Patents

Literature

3755 results about "Nano silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

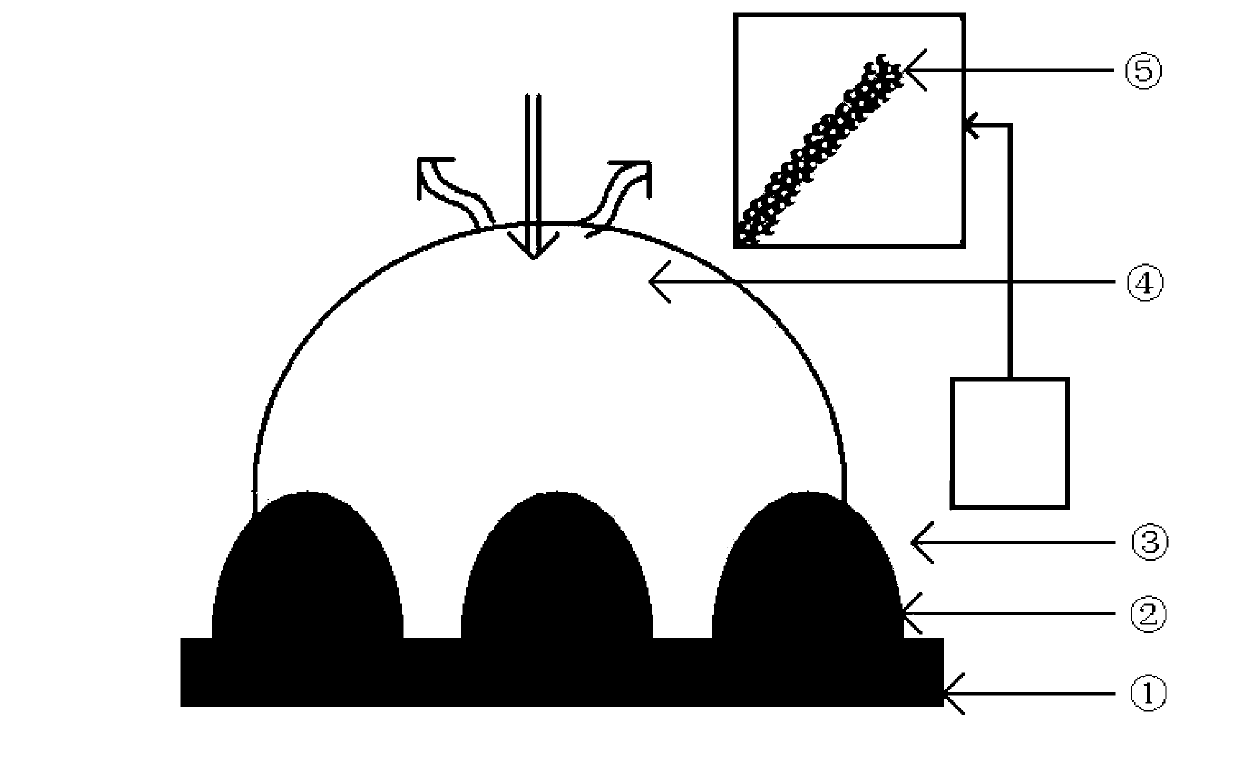

Carbon/silicon/carbon nano composite structure cathode material and preparation method thereof

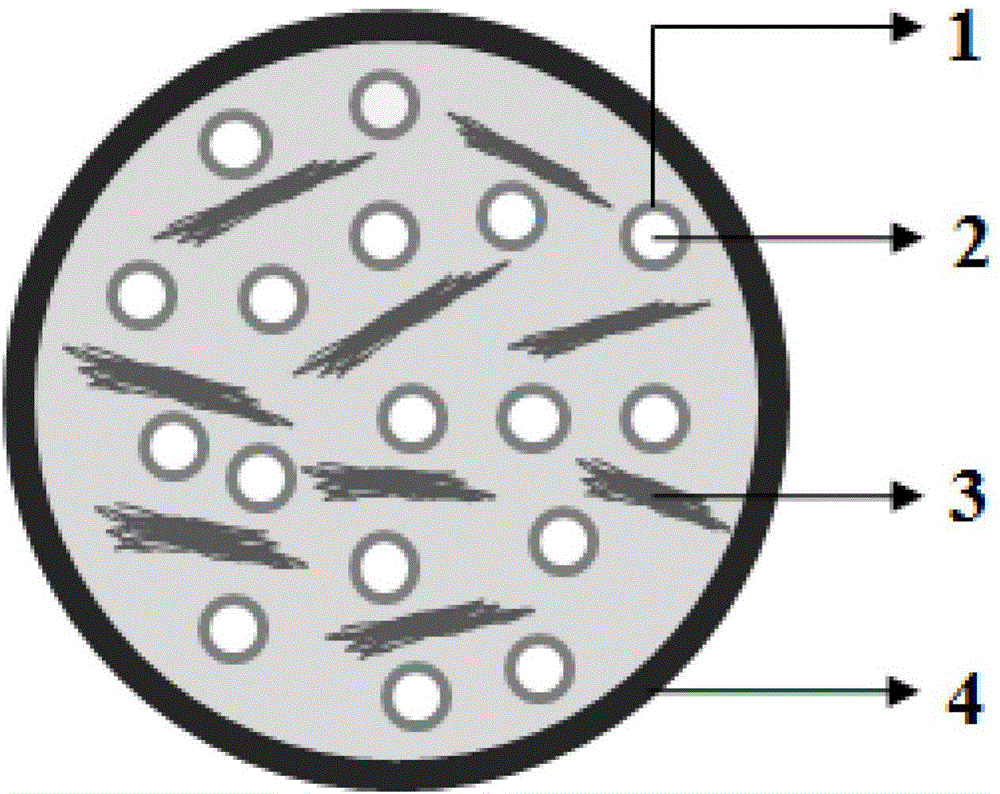

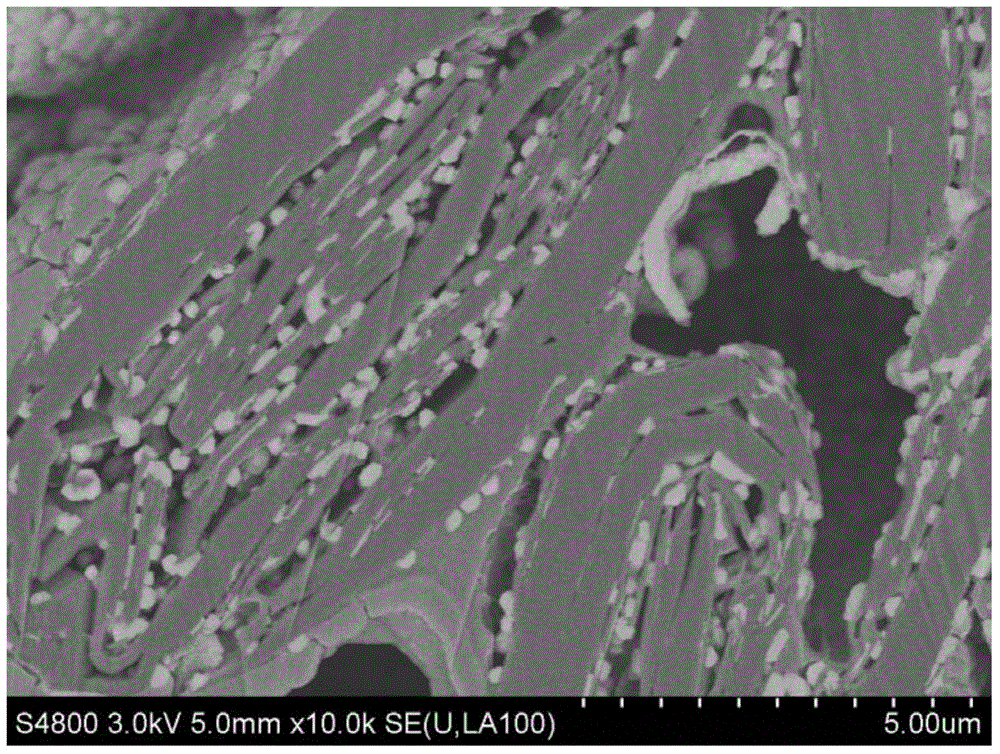

The invention discloses a carbon / silicon / carbon nano composite structure cathode material and a preparation method thereof, belonging to the technical field of electrochemical power supply technologies. The cathode material consists of a carbon-based conductive substrate, nano silicon and a nano carbon coating layer, wherein the nano silicon is uniformly distributed on the carbon-based conductive substrate; the nano carbon coating layer is arranged on the surface of the nano silicon; the carbon-based conductive substrate is porous carbon, a carbon nanotube or graphene; the nano silicon exists in the state of nanoparticles or nano films; the weight percentage of the nano silicon in the cathode material is 10-90 percent; and the thickness of the nano carbon coating layer is 0.1-10 nanometers. The preparation method comprises the following steps of: depositing nano silicon on the carbon substrate in a reaction space in oxygen-free atmosphere by adopting a chemical vapor deposition process; and coating nano carbon on the surface of the nano silicon by adopting the chemical vapor deposition process. In the obtained carbon / silicon / carbon composite cathode material, the volume change of a silicon electrode material is controlled effectively in the charging and discharging processes, the electrode structure is kept complete, the circulation volume is large, the circulation service life is long, and the electrochemical performance is high.

Owner:TSINGHUA UNIV

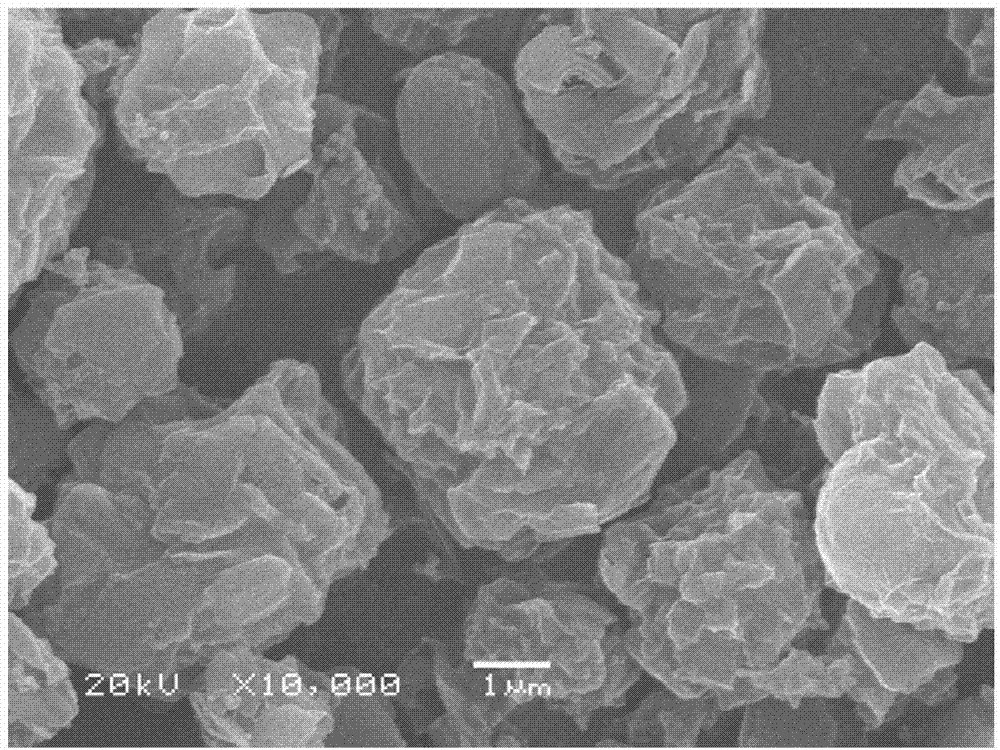

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

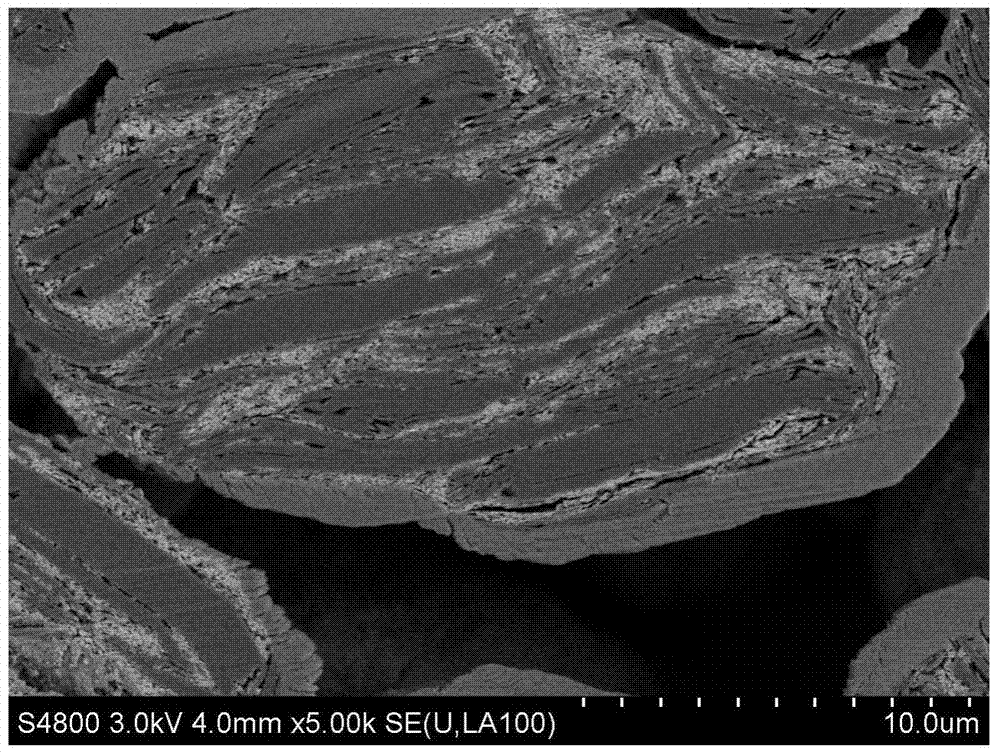

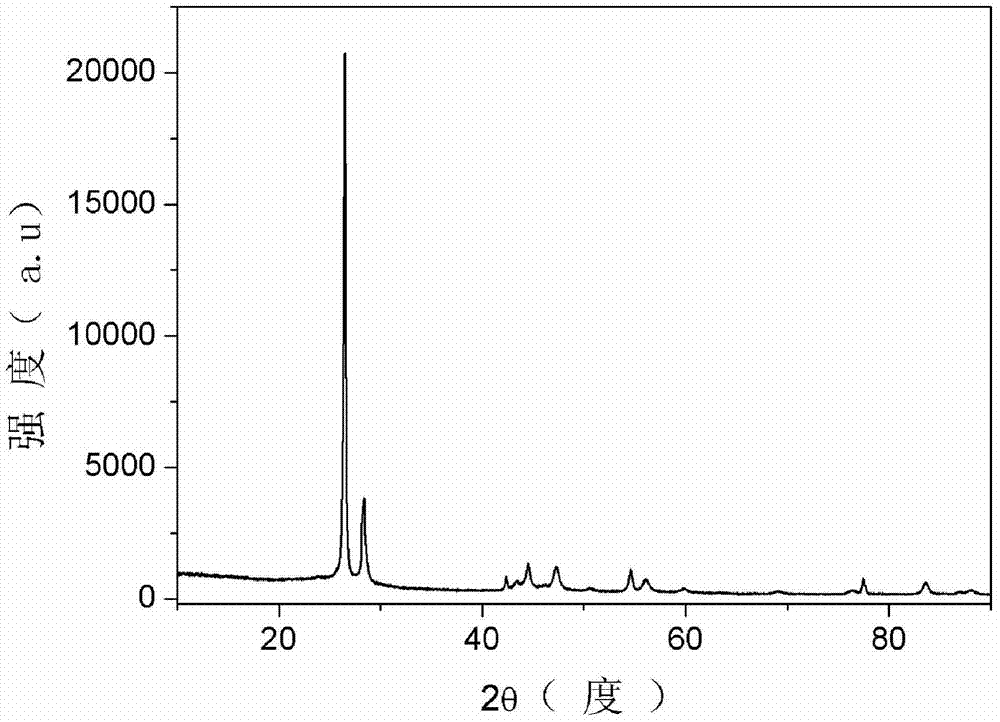

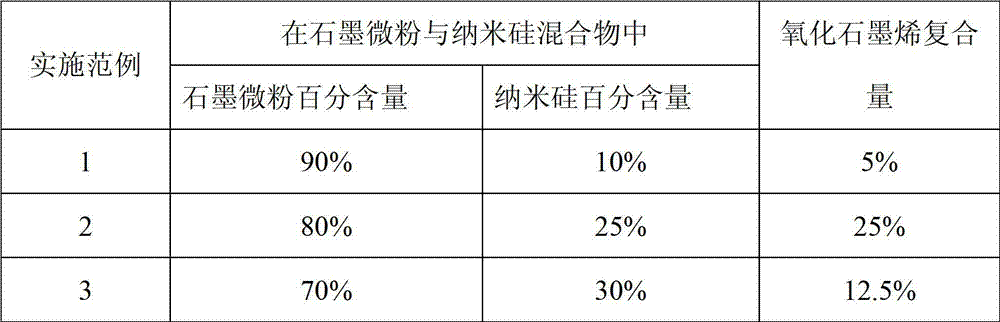

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

Graphene/silicon lithium ion battery cathode material and preparation method thereof

InactiveCN101924211AHigh specific capacityImprove cycle stabilityCell electrodesComposite filmNew energy

The invention discloses a grapheme / silicon composite material for a lithium ion battery cathode material and a preparation method thereof, belonging to the fields of electrochemistry and new energy materials. The method comprises the following steps of: using graphite as a raw material; oxidizing the graphite into oxidized graphite by adopting oxidants of concentrated sulfuric acid and potassium permanganate; then, ultrasonically stripping the oxidized graphite to prepare oxidized graphene; mixing oxidized graphene in different proportions with nano silicon powder; ultrasonically dispersing, filtering or directly drying into a cake / film; and roasting under a reduction atmosphere to prepare self-support graphene / silicon composite film materials in different proportions. Proved by electrochemistry tests, the graphene / silicon composite film material prepared by the method has higher specific capacity and cycle stability, simple preparation method and easy mass production and consequently is an ideal high-energy lithium ion battery cathode material.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing composite material of lithium ion battery cathode, and cathode and battery

ActiveCN101442124AGood lithium intercalation performanceHigh lithium intercalation abilityElectrode manufacturing processesActive material electrodesSlurrySolvent

The invention relates to a method for preparing a composite material for a cathode of a lithium ion battery, and the cathode and the battery which comprise the cathode material. The preparation method comprises: uniformly mixing silicon powder, graphite, pyrolytic carbon precursor and a solvent to prepare slurry, wherein the silicon powder comprises micro-silicon powder and nano-silicon powder, and the weight ratio of the micro-silicon powder and the nano-silicon powder is 2-20:1; and removing the solvent in the slurry, performing primary sintering under the protection of inert gas, performing primary ball grinding, performing secondary sintering under the protection of the inert gas, and performing secondary ball grinding, wherein the temperature of the secondary sintering is higher than that of the primary sintering. The battery made from the composite material for the cathode of the lithium ion battery obtained by the method has good cycling performance and charge and discharge capacity.

