Patents

Literature

1836 results about "Cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

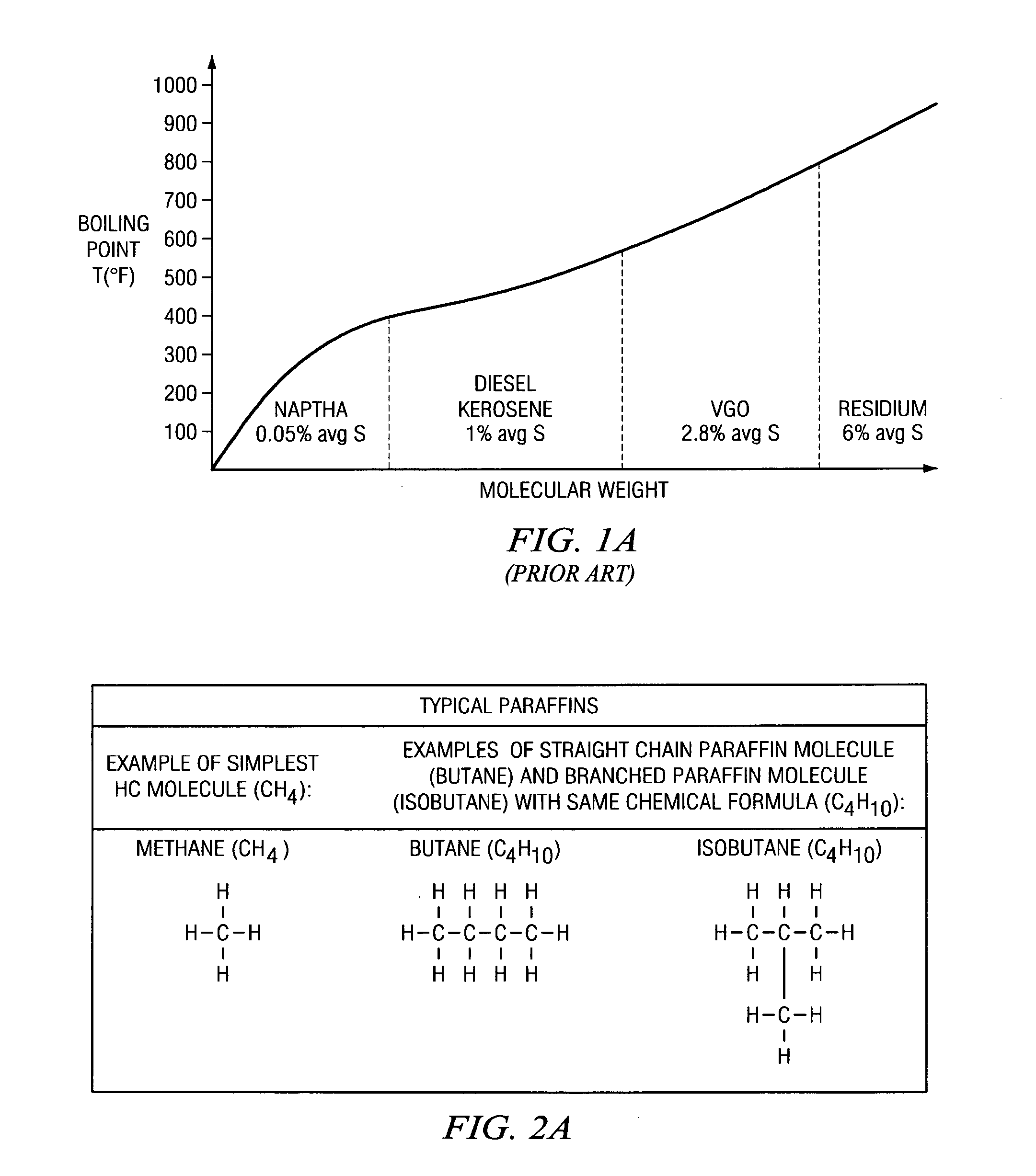

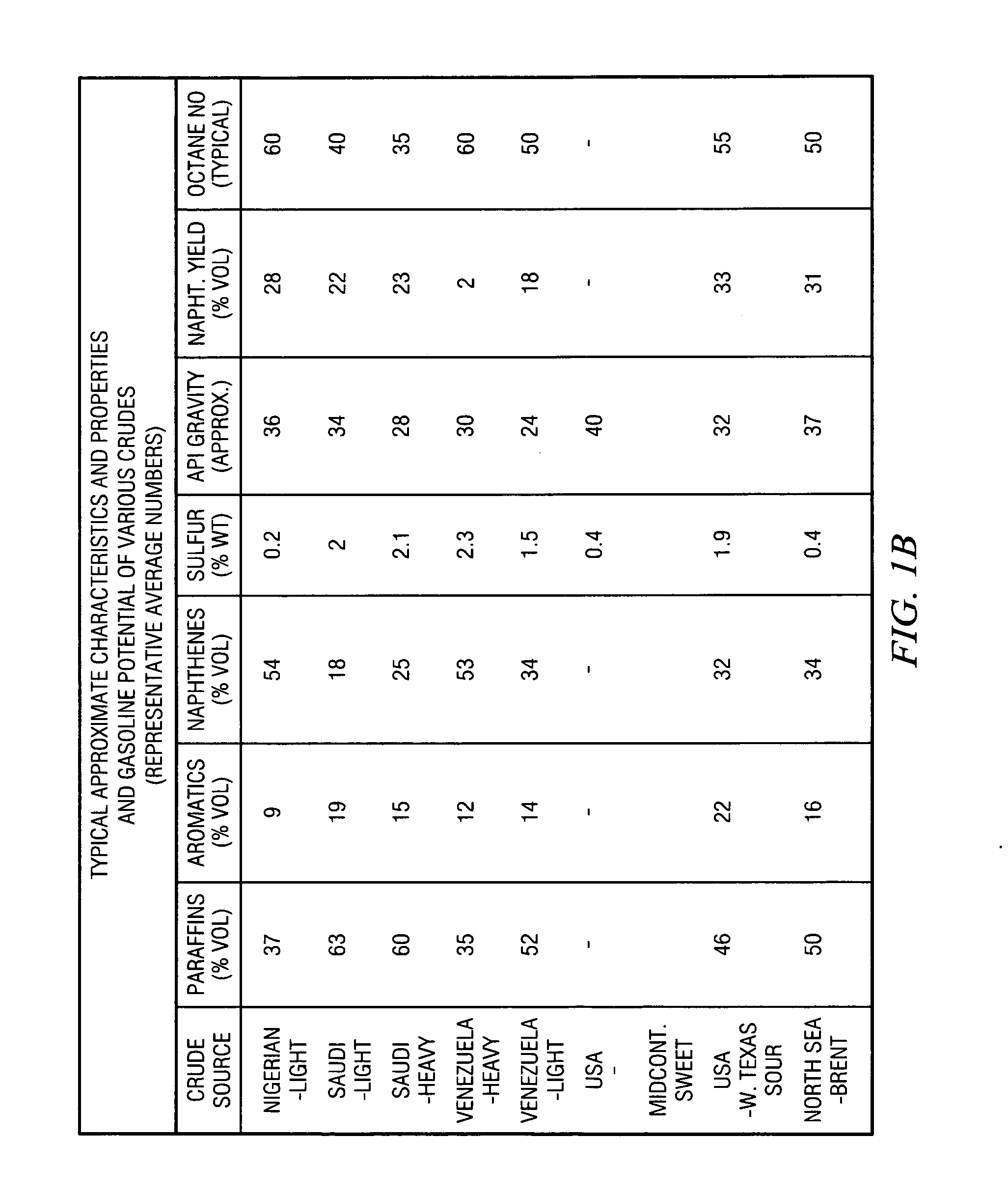

In petrochemistry, petroleum geology and organic chemistry, cracking is the process whereby complex organic molecules such as kerogens or long-chain hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking of carbon-carbon bonds in the precursors. The rate of cracking and the end products are strongly dependent on the temperature and presence of catalysts. Cracking is the breakdown of a large alkane into smaller, more useful alkenes. Simply put, hydrocarbon cracking is the process of breaking a long-chain of hydrocarbons into short ones. This process requires high temperatures and high pressure.

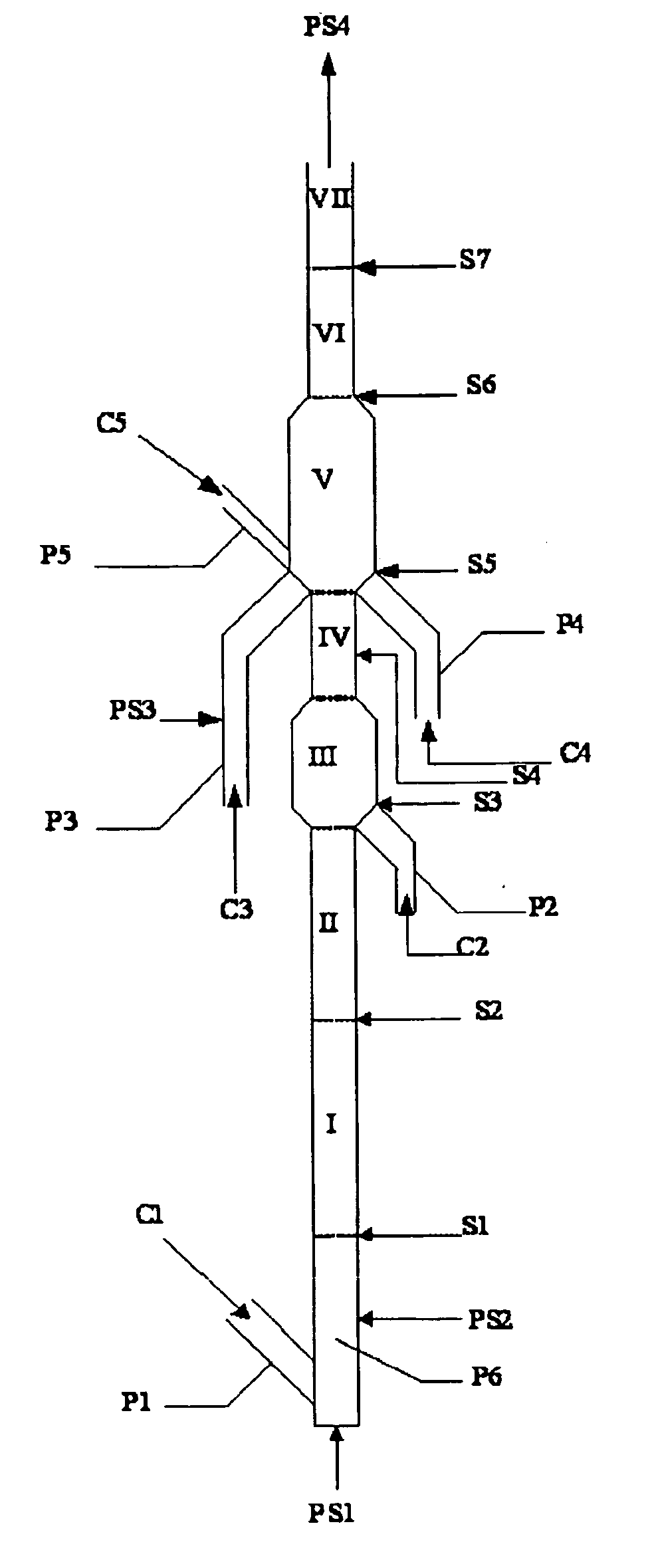

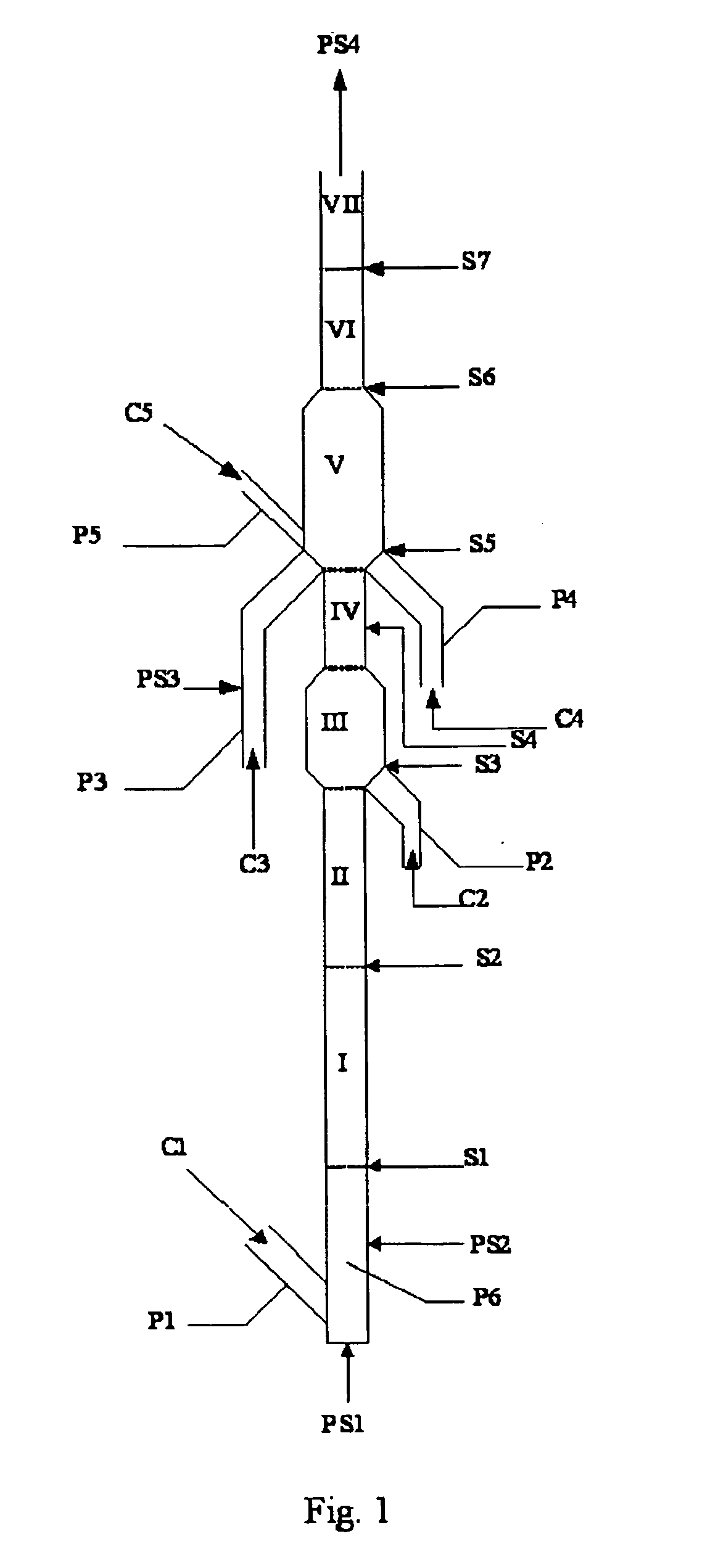

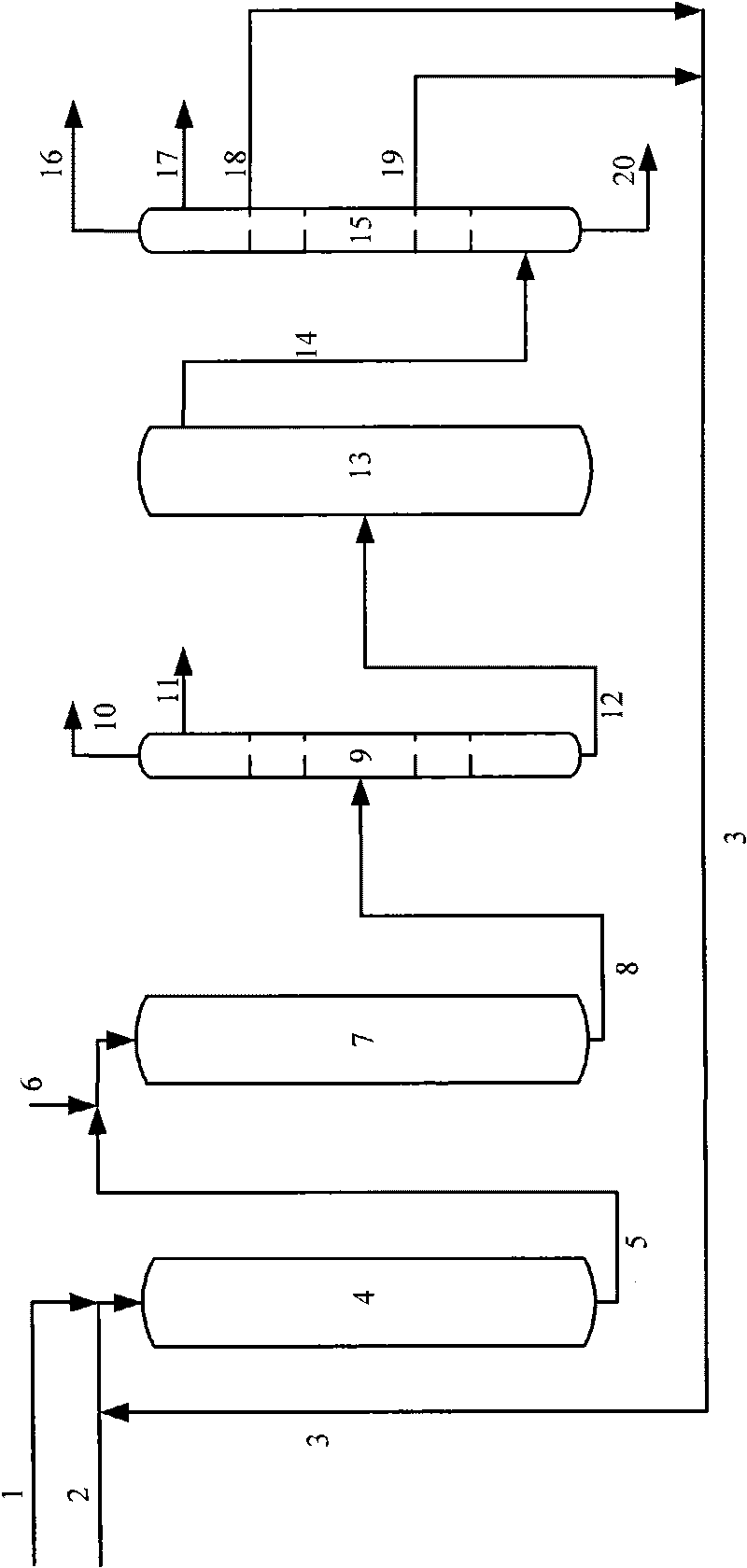

Process for increasing production of light olefins from hydrocarbon feedstock in catalytic cracking

ActiveUS20070083071A1Increase productionEconomical efficiencyTreatment with plural serial cracking stages onlyCatalytic crackingProduction ratePhotochemistry

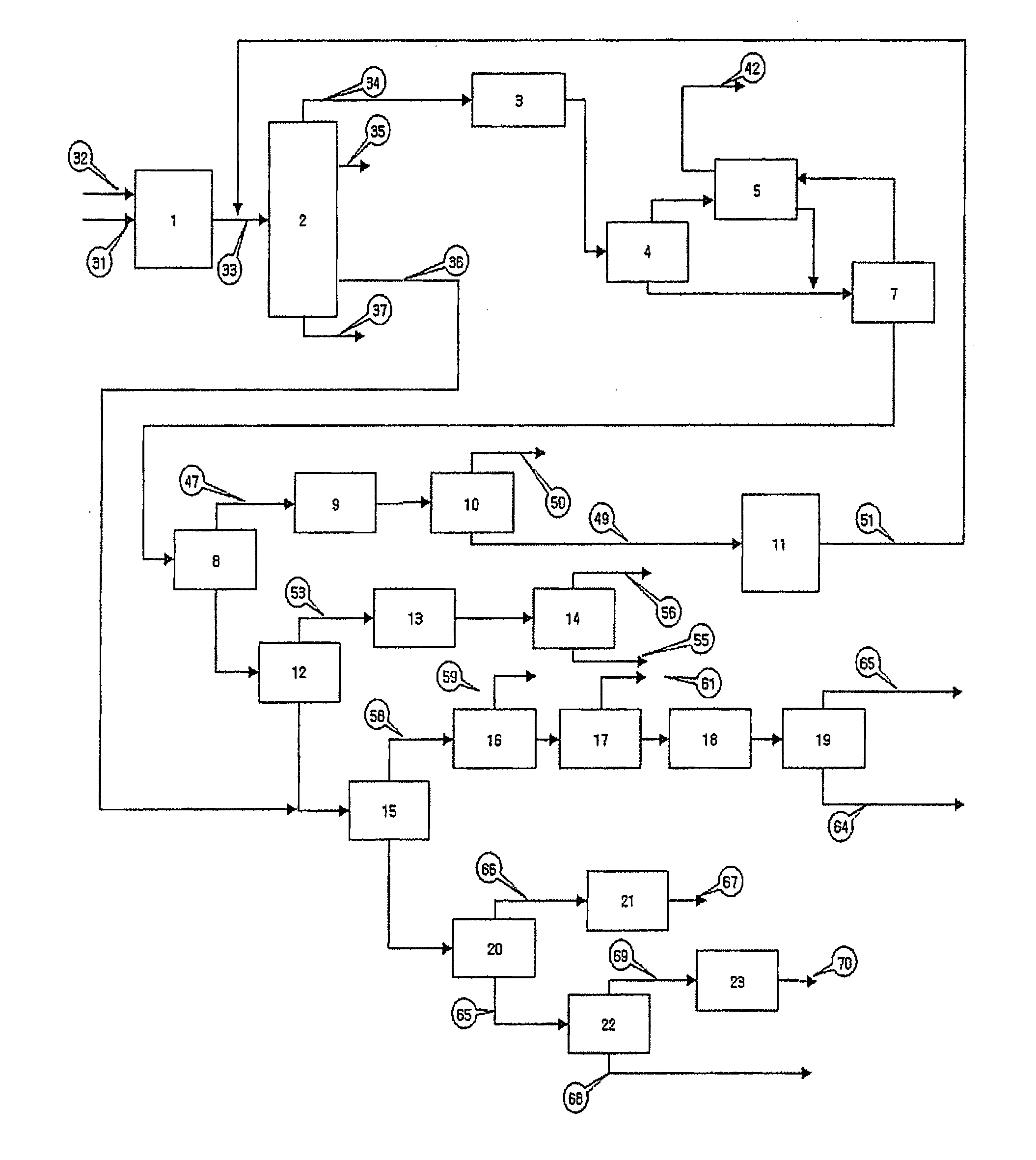

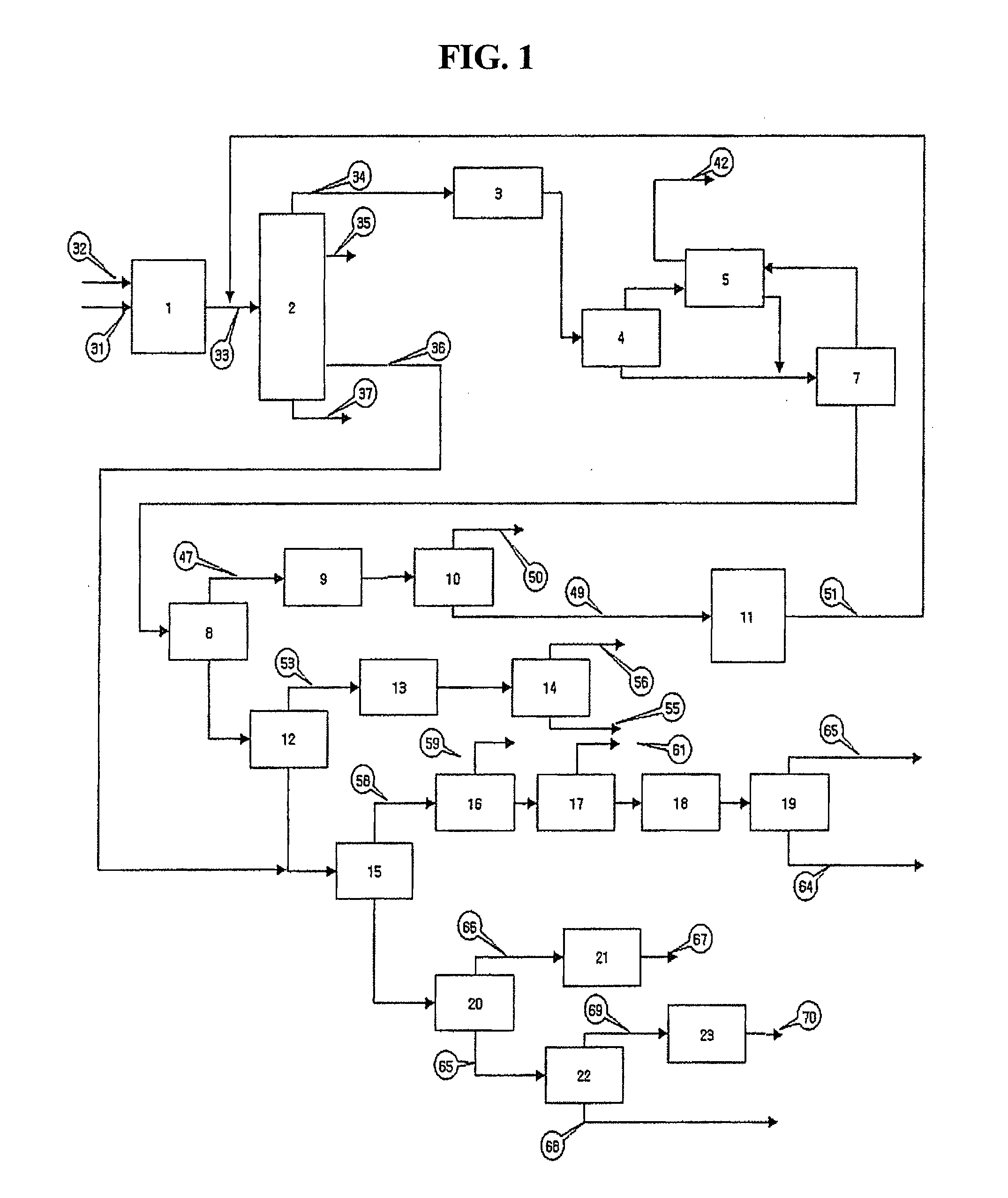

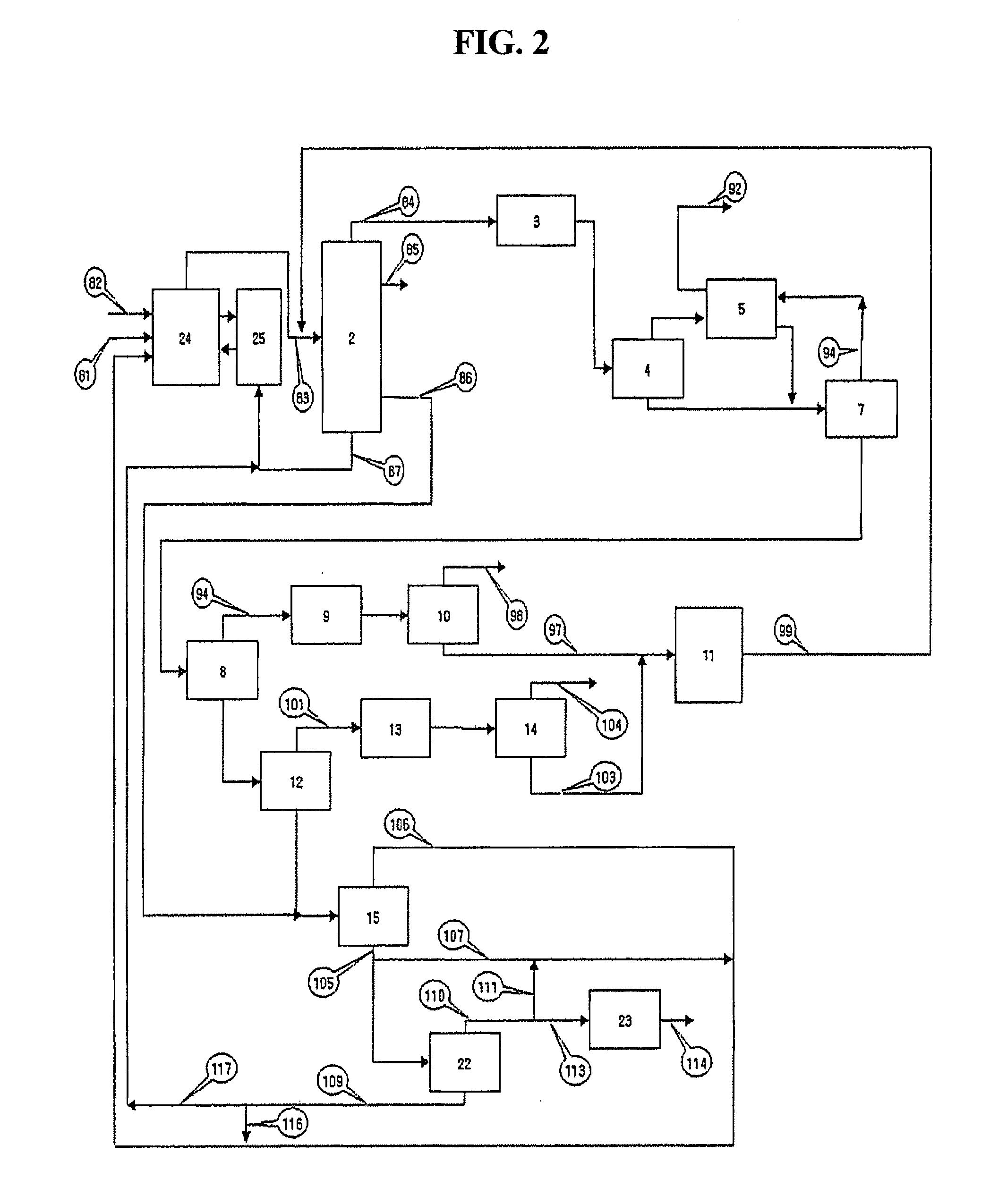

Disclosed is a process for increasing production of light olefinic hydrocarbons from hydrocarbon feedstock by catalytic cracking. In the process, an effective separation process structure and recycle method of light olefins are used not only to increase the productivity and efficiency of an overall process, thus effectively increasing the production of light olefins, but also to simplify the overall process.

