Patents

Literature

200 results about "Colored" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colored is an ethnic descriptor historically used in the United States (predominantly during the Jim Crow era), and the United Kingdom with its former colonies. In the United States, the term denoted non-"white" individuals generally. The term now has essentially the same meaning in the United Kingdom, with "coloured" thus equivalent to "people of colour".

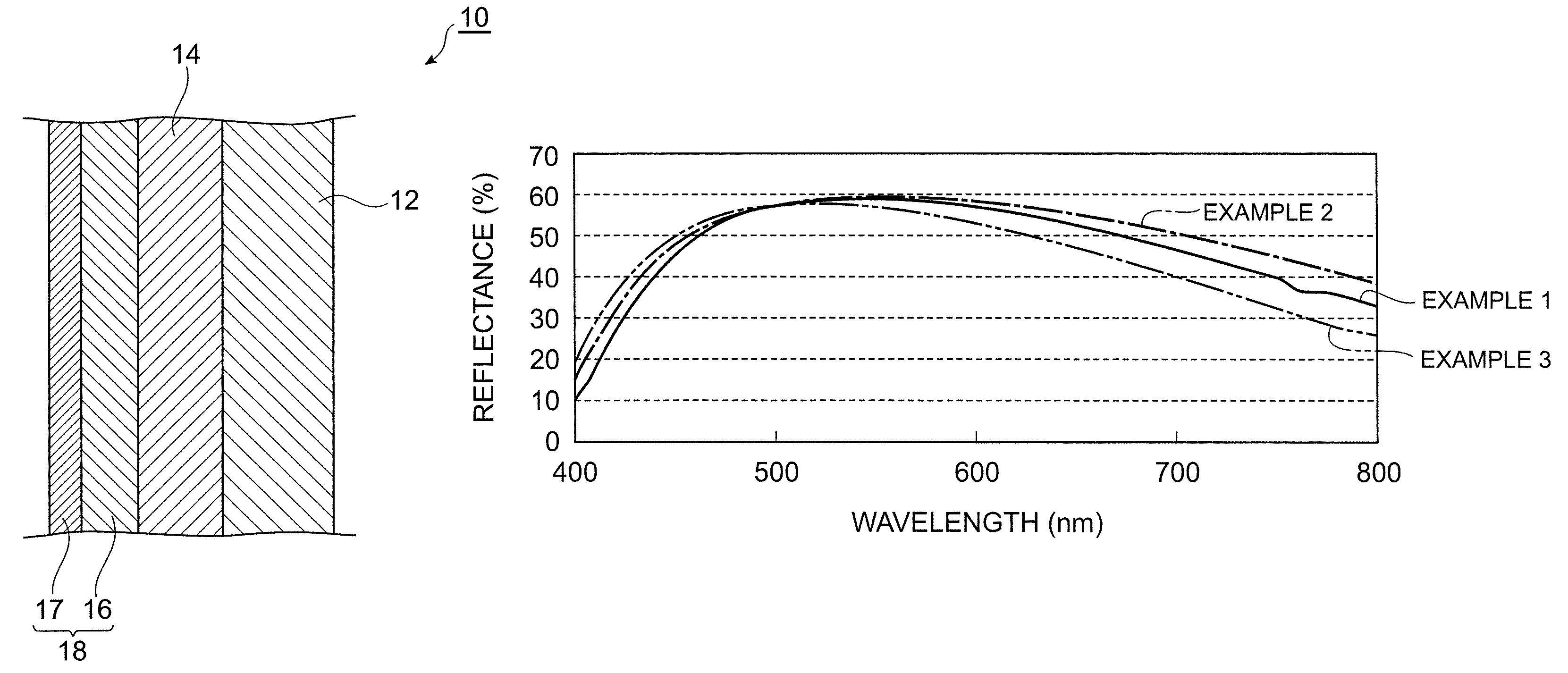

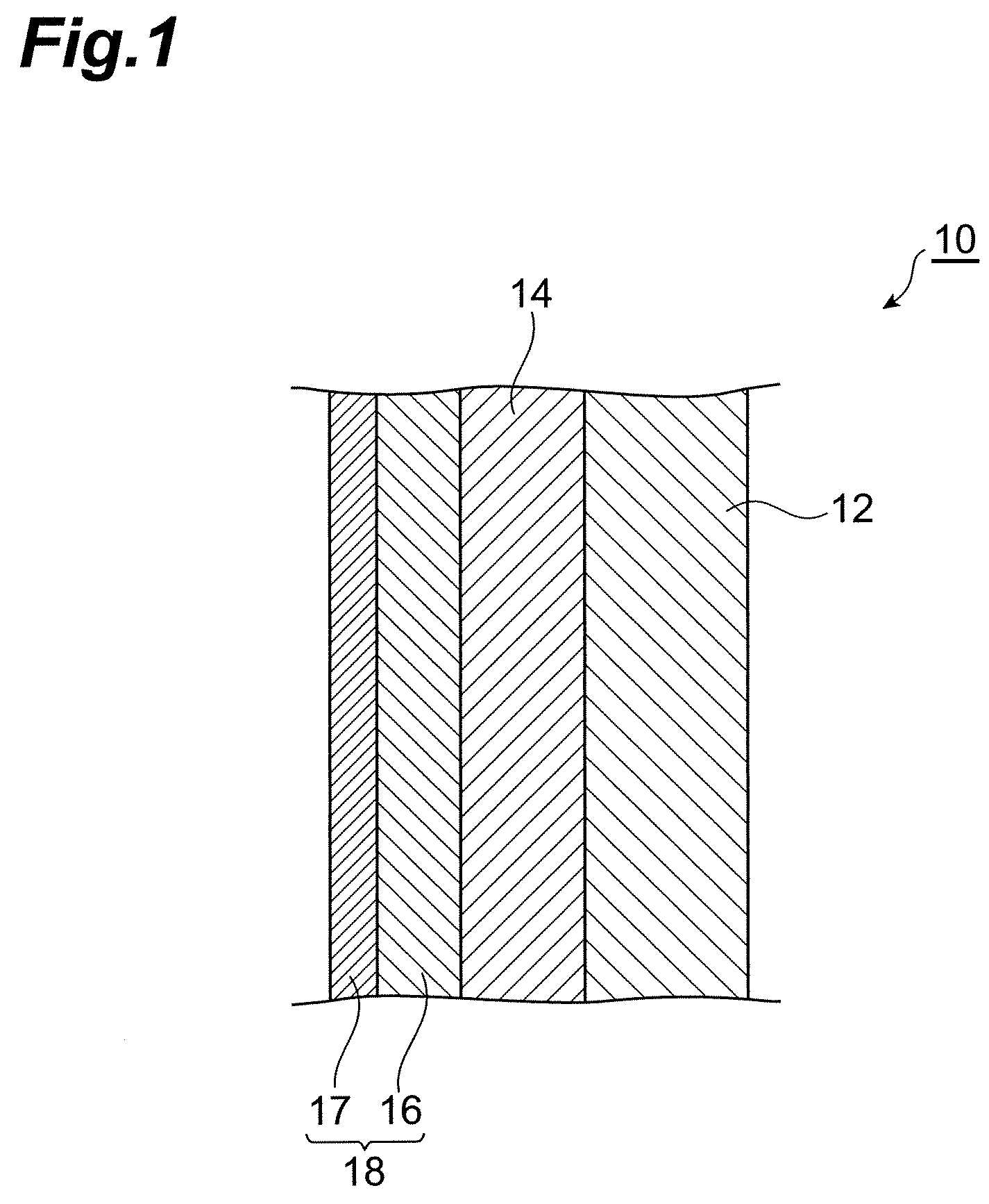

Colored anti-fog mirror

A colored anti-fog mirror that emits reflected light in response to incident light, the colored anti-fog mirror comprising a substrate, a hydrophilic functional layer containing a photocatalytic substance, and a metallic reflecting film provided between the substrate and the hydrophilic functional layer, wherein a material of the metallic reflecting film and a thickness of the hydrophilic functional layer are set such that the reflected light has a spectral reflection spectrum having a maximum reflectance in the visible region over 510 nm and not more than 600 nm.

Owner:MURAKAMI CORP

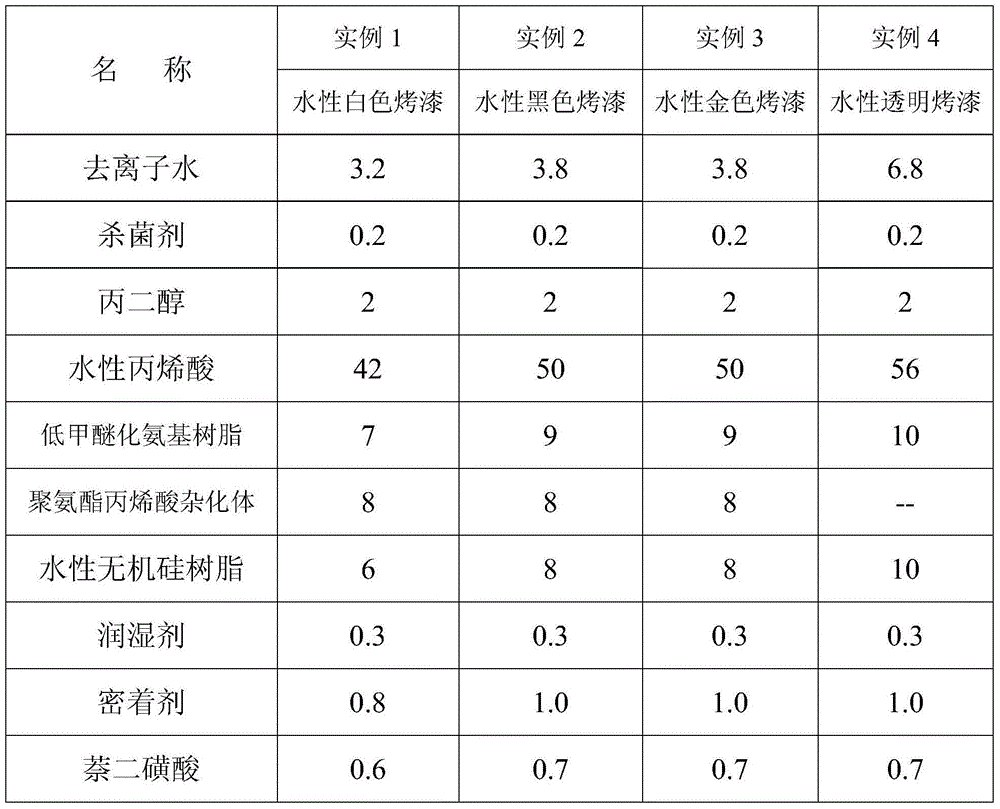

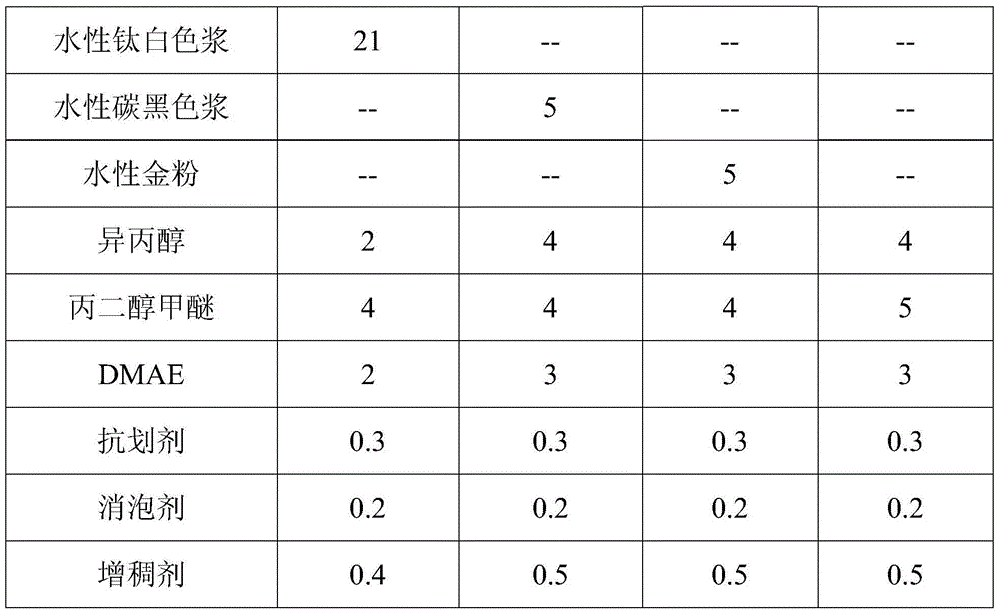

Preparation method for high-hardness water-based glass baking paint

ActiveCN103937354AHigh hardnessNo pollution in the processPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention relates to a preparation method for a high-hardness water-based glass baking paint composed of nano water-based acrylic resin, low-methoxylation amino resin, a water-based polyurethane acrylic hybrid, hardening resin, a colorant, a substrate wetting agent, an adhesive agent, an acid catalyst, a film-forming auxiliary agent, a defoaming agent, an anti-scratch flatting agent, a thickening agent, a bactericide, a pH regulator, a cosolvent and water. The prepared water-based glass baking paint has the advantages of low VOC, no pollution to the environment, no poison and harm to operators, strong coating film adhesive force, good flexibility, high hardness, excellent wear resistance, excellent water resistance, excellent alcohol resistance, excellent salt fog resistance, simple construction, and stable storage. A prepared paint film has the hardness reaching 5 H or more, and has anti-scratch and wear-resistance properties of a ceramic glaze film; a prepared glass product achieves effects of blue and white porcelain, enamel colored glaze porcelain, and white glazed porcelain; and the water-based glass baking paint is widely used for surface protection and decoration of wine bottles, perfume bottles, glass products, lamps, woodware, metals, plastics and other products.

Owner:深圳市莱莉雅环保科技有限公司

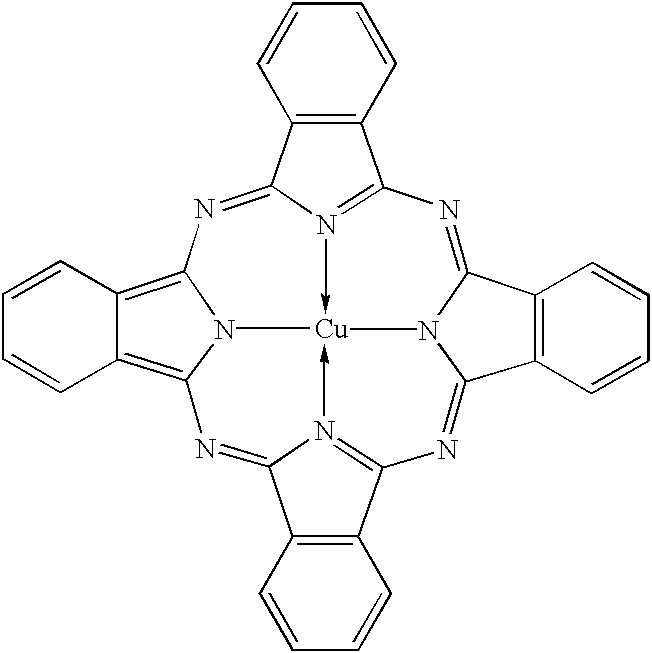

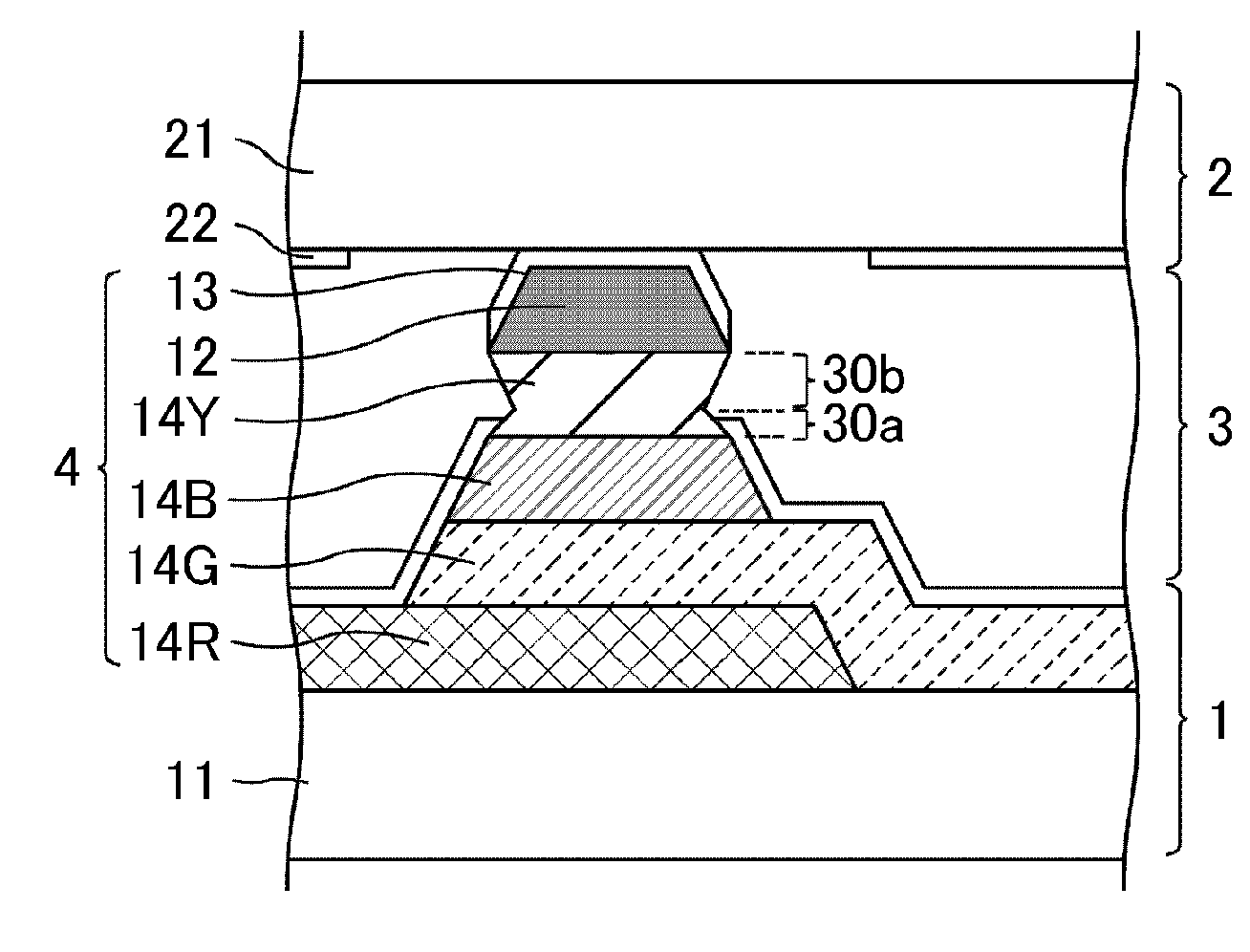

Multi-colored organic EL device with protective layer

InactiveUS6563263B1Discharge tube luminescnet screensElectroluminescent light sourcesCharge carrierFluorescence

A multi-colored organic EL device for a flat display includes a transparent substrate, a plurality of phosphor layers arranged on a surface of the substrate as a color conversion filter, a protective layer flatly coated on the phosphor layers, and an organic EL cell formed directly on the protective layer. The protective layer is formed of a coating resin having a curing temperature not to cause deterioration in the fluorescence of the phosphor layers, a glass transition temperature more than 100° C., and surface hardness more than 2H on the pencil hardness. The organic EL cell includes a light-emitting layer for emitting light when carriers are injected therein. The protective layer keeps the phosphor layers intact and can coat flatly over uneven phosphor layers. The protective layer prevents effects of post-coating processes on the phosphor layers, and allows direct formation of the organic EL cell on the protective layer.