Owner:BYD CO LTD

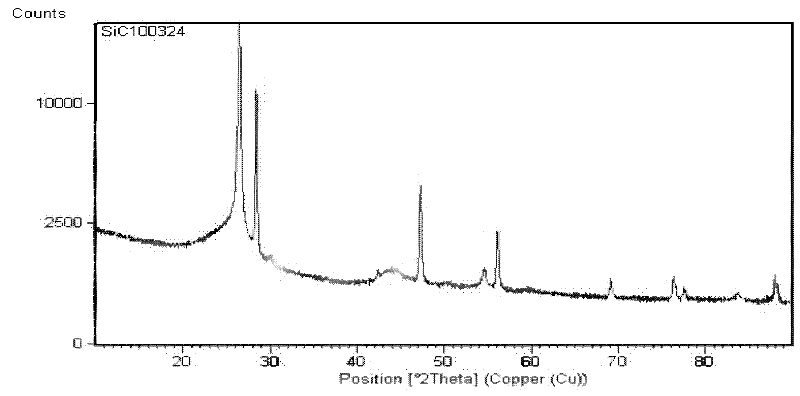

NANO silicon-carbon composite material and preparation method thereof

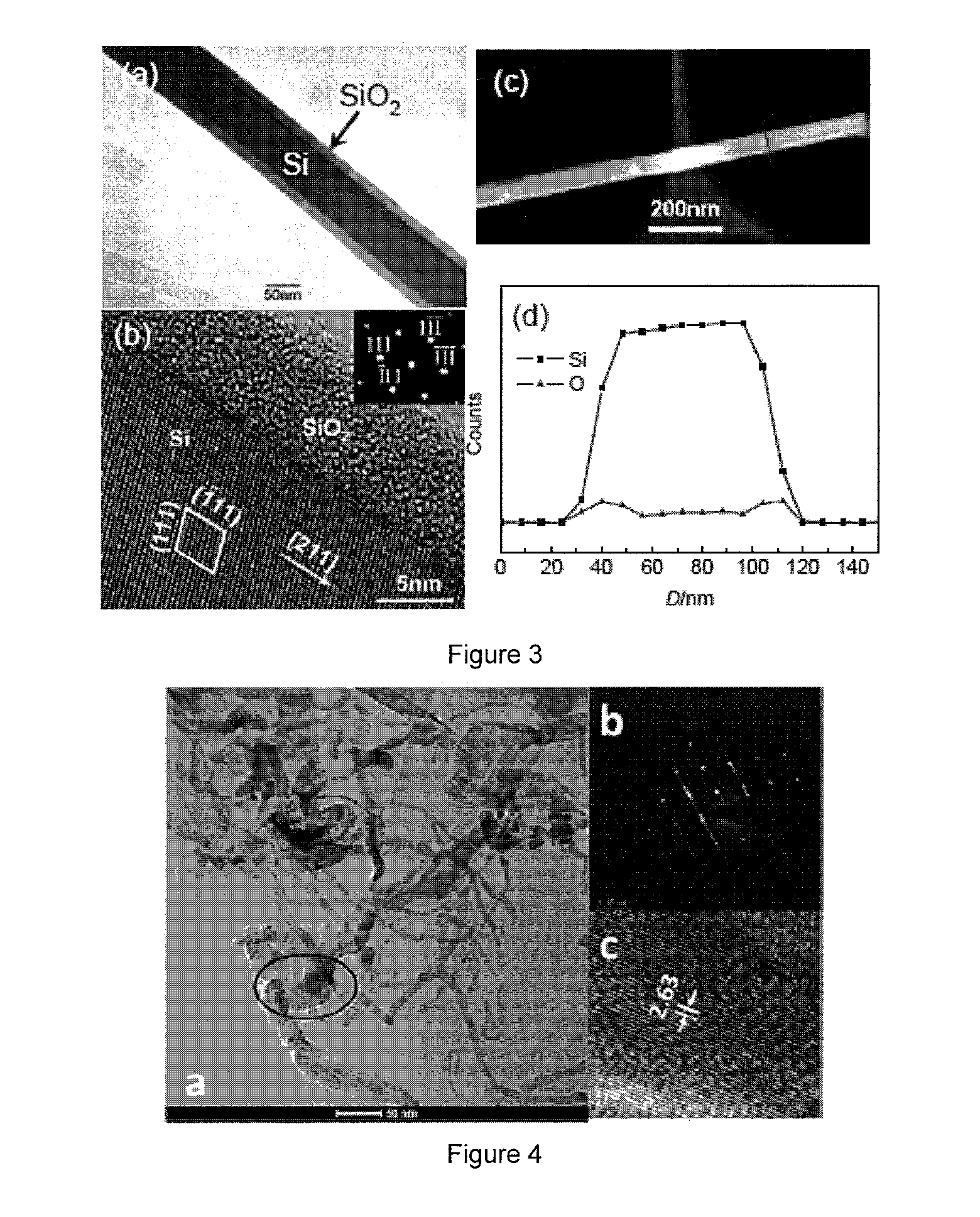

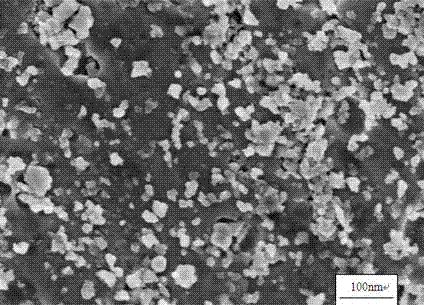

ActiveUS20140302396A1Improve cycle stabilityShort production processMaterial nanotechnologyElectrolysis componentsCarbon compositesSilicon dioxide

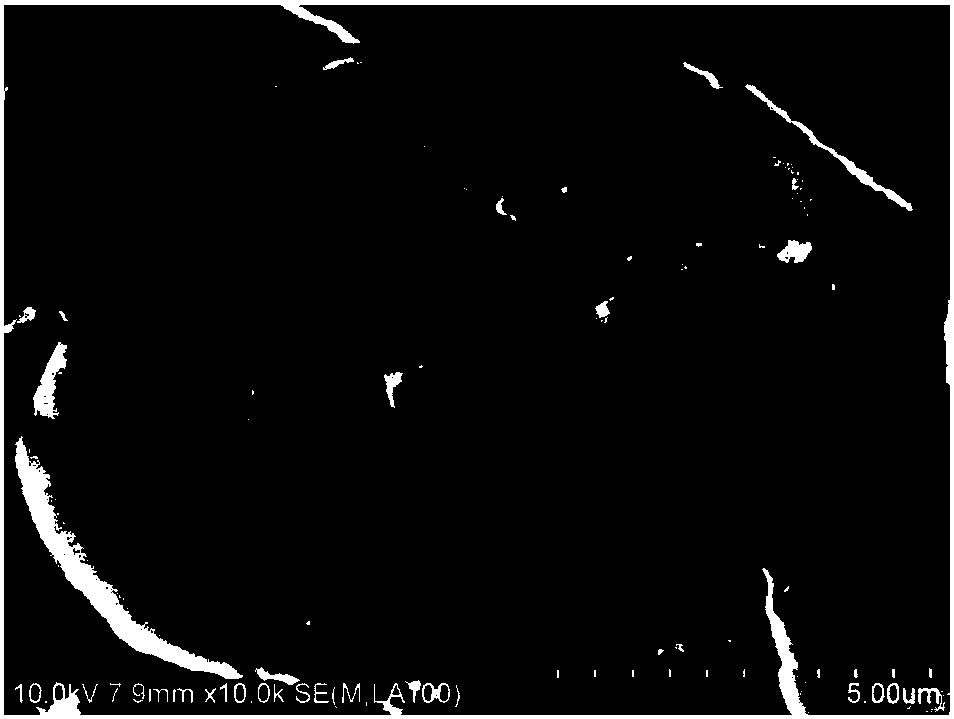

The invention relates to a nano silicon-carbon composite negative material for lithium ion batteries and a preparation method thereof. A porous electrode composed of silica and carbon is taken as a raw material, and a nano silicon-carbon composite material of carbon-loaded nano silicon is formed by a molten salt electrolysis method in a manner of silica in-situ electrochemical reduction. Silicon and carbon of the material are connected by nano silicon carbide, and are metallurgical-grade combination, so that the electrochemical cycle stability of the nano silicon-carbon composite material is improved. The preparation method of the nano silicon-carbon composite material provided by the invention comprises the following steps: compounding a porous block composed of carbon and silica powder with a conductive cathode collector as a cathode; using graphite or an inert anode as an anode, and putting the cathode and anode into CaCl2 electrolyte or mixed salt melt electrolyte containing CaCl2 to form an electrolytic cell; applying voltage between the cathode and the anode; controlling the electrolytic voltage, the electrolytic current density and the electrolytic quantity, so that silica in the porous block is deoxidized into nano silicon by electrolytic reduction, and the nano silicon-carbon composite material for lithium ion batteries is prepared at the cathode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

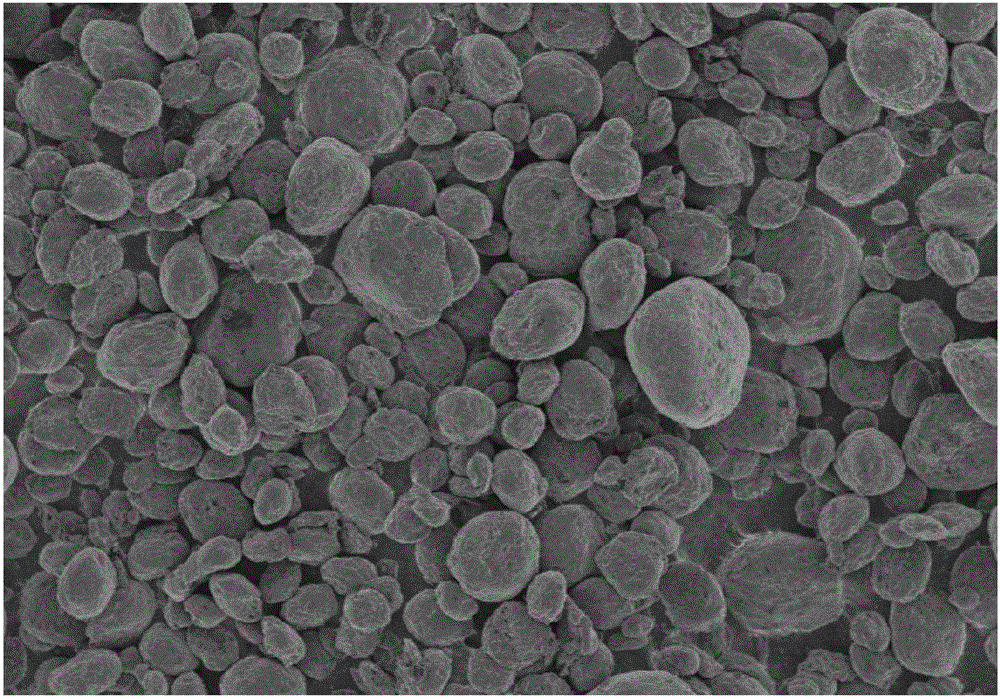

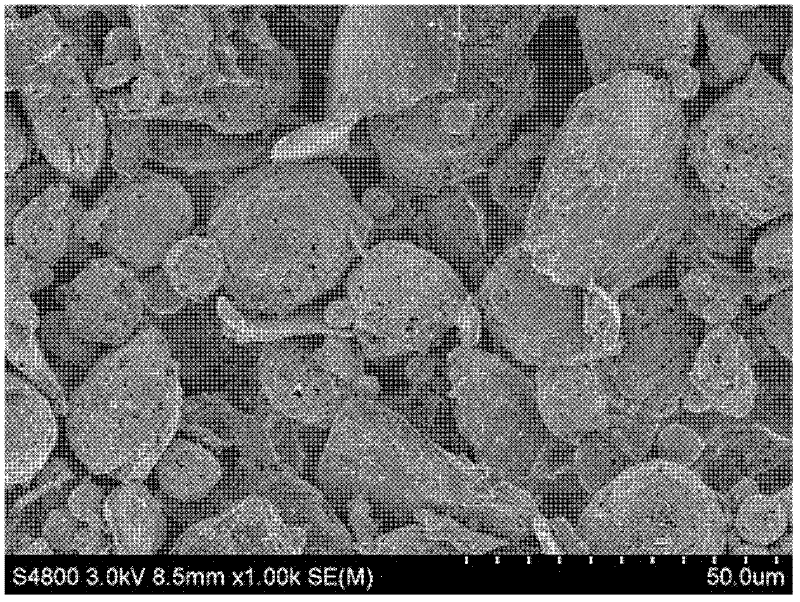

Preparation method of nano silicon carbide reinforced aluminum-based composite material

InactiveCN103045914AAvoid reunionEvenly distributedIncreasing energy efficiencyNano siliconHigh energy

The invention discloses a preparation method of laser forming nano particle reinforced aluminum-based composite material, belonging to the technical field of particle reinforced aluminum-based composite materials. The method comprises the steps of: (1) selecting SiC powder with purity of more than 99.9% and granularity of 40-60 nanometers, and AlSi10Mg powder with purity of more than 99.9% and granularity of 15-30 micrometers; (2) mixing the powders, wherein the weight of the SiC powder is 3%-10% of the total weight of the mixed powder; (3) putting the mixed powder into a planetary high-energy ball mill for milling; (4) taking the milled powder for SLM forming; and (5) repeating the step (4) until a three-dimensional block sample is completed. According to the method provided by the invention, the aluminum-based composite material with uniform microscopic structures can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Silicon-carbon composite material, preparation thereof, battery cathode and lithium ionic cell

ActiveCN101439972AExcellent ElectricalImprove mechanical propertiesElectrode manufacturing processesCarbon compositesLithium

The invention relates to a silicon-carbon composite material, which contains nano-silicon / carbon nanotube composite particles and amorphous carbon, wherein the amorphous carbon is coated on the surfaces of the composite particles. A method for preparing the material comprises the following steps: dispersing the nano-silicon and the carbon nanotubes in a dispersant, and removing the dispersant to obtain the nano-silicon / carbon nanotube composite particles; and contacting the nano-silicon / carbon nanotube composite particles with an amorphous carbon precursor solution, and removing a solvent to carbonize the amorphous carbon precursor. The invention also provides a negative pole of a lithium ion cell made from the composite material. The method for preparing the composite material is simple,the process is easy to control, and a cell made of the negative pole made from the composite material has a lower first irreversible specific capacity, higher specific capacity and excellent cycling performance.

Owner:BYD CO LTD

Preparation and application of lithium battery silicon-carbon composite material taking synthetic graphite as carrier

ActiveCN103346305AImprove integrity and compactnessSmall apertureCell electrodesCarbon sourceCarbon composites

The invention provides preparation and application of a lithium battery silicon-carbon composite material taking synthetic graphite as a carrier. The preparation method comprises the following steps of: dissolving nanometer silicon and synthetic graphite in a dispersant to obtain a uniform dispersion liquid, adding an organic carbon source, stirring uniformly to obtain a mixed liquid, feeding the mixed liquid into a closed circulation spray dryer to prepare composite precursor powder, pre-sintering for 3-10 hours at the temperature of 300-700 DEG C to obtain a silicon-carbon composite material subjected to primary carbon cladding; and further dissolving the silicon-carbon composite material subjected to primary carbon cladding with the organic carbon source in a dispersant, stirring to obtain a uniform mixed liquid, feeding the uniform mixed liquid into a second closed circulation spray dryer to prepare composite powder, and heating the powder for 6-18 hours at the temperature of 700-1000 DEG C, so as to obtain the lithium battery silicon-carbon composite material taking synthetic graphite as a carrier. The lithium battery silicon-carbon composite material prepared by the invention shows such excellent electrochemical properties as high first charge-discharge efficiency, high specific capacity and good cycle performance after being applied to a lithium battery.

