Patents

Literature

29519 results about "High energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation-curable coating compounds

InactiveUS6605669B2Inhibition of polymerizationNo surface defectsPolyurea/polyurethane coatingsPrinting after-treatmentMeth-Functional monomer

Coating compounds curable by means of high-energy radiation, comprising as binderA) at least one (meth)acrylic copolymer containing olefinic double bonds capable of free-radical polymerization and hydroxyl groups with a C=C equivalent weight from 100 to 10,000 and an OH-value from 20 to 250 mg KOH / g, which is prepared from monomers comprising:A1) at least one olefinically unsaturated, epoxy-functional monomer capable of free-radical polymerization,A2) at least one olefinically unsaturated, carboxy-functional monomer capable of free-radical polymerization andA3) at least one further olefinically unsaturated monomer capable of free-radical polymerization which is different from A1) and A2), andB) at least one component with free isocyanate groups and process for multilayer coating using the coating compounds.

Owner:AXALTA COATING SYST IP CO LLC

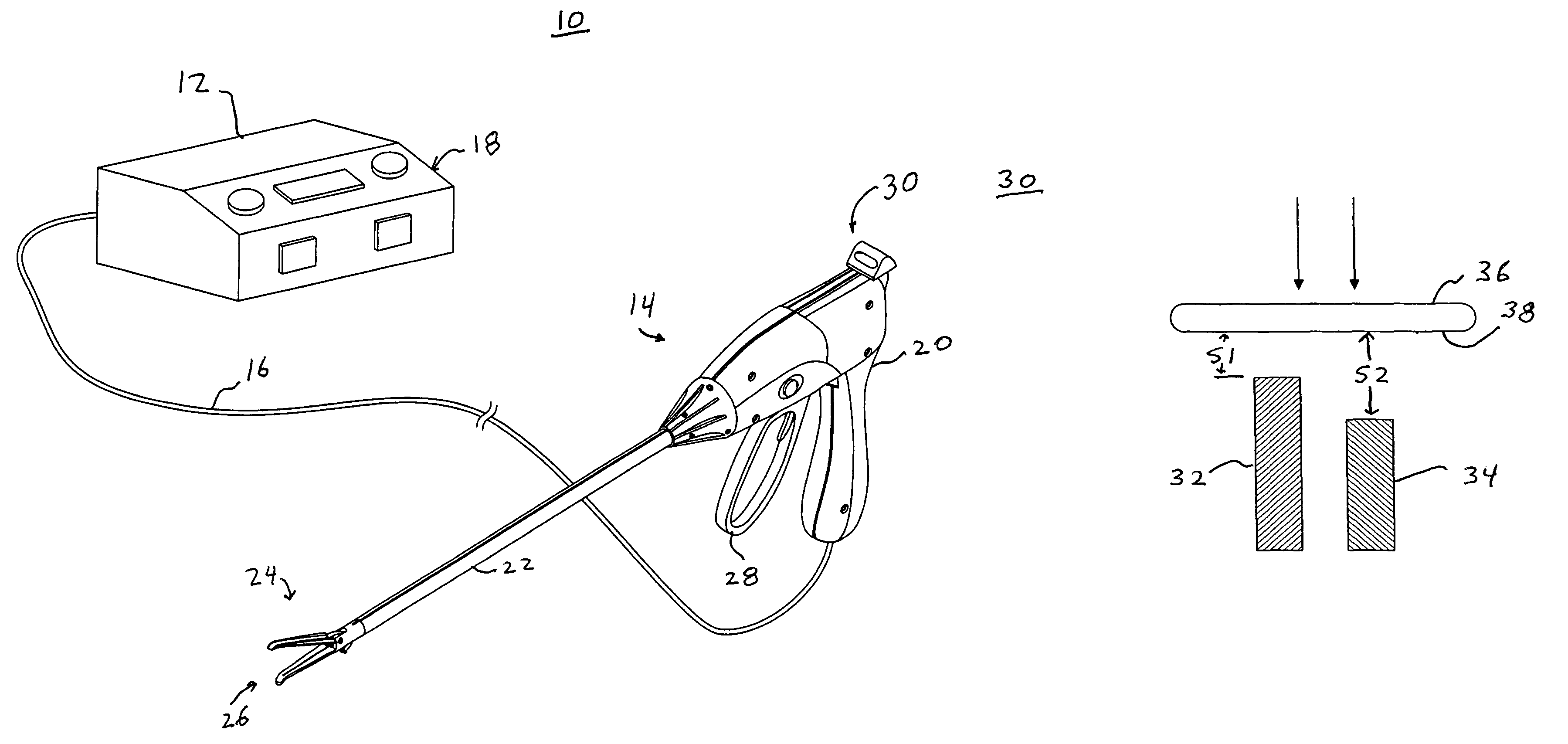

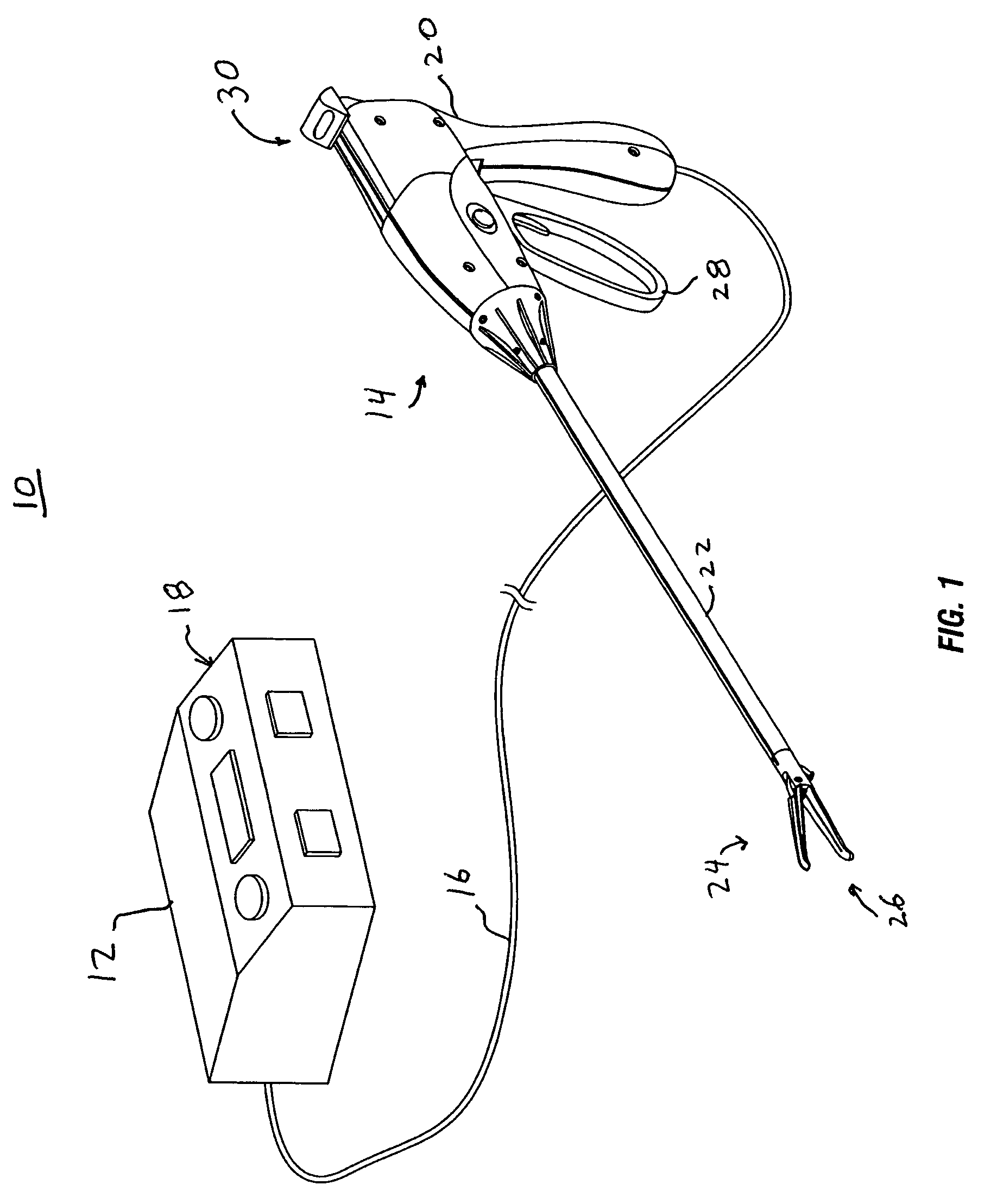

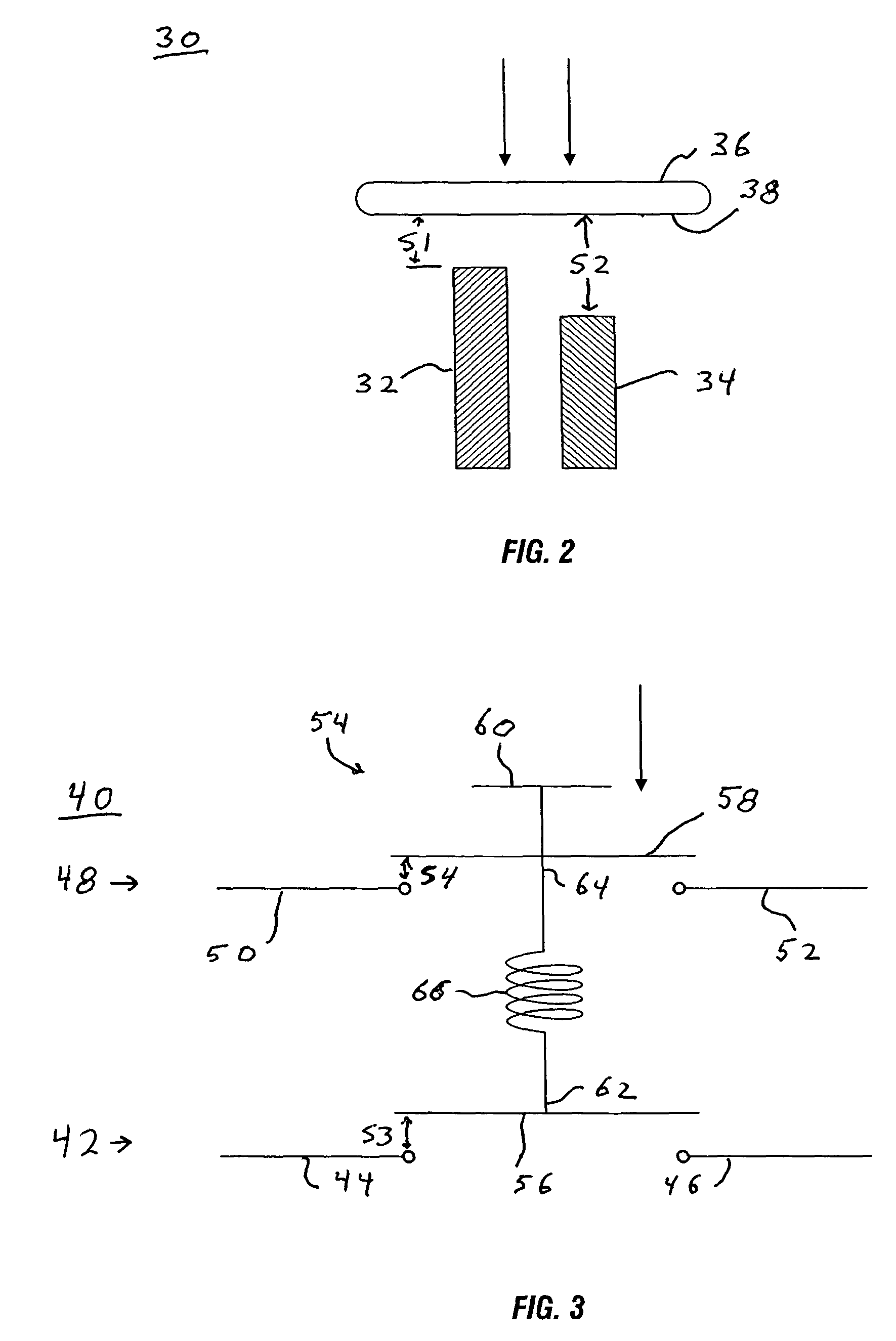

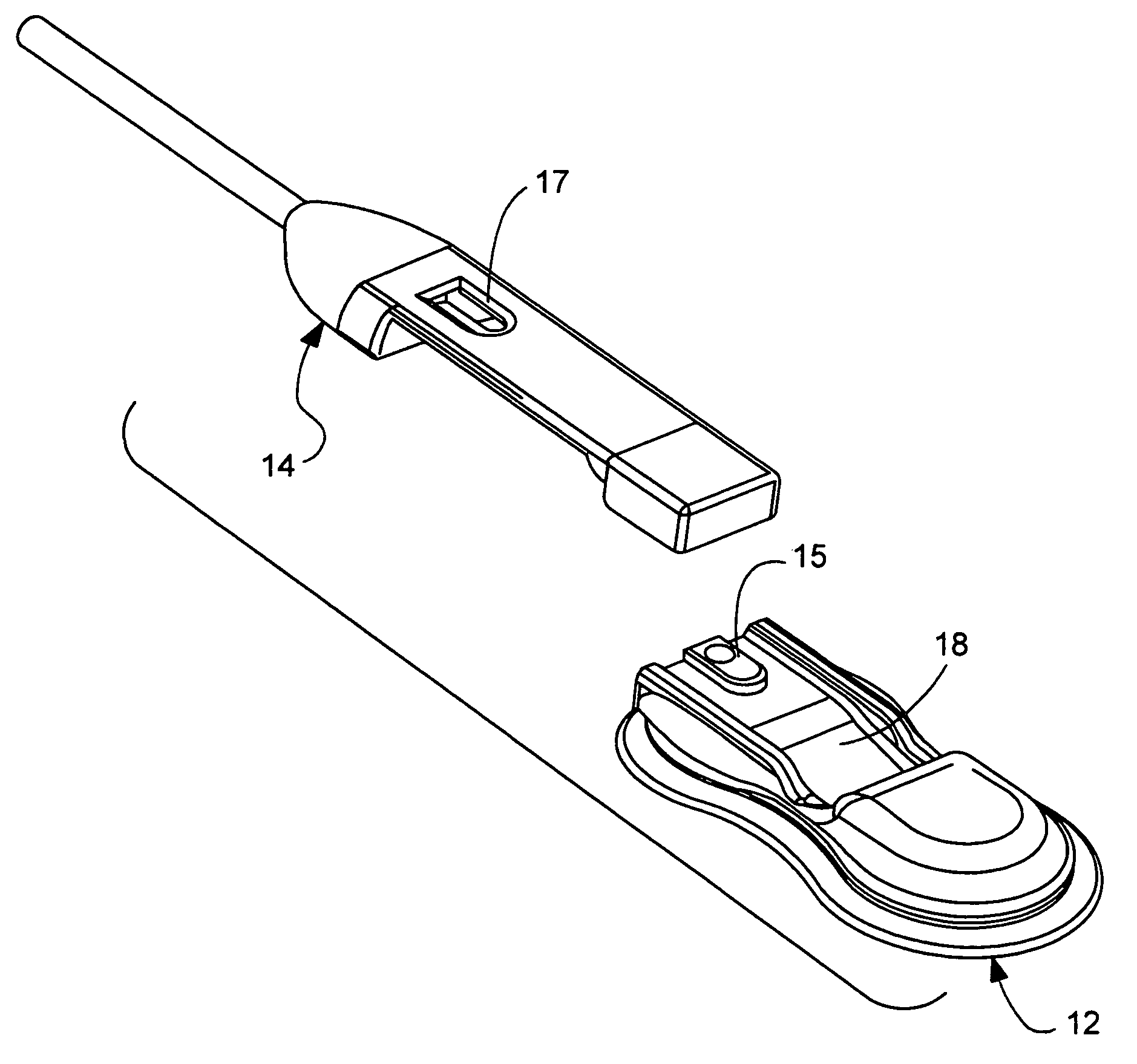

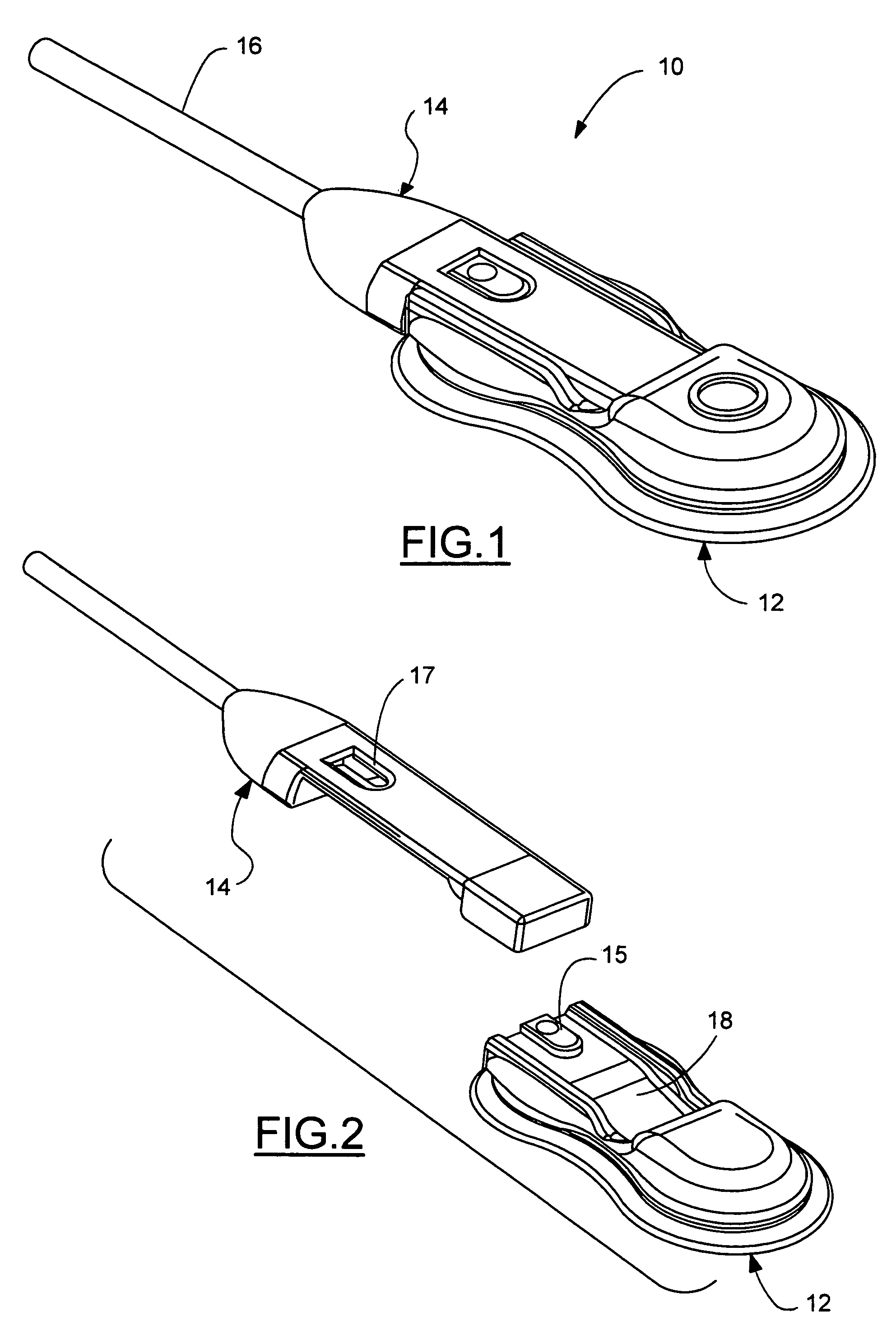

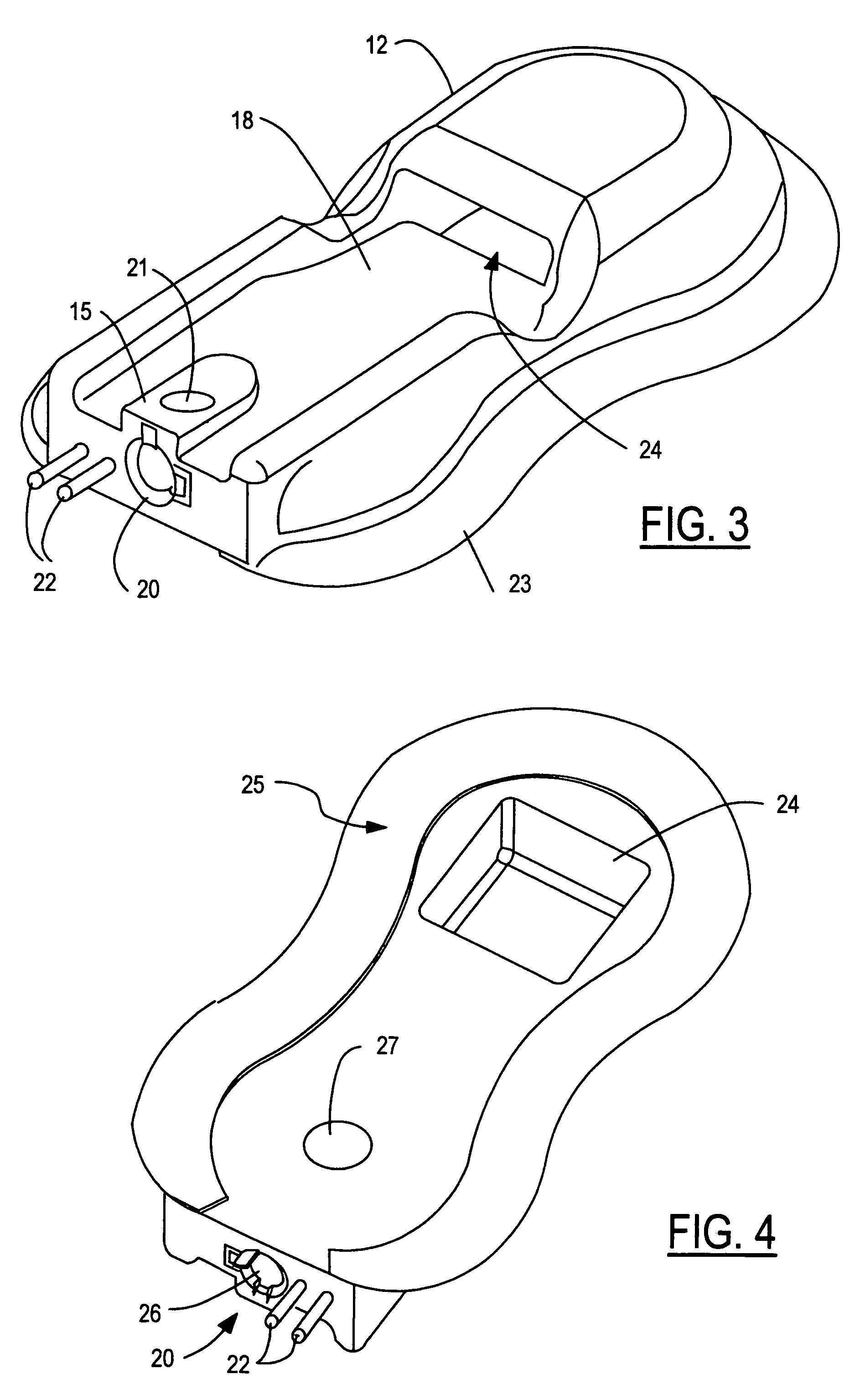

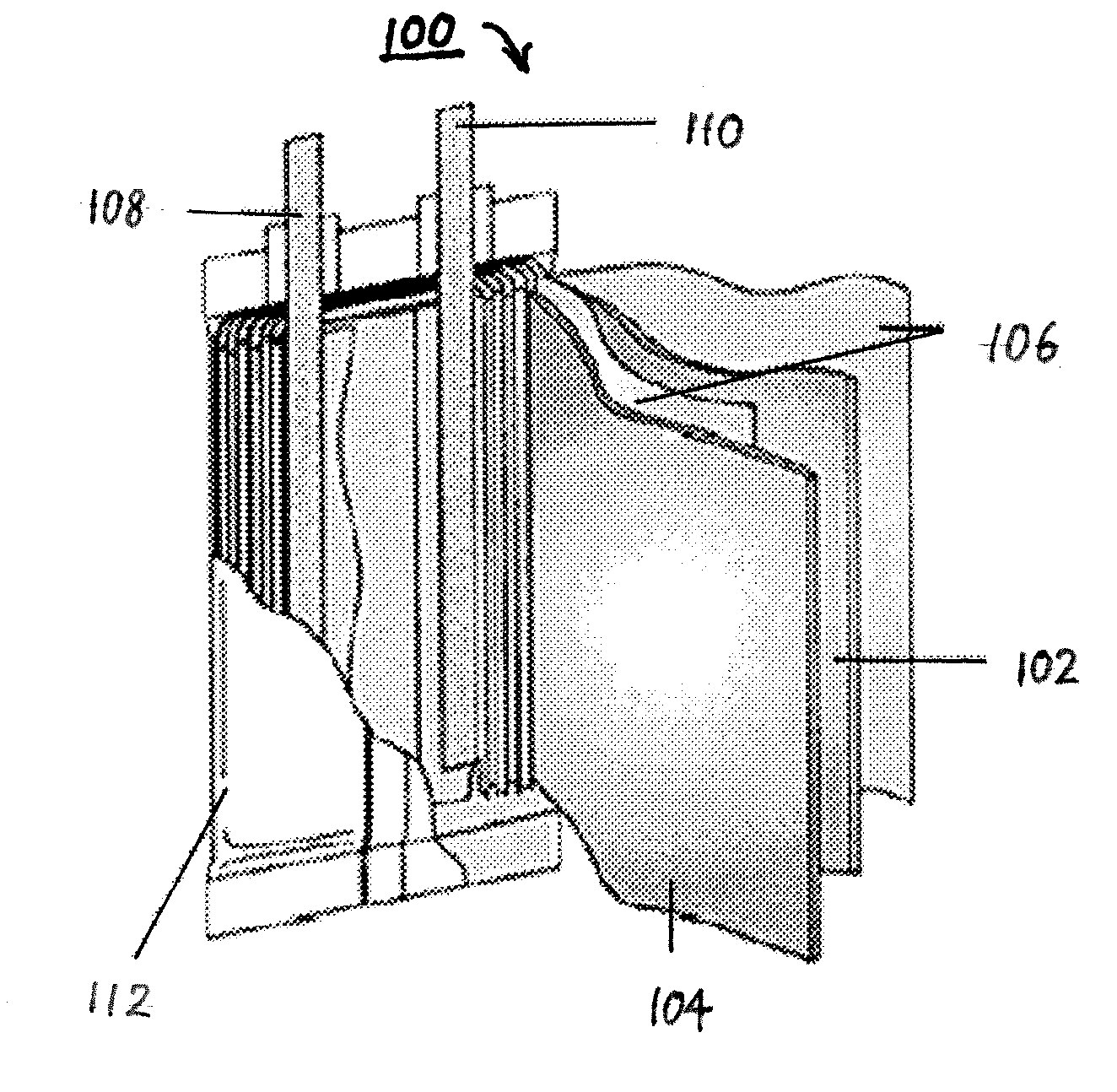

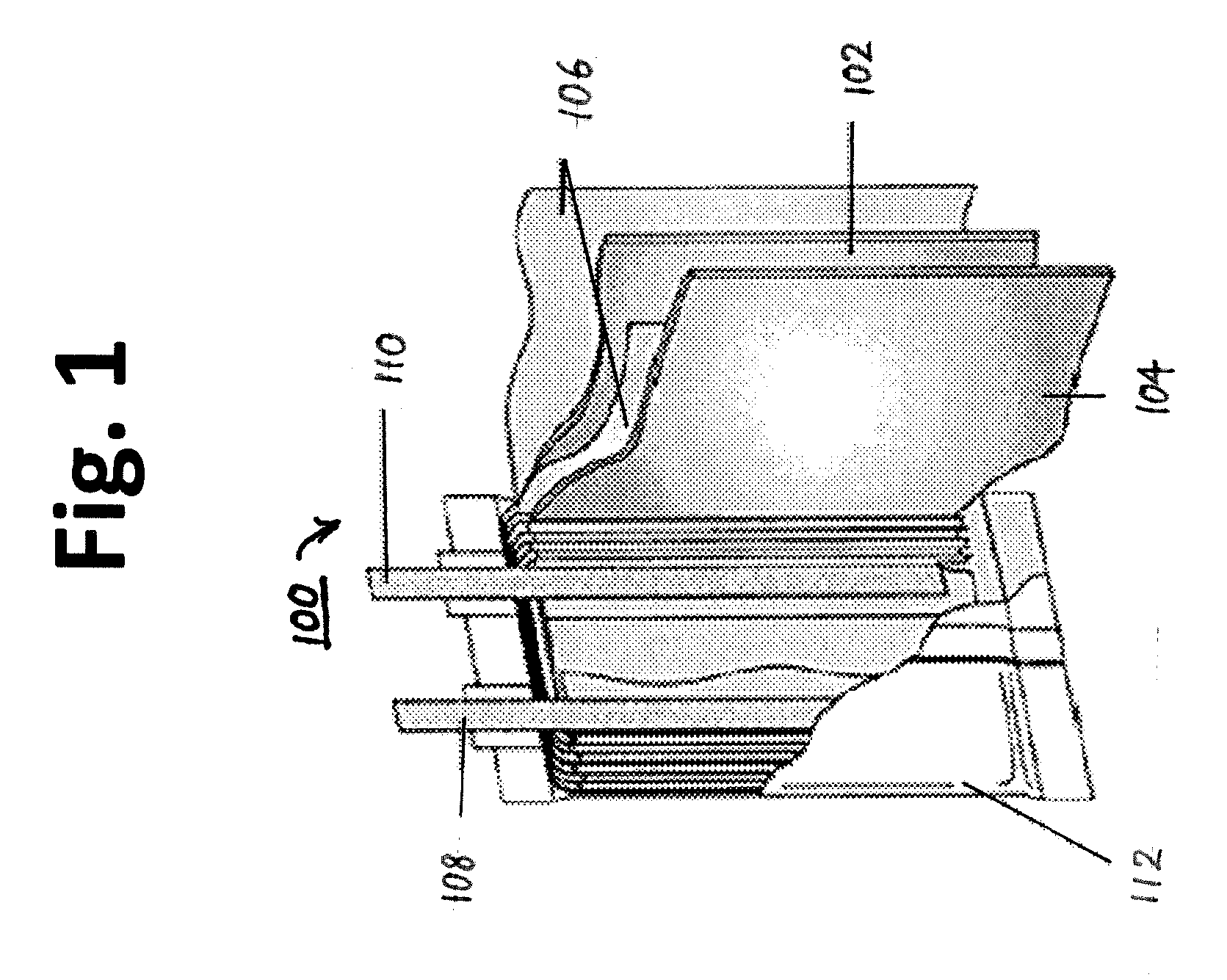

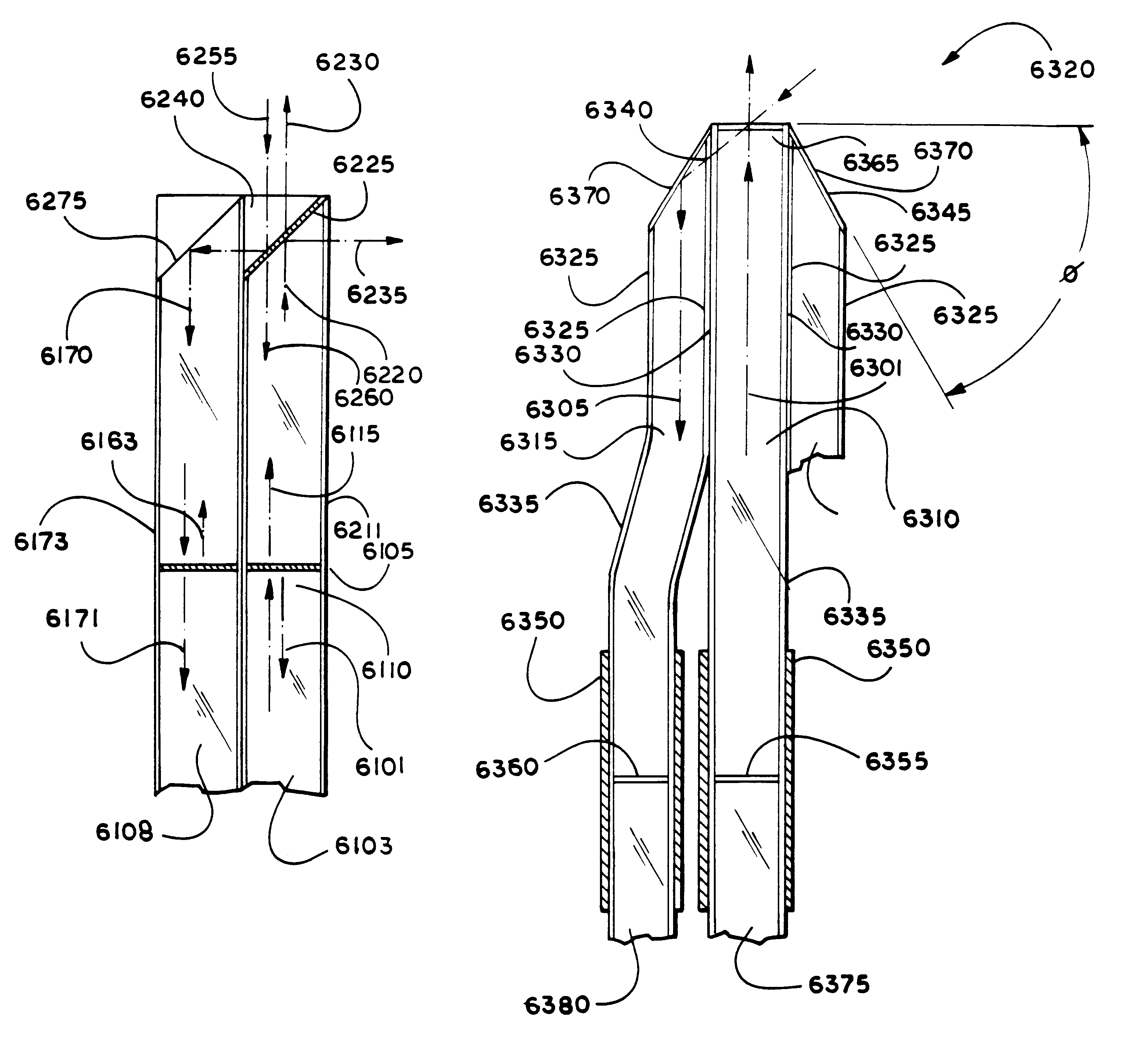

Switch mechanisms for safe activation of energy on an electrosurgical instrument

ActiveUS7837685B2Secure bootElectric switchesSurgical instruments for heatingHigh energyBiological activation

