Patents

Literature

2826results about "Ethylene production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

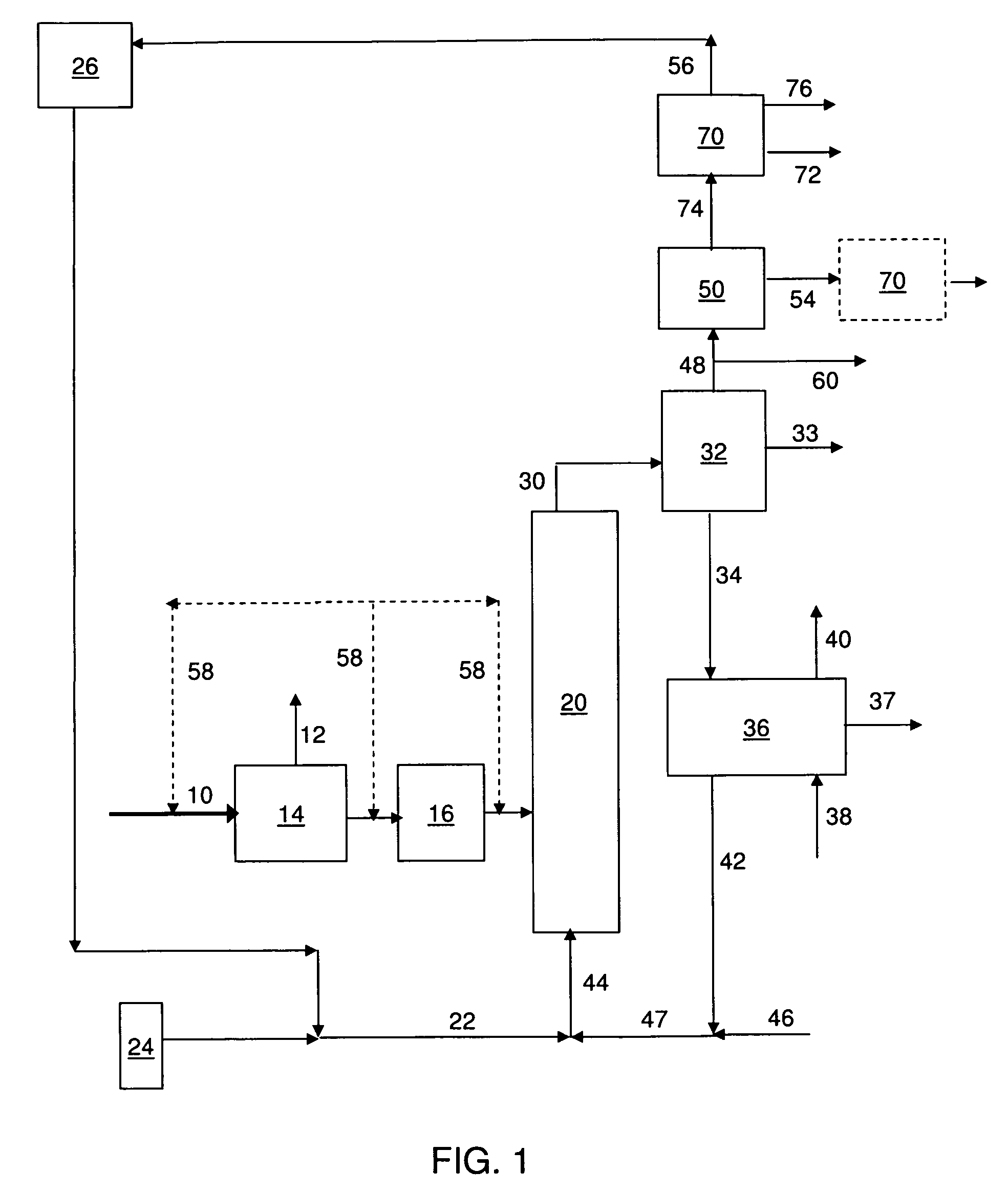

Production of Blended Fuel from Renewable Feedstocks

A process for producing a blended fuel from a paraffin rich component and a cyclic rich component, where each of the components are generated from a renewable feedstock, is presented. The paraffin rich component is generated from a first renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, biomass, lignocellulose, free sugars, and combinations thereof. The cyclic rich component is generated from a second renewable feedstock comprising at least one component selected from the group consisting of glycerides, free fatty acids, free fatty alkyl esters, biomass, lignocellulose, free sugars, and combinations thereof. The blended fuel may a gasoline boiling point range blended fuel, a diesel boiling point range blended fuel, an aviation boiling point range blended fuel, any combination thereof, or any mixture thereof.