Owner:中国有色桂林矿产地质研究院有限公司

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

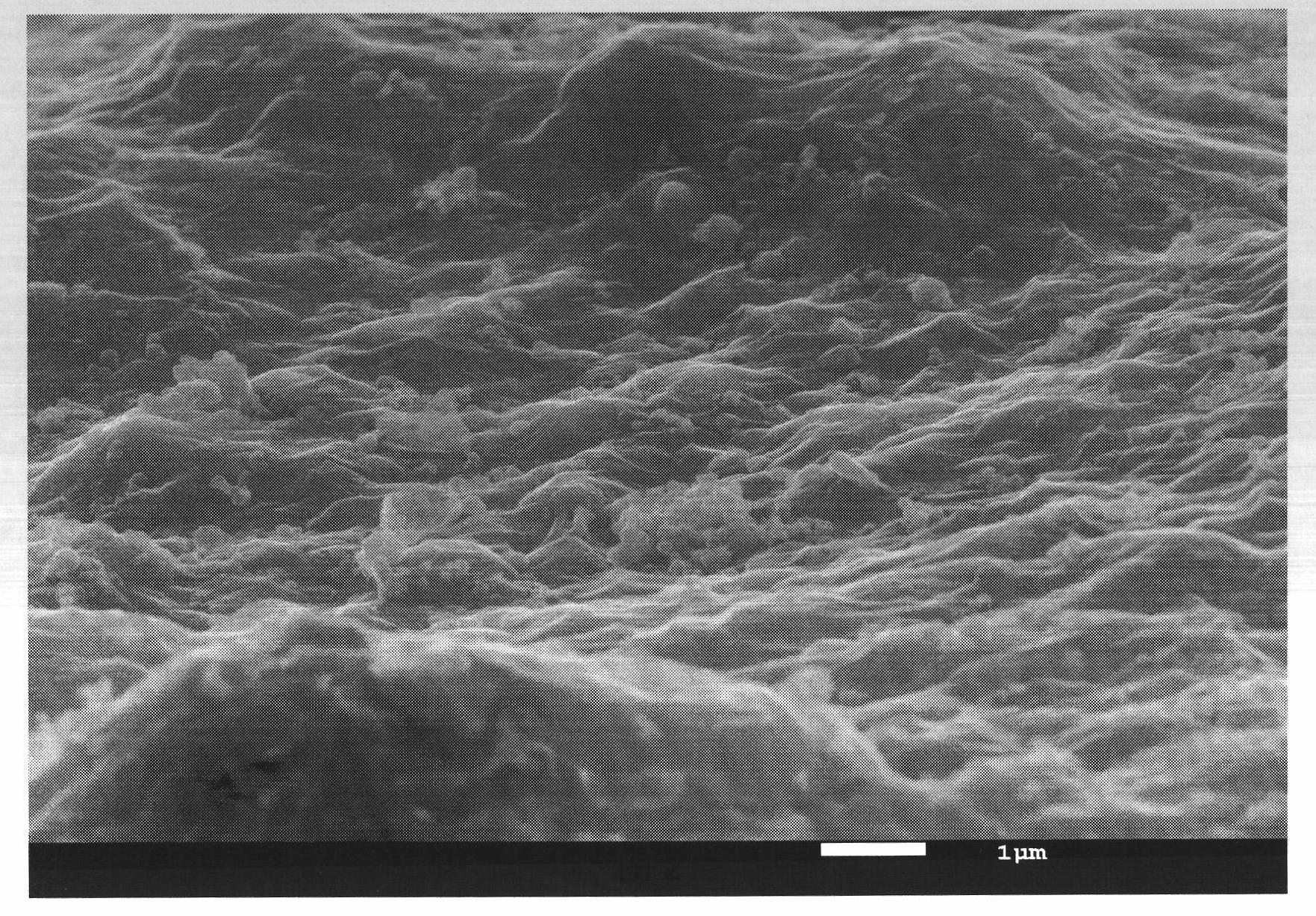

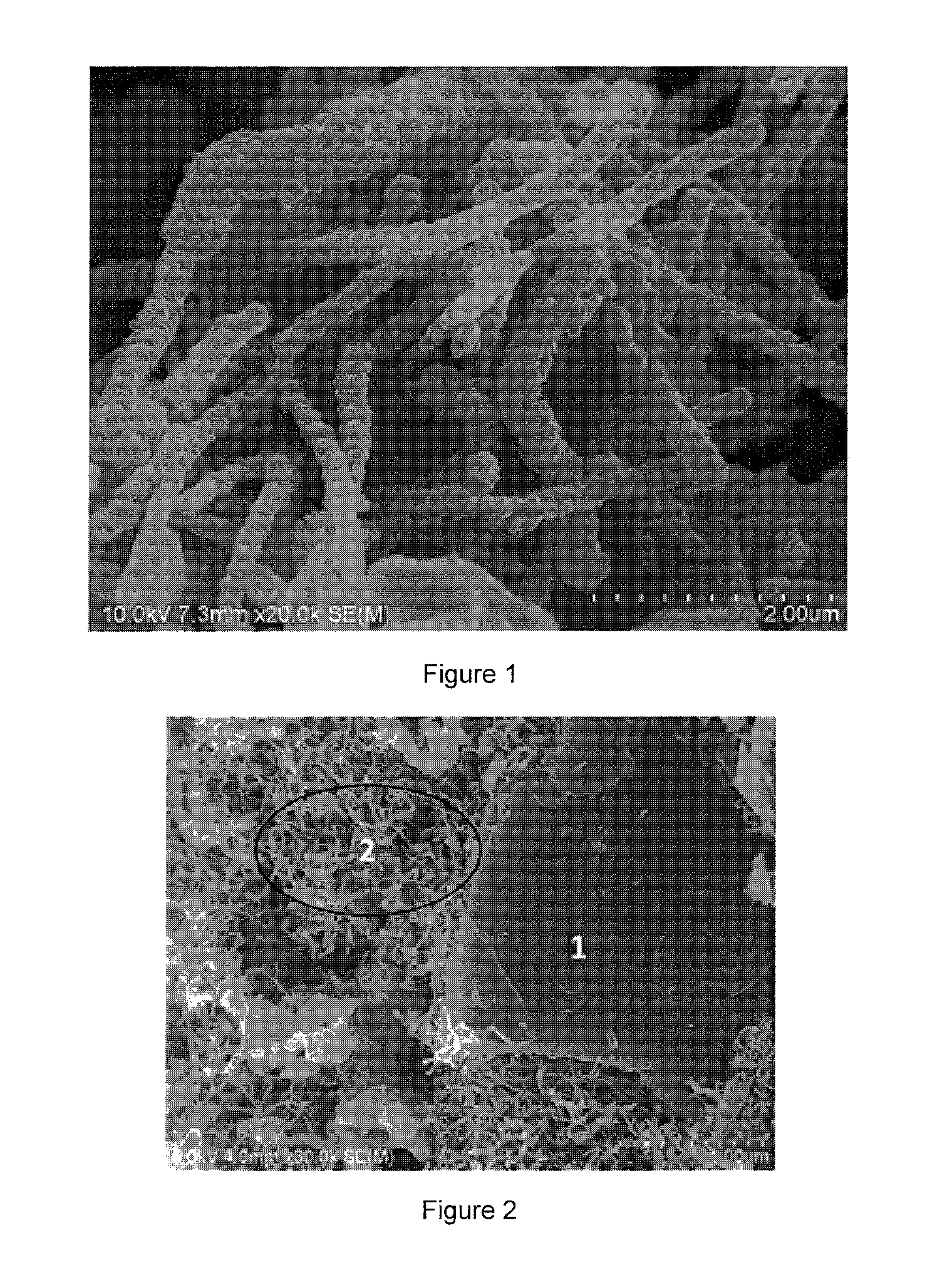

ActiveCN103305965AImprove lithium storage performanceImprove electrochemical performanceCell electrodesFilament/thread formingCarbon compositesCarbon fibers

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein the nano-silicon particles are dispersed in the carbon nanofiber matrix; and nano pores and micropores communicated with the nano pores are distributed in the carbon nanofiber matrix. The method comprises the steps of dissolving the nano-Si particles and polyacrylonitrile (PAN) in a solvent to prepare a mixed spinning solution, then carrying out electrostatic spinning on the mixed spinning solution, and curing spinning trickles in a coagulating bath to obtain a porous PAN-Si composite nanofiber; and then carrying out oxidation and carbonization treatment in sequence to obtain the silicon-carbon composite material with a nano micropore structure. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

Method for preparing nano silicon/polyacrylate composite emulsion

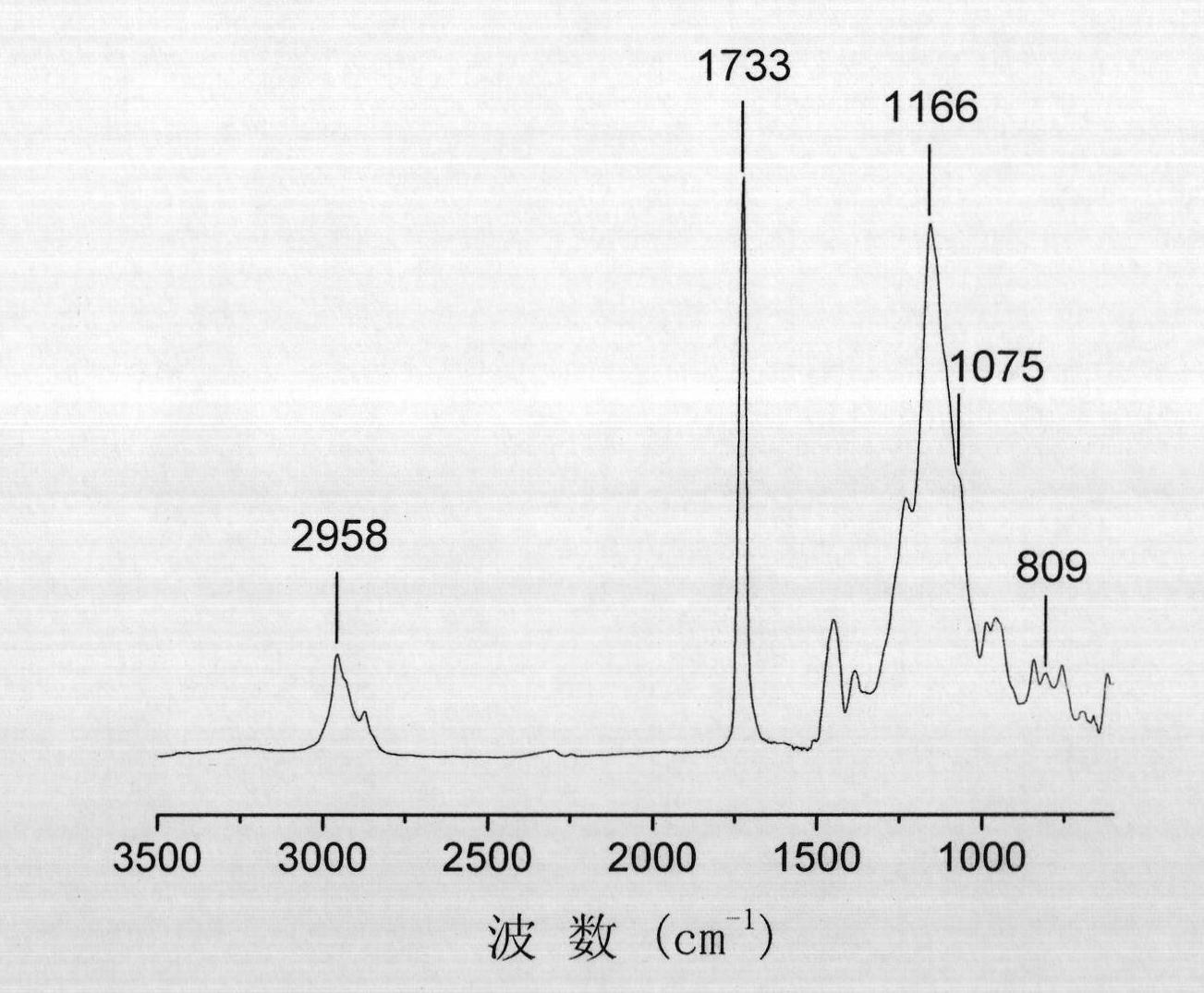

InactiveCN102030873AAvoid the problem of "secondary reunion"Good dispersionCoatingsSilanesCombined method

The invention discloses a method for preparing nano silicon / polyacrylate composite emulsion. The method comprises the following steps of: adding the adding hydrochloric solution and an emulsifier into de-ionized water, mixing the mixed solution and tetraethoxysilane, a silane coupling agent and acrylate monomers and pre-emulsifying to obtain modified nano silicon pre-emulsion; heating, adding an initiator, and preparing the nano silicon / polyacrylate composite emulsion by adopting an in-situ emulsion polymerization and seed emulsion polymerization combined method. The method has a simple process, solves the problem of 'secondary aggregation' of the traditional nano silicon during emulsion polymerization and effectively guarantees the stable proceeding of a polymerization reaction, the prepared nano silicon / polyacrylate composite emulsion has high stability, and the film of the nano silicon / polyacrylate composite emulsion has high heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

Silicon carbon composite negative electrode material for lithium ion battery as well as preparation method and applications of material

ActiveCN102903896AImprove securityImprove cycle performanceCell electrodesCarbon compositesElectrical battery

The invention is applicable to the field of novel materials, and provides a silicon carbon composite negative electrode material for a lithium ion battery, as well as a preparation method and applications of the material. The negative electrode material is of a nuclear-shell-type composite structure, and consists of nano silicon in the core, amorphous carbon at the middle layer and a one-dimensional nano carbon material at the outermost layer, wherein the amorphous carbon at the middle layer forms an elastic loose surface structure, and thus the circulating performance and multiplying performance of silicon are improved; a network structure built by the one-dimensional nano carbon material at the outermost layer not only plays a role in buffering mechanical stress, but also provides a rapid electric conducting channel for active silicon particles, and improves the circulating performance and multiplying performance of silicon further; and meanwhile, a three-dimensional electric-conducting heat-conducting network formed by the one-dimensional nano carbon material can conduct heat generated by a battery during the discharging process to the space around, and the safety performance of the battery is improved. The preparation method of the silicon carbon composite negative electrode material for the lithium ion battery is simple and feasible in process, environment-friendly and energy-saving, low in cost, and easy for industrialization.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Method for producing lithium cell silicon carbon negative pole material and produced silicon carbon negative pole material

InactiveCN101244814ASmall granularityUniform particle size distributionCell electrodesGraphiteNanometre

The invention discloses a method used to prepare silicon and carbon cathode material for lithium battery, which mixes and then carbonizes bitumastic solution, NM silica flour and spherical graphite. The invention also discloses a silicon and carbon cathode material prepared with the method. The method of the invention can effectively prolong the decay rate of the silicon and carbon cathode material and improve the cycle performance of the silicon and carbon cathode material.

Owner:SHENZHEN BAK BATTERY CO LTD

Preparation method of active radical with surface-enhanced Raman scattering (SERS) effect

InactiveCN102759520AQuick checkIncrease surface areaRaman scatteringChemical vapor depositionCadmium Cation

The invention provides a preparation method of an active radical with a surface-enhanced Raman scattering (SERS) effect, belongs to the technical field of spectrum detection, and relates to the preparation technology of the SERS active radical, which is rapid, has high sensitivity and performs a low trace detection function. The preparation method is characterized in that firstly, a nano porous silicon columnar array with a large specific surface area is prepared by utilizing a hydrothermal etching technology; afterwards, a nanowire structure of an II-VI group compound semiconductor (such as zinc oxide, titanium dioxide, cadmium sulfide, cadmium selenide, cadmium telluride, and the like) by utilizing a chemical vapor deposition method; and finally, nano particles of precious metal (such as gold, silver, copper and the like) are finally prepared on the nanowire structure by using a chemical reduction method, so as to obtain an active radical material. The preparation method has a wide application prospect in the aspects of clinical biomolecular fast recognition, trace chemical substance detection, biological sample analysis, and the like. The preparation method has the advantages that the preparation process of each material is simple, the condition is mild and the repetition rate reaches 100 percent.

Owner:BEIJING UNIV OF CHEM TECH

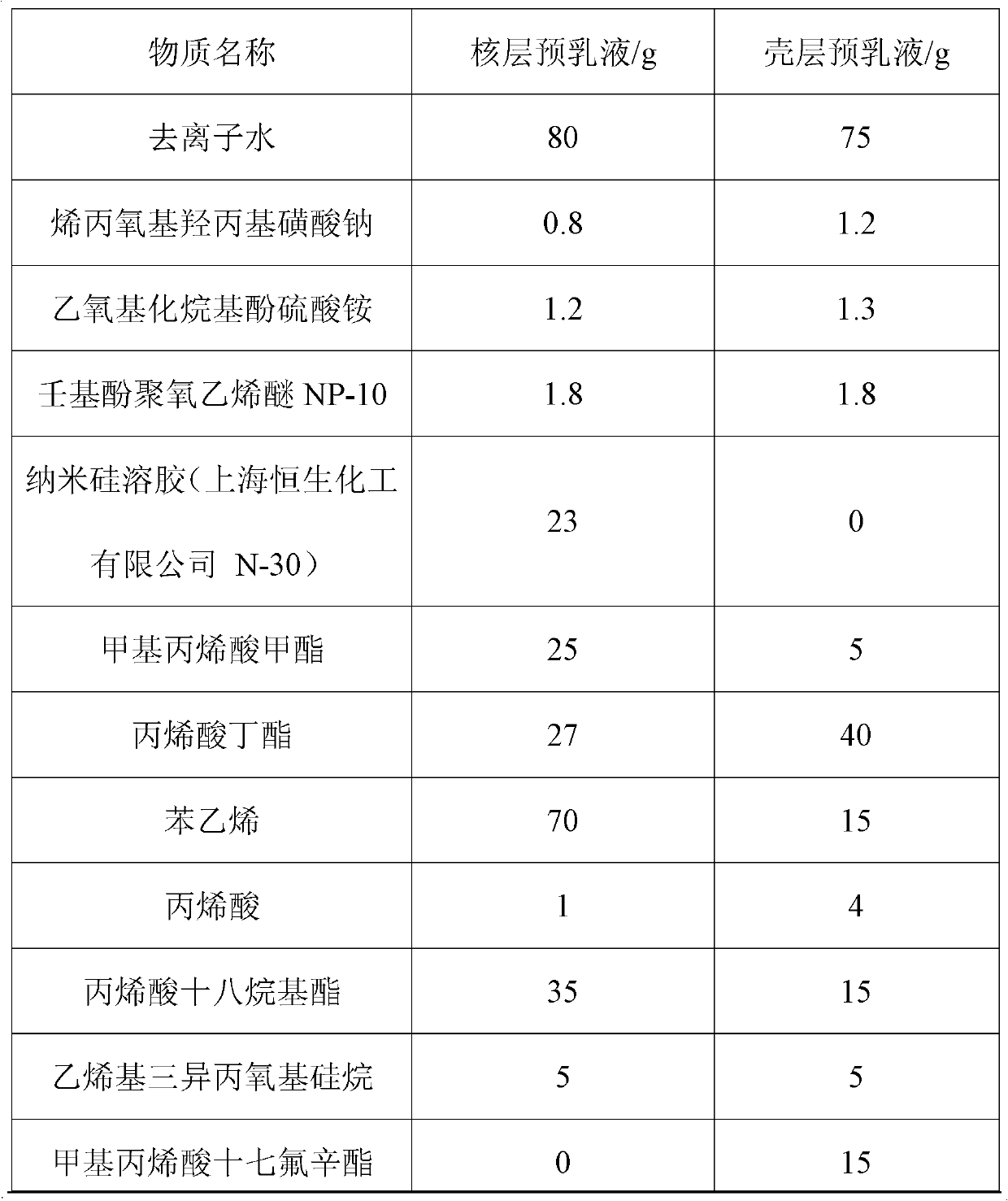

Fluorine silicon-modified acrylic ester emulsion and preparation method thereof

ActiveCN102585073ALow costImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesPolymer scienceSilicon oxide

The invention discloses a fluorine silicon-modified acrylic ester emulsion and a preparation method thereof. The fluorine silicon-modified acrylic ester emulsion is a shell-core emulsion mainly prepared from a fluorine monomer, vinyl triisopropoxysilane, nano silica sol, a vinyl monomer, a long carbon chain monomer, an emulsifier, a pH buffer, an initiator, deionized water and the like. The fluorine monomer is delayed to be dripped during polymerization, so that the fluorine element is enriched on the surfaces of emulsion particles, the hydrophobic and oleophobic properties of fluorine elusion is given full play to, the use of the fluorine monomer is reduced, and the cost is reduced. The composition of inorganic silicon oxide particles and an organic polymer keeps the good film forming property of the polymer and has the weather resistance, high hardness and other characteristics of the inorganic matter, so as to improve the stain resistance of a varnish film.

