Patents

Literature

30465 results about "Carbon fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about 5–10 micrometres in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports. However, they are relatively expensive when compared with similar fibers, such as glass fibers or plastic fibers.

Electrically conductive polymer composition

InactiveUS6184280B1Sufficient electrical conductivityImprove polymer propertiesOther chemical processesConductive materialPolymer scienceCarbon fibers

An electrically conductive polymer composition comprises a moldable organic polymer having hollow carbon microfibers and an electrically conductive white powder uniformly dispersed therein, the carbon fibers being present in an amount of 0.01 wt. % to less than 2 wt. % and the electrically conductive white powder being present in an amount of 2.5-40 wt. %, each percent range based on the total weight of the composition, the amounts of carbon microfibers and white powder being sufficient to simultaneously impart the desired electrical conductivity to the composition and white pigmentation to the composition.

Owner:MITSUBISHI MATERIALS CORP +1

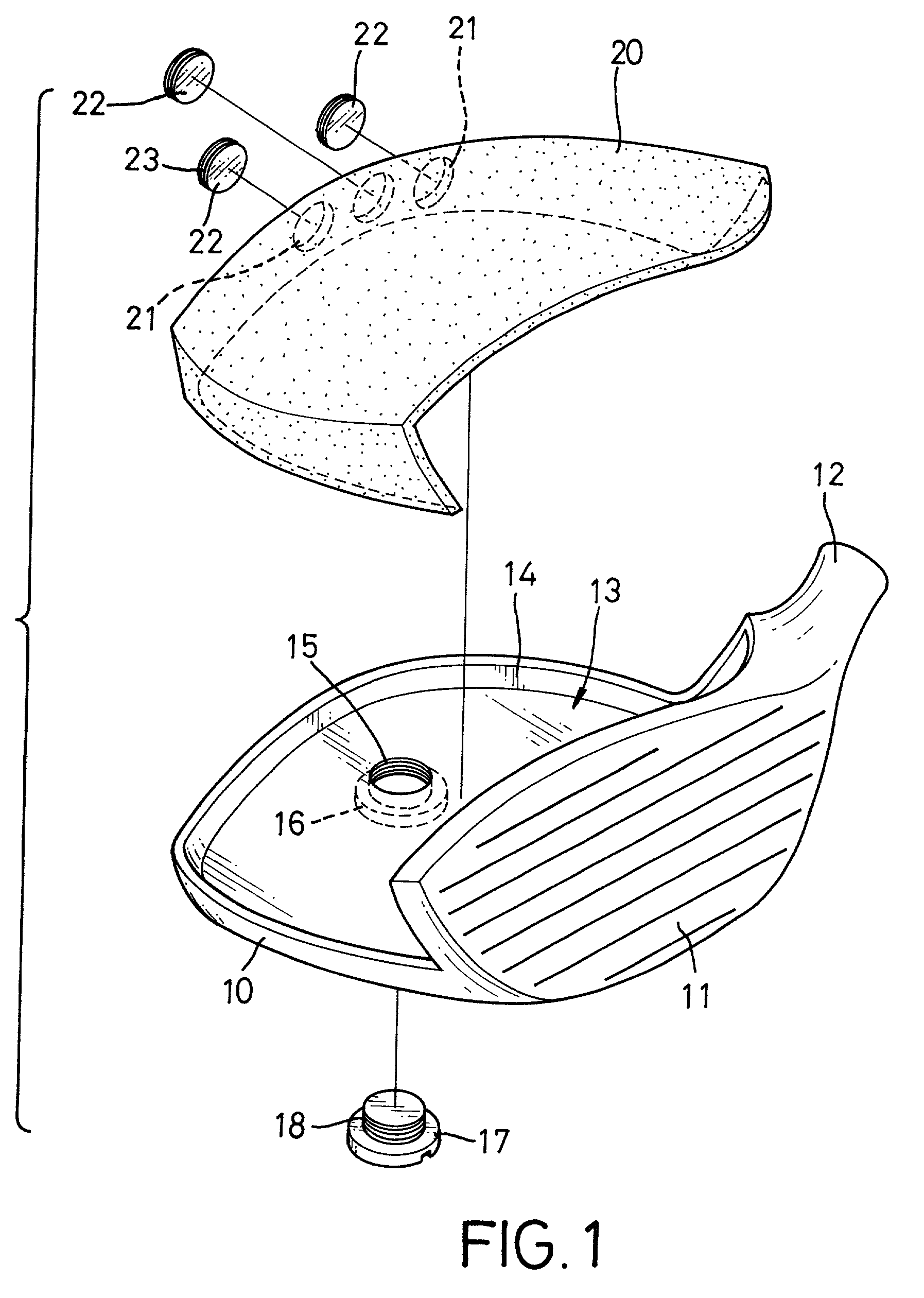

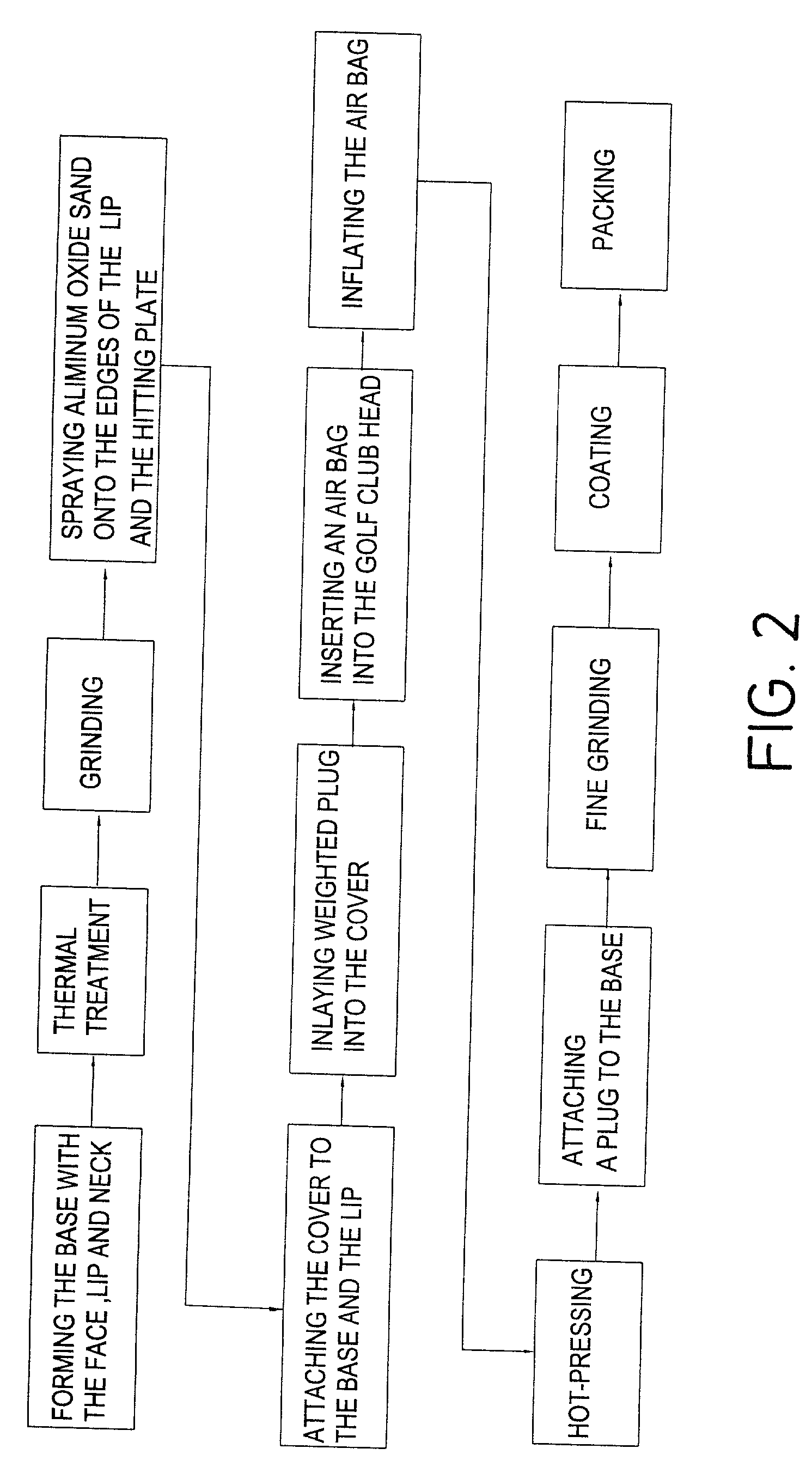

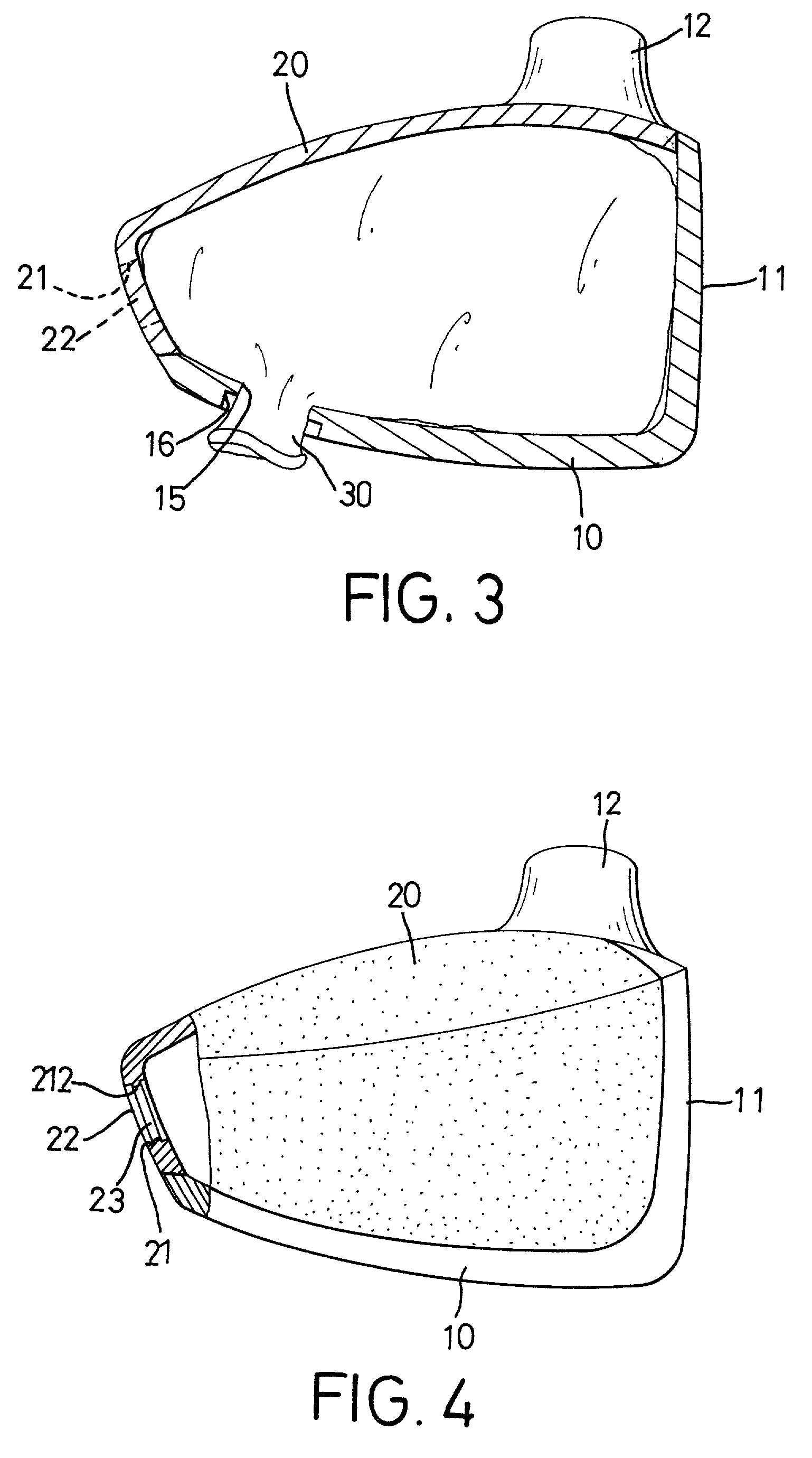

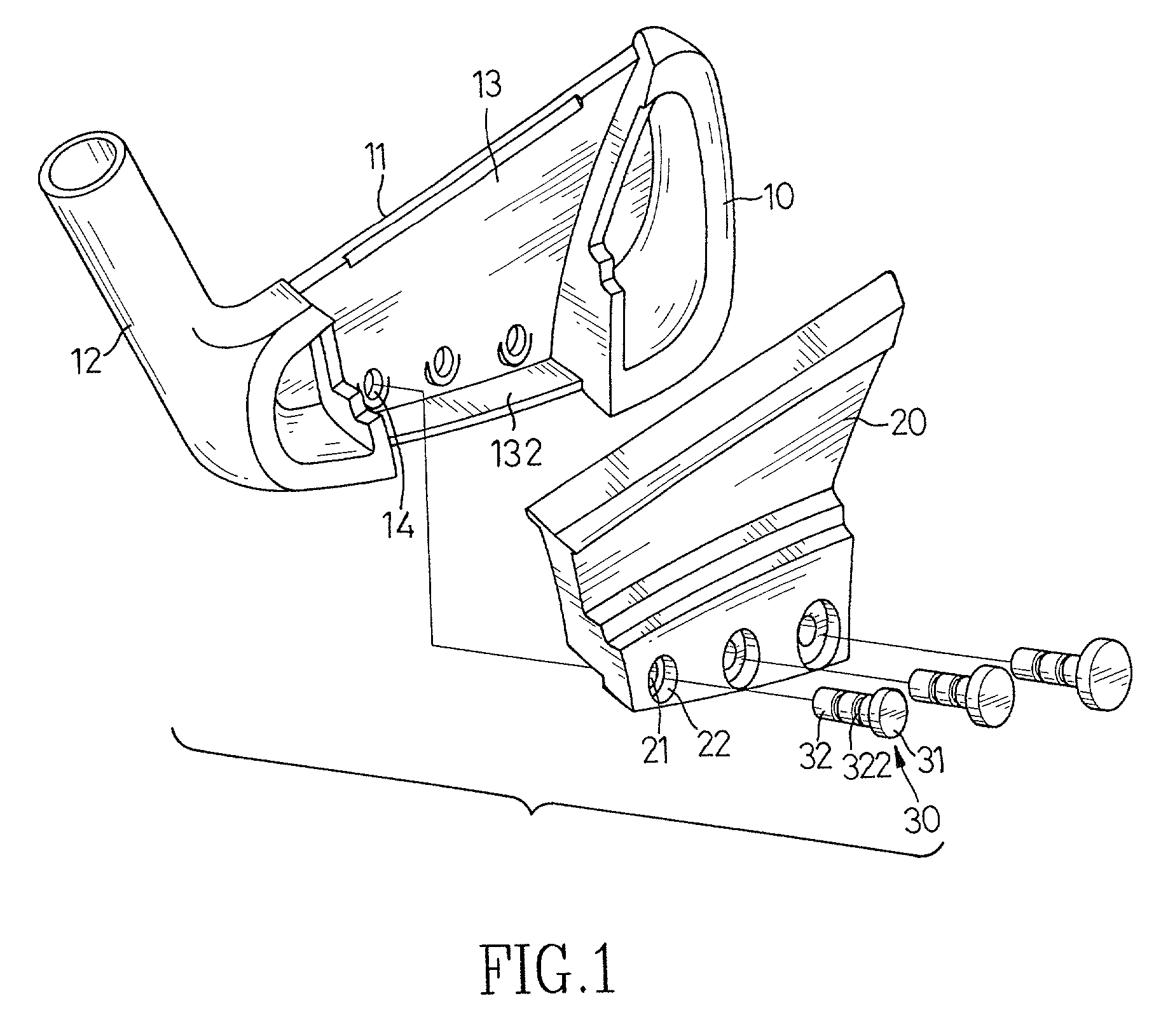

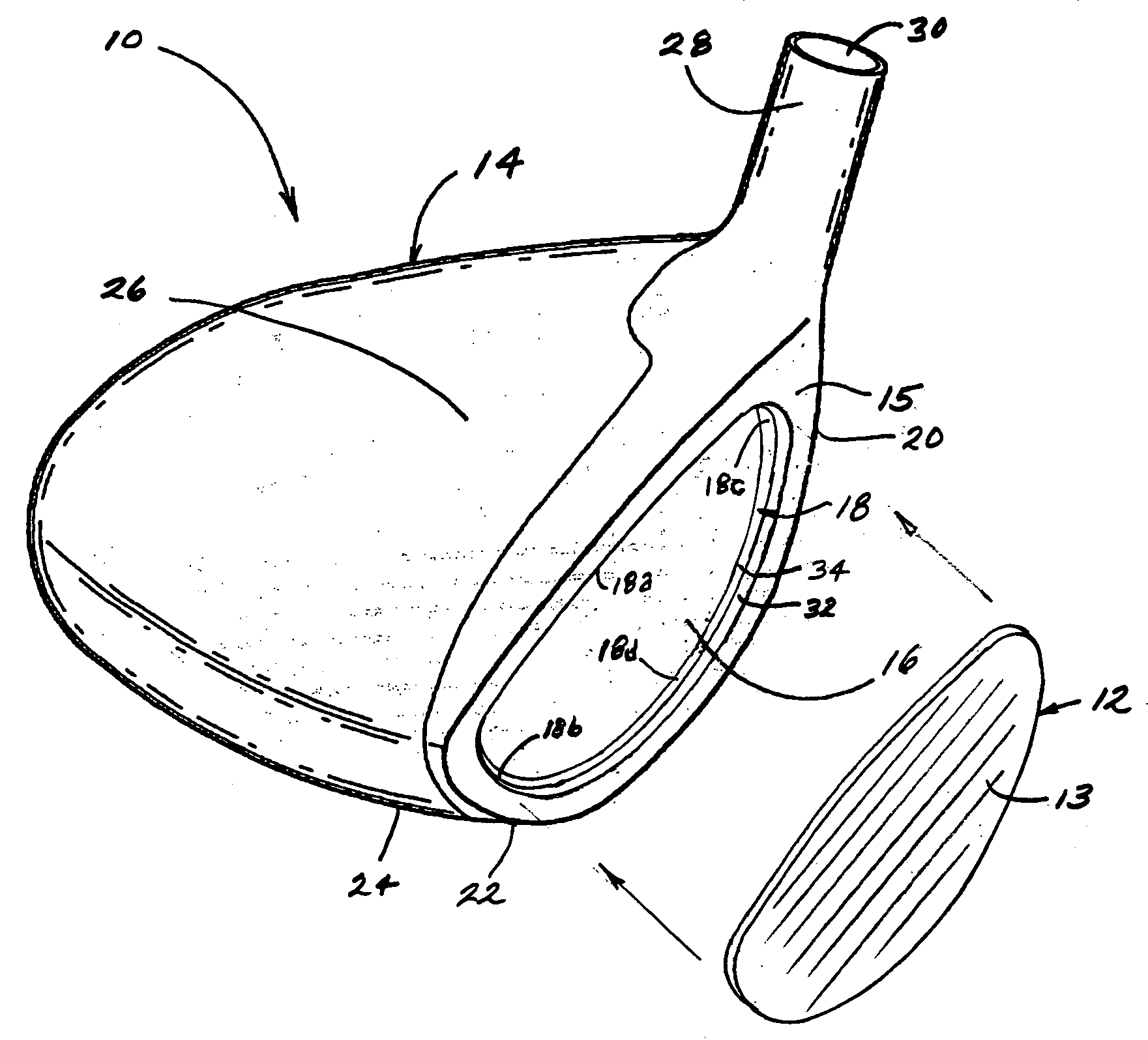

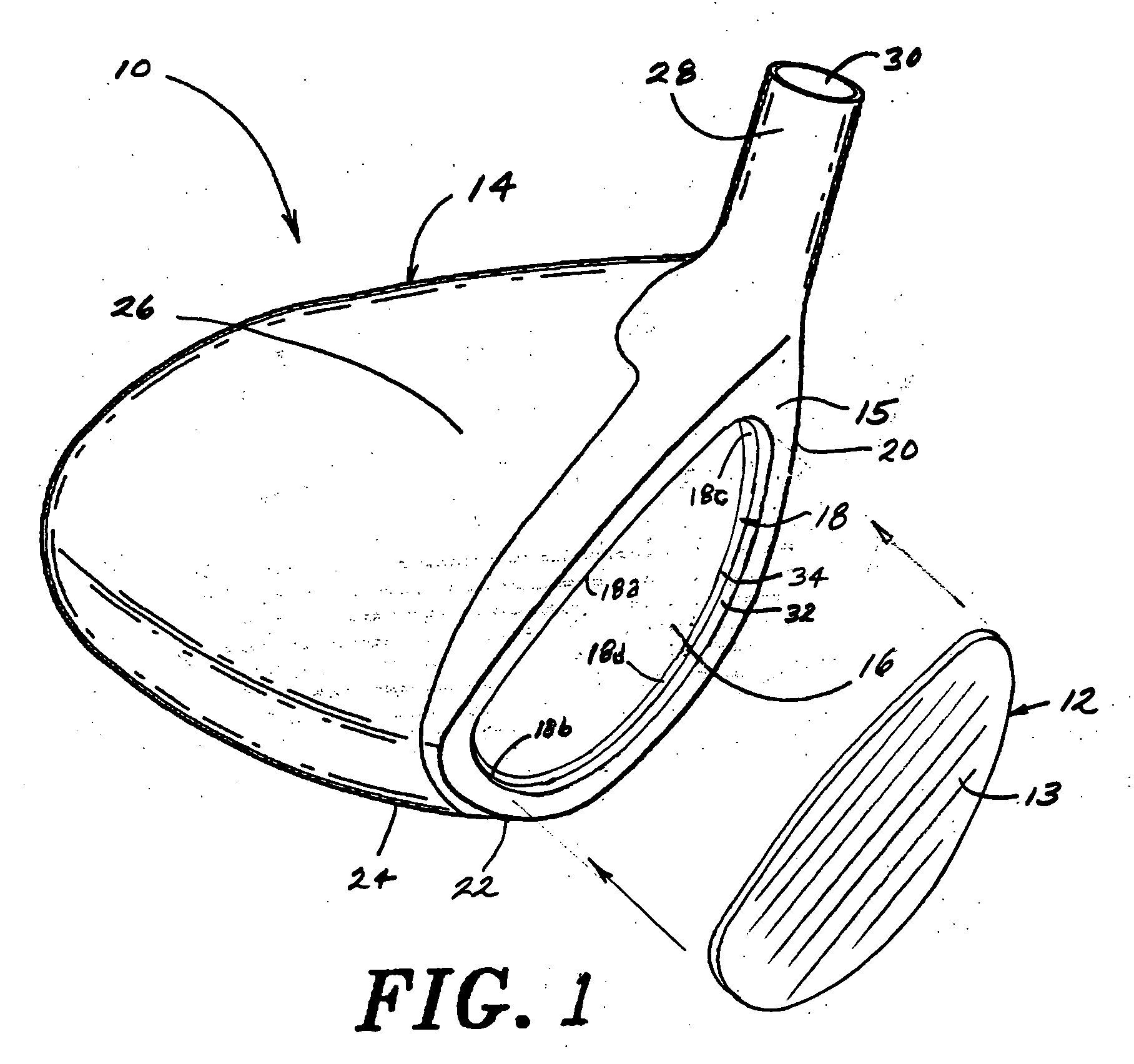

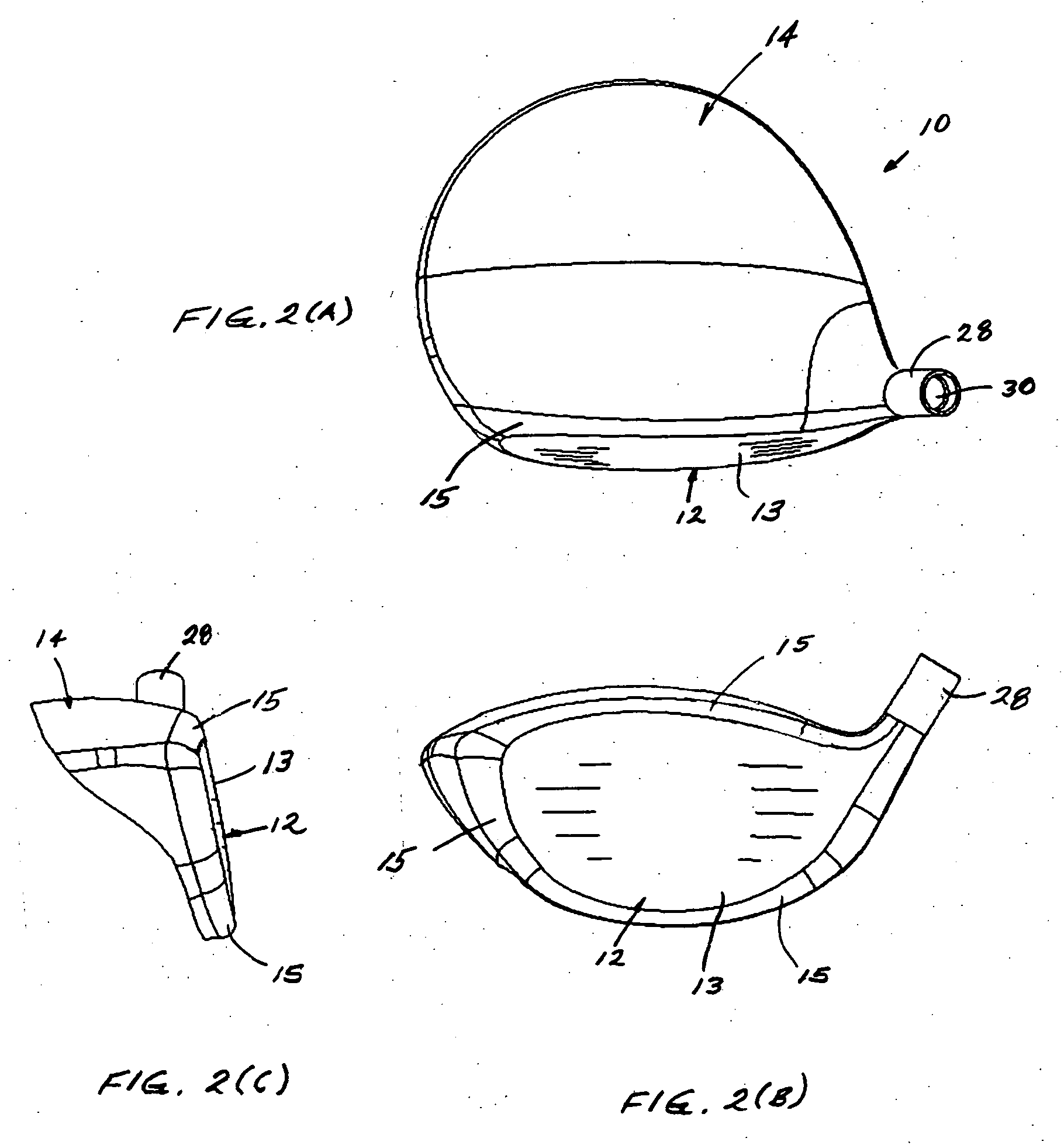

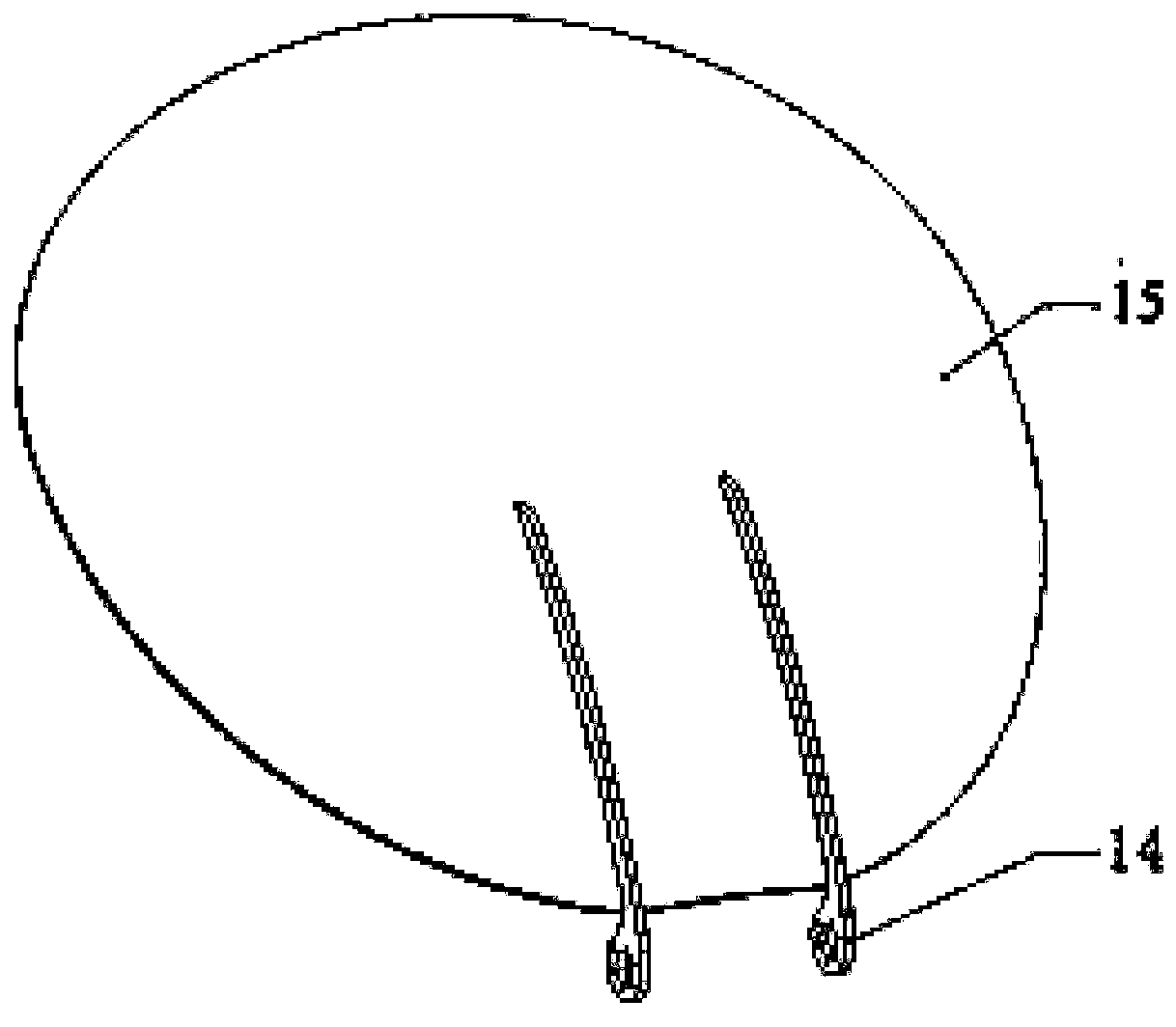

Golf club head and a method for manufacturing the same

A golf club head has a metal base, face and tubular neck and a carbon-fiber cover. The face extends up vertically from one edge of the base. The tubular neck is integrally connected to the base and the face. The cover is made of a carbon-fiber material and is securely attached to the base and the face. Because the carbon-fiber material is lighter than metal, the area of the face is enlarged. In addition, the shock absorbing effect of the golf head club is also improved.