Owner:SHARP KK

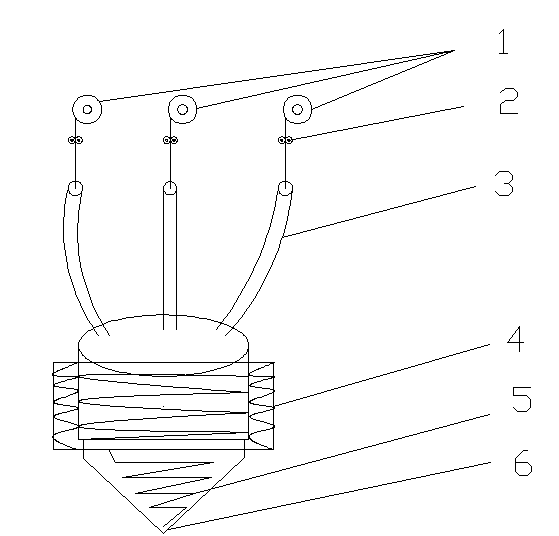

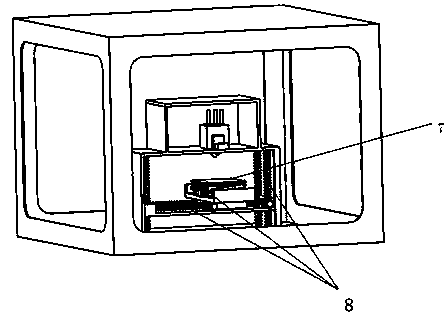

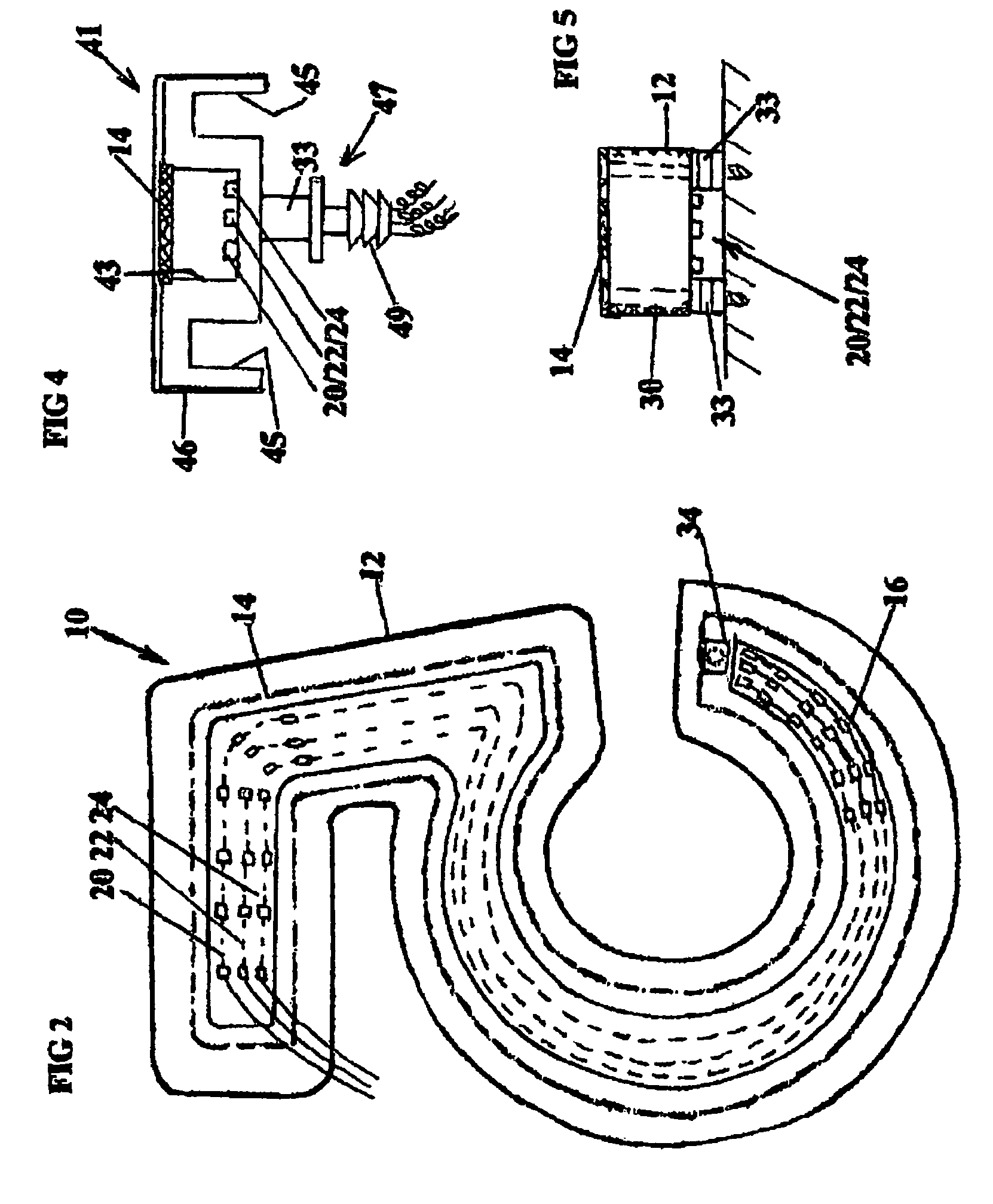

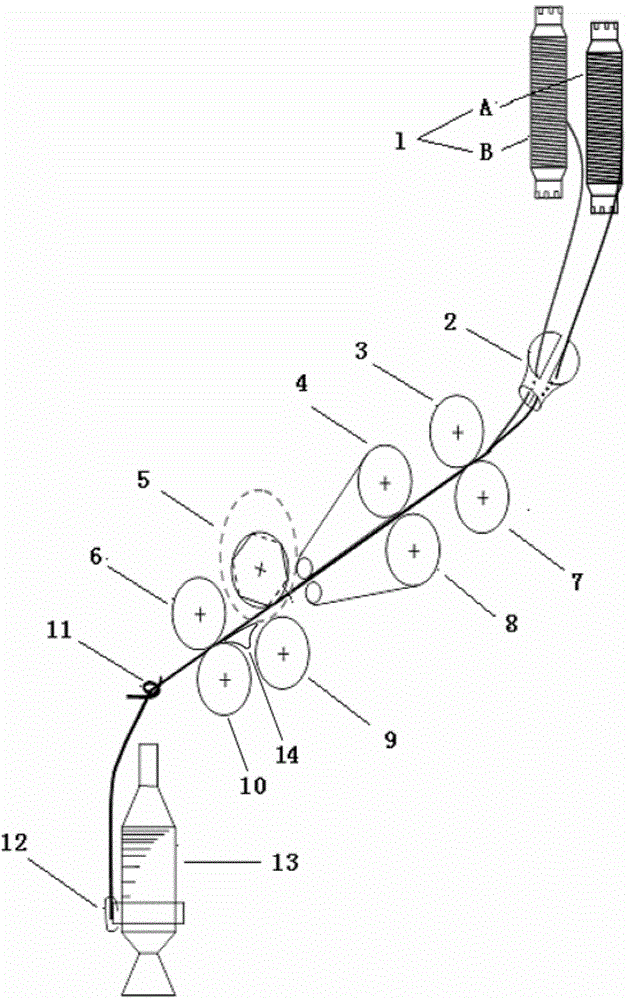

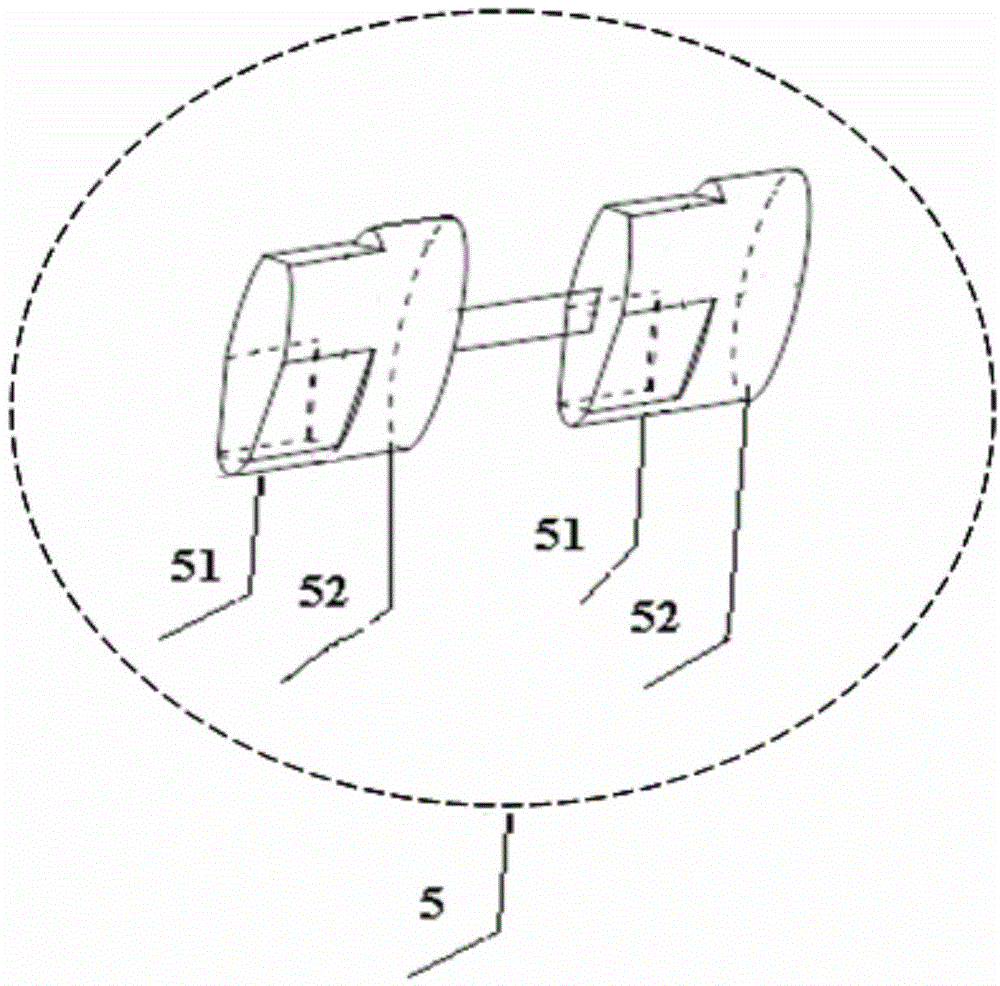

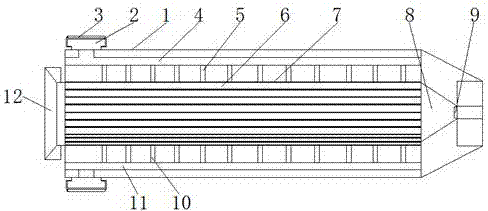

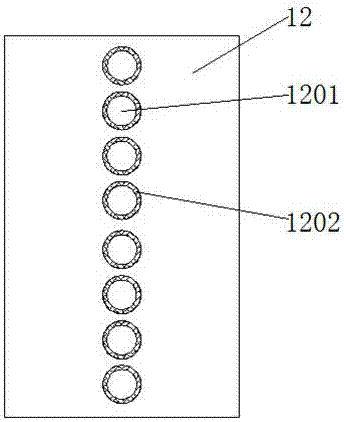

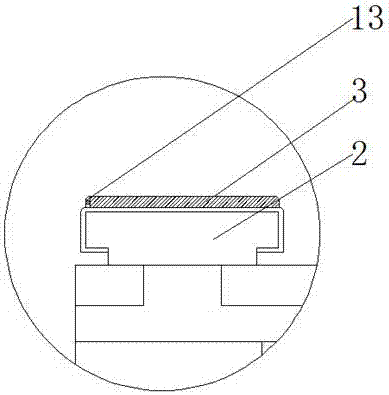

Colored 3D (Three Dimensional) printing equipment using fused deposition modeling method

InactiveCN103895228ARich printing applicationsCan only print monochromeAdditive manufacturing apparatus3D object support structuresControl systemColored

The invention provides colored 3D (Three Dimensional) printing equipment using a fused deposition modeling method. The colored 3D printing equipment comprises three sets of feeding mechanisms for filamentary raw materials with red, yellow and blue base colors, a material mixing heater (4), a static / dynamic pipeline material mixer (5), a replaceable type printing nozzle (6), a three-dimensional motion molding platform (7) with a heating function and an equipment control system, wherein the feeding mechanisms are composed of a discharging scroll (1), a stepping type motor feeding machine (2) and a feeding guide pipe (3). The colored 3D printing equipment is characterized in that a three-primary-color principle is utilized, namely the red, yellow and blue colors are mixed according to a proper ratio to obtain nearly all colors in the natural world; thermoplastic raw material fused wires or powder with the red, yellow and blue colors can be heated and mixed according to different ratios to form different colored printing materials, and then the fused deposition modeling (FDM) method is used for carrying out 3D printing to obtain a colored product. The colored 3D printing equipment has the beneficial effects that the disadvantage that a current colored 3D printing equipment using the fused deposition modeling method only can be used for printing a single-color or double-color product is overcome; the post-period coloring and processing time of the product is shortened, the working efficiency is improved and a 3D printing application is enriched.

Owner:王利民

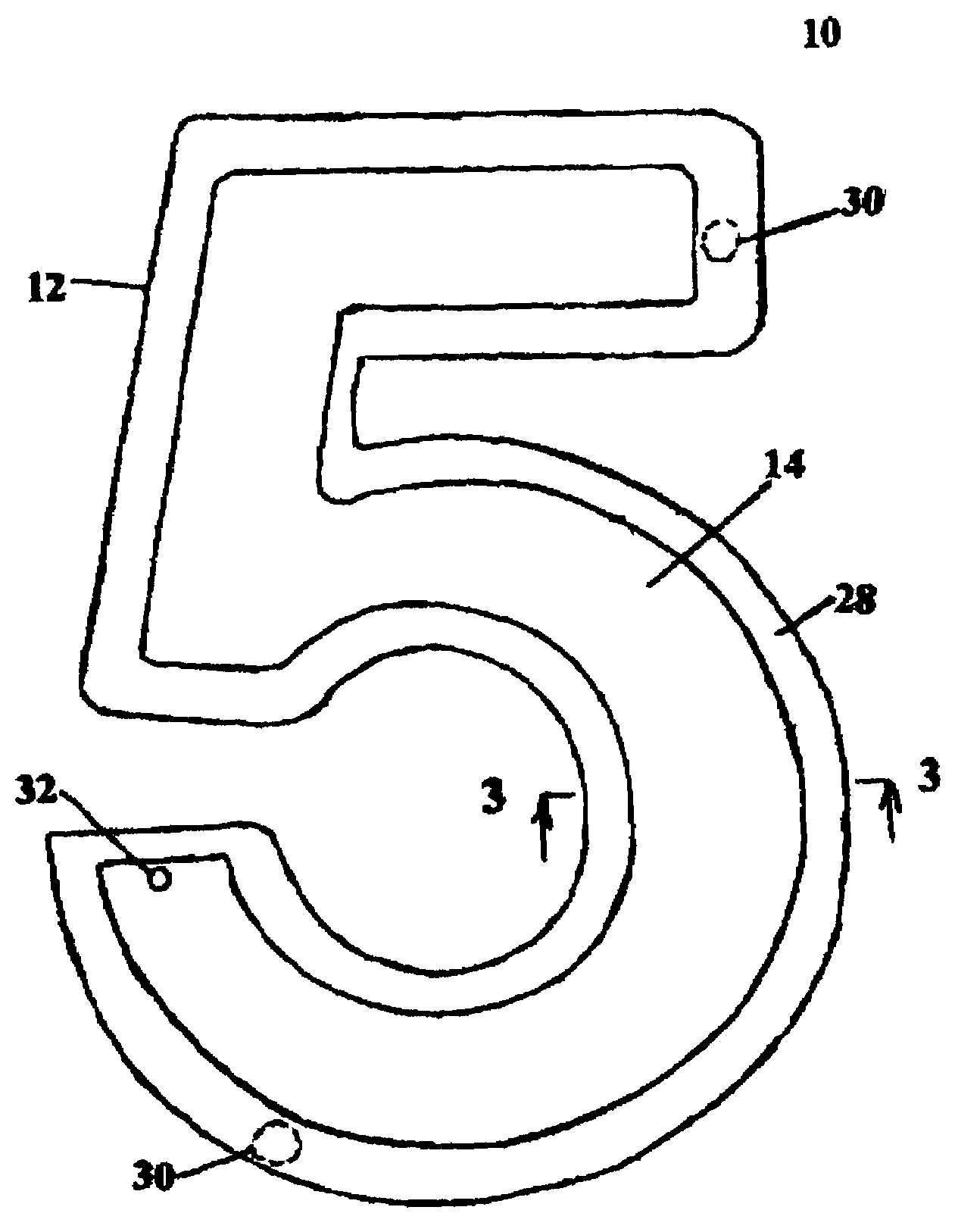

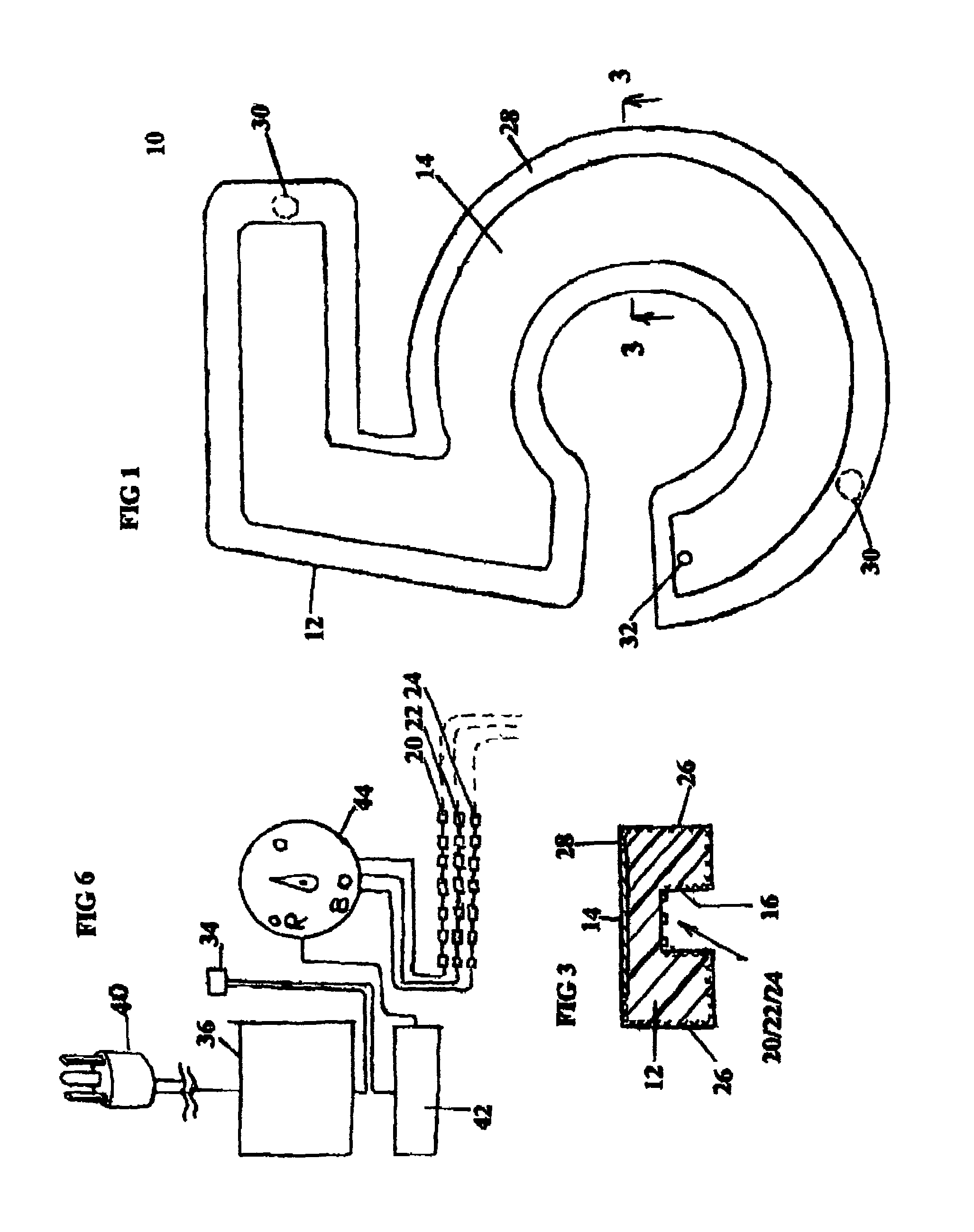

LED illuminated house number and sign characters

InactiveUS7685753B2Protection conditionIncreased longevityLighting support devicesPoint-like light sourceEffect lightColored

