Patents

Literature

5616results about How to "Avoid the need" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrosurgical system

InactiveUS6893435B2Sufficient powerImproving impedanceSurgical instruments for heatingSurgical forcepsEngineeringRadio frequency

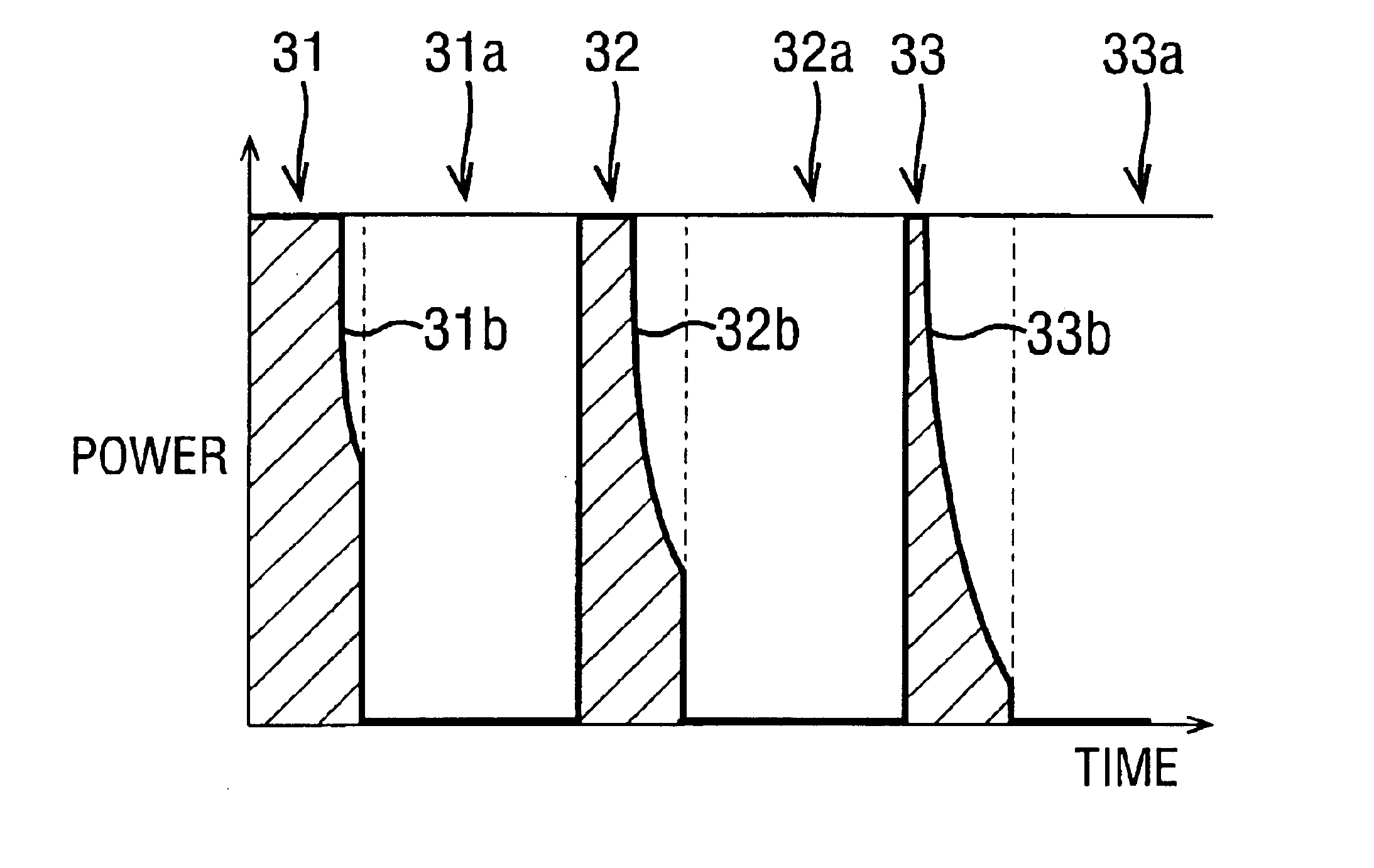

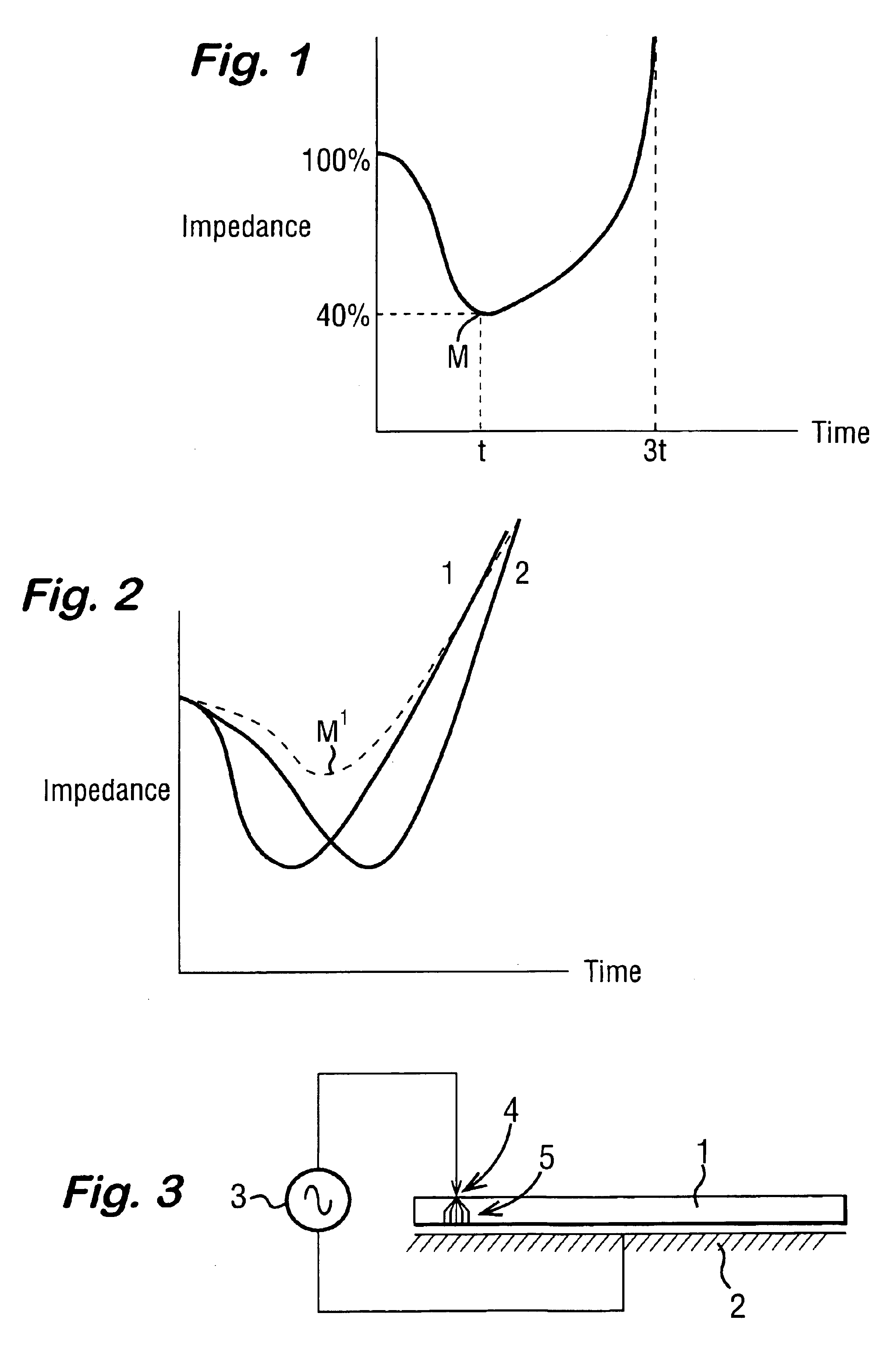

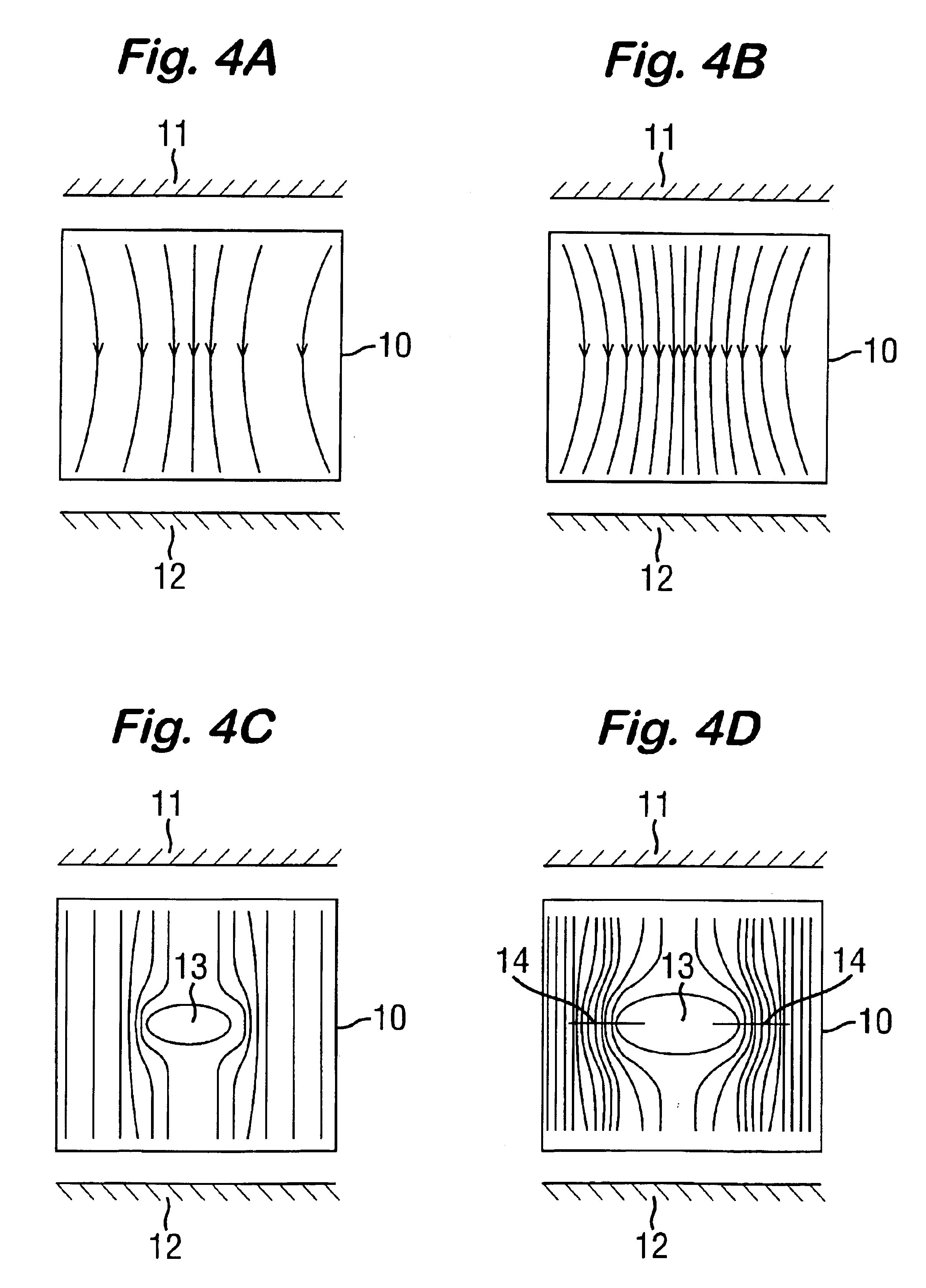

An electrosurgical system has an electrosurgical generator and a bipolar electrosurgical instrument, the generator being arranged to perform a treatment cycle in which radio frequency energy is delivered to the instrument as an amplitude-modulated radio frequency power signal in the form of a succession of pulses characterized by periods of a least 100 milliseconds between successive pulses and by a predetermined pulse mark-to-space ratio. Energy delivery between pulses is substantially zero and the mark-to-space ratio is typically 1:4 or less. Each burst is of sufficiently high power to form vapor bubbles within tissue being treated and the time between successive pulses is sufficiently long to permit condensation of the vapor. The treatment cycles may each include an initial period and a subsequent period, the pulse duty cycle being increased or energy being delivered continuously in the subsequent period in order that tissue coagulation can be achieved quickly despite increasing tissue impedance.

Owner:GYRUS MEDICAL LTD

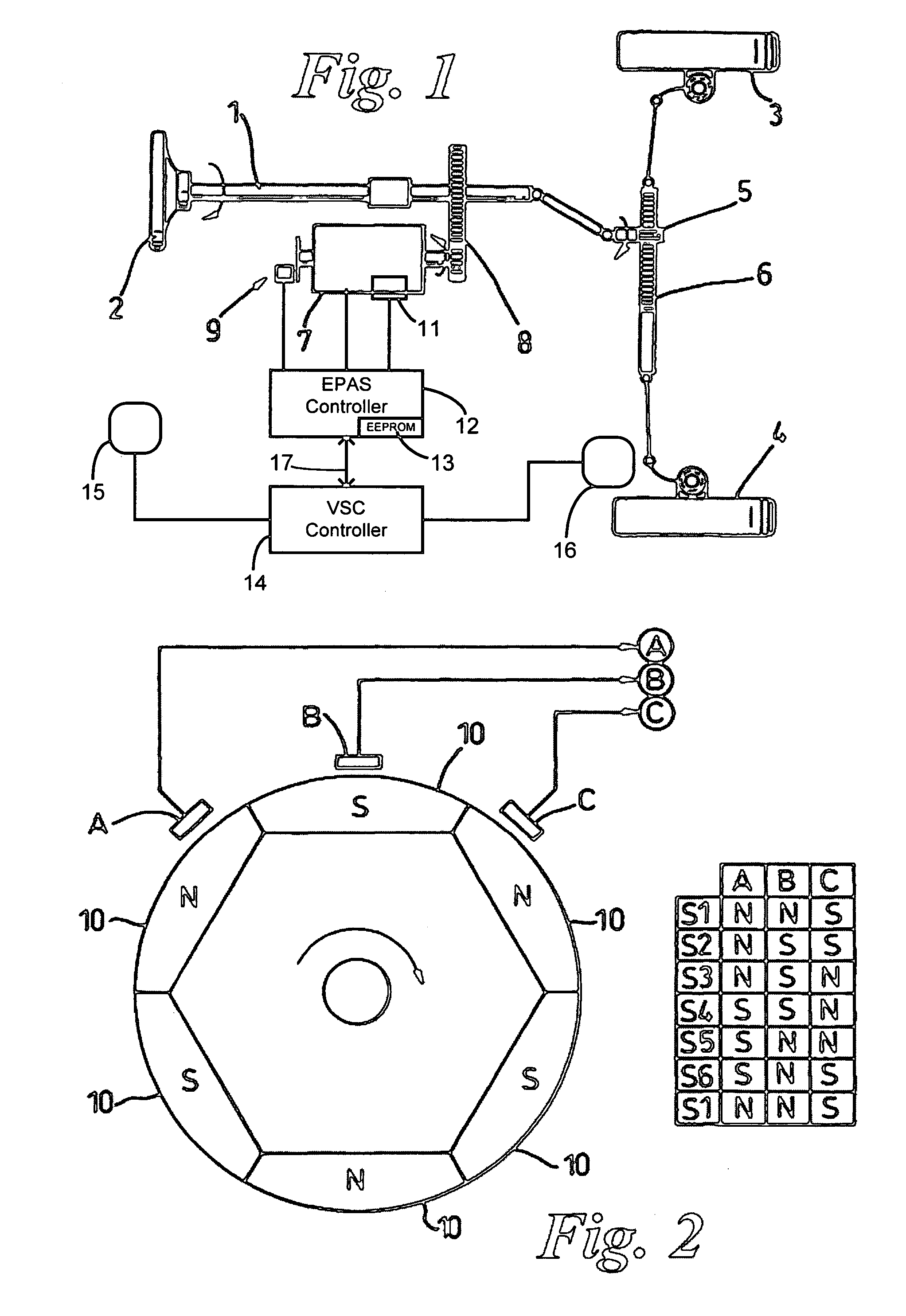

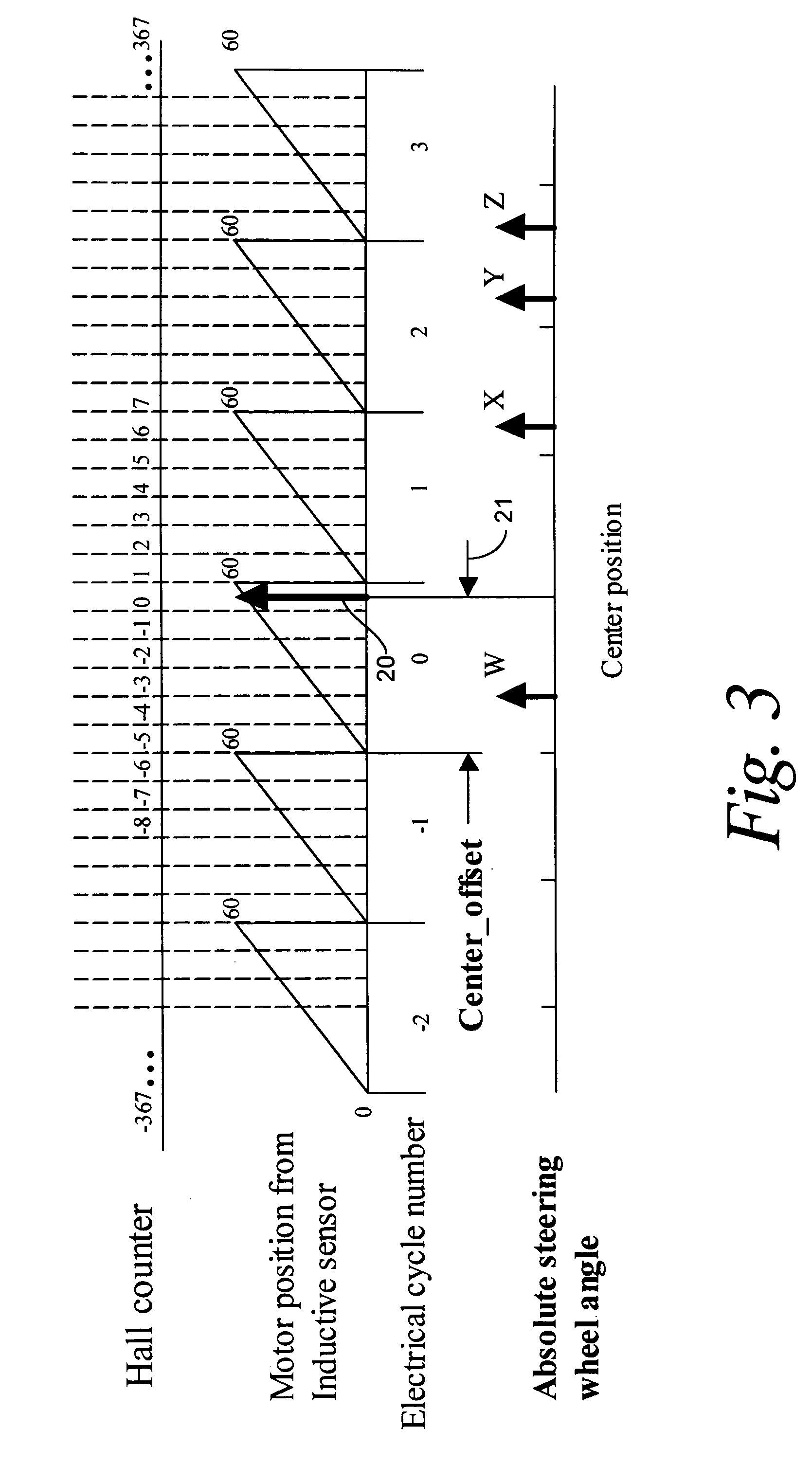

Recovery of calibrated center steering position after loss of battery power

ActiveUS7295907B2Accurate absolute steering angleAvoid the needDigital data processing detailsOptical signallingElectric power steeringSteering angle

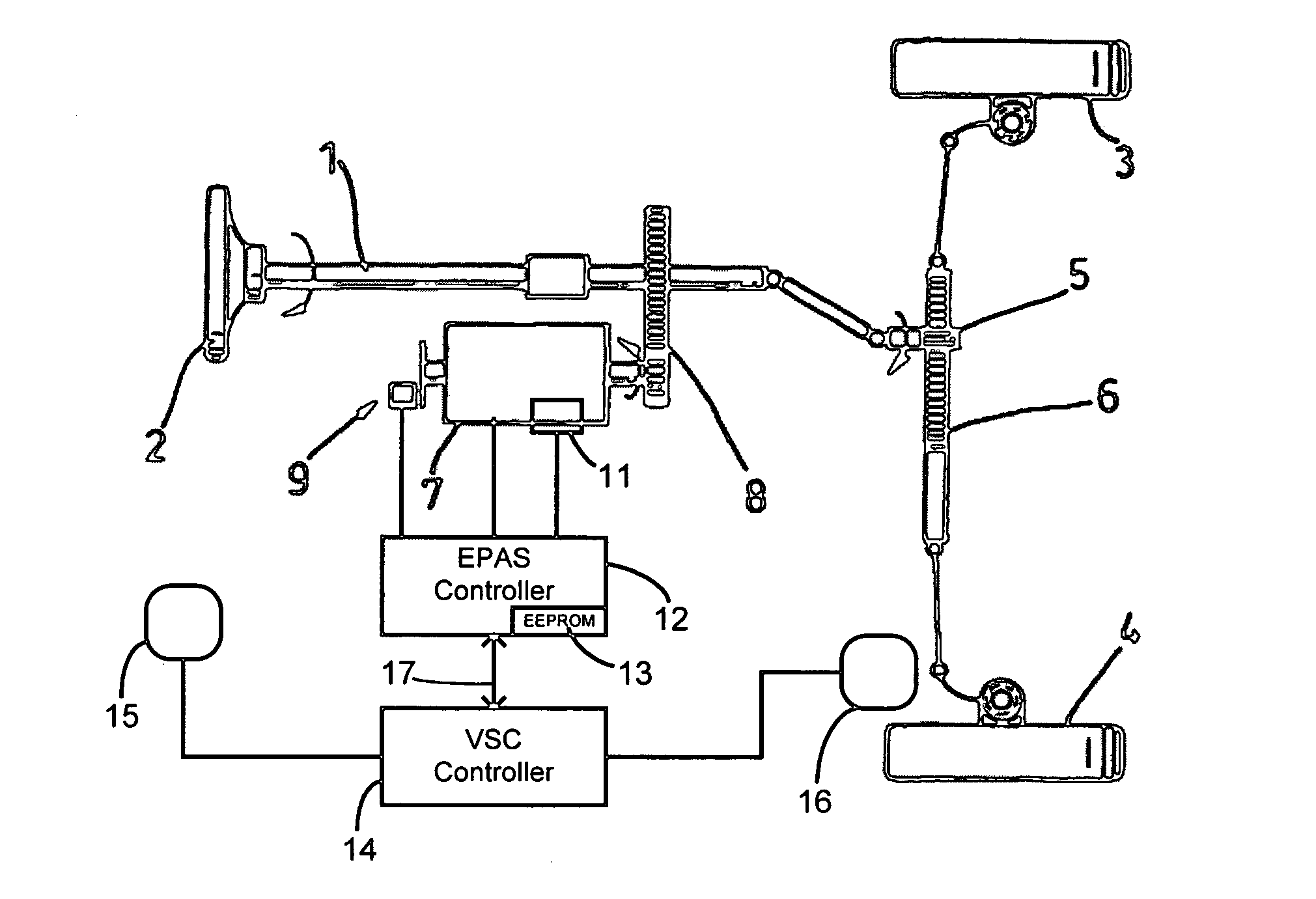

The steering angle of a vehicle is monitored using position sensors of an electric motor of an electric power assisted steering (EPAS) system. A position of the electric motor corresponding to the straight-ahead, center position of the steering system is stored in non-volatile memory during a steering calibration procedure, such as an end-of-line calibration in a vehicle assembly plant. Following power loss due to a dead battery, a steering angle zeroing procedure performed in a vehicle stability control (VSC) system generates a center position with enough accuracy to be within one electrical cycle of the motor. The pre-stored electric motor position is then used to determine the electrical cycle where the center position was located, and accurate monitoring of steering angle is resumed.