Owner:ADVANCED INT MULTITECH CO LTD

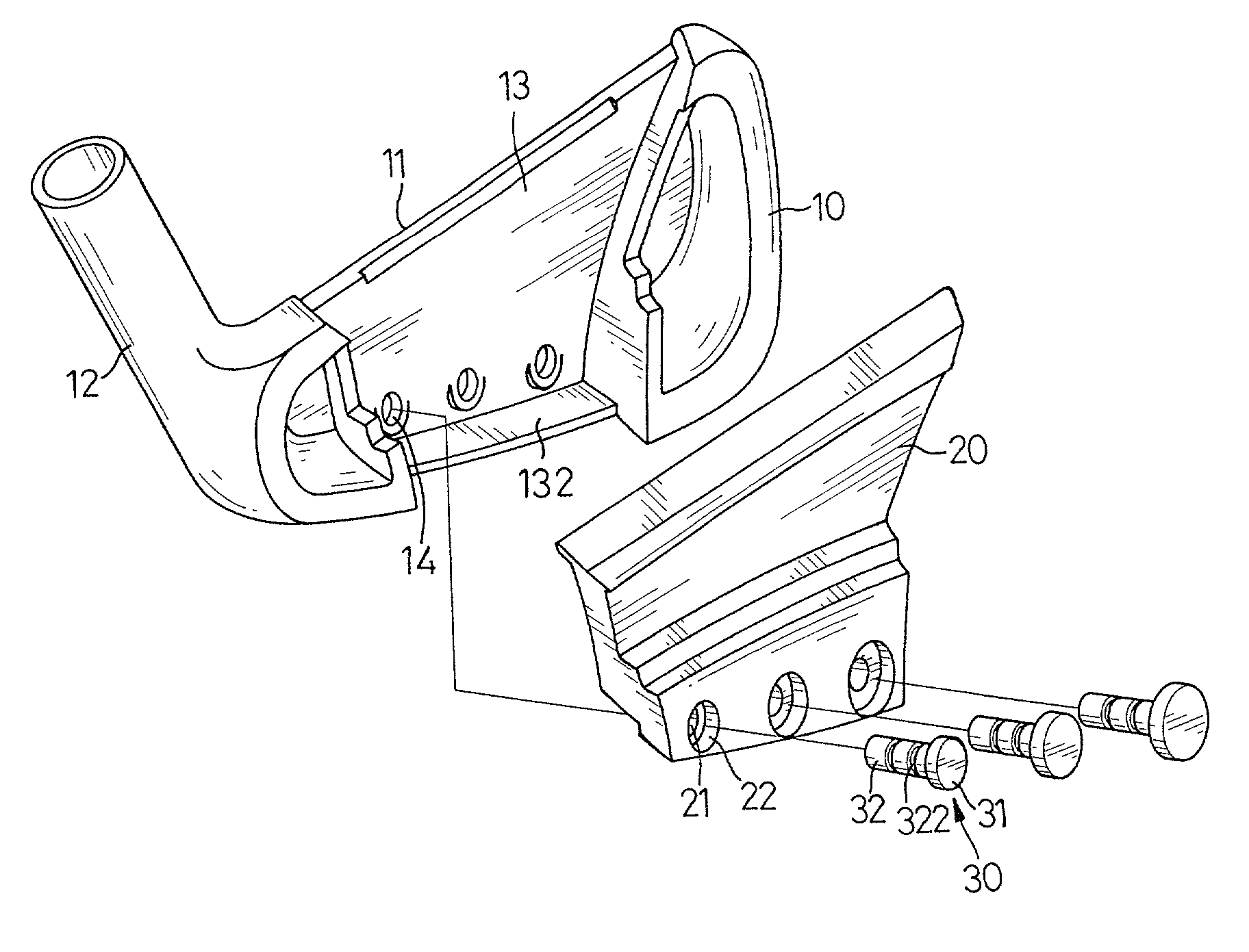

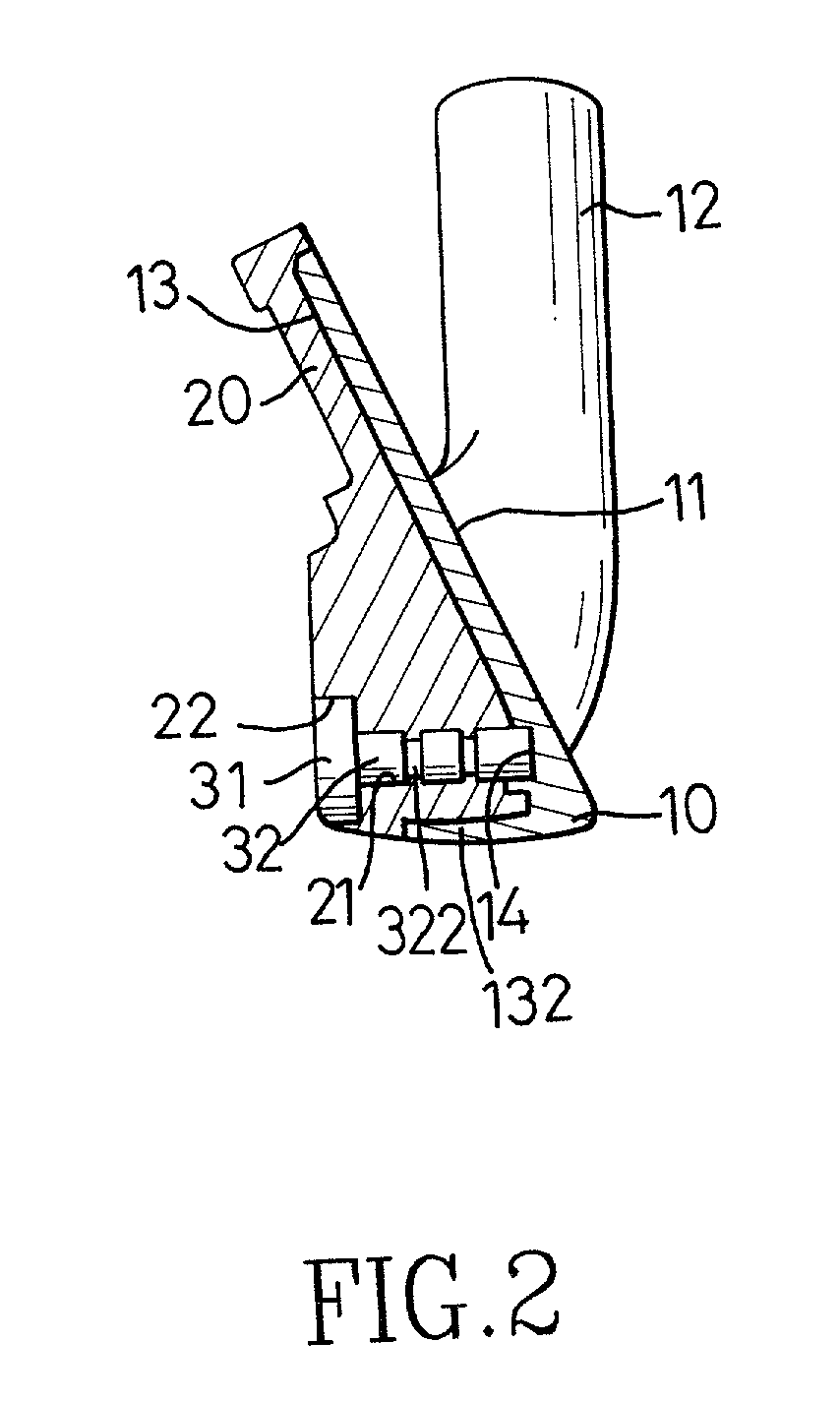

Golf club head with a carbon fiber block

A golf club head has a body and a carbon filter block. The body has a face defined on one side of the body. A tubular neck is integrally formed on one end of the body. A cavity is defined in the body opposite to the face. The carbon fiber block is mounted in the cavity. Because the carbon fiber material is lighter than metal, the area of the face is enlarged. In addition, a better shock absorbing effect is achieved due to the arrangement of the carbon fiber block.

Owner:ADVANCED INT MULTITECH CO LTD

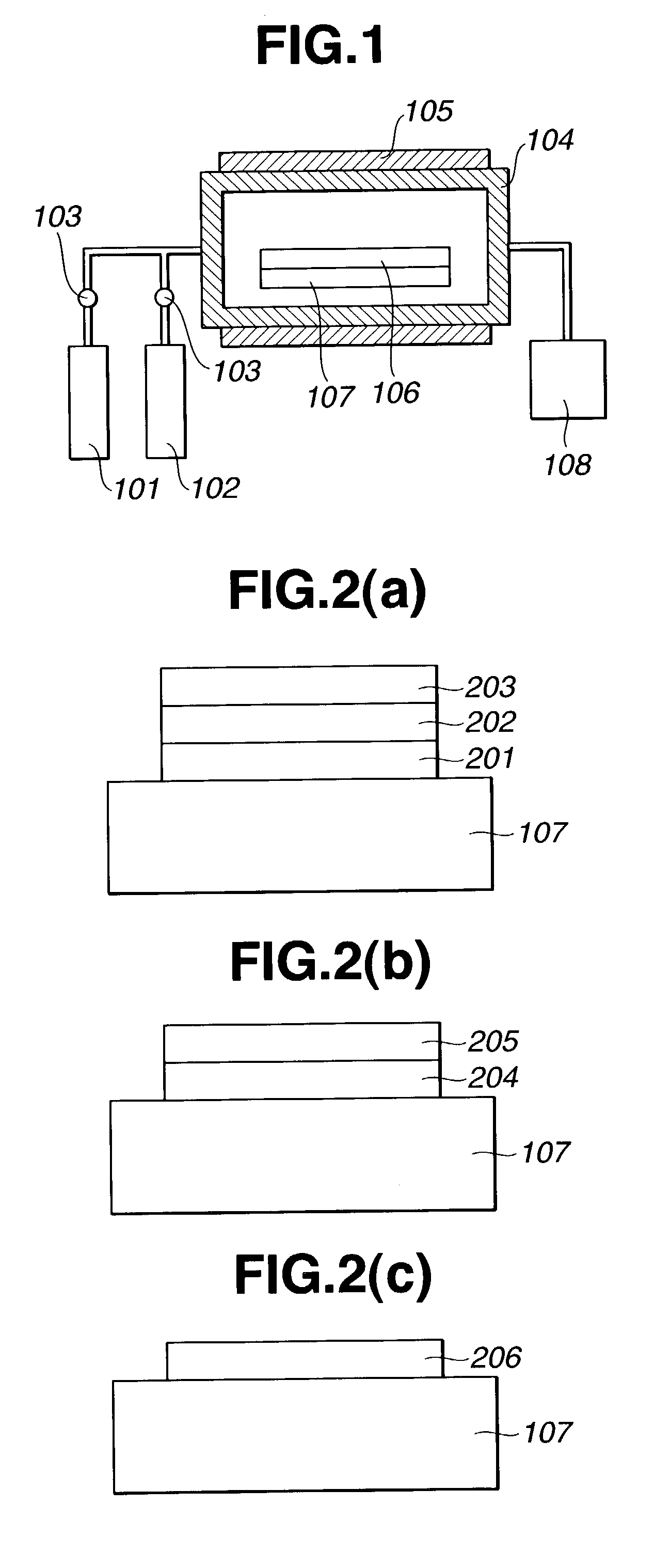

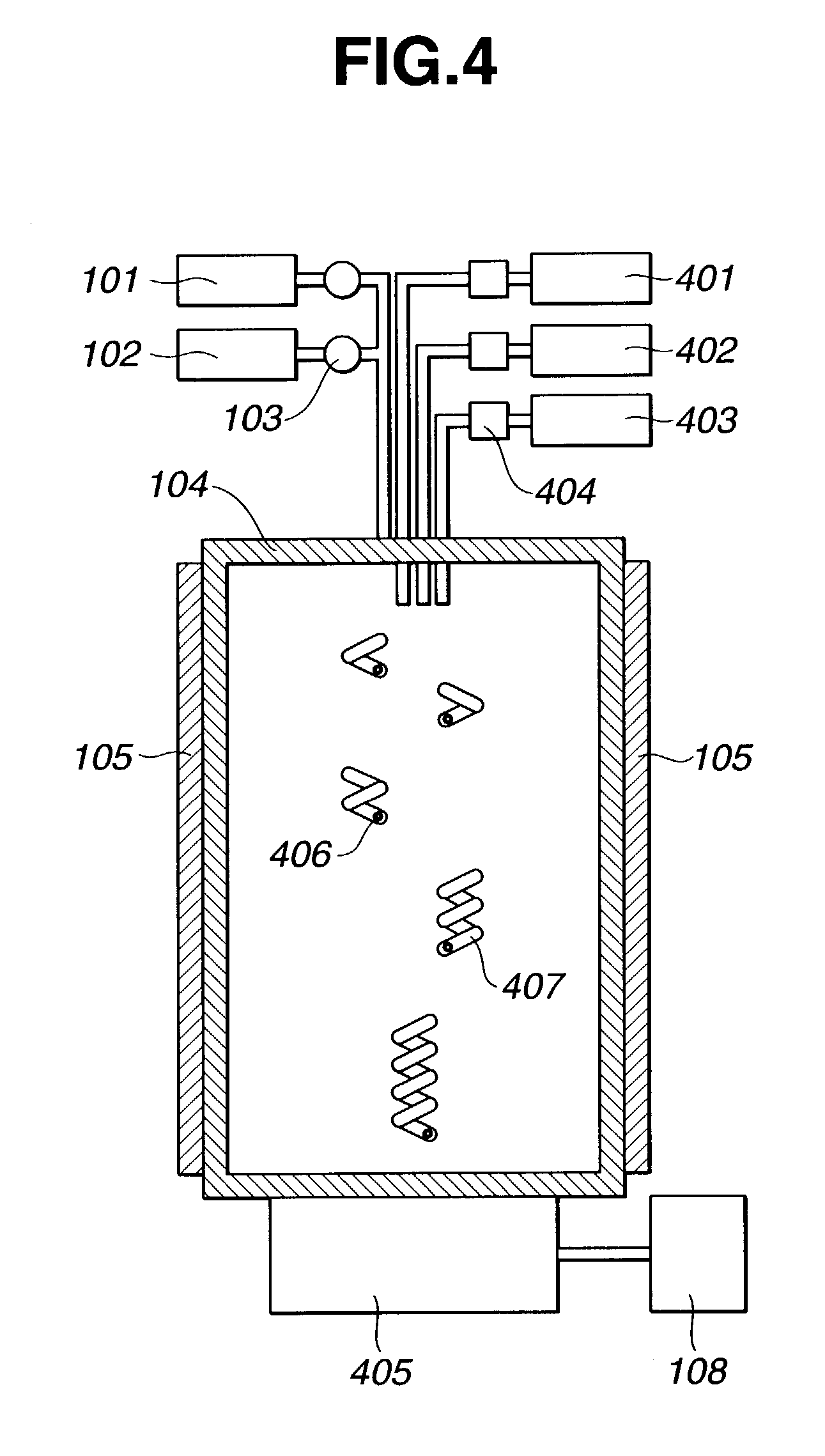

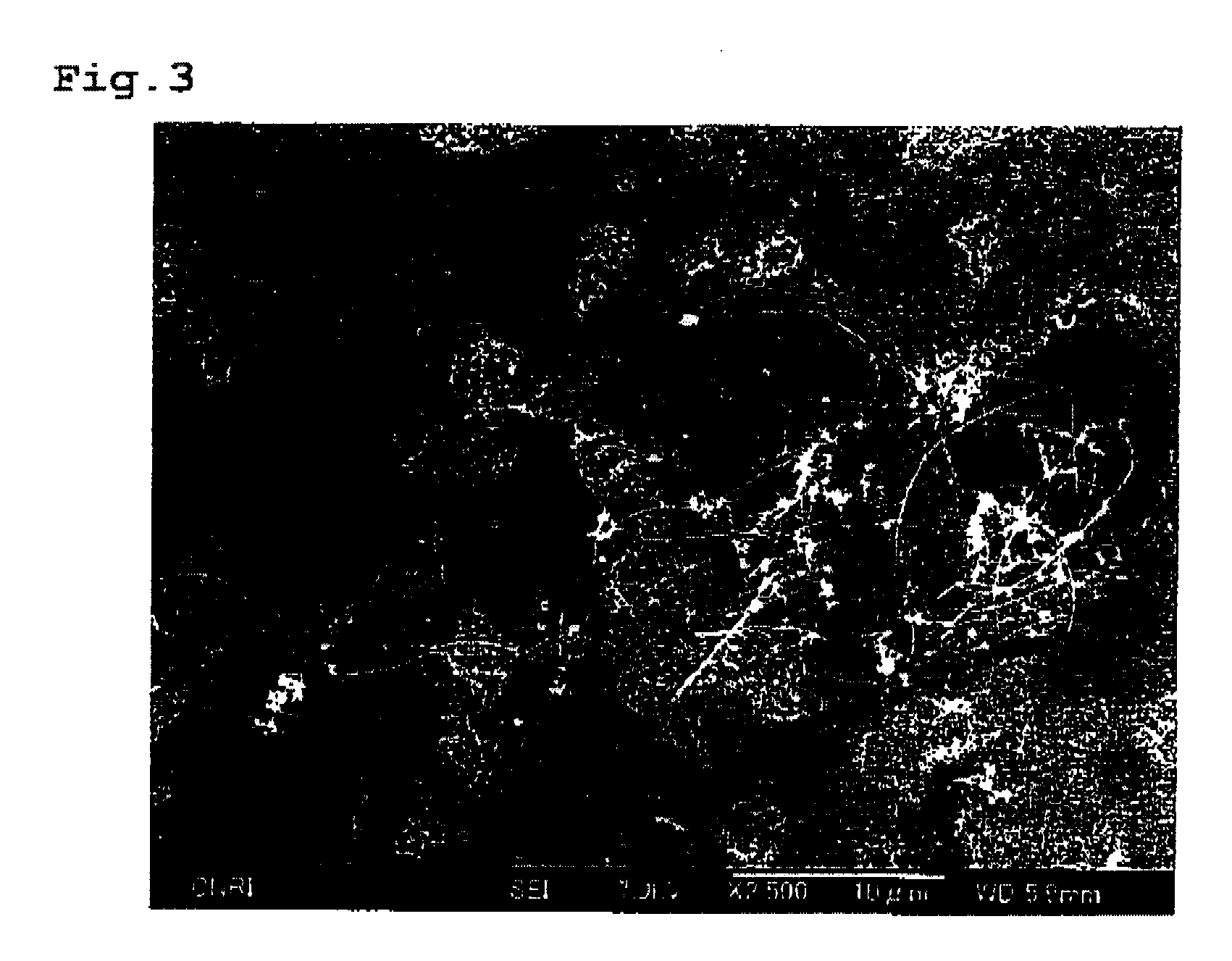

Method for preparing nano-carbon fiber and nano-carbon fiber

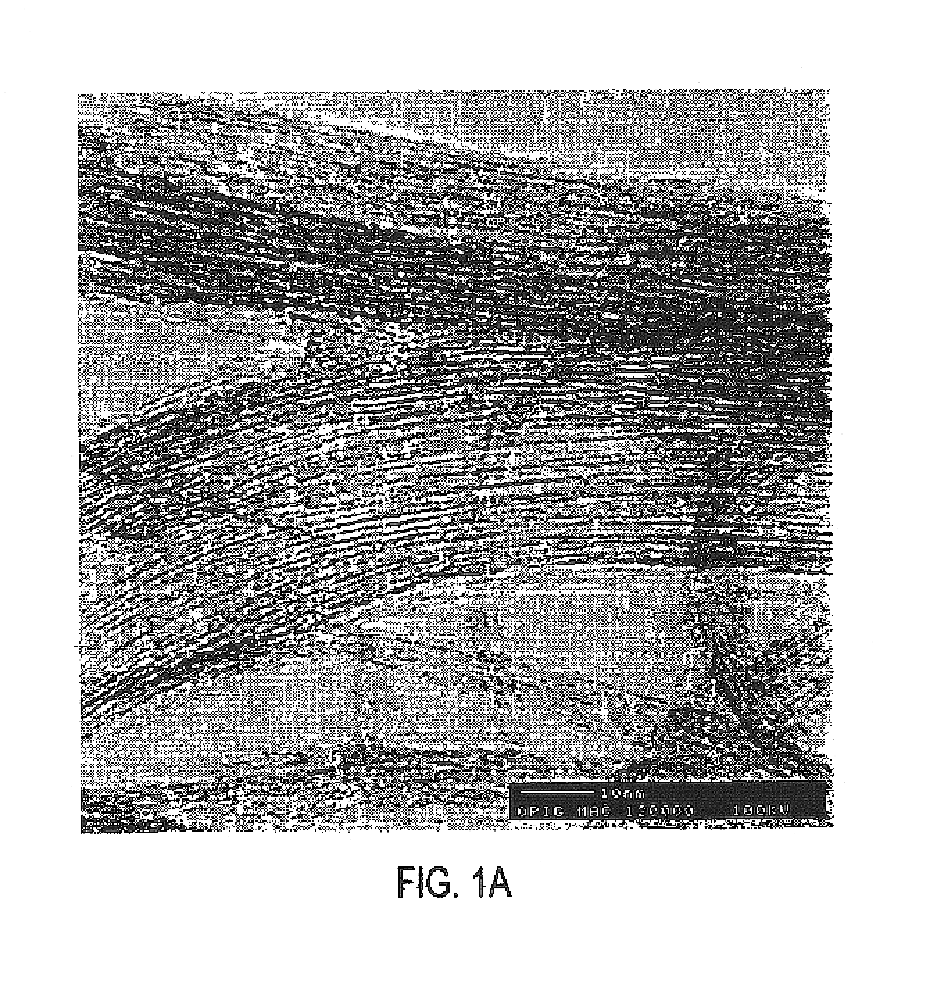

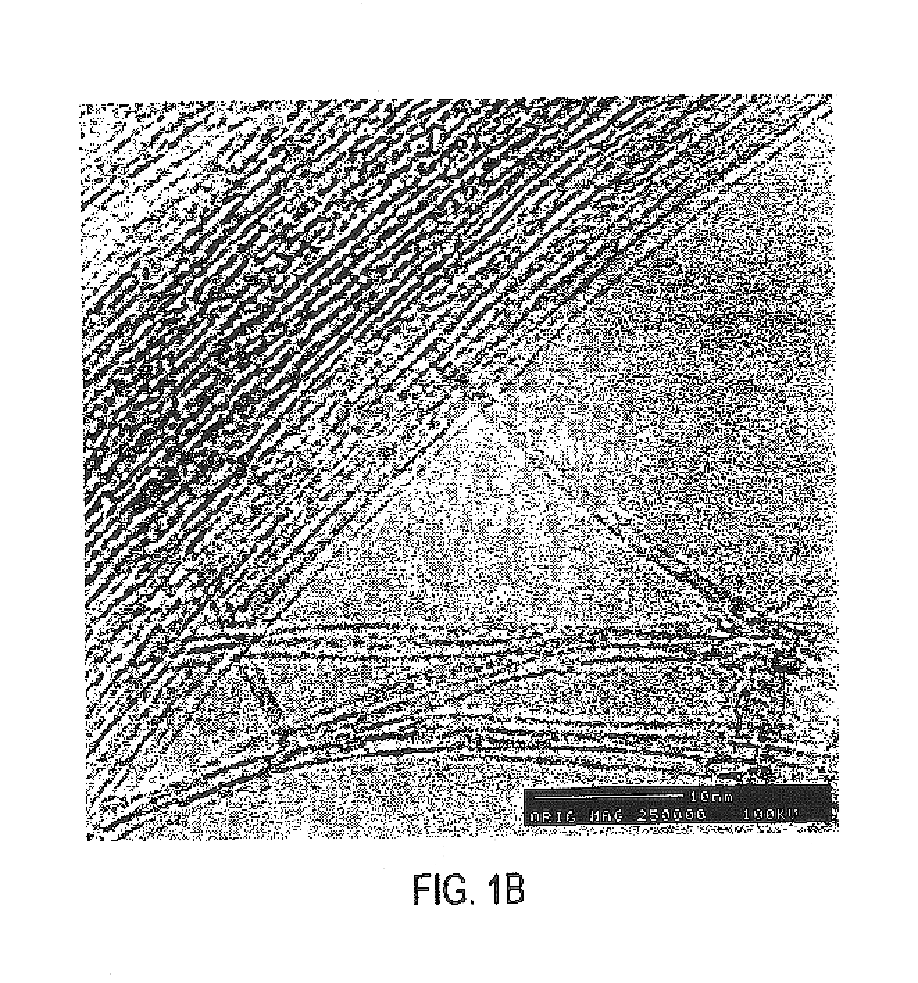

A carbon nano-fiber, particularly twisted carbon nano-fiber such as a carbon nano-coil, carbon nano-twist, carbon nano-rope is produced by means of a catalyst CVD method using carbon-containing gas as a raw material and a catalyst comprising one or plural components selected from the group consisting of Cr, Mn, Fe, Co, Ni and oxide thereof and one or plural components selected from the group consisting of Cu, Al, Si, Ti, V, Nb, Mo, Hf, Ta, W and oxide thereof is used.

Owner:FUTABA CORPORATION

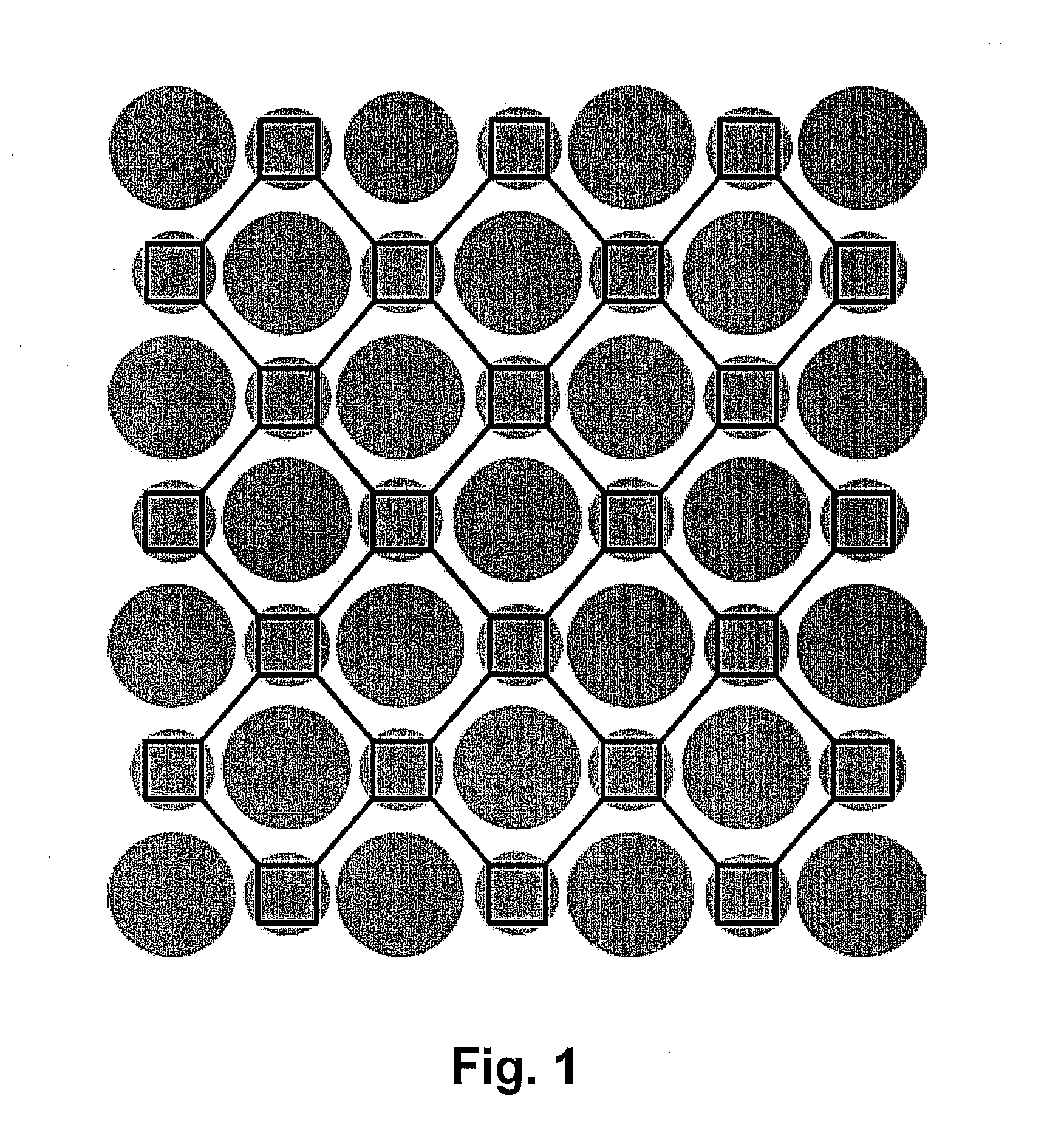

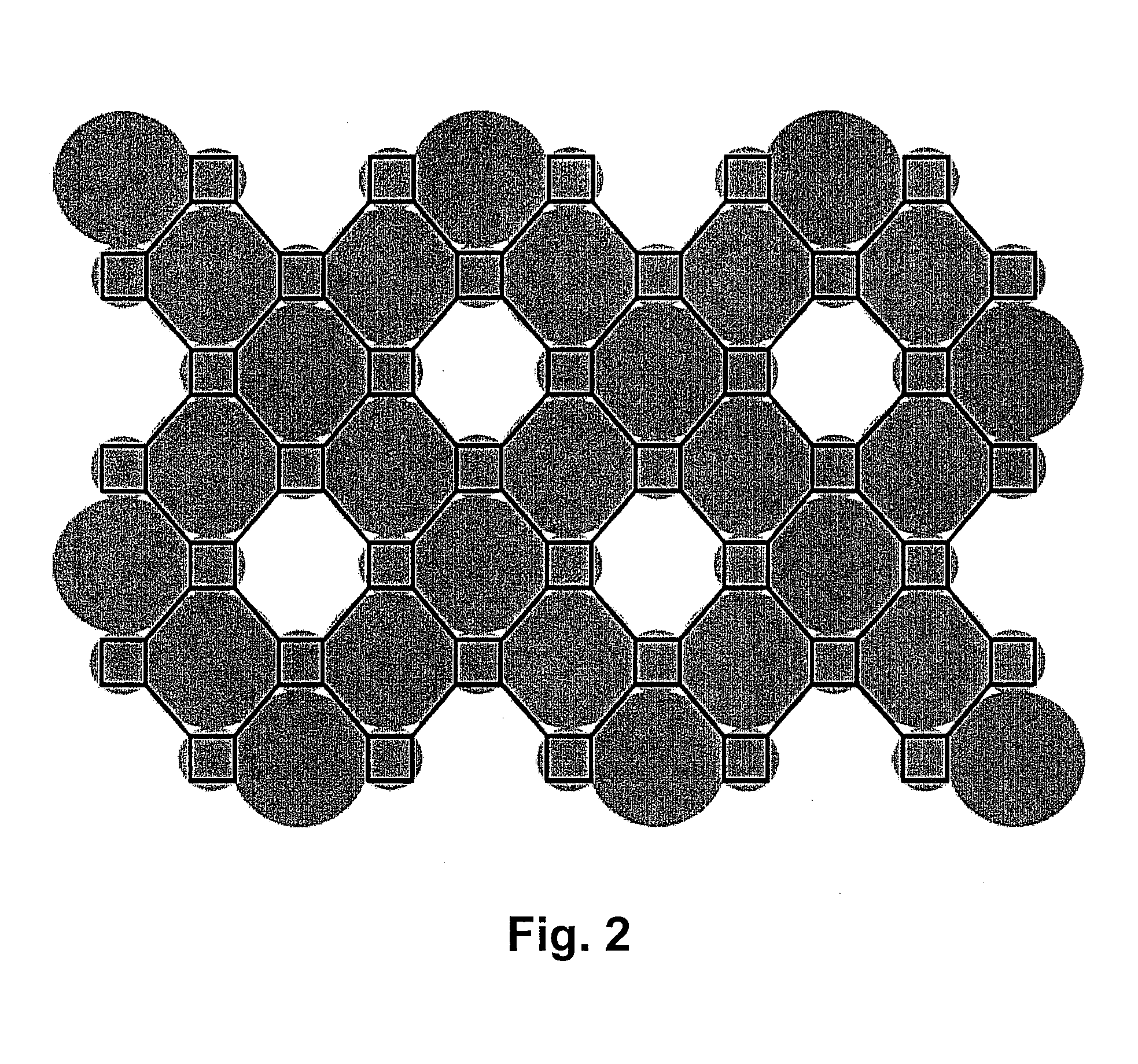

Methods and systems for manufacturing a structure having organized areas

A beaded preform includes a plurality of adjacently positioned beads for forming a plurality of voids in an engineered material. The beaded preforms may be comprised of a filaments (single strand of beads) and mats (two-dimensional and three dimensional arrays of beads). The filaments and mats may be coated to become tows and laminates, respectively, which may then be assembled into composite materials. The preforms may be produced using novel manufacturing apparatuses and methods, and incorporated into known manufacturing processes to produce porous structures, including stress-steering structures, in any material including metals, plastics, ceramics, textiles, papers, and biological materials, for example. Permanent bead material is preferably made of polyacrylonitrile, carbon fiber, or graphite.

Owner:HEX

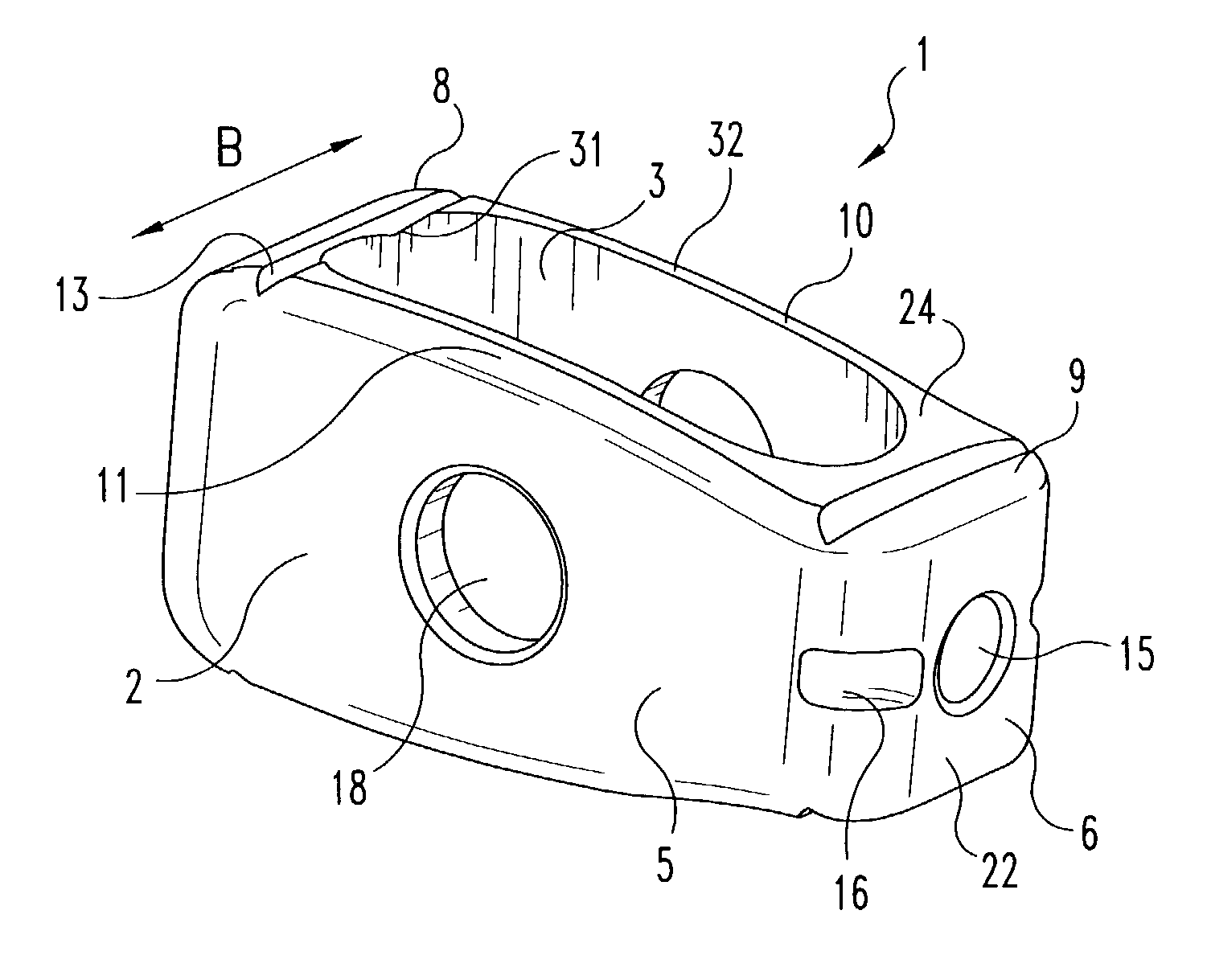

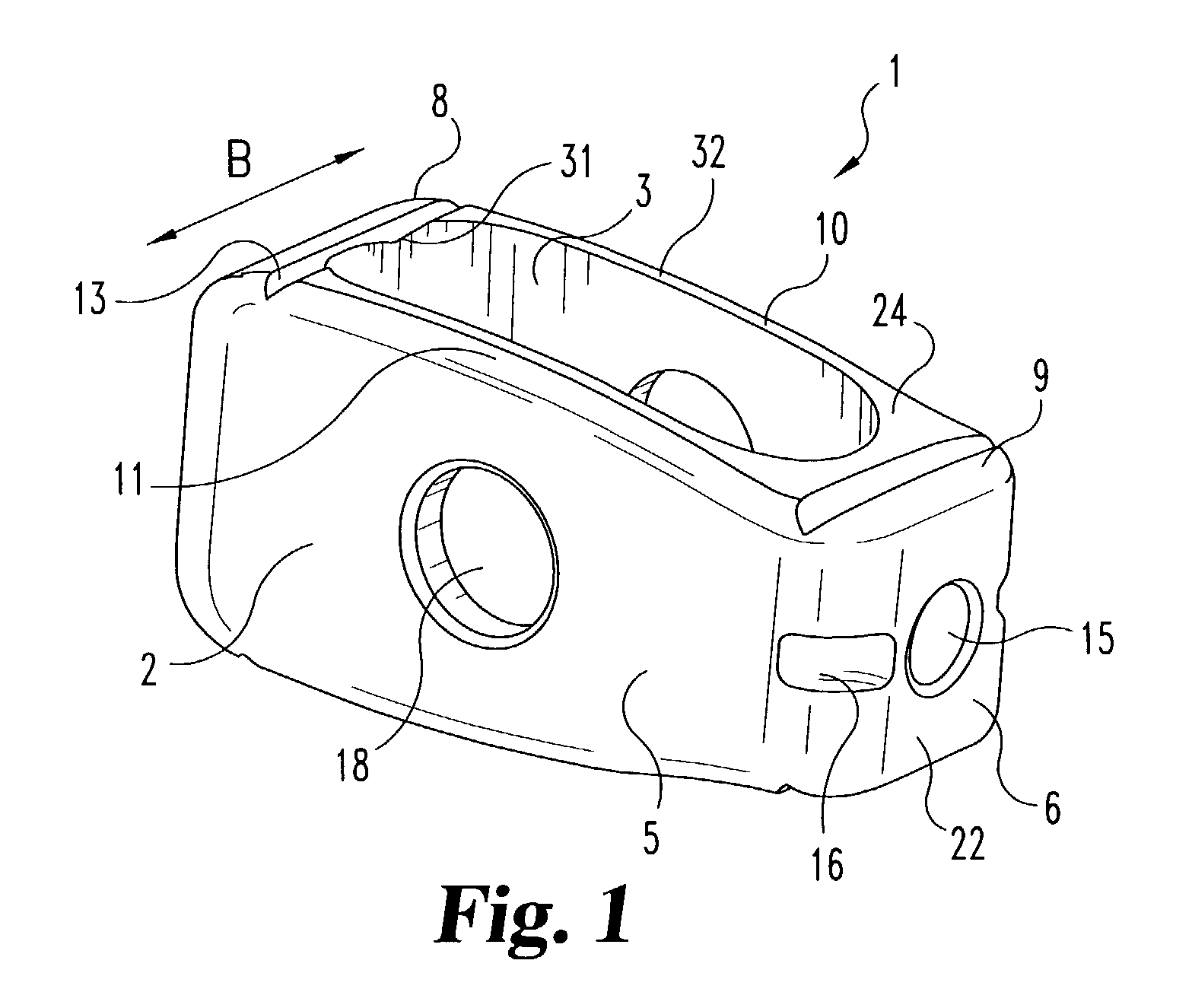

Vertebral implant for promoting arthrodesis of the spine

This invention provides a vertebral implant for impaction in a disc space to restore and / or maintain desired disc space height and spinal orientation. The implant has an elongated basis body having a generally lens-shape provided by convex upper and lower surfaces. Bearing surfaces are provided on the cross-edge surfaces of the endwalls. Grooves are provided in the upper and lower surfaces positioned between the bearing surfaces. The implant can be prepared from a wide variety of materials including metallic materials, synthetic materials, polymeric materials, ceramic materials, and composite materials including reinforced materials i.e. glass, fiber, and / or carbon fiber reinforced materials (CFRP). These preferred materials for fabricating implants in the present invention reduce costs, increase service life and provide excellent physiological compatibility. The non-metallic material can be selected to be either a substantially permanent material, a biodegradable material or a bioerodable material. Further, the implant material can be provided to be radio opaque to facilitate monitoring of bone ingrowth both into the implant and between the opposing endplates of the adjacent vertebrae.

