Patents

Literature

15843results about "Fibre treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

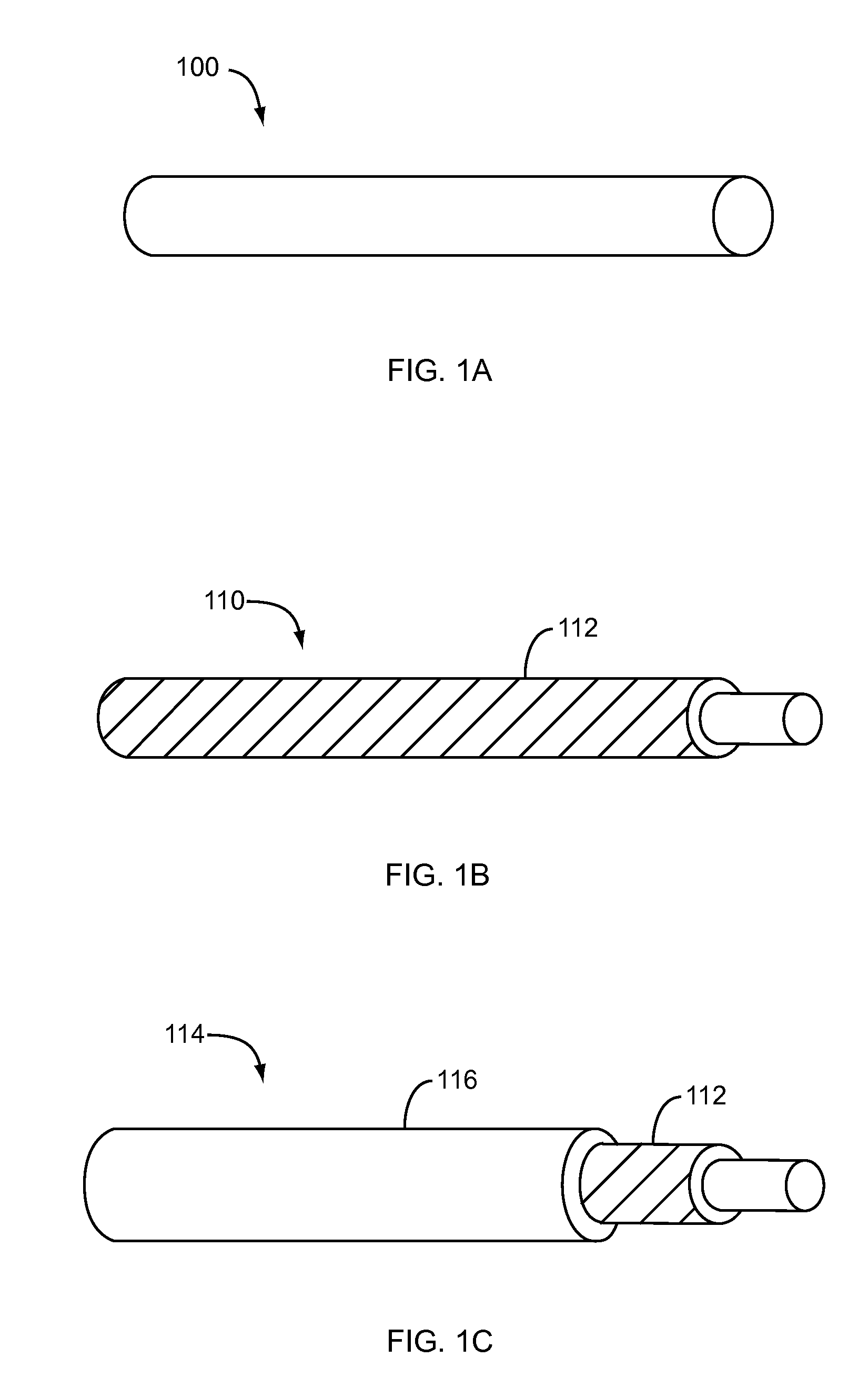

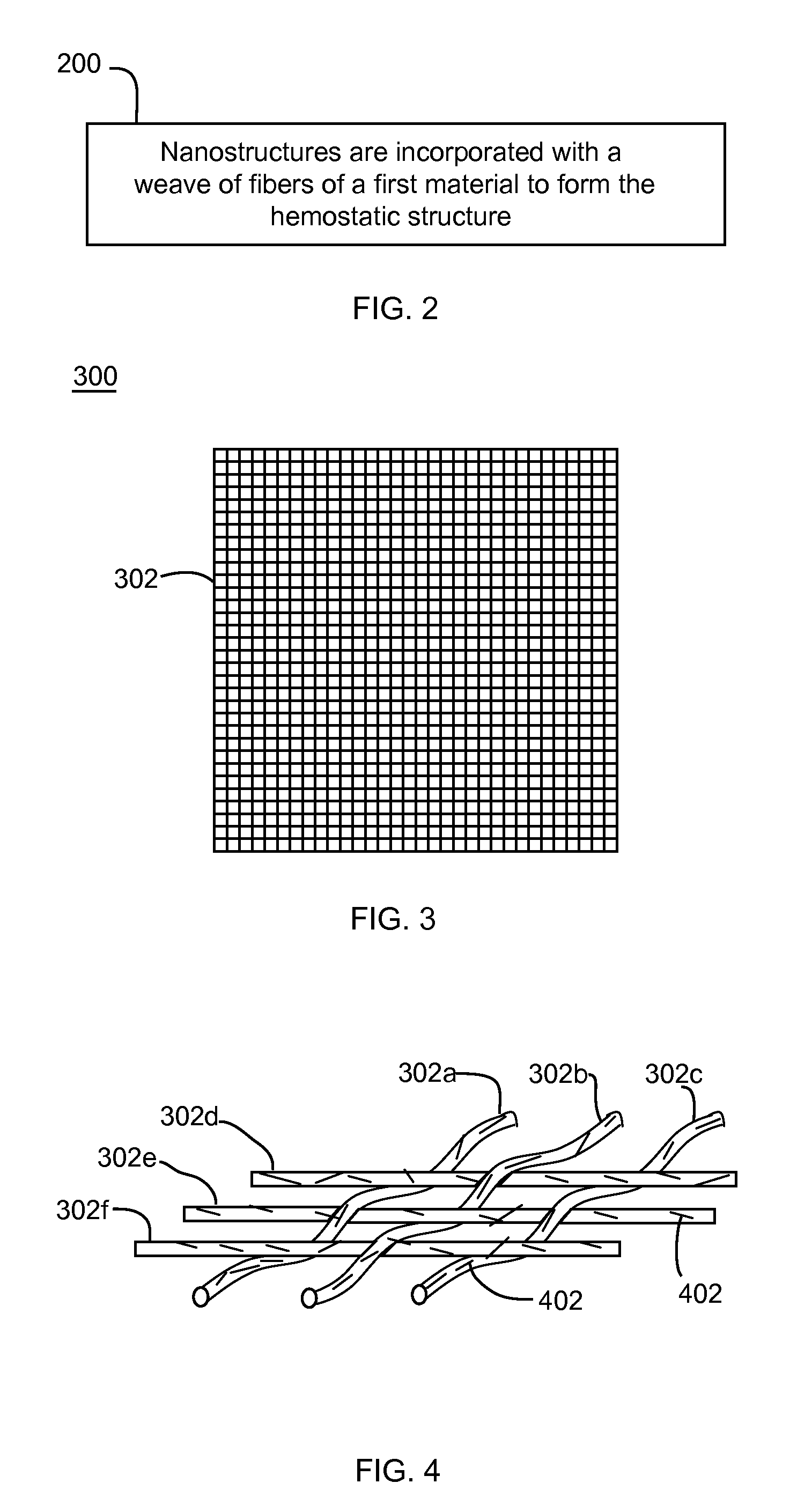

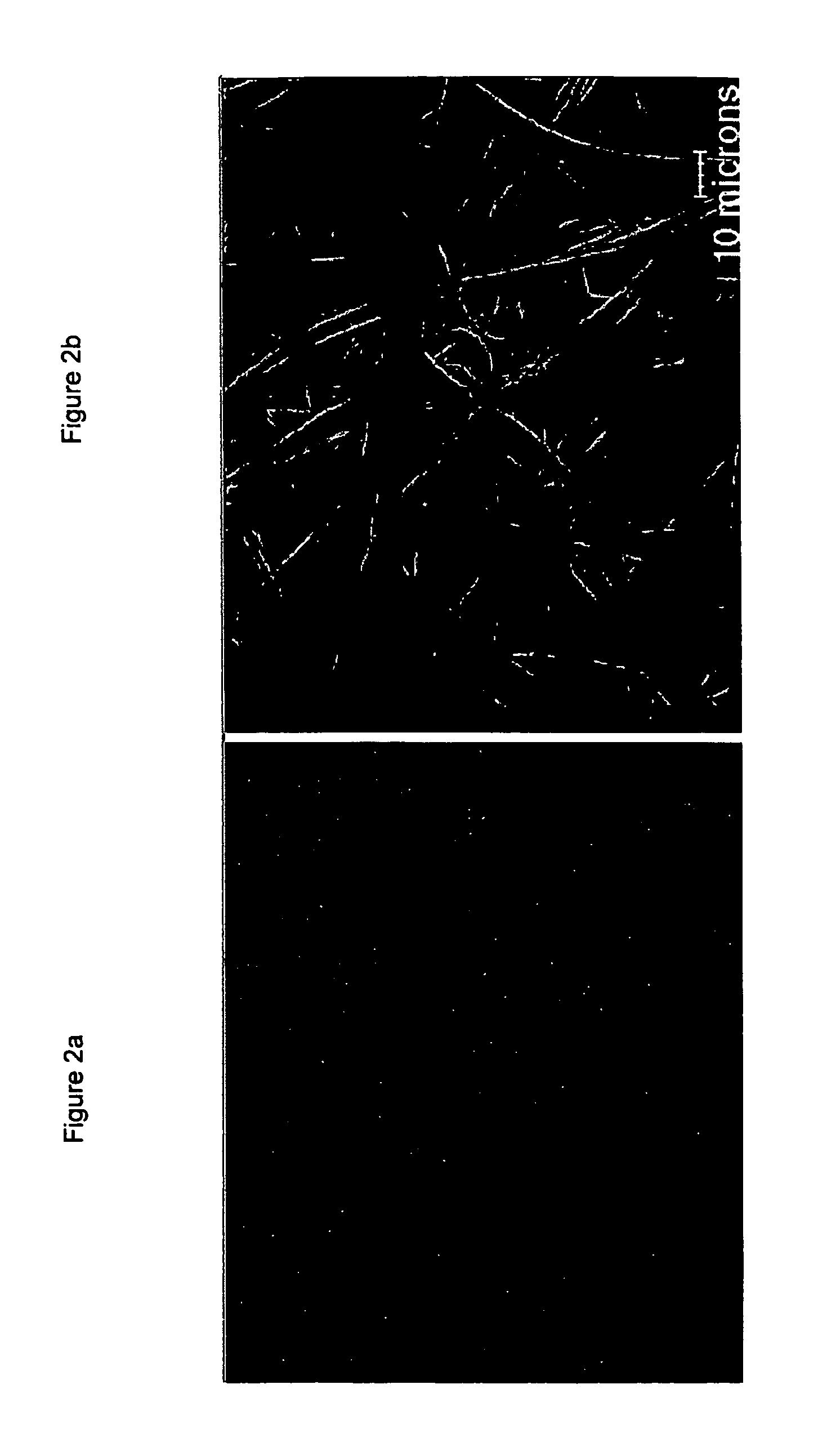

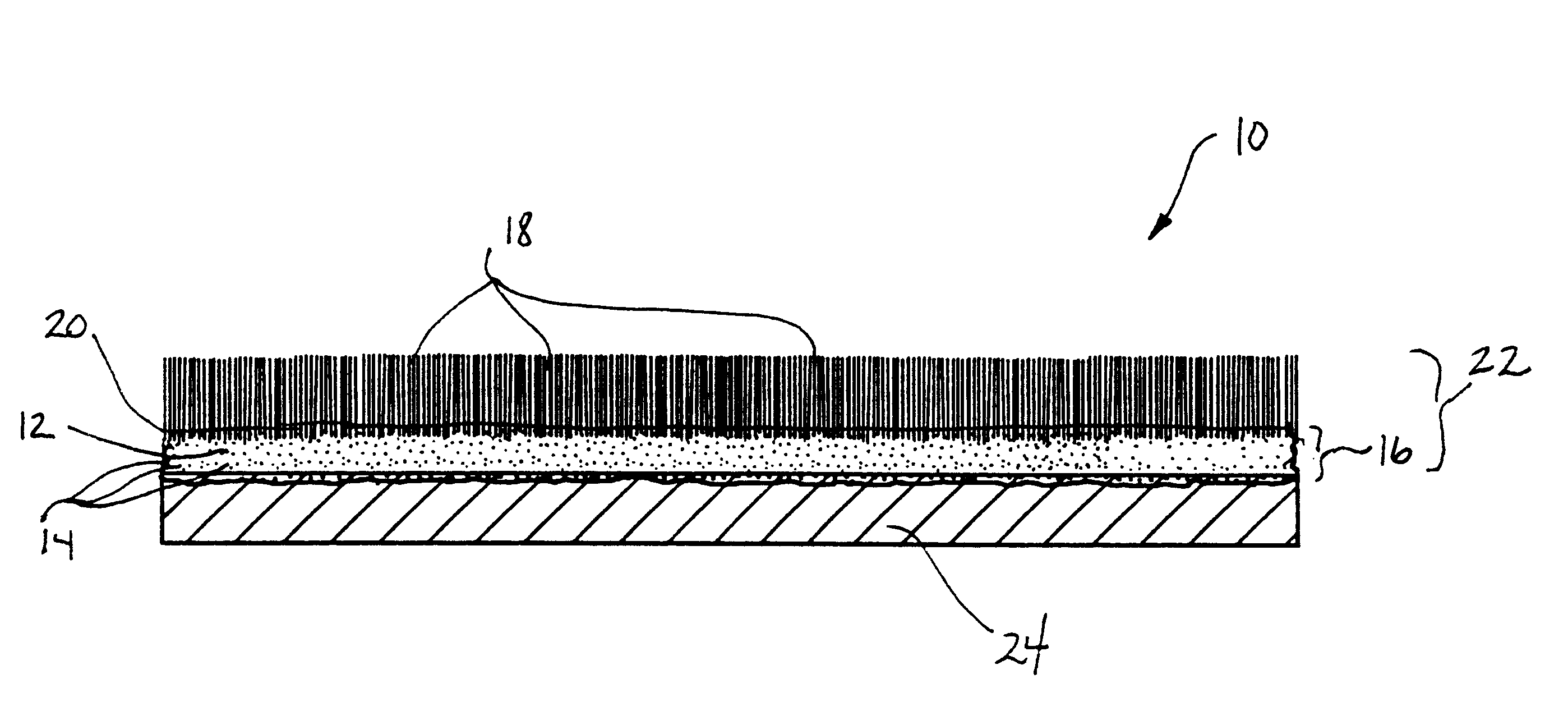

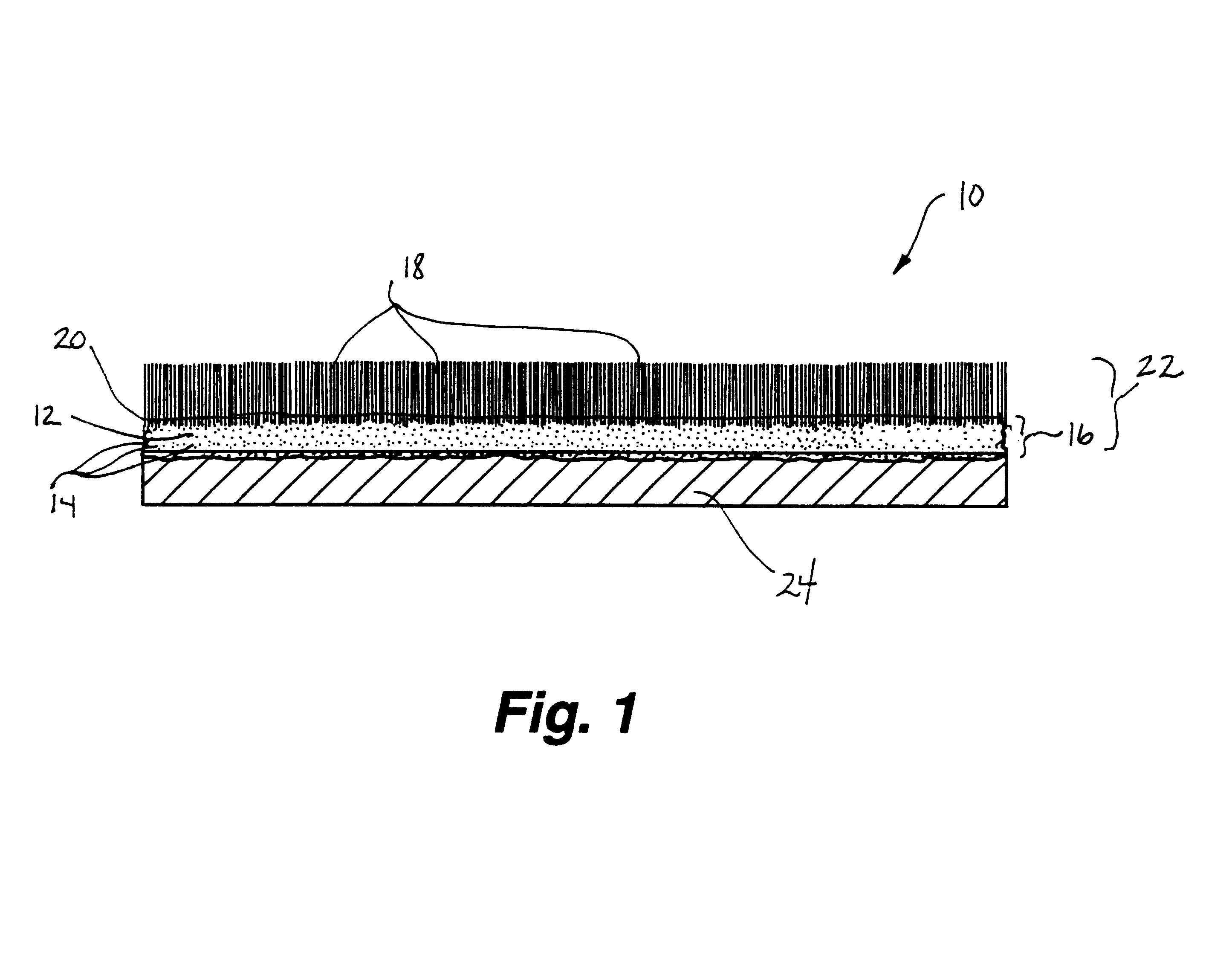

Nanostructure-enhanced platelet binding and hemostatic structures

InactiveUS8319002B2Enhancing overall rate and strengthInduce platelet binding and efficient hemostasisBiocideSurgical adhesivesPlateletNanofiber

