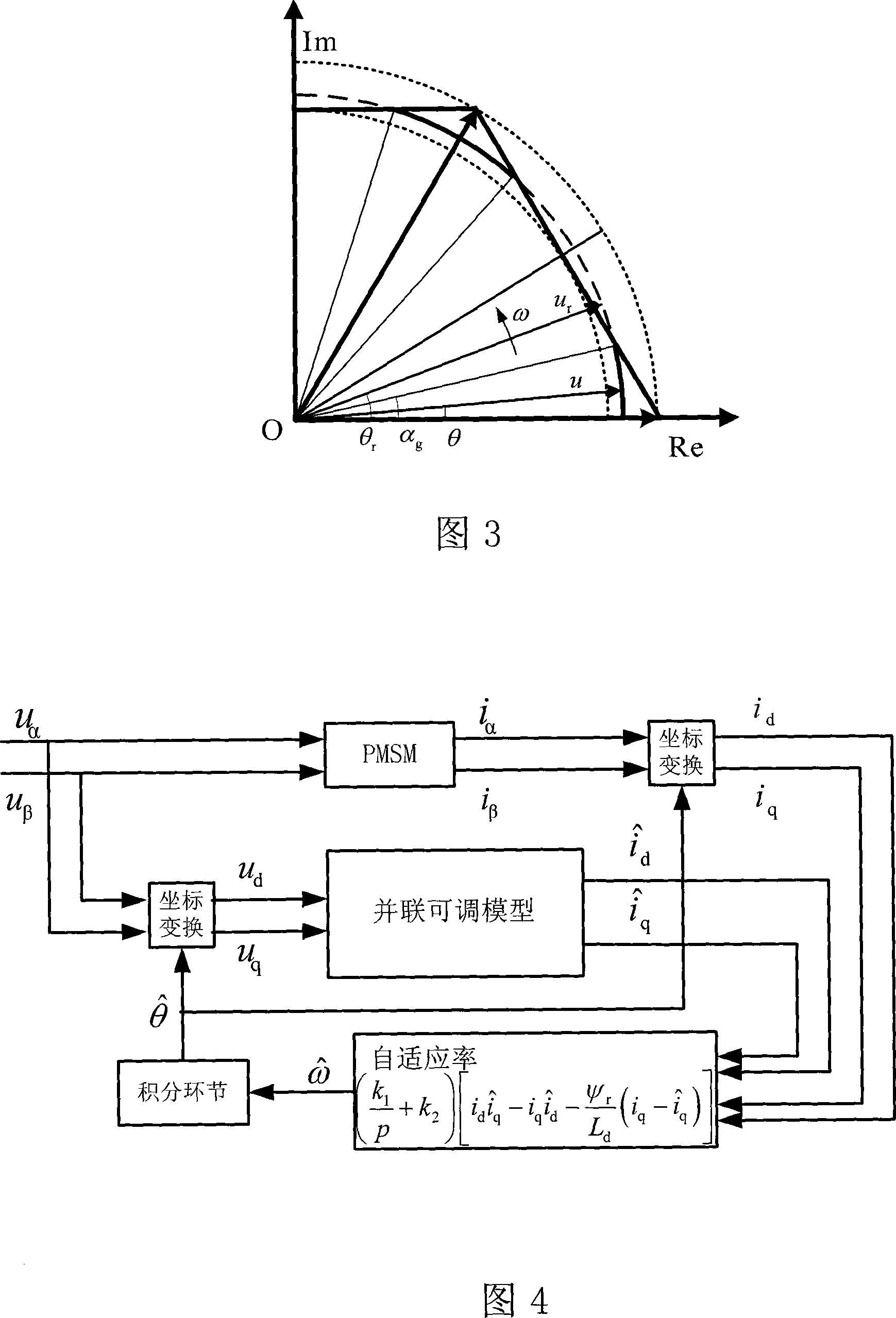

Permanent magnetism synchronous electric machine - compressor system high speed operation control method

InactiveCN101252336AImprove voltage utilizationAC motor controlVector control systemsPhase currentsSynchronous motor

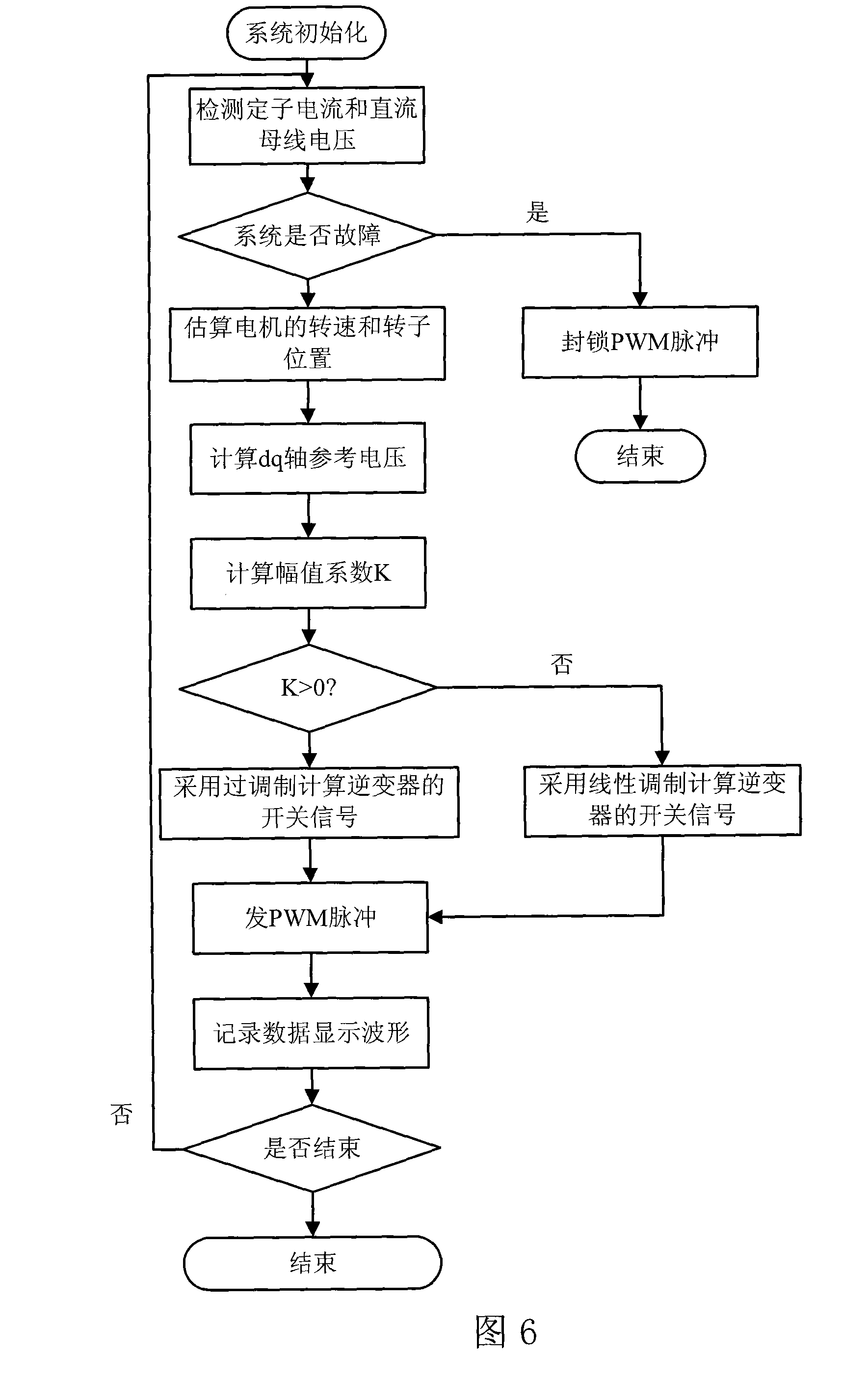

Disclosed is a high-speed control method for a permanent magnet synchronous motor-compressor system, including the following steps: initial design is carried out; a motor is detected through DSP, including detecting the two-phase current of the stator of the motor, the voltage Udc of a DC generatrix; the voltage of a d-p shaft is calculated; faults of overcurrent, overpressure and undervoltage are detected; if any fault exists, the PWM pulse signals are blocked and then the control program is paused; if no fault exists, the following steps will be carried out; the rotating speed of the motor and the position of the rotor are identified in the process of speed-position estimation; the current and the voltage of the reference d-q shaft of the motor are calculated; switching signals of an inverter are acquired through haplotype over-modulation; the data are recorded and waveforms are displayed; judgment of whether to pause the control program is carried out; if not, the second step is carried out again; if yes, the control program will be paused. The control method applies haplotype over-modulation method into the permanent magnet synchronous motor-compressor system, realizing sensorless over-modulation to the synchronous motor-compressor vector control system.