Owner:WARSAW ORTHOPEDIC INC

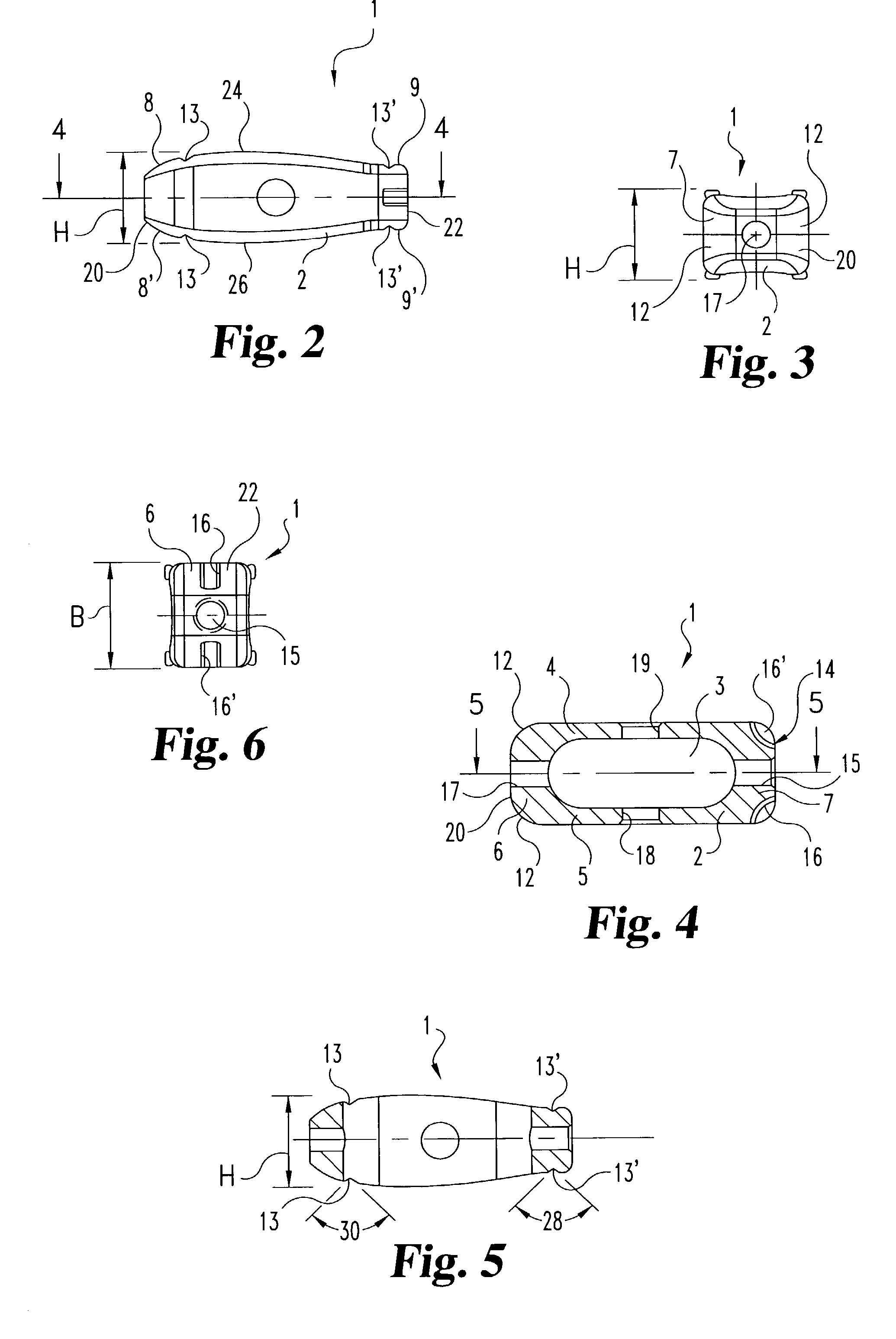

Method and machine for producing multiaxial fibrous webs

InactiveUS6585842B1Reduce manufacturing costLow costLamination ancillary operationsOrnamental textile articlesFiberCarbon fibers

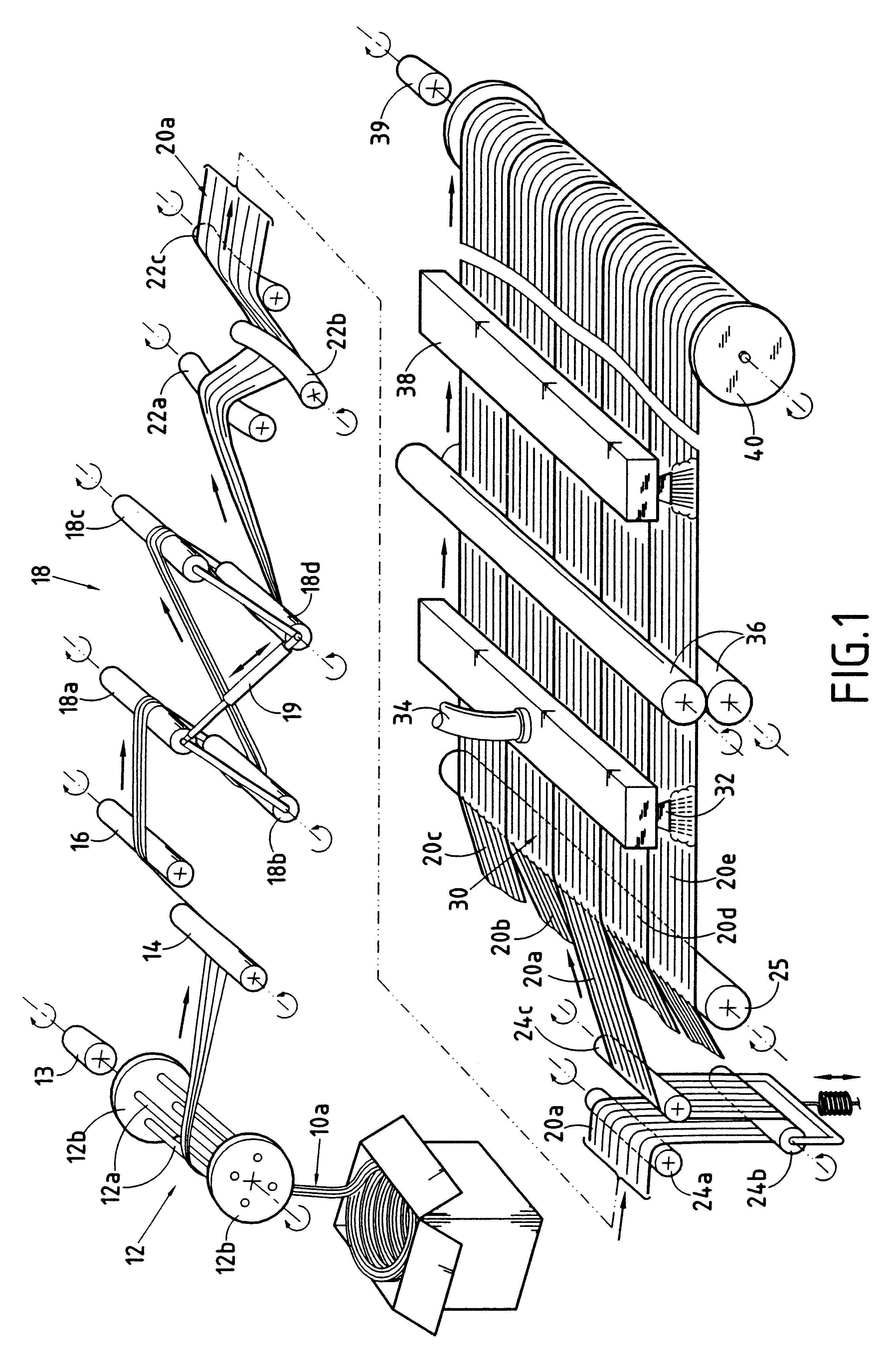

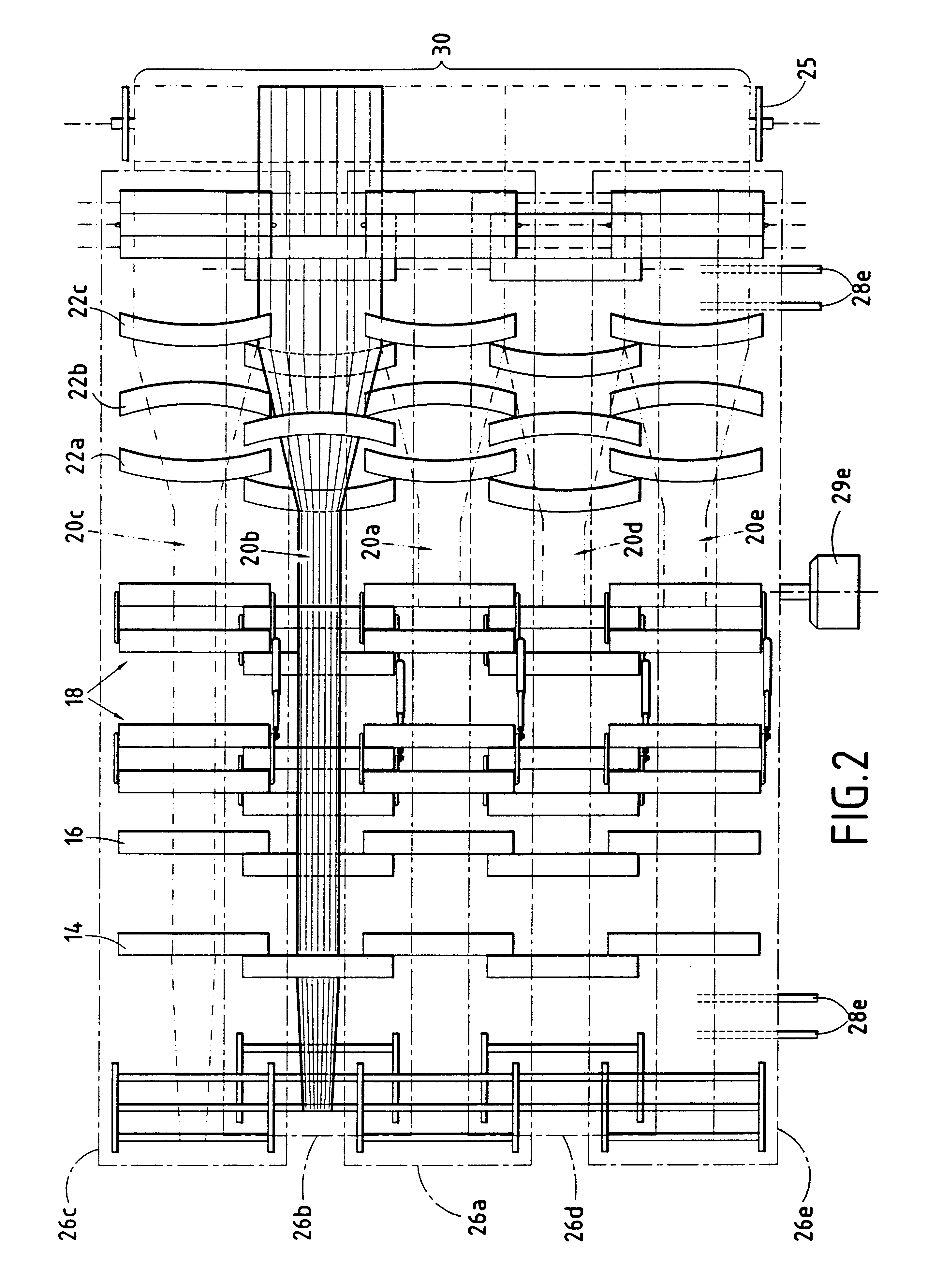

A plurality of unidirectional sheets (30a, 30b, 30c) are superposed in different directions and they are bonded together. At least one of the unidirectional sheets is made by spreading a tow so as to obtain uniform thickness, width not less than 5 cm, and a weight of no more than 300 g / m2, cohesion being imparted to the sheet so as to enable it to be handled prior to being superposed with other sheets. Advantageously, the unidirectional sheets are made of carbon fibers and are obtained by spreading out large tows.

Owner:HEXCEL FABRICS +1

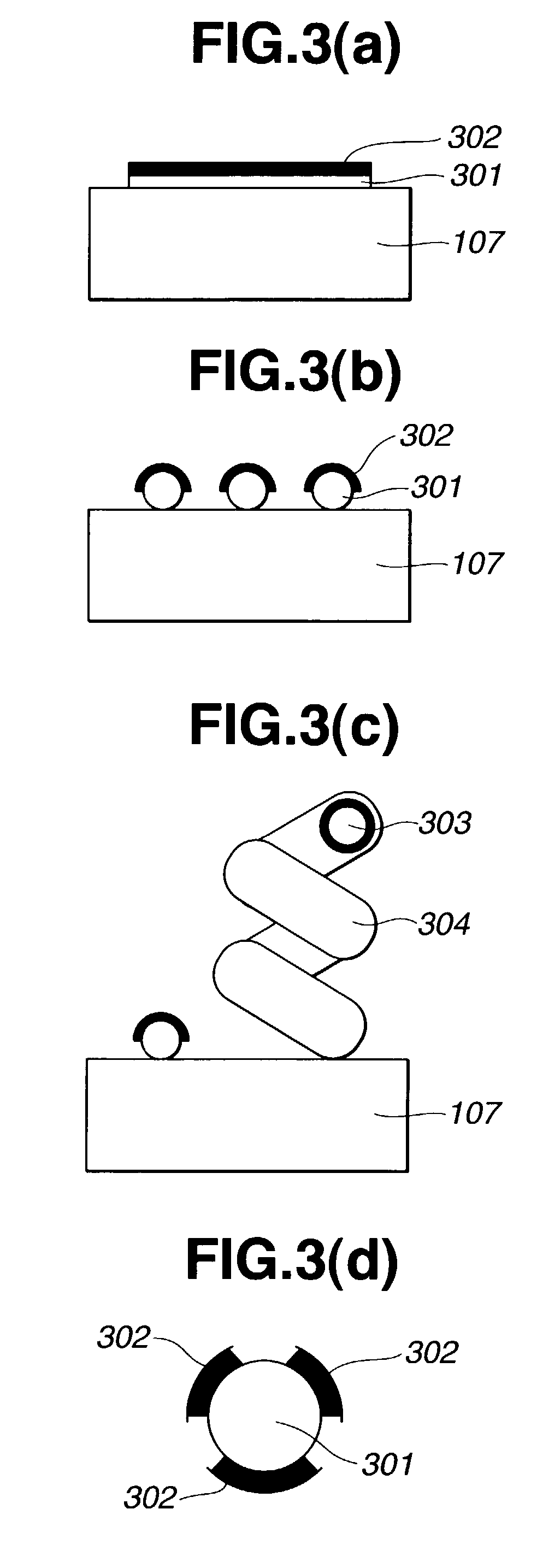

Artificial spinal joints and method of use

InactiveUS20050209694A1Preventing subluxationMaintain strengthInternal osteosythesisJoint implantsFiberCarbon fibers

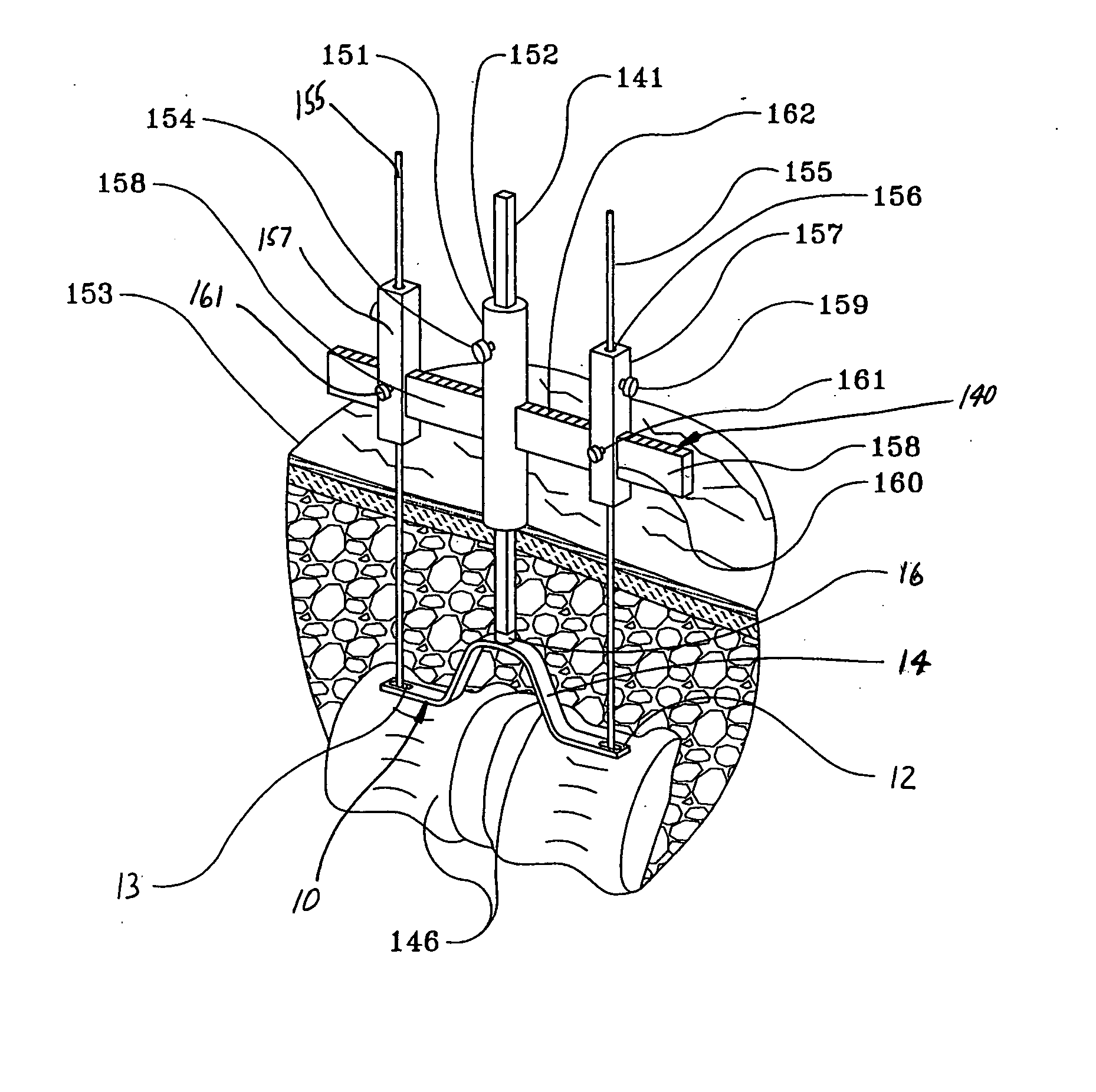

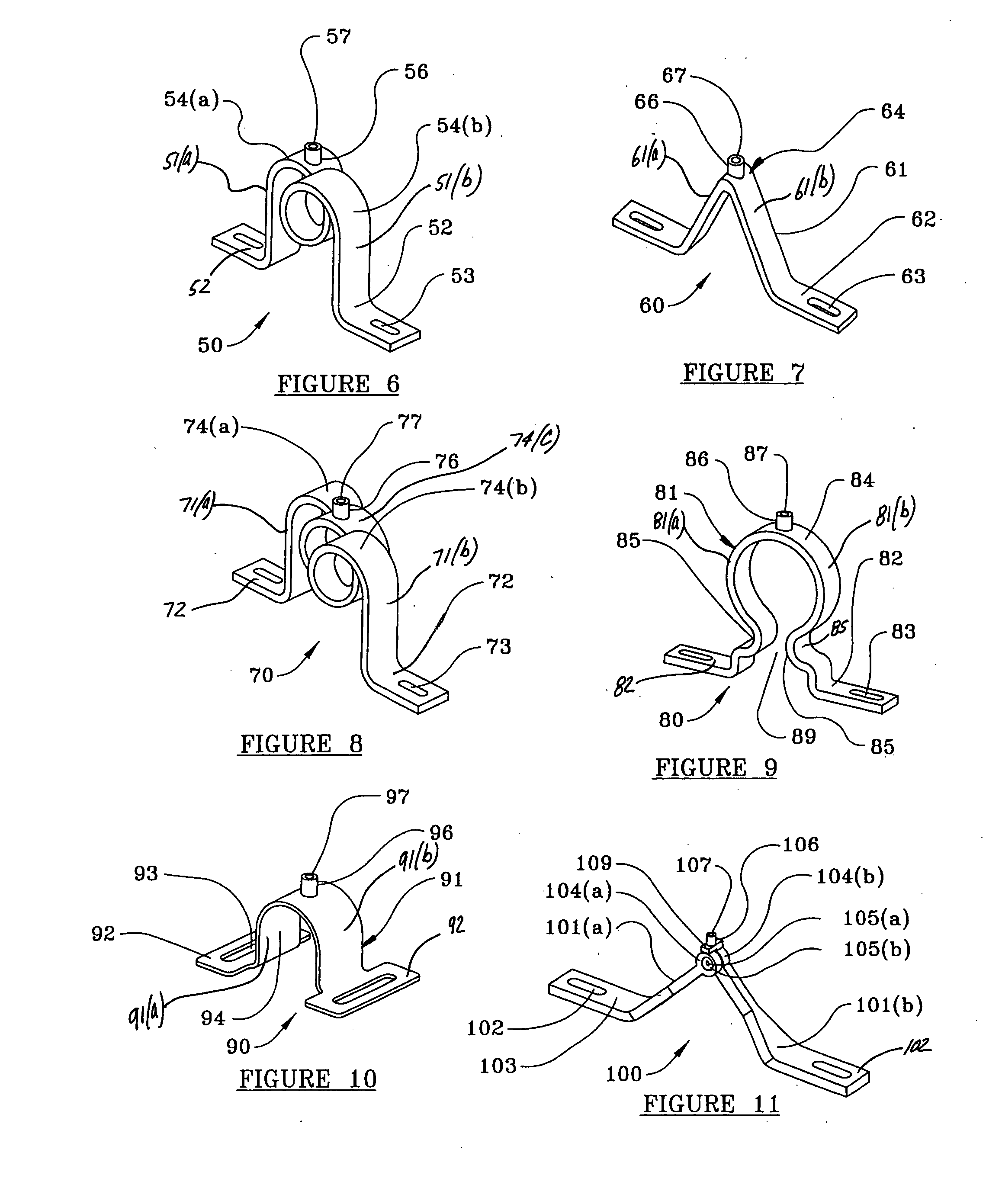

An artificial spinal joint, consisting of a flexible or rigid member or a pair of moveably-joined, flexible or rigid segments, is formed into a spring-like shape, whose distal ends have feet with slots through which screws can be inserted to attach the artificial joint to vertebra whose facets (joints) are non-functional. The artificial spinal joint is able to prevent subluxation of the spine, while retaining the mobility of the spine and permitting angular deflection of the vertebra above and below a non-functional spinal joint. A jig is used to position tools and make passageways for screws to attach the artificial spinal joint to the vertebra or its pedicles or facets in a minimally invasive procedure. The rigid members or segments are bio-compatible and may be made of titanium, a titanium alloy, tantalum, medical grade stainless steel or carbon fibers in a matrix of a rigid, durable plastic. The flexible members or segments may be made of spring steel coated with a durable, bio-compatible material, small diameter carbon fibers in a flexible, durable plastic matrix, or a single shape or dual shape, superelastic memory metal. The feet, made of any of the rigid or flexible materials described above, may also be moveably attached to the proximal ends of the members or segments. Having the feet moveably attached to the segments facilitates insertion of the artificial spinal joint into the body by folding the feet parallel to the axis of the segments during insertion, and then unfolding the feet for attachment to the vertebra or its pedicles or facets. The artificial spinal joint may be inserted and attached to vertebra whose facets are non-functional in minimally invasive, moderately invasive or conventional surgical procedures.

