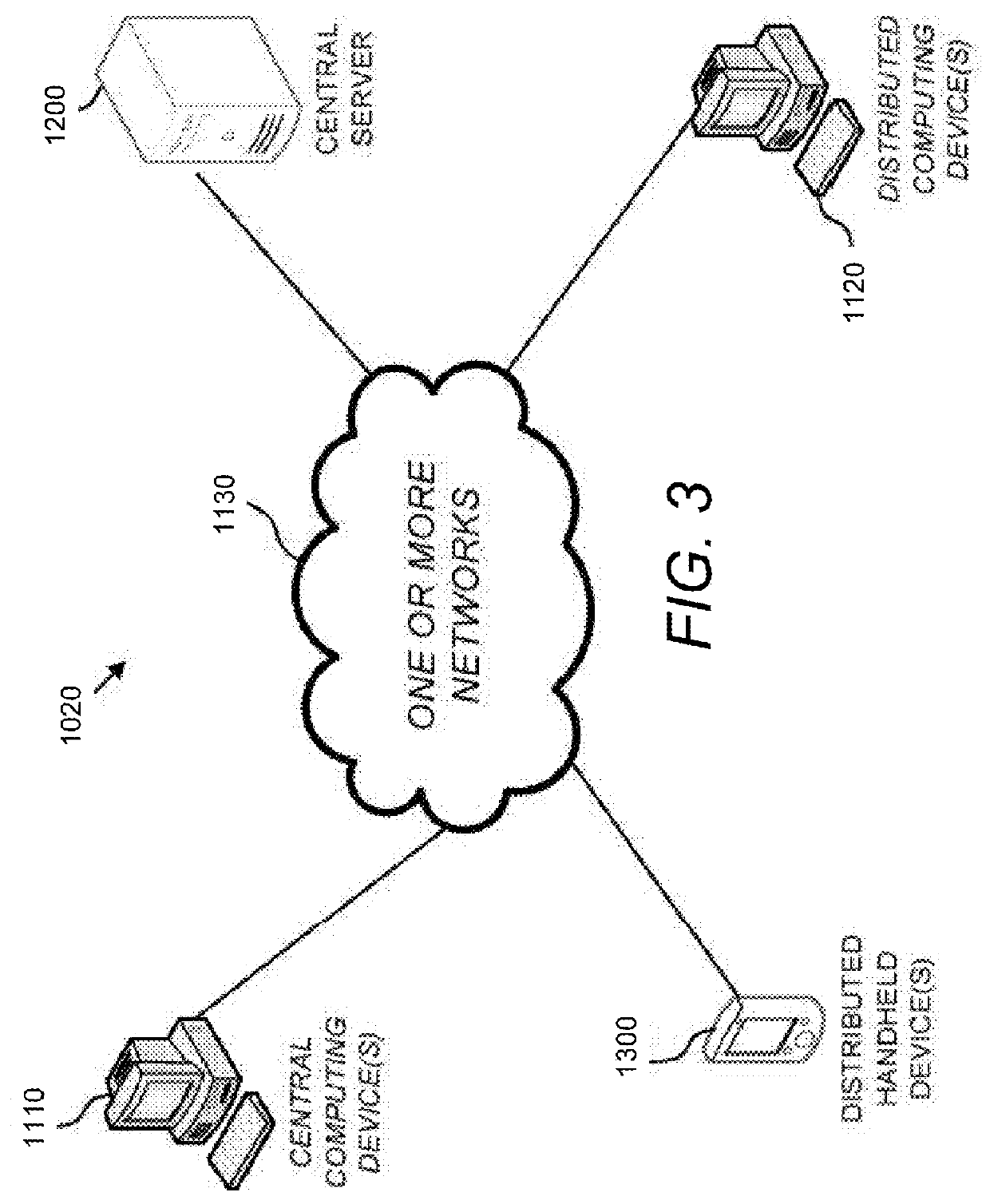

Patents

Literature

2733 results about "Dry gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drygas is an alcohol-based additive used in automobiles to prevent any water in the fuel from freezing, or to restore combustive power to gasoline spoiled by water. The name Drygas is actually a registered trademarked brand name, owned by Cristy Corporation. It is a liquid that is added into the fuel tank, that absorbs the water and keeps it in solution. Some brands contain methanol and some contain isopropyl alcohol.

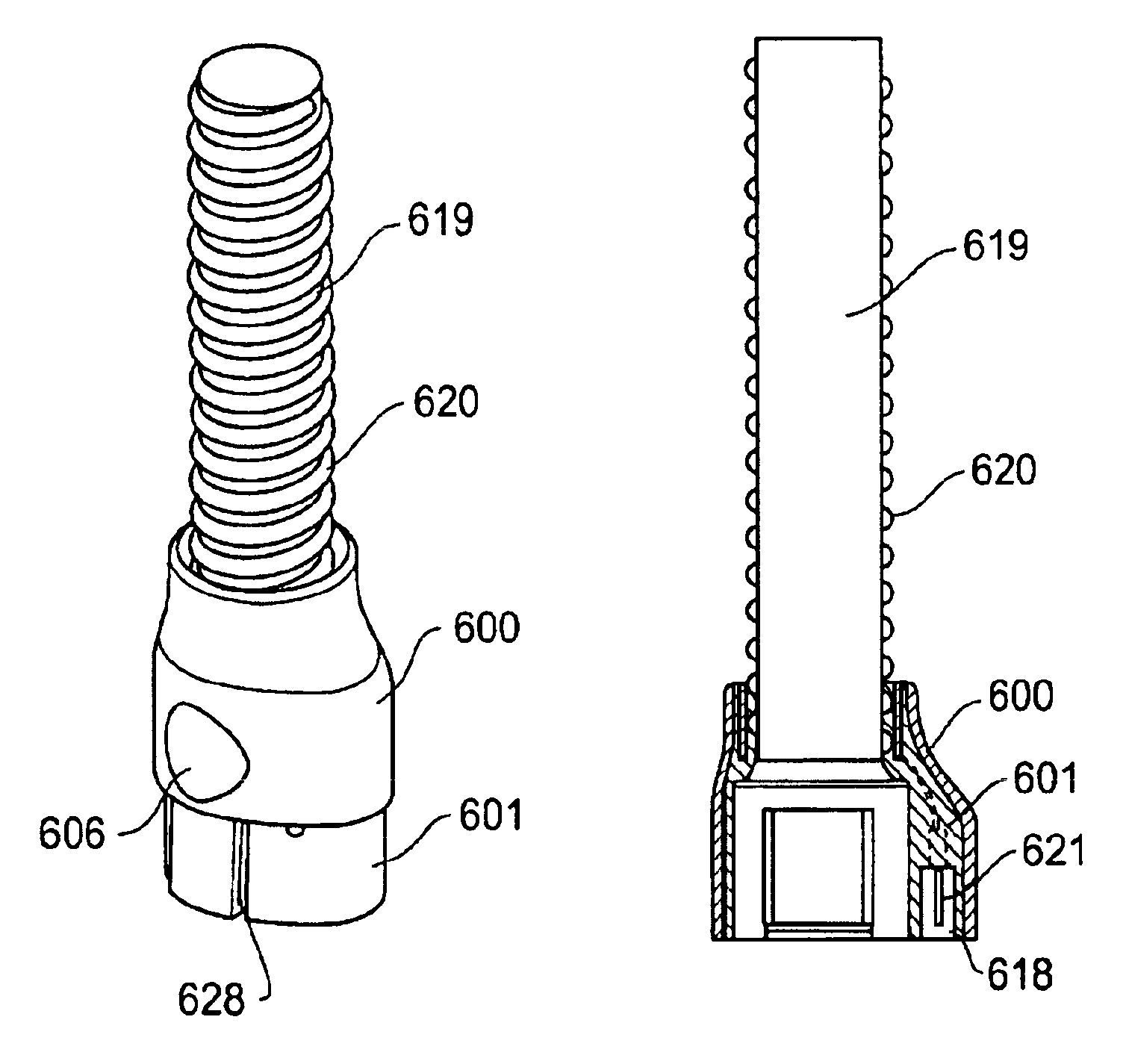

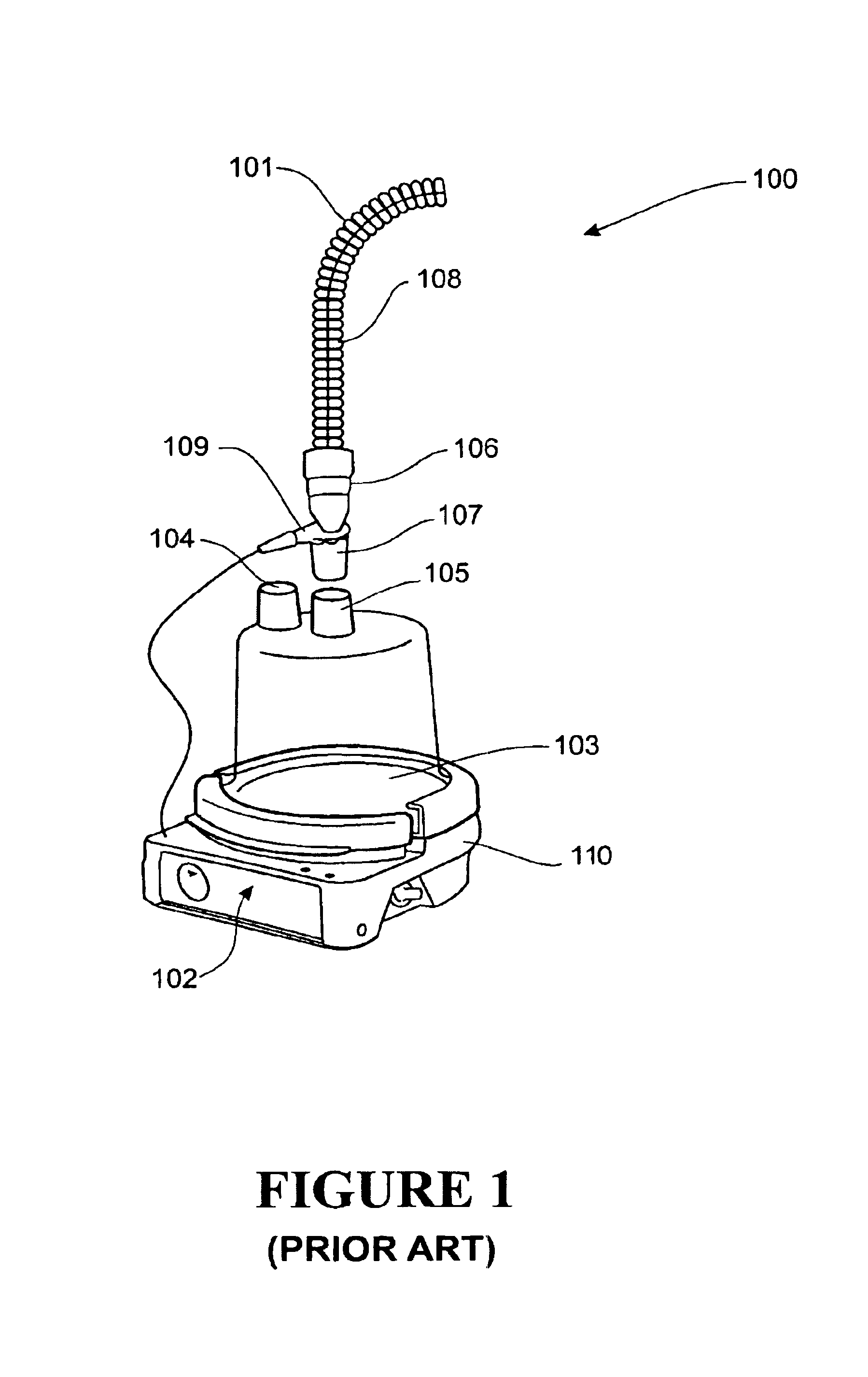

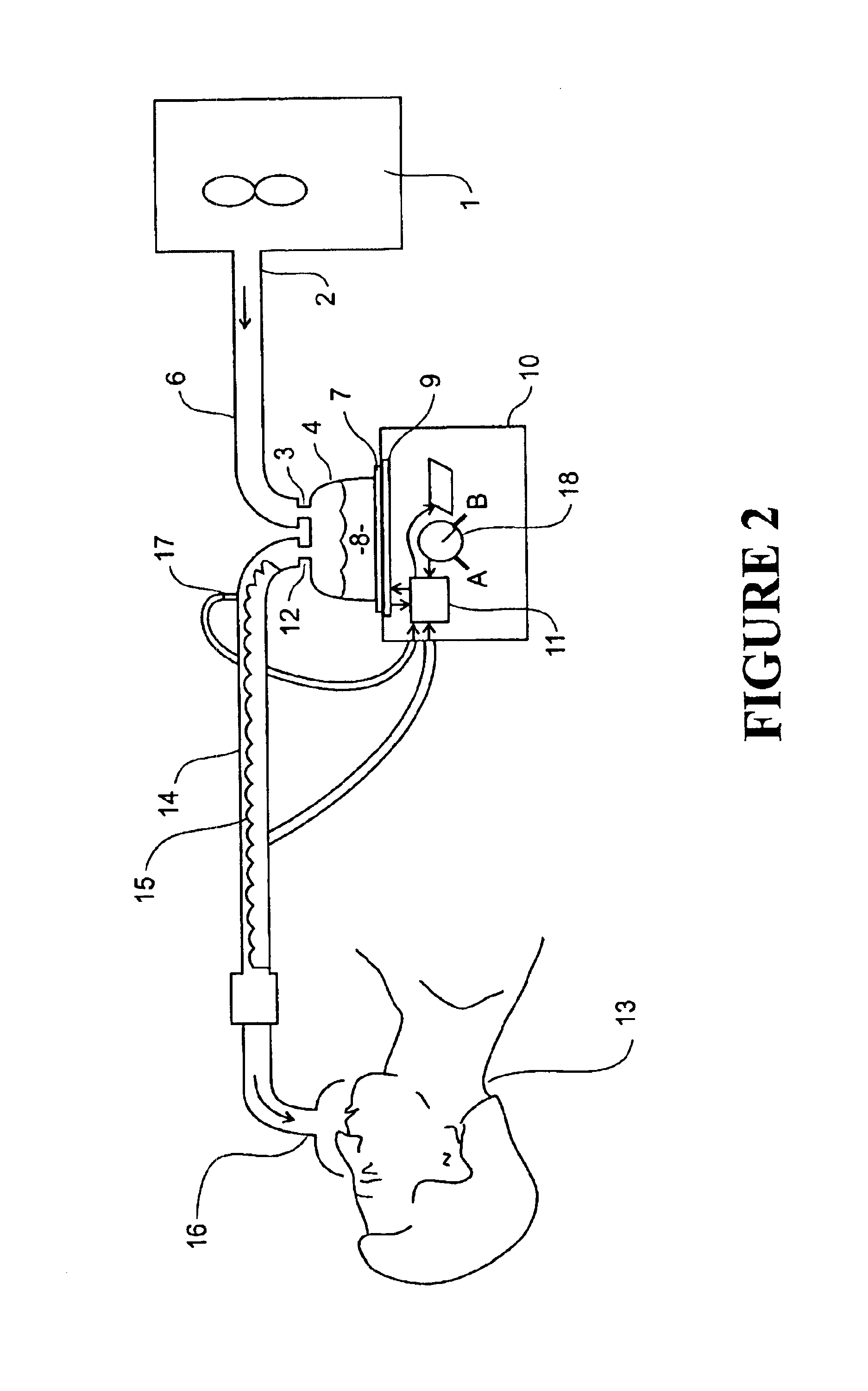

Connector for breathing conduits

The present invention relates to the connections between respiratory humidifiers and / or other such devices and heated breathing conduits used to couple a patient to the humidifier. In particular, the invention is a connector to couple a gases supply means and a conduit, such that the connector causes there to be an electrical and pneumatic, that is, sealed connection between a conduit including an electrical wire extending within, throughout or about it and a gases supply device, such as a humidifier, blower or the like. The connector may be of a single port type or a dual port type. The dual port type connector is suitable for ventilator apparatus that have a dry line (dry breathing conduit) extending from a ventilator or blower that carries dry gas to a humidifier and an inspiratory limb that extends from the humidifier to the patient and carries humidified gases to the patient.

Owner:FISHER & PAYKEL HEALTHCARE LTD

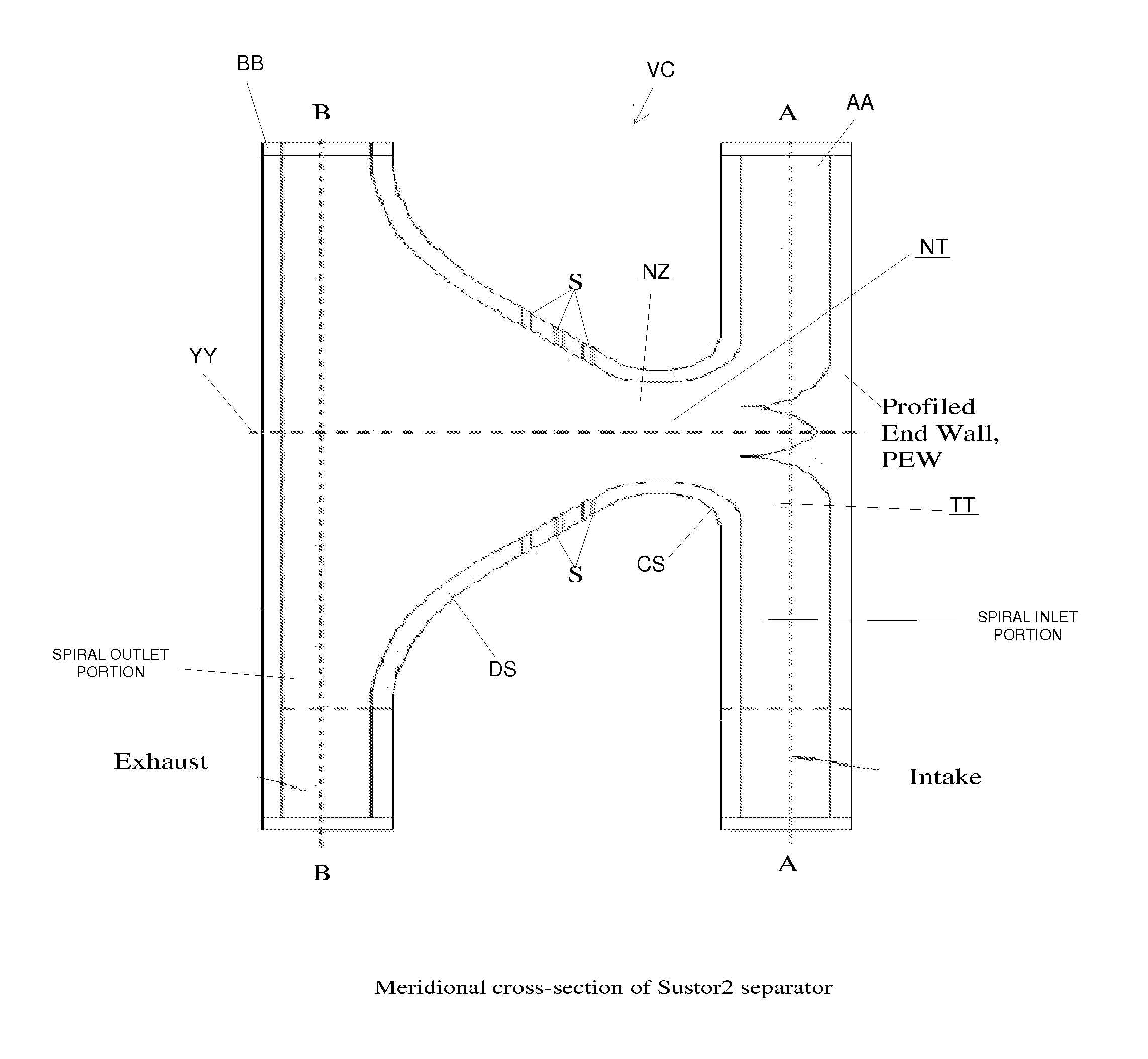

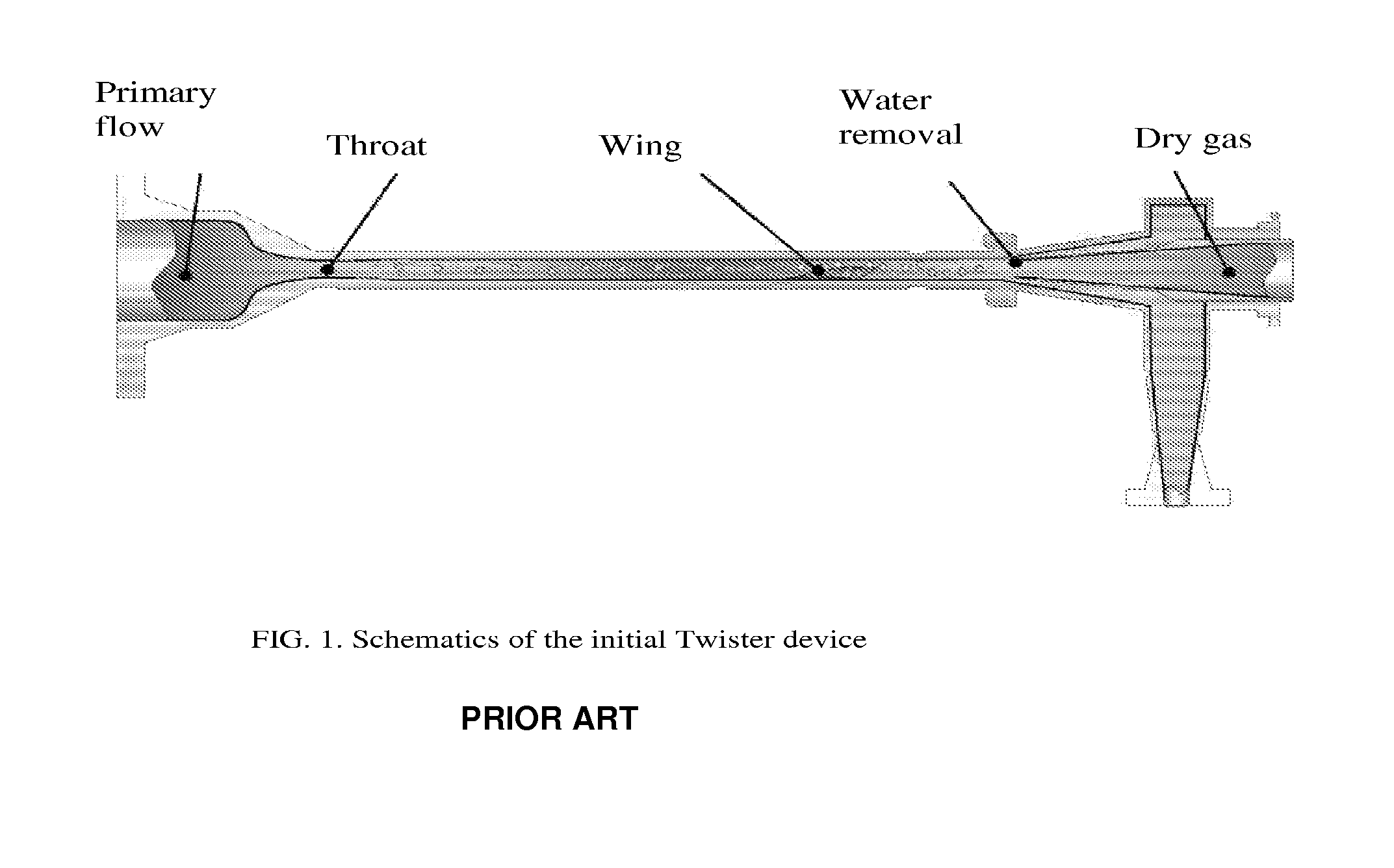

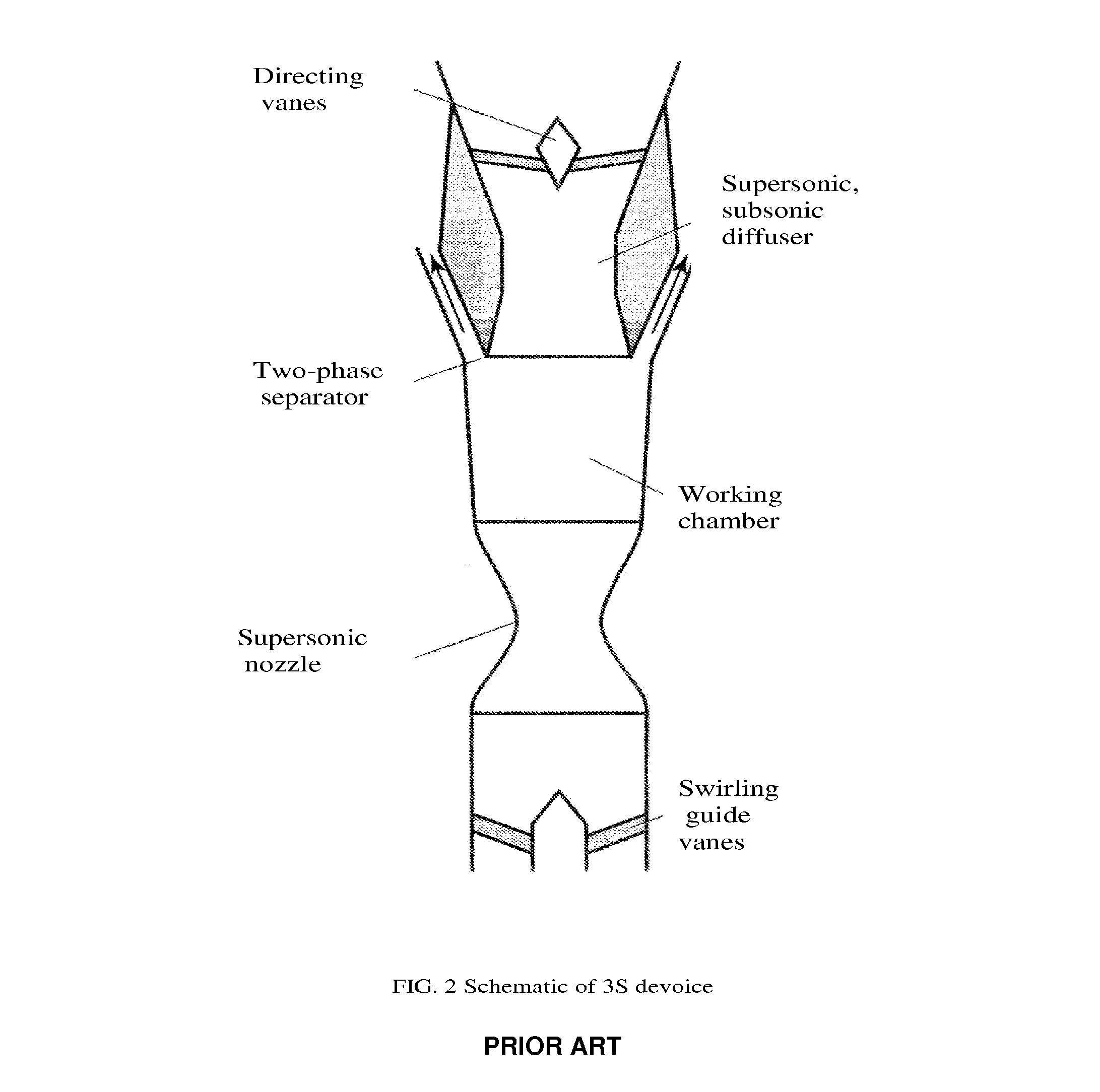

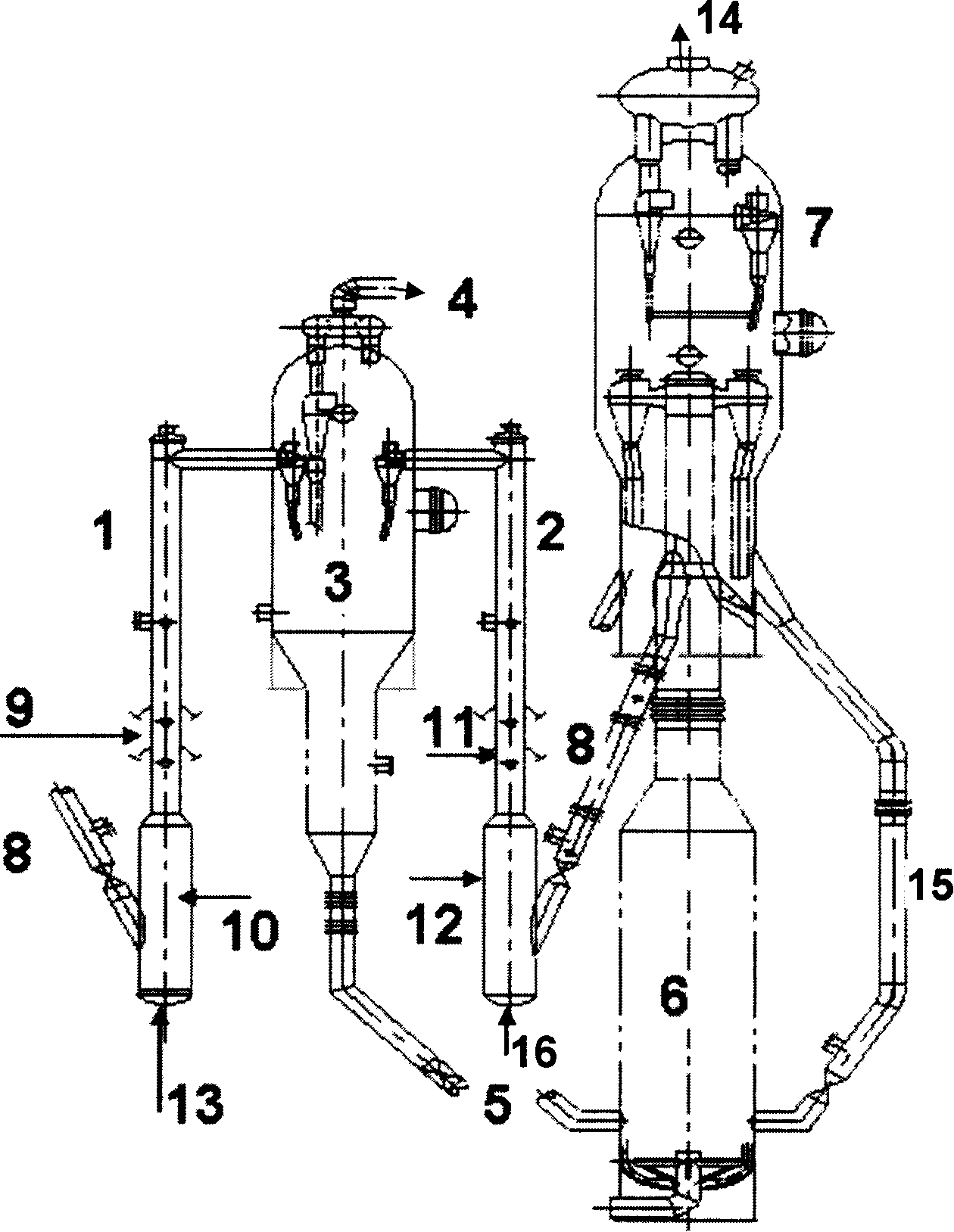

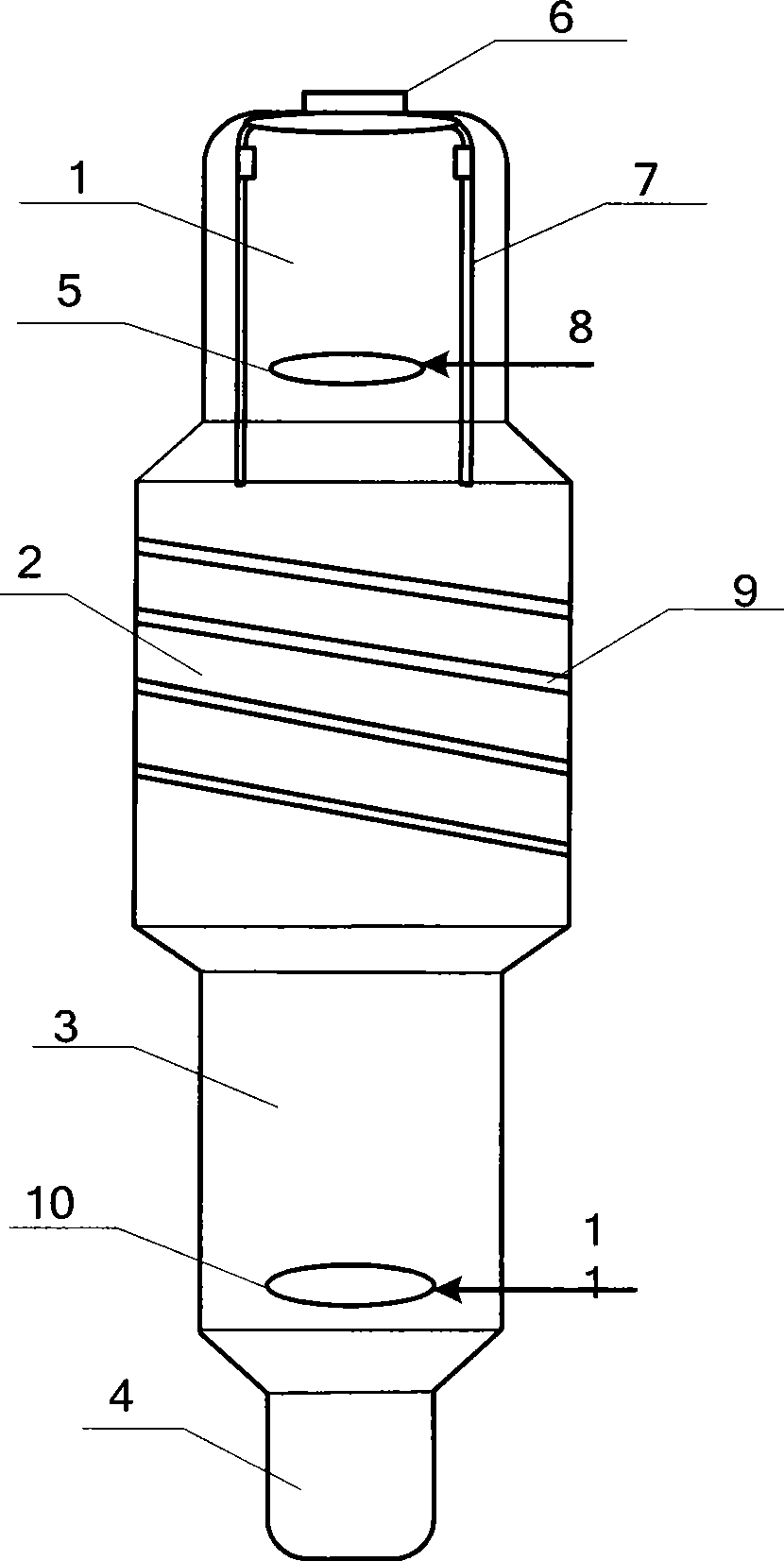

Supersonic swirling separator 2 (Sustor2)