Owner:SUN YAT SEN UNIV +1

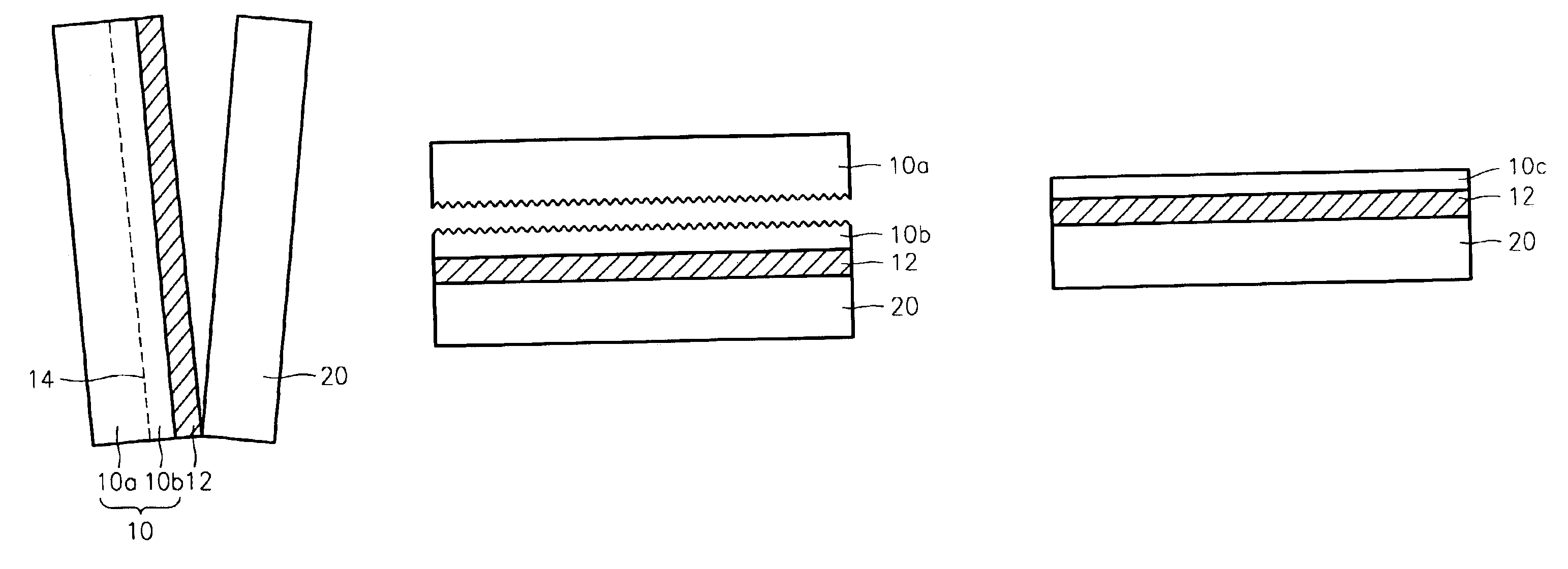

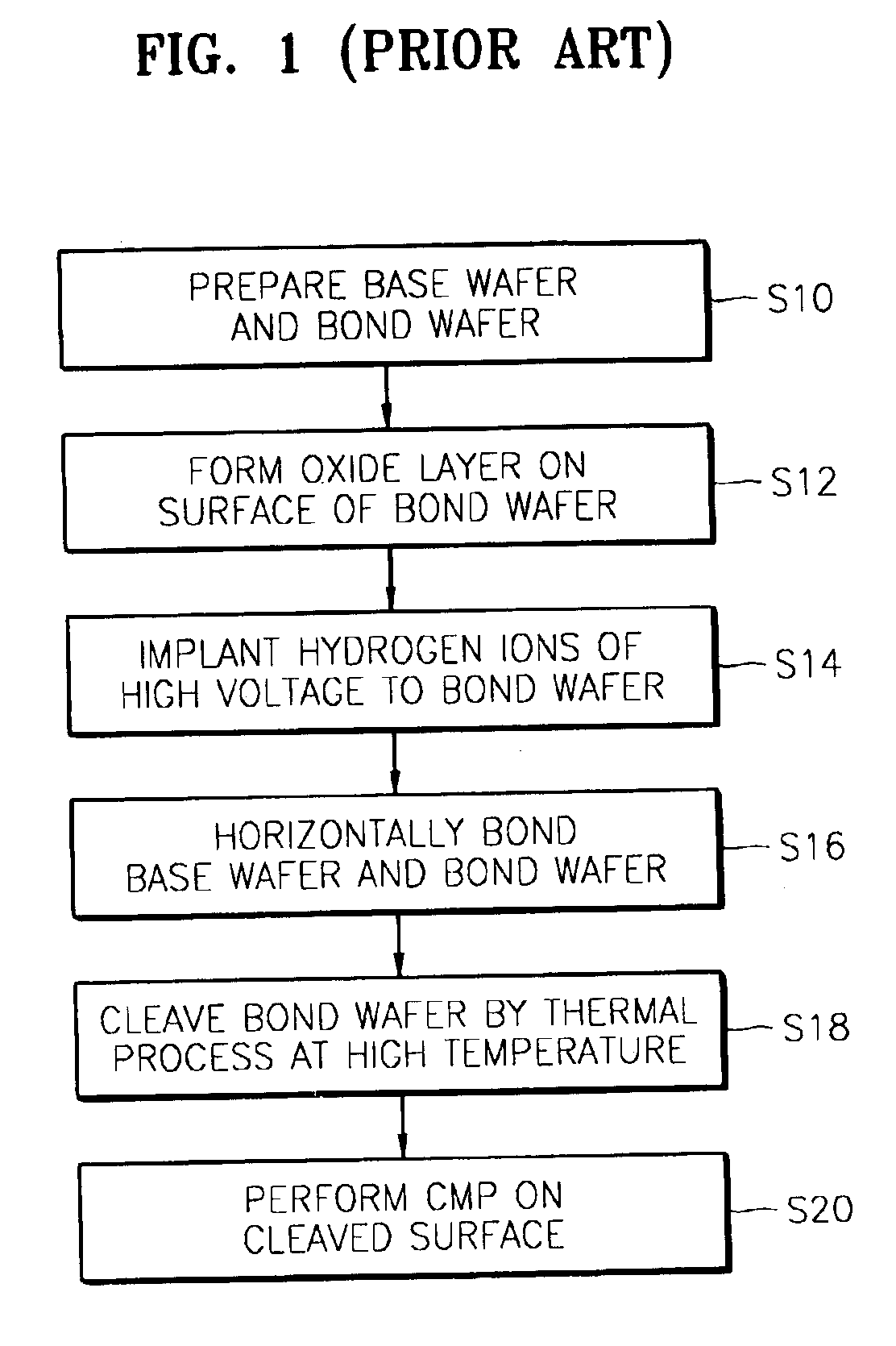

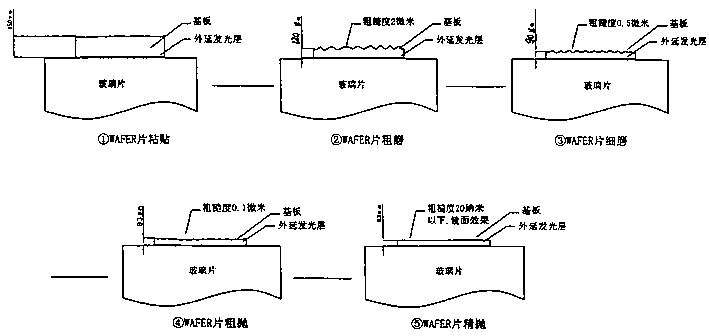

Method of fabricating nano SOI wafer and nano SOI wafer fabricated by the same

InactiveUS6884694B2Improve the bonding force between layersEtch thickness can be made uniformSolid-state devicesSemiconductor/solid-state device manufacturingDielectricNano silicon

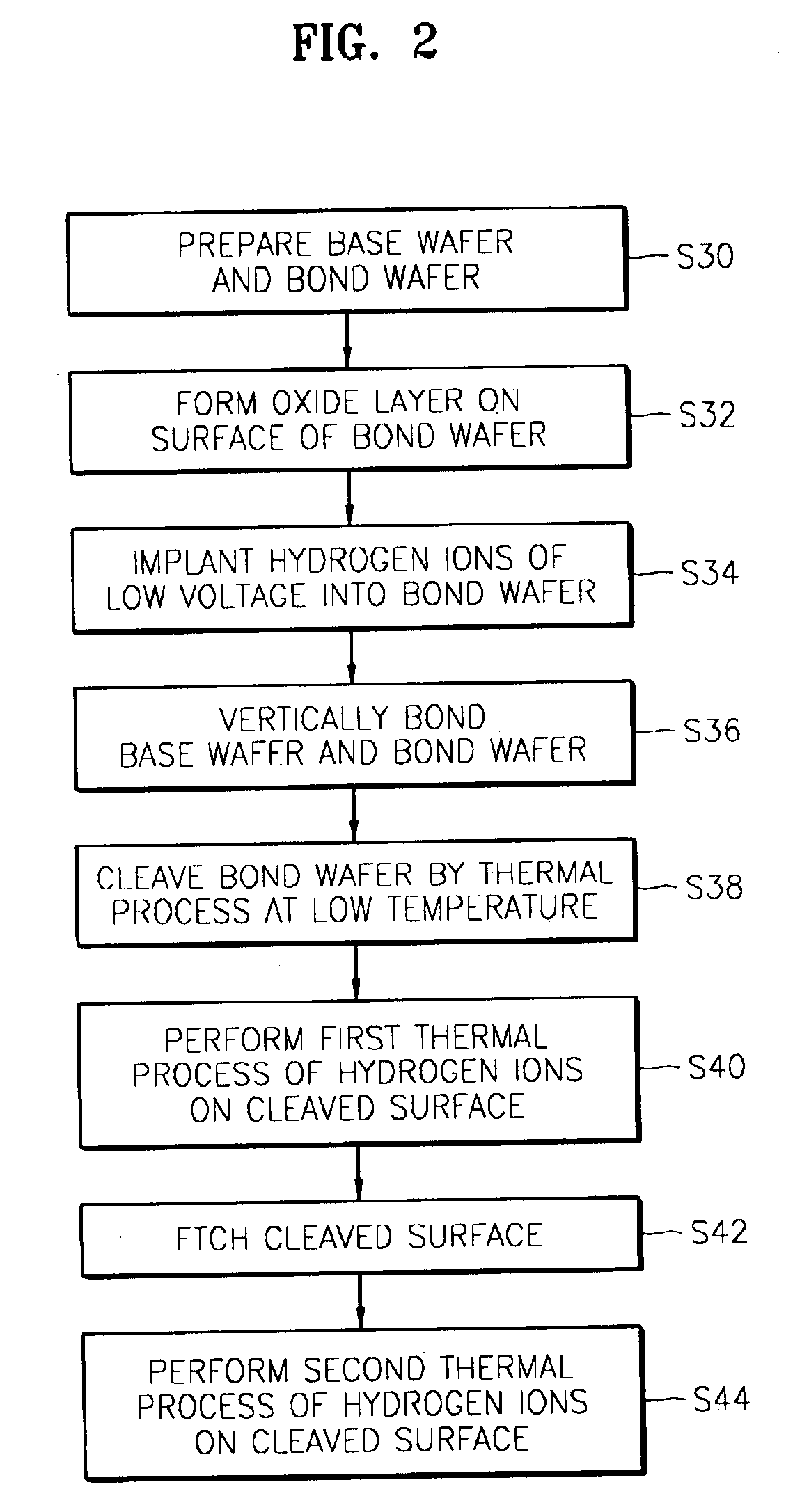

A method of fabricating a nano silicon on insulator (SOI) wafer having an excellent thickness evenness without performing a chemical mechanical polishing (CMP) and a wafer fabricated by the same are provided. The provided method includes preparing a bond wafer and a base wafer, and forming a dielectric on at least on surface of the bond wafer. Thereafter, an impurity ion implantation unit is formed by implanting impurity ions into the bond wafer to a predetermined depth from the surface of the bond wafer at a low voltage. The dielectric of the bond wafer and the base wafer contact each other in order to be bonded. Next, a thermal process of low temperature is performed to cleave the impurity ion implantation unit of the bond wafer. In addition, the cleaved surface of the bond wafer bonded to the base wafer is etched to form a nano scale device region. Here, the cleaved surface may be etched by performing a hydrogen surface process and a wet etching.

Owner:LG SILTRON +1

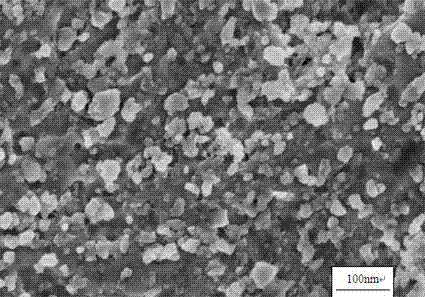

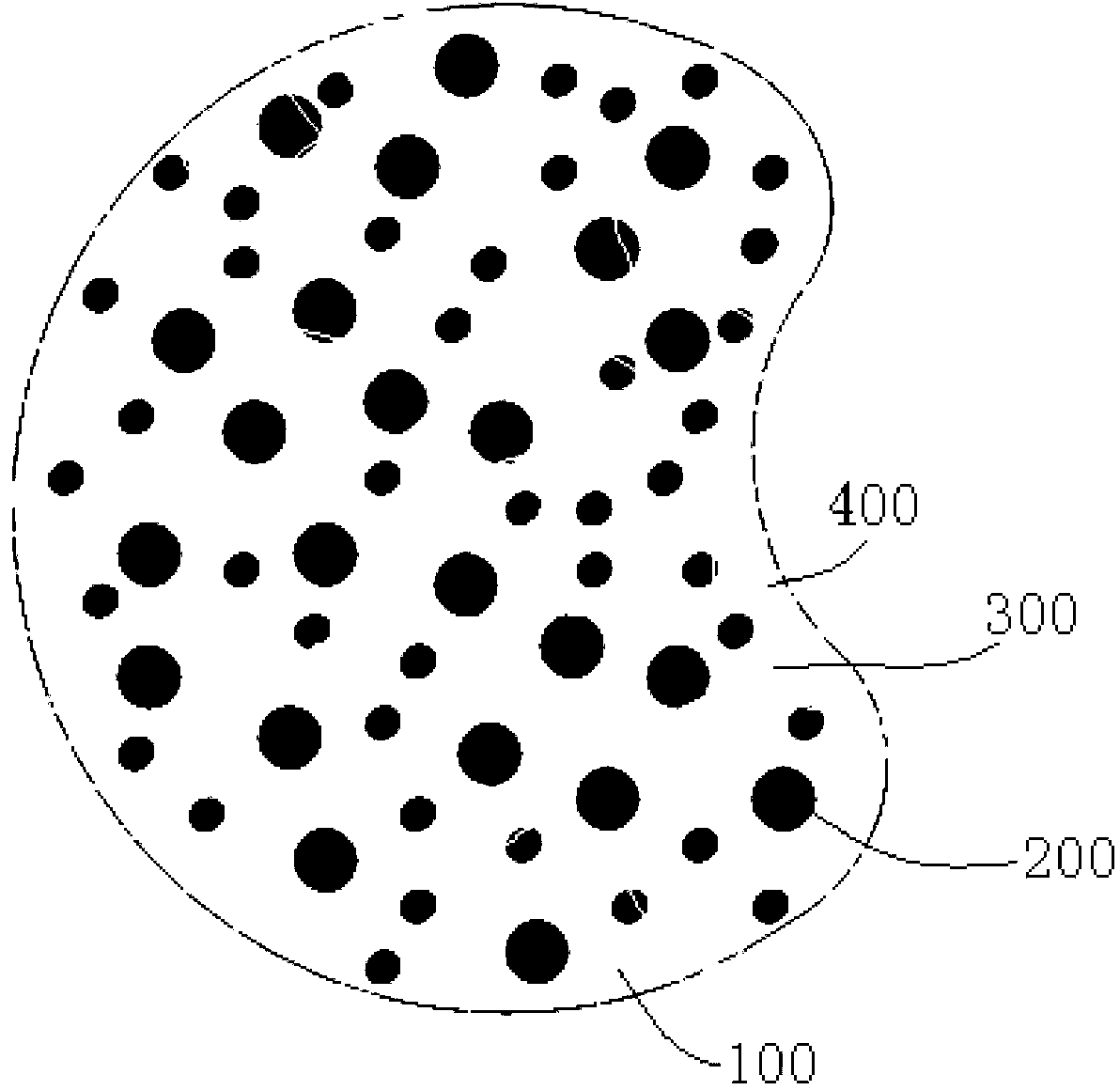

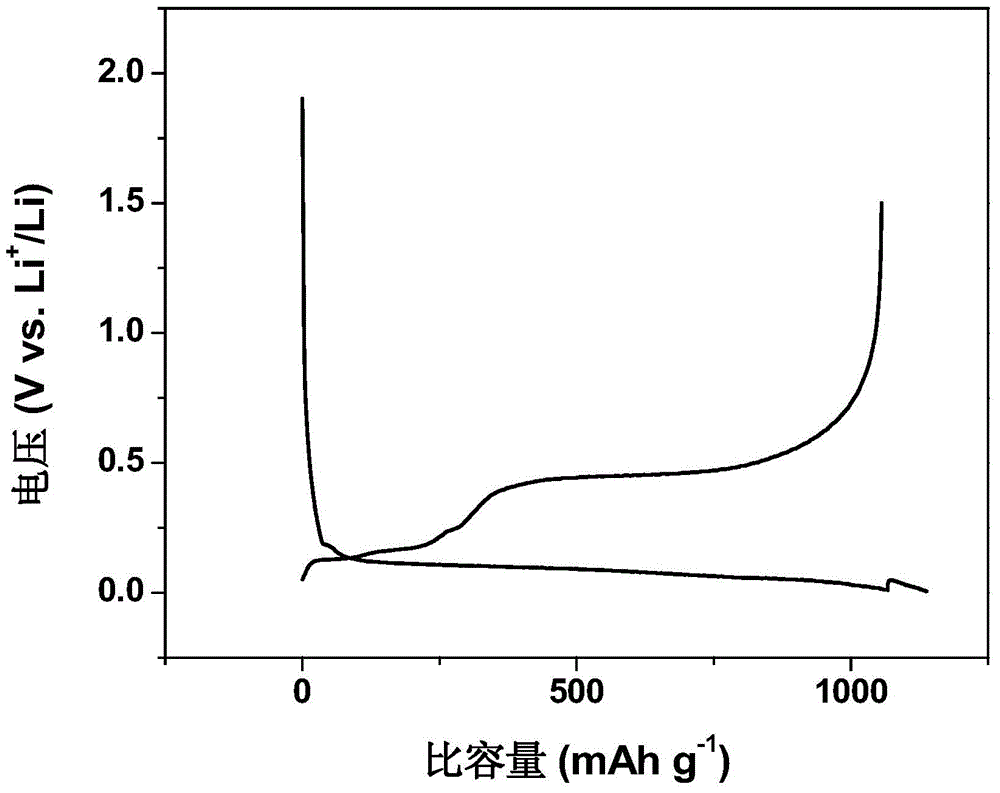

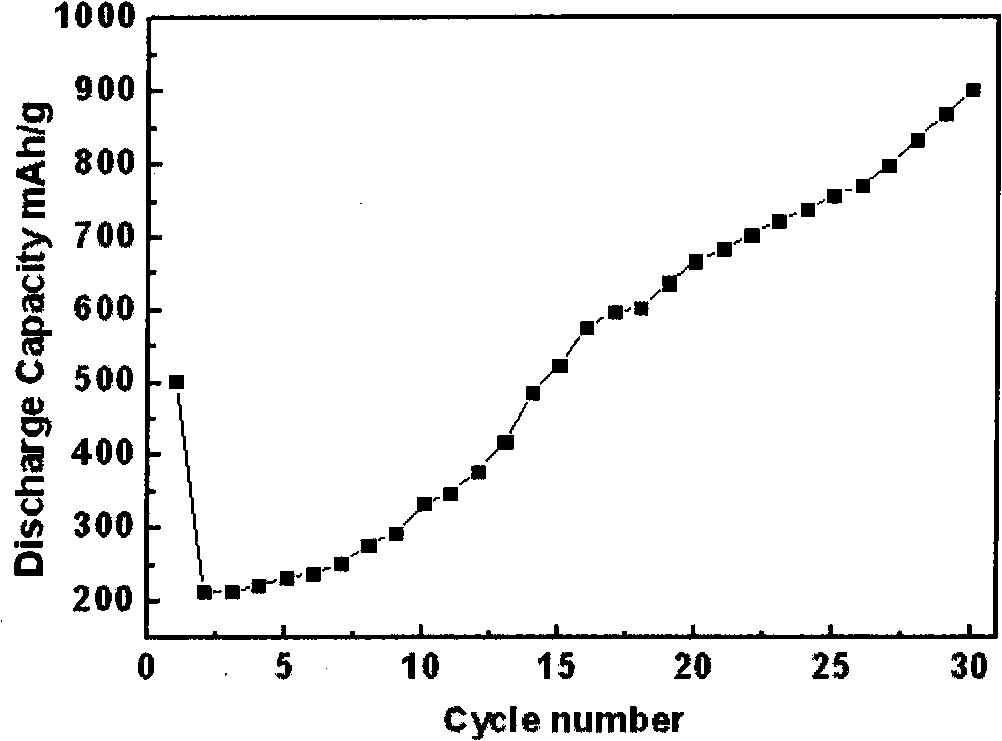

Porous silicon negative material of lithium ion battery and preparation method and application of material