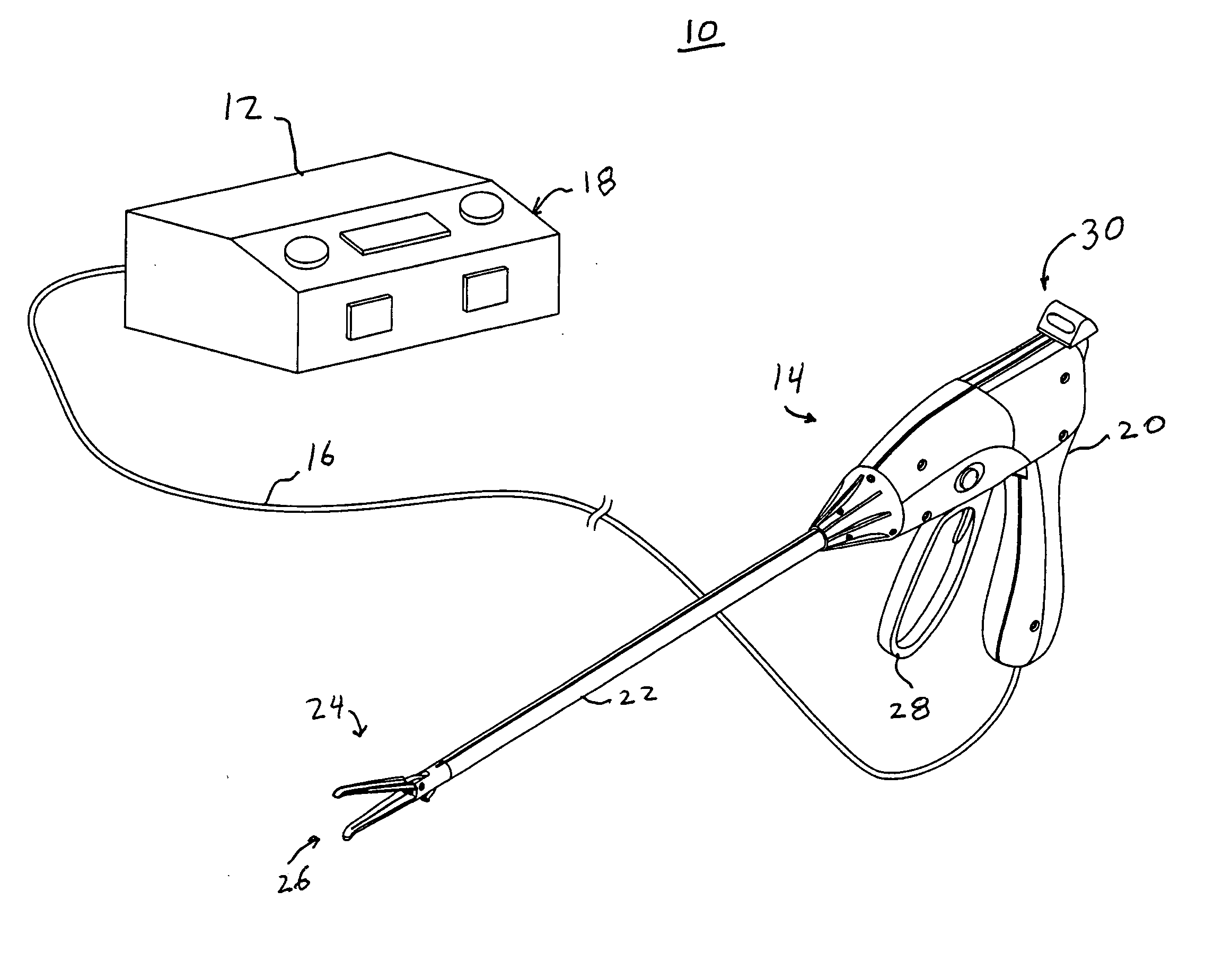

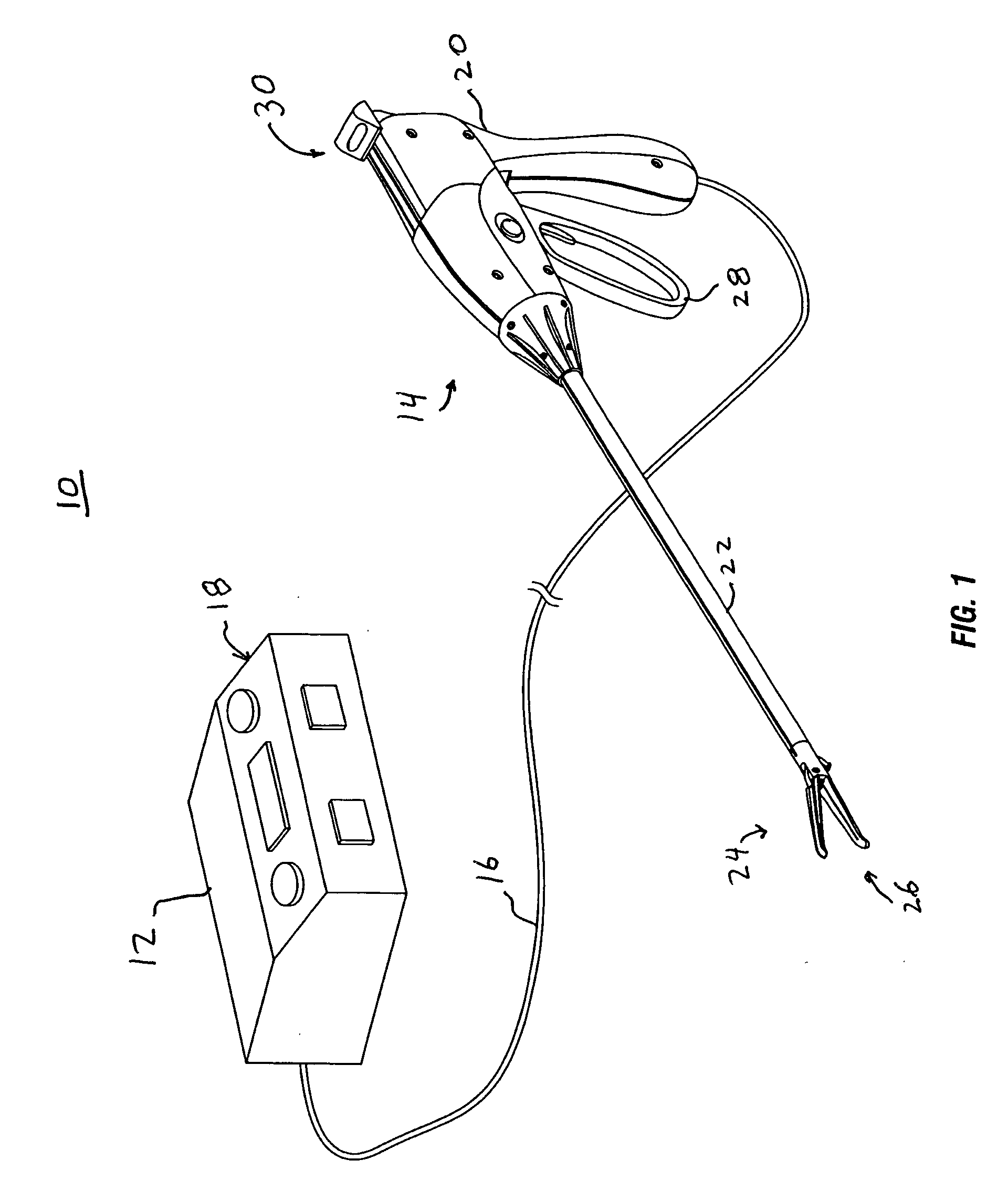

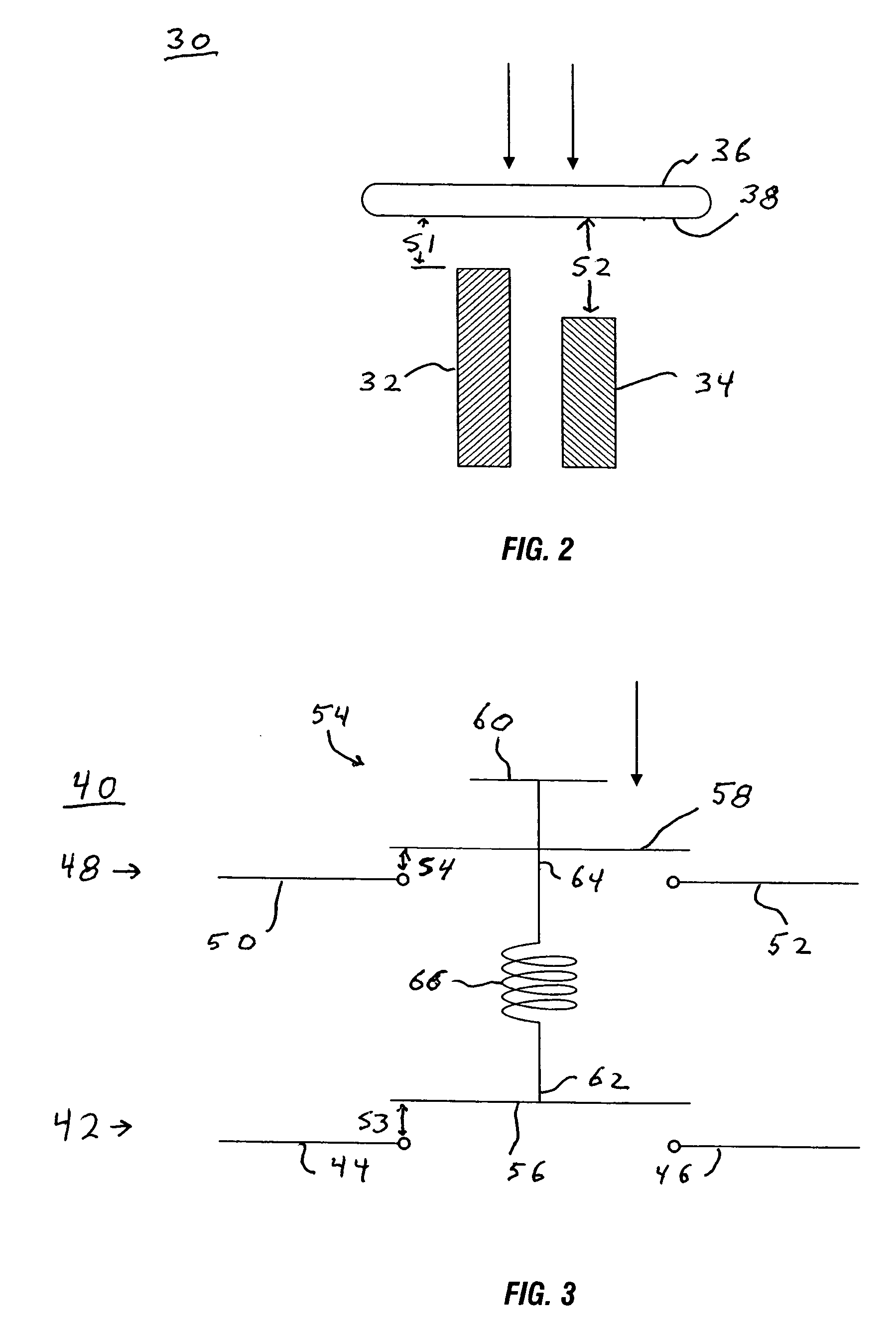

Various safe switching mechanisms are provided for use with electrosurgical instruments which prevent arcing between the high-energy contacts as the high-energy source is activated. The switching mechanisms generally include a pair of high-energy contacts and a pair of activation contacts. An actuator is provided which initially engages the high-energy contacts in advance of engagement of the activation contacts to prevent arcing and subsequently disengages the activation contacts in advance of the high-energy contacts as the energy source is deactivated. A method of switching power to an electrosurgical instrument while avoiding damage to high-energy contacts is also disclosed.

Owner:COVIDIEN AG

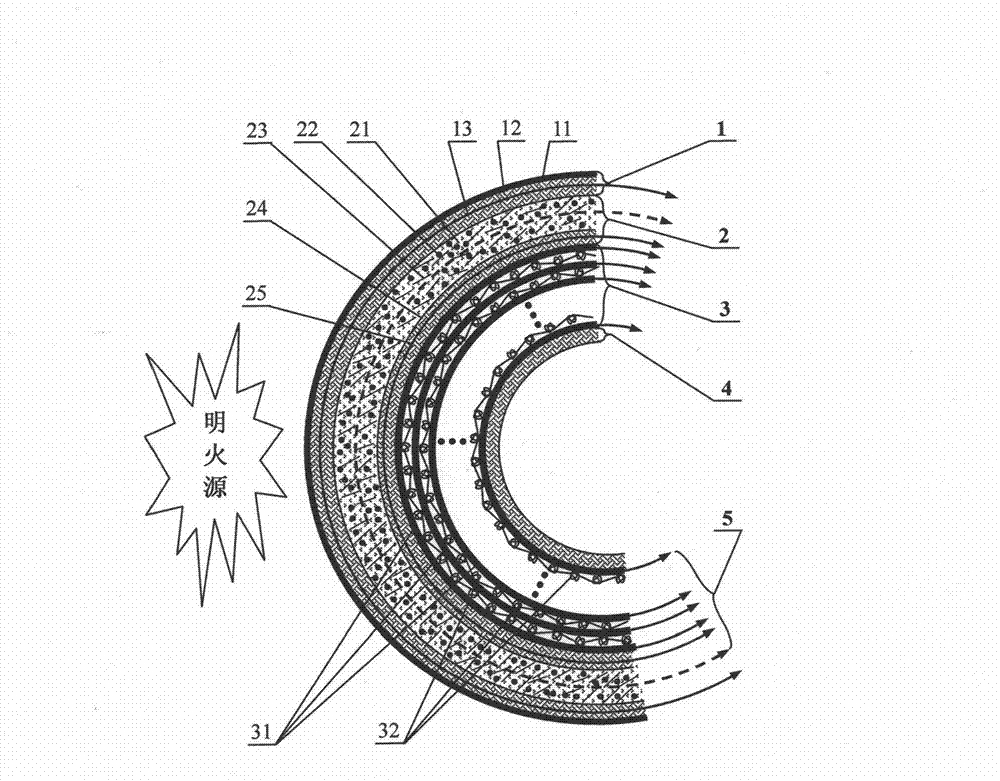

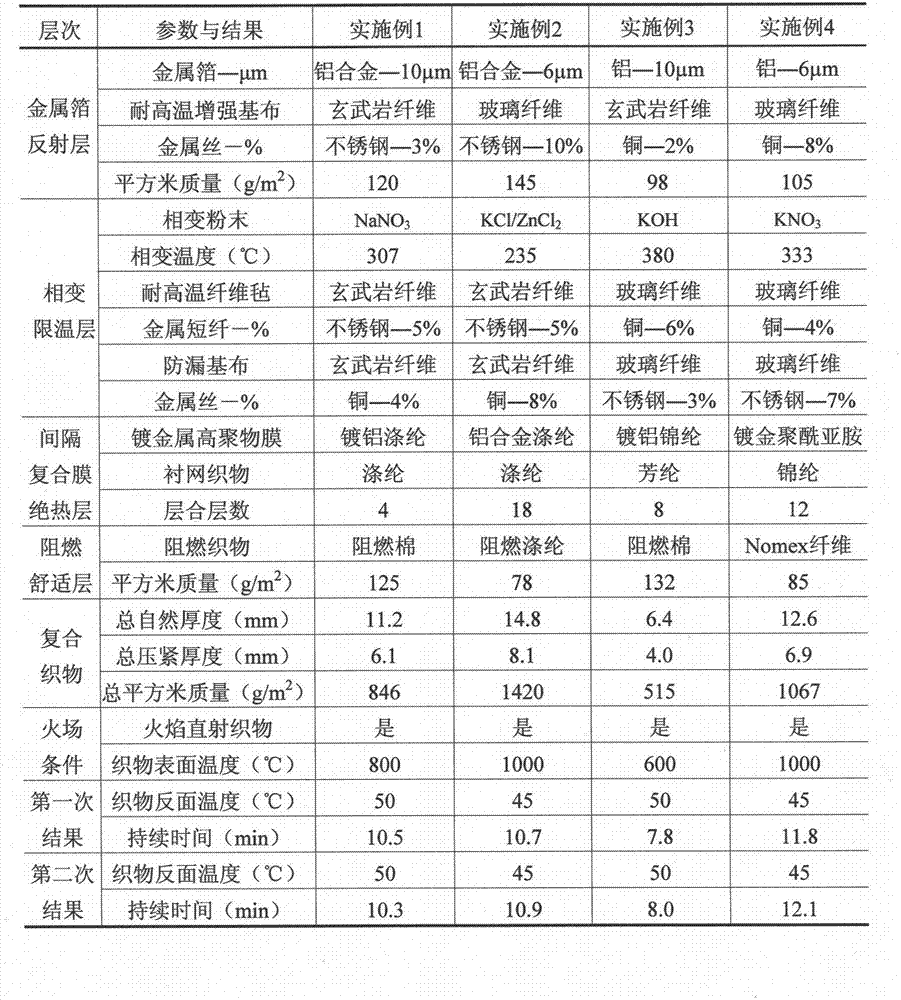

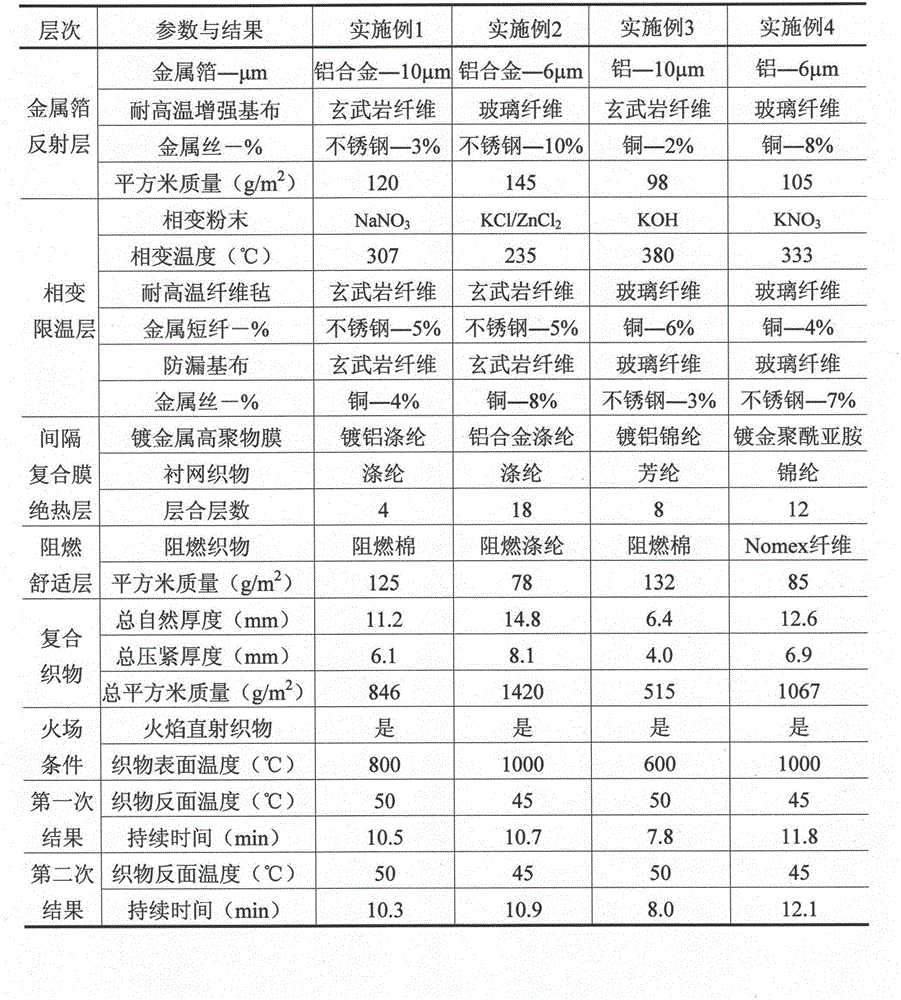

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

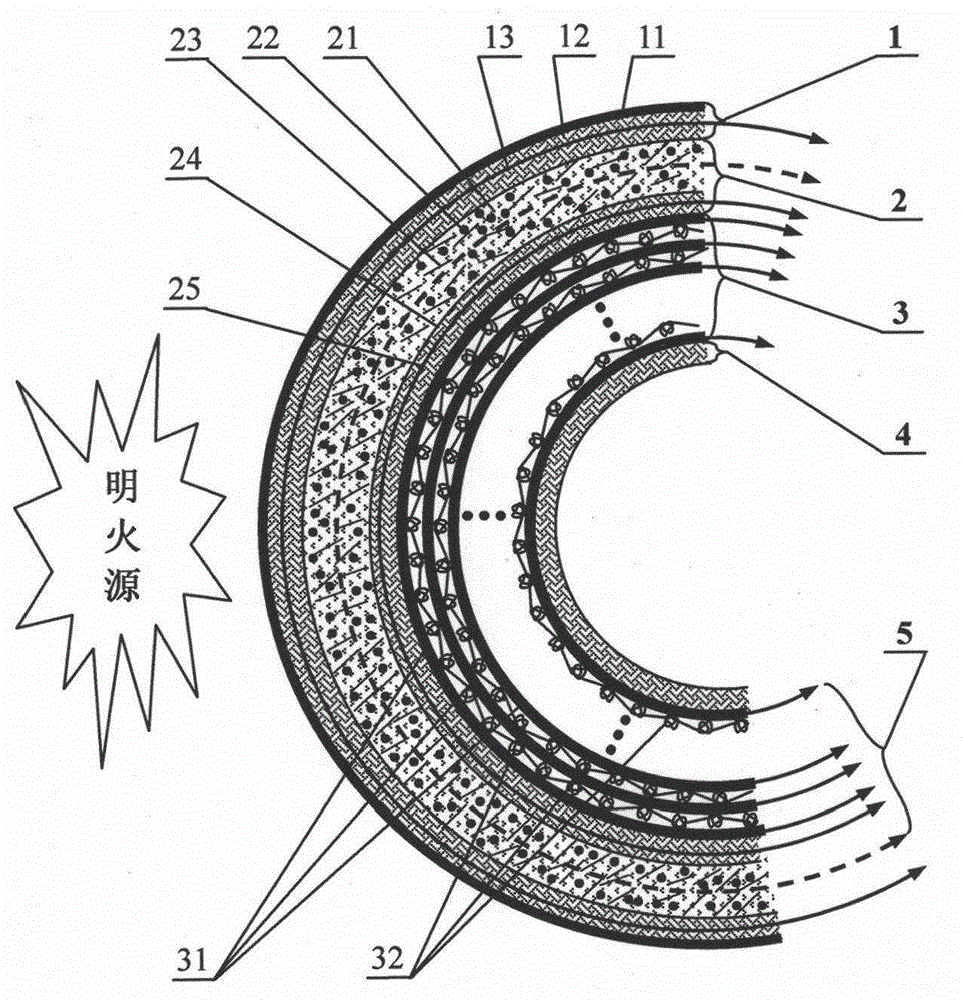

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

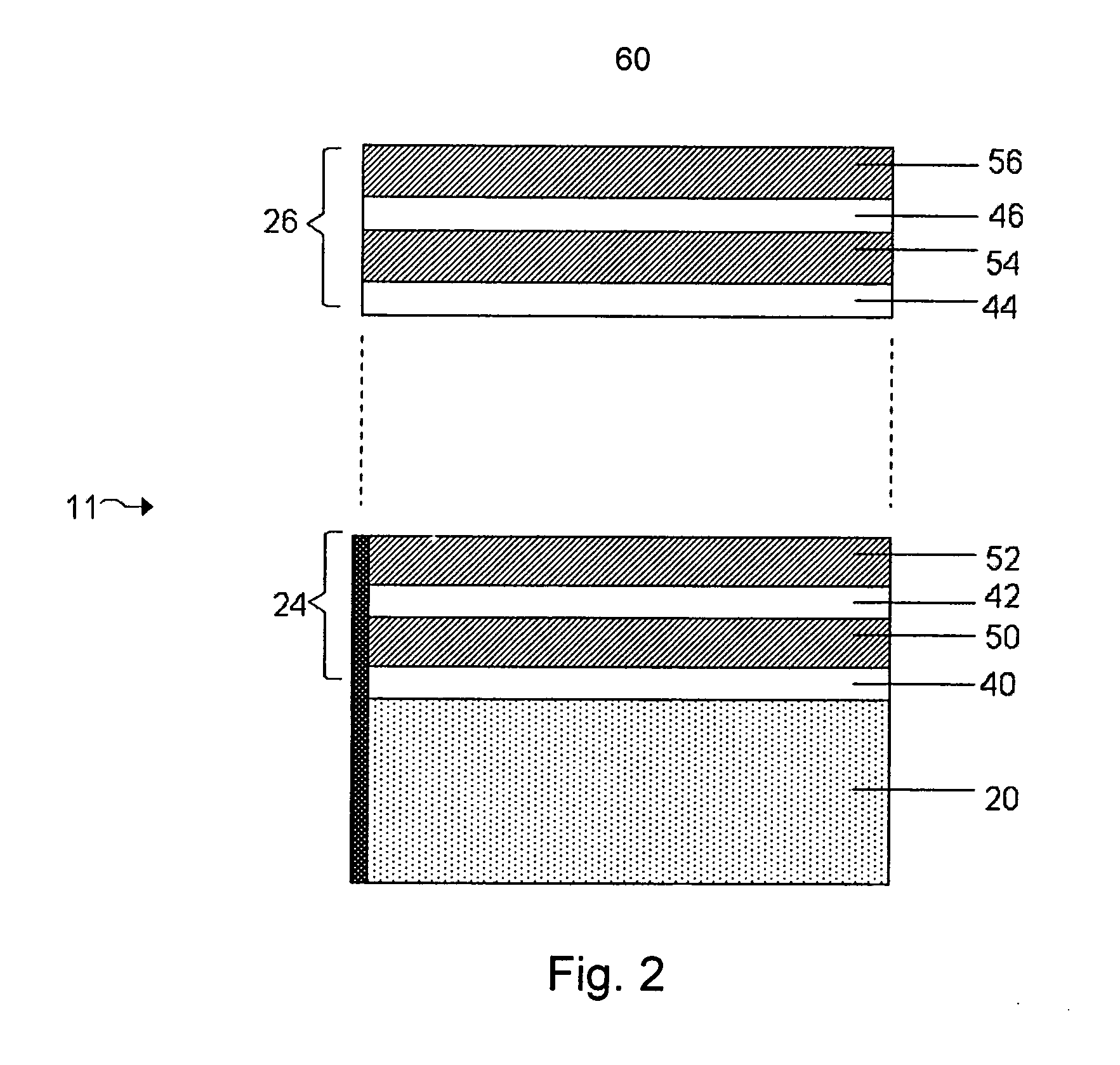

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Method for hydrophilizing materials using hydrophilic polymeric materials with discrete charges

A method of rendering materials having hard and soft surfaces hydrophilic or more hydrophilic is disclosed. The method involves hydrophilizing such materials by applying a high energy treatment and charged particles and / or one or more hydrophilic polymeric materials with discrete charges to such materials.

Owner:THE PROCTER & GAMBLE COMPANY

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

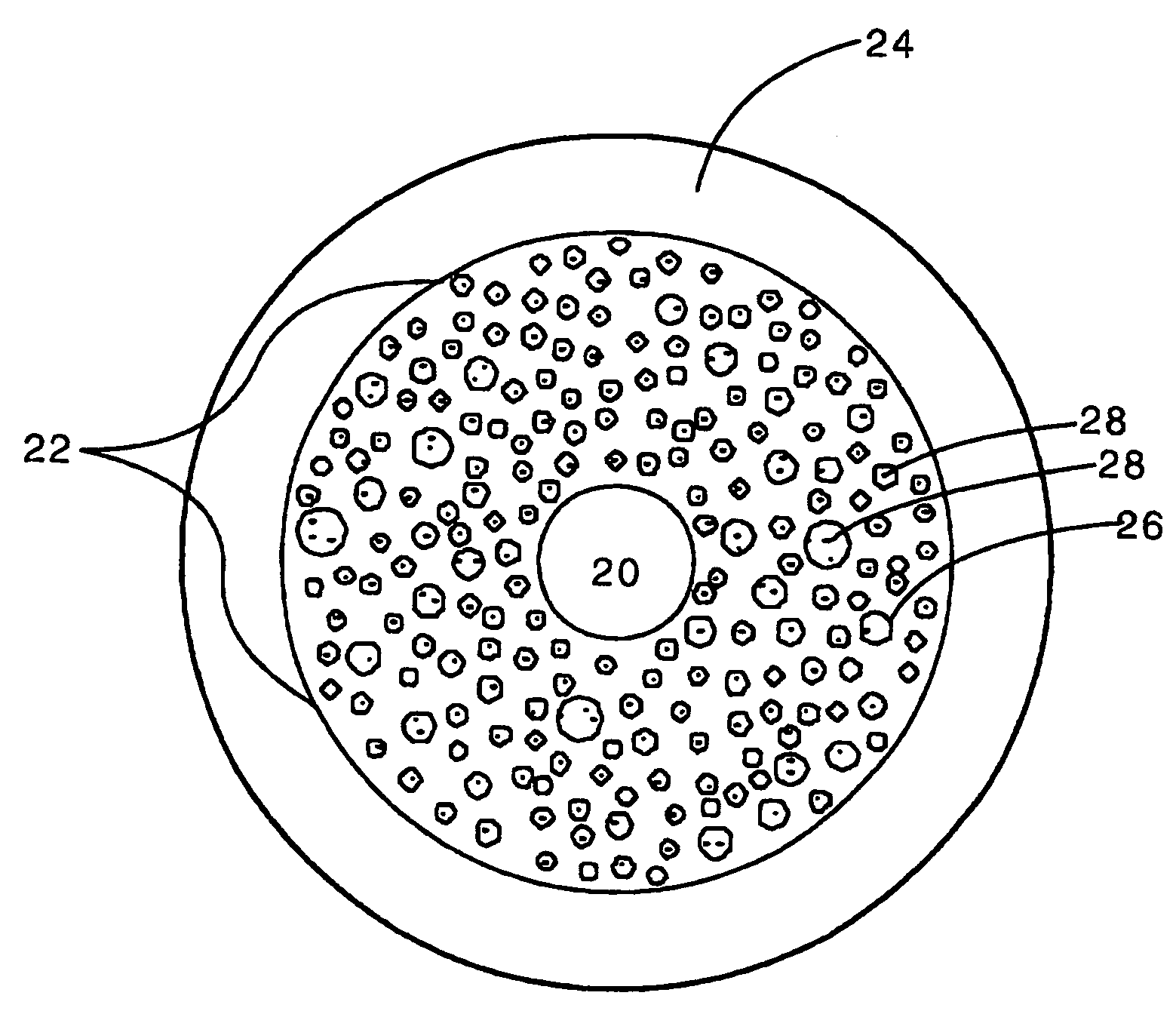

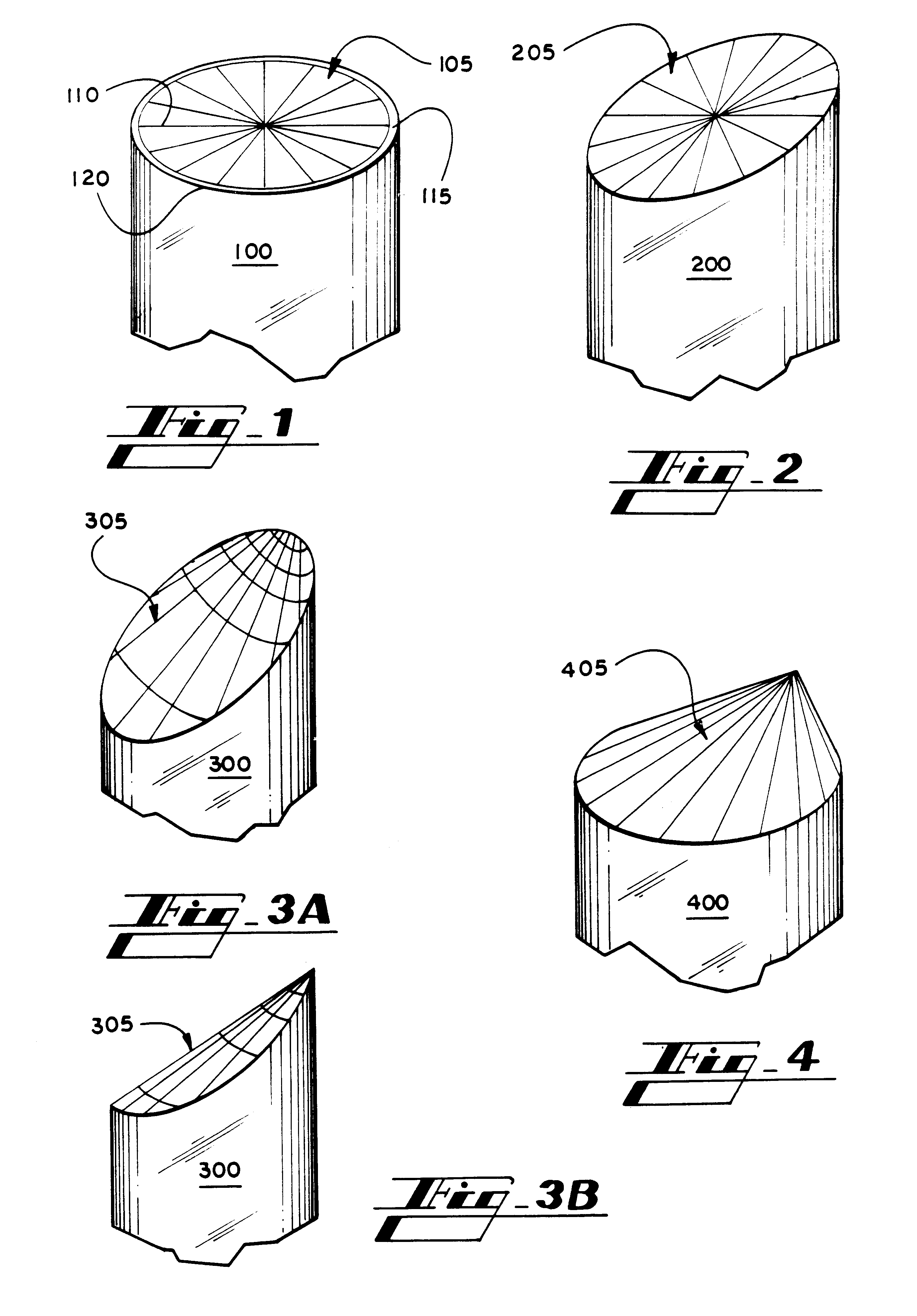

Optical fiber with quantum dots

Holey optical fibers (e.g. photonic fibers, random-hole fibers) are fabricated with quantum dots disposed in the holes. The quantum dots can provide light amplification and sensing functions, for example. When used for sensing, the dots will experience altered optical properties (e.g. altered fluorescence or absorption wavelength) in response to certain chemicals, biological elements, radiation, high energy particles, electrical or magnetic fields, or thermal / mechanical deformations. Since the dots are disposed in the holes, the dots interact with the evanescent field of core-confined light. Quantum dots can be damaged by high heat, and so typically cannot be embedded within conventional silica optical fibers. In the present invention, dots can be carried into the holes by a solvent at room temperature. The present invention also includes solid glass fibers made of low melting point materials (e.g. phosphate glass, lead oxide glass) with embedded quantum dots.