Owner:UOP LLC

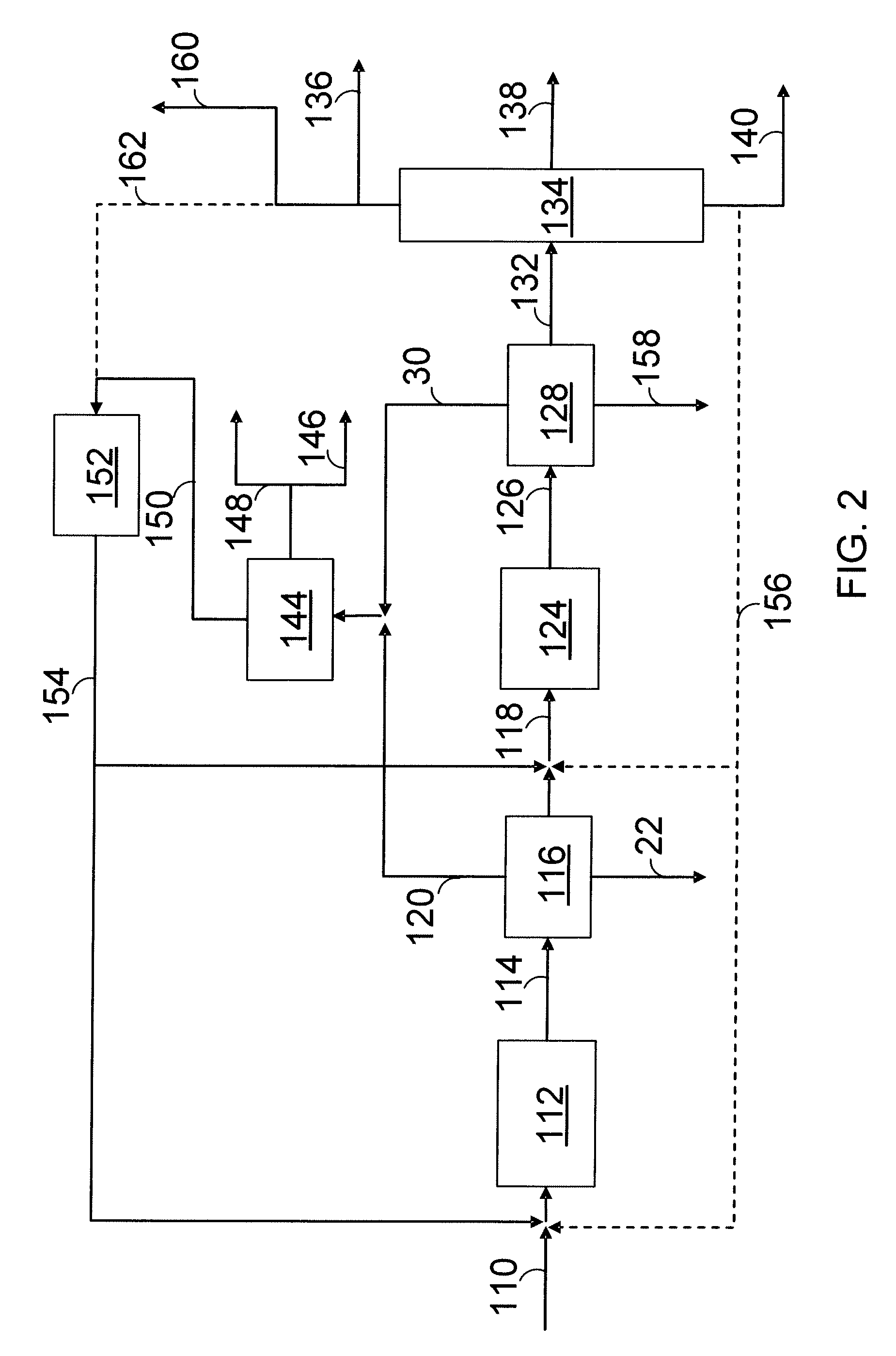

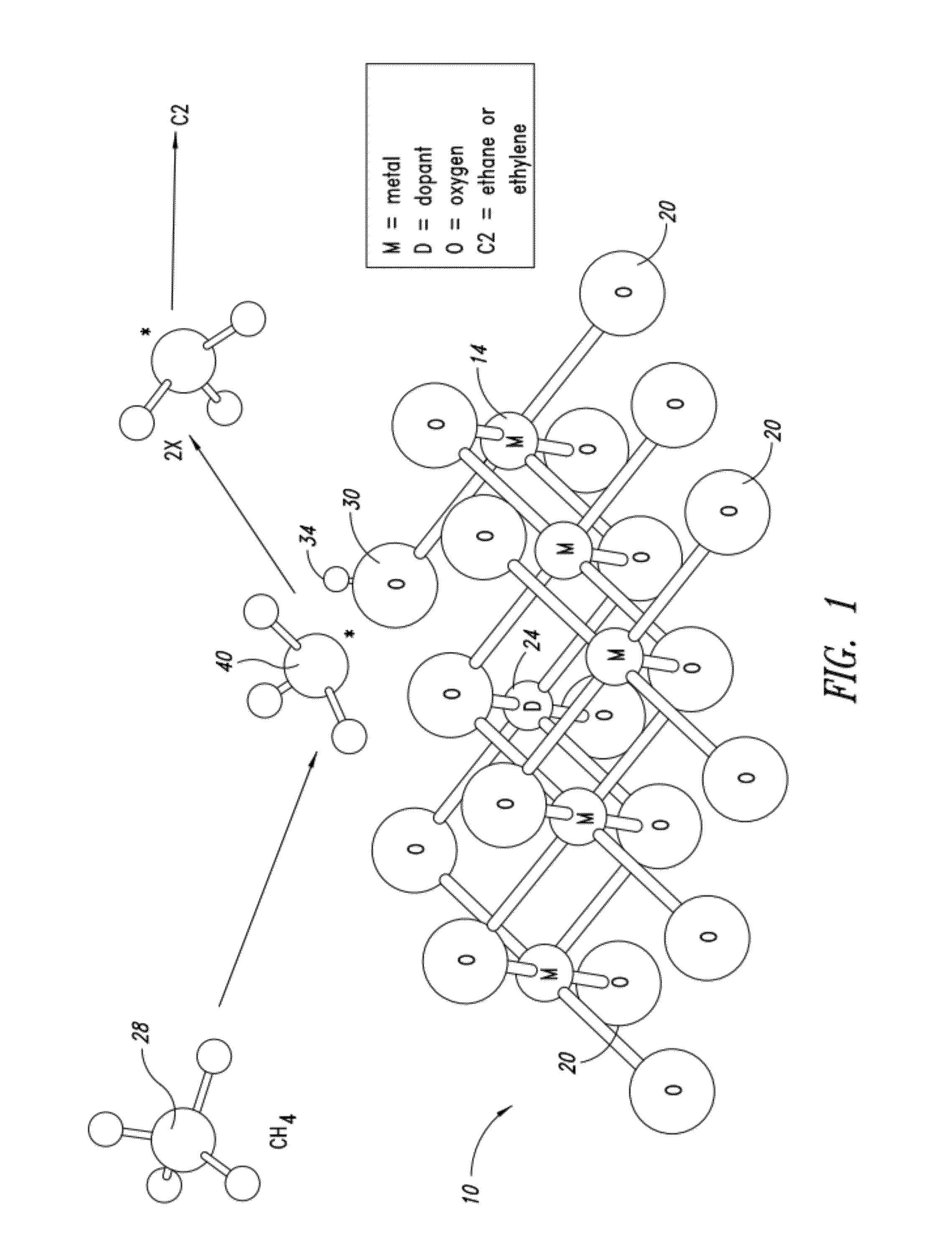

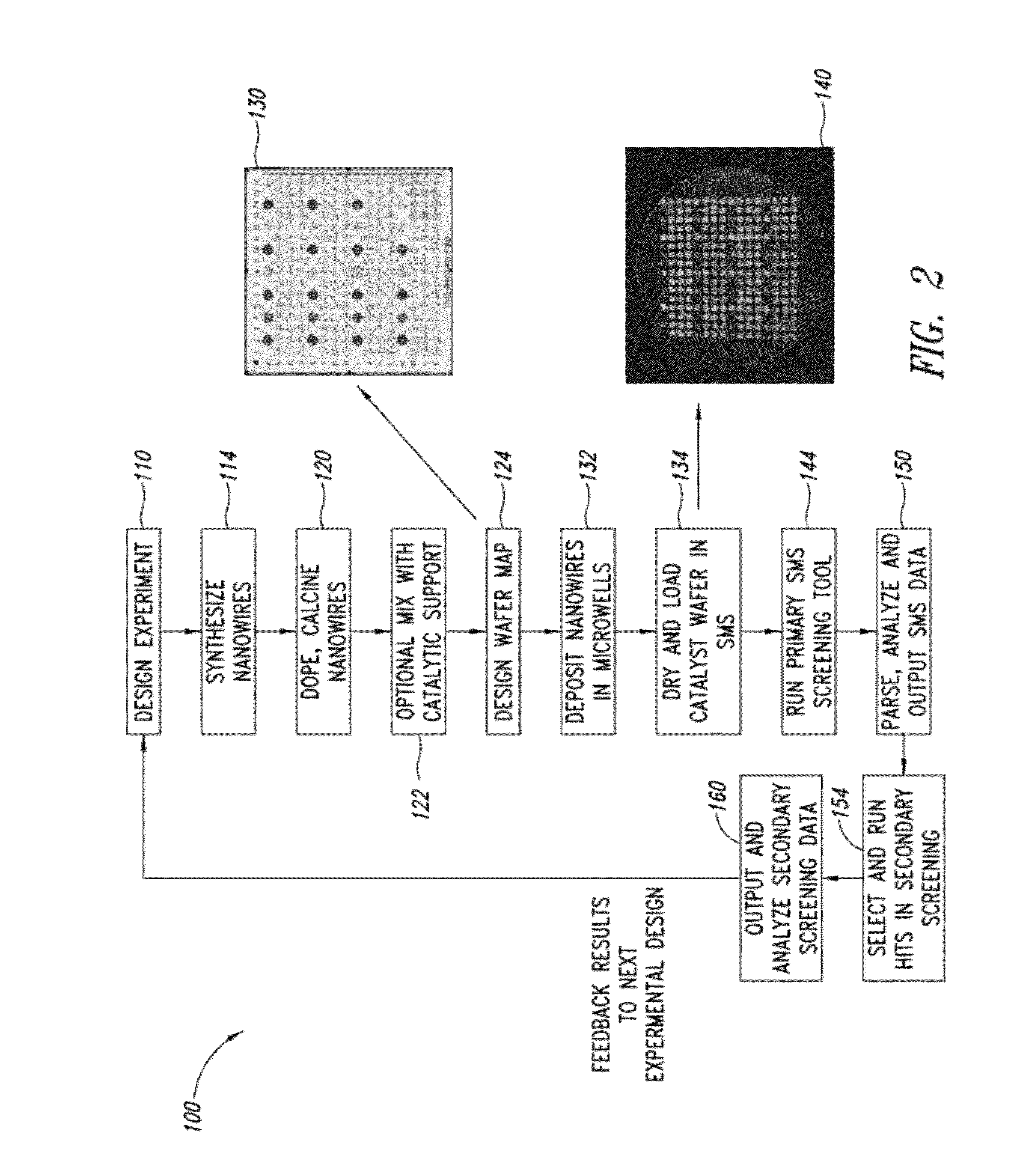

Nanowire catalysts

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Slurry dewatering and conversion of biosolids to a renewable fuel

ActiveUS20060096163A1Readily removed mechanicallyLow oxygenBio-organic fraction processingBiofuelsEmission standardSlurry

In the processes for treating municipal sewage and storm water containing biosolids to discharge standards, biosolids, even after dewatering, contain typically about 80% water bound in the dead cells of the biosolids, which gives biosolids a negative heating value. It can be incinerated only at the expense of purchased fuel. Biosolids are heated to a temperature at which their cell structure is destroyed and, preferably, at which carbon dioxide is split off to lower the oxygen content of the biosolids. The resulting char is not hydrophilic, and it can be efficiently dewatered and / or dried and is a viable renewable fuel. This renewable fuel can be supplemented by also charging conventional biomass (yard and crop waste, etc.) in the same or in parallel facilities. Similarly, non-renewable hydrophilic fuels can be so processed in conjunction with the processing of biosolids to further augment the energy supply.

