Patents

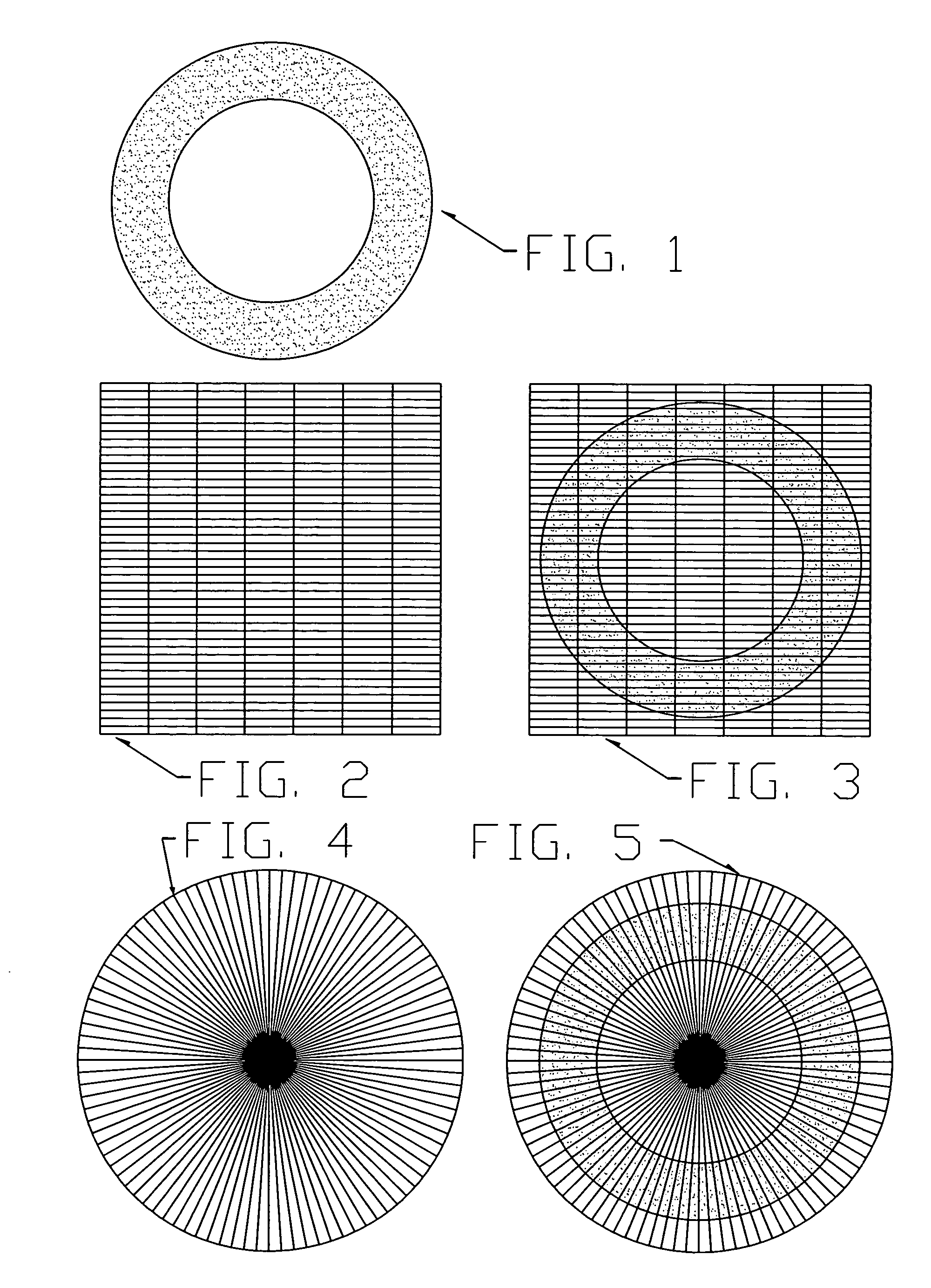

Literature

3869 results about "Softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

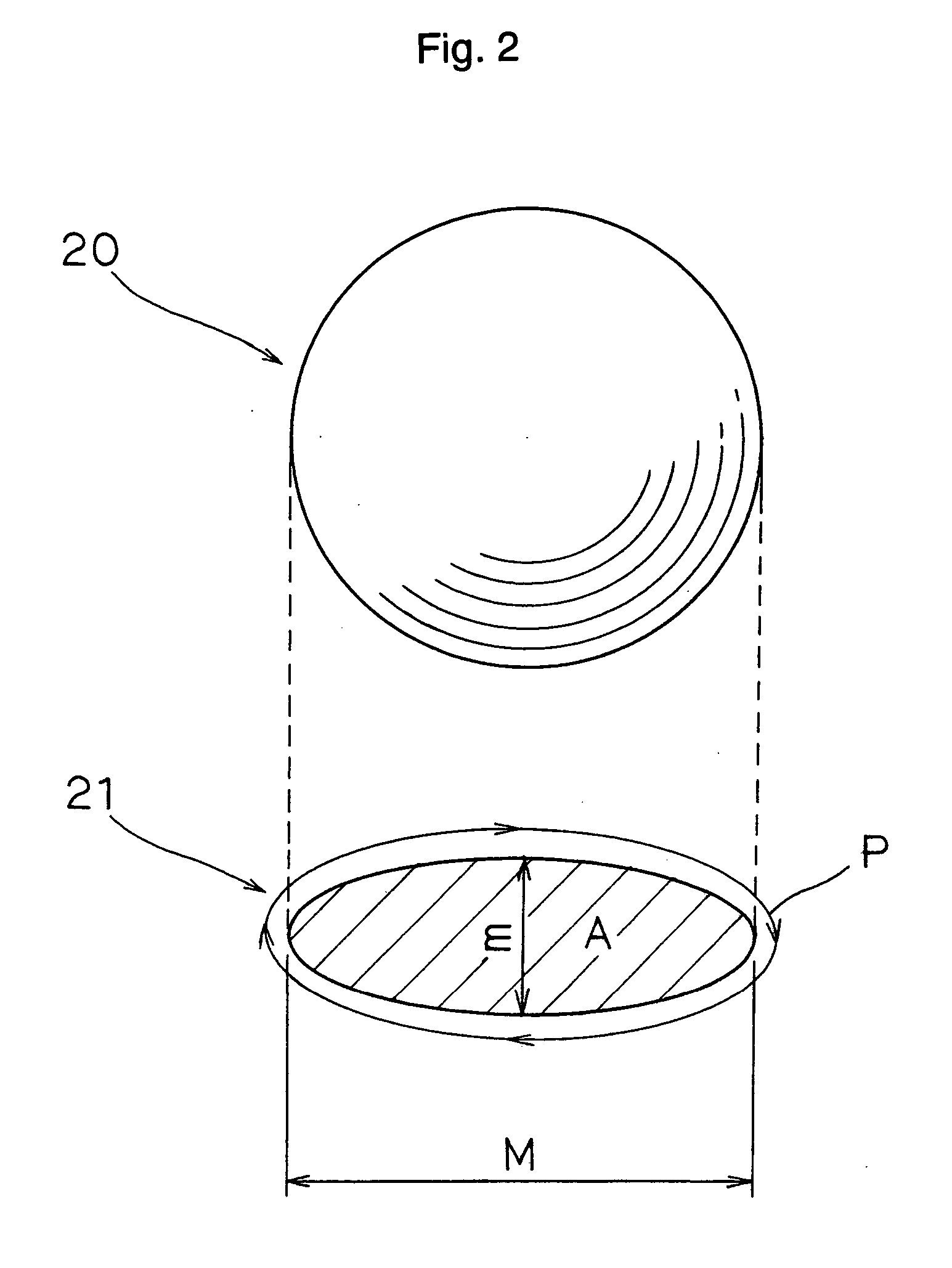

Softening is a numerical trick used in N-body techniques to prevent numerical divergences when a particle comes too close to another (and the force goes to infinity). This is obtained by modifying the gravitational potential of each particle as Φ=-1/(√(r²+ε²)), where ε is the softening parameter. The value of the softening parameter should be set small enough to keep simulations realistic.

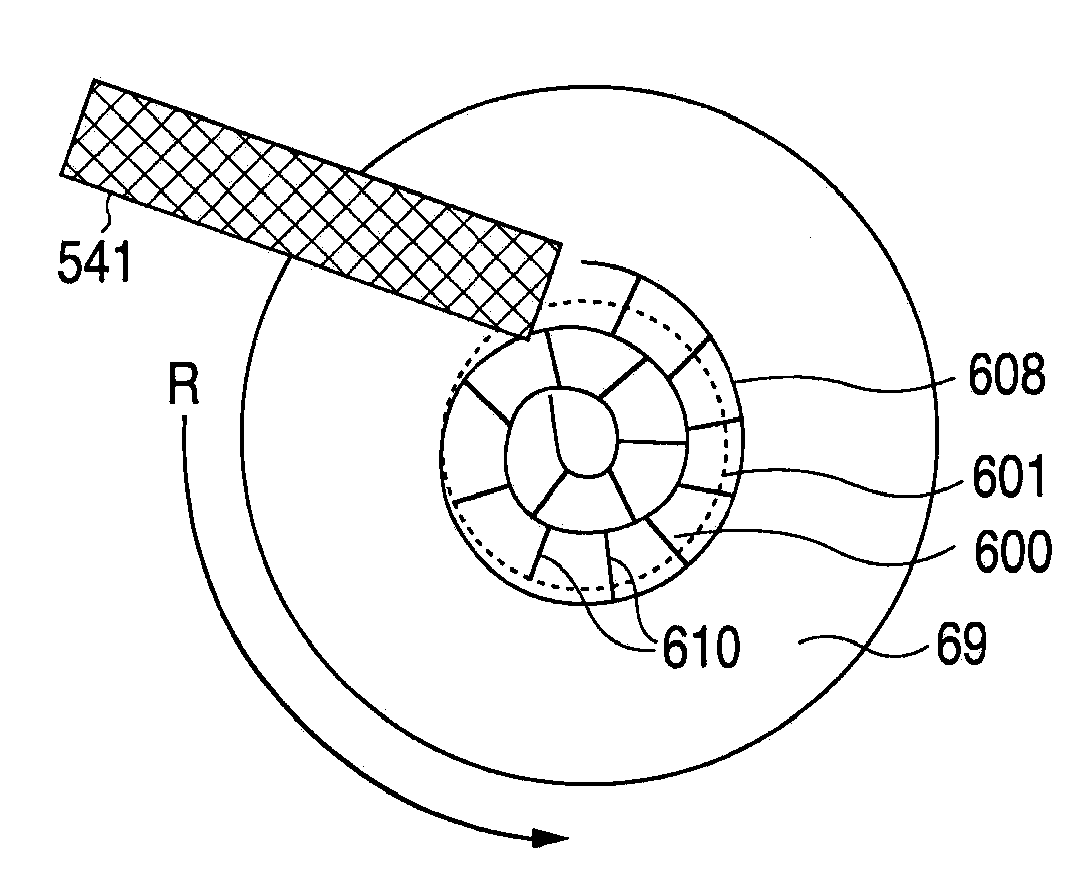

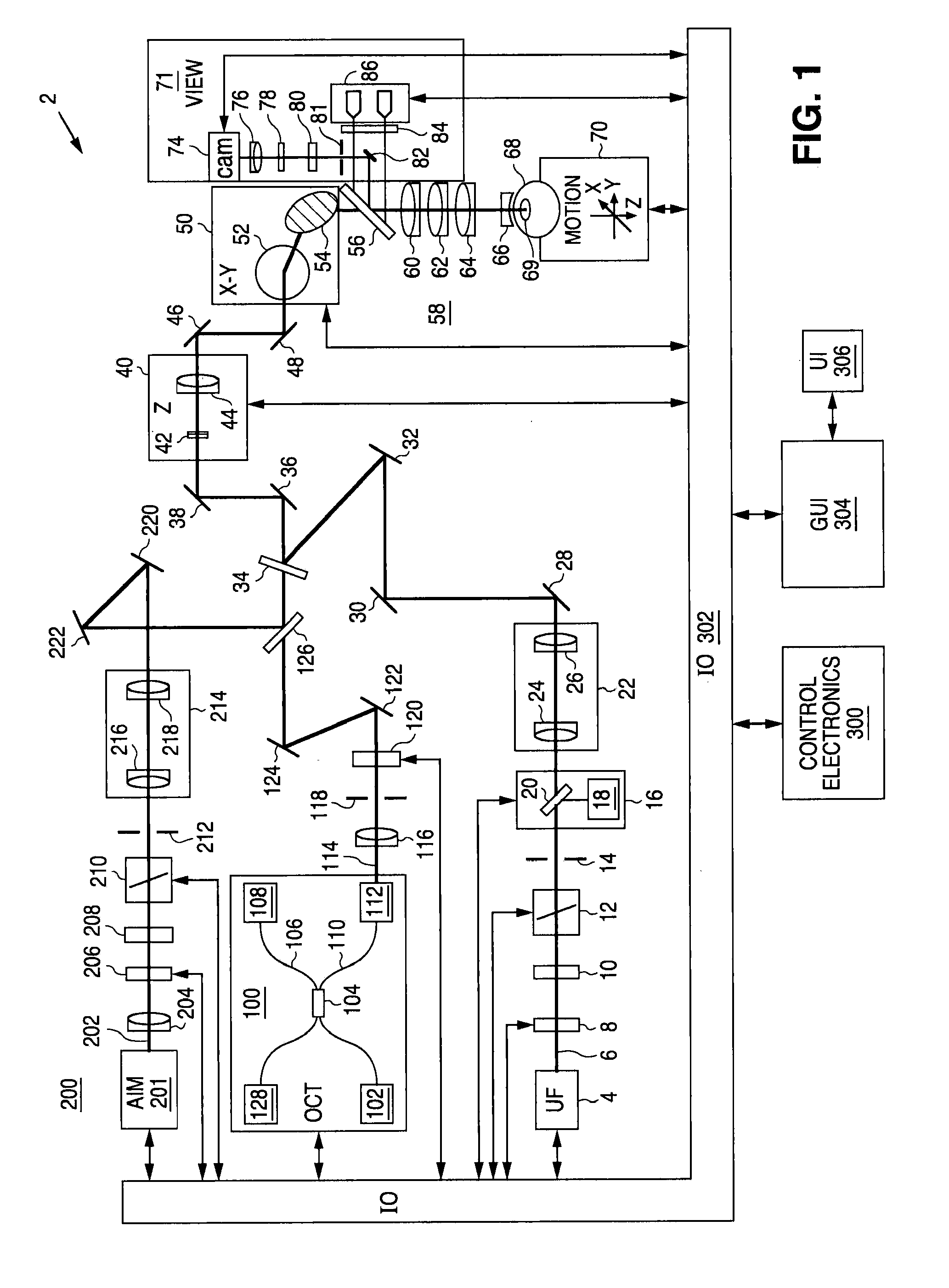

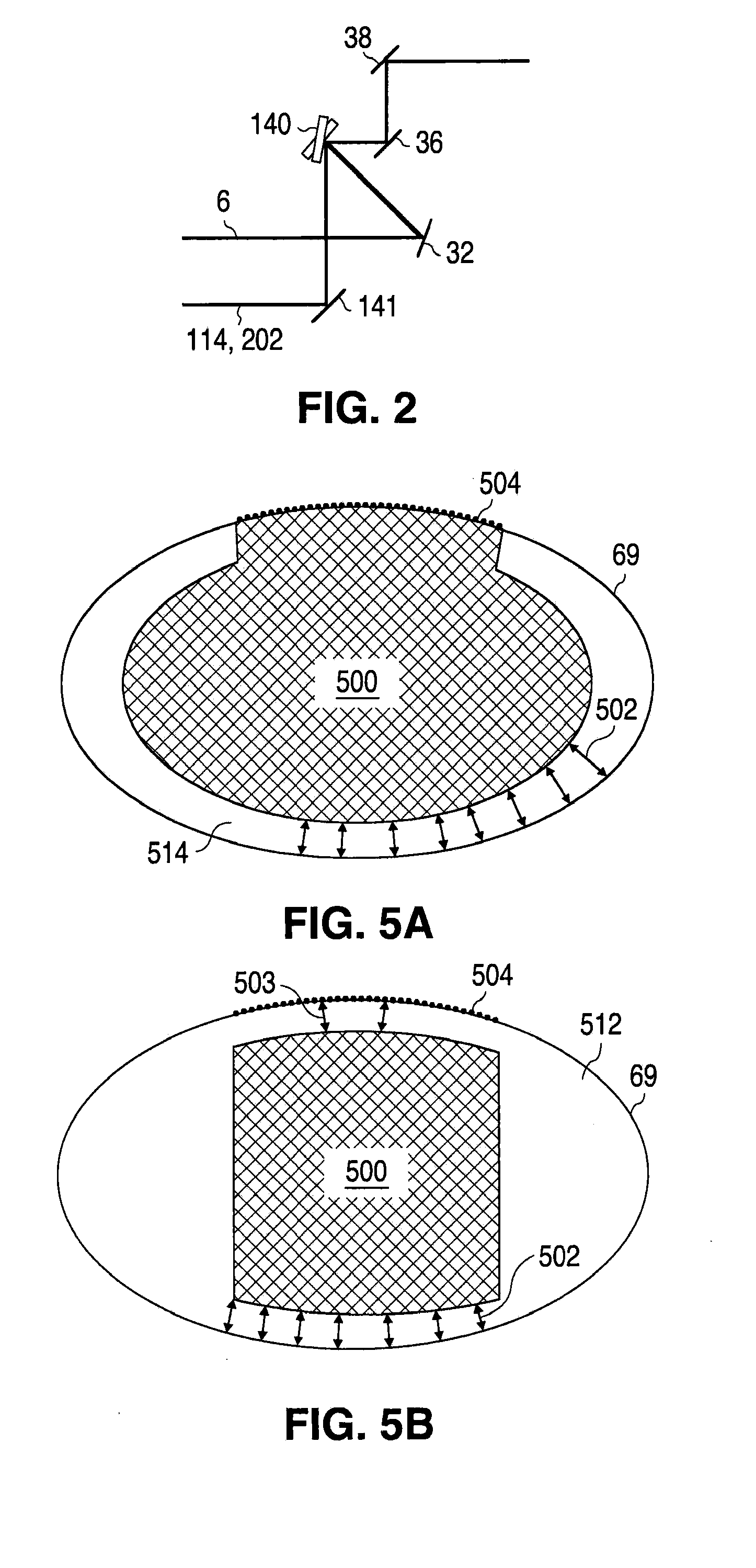

Method for patterned plasma-mediated modification of the crystalline lens

A method of treating a lens of a patient's eye includes generating a light beam, deflecting the light beam using a scanner to form a treatment pattern of the light beam, delivering the treatment pattern to the lens of a patient's eye to create a plurality of cuts in the lens in the form of the treatment pattern to break the lens up into a plurality of pieces, and removing the lens pieces from the patient's eye. The lens pieces can then be mechanically removed. The light beam can be used to create larger segmenting cuts into the lens, as well as smaller softening cuts that soften the lens for easier removal.