Owner:SK INNOVATION CO LTD

Molecular sieve-containing catalyst for cracking hydrocarbons and a method for preparing the same

ActiveUS20040266608A1Reduced activityEasy to crackCatalytic crackingMolecular sieve catalystsReduction ActivityMolecular sieve

A molecular sieve-containing catalyst for cracking hydrocarbons, comprising molecular sieve, refractory inorganic oxide, clay and a metal component, wherein the amount of said molecular sieve is from 1 to 90% by weight, the refractory inorganic oxide is from 2 to 80% by weight, the clay is from 2 to 80% by weight, and the metal component is from 0.1 to 30% by weight, calculated as the oxide of said metal having its maximum valence state, based on the total amount of the catalyst, wherein said metal component exists essentially in a reduction state and is one or more metals selected from the group consisting of metals of Group III A(other than aluminum), and metals of Group IVA, VA, IB, IIB, VB, VIB and VIIB, and non-noble metals of Group VIII of the periodic table. The catalyst has higher cracking activity and higher sulfur reduction activity.

Owner:CHINA PETROCHEMICAL CORP +1

Combined cracking and selective hydrogen combustion for catalytic cracking

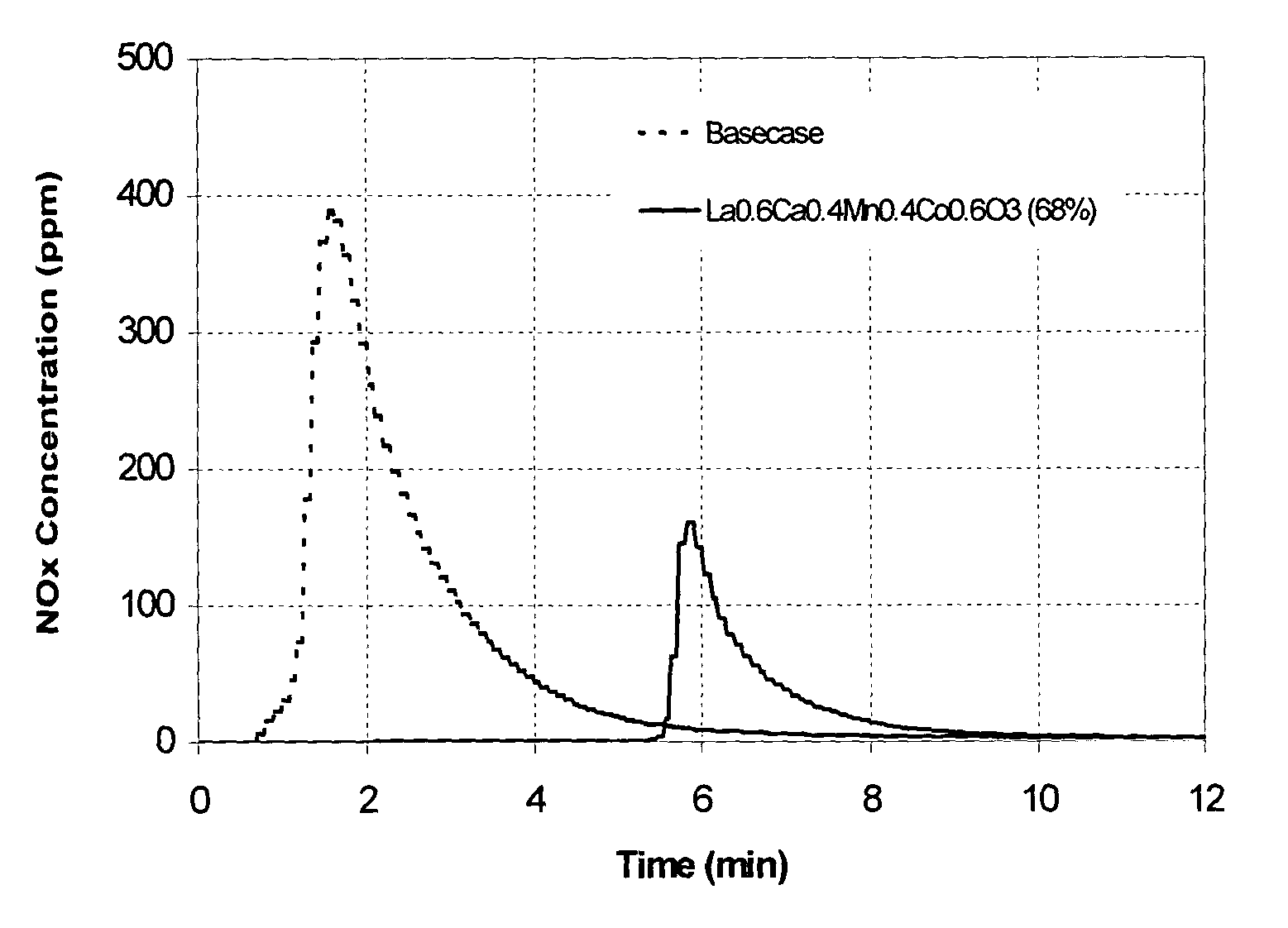

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst system contains at least one solid acid component and at least one metal-based component which consists of (a) oxygen and / or sulfur and (b) a metal combination selected from the group consisting of: i) at least one metal from Group 3 and at least one metal from Groups 4-15 of the Periodic Table of the Elements; ii) at least one metal from Groups 5-15 of the Periodic Table of the Elements, and at least one metal from at least one of Groups 1, 2, and 4 of the Periodic Table of the Elements; iii) at least one metal from Groups 1 and 2, at least one metal from Group 3, and at least one metal from Groups 4-15 of the Periodic Table of the Elements; and iv) two or more metals from Groups 4-15 of the Periodic Table of the Elements, wherein the at least one of oxygen and sulfur is chemically bound both within and between the metals and, optionally, (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone. Further the emissions of NOx from the regeneration cycle of the catalyst system are reduced.

Owner:EXXONMOBIL CHEM PAT INC

Multi component catalyst and its use in catalytic cracking

A multi component catalyst and catalytic cracking process for selectively producing C3 olefins. The catalyst comprises a first molecular sieve having an intermediate pore size, a second molecular sieve and, optionally a third molecular sieve having a large pore size. At least one of the channels of the second molecular sieve has a pore size index that is less than the pore size index of at least one channel of the first molecular sieve. The process is carried out by contacting a feedstock containing hydrocarbons having at least 5 carbon atoms is contacted, under catalytic cracking conditions, with the multi component catalyst. The catalyst finds application in the cracking of naphtha and heavy hydrocarbon feedstocks.

Owner:EXXONMOBIL CHEM PAT INC

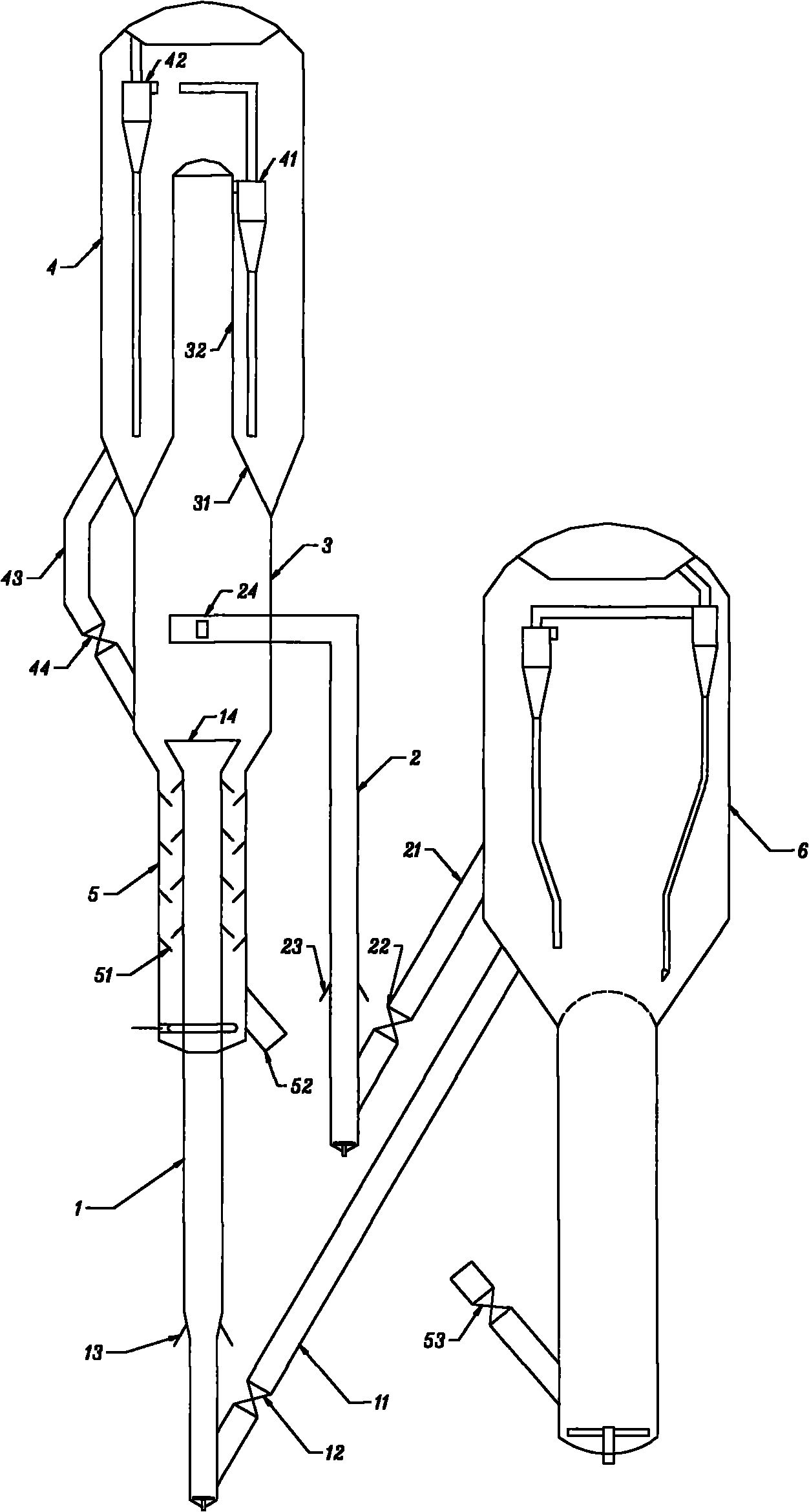

Production of propene and high-quality gasoline and diesel oil by two-stage catalyzed crack

ActiveCN101074392AGood natureQuality improvementOrganic chemistryCatalytic crackingMolecular sieveVegetable oil

A method for producing propylene and gasoline diesel-oil by two-section catalyzed cracking style is carried out by adopting two-section lift pipe catalyzing process and catalyst with molecular sieve, taking heavy petroleum hydrocarbon or various animal and vegetable oils containing hydrocarbon as raw materials, optimization combining by charging style for various reactants, and controlling proper reactive conditions. It can improve propene and light-oil recovery rate and quality, and inhibit to generate dry gas and coke.

Owner:PETROCHINA CO LTD +1

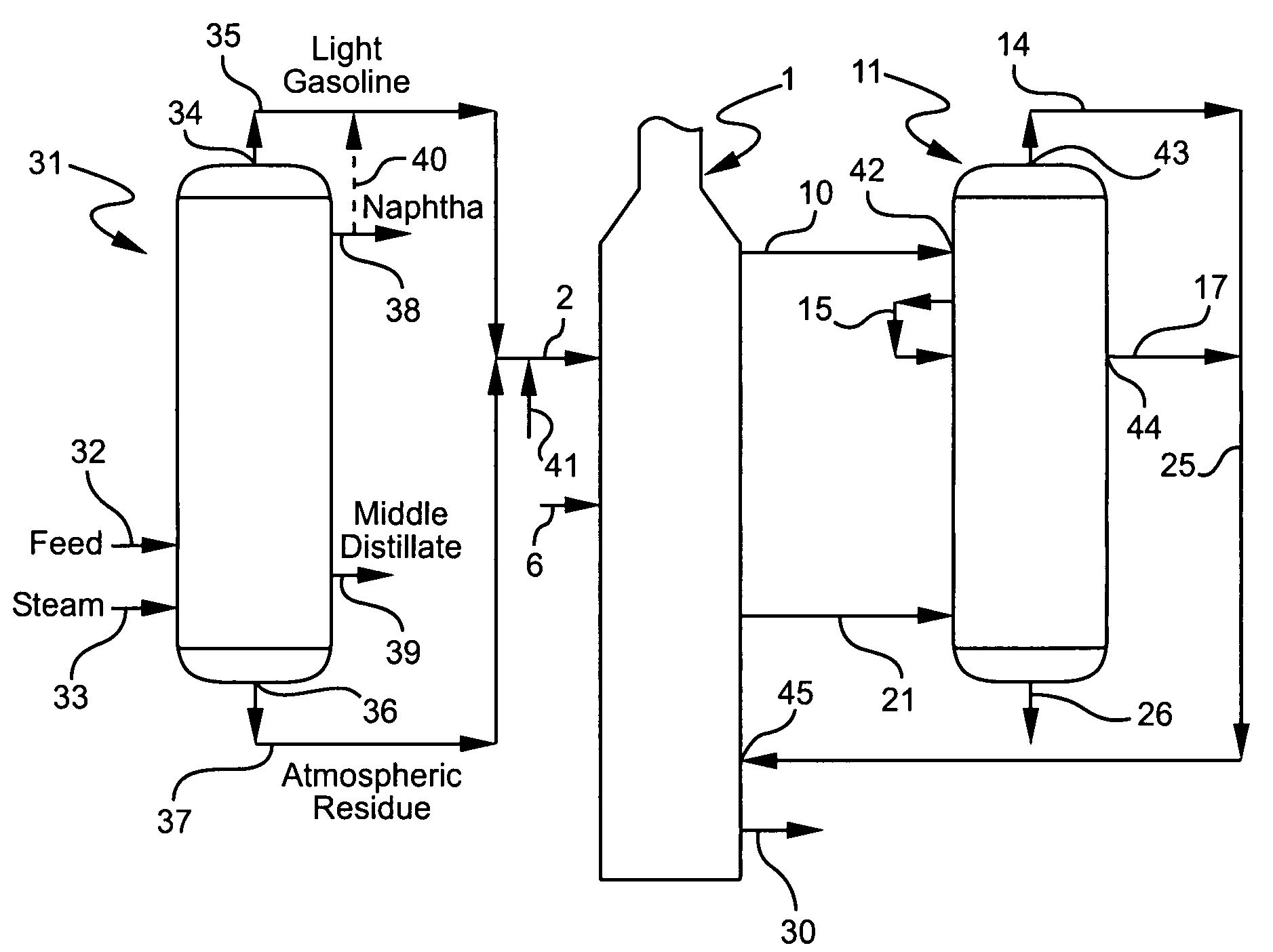

Hydrocarbon thermal cracking using atmospheric distillation

ActiveUS7404889B1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyDistillationGasoline

A method for thermally cracking a hydrocarbonaceous feed wherein the feed is first processed in an atmospheric thermal distillation step to form a light gasoline and atmospheric residuum mixture. The light gasoline / residuum combination is gasified at least in part in a vaporization step, and the gasified product of the vaporization step is thermally cracked.

Owner:EQUSR CHEM LP

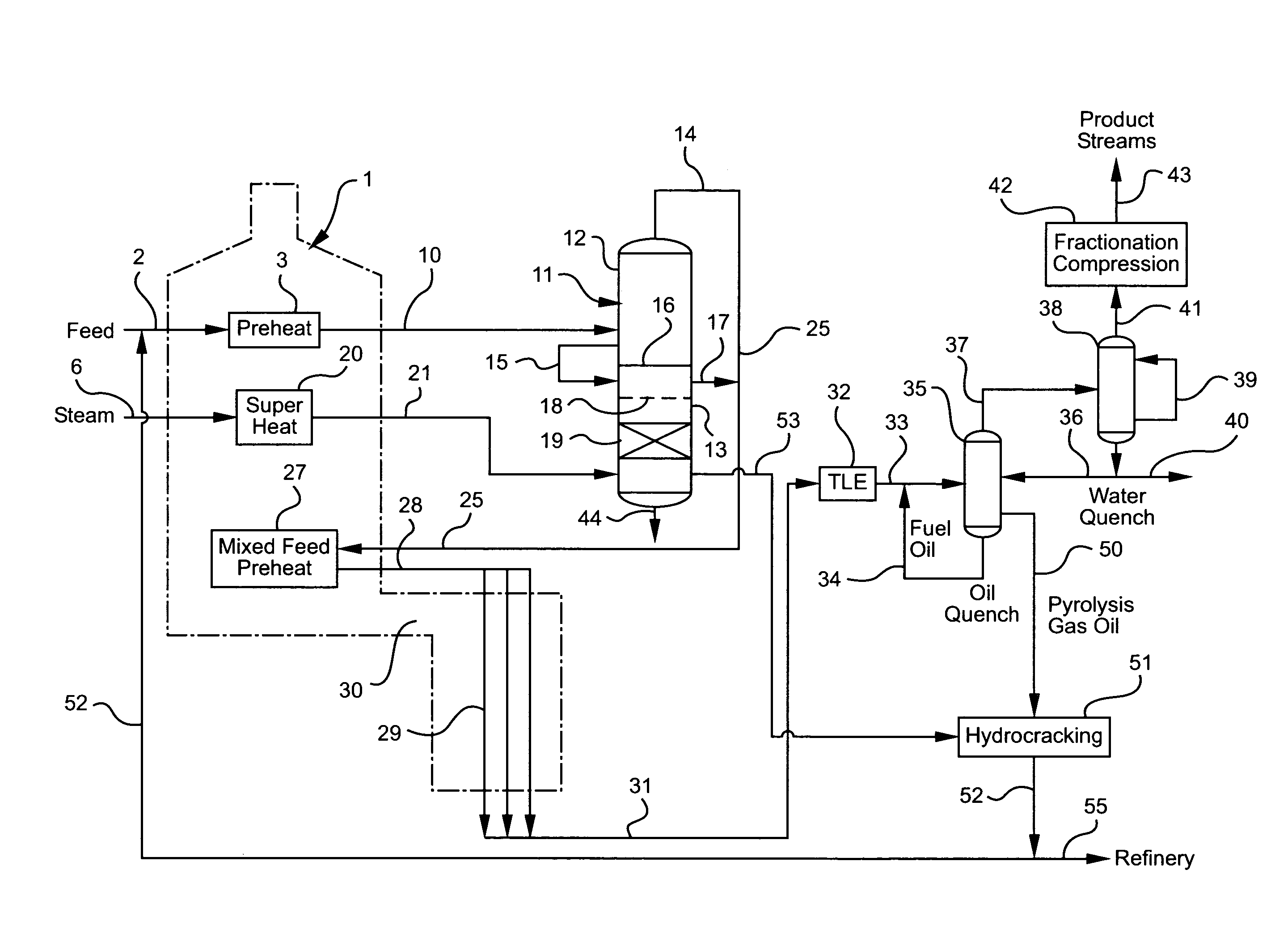

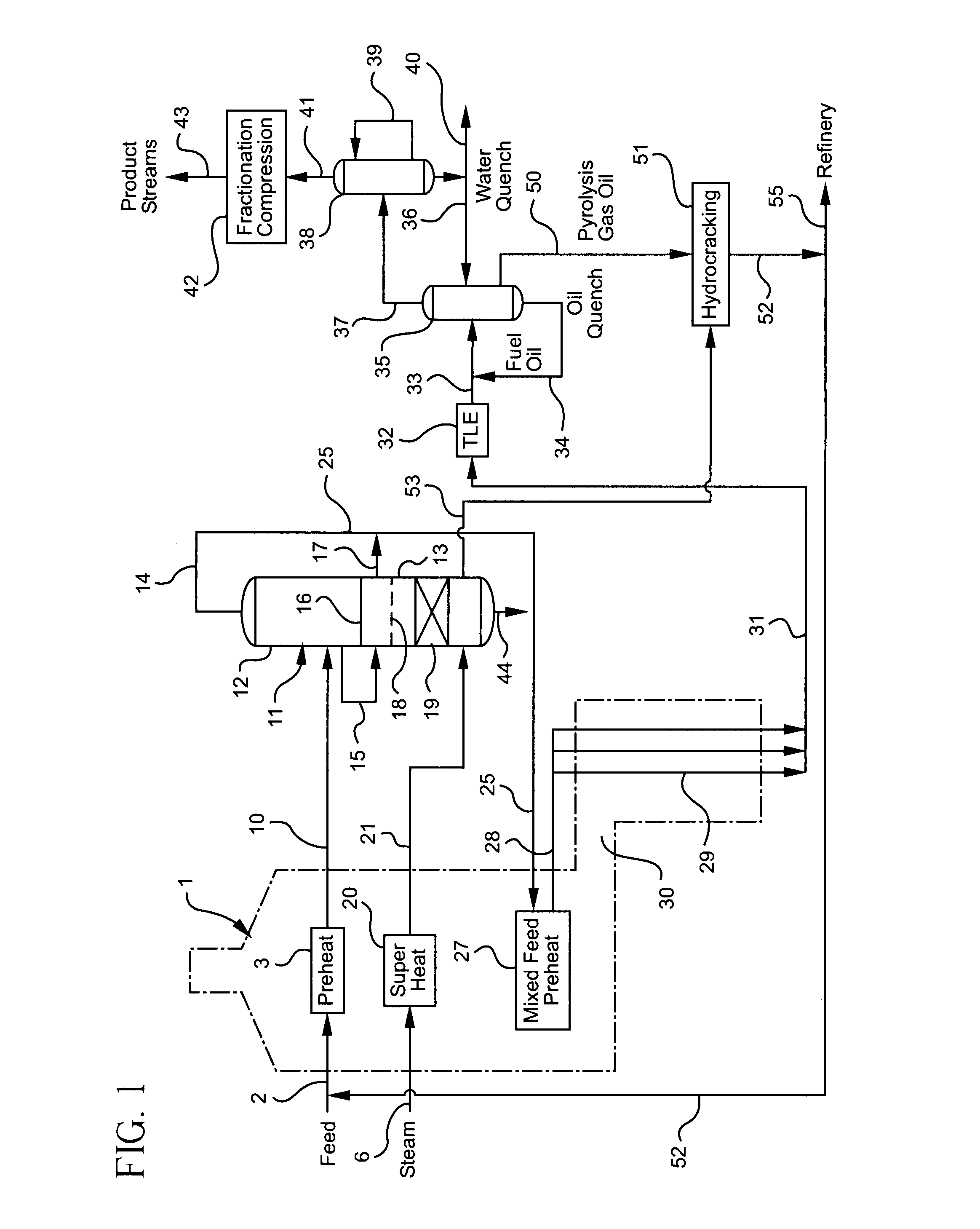

Olefin production utilizing whole crude oil/condensate feedstock and selective hydrocracking

InactiveUS20090050523A1Improve productivityReduce sulfur contentThermal non-catalytic crackingHydrocarbon oil crackingAlkaneNatural-gas condensate

A method for thermally cracking a feed composed of whole crude oil and / or natural gas condensate using a vaporizer to vaporize the feed before cracking same, recovering pyrolysis gas oil from the cracked feed, subjecting the recovered pyrolysis gas oil to hydrocracking to form a paraffinic hydrocracked product, and passing at least part of the hydrocracked product to the vaporizer as additional thermal cracking feed.

Owner:EQUSR CHEM LP

Catalytic cracking diesel fuel hydroconversion method

ActiveCN104611029AReduce hydrogenationHigh yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

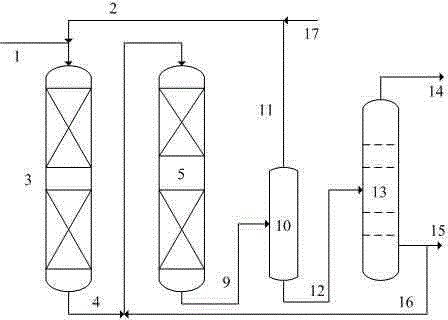

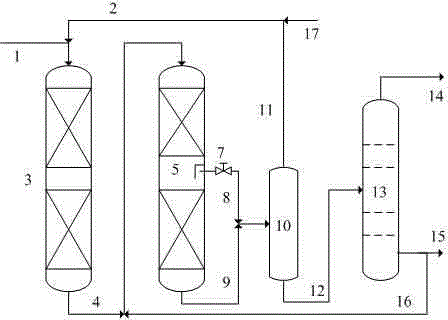

The present invention discloses a catalytic cracking diesel fuel hydroconversion method. According to the method, catalytic diesel fuel and hydrogen are mixed and then enter a hydrorefining reactor to carry out a hydrorefining reaction; the hydrorefining reaction effluent directly enters a hydrocracking reactor and then is subjected to a contact reaction with the grading catalyst bed layer inside the hydrocracking reactor, wherein at least two cracking catalyst bed layers are arranged inside the hydrocracking reactor, and the hydrogenation activity of the hydrocracking catalyst presents the decrease tendency according to the reaction material flowing direction; and the hydrocracking reaction effluent is subjected to separation and fractionation to obtain the naphtha and the diesel fuel. With the method of the present invention, the diesel fuel hydrocracking effect can be ensured while the excessive hydrogenation and the secondary cracking of the naphtha can be reduced and the chemical hydrogen consumption can be reduced so as to increase the octane number and the liquid yield of the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