Owner:TRIMEDYNE

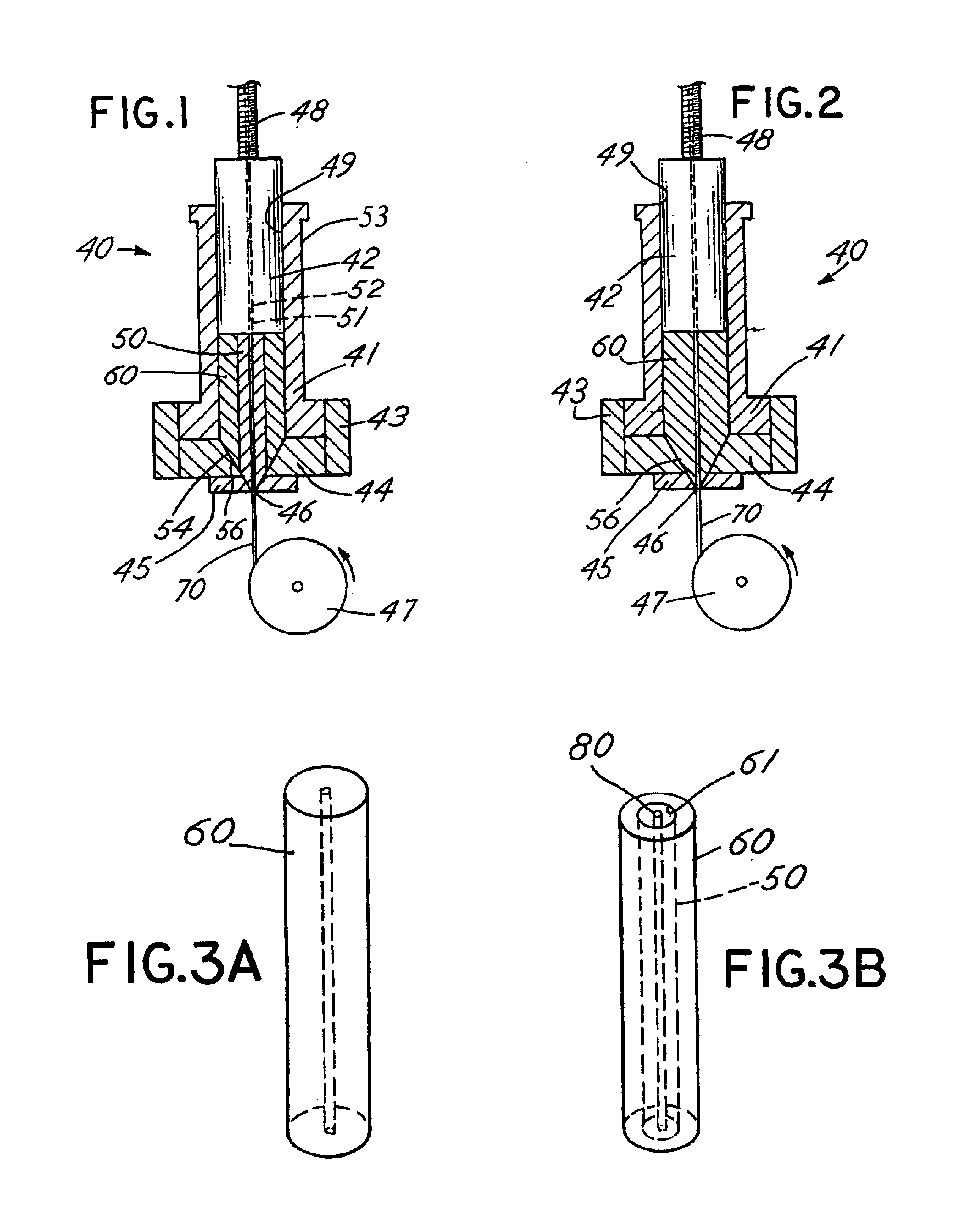

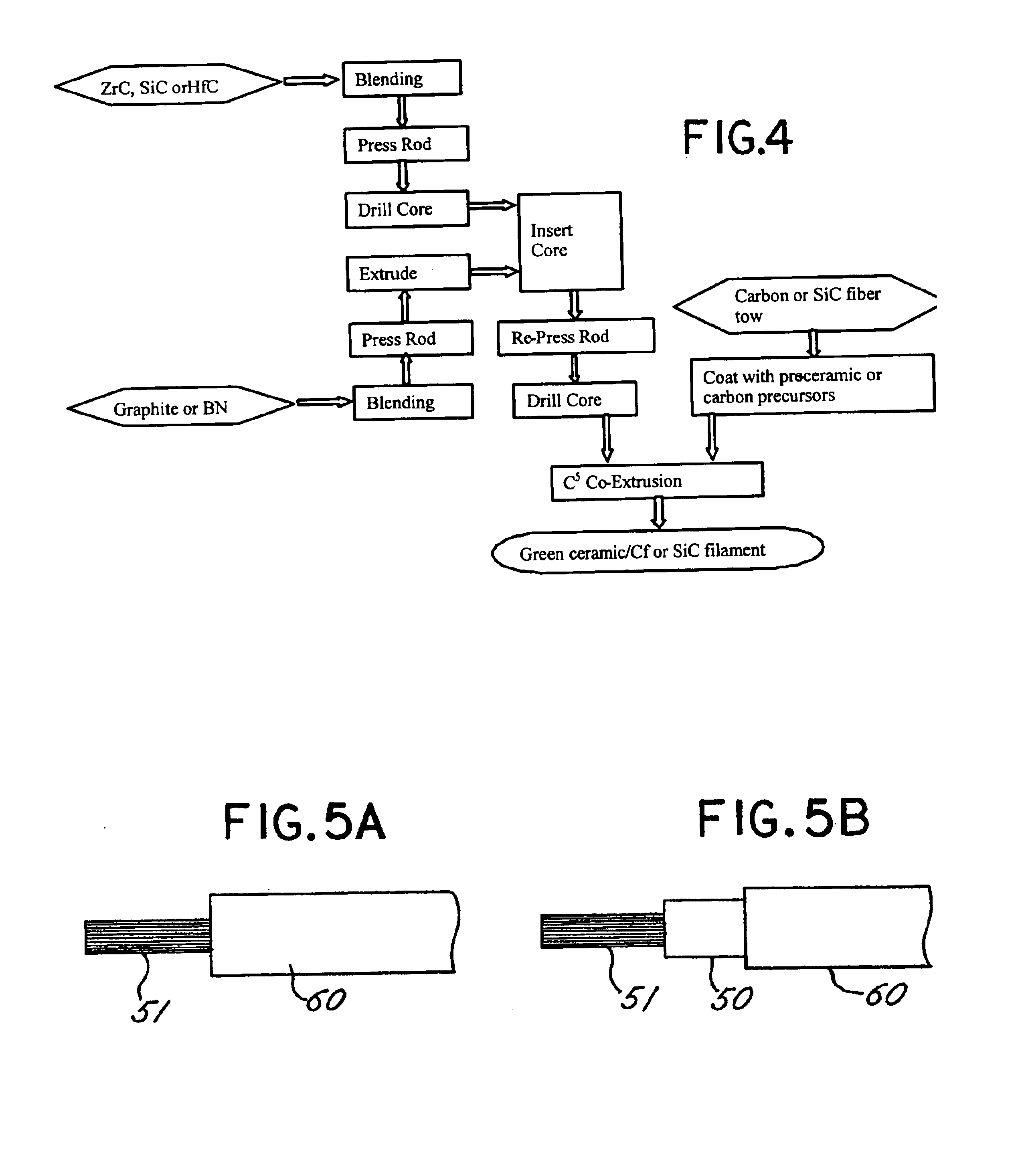

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

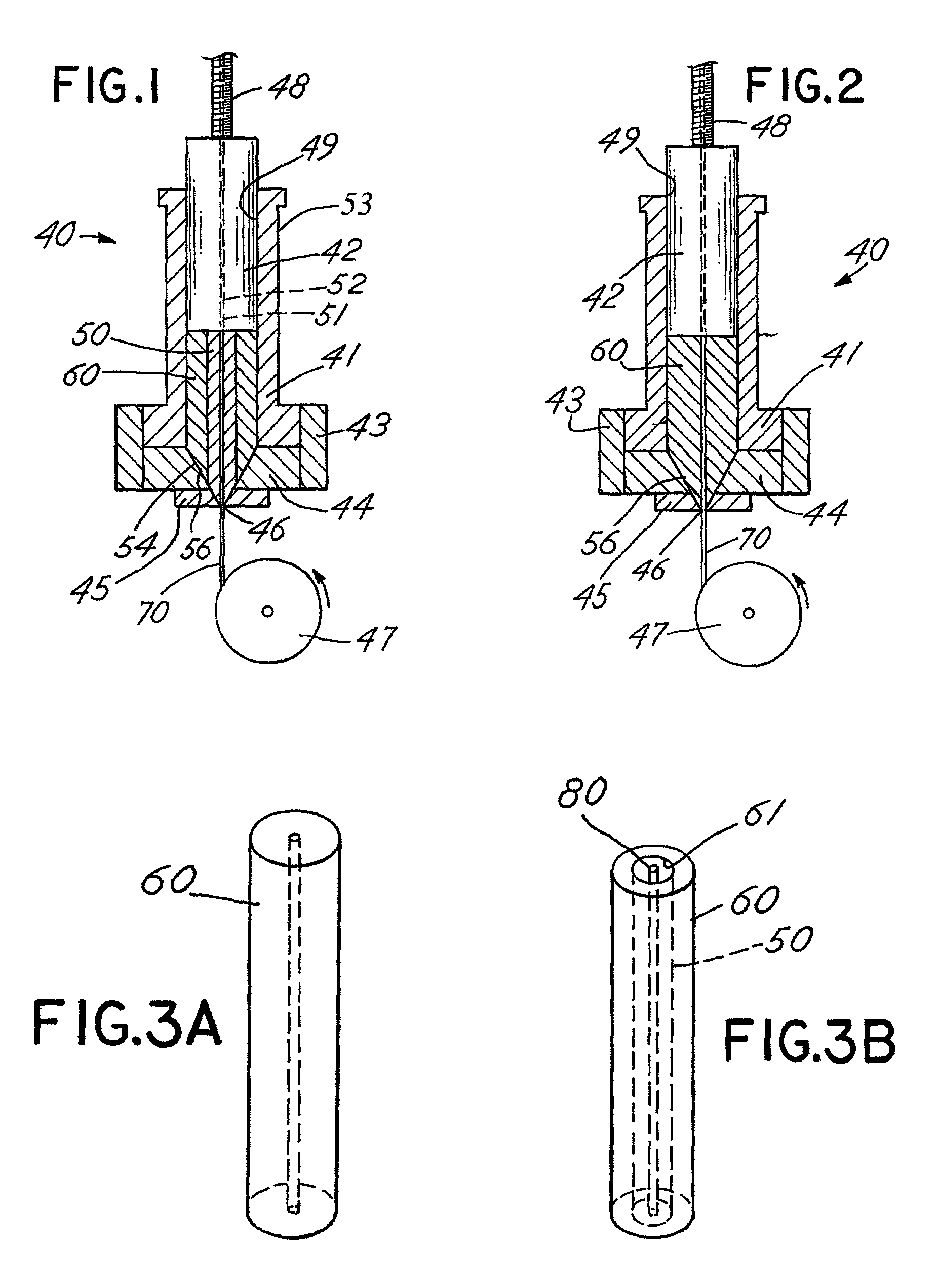

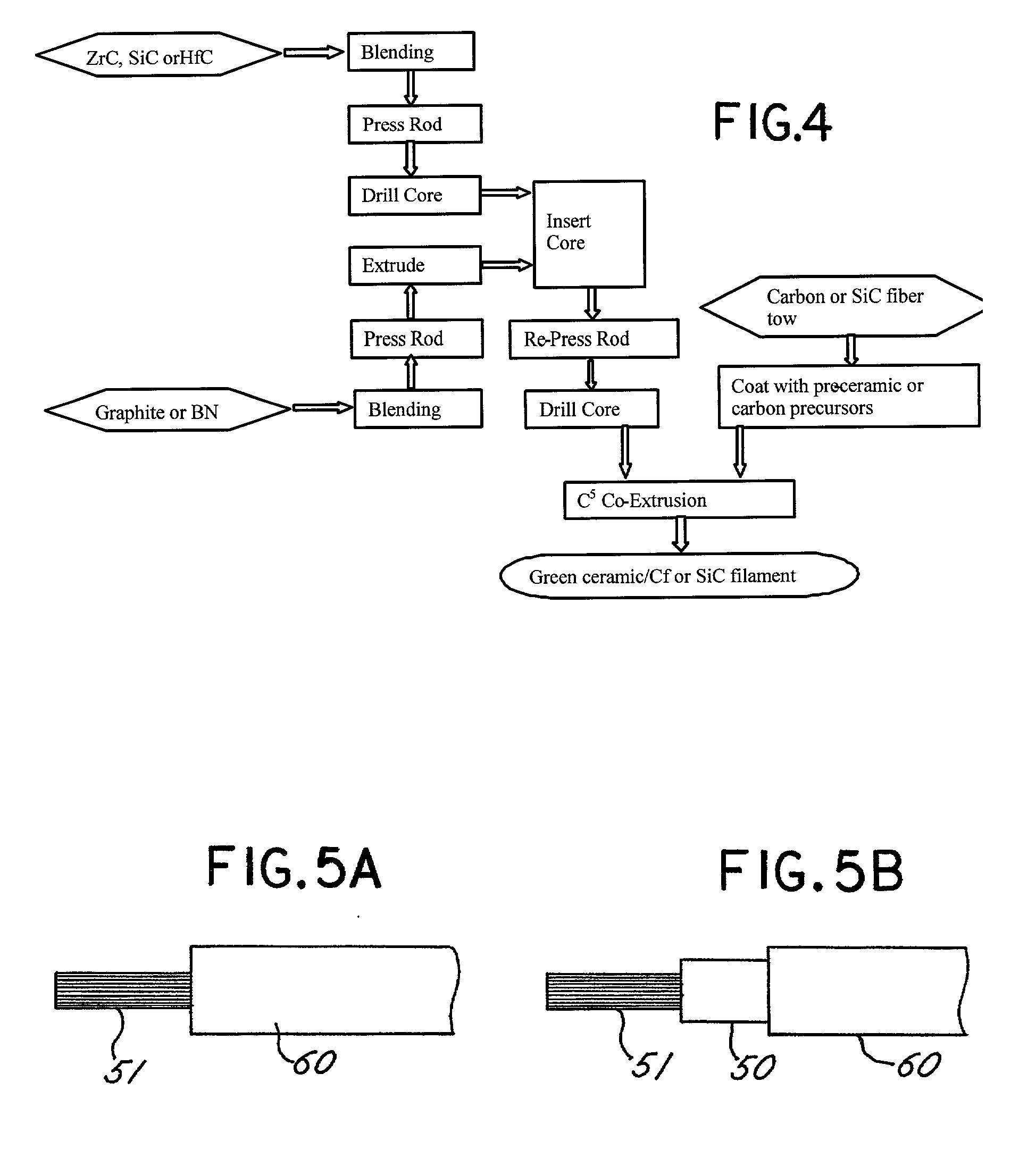

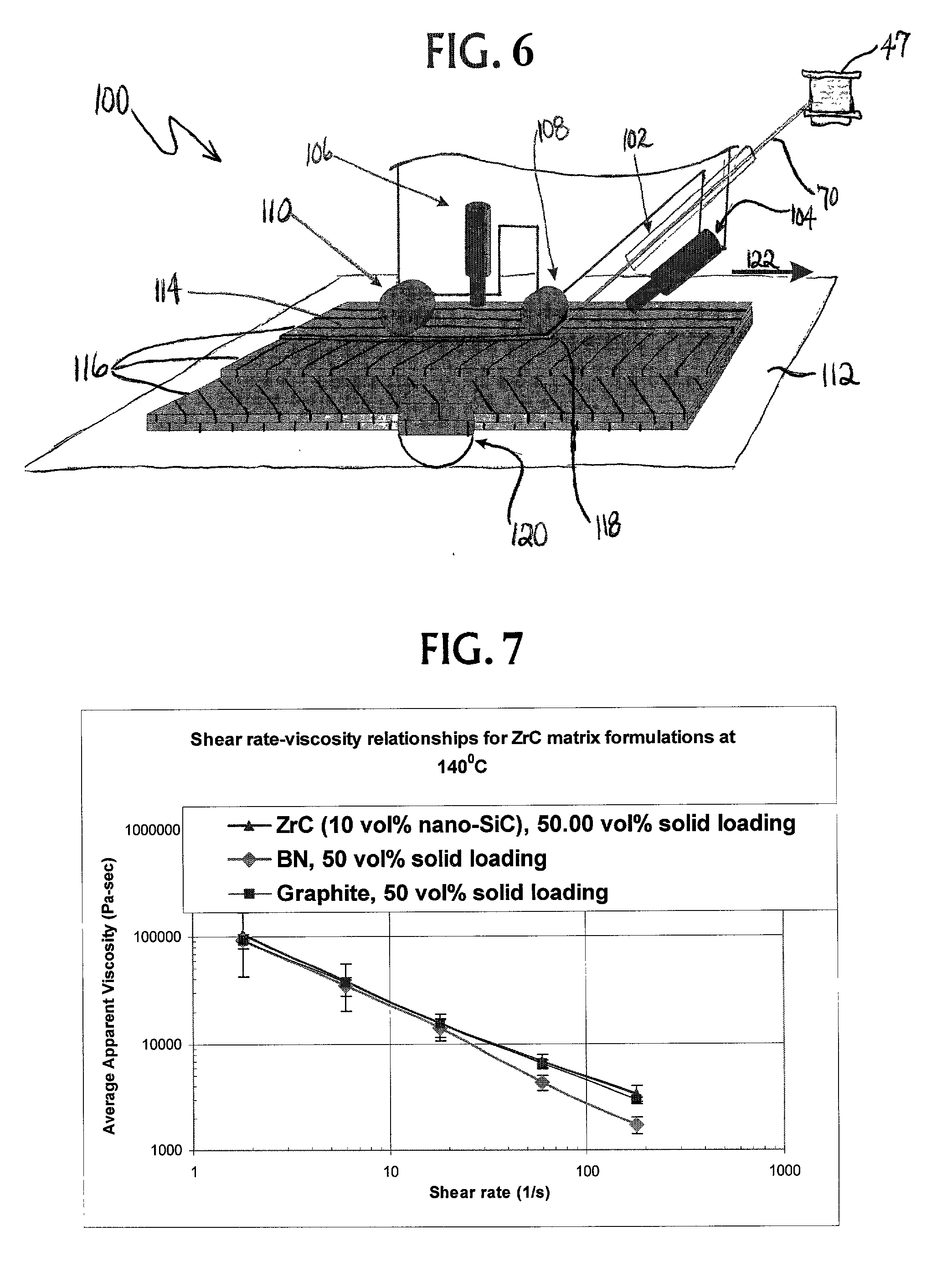

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

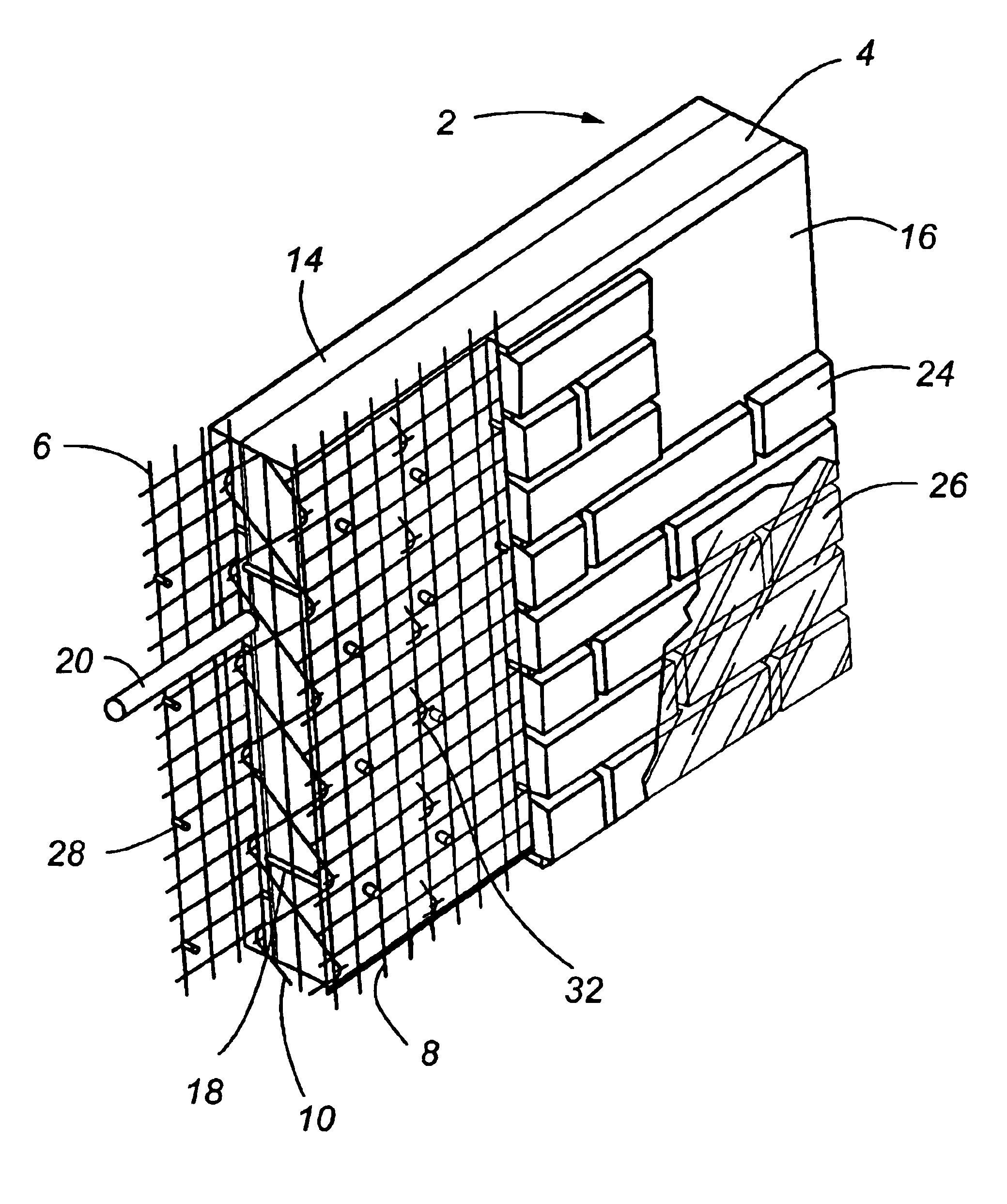

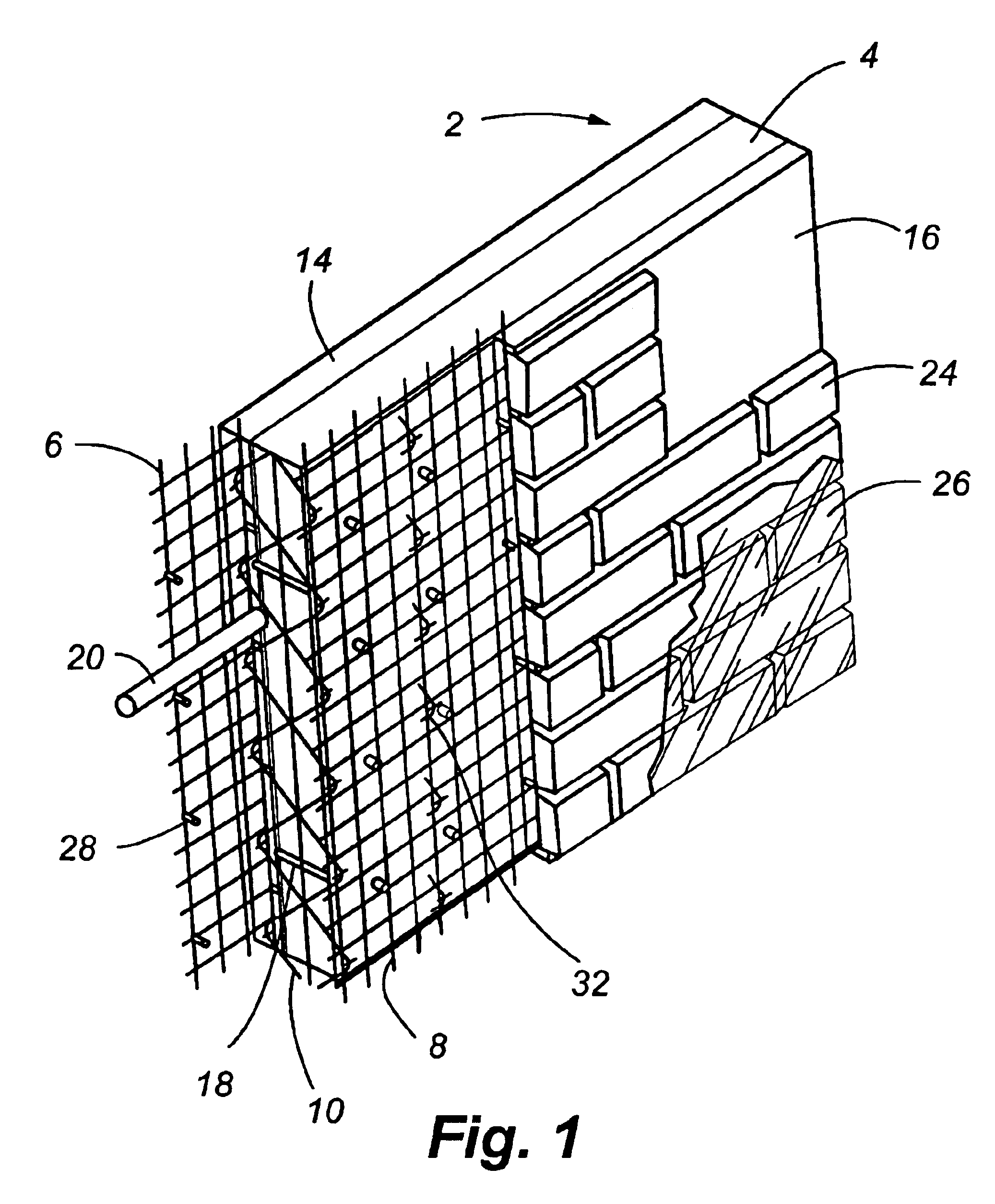

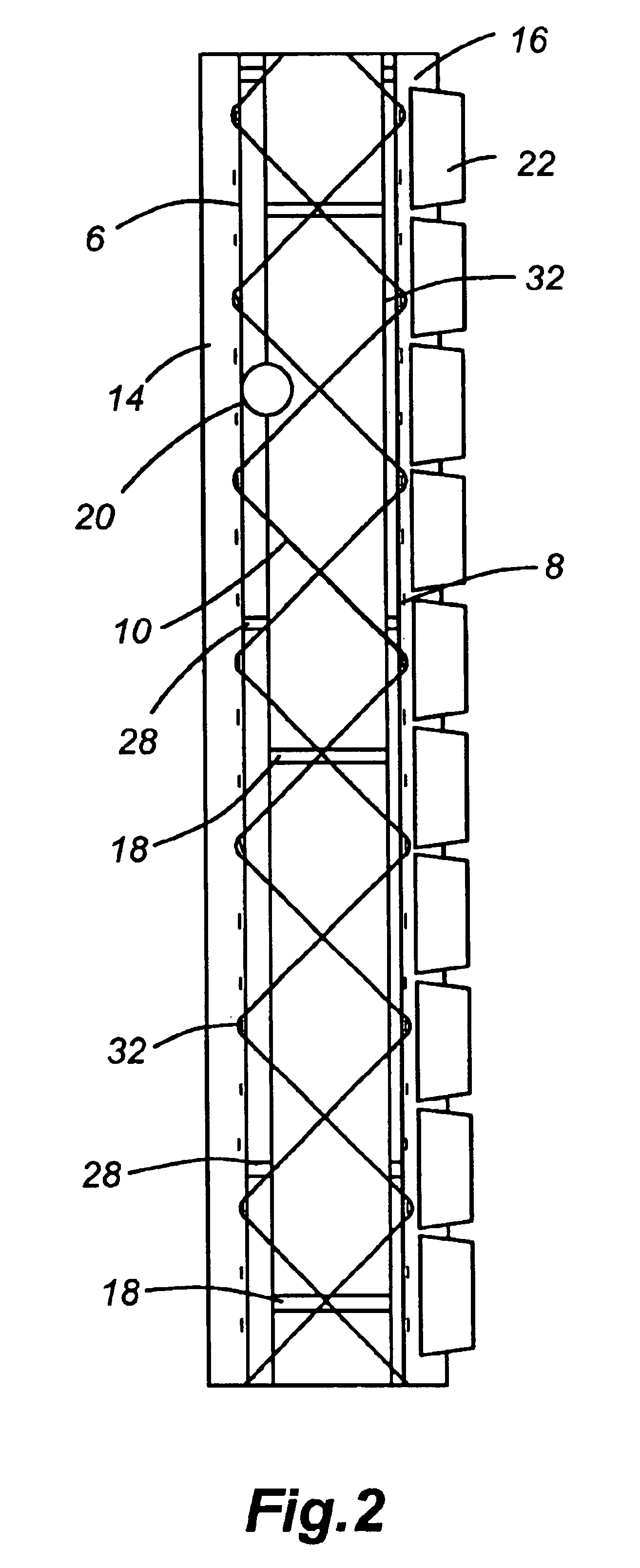

Insulative concrete building panel with carbon fiber and steel reinforcement

InactiveUS6898908B2High strengthImprove insulation performanceBuilding roofsConstruction materialFiberCarbon fibers

An insulative, lightweight concrete building panel is provided with one or more fiber or steel reinforcements which are manufactured in a controlled environment and can be easily transported and erected at a building site.

Owner:OLDCASTLE PRECAST

Golf club-heads having a particular relationship of face area to face mass

Golf clubs and club-heads for same are disclosed. An exemplary club-head has a hollow body and a face plate. The body defines a front opening and a face support, wherein the face plate is affixed to the face support and covers the front opening. The “face portion” of the club-head has a face area (Af, in mm2) and a face mass (Mf, in grams), wherein Af>5400 mm2, and in a plot of Mf as a function of Af, Mf is below Mf=0.0072(Af)+18. At least a portion of the face plate can be made of composite. E.g., the face plate can include a composite plate made of carbon fiber and cured epoxy resin. The strike face of the face plate can include a composite plate and a cap bonded to the composite plate on the strike face. The cap can be made of a metallic material, such as (but not limited to) titanium alloy or stainless steel.

