Patents

Literature

309results about How to "Improve power characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

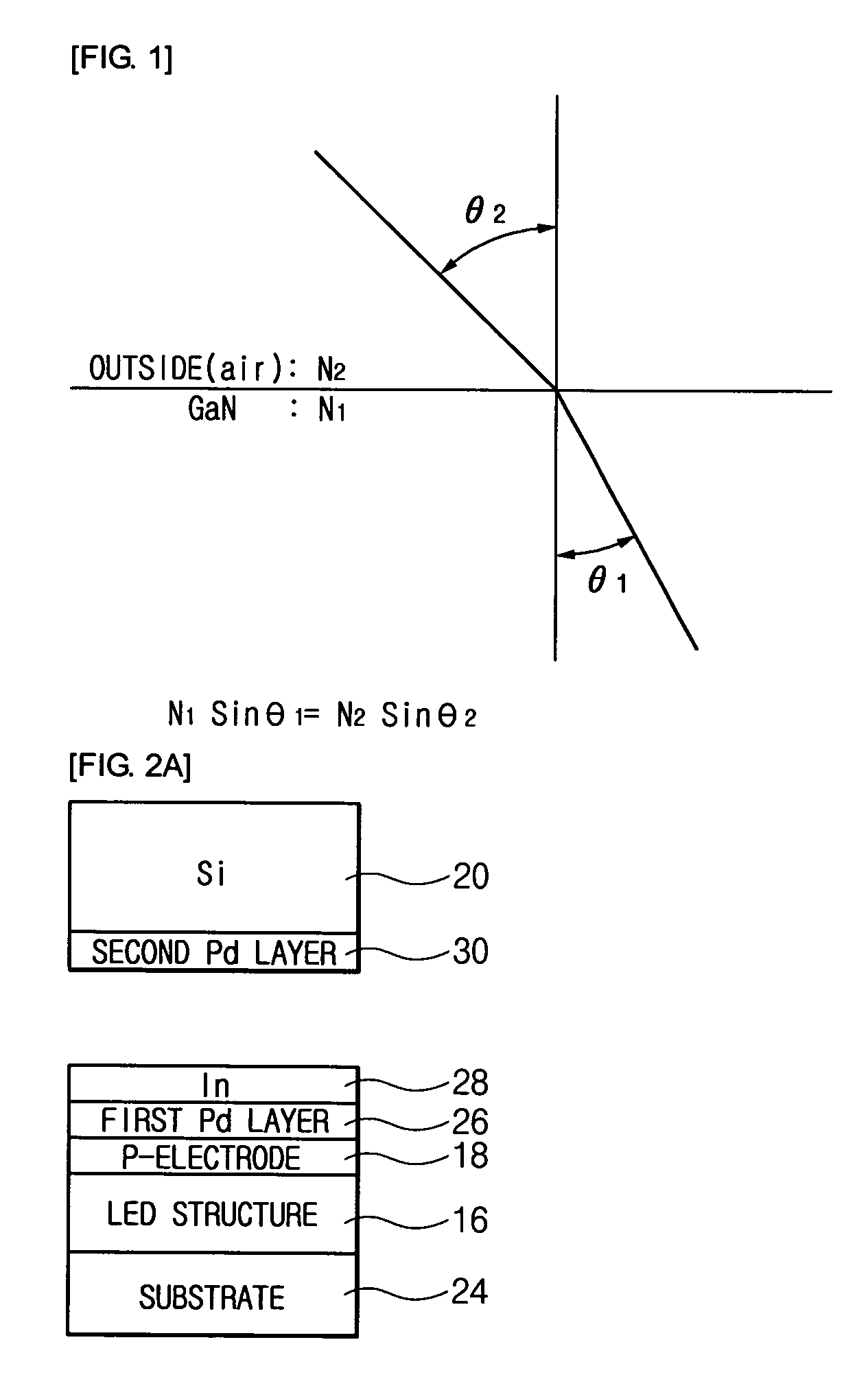

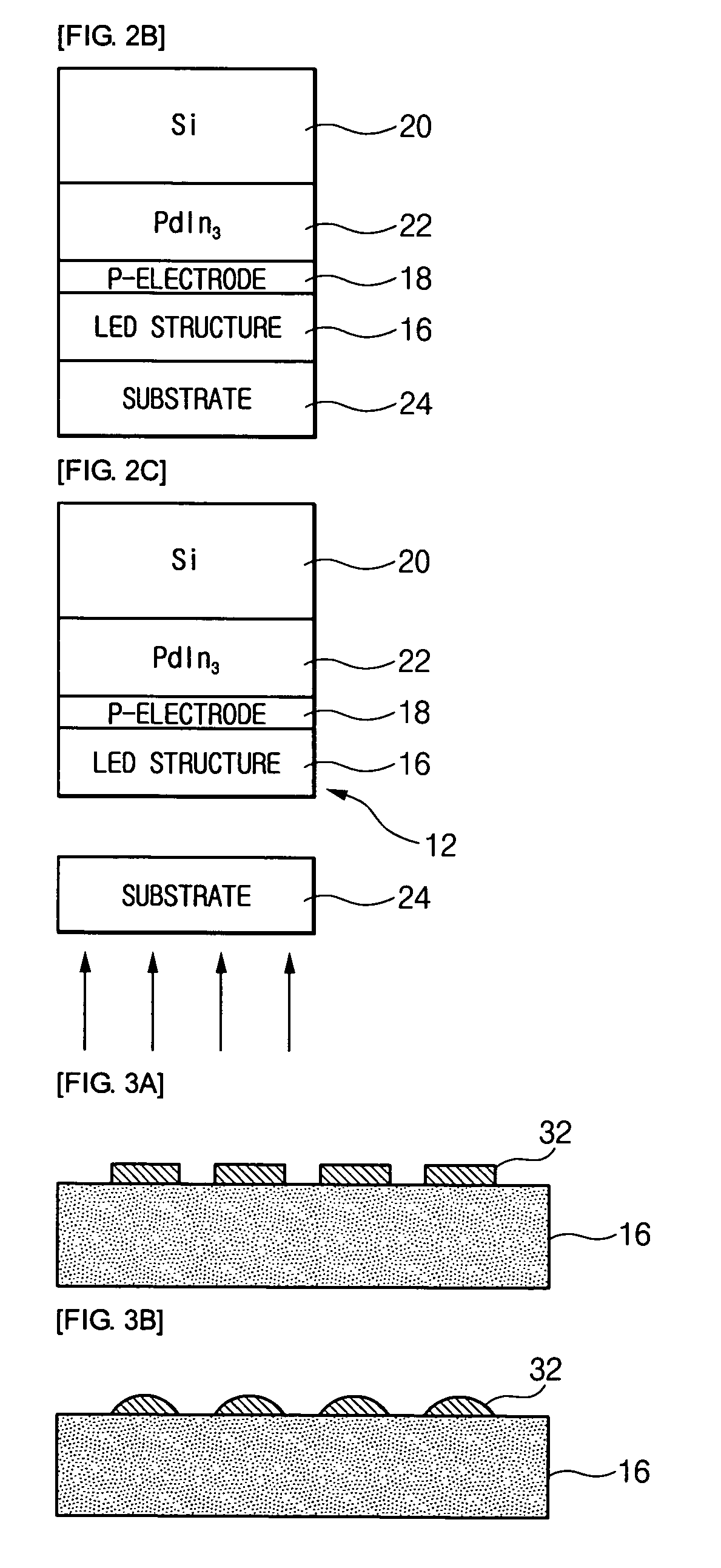

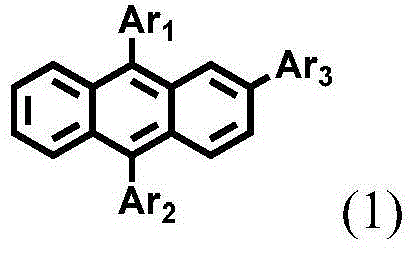

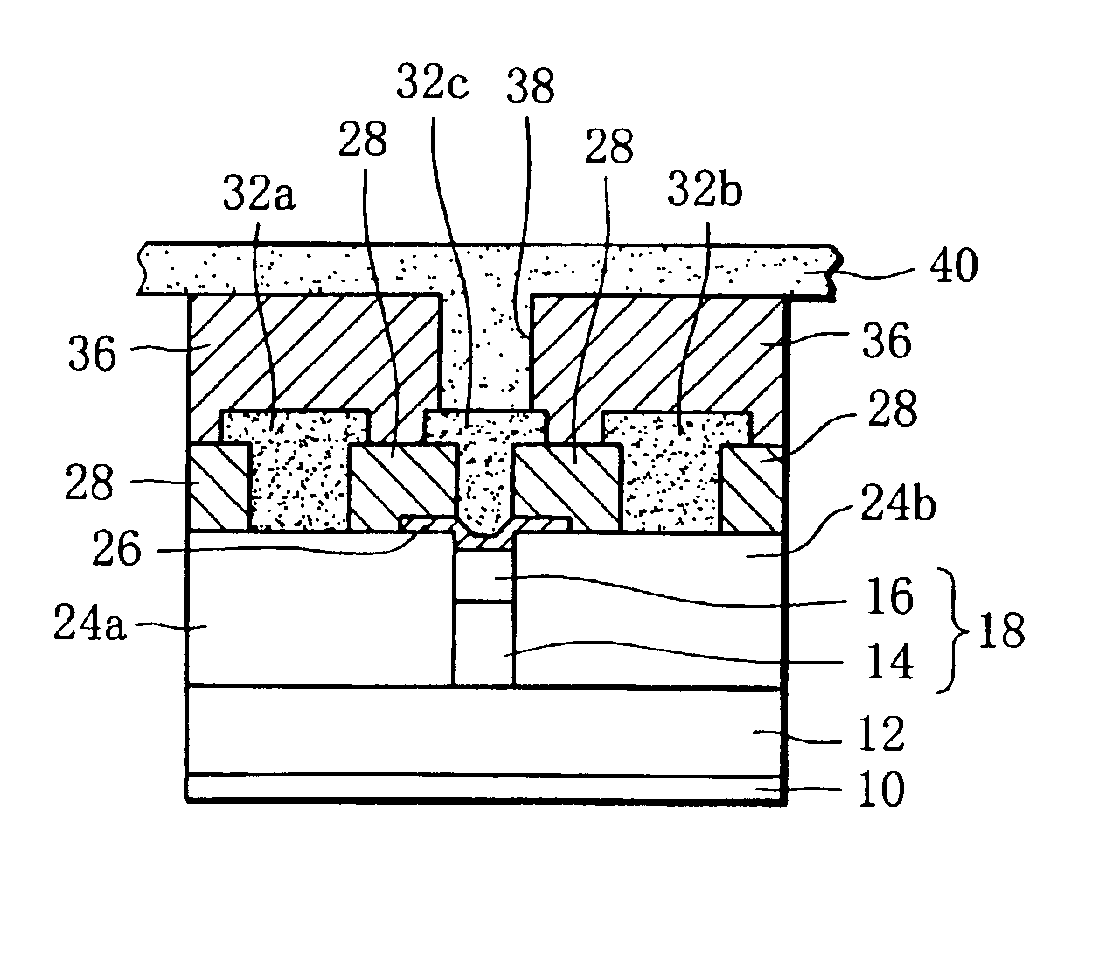

Vertical GaN-based LED and method of manfacturing the same

ActiveUS20070018187A1Maximize improvementImprove power characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringActive layer

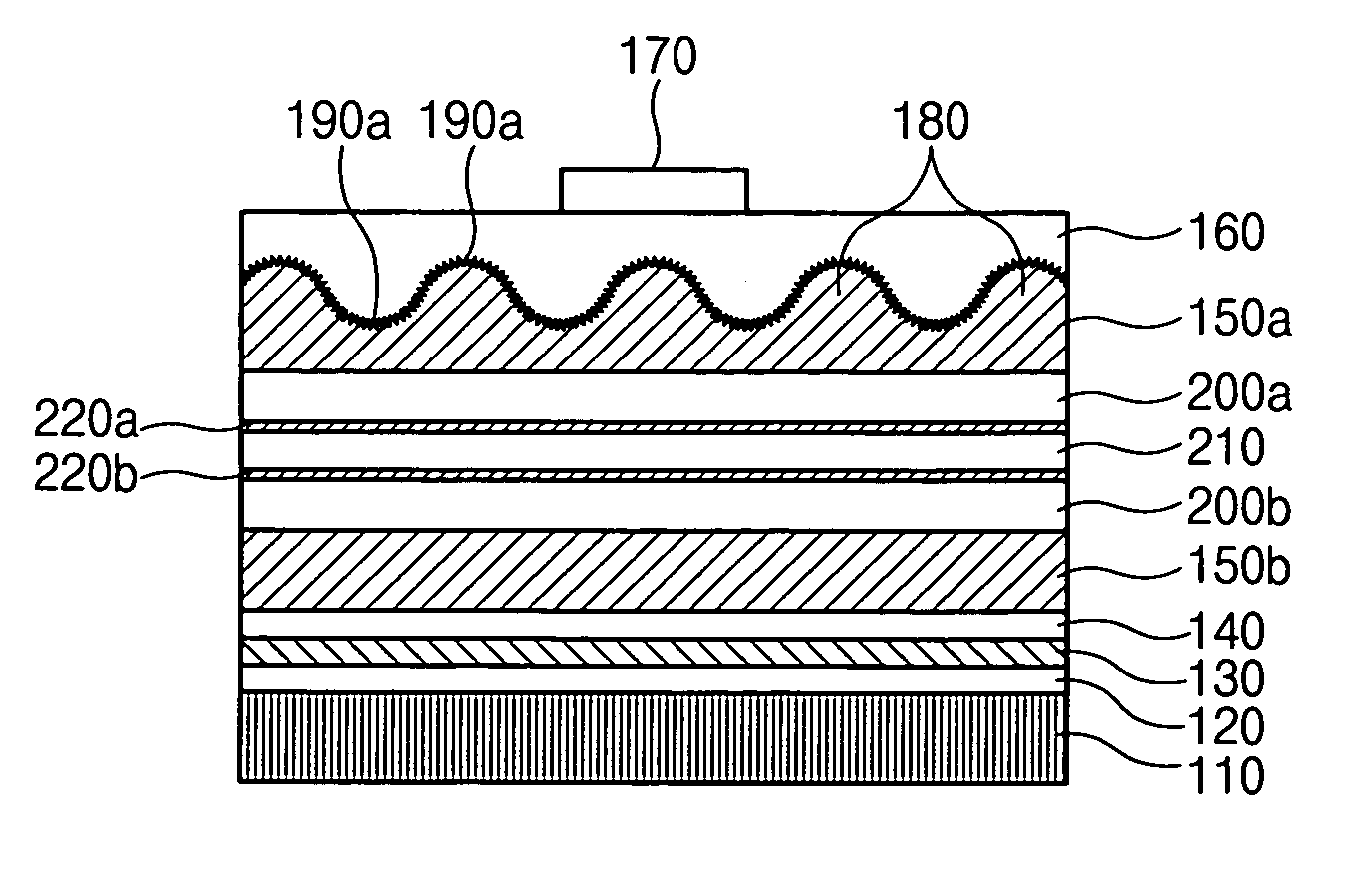

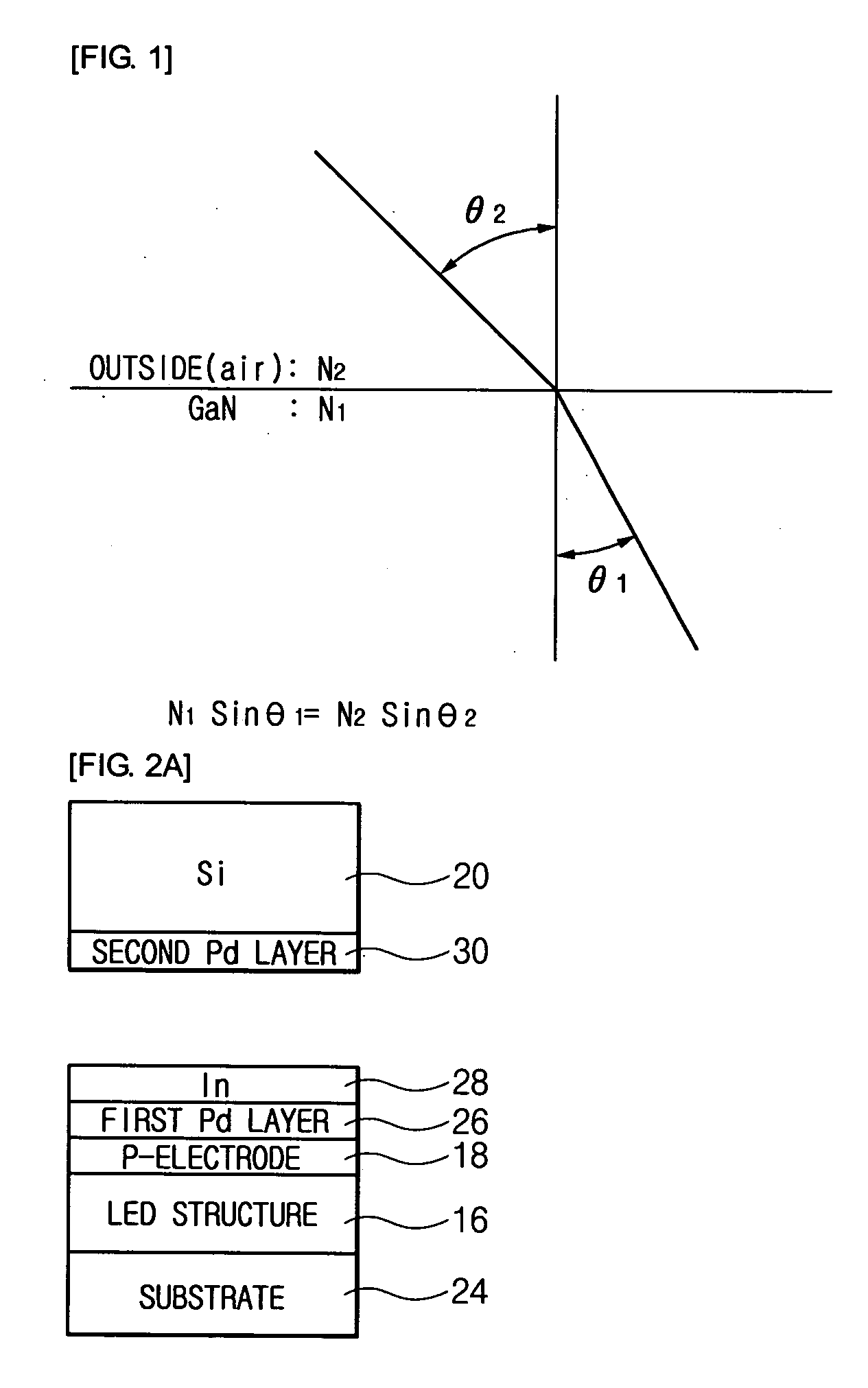

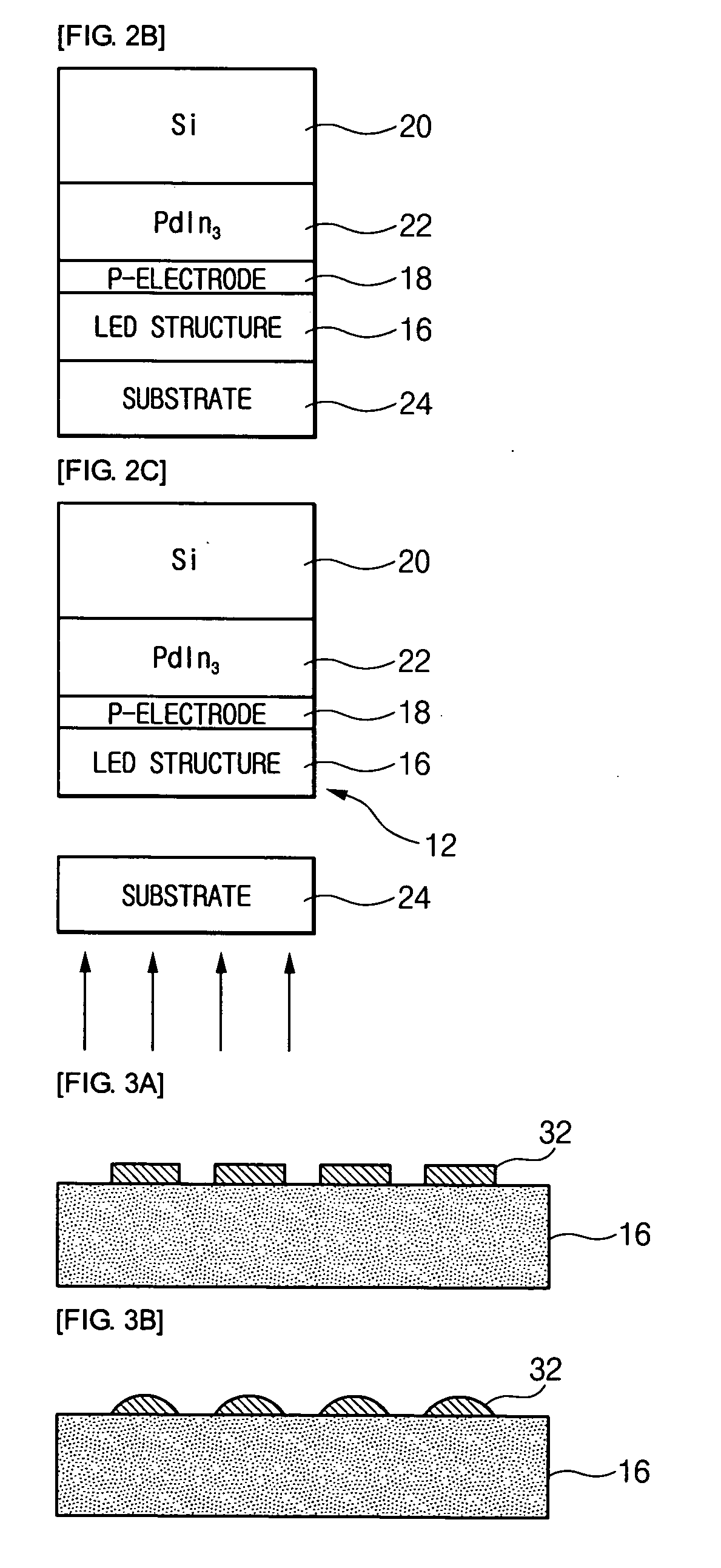

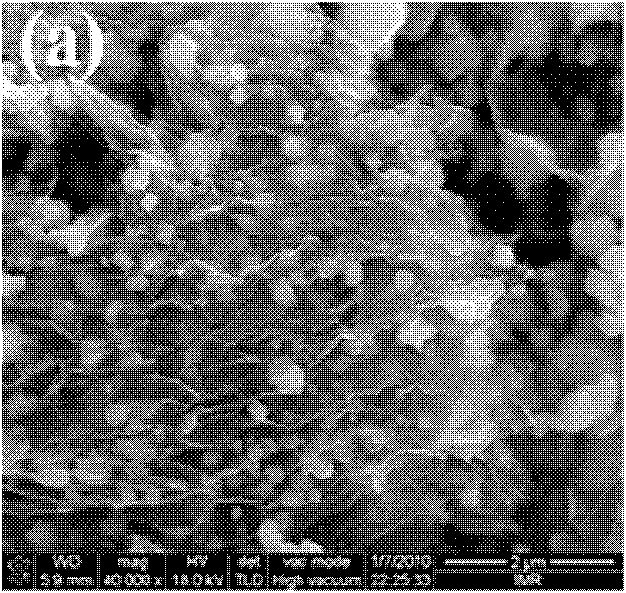

A vertical GaN-based LED and a method of manufacturing the same are provided. The vertical GaN-based LED includes an n-electrode, a first n-type GaN layer, a first AlGaN layer, a GaN layer, a second AlGaN layer, a second n-type GaN layer, an active layer, a p-type GaN layer, and a structure support layer. The first n-type GaN layer has uneven patterns having a plurality of protuberances. The first AlGaN layer is formed under the first n-type GaN layer, and the GaN layer is formed under the first AlGaN layer. The active layer is formed under the second n-type GaN layer, and the p-type GaN layer is formed under the active layer. A p-electrode is formed under the p-type GaN layer, and the structure support layer is formed under the p-electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

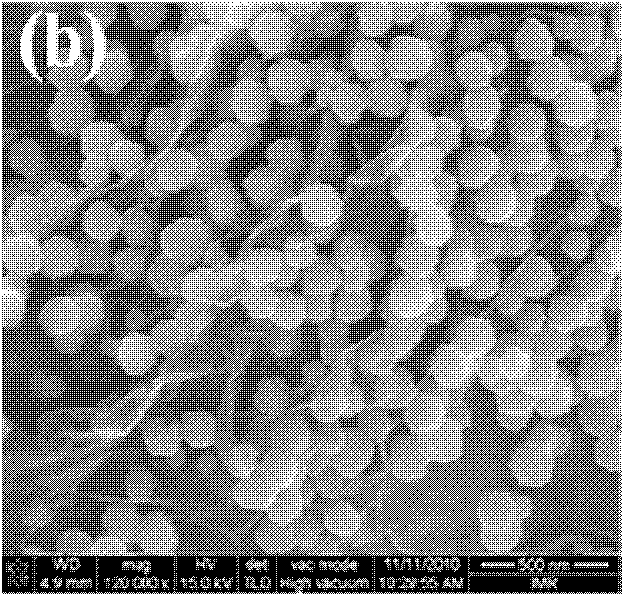

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

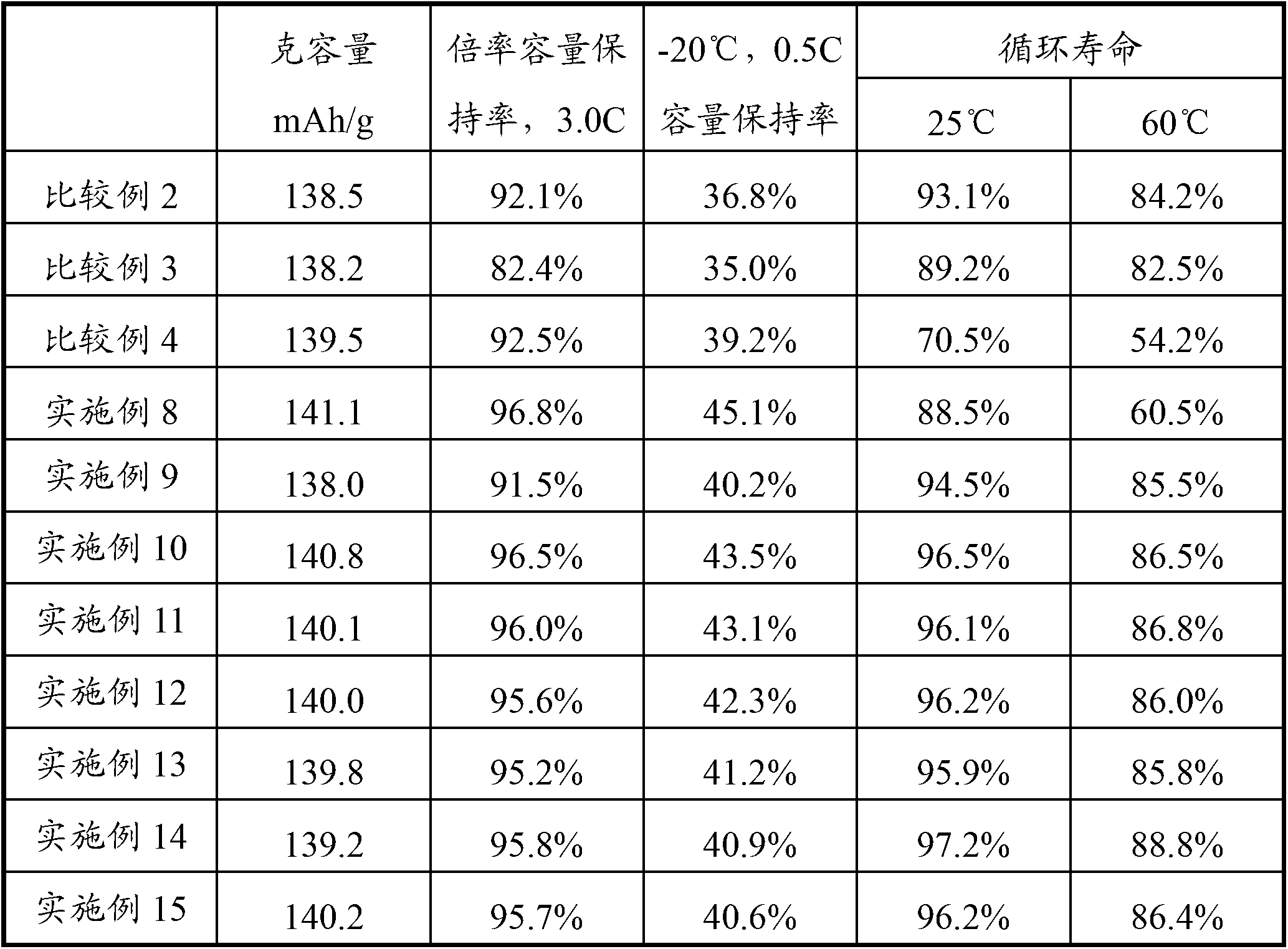

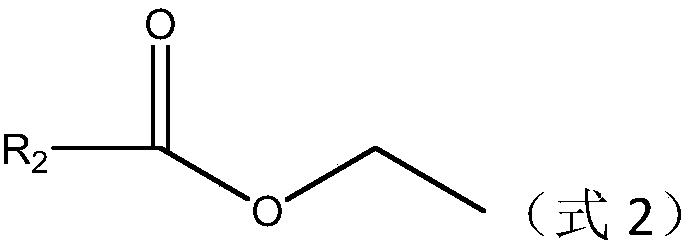

Lithium-ion secondary battery and electrolyte thereof

InactiveCN103078141AFacilitated DiffusionImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMethyl carbonateCarbonate

The invention discloses a lithium-ion secondary battery and an electrolyte thereof. The electrolyte comprises a solvent, lithium salt and a film forming additive, wherein the solvent comprises a first solvent and a second solvent; the first solvent comprises linear carboxylic ester and ethylene carbonate; the second solvent is one or more of ethyl methyl carbonate, diethyl carbonate, dimethyl carbonate and propylene carbonate; and the film forming additive is one or more of fluoroethylene carbonate, vinylene carbonate, 1,3-propane suhone, succinonitrile, adiponitrile, lithium bis(oxalato)borate, and lithium oxalyldifluoroborate. Due to the collocation of linear carboxylic ester and ethylene carbonate, a solvent system with a higher dielectric constant and low viscosity is obtained; the film forming additive improves poor compatibility between linear carboxylic ester and graphite; and finally the lithium-ion secondary battery adopting the electrolyte presents high-power discharge capacity, excellent high-temperature cycling stability and low-temperature charge and discharge properties.