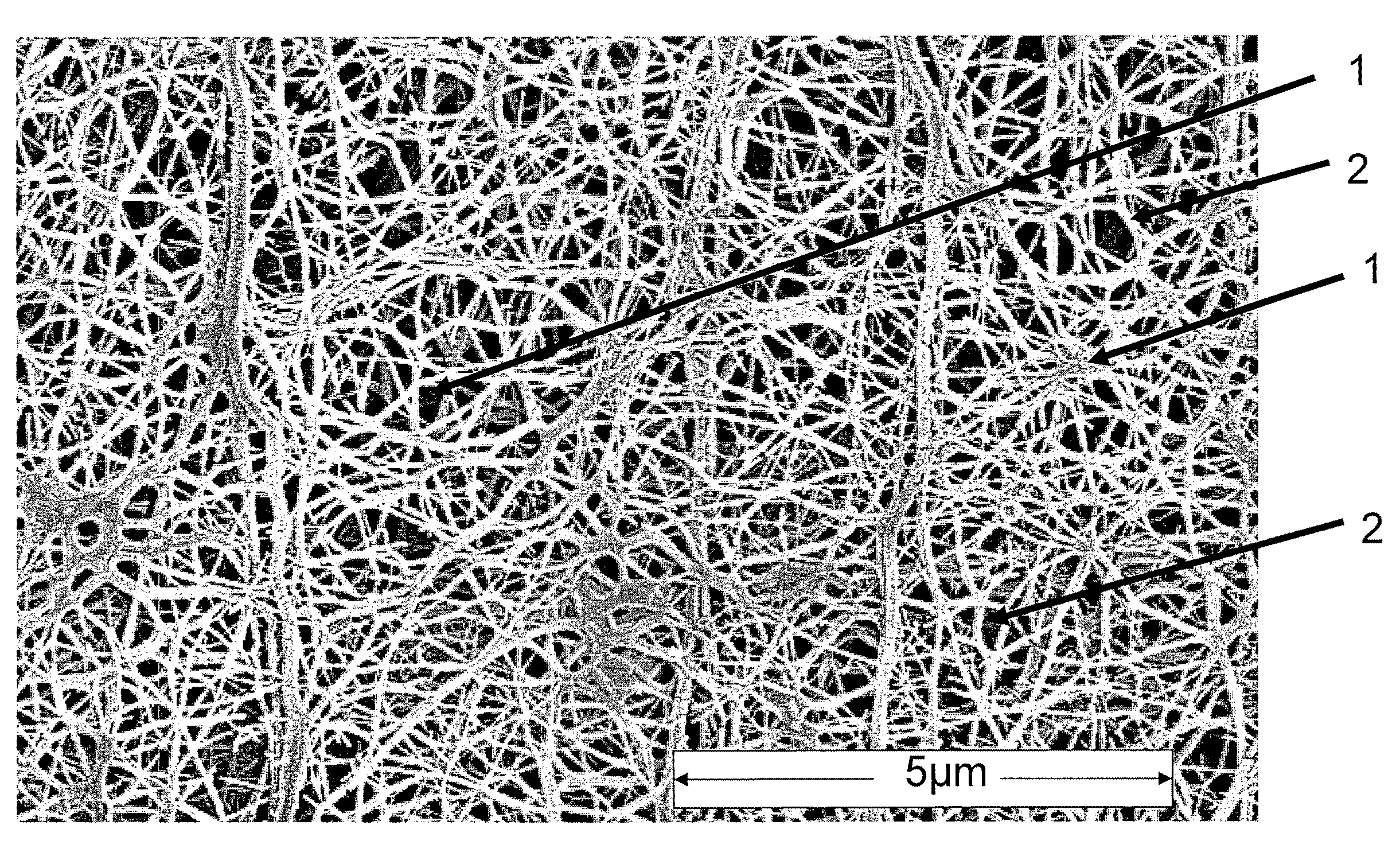

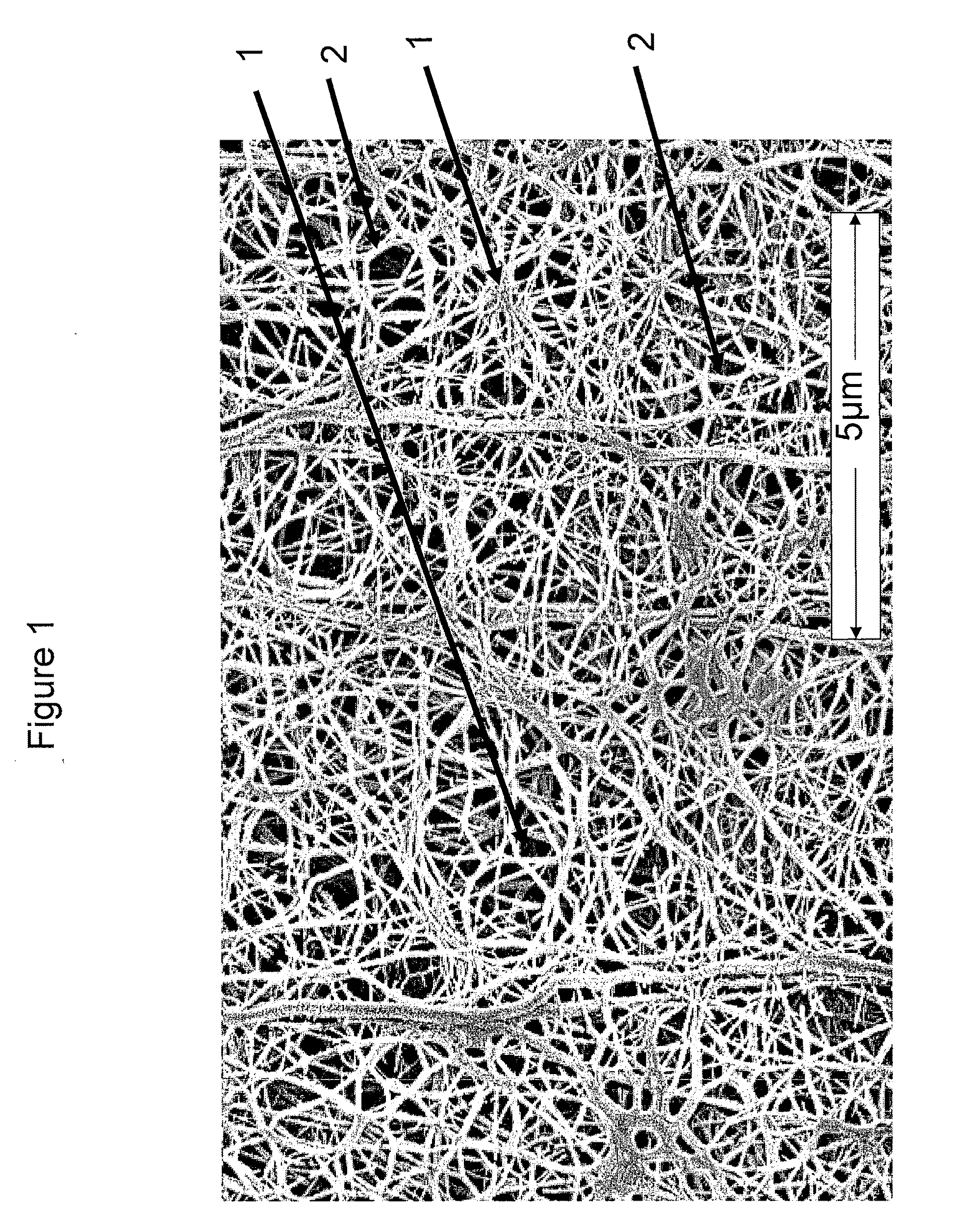

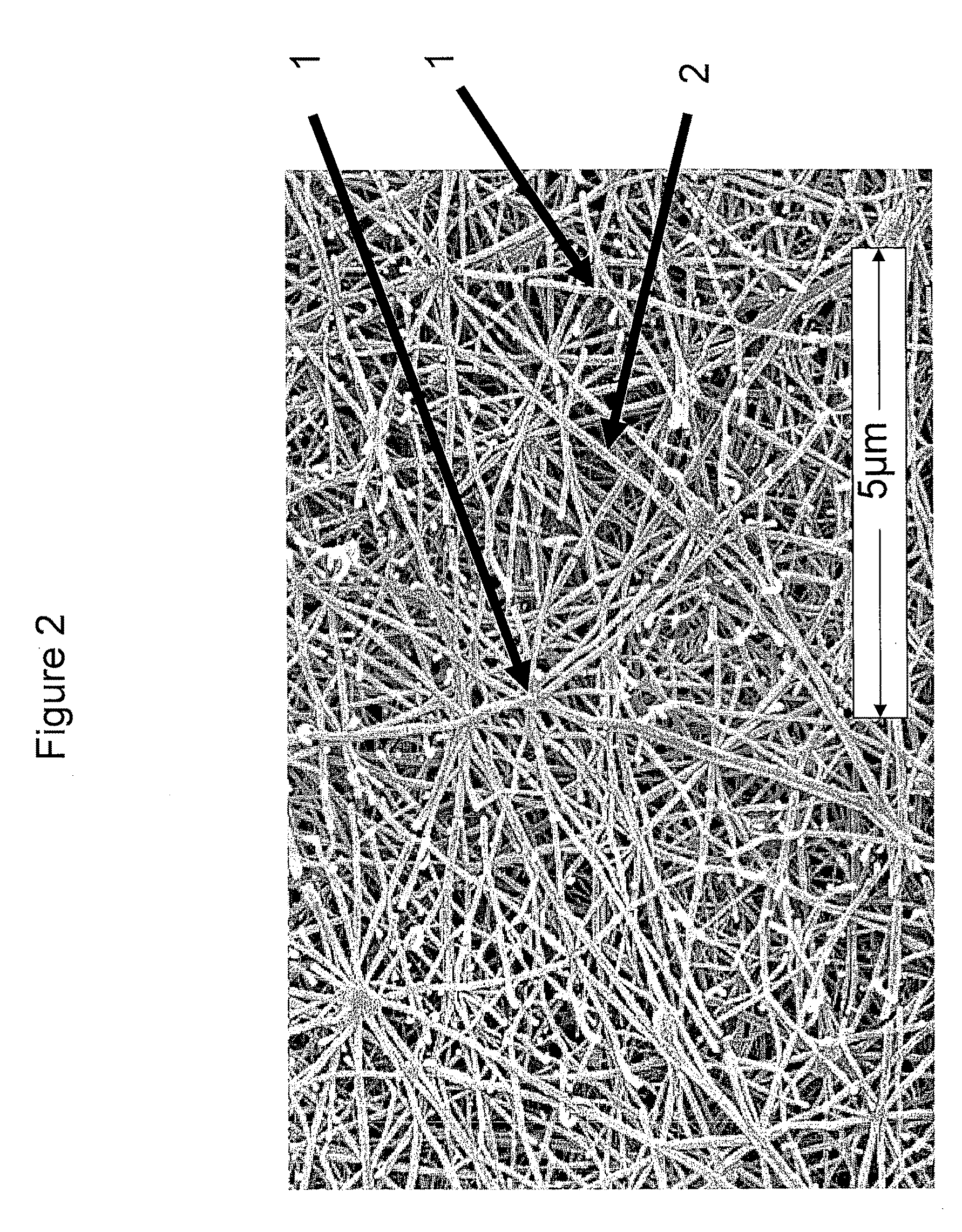

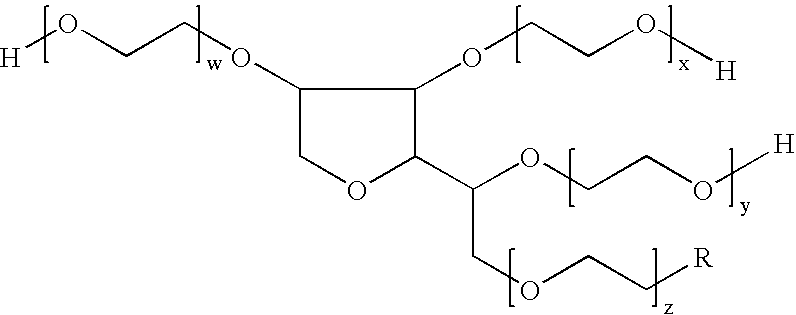

Methods, systems, and apparatuses for nanomaterial-enhanced platelet binding and hemostatic medical devices are provided. Hemostatic materials and structures are provided that induce platelet binding, including platelet binding and the coagulation of blood at a wound / opening caused by trauma, a surgical procedure, ulceration, or other cause. Example embodiments include platelet binding devices, hemostatic bandages, hemostatic plugs, and hemostatic formulations. The hemostatic materials and structures may incorporate nanostructures and / or further hemostatic elements such as polymers, silicon nanofibers, silicon dioxide nanofibers, and / or glass beads into a highly absorbent, gelling scaffold. The hemostatic materials and structures may be resorbable.