Owner:TSINGHUA UNIV

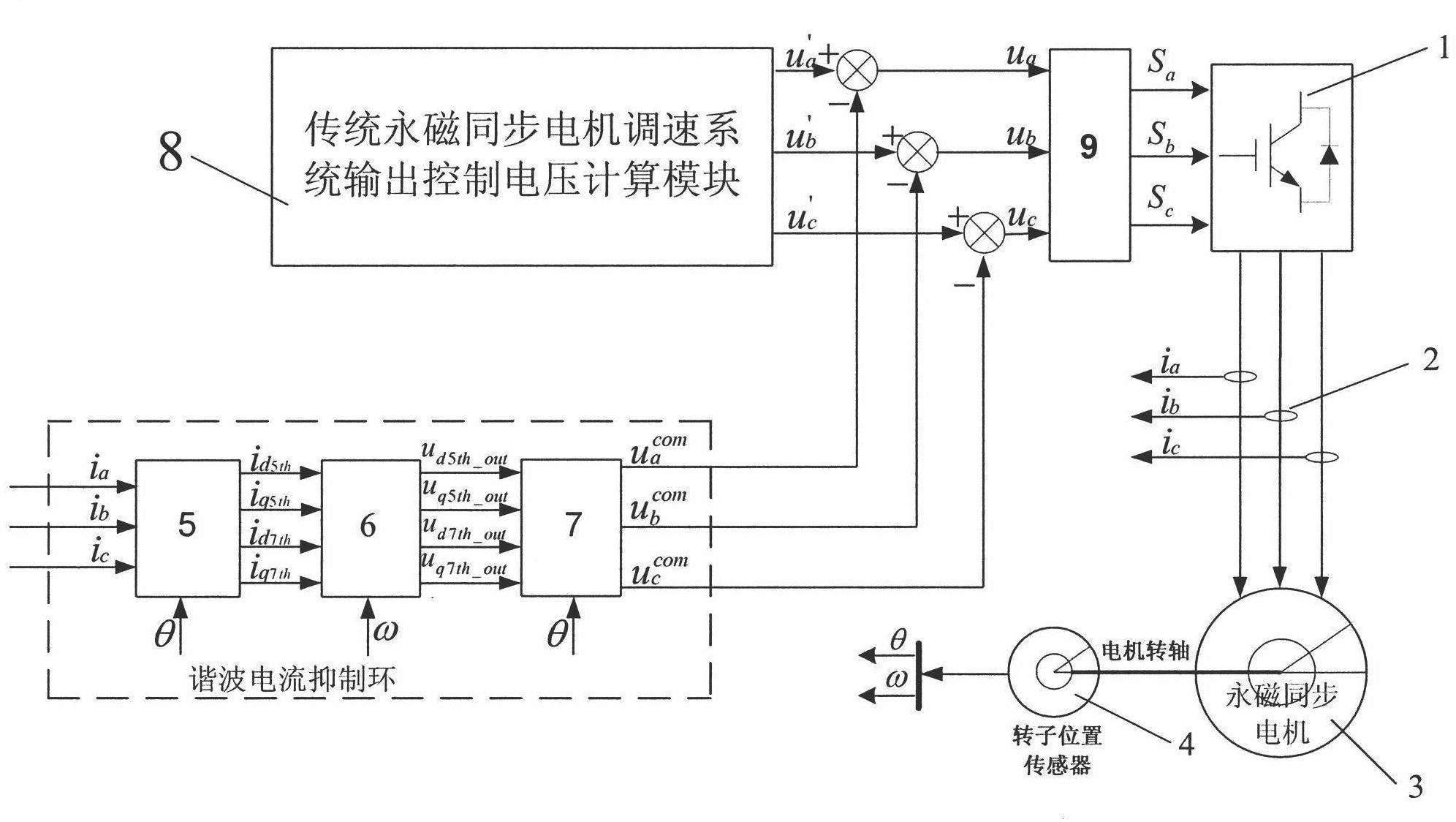

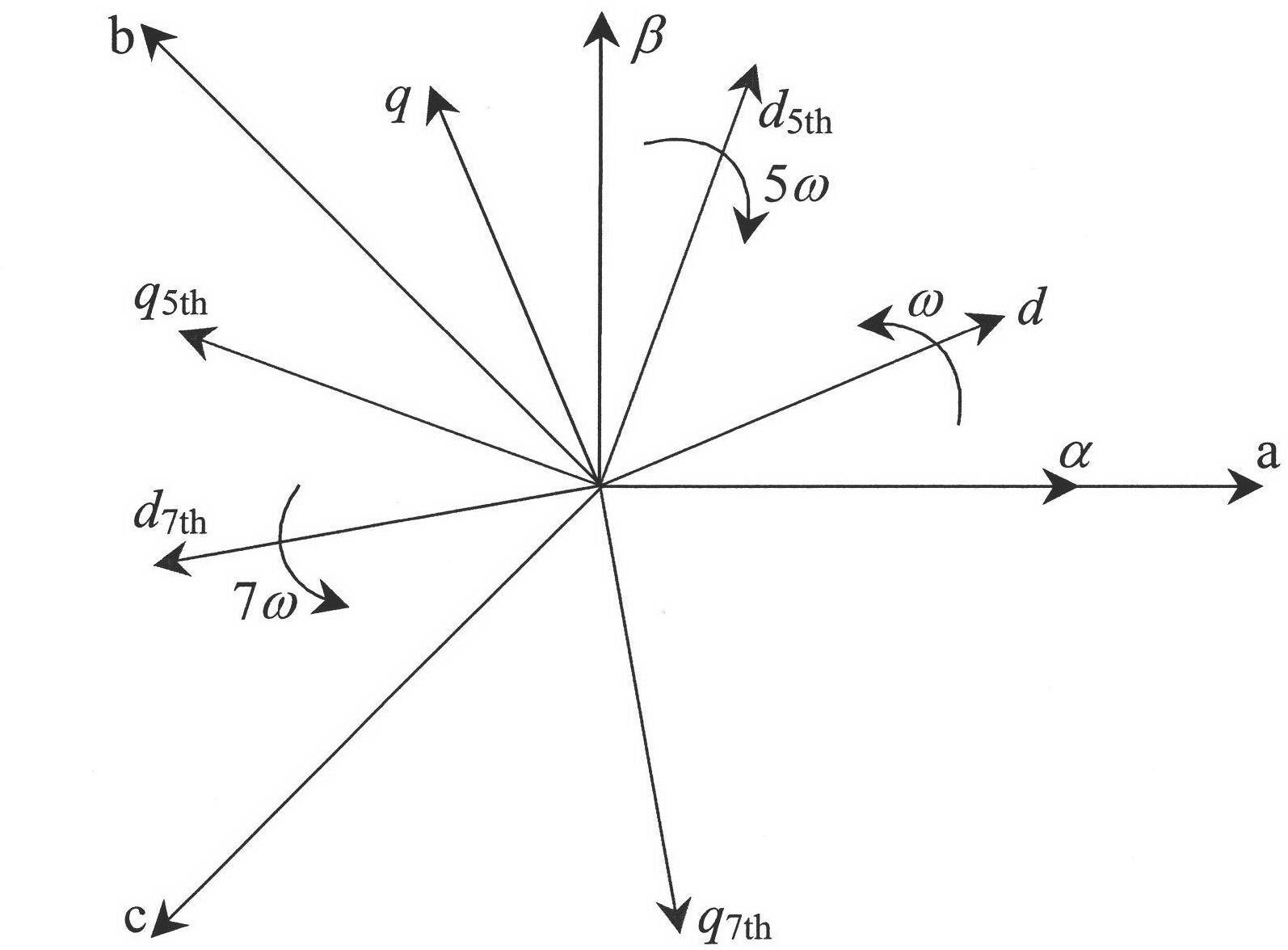

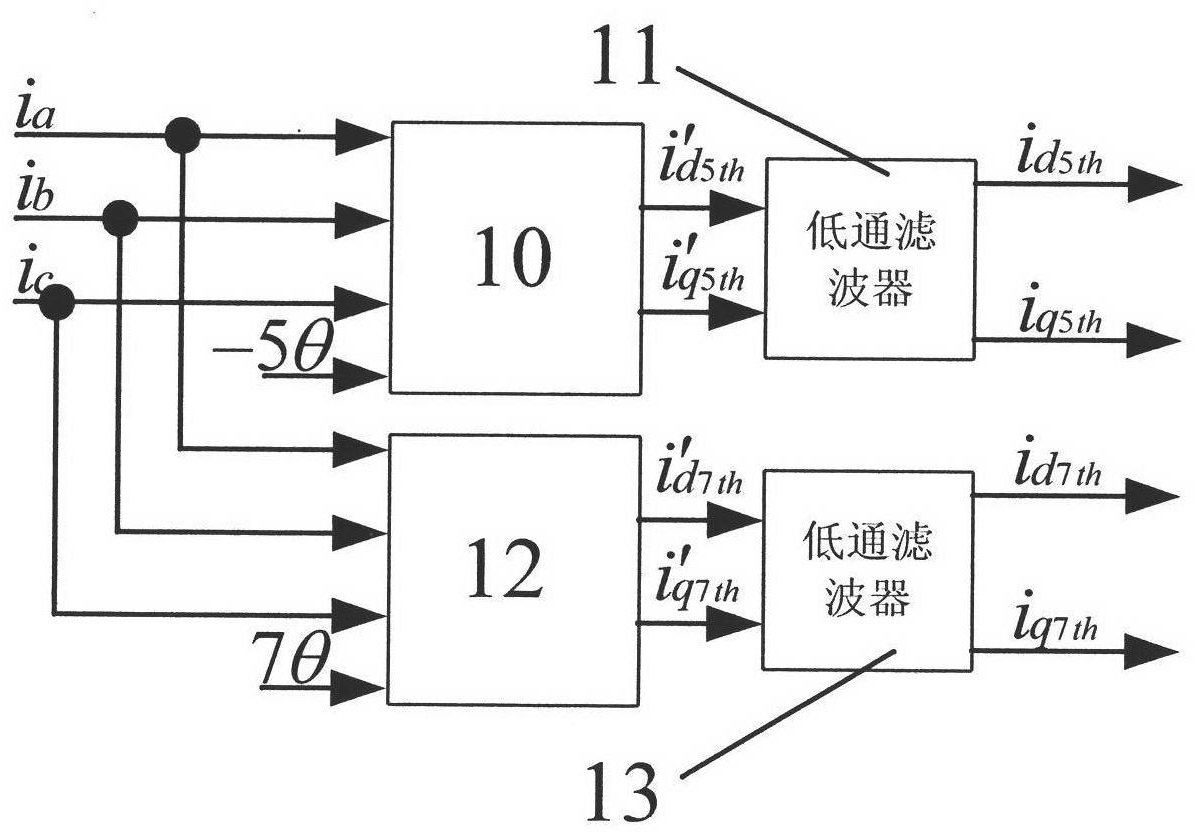

Method for injecting harmonic voltage to restrain harmonic current of PMSM (permanent magnet synchronous motor)

InactiveCN102201770AVector control systemsSingle motor speed/torque controlPermanent magnet synchronous motorClosed loop

The invention provides a method for injecting a harmonic voltage to restrain a harmonic current of a PMSM (permanent magnet synchronous motor), which is characterized in that a ring to restrain the harmonic current is added to realize the closed-loop control for the harmonic current on the basis of extracting harmonic current components in the PMSM in real time, thus calculating to obtain harmonic voltage components which are required to be injected to restrain 5-order and 7-order harmonic currents of the PMSM; and then the obtained harmonic voltage components are injected into a three-phase control voltage in a speed control system of the PMSM so as to offset the 5-order and 7-order harmonic components in a motor current when the PMSM runs, thereby reaching the purpose of restraining the 5-order and 7-order harmonic currents. The method is used to solve the technical difficulty that current ZCP (zero crossing point) is required to detect accurately in a traditional mode to restrain the harmonic current, remarkably improves the current waveform of the motor, effectively restrains the 5-order and 7-order harmonic currents caused by the nonlinear characteristics of an inverter and the air-gap field distortion of the motor, effectively reduces the additional loss caused by the 5-order and 7-order harmonic current components, reduces the electromagnetic torque and the revolving speed pulse of the PMSM and improves the running efficiency and the running reliability of the PMSM.

Owner:CHONGQING UNIV

Hybrid electric linear actuator

InactiveUS6982502B1Piezoelectric/electrostriction/magnetostriction machinesMechanical actuated clutchesElectric machinePermanent magnet synchronous motor

A hybrid linear actuator features a central load shaft on which a plurality of solid-state magnetostrictive thrusters are positioned in operative relation to electric motors of a permanent magnet synchronous type to impart linear thrust force to the load shaft through clutch units also positioned thereon and under control of force and stroke amplification of output force from motor shafts projecting from the motors.

Owner:TOYOTA JIDOSHA KK +1

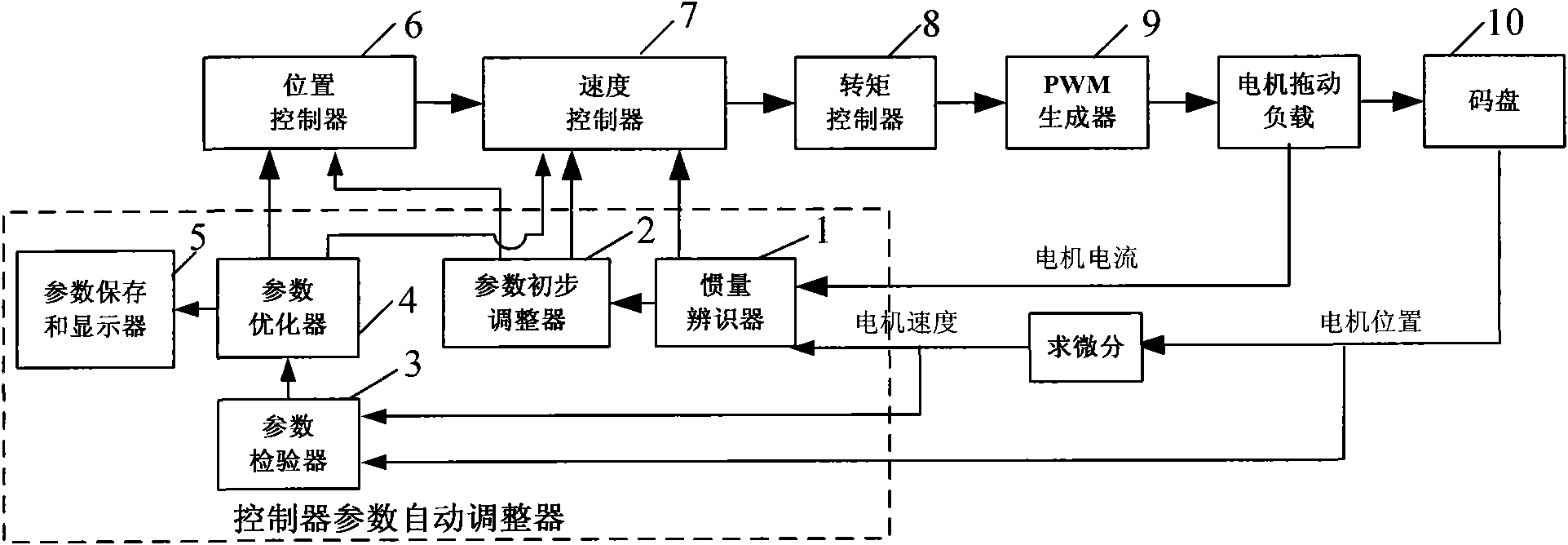

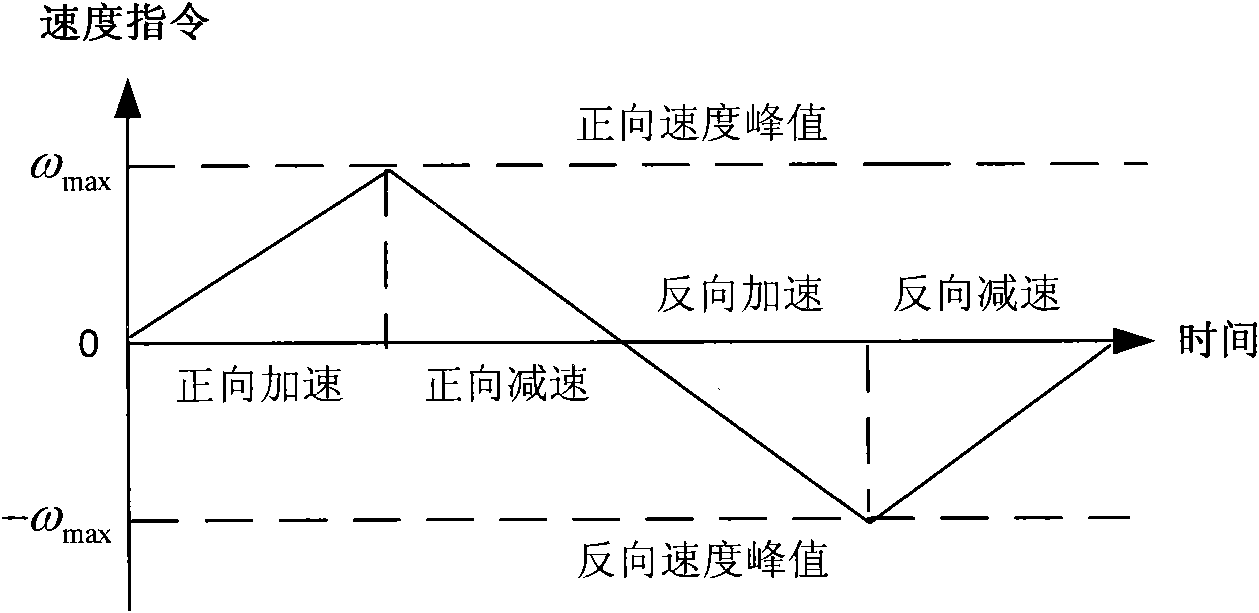

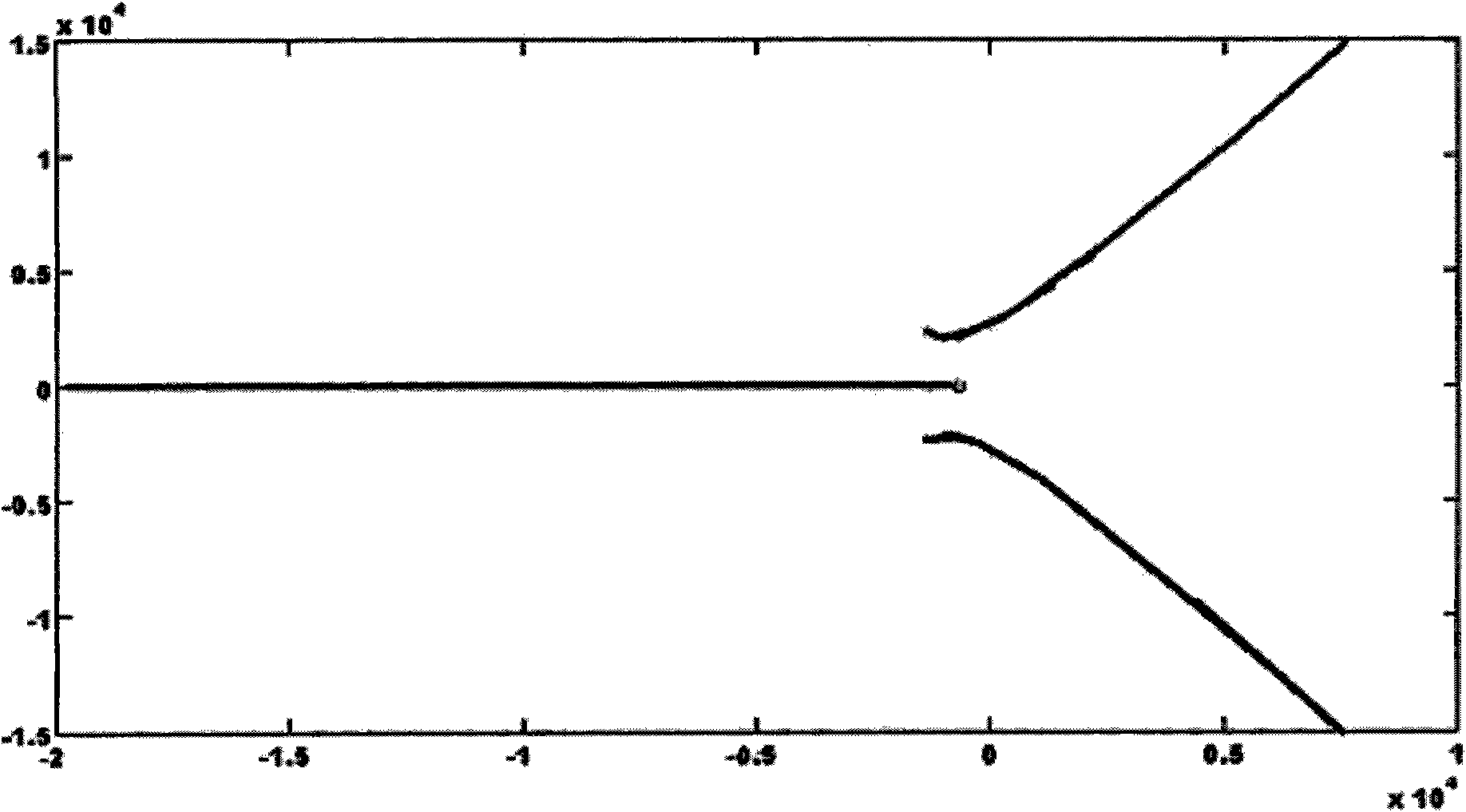

Automatic regulating apparatus for controller parameters of servo driver of motor and method thereof

ActiveCN101895252AGood control effectAvoid misalignmentMotor parameters estimation/adaptationPermanent magnet synchronous motorDisplay device

The invention discloses an automatic regulating apparatus for controller parameters of a servo driver of a motor and a method thereof. The apparatus comprises an inertia identifier, a parameter initial regulator, a parameter checker, a parameter optimizer, a parameter saving and displaying device, a speed controller, a position controller, a torque controller, a PWM (Pulse-Width Modulation) generator and a coded disc. In the invention, the servo driver of an alternating current permanent magnet motor automatically configures the parameters of the position controller and the speed controller according to different rotary inertias of mechanic load, checks and further optimizes the automatically configured parameters through the parameter checker and the parameter optimizer so that the position response and the speed response of the servo driver are relatively optimal. The servo driver of the alternating current permanent magnet synchronous motor automatically regulates the control parameters according to work occasions and achieves ideal control effect. The whole process is manual participation free and completed fully by the servo motor of the alternating current permanent magnet synchronous motor.