Owner:SLOWSKI DARREL R

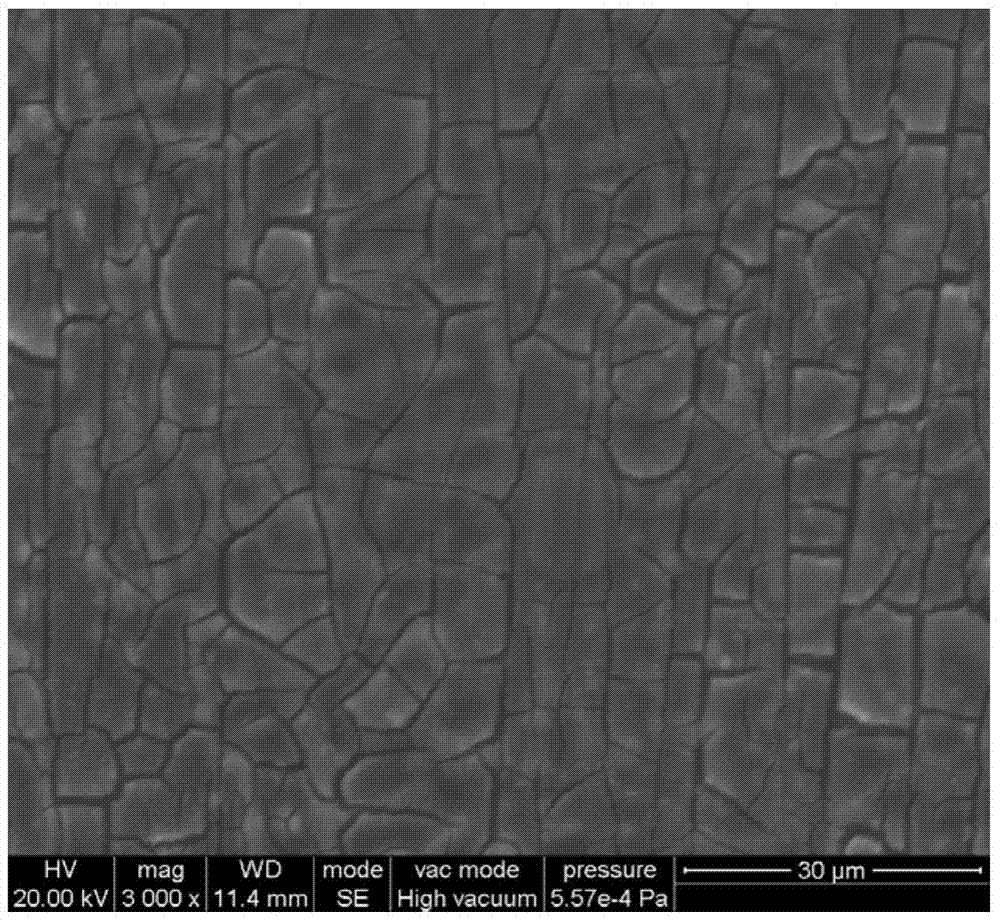

Antibacterial colored profiled ultrafine denier polyester filament and preparation method thereof

InactiveCN104562236AReduce releaseRelease rate is stable and long-lastingFilament forming substance formingMelt spinning methodsPolyesterBreaking strength

The invention relates to an antibacterial colored profiled ultrafine denier polyester filament and a preparation method thereof. The antibacterial colored profiled ultrafine denier polyester filament is that the elongation of single fiber under the temperature of 30 DEG C is 25 to 30%, the breaking strength is 2 to 3.5cN / dtex, and the boiling water shrinkage is 1 to 7%. The preparation method comprises two steps, namely, preparing antibacterial colored master batch, and preparing antibacterial colored profiled ultrafine denier fibers. The antibacterial colored profiled ultrafine denier polyester filament is colored, antibacterial, ultrafine denier, and profiled; the ultrafine denier fibers have capillary effect and slots are formed in the fiber surface due to the profiled performance, so that sweet on the body surface can be conveyed out of the body and volatilized under the negative pressure effect of capillary and by the slots; the prepared fibers have the characteristics of absorbing moisture and releasing sweat, being dry and comfortable, antibacterial, antiseptic, rich in color, and soft to touch.

Owner:嘉兴金旭新材料科技有限公司 +1

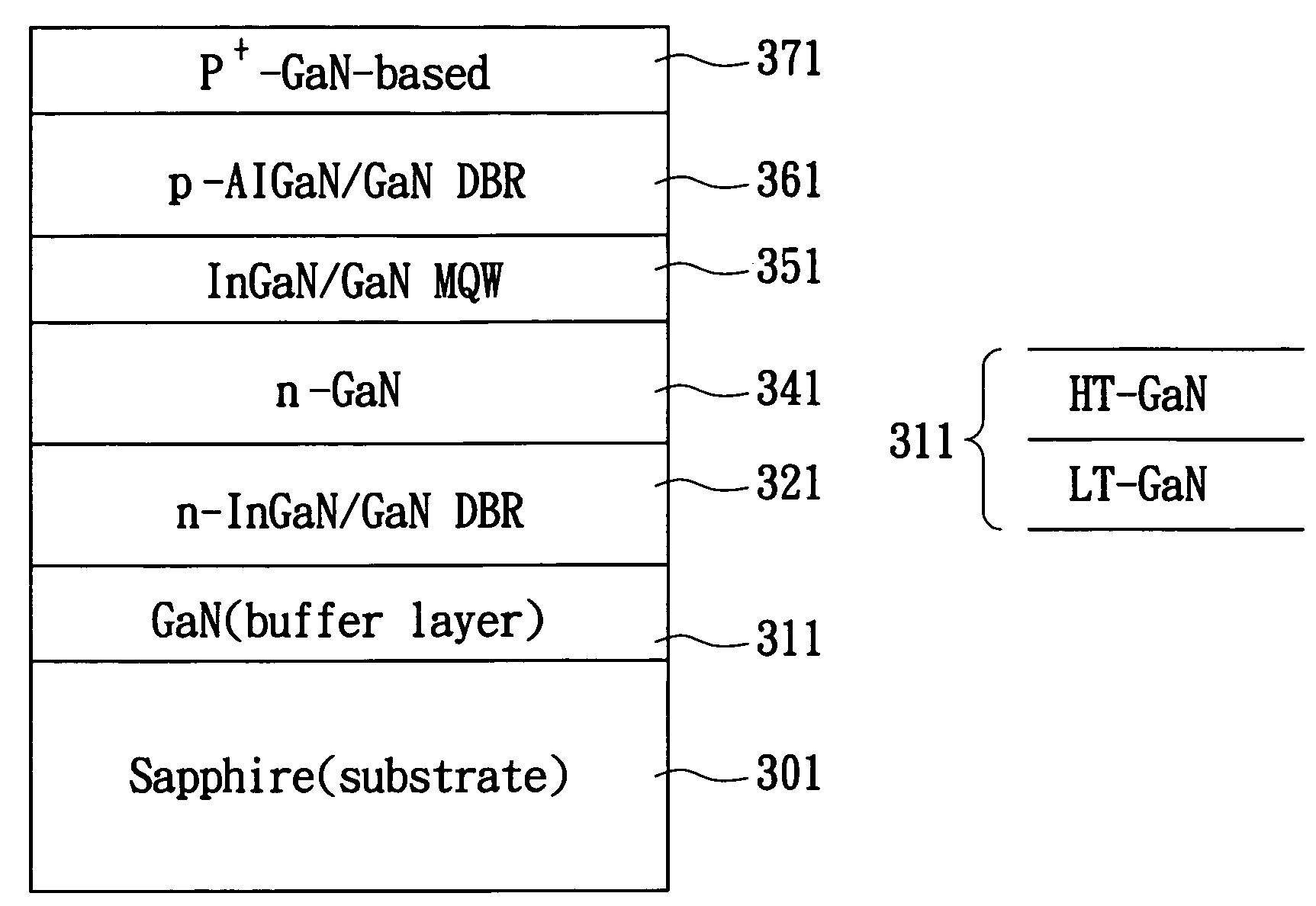

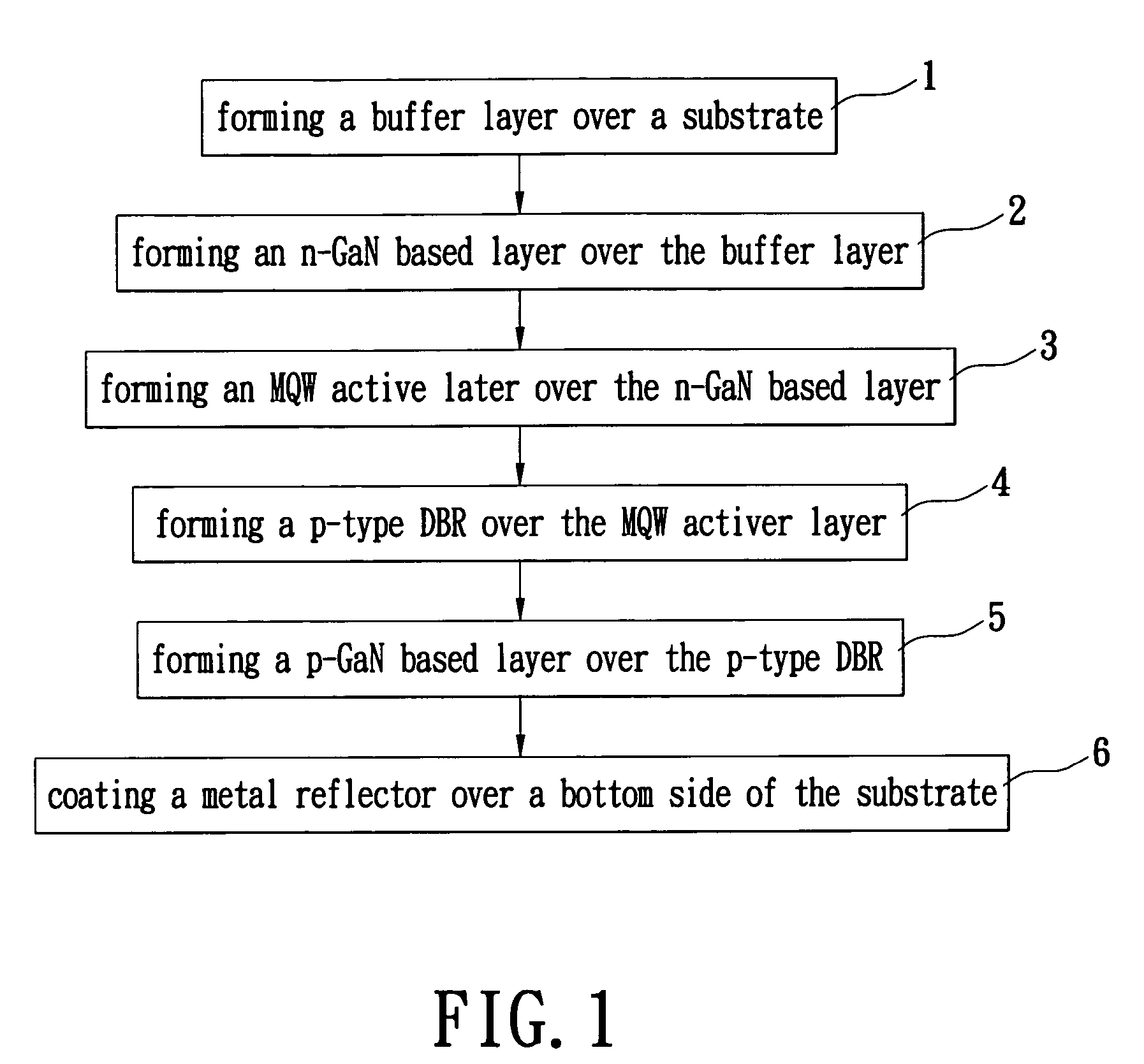

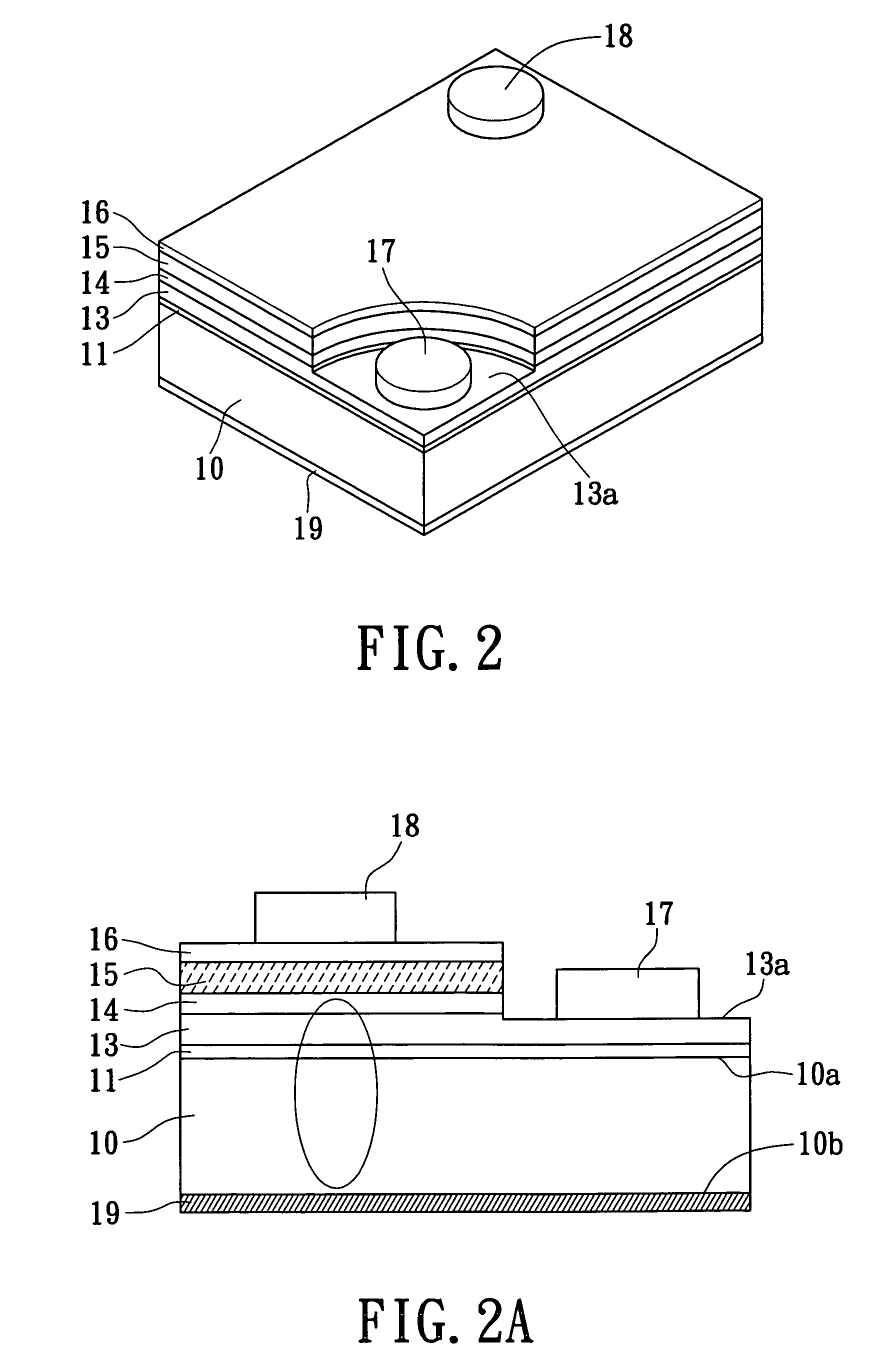

Gallium nitride based light-emitting device

InactiveUS7345315B2Low costSimple manufacturing processSemiconductor/solid-state device manufacturingSemiconductor devicesResonant cavityColored

A manufacturing method and a thus produced light-emitting structure for a white colored light-emitting device (LED) and the LED itself are disclosed. The white colored LED includes a resonant cavity structure, producing and mixing lights which may mix into a white colored light in the resonant cavity structure, so that the white colored LED may be more accurately controlled in its generated white colored light, which efficiently reduces deficiency, generates natural white colored light and aids in luminous efficiency promotion. In addition to the resonant cavity structure, the light-emitting structure also includes a contact layer, an n-type metal electrode and a p-type metal electrode.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

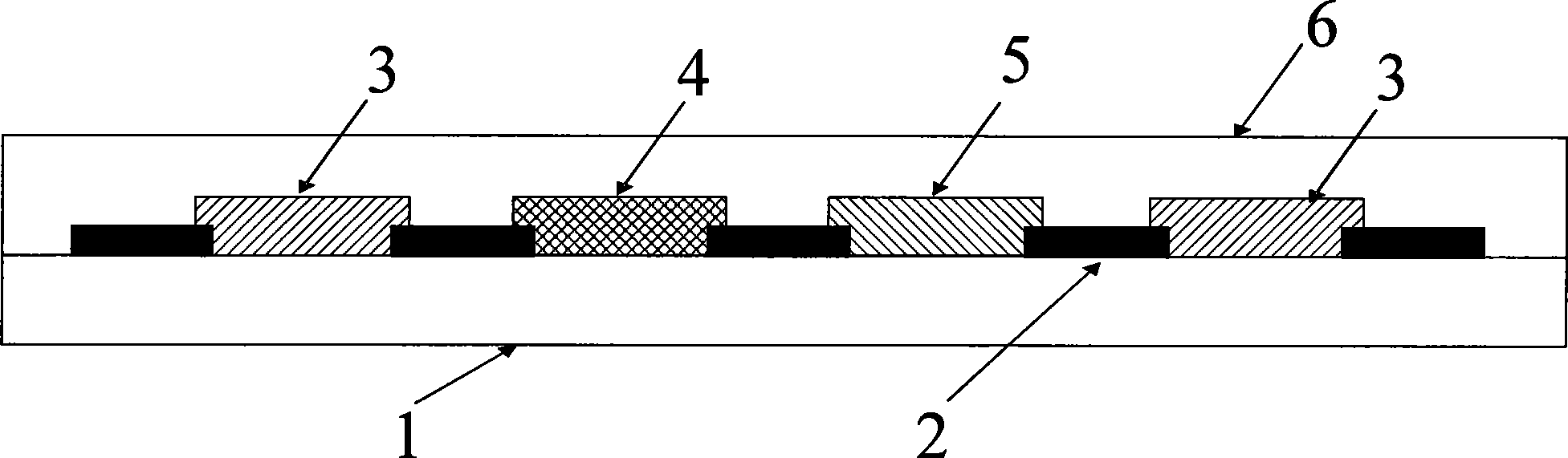

Colored filter board

InactiveCN101430397AReduce production processReduce manufacturing costNon-linear opticsOptical elementsColoredEngineering

The invention relates to a color filter plate which comprises a glass substrate, a blue light filter and a red light filter which is formed on the glass substrate, wherein, the red light filter is partially overlapped with the blue light filter to form a shading region. The color filter plate does not need a manufacturing process of a black matrix in a black filter plate, and lower the production cost of the color filter plate.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

