Patents

Literature

6445 results about "Porous carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

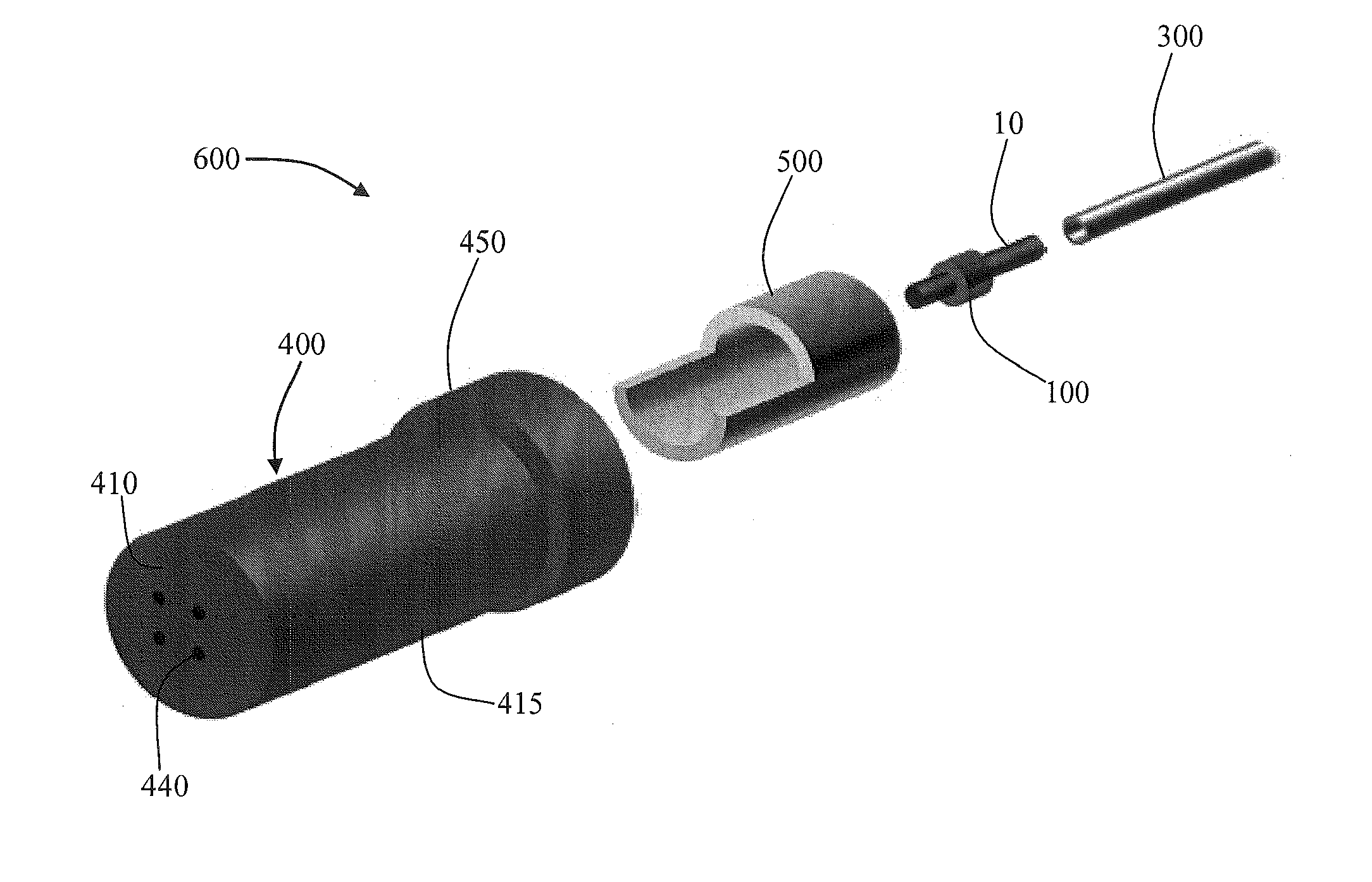

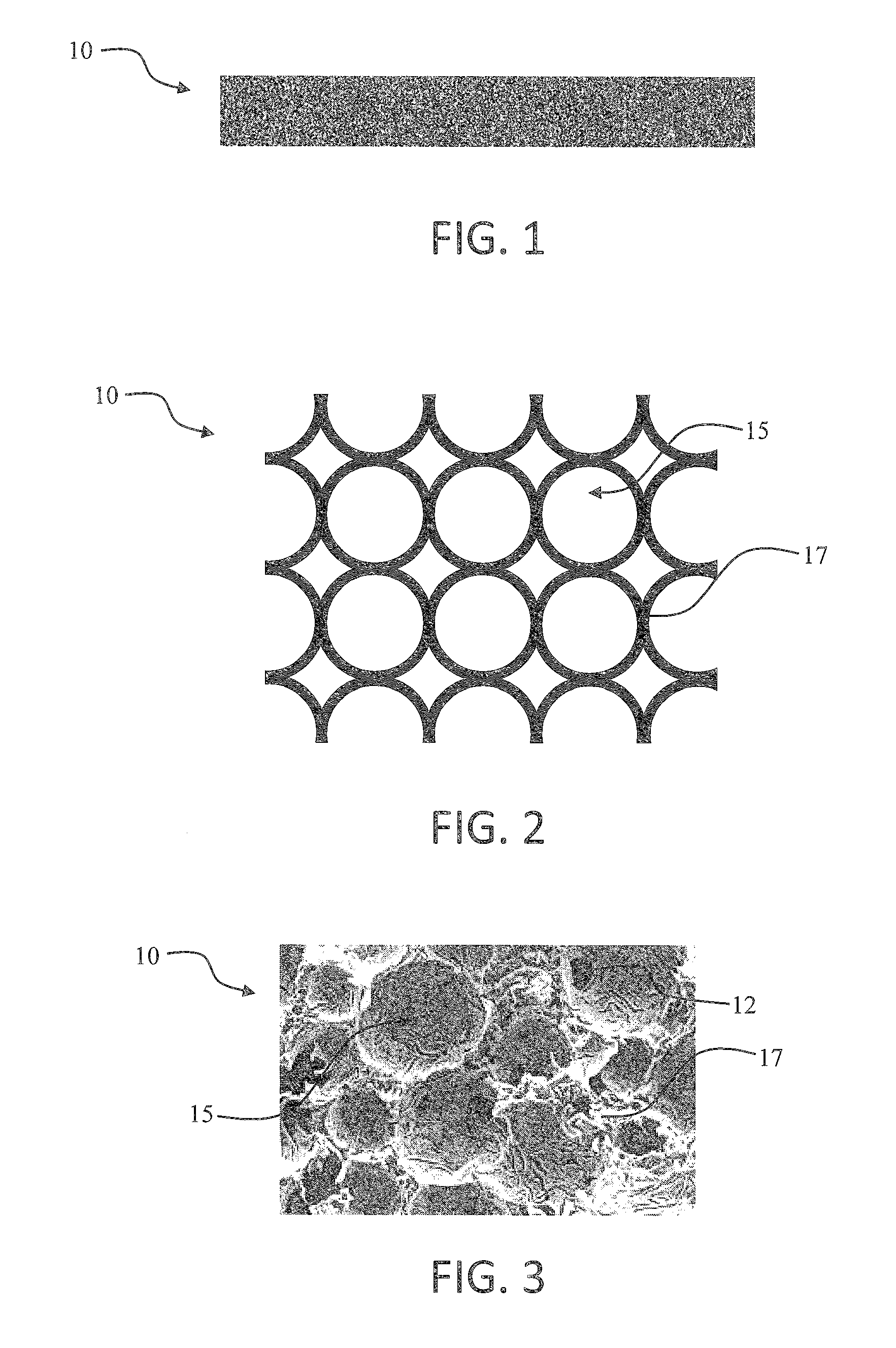

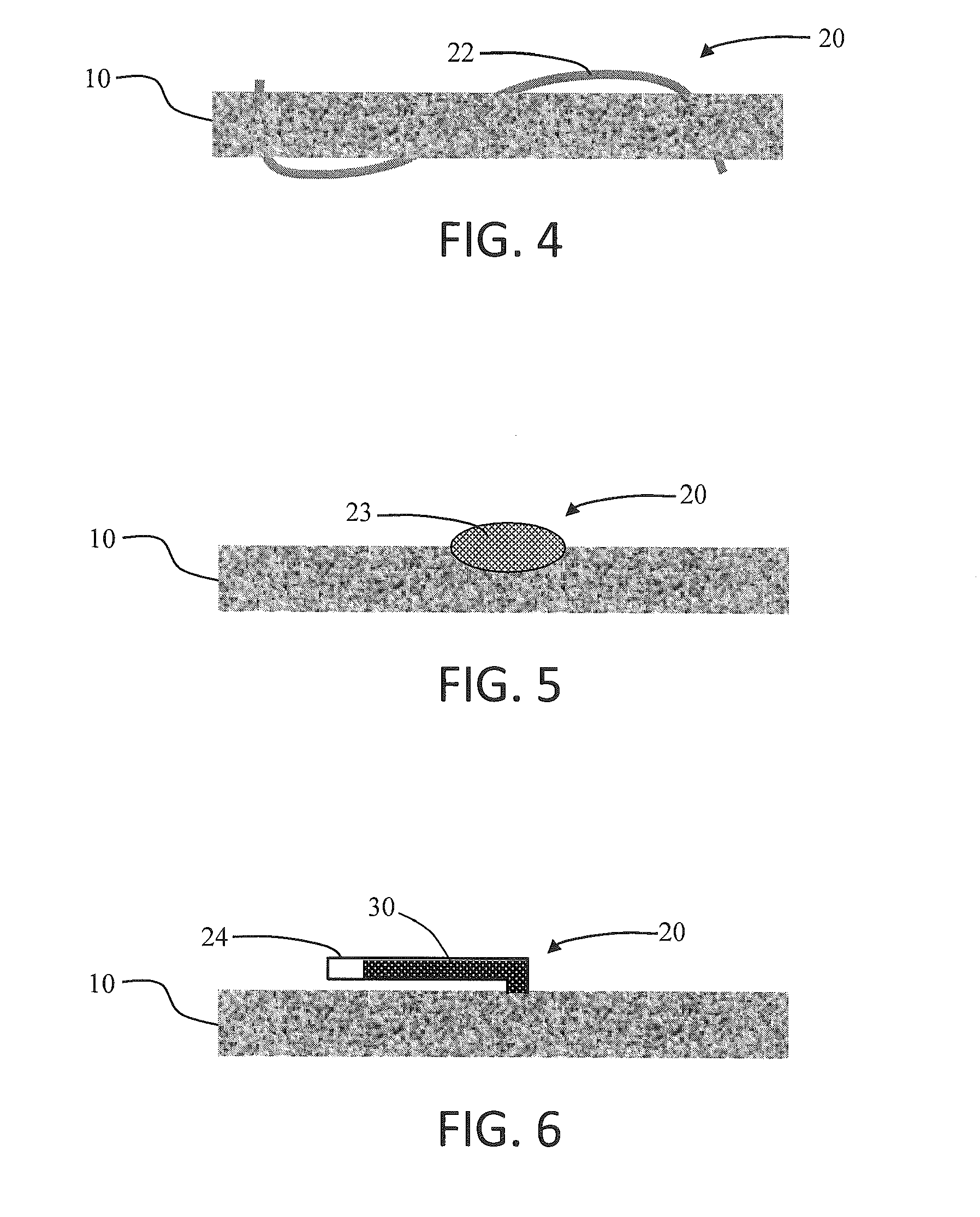

Carbon conductive substrate for electronic smoking article

ActiveUS20150059780A1Improve natureReduce materialSteam generation using steam absorptionTobacco pipesPorous carbonEngineering

The present disclosure provides components useful in heating, particularly heating of an aerosol precursor solution so as to vaporize the solution and form an aerosol. The disclosure particularly provides an electrically conductive, porous carbon heater. The heater may be combined with an aerosol precursor transport element that also is formed of carbon. The heater and transport element may form an atomizer that can be useful in an electronic smoking article, such as in a cartridge that is adapted for attachment to a control body. In some embodiments, the disclosure provides a cartridge of an electronic smoking article, the cartridge being formed substantially completely of carbon.

Owner:RAI STRATEGIC HLDG INC

Rigid porous carbon structures, methods of making, methods of using and products containing same

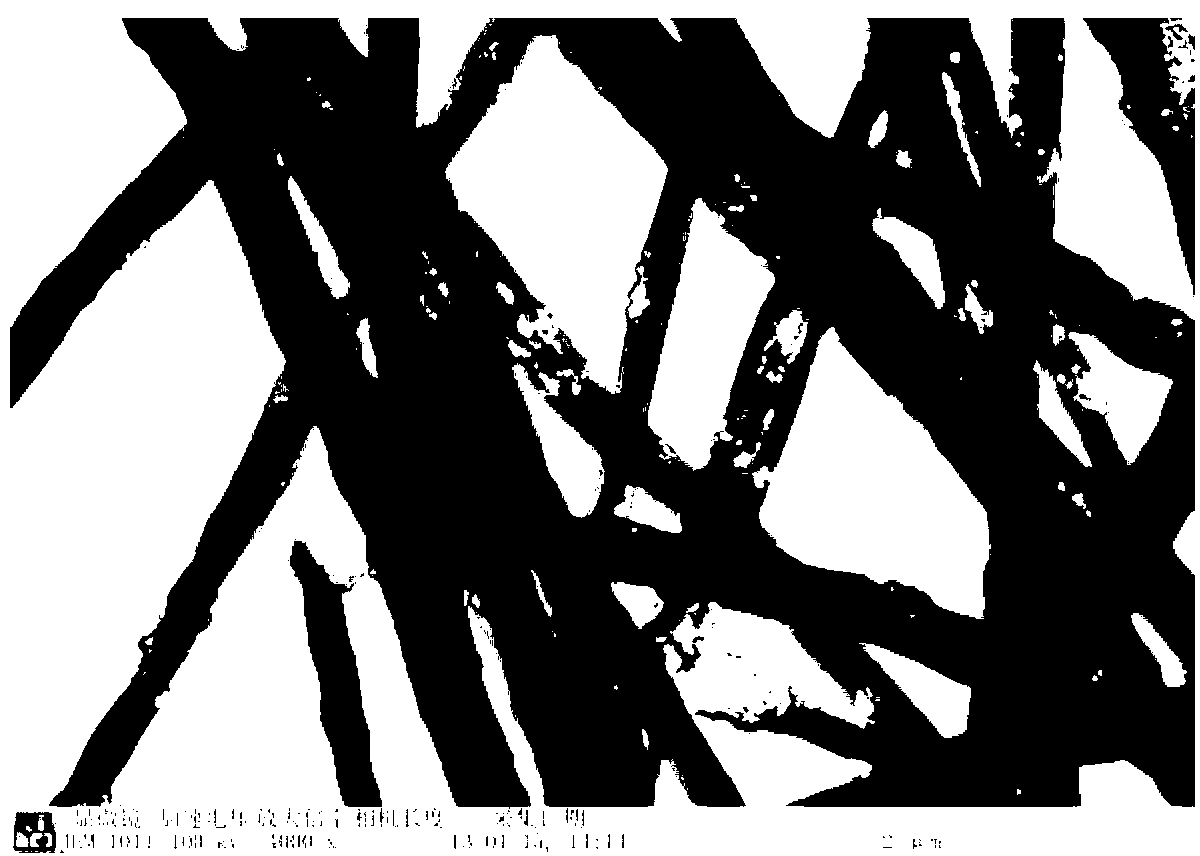

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

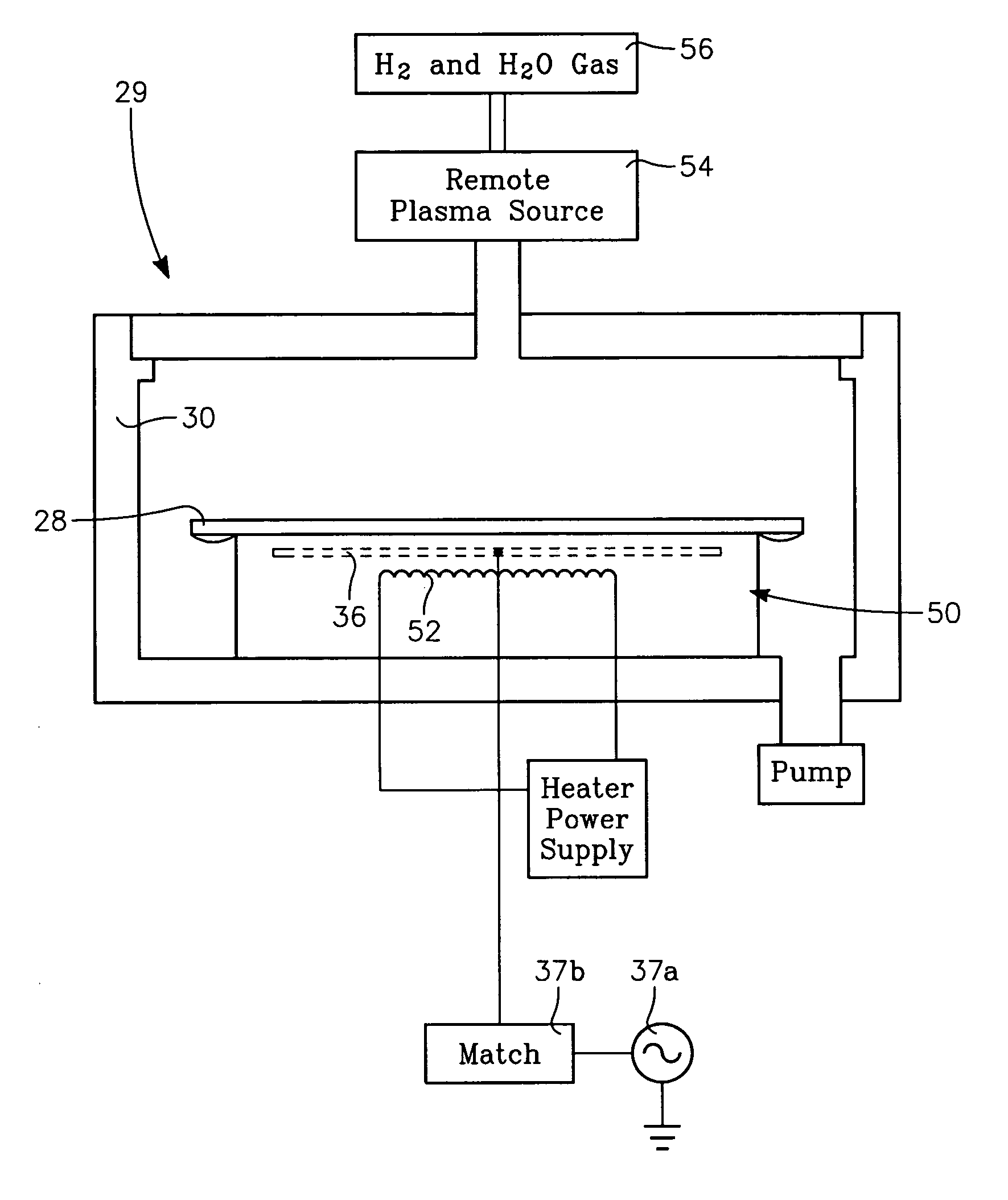

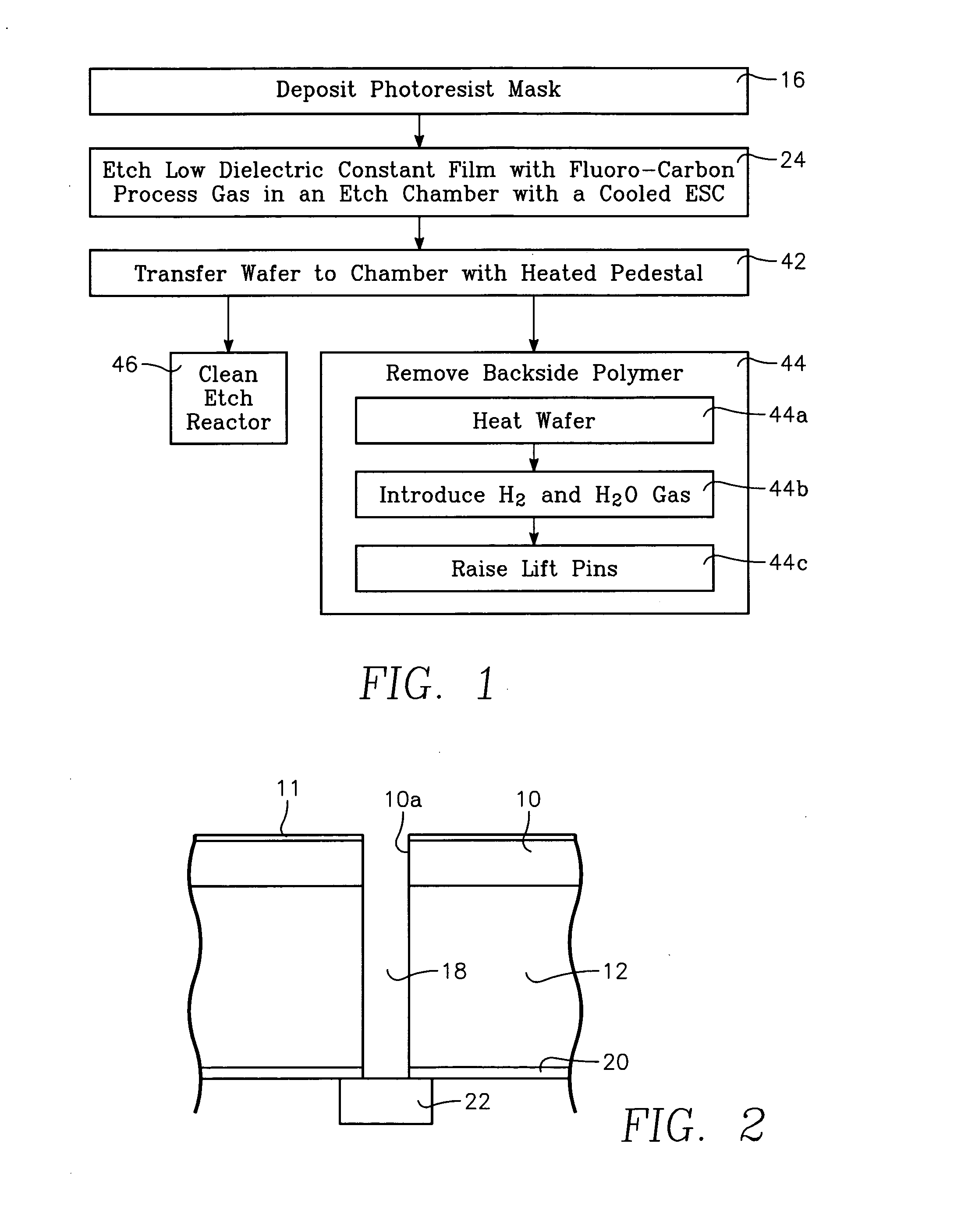

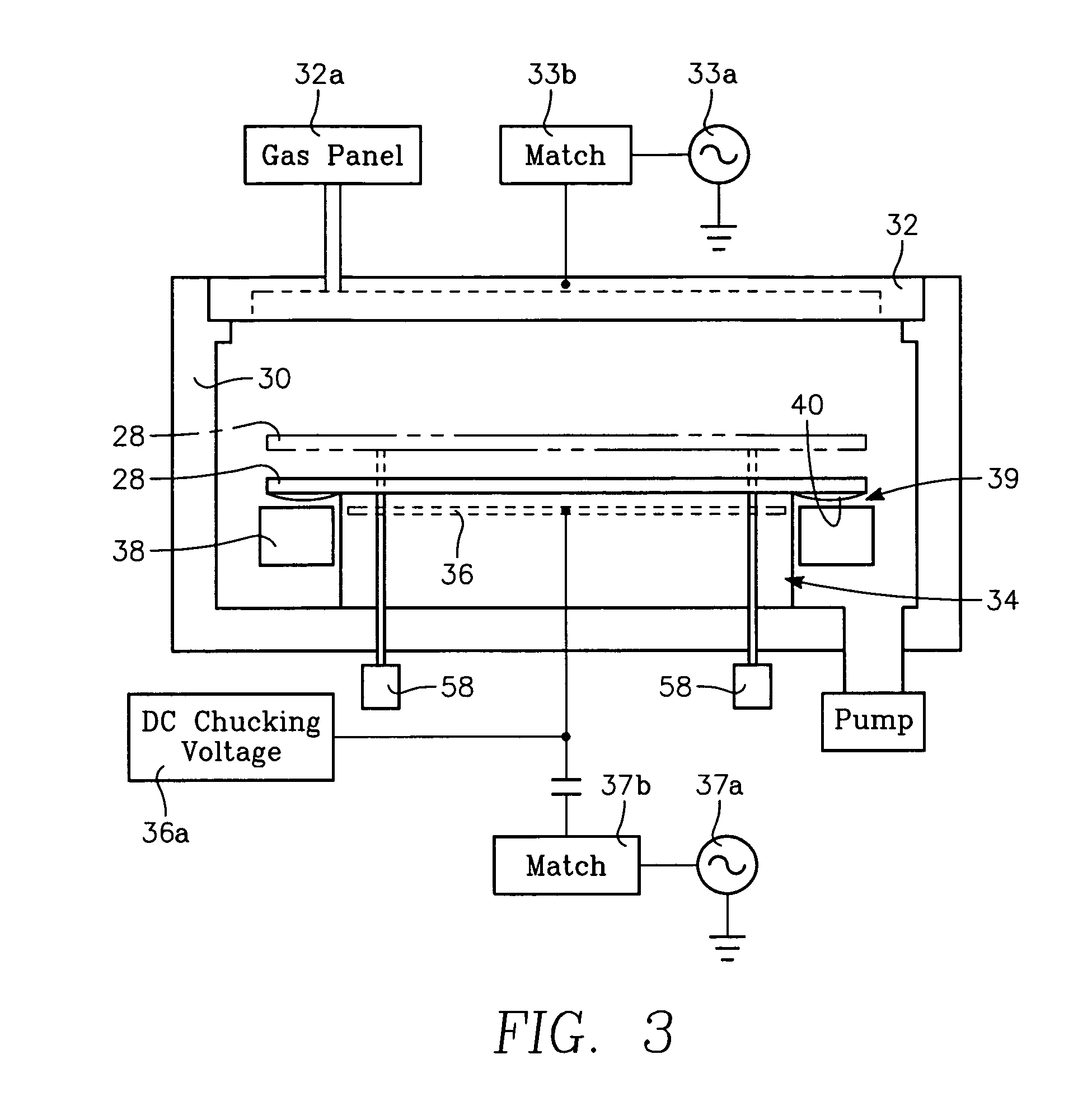

Plasma dielectric etch process including ex-situ backside polymer removal for low-dielectric constant material

A plasma etch process for etching a porous carbon-doped silicon oxide dielectric layer using a photoresist mask is carried out first in an etch reactor by performing a fluorocarbon based etch process on the workpiece to etch exposed portions of the dielectric layer while depositing protective fluorocarbon polymer on the photoresist mask. Then, in an ashing reactor, polymer and photoresist are removed by heating the workpiece to over 100 degrees C., exposing a peripheral portion of the backside of said workpiece, and providing products from a plasma of a hydrogen process gas to reduce carbon contained in polymer and photoresist on said workpiece until the polymer has been removed from a backside of said workpiece. The process gas preferably contains both hydrogen gas and water vapor, although the primary constituent is hydrogen gas. The wafer (workpiece) backside may be exposed by extending the wafer lift pins.