Owner:NANOSYS INC

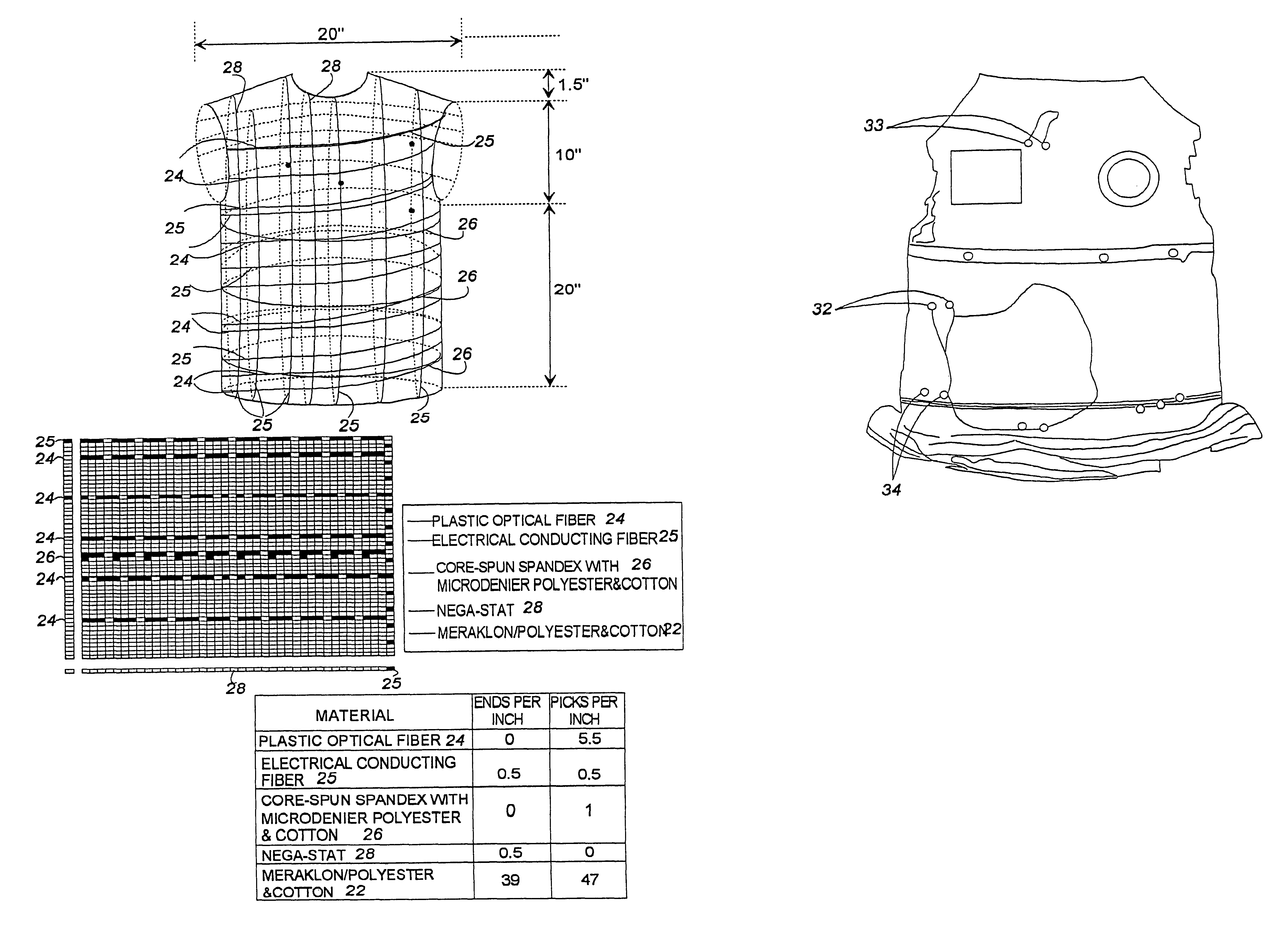

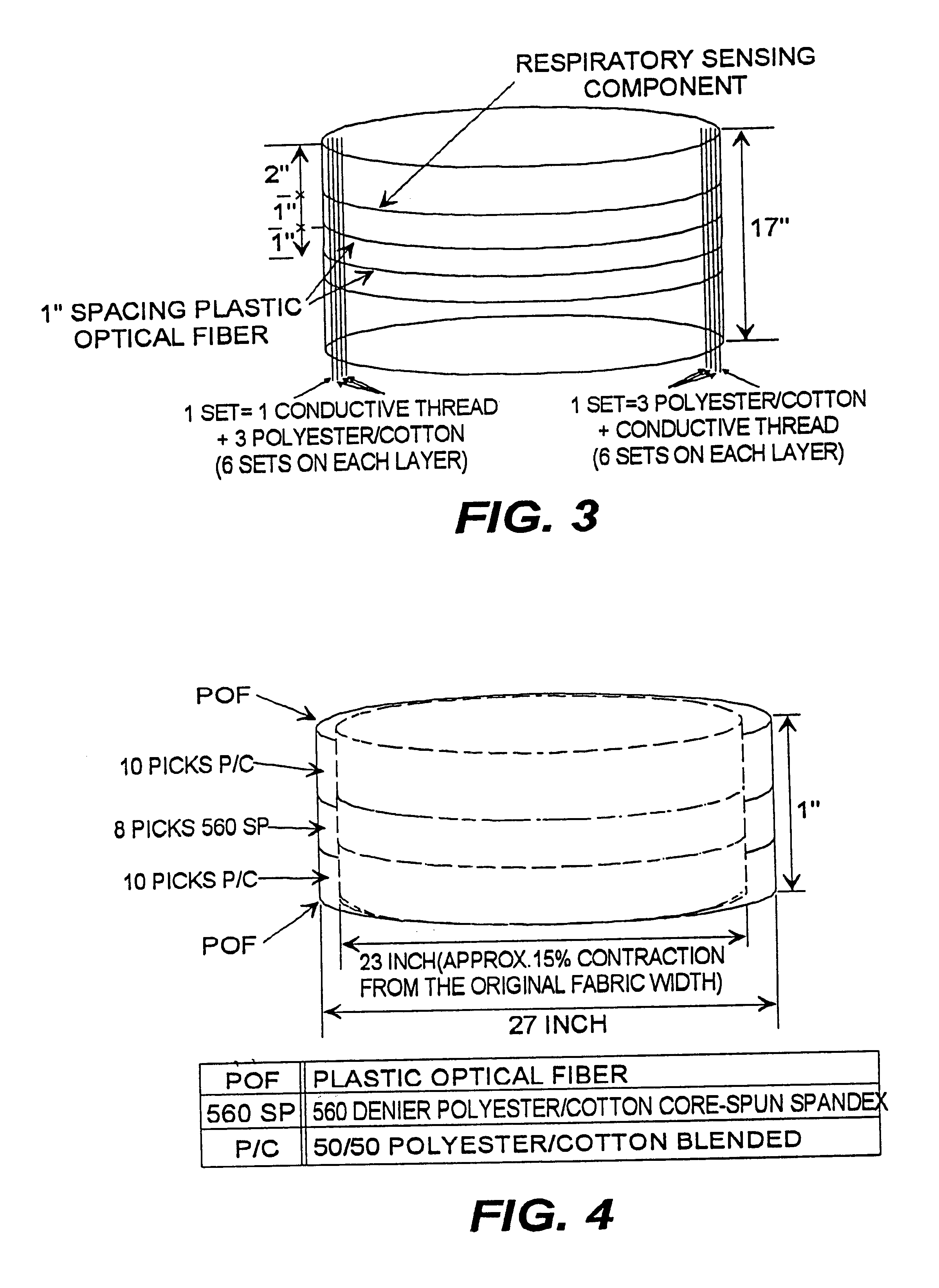

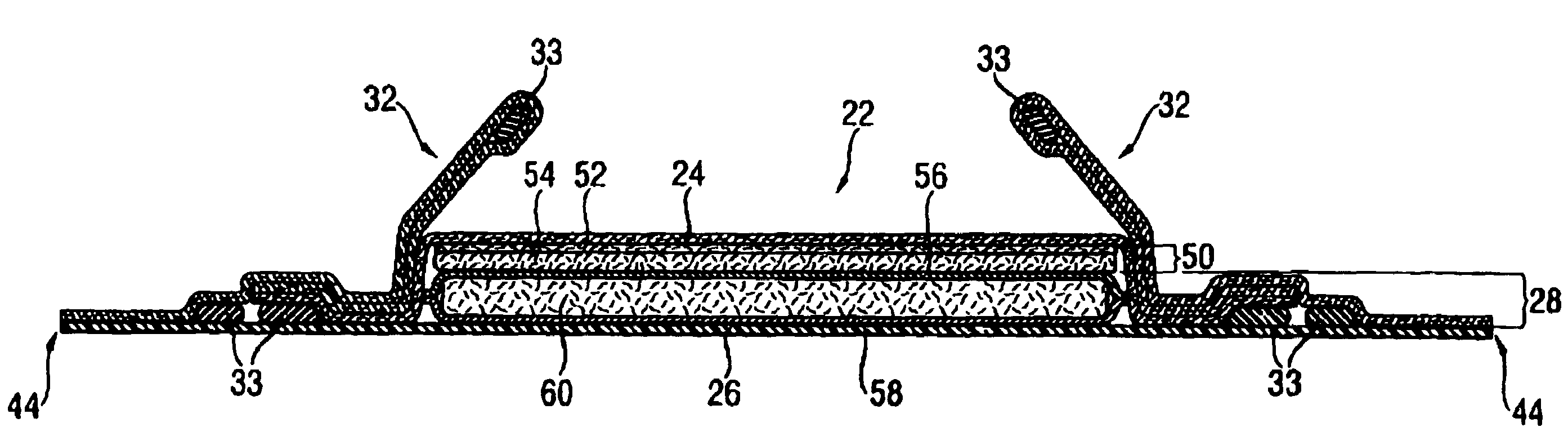

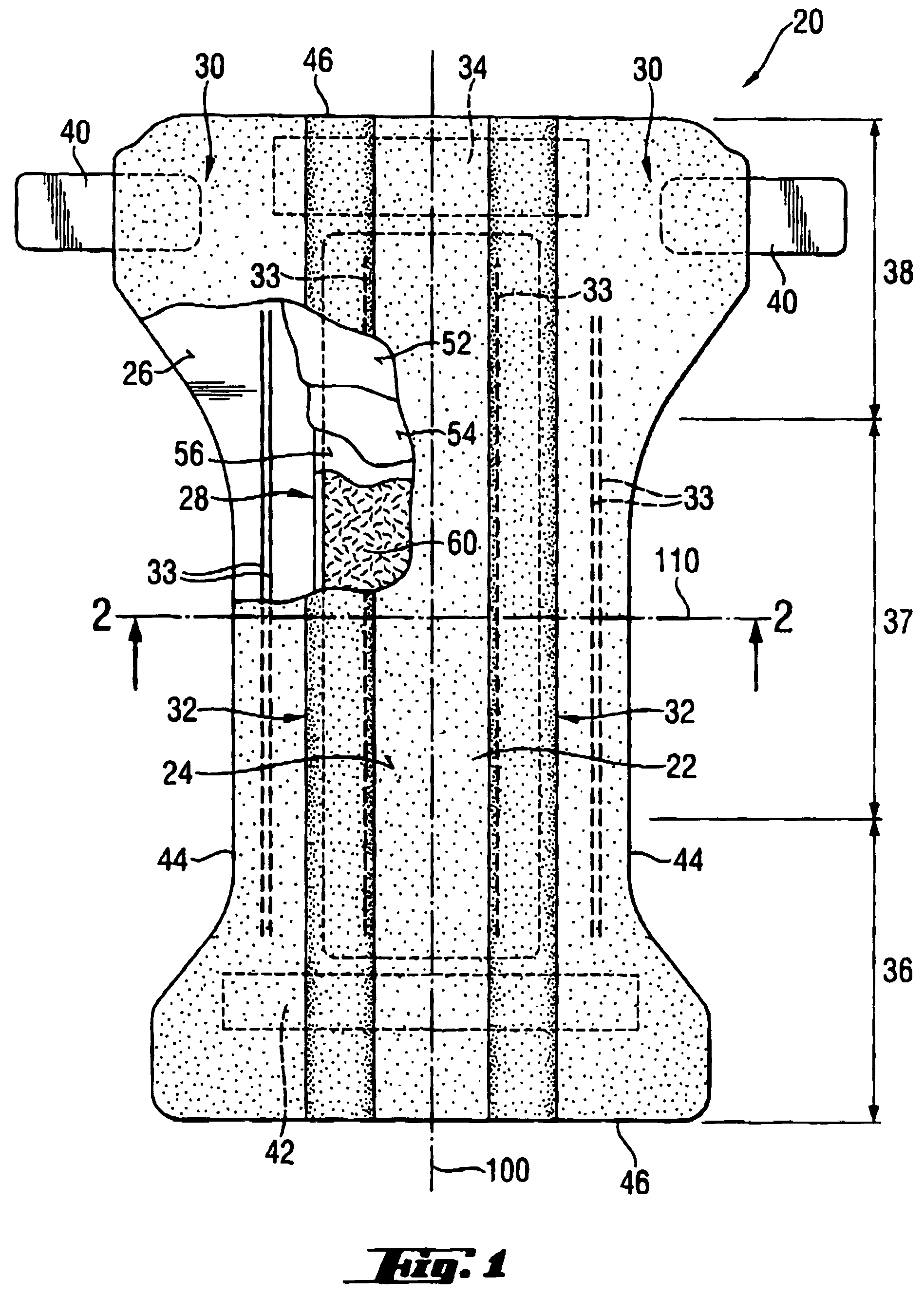

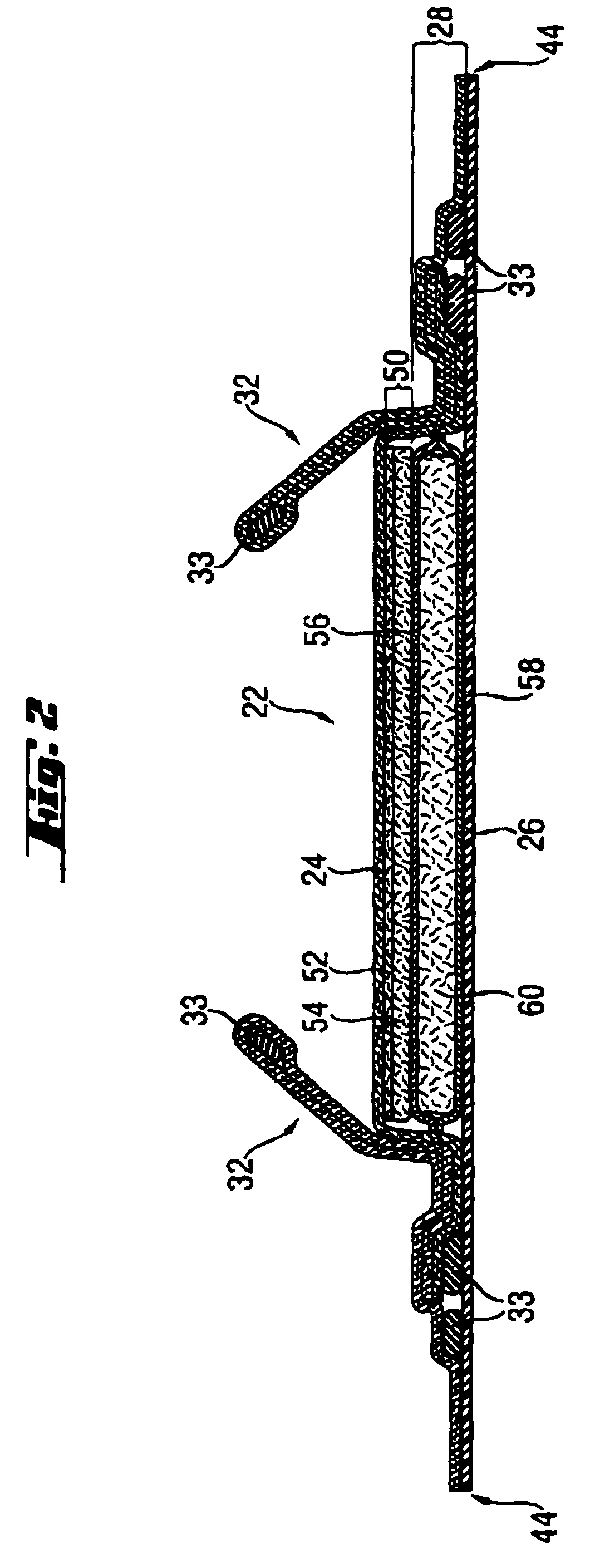

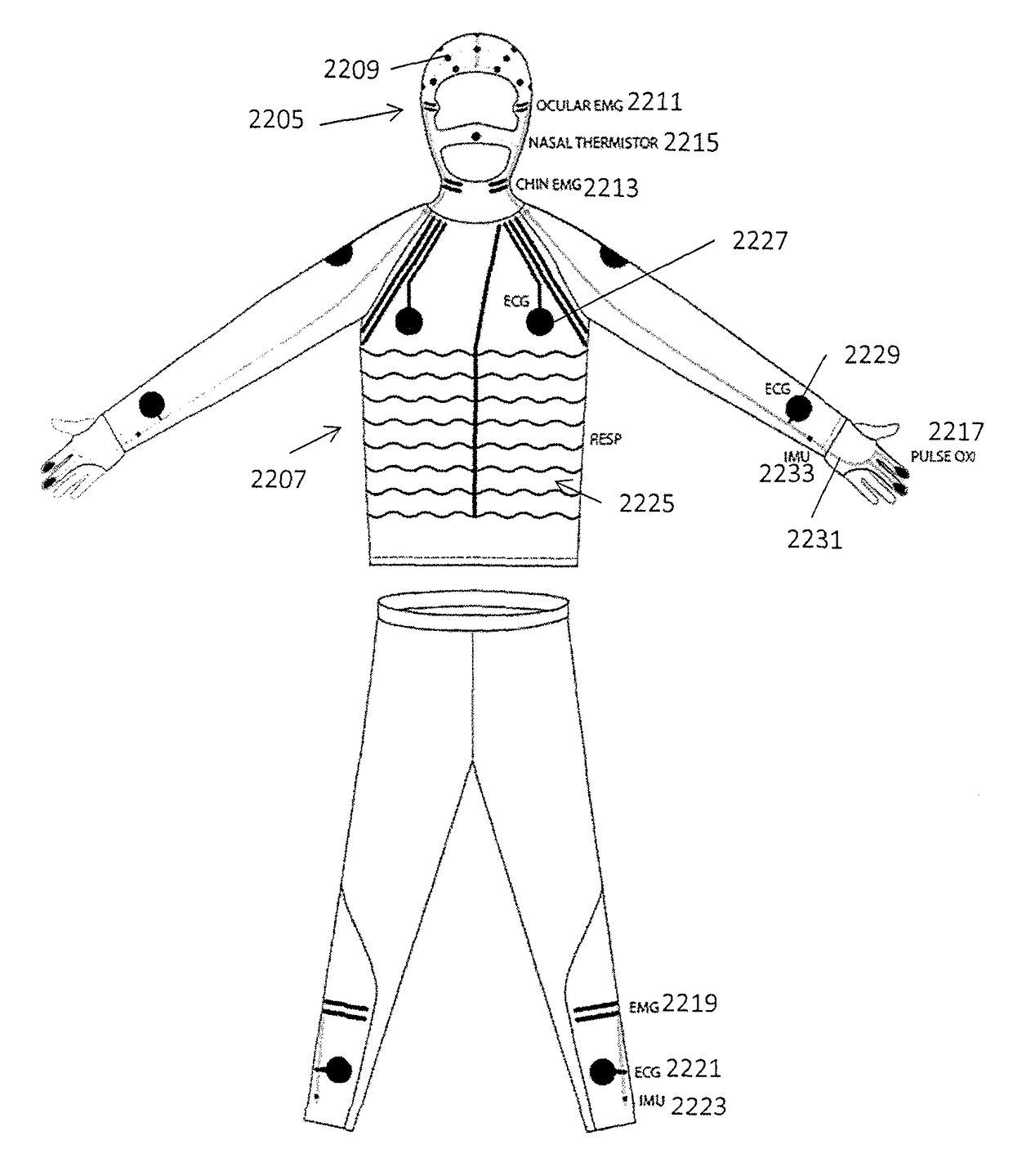

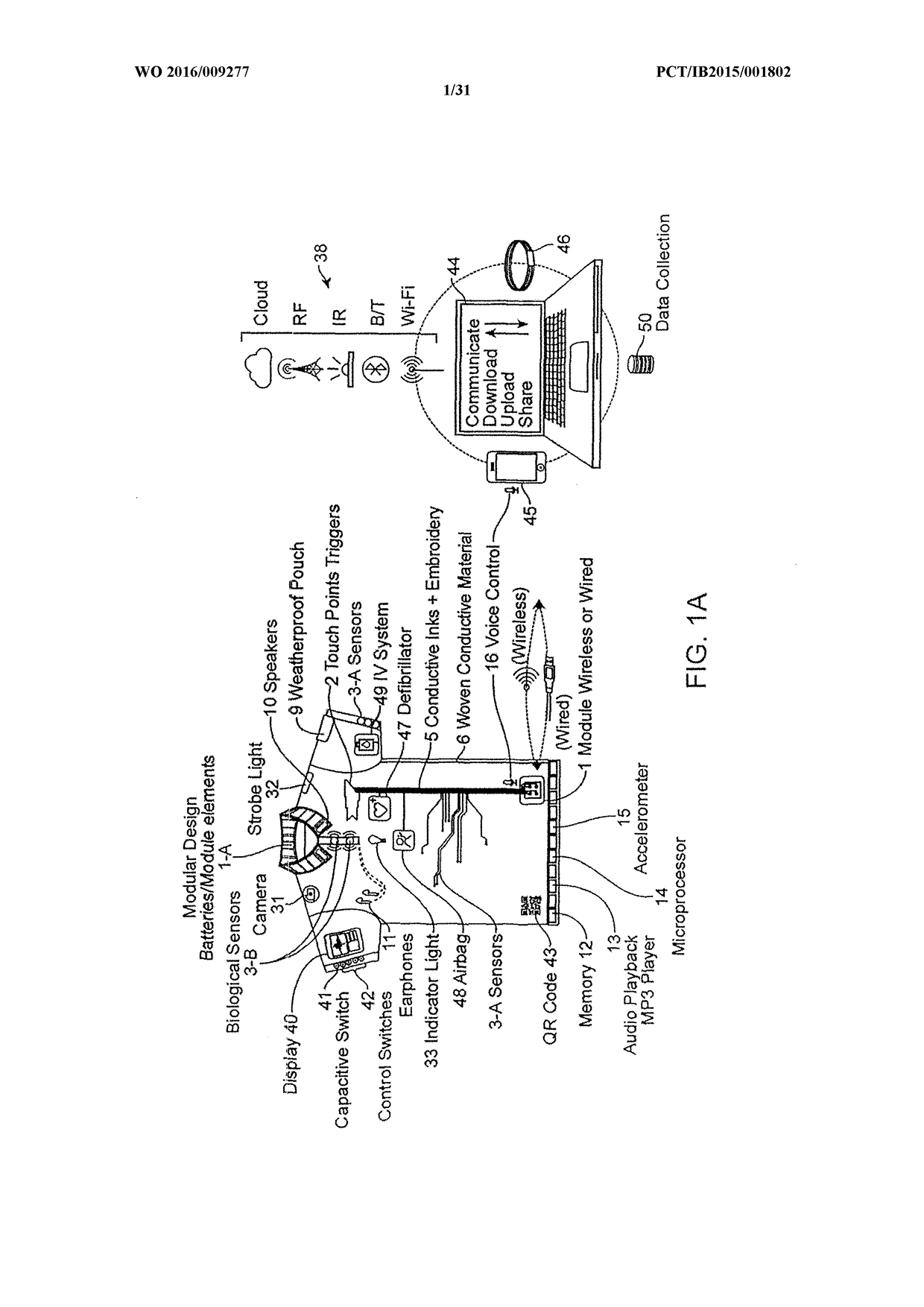

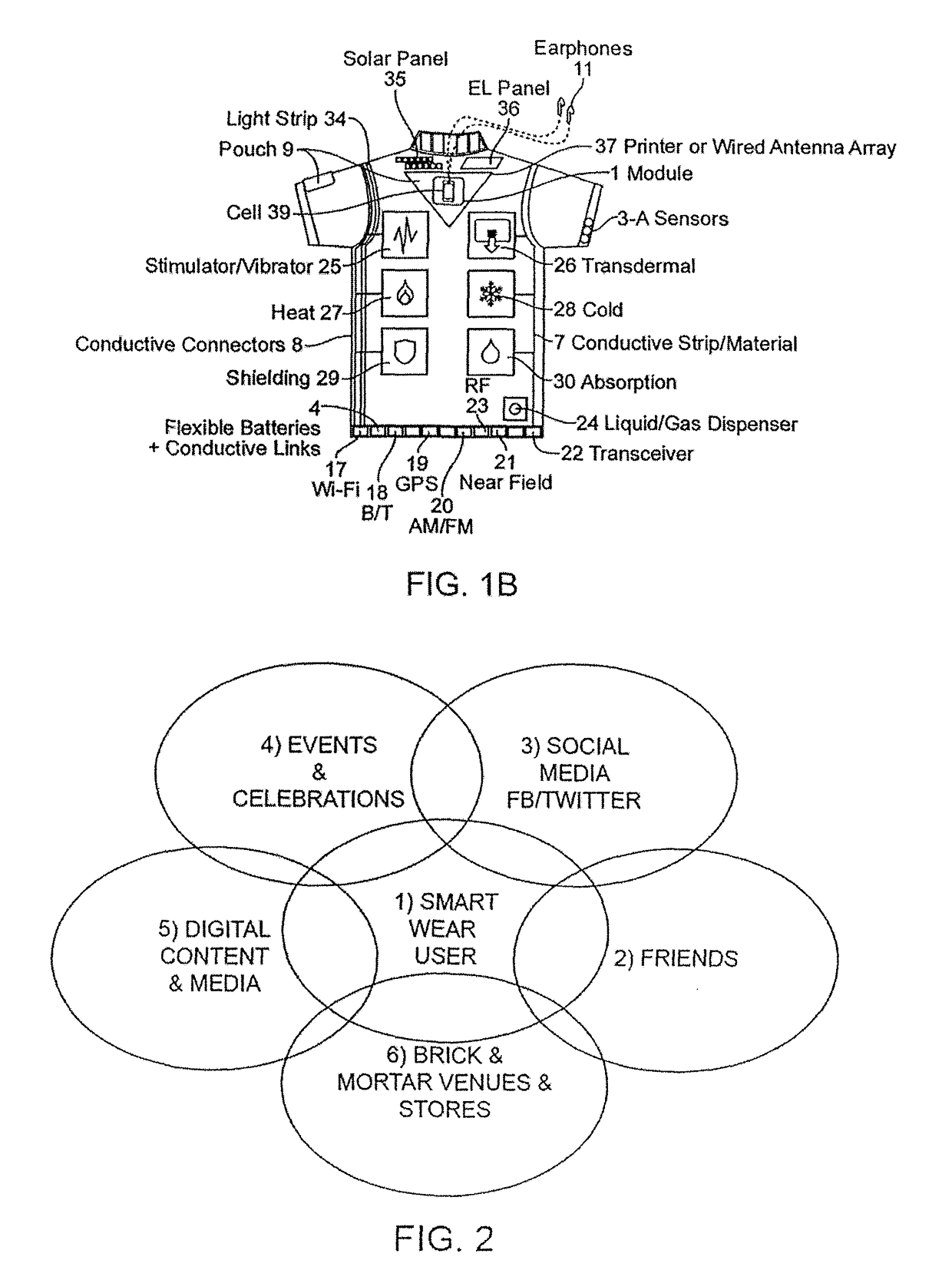

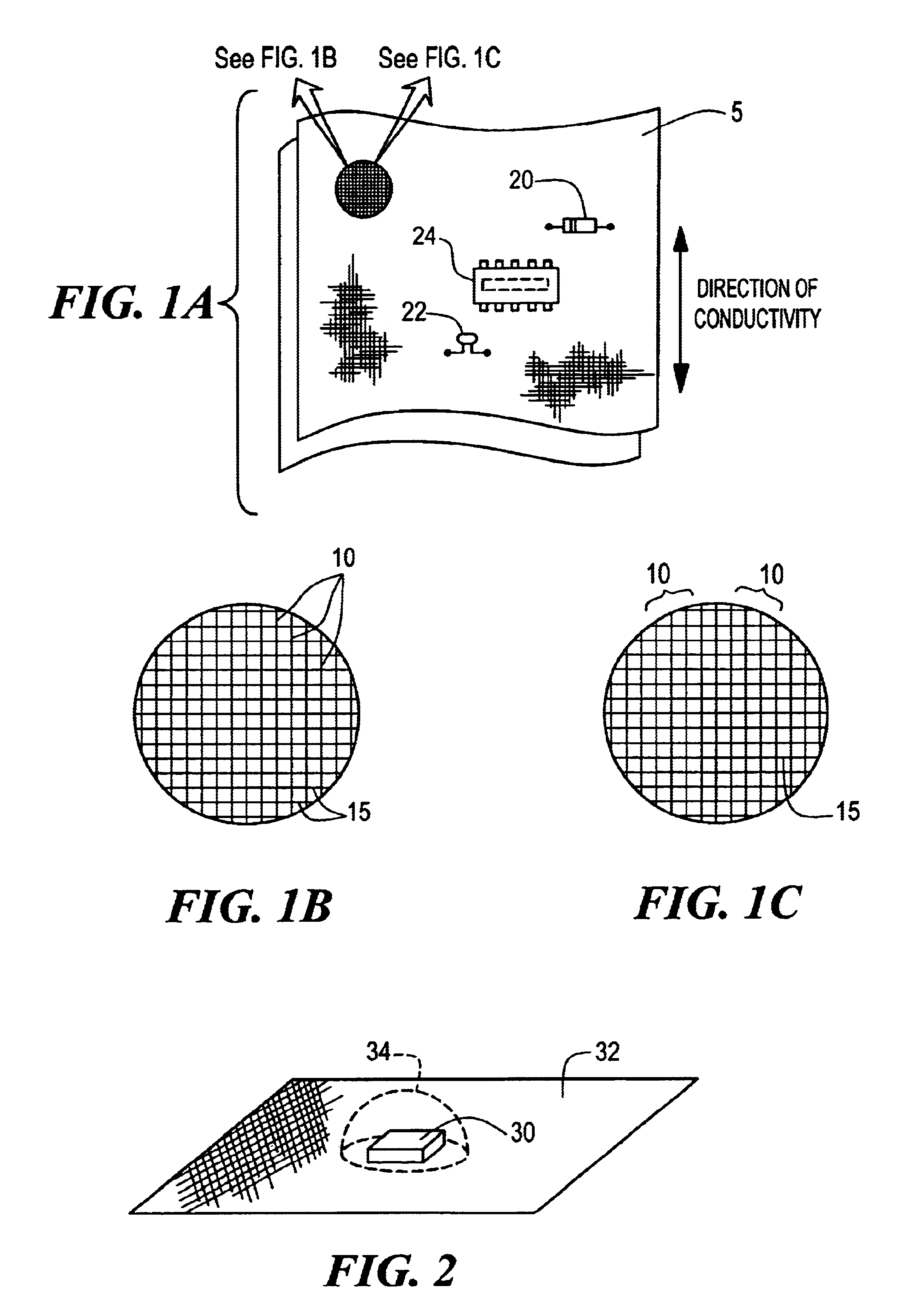

Fabric or garment with integrated flexible information infrastructure

InactiveUS6381482B1Raise the ratioImprove high temperature stabilityWeft knittingOrnamental textile articlesInformation processingEngineering

