Patents

Literature

721 results about "Coulomb" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The coulomb (symbol: C) is the International System of Units (SI) unit of electric charge. It is the charge (symbol: Q or q) transported by a constant current of one ampere in one second: 1 C=1 A×1 s Thus, it is also the amount of excess charge on a capacitor of one farad charged to a potential difference of one volt: 1 C=1 F×1 V Under the 2019 redefinition of the SI base units, which took effect on 20 May 2019, the elementary charge (the charge of the proton) is exactly 1.602176634×10⁻¹⁹ coulombs.

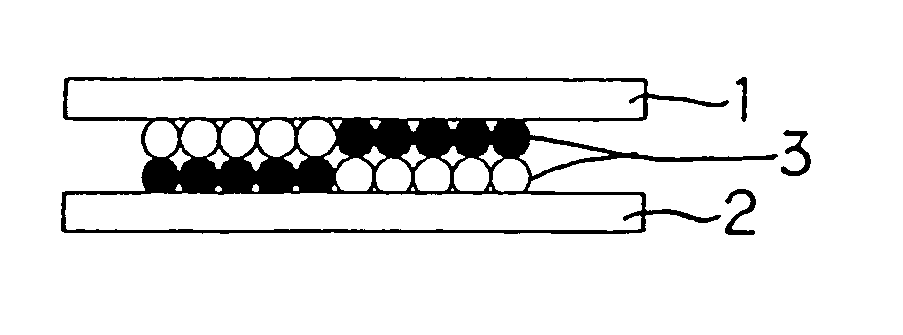

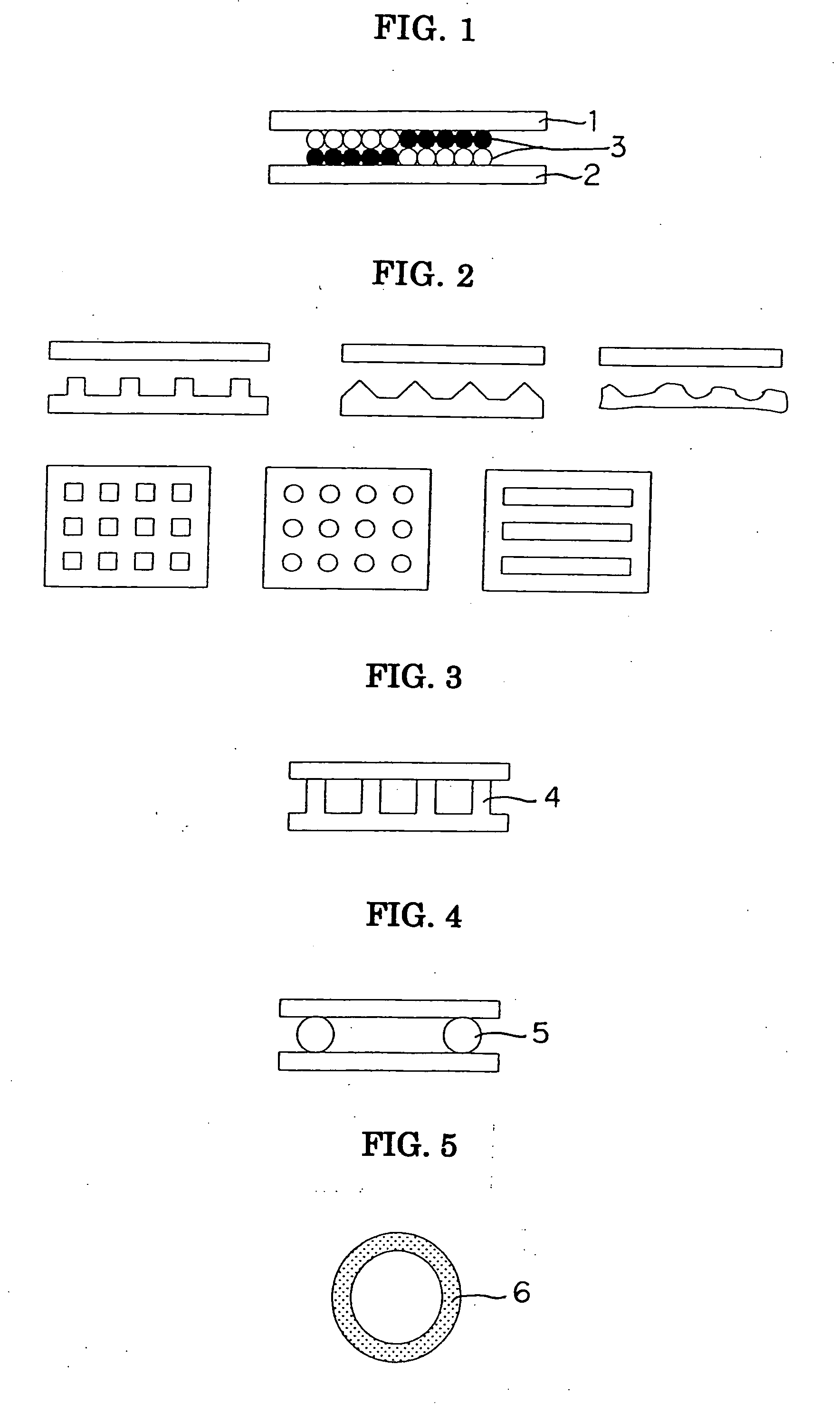

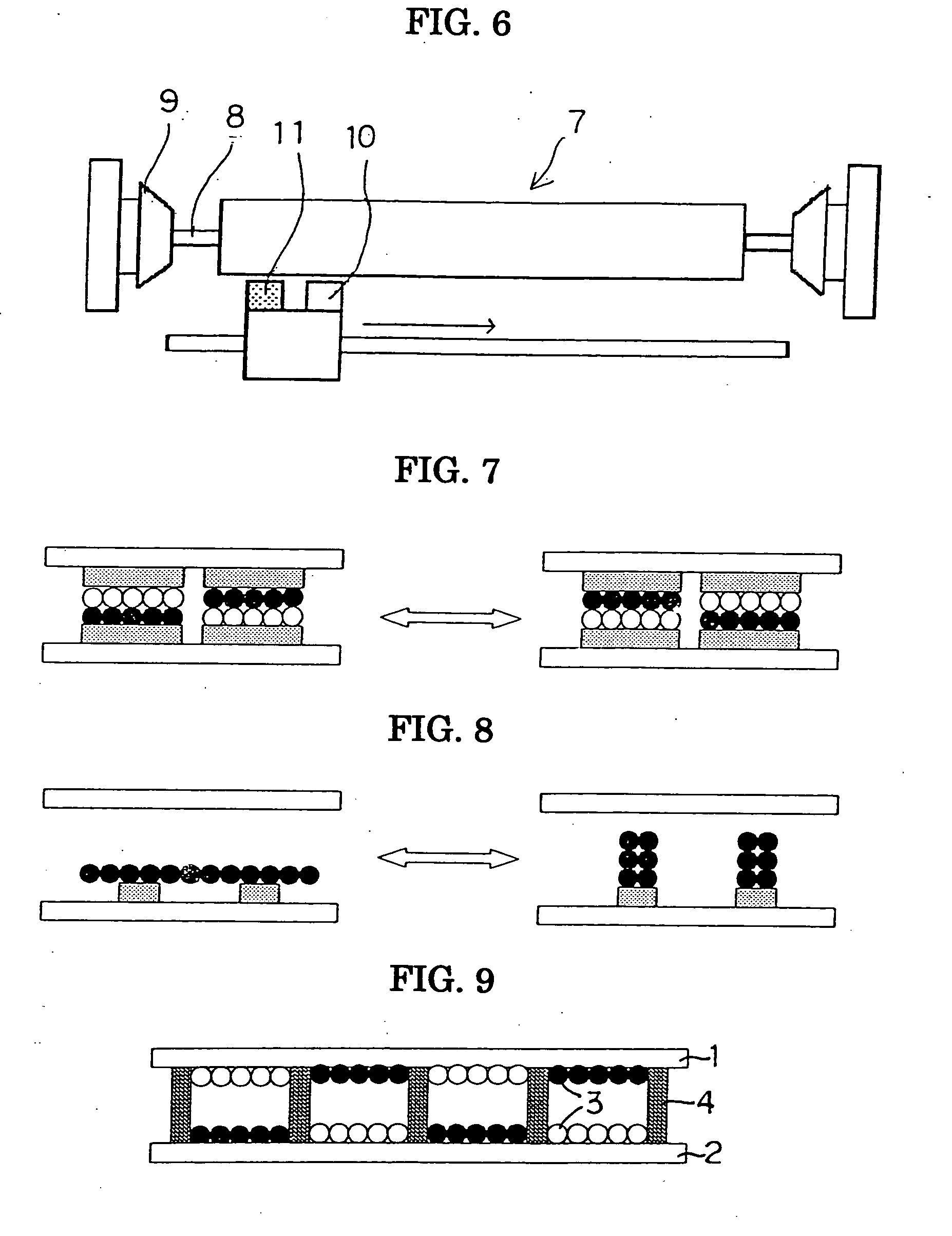

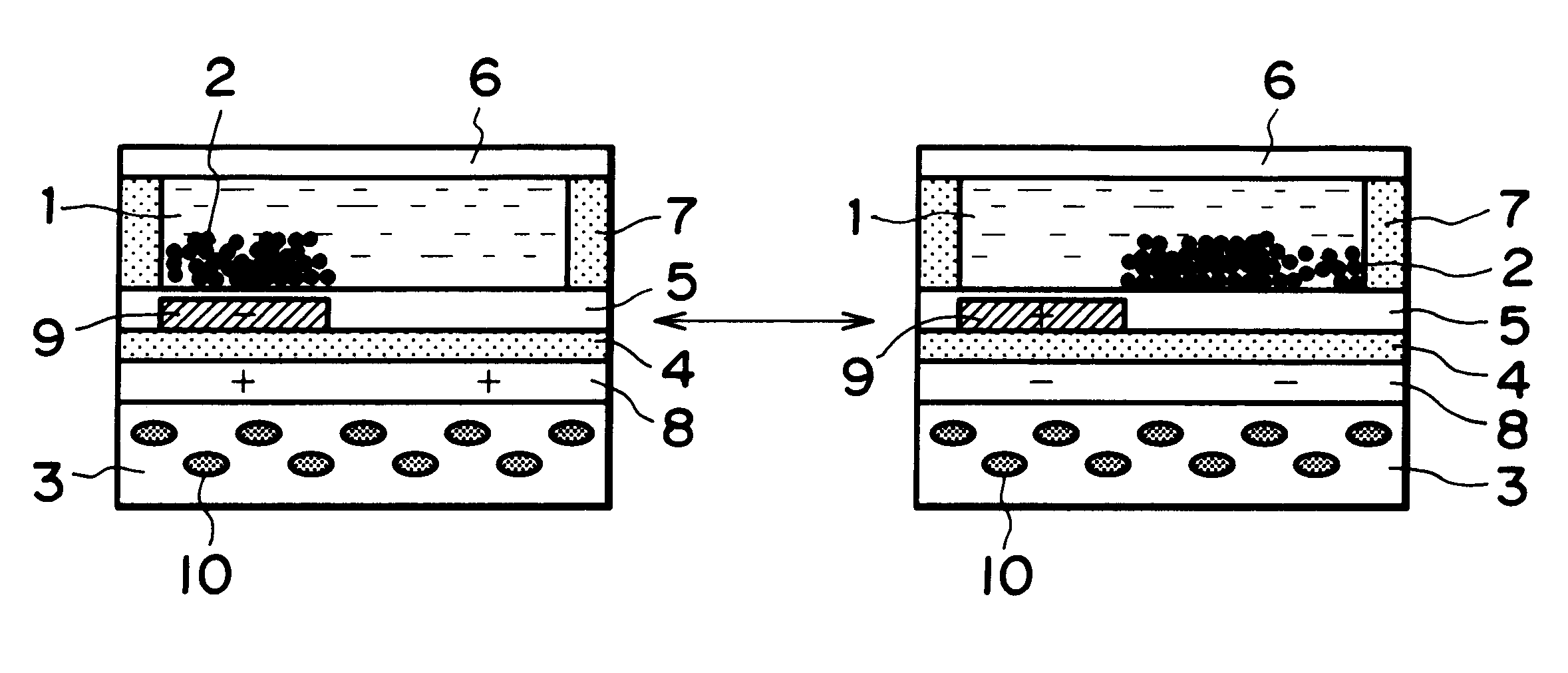

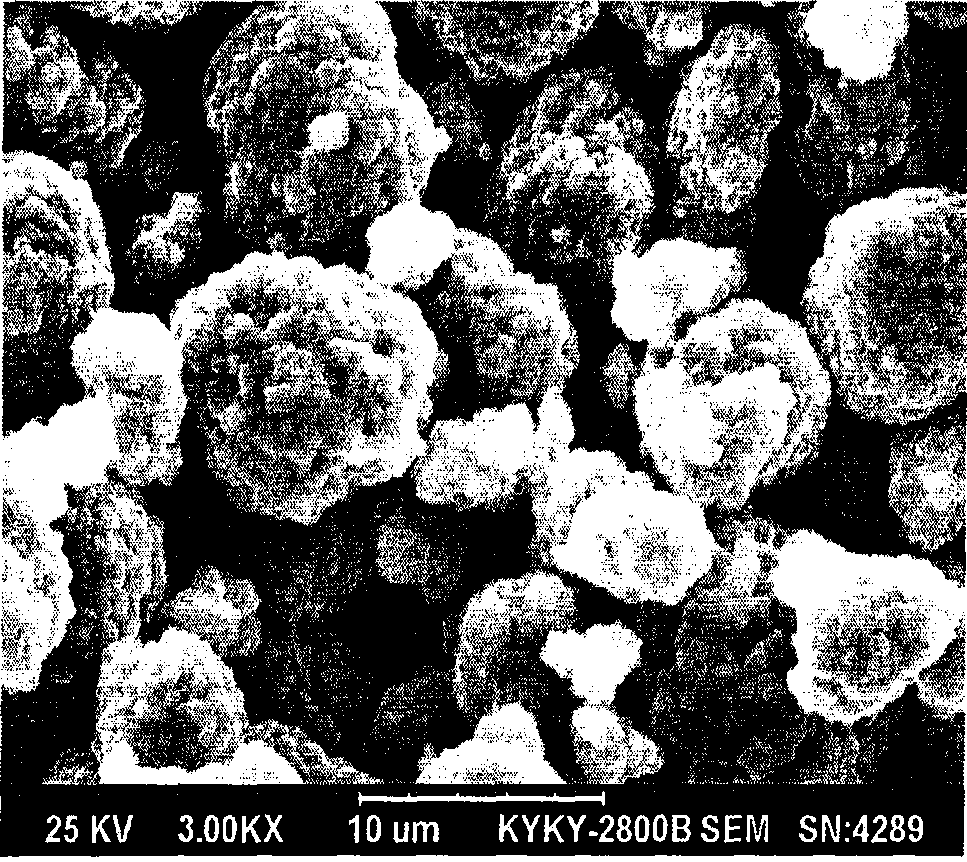

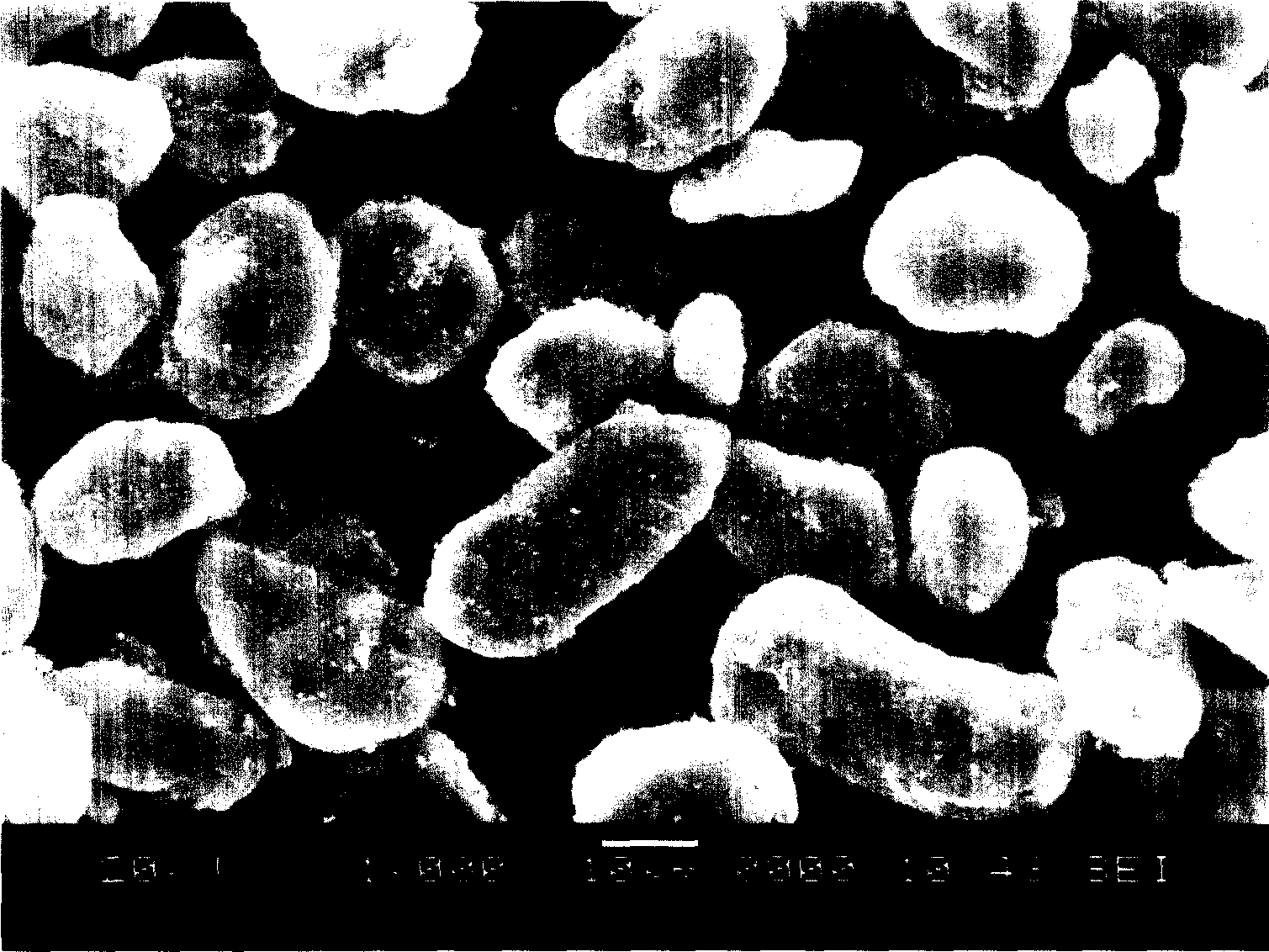

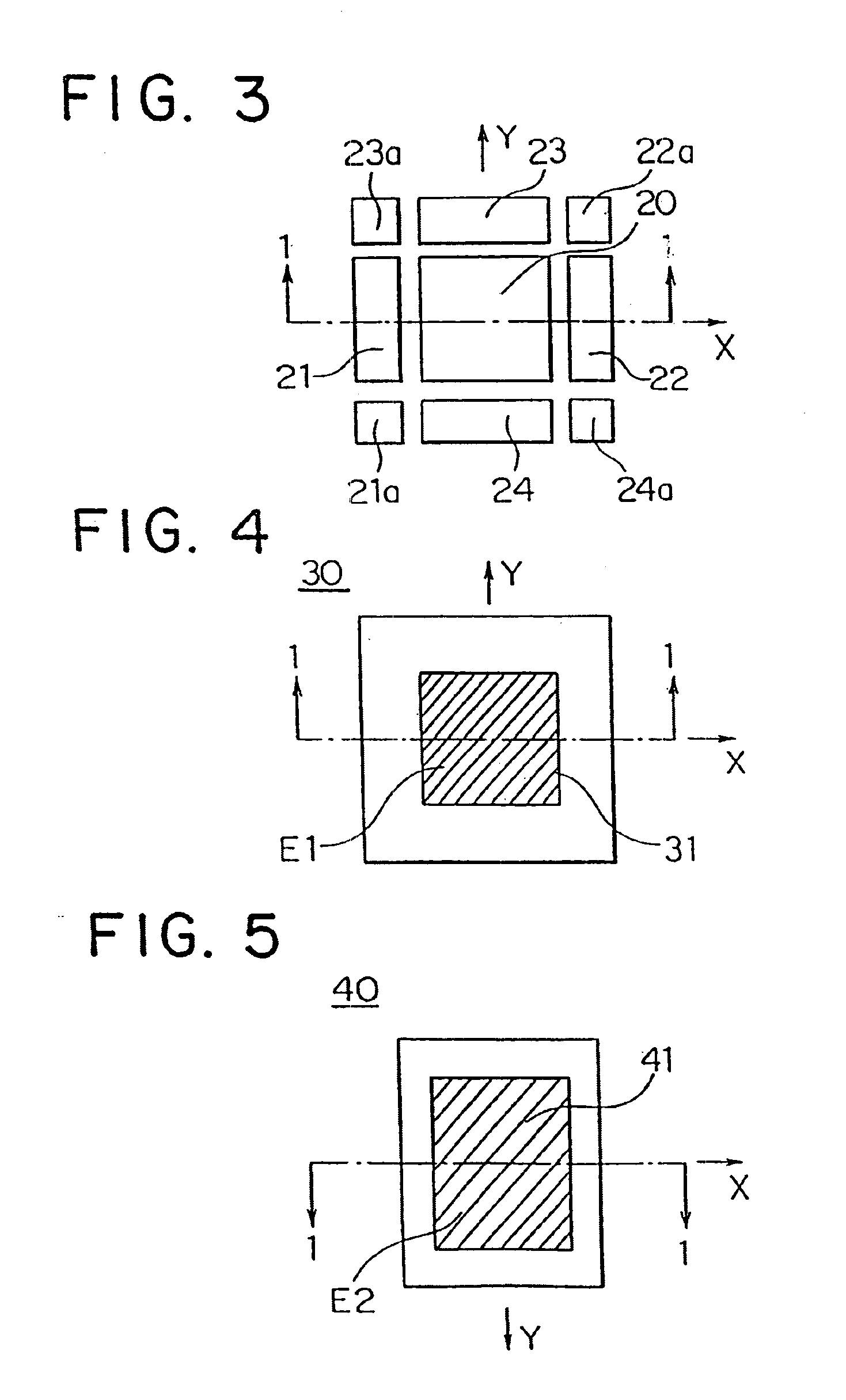

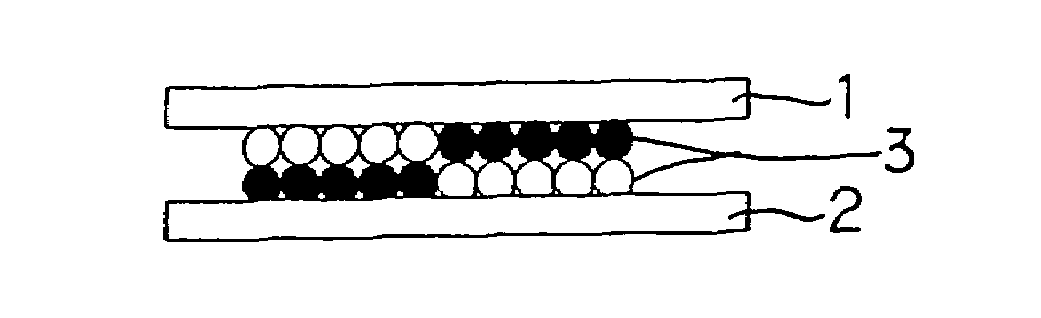

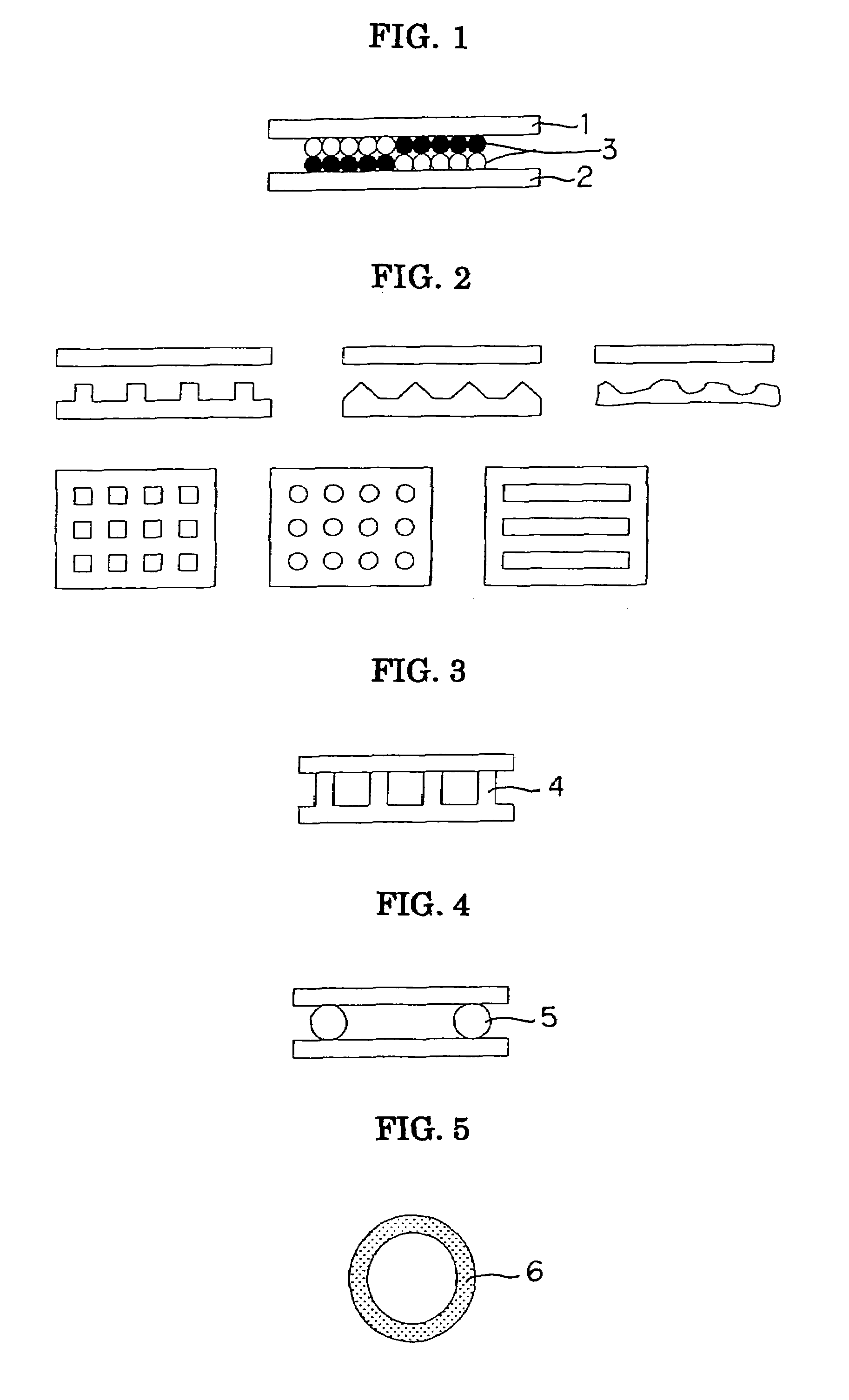

Particles and device for displaying image

InactiveUS20050001810A1Improve stabilityEnhance the imageStatic indicating devicesNon-linear opticsBreaking strengthUltrasound attenuation

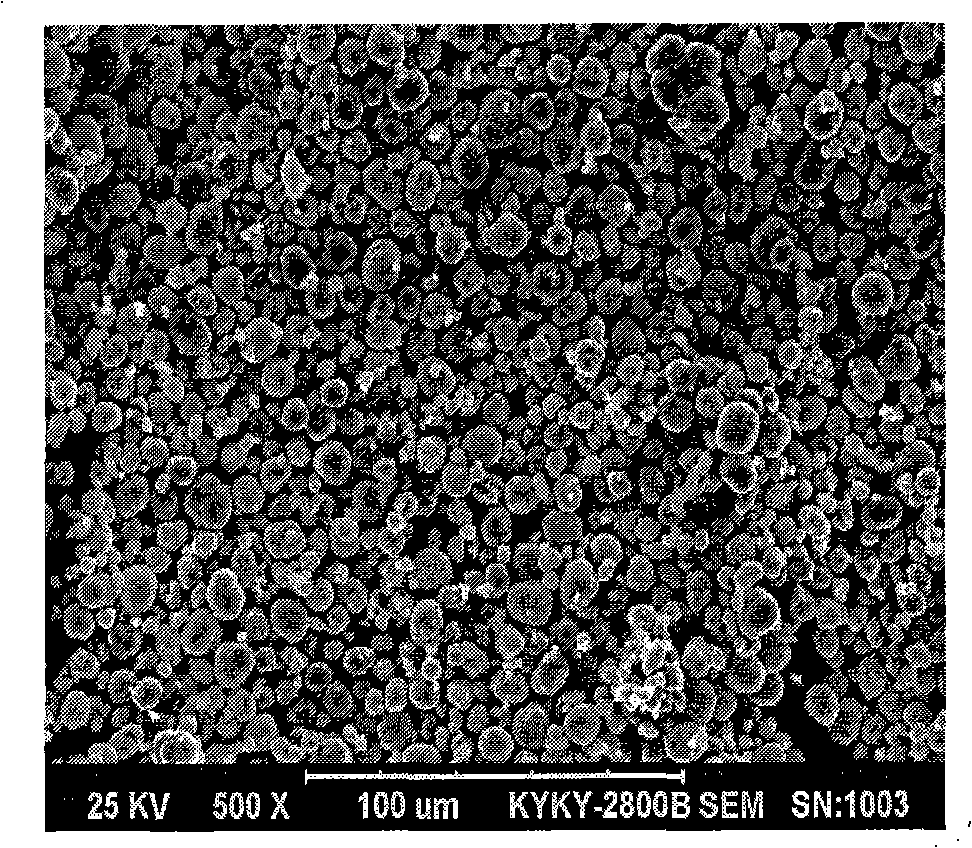

The present invention intends to provide particles for displaying images used in an image display device capable of displaying and eliminating repeatedly accompanied by flight and movement of particles utilizing Coulomb force, being superior in stability, particularly in repetition durability, memory characteristic stability, adaptability for temperature change, having capability of regulating charge amount, and accordingly, favorable images with sufficient contrast should be stably obtained. The present invention provides particles coated with a resin; specifying Span of particle diameter distribution, charge attenuation property, thermal change of the surface hardness, tensile break strength, Izod impact strength (with a notch), abrasion loss (Taber), tensile elastic modulus, flexural elastic modulus, or tear strength. The present invention also proposes about the structure of the particles.