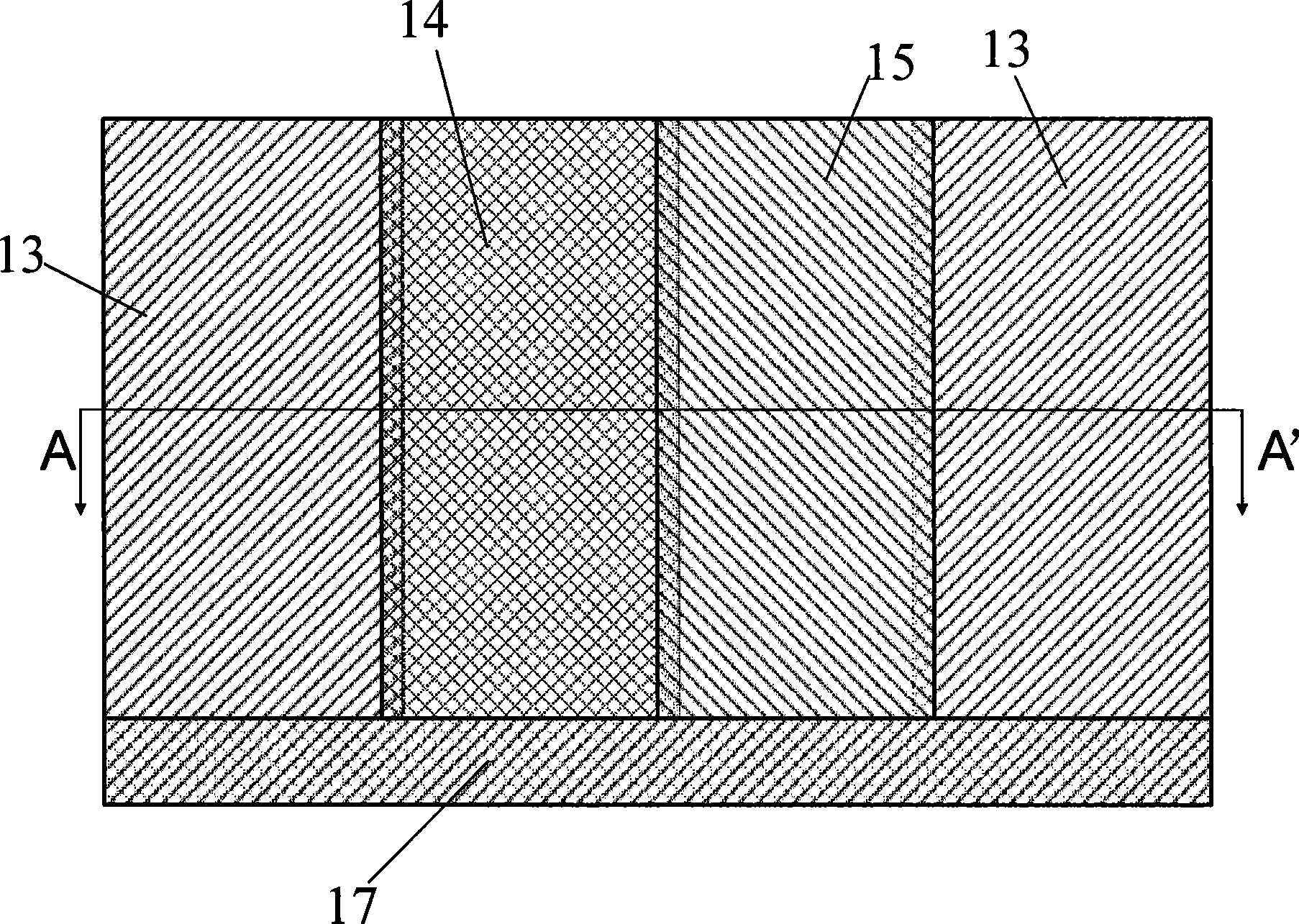

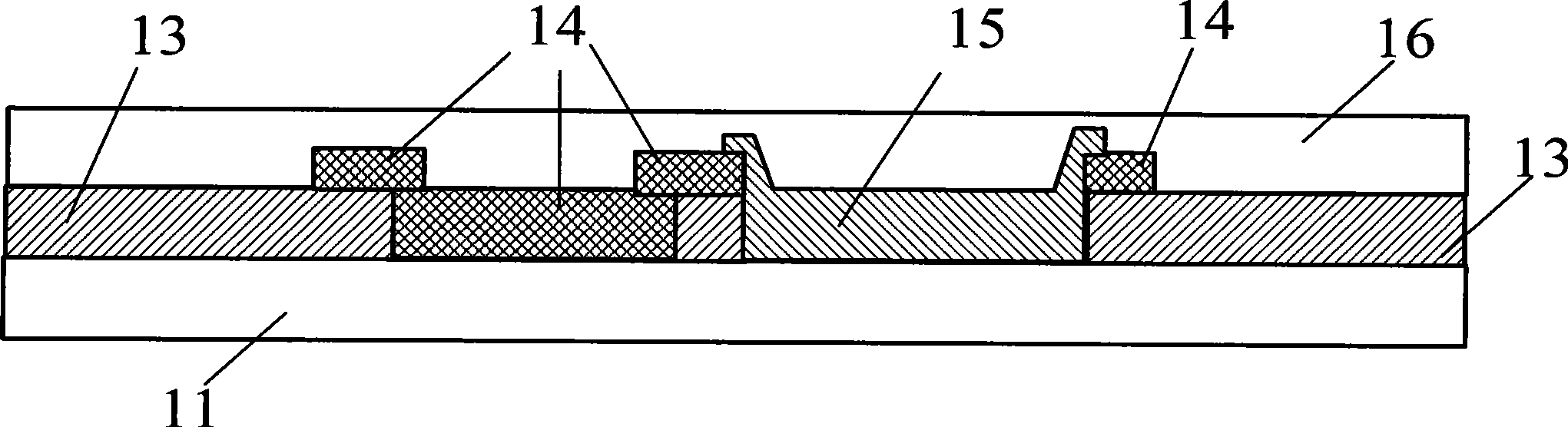

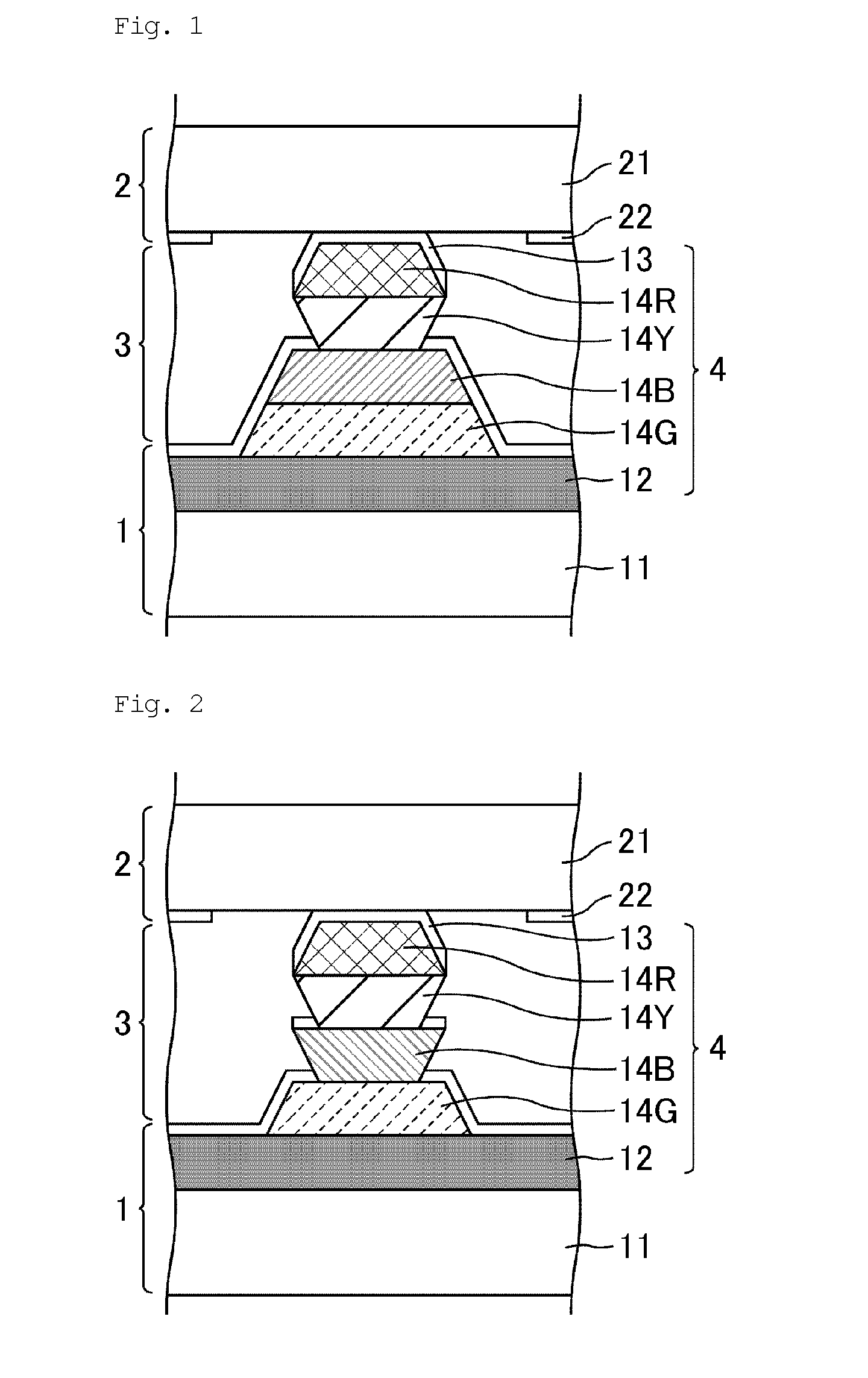

Color filter substrate and liquid crystal display device

The present invention provides a color filter substrate for preventing an electrical short circuit between an electrode and other members at a place upper than the colored transparent layers disposed in a stack, and further preventing electrical disconnection on colored transparent layers other than the colored transparent layers in a stack, in the case where colored transparent layers are disposed in a stack and an electrode is stacked over the entire surface. The color filter substrate of the present invention comprises:colored transparent layers disposed side by side; andcolored transparent layers disposed in a stack,wherein an electrode is disposed at a place upper than the colored transparent layers disposed side by side and an electrode is disposed at a place upper than the colored transparent layers disposed in a stack,the colored transparent layers disposed in a stack include a colored transparent layer having a reverse tapered shape, andthe uppermost layer of the colored transparent layers disposed in a stack has a forward tapered shape.

Owner:SHARP KK

Colored union yarn containing cashmere and processing method thereof

The invention discloses a colored union yarn containing cashmere and a processing method thereof, wherein the union yarn comprises viscose fibers with weight ratio of 50 %, 45% lustre wool fibers and 5% cashmere fibers, wherein at least part of or the whole of one of the fibers is dyed, the dyed fiber and unfinished fibers are spun into the colored union yarn containing cashmere after mixing through spinning procedures. The process method comprises that dying the fibers, then spraying oil solution on the dyed fibers to stew for tens of hours, and mixing the fibers in different colors and different proportions after weighing, and installing the fibers on a spinning machine to be spun into the colored union yarn. The technical scheme of the invention can reduce the pollution of the dying process to environment, can enrich the color of the union yarn, and reduces the cost required by the finishing process after dying.

Owner:江阴市茂达棉纺厂有限公司

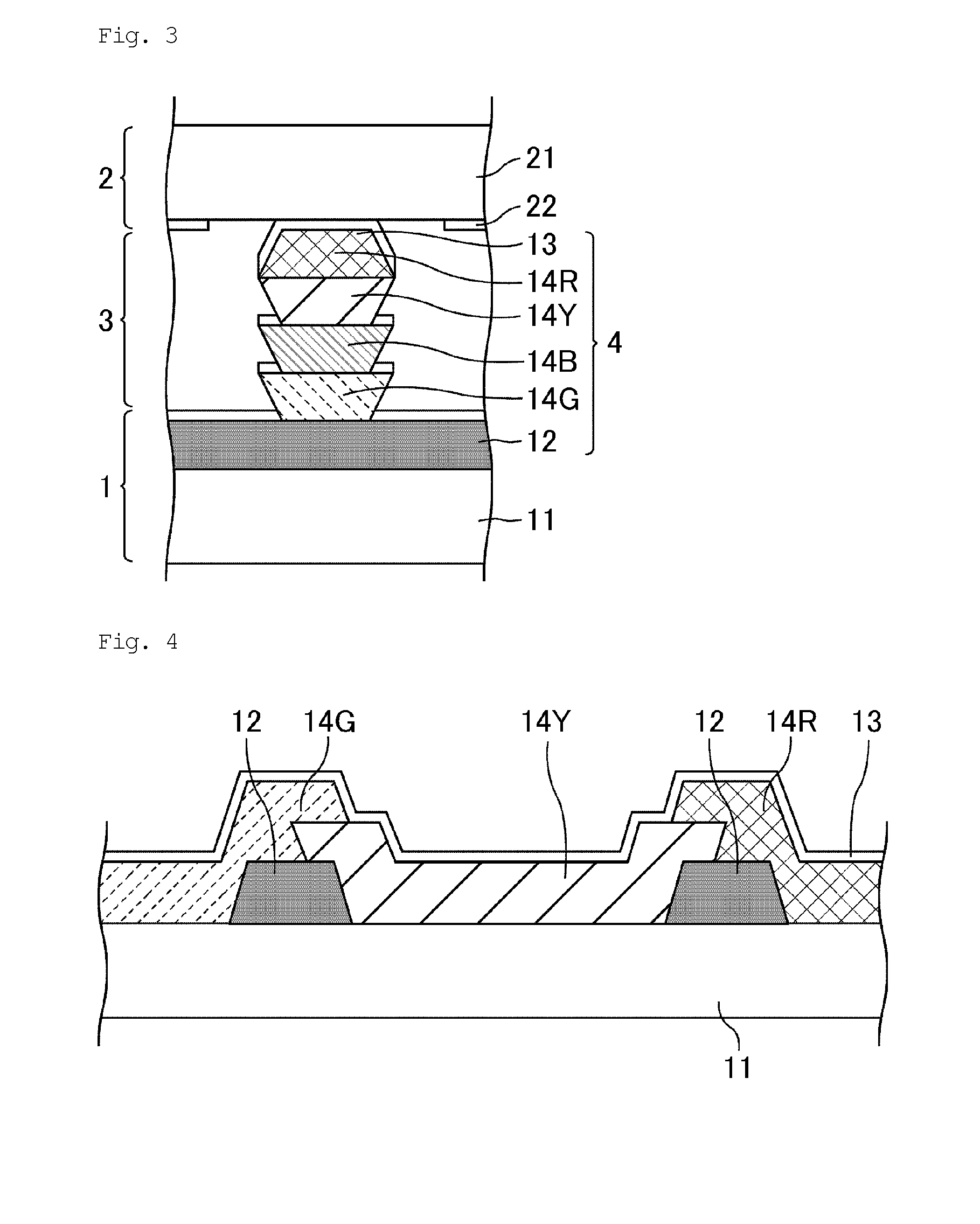

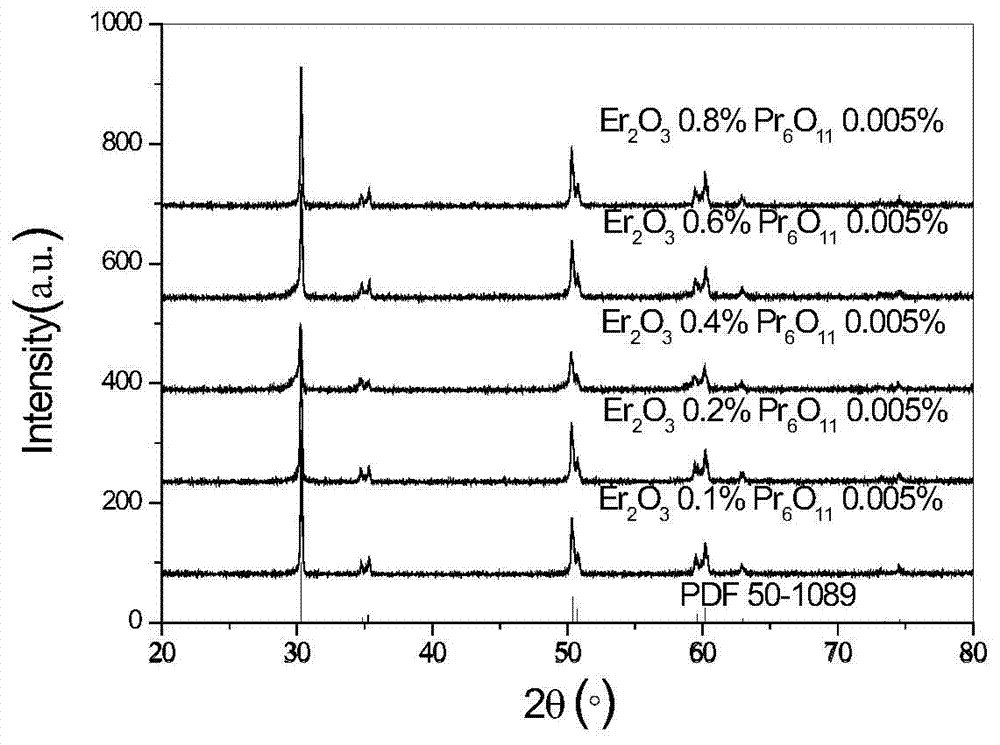

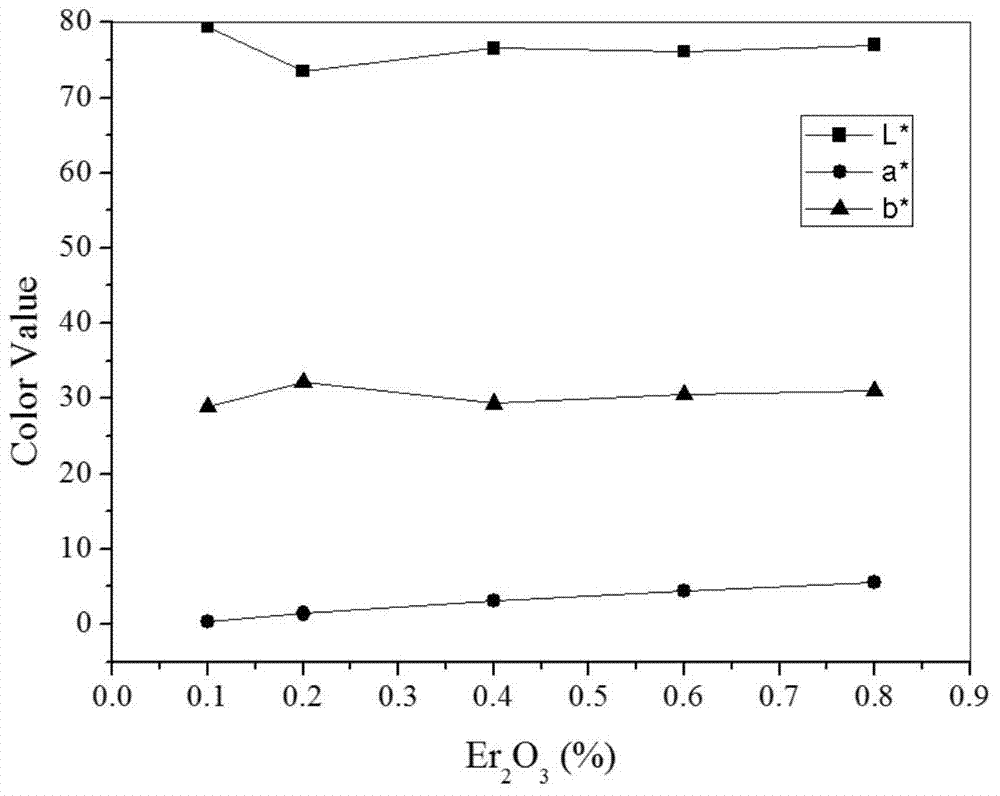

Dental colored zirconia ceramic material and its preparation method

The invention discloses a dental colored zirconia ceramic material and its preparation method. The method comprises the steps of: (1) weighing ZrO2, Pr6O11 and Er2O3, employing a ball mill to conduct ball milling and drying; (2) adding a high polymer binder into the dried powder to perform granulation; (3) subjecting the granulated powder to dry-pressing molding; (4) conducting isostatic cool pressing on a molded ceramic block; and (5) sintering the ceramic block subjected to isostatic cool pressing, thus obtaining the dental colored zirconia ceramics. The dental colored zirconia ceramics provided by the invention have a color close to that of natural teeth, its chromatic value distribution can cover an entire shade guide, and the color stability is good.

Owner:TSINGHUA UNIV

Production technology of colored spun yarn woven fabric

ActiveCN106283351AEmission reductionSubtle colorDry-cleaning apparatus for textilesDyeing processPolyesterYarn

The invention relates to a production technology of colored spun yarn woven fabric. The production technology specifically comprises (1) selection of raw materials: cotton fibers are taken as the main raw material and viscose, tencel and polyester are also included; (2) pretreatment of the cotton fibers: the cotton fibers are subjected to soda boiling and oxygen bleaching; (3) dyeing: anhydrous sodium sulfate is added twice in the dyeing process; (4) aftertreatment of the fibers: the dyed fibers are further softened; (5) spinning; (6) weaving; (7) performing of a gray fabric finishing process. The prepared colored spun yarn has a dim three-dimensional effect, has implicit color, is pure, natural and layered and touches soft, and the production process is environment-friendly.