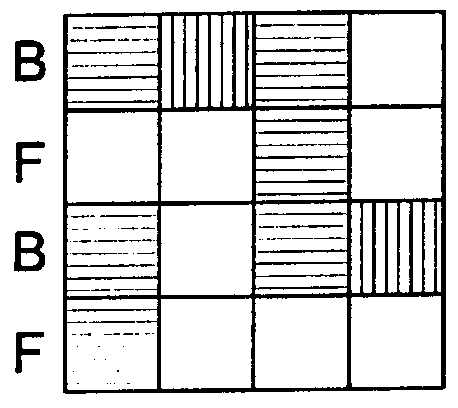

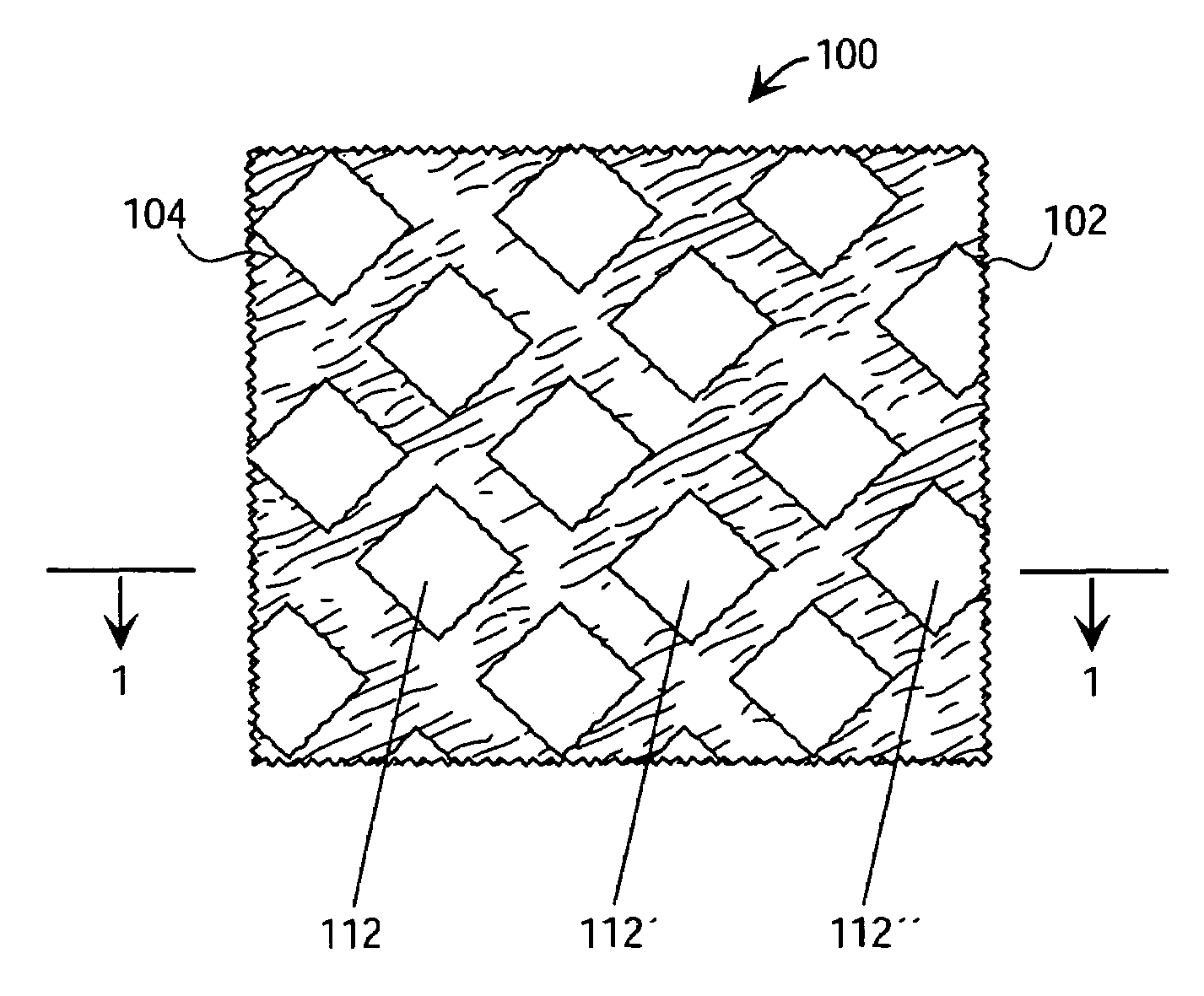

A fabric, in the form of a woven or knitted fabric or garment, including a flexible information infrastructure integrated within the fabric for collecting, processing, transmitting and receiving information concerning-but not limited to-a wearer of the fabric. The fabric allows a new way to customize information processing devices to "fit" the wearer by selecting and plugging in (or removing) chips / sensors from the fabric thus creating a wearable, mobile information infrastructure that can operate in a stand-alone or networked mode. The fabric can be provided with sensors for monitoring physical aspects of the wearer, for example body vital signs, such as heart rate, EKG, pulse, respiration rate, temperature, voice, and allergic reaction, as well as penetration of the fabric. The fabric consists of a base fabric ("comfort component"), and an information infrastructure component which can consist of a penetration detection component, or an electrical conductive component, or both. The preferred penetration detection component is a sheathed optical fiber. The information infrastructure component can include, in addition to an electrically conductive textile yarn, a sensor or a connector for a sensor. A process is provided for making an electrical interconnection between intersecting electrically conductive yarns. Furthermore, a process is established for sheathing the plastic optical fiber and protecting it.

Owner:GEORGIA TECH RES CORP

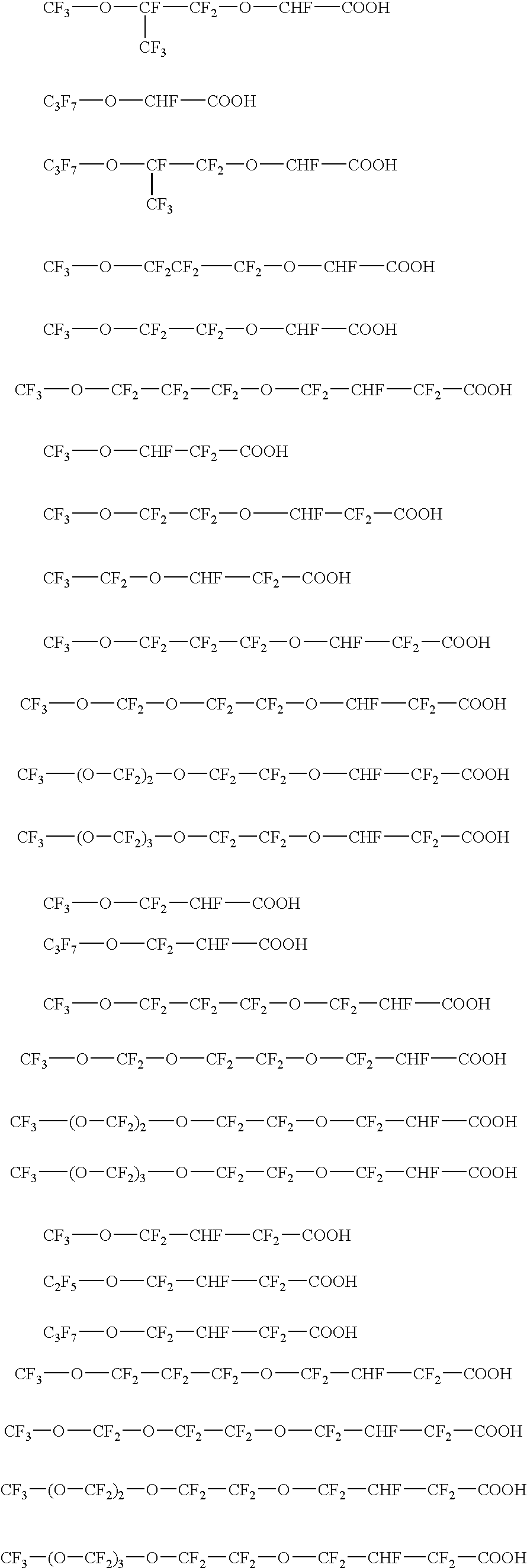

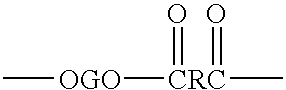

Aqueous emulsion polymerization of fluorinated monomers using a perfluoropolyether surfactant

The invention relates to an aqueous emulsion polymerization of fluorinated monomers using perfluoropolyethers of the following formula (I) or (II). In particular, the perfluoropolyether surfactants correspond to formula (I) or (II) CF3—(OCF2)m—O—CF2—X (I) wherein m has a value of 1 to 6 and X represents a carboxylic acid group or salt thereof, CF3—O—(CF2)3—(OCF(CF3)—CF2)z—O-L-Y (II) wherein z has a value of 0, 1, 2 or 3, L represents a divalent linking group selected from —CF(CF3)—, —CF2— and —CF2CF2— and Y represents a carboxylic acid group or salt thereof. The invention further relates to an aqueous dispersion of a fluoropolymer having the aforementioned perfluoropolyether surfactant(s).