Owner:NINGDE AMPEREX TECH

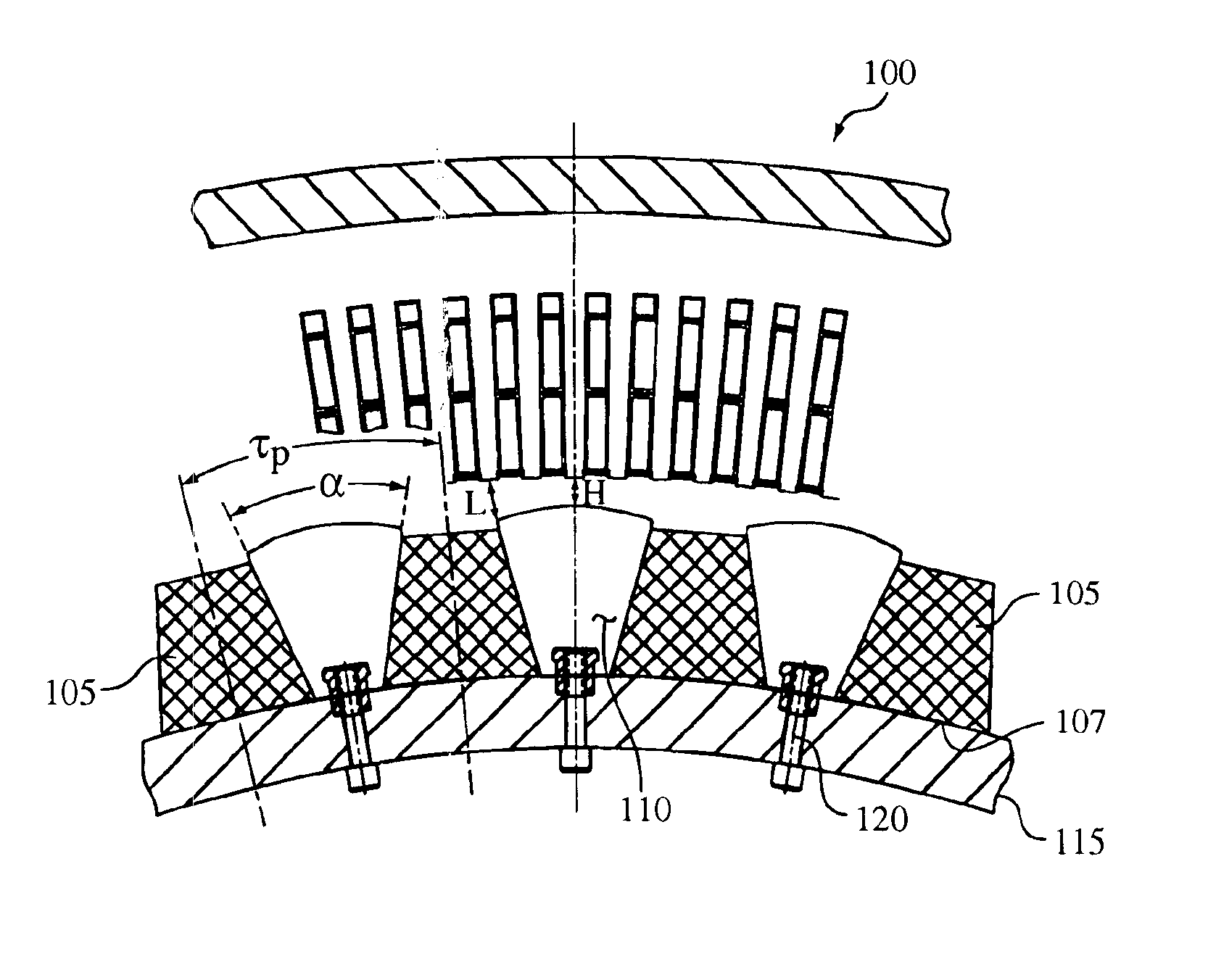

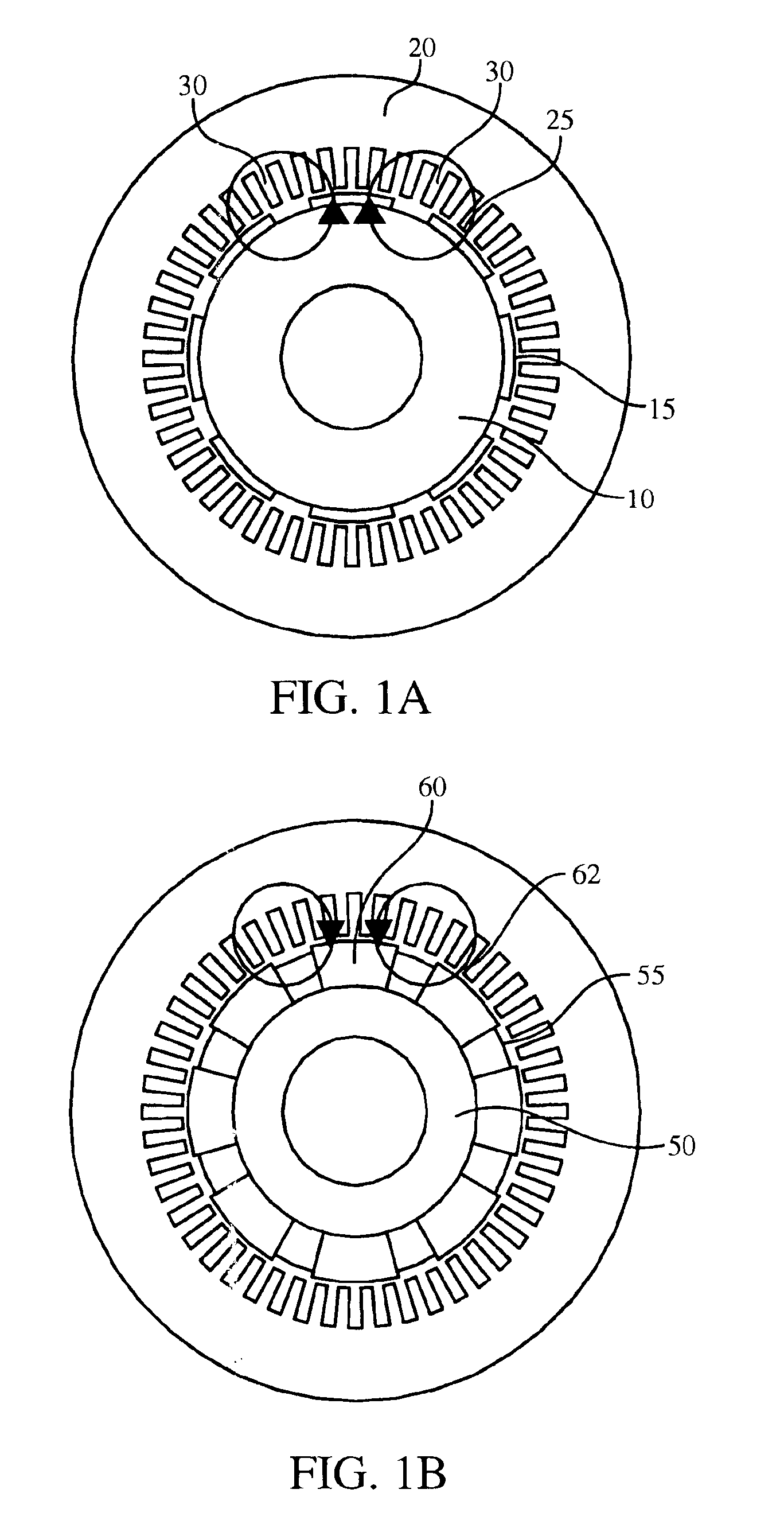

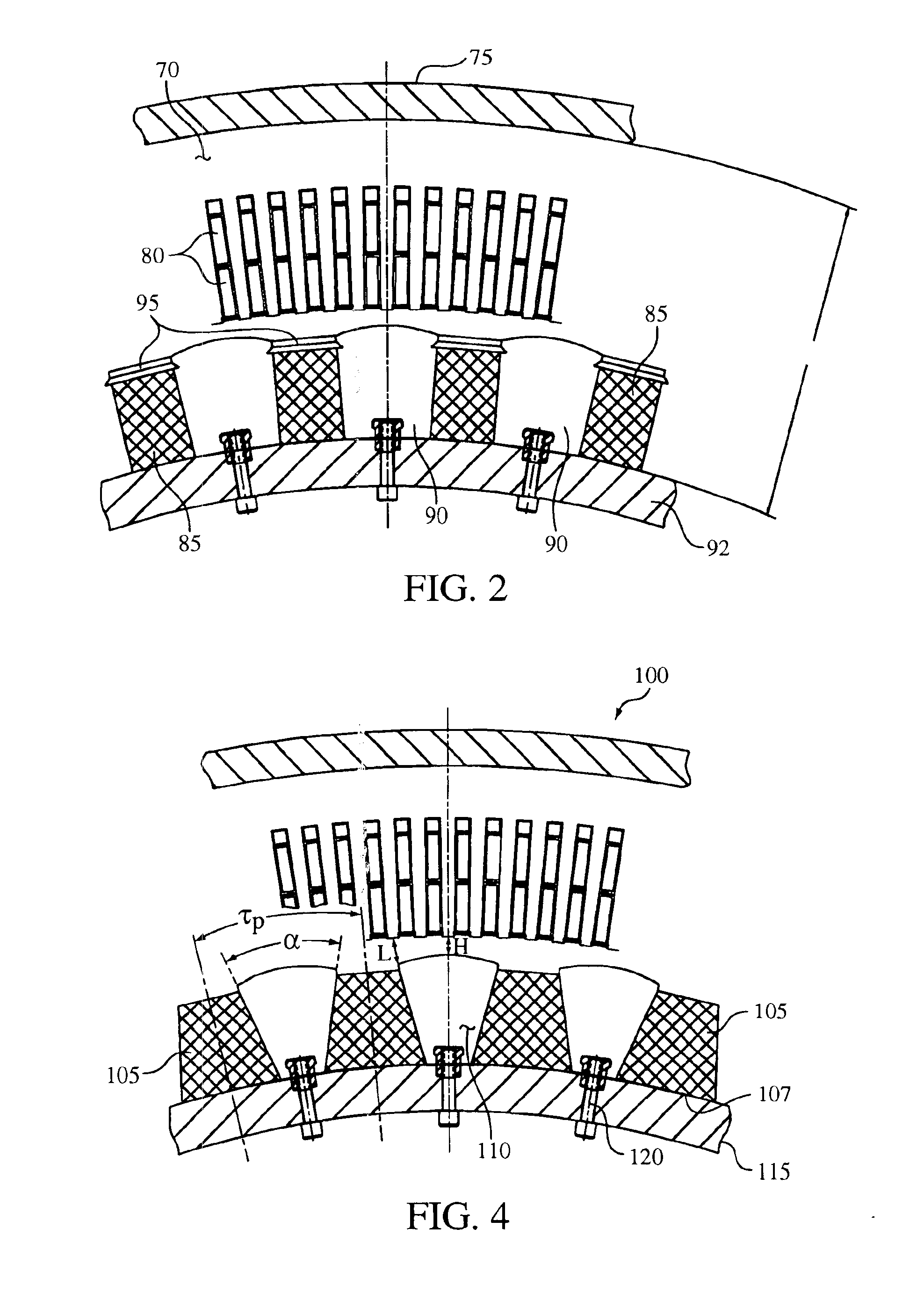

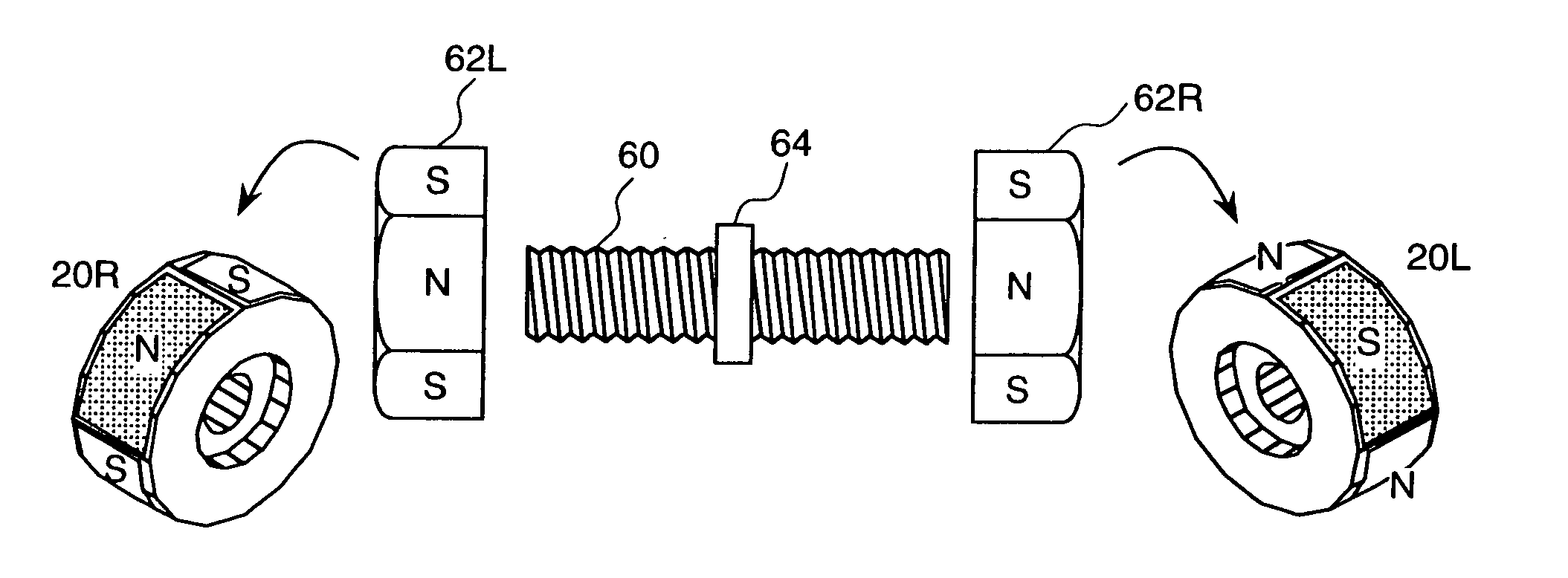

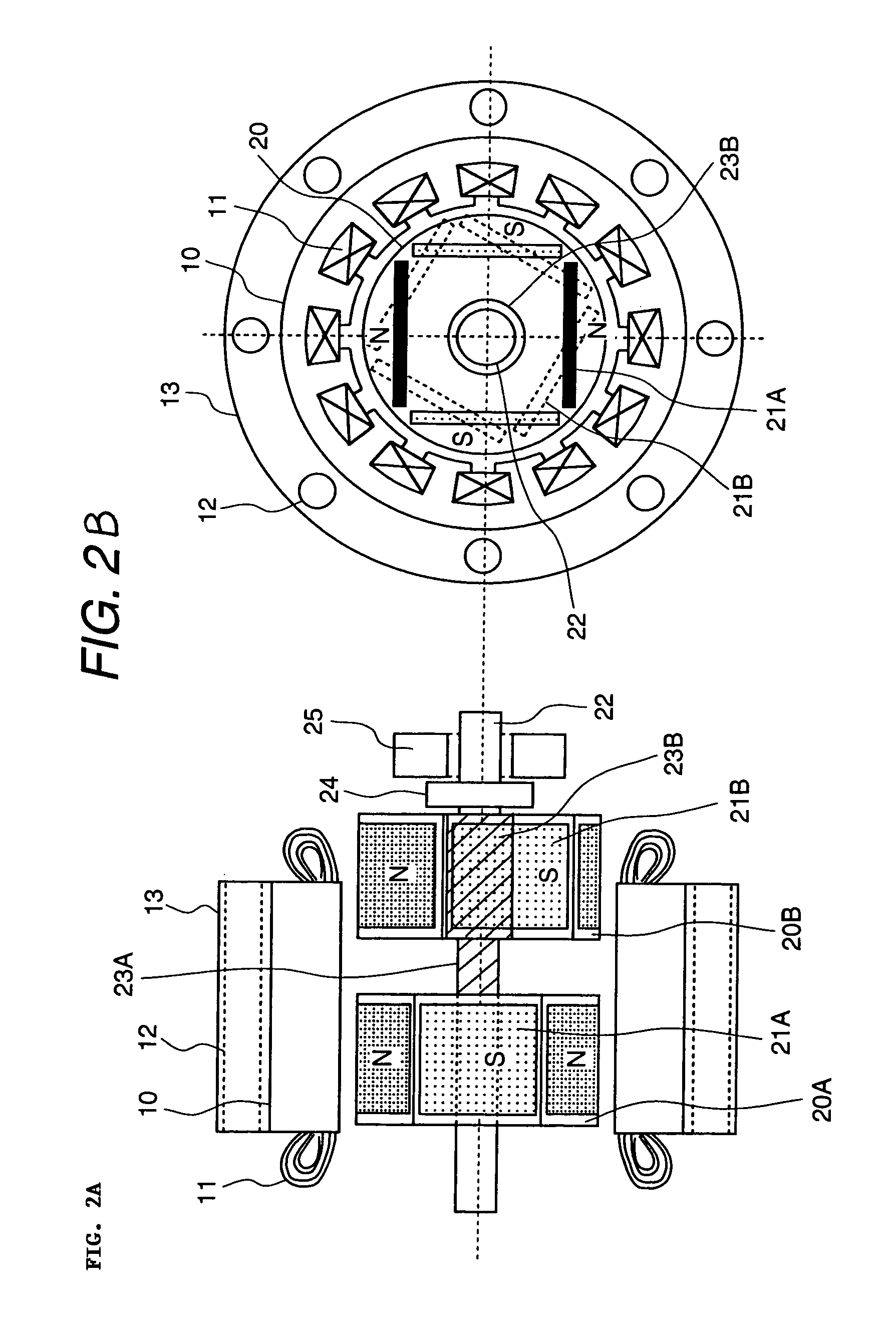

Trapezoidal shaped magnet flux intensifier motor pole arrangement for improved motor torque density

InactiveUS6879075B2Increase torqueImprove power characteristicsSynchronous generatorsWindingsPermanent magnet synchronous machineElectric machine

A permanent magnet synchronous machine with improved torque and power characteristics. A circumferential-oriented rotor assembly is provided with alternating permanent magnets and magnetic pole pieces. In order to reduce the amount of leakage flux in the rotor and increase the effective length of the permanent magnet, a trapezoidal or otherwise tapered permanent magnet structure is used. By alternating trapezoidal permanent magnet, and magnetic pole pieces, a higher intensity magnetic field is created in the air gap utilizing the same radial space in the motor without altering the weight or volume of the motor compared to conventional machines.

Owner:CURTISS WRIGHT ELECTRO MECHANICAL

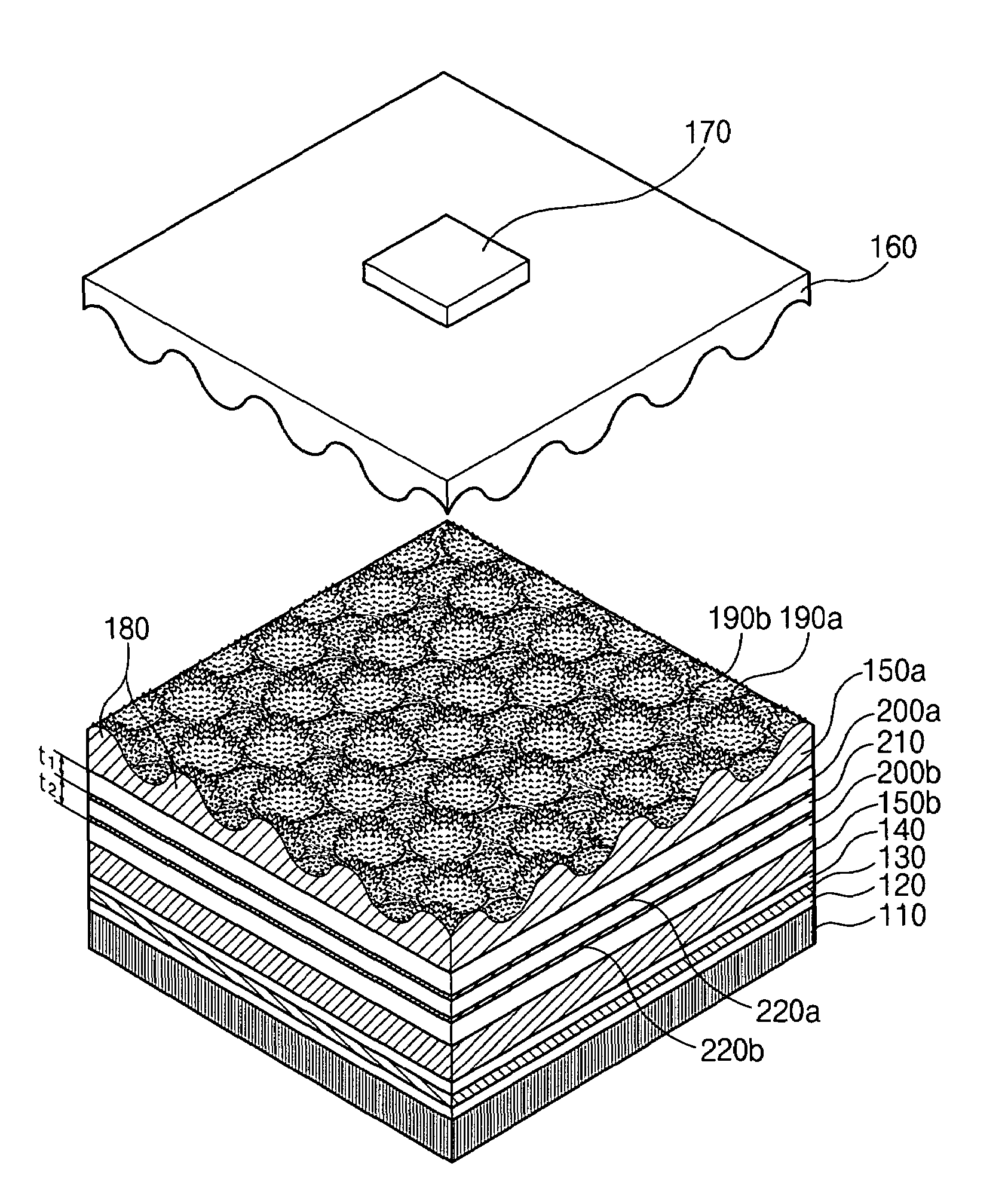

Vertical GaN-based LED and method of manufacturing the same

ActiveUS7436001B2Maximize improvementImprove power characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringActive layer

A vertical GaN-based LED and a method of manufacturing the same are provided. The vertical GaN-based LED includes an n-electrode, a first n-type GaN layer, a first AlGaN layer, a GaN layer, a second AlGaN layer, a second n-type GaN layer, an active layer, a p-type GaN layer, and a structure support layer. The first n-type GaN layer has uneven patterns having a plurality of protuberances. The first AlGaN layer is formed under the first n-type GaN layer, and the GaN layer is formed under the first AlGaN layer. The active layer is formed under the second n-type GaN layer, and the p-type GaN layer is formed under the active layer. A p-electrode is formed under the p-type GaN layer, and the structure support layer is formed under the p-electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Organic Electroluminescent Device

InactiveCN104835921AReduce the driving voltageImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingNitrogenOrganic electroluminescence

The invention relates to an organic electroluminescent device; in the device, a luminescent layer comprises a substrate compound and a doped compound; a nitrogen-containing aromatic heterocyclic derivative is set between the luminescent layer and a cathode. The organic electroluminescent device has a low driving pressure, and is improved in luminous efficiency, power efficiency and service life.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

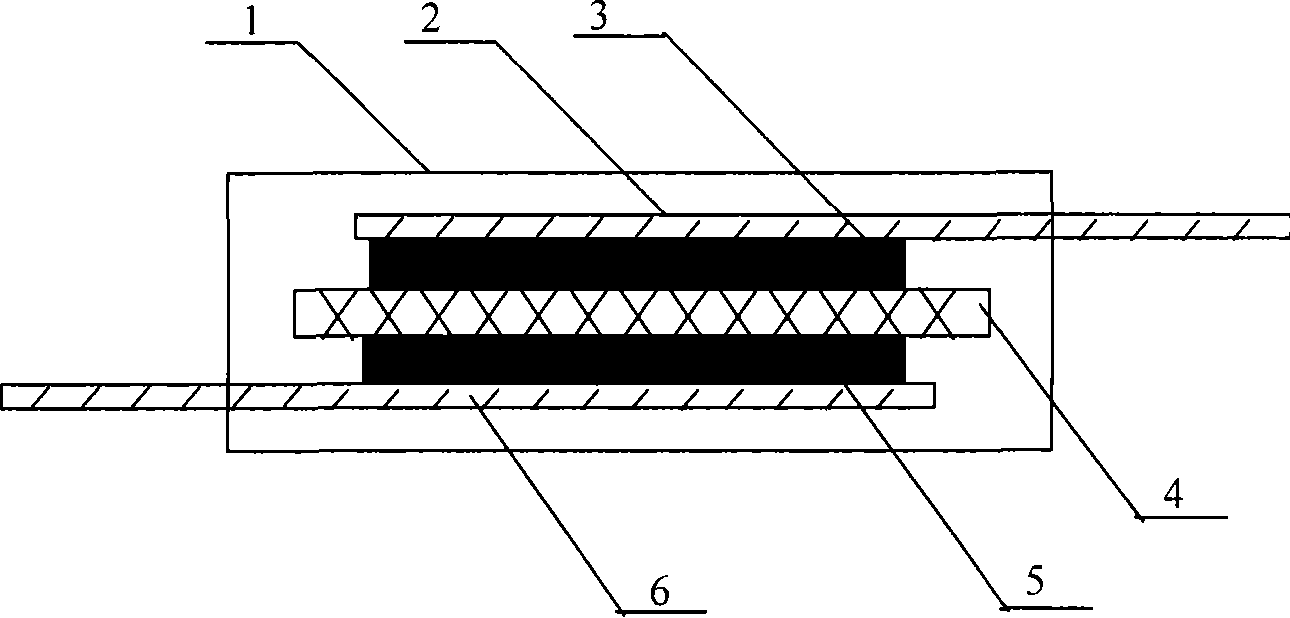

Flexible thin film type solid-state super capacitor and its manufacture process

ActiveCN101162650ALower internal resistanceGood power characteristicsSolid electrolytic capacitorsHybrid capacitor electrodesSolid-stateEngineering

The invention discloses a flexible film type solid state super capacitor and a method for manufacturing the same; the flexible film type solid state super capacitor comprises a positive electrode, a negative electrode, an outer electrode and an encapsulation film, wherein a flexibility solid state electrolyte membrane is arranged between the positive and the negative electrodes. The manufacturing method is as follows: the outer electrode pasting, the electrode pasting, the flexibility solid state electrolyte pasting, the electrode pasting, the outer electrode pasting and the encapsulation pasting are orderly and precisely coated on a basal body by the printing technique; by fitting the corresponding pressing, drying, cutting and packaging techniques, the flexible film type solid state super capacitor with electrode-membrane-electrode structure is finally formed. The flexible film type solid state super capacitor has the advantages of low product internal resistance and good power characteristic, and is suitable for the large scale production and particularly applied to flexible electric products such as electric papers, intelligent name cards and plastics electric products, etc.