Owner:SGC ADVISORS

Processes for making ethanol from acetic acid

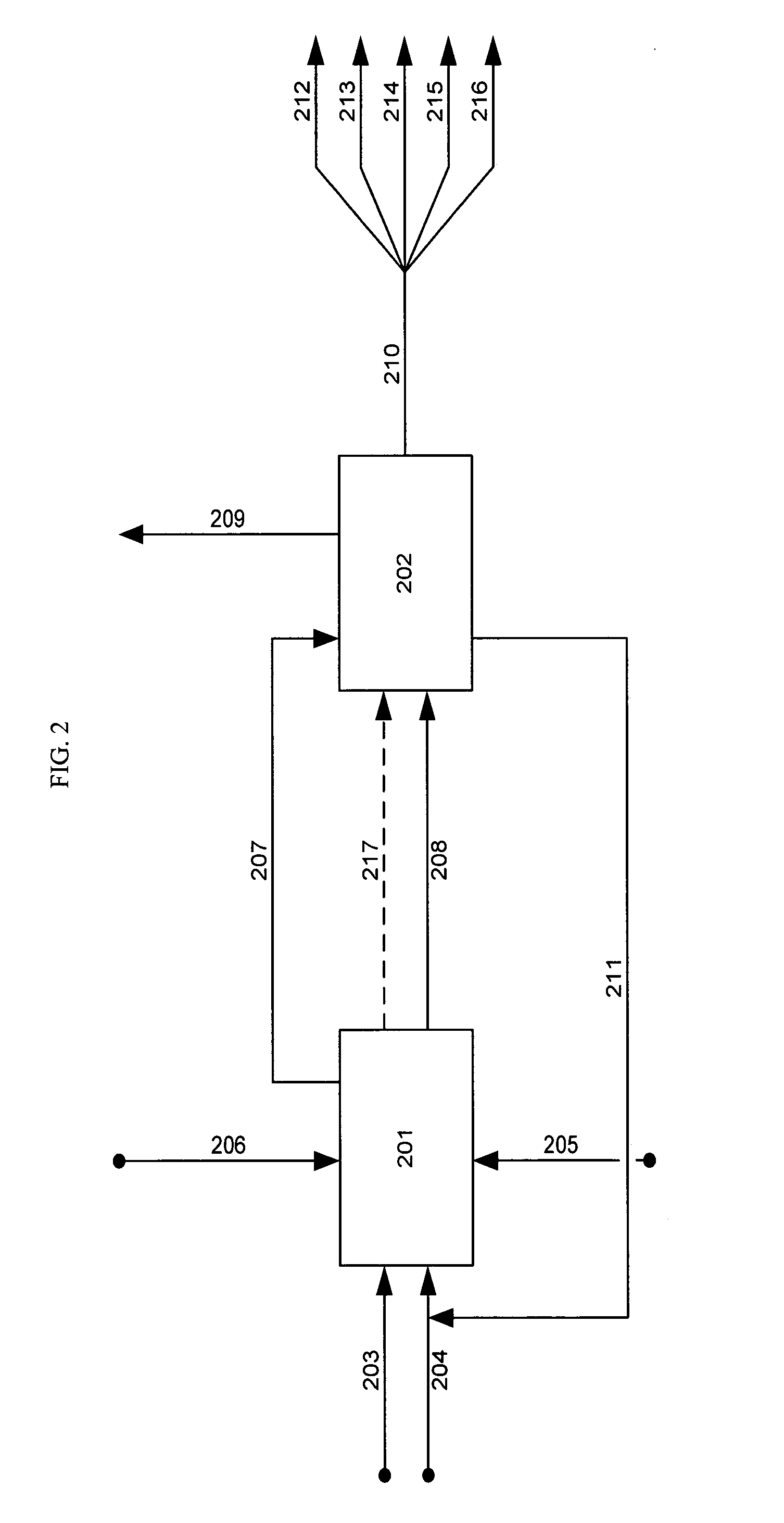

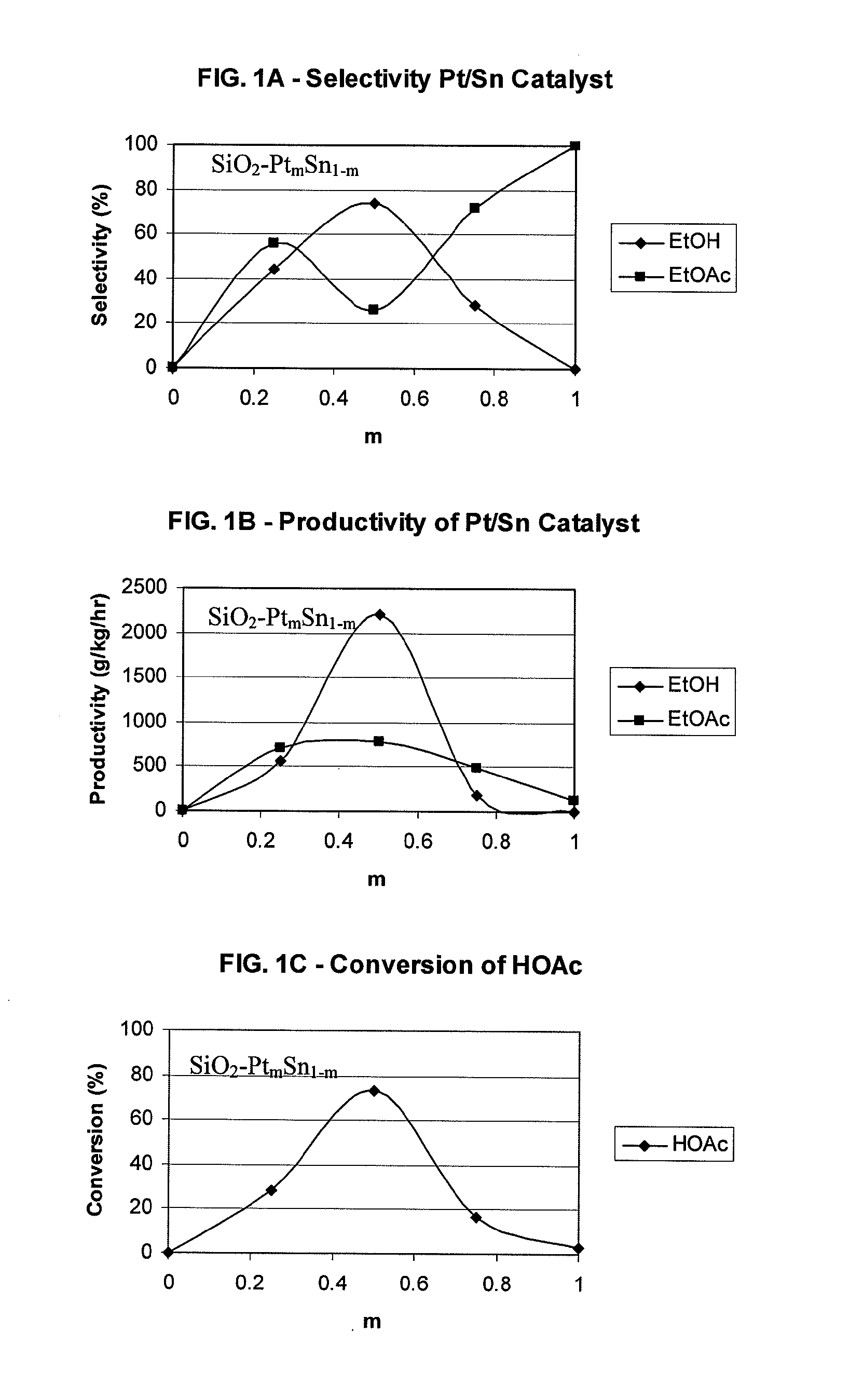

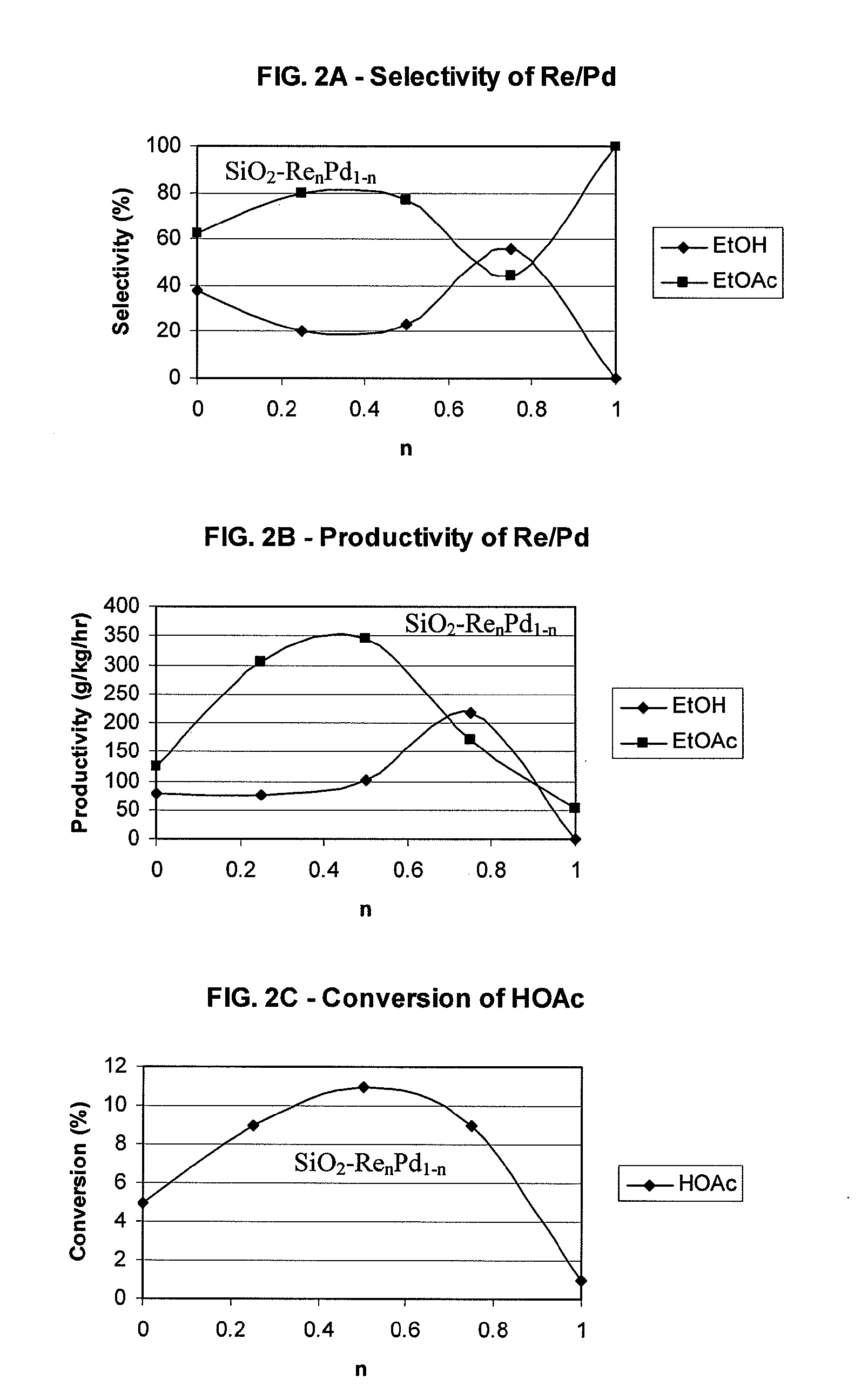

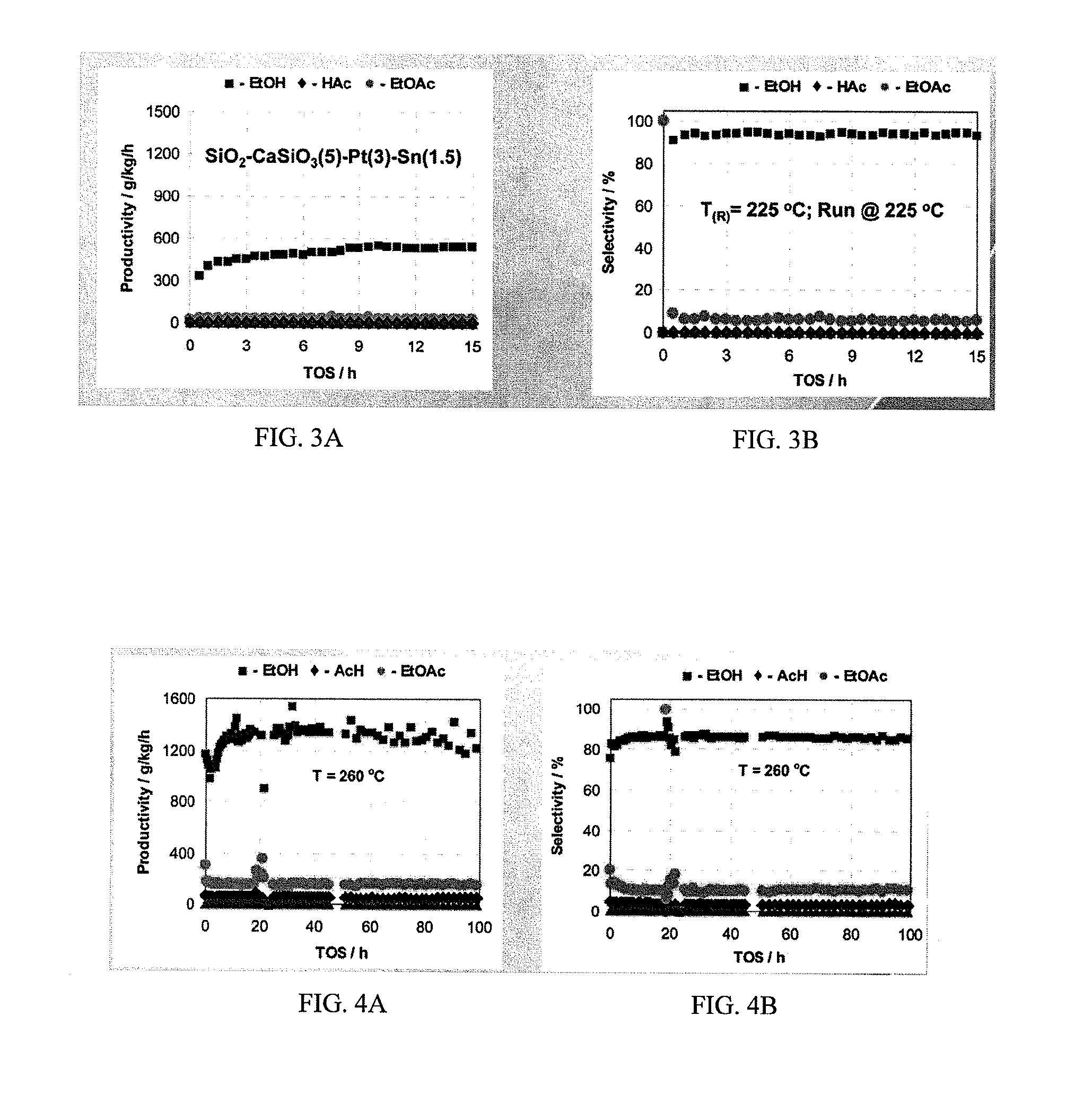

InactiveUS20100197985A1High selectivityPreparation by oxo-reaction and reductionEthylene productionCeriumCobalt

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of first metal, a silicaceous support, and at least one support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