Owner:TRW AUTOMOTIVE US LLC

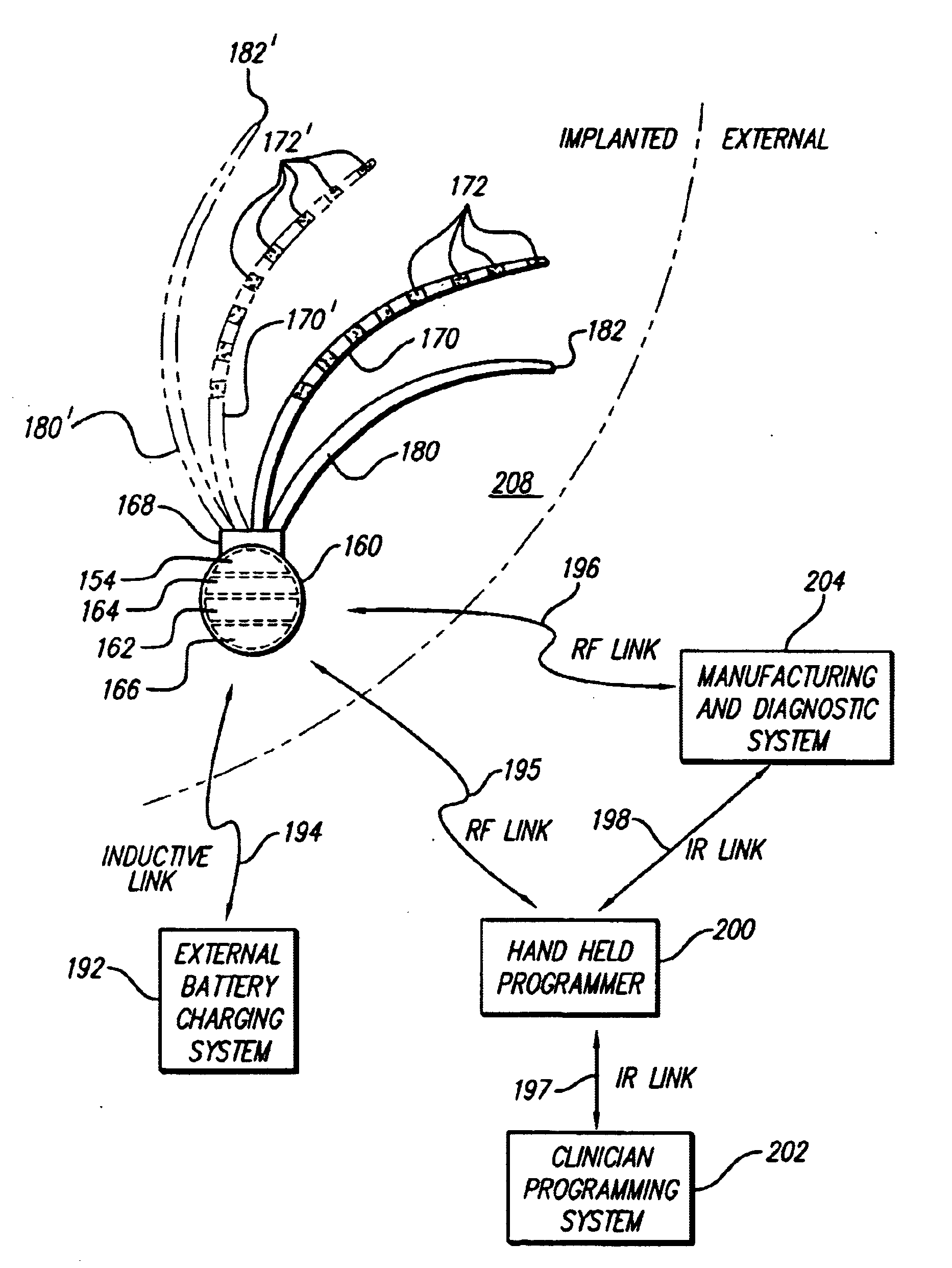

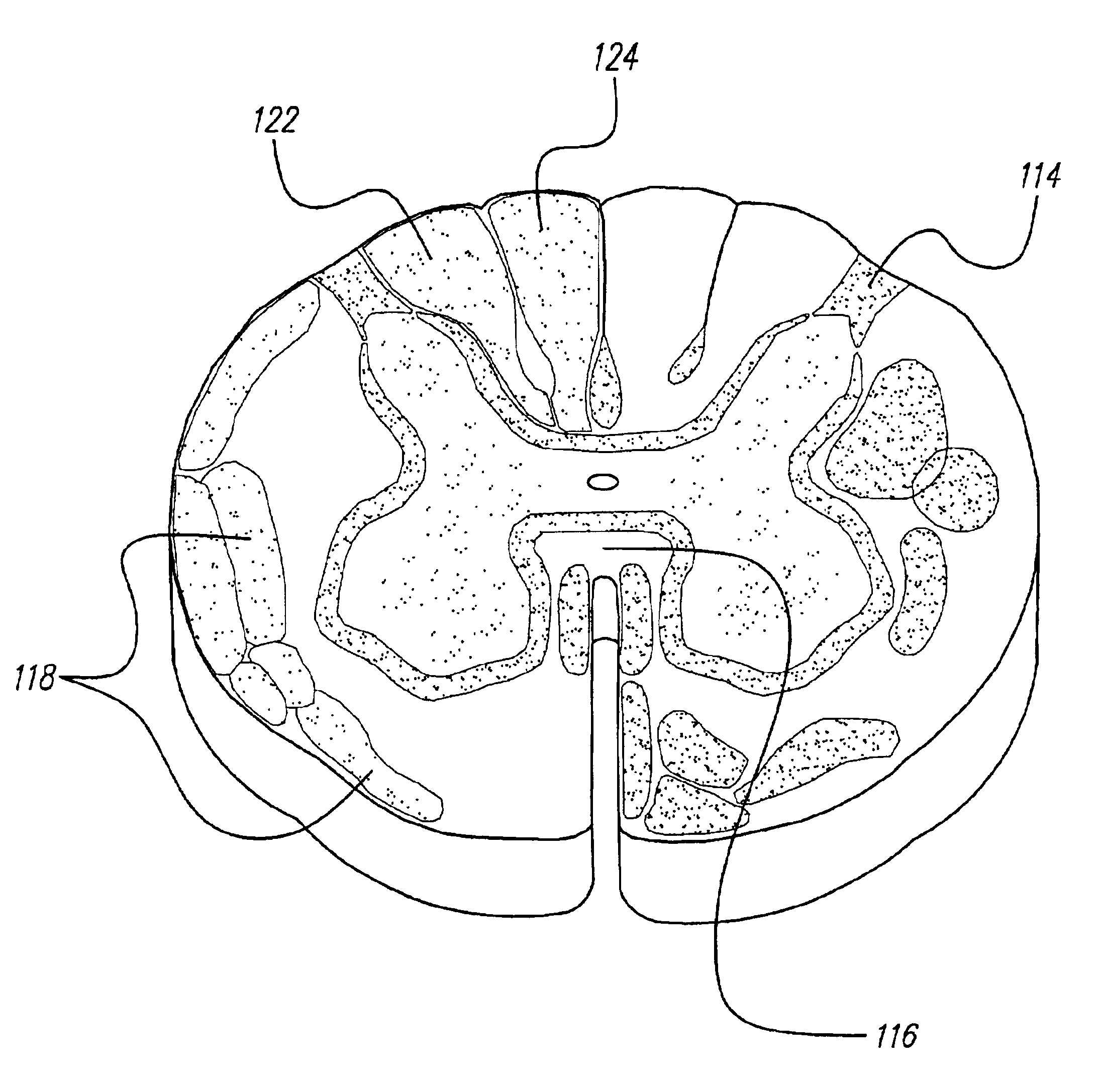

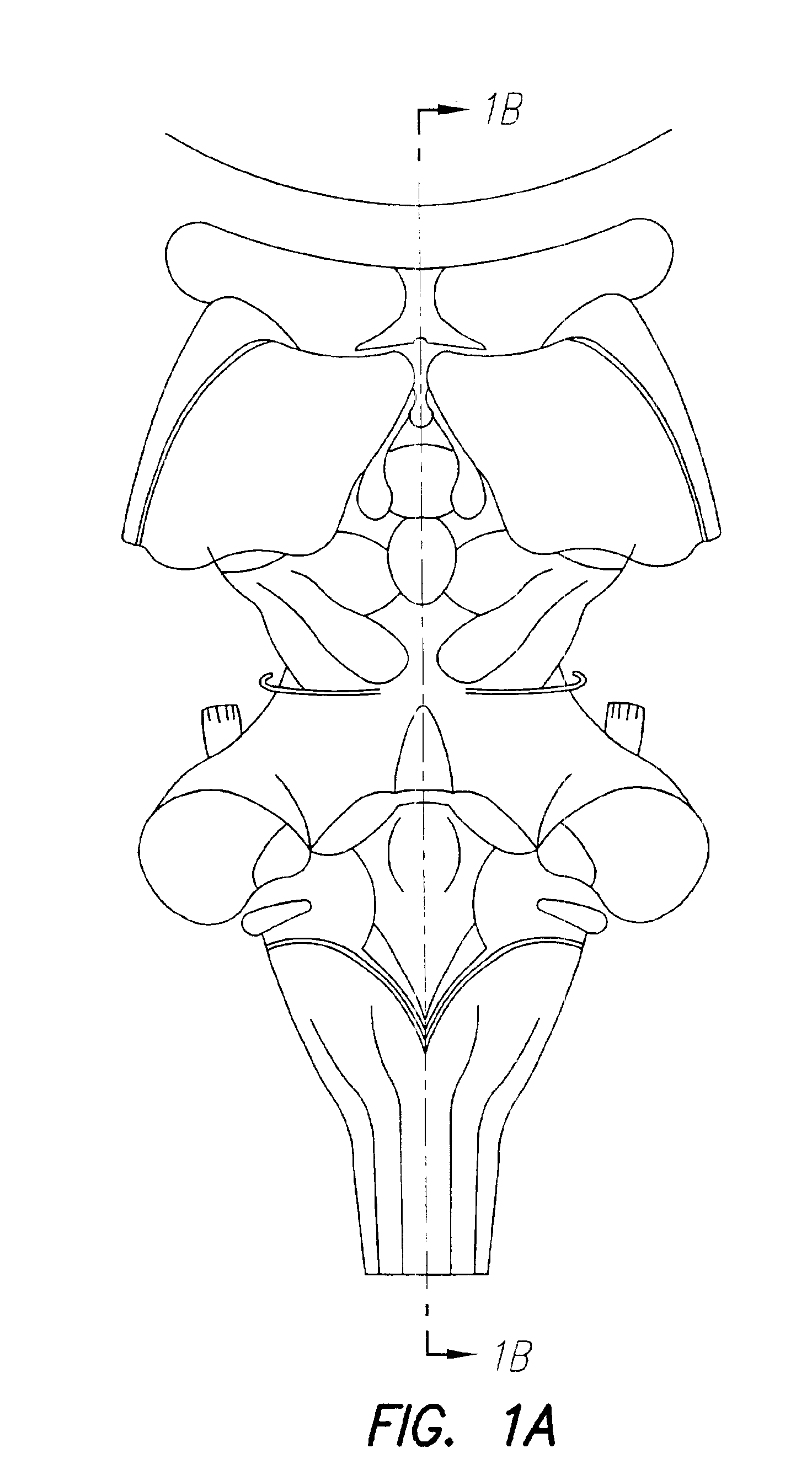

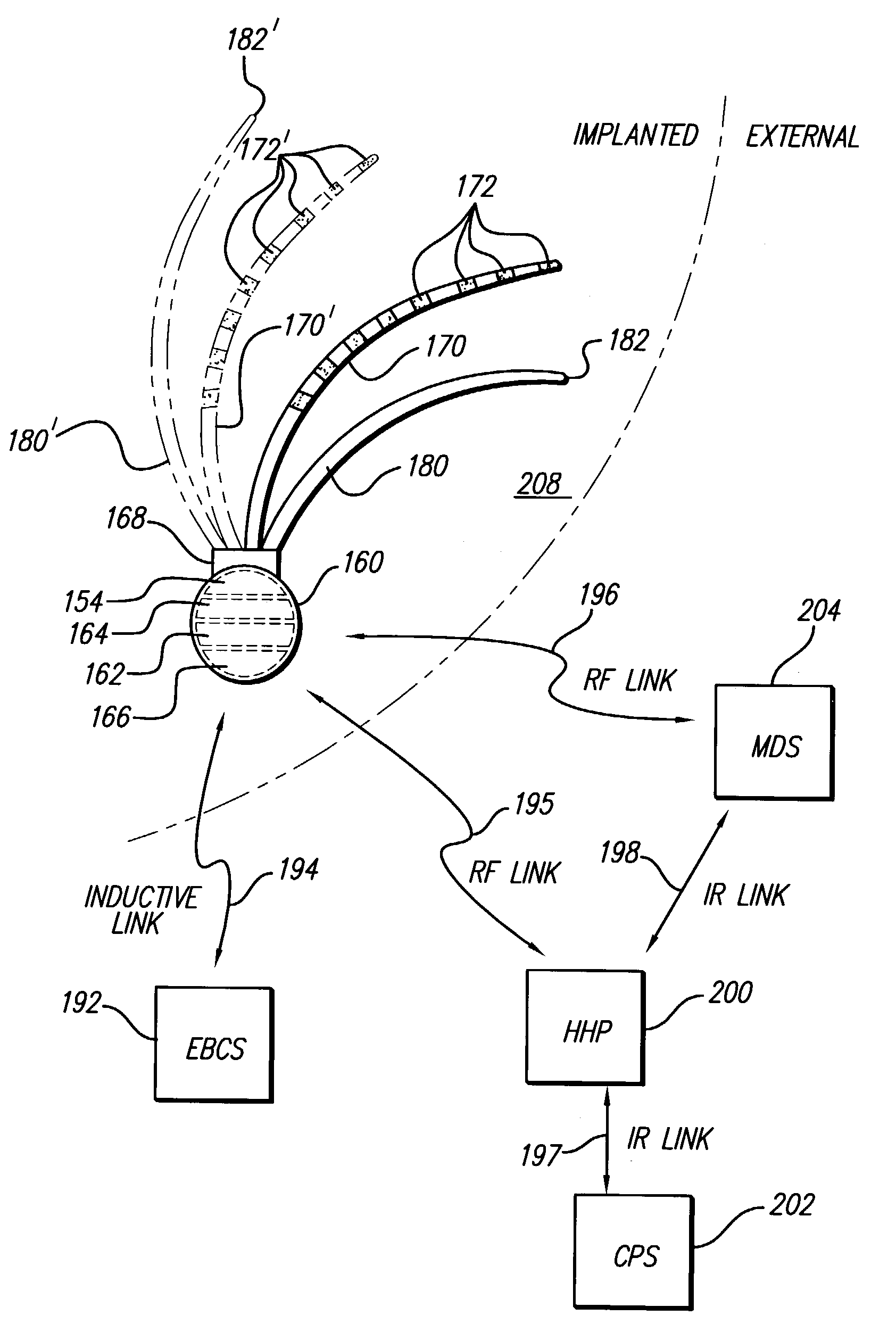

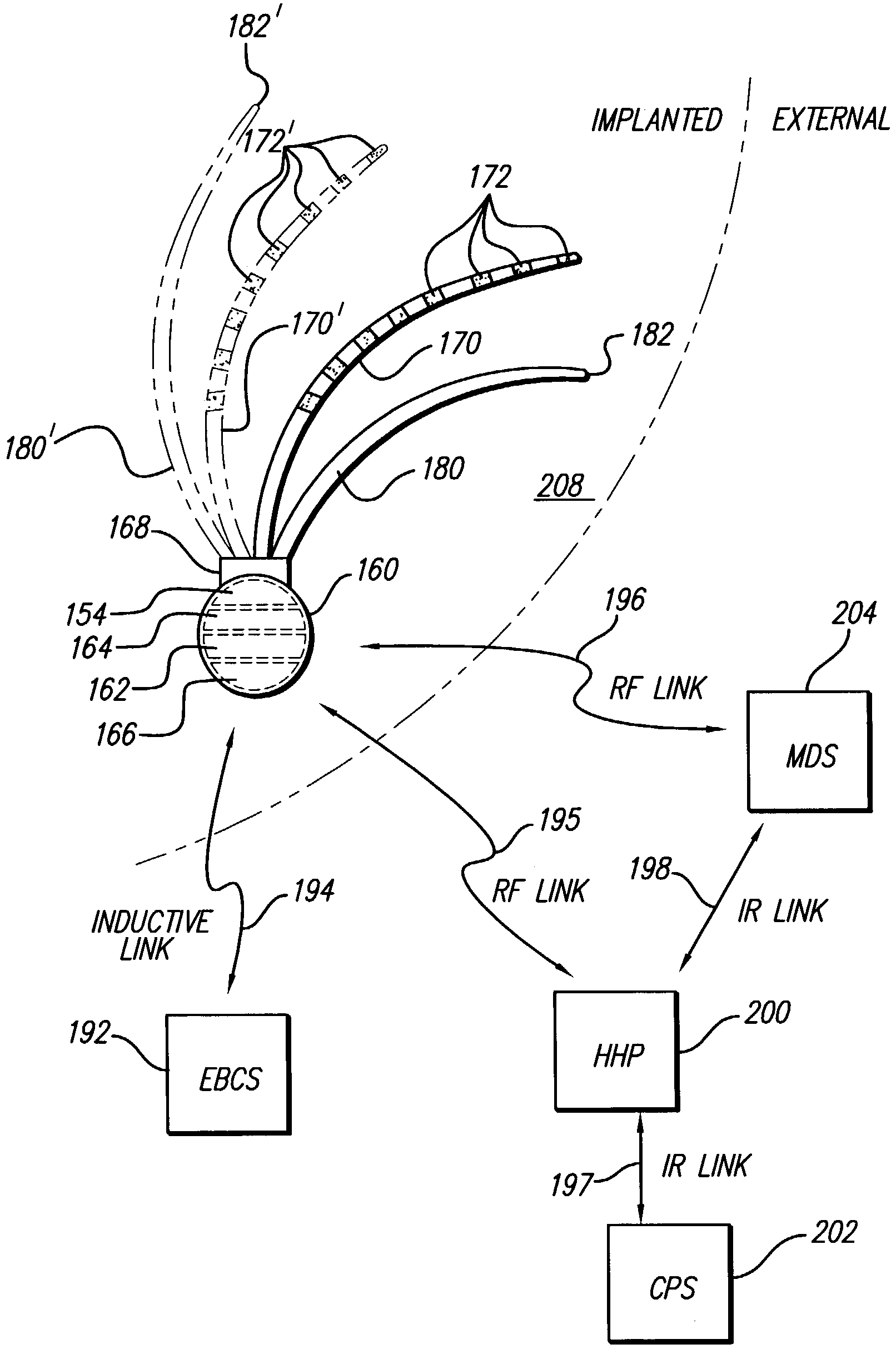

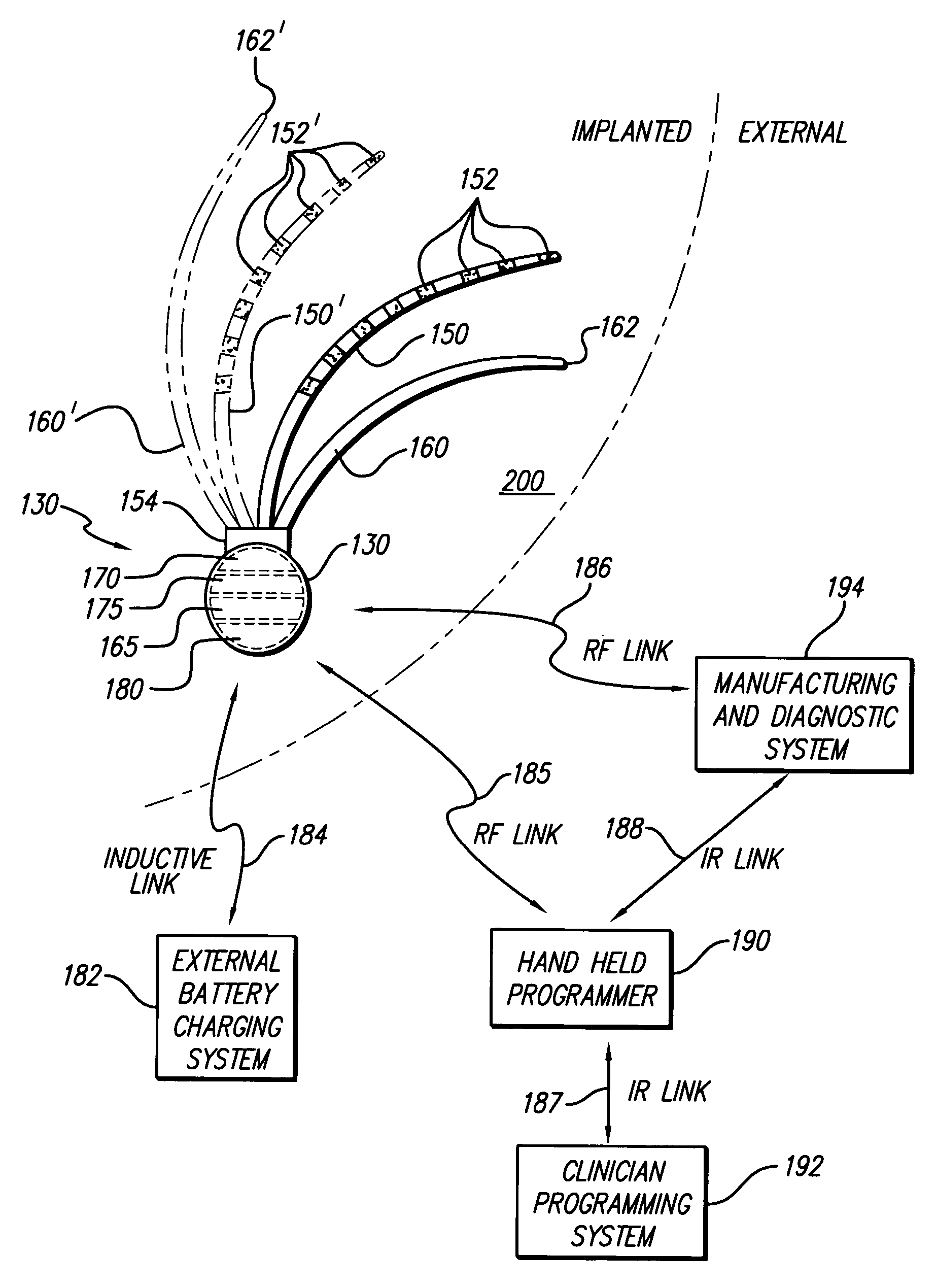

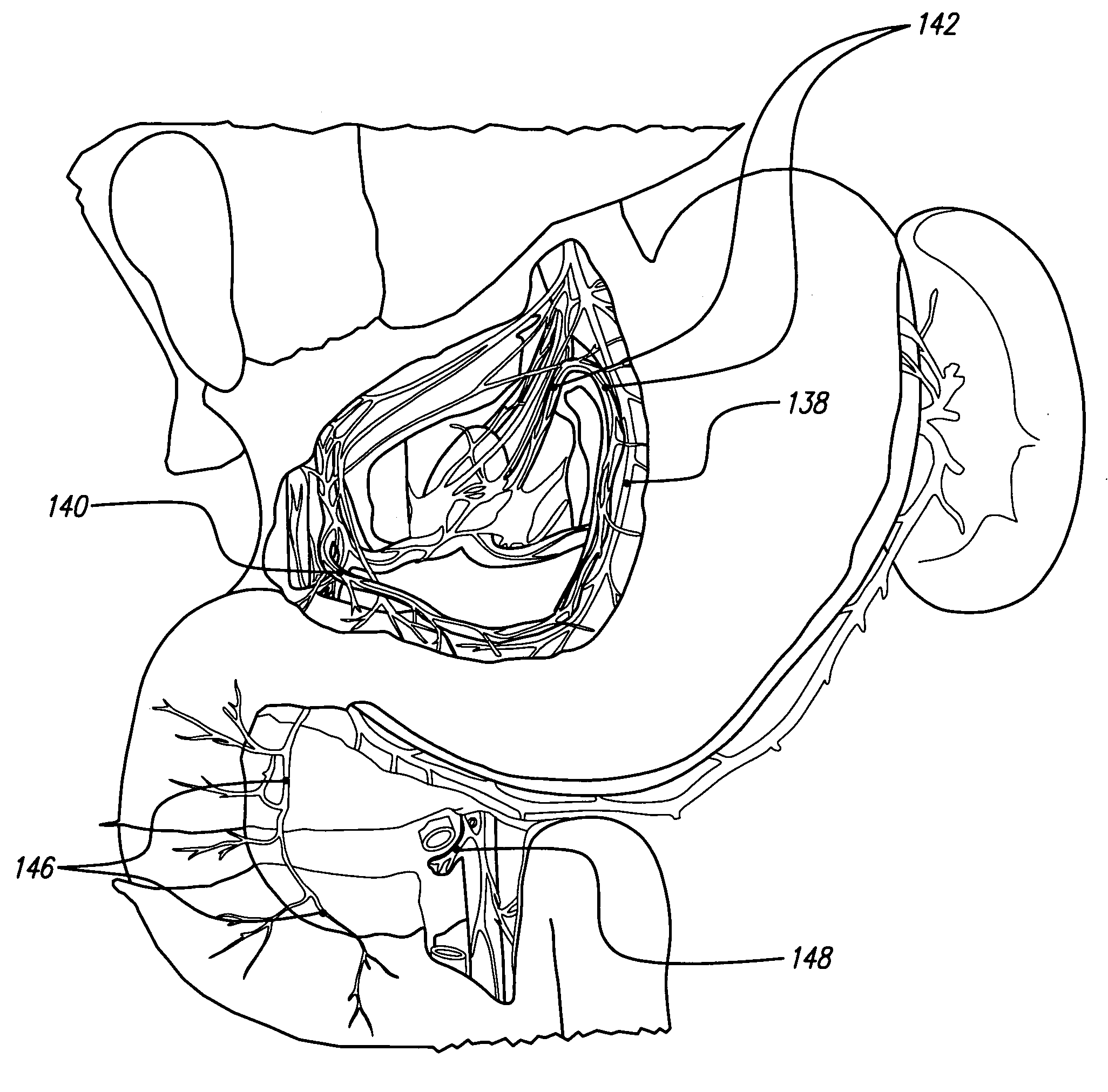

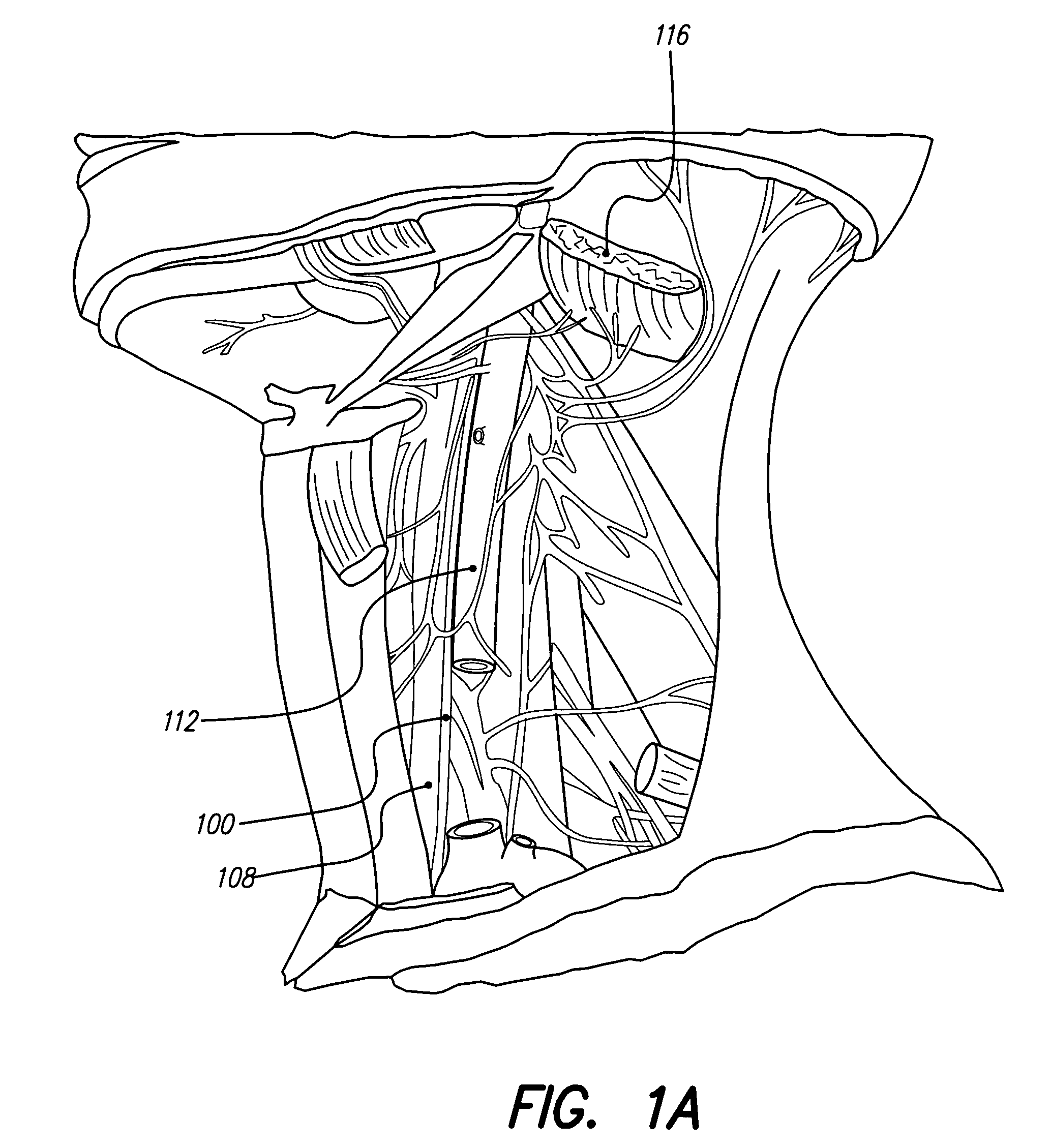

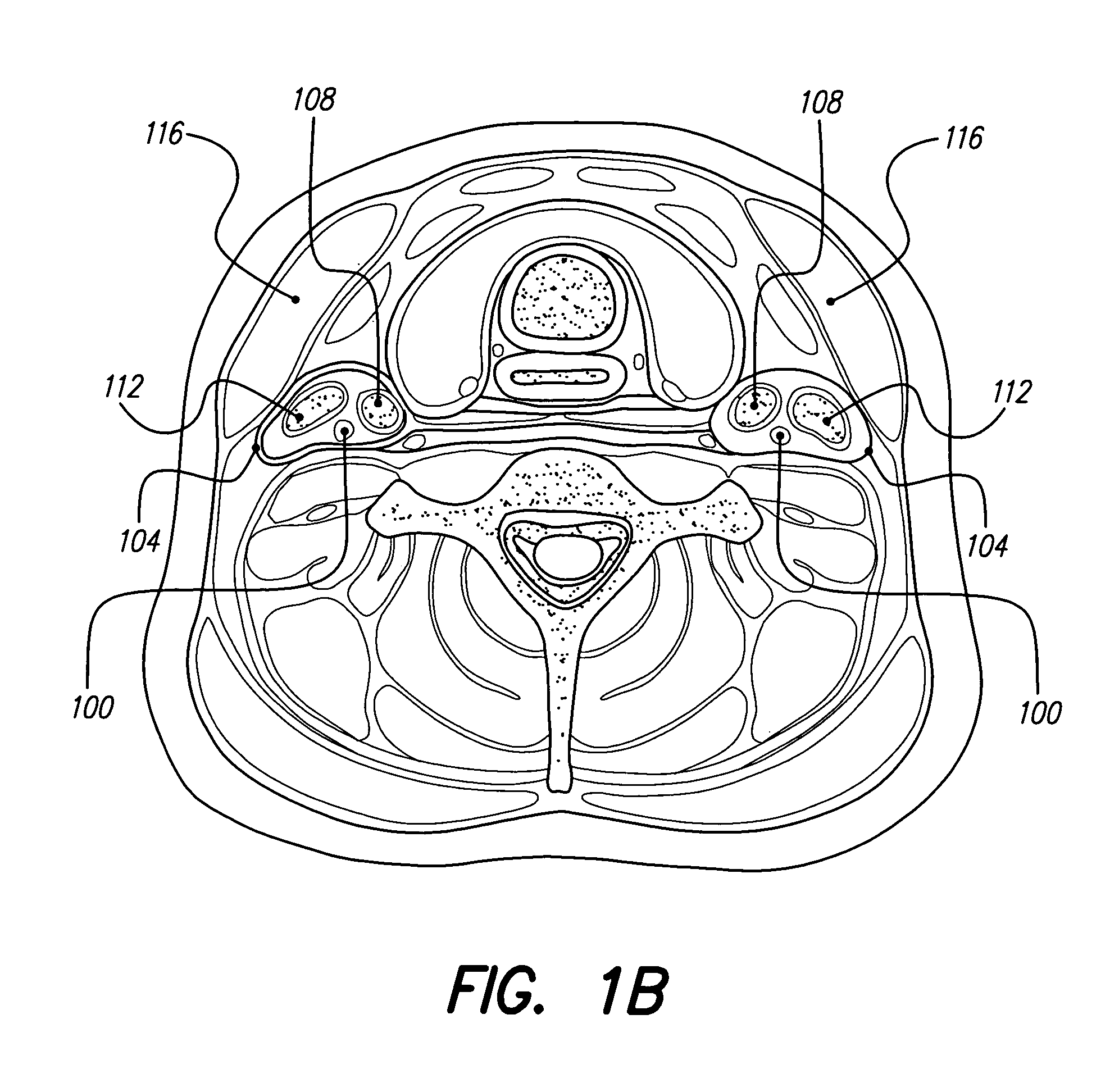

Systems and methods for modulation of circulatory perfusion by electrical and/or drug stimulation

InactiveUS6845267B2Minimal discomfortAvoid the needElectrotherapyPharmaceutical delivery mechanismElectrical batteryClosed loop

One or more implantable system control units (SCU) apply one or more stimulating drugs and / or electrical pulses to one or more predetermined areas affecting circulatory perfusion. The SCU preferably includes a programmable memory for storing data and / or control parameters, and preferably uses a power source / storage device, such as a rechargeable battery. If necessary, periodic recharging of such a power source / storage device is accomplished, for example, by inductive coupling with an external appliance. The SCU provides a means of stimulating a nerve(s) or other tissue with electrical and / or infusion pulses when desired, without the need for external appliances during the stimulation session. When necessary, external appliances are used for the transmission of data to and / or from the SCU(s) and / or for the transmission of power. In a preferred embodiment, the system is capable of open- and closed-loop operation. In closed-loop operation, at least one SCU includes a sensor, and the sensed condition is used to adjust electrical and / or drug stimulation parameters.

Owner:BOSTON SCI NEUROMODULATION CORP

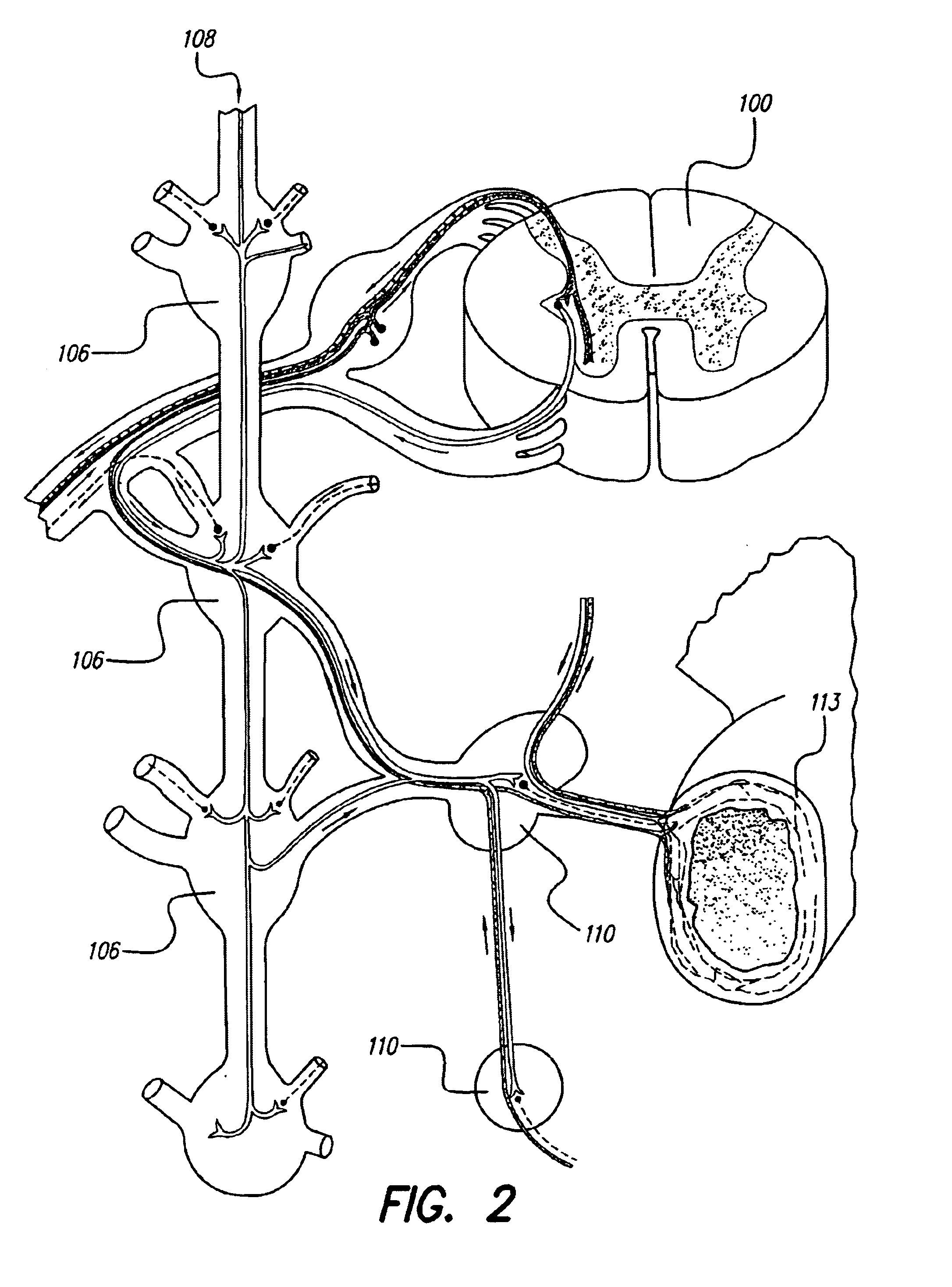

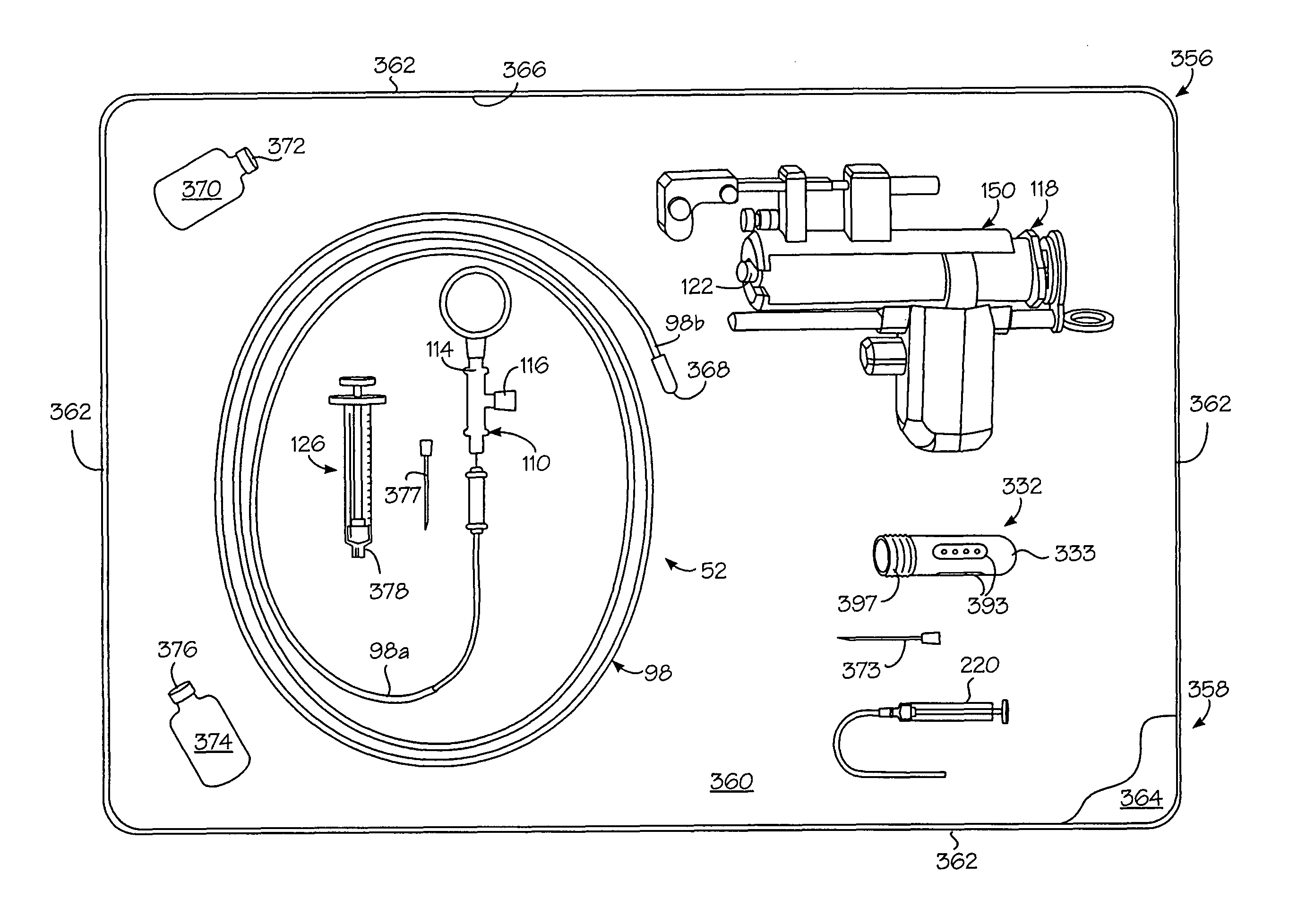

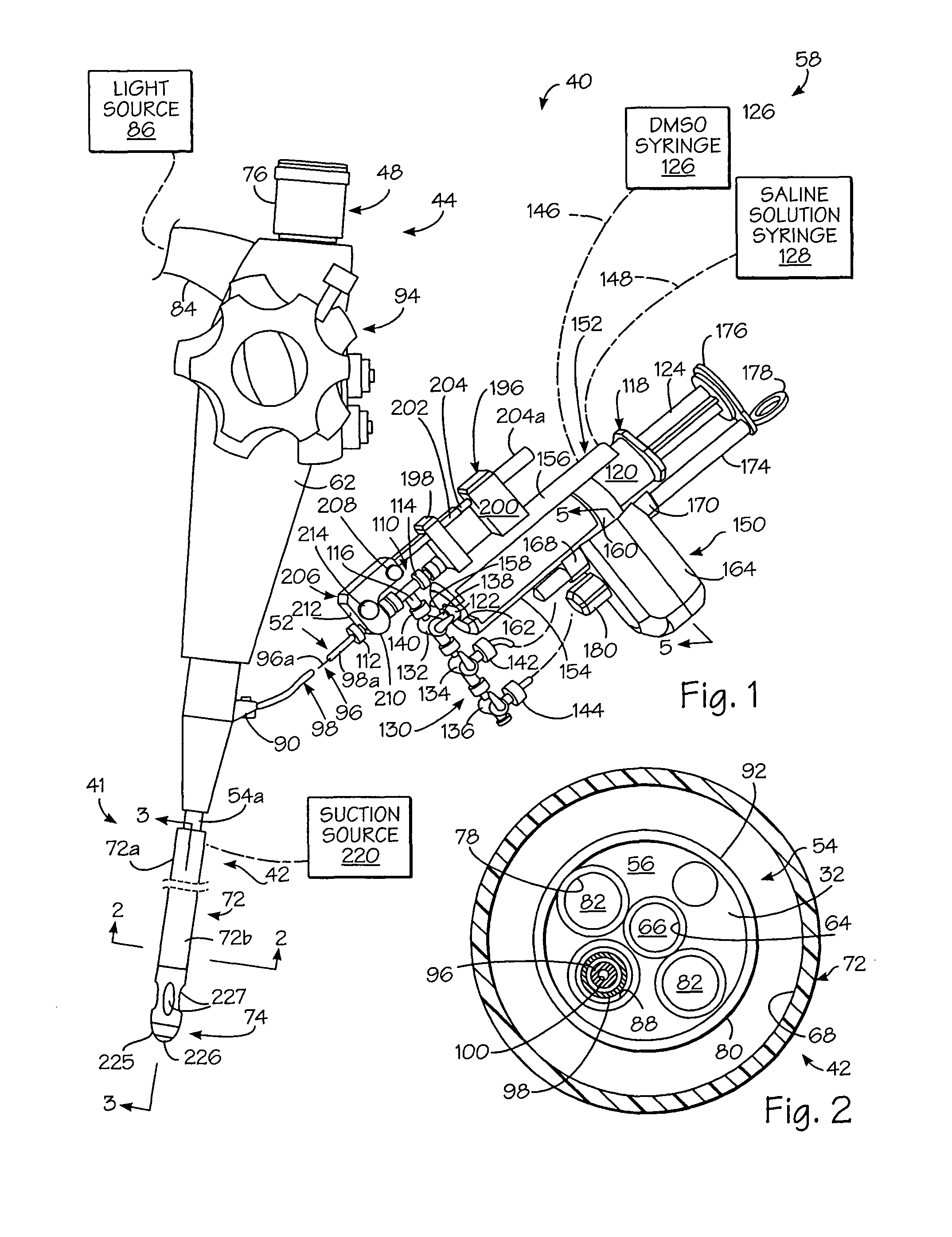

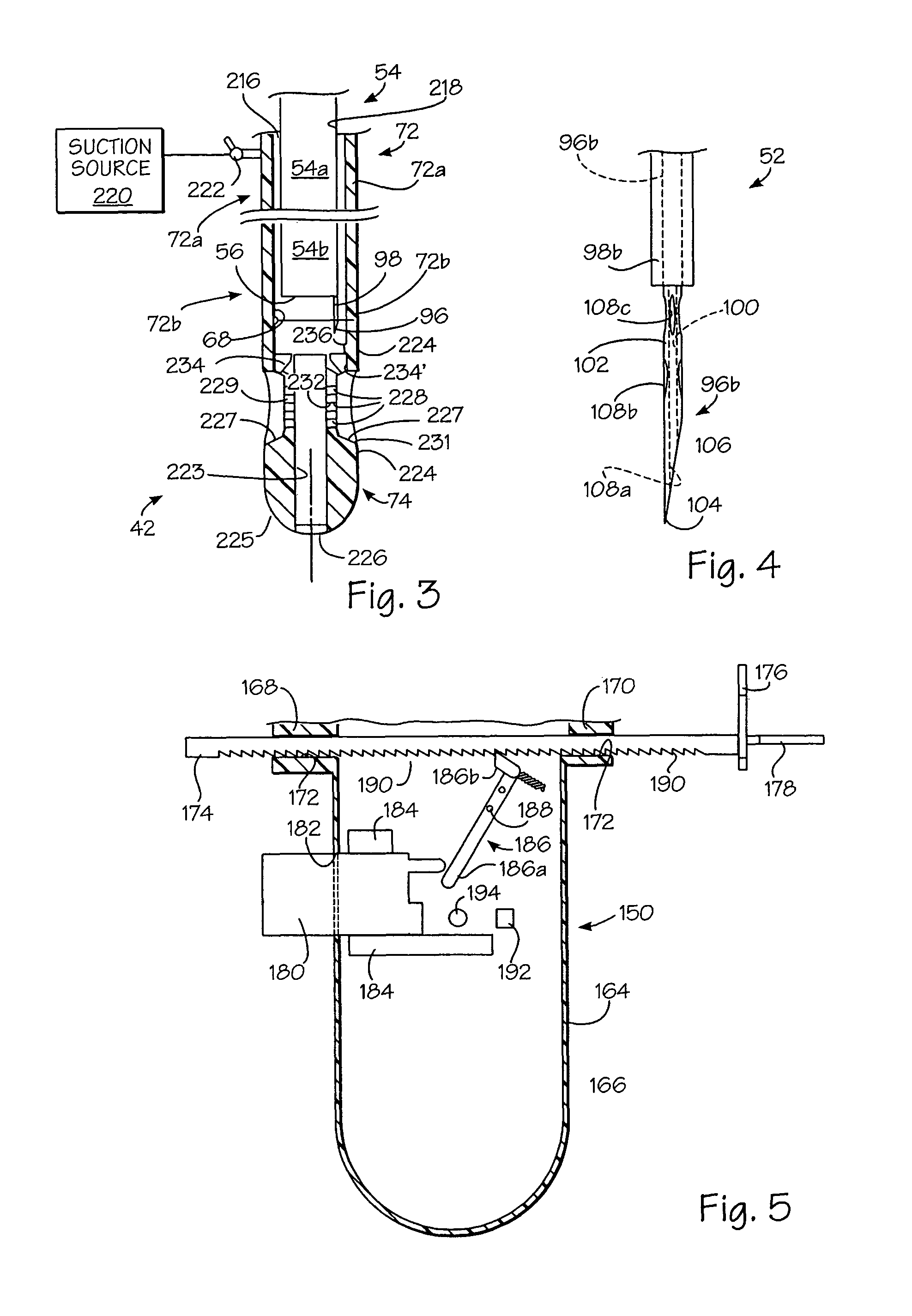

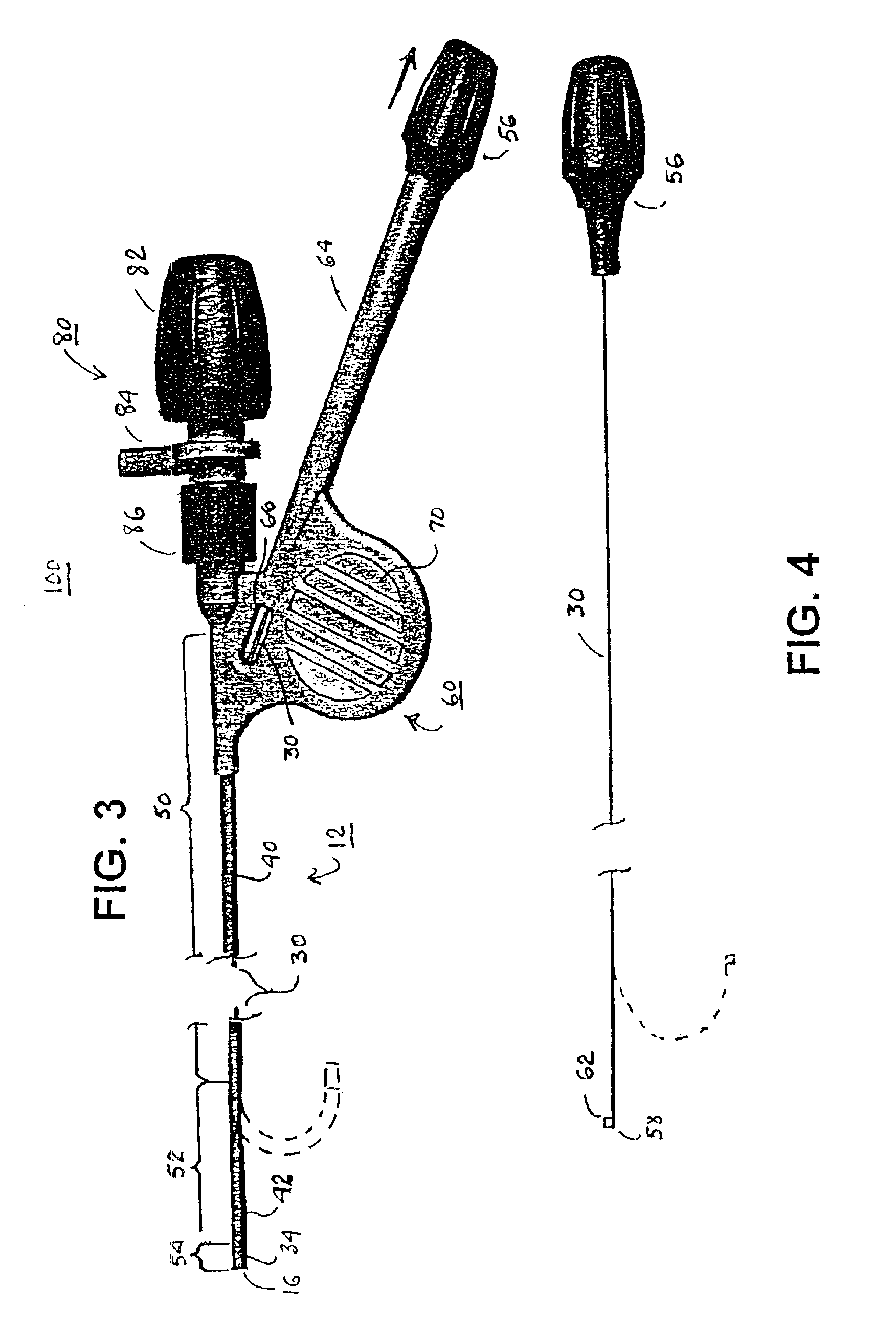

Kit for forming implants in wall of gastrointestinal tract

InactiveUS7846085B2Inhibit injectionAvoid the needSurgical needlesMedical devicesGastrointestinal tractGeneral surgery

A kit for treating a gastrointestinal tract of a mammal and including a package and a tubular needle, an end piece and a container of an implant-forming material carried within the package. The end piece has an outer surface provided with at least one recess and an internal passageway communicating with the recess. The end piece is mounted on the distal extremity of an elongate probe member and introduced into the upper portion of the gastrointestinal tract. A portion of the wall of the gastrointestinal tract is drawn into the recess and the tubular needle is extended through the elongate probe member and the internal passageway into the portion of the wall in the recess. Material from the container is loaded into the tubular needle and injected into the portion of the wall to form an implant in the wall.