Owner:APPLIED MATERIALS INC

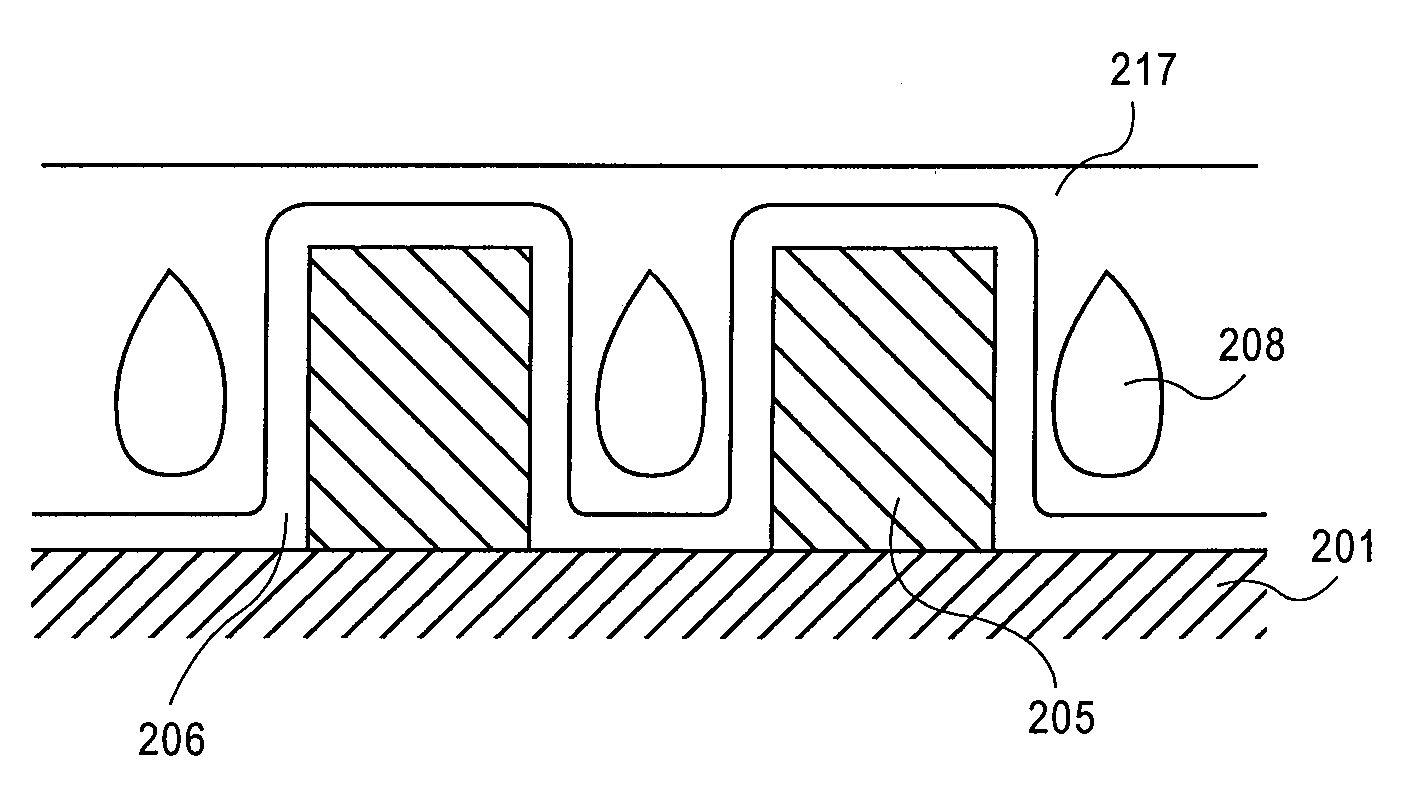

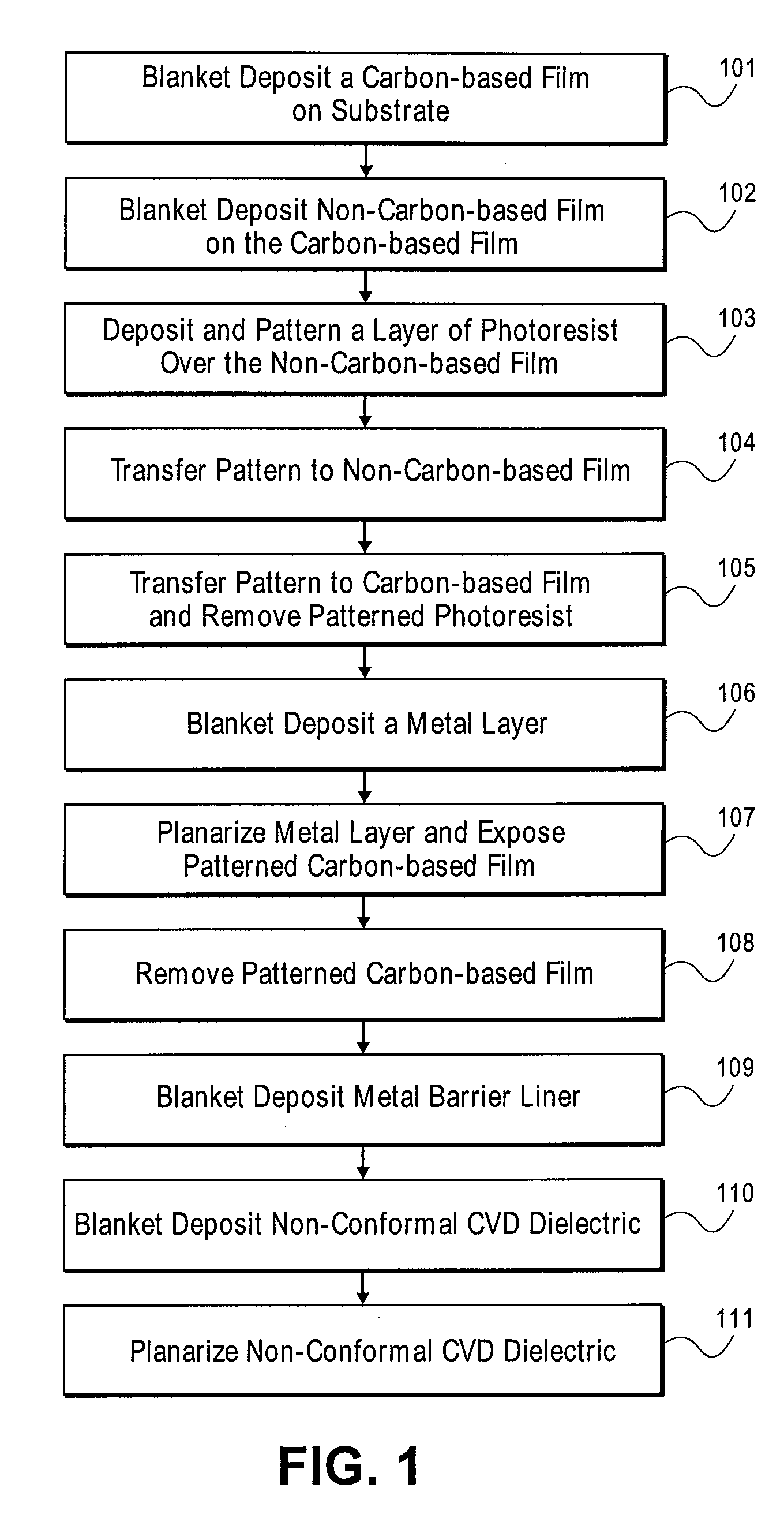

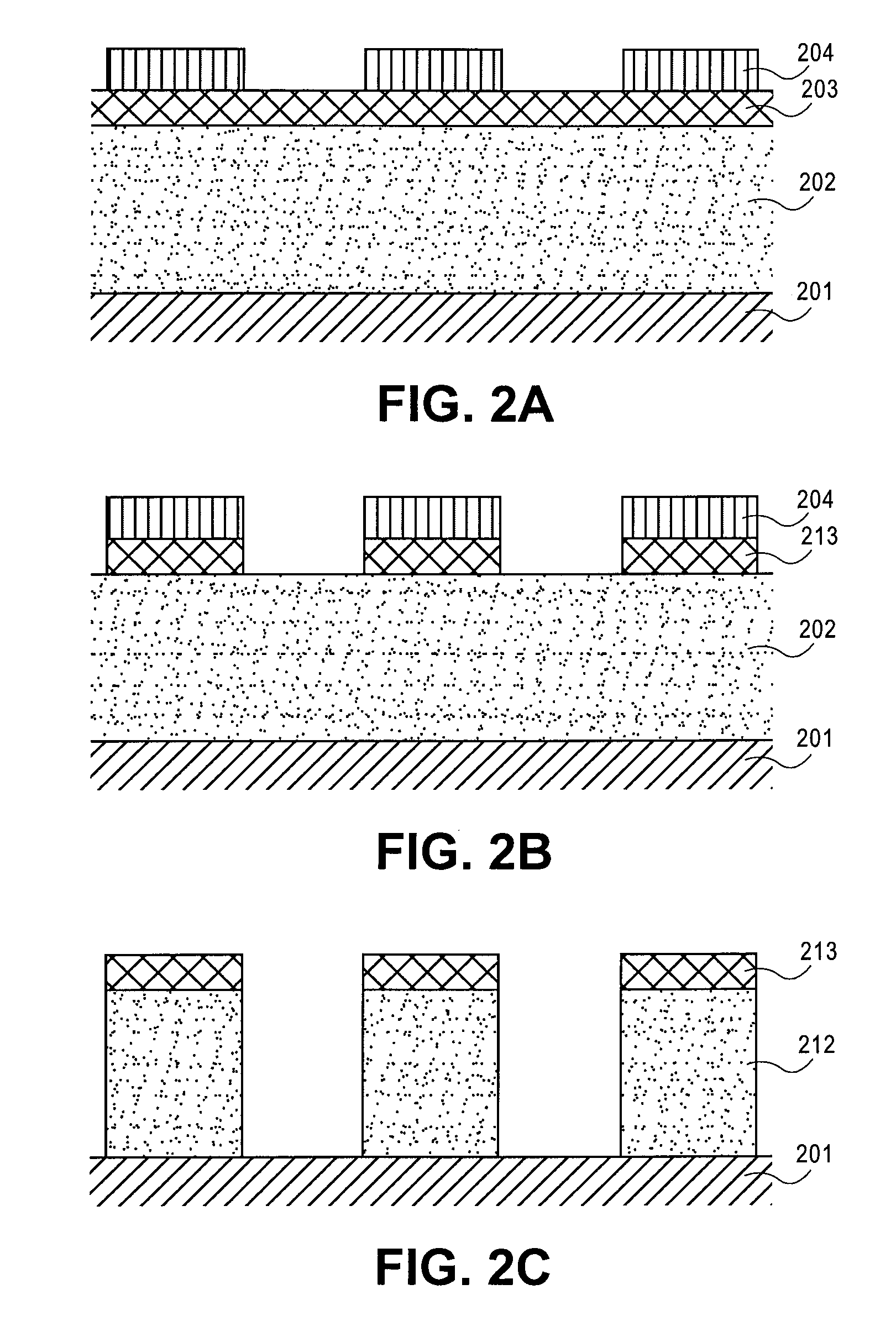

Air gap interconnects using carbon-based films

InactiveUS20100093168A1Improve electrical isolationSemiconductor/solid-state device manufacturingMetal interconnectPorous carbon

A method of forming an interconnect structure comprising: forming a sacrificial inter-metal dielectric (IMD) layer over a substrate, wherein the sacrificial IMD layer comprising a carbon-based film, such as amorphous carbon, advanced patterning films, porous carbon, or any combination thereof; forming a plurality of metal interconnect lines within the sacrificial IMD layer; removing the sacrificial IMD layer, with an oxygen based reactive process; and depositing a non-conformal dielectric layer to form air gaps between the plurality of metal interconnect lines. The metal interconnect lines may comprise copper, aluminum, tantalum, tungsten, titanium, tantalum nitride, titanium nitride, tungsten nitride, or any combination thereof. Carbon-based films and patterned photoresist layers may be simultaneously removed with the same reactive process. Highly reactive hydrogen radicals processes may be used to remove the carbon-based film and simultaneously pre-clean the metal interconnect lines prior to the deposition of a conformal metal barrier liner.

Owner:APPLIED MATERIALS INC

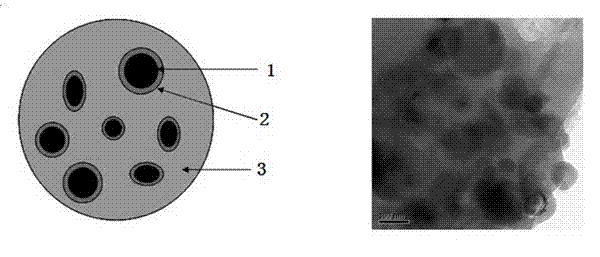

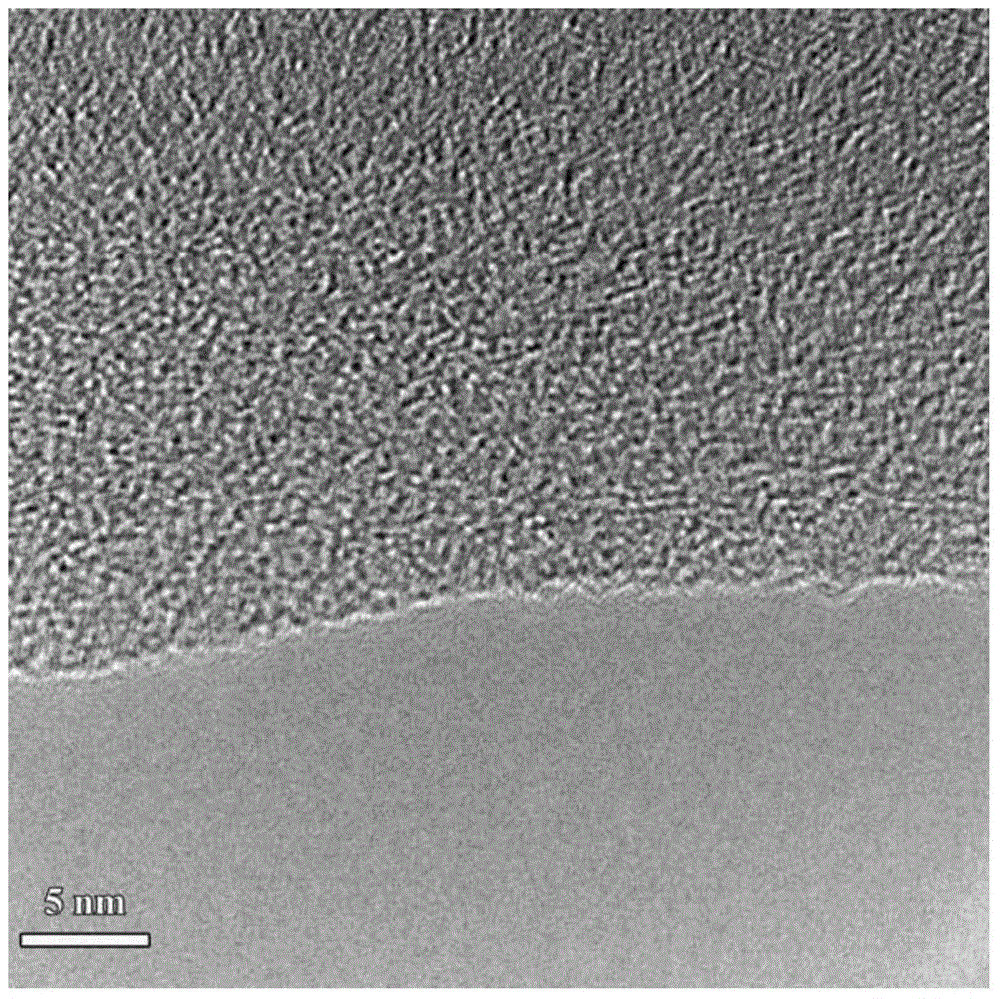

Carbon/silicon/carbon nano composite structure cathode material and preparation method thereof

The invention discloses a carbon / silicon / carbon nano composite structure cathode material and a preparation method thereof, belonging to the technical field of electrochemical power supply technologies. The cathode material consists of a carbon-based conductive substrate, nano silicon and a nano carbon coating layer, wherein the nano silicon is uniformly distributed on the carbon-based conductive substrate; the nano carbon coating layer is arranged on the surface of the nano silicon; the carbon-based conductive substrate is porous carbon, a carbon nanotube or graphene; the nano silicon exists in the state of nanoparticles or nano films; the weight percentage of the nano silicon in the cathode material is 10-90 percent; and the thickness of the nano carbon coating layer is 0.1-10 nanometers. The preparation method comprises the following steps of: depositing nano silicon on the carbon substrate in a reaction space in oxygen-free atmosphere by adopting a chemical vapor deposition process; and coating nano carbon on the surface of the nano silicon by adopting the chemical vapor deposition process. In the obtained carbon / silicon / carbon composite cathode material, the volume change of a silicon electrode material is controlled effectively in the charging and discharging processes, the electrode structure is kept complete, the circulation volume is large, the circulation service life is long, and the electrochemical performance is high.

Owner:TSINGHUA UNIV

Method for preparing loading functional oxide porous carbon

InactiveCN101780952AThe shape is fine and differentFine and varied structureOther chemical processesBy adsorptionPorous carbonMaterials science

The invention relates to a method for preparing a loading functional oxide porous carbon, which belongs to the technical field of carbon material. The method comprises the following steps of: selecting biomass material, and carbonizing at the temperature of 400-1000 DEG C in vacuum or on inert condition; preparing porous carbon by a physical activating or chemical activating process according to the requirement on the pore structure by the carbonized porous carbon; immersing the porous carbon into a precursor solution of an element M, cleaning many times with distilled water, and drying; roasting on the porous carbon at the temperature of 300-1000 DEG C in vacuum or on inert atmosphere, and then the active carbon of the loading functional oxide MxOy is prepared. The active carbon of the loading functional oxide MxOy prepared by the invention has the special pore structure of the biomass, also has the functions performed by the oxides, and has important application value in water treatment, hydrogen storage, photocatalysis, fuel cells and relevant fields.

Owner:SHANGHAI JIAO TONG UNIV

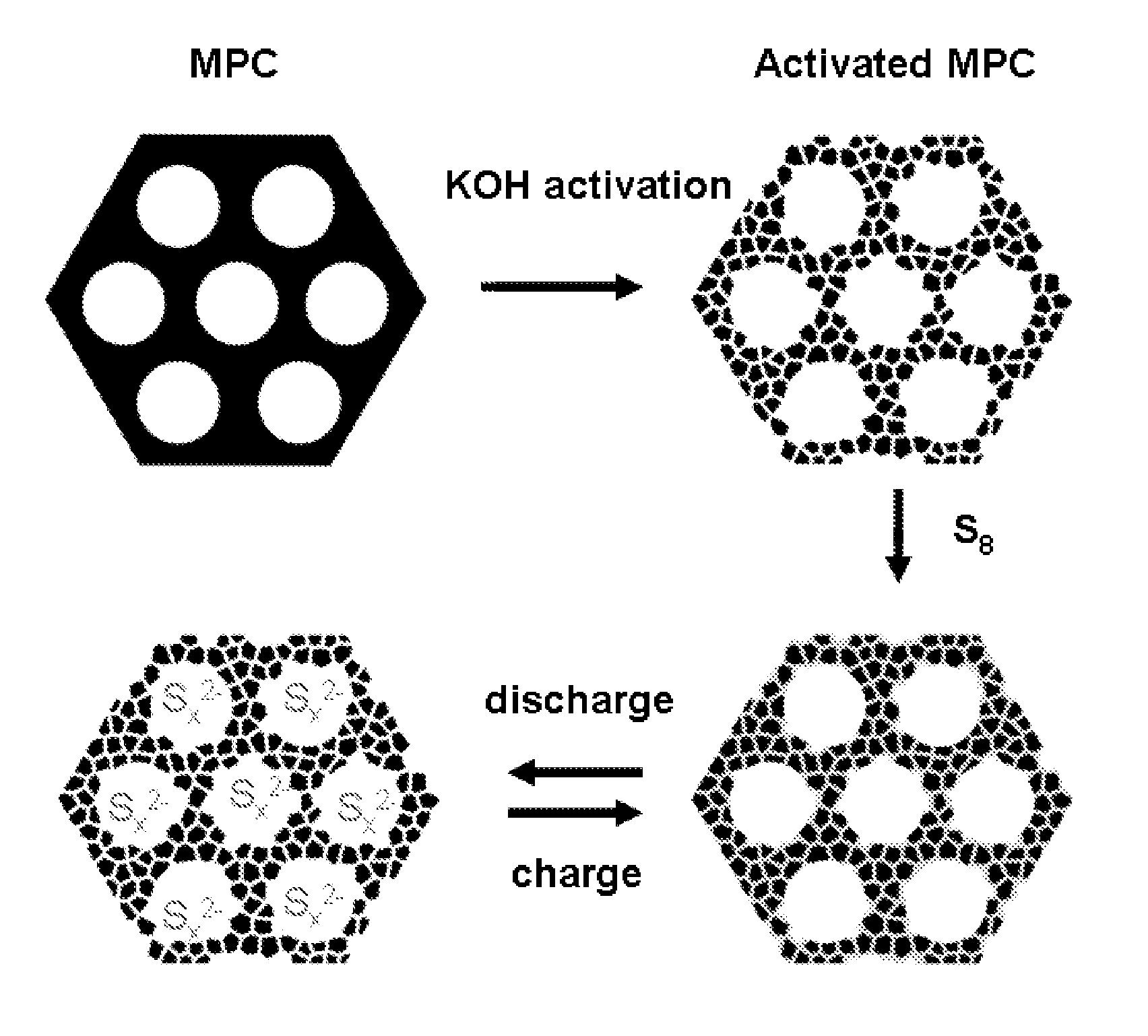

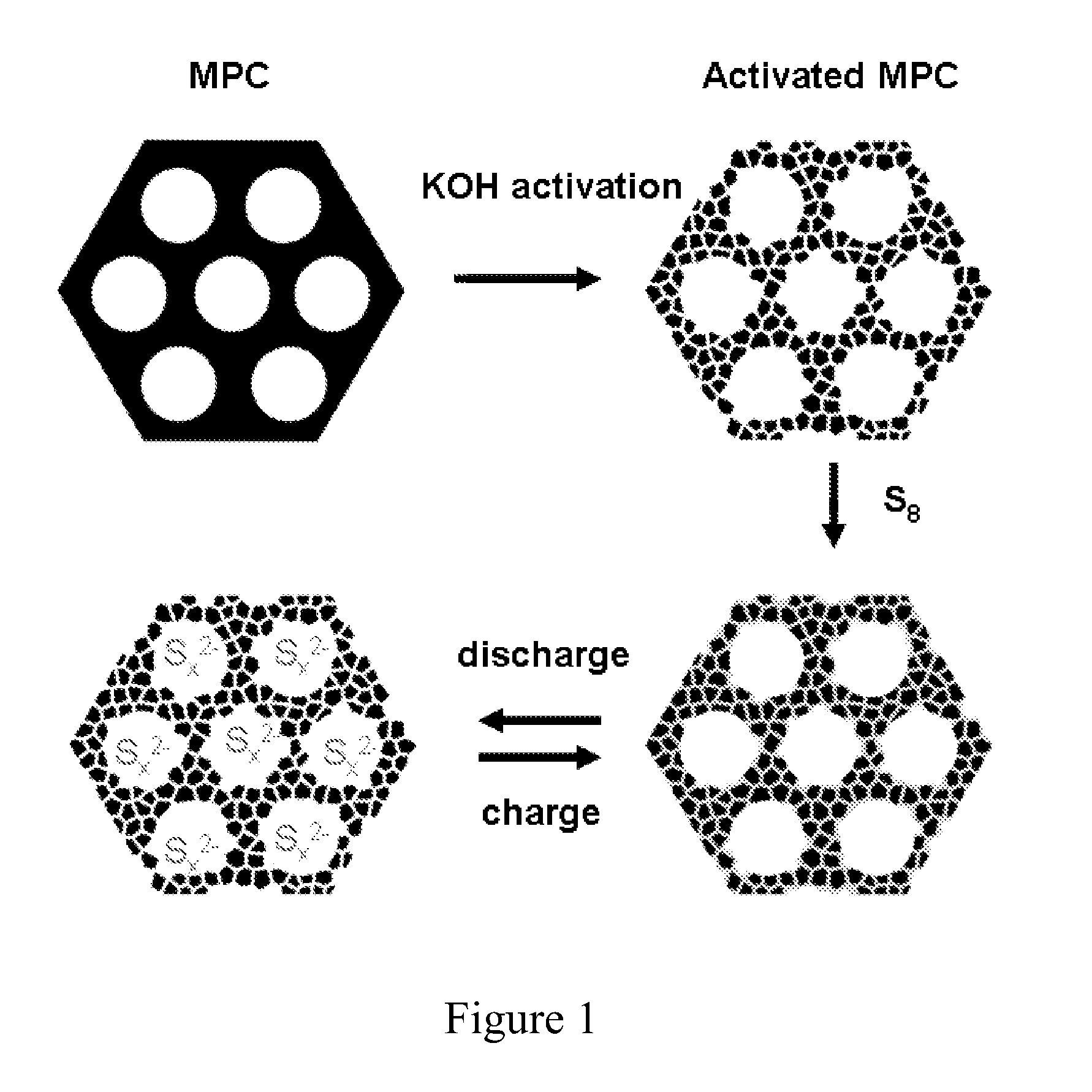

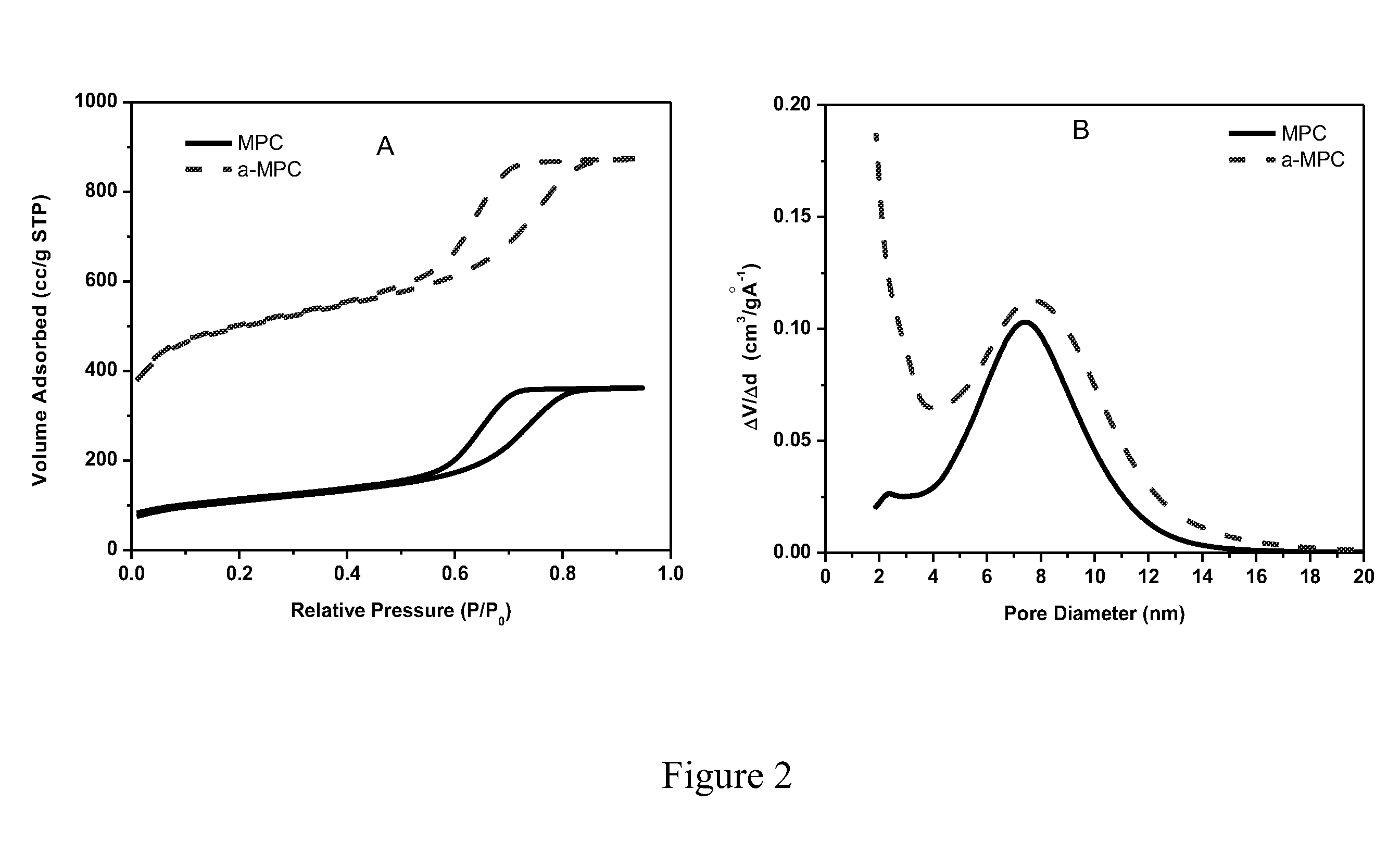

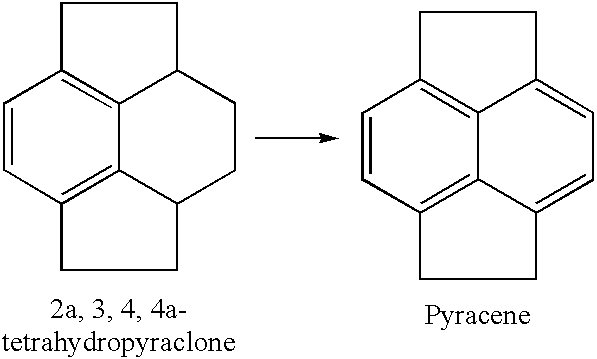

Sulfur-carbon nanocomposites and their application as cathode materials in lithium-sulfur batteries

ActiveUS20110052998A1Minimize formationEasy to transportAlkaline accumulatorsElectrode thermal treatmentCarbon compositesPorous carbon

The invention is directed in a first aspect to a sulfur-carbon composite material comprising: (i) a bimodal porous carbon component containing therein a first mode of pores which are mesopores, and a second mode of pores which are micropores; and (ii) elemental sulfur contained in at least a portion of said micropores. The invention is also directed to the aforesaid sulfur-carbon composite as a layer on a current collector material; a lithium ion battery containing the sulfur-carbon composite in a cathode therein; as well as a method for preparing the sulfur-composite material.