Owner:LAMBDA LABORATORY INSTRUMENTS +1

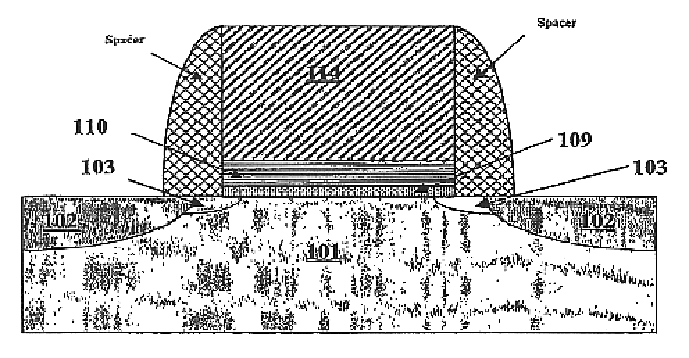

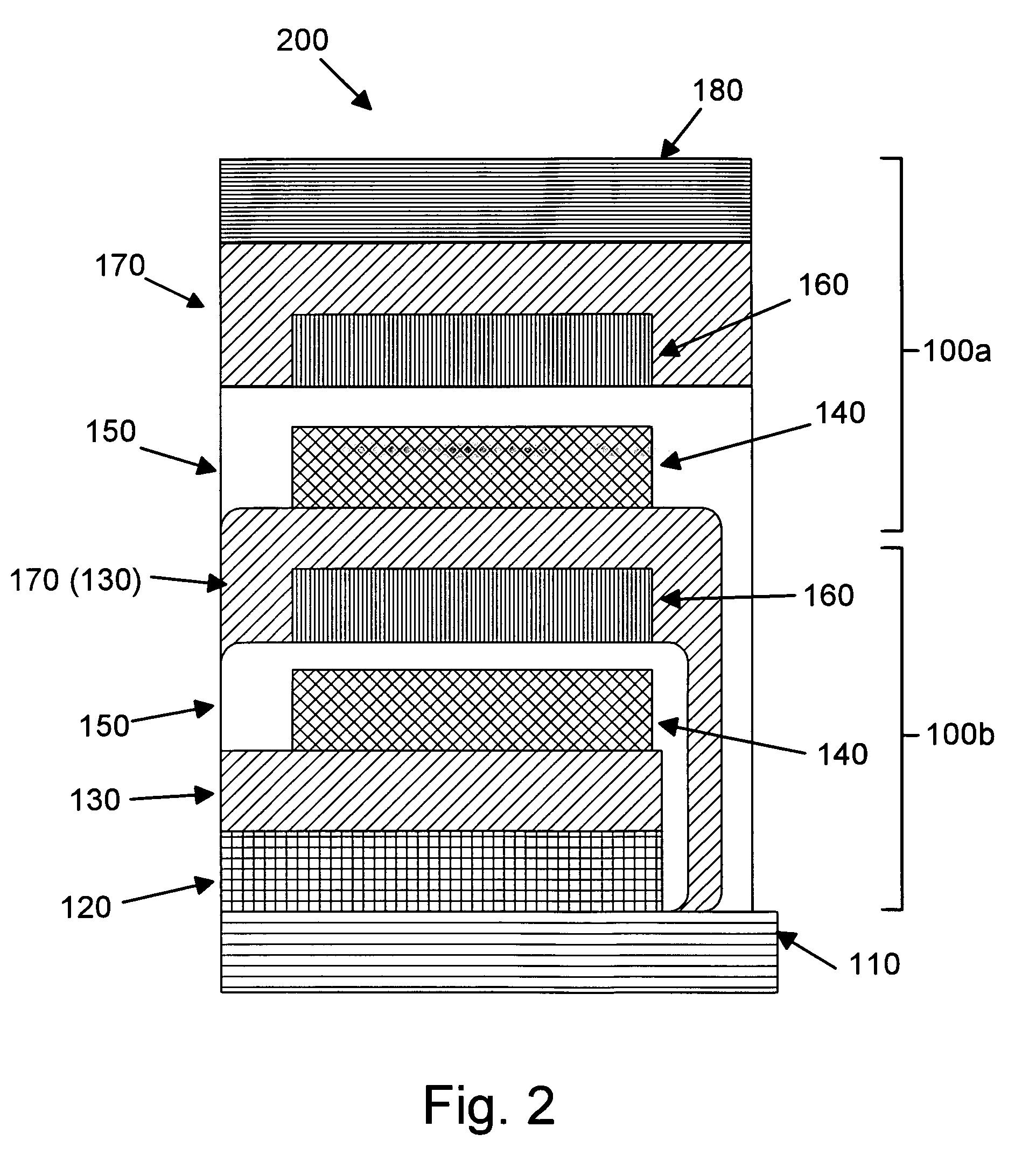

Method of depositing barrier layer for metal gates

InactiveUS6858524B2Eliminate the problemEasy to controlSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricRemote plasma

A method of manufacturing a high performance MOS device and transistor gate stacks comprises forming a gate dielectric layer over a semiconductor substrate; forming a barrier layer over the gate dielectric layer by an ALD type process; and forming a gate electrode layer over the barrier layer. The method enables the use of hydrogen plasma, high energy hydrogen radicals and ions, other reactive radicals, reactive oxygen and oxygen containing precursors in the processing steps subsequent to the deposition of the gate dielectric layer of the device. The ALD process for forming the barrier layer is performed essentially in the absence of plasma and reactive hydrogen radials and ions. This invention makes it possible to use oxygen as a precursor in the deposition of the metal gates. The barrier film also allows the use of hydrogen plasma in the form of either direct or remote plasma in the deposition of the gate electrode. Furthermore, the barrier film prevents the electrode material from reacting with the gate dielectric material. The barrier layer is ultra thin and, at the same time, it forms a uniform cover over the entire surface of the gate dielectric.

Owner:ASM INTERNATIONAL

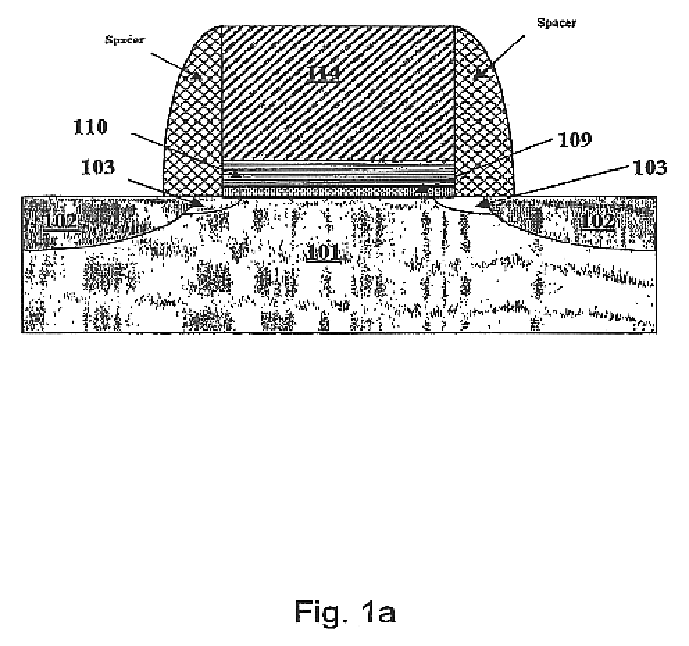

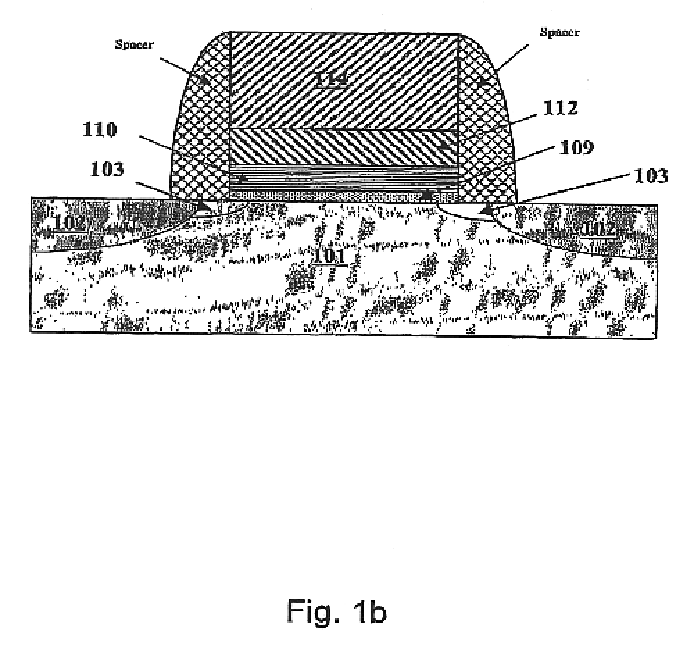

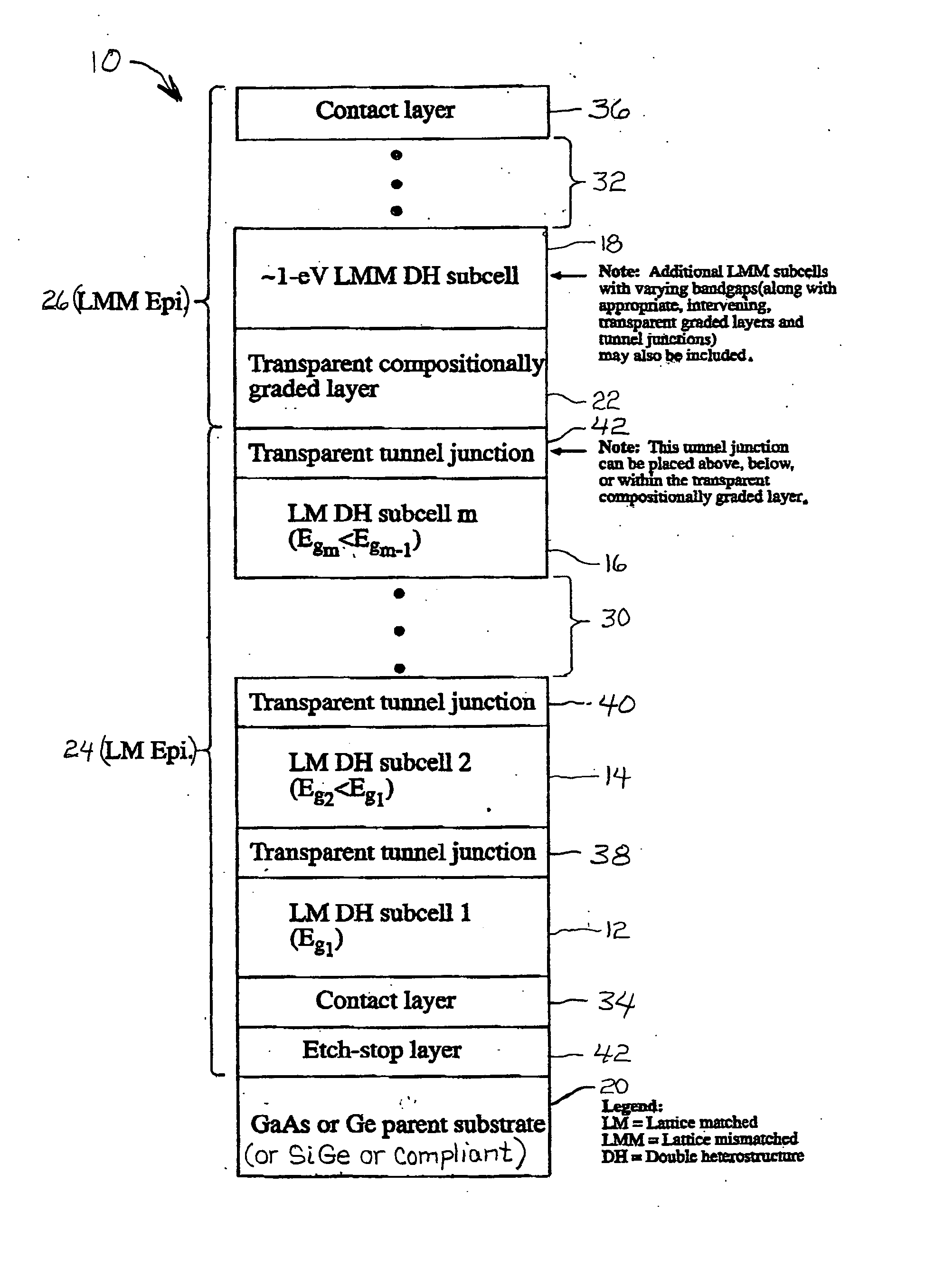

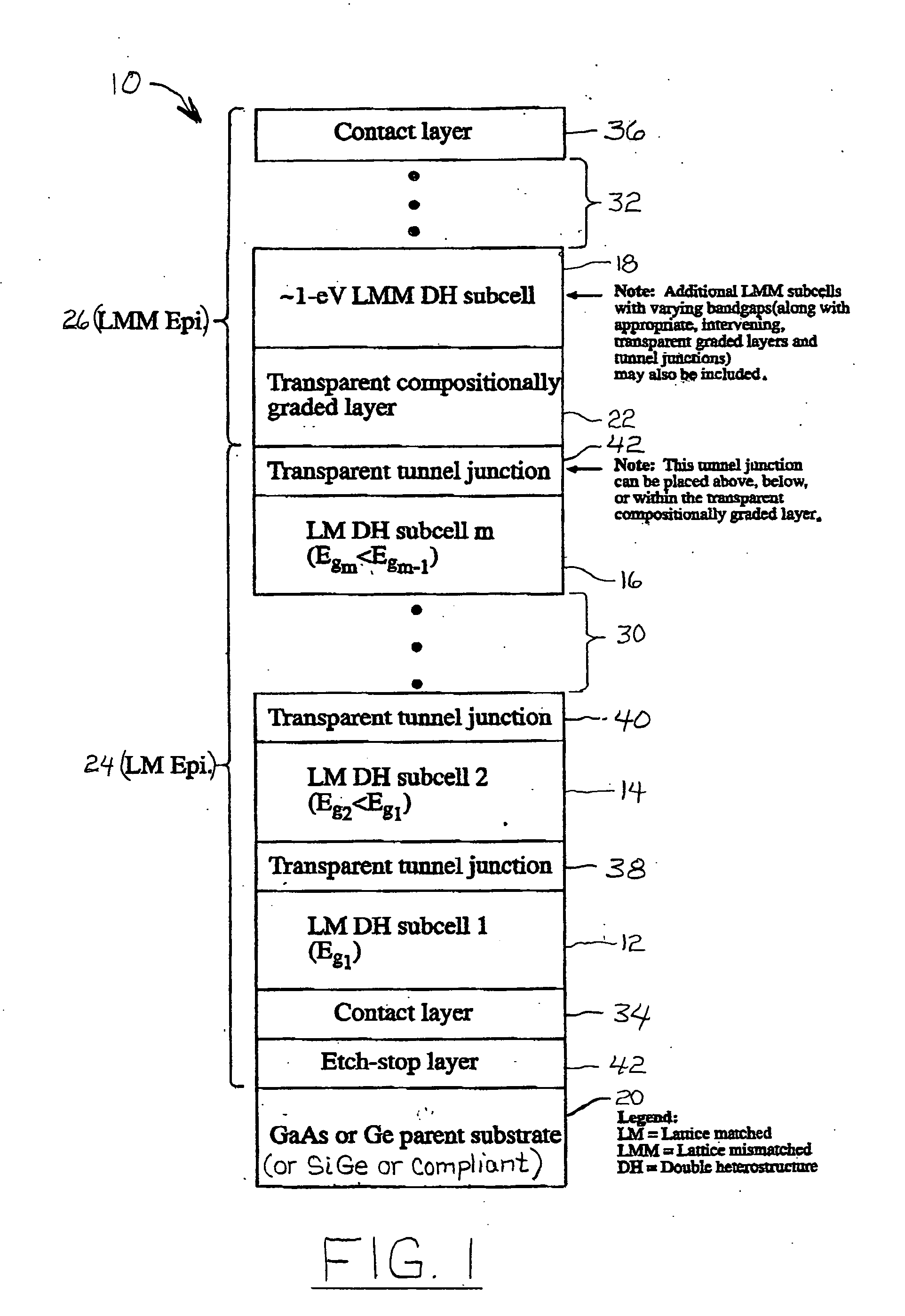

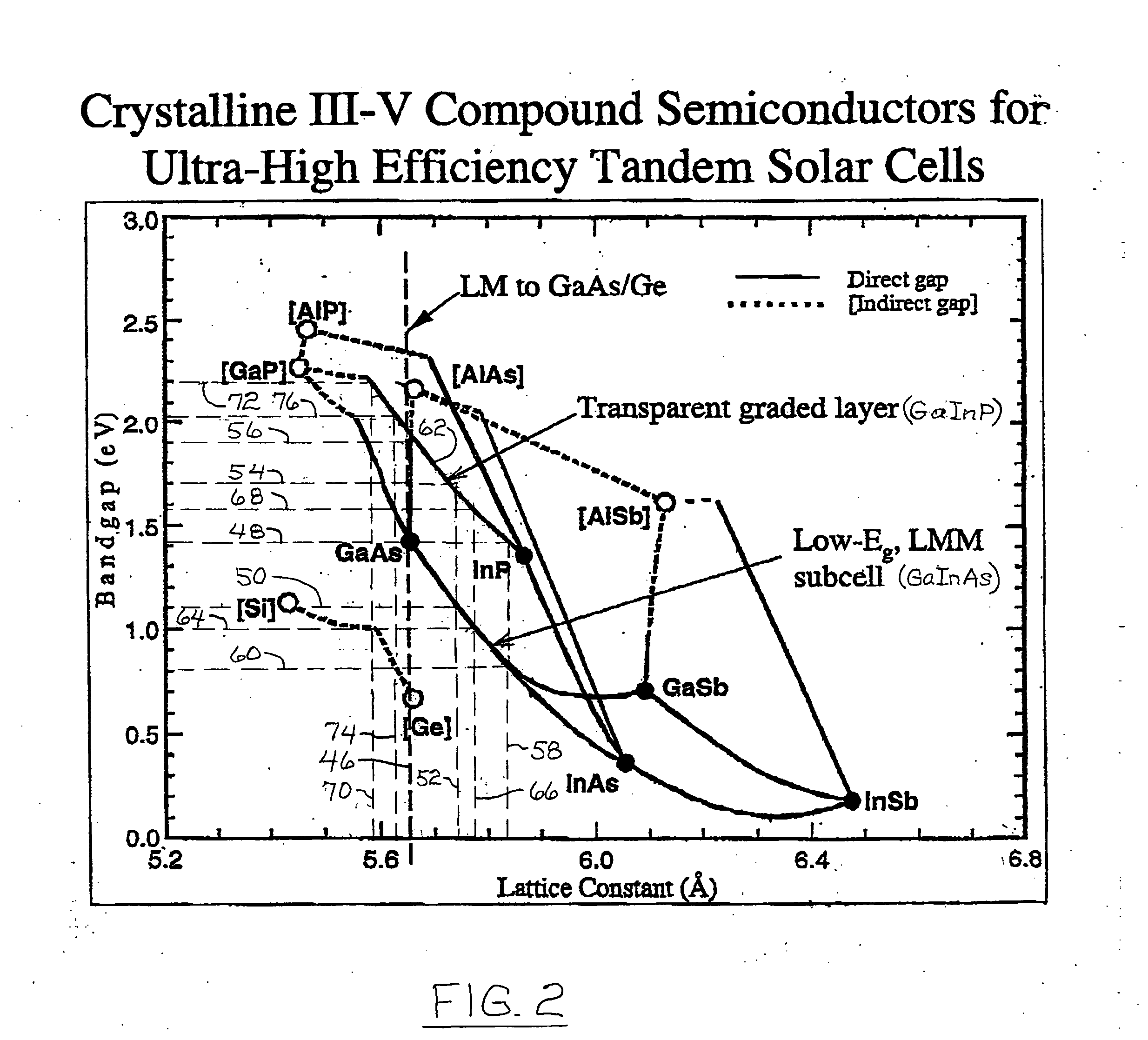

High-efficiency, monolithic, multi-bandgap, tandem photovoltaic energy converters

ActiveUS20060144435A1Improved thermal managementIncrease flexibilityPV power plantsSemiconductor/solid-state device manufacturingHigh energyLattice mismatch

A monolithic, multi-bandgap, tandem solar photovoltaic converter has at least one, and preferably at least two, subcells grown lattice-matched on a substrate with a bandgap in medium to high energy portions of the solar spectrum and at least one subcell grown lattice-mismatched to the substrate with a bandgap in the low energy portion of the solar spectrum, for example, about 1 eV.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

