Patents

Literature

1478results about How to "Coated evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for cladding surfaces of active material of anode and/or anode and methods manufacturing anode and battery

InactiveCN102244231AStructurally intactStable structureNon-aqueous electrolyte accumulator electrodesMetallurgyLithium-ion battery

The invention provides a method for cladding surfaces of an active material of an anode and / or the anode and methods for manufacturing the anode and a battery. In the cladding method, an atomic layer deposition technology is adopted to deposit surface modification substances on the surfaces of the active material of the anode and / or the anode of a lithium battery. According to the invention, the cycle performance and the specific capacity of the lithium-ion battery can be improved obviously and electrode materials are more stable.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Latent coating for metal surface repair

InactiveUS6075072AEasy curingExtended service lifeLiquid surface applicatorsSynthetic resin layered productsCorrosion inhibitorMetal

A corrosion protective coating composition, applied over a metal surface, contains frangible microcapsules which rupture and release fluid upon impact or other stress likely to damage the coating. The fluid, from the microcapsules, contains a film forming component to cover the damaged area of the coating and a corrosion inhibitor for the metal surface.

Owner:3M INNOVATIVE PROPERTIES CO

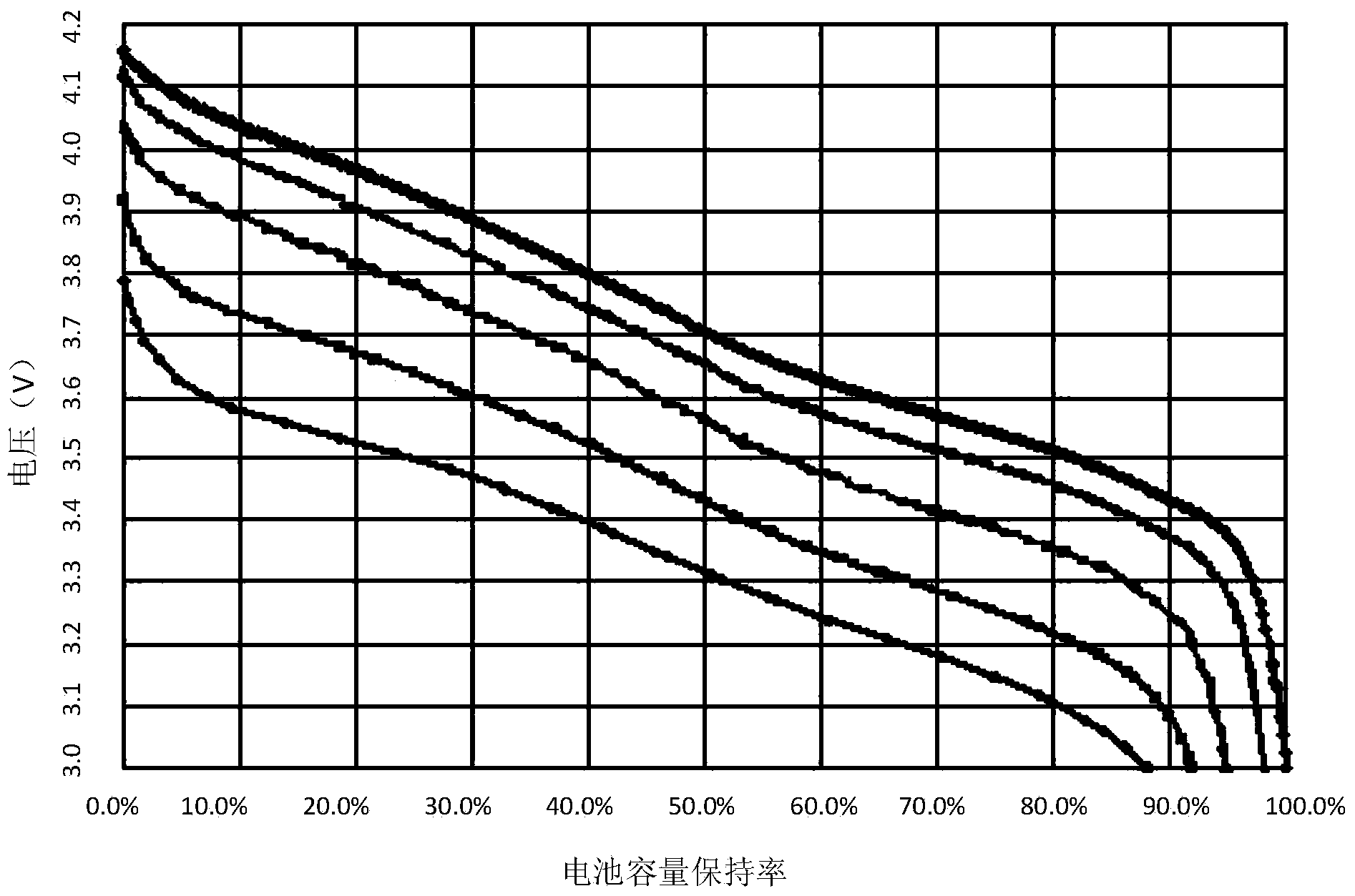

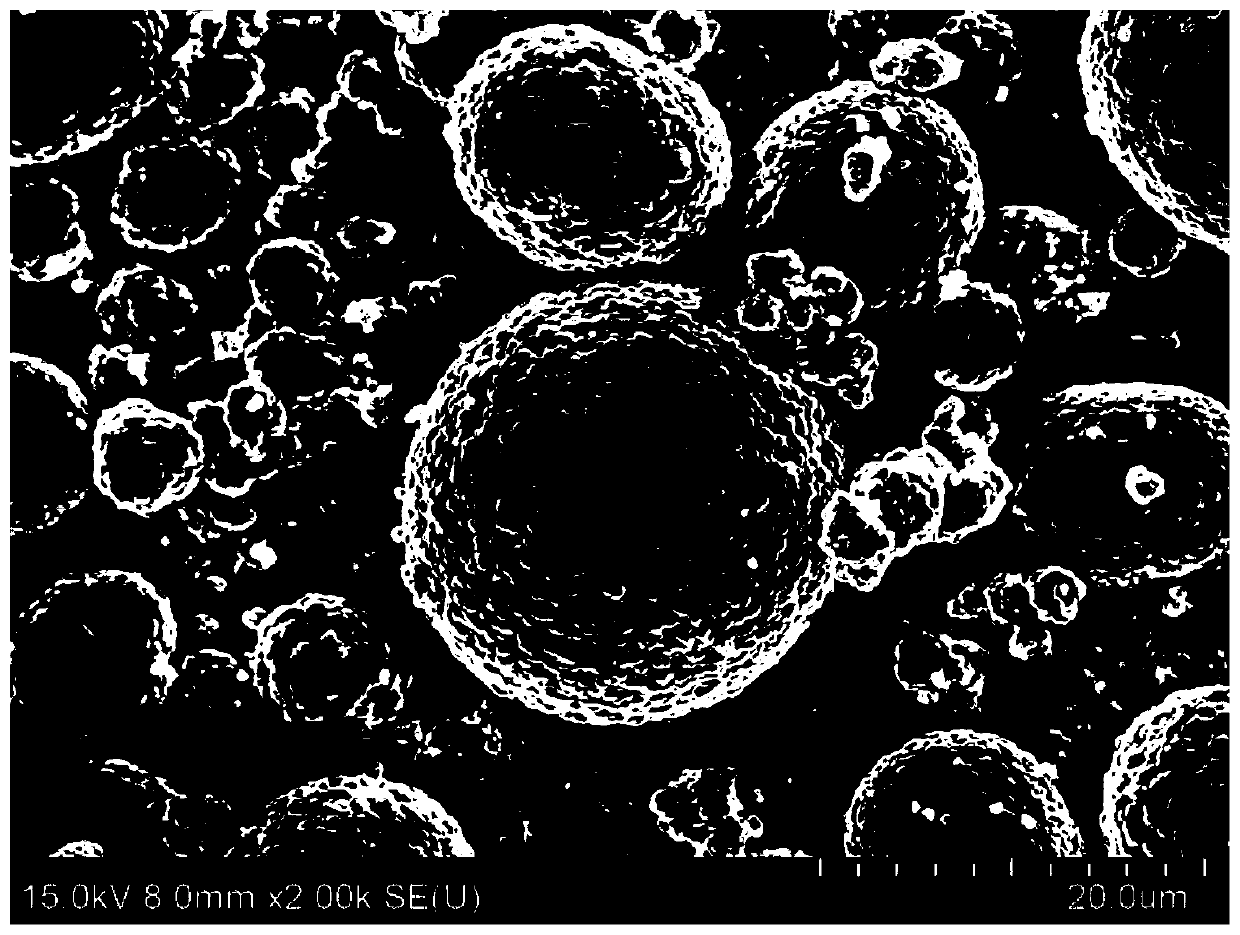

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

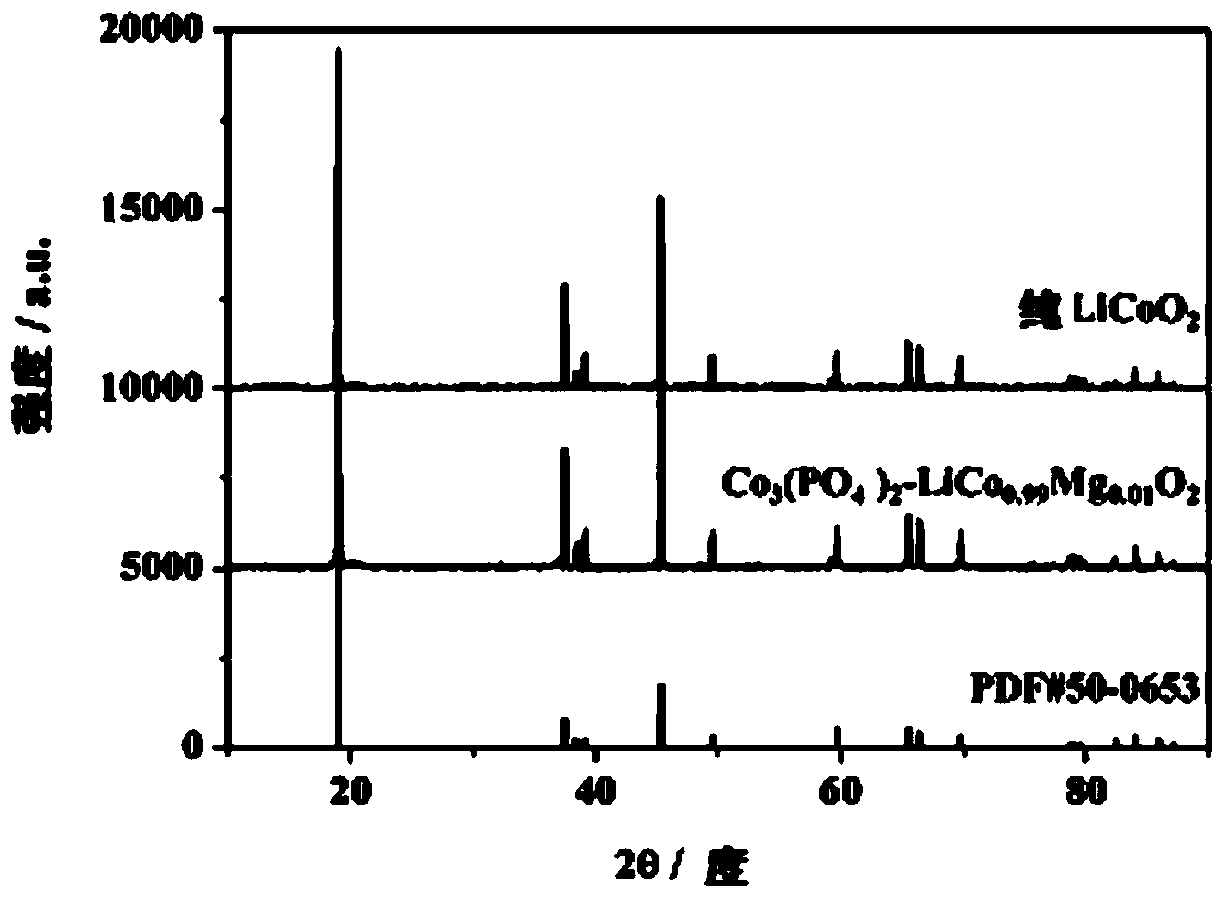

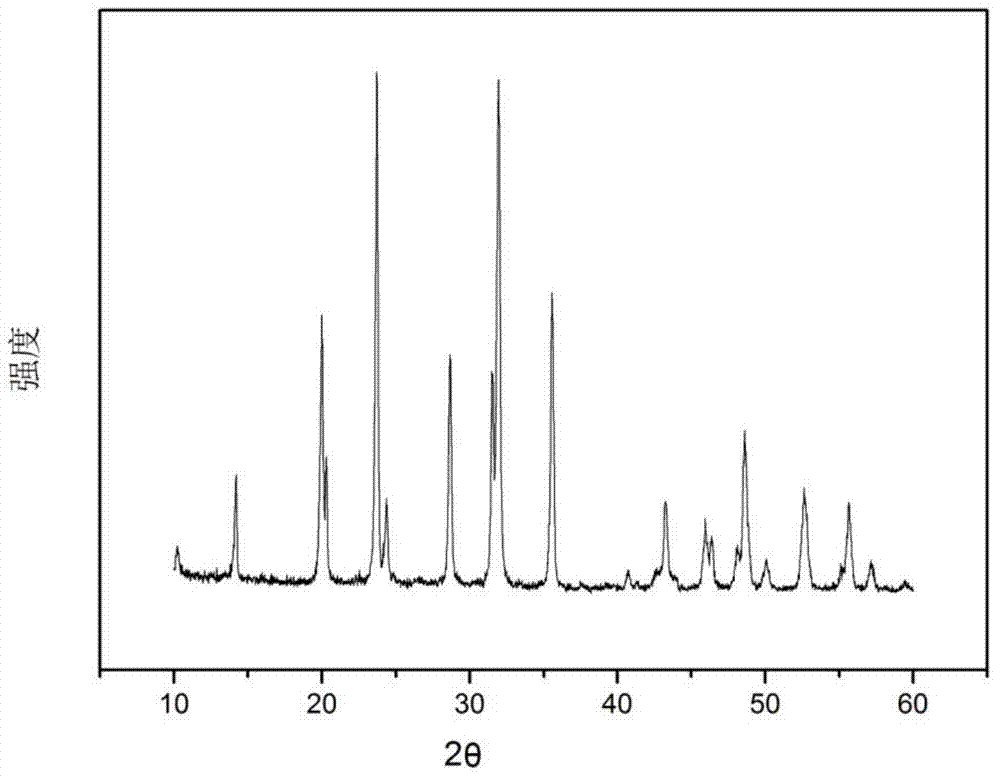

Doped and surface coating co-modified anode material for lithium ion battery and preparation method thereof

InactiveCN103779556APromote circulationEasy to operateSecondary cellsPositive electrodesEnvironmental resistancePhosphate

The invention discloses a doped and surface coating co-modified anode material for a lithium ion battery and a preparation method thereof. The anode material uses doped lithium cobalt oxide as a matrix, the surface of which is coated with Co3(PO4)2, AlPO4, Mn3(PO4)2, FePO4, Ni3(PO4)2, Mg3(PO4)2 and other phosphates, therefore, the electric conductivity, the circulating performance, the high temperature and high pressure resistance and other performances are improved. The preparation method has the advantages that the coating material is uniformly coated on the surface of the anode material to be beneficial to improving the electrochemical performance; the method is simple to operate, is green and environment-friendly and has industrial applicability.