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

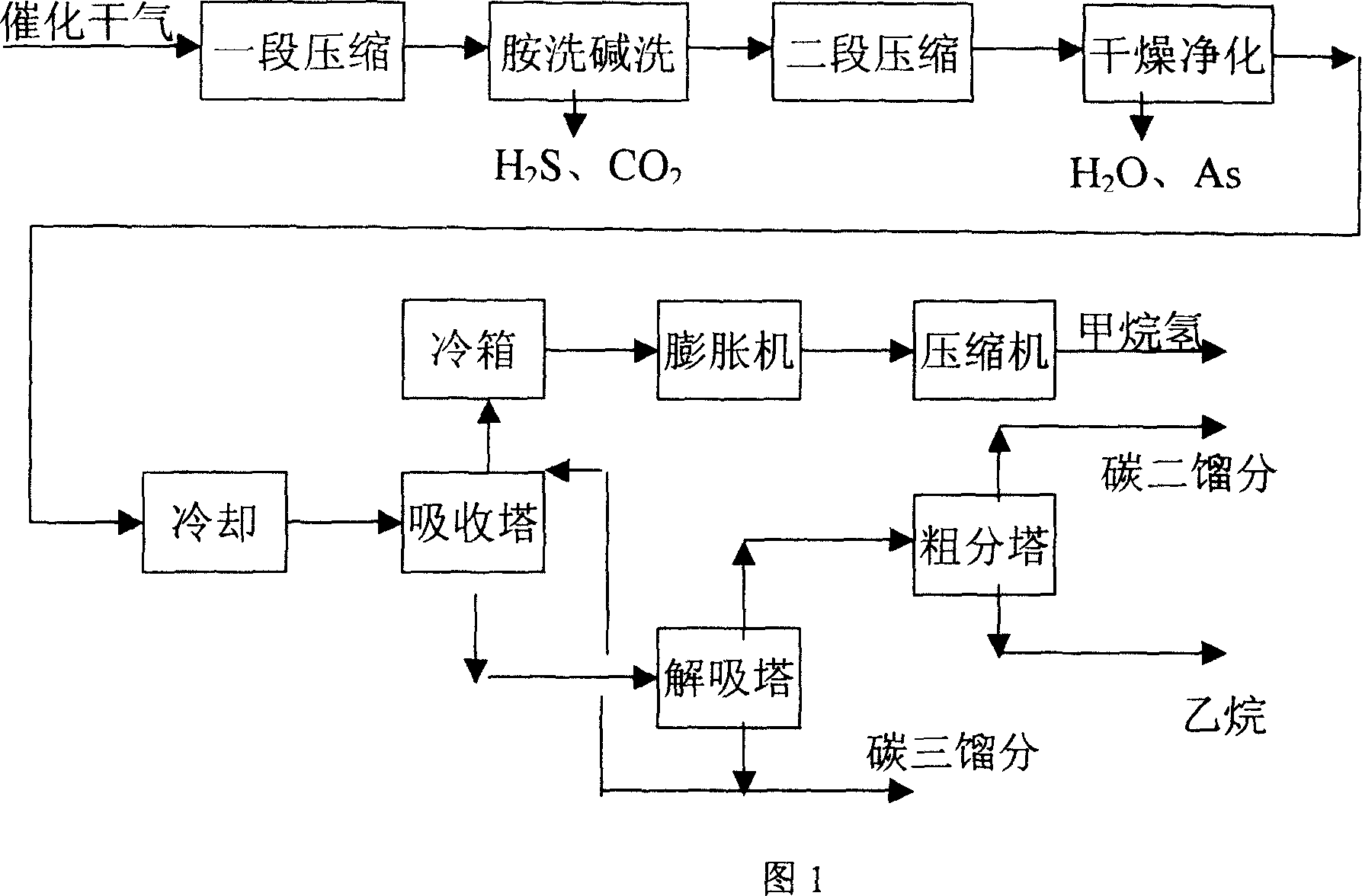

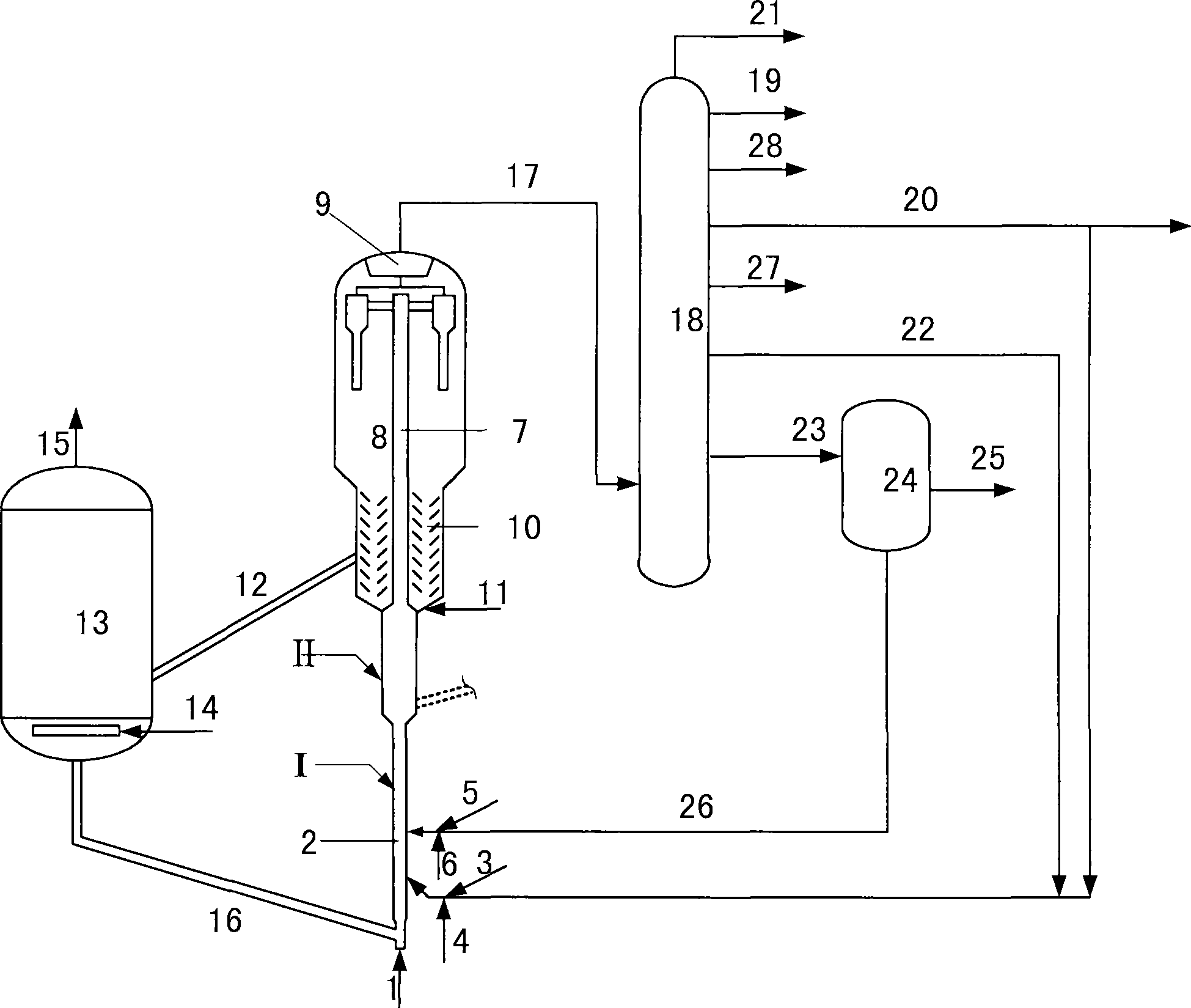

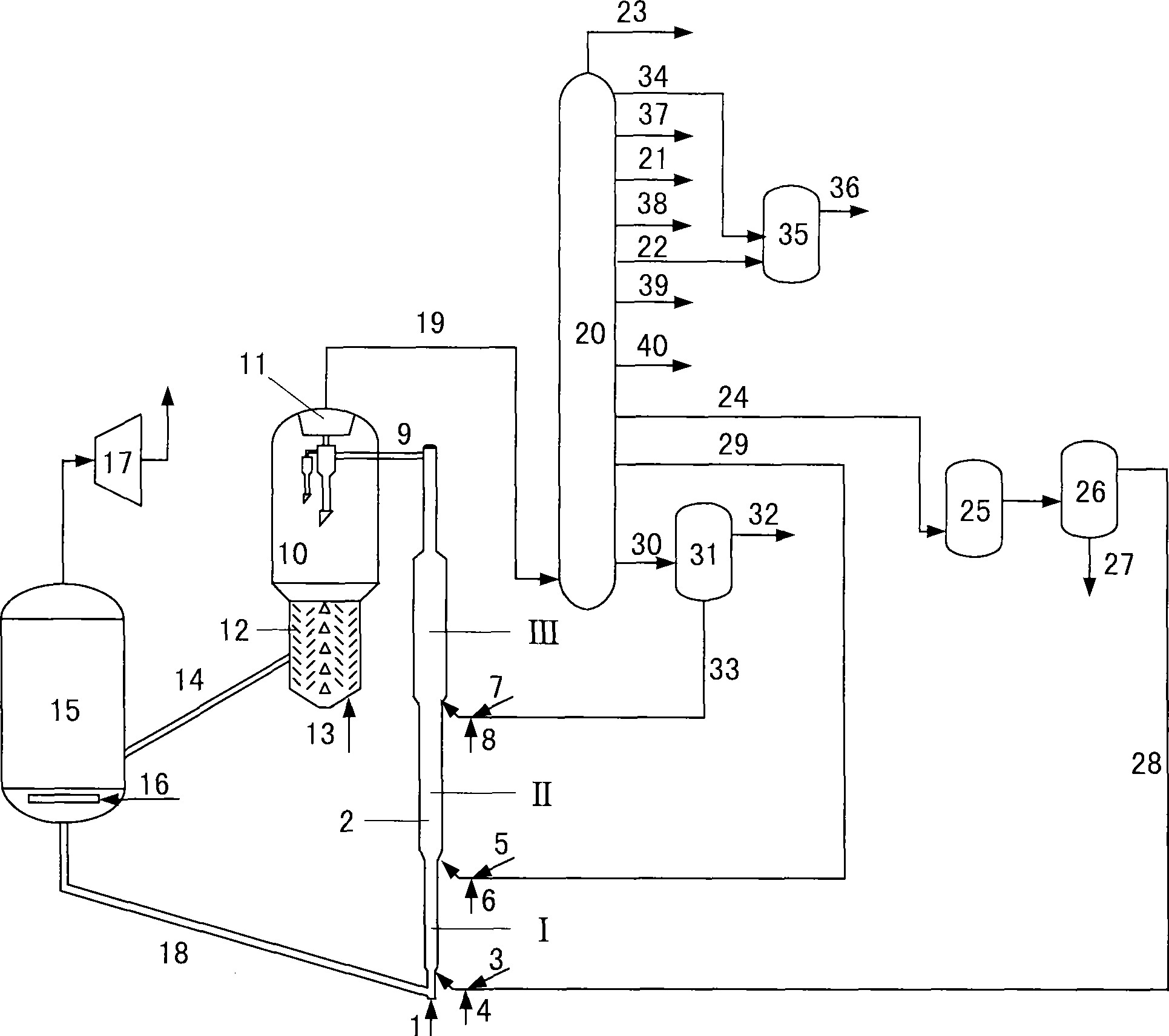

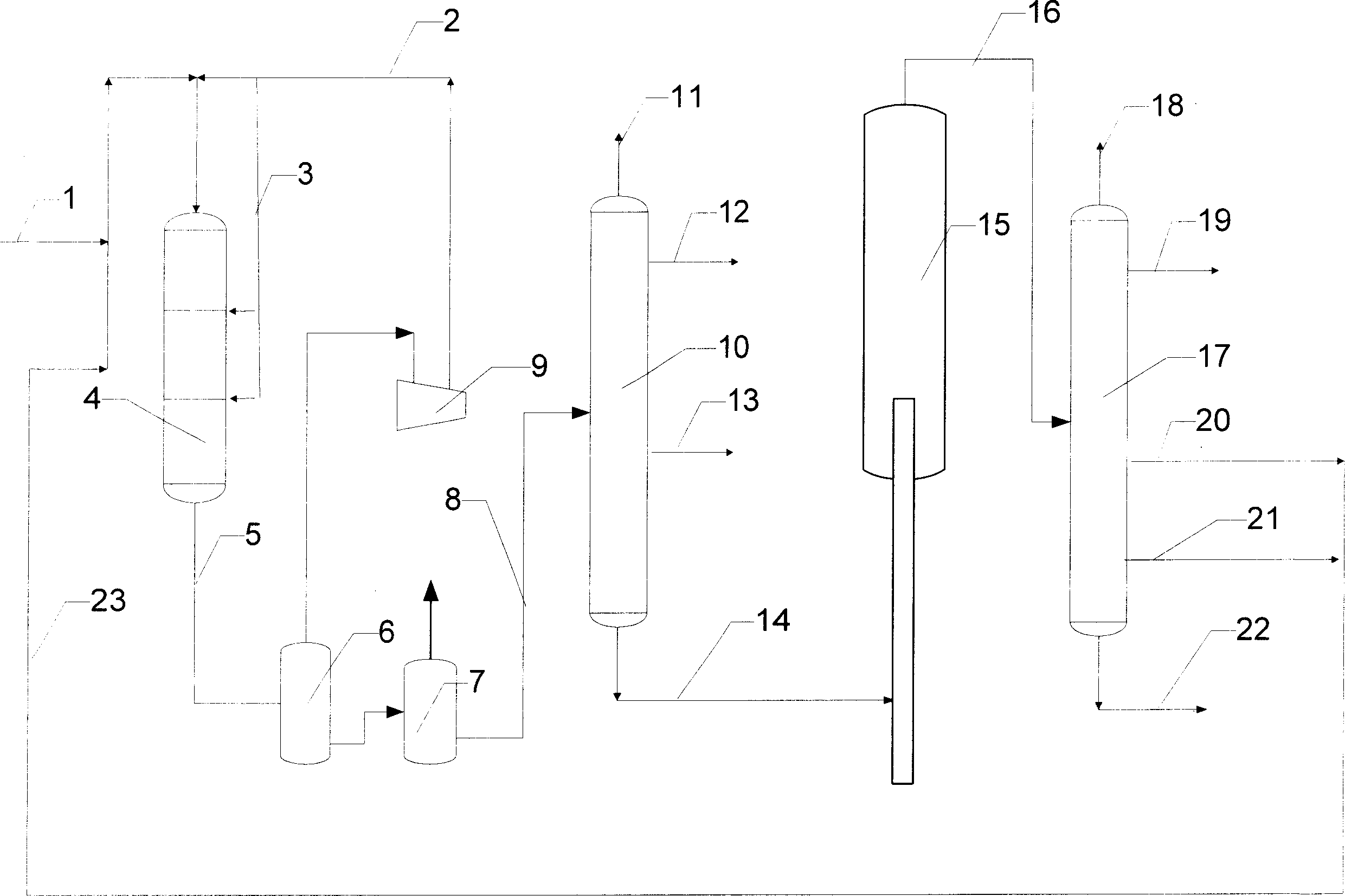

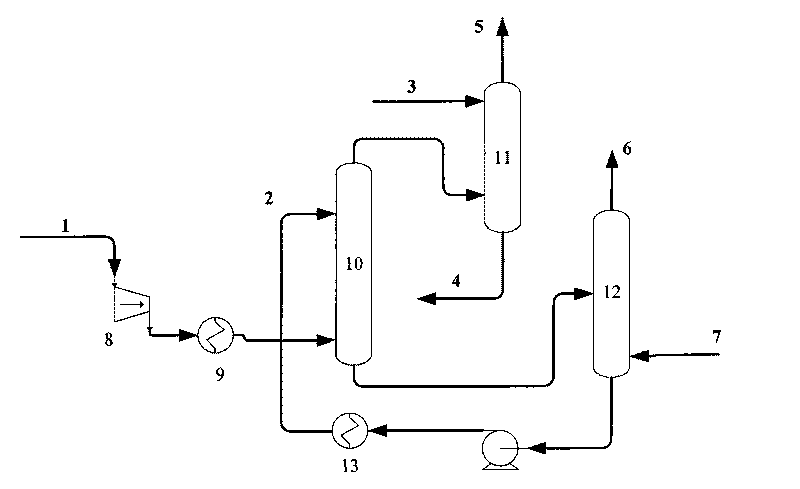

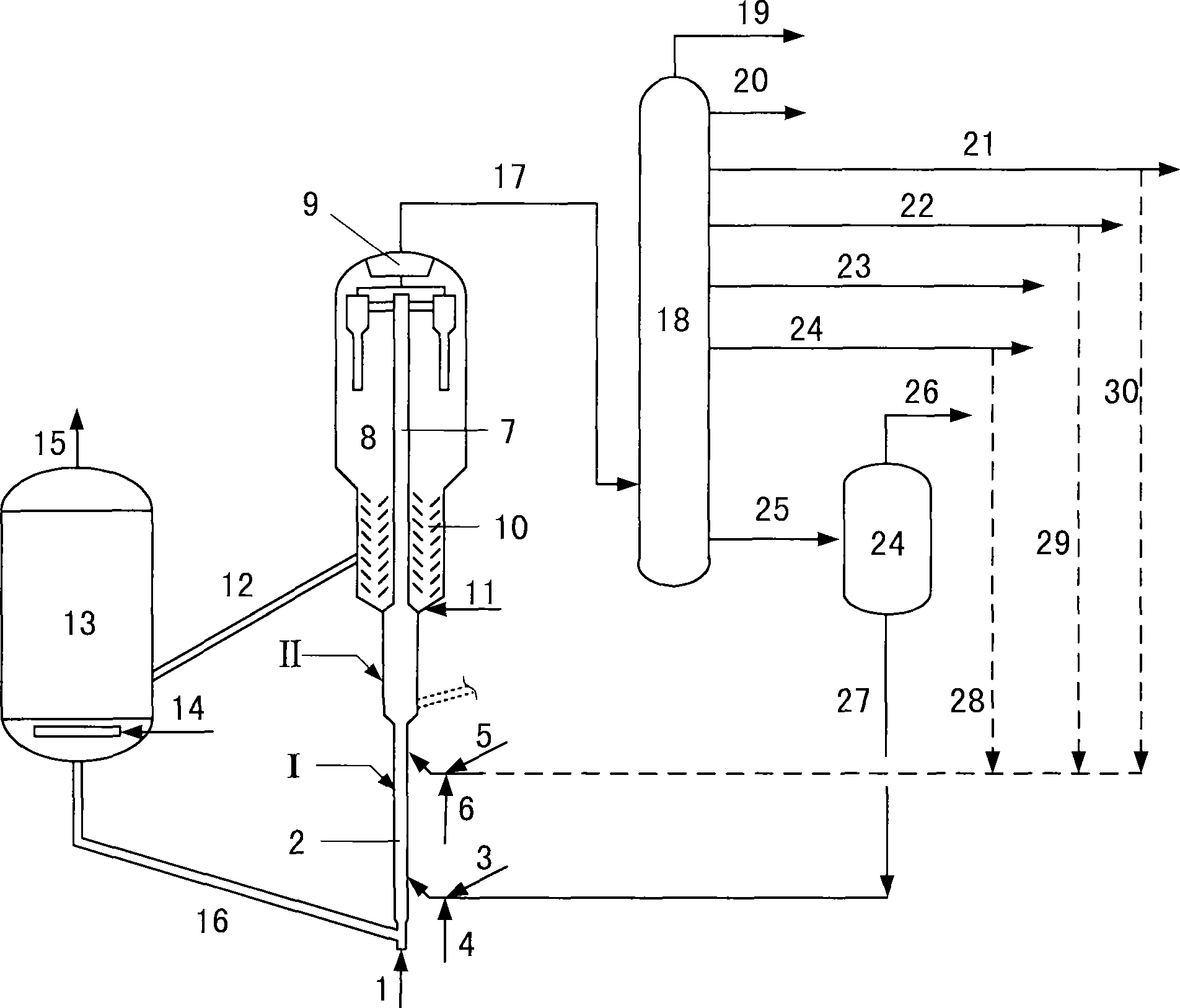

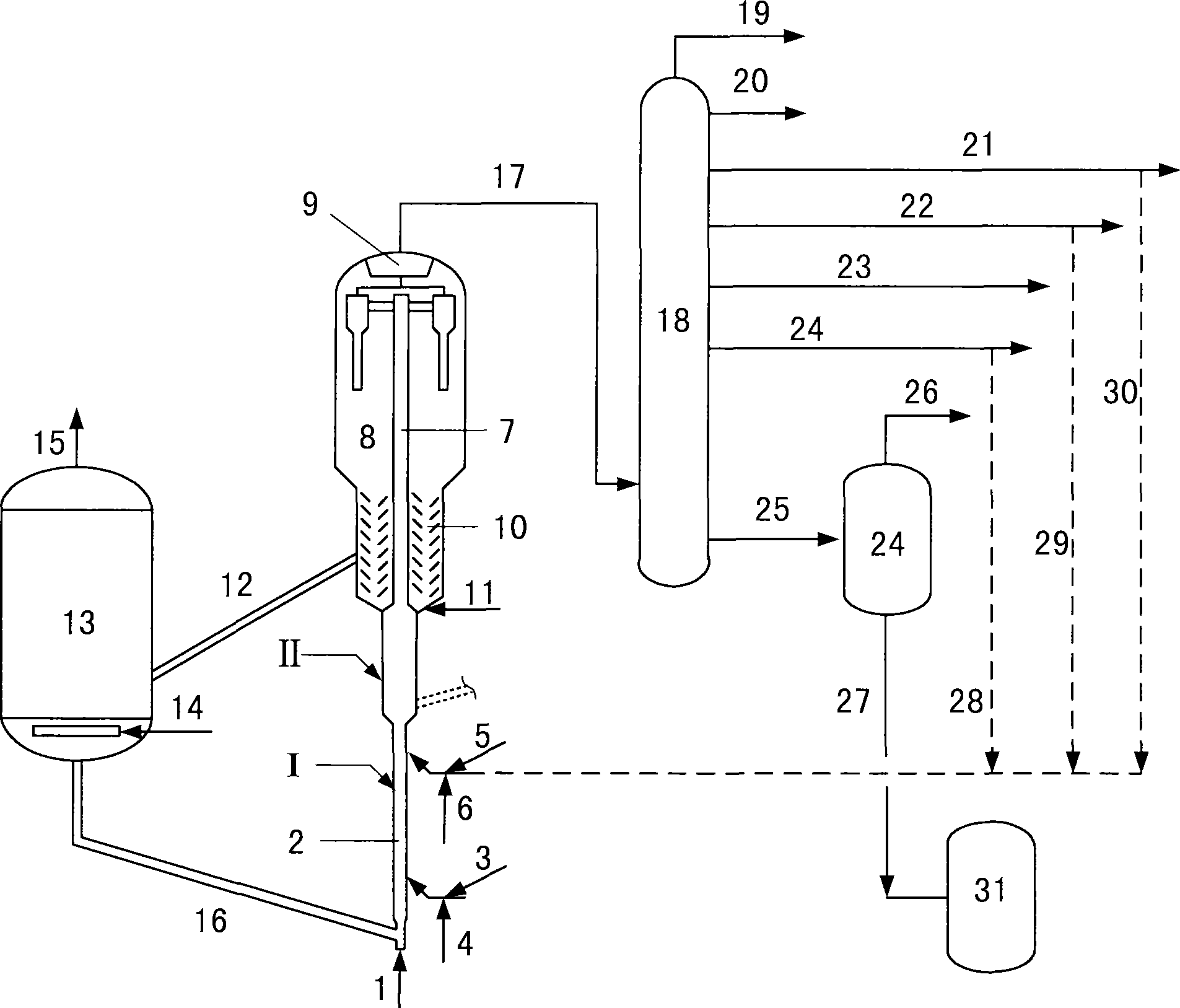

Method for separating plant catalytic dry gas by employing middle-cool-oil absorption process

InactiveCN101063048AEasy to getLow costOrganic chemistryEthylene productionProduct gasEnergy consumption

The invention discloses a separating refinery catalytic dry gas method with middle cold oil absorptive method in separating refinery catalytic dry gas technical domain, which comprises the following steps: compressing; stripping acid gas; drying; purifying; absorbing; desorbing; reclaiming cold energy; crude-separating. This invention possesses cheap cost, low lost, simple operation, little investment and low energy consumption, which can get C2 fraction and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