Owner:AMO DEVMENT

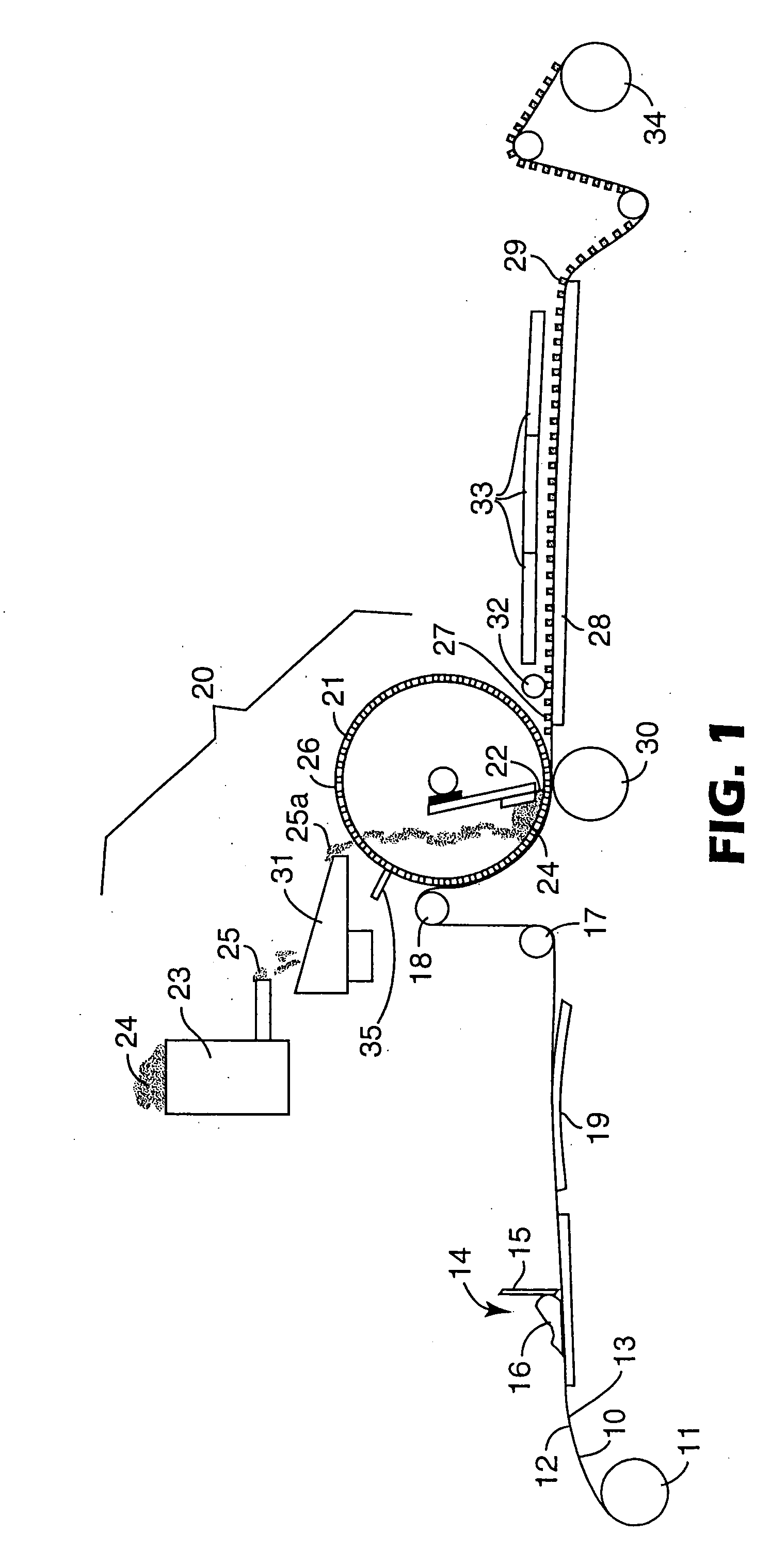

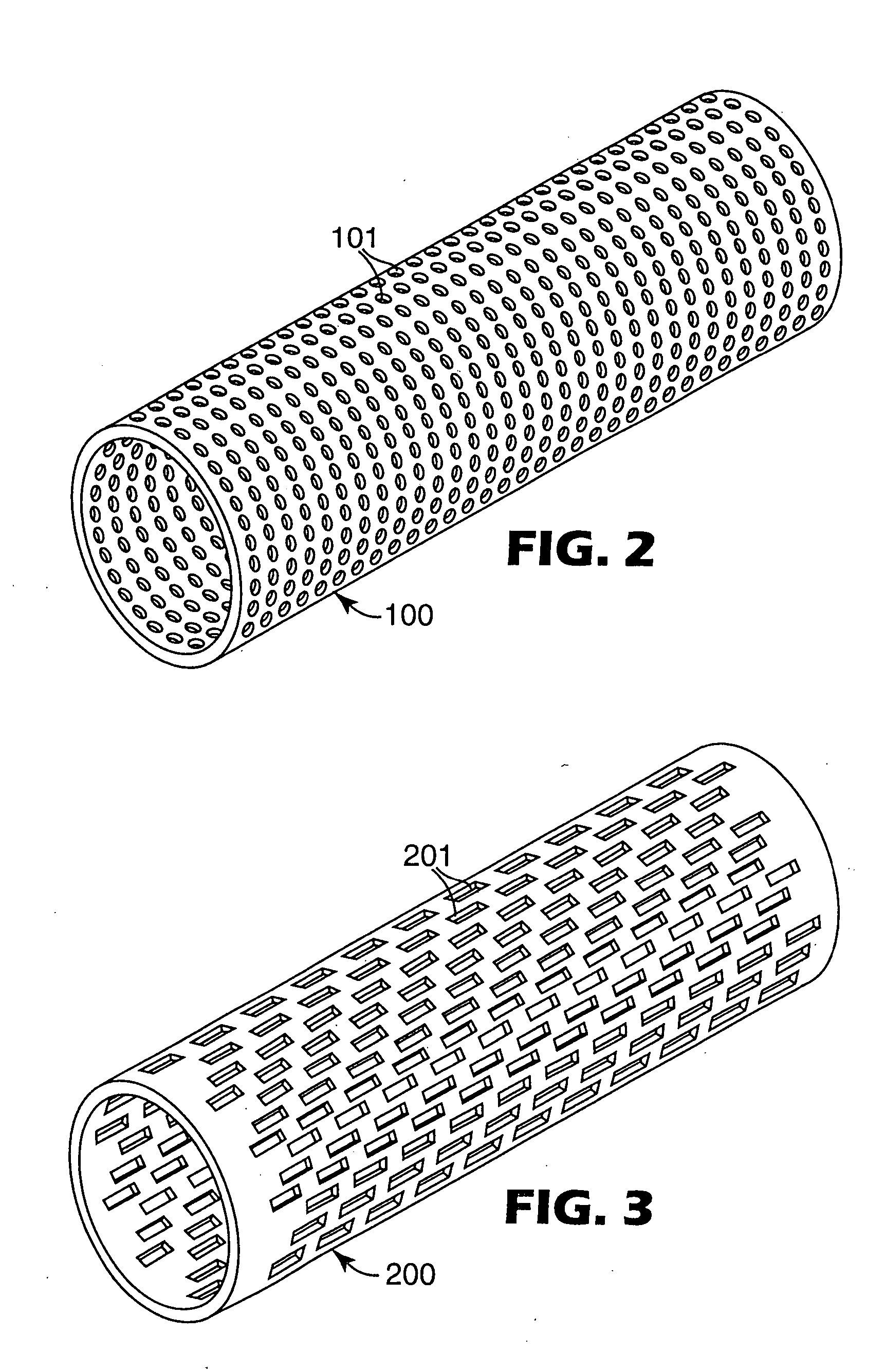

Abrasive product, method of making and using the same, and apparatus for making the same

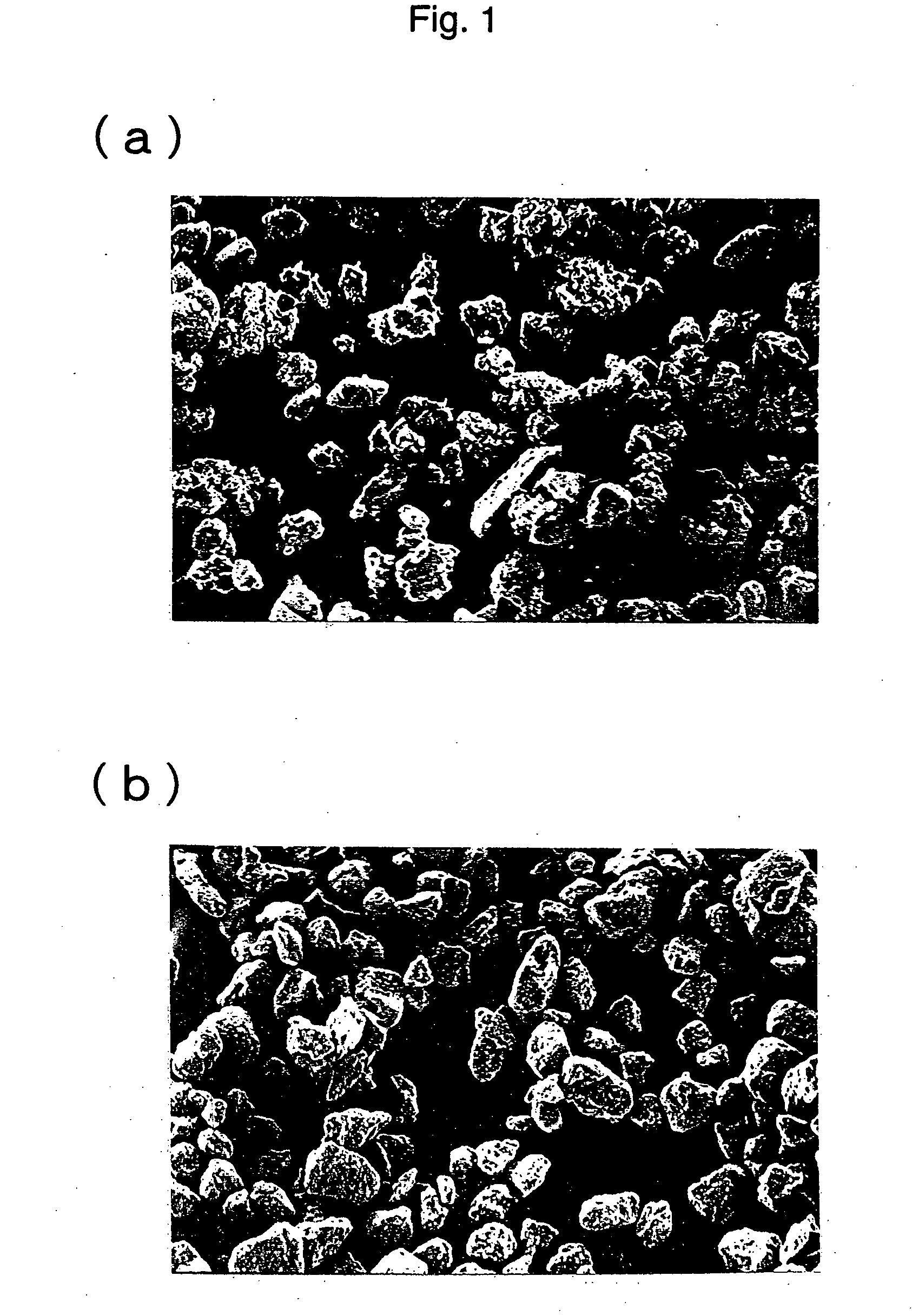

The invention provides a method and apparatus for making an abrasive product comprising providing a substantially horizontally deployed flexible backing having a first surface bearing an at least partially cured primer coating and an opposite second surface; providing a dry flowable particle mixture comprising abrasive particles and particulate curable binder material; depositing a plurality of temporary shaped structures comprised of said particle mixture on the at least partially cured primer coating of the first surface of the backing; softening said particulate curable binder material to provide adhesion between adjacent abrasive particles; and curing the softened particulate curable binder material to convert said temporary shaped structures into permanent shaped structures and cure the at least partially cured primer coating on the first surface of the backing. The invention also provides an abrasive product made by the method.

Owner:3M INNOVATIVE PROPERTIES CO

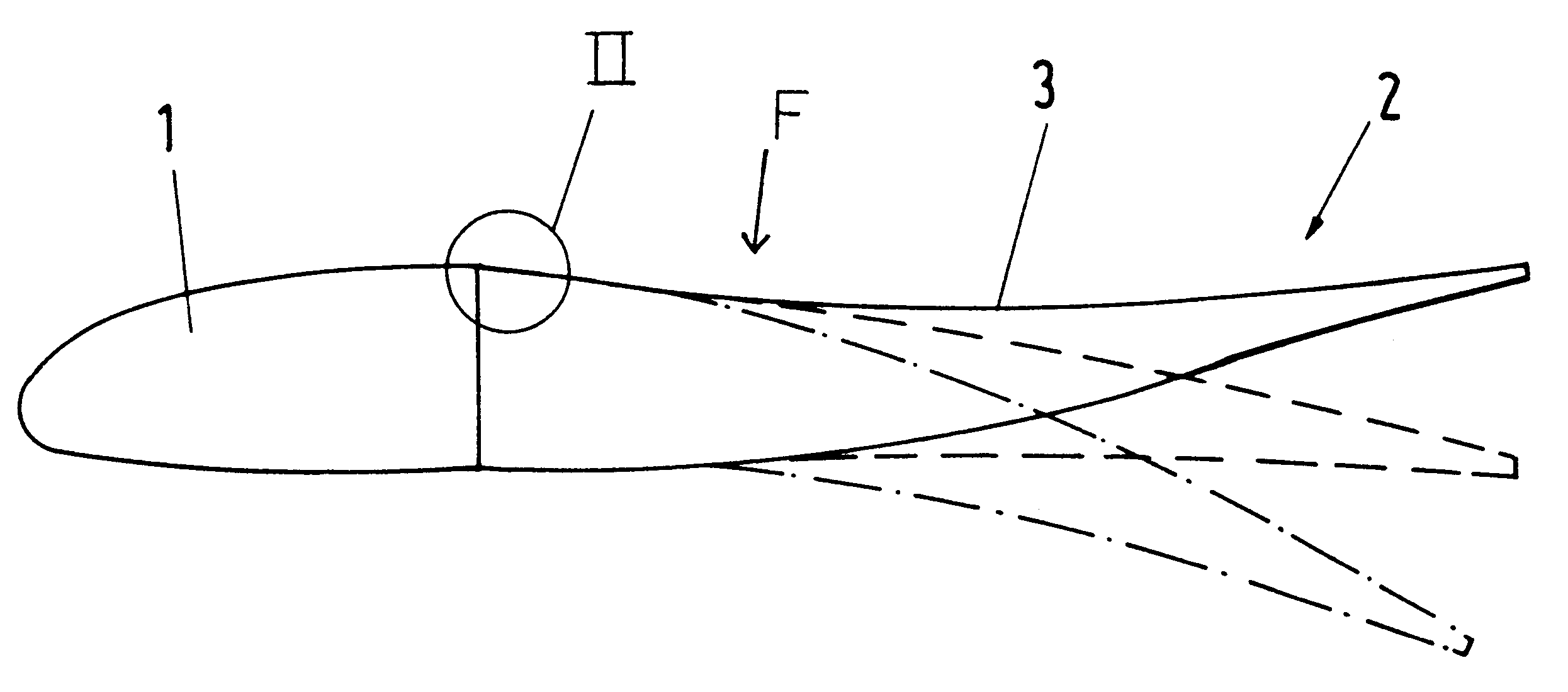

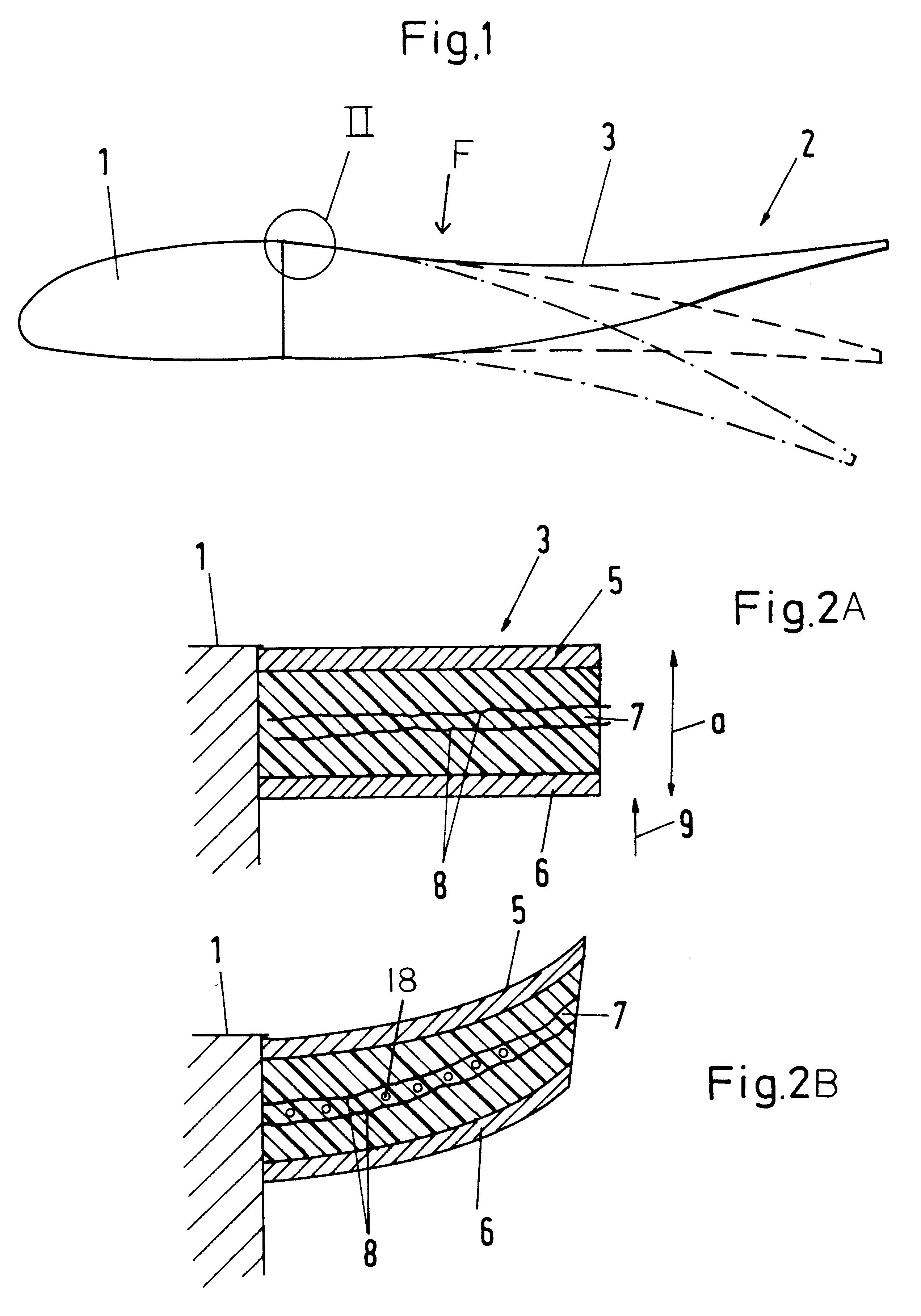

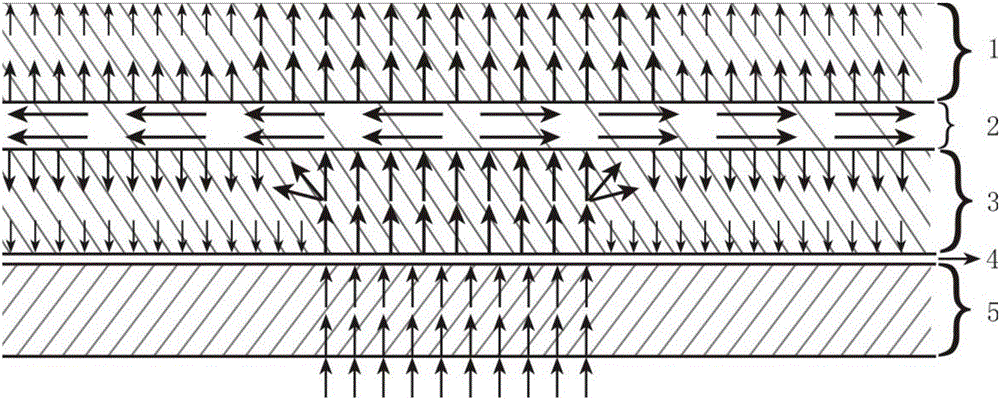

Load carrying structure having variable flexibility

InactiveUS6182929B1Simple wayReduce stiffnessPropellersPump componentsShape-memory alloyOperating temperature range

A load carrying structure having a selectively rigid or flexible characteristic includes a thermoplastic material (7) having a softening temperature above the operating temperature range of the load carrying structure, and a heating arrangement (8) provided to selectively heat the thermoplastic material to above its softening temperature. During normal operation, the thermoplastic material is in a rigid state and the overall load carrying structure is rigid to the prevailing loads. By activating the heating arrangement to heat the thermoplastic material to at least its softening temperature, the thermoplastic material and therewith the load carrying structure becomes flexible so that it may be deformed to a different configuration by applying a deforming load. Once the desired deformed configuration is achieved, the heating arrangement is deactivated, and the thermoplastic material is allowed to cool below its softening temperature so that it once again becomes rigid and rigidly fixes the new deformed configuration. The deforming force may be applied by any actuating mechanism, or for example by arranging shape memory alloys in connection with the thermoplastic material.

Owner:INST FUER VERBUNDWERKSTOFFE GMBH +1

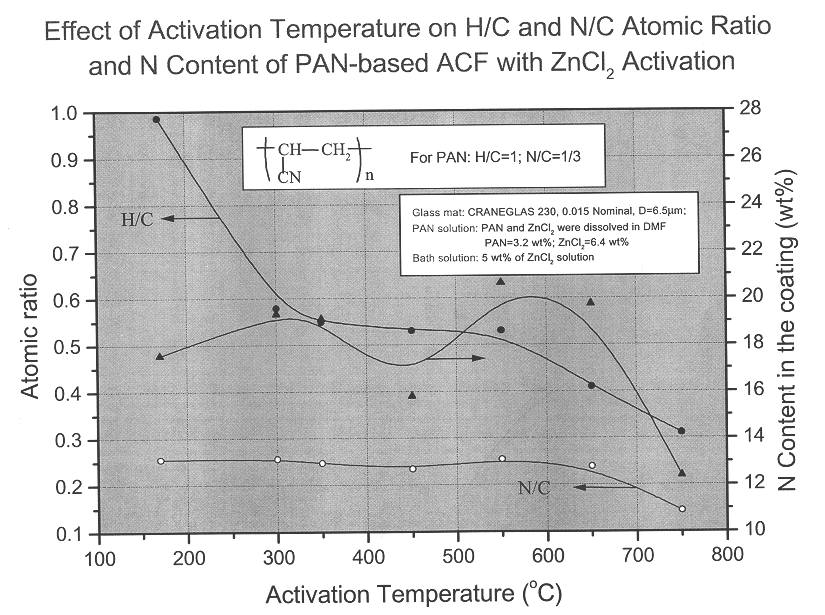

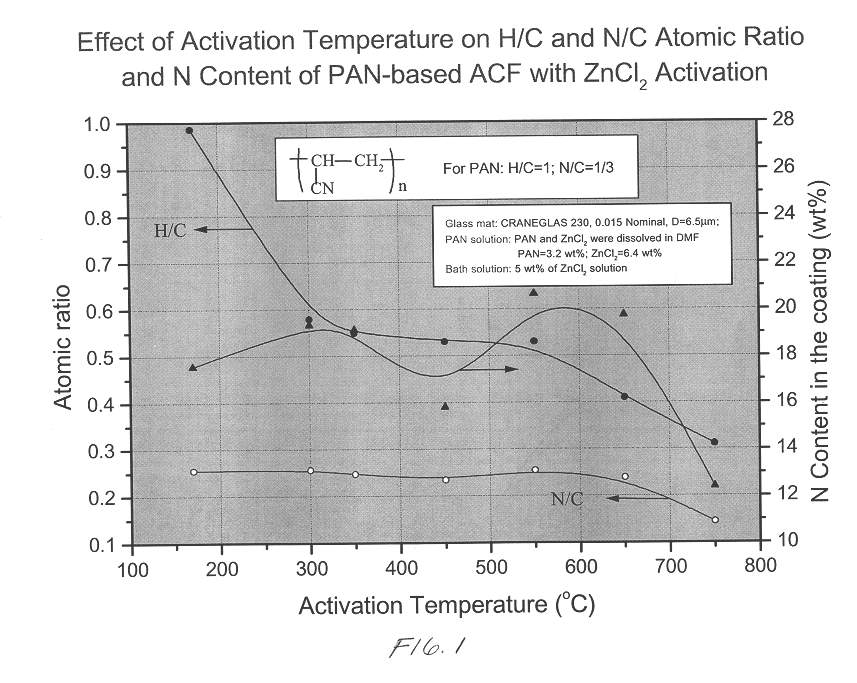

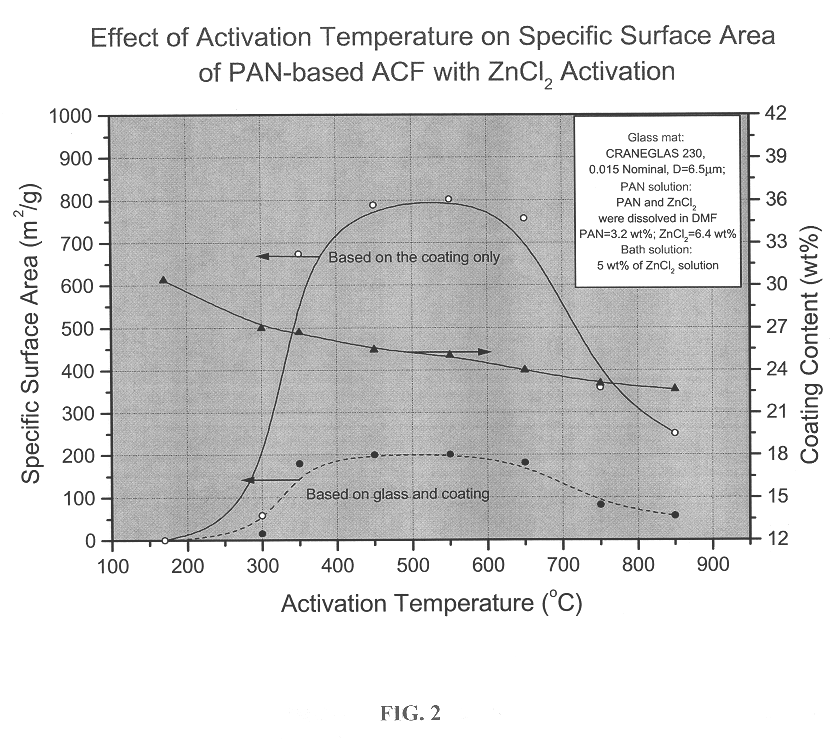

Activated organic coatings on a fiber substrate

InactiveUS6517906B1Easy and less-expensive to manufactureImprove versatilityOther chemical processesFibre typesFiberDecomposition

A composite contains substrate fibers, and an activated organic coating, on the substrate fibers. The activated organic coating is formed at a low temperature, making possible the use of substrate fibers have a softening or decomposition temperature of at most 500° C.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Polymer blend for matte injection moulded parts

The invention relates to a polymer mixture, comprising a) a polymer matrix which is composed of a (meth)acrylate(co)polymer or of a mixture of (meth)acrylate(co)polymers with a Vicat softening point VSP (ISO 306-B50) of at least 104° C. and / or of a (meth)acrylimide(co)polymer, b) an impact modifier which is based on crosslinked poly(meth)acrylates and which does not have covalent bonding to the polymer matrix a), c) from 1 to 15% by weight of plastics particles composed of crosslinked polymers based on polymethyl methacrylate, on polystyrene and / or on polysilicones. The polymer mixture can be used to obtain injection mouldings with matt surfaces and Vicat softening points VSPs (ISO 306-B50) of at least 90° C.