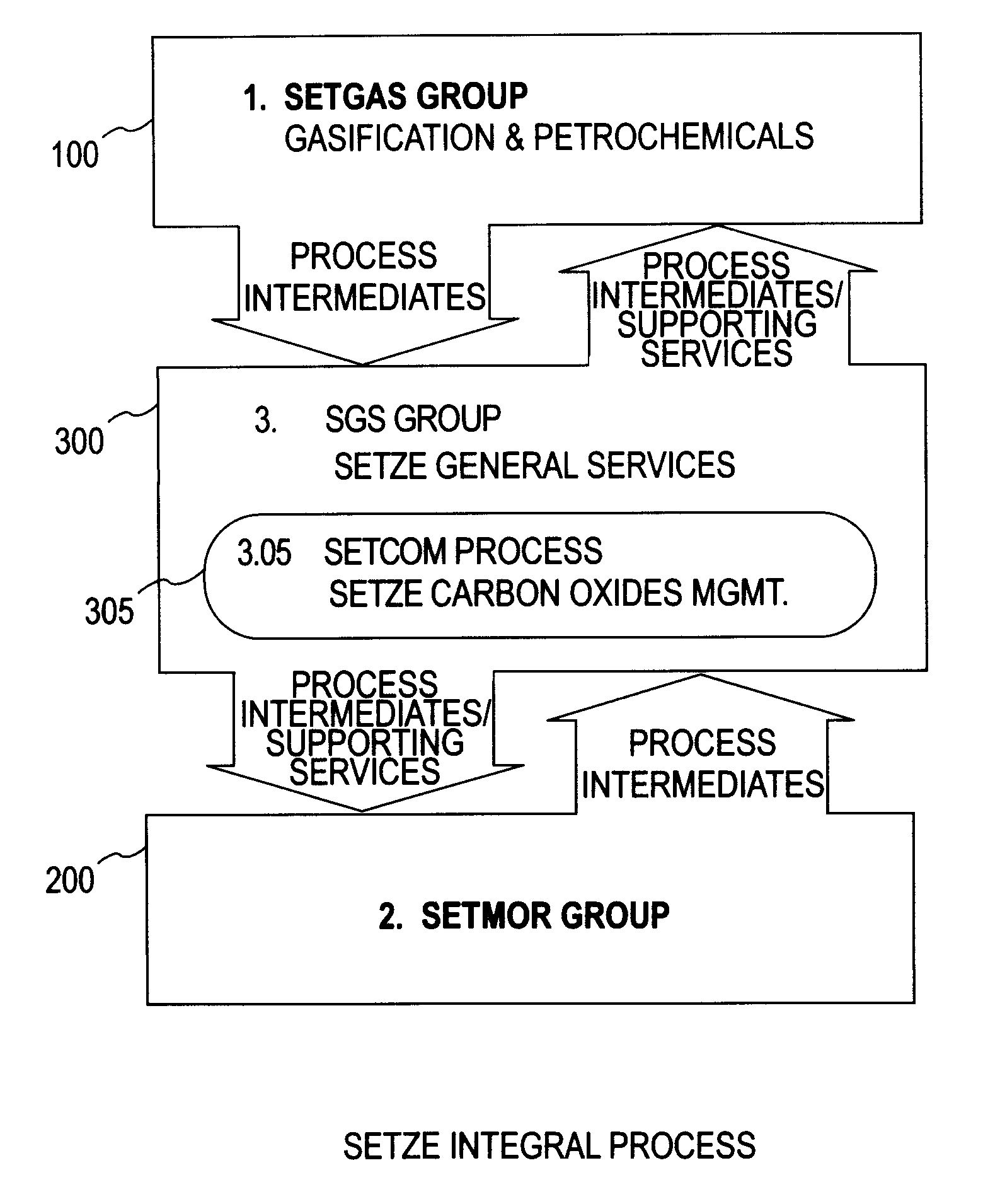

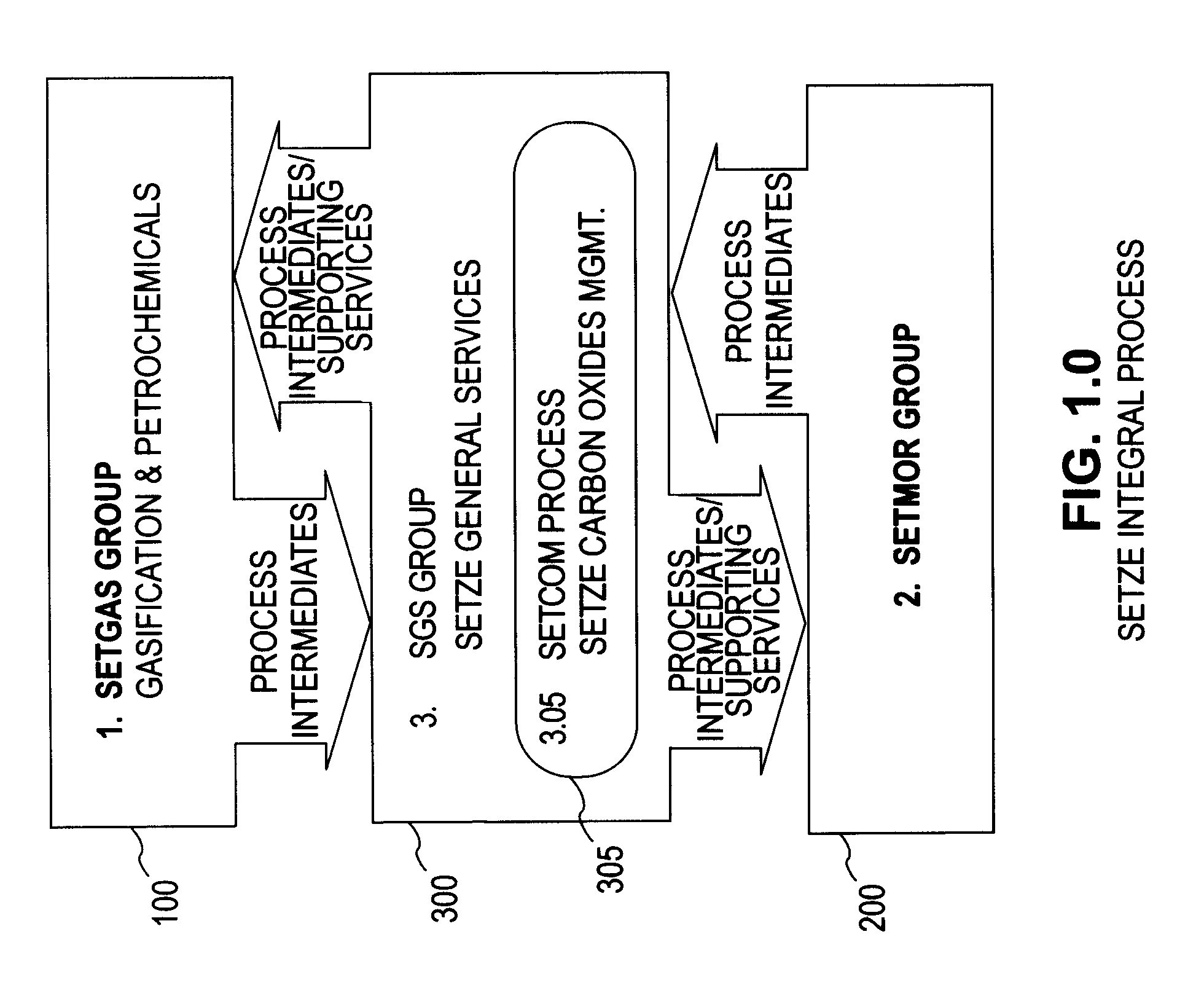

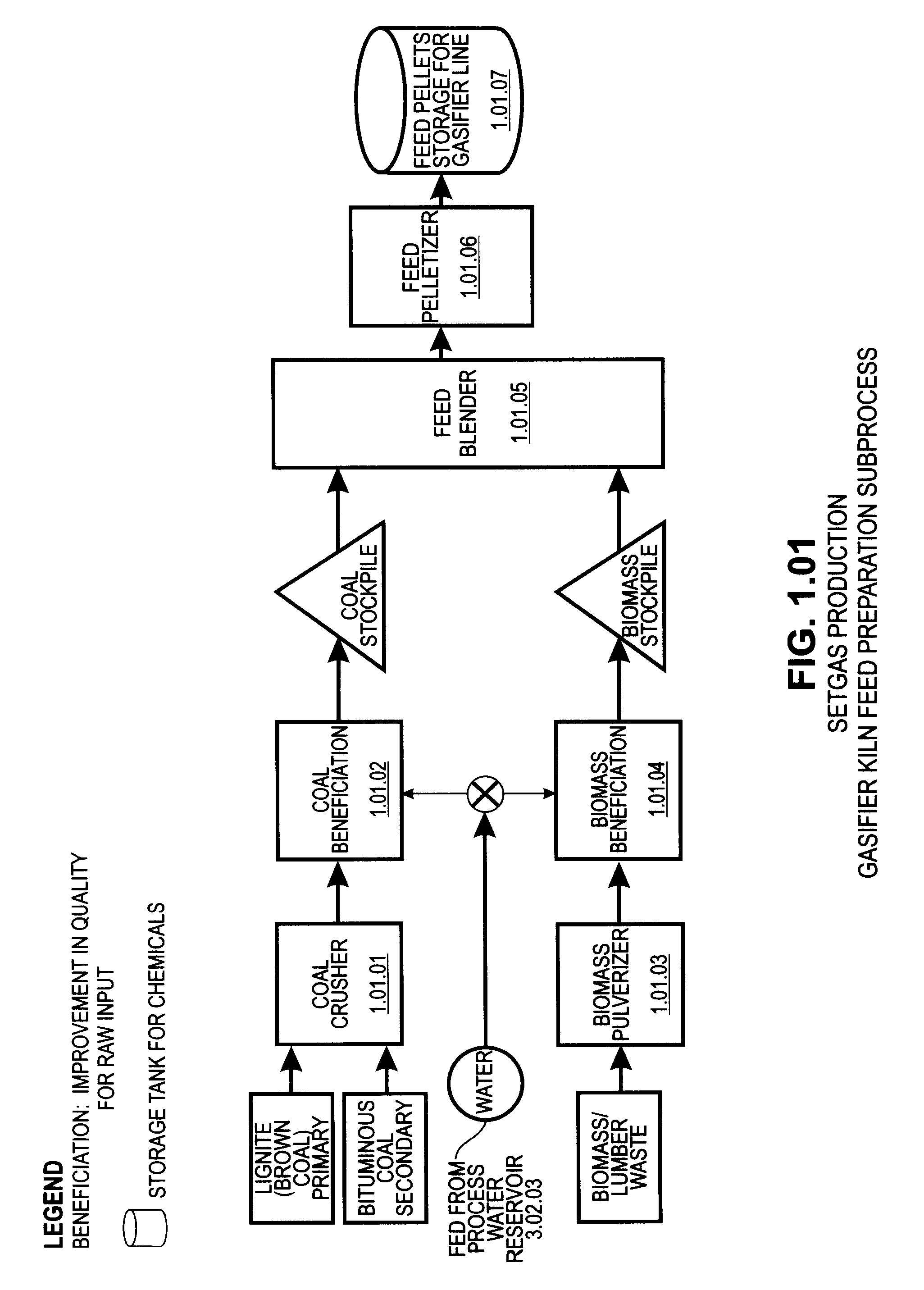

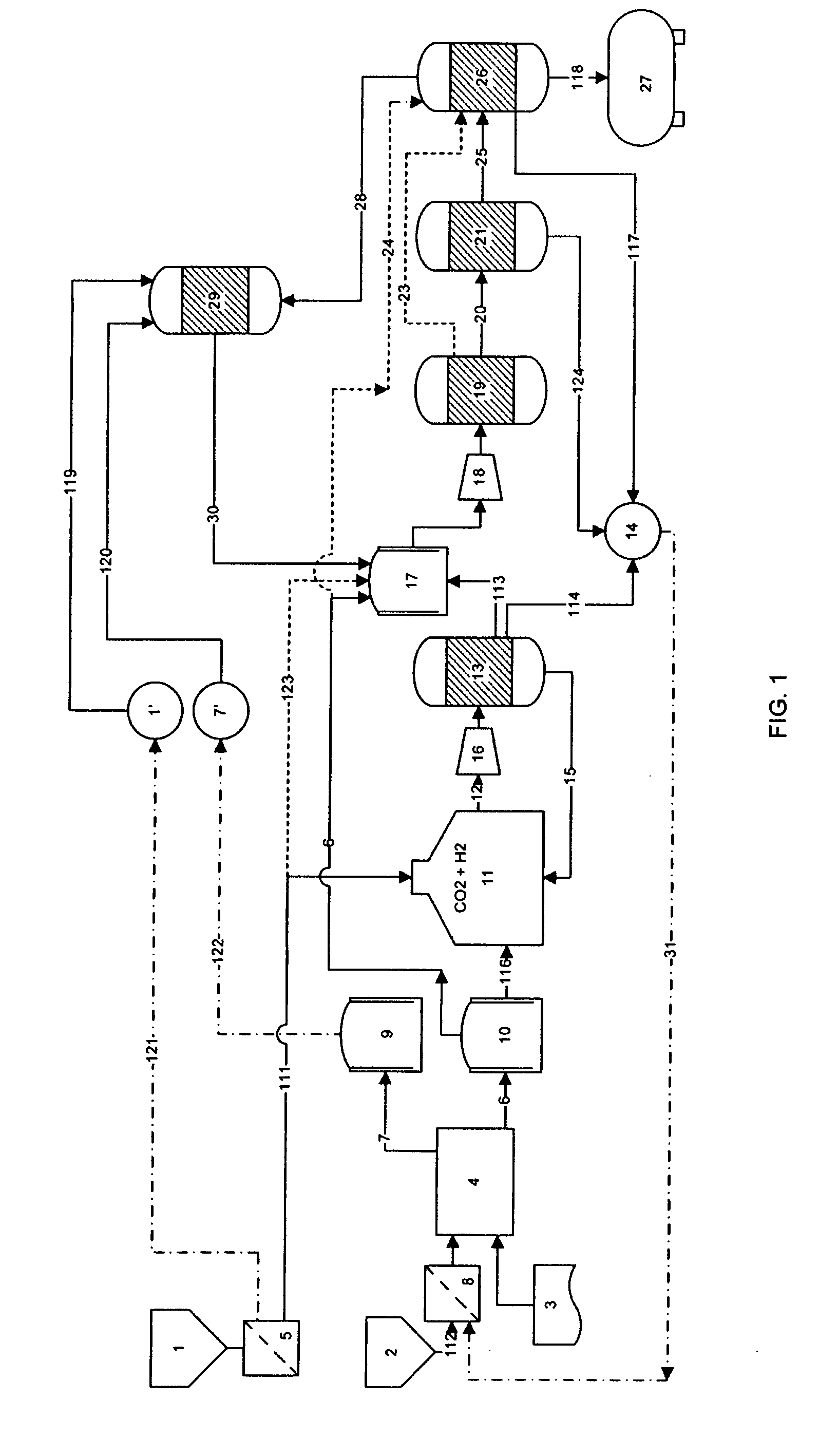

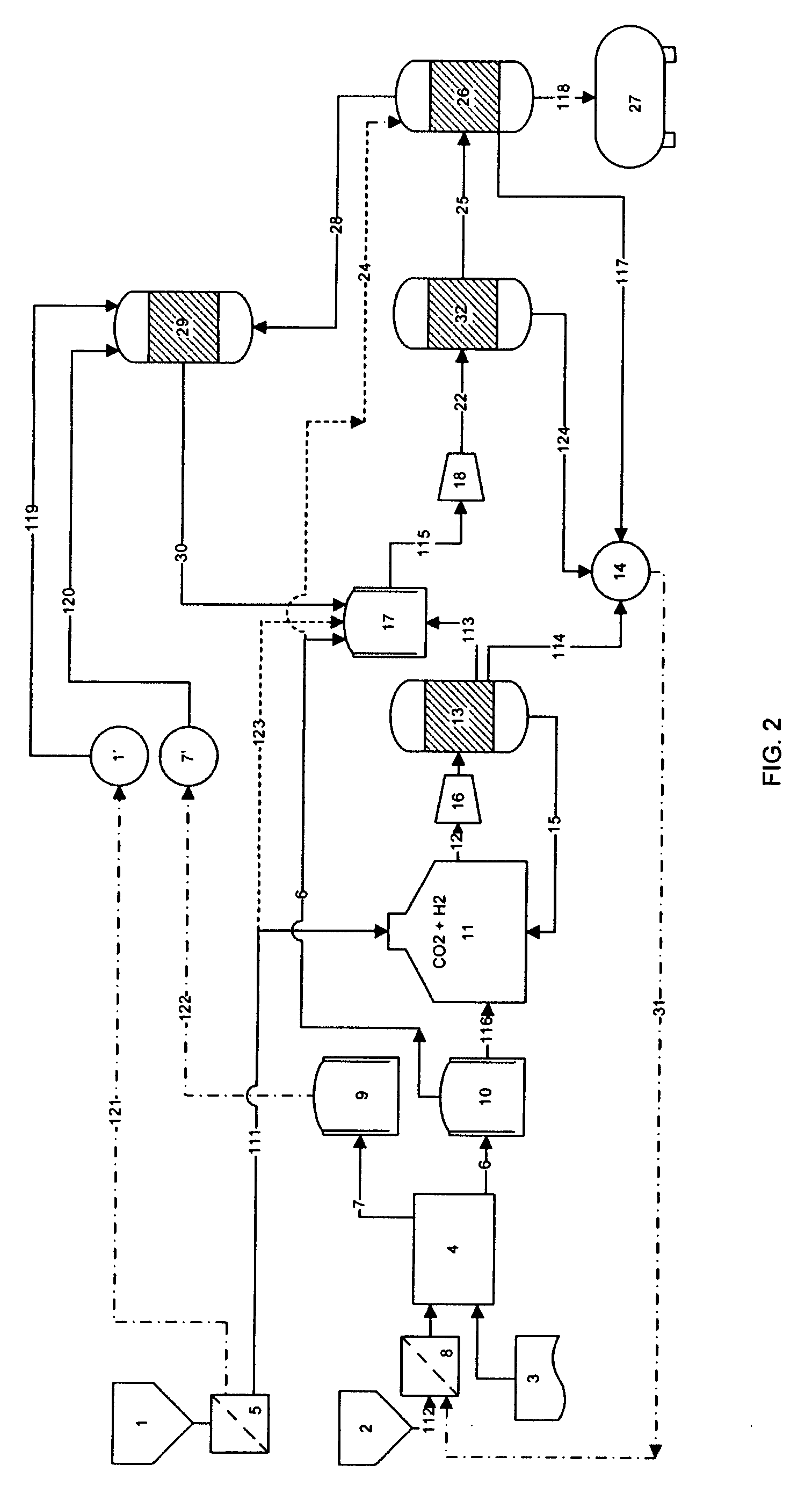

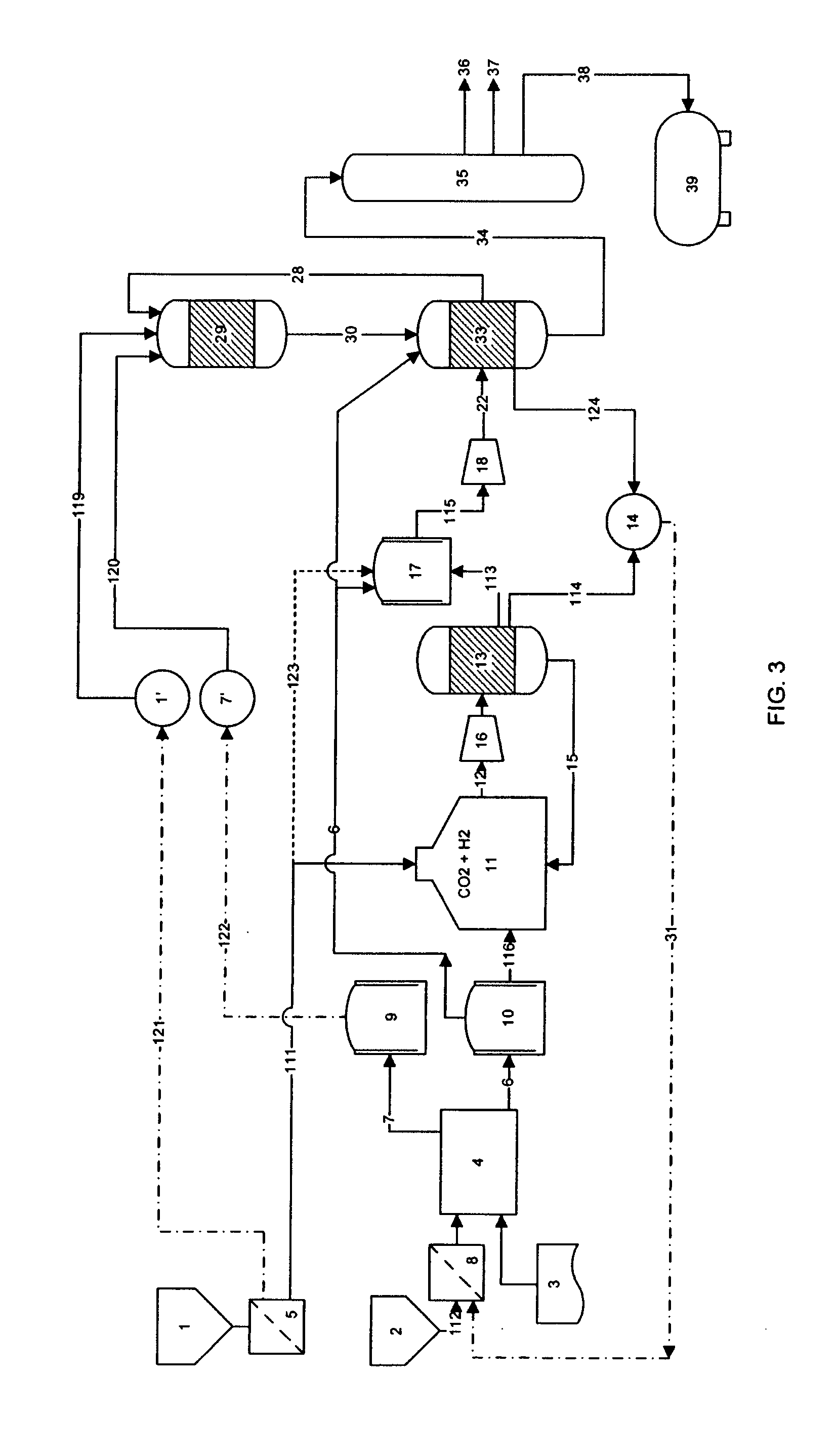

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

Porous composite materials having micro and meso/macroporosity

InactiveUS20070087934A1Molecular sieve catalystsOrganic compound preparationMaterials scienceInorganic oxide

A composite material comprises: (a) a porous crystalline inorganic oxide material comprising a first framework structure defining a first set of uniformly distributed pores having an average cross-sectional dimension of from 0.3 to less than 2 nanometers and comprising a second framework structure defining a second set of uniformly distributed pores having an average cross-sectional dimension of from 2 to 200 nanometers and (b) a co-catalyst within the second set of pores of the porous crystalline inorganic oxide material (a).