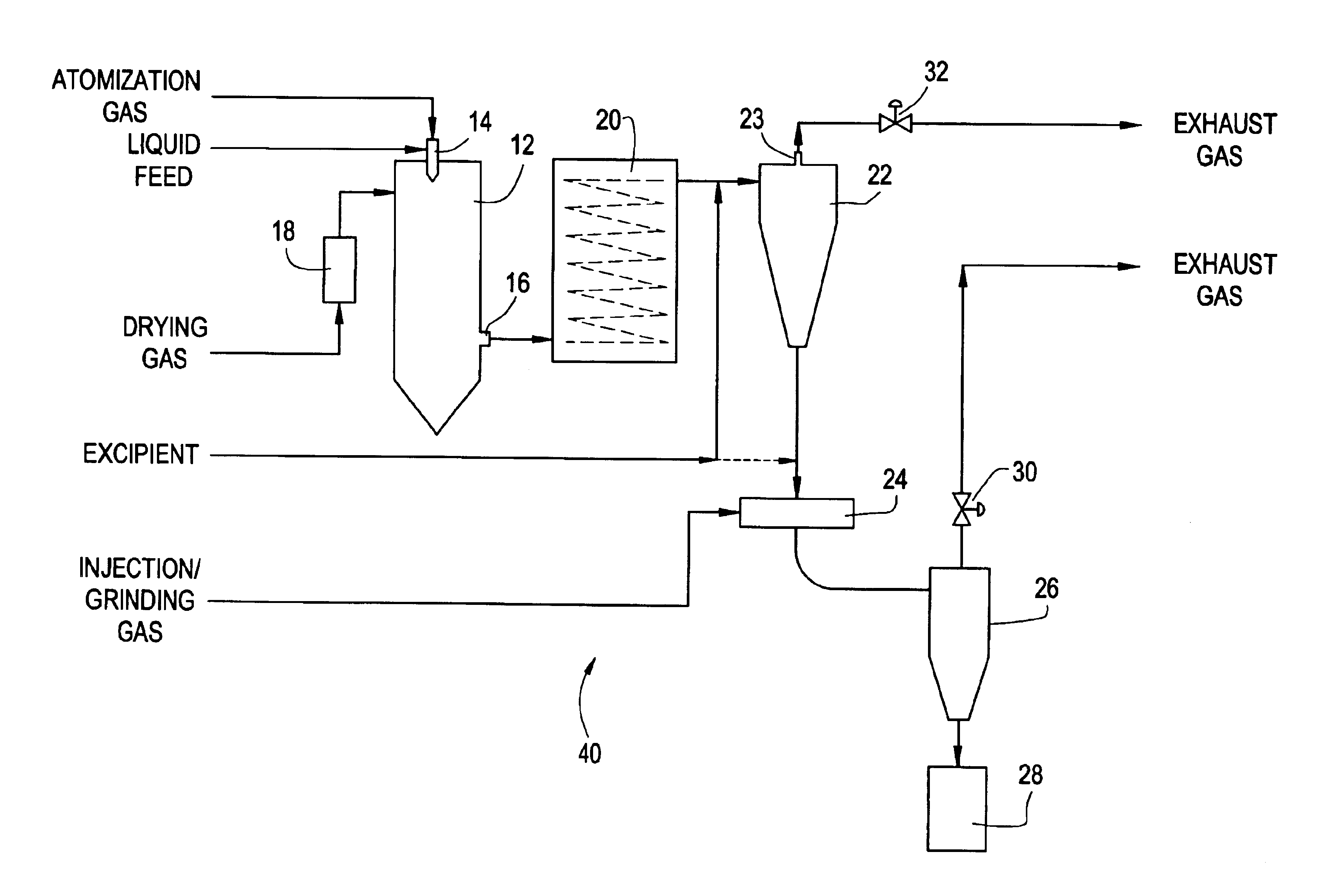

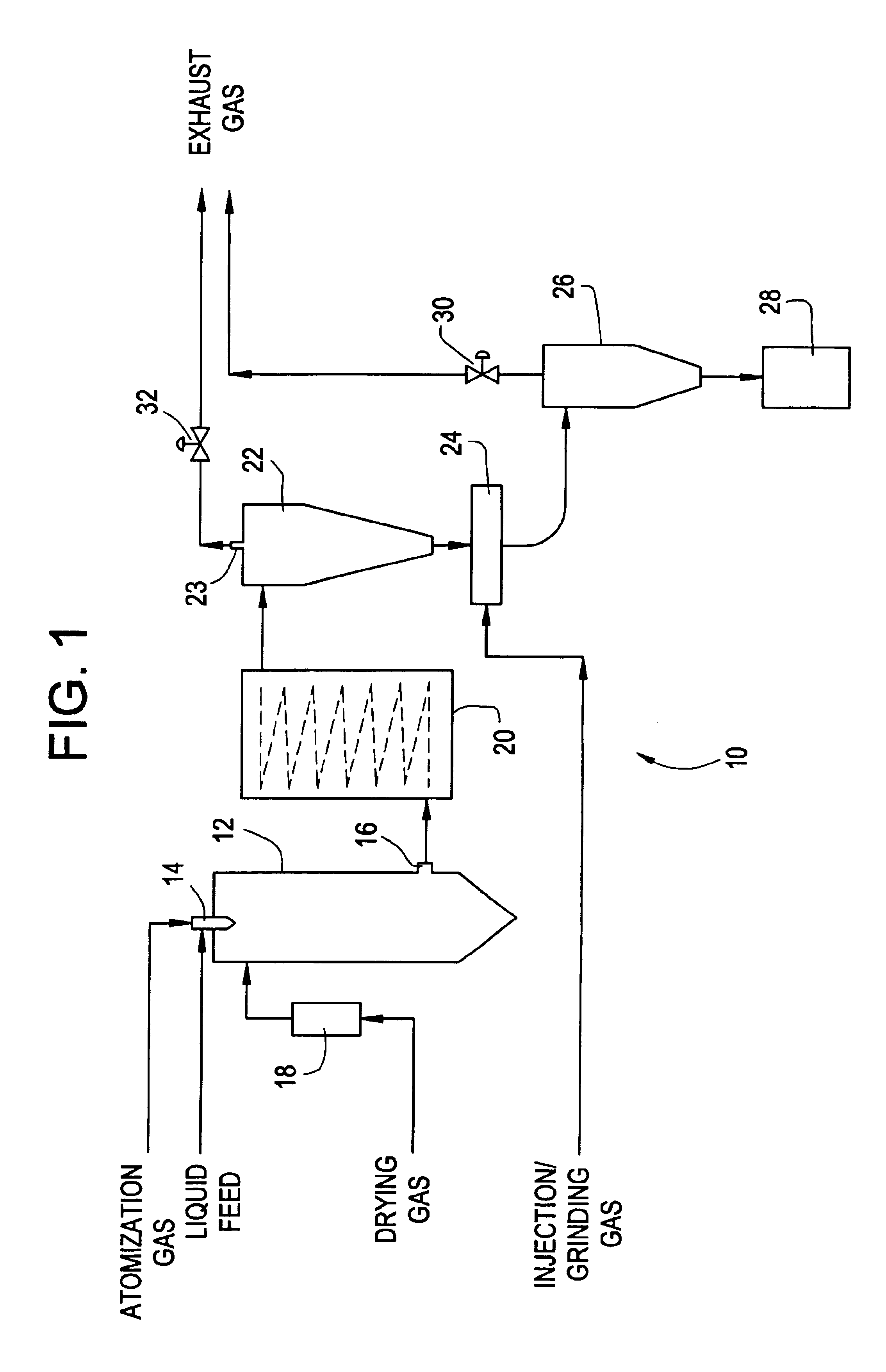

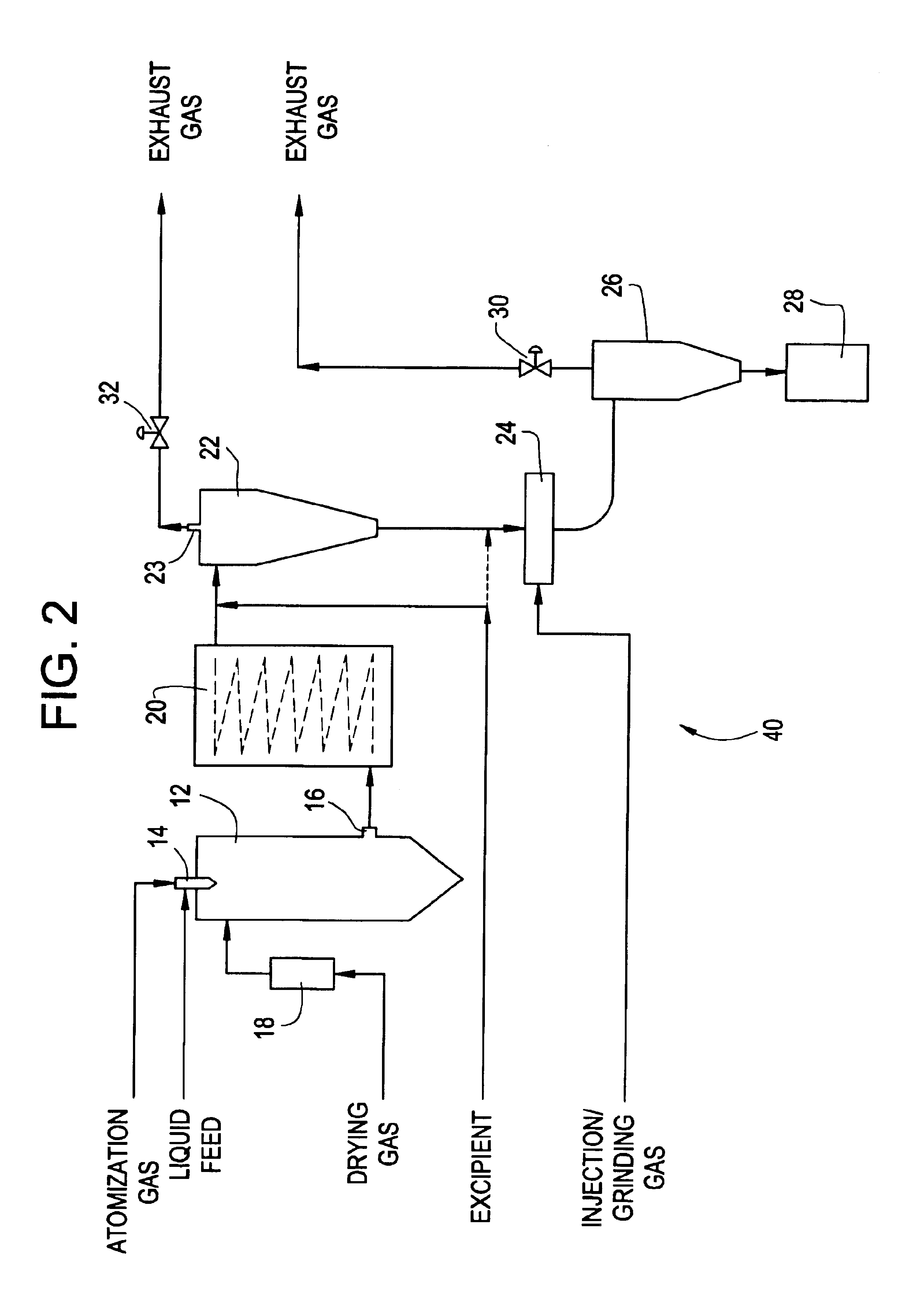

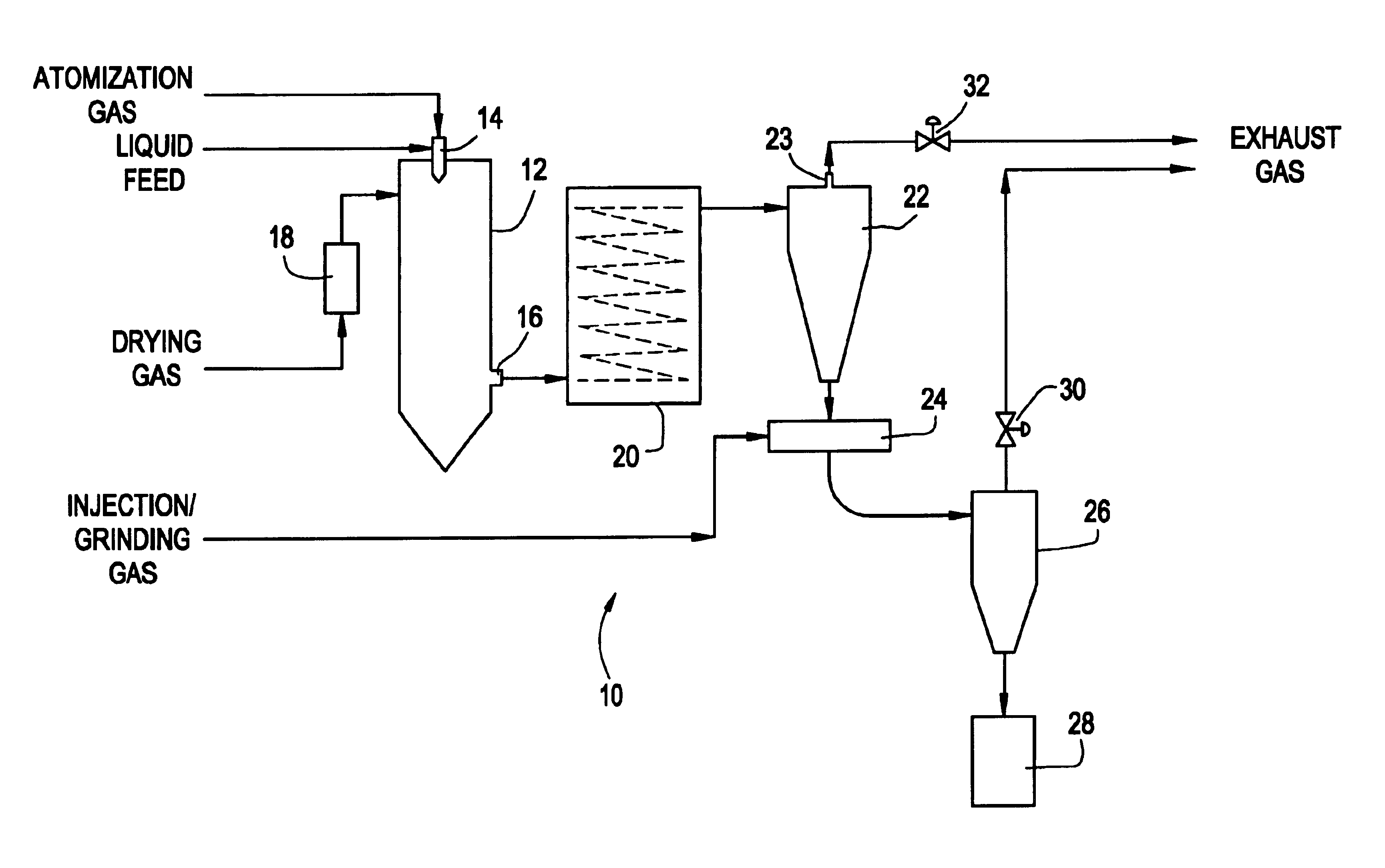

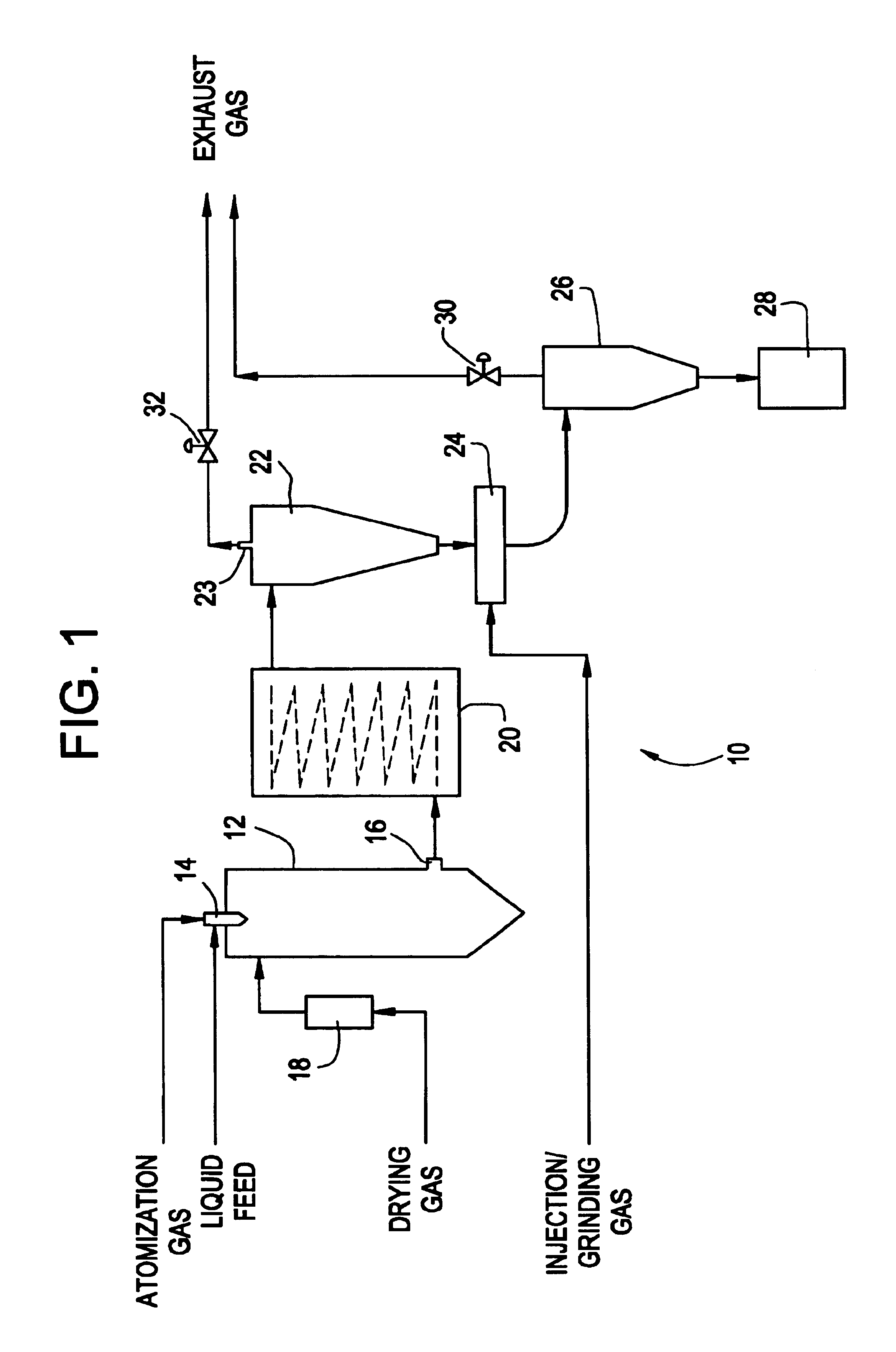

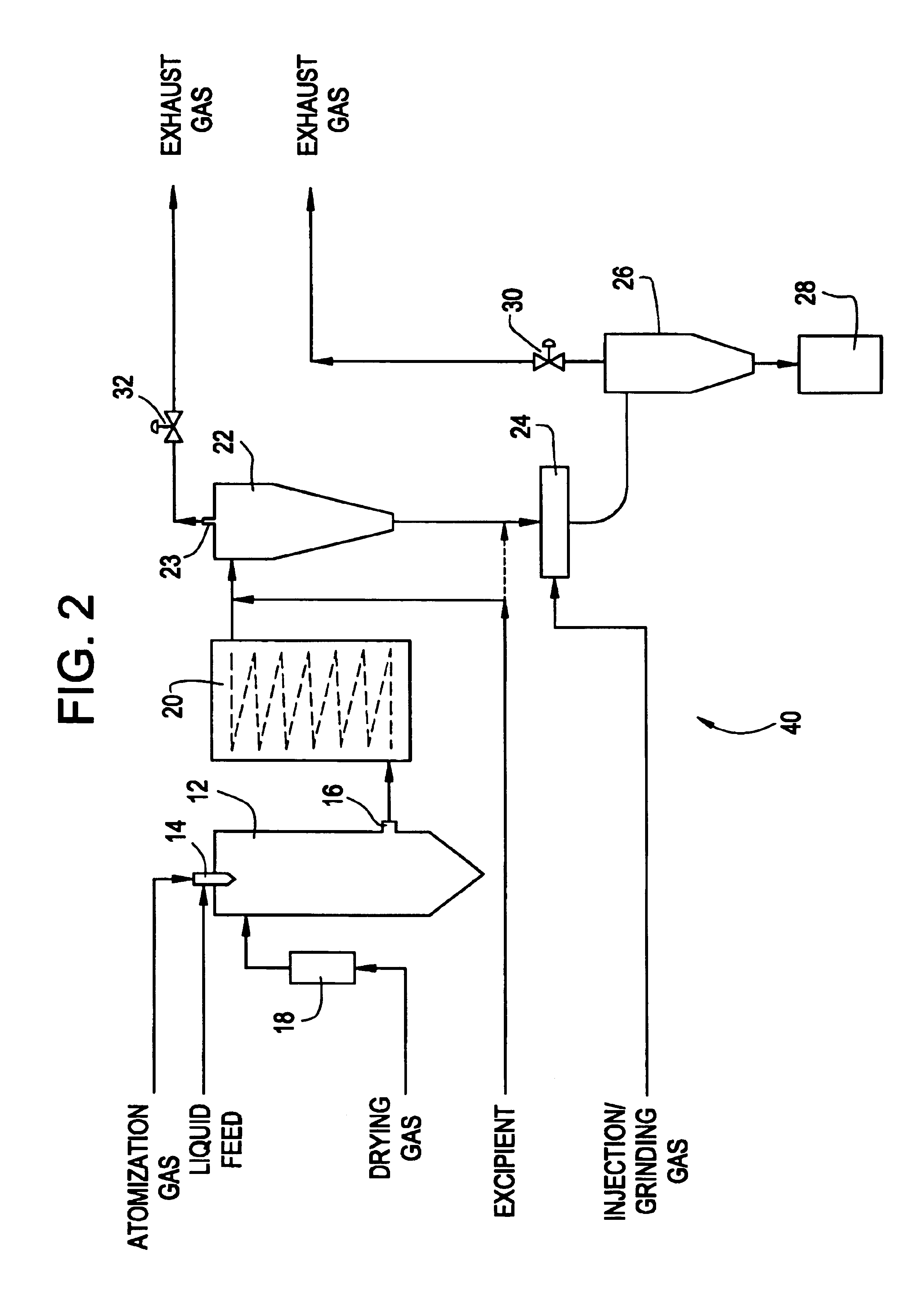

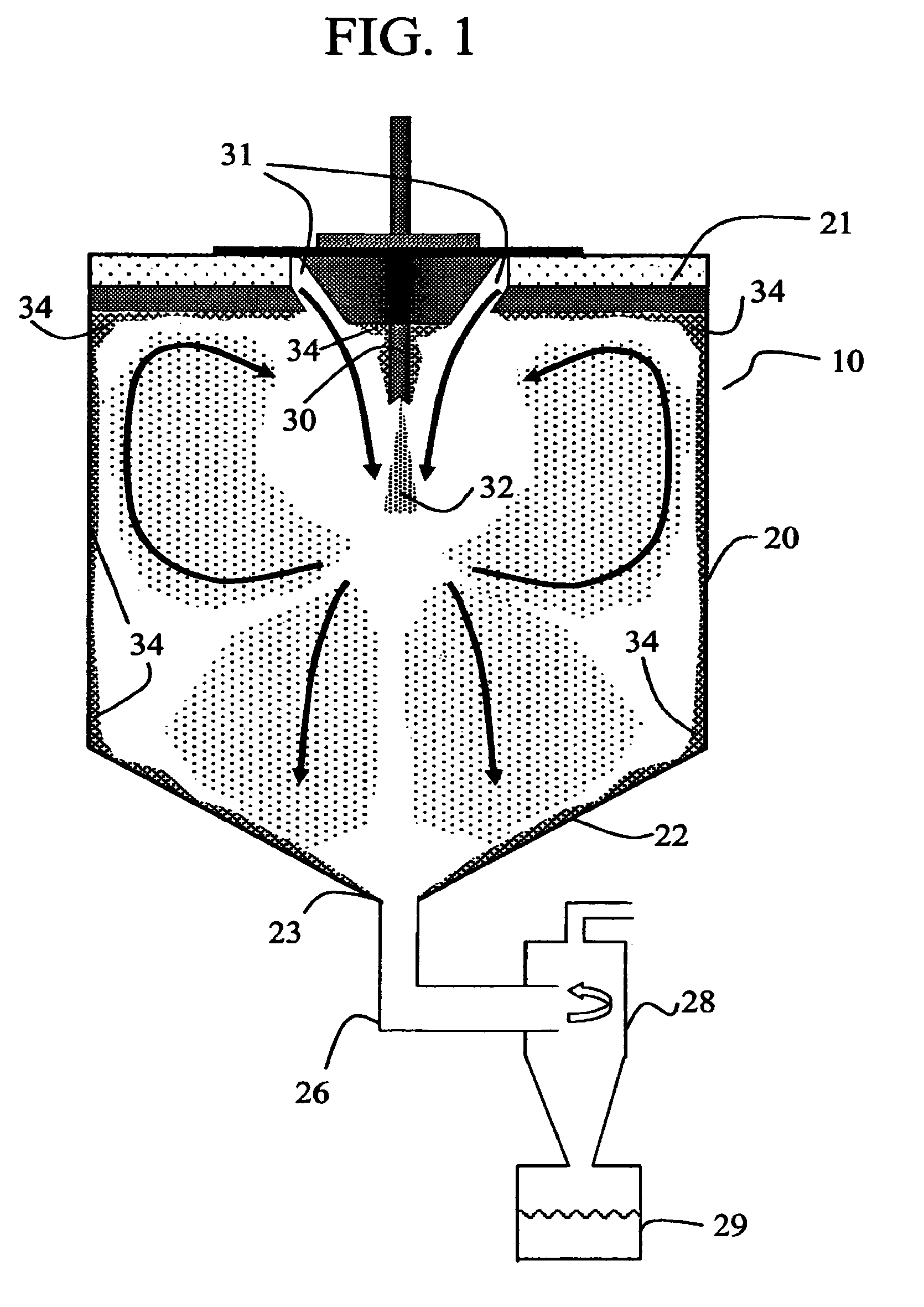

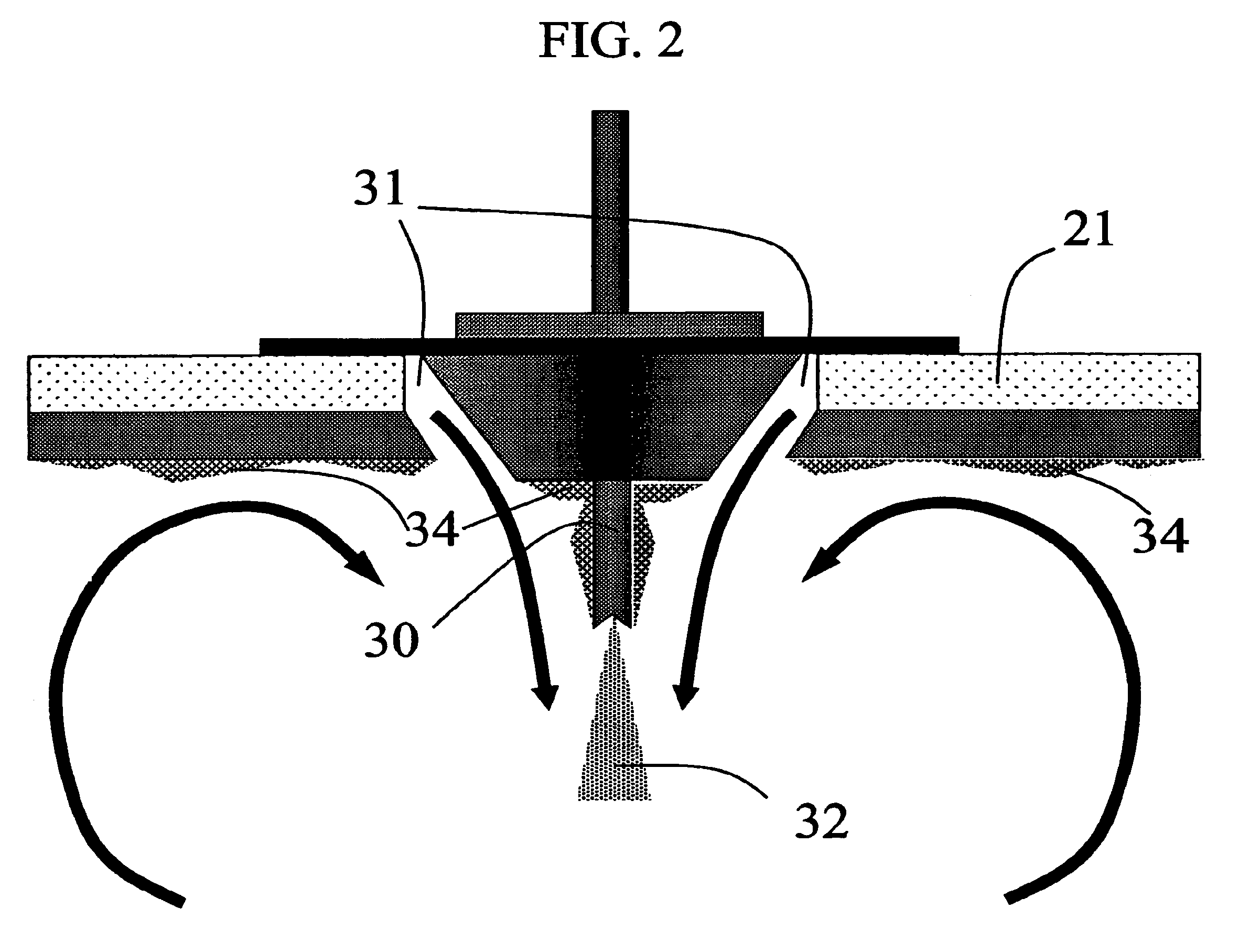

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6918991B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

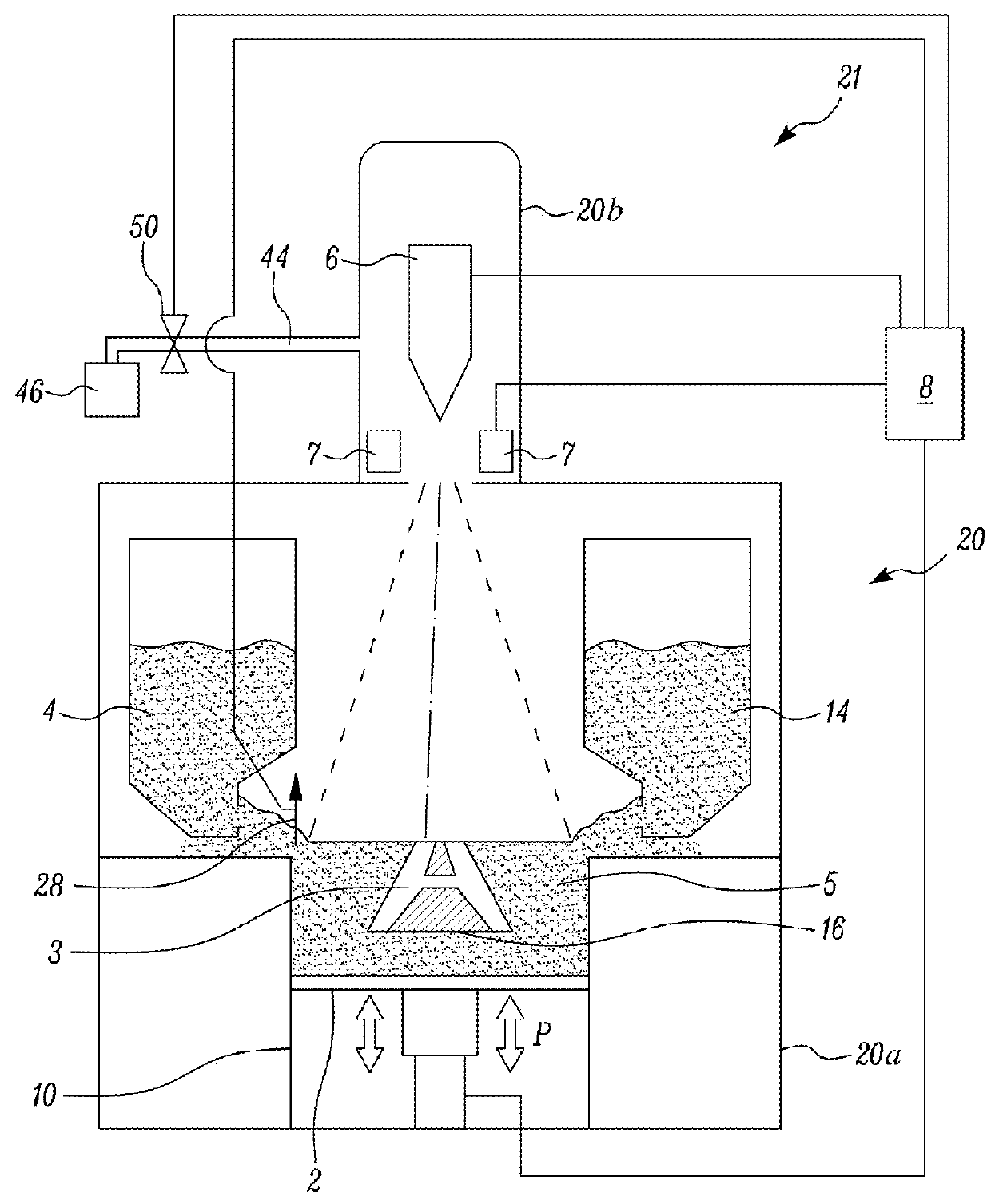

Enhanced additive manufacturing

InactiveUS20160052079A1Shorten the timeSmall volumeAdditive manufacturing apparatusElectric discharge tubesBeam sourceVacuum level

Various embodiments of the present invention relate to a method for operating an additive manufacturing apparatus in which a three-dimensional article is formed. Said method comprising the steps of: providing a vacuum chamber having at least a first and a second section, wherein said first and second sections are openly connected to each other, providing a predetermined vacuum level inside said vacuum chamber, providing a layer of powder material on a work table in said first section of said vacuum chamber, directing an electron beam from said at least one electron beam source provided in said second section over said work table to fuse in first selected locations according to said model to form a first cross section of said three-dimensional article, purging said second section with a dry gas when said vacuum chamber is open for prohibiting ambient air into said second section.

Owner:ARCAM AB

Production of propene and high-quality gasoline and diesel oil by two-stage catalyzed crack

ActiveCN101074392AGood natureQuality improvementOrganic chemistryCatalytic crackingMolecular sieveVegetable oil

A method for producing propylene and gasoline diesel-oil by two-section catalyzed cracking style is carried out by adopting two-section lift pipe catalyzing process and catalyst with molecular sieve, taking heavy petroleum hydrocarbon or various animal and vegetable oils containing hydrocarbon as raw materials, optimization combining by charging style for various reactants, and controlling proper reactive conditions. It can improve propene and light-oil recovery rate and quality, and inhibit to generate dry gas and coke.