Owner:EVONIK ROEHM GMBH

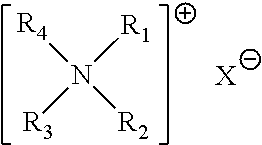

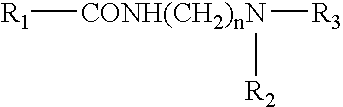

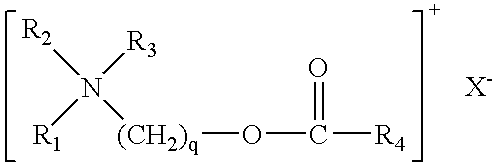

Softening laundry detergent

InactiveUS20060030513A1Effective conditioningOrganic detergent compounding agentsSURFACTANT BLENDSoftening

The present invention is directed to laundry compositions which deliver both effective softening and effective cleaning, containing: (a) a cationic polymer having a weight average molecular weight of less than about 850,000 daltons; (b) about 1% to about 60% of a nonionic oil; and (c) at least about 5% of anionic surfactant, wherein the ratio of said cationic polymer to said nonionic oil is less than about 0.25; wherein the ratio of cationic monomeric surfactant to said nonionic oil is less than about 0.2; and having a Softening Parameter of greater than about 70. A method of conditioning articles using the inventive compositions is also disclosed.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Crosslinked, heat shrinkable polypropylene compositions

InactiveUS6569915B1Reduced effectivenessReduce the degree of crosslinkingElastomerEthylene Homopolymers

A heat-shrinkable article suitable for use as an insulating or coating material comprises a crosslinked composition of a polypropylene homopolymer or copolymer and an ethylene-propylene elastomer. The article is formed by a process comprising: i) creating a blend of the polypropylene homopolymer or copolymer and the ethylene-propylene elastomer by melt mixing; ii) melt processing the blend produced in i) to produce a melt processed material; iii) crosslinking the melt processed material produced in ii) by exposing it to radiation to produce a crosslinked material; iv) stretching the crosslinked material at a first temperature close to or above its softening or melting point and subsequently cooling it to a second temperature below its softening or melting point, to thereby freeze the crosslinked material in its stretched form. Subsequent heating of the article close to or above its softening point or crystalline melting point results in recovery of the pre-stretched dimensions of the article. Due to its relatively high content of polypropylene, the heat-shrinkable article thus produced has greater toughness and rigidity than polyethylene-based systems, making it suitable for use as insulation for wires and cables a heat-shrinkable corrosion resistant sleeves for high-temperature transmission pipeline joints, and for heat-shrinkable tubing or shapes for electrical insulation and mechanical protection.

Owner:SHAWCOR LTD

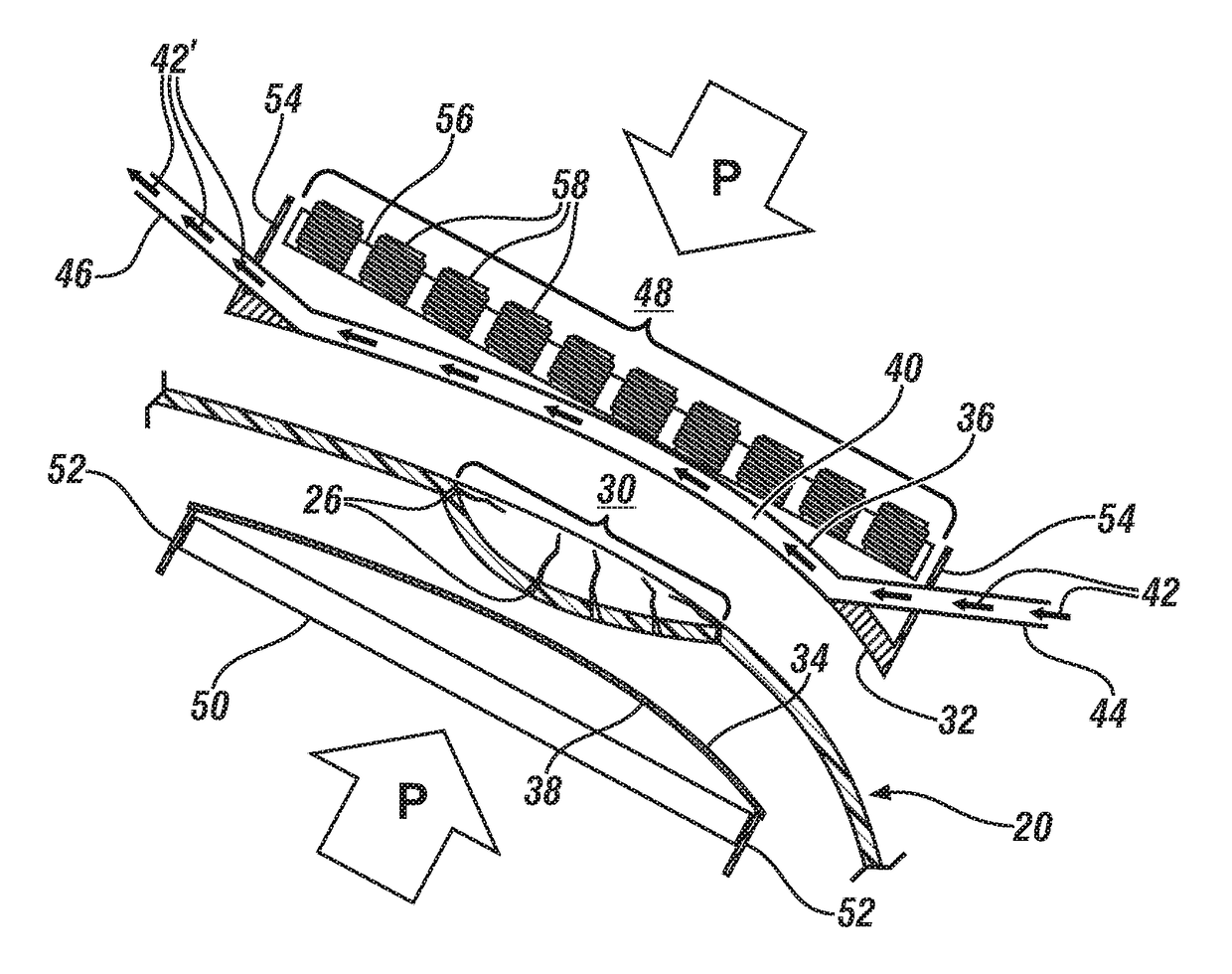

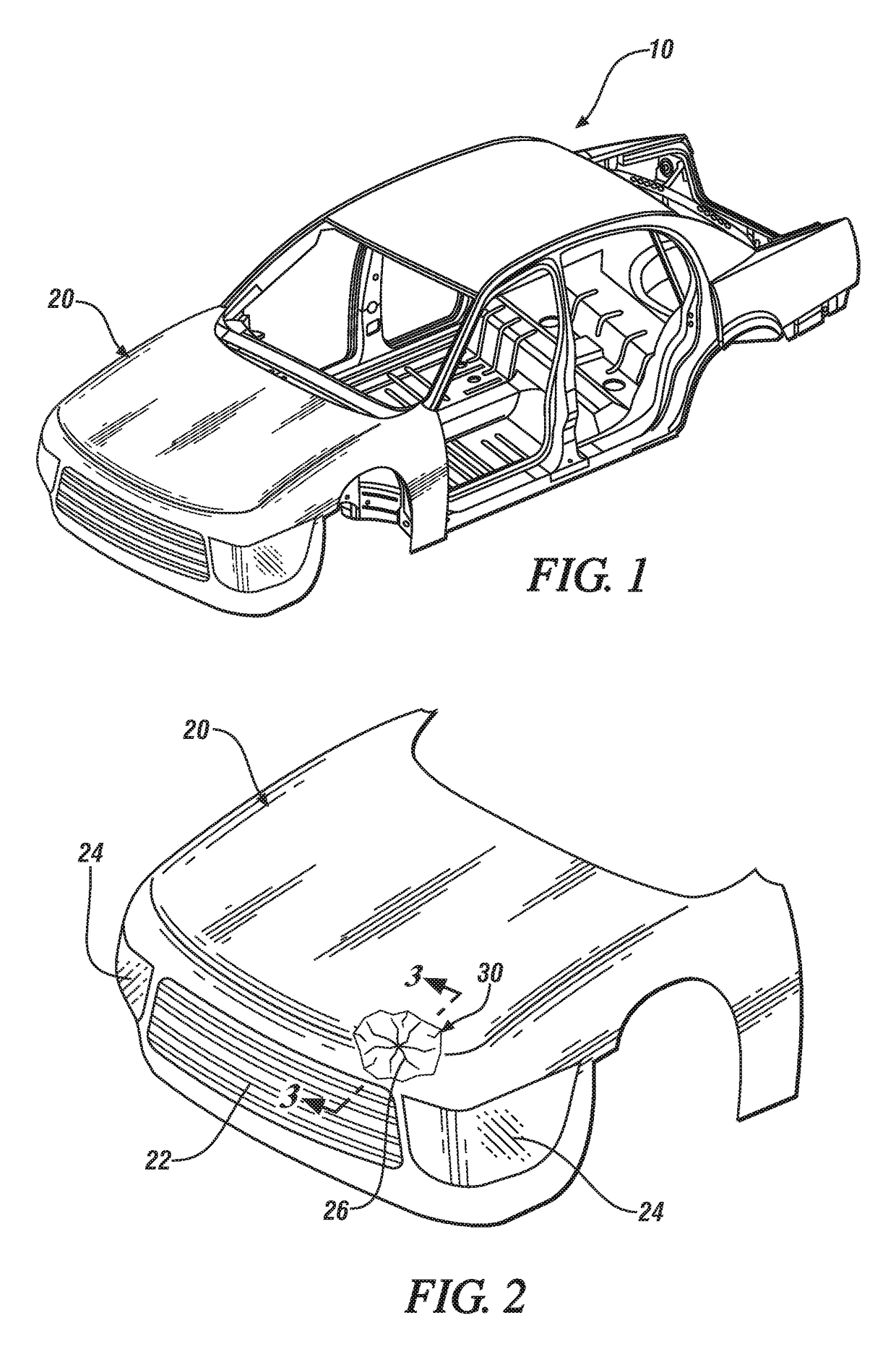

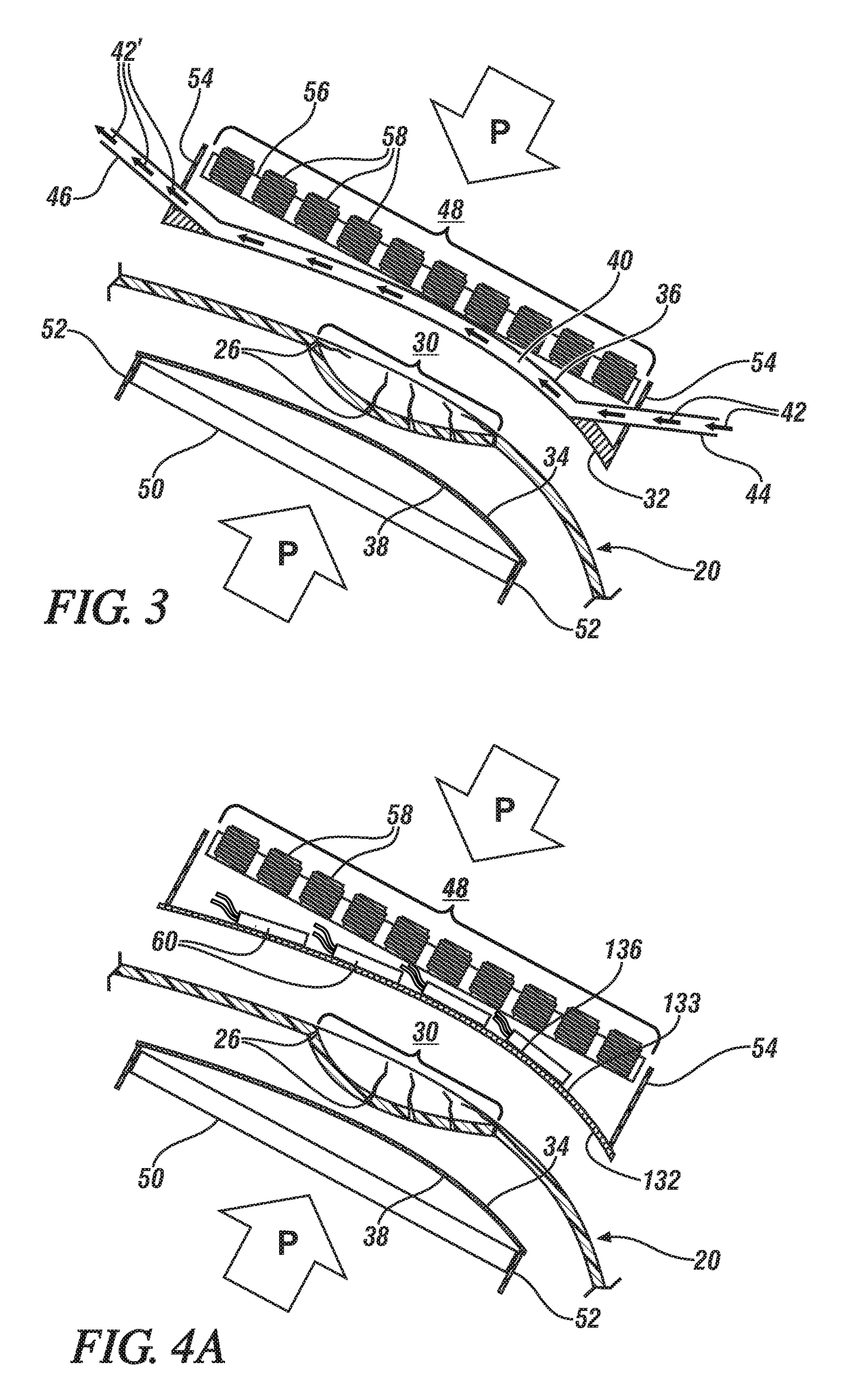

Thermoplastic component repair

Thermoplastic components may experience local damage, including cracks and decohesion of fiber reinforcements, among others. Such thermoplastics may be repaired by heating them to a suitable softening / melting temperature under pressure and maintaining them under pressure and at elevated temperature until the damage is healed. This may be done in-place using custom-fabricated, suitably-shaped die portions maintained under pressure by magnetic attraction. Various heating methods and die portion fabrication methods are described.