Owner:北京盟固利新材料科技有限公司

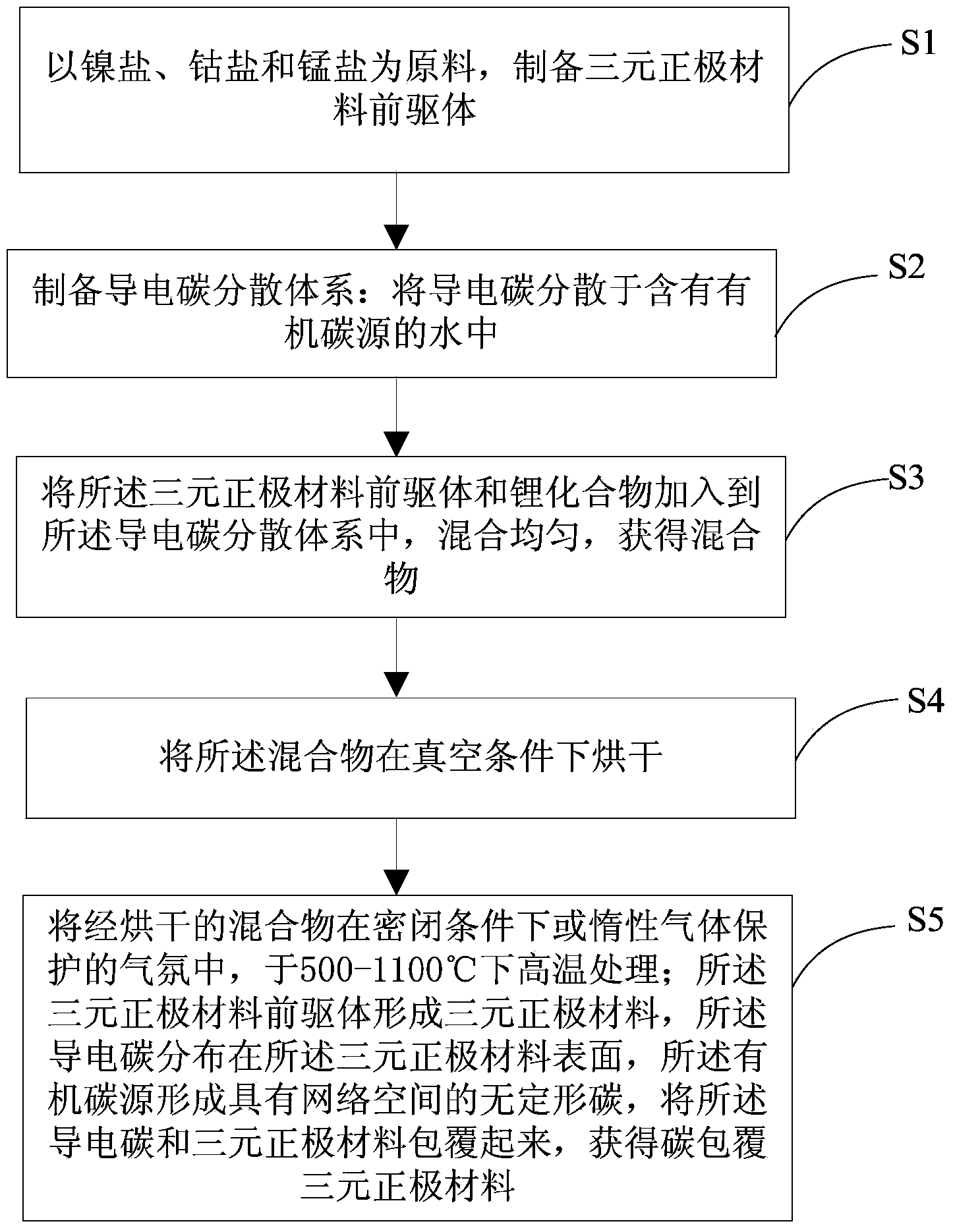

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

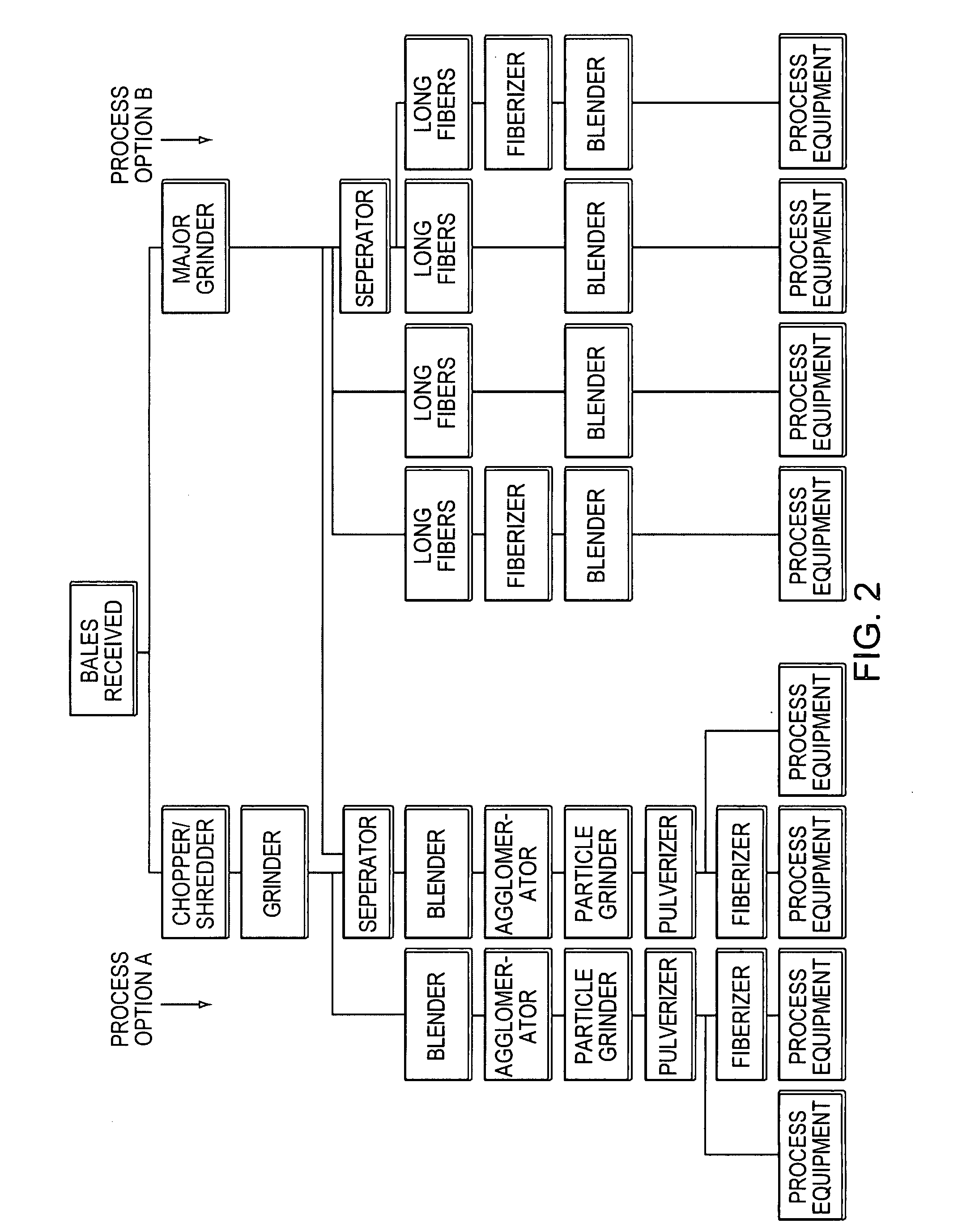

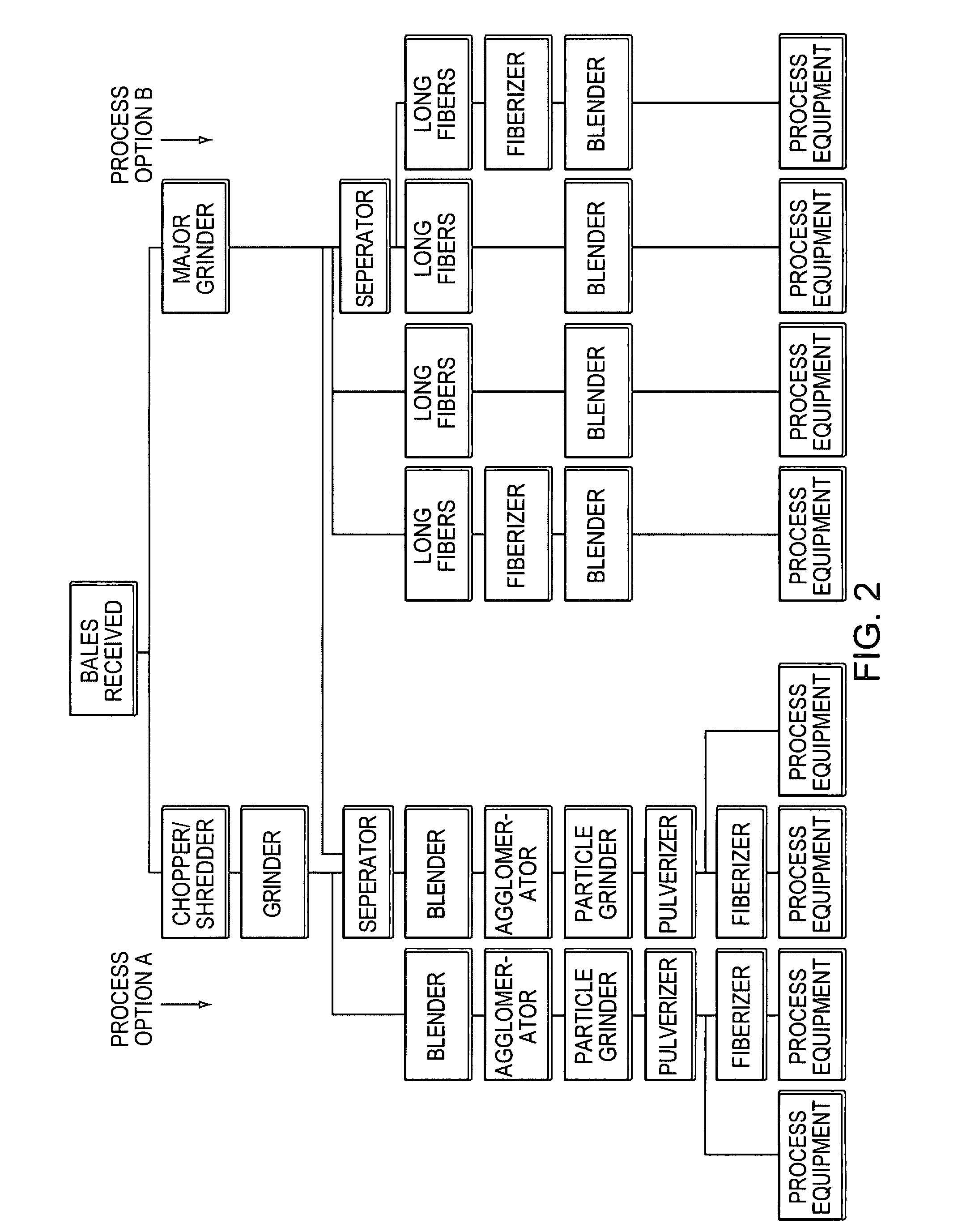

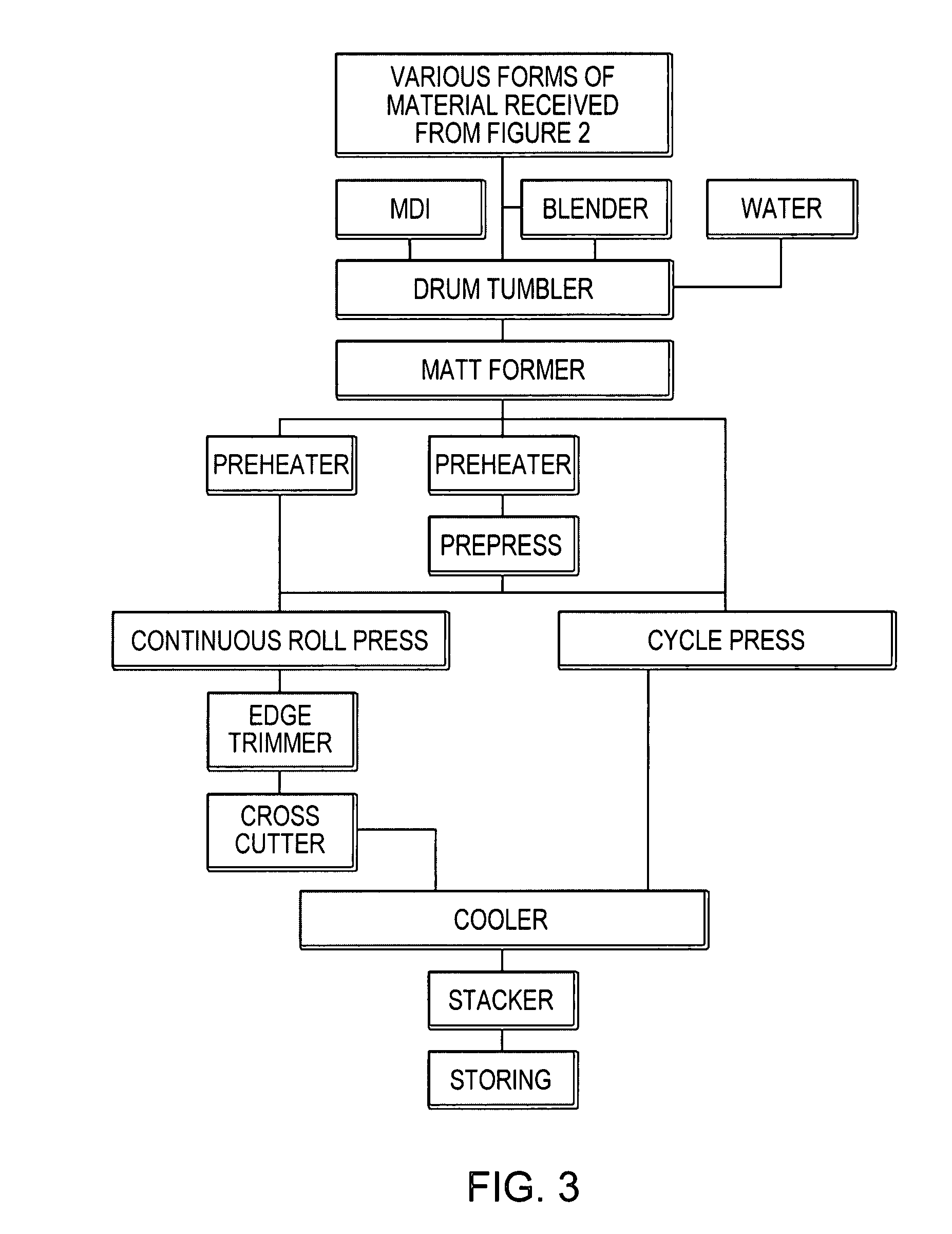

Carpet Waste Composite

A composite material is produced from carpet waste and a binding agent, in intimate association, and may also include wood fiber or chips and / or other additives. A method of manufacturing a composite material includes shredding carpet waste, coating the carpet waste with a binding agent, and subjecting the shredded, coated carpet waste to elevated heat and pressure. As an additional step, the composite material may be actively cooled to prevent deformation of the material.

Owner:MATERIAL INNOVATIONS LLC

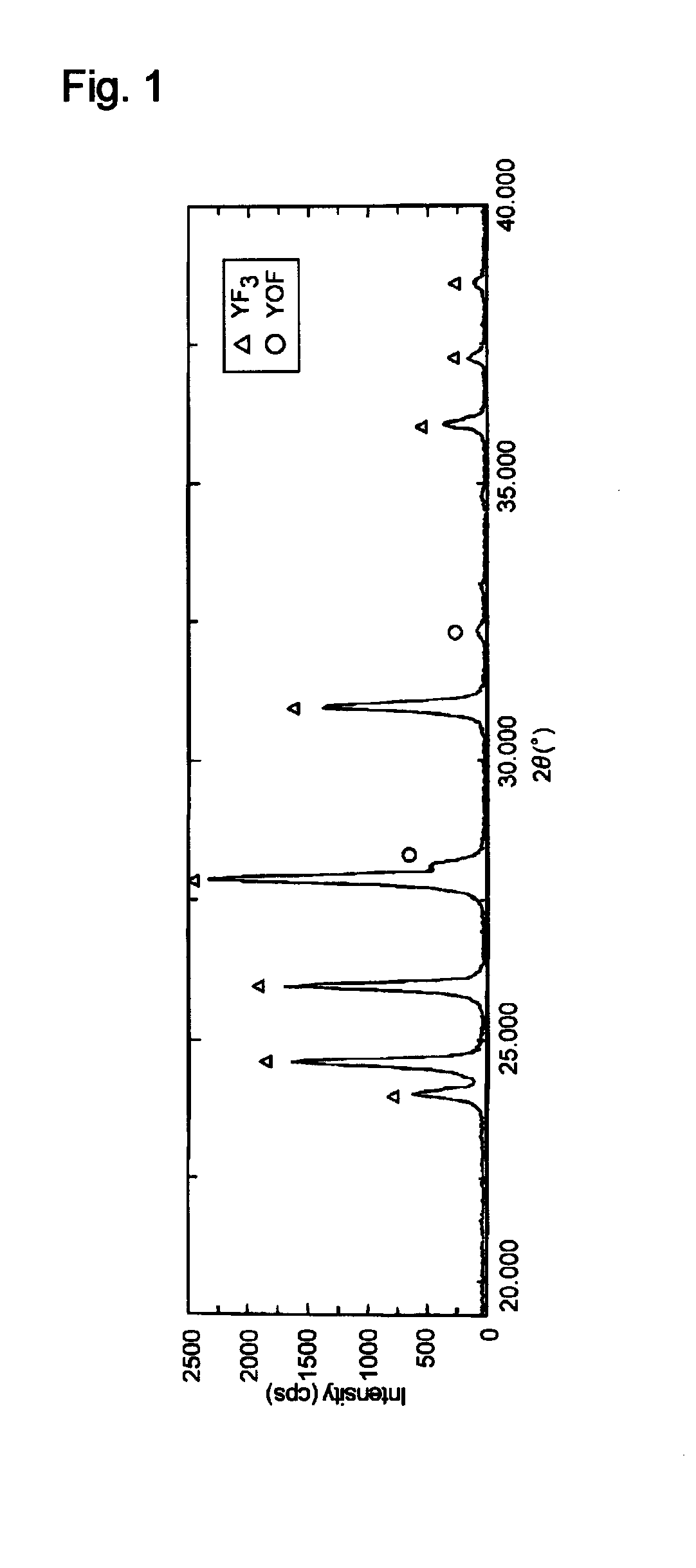

Thermal spray material and process for preparing same

ActiveUS20150096462A1Smooth thermal spray coatingFormed with easeMolten spray coatingRare earth metal compoundsRare-earth elementThermal spraying

A thermal spray material includes granules of an oxyfluoride of yttrium (YOF). The granules may contain a fluoride of yttrium (YF3). The granules preferably have an oxygen content of 0.3 to 13.1 mass %. The granules preferably have a fracture strength of 0.3 MPa or more and less than 10 MPa. Part of yttrium (Y) of the granules may be displaced with at least one rare earth element (Ln) except yttrium, the molar fraction of Ln relative to the sum of Y and Ln being preferably 0.2 or less.

Owner:NIPPON YTTRIUM

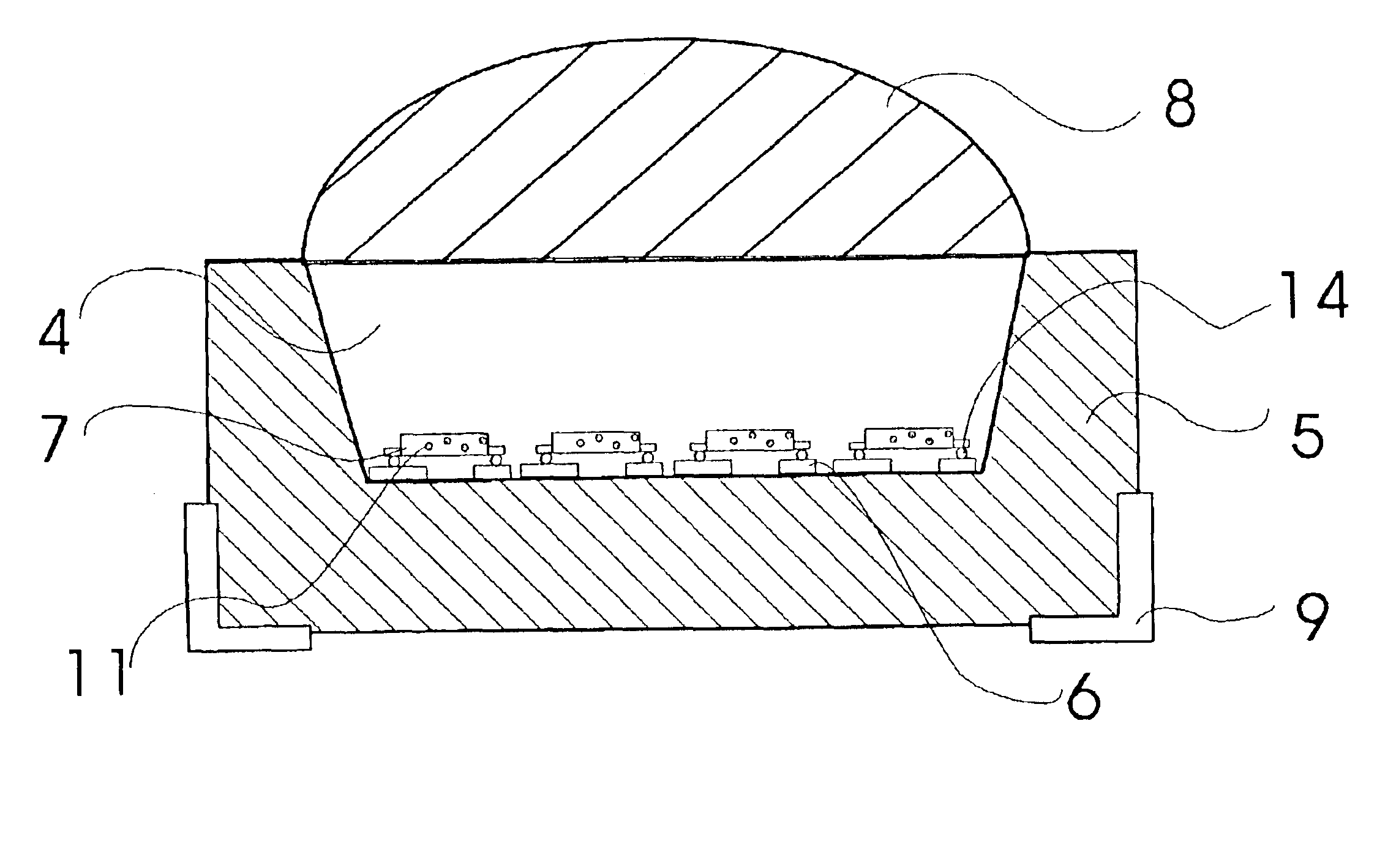

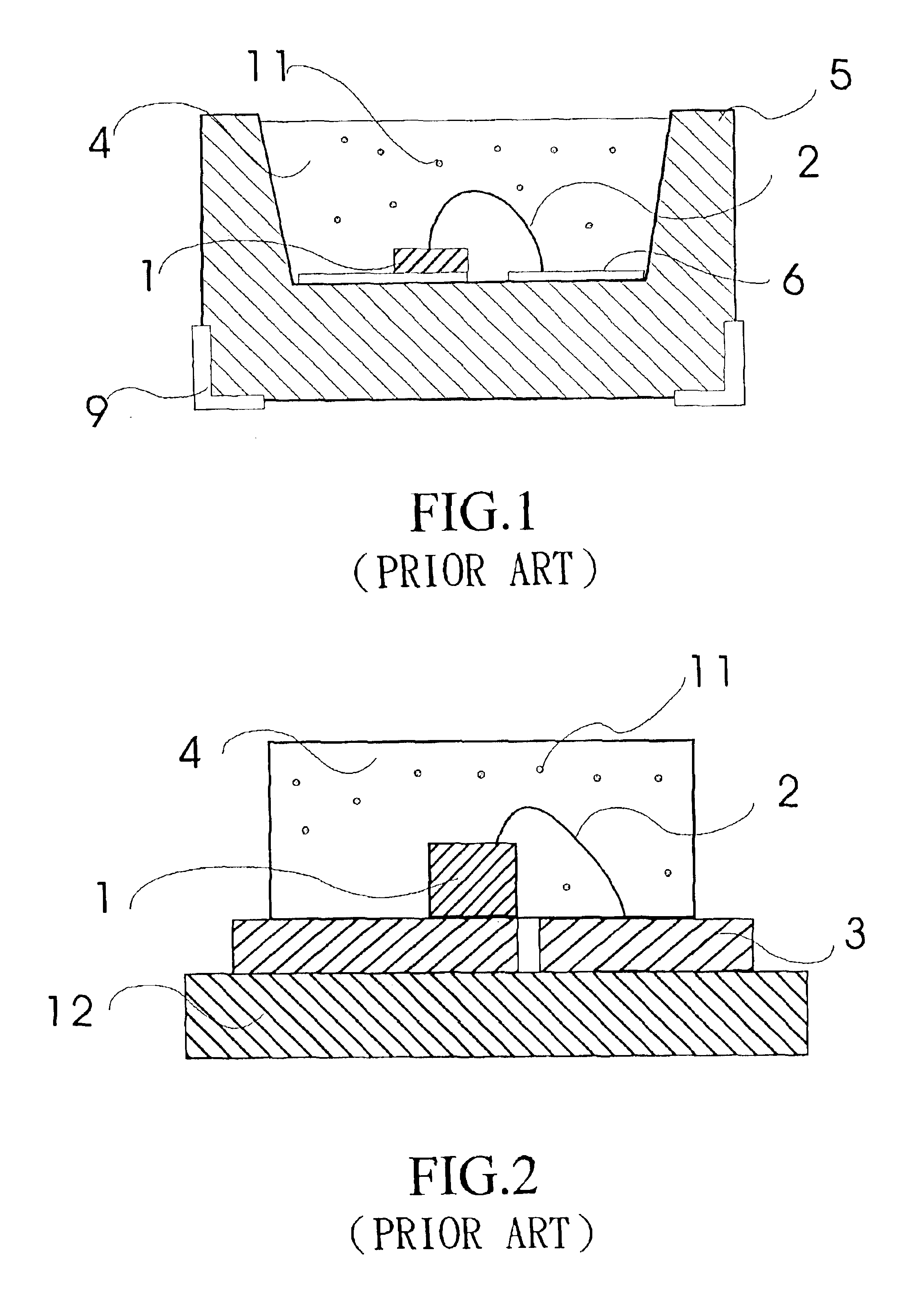

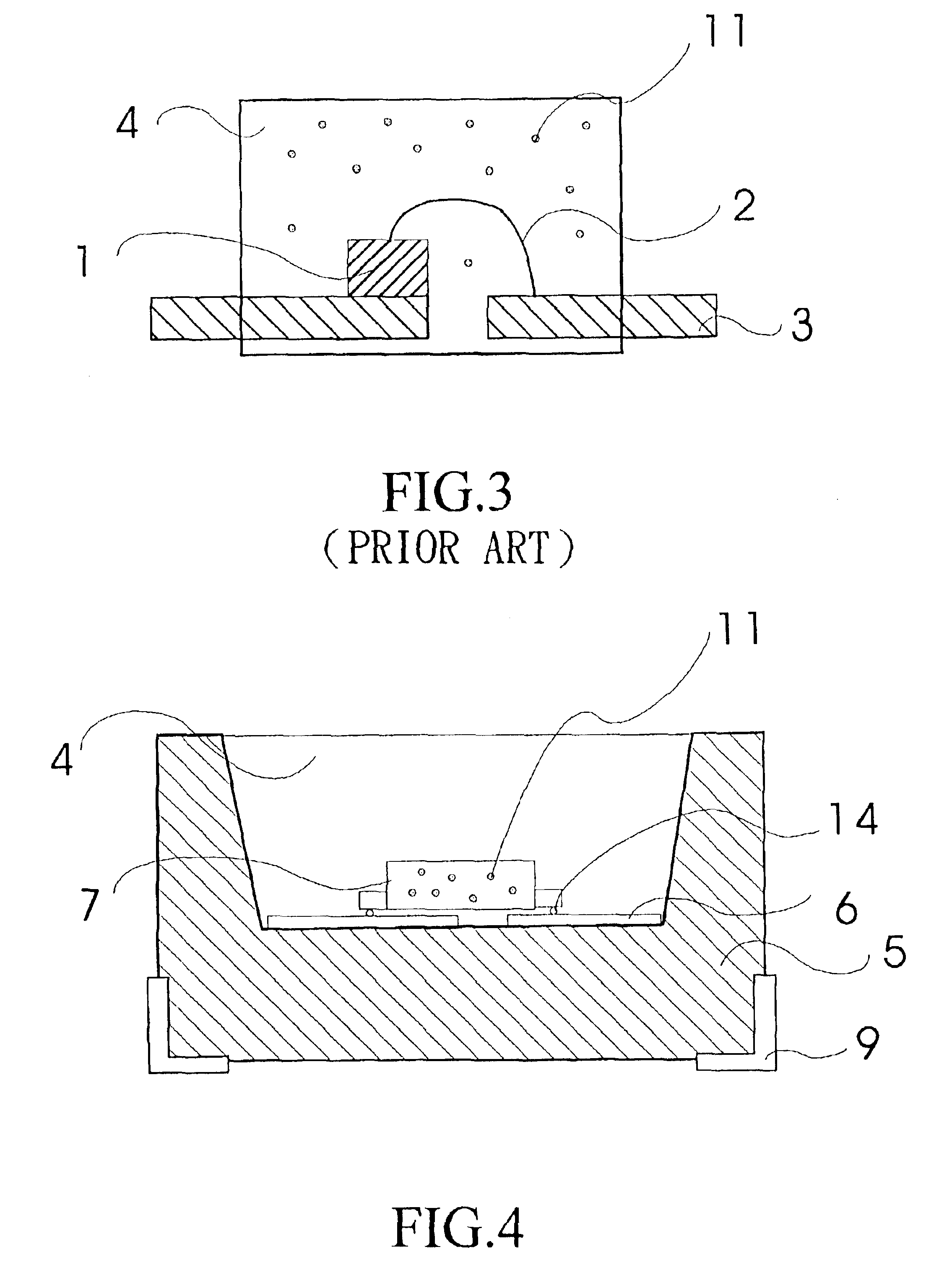

Package structure of a composite LED

InactiveUS6909234B2Reduce volumeGreat brightnessDischarge tube luminescnet screensSemiconductor/solid-state device detailsEngineeringColor shift

A package structure of a composite LED is to package an LED chip into a SMD LED package subbody component. Then, a single SMD LED package subbody component or multiple SMD LED package subbody components may be packaged into a large sized recessed package mother body, thereby forming the package structure of a composite LED. Thus, the quality is better, and the color shift is less, thereby enhancing the quality of production, and thereby decreasing the cost of production. In addition, the SMD LED may be previously classified according to the features, and may then be packaged into the mother body, thereby obtaining better features, such as Vf, color, brightness or the like.