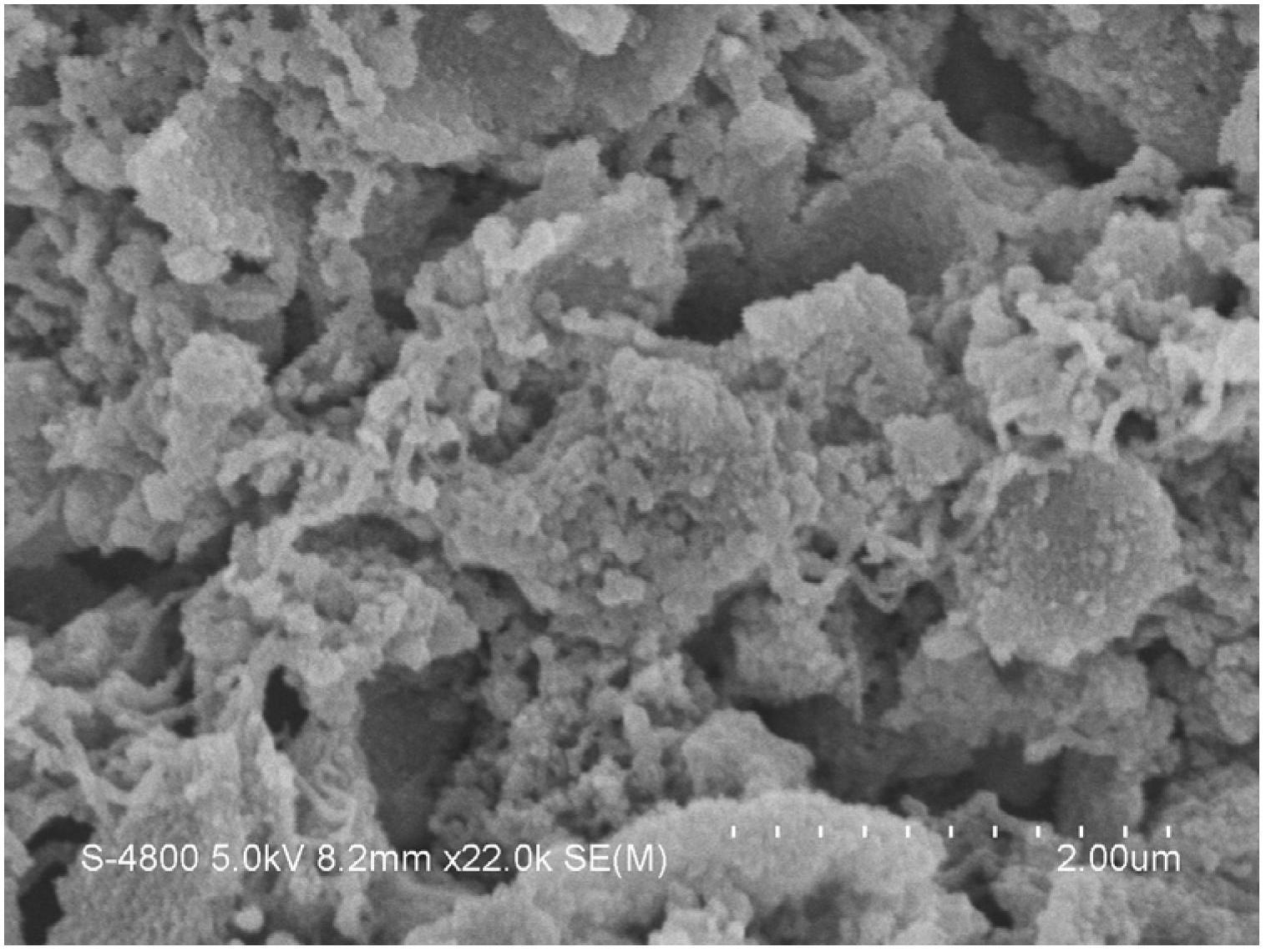

The invention discloses a porous silicon negative material of a lithium ion battery, and a preparation method and application of the material. The method comprises the following steps of: reacting silicon alloy powder, which is taken as a raw material, with inorganic acid to generate porous silicon particles; and washing the porous silicon particles by an HF (Hydrogen Fluoride) acid solution to eliminate surface silicon oxide, and washing and drying the washed porous silicon particles so as to obtain the porous silicon material. The porous silicon material prepared by the method has a sponge-shaped structure which is formed by linking nano silicon particles; the particle sizes of the particles of the porous silicon negative material range from 0.01 micron to 50 microns; the specific surface area of the material is 30-600cm<2> / g; the porous silicon negative material can be taken as a negative material of a lithium ion battery; and in a lithium ion battery electrolyte, the porous silicon powder shows high specific discharge capacity and charge-discharge circulation stability. The porous silicon negative material has the advantages of low cost, simplicity and convenience in method and high electrochemical property, and can be applied to production of silicon negative materials of high-performance lithium ion batteries.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

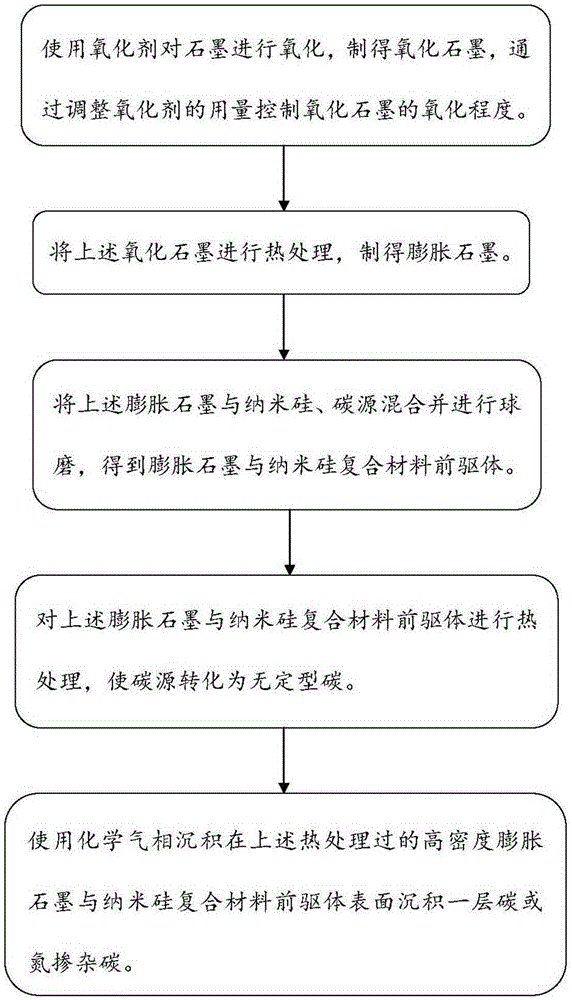

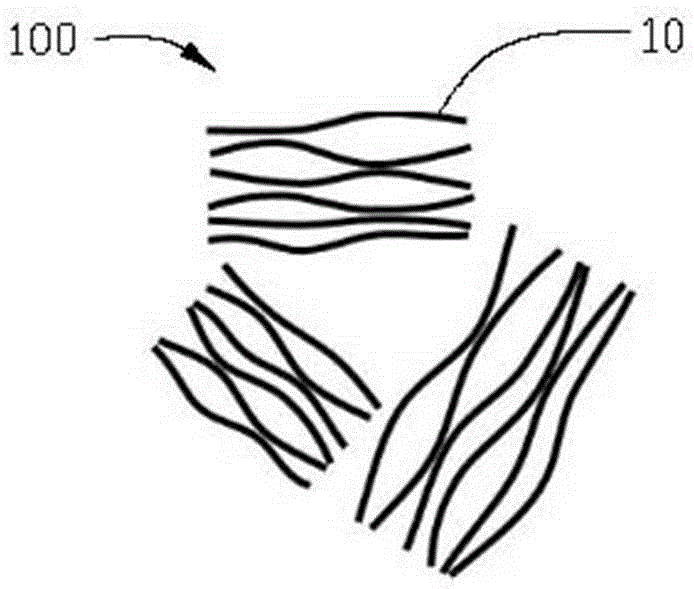

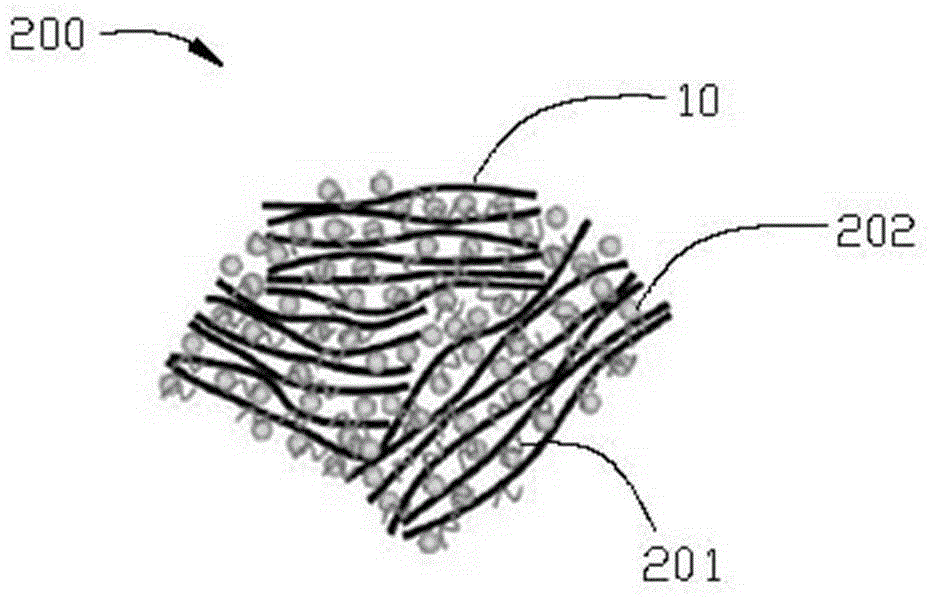

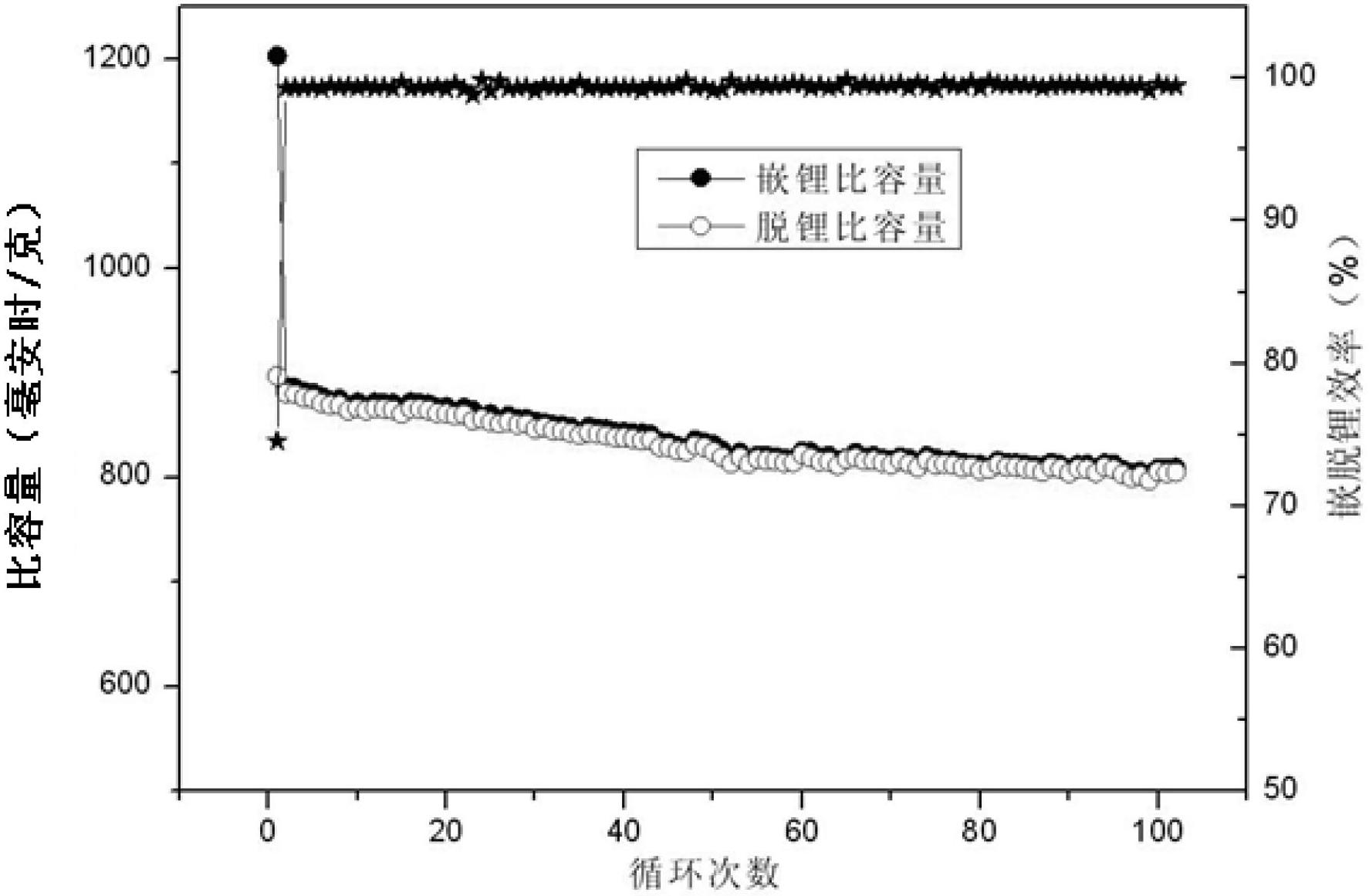

Expanded graphite and nano-silicon composite material, preparation method thereof, electrode plate and battery

ActiveCN105355870AHigh tap densityHigh solid densityMaterial nanotechnologyCell electrodesNano siliconHigh density

The invention provides a preparation method of a high-density expanded graphite and nano-silicon composite material. The preparation method comprises the following steps: step S1, oxidizing graphite to manufacture graphite oxide; step S2, carrying out heat treatment on the graphite oxide to manufacture expanded graphite; step S3, mixing the expanded graphite with nano-silicon and a carbon source and carrying out ball-milling to obtain a high-density expanded graphite and nano-silicon composite material precursor comprising a plurality of graphite layers, the carbon source and the nano-silicon filled among the graphite layers; step S4, carrying out heat treatment on the high-density expanded graphite and nano-silicon composite material precursor so that the carbon source is converted into amorphous carbon; and step S5, depositing carbon or doped carbon on the surface of the high-density expanded graphite and nano-silicon composite material precursor after the heat treatment. Moreover, the invention also provides the high-density expanded graphite and nano-silicon composite material, an electrode plate applying the high-density expanded graphite and nano-silicon composite material, and a lithium ion battery applying the electrode plate.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Silicon-carbon composite material, preparation method thereof and lithium ion battery employing same

ActiveCN102694155APossesses electrochemical reversible intercalation and delithiation performanceAlleviate chalking and sheddingMaterial nanotechnologyCell electrodesCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a preparation method thereof and a lithium ion battery prepared by adopting the material. The preparation method of the silicon-carbon composite material comprises the following steps: (1) mixing a composite material (silica-coated nano-silicon) manufactured by silicon monoxide, a porous carbon-based material and excessive hydrofluoric acid solution to obtain another composite material in which nano-silicon particles are compounded in pores of the porous carbon-based material; and (2) heating a composite material in which nano-silicon particles are compounded in pores of a high polymer-coated porous carbon-based material under an inert atmosphere to obtain the silicon-carbon composite material coated by porous carbon spheres. The process raw materials are accessible and simple to prepare. The silicon-carbon composite material has electrochemical reversible embedded lithium removal performance, greatly relieves efflorescence and falling-off phenomena of active particles in the charge-discharge process and has the high lithium storage capacity characteristic of silicon materials and the high cycling stability of carbon materials, and a battery prepared by the silicon-carbon composite material has better cyclicity.

Owner:CHERY AUTOMOBILE CO LTD

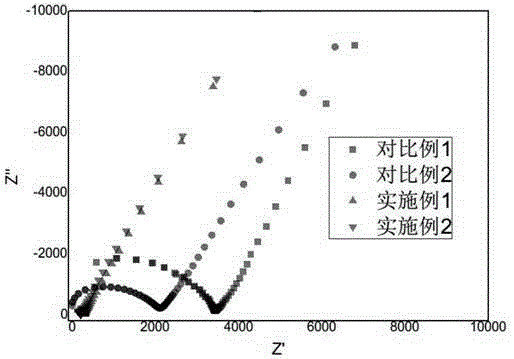

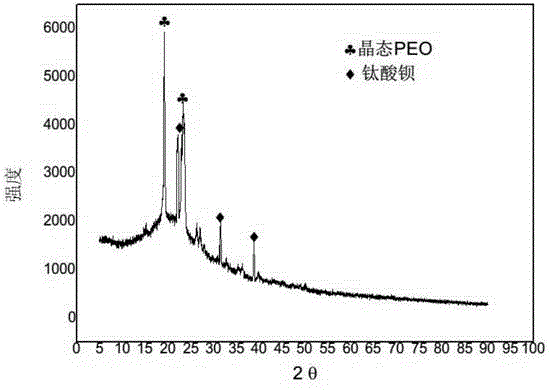

All-solid polymer electrolyte, and preparation method and application of all-solid polymer electrolyte

InactiveCN104538670AImprove conductivityHigh mechanical strengthSolid electrolytesFinal product manufacturePolyethylene oxideBarium titanate

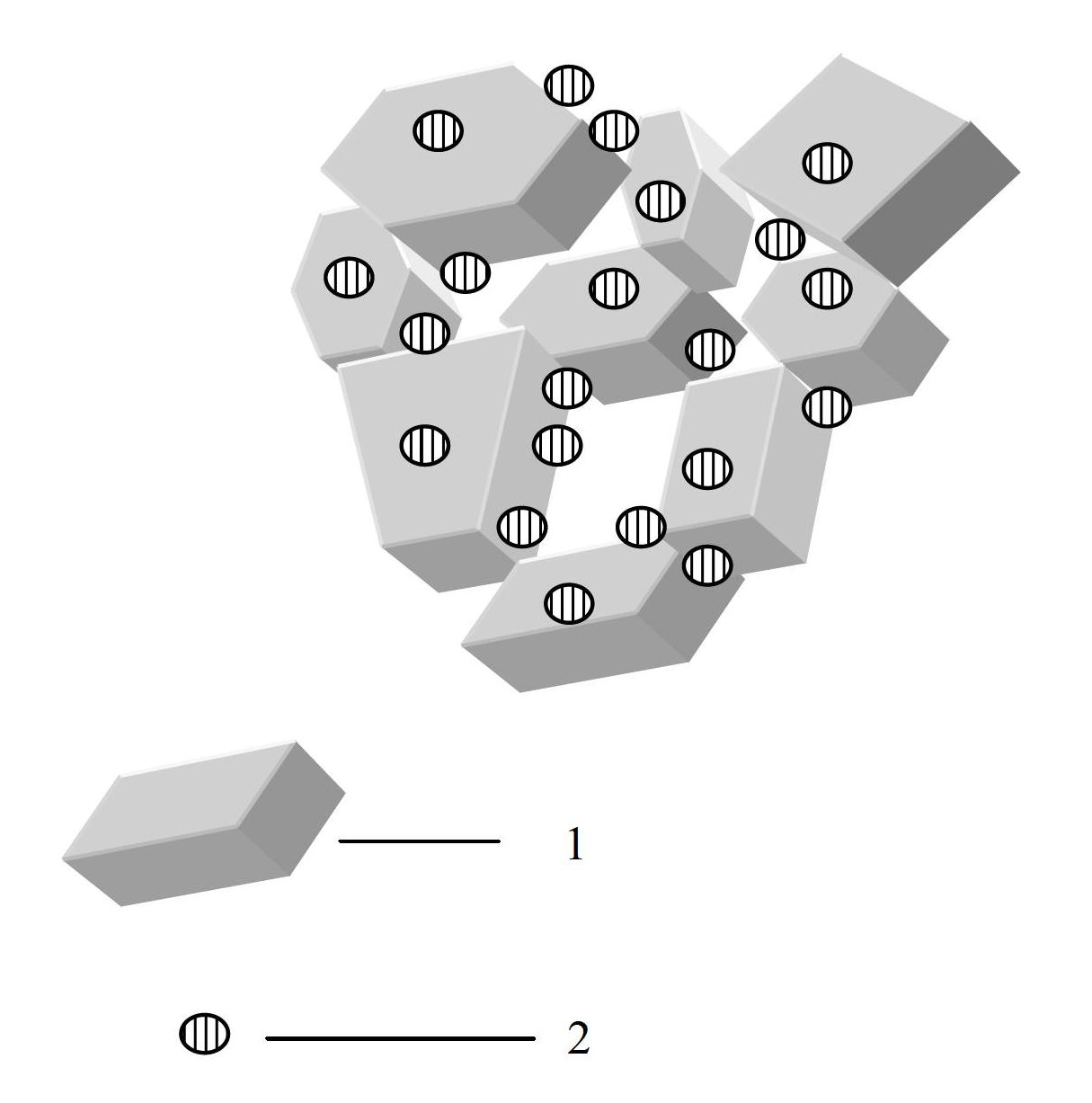

The invention discloses an all-solid polymer electrolyte, and a preparation method and an application of the all-solid polymer electrolyte, and belongs to the field of lithium ion batteries. The all-solid polymer electrolyte comprises polyethylene oxide, lithium salt, inorganic nano particles and ion liquid, wherein a mass ratio of the lithium salt to polyethylene oxide is 0.1-0.5; the mass sum of the inorganic nano particles and the ion liquid is 10-30% of the mass of the all-solid polymer electrolyte; the lithium salt comprises one or several of bistrifluoromethane sulfonimide lithium salt, lithium tetrafluoroborate, lithium perchlorate, lithium hexafluorophosphate, lithium hexafluoroarsenate, lithium trifluoromethanesulfonate and lithium bis borate; and the inorganic nano particles comprise one or several of nano aluminum oxide, nano silicon oxide, nano zirconium oxide and nano barium titanate. The all-solid polymer electrolyte has better mechanical strength and higher ion conductivity. The method is simple in technology and low in cost; and raw materials are easy to obtain.