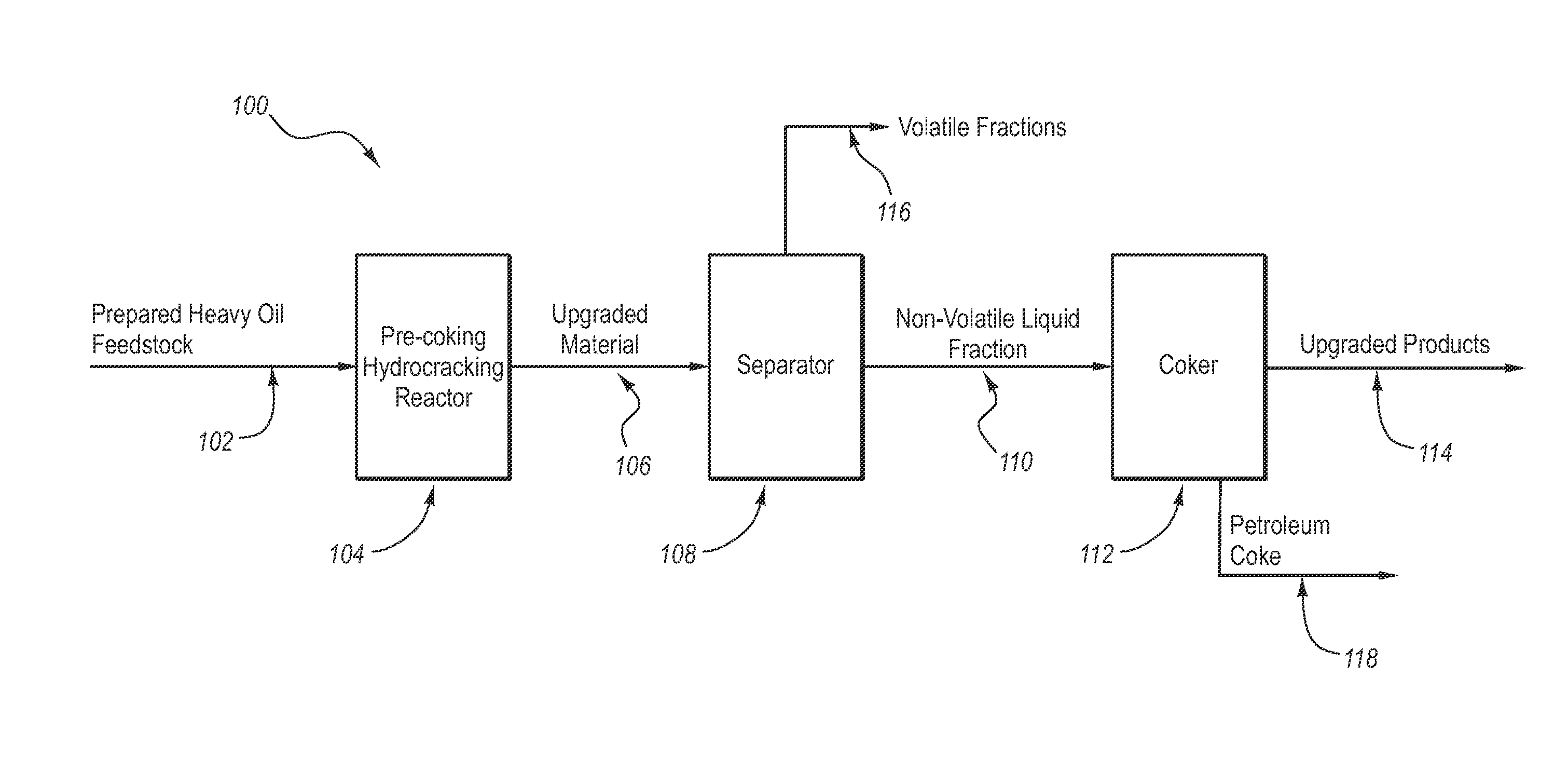

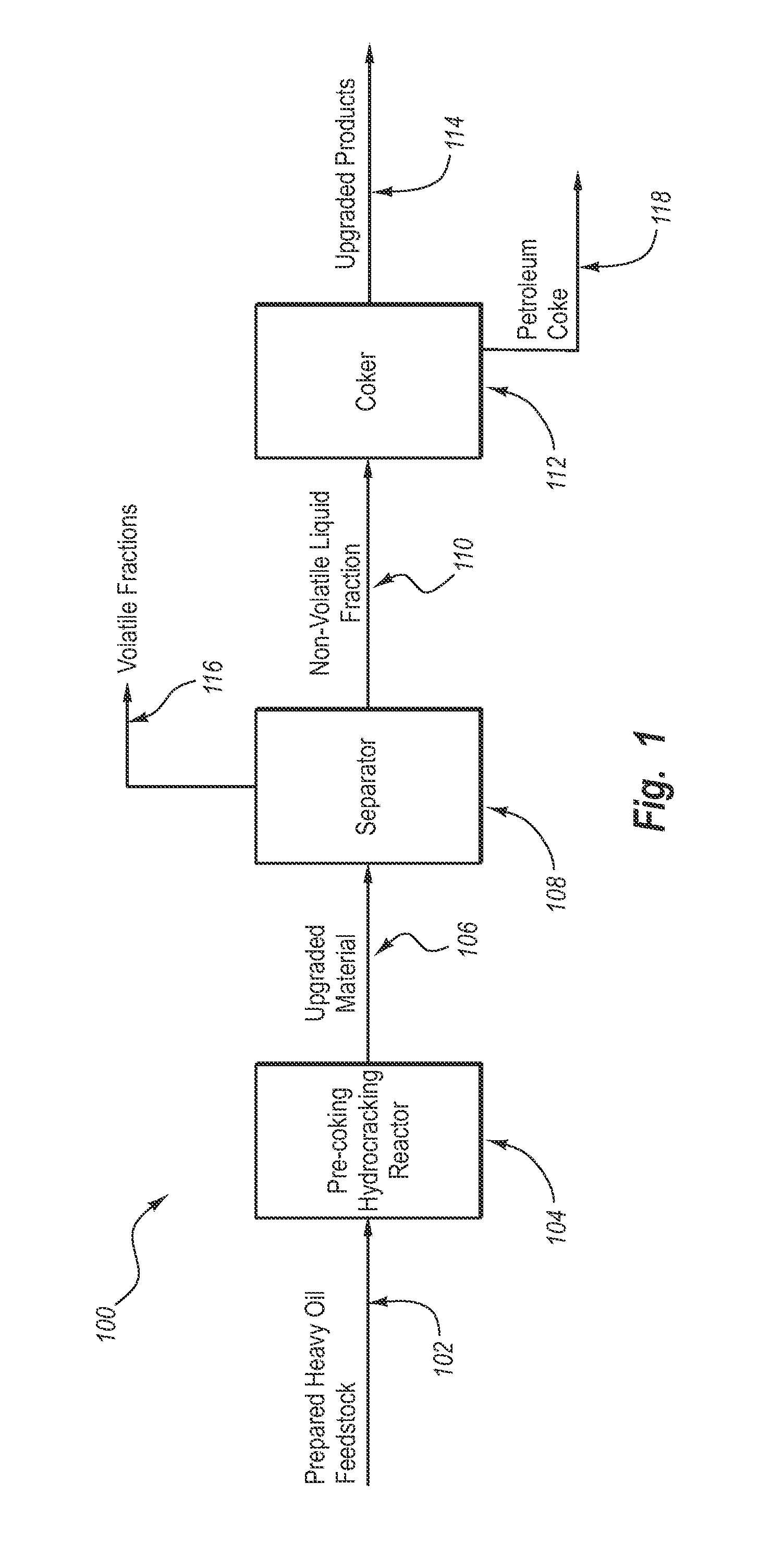

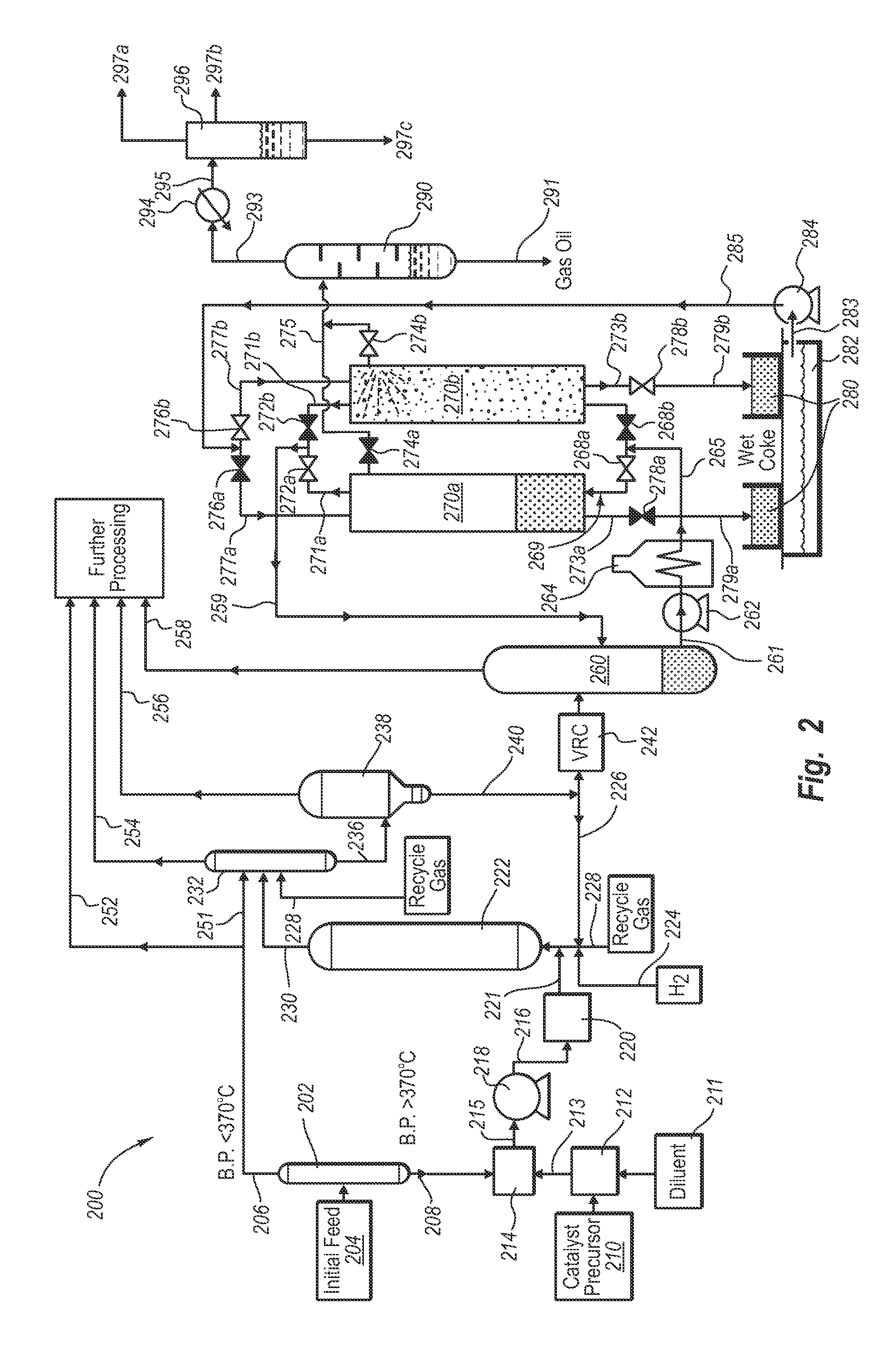

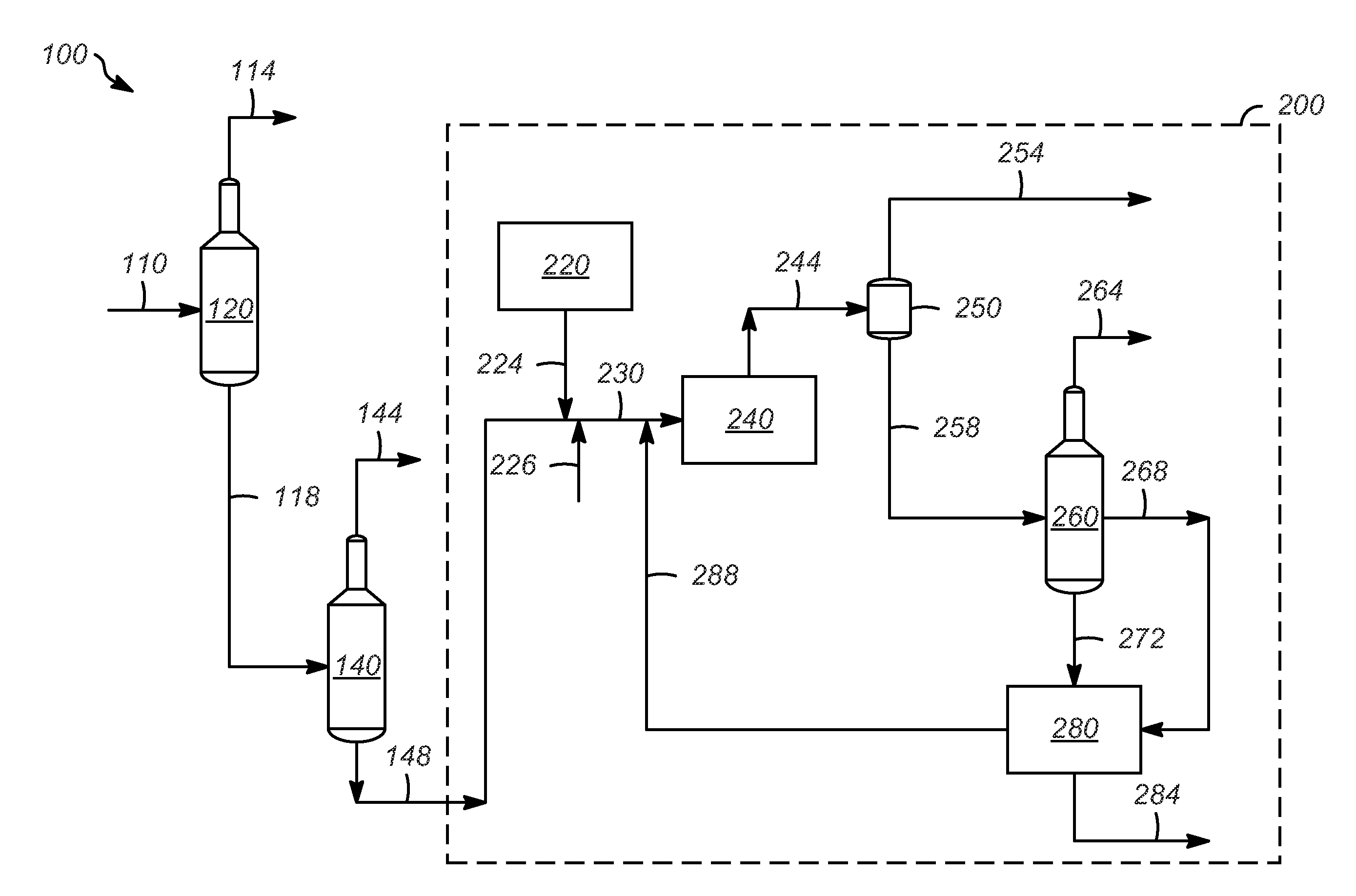

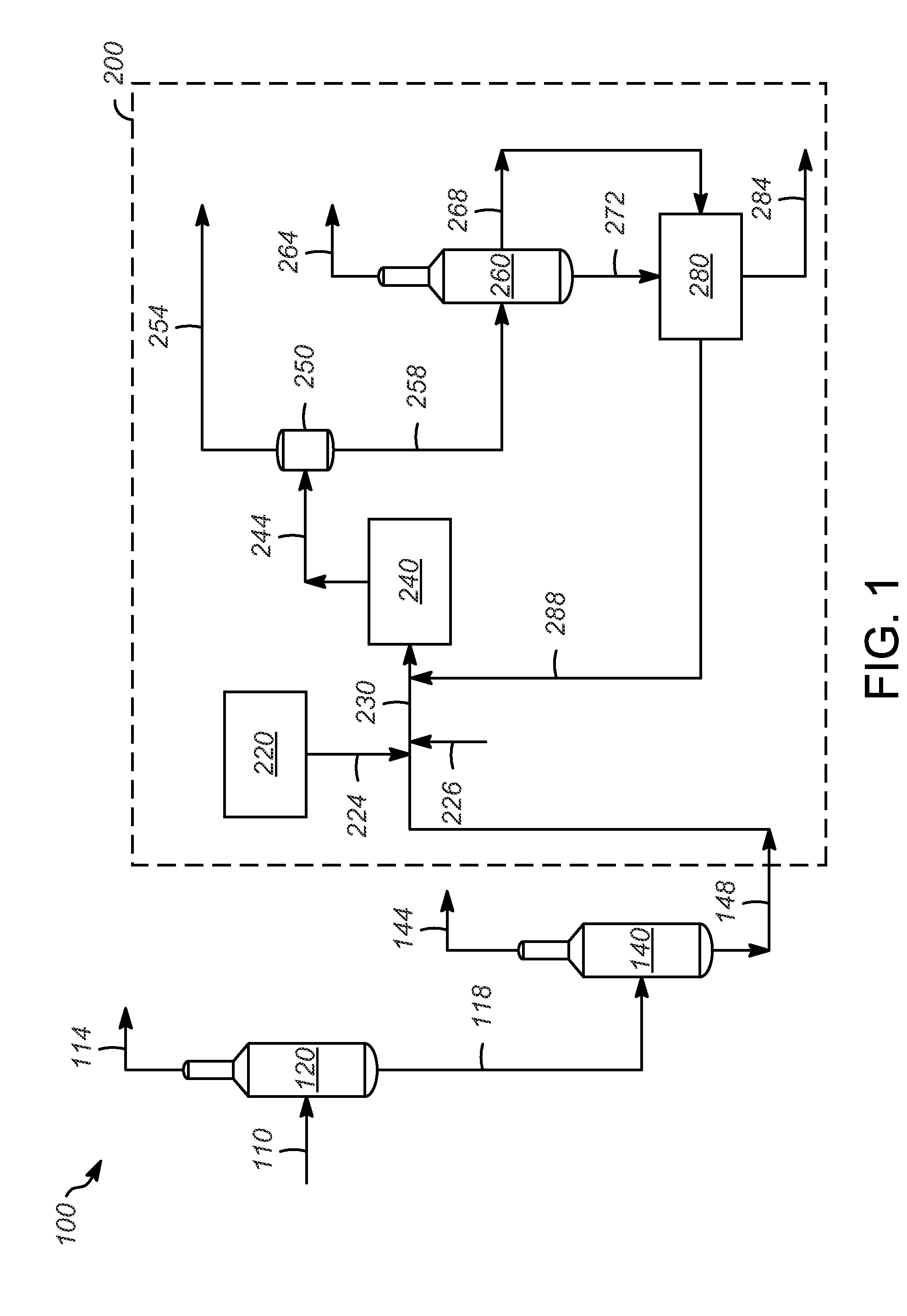

Methods and systems for upgrading heavy oil using catalytic hydrocracking and thermal coking

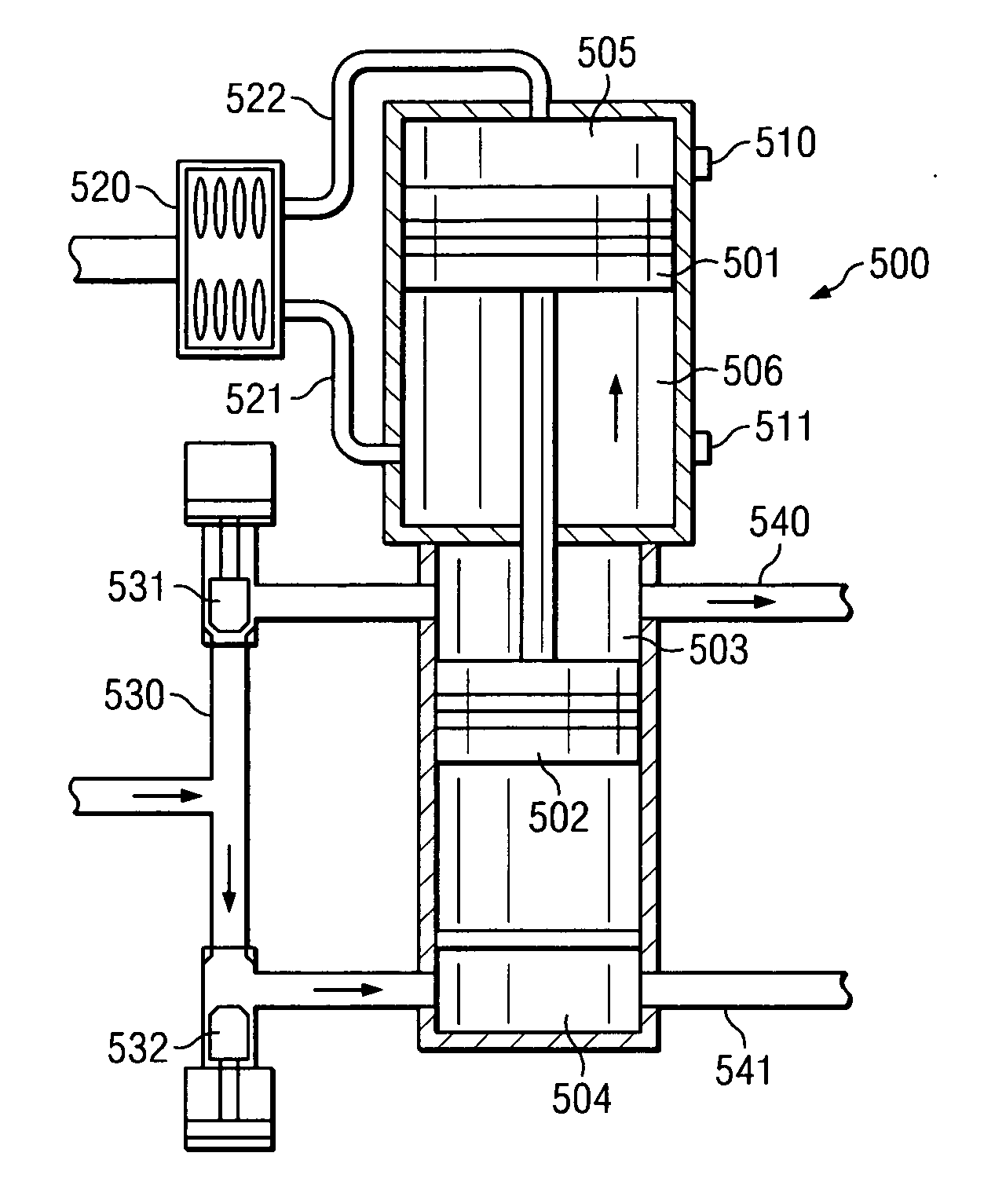

ActiveUS20140027344A1Speed up the conversion processImprove distillation yieldThermal non-catalytic crackingCatalyst activation/preparationHydrogenBoiling point

Methods and systems for hydroprocessing heavy oil feedstocks to form upgraded material use a colloidal or molecular catalyst dispersed within heavy oil feedstock, pre-coking hydrocracking reactor, separator, and coking reactor. The colloidal or molecular catalyst promotes upgrading reactions that reduce the quantity of asphaltenes or other coke forming precursors in the feedstock, increase hydrogen to carbon ratio in the upgraded material, and decrease boiling points of hydrocarbons in the upgraded material. The methods and systems can be used to upgrade vacuum tower bottoms and other low grade heavy oil feedstocks. The result is one or more of increased conversion level and yield, improved quality of upgraded hydrocarbons, reduced coke formation, reduced equipment fouling, processing of a wider range of lower quality feedstocks, and more efficient use of supported catalyst if used with the colloidal or molecular catalyst, as compared to a conventional hydrocracking process or a conventional thermal coking process.

Owner:HEADWATERS TECH INNOVATION LLC

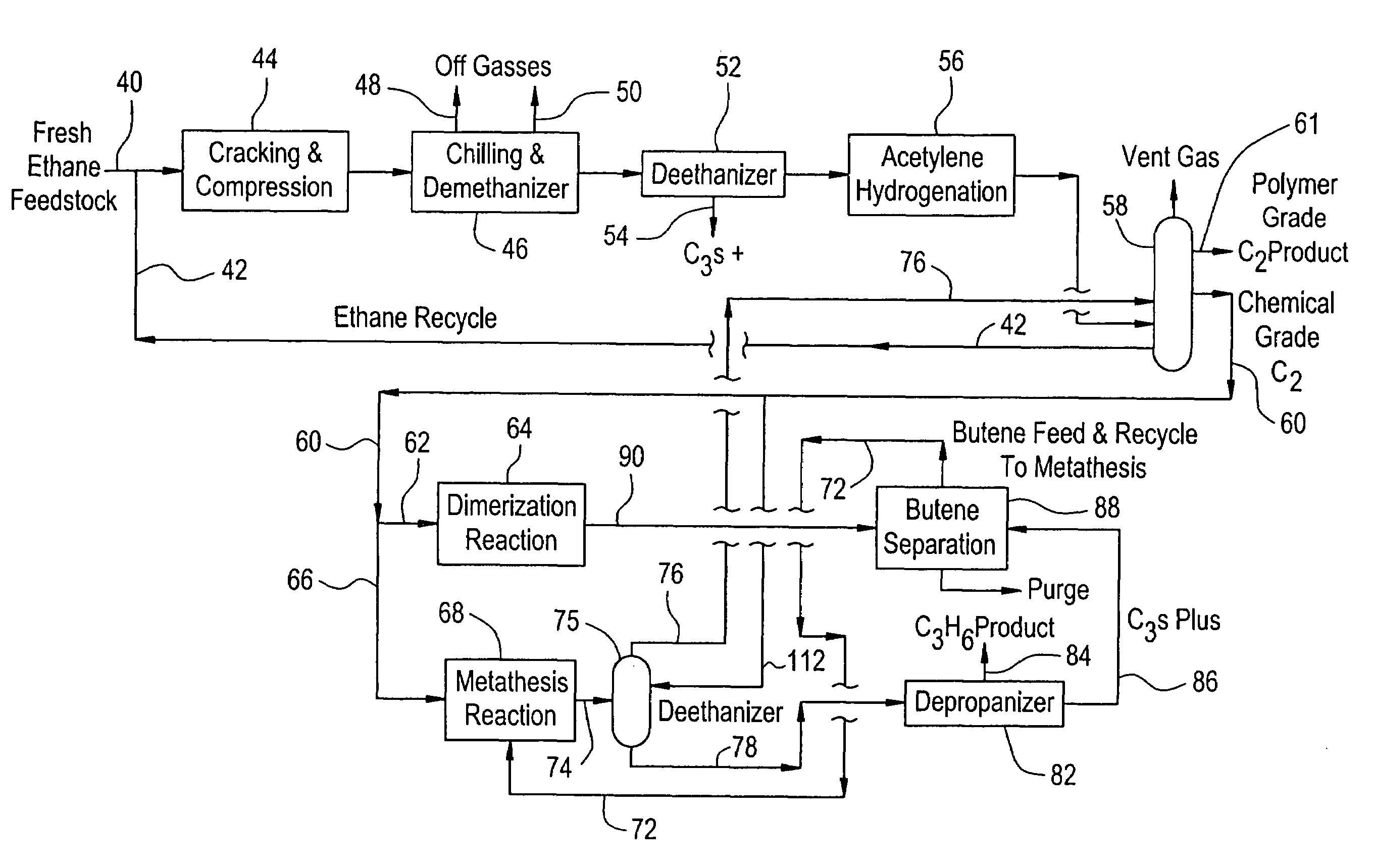

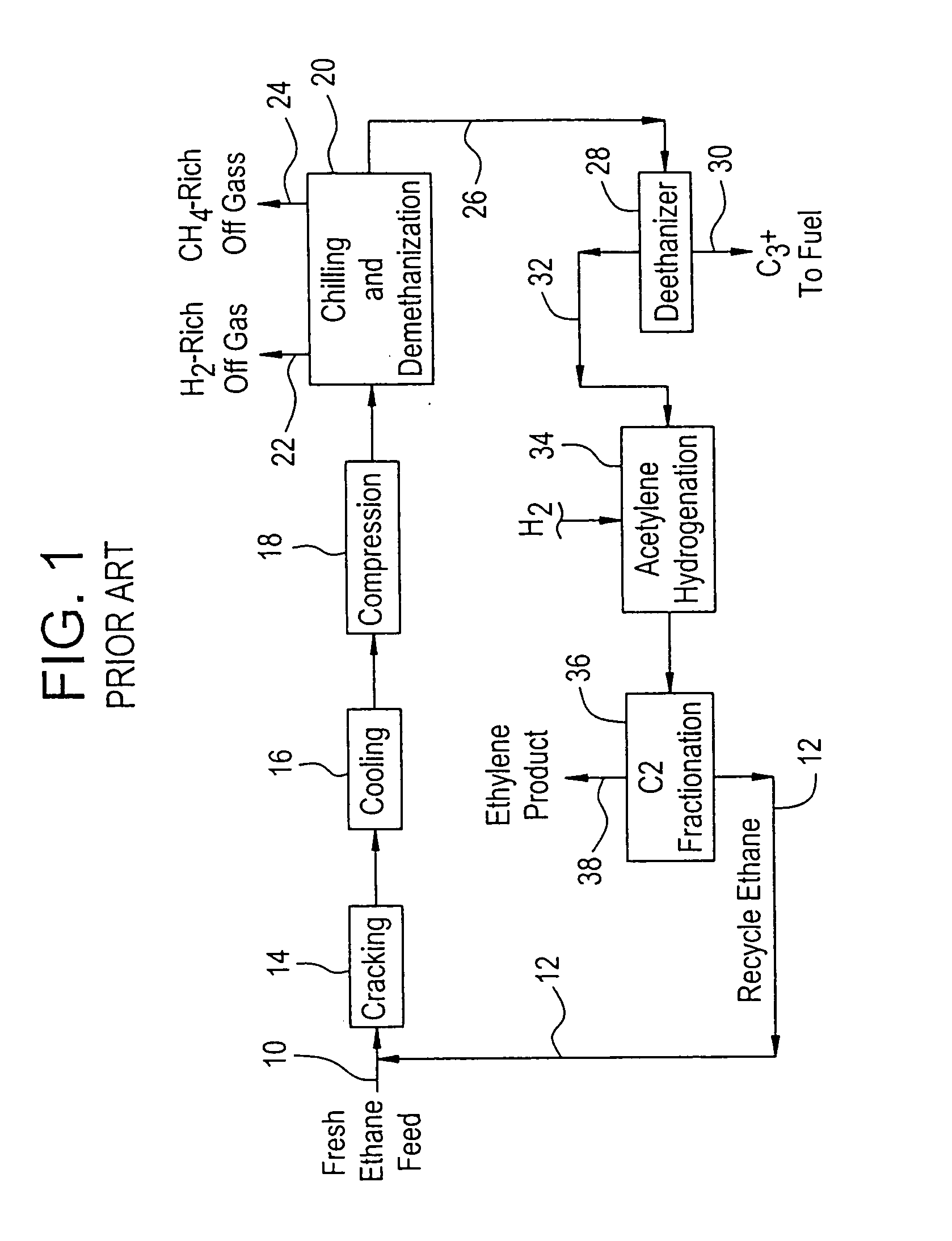

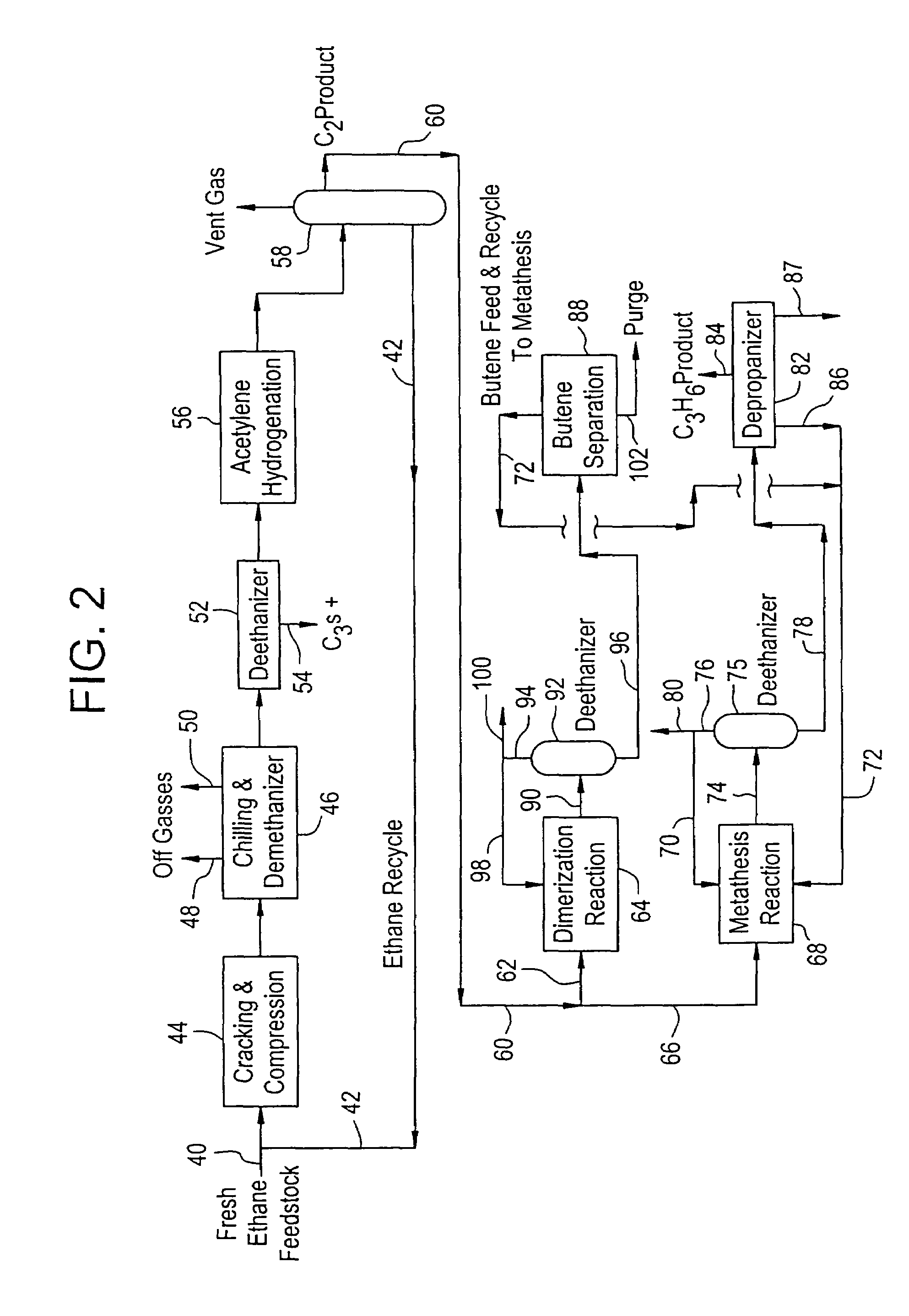

Production of propylene from steam cracking of hydrocarbons, particularly ethane

ActiveUS7223895B2Thermal non-catalytic crackingHydrocarbons from unsaturated hydrocarbon additionButenePolymer science

An ethane or other hydrocarbon feedstock is steam cracked to produce an ethylene stream which is processed in an ethylene plant recovery section to separate an ethane recycle and a polymer grade or chemical grade ethylene product stream. A portion of the ethylene product stream may then be reacted by dimerization to produce a butene stream. These formed butenes and / or butenes recovered from other sources and another portion of the ethylene product stream are reacted by metathesis to produce a propylene stream which is deethanized and separated from heavier hydrocarbons to produce the propylene product. The butene product stream may also be deethanized and is separated from heavier hydrocarbons. The overhead from the metathesis section deethanizer may be recycled to the ethylene plant recovery section. The reflux for the metathesis section deethanizer may be generated from the overhead or may be a portion of the ethylene product stream.

