Preparation method and application of electrochemical micro-fluidic sensing chip

A sensor chip and microfluidic technology, applied in chemical instruments and methods, scientific instruments, laboratory containers, etc., can solve the problems of poor repeatability of electrochemical detection, complicated preparation process, high cost, etc., and achieve ultra-high detection Sensitivity and accuracy, detection repeatability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

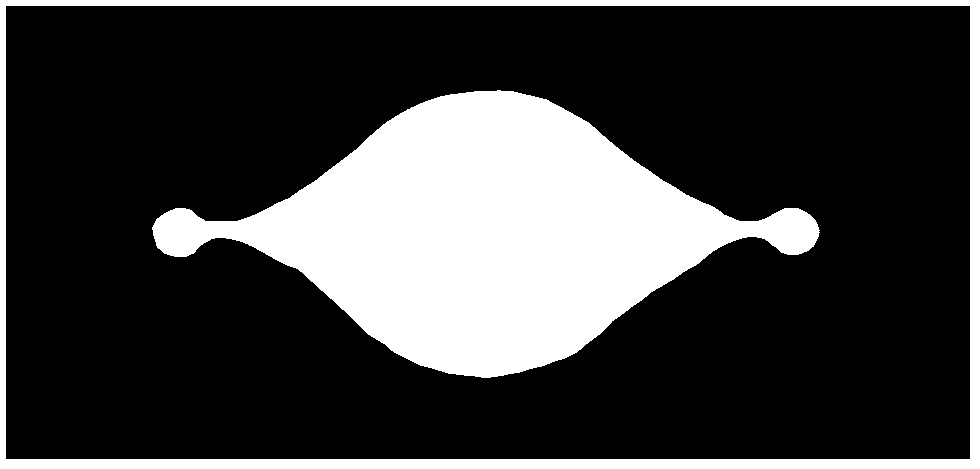

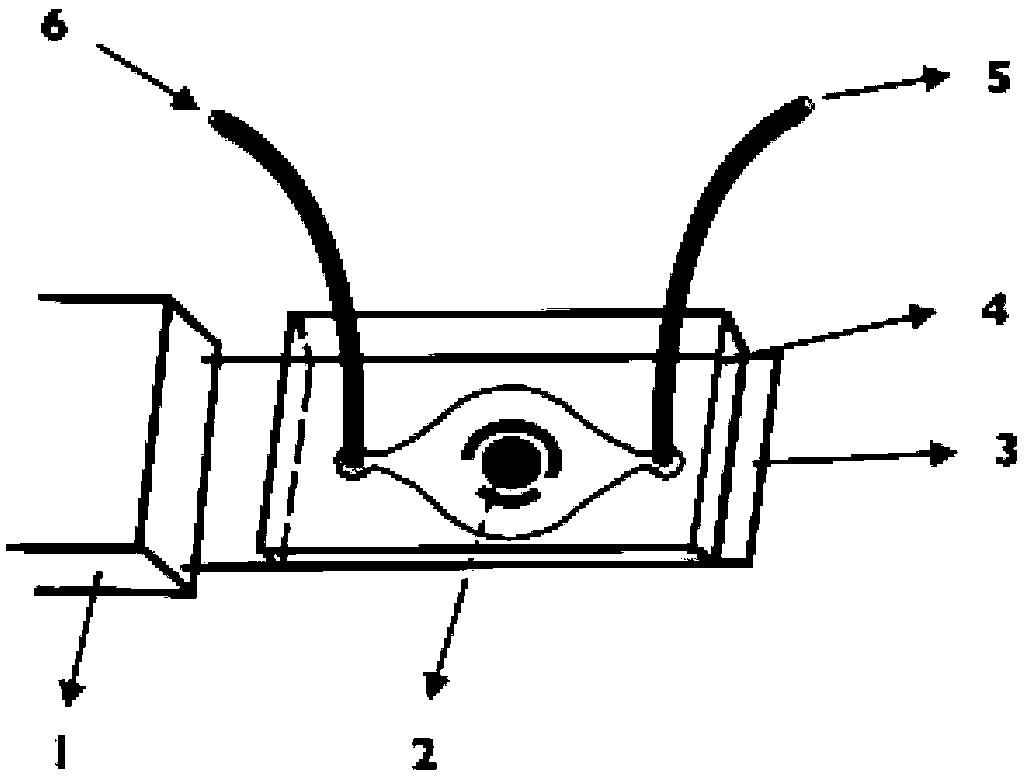

[0043] (a) Using Freehand drawing software to design the microfluidic pipeline drawing mask, the pipeline design is based on the fluid mechanics design such as figure 1 As shown, the inlet and outlet are designed with a certain radian, and there is no right angle. The middle of the pipe is oval to ensure that the liquid passes smoothly and evenly across the surface of the working electrode. This technology is different from other microfluidic chips that usually use rectangular pipe design.

[0044] (b) Fabrication of PDMS chips using soft lithography standard microfabrication techniques.

