Colored ultra-high molecular weight polyethylene fiber and preparation method thereof

An ultra-high molecular weight, polyethylene fiber technology, applied in dyeing polymer organic compound treatment, single-component polyolefin rayon, spinning solution preparation, etc. No problem, adverse effects on color uniformity and color fastness, low dyeing temperature, etc., to achieve the effects of excellent color uniformity and color fastness, excellent color fastness, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

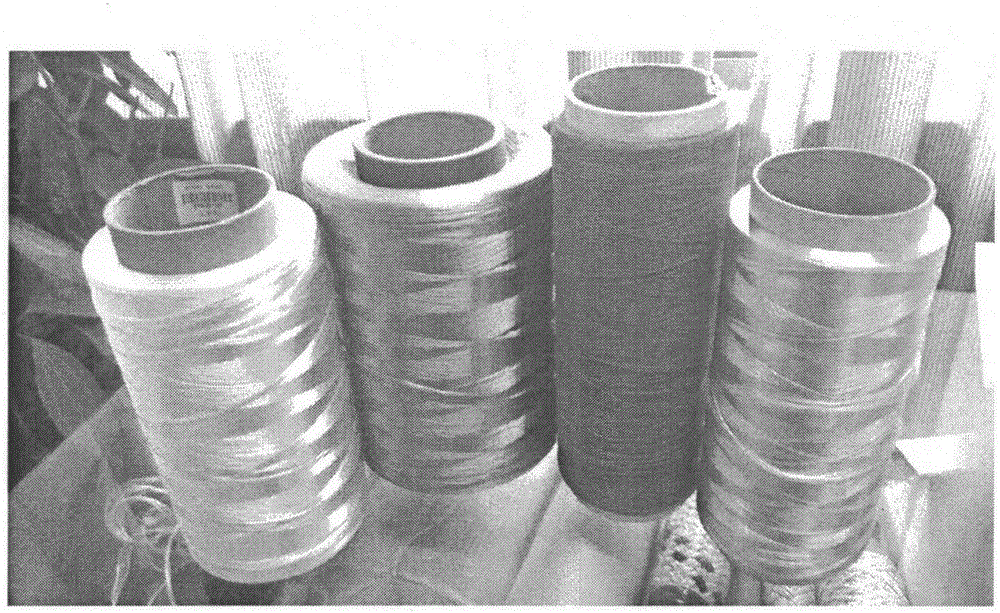

Image

Examples

preparation example B1

[0057] Use jet milling method to crush 1 kg of disperse disperse dye fa material powder to a particle size of no more than 150 nanometers, and then use emulsion polymerization to coat it with polymers. The specific steps are: dissolve 50 g of emulsifier ra in 50 L of deionized Then add 1 kg of disperse dye powder into the water, and stir slowly until the disperse dye is wetted; after stirring for 1 h (1500 r / min) under the IKA high-speed mixer, the dispersion is transferred to an ultrasonic pulverizer for ultrasonic dispersion for 2 h, and dispersed in the ultrasonic process The liquid is cooled by a water bath to prevent the temperature rise from affecting the dispersion effect. Thereafter, 0.3 kg of styrene monomer and 0.5 g of azobisisobutyronitrile initiator were added, and stirred at a high speed of 2000 r / min for 3 h for emulsification. Finally, the emulsification system was transferred from the stainless steel drum to a 150L polymerization kettle, and the temperature wa...

preparation example B2

[0059] Use jet milling method to crush 1kg of disperse disperse dye fb material powder to a particle size of no more than 150 nanometers, and then use emulsion polymerization to coat it with polymer. The specific steps are: dissolve 80g of emulsifier rb in 50L of deionized In water, then add 1Kg of disperse dye fb material powder, and stir slowly until the disperse dye is wetted; after stirring for 1h (1500r / min) under the IKA high-speed mixer, the dispersion is transferred to an ultrasonic pulverizer for ultrasonic dispersion for 2h, and dispersed in the ultrasonic process The liquid is cooled by a water bath to prevent the effect of temperature rise from affecting the dispersion effect. Then add 0.4kg of methyl acrylate monomer and 0.5g of azobisisobutyronitrile initiator, and stir at a high speed of 2000r / min for 3h to emulsify. Finally, the emulsification system was transferred from the stainless steel drum to a 150L polymerization kettle, and the temperature was raised to ...

preparation example B3

[0061] Grinding 1 kg of disperse disperse dye fc material powder by jet milling until the particle size does not exceed 150 nanometers, and then coating it with polymer by emulsion polymerization. The specific steps are: dissolve 80 g of emulsifier rc in 50 L of deionized In water, then add 1Kg of disperse dye fc material powder, and stir slowly until the disperse dye is wetted; after stirring for 1h (1500r / min) under the IKA high-speed mixer, the dispersion is transferred to an ultrasonic pulverizer for ultrasonic dispersion for 2h, and dispersed in the ultrasonic process The liquid is cooled by a water bath to prevent the effect of temperature rise from affecting the dispersion effect. Then add 0.5kg of methyl methacrylate monomer and 0.6g of azobisisobutyronitrile initiator, and stir at a high speed of 2000r / min for 3h to emulsify. Finally, the emulsification system was transferred from the stainless steel drum to a 150L polymerization kettle, and the temperature was raised ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com