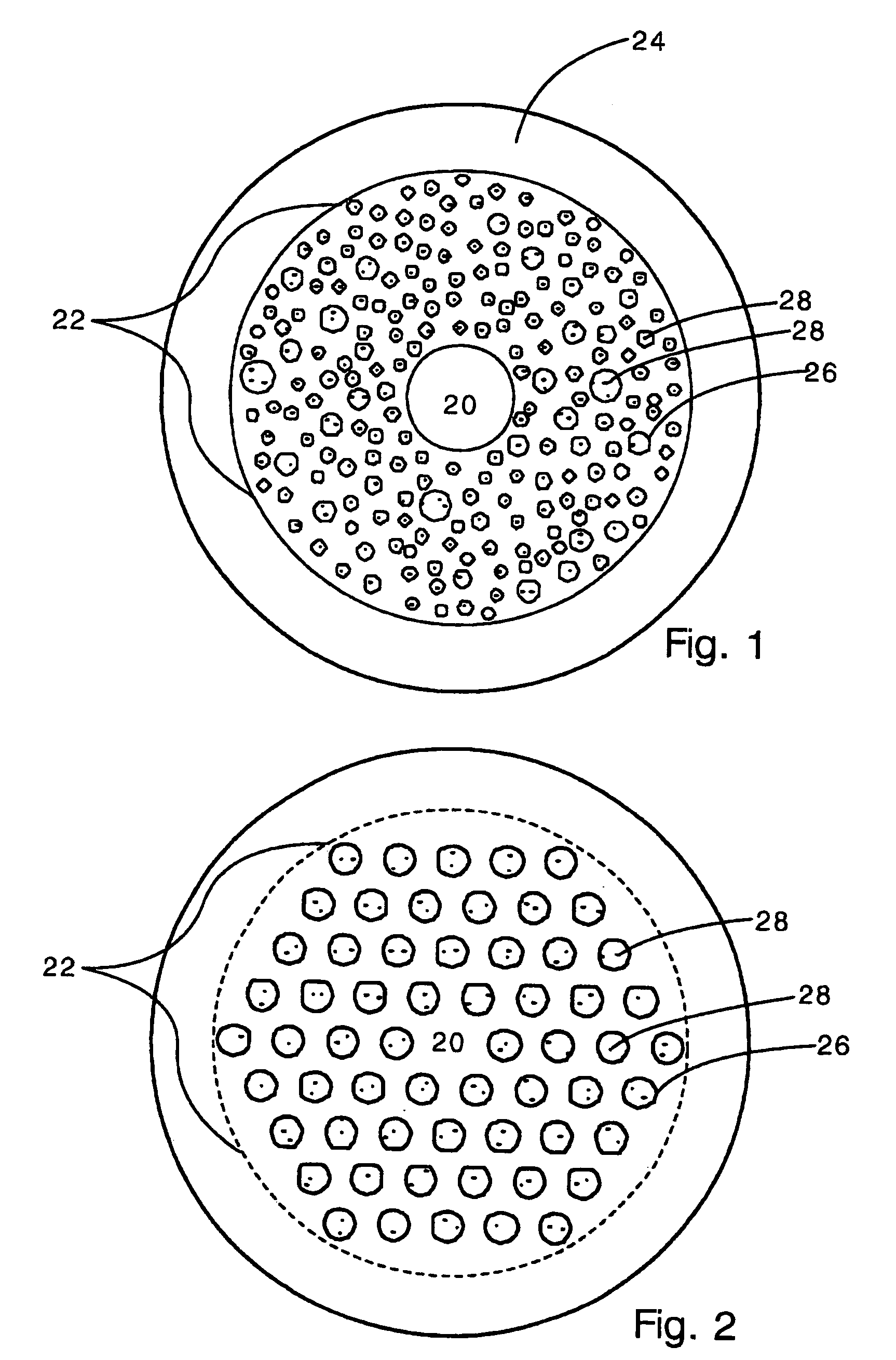

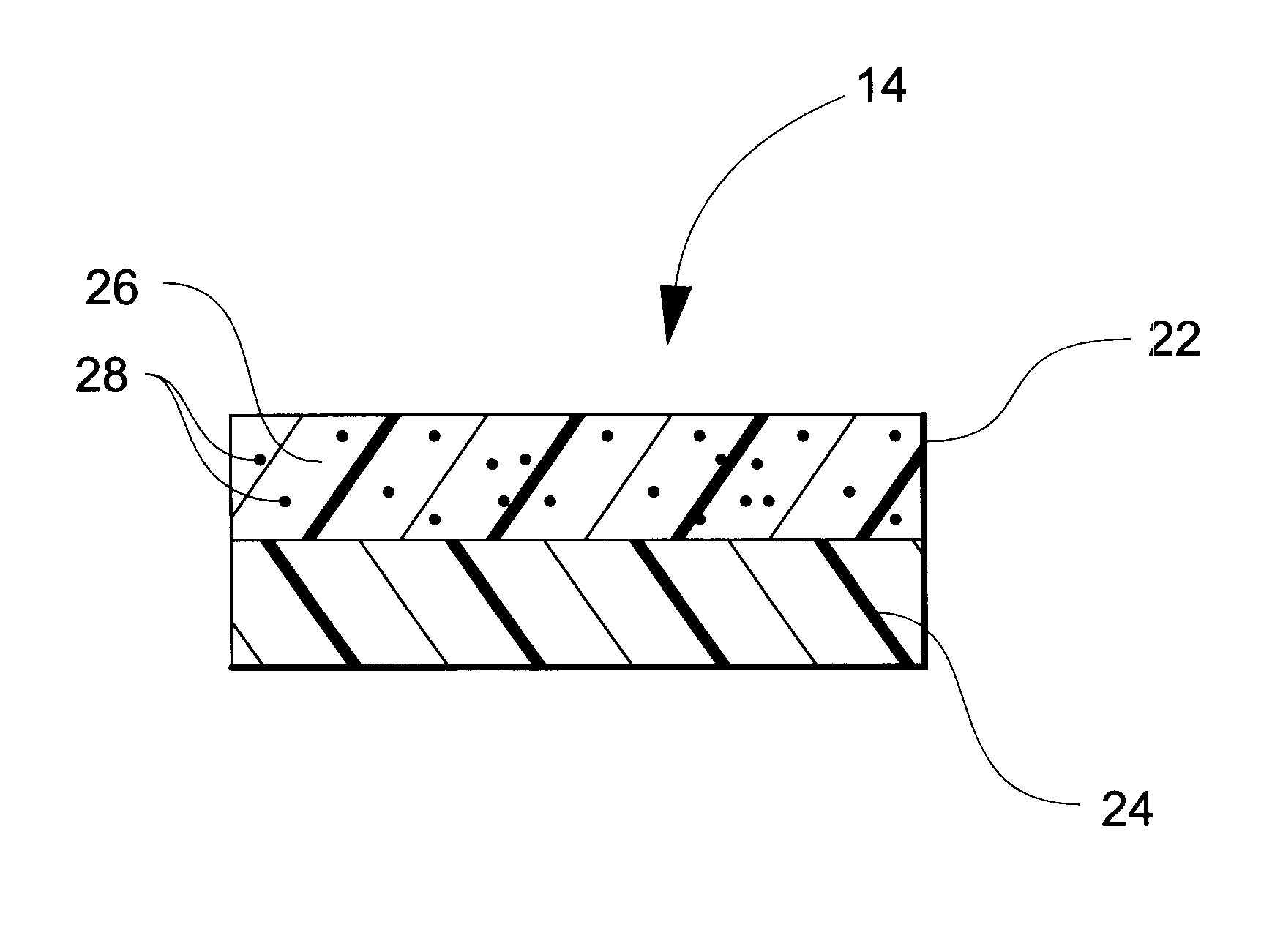

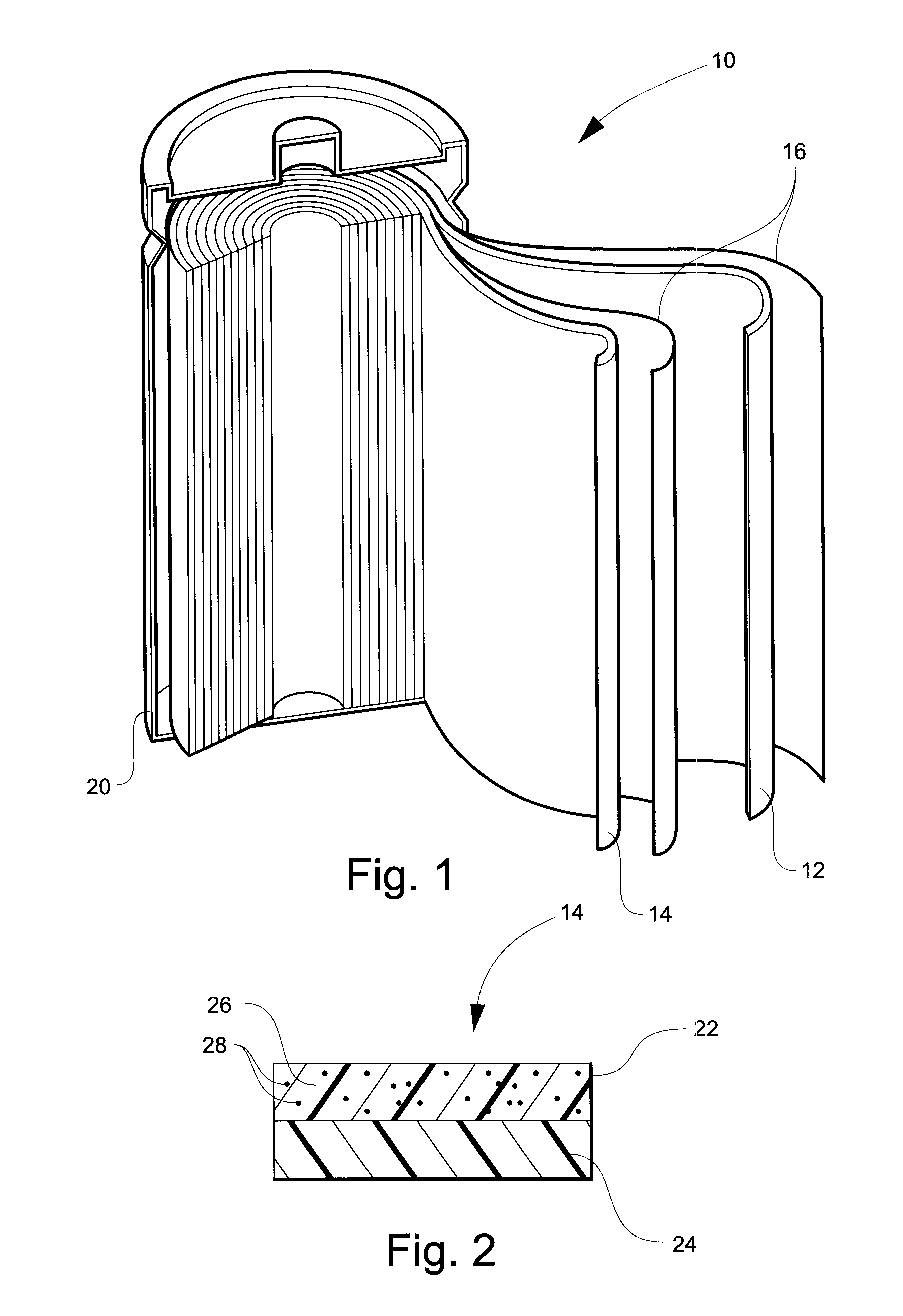

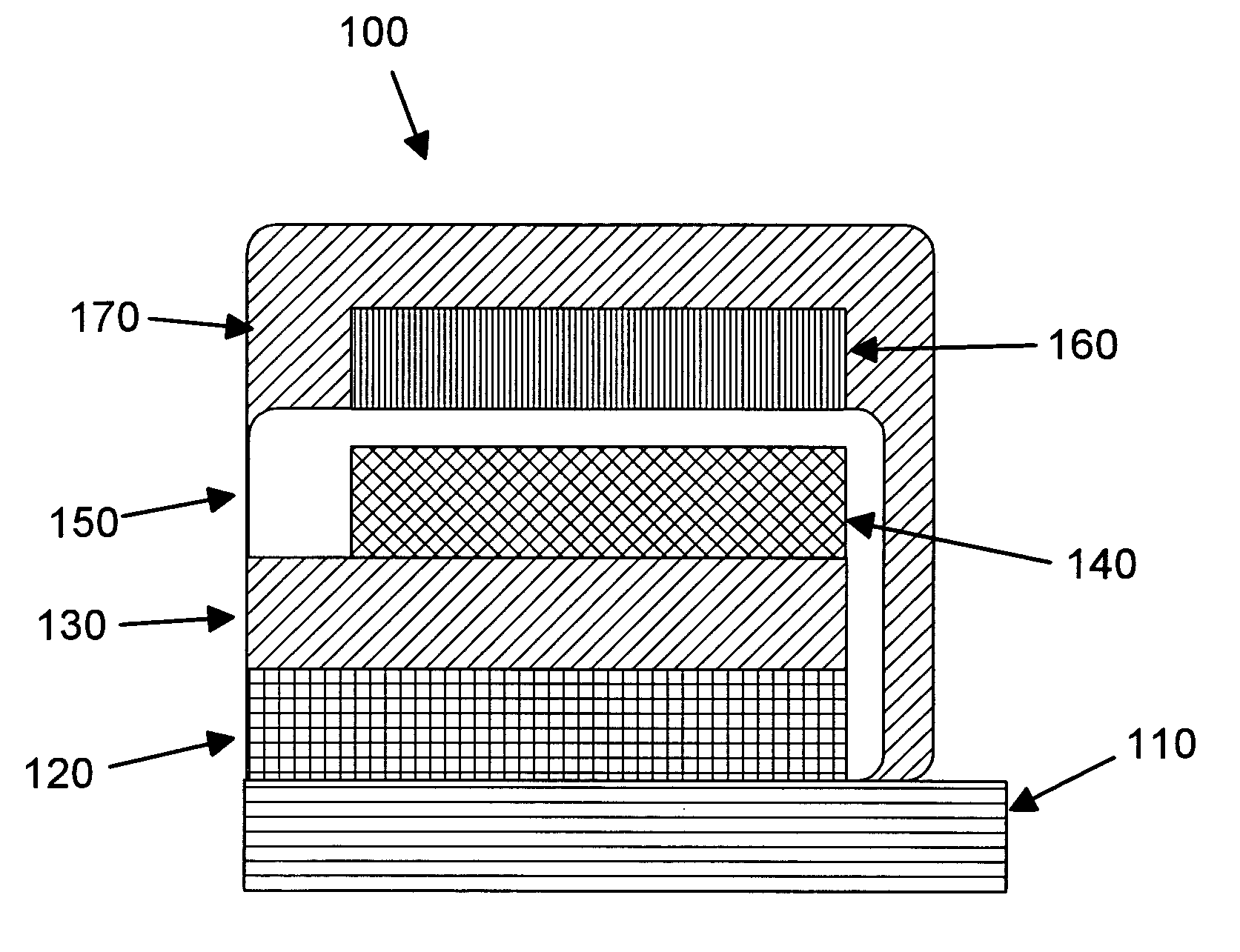

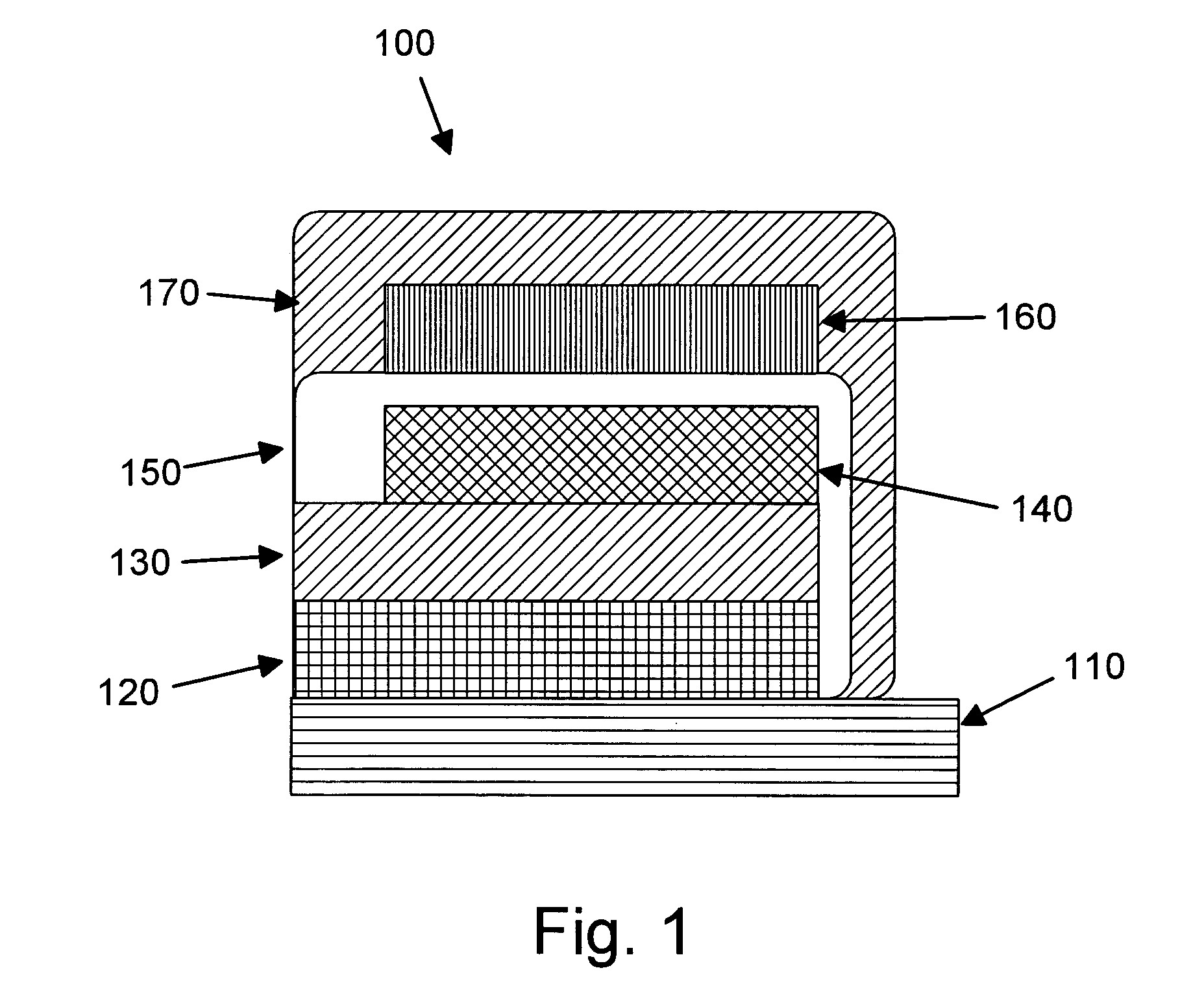

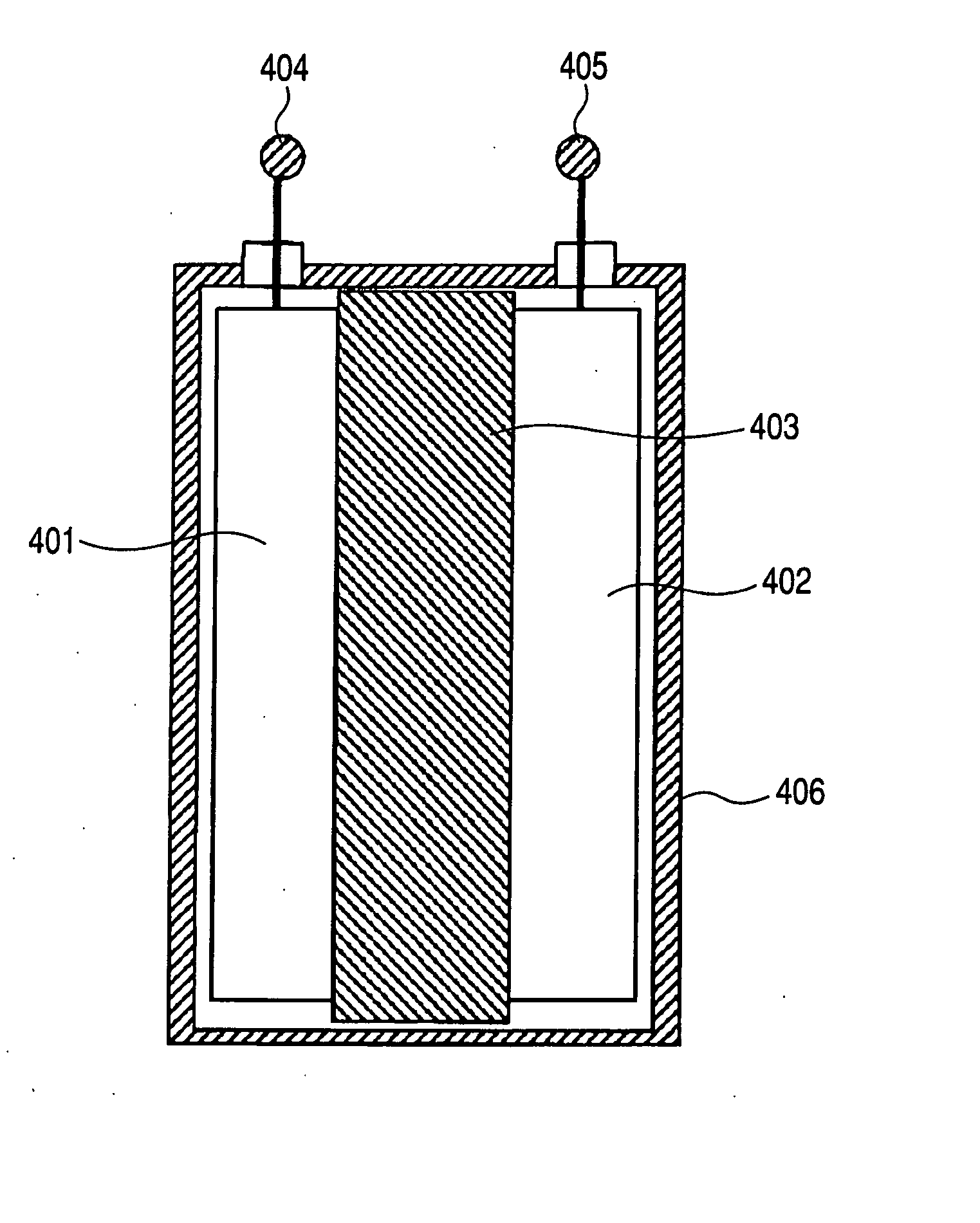

Separator for a high energy rechargeable lithium battery

InactiveUS6432586B1Cell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte accumulator electrodesCeramic compositeMetallurgy

The instant invention is directed to a separator for a high energy rechargeable lithium battery and the corresponding battery. The separator includes a ceramic composite layer and a polymeric microporous layer. The ceramic layers includes a mixture of inorganic particles and a matrix material. The ceramic layer is adapted, at least, to block dendrite growth and to prevent electronic shorting. The polymeric layer is adapted, at least, to block ionic flow between the anode and the cathode in the event of thermal runaway.

Owner:CELGARD LLC

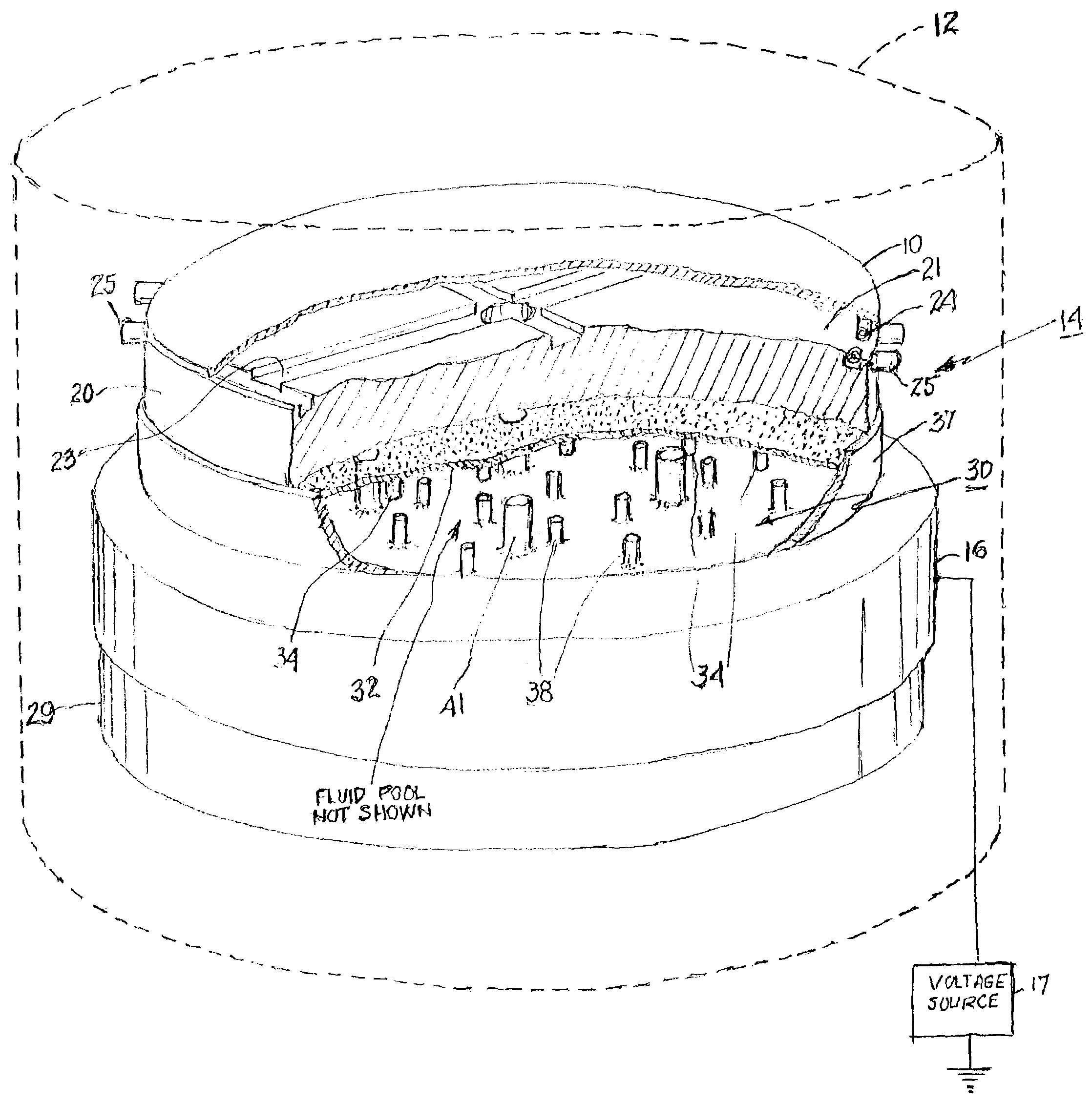

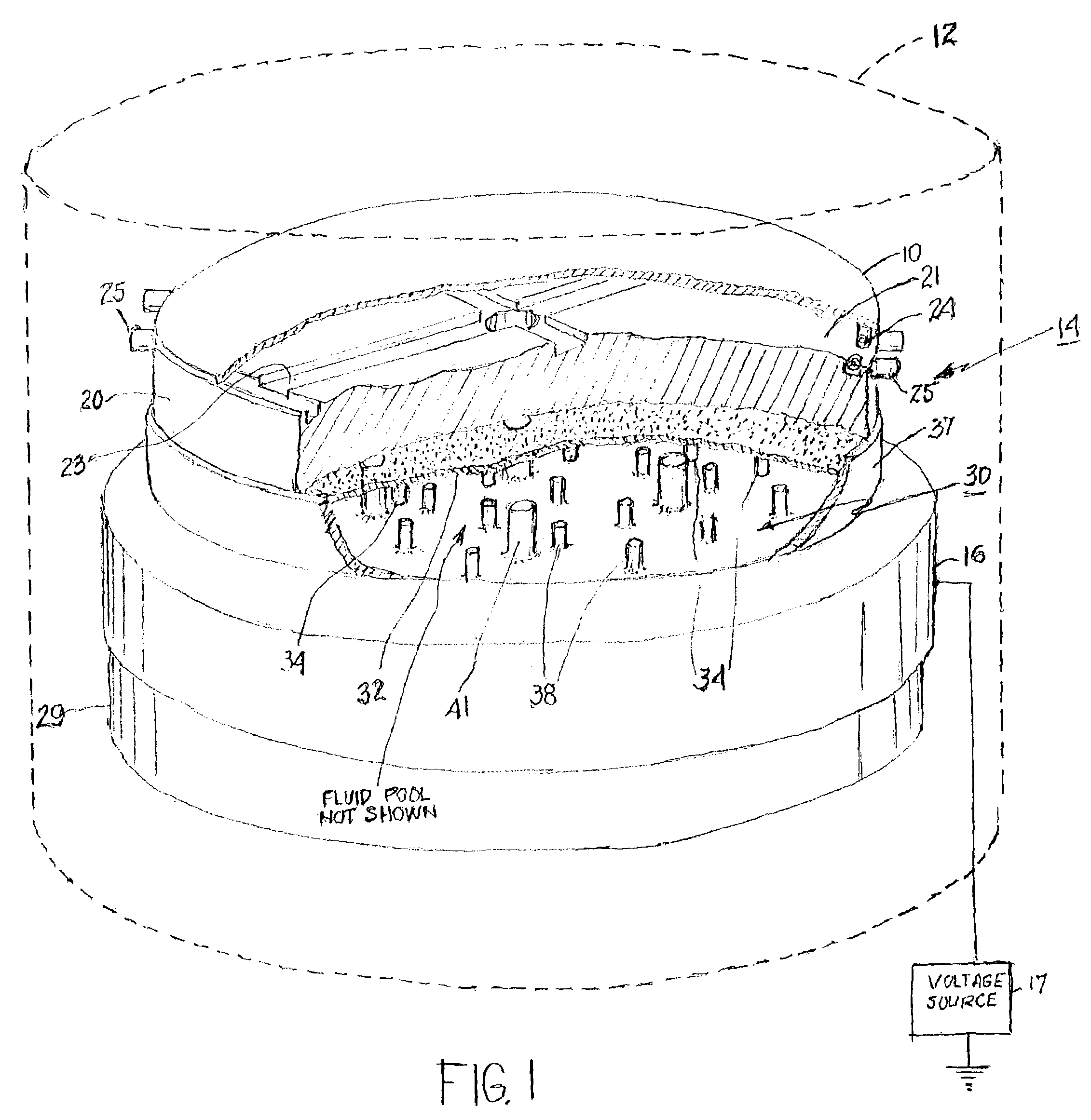

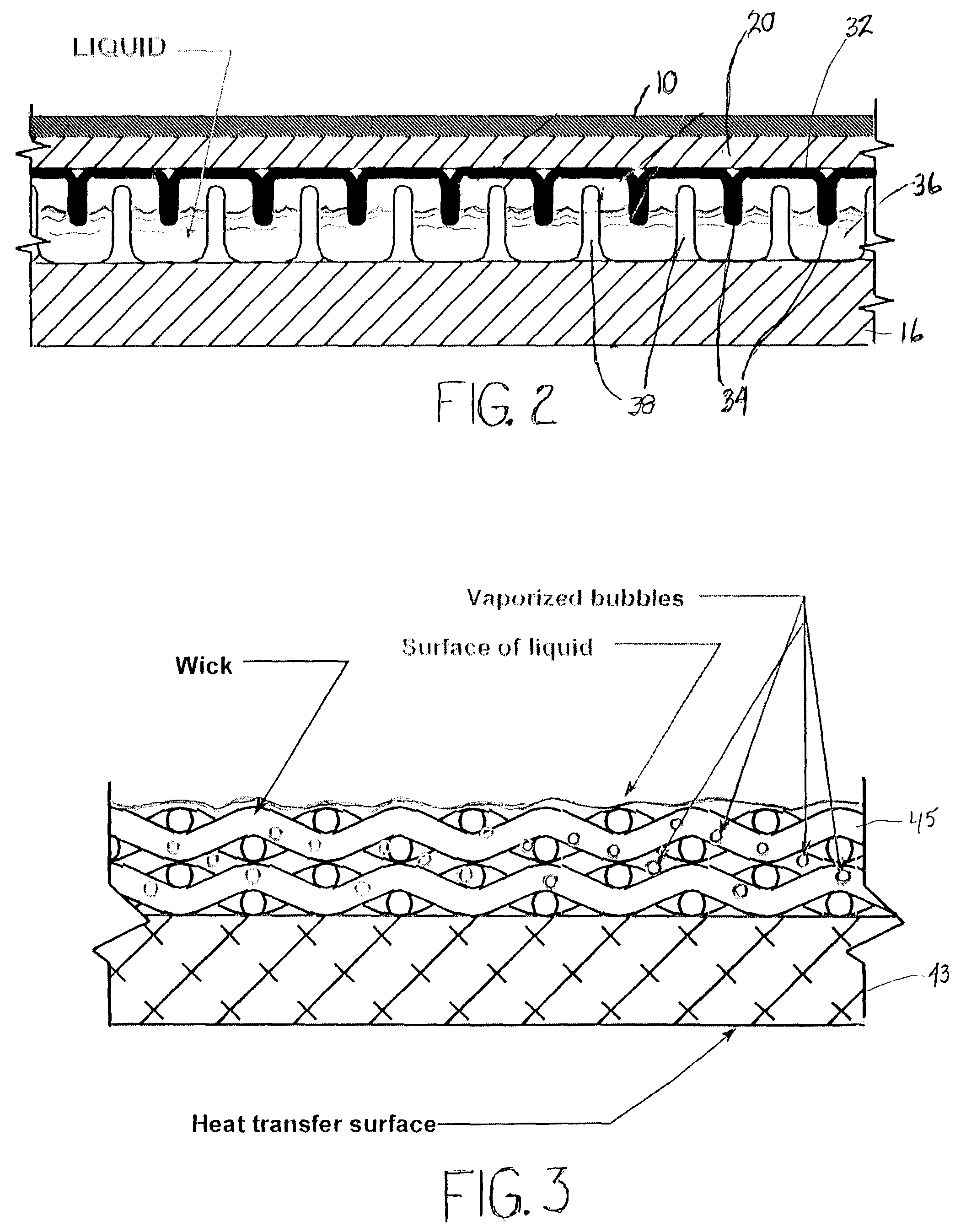

Lateral temperature equalizing system for large area surfaces during processing

ActiveUS7195693B2Rapid temperature stabilizationLittle changeElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energyShortest distance

In many processes used in fabricating semiconductors the wafer is seated on the top surface of a pedestal and heated in a high energy process step, such as plasma etching. The pedestal, chuck or platen may be cooling but the wafer gradually heats until the process can no longer continue. Where large, e.g. 300 mm diameter, wafers are being processed the temperature level across the wafer is difficult to maintain substantially constant. In this system and method the lateral temperature distribution is equalized by a heat sink structure in a chamber immediately under the wafer support on top of the pedestal. A number of spatially distributed wicking posts extend downwardly from a layer of wicking material across the top of the chamber, into a pool of a vaporizable liquid. At hot spots, vaporized liquid is generated and transported to adjacent condensation posts extending up from the liquid. The system thus passively extracts heat to equalize temperatures while recirculating liquid and assuring adequate supply. The free volume above and within the liquid, and the short distances between posts, assure adequate heat transfer rates.

Owner:BE AEROSPACE INCORPORATED

Near infrared spectroscopy device with reusable portion

InactiveUS7706853B2Small sizeFirmly attachedMaterial analysis by optical meansDiagnostic recording/measuringSurgical operationHigh energy

A NIRS sensor device for brain monitoring is small in size, provides reliable attachment to a patient, blocks ambient light, is easy to use, is hygienic, and supports data integration with surgical and monitoring systems. The sensor device is coupled to a remote near infrared light source via a hybrid cable. Since the light source is remotely located, a source adapted for providing high energy, short pulses can easily be used so that there is less chance of interference by superficial non-brain tissues and less interference from ambient light. In addition, the remote location avoids changes in output of local light sources experienced in the prior art during hypothermia procedures (e.g., bandwidth shifts in LEDs as a result of lowered temperature). The higher energy may be achieved by the use of laser diodes as opposed to locally-mounted LEDs typically used in the prior art. The sensor device is a two-piece design comprising a reusable portion containing the photodetector(s) and a disposable portion that receives the light from the reusable portion and bends it to direct the light into the brain.

Owner:TERUMO CARDIOVASCULAR SYST CORP

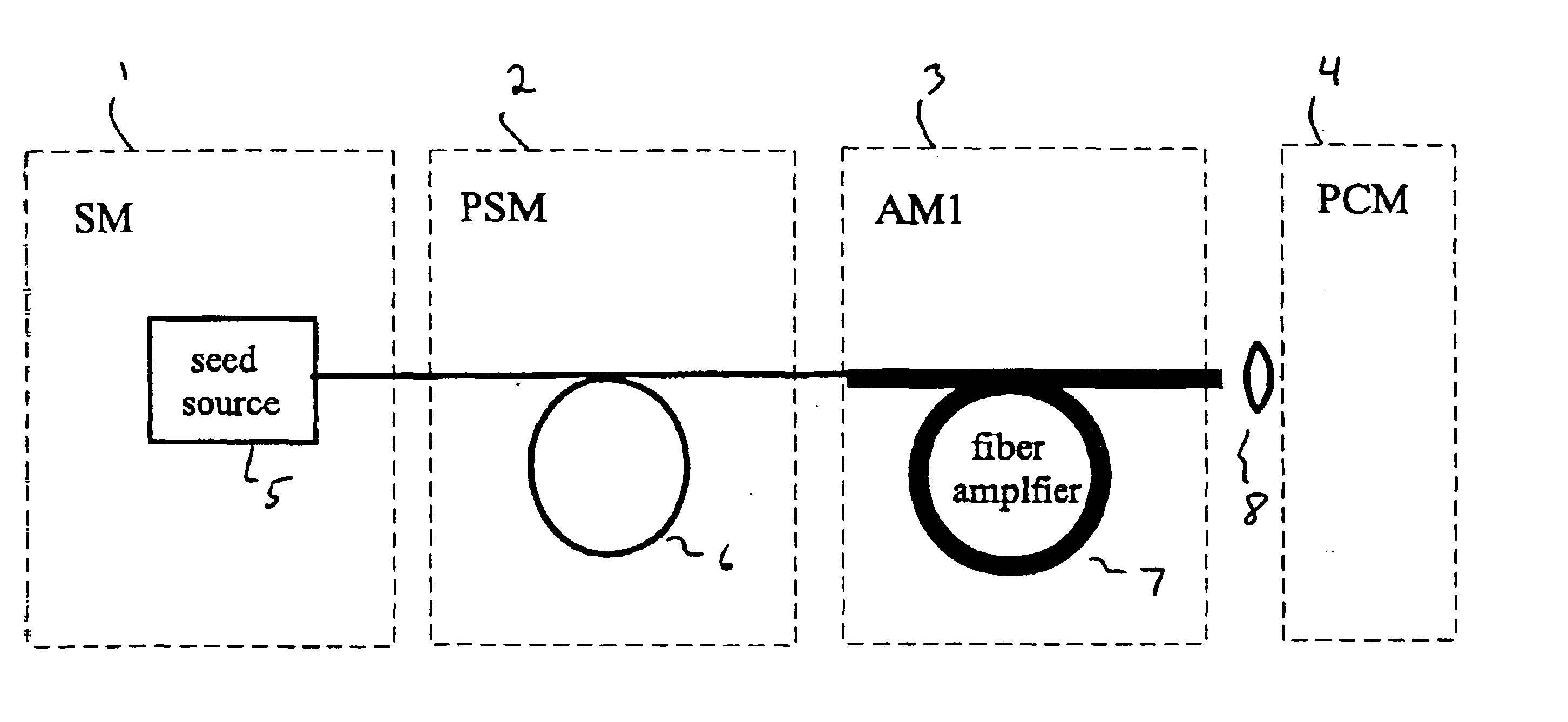

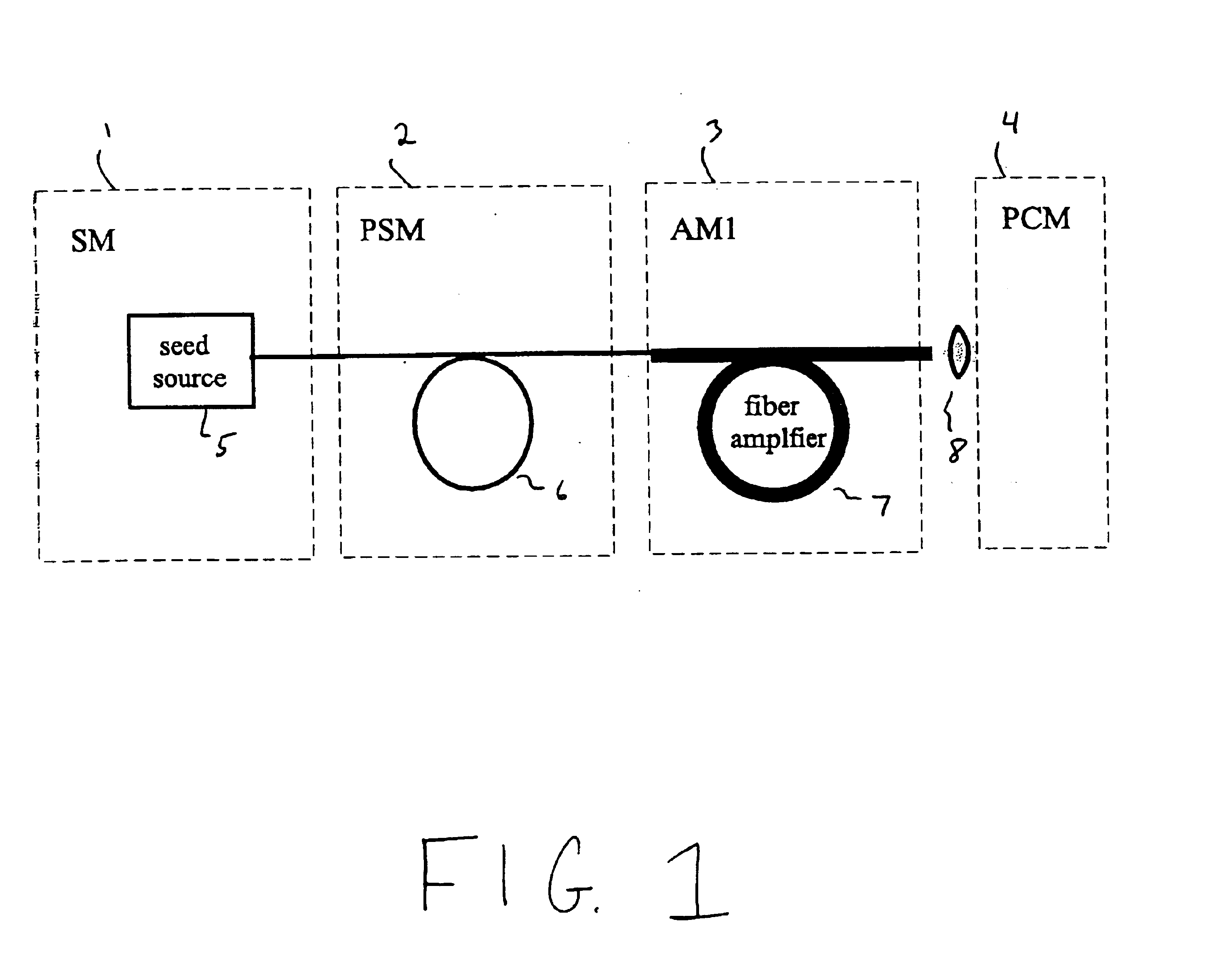

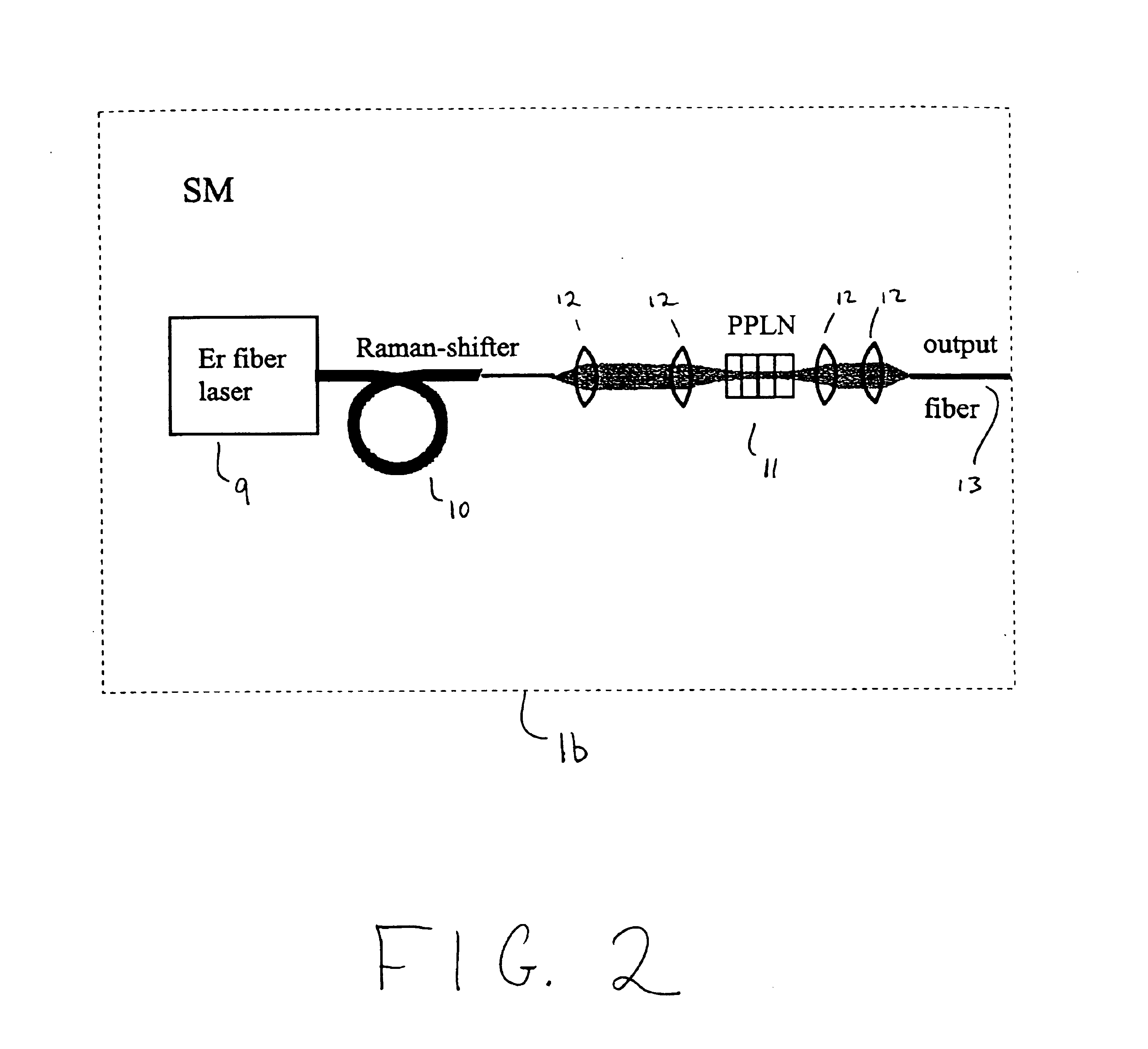

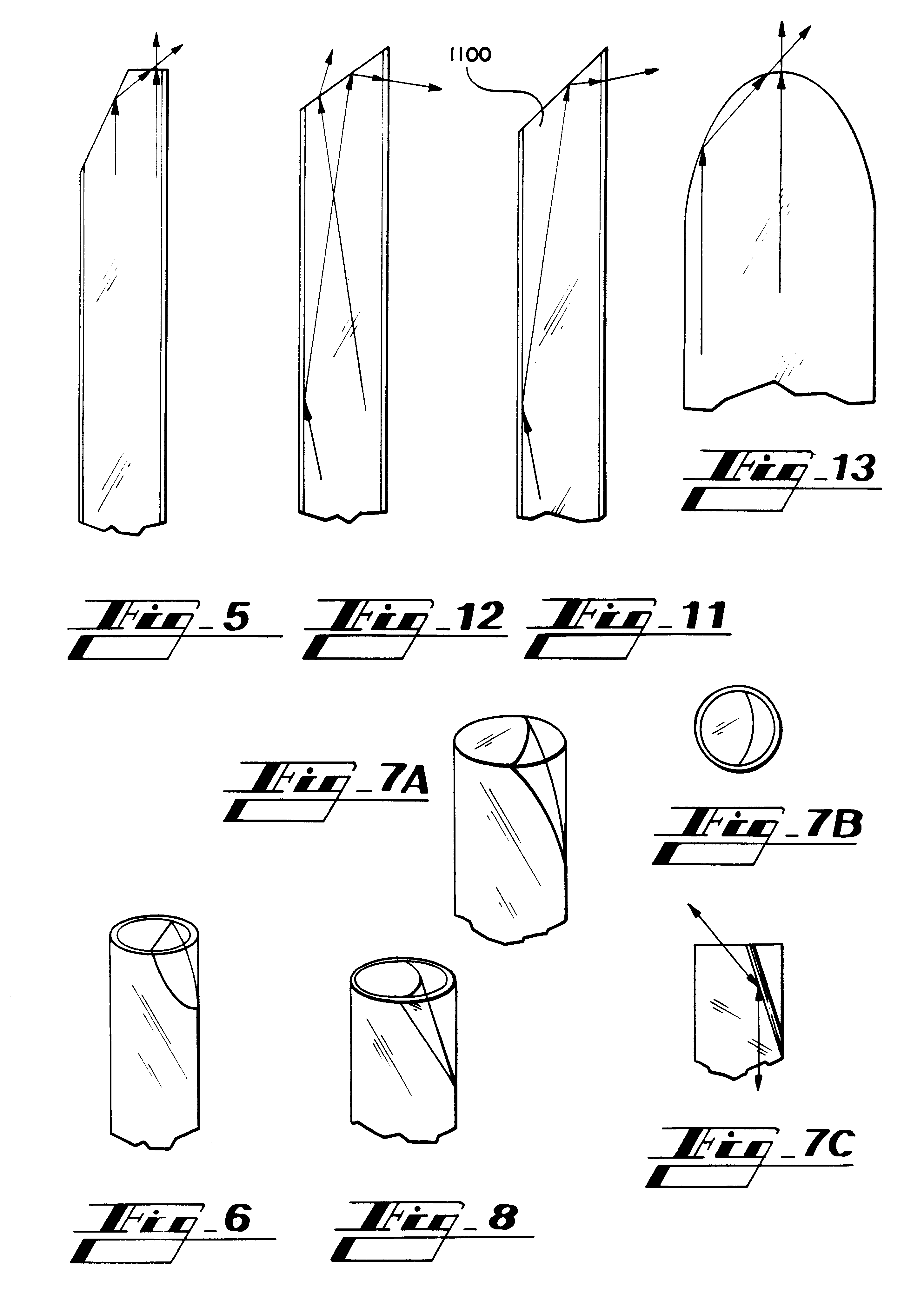

Modular, high energy, widely-tunable ultrafast fiber source

InactiveUS6885683B1High peak and high average powerReduce noiseCladded optical fibreLaser using scattering effectsNonlinear optical crystalHigh peak

A modular, compact and widely tunable laser system for the efficient generation of high peak and high average power ultrashort pulses. Modularity is ensured by the implementation of interchangeable amplifier components. System compactness is ensured by employing efficient fiber amplifiers, directly or indirectly pumped by diode lasers. Peak power handling capability of the fiber amplifiers is expanded by using optimized pulse shapes, as well as dispersively broadened pulses. After amplification, the dispersively stretched pulses can be re-compressed to nearly their bandwidth limit by the implementation of another set of dispersive delay lines. To ensure a wide tunability of the whole system, Raman-shifting of the compact sources of the ultrashort pulses in conjunction with frequency-conversion in nonlinear optical crystals can be implemented, or an Anti-Stokes fiber in conjunction with fiber amplifiers and Raman-shifters are used.