Owner:BRIDGESTONE CORP

Electrophotographic display device and driving method therefor

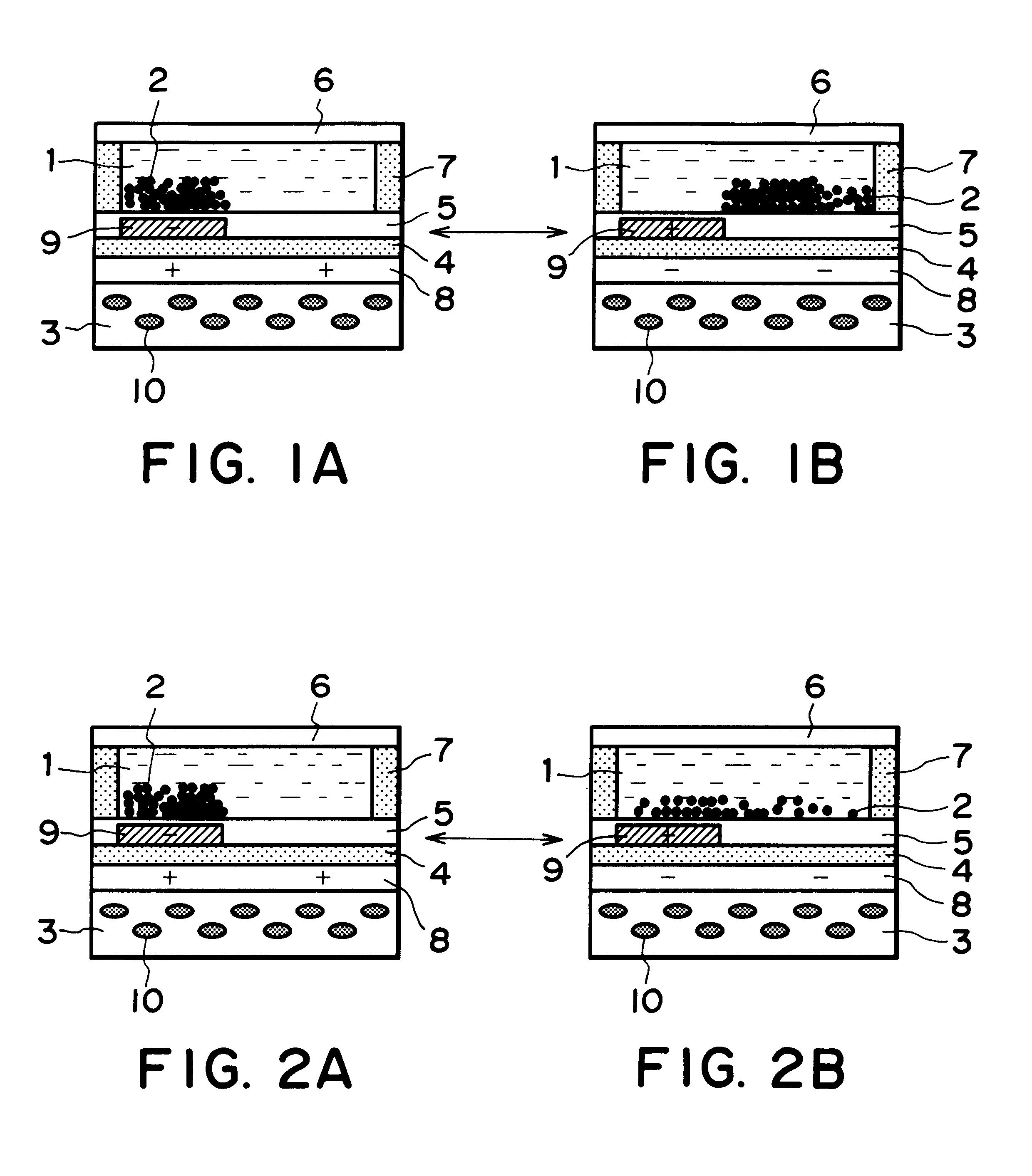

An electrophoretic display device exhibiting a memory characteristic, i.e., capable of holding a display state even after removal of an applied voltage, is provided by introducing a mechanism that colored electrophoretic particles are retained in position for display in the absence of an electric field. For the purpose, at least one of a pair of substrates holding therebetween colored electrophoretic particles together with an insulating liquid is provided with a magnetism by disposing a magnetic material on or in the substrate together with the use of magnetized colored electrophoretic particles so as to retain the colored electrophoretic particles in position under the action of a magnetic Coulomb force exerted by the magnetized substrate.

Owner:CANON KK

Ionization by droplet impact

ActiveUS20060108539A1Minimize the numberIncrease kinetic energySamples introduction/extractionMaterial analysis by electric/magnetic meansThermal energyMass spectrometric

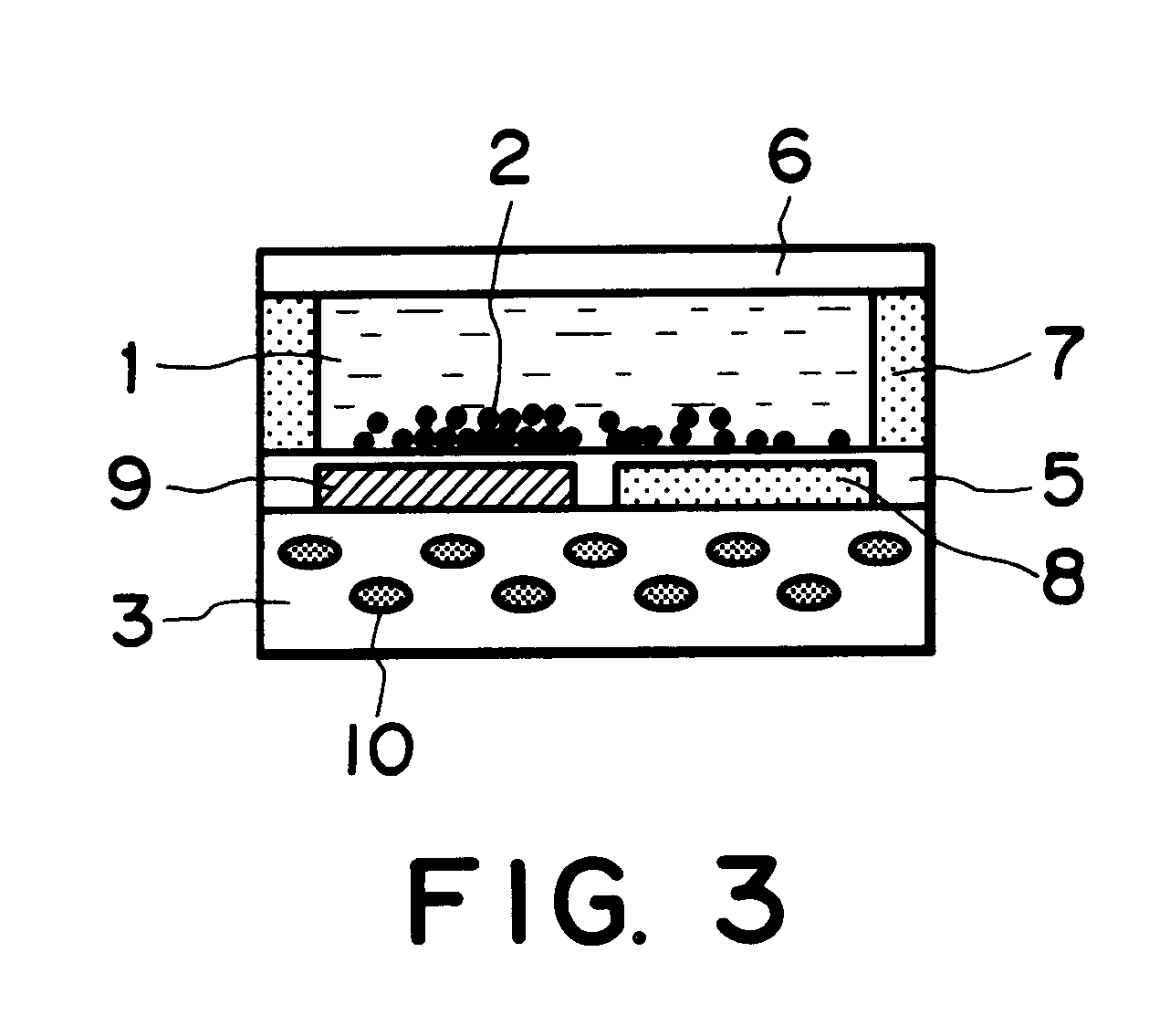

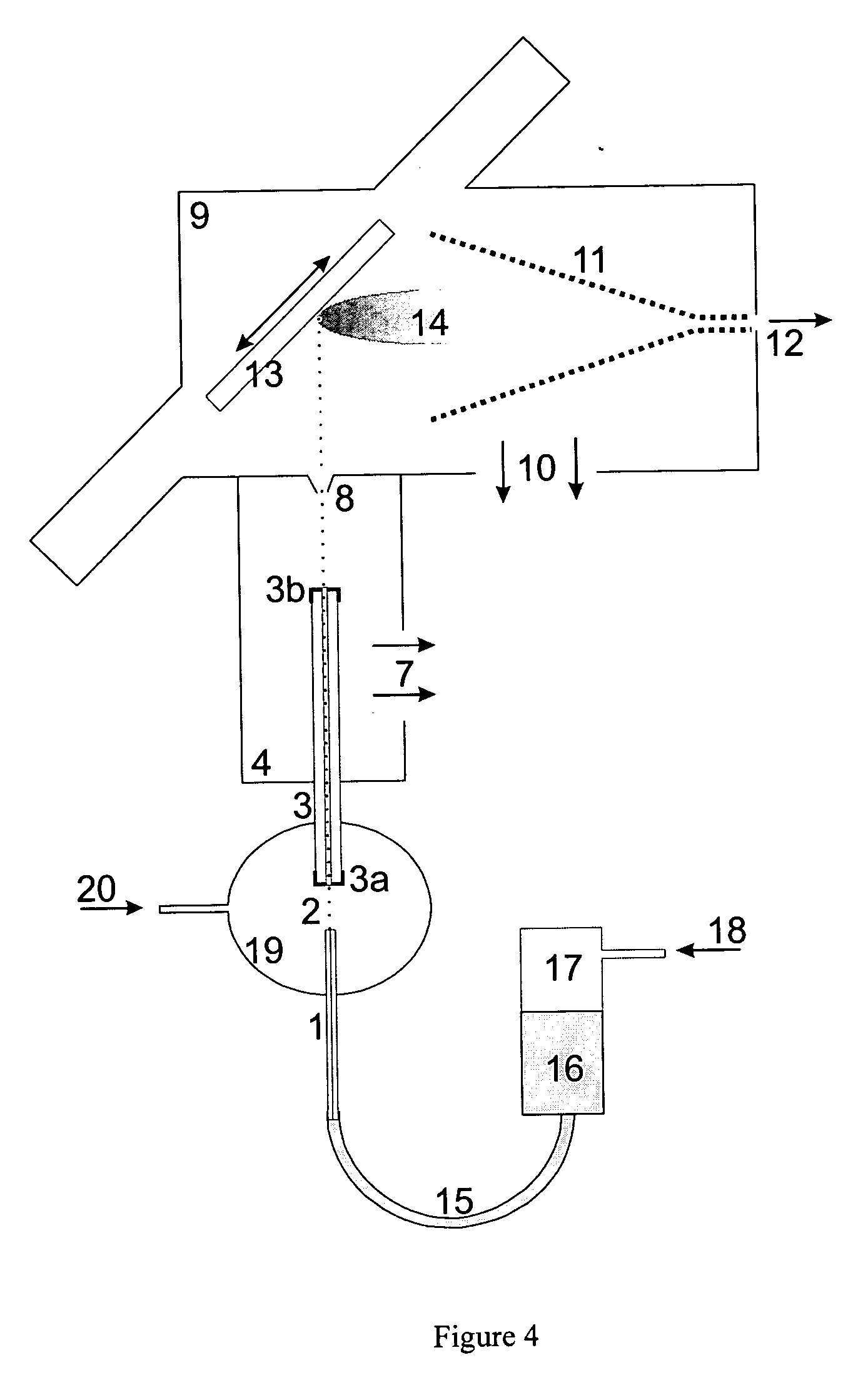

The invention relates to methods and instruments for ionizing analyte molecules, preferably biomolecules, which are dissolved in liquids or firmly adsorbed on surfaces. Liquids are nebulized at atmospheric pressure by electrospraying. Highly charged microdroplets, which enter the vacuum of the mass spectrometer through the inlet capillary, strike an impact plate when energy is fed in. The repulsive Coulomb force of the charges, the absorption of additional thermal energy and / or the conversion of their kinetic energy into thermal energy cause the microdroplets to burst and evaporate. Analyte molecules which are located in the nebulized liquid or on the impact plate are released in charged form and can be fed to the mass spectrometer for analysis by the extraction and collection effect of an ion funnel operated with RF and DC voltages.

Owner:BRUKER DALTONIK GMBH & CO KG

Coulomb friction damped disc brake rotors

InactiveUS20060076200A1Average thicknessSmall thicknessNoise/vibration controlBraking discsEngineeringMechanical engineering

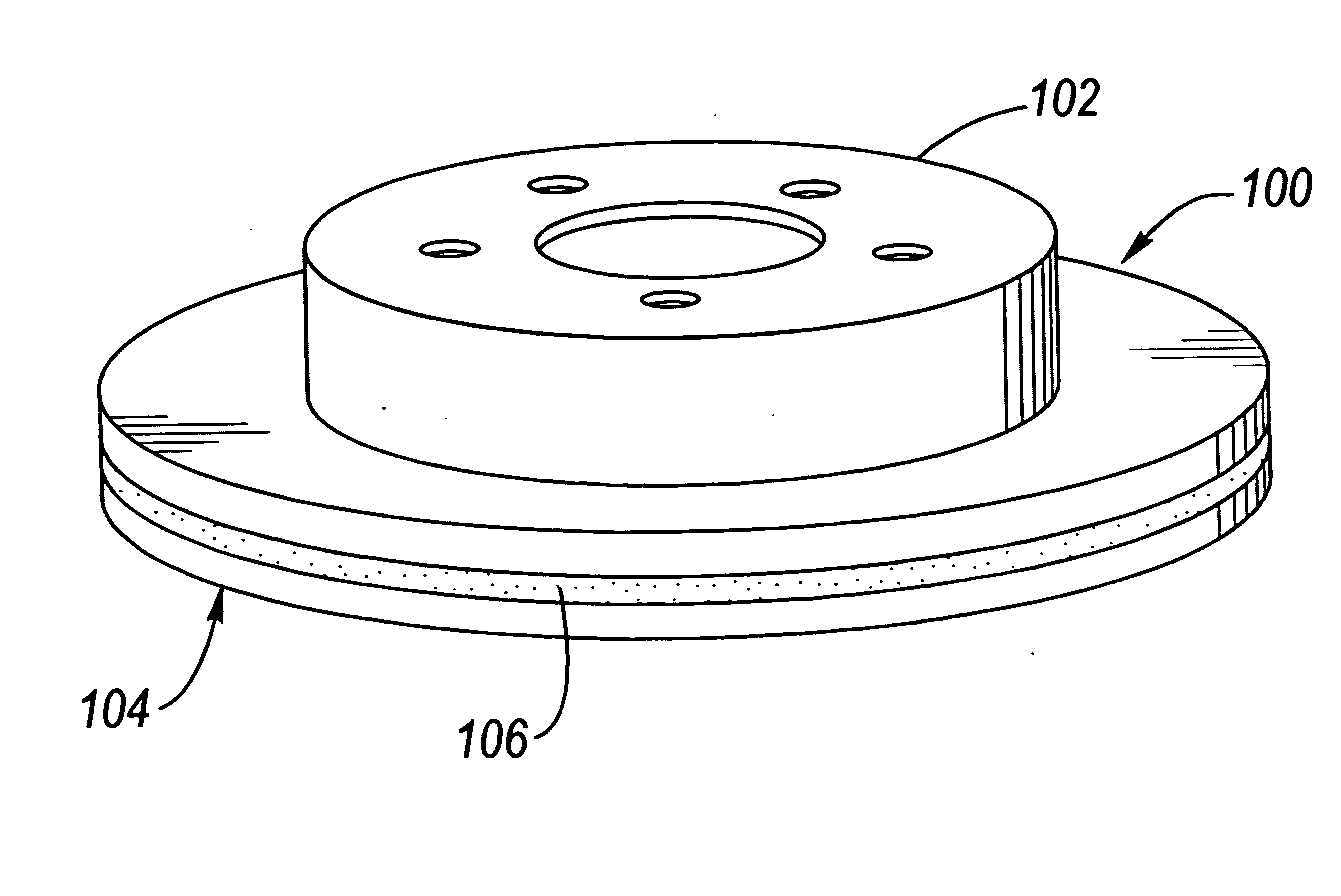

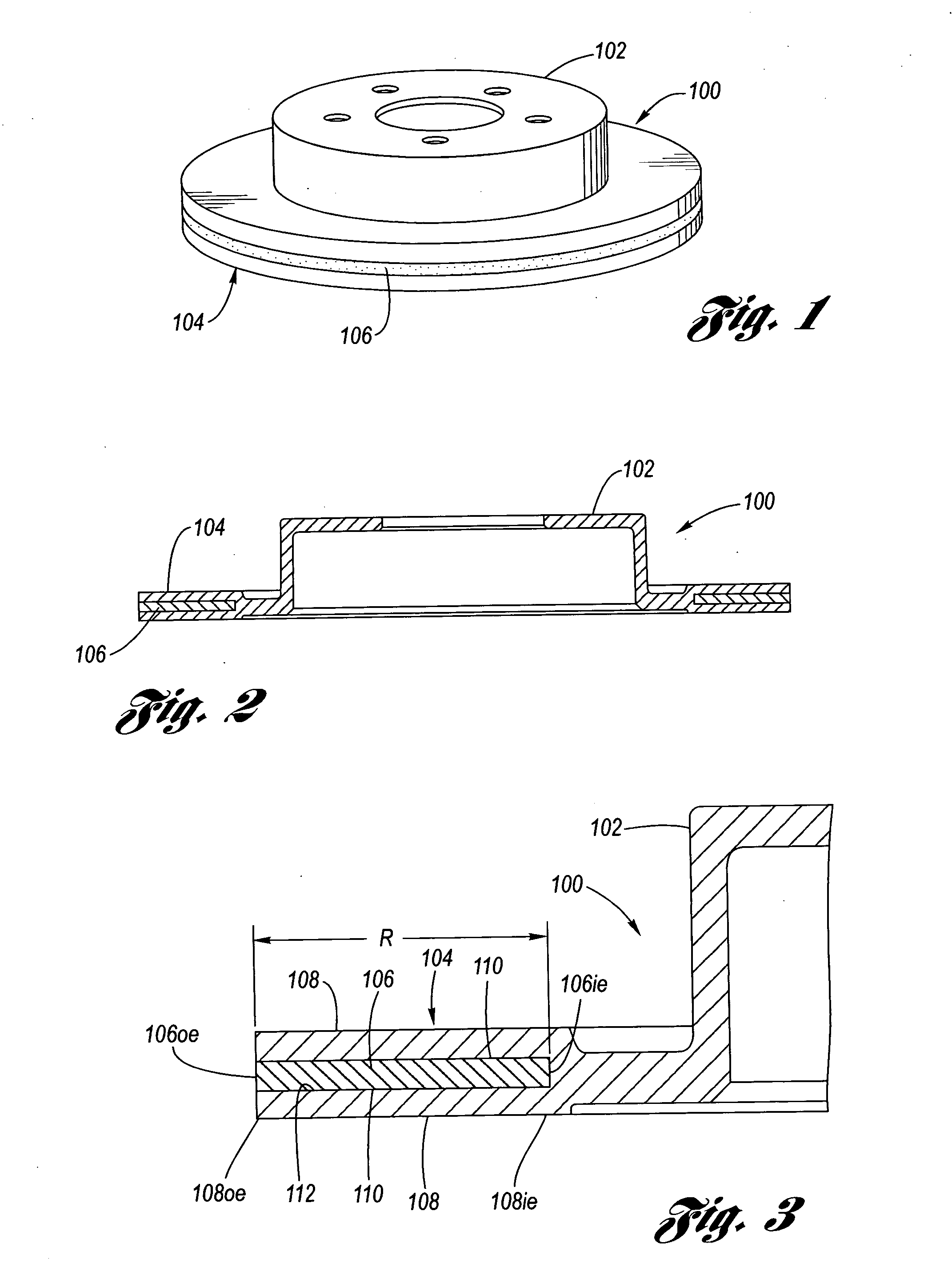

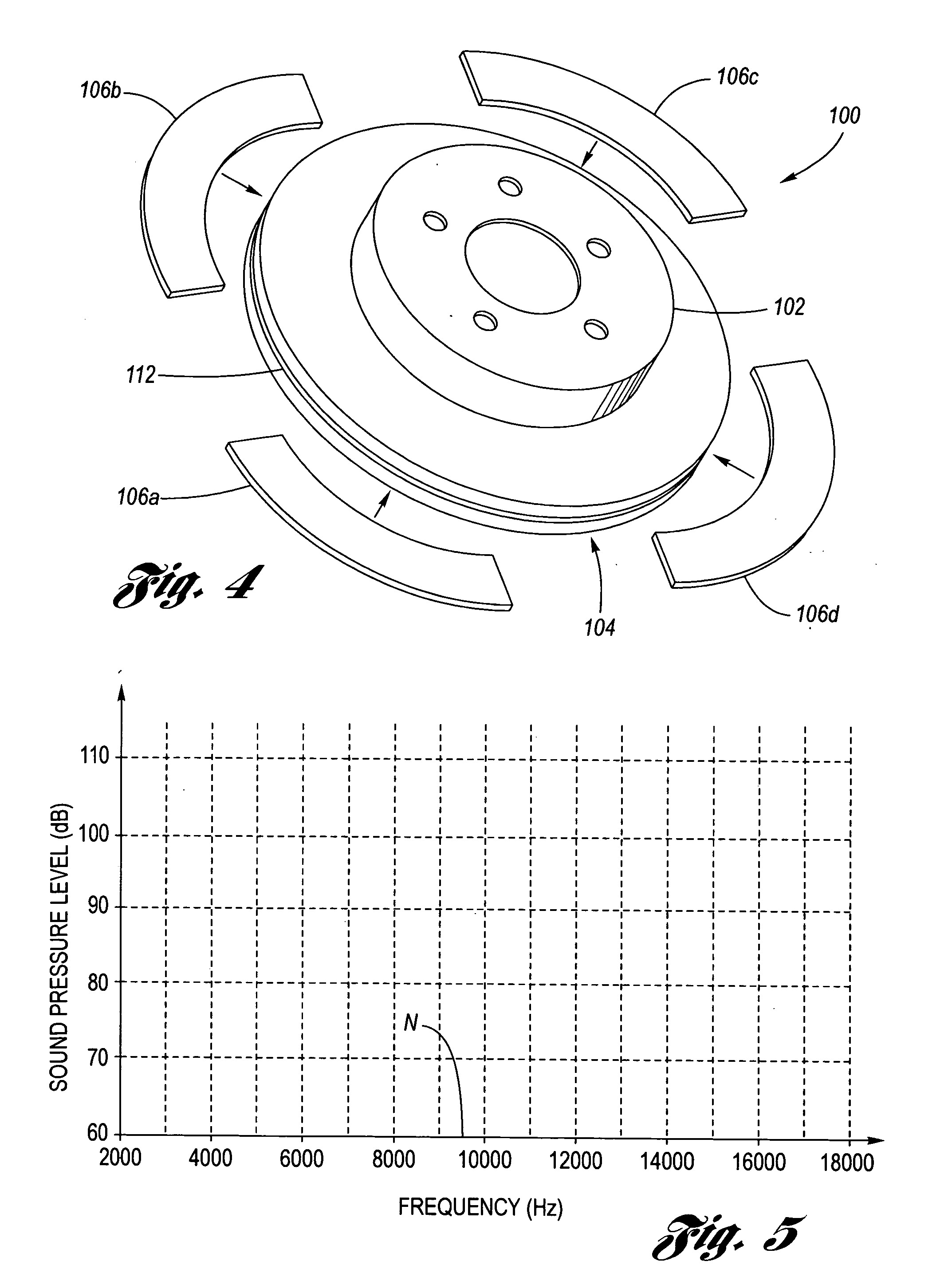

A Coulomb friction damped disc brake rotor, wherein damping is provided Coulomb friction in generally coextensive relation with the braking surfaces of the one or more rotor cheeks. The Coulomb friction damped disc brake rotor has at least one interfacial boundary formed in at least one rotor cheek disposed in generally coextensive relation to the braking surface thereof. The interfacial boundary provides a mechanically distinguishable surface boundary between two surfaces which are in mutual contact such that a state of Coulomb friction exists therebetween.