Owner:CENT SOUTH UNIV

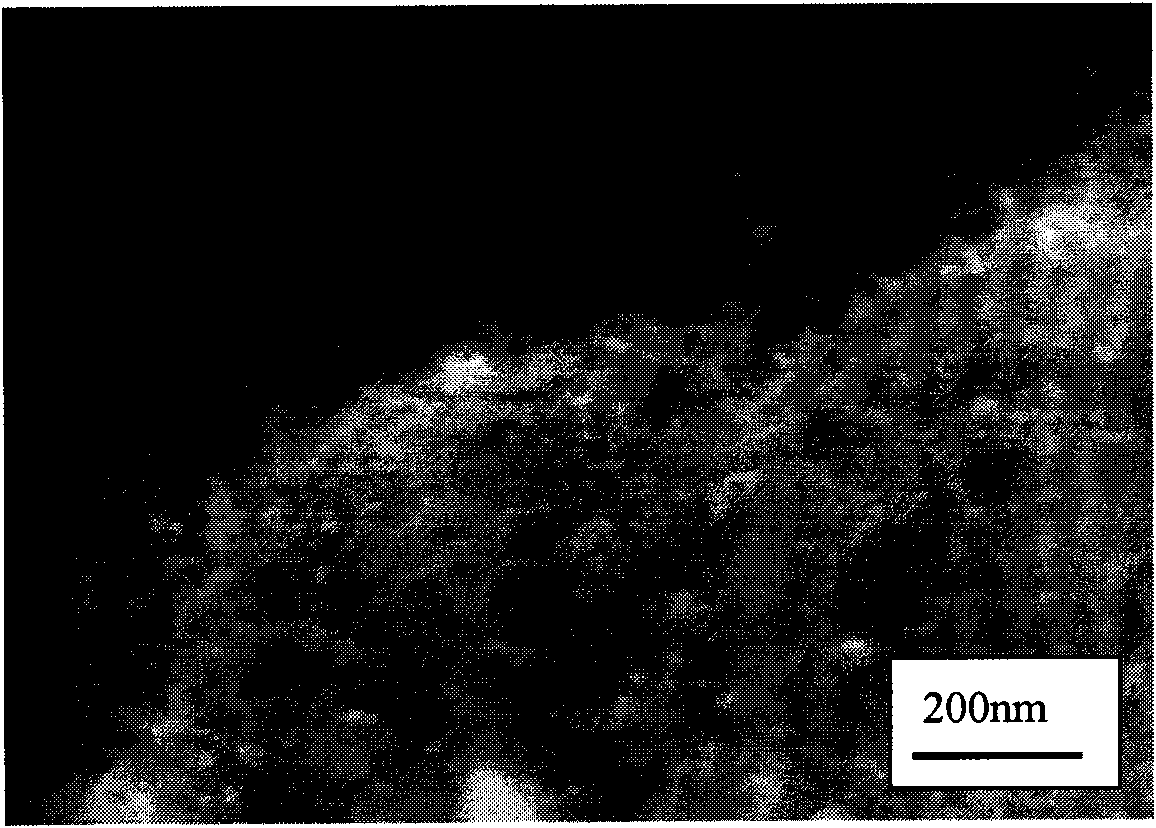

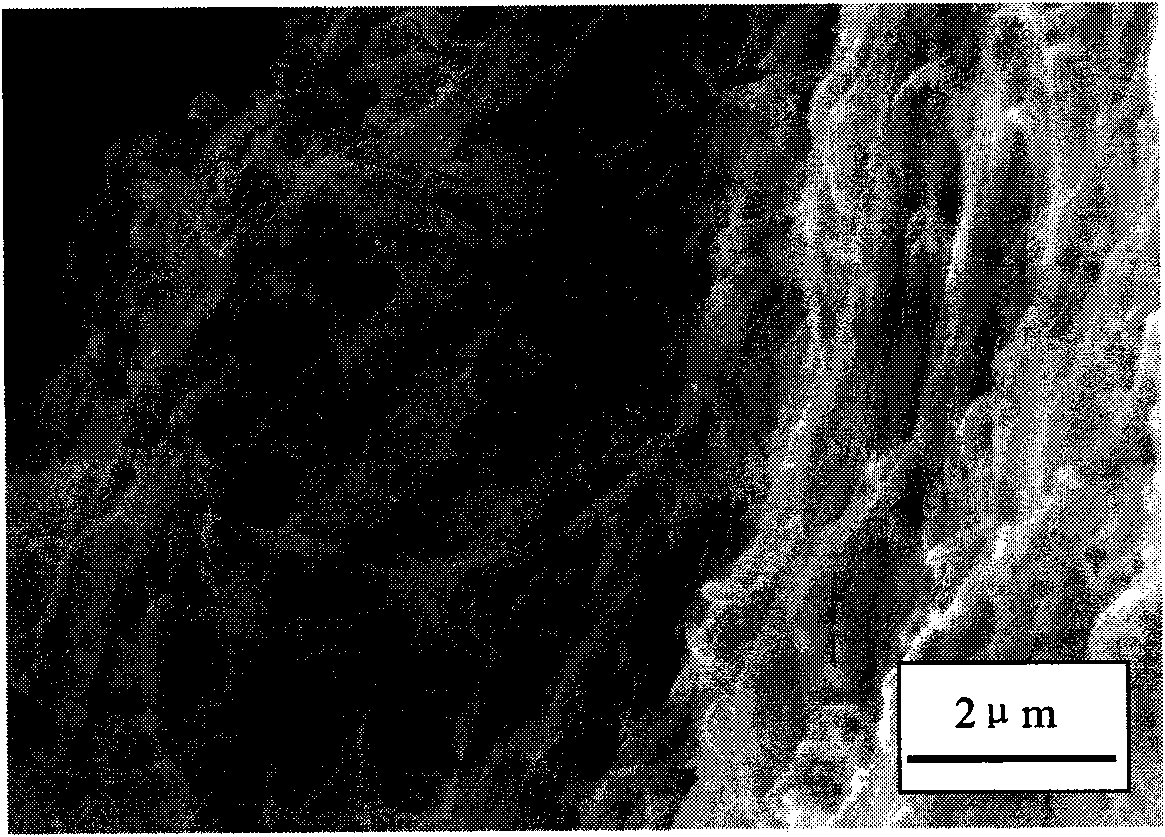

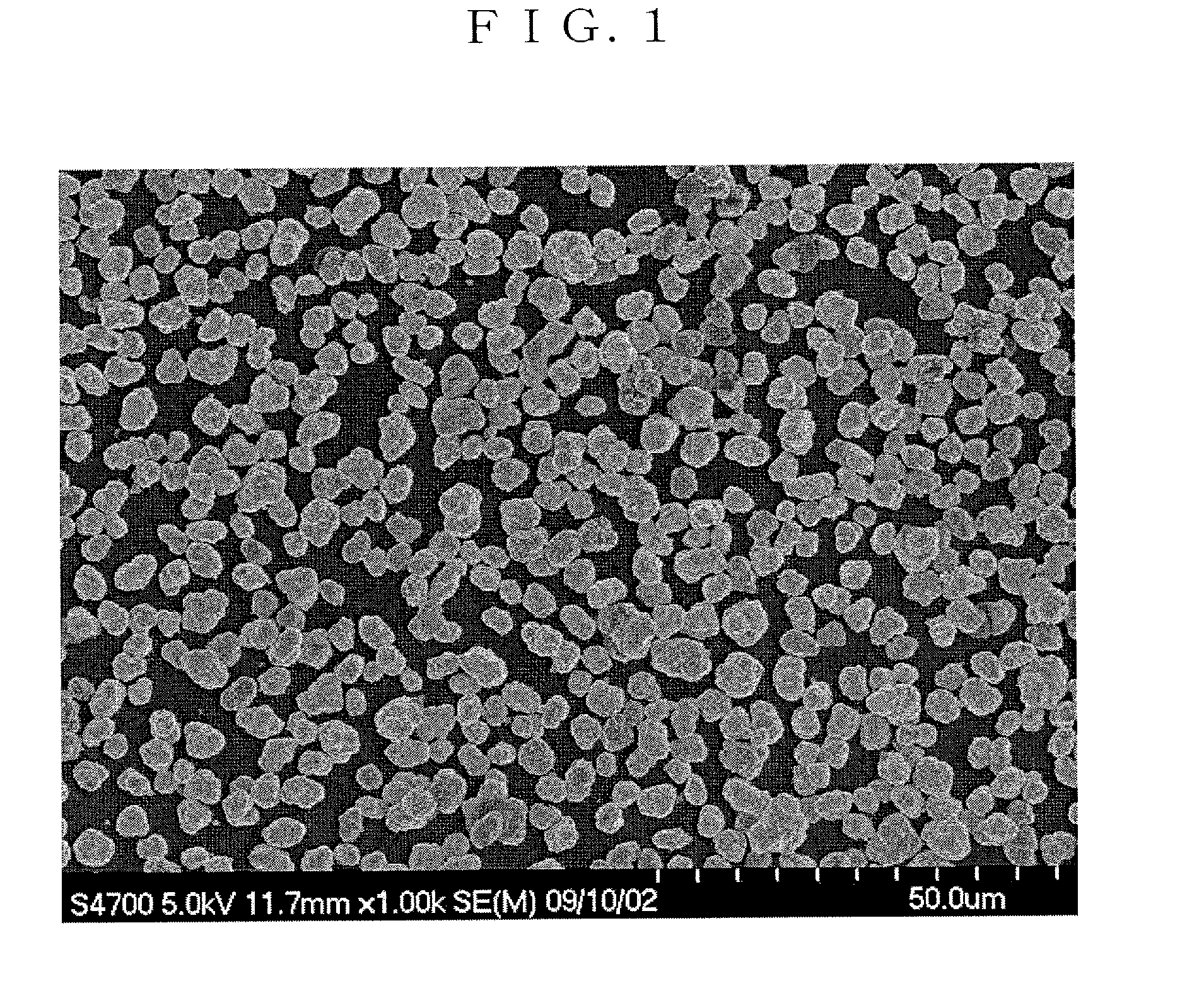

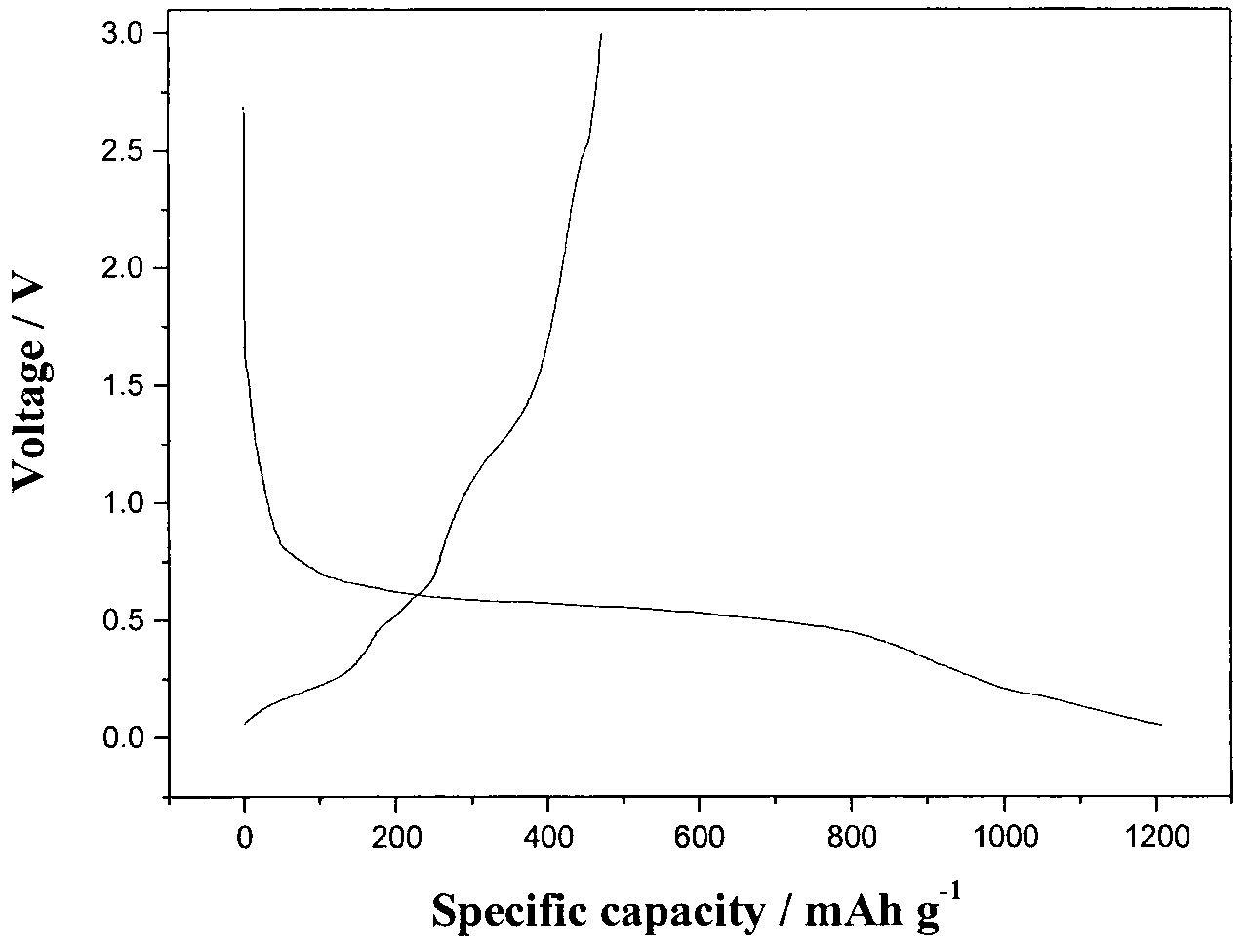

Core-shell structured carbon for cathode material of lithium ion battery and preparation method thereof

InactiveCN101969122AImprove energy density and power densityGood coulombic efficiencyCell electrodesSecondary cellsLithium electrodeLarge capacity

The invention relates to the technical field of lithium ion batteries, in particular to core-shell structured carbon for a cathode material of a lithium ion battery and a preparation method thereof, and the lithium ion battery taking the core-shell structured carbon as the cathode material and a preparation method thereof. The core-shell structured carbon comprises a hard carbon material serving as a 'core' and soft carbon 'shell' which is coated on the surface of the 'core'. On the one hand, the hard carbon material serving as the 'core' provides a large number of spaces for storing lithium and channels for lithium ions to move, and the energy density and power density of the material are improved, and on the other hand, the soft carbon 'shell' with a graphite structure ensures that the material has high coulombic efficiency and cycle performance, so that the lithium ion battery made of the core-shell structured carbon serving as the cathode material has high capacity, high power characteristic, high cycle performance and high first charge and discharge coulombic efficiency, the preparation method is simple, and the cost is low.

Owner:DONGGUAN MCNAIR NEW POWER

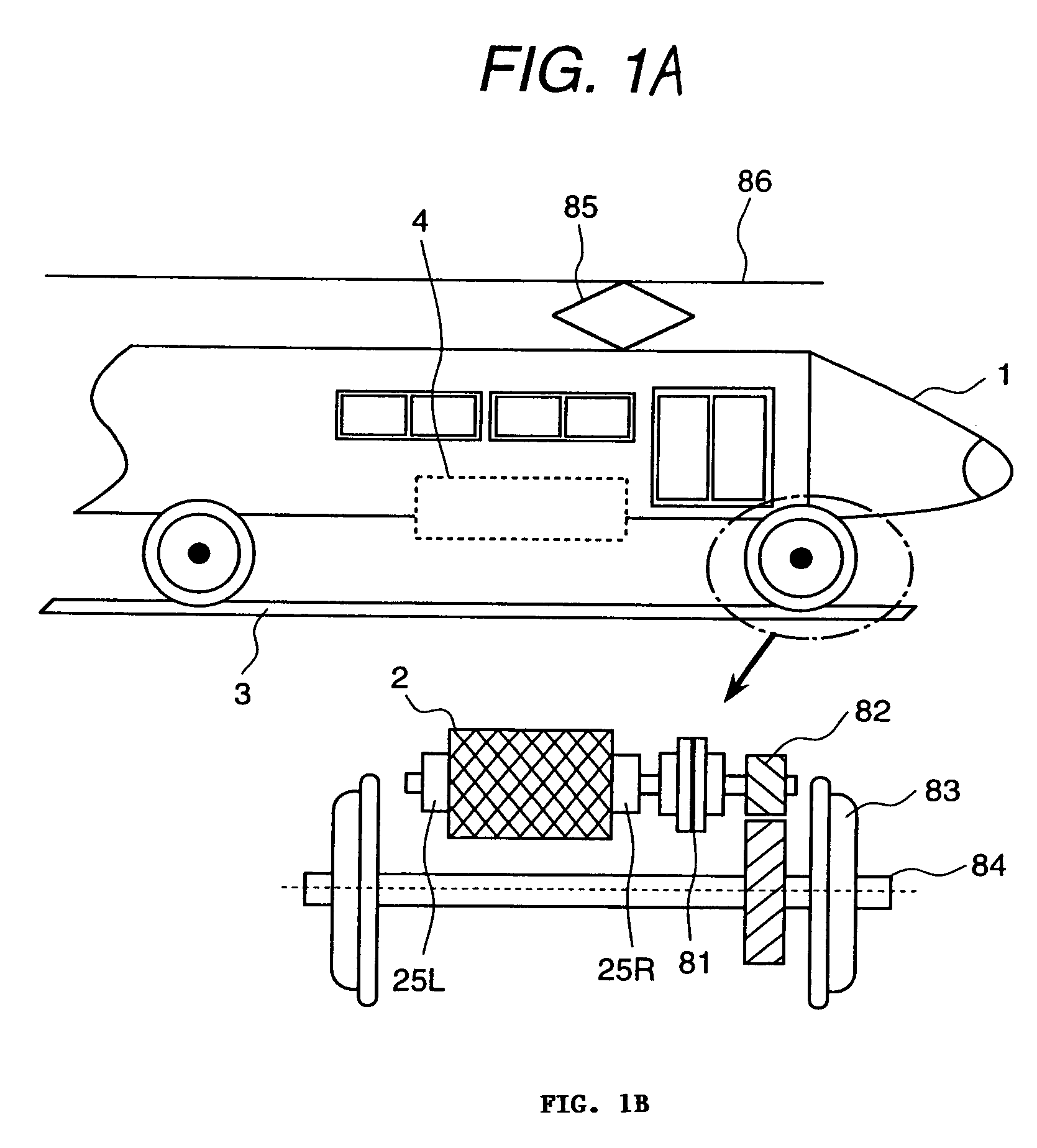

Dynamo-electric machine having a rotor with first and second axially or rotationally displaceable field magnets

InactiveUS6975055B2Reduce decreaseSimple structureSynchronous generatorsWindingsElectric machineElectrical polarity

A dynamo-electric machine has a stator with a primary winding and a rotor with a field magnet and a shaft. the field magnet includes a first field magnet having diferent polarity magnetic poles sequentially arranged in a rotation direction and a second field magnet having diferent polarity magnetic poles sequentially arranged in a rotation direction. The machine further has a mechanism for shifting the first and the second field magnets in axial and rotation directions.

Owner:HITACHI LTD

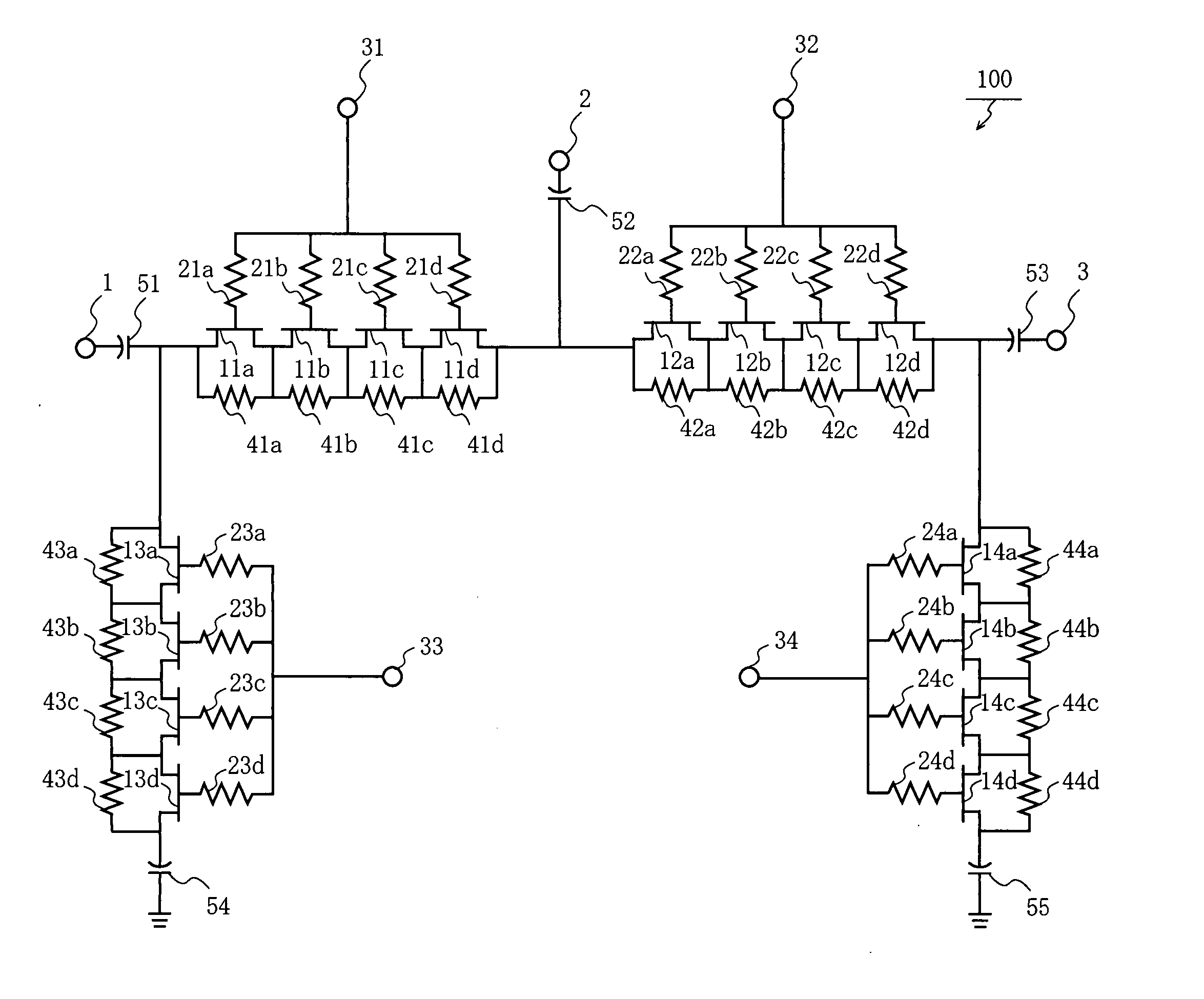

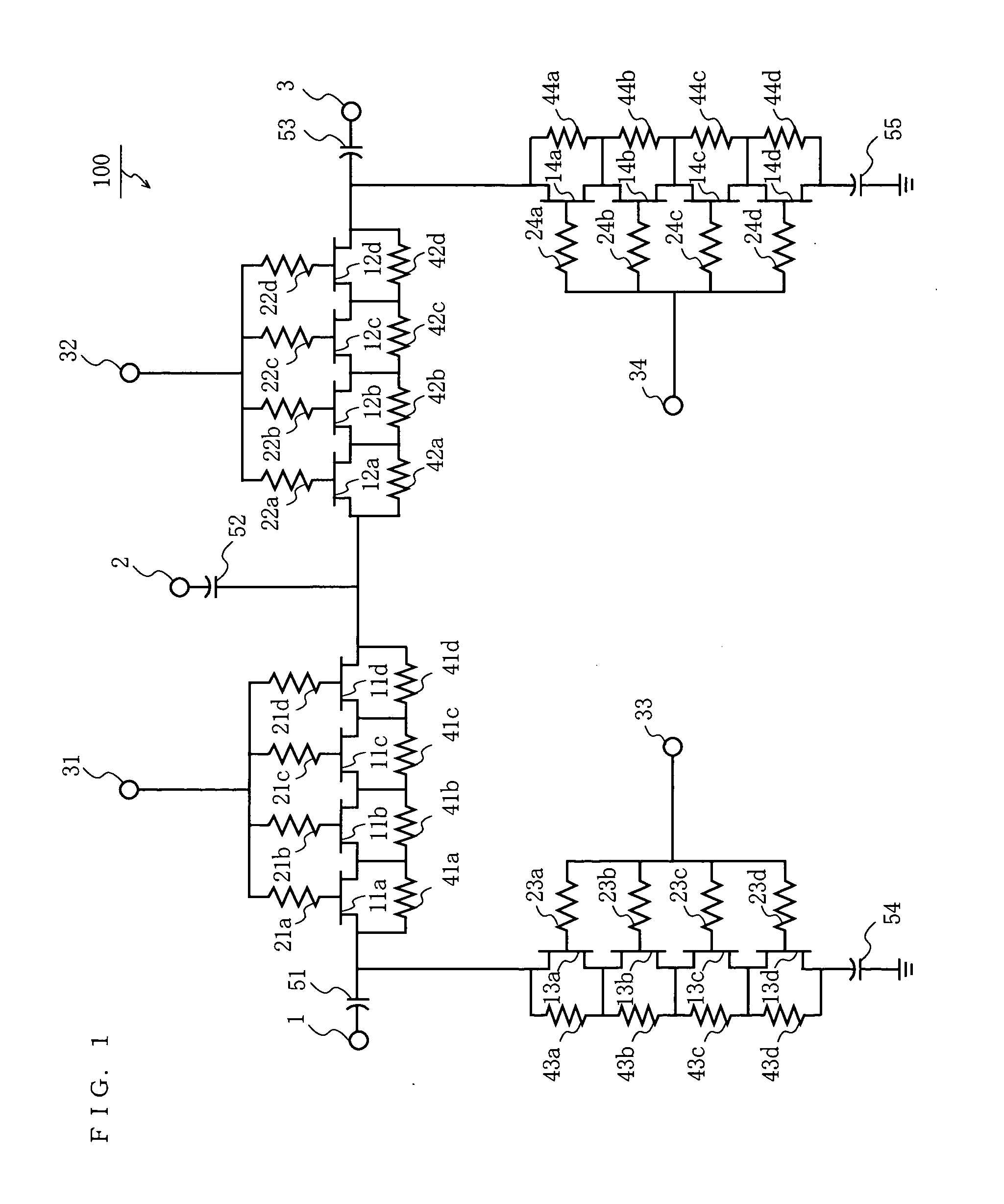

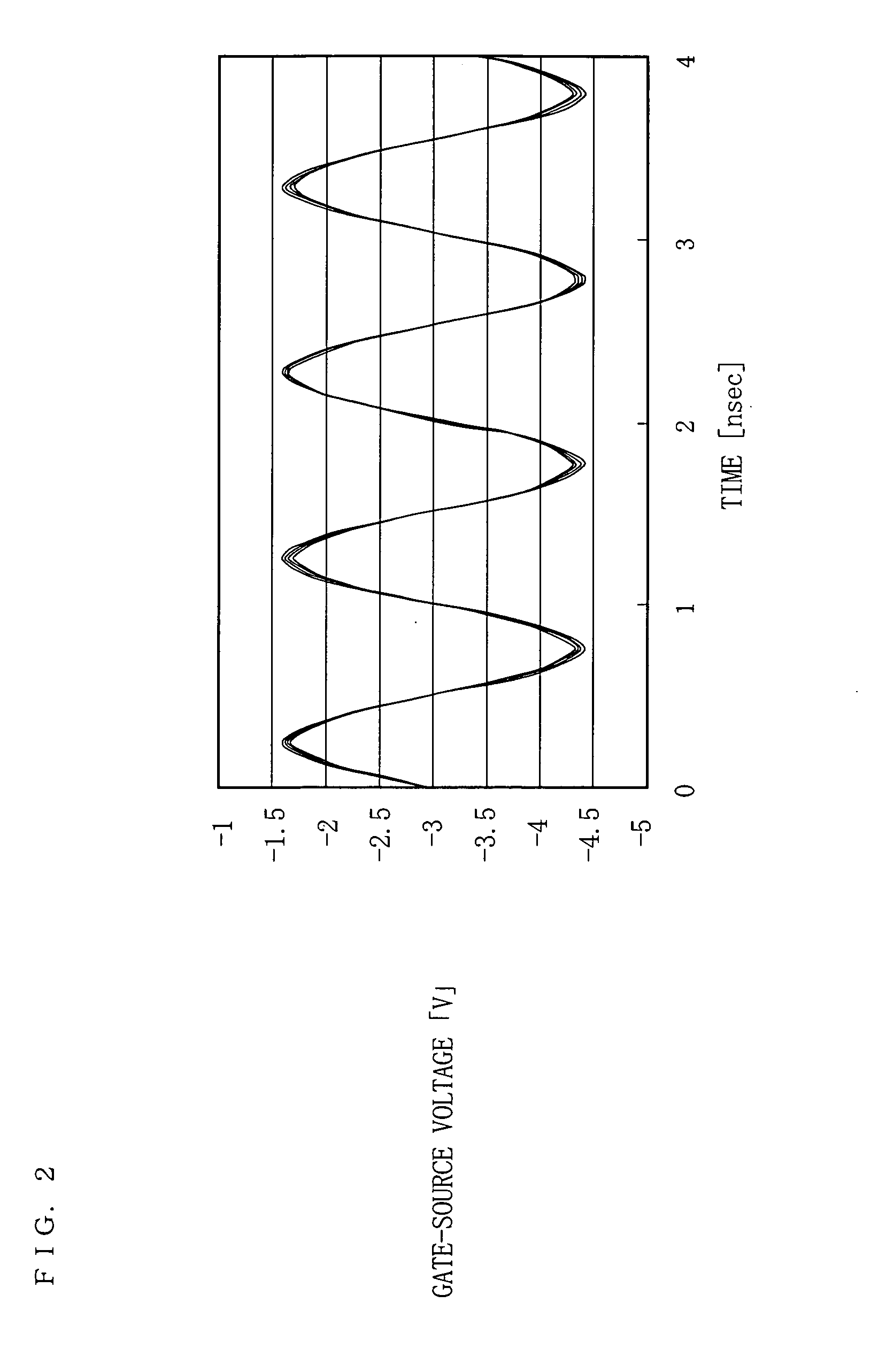

Radio frequency switching circuit and semiconductor device including the same

InactiveUS20060261912A1Improve characteristicImprove power characteristicsElectronic switchingCoupling devicesRadio frequencyInput/output

A radio frequency switching circuit having improved input / output power characteristics is provided. The circuit includes basic switching sections each including a plurality of FETs 13a-13d, 14a-14d, 11a-11d or 12a-12d connected in series. The basic switching sections are respectively provided between an input / output terminal 1 and the ground, between an input / output terminal 3 and the ground, between the input terminals 1 and 2, and between the input terminals 2 and 3. The circuit also includes a plurality of resistors 43a-43d, 44a-44d, 41a-41d and 42a-42d, each having one terminal connected to a drain electrode of a corresponding FET and the other terminal connected to a source electrode of the corresponding FET. A resistor connected between the drain and source electrodes of an FET, among the FETs included in a basic switching section in an OFF state, closer to the input / output terminal to which a signal is inputted has a smaller resistance value.

Owner:PANASONIC CORP

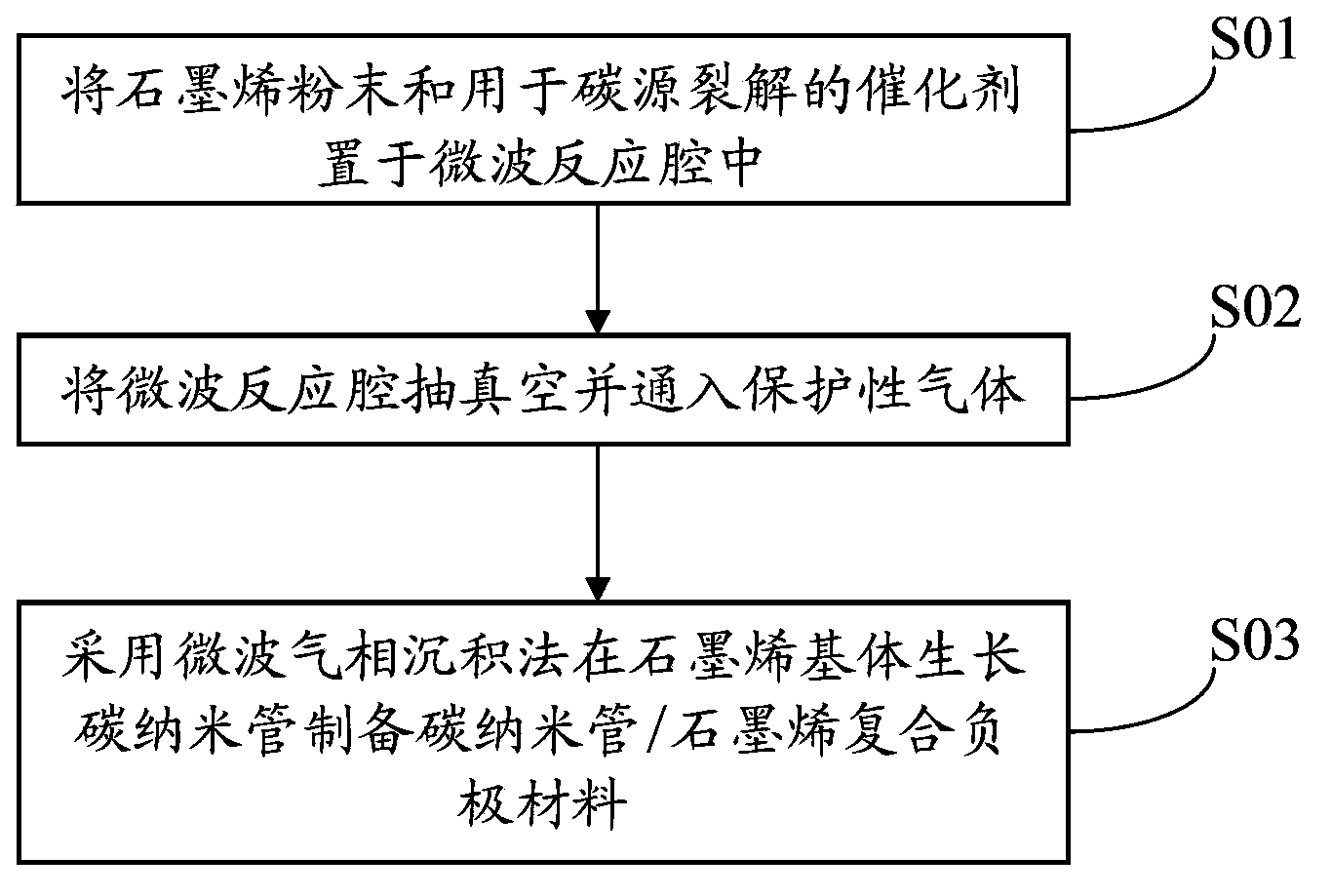

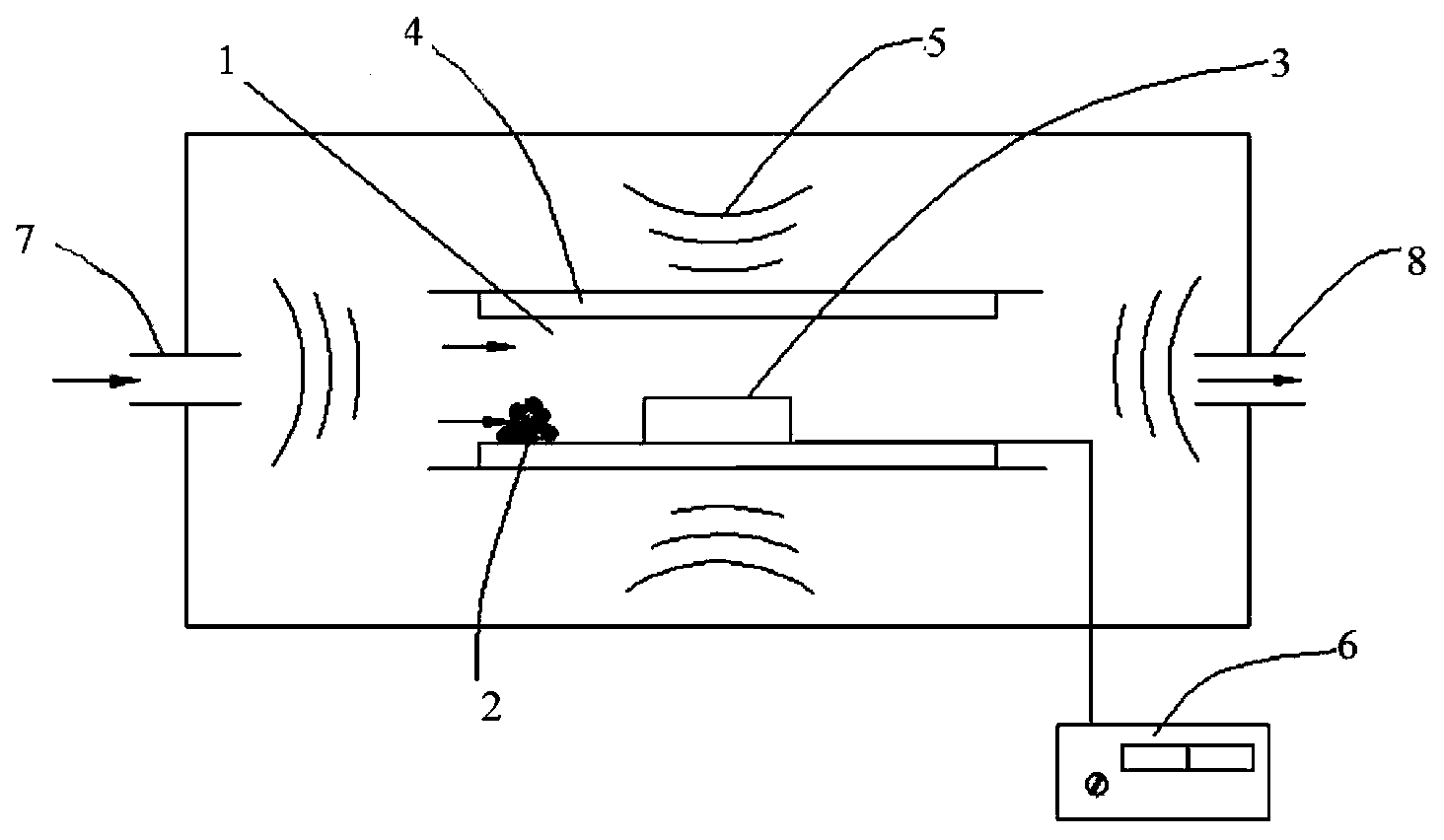

Carbon nano tube/graphene composite negative pole material, preparation method thereof and lithium battery

The invention discloses a carbon nano tube / graphene composite negative pole material, a preparation method thereof and a lithium battery. The preparation method of the carbon nano tube / graphene composite negative pole material comprises the steps of placing graphene powder and a catalyst for carbon source splitting decomposition in a microwave reaction cavity, vacuumizing the microwave reaction cavity and leading protective gas into the microwave reaction cavity and using a microwave vapor deposition method to prepare the carbon nano tube / graphene composite negative pole material on a graphene base body growing carbon nano tube. A negative pole of the lithium battery contains the carbon nano tube / graphene composite negative pole material. The preparation method of the carbon nano tube / graphene composite negative pole material adopts the microwave vapor deposition method to perform in-situ preparation of the carbon nano tube / graphene composite negative pole material, does not needs a pre-synthesis process, reduces the production cost, adopts microwave heating and is efficient, low in energy consumption and short in production period. Due to the fact that the lithium battery contains the carbon nano tube / graphene composite negative pole material, embedding and taking-out of lithium are facilitated, the inreversible capacity of first-time charging and discharging is reduced, and the lithium battery is good in safety and high in power.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

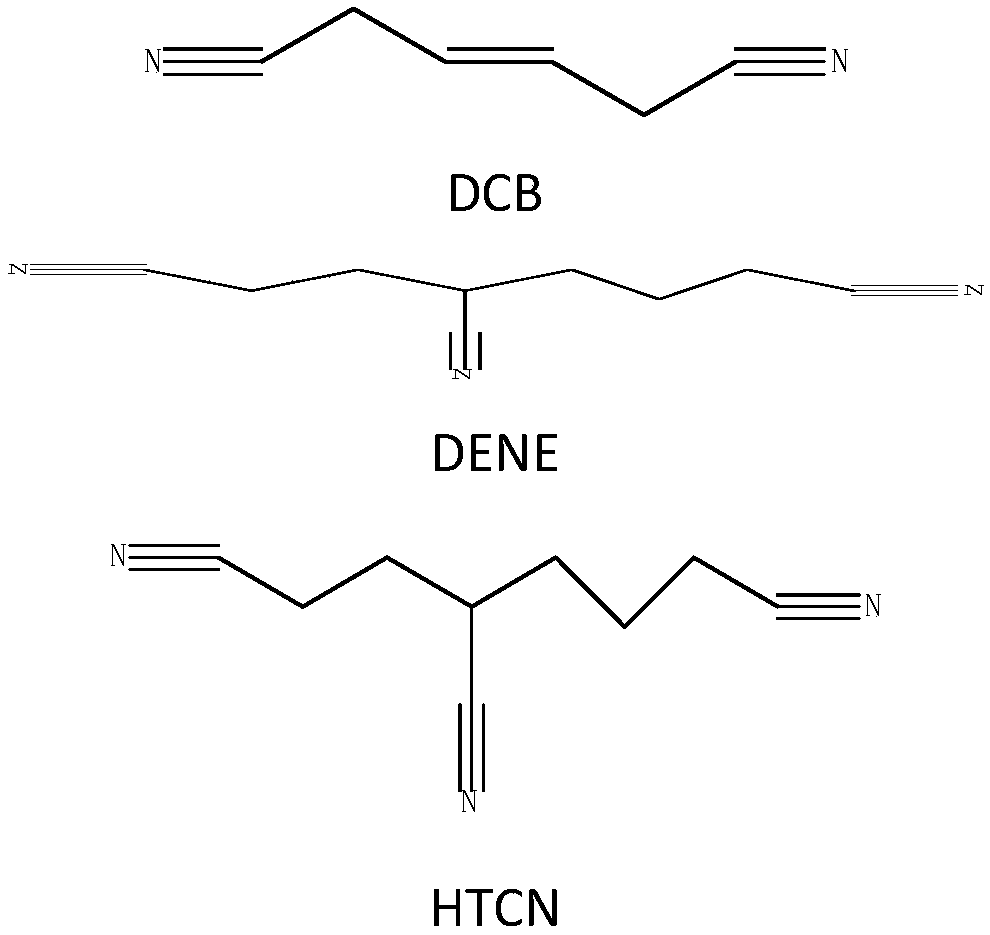

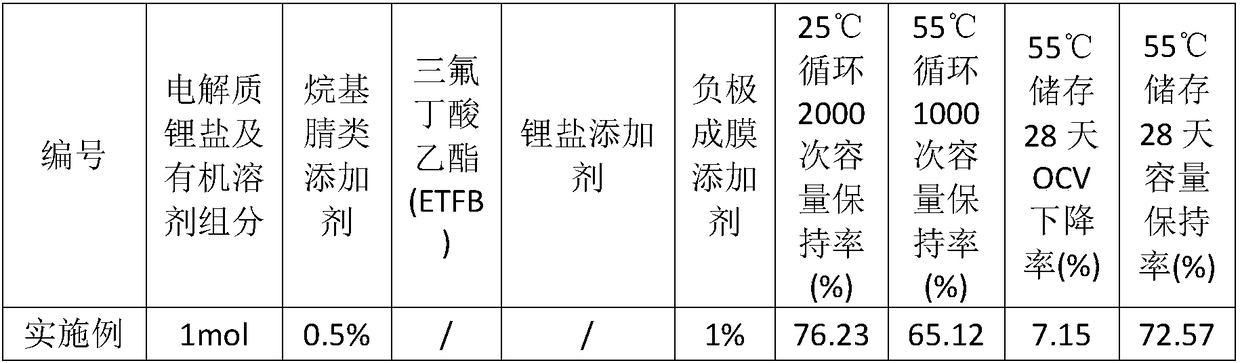

Nickelic ternary anode material power lithium ion battery electrolyte and preparation method thereof

InactiveCN109461967AImprove cycle performanceImprove thermal stabilityFinal product manufactureElectrolyte accumulators manufactureHigh temperature storageCarboxylic salt

The invention belongs to the technical field of lithium ion battery preparation, and specifically relates to nickelic ternary anode material power lithium ion battery electrolyte and a preparation method thereof. The electrolyte consists of electrolyte lithium salt, a non-aqueous organic solvent and functional additives, wherein the functional additives comprise an alkyl nitrile additive, fluorinated chain carboxylate, a lithium salt additive and a cathode film forming additive; and the content of the functional additives is 0.5-10% of the weight of the electrolyte. The electrolyte provided bythe invention interacts with transition metal in a nickelic ternary anode material through the functional additives and is decomposed on the surfaces of the anode and cathode to form stable interfacefilms, so as to inhibit the metal ionic catalysis activity and decrease battery side reactions, so that the electrolyte has favorable anti-oxidant and film forming characteristics, is capable of effectively improving the high-temperature storage performance, safety performance and cycle life of nickelic ternary anode material power lithium ion batteries, effectively inhibiting the generation of battery expansion and ensuring the high power characteristic of the batteries at the same time.