Owner:UT BATTELLE LLC

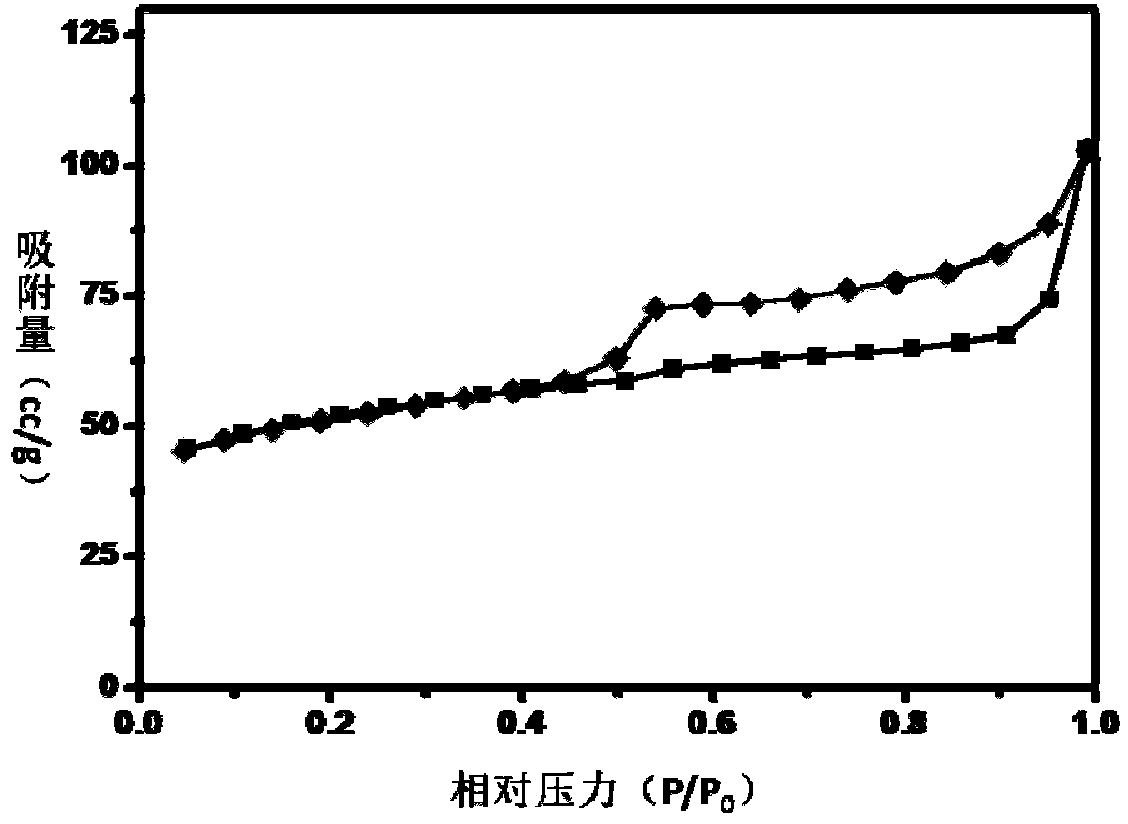

Method for preparing carbon material with rich mesopores and macropores

The invention relates to a method for preparing a carbon material with rich mesopores and macropores. Inorganic nano-particles are used as pore-forming template agent to be uniformly distributed in a carbon-contained organic precursor and then the carbon-contained organic precursor carries out high-temperature carbonization, template agent washing-out and drying to obtain a porous carbon material. The carbon material prepared by the method has the specific surface area of 50-1,900 m / g and a pore diameter mainly between 2-900 nm, can be conveniently adjusted by the size control of the selected nano-particles, removes a template without using high corrosive HF and has the advantages of simple method, convenient operation, free pore diameter adjustment and control in a mesopore and macropore range, and the like. The carbon material has a wide application prospect in fields of electrochemical energy accumulation, macromolecular adsorption, catalyst carriers, composite materials, and the like.

Owner:NO 63971 TROOPS PLA

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6432866B1High accessible surface areaHigh activityMaterial nanotechnologyLayered productsFiberPorous carbon

Owner:HYPERION CATALYSIS INT

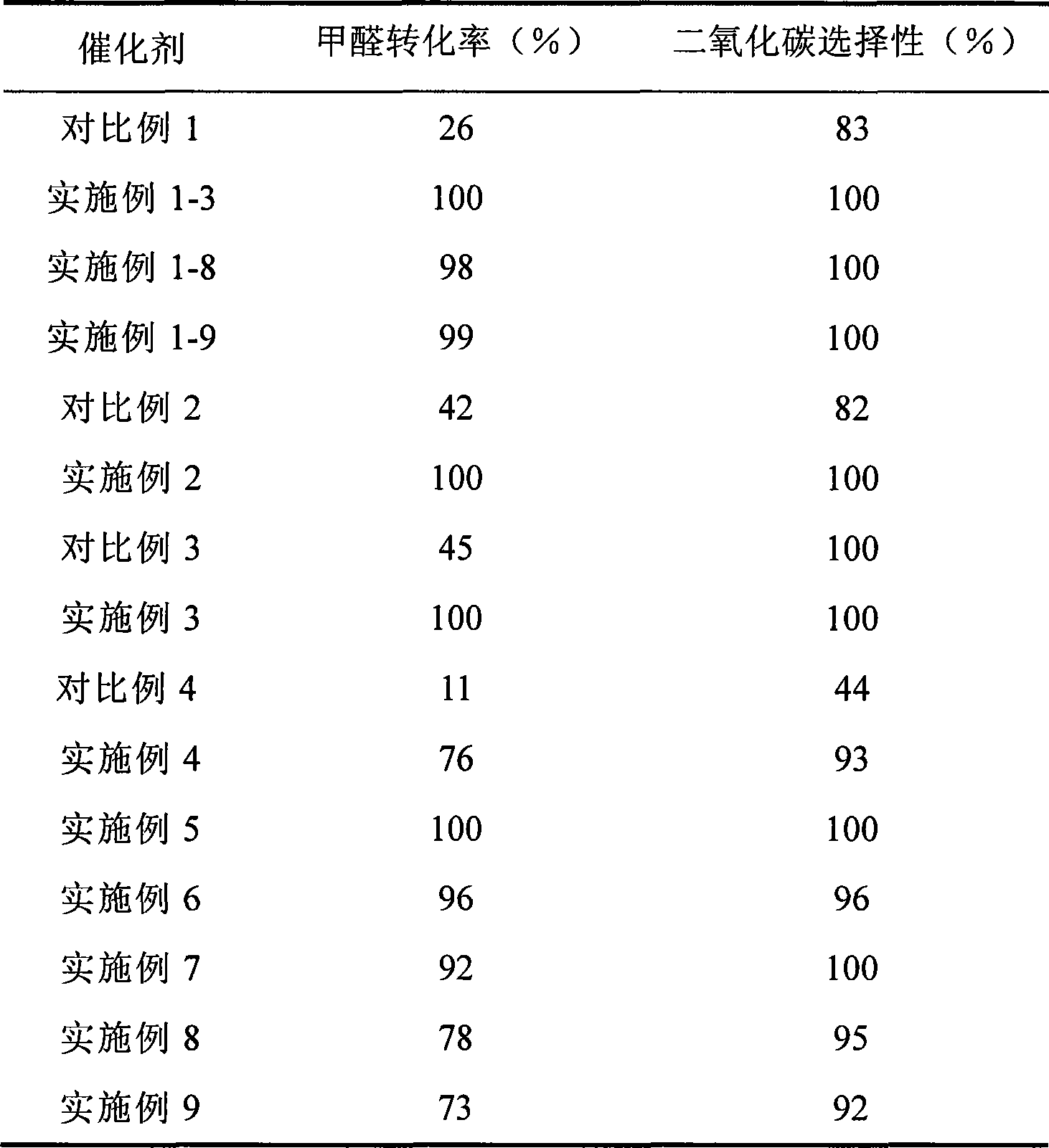

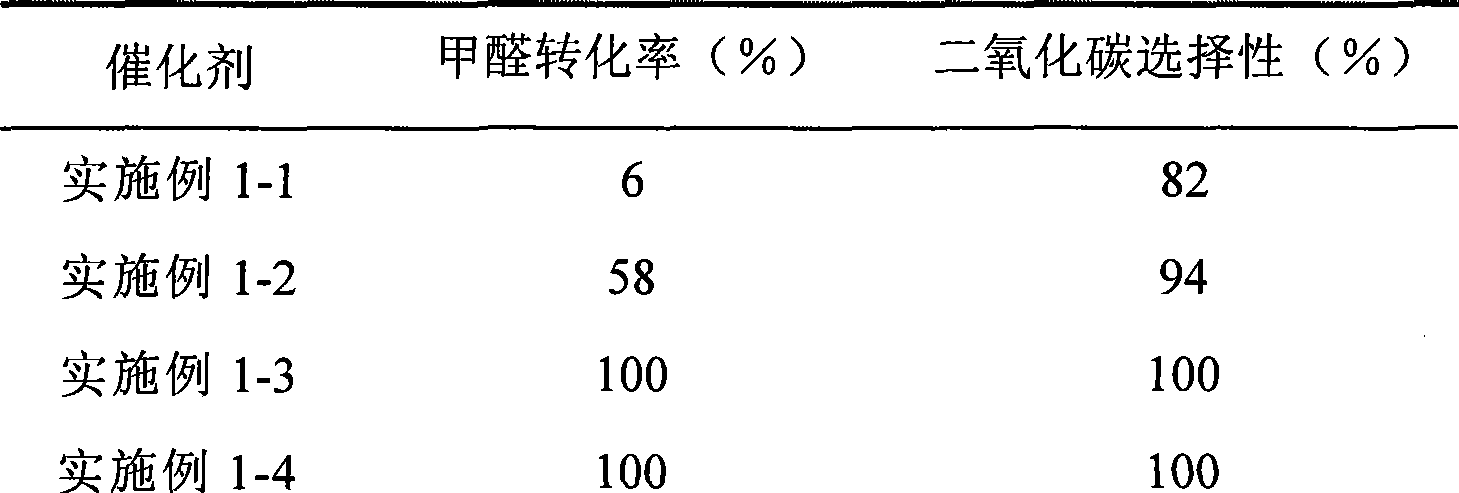

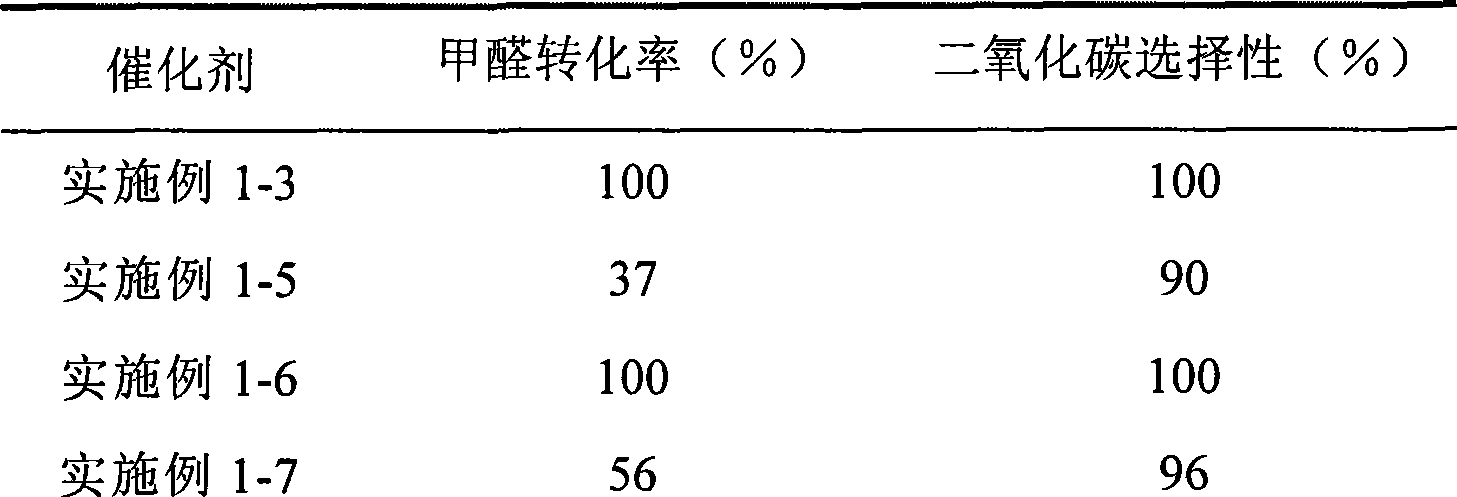

Catalyst for complete oxidation of formaldehyde at room temperature

ActiveCN101380574AEasy to makeEasy to operateDeodrantsMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

The invention provides a high selectivity catalyst used for catalyzing and completely oxidizing formaldehyde with low concentration at room temperature. The catalyst can catalyze formaldehyde completely so as to lead the formaldehyde to be converted into carbon dioxide and water at room temperature. In addition, the conversion rate of formaldehyde remains 100% within a long period of time, without complex auxiliary facilities such as light source, a heating oven and the like, and external conditions. The catalyst comprises three parts which are inorganic oxide carrier, noble metal component and auxiliary ingredient. Porous inorganic oxide carrier is one of cerium dioxide, zirconium dioxide, titanium dioxide, aluminium sesquioxide, tin dioxide, silicon dioxide, lanthanum sesquioxide, magnesium oxide and zinc oxide or the mixture thereof or composite oxide thereof, zeolite, sepiolite and porous carbon materials. The noble metal component of the catalyst is at least one of platinum, rhodium, palladium, gold and silver. The auxiliary ingredient is at least one of the alkali metals of lithium, sodium, kalium, rubidium and cesium. The loading of the noble metal component used in the catalyst of the invention is 0.1 to 10% according to weight converter of metal elements and the selective preference is 0.3 to 2%. The loading of the auxiliary ingredient is 0.2 to 30% according to weight converter of metal elements and the selective preference is 1 to 10%. When the loading of the auxiliary ingredient is lower than 0.2% or higher than 30%, the activity of the catalyst for catalyzing and oxidizing formaldehyde at room temperature is decreased remarkably.

Owner:广东顺德中科鸿图环境材料有限公司

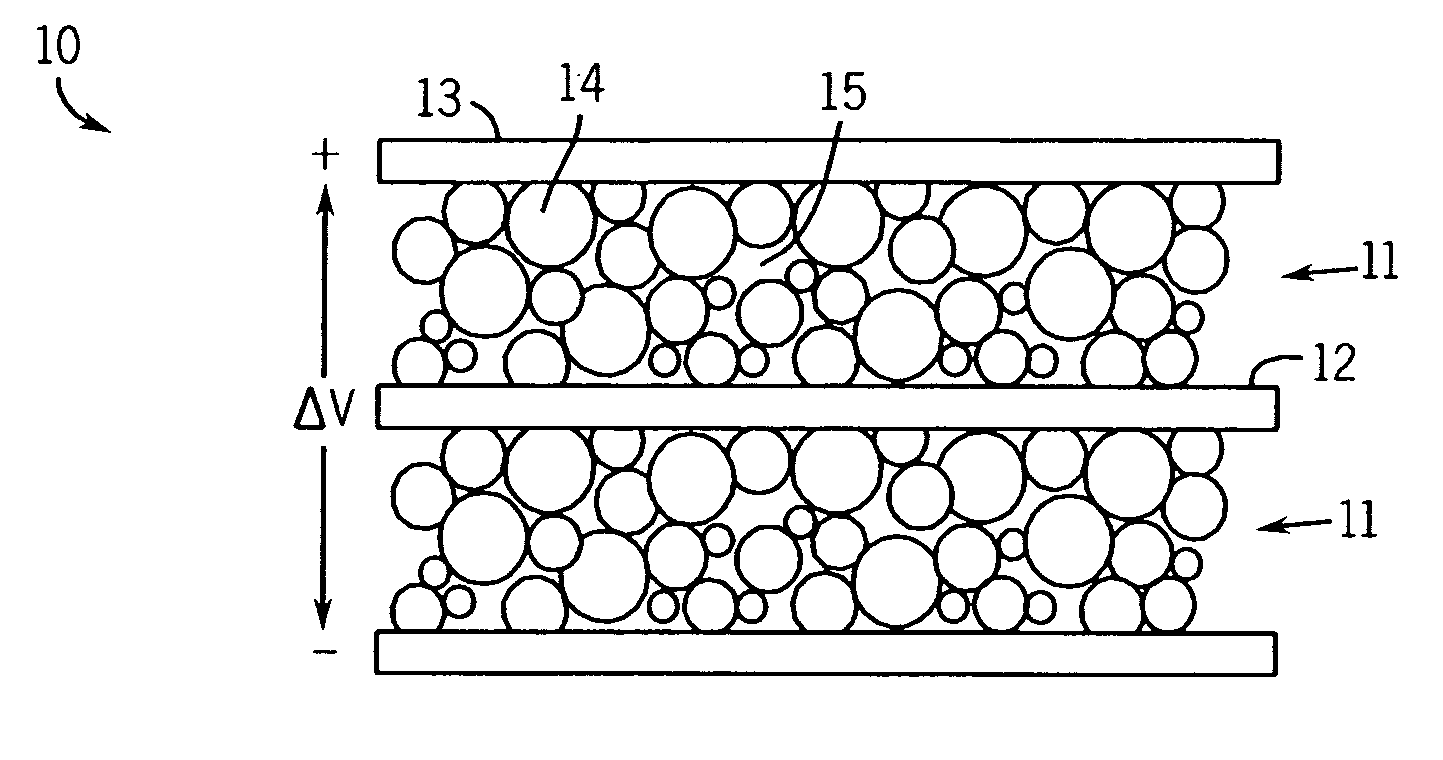

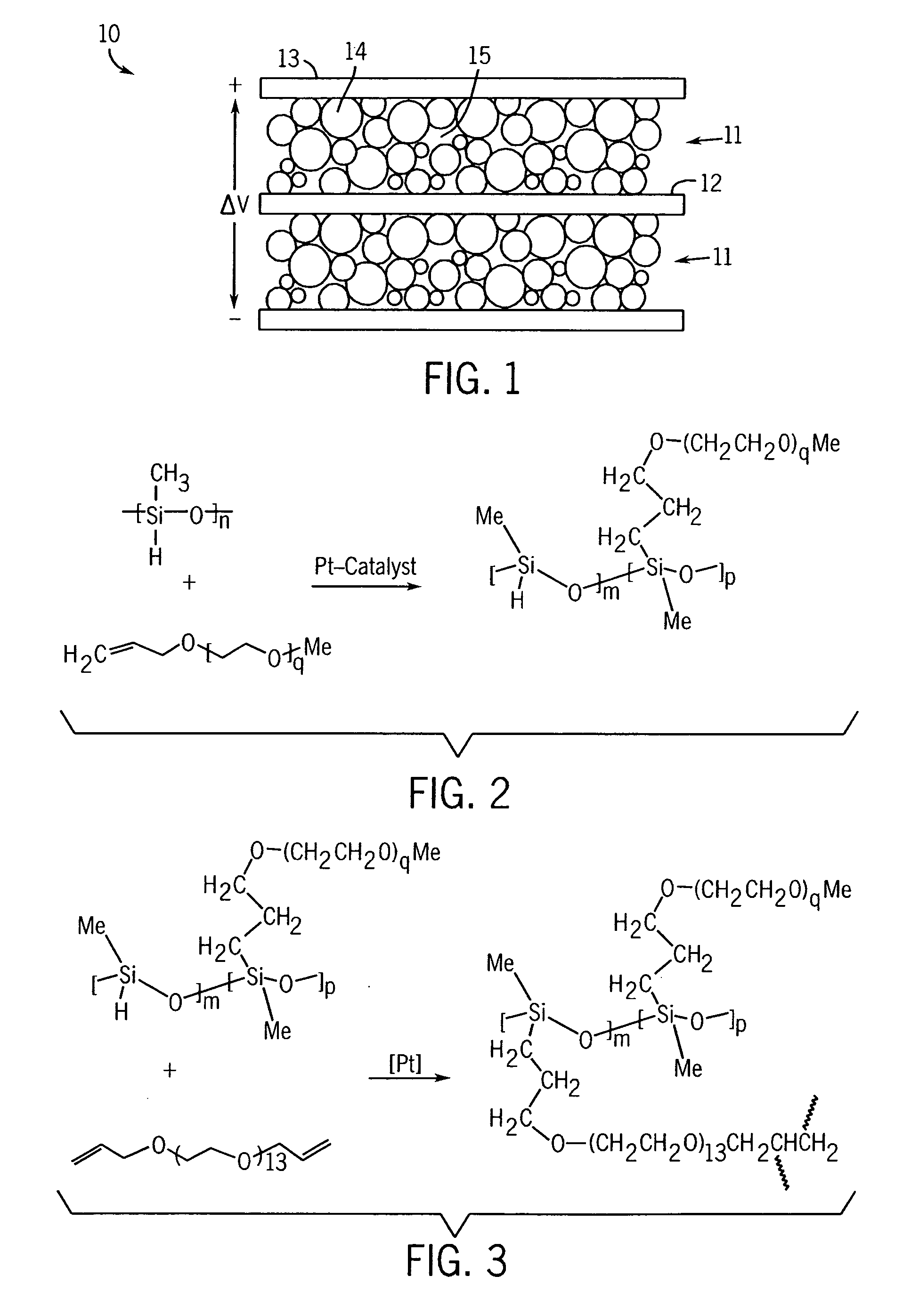

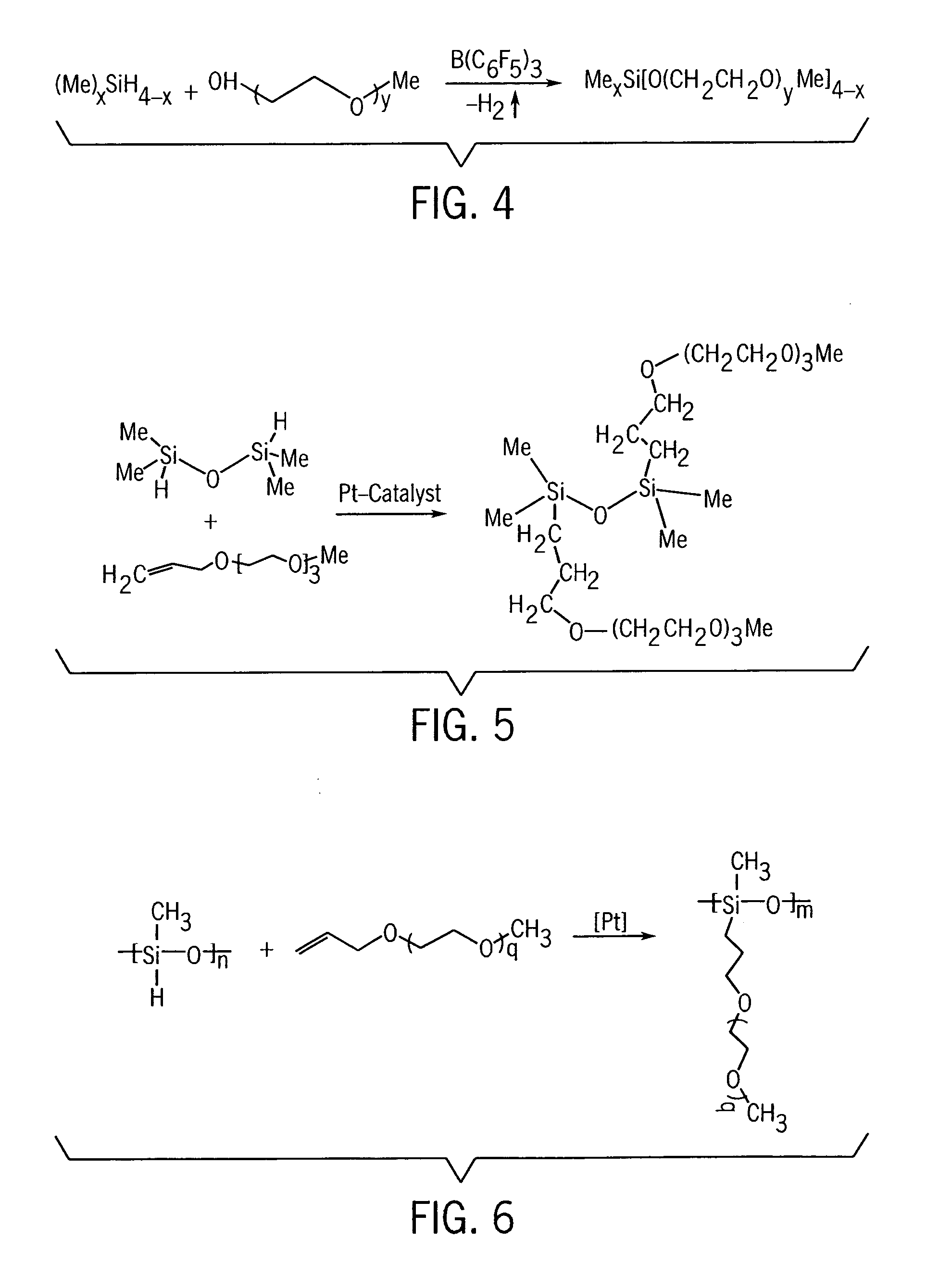

Electrochemical double-layer capacitor using organosilicon electrolytes

ActiveUS20070076349A1Simple processStable storageHybrid capacitor electrolytesLiquid electrolytic capacitorsPorous carbonElectrochemical double layer capacitor

Owner:WISCONSIN ALUMNI RES FOUND

Method for the production of porous carbon-based molded bodies, and use thereof as cell culture carrier systems and culture systems

The present invention relates to methods for producing carbon-based molded bodies. In particular, the present invention relates to methods for producing porous carbon-based molded bodies by carbonizing organic polymer materials mixed with non-polymeric fillers and subsequently dissolving the fillers out from the carbonized molded bodies. The present invention further relates to methods for producing porous carbon-based molded bodies by carbonizing organic polymer materials mixed with non-polymeric fillers which are substantially completely decomposed during the carbonization. The present invention also relates to a method for producing porous carbon-based molded bodies by carbonizing organic polymer materials, the carbon-based molded bodies being partially oxidized following carbonization so as to produce pores. In addition, the present invention relates to porous molded bodies produced according to one of said methods and the use thereof, especially as cell culture carriers and / or culture systems.