Owner:BOSTON SCI SCIMED INC

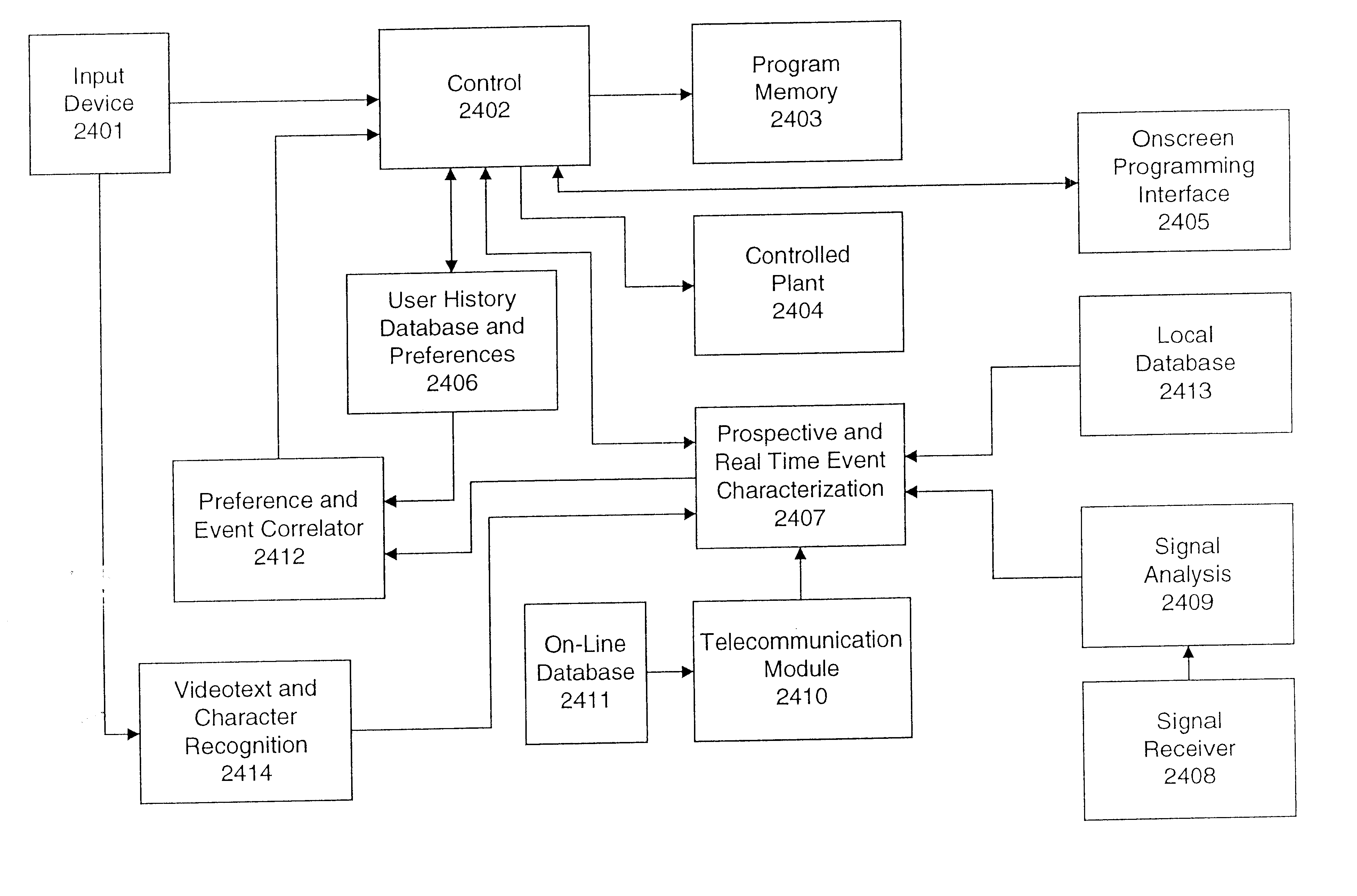

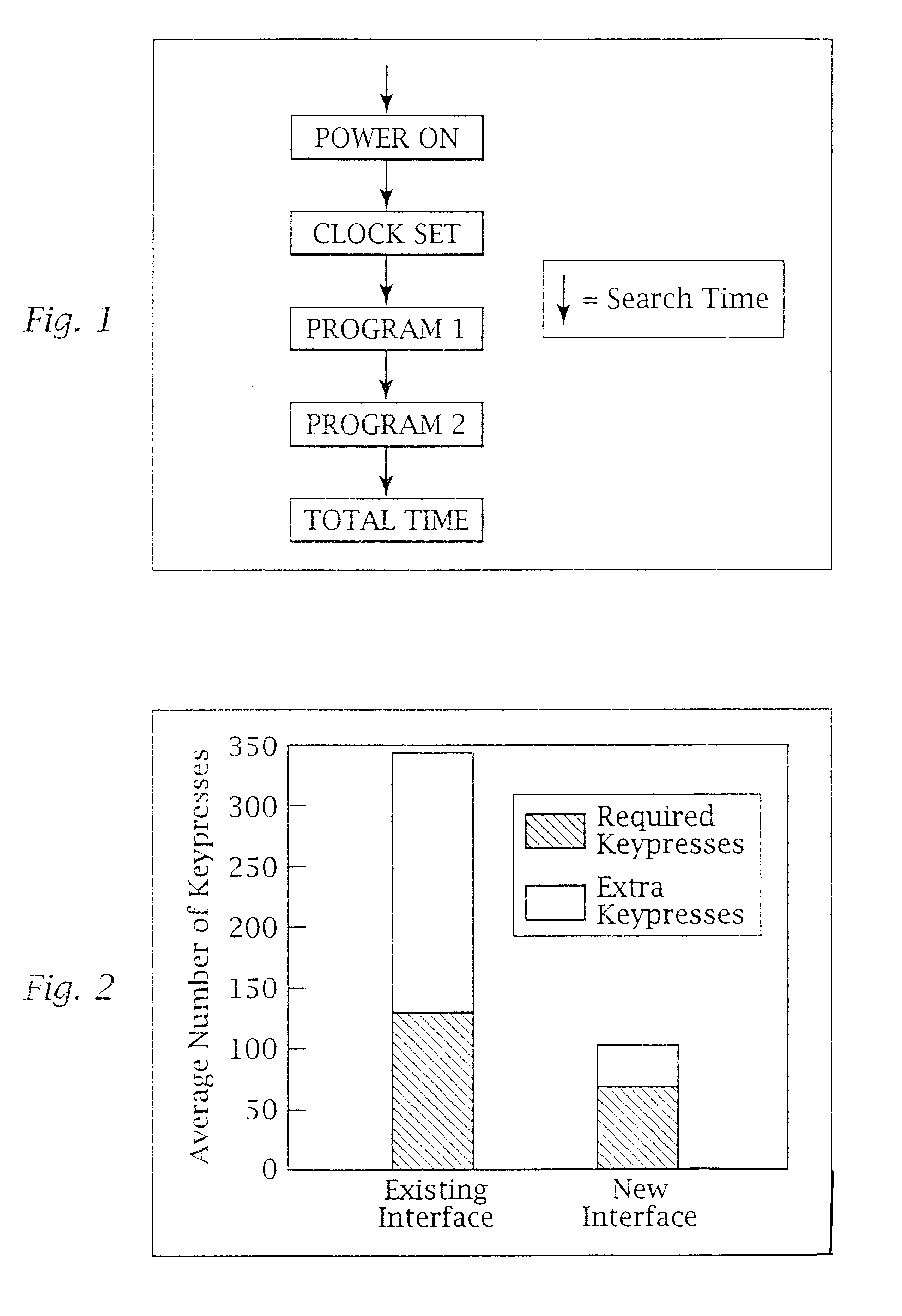

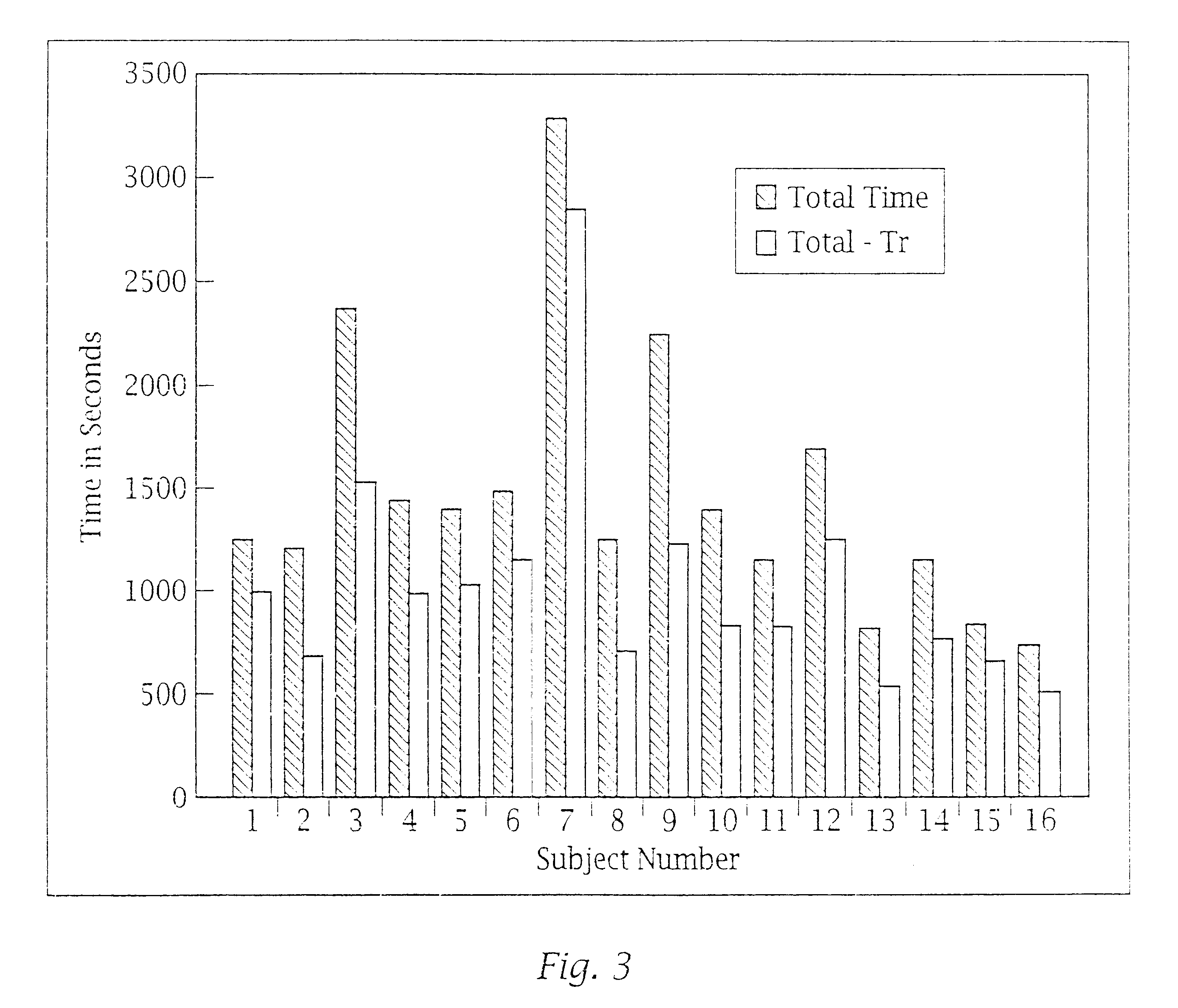

Ergonomic man-machine interface incorporating adaptive pattern recognition based control system

InactiveUS6418424B1Minimal costAvoid the needTelevision system detailsDigital data processing detailsHuman–machine interfaceData stream

An adaptive interface for a programmable system, for predicting a desired user function, based on user history, as well as machine internal status and context. The apparatus receives an input from the user and other data. A predicted input is presented for confirmation by the user, and the predictive mechanism is updated based on this feedback. Also provided is a pattern recognition system for a multimedia device, wherein a user input is matched to a video stream on a conceptual basis, allowing inexact programming of a multimedia device. The system analyzes a data stream for correspondence with a data pattern for processing and storage. The data stream is subjected to adaptive pattern recognition to extract features of interest to provide a highly compressed representation which may be efficiently processed to determine correspondence. Applications of the interface and system include a VCR, medical device, vehicle control system, audio device, environmental control system, securities trading terminal, and smart house. The system optionally includes an actuator for effecting the environment of operation, allowing closed-loop feedback operation and automated learning.

Owner:BLANDING HOVENWEEP

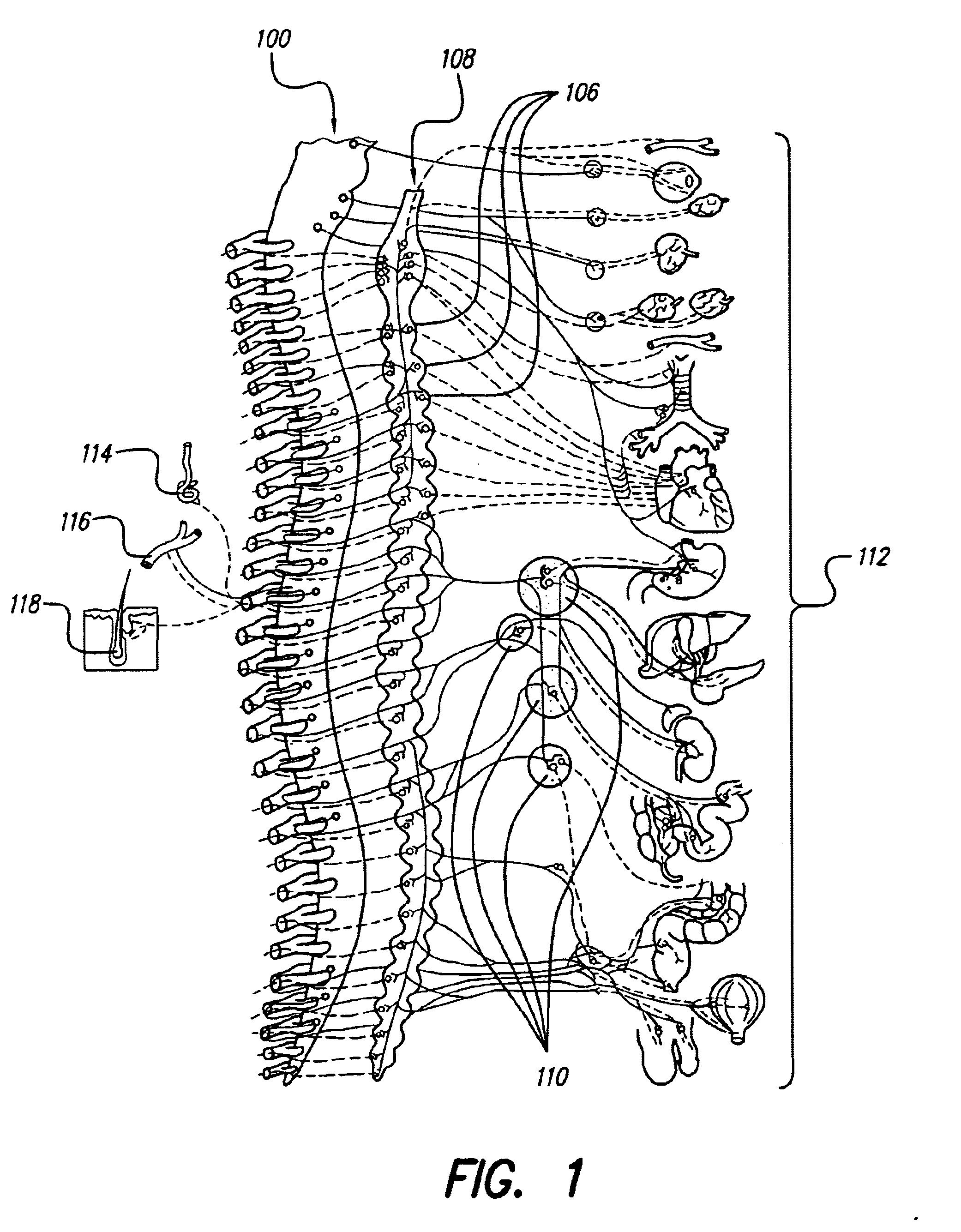

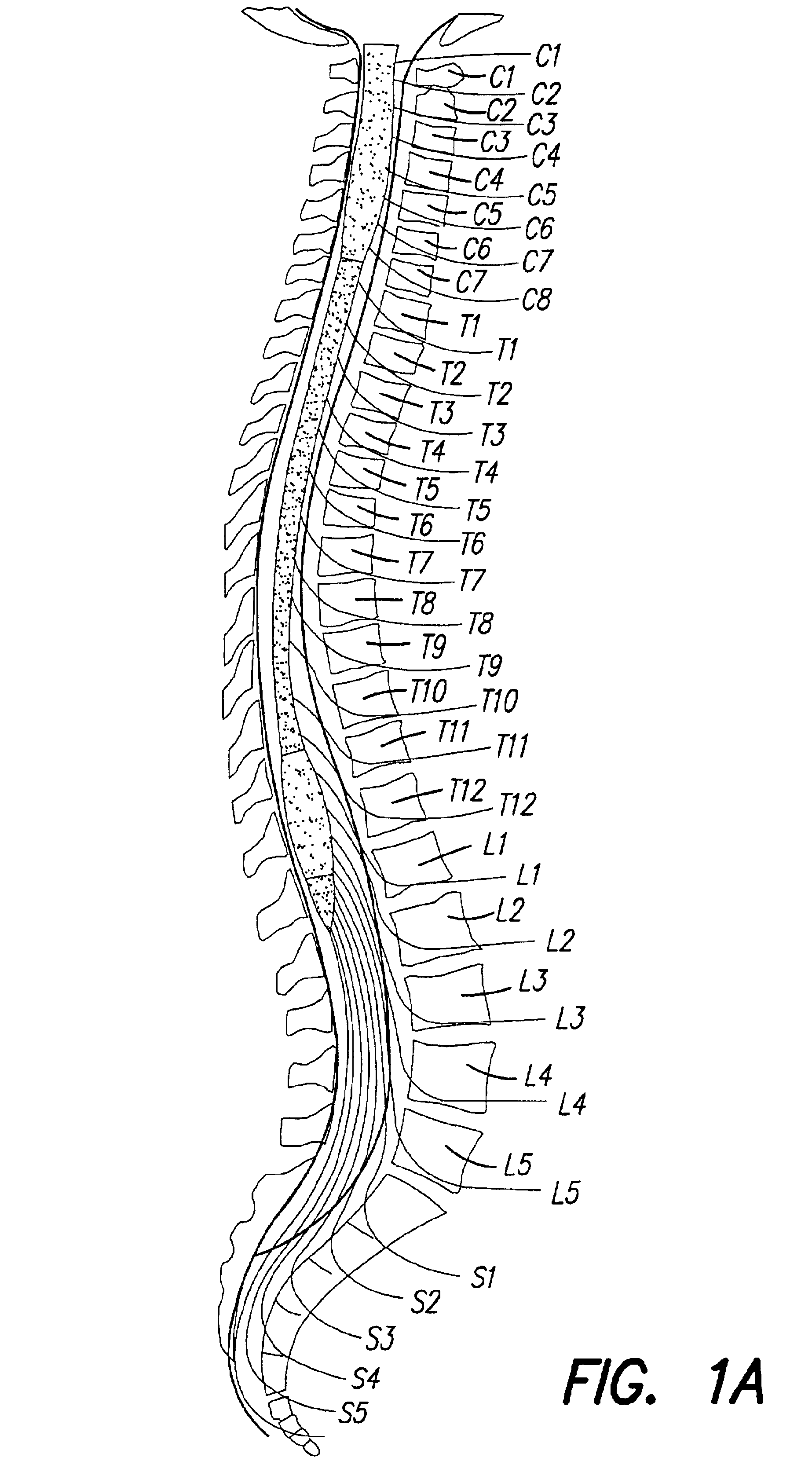

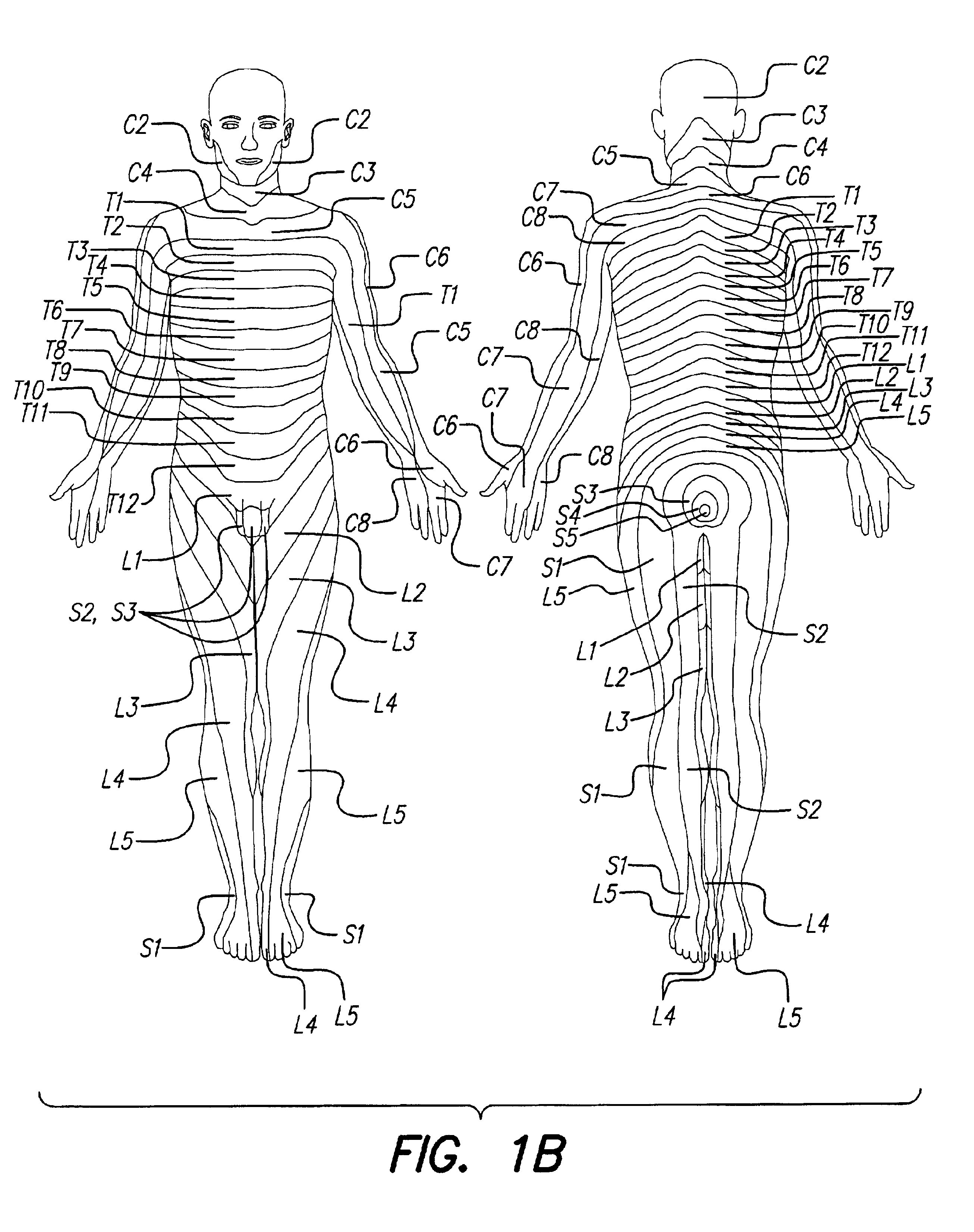

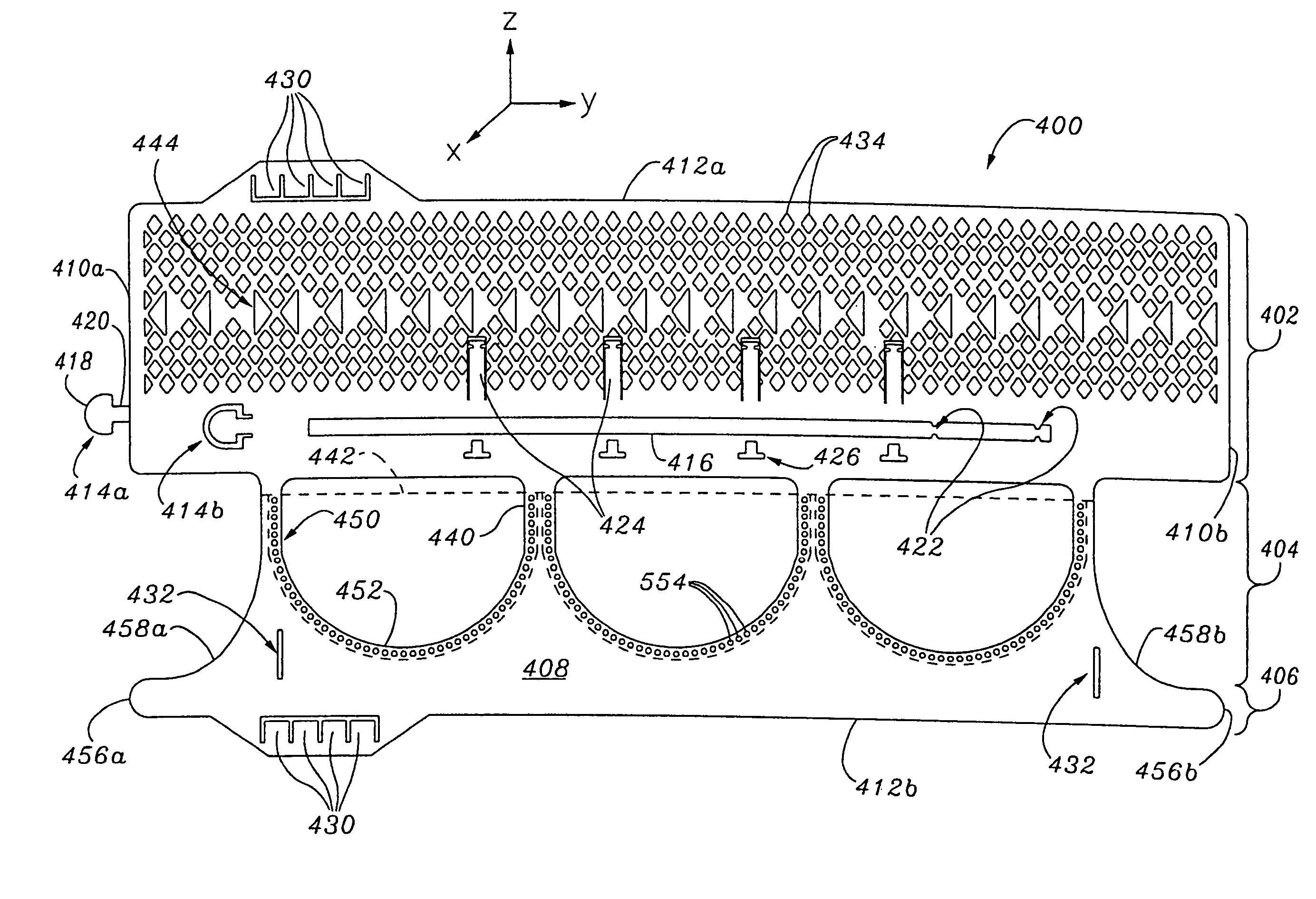

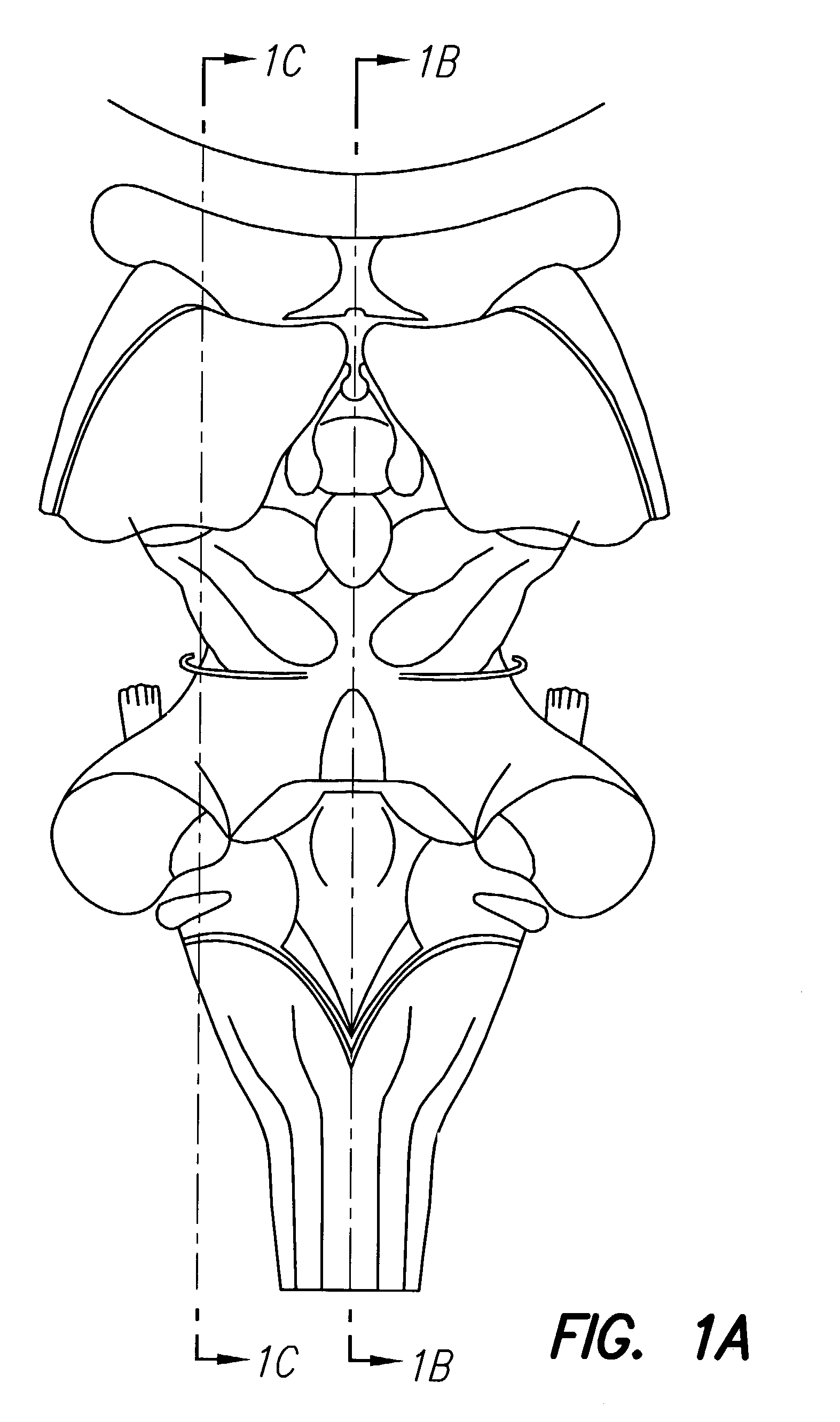

Fully implantable microstimulator for spinal cord stimulation as a therapy for chronic pain

An implantable stimulator(s), small enough to be located near or within an area of the spine responsible for sensations in a region experiencing chronic pain uses a power source / storage device, such as a rechargeable battery. Periodic recharging of such a power source / storage device is accomplished, for example, by inductive coupling with an external appliance. The small stimulator provides a means of stimulating a nerve(s) or other tissue when desired, without the need for external appliances during the stimulation session. When necessary, external appliances are used for the transmission of data to and / or from the stimulator(s) and for the transmission of power, it necessary. In a preferred embodiment, the system is capable of open- and closed-loop operation. In closed-loop operation, at least one implant includes at least one sensor, and the sensed condition is used to adjust stimulation parameters.

Owner:BOSTON SCI NEUROMODULATION CORP

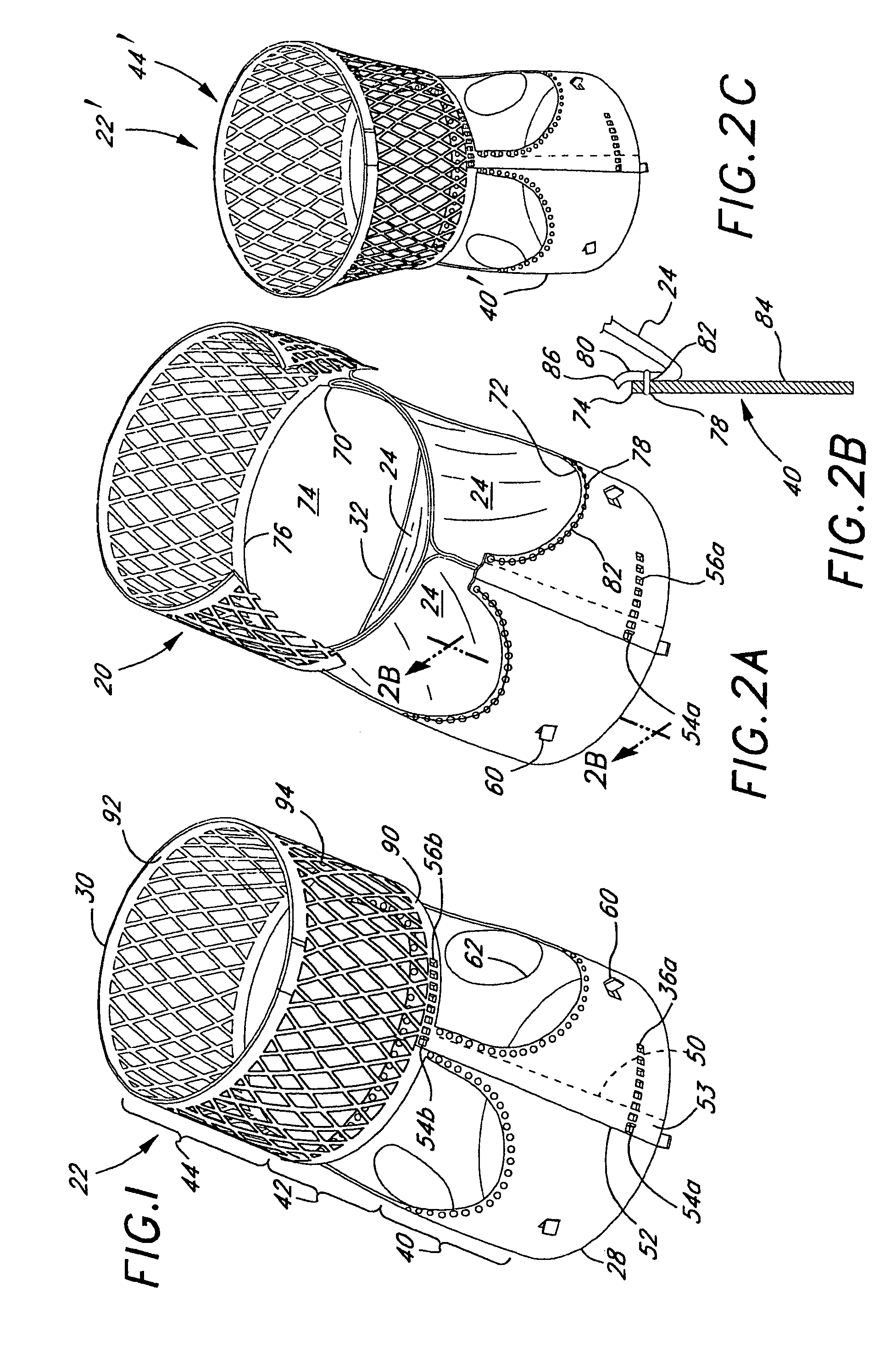

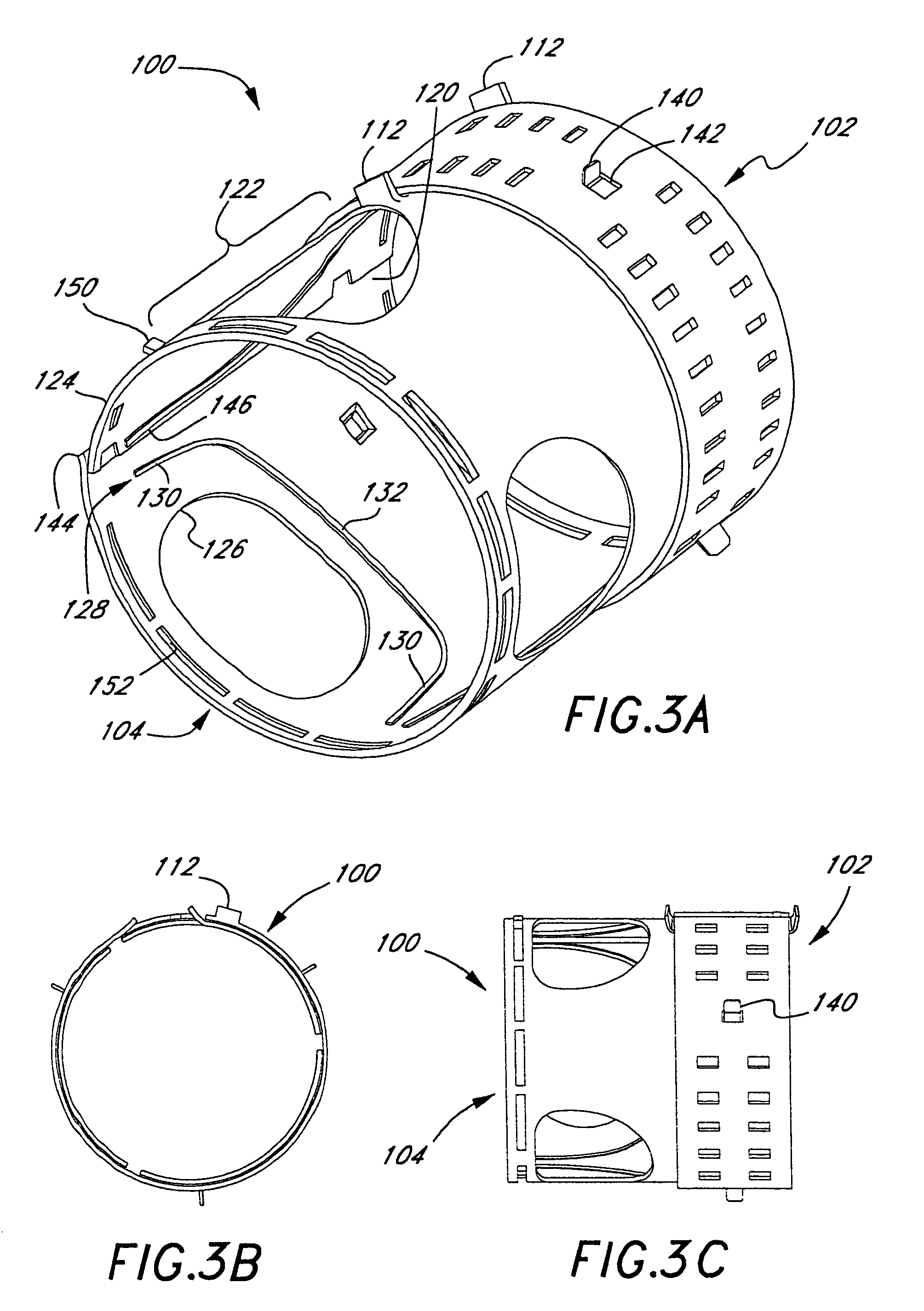

Rolled minimally invasive heart valves

Expandable heart valves for minimally invasive valve replacement surgeries are disclosed. The valves are rolled into a first, contracted configuration for minimally invasive delivery and then unrolled or unfurled at the implantation site. One- and two-piece stents may be used in conjunction with a plurality of flexible leaflet-forming membranes. The one-piece stents may include an annulus anchoring section, a sinus section with the membranes attached over sinus apertures, and a rigid outflow section. The two-piece stent may include a primary stent to provide a tubular base at the annulus, and a secondary stent having the membranes that couples within the primary stent. Lockout tabs to secure the stents in their expanded shapes are provided. Also, alignment structure may be provided to ensure concentric unfurling. Anchoring barbs at the stent edges or in the stent body secure the valve within the annulus. Methods of implantation are also provided.

Owner:EDWARDS LIFESCIENCES CORP

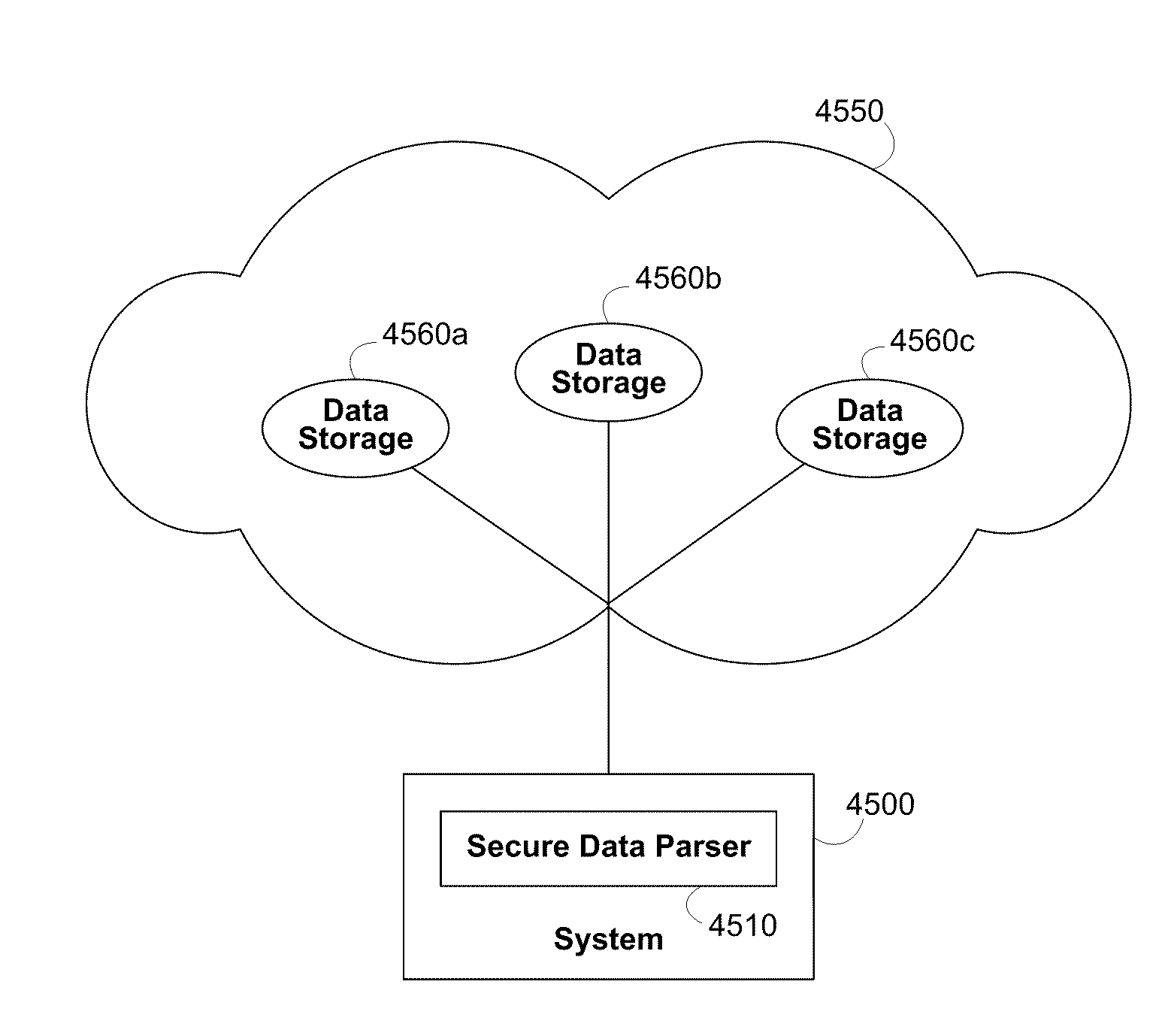

Systems and methods for securing data in the cloud

ActiveUS20100299313A1Minimal compute resourceAvoid the needMultiple keys/algorithms usageDigital data processing detailsCloud computingEncryption

A secure data parser is provided that may be integrated into any suitable system for securely storing data in and communicating data with cloud computing resources. The secure data parser parses data and then splits the data into multiple portions that are stored or communicated distinctly. Encryption of the original data, the portions of data, or both may be employed for additional security.