Owner:上海新时达线缆科技有限公司 +2

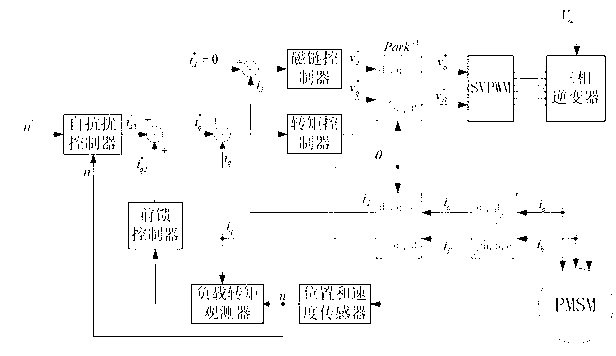

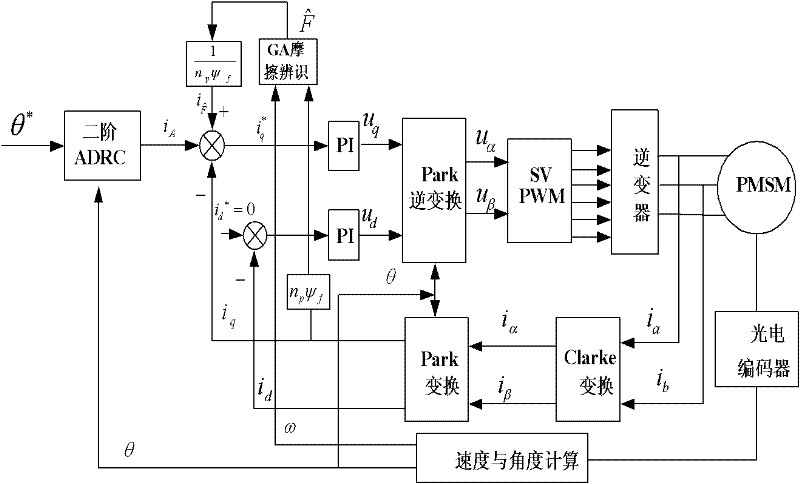

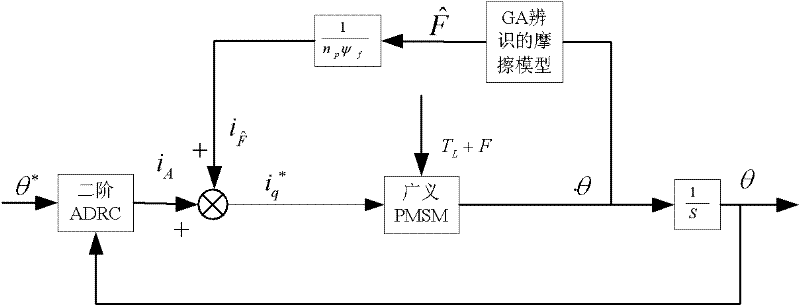

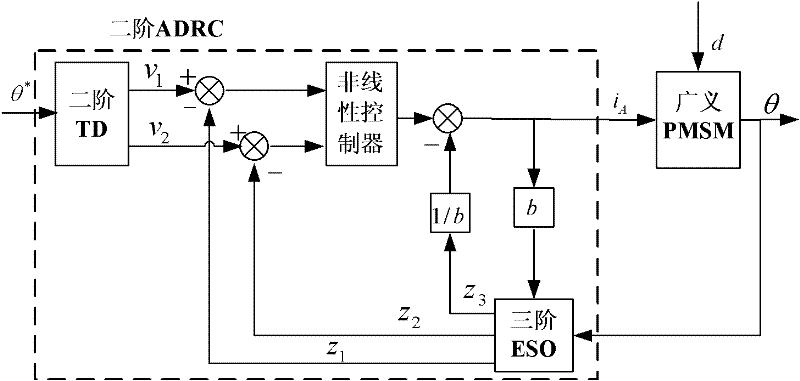

Method for controlling PMSM (permanent magnet synchronous motor) servo system based on friction and disturbance compensation

ActiveCN102208891AOvercome precisionAvoid local smallVector control systemsSingle motor speed/torque controlLow speedNonlinear control law

The invention discloses a method for controlling a PMSM (permanent magnet synchronous motor) servo system based on friction and disturbance compensation. In the method, a feedforward compensation method based on a friction model is combined with an auto disturbance rejection technology and the feedforward compensation method is complementary with the auto disturbance rejection technology mutually. In the method, a Stribeck friction model is utilized to carry out modeling on system frictions, a GA (genetic algorithm) is adopted to carry out offline identification on parameters, and an estimated value generated by an identification model carries out feedforward compensation; a state observer in the auto disturbance rejection technology observes and compensates overcompensation or undercompensation of the frictions as well as nondeterminacy and external disturbance caused by modeling errors in the system; and finally a differential tracker and a nonlinear control law are used to arrange a transient process for fixed position signals, thus solving the conflict between rapidity and overstrike and ensuring stability of the system and finite time convergence. By using the combined control, the compensation capacity of the system for the frictional nonlinearity can be improved effectively, the low-speed performance of the system is improved, and the tracking accuracy and the anti-disturbance capacity of the system are enhanced.

Owner:SOUTHEAST UNIV +1

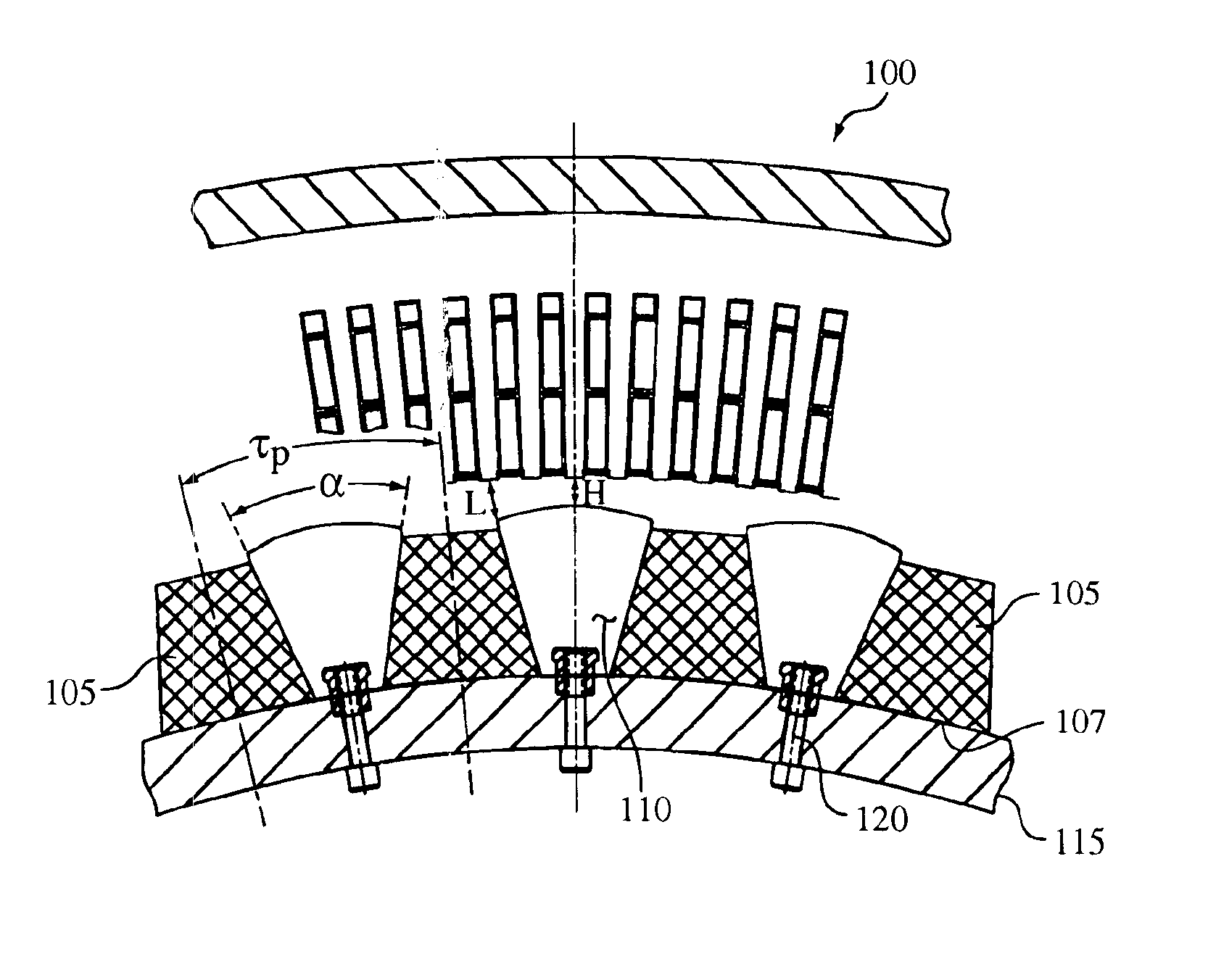

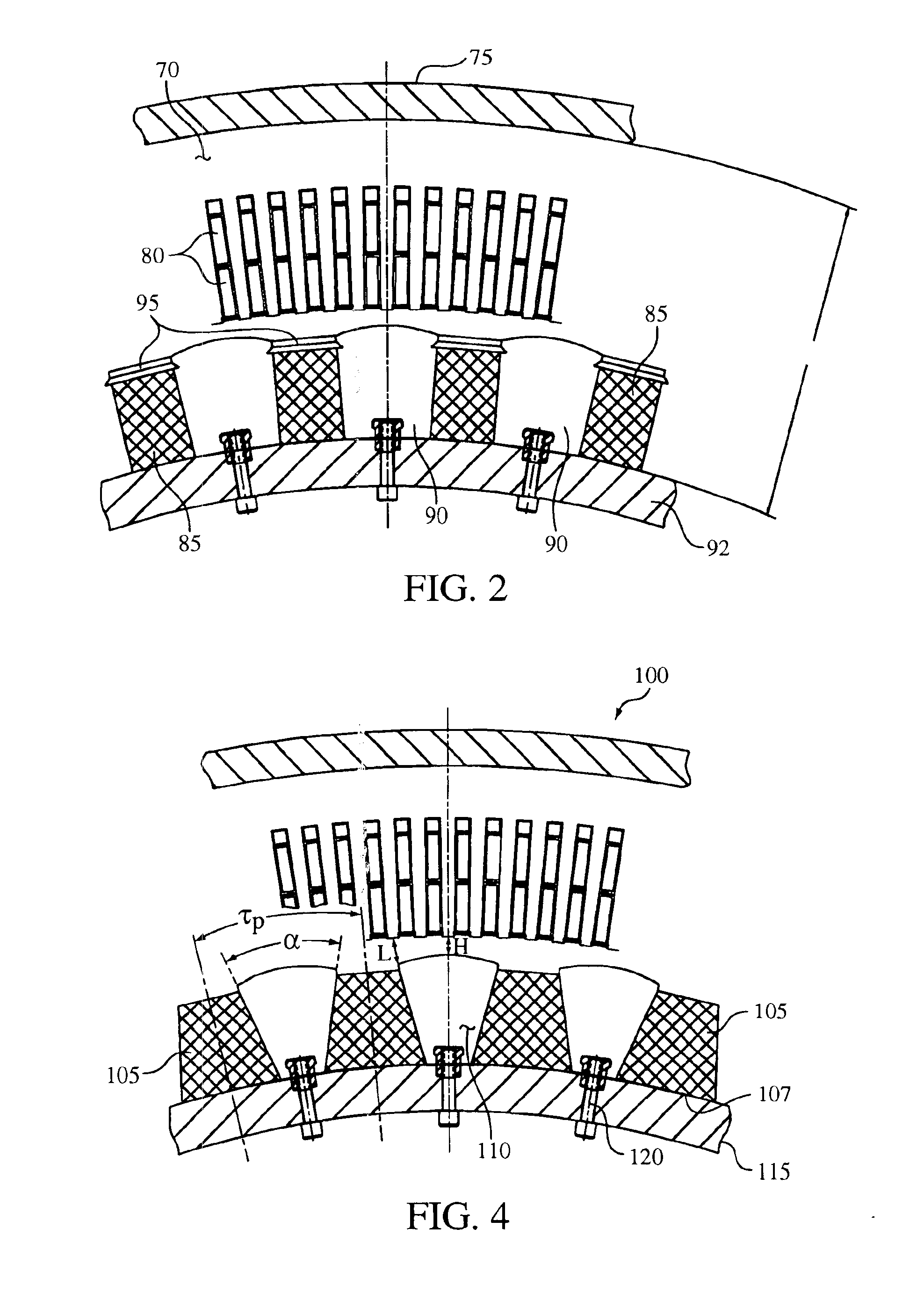

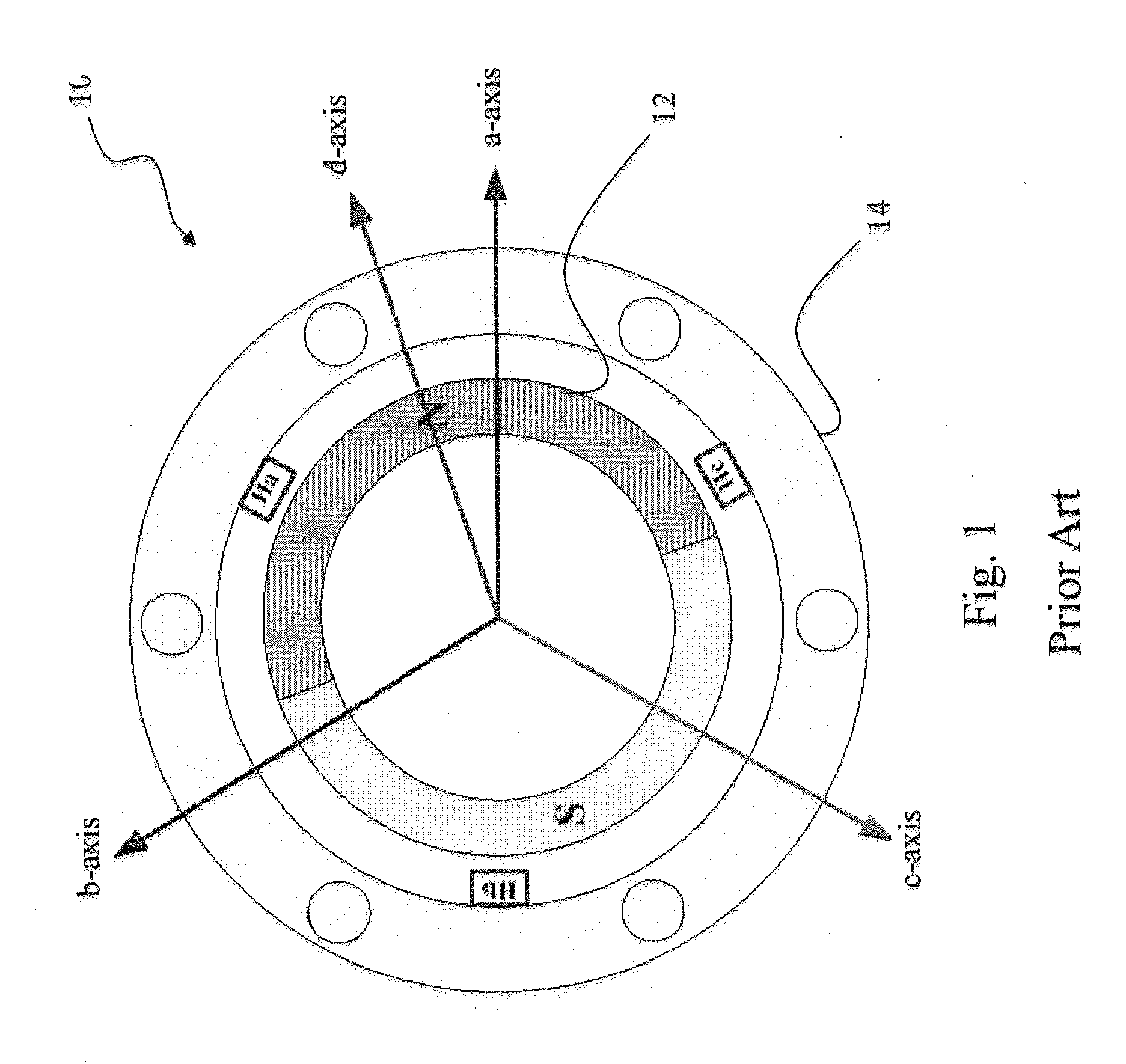

Trapezoidal shaped magnet flux intensifier motor pole arrangement for improved motor torque density

InactiveUS6879075B2Increase torqueImprove power characteristicsSynchronous generatorsWindingsPermanent magnet synchronous machineElectric machine

A permanent magnet synchronous machine with improved torque and power characteristics. A circumferential-oriented rotor assembly is provided with alternating permanent magnets and magnetic pole pieces. In order to reduce the amount of leakage flux in the rotor and increase the effective length of the permanent magnet, a trapezoidal or otherwise tapered permanent magnet structure is used. By alternating trapezoidal permanent magnet, and magnetic pole pieces, a higher intensity magnetic field is created in the air gap utilizing the same radial space in the motor without altering the weight or volume of the motor compared to conventional machines.