Owner:JIANGXI YOULI NEW MATERIALS

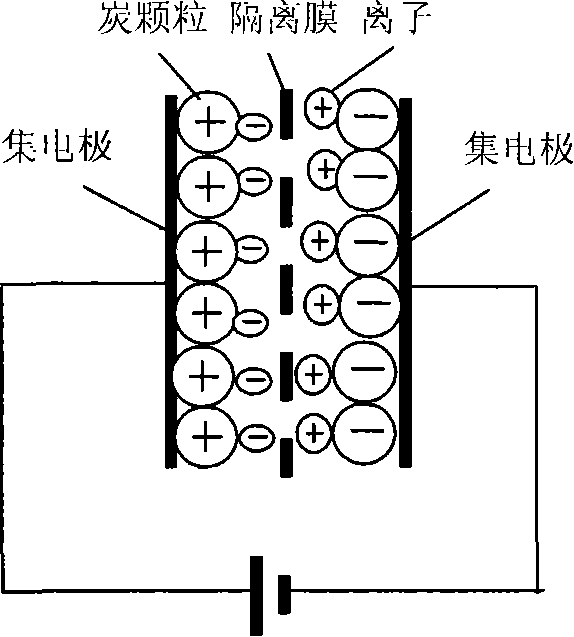

Preparation method of super capacitor

InactiveCN101661840AEasy to manufactureLower internal resistanceElectrolytic capacitorsHybrid/EDL manufactureGas phaseArgon atmosphere

The invention relates to a preparation method for a super capacitor, comprising the following steps: (1) placing a foam nickel substrate in a chemical gas phase deposition reacting furnace, introducing argon for 10-60 minutes, exhausting air in the furnace, then heating the furnace to 450-750 DEG C, introducing hydrocarbon gases in an argon atmosphere at a flow rate between 25ml / min and 40ml / min,reacting the mixture for 30 seconds to 50 minutes at a temperature of 450-750 DEG C, and obtaining foam nickel on which carbon nano tubes grow after finishing the reaction; (2) removing surface loosing layer products, directly using the foam nickel substrate on which the carbon nano tubes grow as electrodes of the super capacitor; and (3) drying the electrodes with same thickness and size, which are obtained from the step (2), fully soaking the electrode with electrolyte for 1-36 hours, separating a diaphragm soaked with the electrolyte and assembling the components to obtain the super capacitor; and the hydrocarbon gases are acetylene, methane, ethylene or propylene. The carbon nano tubes directly grow on the foam substrate without a binding agent; and the foam nickel is used as the substrate, the volume density of electrode substances is higher and holes are reasonably distributed.

Owner:JIANGSU CHUANGLAN SOLAR AIR CONDITIONER

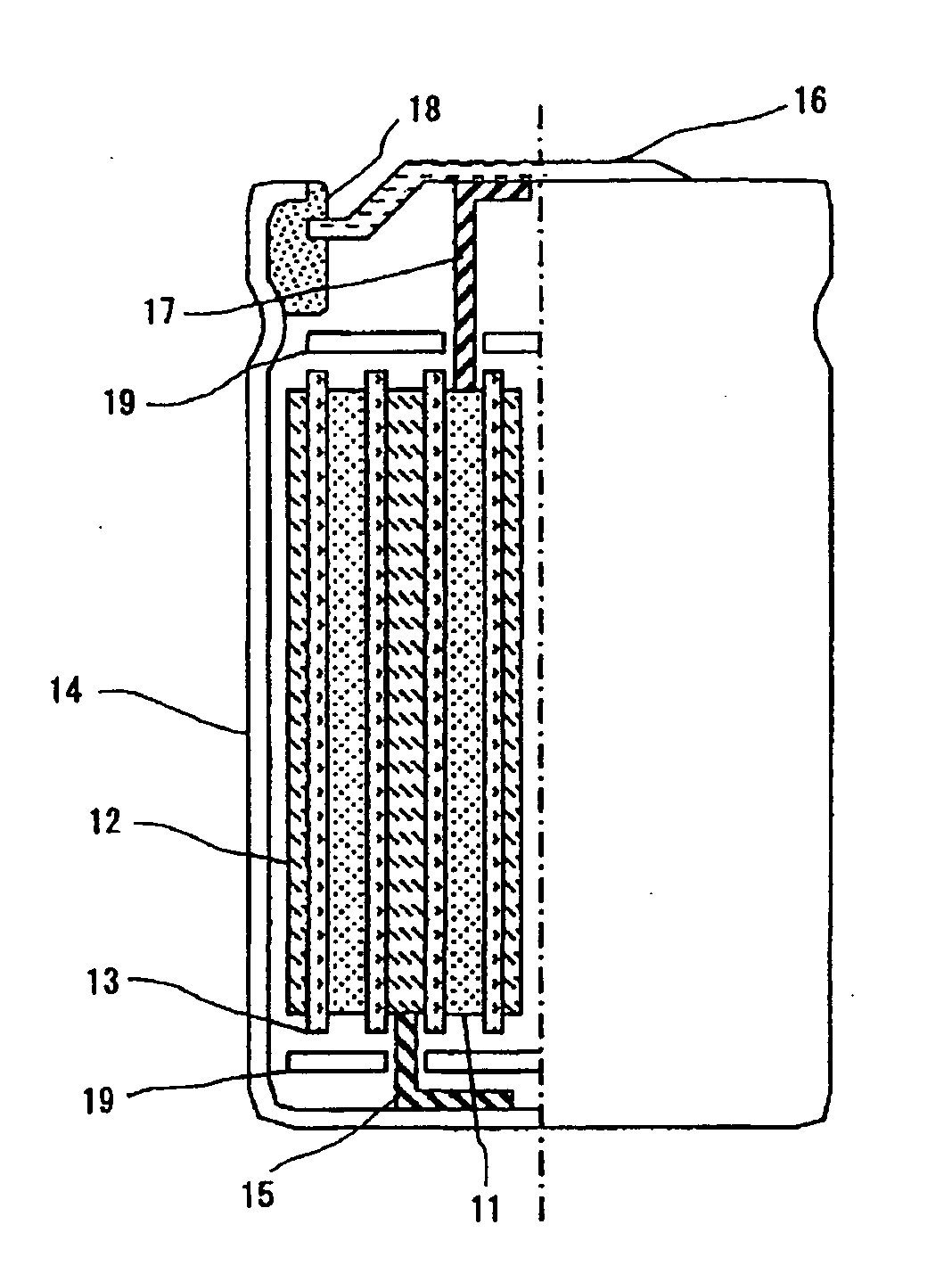

Non-aqueous electrolytic solution secondary battery

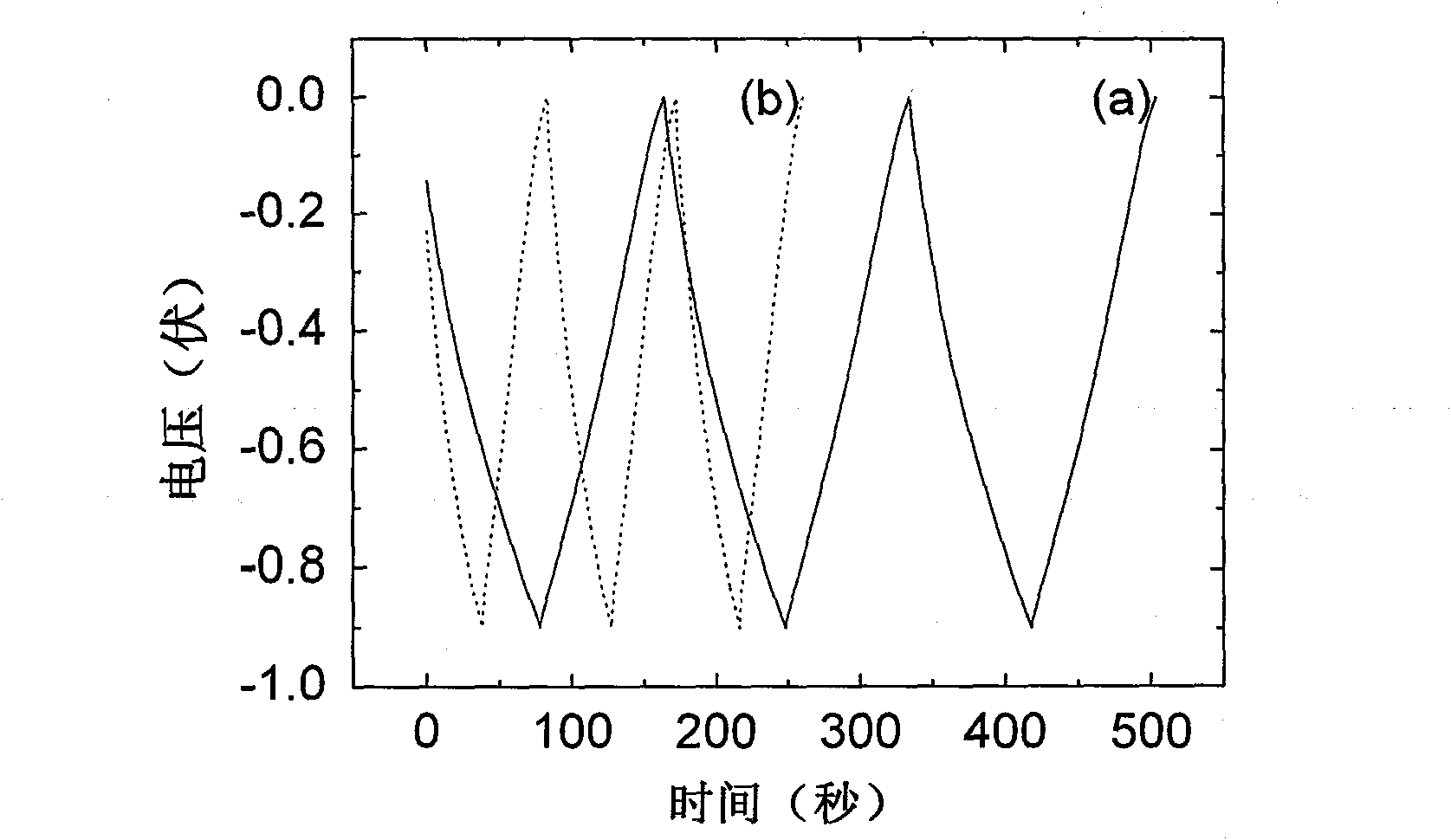

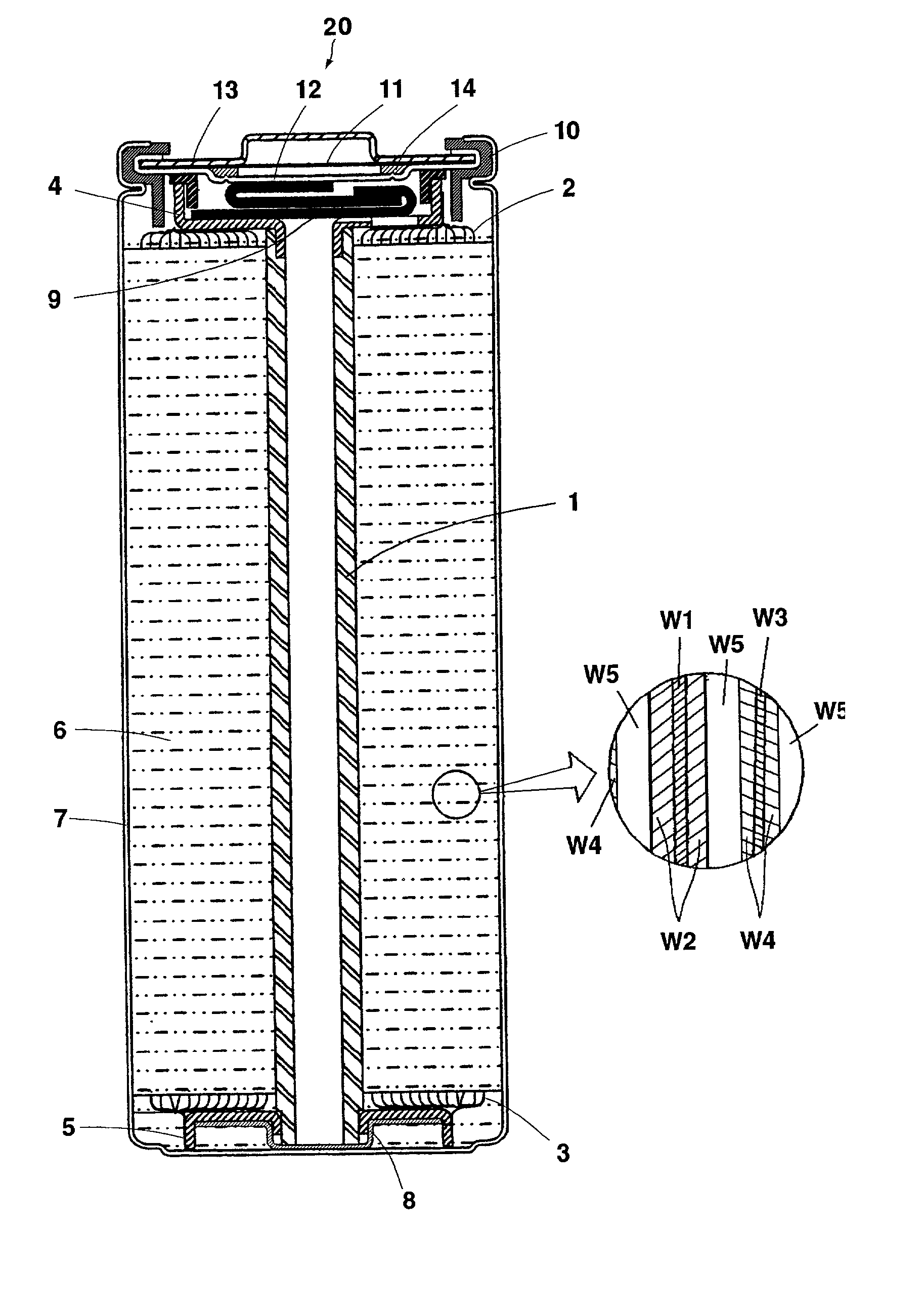

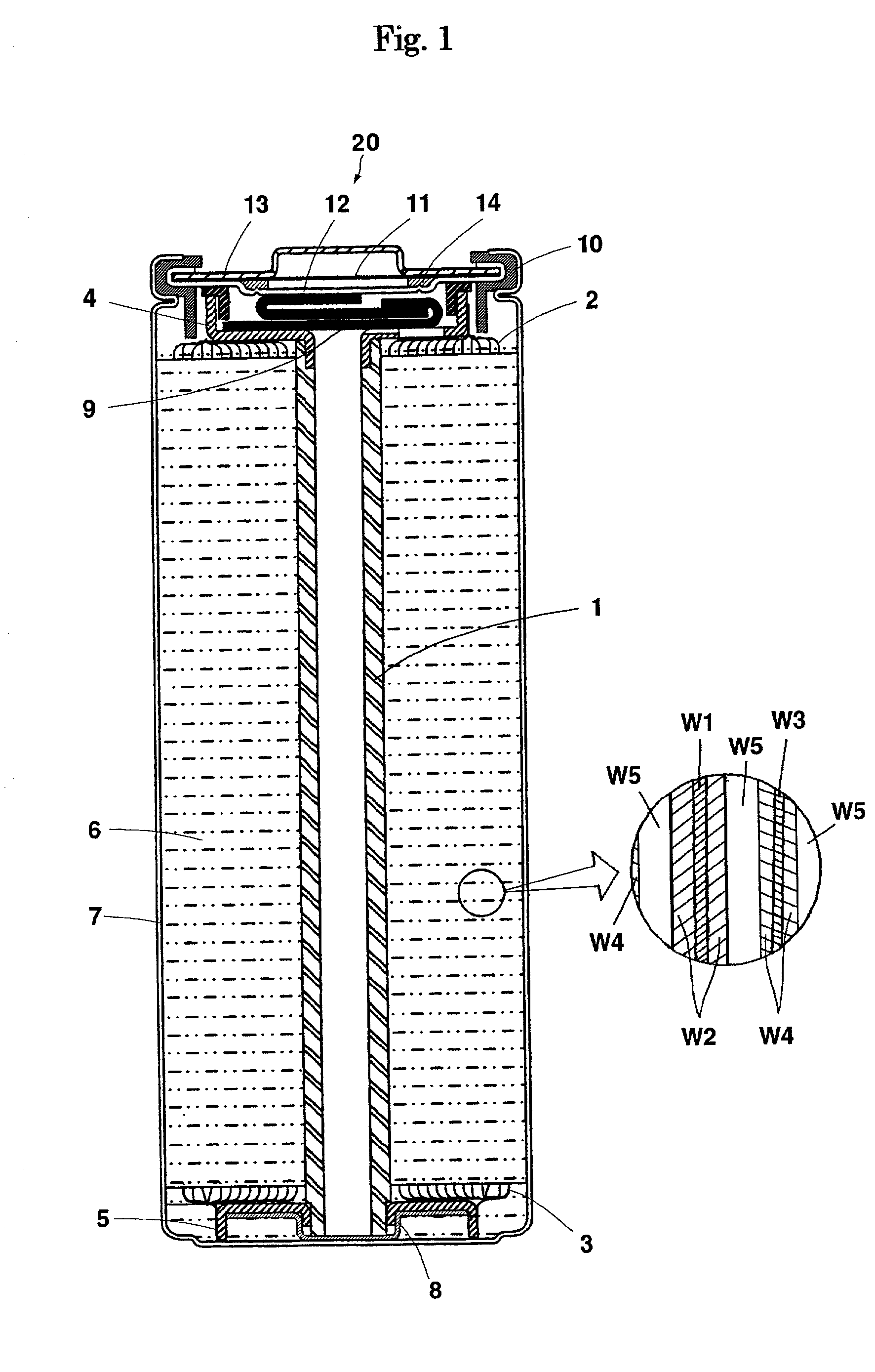

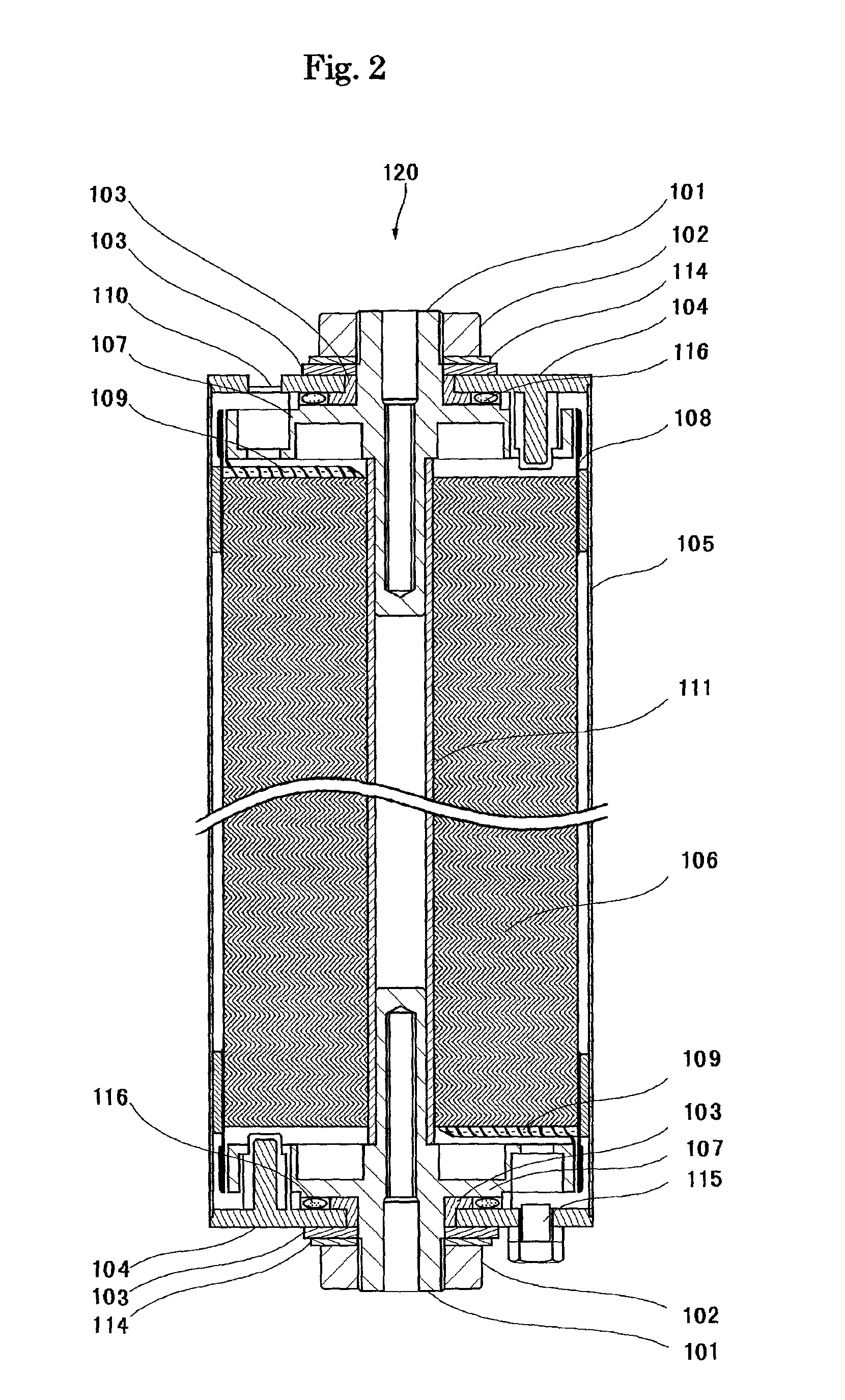

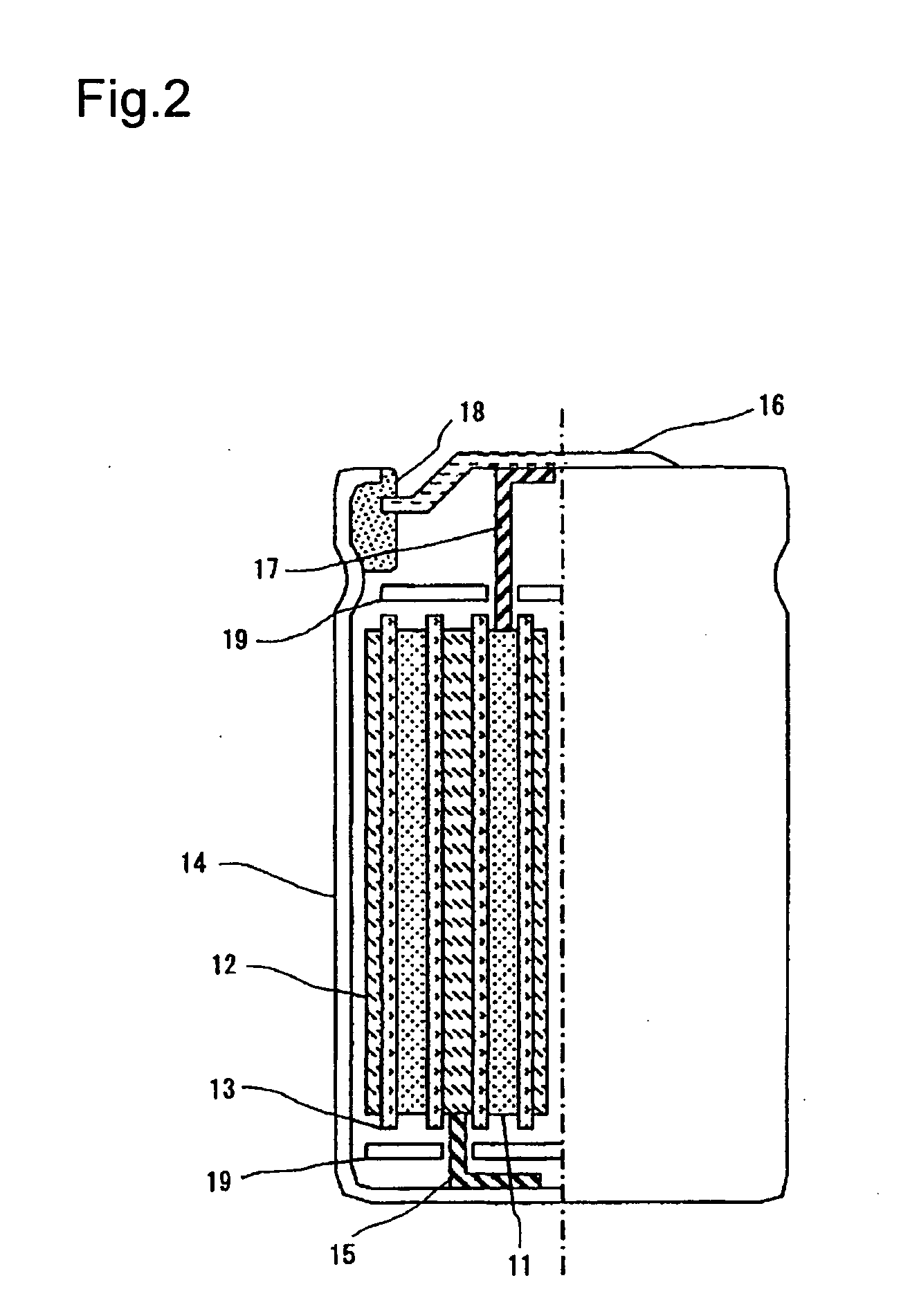

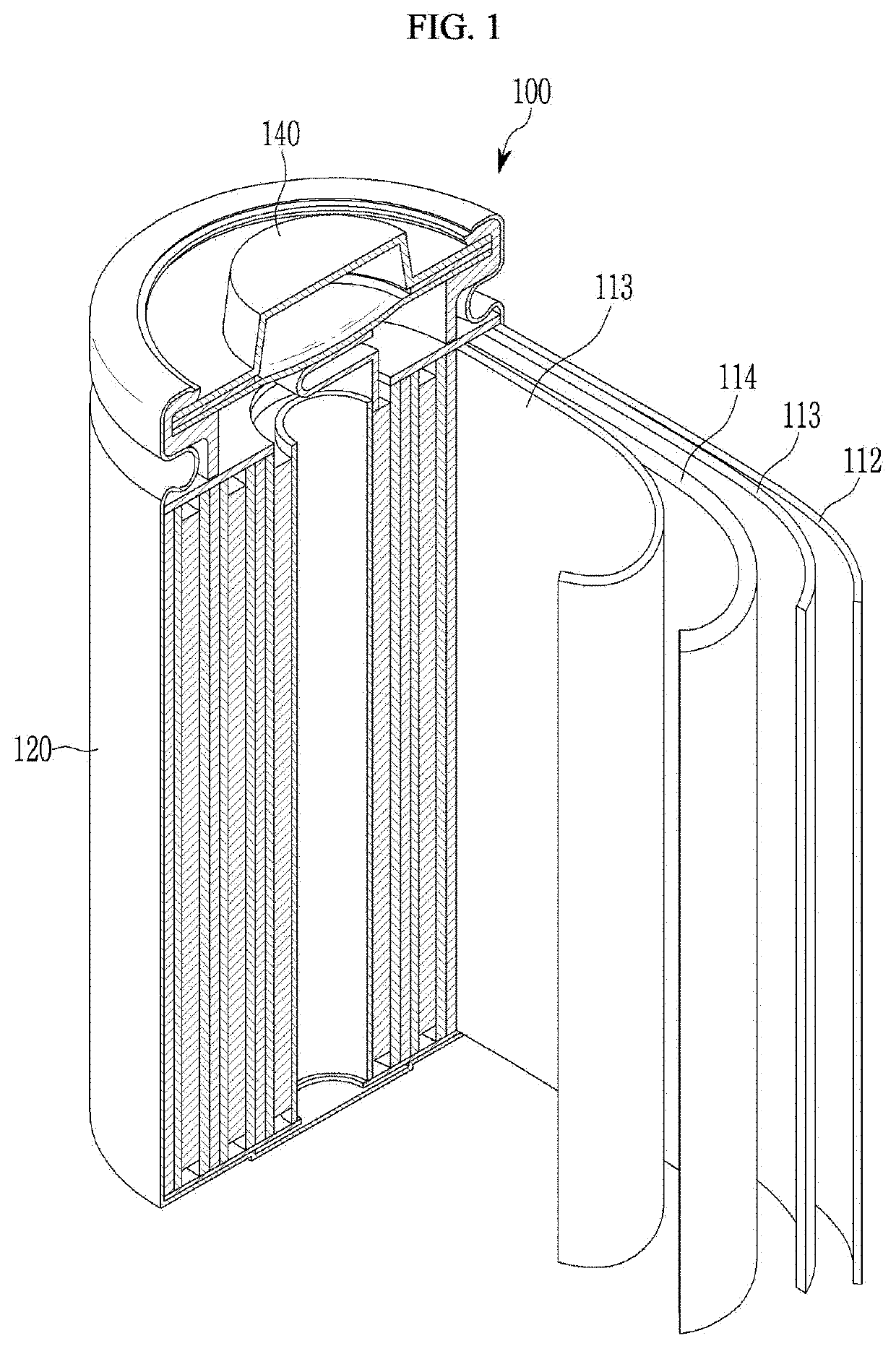

InactiveUS20020122983A1Improve the immunityReduce total powerFinal product manufactureSmall-sized cells cases/jacketsManganateEngineering

The present invention provides a lithium-ion secondary battery whose power characteristic has been improved without widening a battery size. A cylindrical lithium-ion battery 20 accommodates a winding group 6 and a non-aqueous electrolytic solution within a battery container 7. The winding group 6 is structured by winding a positive electrode using lithium manganate (Li1+xMn2-xO4 or Li1+xMn2-x-yAlyO4) where an average particle diameter of primary particles is in a range of from 0.1 mum to 2 mum as a positive electrode active material and a negative electrode using amorphous carbon as a negative electrode active material via a separator. The reaction area of the positive electrode active material is optimized.