Owner:3M INNOVATIVE PROPERTIES CO

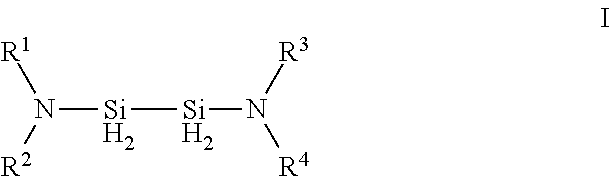

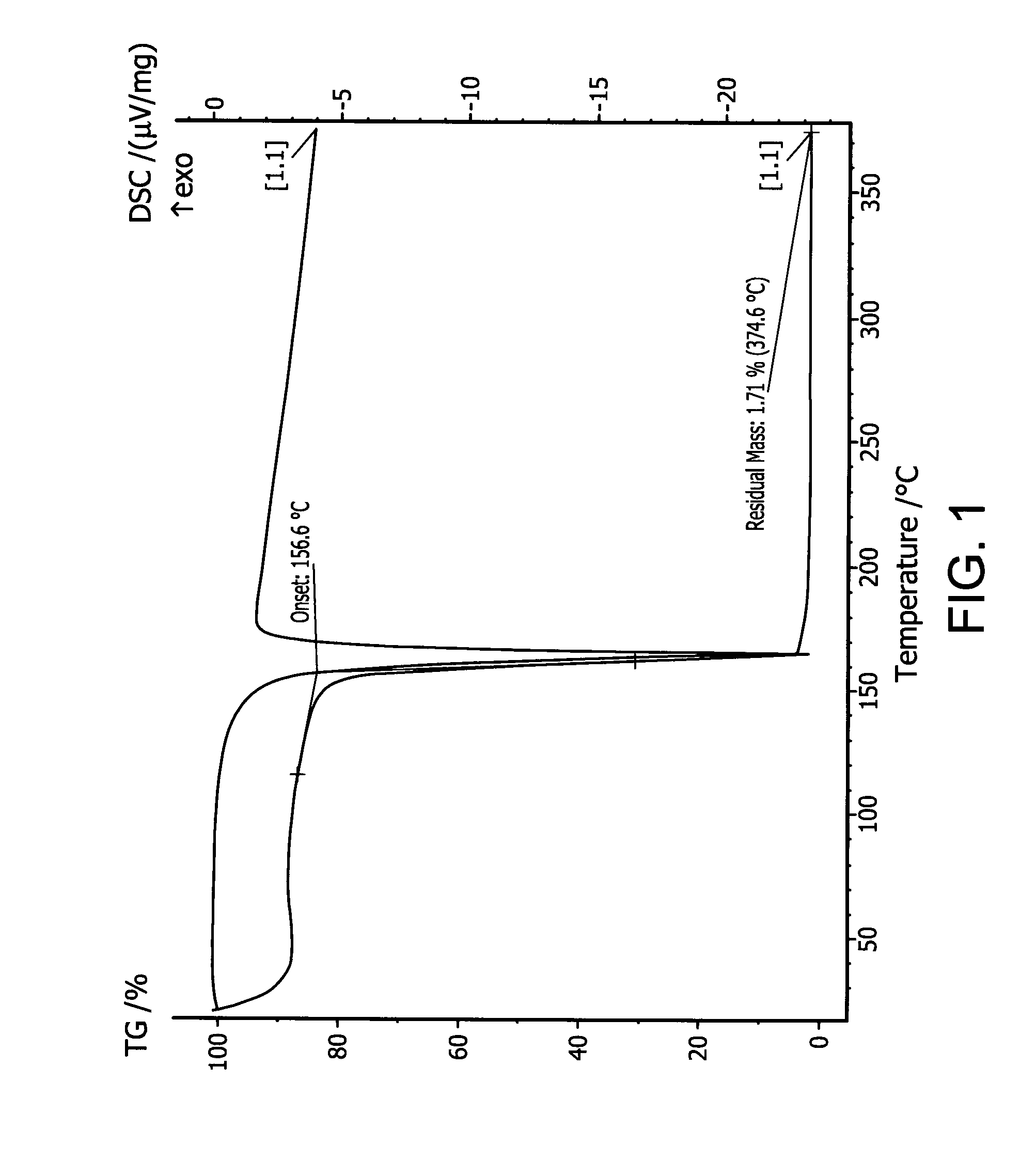

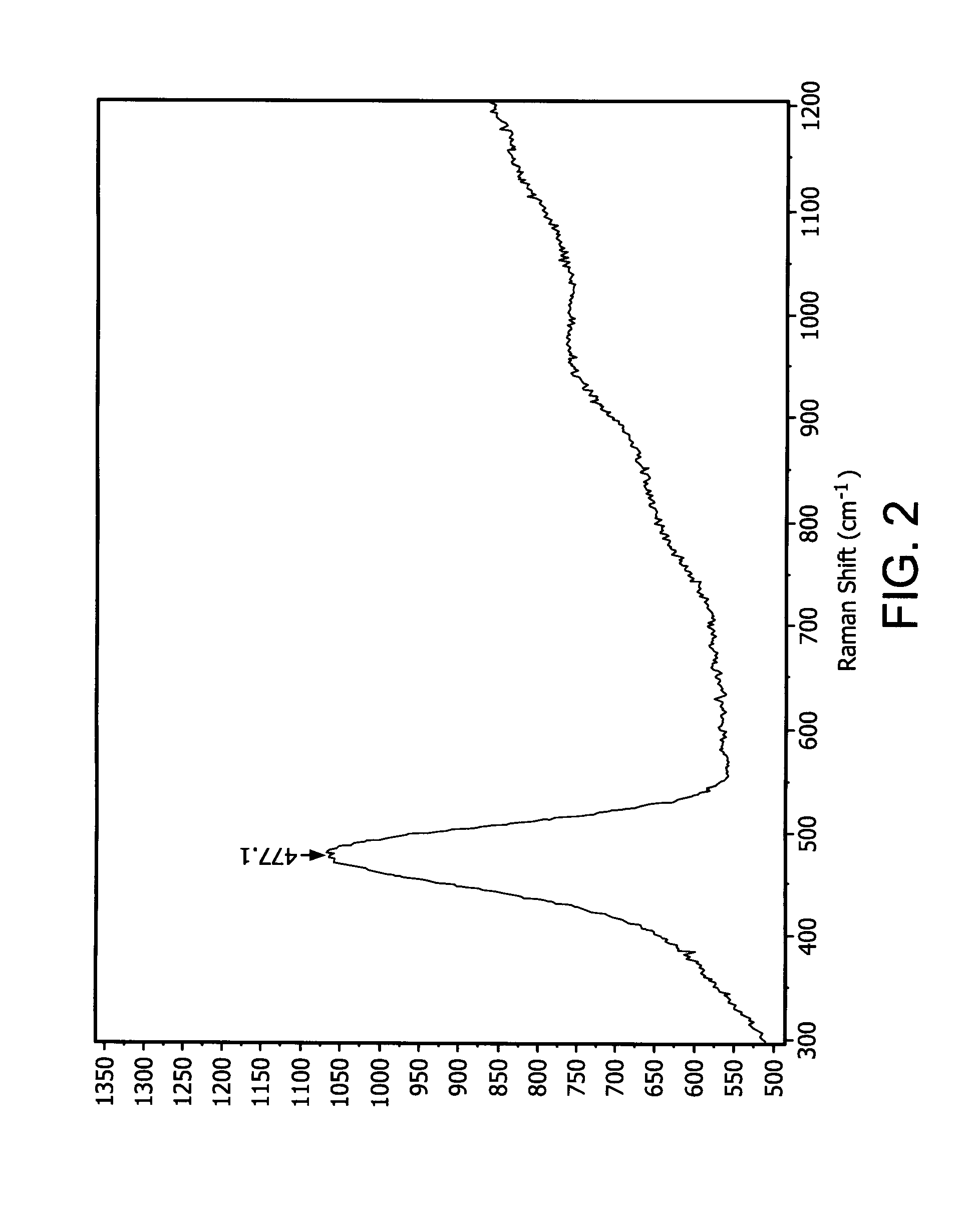

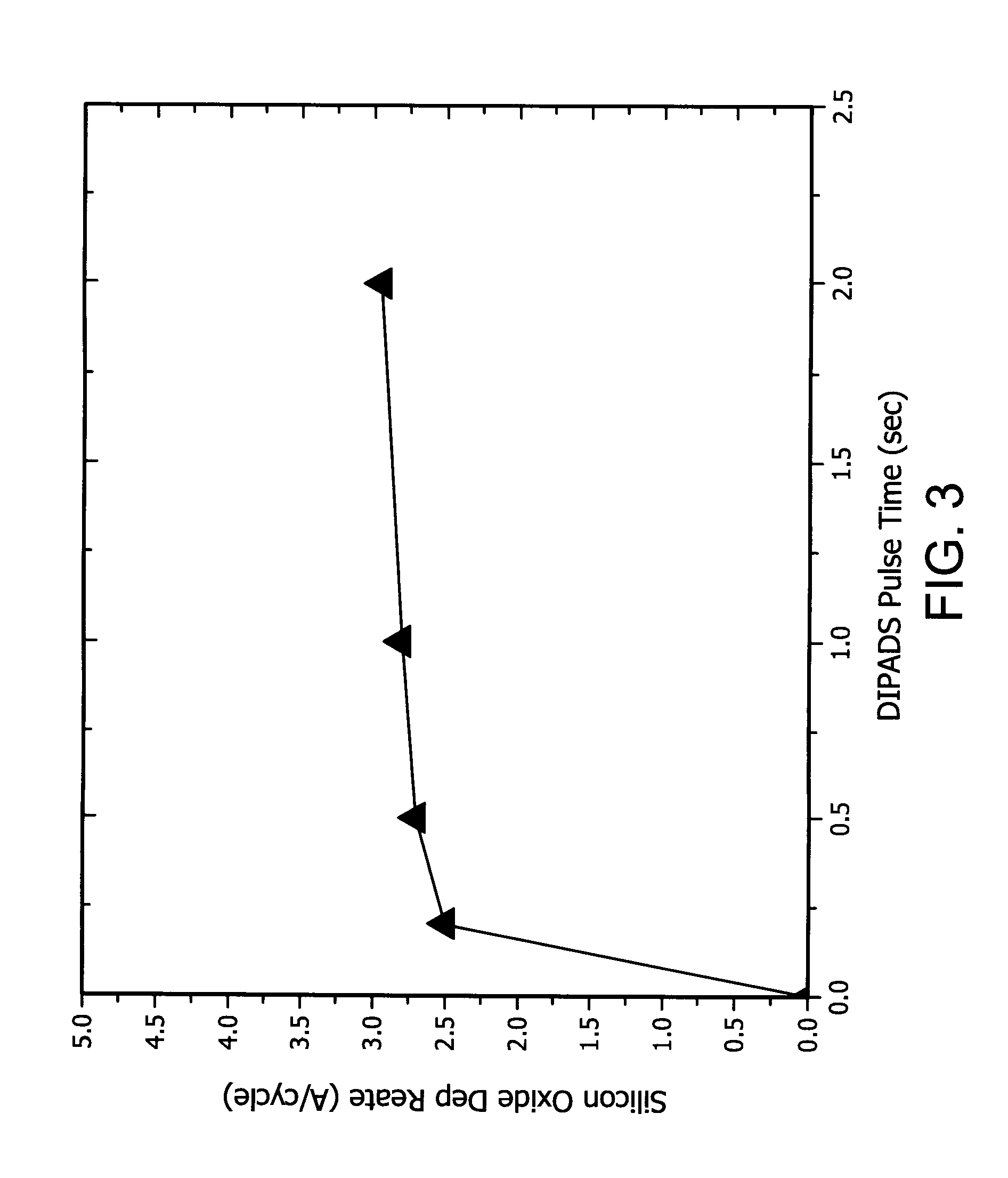

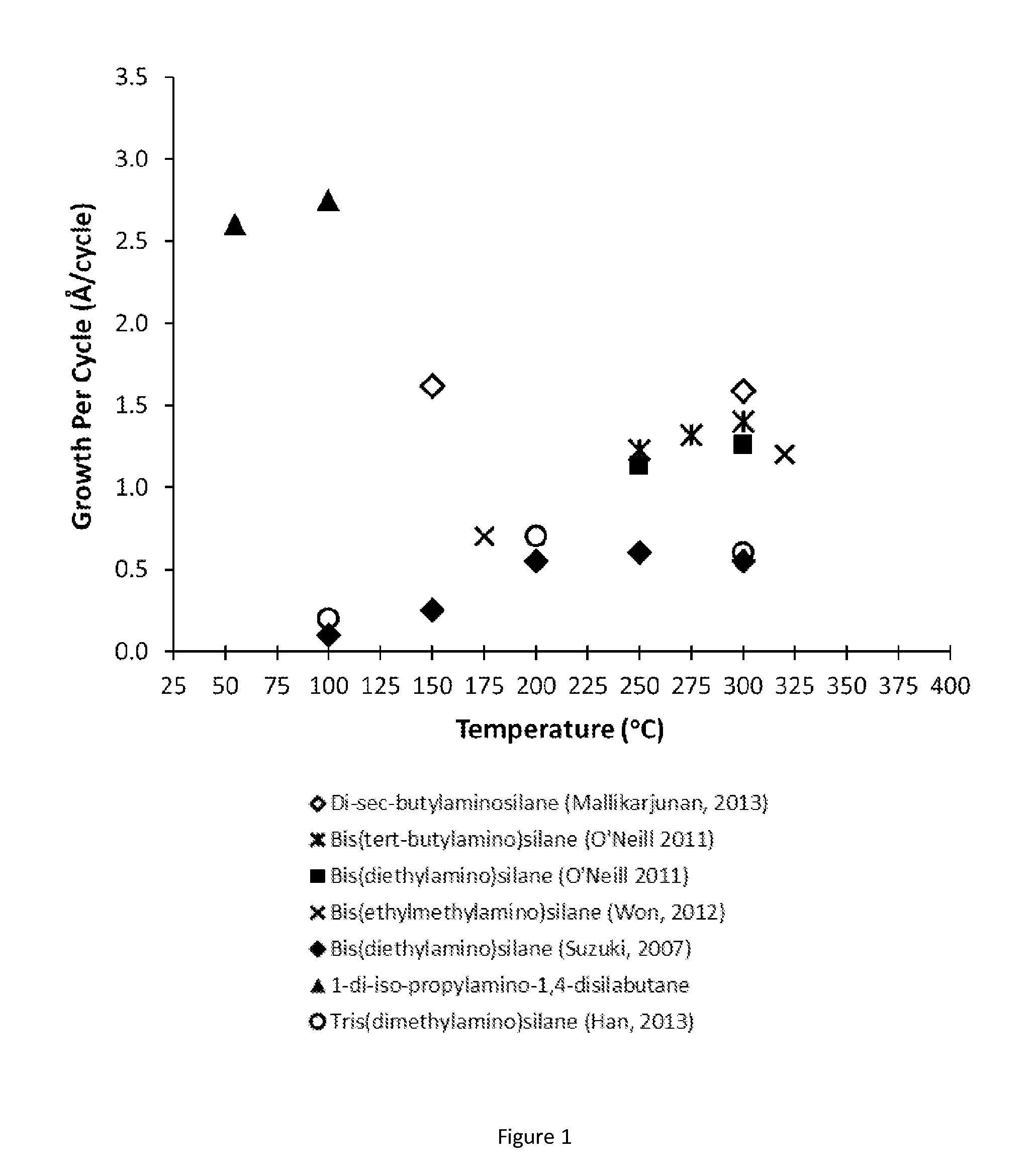

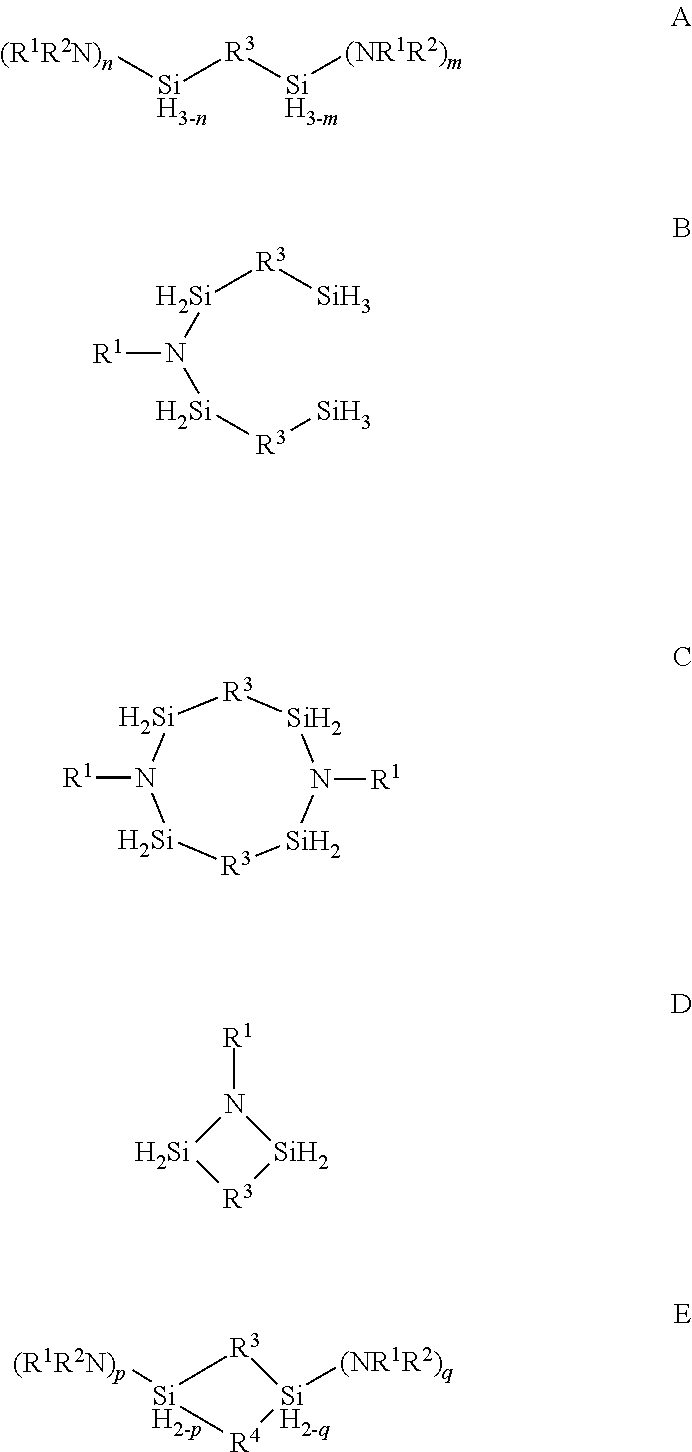

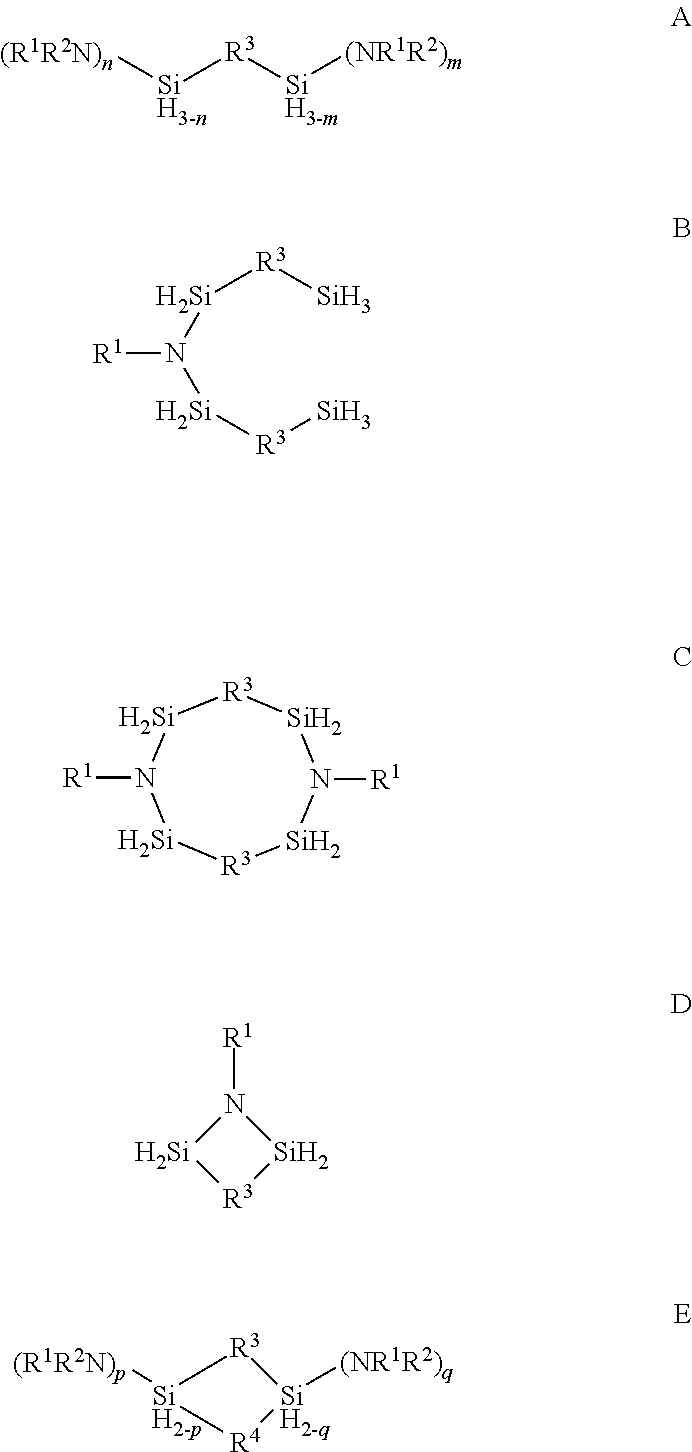

Organoaminodisilane precursors and methods for depositing films comprising same

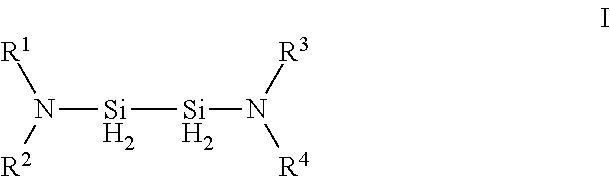

Described herein are precursors and methods for forming silicon-containing films. In one aspect, there is a precursor of following Formula I:wherein R1 and R3 are independently selected from linear or branched C3 to C10 alkyl group, a linear or branched C3 to C10 alkenyl group, a linear or branched C3 to C10 alkynyl group, a C1 to C6 dialkylamino group, an electron withdrawing and a C6 to C10 aryl group; R2 and R4 are independently selected from hydrogen, a linear or branched C3 to C10 alkyl group, a linear or branched C3 to C10 alkenyl group, a linear or branched C3 to C10 alkynyl group, a C1 to C6 dialkylamino group, an electron withdrawing, and a C6 to C10 aryl group; and wherein any one, all, or none of R1 and R2, R3 and R4, R1 and R3, or R2 and R4 are linked to form a ring.

Owner:VERSUM MATERIALS US LLC

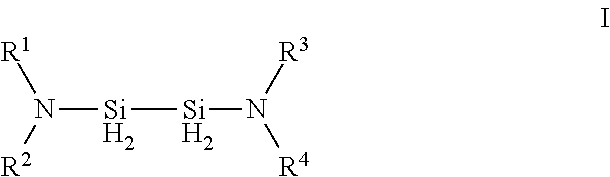

Organoaminodisilane precursors and methods for depositing films comprising same

Described herein are precursors and methods for forming silicon-containing films. In one aspect, there is provided a precursor of Formula I:wherein R1 is selected from linear or branched C3 to C10 alkyl group, linear or branched C3 to C10 alkenyl group, linear or branched C3 to C10 alkynyl group, C1 to C6 dialkylamino group, electron withdrawing group, and C6 to C10 aryl group; R2 is selected from hydrogen, linear or branched C1 to C10 alkyl group, linear or branched C3 to C6 alkenyl group, linear or branched C3 to C6 alkynyl group, C1 to C6 dialkylamino group, C6 to C10 aryl group, linear or branched C1 to C6 fluorinated alkyl group, electron withdrawing group, and C4 to C10 aryl group; optionally wherein R1 and R2 are linked together to form ring selected from substituted or unsubstituted aromatic ring or substituted or unsubstituted aliphatic ring; and n=1 or 2.