Owner:HUAFANG

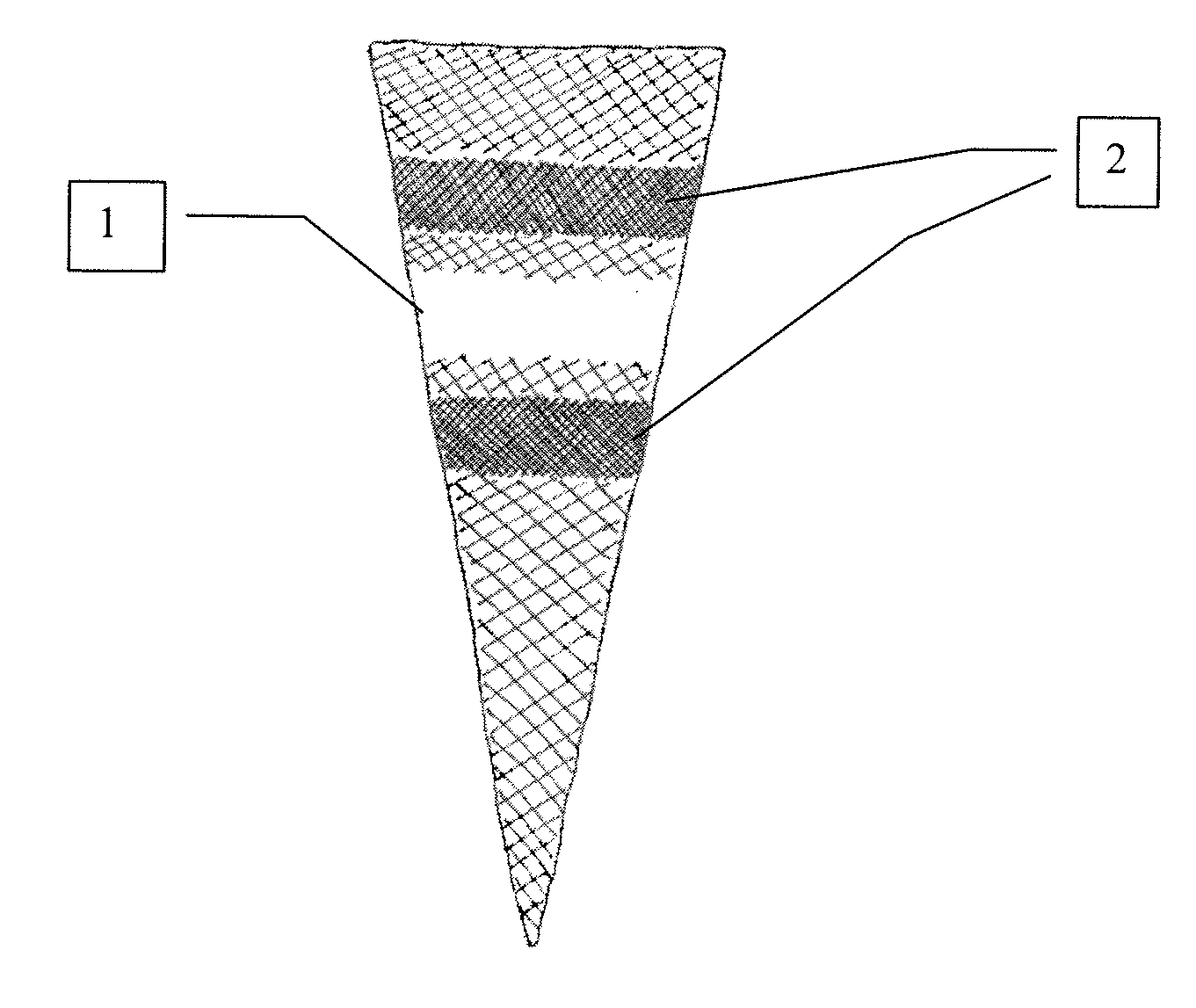

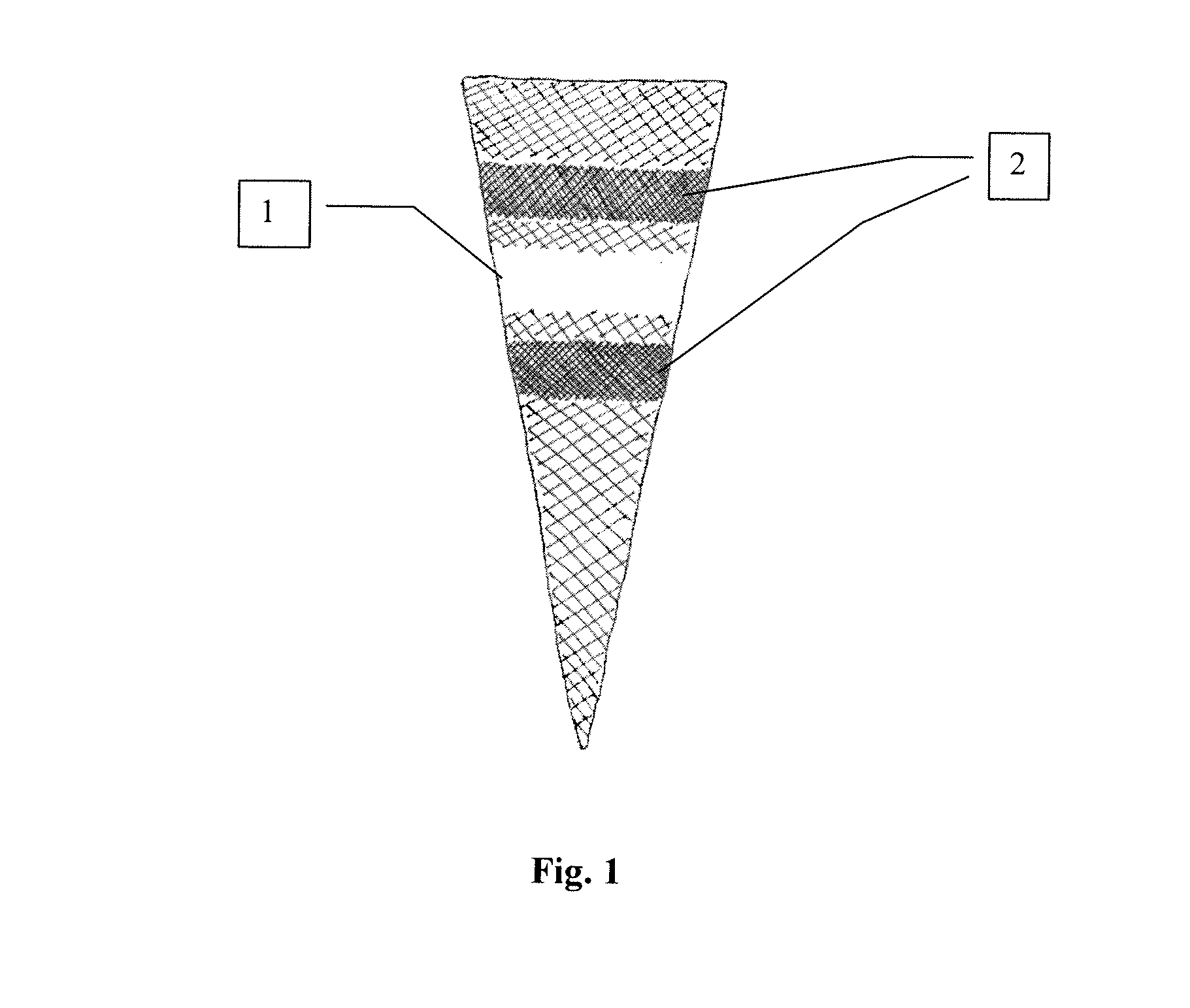

Multi-colored cake cones

The present invention relates to a multi-colored baked cake cone typically for holding ice cream or other confection novelties. This cone is made of a dough bi-layer that includes at least a first layer of a conventional cake dough that contains sugar and a second layer of a modified cake dough that imparts at least one color other than brown to the cone after baking. The cone is typically associated with a sleeve that is at least partially transparent to display the multicolor cone.

Owner:SOC DES PROD NESTLE SA

Colored spun yarn color matching method based on neural network

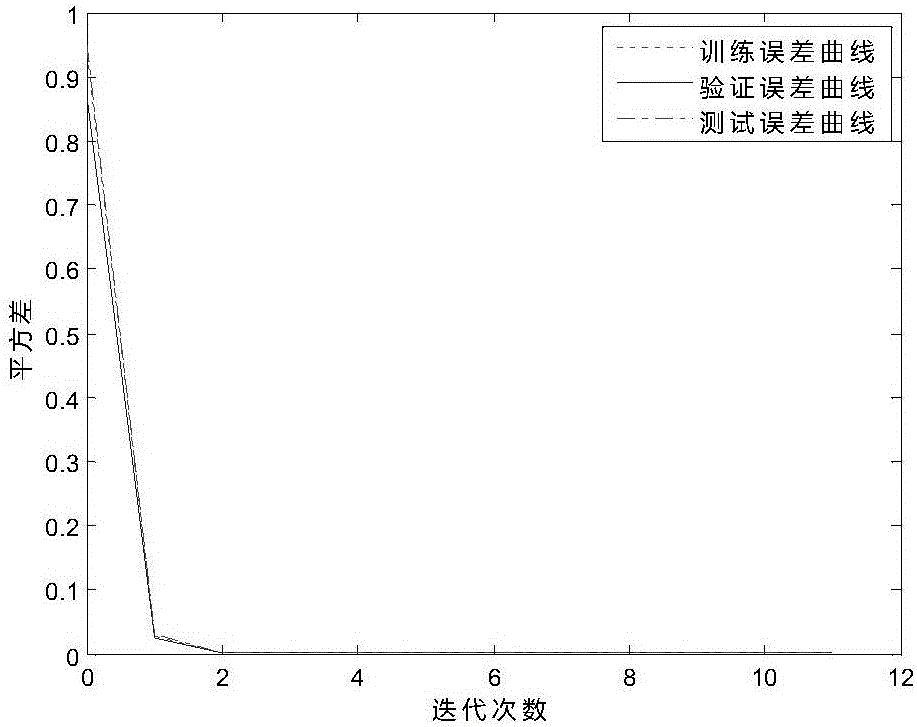

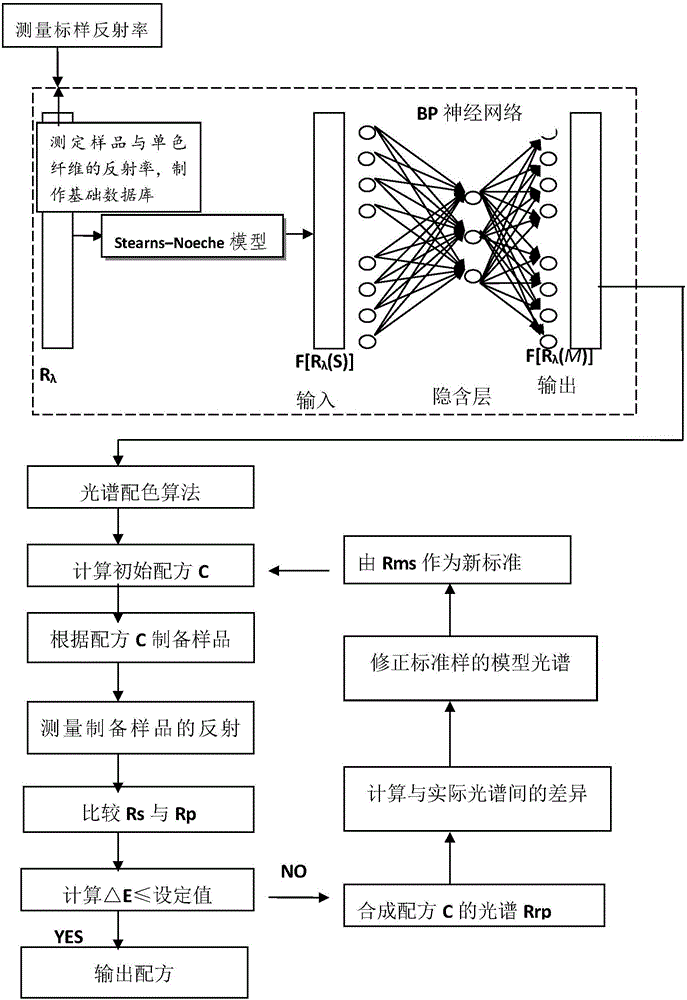

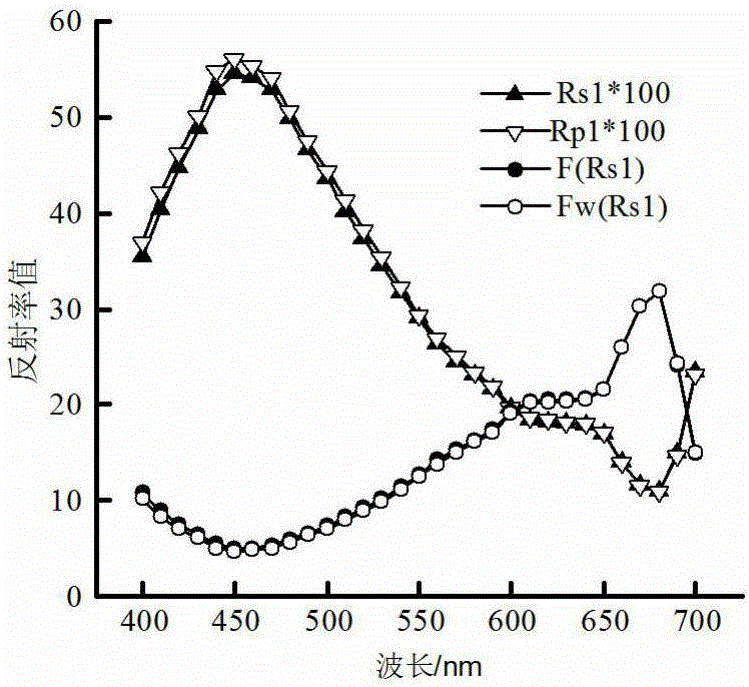

ActiveCN105787559AAccurate color matching methodAccurate color matchingNeural learning methodsYarnPattern recognition

The invention relates to a colored spun yarn color matching method based on a neural network. The method comprises the following steps of: (1) measuring a standard sample reflectivity, and converting the standard sample reflectivity into a model reflectivity; (2) utilizing a BP neural network to calculate a weight-average model reflectivity F(Rw); (3) utilizing a constraint least square method to obtain a formula C forecast scheme; (4) according to the forecasted formula, carrying out sample making, and measuring the reflectivity Rp of the sampled color; and (5) calculating the color difference between the standard sample reflectivity Rs and the reflectivity Rp of the sampled color, if the color difference meets a set requirement, completing color matching, and if not, entering a formula correcting program.

Owner:JIAXING UNIV

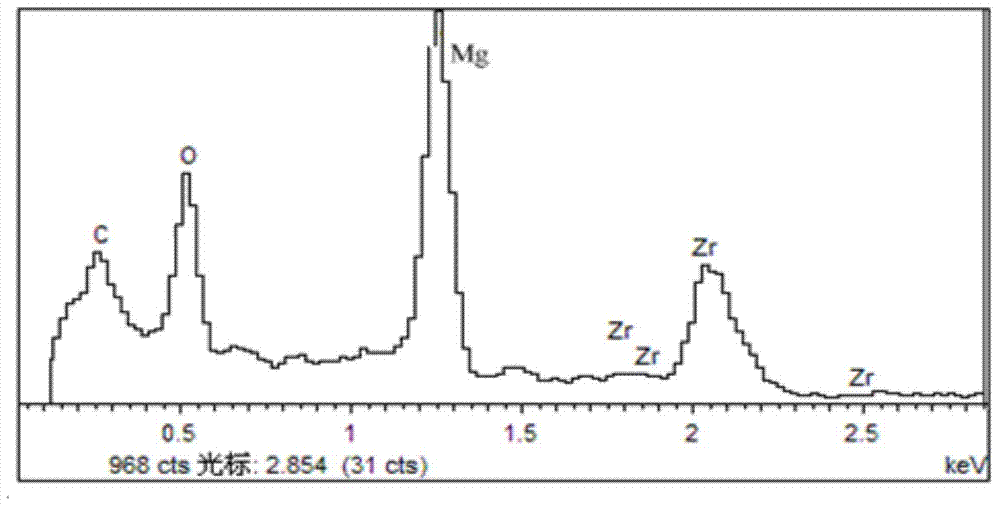

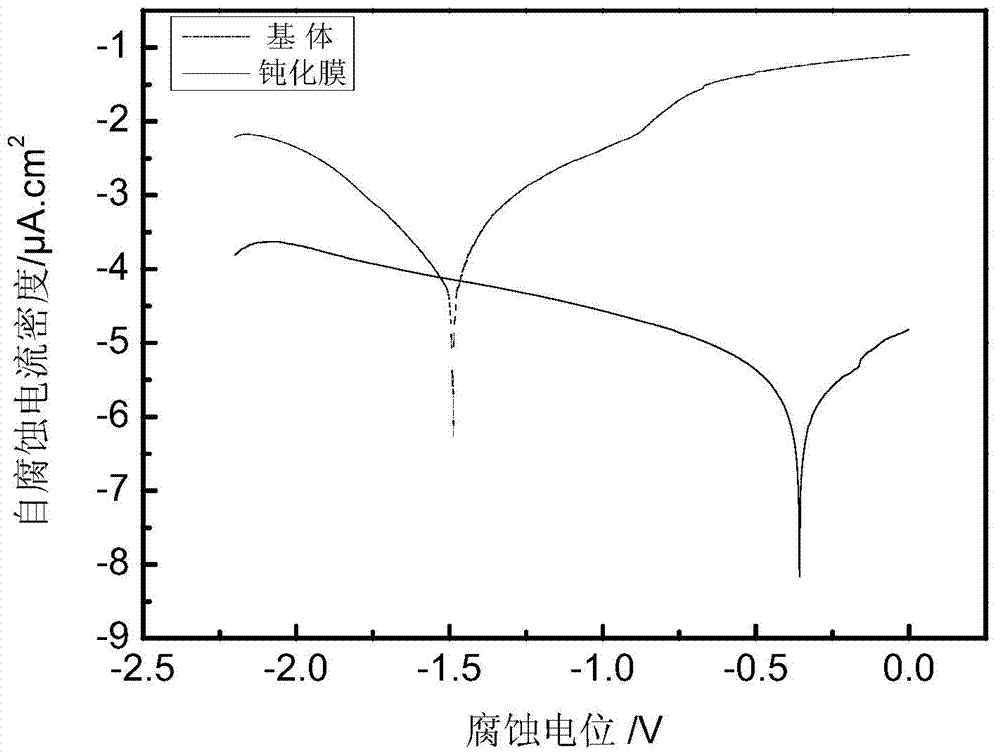

Treatment liquid and treatment method for preparing zirconium-based colored conversion film on magnesium alloy surface

The invention discloses treatment liquid for preparing a zirconium-based colored conversion film on a magnesium alloy surface, wherein each liter of treatment liquid contains 0.2-2.5 g of zirconium-containing main film forming agent, 0.2-1.5 g of zirconium-containing film forming oxidant, 0.5-1.5 g of film forming aid, 0.5-3.0 g of complexation colorant, 0.5-2.0 g of solution pH buffer agent and 0.01-0.05 g of solution pH regulator; the zirconium-containing main film forming agent is composed of fluorozirconic acid and fluorozirconate, which are mixed in any proportion; the zirconium-containing film forming oxidant is zirconium oxychloride; the film forming aid is any one of fluorotitanic acid, potassium fluotitanate, ammonium fluorotitanate or sodium fluorotitanate; the complexation colorant is tannic acid or citric acid. The invention further discloses a treatment method for preparing zirconium-based colored conversion film on the magnesium alloy surface by utilizing the treatment liquid. The conversion film generated by using the treatment liquid and the treatment method disclosed by the invention is good in corrosion resistance, colored, high in film forming speed and environmental-friendly.

Owner:东莞市镁皓镁合金科技有限公司

Colored kraft paper and production method thereof

ActiveCN102251429AImprove physical strengthReduce manufacturing costPaper recyclingPulp bleachingFiberRegenerating fibers

The invention discloses colored kraft paper and a production method thereof. The production method comprises the following steps: pulping waste paper, screening, purifying, floating, concentrating, dewatering, carrying out heat dispersion, and bleaching to obtain waste paper deinked pulp; mixing the waste paper deinked pulp with beaten commercial softwood pulp; and desanding, blending (including color mixing), screening, purifying, carrying out net shaping, squeezing, drying, calendering, winding, rewinding, and packing, wherein the absolute dry mass ratio of the waste paper deinked pulp to the commercial softwood pulp is 70-80%:20-30%. The colored kraft paper produced by the method has high physical strength, low production cost and good tissue evenness, the color of the paper can be adjusted in accordance with user preferences by adding dyes, and the appearance quality is obviously improved; as the used waste paper pulp is subjected to TCF (Total Chlorine Free) bleaching in the pulping process, organic halides (AOX) and dioxin which are difficult to biodegrade can not be produced in the production process, thereby having the advantage of realizing clean production; and 70% of regenerated fibers are used to reduce the consumption of virgin fibers, thereby saving wood and being environment friendly.