Owner:HITACHI AUTOMOTIVE SYST LTD

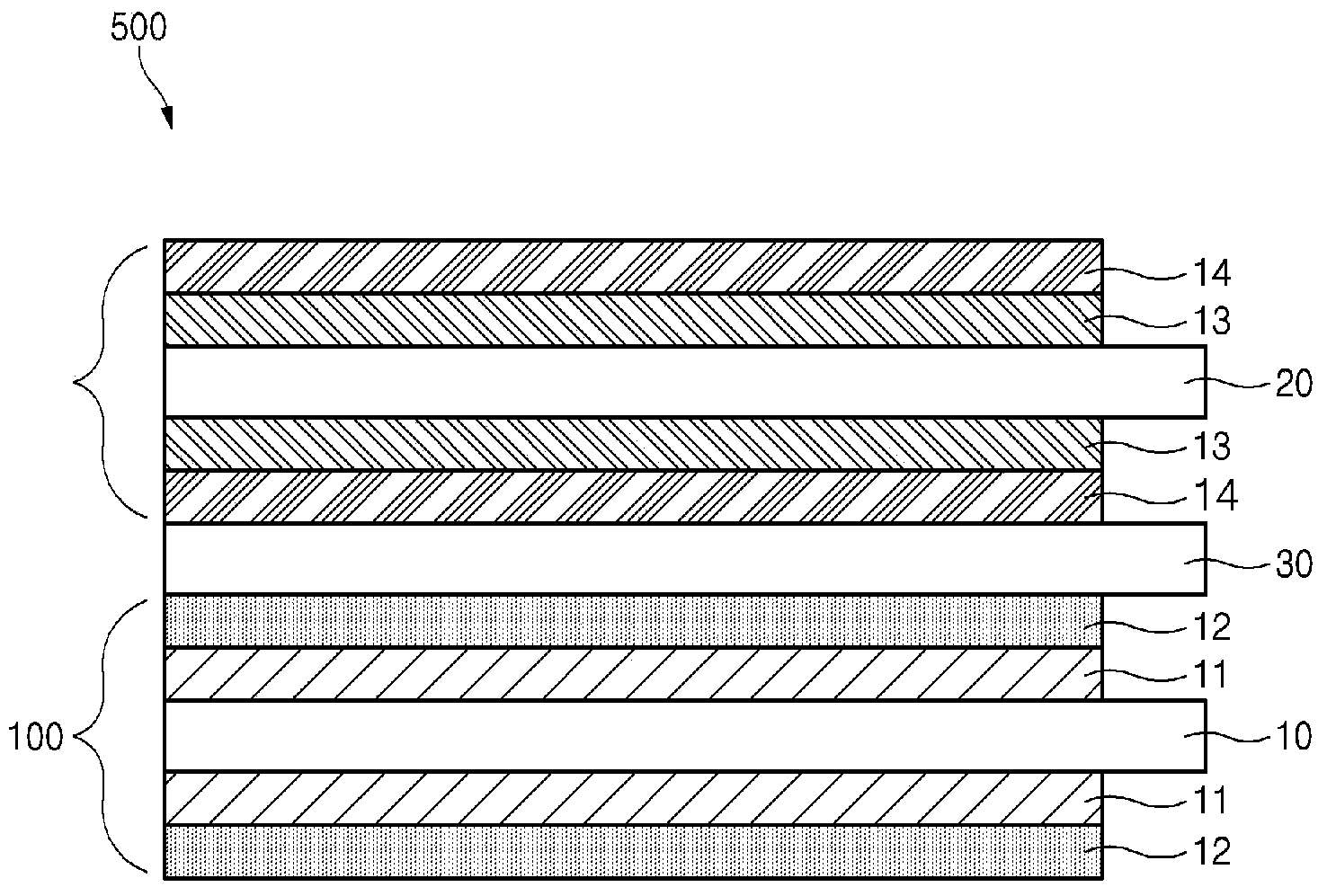

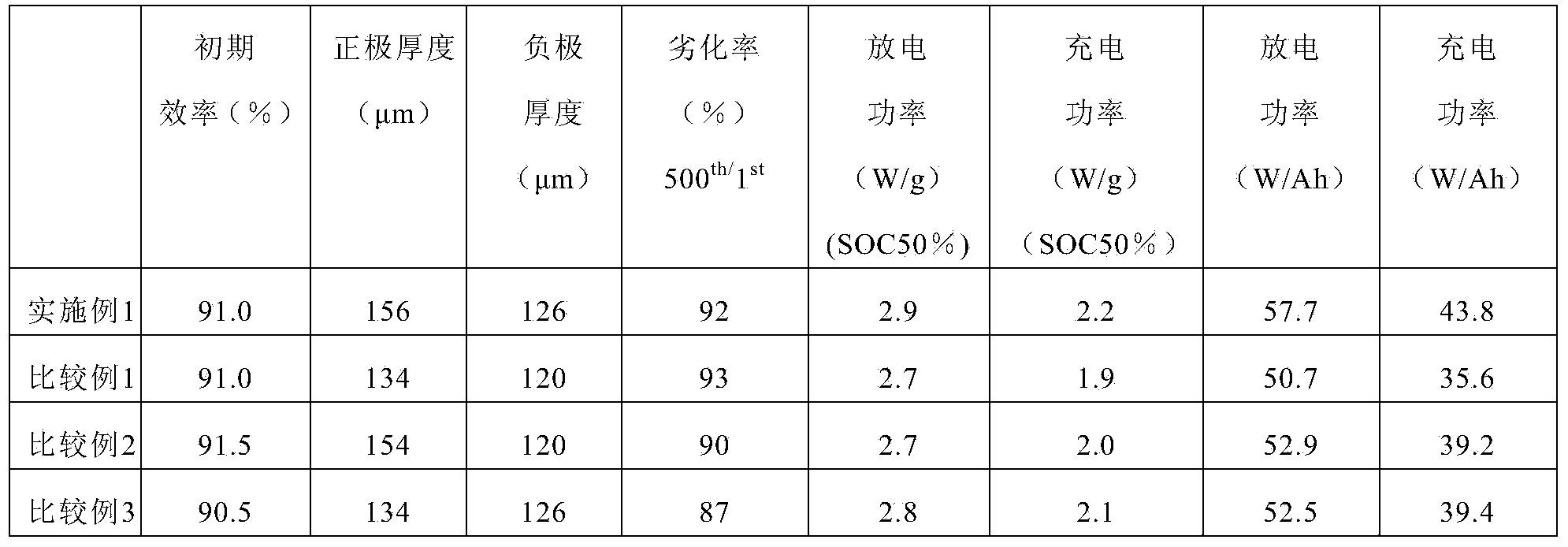

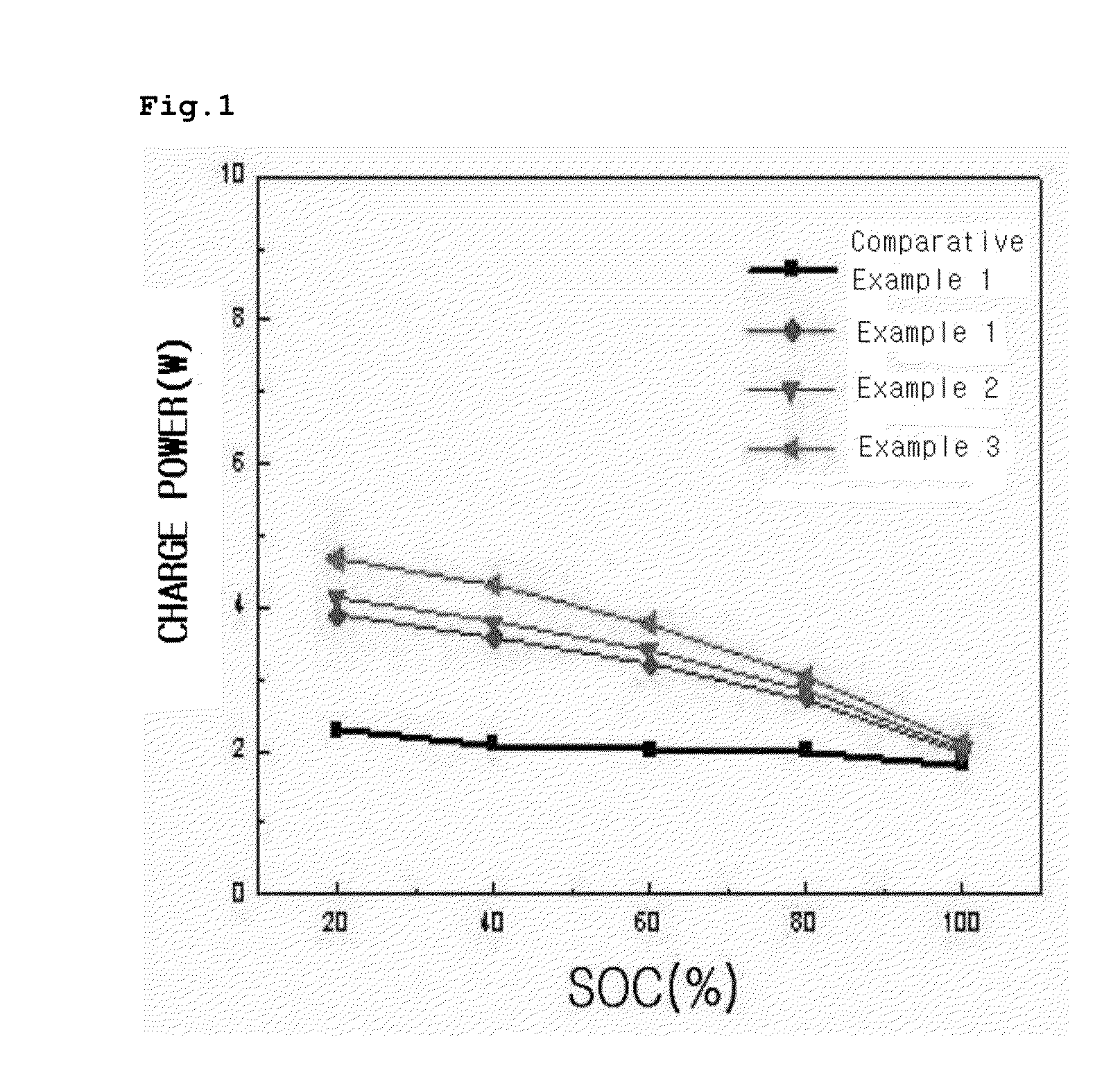

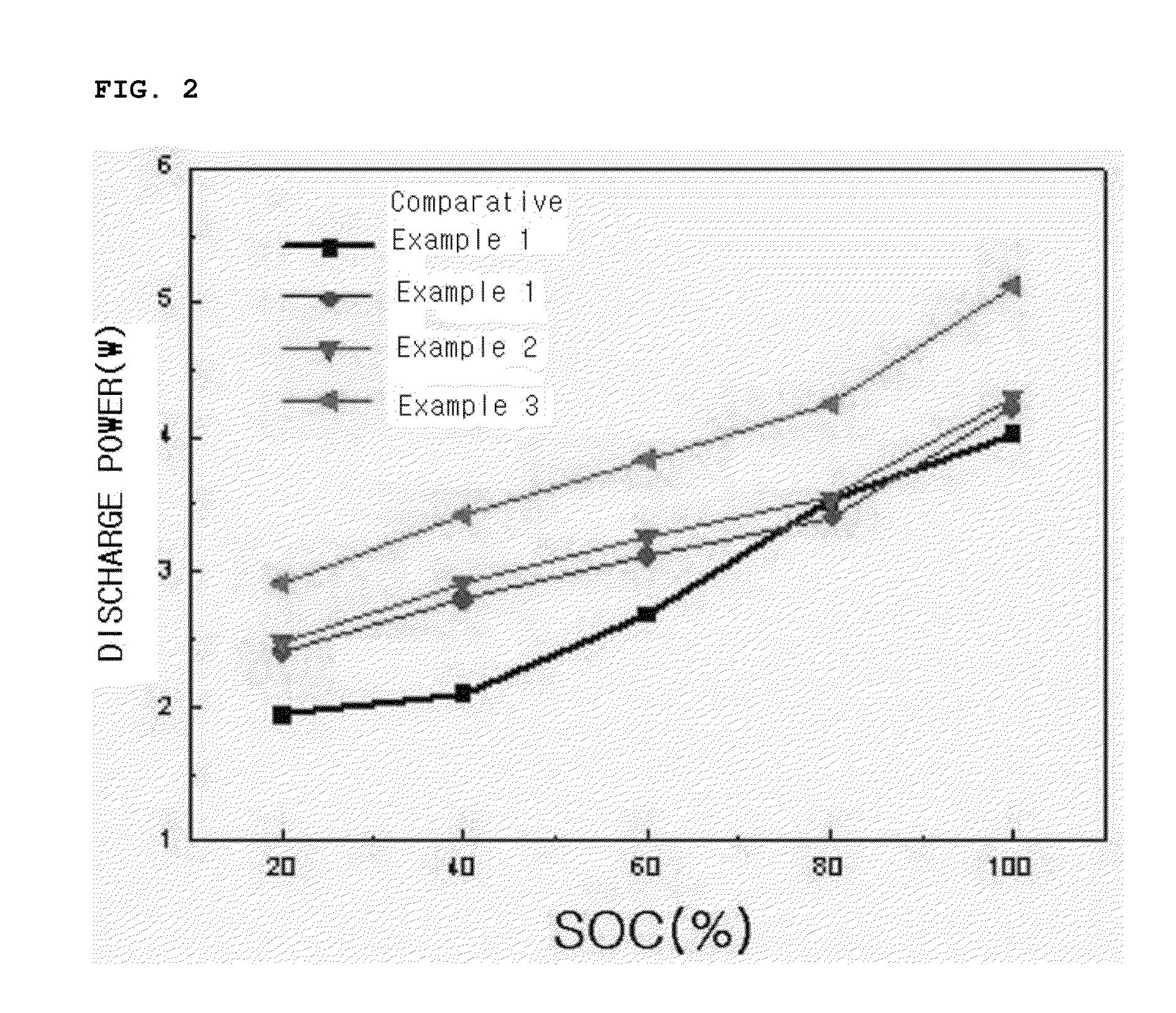

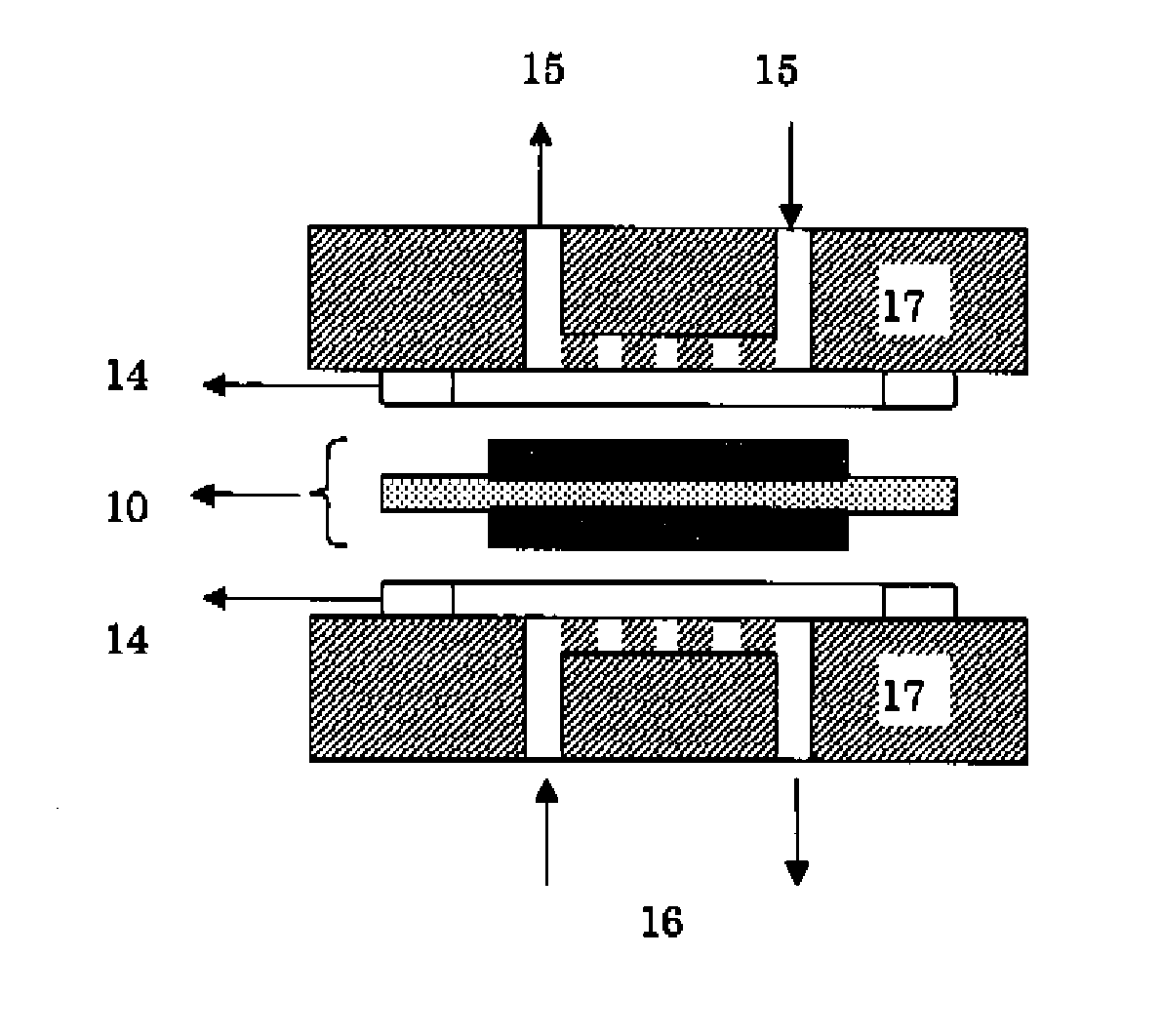

Lithium secondary battery comprising multilayered active material layer

ActiveCN104321912AIncrease powerImprove power characteristicsNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumEngineering

A lithium secondary battery of the present invention may simultaneously improve high output and high capacity characteristics by including a first active material layer having high output characteristics and a second active material layer having high capacity characteristics respectively on a cathode collector and an anode collector.

Owner:LG ENERGY SOLUTION LTD

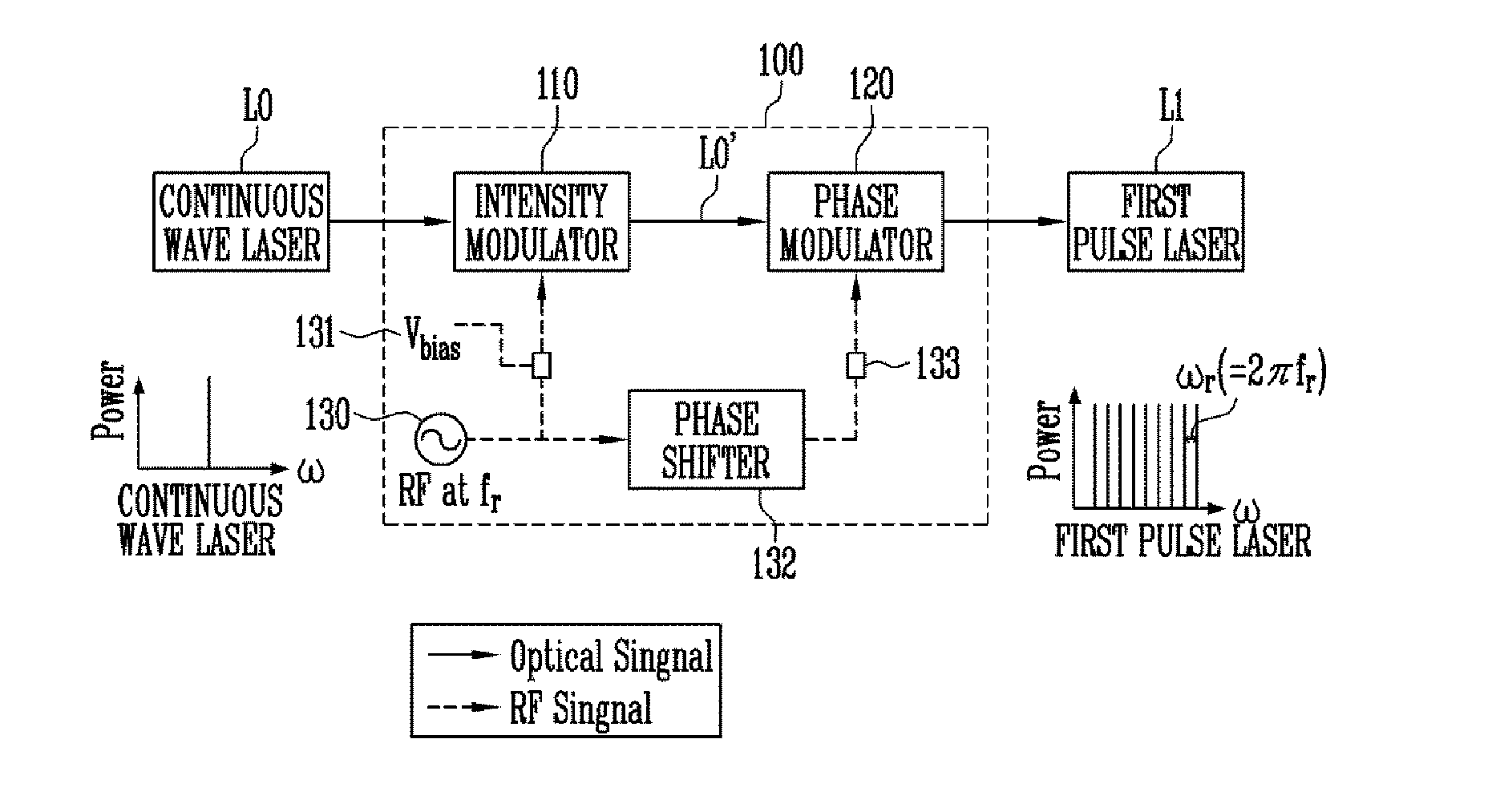

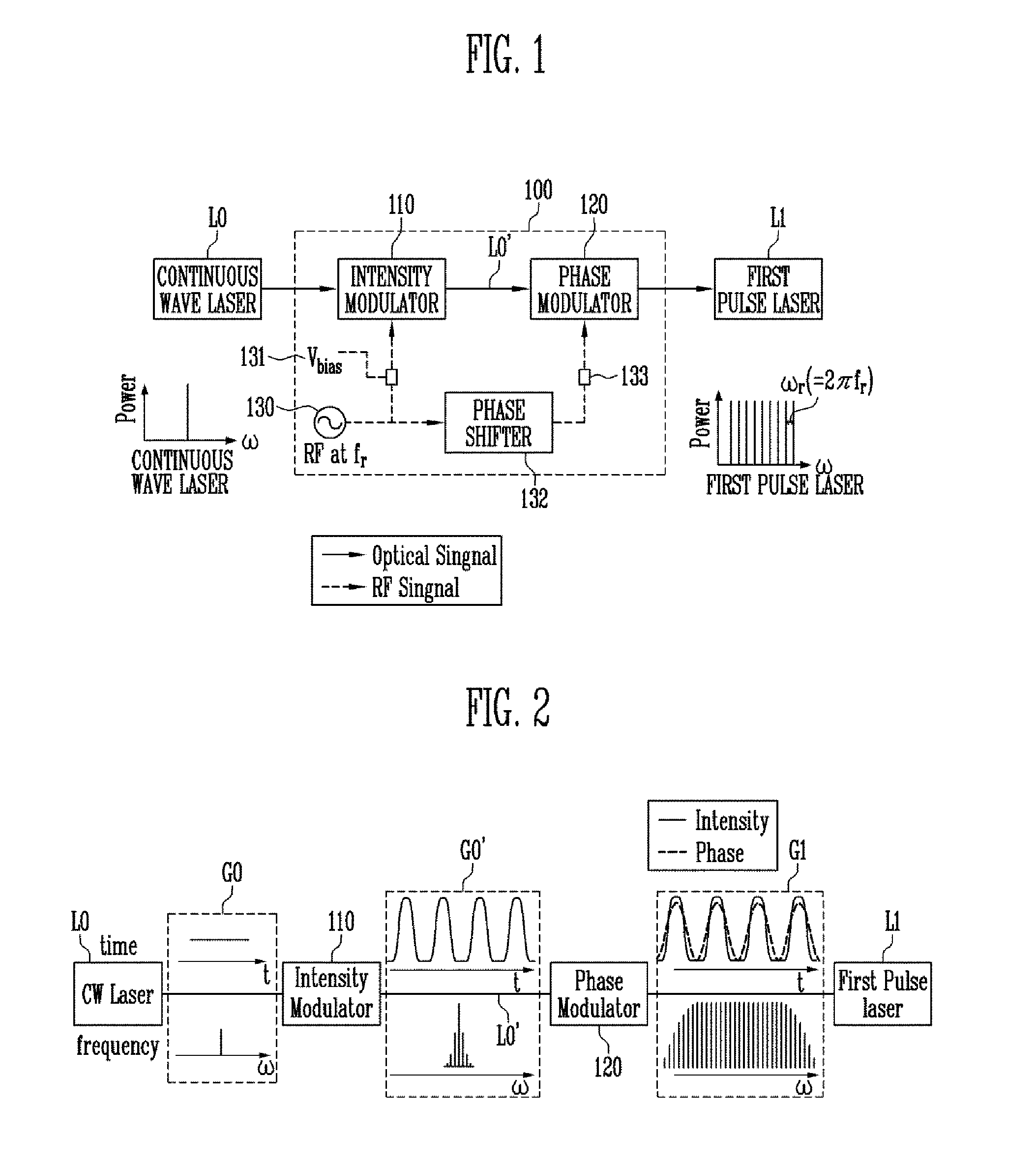

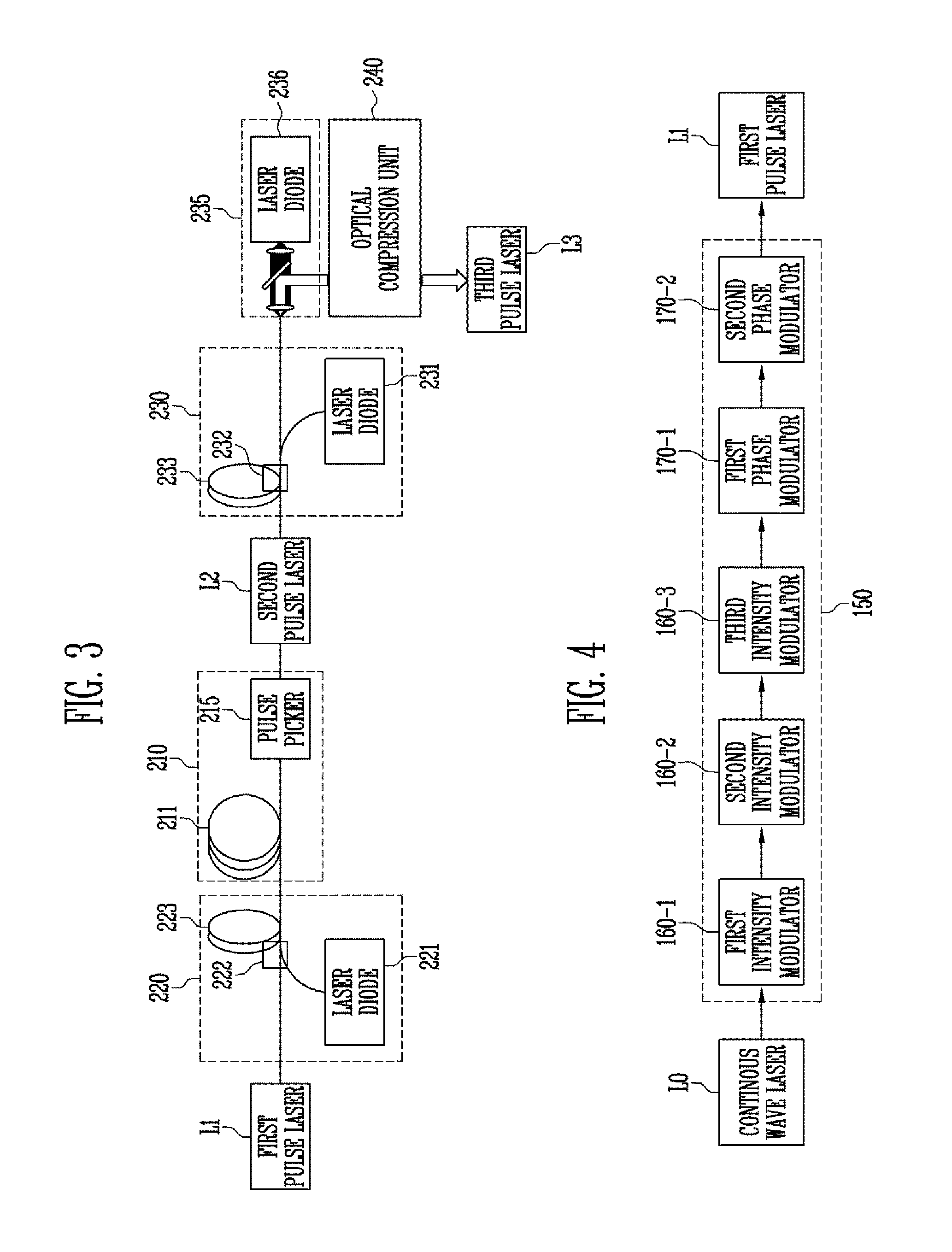

Apparatus and method for generating pulse laser

InactiveUS20150372447A1Costly maintenance costLarge volumeActive medium shape and constructionSemiconductor lasersModulated continuous wavePulsed laser

Provided herein is a pulse laser generator including a modulator configured to receive a continuous wave laser, and to modulate an intensity and phase of the continuous wave laser to generate a first pulse laser; and a chirping unit configured to chirp the first pulse laser to generate a second pulse laser.