Owner:PETROCHINA CO LTD +1

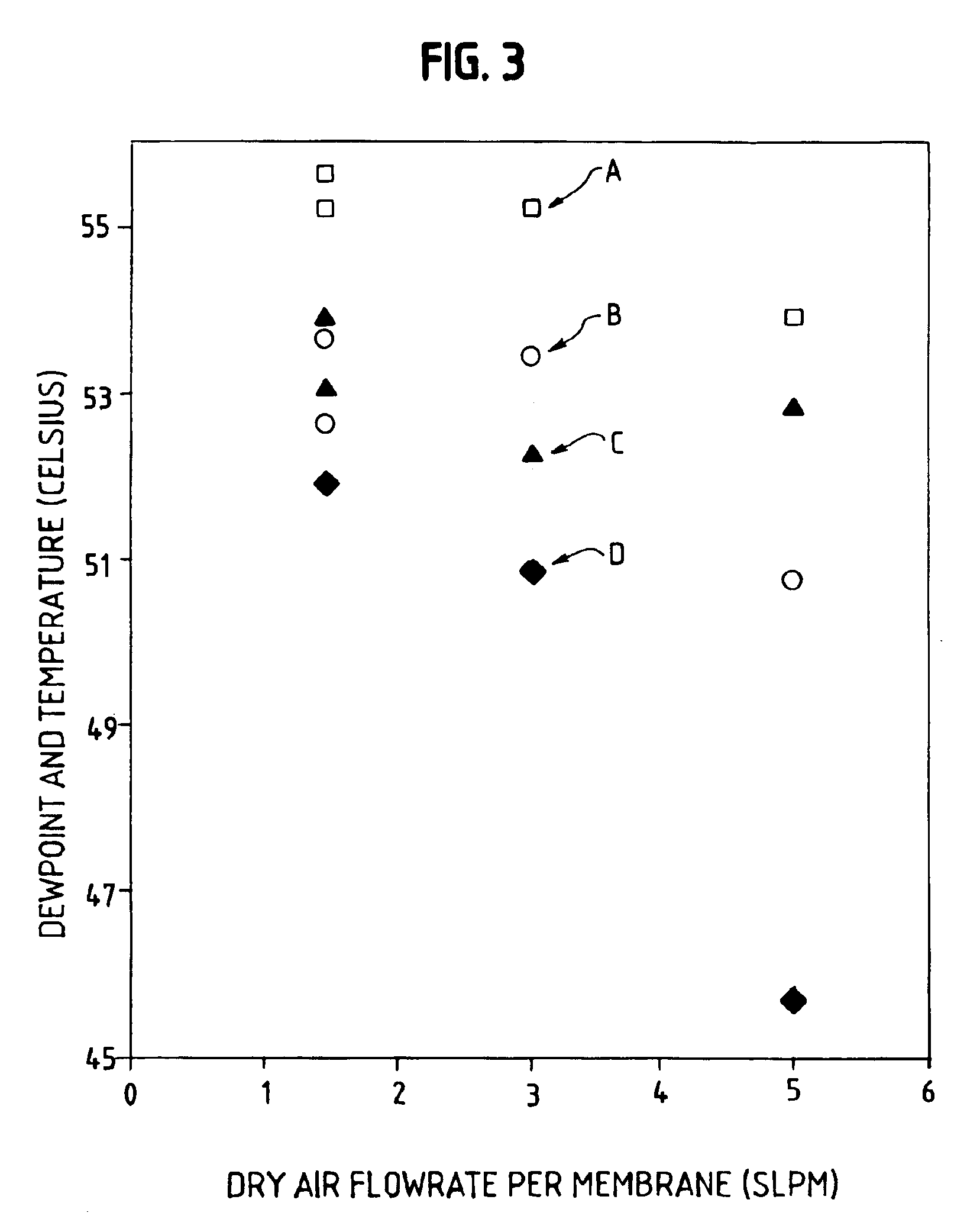

Membrane exchange humidifier for a fuel cell

InactiveUS6864005B2Simpler humidifier constructionFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsLiquid water

Owner:BDF IP HLDG

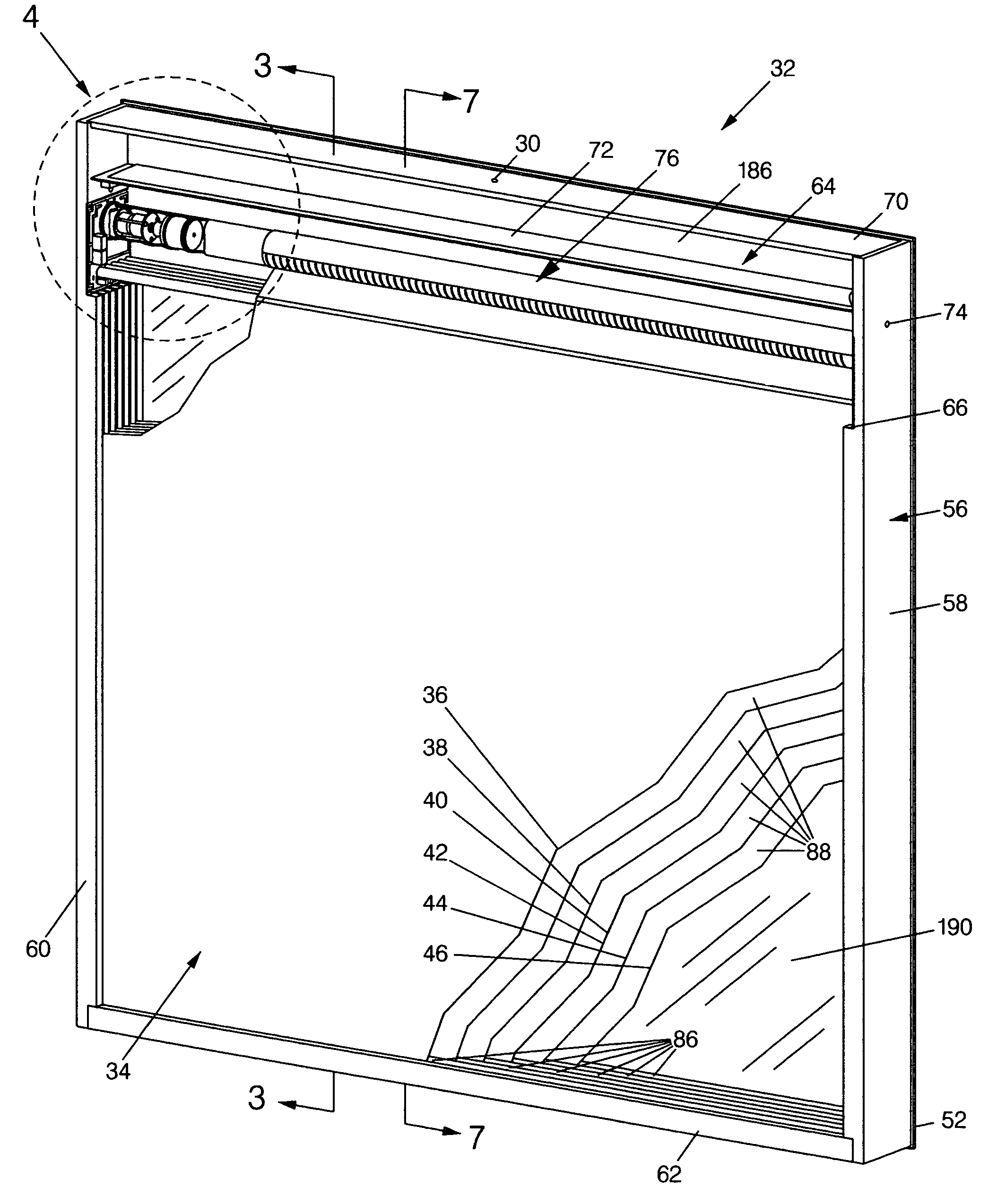

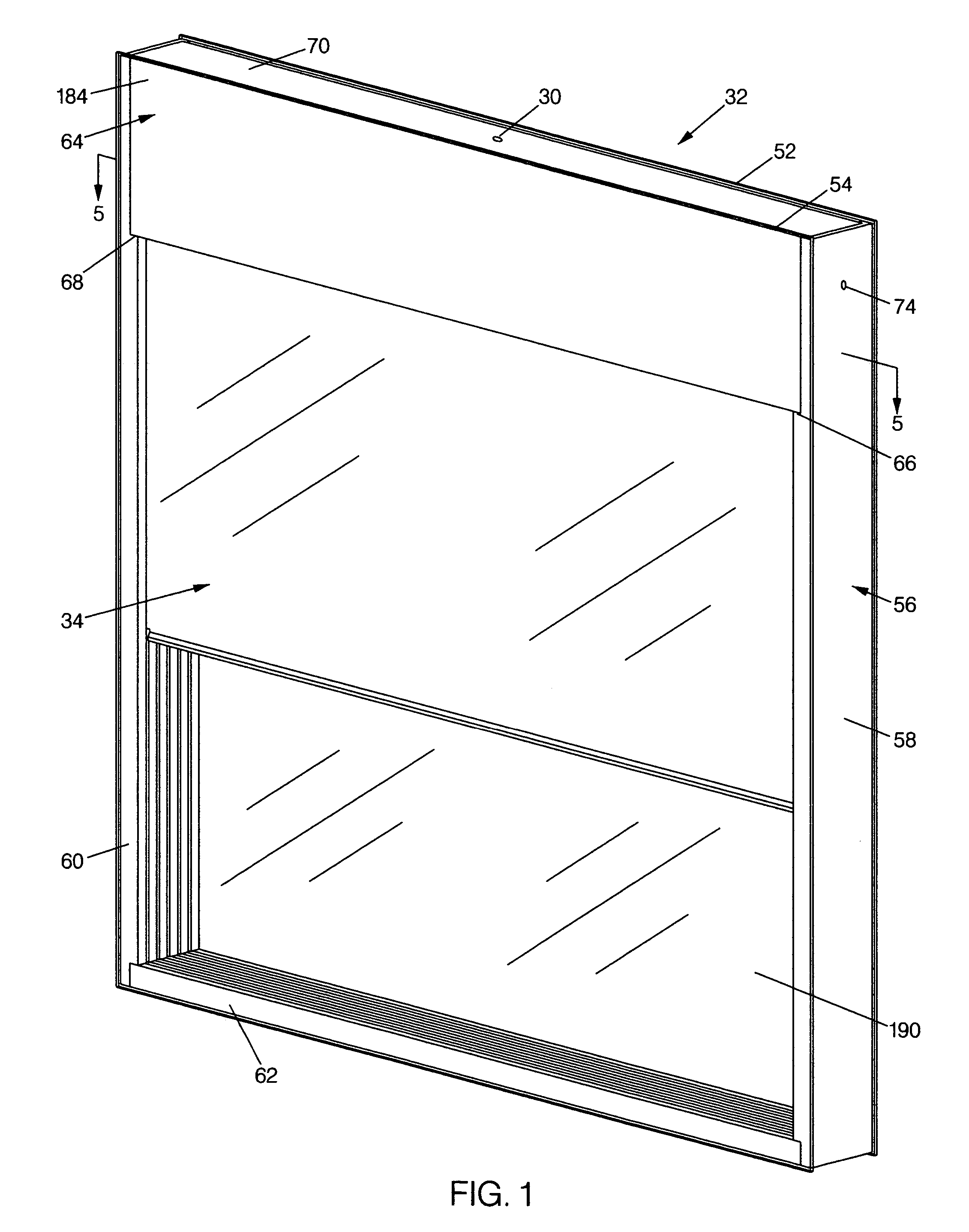

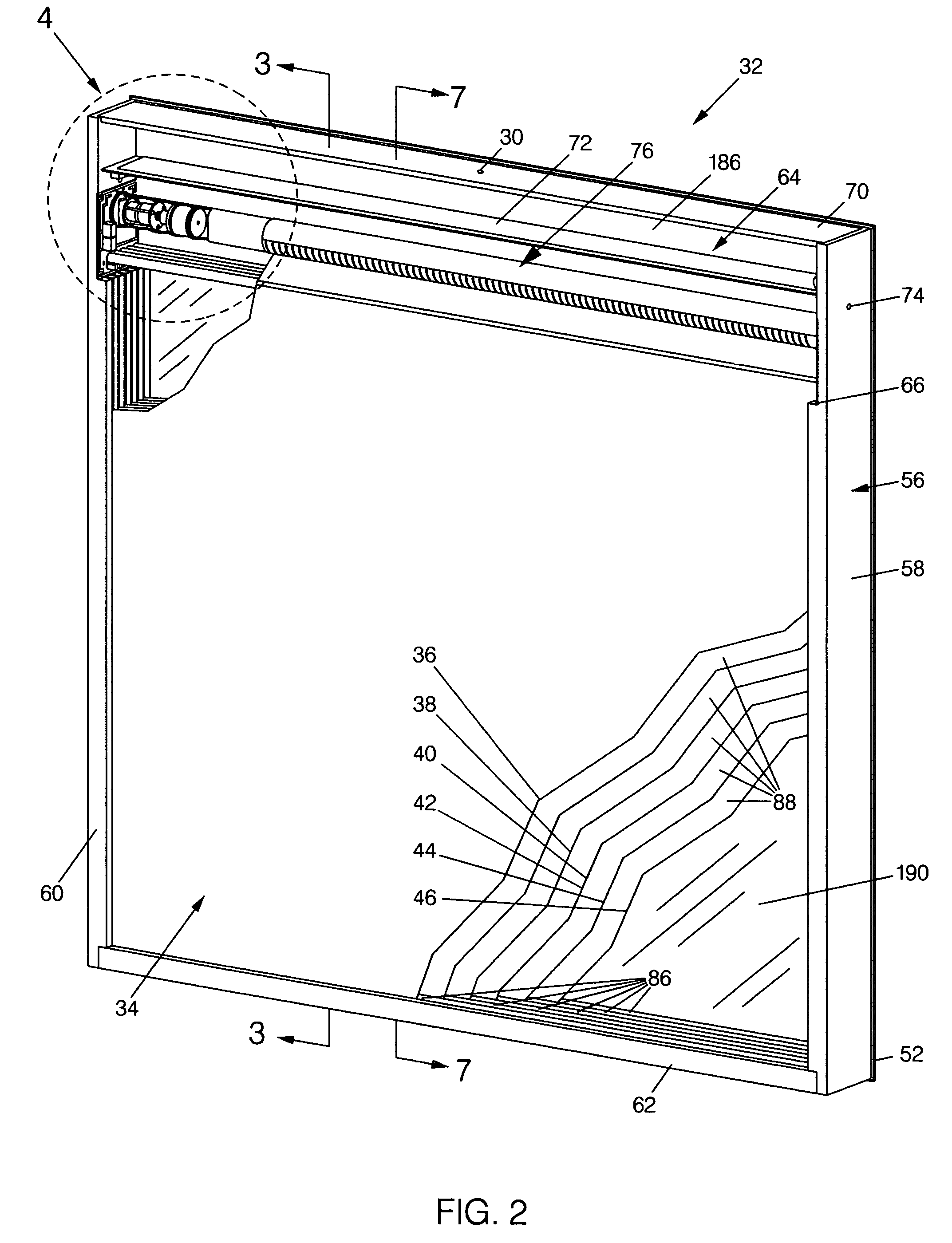

Multi-layered film window system

InactiveUS7281561B2Improve reflectivityReduce transmissionShutters/ movable grillesLight protection screensControl systemSheet film

A high R-rating window assembly storing multiple, reciprocating reflective flexible film layers in a sealed housing between rigid (e.g. glazed) layers. The glazed layers are separated on the order of 3 to 5-inches and are secured to low thermal conductivity framework pieces. The framework is capped with a motorized roller and film housing and the assembly is evacuated and filled with a desiccated, inert dry gas. Several plastic, reflective coated films are supported under tension in planar parallel relation between the glazing layers from the motorized roller and several guide rollers and guide tracks. Location sensors responsive to indicia on the films identify film position. Temperature sensors monitor ambient, internal and user set thermal conditions to control film exposure. The films are operable via a room control system and window controllers to define open, closed and partial exposure conditions. Alternative control functions may control film exposure in relation to room occupancy.

Owner:ANDERSON DONALD +1

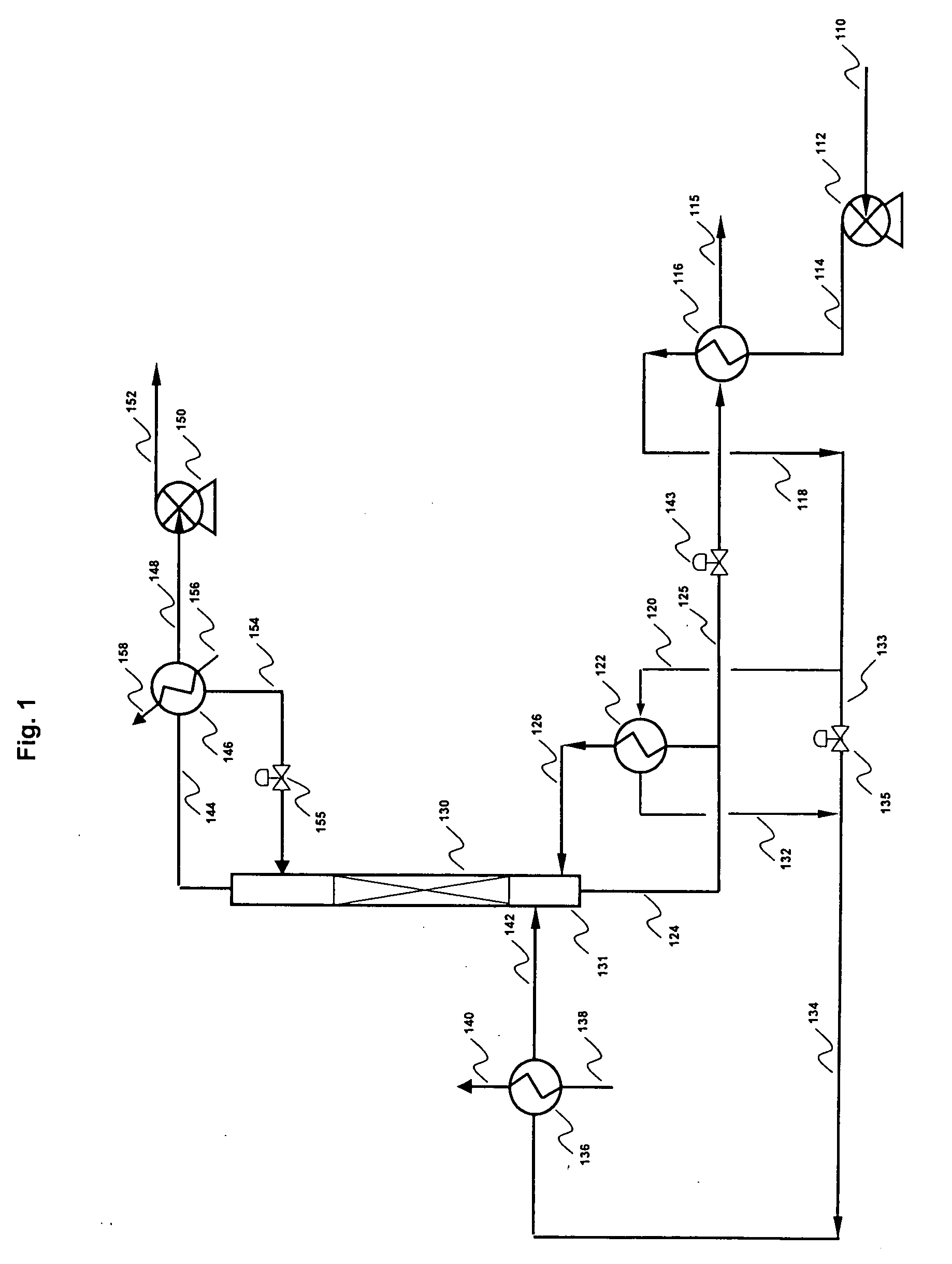

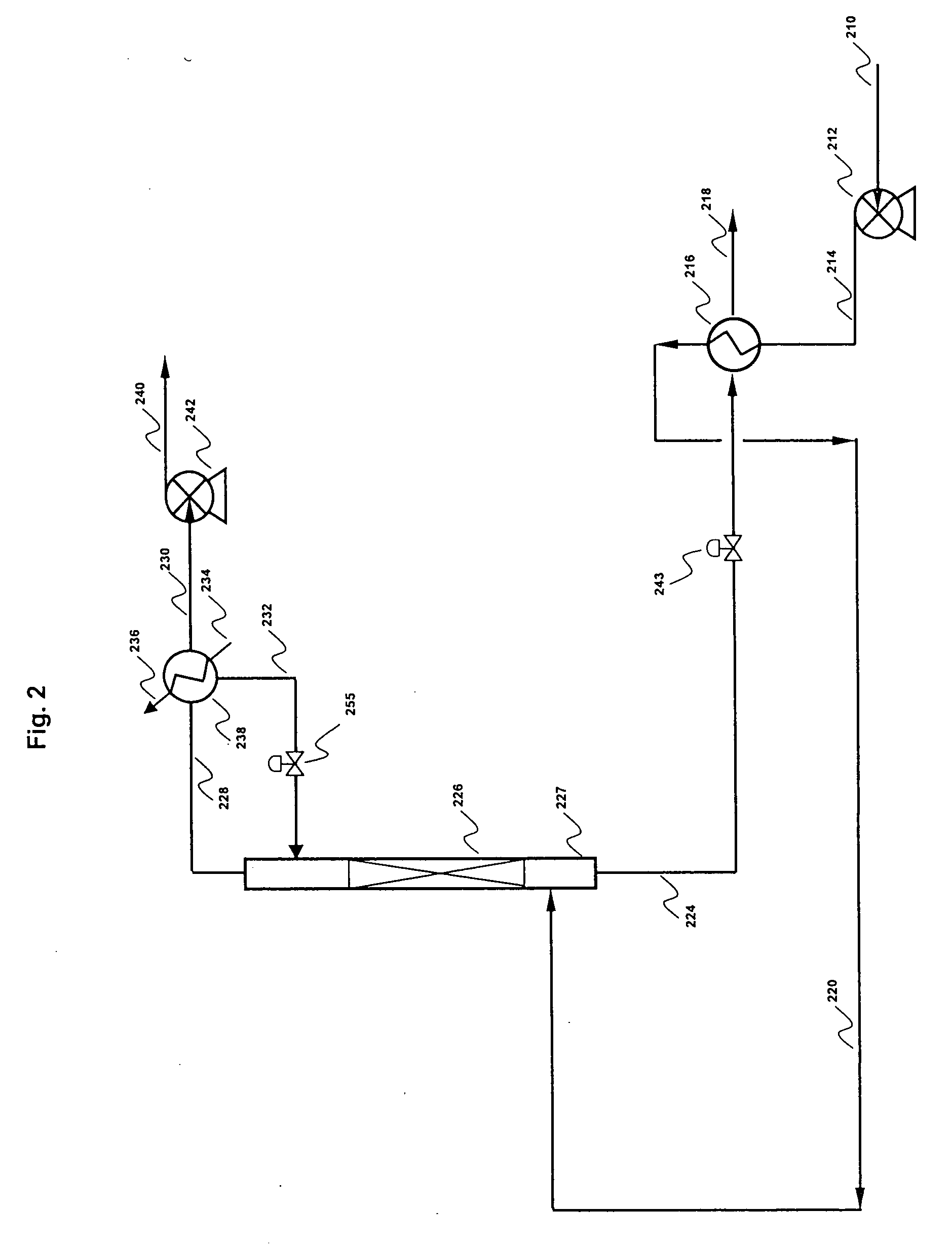

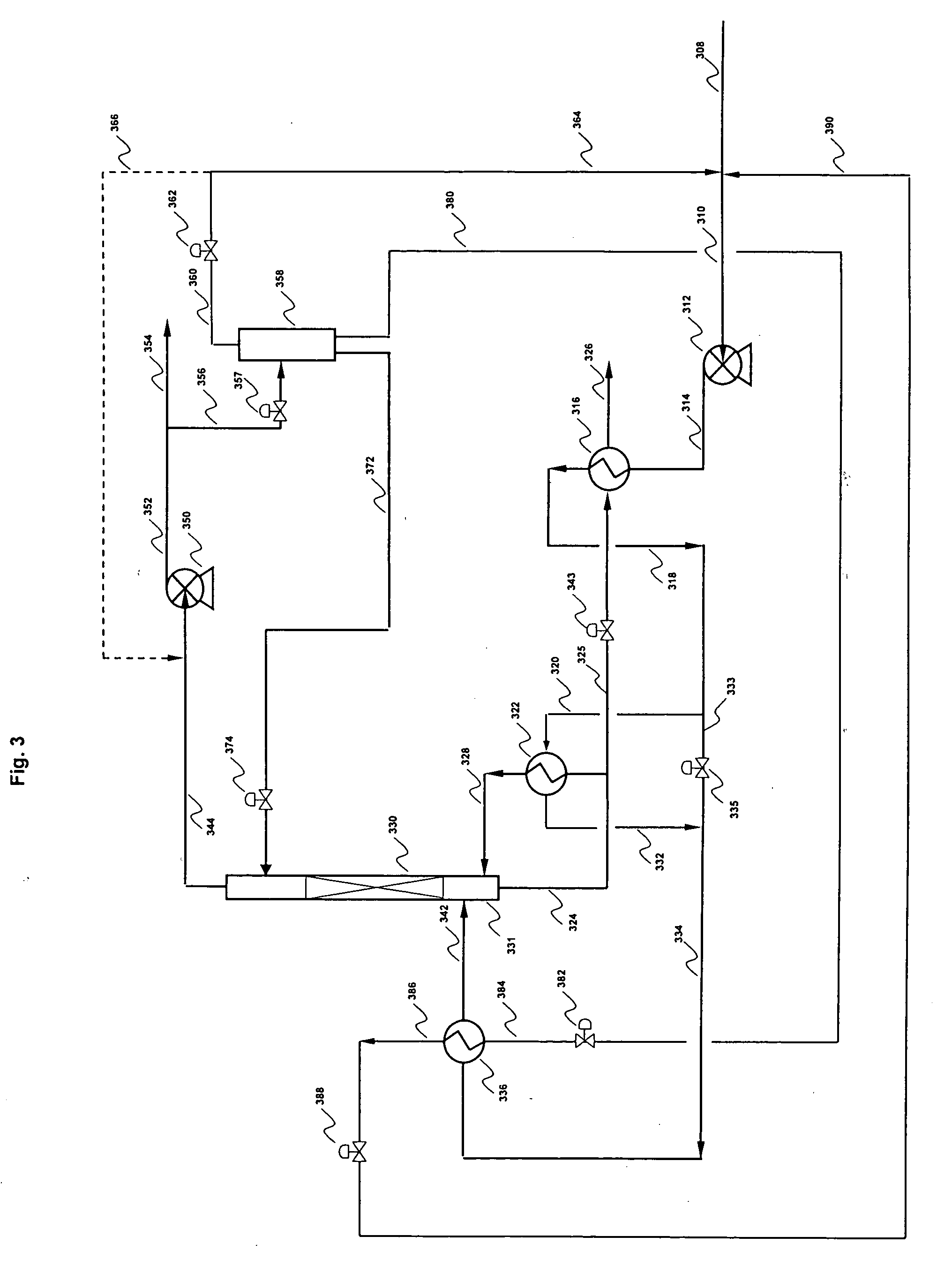

Removal of methyl mercaptan from gas streams

InactiveUS20050287056A1Efficient productionGas treatmentDispersed particle separationHigh concentrationThiol

The invention described herein is a method for selectively removing mercaptans such as methyl mercaptan from dry gas mixtures containing high concentrations of carbon dioxide. In the method, the carbon dioxide-rich gas (sour gas) is passed through an absorption vessel or distillation column in which it is contacted with an absorbent such as liquid carbon dioxide in order to selectively absorb the mercaptans. The treated gas, which is now free of mercaptans, leaves the top of the vessel as a sales gas suitable for use in enhanced oil recovery applications. Preferably, a portion of the carbon dioxide in the sales gas is condensed and the liquid is returned to the absorber or distillation column as the scrubbing agent. At least part of this scrubbing agent leaves the bottom of the absorber or distillation column enriched in methyl mercaptan and other sulfur compounds. The stream from the absorption vessel containing the mercaptans can be incinerated or otherwise processed to utilize or dispose of the methyl mercaptan.

Owner:DAKOTA GASIFICATION COMPANY

Catalytic conversion method for preparing propylene and high-octane gasoline

ActiveCN101531923AHigh selectivityHigh yieldOrganic chemistryTreatment with hydrotreatment processesGasolineReaction temperature

A catalytic conversion method for preparing propylene and high-octane gasoline comprises the following steps: raw materials which are difficult to be cracked are firstly contacted with a thermal regeneration catalytic cracking catalyst to carry out cracking reaction under the conditions that the reaction temperature is 600-750 DEG C and the weight hourly space velocity is 100-800h<-1>, the reactant flow is mixed with raw oil which is easy to be cracked to carry out the cracking reaction under the conditions that the reaction temperature is 450-620 DEG C and the weight hourly space velocity is 0.1-100h<-1>; the spent catalyst and reaction oil and gas are separated, the spent catalyst returns to a reactor after regeneration, the reaction oil and gas are separated to obtain propylene and gasoline, and hydrogenated heavy oil obtained by hydrotreating fractions above 260 DEG C is taken as raw oil of the catalytic cracking device or a conventional catalytic cracking device. The method improves the yield and the selectivity of the propylene, increases the yield of the high-octane gasoline, reduces the yield of dry gas, greatly increases the yield of liquid and realizes the high-efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

