Water-repellent anti-contamination hygroscopic perspiratory composite tissue knitted fabric and production method thereof

A moisture-absorbing and sweat-wicking technology for knitted fabrics, applied in knitting, weft knitting, dyeing, etc., can solve the problems of easy mutual interference between waterproof and moisture absorption, high cost, and difficult control of covering thickness and uniformity. Good moisture absorption and perspiration function, reliable product quality, and the effect of production technology control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Dyeing and finishing process of different yarns used:

[0059] (1) In the dyeing and finishing process of 14.5tex cotton yarn for the outer coil, the water and oil repellent finishing is impregnated with 50 g / L of Jieershuang FG910 perfluorinated finishing agent and 30 g / L of FBA crosslinking agent. The value is 6. Dry at 110°C after dehydration, bake at 170°C for 1min, and other processes are conventional processes.

[0060] (2) In the dyeing and finishing process of the 18.0tex cotton yarn used for the intermediate connecting layer coils, the hydrophilic finishing agent is impregnated with 40g / L of Jieershuang SW moisture-absorbing and sweat-wicking finishing agent, dried at 110°C after dehydration, and other processes are conventional processes.

[0061] (3) In the dyeing and finishing process of 8.3tex polyester filament used for the inner layer coil, the hydrophilic finishing is impregnated with 50g / L of Jieershuang SW moisture-absorbing and sweat-wicking finishing...

Embodiment 2

[0063] Weaving process:

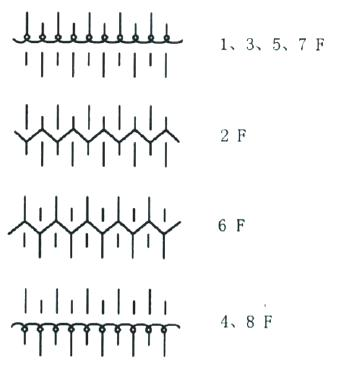

[0064] 2+2 needle track double-sided circular weft machine is used for weaving, the cylinder diameter is 863.6mm, the gauge is 28 needles / 25.4mm, and the number of incoming lines is 72F;

[0065] knitting figure such as figure 2 shown.

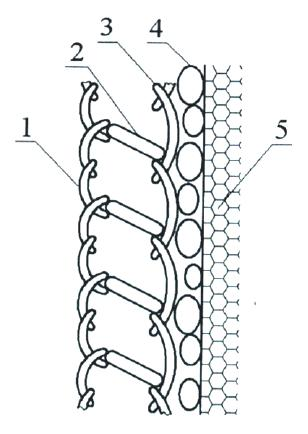

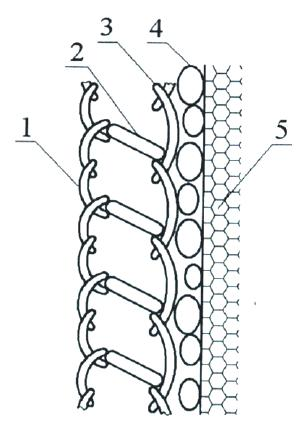

[0066] another example figure 1 As shown, when the human body 5 sweats, the sweat droplets 4 rely on the capillary wicking effect of the moisture-conducting fiber groove of the inner layer coil 3, and are instantly transferred from the skin to the fibers of the inner layer coil 3, because the middle connecting layer coil 2 It is a natural fiber, and its binding force with water molecules is stronger than that of the inner coil 3. The sweat drop 4 is quickly transferred from the inner coil 3 to the fibers of the middle connecting layer coil 2. Although the outer coil 1 is water-repellent, it is breathable. With a good coil structure, the sweat on the fibers of the coil 2 in the middle connection layer passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com