Owner:SOLIDLITE CORP

Modified lithium ion battery positive electrode material and preparation method therefor

InactiveCN105470455AImprove performanceImprove cycle stabilityCell electrodesLithium aluminateLithium-ion battery

The invention provides a modified lithium ion battery positive electrode material. The modified lithium ion battery positive electrode material is characterized in that LiNi0.8Co0.15Al0.05O2 is taken as a core and a lithium-containing composite oxide is taken as a shell; and the lithium-containing composite oxide is selected from one or more of Li2TiO3, Li2SiO3, Li4SiO4, Li3PO4, Li4P2O7 and Li2ZrO3. According to the surface modified nickel cobalt lithium aluminate positive electrode material provided by the invention, a coating material with electronic conductivity or lithium ion conductivity is taken as the shell, so that the modified material has a surface layer with a lithium ion conductivity property; a surface solid solution layer with stable chemical stability endows the nickel cobalt lithium aluminate positive electrode material and an electrolyte with high interfacial compatibility and interfacial structural stability, so that the charge-discharge cycling stability of the product is improved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Novel aluminum alloy and heat tinting process for the aluminum alloy product

The invention relates to the technical field of aluminum alloy products, in particular to an aluminum alloy suitable for extrusion process and capable of obtaining the oxidizing protection and an oxidizing colored process thereof. The aluminum alloy suitable for extrusion process and capable of obtaining the oxidizing protection contains ADC12 and 6# aluminum, wherein the mass percentage of the ADC12 is 20% to 80%, mass percentage of the 6# aluminum is 80%-20%. The invention combines performance complement between the ADC12 and the 6# aluminum to obtain oxidation protection without changing the physical properties of die-casting aluminum alloy ADC12 and greatly enhance the use performance of the aluminum alloy, and leads the whole interior and exterior profiles to be colorful by adding pigments in the novel aluminum alloy so that hue of the profiles is no longer dull by different colors, so as to meet the requirement of consumers. The oxidizing colored process of the aluminum alloy products has the advantages of plumpy, uniform, level and smooth coatings and obviously better rigidity, adhesive force, erosion resistance, impact property and permeability than other coating techniques.

Owner:东莞市东兴铝业有限公司

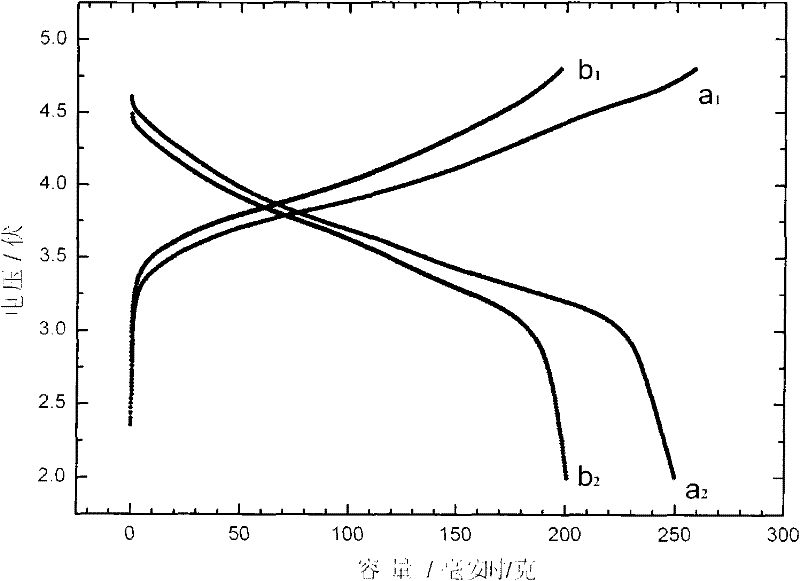

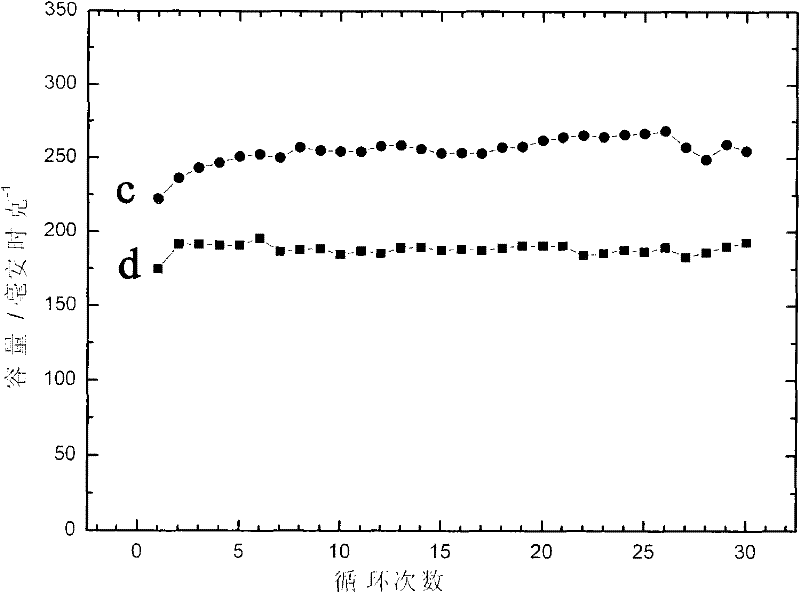

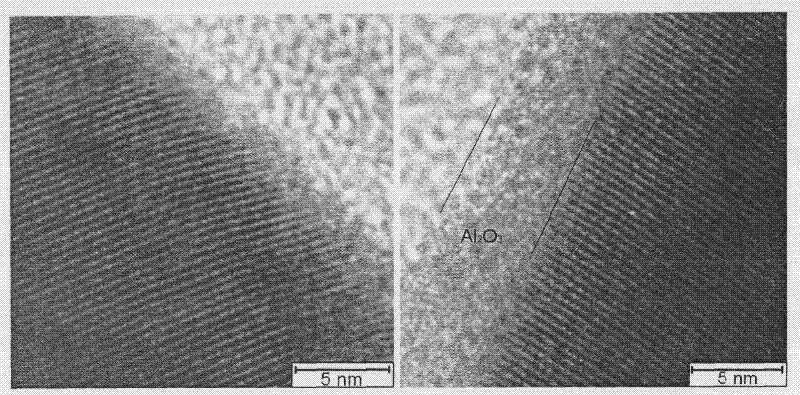

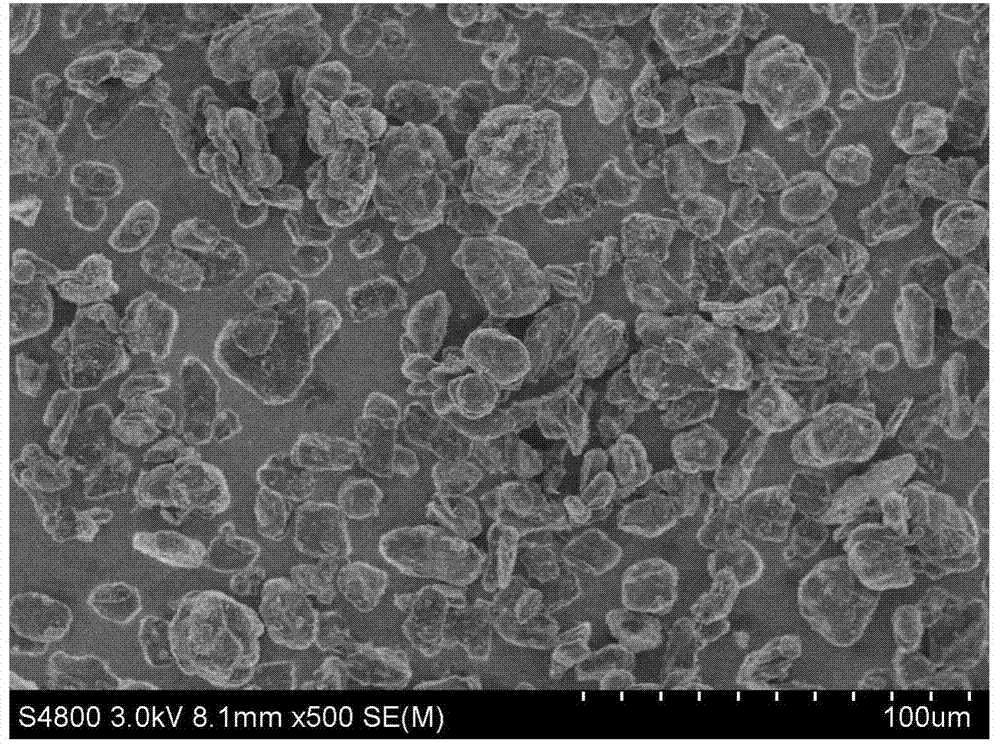

Modification method for improving high-temperature cycle performance and ionic conductance of lithium iron phosphate material

The invention discloses a modification method for improving the high-temperature cycle performance and ionic conductance of a lithium iron phosphate material. The method mainly comprises the following steps of: mixing an organic compound which contains silicon, aluminum and titanium with lithium iron phosphate; performing certain heat treatment; and coating silicon dioxide, aluminum oxide or titanium oxide onto the surface of the lithium iron phosphate material to fulfill the aim of improving the electrochemical performance of the lithium iron phosphate material. The high-temperature cycle performance and the high-magnification charging-discharging current cycle capacity of coating-modified lithium iron phosphate are enhanced, and the impedance of a prepared electrode is remarkably reduced. The lithium iron phosphate material can be applied to more fields. A coating method has the advantages of simple process, low cost, stable and controllable product performance and suitability for industrial production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