Owner:CINVENTION AG

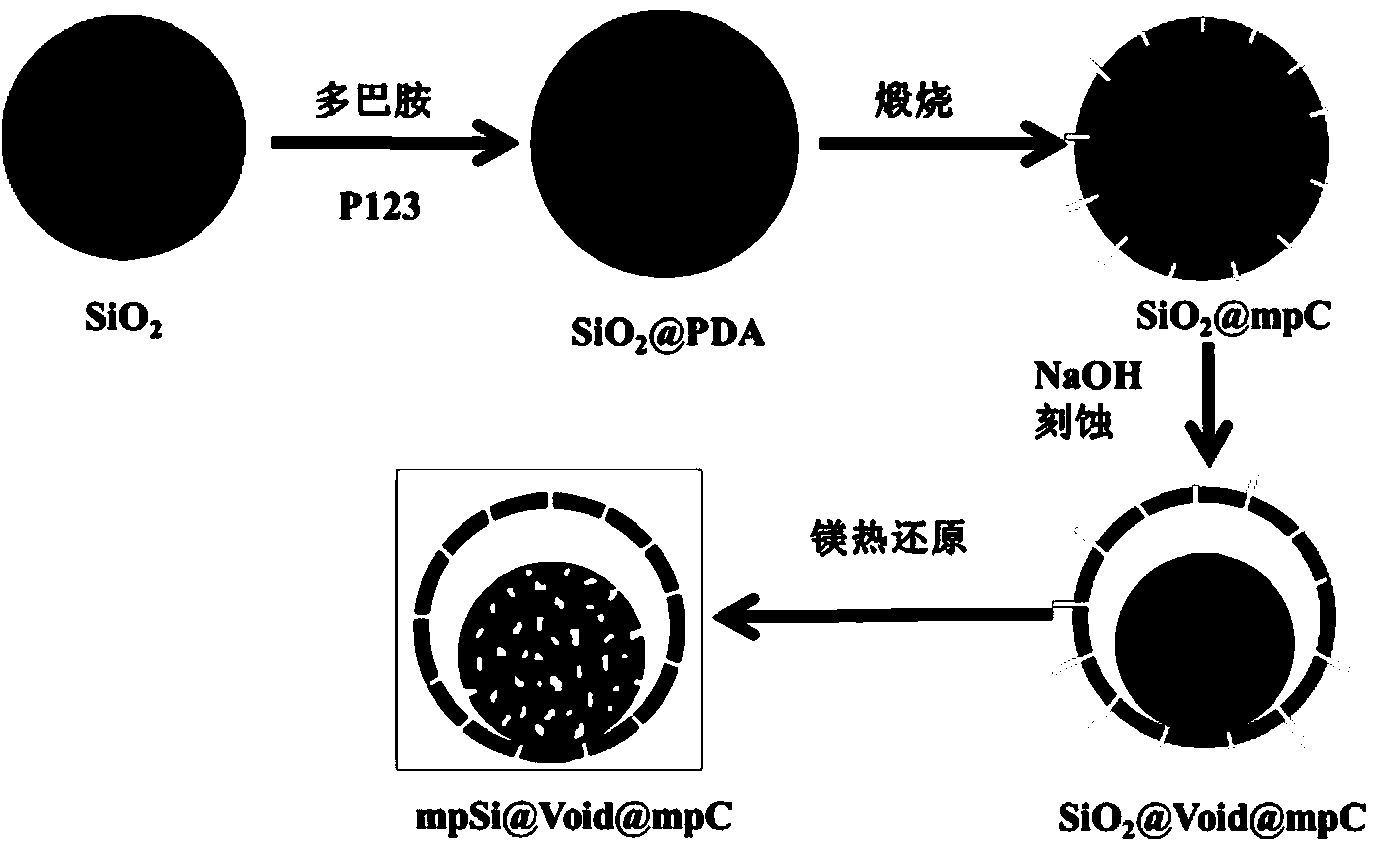

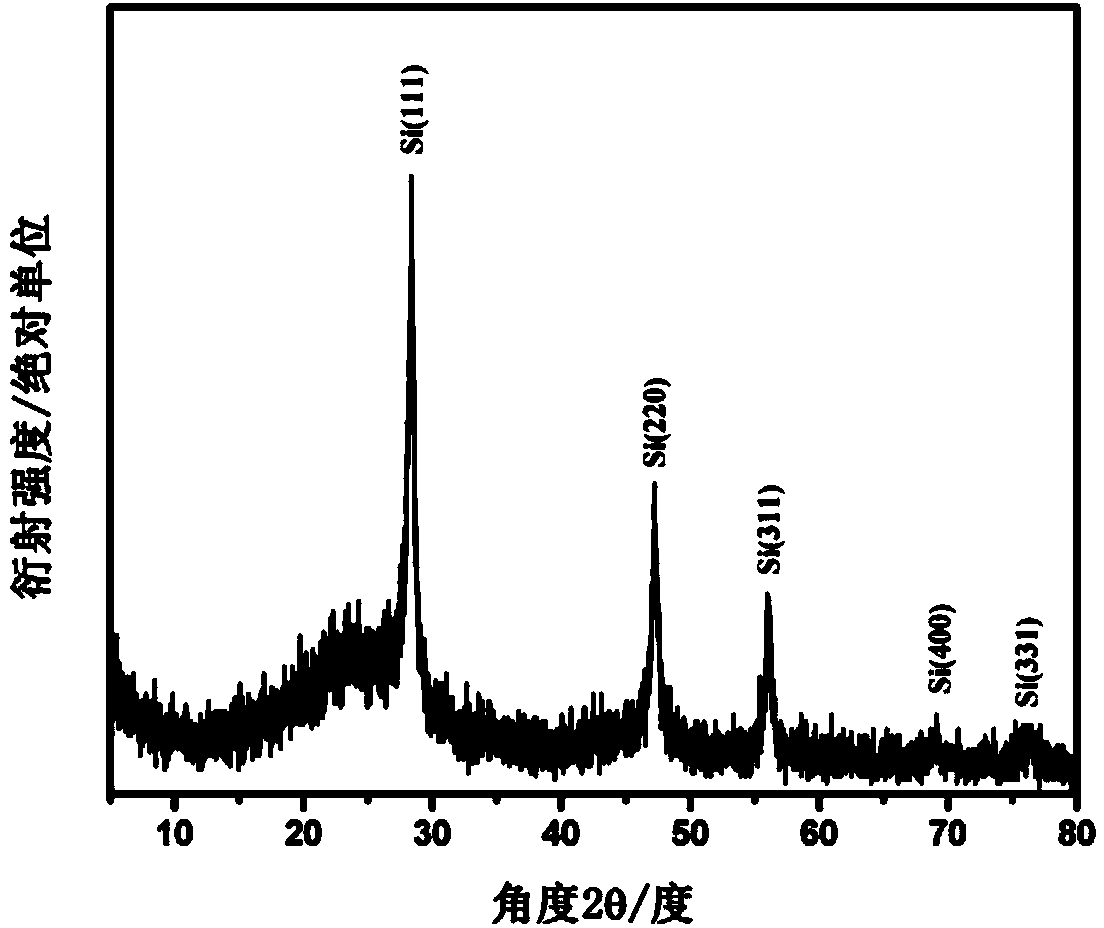

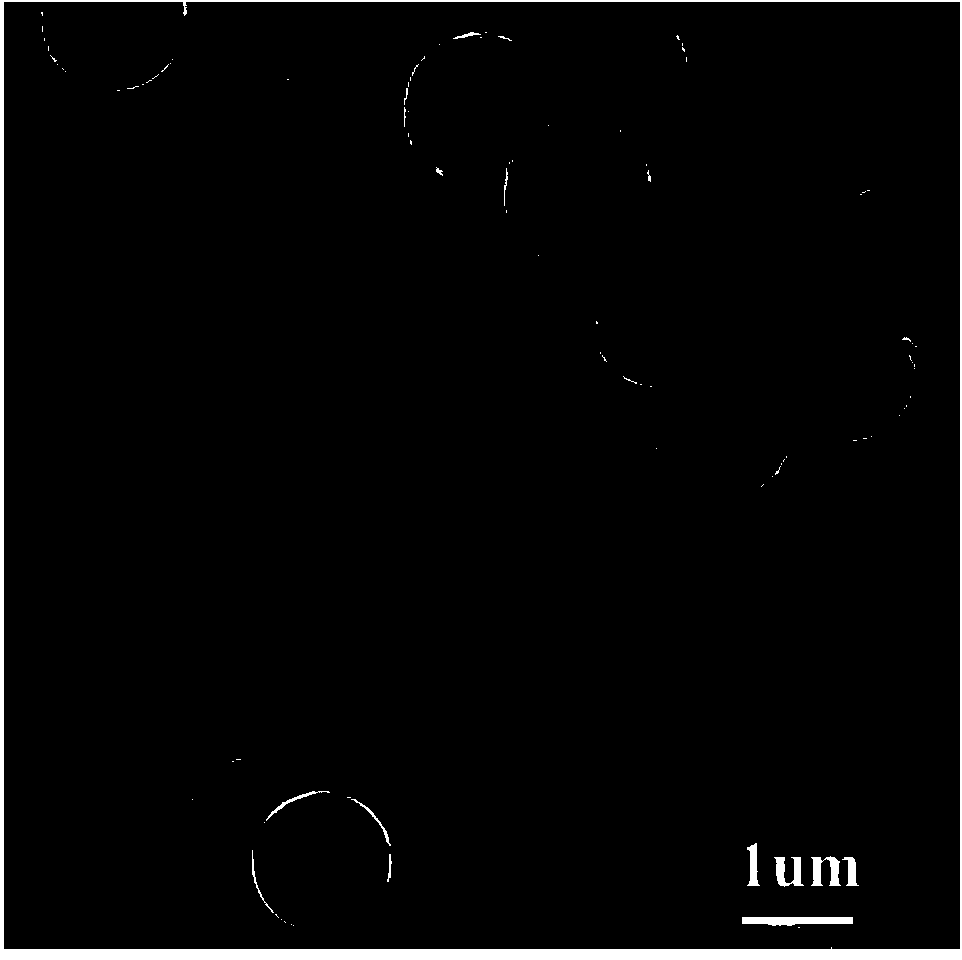

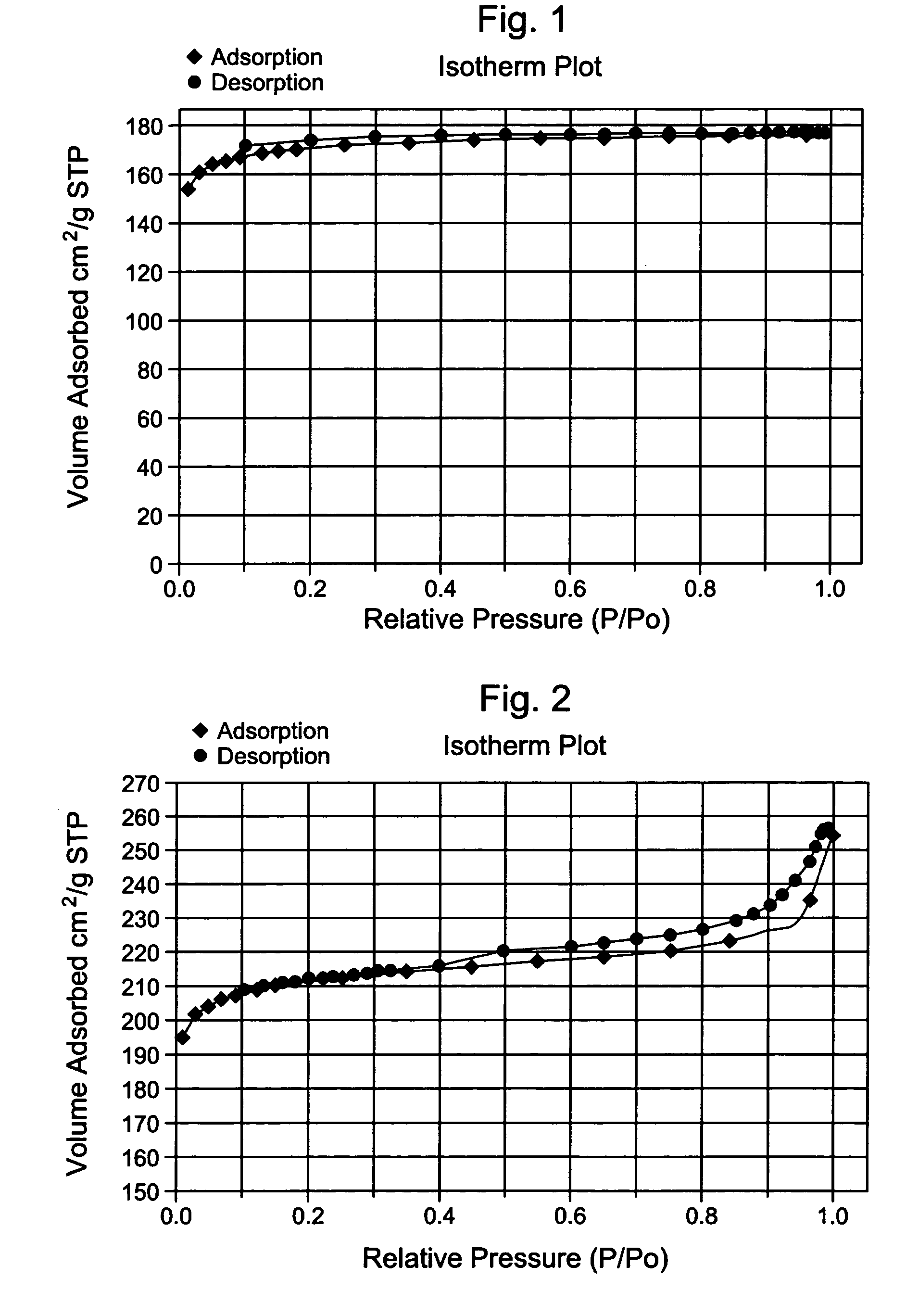

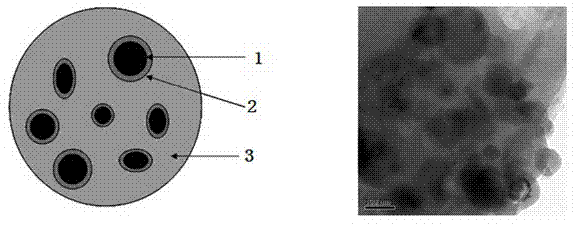

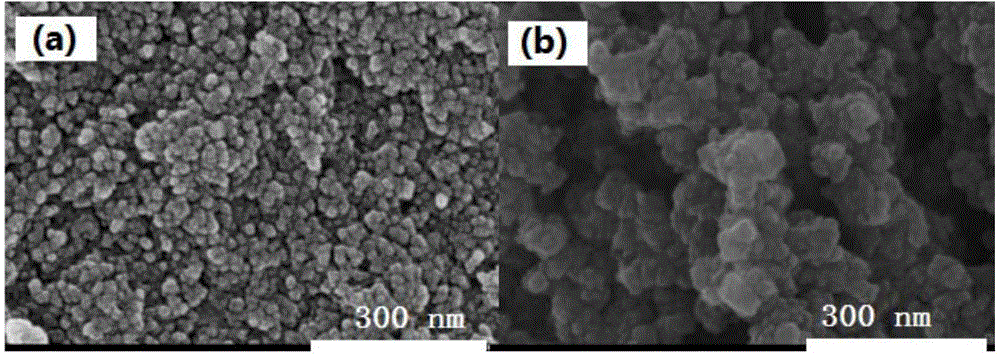

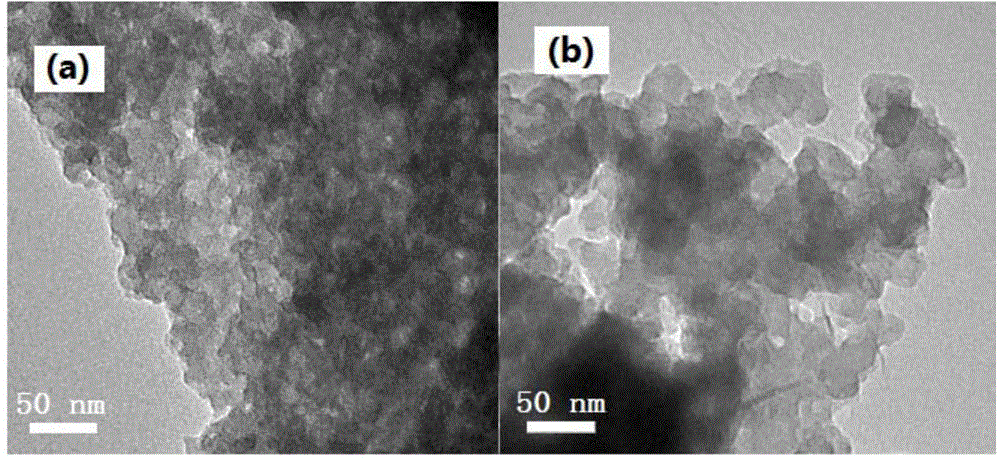

Porous silicon carbon composite microsphere with yolk-eggshell structure and preparation method therefor

InactiveCN103531760AEase of mass productionPromote infiltrationMaterial nanotechnologyCell electrodesCarbon compositesYolk

The invention provides a porous silicon carbon composite microsphere with a yolk-eggshell structure and a preparation method therefor, and belongs to the lithium ion battery electrode material technology field. The porous silicon carbon composite microsphere takes a porous submicron silicon sphere mpSi as a core with a diameter of 400-900 nm, and takes porous carbon mpC as a shell with a thickness of 10-60 nm. The inner diameter of a cavity Void is 800-1400 nm. The composition of the silicon carbon composite microsphere can be described as mpSi@Void@mpC. In addition, In the preparation method, cheap silicon dioxide is taken as a silicon source, silicon dioxide is conversed into silicon materials with electrochemical activities through a magnesiothermic reduction method. The size of gaps can be regulated and controlled through control of etching conditions. The preparation method is advantaged in that the material structure can be controlled, the cost is low, the process is simple, and the composite microsphere is convenient for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Porous carbons from carbohydrates

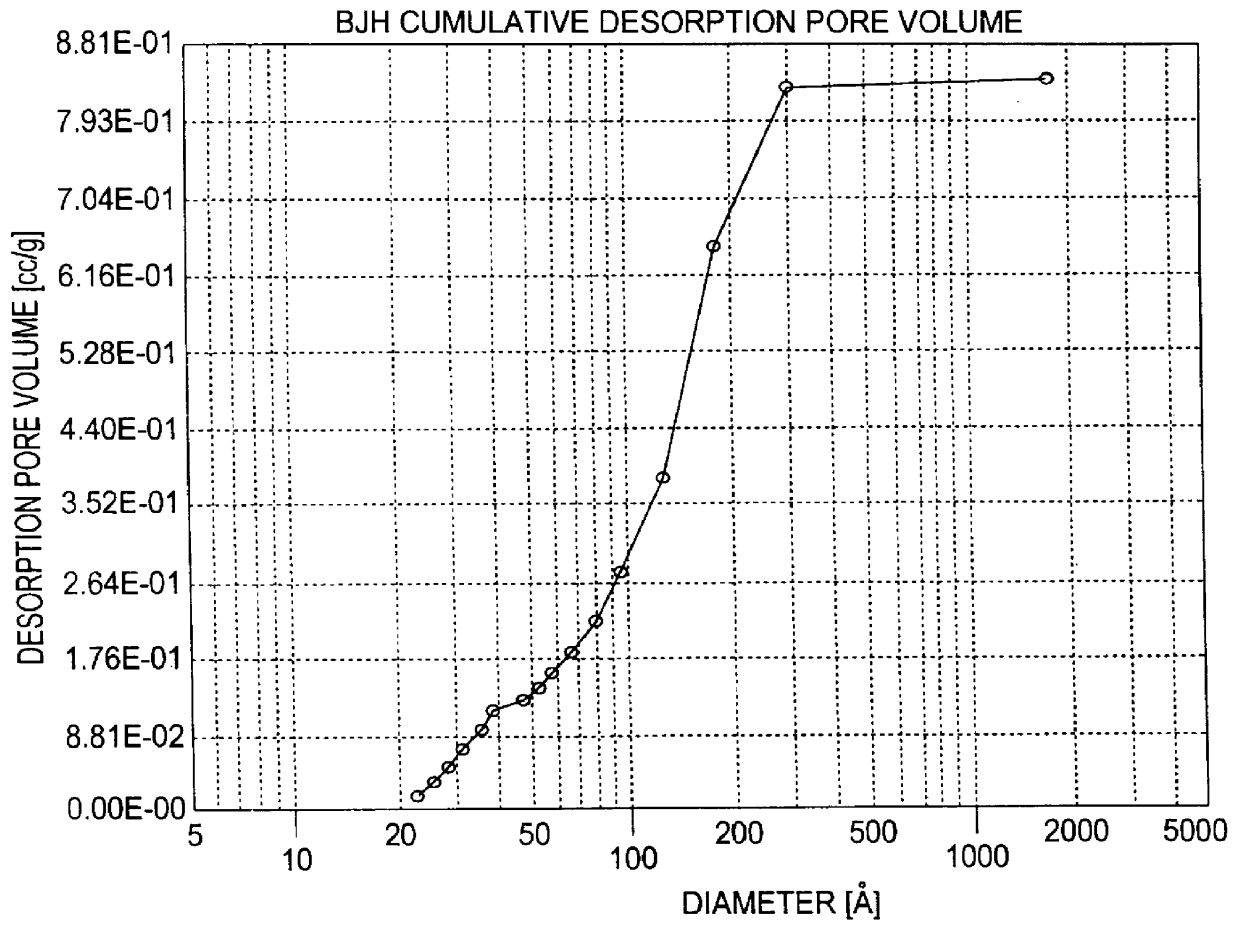

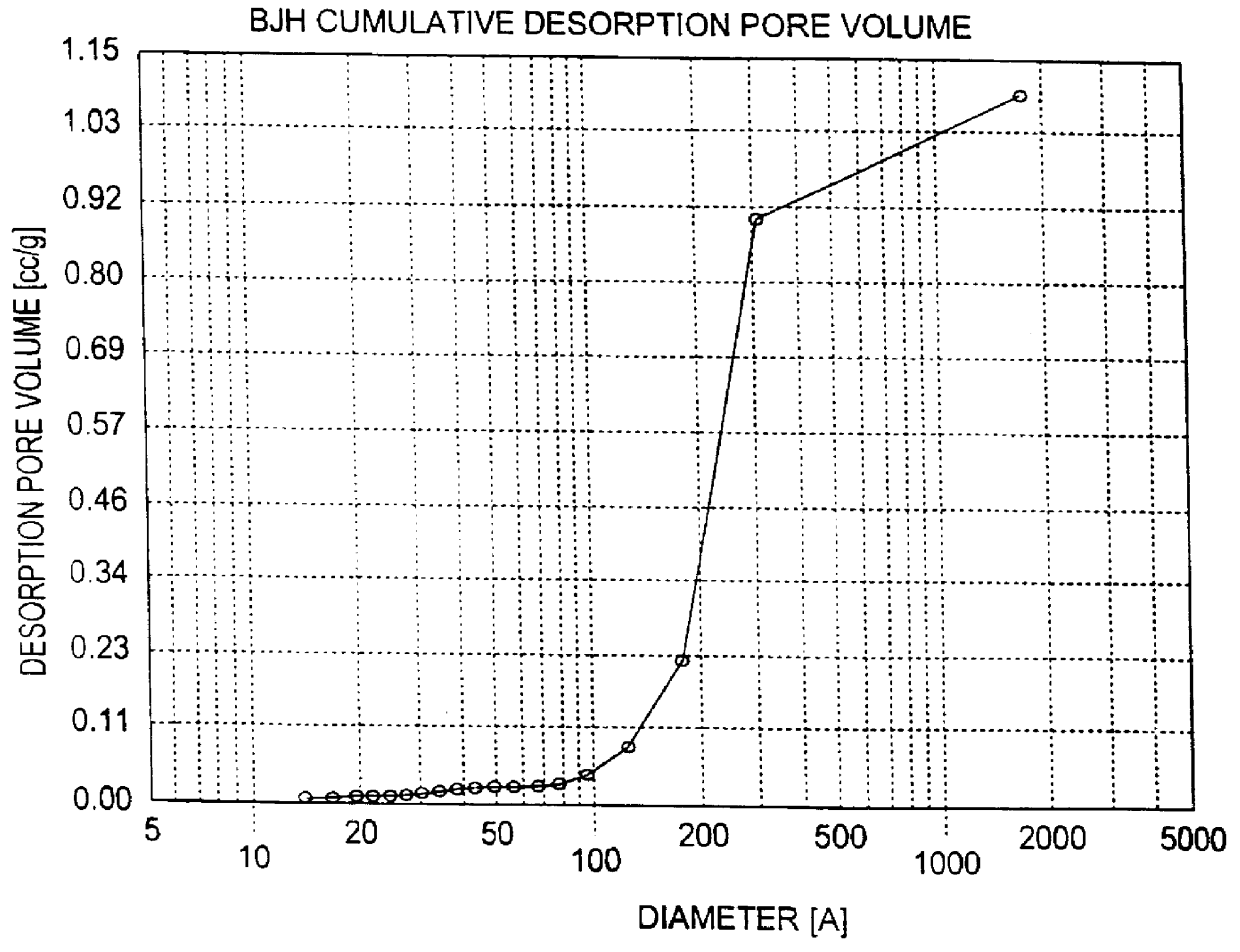

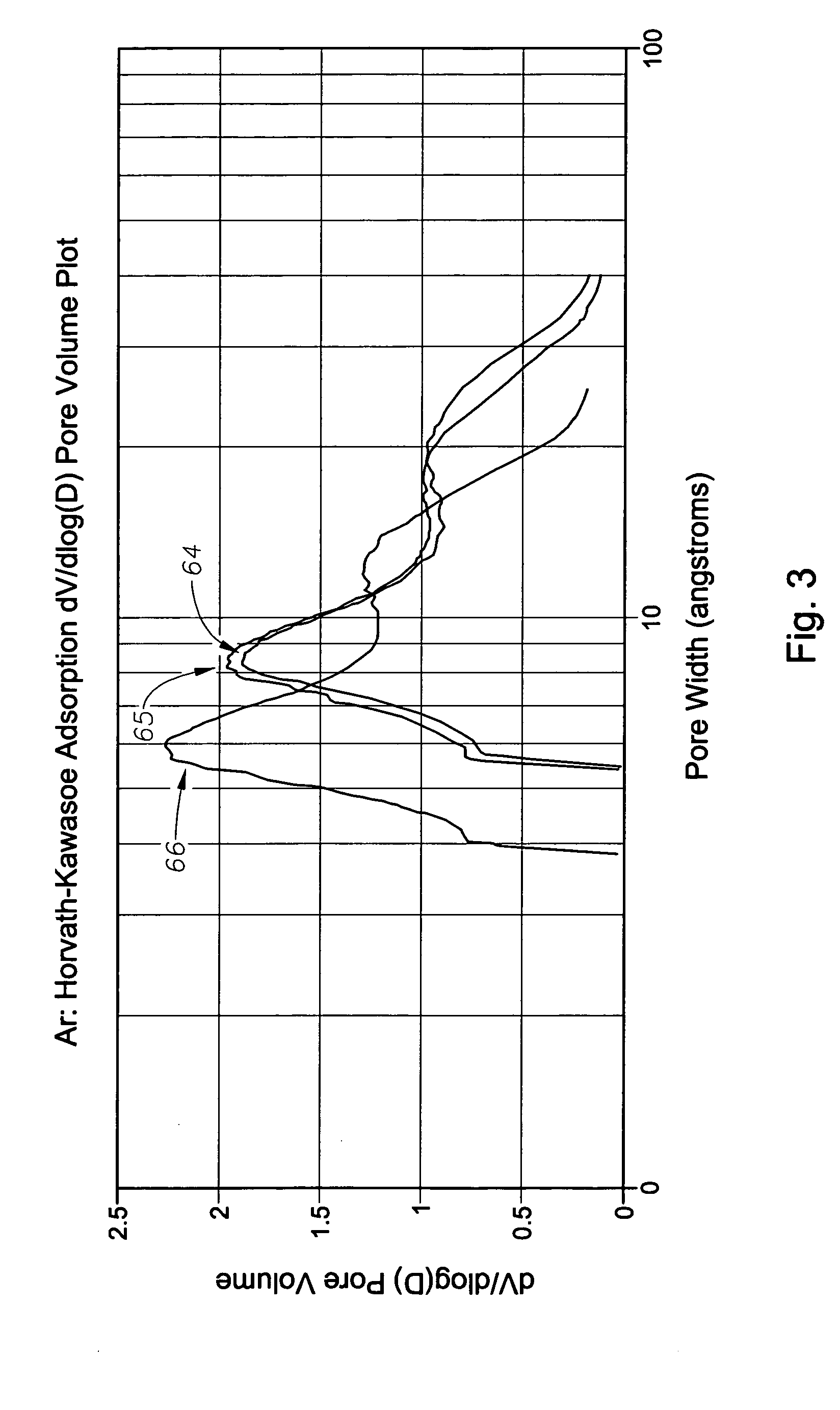

ActiveUS20050207962A1Small surface areaIncreased proportion of mesoporesHybrid capacitor electrodesCeramicwarePorous carbonPore diameter

A porous carbon characterized by a volumetric pore size distribution having two peaks, a first of said peaks being between 0.5 and 1.0 nm and a second of said peaks being between 1.0 and 5.0 nm. The porous carbon may have a volumetric capacitance in an organic electrolyte of at least 40 F / cm3, an average pore diameter between about 2 nm and about 30 nm, a surface area of at least 900 m2 / g, and / or a density of at least 0.4 g / cm3. A method for making such a carbon includes a) curing a mixture comprising a carbohydrate, a dehydrating component, and a nonmetallic cationic pore-forming agent and b) carbonizing the cured carbon under conditions effective to provide a porous carbon having a surface area between about 100 m2 / g and about 3000 m2 / g. The the dehydrating component and nonmetallic cationic component may comprise two moieties of one compound.

Owner:TDA RES

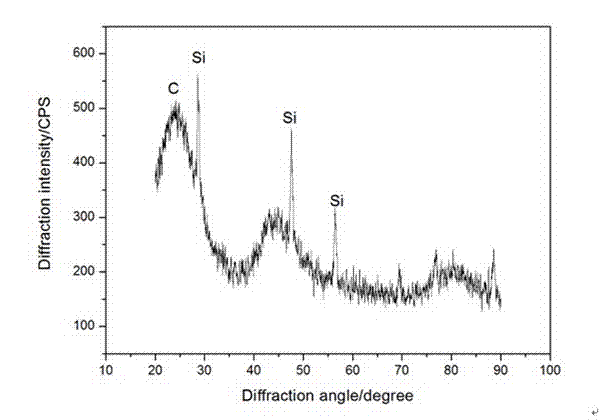

Silicon-carbon composite anode material and preparing method thereof

ActiveCN102509781AHigh specific capacityImprove cycle performanceCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite anode material, which comprises a nuclear shell structure and a support substrate, wherein particle size of the silicon-carbon composite anode material is 1-200 micrometers, and porous carbon serving as the support substrate is obtained through decomposition of biomass materials. The invention further provides a preparing method of the silicon-carbon composite anode material, which includes the following steps: 1 reaming the biomass materials in physical activation or chemical activation mode to prepare the porous carbon, or preparing small molecular organics serving as a precursor of the porous carbon in hydrolyzing mode; 2 mixing silica particles and the obtained porous carbon or the precursor of the porous carbon in solution and performing ultrasonic treatment; 3 evaporating the solution mixture to dry so as to obtain solid-state powder; and 4 drying the solid-state powder, and performing thermal treatment, crushing and sieving on the solid-state powder to obtain the silicon-carbon composite anode material. The silicon-carbon composite anode material and the preparing method thereof are simple in process, short in flow path, easy to operate and low in cost, and lithium ion batteries manufactured by the silicon-carbon composite anode material are suitable for various mobile electronic equipment or devices driven by mobile energy.