Owner:IMRA AMERICA

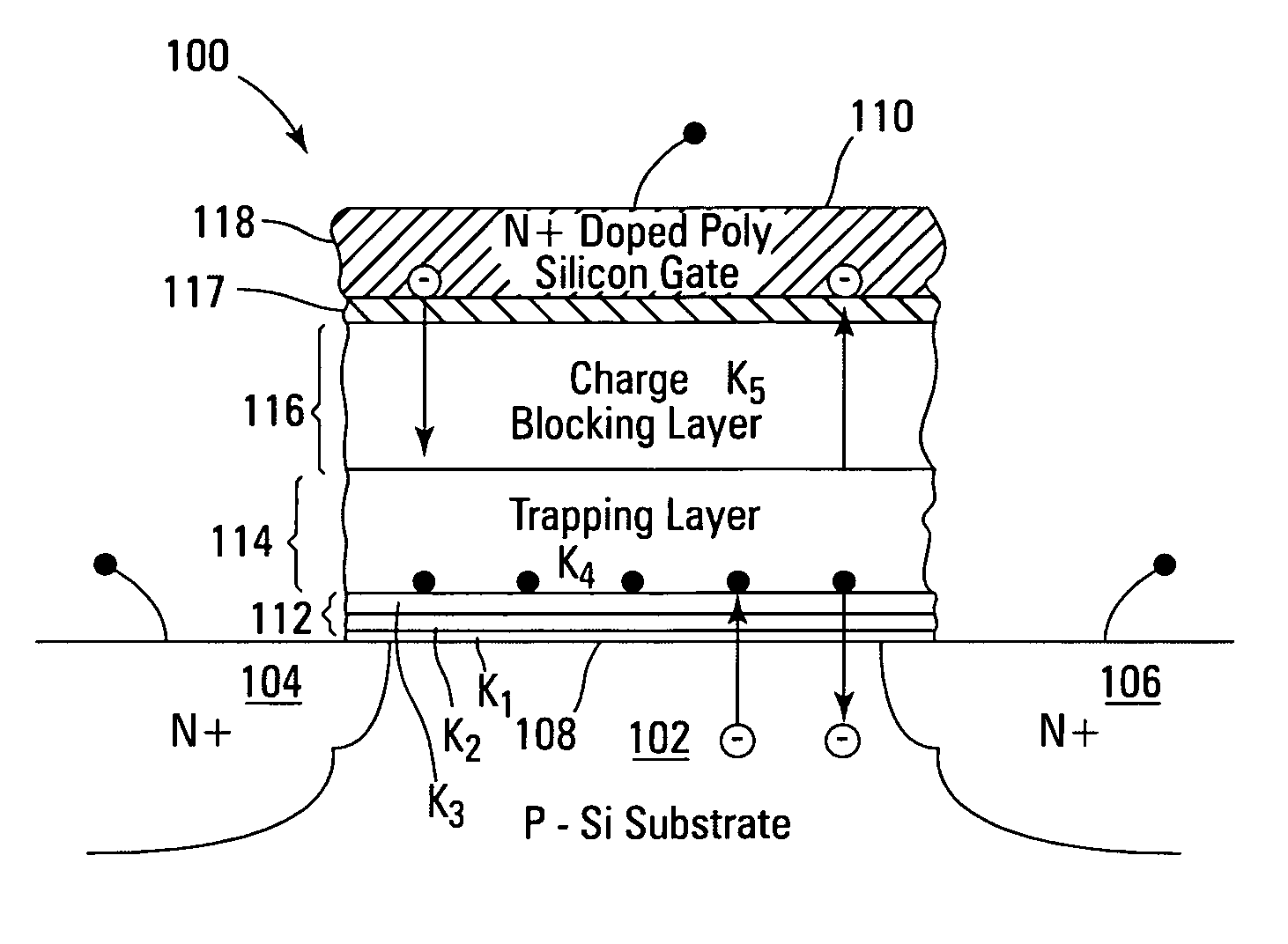

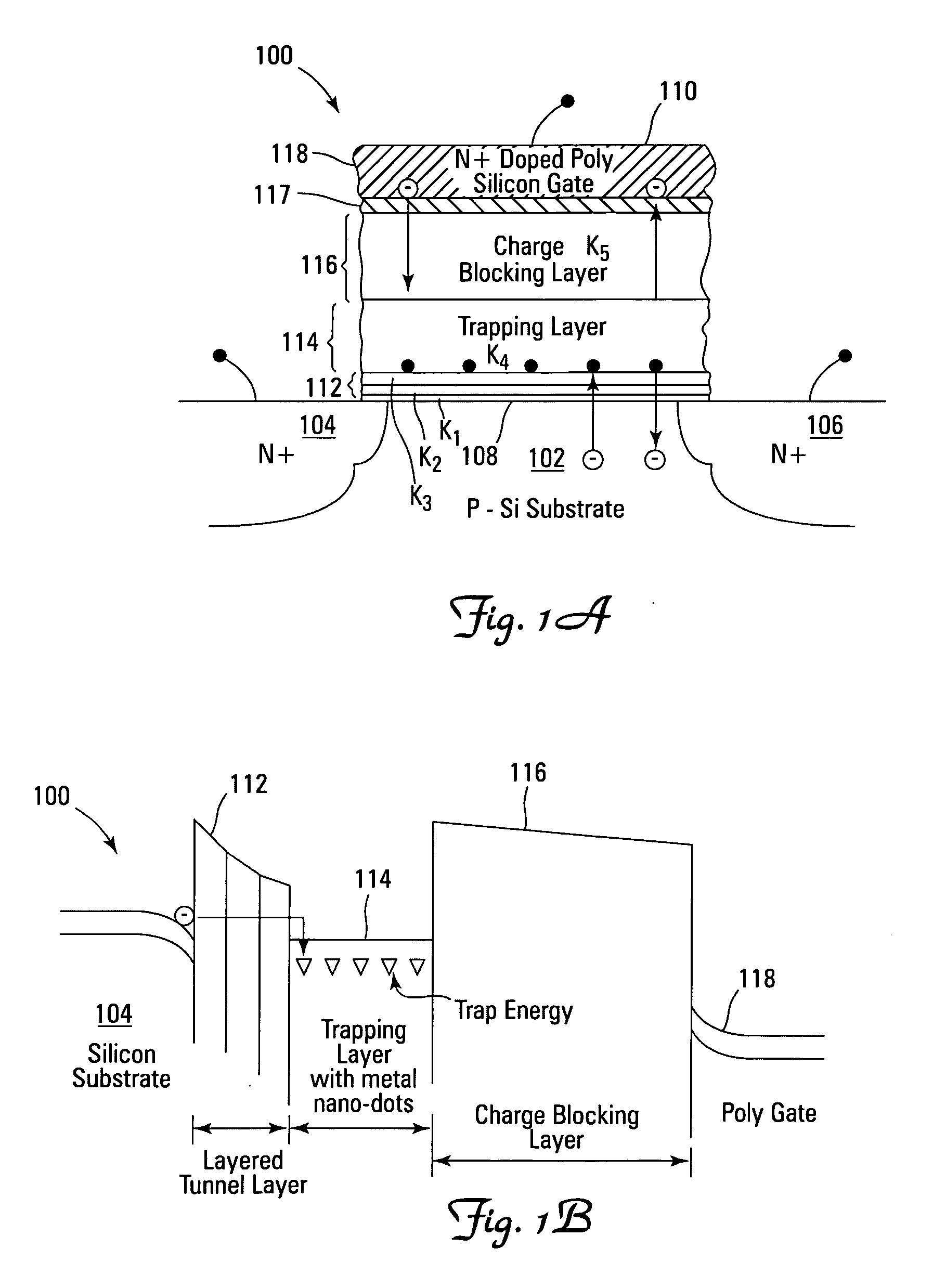

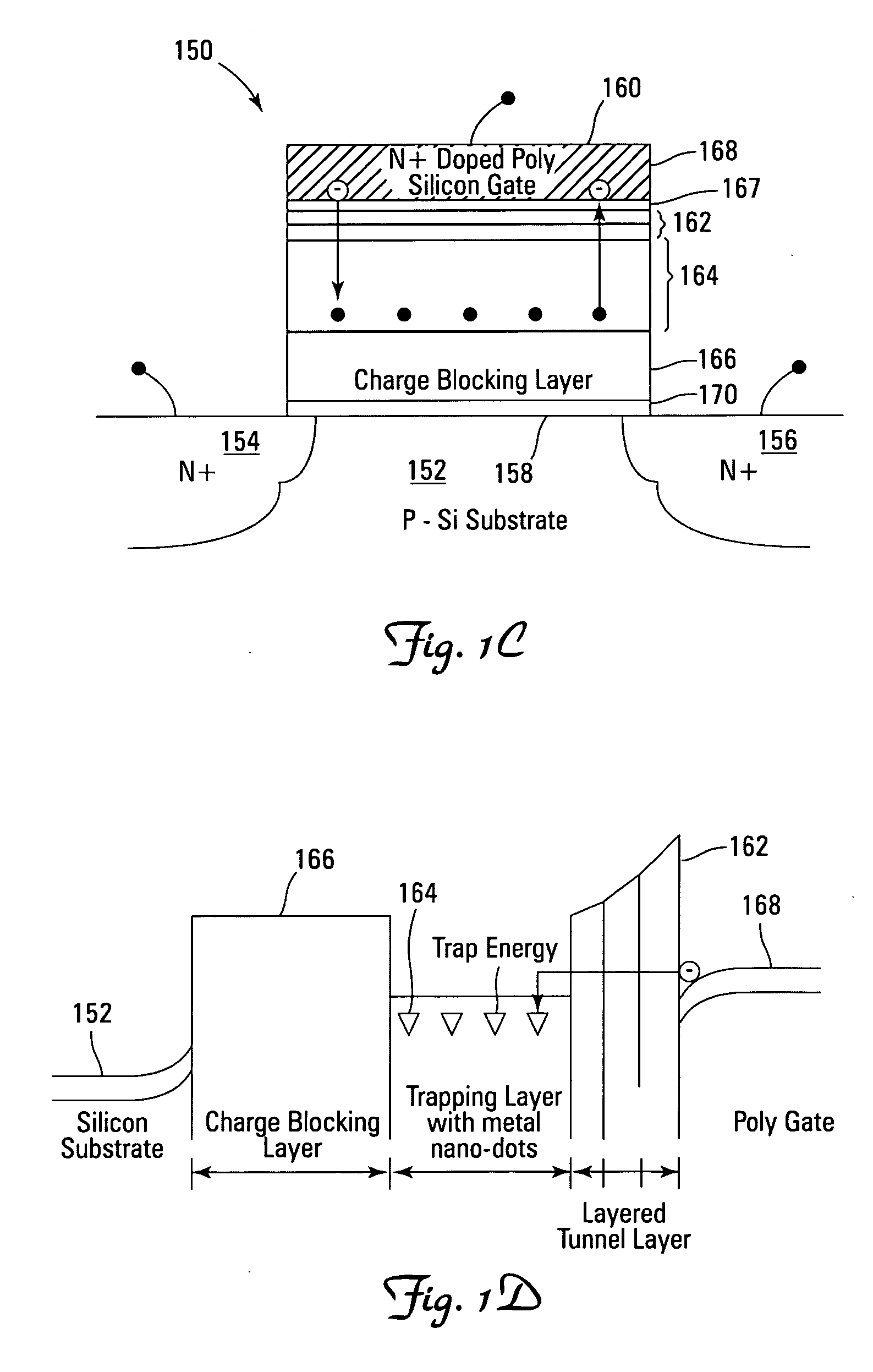

Novel low power non-volatile memory and gate stack

ActiveUS20060261401A1High charge blocking barrierExcellent charge retentionTransistorNanoinformaticsCharge retentionLow voltage

Non-volatile memory devices and arrays are described that facilitate the use of band-gap engineered gate stacks with asymmetric tunnel barriers in reverse and normal mode floating node memory cells in NOR or NAND memory architectures that allow for direct tunnel programming and erase, while maintaining high charge blocking barriers and deep carrier trapping sites for good charge retention. The low voltage direct tunneling program and erase capability reduces damage to the gate stack and the crystal lattice from high energy carriers, reducing write fatigue and enhancing device lifespan. The low voltage direct tunnel program and erase capability also enables size reduction through low voltage design and further device feature scaling. Memory cells of the present invention also allow multiple bit storage. These characteristics allow memory device embodiments of the present invention to operate within the definition of a universal memory, capable of replacing both DRAM and ROM in a system.

Owner:MICRON TECH INC

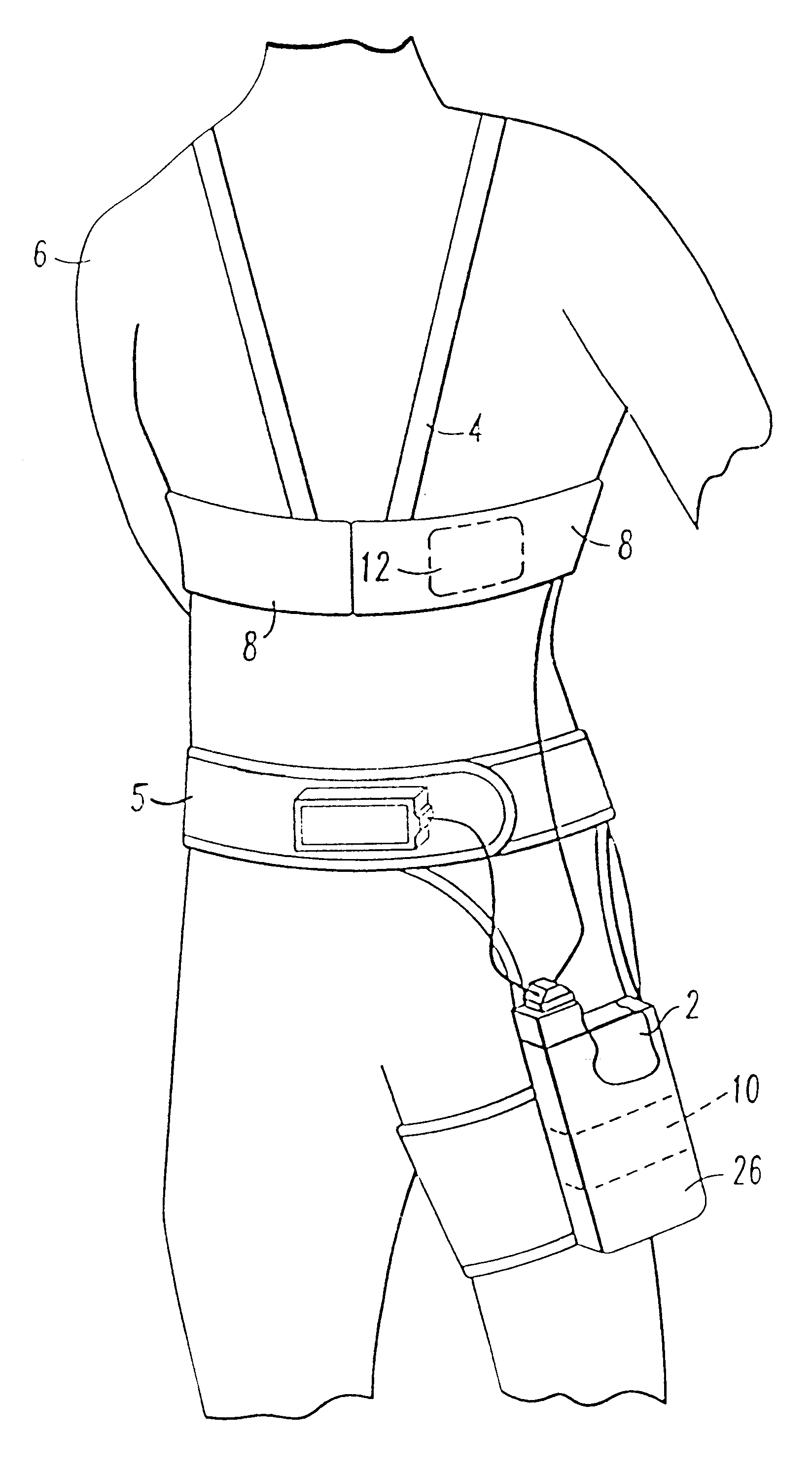

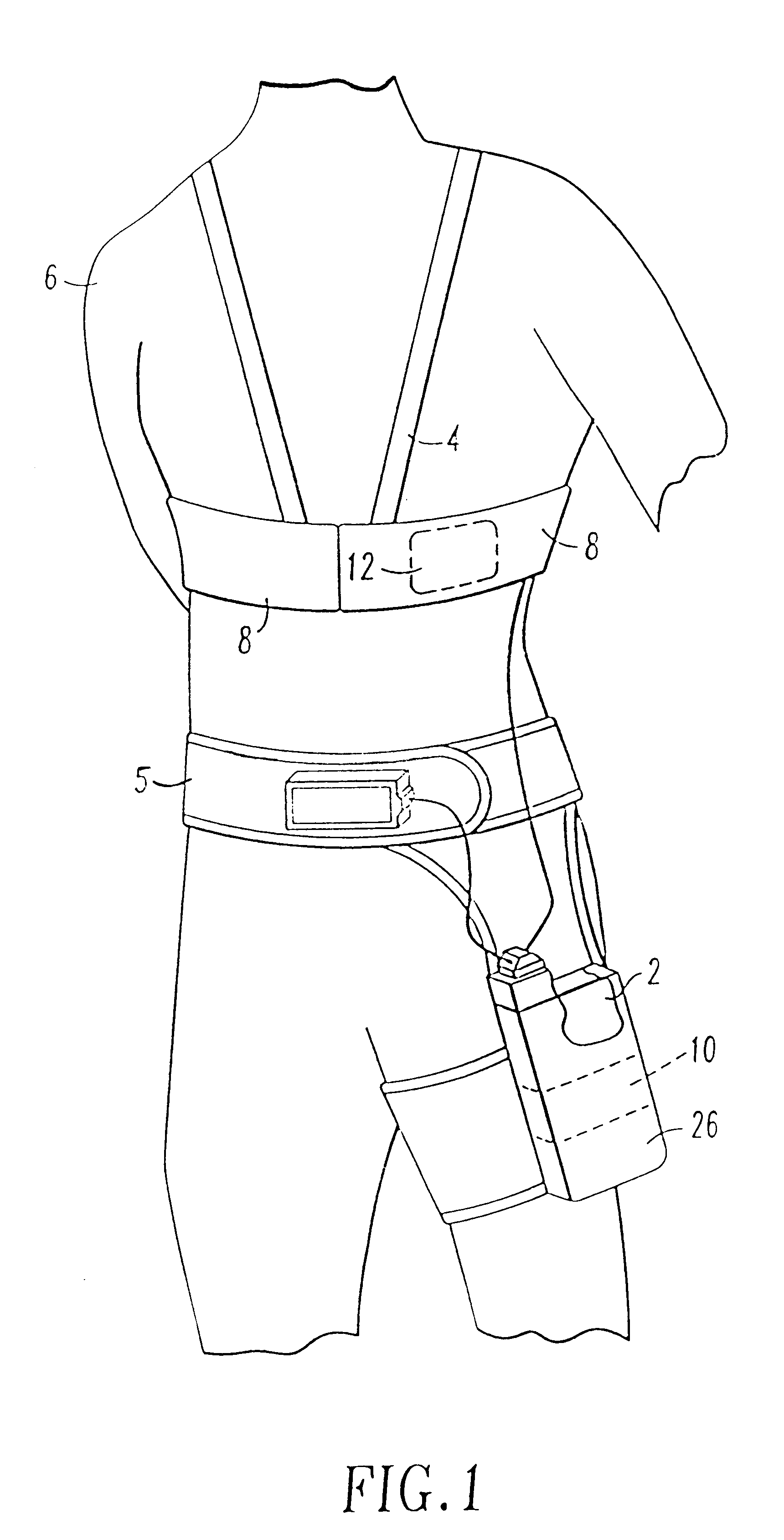

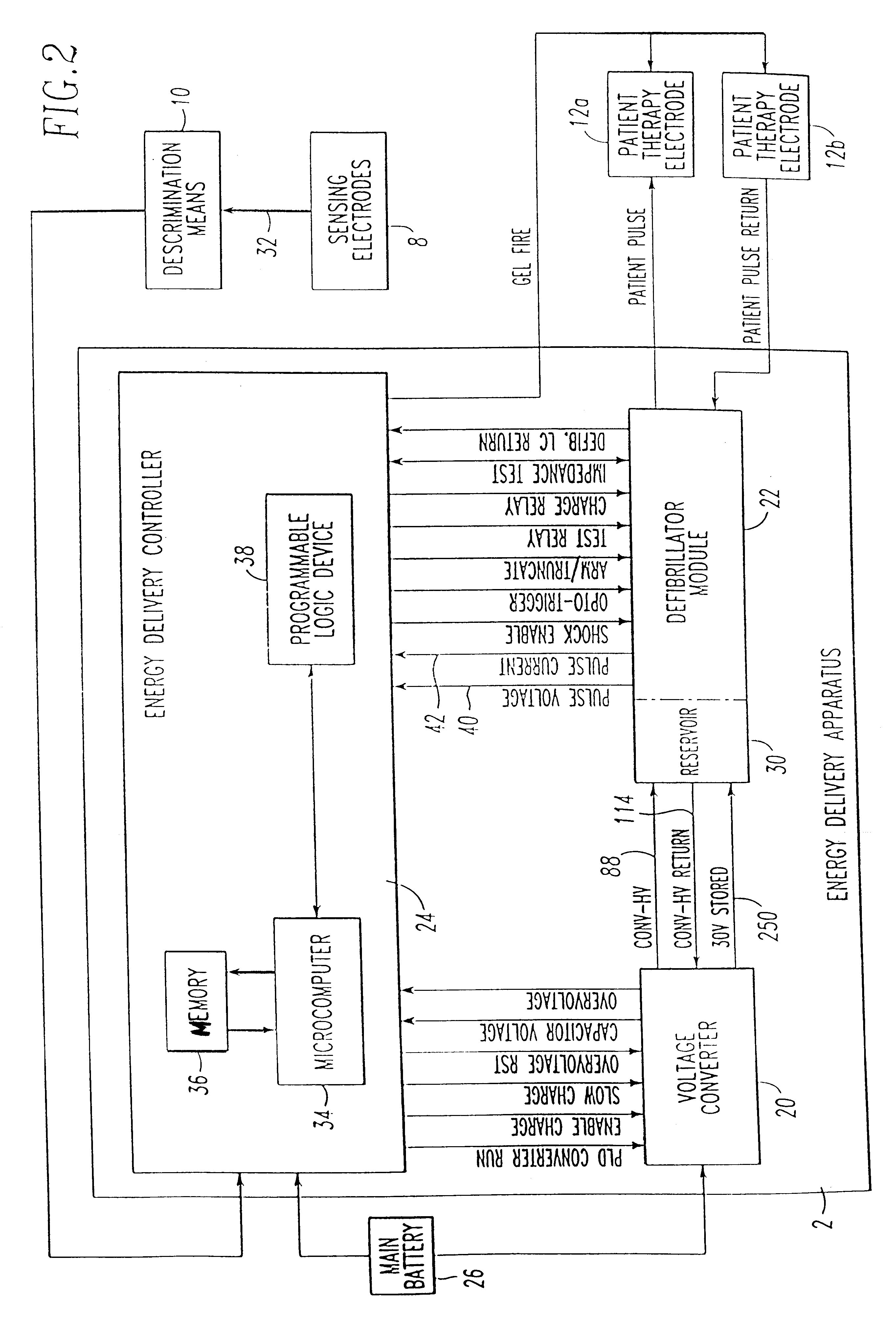

Patient-worn energy delivery apparatus

A patient-worn energy delivery apparatus for imparting electrical therapy to the body of a patient responsive to an occurrence of a treatable condition includes a voltage converter for converting electrical energy from an initial voltage to a final voltage, and a defibrillator electrically coupled between the converter and the patient and having an energy reservoir for receiving the electrical energy. The defibrillator produces preshaped electrical pulses such as defibrillation pulses and cardioversion pulses. The apparatus additionally includes an energy delivery controller electrically coupled to the patient and the converter and the defibrillator. The controller causes the converter to provide the electrical energy to the defibrillator at a specific charging rate in response to an energy level in the reservoir. The apparatus may include a plurality of electrodes interposed between the defibrillator and the patient and each electrode preferably has an impedance reducing means contained therein. One embodiment of the apparatus may include a H-bridge to produce a positive-going pulse segment and the negative-going pulse segment within the biphasic exponential signals. The apparatus periodically measures the energy as it is being delivered to the patient and can pre-emptively stop or truncate the pulse in the event an error condition is detected, such as an overvoltage condition or if the energy level approaches a predetermined level. The electrical components which store and release the energy minimize the size and expense of the apparatus, while isolating the microcomputer from the high energy levels as the therapeutic pulse is delivered.

Owner:ZOLL MEDICAL CORPORATION

Rechargeable thin film battery and method for making the same

InactiveUS6982132B1Improve lithium ion mobilityHigh voltageElectrode thermal treatmentFinal product manufactureElectrical batteryHigh energy

A rechargeable, stackable, thin film, solid-state lithium electrochemical cell, thin film lithium battery and method for making the same is disclosed. The cell and battery provide for a variety configurations, voltage and current capacities. An innovative low temperature ion beam assisted deposition method for fabricating thin film, solid-state anodes, cathodes and electrolytes is disclosed wherein a source of energetic ions and evaporants combine to form thin film cell components having preferred crystallinity, structure and orientation. The disclosed batteries are particularly useful as power sources for portable electronic devices and electric vehicle applications where high energy density, high reversible charge capacity, high discharge current and long battery lifetimes are required.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Materials and devices for blue phosphorescence based organic light emitting diodes

InactiveUS7294849B2Effective lightingElectroluminescent light sourcesSolid-state devicesHigh energyTriplet state

An OLED includes a wide gap inert host material doped with two dopants. One of the dopants is an emissive phosphorescent material that can transport either electrons or holes. The other dopant is a charge carrying material that can transport whichever of the electrons and holes that is not transported by the phosphorescent dopant. The materials are selected so that the lowest triplet energy level of the host material and the lowest triplet energy level of the charge carrying dopant material are each at a higher energy level than the lowest triplet state energy level of the phosphorescent dopant material. The device is capable, in particular, of efficiently emitting light in the blue region of the visible spectrum.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

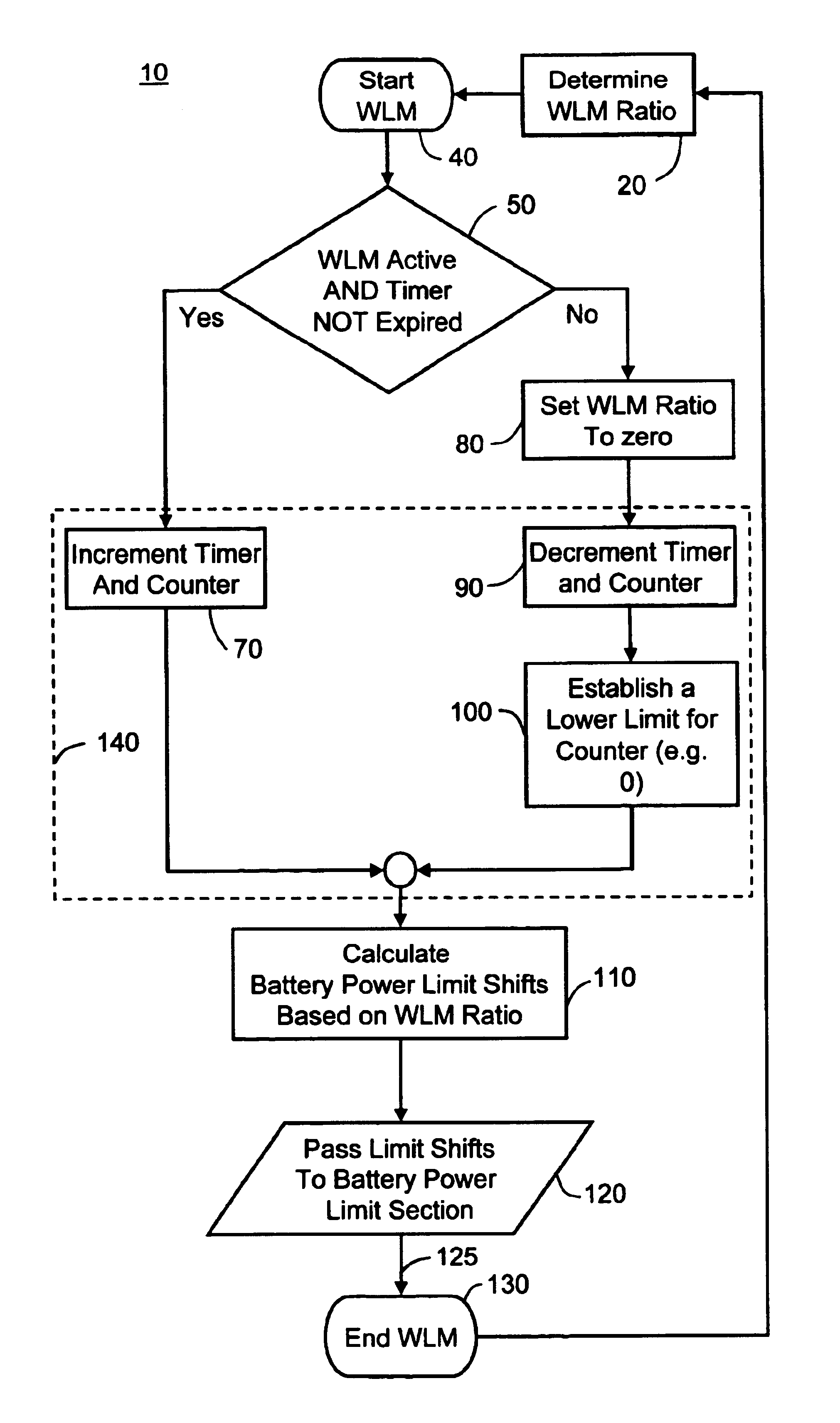

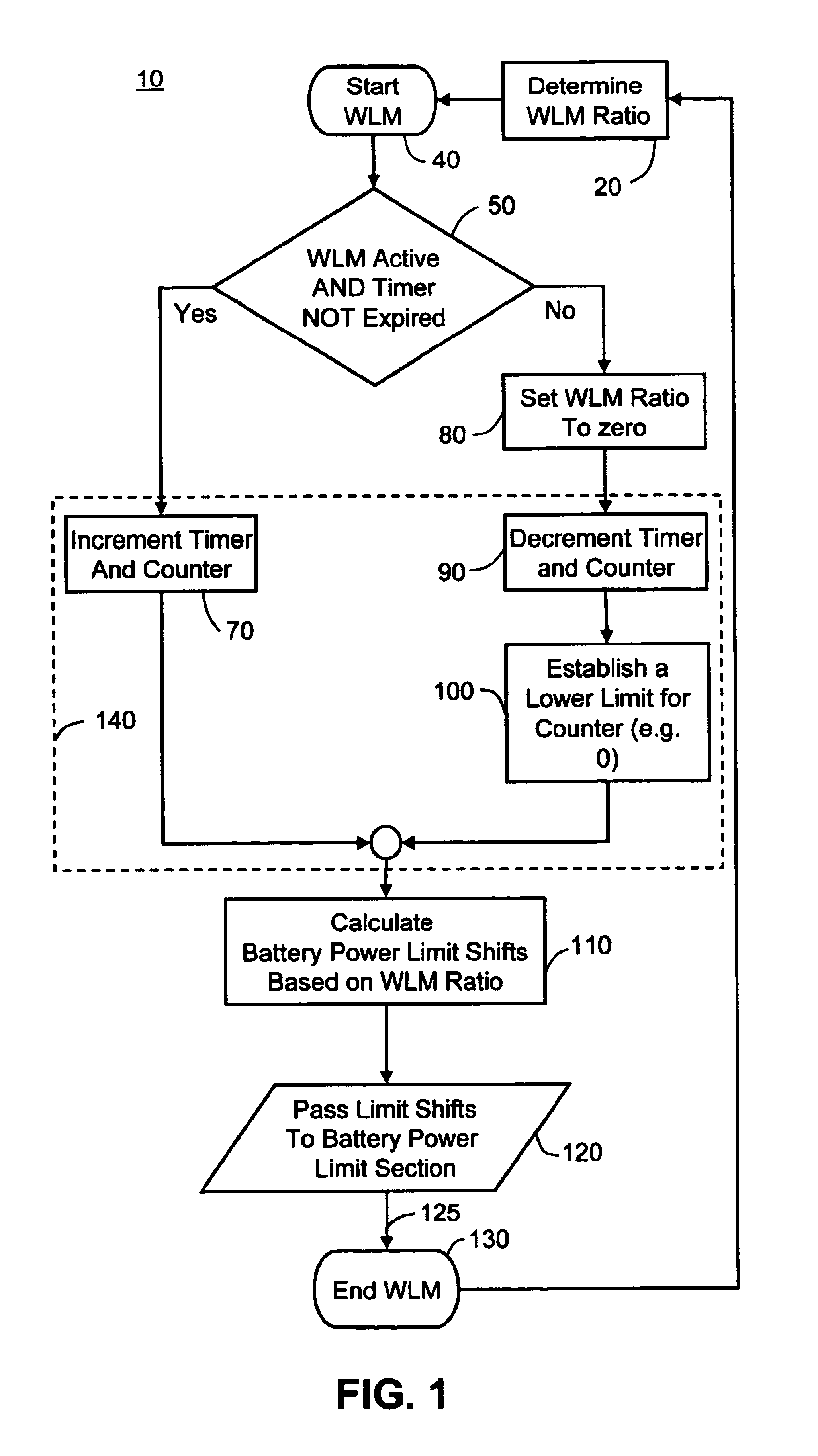

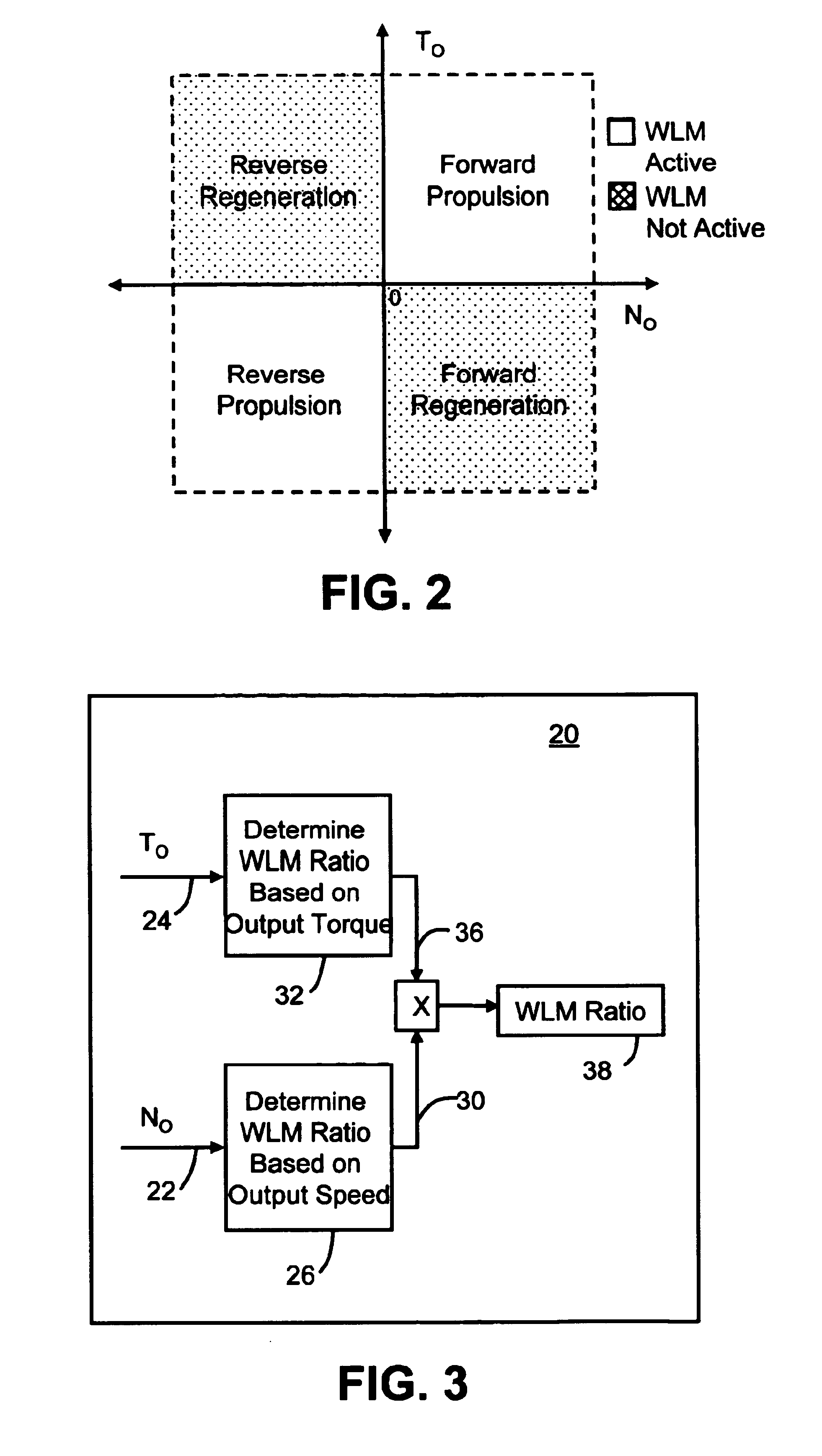

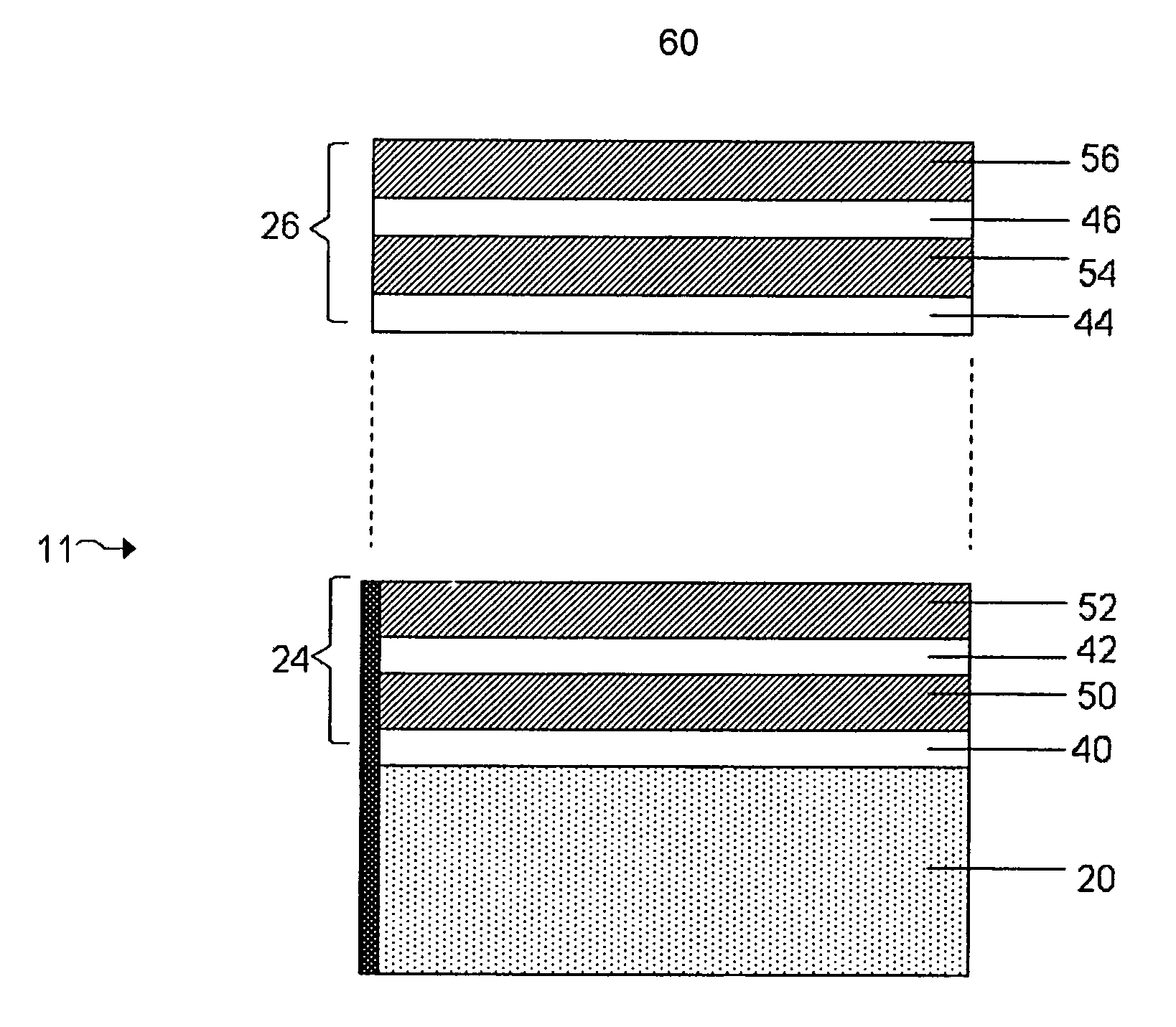

Method for adjusting battery power limits in a hybrid electric vehicle to provide consistent launch characteristics