Owner:ABB LUMMUS GLOBAL INC

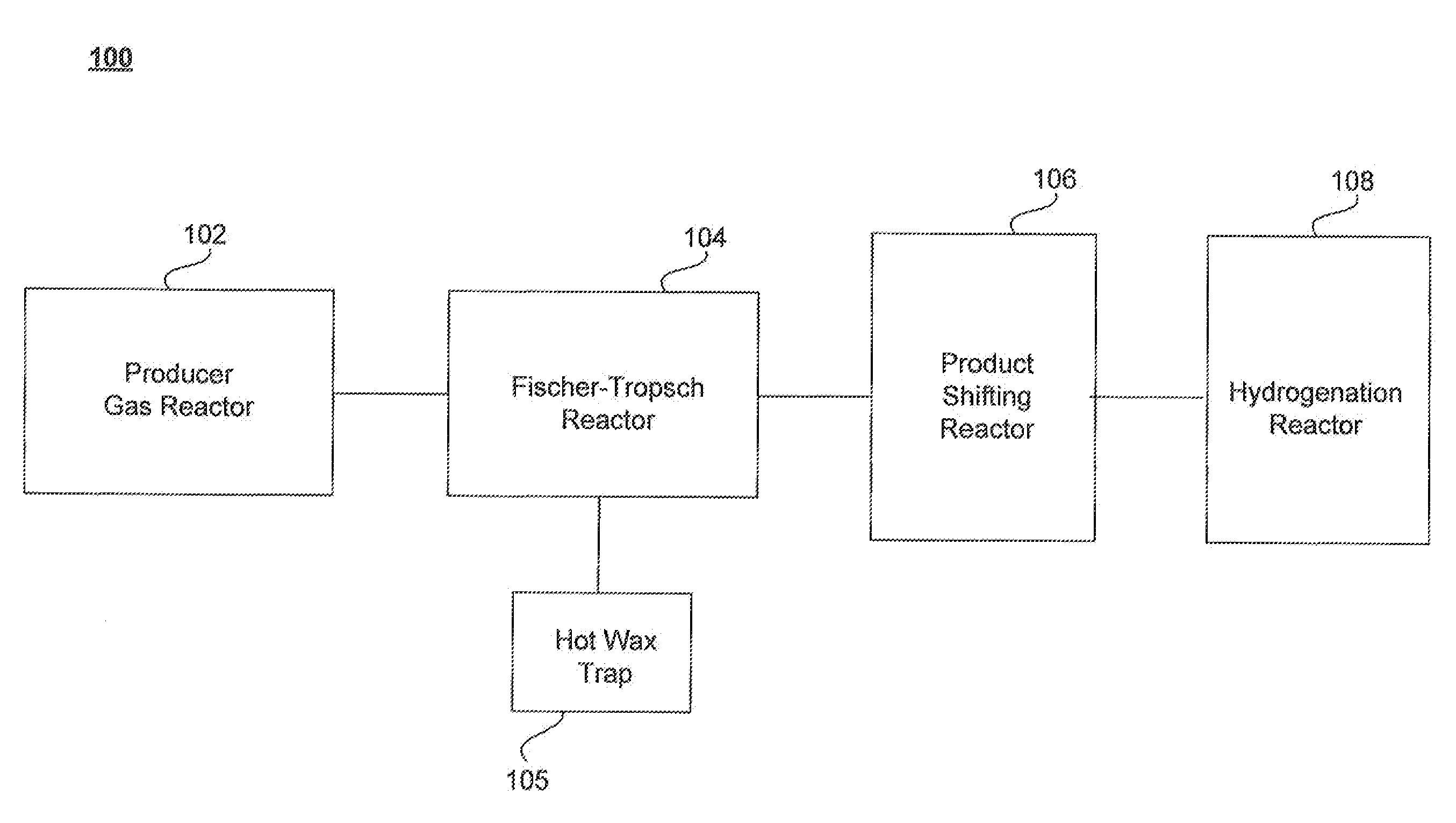

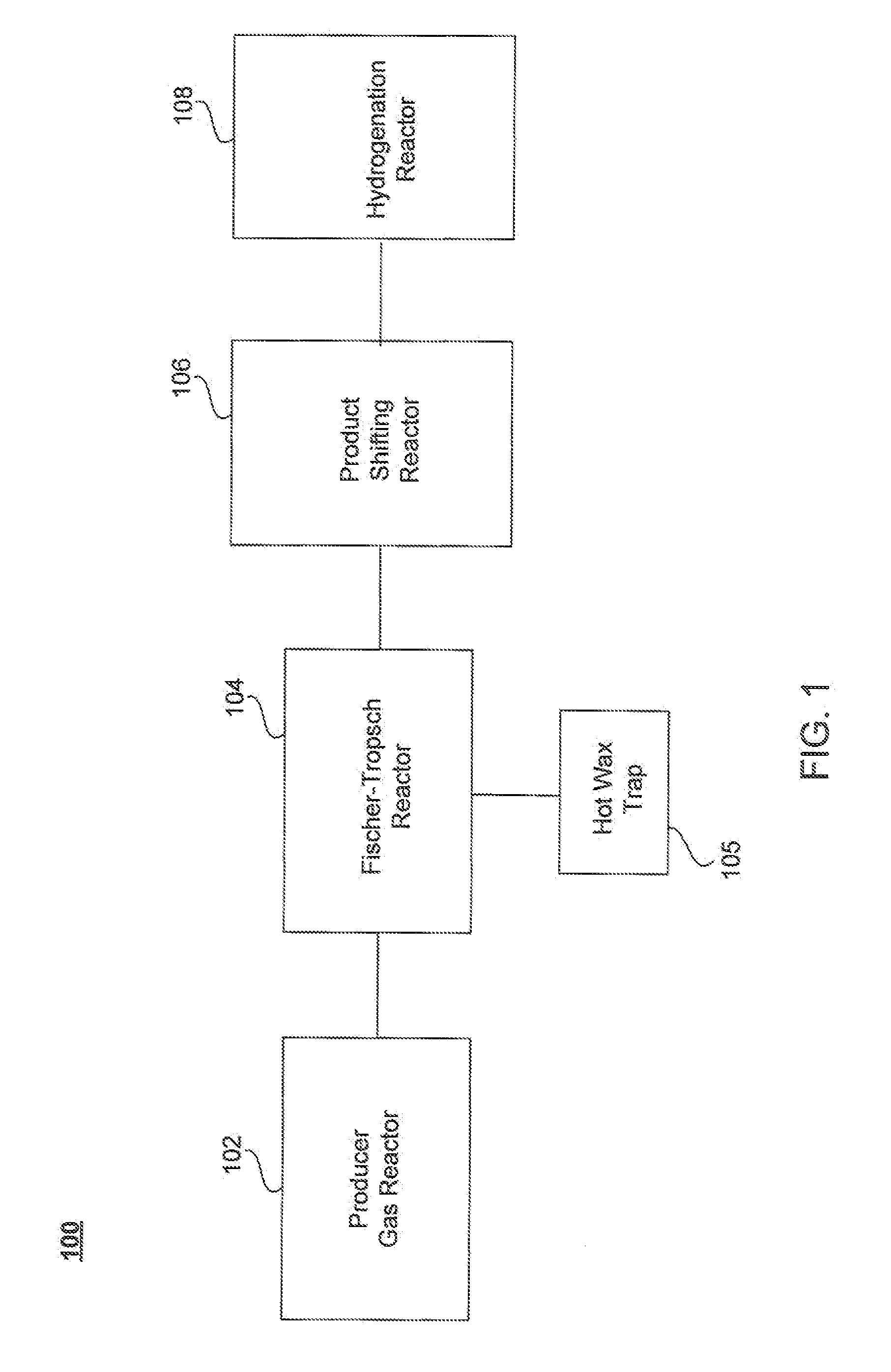

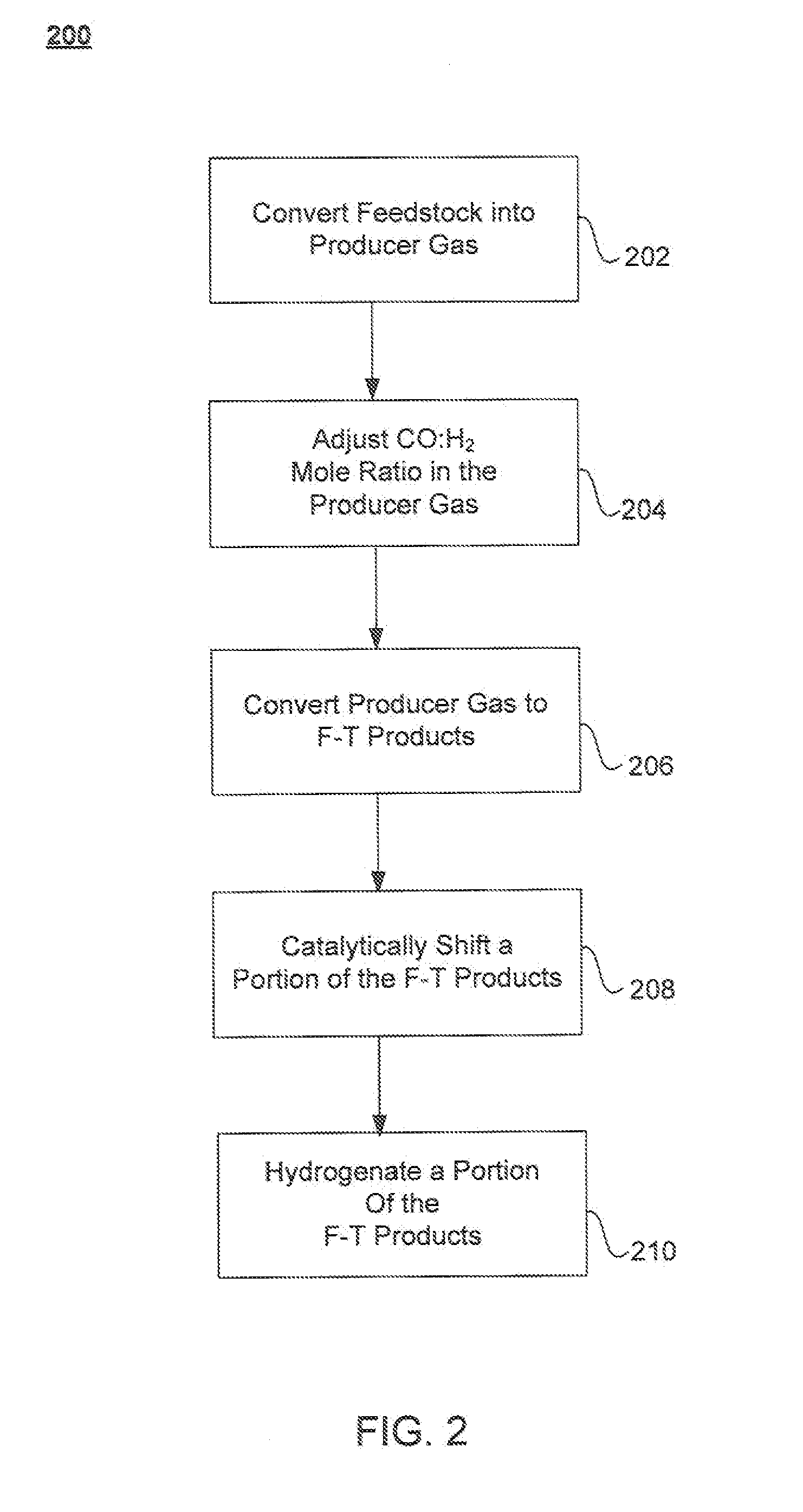

Conversion of biomass feedstocks into hydrocarbon liquid transportation fuels

InactiveUS20100036181A1Reducing and even eliminating transportationReducing and even eliminating and distribution costLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesProduct gasHydrocarbon

Methods for converting a carbon-containing feedstock into a fluid transportation fuel are described. The methods may include converting the carbon-containing feedstock into a producer gas comprising H2, CO, CO2, and N2, and reacting the producer gas with a substrate catalyst to produce a combination of Fischer-Tropsch (F-T) products, the F-T products including the fluid transportation fuel. A portion of the F-T products may be catalytically cracked to produce additional amounts of the fluid transportation fuel. A portion of the F-T products may also be hydrogenated to produce additional amounts of the fluid transportation fuel. Apparatuses are also described or converting a carbon-containing feedstock into a fluid transportation fuel. The apparatuses may include a producer gas reactor, a Fischer-Tropsch reactor, a cracking reactor, and a hydrogenation reactor.

Owner:COMMUNITY POWER CORP

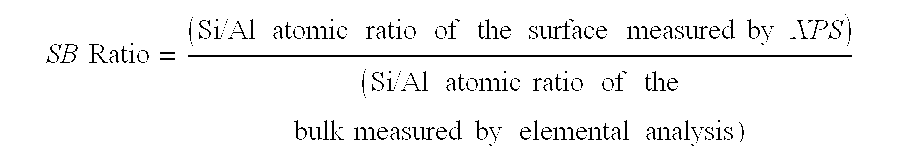

Extremely low acidity USY and homogeneous, amorphous silica-alumina hydrocracking catalyst and process

InactiveUS6902664B2High catalytic activityLow pollution rateMolecular sieve catalystsRefining to change hydrocarbon structural skeletonSingle stageAmorphous silica-alumina

A catalyst composition comprising a minor amount of a low acidity, highly dealuminated ultra stable Y zeolite having an Alpha value of less than about 5, preferable less than about 3 and Broensted acidity measured by FT-IR from about 1 to about 20, preferably from about 1-10, micro mole / g of, a homogeneous, amorphous silica-alumina cracking component having an SB ratio of from about 0.7 to about 1.3, wherein a crystalline alumina phase is present in an amount of no greater than about 10%, preferably no greater than 5% and a catalytic amount of hydrogenation component selected from the group consisting of a Group VI metal, a Group VIII metal, and mixtures thereof is disclosed. The present invention provides for a process for converting hydrocarbonaceous oils comprising contacting the hydrocarbonaceous oils with the catalyst under suitable hydrocarbon conversion conditions. Such processes in include, but are not limited to, single stage hydrocracking, two-stage hydrocracking, series-flow hydrocracking, mild hydrocracking, lube hydrocracking, hydrotreating, lube hydrofinishing, hydrodesulphurization, hydrodenitrification, catalytic dewaxing and catalytic cracking.

Owner:CHEVROU USA INC

Process for producing light olefins and aromatics

ActiveUS20090288985A1High yield of propyleneTreatment with plural serial cracking stages onlyCatalytic crackingPropeneXylene

A process for producing light olefins and aromatics, which comprises reacting a feedstock with a catalytic cracking catalyst in at least two reaction zones, wherein the reaction temperature of at least one reaction zone downstream of the first reaction zone is higher than that of the first reaction zone and its weight hourly space velocity is lower than that of the first reaction zone. The spent catalyst is separated from the reaction product vapor, regenerated and then returned to the reactor. The reaction product vapor is separated to obtain the desired products, light olefins and aromatics. This process efficiently produces light olefins such as propylene, ethylene, etc. from heavy feedstocks, wherein the yield of propylene exceeds 20% by weight, and produces aromatics such as toluene, xylene, etc. at the same time.

Owner:CHINA PETROCHEMICAL CORP +1

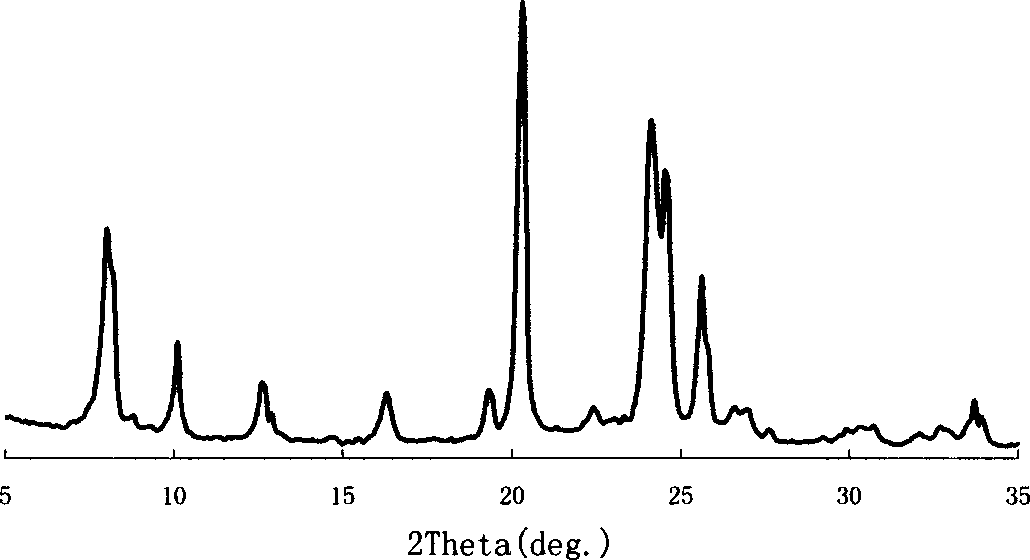

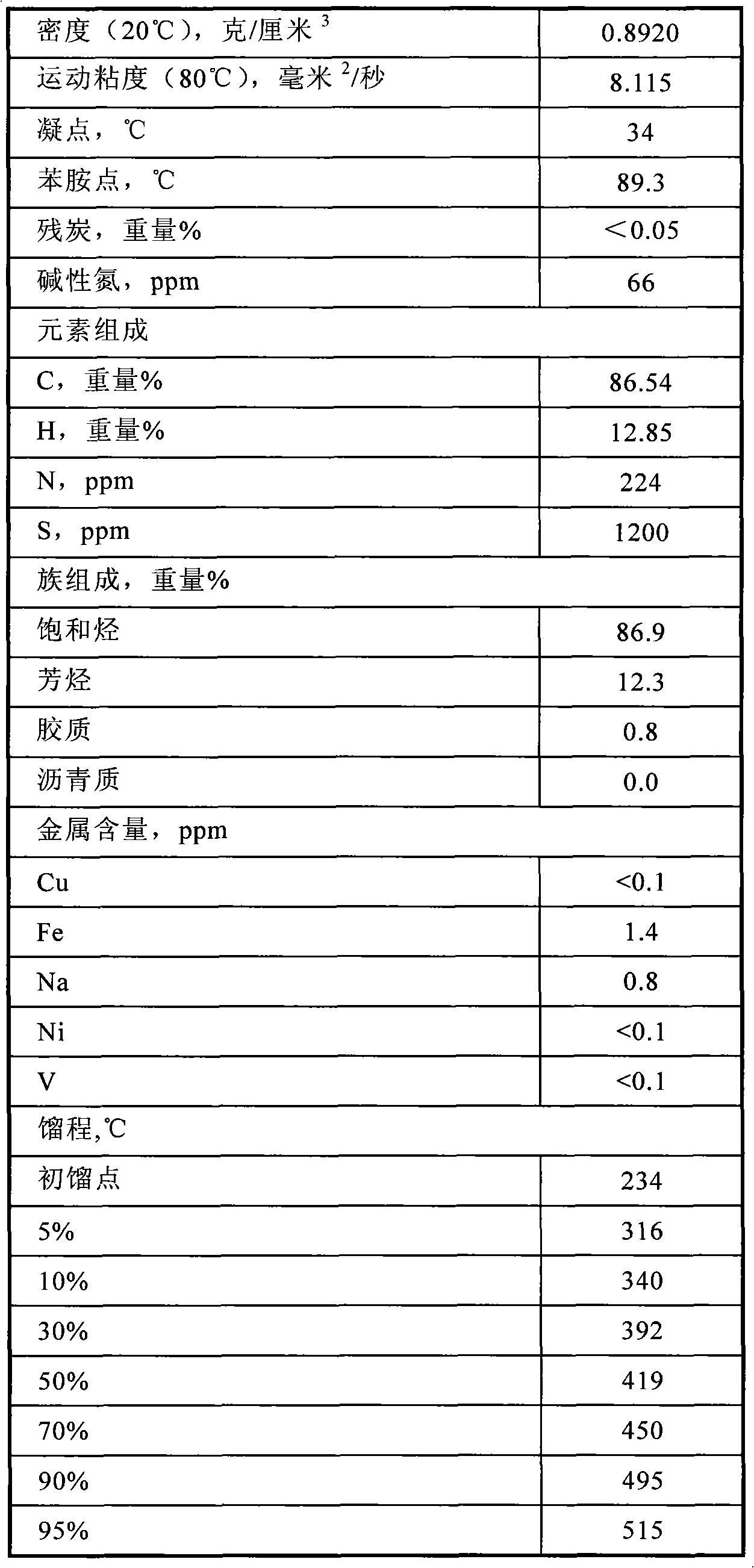

Hydrocracking catalyst and preparation method thereof

ActiveCN103100417AHigh selectivityLarge freezing pointMolecular sieve catalystsHydrocarbon oil crackingAlkaneMolecular sieve

The invention discloses a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst comprises: a carrier composed of a modified beta molecular sieve, a modified Y type molecular sieve and alumina, and hydrogenation active metal components. Specifically, the modified beta molecular sieve is prepared by: subjecting a crystallized beta molecular sieve slurry directly to ammonium exchange and a template agent removal treatment, then first conducting a hydrothermal treatment, and performing an aluminum salt solution treatment, under the condition of maintaining a high beta molecular sieve crystallinity, removing part of non-framework aluminum uniformly, thus obtaining the beta molecular sieve with the characteristics of high Si / Al ratio, large specific surface area, appropriate acidity and acid distribution, and reasonable structure, etc. The modified beta molecular sieve especially has a suitable cracking effect and a very good isomerization effect on long-chain alkane and the long side chain alkyl of aromatic hydrocarbon and cyclane, and has a synergistic effect with the Y type molecular sieve, so that the hydrocracking catalyst can have very high catalytic activity and middle distillate selectivity. And the condensation point of diesel fraction is substantially reduced, and the product properties of middle distillate are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

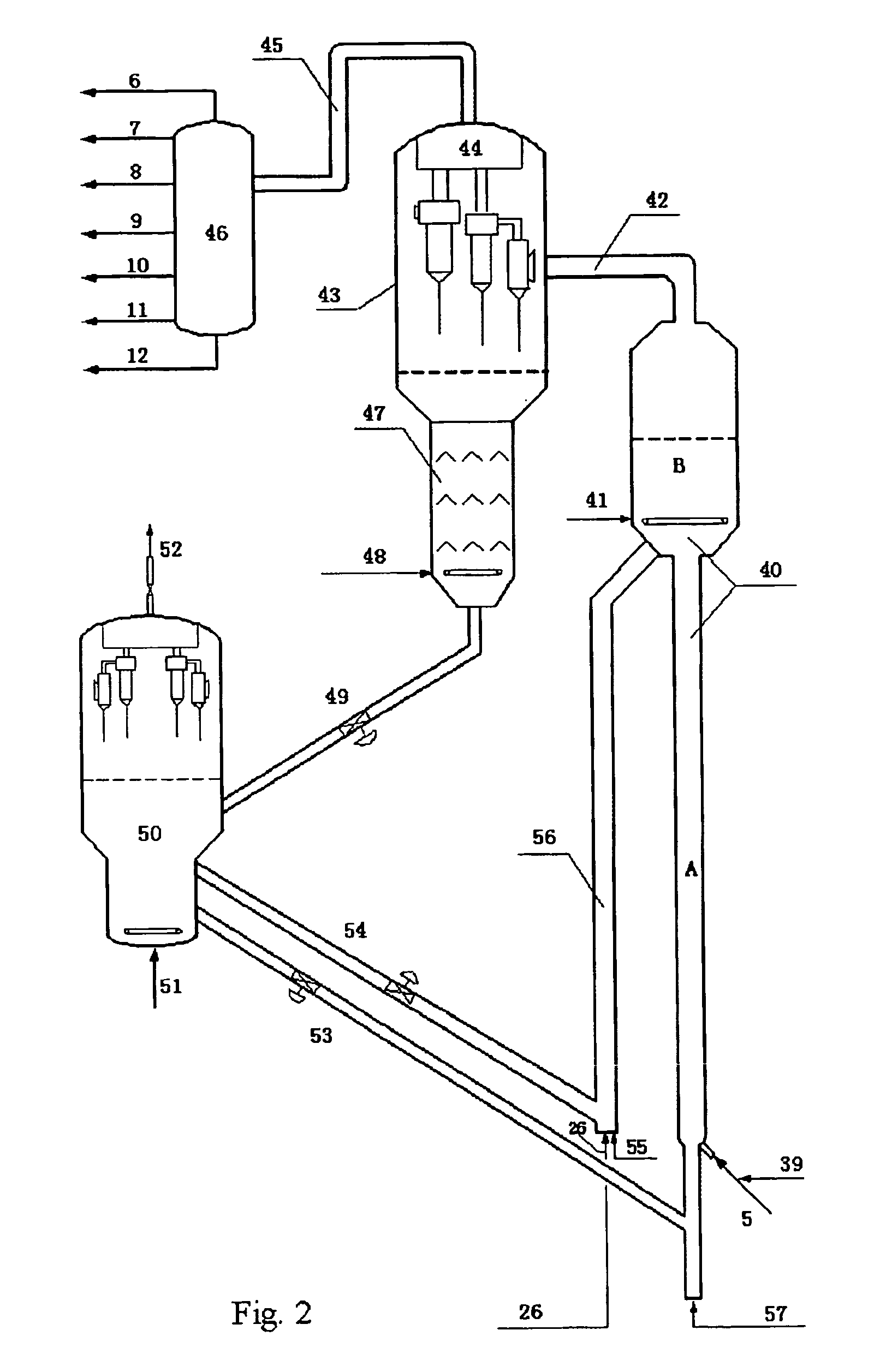

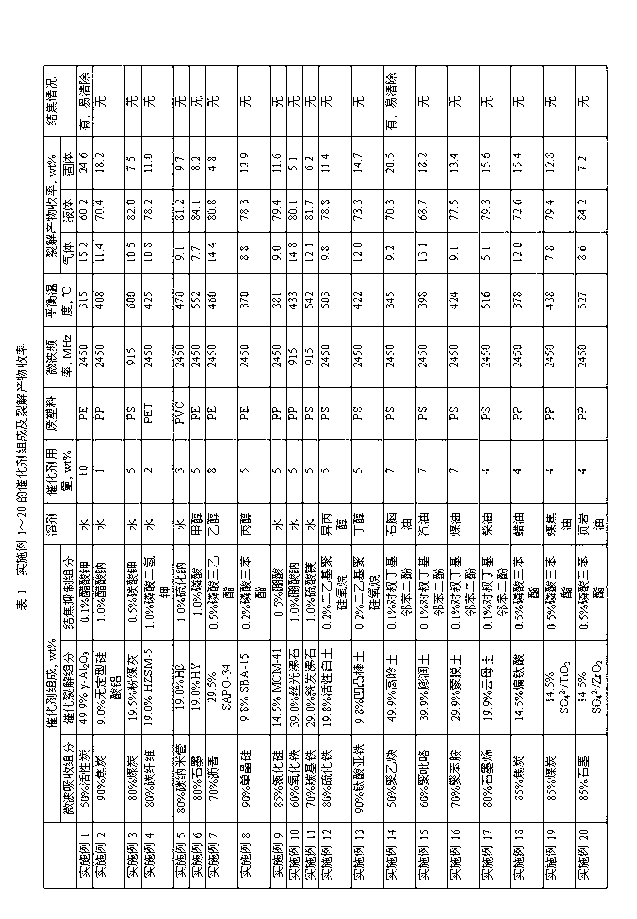

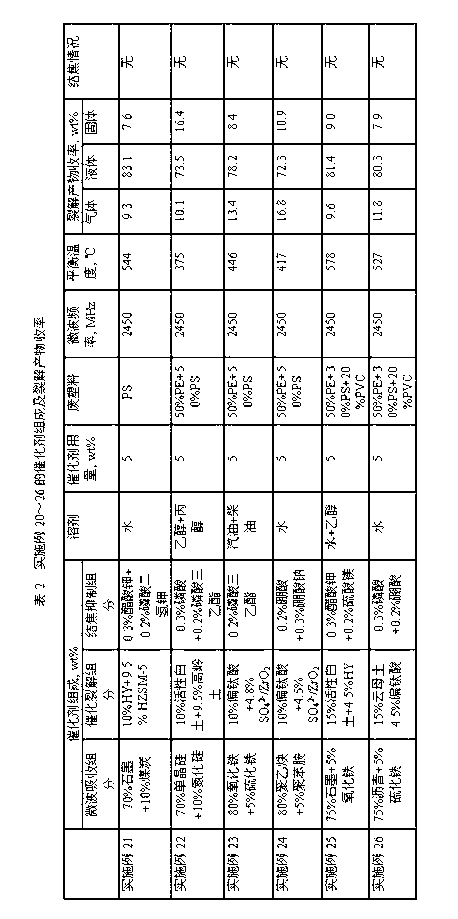

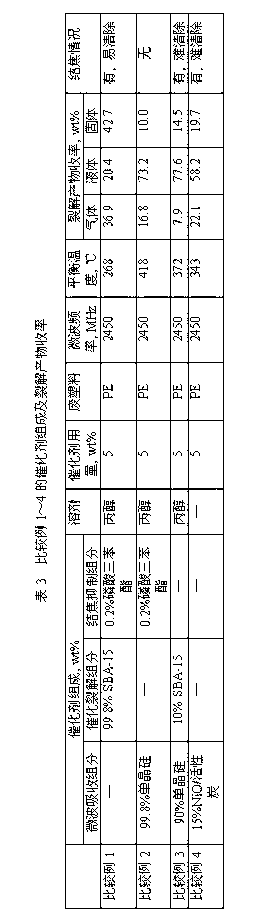

Catalyst for waste plastic microwave pyrolysis and preparation method thereof

InactiveCN103252226AEasy to prepareHigh yieldMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMicrowave pyrolysisPtru catalyst

The invention discloses a catalyst for waste plastic microwave pyrolysis and a preparation method thereof. The catalyst comprises the following components by mass percent: 50.0-90.0% of a microwave absorption component, 9.0-49.9% of a catalytic cracking component, and 0.1-1.0% of a coking inhibiting component. The invention also discloses the preparation method of the catalyst. Compared with the prior art, the catalyst has the advantages that firstly, the catalyst has multiple functions, can effectively convert the microwave electromagnetic energy into heat, provides necessary energy for waste plastic pyrolysis and catalytic cracking, and can reach high equilibrium temperature in action; secondly, the yield of liquid pyrolysis oil is high, no coke is generated in the pyrolysis or the coke is loose and is easy to clear away; and thirdly, the preparation method of the catalyst is simple and is applicable to industrial production.