Owner:CURTISS WRIGHT ELECTRO MECHANICAL

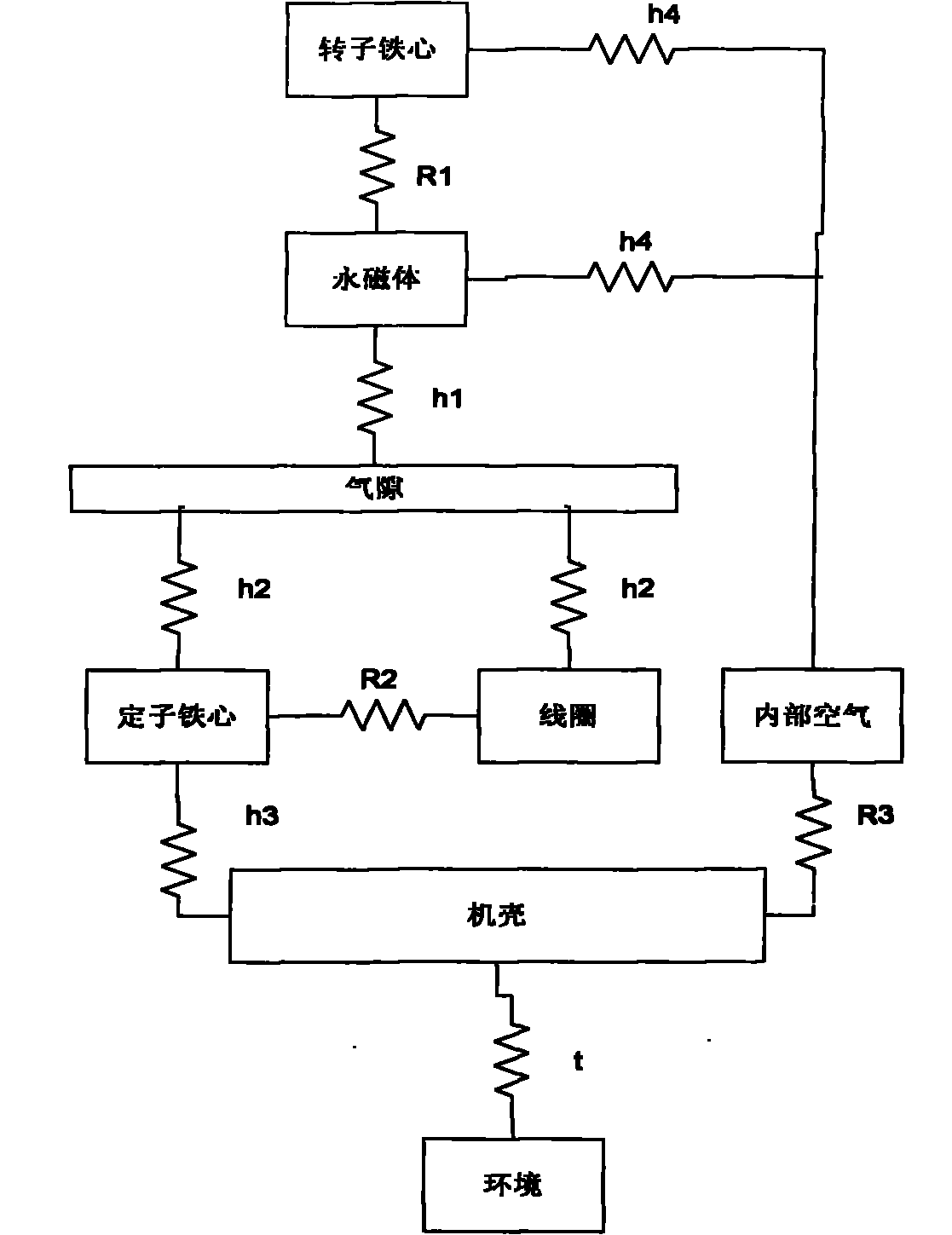

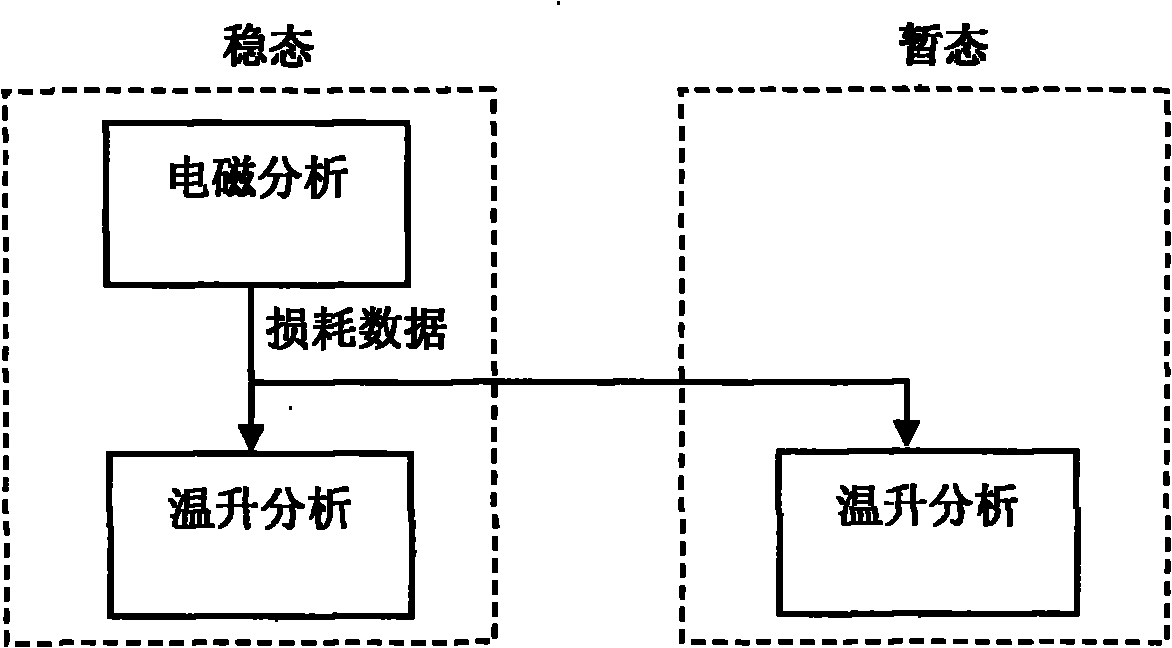

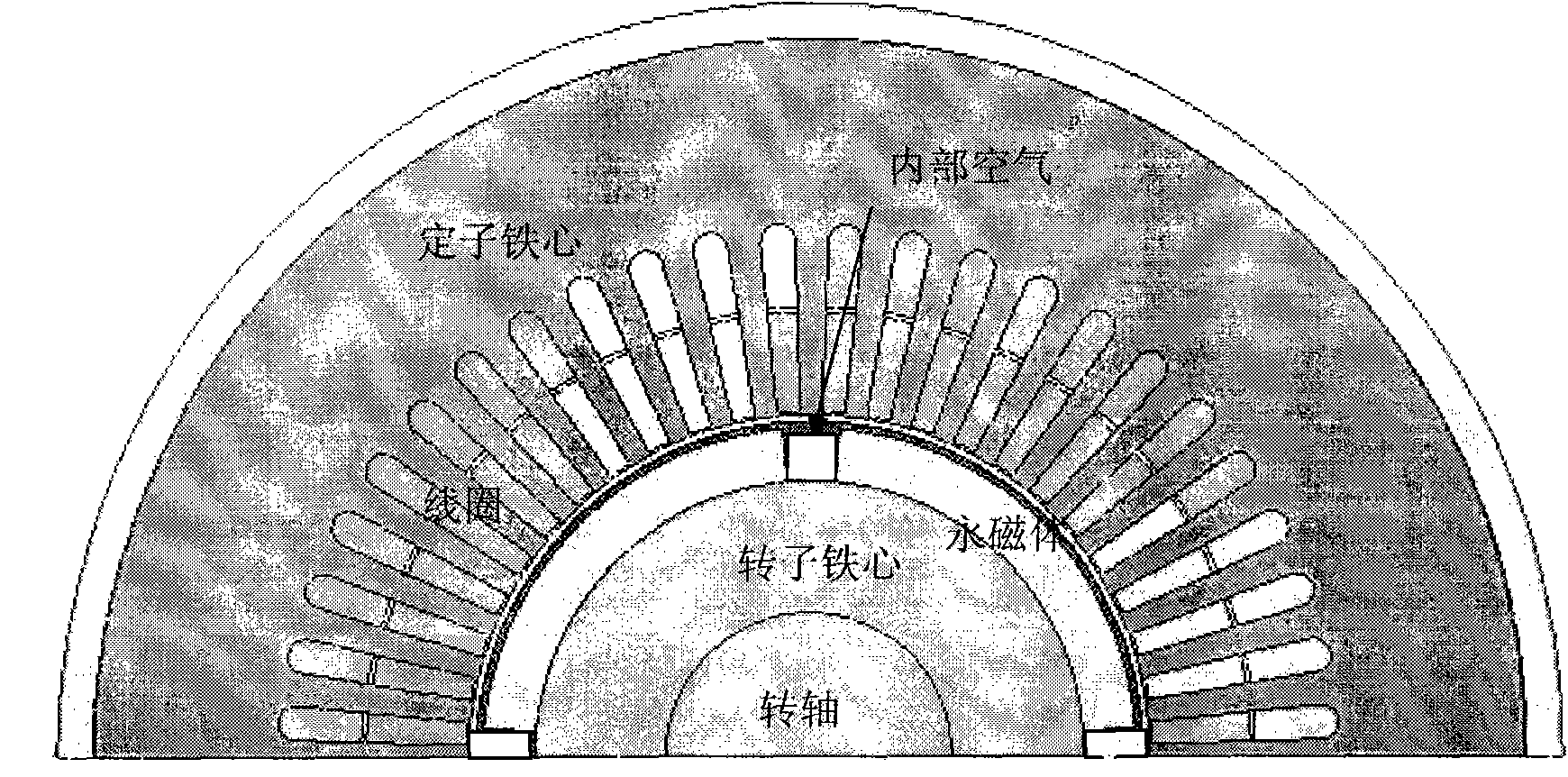

Temperature rise analytical method for predicting temperature of permanent magnet in permanent magnet synchronous motor

InactiveCN101769797AAccurate predictionAvoid difficulties such as air gap temperature measurementThermometerDynamo-electric machine testingModel selectionPermanent magnet synchronous motor

The invention relates to a temperature rise analytical method for predicting temperature of a permanent magnet in a permanent magnet synchronous motor (PMSM), belonging to the application electrical engineering design field; the method is characterized in that: distributed heat source of a motor is analyzed by a filed-circuit compact coupling method, comprising eddy current loss in the permanent magnet, iron loss in an iron core and copper loss in armature; on the consideration of precision requirements, the coupling analysis of a magnetic field and a temperature filed can be realized by single-way coupling mode. A thermal model of the permanent magnet synchronous motor is built based on a mixing method of a novel equivalent heat network and a finite element, heat parameters are rationally selected by adopting a combining mode of experimental measurement and empirical formula, the heat transferring coefficient and cooling condition of the motor are described completely, a stator and a rotor can be systematically combined by adopting air gap joints in the heat network, the stator and rotor unified temperature rise model is formed, the difficulty of measuring air gap temperature is avoided, material parameters are adopted at the practical working temperature, so as to lead the analysis to be rational; the accurate and optical method for predicting the temperature of the permanent magnet is realized by special correction processing in experimental links; in addition, the design method is used to give suggestions for model selection of the permanent magnet material in the motor.