Owner:GM GLOBAL TECH OPERATIONS LLC

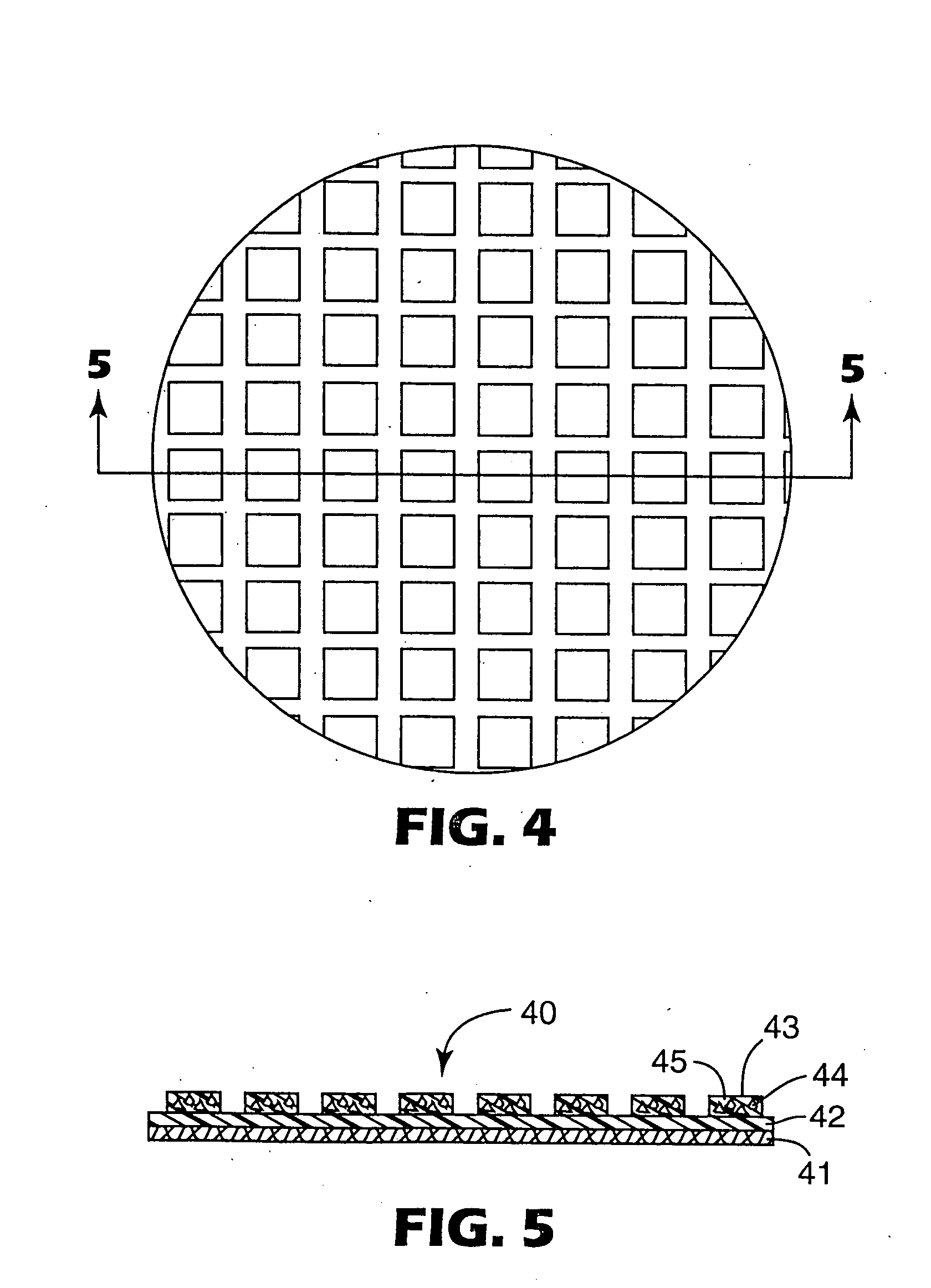

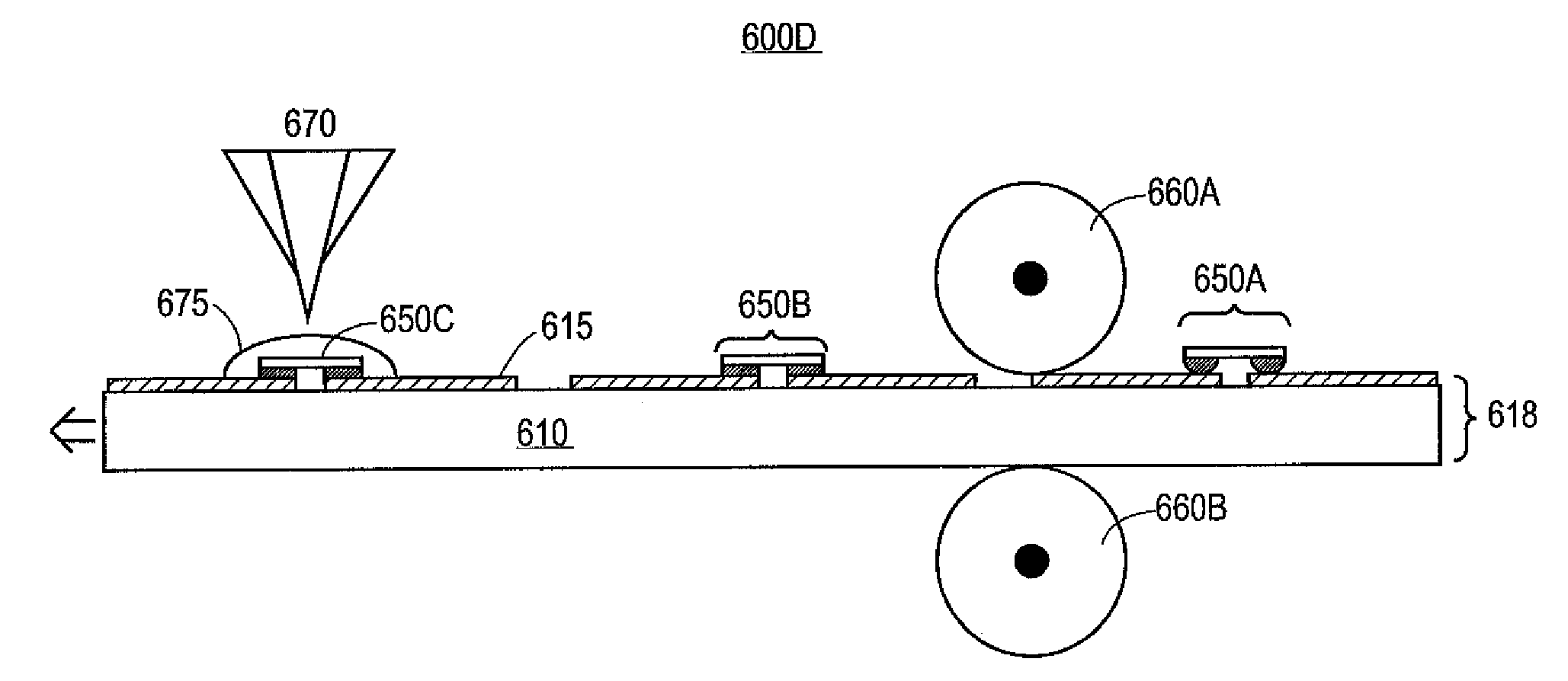

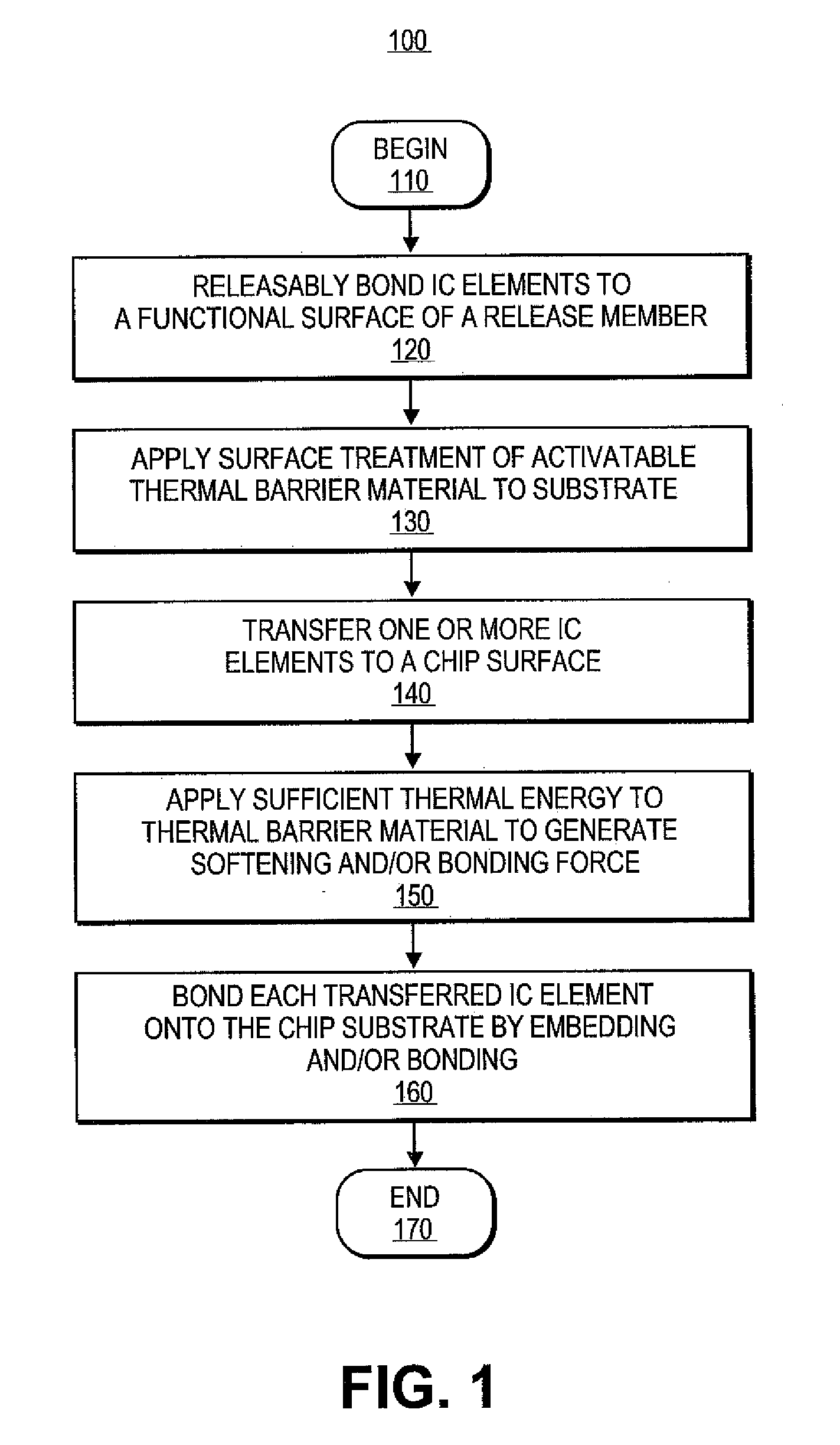

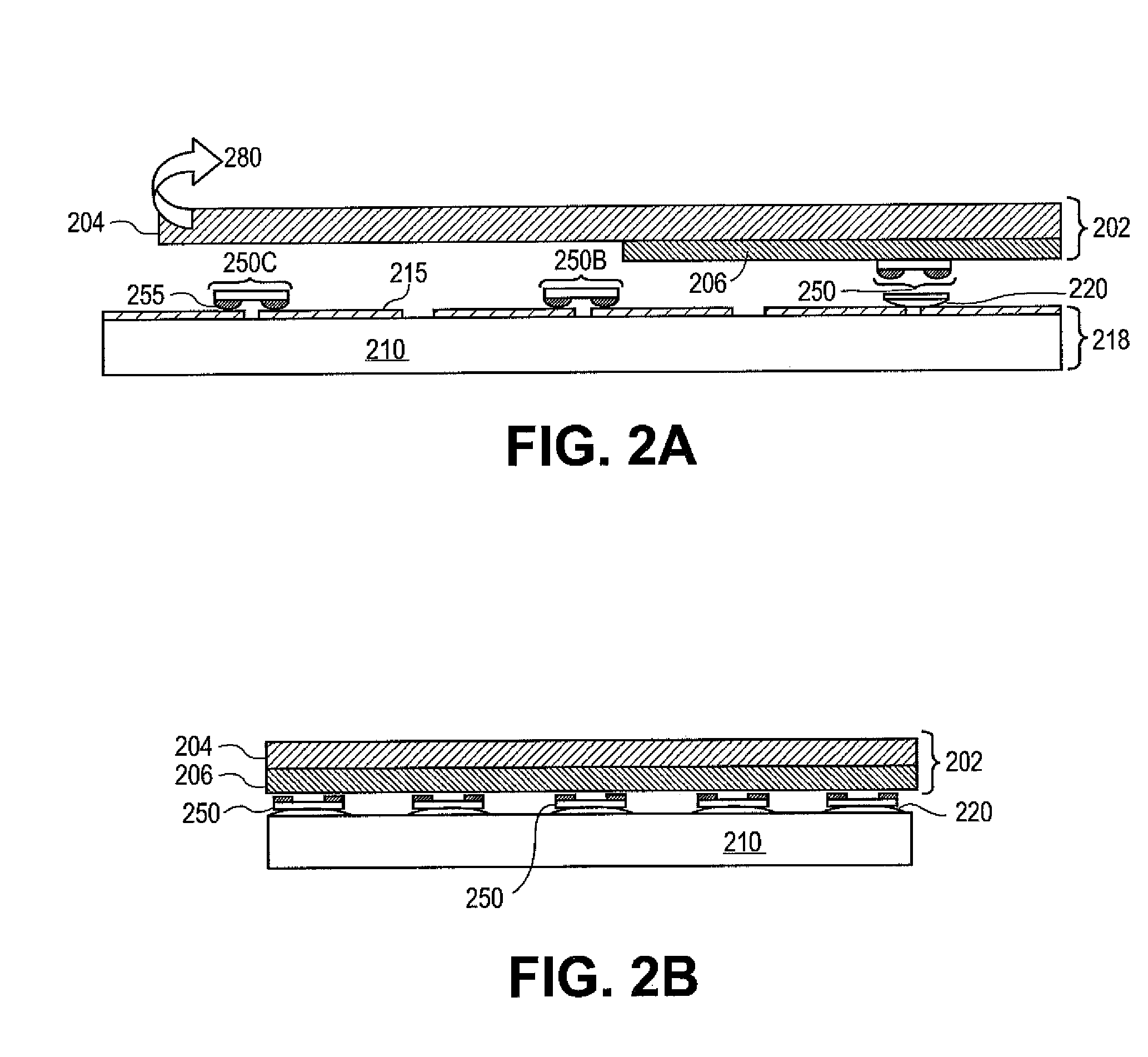

Thermal barrier layer for integrated circuit manufacture

InactiveUS20100075459A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringThermal barrier coating

Exemplary embodiments provide methods and systems for assembling electronic devices, such as integrated circuit (IC) chips, by selectively and scalably embedding or seating IC elements onto / into a receiving substrate, such as a chip substrate. Preparing of the chip substrate can be performed by depositing or patterning an activatable thermal barrier material on a surface of the substrate. The IC chips are secured on the prepared substrate by activating the thermal barrier material between the chip substrate and IC chips. Securing can include softening of the chip substrate with the activated thermal barrier material to an amount suitable for embedding the IC chips. Securing can also include adhesively bonding the IC chips to the substrate with the activated thermal barrier material in the case of a non-pliable substrate.