Owner:SHANGHAI JIAO TONG UNIV

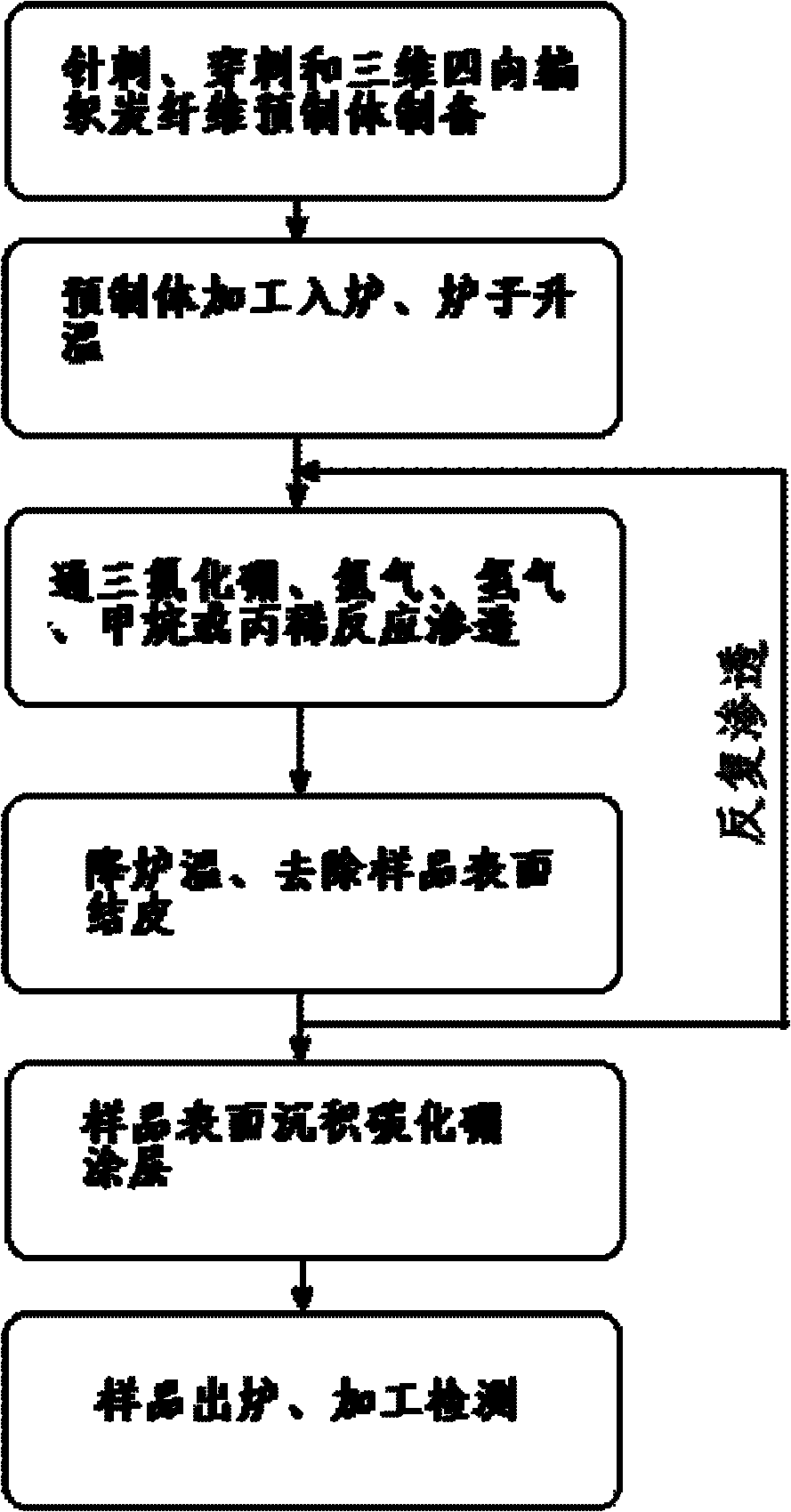

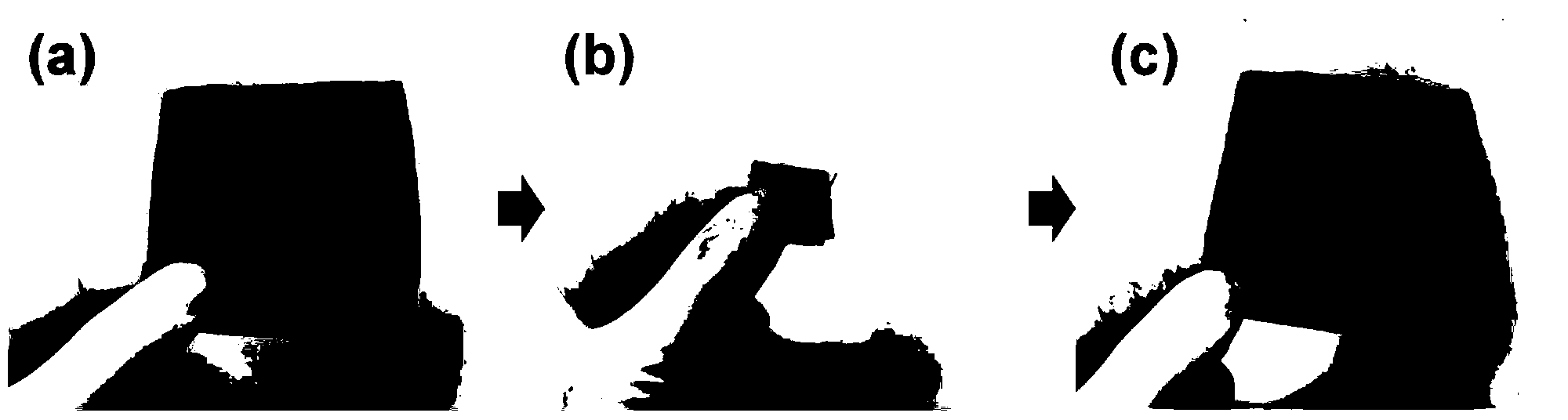

Carbon fiber reinforced boron carbide composite material and preparation method thereof

The invention relates to a carbon fiber reinforced boron carbide composite material and a preparation method thereof. The preparation method comprises the following steps of: preparing a carbon fiber preform by adopting a needling, puncturing or three-dimensional weaving process; and depositing boron carbide matrix in the porous carbon fiber preform by osmosis to form the compact carbon fiber reinforced boron carbide composite material. Aiming at a certain specific application environment, a boron carbide coat can be deposited on the surface of a sample by adopting the same chemical vapor osmosis process. The carbon fiber reinforced boron carbide-based composite material manufactured by the method has the characteristics of good mechanical property, toughness superior to that of the traditional sintered boron carbide, compact structure, light weight, abrasion resistance and high hardness, and is suitable to be applied to a high-temperature light structural component.

Owner:CENT SOUTH UNIV

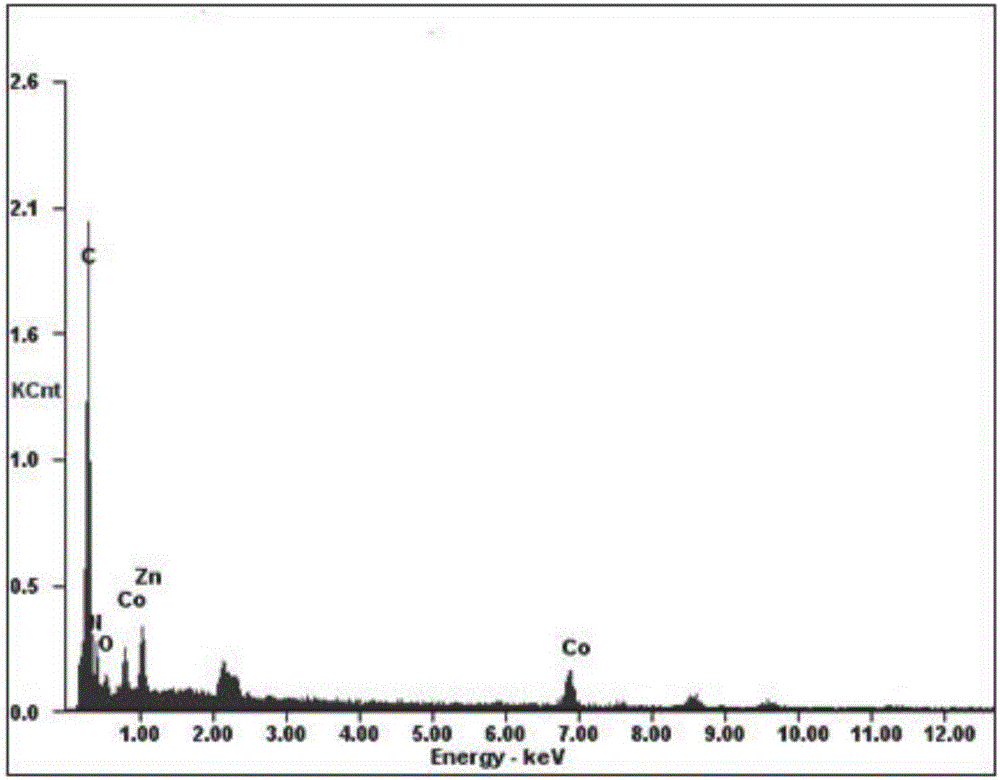

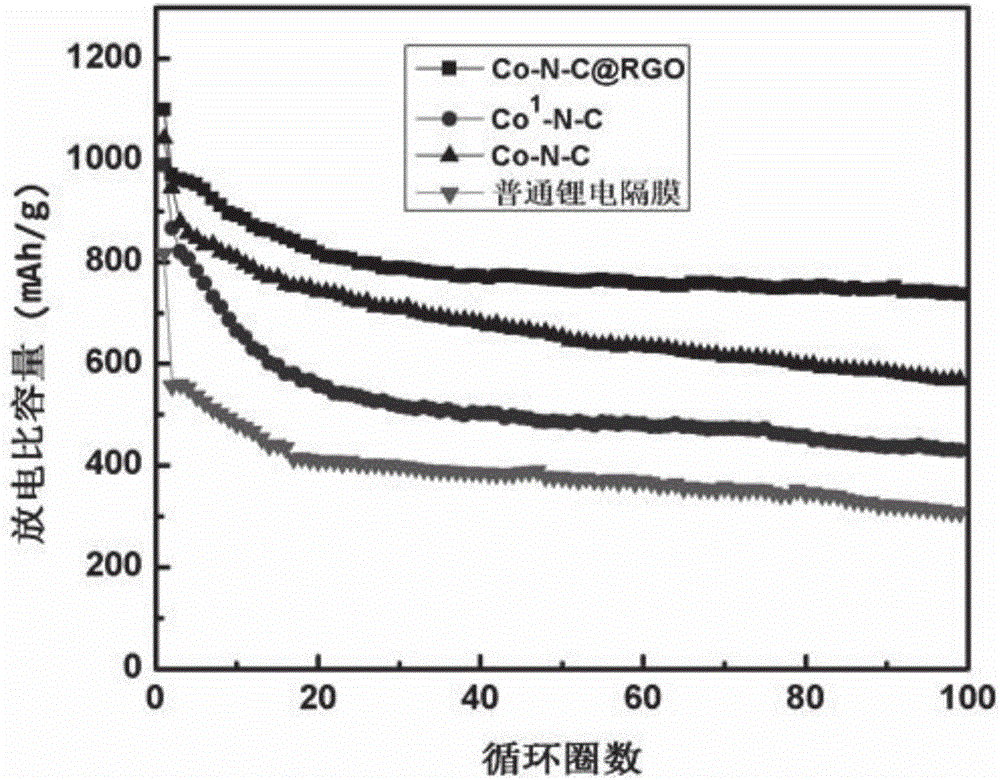

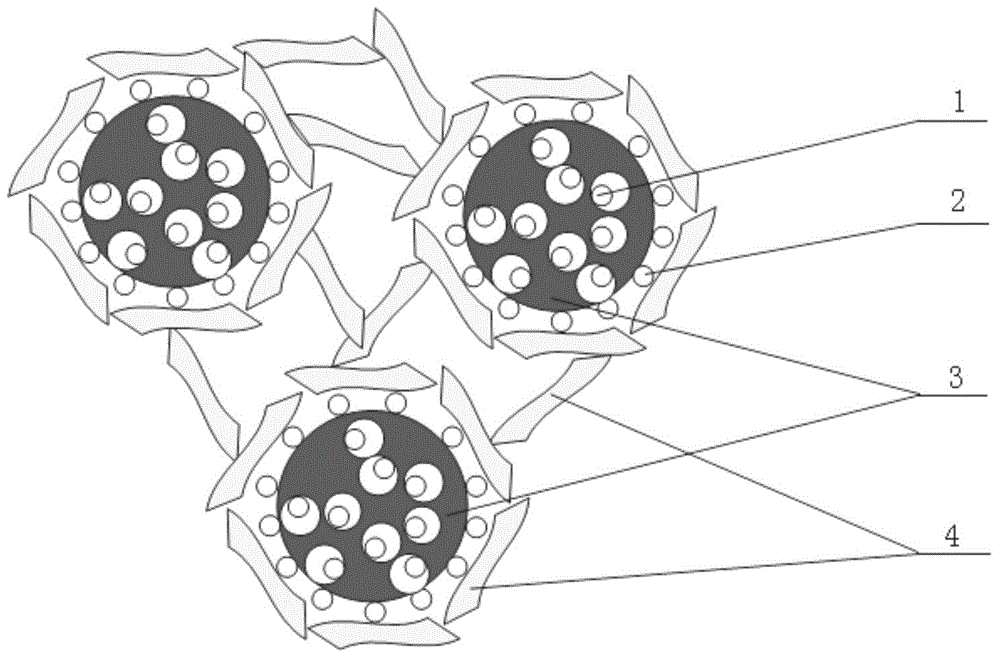

Co-N-C@RGO composite material, preparation method and application to modification of lithium-sulfur battery diaphragms

ActiveCN106784525AIncrease the areaHigh porosityLi-accumulatorsCell component detailsPorous carbonElectrical battery

The invention discloses a method for preparing porous carbon@graphene composite material by taking a bimetal organic framework material as a precursor and application to modification of lithium-sulfur battery diaphragms thereof. The preparation method comprises the following steps: taking zinc salt and cobalt salt in a certain ratio as the raw materials, synthesizing a zinc / cobalt-bimetal organic framework@graphene composite material through a room-temperature liquid phase method, taking the zinc / cobalt-bimetal organic framework@graphene composite material as the precursor, carrying out high-temperature reaction under inert atmosphere, pickling and drying to obtain a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite material. Co-N-C@RGO has high conductivity; the specific surface area of Co-N-C@RGO reaches up to 750-1000m<2> / g; the content of Co is 2-4At%; the content of N is 10-20At%. When the material is applied to the modification of the lithium-sulfur battery diaphragms, the material has the function of obviously inhibiting polysulfide shuttle effect and is capable of greatly improving actual specific capacity and cyclic performance of the lithium-sulfur batteries; meanwhile, the raw materials needed for synthesizing the material are simple; the operation is convenient; the large-scale production can be achieved; the material has certain promoting effect on commercialization of lithium-sulfur battery systems.

Owner:CENT SOUTH UNIV

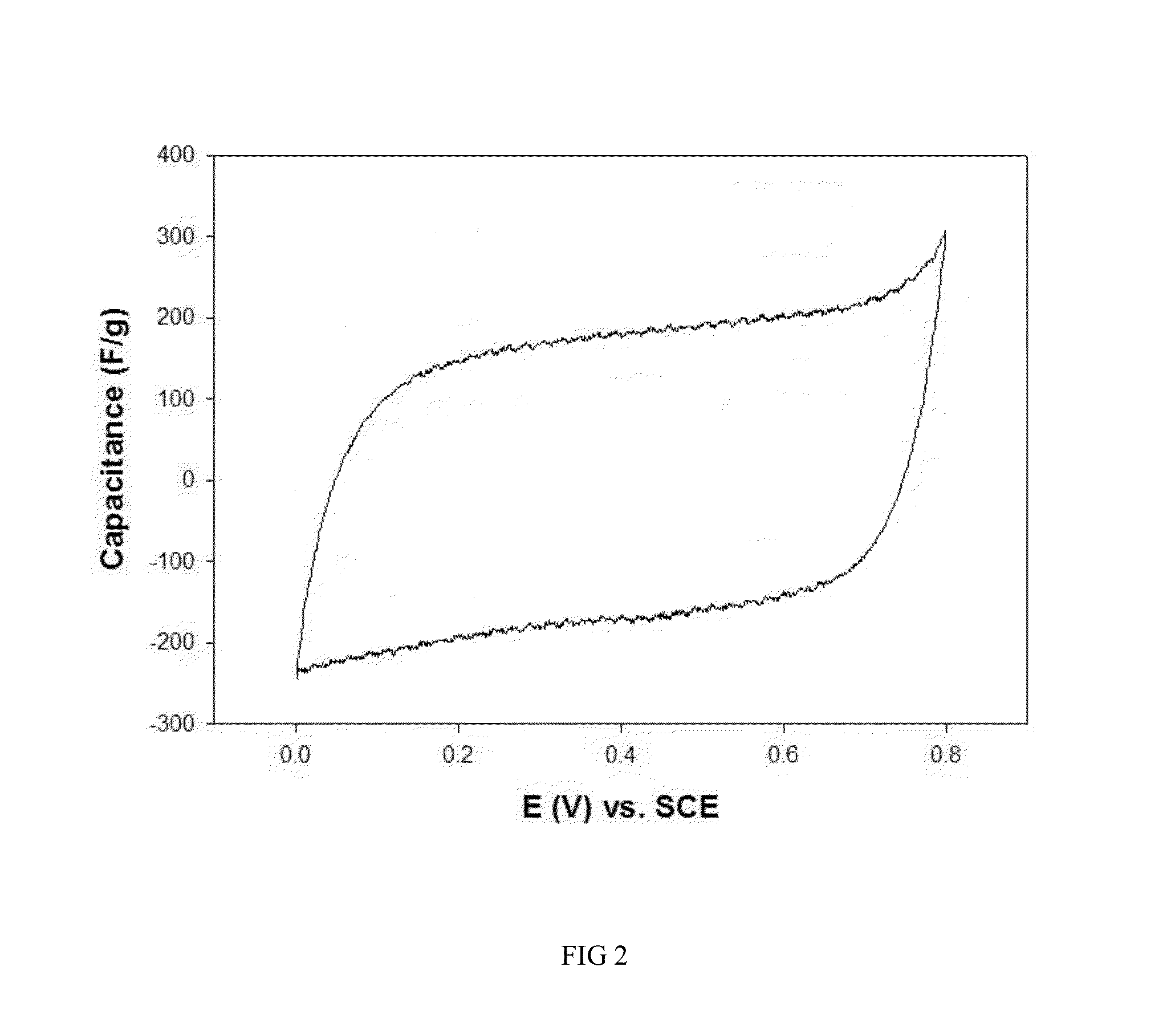

Functionalized Carbon Electrode, Related Material, Process for Production, and Use Thereof

InactiveUS20140113200A1Low costSimple processElectrolytic capacitorsHybrid capacitor electrodesFuel cellsPorous carbon

The present invention relates to a material for use as an electrode for electrochemical energy storage devices such as electrochemical capacitors (ECs) and secondary batteries, primary batteries, metal / air batteries, fuel cells, flow batteries and a method for producing the same. More specifically, this invention relates to an electrode material consisting of a functionalized porous carbon, a method for producing the same, and an energy storage device using said electrode materials.

Owner:SEYMOUR FRASER

Porous carbon fiber, and preparation method and application thereof

ActiveCN103225135AEasy to makeLow costFilament/thread formingArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a porous carbon fiber and a preparation method thereof. The method comprises the following steps: spinning a spinning liquid composed of a pore forming agent, a high polymer and an organic solvent, carbonizing, and pickling to obtain the porous carbon fiber. The method has the advantages of simple preparation, high output and low cost, and allows the porous carbon fiber simultaneously having micro-pores, meso-pores and macro-pores to be prepared; and the carbon fiber prepared in the invention is more flexible than that of carbon fibers prepared through other methods.

Owner:INST OF CHEM CHINESE ACAD OF SCI

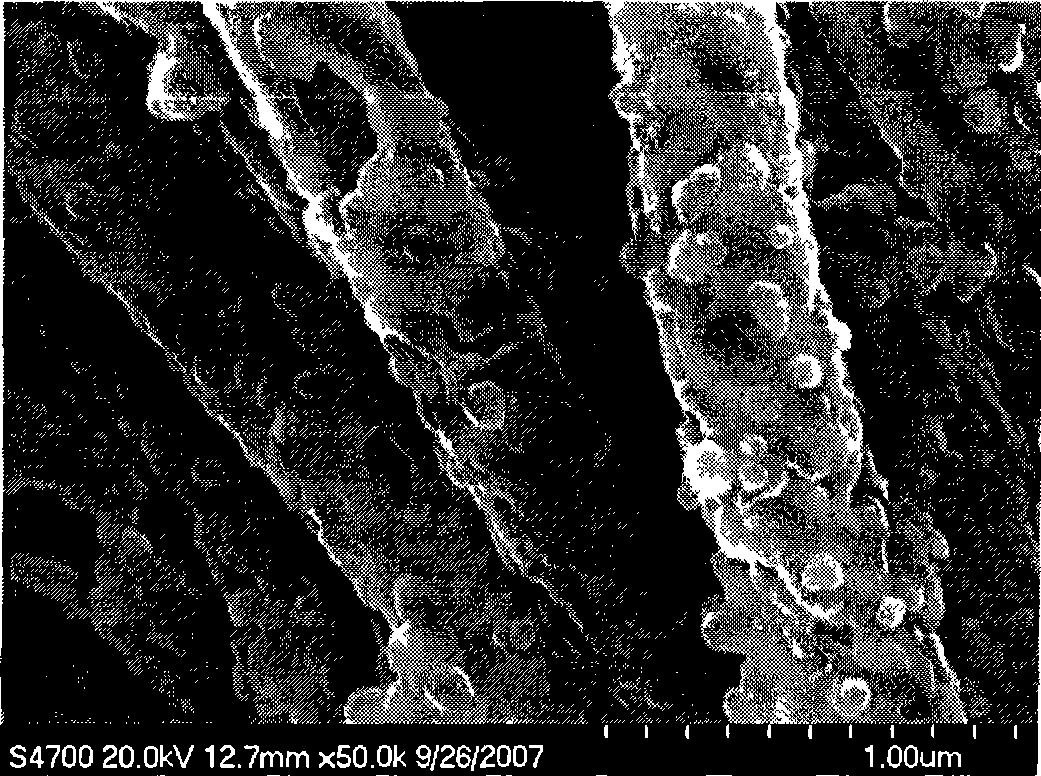

Porous carbon nanometer fiber-supported nanocrystal catalyst and preparation method thereof

InactiveCN101455975AModerate grain sizeSuitable structurePhysical/chemical process catalystsPorous carbonElectrospinning

The invention provides a porous-carbon nano-fiber supported nano-grain catalyst and a preparation method thereof. A porous polyacrylonitrile-based carbon nano-fiber supported nano-grain catalyst is prepared by adopting an electrostatic spinning process, constant-tension hot stretching, preoxidation and chemical activation at a temperature between 500 and 1,000 DEG C. Porous-carbon nano-fiber has the diameter between 100 and 500 nanometers, the aperture between 1 and 500 nanometers, the porosity between 0.1 and 1.0 cm<3> / g and the specific surface area between 100 and 2,000 m<2> / g, and catalyst particles supported on the surface of the nano-fiber has the aperture between 1 and 100 nanometers and the weight percentage content between 1 and 40 percent. The preparation method has the advantage of simple process, and can prepare the porous-carbon nano-fiber supported nano-grain catalyst with high porosity, large specific surface area, strong adsorption activity and catalytic efficiency through the chemical activation at a low temperature.