Owner:TAYLOR MADE GOLF

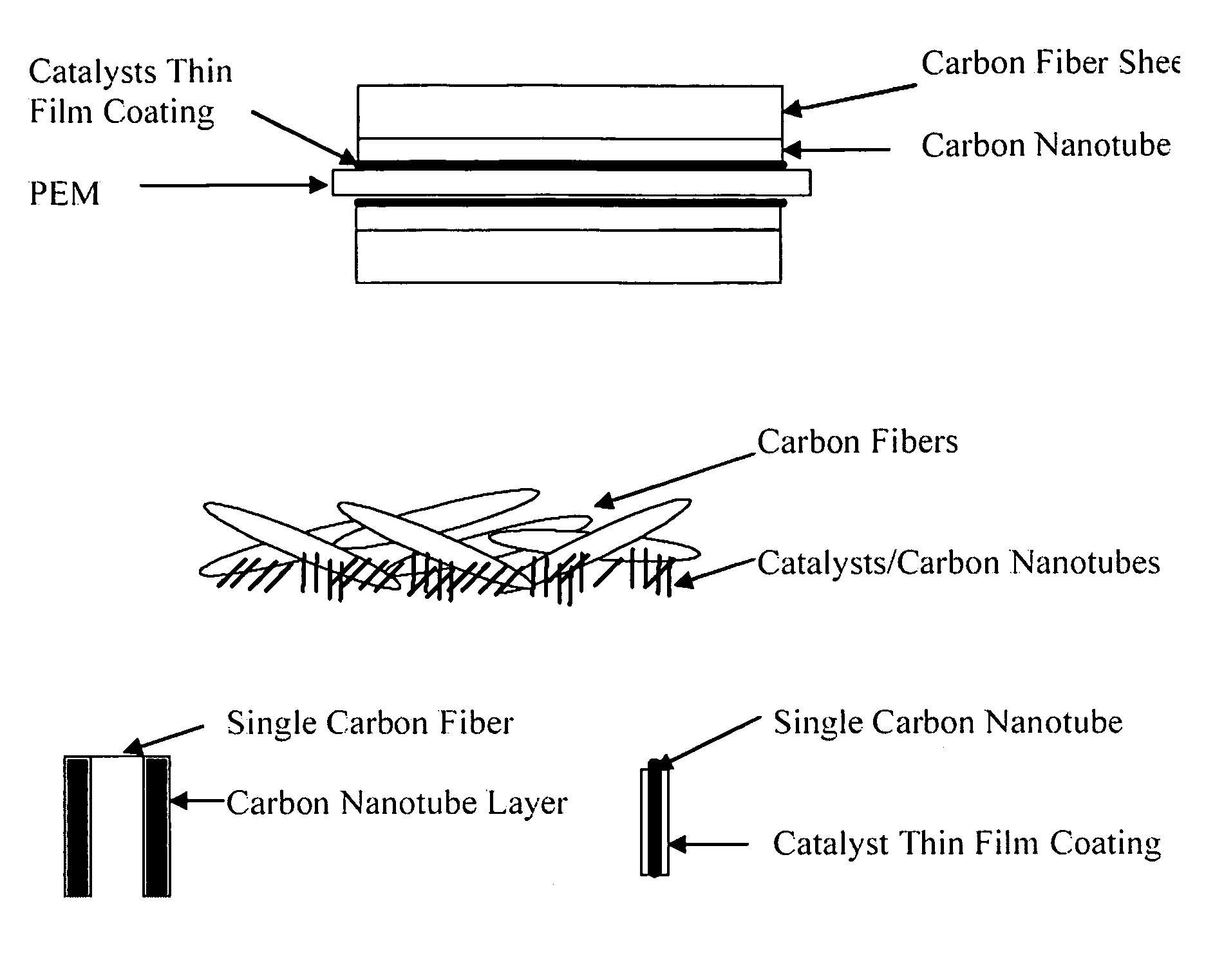

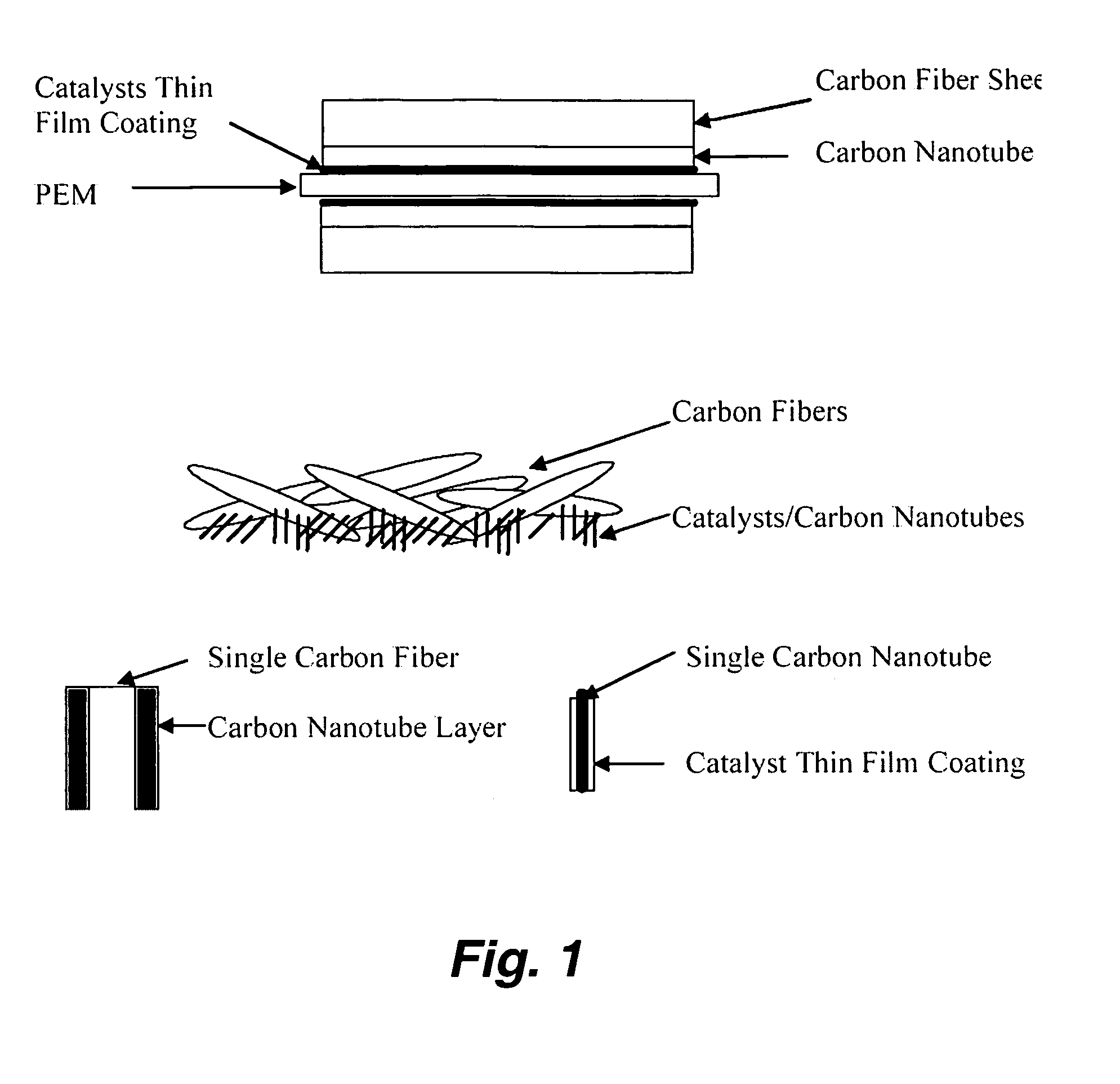

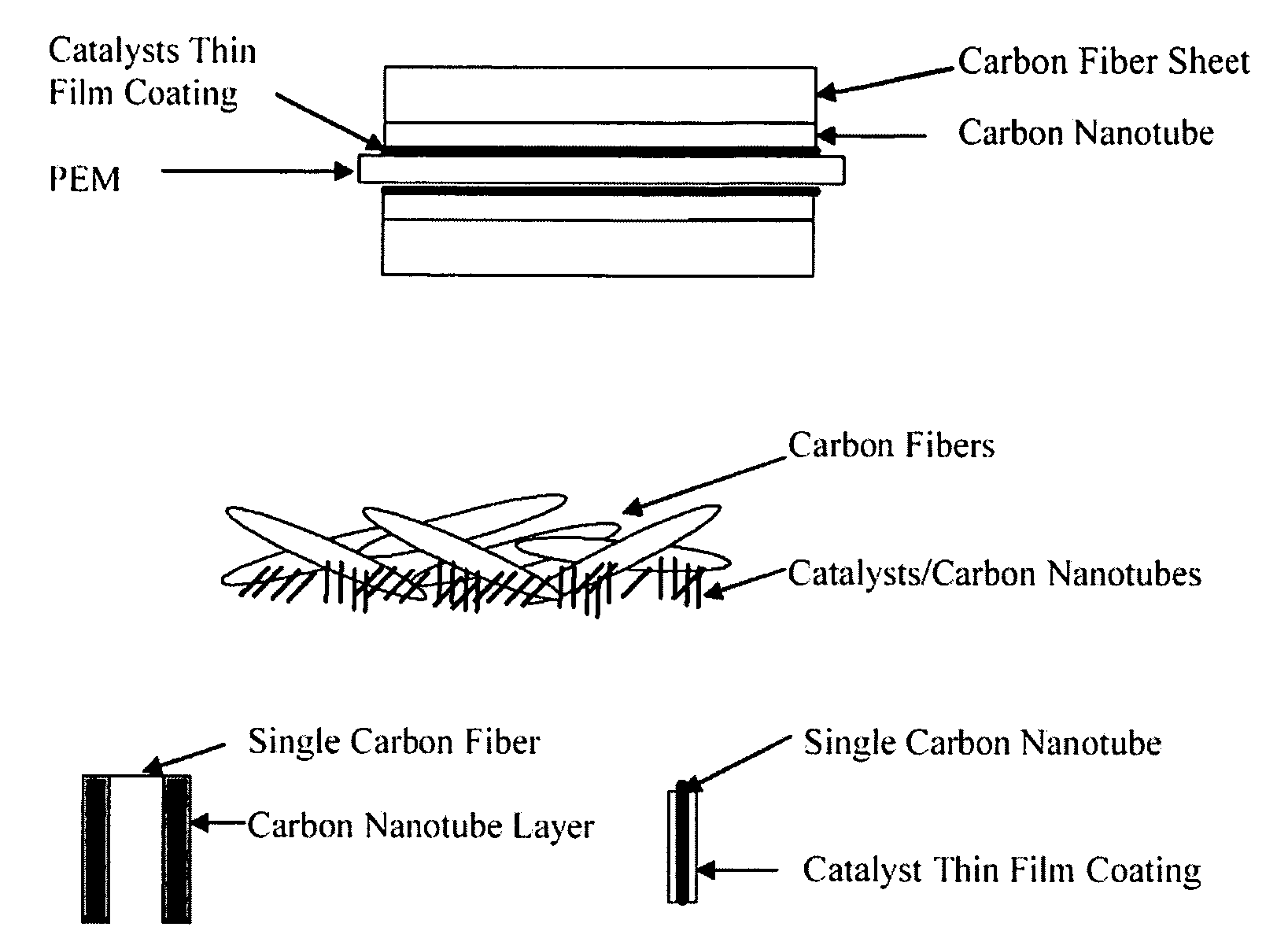

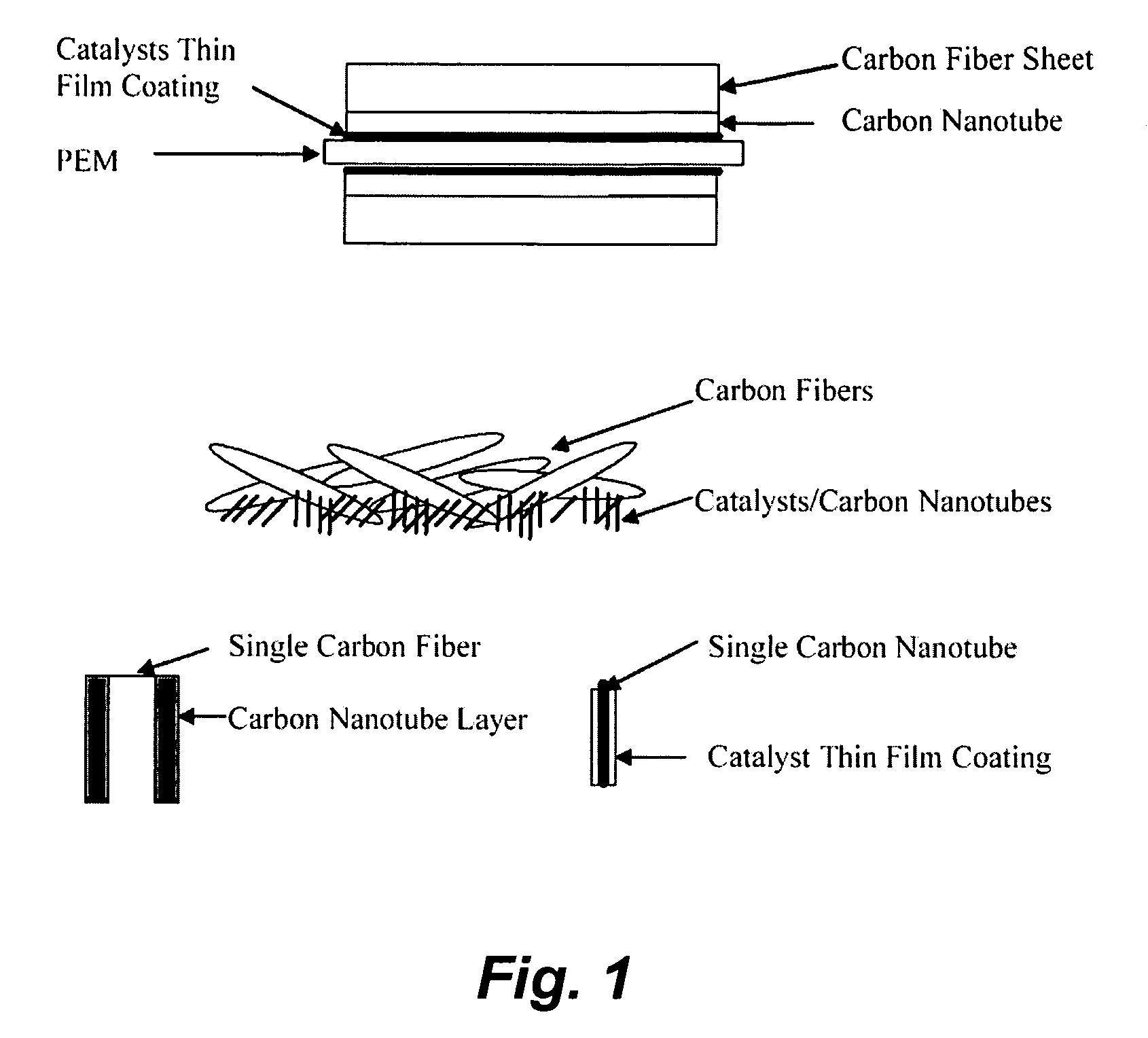

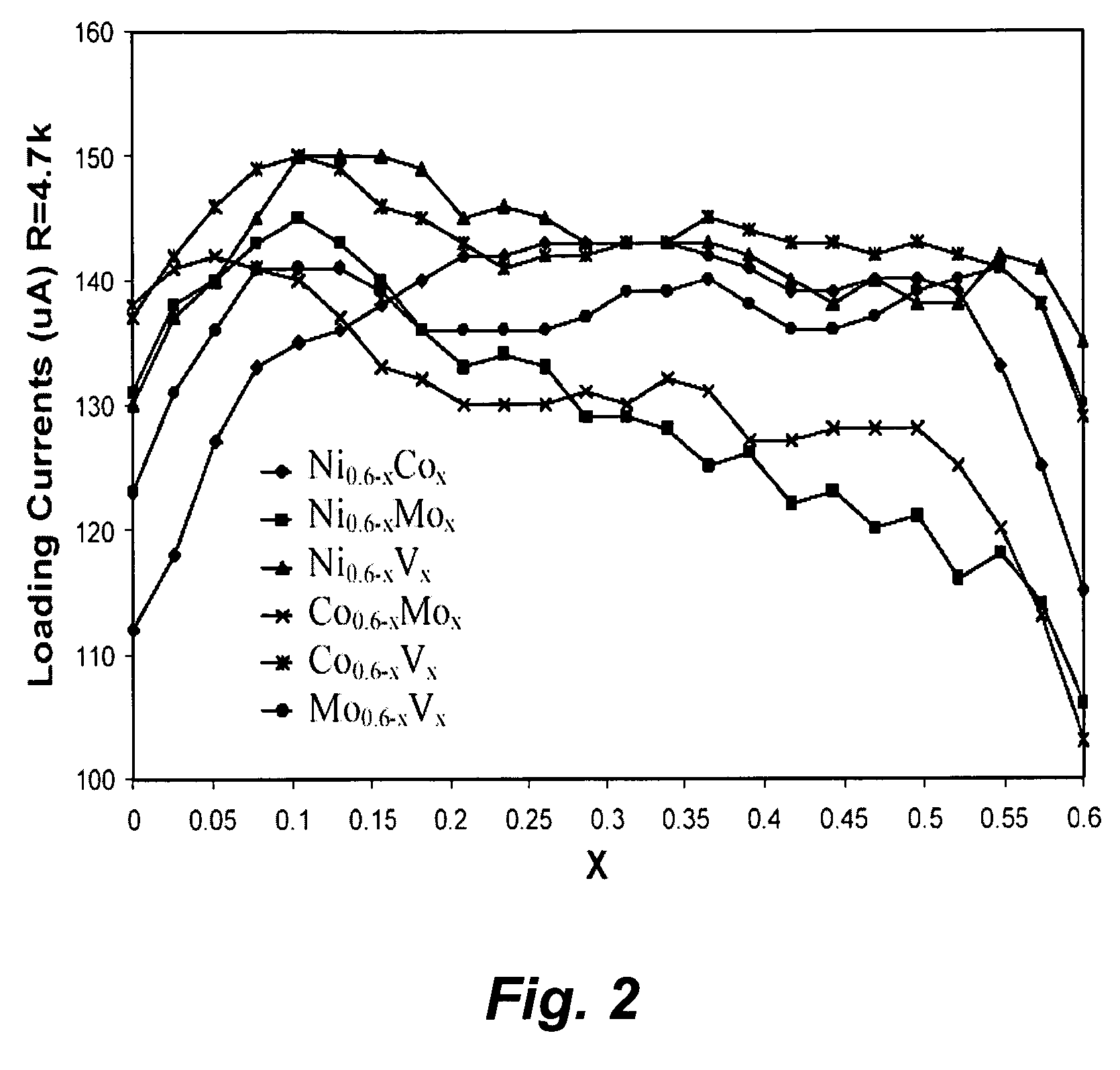

Low platinum fuel cell catalysts and method for preparing the same

InactiveUS20050053826A1Good dispersionEfficient CatalysisMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell catalysts comprising new series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticales into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