Owner:EASTMAN KODAK CO

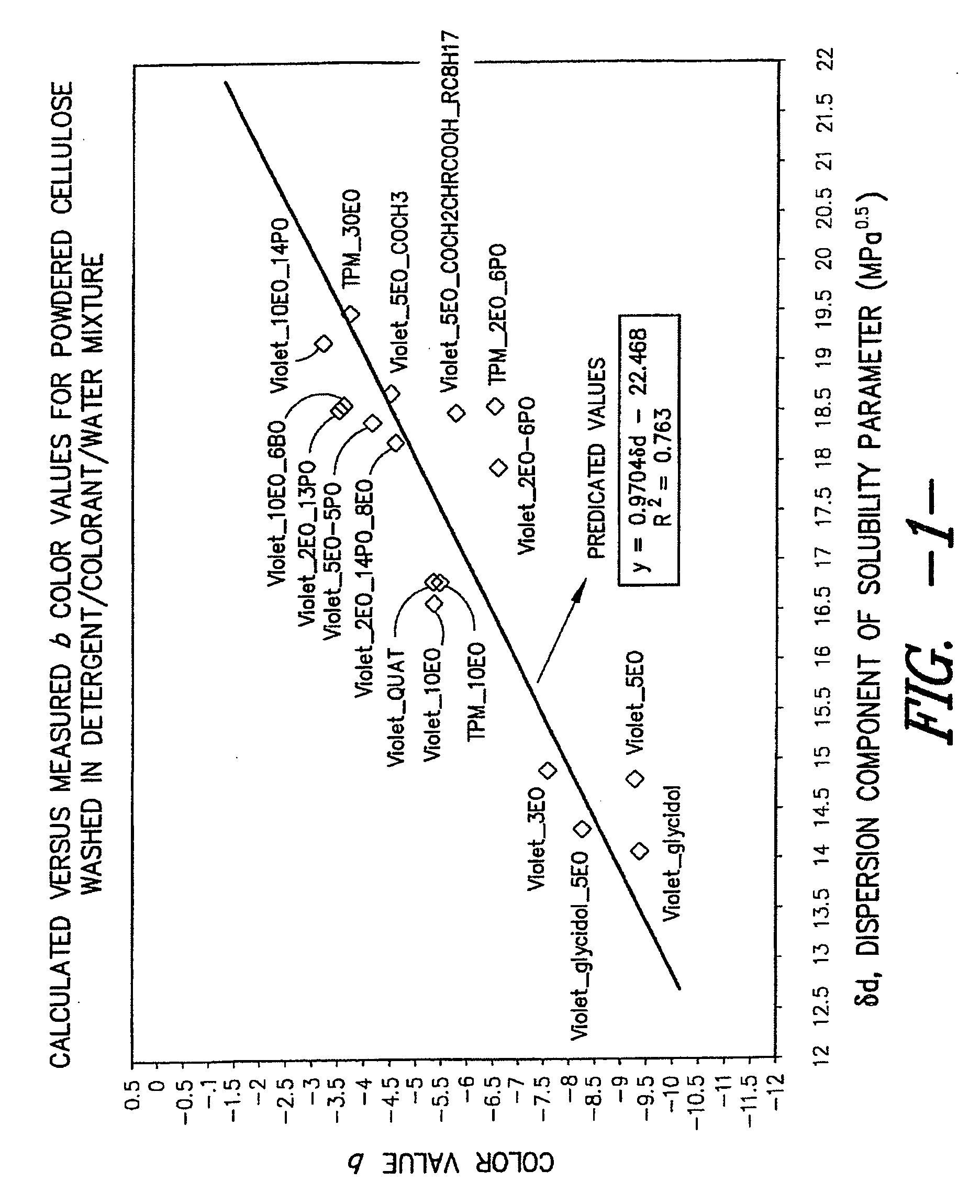

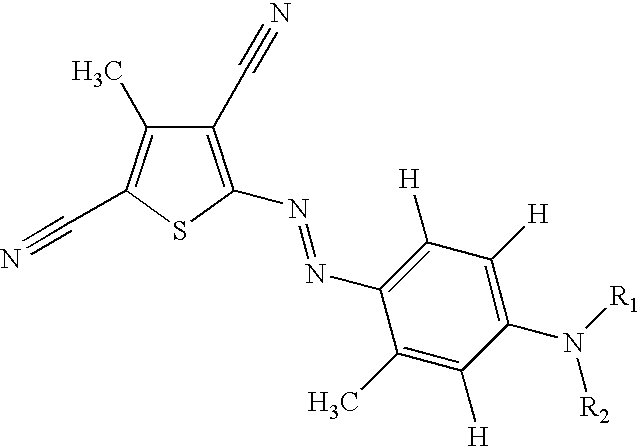

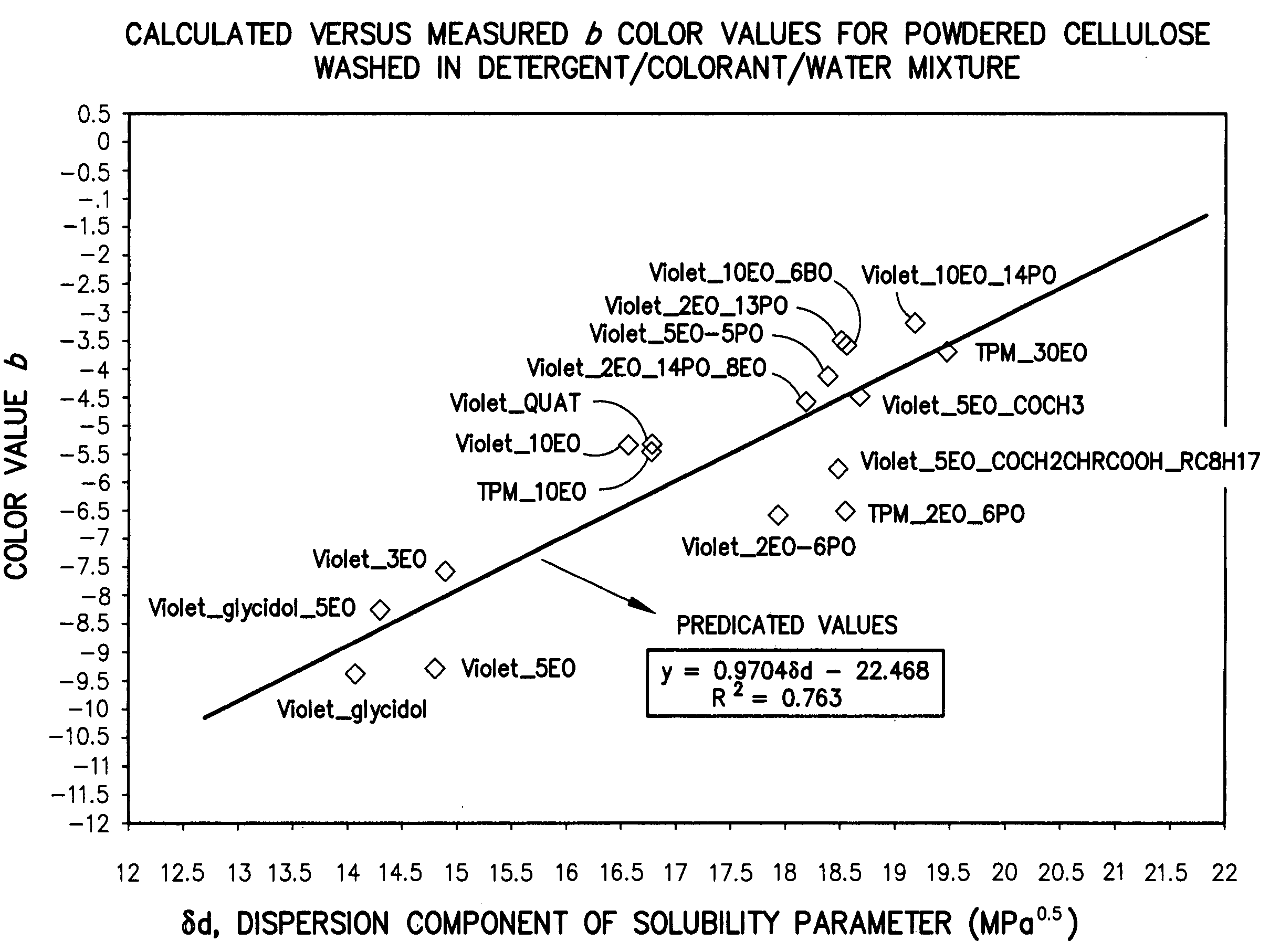

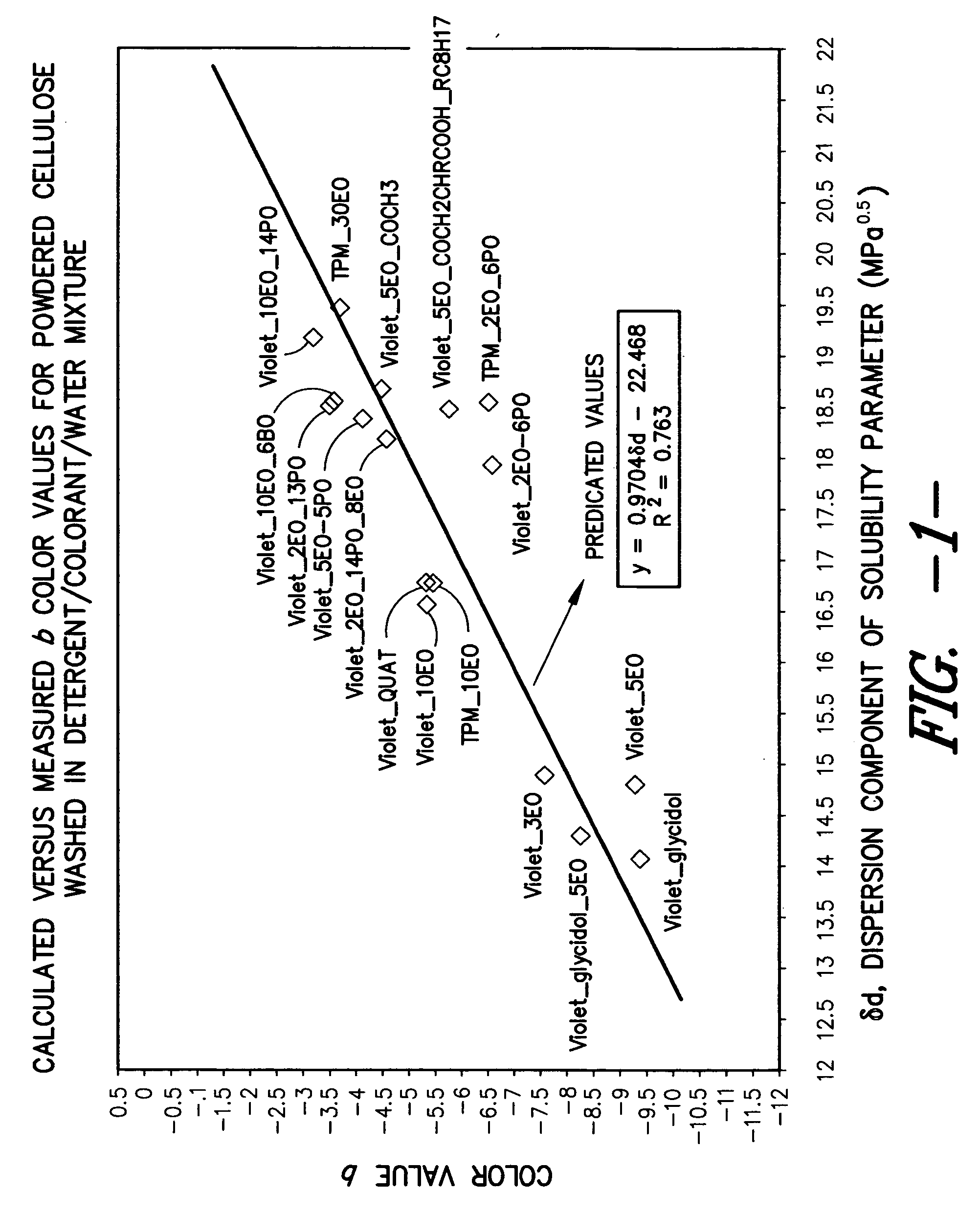

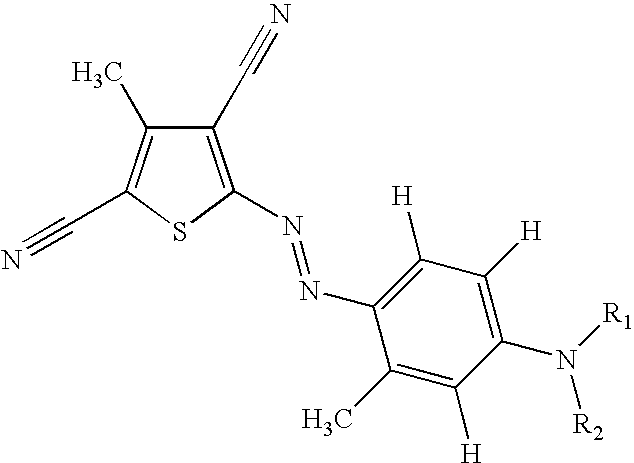

Novel whitening agents for cellulosic substrates

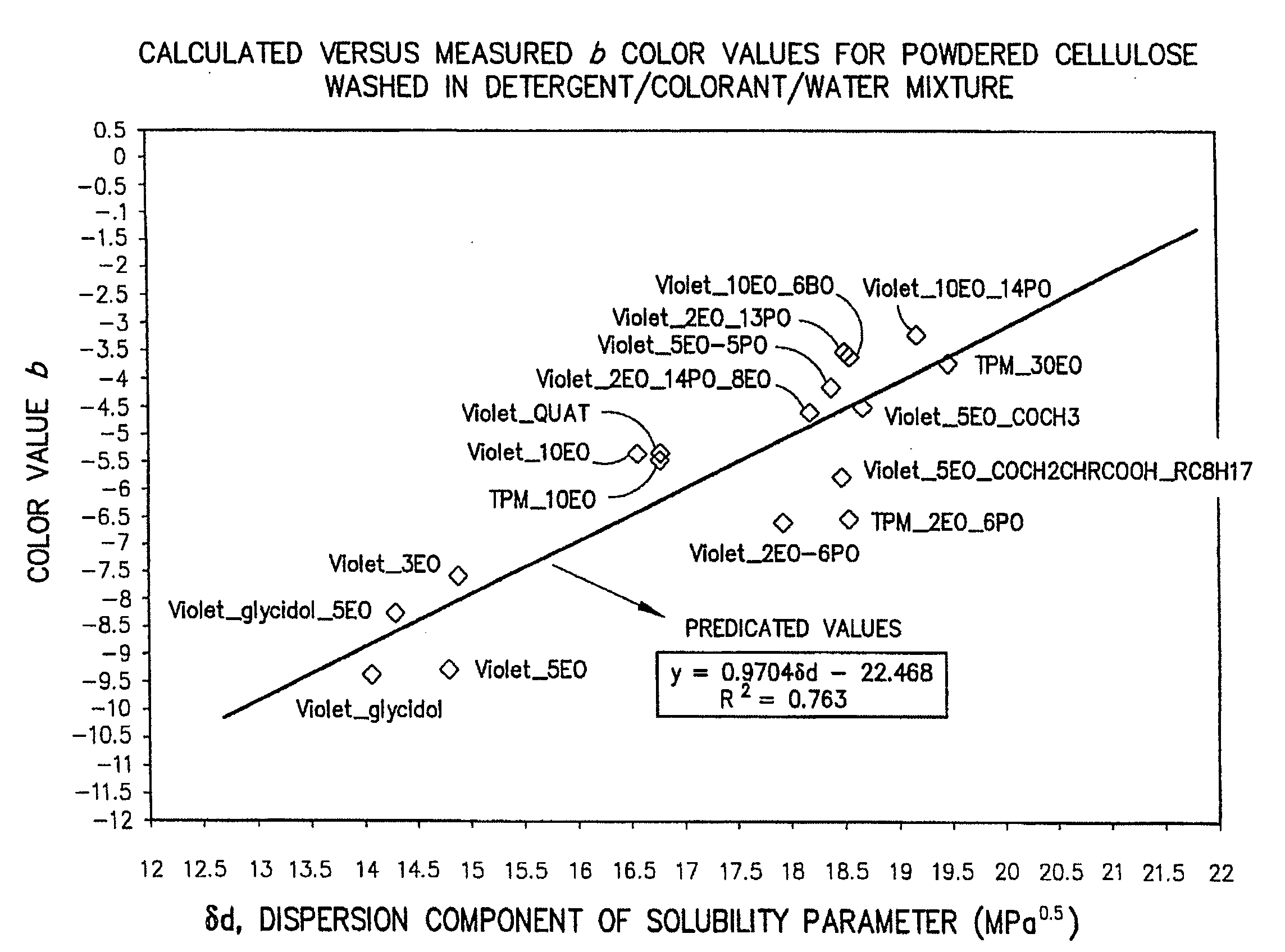

This invention relates to novel whitening agents for cellulosic substrates. The whitening agents are comprised of at least two components: at least one chromophore component and at least one polymeric component. Suitable chromophore components generally fluoresce blue, red, violet, or purple color when exposed to ultraviolet light, or they may absorb light to reflect these same shades. The whitening agents are further characterized by having a dispersion component value of the Hansen Solubility Parameter of less than or equal to about 17 MPa0.5. This invention also relates to laundry care compositions including but not limited to liquid and / or powder laundry detergent formulations and rinse added fabric softening (RAFS) compositions that comprise such whitening agents.

Owner:THE PROCTER & GAMBLE COMPANY

Novel whitening agents for cellulosic substrates

This invention relates to novel whitening agents for cellulosic substrates. The whitening agents are comprised of at least two components: at least one chromophore component and at least one polymeric component. Suitable chromophore components generally fluoresce blue, red, violet, or purple color when exposed to ultraviolet light, or they may absorb light to reflect these same shades. The whitening agents are further characterized by having a dispersion component value of the Hansen Solubility Parameter of less than or equal to about 17 MPa0.5. This invention also relates to laundry care compositions including but not limited to liquid and / or powder laundry detergent formulations and rinse added fabric softening (RAFS) compositions that comprise such whitening agents.

Owner:MILLIKEN & CO

Fabric treatment compositions

ActiveUS20130310301A1Improve softeningEnhanced color benefitCationic surface-active compoundsOrganic detergent compounding agentsMedicineWrinkle reduction

The present invention relates to fabric treatment compositions containing multi-phase systems, polymers for use in multi-phase systems as well as products comprising such systems and methods of making and using same. Such treatment compositions may be used for example as laundry additives, and / or through the rinse to provide benefits including enhanced softening, color benefits, and wrinkle reduction.

Owner:THE PROCTER & GAMBLE COMPANY

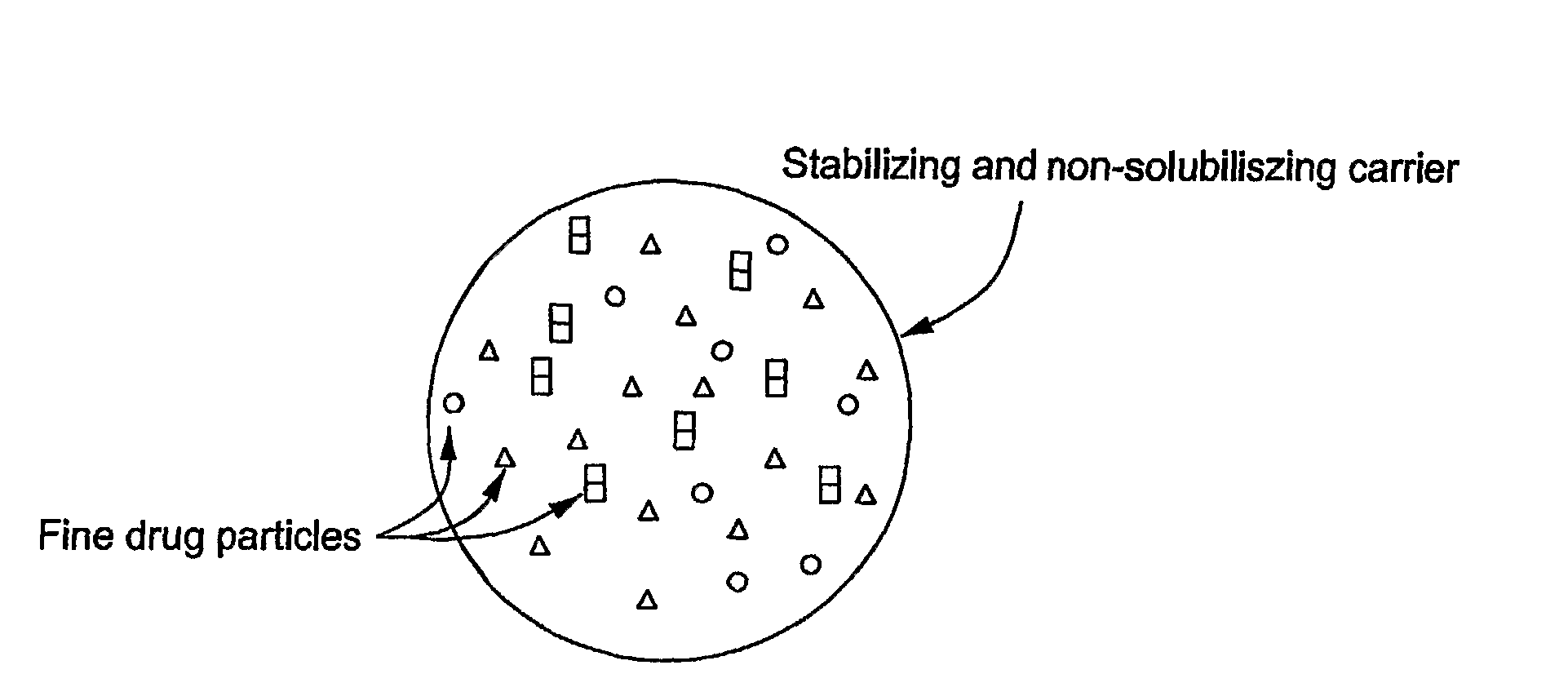

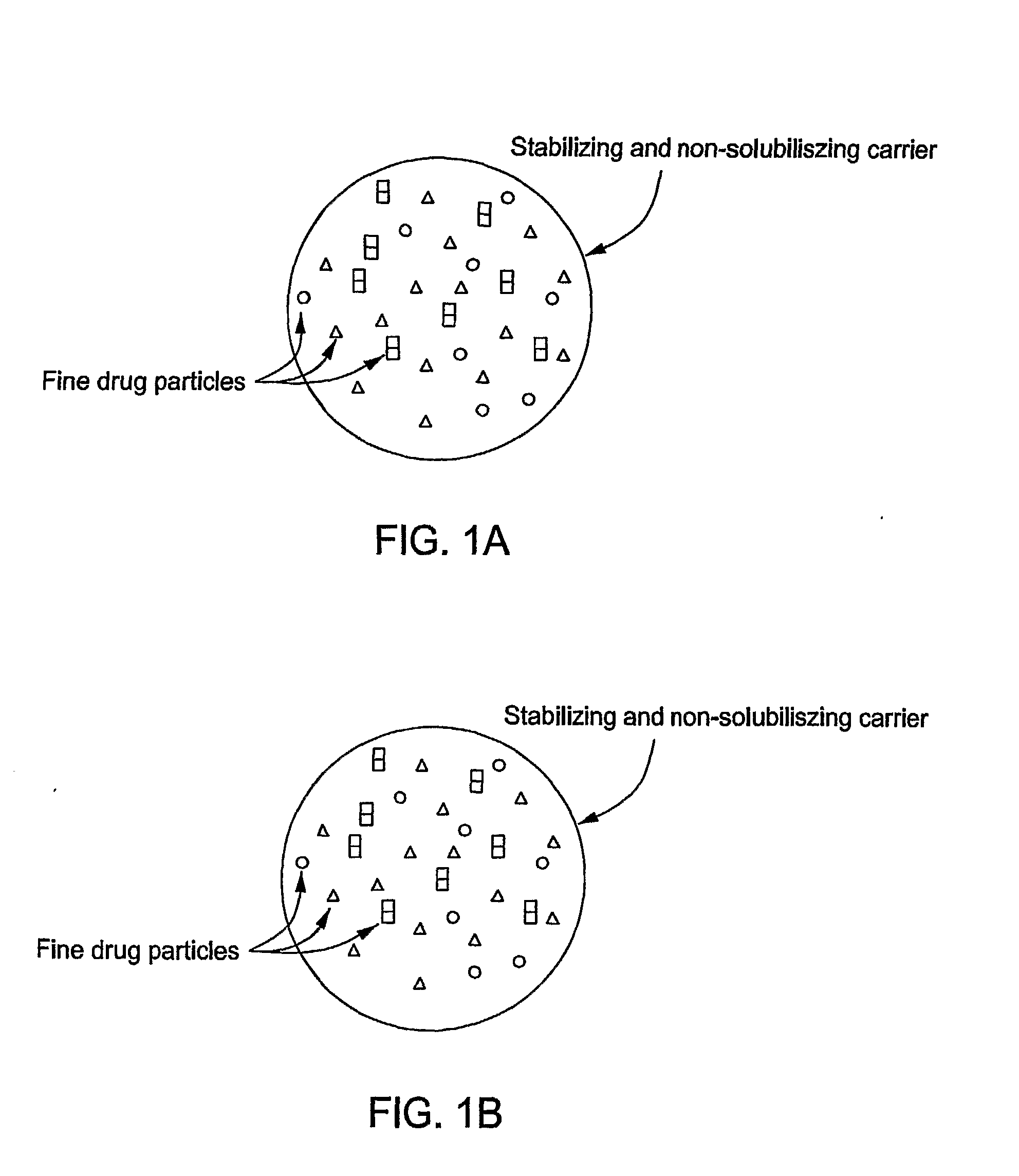

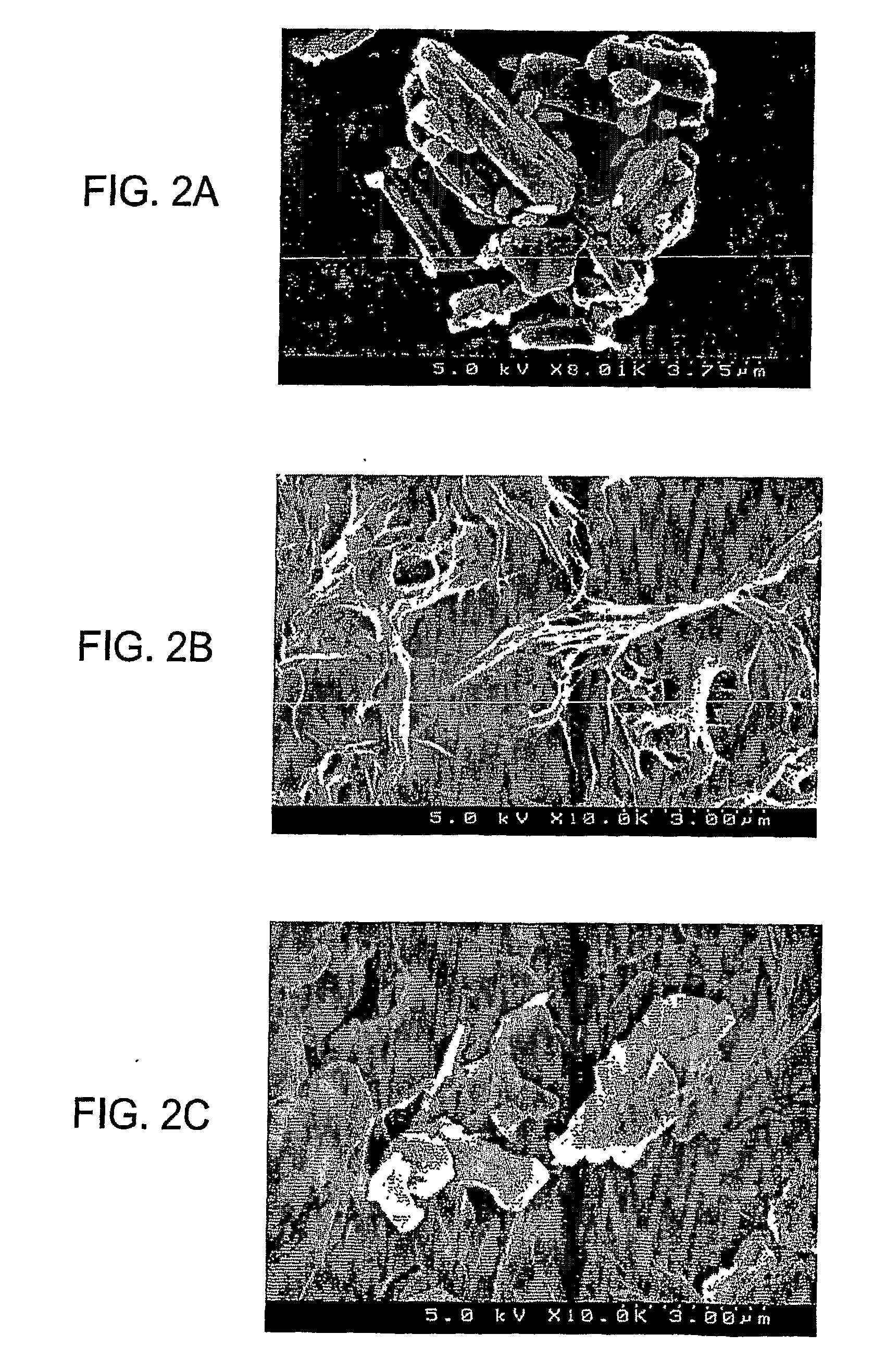

Stabilized Hme Composition With Small Drug Particles

ActiveUS20080274194A1Facilitated releaseReduce releasePowder deliveryCyclic peptide ingredientsAntioxidantCarrier system

A hot-melt extruded composition having finely divided drug-containing particles dispersed within a polymeric and / or lipophyllic carrier matrix is provided. The carrier softens or melts during hot-melt extrusion but it does not dissolve the drug-containing particles during extrusion. As a result, a majority or at least 90% wt. of the drug-containing particles in the extrudate are deaggregated during extrusion into essentially primary crystalline and / or amorphous particles. PEO is a suitable carrier material for drugs insoluble in the solid state in this carrier. Various functional excipients can be included in the carrier system to stabilize the particle size and physical state of the drug substance in either a crystalline and / or amorphous state. The carrier system is comprised of at least one thermal binder, and may also contain various functional excipients, such as: super-disintegrants, antioxidants, surfactants, wetting agents, stabilizing agents, retardants, or similar functional excipients. A hydrophilic polymer, such as hydroxypropyl methylcellulose (HPMC E15), polyvinyl alcohol (PVA), or poloxamer, and / or a surfactant, such as sodium lauryl sulfate (SLS), can be included in the composition. A process for preparing the extrudate is conducted at a temperature approximating or above the softening or melting temperature of the matrix and below the point of solubilization of drug-containing particles in the carrier system, and below the recrystallization point in the case of amorphous fine drug particles.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

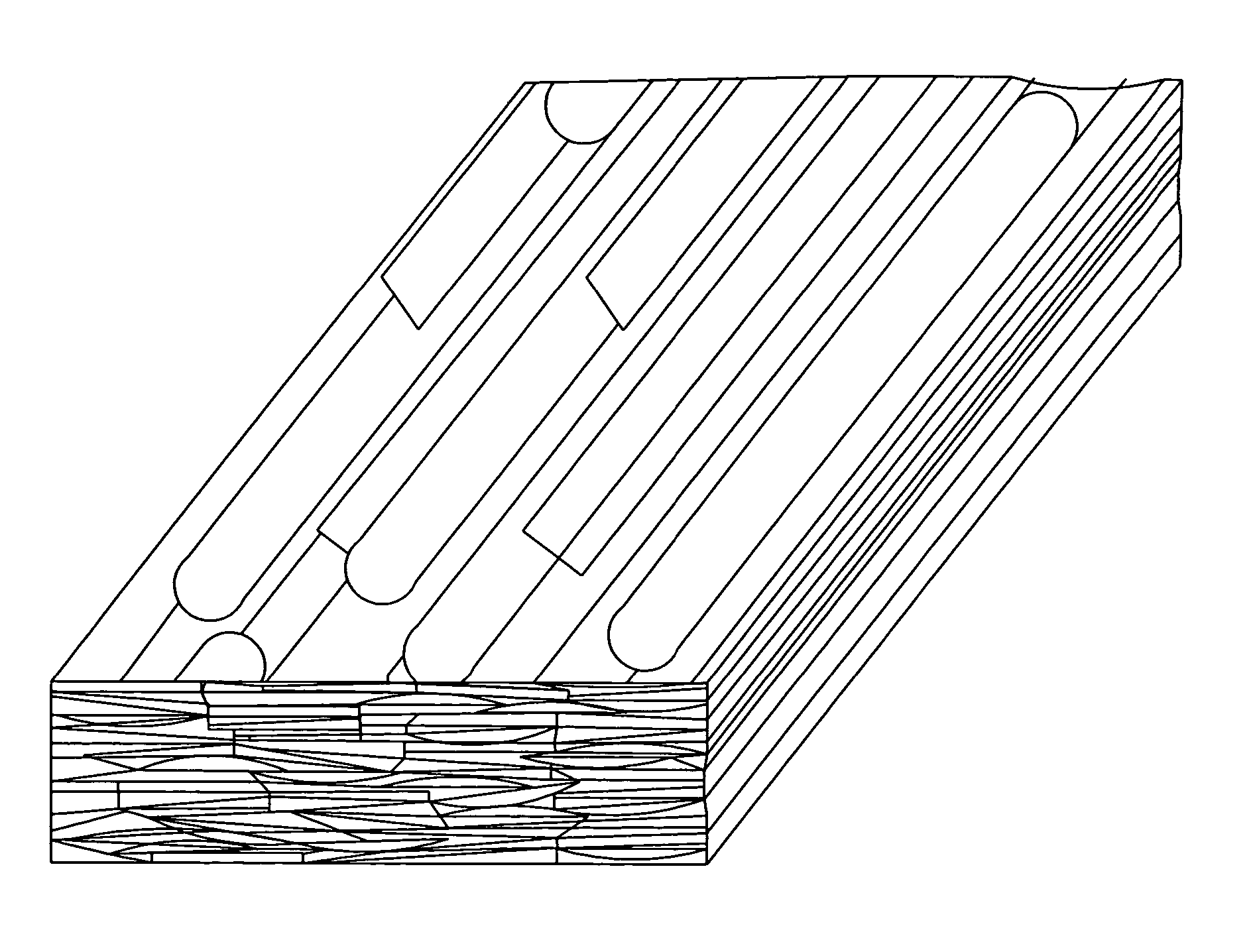

Bamboo chip treatment and products

InactiveUS20050161852A1Equally distributedVoid space is smallWood working apparatusAbsorbent padsEngineeringUltimate tensile strength

Thin elongated bamboo chips are produced and then are softened and dried. The softening of the chips reduces void spaces which uses less glue and produces stronger members. The chips are then joined together with glue under pressure to form a bamboo board. By varying the depth and length of the chip form, the member produced can form a board, chipboard, beams, or columns of any size. Additional boards may be produced and glued together to form a larger board, beam, or column. Several chipboard layers fabricated in large sheets and glued together will form ‘multi-ply bamboo’, a bamboo substitute for plywood. Once cured, the member is kiln dried and sealed for moisture. The resulting bamboo member's strength and geometrical form is stable and consistent enough to be used as a structural grade member for frames, homes, buildings, and furniture.