Owner:ELECTRONICS & TELECOMM RES INST

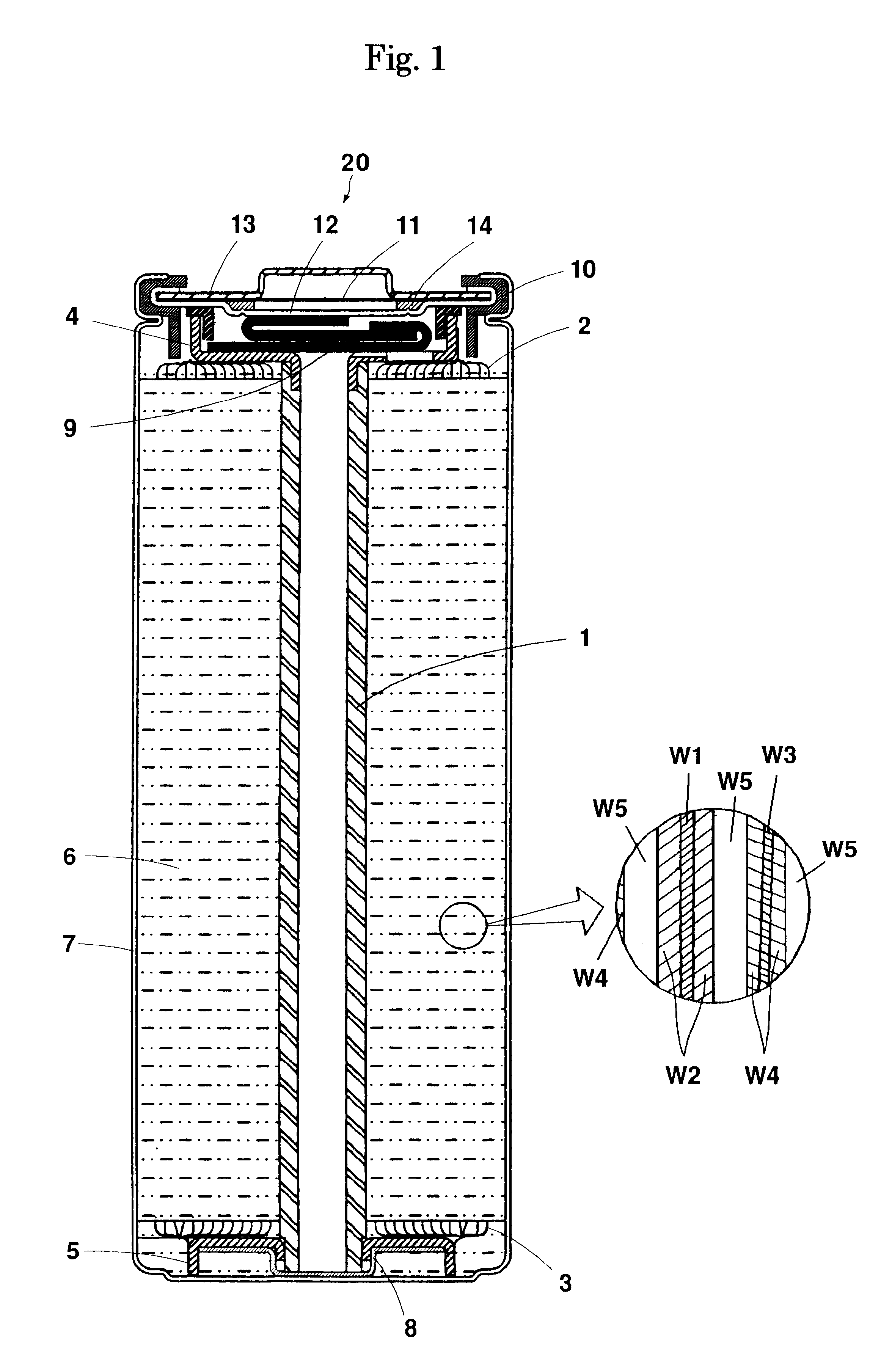

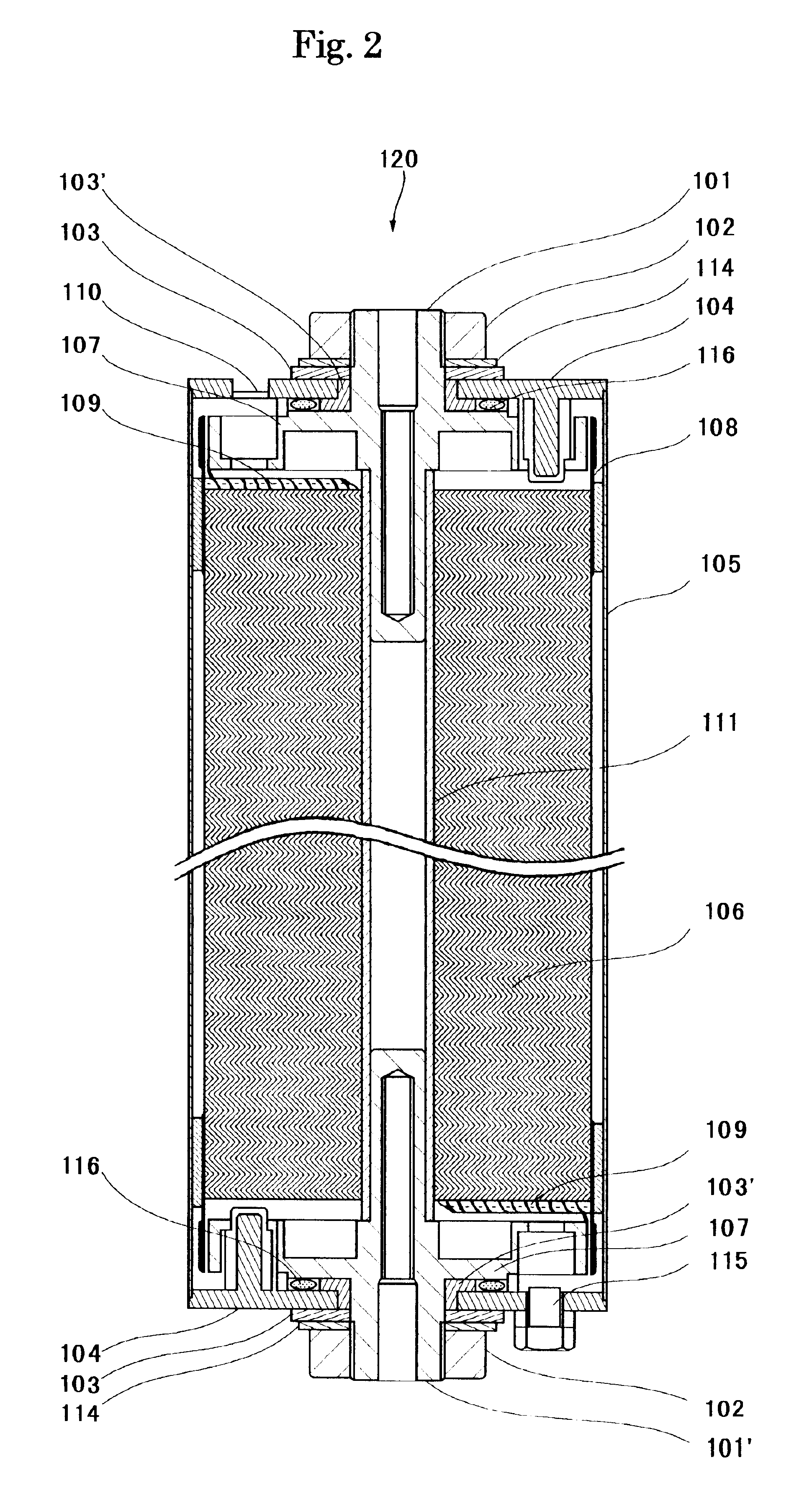

Non-aqueous electrolytic solution secondary battery

InactiveUS6706446B2Improve the immunityReduce total powerFinal product manufactureSmall-sized cells cases/jacketsManganateEngineering

A cylindrical lithium-ion battery 20 accommodates a winding group 6, is structured by winding a positive electrode using lithium manganate (Li1+xMn2-xO4 or Li1+xMn2-x-yAlyO4) having an average particle diameter of primary particles in a range of from 0.1 mum to 2 mum as a positive electrode active material and a negative electrode using amorphous carbon as a negative electrode active material via a separator, and a non-aqueous electrolytic solution within a battery container 7.

Owner:HITACHI AUTOMOTIVE SYST LTD

High-elasticity conductive fiber and preparation method thereof

ActiveCN102953137AImprove uniform dispersion and orderly arrangementImprove securityElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentIonElectrically conductive

The invention discloses high-elasticity conductive fiber comprising the raw materials of: carbon nano-tubes, ionic liquid, and a high-elasticity polymer. A weight ratio of the carbon nano-tubes to the high-elasticity polymer is 1:8-20, and a weight ratio of the carbon nano-tubes to the ionic liquid is 4-6:1. The invention also discloses a preparation method of the high-elasticity conductive fiber. The high-elasticity conductive fiber provided by the invention has both the high conductivity of carbon nano-tubes, and the mechanical properties of polymer fiber. Also, the high-elasticity conductive fiber can be uniaxially stretched by 100% with no substantial change in electrical properties.

Owner:THE HONG KONG POLYTECHNIC UNIV

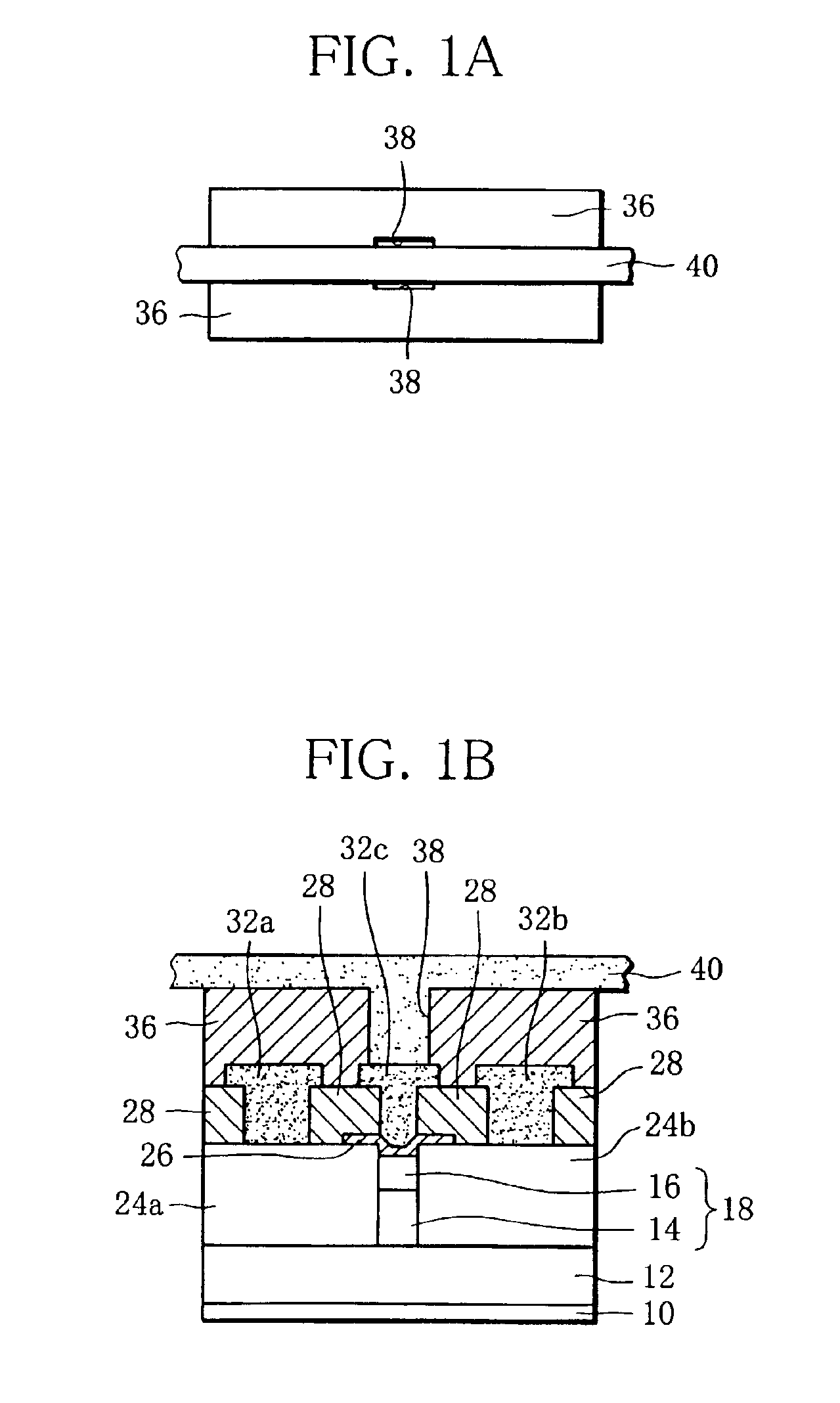

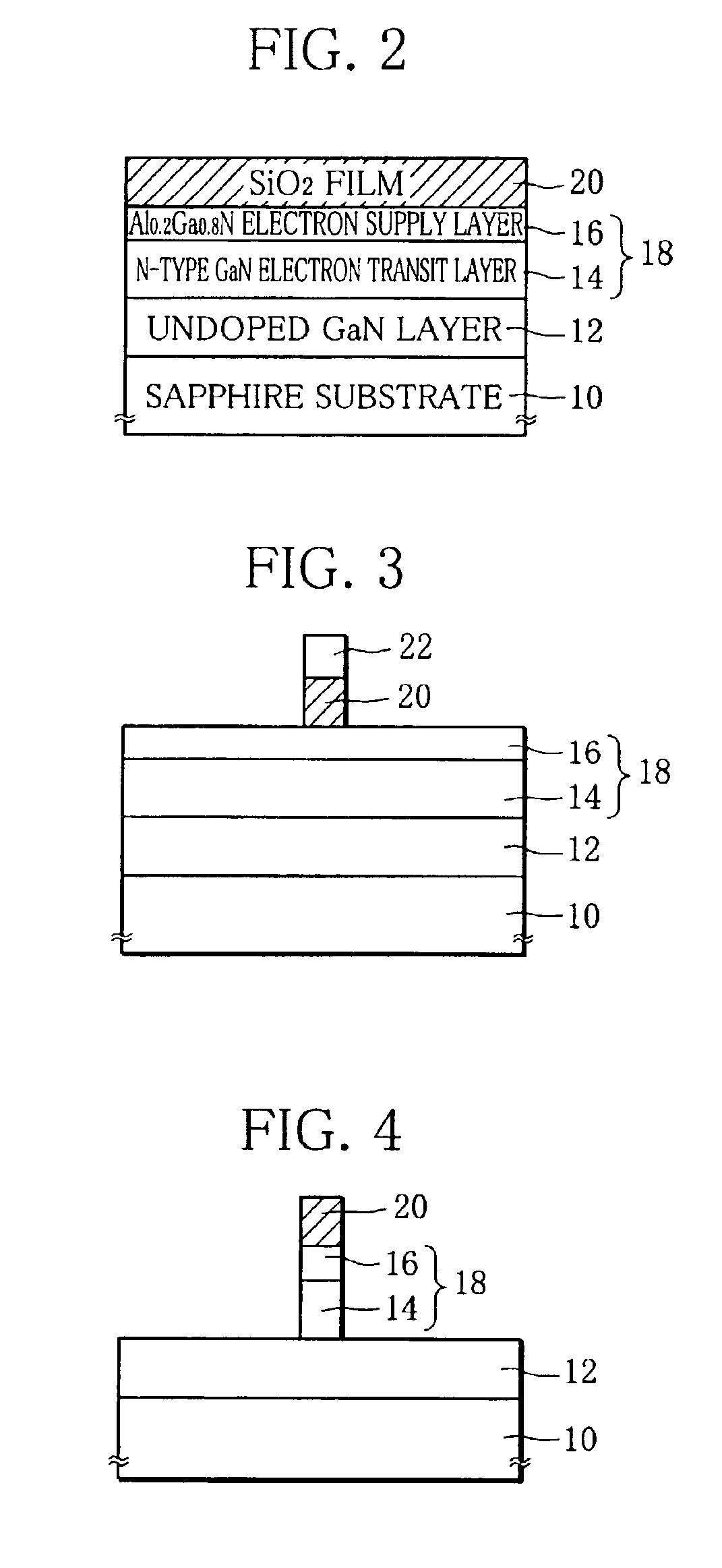

Field effect transistor and manufacturing method therefor

InactiveUS6897495B2Improve power characteristicsSimple processTransistorSemiconductor/solid-state device manufacturingElectronic transmissionField-effect transistor

GaN-based FET has a sapphire substrate of about 50 nm thick on which an n-type GaN electron transit layer and an Al0.2Gao0.8N electron supply layer are formed, together with n+-type GaN contact regions sandwiching the electron transit and supply layers therebetween. On the entire faces of these layer and regions is formed a polyimide interlayer insulating film of about 3000 nm thick that is formed with contact holes in which source, drain and gate electrodes are formed, each of which is comprised of a TaSi / Au layer and about 5000 nm in thickness. The source and drain electrodes are ohmic-connected to the n+-type GaN contact regions and the gate electrode is in contact with an SiO2 gate insulating film.

Owner:FURUKAWA ELECTRIC CO LTD

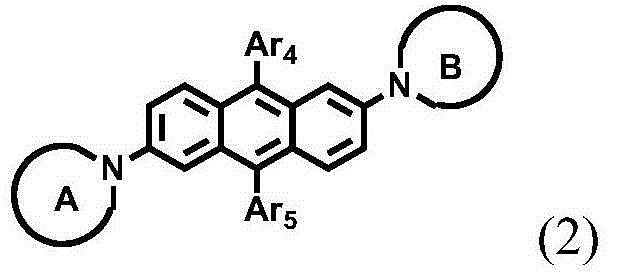

Additive for electrolyte solution, non-aqueous electrolyte solution including the additive and lithium secondary battery including the electrolyte solution

ActiveUS20140011081A1Improve featuresReduce resistanceCell electrodesLi-accumulatorsPhysical chemistryLithium-ion battery

An additive for an electrolyte solution includes a lithium salt having an oxalato complex as an anion and a compound represented by following Chemical Formula 1.Wherein, a represents C or Si, b represents H or F, and n represents an integer of 1 to 5. A non-aqueous electrolyte solution including the additive and a lithium secondary battery including the electrolyte solution also are provided.

Owner:LG ENERGY SOLUTION LTD

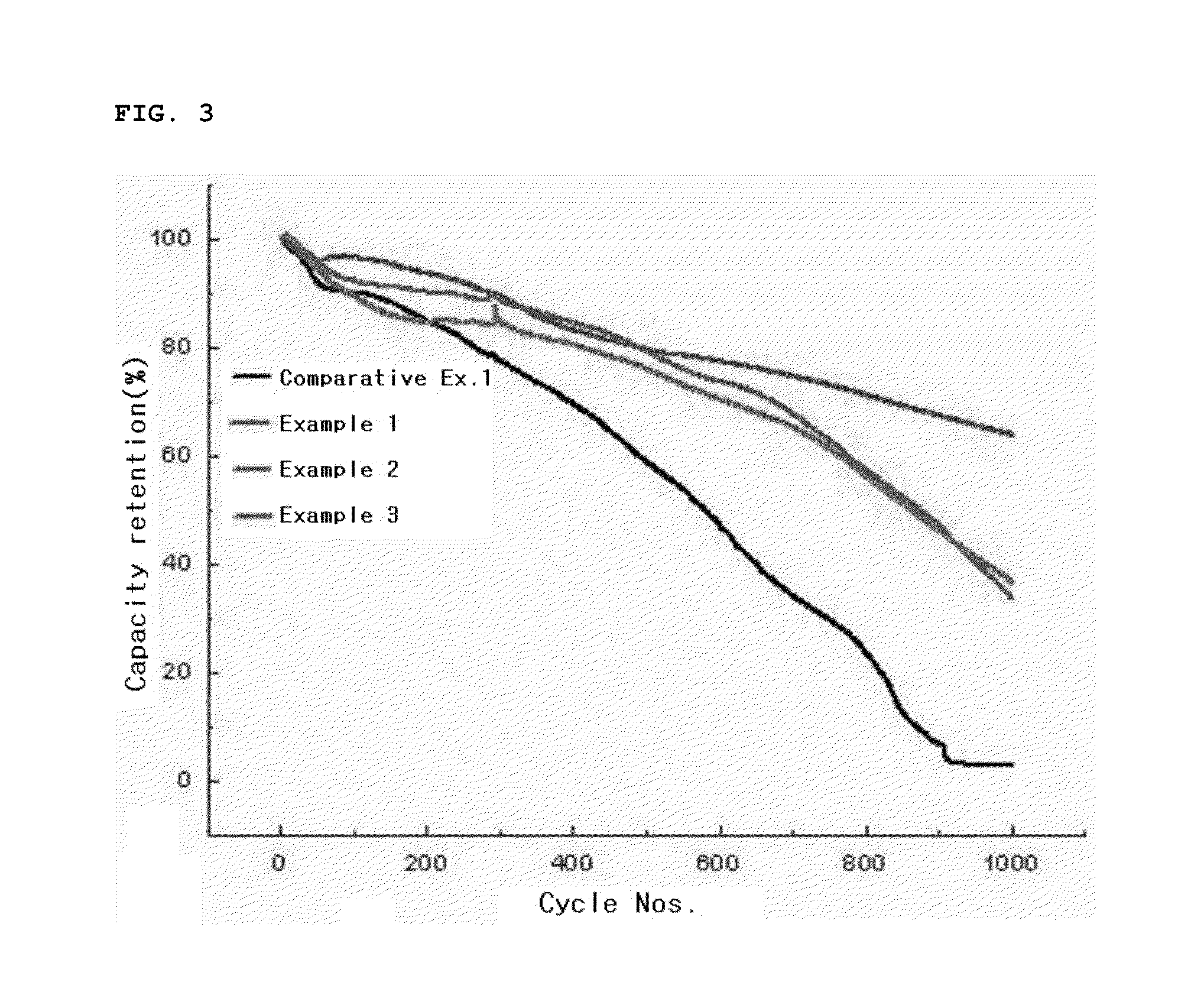

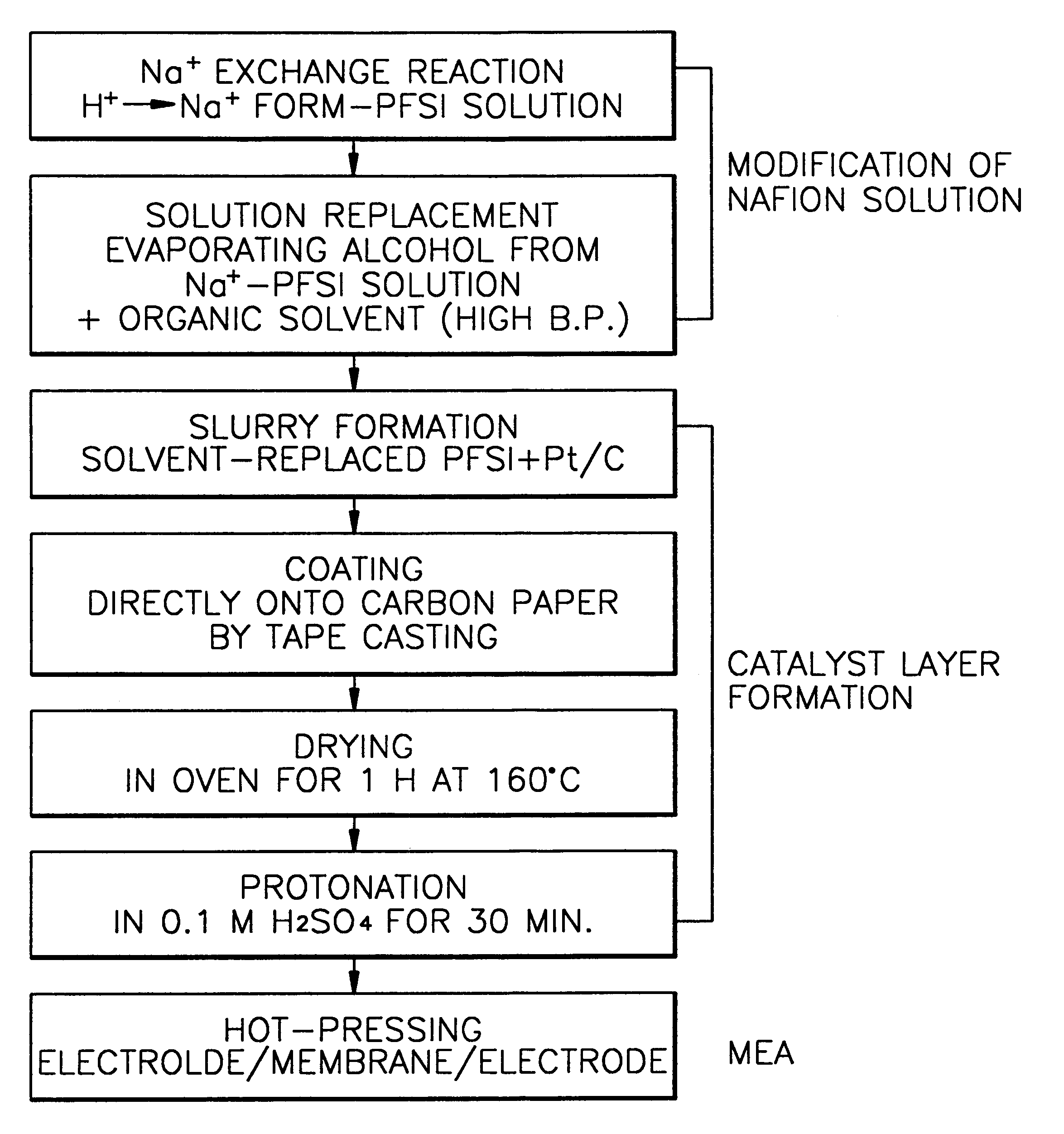

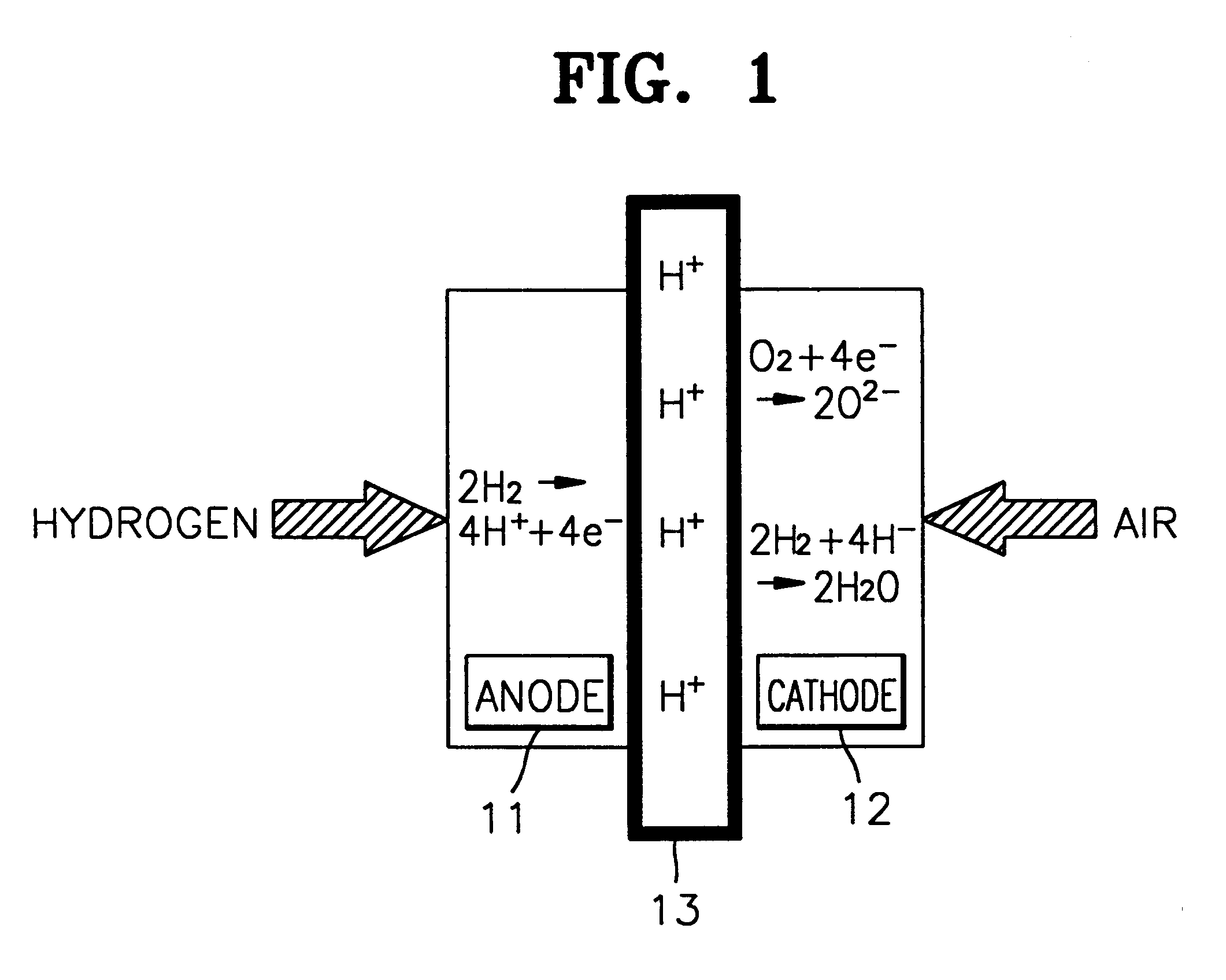

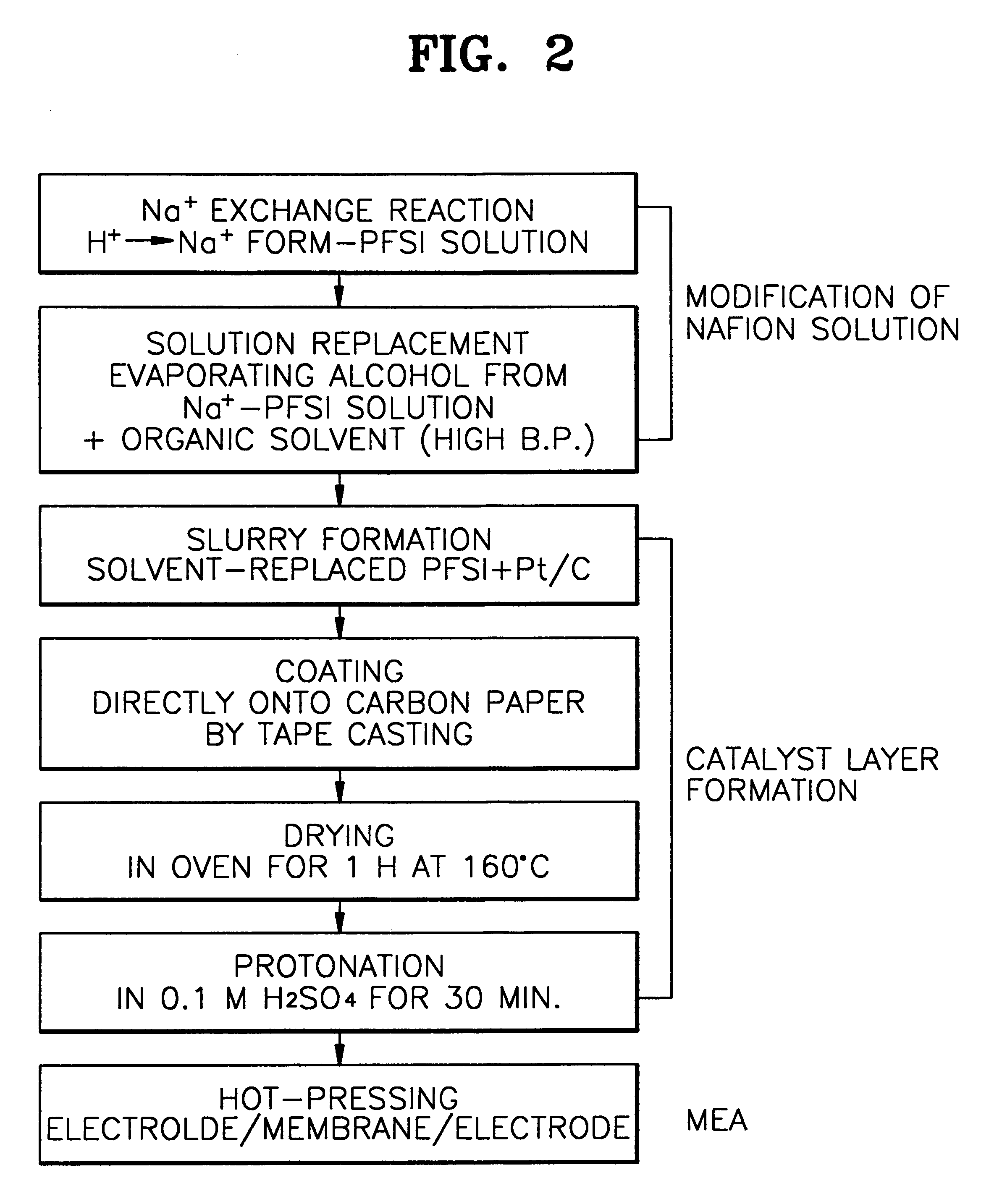

Method of forming catalyst layer for fuel cell

A method for preparing a slurry for forming a catalyst layer of a PEM fuel cell electrode and a method for fabricating the PEM fuel cell produced thereby are provided. The method for preparing a slurry for forming a catalyst layer of a proton exchange membrane (PEM) fuel cell according to the present invention comprises the steps of (a) adding an MOH solution to a perfluorosulfonate ionomer (PFSI) solution to convert PFSI in the PFSI solution into an M+ form-PFSI solution, wherein M is an alkaline metal selected from the group consisting of Li, Na and K; (b) adding an organic polar solvent having a higher boiling point than that of alcohol remaining in the PFSI solution to a mixed solution obtained in step (a) and heating the mixture at a temperature range of the boiling point of the alcohol to 20° C. higher than the boiling point to remove the remaining alcohol to obtain a pretreated PFSI solution; and (c) mixing the pretreated PFSI solution with Pt / C to form a slurry for forming a catalyst layer of a PEM fuel cell. Since processing stability is improved and the slurry can be easily prepared, Pt loading greater than a conventional level can be achieved by a single coating step by preventing a Pt catalyst from penetrating into a backing layer, the electrode characteristics are improved. Also, mass production of the PEM fuel cells is possible.