Owner:王文平 +2

System for improving crude oil

InactiveUS20060231462A1Increase heightEnhancing crude oilThermal non-catalytic crackingSemi-permeable membranesAPI gravityFiltration

Crude oil can be refined through a filtration media. Cavitation bubbles having localized areas of very high temperatures and pressures may be created thereby causing several physical and chemical phenomena, including thermal cracking of carbon-carbon bonds as the crude moves through the flux cartridge membrane. Heavy hydrocarbons are residues are thereby cracked into smaller lowering boiling molecules having a higher API gravity. Once the relatively smaller hydrocarbons pass through the flux cartridge membrane into the flux cartridge, the effluent can be routed to a second separator annulus. It should also be pointed out that lighter hydrocarbons formed can volatilize and special provisions may be needed to efficiently capture these gases.

Owner:LJC TECH

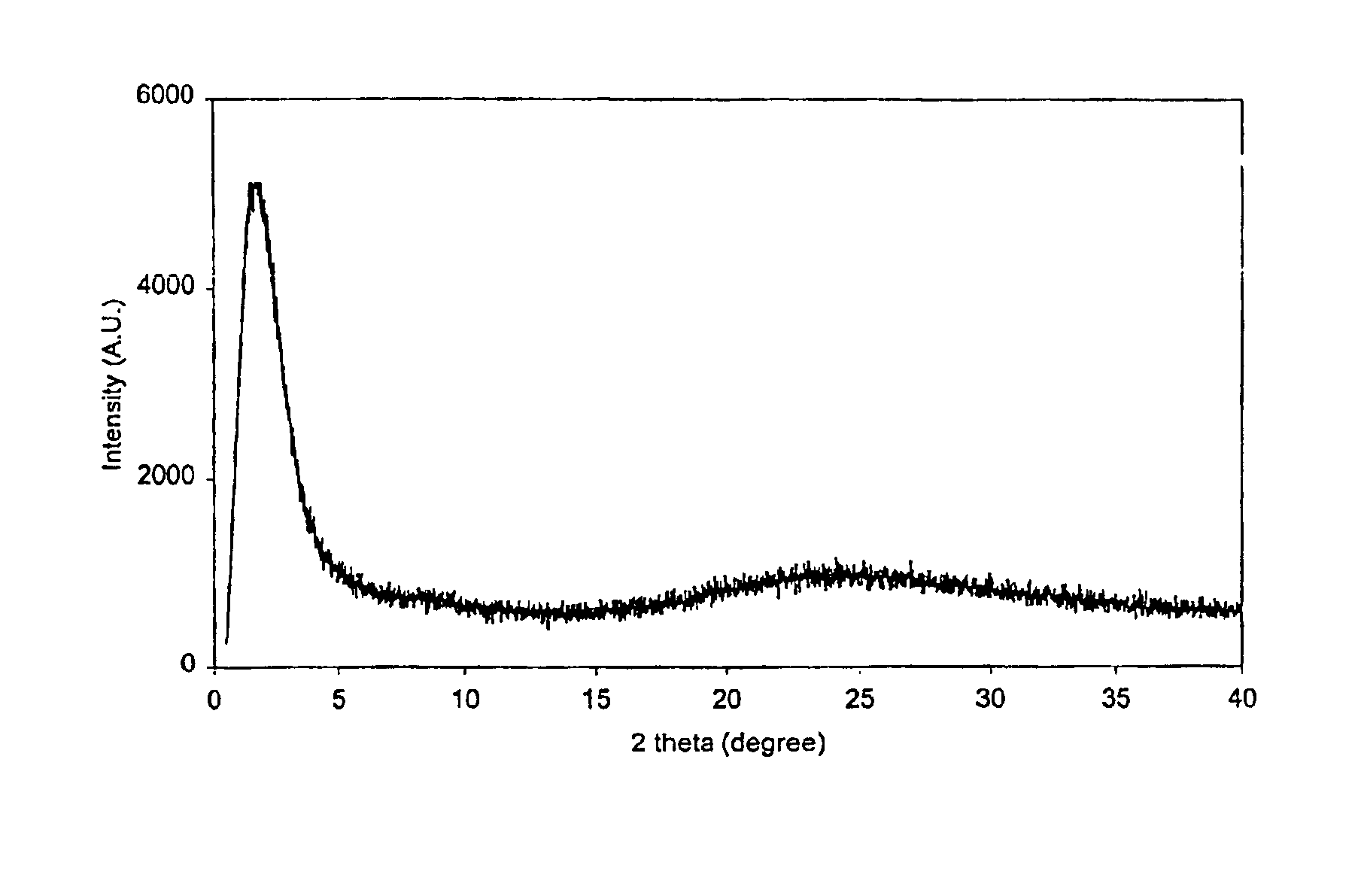

Mesoporous material with active metals

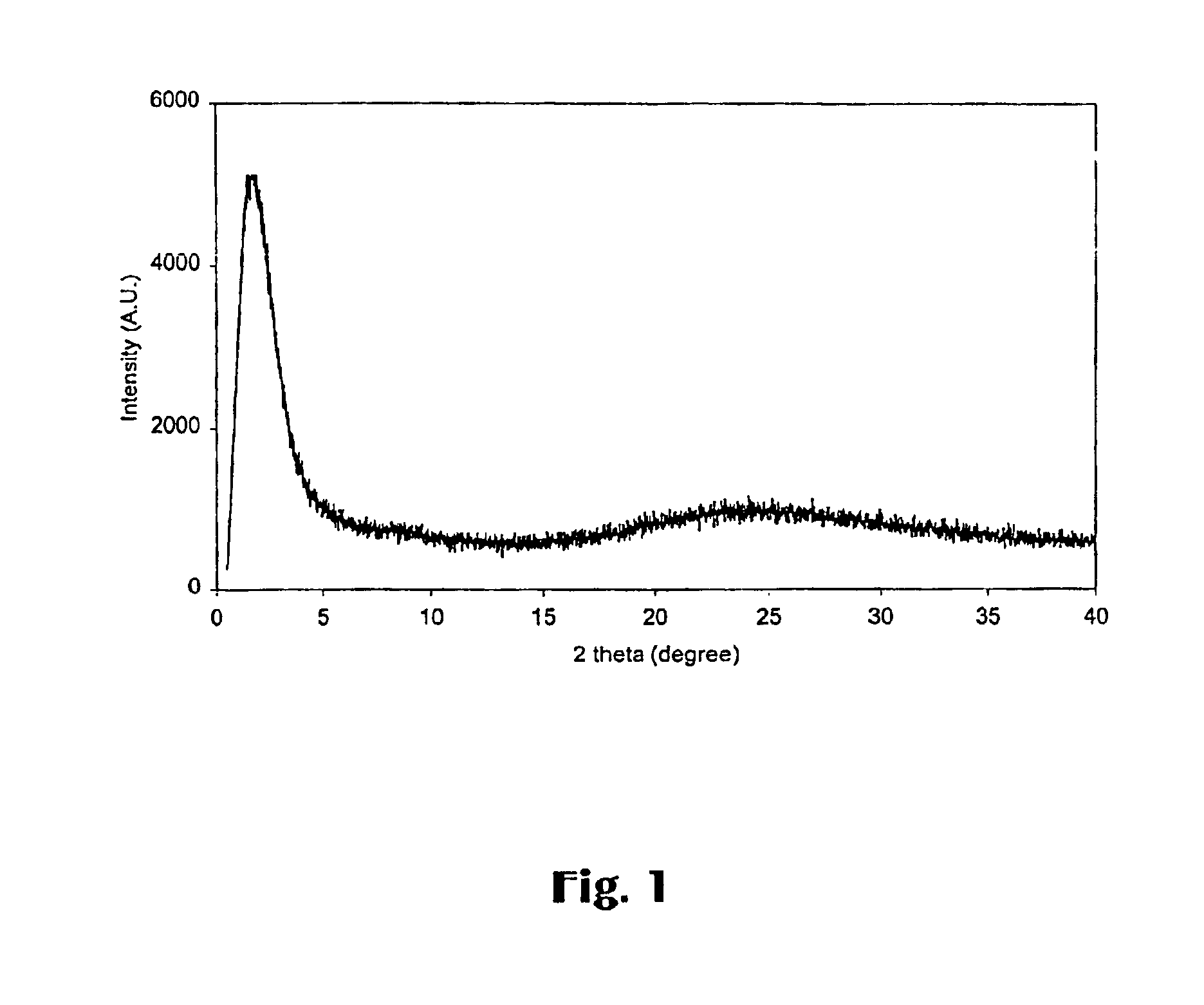

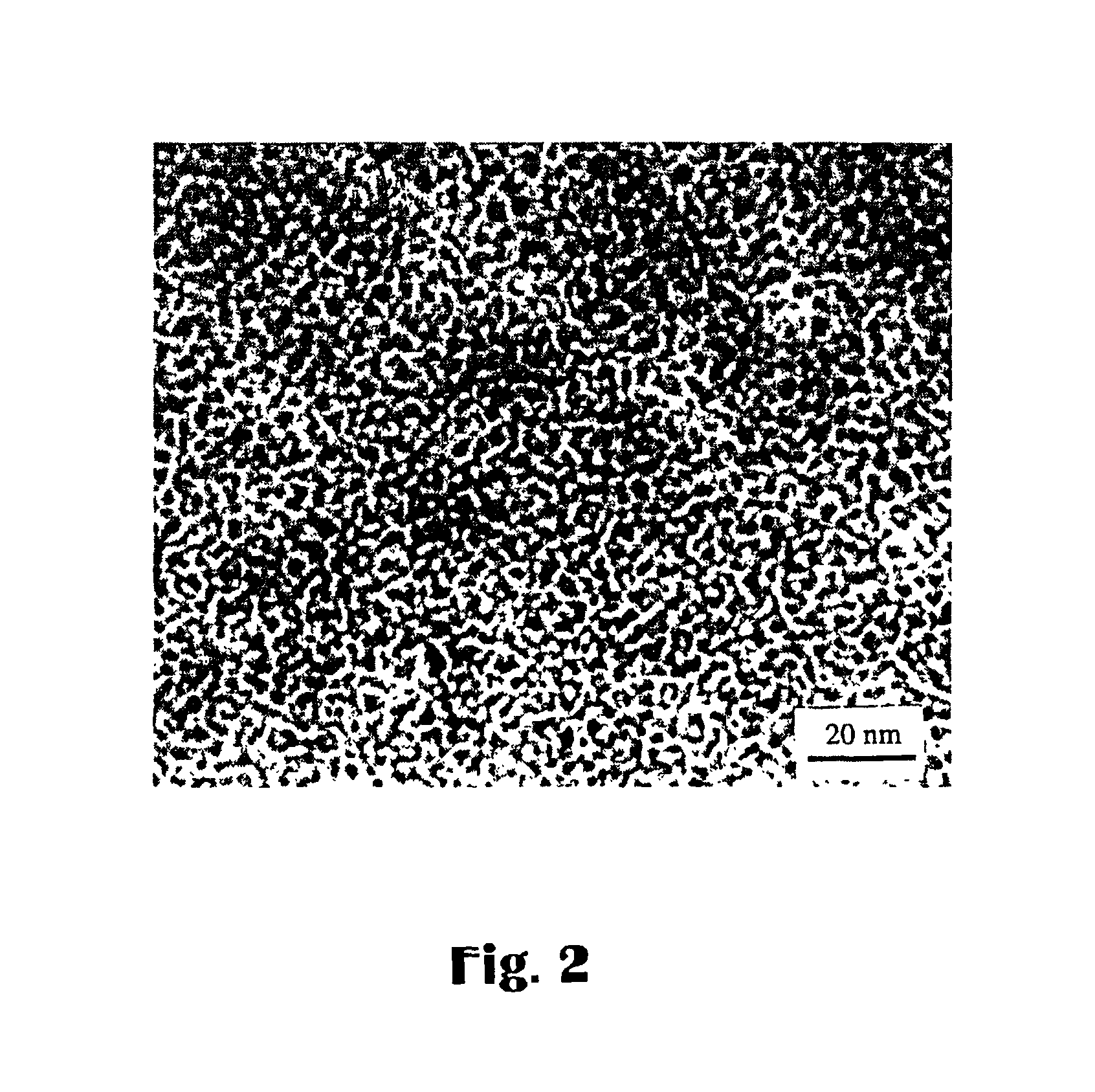

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:ABB LUMMUS GLOBAL INC

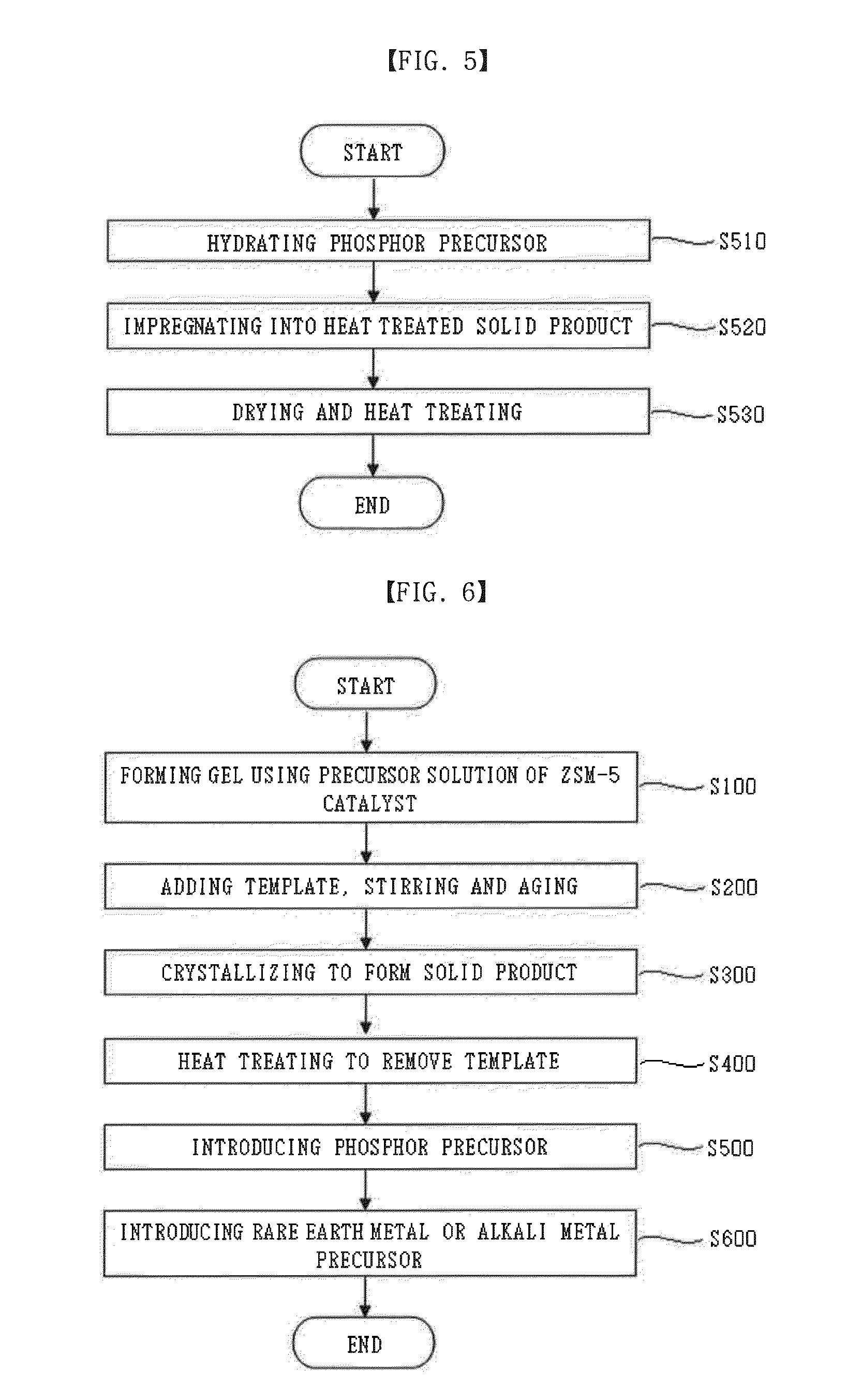

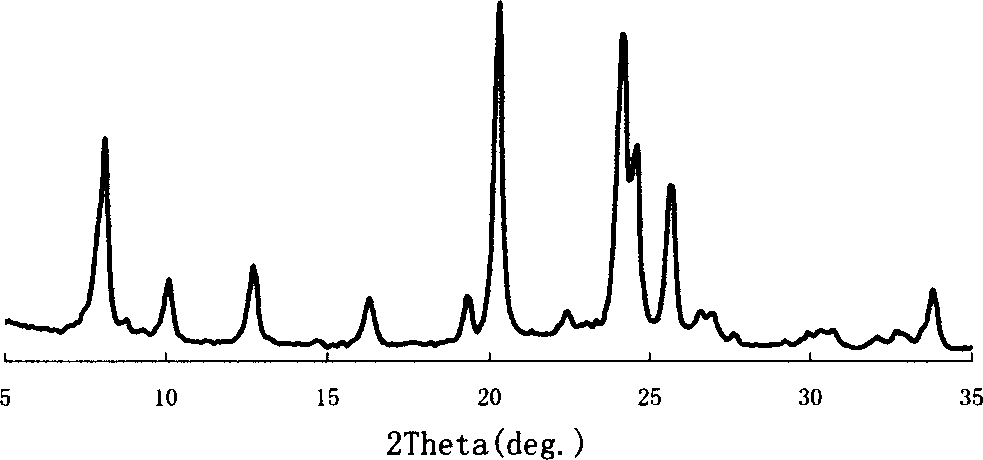

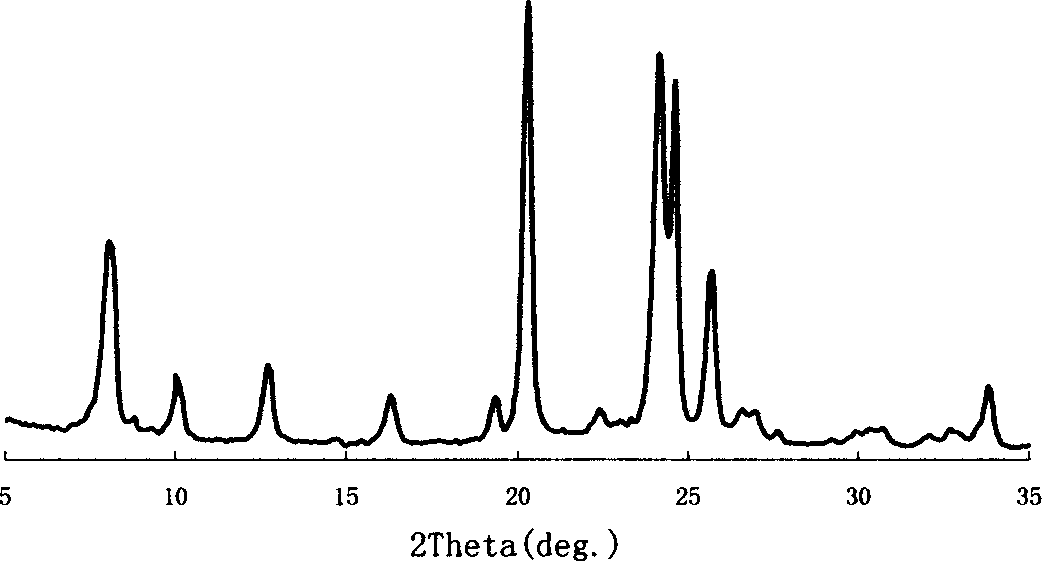

ZSM-5 catalyst with micropores and mesopores, preparation method thereof and production method of light olefins through catalytic cracking of hydrocarbons using the catalyst

InactiveUS20130085311A1Increase productionImprove featuresTreatment with plural serial cracking stages onlyCatalytic crackingHydrocarbon mixturesNaphtha

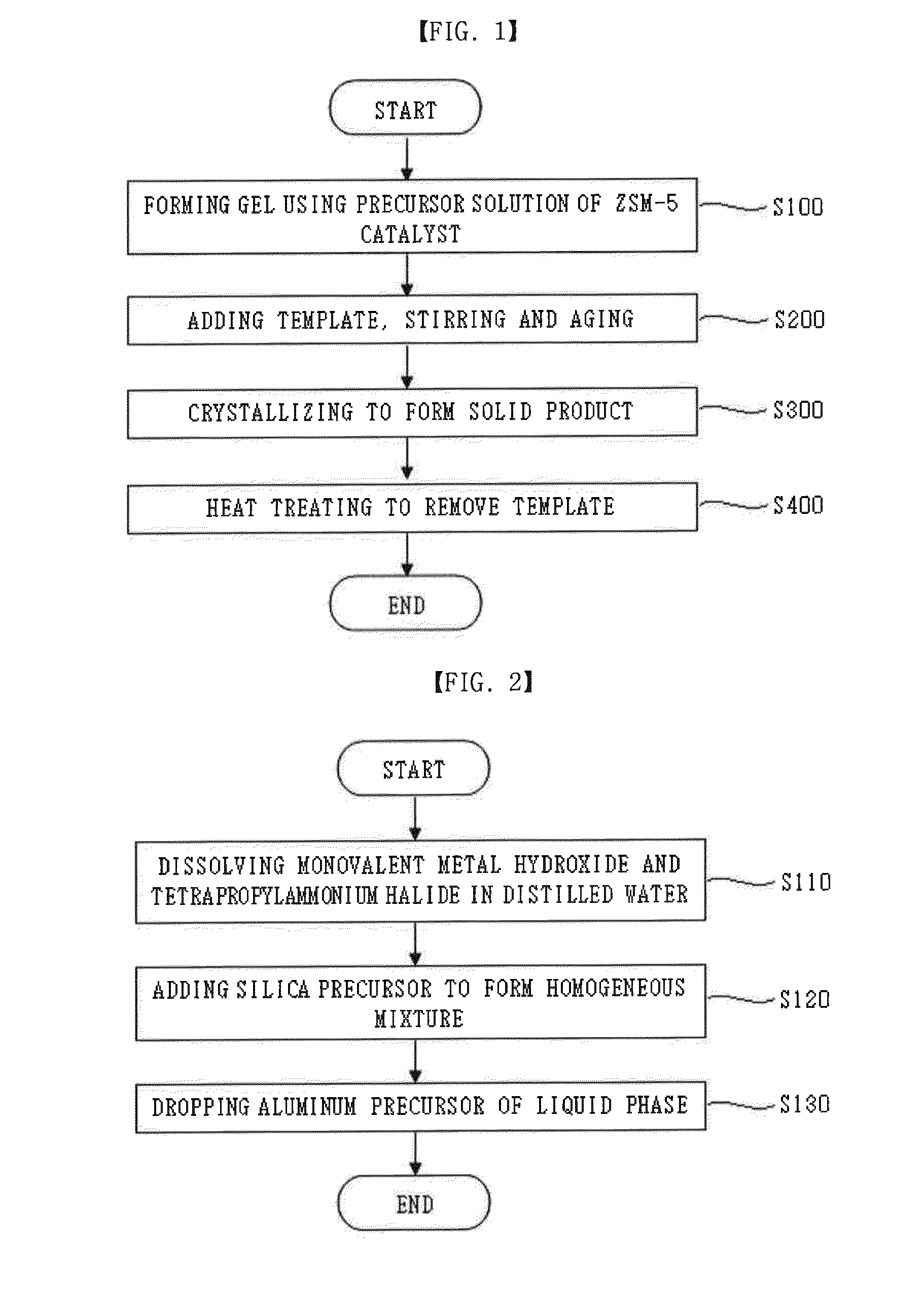

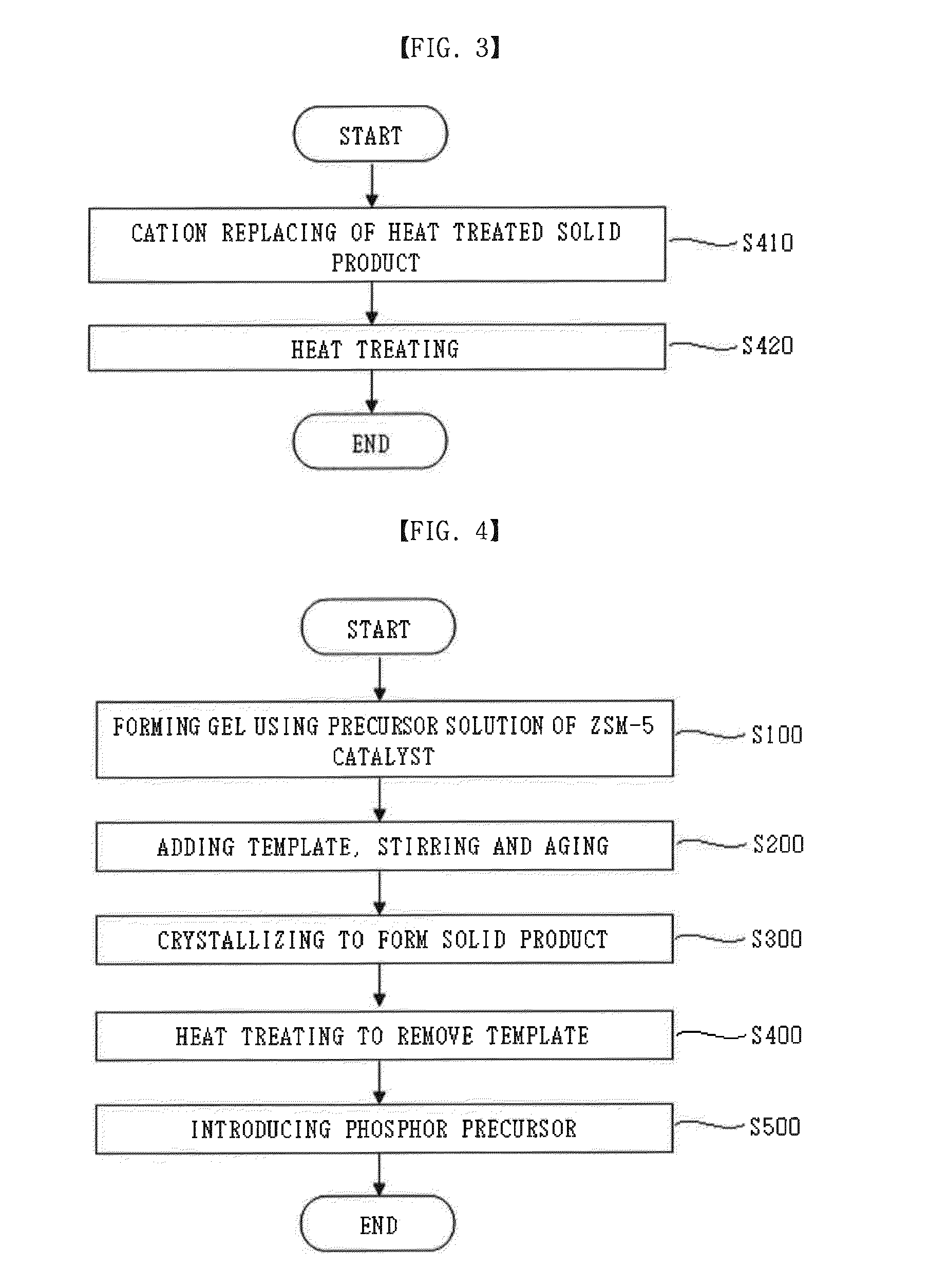

Provided is a method of preparing a ZSM-5 catalyst for preparing light olefins including ethylene and propylene through a catalytic cracking of a hydrocarbon mixture of C4 to C7 produced after a naphtha cracking. The method includes (a) forming a gel by aging a mixture solution including a silica precursor and an aluminum precursor; (b) adding a template possibly forming mesopores through a heat treatment, into the gel, stirring and then aging; (c) forming a solid product by crystallizing the aged mixture in step (b); and (d) heat treating the solid product to remove the template. The ZSM-5 catalyst may include micropores and mesopores and may have good physical and chemical properties along with a good pore property. The production yield of the light olefins may be increased.