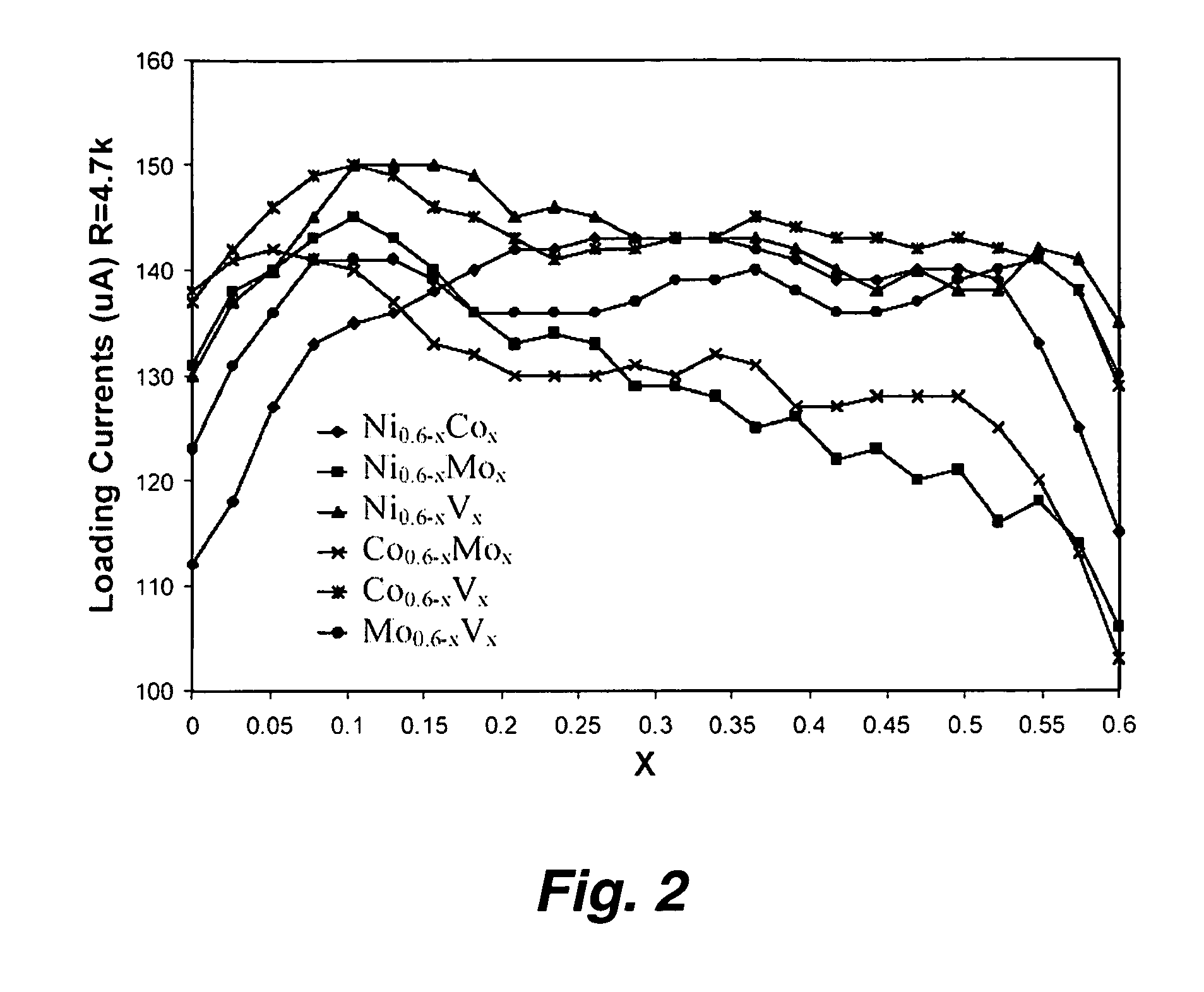

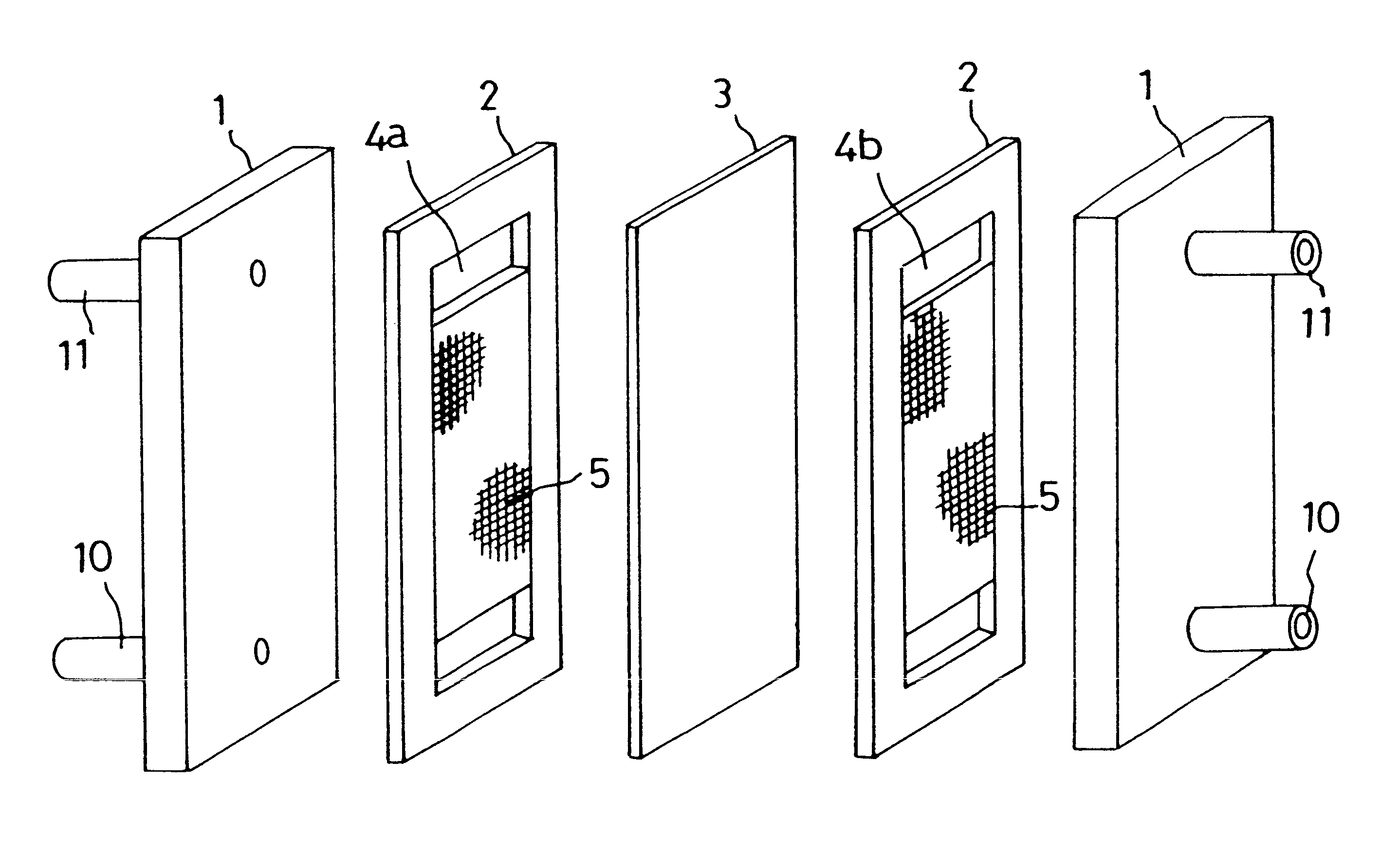

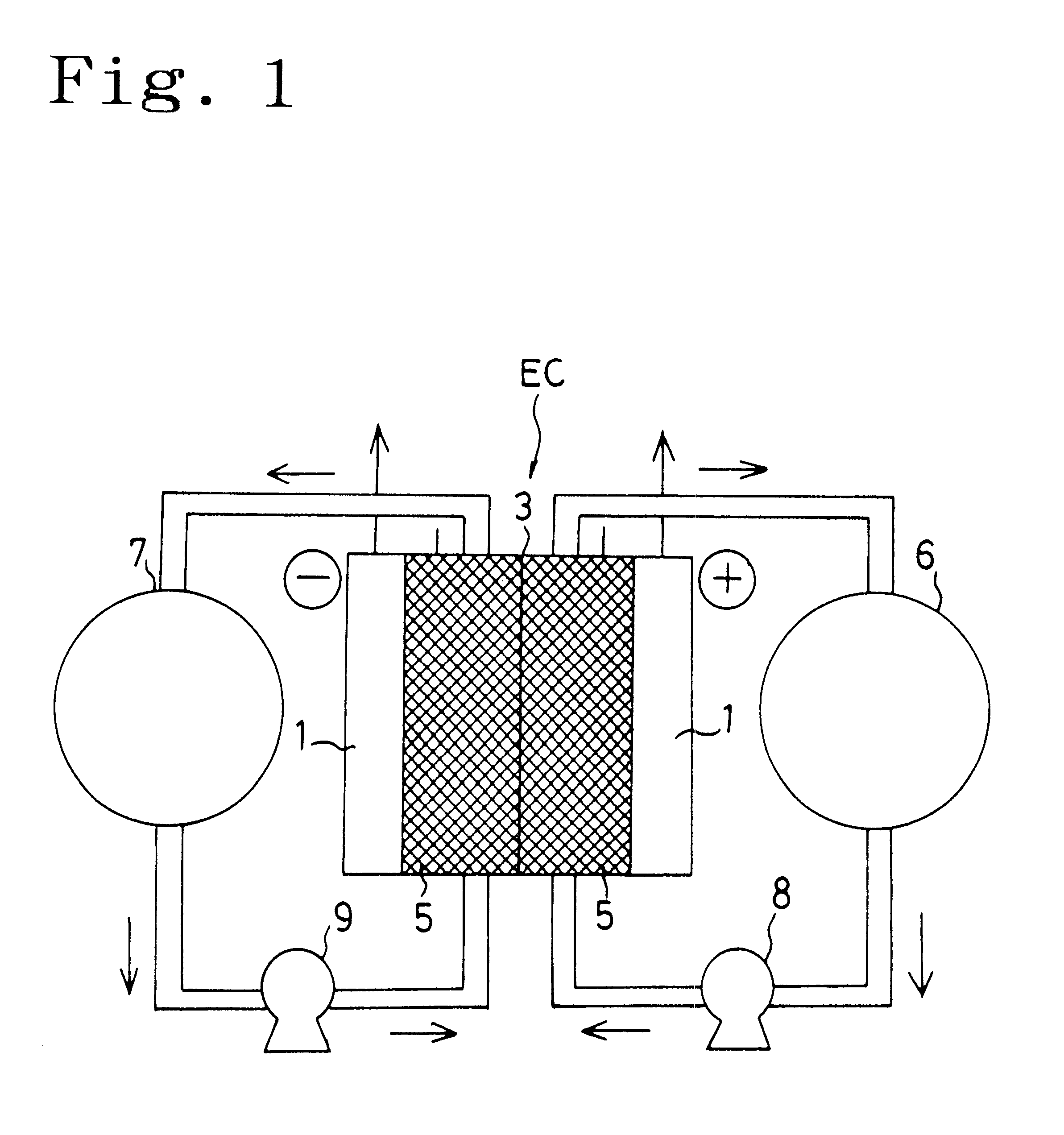

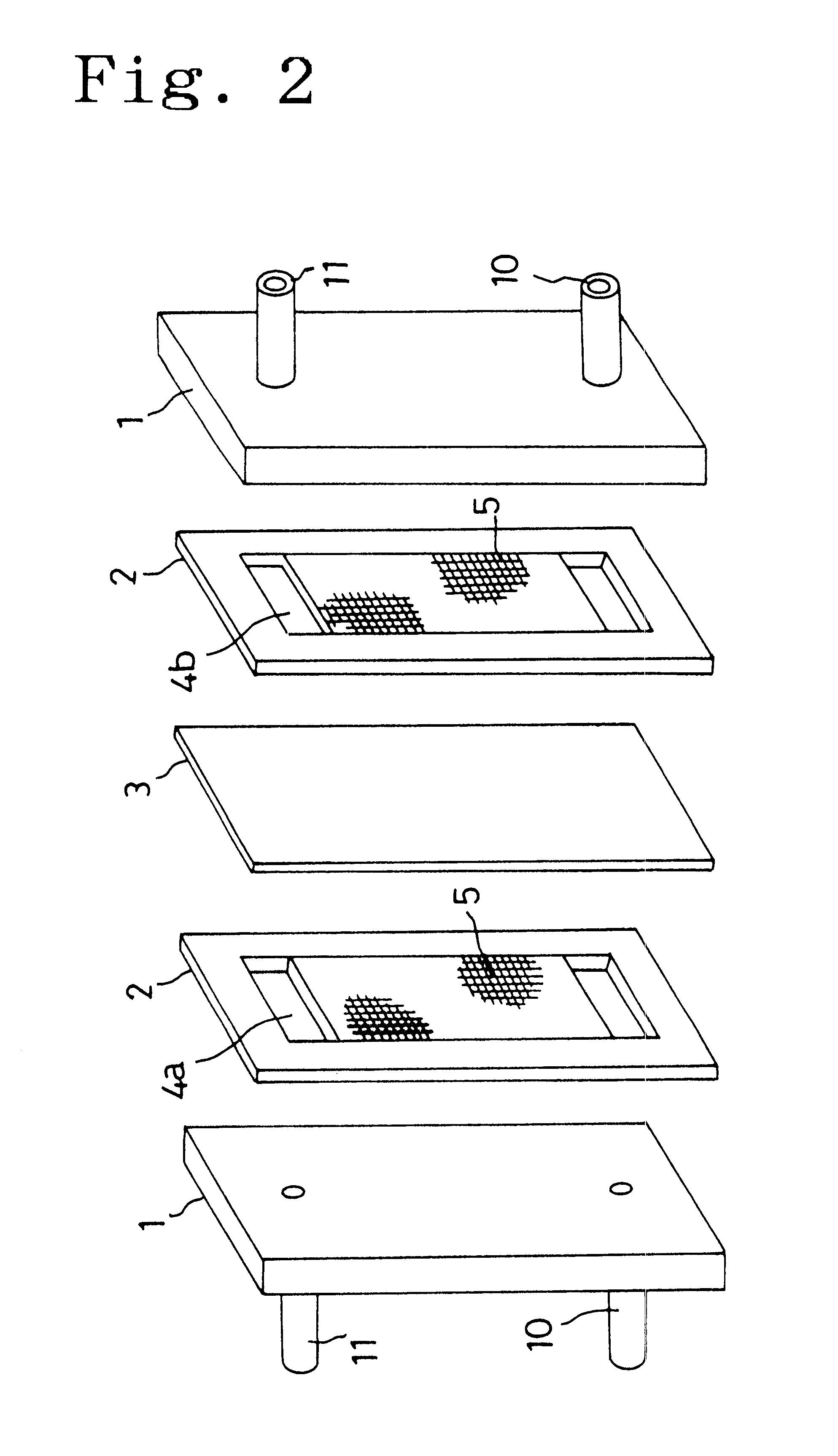

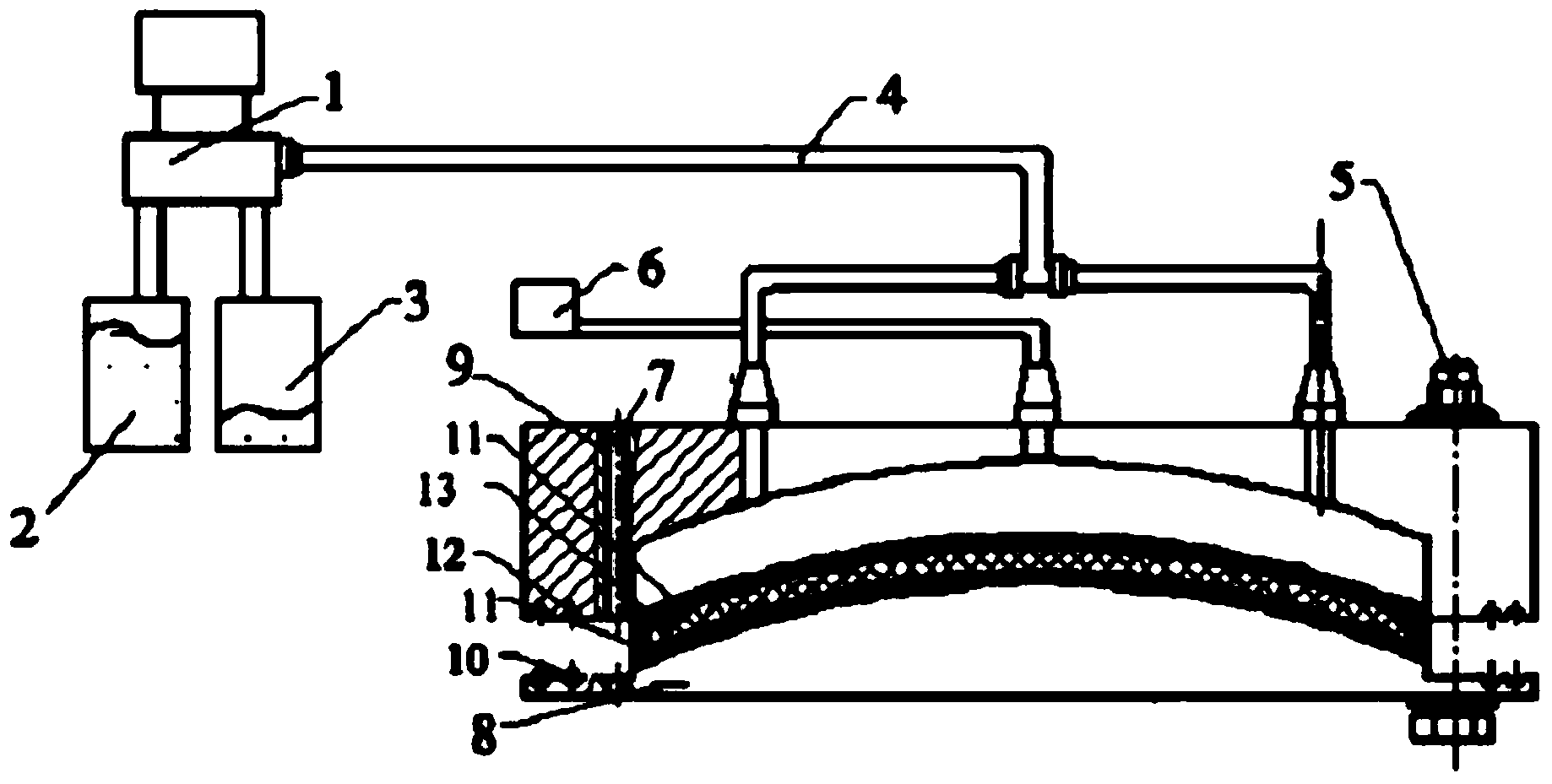

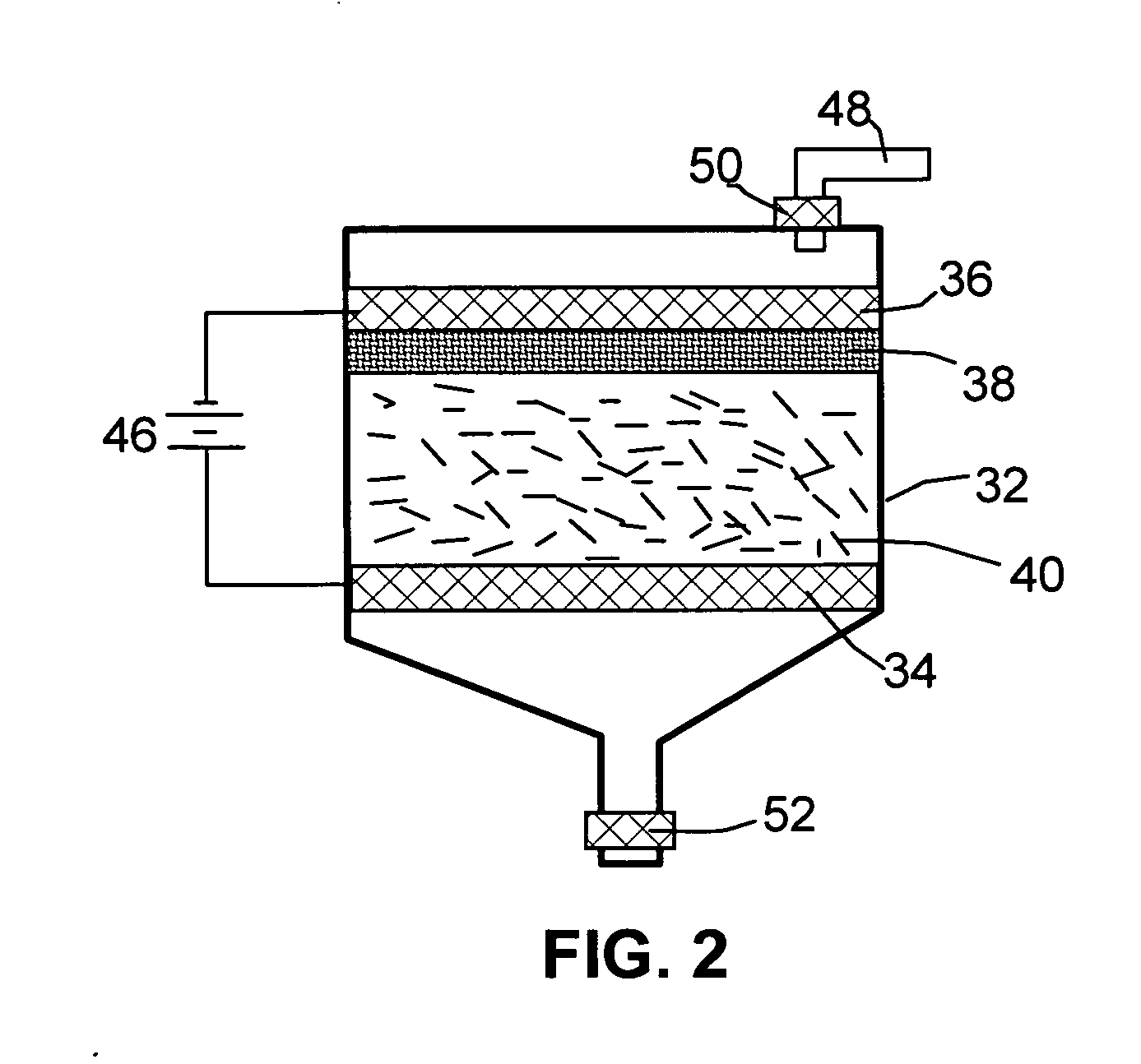

Carbon electrode material for a vanadium-based redox-flow battery

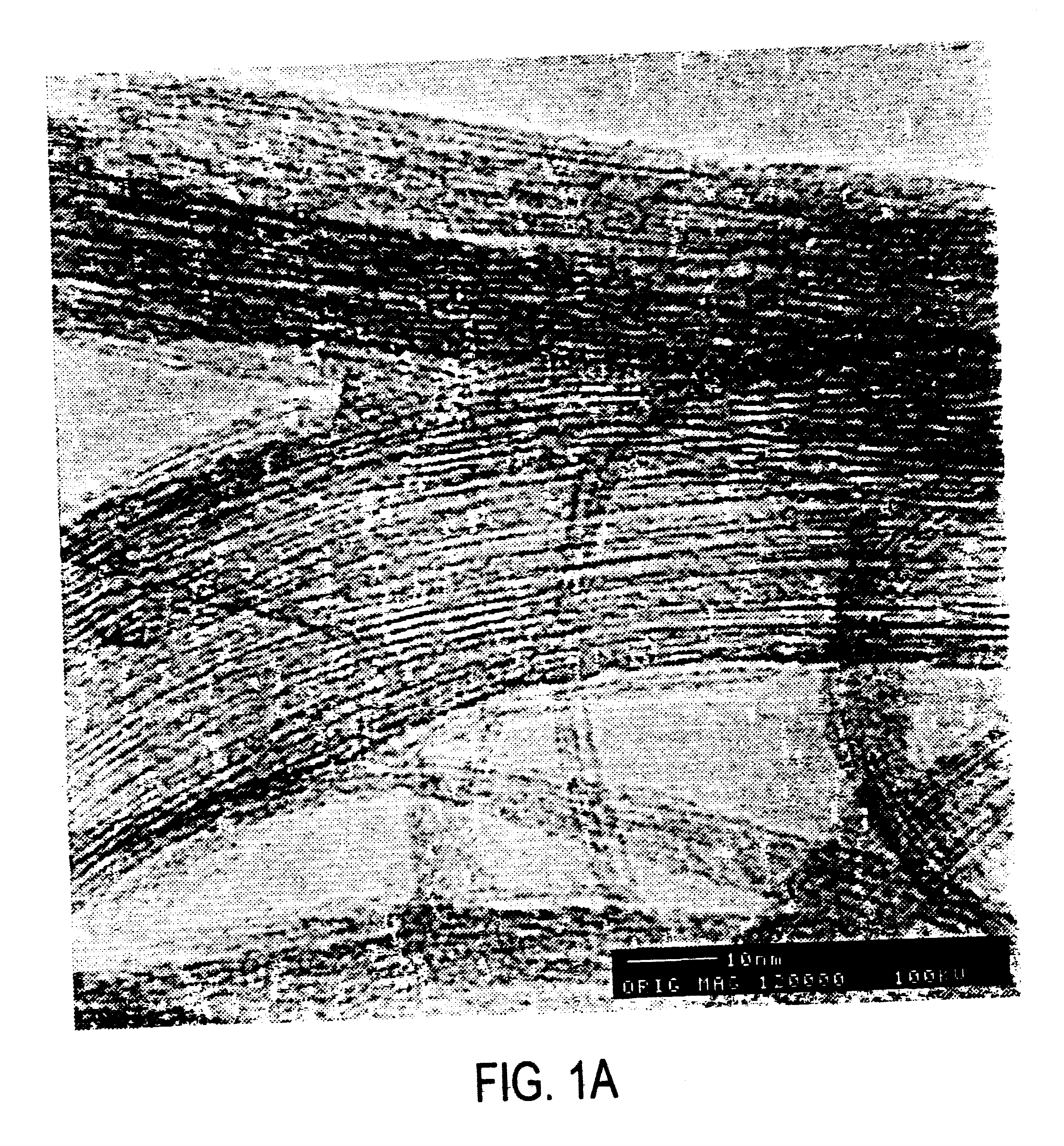

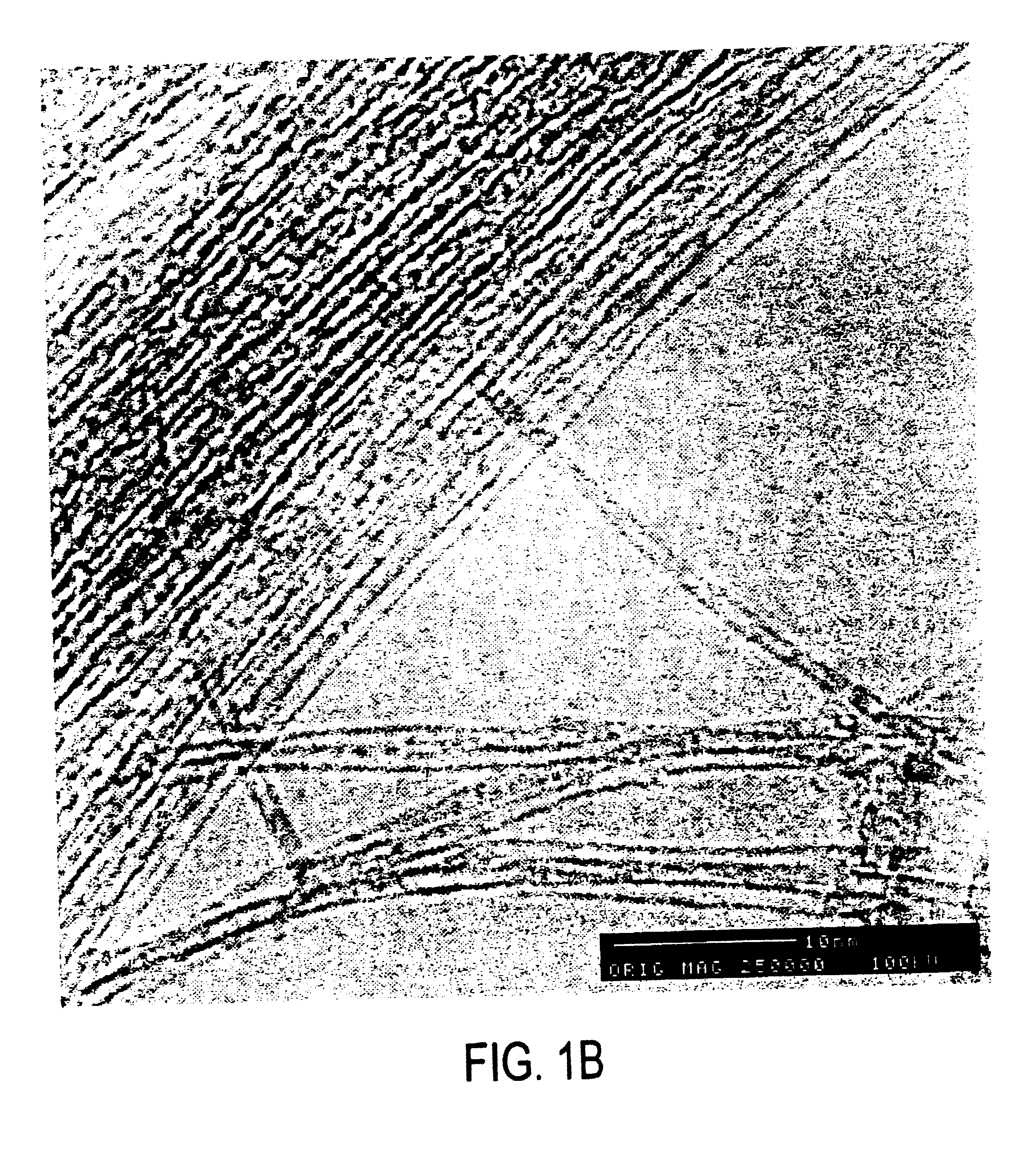

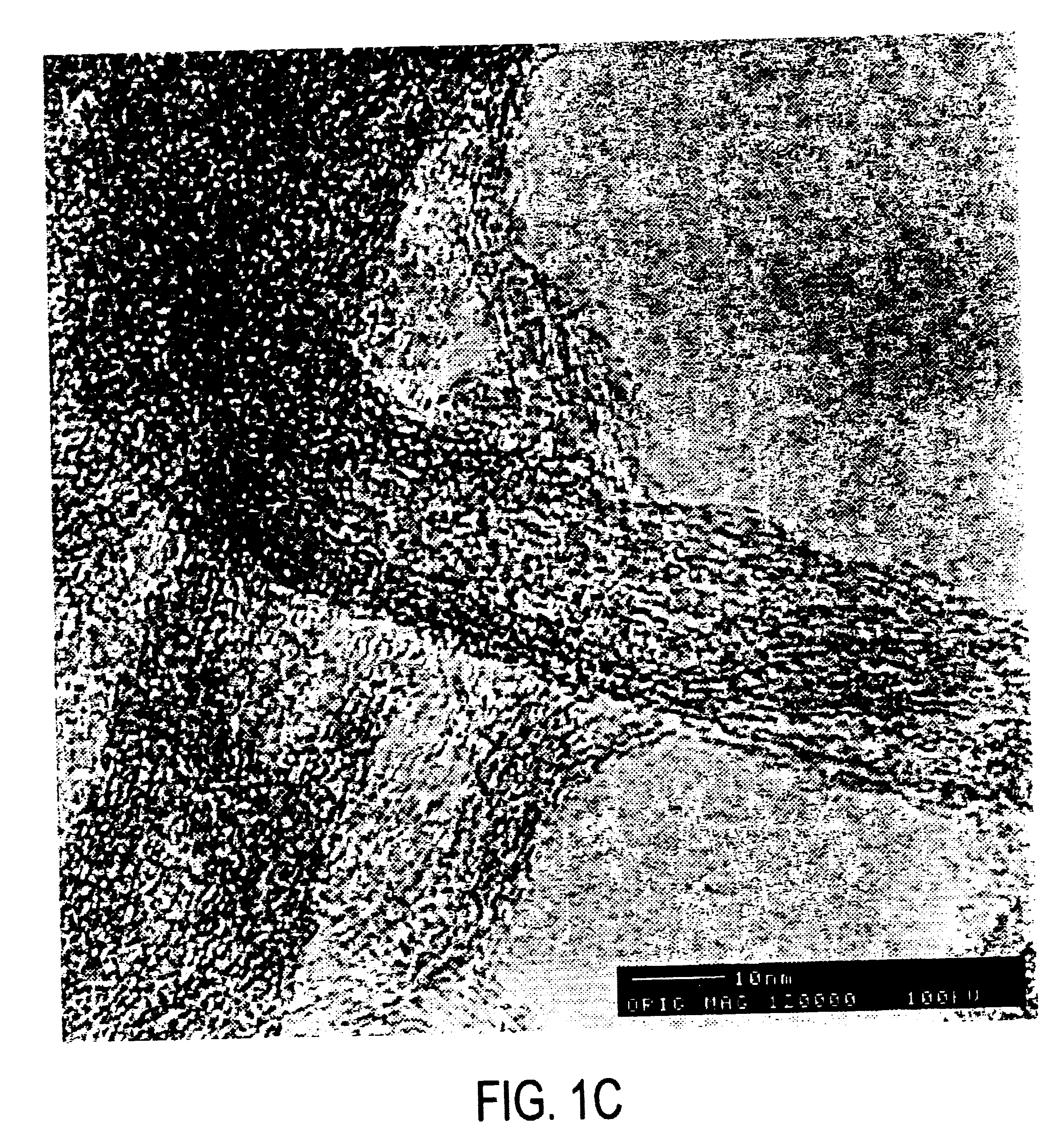

The carbon electrode material of the present invention is used for a vanadium redox-flow cell. The carbon electrode material has quasi-graphite crystal structure in which <002> spacing obtained by X-ray wide angle analysis is 3.43 to 3.60 Å, size of a crystallite in c axial direction is 15 to 33 Å and size of crystallite in a axial direction is 30 to 70 Å. In addition, an amount of surface acidic functional groups obtained by XPS surface analysis is 0.1 to 1.2% and total number of surface bound-nitrogen atoms is 5% or smaller relative to total number of surface carbon atoms. The carbon electrode materials formed of a non-woven fabric of a carbonaceouss fiber is preferable.

Owner:TOYO TOYOBO CO LTD

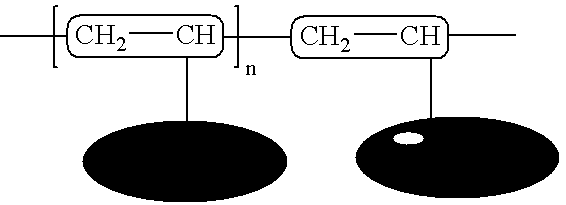

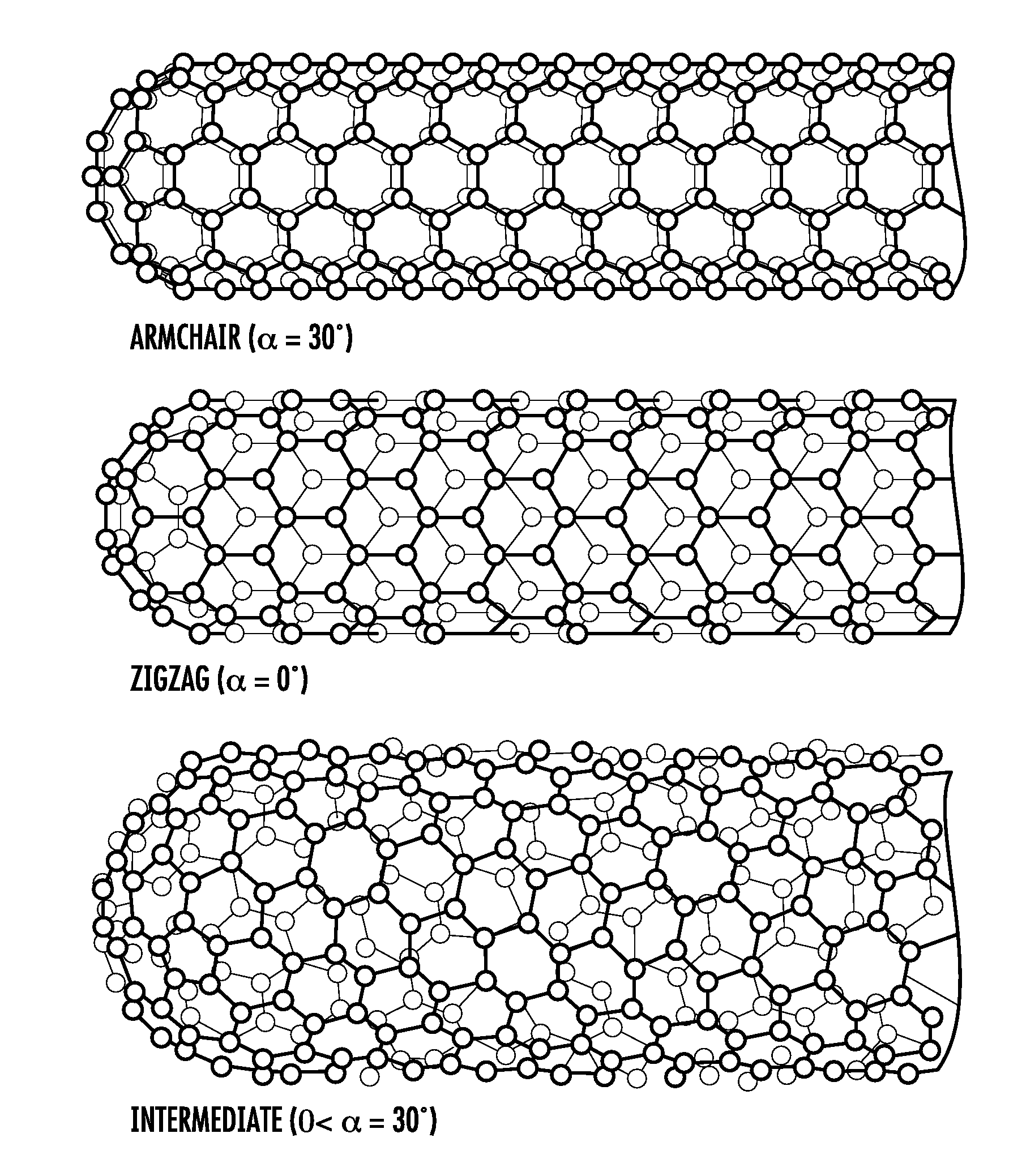

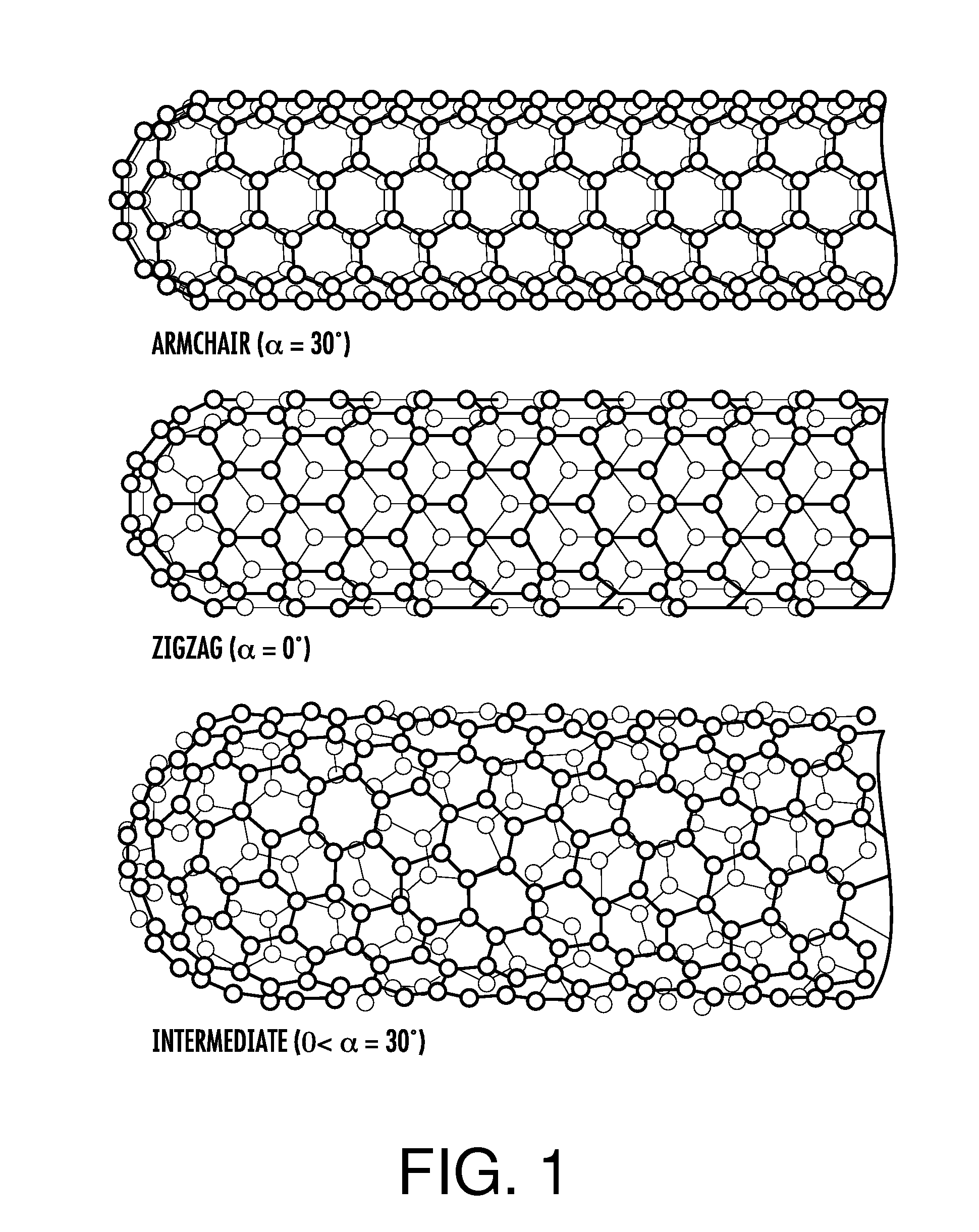

Methods of chemically derivatizing single-wall carbon nanotubes

InactiveUS6841139B2Increase resistanceHigh yieldMaterial nanotechnologyPigmenting treatmentFiberLithium

This invention is directed to making chemical derivatives of carbon nanotubes and to uses for the derivatized nanotubes, including making arrays as a basis for synthesis of carbon fibers. In one embodiment, this invention also provides a method for preparing single wall carbon nanotubes having substituents attached to the side wall of the nanotube by reacting single wall carbon nanotubes with fluorine gas and recovering fluorine derivatized carbon nanotubes, then reacting fluorine derivatized carbon nanotubes with a nucleophile. Some of the fluorine substituents are replaced by nucleophilic substitution. If desired, the remaining fluorine can be completely or partially eliminated to produce single wall carbon nanotubes having substituents attached to the side wall of the nanotube. The substituents will, of course, be dependent on the nucleophile, and preferred nucleophiles include alkyl lithium species such as methyl lithium. Alternatively, fluorine may be fully or partially removed from fluorine derivatized carbon nanotubes by reacting the fluorine derivatized carbon nanotubes with various amounts of hydrazine, substituted hydrazine or alkyl amine. The present invention also provides seed materials for growth of single wall carbon nanotubes comprising a plurality of single wall carbon nanotubes or short tubular molecules having a catalyst precursor moiety covalently bound or physisorbed on the outer surface of the sidewall to provide the optimum metal cluster size under conditions that result in migration of the metal moiety to the tube end.

Owner:RICE UNIV

Manufacturing method for carbon fiber antenna surface

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

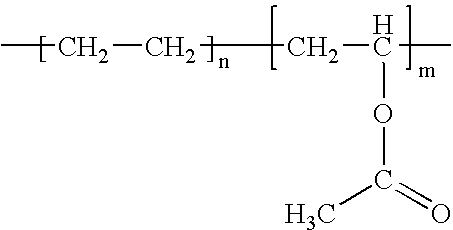

Compositions comprising carbon nanotubes and articles formed therefrom

InactiveUS20050186378A1Easy injectionImprove the immunityMaterial nanotechnologyCell electrodesFiberPolymer science

Improved compositions comprise a polymer and carbon fibers, such as nanotubes. In some embodiments, the carbon fibers, e.g., nanotubes, can be mechanically blended or incorporated into the polymer, while in some embodiments carbon nanotubes also may be covalently bonded to the polymer to form corresponding covalent materials. In particular, the polymer can be covalently bonded to the side walls of the carbon nanotubes to form a composite with particularly desirable mechanical properties. Specifically, the bonding of the polymer to the nanotube sidewall can provide desirable mechanical properties of the composite due to the orientation relative to other types of association between the nanotubes and the polymer. The processing of the nanotubes can be facilitated by the dispersion of the nanotubes in an aqueous solution comprising a hydrophylic polymer, such as ethyl vinyl acetate. A dispersion of nanotubes can be combined with a polymer in an extrusion process to blend the materials under high shear, such as in an extruder. In general, various articles can be formed that take advantage of the properties of the composite materials incorporating a polymer and carbon fibers, such as carbon nanotubes.

Owner:ENTEGRIS INC

Activated carbon fibers, methods of their preparation, and devices comprising activated carbon fibers

Catalytically activated carbon fibers and methods for their preparation are described. The activated carbon fibers are engineered to have a controlled porosity distribution that is readily optimized for specific applications using metal-containing nanoparticles as activation catalysts. The activated carbon fibers may be used in all manner of devices that contain carbon materials, including but not limited to various electrochemical devices (e.g., capacitors, batteries, fuel cells, and the like), hydrogen storage devices, filtration devices, catalytic substrates, and the like.

Owner:NANOCARBONS LLC

Low platinum fuel cells, catalysts, and method for preparing the same

InactiveUS20060172179A1Efficient processingImprove throughputMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell electrodes and catalysts comprising a series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). Processing of the electrodes and catalysts can include electrodeposition methods, and high-pressure coating techniques. In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticles into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

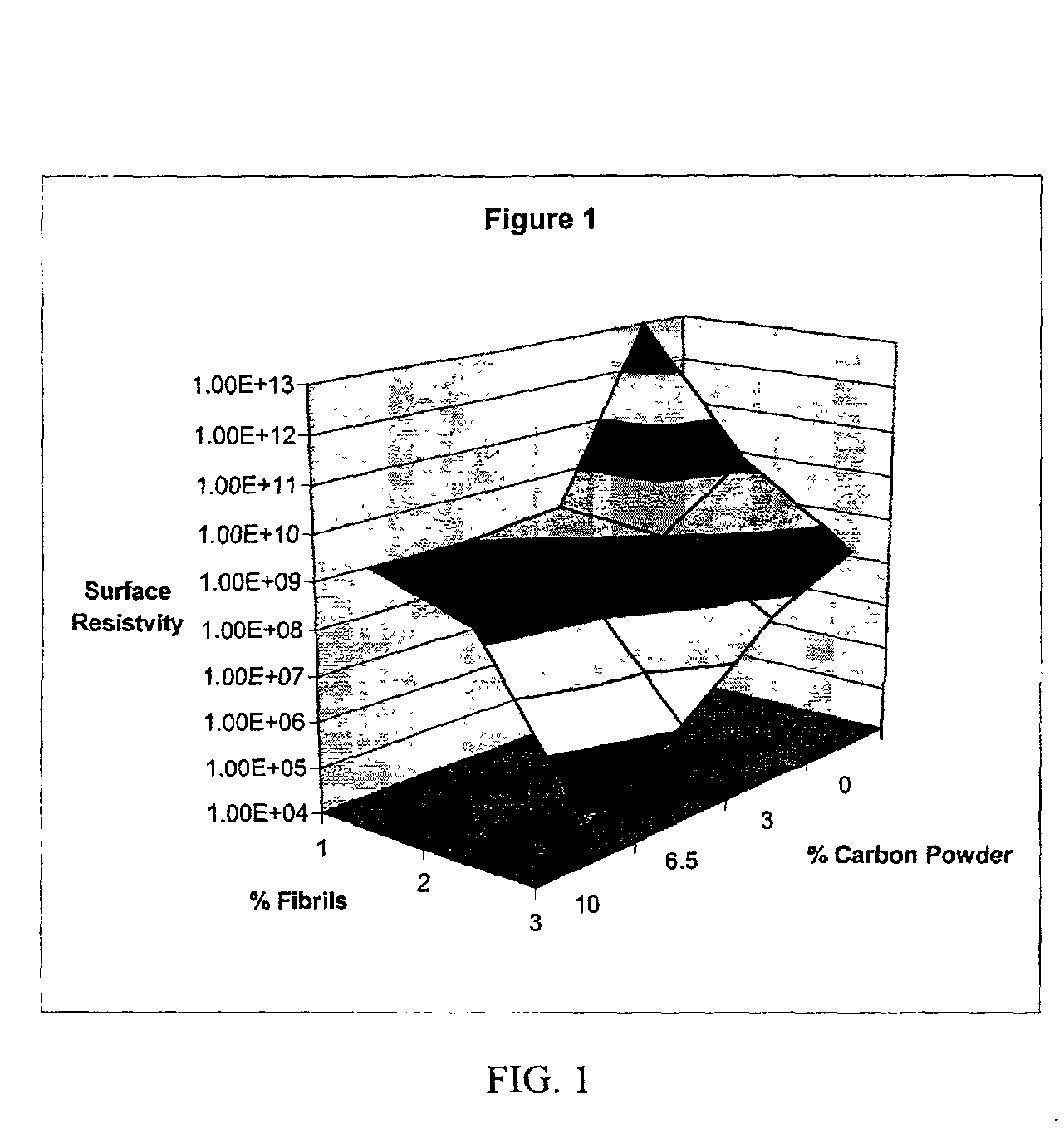

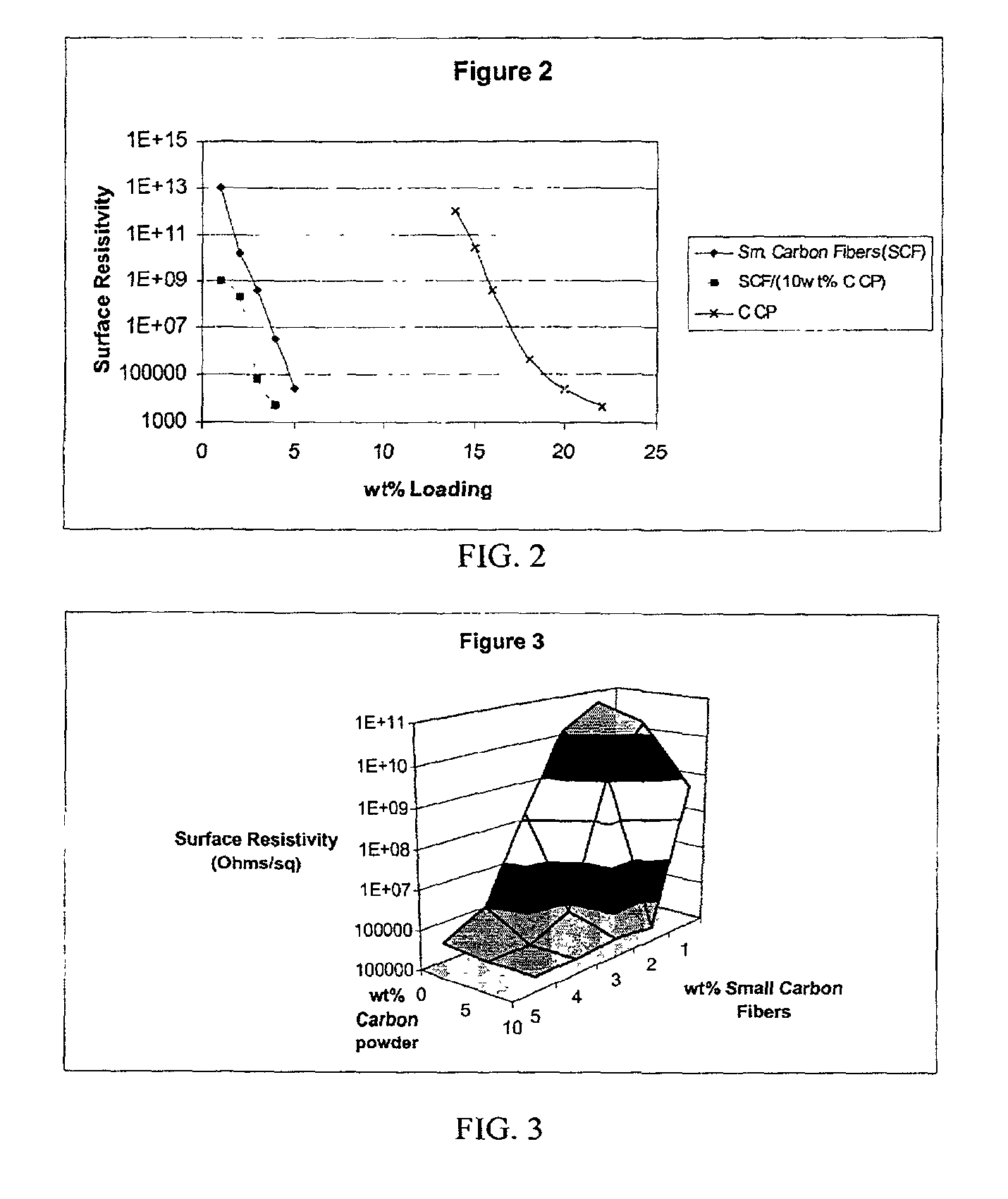

Conductive plastic compositions and method of manufacture thereof

InactiveUS20020183438A1Reduce concentrationSame surface resistivitySpecial tyresNon-conductive material with dispersed conductive materialFiberCarbon fibers

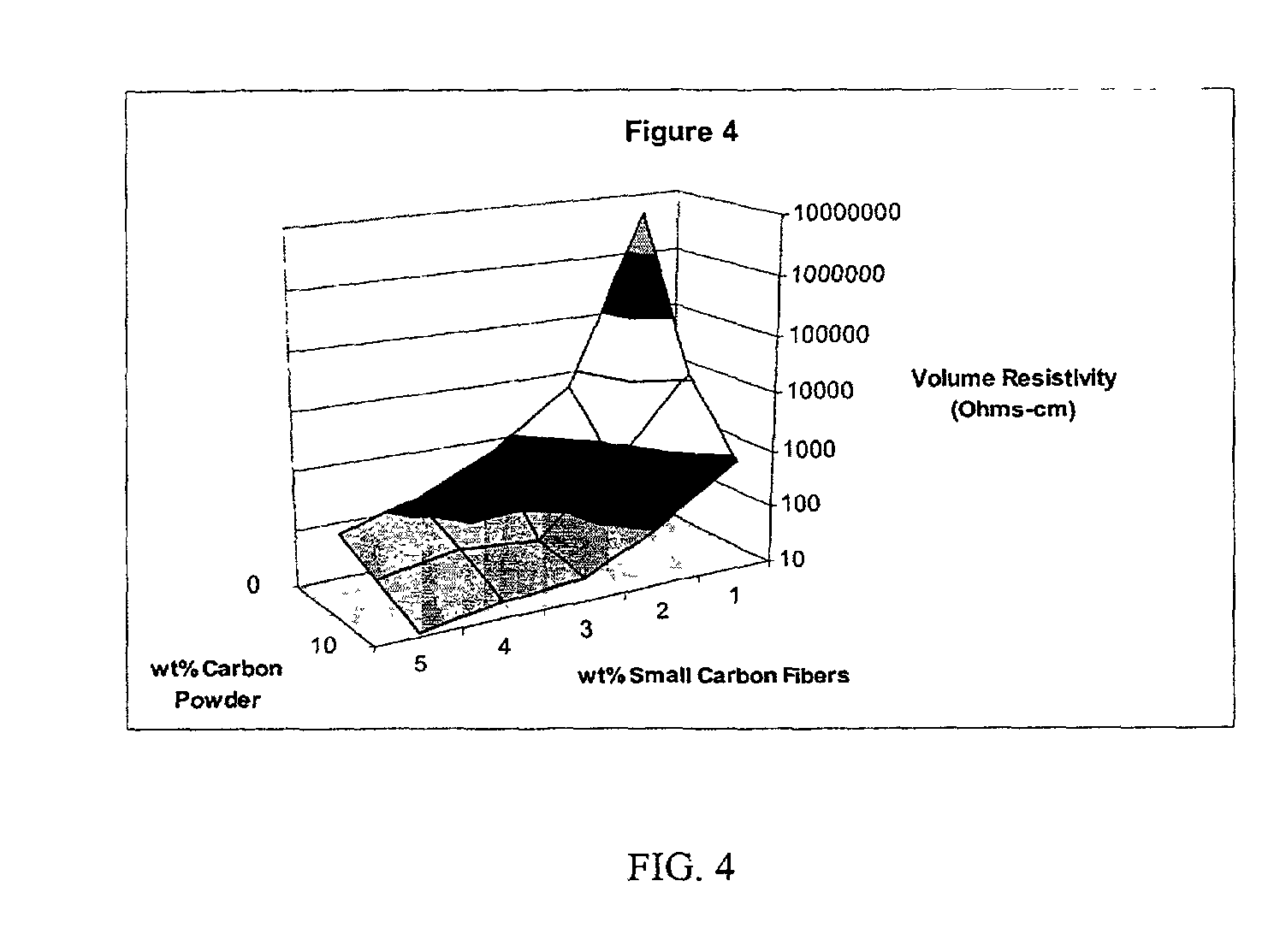

An improved, conductive, polymeric composition comprises a polymeric resin; an electrically conductive filler system comprising small carbon fibers and either carbon powder or fibrous non-conductive filler or a combination of both. The amount of the conductive filler system utilized is dependent upon the desired electrical conductivity (surface and volume conductivity or resistivity) while preferably preserving intrinsic properties of the polymeric resin such as impact, flex modulus, class A finish, and the like. The conductive articles made from these compositions can therefore be used for electromagnetic shielding, electrostatic dissipation or antistatic purposes in packaging, electronic components, housings for electronic components and automotive housings.