Owner:HUAZHONG UNIV OF SCI & TECH RES INST SHENZHEN

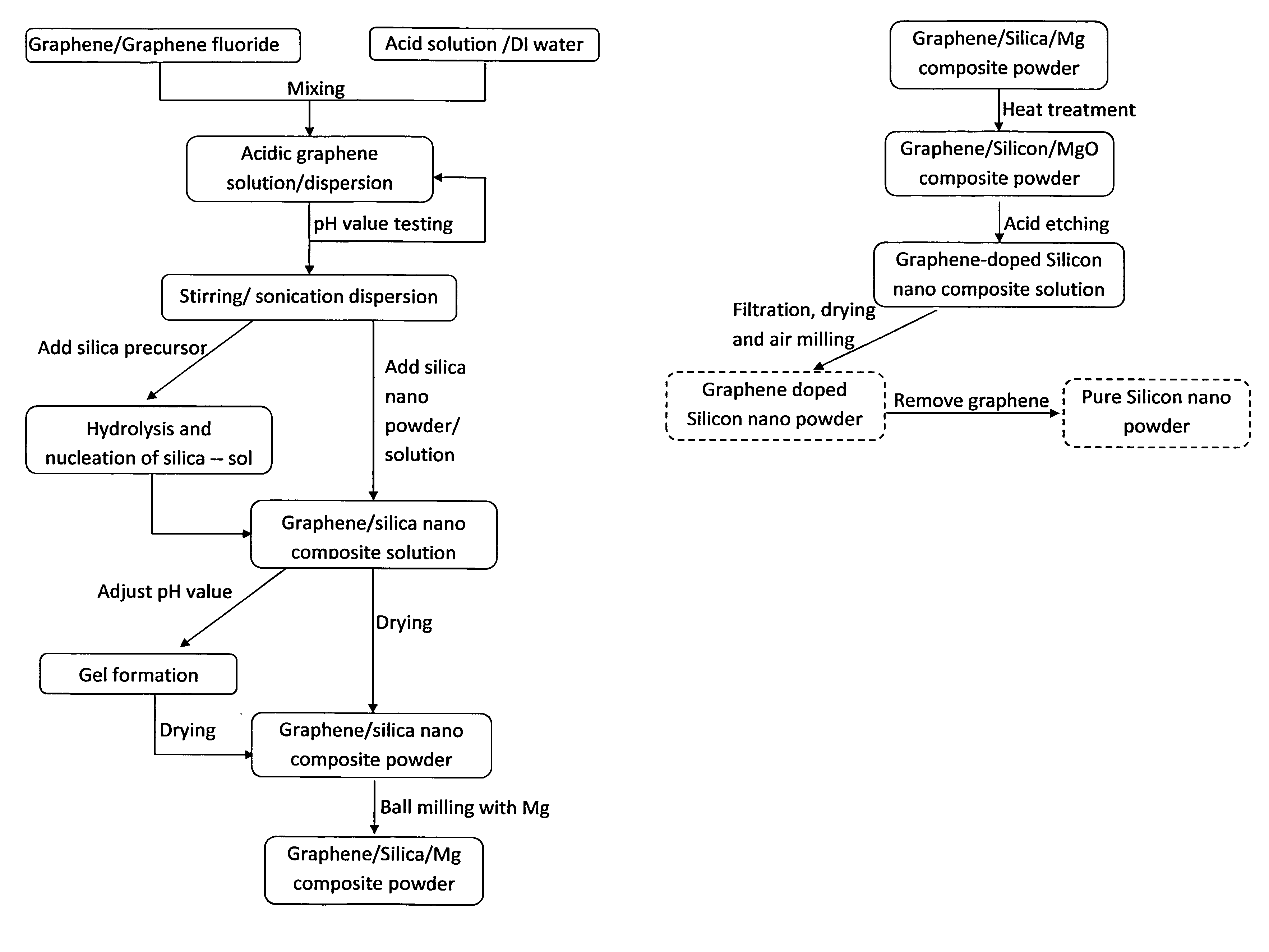

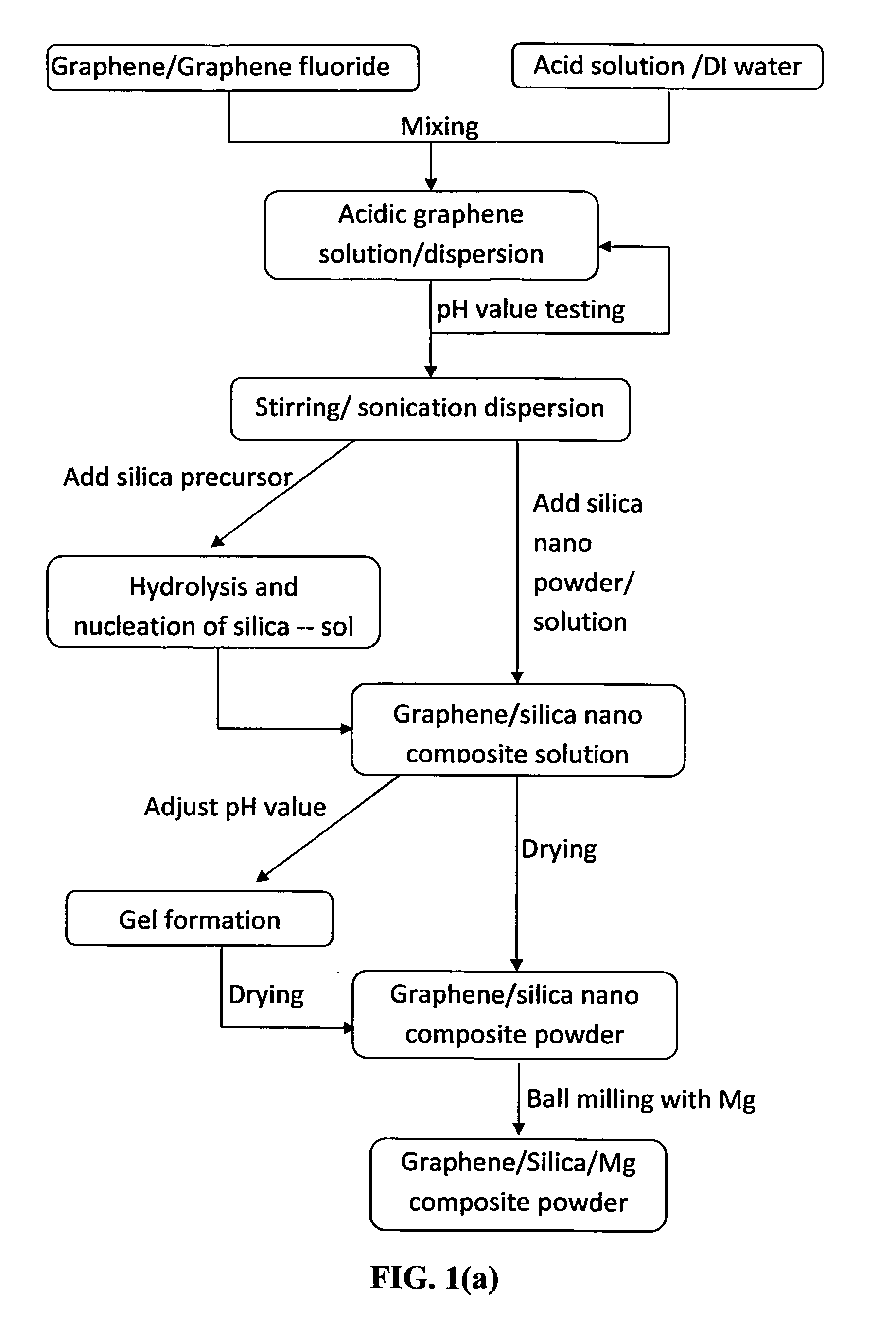

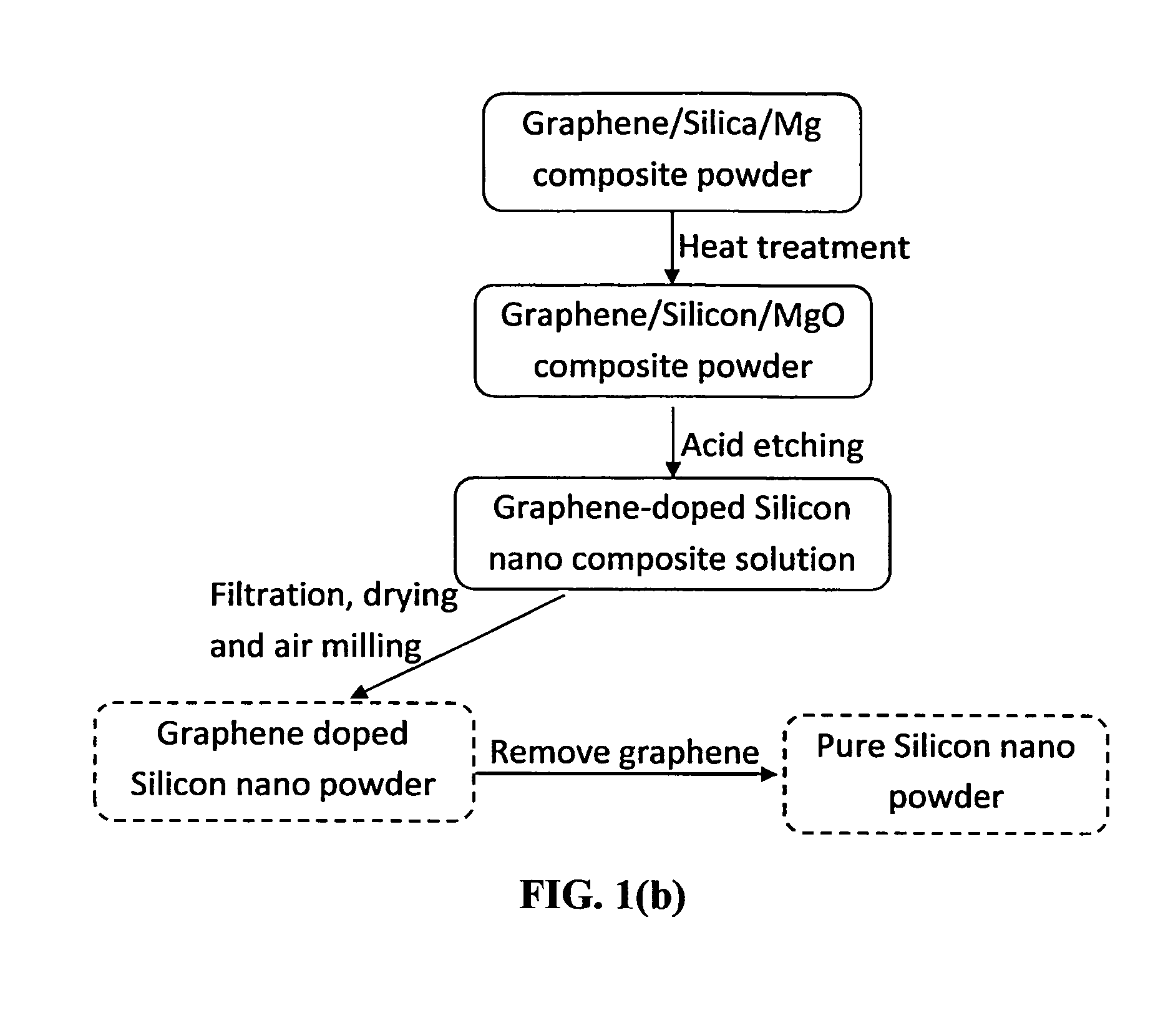

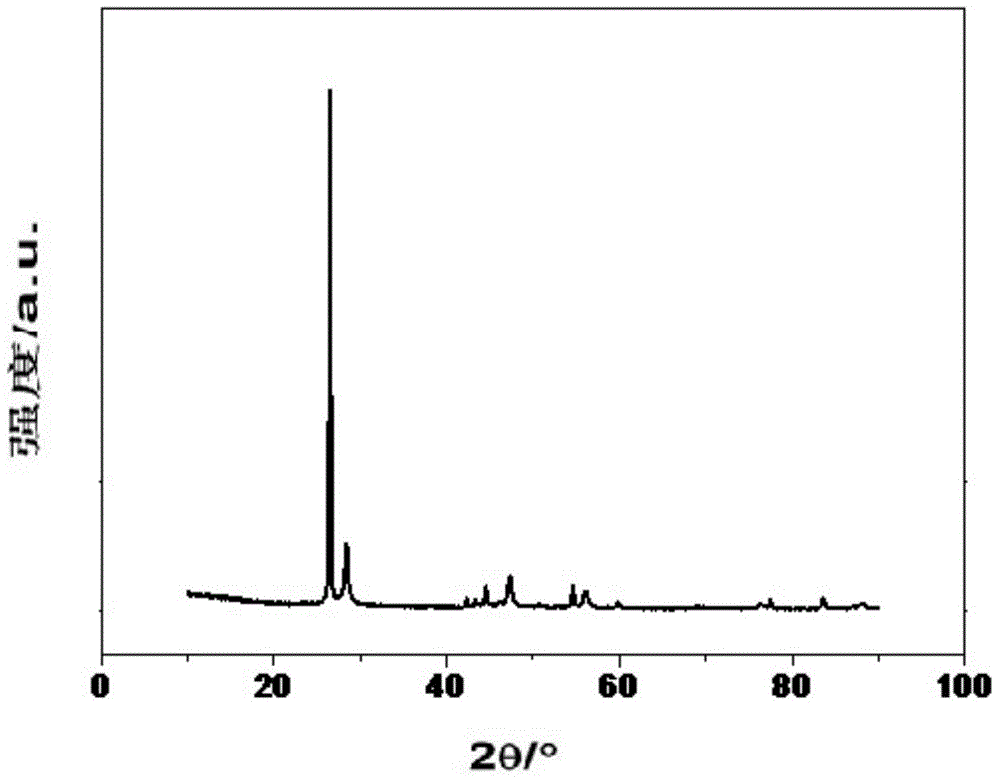

Methods for mass-producing silicon nano powder and graphene-doped silicon nano powder

Disclosed is a facile and cost effective method of producing nano silicon powder or graphene-doped silicon nano powder having a particle size smaller than 100 nm. The method comprises: (a) preparing a silicon precursor / graphene nano composite; (b) mixing the silicon precursor / graphene nano composite with a desired quantity of magnesium; (c) converting the silicon precursor to form a mixture of graphene-doped silicon and a reaction by-product through a thermal and / or chemical reduction reaction; and (d) removing the reaction by-product from the mixture to obtain graphene-doped silicon nano powder.