Owner:VERSUM MATERIALS US LLC

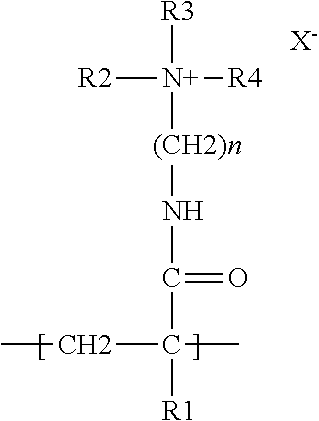

Benefit agent containing delivery particle

Owner:THE PROCTER & GAMBLE COMPANY

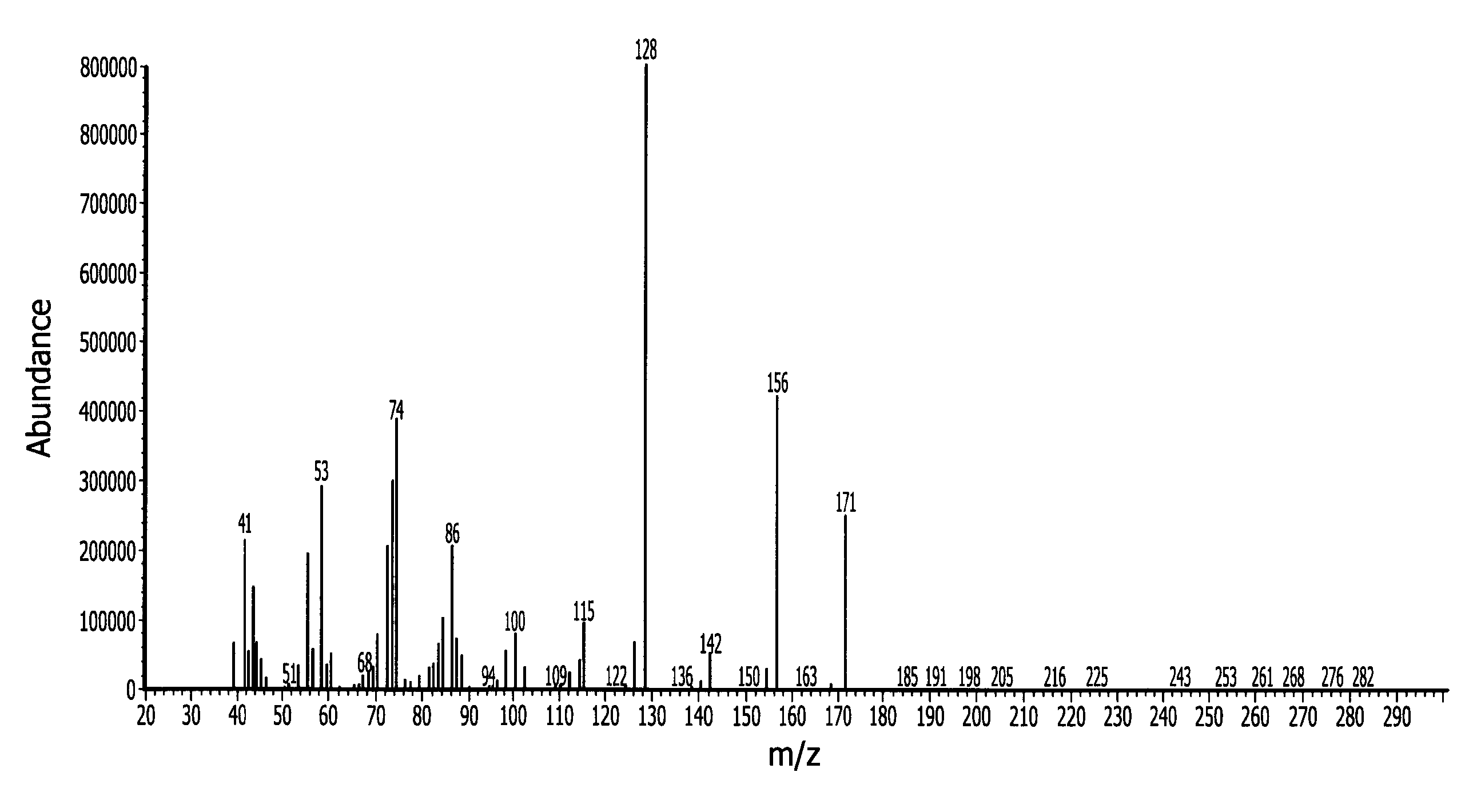

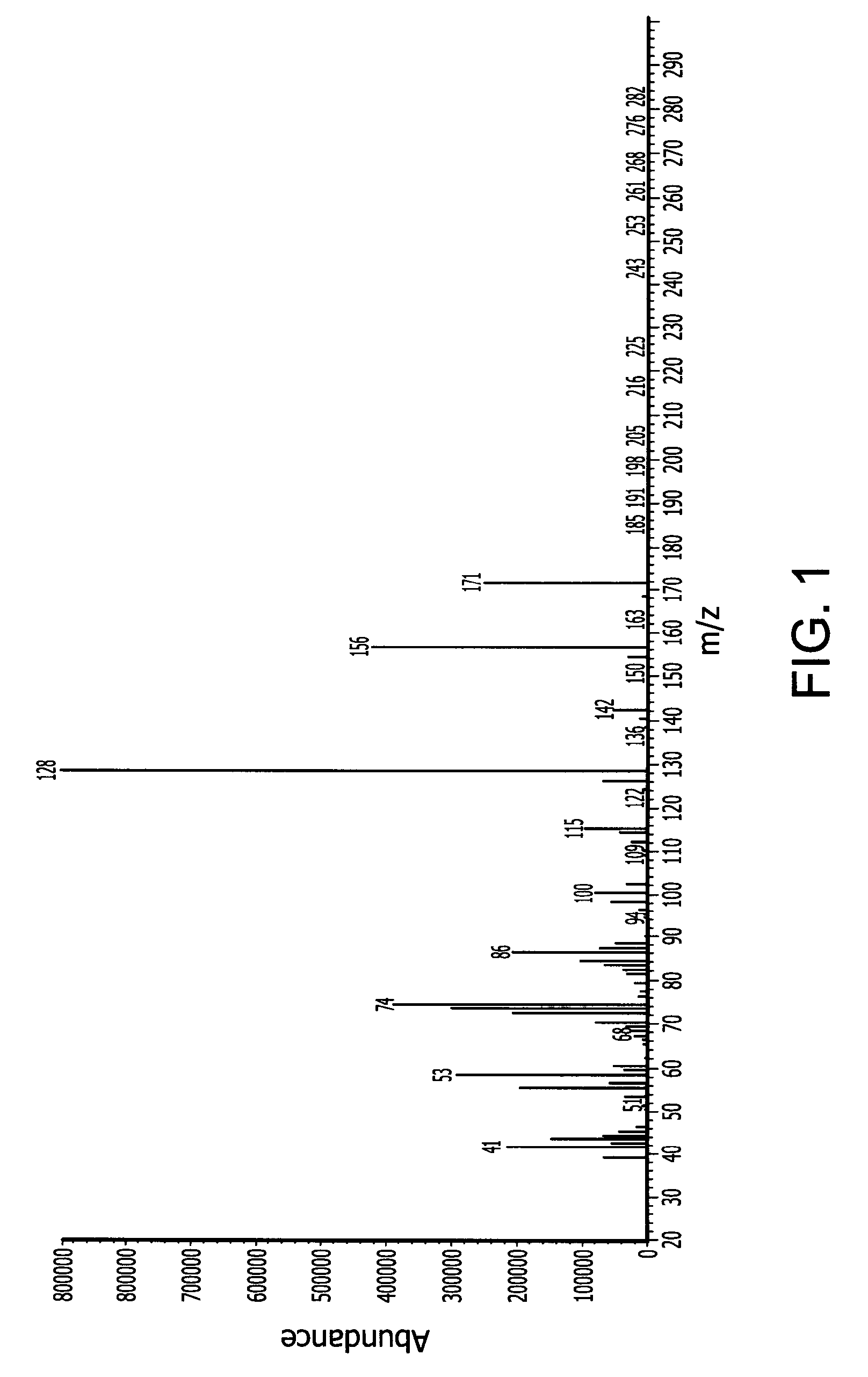

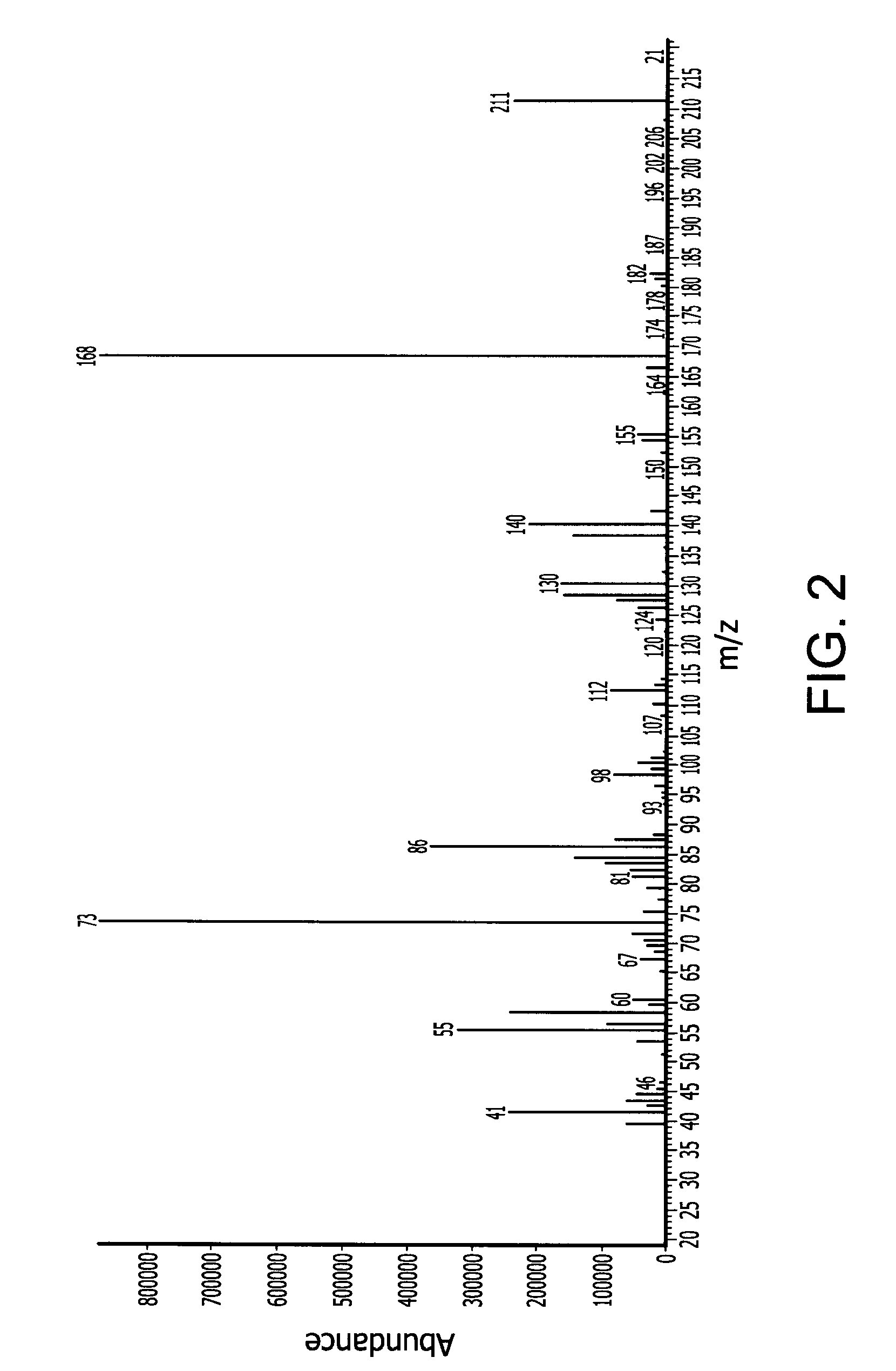

Fluorinated surfactants for making fluoropolymers

ActiveUS20070142541A1Easy to preparePrepared cost-effectivelyLiquid surface applicatorsTransportation and packagingEmulsion polymerizationFluoropolymer

The invention provides a fluorinated surfactant having the general formula: [Rf—(O)t—CHF—(CF2)n—COO—]iXi+ (I) wherein Rf represents a partially or fully fluorinated aliphatic group optionally interrupted with one or more oxygen atoms, t is 0 or 1 and n is 0 or 1, Xi+ represents a cation having a valence i and i is 1, 2 or 3. The surfactant can be used in emulsion polymerization of fluoromonomers to prepare fluoropolymers.

Owner:3M INNOVATIVE PROPERTIES CO

Organoaminosilane precursors and methods for making and using same

Described herein are organoaminosilane precursors which can be used to deposit silicon containing films which contain silicon and methods for making these precursors. Also disclosed herein are deposition methods for making silicon-containing films or silicon containing films using the organoaminosilane precursors described herein. Also disclosed herein are the vessels that comprise the organoaminosilane precursors or a composition thereof that can be used, for example, to deliver the precursor to a reactor in order to deposit a silicon-containing film.

Owner:VERSUM MATERIALS US LLC

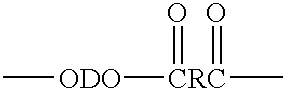

Aqueous emulsion polymerization of fluorinated monomers using a fluorinated surfactant

InactiveUS20070015866A1Low toxicityGood chemical stabilityLiquid surface applicatorsFibre treatmentEmulsion polymerizationEther

The present invention provides an aqueous emulsion polymerization of fluorinated monomers including gaseous fluorinated monomers using a perfluoro ether surfactant as an emulsifier. The perfluoro ether surfactants correspond to formula (I) Rf—O—CF2CF2—X (I) wherein Rf represents a linear or branched perfluoroalkyl group having 1, 2, 3 or 4 carbon atoms and X represents a carboxylic acid group or salt thereof. In a further aspect, the invention also provides an aqueous fluoropolymer dispersion comprising the perfluoro ether surfactant and the use of such dispersion in the coating or impregnation of substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Expandable Functional TFE Copolymer Fine Powder, the Expandable Functional Products Obtained Therefrom and Reaction of the Expanded Products

A functional TFE copolymer fine powder is described, wherein the TFE copolymer is a polymer of TFE and at least one functional comonomer, and wherein the TFE copolymer has functional groups that are pendant to the polymer chain. The functional TFE copolymer fine powder resin is paste extrudable and expandable. Methods for making the functional TFE copolymer are also described. The expanded functional TFE copolymer material may be post-reacted after expansion.

Owner:WL GORE & ASSOC INC

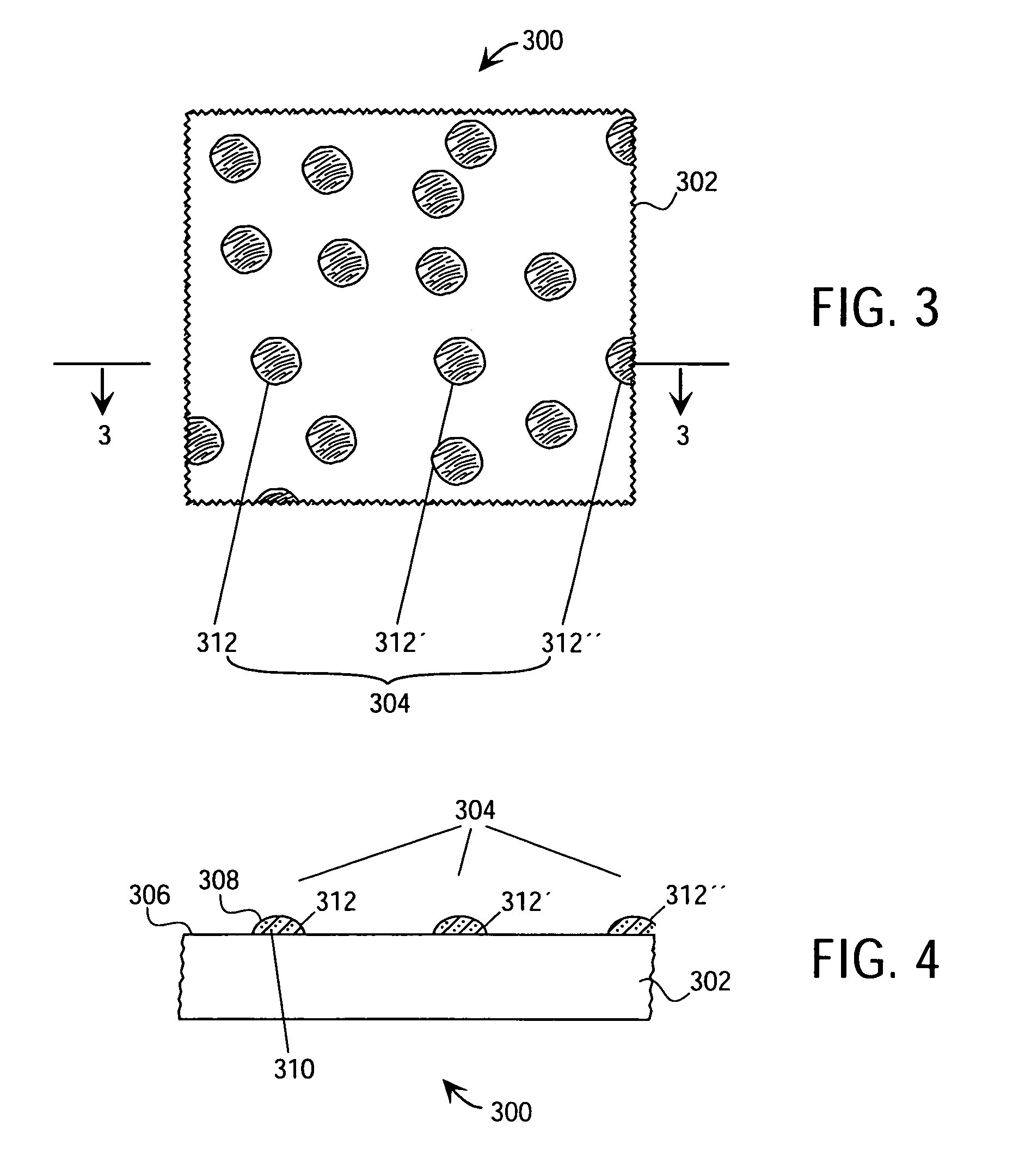

Fabric coating composition containing energy absorbing phase change material

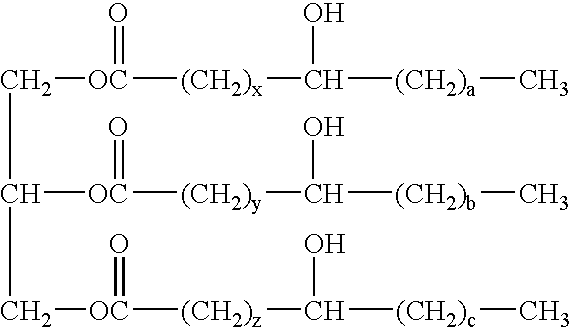

InactiveUS6207738B1Solve the lack of densityReduce and eliminate heat transferHeat storage plantsFibre treatmentMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric.

Owner:OUTLAST TECH LLC

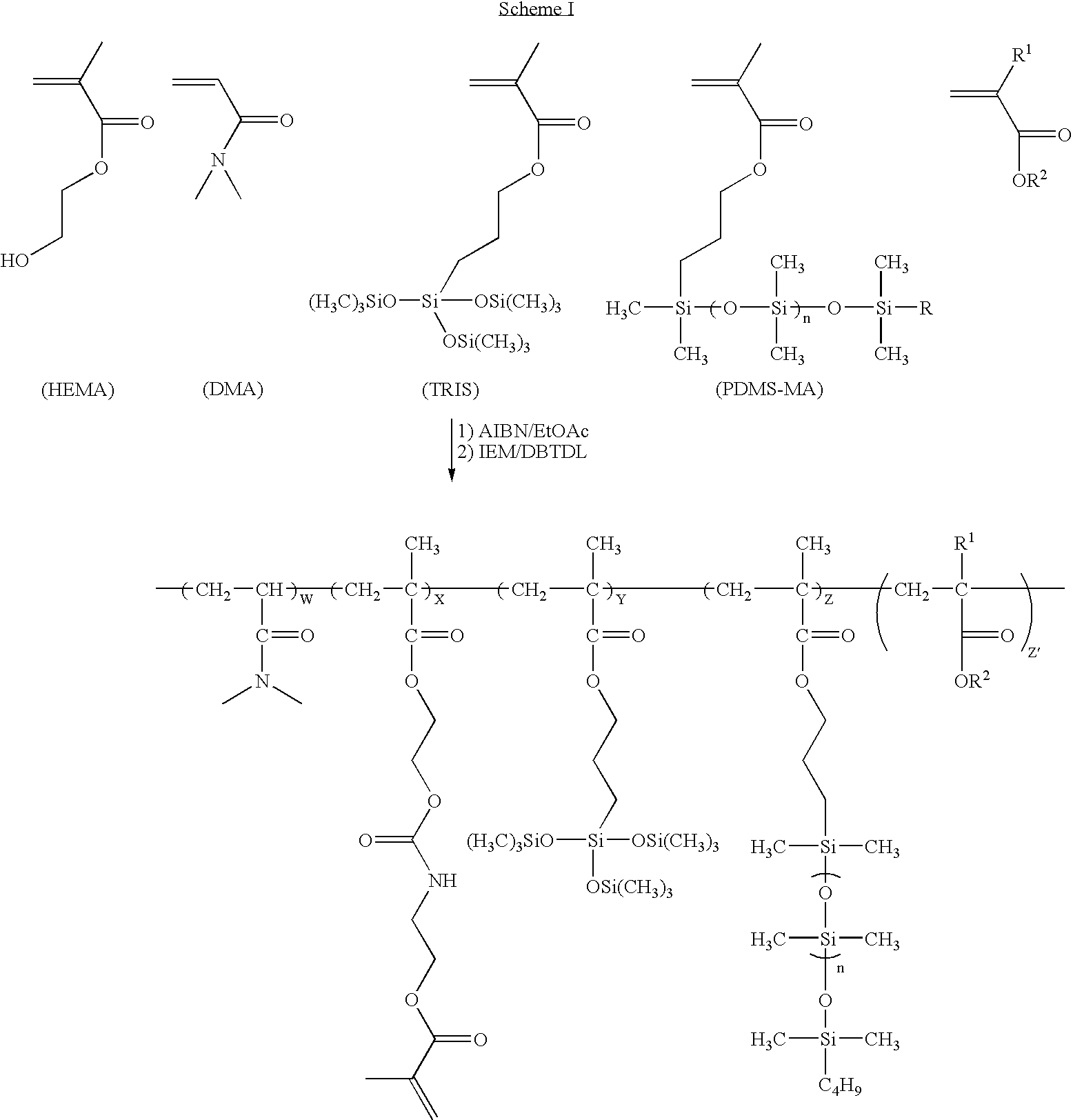

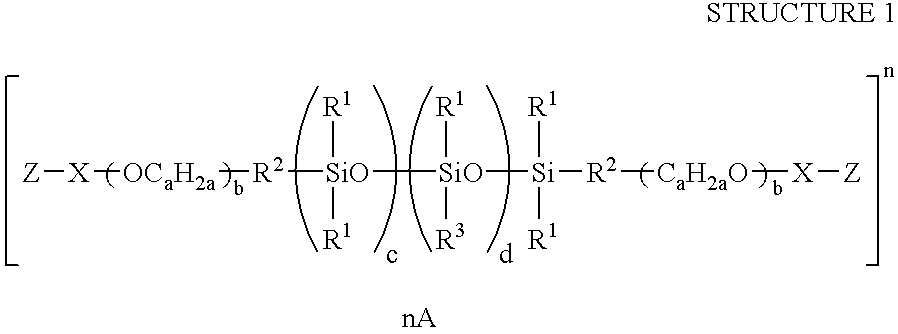

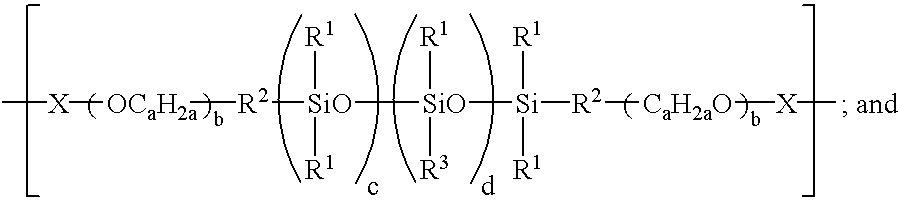

Actinically curable silicone hydrogel copolymers and uses thereof

The present invention provides inks and methods for making colored silicone hydrogel contact lenses. The ink of the invention comprises an actinically-curable binder copolymer comprising fluorine-containing segments and is characterized by having capability to be cured actinically or thermally to form a colored film on a molding surface of a mold or a silicone hydrogel contact lens and by having an increased durability in a solvated state in a silicone-hydrogel lens formulation in relation to a control colored film obtained from a control ink including an actinically-curable fluorine-free binder copolymer. The invention also provides methods for making colored silicone hydrogel contact lenses based on print-on-mold processes for producing colored contact lenses.