Owner:GM GLOBAL TECH OPERATIONS LLC

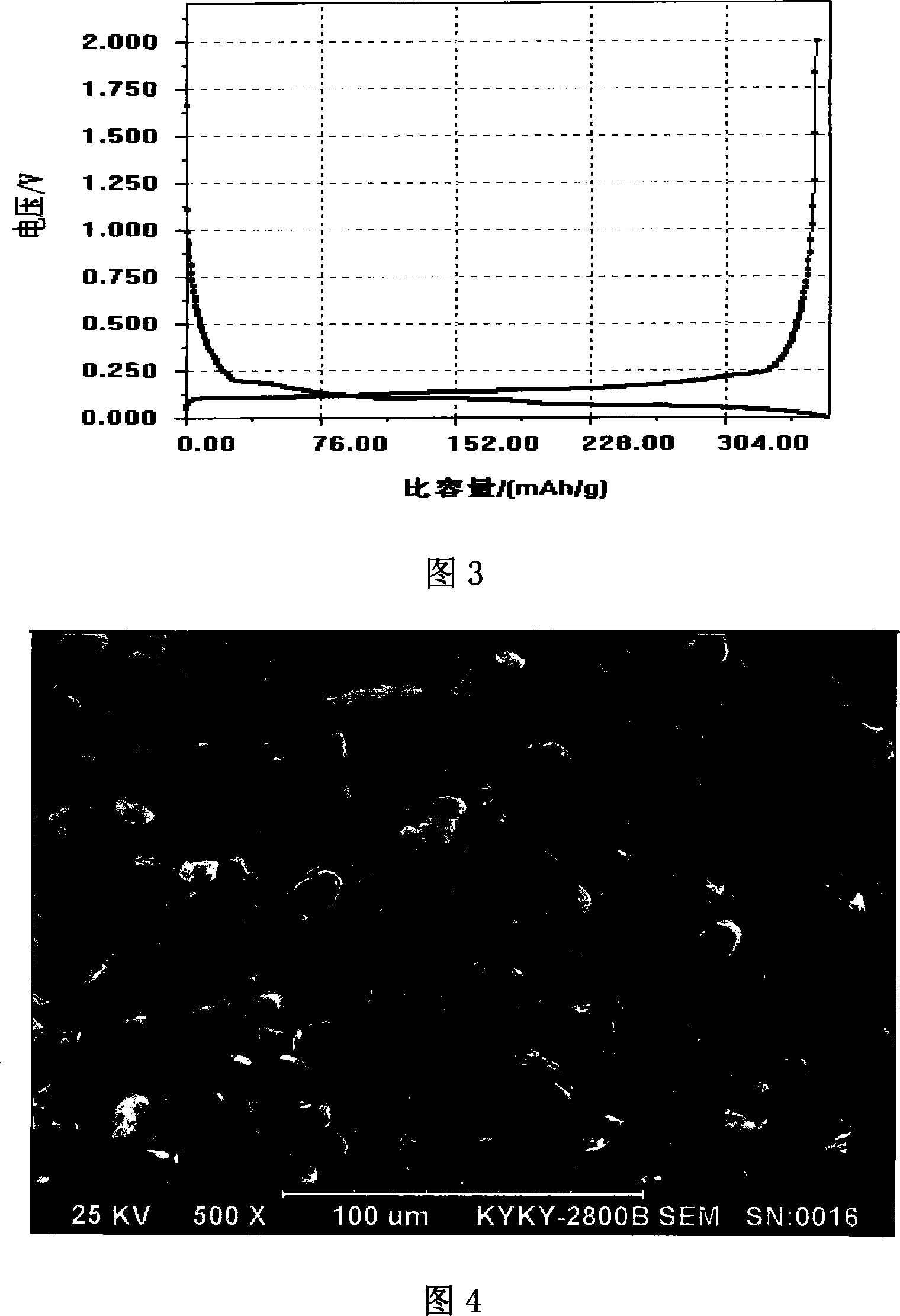

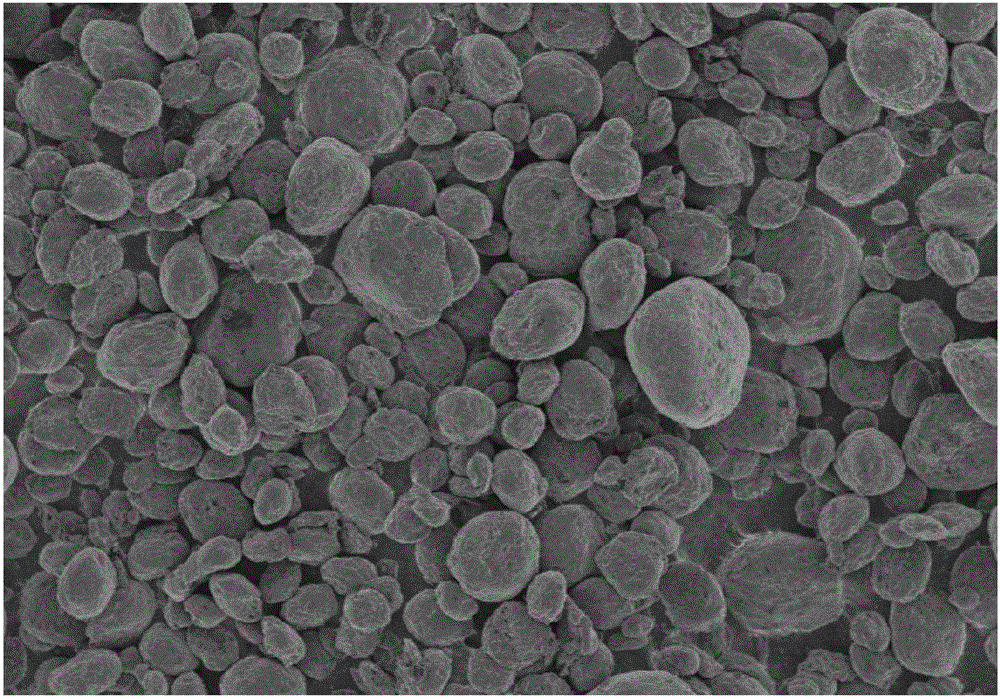

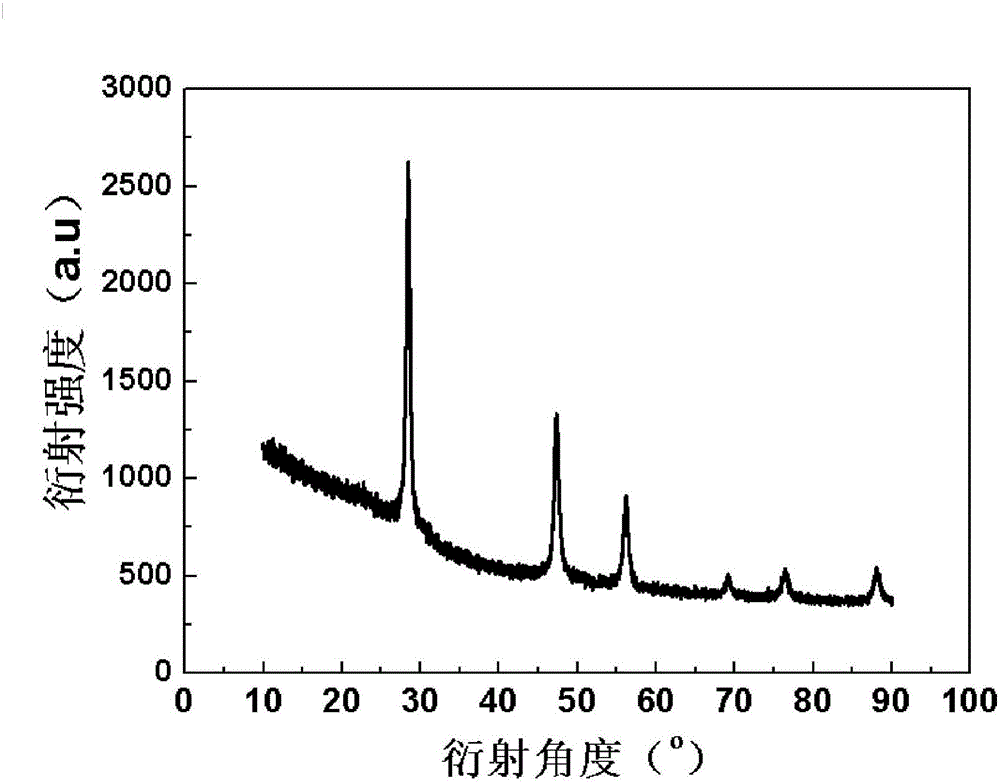

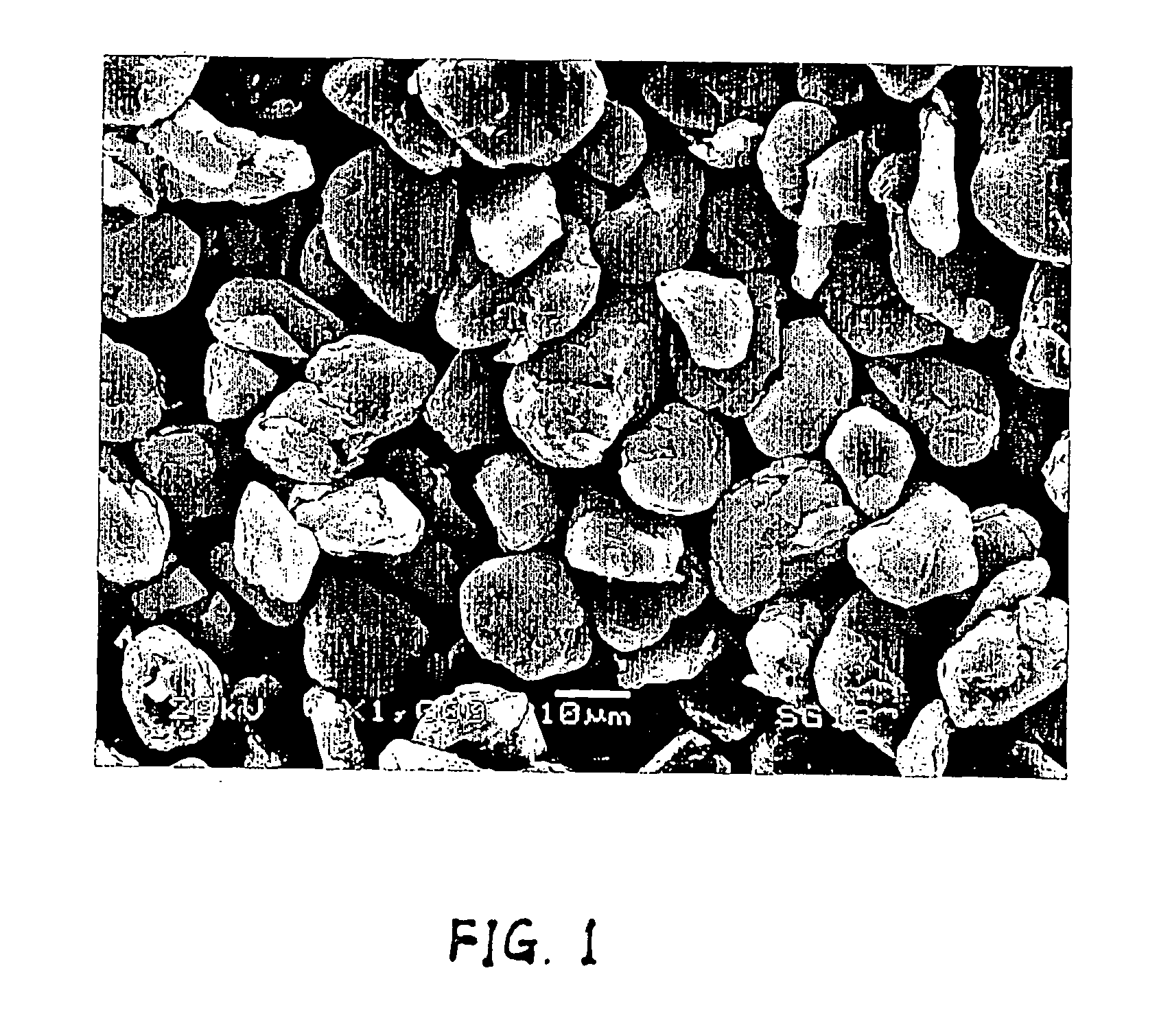

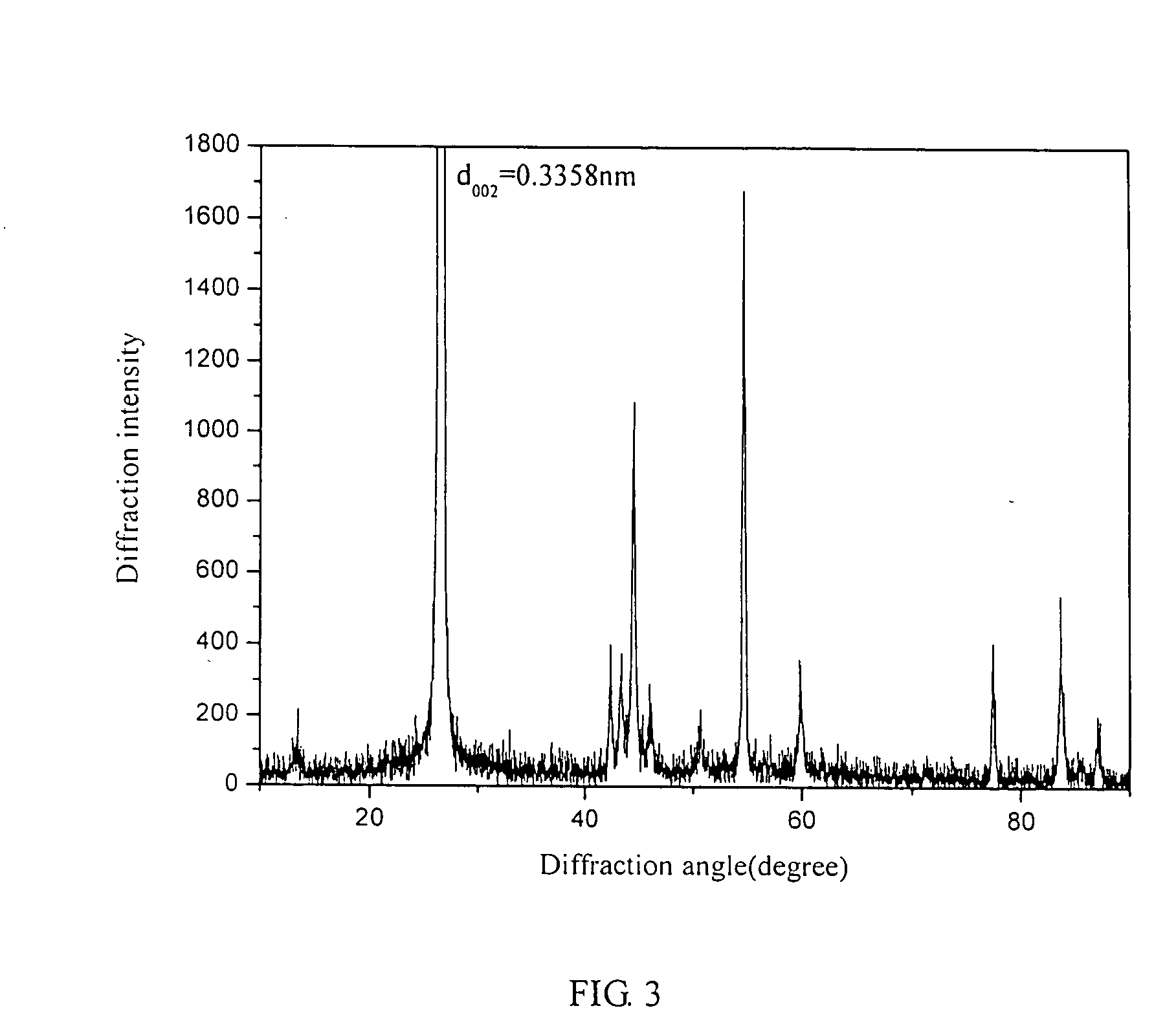

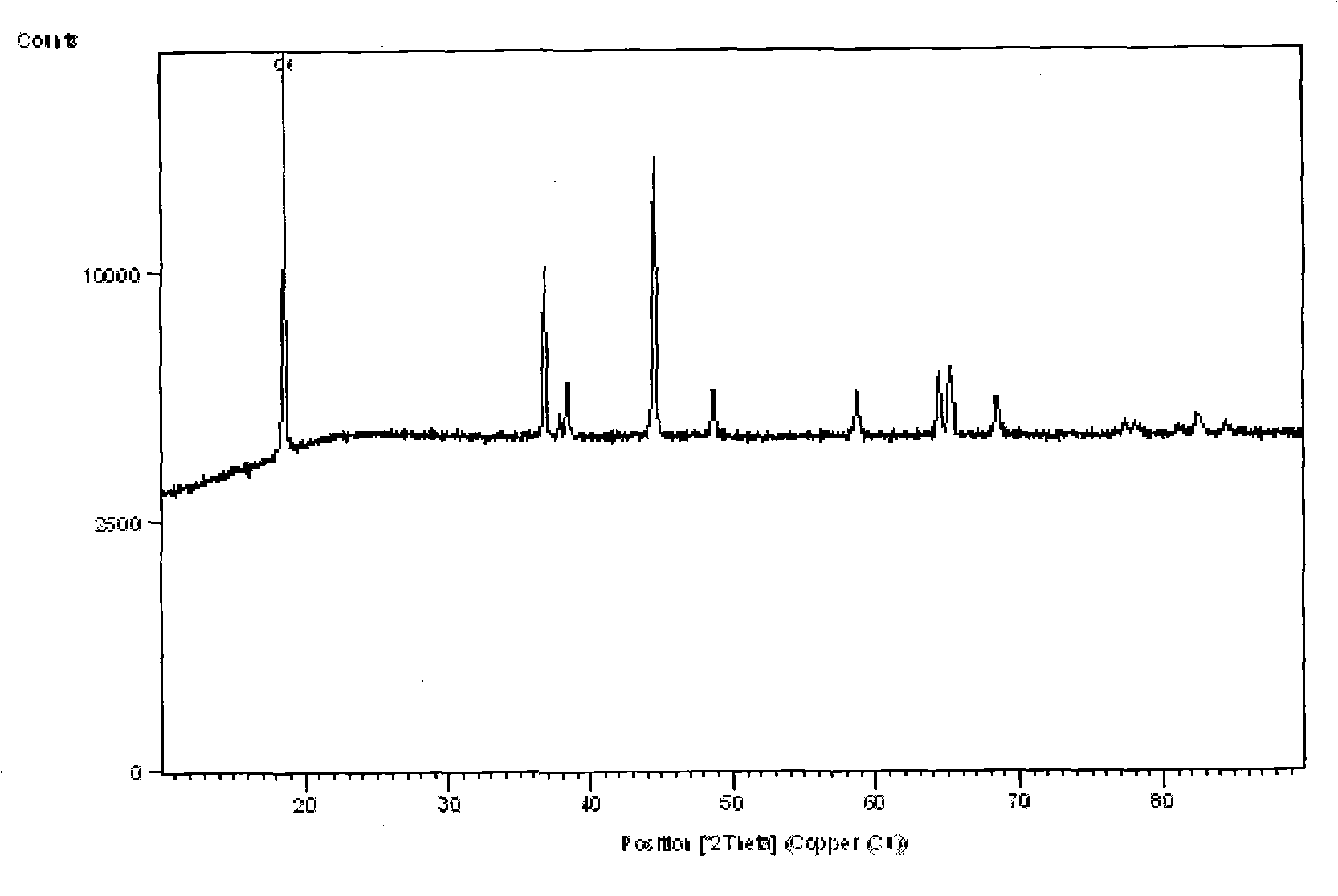

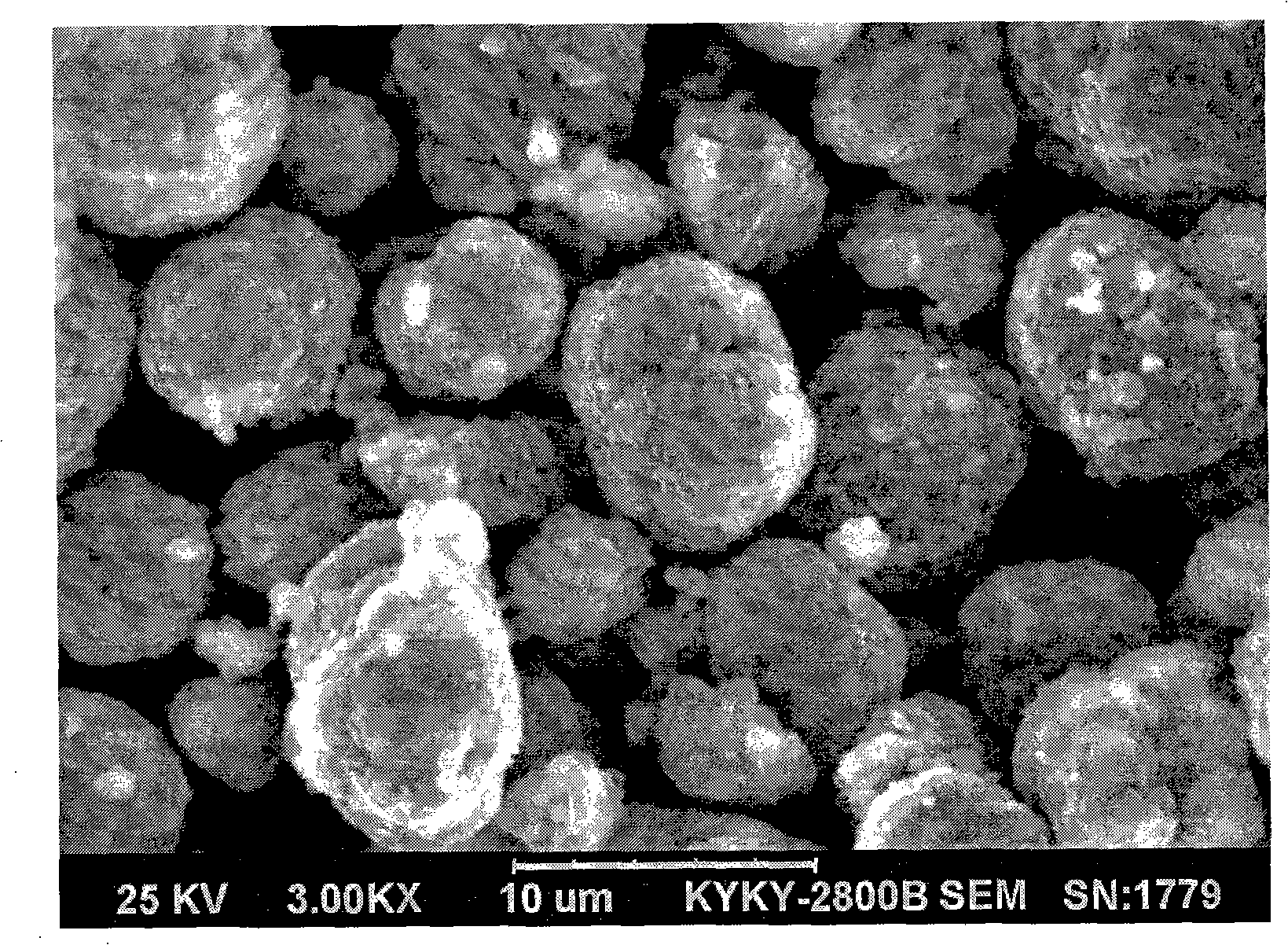

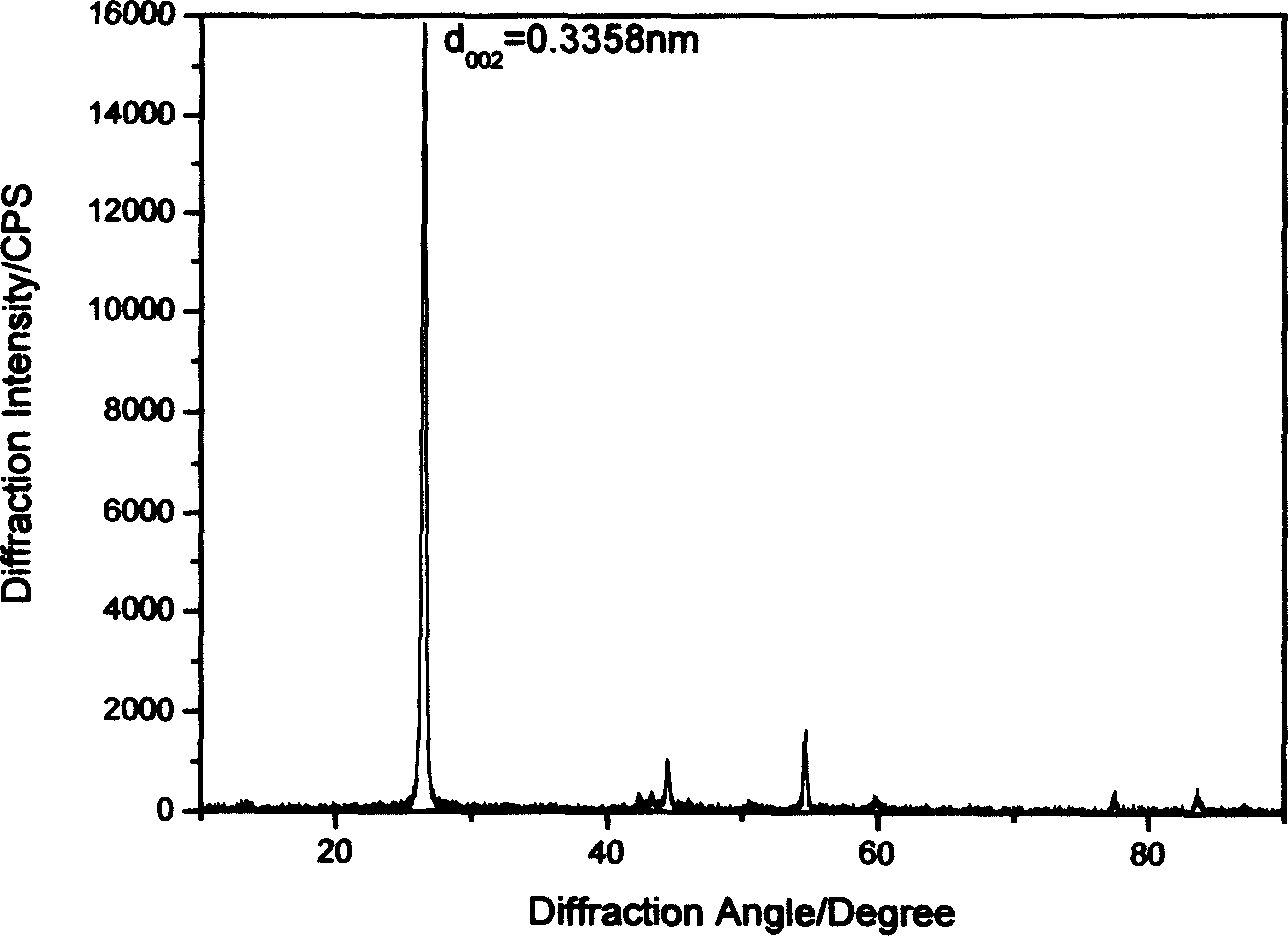

Man-made graphite cathode material for lithium ion battery and its making method

ActiveCN101087021AImprove discharge capacityPromote circulationCell electrodesAluminium-ion batteryElectrical battery

The invention discloses a preparing method of an artificial graphite cathode material used in lithium ion battery; it aims at resolving problems that cathode material possesses higher discharging capacity, coulomb efficiency and long circle life. The preparing method includes following steps: coal or petroleum needle-type coke is comminuted, and hot processed for 1-48 hours at 800deg.C-3000deg.C, comparing with current technique, the cathode material adopts needle-type coke to be comminuted, and hot process, defect that high crystallinity graphite material can not be circled in electrolyte system of PC solvent stably, and it can discharge in big times, it can be used in lithium ion drive battery, and craft is easy, and it fits for industrialization production.