Owner:SECURITY FIRST INNOVATIONS LLC

Systems and methods for treatment of obesity and eating disorders by electrical brain stimulation and/or drug infusion

InactiveUS6950707B2Reduced activityIncrease excitementHead electrodesPharmaceutical delivery mechanismElectricityMedicine

Owner:BOSTON SCI NEUROMODULATION CORP

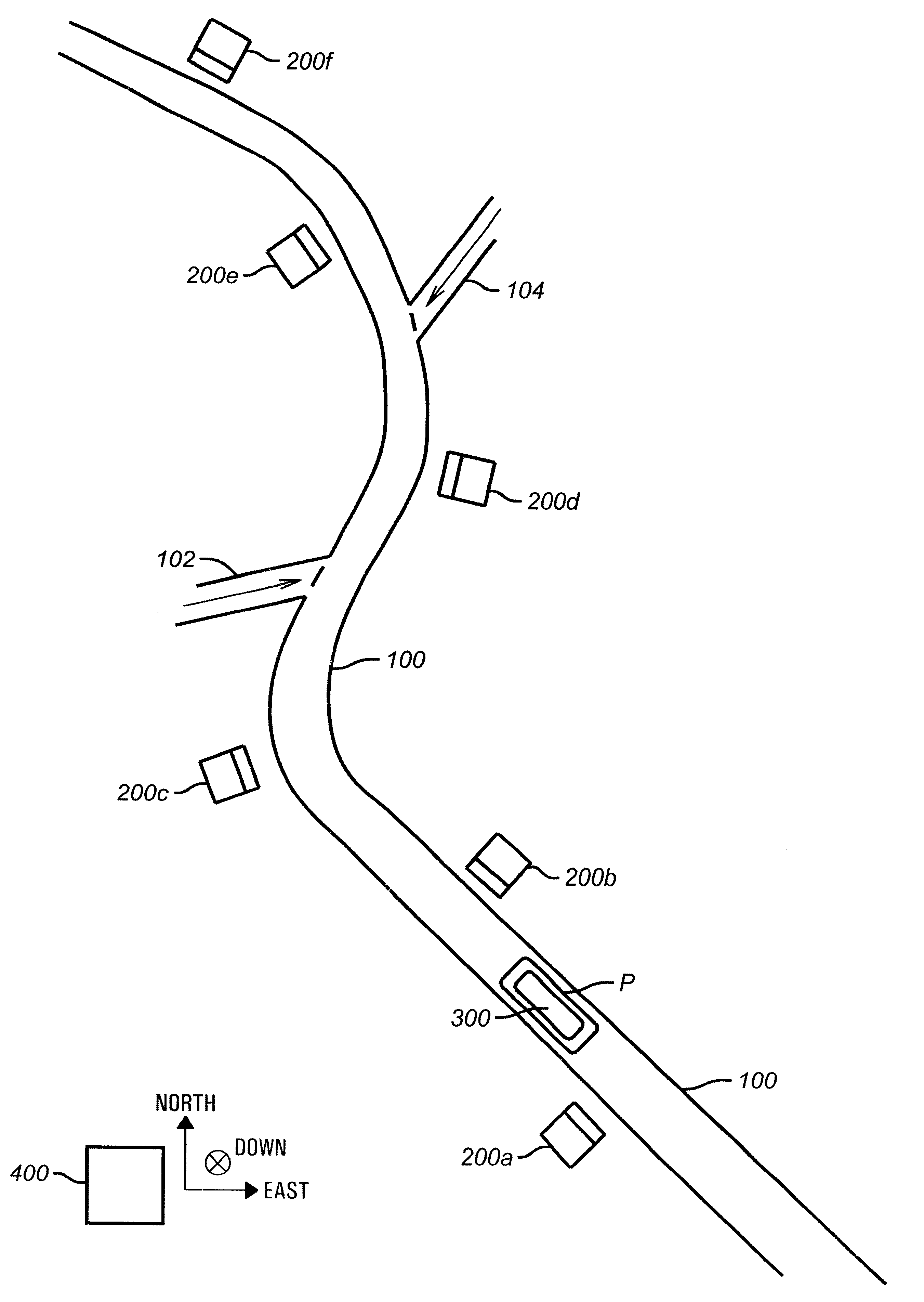

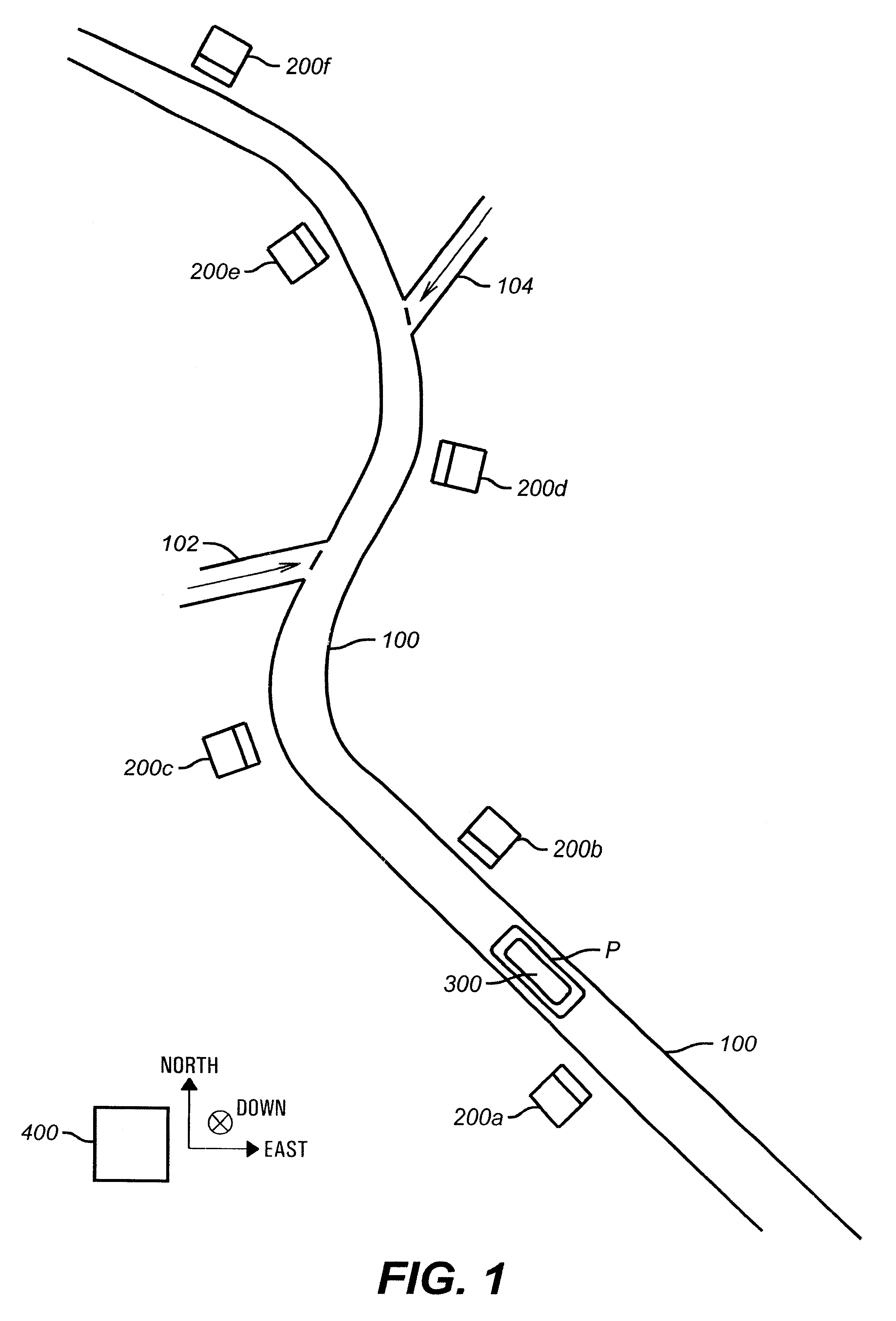

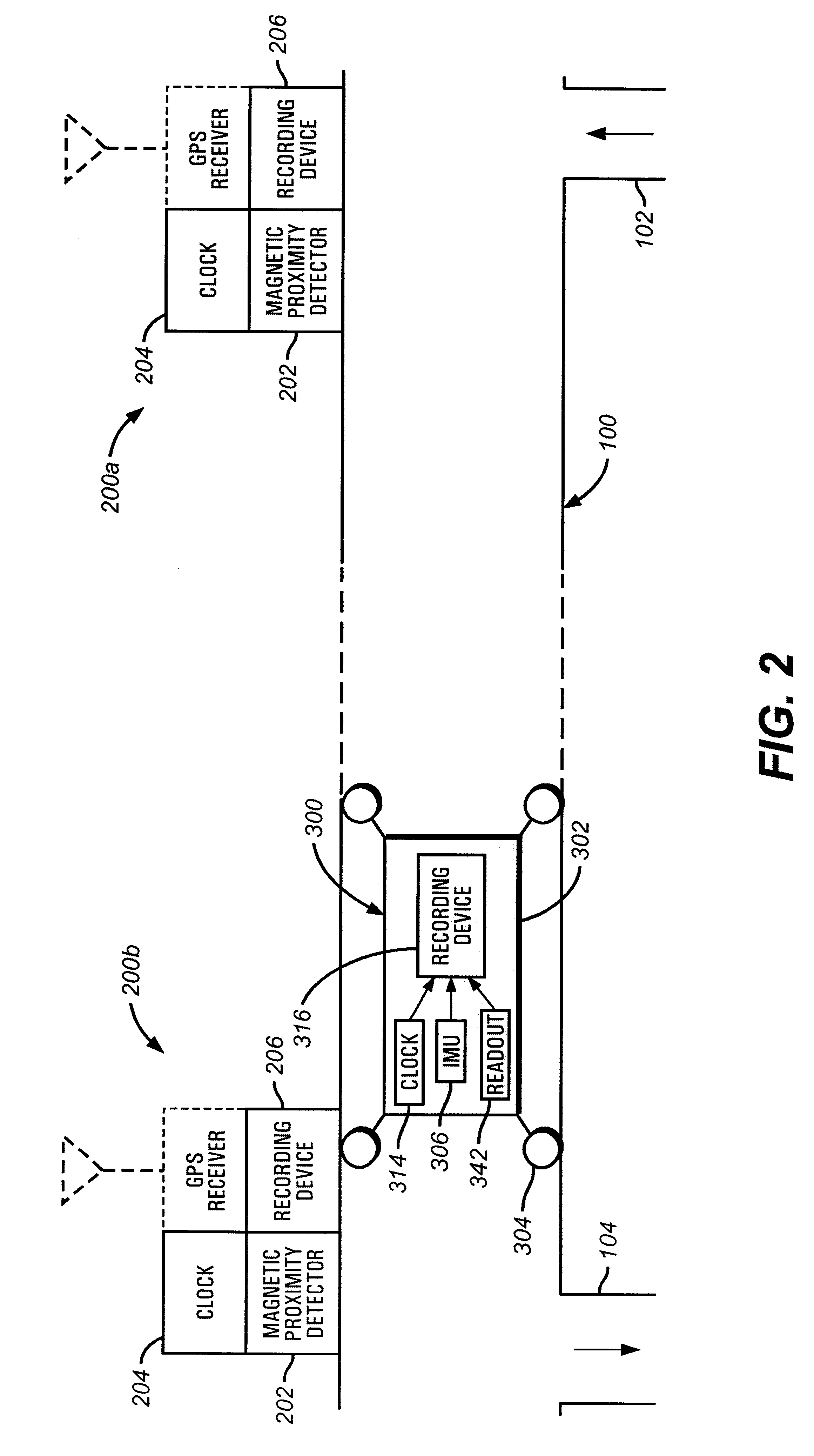

Method and apparatus for determining location of characteristics of a pipeline

InactiveUS6243657B1High degreeHigh precisionTime indicationSynchronous motors for clocksKaiman filterComputerized system

A pipeline inspection and defect mapping system includes a pig having an inertial measurement unit and a pipeline inspection unit for recording pig location and defect detection events, each record time-stamped by a highly precise onboard clock. The system also includes several magloggers at precisely known locations along the pipeline, each containing a fluxgate magnetometer for detecting the passage of the pig along the pipeline and further containing a highly precise clock synchronized with the clock in the pig. The locations of the various magloggers are known in a north / east / down coordinate system through a differential global positioning satellite process. Finally, a postprocessing off-line computer system receives downloaded maglogger, inertial measurement, and odometer data and through the use of several Kalman filters, derives the location of the detected defects in the north / east / down coordinate frame. Consequently, a task of identifying sites for repair activity is much simplified.

Owner:PIPELINE INTEGRITY INT INC FORMERLY BRITISH GAS INSPECTION SERVICES INC +1

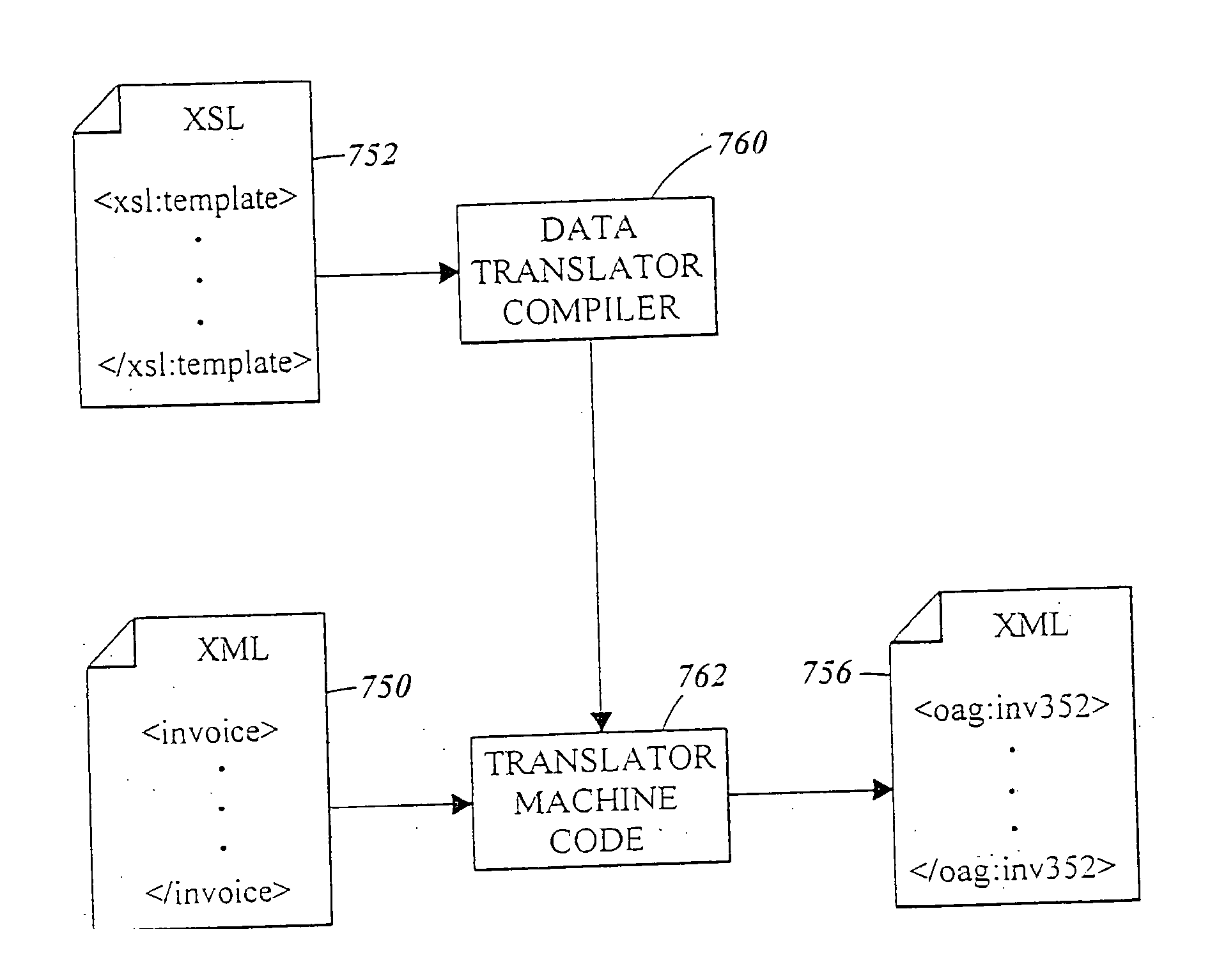

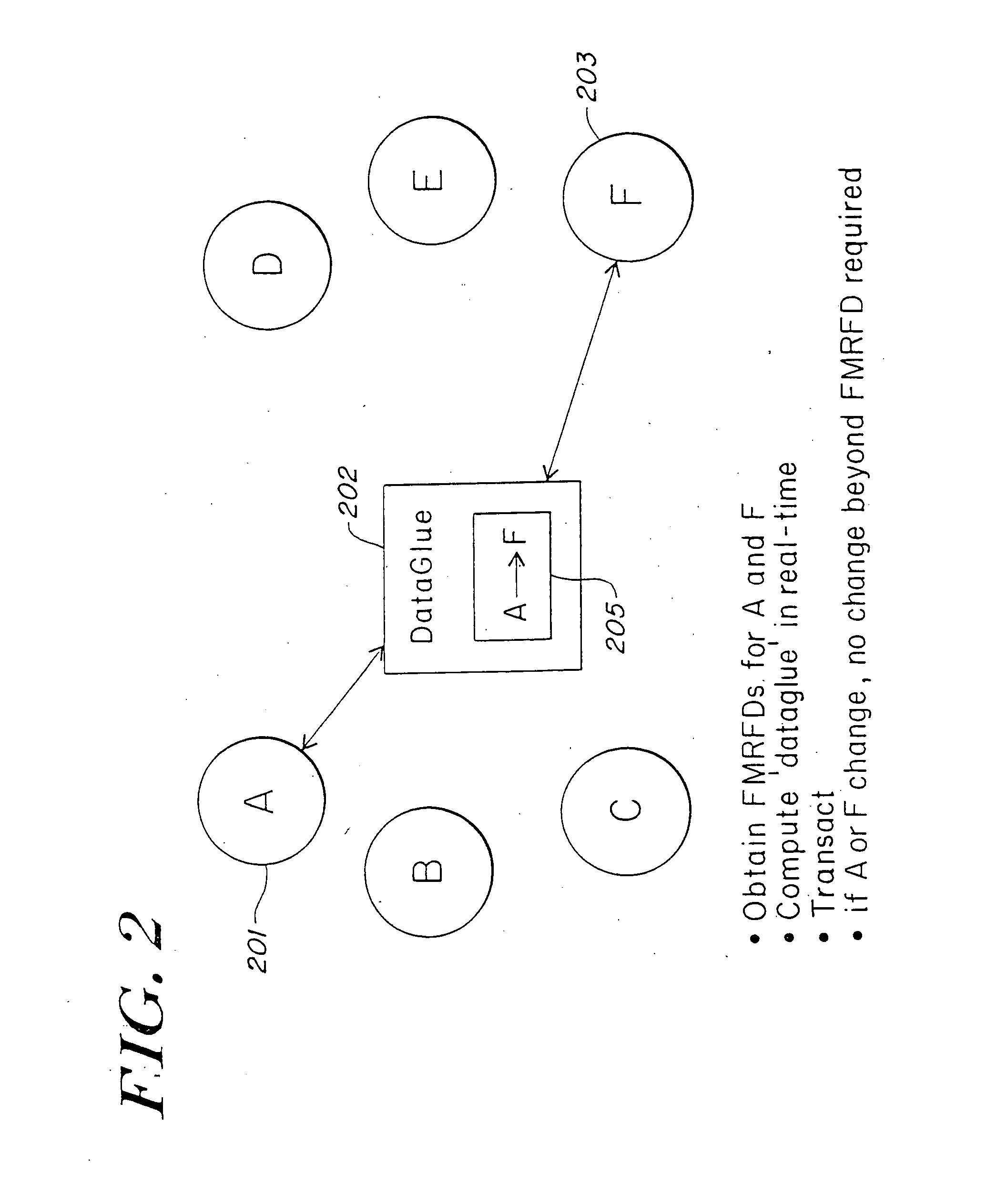

Method and apparatus of streaming data transformation using code generator and translator

InactiveUS20050273772A1Promote generationStay flexibleNatural language data processingMultiple digital computer combinationsStreaming dataObject code

A high level transformation method and apparatus for converting data formats in the context of network applications, among other places. A flexible transformation mechanism is provided that facilitates generation of translation machine code. A translator is dynamically generated by a translator compiler engine. When fed an input stream, the translator generates an output stream by executing the native object code generated on the fly by the translator compiler engine. In addition, the translator may be configured to perform a bi-directional translation between the two streams as well as translation between two distinct protocol sequences. Further a translator may working in streaming mode, to facilitate streaming processing of documents.

Owner:IBM CORP

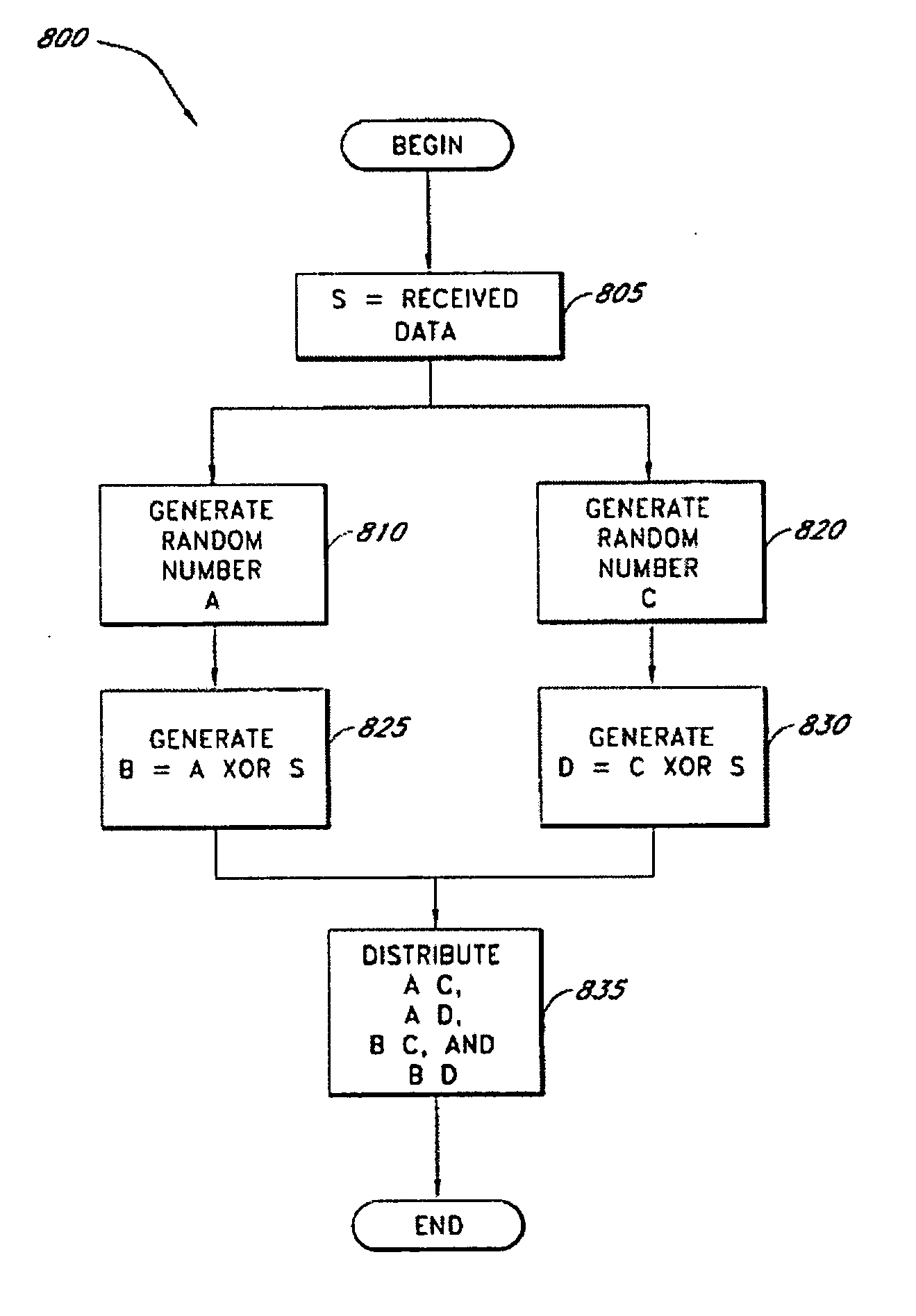

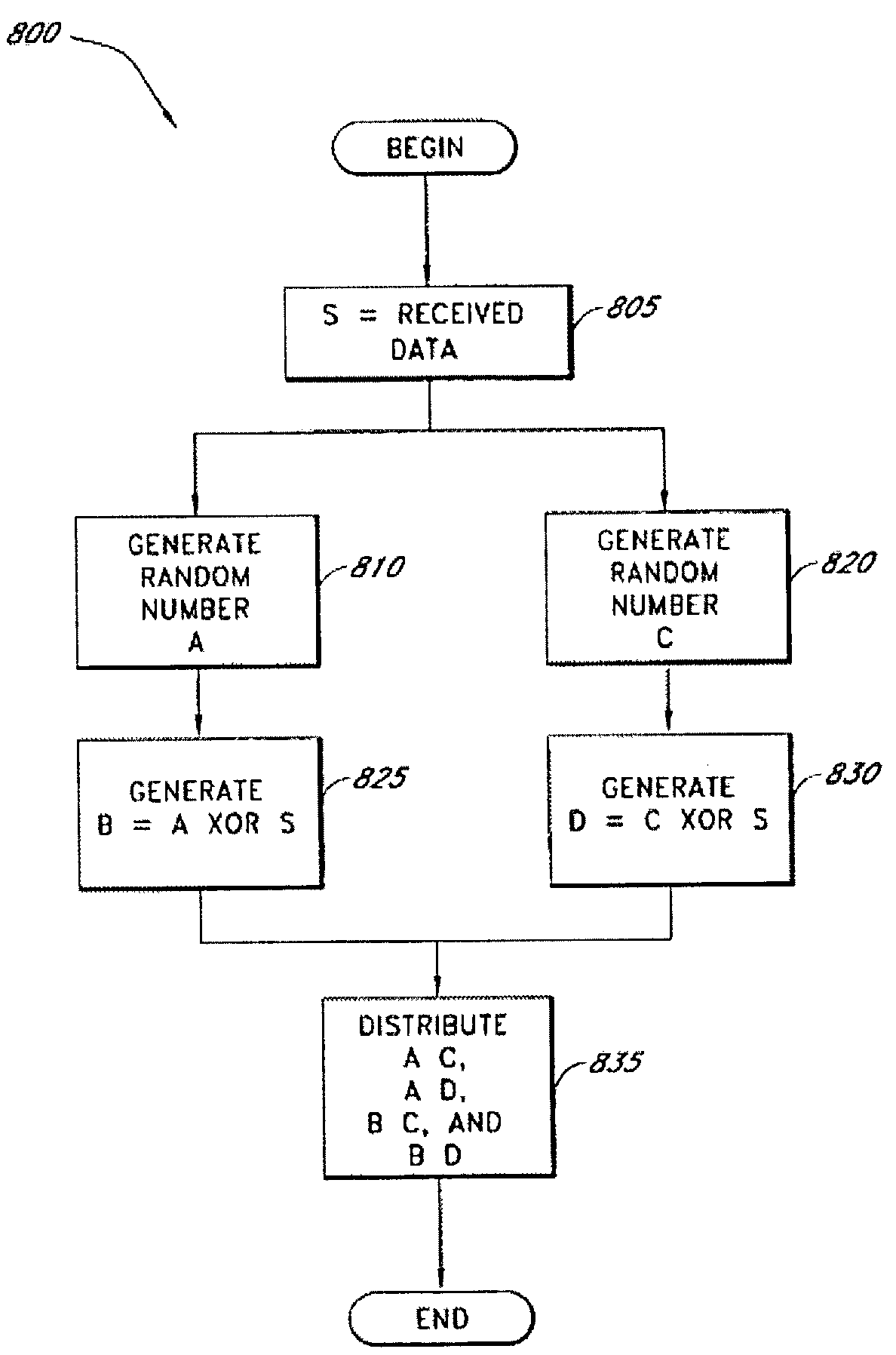

Secure data parser method and system

InactiveUS20060177061A1Minimal compute resourceAvoid the needKey distribution for secure communicationError detection/correctionOriginal dataEncryption

A secure data parser is provided that may be integrated into any suitable system for securely storing and communicating data. The secure data parser parses data and then splits the data into multiple portions that are stored or communicated distinctly. Encryption of the original data, the portions of data, or both may be employed for additional security. The secure data parser may be used to protect data in motion by splitting original data into portions of data, that may be communicated using multiple communications paths.