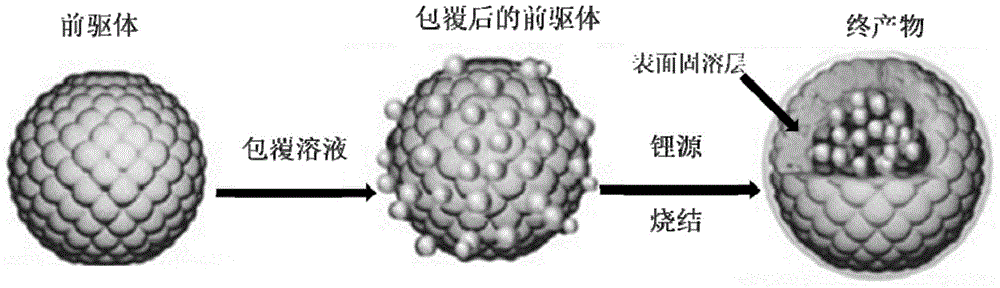

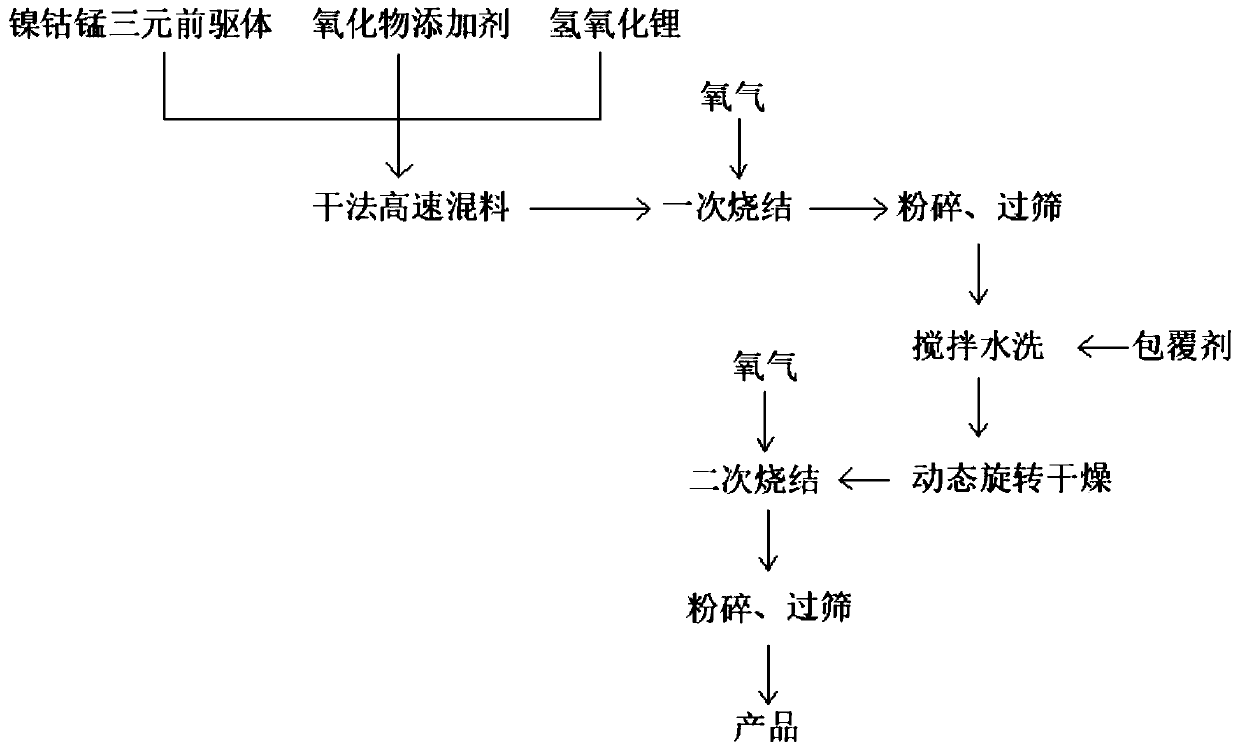

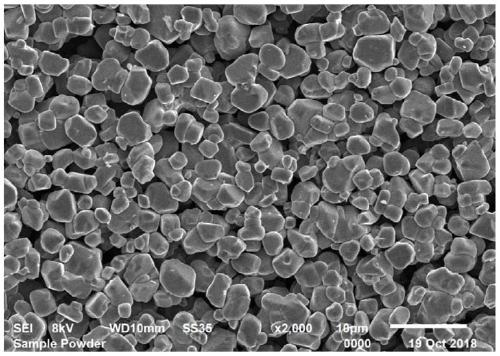

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

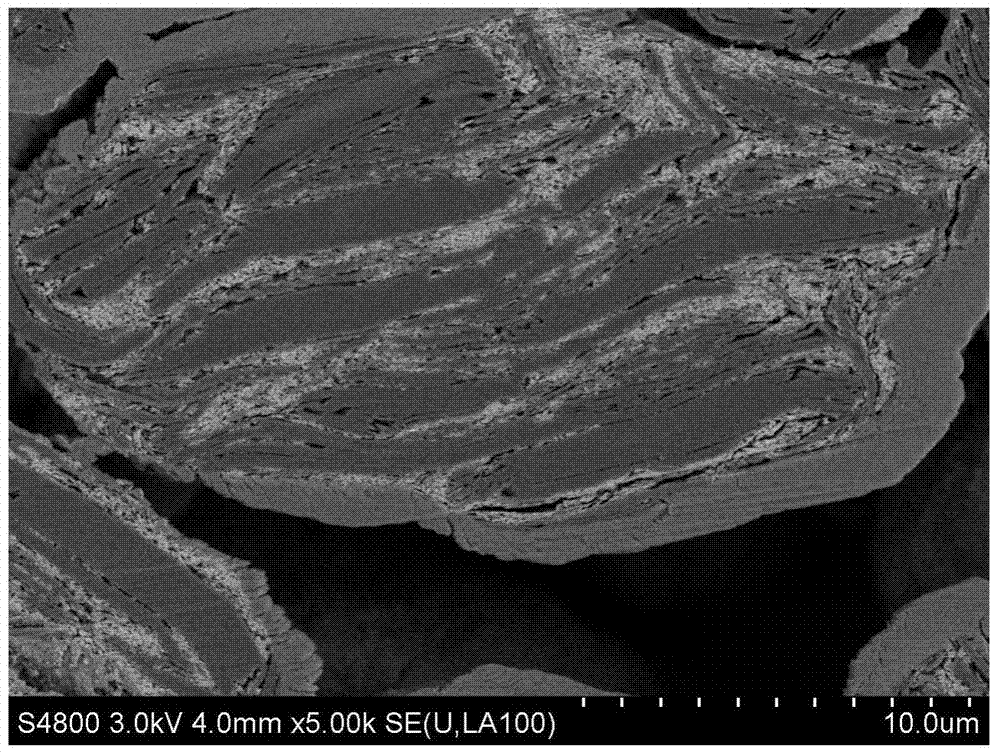

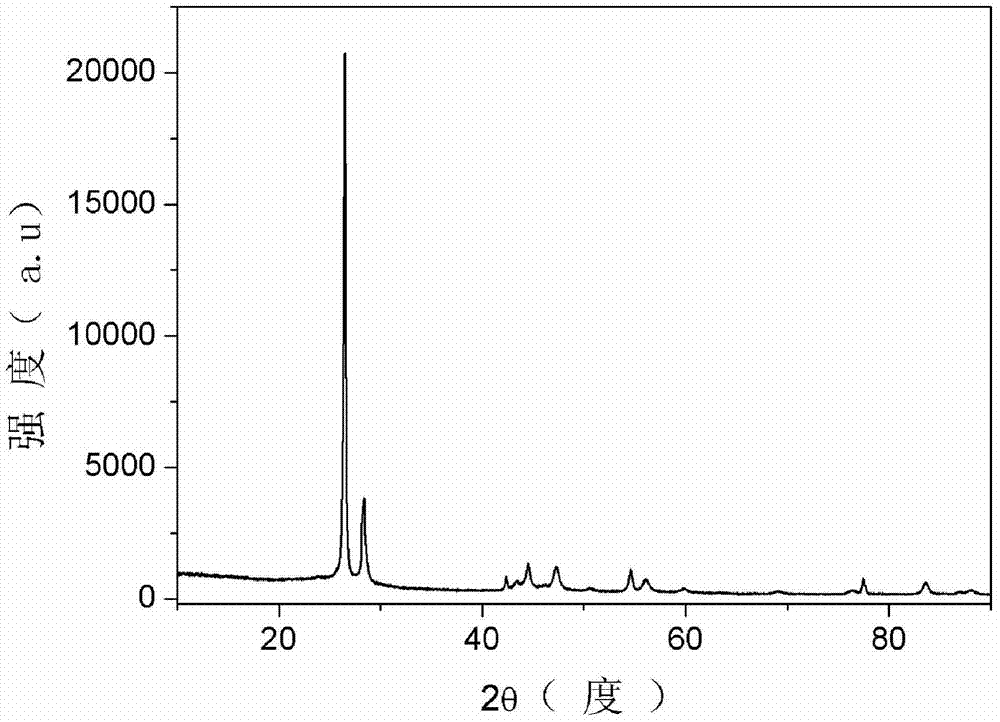

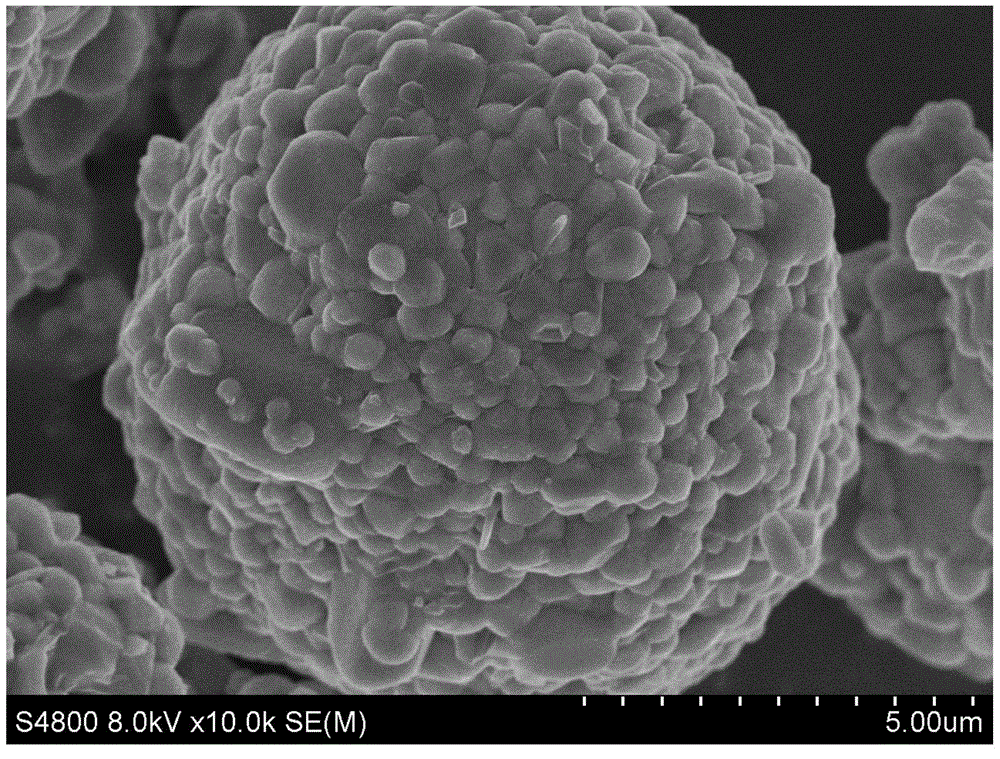

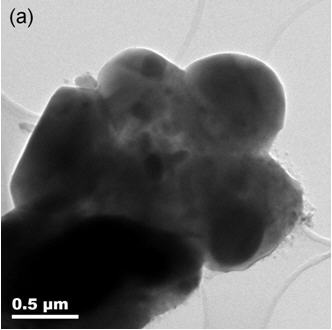

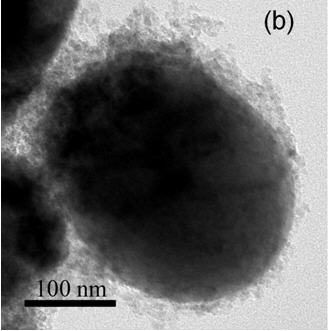

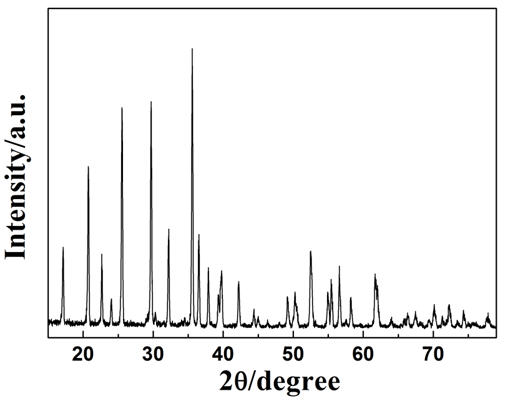

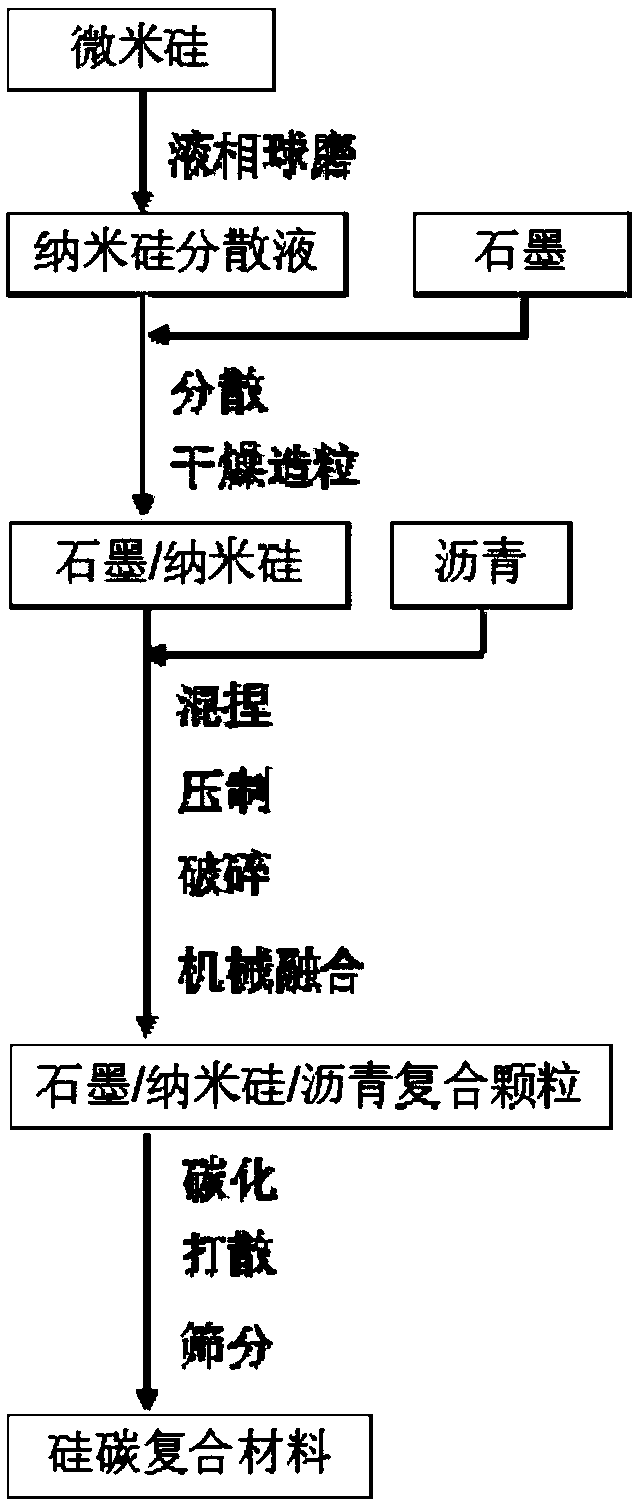

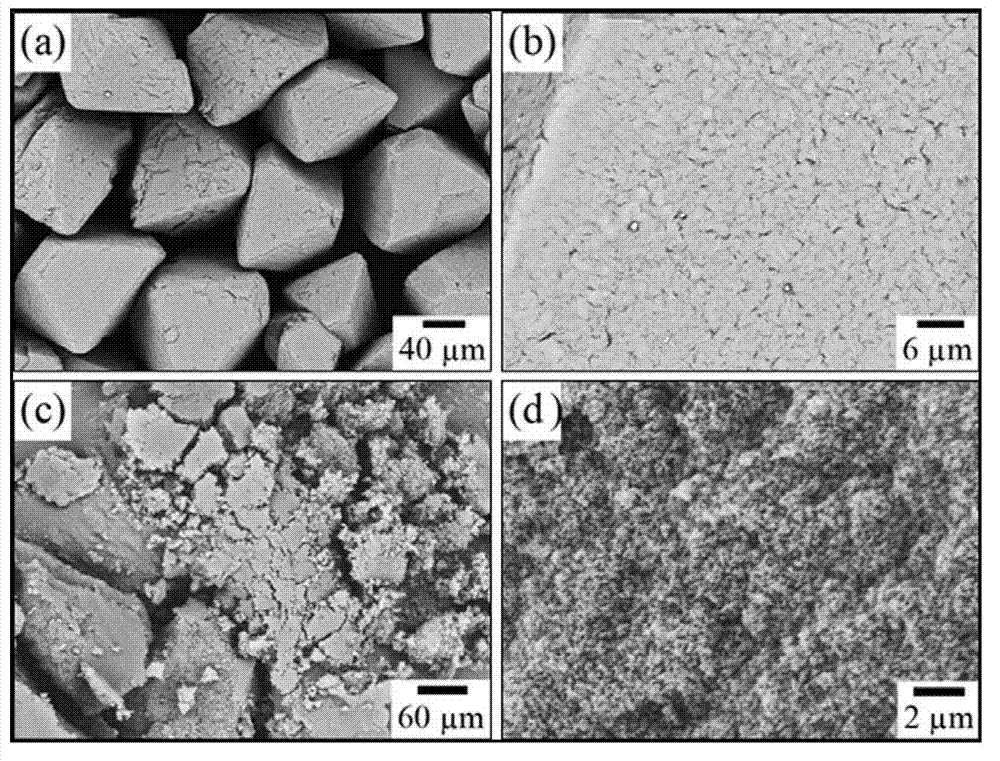

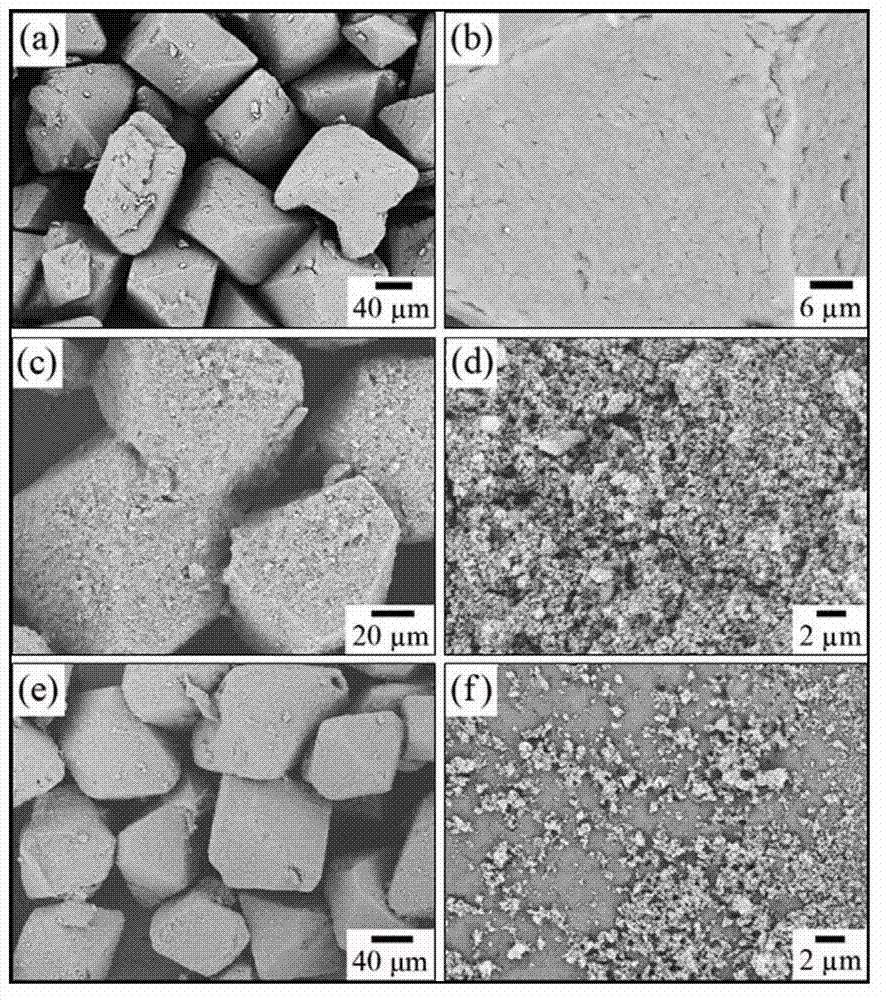

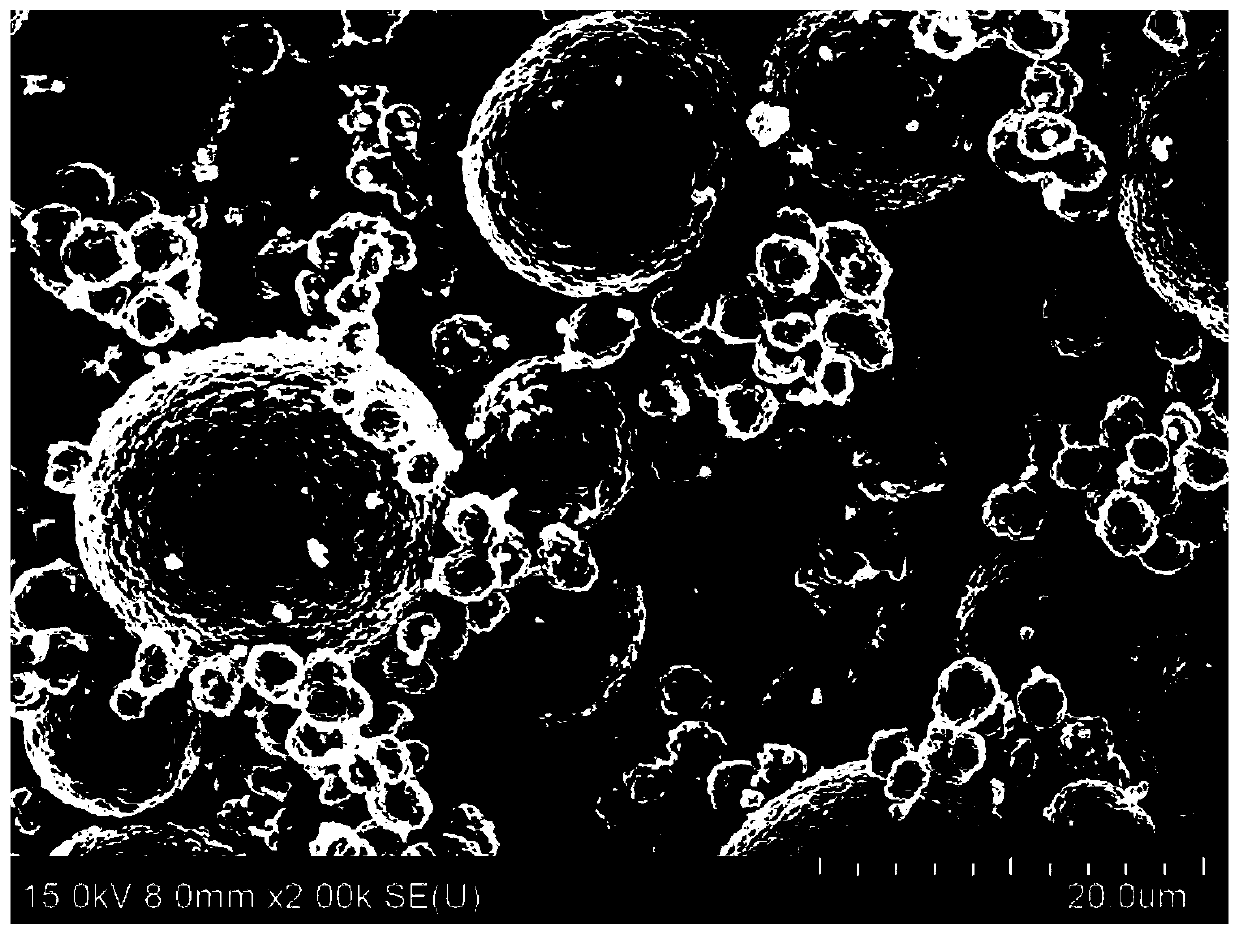

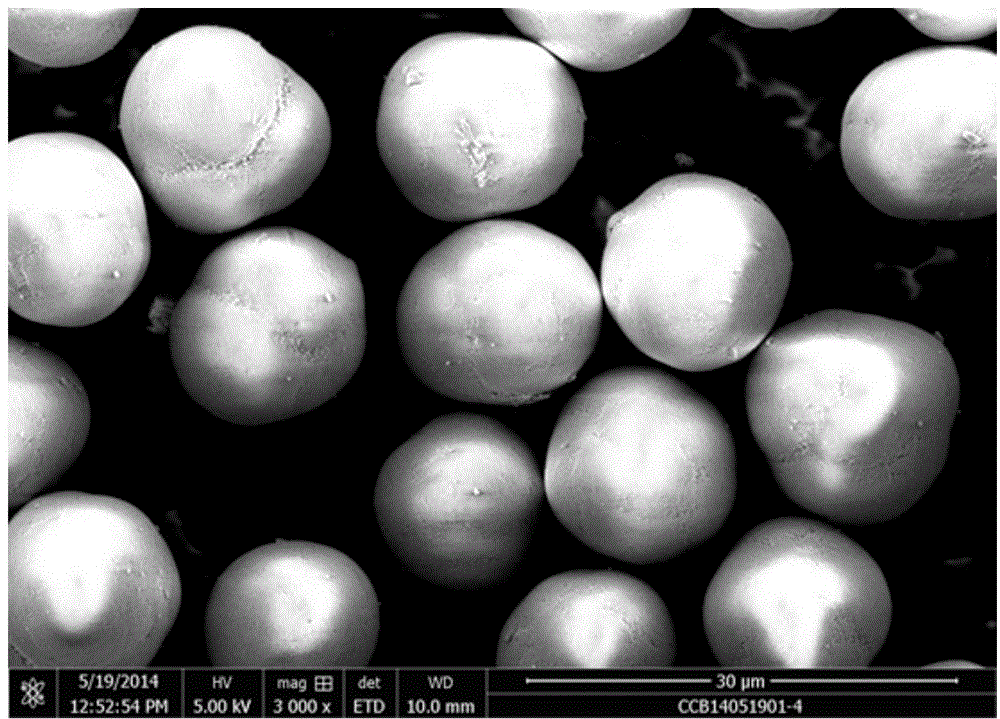

High-performance silicon-carbon cathode material and preparation method thereof

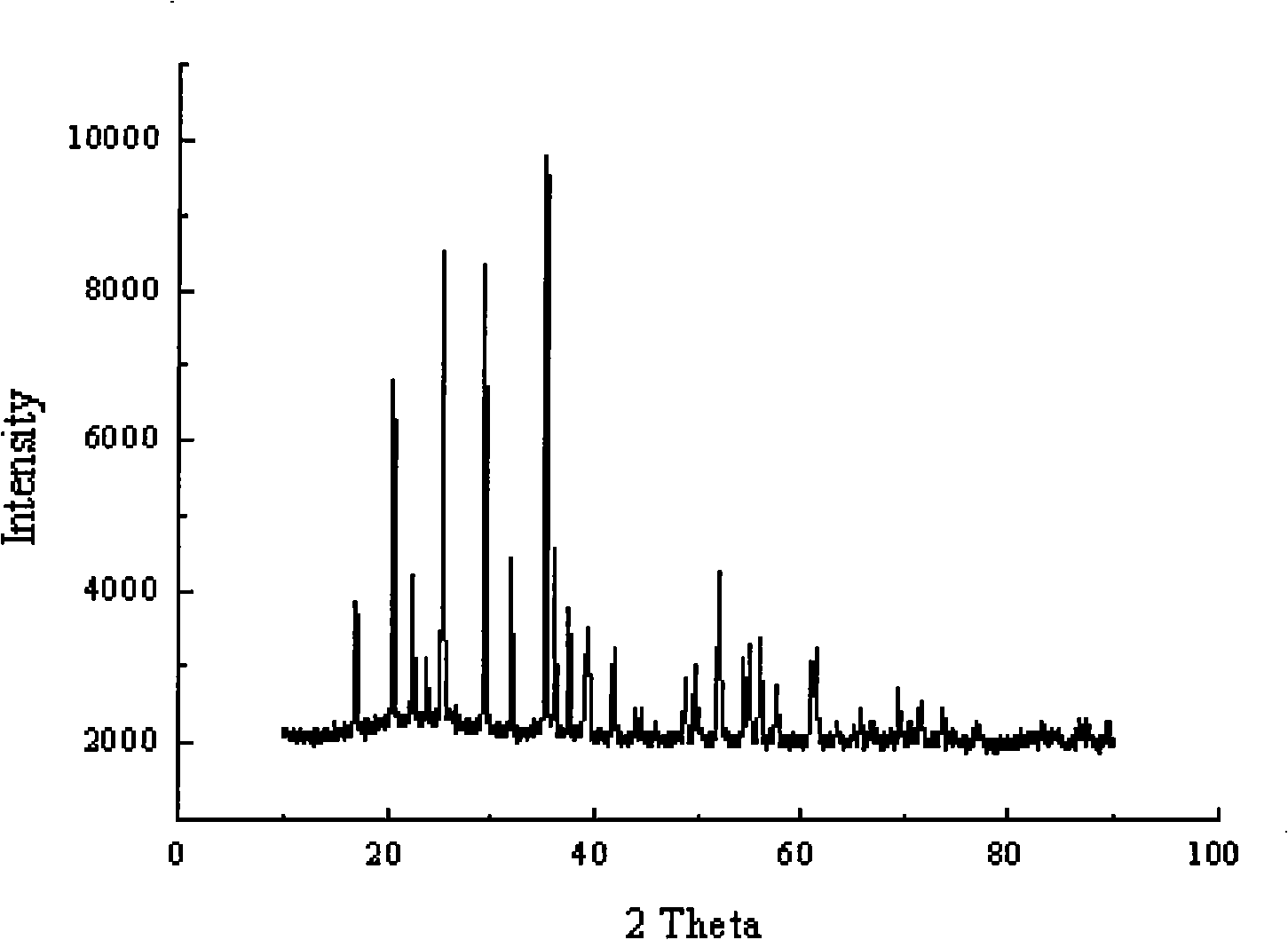

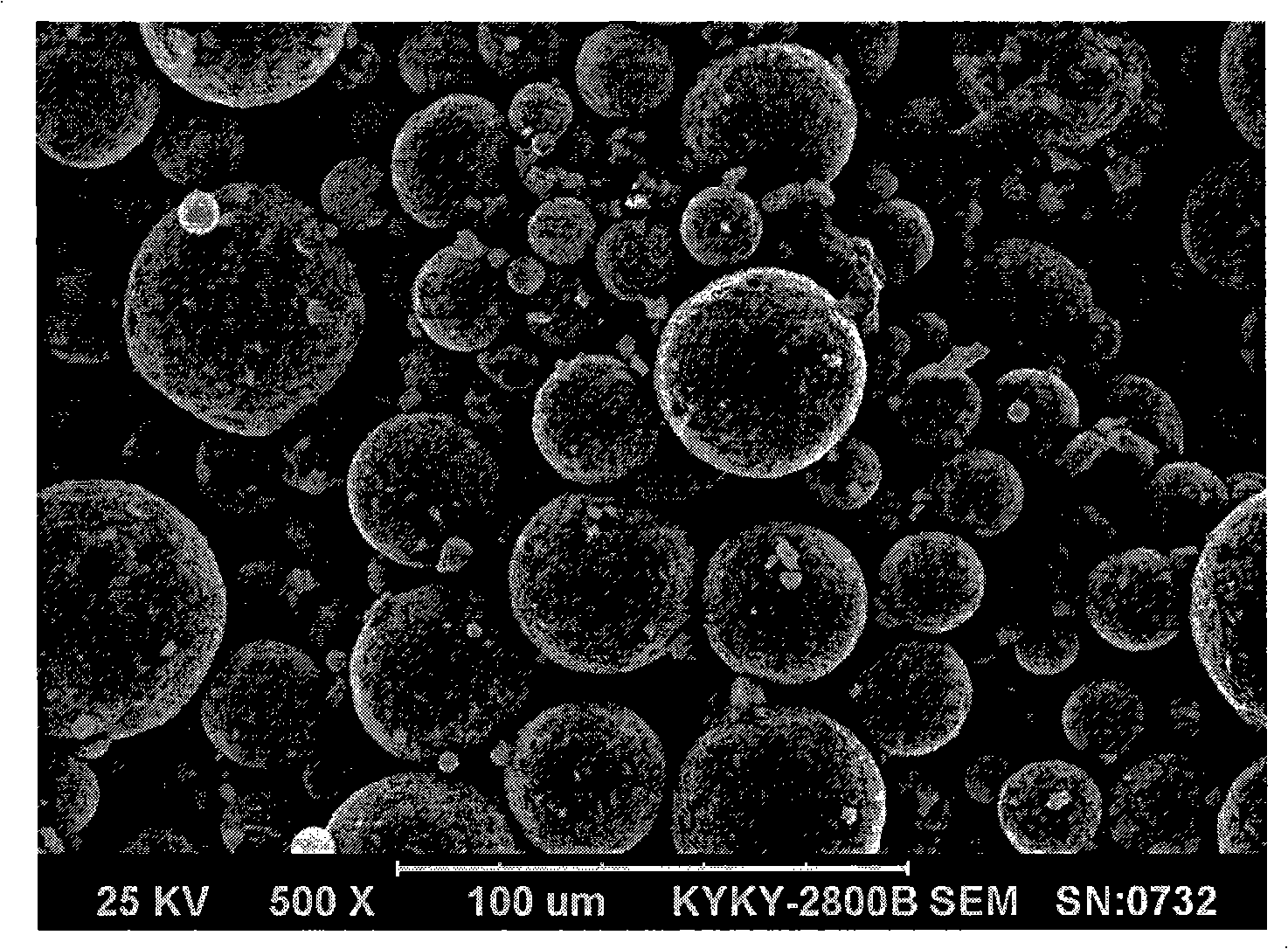

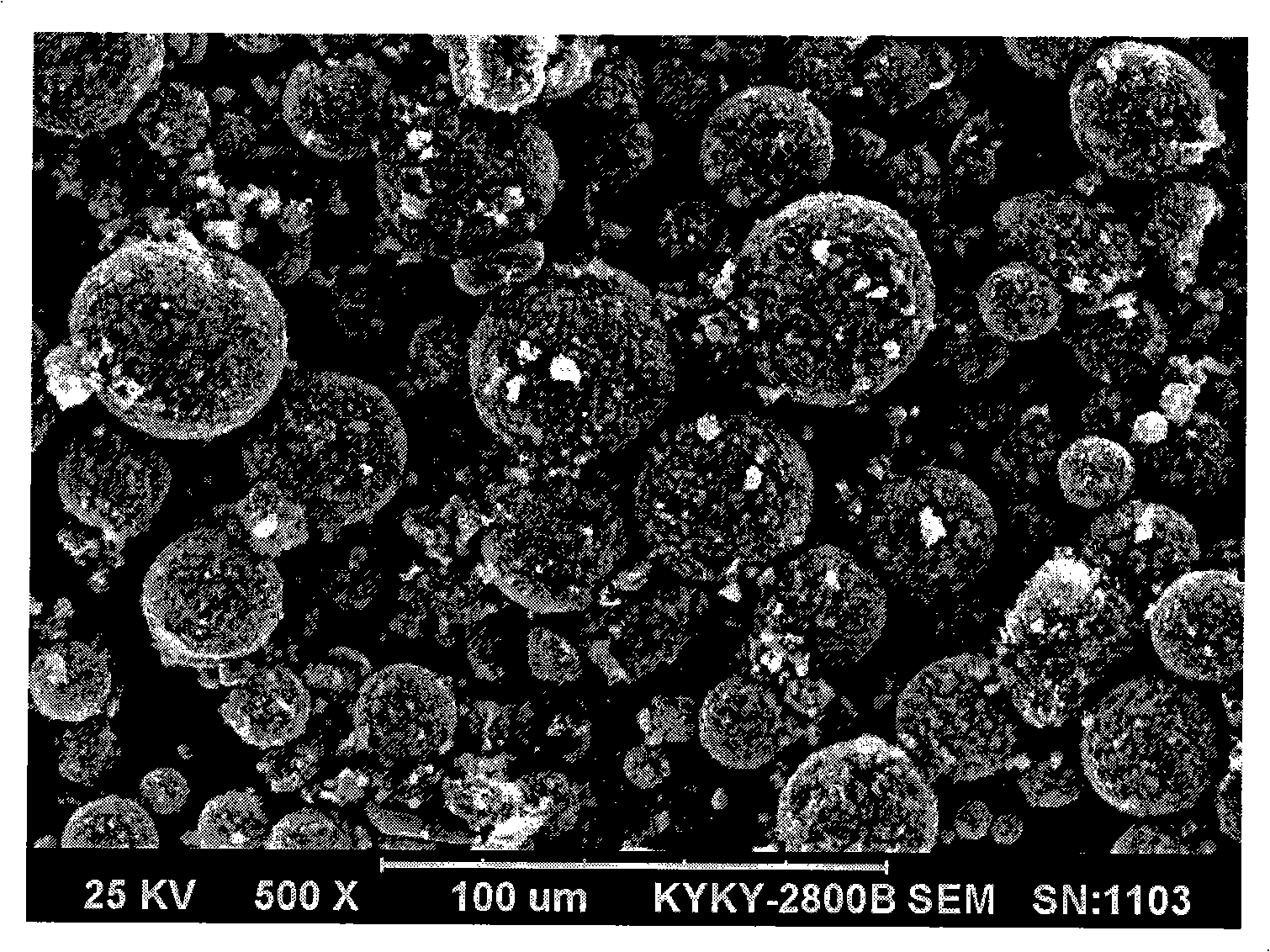

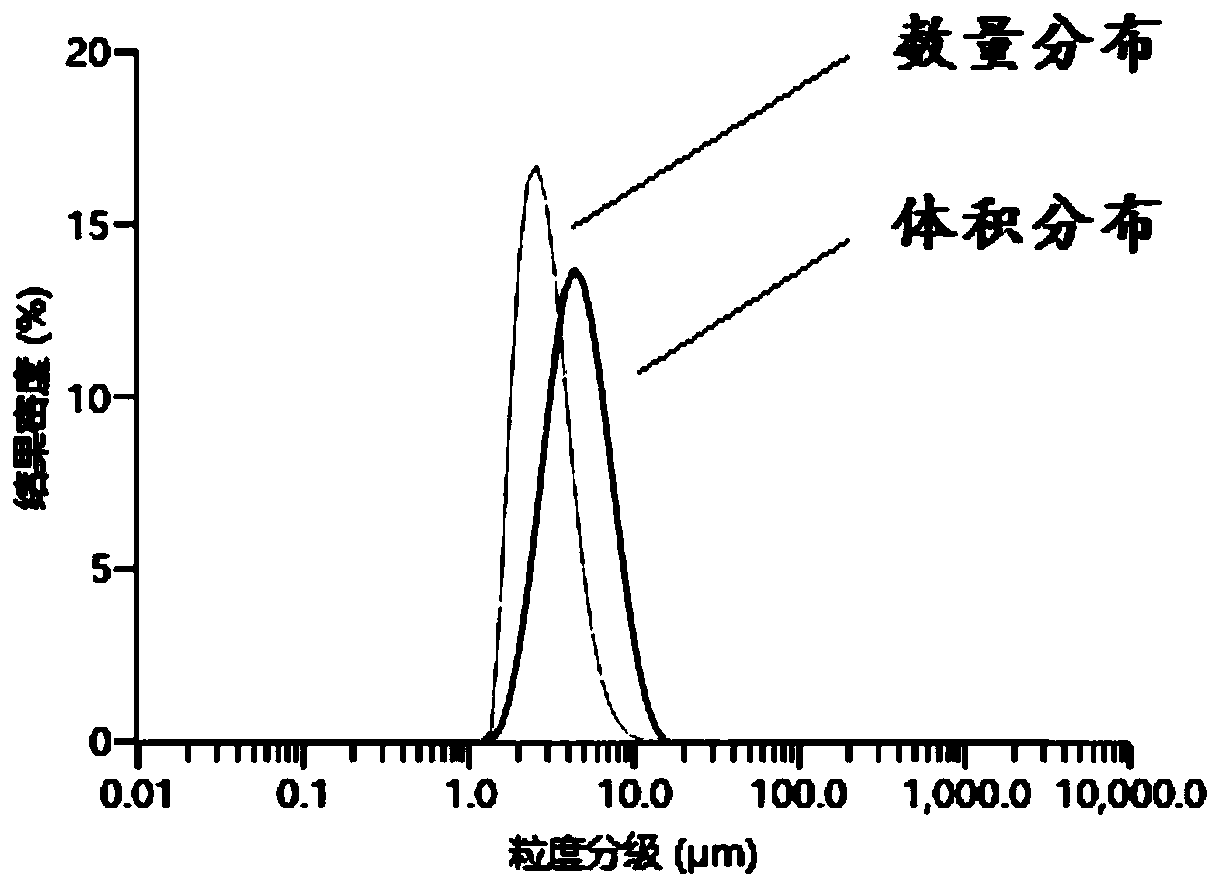

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

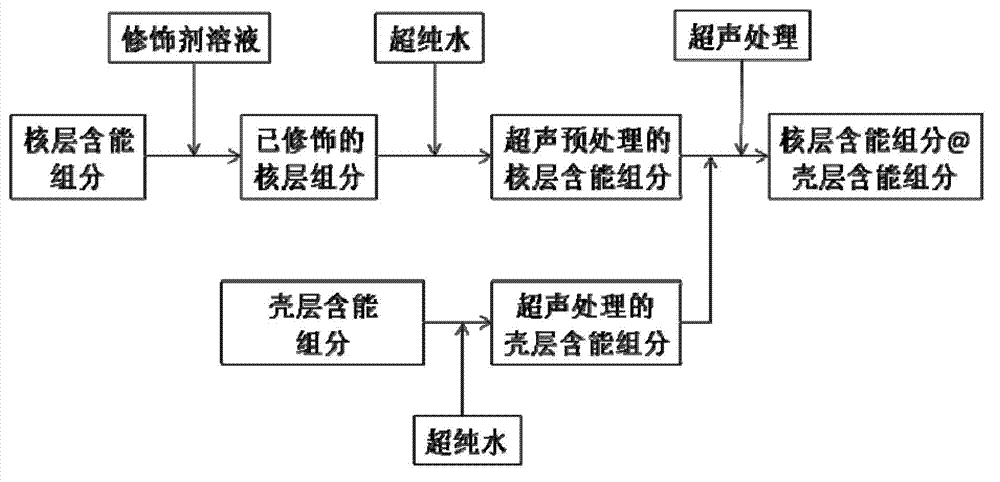

Preparation method of bicomponent energetic material core-shell structure

ActiveCN103086812AReduce rubbing sensitivity and property dropMaintain energy levelsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPre treatmentHigh energy

The invention discloses a preparation method of a bicomponent energetic material core-shell structure. The method comprises the following steps: 1, adding a core layer energetic component to a core layer energetic component modifier solution, stirring at room temperature for 30min, filtering, and drying; 2, adding a core layer component obtained in step 1 into ultrapure water, and carrying out ultrasonic pretreatment for 30min; 3, adding shell layer energetic component powder to the ultrapure water, and carrying out ultrasonic treatment for 15-60min; and 4, adding a shell layer component suspension obtained in step 3 to a core layer component suspension obtained in step 2, continuously carrying out ultrasonic treatment for 5-360min, filtering, drying to obtain a bicomponent energetic material having a core-shell structure, and marking as the core layer energetic component @ the shell layer energetic component. The core-shell structure prepared in the invention can substantially reduce the friction sensitivity and the characteristic fall height of the core layer energetic component and maintain a high energy level, and the preparation method has the advantages of simple process, mild conditions and good safety.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Preparation method of high-heat-conduction flexible graphene film