Owner:李虎

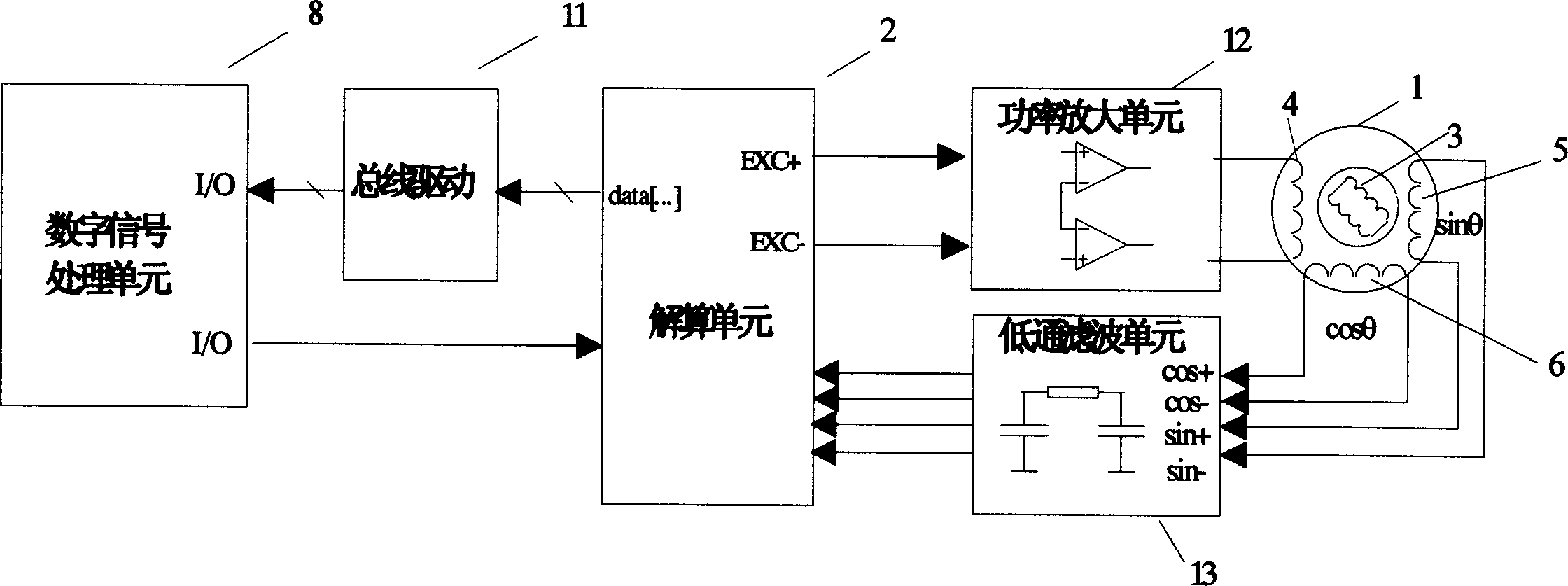

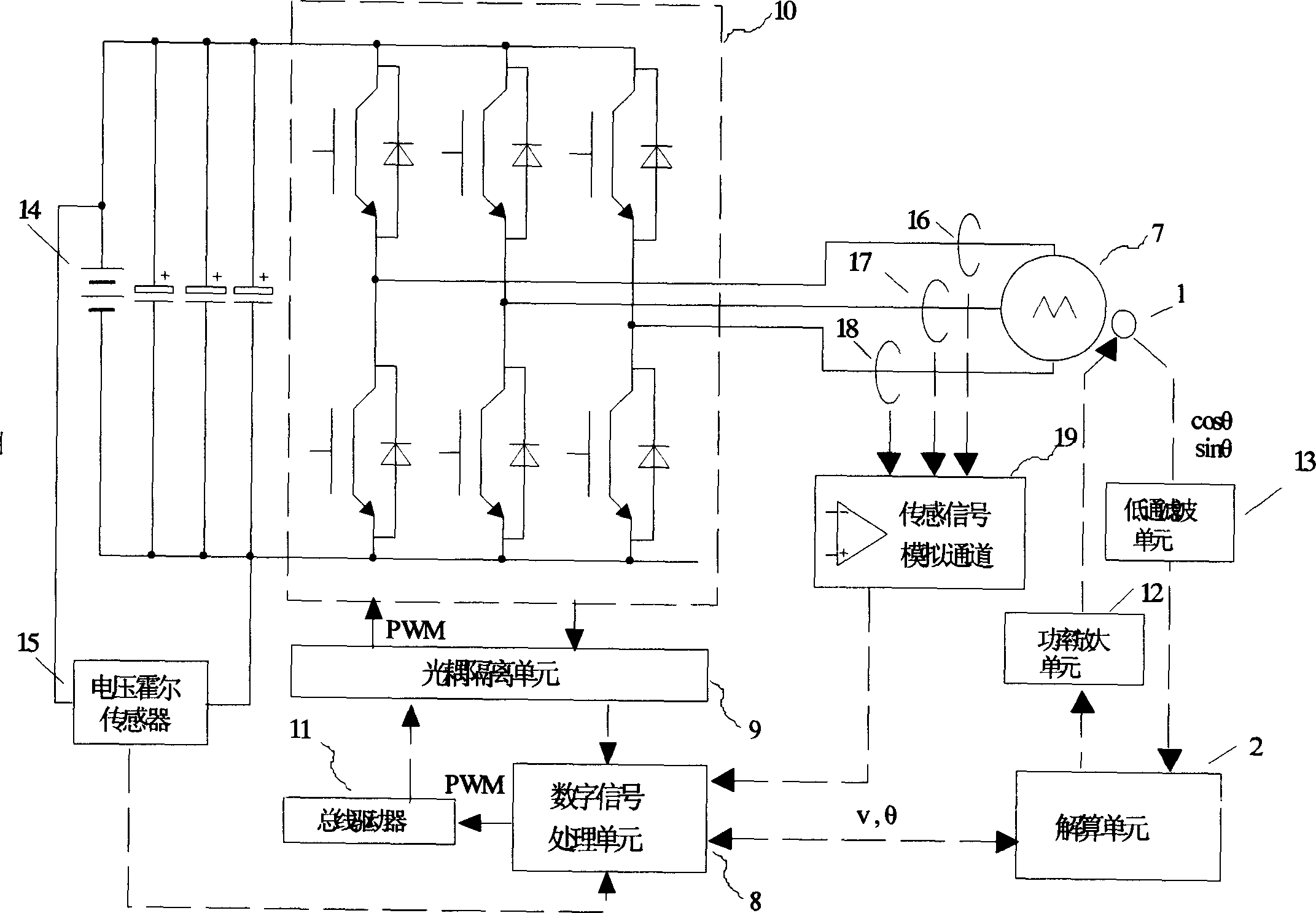

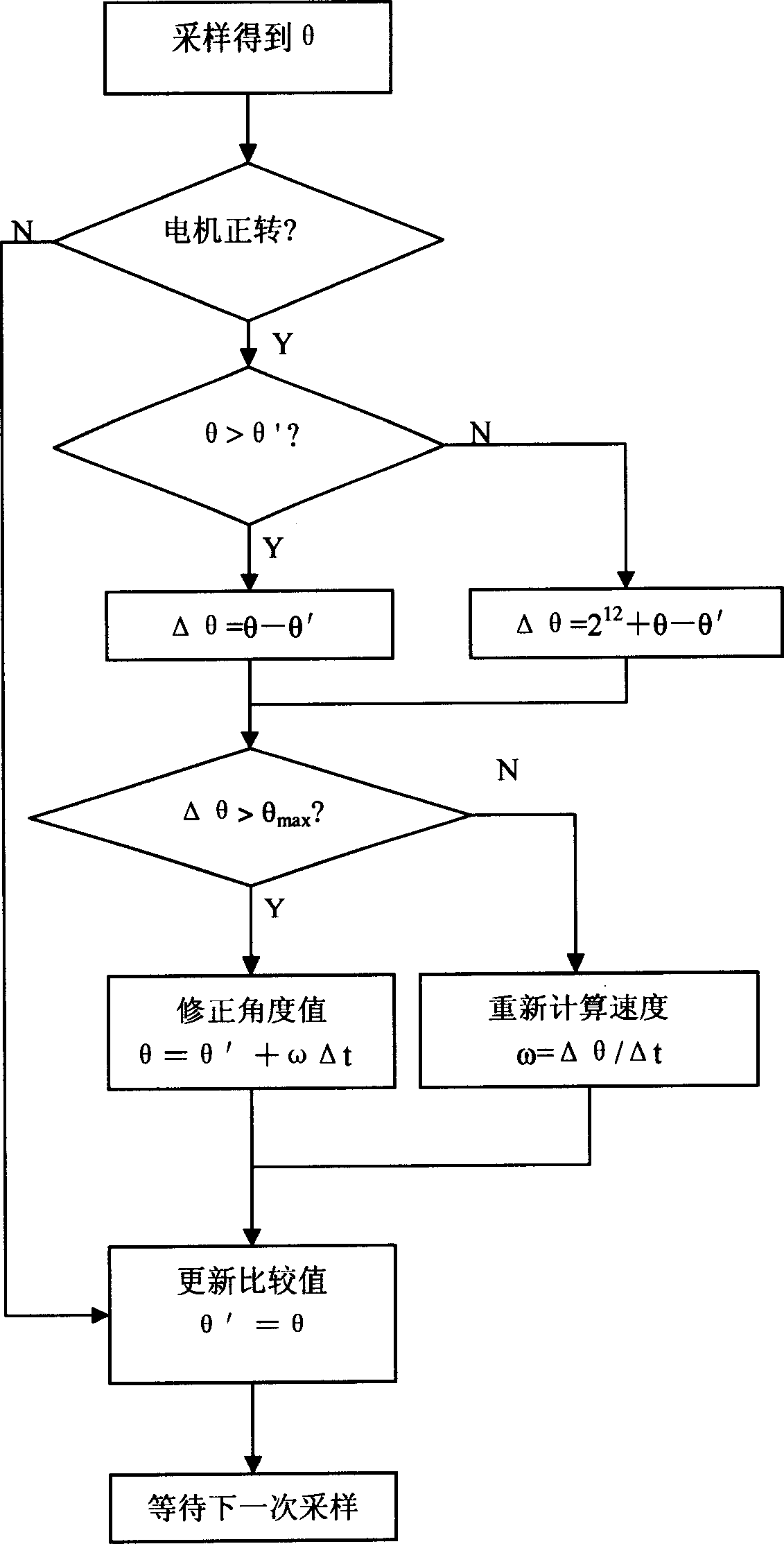

Permanent-magnet synchronous motor rotor position sensing method and position sensing device

ActiveCN1838523AHigh precisionImprove performanceElectronic commutatorsDigital signal processingPermanent magnet synchronous motor

This invention discloses a permanent synchronous generator rotor location sensing method and location sensing device, which uses rotary transformer and solving cell as sensor, and it has digit signal dealing cell, where the solving cells samples detection generator location angle in real time and fixing time interval, and it judges the change of the generator location angle after each sampling to determine whether to complement and correction. If the solving cell checks out that the extent of the rotary transformer's sensing signal of the output exceeds the allowing range, then it sends the demand to control the permanent synchronous generator to stop running to the digit signal dealing cell. This invention also discloses a permanent synchronous rotor location sensing device, which is compatible with bad magnetic environment of motor car or mixed motor car, and it can keep the generator running stably under the environment that the rotary transformer or solving cell has big error or invalidate. So this invention can be applied extensively in electric servo system of middle or small power including electric automobile and mixing motor car' driving part.

Owner:BYD CO LTD

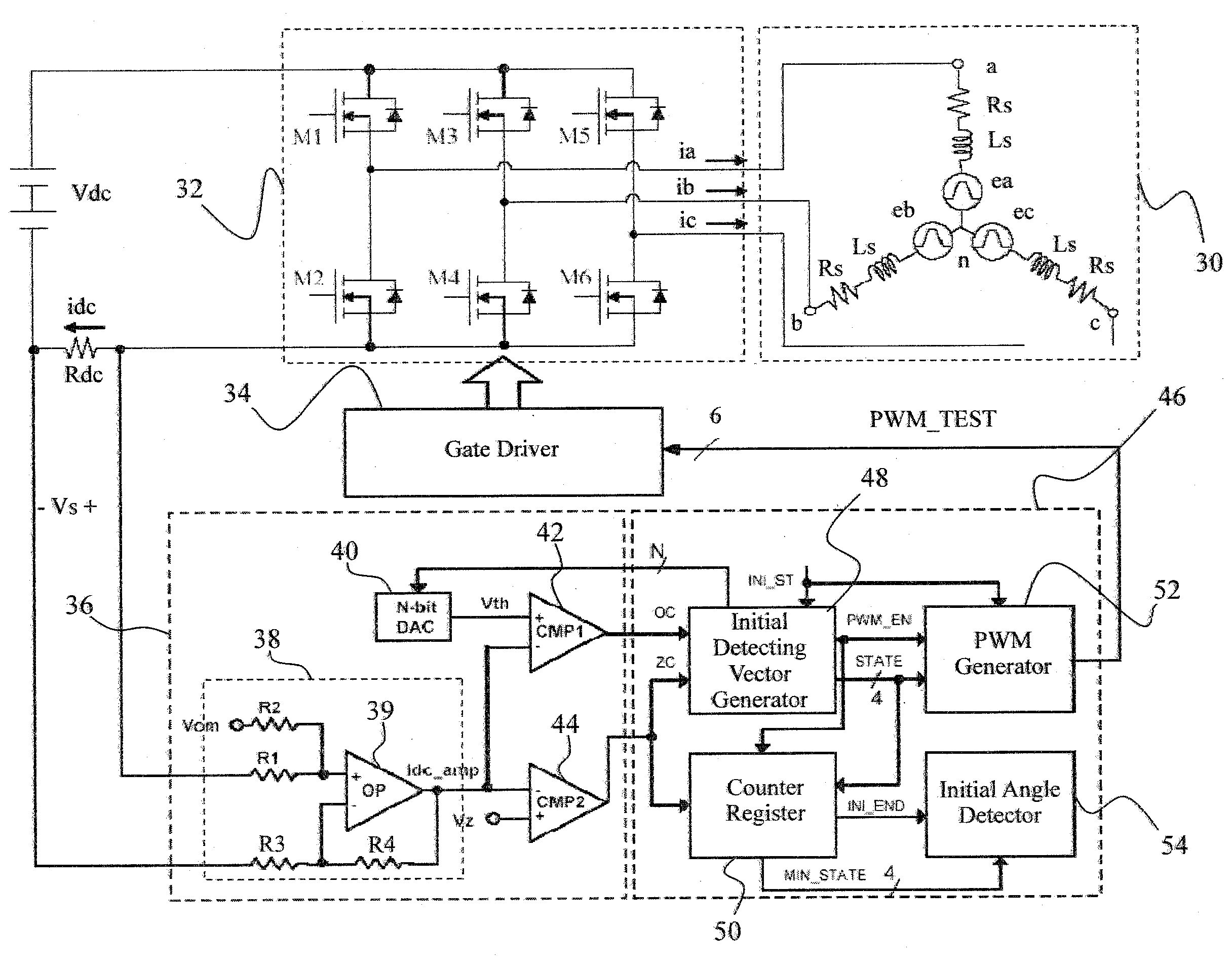

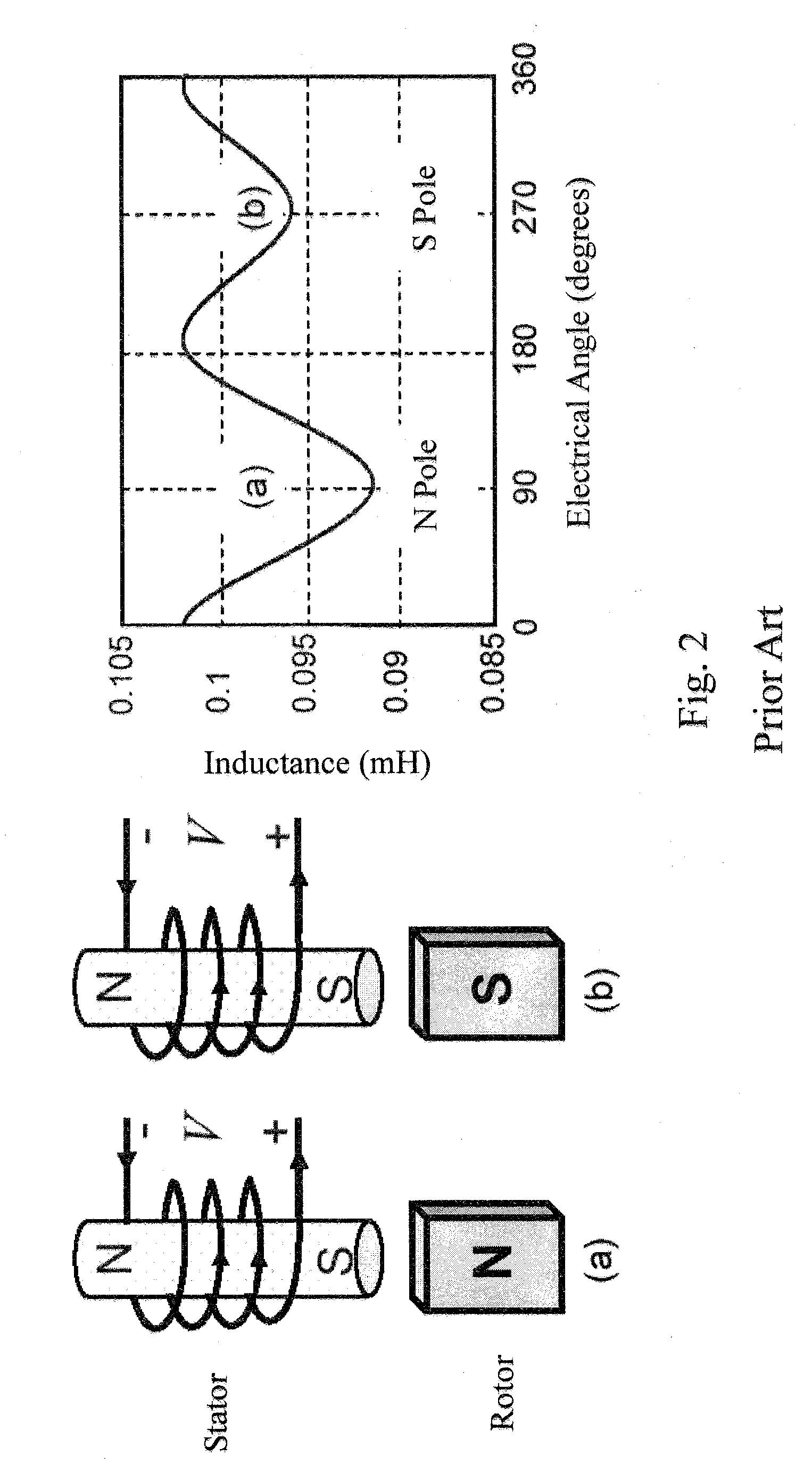

Initial rotor position detection for permanent magnet synchronous motors

ActiveUS20100181952A1High sensitivityAvoid uneven performanceMotor/generator/converter stoppersSynchronous motors startersFall timeVoltage vector