Owner:SECURITY FIRST INNOVATIONS LLC

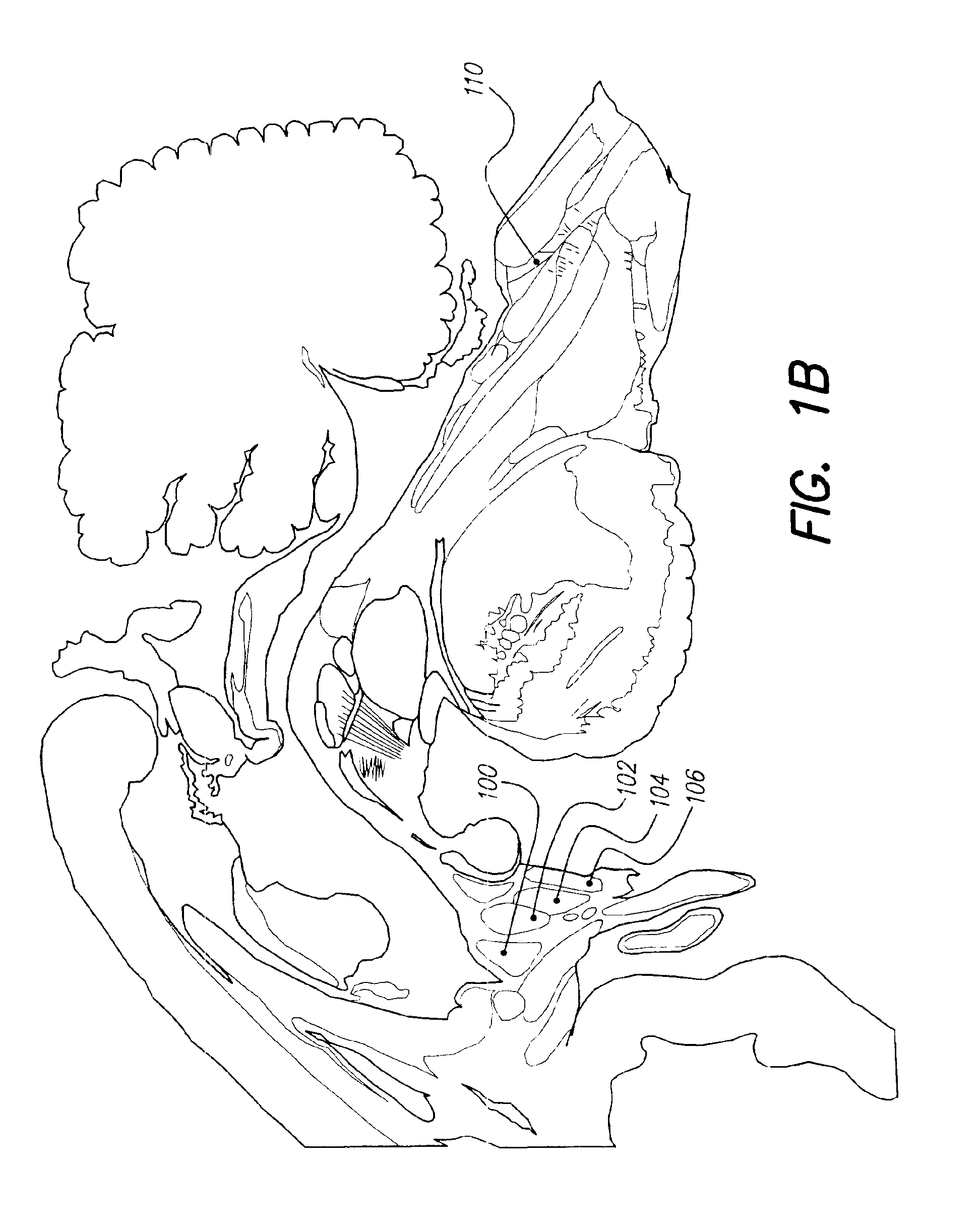

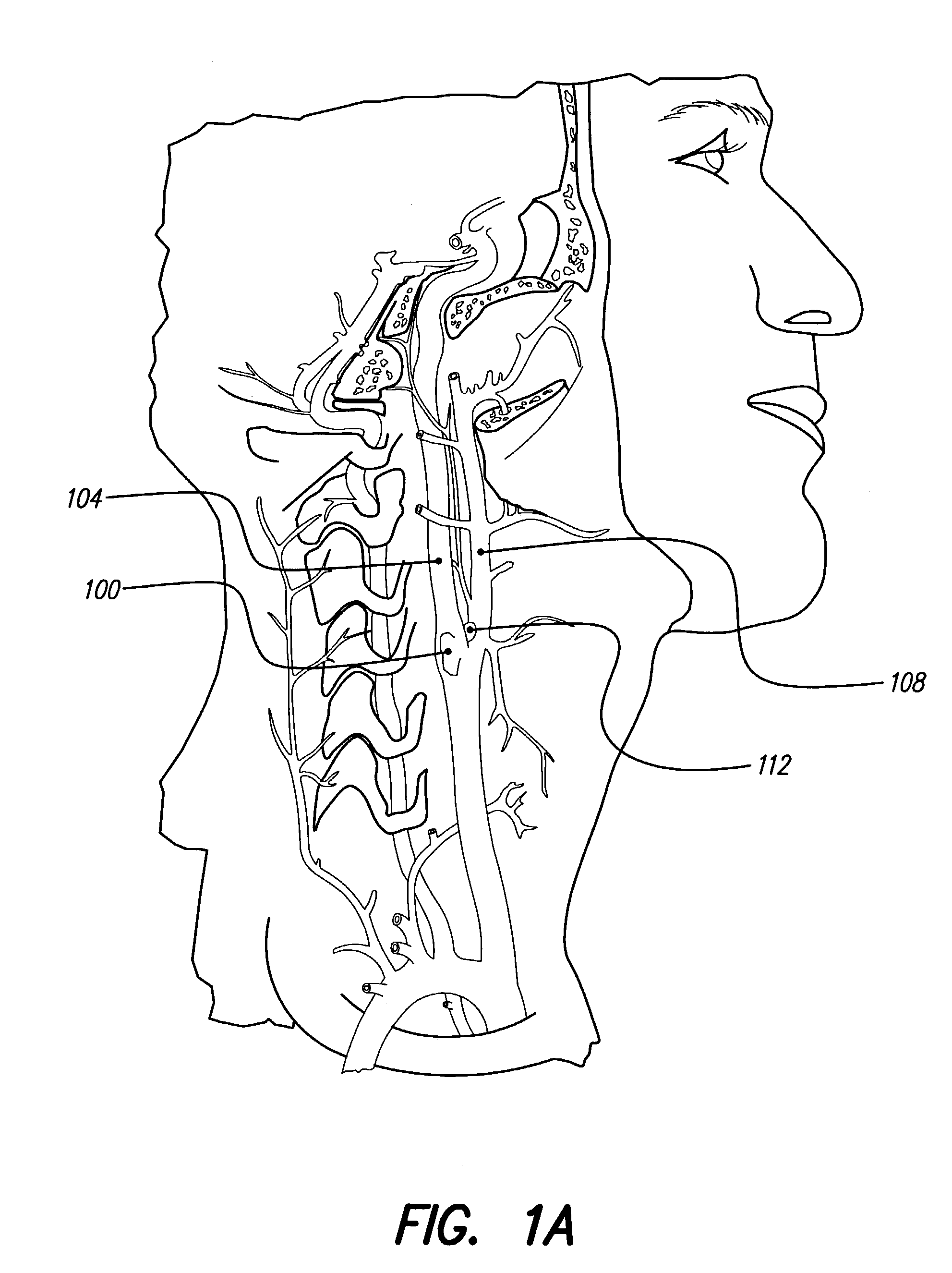

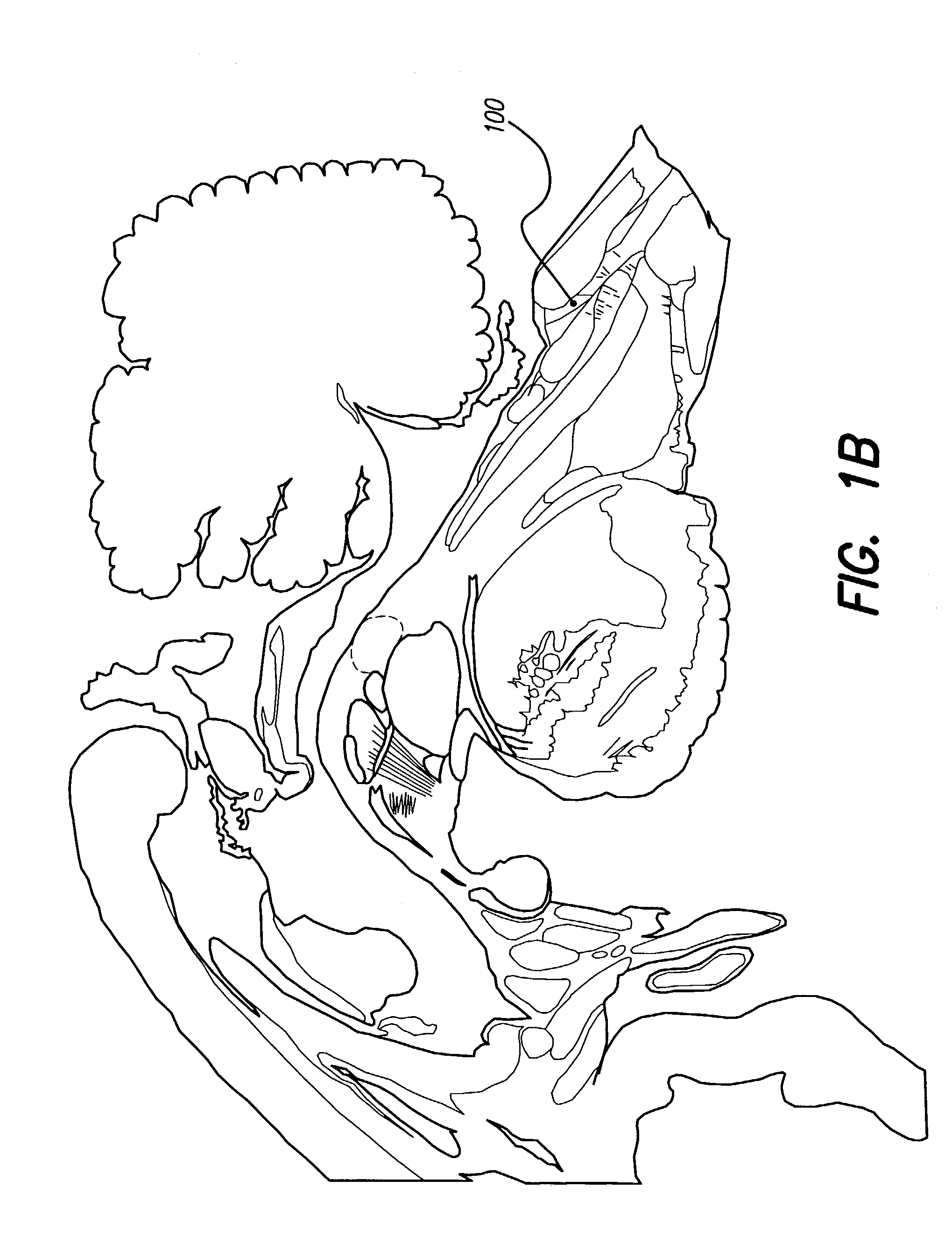

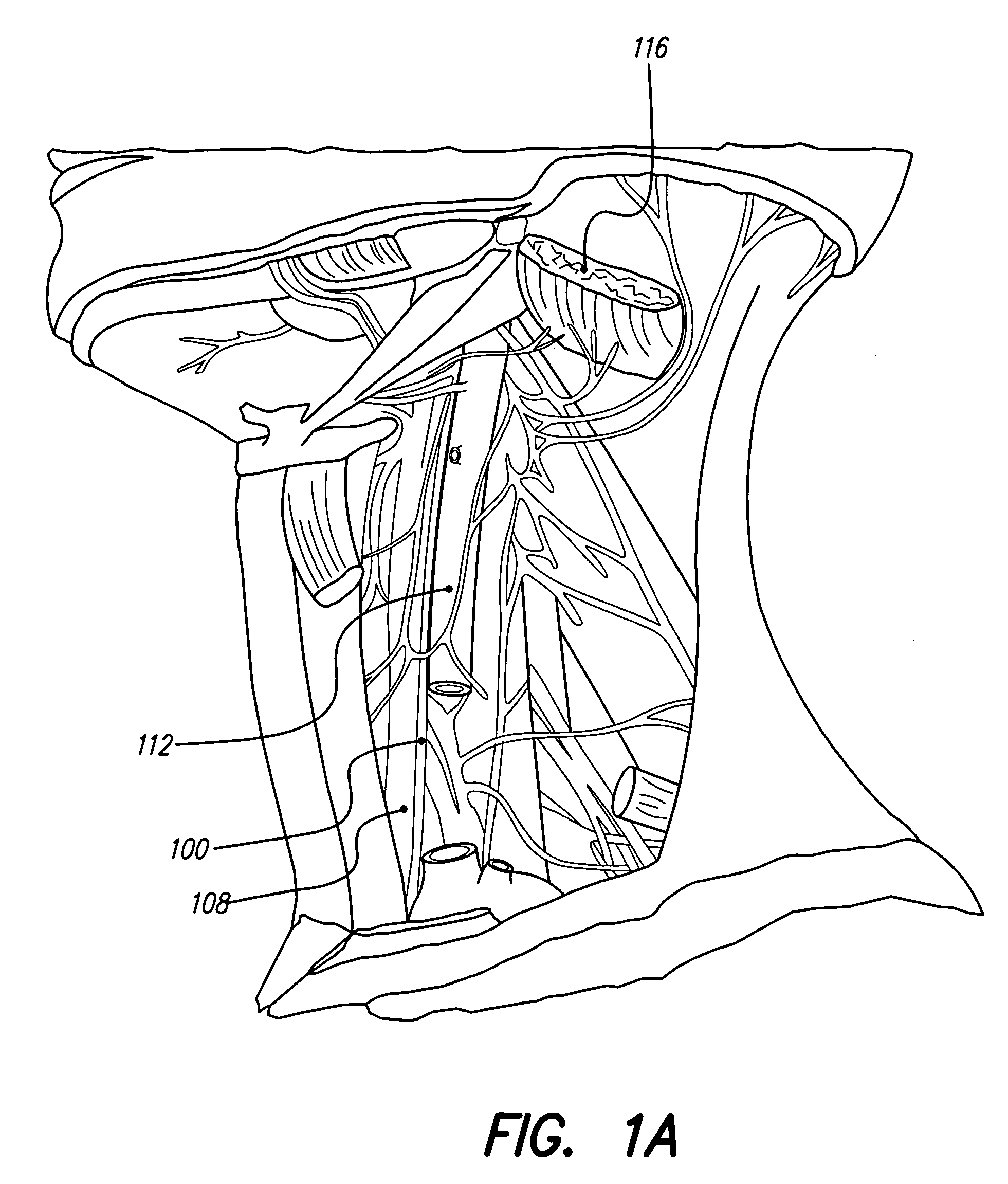

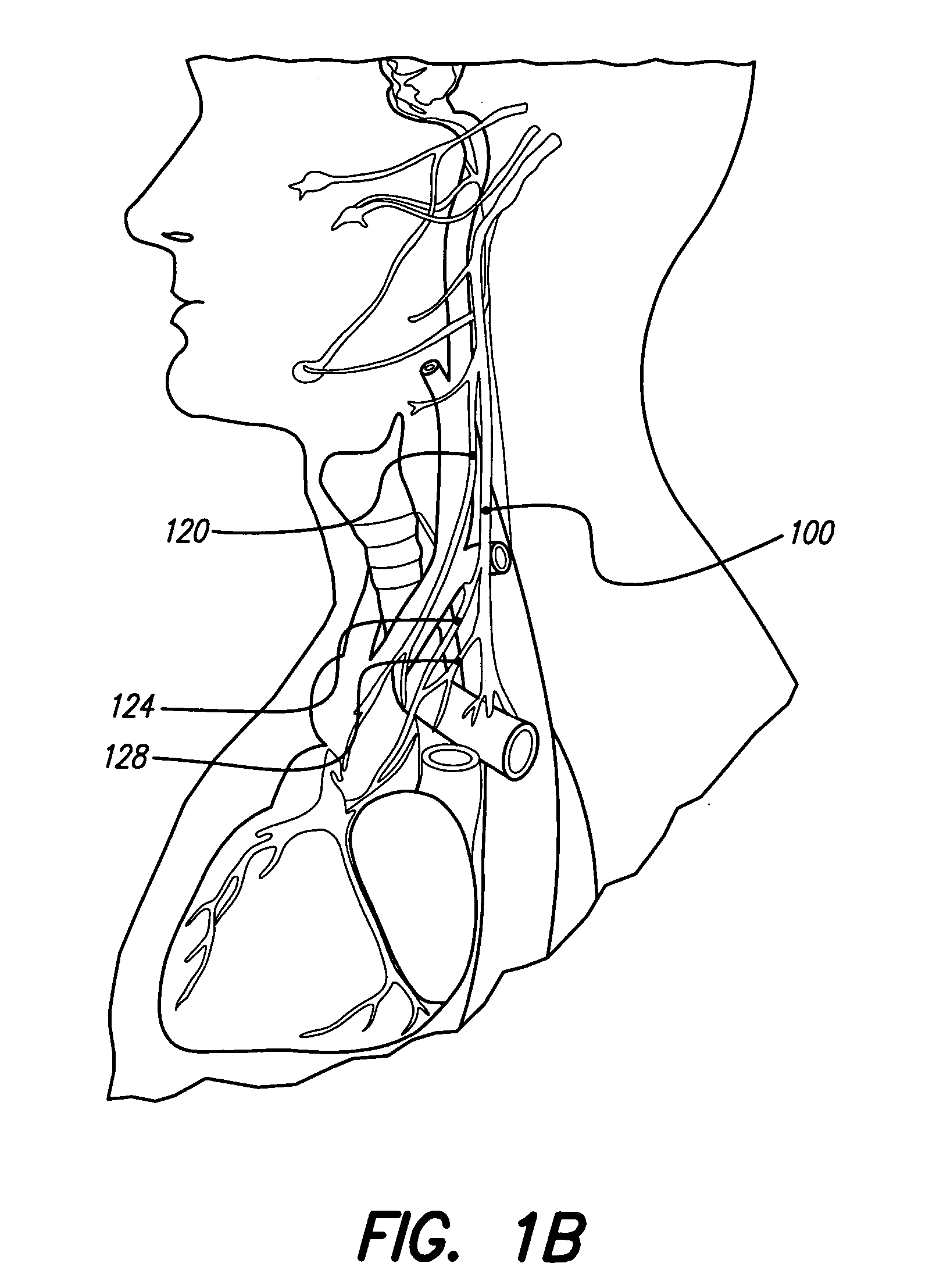

Treatment of hypertension

InactiveUS7155284B1Sufficient amountAvoid the needPharmaceutical delivery mechanismImplantable neurostimulatorsCarotid bodyElectrical stimulations

Treatment of hypertension includes implantation of the discharge portion(s) of a catheter and / or electrical stimulation electrode(s) adjacent the tissue(s) to be stimulated. Stimulation pulses, i.e., drug infusion pulses and / or electrical pulses, are supplied by one or more implanted stimulators, through the catheter and possibly also a lead, tunneled subcutaneously between the stimulator and stimulation site. A microstimulator(s) may also / instead deliver electrical stimulation pulses. Stimulation sites include the carotid sinus and carotid body, among other locations. Treatments include drugs used for acute and / or chronic treatment of hypertension. In a number of embodiments, a need for or response to treatment is sensed, and the electrical and / or infusion pulses adjusted accordingly.

Owner:BOSTON SCI NEUROMODULATION CORP

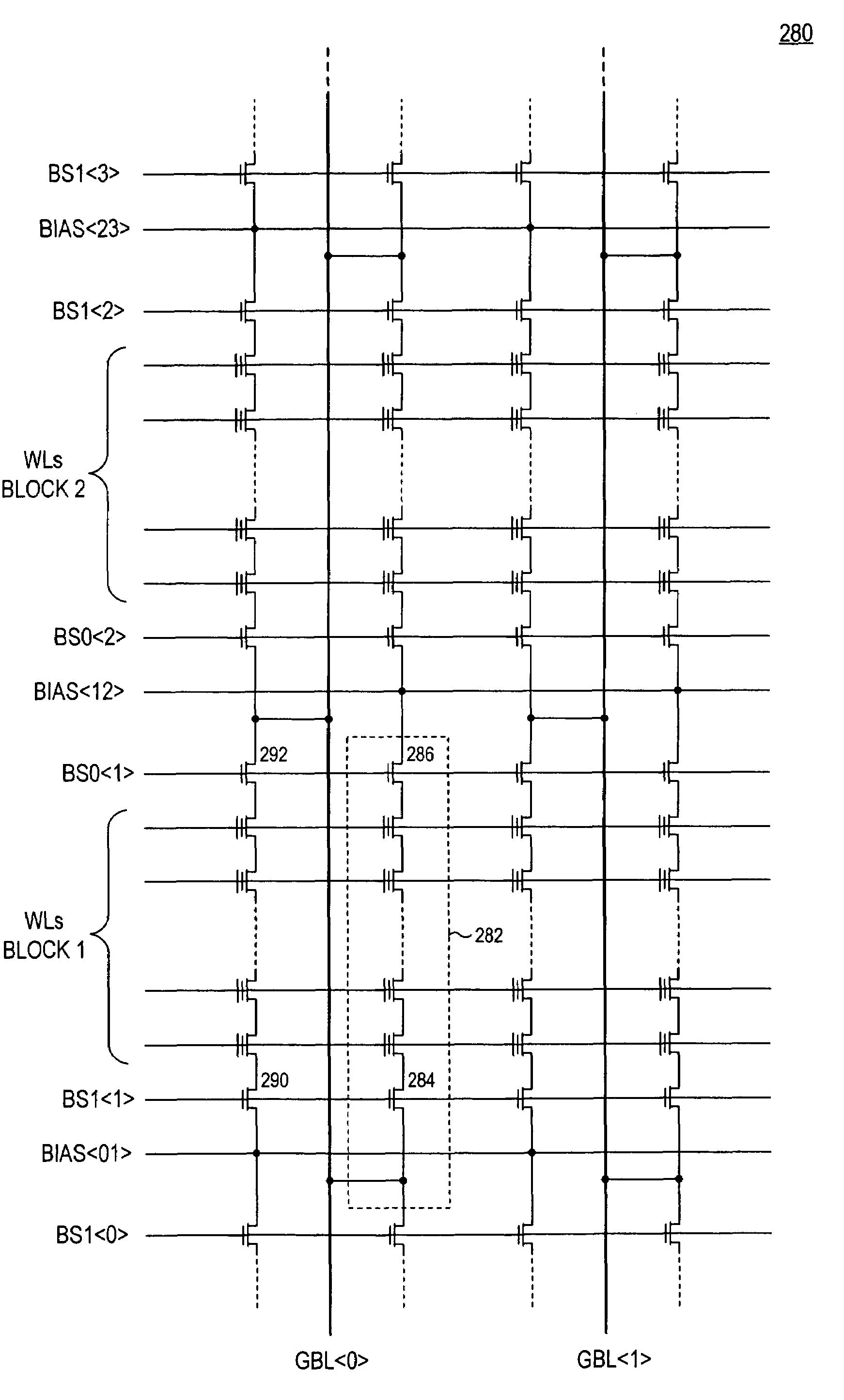

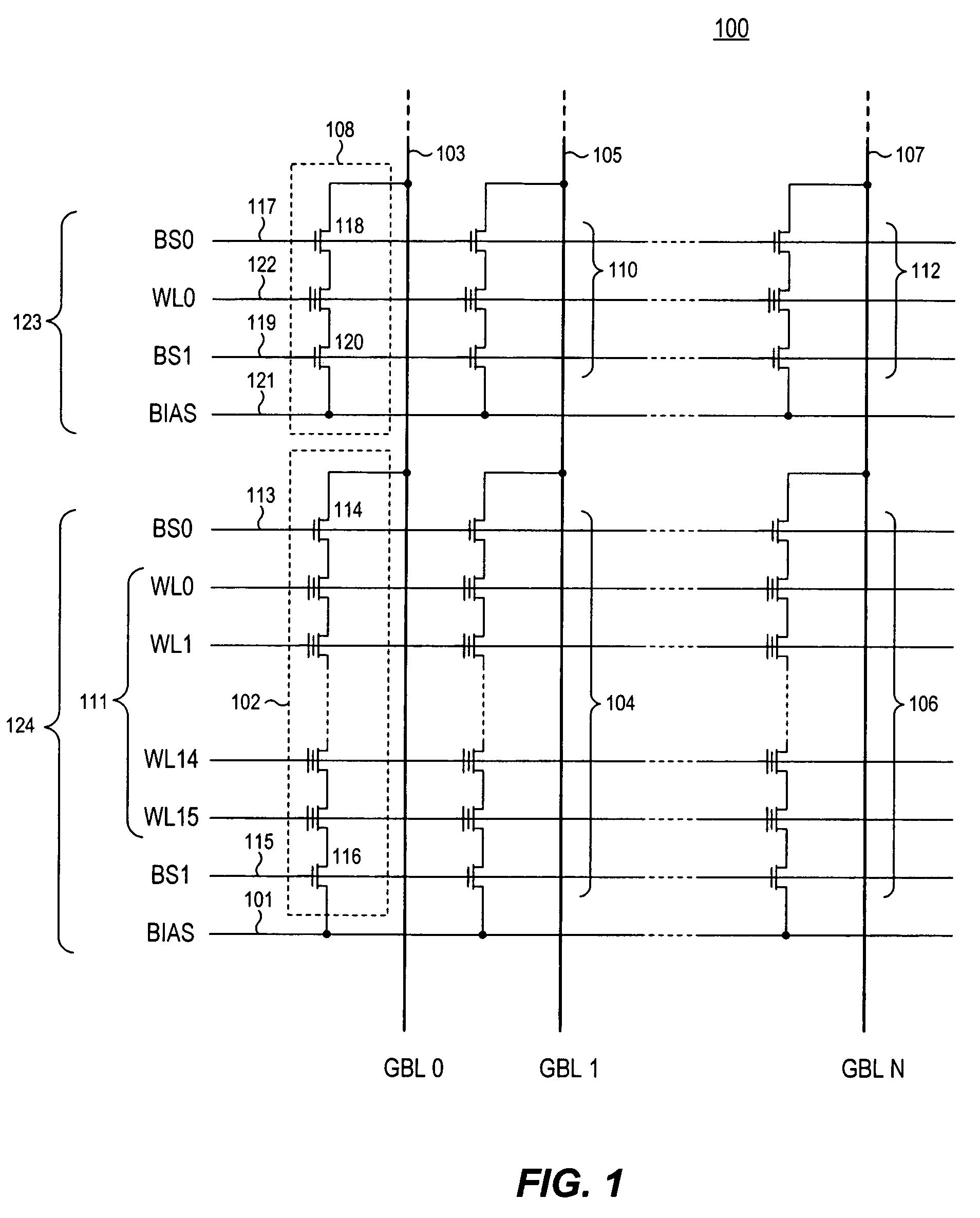

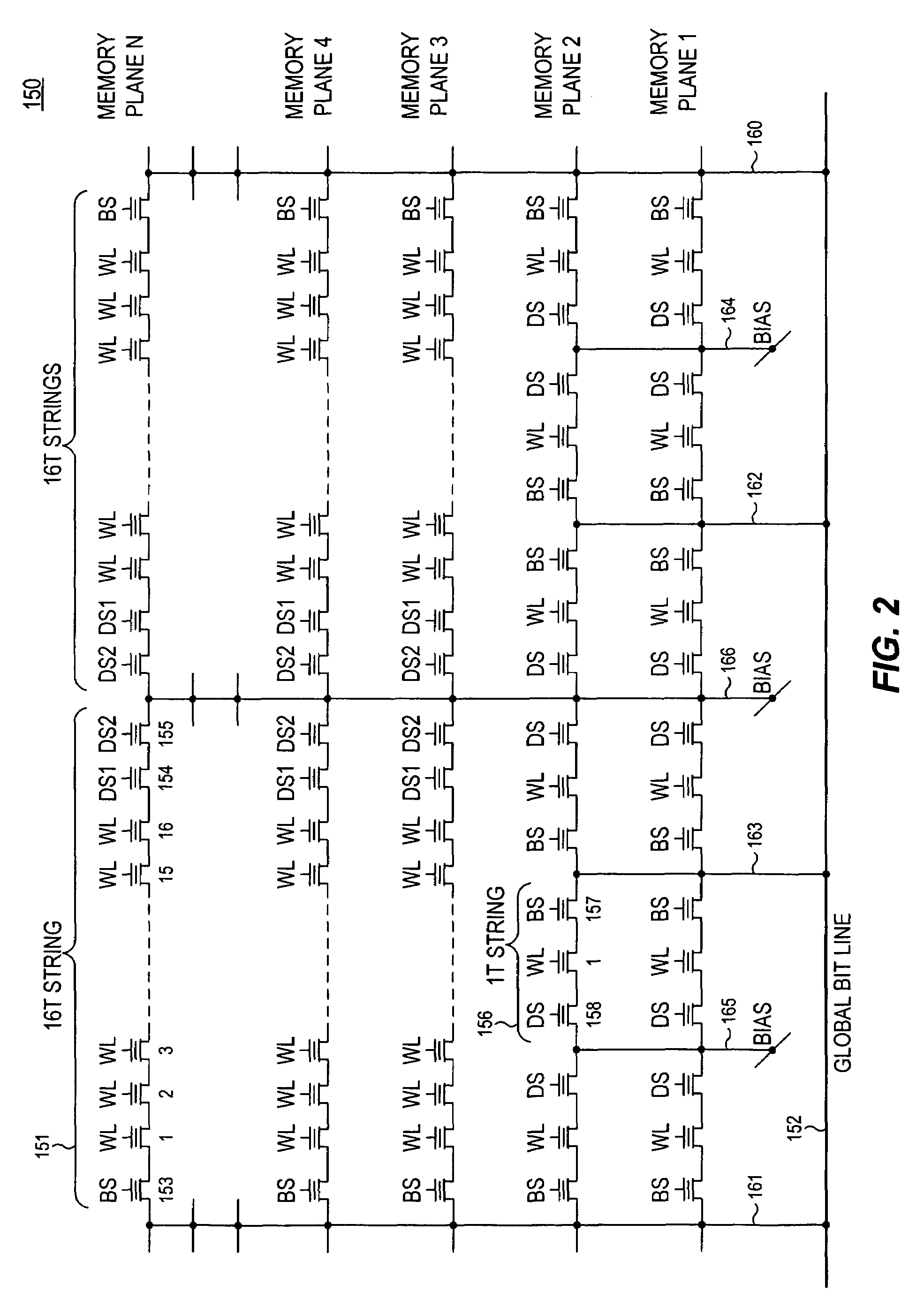

Integrated circuit including memory array incorporating multiple types of NAND string structures

ActiveUS7177191B2High densityGood flexibilitySolid-state devicesRead-only memoriesDevice formParallel computing

Owner:SANDISK TECH LLC

Secure data parser method and system

ActiveUS20070160198A1Minimal compute resourceAvoid the needDigital data protectionSecret communicationOriginal dataComputer science

A secure data parser is provided that may be integrated into any suitable system for securely storing and communicating data. The secure data parser parses data and then splits the data into multiple portions that are stored or communicated distinctly. Encryption of the original data, the portions of data, or both may be employed for additional security. The secure data parser may be used to protect data in motion by splitting original data into portions of data, that may be communicated using multiple communications paths.

Owner:SECURITY FIRST INNOVATIONS LLC

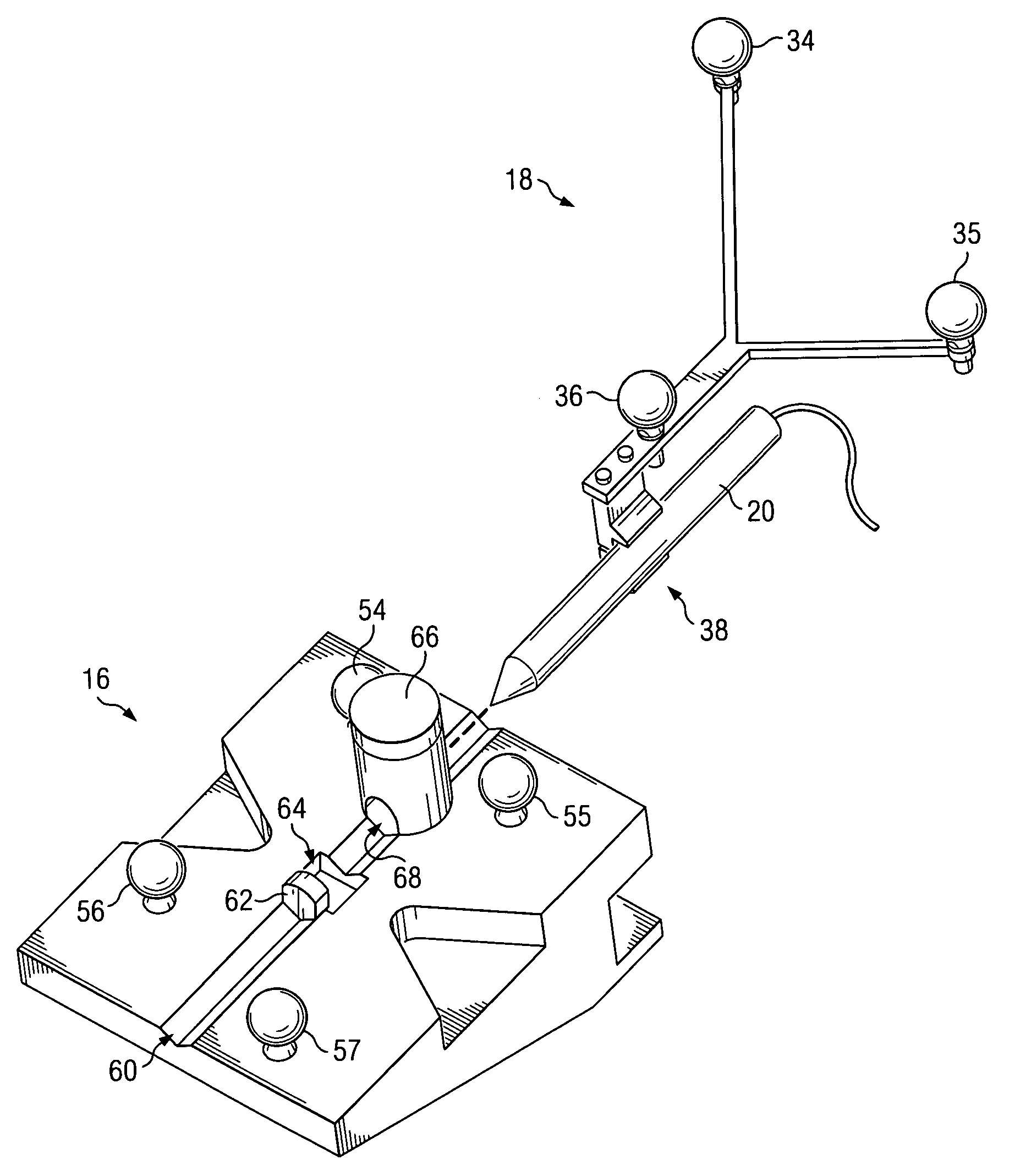

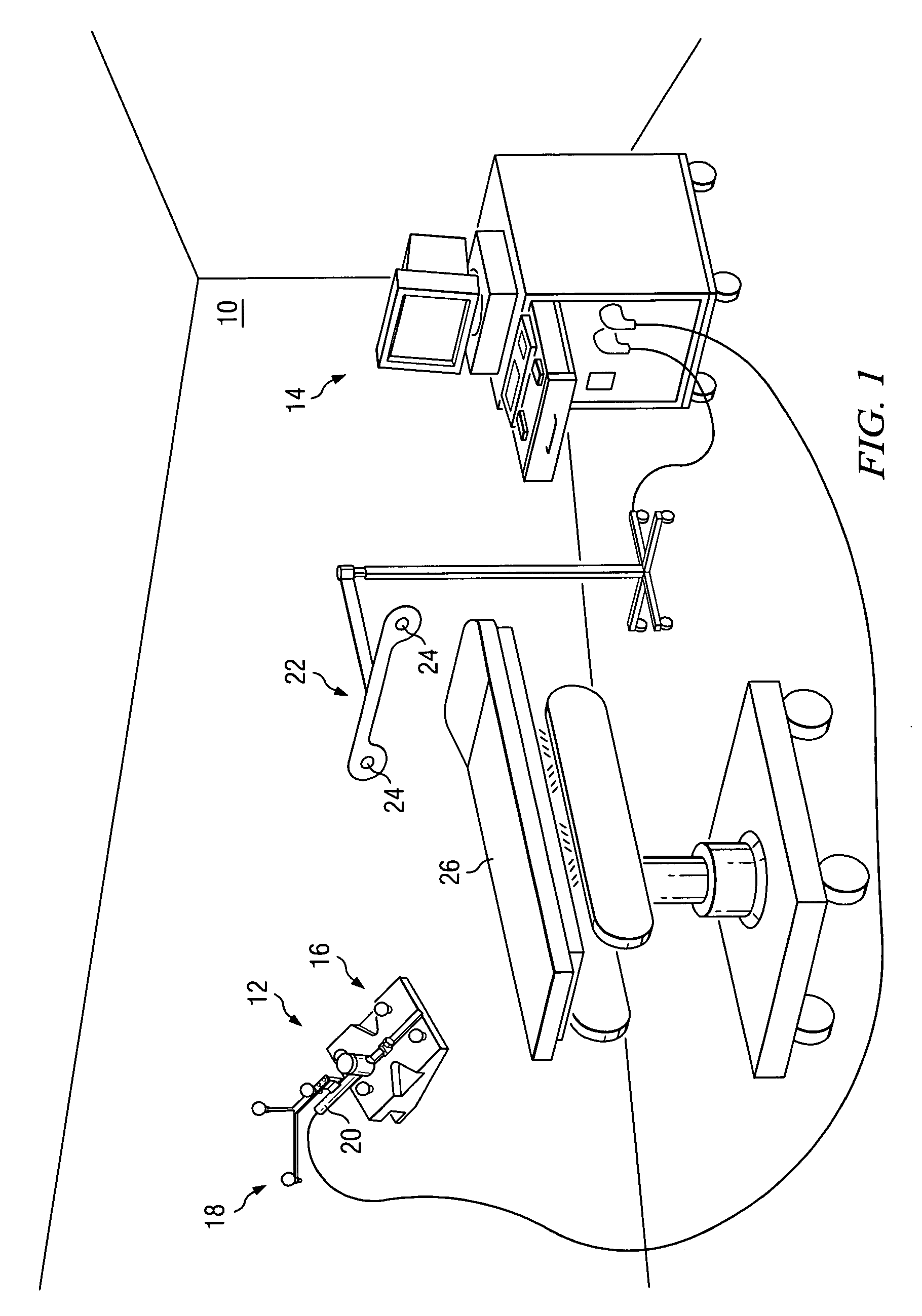

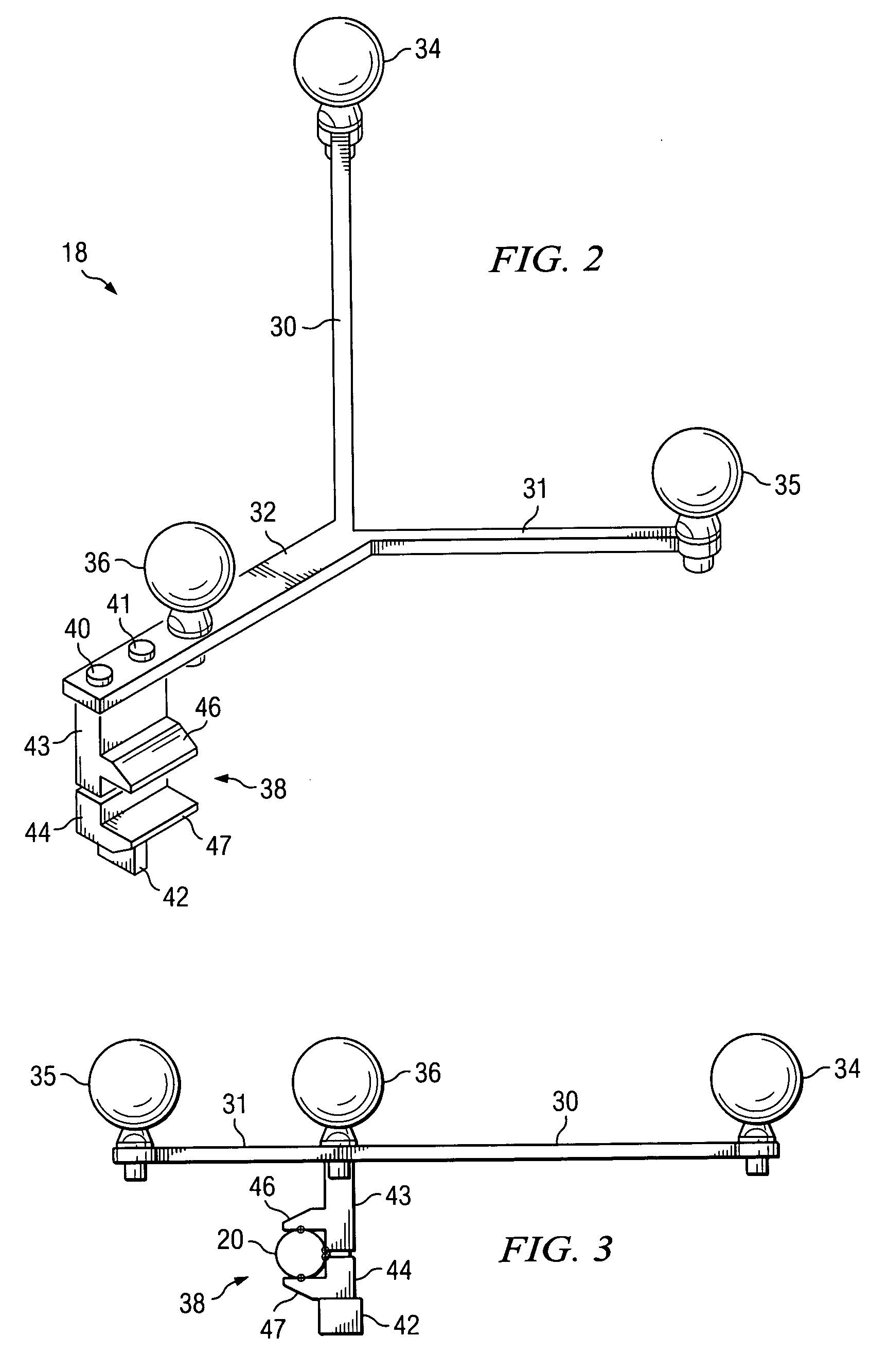

Tool calibrator and tracker system

InactiveUS7043961B2Accurately processSimplifyWave based measurement systemsDiagnosticsEngineeringMechanical engineering

Owner:MAKO SURGICAL CORP

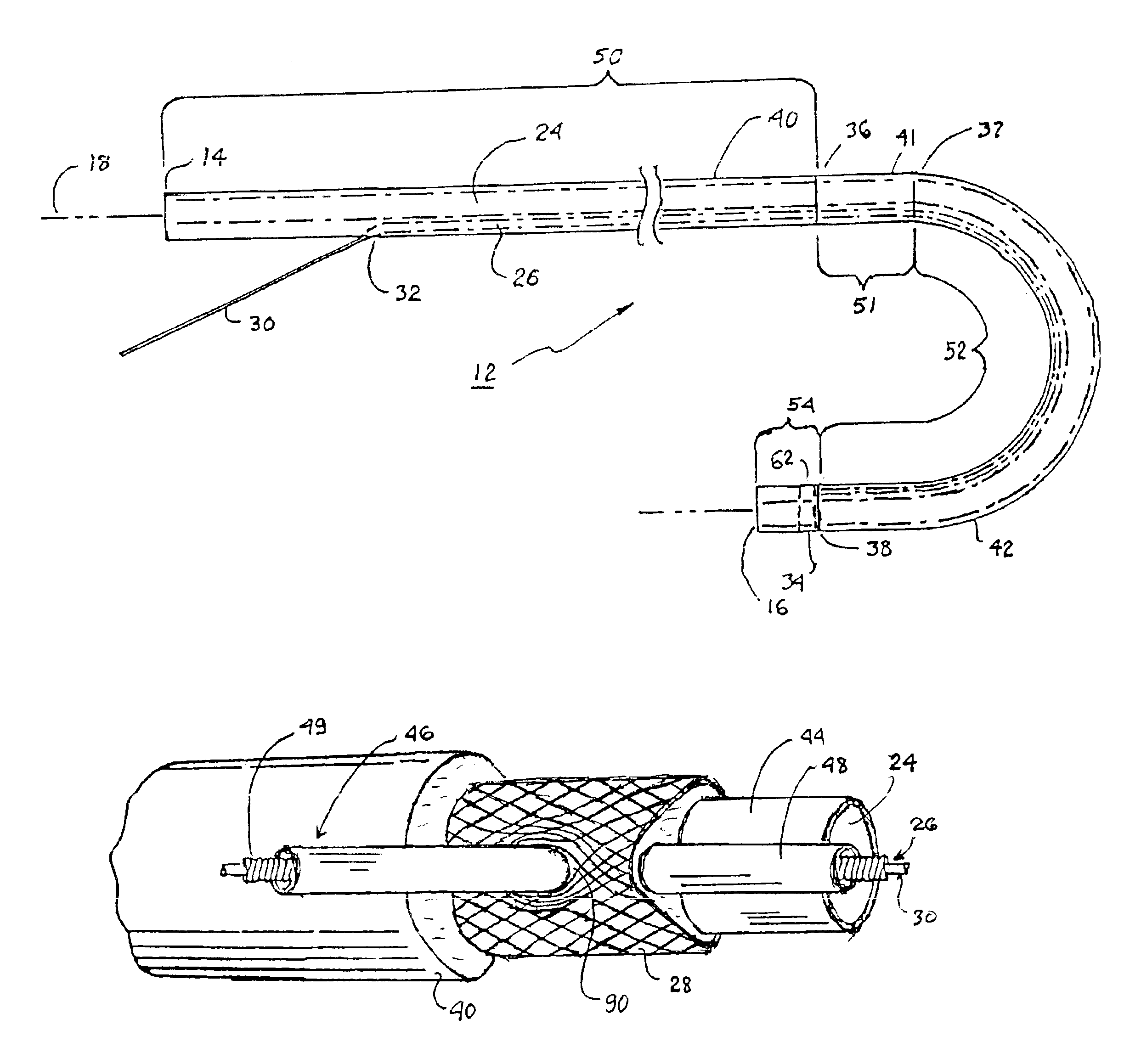

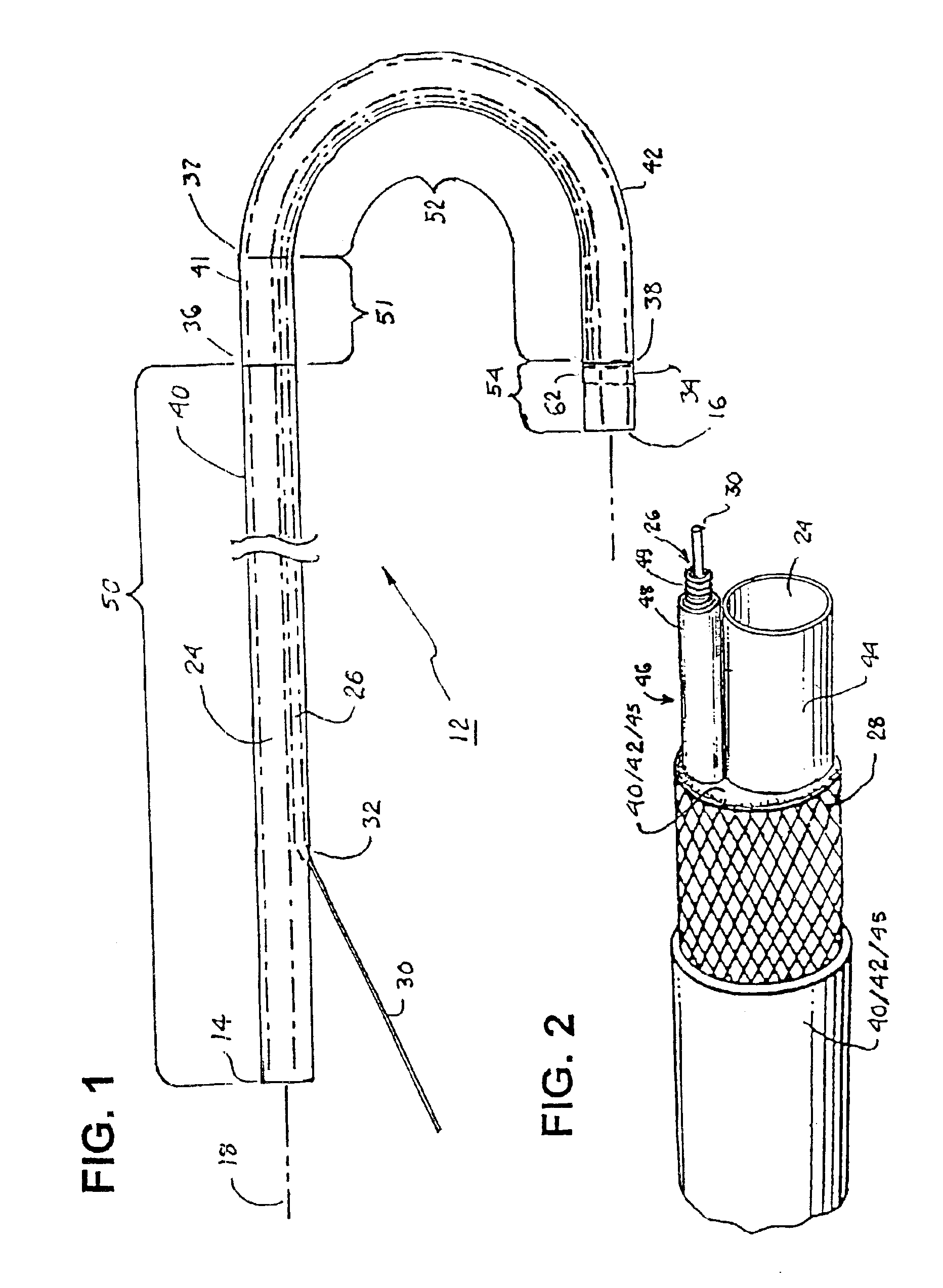

Steerable catheter

InactiveUS6945956B2Easy to insertHigh tensile strengthMulti-lumen catheterMedical devicesDistal segmentCatheter device

A steerable catheter and methods of fabrication including a catheter body formed of a continuous wire braid formed of wires braided over a delivery lumen liner and a pull wire lumen liner distal to a pull wire jacket port, braided around the pull wire jacket port to form a braid port, and over at least a portion of the delivery lumen liner proximal to the pull wire jacket port. A pull wire extends from a pull wire proximal end through the pull wire lumen port and through the pull wire lumen to a pull wire distal end. A band is attached to the pull wire distal end and fitted over a distal segment of the wire braid proximal to the catheter body distal end to fix the pull wire distal end to the catheter body and restrain the wire distal end from flaring away from the delivery lumen liner.