Owner:BTR NEW MATERIAL GRP CO LTD

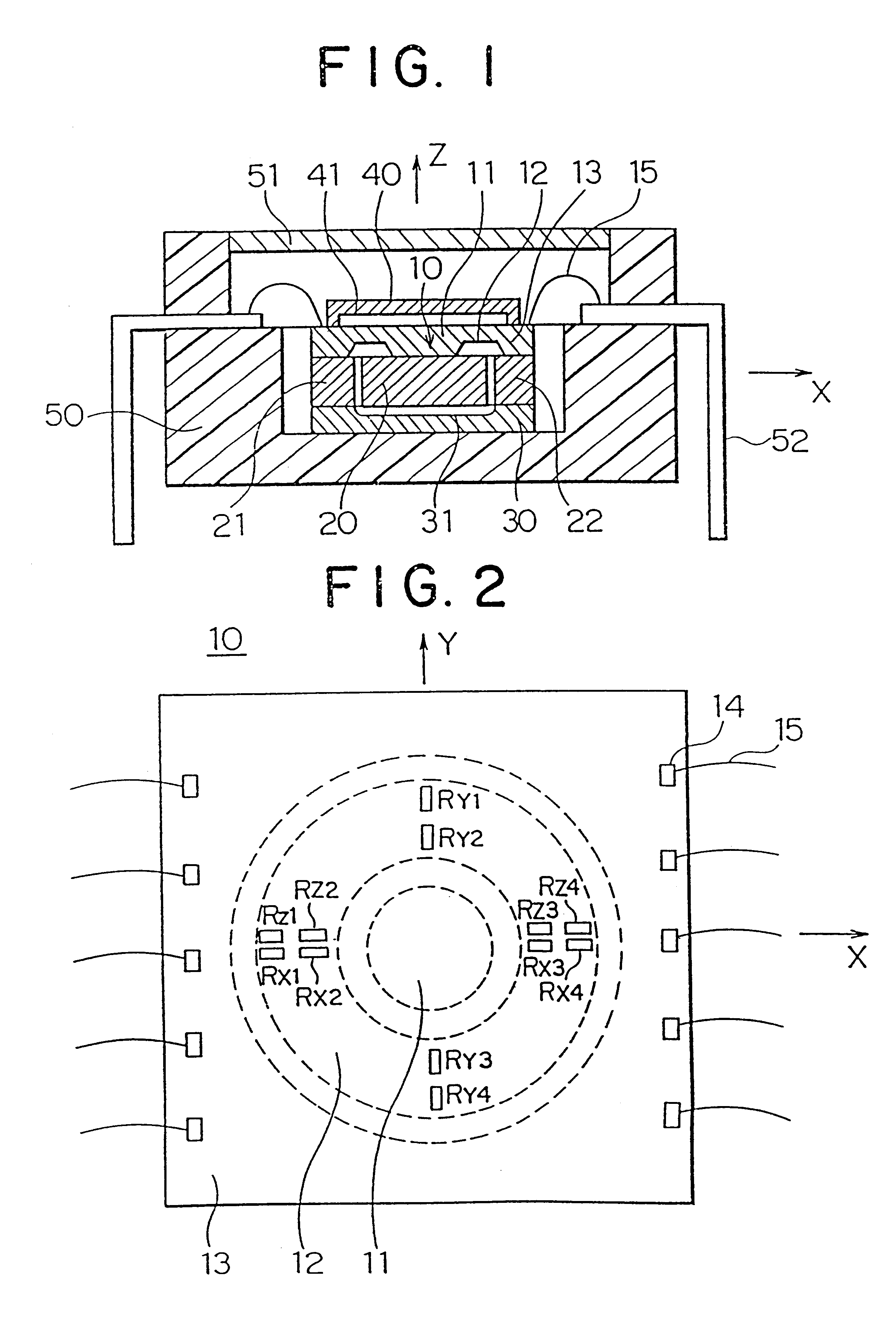

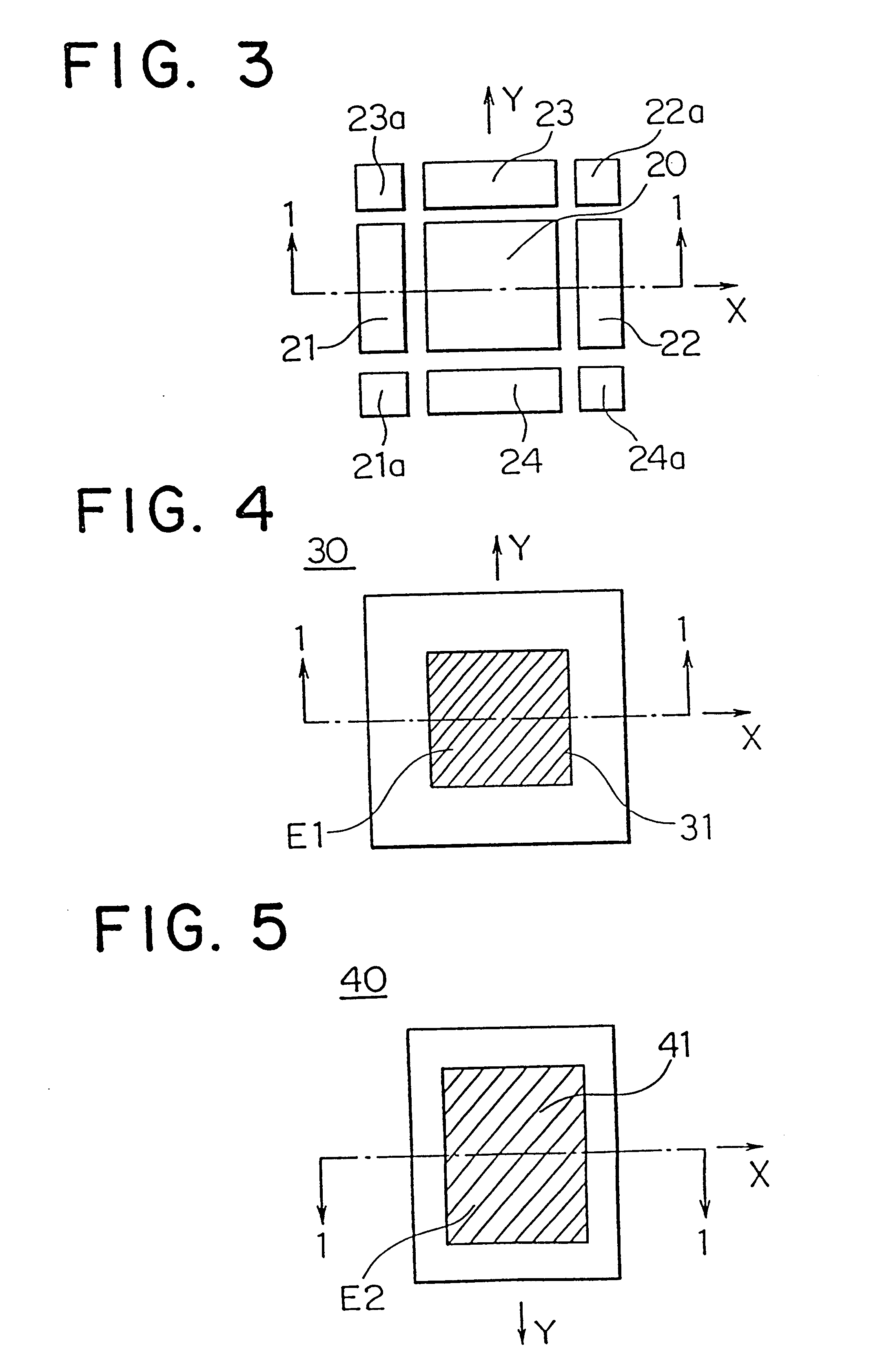

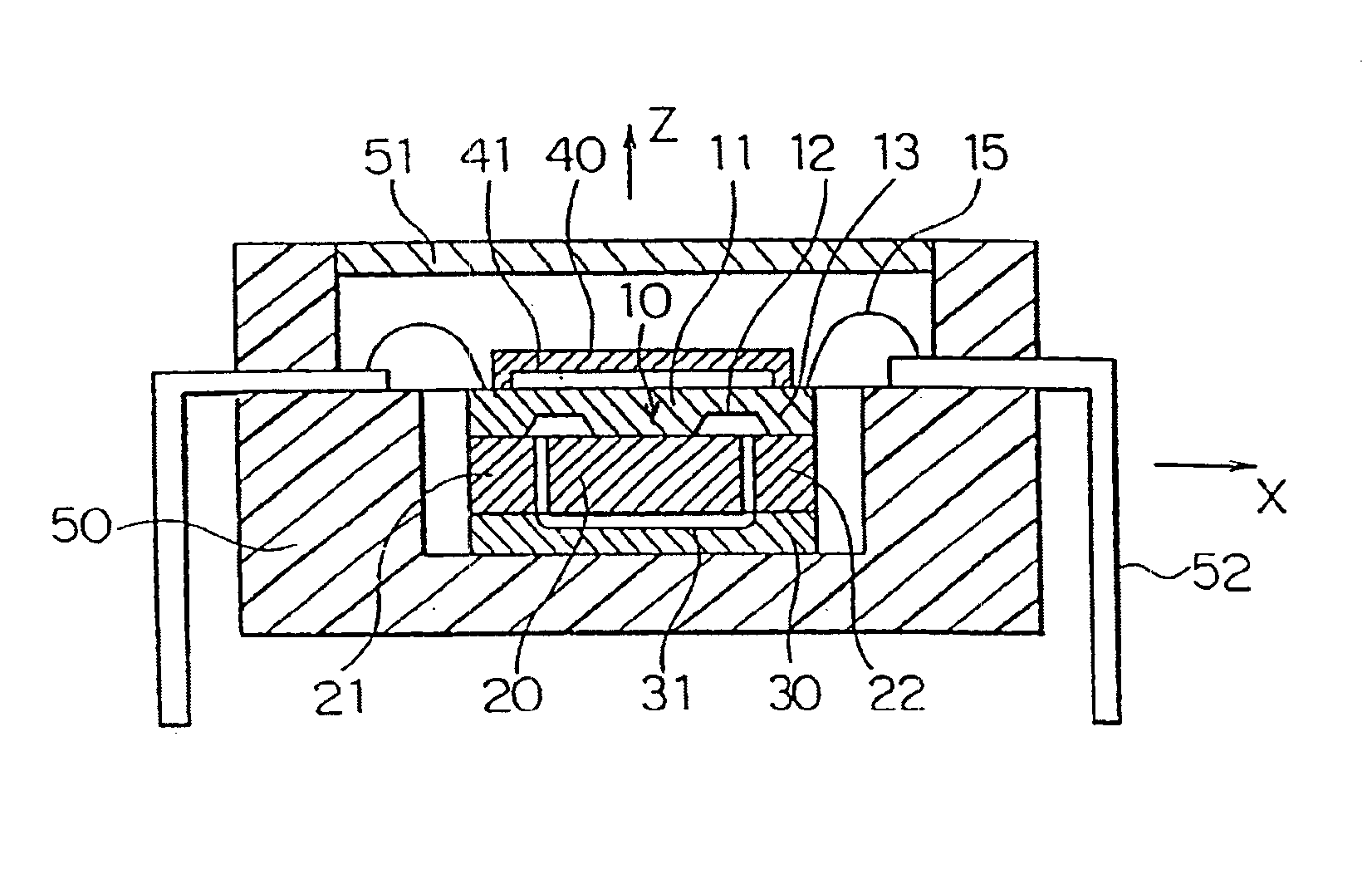

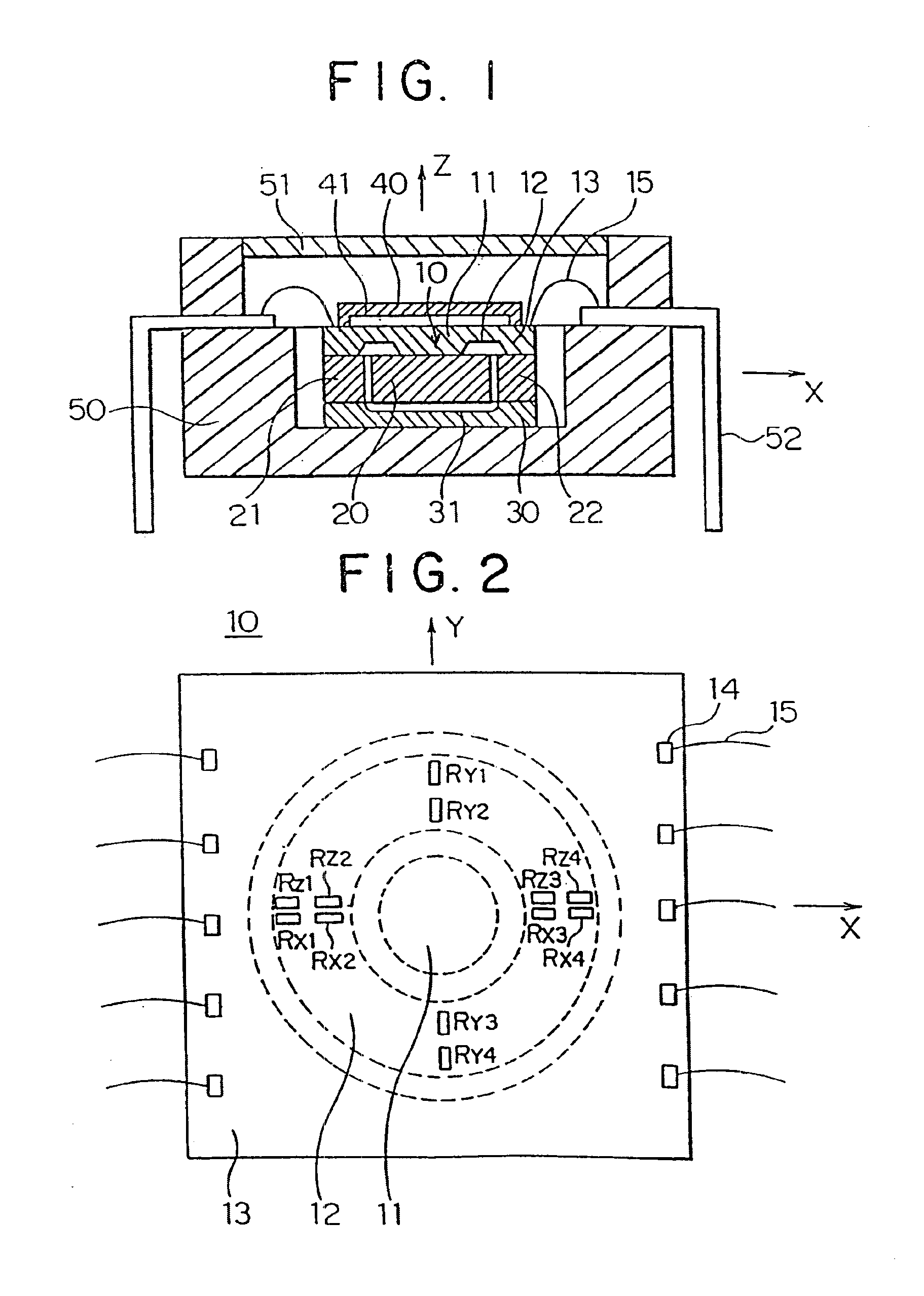

Method of manufacturing a sensor detecting a physical action as an applied force

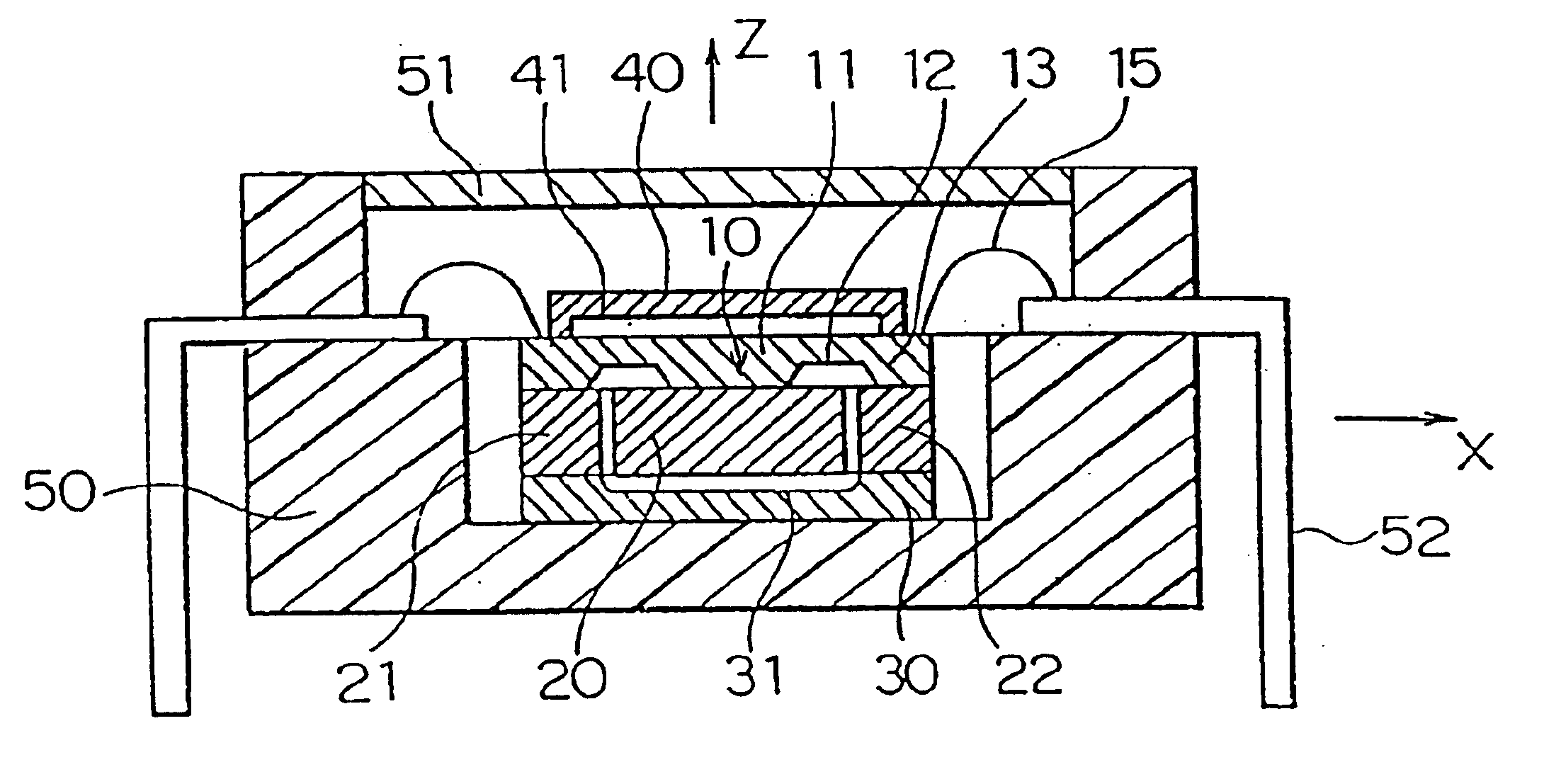

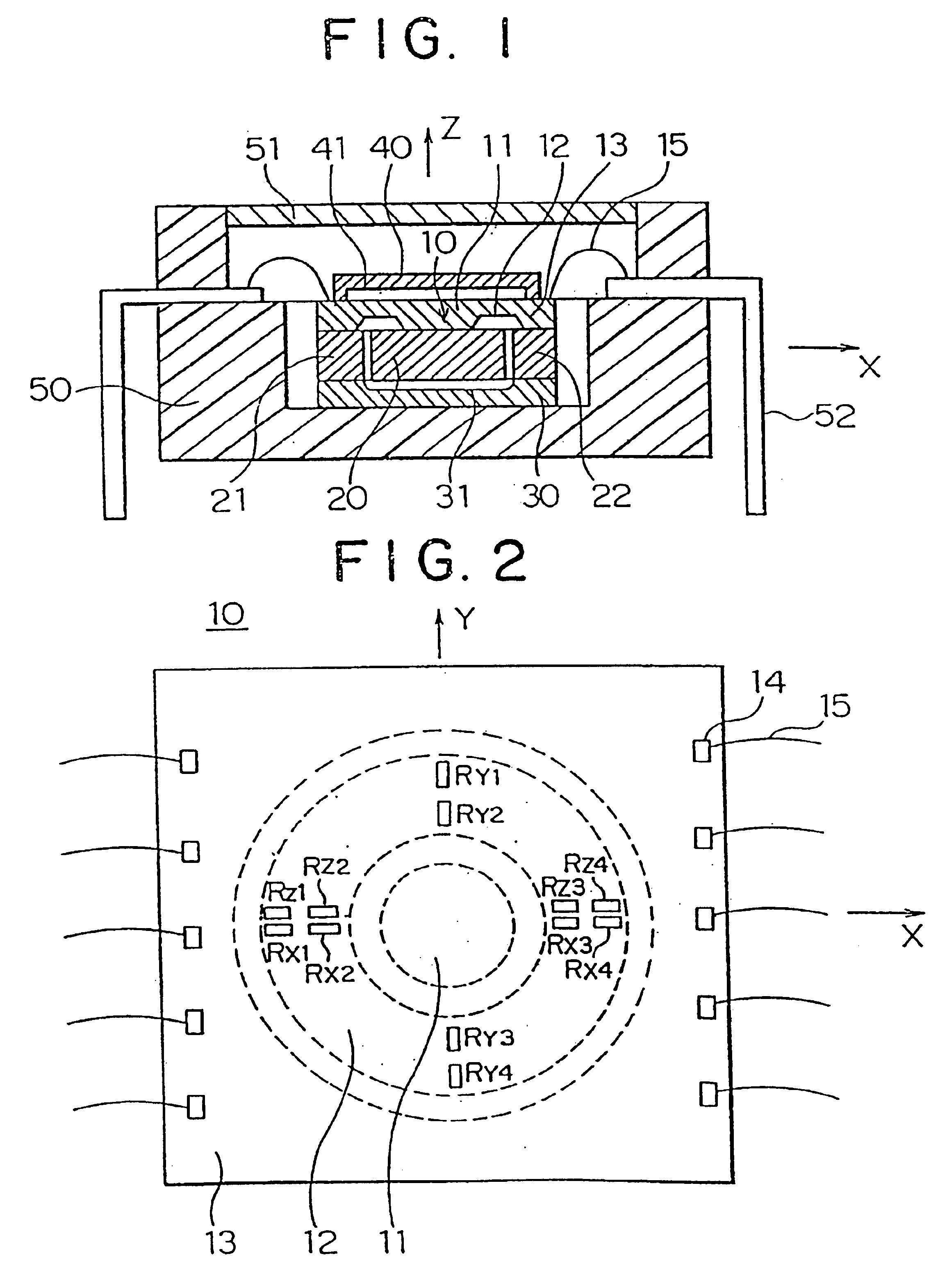

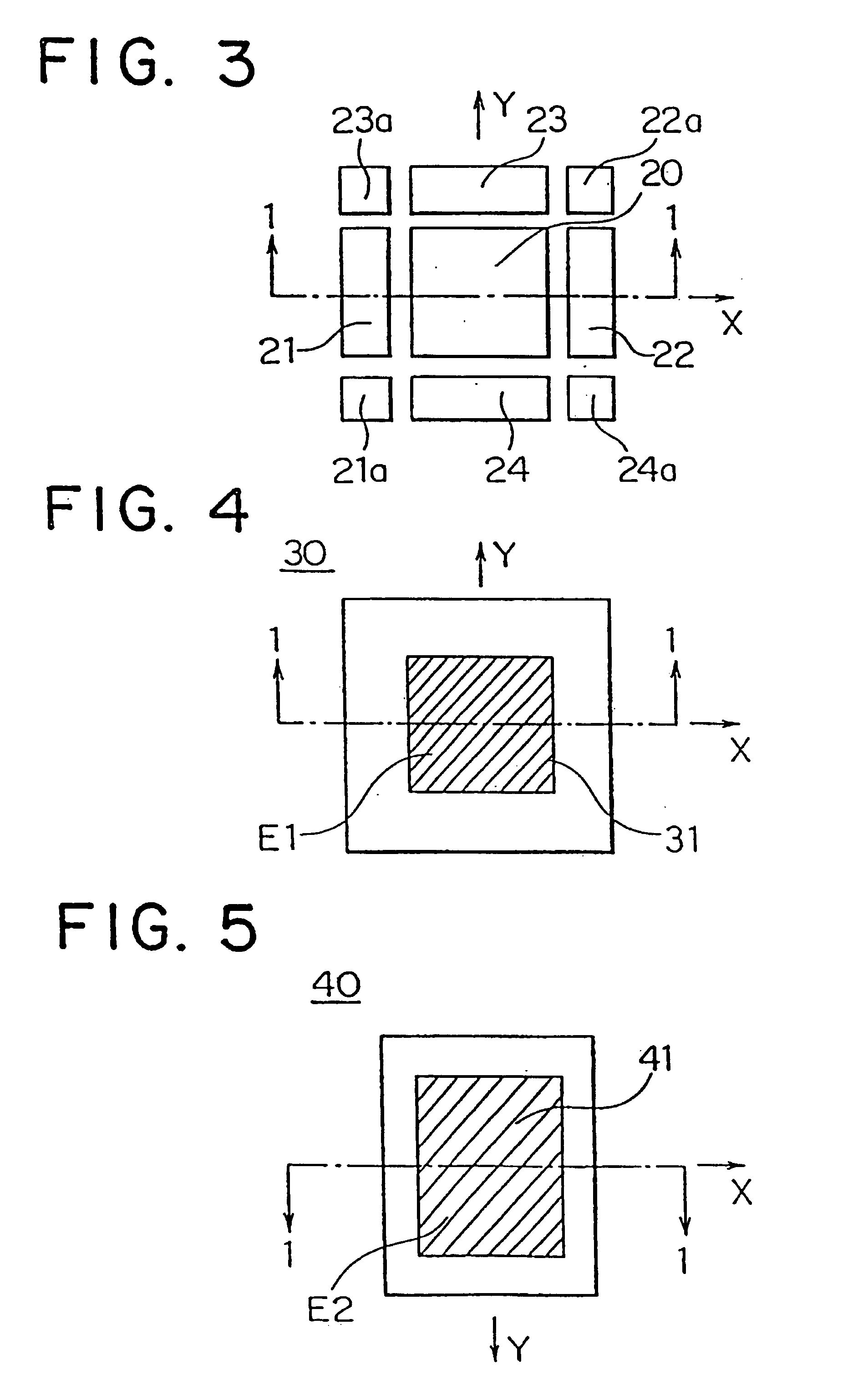

InactiveUS6185814B1Low costSimple circuit configurationAcceleration measurement using interia forcesForce measurement using piezo-resistive materialsSignal processing circuitsSemiconductor chip

A sensor comprises a semiconductor pellet (10) including a working portion (11) adapted to undergo action of a force, a fixed portion (13) fixed on the sensor body, and a flexible portion (13) having flexibility formed therebetween, a working body (20) for transmitting an exterted force to the working portion, and detector means (60-63) for transforming a mechanical deformation produced in the semiconductor pellet to an electric signal to thereby detect a force exerted on the working body as an electric signal. A signal processing circuit is applied to the sensor. This circuit uses analog multipliers (101-109) and analog adders / subtracters (111-113), and has a function to cancel interference produced in different directions. Within the sensor, two portions (E3, E4-E8) located at positions opposite to each other and producing a displacement therebetween by action of a force are determined. By exerting a coulomb force between both the portions, the test of the sensor is carried out. Further, a pedestal (21, 22) is provided around the working body (20). The working body and the pedestal are located with a predetermined gap or spacing therebetween. A displacement of the working body is caused to limitatively fall within a predetermined range corresponding to the spacing. The working body and the pedestal are provided by cutting a same common substrate (350, 350')