Owner:EXXONMOBIL CHEM PAT INC

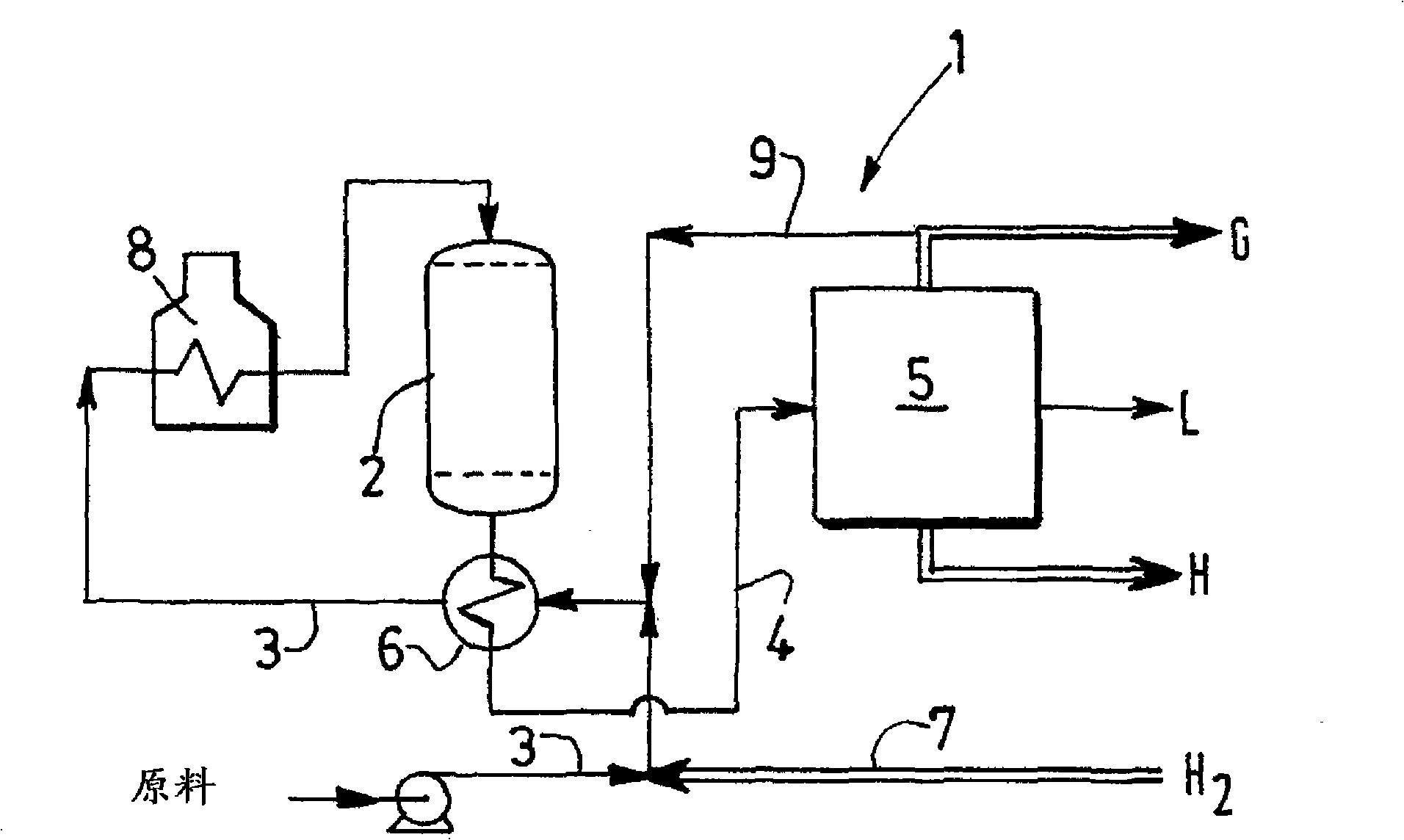

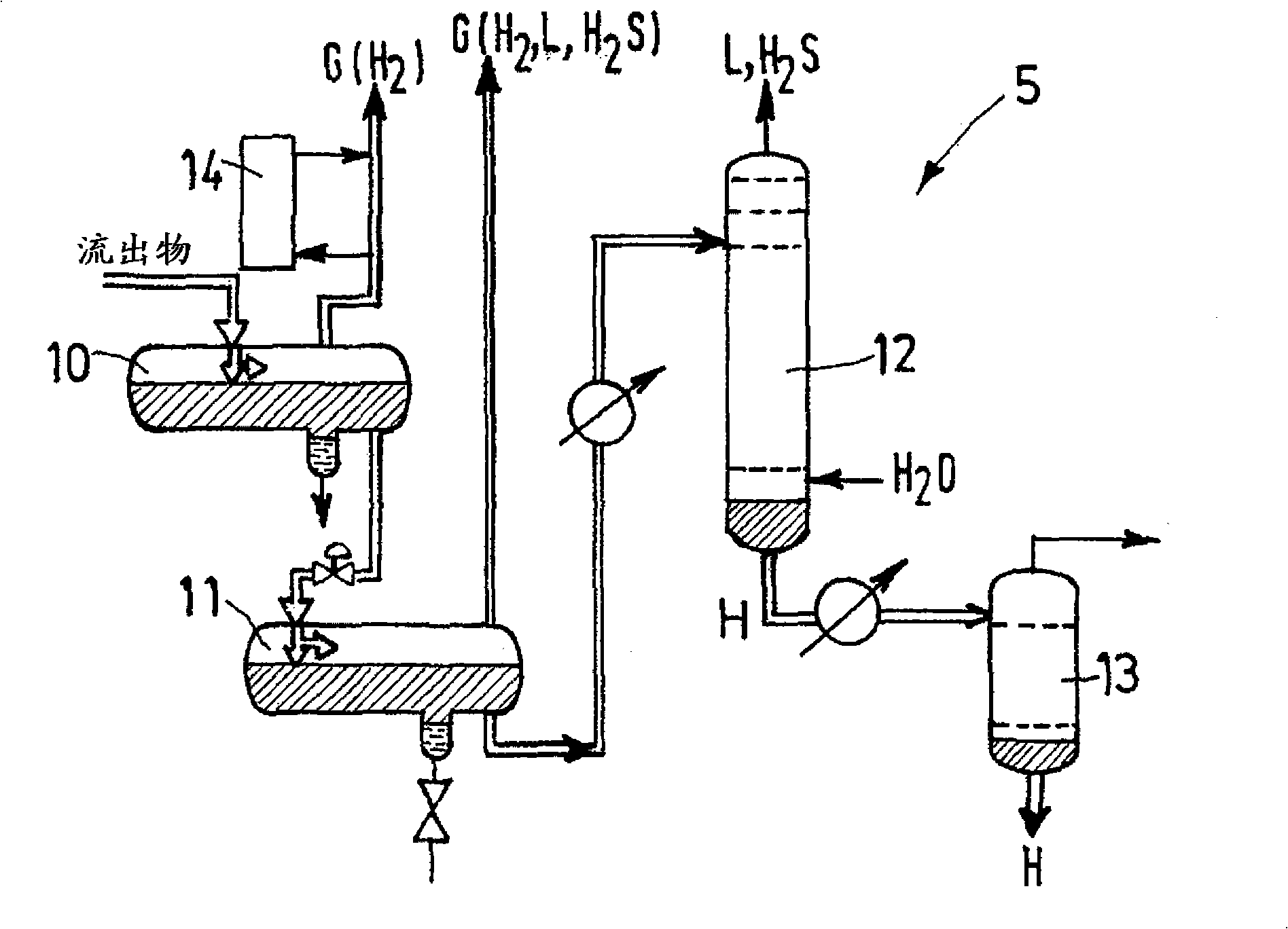

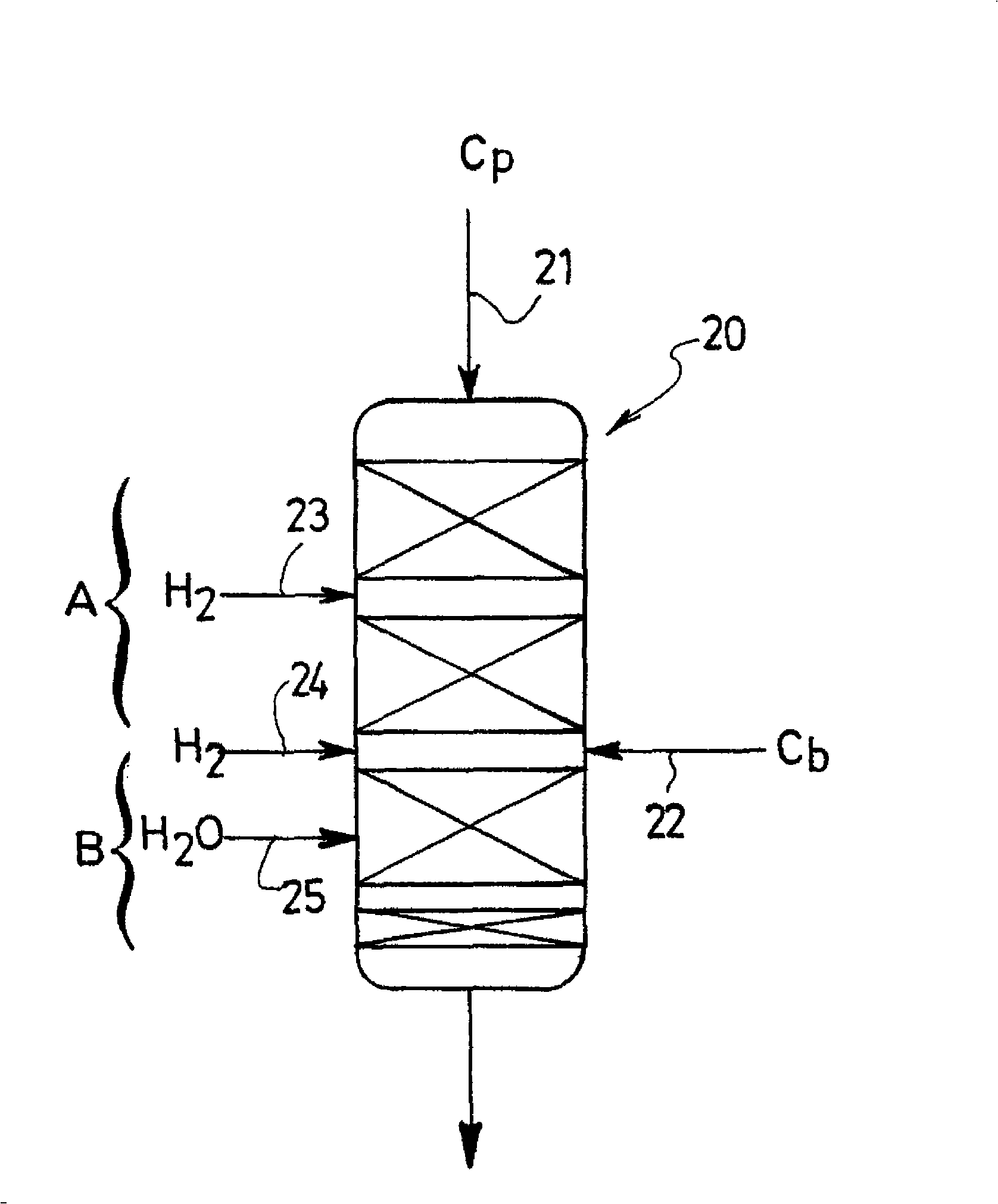

Method for the hydro-processing of a gas oil feedstock, and corresponding hydro-refining unit

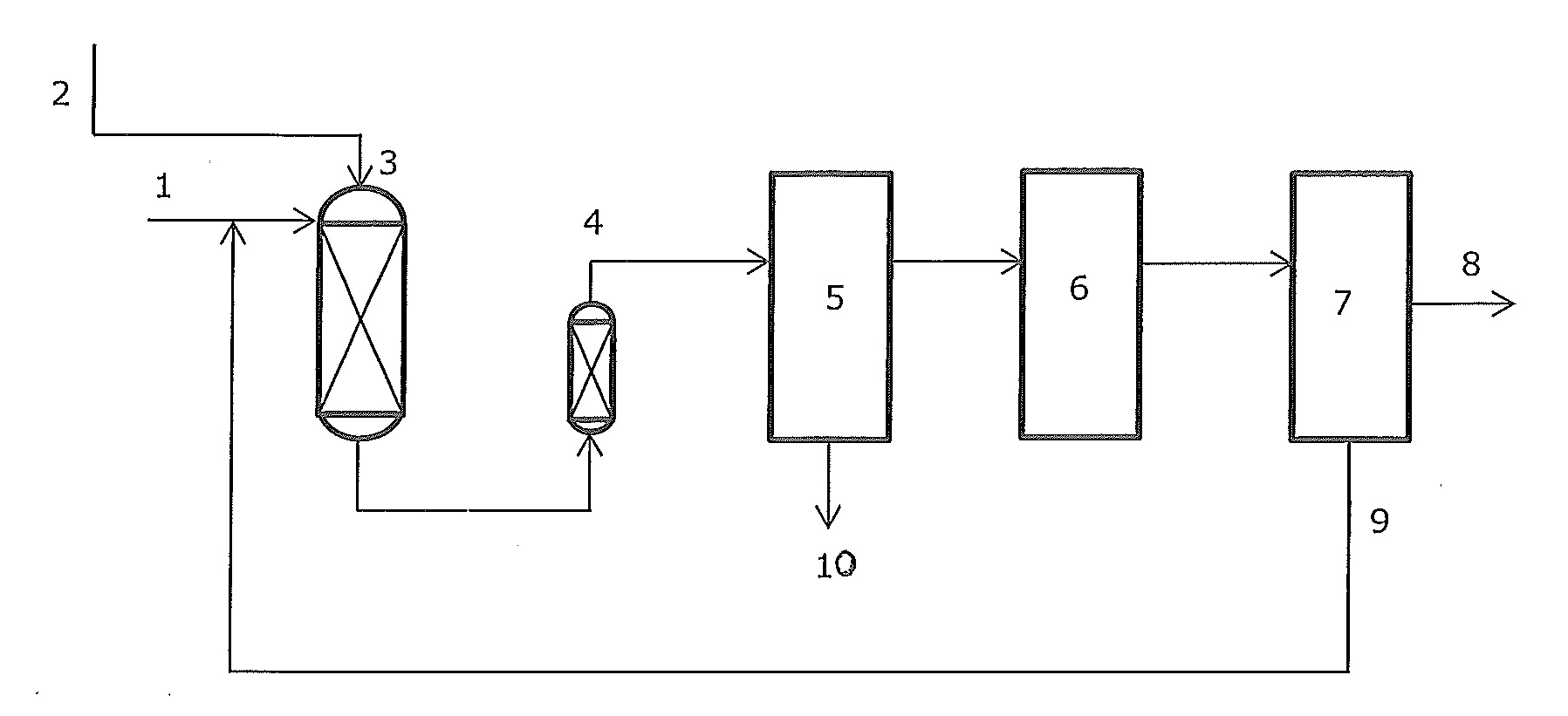

InactiveCN101517038AShort stayReduce volumeLiquid hydrocarbon mixture productionEthylene productionFixed bedPetroleum

The invention relates to a method for the catalytic hydro-processing of a petroleum feedstock of the gas oil type and of a biological feedstock containing vegetal oils and / or animal fats, in a catalytic fixed-bed hydro-processing unit, said method being characterised in that the petroleum feedstock is introduced into the reactor upstream from the biological feedstock. The invention also relates to a catalytic hydro-processing unit for implementing said method, and to a corresponding hydro-refining unit.