Owner:RICHTEK TECH

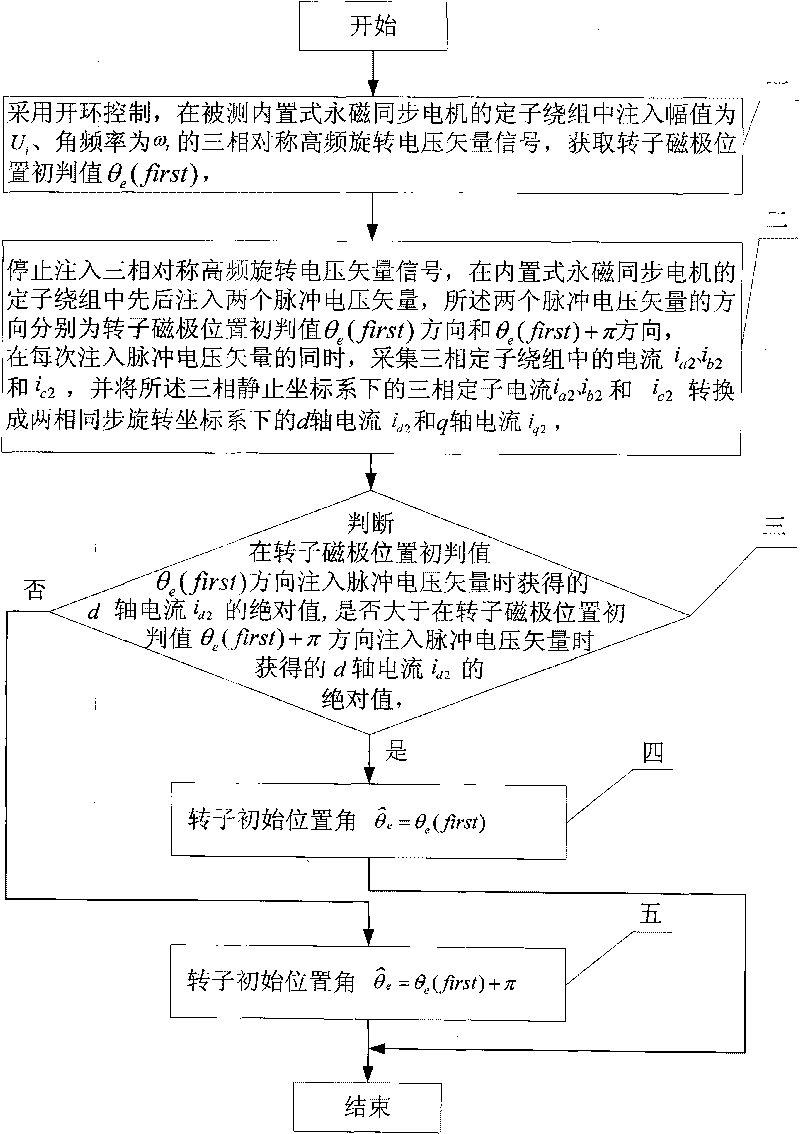

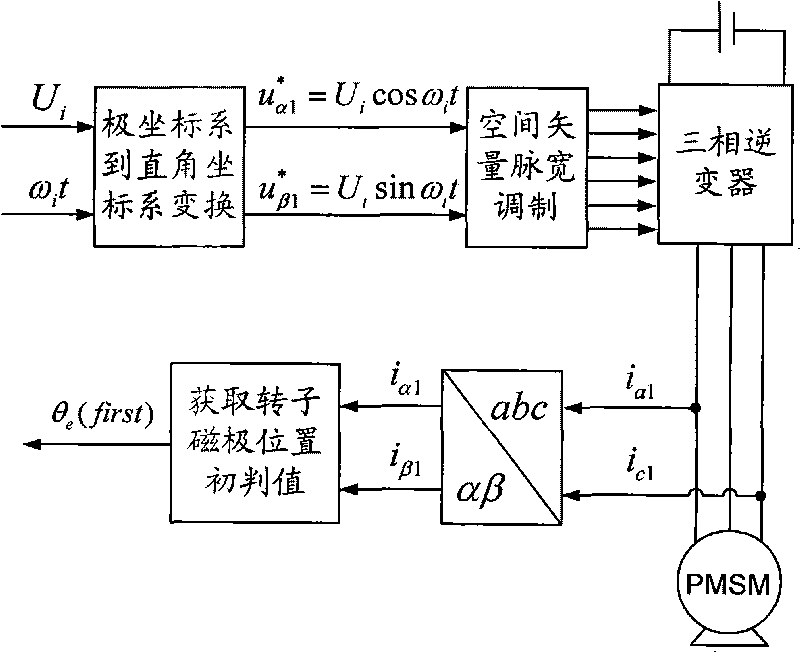

Method for detecting initial position of magnetic pole of rotor of built-in permanent magnetic synchronous motor

InactiveCN101714844AKeep stillEfficient detectionVector control systemsDynamo-electric converter controlSynchronous motorVoltage vector

The invention provides a method for detecting the initial position of a magnetic pole of a rotor of a built-in permanent magnetic synchronous motor, belongs to the field of motor control, and solves the problems of over-complicated processing, easy occurrence of polarity misjudging, poor practicality and the like existing in the conventional method based on high-frequency signal injection for detecting the initial position of the rotor. The method comprises the following steps: constantly maintaining the stationary state of the rotor; injecting a rotating high-frequency voltage signal into a stator winding; detecting three-phase stator current and converting the three-phase stator current into two-phase static coordinates; acquiring an error signal capable of reflecting position information of the magnetic pole of the rotor through signal processing; adjusting the error signal by using a PI tracker so as to acquire an initial judging value of the position of the magnetic pole of the rotor; and injecting two impulse voltage vectors in opposite directions into the stator winding, comparing values of direct axis current components by detecting the three phase current and converting the rotating coordinates so as to determine the polarity of the magnetic pole, and finally acquiring the initial position angle of the magnetic pole of the rotor of the built-in permanent magnetic synchronous motor.

Owner:哈尔滨同为电气股份有限公司 +1

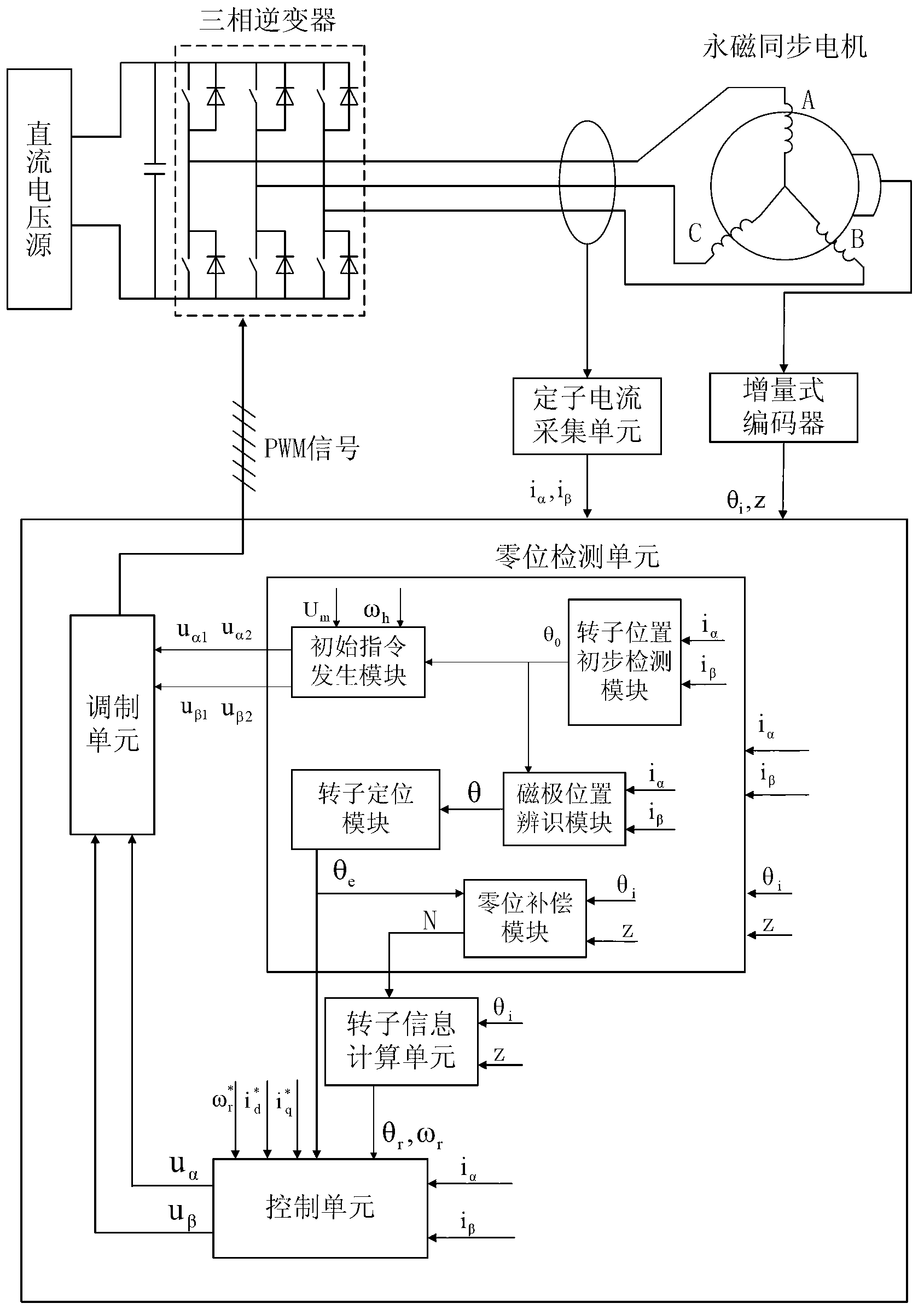

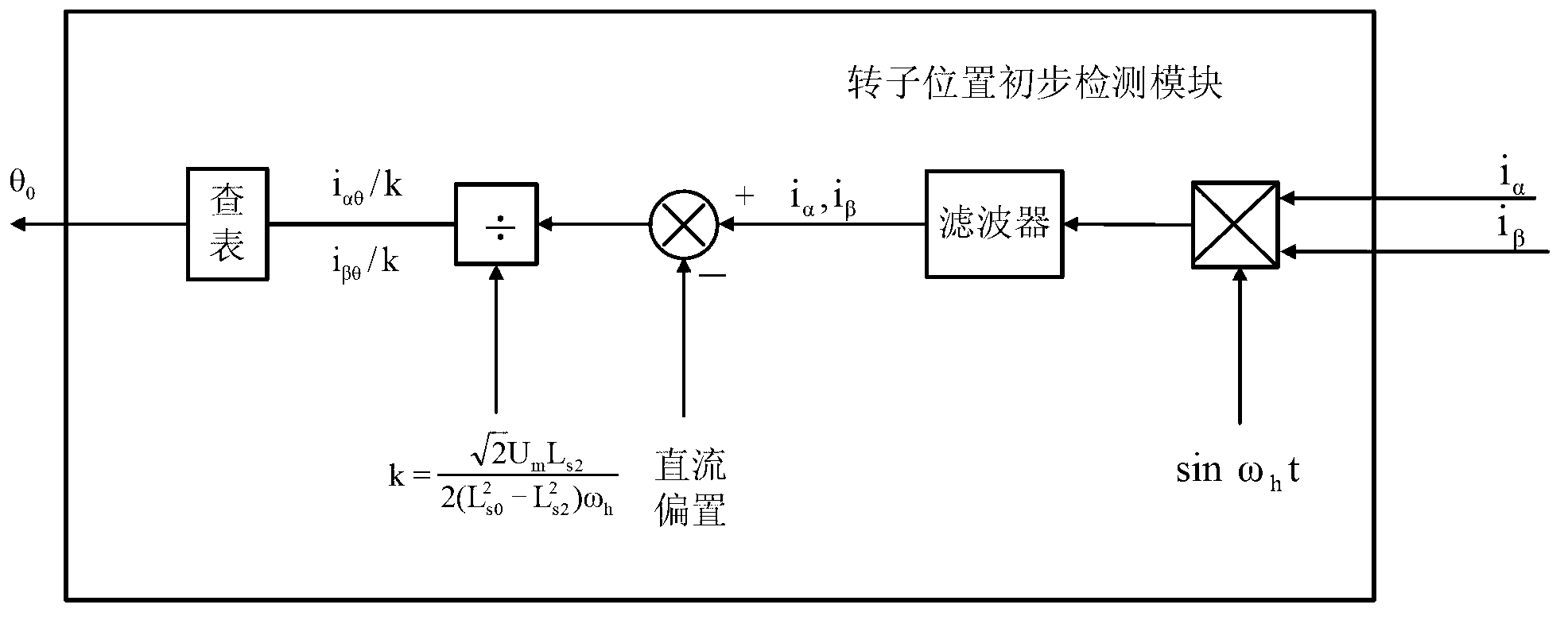

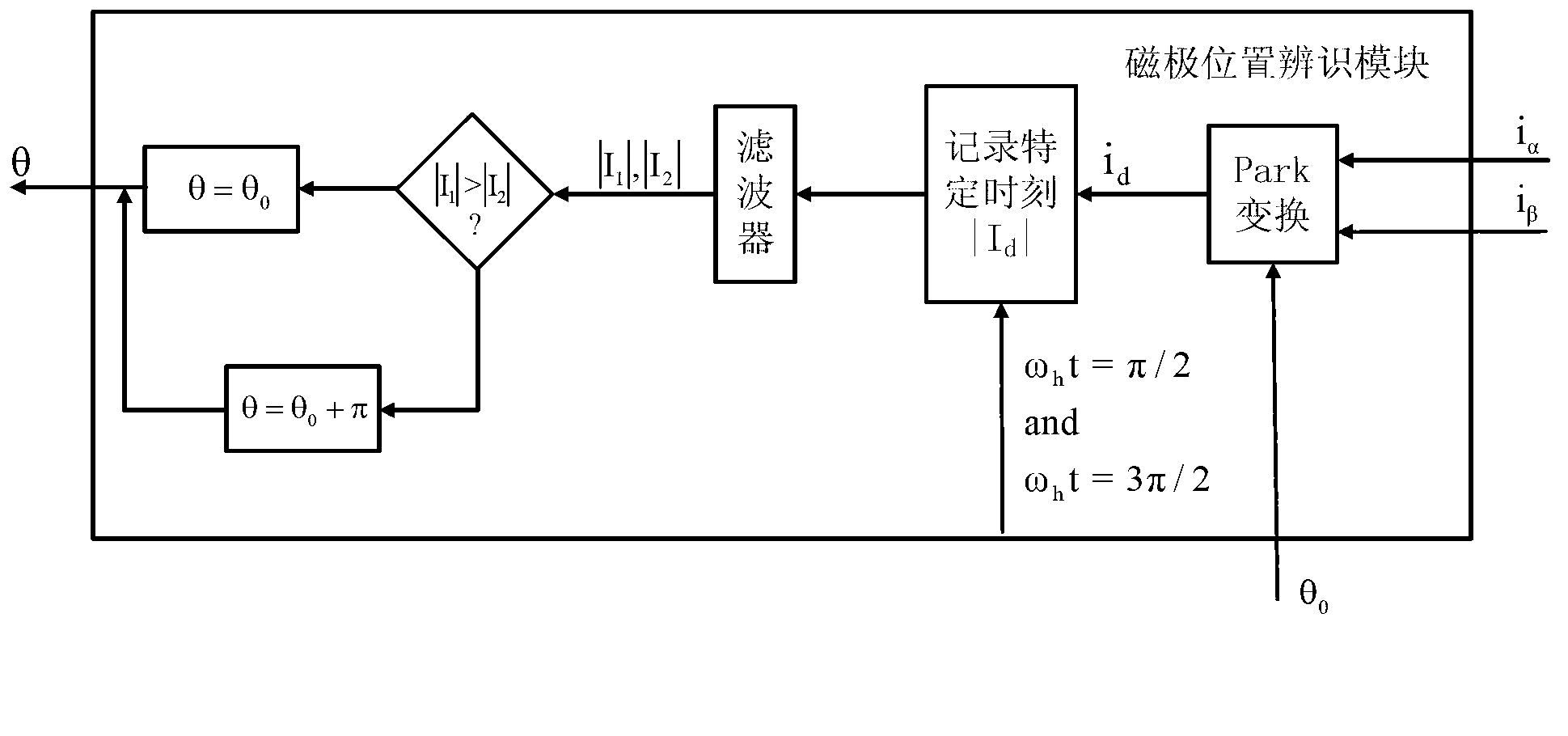

Permanent magnet synchronous motor control method and system based on encoder automatic zero set

ActiveCN103269198AClarify initial positioningPrevent inversionElectronic commutation motor controlAC motor controlVoltage vectorControl system

The invention discloses a permanent magnet synchronous motor control method based on encoder automatic zero set. An improved high-frequency voltage injection method is used for detecting the initial position of a rotor, the initial position of the rotor is clear, voltage vectors can be applied conveniently, and a motor rotor reverse rotating phenomenon is avoided. Meanwhile, encoder zero compensation is carried out automatically, a compensation value is stored, direct calling in the future is convenient, and trouble of manual zero set is removed. Once calibration or zero reset is needed, operation through the method is carried out for one time, an encoder is subjected to accurate zero set again, a process is simple, and accuracy is high. The invention further discloses a control system which achieves the control method. After the initial position of the rotor is obtained through a rotor locating module, a voltage vector closest to the position is chosen to be applied, so that a rotor back-and-forth vibration phenomenon during locating is avoided, a high-frequency voltage signal is injected only before the rotor is located initially, phase lag and time lag cannot be brought to system operation, and noise cannot be introduced during operation.