Owner:BEIJING UNIV OF CHEM TECH

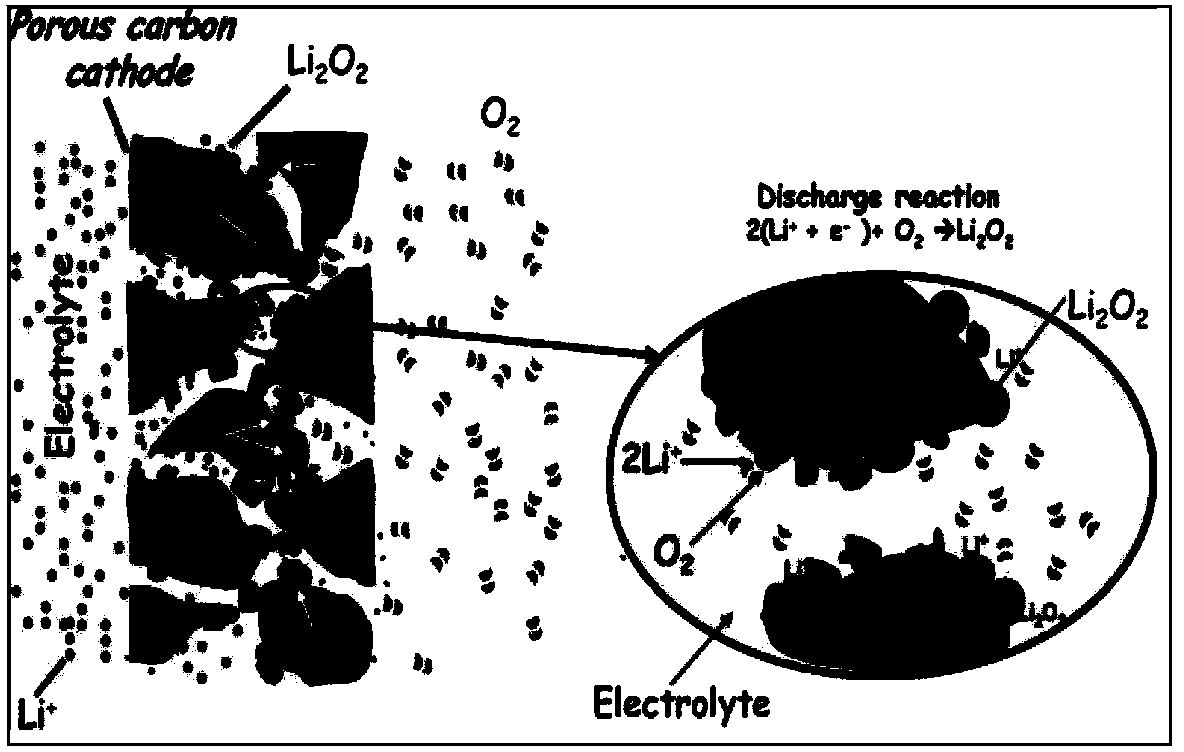

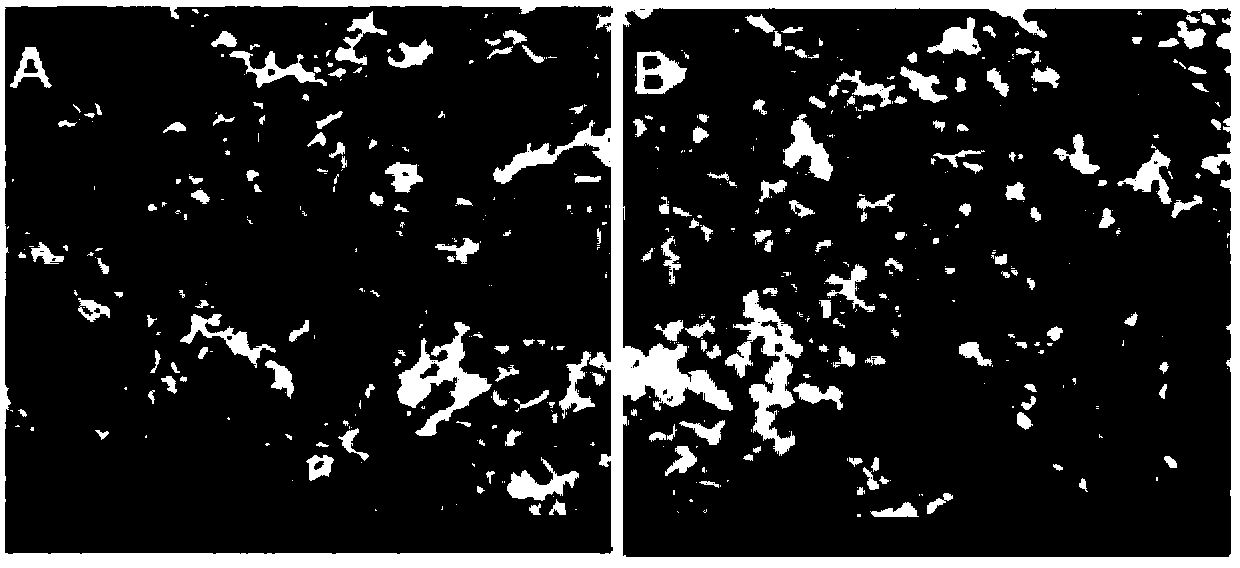

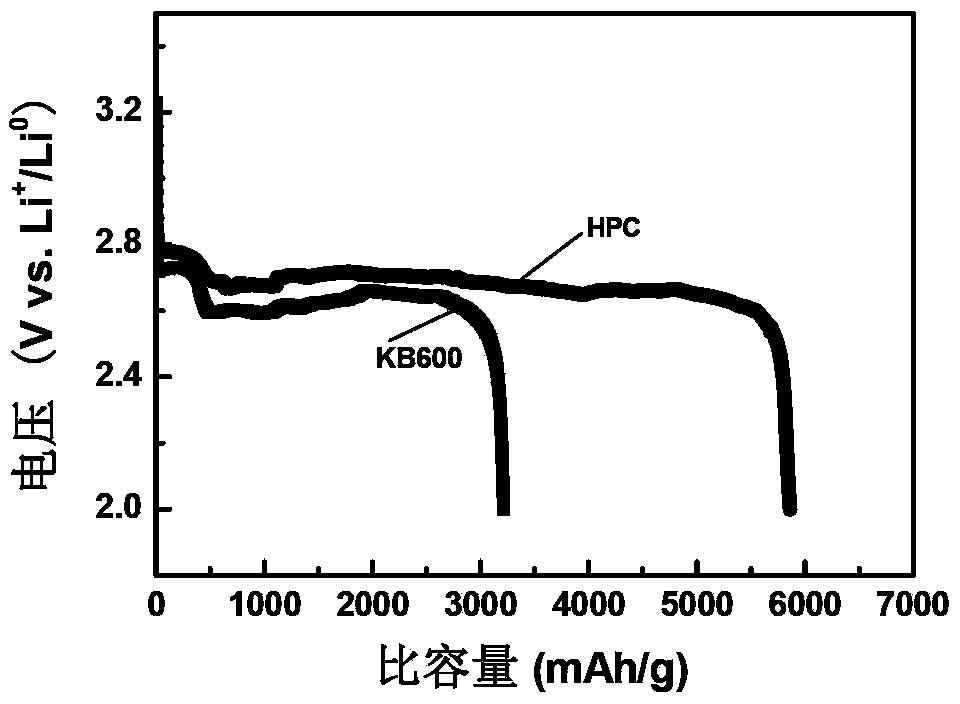

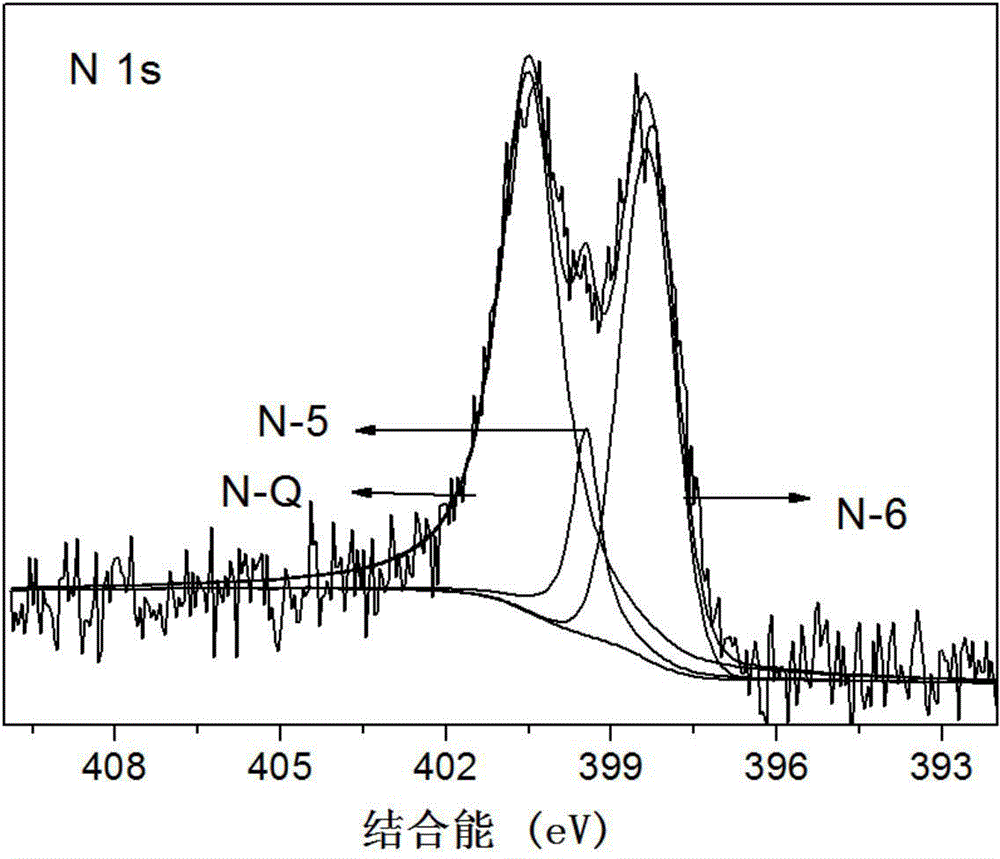

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

ActiveCN103855366AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

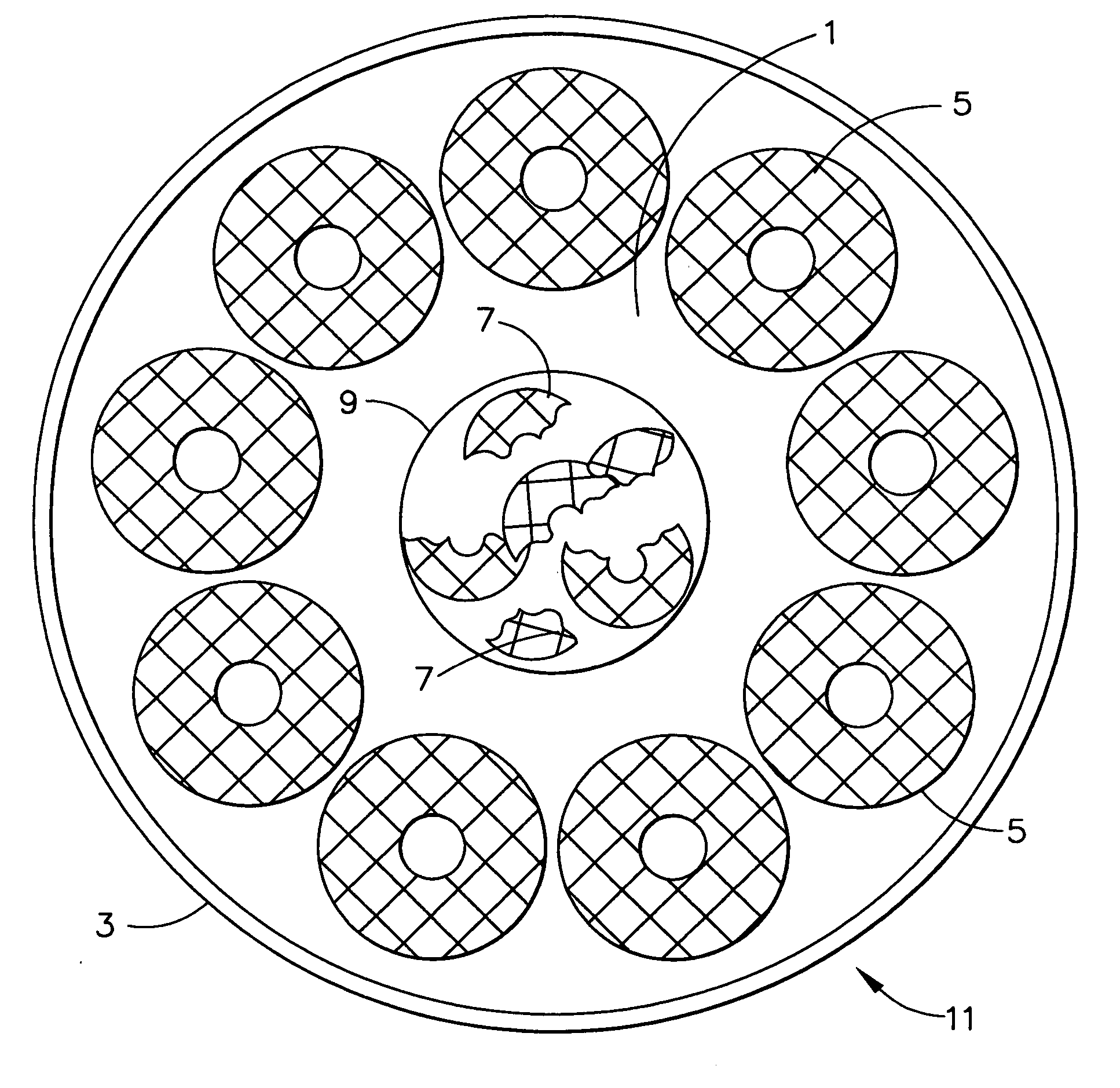

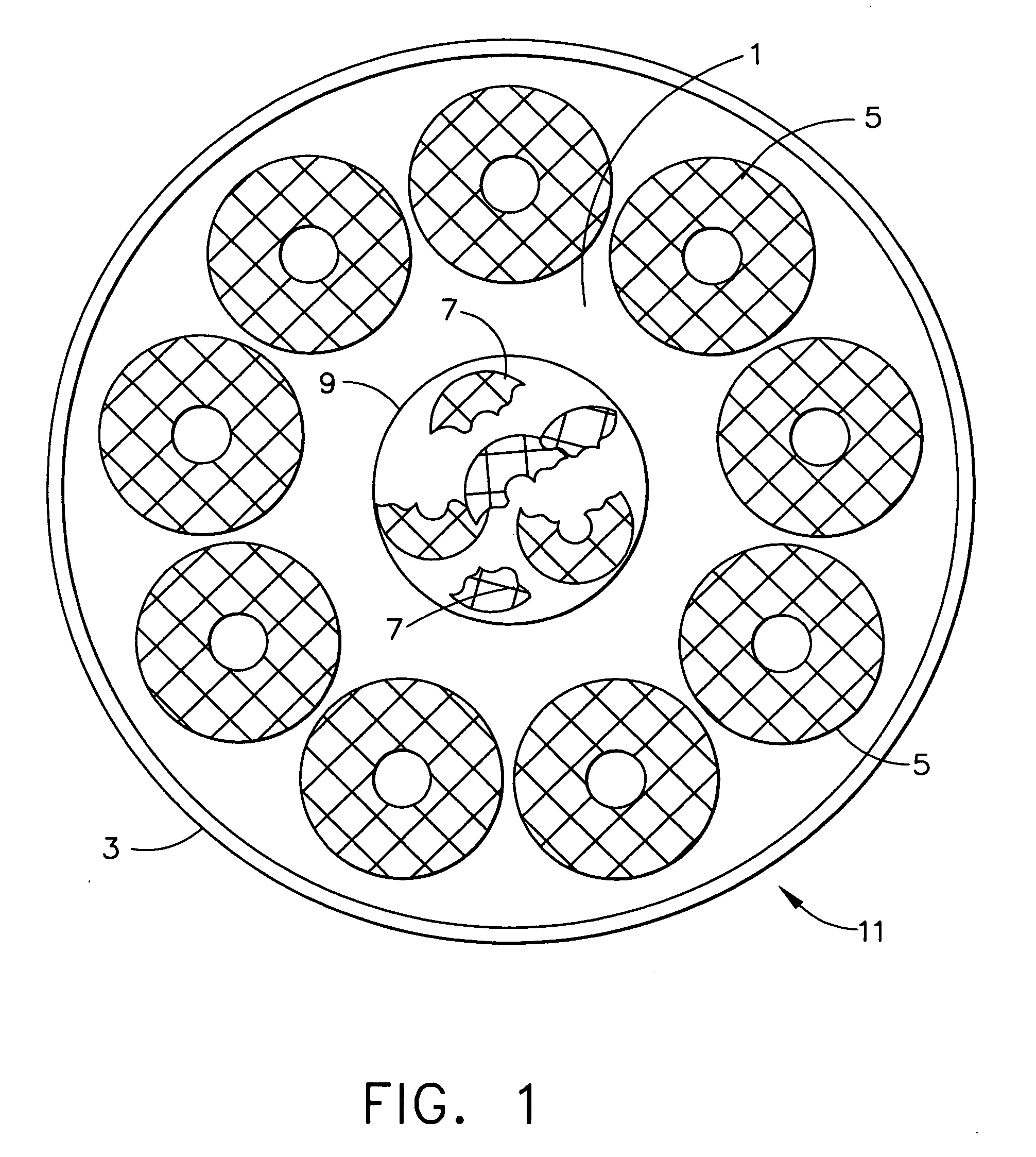

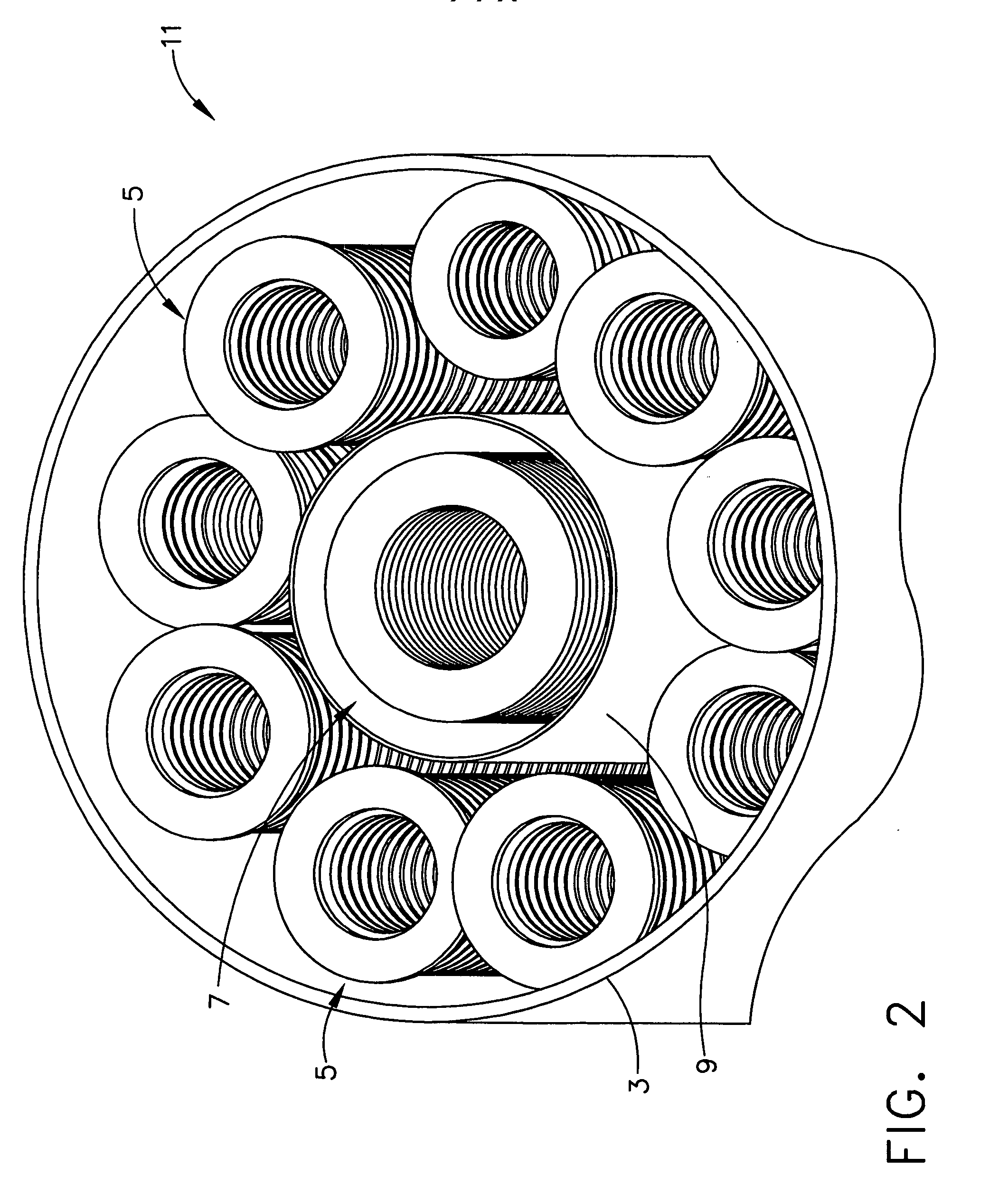

Chemical vapor deposition apparatus and method

InactiveUS20060046059A1High densityGreat and uniform weightLayered productsChemical vapor deposition coatingCarbon compositesCircular disc

Apparatus such as a furnace muffle (11) for use in a CVI / CVD furnace. The apparatus includes a bottom (12), a top (13), and an outer wall (3) defining an interior space (1) in the apparatus, and a passive heat distribution element (7, 9) located within the interior space (1) and apart from the outer wall (3). Preferably, the bottom (12) and top (12) include perforated plates and the outer wall (3) is cylindrical in shape and all are made of graphite or carbon-carbon composite material and the passive heat distribution element (7, 9) is cylindrical in shape and includes graphite or carbon-carbon composite discs having no spacers therebetween. Also, a method for densifying a porous carbon preform (5), which method includes the steps of: (a) providing the apparatus (11); (b) charging the apparatus (11) with a plurality of stacks of annular porous carbon preforms (5), the preforms being separated from one another by spacers (15); (c) locating the charged apparatus (11) in a furnace at a temperature in the range of 950-1100° C. and a pressure in the range of 5-40 torr; and (d) circulating a natural gas reactant blended with up to 15% propane through the apparatus for 150-900 hours. Also, a batch of carbon-carbon composite preforms made by the method, wherein the density of the batch of preforms is at least 0.5 g / cc higher than the density of a batch of preforms made by an otherwise identical process in which the apparatus does not contain a passive heat distribution element located within its interior. The preforms may be configured as aircraft landing system brake discs or racing car brake discs.

Owner:HONEYWELL INT INC

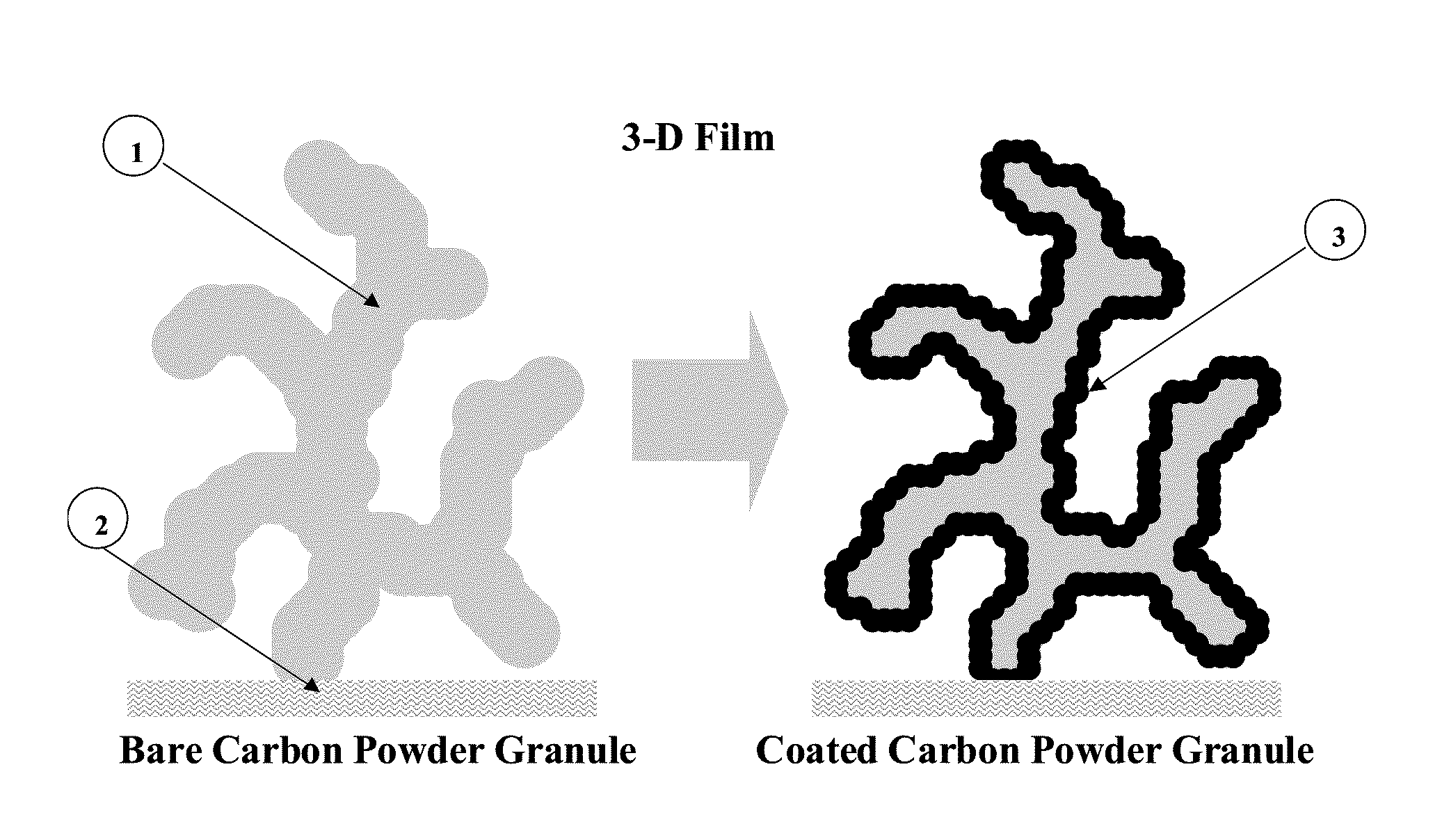

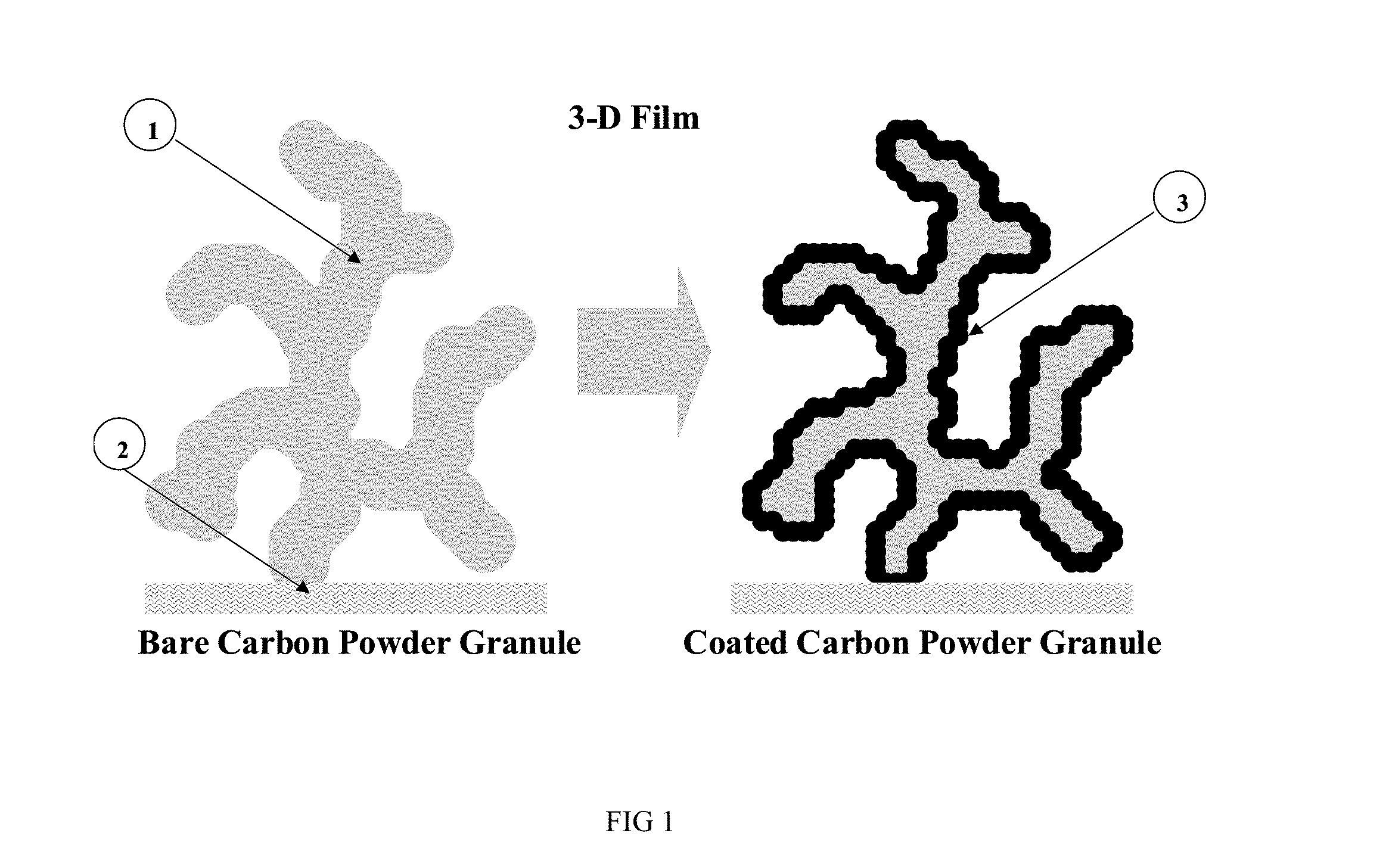

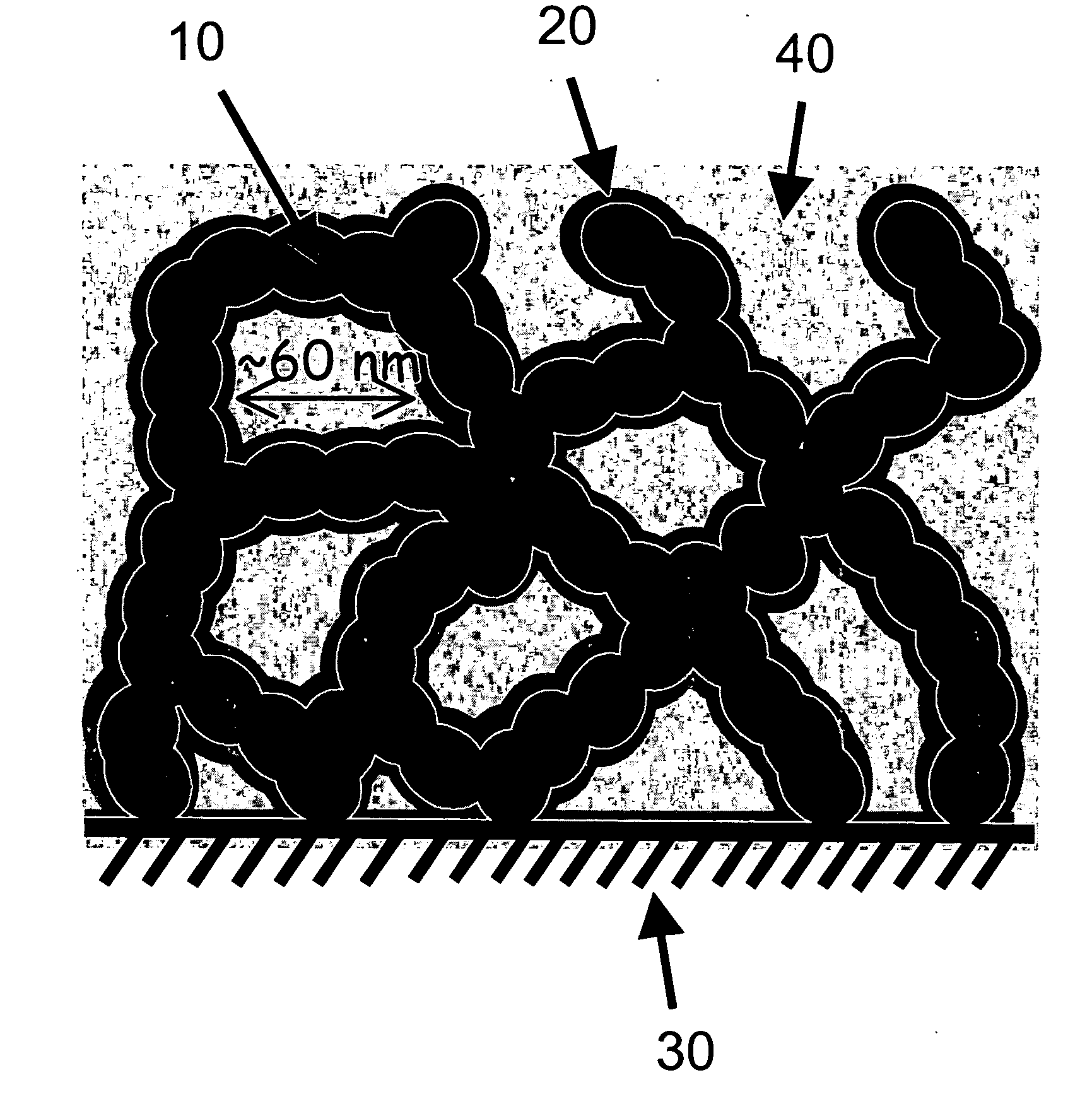

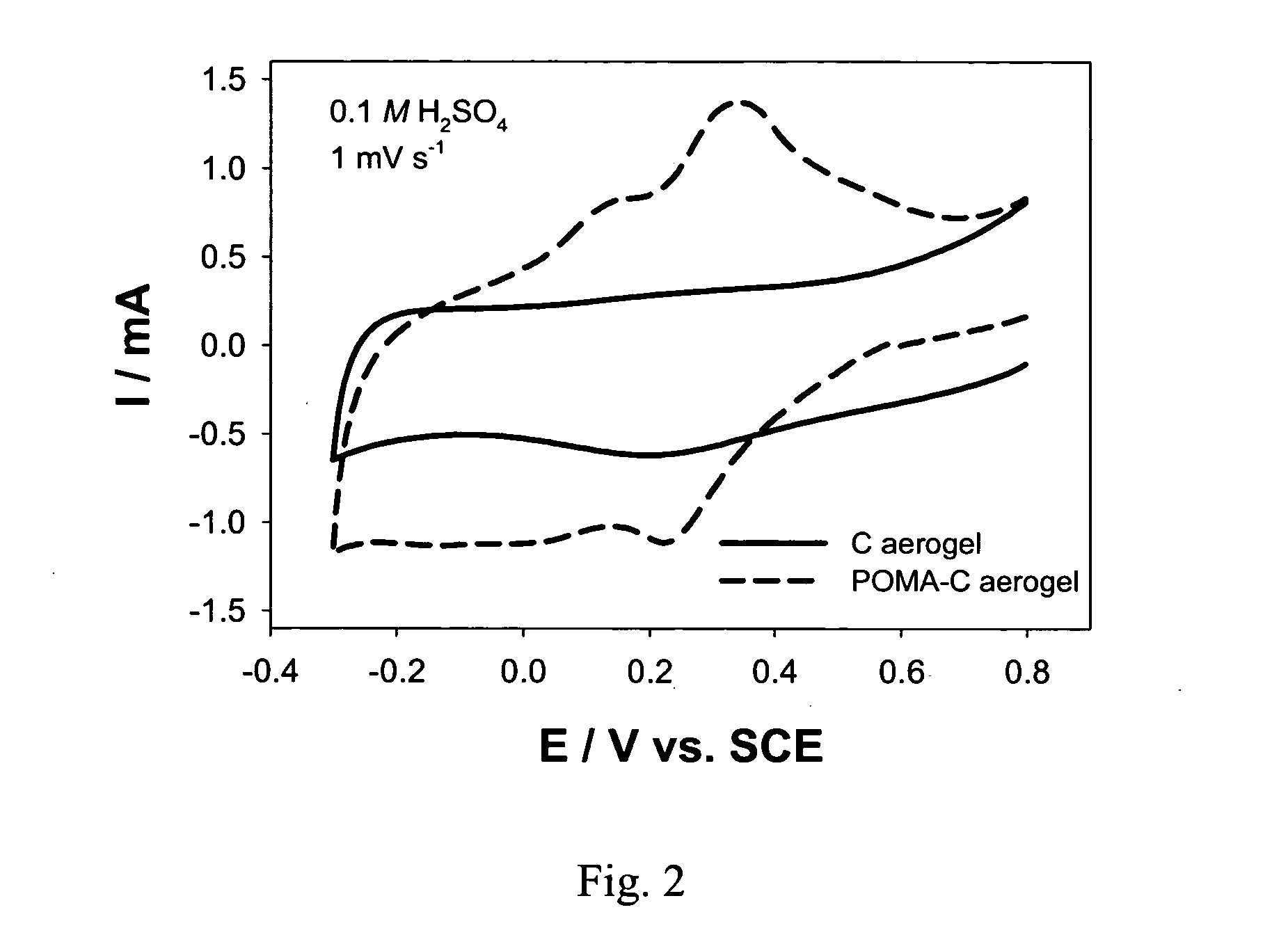

Carbon nanoarchitectures with ultrathin, conformal polymer coatings for electrochemical capacitors