Owner:YUEYANG FOREST & PAPER CO LTD +1

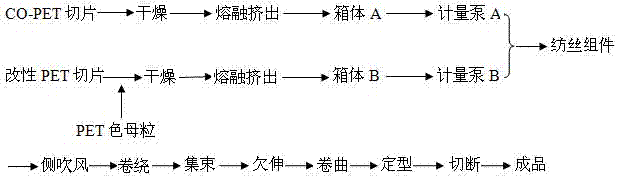

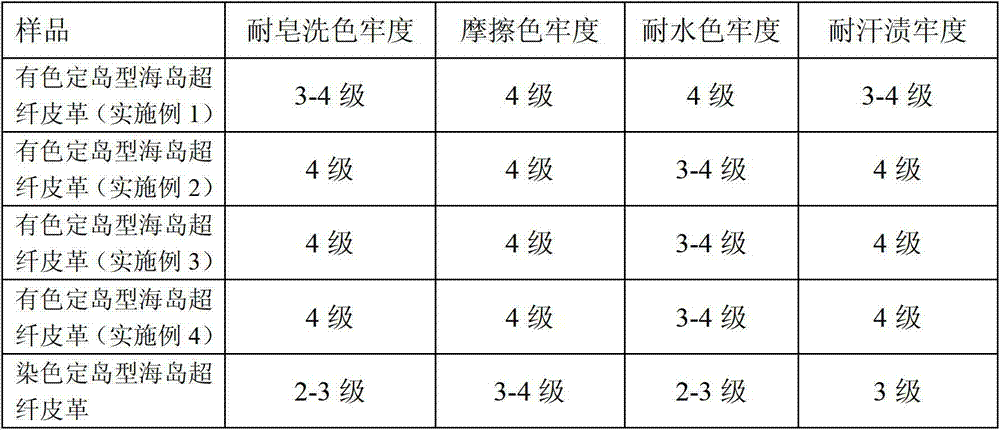

Colored figured sea-island composite ultrafine short fiber and preparation method thereof

ActiveCN103114350ANo base reductionColorfulFilament forming substance formingArtificial filament washing/dryingFiberPolyethylene terephthalate

The invention relates to a colored figured sea-island composite ultrafine short fiber. The section is round and comprises island components and sea components; the mass ratio of the island components to the sea components is (60-75):(25-40); the island components are evenly distributed in the sea components; the sea components are CO-PET (copolyester); and the island components are prepared from modified PET (polyethylene terephthalate) and PET color master batches in a mixing manner. The preparation method comprises the steps of pre-crystallizing and dying the island components and the sea islands, fusing and extruding by a twin screw extruder respectively and feeding to two box bodies, and metering through a metering pump respectively to enter a spinning component in common; spraying the mixed melt in the spinning component from a spinneret plate; oiling to wind after laterally blowing, cooling and molding, bundling, entering into an oil bath groove to stretch, crimping, sizing and baking through hot steam, and finally cutting off and packing tows. The short fiber disclosed by the invention is better in dye performance because the island components are modified; and the prepared color fiber is more bright-colored than the common dye fiber in color, and high in color fastness.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

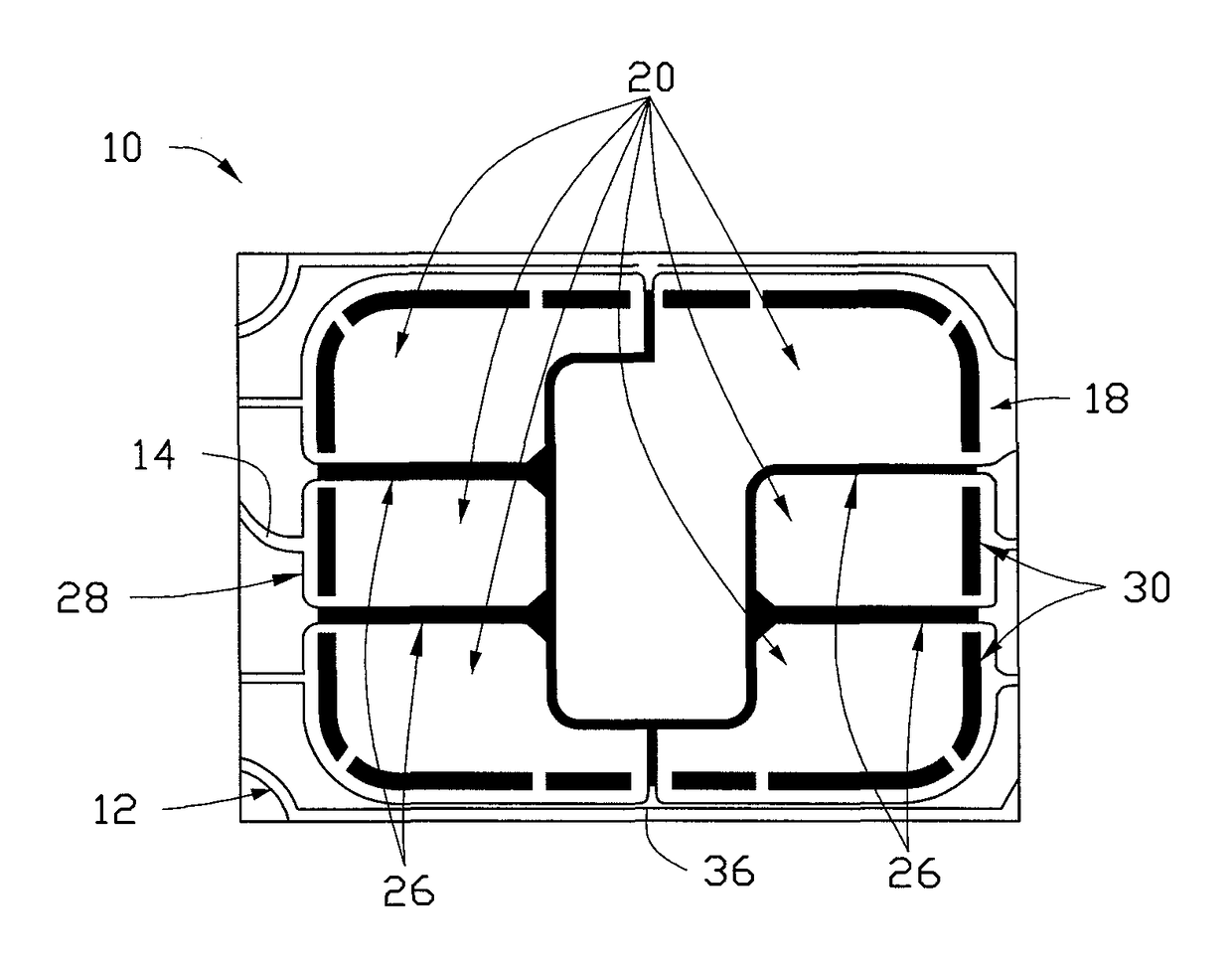

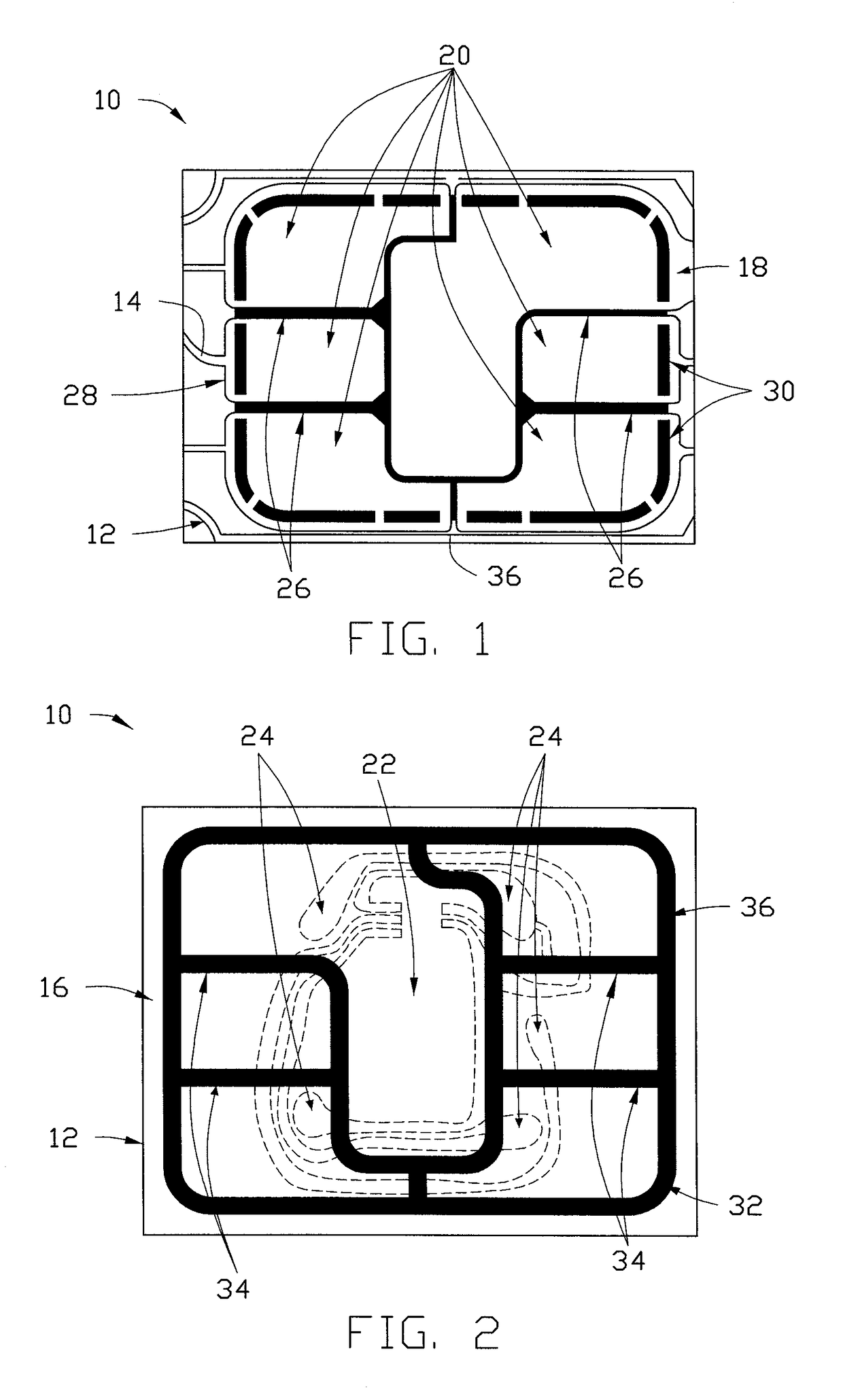

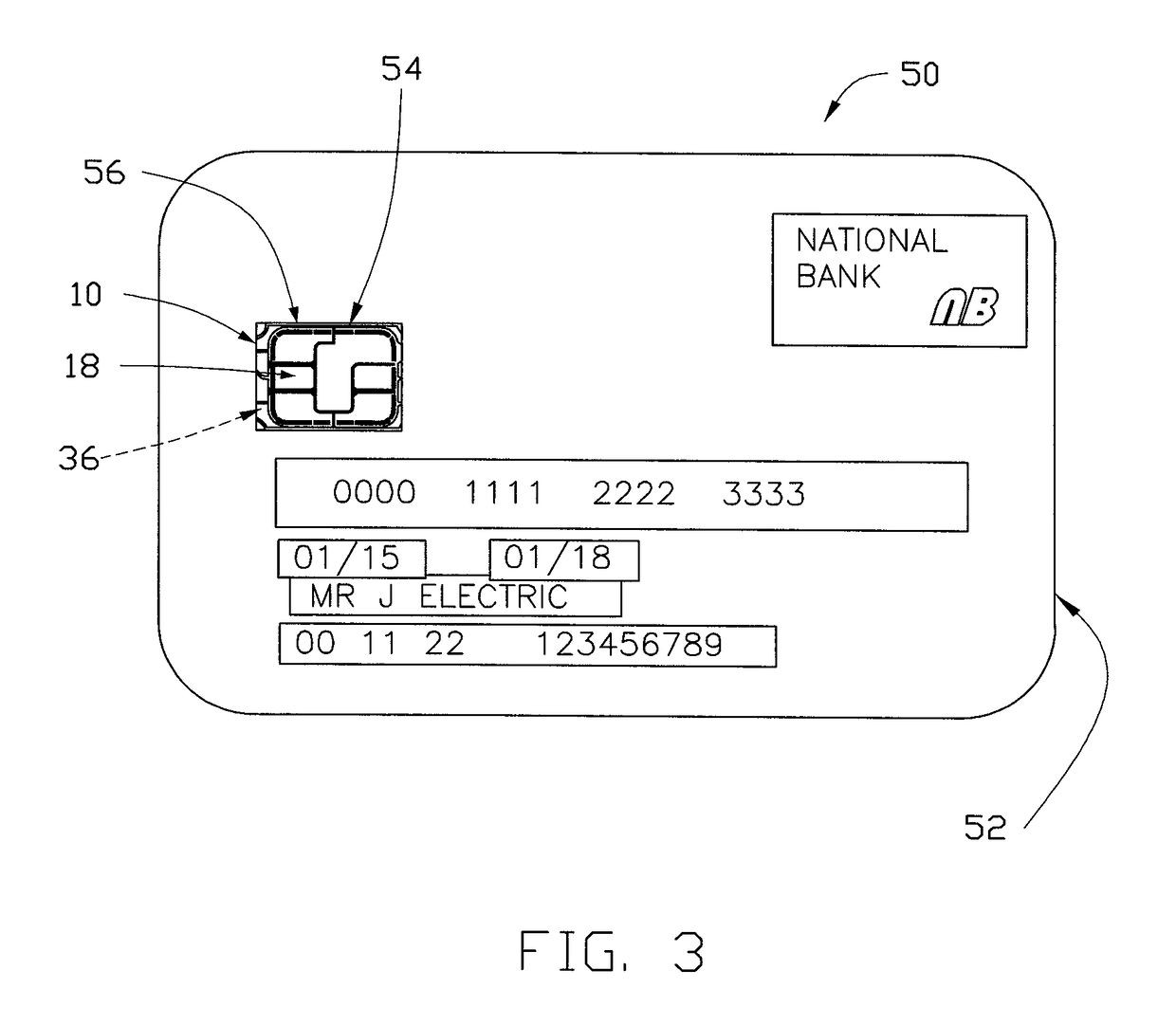

Colored smart card module

ActiveUS9619744B2Enhance visual appealPrecise positioningRecord carriers used with machinesColoredComputer module

A colored smart card module having a light-transmissible substrate with first and second sides; a card-reader contact element formed on the first side of the substrate; and a colored ink layer printed on the second side of the substrate. The printed colored ink layer is then at least in part visible from the first side of the substrate around the card-reader contact element. A smart card including such a colored smart card module is also provided.

Owner:PARLEX PACIFIC LTD

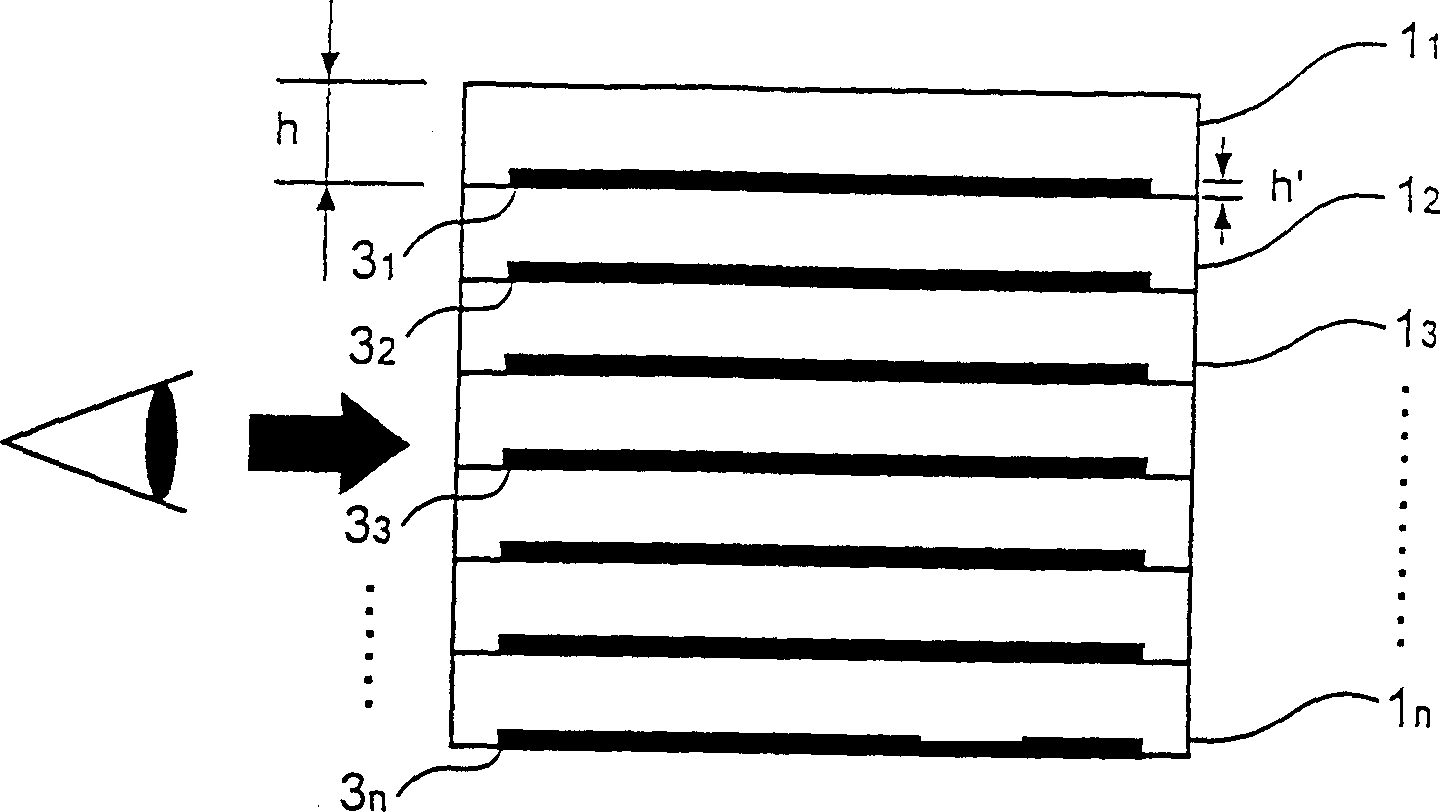

Process for producing colored shaped article from curable resin, colored shaped article produced from curable resin, and shaping apparatus