ActiveUS6868318B1Lower performance requirementsOvercome deficienciesHybrid vehiclesBatteries circuit arrangementsElectrical energy storageAutomotive engineering

A method is disclosed for improving the performance of an energy storage system that incorporates a high density electrical energy storage device, such a battery or ultracapacitor. The method may be implemented in an energy storage system of a hybrid electric vehicle (HEV) as a computer control algorithm for controlling the discharge power limits of an energy storage device, such as a battery. The method allows the discharge power limits of the battery to be temporarily expanded under vehicle launch conditions where the power demands are high, thereby making additional stored energy available for use under such conditions by improving battery utilization and providing more consistent vehicle launch characteristics than would otherwise be available.

Owner:GM GLOBAL TECH OPERATIONS LLC

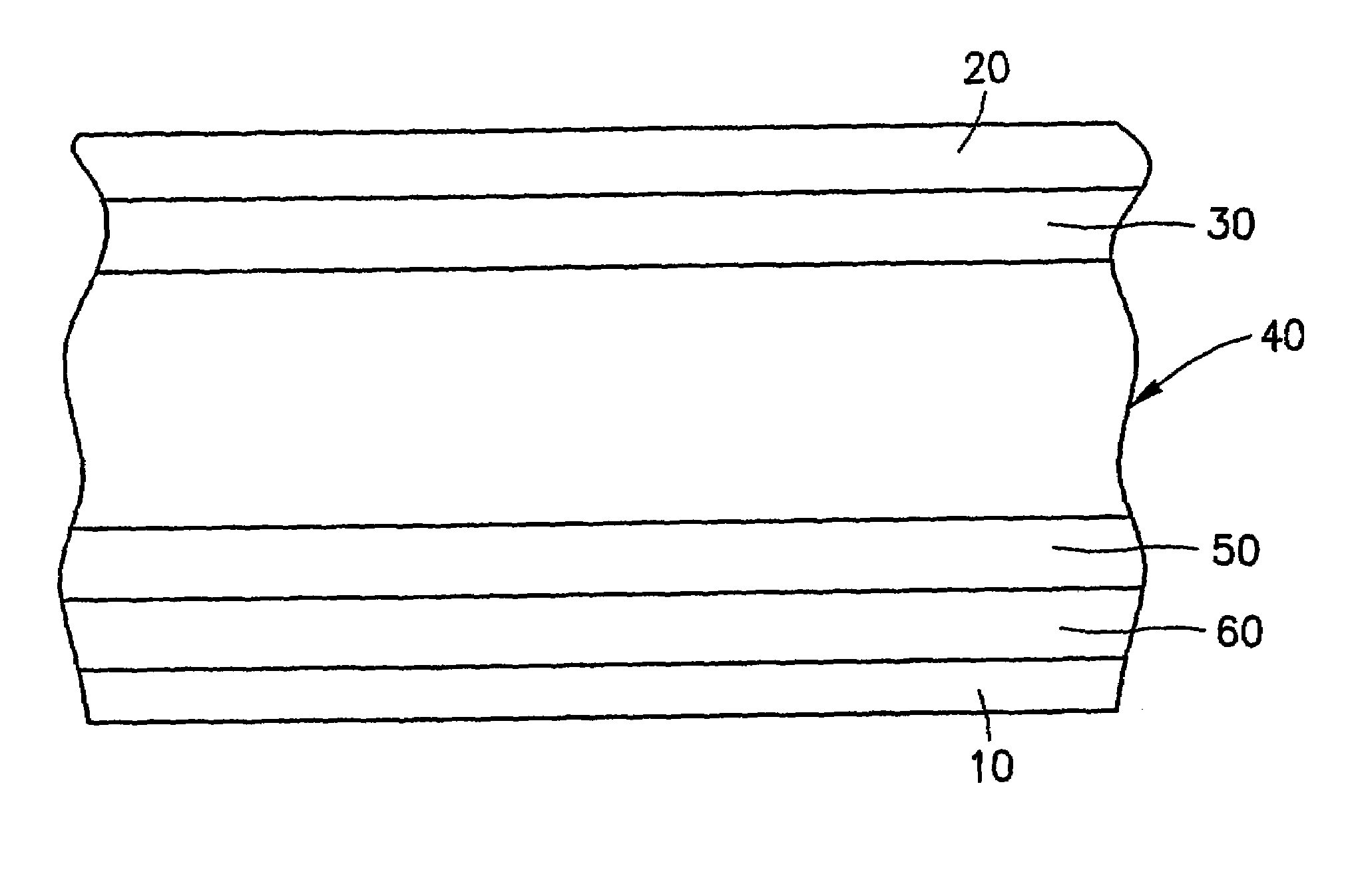

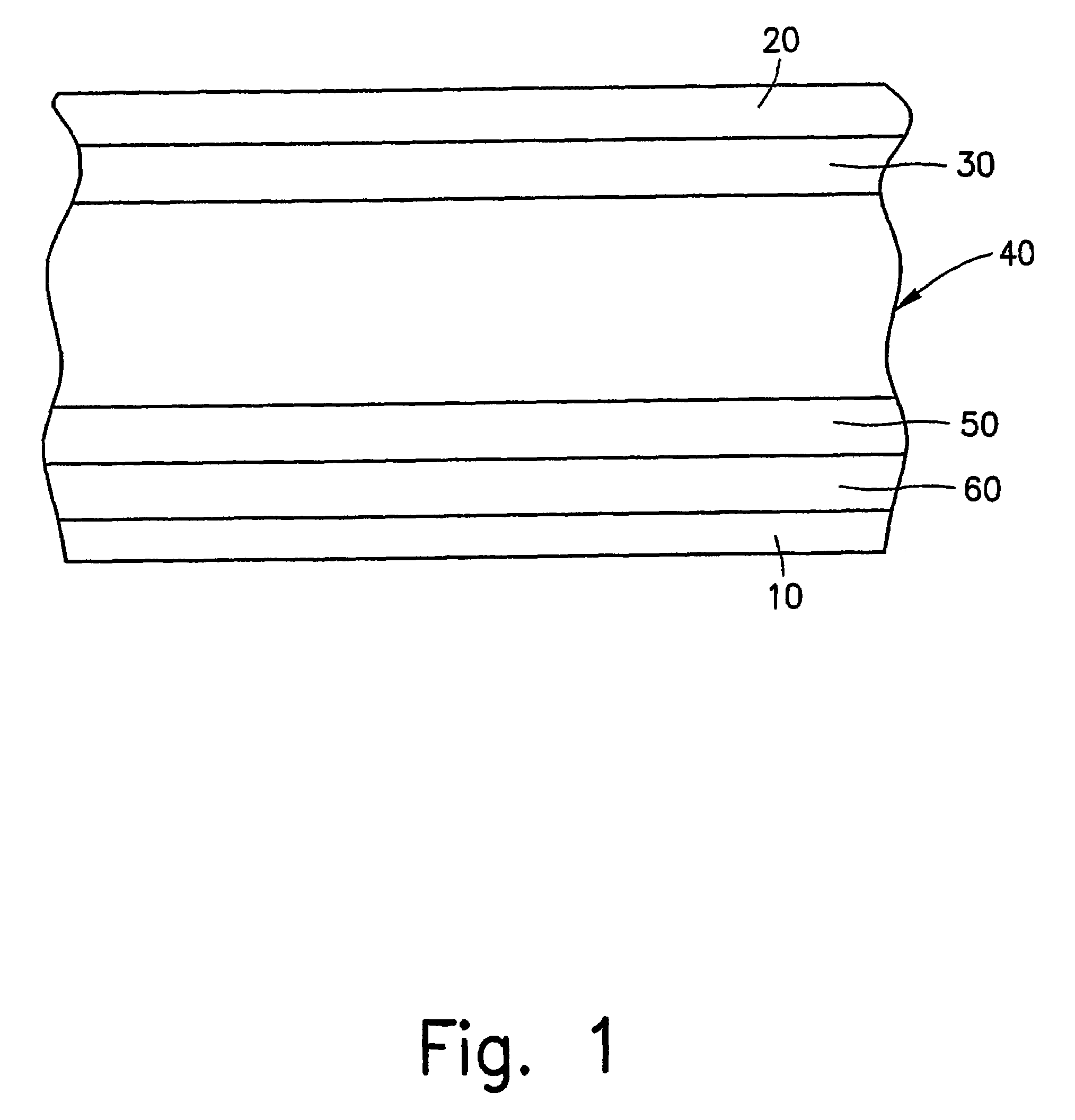

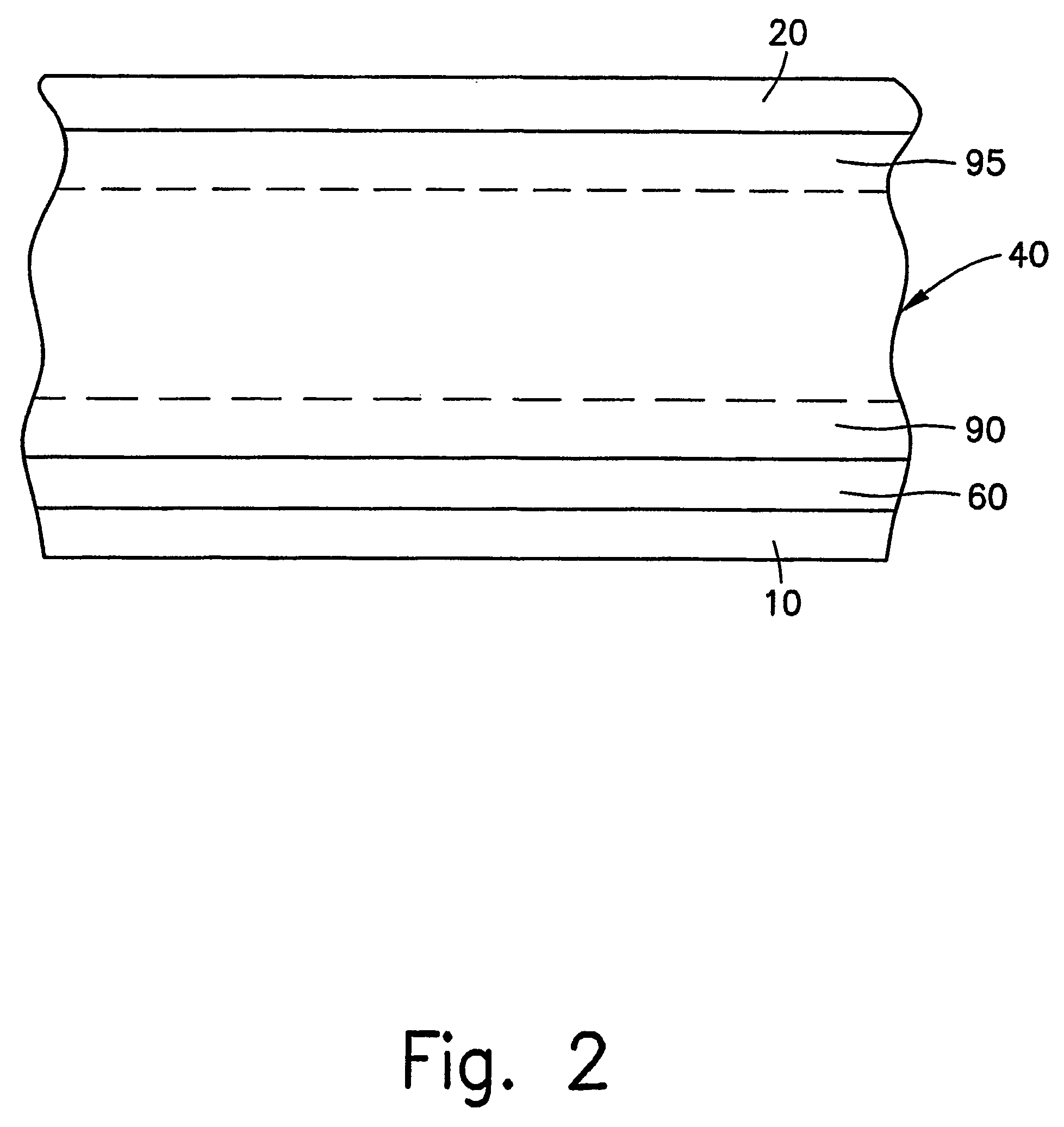

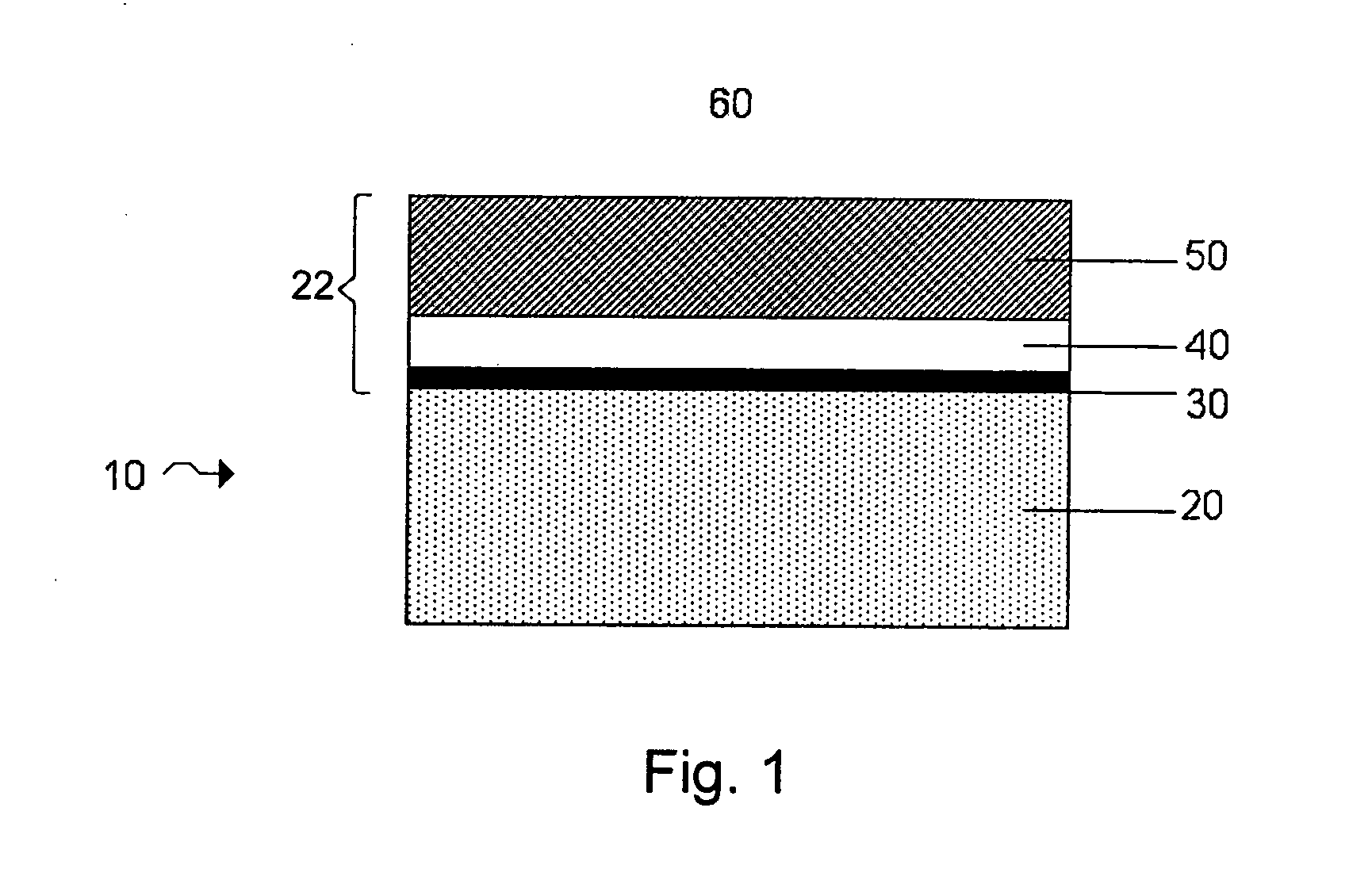

Rechargeable lithium/water, lithium/air batteries

InactiveUS20070221265A1Improve protectionEasy to controlFinal product manufacturePV power plantsHigh energyOptoelectronics

Electrochemical cells, and more specifically, rechargeable batteries comprising lithium anodes for use in water and / or air environments, as well as non-aqueous and non-air environments, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

Switch mechanisms for safe activation of energy on an electrosurgical instrument

ActiveUS20070016187A1Secure bootElectric switchesSurgical instruments for heatingHigh energyActuator

Various safe switching mechanisms are provided for use with electrosurgical instruments which prevent arcing between the high-energy contacts as the high-energy source is activated. The switching mechanisms generally include a pair of high-energy contacts and a pair of activation contacts. An actuator is provided which initially engages the high-energy contacts in advance of engagement of the activation contacts to prevent arcing and subsequently disengages the activation contacts in advance of the high-energy contacts as the energy source is deactivated. A method of switching power to an electrosurgical instrument while avoiding damage to high-energy contacts is also disclosed.

Owner:COVIDIEN AG

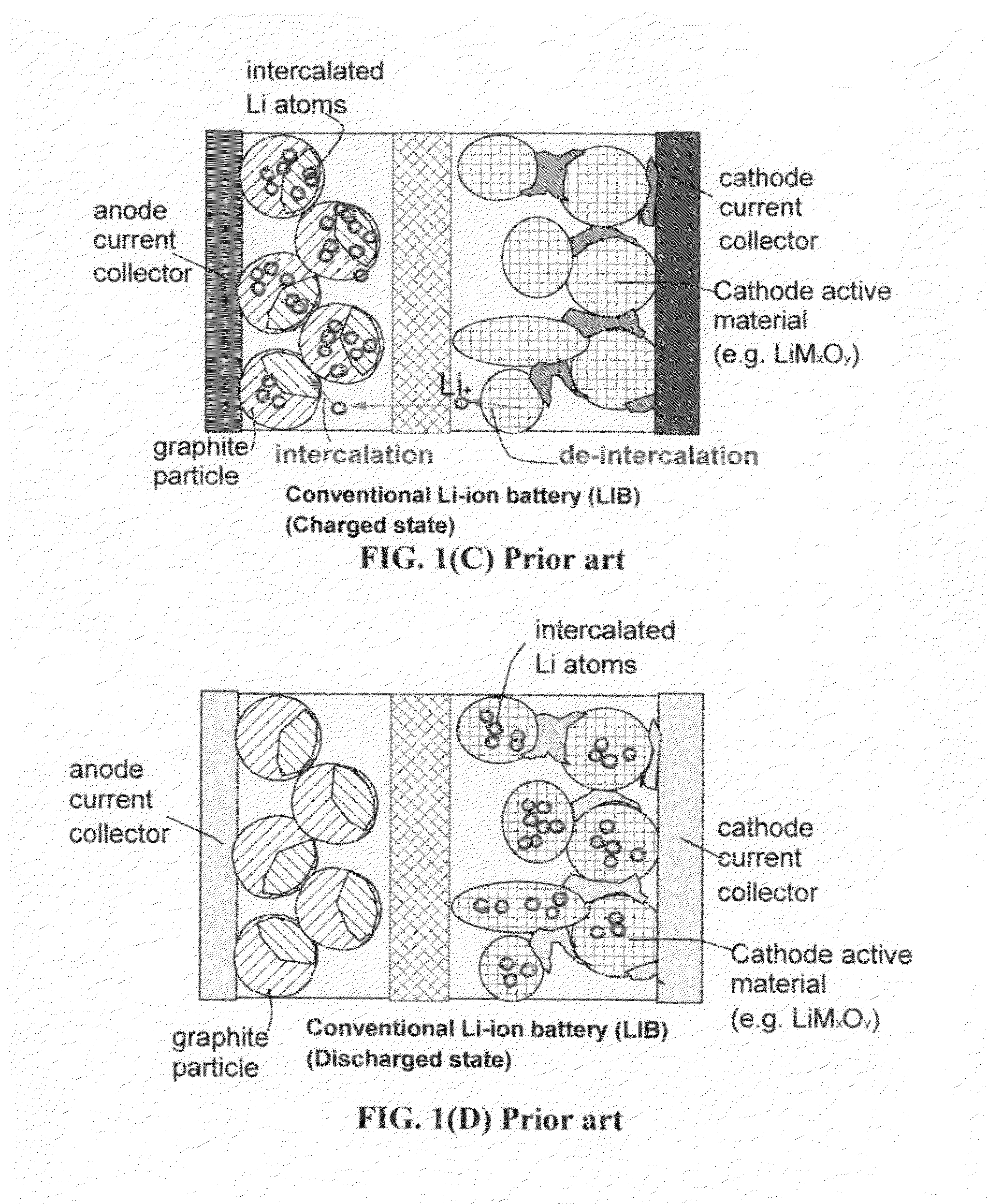

High energy lithium ion batteries with particular negative electrode compositions

ActiveUS20090305131A1Degree of crystallinity of will decreaseAlkaline accumulatorsElectrode manufacturing processesHigh energyMetal alloy

Combinations of materials are described in which high energy density active materials for negative electrodes of lithium ion batteries. In general, metal alloy / intermetallic compositions can provide the high energy density. These materials can have moderate volume changes upon cycling in a lithium ion battery. The volume changes can be accommodated with less degradation upon cycling through the combination with highly porous electrically conductive materials, such as highly porous carbon and / or foamed current collectors. Whether or not combined with a highly porous electrically conductive material, metal alloy / intermetallic compositions with an average particle size of no more than a micron can be advantageously used in the negative electrodes to improve cycling properties.

Owner:IONBLOX INC

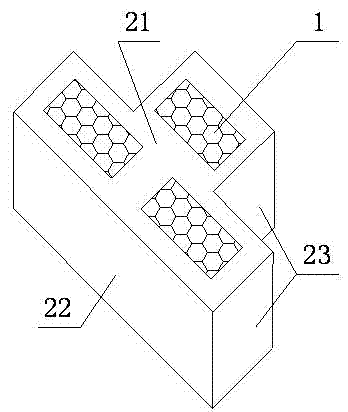

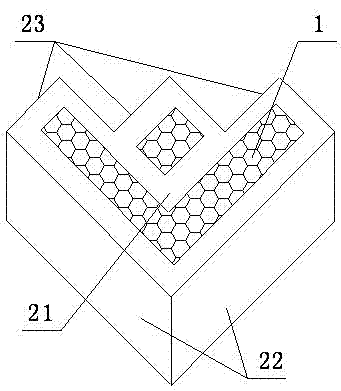

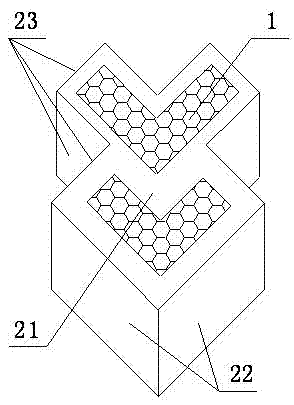

Self-insulation wall with high energy conservation property

The invention discloses a self-insulation wall with a high energy conservation property, and belongs to the field of building wall materials. The self-insulation wall with the high energy conservation property is mainly characterized in that building blocks of a self-insulation wall body are shaped like a T, building blocks of a self-insulation right-angle wall corner are in a flower shape and a scissor shape, building blocks of a self-insulation T-shaped wall corner are provided with either a T-shaped top with a handle or a T-shaped bottom with a handle, when the wall body is built, one of every two horizontally adjacent self-insulation wall bricks is placed in a T shape, the other one is placed in a reverse T shape, when the right-angle wall corner is built, the flower-shaped and scissor-shaped building blocks of the self-insulation right-angle wall corner are alternatively placed, and when the T-shaped wall corner is built, the building blocks, provided with either the T-shaped top with the handle or the T-shaped bottom with the handle, of the self-insulation T-shaped wall corner are alternatively placed. The self-insulation wall with the high energy conservation property has the advantage of improving the energy conservation property.

Owner:SHANDONG UNIV OF SCI & TECH

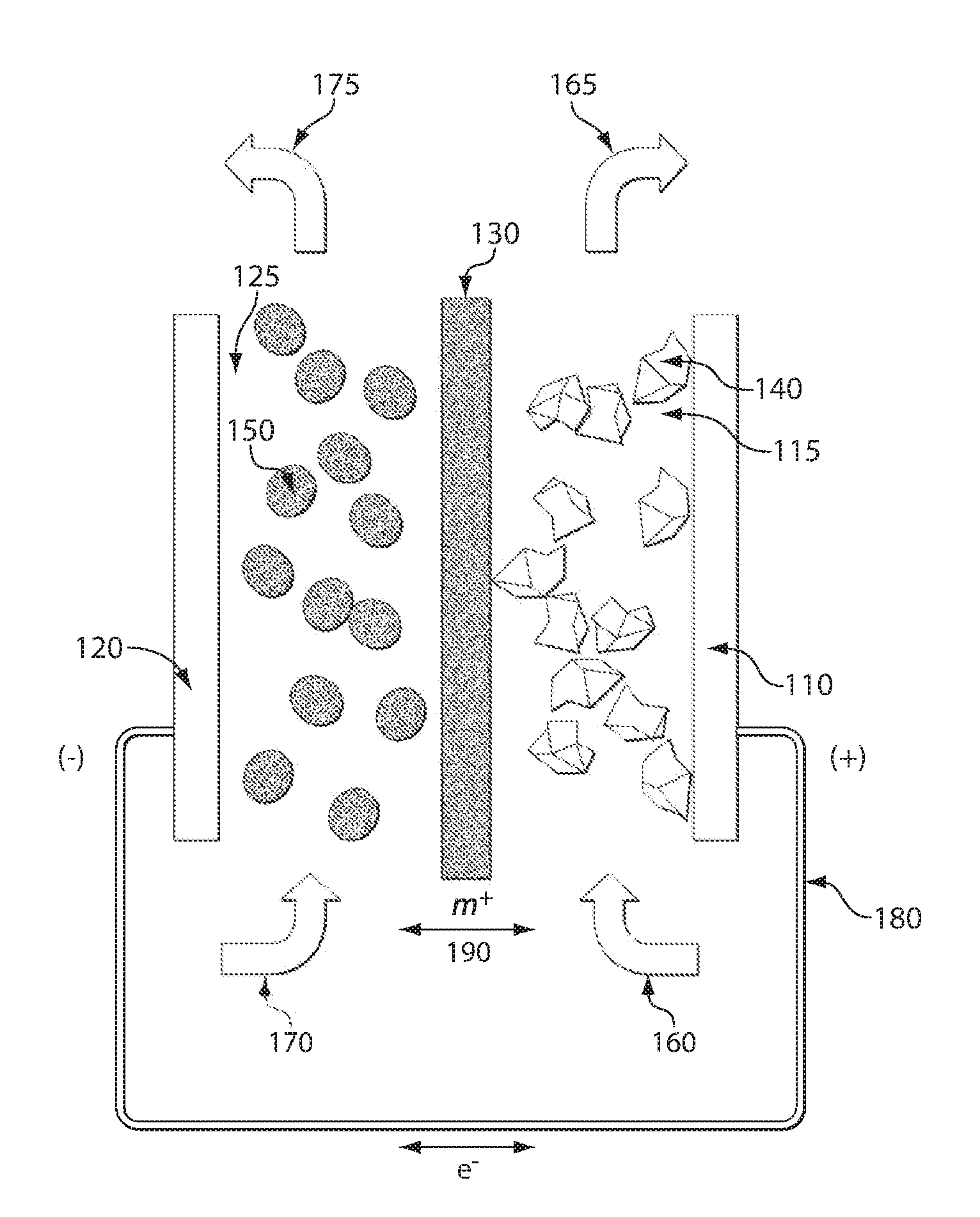

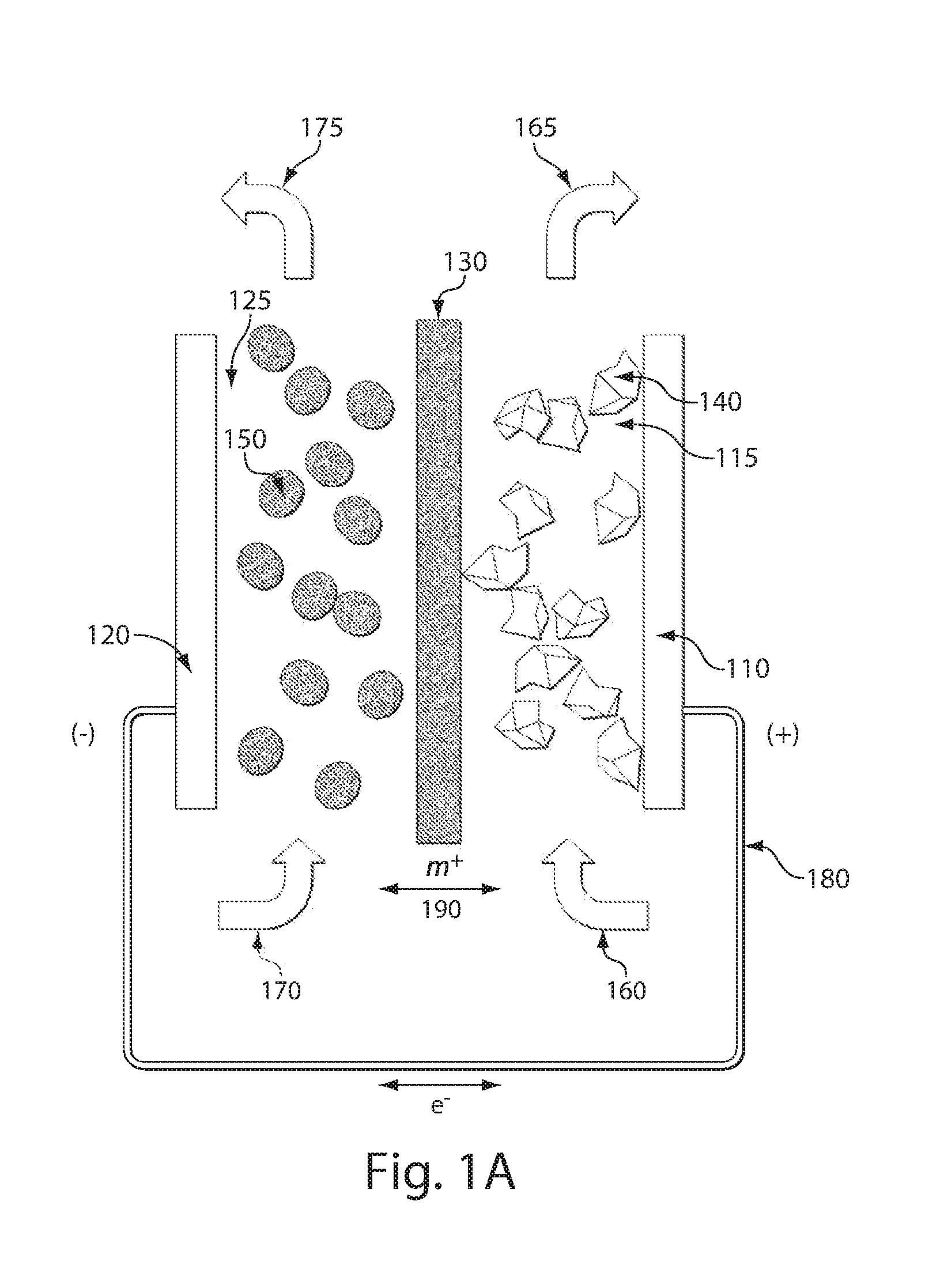

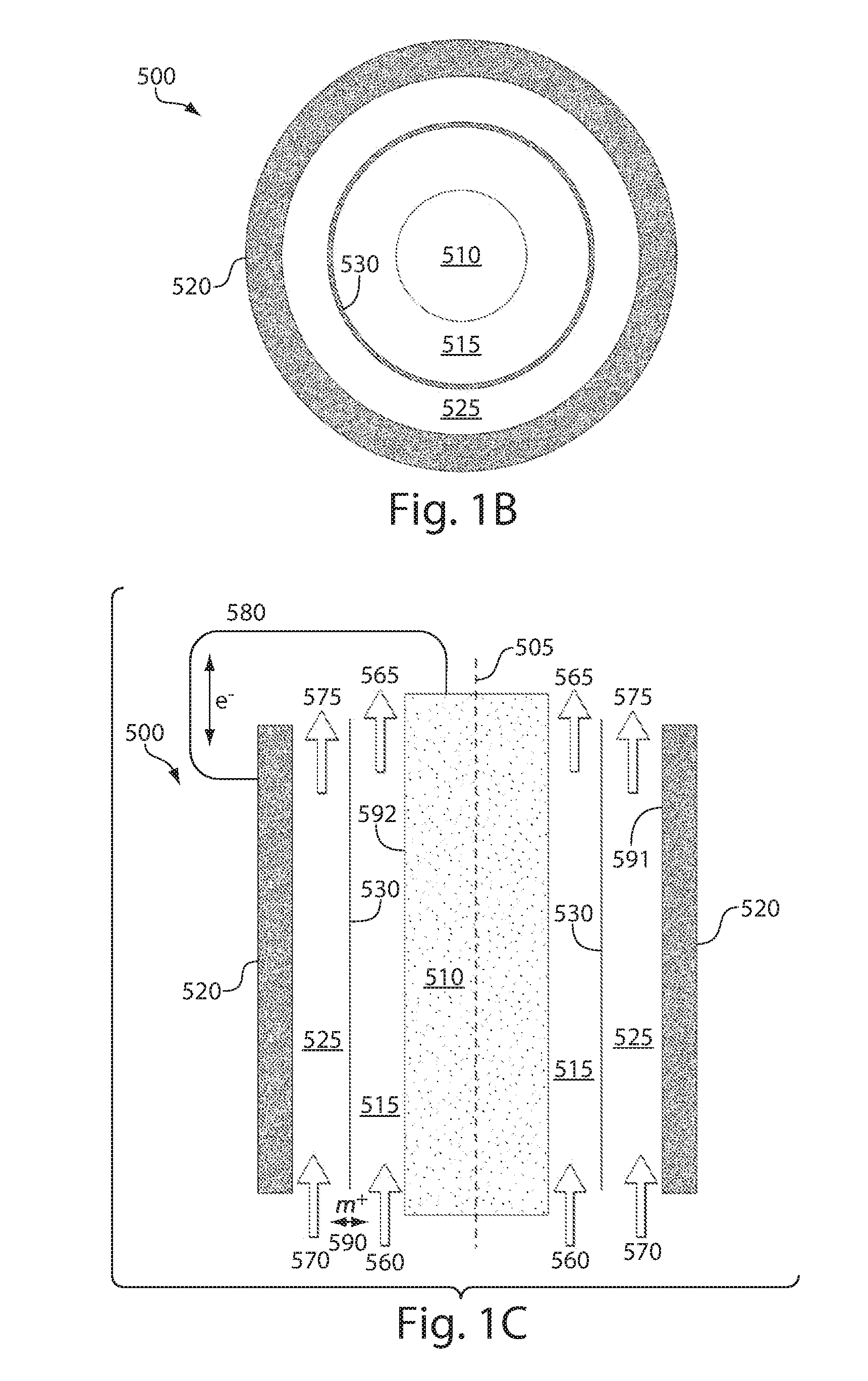

High energy density redox flow device

ActiveUS20110200848A1Avoid accumulationHigh enough specific energyOrganic chemistryFlow propertiesElectrochemical responseHigh energy

Redox flow devices are described in which at least one of the positive electrode or negative electrode-active materials is a semi-solid or is a condensed ion-storing electroactive material, and in which at least one of the electrode-active materials is transported to and from an assembly at which the electrochemical reaction occurs, producing electrical energy. The electronic conductivity of the semi-solid is increased by the addition of conductive particles to suspensions and / or via the surface modification of the solid in semi-solids (e.g., by coating the solid with a more electron conductive coating material to increase the power of the device). High energy density and high power redox flow devices are disclosed. The redox flow devices described herein can also include one or more inventive design features. In addition, inventive chemistries for use in redox flow devices are also described.