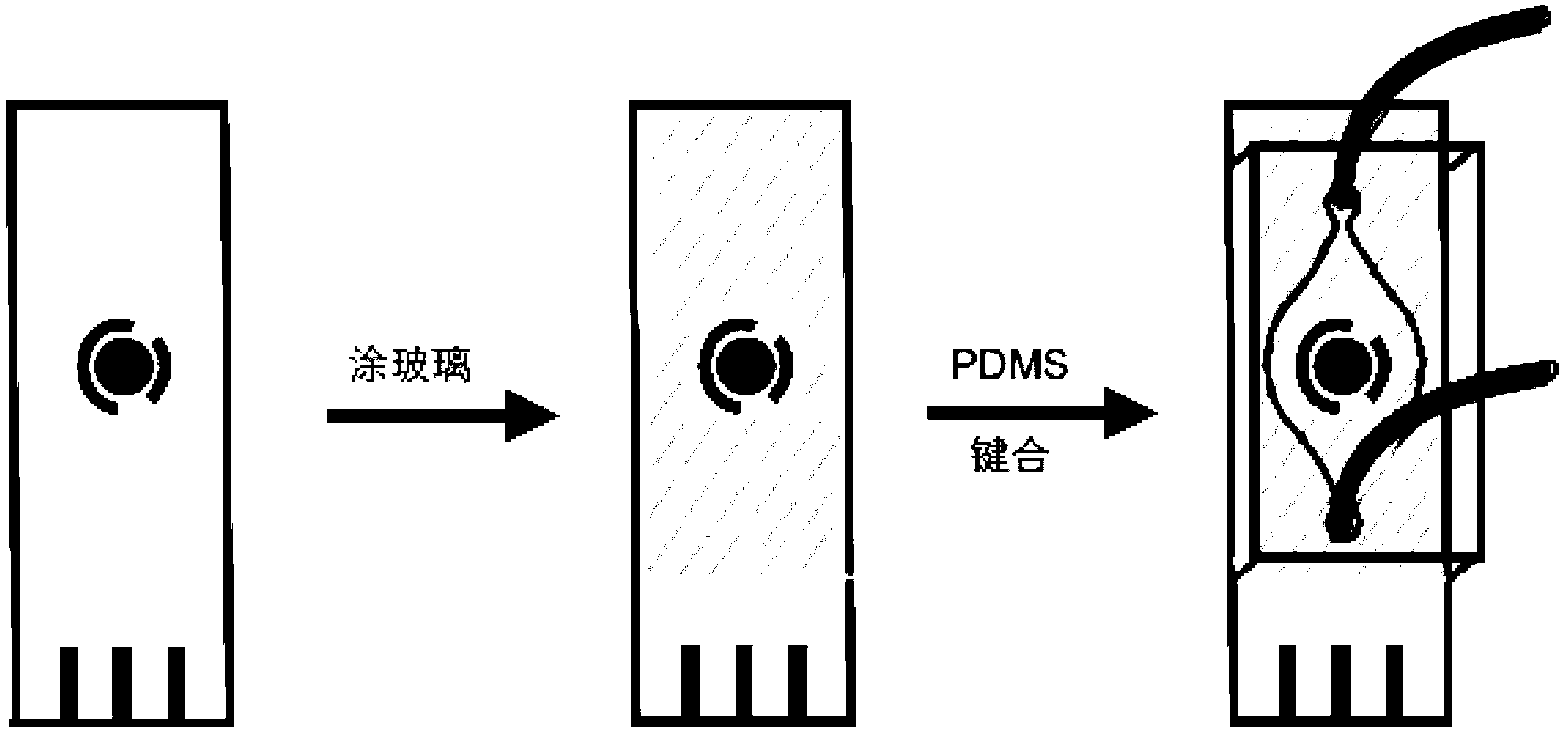

[0045] (c) Preparation of glass solution, 3-aminopropyltriethoxysilane (APTS), ethyl orthosilicate (TEOS), ethanol (Et OH), water (H 2 O pH=2–8) mixed at a volume ratio of 1:1:1:1, ultrasonicated for 5–30 minutes, and aged at 20-90°C for 2–24 hours. , For example, the ultrasound can be 5min, 15min, 30min, the curing temperature can be 20°C, 50°C, 90°C, the curing time can be 2h, 15h, 24h an...

Embodiment 2

[0054] (a) Use the Freehand drawing software to design the microfluidic pipeline drawing mask, the specific design is shown in the appendix figure 1 .

[0055] (b) Fabrication of PDMS chips using soft lithography standard microfabrication techniques.

[0056] (c) Preparation of glass solution, 3-aminopropyltriethoxysilane (APTS), ethyl orthosilicate (TEOS), ethanol (Et OH), water (H 2 O pH=2-8) mixed according to the volume ratio of 5:1:1:1 to 1:5:10:20, ultrasonicated for 5-15min, and aged at 20-90℃ for 2-24h.

[0057] (d) Apply a layer of glass solution evenly on the surface of the standardized printed electrode, and let it dry at room temperature.

[0058] (e) A PDMS chip and a glass-coated printed electrode O 2 Plasma treatment for 60s, then bonding.

[0059] (f) Immobilize 50 μL of 0.05-0.5 mg / m magnetic beads with CEA capture antibody to the working area of the electrode of the chip under the action of an external magnetic field.

[0060] (g) Inject 100 μL of 0.1 ...

Embodiment 3

[0065] (a) Use the Freehand drawing software to design the microfluidic pipeline drawing mask, the specific design is shown in the appendix figure 1 .

[0066] (b) Fabrication of PDMS chips using soft lithography standard microfabrication techniques.

[0067] (c) Preparation of glass solution, 3-aminopropyltriethoxysilane (APTS), ethyl orthosilicate (TEOS), ethanol (Et OH), water (H 2 O pH=2-8) mixed at a volume ratio of 1:5:10:20, ultrasonicated for 5-20min, and aged at 20-90°C for 2-24h.

[0068] (d) Apply a layer of glass solution evenly on the surface of the standardized printed electrode, and let it dry at room temperature.

[0069] (e) A PDMS chip and a glass-coated printed electrode O 2 Plasma treatment for 90s, followed by bonding.

[0070] (f) Immobilize 50 μL of 0.05–0.5 mg / m magnetic beads with CA199 capture antibody to the working area of the chip electrode under the action of an external magnetic field.

[0071] (g) Inject 100 μL of 10 ng / mL CA199 antigen i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com