Owner:OKADA KAZUHIRO

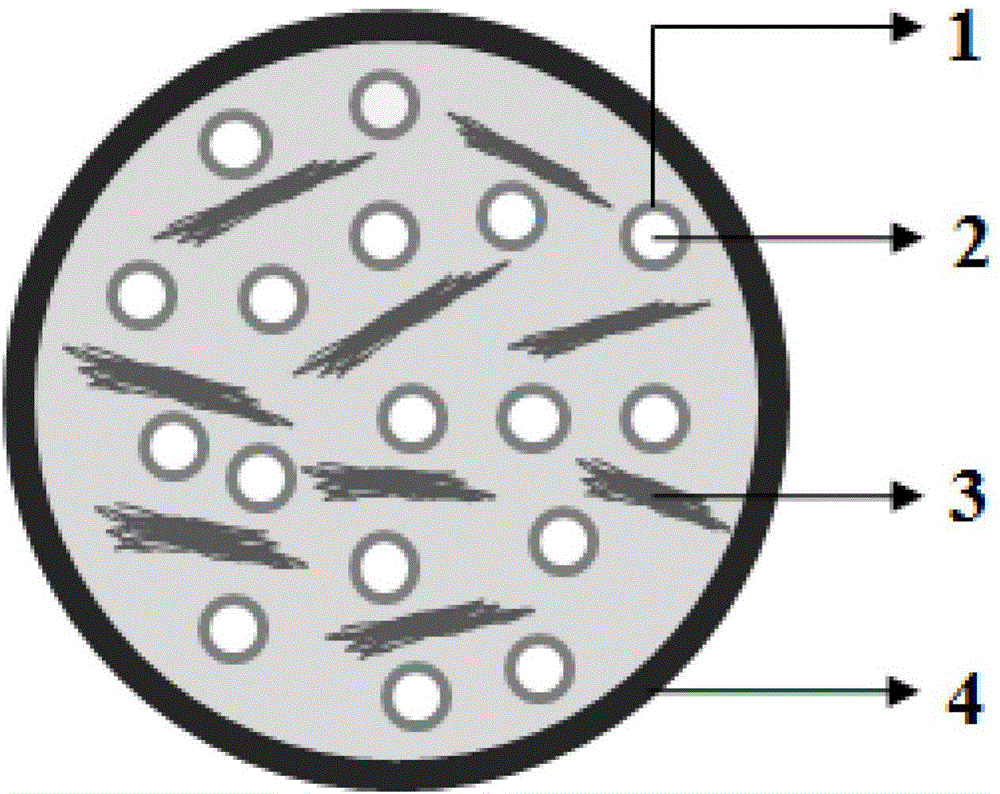

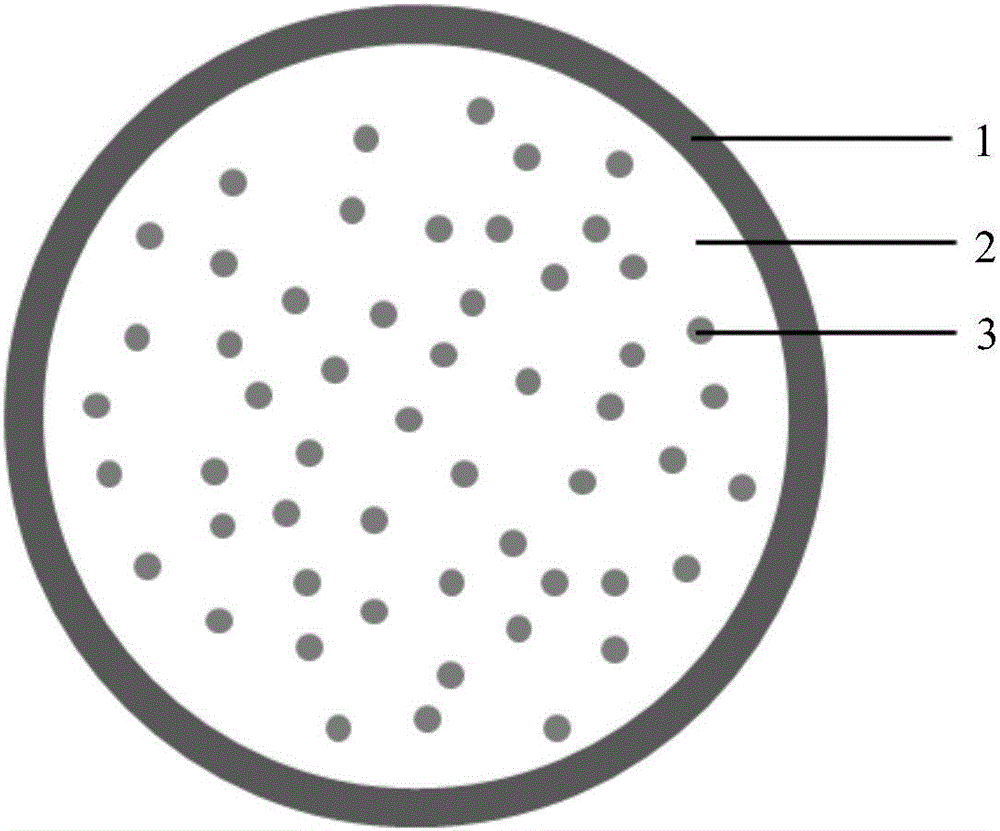

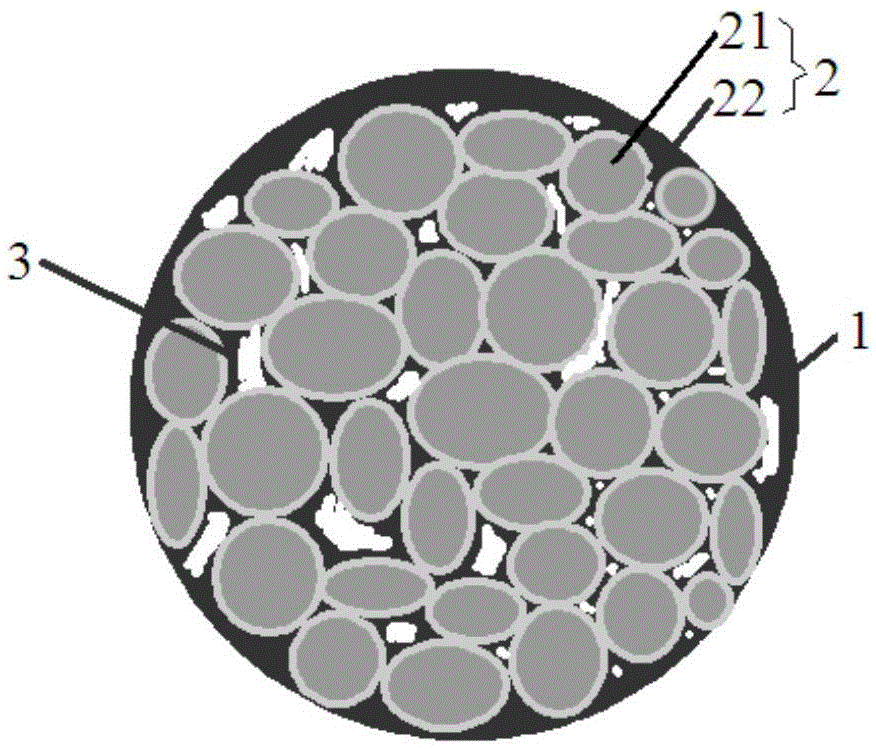

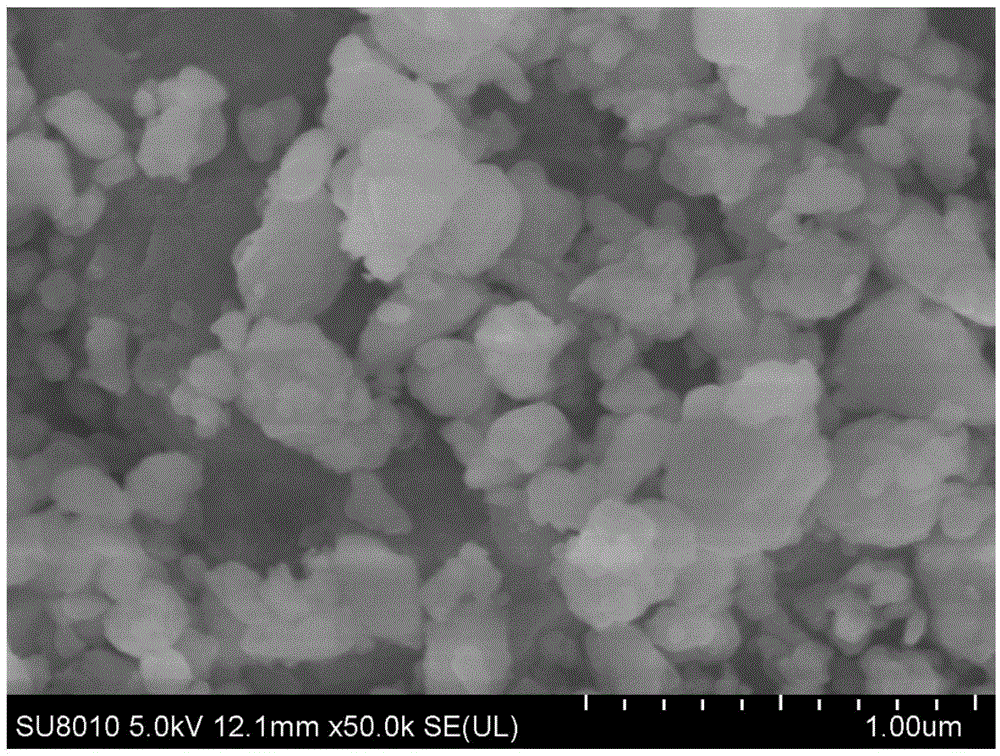

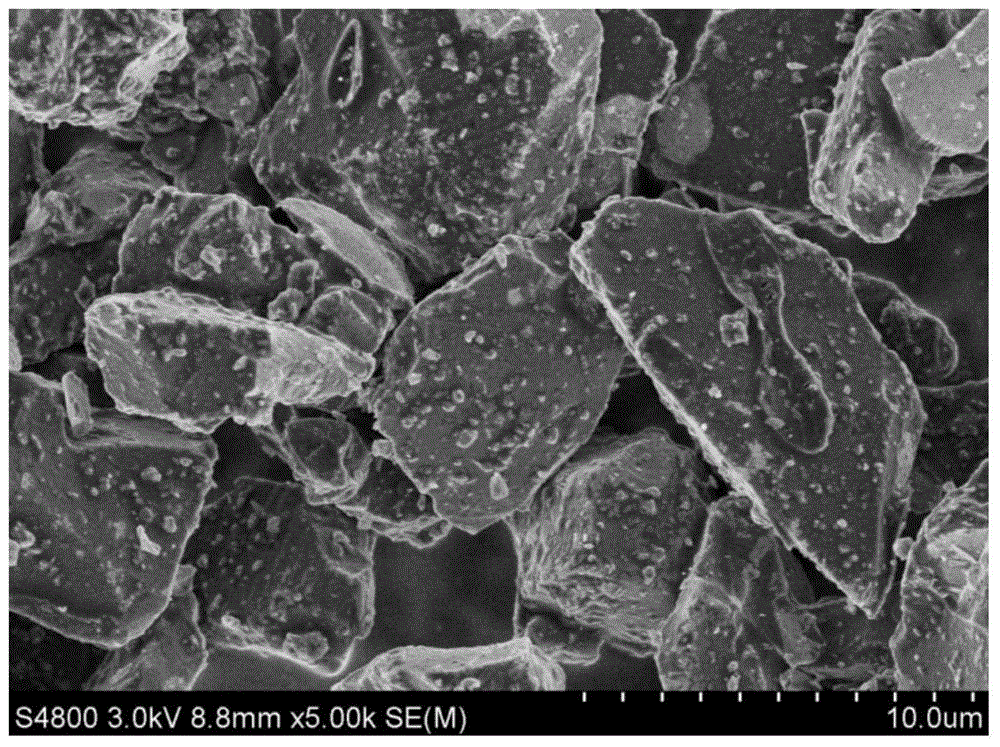

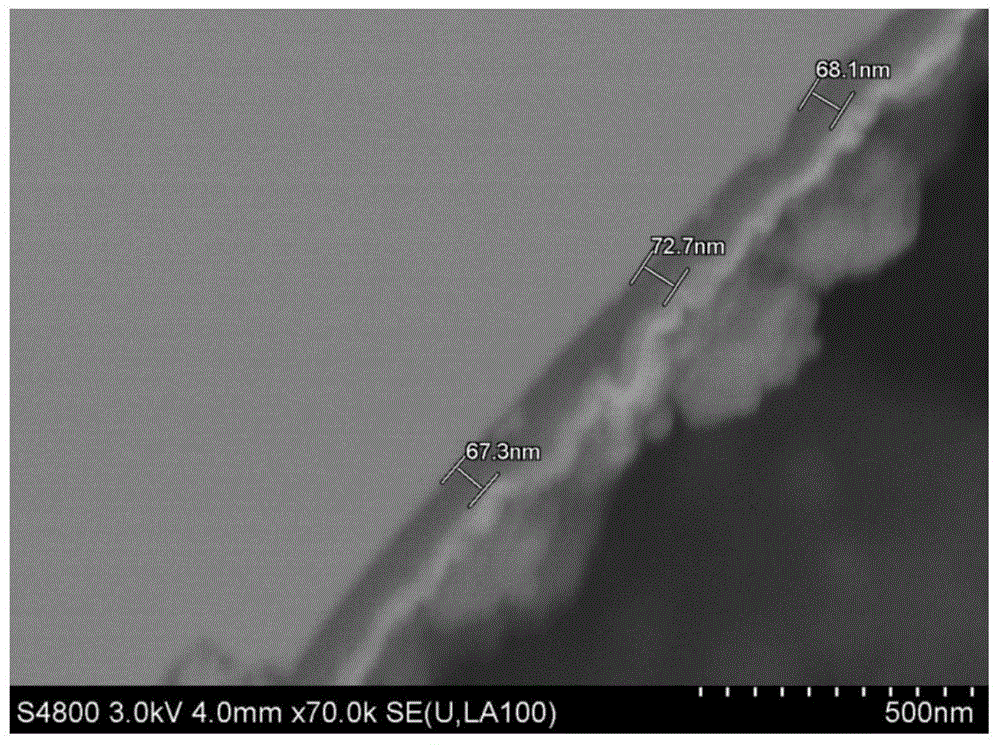

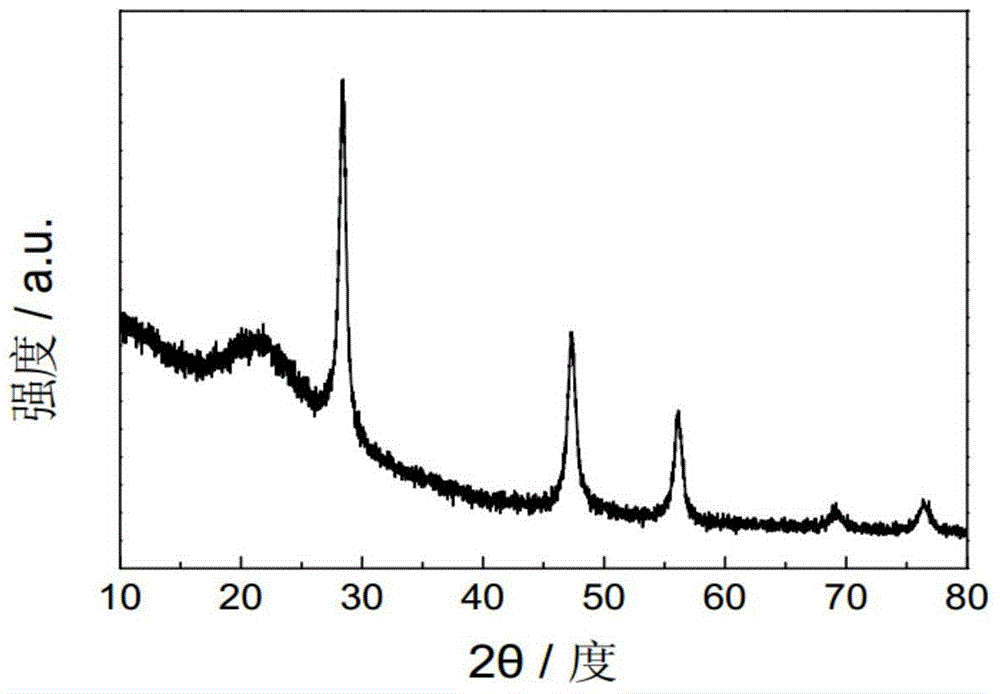

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

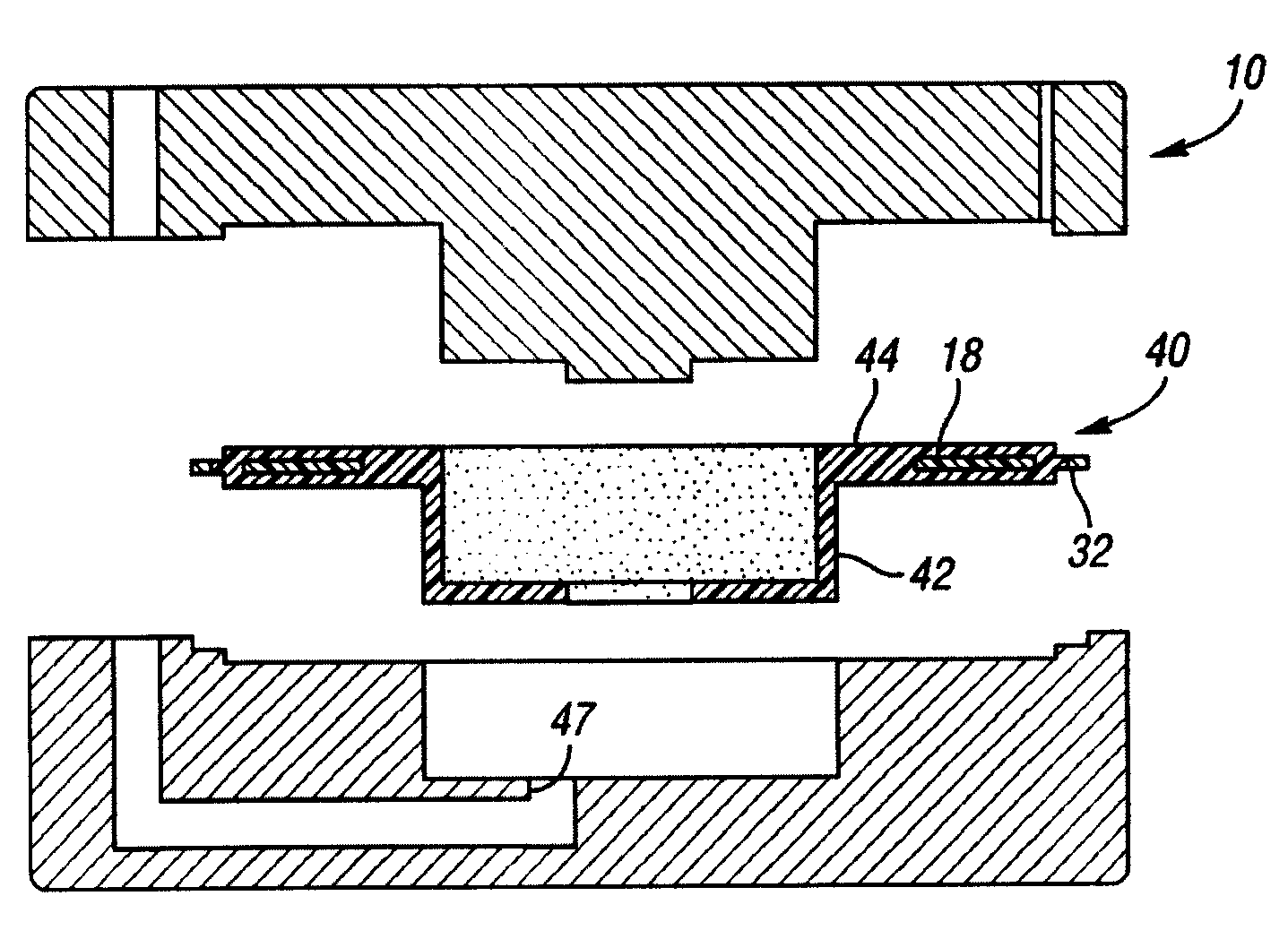

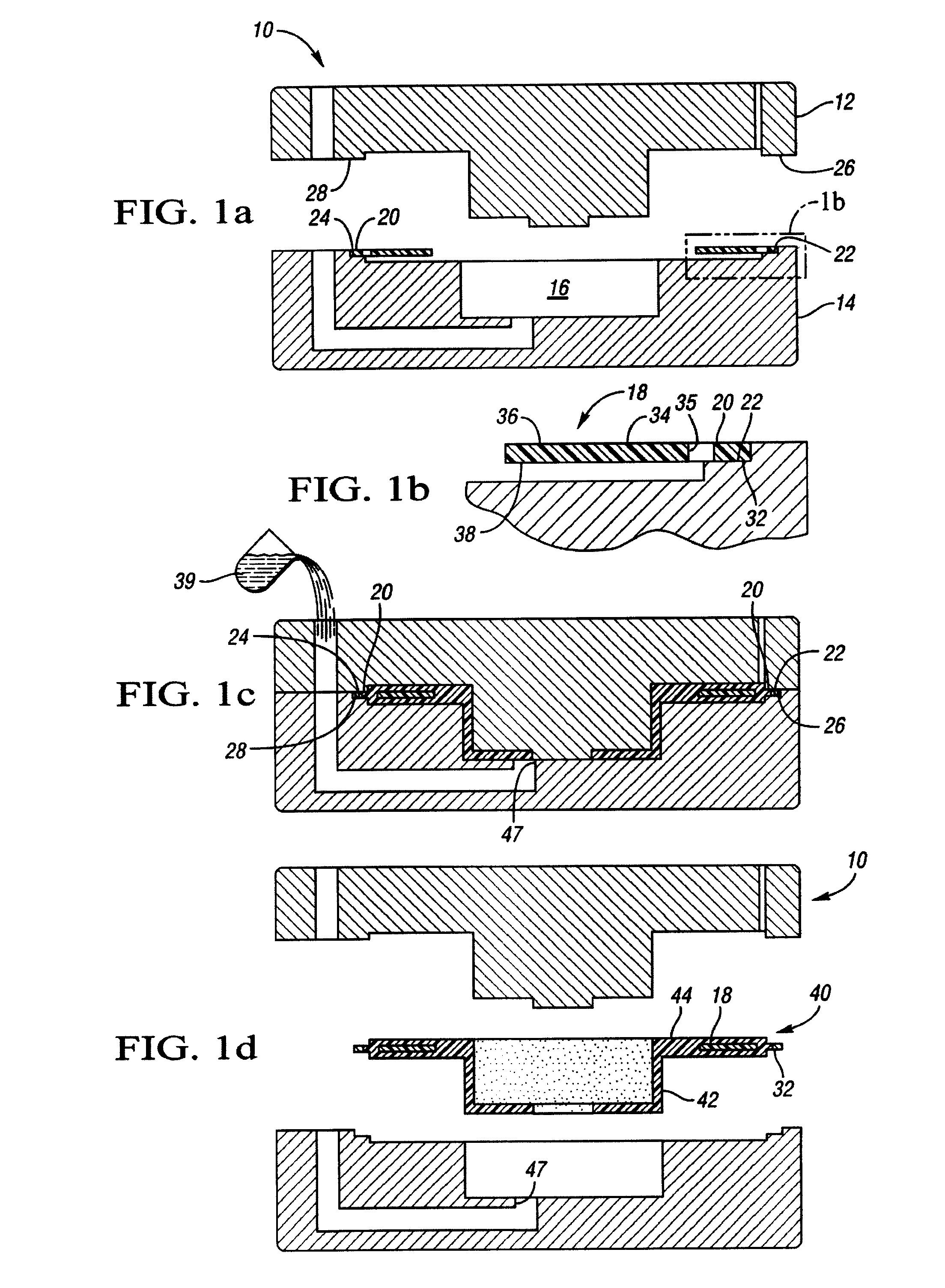

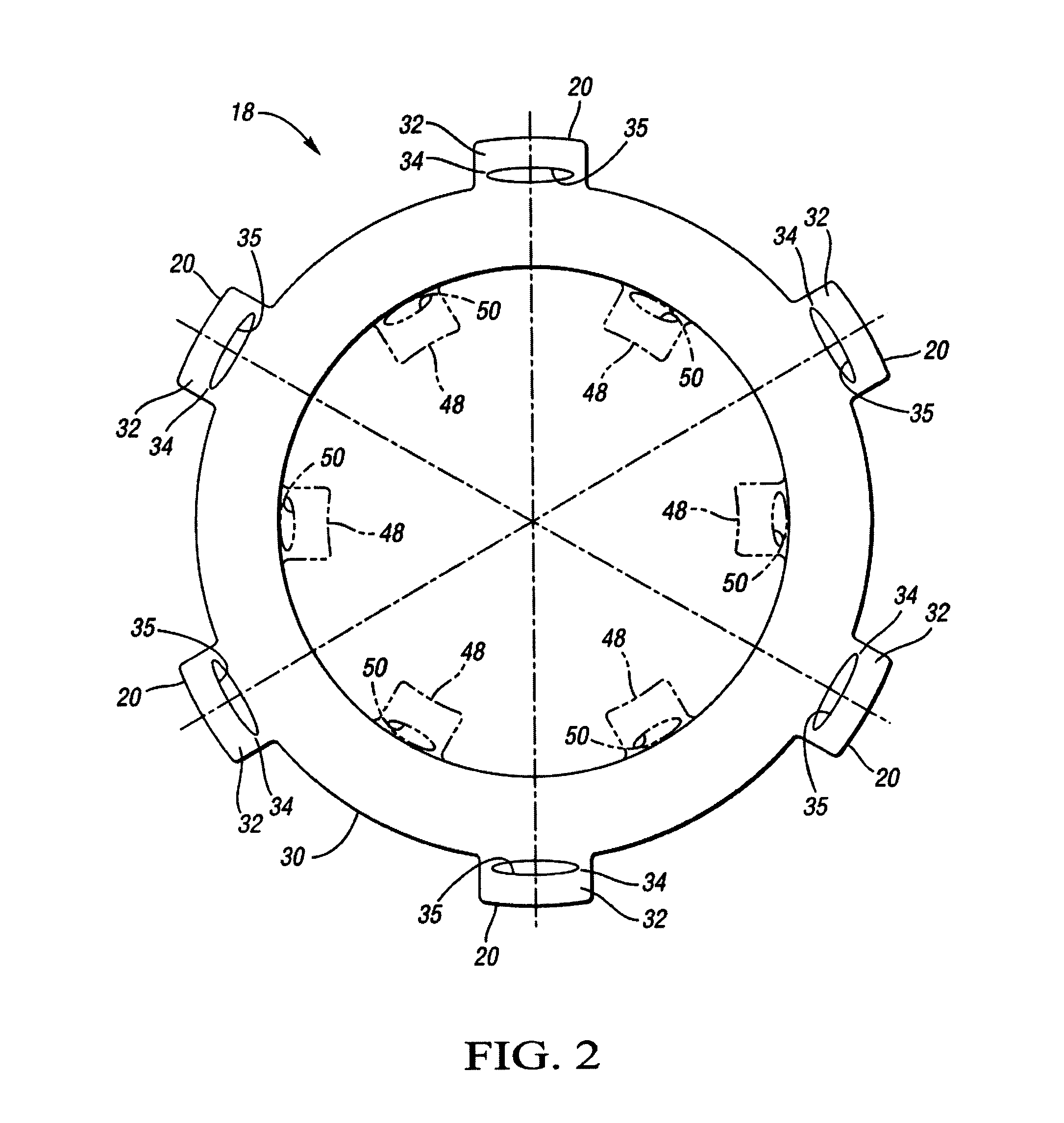

Coulomb damped disc brake rotor and method of manufacturing

InactiveUS20080099289A1Avoid bondingExternal exposure is reducedNoise/vibration controlBraking discsEngineeringMechanical engineering

The invention provides a method for manufacturing a coulomb damped disc brake rotor, including the steps of: (A) providing a mold having the general shape of the coulomb damped disc brake rotor; (B) placing a coulomb damper insert having a generally annular body and at least one tab extending generally radially from the generally annular body, wherein the at least one tab operates to locate the coulomb damper insert within the mold, and wherein the at least one tab at least partially defines an orifice with its major axis generally coincident with the periphery of the coulomb damped disc brake rotor; and (C) causing casting material to enter the mold to substantially encapsulate the coulomb damper insert with the casting material to form a rotor cheek of the coulomb damped disc brake rotor. A coulomb damper insert and coulomb damped disc brake rotor are also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

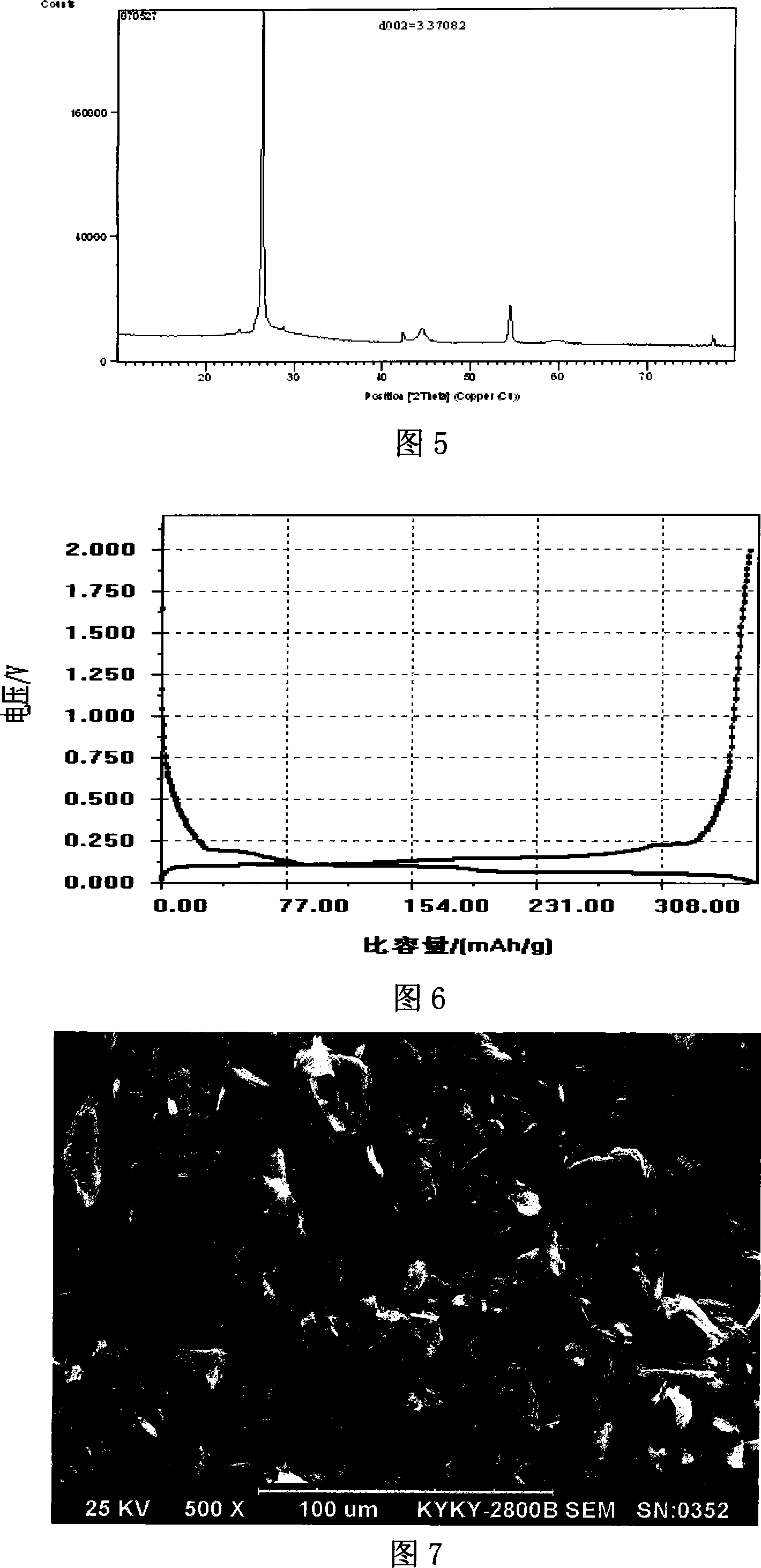

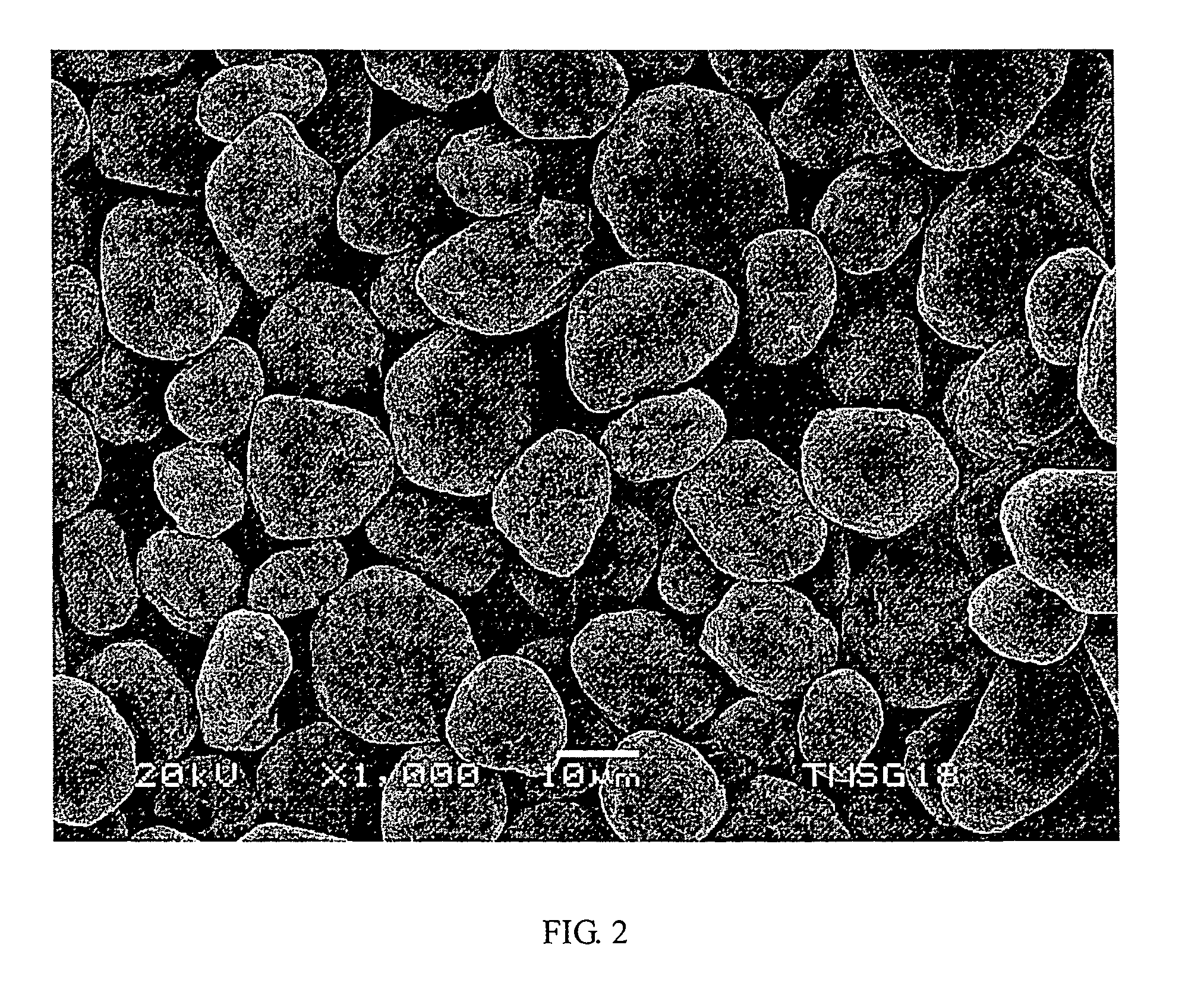

Composite carbon material of negative electrode in lithuim ion battery and its preparation method

ActiveUS20090136849A1Improve rendering capabilitiesImprove cycle stabilityElectrode manufacturing processesActive material electrodesSpherical shapedSodium-ion battery

A composite carbon material of negative electrode in lithium ion, which is made of composite graphite, includes a spherical graphite and a cover layer, wherein the cover layer is pyrolytic carbon of organic substance. Inserted transition metal elements are contained between layers of graphite crystal. Preparation of the negative electrode includes the steps of: crushing graphite, shaping to form a spherical shape, purifying treatment, washing, dewatering and drying, dipped in salt solution doped by transition metal in multivalence, mixed with organic matter, covering treatment, and carbonizing treatment or graphitization treatment. The negative electrode provides advantages of reversible specific capacity larger than 350 mAh / g, coulomb efficiency higher than 94% at first cycle, conservation rate for capacity larger than 8-% in 500 times of circulation.

Owner:BTR NEW MATERIAL GRP CO LTD

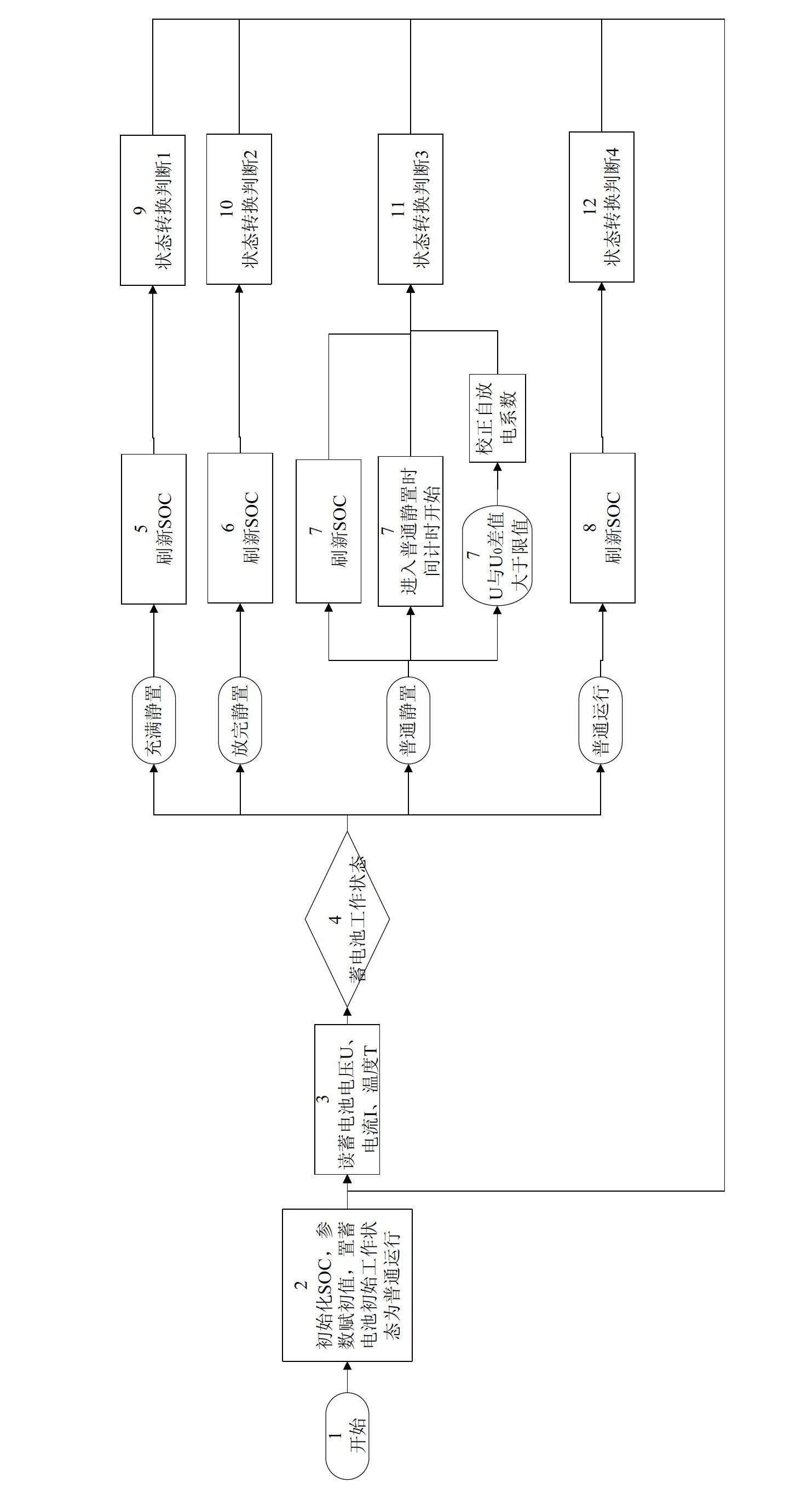

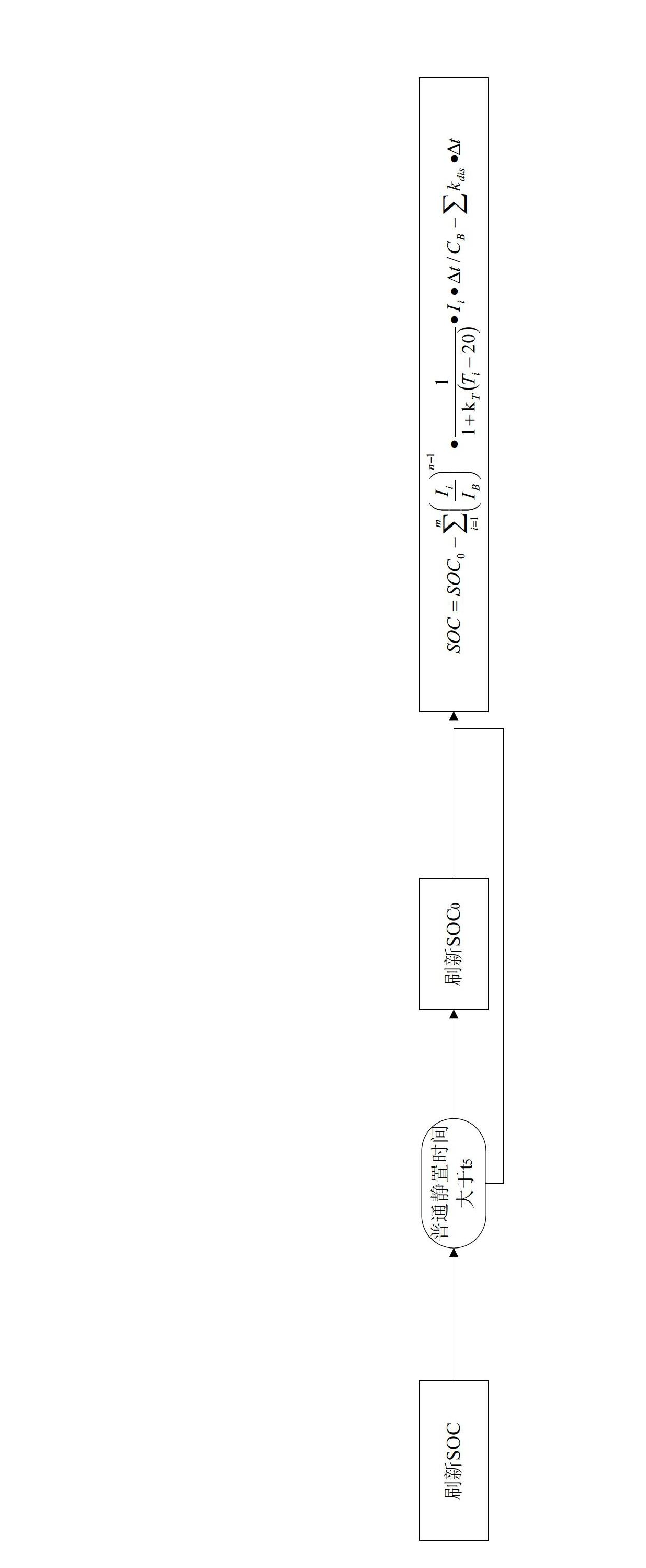

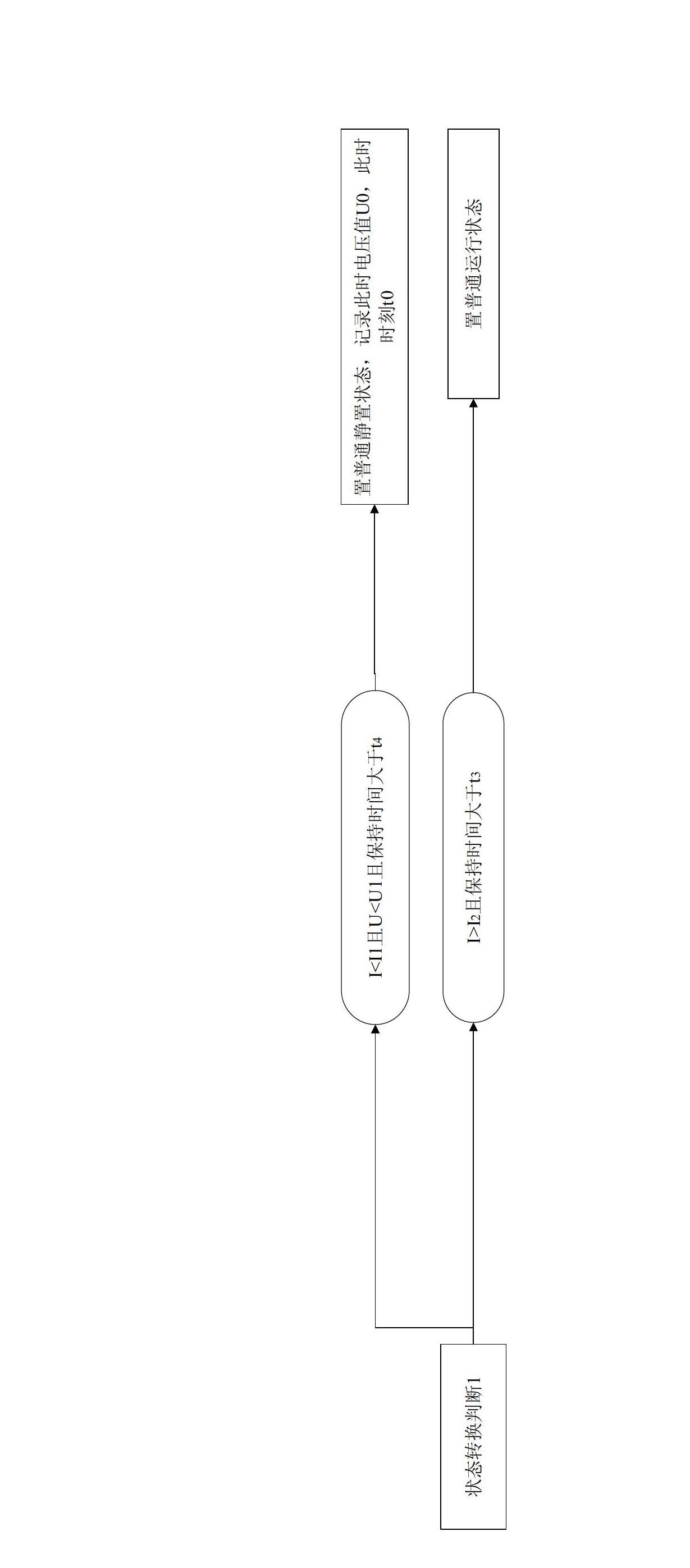

On-line feedback battery state of charge (SOC) predicting method

InactiveCN102662148AThe estimated result is close to the true valueImprove accuracyElectrical testingBattery state of chargeModel parameters

The invention relates to the technical field of storage battery state of charge prediction, and discloses an on-line feedback battery state of charge (SOC) predicting method. According to the method, SOC valuation model parameters are corrected according to historical data in the on-line operating process of a storage battery. The influence of temperature, coulomb efficiency and self discharge on battery SOC is considered, basic operating parameters of the storage battery are only required to be monitored, related coefficients are corrected as long as conditions are met in the operating process of the battery, coefficient values are repeatedly corrected, and an SOC estimation result is close to a true value along time, so the accuracy is high and the storage battery SOC can be predicted on line.