Owner:ALCON INC

Absorbent hygiene product

InactiveUS20050159720A1Surface area can be easilyUniform and stableLayered productsFibre treatmentAbsorbent materialPolymer chemistry

Owner:FREUDENBERG NONWOVENS LTD

Delivery particle

Owner:THE PROCTER & GAMBLE COMPANY

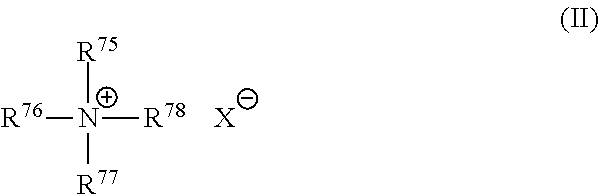

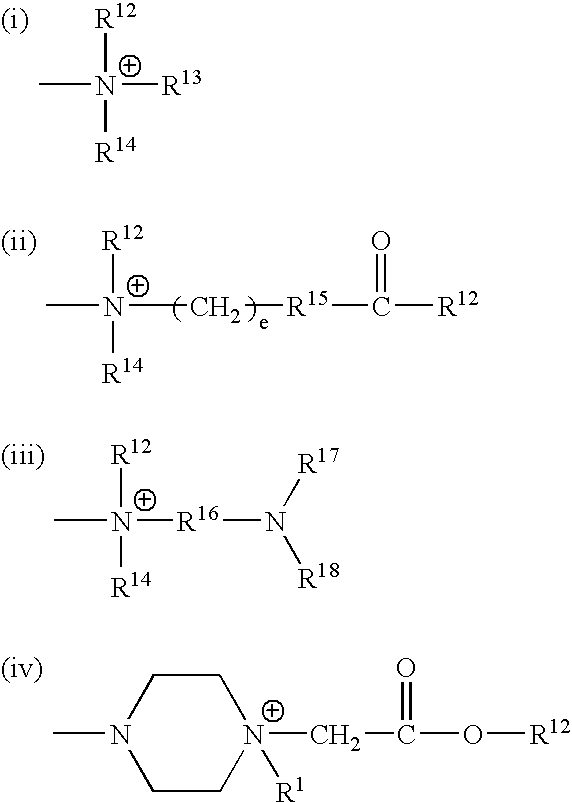

Structured liquid fabric treatment compositions

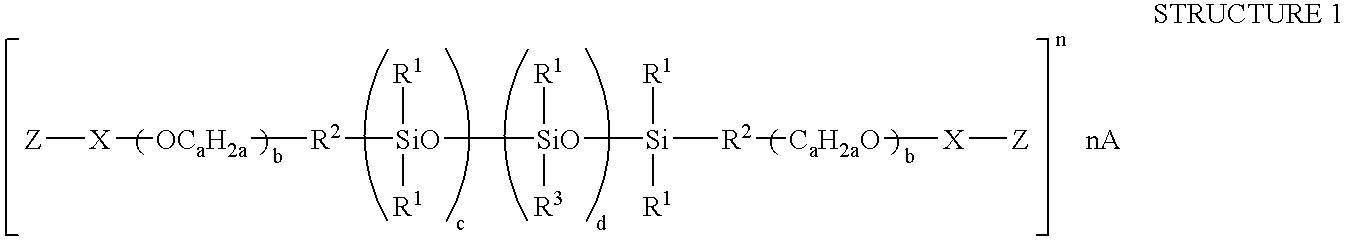

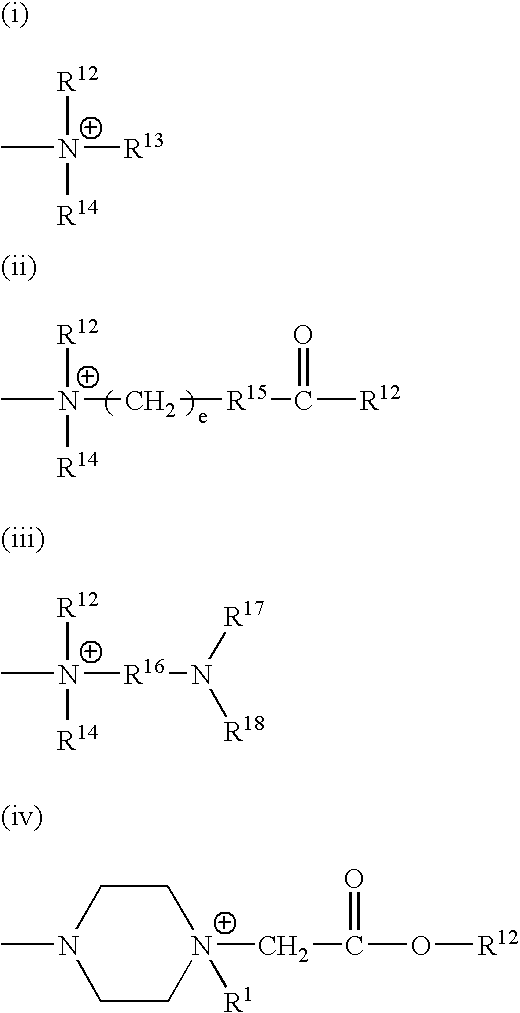

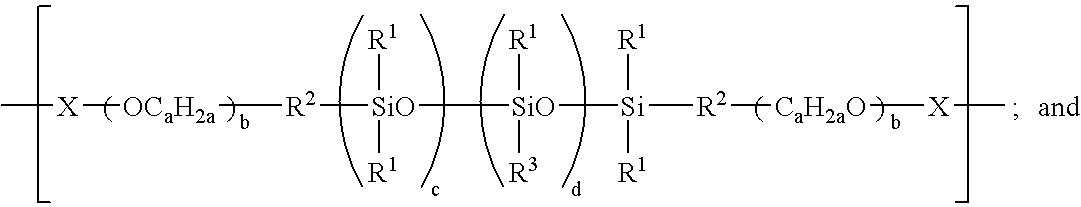

InactiveUS7294611B2Imparting fabric care benefitCationic surface-active compoundsOrganic detergent compounding agentsNitrogenStructure system

The invention is directed to a structured liquid fabric treatment composition comprising as added components one or more silicone-based cationic fabric care ingredients preferably selected from the group consisting of cationic silicone polymers comprising one or more polysiloxane units and one or more quaternary nitrogen units; a structuring system comprising a structuring agent, a nonionic emulsifier and an anionic emulsifier; a cationic scavenging agent for the anionic emulsifier and a liquid carrier.

Owner:PROCTER & GAMBLE CO

Organoaminosilane precursors and methods for depositing films comprising same

ActiveUS20150087139A1Low temperature efficientlySilicon organic compoundsOrganic compound preparationSilanesPhysical chemistry

Described herein are precursors and methods for forming silicon-containing films. In one aspect, the precursor comprises a compound represented by one of following Formulae A through E below:In one particular embodiment, the organoaminosilane precursors are effective for a low temperature (e.g., 350° C. or less), atomic layer deposition (ALD) or plasma enhanced atomic layer deposition (PEALD) of a silicon-containing film. In addition, described herein is a composition comprising an organoaminosilane described herein wherein the organoaminosilane is substantially free of at least one selected from the amines, halides (e.g., Cl, F, I, Br), higher molecular weight species, and trace metals.

Owner:VERSUM MATERIALS US LLC

Fabric coating containing energy absorbing phase change material and method of manufacturing same

InactiveUS6514362B1Evenly dispersedEqually distributedDecorative surface effectsHeat storage plantsMicrosphereEnergy absorption

A coating composition for fabrics includes wetted microspheres containing a phase change material dispersed throughout a polymer binder, a surfactant, a dispersant, an antifoam agent and a thickener. Preferred phase change materials include paraffinic hydrocarbons. The microspheres may be microencapsulated. To prepare the coating composition, microspheres containing phase change material are wetted and dispersed in a dispersion in a water solution containing a surfactant, a dispersant, an antifoam agent and a polymer mixture. The coating is then applied to a fabric. In an alternative embodiment, an extensible fabric is coated with an extensible binder containing microencapsulated phase change material to form an extensible, coated fabric. The coated fabric is optionally flocked. The coated fabrics are manufactured using transfer techniques.

Owner:OUTLAST TECH LLC

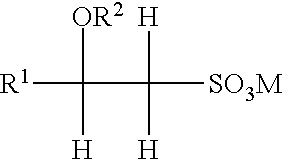

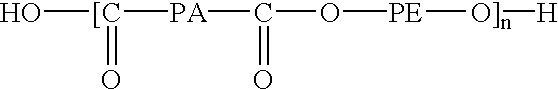

Absorbent articles comprising hydrophilic nonwoven fabrics

InactiveUS7521587B2Hydrophilic lastingIncrease surface tensionFibre treatmentSynthetic resin layered productsPolymer scienceHydrophile

The present invention relates to absorbent articles comprising nonwoven fabrics, which are made hydrophilic by polymers chemically bonded to the surface of the nonwoven fabrics.Moreover, the invention relates to a process for making hydrophilic fibers, which can be formed into a nonwoven fabric.

Owner:THE PROCTER & GAMBLE COMPANY

Fluorinated surfactants for use in making a fluoropolymer

InactiveUS20070117914A1Convenient and easy preparationPrepared cost-effectivelyOrganic active ingredientsOrganic compound preparationEmulsion polymerizationCarboxylic acid

The present invention provides a fluorinated surfactant having the general formula:[Rf—(O)t—CQH—CF2—O]n—R-G (I)wherein Rf represents a partially or fully fluorinated aliphatic group optionally interrupted with one or more oxygen atoms, Q is CF3 or F, R is an aliphatic or aromatic hydrocarbon group, G represents a carboxylic or sulphonic acid or salt thereof, t is 0 or 1 and n is 1, 2 or 3. The surfactant is particularly useful in polymerizing fluorinated monomers in an aqueous emulsion polymerization.

Owner:3M INNOVATIVE PROPERTIES CO

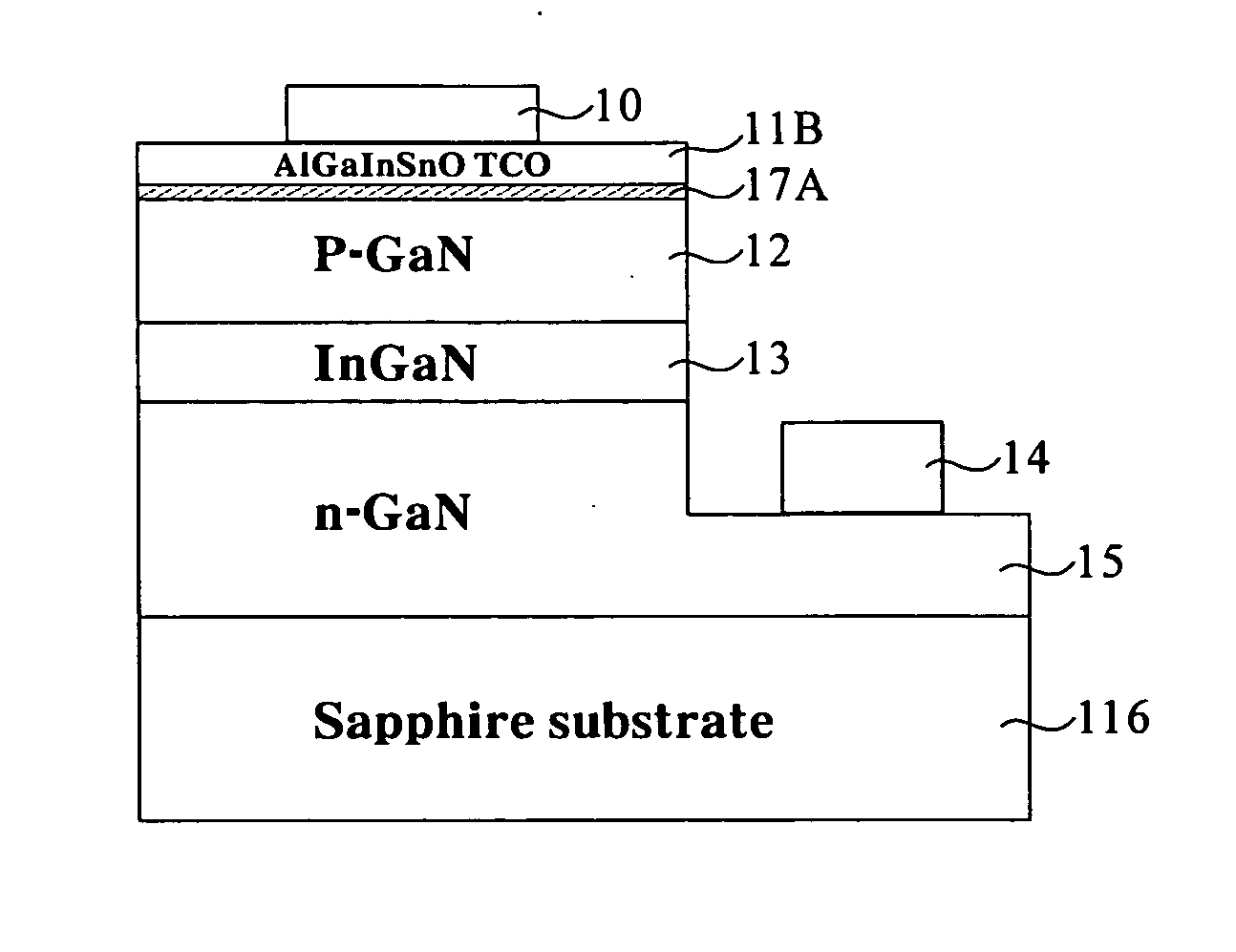

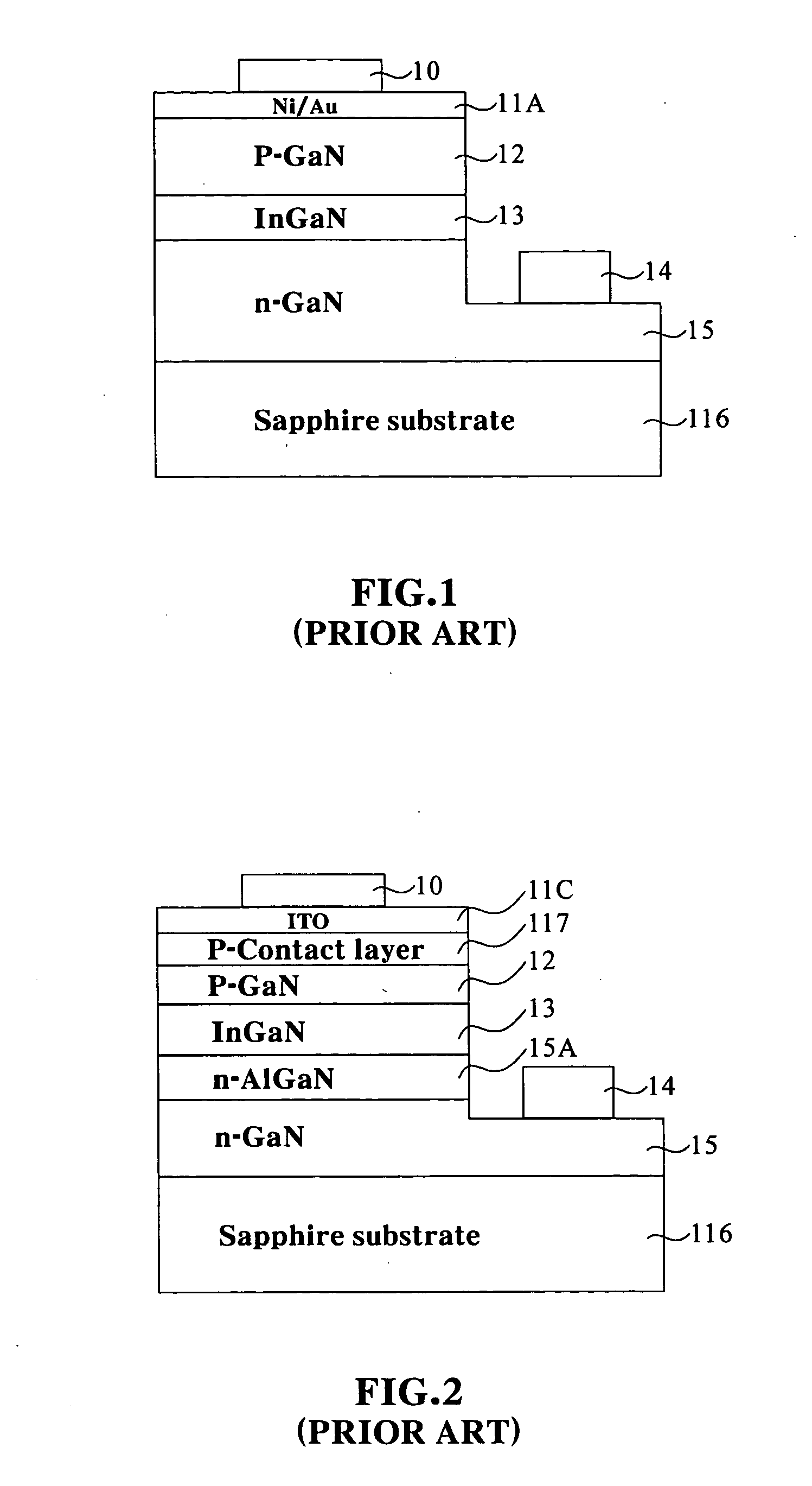

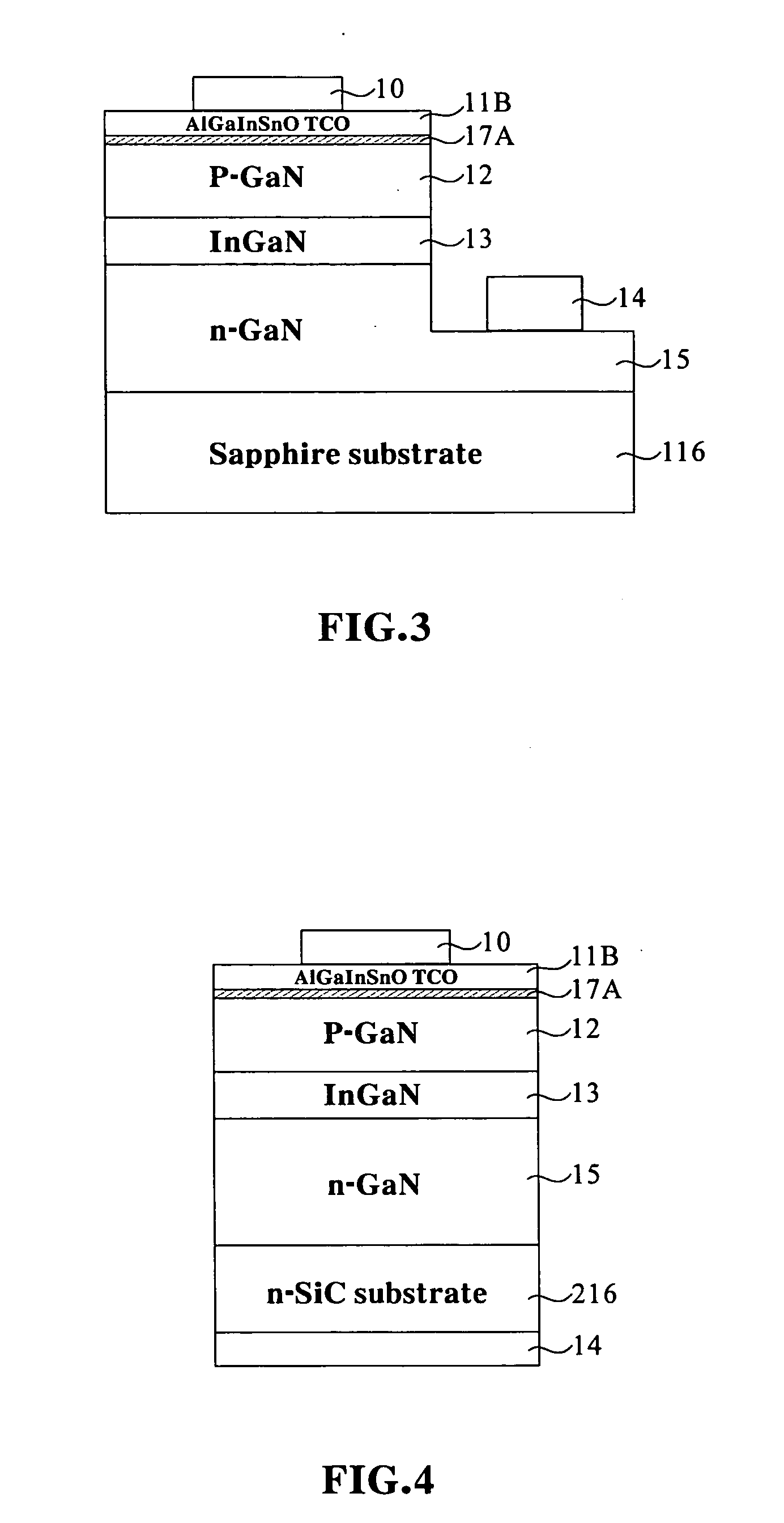

High brightness gallium nitride-based light emitting diode with transparent conducting oxide spreading layer

InactiveUS20050230701A1Reduce contact resistanceReduce the impactFibre treatmentSolid-state devicesOptical propertyGallium

A new transparent conducting oxide (TCO), which can be expressed as AlxGa3−x−yIn5+ySn2−zO16−2z; 0≦x<1, 0<y<3, 0≦z<2, has been used to improve the brightness and current spreading in GaN base LED process. The optical properties of this system are superior to regular Ni / Au transparent conducting layer in blue-green region, and the new Al2O3—Ga2O3—In2O3—SnO2 system is able to increase the brightness at 1.5˜2.5 time to compare to regular process. Furthermore, the new transparent conducting oxide thin film has the highest conductivity, which is better than the Ni / Au transparent conducting thin film.