Owner:SAMSUNG SDI CO LTD

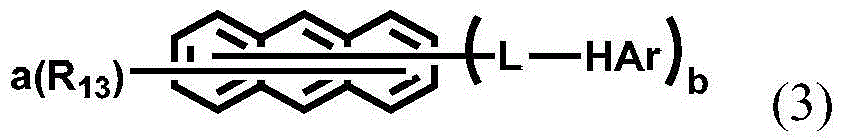

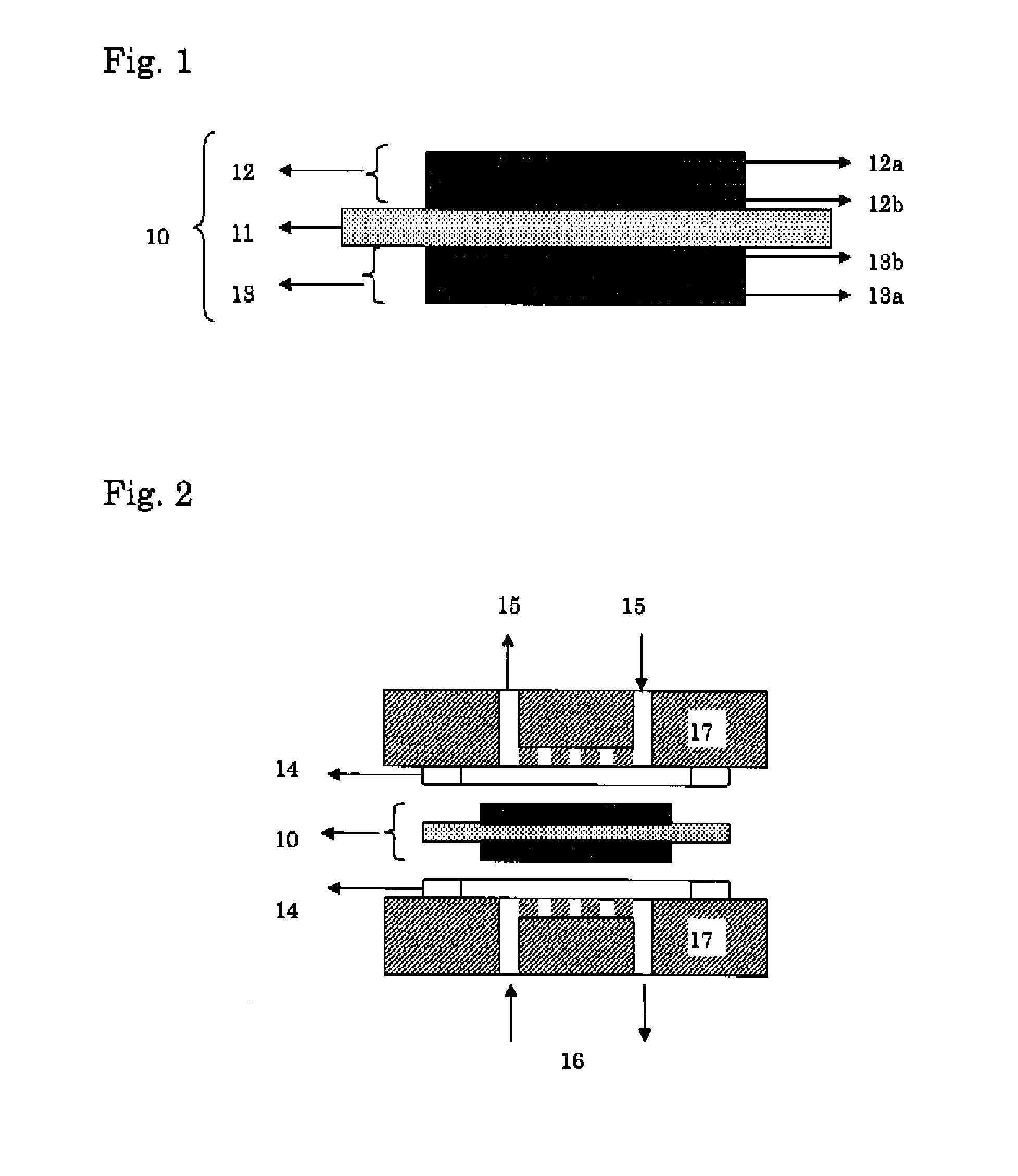

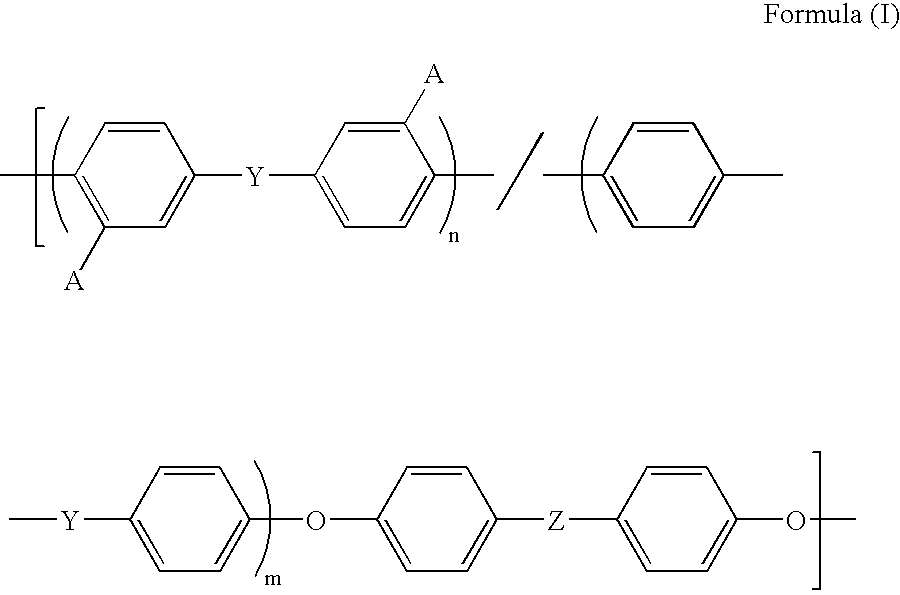

Membrane/Electrode Assembly and Fuel Cell

InactiveUS20070264551A1Good power characteristicsImproved proton conductionSolid electrolytesActive material electrodesIon-exchange membranesChemistry

A membrane / electrode assembly comprising a pair of electrodes and an ion exchange membrane disposed therebetween wherein the ion exchange membrane contains a repetitive unit represented by the formula (I), and the minimum value of the internal resistance of the assembly at 80° C. and 120° C. is 100 mΩ·cm2 or less and 600 mΩ·cm2 or less, respectively: in which, m and n is a positive integer, n / n+m is 0.001 to 1, Y is —S—, —S(O)—, —S(O)2—, —C(O)—, —P(O)(C6CH5)— or a combination thereof, Z is a single bond, —C(CH3)2—, —C(CF3)2—, —C(CF3)(C6H5)—, —C(O)—, —S(O)2— or —P(O)(C6H5)—, and A represents a sulfonate-containing moiety.

Owner:FUJIFILM CORP

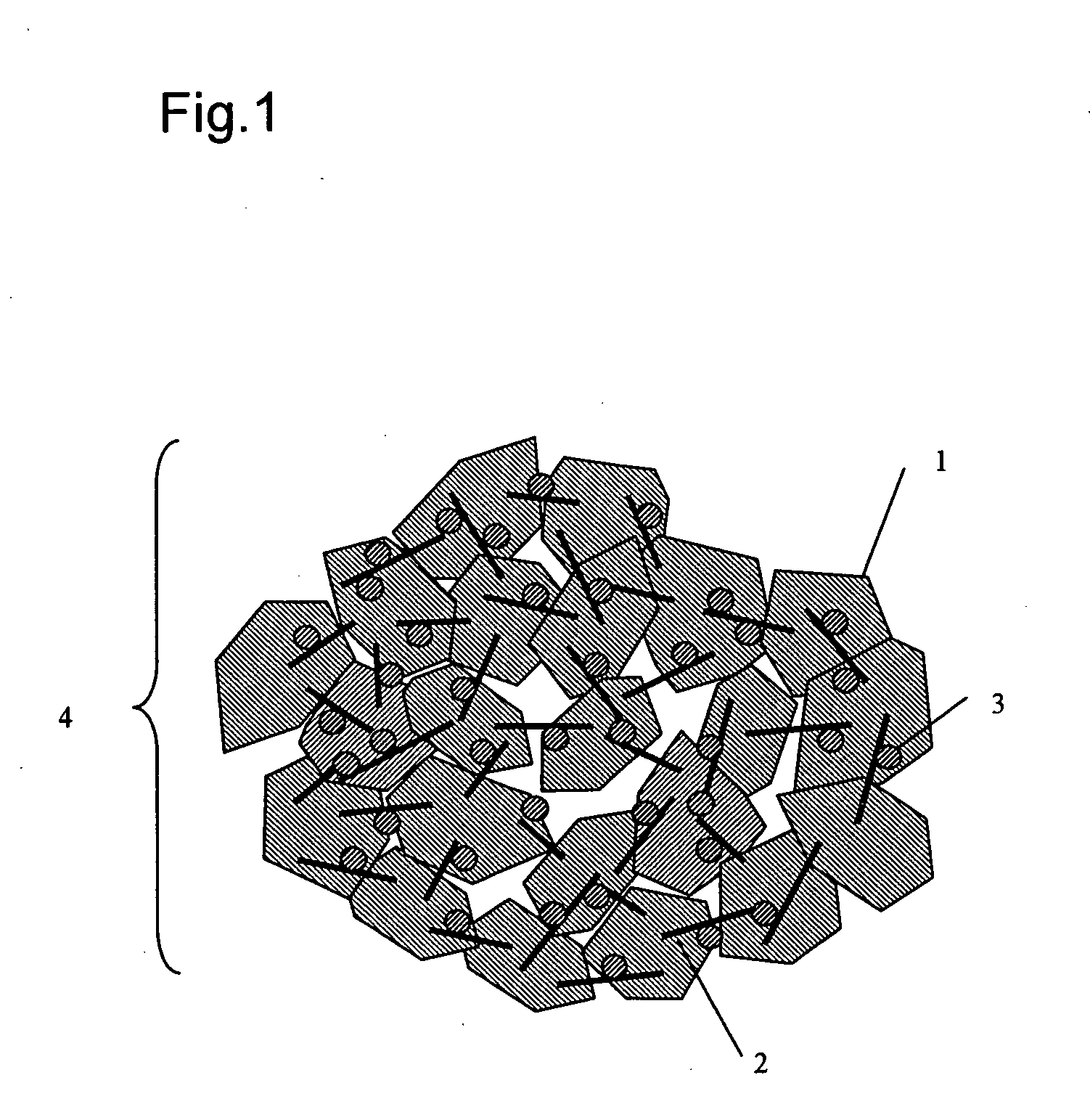

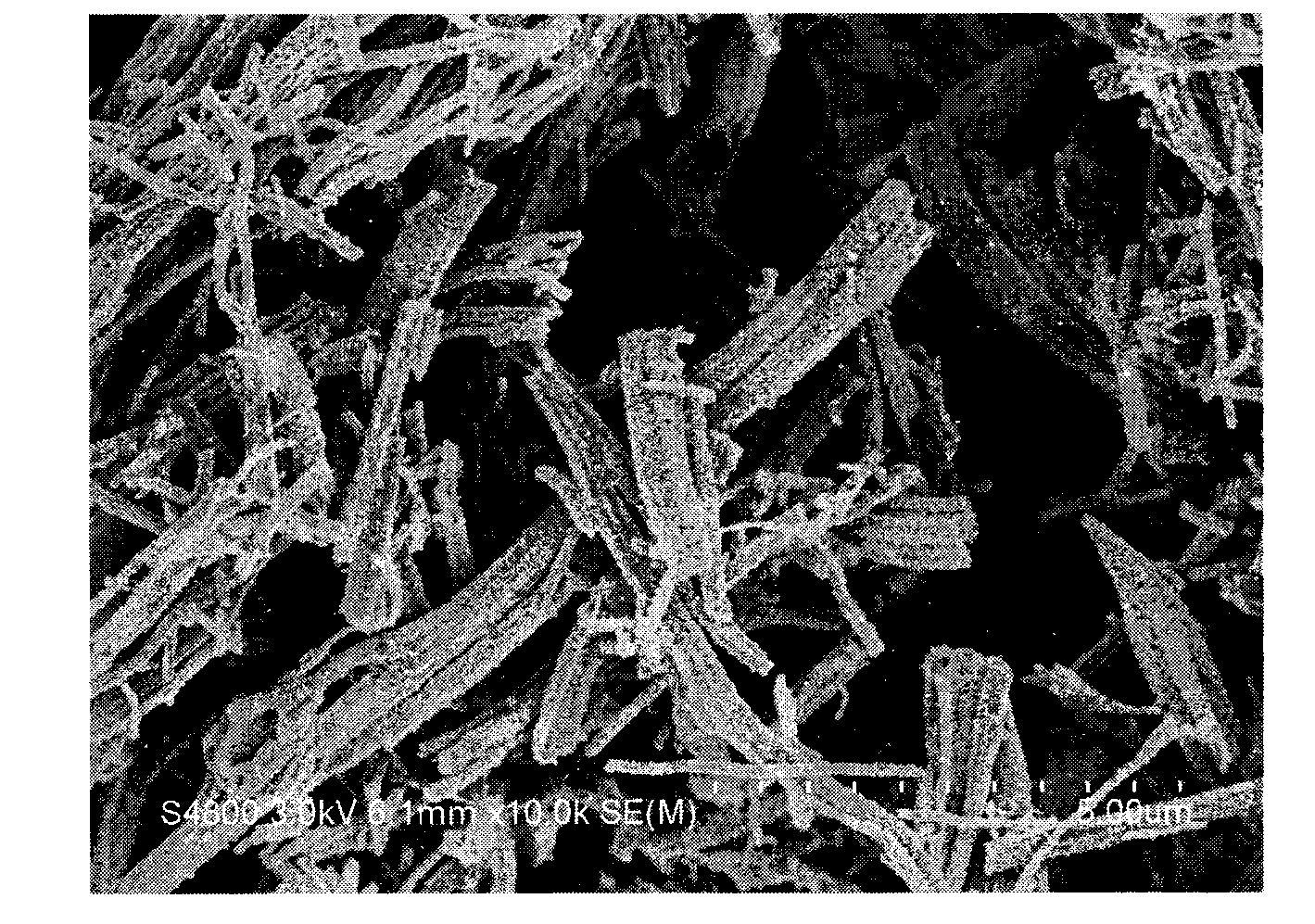

Positive electrode material for lithium secondary battery, positive electrode plate for lithium secondary battery, and lithium secondary battery using the same

InactiveUS20100261061A1Increase speedEasily penetrated into carbon fiberActive material electrodesNanotechnologyLithium oxideCarbon composites

A positive electrode material for a lithium secondary battery according to the invention includes a positive electrode active material containing lithium oxide and a carbon composite obtained by dispersing carbon fiber and a clamped shape carbon material, and the positive electrode active material is combined with the carbon composite. In the positive electrode material for a lithium secondary battery constructed as described above, a conductive network between primary particles is formed by the carbon composite while the positive electrode active material (primary particles) are condensed to form secondary particles.

Owner:HITACHI LTD

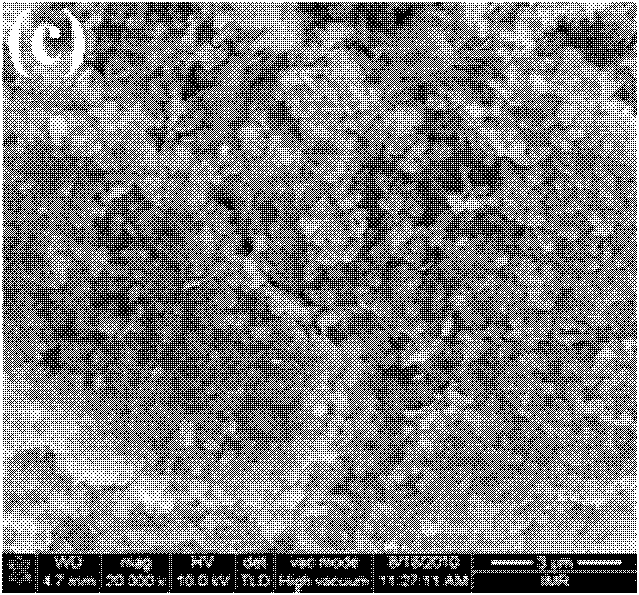

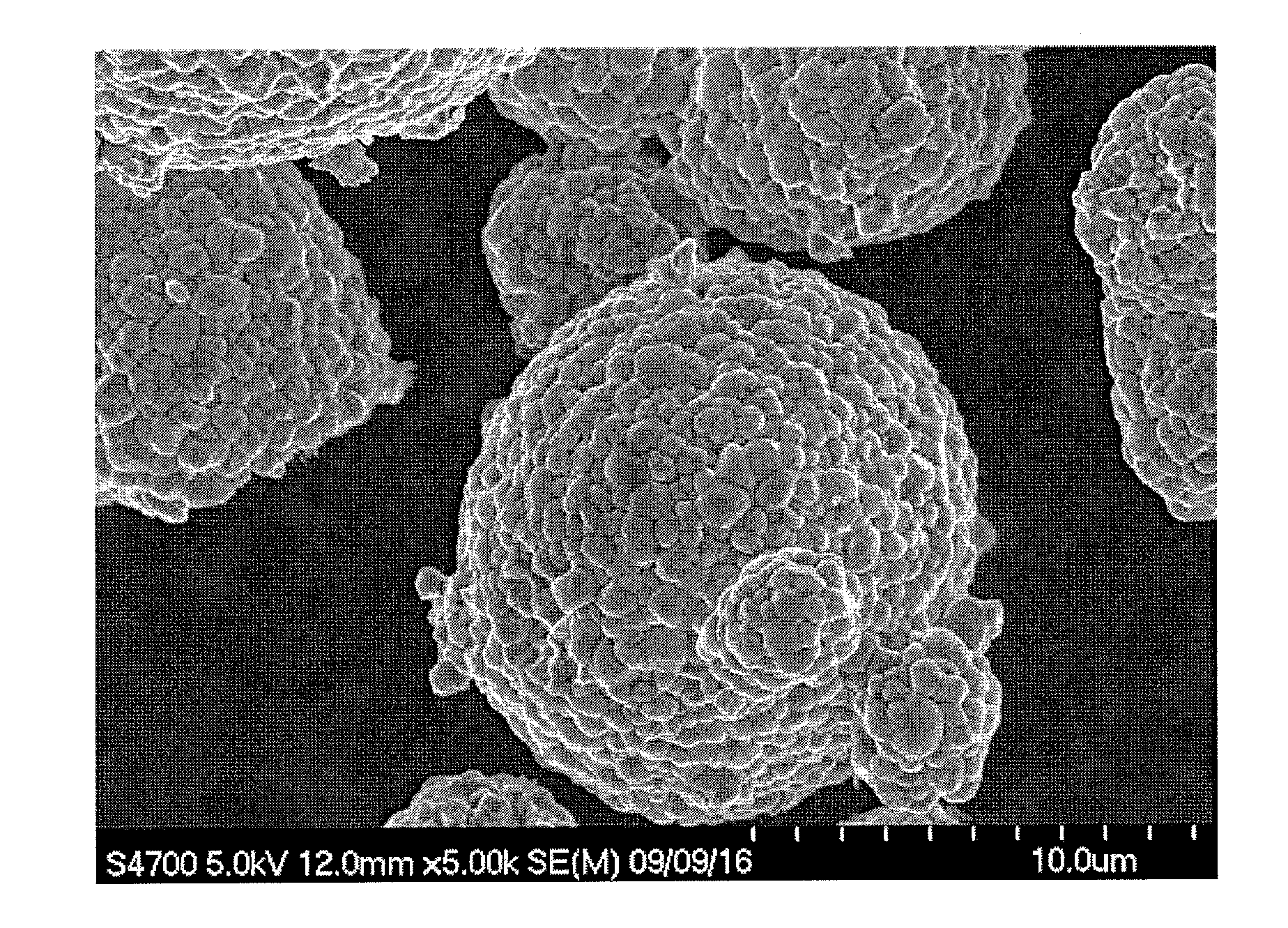

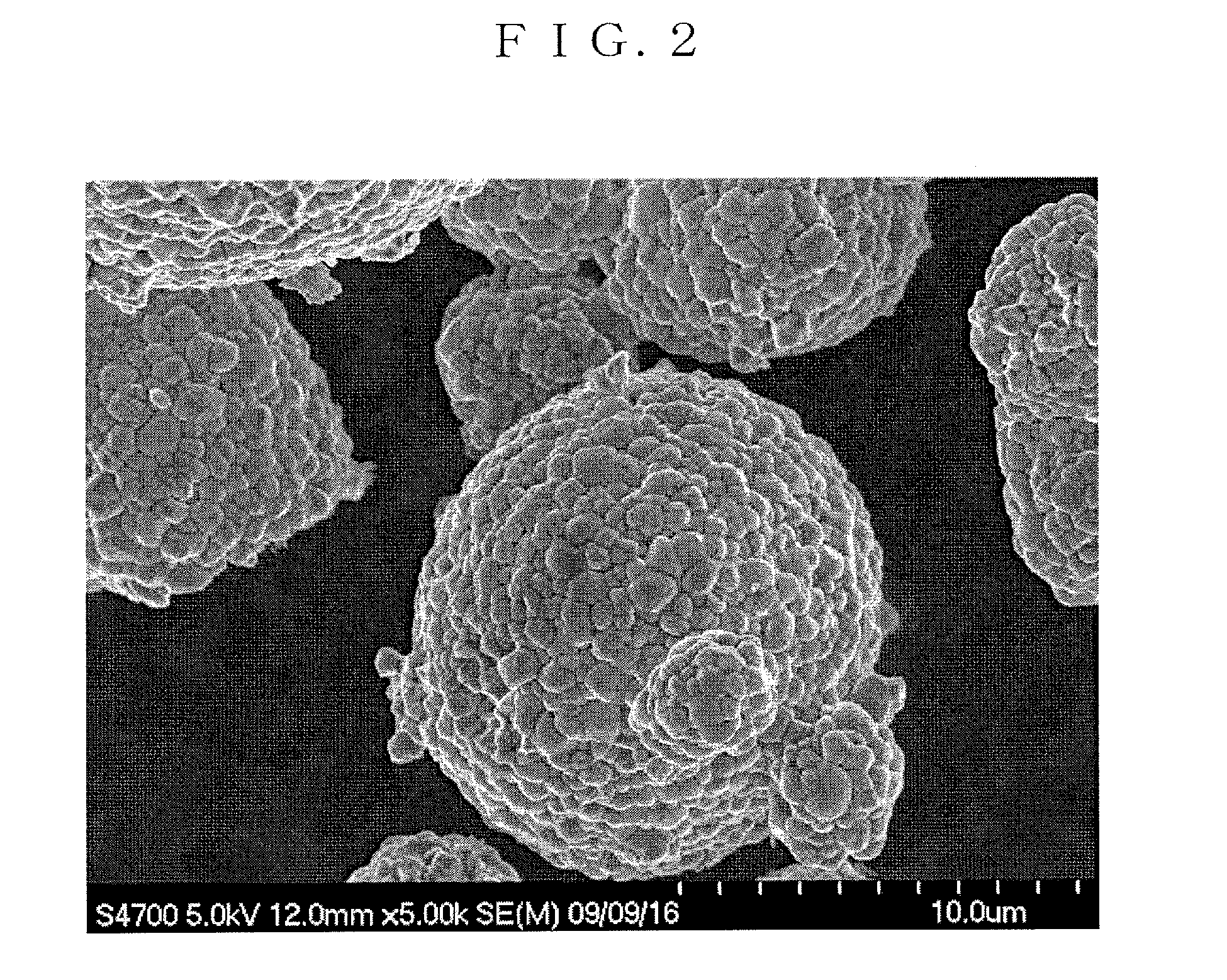

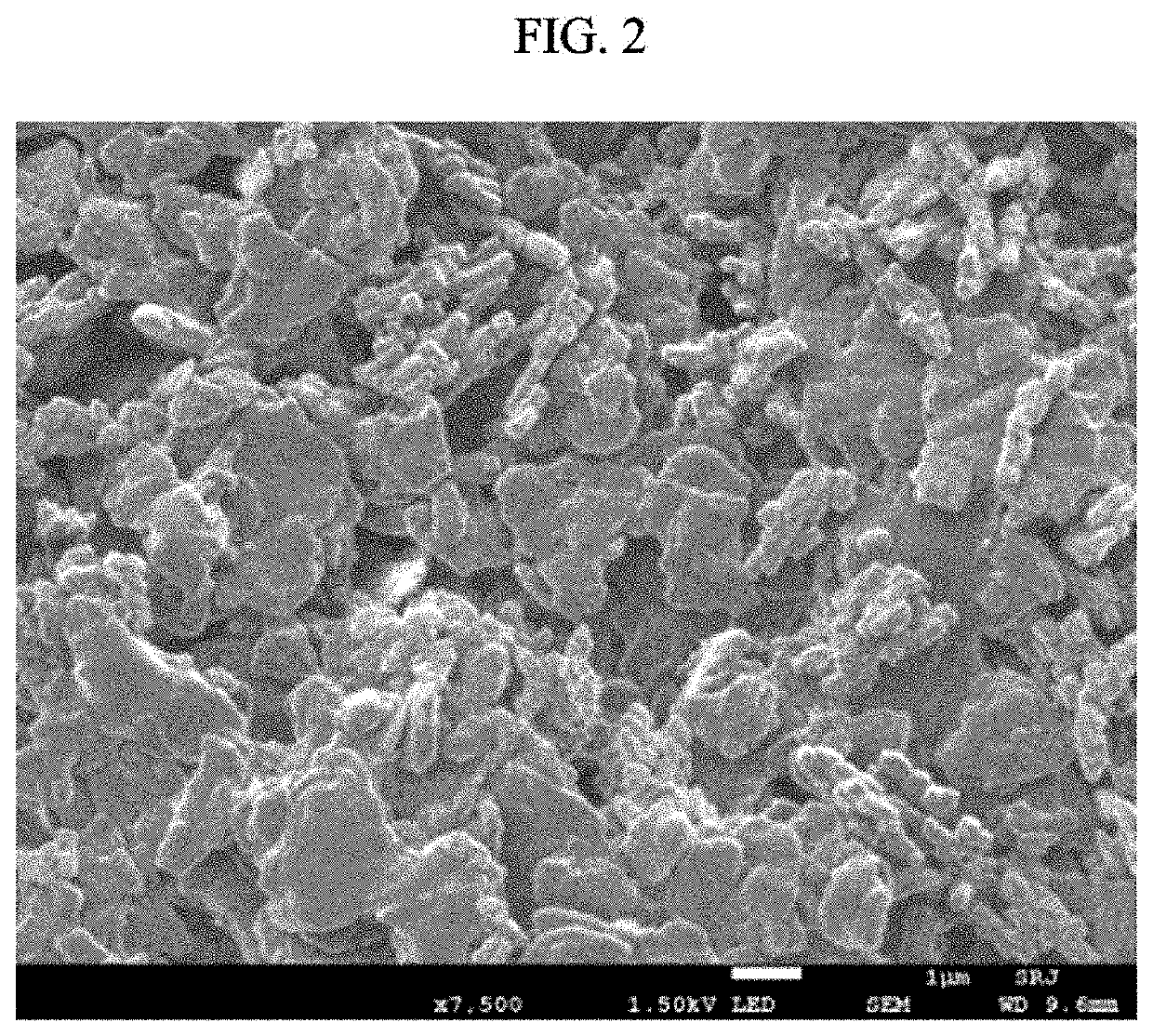

Positive-electrode active material for nonaqueous electrolyte secondary battery and method for producing the same, and nonaqueous electrolyte secondary battery

The present invention provides a cathode active material for a nonaqueous electrolyte secondary battery with a high capacity, high stability and excellent output characteristics and a method for producing the same, and a nonaqueous electrolyte secondary battery using the cathode active material.The cathode active material for a nonaqueous electrolyte secondary battery is represented by a general formula: LitNi1.x.y.zCoxAlyTizO2 wherein 0.98≦t≦1.10, 0<x≦0.30, 0.03≦y≦0.15, 0.001≦z≦0.03; and includes a hexagonal lithium-containing composite oxide with a layer structure of secondary particles having primary particles, in which a titanium-enriched layer is formed on a surface of the primary particles and / or a grain boundary between the primary particles. The titanium-enriched layer on the surface of the primary particles and / or a grain boundary between the primary particles serves as a lithium ion conductor, yielding smooth extraction and insertion of lithium ions. Accordingly, the secondary battery with a high capacity, high stability and excellent output characteristics can be produced when a positive electrode is formed with the lithium nickel composite oxide as a cathode active material.

Owner:SUMITOMO METAL MINING CO LTD

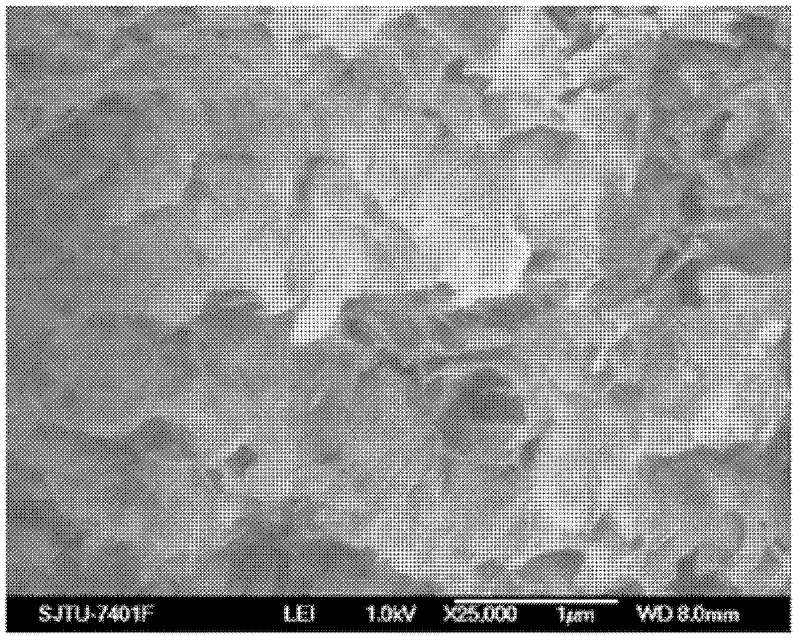

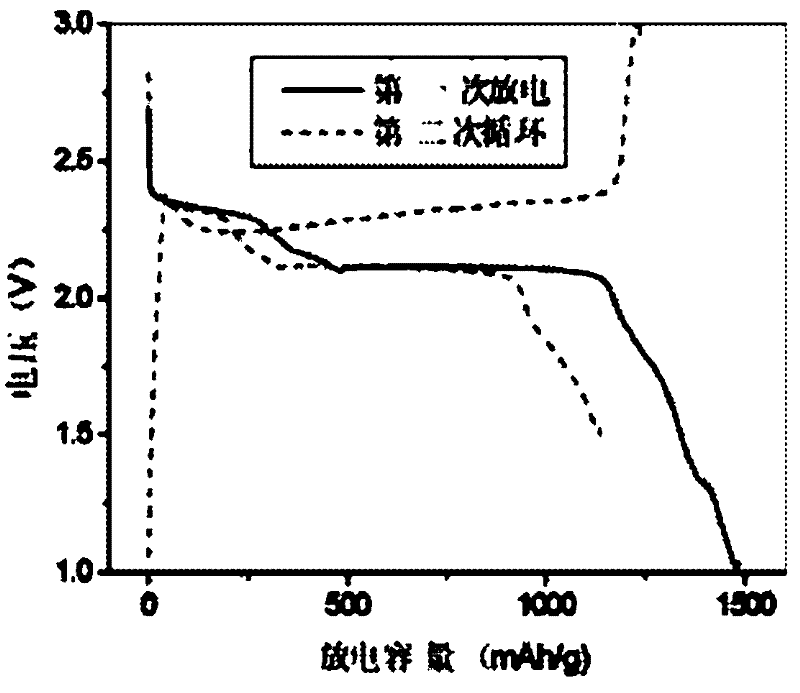

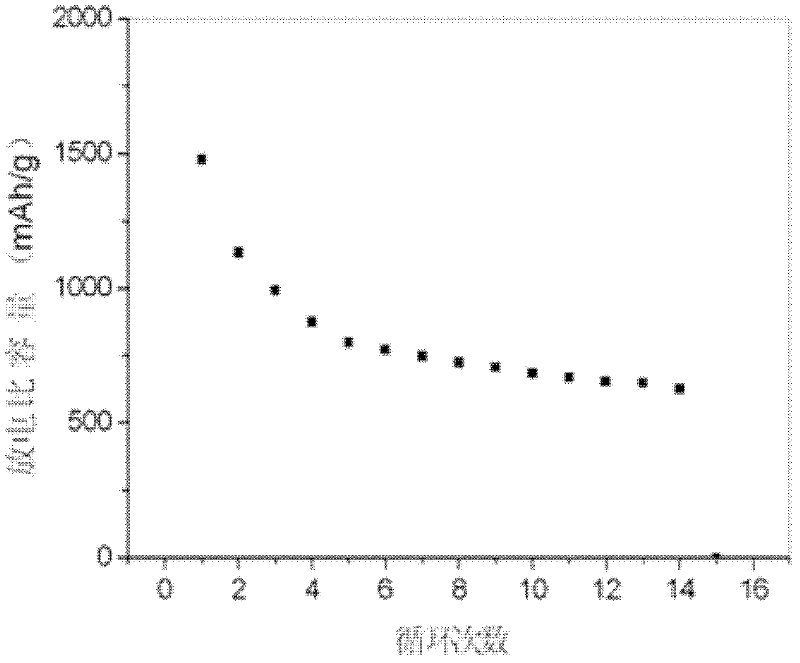

Elemental sulfur composite material containing graphene and preparation method thereof

InactiveCN102522542AIncrease profitIncrease energy densityCell electrodesLithium sulfurSodium–sulfur battery

The invention provides an elemental sulfur composite material containing graphene and a preparation method of the composite material. The composite material is a binary material AxBy, wherein A is grapheme, and B is elemental sulfur, x is more than or equal to 1 percent and less than or equal to 90 percent while y is more than or equal to 10 percent and less than or equal to 99, and x plus y equals to 100 percent, and B is dispersed on the surface of A in a nanometer state. The preparation method comprises the steps of carrying out hydro-thermal treatment on the elemental sulfur and the graphene oxide between 50 and 500 degrees; and reducing the graphene oxide into the graphene by the elemental sulfur, and obtaining the elemental sulfur composite material containing grapheme of which nano-sulfur is uniformly dispersed on the surface of the grapheme at the same time. Lithium sulfur batteries or sodium sulfur batteries are prepared by using the composite material as an anode and a metal lithium or metal sodium as a cathode; moreover, the lithium sulfur batteries can be charged or discharged under the room temperature, and the reversibility specific capacity of the sulfur-based composite material containing grapheme is up to 1480mAh / g.