Owner:HONAM PETROCHEM

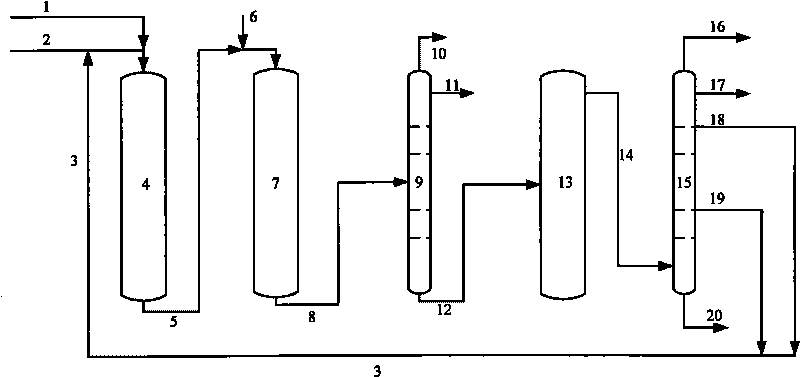

Process for producing lower olefins by using multiple reaction zones

ActiveUS20070038010A1Easy to processStable periodTreatment with plural serial cracking stages onlyCatalytic crackingReaction temperatureReaction zone

The present invention provides a process for producing lower olefins by catalytic cracking a feedstock comprising an olefins-enriched mixture containing C4 or higher olefins and optionally an organic oxygenate compound. The technical problem mainly addressed in the present invention is to overcome the defects presented in the prior art including low yield and selectivity of lower olefins as the target products, and short regeneration period of catalyst. The present process, which is carried out under the conditions of catalytic cracking olefins and adopts as a feedstock an olefins-enriched mixture containing one or more C4 or higher olefins and optionally an organic oxygenate compound, comprises the steps of: a) letting the feedstock firstly enter a first reaction zone to contact with a first crystalline aluminosilicate catalyst having a SiO2 / Al2O3 molar ratio of at least 10, to thereby produce a first reaction effluent containing lower olefins; b) letting the first reaction effluent enter in turn at least one second reaction zone to contact with a second crystalline aluminosilicate catalyst having a SiO2 / Al2O3 molar ratio of at least 10, to thereby produce a second reaction effluent containing lower olefins; and c) separating lower olefins from the second reaction effluent; wherein the reaction temperatures in the first and second reaction zones are controlled. The present process, which desirably solves the above technical problem, can be used in industrial production of lower olefins.

Owner:CHINA PETROCHEMICAL CORP +1

Slurry hydrocracking apparatus or process

InactiveUS20110303580A1Easy to separateAvoid disintegrationWorking-up pitch/asphalt/bitumenHydrocarbon oil crackingSlurryProcess engineering

One exemplary embodiment can include a slurry hydrocracking process. The process can include combining one or more hydrocarbons and a slurry hydrocracking catalyst as a feed to a slurry hydrocracking reaction zone, fractionating an effluent from the slurry hydrocracking reaction zone, separating the pitch from at least a portion of the slurry hydrocracking catalyst, and recycling the suspension to the slurry hydrocracking reaction zone. The slurry hydrocracking catalyst may include a support. Fractionating the effluent may provide a light vacuum gas oil, a heavy vacuum gas oil, and a mixture comprising a pitch and the slurry hydrocracking catalyst. Generally, the separated slurry hydrocracking catalyst is comprised in a suspension.

Owner:UOP LLC

Hydroprocessing catalyst and its prepn process

The present invention is hydroprocessing catalyst and its preparation process. The catalyst includes one kind of molecular sieve with TON type structure and active metal component, and the molecular sieve has the features of surface Si / Al ratio higher than the bulk Si / Al ratio, proper acidity and channel structure for paraffin hydrocarbon to generate shape-selective cracking-isomerizing reaction, etc. The catalyst is used in hydroprocessing intermediate fraction oil and heavy fraction product, and has the features of high activity, high isomerizing selectivity, low cracking performance, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons

ActiveCN101747935AImprove propertiesDoes not affect activityTreatment with hydrotreatment processesWaxResidual oil

The invention provides a method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons. The method produces qualified catalytic cracking raw materials through hydrogenation by taking wax oil and residual oil as raw materials, returns light cycle oil and heavy cycle oil which are catalytic cracking by-products to a hydrogenation unit for the catalytic cracking rawmaterials at the same time, hydrogenates the catalytic cracking by-products together with the catalytic cracking raw materials, and then takes the obtained product as the catalytic cracking raw materials to produce light olefins and monocyclic aromatic hydrocarbons. By introducing the residual oil before a second reaction zone of hydrogenation, the method widens the sources of the catalytic cracking raw materials, increases the processing amount of low-value residual oil, and solves the problem of the heat balance of catalytic cracking units. The light and heavy cycle oil of catalytic cracking is introduced into the hydrogenation unit, hydrogenated and then taken as the catalytic cracking raw materials, so that the yield of high-value products of the catalytic cracking units can be increased, and the deactivation of hydrogenation catalysts is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

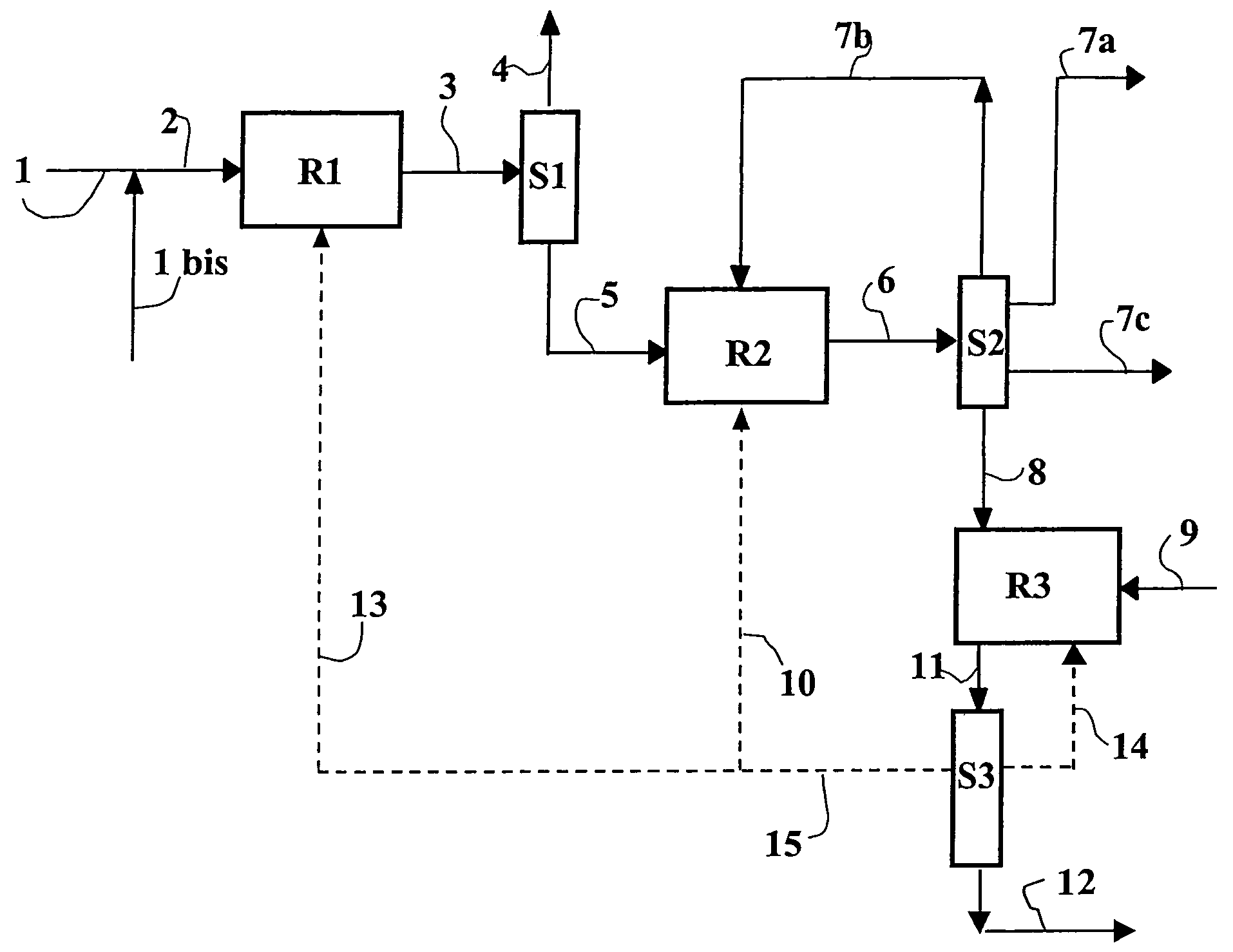

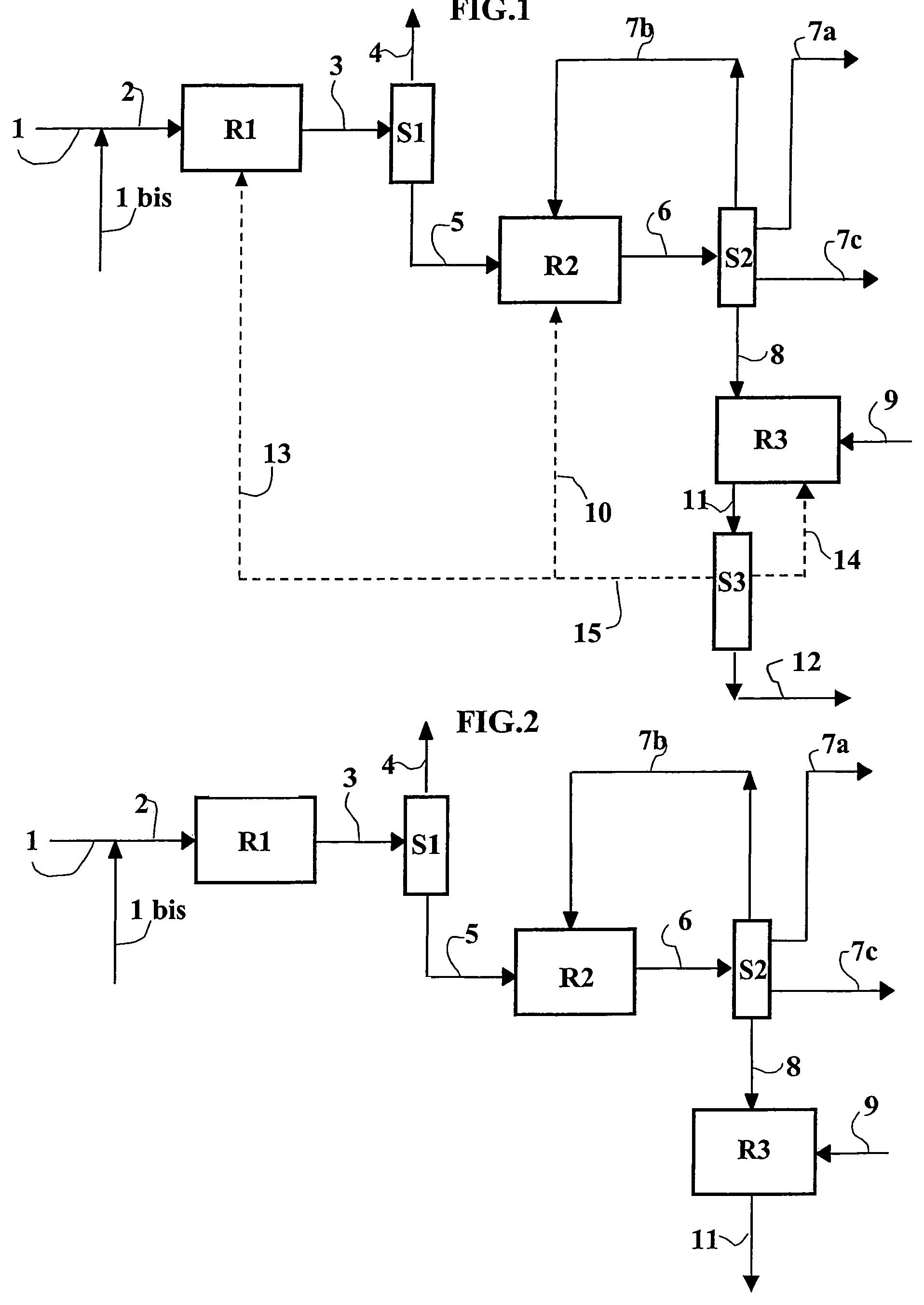

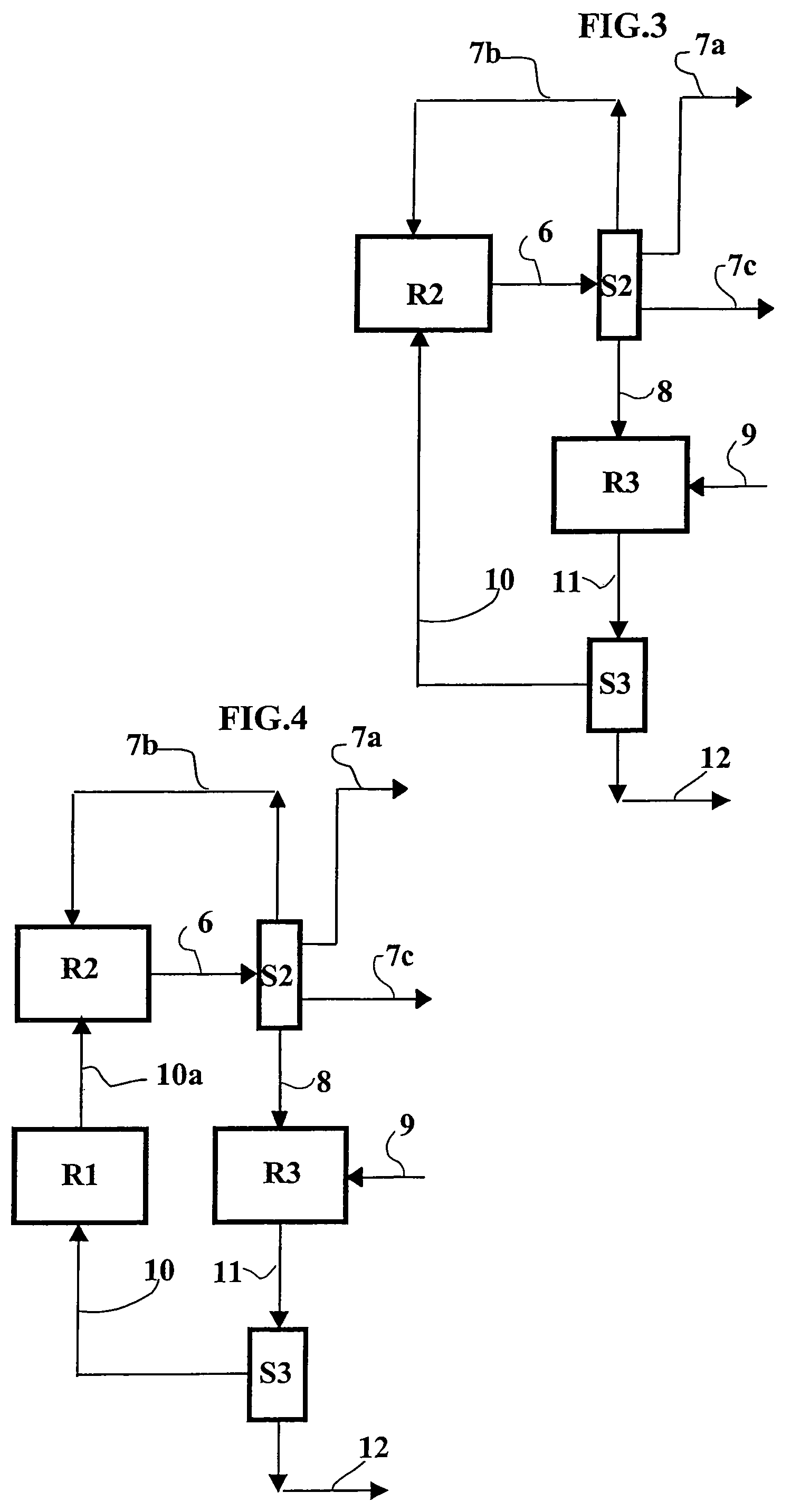

Method for jointly producing propylene and petrol from a relatively heavy charge

ActiveUS7374662B2Increase in severityReaction can be limitedCatalytic crackingOrganic chemistry methodsOligomerFluidized bed

A process for conversion of a hydrocarbon feedstock comprising a relatively heavy main feedstock with a boiling point above approximately 350° C., and a relatively light secondary feedstock with a boiling point below approximately 320° C., wherein,the main feedstock, representing at least 50 wt. % of the hydrocarbon feedstock, is cracked in a fluidized-bed reactor in the presence of a cracking catalyst,the secondary feedstock is cracked in a fluidized bed with the same cracking catalyst, separately or mixed with the main feedstock, said secondary feedstock comprising oligomers with at least 8 carbon atoms of light olefins with 4 and / or 5 carbon atoms.

Owner:INST FR DU PETROLE

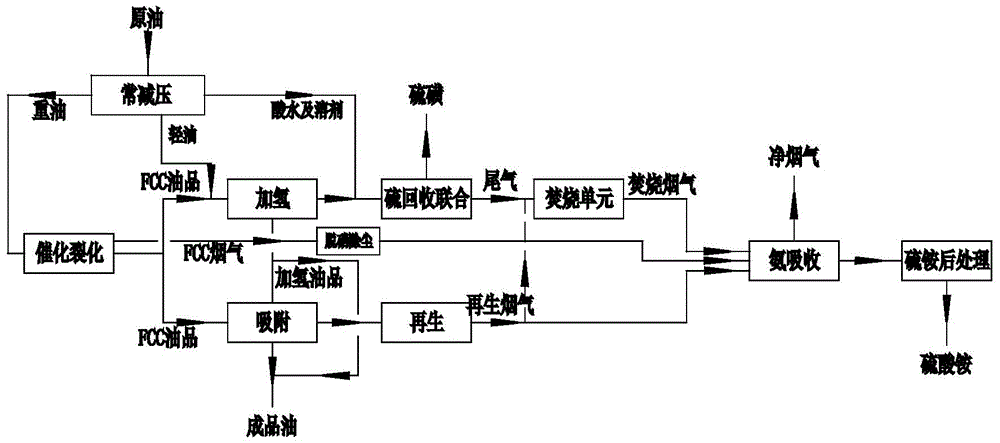

Integrated ammonia-process desulfurization method of various acidic gases in oil refining device

ActiveCN105126573ASimple processLess investmentDispersed particle separationSulfur preparation/purificationPtru catalystFlue gas

An integrated ammonia-process desulfurization method of various acidic gases in an oil refining device includes the following steps: (1) preparing heavy oil, light oil, acidic liquid and solvents through an atmospheric and vacuum distillation unit from crude oil, and feeding the heavy oil into a catalytic cracking device, the light oil into a hydrogenation device, and the acidic liquid and the solvents into a sulfur recovery combined device; (2) mixing a part of FCC oil, which is produced through the catalytic cracking device, with the light oil and feeding the mixed oil into the hydrogenation device to produce hydrogenated oil, the acidic liquid and solvents, wherein a part of the hydrogenated oil is fed into an adsorption device while the other part of the hydrogenated oil is stored and marketed as product oil; (3) feeding the acidic liquid and solvents and the acidic liquid and solvents prepared from the atmospheric and vacuum distillation unit into the sulfur recovery combined device to produce sulfur, and feeding the tail gas into an incineration unit for incineration to obtain incinerated flue gas; (4) feeding a part of the FCC oil which is produced in the catalytic cracking device into the adsorption device, performing adsorption desulfurization, and feeding an adsorption catalyst into a regenerative device to regenerate the adsorption catalyst in an oxidizing manner to obtain regenerated flue gas; and (5) feeding the FCC flue gas, the incinerated flue gas and the regenerated flue gas into an ammonia absorption device to perform absorption desulfurization and discharging cleaned flue gas after the flue gas meets standard.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Method for catalytic conversion production of propylene and light aromatics

ActiveCN102337154AIncreased processing flexibilityImprove conversion rateTreatment with hydrotreatment processesChemical recyclingCatalytic transformationPtru catalyst

The invention provides a method for catalytic conversion production of propylene and light aromatics, which is characterized in that a hydrocarbon raw material and a catalytic cracking catalyst are contacted in a composite reactor for reacting under the catalytic cracking condition, the reaction products and the to-be-regenerated catalyst are separated, the separated to-be-regenerated catalyst is circularly used through stripping and performing coke burn-off regeneration, the separated reaction products is fractionated to obtain low carbon olefin, gasoline containing light aromatics and the like, and separated to obtain the light aromatics further; the composite reactor comprises a riser reactor and a fluidized bed reactor, an outlet of the riser reactor is communicated with a lower part of the fluidized bed reactor, a stripper is positioned at the lower part of the fluidized bed reactor, an upper part of the stripper is communicated with the bottom of the fluidized bed reactor, and the outlet of the fluidized bed reactor is communicated with the inlet of a gas solid separation device in a settler though a conveying pathway, a catalyst outlet of the settler is communicated with the lower part of the fluidized bed reactor. According to the invention, propylene and light aromatics enable high yield by using the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