The invention provides a preparation method of a high-heat-conduction flexible graphene film. Oxidized graphene powder is frozen, dried and dispersed in a solvent, and an oxidized graphene dispersion liquid with the concentration being 0.1-10 mg / ml is obtained; the oxidized graphene dispersion liquid is added to a spraying device and sprayed on a substrate, the substrate is heated at the temperature of 50-150 DEG C for 0.5-5 h, and the oxidized graphene film is formed on the substrate after the dispersion liquid is evaporated; the oxidized graphene film is peeled off and rolled; hot-pressing carbonization and high-temperature graphitization are performed under the protection of a protective atmosphere, and the heat-conduction graphene film is obtained. With the adoption of the method, the high-heat-conduction flexible graphene film with the size and the thickness being controllable can be effectively prepared to meet requirements of different heat dissipation devices and can be applied to various wearable equipment, smart phones, smart televisions and LEDs on a large scale to improve the heat dissipation effect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Surface modified positive pole material of lithium ion cell and preparation method thereof

InactiveCN1731605ALow costCoated evenlyElectrode manufacturing processesLithium compoundsMetal nitrateMolten salt

The invention relates to a lithium battery anode material and method for making same. The said anode comprises base material and surface modification layer or surface coating layer or both of them. The inventive method comprises steps of mixing metal nitrate or other low melting point molten salt with anode material base material; rising temperature 1 to melting the salt and forming perfect lubrication and coating on the surface of base particles; decomposing the salts into oxide in temperature 2 and coating on the base material surface, diffusing into the internal part of particles to form surface modification layer. The invention has the advantages of protecting anode material resolving and phase-change in electrolytic solution.

Owner:ZHEJIANG UNIV

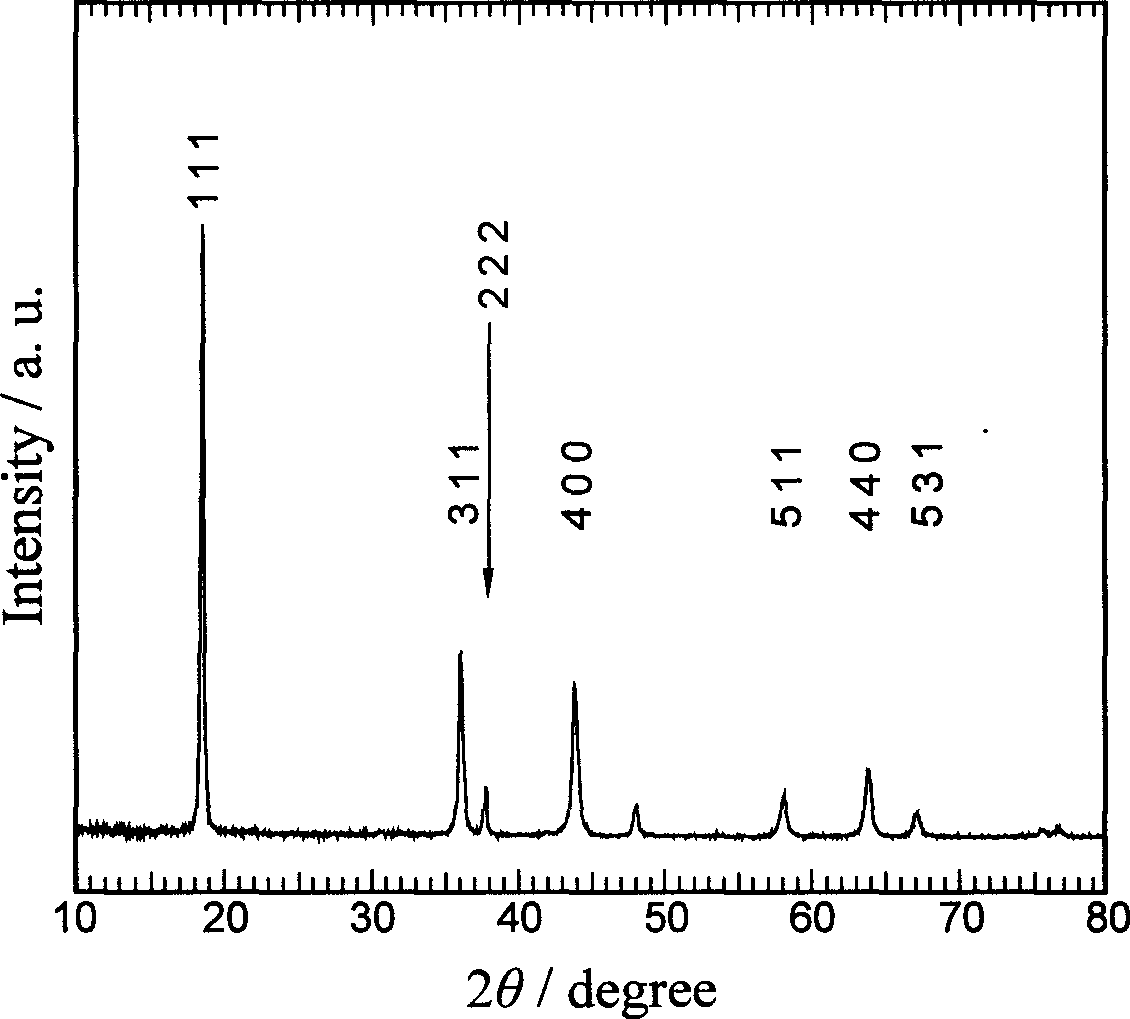

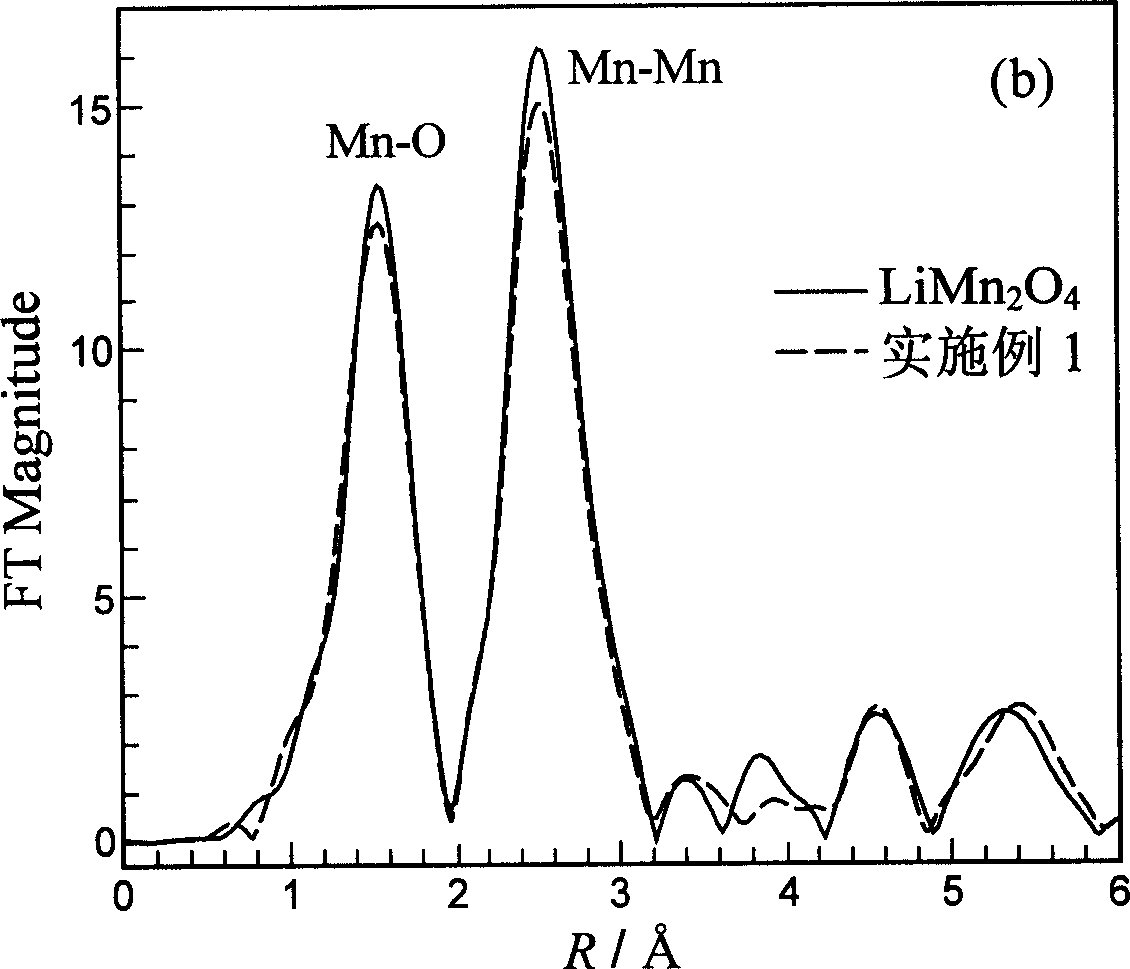

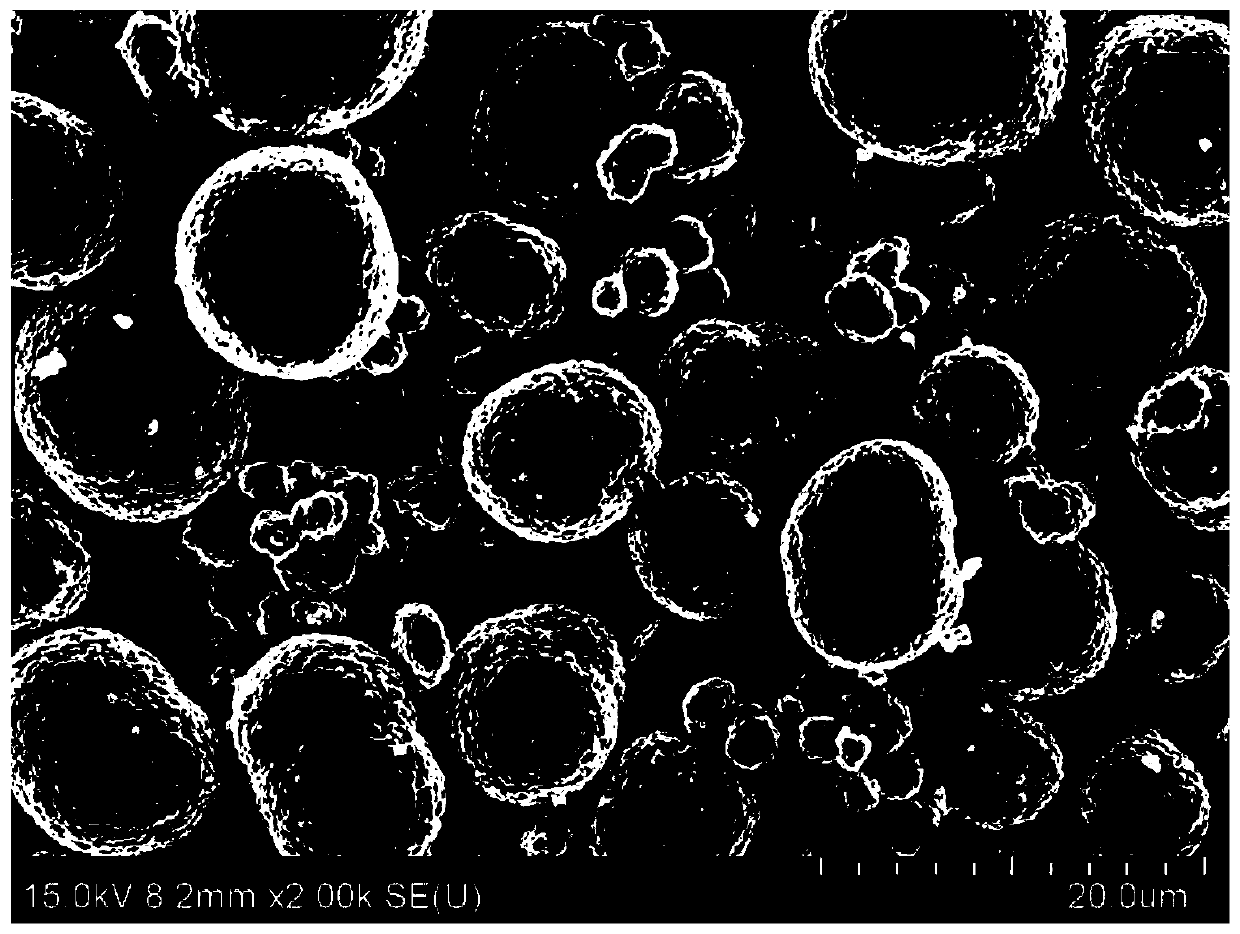

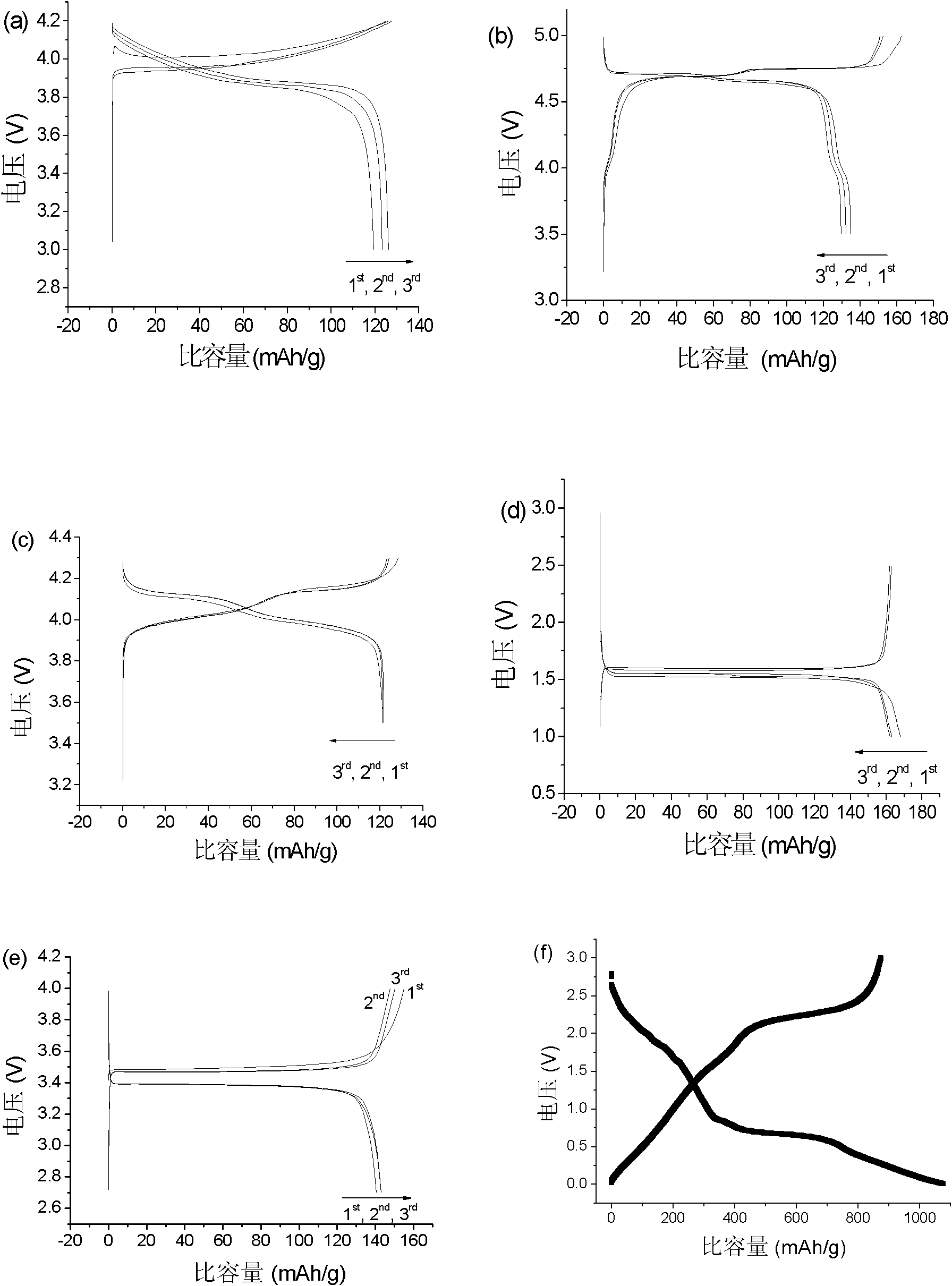

Lithium manganate composite positive electrode material, a preparing method thereof and a lithium-ion battery