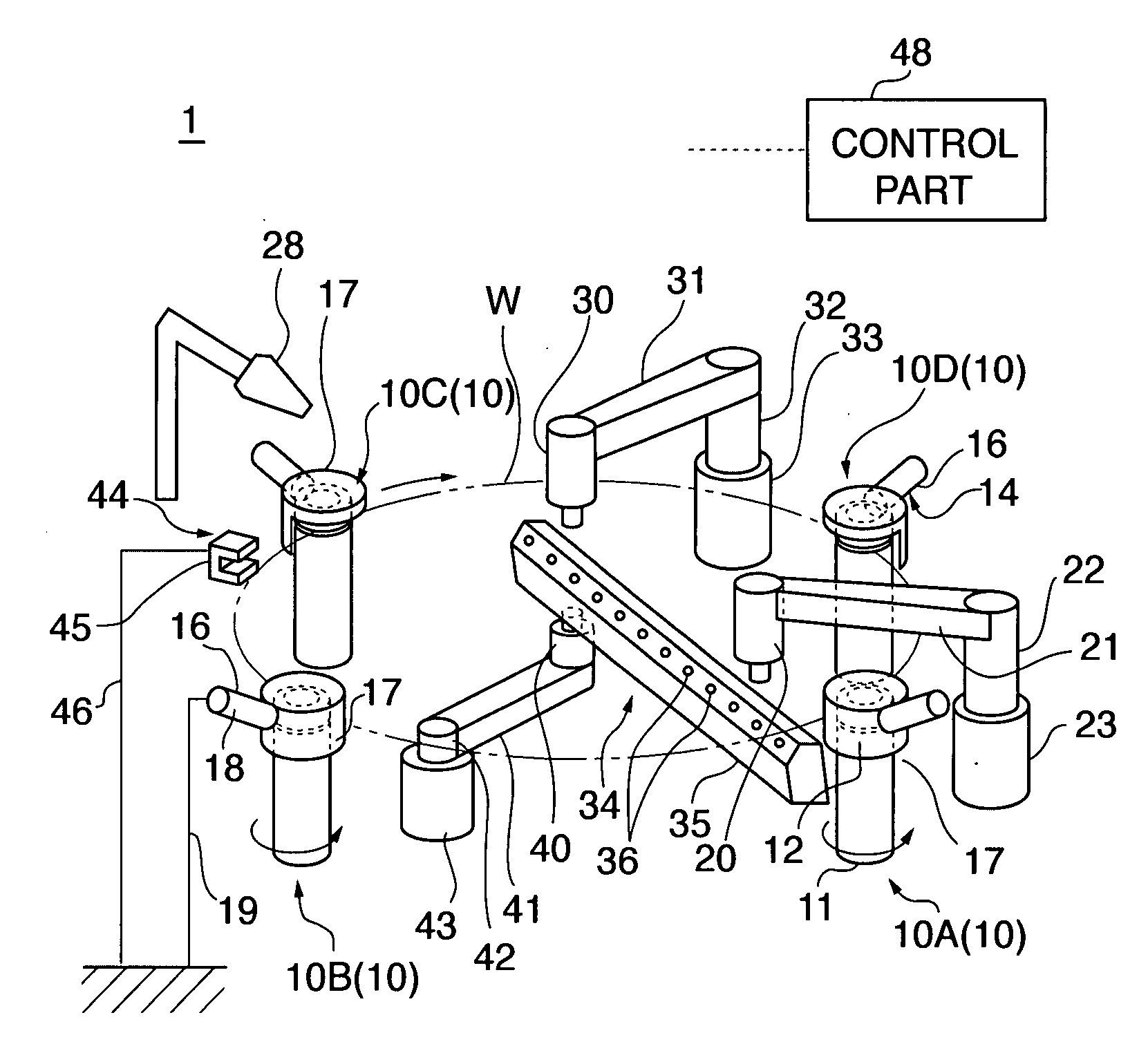

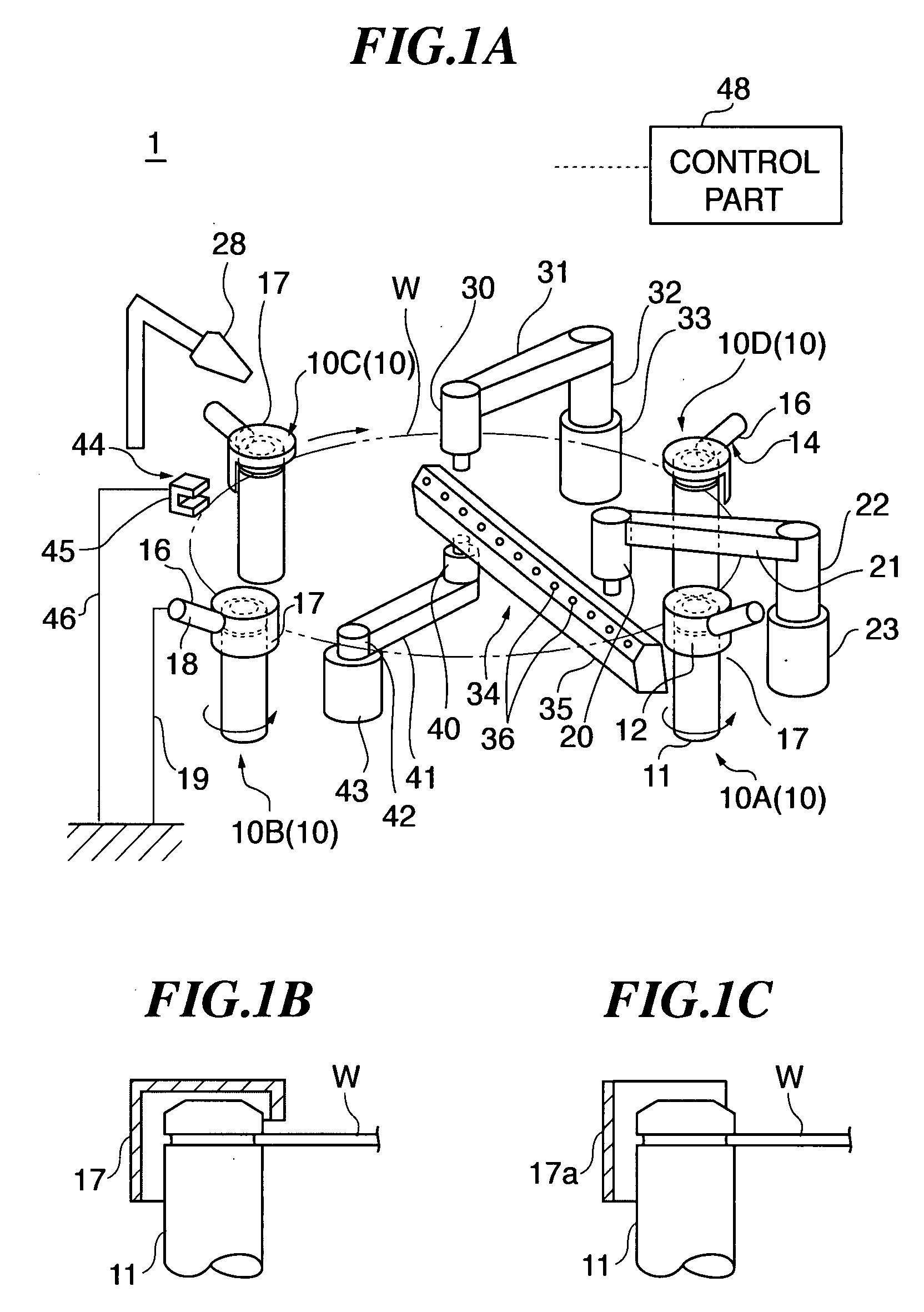

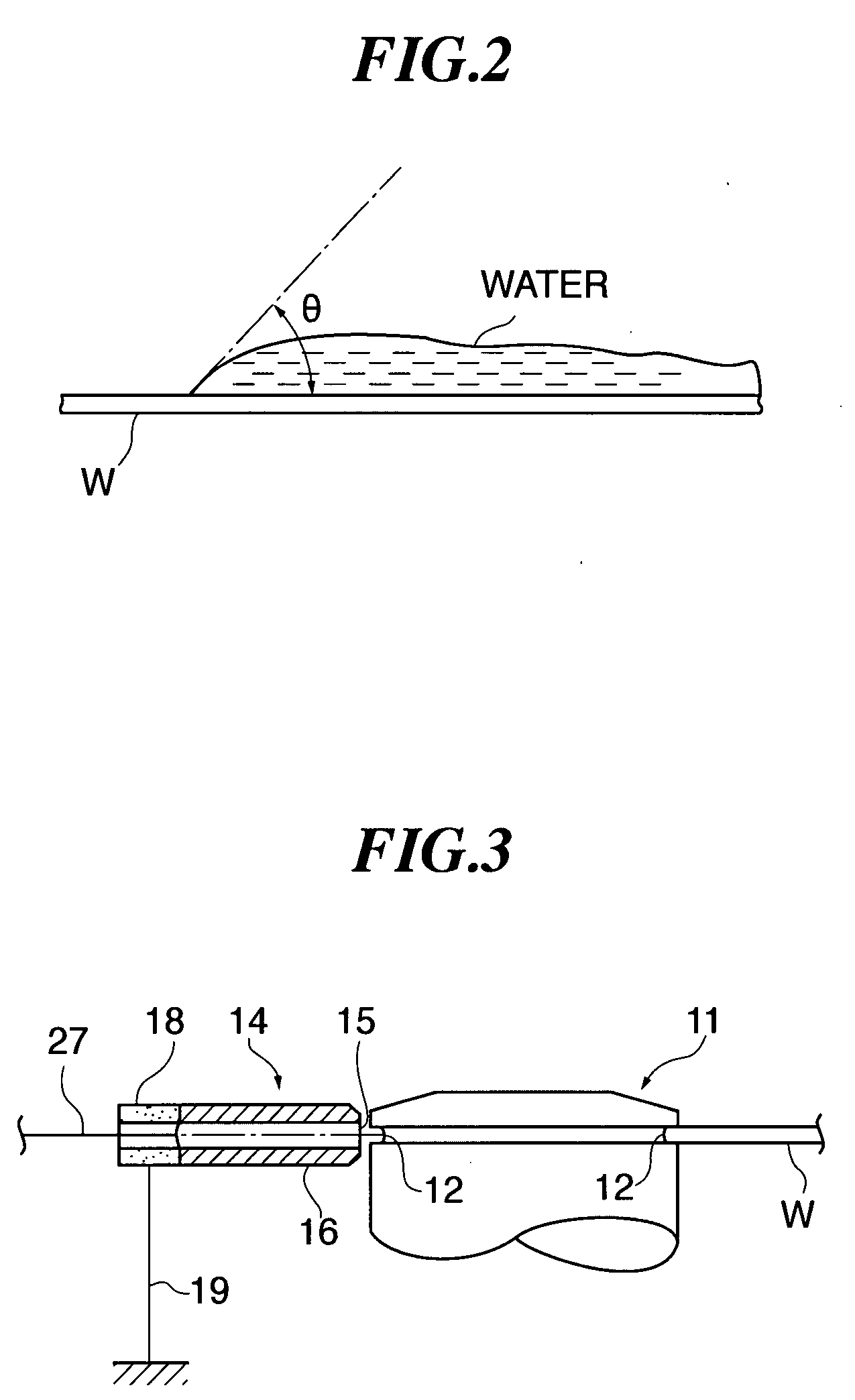

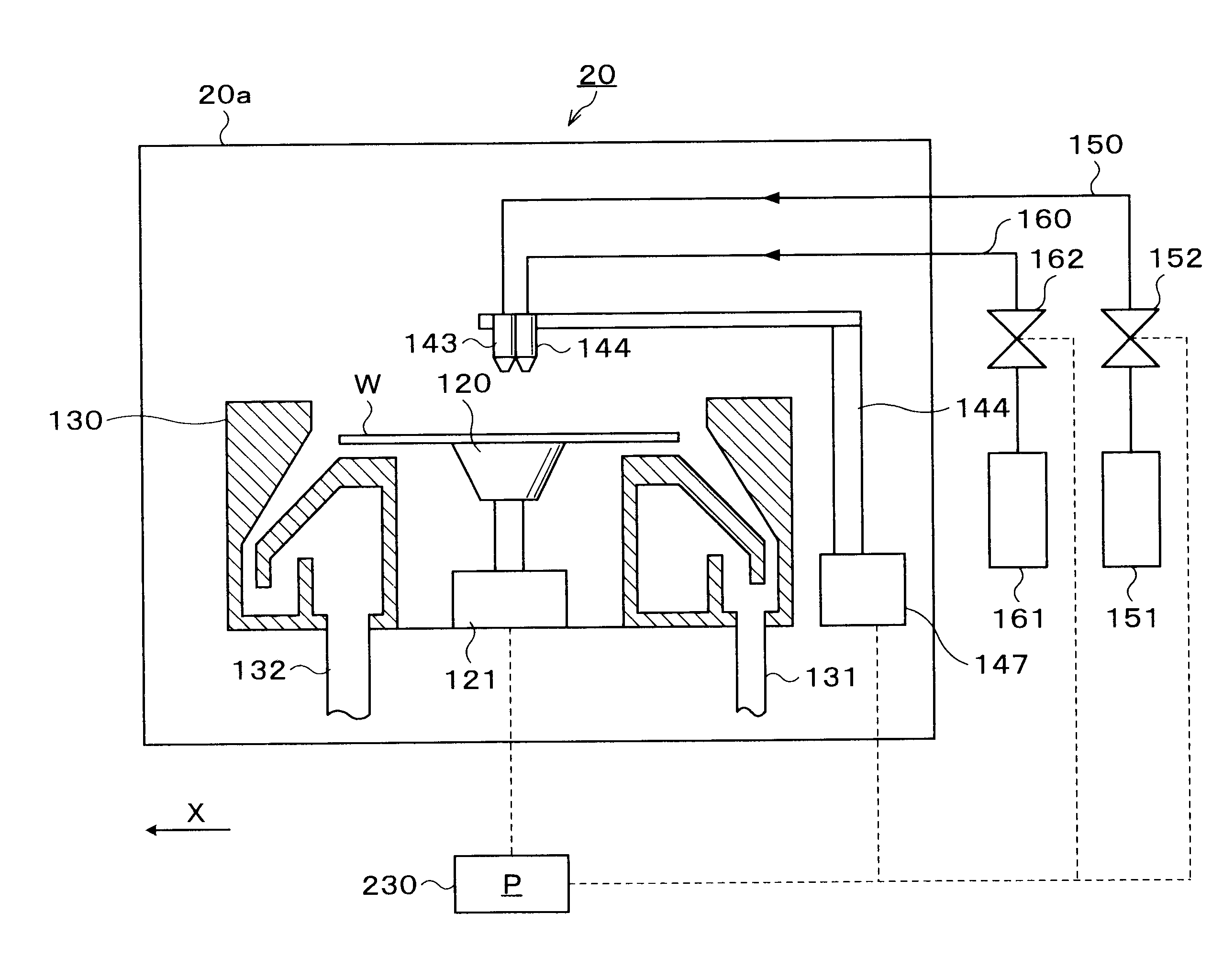

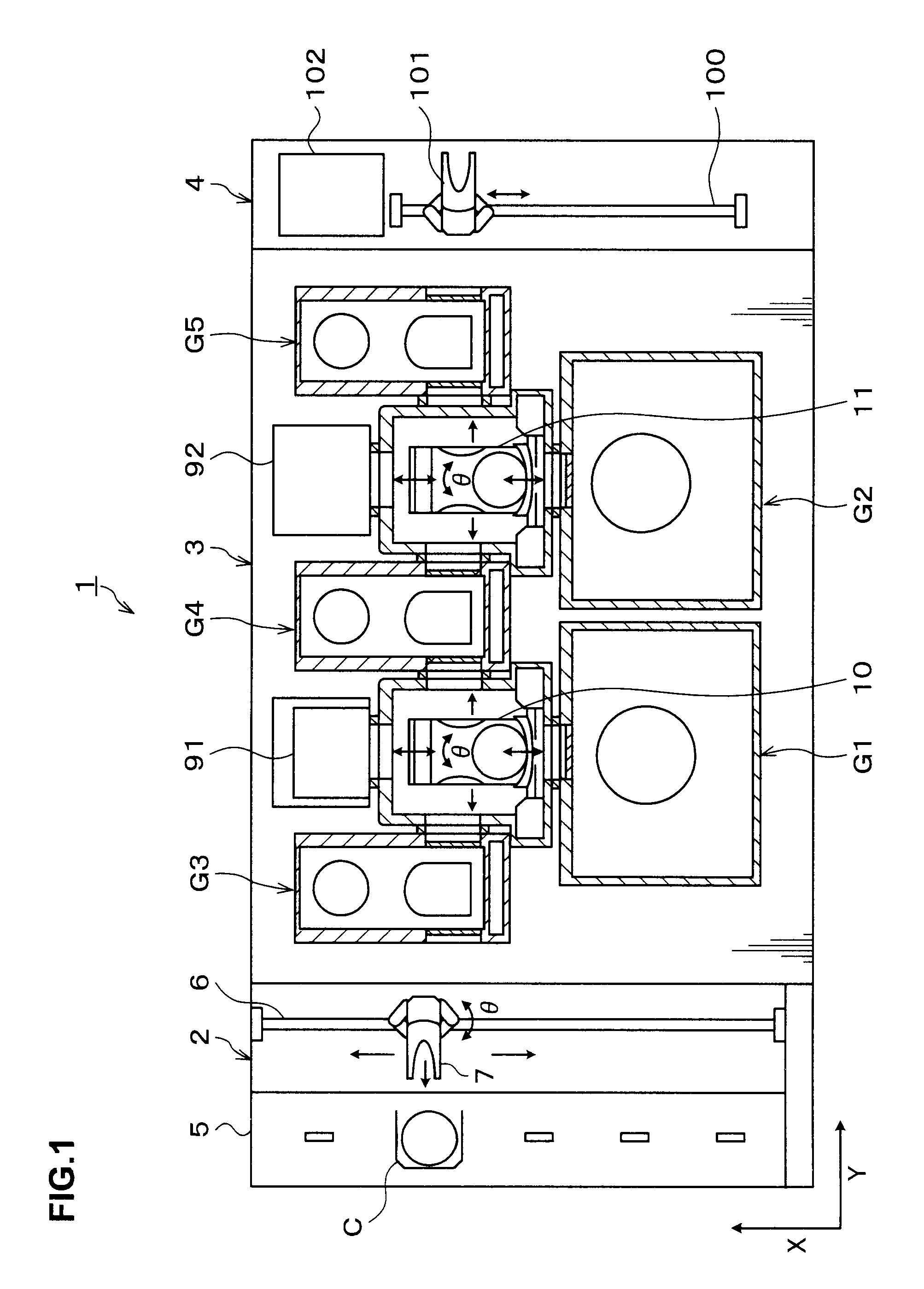

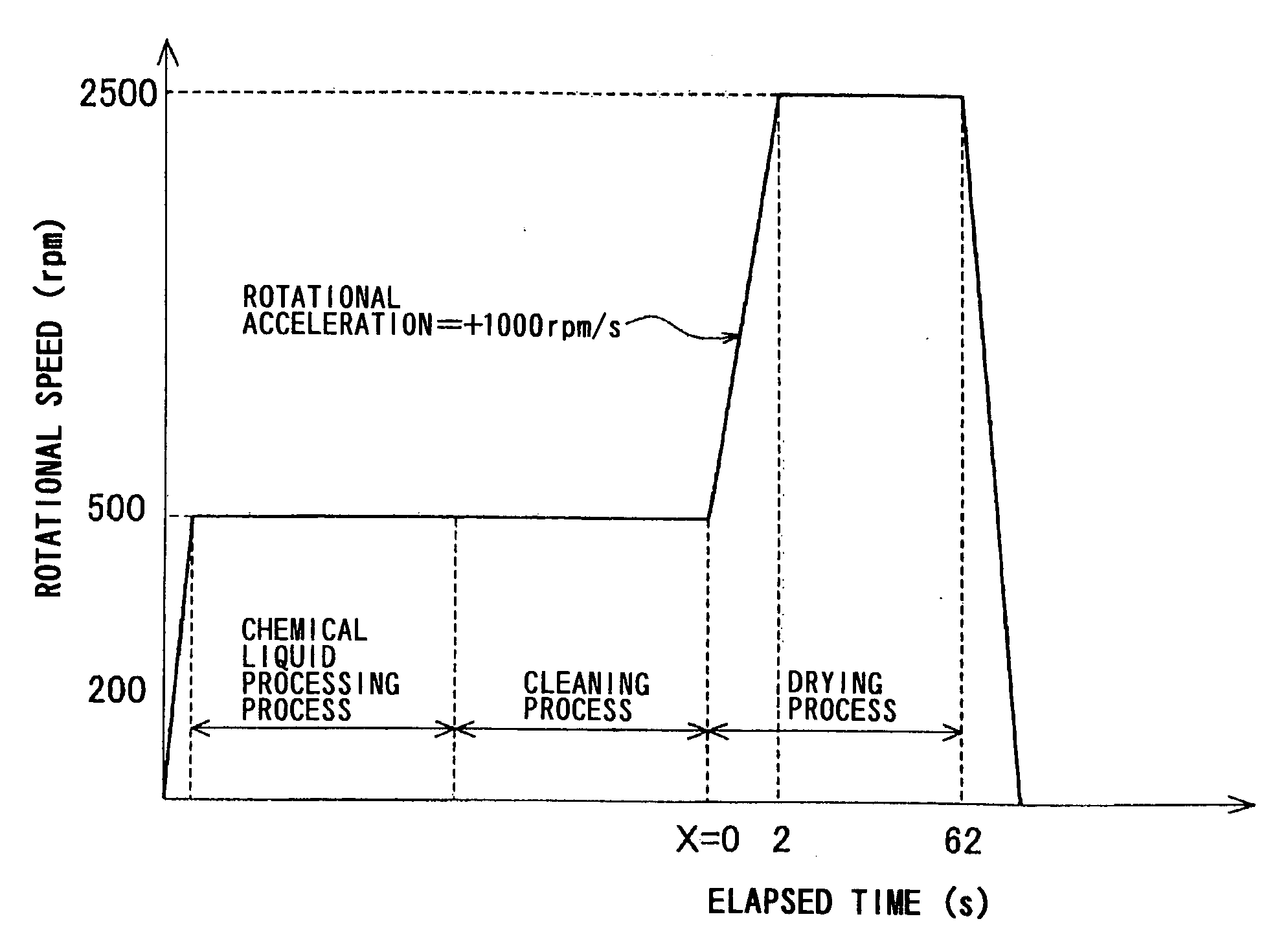

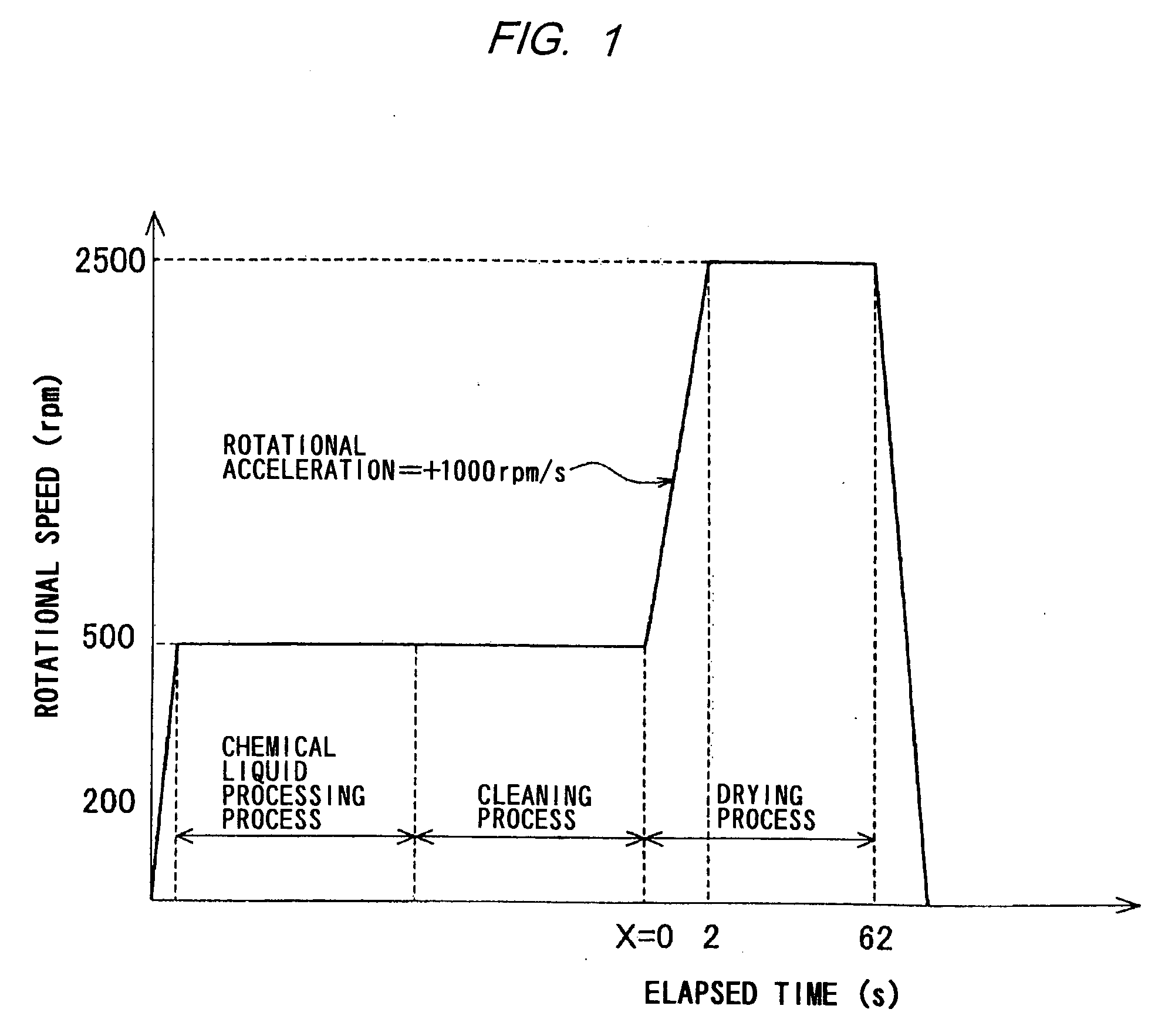

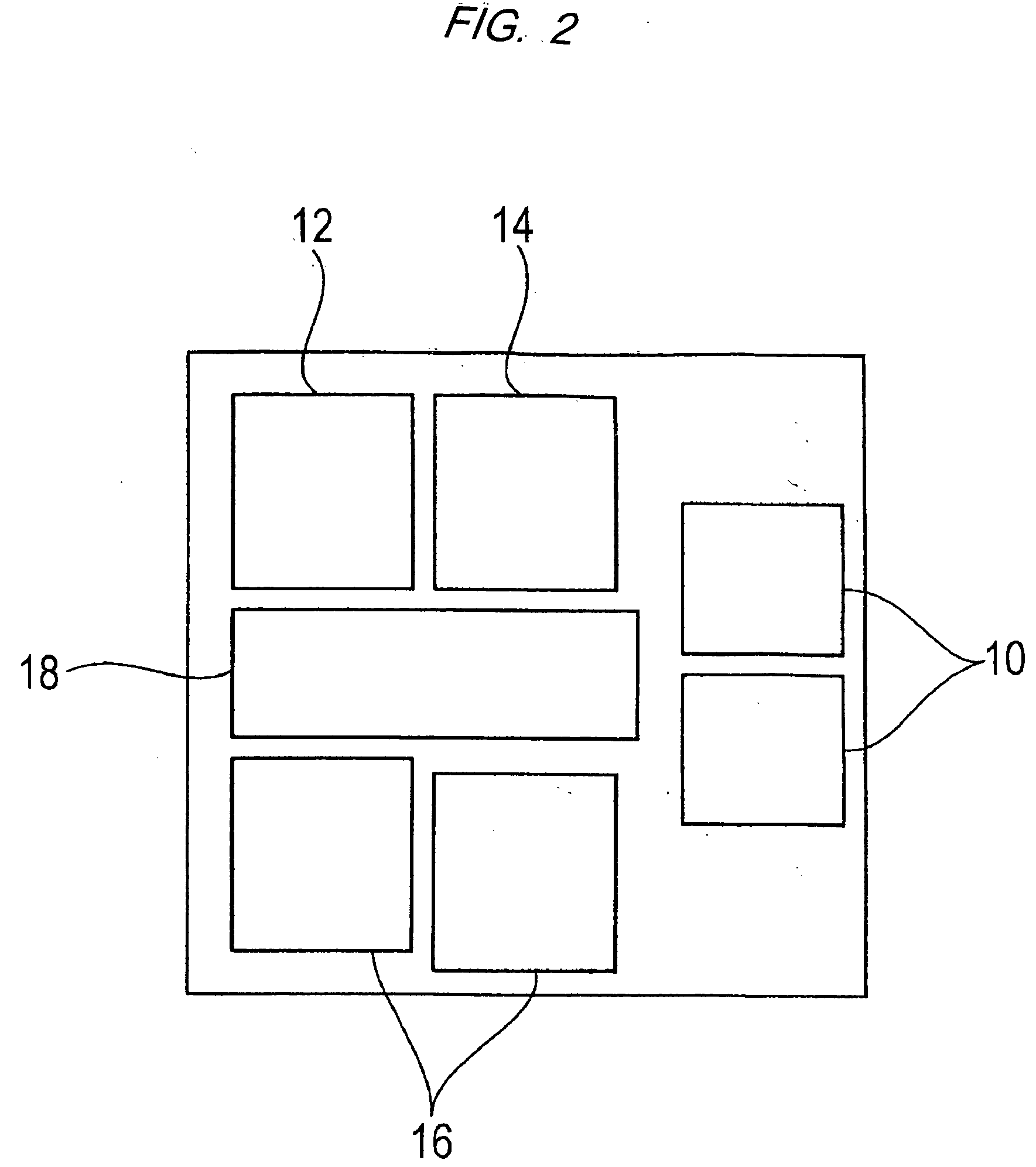

Substrate Processing Method, Substrate Processing Apparatus, and Control Program

ActiveUS20080314870A1Assisted movementDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringAirflow

This invention provides a substrate processing method including a step of covering in advance the surface of a substrate W with water (28), a step of holding the substrate W generally horizontally with the surface facing upward and rotating it in a horizontal plane (10), and a step of blowing to the substrate top surface drying gas flow that is thin in area in comparison with the substrate W surface (30, 40), in which the water is removed from the substrate top surface by the rotation in the horizontal plane while blowing the drying gas flow, a substrate processing apparatus for implementing the above method, and a control program for use with the above method and apparatus. With this invention, it is possible to dry a cleaned substrate without locally leaving water droplets.

Owner:EBARA CORP

Catalytic conversion method for preparing propylene and aromatic hydrocarbons

ActiveCN101531558AHydrocarbon purification/separationHydrocarbon oil crackingWater vaporFluidized bed

A catalytic conversion method for preparing propylene and aromatic hydrocarbons comprises the following steps: hydrocarbon raw materials with different cracking performances are contacted with a catalytic cracking catalyst to carry out cracking reaction in a fluidized-bed reactor under the conditions that the temperature is 450-750 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10-1.0MPa, the weight ratio of the catalytic cracking catalyst to the raw materials is 1-150 and the weight ratio of water vapor to the raw materials is 0.05-1.0, the spent catalyst and reaction oil and gas are separated, the spent catalyst returns to the reactor after the regeneration, the separated reaction oil and gas are separated to obtain target products of low-carbon olefins, aromatic hydrocarbons and the raw materials for re-cracking, wherein the raw materials for re-cracking are re-cracked after hydrotreating. The method can product the propylene and other low-carbon olefins from the heavy raw materials to the maximum extent, wherein the yield of the propylene is more than 40 percent by weight; meanwhile, the method can co-produce toluene, xylene and other aromatic hydrocarbons, and the yield of the dry gas is unexpectedly reduced by more than 80 percent by weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6921458B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