Owner:GLOBAL GRAPHENE GRP INC

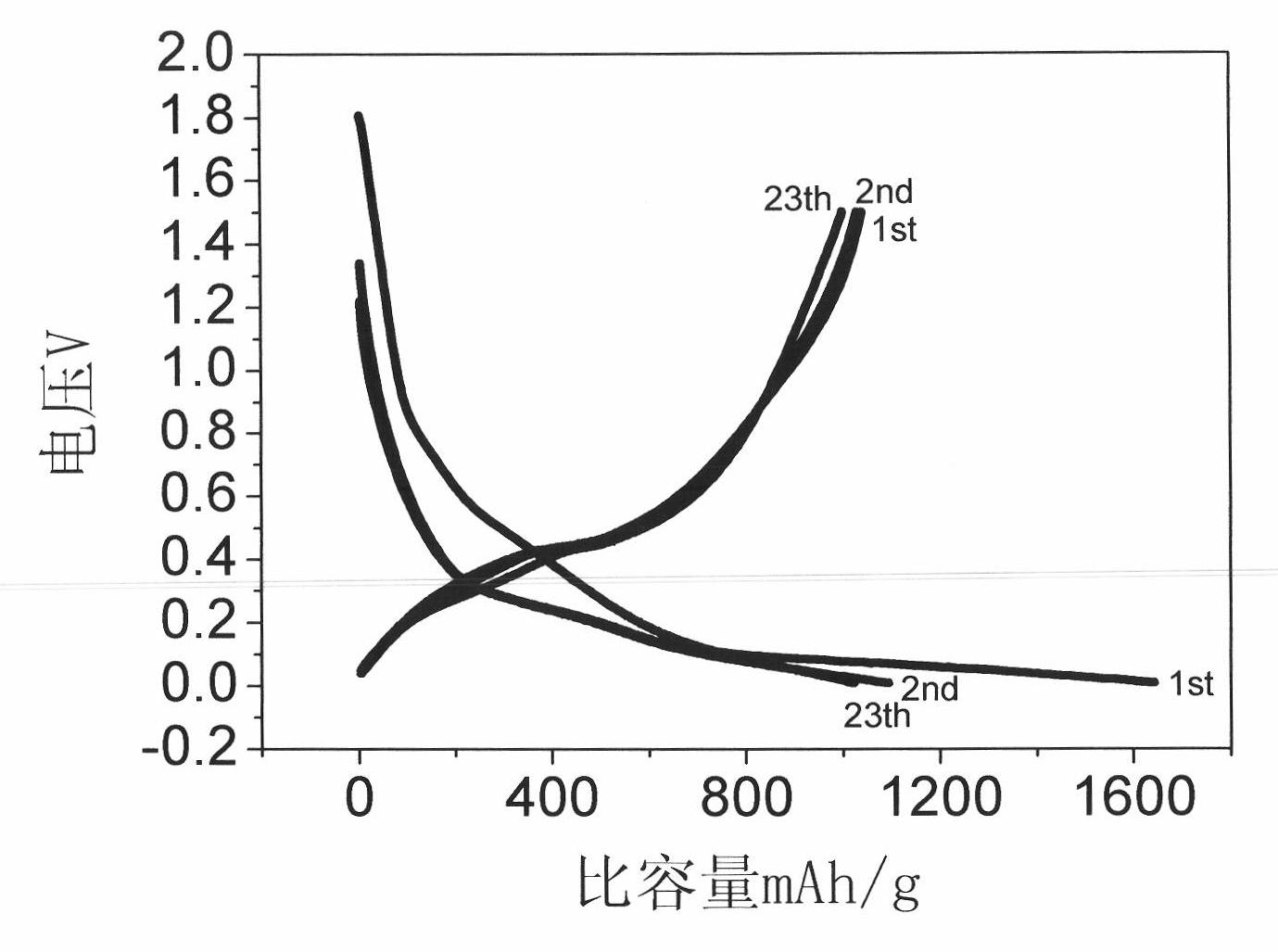

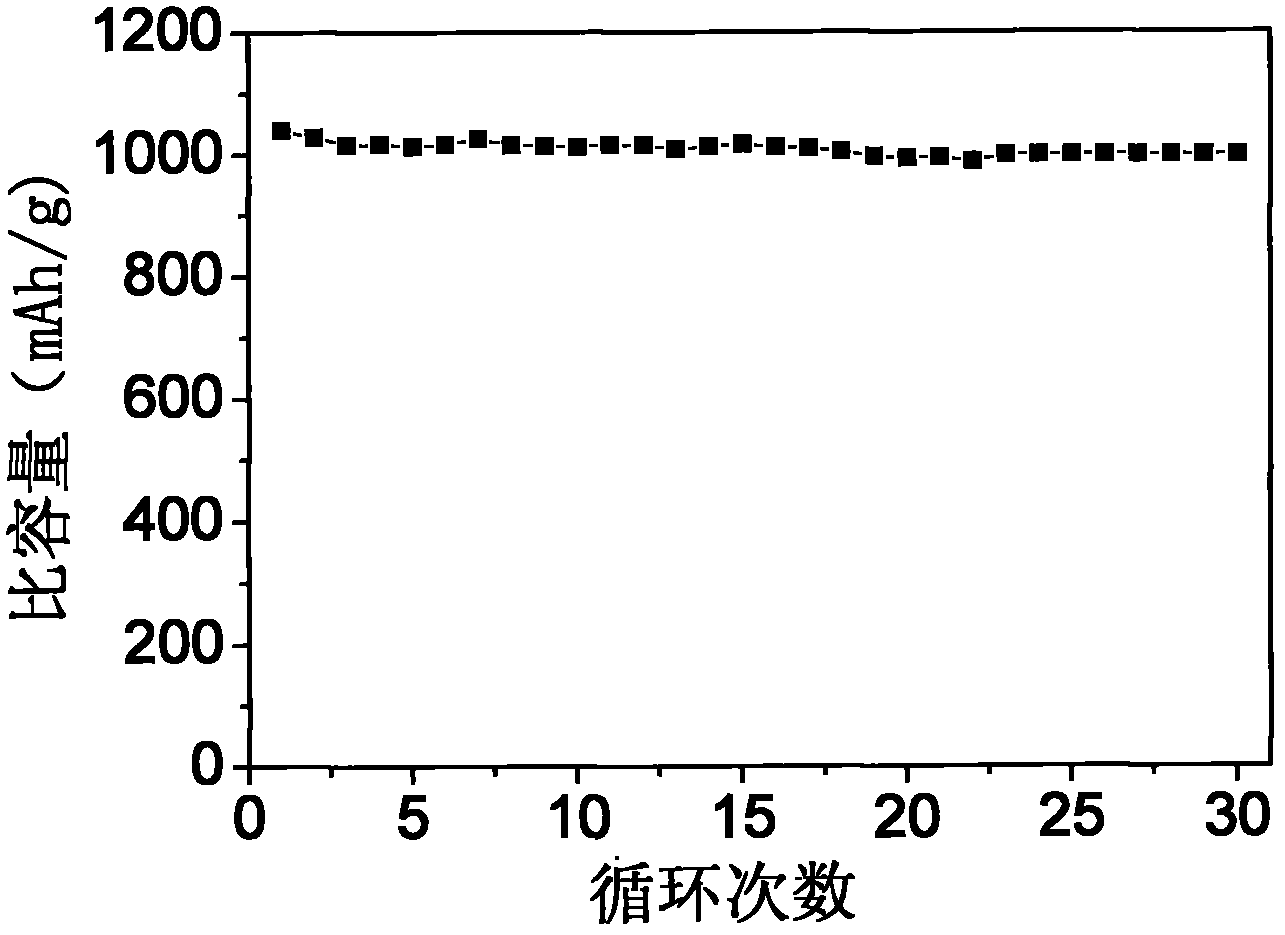

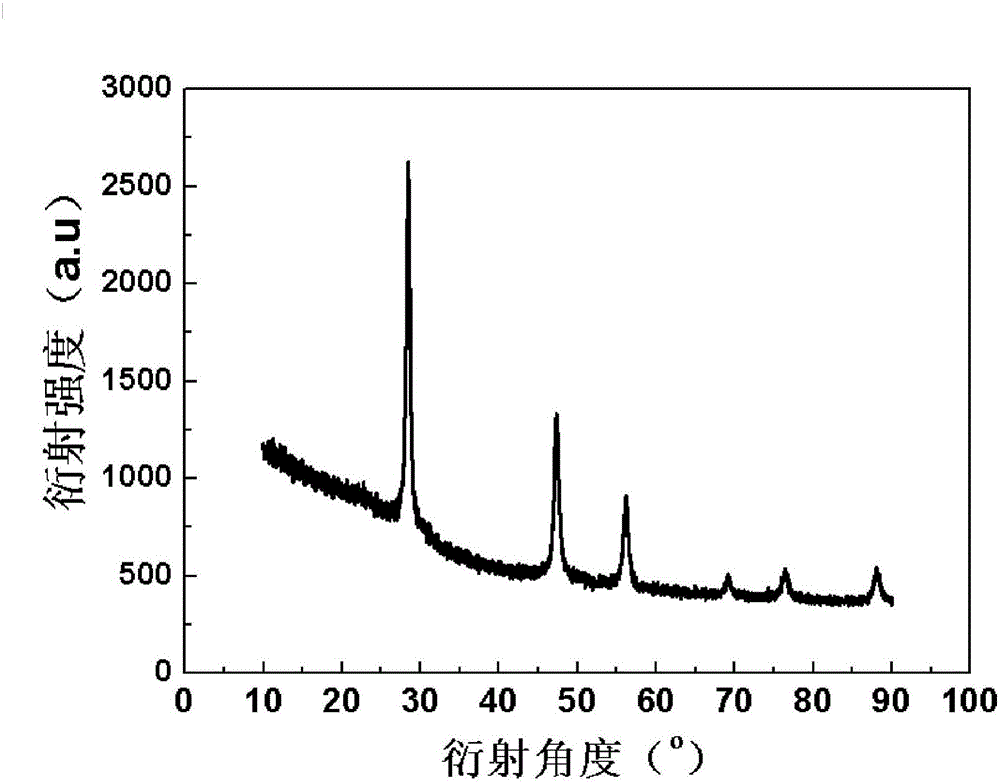

Nano silicon composite negative electrode material for lithium ion battery, preparation method and lithium ion battery

InactiveCN104577084AHigh specific capacityImprove the first charge and discharge efficiencyMaterial nanotechnologyElectrode thermal treatmentNano siliconGas phase

The invention discloses a nano silicon composite negative electrode material, which comprises graphite matrix and a nano silicon material which is evenly deposited in the graphite matrix, wherein the nano silicon composite negative electrode material is prepared by chemical vapor deposition of nano silicon particles in hollow graphite with a silicon source. The nano silicon composite negative electrode material disclosed by the invention has the characteristics of high specific capacity (greater than 1,000mAh / g), high initial charge-discharge efficiency (greater than 93%) and high conductivity. The preparation method disclosed by the invention is simple to operate, easy to control, low in production cost and suitable for industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

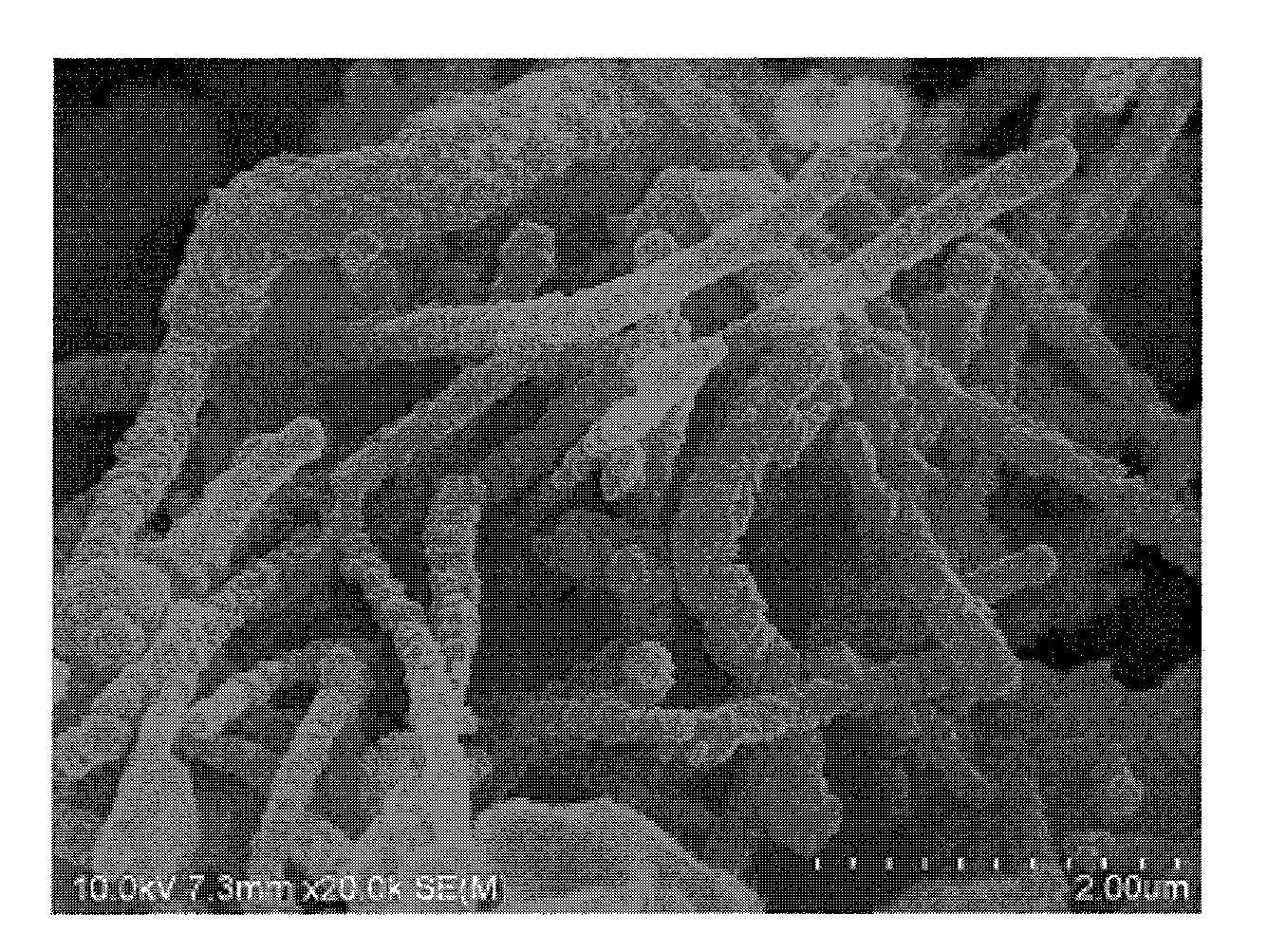

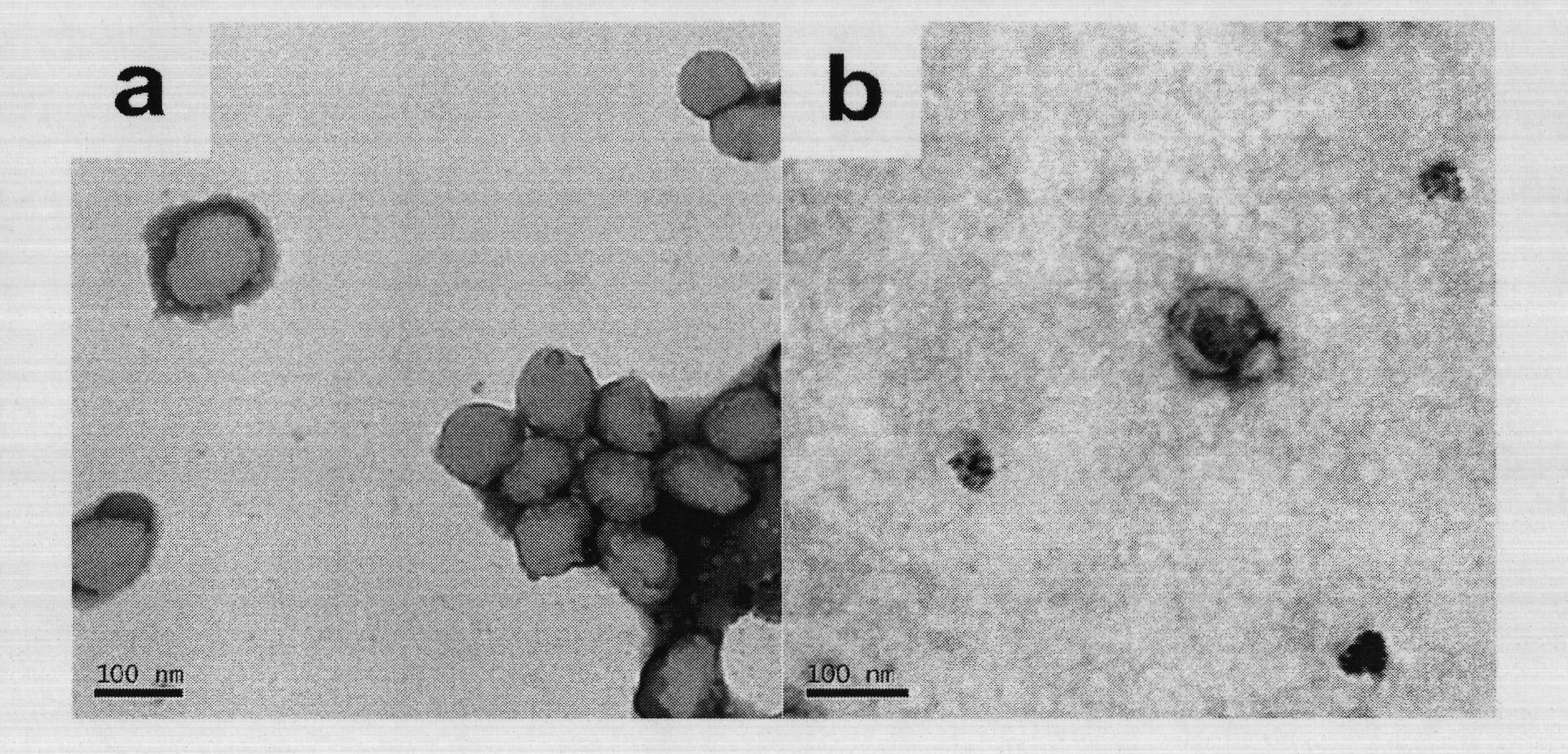

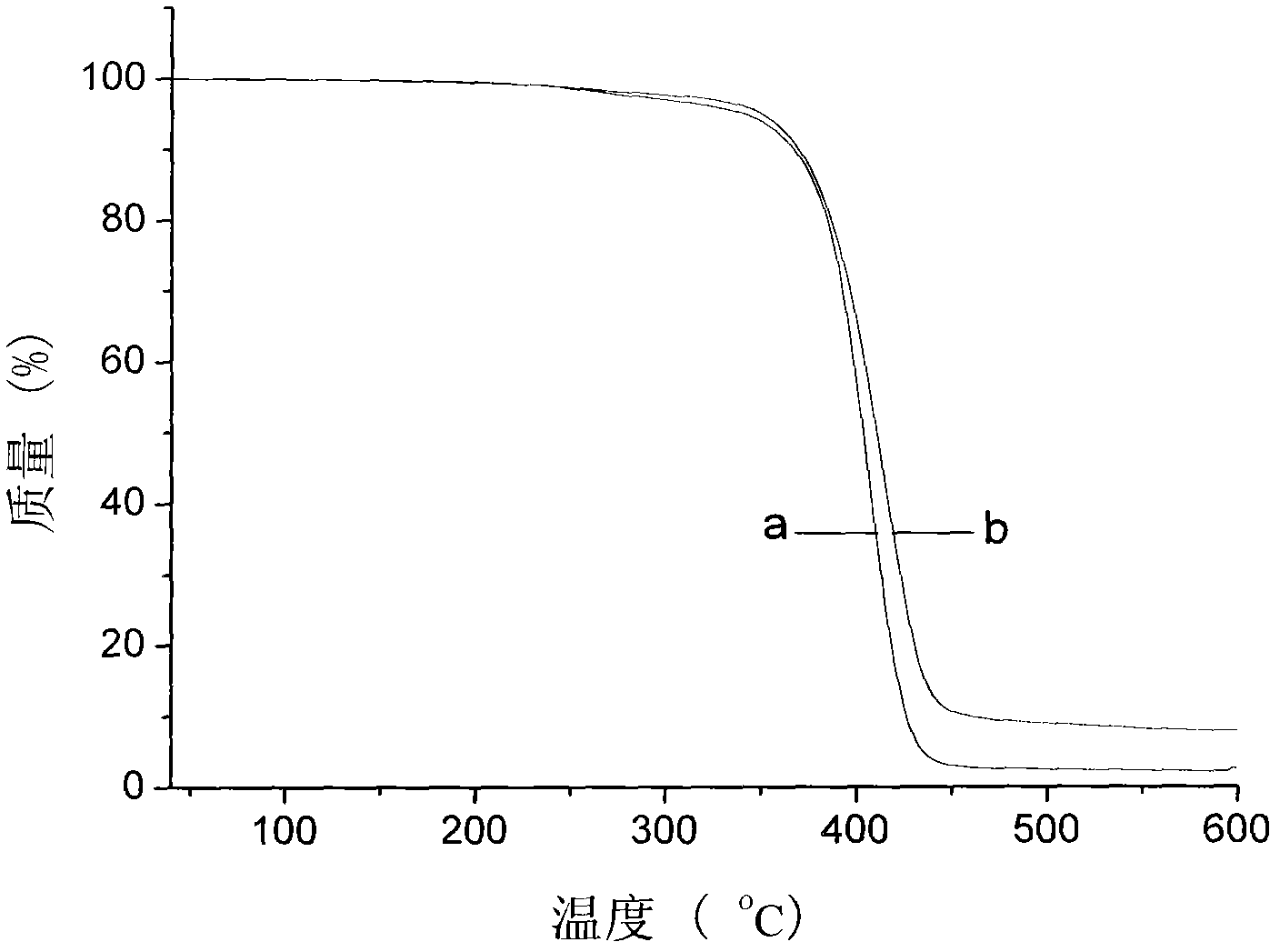

Nano-silicon amorphous carbon composition lithium ion battery cathode material and preparation method therefor

InactiveCN101527357ALarge capacityImprove cycle lifeElectrode manufacturing processesCarbonizationSolvent

The invention relates to a nano-silicon amorphous carbon composition lithium ion battery cathode material and a preparation method therefore, belonging to the field of electrochemistry power supply. The cathode material consists of a substrate and granules distributed evenly thereon, wherein, cores of the nano-granules are nano-silicon while shells thereof are amorphous carbon obtained by pyrogenation of organic substance; and the substrate thereof is obtained by pyrogenation and carbonization of organic electrospun fibre; wherein, content range of monomer silicon is 10%-50% and content range of amorphous carbon is 90%-50%. The preparation method comprises that nano-silicon granules and electrospun-available organic substances are uniformly stirred and mixed in solvent; high-voltage static electrospun is carried out to obtain fibrous composition; temperature is maintained at 80-200 DEG C, so as to volatilize the solvent completely; and carbonization is then carried out at 400-1000 DEG C. The silicon / carbon composition cathode material prepared by the method can effectively control volume change of silicon electrode material in charging and discharging process. Therefore, the electrode structure is maintained integral; the volume is released gradually. And the silicon / carbon composition cathode material has large circular volume, long circular service life and excellent electrochemical performance.