ActiveCN104347853AHigh specific capacityCapacity decaySecondary cellsPositive electrodesManganeseManganate

The invention provides a lithium manganate composite positive electrode material, a preparing method thereof and a lithium-ion battery. The composite positive electrode material is of a core-shell structure. The inner layer of the composite positive electrode material is an in-situ composite of lithium manganate and nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate LiMn2O4-LiNi1-x-yCox(Al / Mn)yO2, wherein x is more than 0 and less than or equal to 0.25, and y is more than 0 and less than or equal to 0.15; the outer shell of the composite positive electrode material is a metal oxide coated layer. According to the lithium manganate composite positive electrode material and the preparing method thereof, the in-situ composite of lithium manganate and nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate is obtained after in-site sintering of a manganese source, a nickel-rich concentration gradient type nickel cobalt manganese / lithium aluminate precursor, and a lithium source, then shell-layer metal oxide is cladded by using spray drying, and finally the composite positive electrode material is obtained by combining a microwave sintering process. The composite positive electrode material provided by the invention has relatively high specific capacity, and excellent high temperature cycling and storage performances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

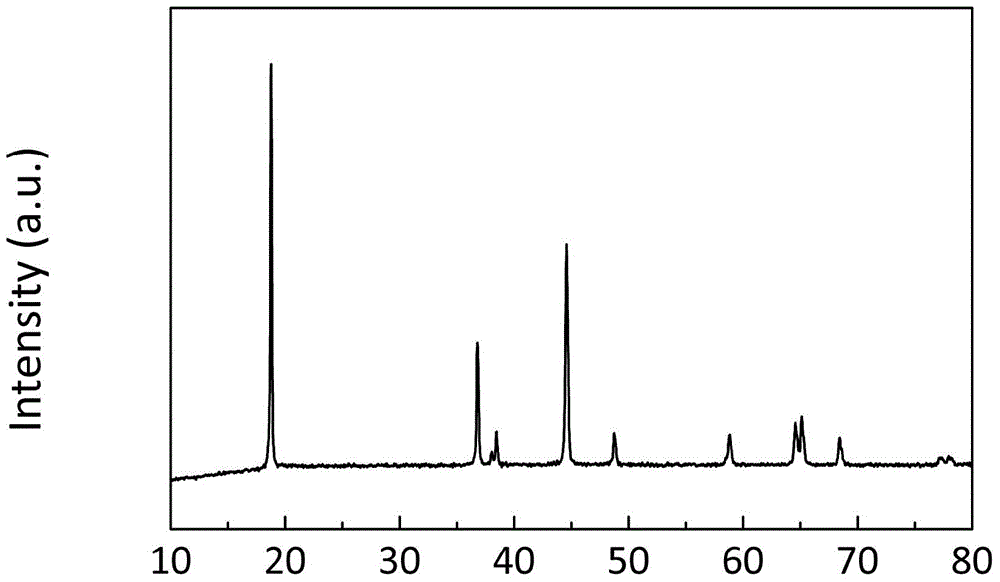

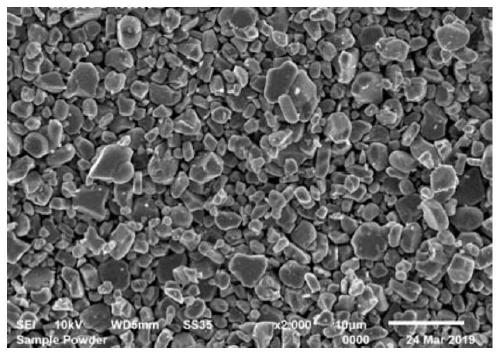

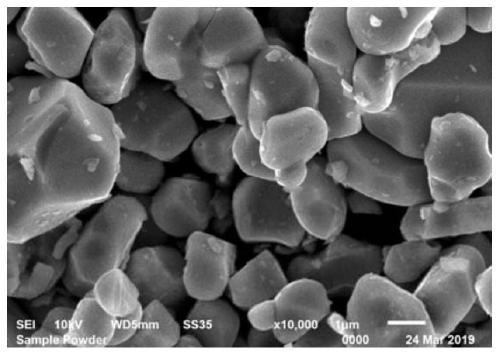

High-compaction and high-stability high-nickel cathode material and preparation method thereof, and lithium ion battery

ActiveCN110010889AImprove powder compactionIncrease the ultimate compaction densitySecondary cellsPositive electrodesHigh energyCerium

The invention discloses a high-compaction and high-stability high-nickel cathode material and a preparation method thereof, and a lithium ion battery. The high-nickel cathode material comprises a basematerial and a coating layer coating the surface of the base material, the base material is a compound as shown in the formula I: LinNixMyO2, wherein in the formula I, 0.98<n<=1.20, 0.50<x<1.00, 0.00<y<1.00, and 0.00<x+y<=1.00; the base material is consisted of a large-particle substrate and a small-particle substrate; and M is at least one selected from a group consisting of lithium, manganese,aluminum, molybdenum, chromium, vanadium, lanthanum, scandium, cerium, niobium, molybdenum, cobalt, magnesium, zirconium, strontium, yttrium, barium, titanium, fluorine, silicon, boron and phosphorus.The cathode material prepared by the invention has low residual alkali, uniform primary particle coating, primary particle pressure resistance and difficult breakage, so that the prepared lithium ionbattery has high energy density, lower internal resistance and excellent rate capability, safety performance and cycle performance.

Owner:GUIZHOU RONGBAI LITHIUM BATTERY MATERIAL CO LTD

Method for preparing uniform carbon-coated vanadium phosphate sodium material

ActiveCN104733731AUniform sizeInhibition of agglomerationCell electrodesPhosphorus compoundsCarbon layerWater baths

The invention provides a method for preparing a uniform carbon-coated vanadium phosphate sodium material. The method comprises the following steps: dissolving V2O5, NH4H2PO4 and Na2CO3 or NH4VO3, H3PO4 and Na2CO3 in distilled water; uniformly mixing Na3V2(PO4)2 and glucose at a molar ratio of 2: (3-4); transferring the mixed solution into a hydrothermal reaction kettle, and carrying out the glycosidation reaction; cooling the hydrothermal reaction kettle at the room temperature, opening the hydrothermal reaction kettle, ultrasonic uniformly dispersing the obtained turbid liquid, magnetically stirring the turbid liquid in a water bath, and evaporating the water to obtain sol, and drying the sol in a drying oven to obtain gel; adequately grinding gel, and pre-burning the ground gel in argon; adequately grinding the pre-burned gel again, and calcining in argon to obtain the uniform carbon-coated Na3V2(PO4)3 material. The carbon-source glucose is added in the hydrothermal process, the surface of the particle is coated with a carbon layer, the conductivity of the material is improved, the clustering phenomenon of the particle in the sintering process can be inhibited, and a product with uniform size can be obtained.

Owner:TIANJIN UNIV

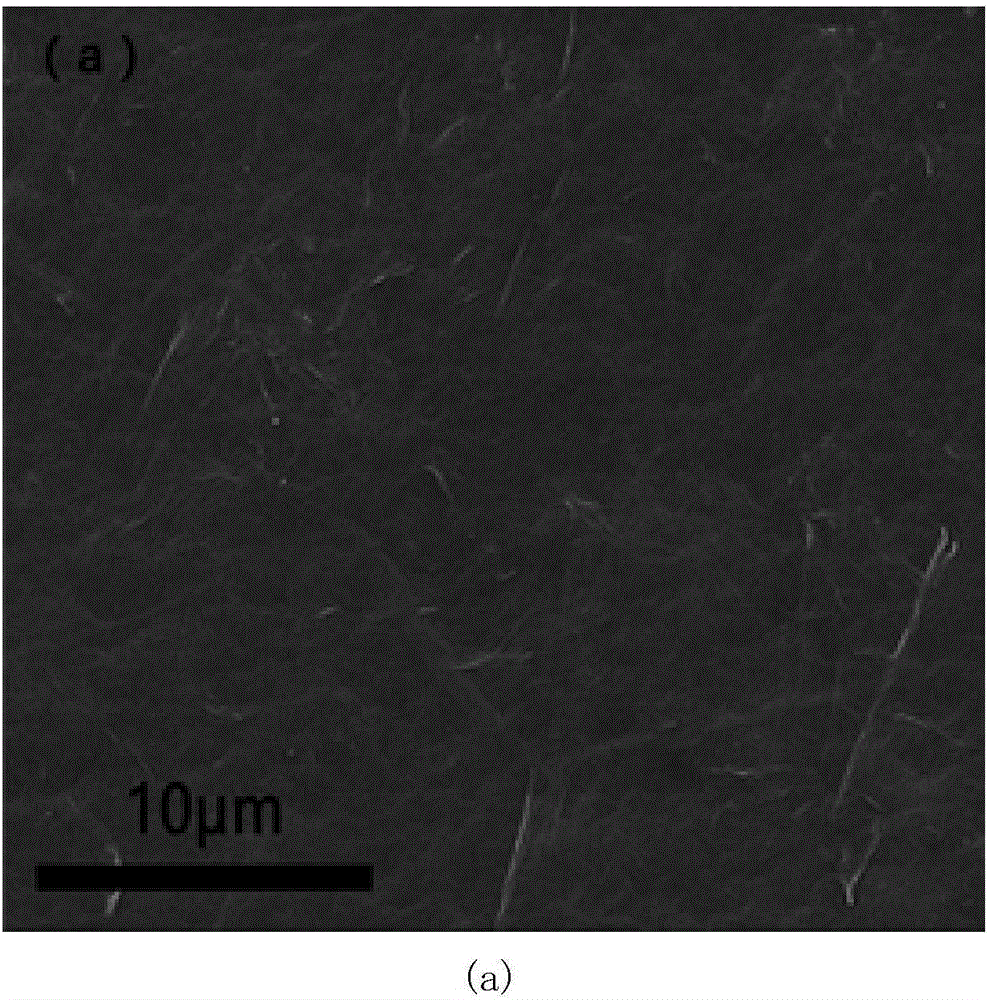

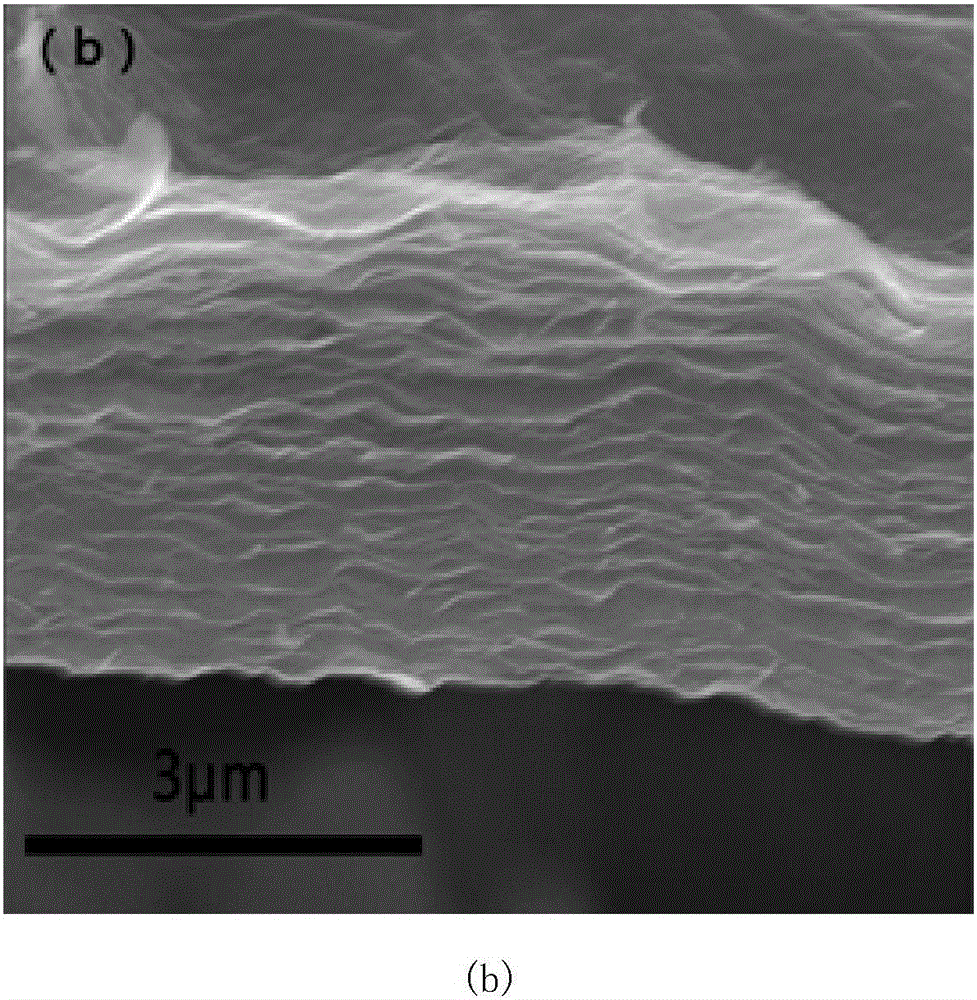

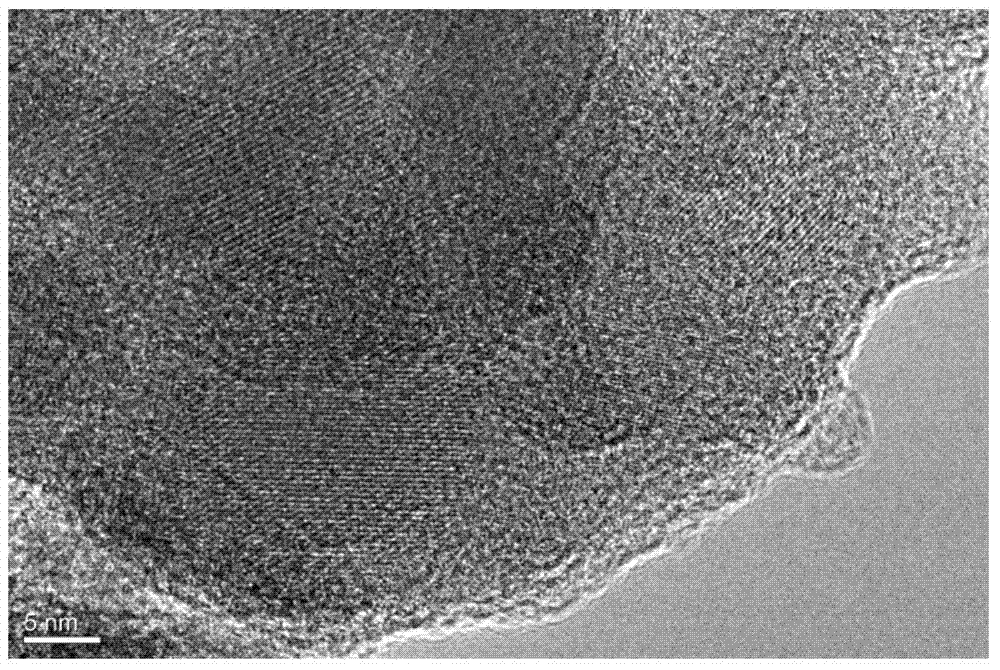

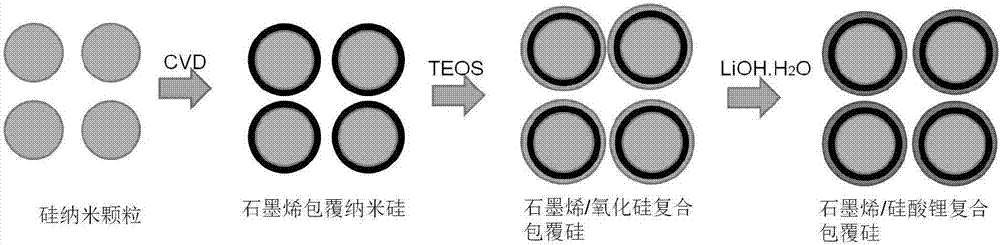

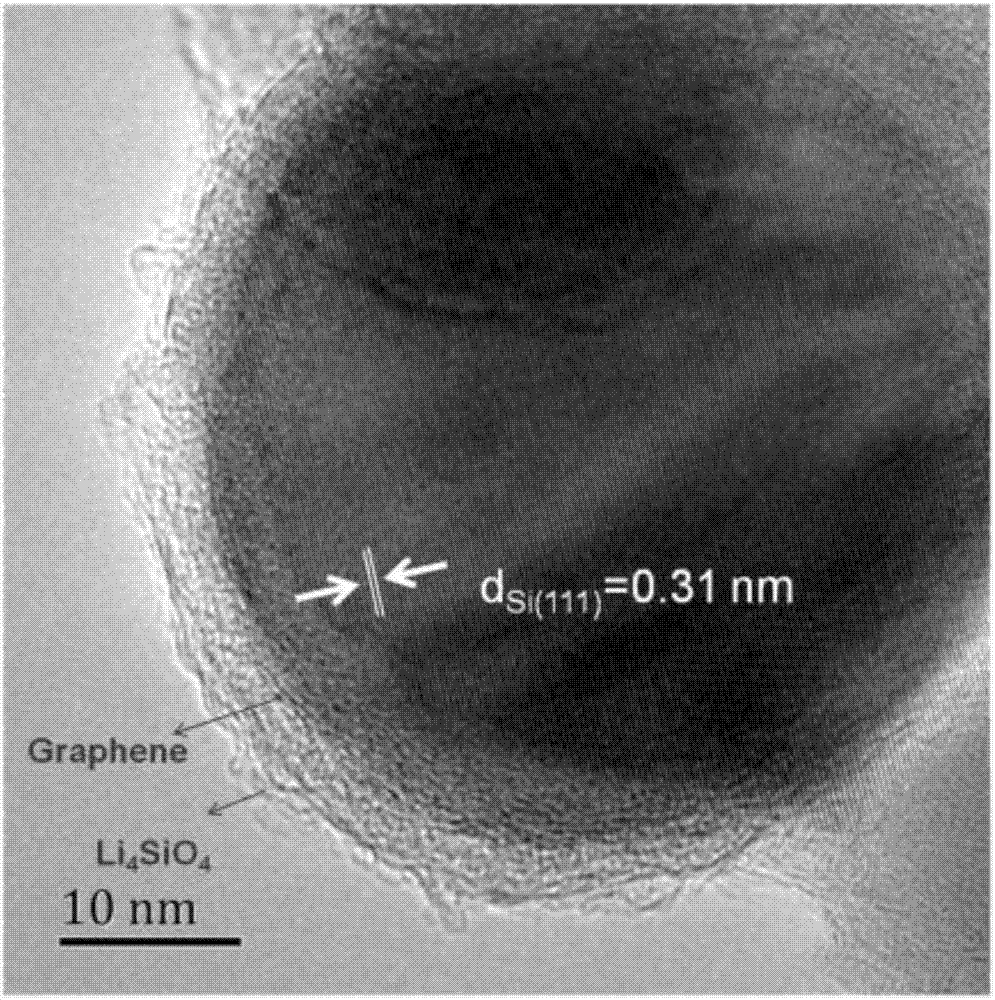

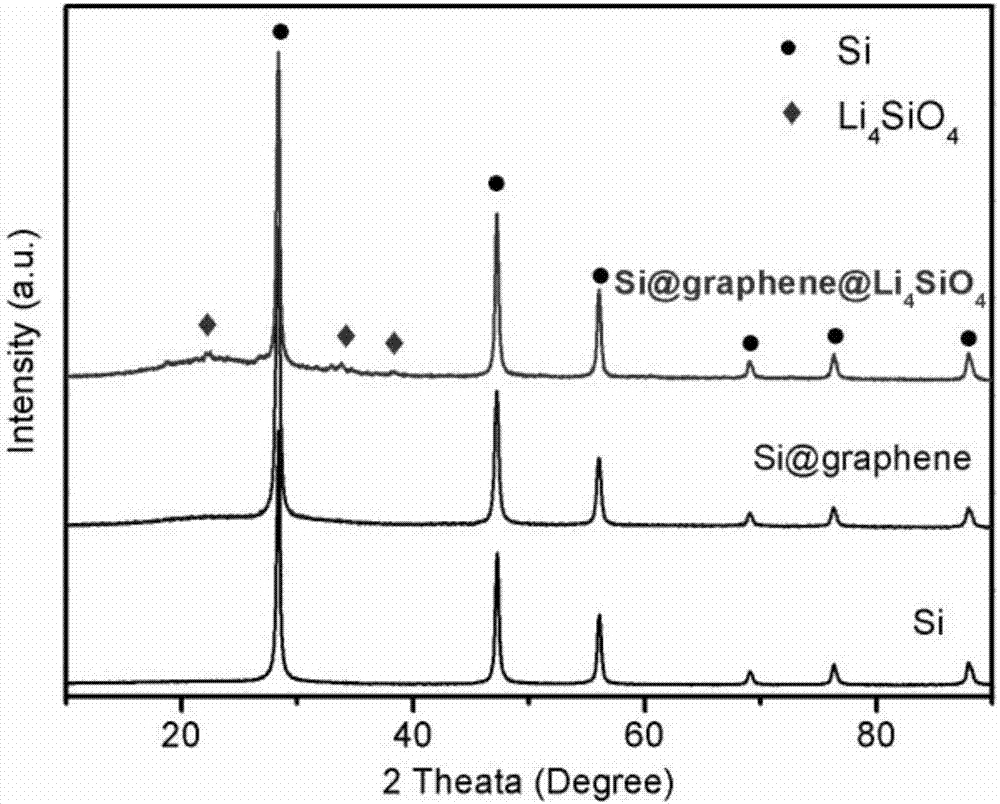

Graphene/solid-state electrolyte composite coated silicon composite negative electrode and preparation method thereof

ActiveCN107579239ASimple processCoated evenlyCell electrodesSecondary cellsElectrochemical responseSolid state electrolyte

The invention discloses a graphene / solid-state electrolyte coated silicon composite material and a preparation method thereof. The preparation method comprises the following steps: coating a silicon-based material with a layer of graphene through a chemical vapor deposition method, and accumulating concentrated ammonia water into an oxide through a precursor ester of an oxide for coating to obtainan oxide and graphene co-coated silicon negative electrode material; performing lithiation on the composite material with lithium hydroxide monohydrate to finally obtain the graphene / solid-state electrolyte coated silicon composite material. In the composite material, graphene directly grows on the surfaces of silicon particles, and the surface of graphene is coated with solid-state electrolyte,thereby forming double-layer coating. The graphene inside can increase the electronic conductivity of the silicon-based material, and relieve volume expansion of silicon. The coating solid-state electrolyte outside can improve the Coulomb efficiency and the magnification performance of the silicon-based negative electrode material, reduce the electrochemical reaction between the negative electrodematerial and electrolyte, increase the Coulomb efficiency of the silicon-based negative electrode and improve the high current charging and discharging performance of the material.