Owner:MEDTRONIC INC

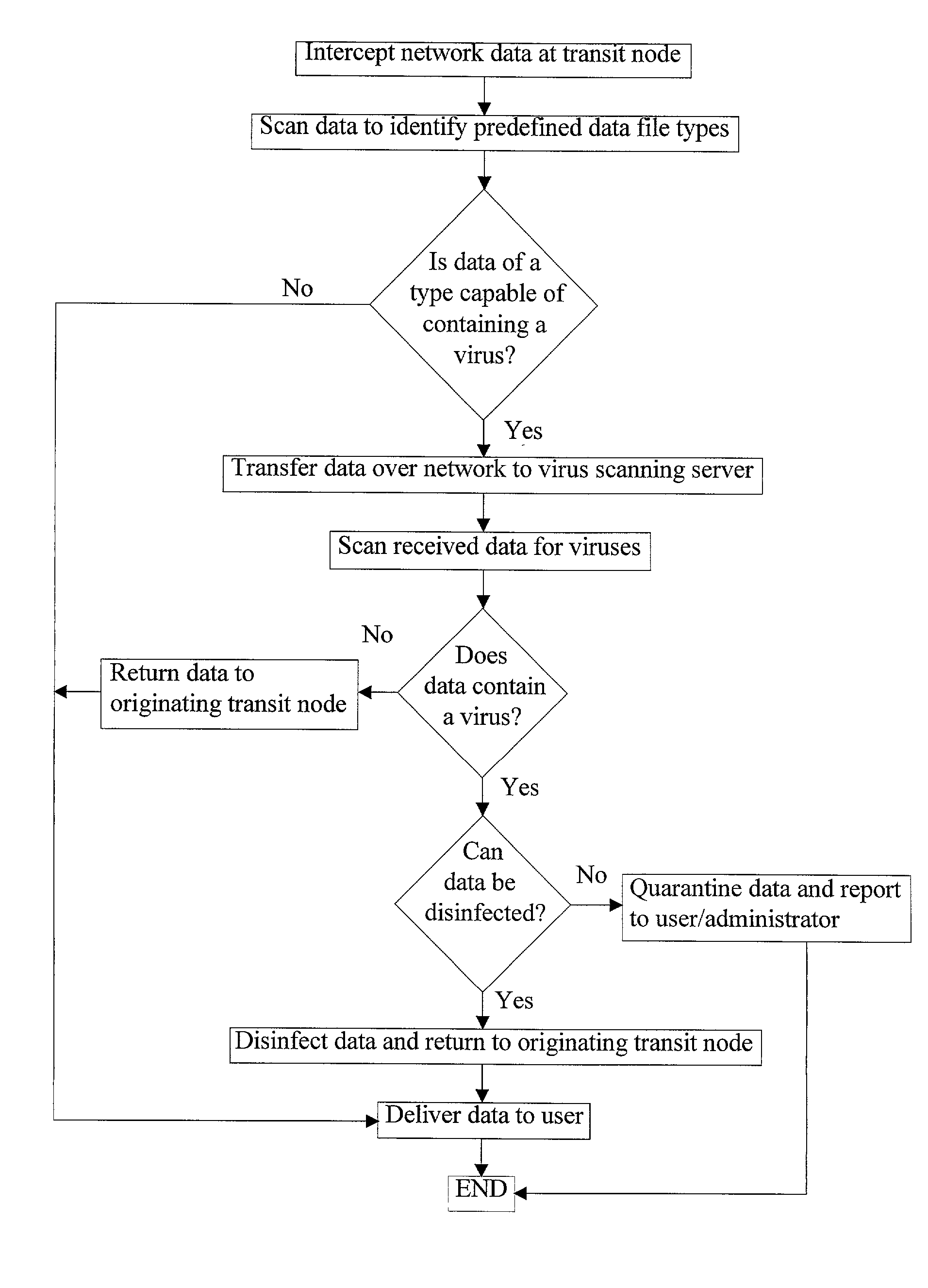

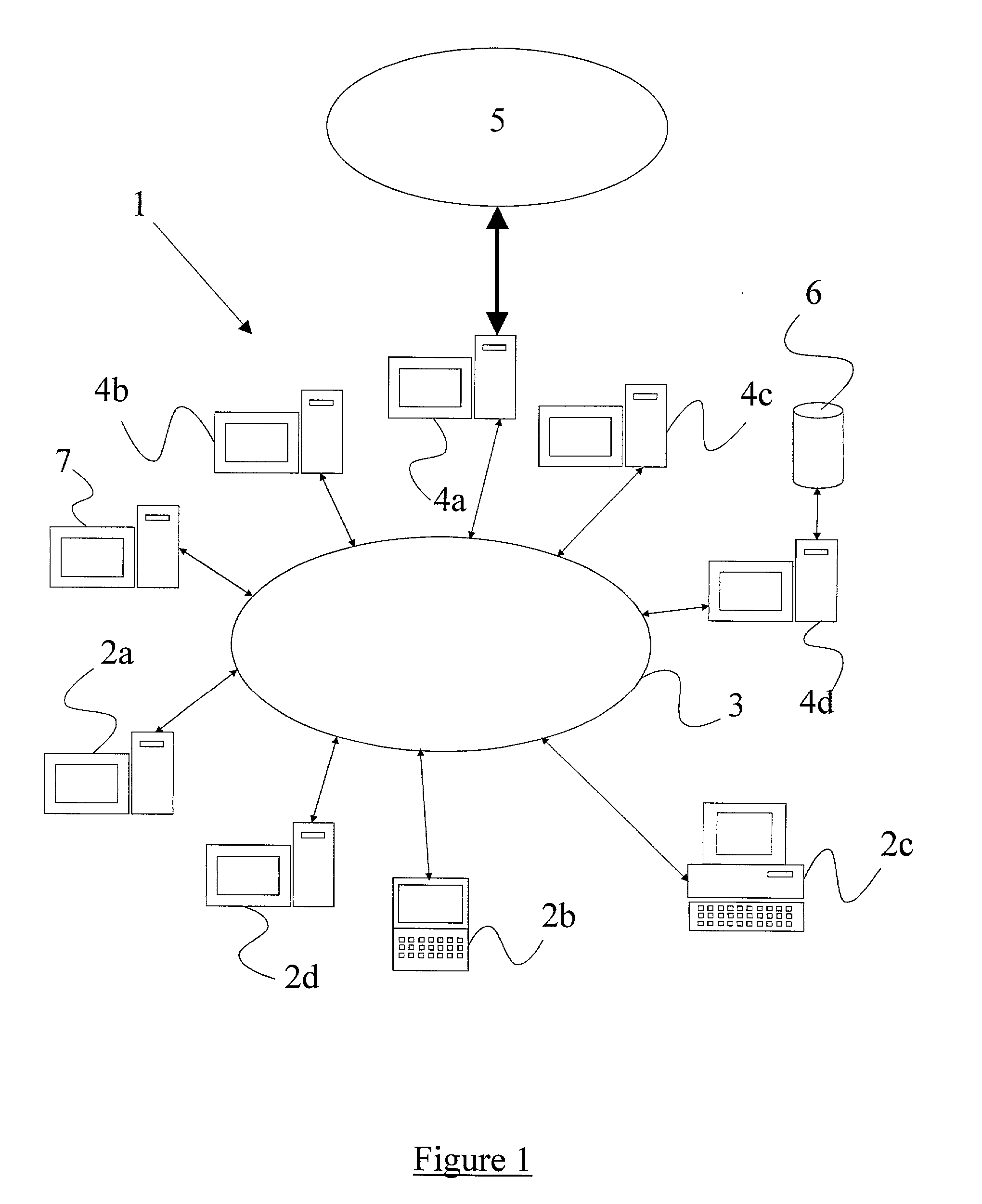

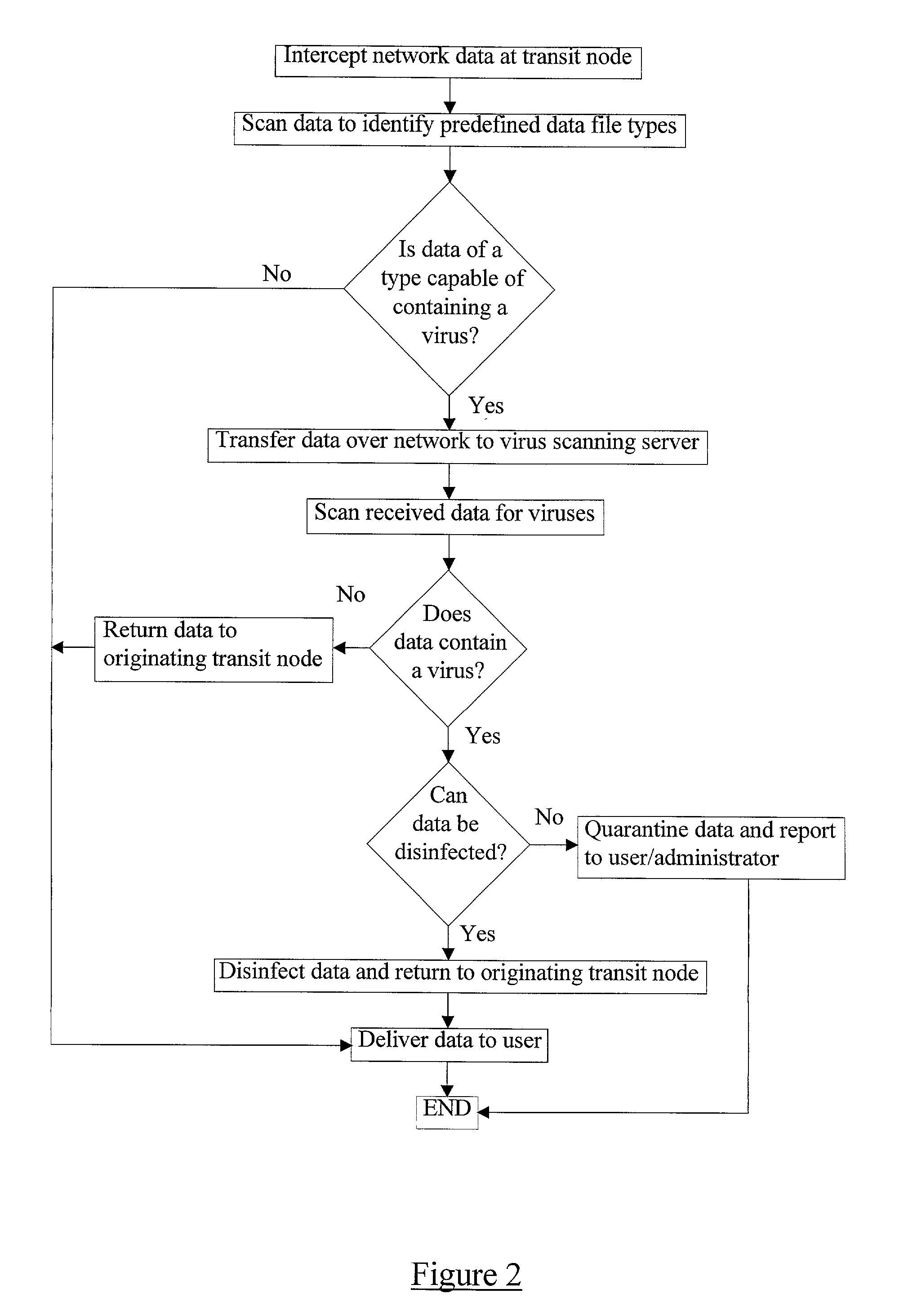

Distributed computer virus detection and scanning

InactiveUS20030191957A1Avoid the needEasy to identifyMemory loss protectionError detection/correctionVirus presentData transmission

A method of detecting viruses in a computer network 1 comprising intercepting data at at least one data transit node 4 of the network 1. The transit node 4 identifies which of the data is of a type capable of containing a virus and transfers the identified data to a virus scanning server 7 over the network 1. The identified data is received at the virus scanning server 7 which scans the data to identify viruses present therein. The server 7 subsequently acts in dependence upon the outcome of the virus scan.