Owner:TSINGHUA UNIV

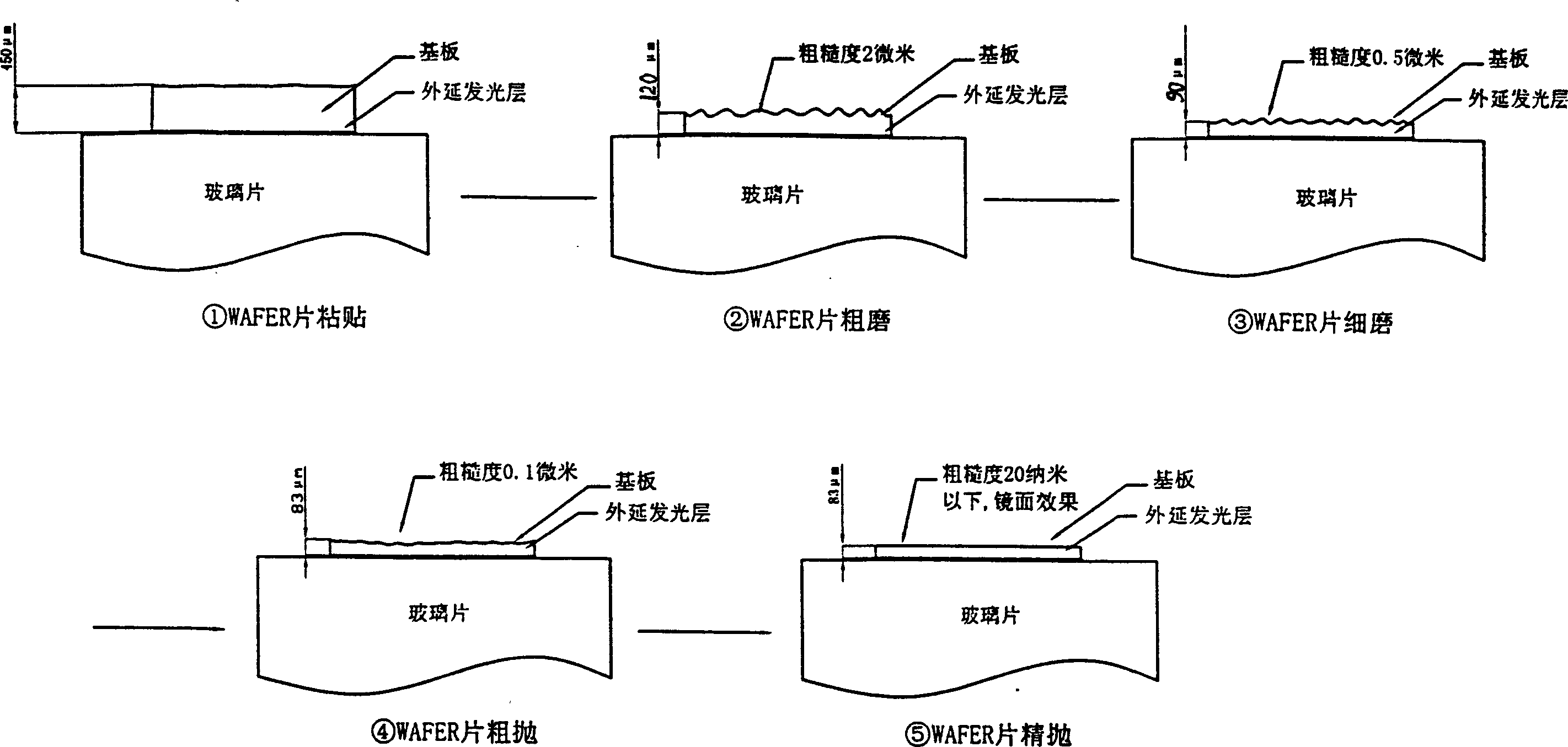

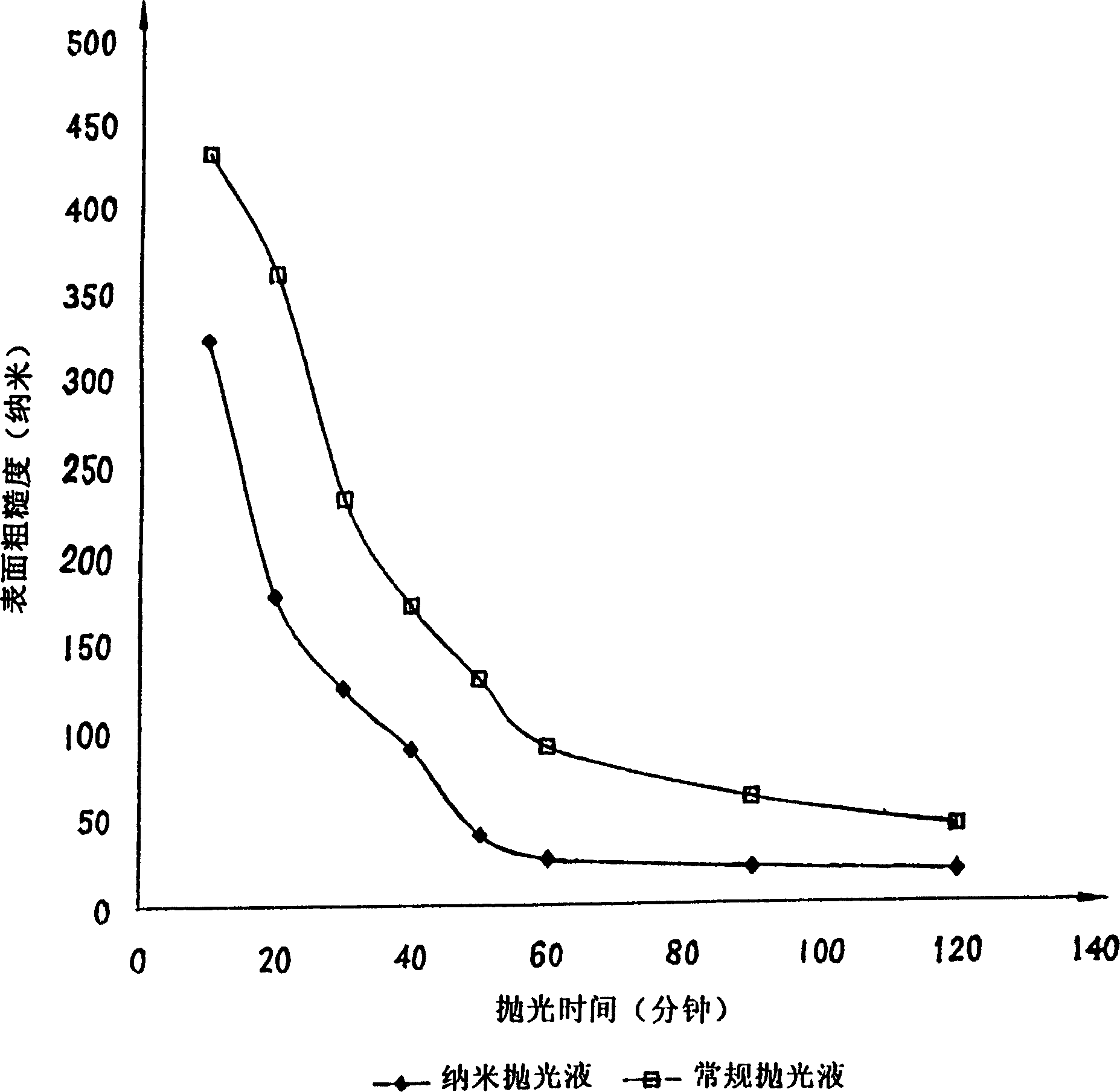

Processing method of nano level saphire substrate and its special polishing liquid

InactiveCN1469459AHigh surface finishExtended service lifeOther chemical processesSemiconductor/solid-state device manufacturingSurface finishNano silicon

The present invention relates to the processing technology of semiconductor device and is especially the processing method of sapphire substrate for HB-LED tube core and special polishing liquid. The processing method includes the steps of adhering, coarse grinding, fine grinding, coarse polishing and fine polishing. The nano polishing liquid consists of nano silicon powder, glycol, glycerine, ethanolamine and deionized water. The present invention can raise surface smoothness to obtain the mirror polishing effect, eliminate stress, lower loss of cutting tool, raise product quality and lower production cost. In addition, the polishing liquid can shorten polishing period greatly compared with micron level polishing liquid.

Owner:东莞市福地电子材料有限公司

Wear-resistance halogen-free low-smoke expansion flame-retarding polyolefin sheath plastic and preparation method thereof

ActiveCN102101922AImprove wear resistanceExtended service lifePlastic/resin/waxes insulatorsInsulated cablesNano siliconPolymer science

The invention discloses wear-resistance halogen-free low-smoke expansion flame-retarding polyolefin sheath plastic and a preparation method thereof. The plastic comprises the following components in part by weight: 50 to 80 parts of polyolefine resin, 0 to 20 parts of compound resin, 3 to 15 parts of grafted material, 10 to 60 parts of halogen-free expansion flame retardant, 0.5 to 3 parts of coupling agent, 0.5 to 1.5 parts of antioxygen and 1 to 10 parts of nano silicon carbide. In the thermoplastic halogen-free low-smoke expansion flame-retarding polyolefin sheath plastic and the preparation method thereof, the nano silicon carbide is added into a blend system, so the wear resistance of the thermoplastic halogen-free low-smoke expansion flame-retarding polyolefin sheath plastic is improved, the thermoplastic halogen-free low-smoke expansion flame-retarding polyolefin sheath plastic meet the requirement for normal use in severe environments and the service life of the thermoplastic halogen-free low-smoke expansion flame-retarding polyolefin sheath plastic is prolonged.

Owner:上海新上化高分子材料有限公司

Silicon-carbon cathode material for lithium ion battery and manufacturing method thereof

ActiveCN102394288ALow costHigh specific gram capacityMaterial nanotechnologyCell electrodesCarbon compositesMass ratio

The invention discloses a silicon-carbon cathode material for a lithium ion battery and a manufacturing method thereof, aiming at solving the technical problem of improving the circulating performance of the silicon-carbon cathode material. The silicon-carbon cathode material comprises a silicon-carbon composite material and graphite powder, and comprises the components by mass ratio as follows: 1-20% of nano-silicon powder, 1-40% of carbon material presoma and the balance of graphite powder. The preparing method of the invention comprises the following steps: mixing, thermal processing, smashing, removing silicon powder with defects at the wrapping layer, mixing, thermal processing and smashing the silicon powder, and mixing the silicon powder with the graphite powder. Compared with the prior art, the material has higher specific capacity, and has a better circulating performance than that of a common alloy cathode material; the specific capacity of the material is 400-1000mAh / g according to different technological parameters, and the capacity retention ratio of the material is maintained to be above 95% with 50 times of circulation; and the preparing process is simple, and the material cost is low, so that the method is applicable to mass production of high-capacity lithium ion battery cathode materials.

Owner:BTR NEW MATERIAL GRP CO LTD

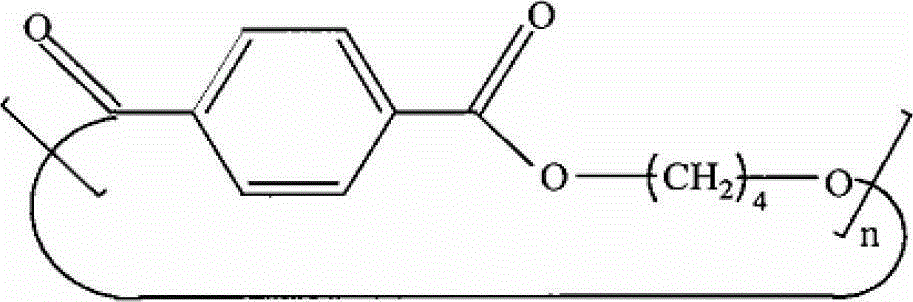

Preparation method of functional polyester fibers

ActiveCN102719932AHigh crystallinityImprove mechanical propertiesFilament forming substance formingMelt spinning methodsPolytetramethylene terephthalatePolyethylene glycol

The invention provides a preparation method of functional polyester fibers. The preparation method mainly comprises the following two steps of: firstly, mixing functional powders, polybutylene terephthalate cyclic oligomer (CBT) and a dispersing agent, performing reactive extrusion on the mixture by double screws to prepare a polybutylene terephthalate (PBT) functional master batch, wherein the functional powders are one of or several of a carbon nano tube, nano titanium dioxide, tourmaline powders, a nano-silver antibacterial agent, a nano silicon oxide and fluorescent powders; and secondly, blending and spinning the master batch, the PBT, polyethylene glycol terephthalate (PET) or polytrimethylene terephthalate (PTT) to prepare the functional polyester fibers. According to the method, the reactive extrusion process is adopted, the operation is simple and convenient, the process flow is shortened greatly, the obtained PBT functional master batch contains 30wt%-40wt% of the functional powders, and can be well dispersed in a base body, the compatibility of the obtained functional master batch and polyester polymer is good, and the fiber obtained by the method has an obvious functional effect.

Owner:ZHOUSHAN XINXIN CHEM FIBER

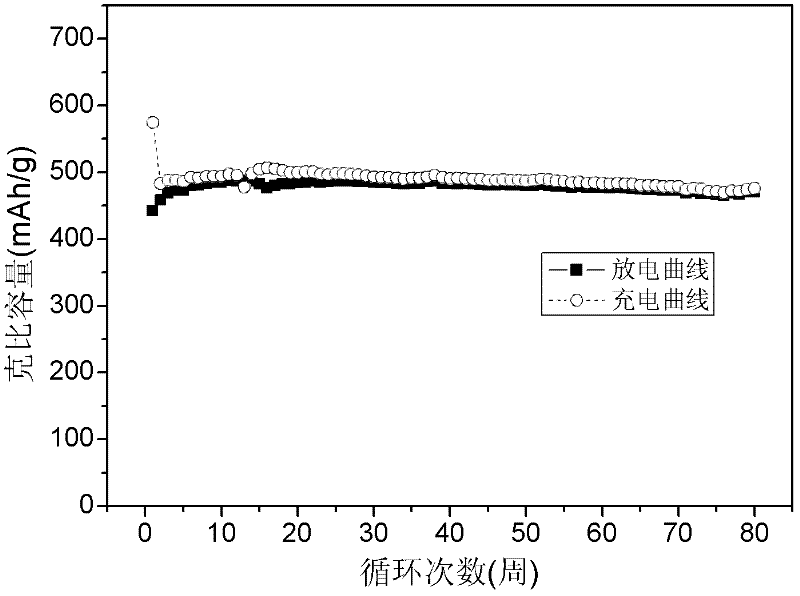

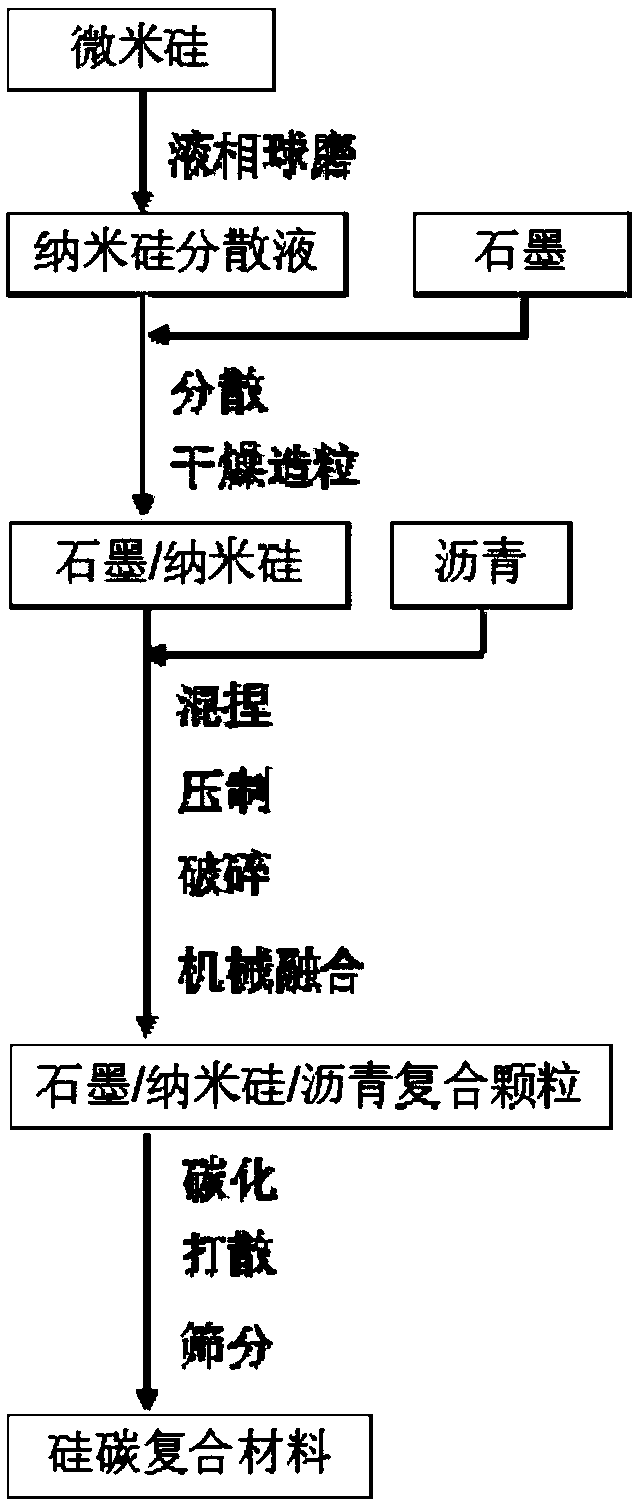

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com