ActiveUS20050153130A1Hybrid capacitor electrolytesElectrolysis componentsSelf limitingPolymer science

A composite having an electroactive polymer coating on a porous carbon structure is disclosed. The composite may be used in capacitor electrodes. The composite may be made by self-limiting electropolymerization of a monomer on the carbon structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

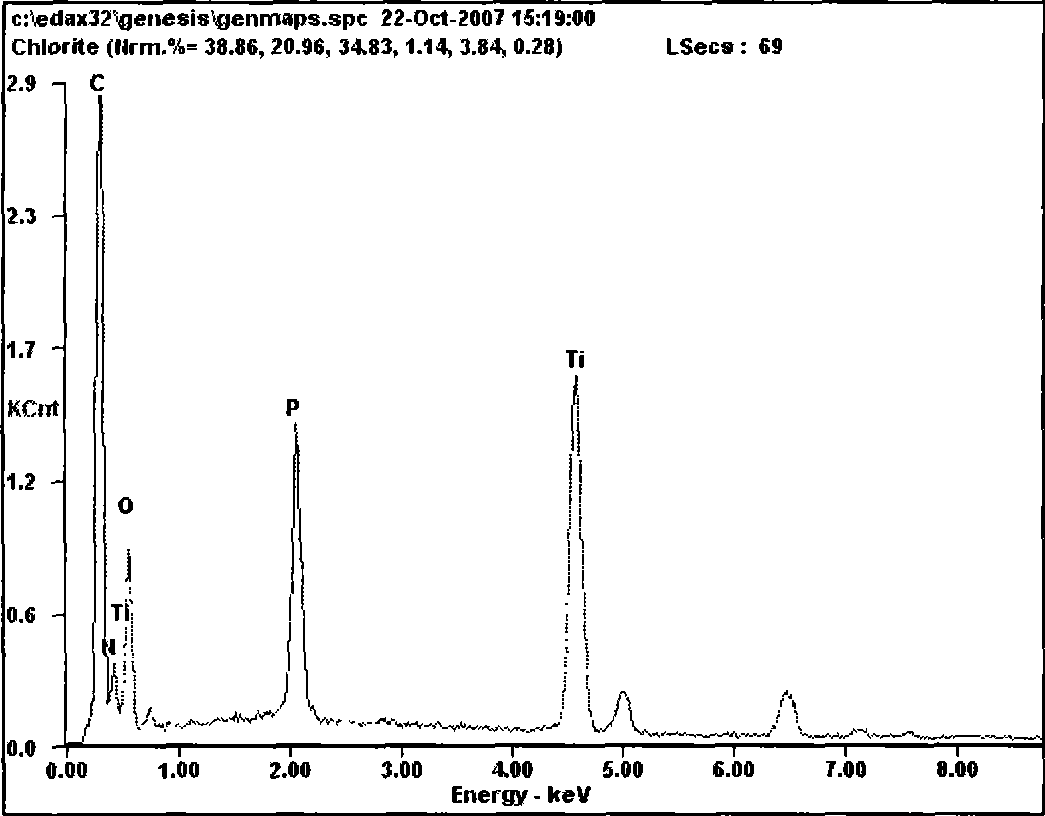

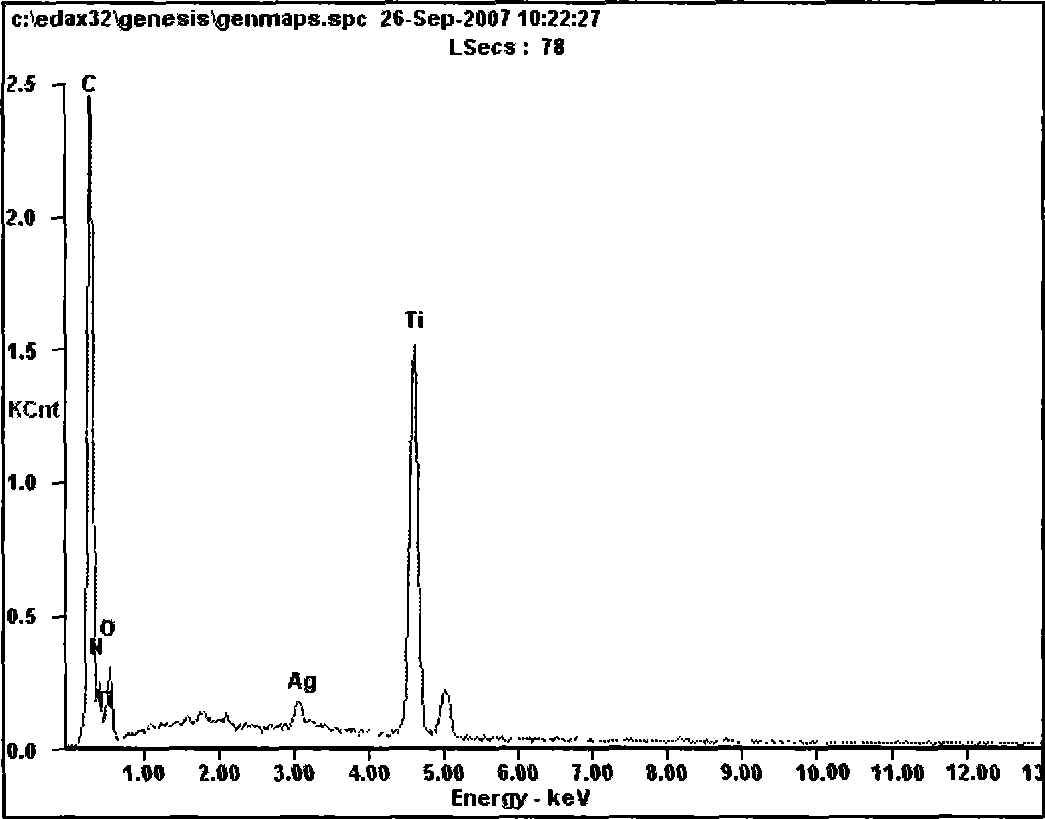

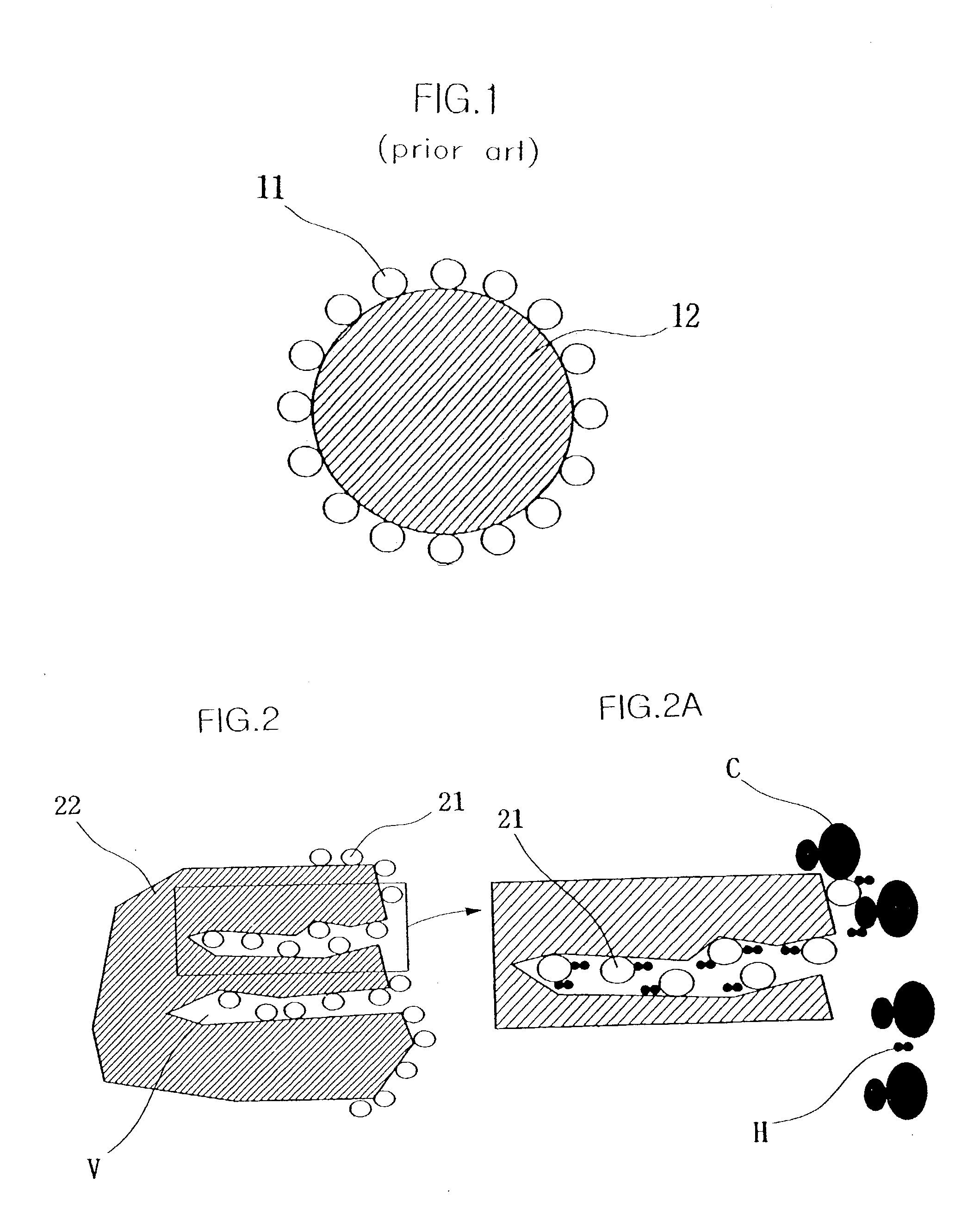

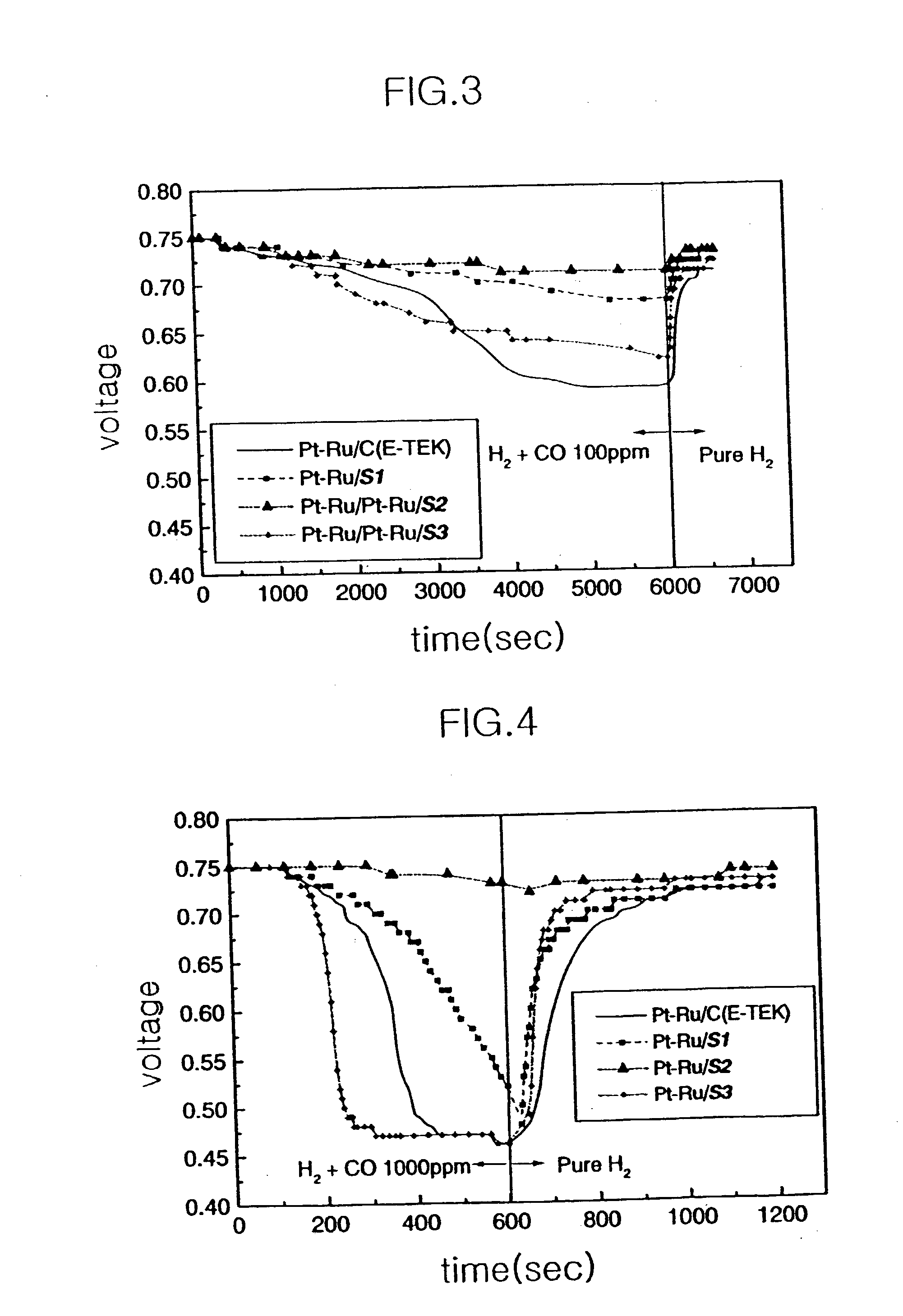

Electrocatalyst for fuel cells using support body resistant to carbon monoxide poisoning

InactiveUS20040248730A1Cell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

Disclosed is an electrocatalyst for fuel cells, in which a porous carbon material including pores having a diameter smaller than a kinetic diameter of carbon monoxide is used as a support body and contact probability between an activated metal and carbon monoxide is decreased, thereby preventing fuel cell performance from being degraded by carbon monoxide. The electrocatalyst is obtained by adsorbing 10-80 parts by weight of an activated metal to 20-90 parts by weight of a porous support body, characterized in that the porous support body has a total surface area of 200-2,500 m<2> / g including an outer surface thereof and an inner surface of pores thereof, and has a plurality of pores penetrating into an interior of the support body with an average diameter of 2-15 nm and a total volume of 0.4-2.0 m<3> / g, and the activated metal is alloyed with 20-95 at % of platinum and 5-80 at % of one metal selected from among Ru, Sn, Os, Rh, Ir, Pd, V, Cr, Co, Ni, Fe and Mn. As for such an electrocatalyst, carbon monoxide does not fundamentally come in contact with the activated metal adsorbed to the inner surface of the pores of the support body, thereby minimizing degradation of fuel cell performance, thus overcoming fuel-feeding problems.

Owner:KOREA INST OF ENERGY RES

Intercalation of silicon and/or tin into porous carbon substrates

The invention relates to a process for producing an electrically conductive, porous, silicon- and / or tin-containing carbon material which is suitable in particular for the production of an anode material, preferably for lithium ion batteries; in a first step of the process, preferably crystalline silicon nanoparticies and / or tin nanoparticies and / or silicon / tin nanoparticles are introduced into a matrix based on at least one organic polymer, being more particular dispersed therein, and subsequently, in a second step of the process, the resultant polymer matrix containing the silicon, tin and / or silicon / tin nanoparticies is carbonized to form carbon.

Owner:UNIV DUISBURG ESSEN

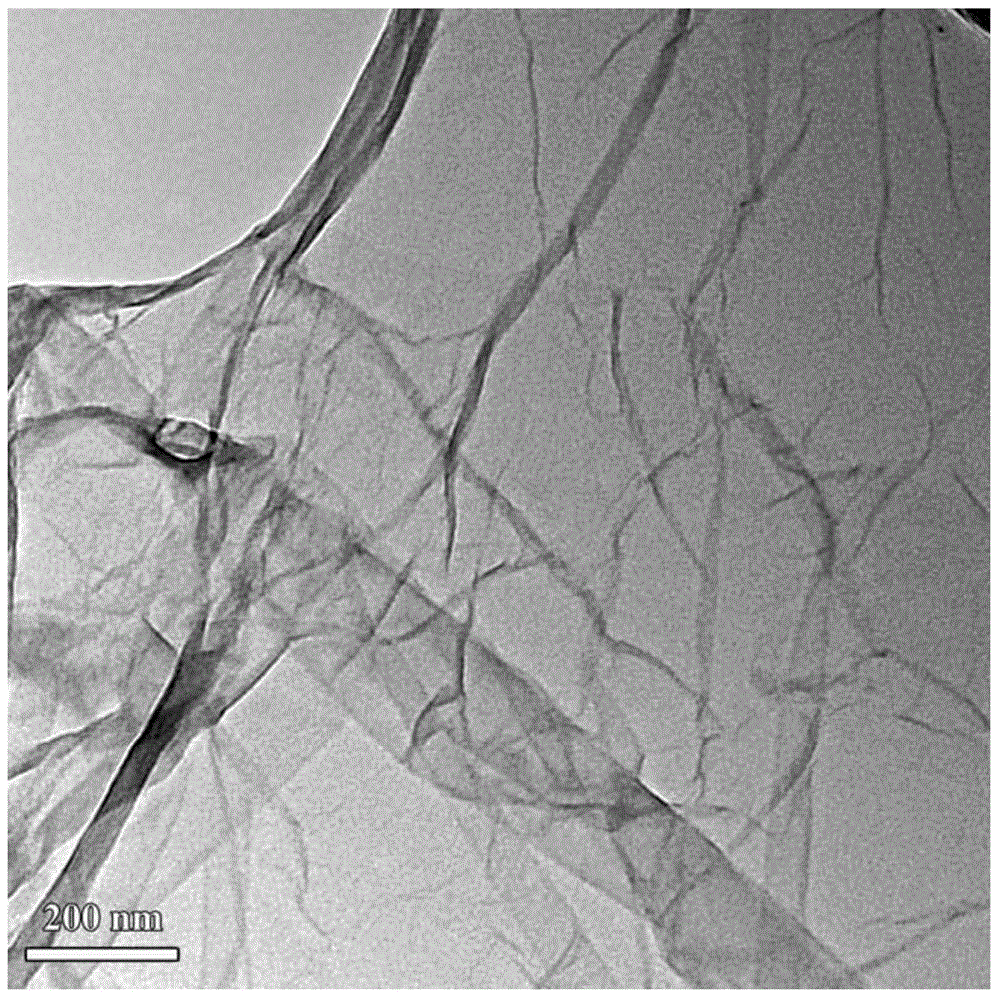

Preparing method for nitrogen-doped porous carbon material, catalyst comprising material and application of material

ActiveCN104689857AGood dispersionHigh bonding strengthCatalyst carriersOrganic compound preparationDispersityIn situ doping

The invention relates to a novel preparing method for an in-situ nitrogen-doped porous carbon material, the application of the in-situ nitrogen-doped porous carbon material serving as a carrier of a load type catalyst, the load type catalyst comprising the in-situ nitrogen-doped porous carbon material, and the application of the load type catalyst in the water phase alcohol condensation reaction. Cheap micromolecule nitrogen substances serve as a nitrogen source of the in-situ nitrogen-doped porous carbon material, nitrogen atom in-situ doping is achieved in the carbon material preparing process, the doping content of the in-situ nitrogen-doped porous carbon material is controllable, the in-situ nitrogen-doped porous carbon material is distributed evenly, the dispersity of metal in the carrier and the combining strength with the carrier can be improved through doping of nitrogen atoms, and therefore the catalytic activity of the nitrogen-doped porous carbon material can be improved, and the service life of the nitrogen-doped porous carbon material can be prolonged.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

ActiveCN103560235AUnique hierarchical core-shell structureIncrease contentCell electrodesHigh ratePorous carbon

The invention provides a grapheme-coated sulfur / porous carbon composite material and a preparation method thereof, and relates to a grapheme-coated sulfur / porous carbon composite material used as the positive electrode material of a lithium-sulfur secondary battery and a preparation method thereof. The grapheme-coated sulfur / porous carbon composite positive electrode material provided by the invention can be used for solving the technical problem that the existing grapheme-coated sulfur-containing composite material used as the positive electrode material of a lithium-sulfur battery is low in electrochemical properties. The external surface of each of the particles of the grapheme-coated sulfur / porous carbon composite material provided by the invention is evenly covered with a graphene sheet, and a graphene conductive network is formed between the particles; the obtained grapheme-coated sulfur / porous carbon composite material has a hierarchical core-shell structure. The preparation method of the grapheme-coated sulfur / porous carbon composite material is obtained by adding a sulfur / porous carbon composite material to graphene slurry which is stable for a long time and in which graphene sheets are highly dispersed in water for mixing and coating. The positive electrode material has high specific capacity, long cycle life and excellent high-rate performance. Besides, the grapheme-coated sulfur / porous carbon composite material can be used as the positive electrode material of a lithium secondary battery.

Owner:HARBIN INST OF TECH

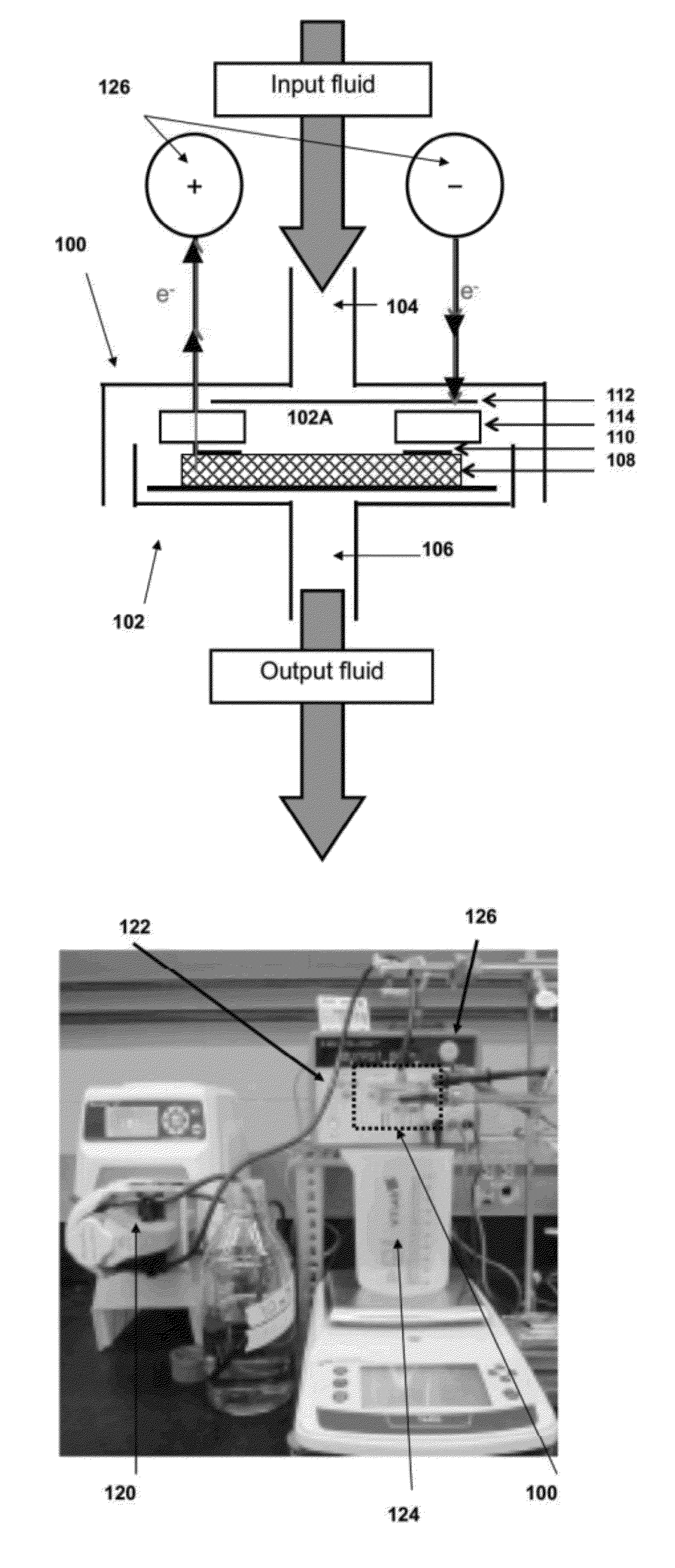

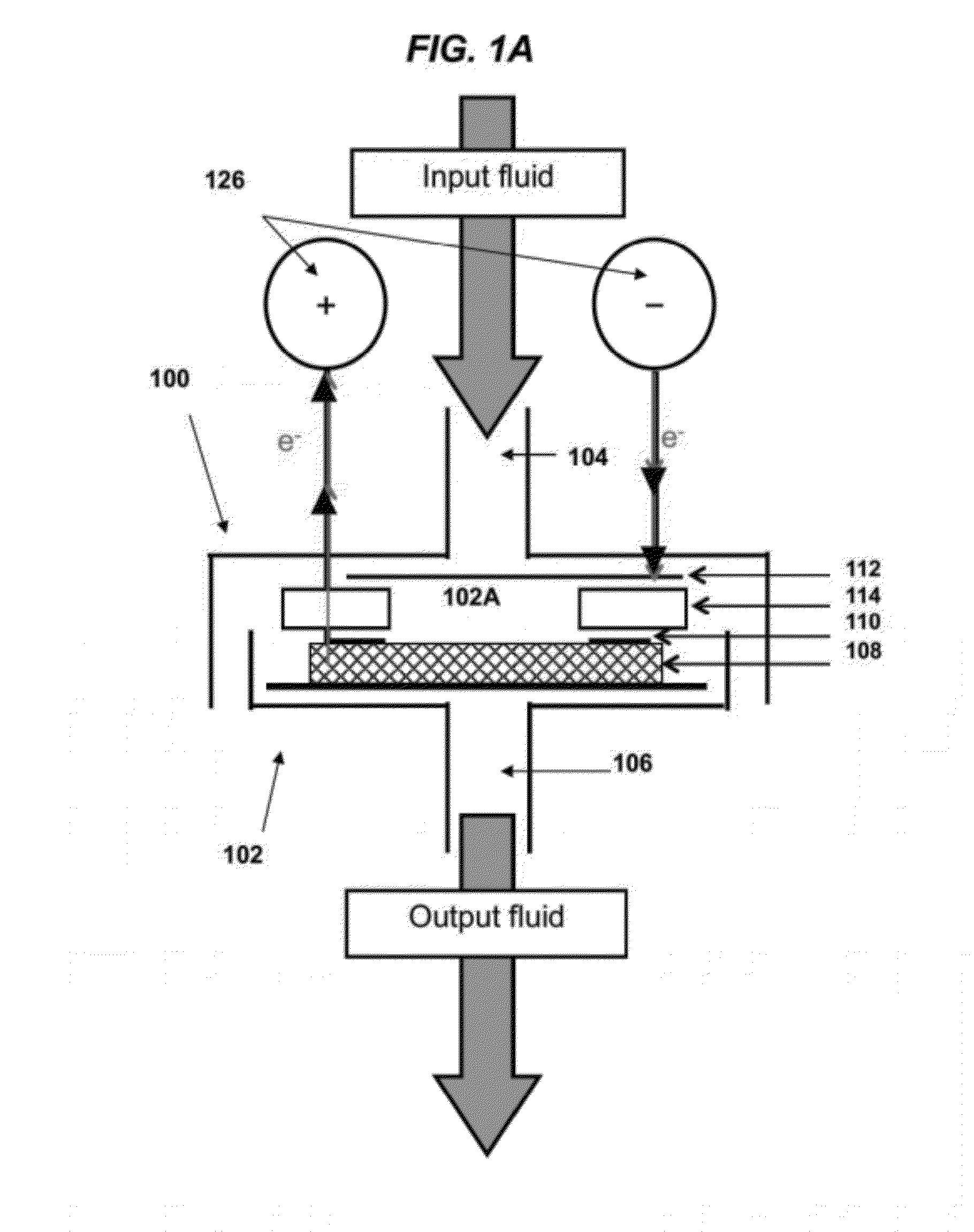

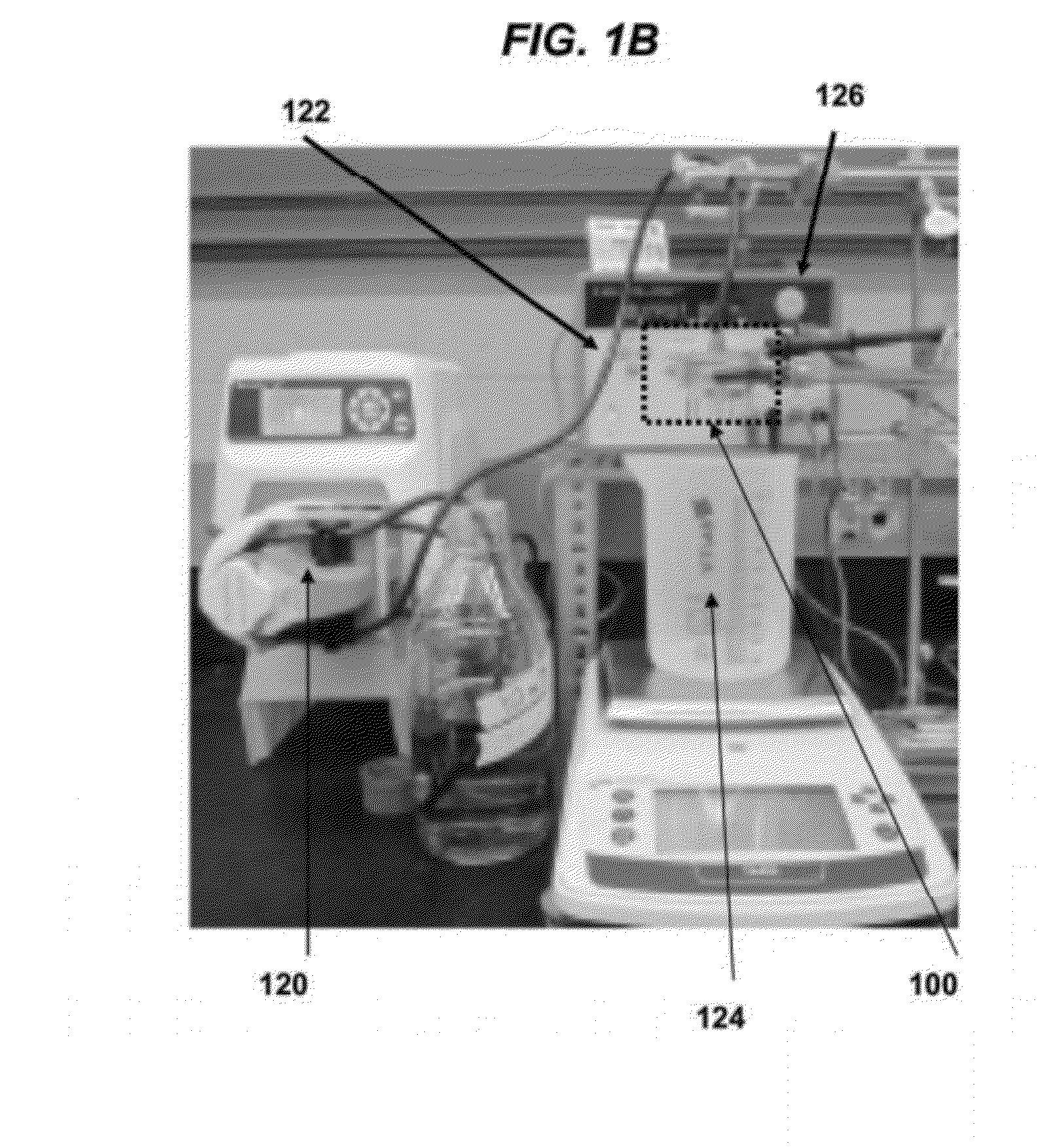

Electrochemical carbon nanotube filter and method

ActiveUS20120234694A1Minimize flow resistanceImprove stabilityMaterial nanotechnologyFrom normal temperature solutionsPorous carbonFiltration