Owner:SABIC GLOBAL TECH BV

Chemically modifying single wall carbon nanotubes to facilitate dispersal in solvents

InactiveUS6875412B2High yieldIncrease resistanceMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

Owner:RICE UNIV

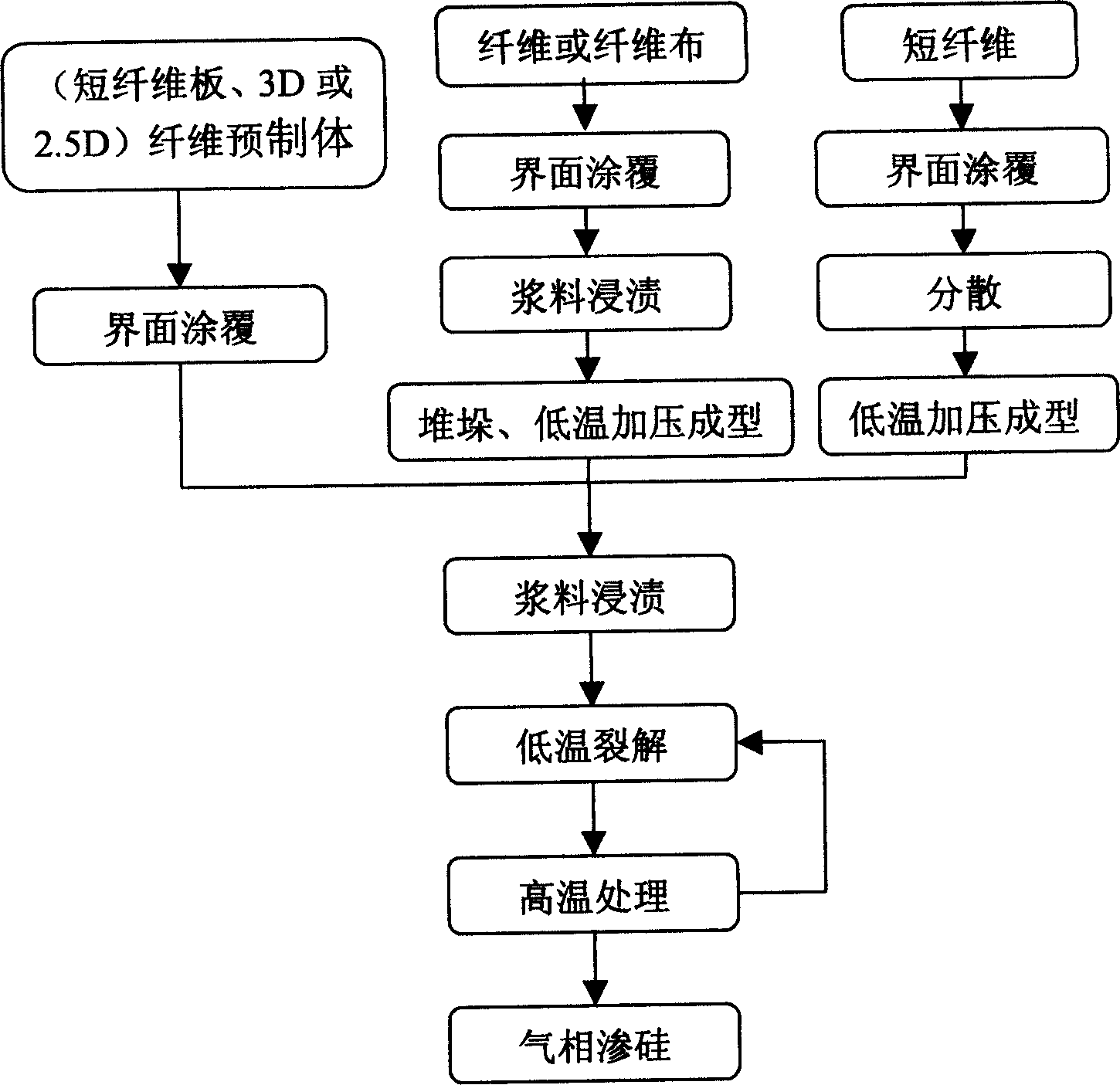

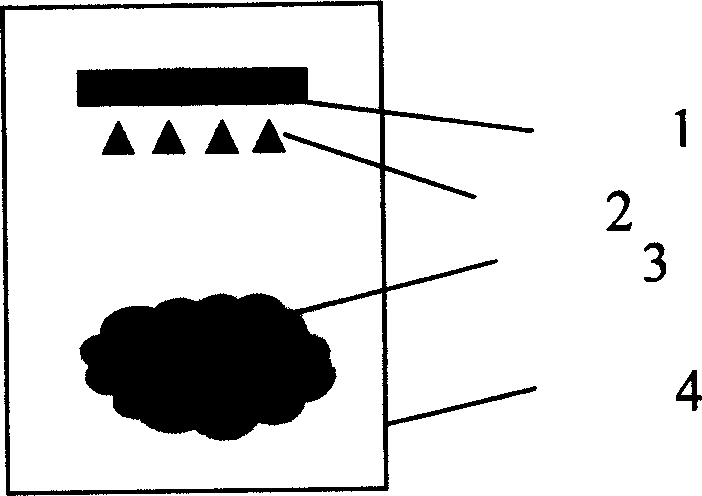

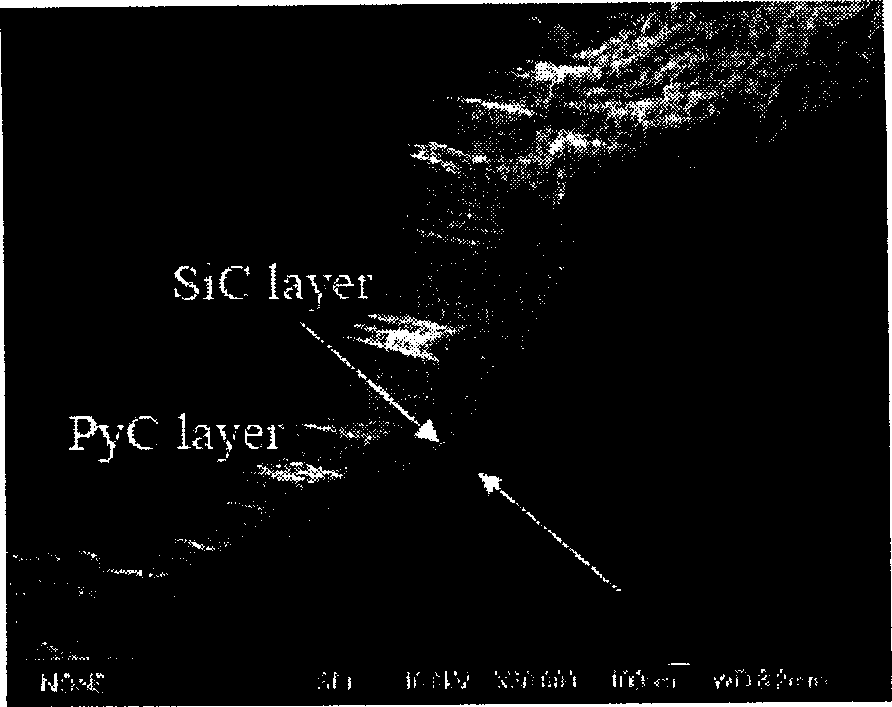

Method for preparing carbon-fiber reinforced silicon carbonate base composite by gas-phase siliconizing technology

This invention relates to preparation method gas phase siliconizing technique preparing high compact fiber reinforcement SiC group composite material. Protection layer interface is formed on fiber surface through gas phase or liquid phase, then they are dipped and cracked through nm SiC slime to make certain density precast body of fiber reinforcement SiC group. Carbon is added into the body through dipping and cracking way to form group body with certain pore, the group body penetrates inner part of the multi-hole body through gas phase silicon after it is high temperature treated, then it reacts with carbon and fills the pore to get compact basal body. The density of the material can reach 2.25-2.30g / cm3, open porosity is 3-6 percent; it is large more higher than traditional method of getting Cf / SiC material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

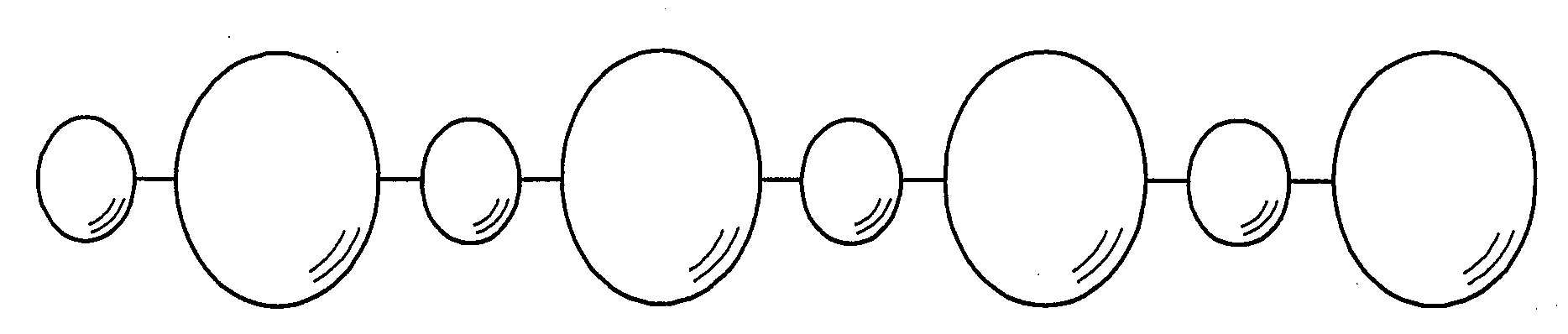

Carbon Fibrous Conjunct and Composite Material Using Thereof

InactiveUS20080254296A1High strengthImprove abilitiesMaterial nanotechnologyNon-macromolecular adhesive additivesFiberCarbon fibers

Carbon fibrous conjunct is provided by adding to carbon fibrous structures, which each comprises a three dimensional network of carbon fibers each having an outside diameter of 15-100 nm, wherein the carbon fibrous structure further comprises a granular part with which the carbon fibers are bound in the state that the carbon fibers extend outwardly from the granular part, a binder for binding the carbon fibrous structures. The fine carbon fibrous structures having such unique configuration and also bearing physical properties suitable for a filler for a composite material can be provided with a good handleability by this carbon fibrous conjunct. Composite material is prepared by adding to the matrix the carbon fibrous conjuncts, at an amount of 0.1 to 30% by weight based on the total weight of the composite material.

Owner:HODOGOYA CHEMICAL CO LTD

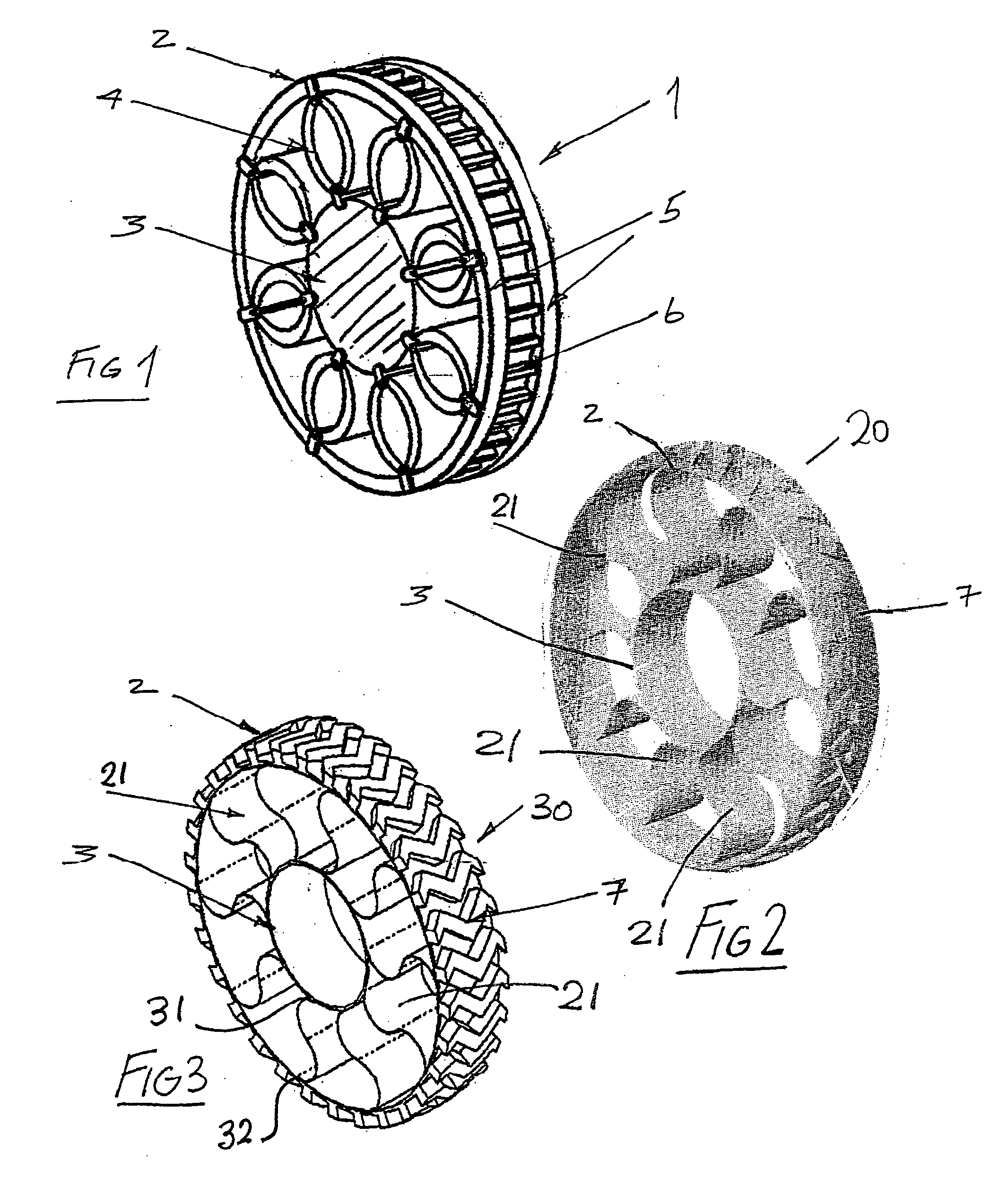

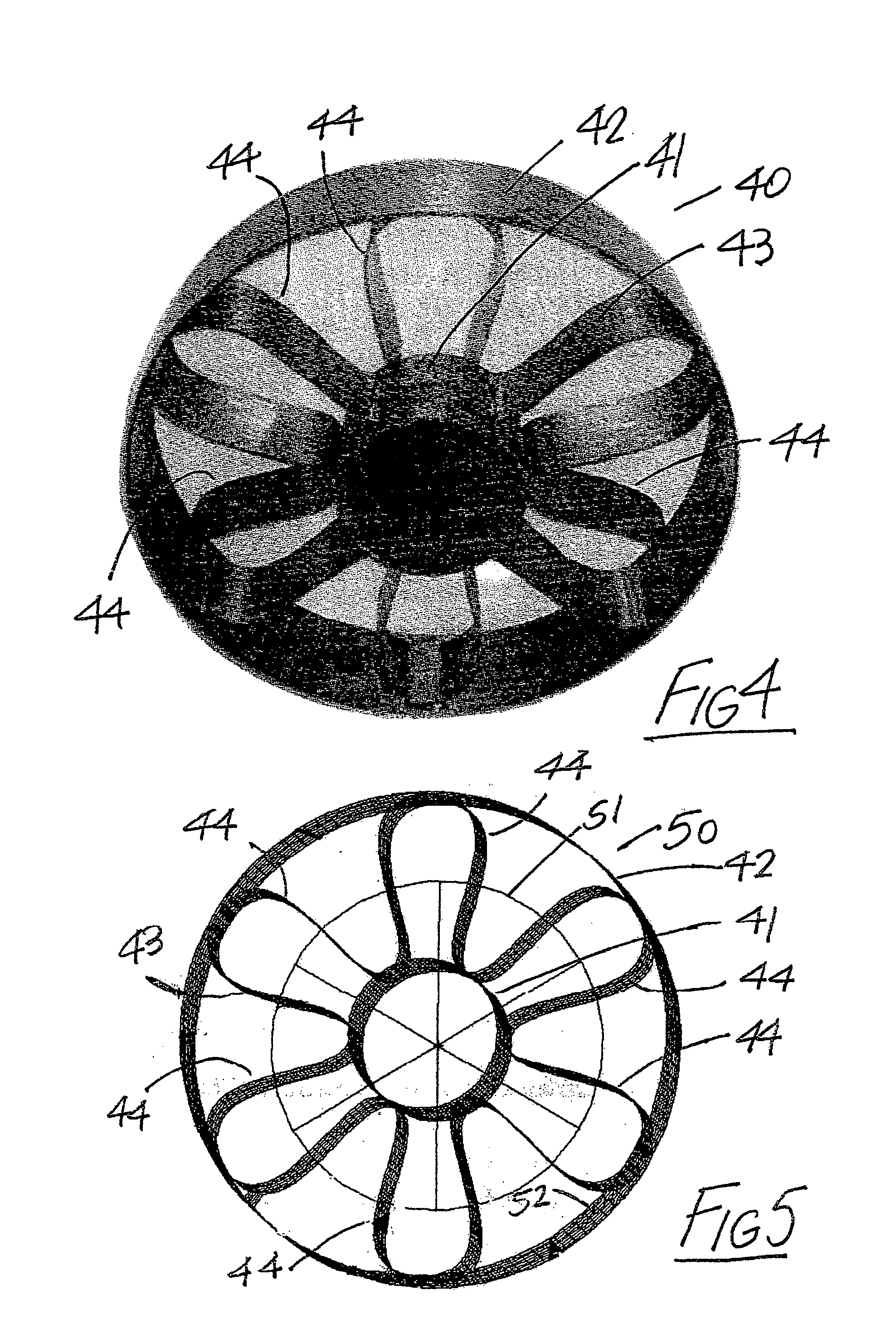

Wheel

InactiveUS20040069385A1Improve gripGreat tractionNon-inflatable tyresHigh resiliency wheelsCarbon fibersMechanical engineering

A lightweight wheel is constructed of titanium or a composite material such as carbon fibre reinforced nylon material. The wheel has a central hub and a circular rim which are interconnected by sprig elements such as may be formed by a looped spring band having a number of radial loops extending between the hub and rim. A tyre strip may be mounted around an outer circumferential face of the rim.

Owner:TECH INVESTMENTS

Method for growing continuous fiber

This invention relates generally to a method for growing carbon fiber from single-wall carbon nanotube (SWNT) molecular arrays. In one embodiment, the present invention involves a macroscopic molecular array of at least about 106 tubular carbon molecules in generally parallel orientation and having substantially similar lengths in the range of from about 50 to about 500 nanometers. The hemispheric fullerene cap is removed from the upper ends of the tubular carbon molecules in the array. The upper ends of the tubular carbon molecules in the array are then contacted with a catalytic metal. A gaseous source of carbon is supplied to the end of the array while localized energy is applied to the end of the array in order to heat the end to a temperature in the range of about 500° C. to about 1300° C. The growing carbon fiber is continuously recovered.

Owner:RICE UNIV

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

InactiveUS6899777B2Improved non-brittle failure characteristicFast preparationCeramic shaping apparatusCoatingsMetal fiberPolymer science

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

Modification of reinforcing fiber tows used in composite materials by using nanoreinforcements

ActiveUS20090176112A1High strengthIncrease stiffnessMaterial nanotechnologyPump componentsFiberCarbon fibers

This invention is directed to nacelles and nacelle components for use in aircraft engines. The nacelles and components comprise composite material containing carbon fiber. The carbon fiber comprises from 0.1 to 20 percent by weight nanoreinforcement material.

Owner:THE BF GOODRICH CO +1

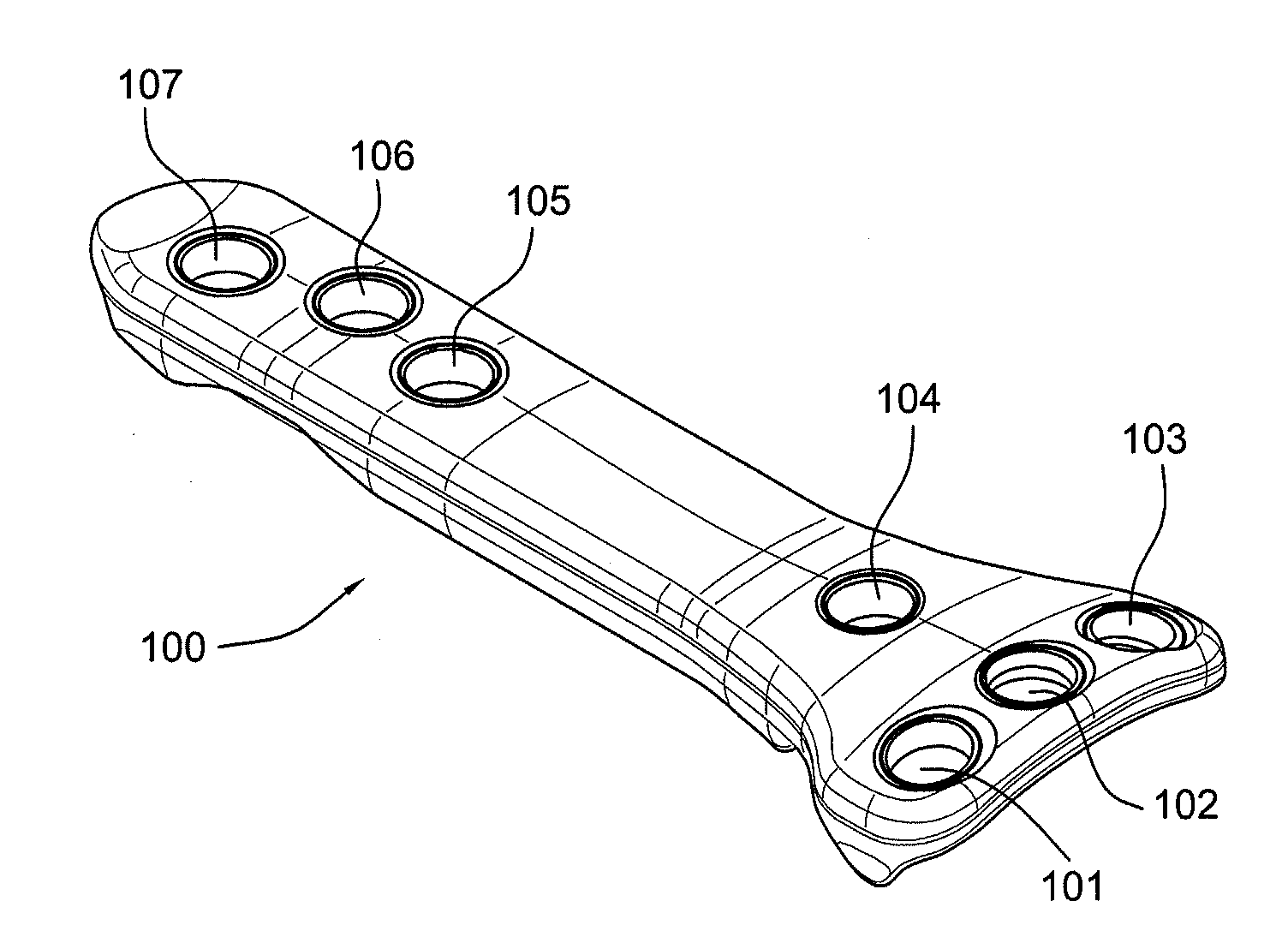

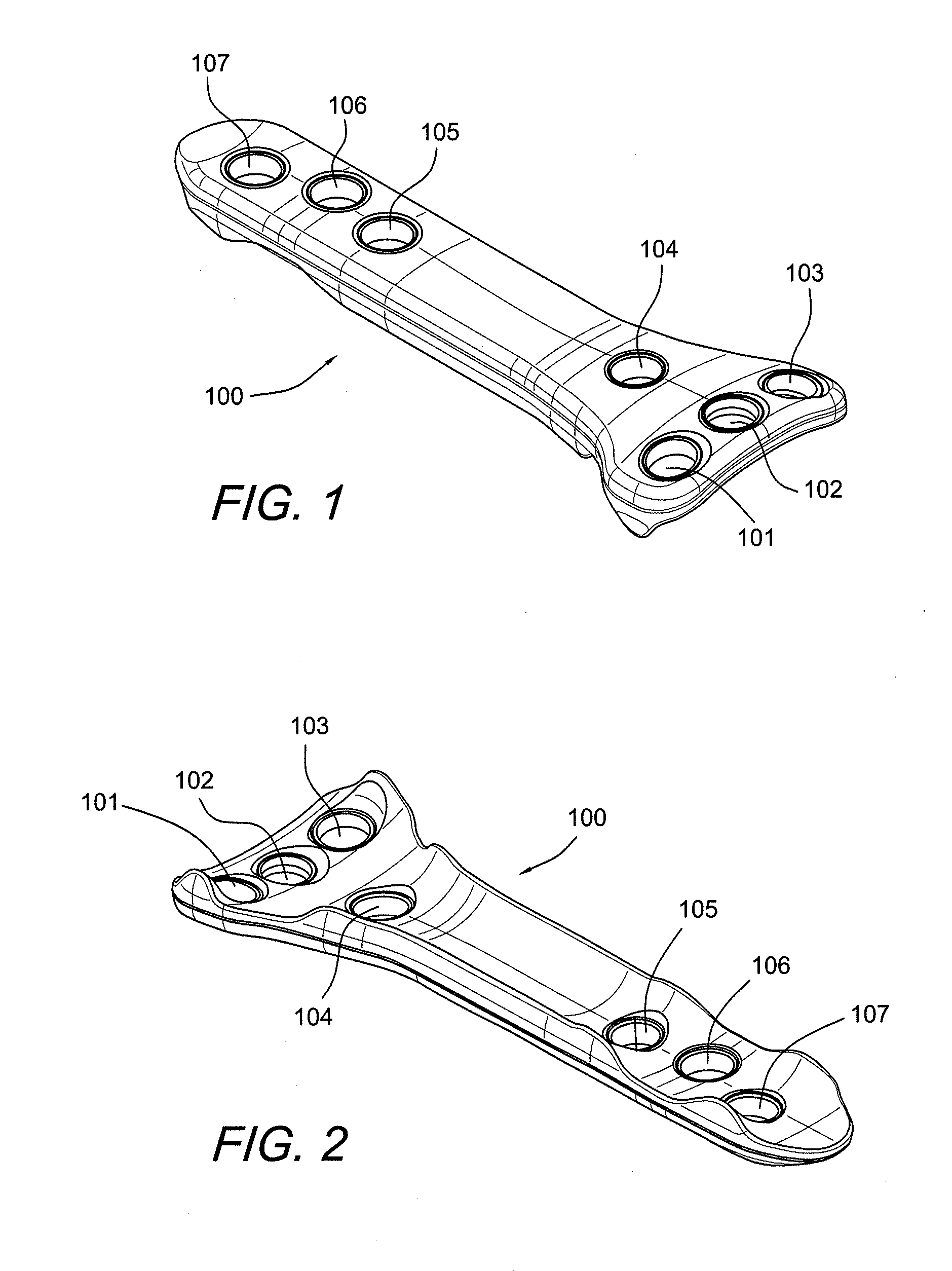

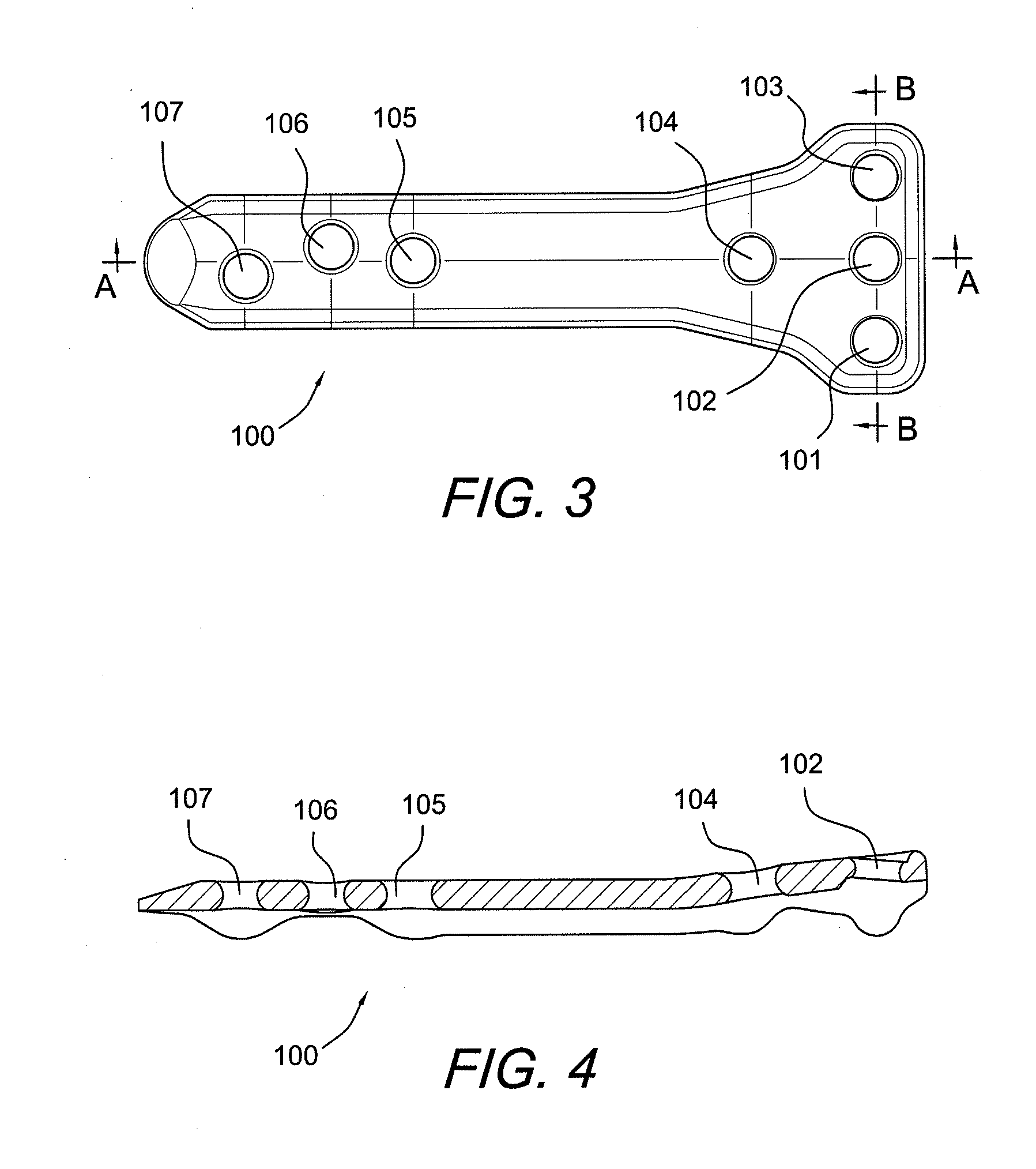

Carbon Fiber Reinforced Peek Bone Plate With Titanium Fixation Screws

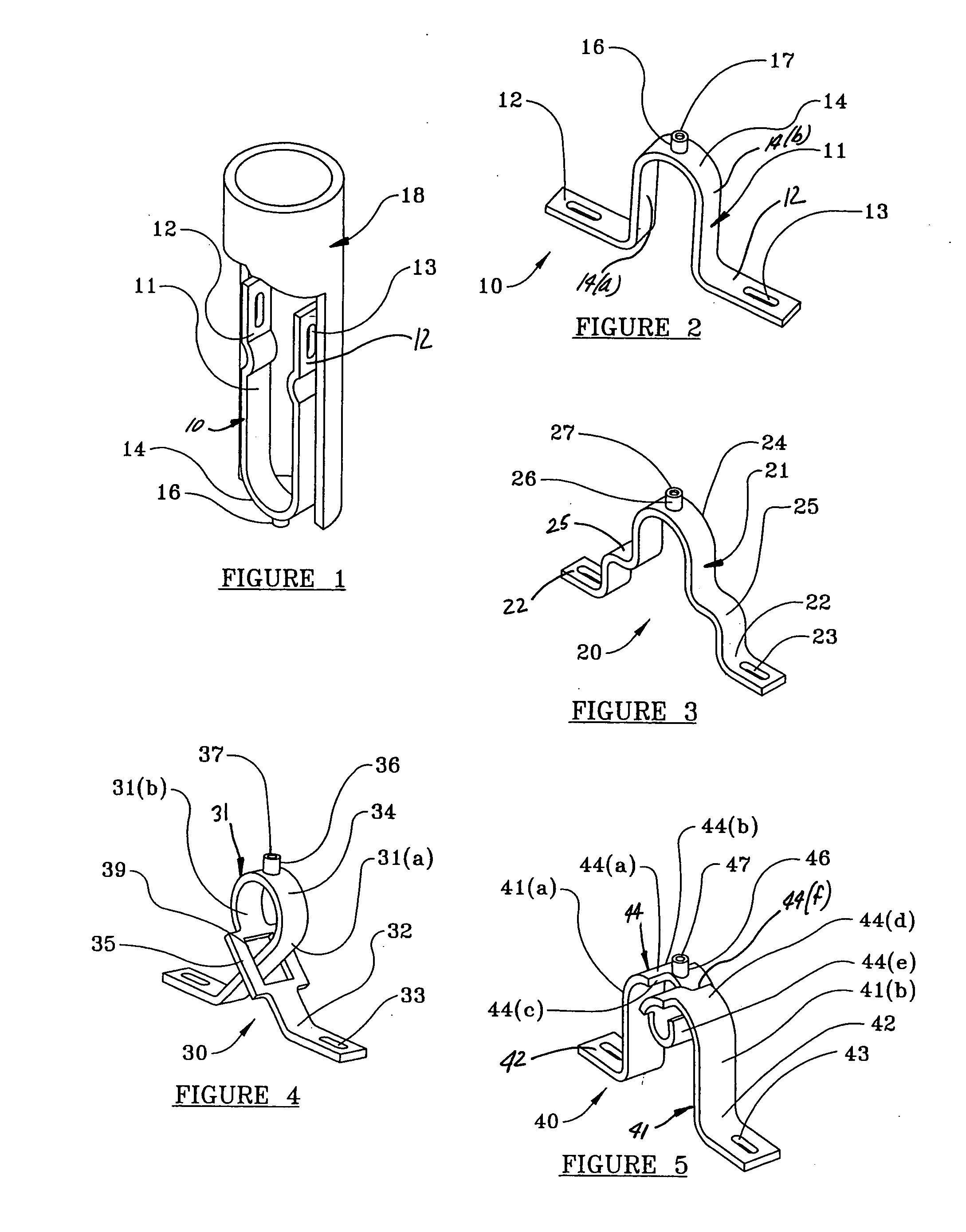

Apparatus and methods for tissue fixation using a bone plate configured to accommodate fixation devices (such as screws, for example) inserted at various angles. The bone plate is formed of a material softer than the material of the fixation devices, and is provided with fixation holes with rounded, curved interior walls (i.e., non-threaded holes) that allow the fixation devices to be inserted at various angles. The fixation holes have a diameter smaller than that of the fixation devices. As a result of the difference between the materials of the plate and of fixation devices, and of the difference between the diameters of the fixation holes and of the fixation devices, the fixation devices deform the interior walls of the fixation holes, therefore self-threading the holes at an advantageous angle.