Owner:CHINA AGRI UNIV

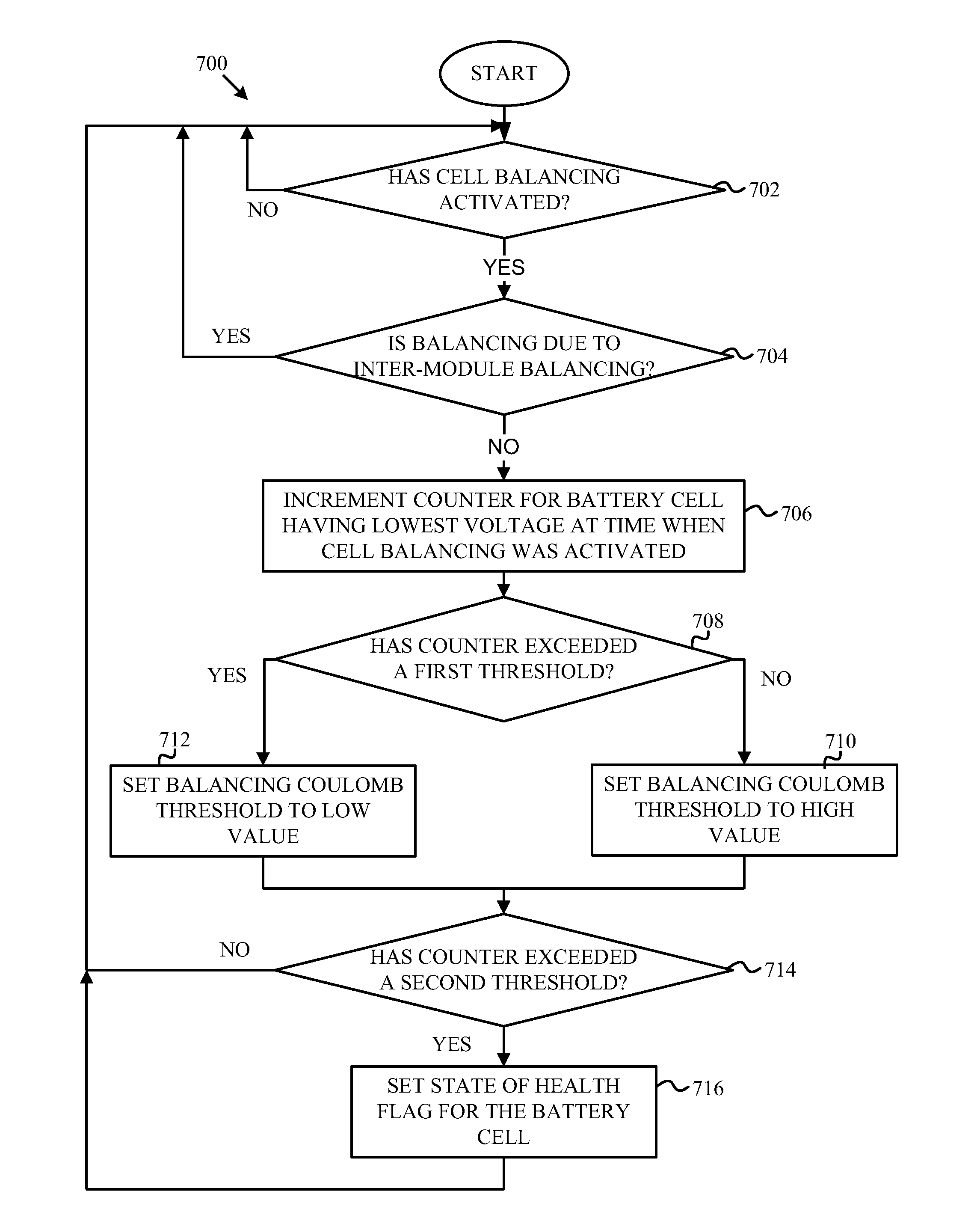

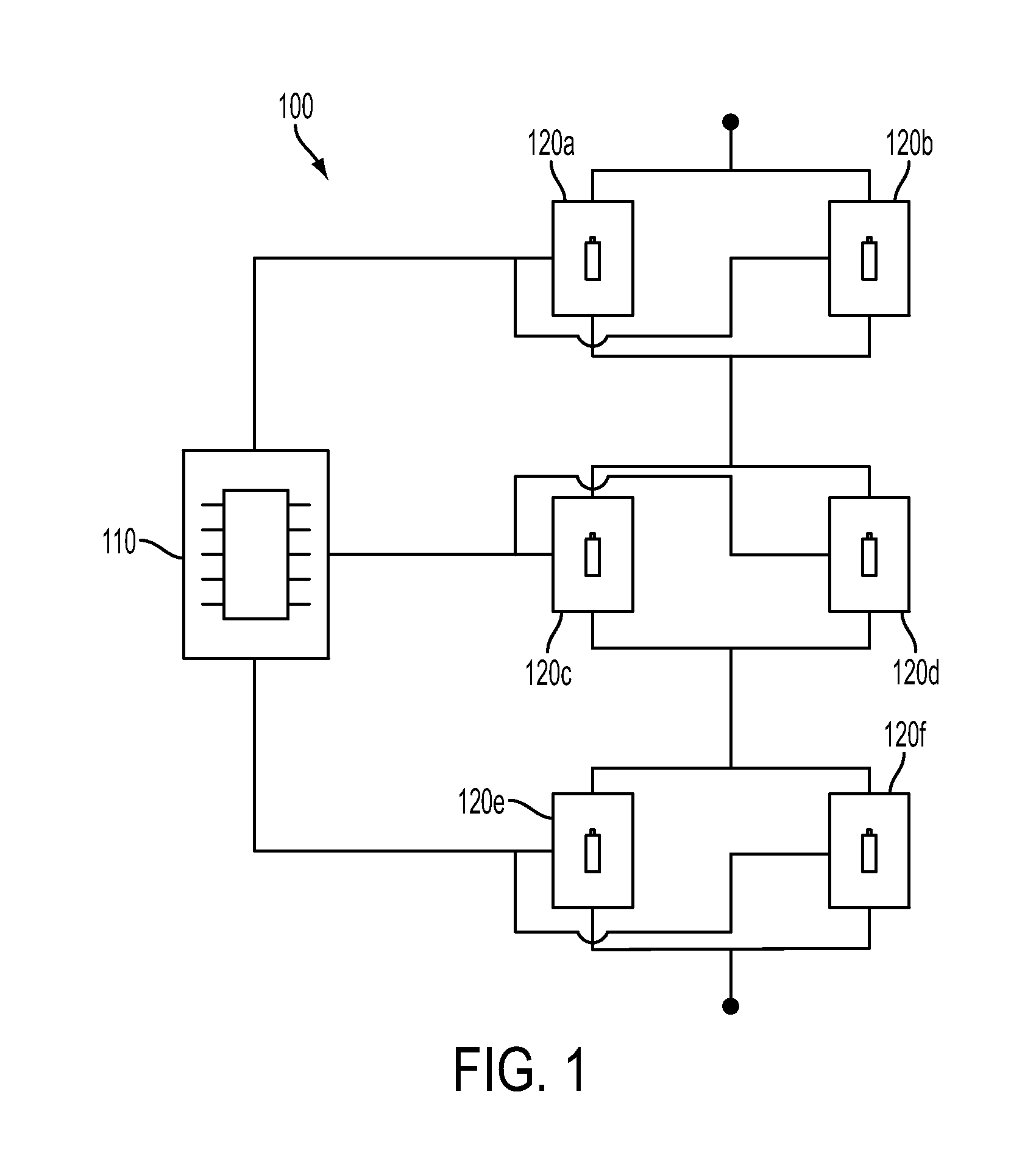

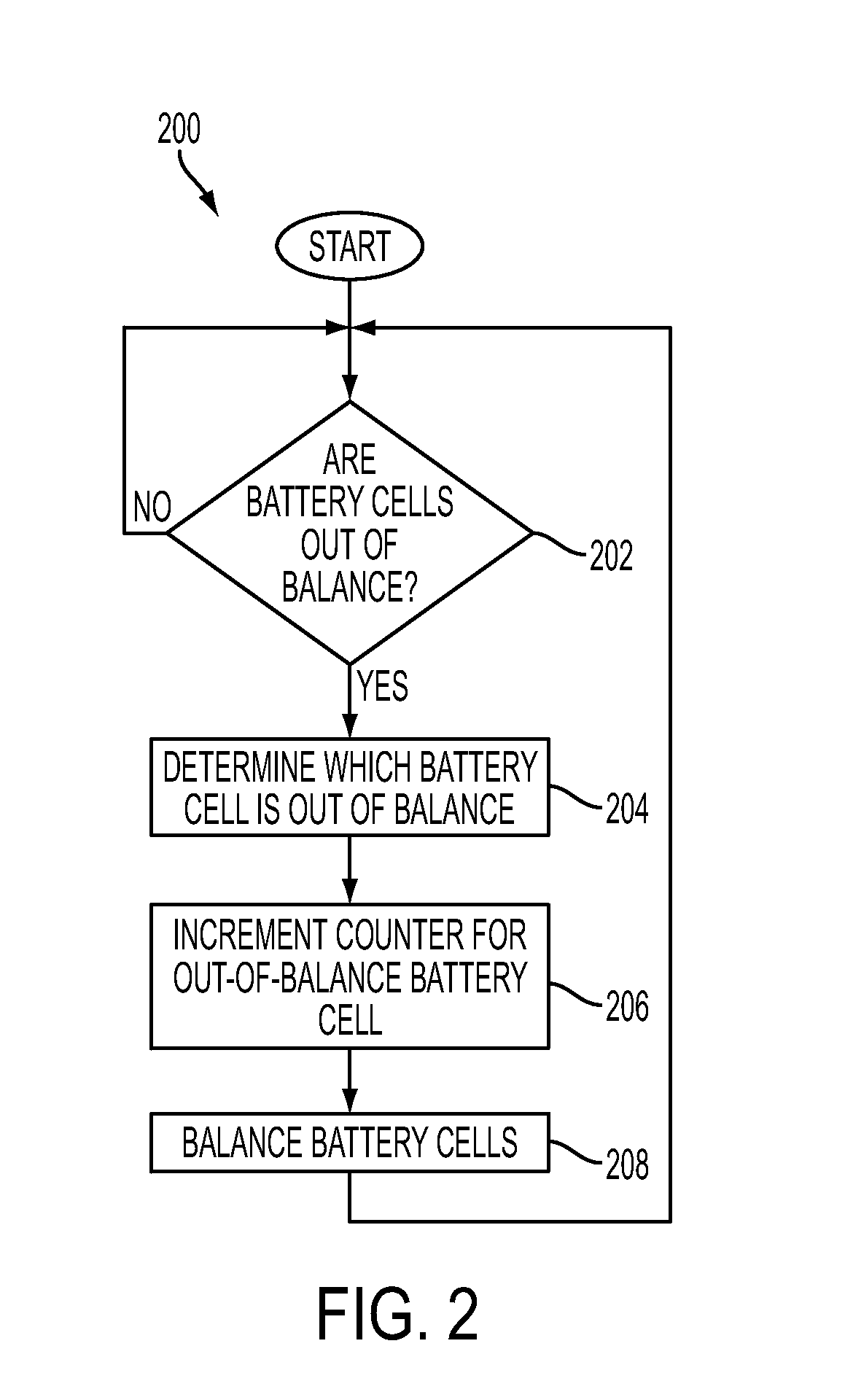

Historical Analysis of Battery Cells for Determining State of Health

ActiveUS20130065093A1Electrical testingSecondary cells charging/dischargingState of healthEngineering

Battery cells may be monitored and a historical profile of the battery generated. The historical profile may be used to analyze a state-of-health of the battery cell. For example, the historical profile may be used to determine when a battery cell has developed an internal short that creates a safety hazard. The historical profile may include a count of the number of times the battery cell was out of balance and a count of the number of Coulombs the battery cell was out of balance. The number of Coulombs may be counted for a window of time. When the number of Coulombs exceeds a Coulomb threshold, a state-of-health flag may be set for the battery cell. The Coulomb threshold may be adjusted based, in part, on the counted number of times the battery cell is out of balance.

Owner:SOUTHWEST ELECTRONICS ENERGY CORP

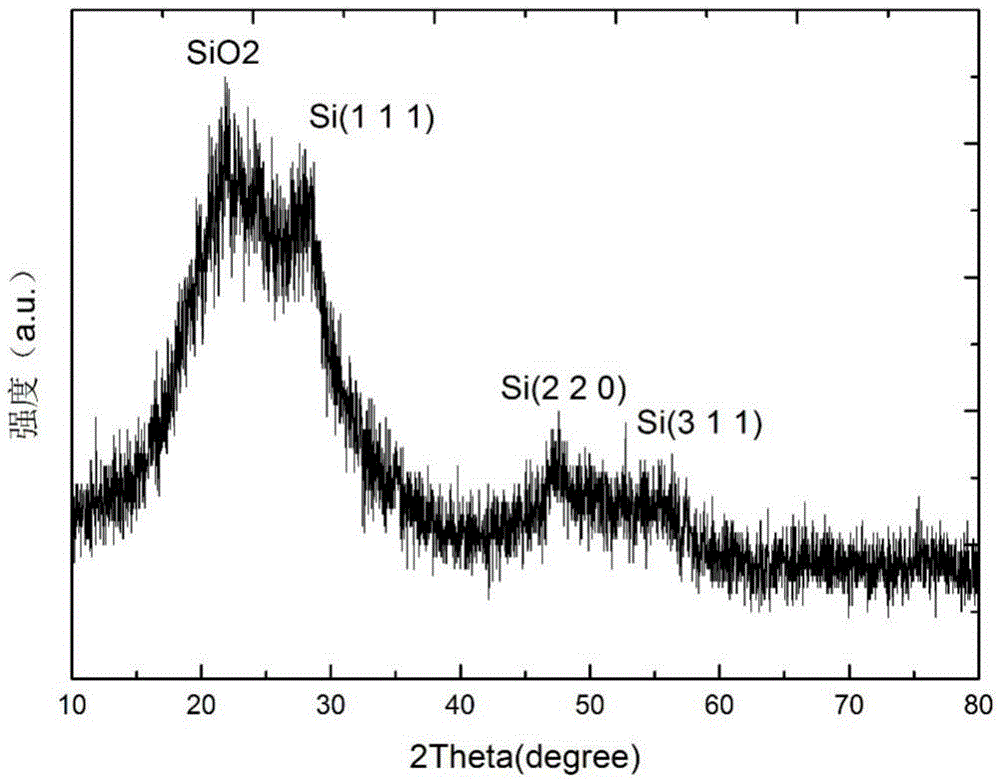

Composite, preparation method and application thereof in lithium ion secondary battery

ActiveCN106816594AImprove performanceRaw materials are easy to getMaterial nanotechnologySilicaCarbon coatingSilicon oxide

The invention discloses a composite. The composite comprises nanometer silicon, a lithium-containing compound and a carbon coating, or comprises nanometer silicon, a silicon oxide, a lithium-containing compound and a carbon coating. The method comprises the following steps: (1) mixing a carbon-coated silicon oxide and a lithium-source solid phase; and (2) thermally processing a prefabricated lithium precursor obtained in step (1) in a vacuum or non-oxidative atmosphere to obtain the composite. The method is simple, small in requirement on equipment, and low in cost; the obtained composite is stable in structure; the structure and property cannot be degraded after long-term storage; a battery prepared from a negative electrode material containing the composite is high in lithium taking-off capacity, high in first coulomb efficiency, and high in circulating performance; the charging capacity is equal to or above 1920mAh / g; the discharging capacity is equal to or above 1768mAh / g; and the first effect is equal to or more than 90.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

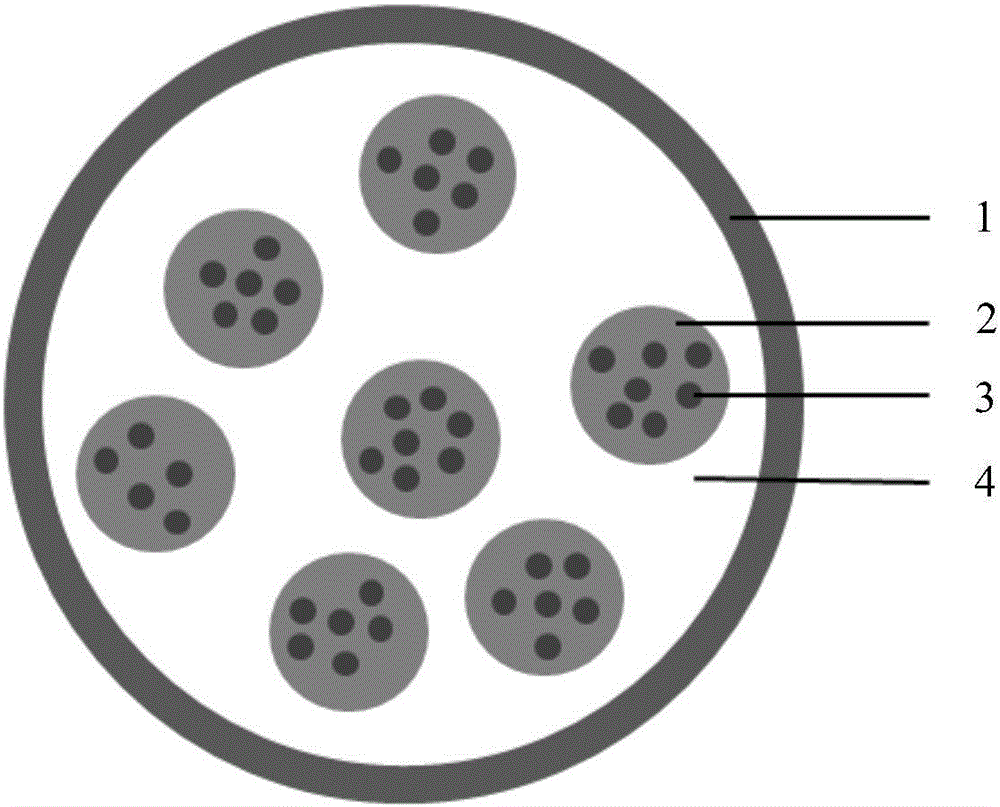

SiO<x>/C composite cathode material, method for preparing same and application of SiO<x>/C composite cathode material

ActiveCN105655564AImprove conductivityIncrease capacityCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention provides an SiO<x> / C composite cathode material, a method for preparing the same and application of the SiO<x> / C composite cathode material. The SiO<x> / C composite cathode material is of a core-shell structure. A shell layer of the SiO<x> / C composite cathode material is a carbon layer, a core of the SiO<x> / C composite cathode material comprises a plurality of silicon carbon composite material particles, the silicon carbon composite material particles include SiO<x> particles and amorphous conductive carbon layers, the amorphous conductive carbon layers cover the surfaces of the SiO<x> particles, and free spaces are reserved between the silicon carbon composite material particles. The SiO<x> / C composite cathode material, the method and the application have the advantages that the SiO<x> / C composite cathode material is excellent in conductivity, firm in structure and stable in capacity, the coulomb efficiency and the cycle performance can be greatly improved, technological conditions for the method are controllable, the SiO<x> / C composite cathode material prepared by the aid of the method is stable in performance and high in production efficiency, and the production cost can be reduced.

Owner:王凤鸣

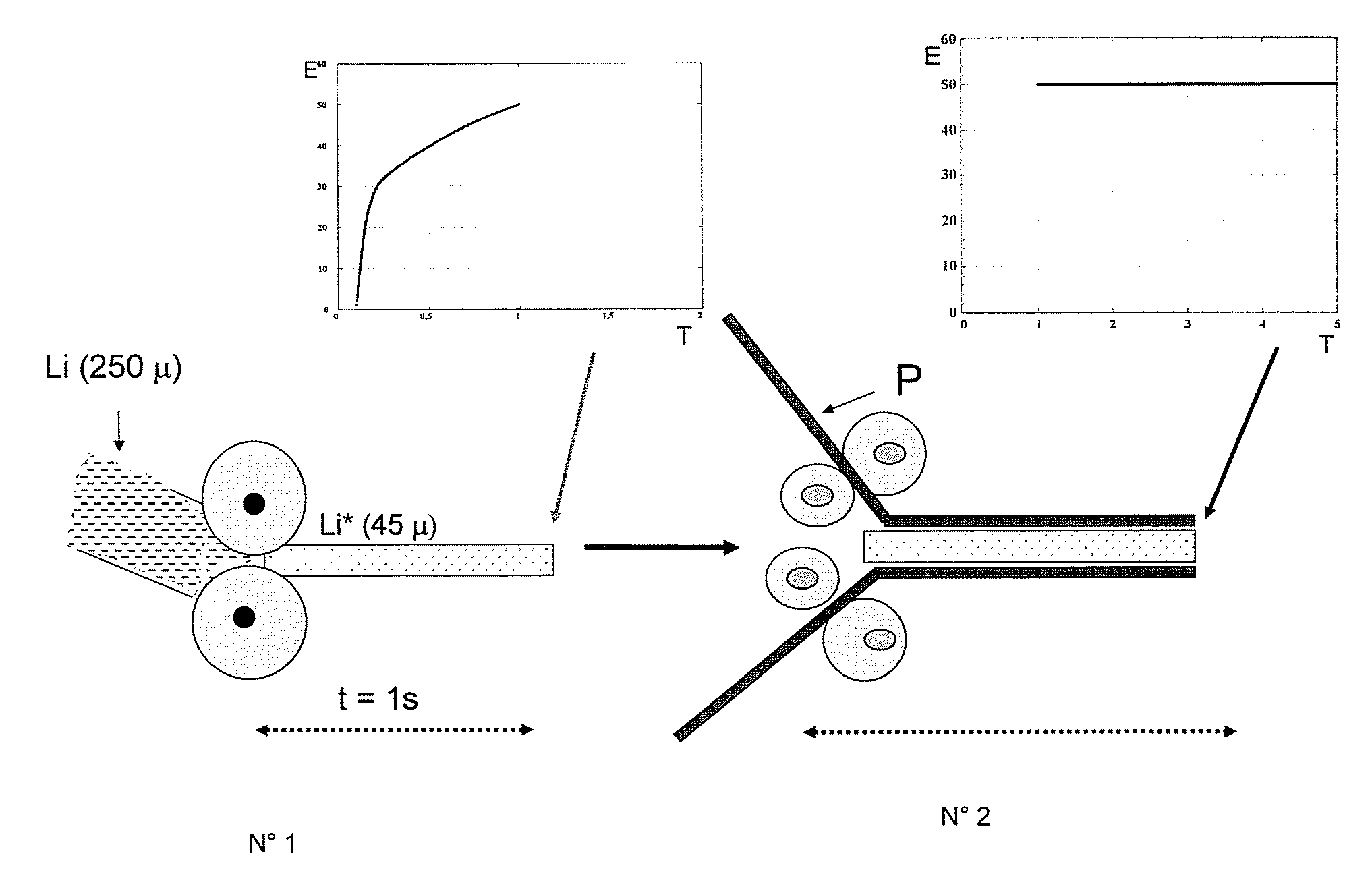

Multilayer material based on active lithium, method of preparation and applications in electrochemical generators

InactiveUS20090280410A1Improve adhesionExcellent impedance stabilityMolten spray coatingFinal product manufactureLithiumSufficient time

A method for preparing a multilayer material based on active lithium, by depositing a film of active lithium on a protective layer at a sufficient speed so that substantially no oxidation of the lithium occurs, and / or during a sufficient time for the adhesion of the lithium to develop after contact with the protective layer. The multilayer material, when incorporated in an electrochemical battery as an anode, has excellent impedance stability and no formation of dendrites during the cycling. Batteries where the anode is the multilayer material are particularly efficient in terms of their coulomb efficiency.

Owner:HYDRO QUEBEC CORP

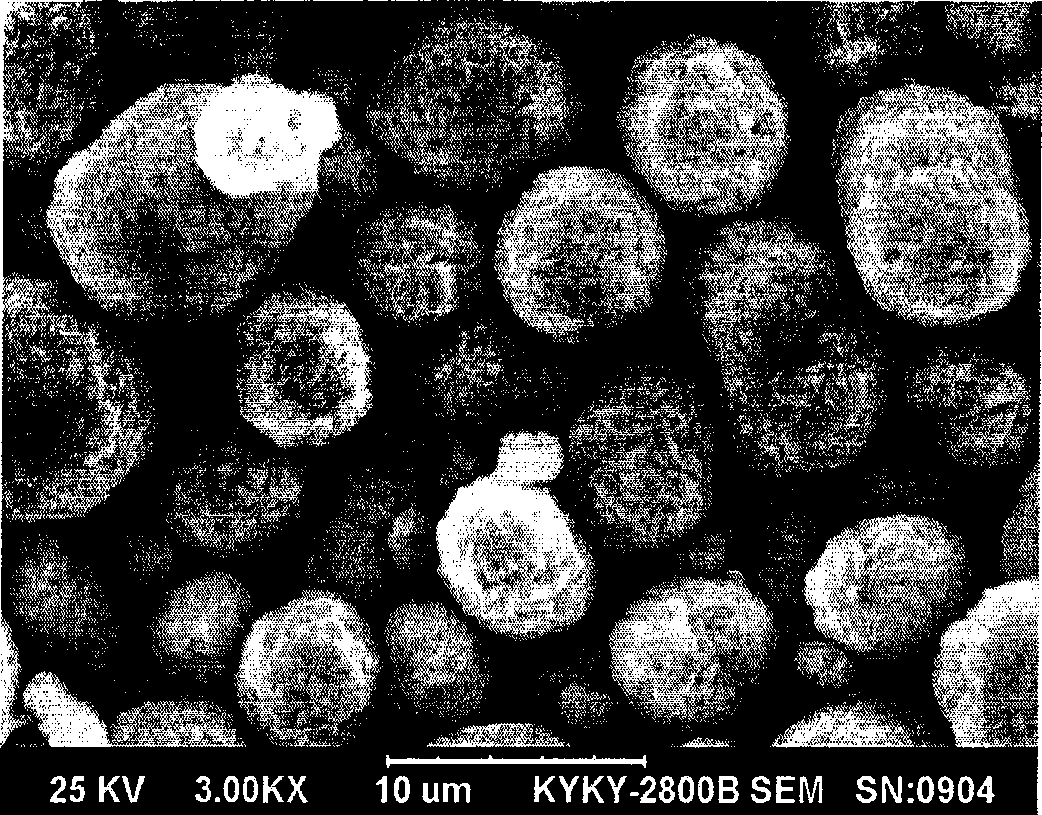

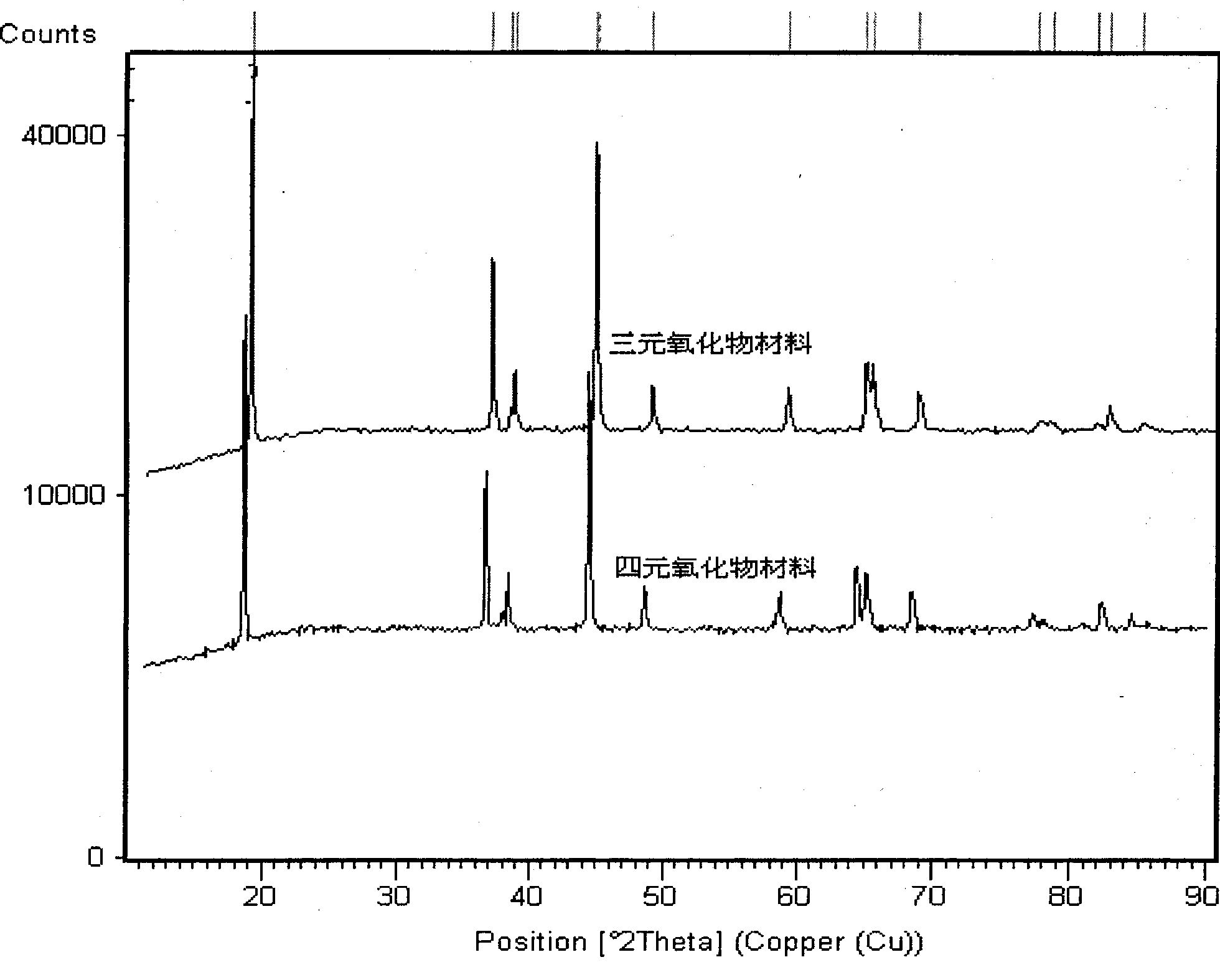

Metal oxide lithium ionic cell positive pole material and preparation thereof

ActiveCN101483265ALow raw material costReduce manufacturing costElectrode manufacturing processesLithium compoundsElectrochemistryLithium-ion battery

The invention discloses a metal oxide lithium ion battery positive material and a preparation method thereof. The problem to be solved is to improve the electrochemistry property of the positive material. The material formula of the invention is LiNi1-x-y-zMnxCoyMzO2, wherein the x+y+z is less than 1, or a quaternary or a quinary metal oxide material of the LiNi1-x-y-z-rMnxCoyMzNrO2, wherein the x+y+z+r is less than 1, and the M and N are selected from one of the Al, Ti, Cr, Mg, V, Zn and Zr, x is equal to 0.01-0.8, y is equal to 0.01-0.8, z is equal to 0.01-0.8 and r is equal to 0.01-0.8. The preparation method comprises: preparing a precursor mixture, mixing and sintering. Comparing with the prior art, the invention prepares the oxide lithium ion battery material by a liquid phase multi-element mixing reaction, a mixing method and a solid state sintering method, the maximum discharging capacity is larger than 150mAh / g, the primary coulomb efficiency is more than 90, the capacity conservation rate after 300 cycles is more than 95 The metal oxide lithium ion battery positive material is suitable for industrial scale production.