Owner:SHANGHAI JIAO TONG UNIV

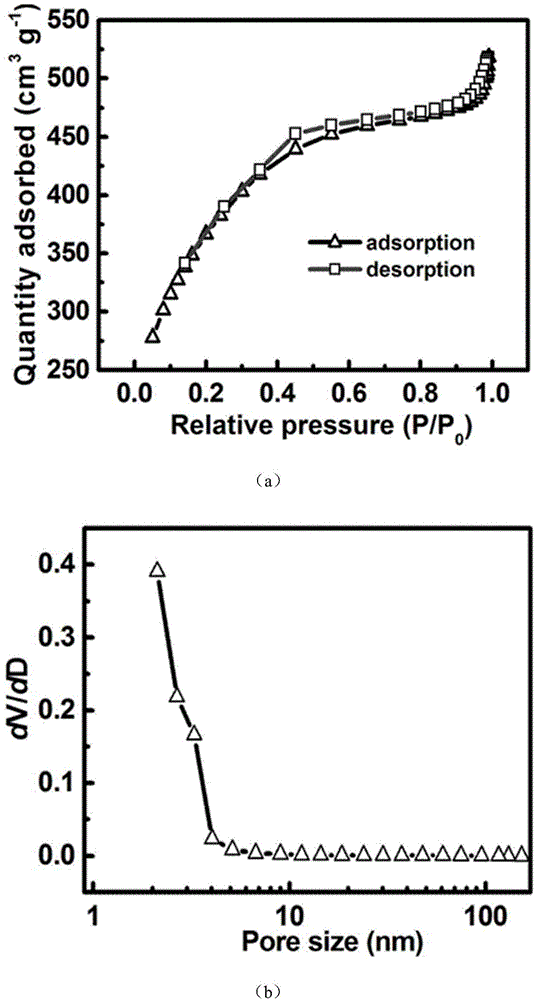

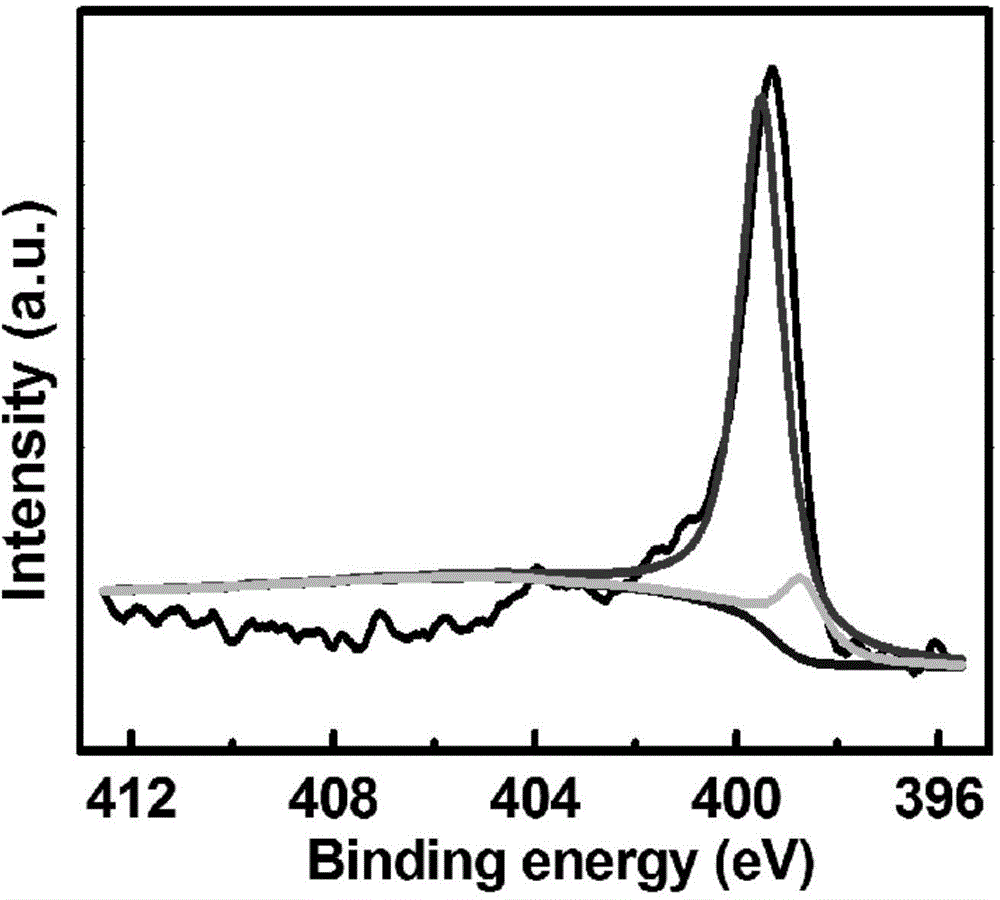

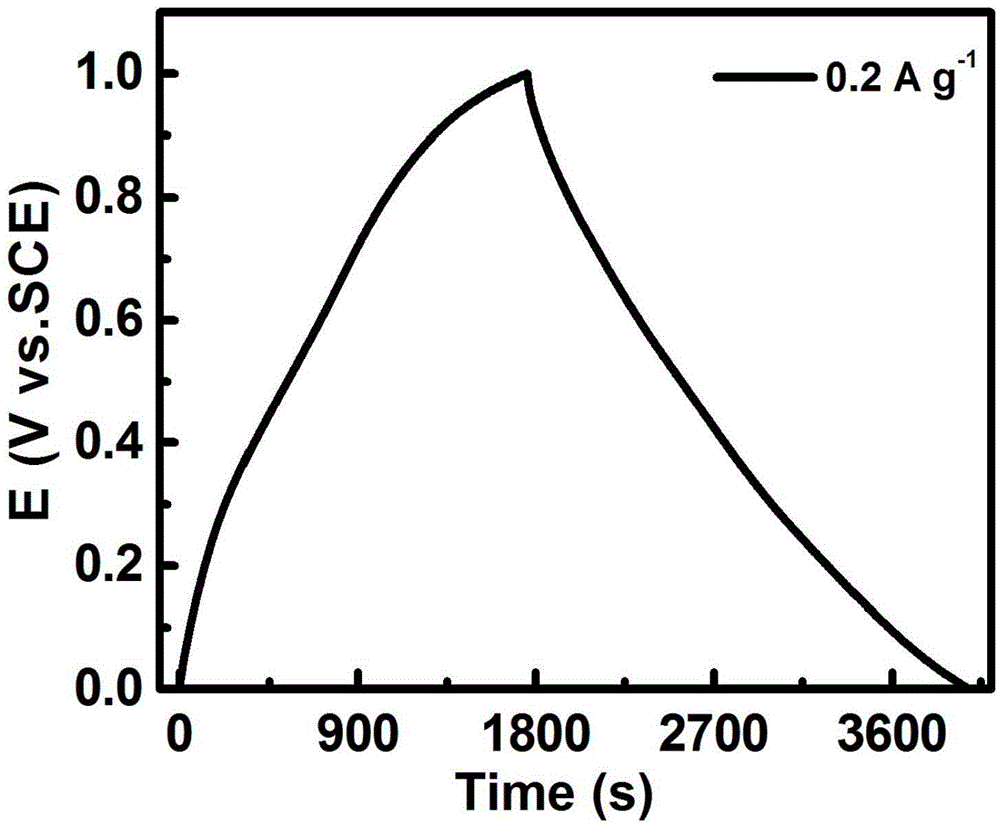

Method for preparing nitrogen-enriched porous carbon material for supercapacitor by taking lignite as raw material

The invention discloses a method for preparing a nitrogen-enriched porous carbon material for a supercapacitor by taking lignite as the raw material and belongs to the technical field of new energy. The method comprises the following steps: smashing the lignite, washing by deionized water to remove the surface impurities, washing and baking, heating up to a pre-carbonization temperature in an inert gas at the speed of 1-10 DEG C / min, and keeping the temperature for 2h to obtain the carbon precursor; grinding the carbon precursor, uniformly mixing with the alkali metal hydroxide, putting into the inert gas, heating up to an activation temperature in the inert gas at the speed of 1-10 DEG C / min, and keeping the temperature for 1-10h to obtain the activation product; and performing acid pickling and neutralization on the activation product, washing to be neutral by deionized water, drying and grinding to obtain the nitrogen-enriched porous carbon material for the supercapacitor. The high-performance nitrogen-enriched porous carbon material for the supercapacitor can be prepared from the lignite so that the nitrogen-enriched porous carbon material is excellent in performance, energy-saving, environmentally friendly, simple in process and low in cost and has a wide industrial application prospect by being used as the supercapacitor electrode material.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

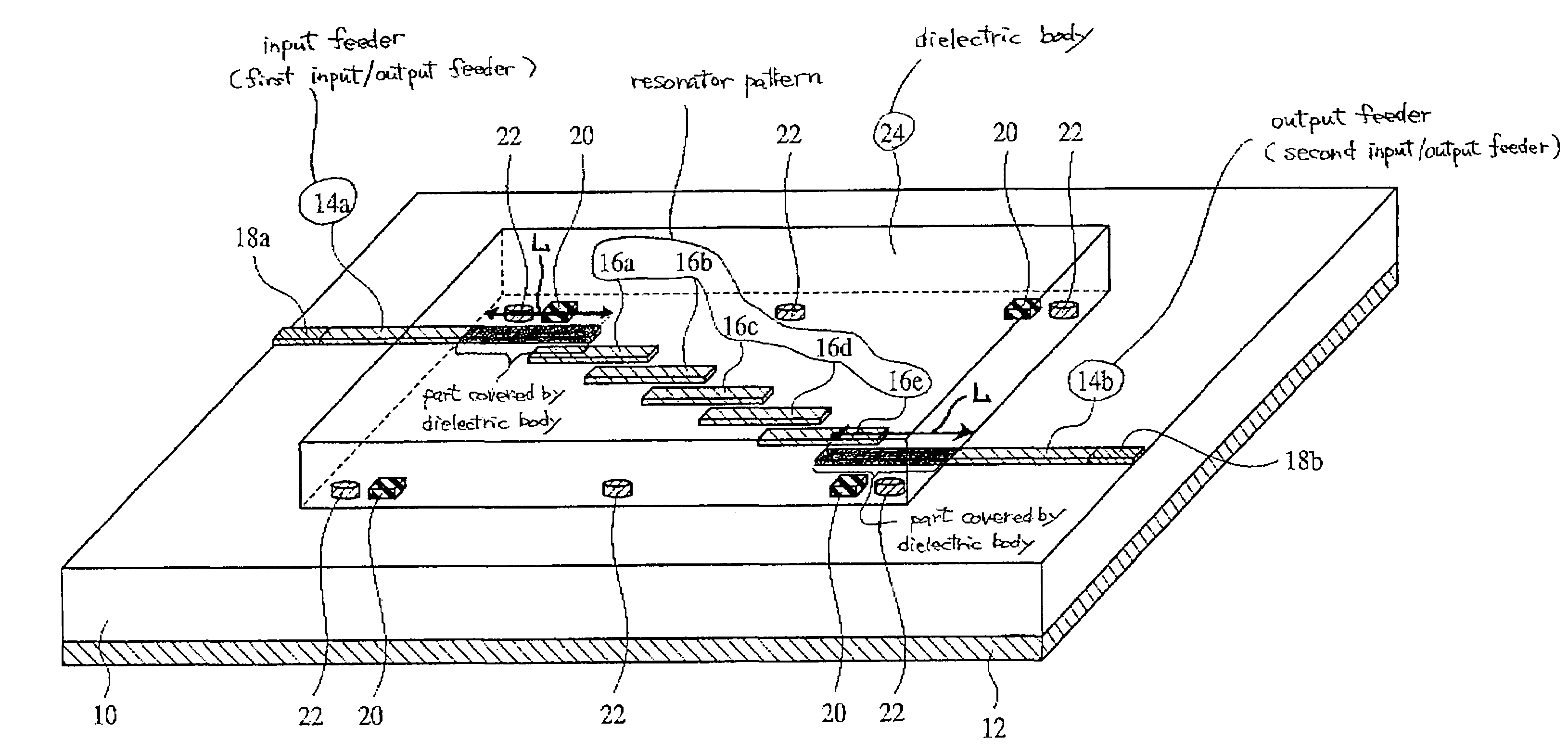

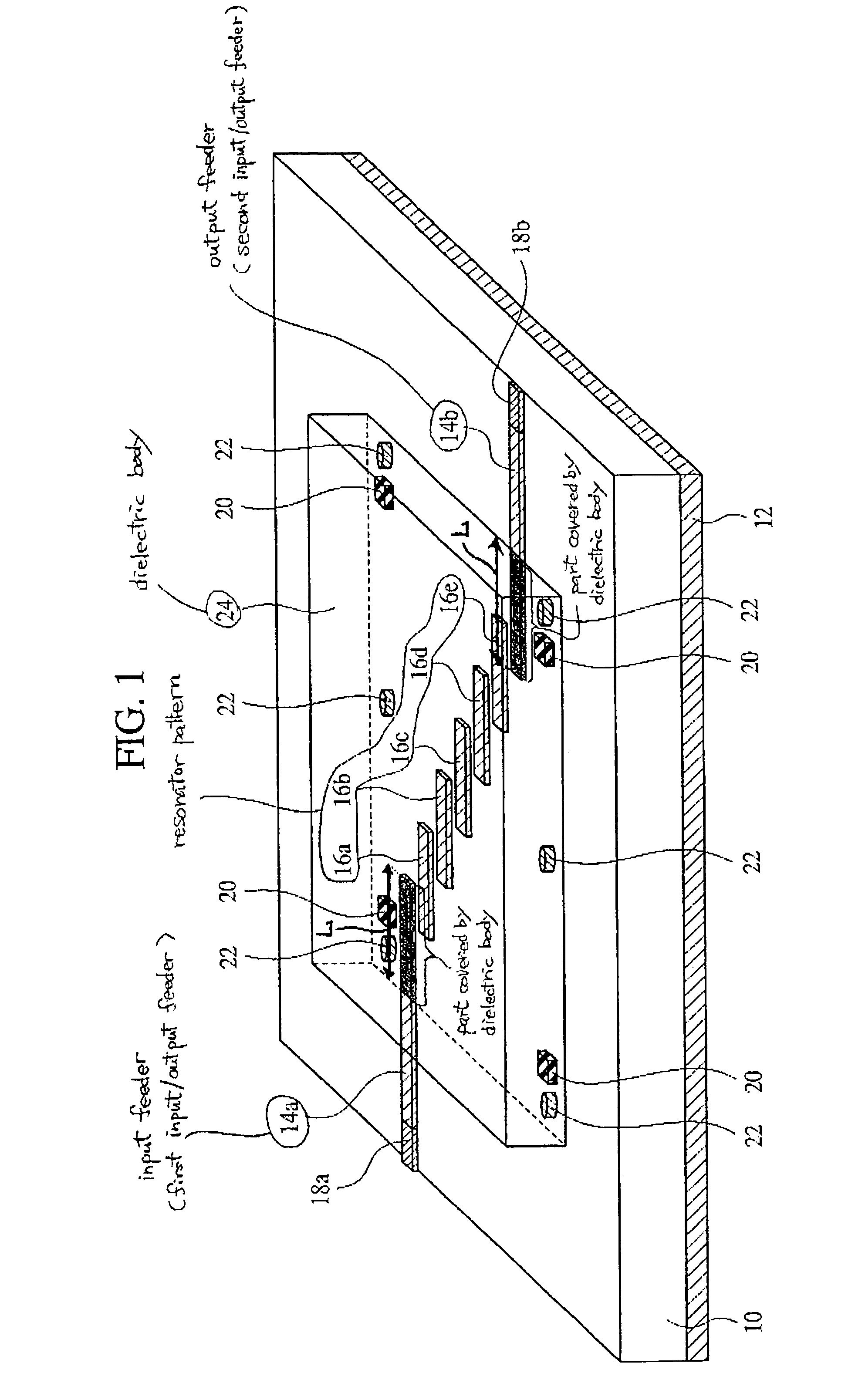

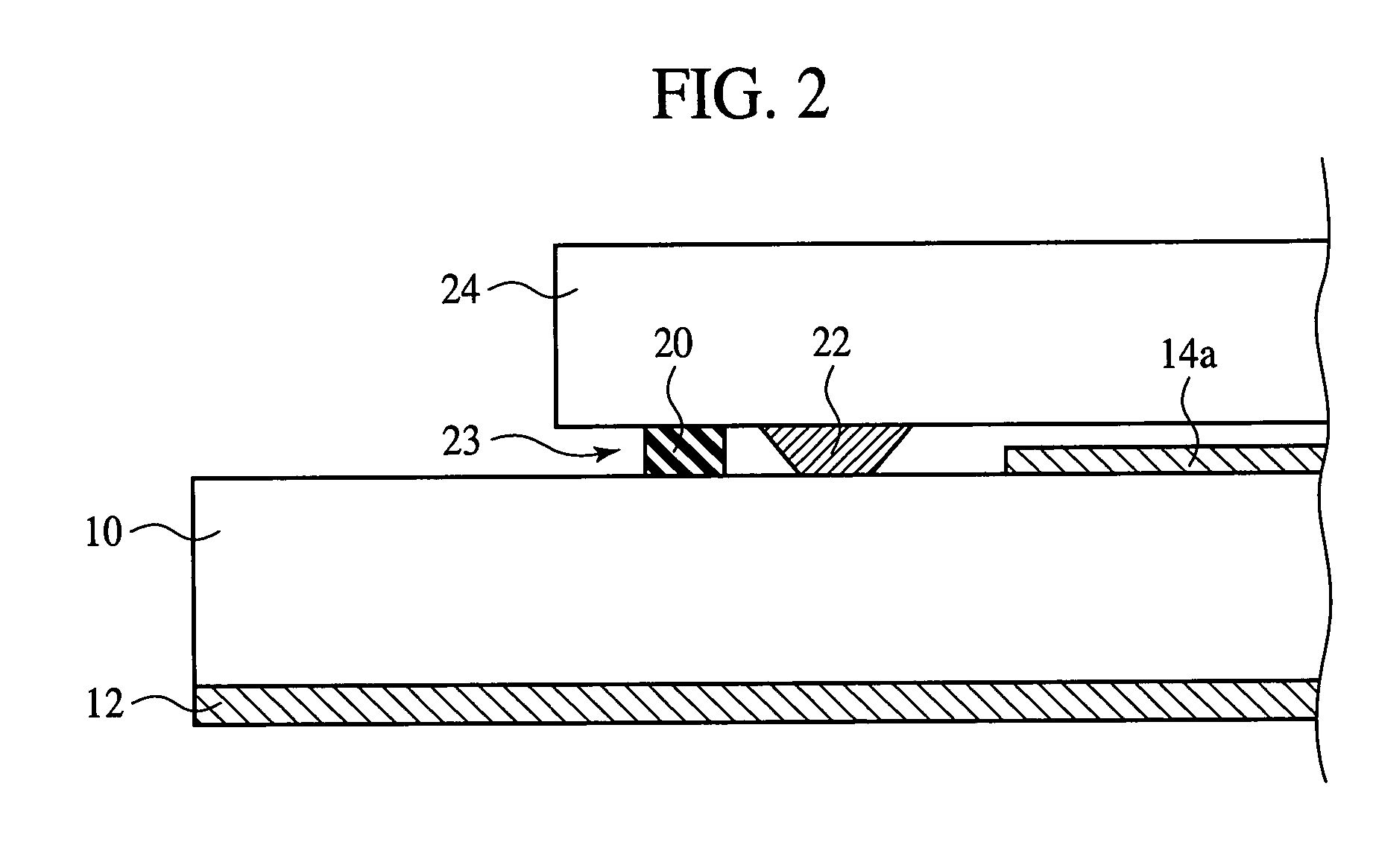

Superconducting filter

ActiveUS7218184B2Improve power characteristicsGood repeatabilitySuperconductors/hyperconductorsSuperconductor devicesDielectric plateDielectric substrate

A superconducting filter including input / output feeders formed on one surface of a dielectric substrate, resonator patterns formed on one surface of the dielectric substrate, and a dielectric plate mounted on the one surface of the dielectric substrate with a plurality of spacers formed on said one surface of the dielectric substrate disposed therebetween. The dielectric plate covers the region including the resonator patterns, and the input / output feeders length-wise over the length within ±20% of positive integer times a ¼ effective wavelength from the sides nearer to the resonator patterns.

Owner:FUJITSU LTD

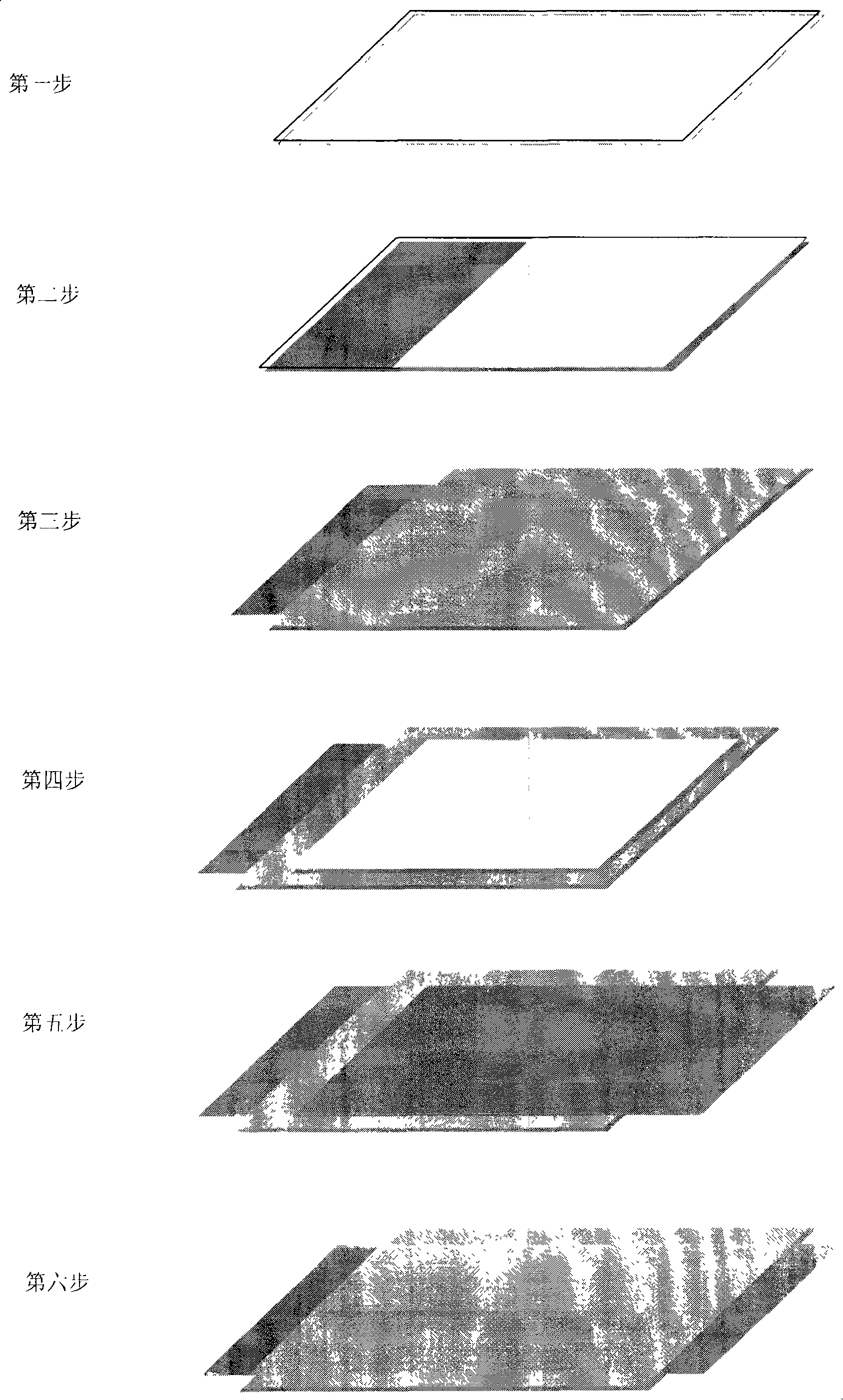

Supercapacitor flexible self-supporting full-carbon electrode with graphene as binder and preparation method thereof

ActiveCN107946086AIncrease energy densityHigh surface areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceComposite film

The invention relates to a supercapacitor flexible self-supporting full-carbon electrode with graphene as a binder. The electrode is composed of two components of a micro-grade porous carbon materialand the graphene, and the thickness is 10-200 [mu]m, wherein the ratio of the porous carbon particle with dimension of 2-10 [mu]m as the active material in the total electrode mass is 80-95%. The ratio of the graphene with dimension of 3-15 [mu]m and slice layer thickness of 1-5 as the binder in the total electrode mass is 5-20%. The whole electrode has high flexibility and can be directly used asthe electrode of the flexible supercapacitor. The invention further provides a preparation method of the carbon electrode, wherein the preparation method comprises the steps of dispersing the porouscarbon into graphene oxide solution, performing vacuum pumping and filtering on the mixed solution for forming a film, and finally performing high-temperature thermal treatment on the composite film of the porous carbon and the graphene oxide through protection of an inert atmosphere, thereby converting the graphene oxide to graphene through reduction reaction, thereby obtaining the porous carbonmaterial / graphene flexible self-supporting composite film electrode. In the electrode, the porous carbon is the active material, and the graphene is used as the binder, a conductive agent and an auxiliary active material. Compared with a traditional electrode forming method in which insulating high-molecular materials such as PTFE and PVDF are used as the binder, the carbon electrode which is prepared through using the graphene as a multifunctional conductive binder has higher specific capacity and better multiplying power performance. Furthermore the electrode forming method has advantages ofsimple operation and environment-friendly performance.

Owner:BEIJING UNIV OF CHEM TECH

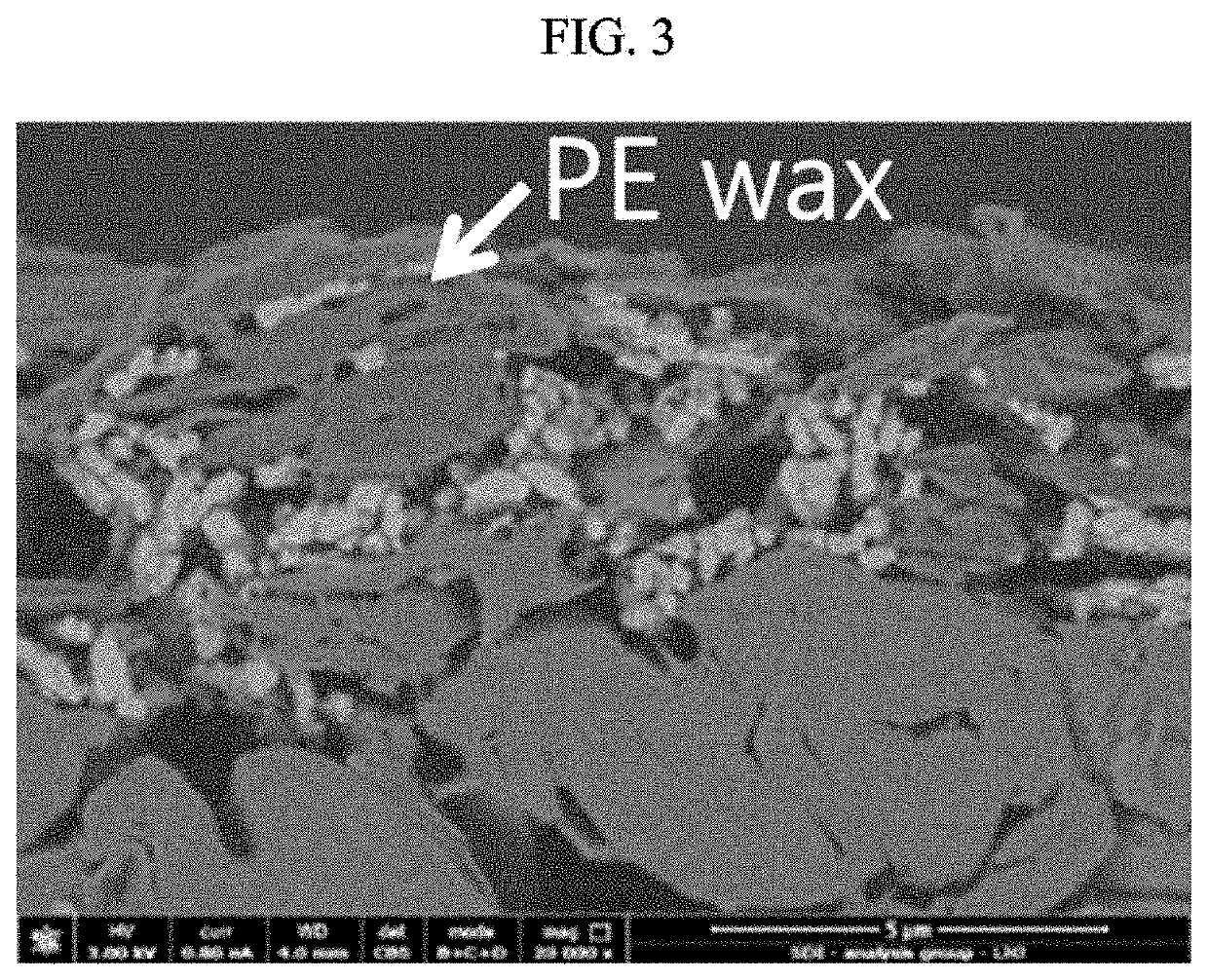

Rechargeable lithium battery

ActiveUS20200350566A1Large capacityImprove power characteristicsNegative electrodesLi-accumulatorsPositive currentNanotube

A rechargeable lithium battery includes a negative electrode including a negative current collector, a negative active material layer disposed on the negative current collector, and a negative electrode functional layer disposed on the negative active material layer; and positive electrode including a positive current collector and a positive active material layer disposed on the positive current collector, wherein the negative electrode functional layer includes flake-shaped polyethylene particles, the positive active material layer includes a first positive active material including at least one of a composite oxide of a metal selected from cobalt, manganese, nickel, and a combination thereof and lithium, a second positive active material including a compound represented by Chemical Formula 1, and carbon nanotubes, and the carbon nanotubes have an average length of 30 μm to about 100 μm.LiaFe1-x1Mx1PO4 [Chemical Formula 1]In Chemical Formula 1, 0.90≤a≤1.8, 0≤x1≤0.7, and M is Mn, Co, Ni, or a combination thereof.

Owner:SAMSUNG SDI CO LTD

Preparation method of zinc oxide nanometer fiber cathode material for lithium ion battery

A zinc oxide nanometer fiber cathode material for lithium ion battery and a preparation method thereof belong to the technical fields of high polymer material and chemical power source. The zinc oxide nanometer fiber material for lithium ion battery provided by the invention has large specific surface area. The method first prepares composite nanometer fiber by electrospinning, and then the nanometer fiber is subjected to high-temperature calcination to obtain the zinc oxide nanometer fiber. The preparation process provided by the invention is simple and easy to control, and has low production cost. The cathode electrode material for lithium ion battery provided by the invention overcomes the disadvantages of zinc oxide nanorod prepared by other methods as cathode material for lithium ion battery, such as low first cycling efficiency, weak cycle stability and high-rate discharge ability. The invention provides a zinc oxide nanometer fiber cathode material for lithium ion battery and the preparation method thereof. The material has high initial discharge capacity and cycling stability, improves high power characteristic and high-rate discharge capacity of cathode material, and is suitable for development requirements of lithium ion power battery for electric vehicles.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com