Owner:TOTAL RAFFINAGE MARKETING

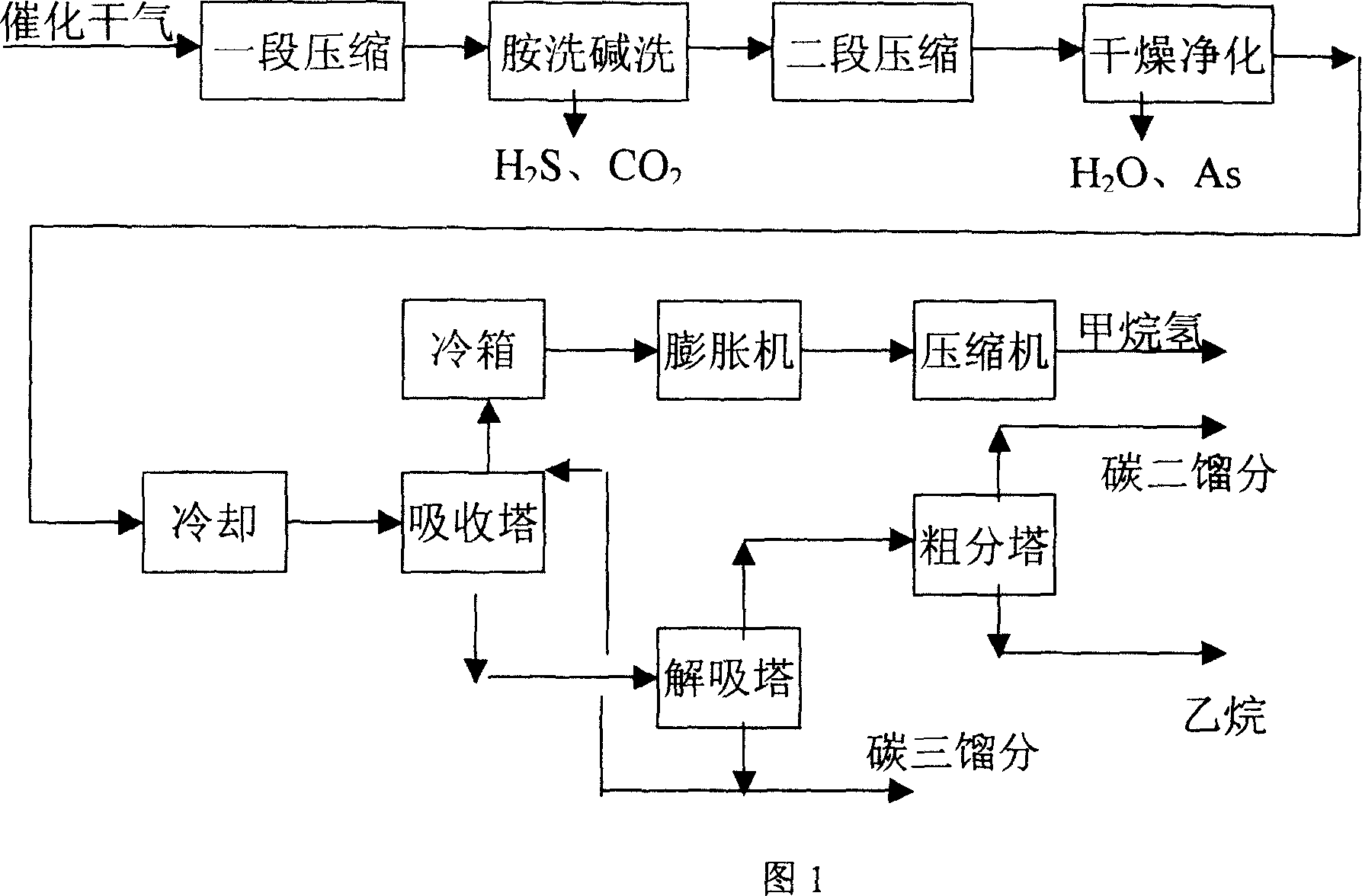

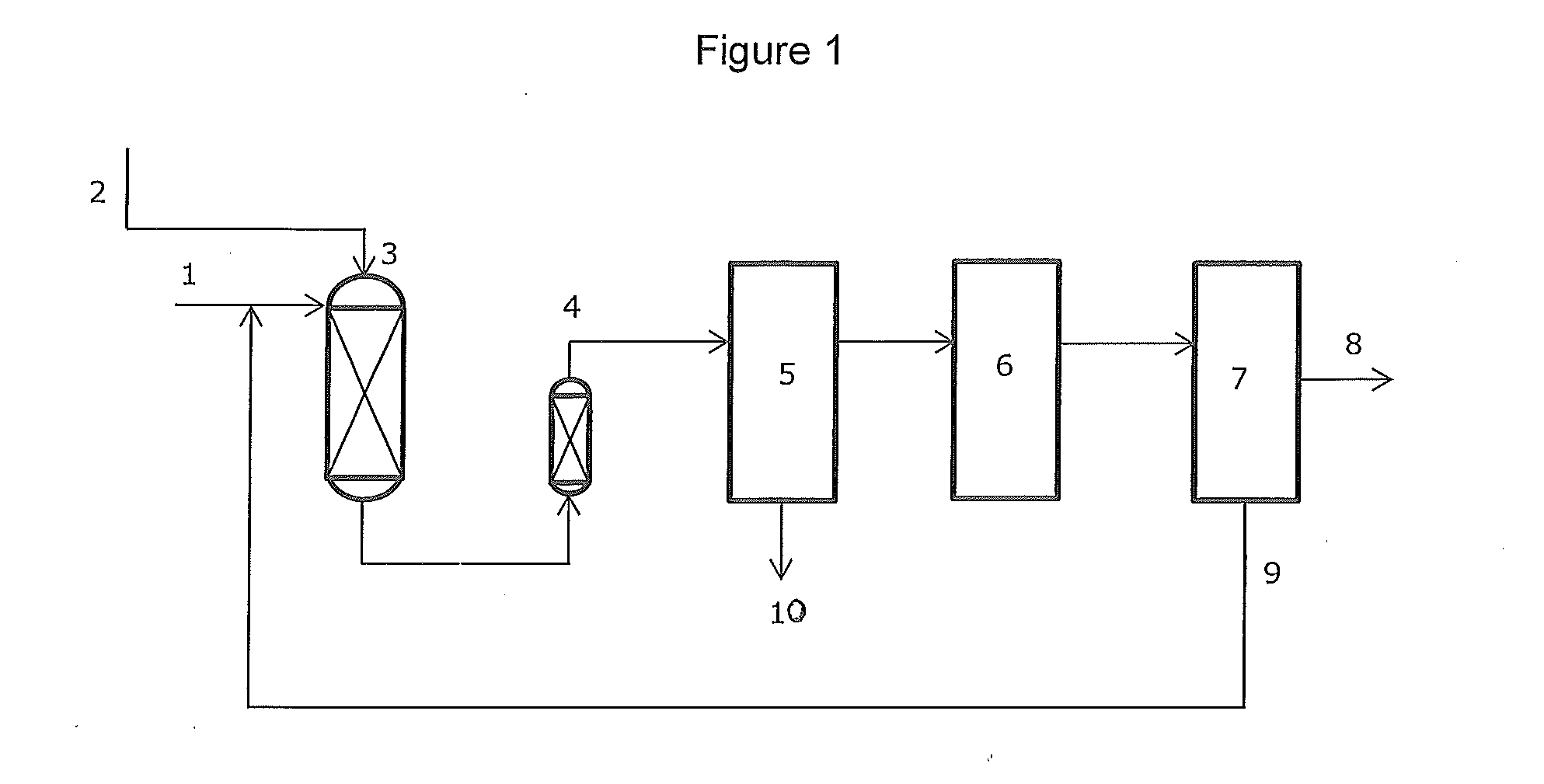

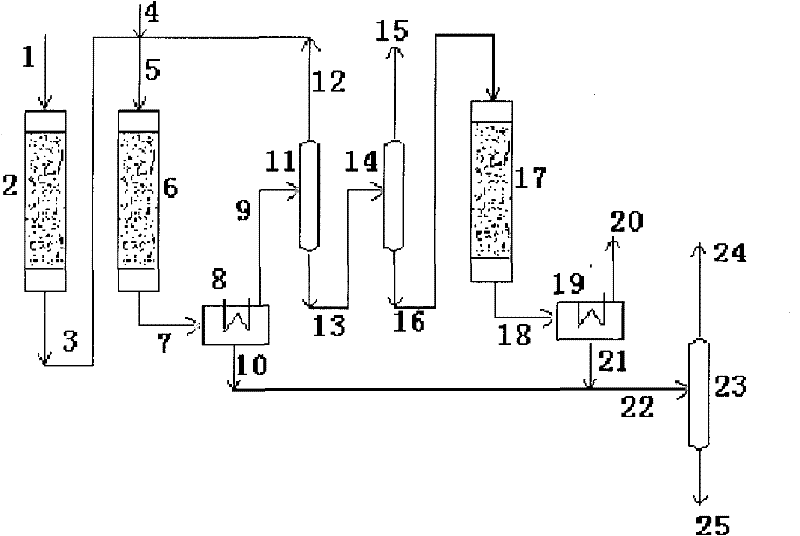

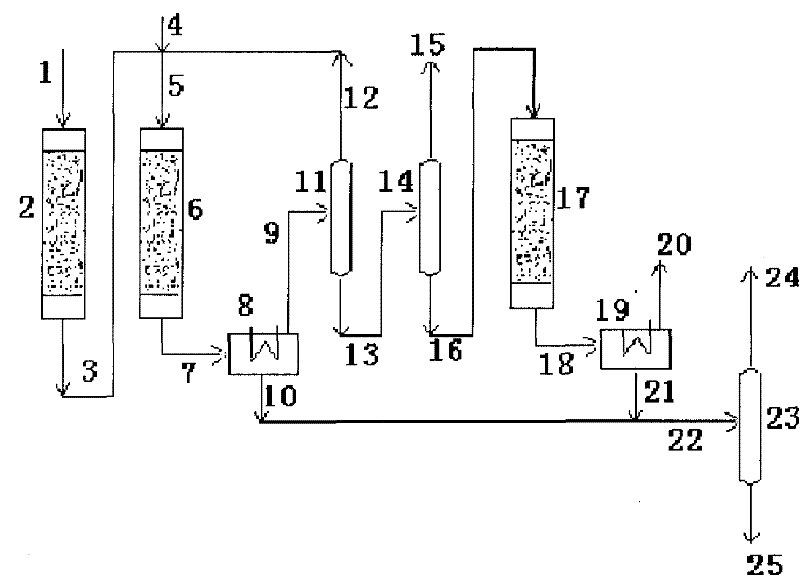

Method for separating plant catalytic dry gas by employing middle-cool-oil absorption process

InactiveCN101063048AEasy to getLow costOrganic chemistryEthylene productionProduct gasEnergy consumption

The invention discloses a separating refinery catalytic dry gas method with middle cold oil absorptive method in separating refinery catalytic dry gas technical domain, which comprises the following steps: compressing; stripping acid gas; drying; purifying; absorbing; desorbing; reclaiming cold energy; crude-separating. This invention possesses cheap cost, low lost, simple operation, little investment and low energy consumption, which can get C2 fraction and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