Owner:ARTHREX

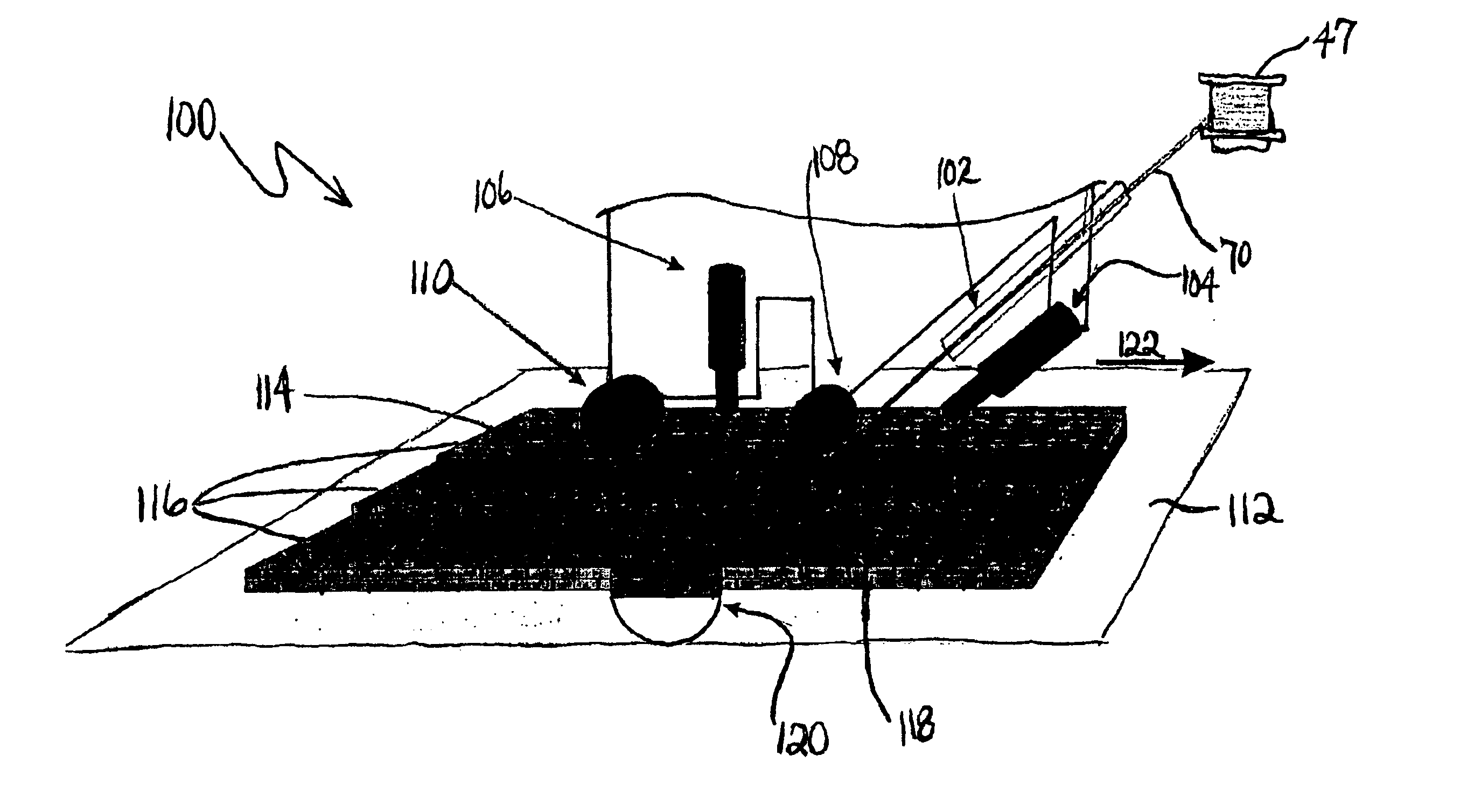

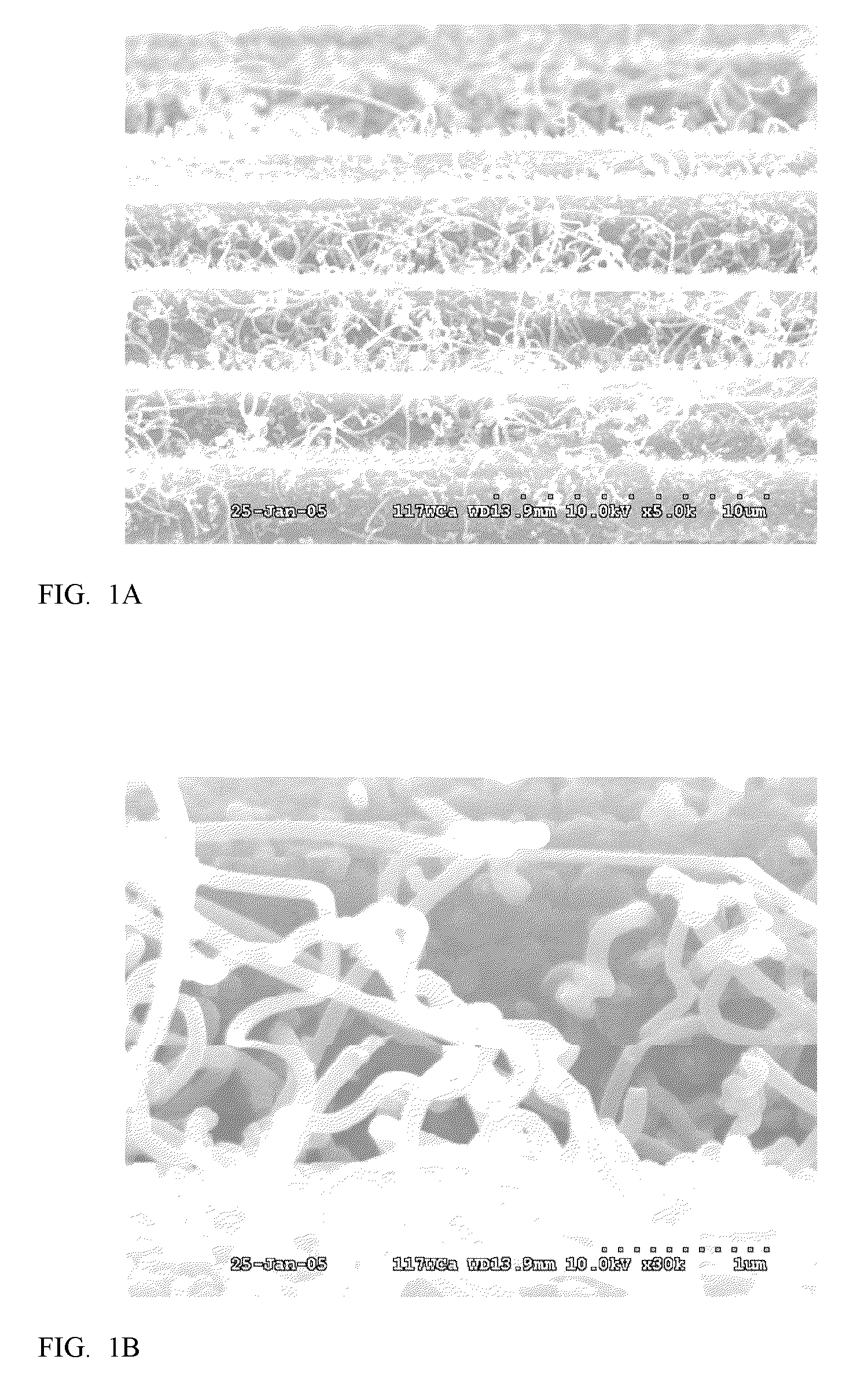

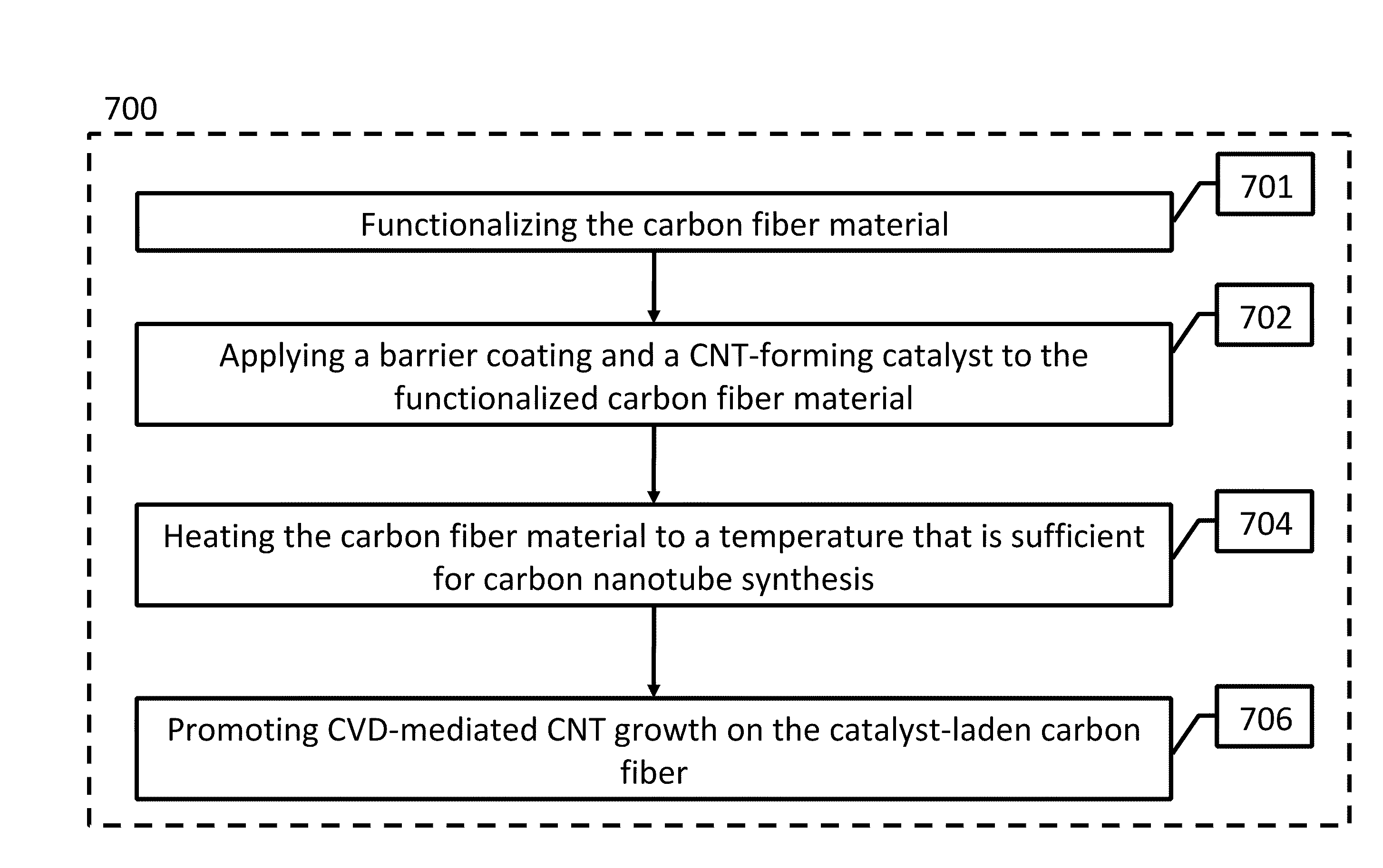

Continuous process for the production of carbon nanofiber reinforced continuous fiber preforms and composites made therefrom

ActiveUS20090220409A1Limited utilityLow yieldMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

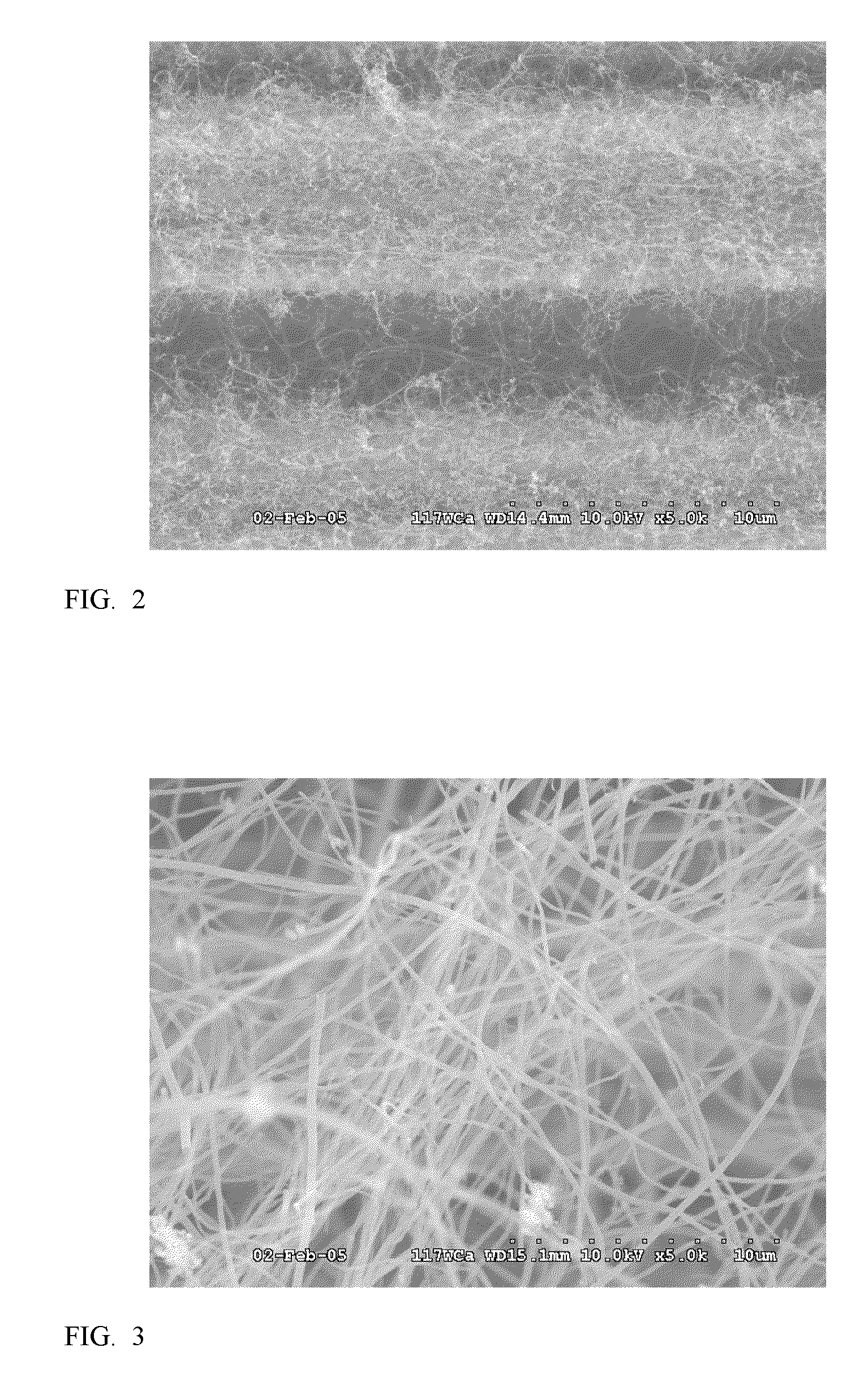

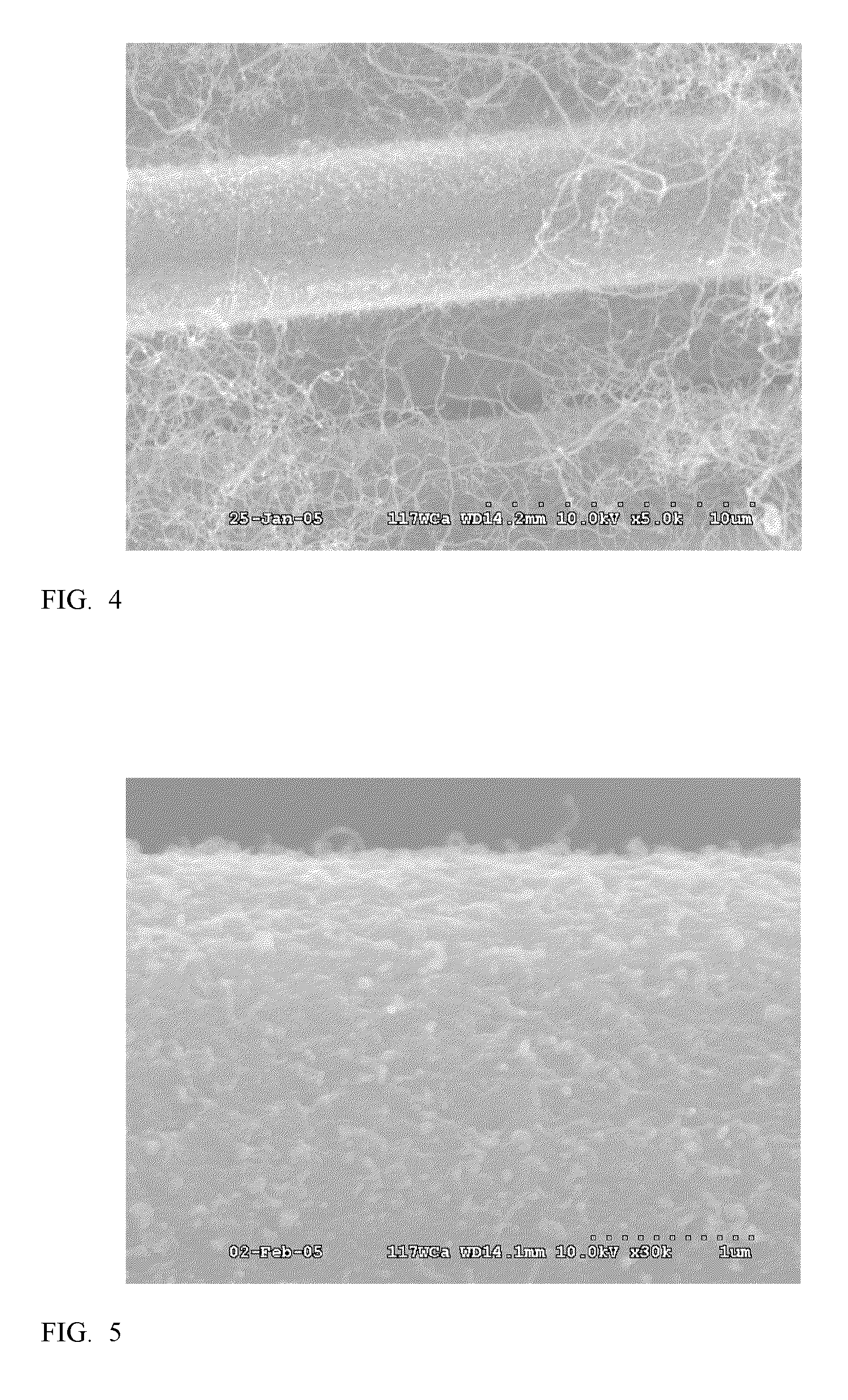

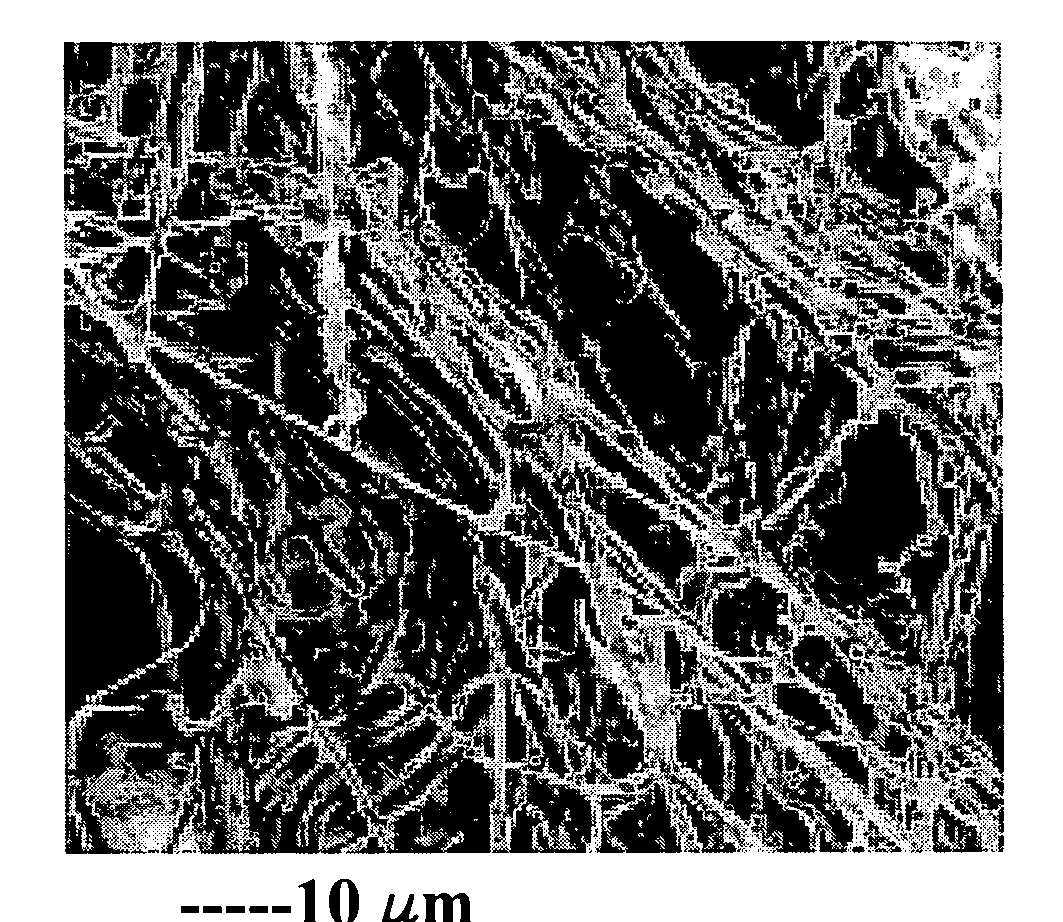

This invention provides a continuous process for the growth of vapor grown carbon fiber (VGCNT) reinforced continuous fiber preforms for the manufacture of articles with useful mechanical, electrical, and thermal characteristics. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCNT produced in situ resulting in a highly entangled mass of VGCNT infused with the continuous fiber preform. The continuous process disclosed herein provides denser and more uniform carbon nanotubes and provides the opportunity to fine-tune the variables both within an individual preform and between different preforms depending on the characteristics of the carbon nanotubes desired. The resulting continuous fiber preforms are essentially endless and are high in volume fraction of VGCNT and exhibit high surface area useful for many applications. The invention also provides for composites made from the preforms.

Owner:PERFORMANCE POLYMER SOLUTIONS

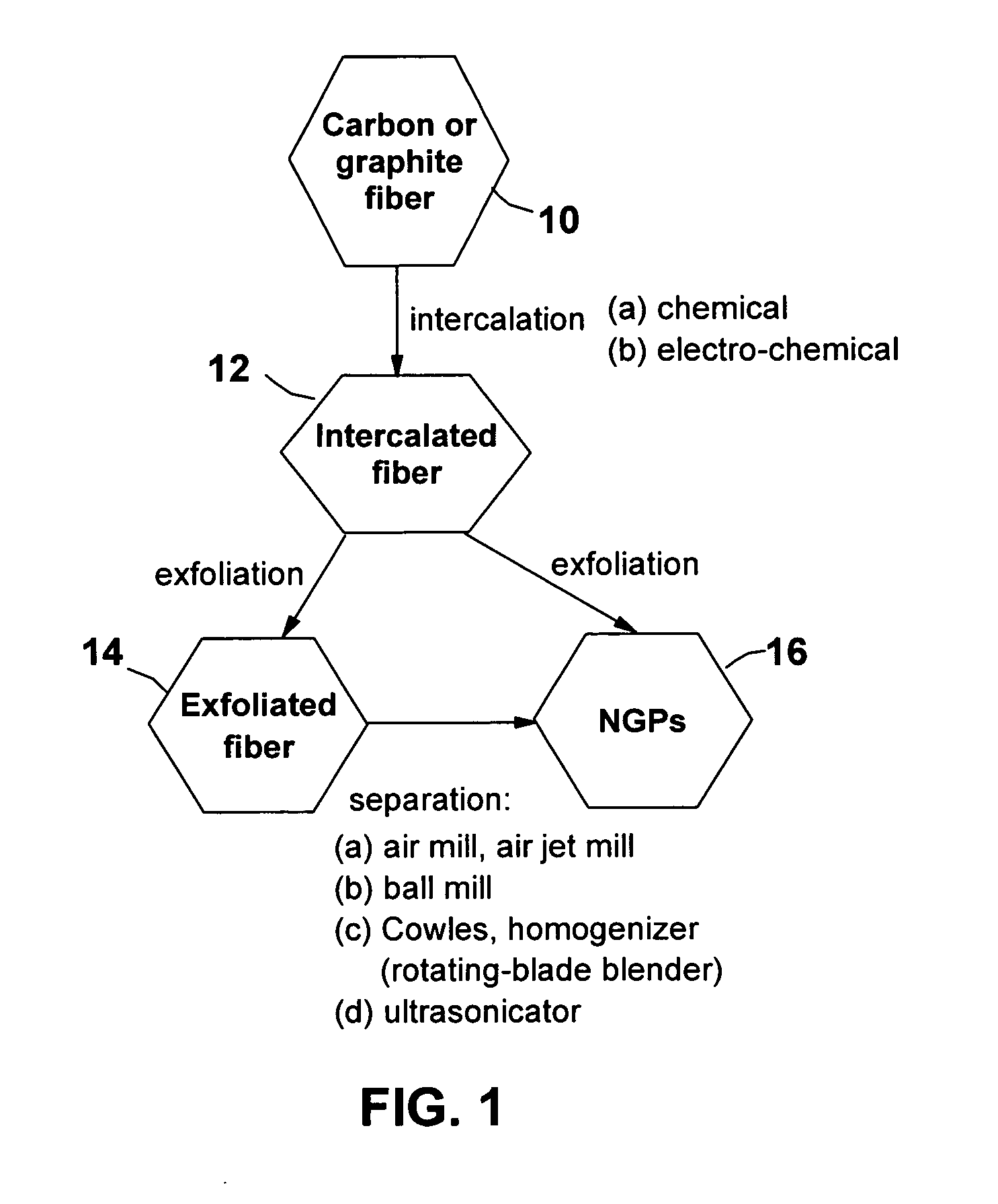

Nano-scaled graphene platelets with a high length-to-width aspect ratio

ActiveUS20090155578A1High aspect ratioHigh stiffnessMaterial nanotechnologyShielding materialsFiberCarbon fibers

This invention provides a nano-scaled graphene platelet (NGP) having a thickness no greater than 100 nm and a length-to-width ratio no less than 3 (preferably greater than 10). The NGP with a high length-to-width ratio can be prepared by using a method comprising (a) intercalating a carbon fiber or graphite fiber with an intercalate to form an intercalated fiber; (b) exfoliating the intercalated fiber to obtain an exfoliated fiber comprising graphene sheets or flakes; and (c) separating the graphene sheets or flakes to obtain nano-scaled graphene platelets. The invention also provides a nanocomposite material comprising an NGP with a high length-to-width ratio. Such a nanocomposite can become electrically conductive with a small weight fraction of NGPs. Conductive composites are particularly useful for shielding of sensitive electronic equipment against electromagnetic interference (EMI) or radio frequency interference (RFI), and for electrostatic charge dissipation.

Owner:GLOBAL GRAPHENE GRP INC

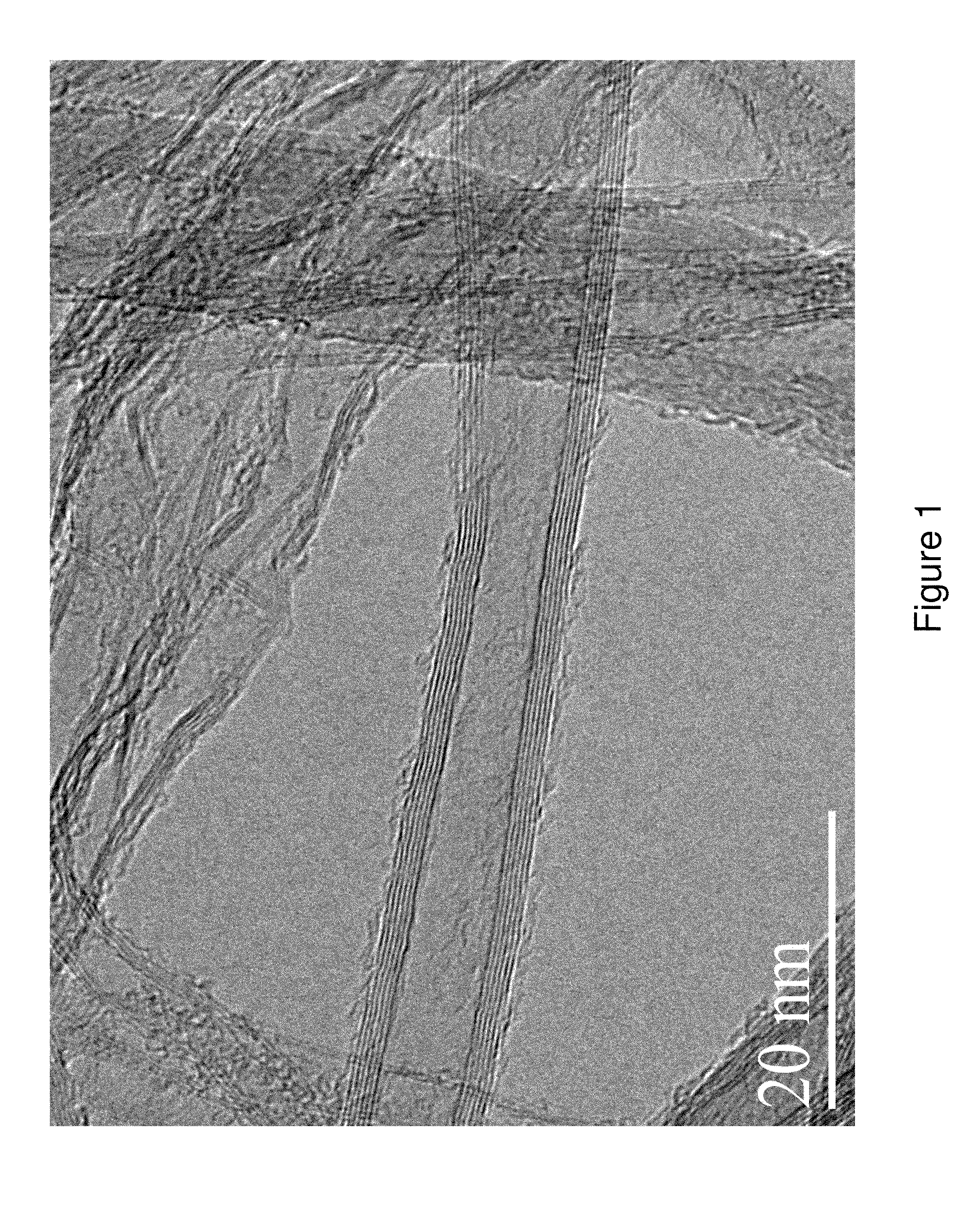

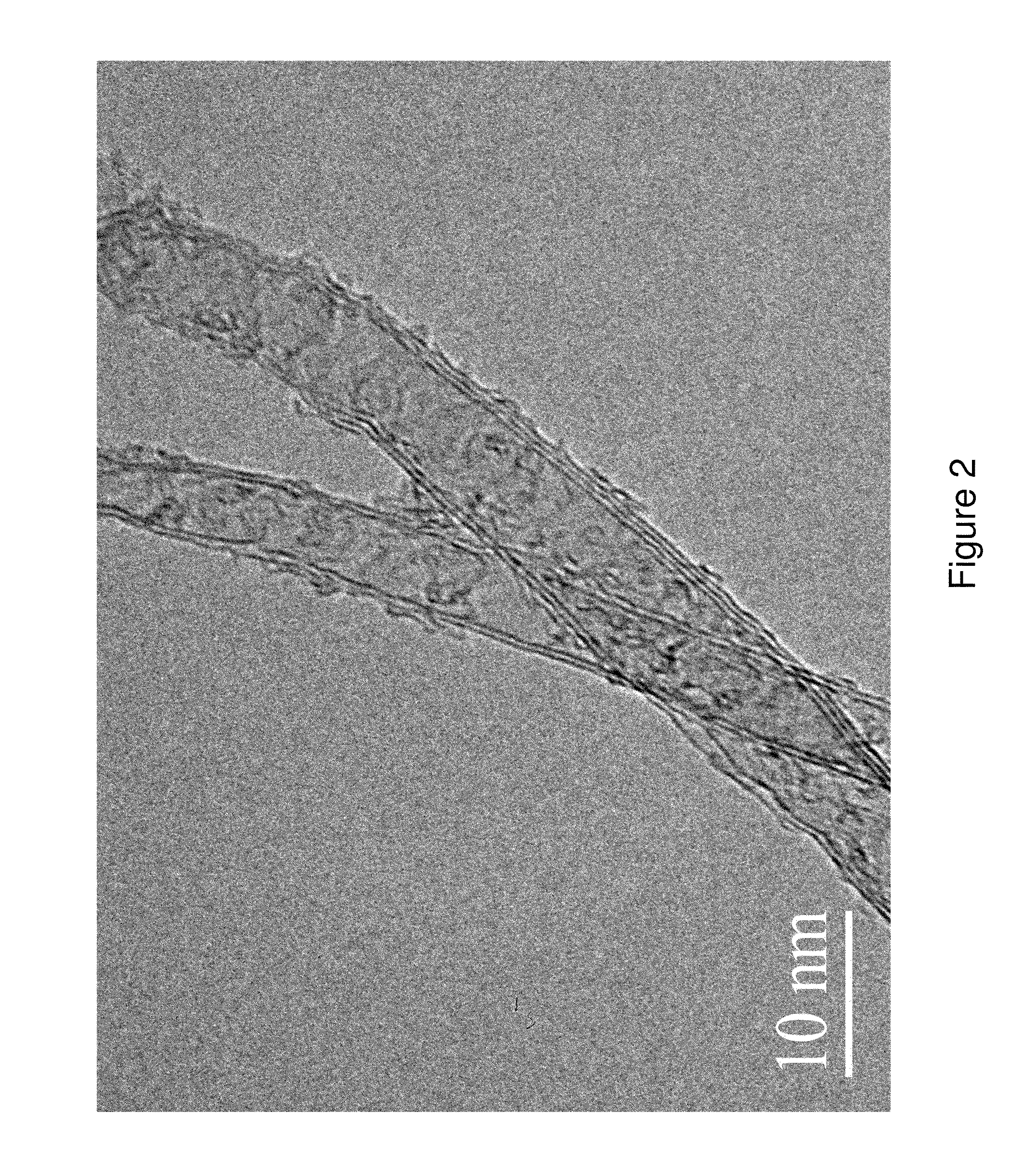

Cnt-infused carbon fiber materials and process therefor

A composition includes a carbon nanotube (CNT)-infused carbon fiber material that includes a carbon fiber material of spoolable dimensions and carbon nanotubes (CNTs) infused to the carbon fiber material. The infused CNTs are uniform in length and uniform in distribution. The CNT infused carbon fiber material also includes a barrier coating conformally disposed about the carbon fiber material, while the CNTs are substantially free of the barrier coating. A continuous CNT infusion process includes: (a) functionalizing a carbon fiber material; (b) disposing a barrier coating on the functionalized carbon fiber material (c) disposing a carbon nanotube (CNT)-forming catalyst on the functionalized carbon fiber material; and (d) synthesizing carbon nanotubes, thereby forming a carbon nanotube-infused carbon fiber material.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com