A filtration apparatus and filtration method can be used to reduce at least one contaminant (e.g., organic molecules, ions and / or biological microorganisms) in an aqueous fluid. The filtration apparatuses and methods of the invention can separate at least one contaminant from an aqueous fluid and / or oxidize at least one contaminant. In operation, an aqueous fluid is flowed through a filtration apparatus comprising a porous carbon nanotube filter material at an applied voltage. In some embodiments, the filtration apparatus described herein can be used for dead-end filtration. In some embodiments, the filtration apparatus described herein can be used for cross-over filtration.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

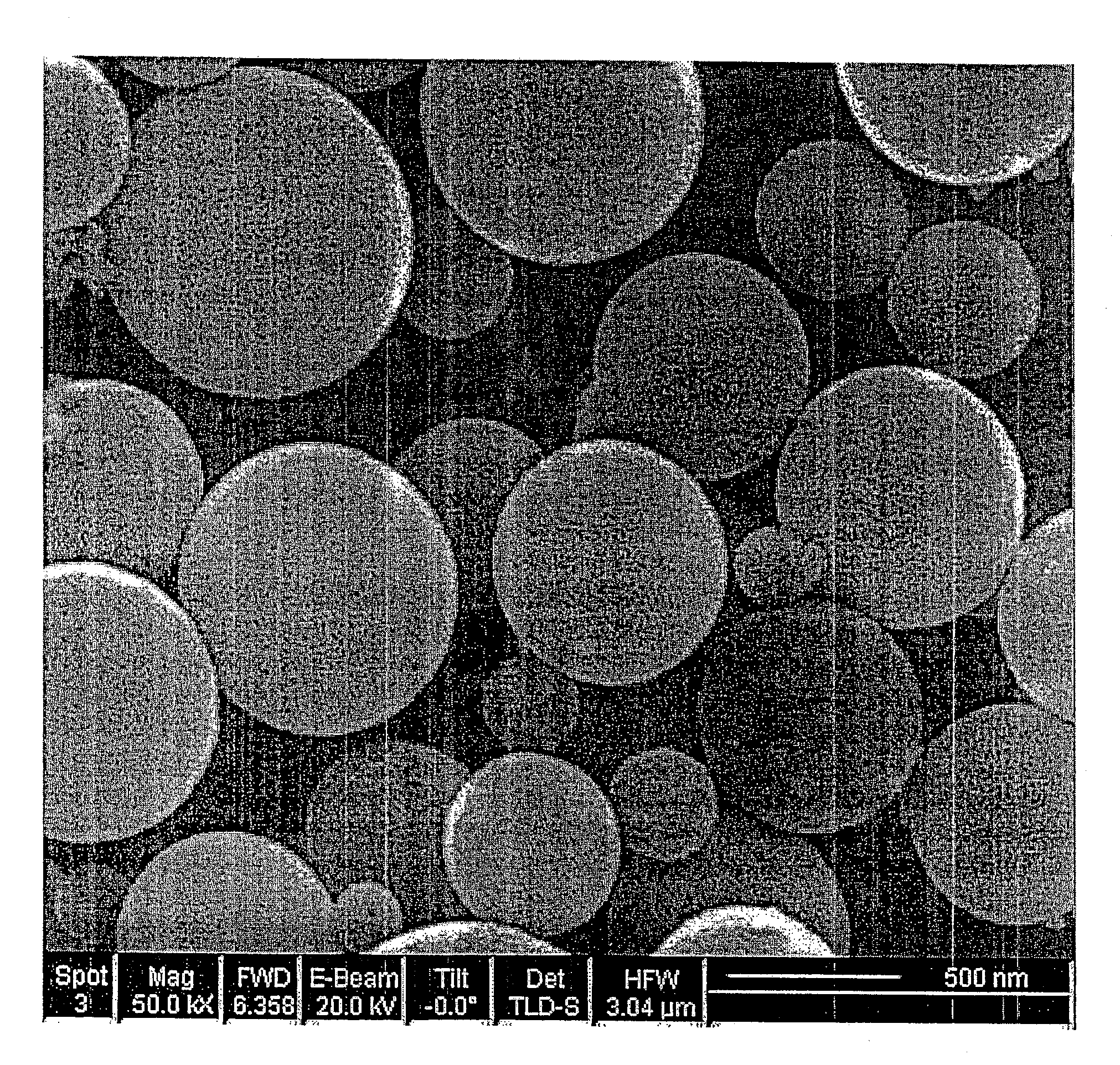

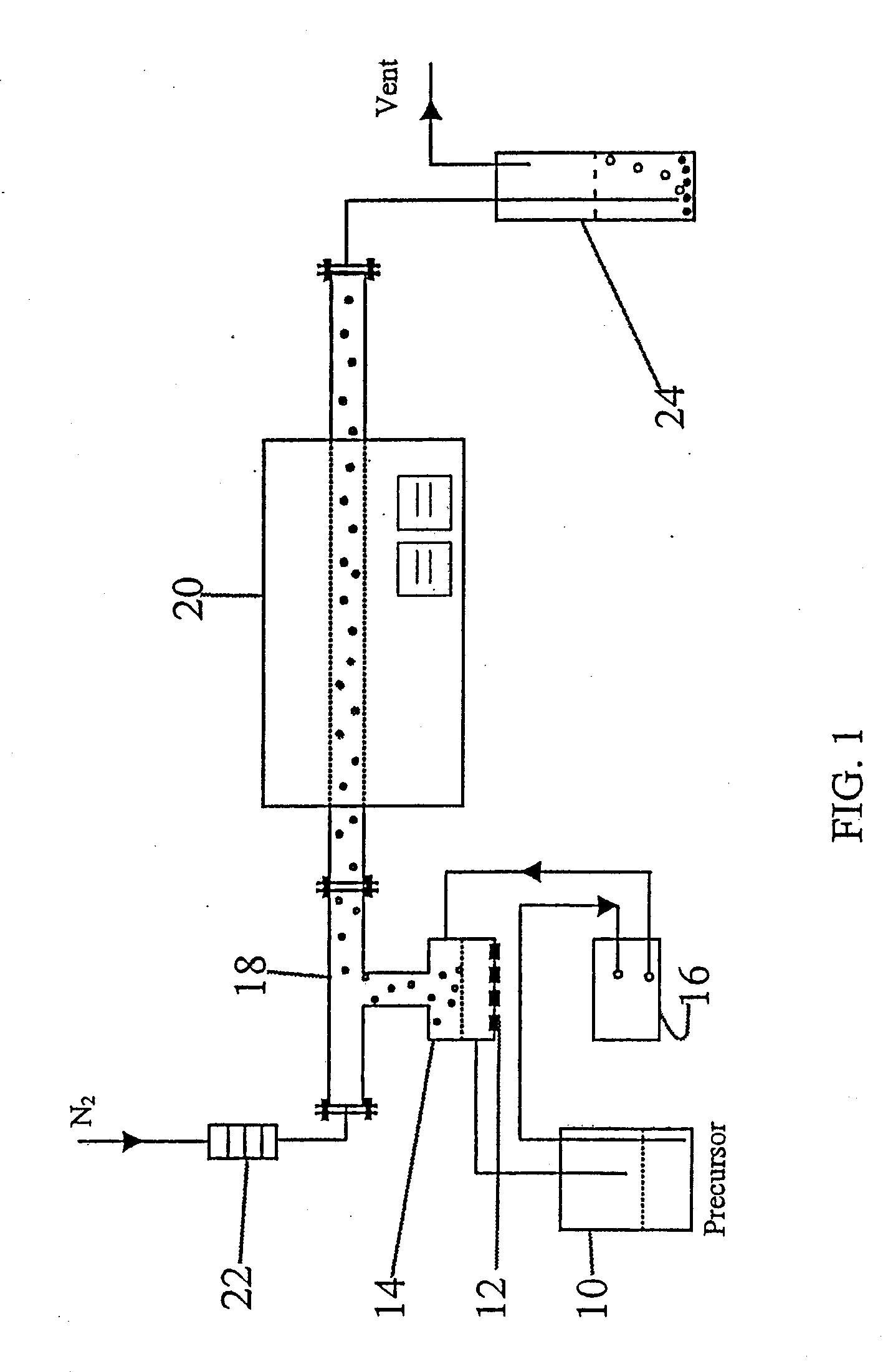

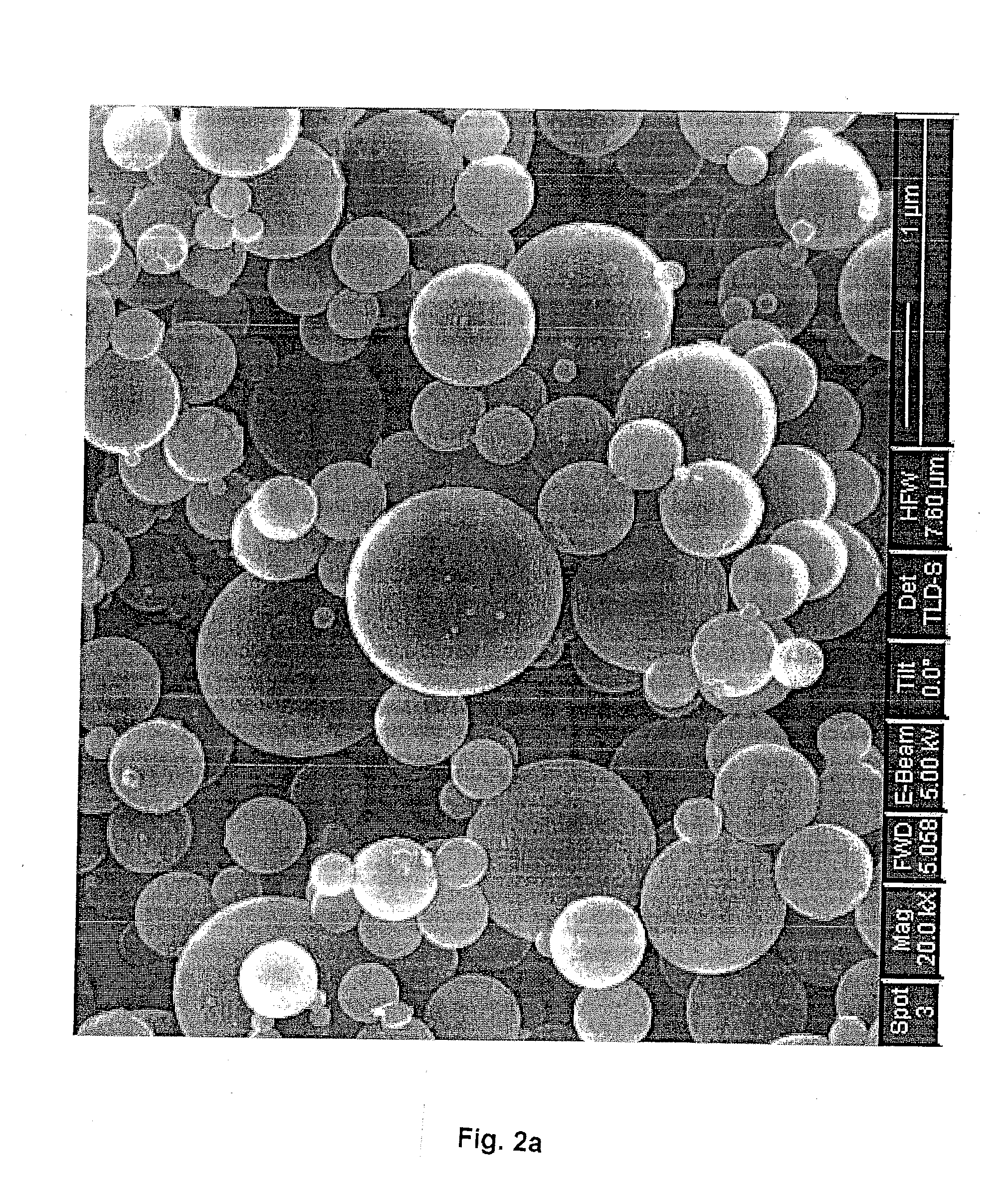

Controllable Synthesis of Porous Carbon Spheres, and Electrochemical Applications Thereof

InactiveUS20110082024A1Good dispersionExcellent ORR activityMaterial nanotechnologyReactant parameters controlColloidal silicaSmall droplet

The invention disclosed relates to porous carbon of spherical morphology having tuned porosity and to a method of making same, comprising: (a) providing a precursor solution, by combining in an aqueous solution a colloidal silica template material and a water-soluble pyrolyzable carbon source, wherein the particle size of the colloidal silica template and the colloidal silica / carbon source weight ratio are controlled, (b) atomizing the precursor solution into small droplets by ultrasonic spray pyrolysis (c) directing the droplets into a high temperature furnace operating at a temperature of 700-1200° C., under an inert gas atmosphere, where the droplets are transformed into solid spherical composite carbon / silica particles, (d) collecting the resulting composite carbon / silica particles exiting from the furnace, and (e) removing the silica from the particles, to provide substantially pure porous carbon of spherical morphology having tuned porosity defined by surface area and pore size. The porous carbon according to the invention is used as catalyst supports in PEM fuel cells, as electrodes in supercapacitors and lithium in batteries, for hydrogen storage and as earners for drug delivering.

Owner:NAT RES COUNCIL OF CANADA

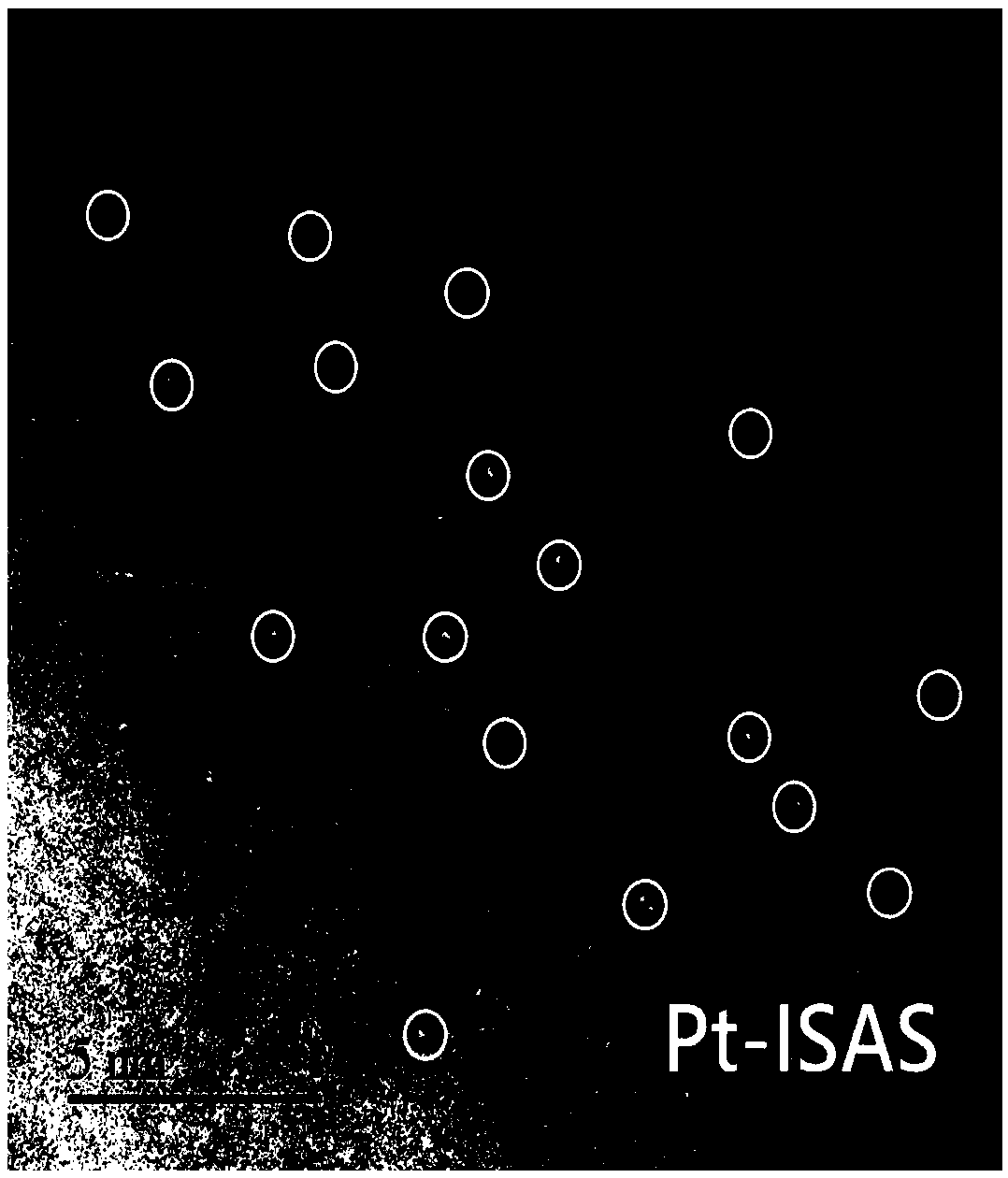

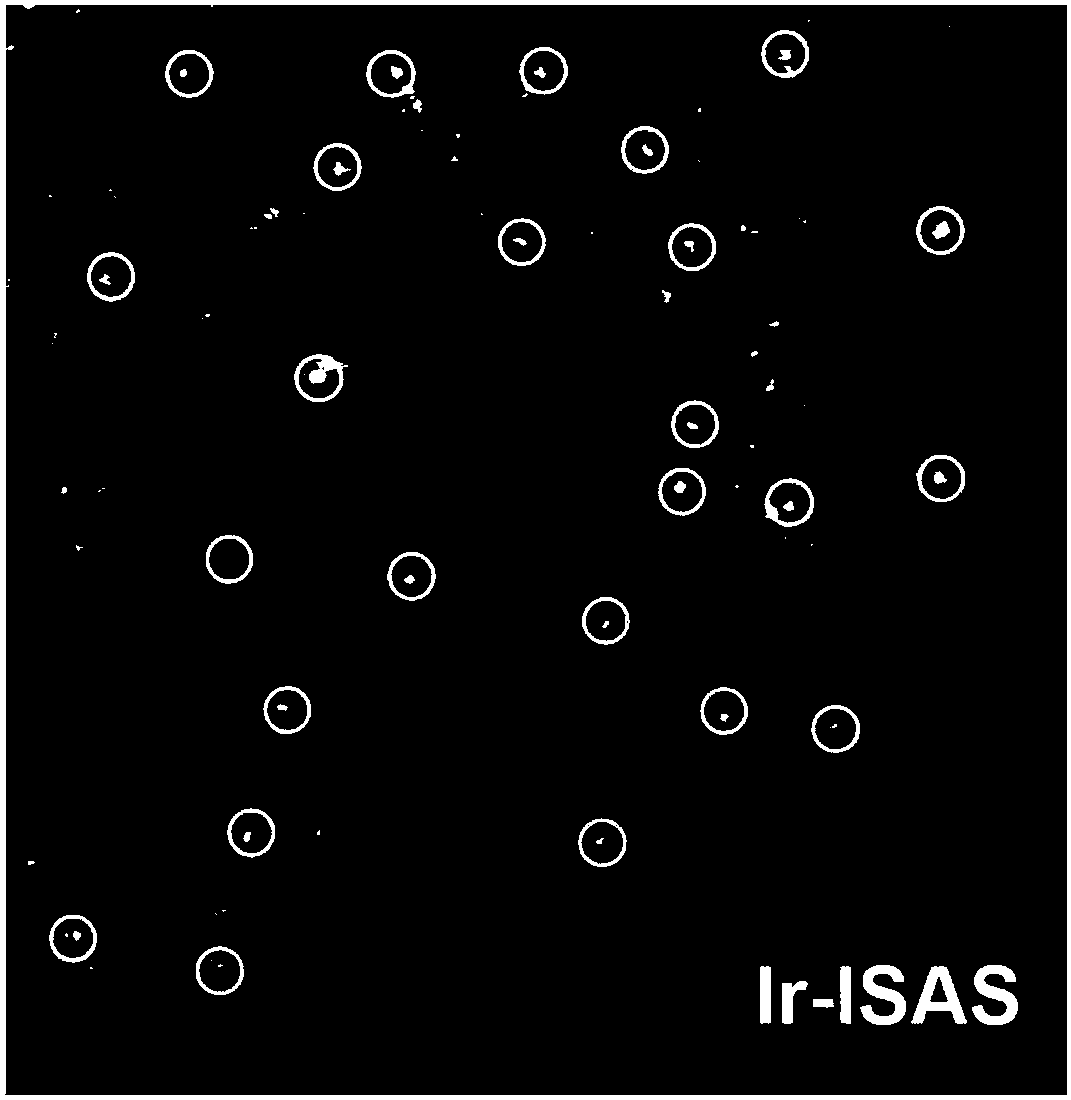

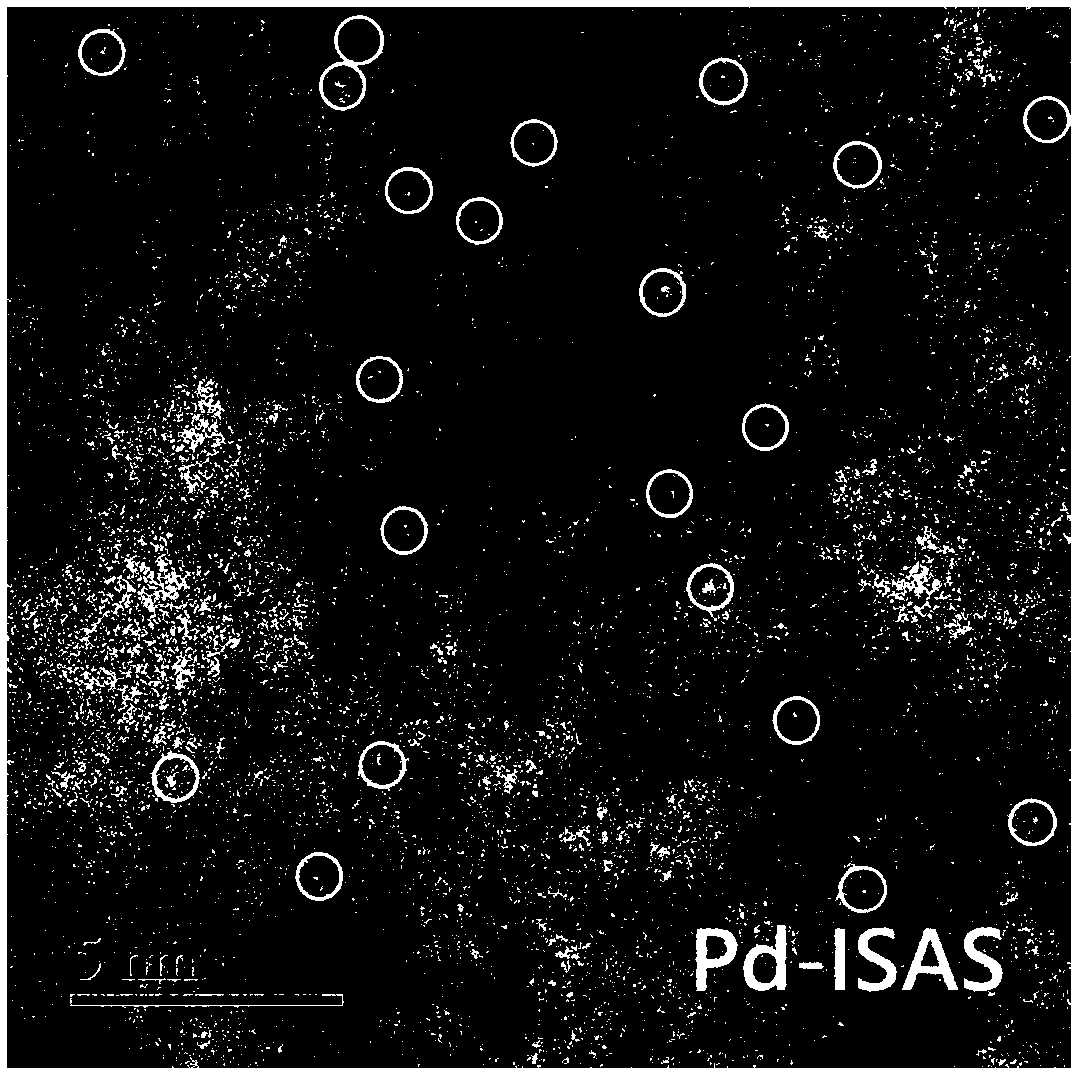

Preparation method of metal monatomic site catalyst

ActiveCN107626294ASmall particlesUniform particle size distributionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsPorous carbon

The invention provides a preparation method of a metal monatomic site catalyst. According to the synthetic strategy, a porous complex composite material coated with an acetylacetone metal salt is formed from a zinc compound and an imidazole organic ligand through coordination in a methanol solution of the acetylacetone metal salt, and then a porous carbon support doped with nonmetal heteroatomic nitrogen is formed from the imidazole organic ligand through a high-temperature pyrolytic reaction in an inert gas atmosphere, wherein metal atoms interact with surrounding nonmetal heteroatomic nitrogen and exist in the form of single atoms. The method is simple, safe, low in cost and applicable to synthesis of various noble metal and non-noble metal monatomic site catalysts, and the obtained metal monatomic site catalyst is high in metal concentration and good in heat stability, can be applied to the fields of energy, catalysis, medicine, biology and the like and has quite broad market prospect.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com