Owner:F SECURE CORP

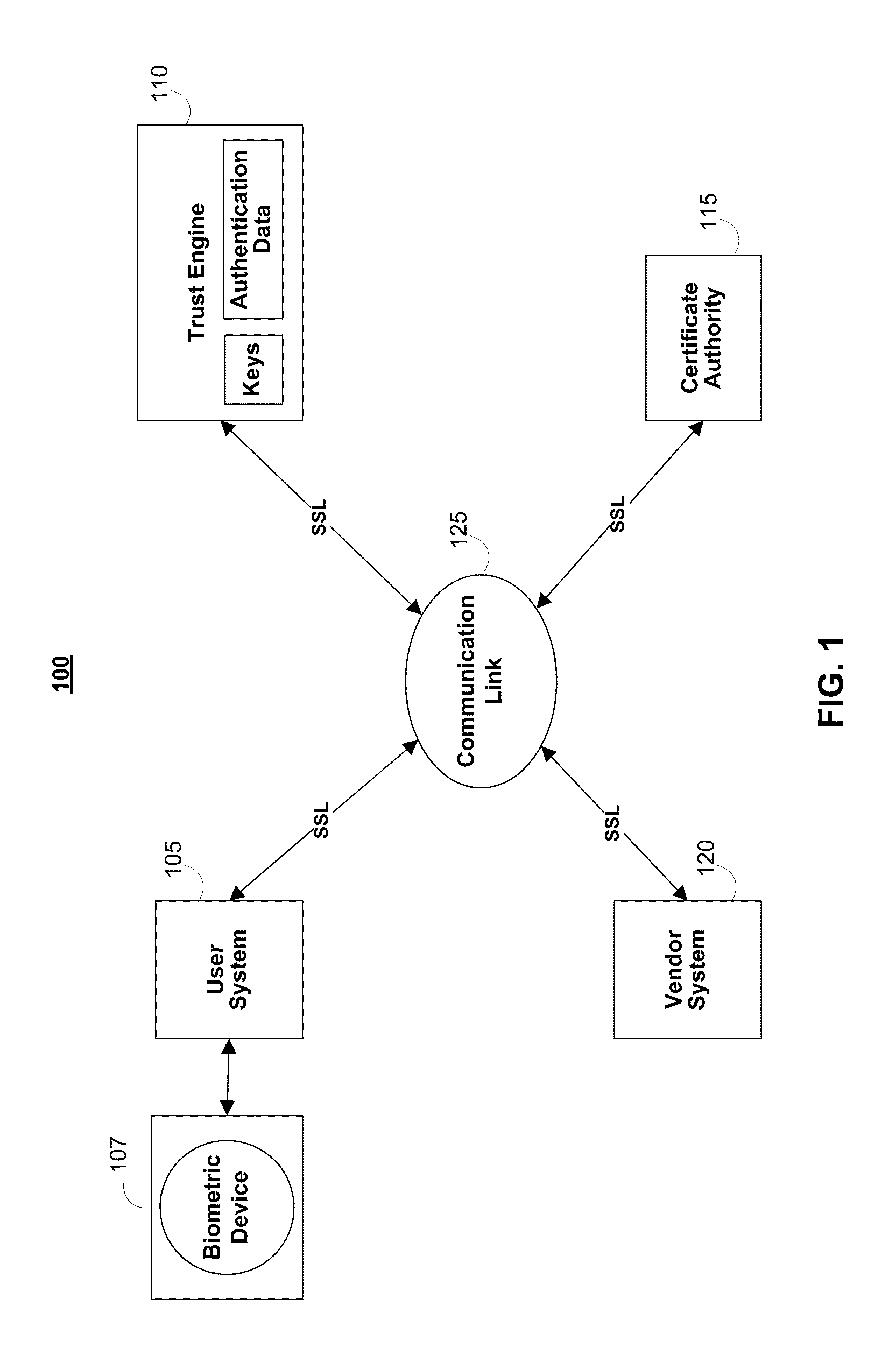

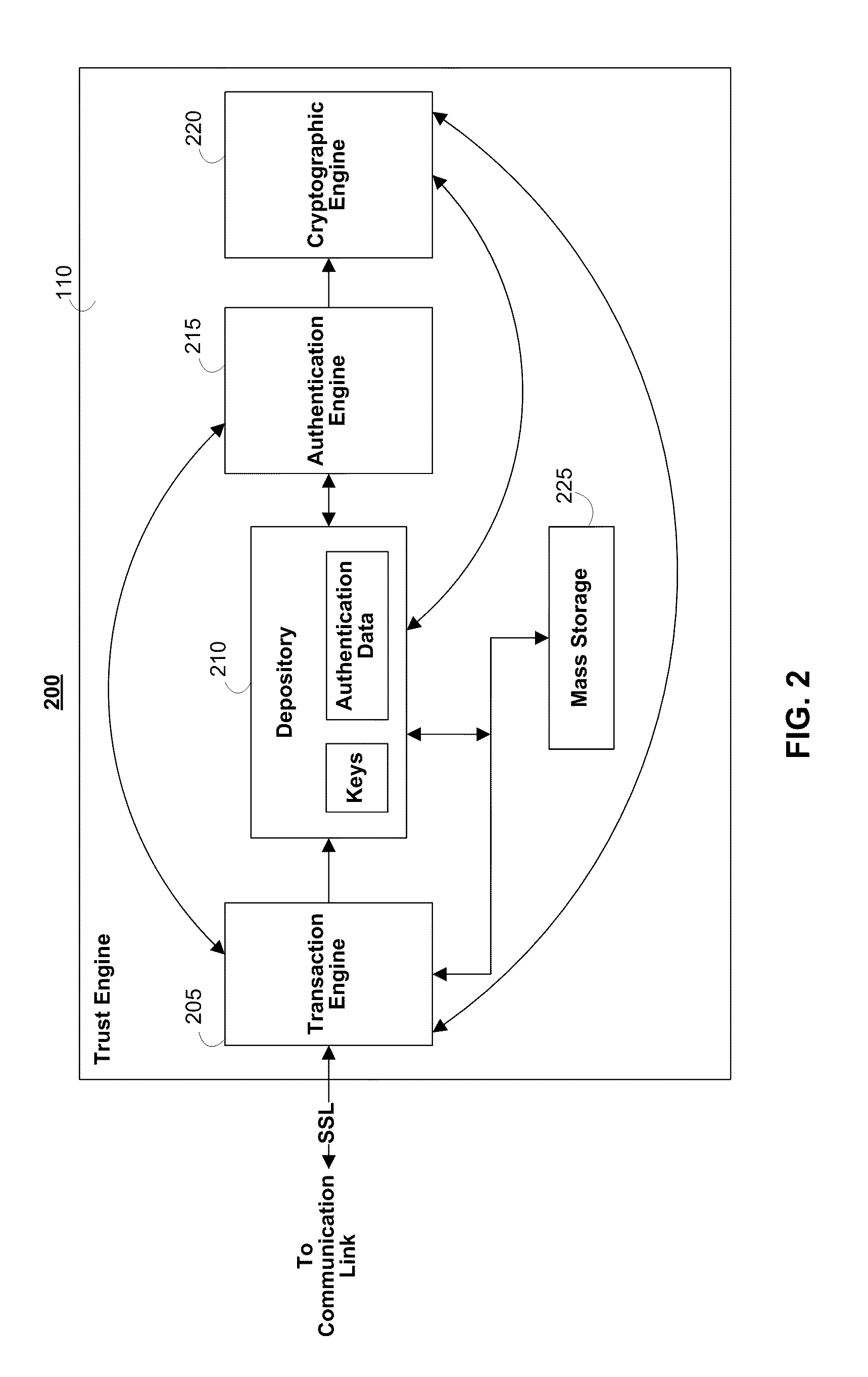

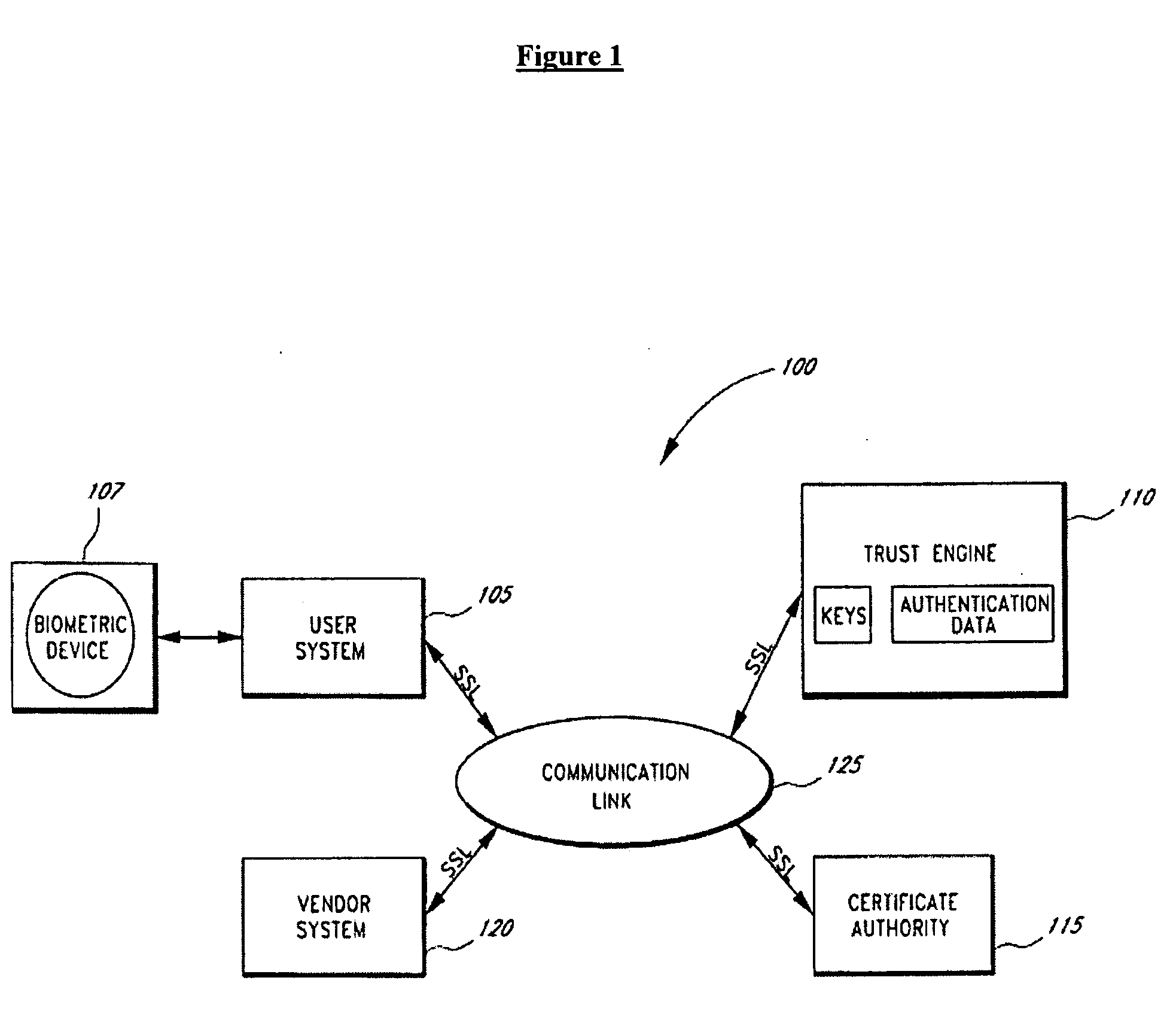

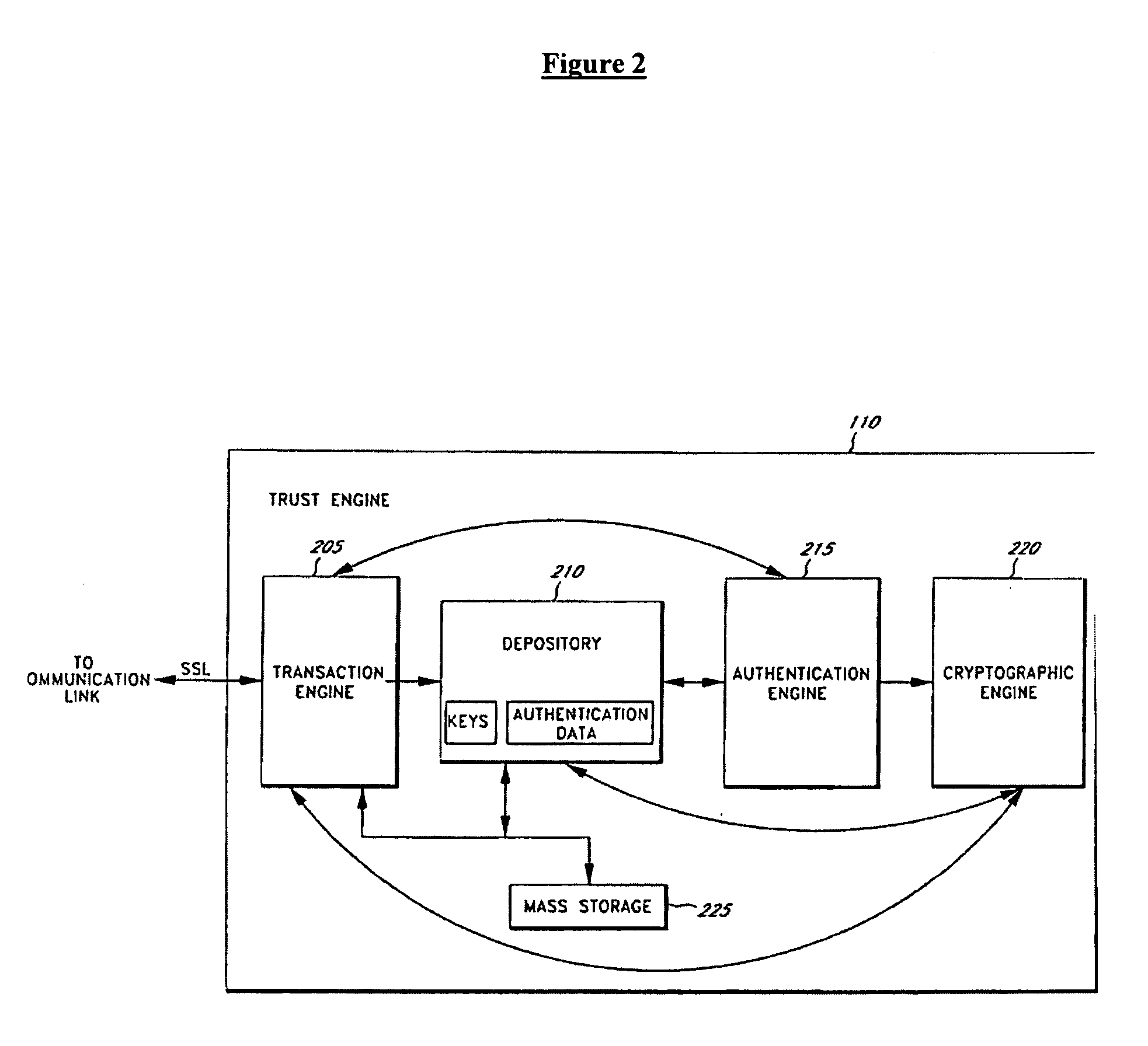

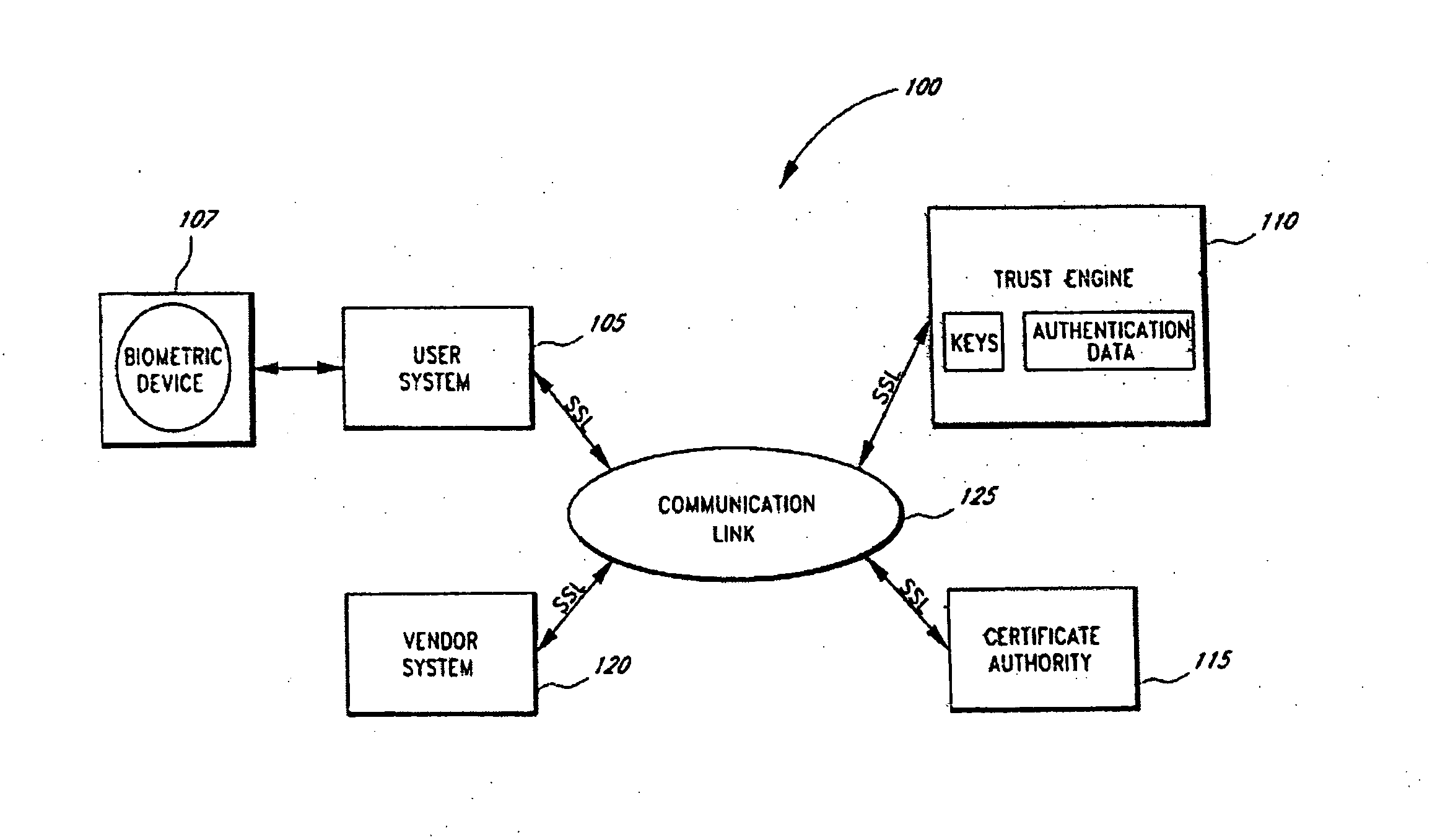

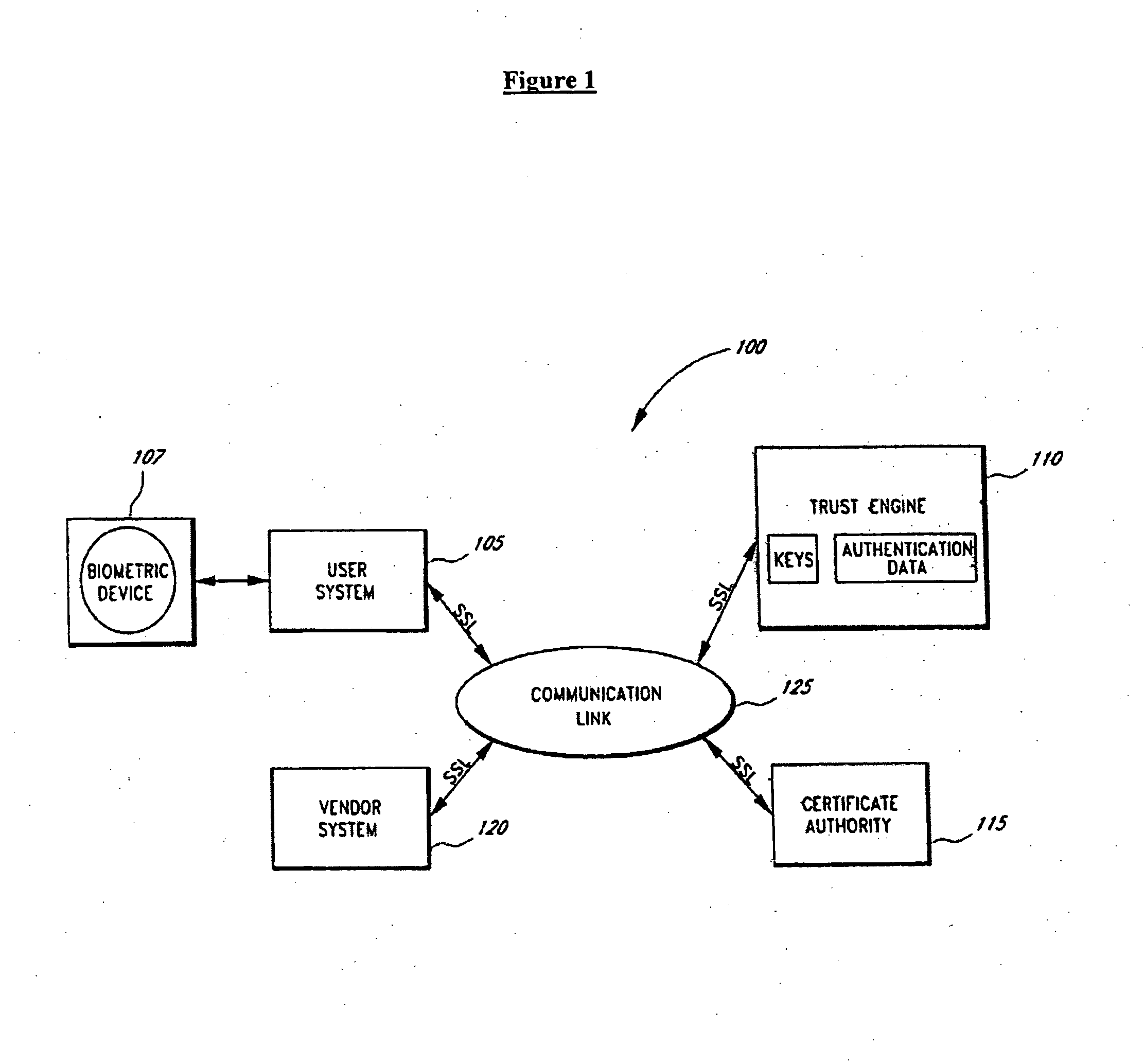

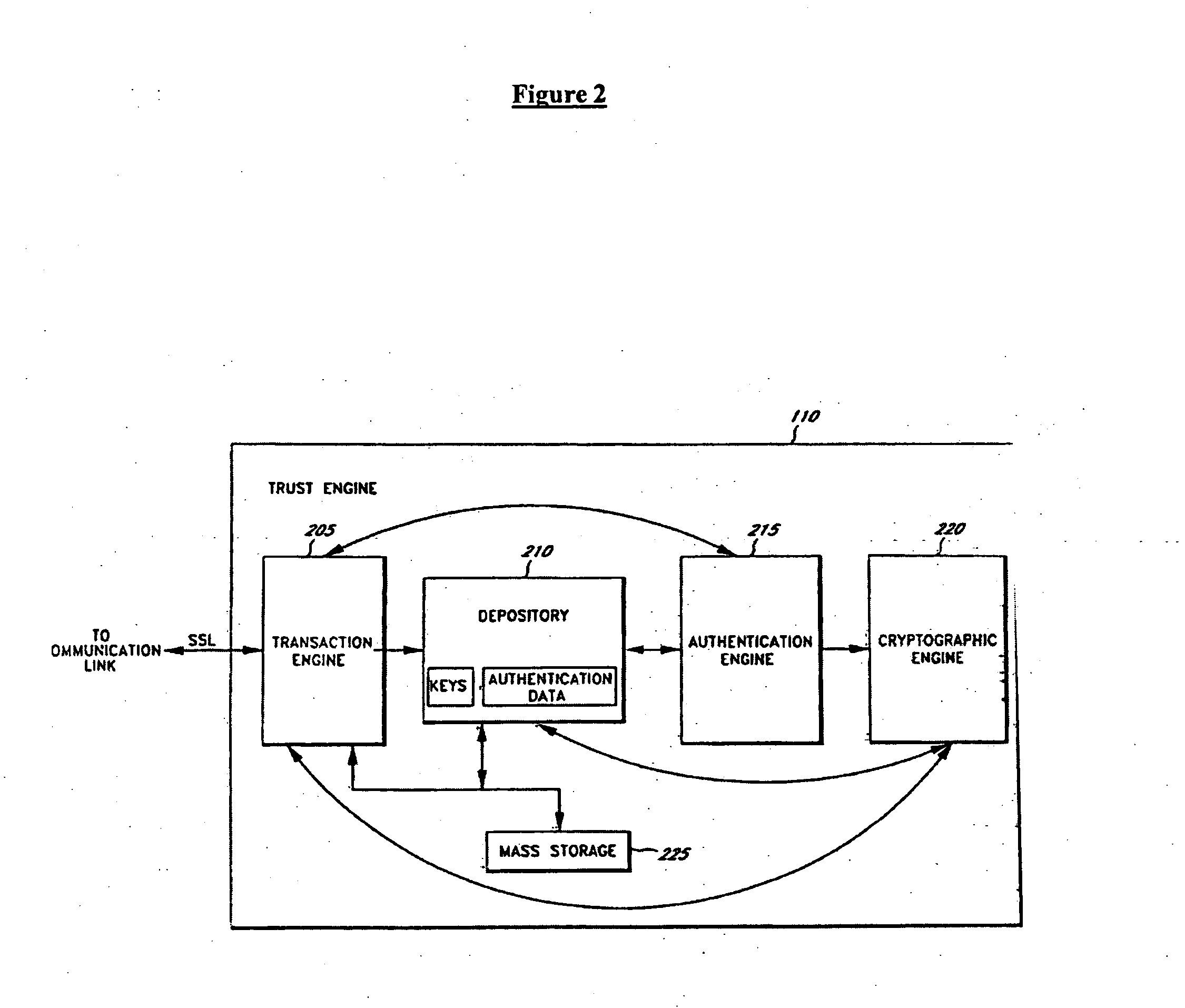

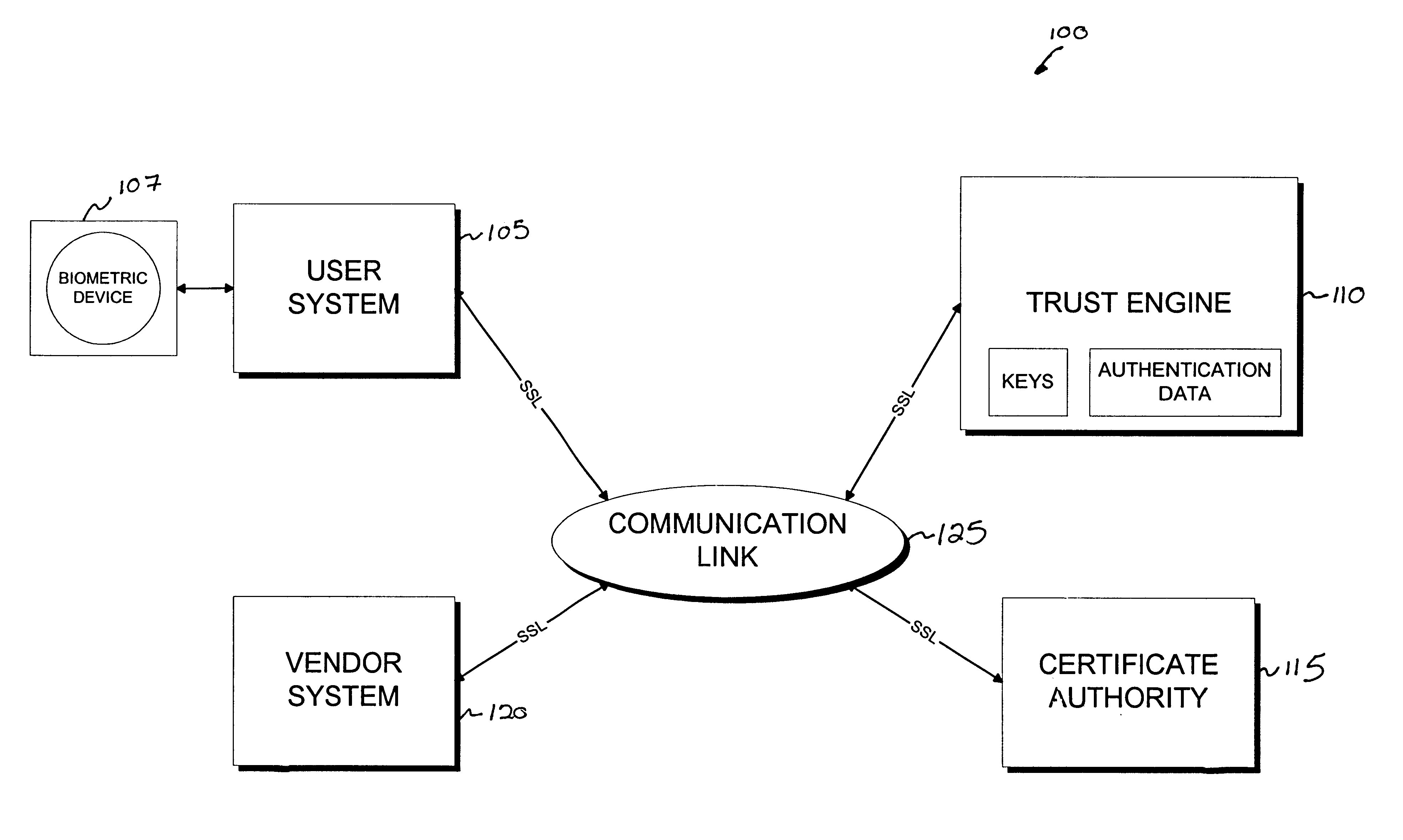

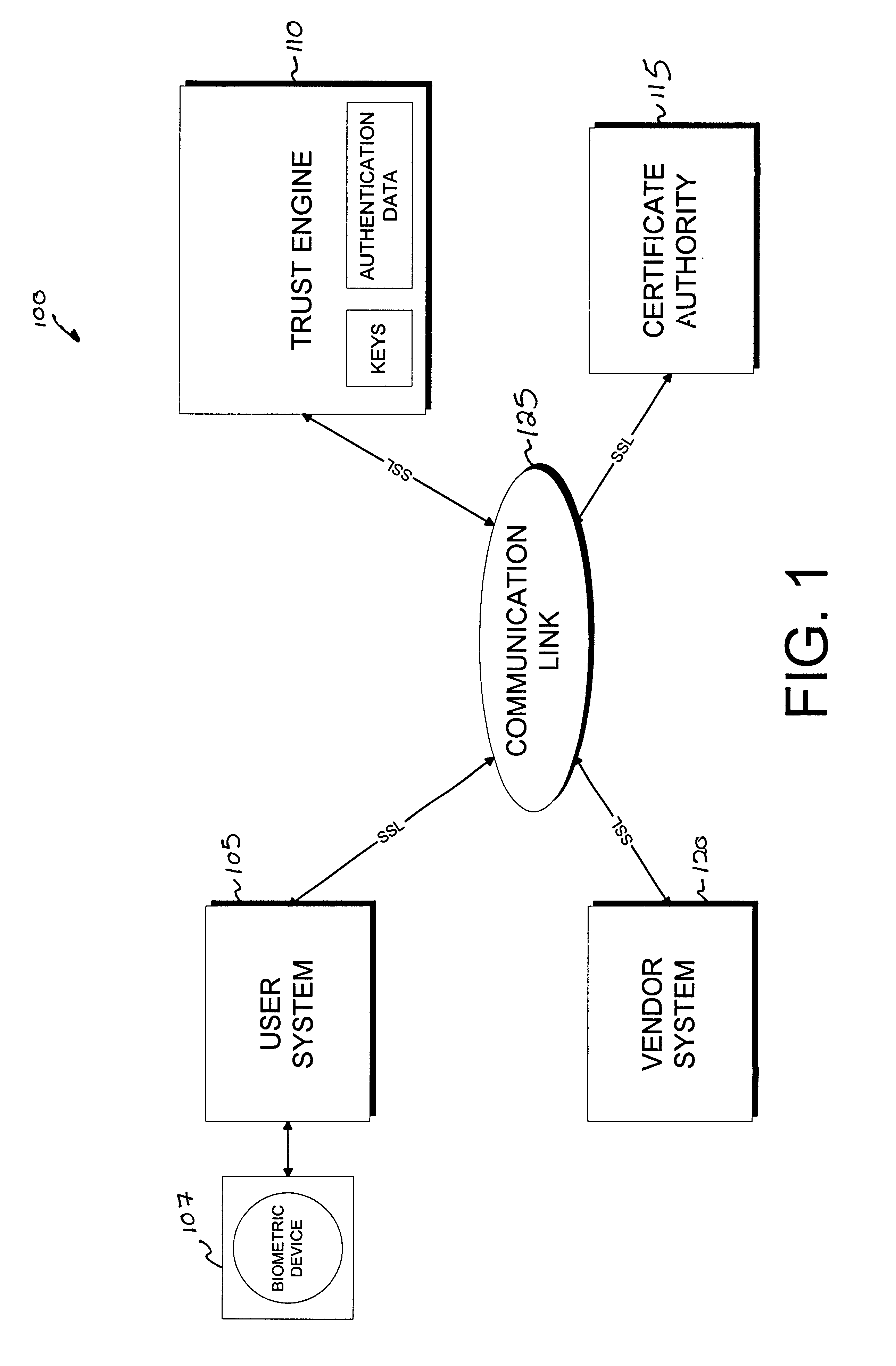

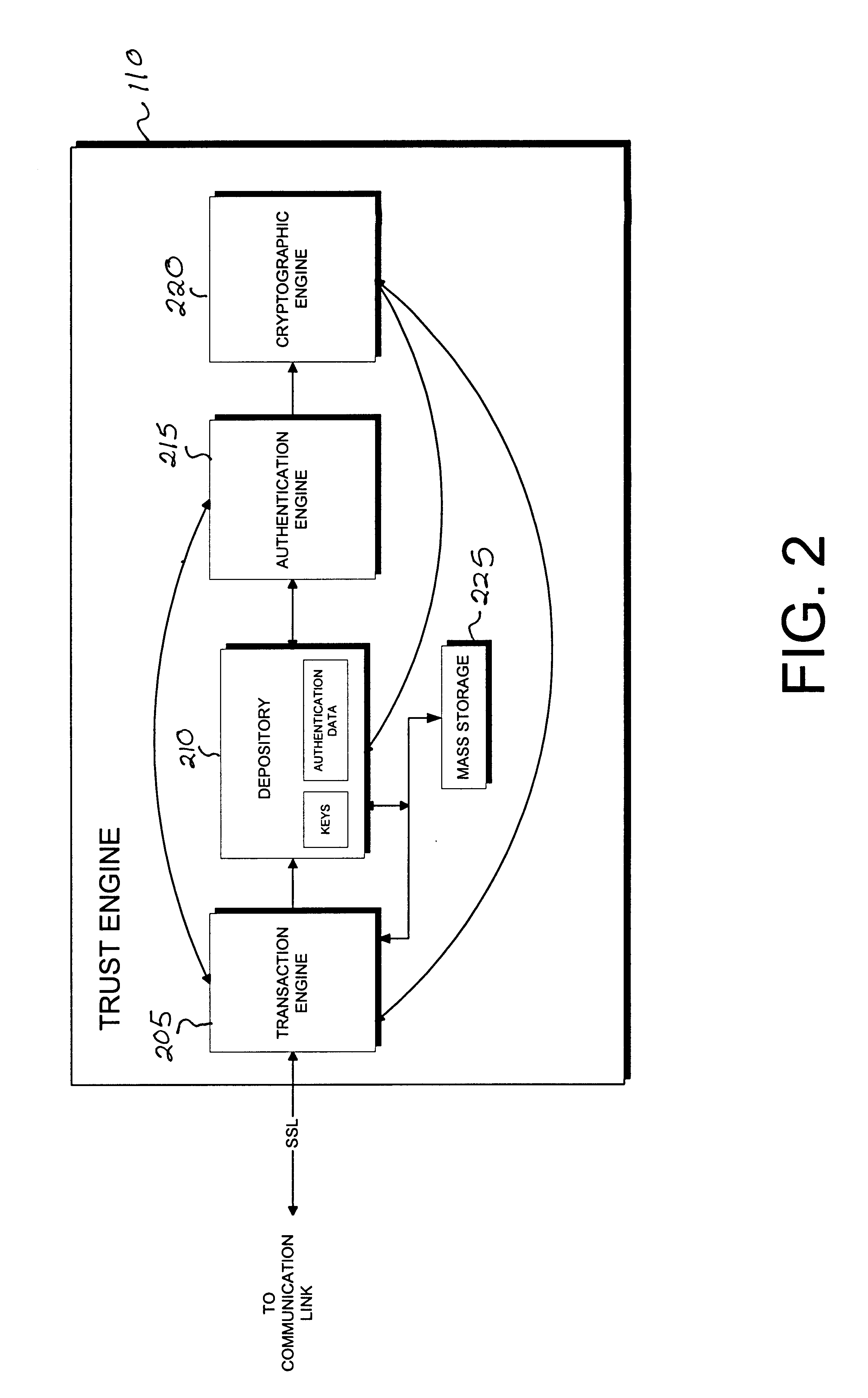

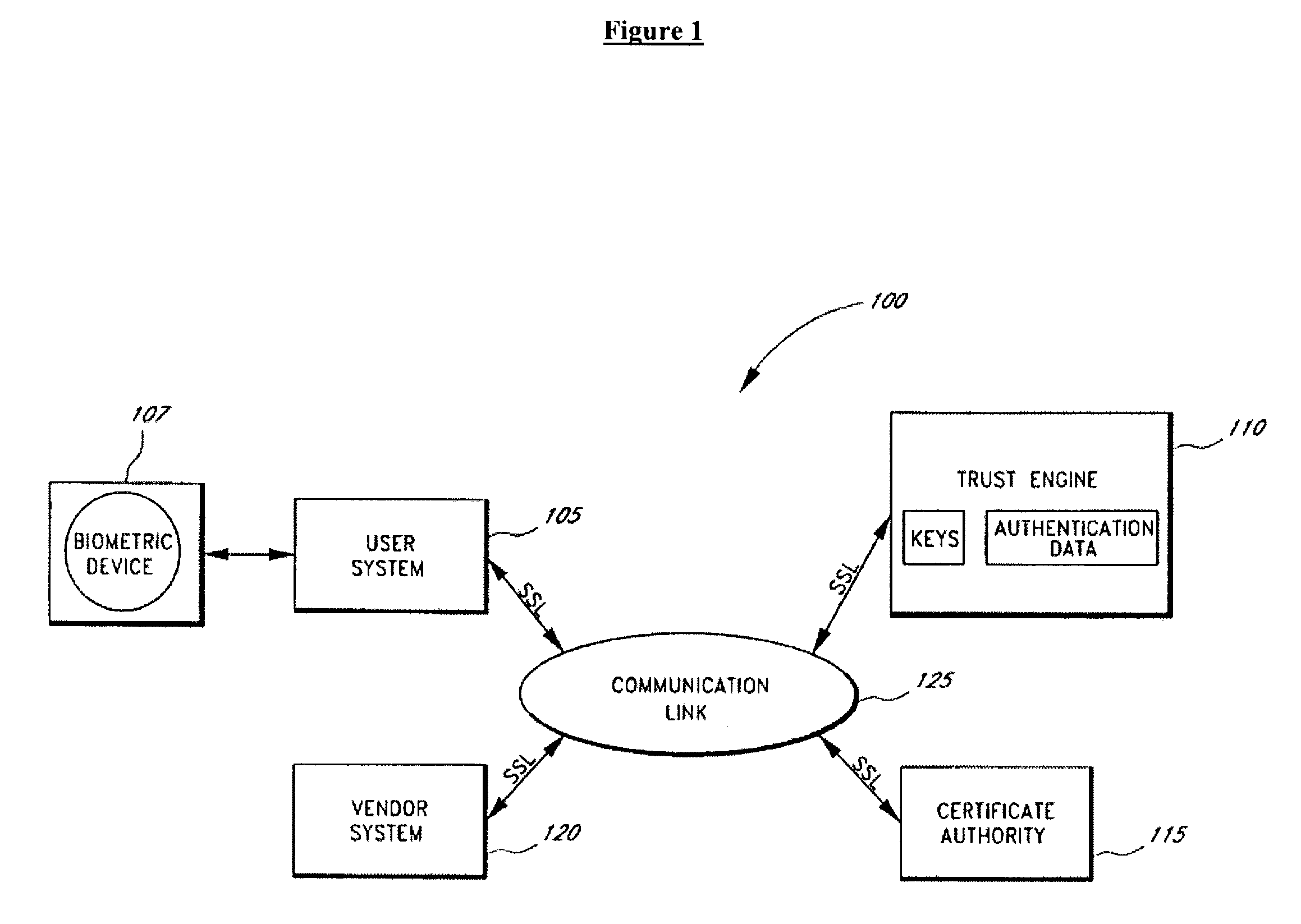

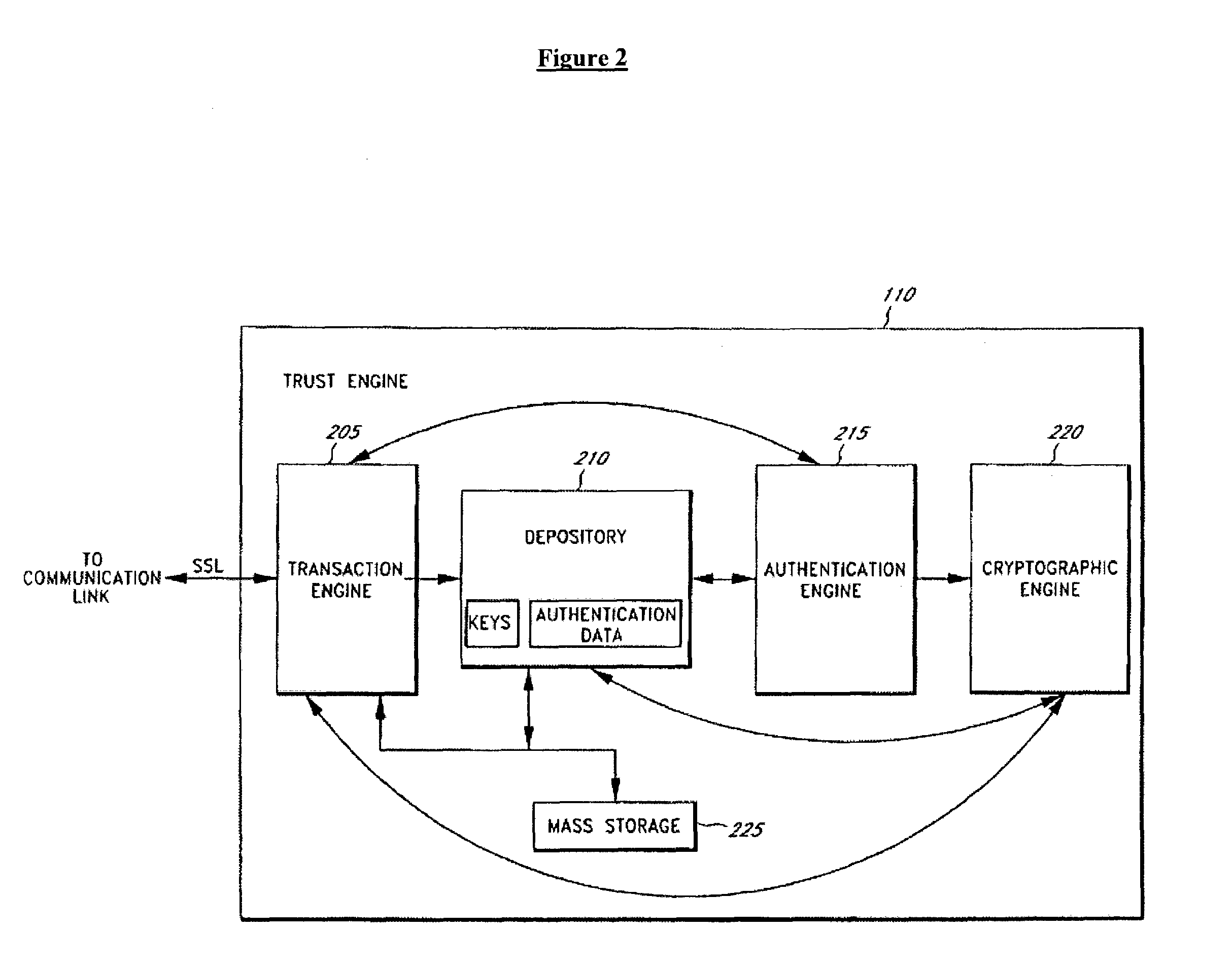

Cryptographic server with provisions for interoperability between cryptographic systems

InactiveUS6853988B1Reduce the number of timesMinimal compute resourceDigital data authenticationBuying/selling/leasing transactionsComputer hardwareKey storage

The invention is a cryptographic server providing interoperability over multiple algorithms, keys, standards, certificate types and issuers, protocols, and the like. Another aspect of the invention is to provide a secure server, or trust engine, having server-centric keys, or in other words, storing cryptographic keys on a server. The server-centric storage of keys provides for user-independent security, portability, availability, and straightforwardness, along with a wide variety of implementation possibilities.

Owner:SECURITY FIRST INNOVATIONS LLC

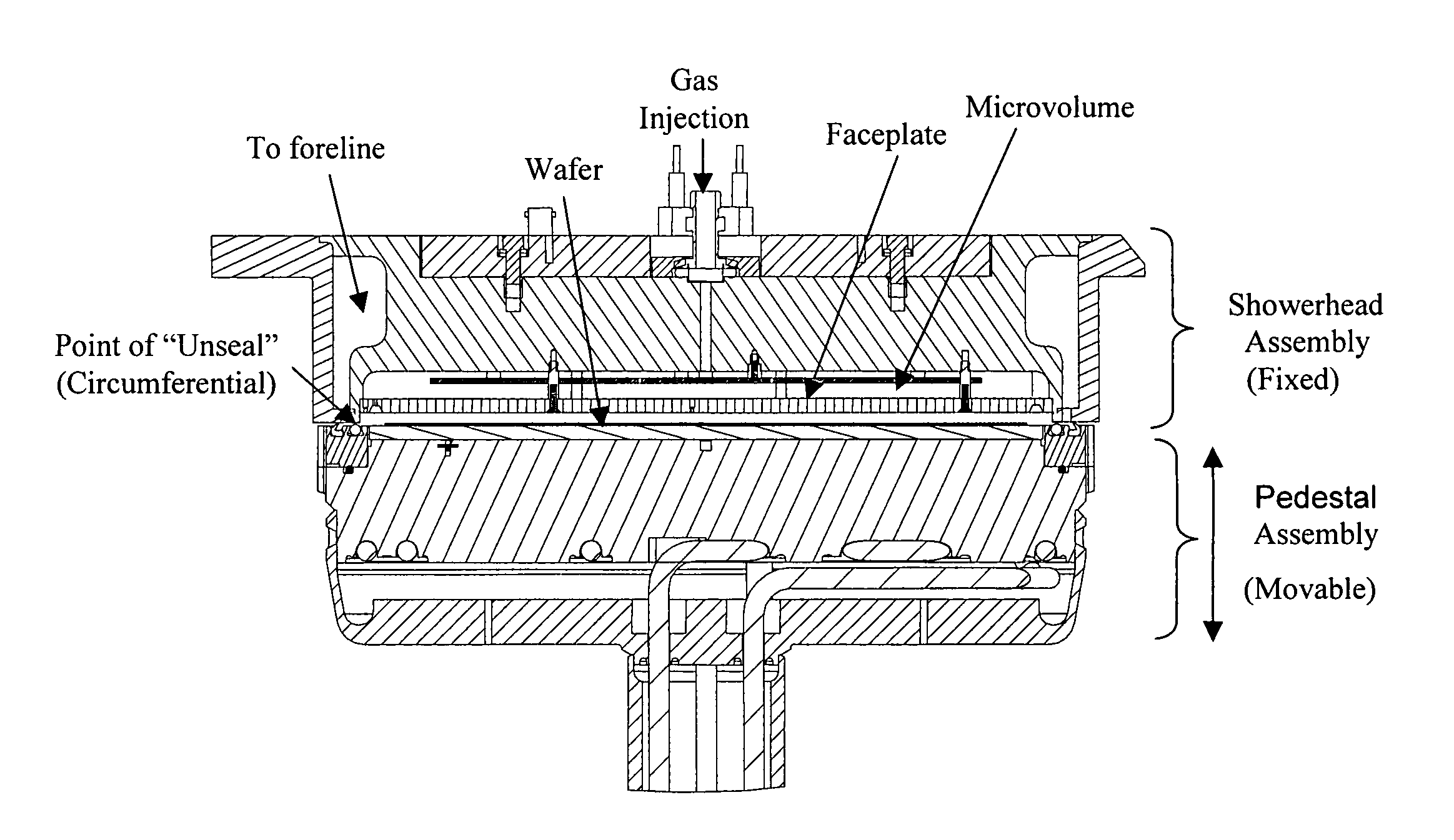

Dual seal deposition process chamber and process

ActiveUS7737035B1Minimal chamber volumeReducing or eliminating dead legsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

An apparatus and method for sealing and unsealing a chemical deposition apparatus in a chemical deposition process chamber includes a microvolume that has dual sealing elements at its periphery. One seal, the outer seal, is used to seal the inside of the microvolume from the main process chamber. The second (inner) seal is used to seal the inside of the microvolume from a vacuum source. The apparatus and process of the present invention has several advantages for enhanced chamber performance.

Owner:NOVELLUS SYSTEMS

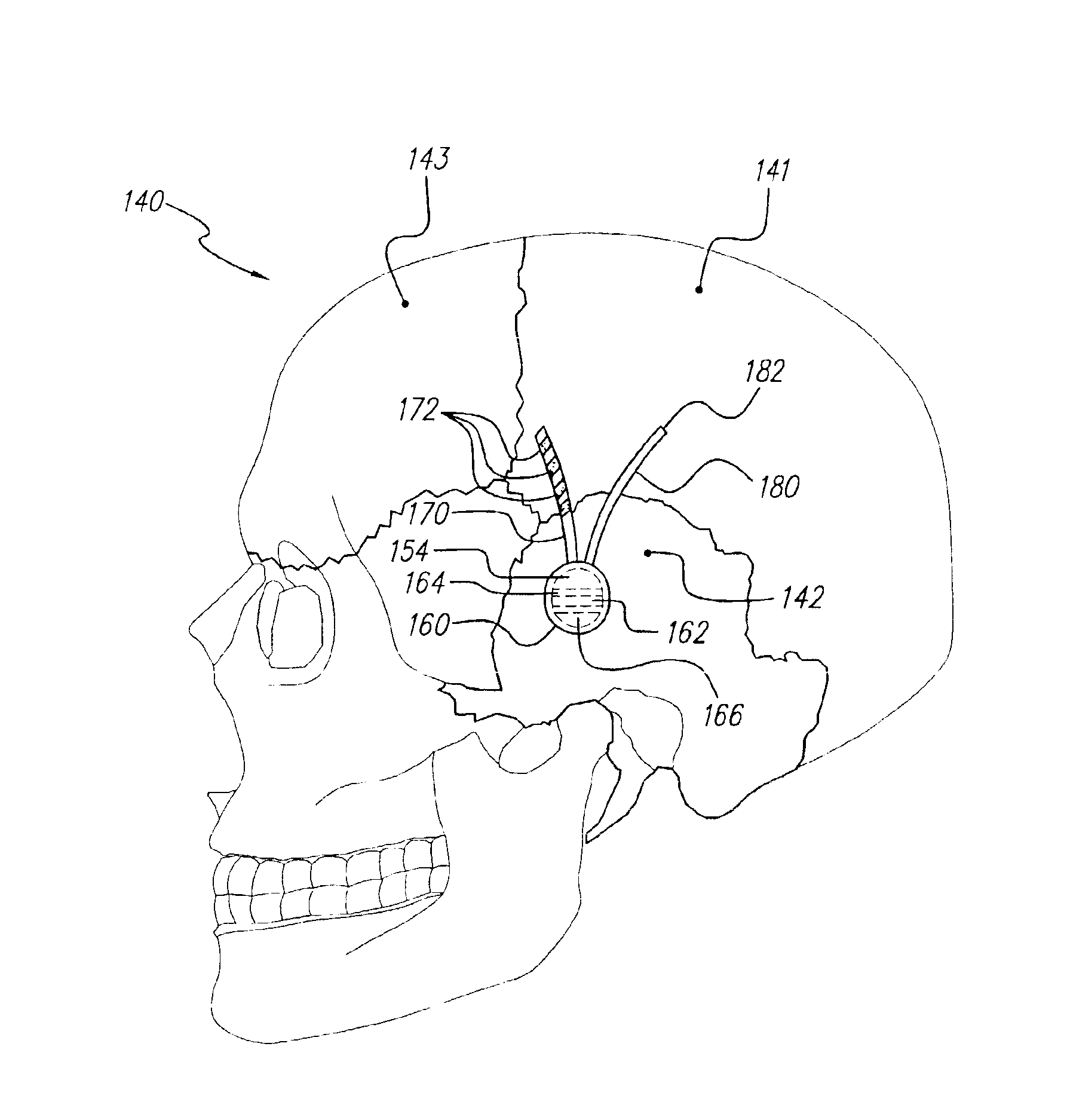

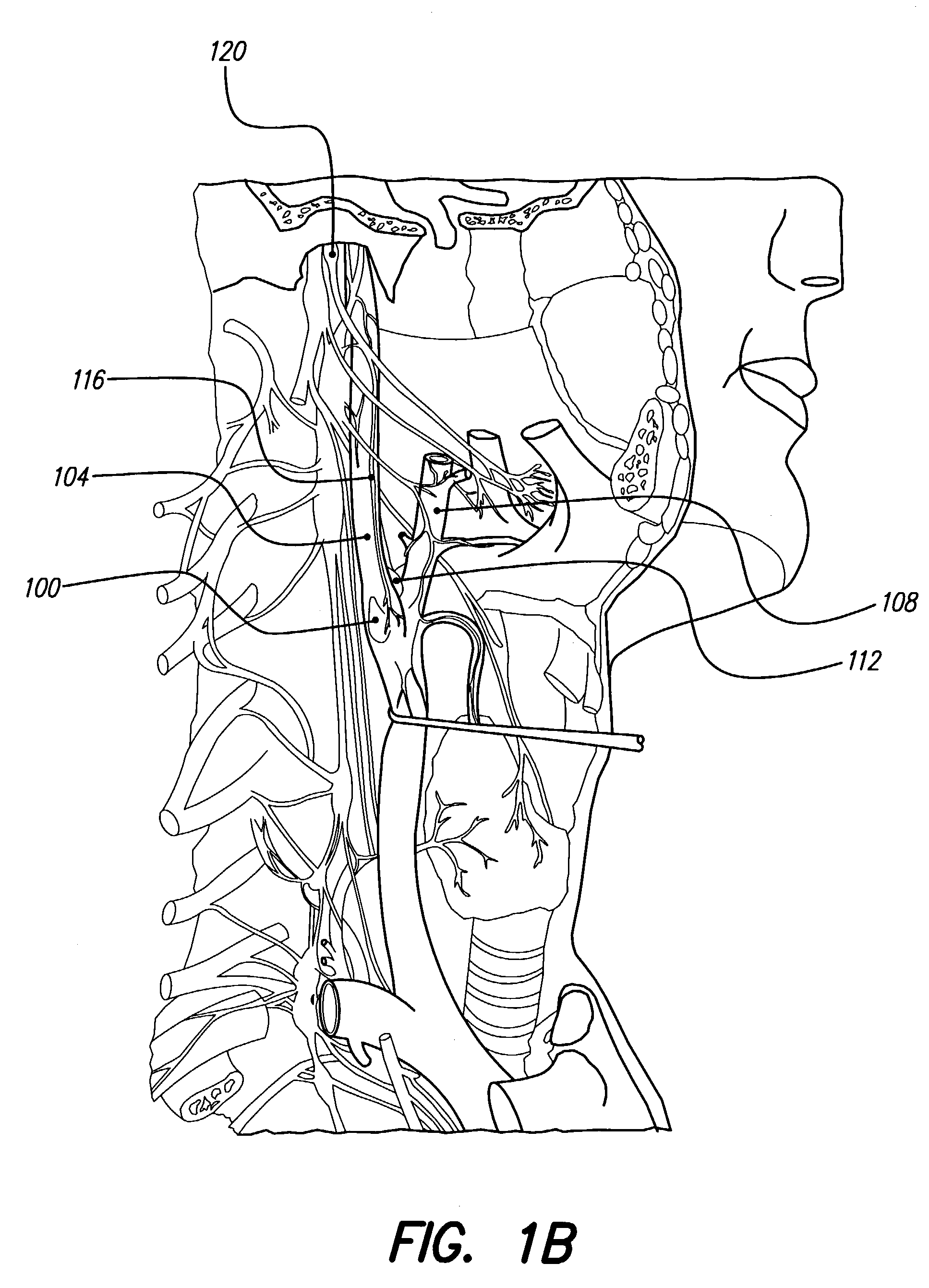

Treatment of epilepsy by brain stimulation

InactiveUS7003352B1Small sizeInhibition amountElectrotherapyPressure infusionMedicineElectrical stimulations

Introducing one or more stimulating drugs to the brain and / or applying electrical stimulation to the brain is used to treat epilepsy. At least one implantable system control unit (SCU) produces electrical pulses delivered via electrodes implanted in the brain and / or drug infusion pulses delivered via a catheter implanted in the brain. The stimulation is delivered to targeted brain structures to adjust the activity of those structures. The small size of the SCUs of the invention allow SCU implantation directly and entirely within the skull and / or brain. Simplicity of the preferred systems and methods and compactness of the preferred system are enabled by the modest control parameter set of these SCU, which do not require or include a sensing feature.

Owner:BOSTON SCI NEUROMODULATION CORP

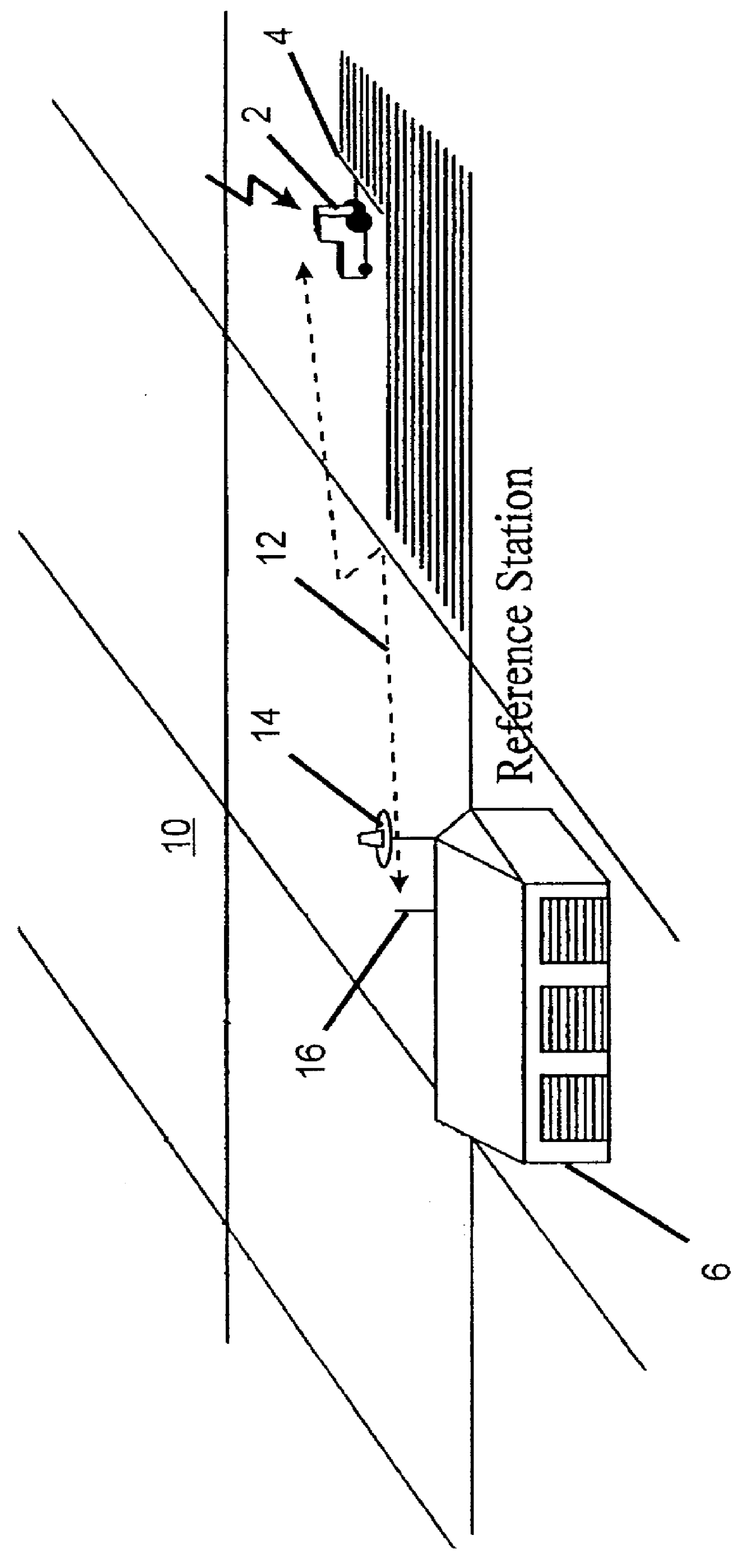

Method and system for automatic control of vehicles based on carrier phase differential GPS

InactiveUS6052647AImprove system stabilitySimple processDigital data processing detailsPosition fixationAutomatic train controlAutomatic control

Described is an automatic control system for land (and possible marine) vehicles based on carrier phase differential GPS (CPGPS). The system relies on CPGPS to determine vehicle position and attitude very precisely (position to within 1 cm and attitude to within 0.1 DEG ). A system incorporates a technique to calculate and compensate for antenna motion due to vehicle roll and pitch. One aspect of the system utilizes an intelligent vehicle controller that recognizes and adapts to changing conditions, such as vehicle speed, implements towed by the vehicle, soil conditions, and disturbance level. The system provides the capability to control the vehicle on various paths, including straight lines and arbitrary curves. Also described is a technique for initialization and vehicle control using only a single pseudolite.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

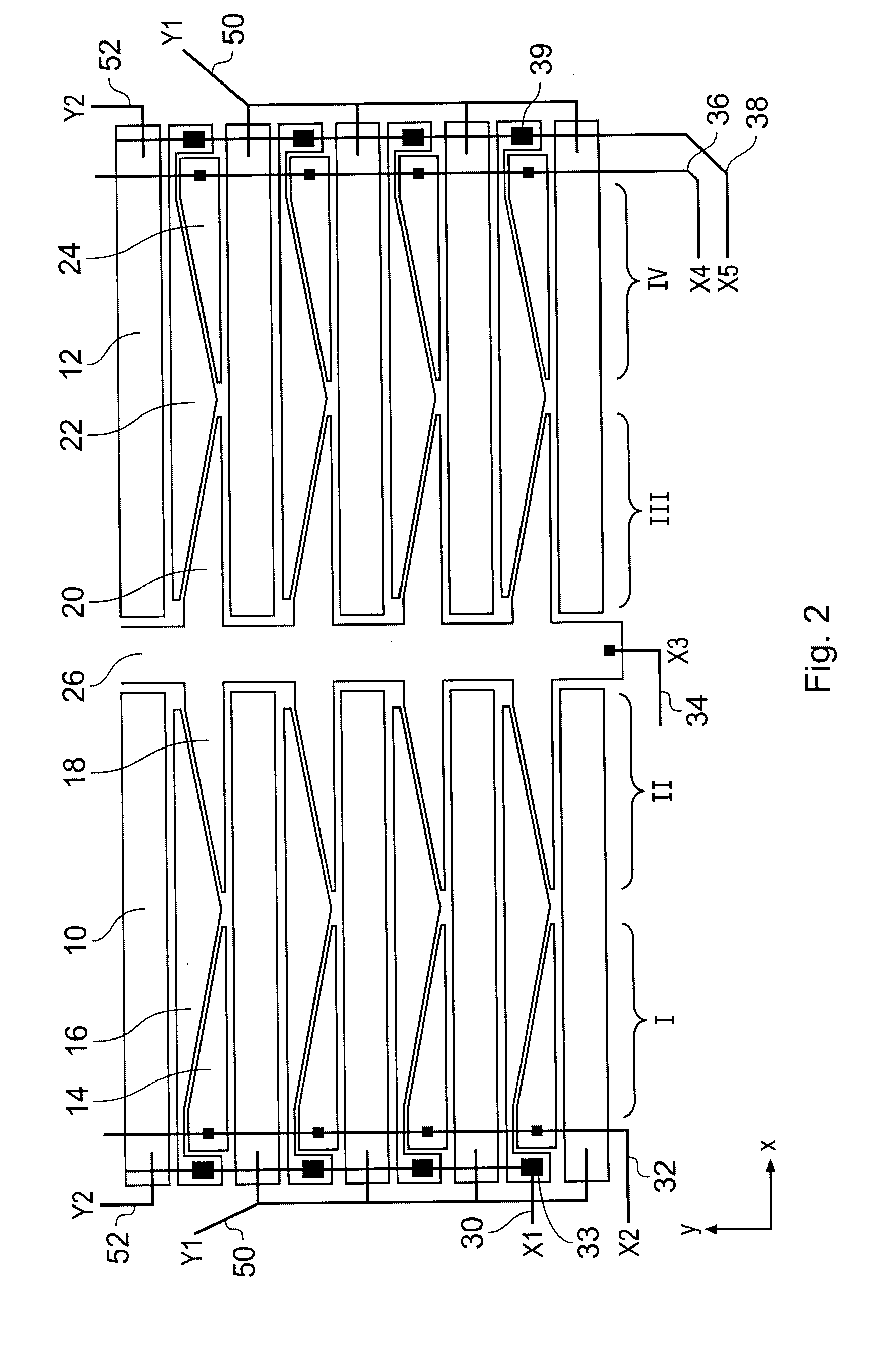

Two Dimensional Position Sensor

InactiveUS20070279395A1Avoid the needCapacitance measurementsInput/output processes for data processingElectrical resistance and conductanceCapacitance

A two-dimensional position sensor comprising a substrate with a sensitive area defined by a pattern of electrodes including electrodes for determining x-position and electrodes for determining y-position. The x-electrodes and y-electrodes generally extend in the x-direction and are interleaved in the y-direction. The x-electrodes comprise at least first, second and third groups of elements shaped such that adjacent ones of the elements of the different x-electrode groups co-extend in the x-direction so that the x-electrodes provide ratiometric capacitive signals, thereby providing quasi-continuous x-position sensing across the sensitive area. In addition, the y-electrodes may be resistively connected or arranged in ratiometric pairs to provide quasi-continuous y-position sensing. Alternatively, the x-electrode groups may be interdigitated to form pairs of x-adjacent blocks of differing area to provide stepwise x-position sensing in combination with stepwise y-position sensing provided by the y-electrodes.

Owner:NEODRON LTD

Treatment of movement disorders with drug therapy

ActiveUS7155279B2Increase excitementPrevent movementElectrotherapyDiagnosticsTherapeutic exerciseMedicine

Introducing one or more stimulating drugs to the vagus nerve and / or one or more branches of the vagus nerve to treat movement disorders uses at least one implantable system control unit (SCU) with an implantable pump with at least one infusion outlet. Optional electrical stimulation may additionally be supplied by an implantable signal / pulse generator (IPG) with one or more electrodes. In certain embodiments, a single SCU provides one or more stimulating drugs and the optional electrical stimulation. In some embodiments, one or more sensed conditions are used to adjust stimulation parameters.