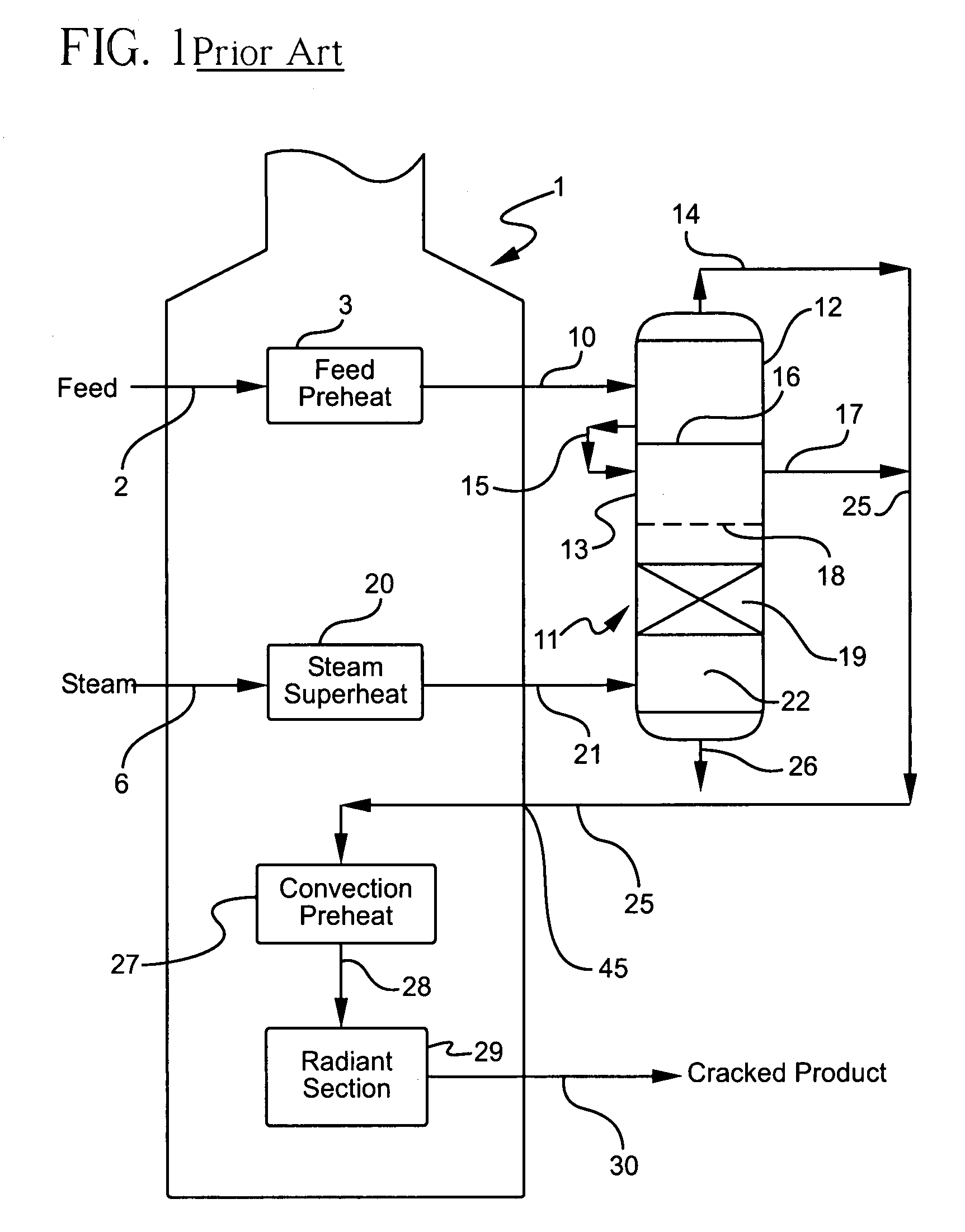

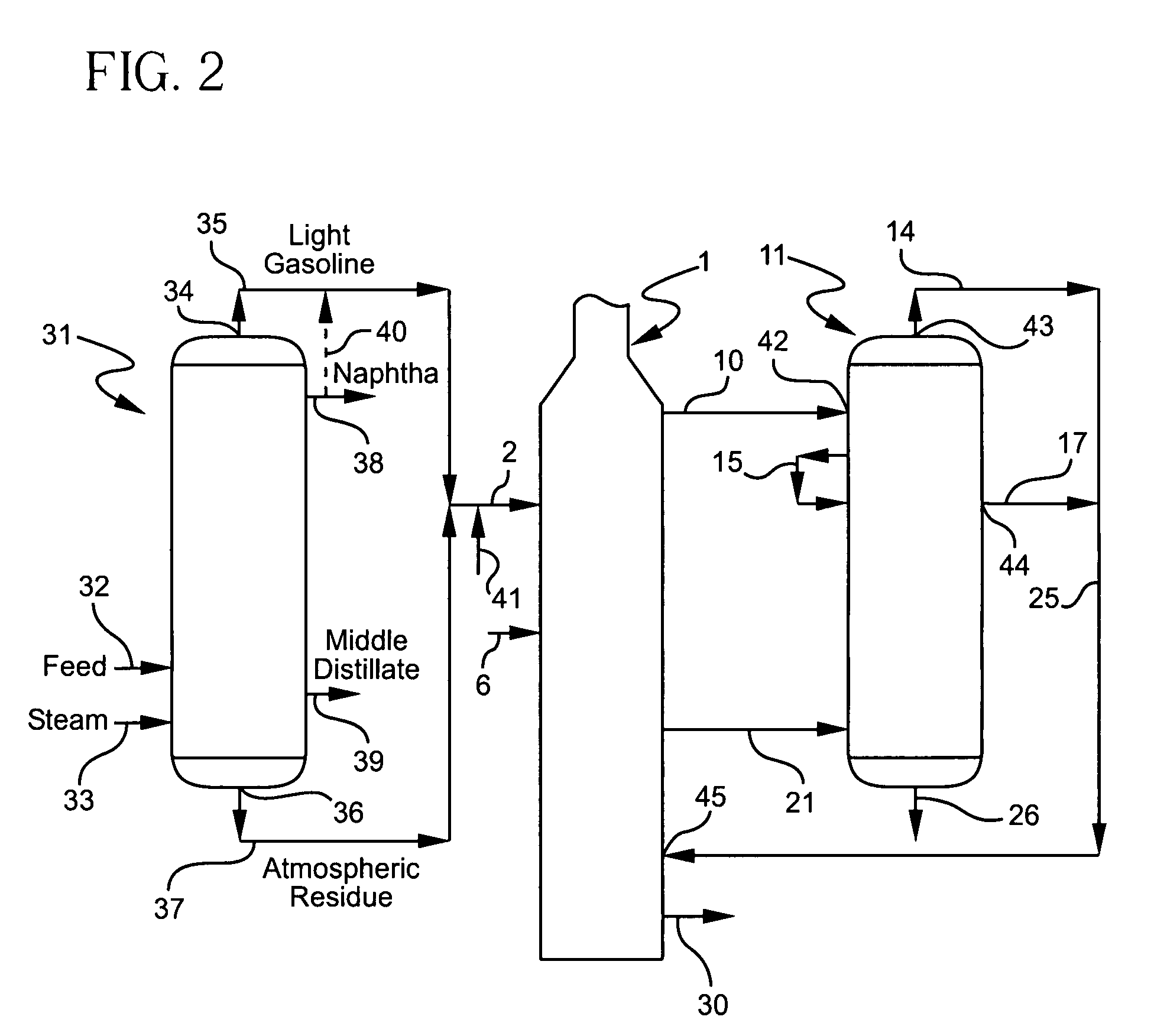

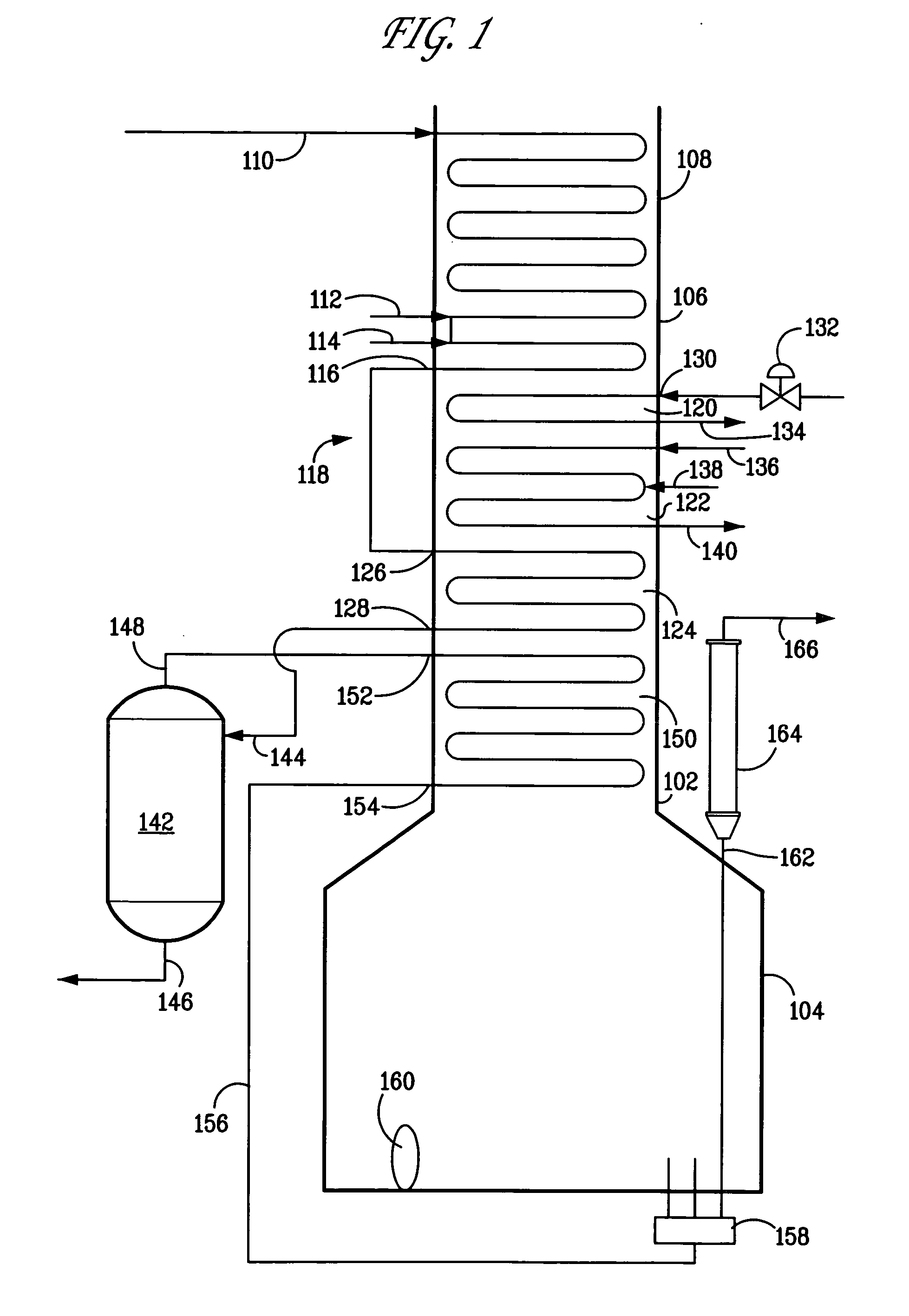

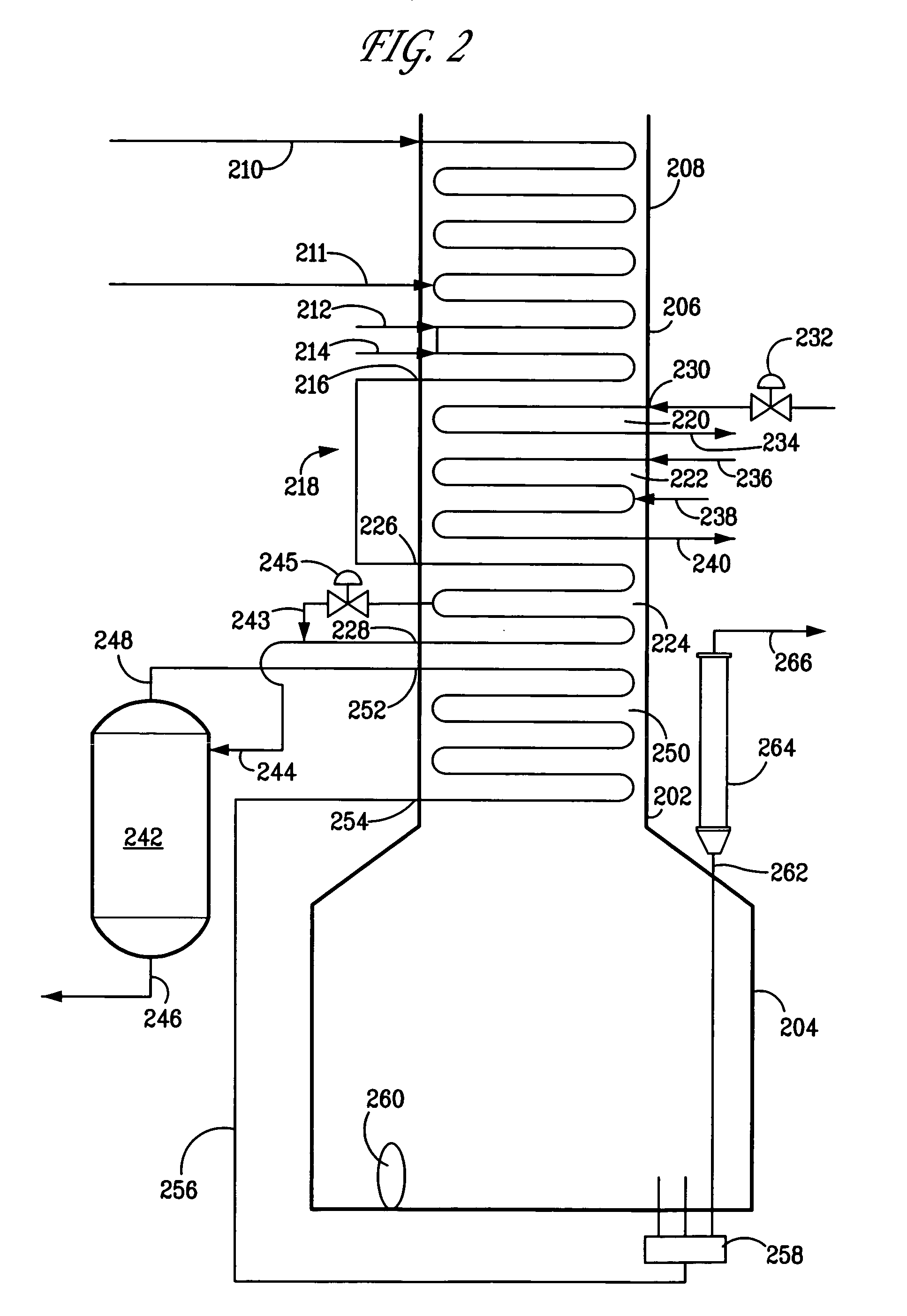

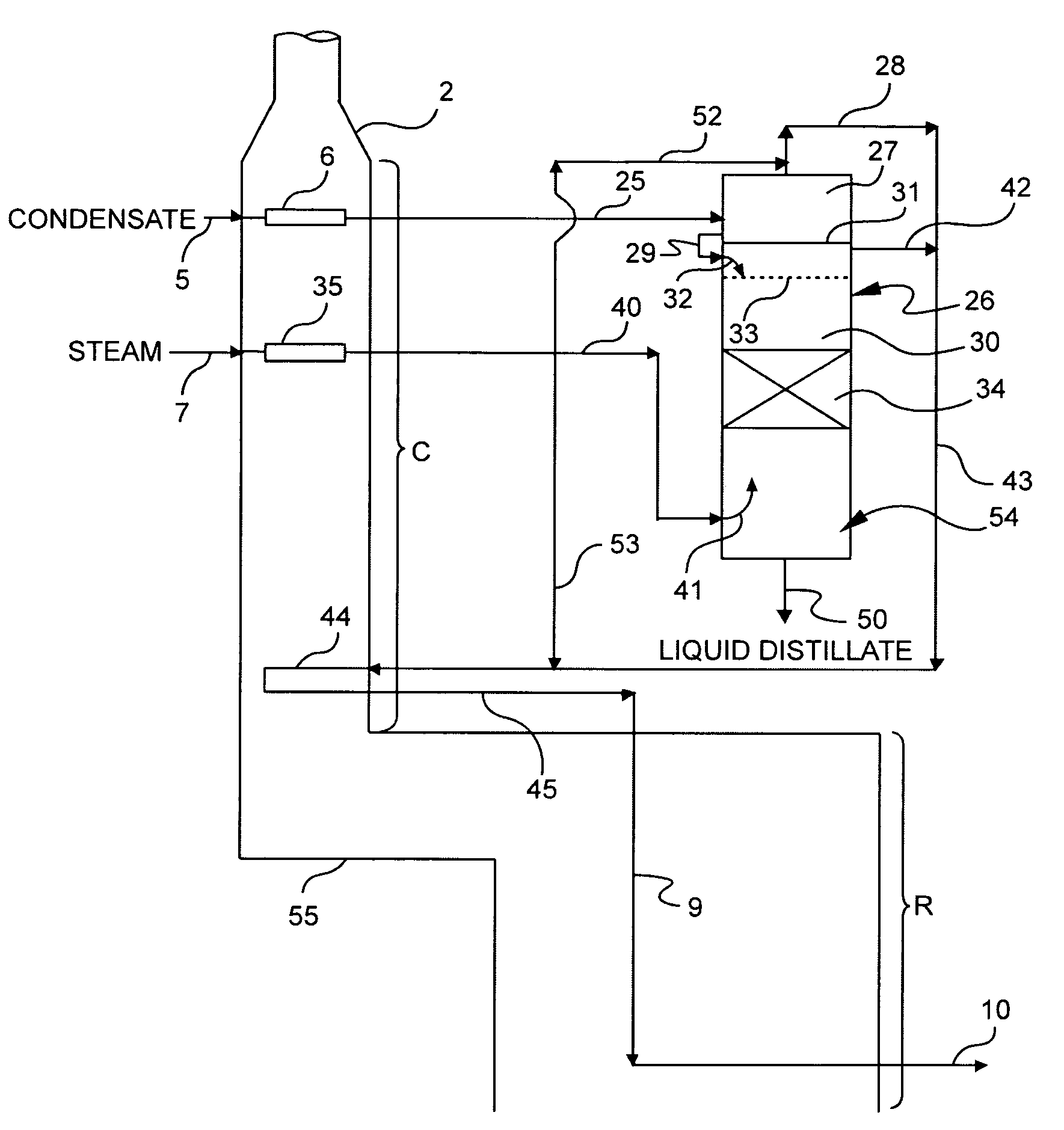

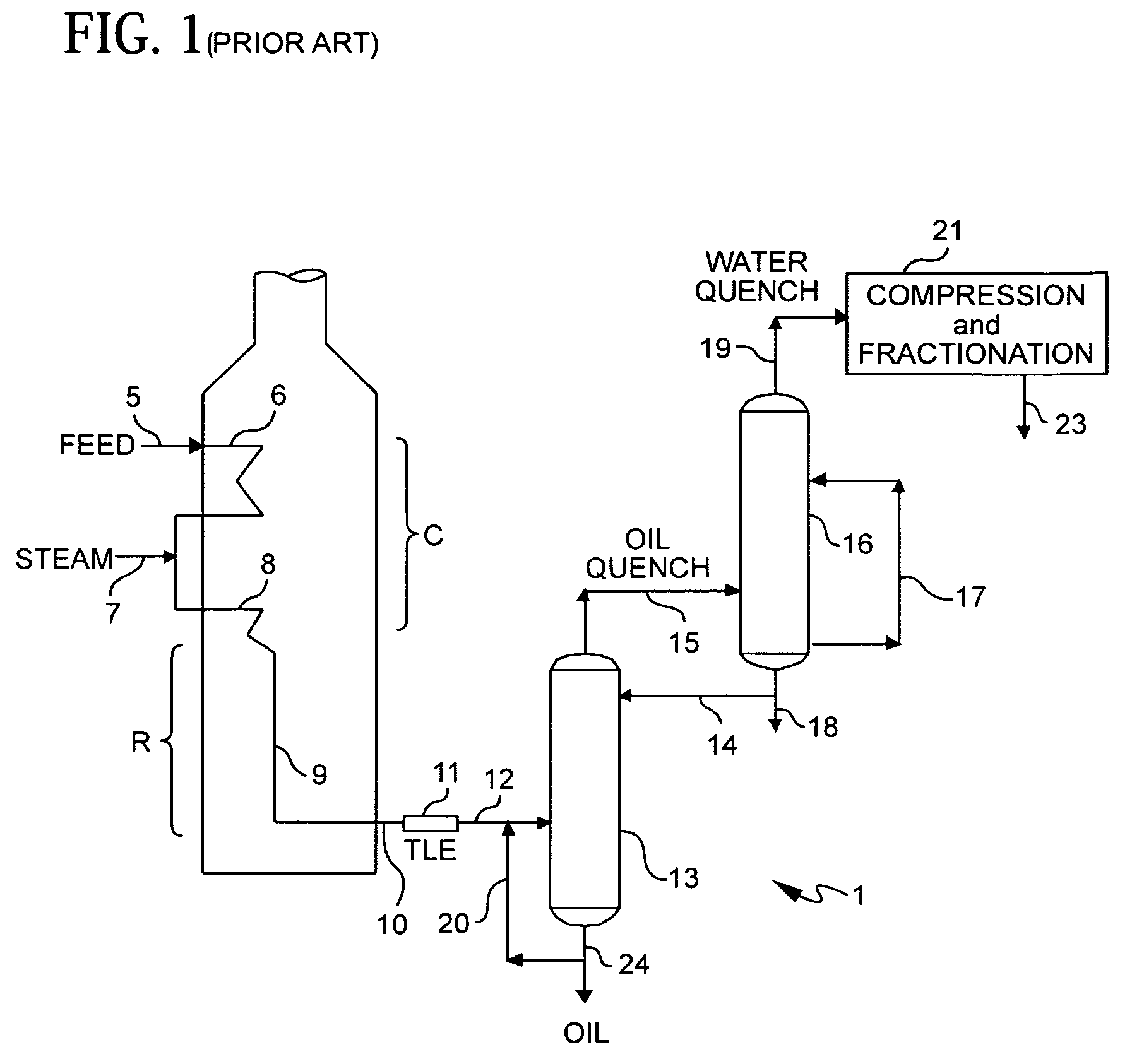

Apparatus and process for controlling temperature of heated feed directed to a flash drum whose overhead provides feed for cracking

InactiveUS20050261536A1Great heat contentThermal non-catalytic crackingHydrocarbon oil cracking processVapor liquidTemperature control

An apparatus and process are provided for cracking hydrocarbonaceous feed, wherein the temperature of heated effluent directed to a vapor / liquid separator, e.g., flash drum, whose overhead is subsequently cracked, can be controlled within a range sufficient so the heated effluent is partially liquid, say, from about 260 to about 540° C. (500 to 1000° F.). This permits processing of a variety of feeds containing resid with greatly differing volatilities, e.g., atmospheric resid and crude at higher temperature and dirty liquid condensates, at lower temperatures. The temperature can be lowered as needed by: i) providing one or more additional downstream feed inlets to a convection section, ii) increasing the ratio of water / steam mixture added to the hydrocarbonaceous feed, iii) using a high pressure boiler feed water economizer to remove heat, iv) heating high pressure steam to remove heat, v) bypassing an intermediate portion of the convection section used, e.g., preheat rows of tube banks, and / or vi) reducing excess oxygen content of the flue gas providing convection heat.

Owner:EXXONMOBIL CHEM PAT INC

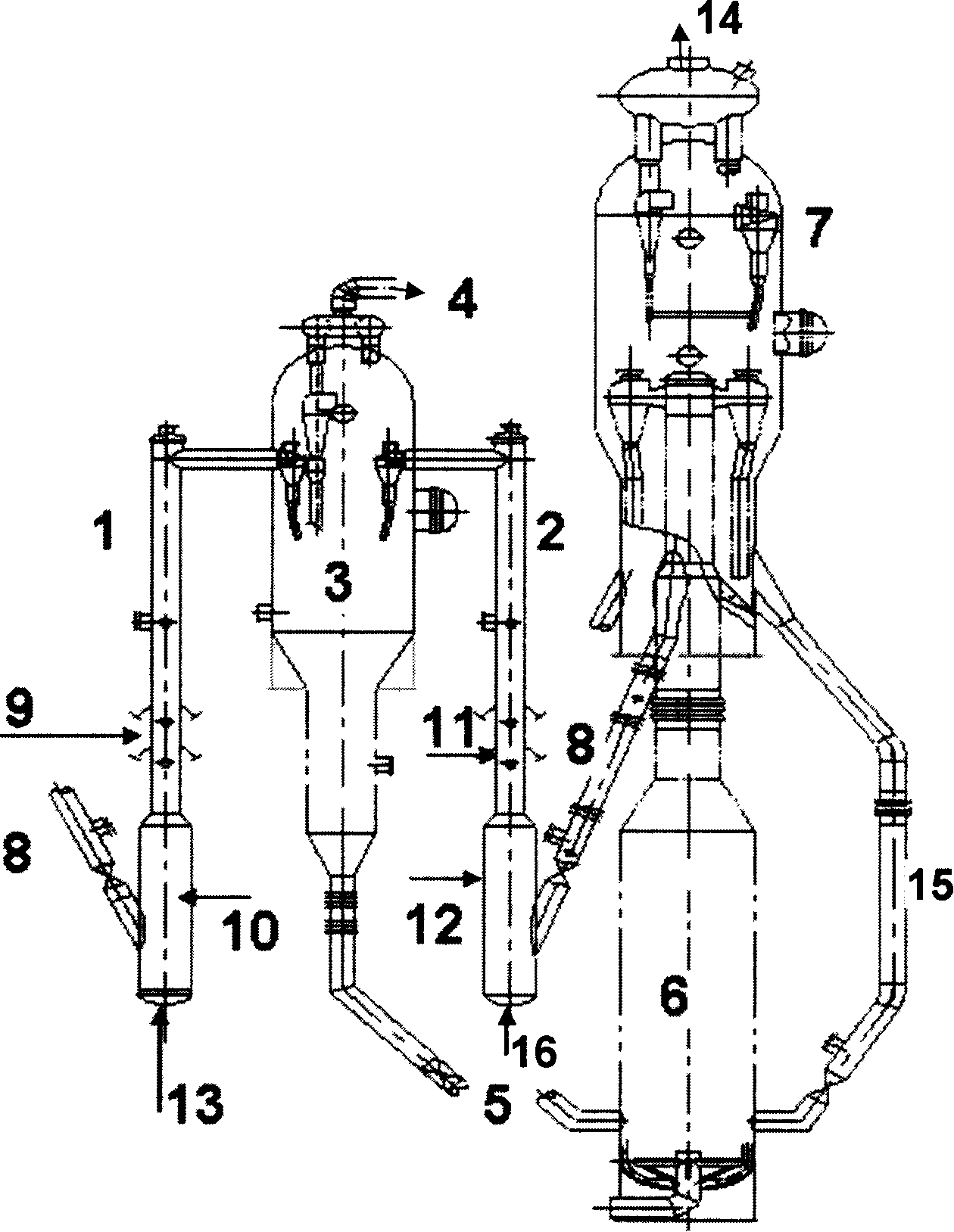

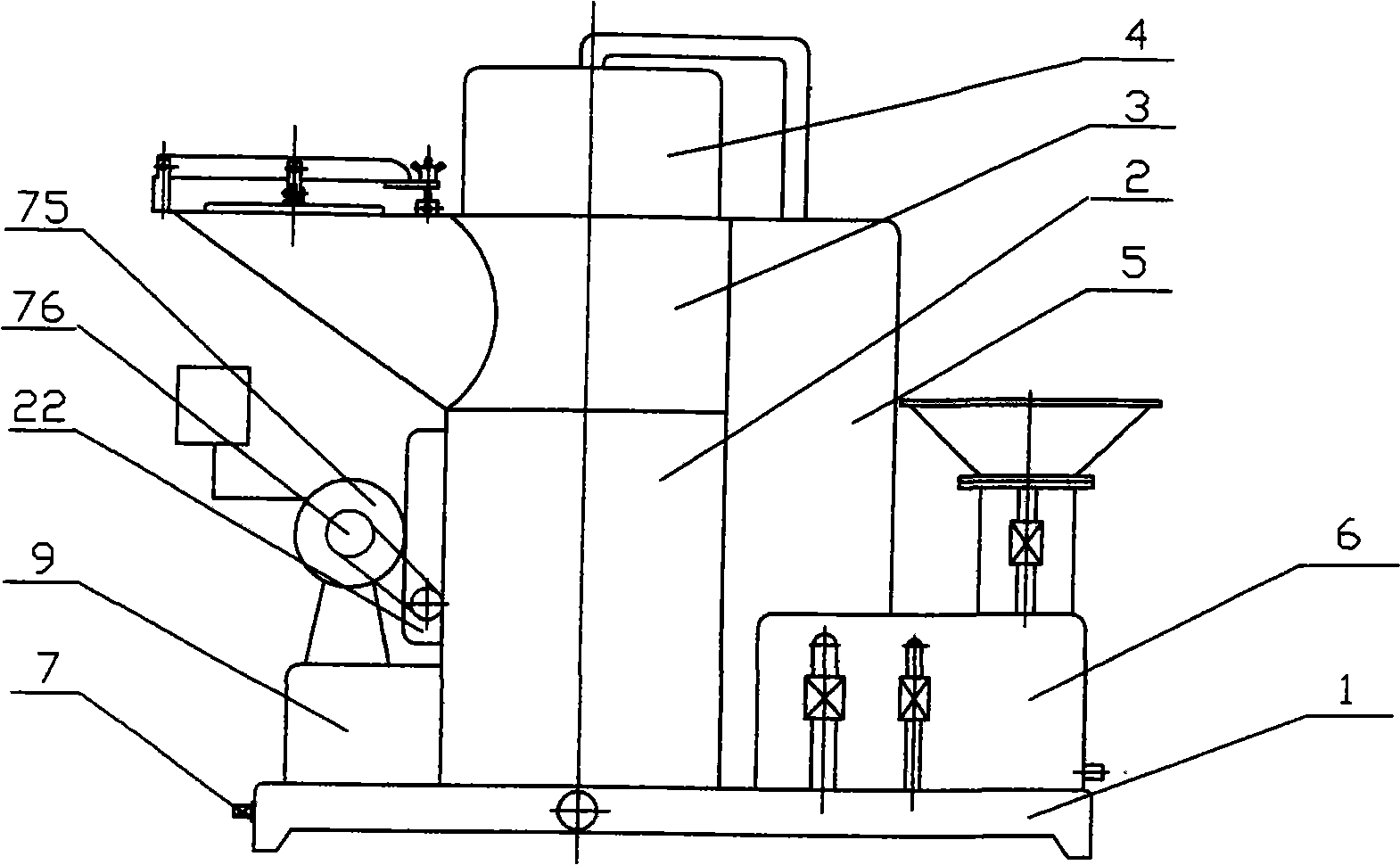

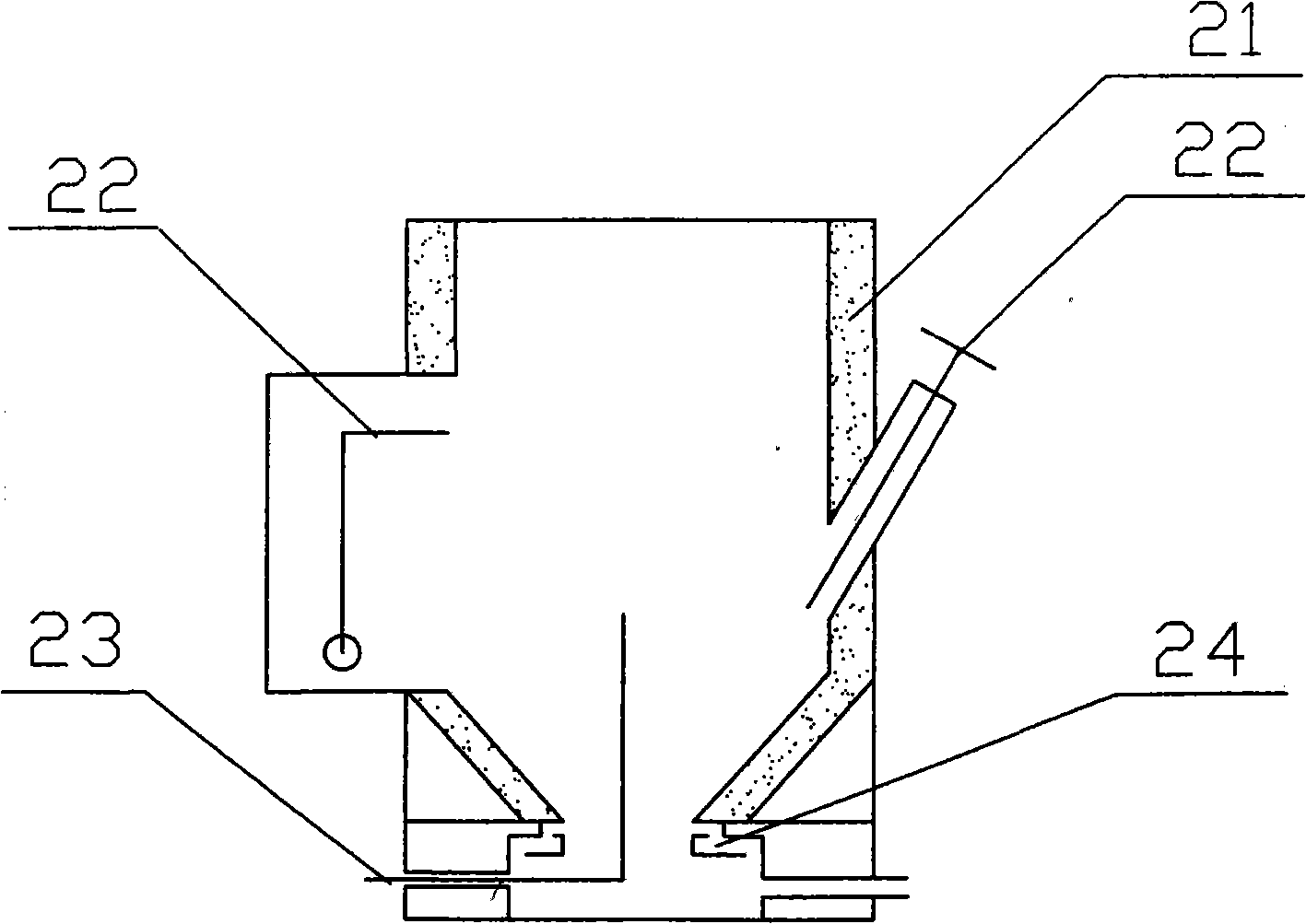

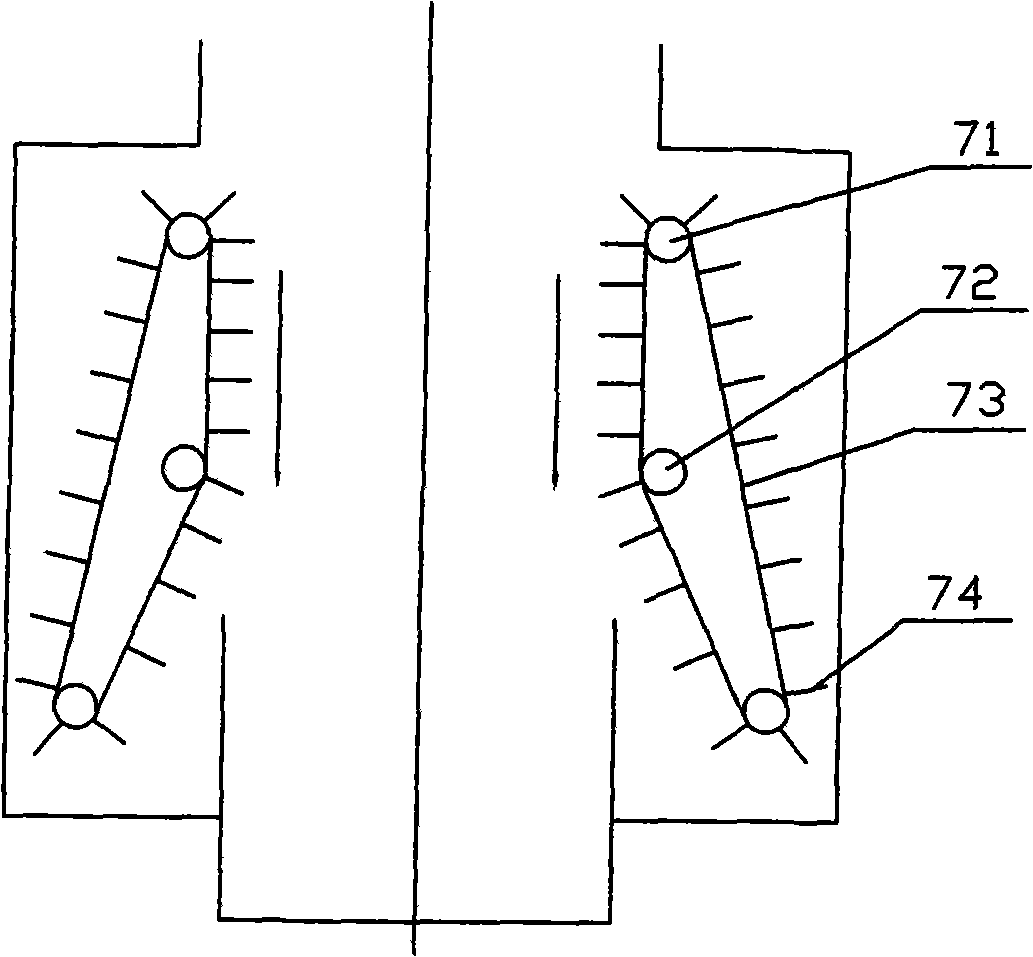

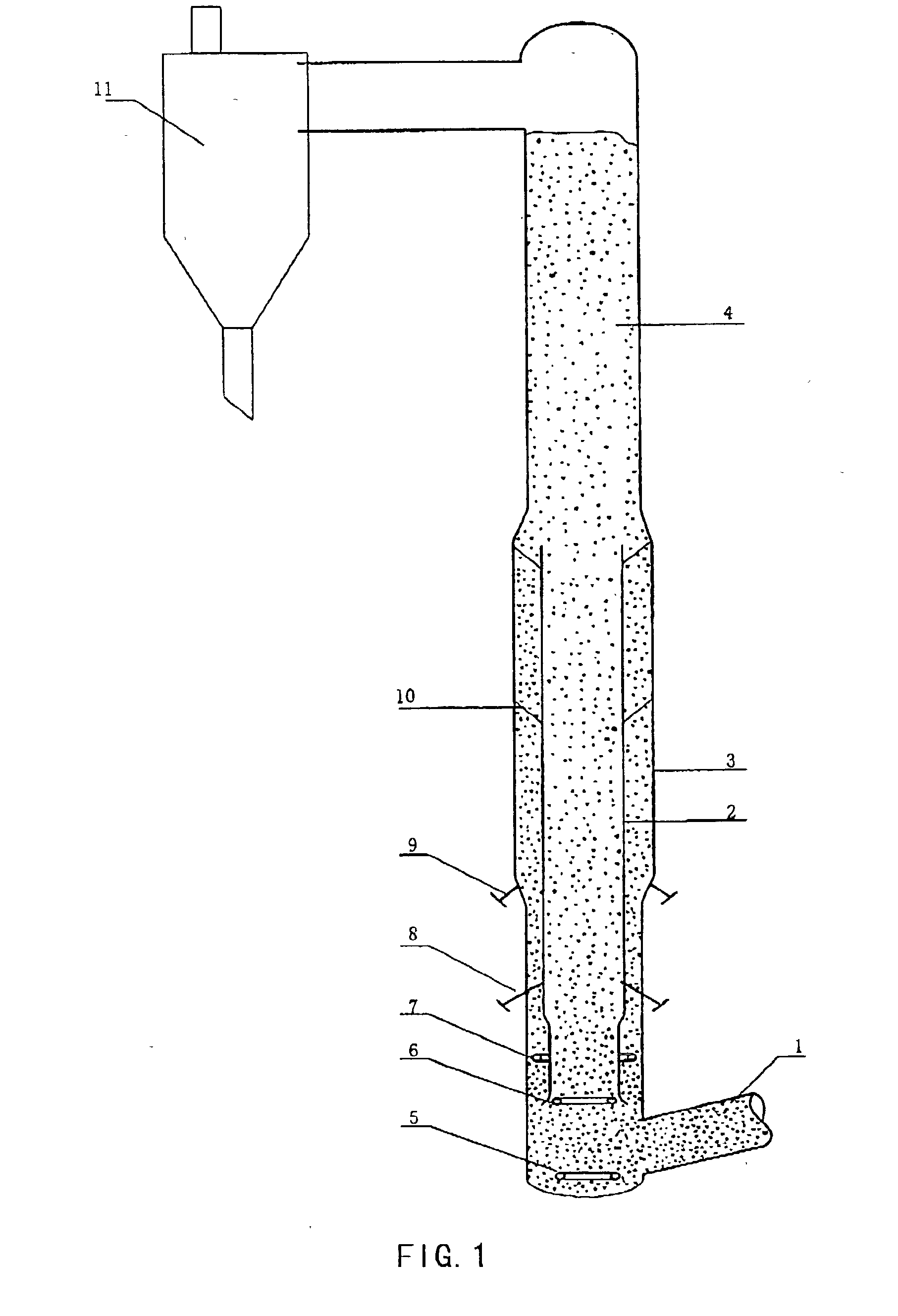

Process and apparatus for producing biomass gas

InactiveCN101294085ARepeated lysis eliminationSave energySpecial form destructive distillationWater vaporEngineering