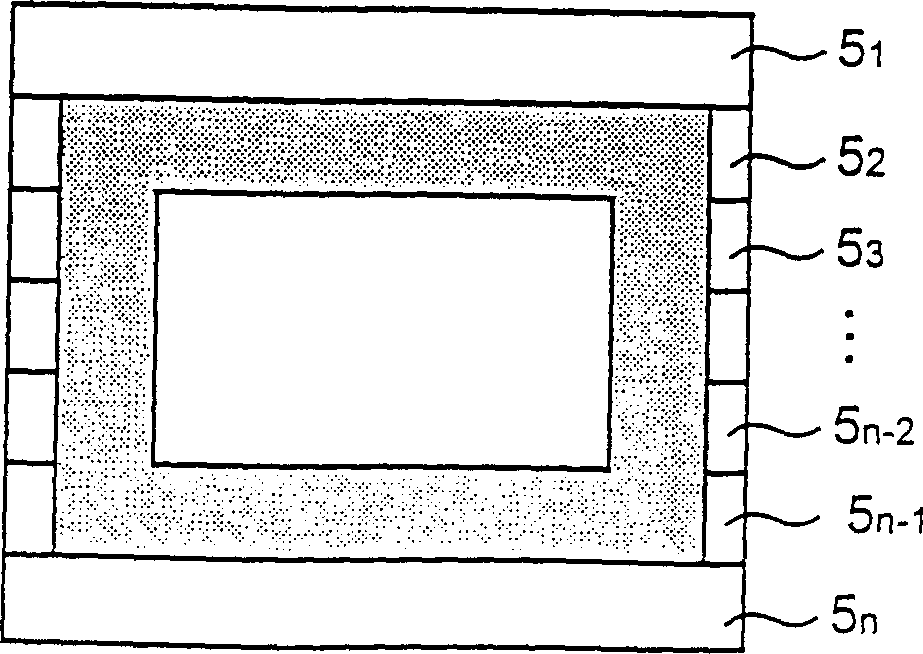

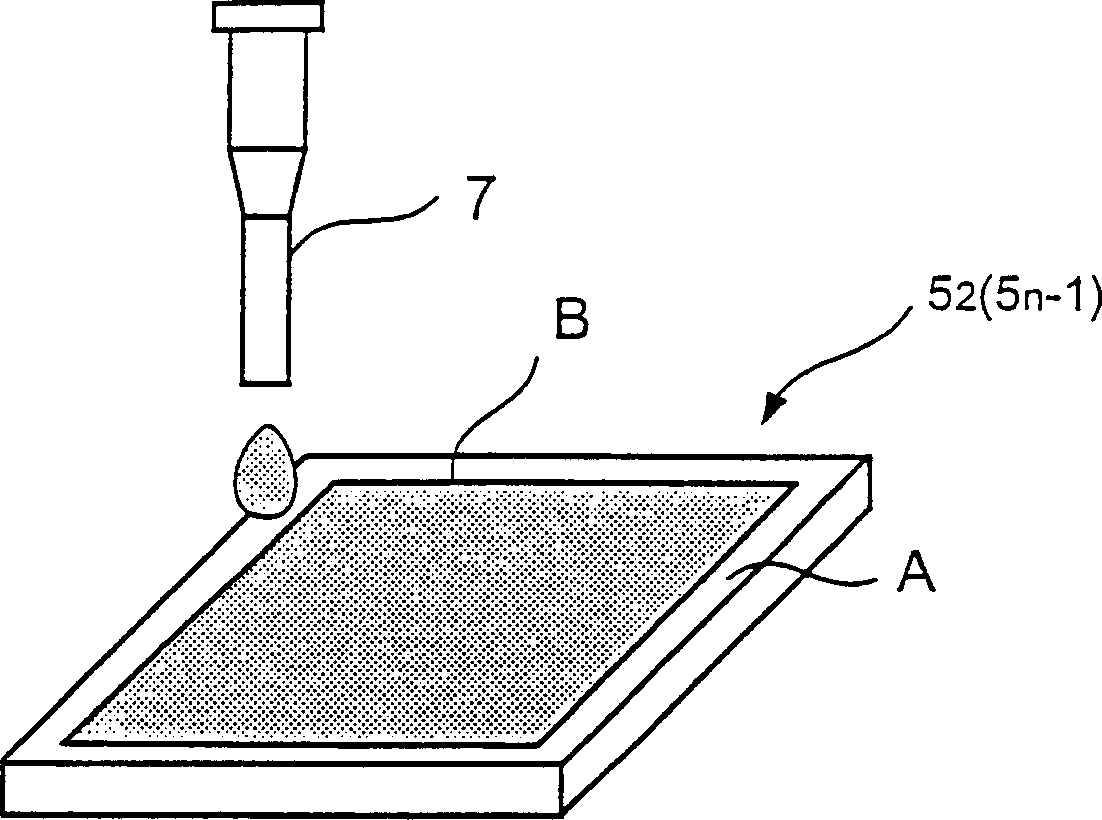

The liquid-phase non-colored photocurable resin is irradiated with laser light to be cured to form the lowermost layer 5n. A liquid-phase photocurable resin is coated thereon to form a colored layer 5n-1 composed of a cured non-colored region and a liquid-phase pooled region. Drops of colored ink in the liquid phase of the pool area. Irradiate the pool area with laser light to cure it to the same level of hardness as the non-colored area. A planar coat of colored ink covering the pool area creates a seal coat of set thickness. Therefore, the formation of the next layer (colored layer 5n-2) on the colored layer 5n-1 is not affected. This process is repeated to form the colored layer 5n-2 to the colored layer 53 , the colored layer 52 is formed on the colored layer 53 , and the uppermost layer 51 is formed on the colored layer 52 . With this method, regardless of single-color addition or multi-color addition, the addition operation can be performed accurately and reliable coloring effects can be obtained.

Owner:NABLESCO CORP +1

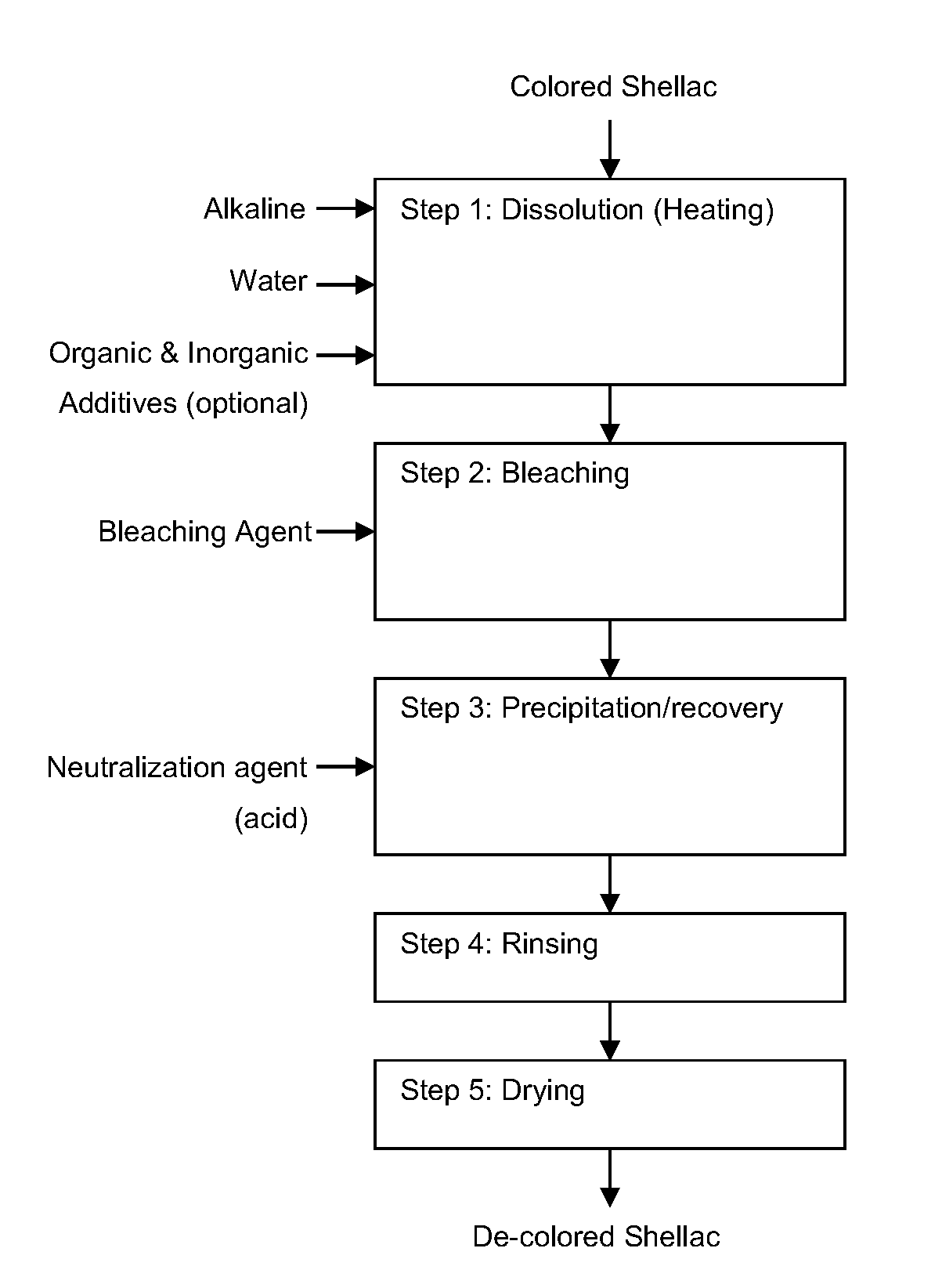

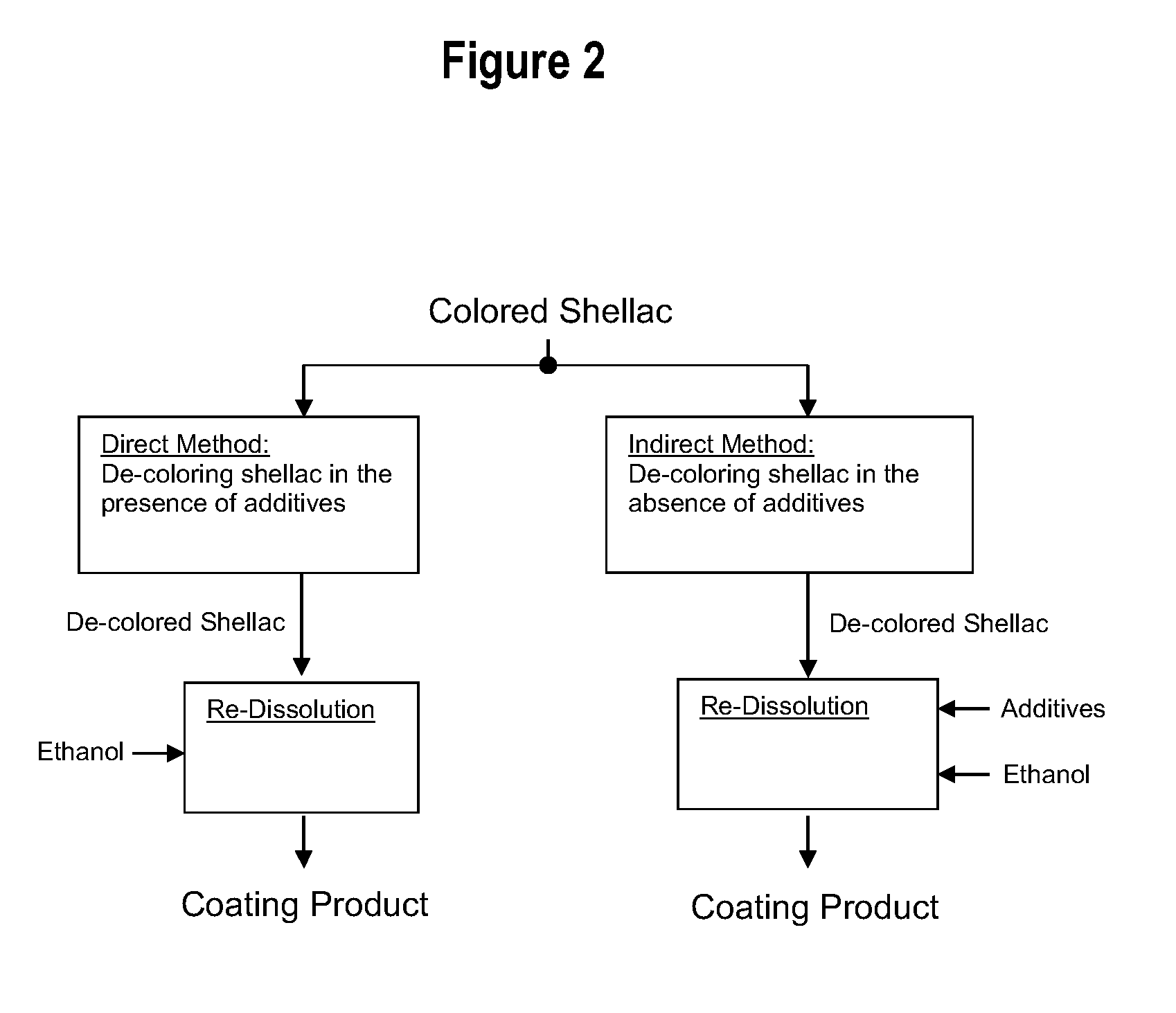

Method for de-coloring shellac, de-colored shellac, compositions comprising same, and uses therefor

Owner:D ANTAEUS

Red stoneware product and firing method thereof

The invention discloses a red stoneware product, which is calcined by the following raw materials in percentage by weight: 75-85% huanglong mountain red mud and 15-25% of huanglong mountain yellow buff-colored clay. According to the red stoneware product provided by the invention, a pot body is filled with sand inside and outside, sand is even to move, and the color and luster are full and mellow.

Owner:任静波

Process for coloring titanium alloy through micro-arc oxidation

InactiveCN103014812ACorrosion resistantHeat resistantSurface reaction electrolytic coatingElectrolysisMicro arc oxidation

The invention belongs to the field of metal coloring and dyeing in a surface treatment technology and specifically relates to a process for coloring titanium alloy through micro-arc oxidation. The method provided by the invention is used for overcoming the shortcomings of the electrolyticaly colored film. The process is characterized in that two-way square waves are employed for coloring through micro-arc oxidation, the frequency of the pulse waveform ranges from 150 Hz to 1700 Hz, the positive current density ranges from 5 A / dm<2> to 15 A / dm<2> and the positive current density also ranges from 5 A / dm<2> to 15 A / dm<2>, the positive duty ratio is 10%-50% and the negative duty ratio is also 10%-50%, and the micro-arc oxidation coloring time is 3-20 minutes. The process is capable of directly forming a bright, fine colored ceramic layer on a titanium alloy substrate through a micro-arc oxidation technique. The decorative ceramic layer produced by the process is especially suitable for the titanium alloy products with high-grade decorative requirements and the film is resistant to corrosion, heat, ultraviolet light, wearing and the like, and simultaneously capable of keeping the metal luster, thereby actually achieving the decoration effect of the colored film. The film is characterized by the ceramic layer with the special color and luster.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Novel colored spun yarn production method

InactiveCN104153058AHas a scaly appearanceAchieve intermittent draftingDrafting machinesContinuous wound-up machinesYarnColored

The invention discloses a novel colored spun yarn production method. The method includes in the procedures of Siro compact fine spinning, feeding a rough yarn A and a rough yarn B into a left hole and a right hole of a double-hole horn of a Siro compact spinning machine to reel on a fine yarn pipe via a rear roller, a middle roller, a front roller, a concentrating roller, a yarn hook and a steel ring sequentially. The front roller comprises a portion a and a portion b axially, the length of the portion a takes 30% to 50% of that of the front roller, the cross sections of the portion a are almost hexagonal consistently, the edges of the almost hexagon are formed by arcs and lines connected alternately, and the central angle of each edge of the almost hexagon is in 60 degrees; the portion b is in a cylindrical structure, and the radius of the arcs of the portion a is the same as that of the cylinder of the portion b. Yarns produced by the production method is capable of weaving colored spun fabrics with the ripple effect and can be widely applied to garment fabrics of knitwear and sweaters.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