Owner:ZHEJIANG UNIV

Sensorless control system of permanent magnet synchronous motor

ActiveCN101964624AImprove estimation accuracyPracticalElectronic commutation motor controlVector control systemsLow speedPermanent magnet synchronous motor

The invention discloses a sensorless control system of a permanent magnet synchronous motor. The sensorless control system comprises a flux linkage / current state observer and a counter electromotive force measurement module, wherein the flux linkage / current state observer is a sliding mode observer; the sliding mode observer is controlled by a sliding mode variable structure; and the coordinate system of the sliding mode observer is an estimated rotary coordinate system, is rotated at an angular speed and lags behind an electrical angle of the coordinate system. In a control parameter computation module, the error of a rotor position is calculated. The sensorless control system of the permanent magnet synchronous motor, can be used on a low-speed observation occasion and a height observation occasion at the same time and has strong practicability.

Owner:ZHEJIANG UNIV OF TECH

Automatic field-weakening method for built-in permanent magnet synchronous motor

InactiveCN101783536AExtended pole-to-pole flux leakage pathsRealize automatic field weakening speed expansionMagnetic circuit rotating partsLow speedPermanent magnet synchronous motor

The invention relates to an automatic field-weakening method for a built-in permanent magnet synchronous motor, which solves the problem that field-weakening speed is difficult to widen due to the fixed rotor excitation and small reactance of armature reaction of a direct axis in the conventional permanent magnet synchronous motor in the market. In a rotor magnetic structure of the permanent magnet synchronous motor, a magnetic flux short-circuit block is arranged in a magnetic flux isolating layer in a quadrature axis direction with the help of an automatic adjustment action of a spring; when the rotary speed of the rotor is low, the short-circuit block is positioned at a low-speed position so that interelectrode magnet leakage through the isolating layer is small; when the rotary speed of the rotor is increased, the short-circuit block gradually deviates from the low-speed position to move towards the edge of the rotor under the action of rotating centrifugal force, which expands the interelectrode magnet leakage path; and the leakage magnet flux passing through the isolating layer is increased and the main magnet flux is reduced so that the aim of automatic filed-weakening widening speed is fulfilled in the motor body and a larger speed-adjusting range is reached. The method can be applied to the permanent magnet motors which have uncertain pole numbers and tangential or radial magnet structures.

Owner:SHANGHAI MARITIME UNIVERSITY

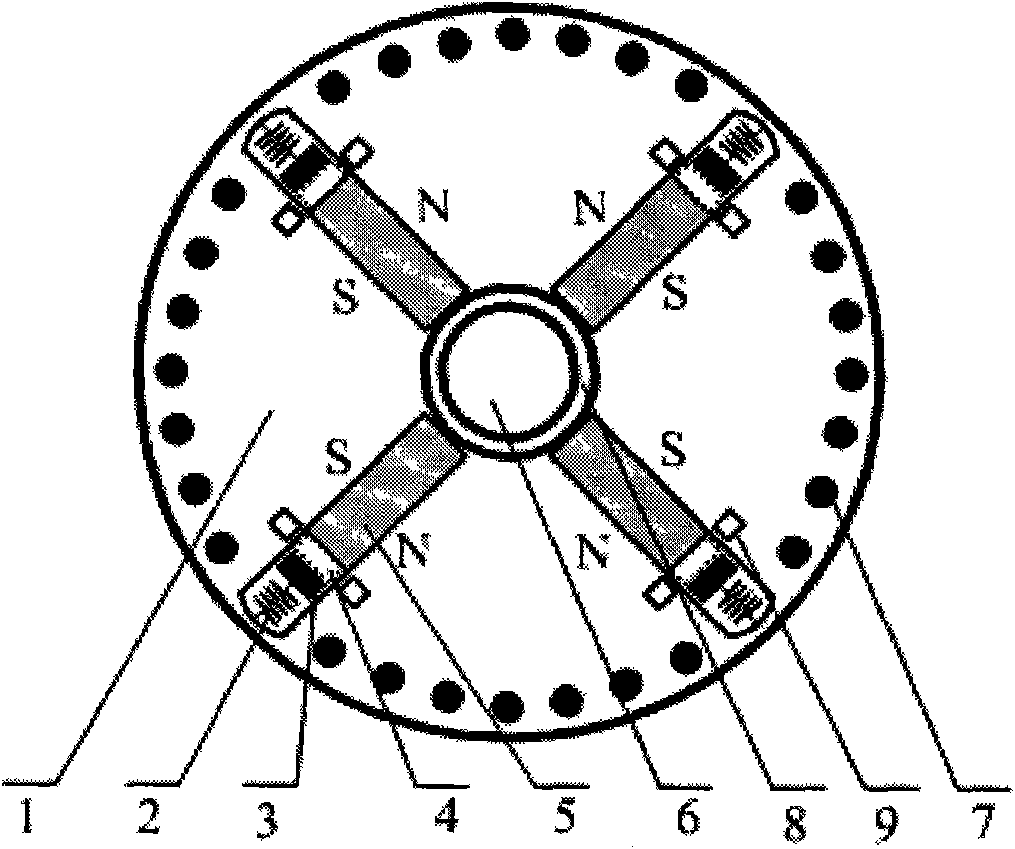

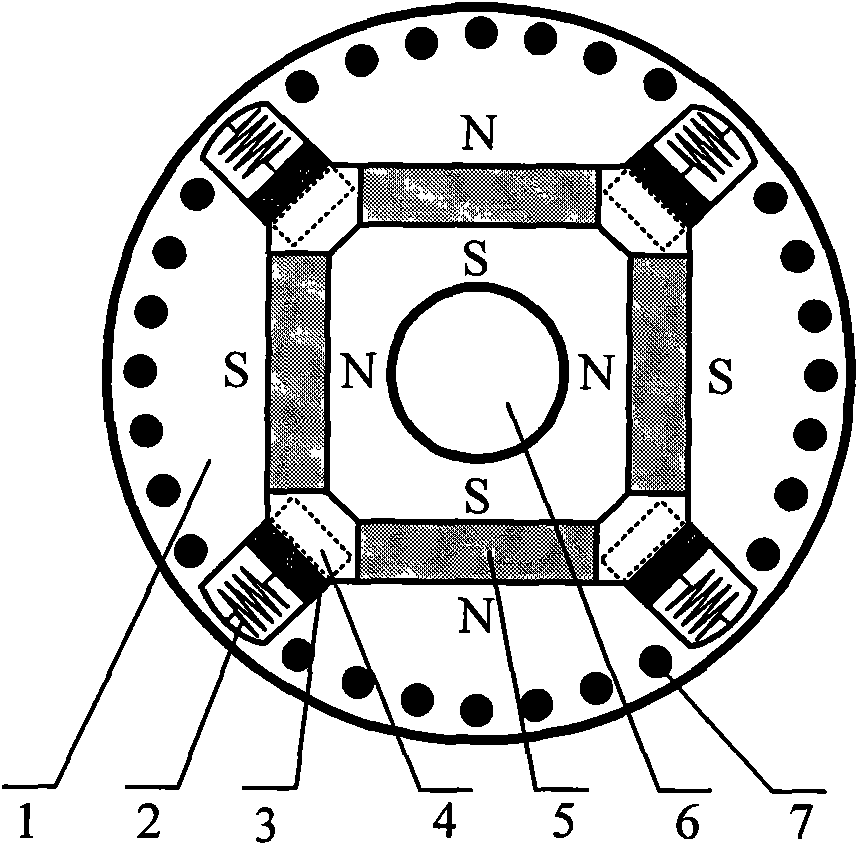

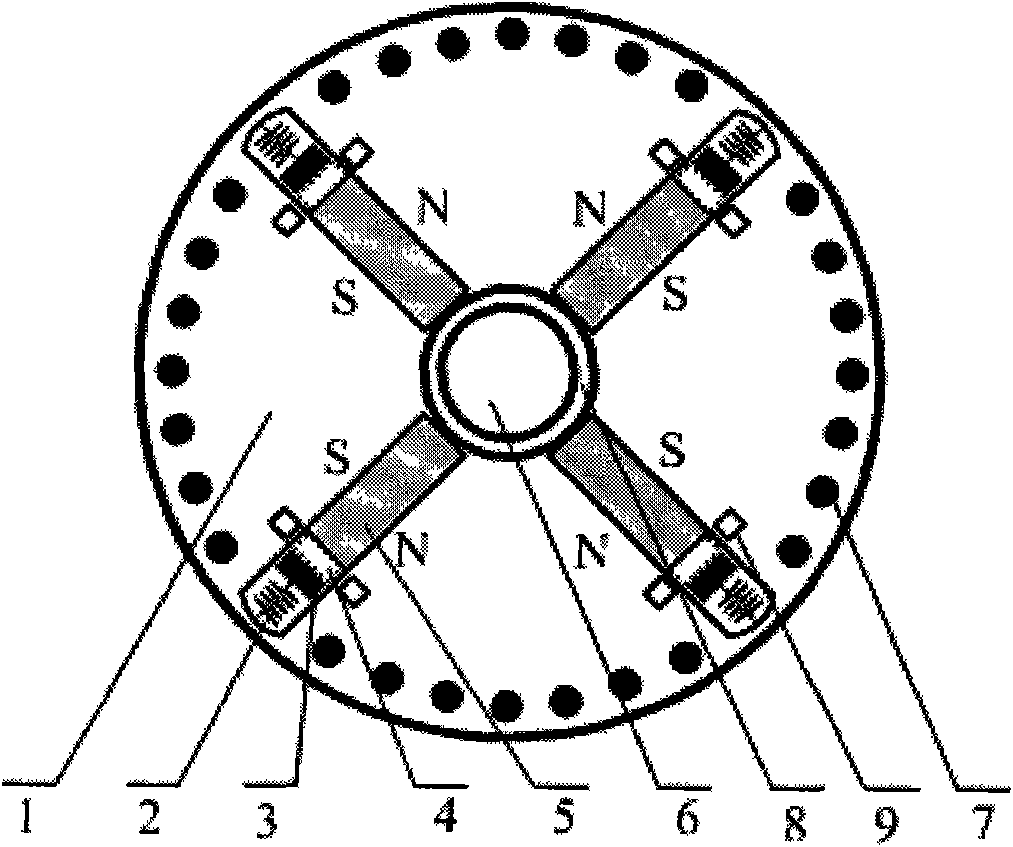

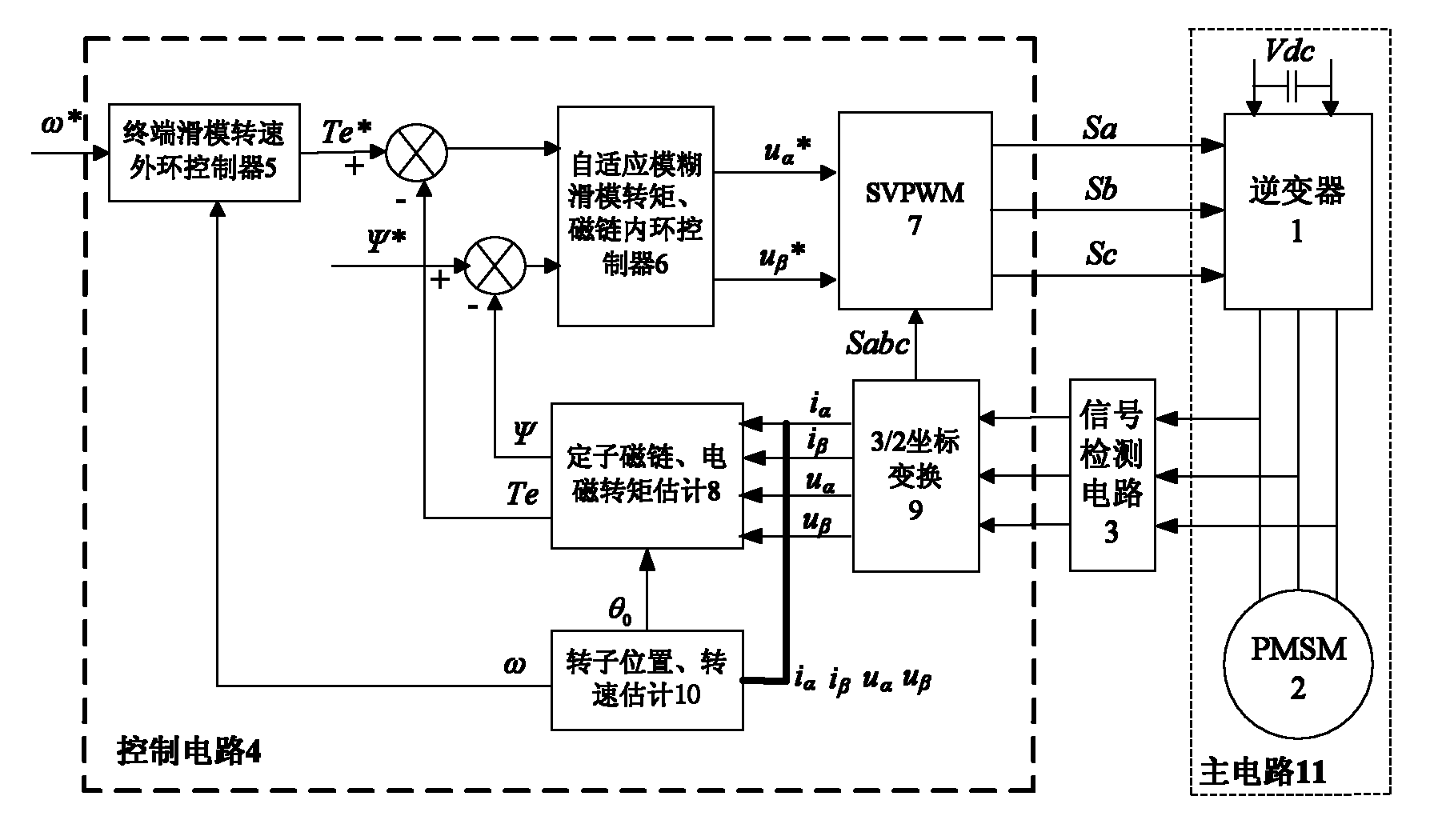

Direct torque control system of permanent magnet synchronous motor based on terminal sliding mode

InactiveCN102035456AAchieving finite-time convergenceRemove uncertaintyElectronic commutation motor controlVector control systemsFuzzy sliding mode controlElectric machine

The invention discloses a direct torque control system of a permanent magnet synchronous motor based on a terminal sliding mode, which belongs to the field of motor control. The system comprises a main circuit, a signal detection circuit, a rotational-speed outer-ring controller for the terminal sliding mode, a torque linkage inner-ring controller for an adaptive fuzzy sliding mode, a stator-linkage electromagnetic torque estimation module, an SVPWM module, a 3 / 2 coordinate transform module, and a rotor position / speed estimation module; the design on the rotational-speed outer-ring controller is realized by using a terminal sliding mode control method based on the adaptive estimation of load disturbance, and the rotational-speed outer-ring controller outputs direct-torque controlled demand signals; and the design on the torque linkage inner-ring controller is realized by using an adaptive fuzzy sliding mode control method, and the torque linkage inner-ring controller outputs two-phase alternating voltages in a two-phase stationary coordinate system; and through carrying out SVPWM transformation on the two-phase alternating voltages, a power switching element acted on an inverter of the main circuit implements the direct torque control of the permanent magnet synchronous motor. The direct torque control system in the invention has the advantages of quick torque response speed, good robustness, small tracking error, and capability of improving the reliability and static / dynamic characteristics of the system.