Owner:ARIMA OPTOELECTRONICS

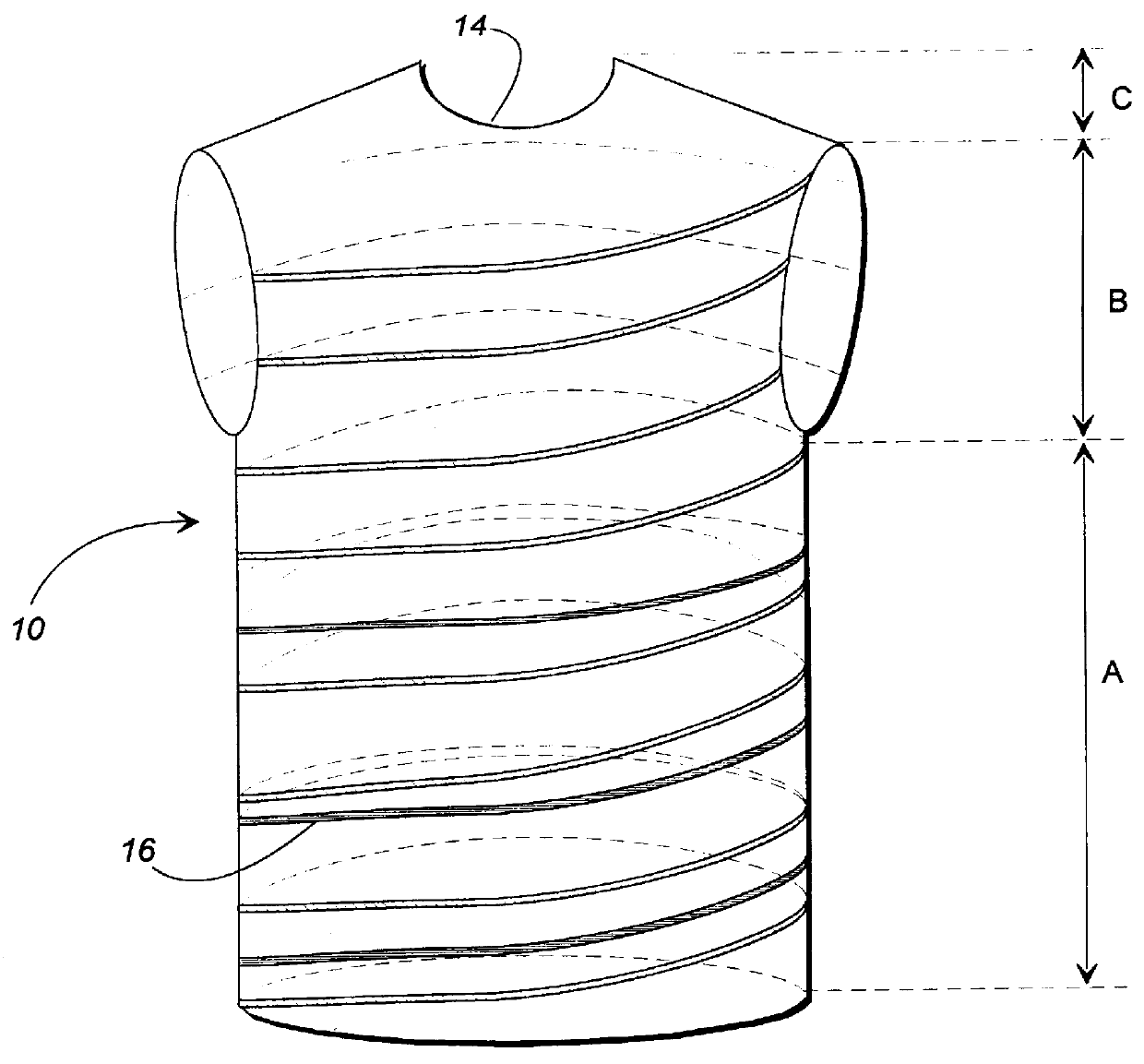

Full-fashioned weaving process for production of a woven garment with intelligence capability

A full-fashioned weaving process for the production of a woven garment which can accommodate and include holes, such as armholes. The garment is made of only one single integrated fabric and has no discontinuities or seams. Additionally, the garment can include intelligence capability, such as the ability to monitor one or more body vital signs, or garment penetration, or both, by including a selected sensing component or components in the weave of the garment.

Owner:GEORGIA TECH RES CORP

Highly-resilient thermoplastic elastomer compositions

A thermoplastic composition of (a) an acid copolymer, (b) a salt of a high molecular weight, monomeric organic acid; (c) a thermoplastic polymer selected from copolyetheresters, elastomeric polyolefins, styrene diene block copolymers, elastomeric polyolefins thermoplastic polyurethanes and copolyetheramides; (d) cation source; and (d) optionally a filler. Also included is use of such compositions in components of one-, two- and three-piece golf balls or multi-layered golf balls made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

Fluoropolymer dispersion containing no or little low molecular weight fluorinated surfactant

ActiveUS6861466B2Good film formingTransportation and packagingFibre treatmentPolymer scienceRoom temperature

In an aspect of the invention, a fluoropolymer dispersion, preferably a PTFE dispersion, is provided that comprises fluoropolymer particles having an average particle size of 10 to 400 nm dispersed in water whereby the dispersion has an amount of solids between 35 and 70% by weight. The dispersion is free of fluorinated surfactant having a molecular weight of less than 1000 g / mol (hereinafter called low molecular weight fluorinated surfactant) or contains the low molecular weight fluorinated surfactant in an amount of not more than 0.05% by weight based on the total weight solids of the dispersion. The dispersion further comprises a non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants and one or more non-fluorinated anionic surfactants. Through the use of a non-fluorinated anionic surfactant, a dispersion is obtained that has a low viscosity at room temperature (20° C.). The dispersion is further free of aromatic group containing non-ionic surfactants and is accordingly environmentally more friendly and can yield coatings that are less susceptible of discoloration. The amount and nature of the non-ionic non-fluorinated surfactant or mixture of non-ionic non-fluorinated surfactants is selected such that the Viscosity Transition Temperature (VTT) (measured as set forth in the examples) of the fluoropolymer dispersion is at least 26, preferably at least 28° C. In a further aspect of the invention, a method is provided to obtain the aforementioned dispersion.

Owner:3M INNOVATIVE PROPERTIES CO

Structuring systems for fabric treatment compositions

InactiveUS20060205631A1Desirable stability and theological characteristicSuperior fabric care benefitCationic surface-active compoundsNon-ionic surface-active compoundsStructured systemsStructure system

The invention is directed to structuring systems suitable for incorporation into liquid fabric treatment compositions. Such structuring systems comprise, as added components, (A) a non-polymeric, crystalline, hydroxyl-containing structuring agent, which can crystallize to form a thread-like structuring network throughout liquid matrices; (B) a nonionic emulsifier; (C) an anionic emulsifier; and (D) a liquid carrier. The anionic emulsifier is present in such structuring systems, at concentrations from 0.1% to 8.0% by weight of the structuring system. The present invention also relates to processes for preparing such structuring systems and to the use of the structuring system of the present invention to control the particle size of a thread-like structuring material by mixing an anionic emulsifier with a structuring agent. Liquid fabric treatment compositions containing such structuring systems are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

Reinforced, laminated, impregnated, and composite-like materials as crosslinked polyvinyl alcohol hydrogel structures

InactiveUS6855743B1High mechanical strengthIncrease modulusFibre treatmentSynthetic resin layered productsPorosityCross-link

Reinforced, laminated, impregnated, and materials with composite properties as cross linked polyvinyl alcohol hydrogel structures in bulk or cellular matrix forms that can take essentially any physical shape, or can have essentially any size, degree of porosity and surface texture. They have a wide range of physical properties, unusual and unique combinations of physical properties and unique responses to stress fields, which allows for their use in many end use applications.

Owner:HYDROMEDICA

Coated articles having enhanced reversible thermal properties and exhibiting improved flexibility, softness, air permeability, or water vapor transport properties

InactiveUS7135424B2Enhanced reversible thermal propertyImprove breathabilityHeat storage plantsDecorative surface effectsWater vaporMedical product

The invention relates to a coated article having enhanced reversible thermal properties. The coated article comprises a substrate having a surface and a coating covering a portion of the surface and comprising a polymeric material and a temperature regulating material dispersed in the polymeric material. The coating is formed with a plurality of regions of discontinuity that are separated from one another and expose a remaining portion of the surface to provide improved flexibility, softness, air permeability, or water vapor transport properties. The coated article may be used in apparel, footwear, medical products, containers and packagings, building materials, appliances, and other products.

Owner:OUTLAST TECH LLC

Garments having stretchable and conductive ink

ActiveUS20170196513A1Improve adhesionGood compatibilityPrinted circuit manufactureMeasuring/recording heart/pulse rateAdhesiveEngineering

Methods of forming garments having one or more stretchable conductive ink patterns. Described herein are method of making garments (including compression garments) having one or more highly stretchable conductive ink pattern formed of a composite of an insulative adhesive, a conductive ink, and an intermediate gradient zone between the adhesive and conductive ink. The conductive ink typically includes between about 40-60% conductive particles, between about 30-50% binder; between about 3-7% solvent; and between about 3-7% thickener. The stretchable conductive ink patterns may be stretched more than twice their length without breaking or rupturing.

Owner:L I F E

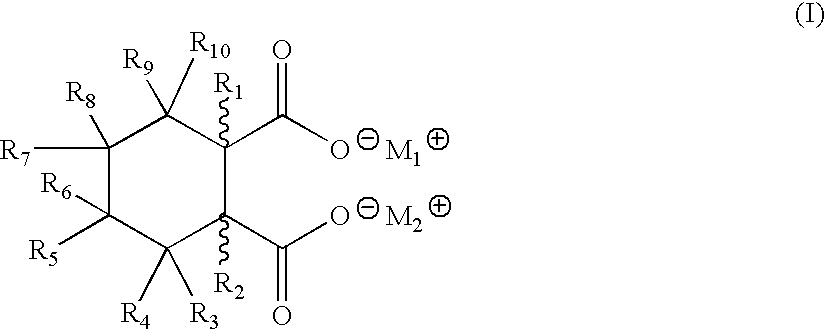

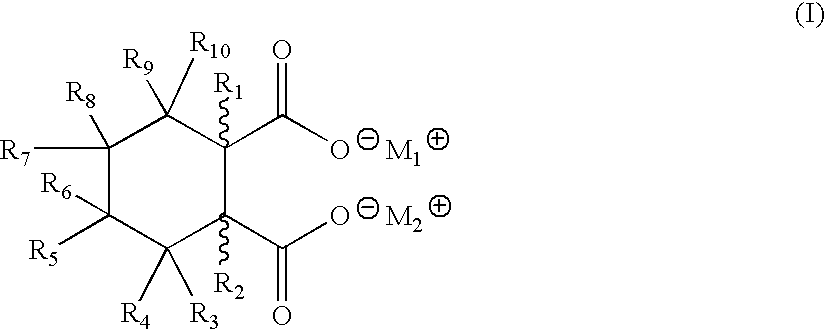

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

InactiveUS6599971B2Excellent calcium stearate compatibilityExcellent high peak crystallization temperatureOrganic compound preparationFibre treatmentThermoplasticScavenger

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

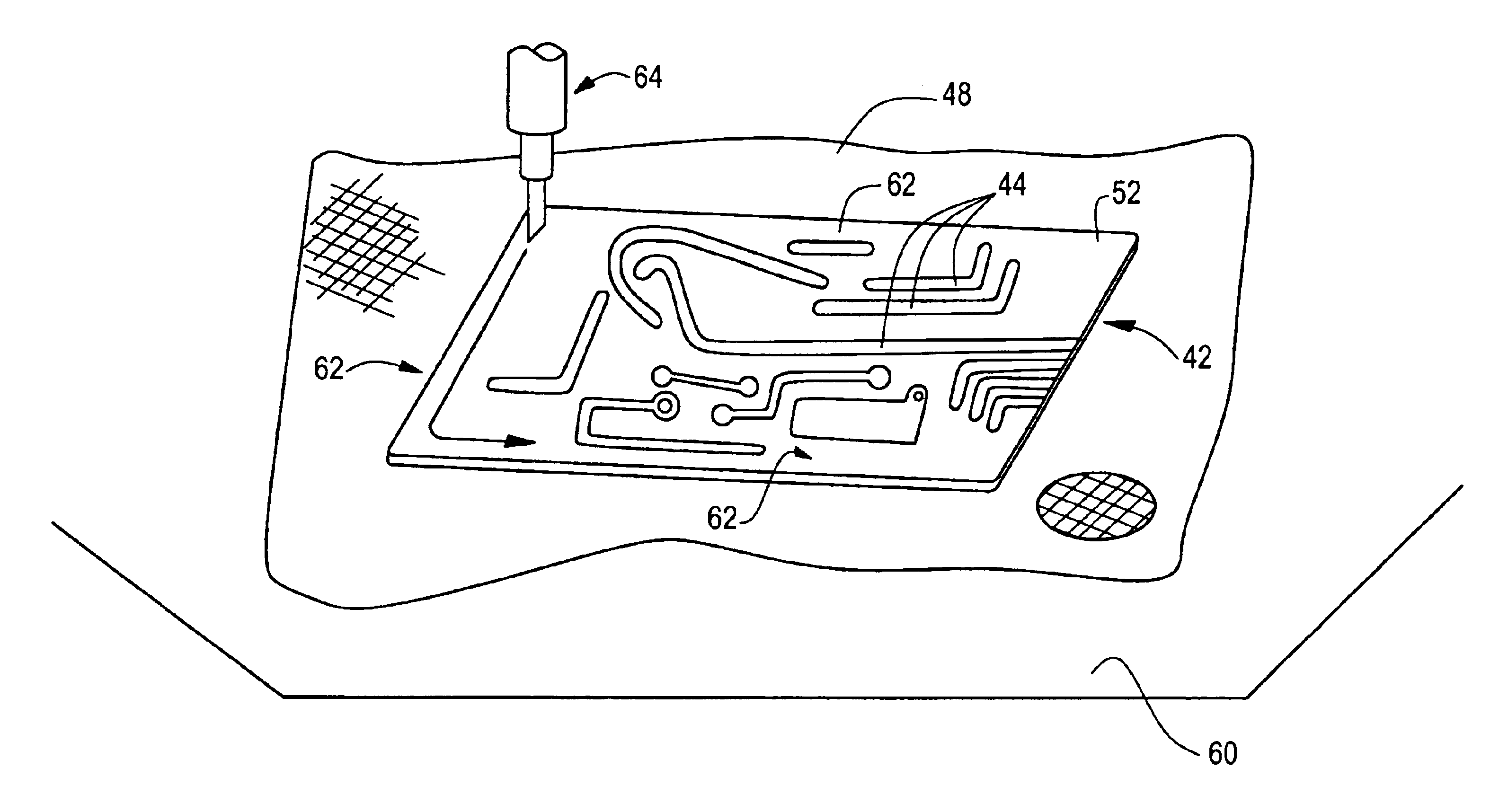

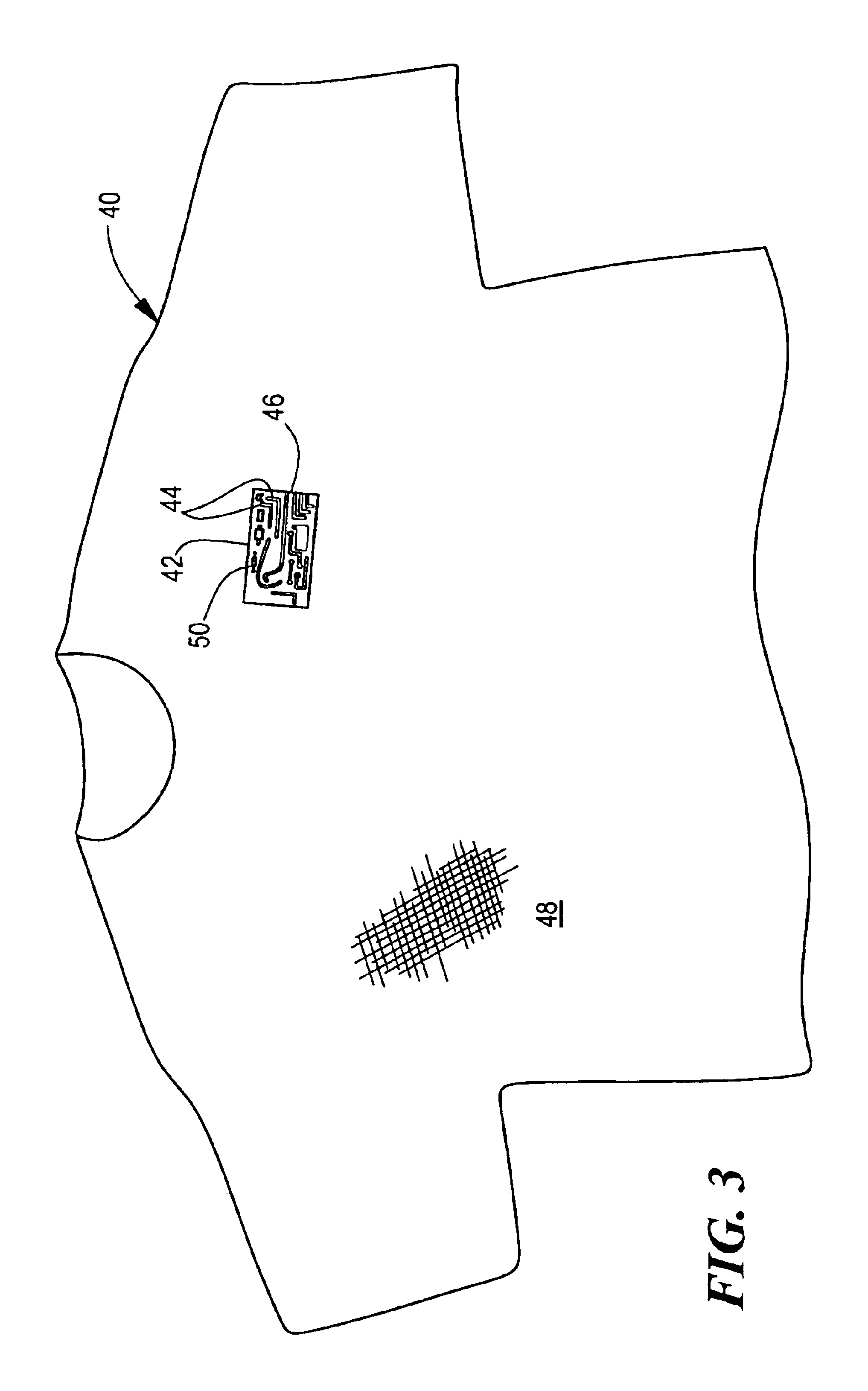

Method of manufacturing a fabric article to include electronic circuitry and an electrically active textile article

InactiveUS6729025B2Low-profileEliminate needLayered productsSemiconductor/solid-state device detailsEngineeringElectron

A method of manufacturing a fabric article to include electronic circuitry in which a flex circuit is assembled to include conductive traces and pads on a flexible substrate, a fabric article is placed on a rigid surface, and the substrate of the flex circuit is secured to the fabric article. Also disclosed is a fabric article which includes electronic circuitry and an electrically active textile article.

Owner:FOSTER-MILLER

Fabric care and perfume compositions and systems comprising cationic silicones and methods employing same

InactiveUS6903061B2Superior fabric careGood lookingInorganic/elemental detergent compounding agentsCationic surface-active compoundsSiliconeChemistry

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com