Owner:深圳索理德新材料科技有限公司

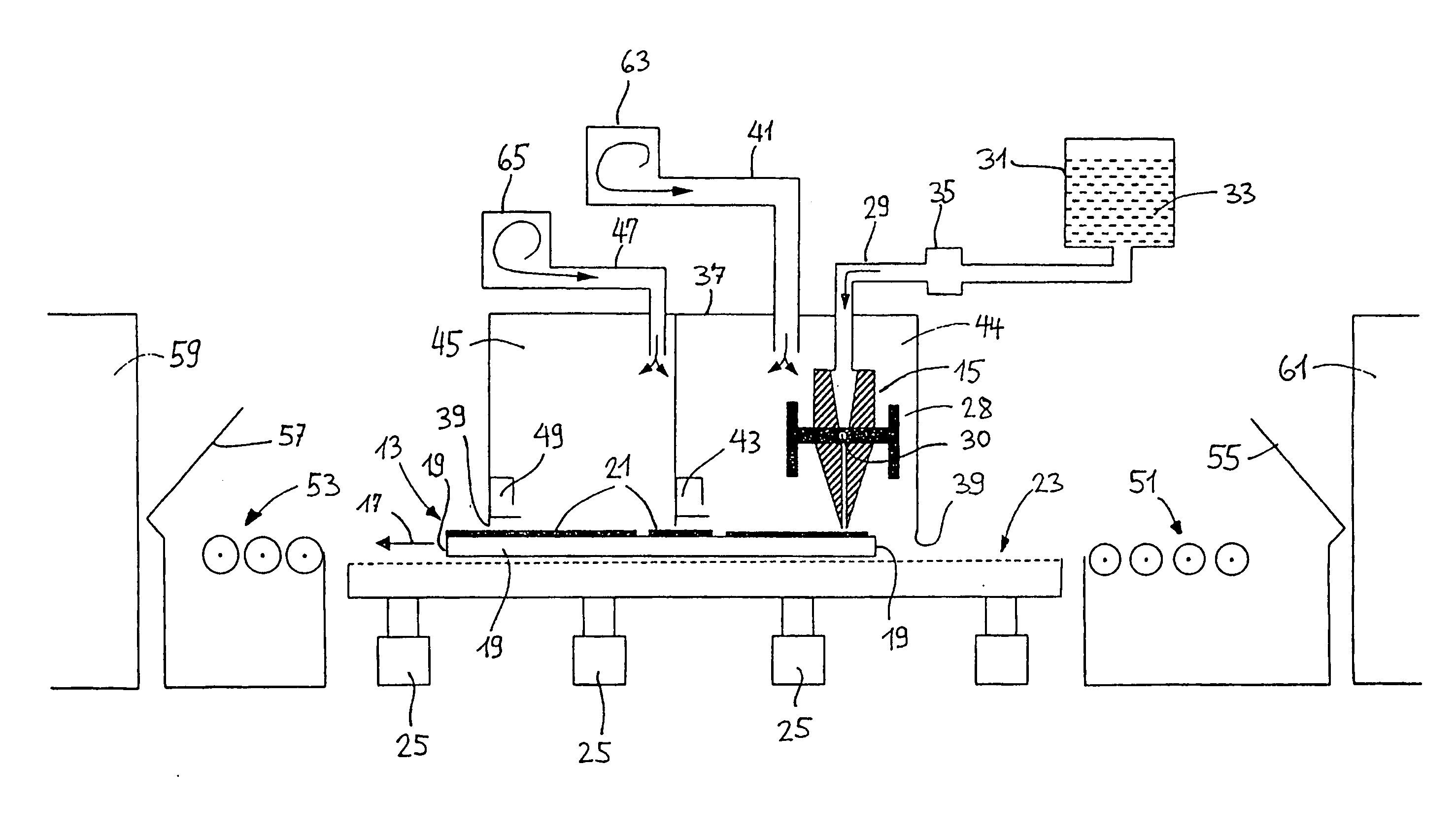

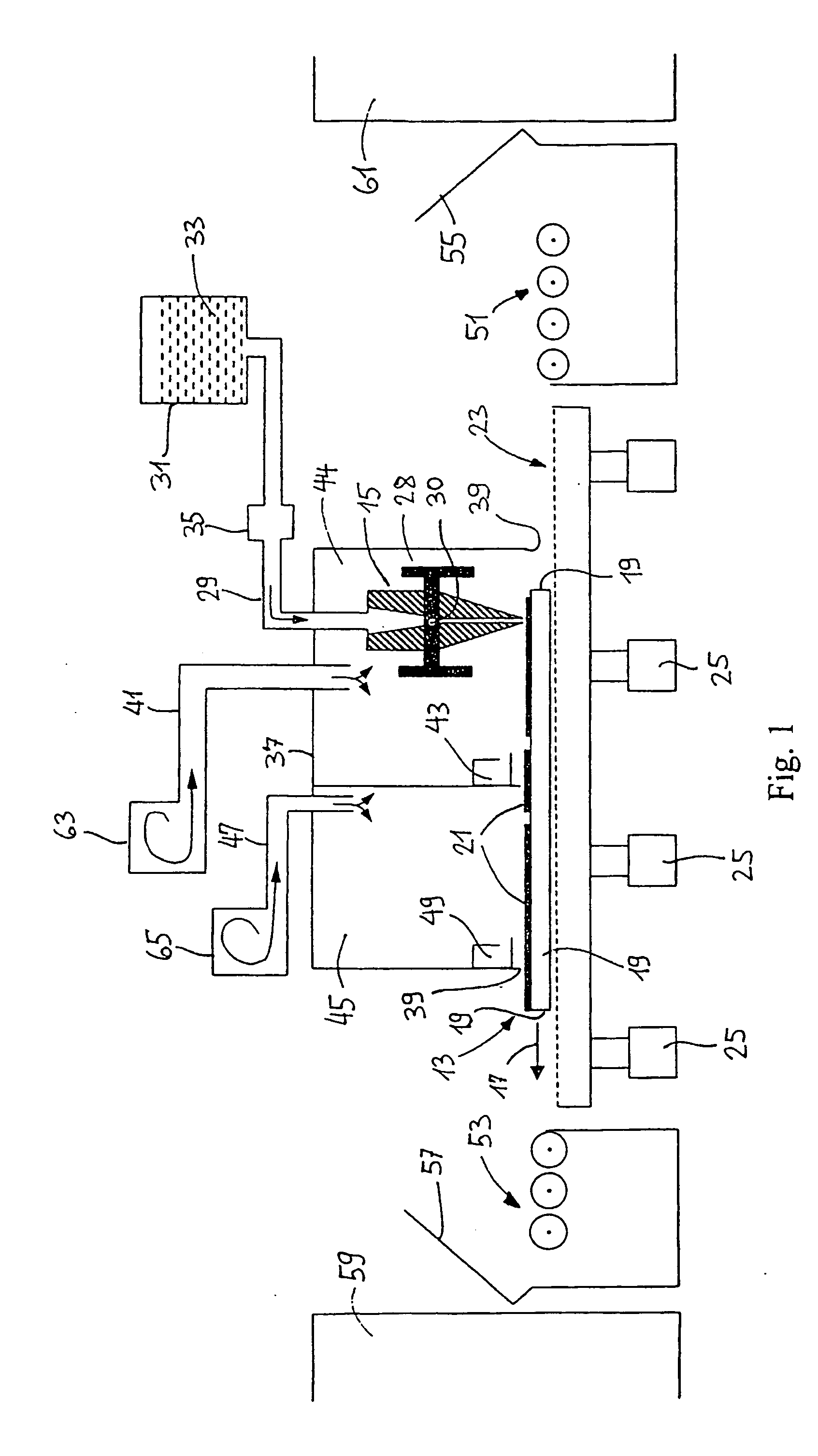

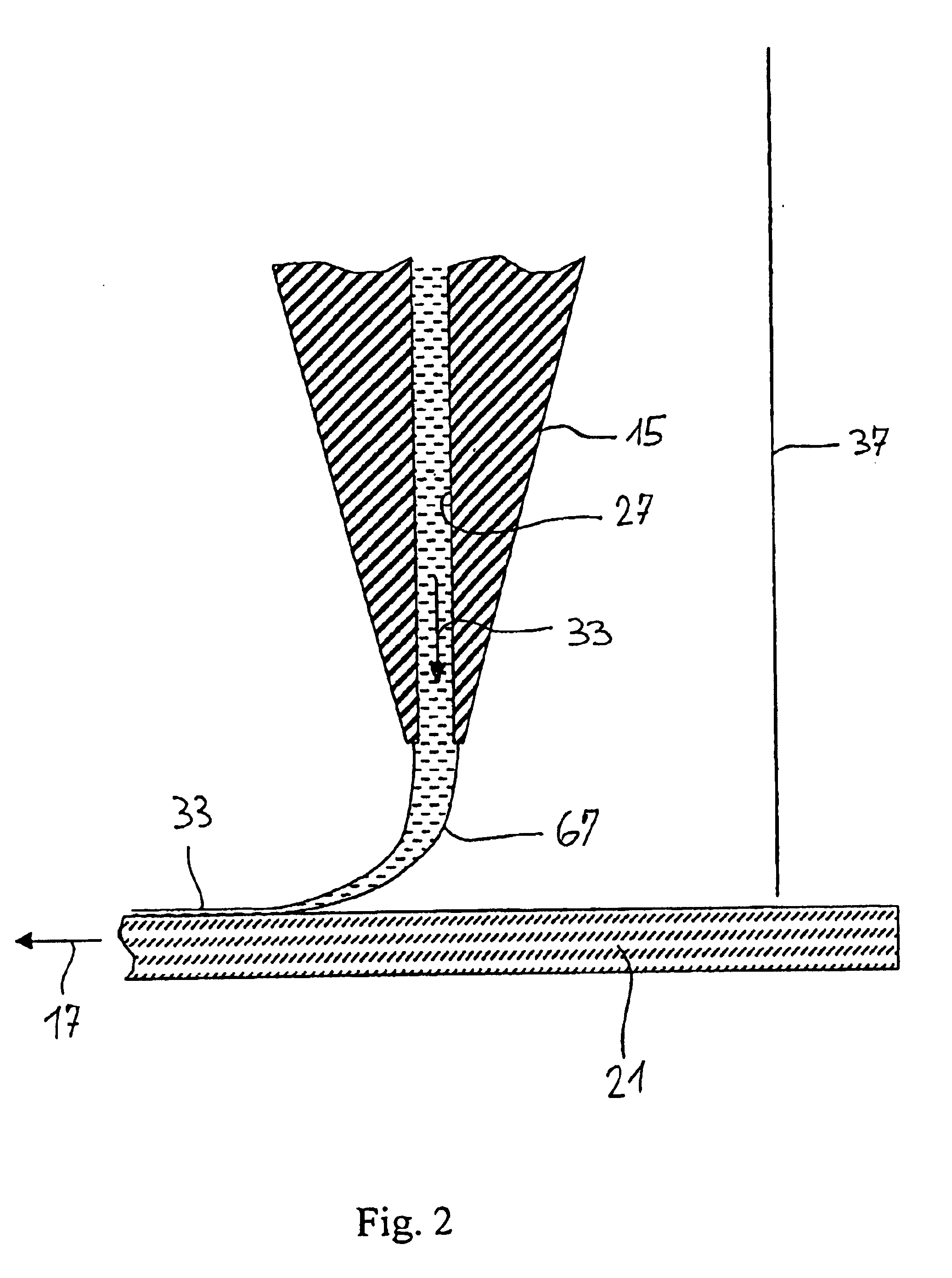

Method and device for the production of an antireflective coating, antireflective coating, and antireflective-coated substrate

InactiveUS20050244571A1Coated evenlySolar heat devicesSpray nozzlesSolid componentCompound (substance)

In order to produce an antireflective layer, a coating solution containing at least one metal alkoxy compound and at least one polymer as solid components that are dissolved in a solvent is applied to a substrate that is to be coated by means of a pouring device with a wide slit, the polymer being immiscible and essentially inert in a chemical manner towards the metal alkoxy compound. A layer which is provided with a nanoporous structure having a refractive index that is preferably smaller than 1.22 as well as good antireflective properties is obtained by selective removal of the polymer and thermochemical hardening of the coating.

Owner:INTERFLOAT CORP

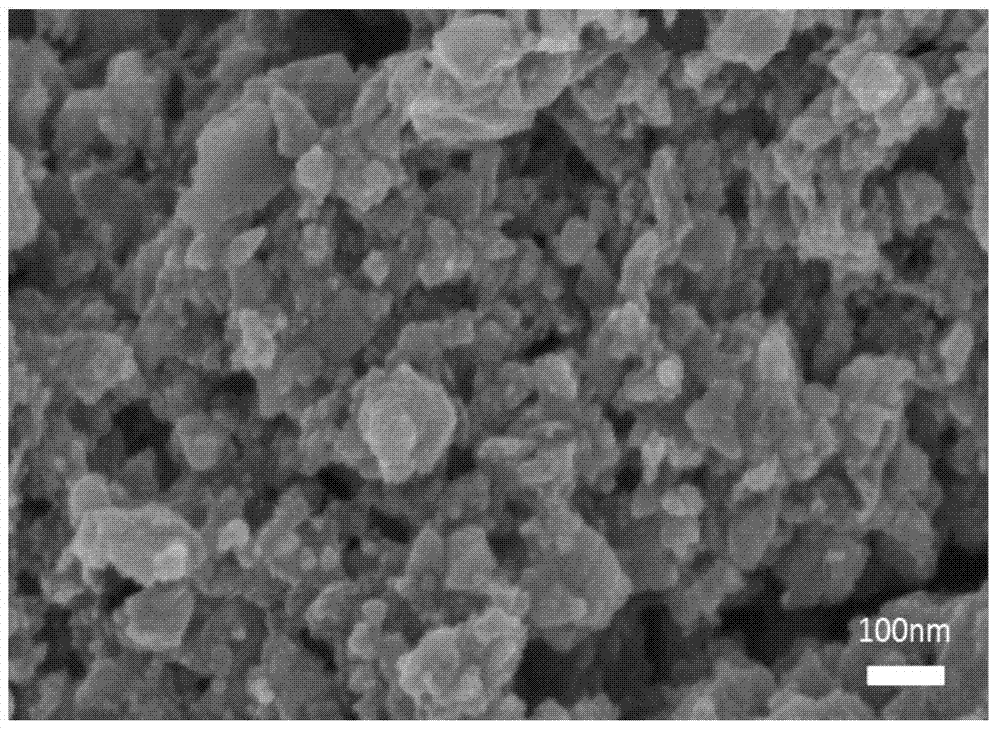

Doped cobalt carbonate, doped tricobalt tetroxide and preparation methods thereof

ActiveCN105731551AUniform particle sizeCoated evenlyCobalt oxides/hydroxidesCobalt carbonatesChemistryCobalt(II,III) oxide

The present invention provides a doped cobalt carbonate preparation method. The preparation method comprises the following steps: cobalt carbonate is prepared; the cobalt carbonate is added into a metal alkoxide solution to be mixed to obtain the cobalt carbonate wrapped by the metal alkoxide; and the wrapped cobalt carbonate is dried to obtain a doped cobalt carbonate. The present invention also provides the doped cobalt carbonate prepared by the doped cobalt carbonate preparation method, a doped tricobalt tetroxide preparation method, and a doped tricobalt tetroxide prepared by the doped tricobalt tetroxide preparation method. The doped cobalt carbonate preparation method and the doped tricobalt tetroxide preparation method can prepare the doped cobalt carbonate and the doped tricobalt tetroxide which are uniform in particle sizes, evenly coated, and large in particle sizes, respectively.

Owner:JINGMEN GEM NEW MATERIAL +1

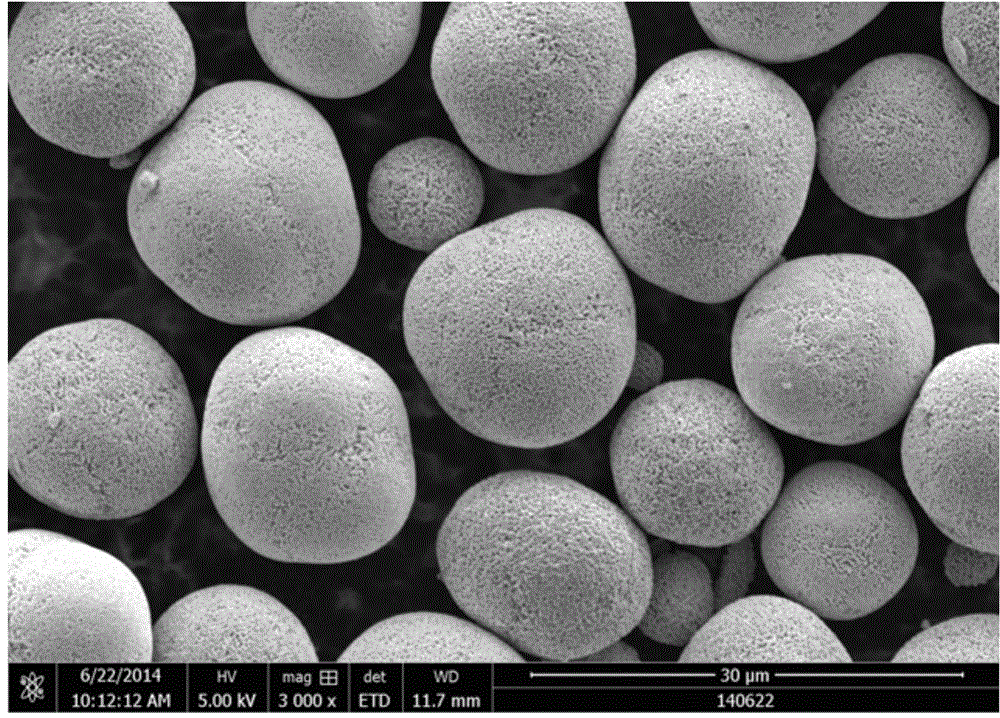

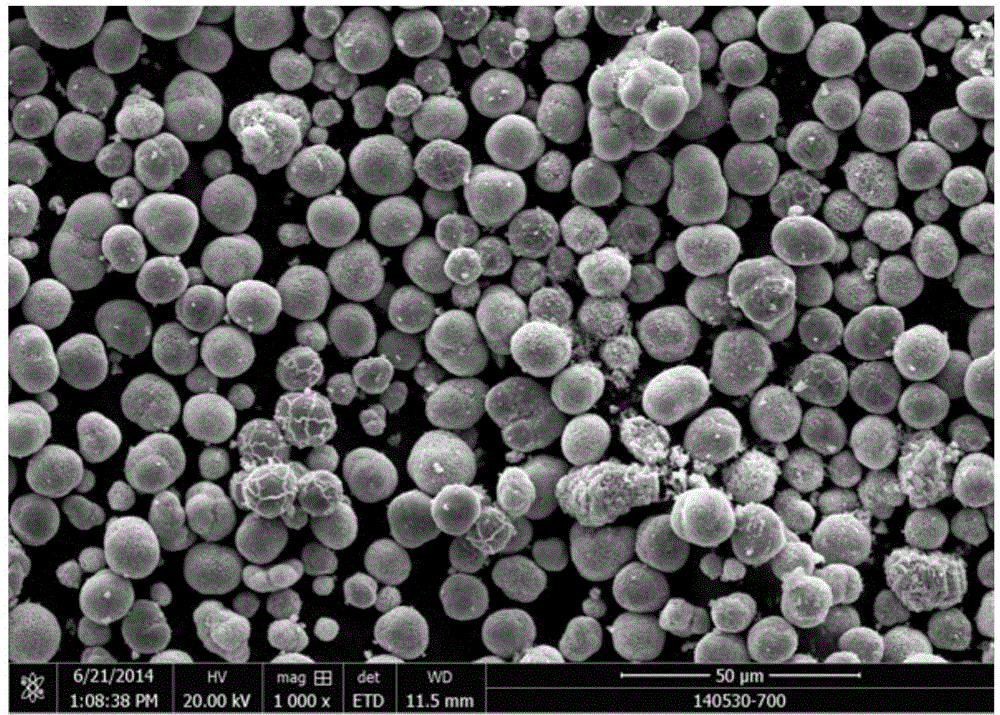

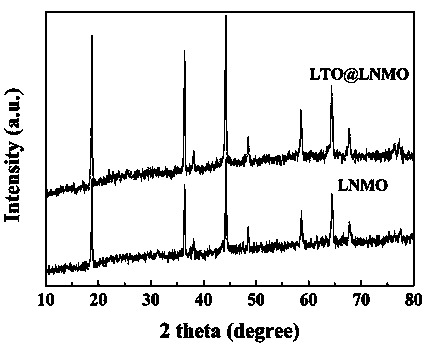

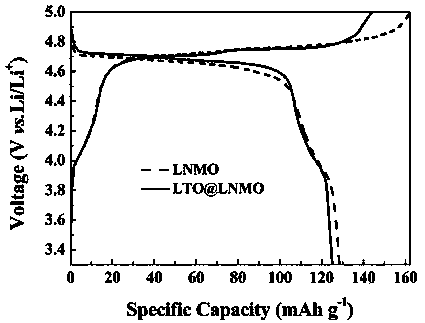

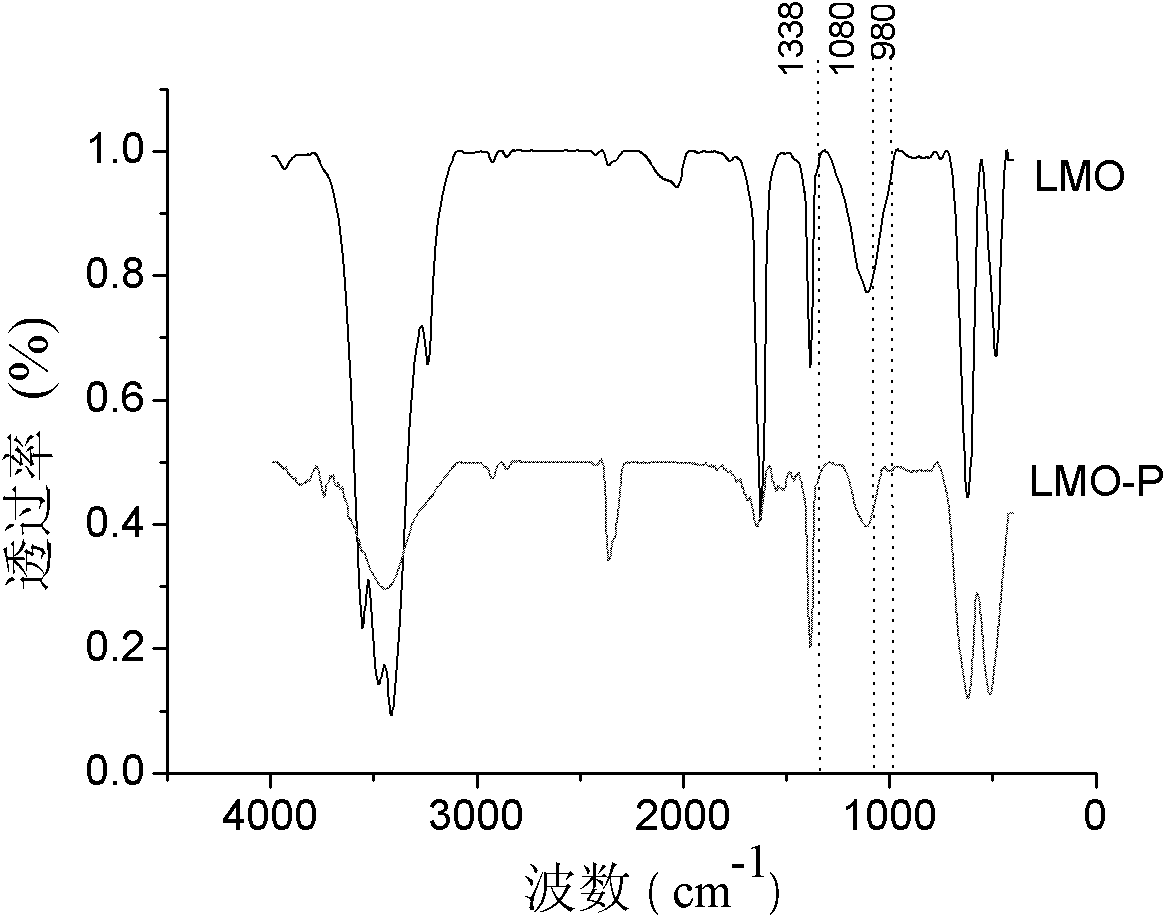

Modified LiNi1/2Mn3/2O4 cathode material prepared by coating with lithium ion conductor Li2MO3 (M=Ti, Si or Zr) and preparation method thereof