Owner:MASSACHUSETTS INST OF TECH +2

Methods and apparatus for filtering an optical fiber

InactiveUS6222970B1Improve responseReduce sensitivityCladded optical fibreMaterial analysis by observing effect on chemical indicatorHigh energyPhotonics

Filtering of optical fibers and other related devices. High-energy methods for depositing thin films directly onto the ends of optical fibers can be used to produce high-quality, high-performance filters in quantity at a reasonable cost. These high-quality filters provide the high performance needed for many demanding applications and often eliminate the need for filters applied to wafers or expanded-beam filtering techniques. Having high-quality filters applied directly to optical fiber and faces permits production of high-performance, micro-sized devices that incorporate optical filters. Devices in which these filters may be used include spectroscopic applications including those using fiber optic probes, wavelength division multiplexing, telecommunications, general fiber optic sensor usage, photonic computing, photonic amplifiers, pump blocking and a variety of laser devices.

Owner:CIRREX SYST

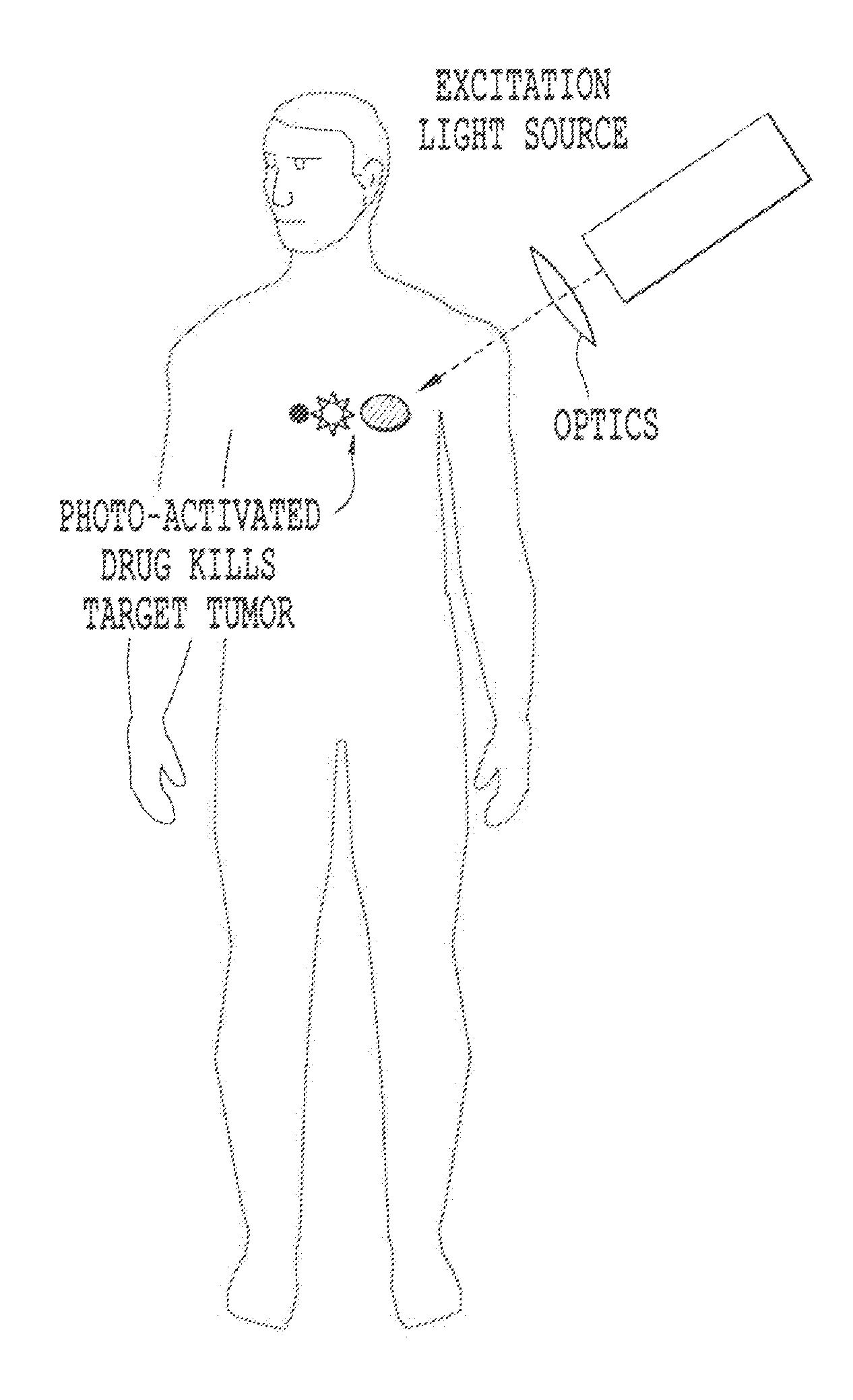

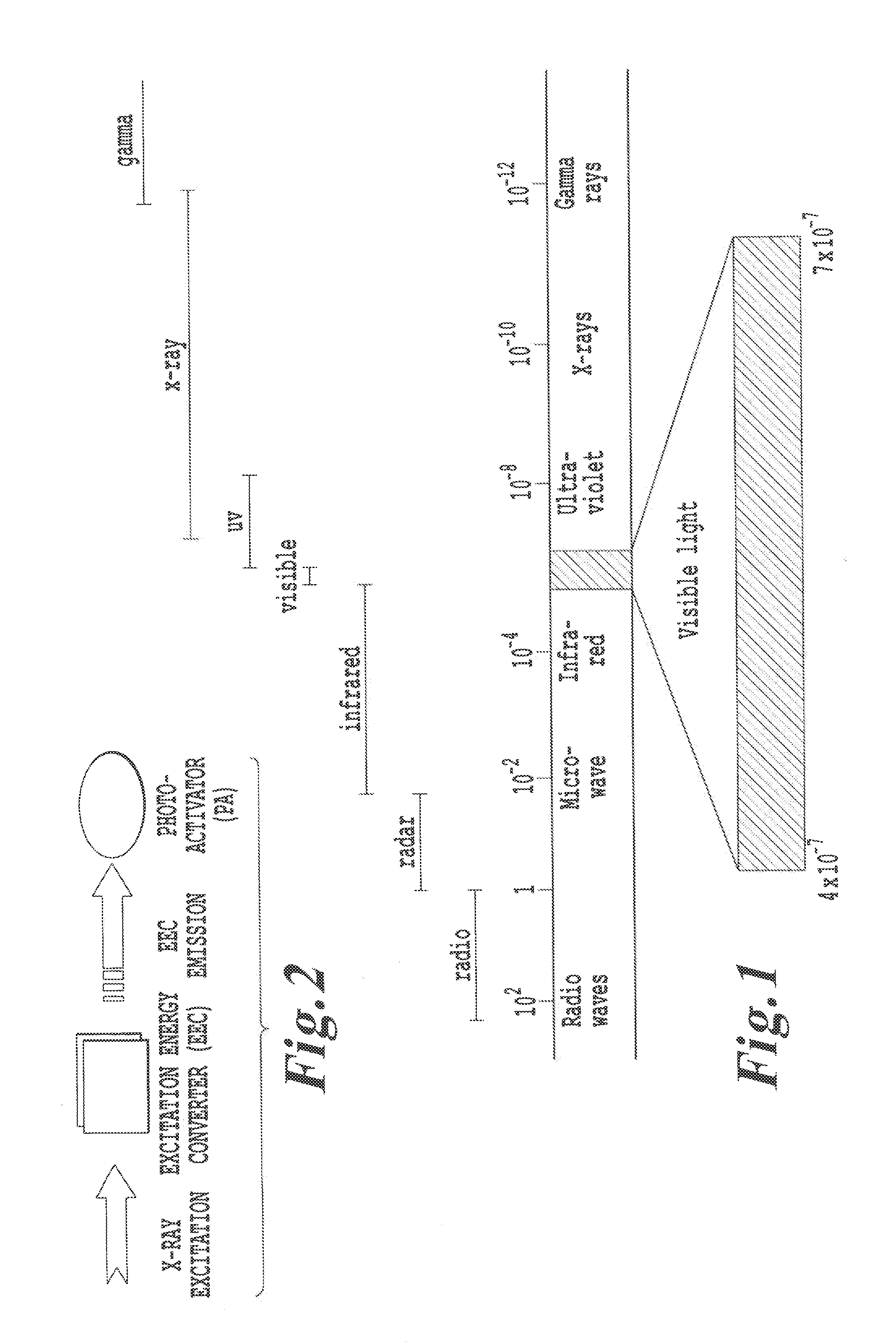

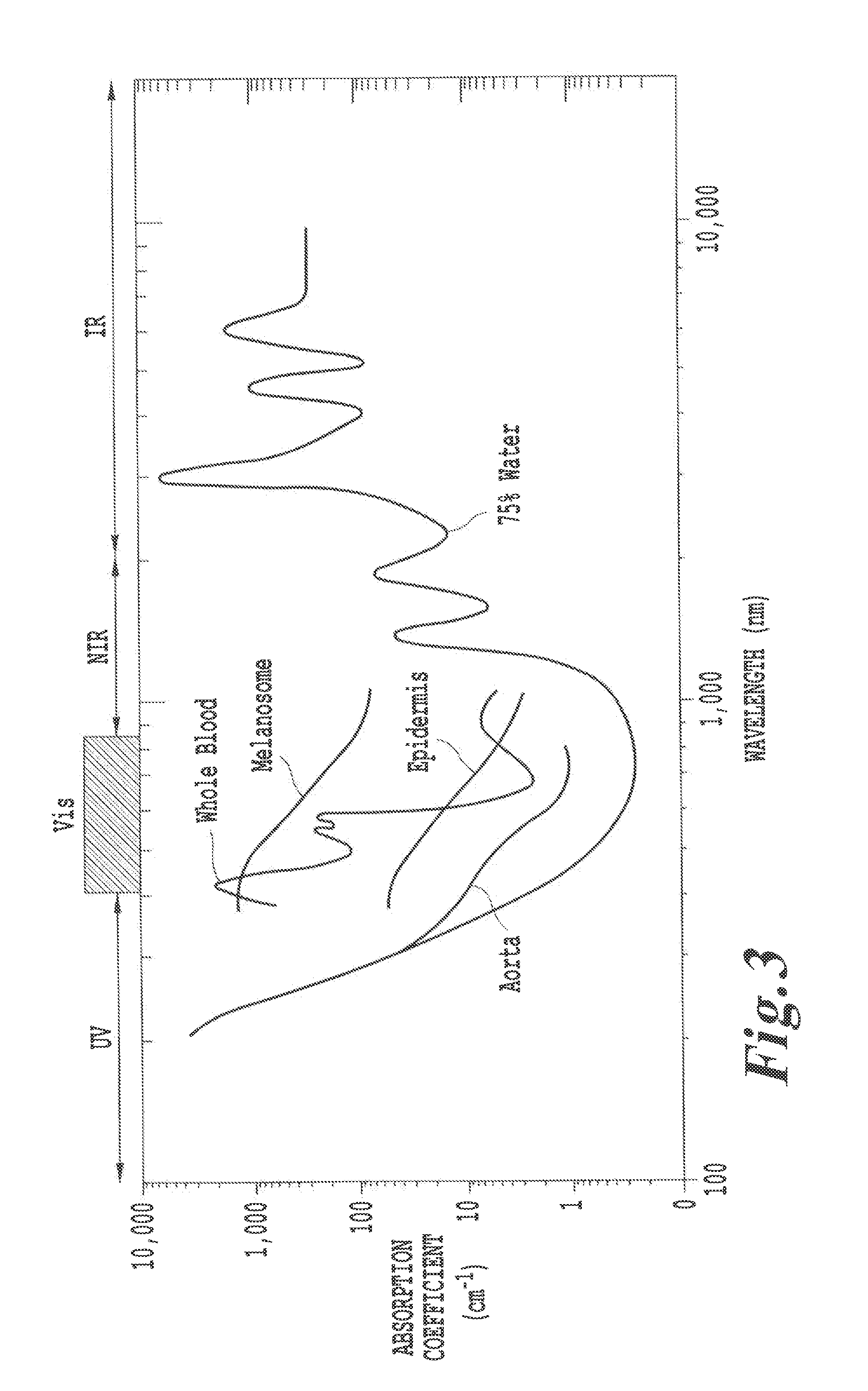

Non-invasive energy upconversion methods and systems for in-situ photobiomodulation

ActiveUS20110021970A1High selectivityAvoid the needAntibacterial agentsSenses disorderDiseaseHigh energy

Products, compositions, systems, and methods for modifying a target structure which mediates or is associated with a biological activity, including treatment of conditions, disorders, or diseases mediated by or associated with a target structure, such as a virus, cell, subcellular structure or extracellular structure. The methods may be performed in situ in a non-invasive manner by placing a nanoparticle having a metallic shell on at least a fraction of a surface in a vicinity of a target structure in a subject and applying an initiation energy to a subject thus producing an effect on or change to the target structure directly or via a modulation agent. The nanoparticle is configured, upon exposure to a first wavelength λ1, to generate a second wavelength λ2 of radiation having a higher energy than the first wavelength λ1. The methods may further be performed by application of an initiation energy to a subject in situ to activate a pharmaceutical agent directly or via an energy modulation agent, optionally in the presence of one or more plasmonics active agents, thus producing an effect on or change to the target structure. Kits containing products or compositions formulated or configured and systems for use in practicing these methods.

Owner:DUKE UNIV +1

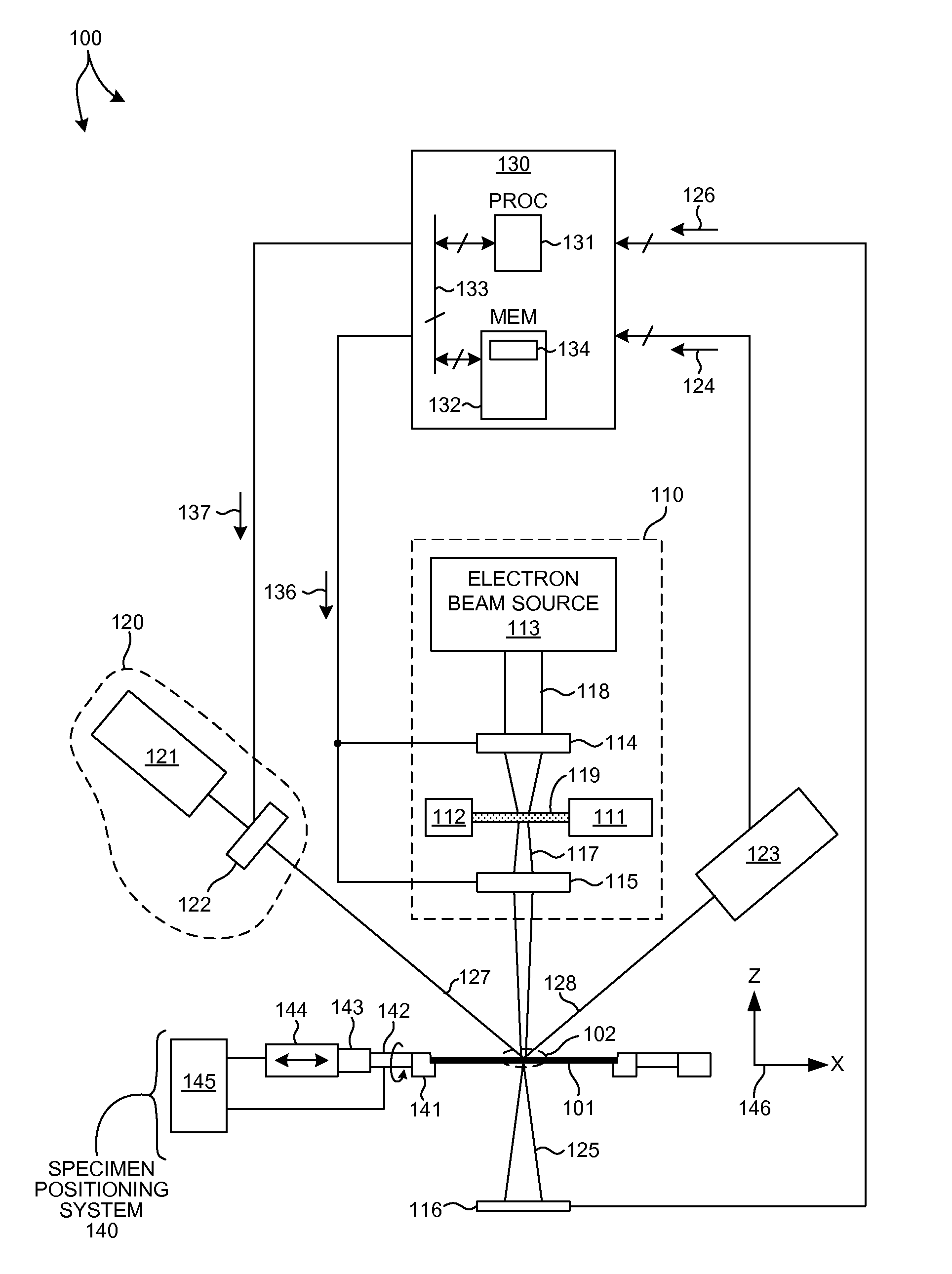

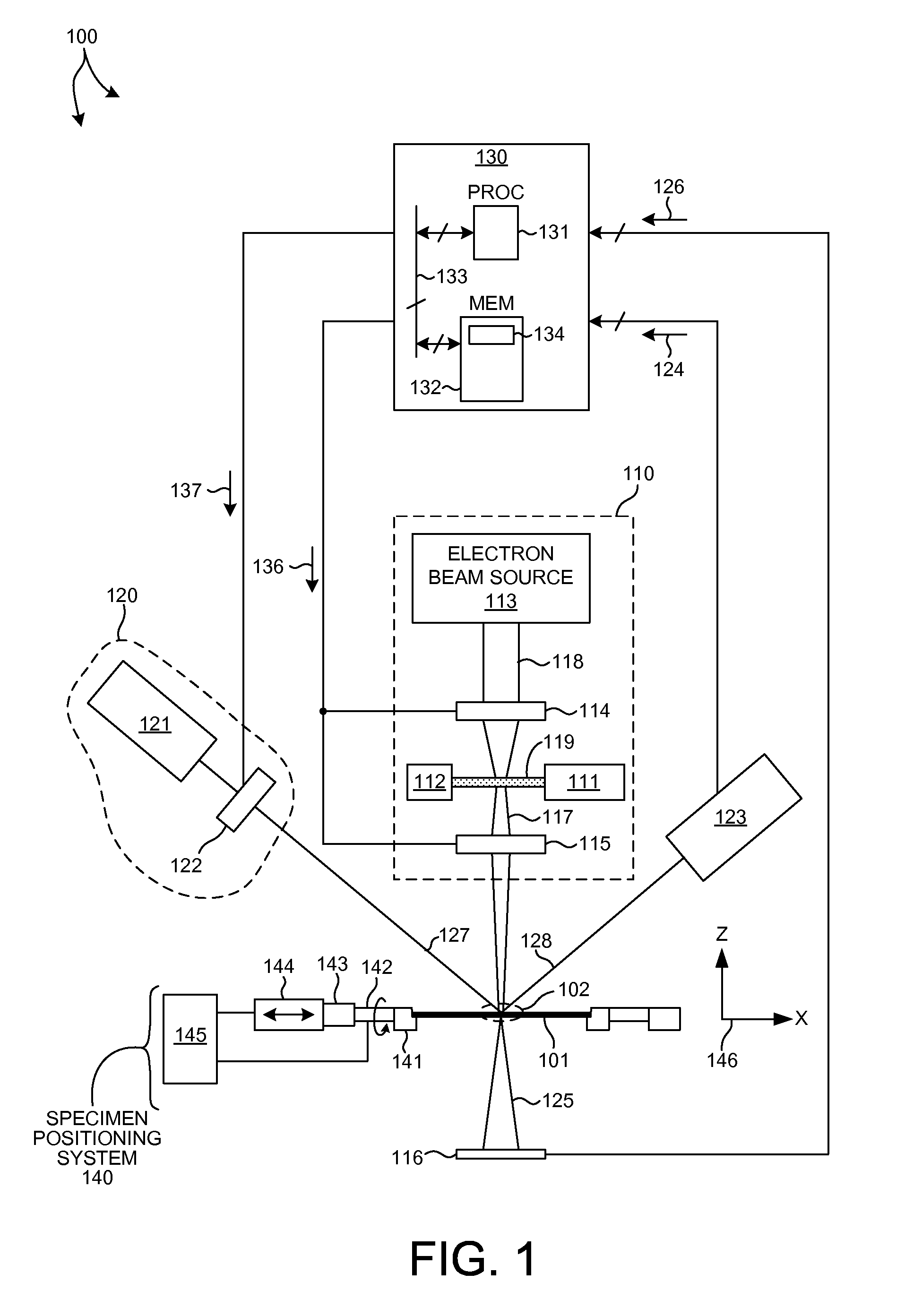

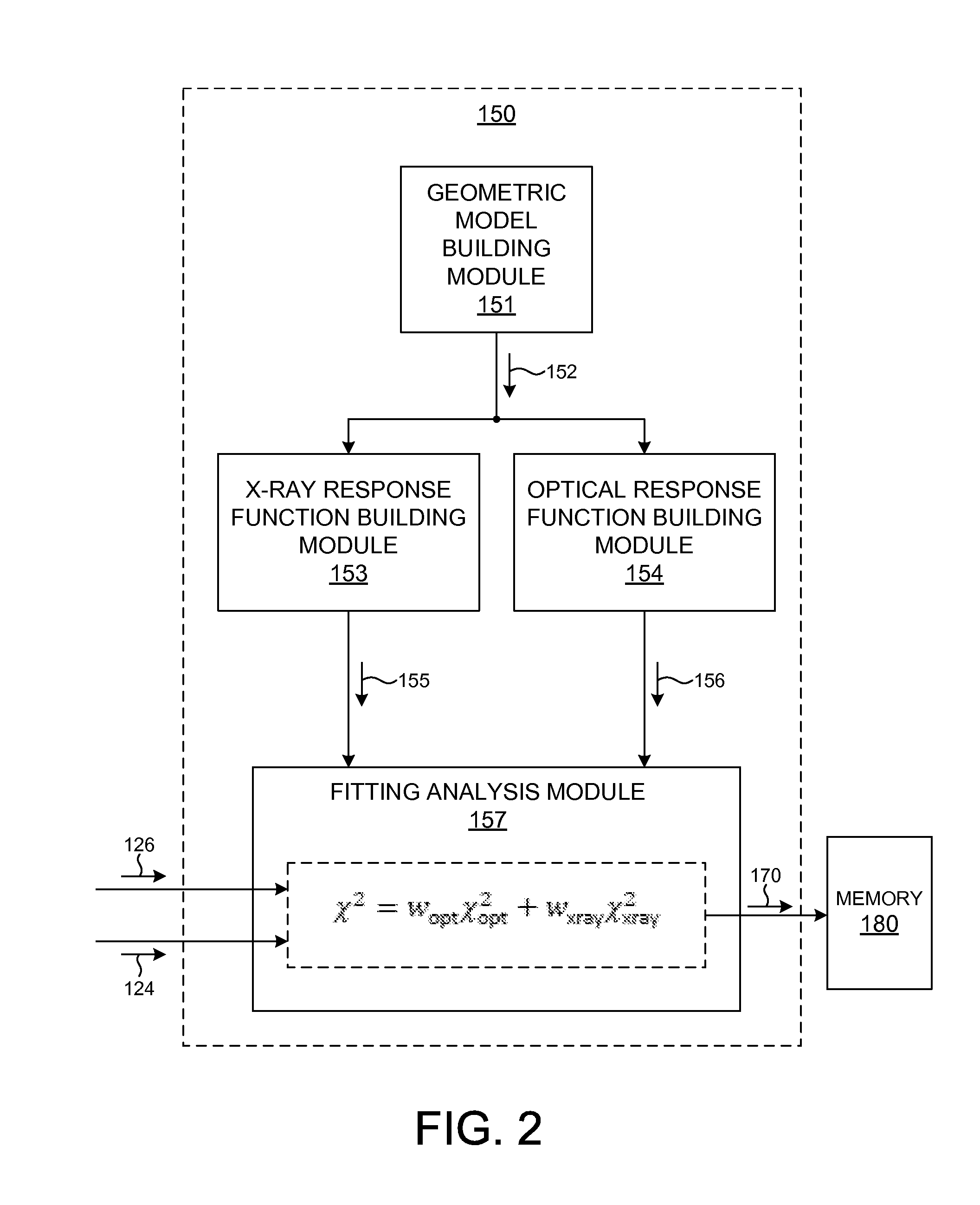

Metrology Tool With Combined X-Ray And Optical Scatterometers

ActiveUS20130304424A1Reduce correlationImprove accuracyMaterial analysis using wave/particle radiationAmplifier modifications to reduce noise influenceData setMetrology

Methods and systems for performing simultaneous optical scattering and small angle x-ray scattering (SAXS) measurements over a desired inspection area of a specimen are presented. SAXS measurements combined with optical scatterometry measurements enables a high throughput metrology tool with increased measurement capabilities. The high energy nature of x-ray radiation penetrates optically opaque thin films, buried structures, high aspect ratio structures, and devices including many thin film layers. SAXS and optical scatterometry measurements of a particular location of a planar specimen are performed at a number of different out of plane orientations. This increases measurement sensitivity, reduces correlations among parameters, and improves measurement accuracy. In addition, specimen parameter values are resolved with greater accuracy by fitting data sets derived from both SAXS and optical scatterometry measurements based on models that share at least one geometric parameter. The fitting can be performed sequentially or in parallel.

