Moisture absorbing and sweat releasing fiber and preparation method thereof

A moisture-absorbing and sweat-wicking fiber and fiber technology, which is applied in fiber processing, melt spinning, stretch spinning, etc., can solve the problem that the moisture-absorbing and sweat-wicking function of the fiber cannot achieve the desired effect, the longitudinal surface wicking ability of the fiber is not ideal, and the fiber The problem of hand feel and softness discount, etc., can achieve the effect of smooth and stable production process, improved hand feel and softness, and good moisture absorption and sweat wicking function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

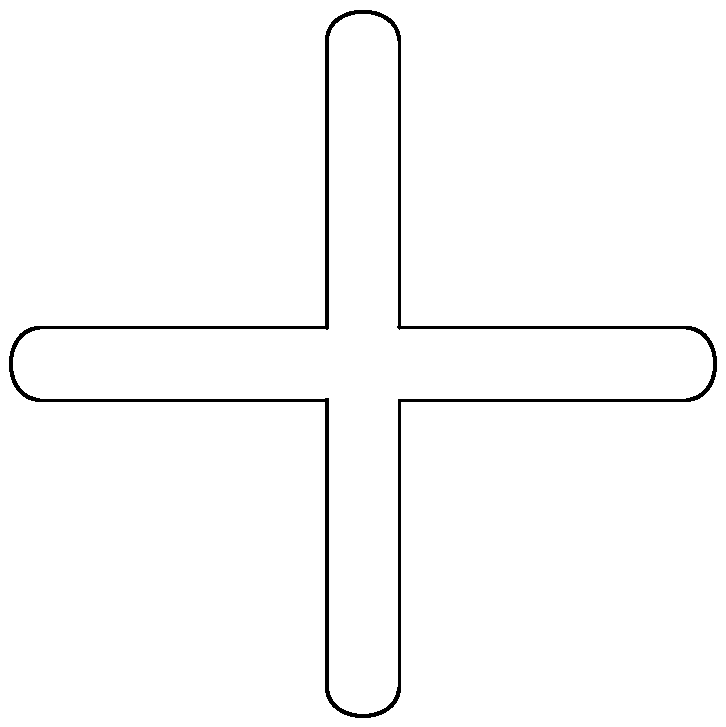

[0030] A moisture-absorbing and perspiration-wicking fiber, the fiber having a triangular cross-section, each corner of the triangle has a strip-shaped body and an enlarged top end, and the adjacent two angles of the triangle are in the longitudinal direction of the fiber Form a tubular cavity.

Embodiment 2

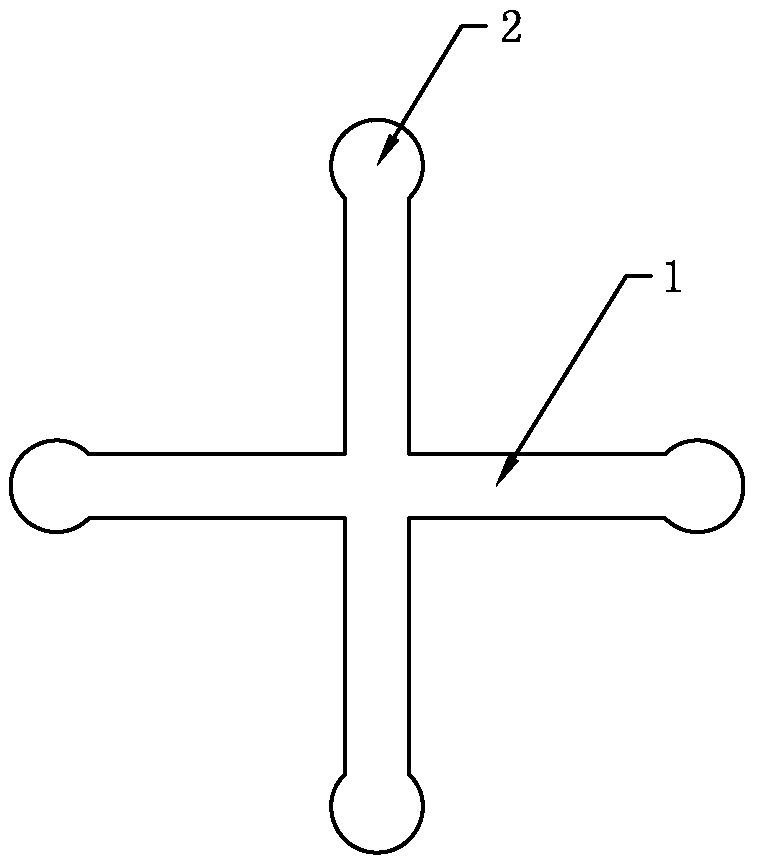

[0032] A moisture-absorbing and perspiration-wicking fiber, the fiber having a cross-shaped quadrangular shape, each corner of the quadrangular shape has a bar-shaped body and a hemispherical top end, and the diameter of the hemispherical shape is the width of the bar-shaped body 1.5 times. A tubular cavity is formed between two adjacent angles of the quadrangle in the longitudinal direction of the fiber.

Embodiment 3

[0034] A moisture wicking fiber, the fiber having a pentagonal cross section, each corner of the pentagon has a bar-shaped body and a hemispherical tip, the diameter of the hemispherical is the width of the bar-shaped body 1.8 times. The two adjacent angles of the pentagon form a tubular cavity in the longitudinal direction of the fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com