ActiveCN103413930ACoated evenlyImproved high temperature cycle stabilityCell electrodesElectrical conductorLithium-ion battery

A modified LiNi1 / 2Mn3 / 2O4 cathode material prepared by coating with lithium ion conductor Li2MO3 (M=Ti, Si or Zr) and a preparation method thereof belong to the technical field of lithium ion battery cathode materials. The coated cathode material in the method is LiNi0.5Mn1.5O4; the chemical constitution of the lithium ion conductor is Li2MO3, wherein M is Ti or Si or Zr; Li2MO3 accounts for 1%-3% of the mass of the coated cathode material. According to the invention, the lithium ion conductor replaces a coating layer, so that the modified cathode material has excellent high-temperature cycling stability and rate capability and can adapt to large-scale production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

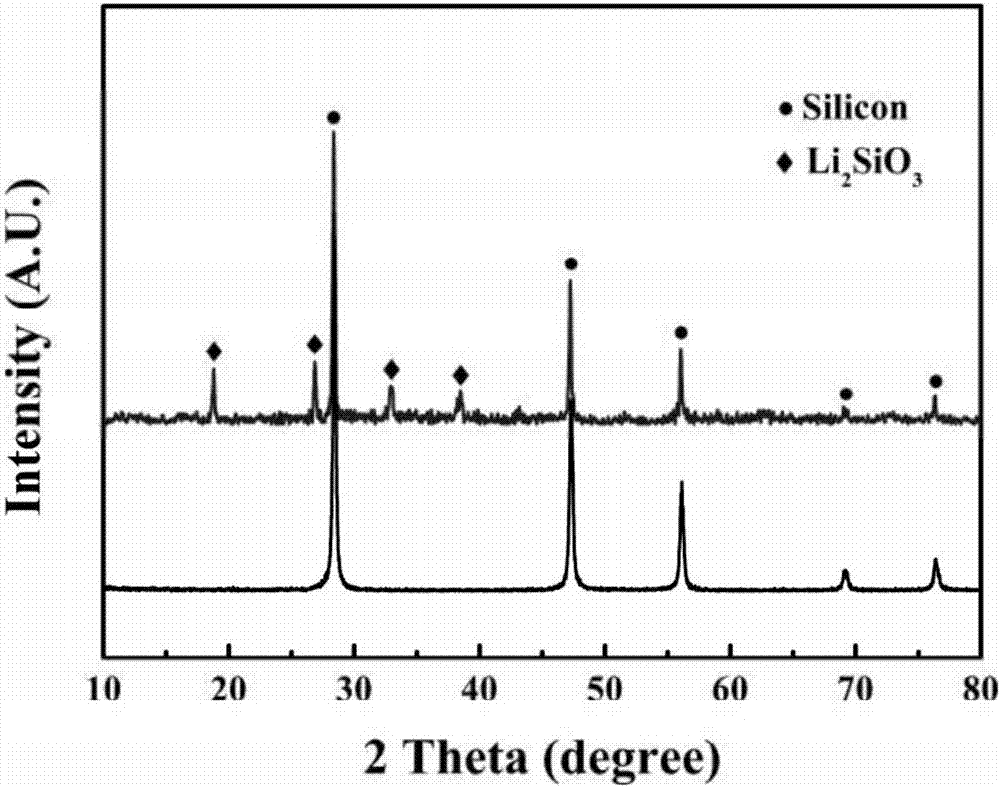

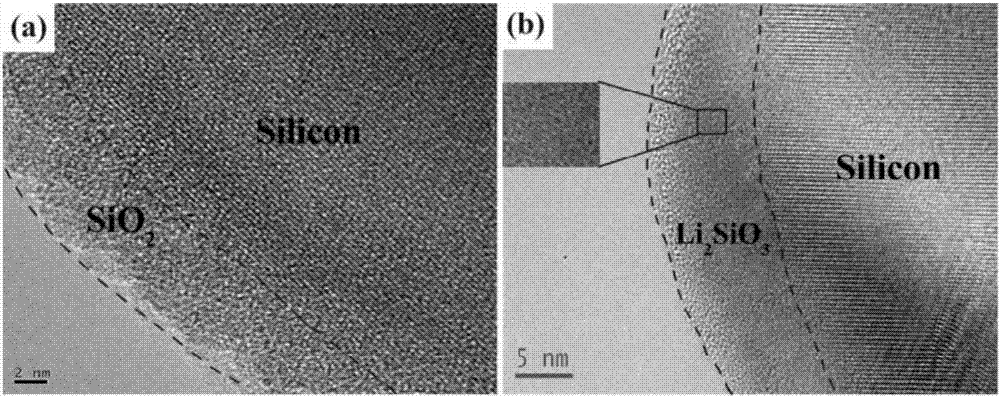

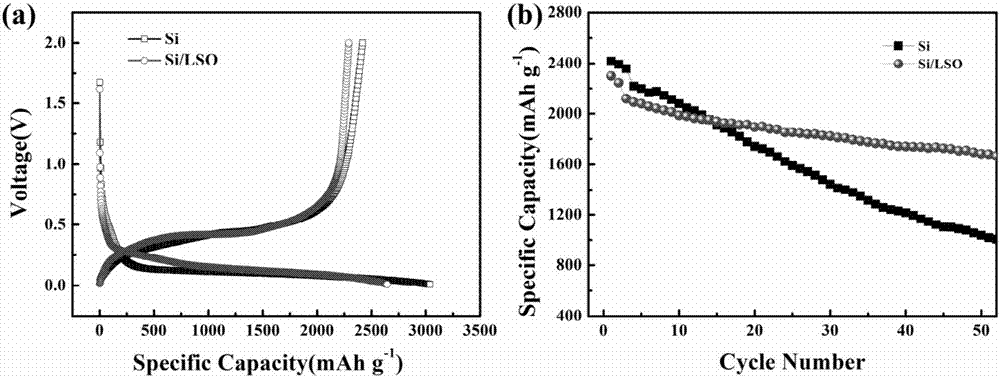

Lithium ion battery composite negative electrode material and preparation method thereof

InactiveCN107887587AImprove storage effectImprove Interface StabilityMaterial nanotechnologyCell electrodesChemical reactionSilicon dioxide

The invention discloses a lithium ion battery composite negative electrode material and a preparation method thereof. The surface of nanometer silicon is subjected to oxidization treatment to obtain nanometer silicon coated with silicon dioxide on the surface; the nanometer silicon coated with silicon dioxide on the surface is mixed with a lithium source uniformly to obtain a precursor; and the obtained precursor is placed into inert gas to be heated to obtain a nanometer silicon material coated with lithium silicate, and the product is subjected to washing, centrifugal separating and drying to obtain the lithium ion battery composite negative electrode material. By taking a uniform primary oxide layer on the surface of the nanometer silicon material as the substrate, an in-situ chemical reaction is performed to realize uniform coating of lithium silicate, so that stability between nanometer silicon and air or an electrolyte interface is improved effectively, thereby greatly improvingelectrochemical performance of the nanometer silicon material.

Owner:CENT SOUTH UNIV

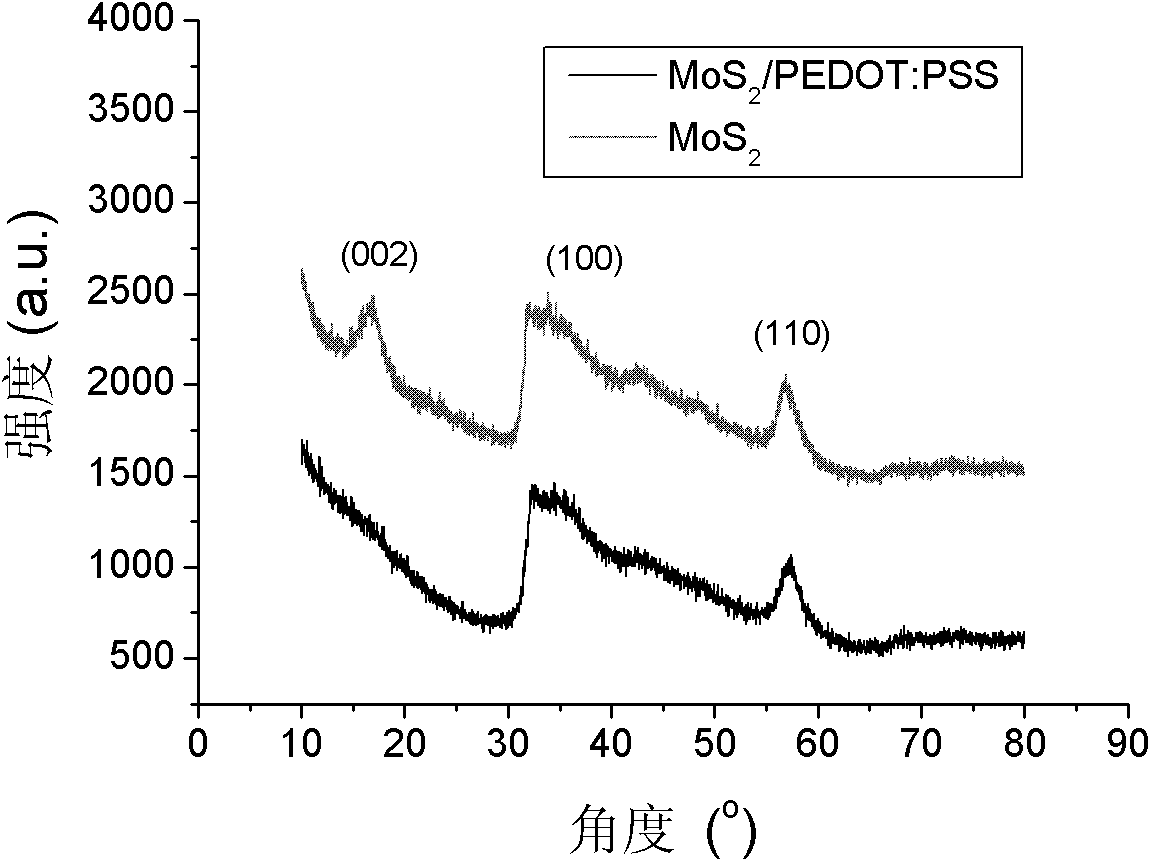

Conducting-polymer dipped and coated lithium-ion battery composite-electrode material and preparation method thereof

InactiveCN102522563ADon't need protectionReduce energy consumptionHybrid capacitor electrodesLi-accumulatorsDischarge efficiencyConductive polymer

The invention provides a conducting-polymer dipped and coated lithium-ion battery composite-electrode material and a preparation method thereof. A high-polymer conducting polymer is coated on the lithium-ion battery electrode material of the composite electrode material, the conducting polymer is the conducting polymer which is easily dispersed into an aqueous solution, and the aqueous solution of dispersants, such as polystyrolsulfon acid and the like is used as a dispersing medium. The composite electrode material is prepared through the following steps of: dipping a lithium-ion anode material or cathode material into the aqueous solution of the high-polymer conducting polymer, and obtaining the surface-coated lithium-ion battery composite-electrode material through dipping and coating processing. The composite electrode material has cheap preparation raw materials, the surface of the novel composite electrode material is uniformly coated, and the composite electrode material has the advantages of high specific capacity, high charging and discharging efficiency and long cycling life. Compared with the prior art, the preparation method of the composite electrode material has the advantages of simple process, low cost, good effect and green and environment-friendly production process, is easy for industrial popularization and is convenient for large-scale industrialized production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

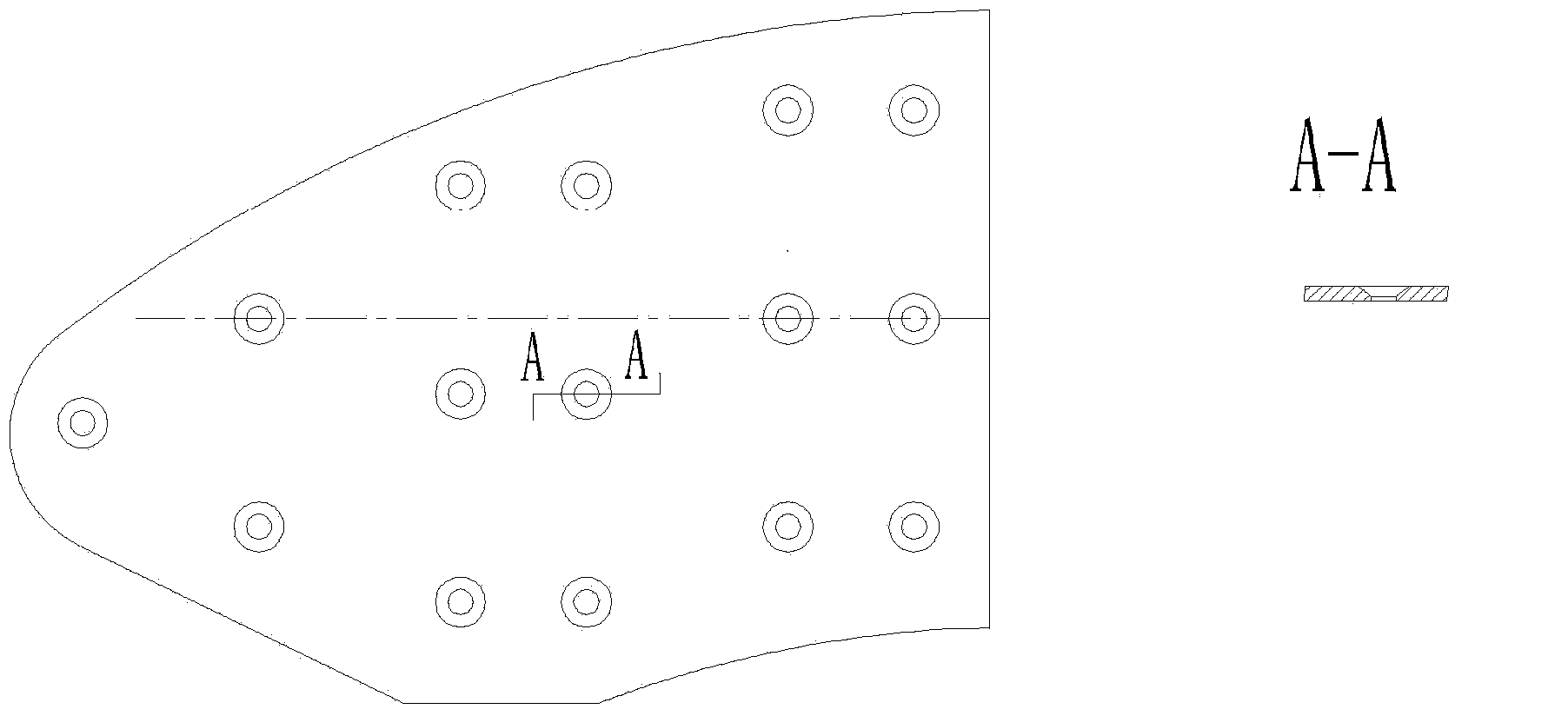

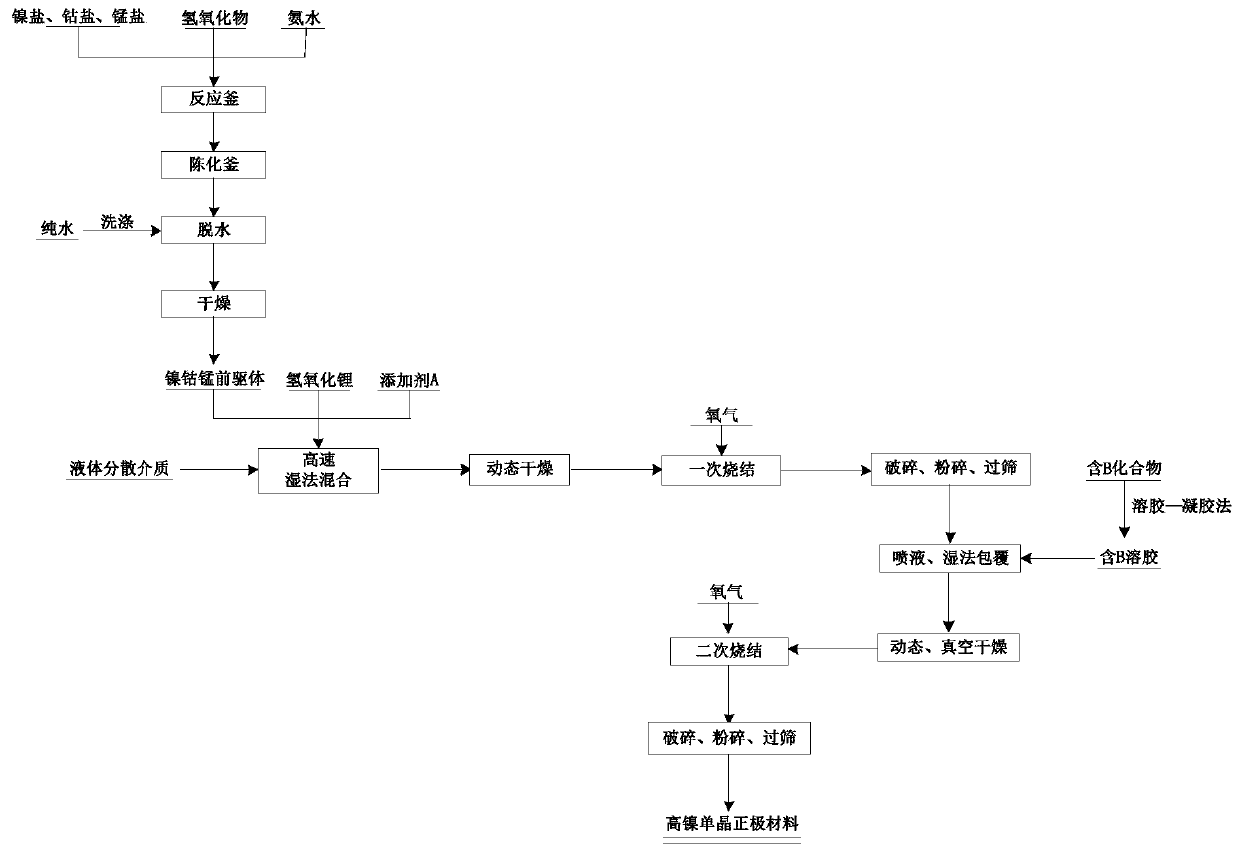

Method for preparing high-nickel long-cycle single-crystal lithium ion battery positive-pole material

InactiveCN110451585AImprove uniformityImprove stabilityCell electrodesSecondary cellsNickel saltLithium hydroxide

The invention relates to a method for preparing a high-nickel long-cycle single-crystal nickel-cobalt-manganese (NCM) lithium ion battery positive-pole material. The preparation method comprises the following steps: (1) mixing a soluble nickel salt, a cobalt salt, a manganese salt, an alkali metal hydroxide and ammonia water, and enabling the mixture to flow into a reaction kettle for constant-temperature coprecipitation to obtain a high-nickel NCM ternary precursor material; (2) uniformly mixing the high-nickel NCM ternary precursor, lithium hydroxide and an additive A in a wet high-speed mixing mode, carrying out drying, then carrying out primary sintering in an oxygen-enriched atmosphere to obtain a spherical high-nickel NCM ternary positive-pole material; (3) carrying out crushing, smashing and sieving to obtain a high-nickel NCM ternary positive-pole material; and (4) carrying out wet mixing and drying on the high-nickel NCM ternary positive-pole material with a coating agent B, carrying out secondary sintering in an oxygen-enriched atmosphere, and carrying out crushing, smashing and sieving to obtain the high-nickel single-crystal NCM lithium ion battery positive-pole material. The positive-pole material prepared by the method has the advantages of high capacity, good cycle performance, high compaction density and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

Carpet waste composite

Owner:MATERIAL INNOVATIONS LLC

Slow release pellet of high-stability type cysteamine hydrochloride and preparation method thereof

InactiveCN101653426AAdd lessIncrease return rateOrganic active ingredientsPharmaceutical delivery mechanismSilicon dioxideWall material

The invention relates to a slow release pellet of high-stability type cysteamine hydrochloride and a preparation method thereof. The slow release pellet comprises the following components in portionsby weight: 30-70 portions of cysteamine hydrochloride, 20-40 portions of silicon dioxide and 5-25 portions of polymer material as coating wall material. The preparation method comprises the followingsteps: firstly, using silicon dioxide pellets to absorb liquid cysteamine hydrochloride in proportion to form cysteamine hydrochloride particles; then, using the coating wall material to encapsulate the cysteamine hydrochloride particles to form a membrane cavity control structure; and drying the structure to obtain slow release pellets of 50% cysteamine hydrochloride. The slow release pellet hasthe characteristics of stable product quality, high content, reasonable preparation method, easy batch production and simple using method and can be added into the premix.

Owner:冯利萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com