Owner:KLA CORP

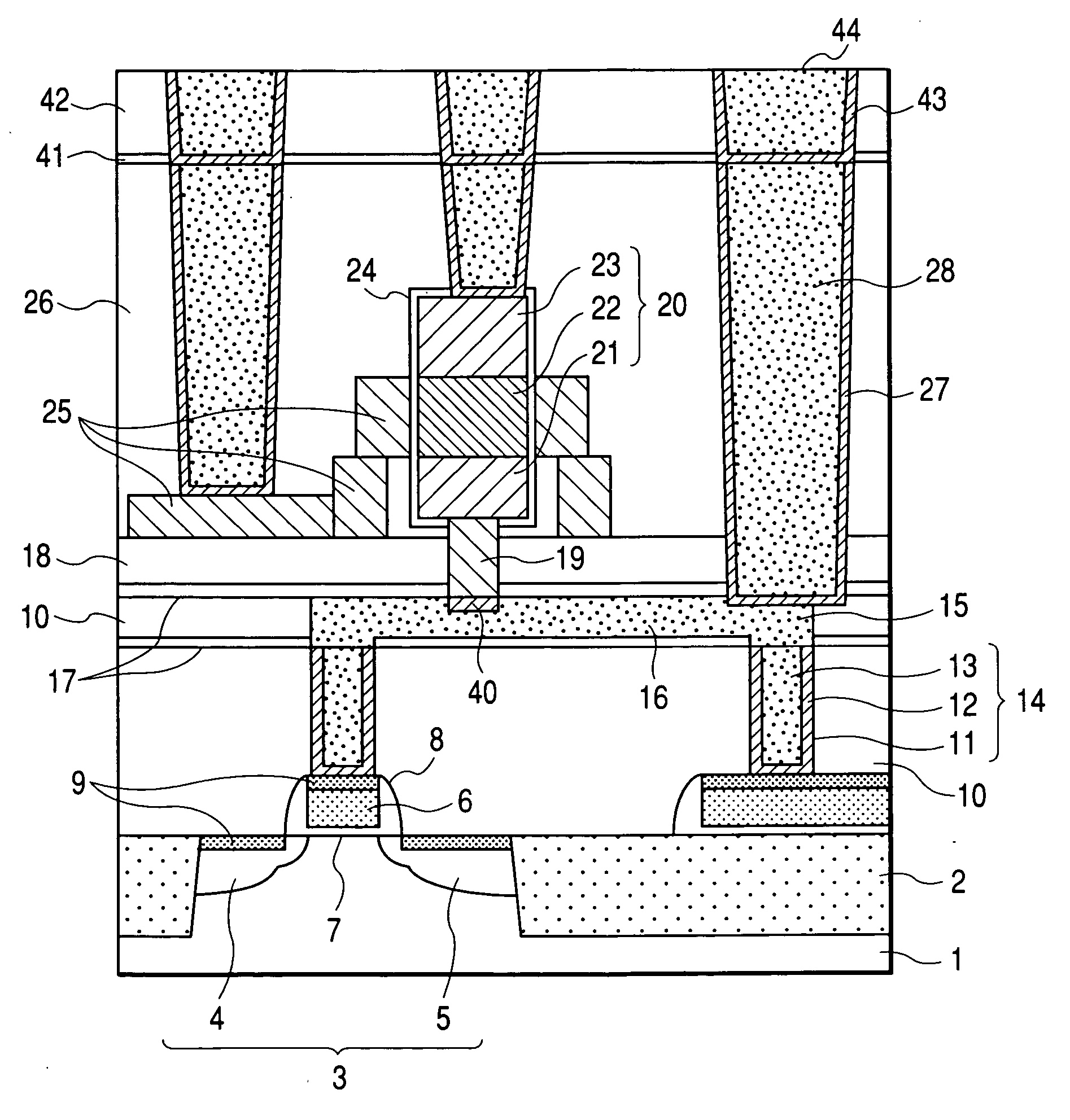

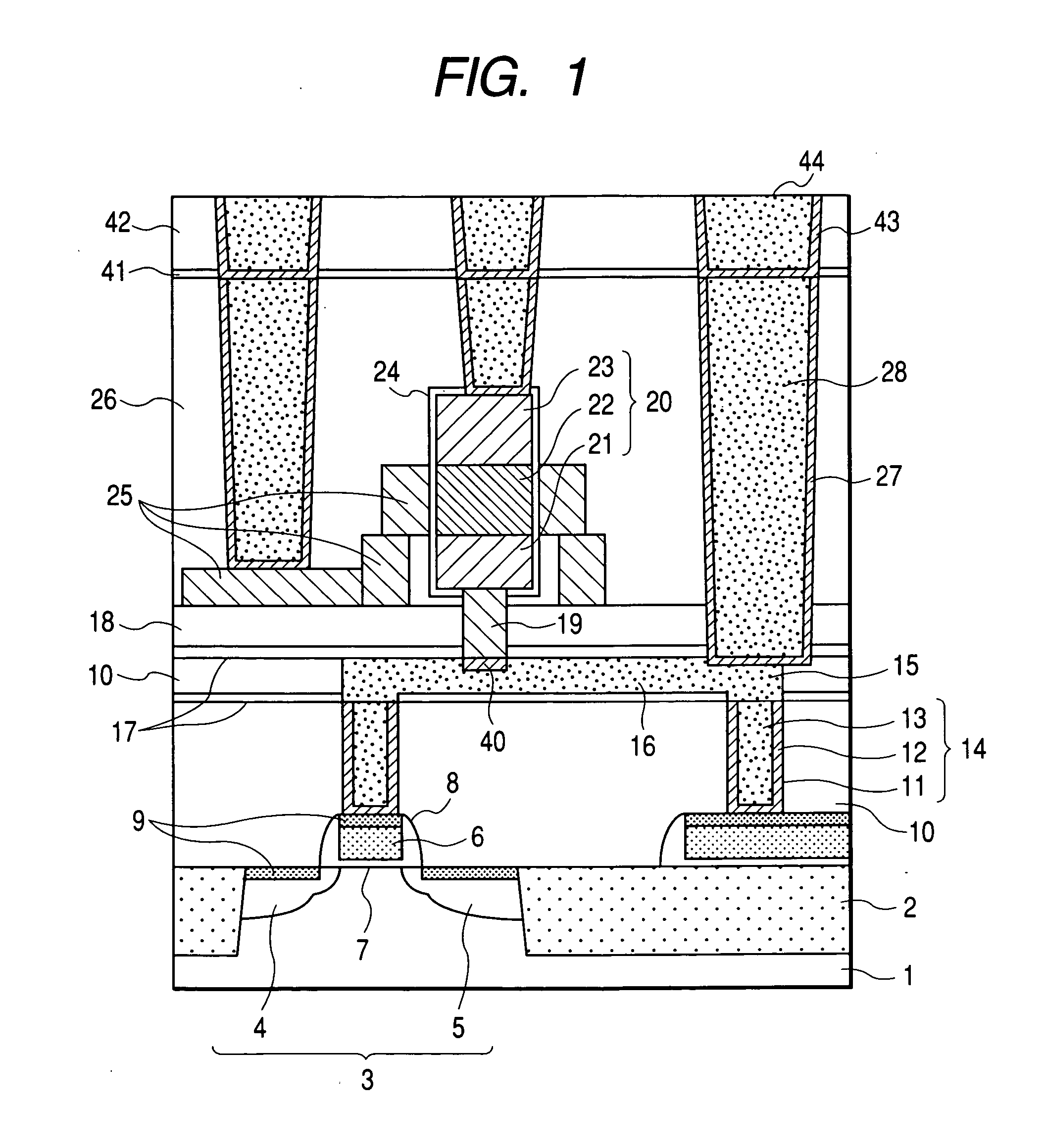

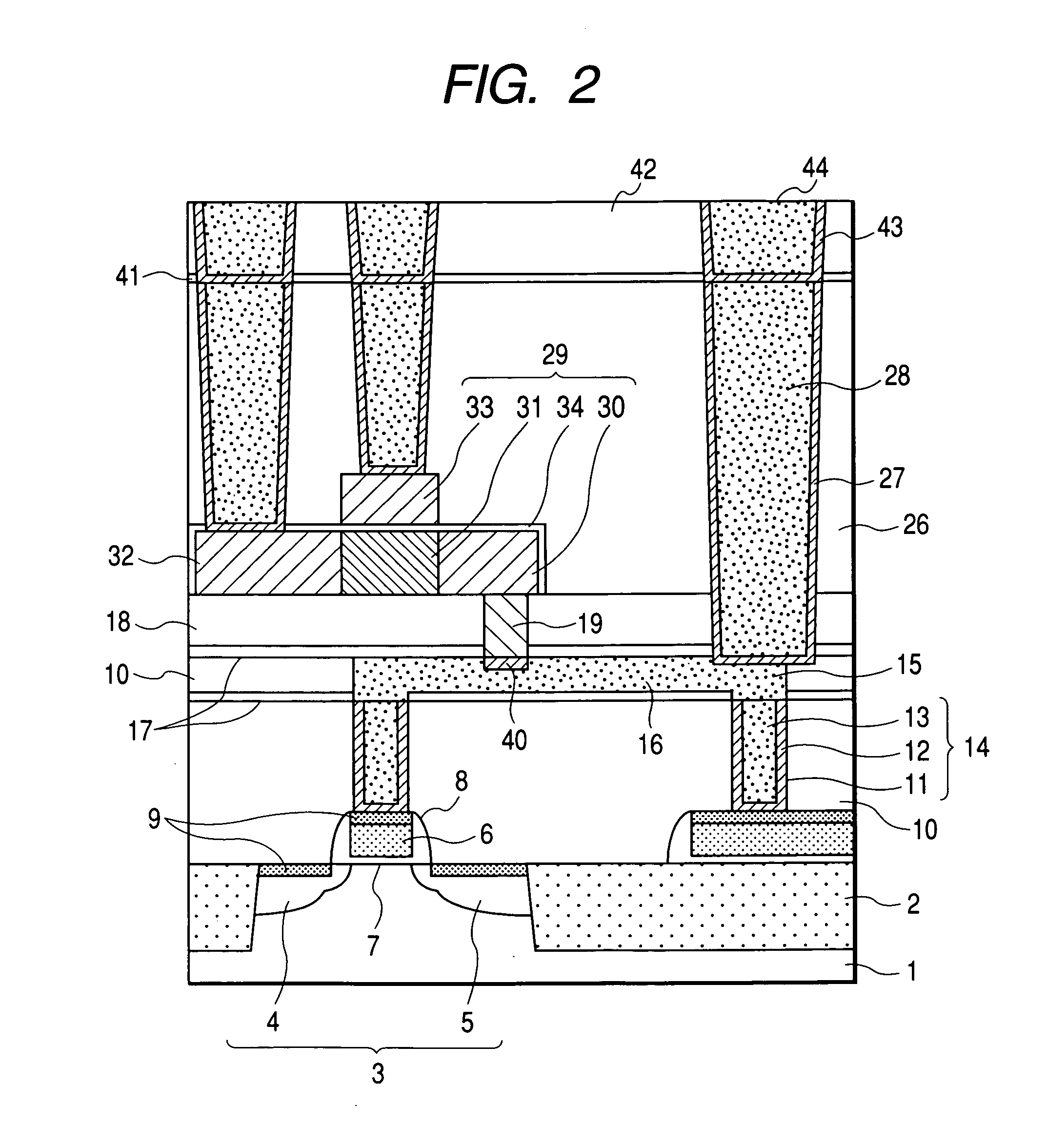

Semiconductor integrated circuit device and manufacturing method thereof

InactiveUS20050073051A1Minimize the possibilityEfficient removalTransistorSemiconductor/solid-state device detailsHigh energyUltraviolet lights

A manufacturing process for a semiconductor integrated circuit device which prevents occurrence of reaction between metal wiring and a boron-doped silicon plug over it in heat treatment for a MOS transistor to be formed over them and reduces the possibility of rise in contact resistance. Metal boride is formed on an exposed metal surface in the bottom of an opening made in an interlayer insulating film over the metal wiring. In order to facilitate formation of such metal boride, metal oxide remaining on the metal surface is removed with an aqueous ammonia solution. The meal surface is irradiated with high energy ultraviolet light in order to remove organic matter remaining in the opening and facilitate removal of the metal oxide with the aqueous ammonia solution.

Owner:RENESAS ELECTRONICS CORP

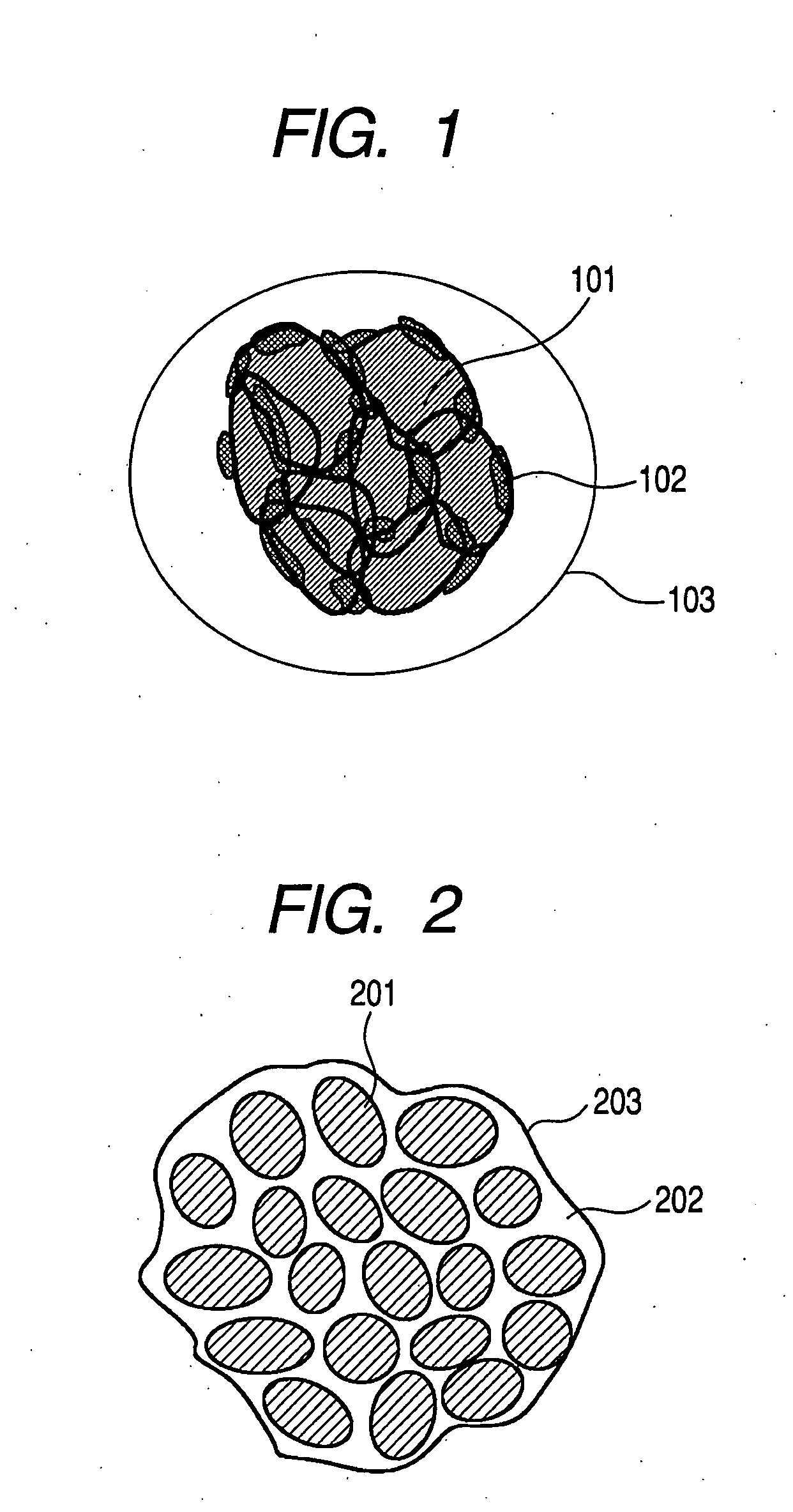

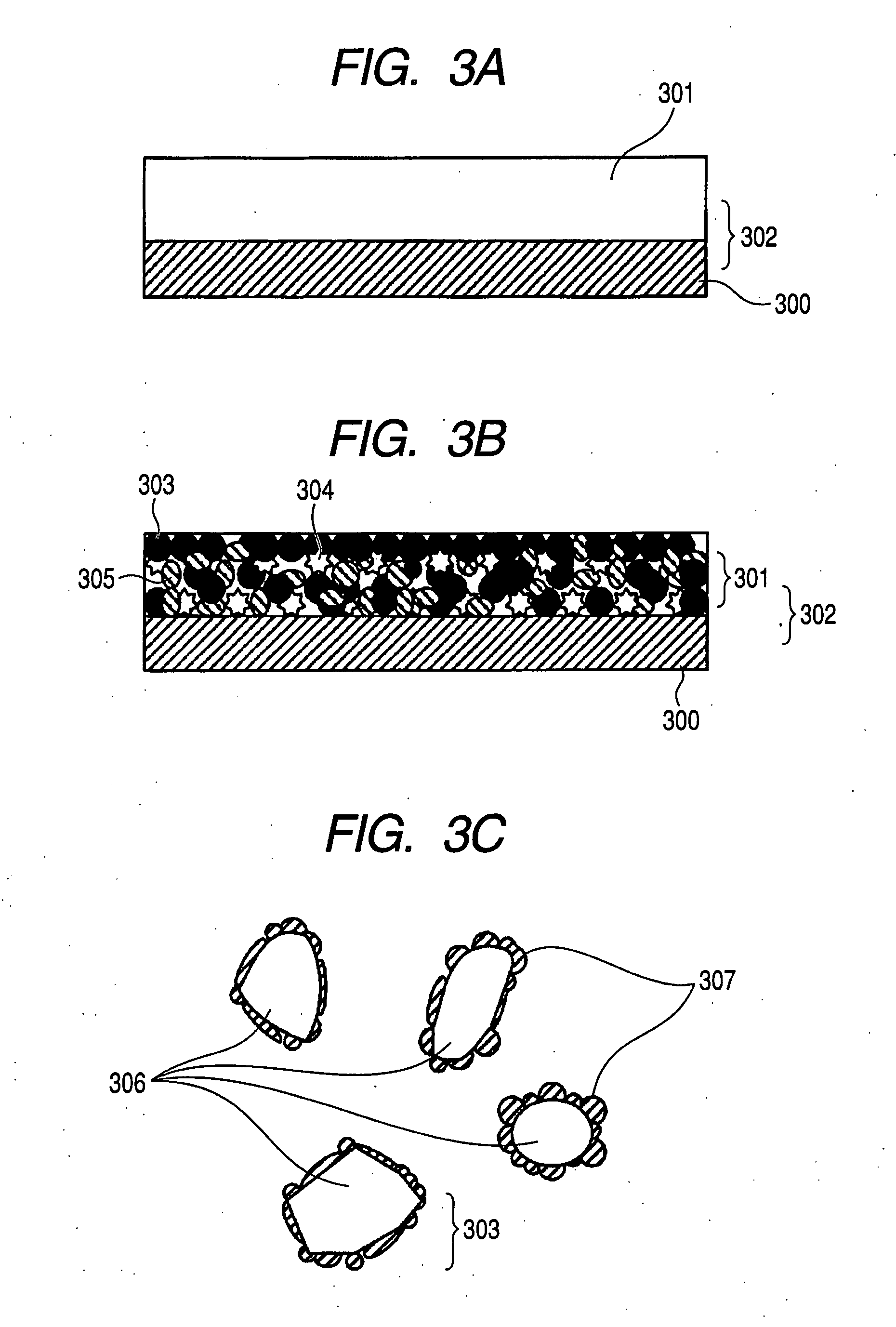

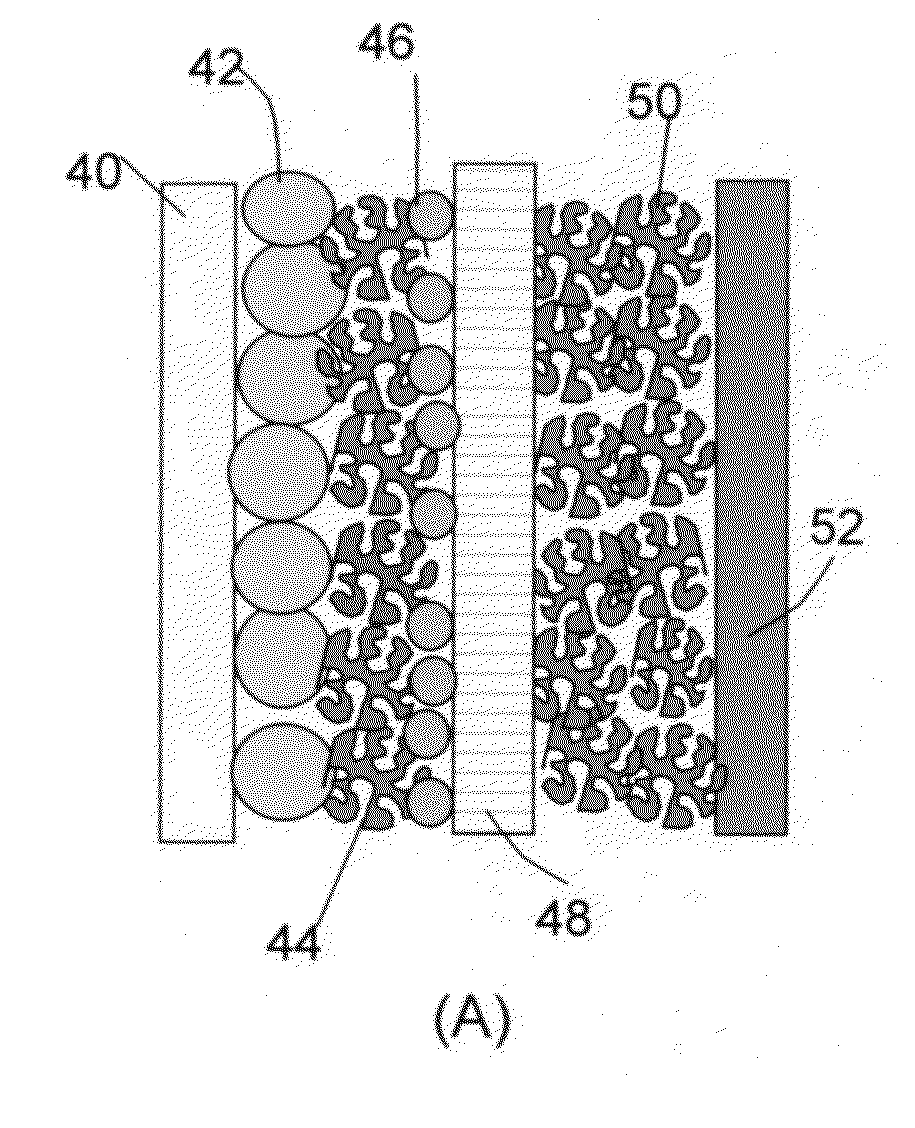

Powder material, electrode structure using the powder material, and energy storage device having the electrode structure

InactiveUS20080003503A1Fast chargingIncrease energy densityNon-metal conductorsElectrode manufacturing processesElectrical conductorHigh energy

A powder material which can electrochemically store and release lithium ions rapidly in a large amount is provided. In addition, an electrode structure for an energy storage device which can provide a high energy density and a high power density and has a long life, and an energy storage device using the electrode structure are provided. In a powder material which can electrochemically store and release lithium ions, the surface of particles of one of silicon metal and tin metal and an alloy of any thereof is coated by an oxide including a transition metal element selected from the group consisting of W, Ti, Mo, Nb, and V as a main component. The electrode structure includes the powder material. The battery device includes a negative electrode having the electrode structure, a lithium ion conductor, and a positive electrode, and utilizes an oxidation reaction of lithium and a reduction reaction of lithium ion.

Owner:CANON KK

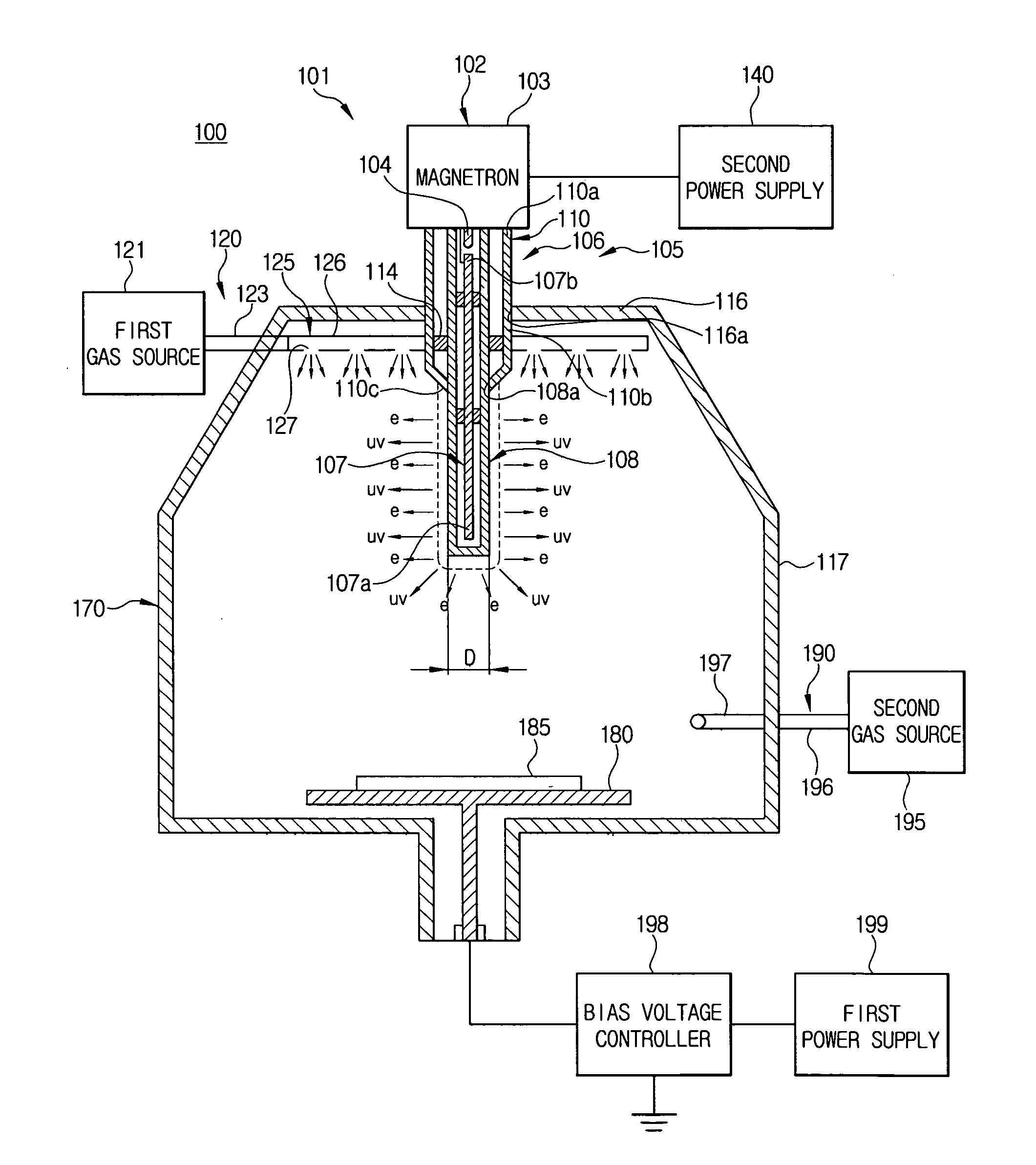

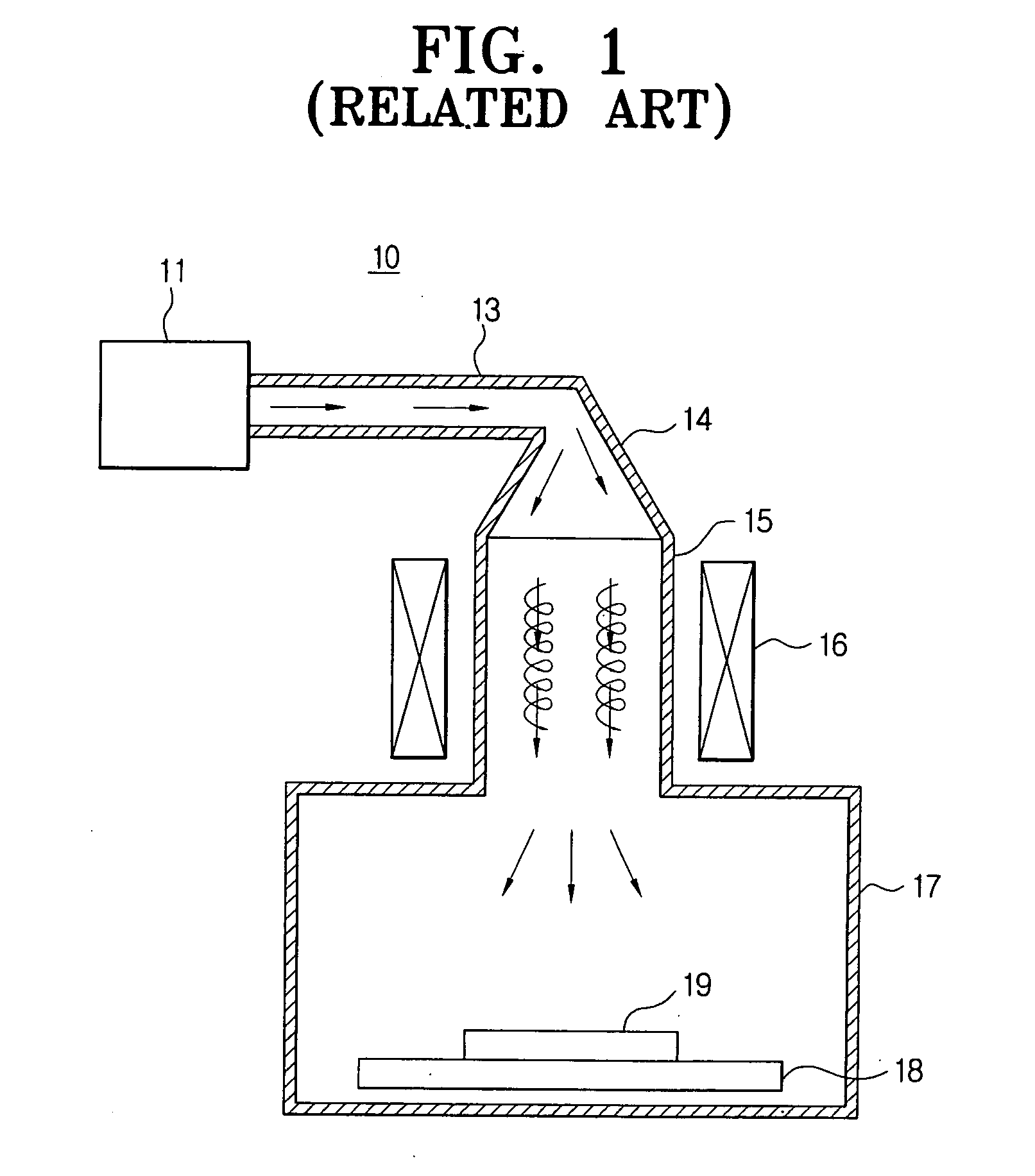

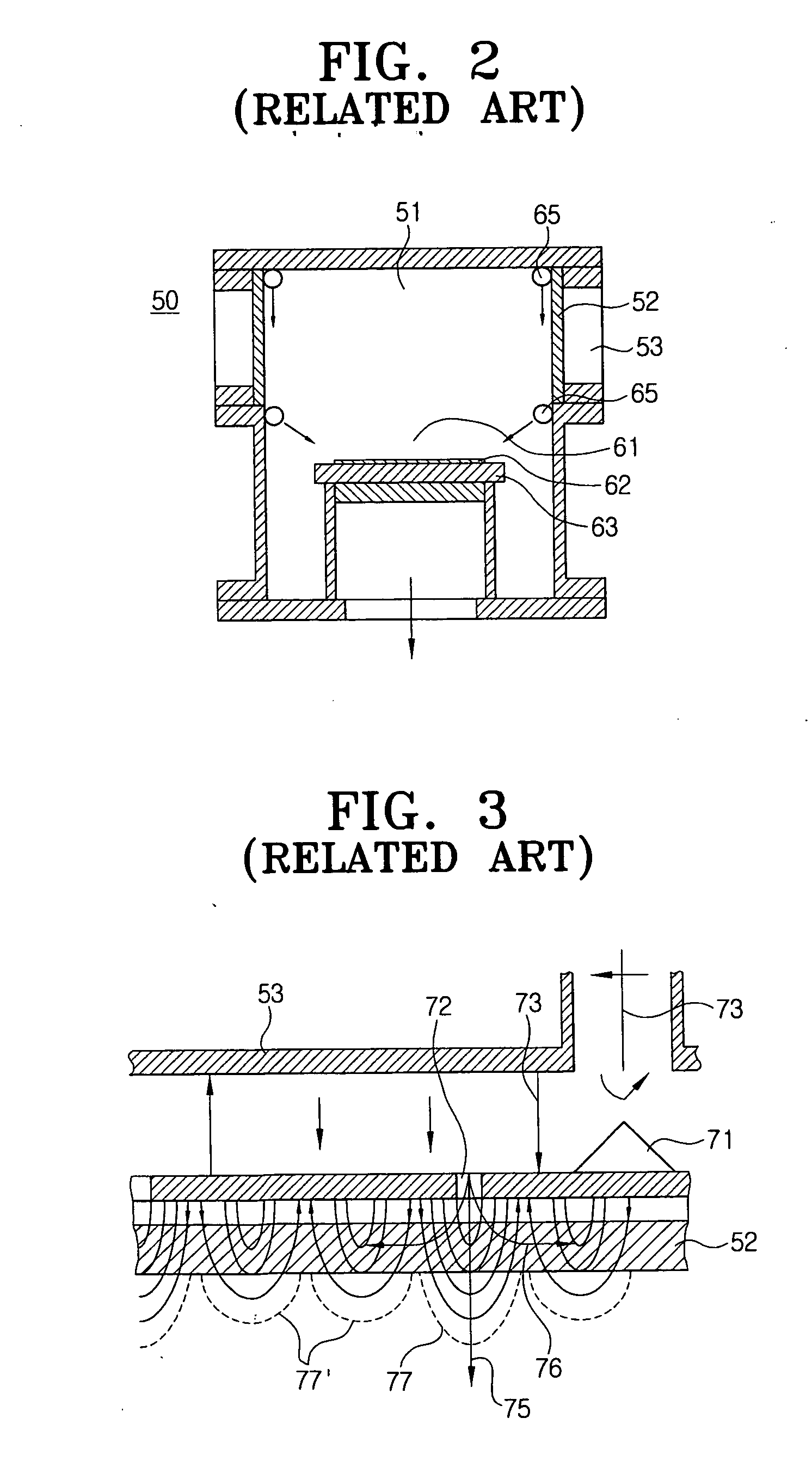

Microwave resonance plasma generating apparatus and plasma processing system having the same

ActiveUS20070045244A1Increase plasma producing efficiencySimple structureElectric discharge tubesElectric arc lampsHigh energyCoaxial waveguides

A microwave resonance plasma generating apparatus, a plasma processing system having the same and a method of generating a microwave resonance plasma are provided. The apparatus includes a microwave generating unit which generates a microwave, and a plasma producing unit which produces electrons and photons of high energy using the microwave generated from the microwave generating unit. The plasma producing unit includes a coaxial waveguide having an inner electrode disposed adjacent to the microwave generating unit, an outer electrode connected to the microwave generating unit and disposed to coaxially surround a portion of the inner electrode, the outer electrode being shorter than the inner electrode, and a dielectric tube disposed between the inner electrode and the outer electrode to insulate between the inner electrode and the outer electrode. The coaxial waveguide utilizes a principle of “cut or truncated electrode of coaxial waveguide” and a resonance phenomenon of Langmiur.

Owner:SAMSUNG ELECTRONICS CO LTD

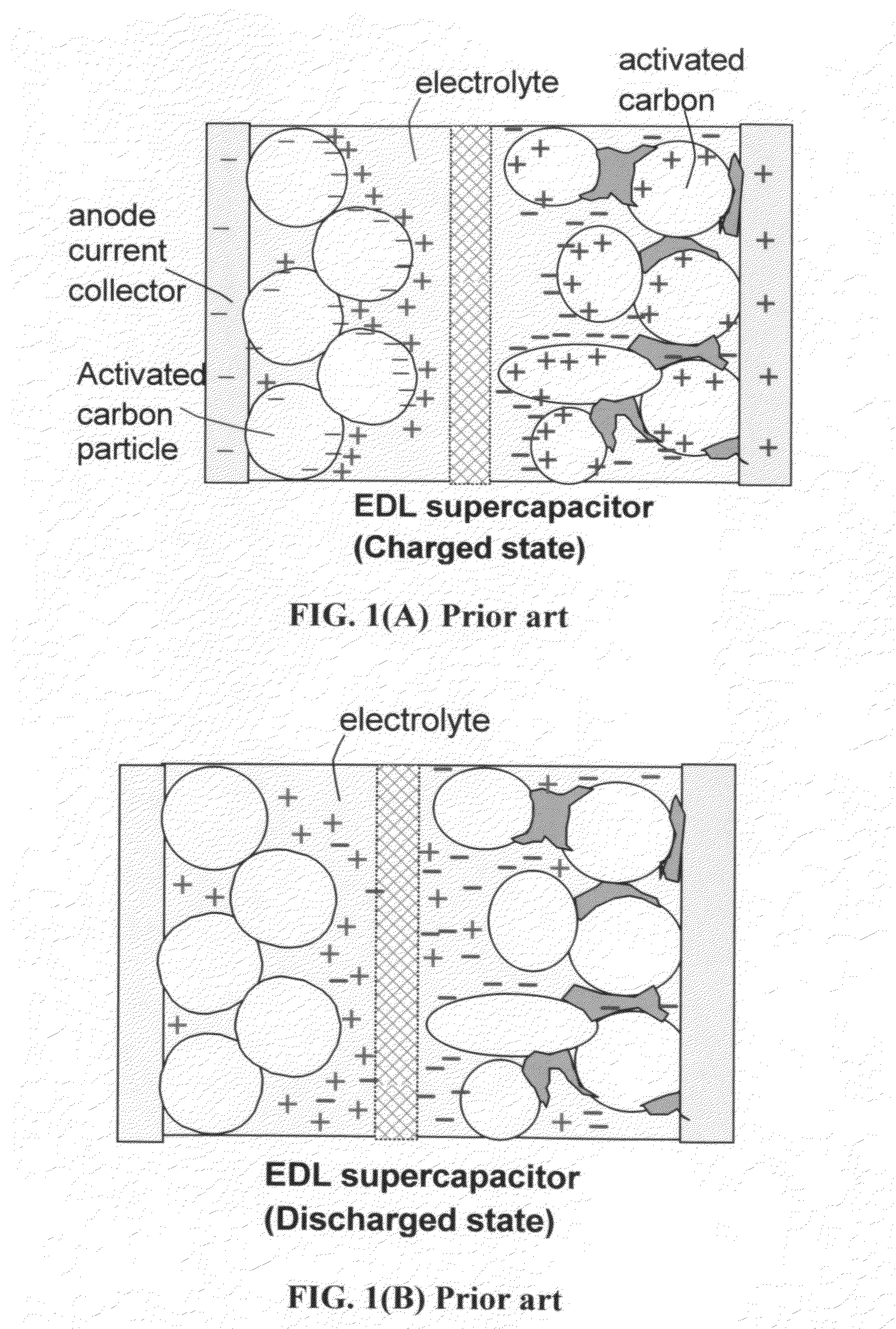

Hybrid electrode and surface-mediated cell-based super-hybrid energy storage device containing same

PendingUS20130171502A1Primary cell to battery groupingMaterial nanotechnologyHigh energyLithium metal

The present invention provides a multi-component hybrid electrode for use in an electrochemical super-hybrid energy storage device. The hybrid electrode contains at least a current collector, at least an intercalation electrode active material storing lithium inside interior or bulk thereof, and at least an intercalation-free electrode active material having a specific surface area no less than 100 m2 / g and storing lithium on a surface thereof, wherein the intercalation electrode active material and the intercalation-free electrode active material are in electronic contact with the current collector. The resulting super-hybrid cell exhibits exceptional high power and high energy density, and long-term cycling stability that cannot be achieved with conventional supercapacitors, lithium-ion capacitors, lithium-ion batteries, and lithium metal secondary batteries.

Owner:GLOBAL GRAPHENE GRP INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com