Owner:DECKER EMIL GUY +1

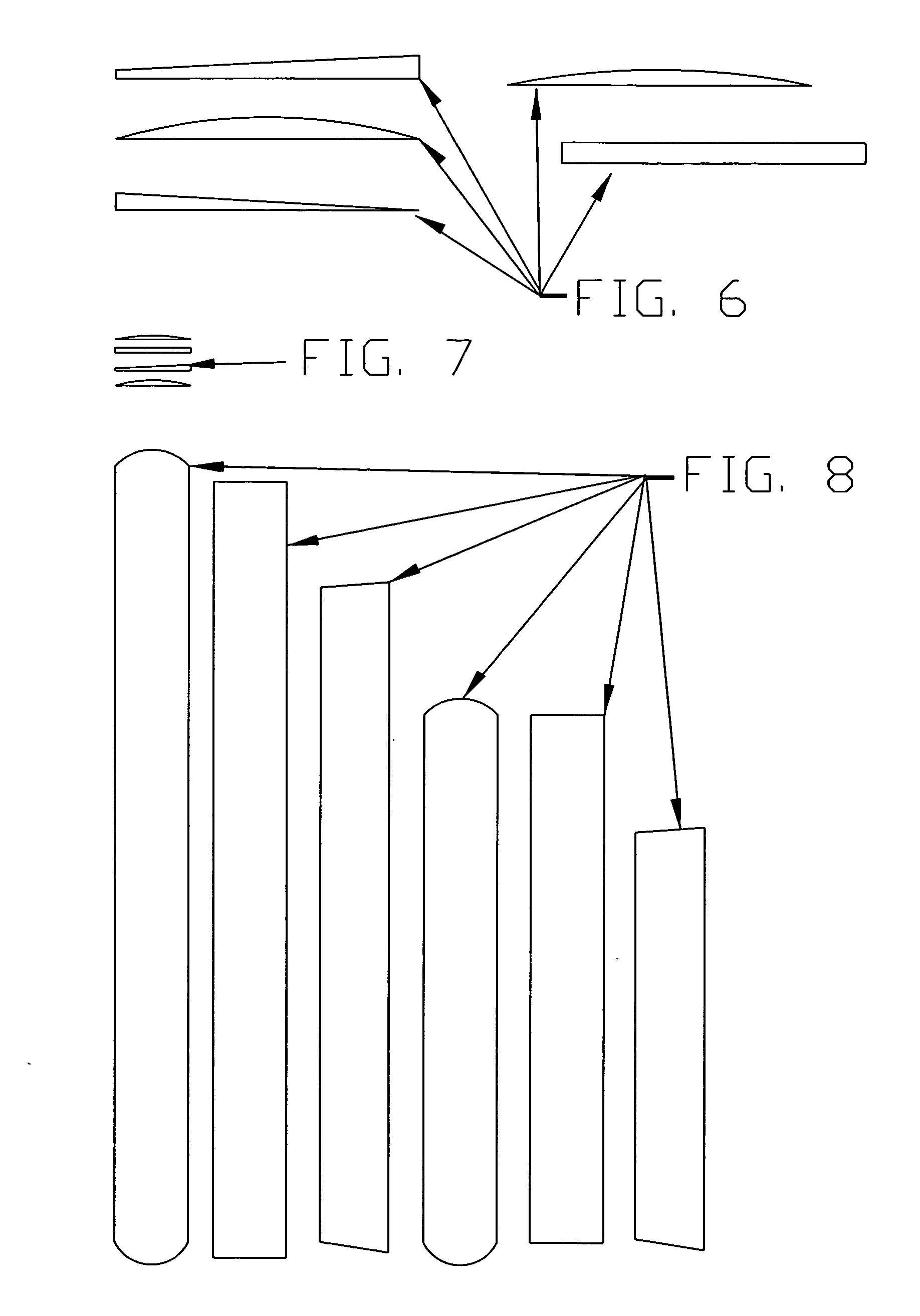

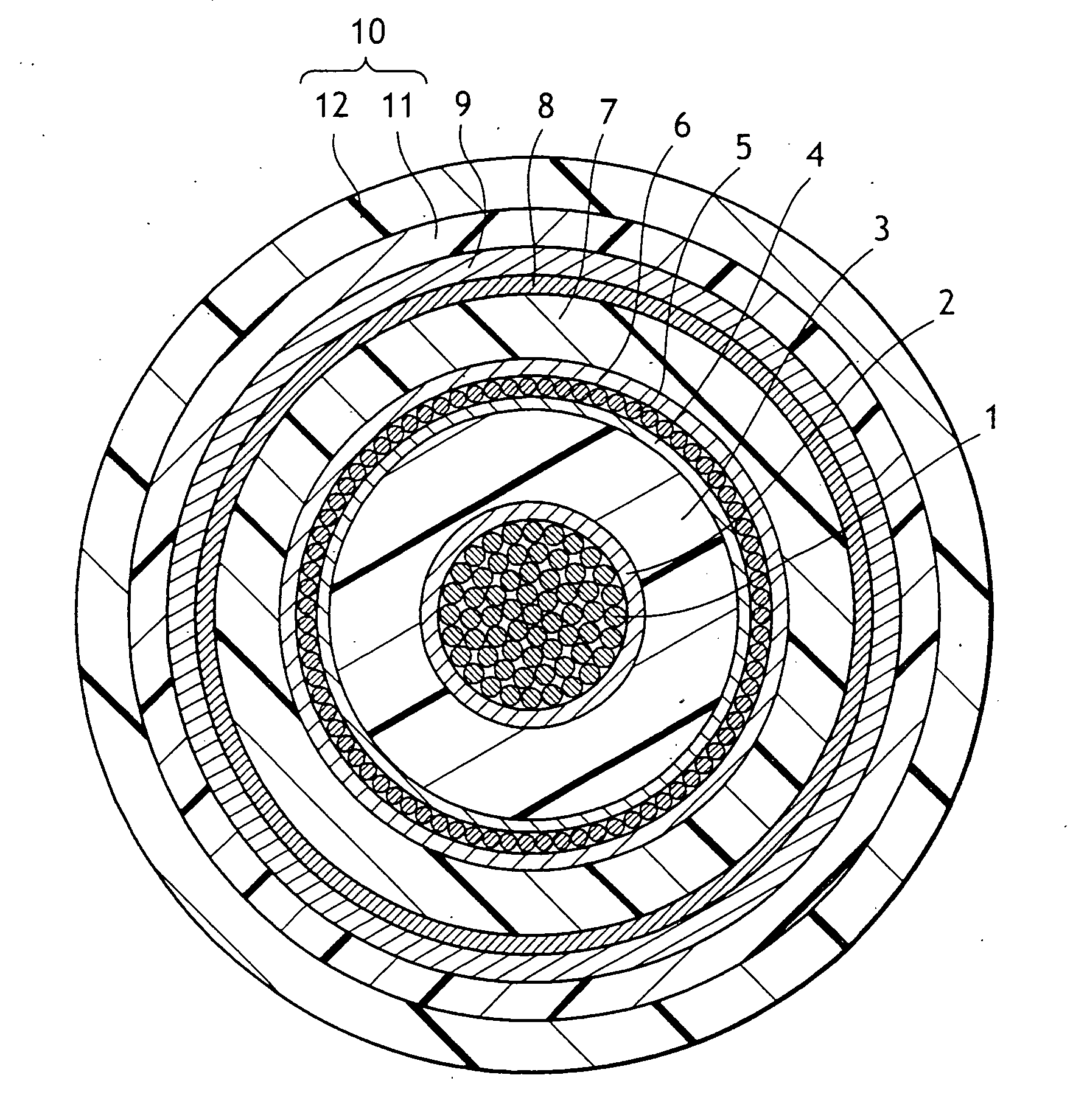

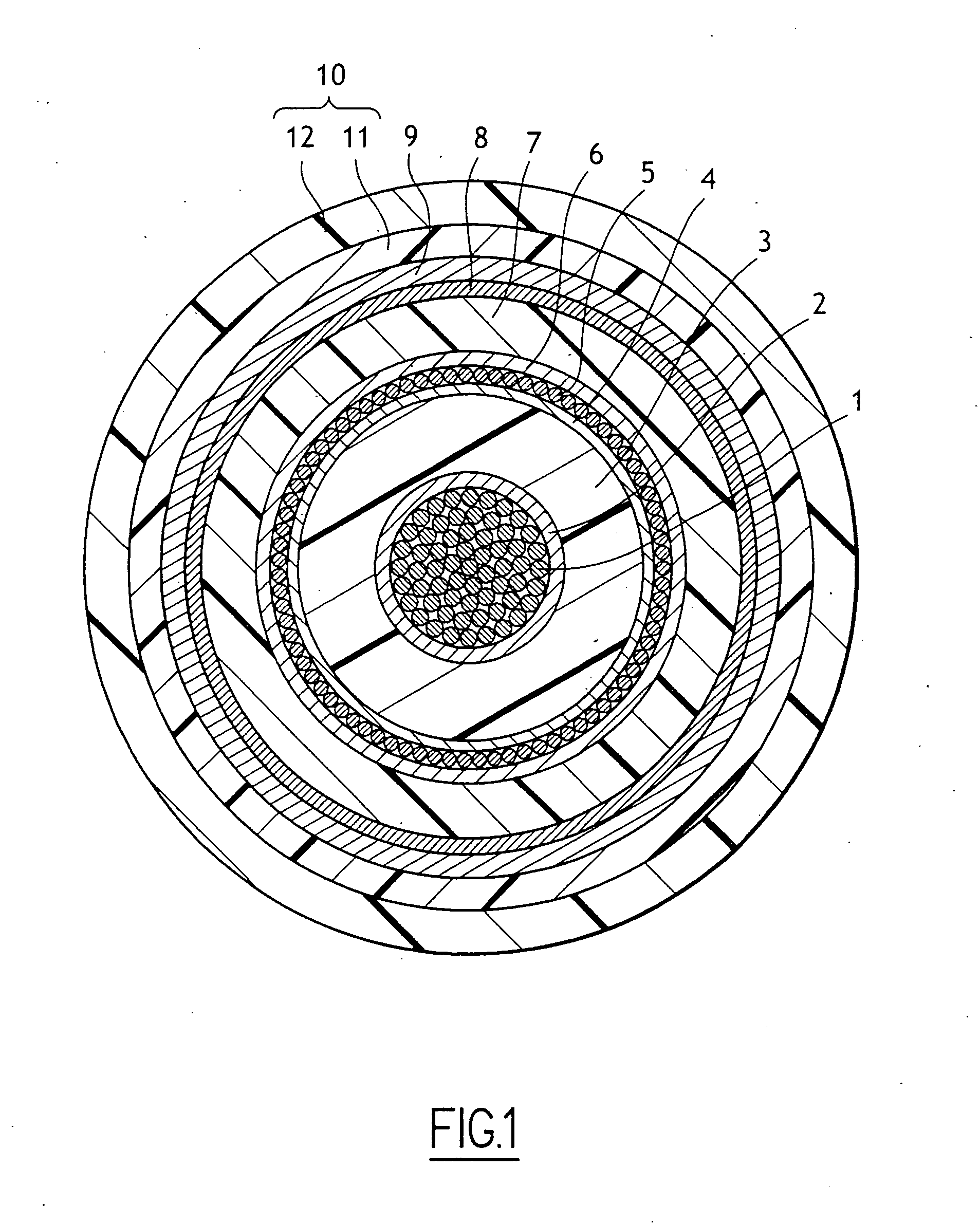

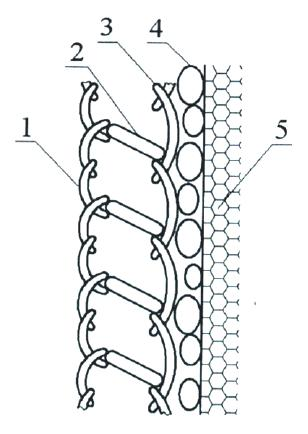

Flame-resistant cable

InactiveUS20050023029A1Minimizing secondary effectPlastic/resin/waxes insulatorsSynthetic resin layered productsElectrical conductorMechanical stability

The flame-resistant electric cable comprising at least one central conductor surrounded by an insulating layer, itself surrounded by an outer sheath comprising an inner layer of flame-resistant synthetic material that conserves mechanical stability when it is subjected to a source of heat leading to softening, and an outer layer of a flame-resistant synthetic material in contact with the inner layer and decomposing into a thermally insulating layer when it is subjected to a source of heat leading to its decomposition.

Owner:SILEC CABLE

Cu-Al2O3 nano strengthened dispersion alloy and preparation method thereof

The invention relates to a Cu-Al2O3 nanometer dispersion strengthening alloy and preparation thereof. The preparation includes the steps of Cu-Al alloy vacuum smelting, pulverizing, screening, internal oxidizing, hydrogen reducing, vacuum hot pressing, canned hot extruding, etc. Comparing with oxygen-free copper, sigma of the alloy of the invention is 2 to 6 times higher that of the oxygen-free copper, the anti-annealing softening temperature is up to over 900 DEG C, the conductivity is up to 96% IACA and more. The process of the invention is simple, the prepared Cu-Al2O3 nanometer dispersion strengthening alloy has high strength, high conductivity, electrical conductivity higher than 96% IACA, and is anti-annealing and antimagnetic. The alloy can not only used for large-scale integrated circuit lead frame, manufacturing of controlled thermonuclear reaction heat sink components, and is expecially suitable for manufacturing of microwave tube grid mesh, inertial instrument sensor, particle accelerator and other high-precise parts.

Owner:CENT SOUTH UNIV

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

Toner coated with thin film

Satisfactory anti-blocking property of powder toner can be realized, while avoiding increase in softening temperature of the powder toner, by coating the surface of a low melting point powder toner with a thermosetting resin. This leads to the realization of toner fixing at lower temperatures and is particularly effective when using a urea resin as the thermosetting resin or employing polymerized toner as the powder toner. Use of the surface-coated powder toner with a low softening temperature and less blocking tendency makes possible reduction of thermal energy and time required for fusing, thereby realizing energy-saving and high-speed fusing process.

Owner:TOPPAN MOORE CO LTD

Damp-absorbing fast-drying and sweat-repelling fabric finishing agent, its preparing method and use

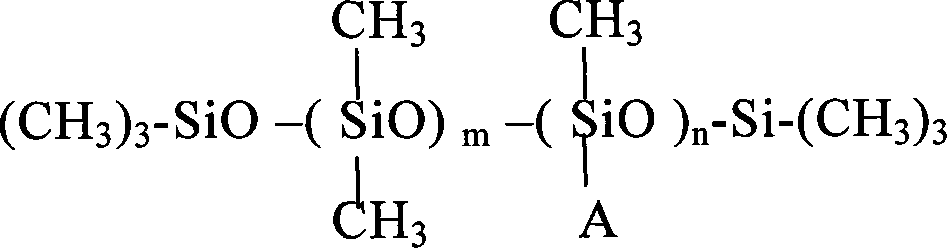

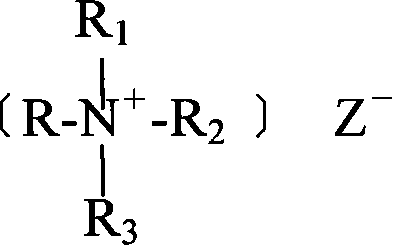

This invention relates to a method of making an absorbing moisture fast and the perspiration fabric finishing agent and its use. The fabric finishing agent including 20-60wt% fabric water affinity finishing agent or antistatic agent, 20-60wt% organosilicon softening agent, 0-20wt% water. Compares with the present technology, this invention's characteristic is as follows: it can enable the fabric to keep the moisture absorption, make the perspiration function fast, has the water affinity anti-static electricity performance, and the soft, smooth feel as well as comfortable when put on it.

Owner:SHANGHAI SAIBO CHEM

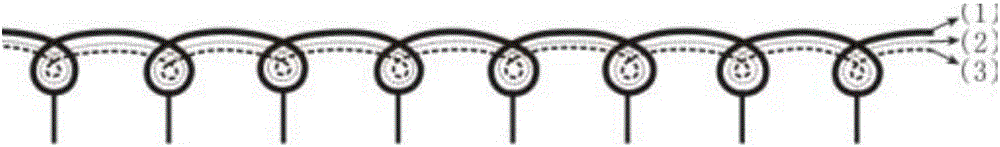

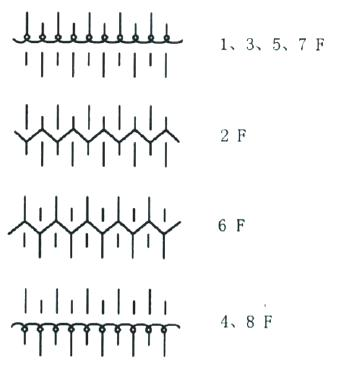

Method for reducing resultant yarn filoplume

The invention relates to a textile processing technology concerning operations after the spinning that can reduce hairiness in finished yarn, and pertains to the technical field of textile processing. The invention provides a hairiness reducer for finished yarn that de-twists and heats on the advancing channel of the yarns, which reduces hairiness of finished yarns by de-twisting, heating, softening and twisting again yarns. The hairiness reducer for finished yarn that de-twists and heats can outstandingly reduce hairiness in finished yarns, and make yarn structure more tight, efficiently avoid the forming of hairiness because the fiber in the yarn stretches out from the yarn surface in subsequent operation. In addition, the hairiness reducer for finished yarn that de-twists and heats can be used on spooling, warping even knitting machines, the reducer consumes low energy, is easy to install and use, and is good for spreading and application widely.

Owner:WUHAN TEXTILE UNIV

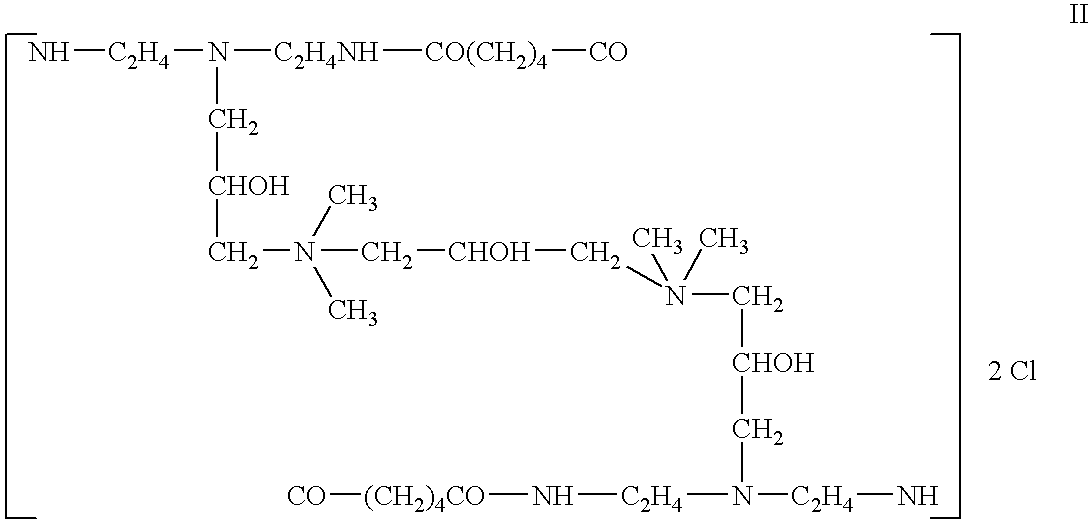

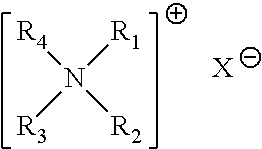

Fabric care composition comprising polymer encapsulated fabric or skin beneficiating ingredient

ActiveUS20050256027A1Cationic surface-active compoundsOrganic detergent compounding agentsCross-linkWater dispersible

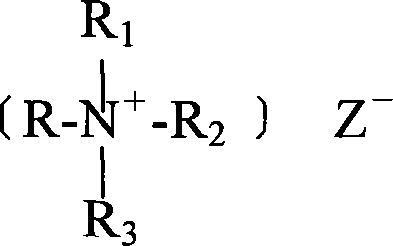

Fabric softening compositions are disclosed comprising: (a) from 0.01% to 50% by weight of a cationic or non-ionic softening compound; (b) at least 0.001% by weight of a water dispersible cross-linked cationic polymer derived from the polymerization of from 5 to 100 mole percent of a cationic vinyl addition monomer, from 0 to 95 mole percent of acrylamide, and from 5 to 500 ppm of a difunctional vinyl addition monomer cross-linking agent (c) from 0 to 5% by weight of a non-confined fragrance oil, (d) an effective amount of at least one fabric or skin beneficiating ingredient encapsulated within a first polymer material to form a polymer encapsulated beneficiating ingredient, said encapsulated ingredient being further coated with a cationic polymer and; (e) balance water and optionally one or more adjuvant materials.