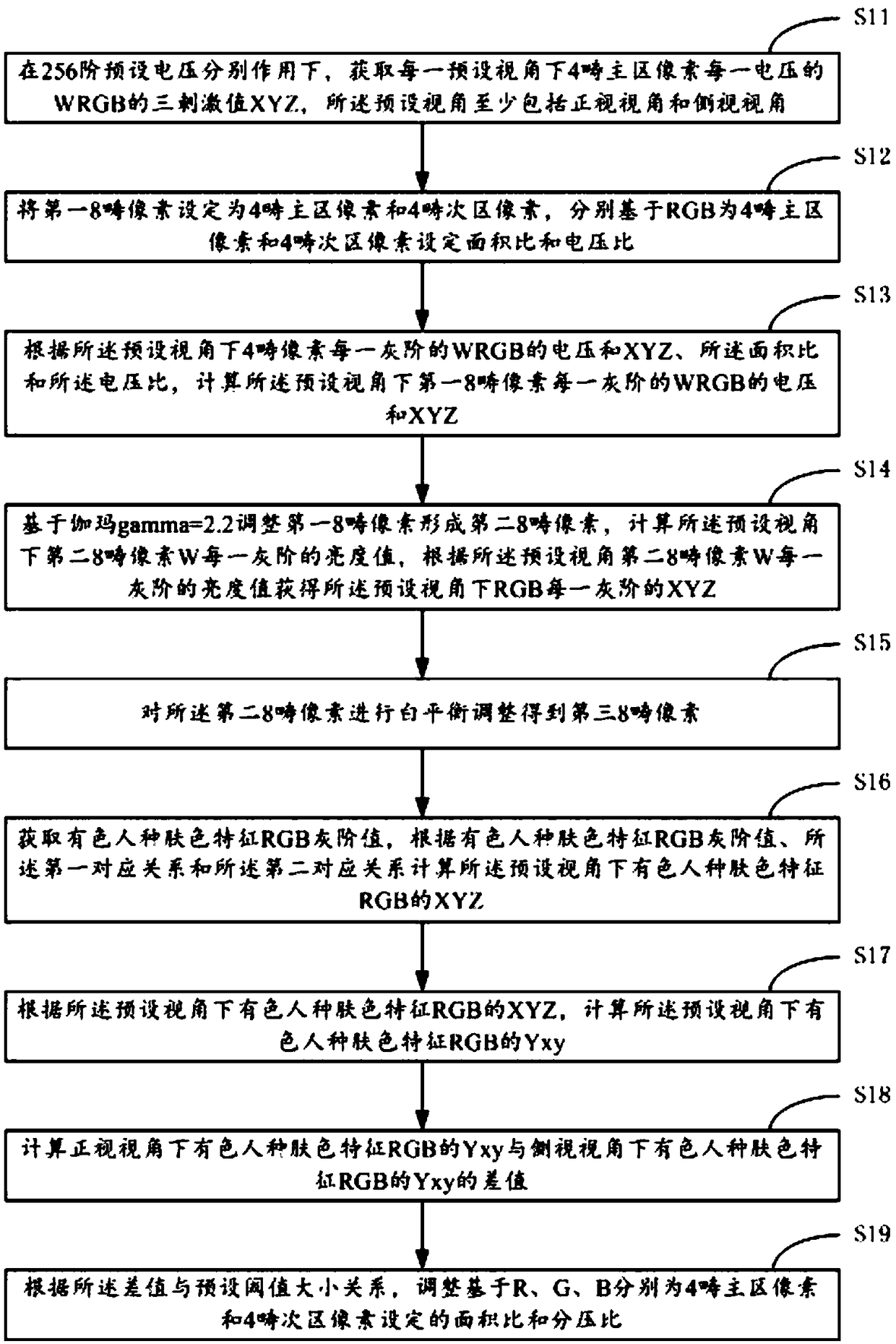

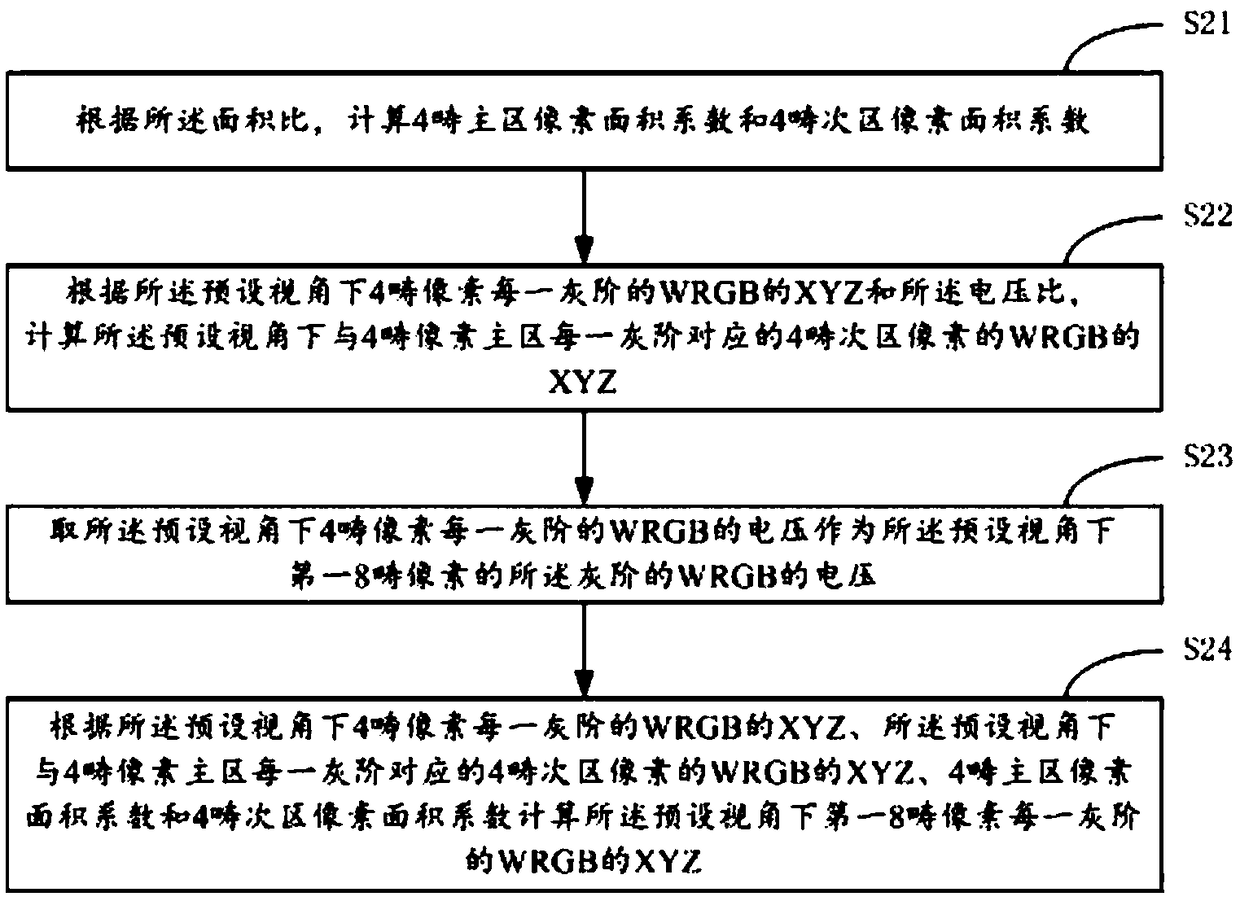

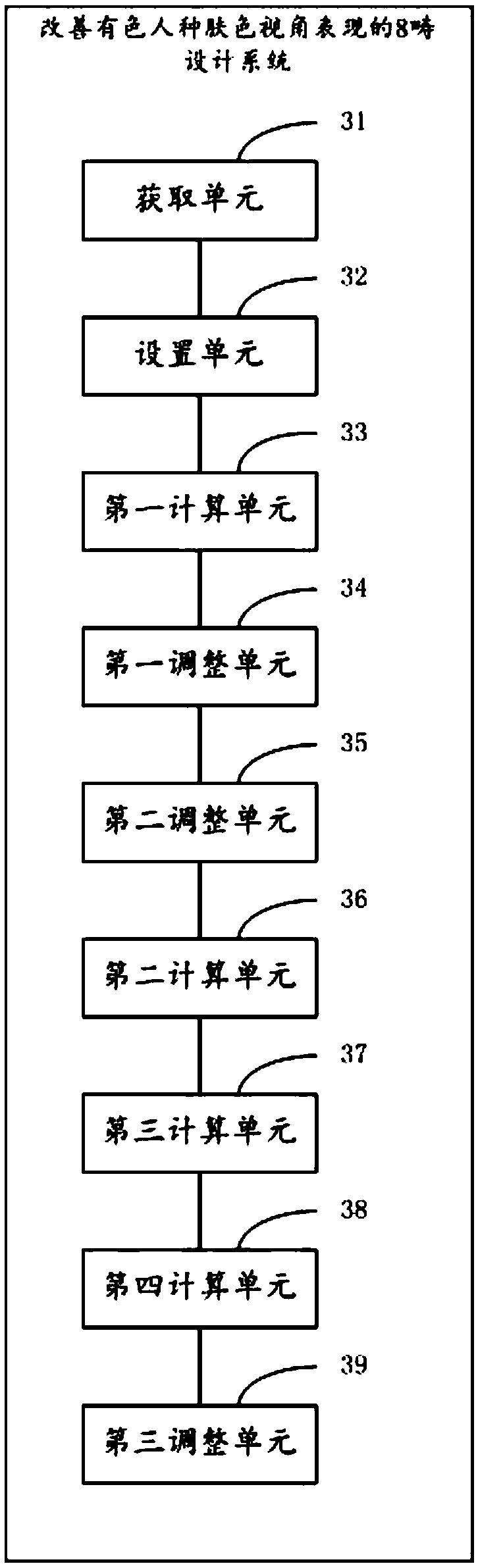

An 8-domain design method and system for improve visual angle performance of skin color of colored race

ActiveCN109215599ASolve the problem of large visual display differencesStatic indicating devicesLateral angleColored

The invention provides an 8-domain design method and a system for improving the visual angle performance of the skin color of a colored race. The method comprises the following steps of: obtaining XYZof WRGB of 4-domain main region pixels under each preset visual angle under 256 preset voltages respectively; Setting an area ratio and a voltage ratio for the 4-domain main region pixel and the 4-domain sub-region pixel. The RGB gray value of the skin color feature of the colored race is obtained, the XYZ of the preset view angle of the RGB of the skin color feature of the colored race is calculated according to the RGB gray value of the skin color feature of the colored race, and the Yxy of the preset view angle of the RGB of the skin color feature of the colored race is further calculated.The difference between RGB emmetropia angle Yxy and lateral angle Yxy is calculated. According to the relation between the difference value and the preset threshold value, the area ratio and the voltage dividing ratio of the pixels in the 4-domain primary region and the pixels in the 4-domain secondary region are adjusted. As that area ratio and the voltage ratio of the 4-domain main region pixeland the 4-domain partition pixels are set for the 8-domain pixel non-colored skin color RGB, the problem of poor viewing angle performance of the non-colored skin color RGB in the prior art is solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Colored ultra-high molecular weight polyethylene fiber and preparation method thereof

ActiveCN106245136AImprove uniformityHigh fastnessMonocomponent polyolefin artificial filamentPigment addition to spinning solutionFiberPolymer science

The invention provides a colored ultra-high molecular weight polyethylene fiber and a preparation method thereof. The colored ultra-high molecular weight polyethylene fiber is characterized by comprising an ultra-high molecular weight polyethylene with the viscosity average molecular weight of 1 million-10 million and a coloring system, wherein the content of the coloring system accounts for 0.1-10% by weight of the ultra-high molecular weight polyethylene, the coloring system is at least one of a coating dye and a coating pigment, the coating dye contains a coating and a dispersive dye, the weight ratio of the coating to the dispersive dye is 10:90 to 80:20; the coating pigment contains a coating and a pigment, and the weight ratio of the coating to the pigment is 10:90 to 80:20. The preparation method is that the coating dye and the pigment are added to a spinning stock solution to prepared the colored ultra-high molecular weight polyethylene fiber through stock solution coloring. The colored fiber prepared by adopting the method is uniform in coloring, and excellent mechanical strength and color fastness are endowed to the fiber while the excellent mechanical strength of the fiber is kept.

Owner:江苏领誉纤维科技有限公司

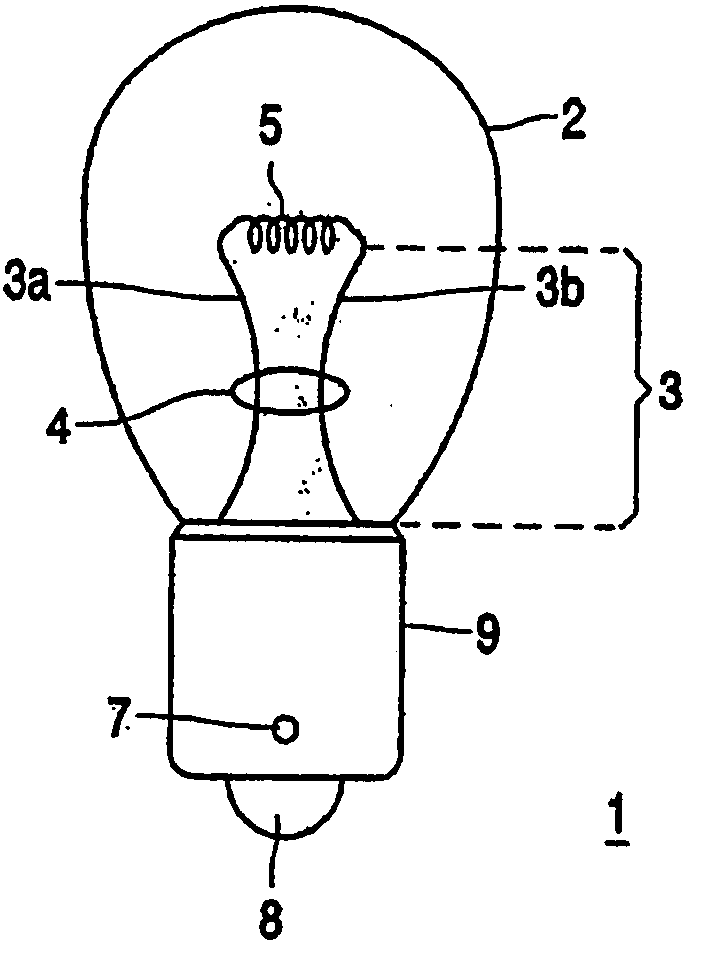

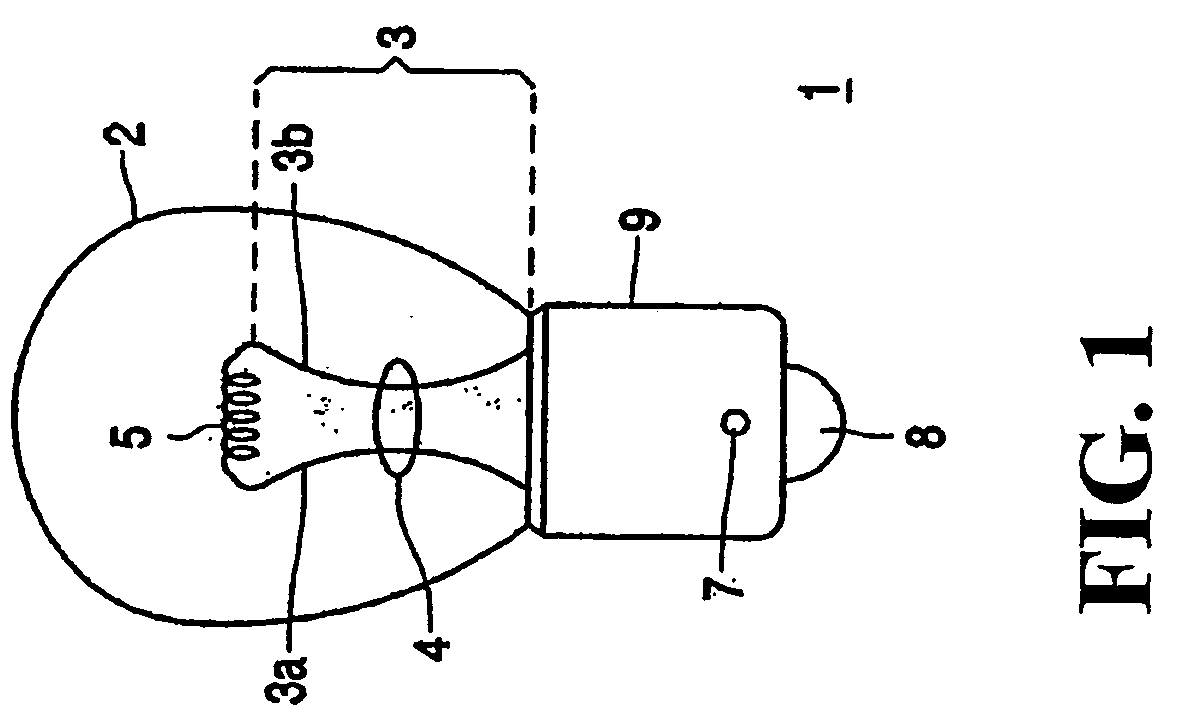

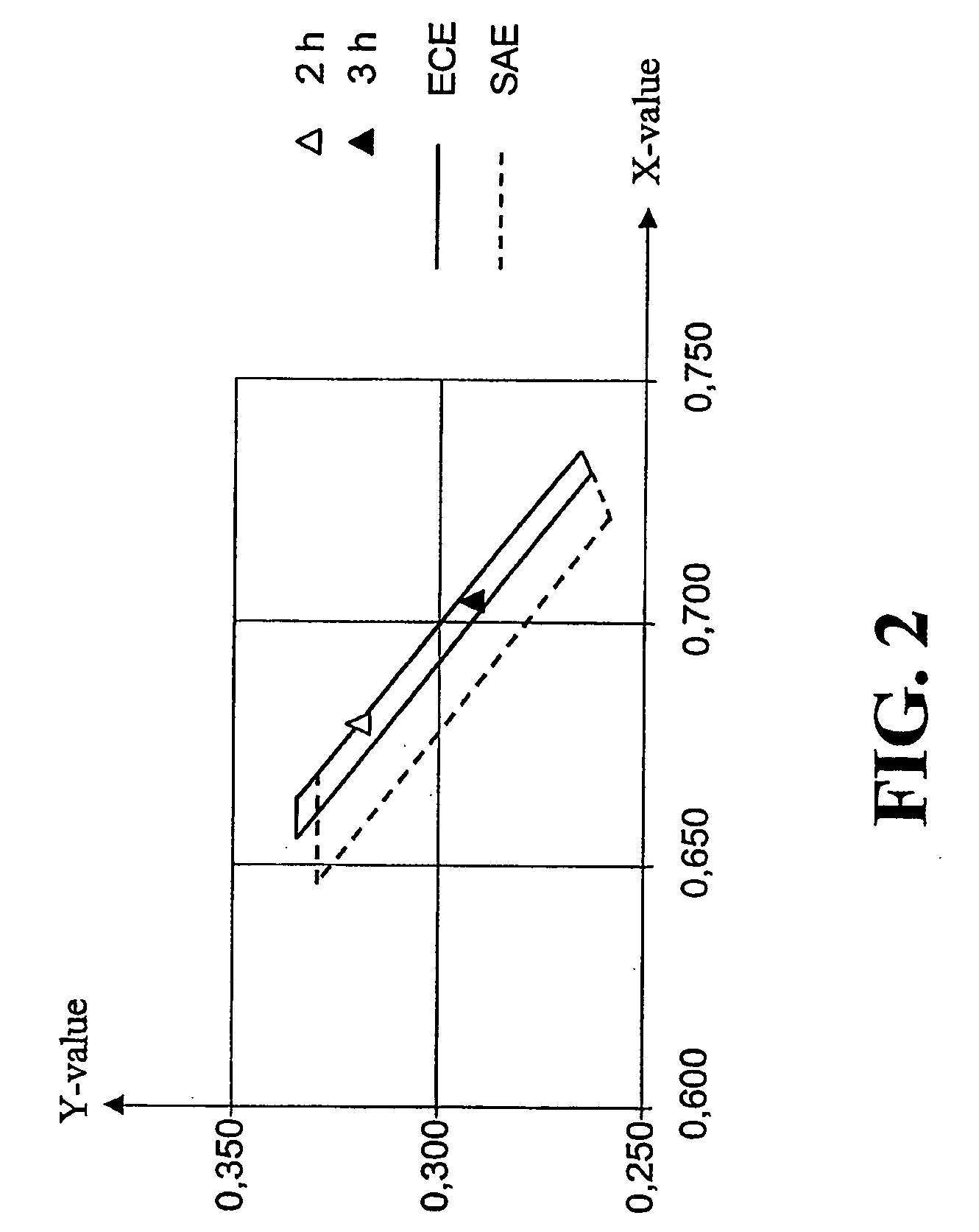

Red-colored electric lamp

InactiveUS20060033440A1Good quality glassReduce conductivitySolid cathode detailsGas discharge lamp detailsElectric lightColored

The invention relates to electric lamps and more particularly to automotive signal lamps. A glass composition is described for use in electric lamps, which glass is red colored. The glass composition comprises copper between 0.1 and 2% by weight, tin between 0.1 and 2% by weight, barium between 7 and 11% by weight, and strontium between 1 and 5% by weight.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Gray coated glass, and preparation method

This invention discloses a method for producing grey-colored coated glass. The grey-colored coated glass comprises at least two layers: a glass plate and a film layer on the surface of the glass plate. The film layer comprises oxides of Co and Mn, and comprises at least one of ZnO, Al2O3, ZrO2, CuO, Fe2O3, Cr2O3 and MgO. The film layer is 40-80nm thick. The grey-colored coated glass has pure color, and can replace bulk-grey-colored glass. The method comprises on-line high-temperature pyrolysis spraying, which is realized during folating galss production process. The method utilizes the heat of the glass plate to pyrolyze, oxidize and deposite metal compounds in spraying solution onto the surface of glass plate to form the film layer. The method realizes continuous production, thus can increase production efficiency, lower the cost, and lower energy consumption. The light permeability of the grey-colored coated glass is 20-65%.

Owner:FUYAO GLASS IND GROUP CO LTD

Nansong offcial kiln cream-colored glaze transmutation formula and making technology

The invention discloses Nansong offcial kiln cream-colored glaze. The Nansong offcial kiln cream-colored glaze is prepared from 38-46% by mass of porcelain stone, 10-14% by mass of dolomite, 8-10% by mass of calcite, 12-16% by mass of Zijin clay, 12-18% by mass of feldspar and 6-8% by mass of Longquan La stone. Sintered chinaware with the Nansong offcial kiln cream-colored glaze has good masking effects, good glaze jade qualitative sense qualitative sense and a brilliant and authentic color. The making technology improves chinaware artistic effects, has simple processes, can be realized easily, produces products with stable quality and is conducive to market popularization and application.

Owner:杨孔星

Colored-spun-yarn dyeing die convenient to clean

InactiveCN106988066ASimple structureEasy to useTextile treatment containersTextile treatment cleaning apparatusYarnColored

The invention discloses a yarn-splitting colored-spun-yarn dyeing die convenient to clean. The colored-spun-yarn dyeing die convenient to clean comprises a die body and material spraying pipes; pigment inlets are formed in the upper end of the die body, stopping plates are arranged on the pigment inlets, rotating shafts are fixed to the left ends of the stopping plates, a flowing channel is formed below the pigment inlets, a pigment flowing pipe is connected to the lower end of the flowing channel, a clamping plate is fixed to the bottom end of the pigment flowing pipe, a dye groove is formed in the inner side of the clamping plate, circular holes are formed in the clamping plate in an embedded mode, a yarn outlet is formed in the right end of the dye groove, a limiting hole is fixed to the right side of the yarn outlet, the clamping plate is installed above the material spraying pipes, a material spraying channel is formed in the bottom sides of the material spraying pipes, and a yarn inlet is formed in the left side of the die body. The yarn-splitting colored-spun-yarn dyeing die convenient to clean is simple in structure and convenient to use, the stopping plates can be buckled through rotating of the rotating shafts when the colored-spun-yarn dyeing die is not used, and it is avoided that impurities fall into the die body.

Owner:响水利滋纺织品有限公司

Colored silicon PU (Polyurethane) waterborne field topcoat and preparation method thereof

ActiveCN103788858AIncreased abrasion and scratch resistanceStrong adhesionPolyurea/polyurethane coatingsCelluloseSodium Bentonite

The invention relates to a colored silicon PU (Polyurethane) waterborne field topcoat and a preparation method thereof. The colored silicon PU waterborne field topcoat is prepared from the following raw materials in parts by weight: 300 parts of deionized water, 4 parts of ethanolamine, 3-5 parts of cellulose, 4.8 parts of defoamer, 4 parts of dispersing agent, 2.8 parts of flatting agent, 40 parts of aluminum silicate, 8 parts of titanium dioxide, 10 parts of bentonite, 600 parts of waterborne acrylic polyurethane resin, 0.8 part of preservative and 65-70 parts of color paste. The colored silicon PU waterborne field topcoat provided by the invention is prepared from a novel multifunctional nano emulsion and a crosslinking agent, is used for coating the surface layer of a silicon PU field, can be used for improving performances such as wear resistance, ageing resistance, pollution resistance, skid resistance and the like of the surface layer, and has favorable color packaging and construction performances; a coating film has excellent adhesive force, physical and mechanical properties, water resistance and oil resistance; a paint film is thick and full, low in luster, good in wear resistance, etching resistance and scratching resistance, sanitary, environment-friendly and free of smell.

Owner:江西功诚泰盛制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com