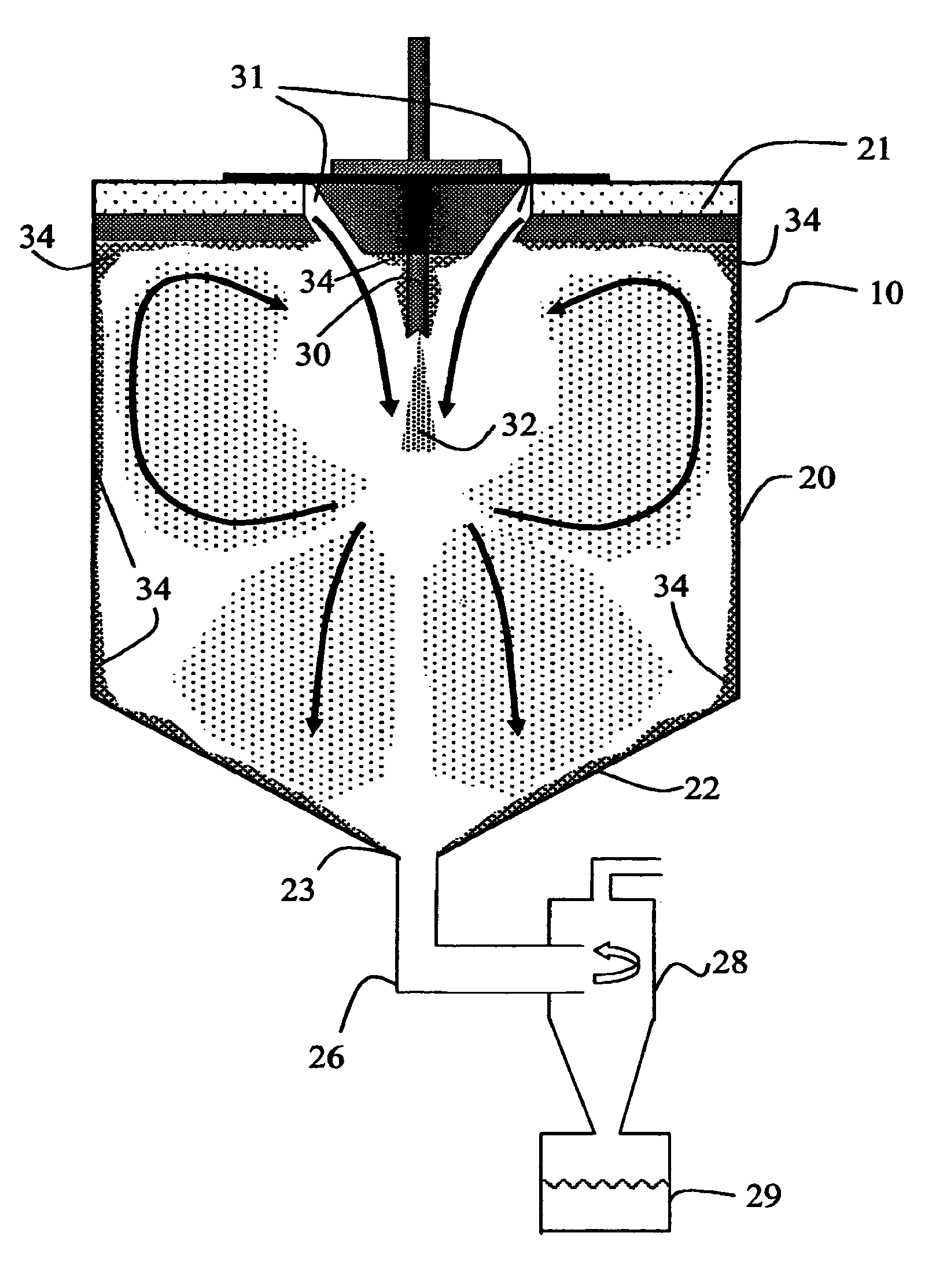

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

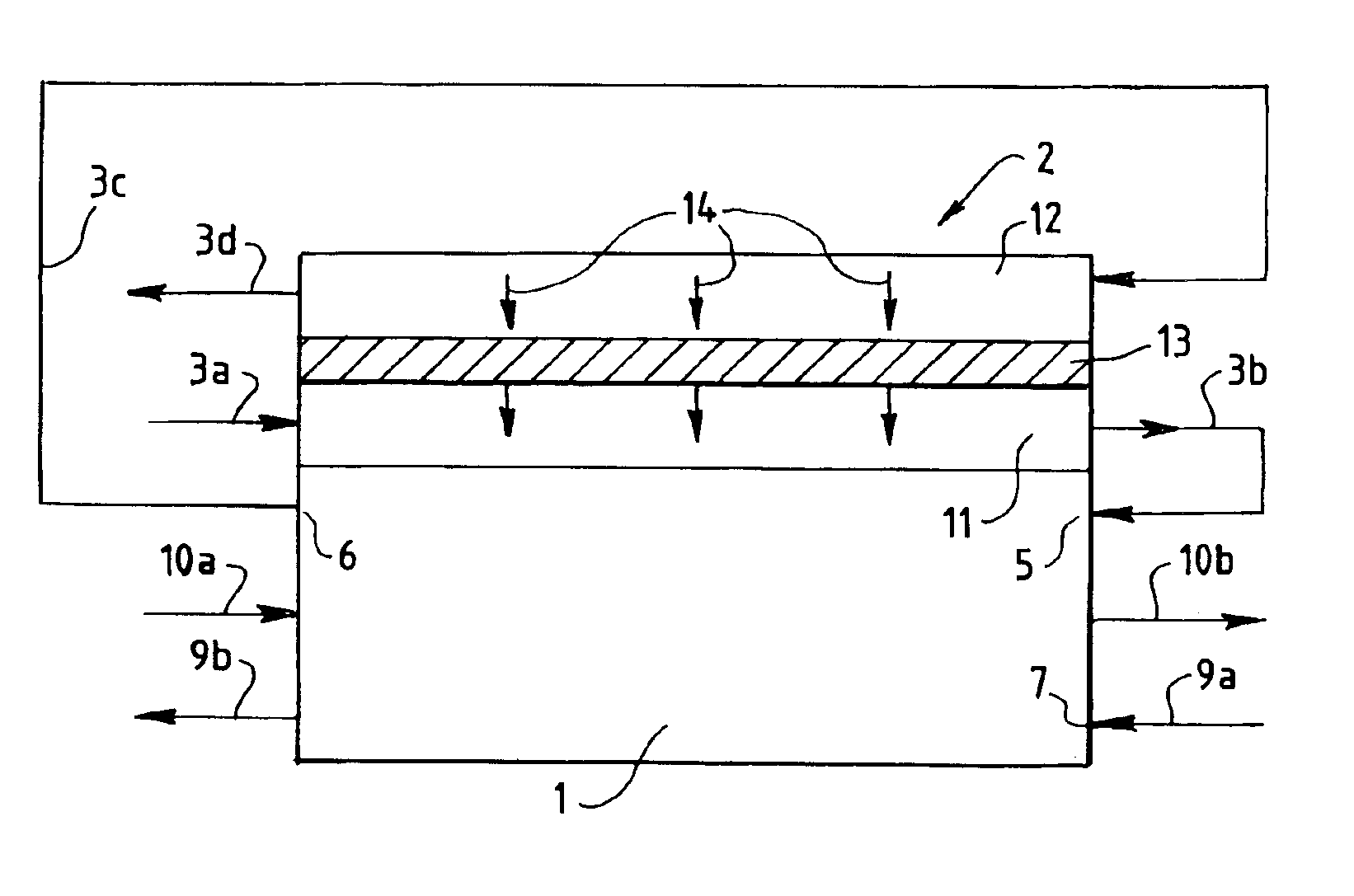

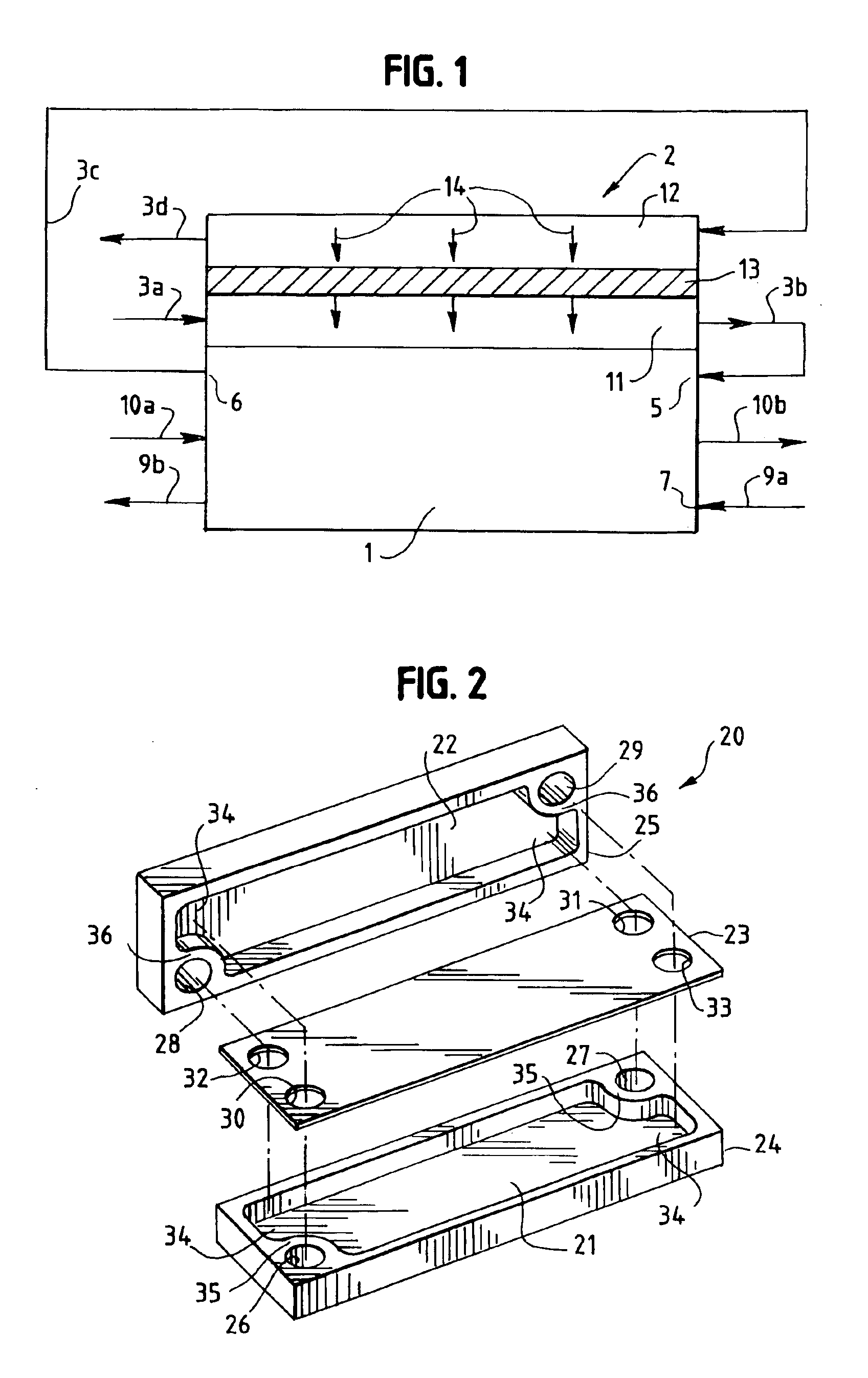

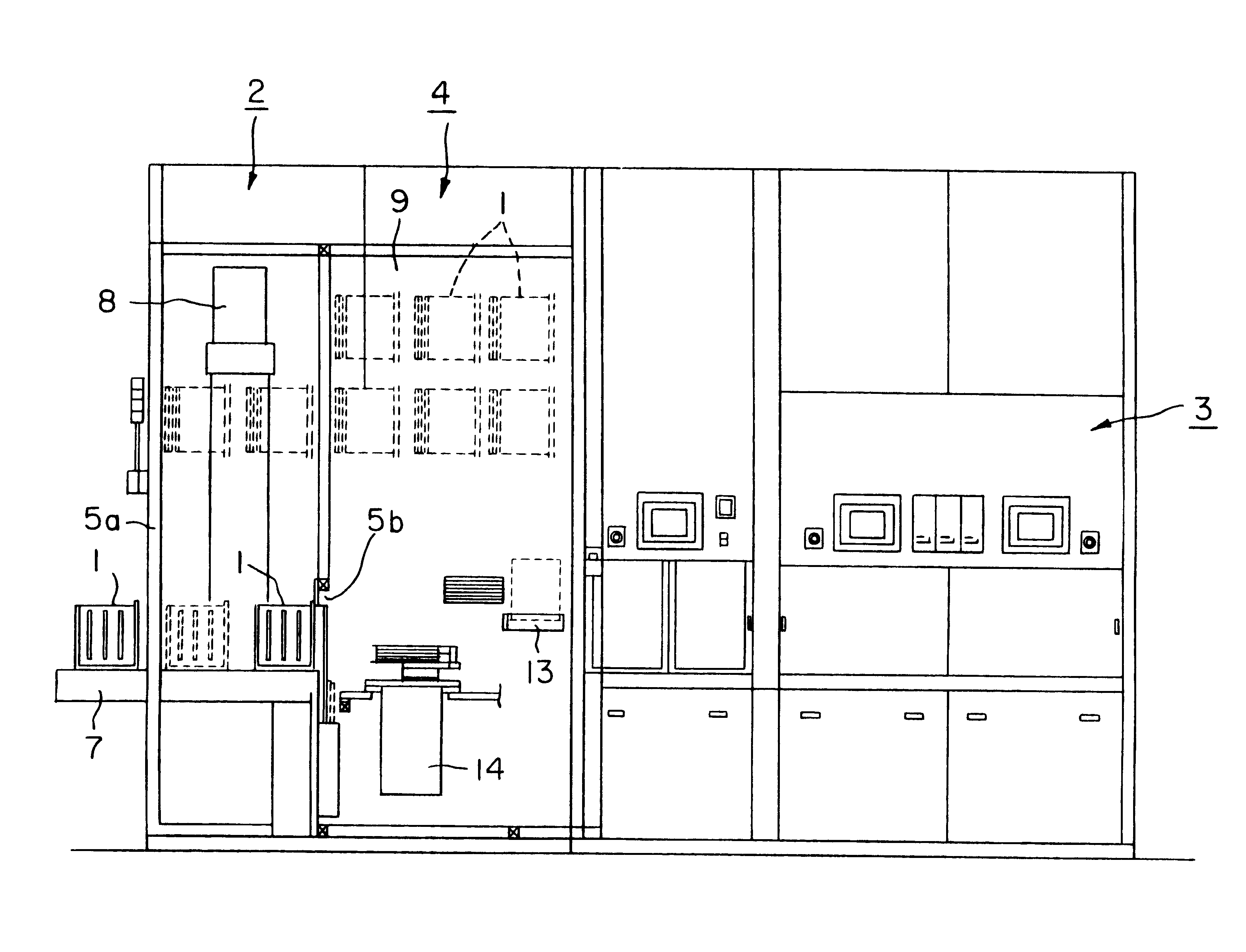

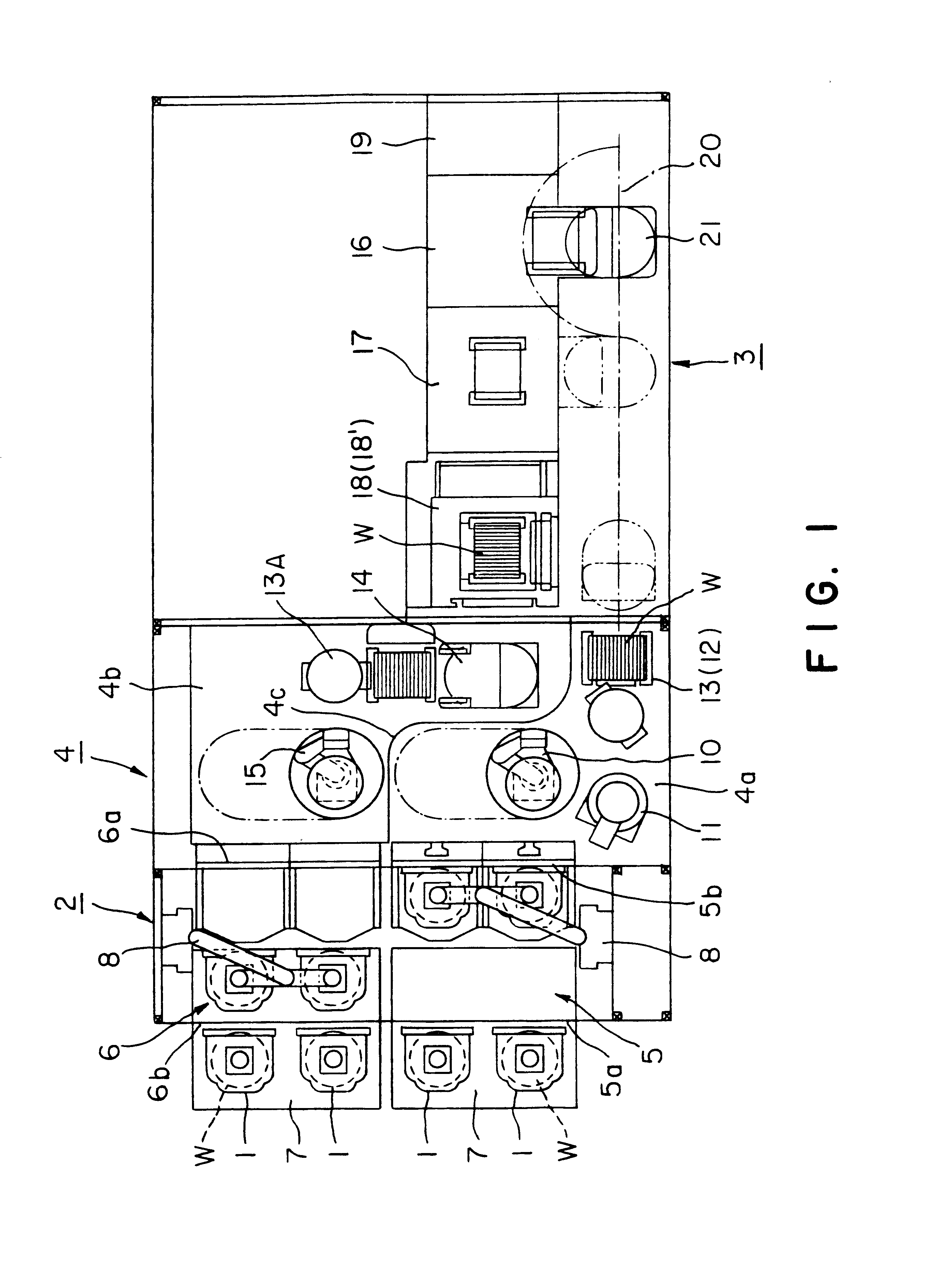

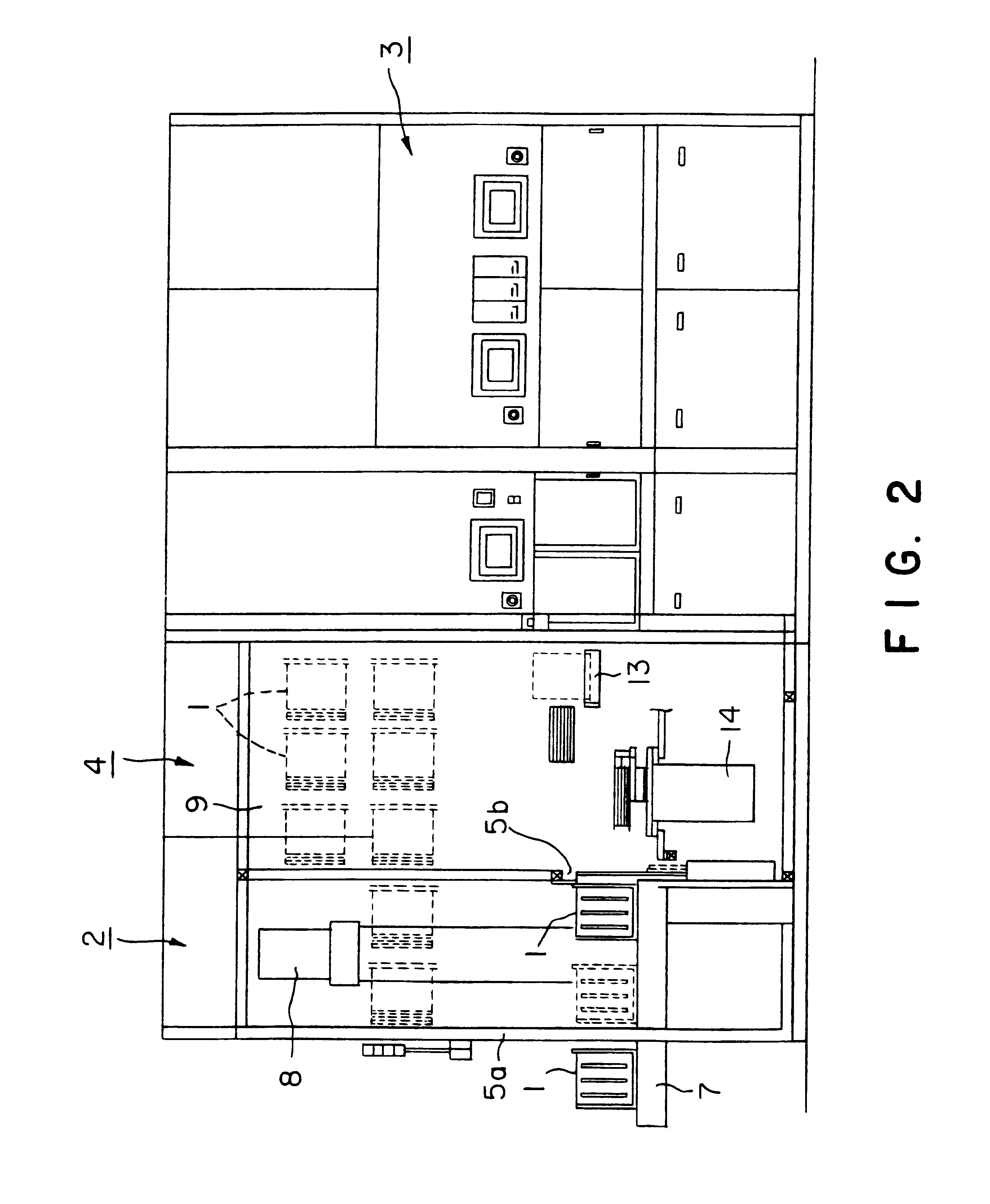

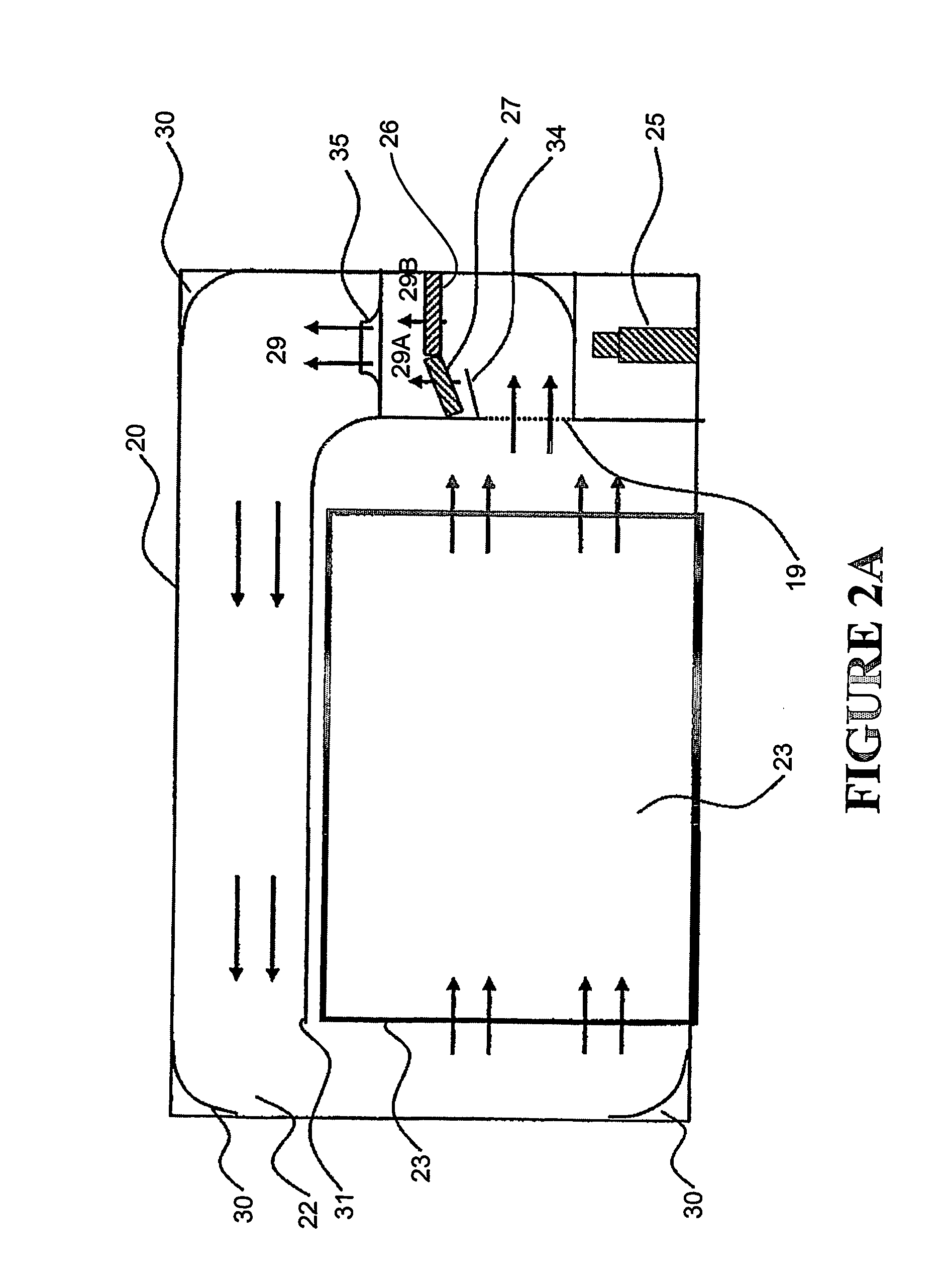

Cleaning and drying method and apparatus

InactiveUS6575178B1Reconditioning/cleaning record carriersSemiconductor/solid-state device manufacturingReverse orderHermetic seal

An enclosure 23A that defines a drying chamber 23 is configured of a pair of enclosing elements 23c and 23d and a base element 23b. When wafers enter or leave the drying chamber 23, the enclosing elements 23c and 23d are lifted upward by vertical air cylinders 42 to separate them from the base element 23b. The enclosing elements 23c and 23d are then moved in directions that mutually separate them. To dry wafers within the drying chamber 23, the enclosing elements and the base element 23b are mutually engaged to form a hermetic seal, in the opposite sequence.The present invention reduces the dimensions of the drying chamber without impeding the work of moving wafers into and out of the drying chamber. This makes it possible to reduce the internal volume of the drying chamber, achieving a reduction is the consumption of drying gas, an improvement in the drying efficiency, and a reduction in overall size of the apparatus.

Owner:TOKYO ELECTRON LTD

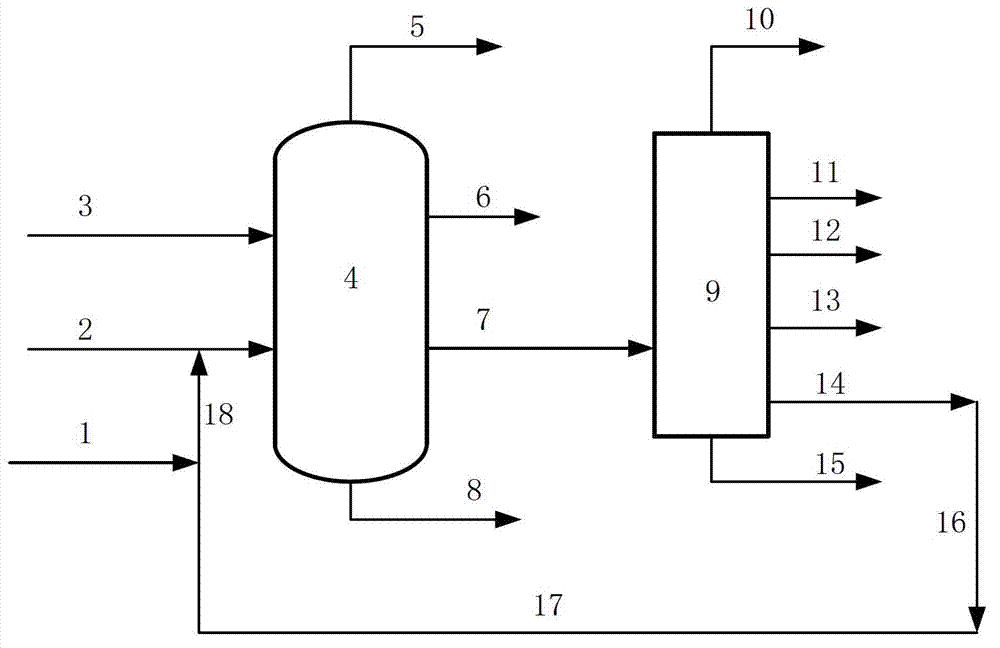

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

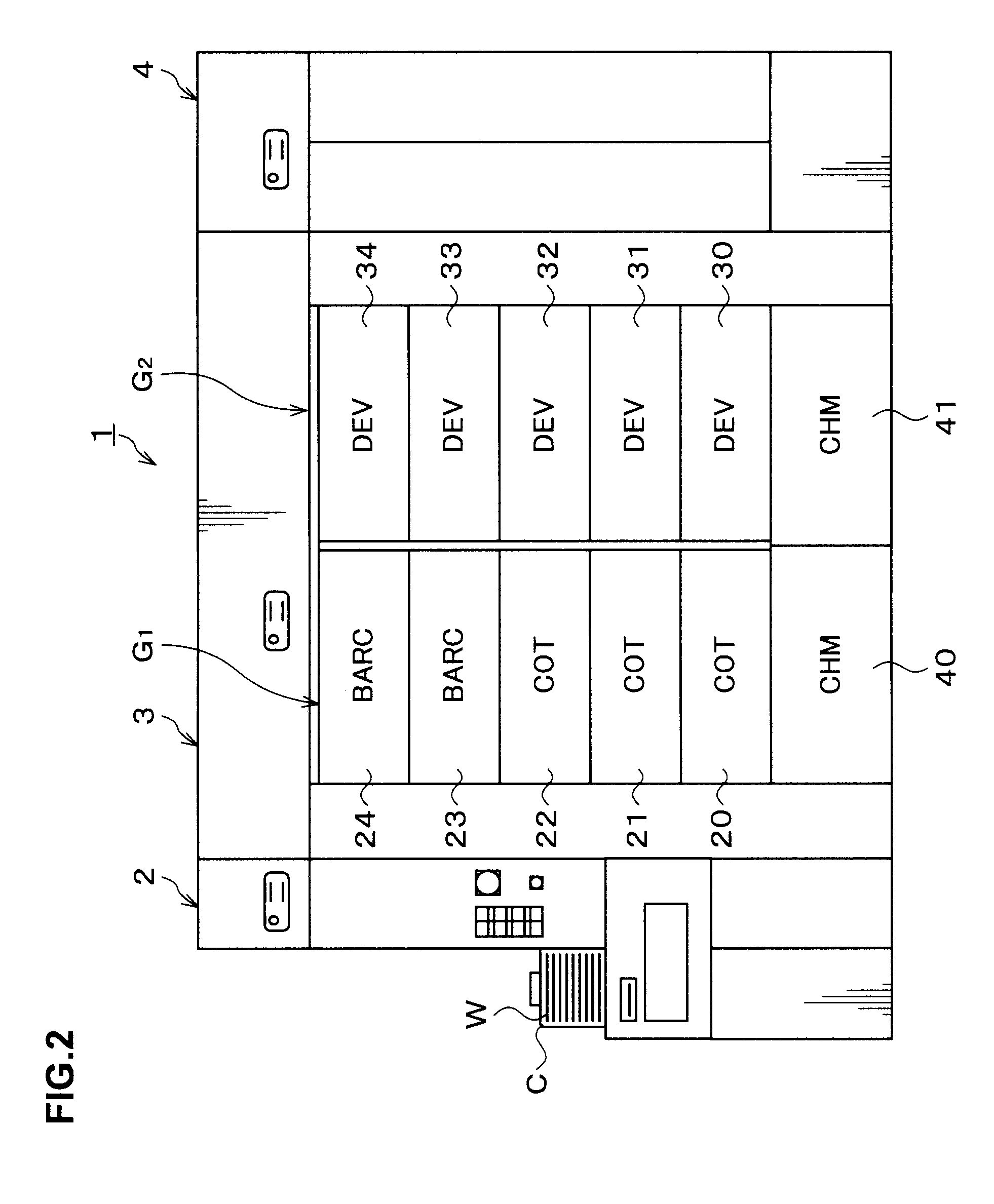

Coating treatment method, computer-readable storage medium, and coating treatment apparatus

ActiveUS20080057194A1Improve liquidityReduce thicknessMovable spraying apparatusPhotomechanical apparatusResistLow speed

In the present invention, a substrate is first rotated at a first rotation speed, and a resist solution is applied to the rotated substrate. Subsequently, the rotation of the substrate is decelerated to a second rotation speed lower than the first rotation speed so that the substrate is rotated at the low speed to smooth the resist solution on the substrate. The rotation of the substrate is then accelerated to a third rotation speed higher than the second rotation speed, and a solvent for the coating solution and / or a dry gas are / is supplied to the resist solution on the substrate. In this event, the solvent gas is supplied to a portion of the resist solution on the substrate thicker than a set thickness, and the dry gas is supplied to a portion of the coating solution on the substrate thinner than the set thickness. This thins the thicker portion of the resist solution and thickens the thinner portion to uniform the resist solution.

Owner:TOKYO ELECTRON LTD

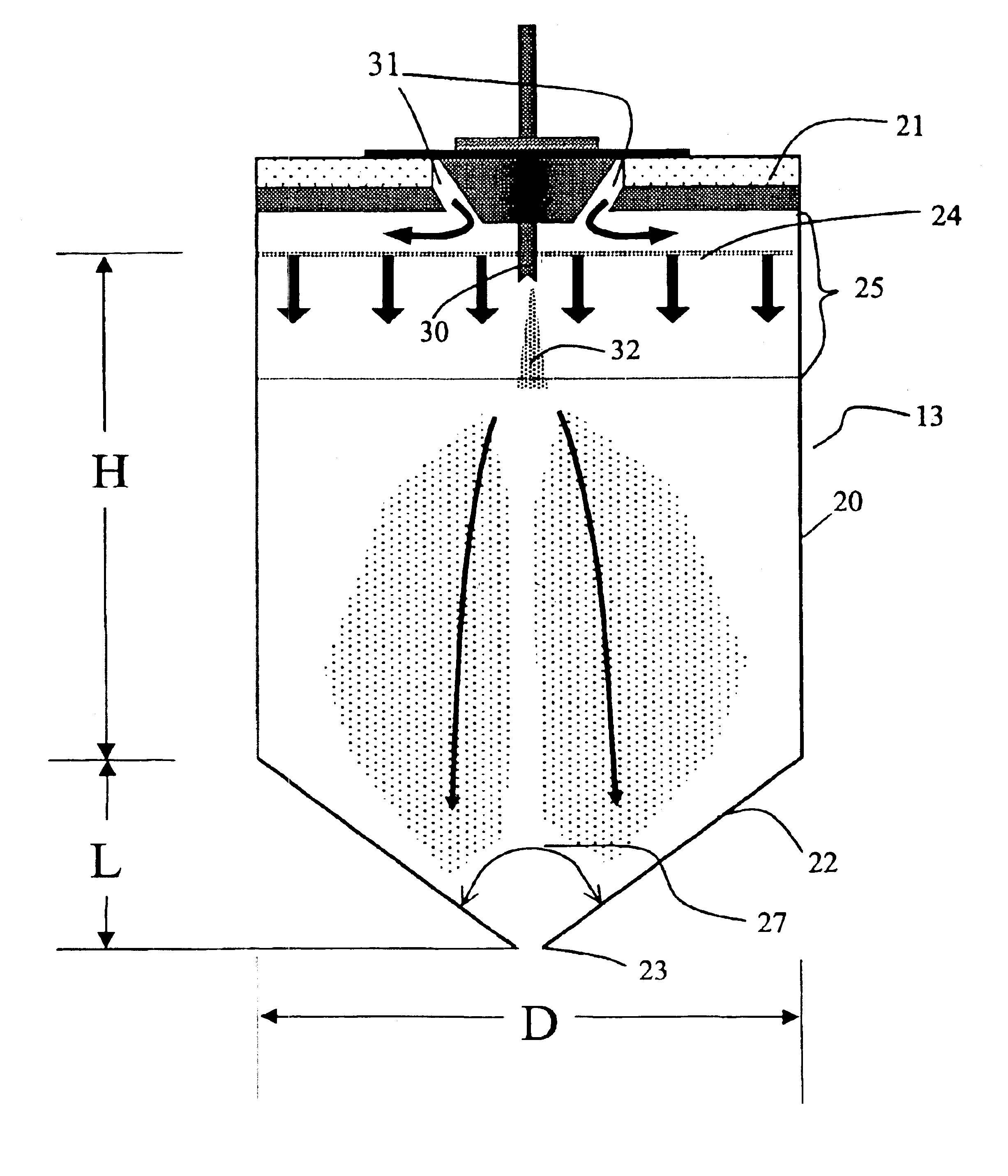

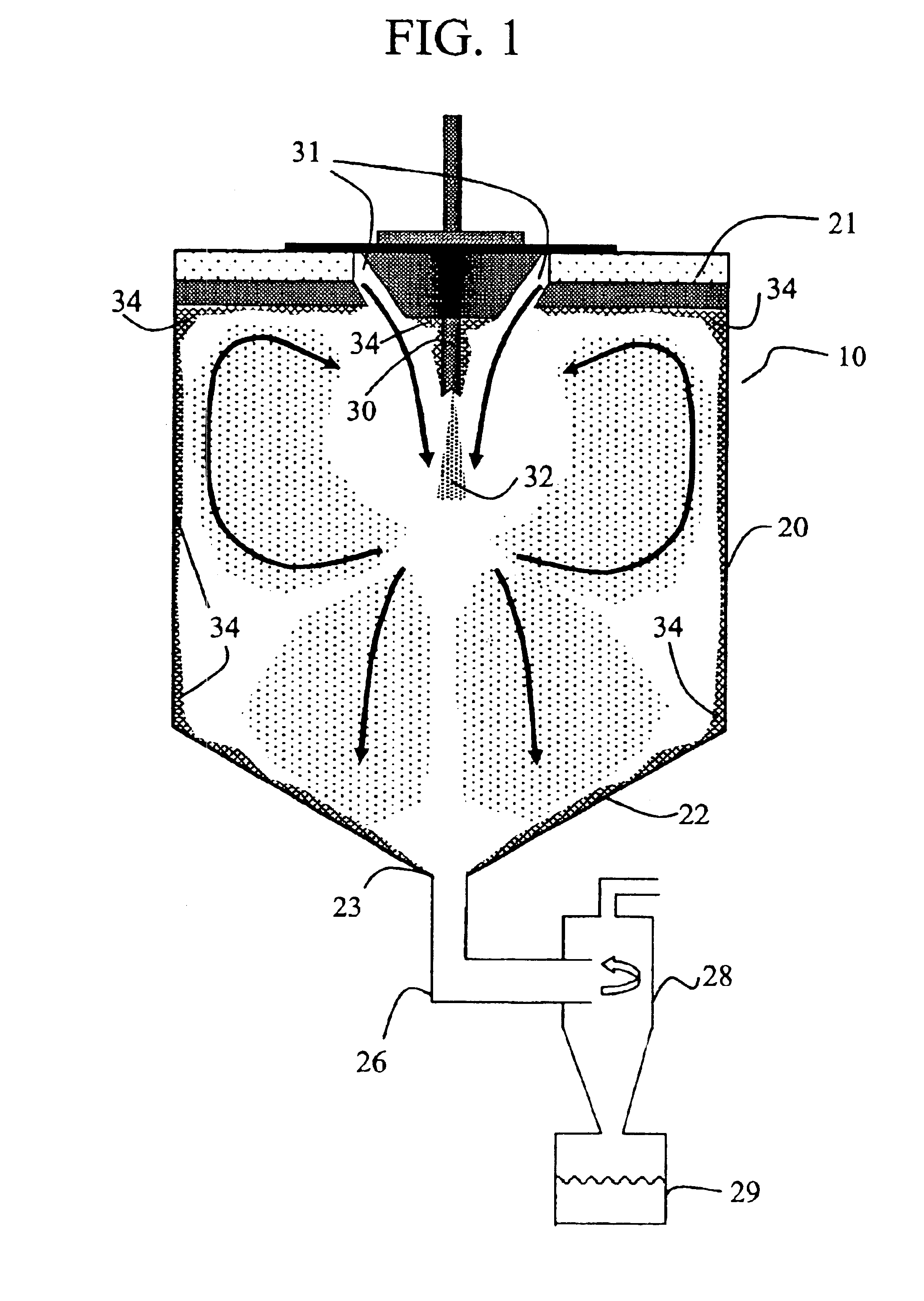

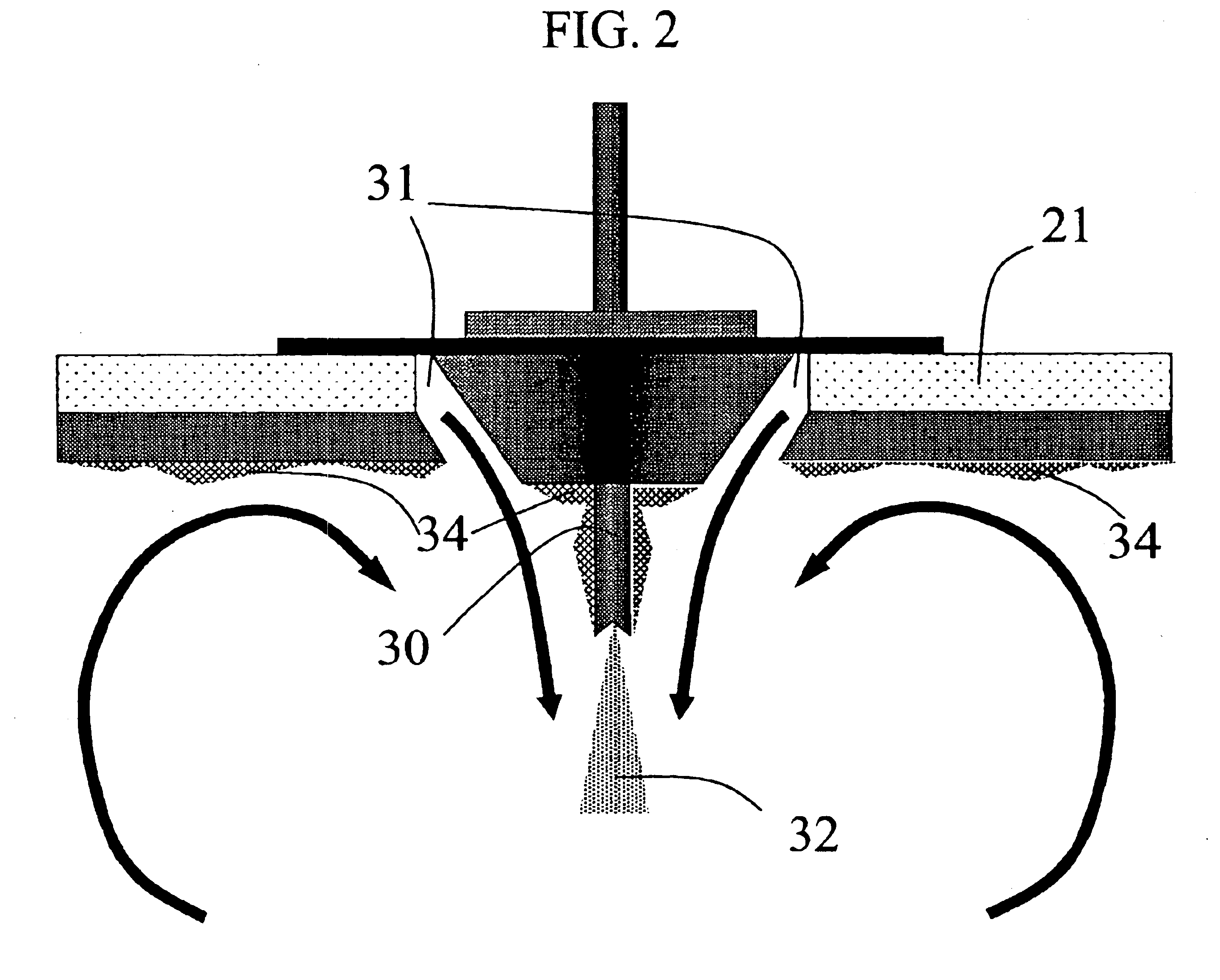

Method for making homogeneous spray-dried solid amorphous drug dispersions utilizing modified spray-drying apparatus

InactiveUS6973741B2Facilitates organized plug flowPowder deliveryDrying solid materials with heatSpray nozzleDrying time

Conventional spray-drying methods are improved by incorporation of a pressure nozzle and a diffuser plate to improve the flow of drying gas and a drying chamber extension to increase drying time, such improvements leading to the formation of homogeneous solid dispersions of drugs in concentration-enhancing polymers.