Owner:MEDTRONIC MIMIMED INC

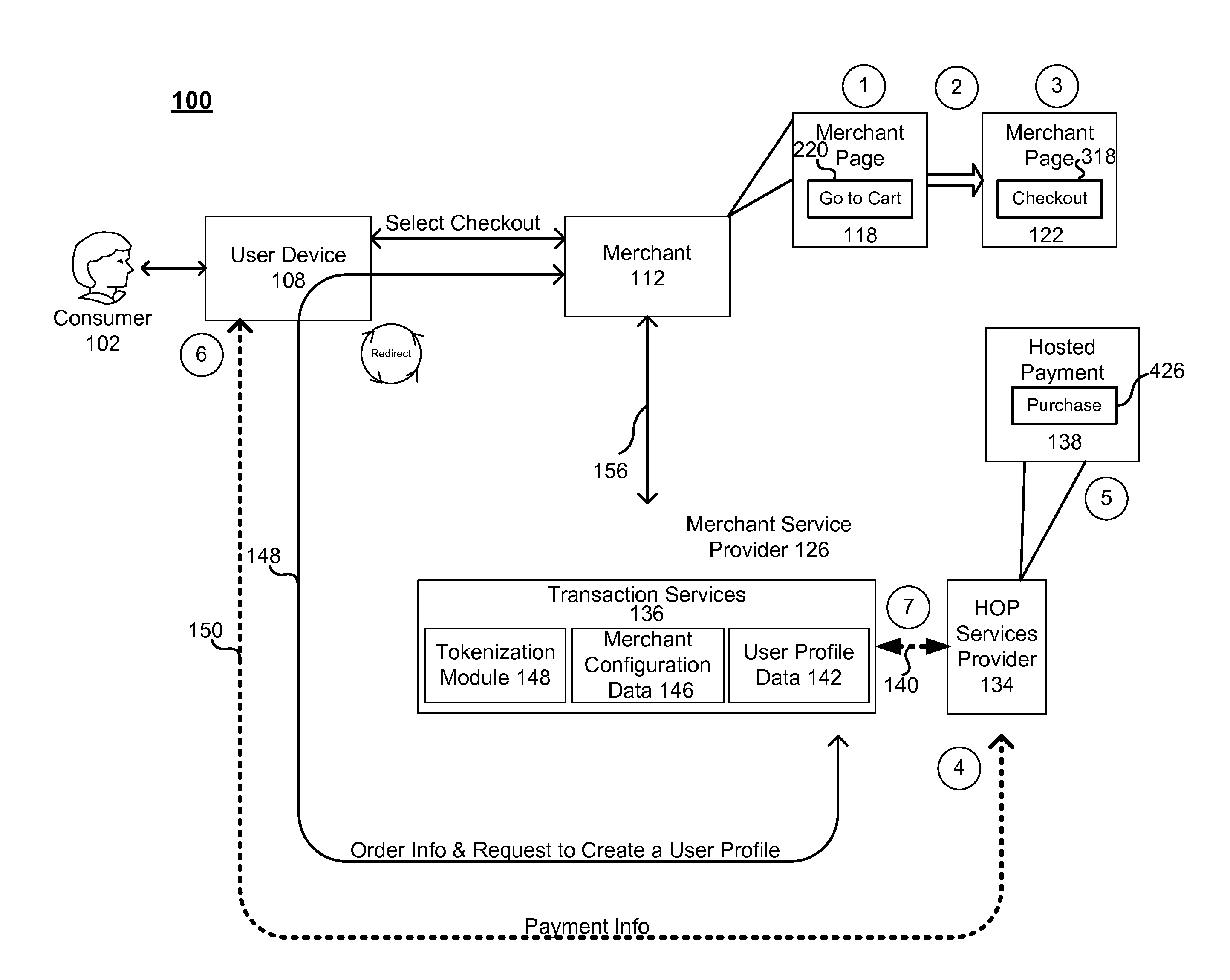

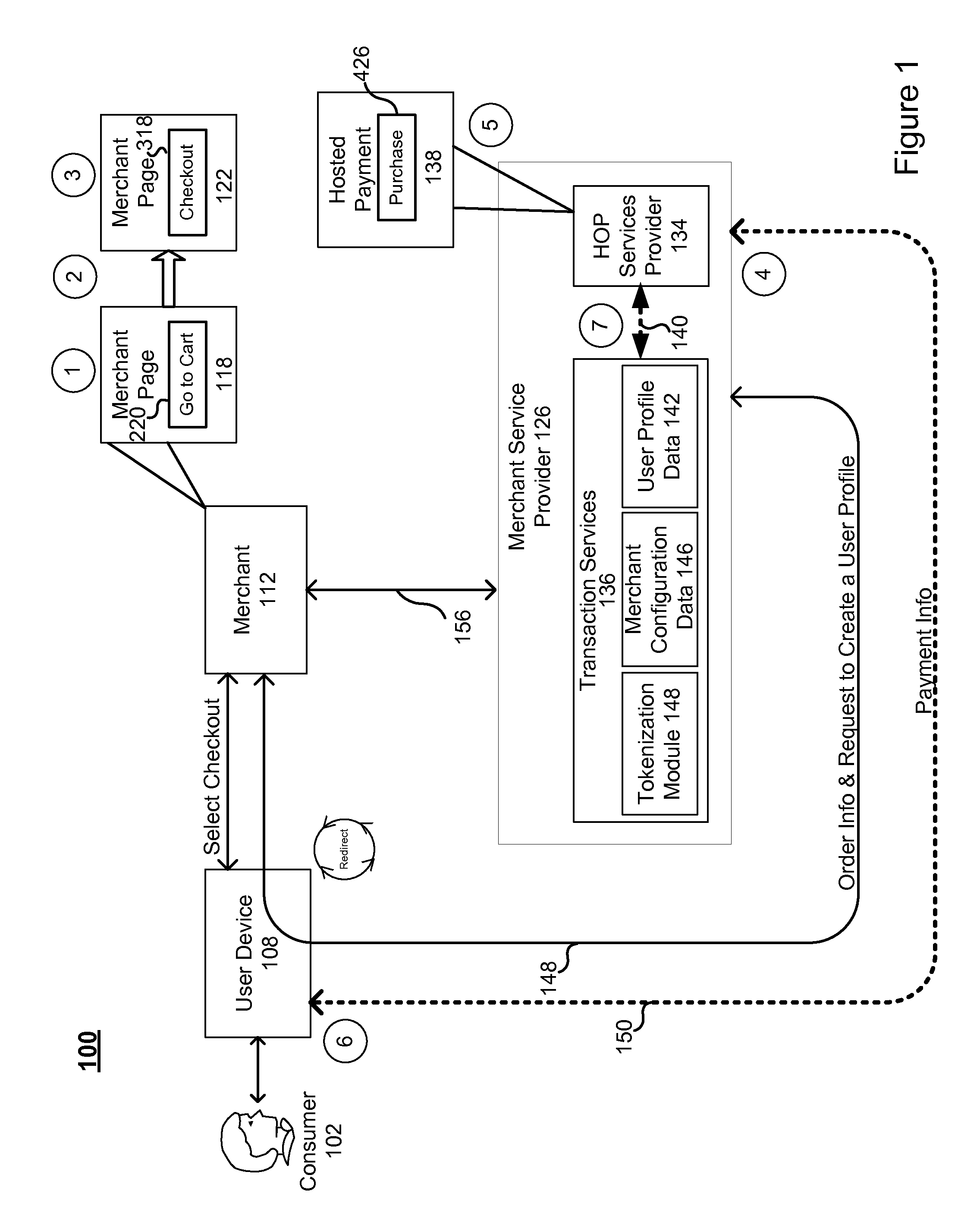

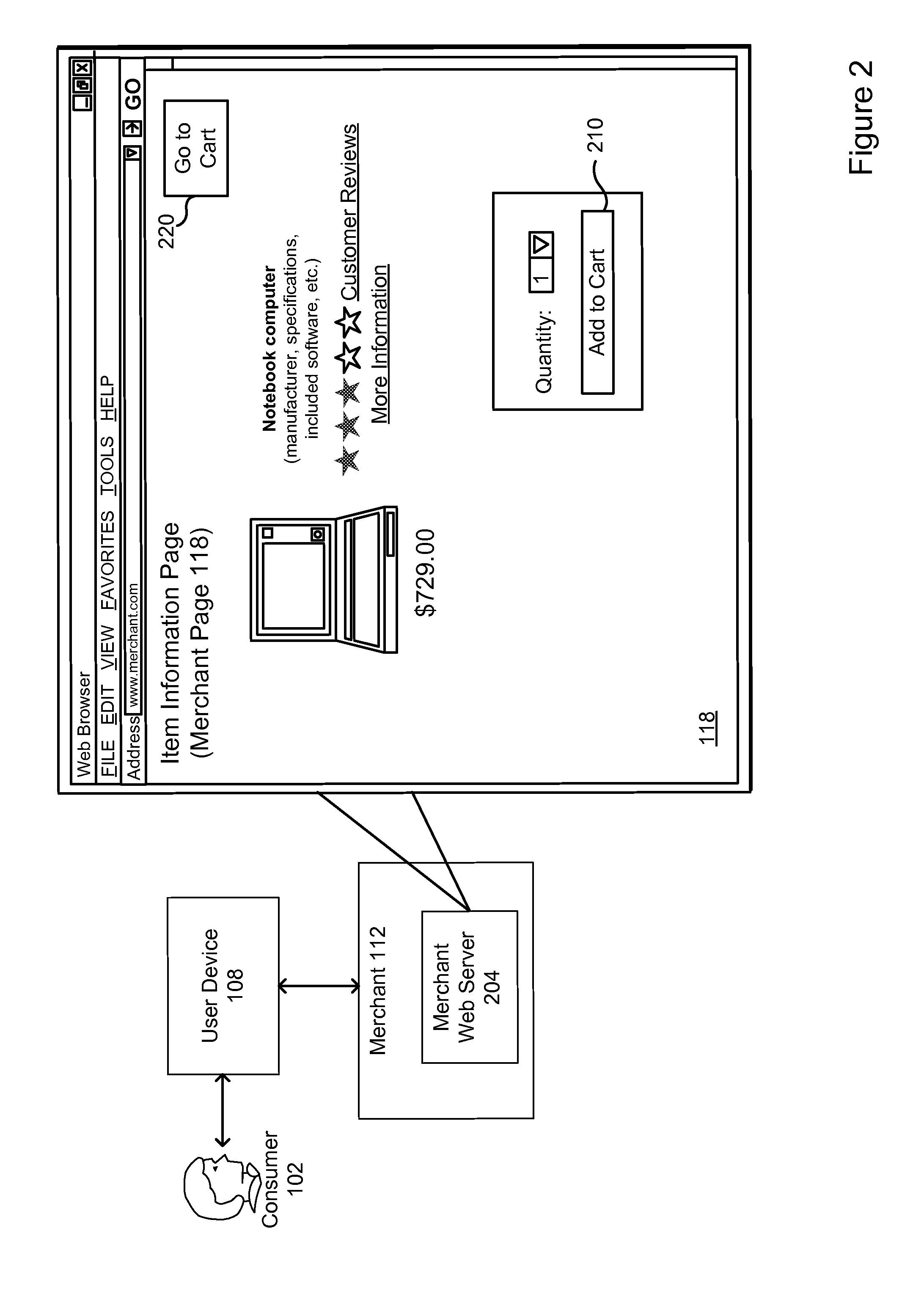

Passing payment tokens through an hop / sop

Embodiments of the invention are directed to methods, a computer-readable medium, servers and systems for enabling merchants to pass payment tokens, instead of actual payment information, to third party HOPs and SOPs. This, for example, enables a merchant to charge a consumer, such as on a recurring basis or for a one-off purchase, without having the consumer enter payment information each time and without the merchant actually having to handle payment information. As such, merchants can avoid costs and responsibilities associated with handling and storing consumer payment data, while at the same time it also gives merchants the benefit of engaging in purchase transactions with consumers without requiring that the consumers reenter payment data each time they want to make a purchase.

Owner:VISA INT SERVICE ASSOC

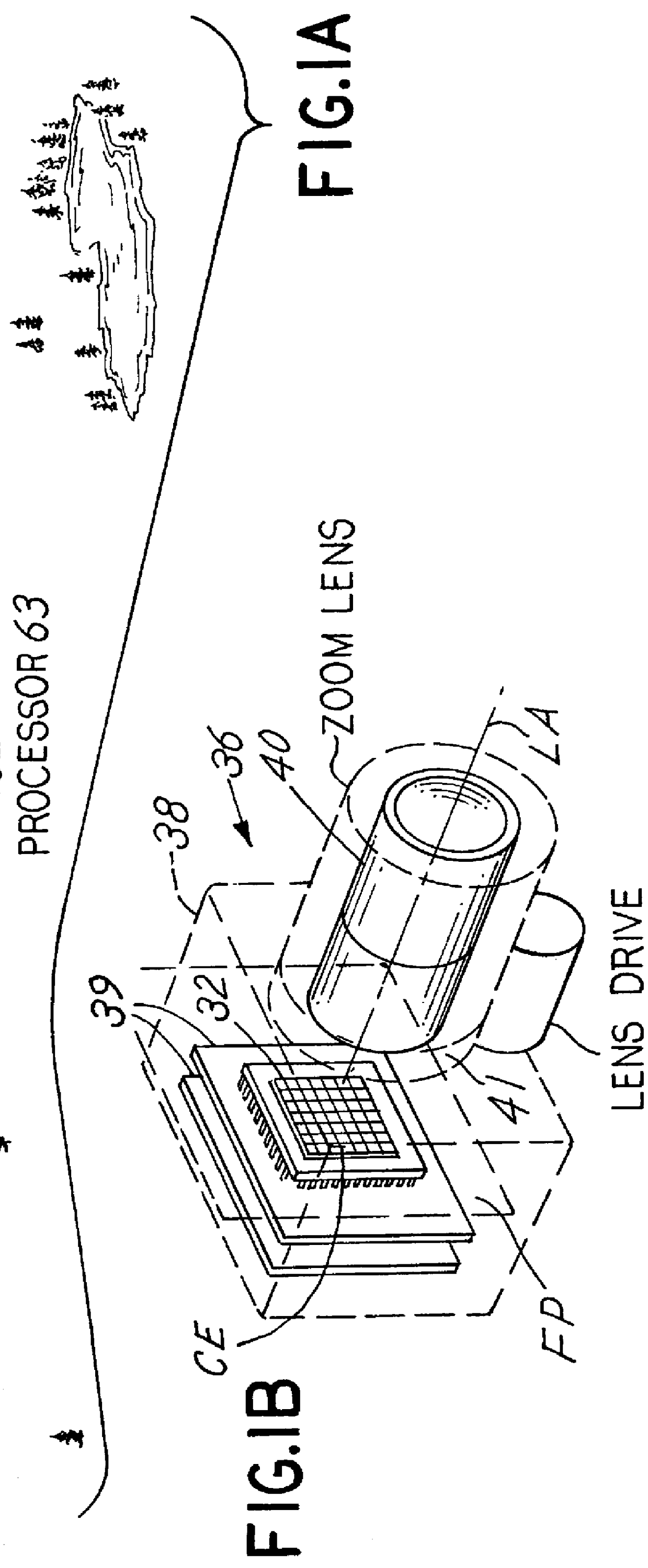

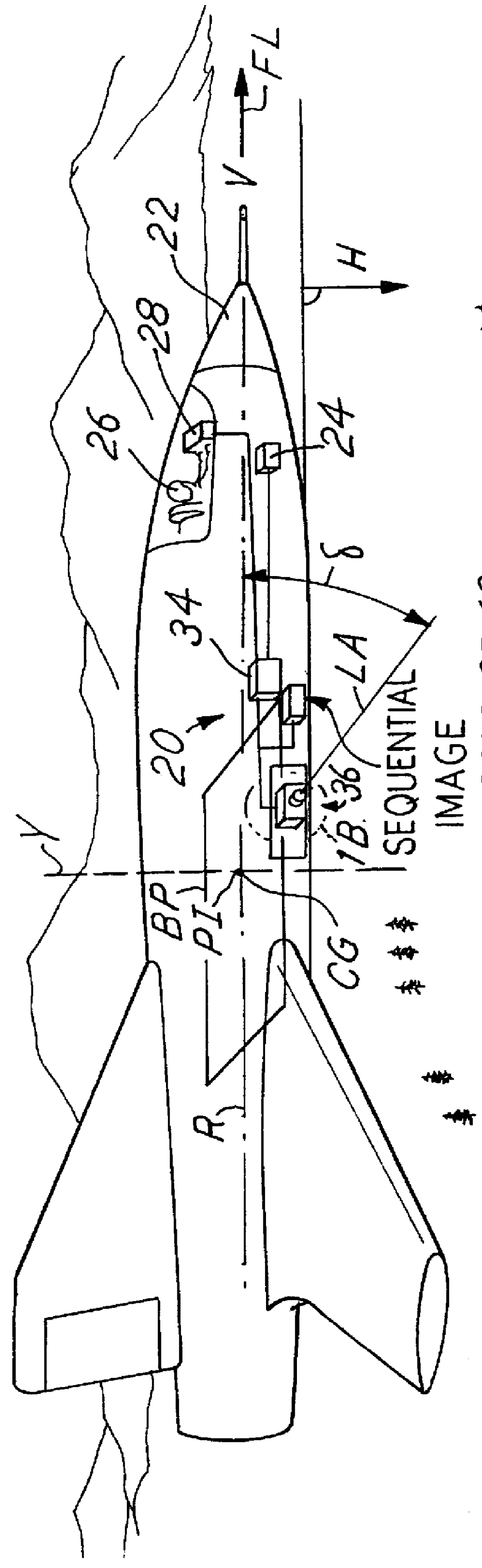

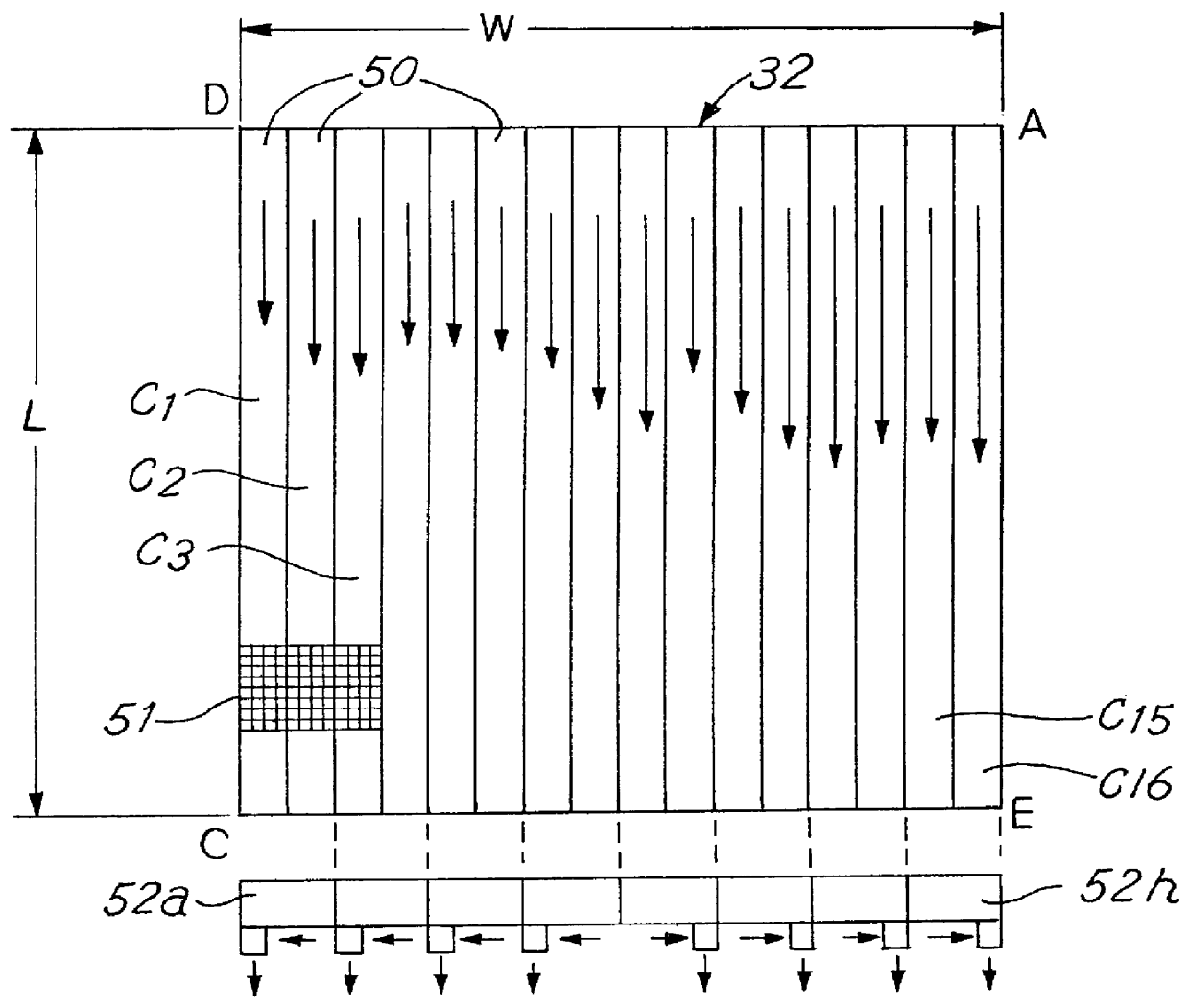

Autonomous electro-optical framing camera system with constant ground resolution, unmanned airborne vehicle therefor, and methods of use

InactiveUS6130705AReduce vibrationIncrease flexibilityTelevision system detailsOptical rangefindersCamera imageImage resolution

An aerial reconnaissance system generates imagery of a scene that meets resolution or field of view objectives automatically and autonomously. In one embodiment, a passive method of automatically calculating range to the target from a sequence of airborne reconnaissance camera images is used. Range information is use for controlling the adjustment of a zoom lens to yield frame-to-frame target imagery that has a desired, e.g., constant, ground resolution or field of view at the center of the image despite rapid and significant aircraft altitude and attitude changes. Image to image digital correlation is used to determine the displacement of the target at the focal plane. Camera frame rate and aircraft INS / GPS information is used to accurately determine the frame to frame distance (baseline). The calculated range to target is then used to drive a zoom lens servo mechanism to the proper focal length to yield the desired resolution or field of view for the next image. The method may be performed based on parameters other than range, such as aircraft height and stand off distance.

Owner:THE BF GOODRICH CO

Method of using a fully implantable miniature neurostimulator for vagus nerve stimulation

InactiveUS7167751B1Minimal surgical procedureSubstantial therapeutic benefitImplantable neurostimulatorsAnesthesiaSurgical procedures

A method of using a small implantable stimulator(s) with at least two electrodes small enough to have the electrodes located adjacent to the vagus nerve. The small stimulator provides a means of stimulating the vagus nerve when desired, and may be implanted via a minimal surgical procedure.

Owner:BOSTON SCI NEUROMODULATION CORP

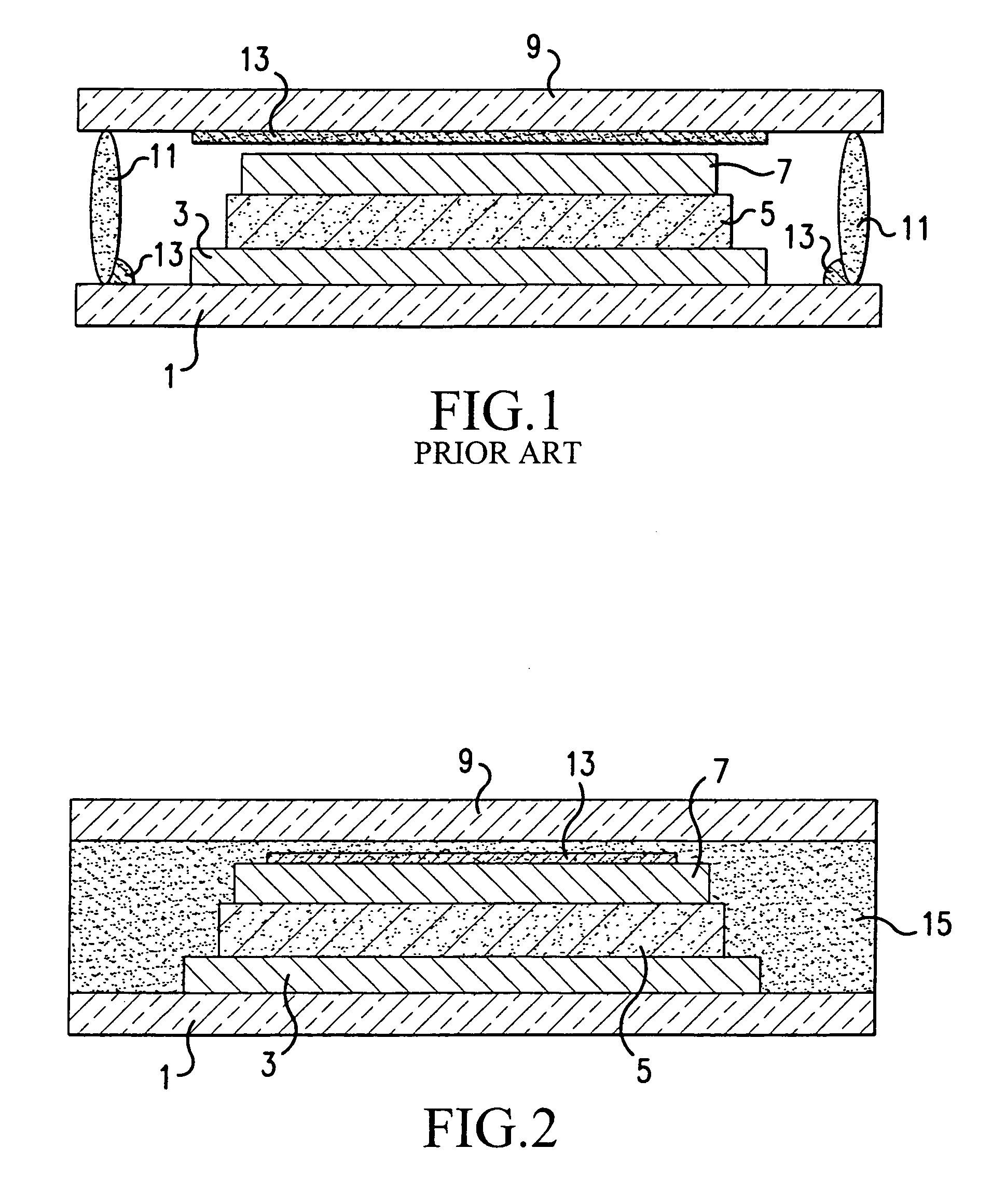

Transformable pressure sensitive adhesive tape and use thereof in display screens

InactiveUS20060100299A1Easy and safe applicationLow level of VOC 'sNanostructure manufactureGas-filled discharge tubesDisplay deviceLight-emitting diode

A transformable pressure sensitive adhesive composition comprised of from about 15 to about 80% by weight of a polymer having a softening point greater than 60° C.; from about 20 to about 85% by weight of a polymerizable resin having a softening point less than 30° C.; a latent initiator in an amount sufficient to cause a reaction between said polymer and said resin; and optionally, a crosslinking agent. The transformable pressure sensitive adhesive has particular applicability in connection with organic light emitting diode display devices, light emitting diode display devices, medical diagnostic testing devices, flexible or rigid LCD display devices, plasma display devices, and electrochromic devices.

Owner:ADHESIVES RES

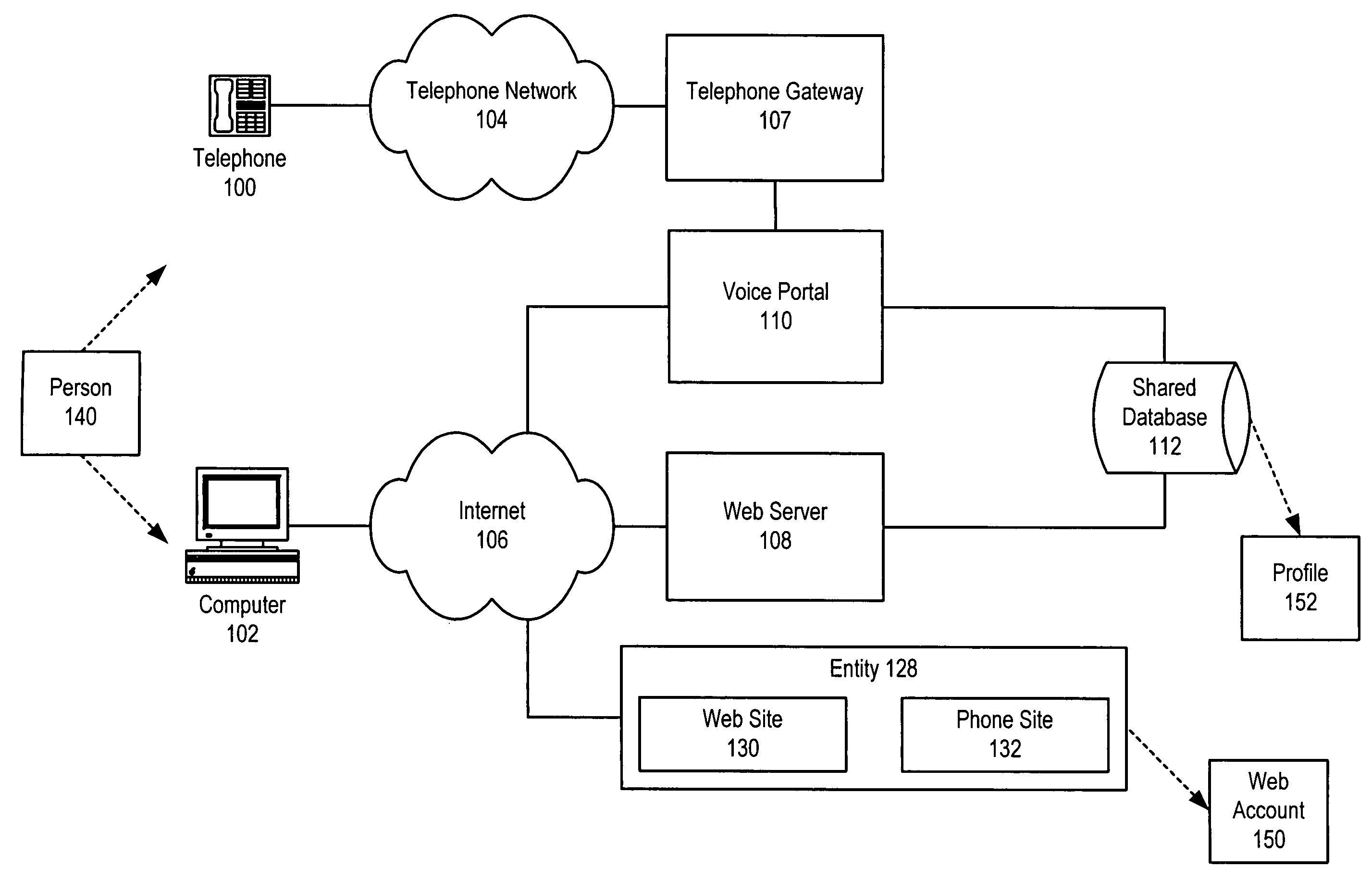

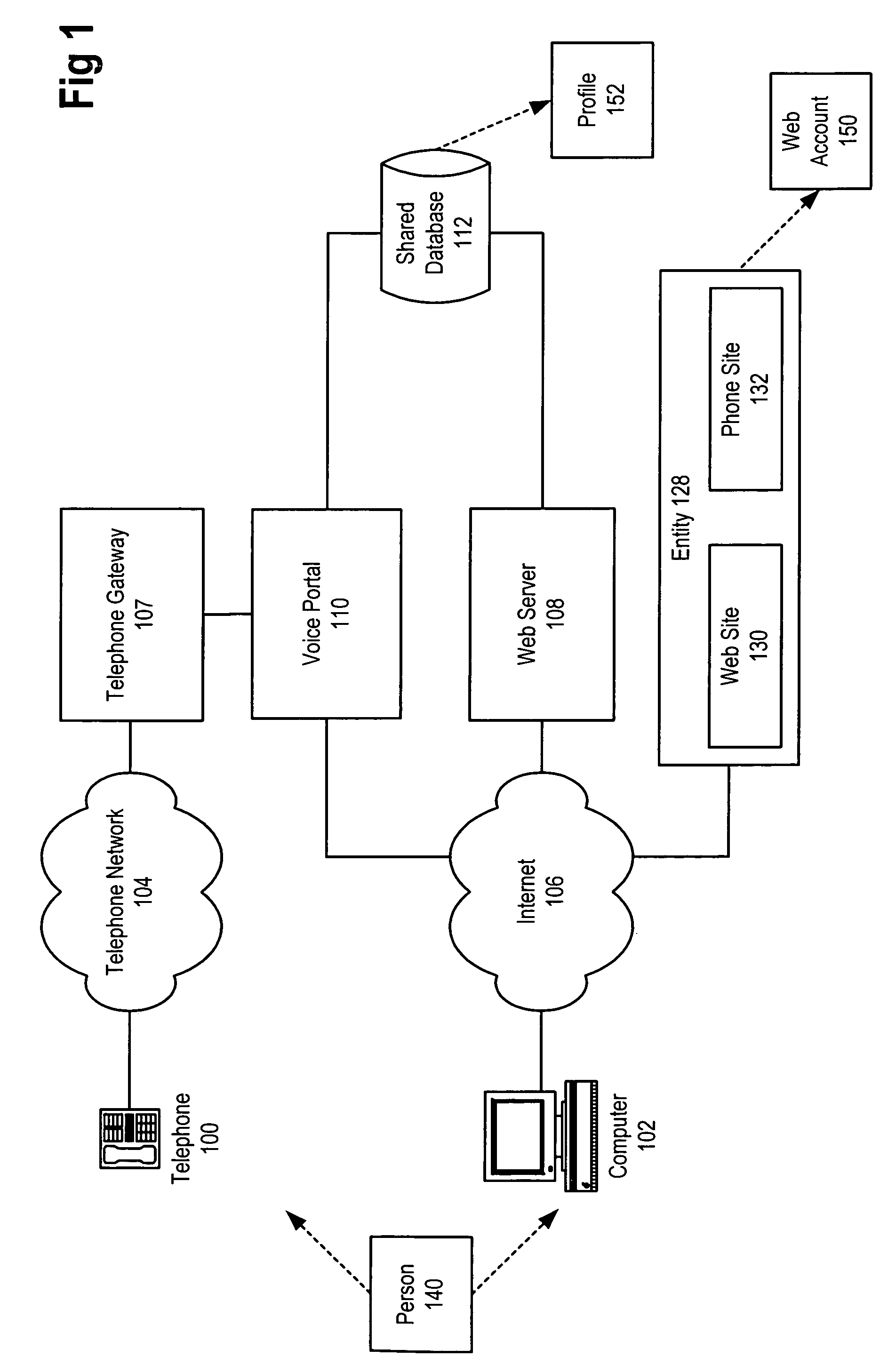

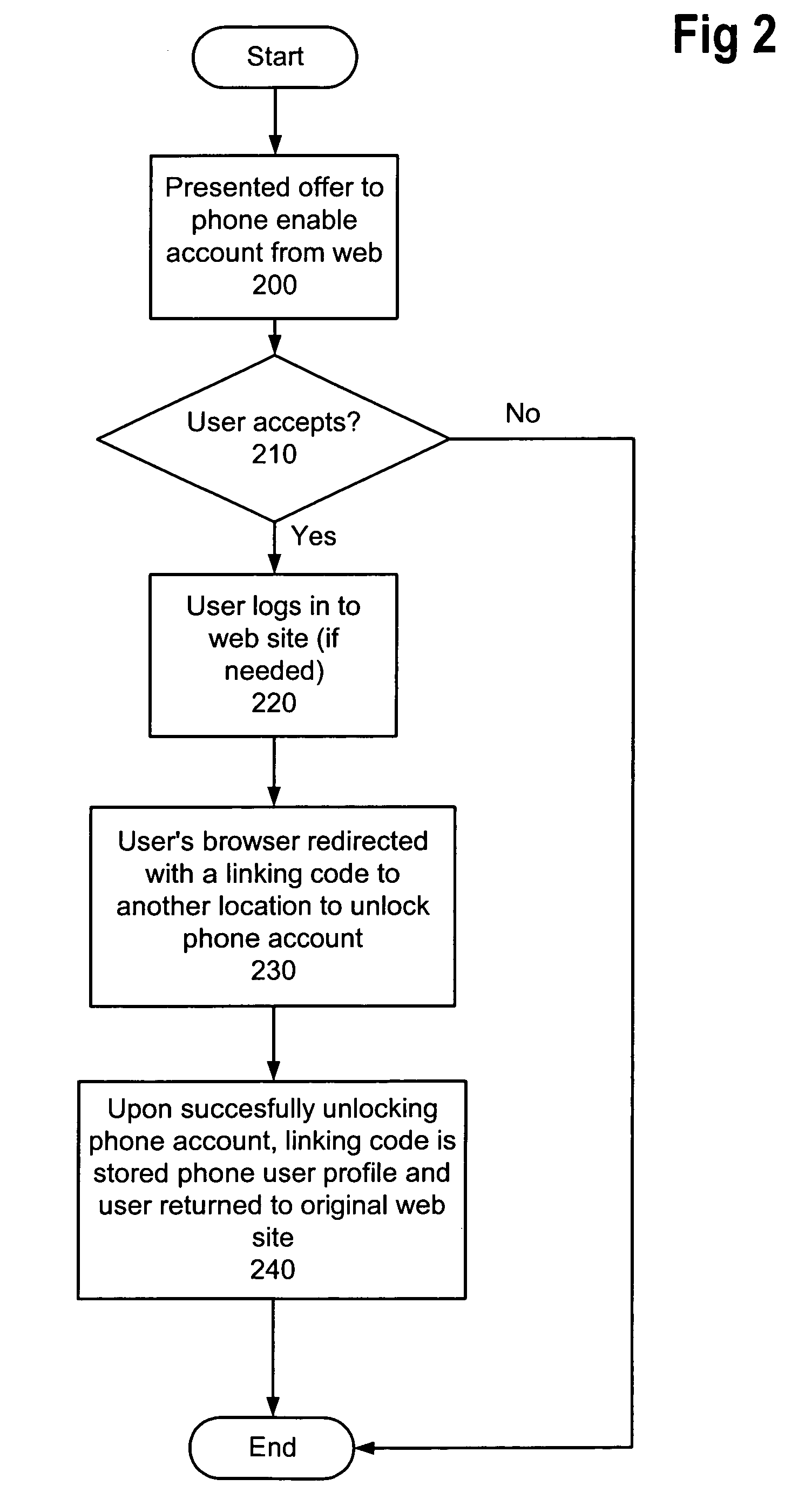

Web-to-phone account linking using a linking code for account identification

InactiveUS7089310B1Avoid the needMultiple digital computer combinationsAutomatic exchangesWeb sitePassword

A method and apparatus for linking a web based account to a phone based account is described. The method avoids the need to directly reveal account information, e.g. username / password, about one account to the provider of the other. The linking occurs on the web in one embodiment, with a user's browser being redirected from the web site to the web site of the provider of the voice service. The redirection URL will include account linking information. Once the user identifies herself to the web site of the provider of the voice service, the linking information can be stored in the user's phone account as a cookie. When the user access the voice service over the phone, her telephone identifying information can be used to identify her profile. When she visits the phone application corresponding to the web site, the cookie—now including linking information—can be passed to the application to identify the appropriate web account.

Owner:MICROSOFT TECH LICENSING LLC

Secure data parser method and system

InactiveUS7391865B2Minimal compute resourceAvoid the needDigital data processing detailsUser identity/authority verificationGovernmental agencyVariospora

The present invention provides a method and system for securing sensitive data from unauthorized access or use. The method and system of the present invention is useful in a wide variety of settings, including commercial settings generally available to the public which may be extremely large or small with respect to the number of users. The method and system of the present invention is also useful in a more private setting, such as with a corporation or governmental agency, as well as between corporation, governmental agencies or any other entity.

Owner:SECURITY FIRST INNOVATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com