Owner:BTR NEW MATERIAL GRP CO LTD

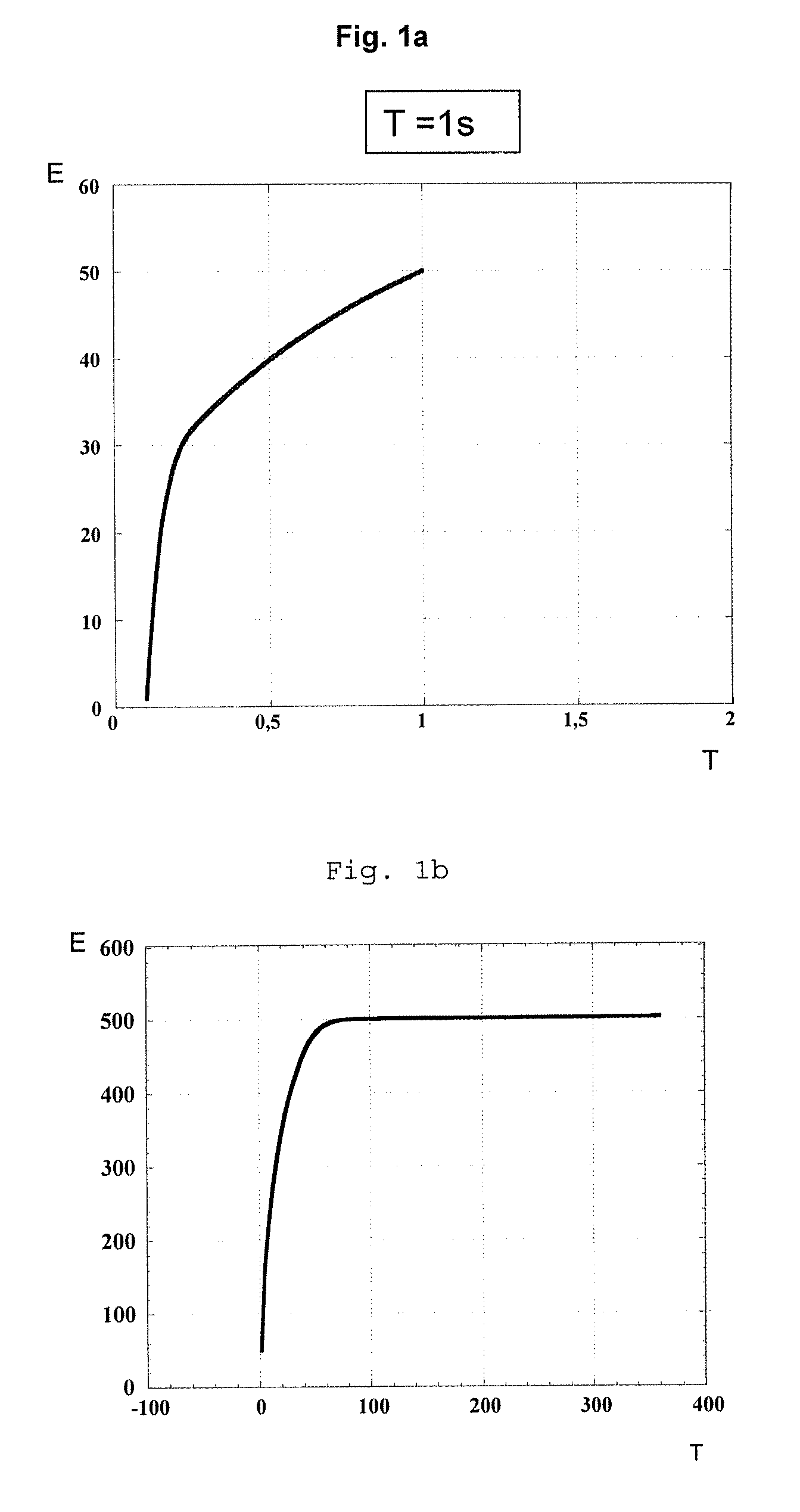

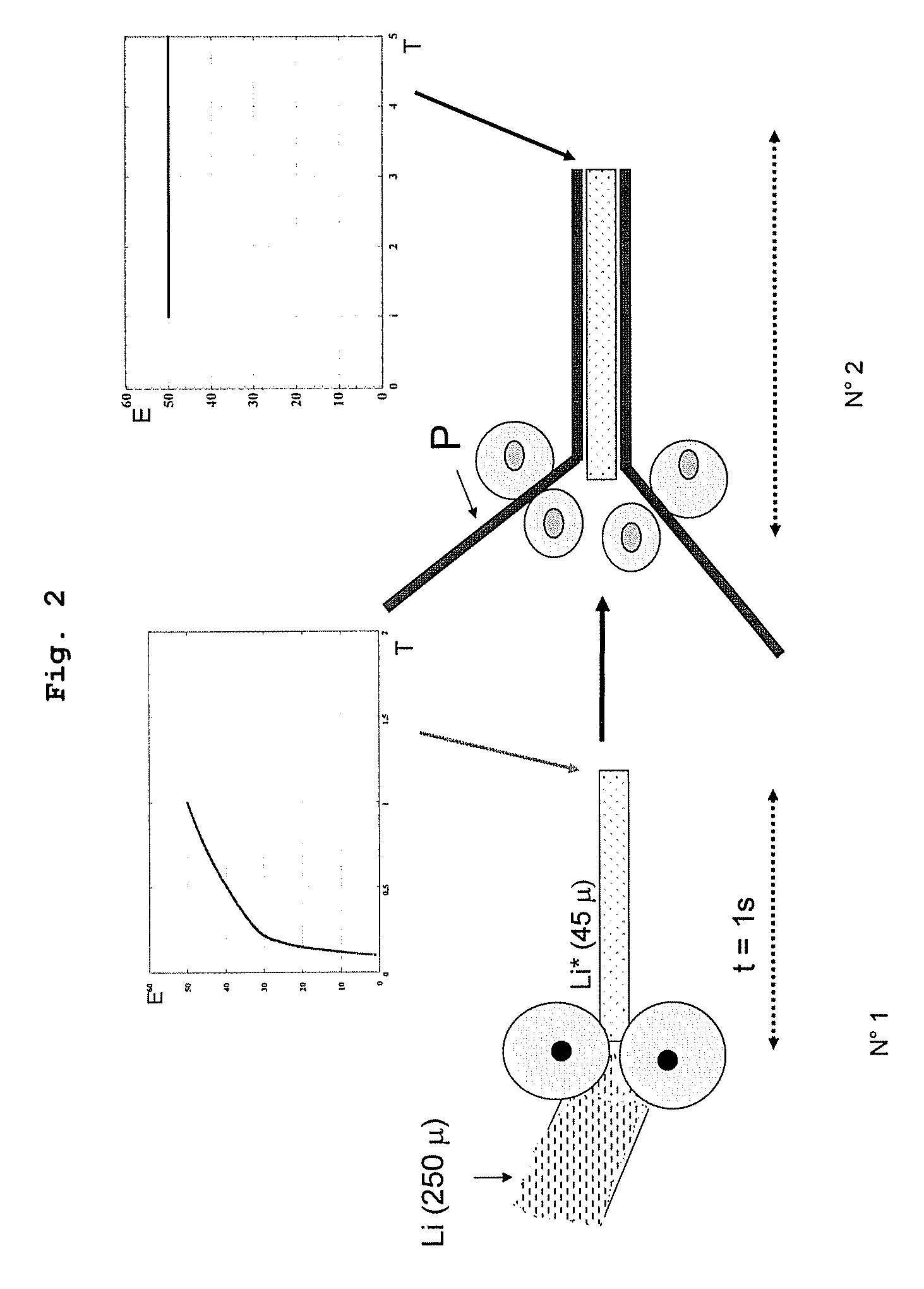

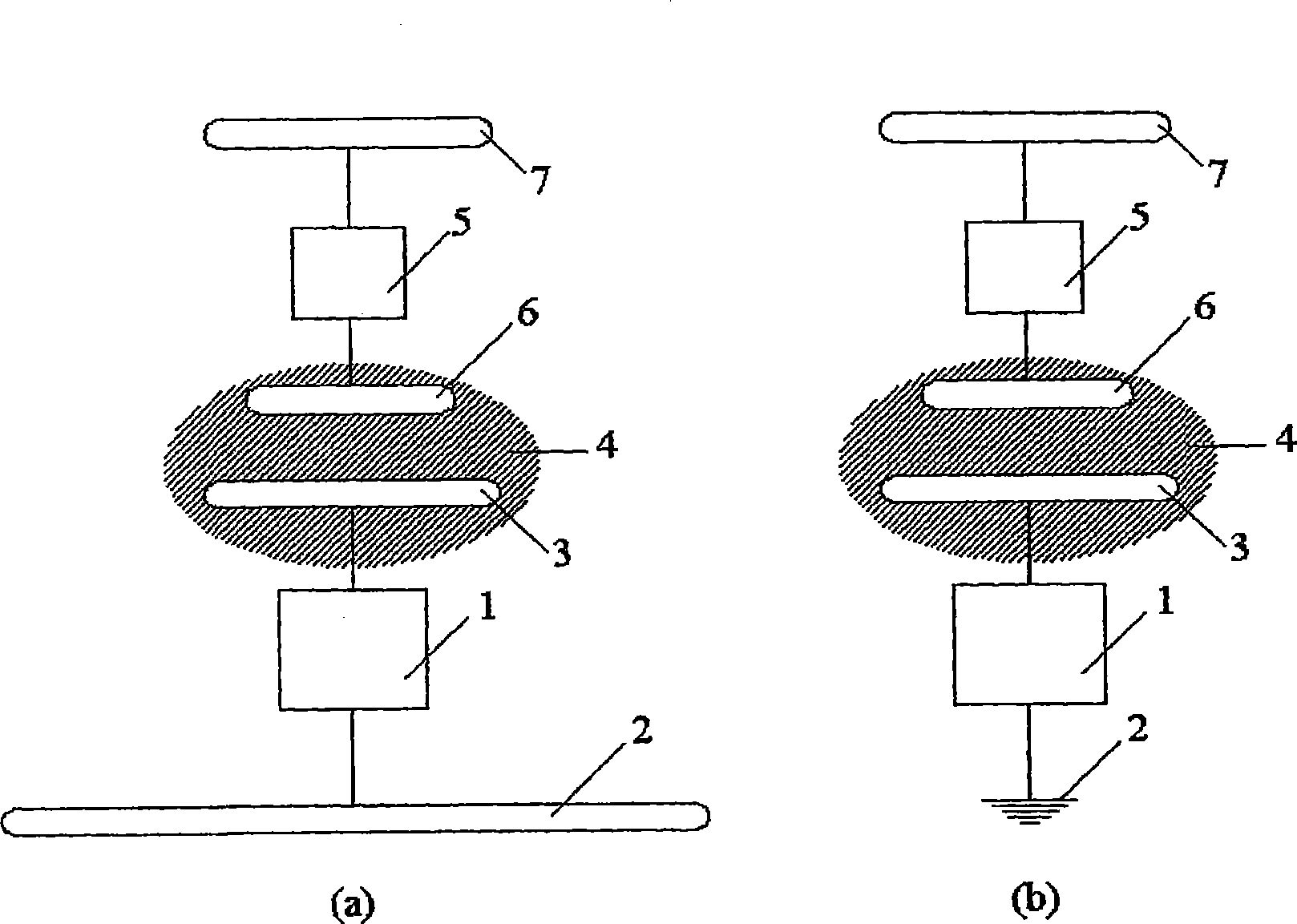

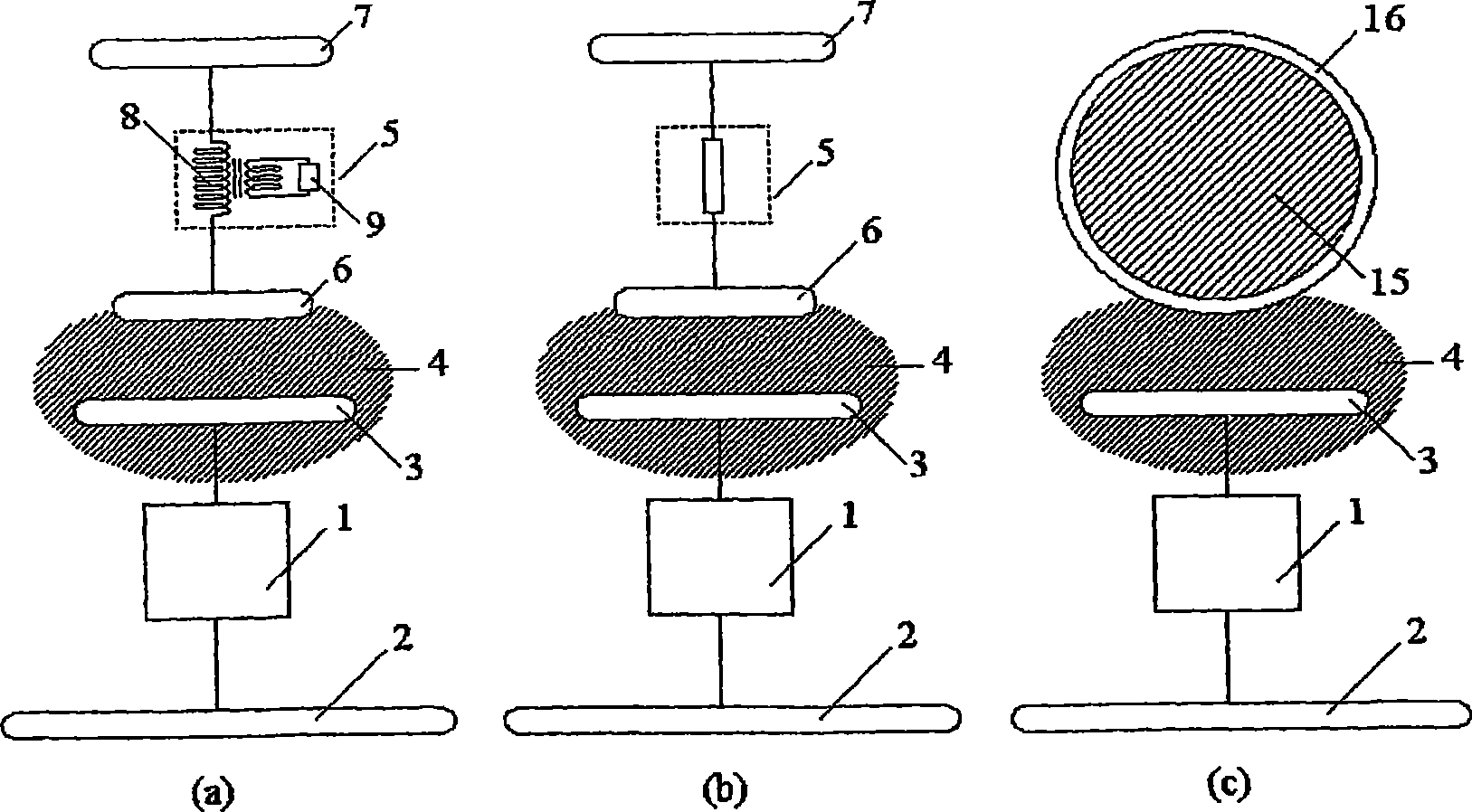

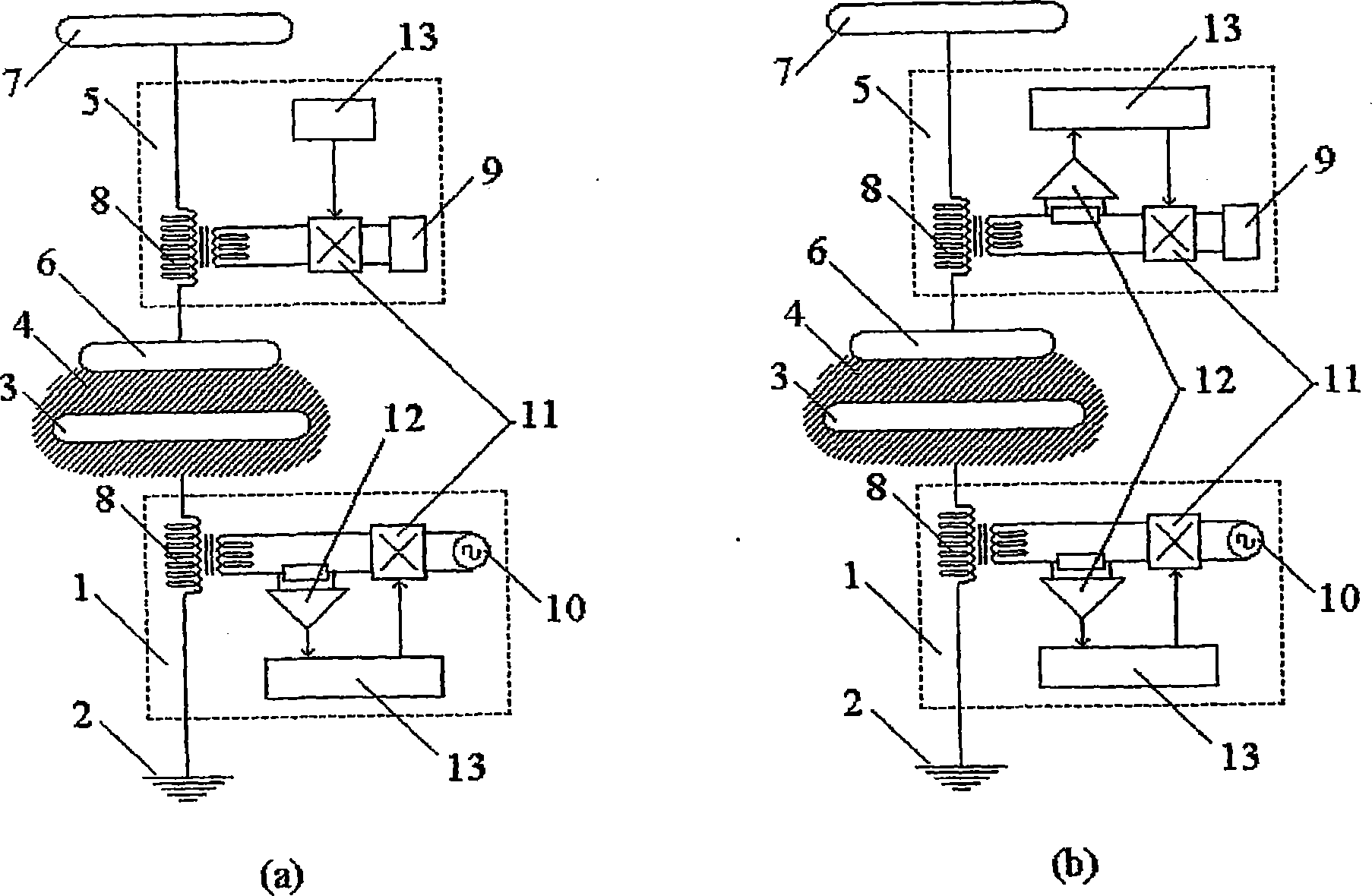

Apparatus for inducting transmission energy locally through crossing dielectric

The invention proposes a means for transporting electrical energy and / or information from a distance by using, at a slowly varying regime, the coulomb field which surrounds any set of charged conductors. The device according to the invention is composed of energy production and consumption devices situated a short distance apart, it uses neither the propagation of electromagnetic waves nor induction and cannot be reduced to a simple arrangement of electrical capacitors. The device is modelled in the form of an interaction between oscillating asymmetric electric dipoles, consisting of a high-frequency high-voltage generator (1) or of a high-frequency high-voltage load (5) placed between two electrodes. The dipoles exert a mutual influence on one another.; The devices according to the invention are suitable for powering industrial and domestic electrical apparatus, they are especially suitable for powering low-power devices moving in a limit environment and for short-distance non-radiating transmission of information.

Owner:MURATA MFG CO LTD

Lithium ion battery SiO composite material as well as preparation method and application thereof

ActiveCN104638237AImprove the first Coulombic efficiencyImprove capacity playCell electrodesSecondary cellsCarbon coatingHigh rate

The invention relates to a lithium ion battery SiO composite material which comprises powder and a conductive carbon coating layer, wherein the chemical formula of the powder is SiOx; x is greater than 0.9 and less than 1.1; the volume of powder with particle diameters below 1.0mu m accounts for less than 15.0% of that of all the SiOx powder; D90 / D10 is greater than 3.0 and less than 15.0; D90 is less than 25.0mu m; Dmax is less than 50.0mu m; and the median particle diameterD50 of the SiOx changes within 0.5-2.0mu m before and after carbon coating. When the composite material charges and discharges at 0-1.5V as a lithium ion battery cathode material, the reversible specific capacity is high (over 1,650mAh / g), the initial coulomb efficiency is up to a theoretical value (over 79.0%), and meanwhile the composite material has excellent cycle performance, excellent conductive performance and low volume expansion, is suitable for high-rate charge and discharge, and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD

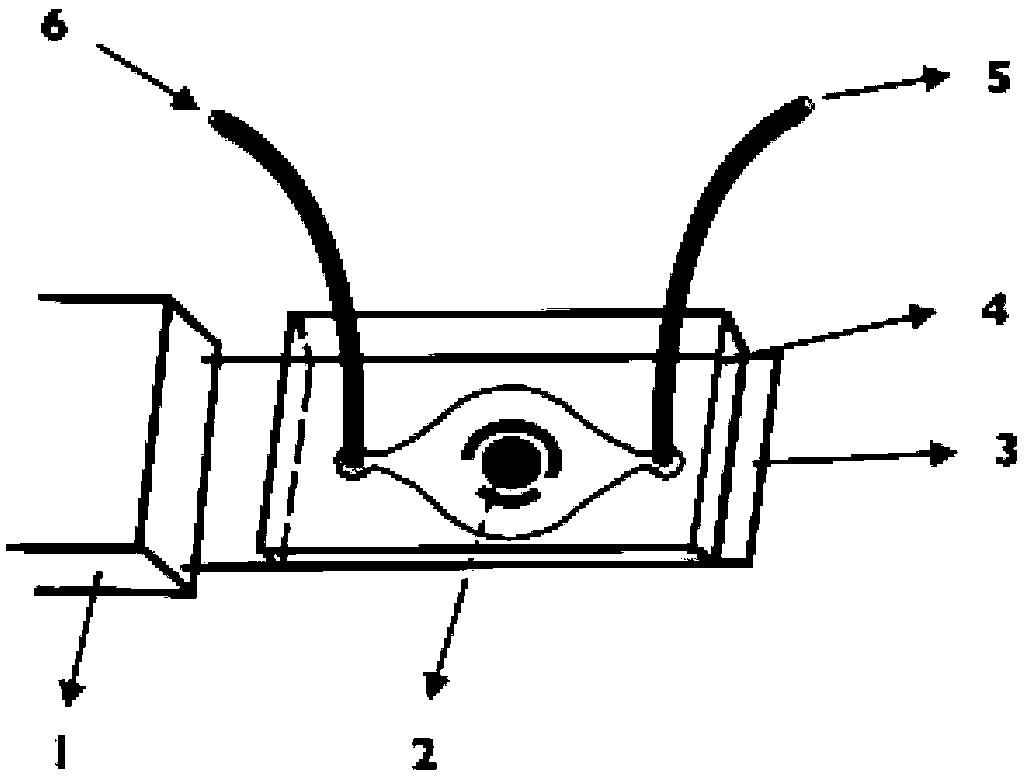

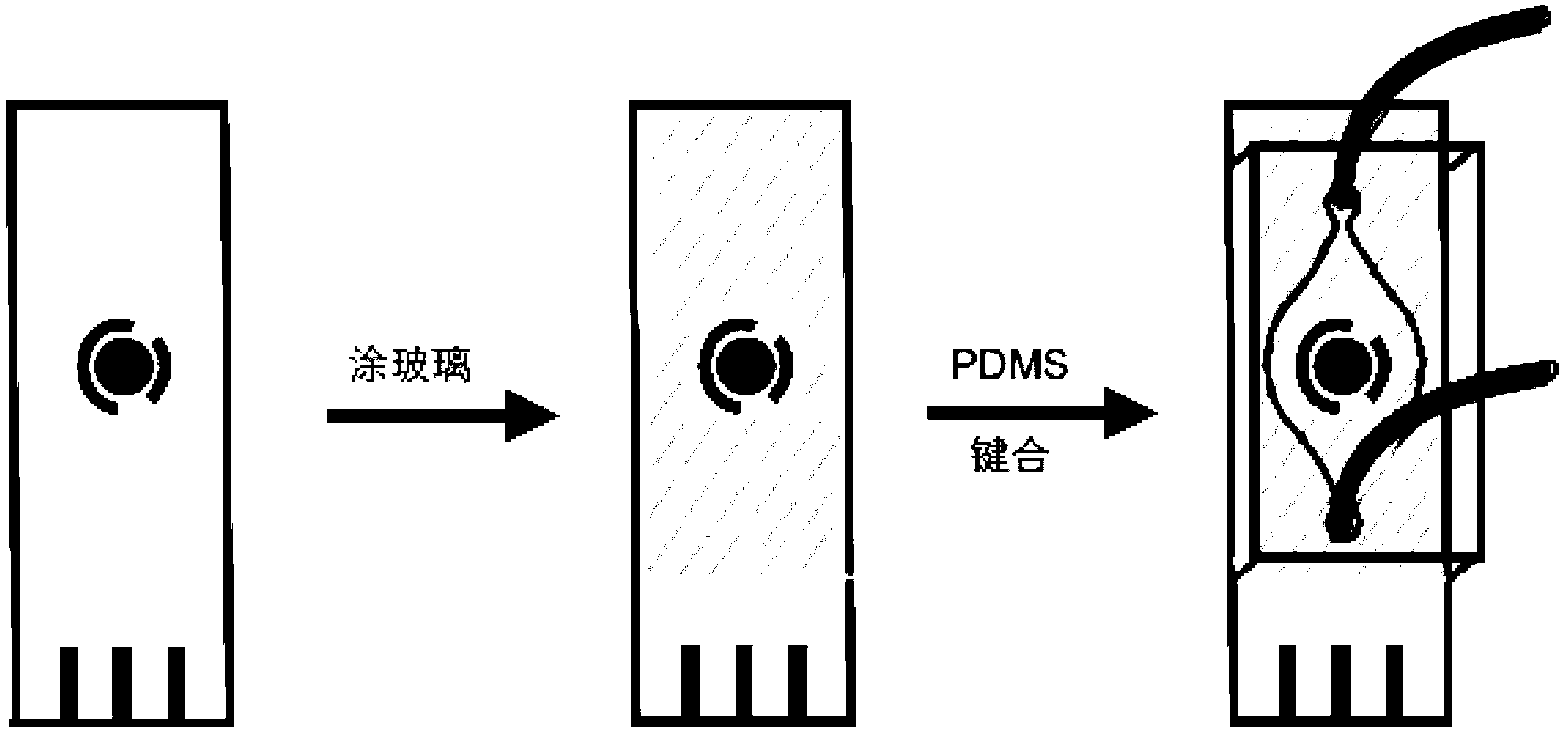

Preparation method and application of electrochemical micro-fluidic sensing chip

ActiveCN103182334AEasy to manufactureReduce weightMaterial analysis by electric/magnetic meansLaboratory glasswaresElectrochemical detectorStandardization

The invention provides a preparation method and the application of an electrochemical micro-fluidic sensing chip. The preparation method comprises the following steps: directly coating an improved glass solution on a commercial standard printed electrode; and performing vacuum plasma treatment on a PDMS (Polydimethylsiloxane) chip with pre-designed pipelines and the printed electrode coated with the glass solution together, and directly bonding the PDMS chip on the commercial standard printed electrode to form a novel electrochemical microfluidic sensing platform. A sensor provided by the invention can perform ultrasensitive detection on various sample analytes in a biological fluid sample, taking the detection of a prostate cancer marker PSA (Prostate-specific Antigen) in human serum as an example, a coulomb amperometry is used for detection, and a result shows that the detection sensitivity can reach 0.84 pg / mL which is improved by two magnitudes than the standardized clinical testing requirement of 0.1 ng / mL, so that the sensor has superhigh detection sensitivity and accuracy, which are higher than those of other electrochemical detection devices, is convenient in operation, and can integrates sample processing, separation and the like on one micro electrochemical microfluidic sensing chip.

Owner:SHANGHAI JIAO TONG UNIV

Positive electrode material of multi-component composite lithium ion cell and its preparation method

ActiveCN101320807ALow raw material costReduce manufacturing costElectrode manufacturing processesChemical/physical/physico-chemical processesCapacitanceMetallic lithium

The invention discloses a positive pole material of multiple composite lithium iron battery and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material, the positive pole material of the invention has the general formula: Li0.8-1.2NixCoyzO2, the crystal structure of the positive pole material is hexagonal system; crystal lattice is doped with more than one elements selected from the group consisting of Ti, Al, Mg, Cr, Zn, Ce, La, Lu, Y and F, the production method of the positive pole material comprises the steps of: synthesis of substrate materials, doping of substrate crystal lattices, mixing with lithium source compounds, sintering. As compared with the prior art, the produced positive pole material of multiple composite lithium iron battery of the invention combines into the simulative battery with metallic lithium sheets, and discharges and charges at 0.3C of discharge and charge current density, when the discharge and charge voltage is 2.5-4.2V, the maximum discharge capacitance reaches over 160mAh / g, the first Coulomb efficiency reaches more than 90%, the capacitance retention rate after circulation for 100 weeks is above 92%, the costs of raw materials and production are low, accordingly, the invention is apt for large-scale industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

Aluminum lithographic substrate and method of making

InactiveUS20080003411A1Reduced blanketReduce depositionDecorative surface effectsDuplicating/marking methodsMetal sheetPlanographic printing

Aluminum-containing metal sheets can be electrochemically grained to provide a center line average roughness (Ra) of less than 0.60 μm and an average maximum pit depth (Rv) of less than 4.5 μm using a current density of at least 50 A / dm2 and a charge density less than or equal to 850 coulombs / dm2. This improved metal sheet can be used as substrates for imageable elements including lithographic printing plates that exhibit reduced blanket toning.

Owner:EASTMAN KODAK CO

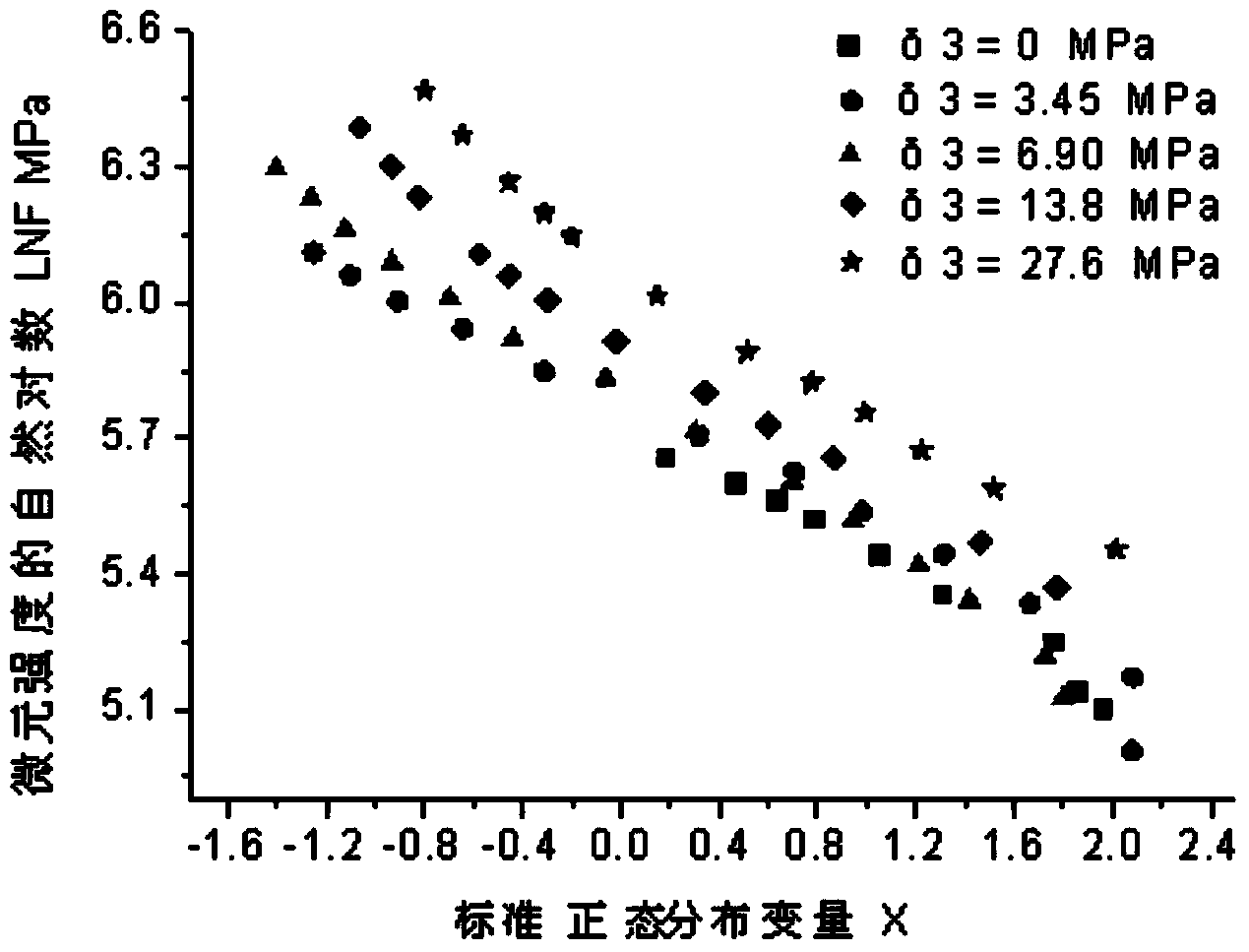

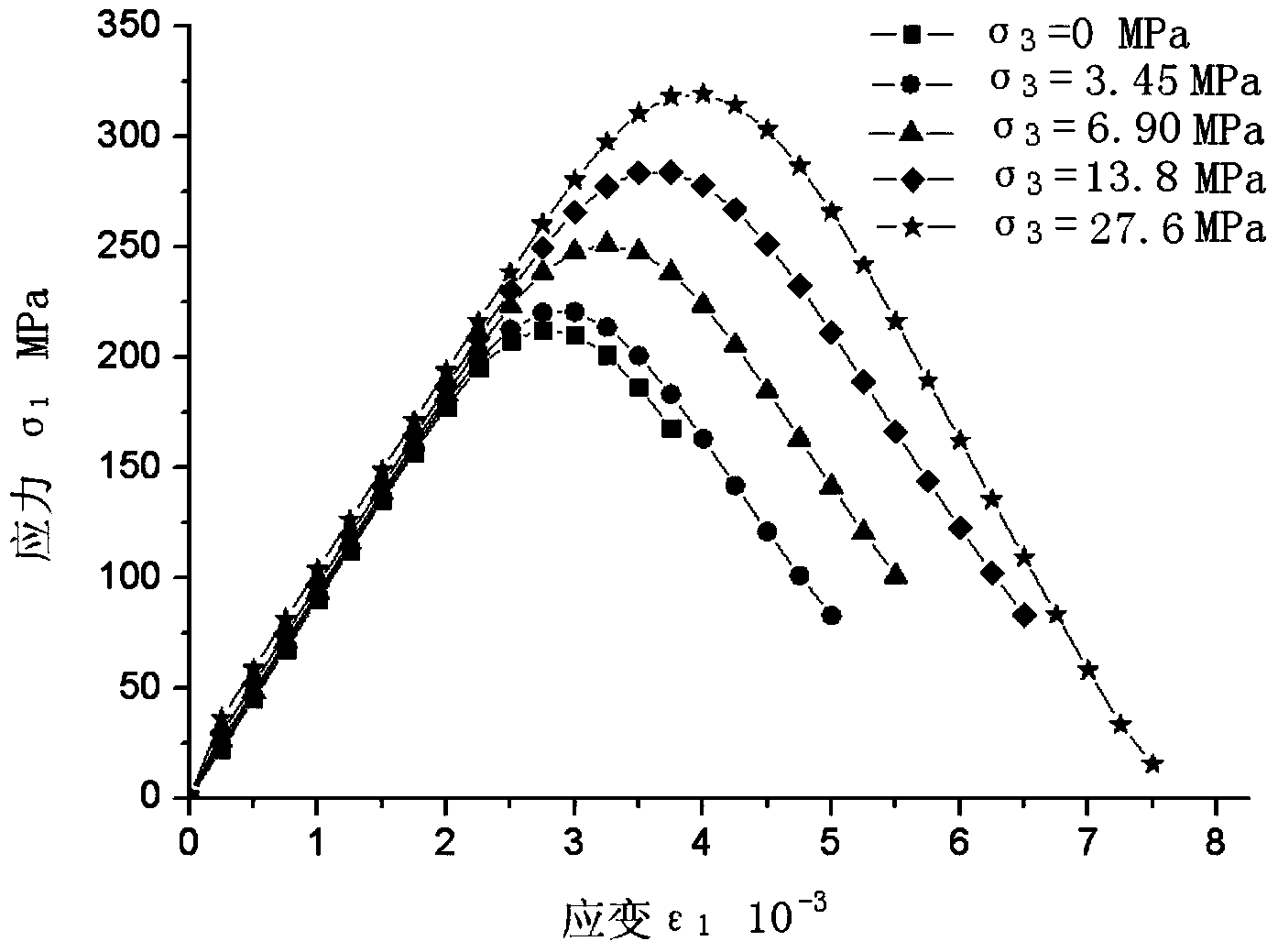

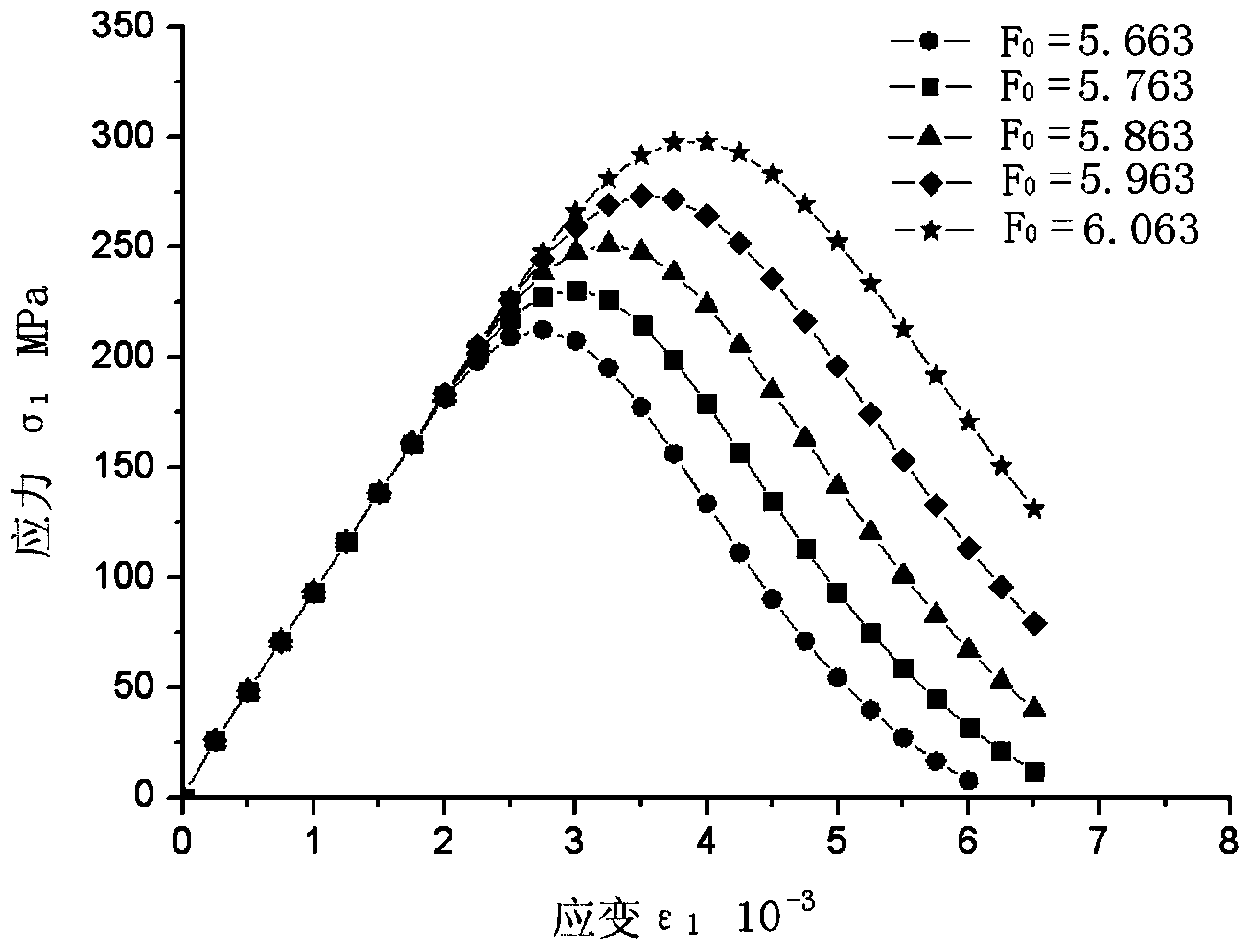

Construction and application method of statistical damage constitutive model of rock