Owner:LONZA BEND INC

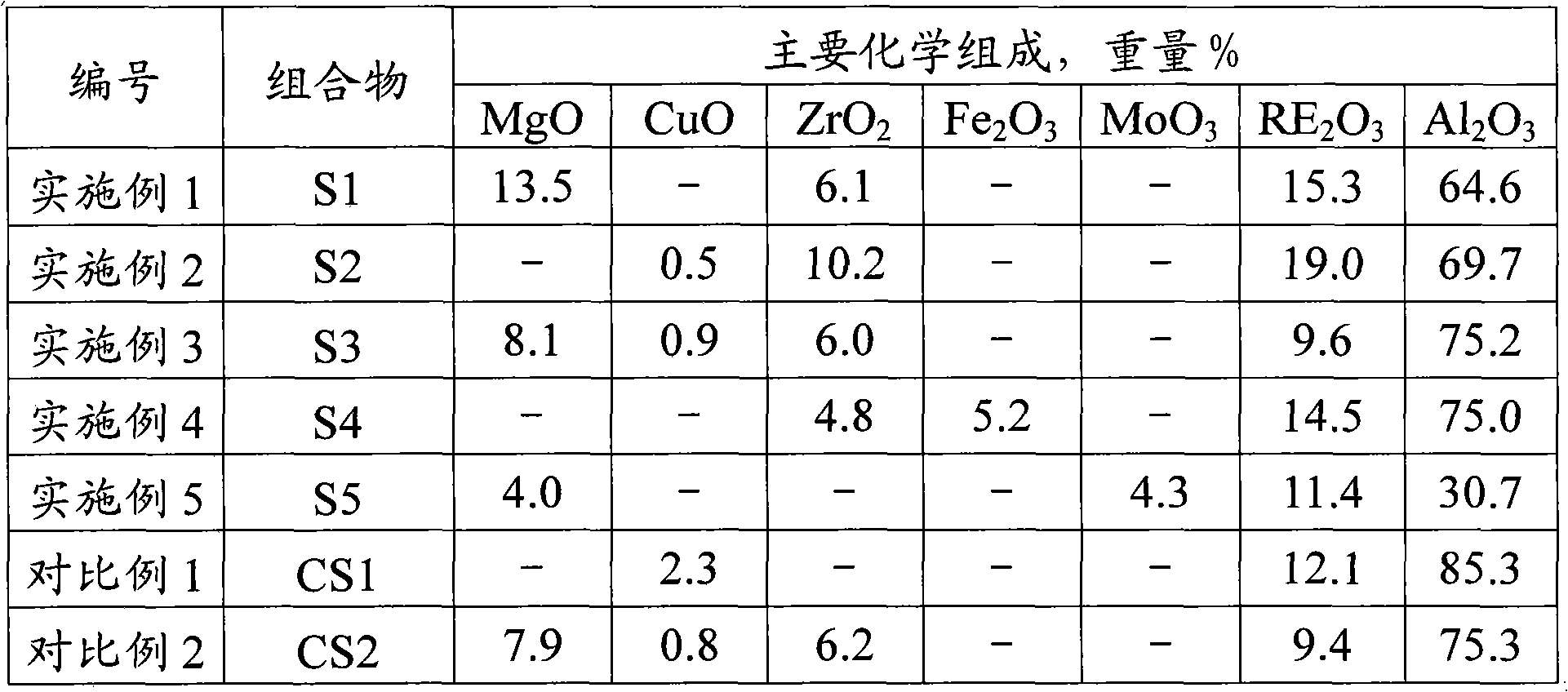

Composition for reducing discharge of NOx in regeneration flue gas of fluid catalytic cracking (FCC)

ActiveCN102371150AReduced activityReduce yieldCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementFlue gas

The invention provides a non-noble metal composition for reducing discharge of NOx in regeneration flue gas of catalytic cracking. The bulk density of the composition is no more than 0.65 g / ml, and the composition comprises, based on the weight of the composition, in terms of oxides, (1) 50 to 99 wt % of an inorganic oxide carrier, (2) 0.5 to 40 wt % of one non-noble metal or more non-noble metals selected from the group consisting of Group IIA, Group IIB, Group IVB and Group VIB, and (3) 0.5 to 30 wt % of a rare earth element. When the composition prepared in the invention is utilized in FCC, the discharge of NOx in regeneration flue gas can be substantially reduced, low yield of dry gas and coke is obtained, and distribution of FCC products is better.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

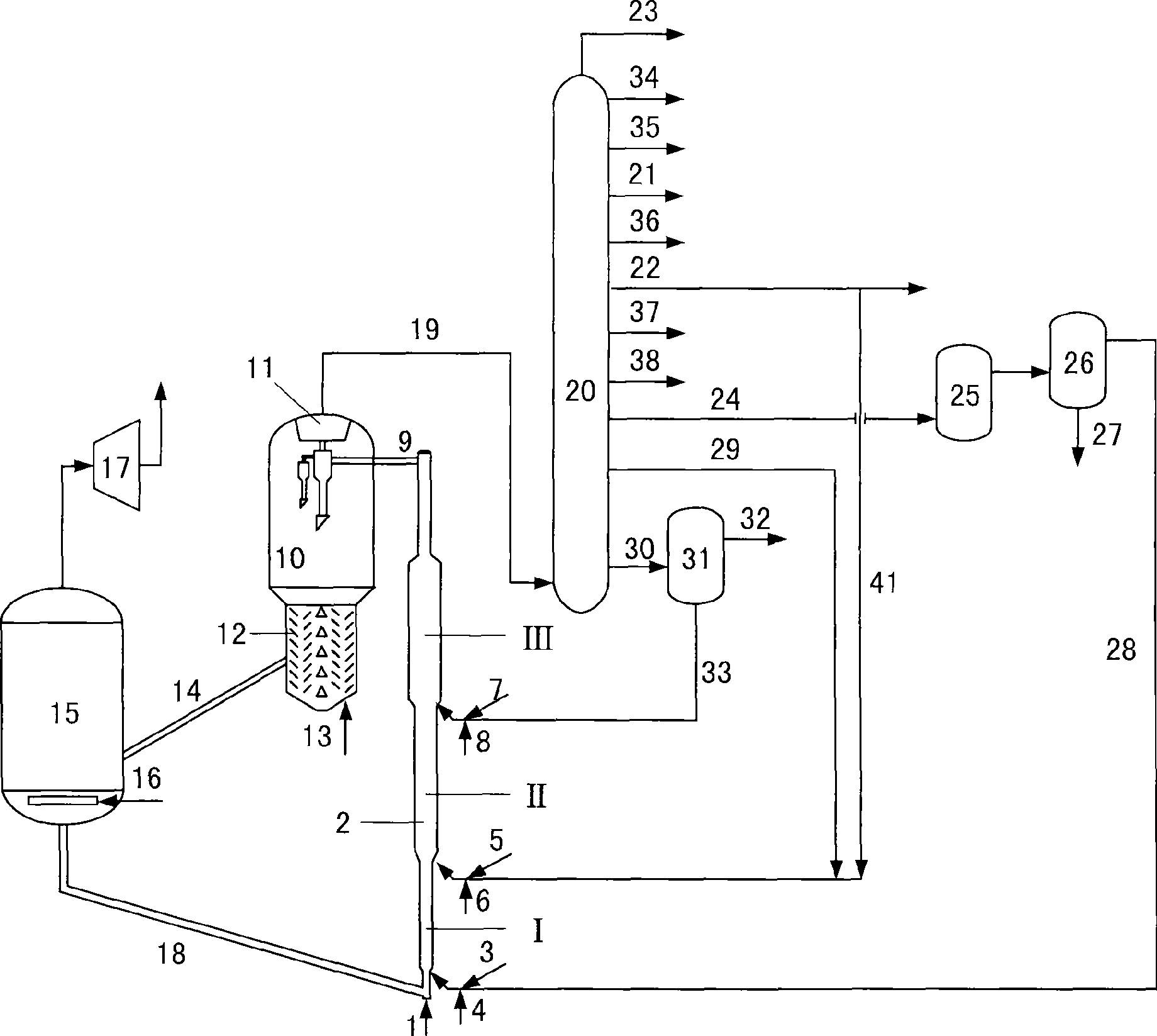

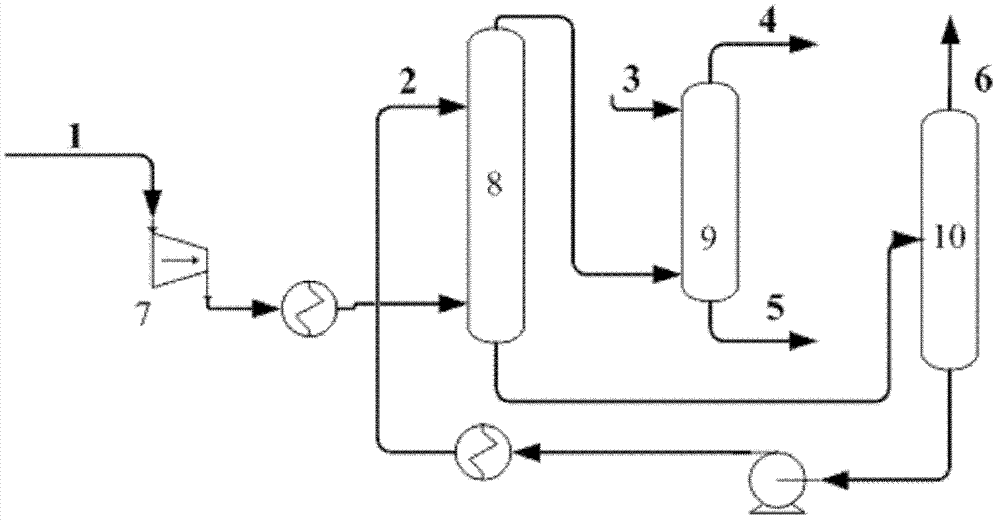

Device and method for separating refinery dry gas through oil absorption

InactiveCN103087772AEasy to getLow costGaseous mixture working upAbsorption purification/separationDesorptionGasoline

The invention discloses a device and a method for separating refinery dry gas through oil absorption. The device comprises a C4 absorption tower and a C4 desorption tower. A gasoline absorption tower is arranged after the C4 absorption tower. A top outlet of the C4 absorption tower is connected to the lower part of the gasoline absorption tower. The bottom and the top of the gasoline absorption tower respectively communicate with the outside world. The method comprises the steps that: catalytic dry gas is subjected to compression and cooling, and is delivered into the C4 absorption tower and is absorbed by using a C4 absorption agent; the tower kettle material of the C4 absorption tower is delivered into the C4 desorption tower; the tower kettle material of the C4 desorption tower is delivered back to the C4 absorption tower; tower top gas of the C4 absorption tower is delivered into the gasoline absorption tower and is absorbed by a gasoline absorption agent. According to the invention, no equipment such as ethylene cooling machine, expansion machine, or cold box is needed, such that investment and energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

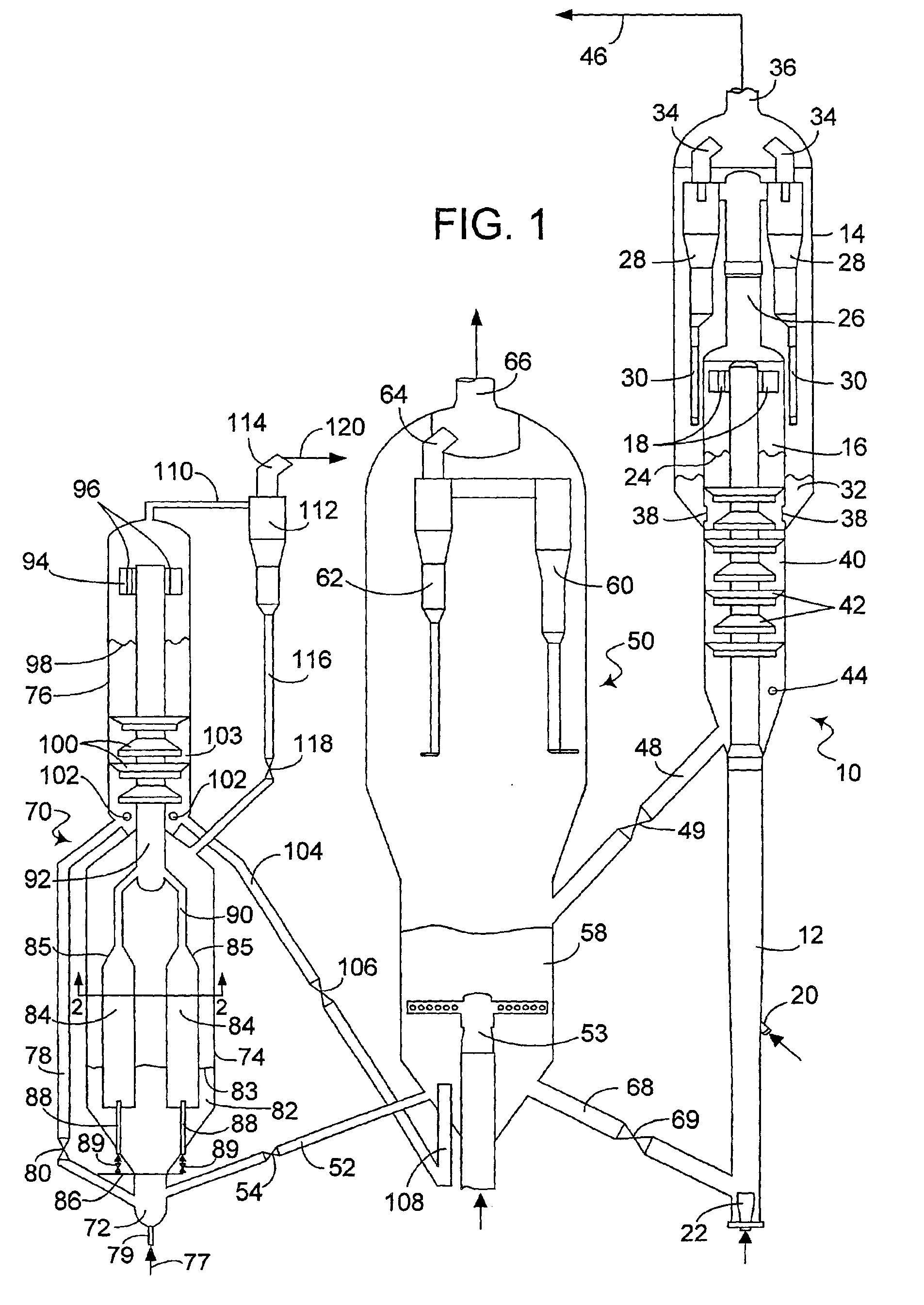

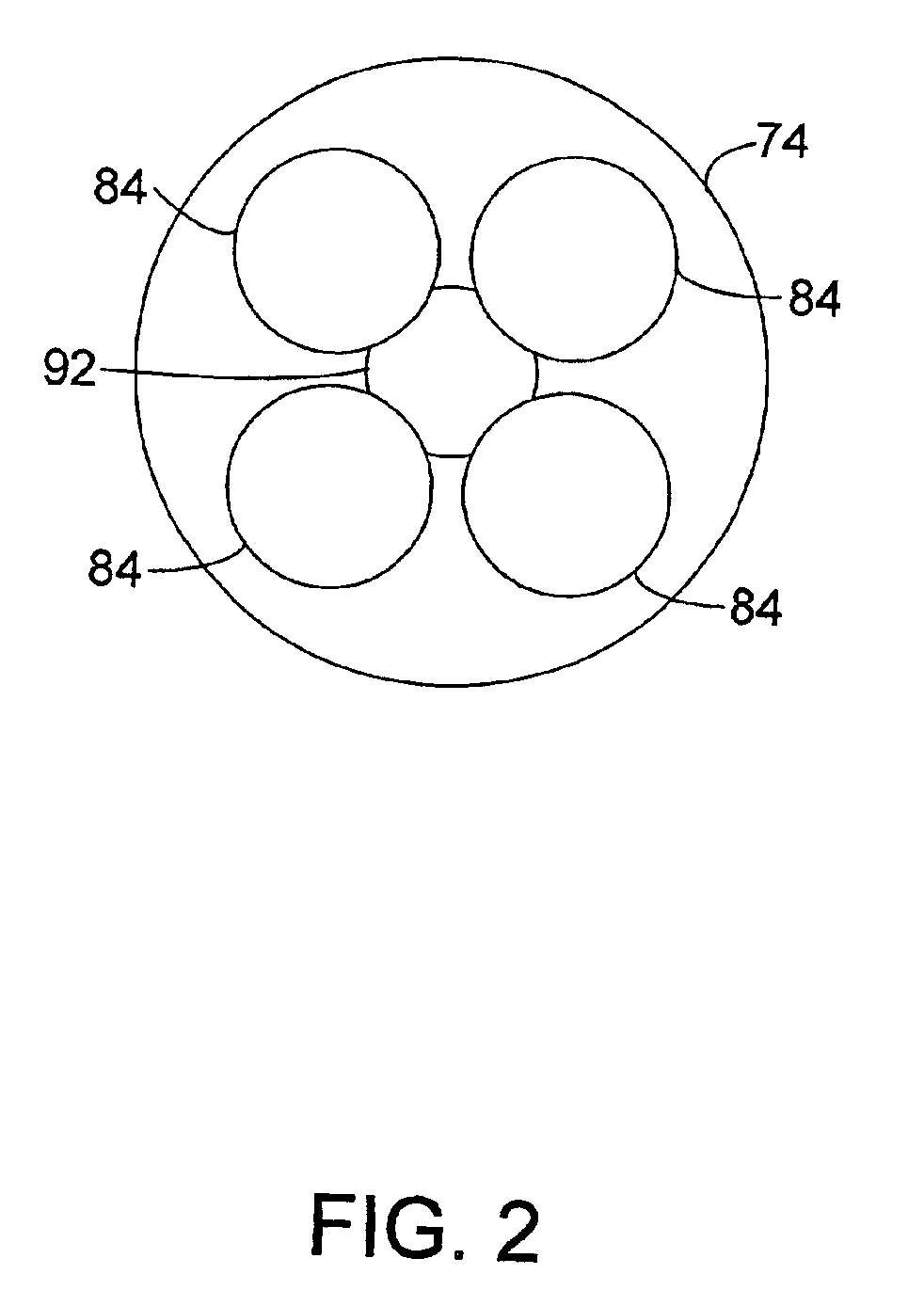

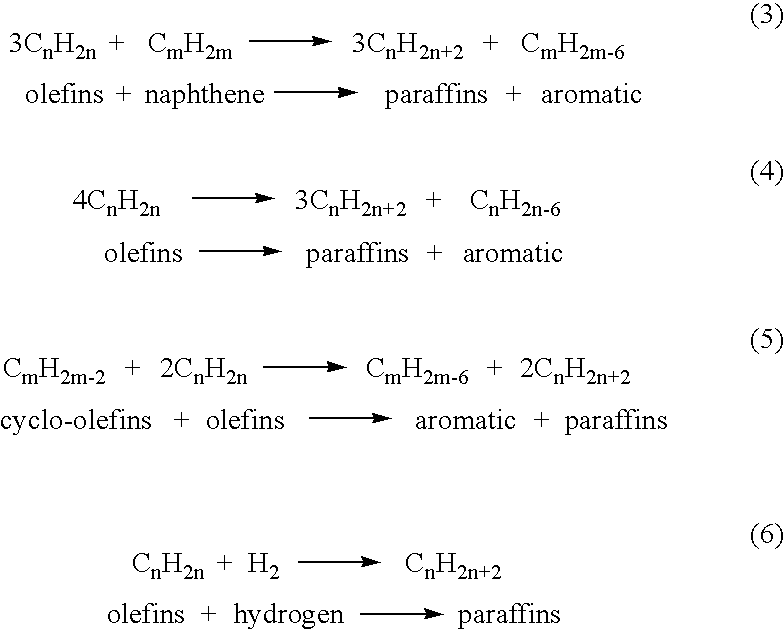

Process and apparatus for upgrading FCC product with additional reactor with thorough mixing

InactiveUS6869521B2Improve responseLess effectivenessTreatment with plural serial cracking stages onlyCatalytic crackingProduct gasHydrocarbon

A process and apparatus are disclosed contacting hydrocarbon feed with catalyst in a reactor vessel under conditions more vigorous than bubbling bed conditions and preferably fast fluidized flow conditions. The vigorous conditions assure thorough mixing of catalyst and feed to suppress formation of dry gas and the promotion of hydrogen transfer reactions.

Owner:UOP LLC

Substrate processing apparatus and substrate processing method

InactiveUS20050026455A1Suppress formationIncreased substrate speedSemiconductor/solid-state device manufacturingEngineeringWet cleaning

The present invention provides a substrate processing apparatus having a drying mechanism for removing water from the surface of a substrate which has been cleaned by a wet cleaning process, and a substrate processing apparatus and a substrate processing method which are capable of efficiently removing an unnecessary thin film deposited on or adhering to a bevel or edge portion of a substrate. The substrate processing apparatus of this invention has a substrate holder for holding a substrate, and a dry gas supply section for turning an atmosphere to which at least a portion of a surface of the substrate held by the substrate holder is exposed into a humidity-controlled dry gas atmosphere.

Owner:EBARA CORP

Method for refining catalysis drying gas by using oil absorption extraction

The invention discloses a method for refining catalysis drying gas by using oil absorption extraction. The method comprises the steps of using the carbon five-hydrocarbon containing pentane as absorbent, absorbing the C2 distillate and more important components in the compressed and cooled catalysis drying gas in a main absorbing tower, sending the matter in the main absorbing tower to a desorbing tower, and recycling the C2 concentrated gas from the top of the desorbing tower. The method of the invention has high absorbing temperature and needs no ethylene, propylene cooling compressor and de-compressor so the energy consumption is less, the investment is low and the operation is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for making homogeneous spray-dried solid amorphous drug dispersions utilizing modified spray-drying apparatus

InactiveUS8343550B2Facilitates organized plug flowPowder deliveryDrying solid materials with heatSpray nozzlePolymer

Conventional spray-drying methods are improved by incorporation of a pressure nozzle and a diffuser plate to improve the flow of drying gas and a drying chamber extension to increase drying time, such improvements leading to the formation of homogeneous solid dispersions of drugs in concentration-enhancing polymers.

Owner:LONZA BEND INC

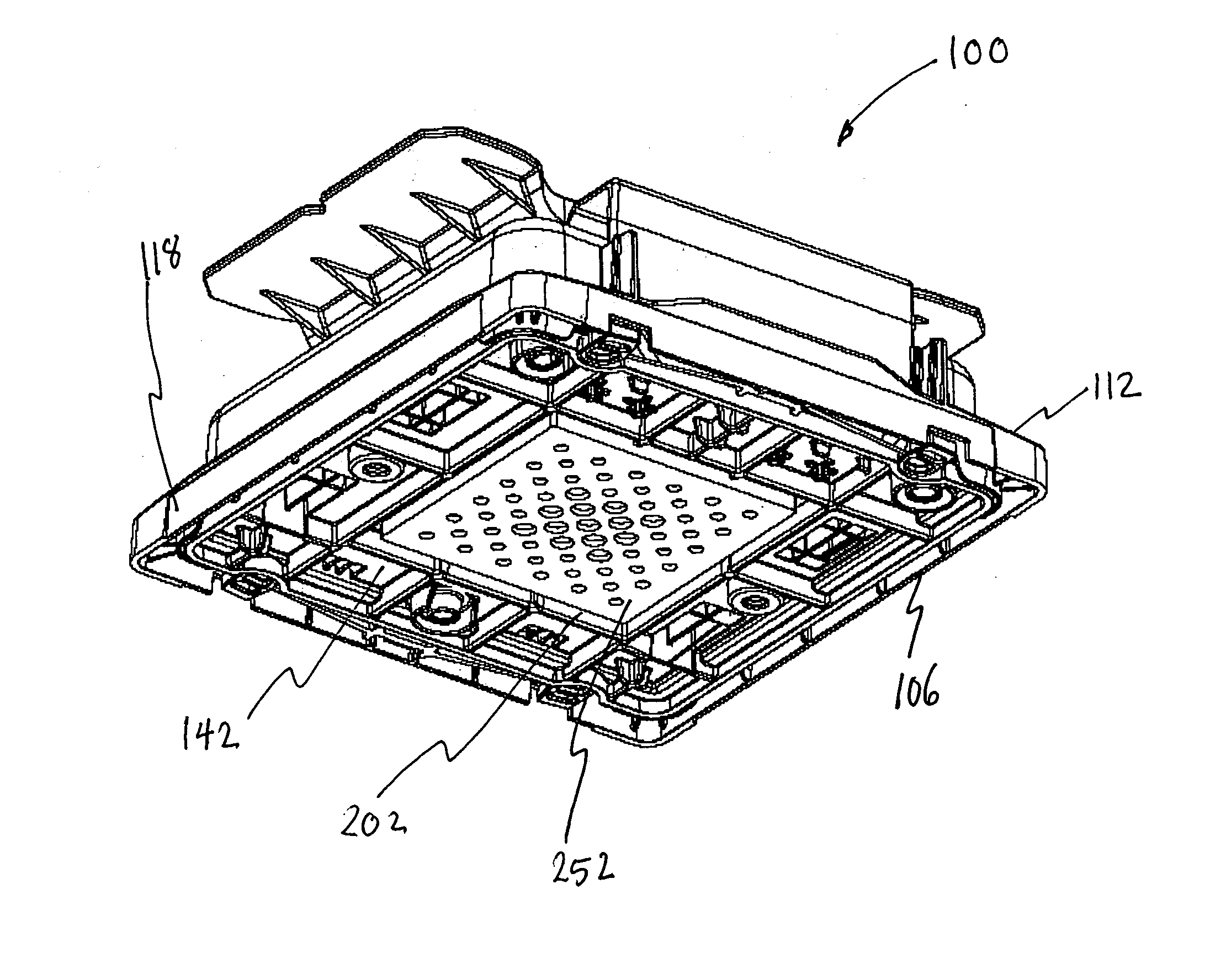

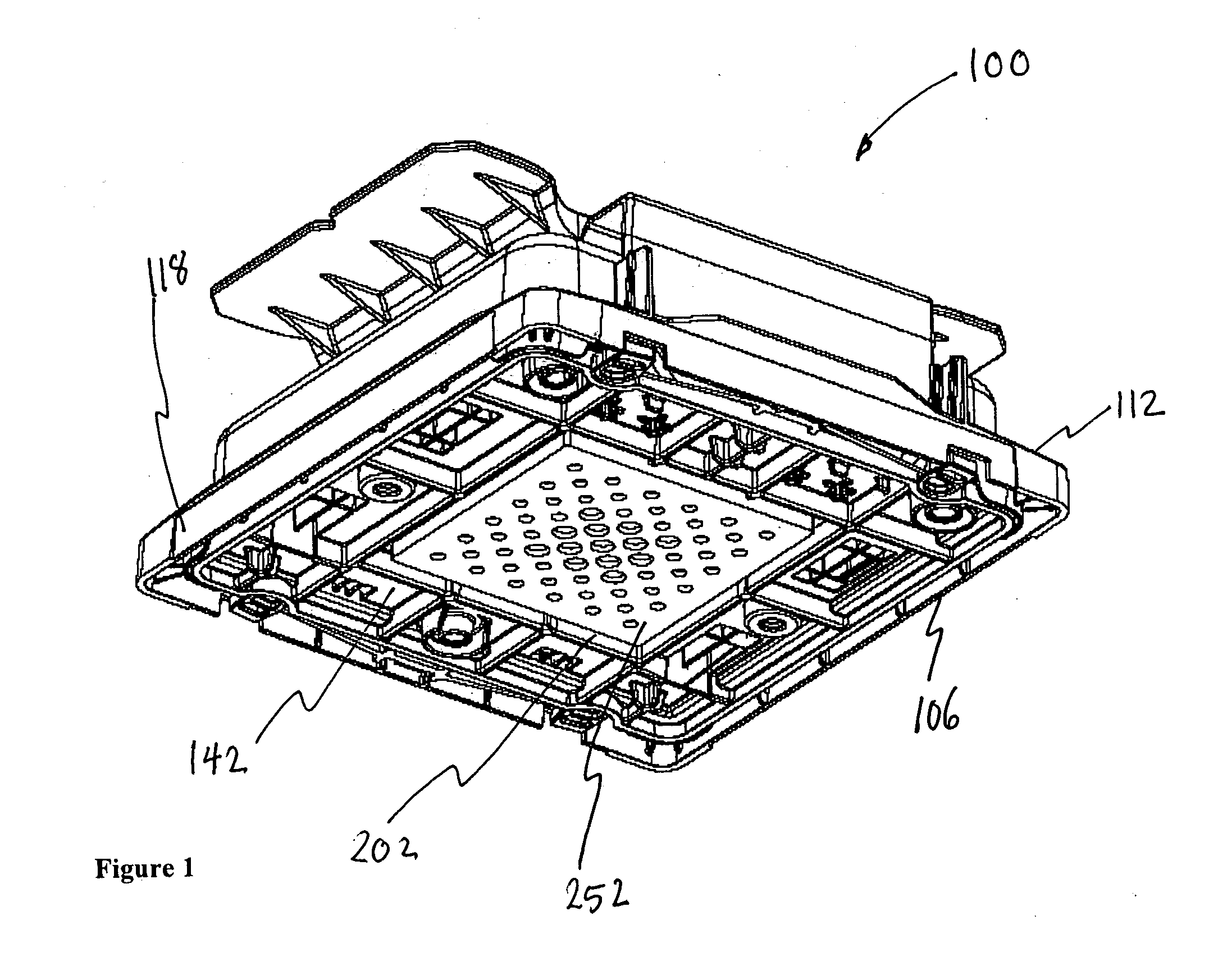

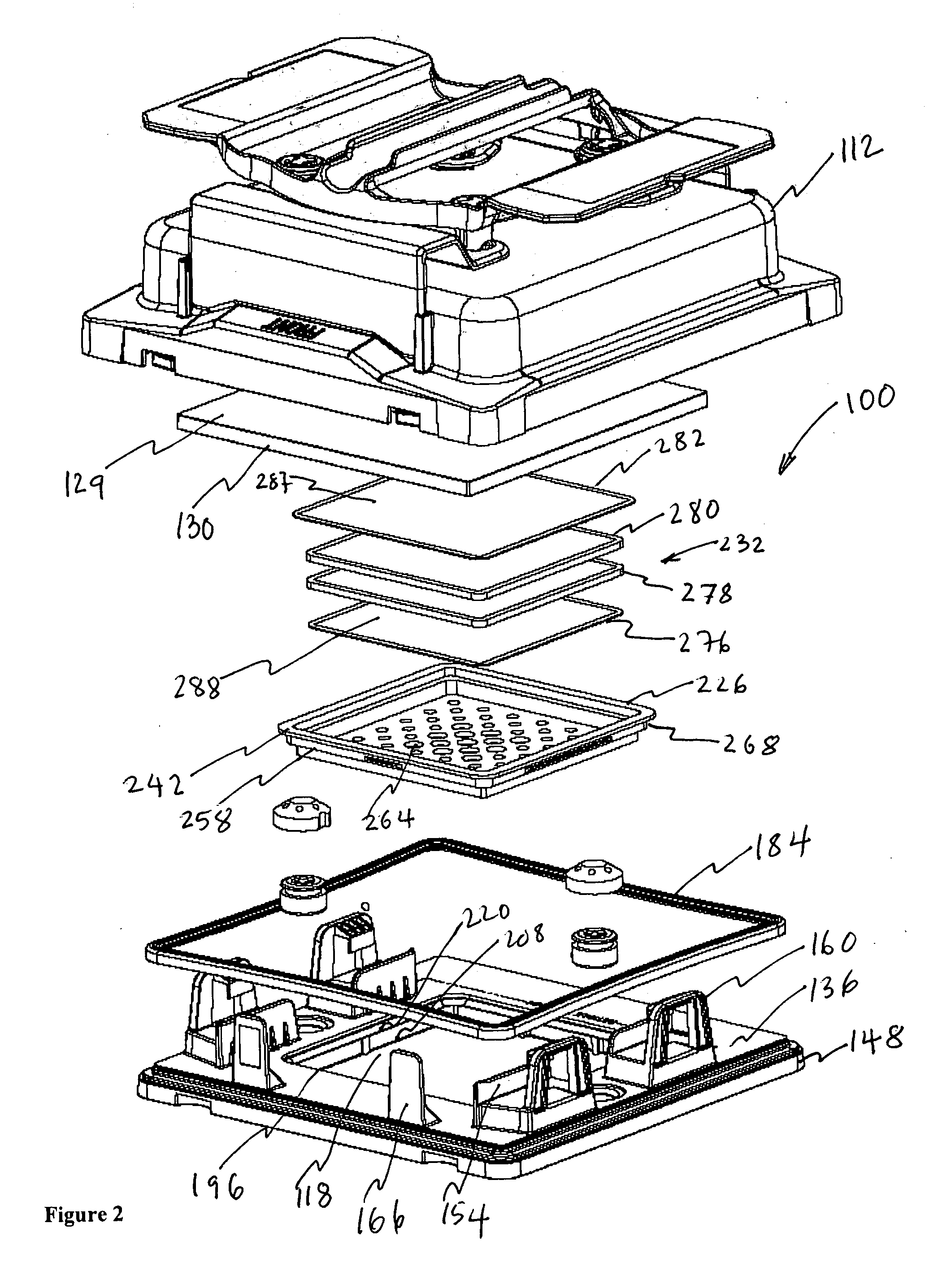

Environmental control in a reticle SMIF pod

ActiveUS20060266011A1RegeneratingReduce the binding forceCombination devicesElectrostatic separationParticulatesSystem configuration

The present invention provides a standardized mechanical interface (SMIF) reticle pod that is configured to provide a controlled environment for supporting a reticle wherein the controlled environment is maintained substantially free of crystal growth causing contaminants. Accordingly, there is provided a layered filter with filter elements capable of filtering particulates and adsorbing gaseous contaminants. The filter has an inwardly facing face generally planar shaped with a surface area that is substantially half or more of the area of the reticle face. The inwardly facing face is placed in close proximity to the reticle patterned surface and has an area that is a significant fraction of the reticle patterned surface area. The SMIF pod is also provided with a purge system configured to inject a very dry gas within the controlled environment to flush the controlled environment of contaminants as well as to regenerate the filter.