Owner:COLGATE PALMOLIVE CO

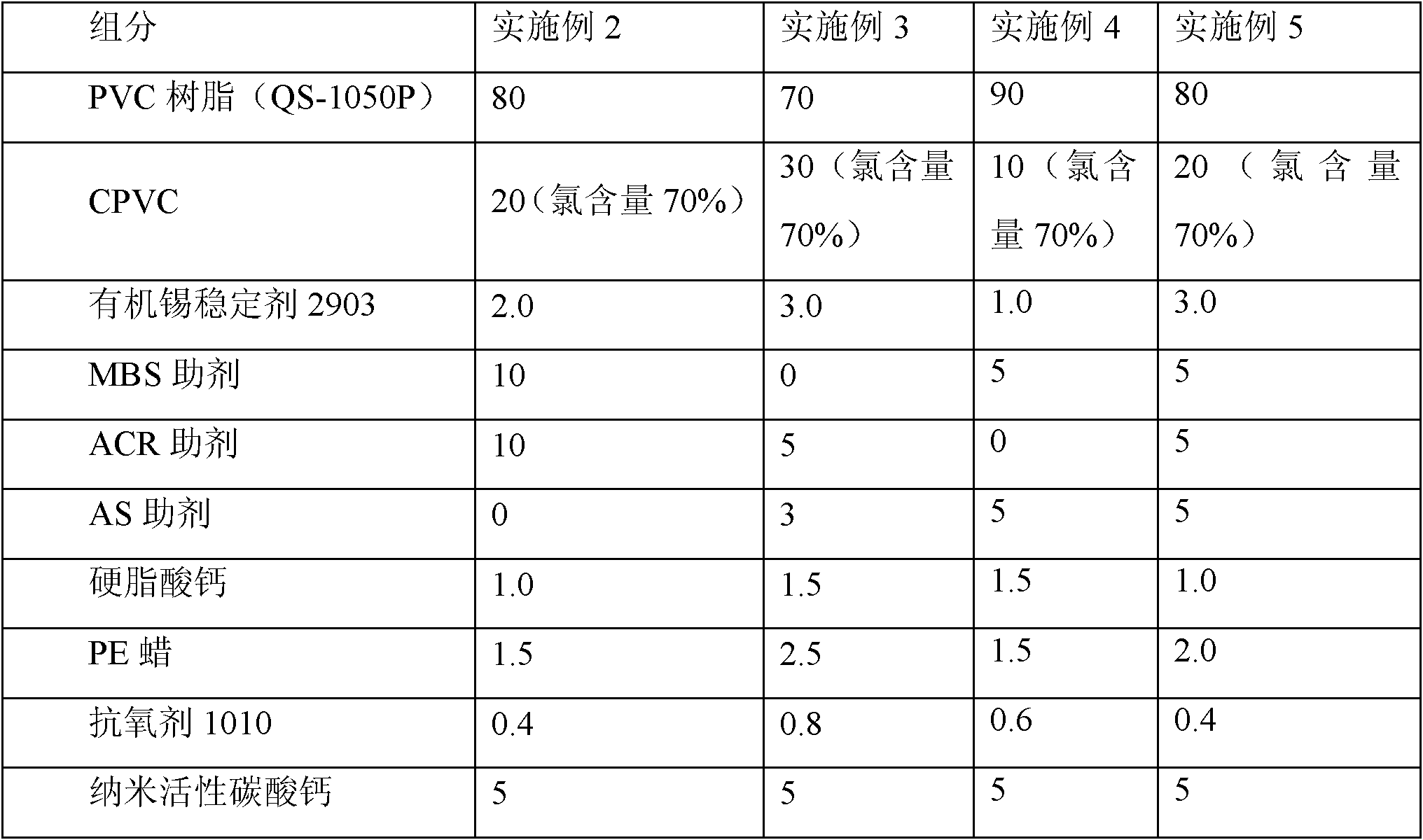

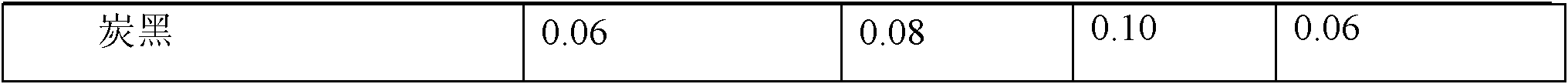

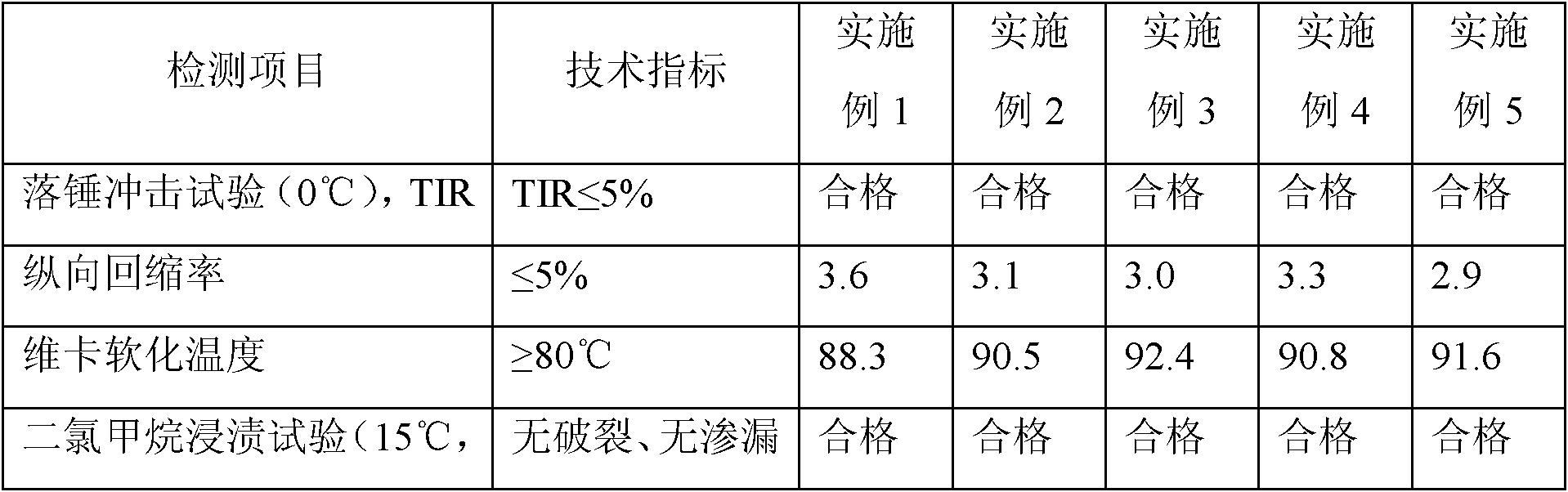

Heat-resisting PVC high impact-resisting tubular product and preparation method thereof

ActiveCN102863711AHigh impact resistanceRaise the Vicat softening temperatureRigid pipesChlorinated polyvinyl chlorideAntioxidant

The invention discloses a heat-resisting PVC high impact-resisting tubular product and a preparation method thereof, belonging to the field of polymer materials. The tubular product disclosed herein comprises the following ingredients: 70-90 weight parts of PVC resin, 10-30 weight parts of chlorinated polyvinyl chloride (CPVC), 1-3 weight parts of stabilizer, 8-20 weight parts of impact modifier, 1.5-4.0 weight parts of lubricant, 0.2-0.8 weight parts of antioxidant, 0.01-0.10 weight parts of coloring agent, and 1-5 weight parts of filler. According to the invention, by using the heat-resisting modified resin CPVC and the heat-resisting impact modifier, the tubular product disclosed herein is guaranteed to have high impact resistance and simultaneously have high vicat softening temperature; and by using the two-step method of firstly granulation and then extrusion molding, the extrusion speed of the tubular product is greatly raised, the raise of the production efficiency is benefited, and the production cost is low.

Owner:CHINA PETROLEUM & CHEM CORP

Technique for producing Jinhuaqianliang tea (flower coil tea)

ActiveCN101352191AQuality improvementUniform qualityPre-extraction tea treatmentCooking & bakingThirst

The technology for producing golden flower Qianliang tea (Hua-juan tea) is characterized in that the technology comprises the process steps as follow: plucking criteria-water removing in high temperature-rolling and shaping-pile-fermentation-dry and adding incense-stems picking and sieving-matching and pile-classificaition and weighting-steam softening-moisture detection-adpressing and sizing-premilary test and baking-cultivating golden flower-aerationagitation. The technology is an improved deep processing technology. The processes of the pile-fermentation and the cultivating golden flower ensure that the appearance of the products is ooiu colour, the interior is brown, and even distributed beneficial organism (namely, golden flower)-eurotium cristatum is clearly saw, the shangse is bright red, the taste is pure and aromatic, and the flower is aromatic, and has the health care functions of promoting sleeping, invigorating stomach and promoting digestion, relaxing bowel, slaking thirst and helping produce saliva, antidiabetics, lowering blood pressure, curing bloated, cuing laxness, etc. The technology fully actives microelements such as vitamins contained in tea, mineral composition, 18 amino acid, protein, glucide, folic acid, catchol which are beneficial to human health and easily absorbed, and the cultivation of golden flower has substantial transformation on tea polyphenols, caffeine, and theophylline that are transferred into elements that are beneficial to human health, all ages, expand market, have high cultural value, provide collection opportunity for black tea lovers.

Owner:湖南省安化县晋丰厚茶行有限公司

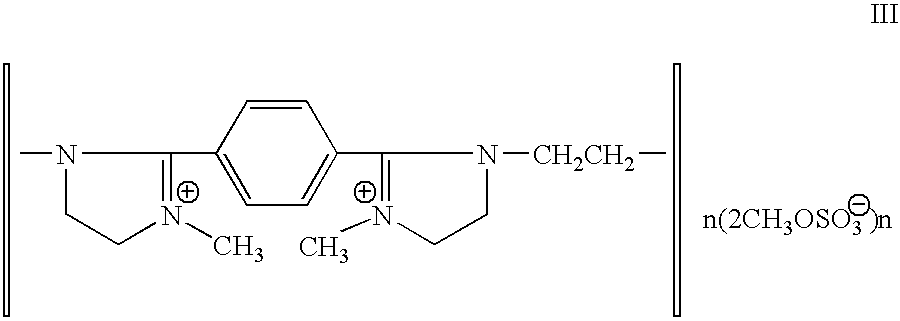

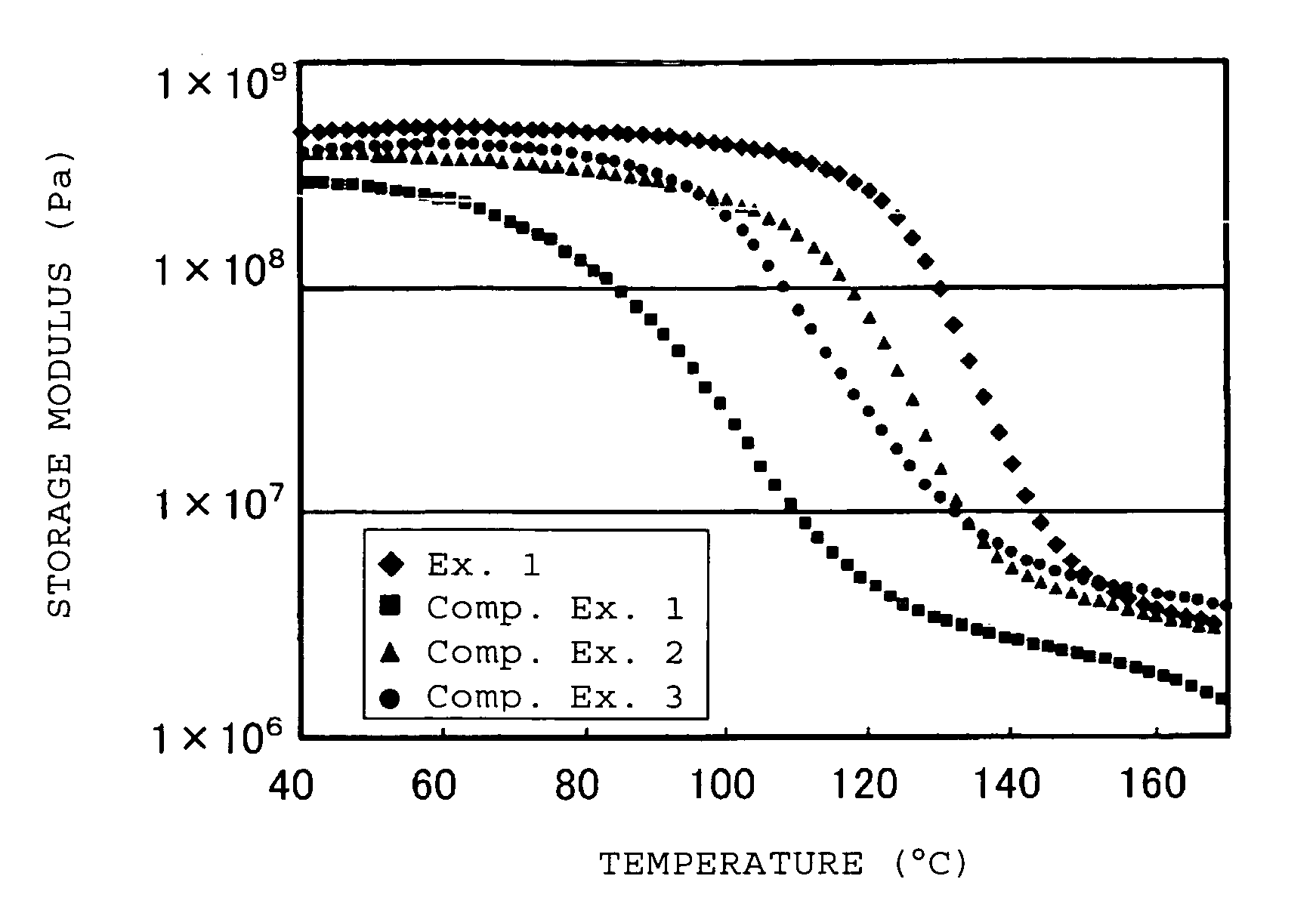

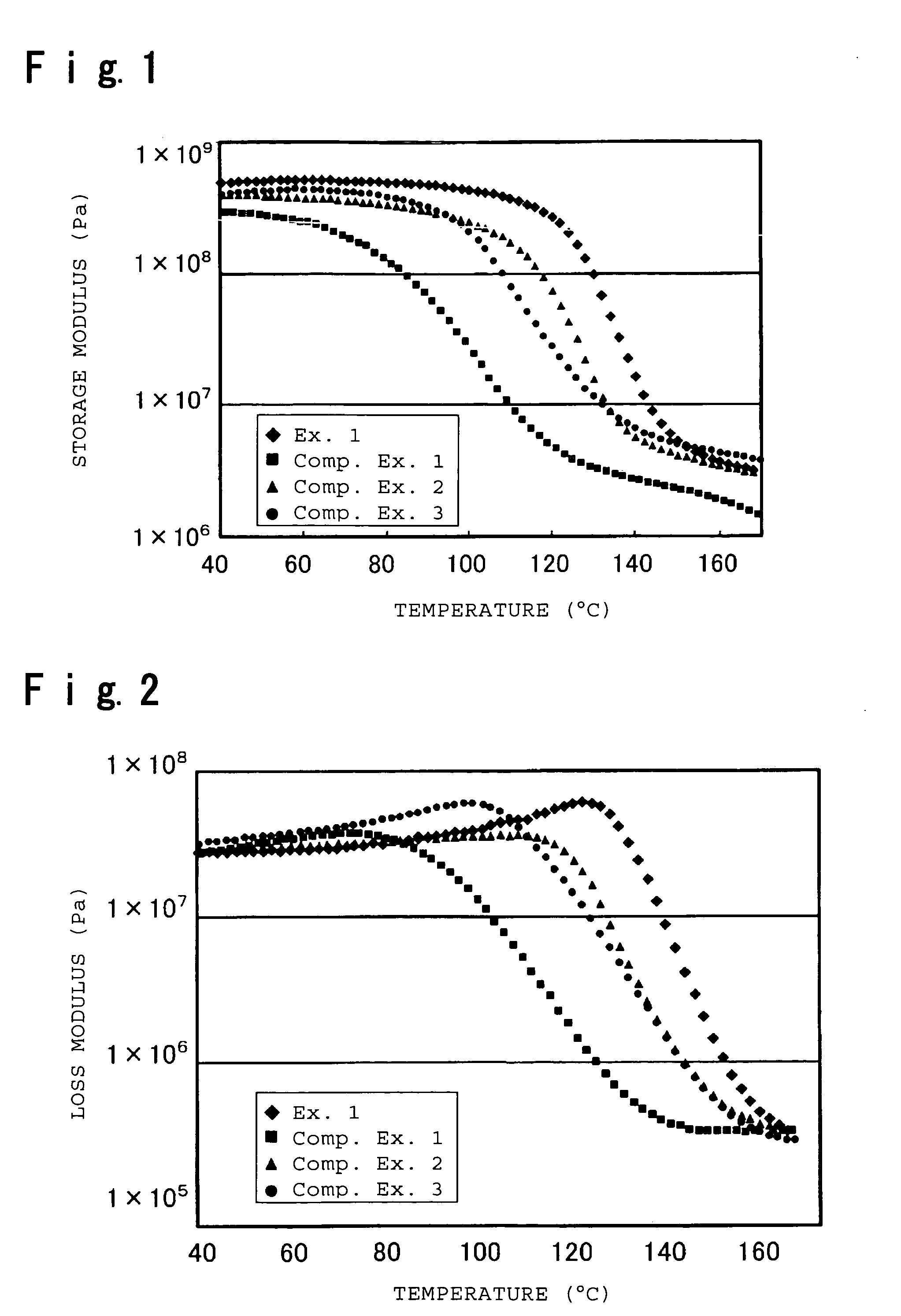

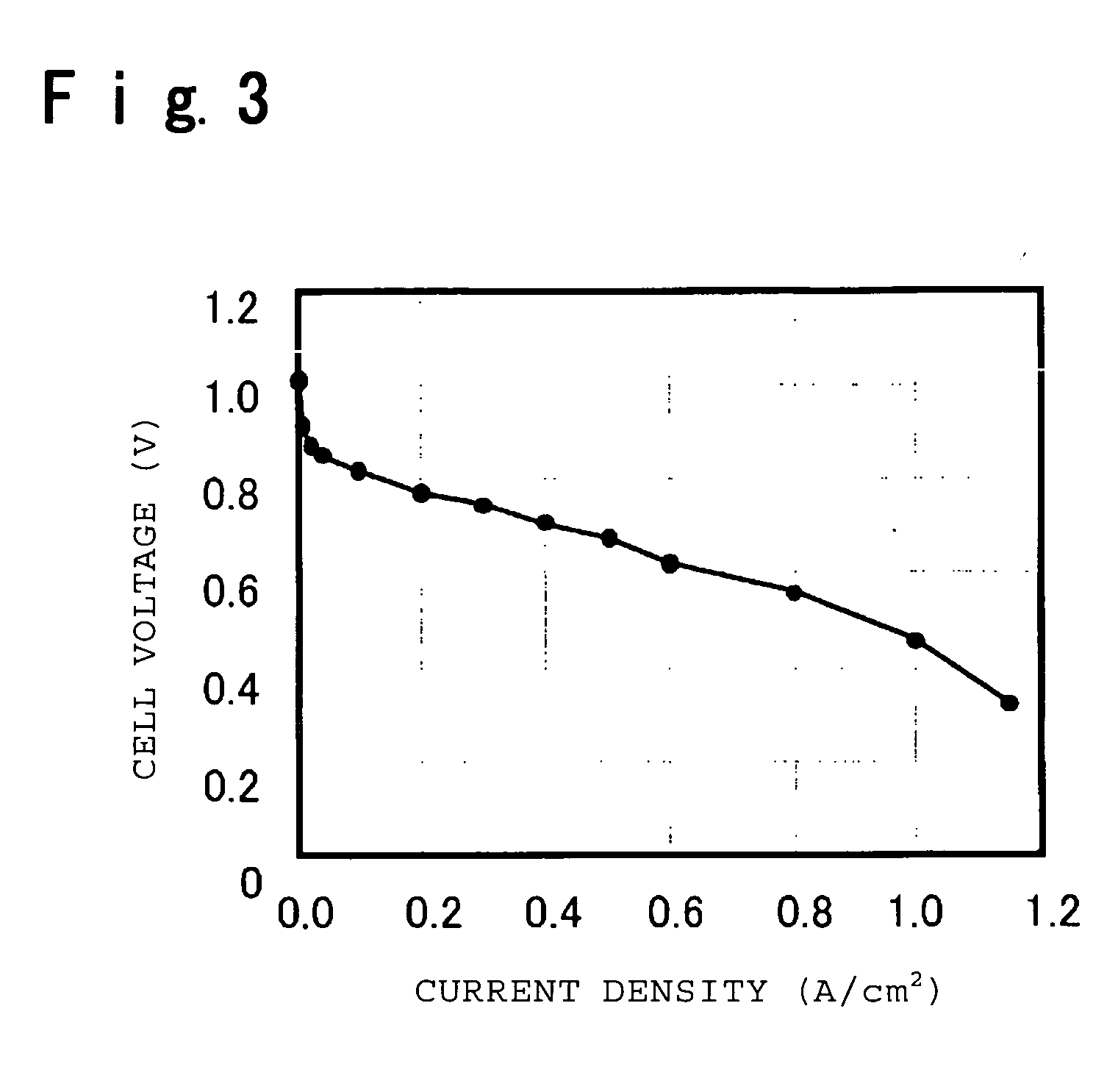

Electrolyte material for polymer electrolyte fuel cells, electrolyte membrane and membrane-electrode assembly

ActiveUS20060099476A1Increase temperatureOrganic chemistryIon-exchanger regenerationOxygenMembrane electrode assembly

To present an electrolyte material having a high softening temperature, which is useful for obtaining a polymer electrolyte fuel cell which can be operated at a high temperature and whereby a high output power can be obtained with little catalyst poisoning. An electrolyte material for polymer electrolyte fuel cells, which is made of a polymer containing repeating units based on a fluoromonomer having a radical polymerization reactivity, wherein the repeating units contain a 5-membered ring (which may contain 1 or 2 oxygen atoms), of which at least one carbon atom is contained in the main chain of the polymer, and an ionic group such as a sulfonic acid group which is bonded to the 5-membered ring directly or via a perfluoroalkylene group having a linear or branched structure; and the polymer has a softening temperature of at least 120° C.