The invention relates to a method and a device for preparing biomass fuel from biomass materials. The method comprises the following steps: loading biomass materials in a gas generating chamber, and carrying out pyrolysis to generate mixed gas; cracking the tar to generate a combustible gas; filtering off fly-ash and residual tar in the combustible gas; carrying out gas-water separation to separate water; and deodorizing to obtain the biomass fuel. The device comprises the gas generating chamber (2) fixed on a pedestal (1), a material storage chamber (3) fixed on the upper side of the gas generating chamber (2), a cracking catalyst absorber (4) fixed on the upper side of the material storage chamber (3), a gas-water separator (5) communicated with the cracking catalyst absorber (4), and a deodorizing and gas storage box (6) communicated with the gas-water separator (5). The device and the method have the advantages that the device and the method can effectively remove tar, fly-ash, vapor, odor, etc. in the biomass fuel without contaminating the environment and can ensure the combustion heat efficiency of the biomass fuel, etc.

Owner:赵靖敏

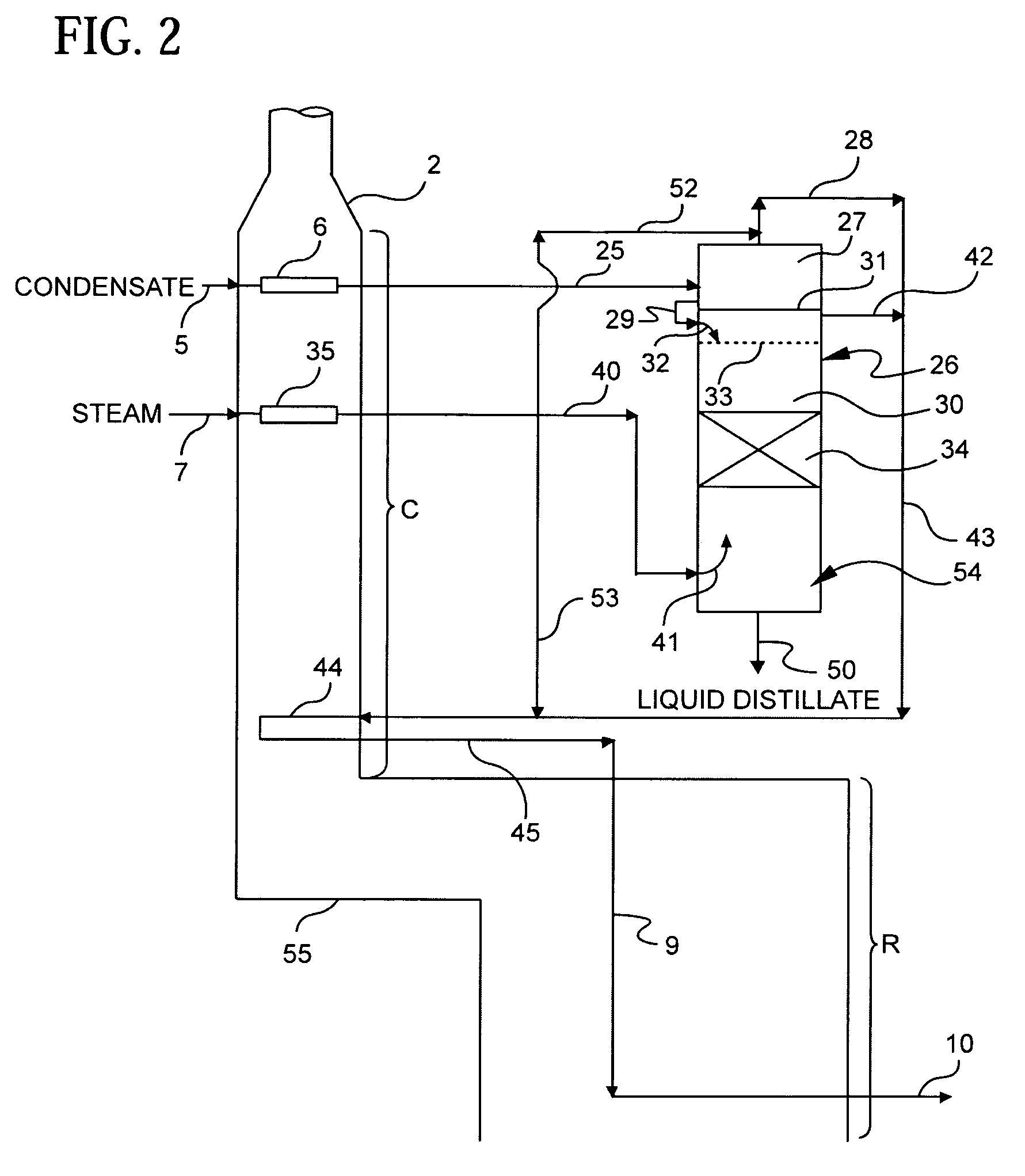

Olefin production utilizing condensate feedstock

InactiveUS7396449B2Maximize recoveryThermal non-catalytic crackingCatalytic crackingNatural-gas condensateThermodynamics

A method for utilizing natural gas condensate as a feedstock for an olefin production plant wherein the feedstock is subjected to vaporization and separation conditions that remove light hydrocarbons from the condensate for thermal cracking in the plant, and leave liquid distillate for separate recovery.

Owner:EQUSR CHEM LP

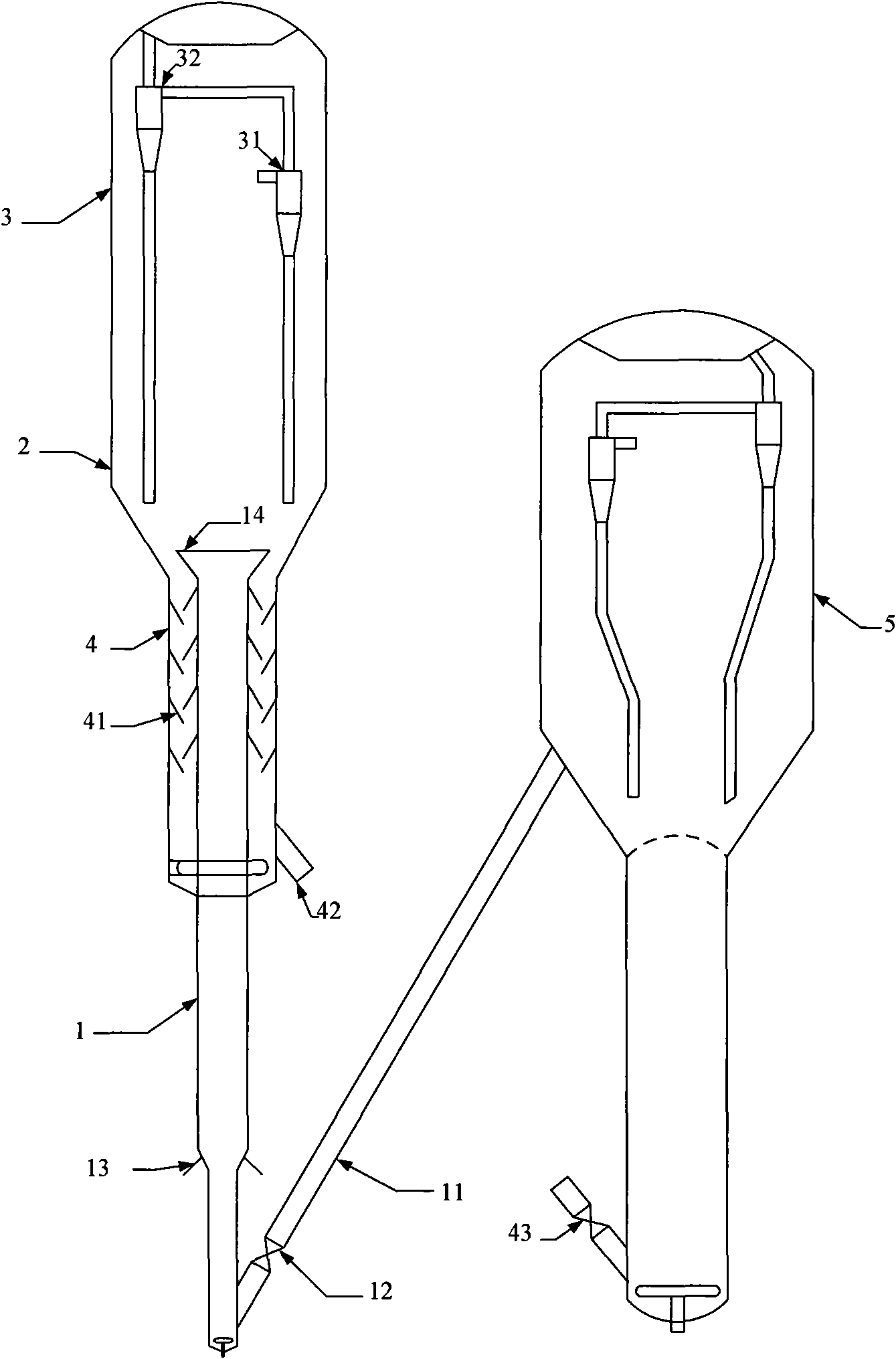

Catalytic cracking process of petroleum hydrocarbons

InactiveUS20030116471A1Easy to operateGood choiceCatalytic crackingCatalytic naphtha reformingThermodynamicsPtru catalyst

The present invention discloses a catalytic cracking process of petroleum hydrocarbons and a tube-in-tube riser reactor used therein. In the present invention, a catalyst is fed via an inlet conduit to an inner tube and an annular space between the inner and outer tubes of the tube-in-tube riser reactor to contact a hydrocarbon feedstock, and the hydrocarbon feedstock is cracked under FCC conditions, then a reaction stream thus produced flows into a separation apparatus via a confluence tube to separate a hydrocarbon product stream from a spent catalyst, the spent catalyst is stripped and regenerated, then a regenerated catalyst is recycled for reuse. The process of the present invention can improve both product distribution and product properties.

Owner:CHINA PETROCHEMICAL CORP +1

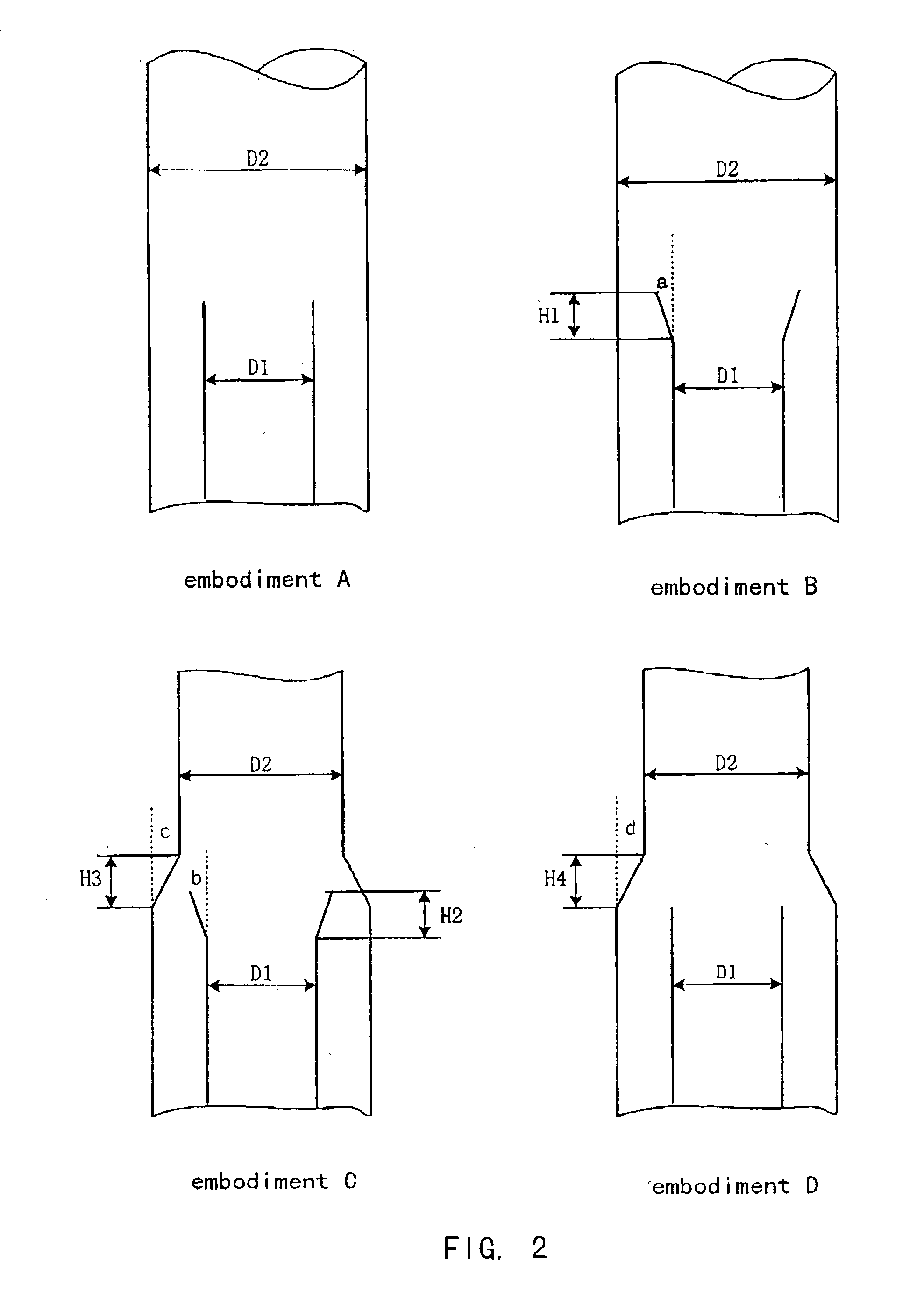

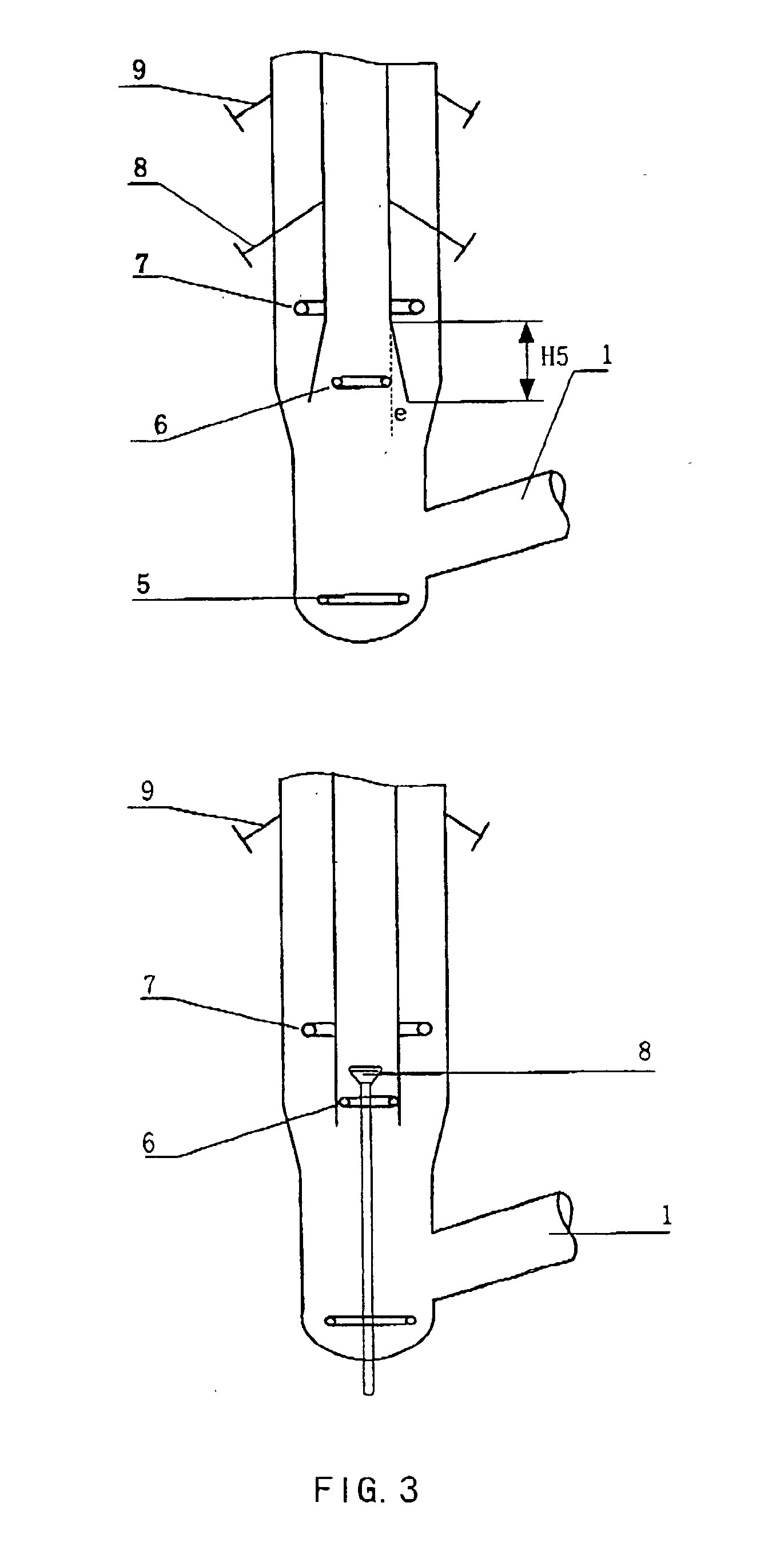

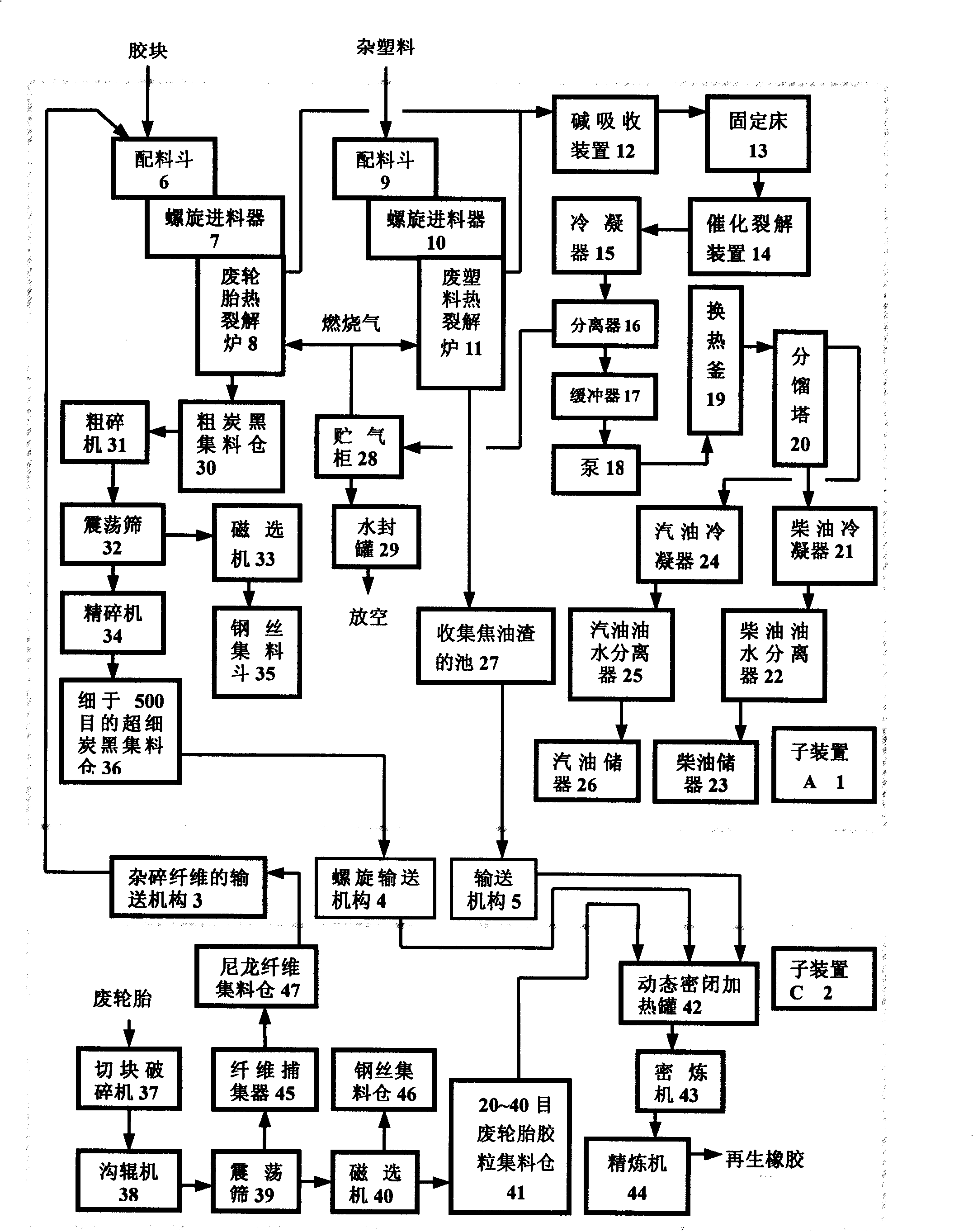

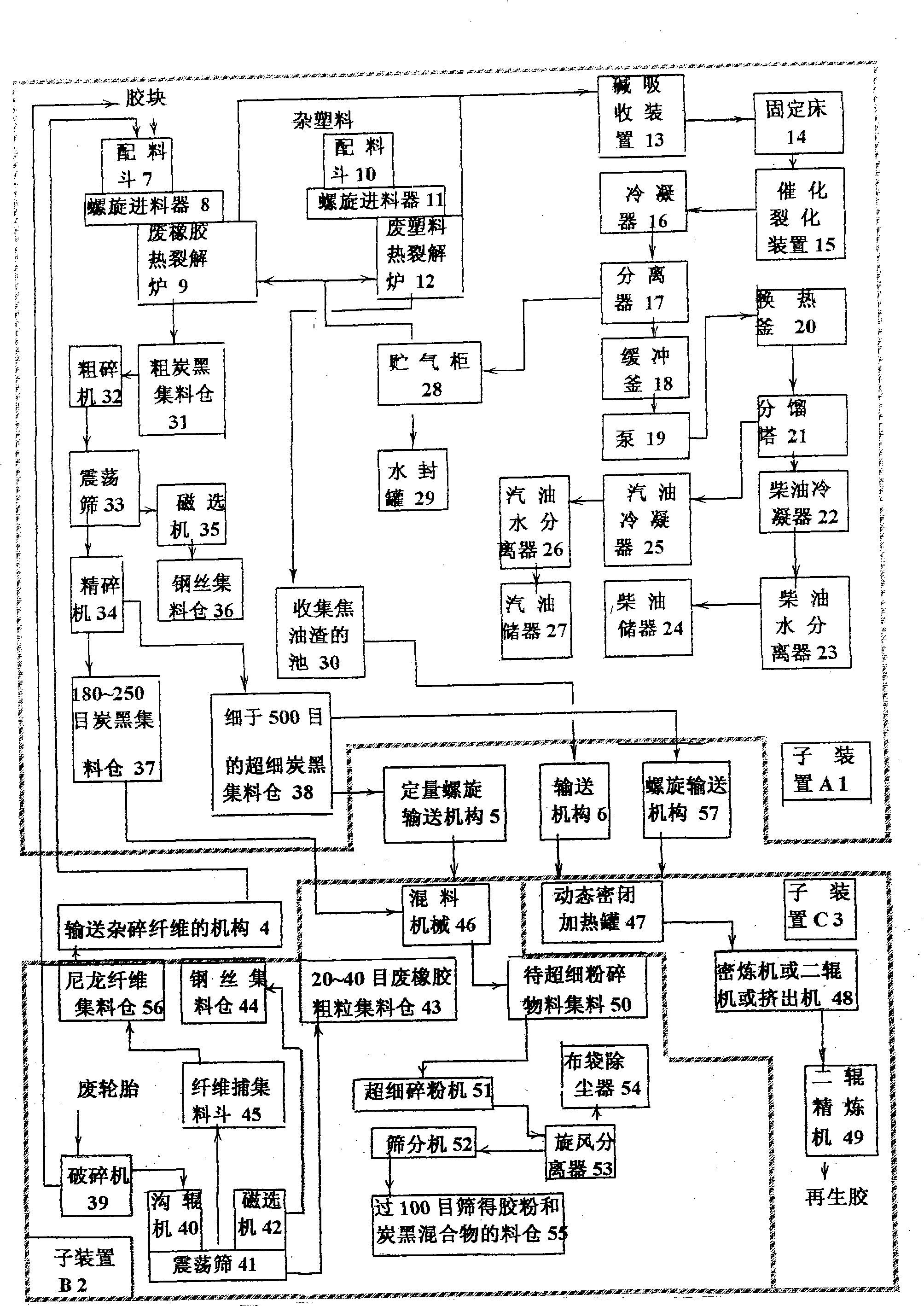

Method and apparatus for combination regeneration, or coproduction with hydrocarbon black of waste and old macromolecule material

ActiveCN101402745AReduce wasteExcellent energy qualityPlastic recyclingLiquid hydrocarbon mixture productionFiberRubber material

The invention discloses a method of combination and regeneration of waste high molecular materials or co-production of the waste high molecular materials and carbon black, and a device thereof, relating to two technologies of existing thermal cracking and non-thermal cracking of the waste high molecular materials and improvement and combination among various technological branches and also relating to the regeneration process of the waste high molecular materials and the combination of the regeneration process of the waste high molecular materials and the production process of general carbon black and an integration device used in the embodiment thereof; and comminution at normal temperature or the combination of the comminution at normal temperature and various branches of renovated rubber technology and an integration device adopted by the embodiment thereof are also included. The method also provides a treatment proposal for applying mixed fiber to recycling and products thereof, which are characterized in that the mixed fiber and plasticized rubber materials or / and oil materials are matched by the weight percentage of 100:5 to 100:100 to obtain a mixture taking the shape of a felt or a rubber felt or a treated felt. The proposal of the integration device also provides a combination device with fractional efficiency higher than that of the existing fractional process for the granularity of rubber powder only by means of a power screen.

Owner:上海橡源驰晨环保科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com