ActiveCN104361211ASolving Functional Relationship ProblemsReasonable delineationEarth material testingSpecial data processing applicationsUltimate tensile strengthSoftware

The invention provides a statistical damage constitutive model of rock. The Mohr-Coulomb criterion is adopted as rock micro-element strength, and the conventional distribution form, namely logarithmic normal distribution, in the field of engineering reliability is adopted as the distribution state of micro-element strength. The mature Mohr-Coulomb criterion with wide application is utilized as the failure criterion of micro-element strength, while the function relationship between the damage parameters A, B, C and H of the constitutive model and the pressure sigma 3 of surrounding rock is given, so that the constitutive model can directly adopt numerical calculation software in the calculation of geotechnical engineering, and the effect is verified in the actual engineering application.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Composite carbon negative electrode material of lithium ion power battery and its preparation method

ActiveCN1885598AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesPower batteryGraphite particle

The disclosed composite carbon cathode material for Li ion electro-kinetic cell is prepared by bonding composite spherical or near-spherical graphite particle, wherein the material composes by: graphous or natural graphite powder or their mixture, 0.1-5wt% additive, and 1-50wt% bonding agent. The preparation method comprises: granulating, baking, dipping, impregnating, carbonizating, and graphitizing. Compared with prior art, this invention has reversible specific capacity more than 350mAh / g, first circulation coulomb efficiency more than 94%, capacity conservation rate more than 80% after 500 times of circulation, and other well performances.

Owner:BTR NEW MATERIAL GRP CO LTD

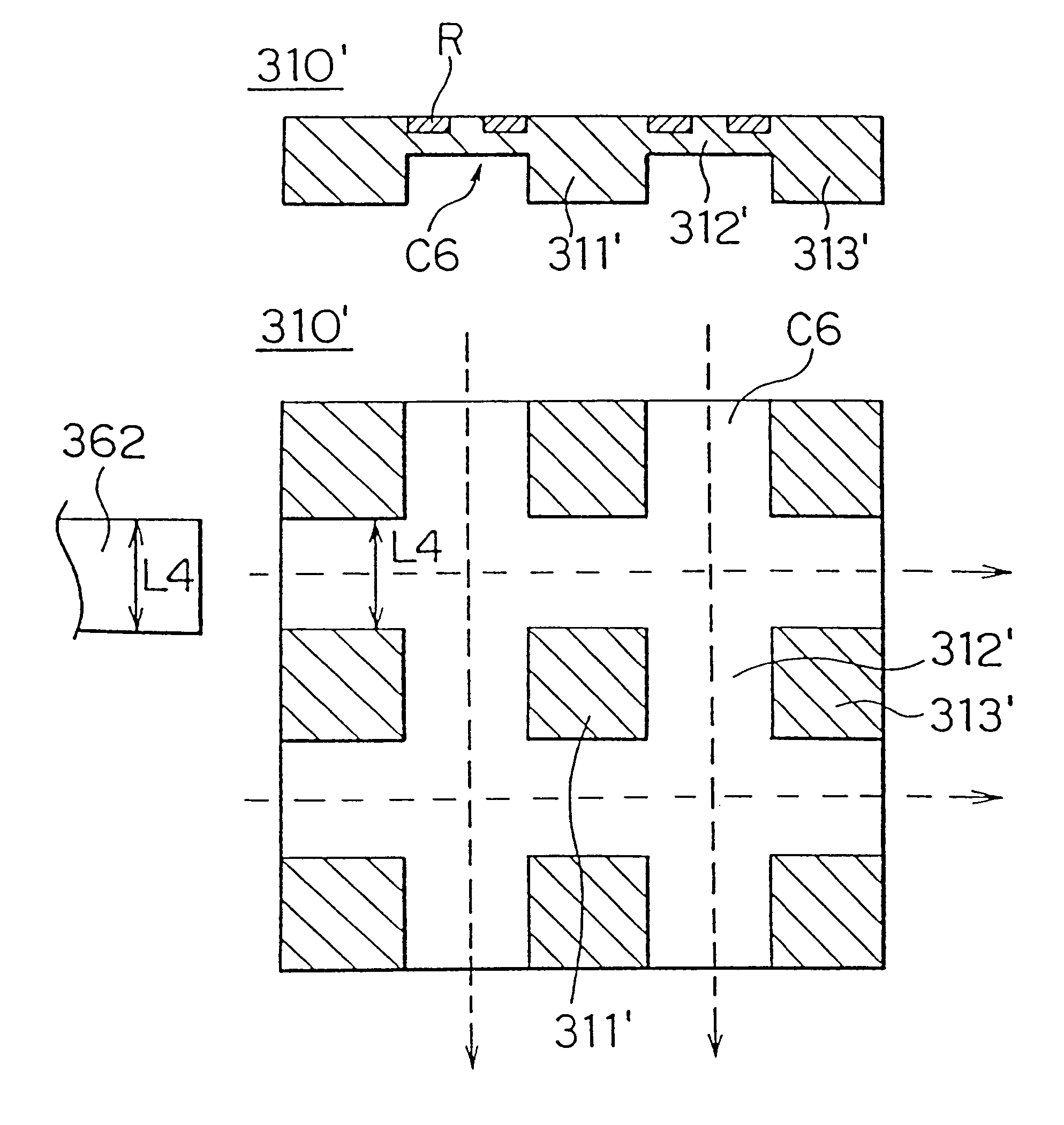

Apparatus for detecting a physical quantity acting as an external force and method for testing and manufacturing this apparatus

InactiveUS6894482B2Low costSimple circuit configurationAcceleration measurement using interia forcesElectrical testingSignal processing circuitsSemiconductor chip

A sensor comprises a semiconductor pellet (10) including a working portion (11) adapted to undergo action of a force, a fixed portion (13) fixed on the sensor body, and a flexible portion (13) having flexibility formed therebetween, a working body (20) for transmitting an exterted force to the working portion, and detector means (60-63) for transforming a mechanical deformation produced in the semiconductor pellet to an electric signal to thereby detect a force exerted on the working body as an electric signal. A signal processing circuit is applied to the sensor. This circuit uses analog multipliers (101-109) and analog adders / subtracters (111-113), and has a function to cancel interference produced in different directions. Within the sensor, two portions (E3, E4-E8) located at positions opposite to each other and producing a displacement therebetween by action of a force are determined. By exerting a coulomb force between both the portions, the test of the sensor is carried out. Further, a pedestal (21, 22) is provided around the working body (20). The working body and the pedestal are located with a predetermined gap or spacing therebetween. A displacement of the working body is caused to limitatively fall within a predetermined range corresponding to the spacing. The working body and the pedestal are provided by cutting a same common substrate (350, 350′).

Owner:WAKO CO LTD

Positive electrode material of multi-element layered lithium ion battery and preparation method thereof

The invention discloses a positive electrode material of a multi-element layered lithium ion battery. The chemical general formula of the positive electrode material is LiNiaMbNcO2, and the Li-Ni mixed ranging degree is less than 2%; in the chemical general formula, M is a transition-metal element, N is one or more of Al, Mg, Ti and Zr, and the values of a, or b, or c meet conditions that a+b+c=1, a>0.3, and c<0.03. The preparation method is as follows: preparing a multi-element precursor by virtue of utilizing a coprecipitation method, and then performing lithiation and sintering, thereby obtaining the positive electrode material of a multi-element layered solid solution. Compared with the prior art, the positive electrode material of the multi-element layered lithium ion battery has the advantages that the Li-Ni mixed ranging degree is reduced to less than 2%, so that the positive electrode material has higher coulomb efficiency, better layer structure and stronger bond energy and shorter bond length of metal-oxygen bond and also has better cycle performance and obviously improved thermal stability at a high temperature and a high pressure.

Owner:DONGGUAN AMPEREX TECH

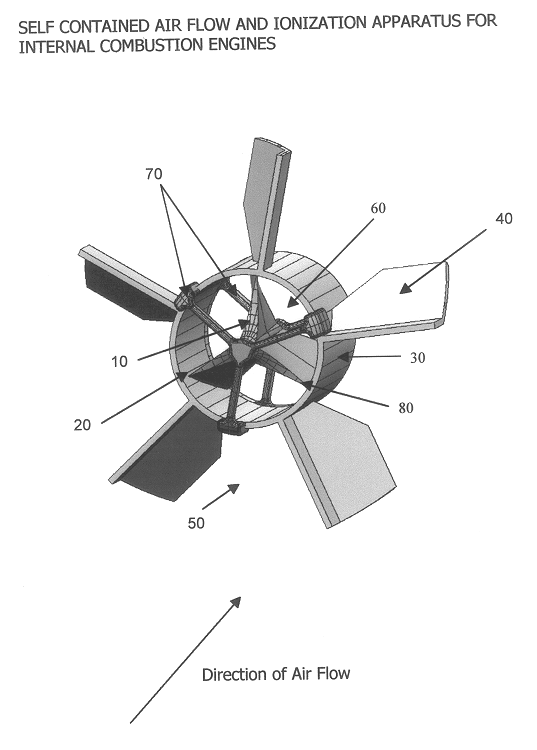

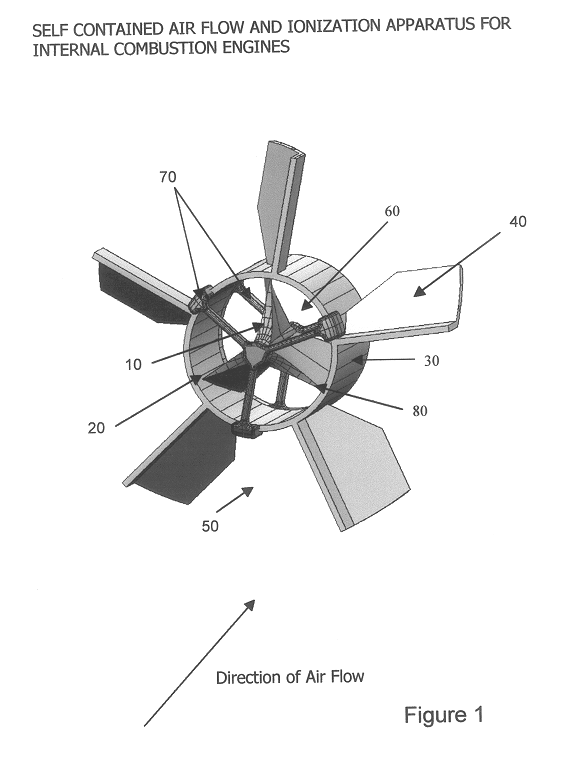

Self contained air flow and ionization method, apparatus and design for internal combustion engines

InactiveUS6601570B2Pump componentsCombustion-air/fuel-air treatmentExternal combustion engineEngineering

This invention method combines numerous disciplines to enhance the performance of internal combustion engines. No prior art embodies the discipline of physics in the creation of a swirling vortex, principles of electrostatics in using tribology and coulomb forces, the utilization of dielectric properties of polymers in an air driven rotating electrophorus and the chemistry of enhanced combustion gases and combustion itself in a single self-contained apparatus and does so without the convention and application of external voltage.

Owner:ZETMEIR KARL D

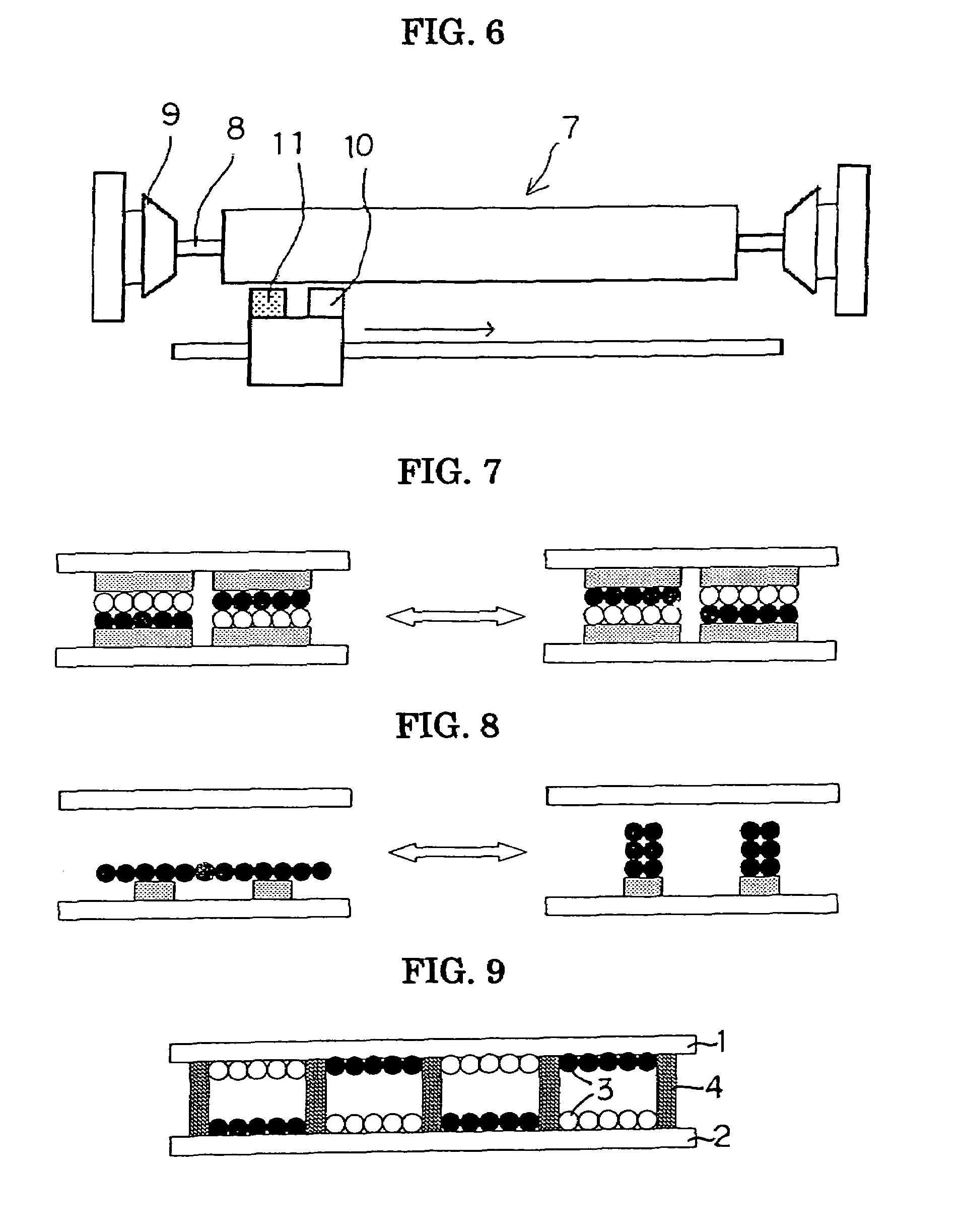

Particles and device for displaying image

InactiveUS7525719B2Improve stabilityRepetition durabilityStatic indicating devicesNon-linear opticsEngineeringMechanical engineering

The present invention intends to provide particles for displaying images used in an image display device capable of displaying and eliminating repeatedly accompanied by flight and movement of particles utilizing Coulomb force, being superior in stability, particularly in repetition durability, memory characteristic stability, adaptability for temperature change, having capability of regulating charge amount, and accordingly, favorable images with sufficient contrast should be stably obtained. The present invention provides particles coated with a resin; specifying Span of particle diameter distribution, charge attenuation property, thermal change of the surface hardness, tensile break strength, Izod impact strength (with a notch), abrasion loss (Taber), tensile elastic modulus, flexural elastic modulus, or tear strength. The present invention also proposes about the structure of the particles.

Owner:BRIDGESTONE CORP

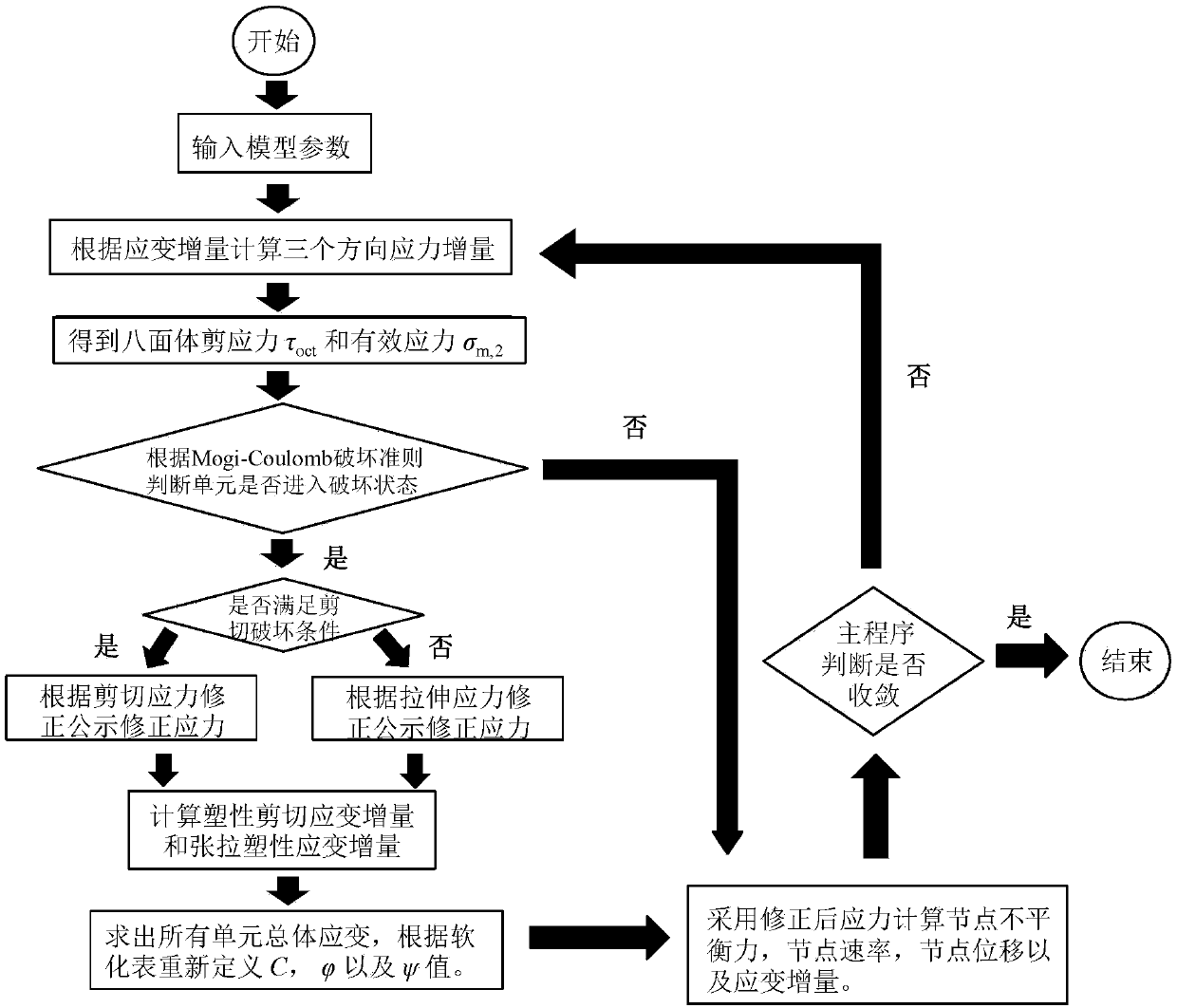

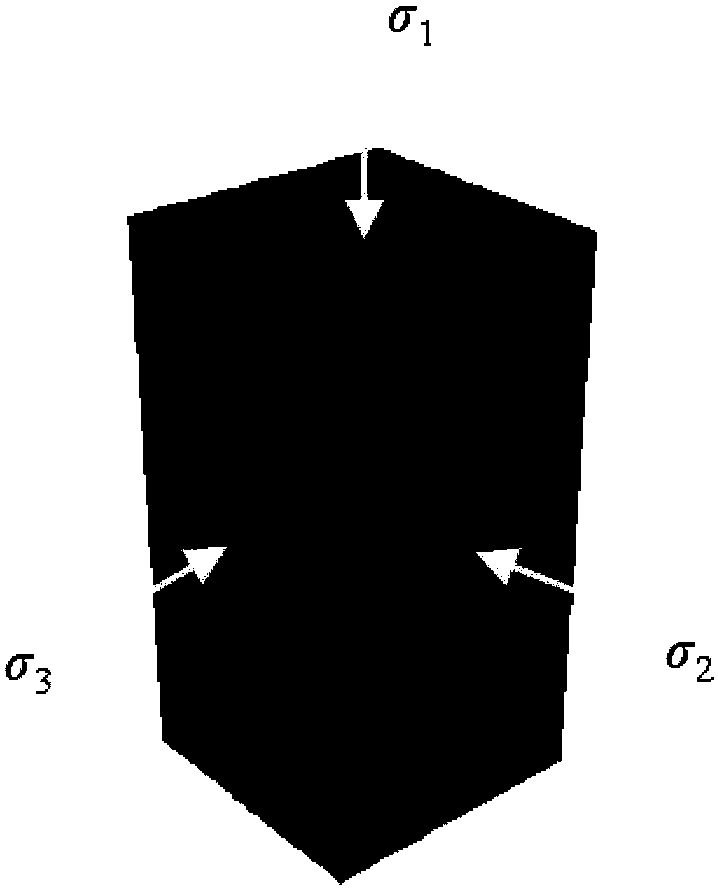

Rock material true triaxial test numerical simulation method considering intermediate principal stress effect

ActiveCN107463740AIn line with the real situationSimple and fast operationDesign optimisation/simulationSpecial data processing applicationsStress conditionsPrincipal stress

The invention relates to the field of numerical simulation technology and discloses a rock material true triaxial test numerical simulation method considering an intermediate principal stress effect to truly reflect strength characteristics and failure modes of rock materials under a true triaxial stress condition. The method comprises the steps that a finite difference increment iterative computing format based on Mogi-Coulomb failure criteria is subjected to secondary development in FLAC3D numerical simulation software, and a Mogi-Coulomb constitutive model is obtained; and a numerical model of the rock materials under the true triaxial stress condition is established, basic physical mechanical parameters are assigned to the numerical model, and the Mogi-Coulomb constitutive model is loaded and called to perform simulation operation to obtain a corresponding numerical simulation computing result. According to the method, influences of intermediate principal stress on rock strength and the failure modes are fully considered during numerical analysis of the failure characteristics of the rock materials under the true triaxial stress condition, so that the simulation result is truer and more reliable.

Owner:CENT SOUTH UNIV

Modified lithium manganese oxide electrode material for lithium ion secondary battery and synthesizing method thereof

InactiveCN102208640AImprove featuresImprove crystallization propertiesCell electrodesAluminium-ion batterySodium-ion battery

The invention provides a modified lithium manganese oxide electrode material for a lithium ion secondary battery, which is characterized in that the general formula is Li(4-x)A(x+y)Mn(5-y)O12.epsilonBOz. The synthesizing method comprises the following steps: weighing and mixing raw materials evenly in accordance with the stoichiometric ratio in the general formula and then adding the mixture of the raw materials to a container; adding an oxidizing solution, evening mixing and reacting for over 10 minutes, and then taking the materials out, washing and drying; and then carrying out high-temperature calcination and reaction for 1-30 hours at a temperature of 400-1200 DEG C under an oxygen-contained atmosphere, and cooling to obtain the modified lithium manganese oxide electrode material. Compared with an existing electrode material and a synthesizing technology, the modified lithium manganese oxide electrode material produced in the production process can improve the crystalline characteristic and the purity of products as well as the specific capacity, the initial coulomb efficiency, the cyclical stability and other characteristics in electrochemical property; and the modified lithium manganese oxide electrode material improves performances of the lithium ion battery, promotes the wider applications of the lithium ion battery and has significant economic meanings and practical value.

Owner:王明月

Electrochemical energy storage device and preparation method hereof

ActiveCN105047986AImprove first-time efficiencyIncrease energy densityCell electrodesFinal product manufactureLithiumElectrical battery

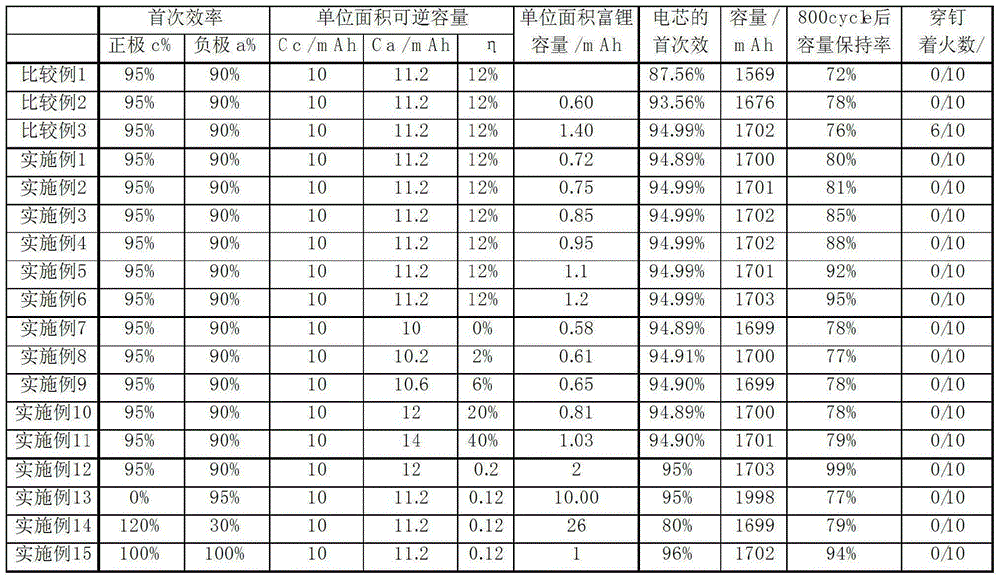

The invention belongs to the technical field of electrochemical energy storage, and particularly relates to an electrochemical energy storage device. The electrochemical energy storage device comprises a cathode plate, an anode plate, an isolating membrane, electrolyte and an outer package, wherein the initial coulomb efficiency of a cathode active substance on the cathode plate is c%; the reversible capacity of the cathode plate in unit area is Cc mAh; the initial coulomb efficiency of an anode active substance on the anode plate is a%; the reversible capacity of the anode plate in unit area is Ca mAh; the anode capacity excess rate eta in unit area is (Ca-Cc) / Cc*100%; electrode plates are subjected to lithium-rich treatment; and the lithium-rich capacity m in unit area is that: Ca*(1-a%) / a%-Cc*(1-c%) / c% is smaller than or equal to m. When lithium-rich treatment is carried out, the lithium-rich capacity m in unit area is that Ca*(1-a%) / a%-Cc*(1-c%) / c% is smaller than or equal to m; the first lithium loss of the anode can be supplemented; and excessive lithium can be used for supplementing lithium consumption in the cycling process, so that the cycle performance of the battery is improved.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

Method of testing a sensor

InactiveUS6864677B1Low costSimple circuit configurationAcceleration measurement using interia forcesWave based measurement systemsSignal processing circuitsSemiconductor chip

A sensor comprises a semiconductor pellet (10) including a working portion (11) adapted to undergo action of a force, a fixed portion (13) fixed on the sensor body, and a flexible portion (13) having flexibility formed therebetween, a working body (20) for transmitting an exterted force to the working portion, and detector means (60-63) for transforming a mechanical deformation produced in the semiconductor pellet to an electric signal to thereby detect a force exerted on the working body as an electric signal. A signal processing circuit is applied to the sensor. This circuit uses analog multipliers (101-109) and analog adders / subtracters (111-113), and has a function to cancel interference produced in different directions. Within the sensor, two portions (E3, E4-E8) located at positions opposite to each other and producing a displacement therebetween by action of a force are determined. By exerting a coulomb force between both the portions, the test of the sensor is carried out. Further, a pedestal (21, 22) is provided around the working body (20). The working body and the pedestal are located with a predetermined gap or spacing therebetween. A displacement of the working body is caused to limitatively fall within a predetermined range corresponding to the spacing. The working body and the pedestal are provided by cutting a same common substrate (350, 350).

Owner:WAKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com