Owner:CHANGCHUN UNIV OF TECH

Direct torque control device and method for permanent magnet synchronous motor

InactiveCN101931362AIncrease the number of optional vectorsReduce torque rippleTorque ripple controlVector control systemsVoltage vectorPermanent magnet synchronous motor

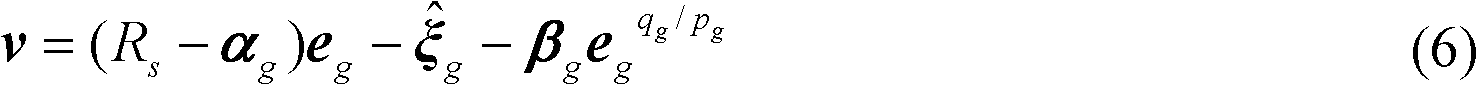

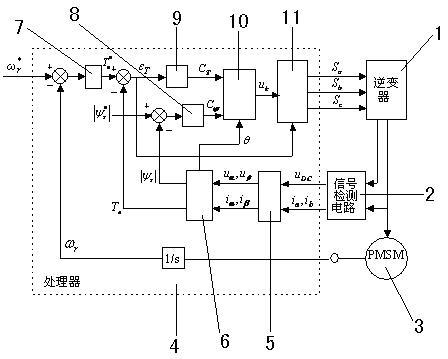

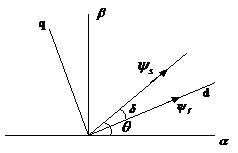

The invention discloses a direct torque control device and a direct torque control method for a permanent magnet synchronous motor. The DC bus voltage of an inverter and a current signal of the permanent magnet synchronous motor are output to a signal detection circuit; the signal detection circuit outputs the DC bus voltage and the current signal to a processor; meanwhile, a rotating speed pulse signal of the permanent magnet synchronous motor is output to the processor and is processed by the processor to form a proper switch signal which is then output to the inverter so as to control the motor. A proper voltage vector is selected from twelve synthesized voltage vectors according to a flux linkage error and a torque error and the position of the flux linkage in twelve sectors, and the duty ratio of the selected voltage vector is determined in real time according to the torque error so as to generate a proper inverter switch signal for controlling the permanent magnet synchronous motor. The number of the selectable voltage vectors in the traditional direct torque control is increased, the duty ratio of an acting vector is adjusted in real time according to the torque error, and the torque pulsation in the traditional direct torque control can be effectively reduced.

Owner:XIAN UNIV OF TECH

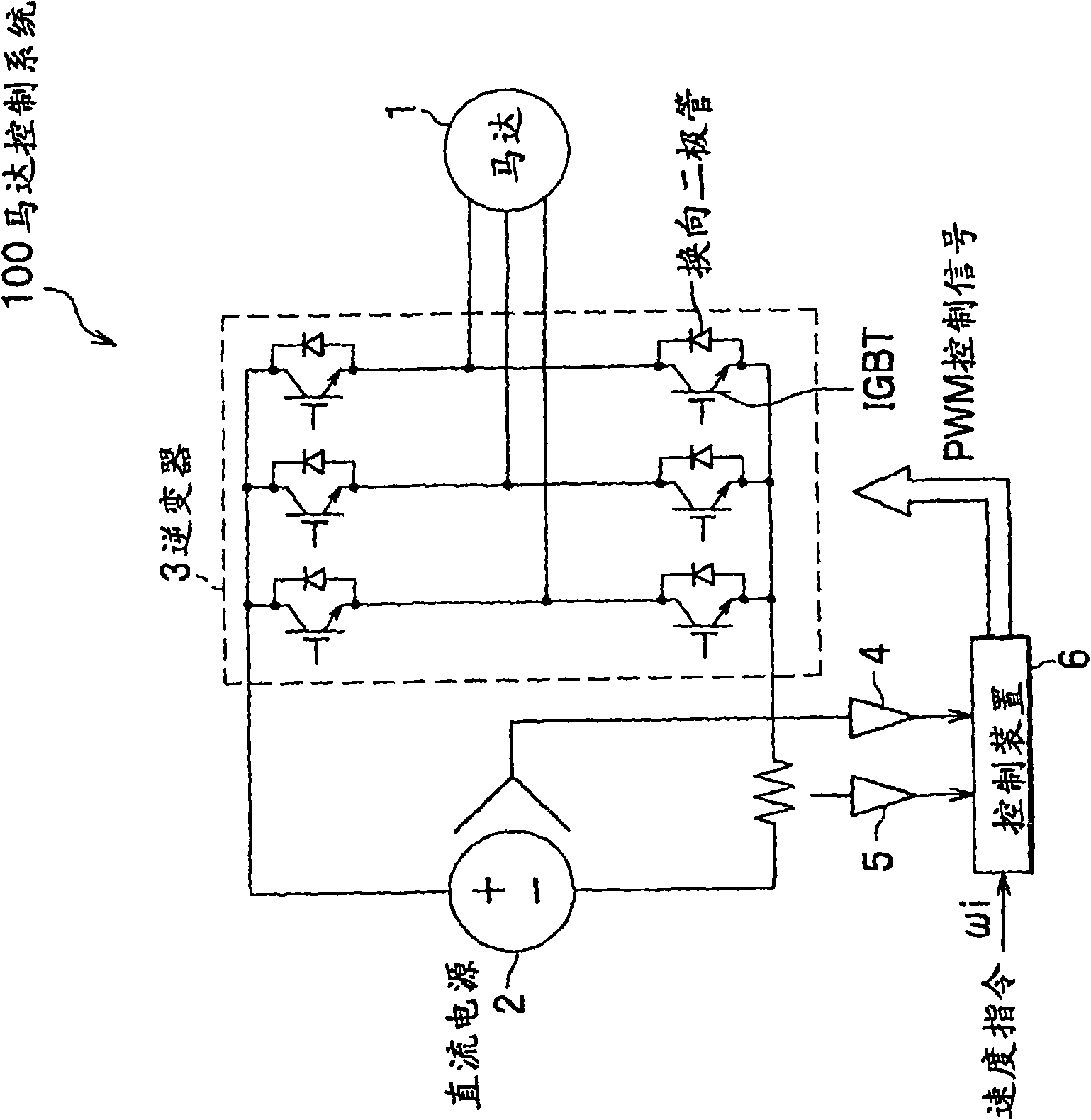

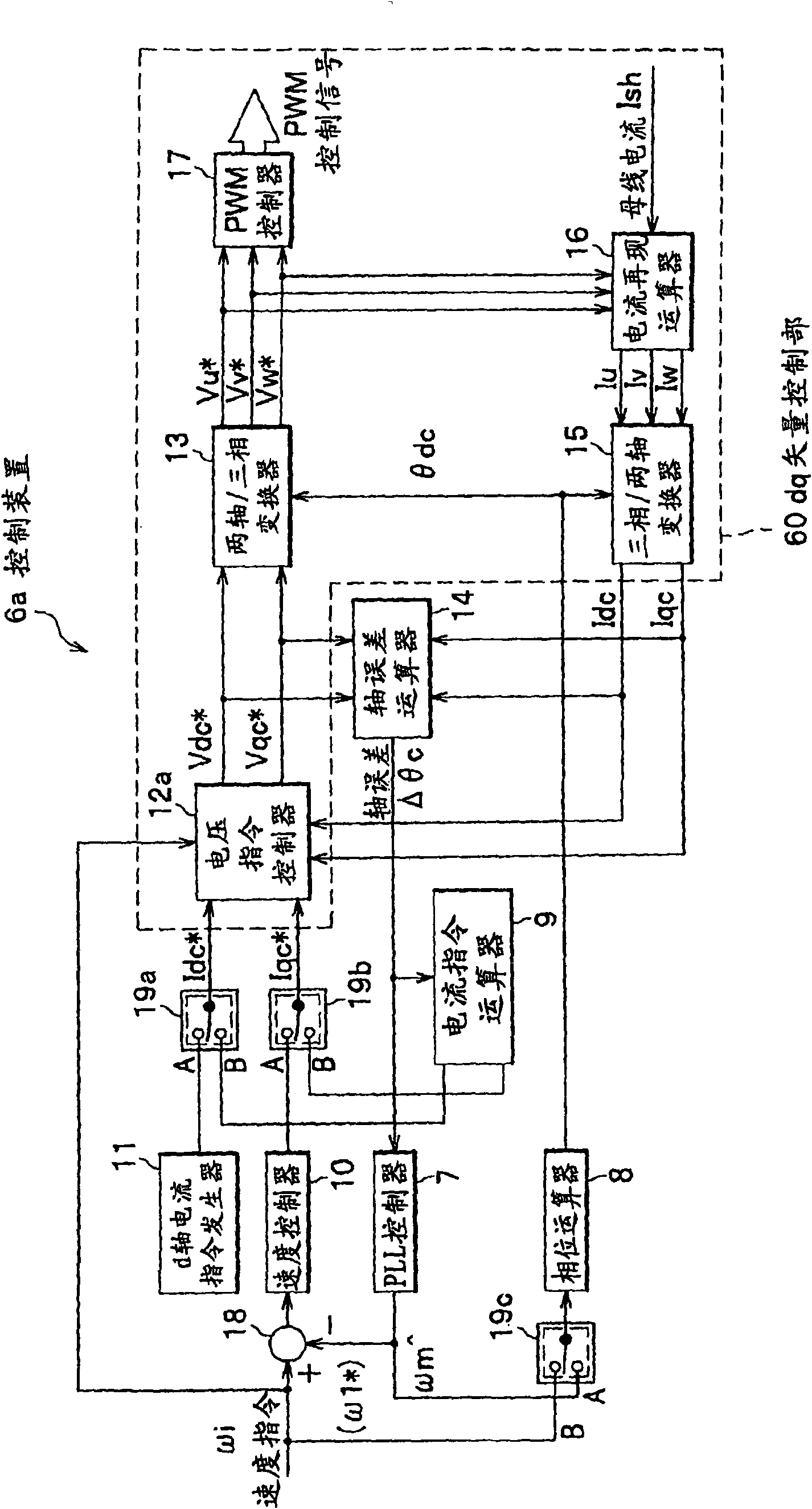

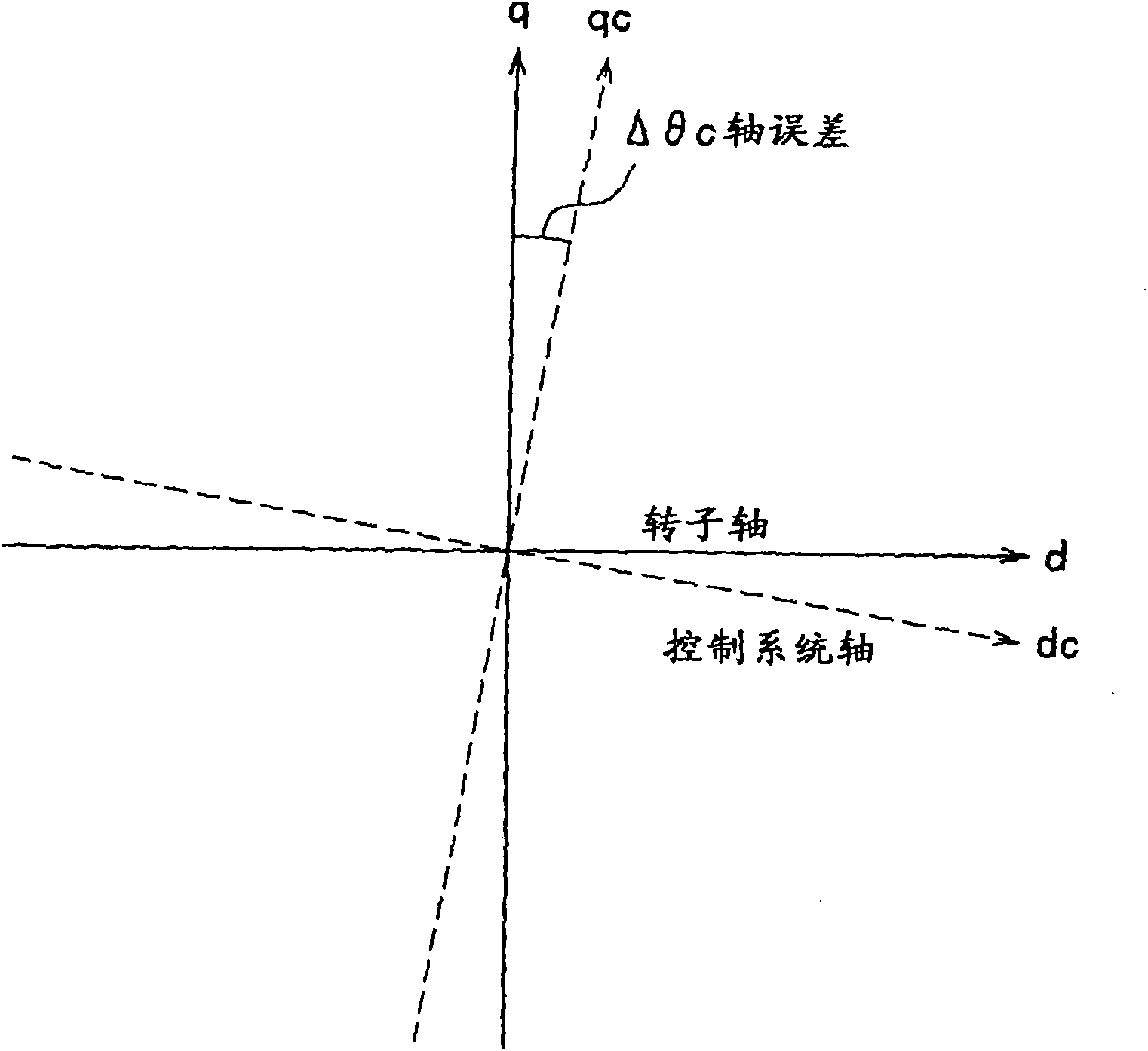

Motor control device, motor control system, motor control module and refrigerating unit

ActiveCN101635555AReduce switching shockVector control systemsSingle motor speed/torque controlSynchronous motorControl vector

The invention provides a motor control device, a motor control system, a motor control module and a refrigerating unit, capable of reducing switching shock when switching from synchrony operation mode to non-position sensor mode. In a control device 6a comprising a dc vector control device for controlling rotating speed of permanent magnet synchronous motor consistent with speed instruction value omega i through an inverter, comprising a synchrony operation mode for driving the permanent magnet synchronous motor together with a rotating angle theta m' obtained by integraling the speed instruction value; and a non-position sensor mode for proceeding feedback control to rotating angle theta m of the permanent synchronous motor, comprising a switcher 19 that speculating shaft error (delta theta c) of the stator shaft of the permanent magnet synchronous motor and control system shaft of the dq vector control part, and when the speculated shaft error almost consistent with phase difference of current instruction value, the synchronous rotating mode is switched into the non-position sensor mode.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com