Owner:ENTEGRIS INC

Method for preparing light fuel oil and propylene from poor-quality raw oil

ActiveCN101531924AImprove propertiesDry gas reductionTreatment with hydrotreatment processesSlurryFuel oil

A method for preparing light fuel oil and propylene from poor-quality raw oil comprises the following steps: the poor-quality raw oil sequentially enters a first reaction zone and a second reaction zone of a catalytic conversion reactor so as to be contacted with a catalytic conversion catalyst to generate first reaction and second reaction respectively, and after gas-solid separation is implemented to reaction products and spent catalyst, the spent catalyst returns to the reactor for recycling after steam stripping and burning; the reaction products are separated to obtain propylene, gasoline, heavy oil and other products, wherein the heavy oil is contacted with hydrogen and a hydrotreating catalyst for reaction, the obtained hydrogenated heavy oil circulates to the first reaction zone of the catalytic conversion reactor or / and other catalytic conversion devices for further reaction to obtain the target products of the propylene and the gasoline. The characteristic of the heavy oil obtained by hydrotreating after the mild catalytic conversion of the poor-quality raw oil is significantly improved, thereby significantly increasing light oil, reducing dry gas, reducing the yield of oil slurry and realizing the high-efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

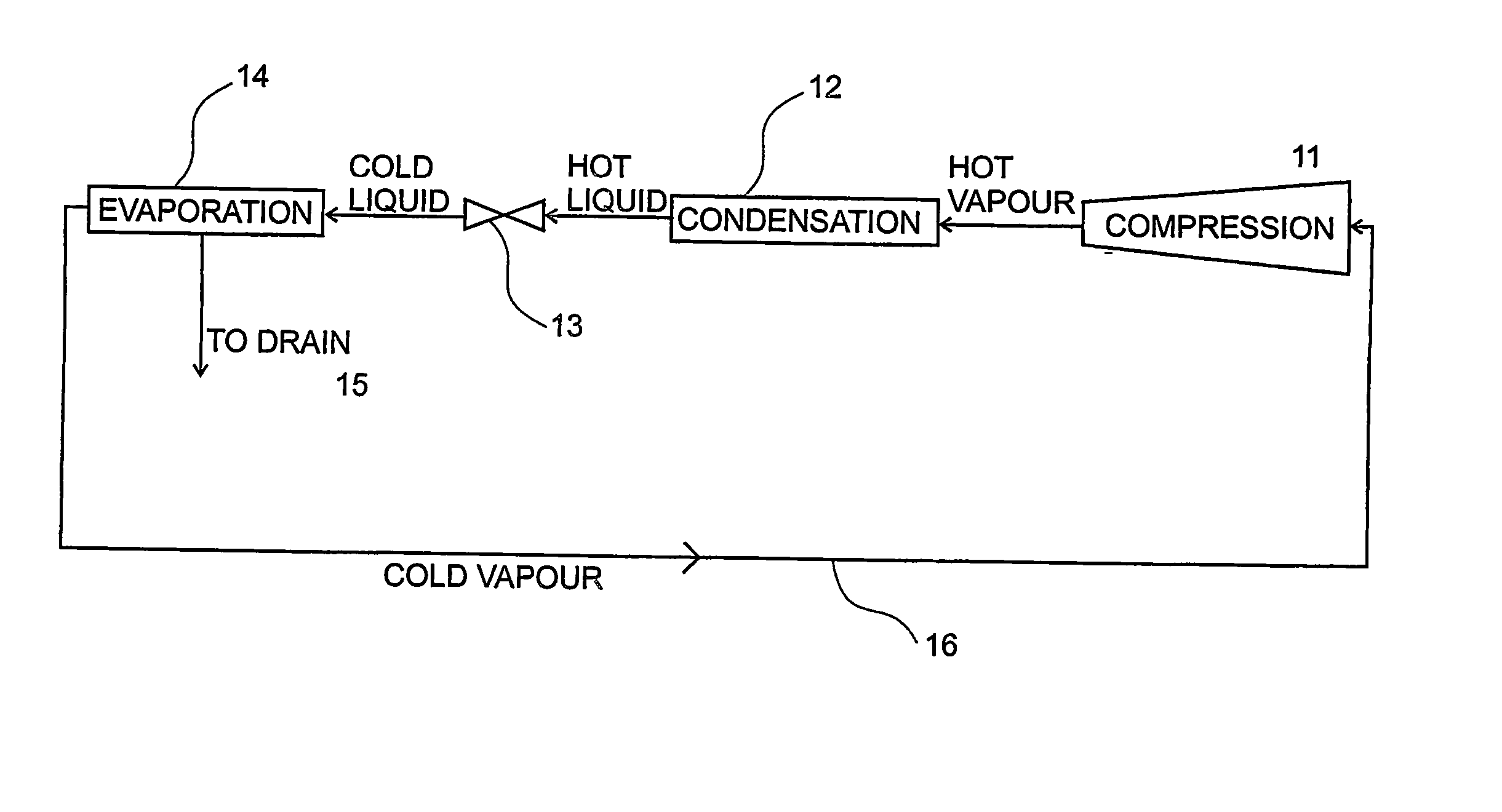

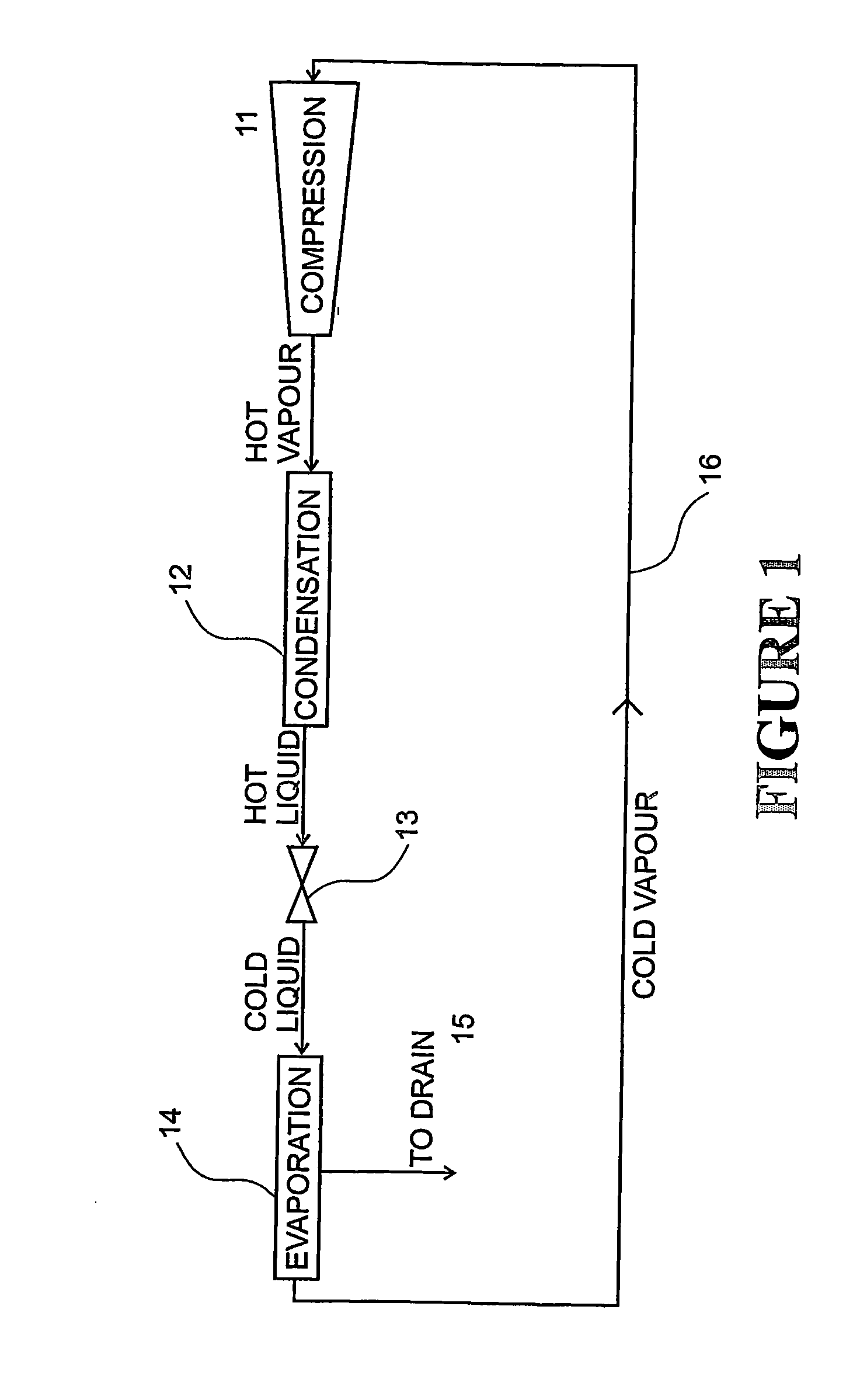

Efficiency dehumidifier drier with reversible airflow and improved control

InactiveUS20070017113A1Improve efficiencyReduce releaseDrying solid materials with heatDrying gas arrangementsProcess engineeringEngineering

An apparatus and process including a heat sink exchanger (26) to cool and condense liquid out of a drying gas with a heat transfer surface arranged to exchange heat with a first sub-stream of the drying gas and a heat source heat exchanger (27) arranged to exchange heat with a second sub-stream of a drying gas and arranged in a functionally parallel configuration with said heat sink heat exchanger (26) so that each of said drying gas sub-streams exchanges heat with one of the two said heat transfer surface per cycle through the heat exchange system and a gas movement device (35) for propelling the drying gas through the heat exchanger system in either a forward or reverse flow path direction. The apparatus and process can also include controlling the amount of heat rejected from apparatus (26) based on maintaining the wet bulb of the drying gas nominally constant and controlling the amount of refrigerant in the heat exchanger circuit based on maintaining the dry bulb temperature of the drying gas within certain limits.

Owner:DELTA V TECH

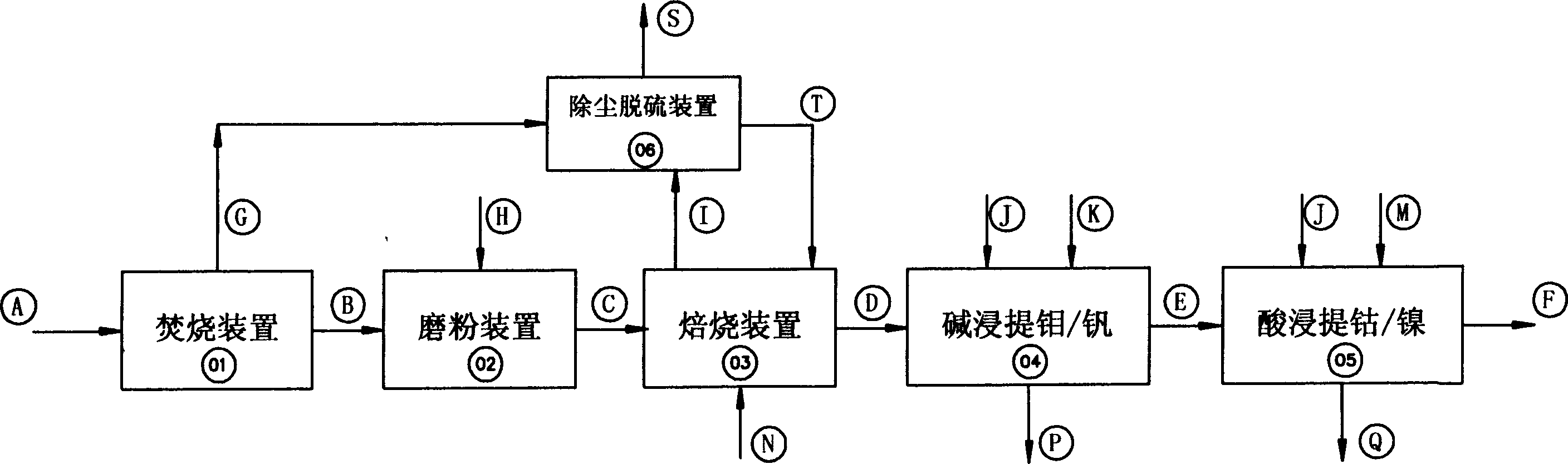

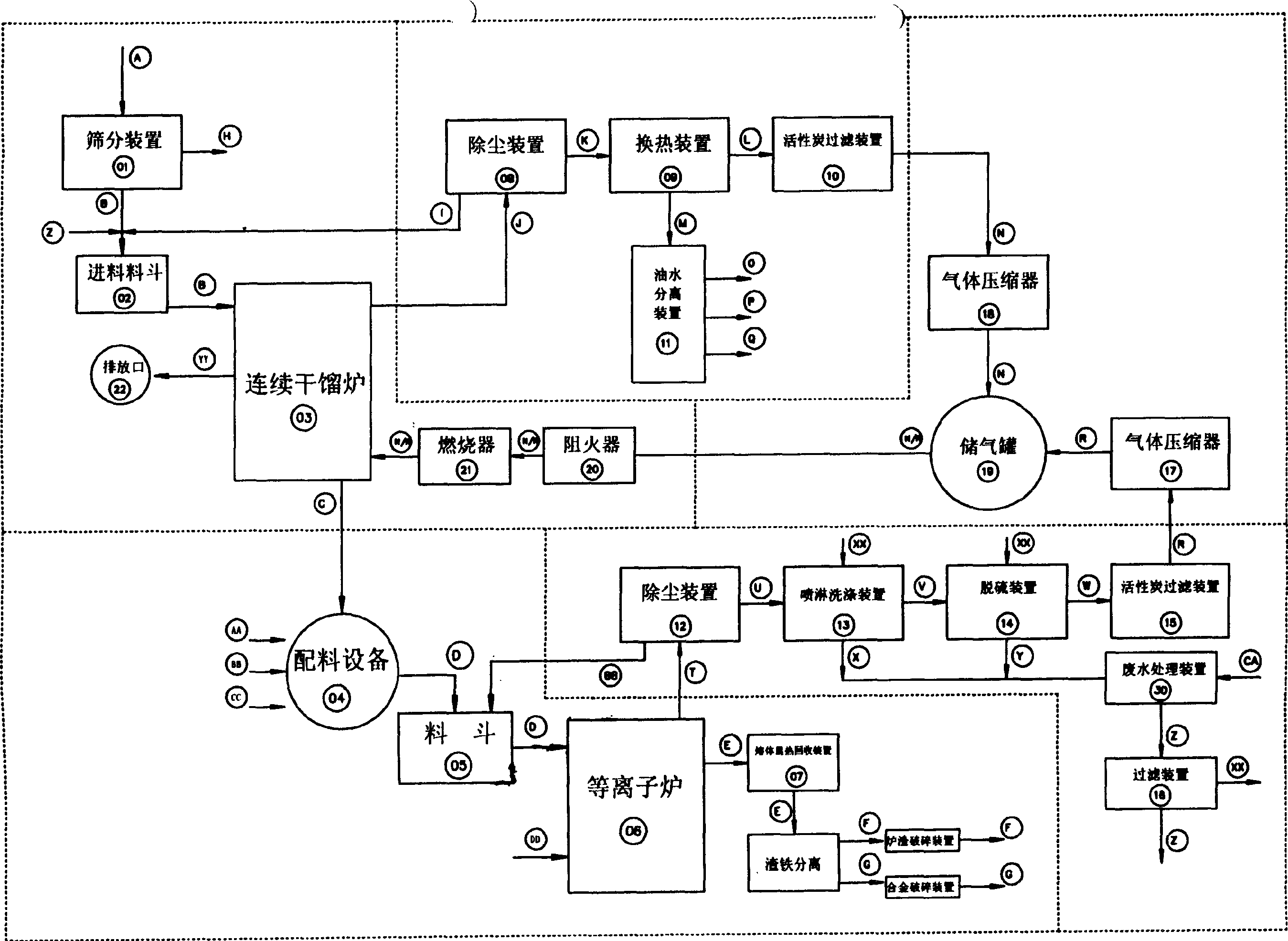

Method of handling spent catalyst

The present invention belongs to the field of environment protection and resource utilization ,and is especially waste catalyst processing method. The waste catalyst processing process includes pre-treatment; dry distillation at temperature 400-800 deg.c for 1-2.5 hr to obtain dewatered, deoiled and desulfurized water catalyst white recovering dried gas; mixing waste catalyst with flux, trapping agent and reductant to obtain mixed material; high temperature smelting at 1500-1900 deg.c to convert into melt and smelted tail gas and treated for reuse. The present invention is one environment protecting process producing no secondary pollutant while recovering the components in waste catalyst, has metal recovering rate as high as 93 % and full utilization of waste catalyst resource.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

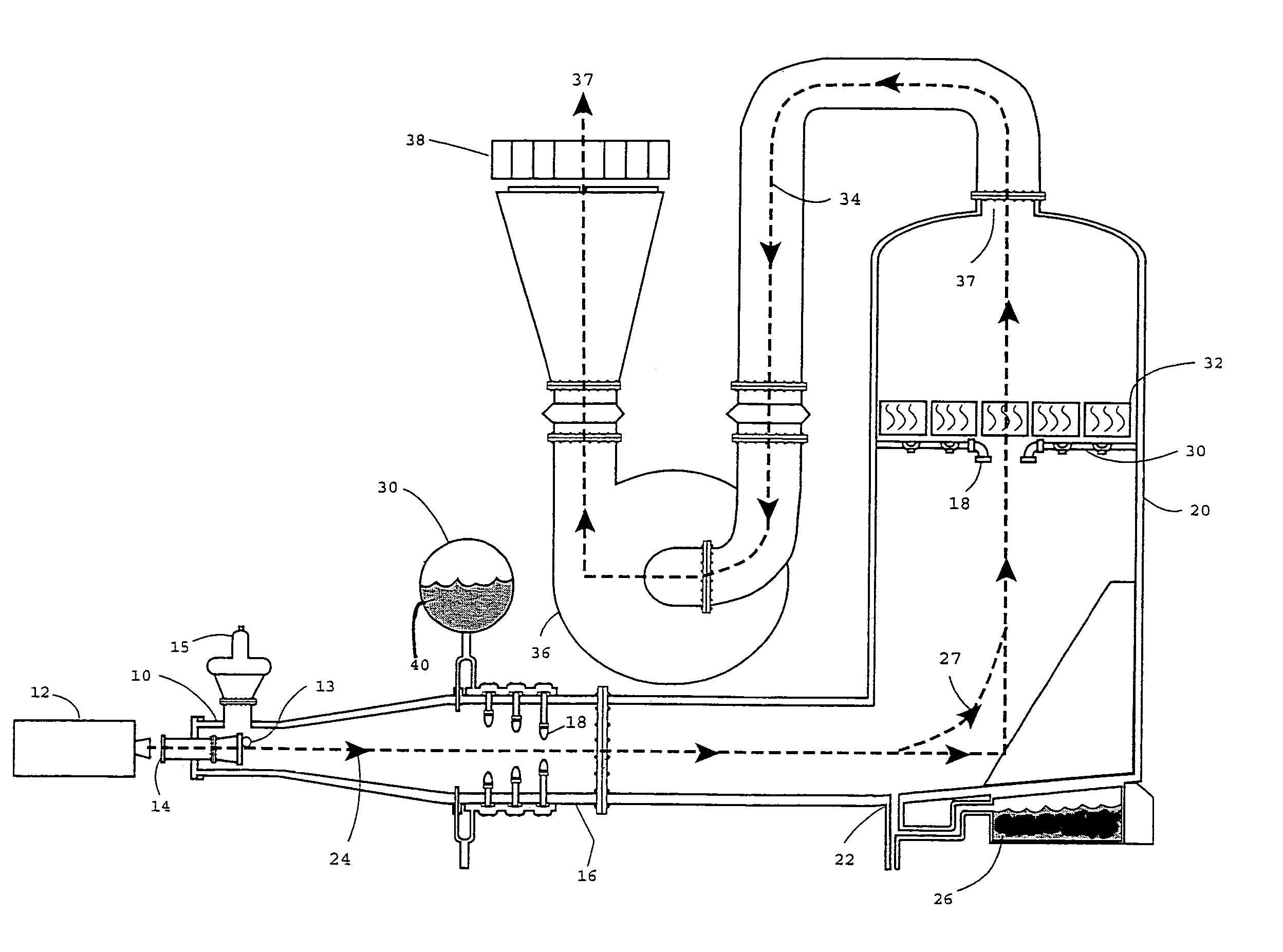

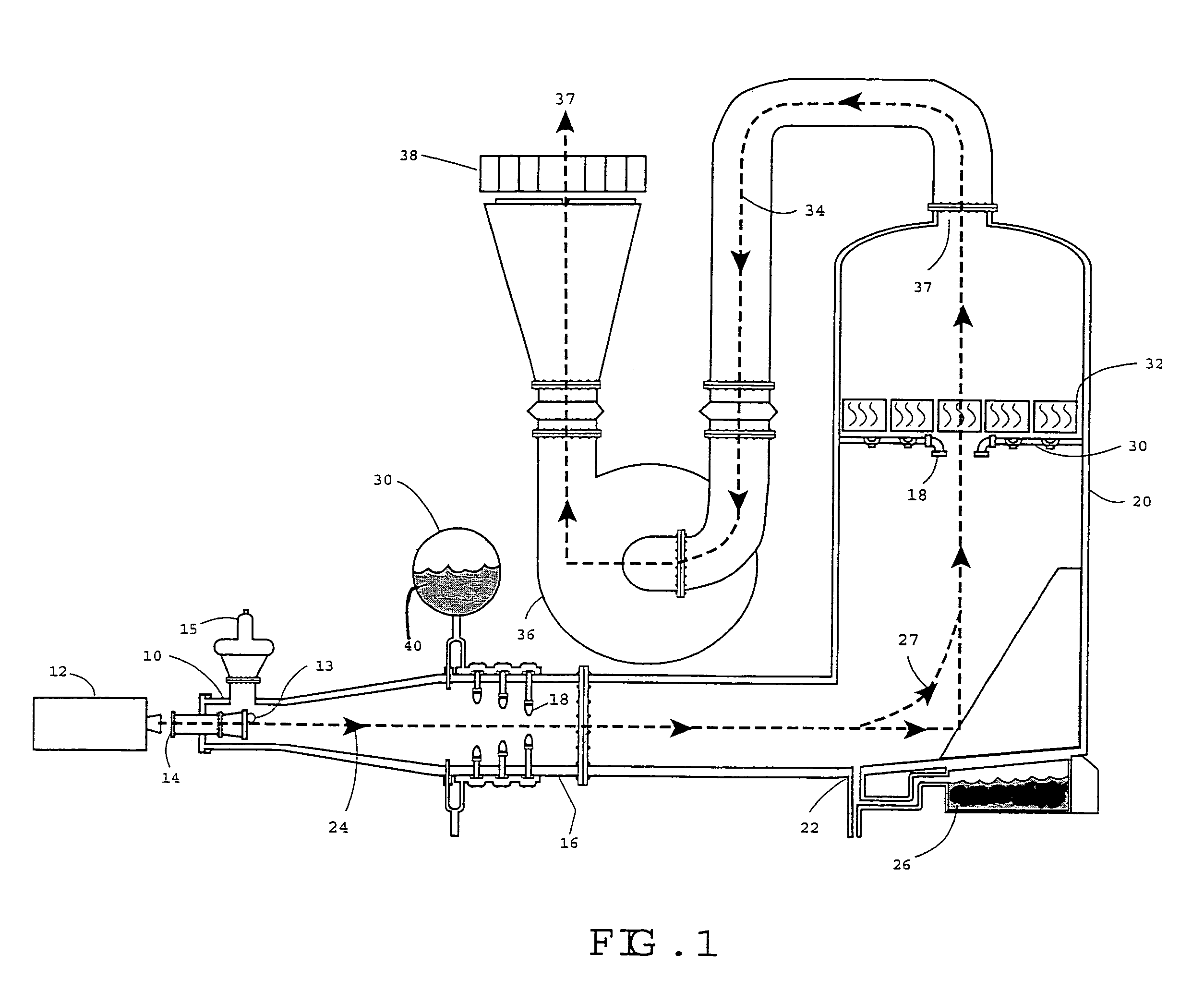

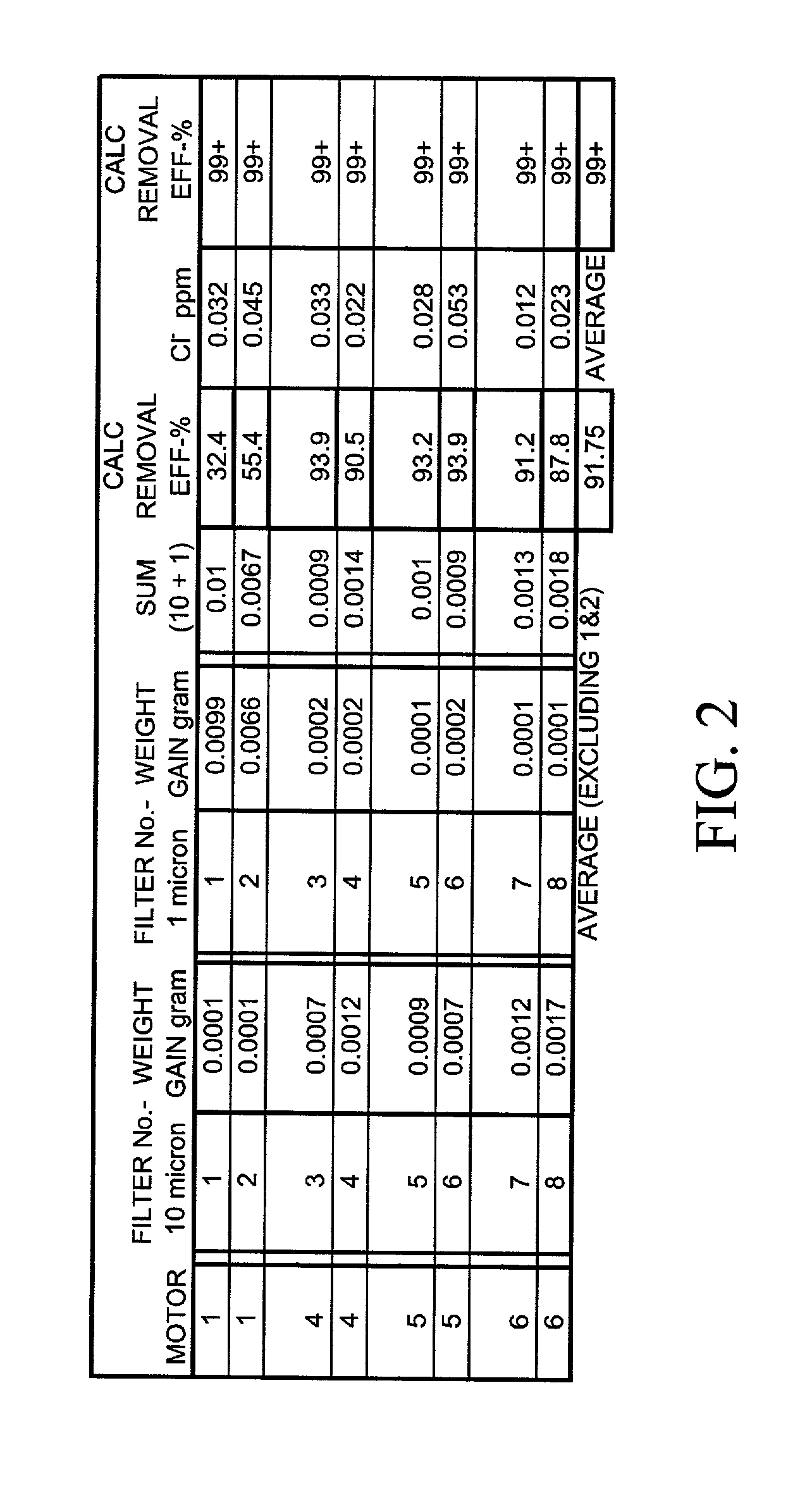

Rocket motor exhaust scrubber

InactiveUS6964699B1Reduce probabilityEfficient captureCombination devicesGas treatmentGas passingEngineering

A wet scrubber having a series of chambers for capturing and cooling exhaust gases generated during static test firing of rocket motors. Exhaust gas enters an inlet to a first chamber and is cooled and slowed by a spray solution. HCL gas is condensed and absorbed by the spray solution and precipitates to a liquid slurry at the bottom of the device. The remaining exhaust products enter a demister chamber where nozzles continue to spray the gasses as they pass upward and through a mesh-style demister at the top of the vessel. The demister filters liquid and solid waste particles from the gas stream, and the clean, dry gases are accelerated through a centrifugal fan into the atmosphere. A deflector is positioned within the inlet to the first chamber for containing parts in the event of a motor mal-function.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com