Owner:ASAHI GLASS CO LTD

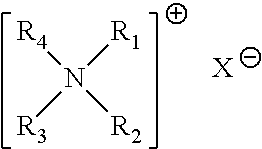

Paper softening compositions containing low levels of high molecular weight polymers and soft tissue paper products comprising said compositions

Disclosed is a composition suitable for atomizing without excessive aerosolization in the form of an oil-in-water emulsion comprising: a) a continuous aqueous phase, and b) a discontinuous oil phase wherein the rheology of the aqueous phase is modified by the addition of a water-in-oil emulsion comprising: i) a high molecular weight polymer in a discontinuous aqueous phase, and ii) a continuous organic solvent phase. Preferred embodiments of the present invention relate to compositions for softening an absorbent paper tissue comprising a) a quaternary ammonium softening active ingredient; b) an electrolyte; c) a high molecular weight polymer emulsion comprising: i) from about 20% to about 40% by weight of the premix of a high molecular weight polymer; ii) from about 40% to about 60% of water; and iii) from about 20% to about 40% of an organic solvent; and d) a vehicle in which said softening active ingredient is dispersed.

Owner:THE PROCTER & GAMBLE COMPANY

Encapsulated cosmetic composition

The present invention relates to encapsulated cosmetic compositions that are topically applied. The compositions contain at least one frangible capsule that has a seamless shell of a thermo-softening material. The shell is solid at about room temperature and melts upon application to the skin. The shell holds a core cosmetic that is added to a clear gel base. Thus, the color of the capsule is visible and multiple colored capsules can be added to the base for a custom colored composition.

Owner:ELC MANAGEMENT LLC

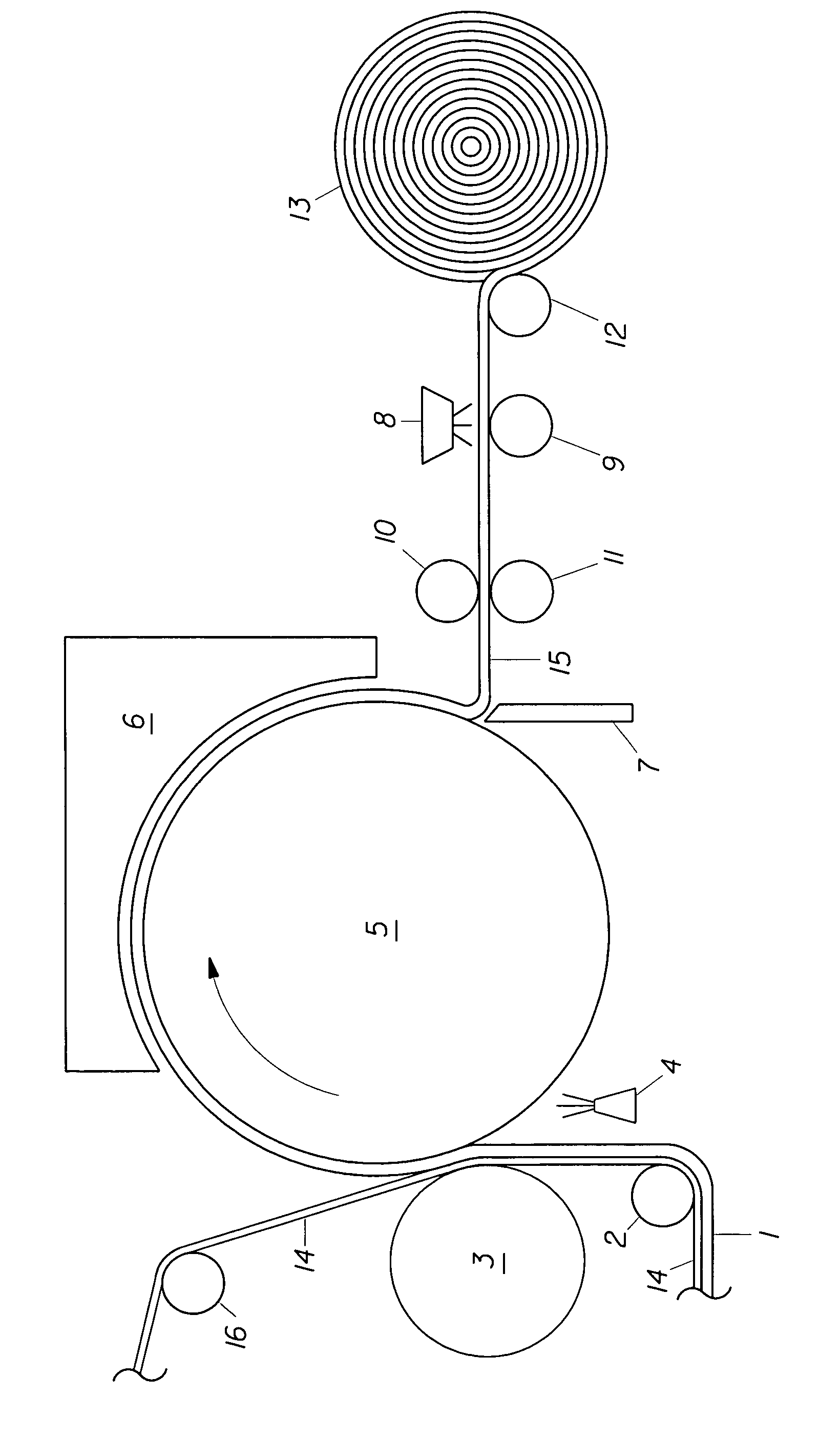

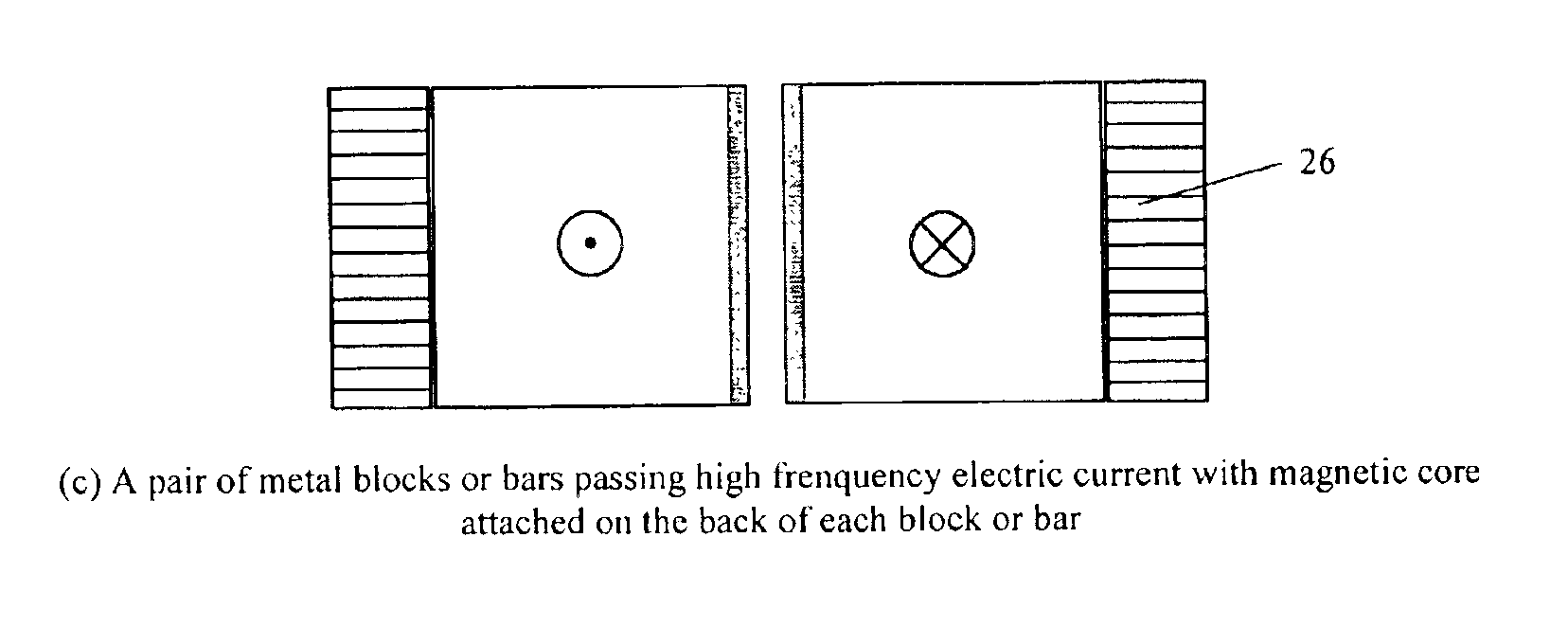

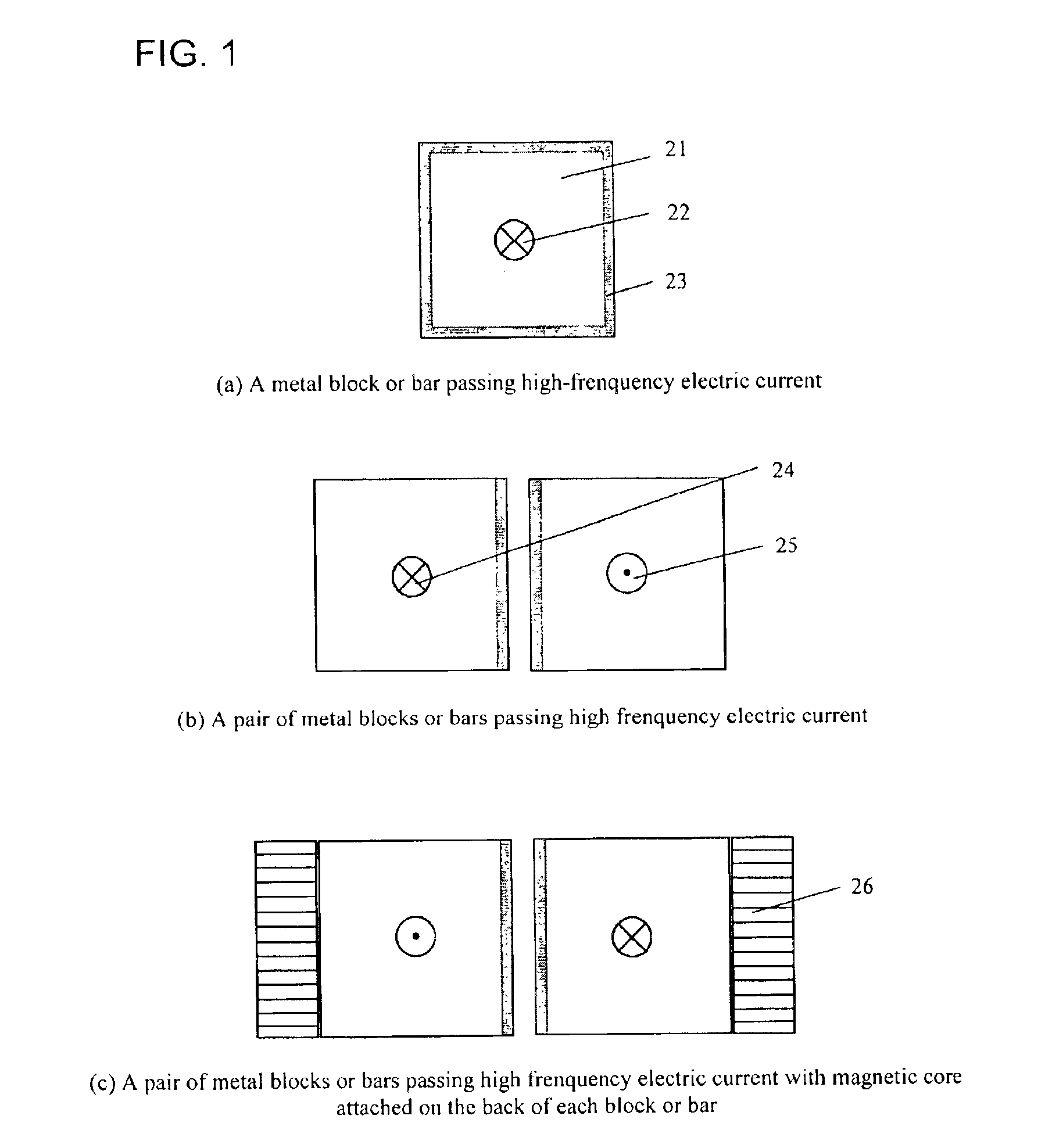

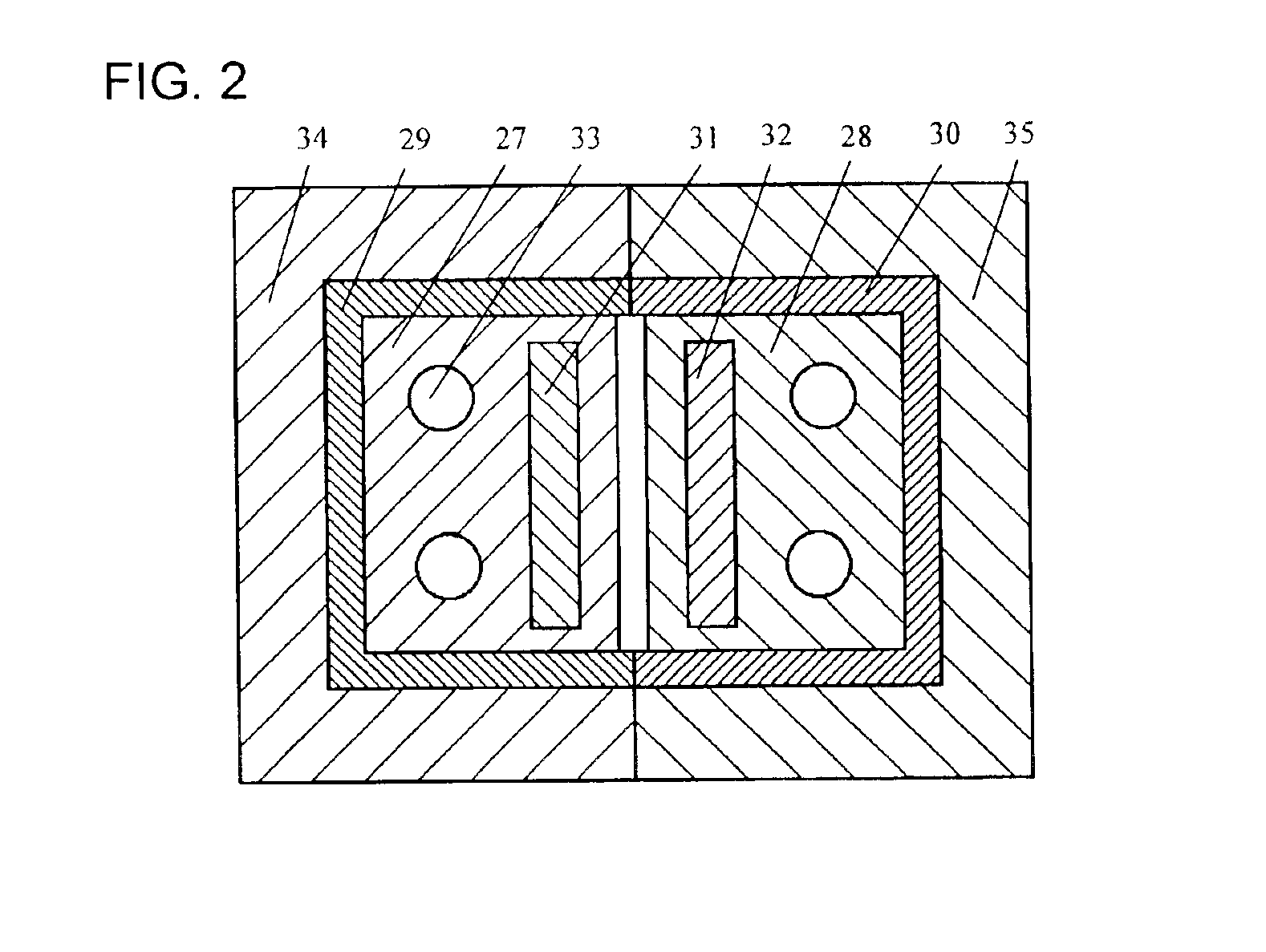

Method for rapid mold heating and cooling

InactiveUS6846445B2Fast heatingFast coolingAdditive manufacturing apparatusDischarging arrangementThermal insulationShell molding

A method for rapidly heating a mold cavity to a predetermined temperature preferably above the softening or melting temperature of the molding material prior to and during the molding stage thereby increasing moldability and improving quality of molded parts. The mold cavity is formed by two metallic halves on which high-frequency electric current is applied and an electric circuit involving the two halves is formed. Due to the proximity effect, the electrical current flows on the inner surfaces of the two cavity halves, thus rapidly heating the mold cavity. Proper use of insulation behind the cavity surface helps increase heating efficiency. Conformal on-off cooling channels provide both thermal insulation during the heating phase and rapidly cooling of the molded article during the cooling phase.

Owner:KIM BYUNG +1

Encapsulated cosmetic composition

The present invention relates to encapsulated cosmetic compositions that are topically applied. The compositions contain at least one frangible capsule that has a seamless shell of a thermo-softening material. The shell is solid at about room temperature and melts upon application to the skin. The shell holds a core cosmetic that is added to a clear gel base. Thus, the color of the capsule is visible and multiple colored capsules can be added to the base for a custom colored composition.

Owner:ELC MANAGEMENT LLC

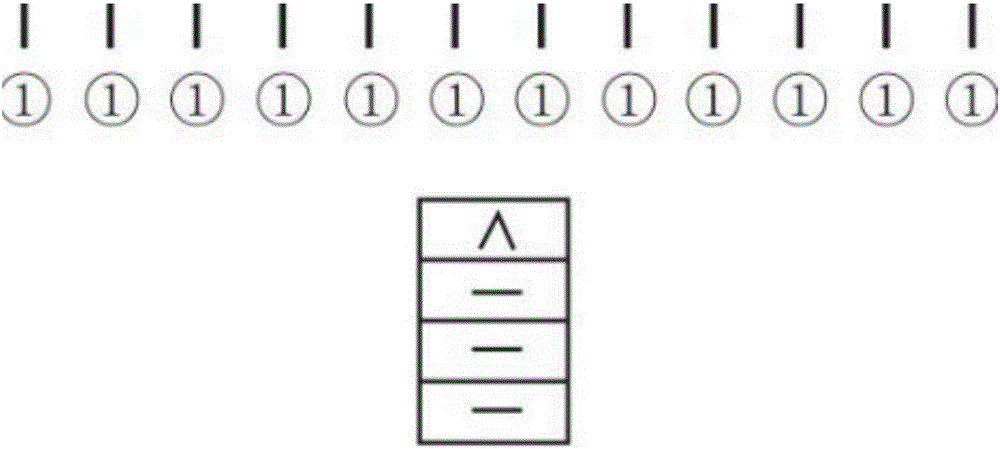

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

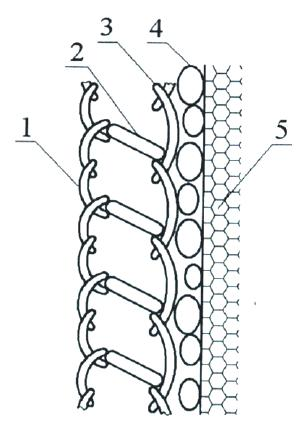

Water-repellent anti-contamination hygroscopic perspiratory composite tissue knitted fabric and production method thereof

ActiveCN102031622AGood water repellency and antifouling functionGood moisture wicking functionWeft knittingBleaching apparatusYarnNatural fiber

The invention relates to a water-repellent anti-contamination hygroscopic perspiratory composite tissue knitted fabric produced in knitting industry and a production method thereof. An outer coil of the knitted fabric is made of yarn treated by water-repellent anti-contamination technology; a coil at a middle connection layer is made of natural fiber yarn with good hygroscopic and water absorbent performance; an inner coil is made of hygroscopic fiber yarn, and the hygroscopic fiber yarn is treated by hydrophilicity, has a microcellular structure and is in a deformed cross section; the fabric tissue is double-rib double-layer composite tissue, and is knitted on a 2+2 needle track double-surface circular knitting machine; and the knitted fabric is subjected to preforming, degreasing and cleaning, softening, dewatering, expanding, drying, forming and the like. The outer layer of the provided knitted fabric has excellent water-repellent anti-contamination function, and the inner layer has excellent hygroscopic perspiratory function; the knitted fabric has soft hand feel, good permeability and elasticity and antistatic performance, and is widely applied to sportswear, summer clothing, work clothes of hotels and oil field, regimentals and the like; three-tissue structure of the knitted fabric is formed by one-step knitting so that the production technology has easiness in control and the product quality is reliable.

Owner:ANHUI HAOBO INT UNDERWEAR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com