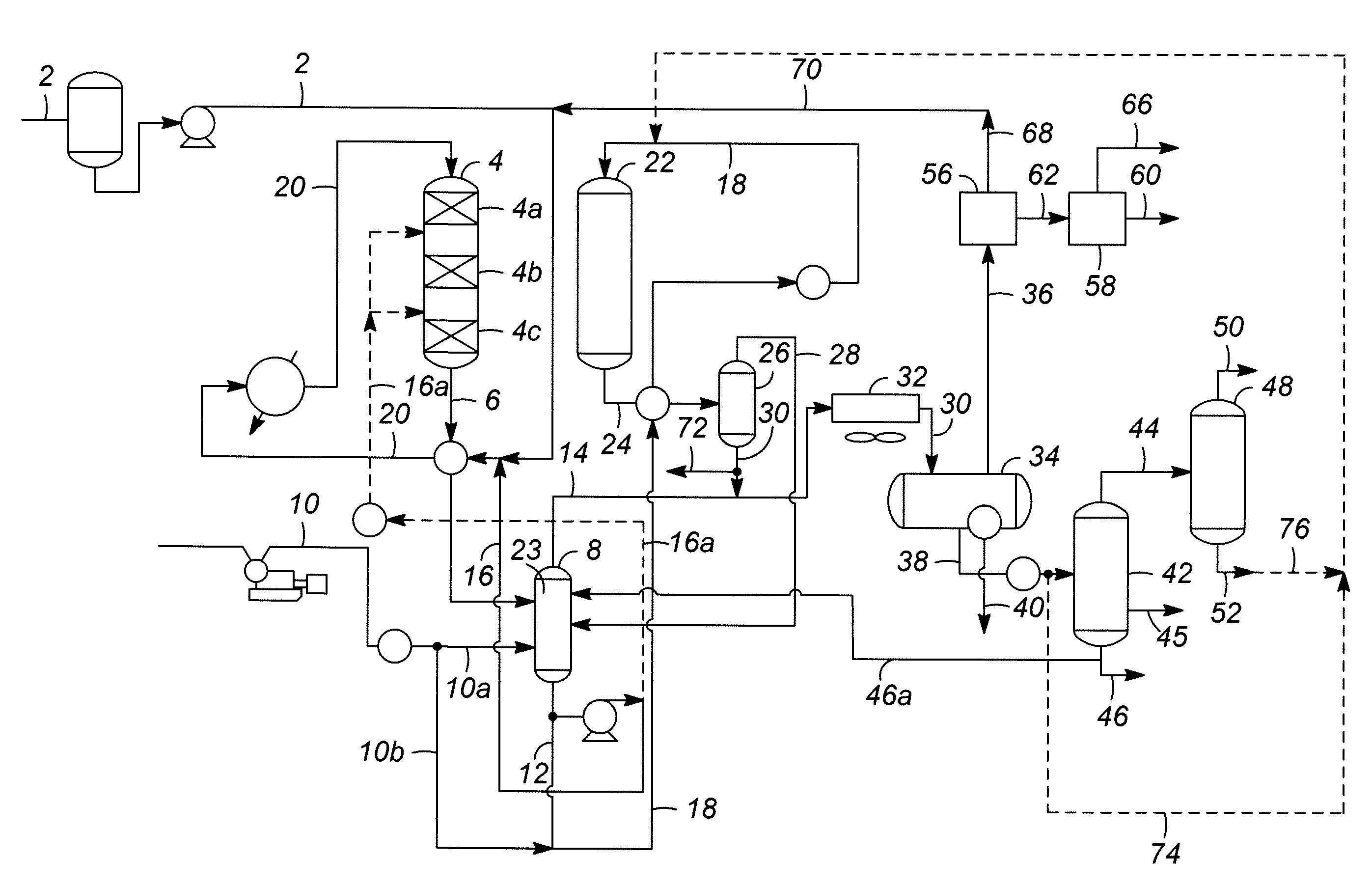

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

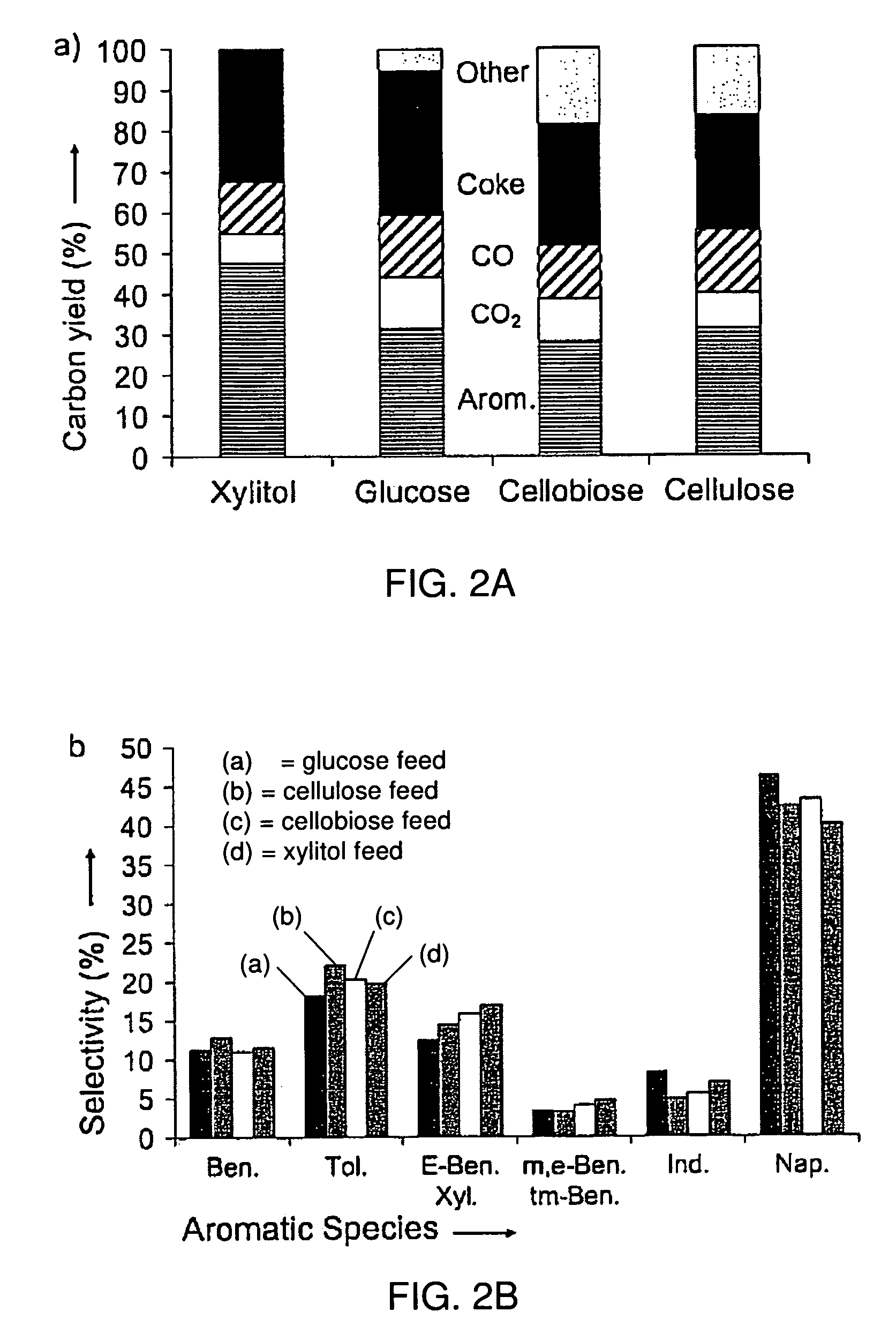

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS8277643B2Minimize coke productionSolid fuelsHydrocarbon from oxygen organic compoundsCatalytic pyrolysisHigh rate

This invention relates to compositions and methods for fluid hydrocarbon product, and more specifically, to compositions and methods for fluid hydrocarbon product via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods may involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. In some embodiments, the mixture may be pyrolyzed at high temperatures (e.g., between 500° C. and 1000° C.). The pyrolysis may be conducted for an amount of time at least partially sufficient for production of discrete, identifiable biofuel compounds. Some embodiments involve heating the mixture of catalyst and hydrocarbonaceous material at high rates (e.g., from about 50° C. per second to about 1000° C. per second). The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used; optionally, the catalysts used herein may have high silica to alumina molar ratios. In some instances, the composition fed to the pyrolysis reactor may have a relatively high catalyst to hydrocarbonaceous material mass ratio (e.g., from about 5:1 to about 20:1).

Owner:UNIV OF MASSACHUSETTS

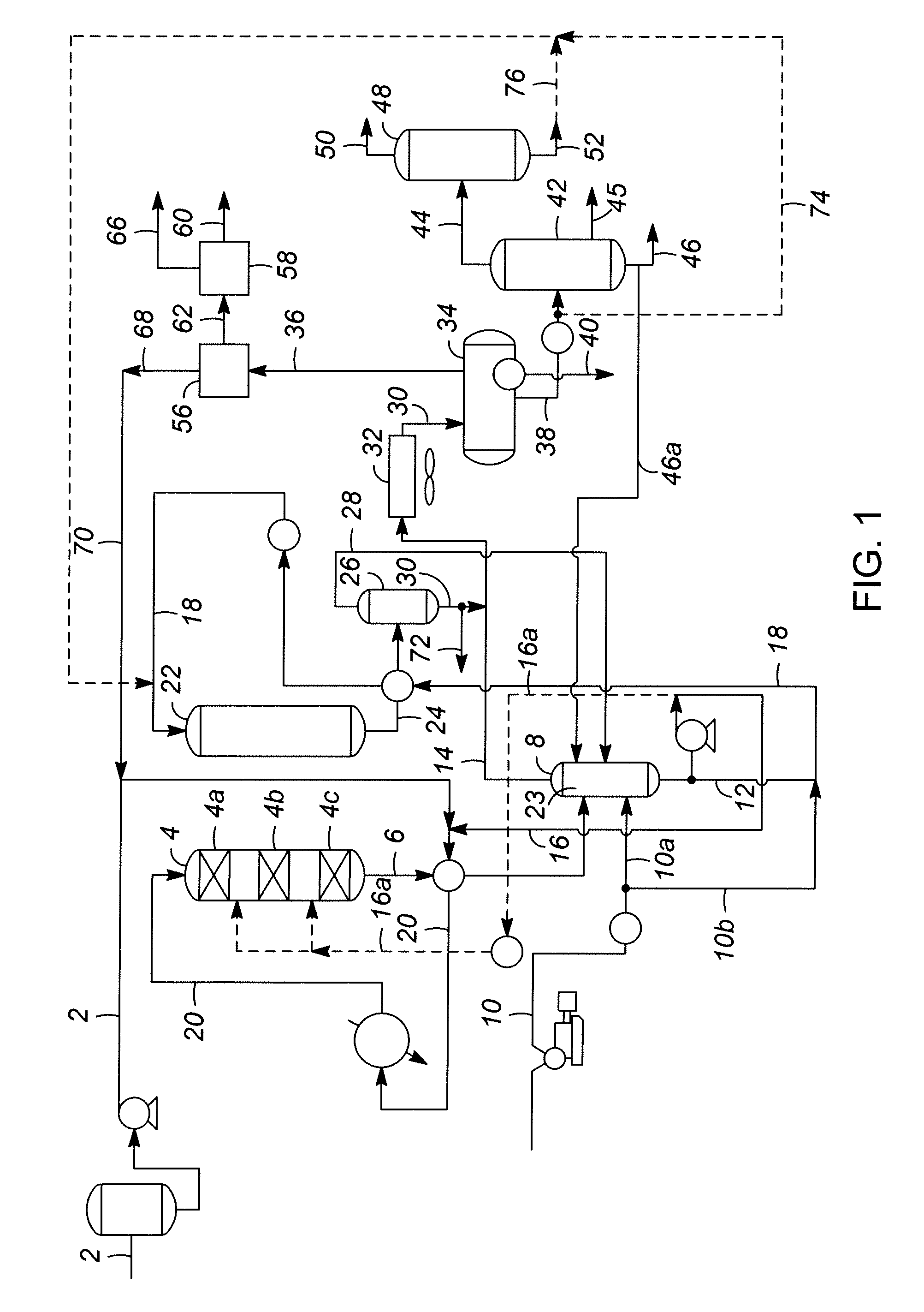

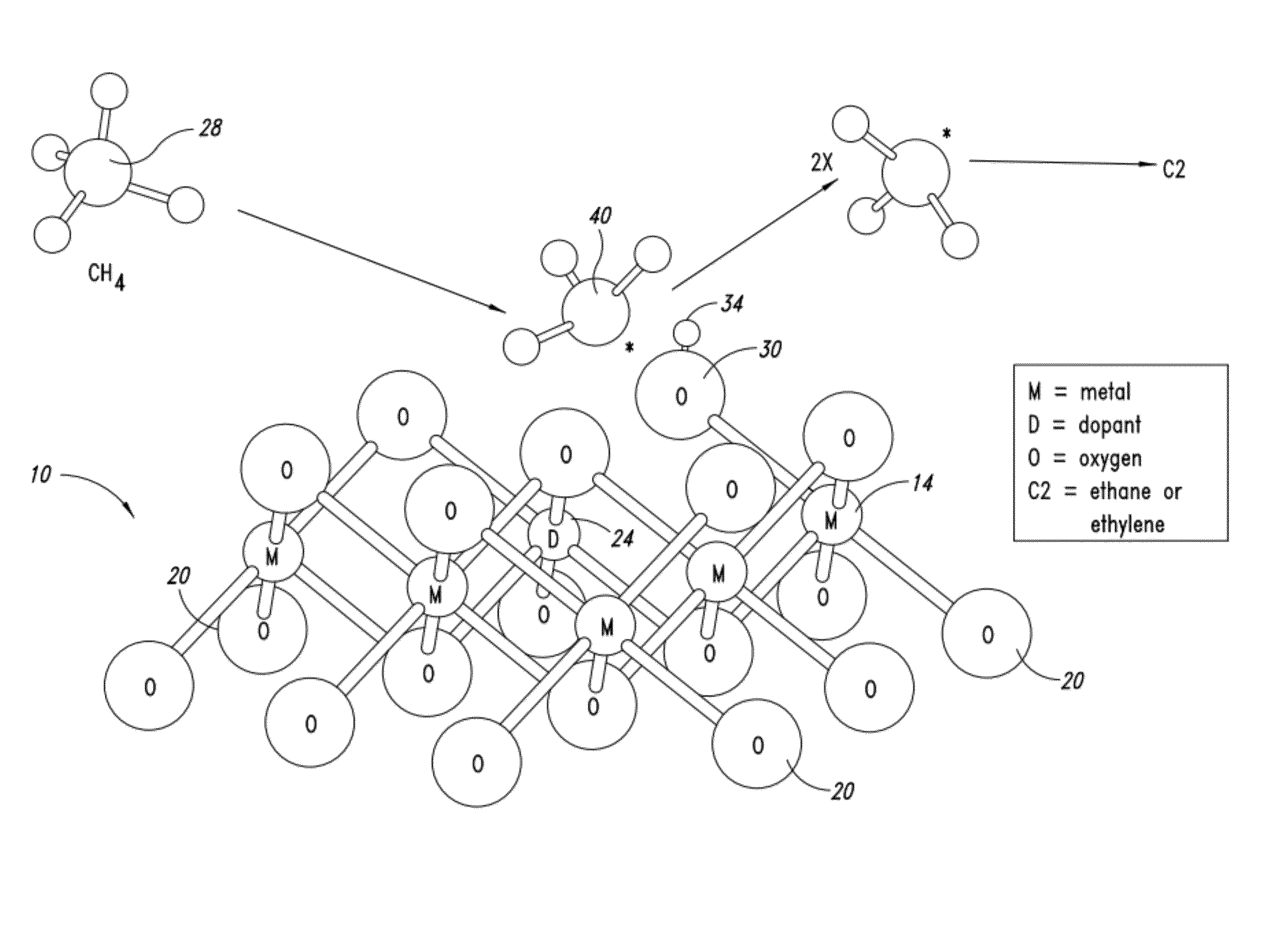

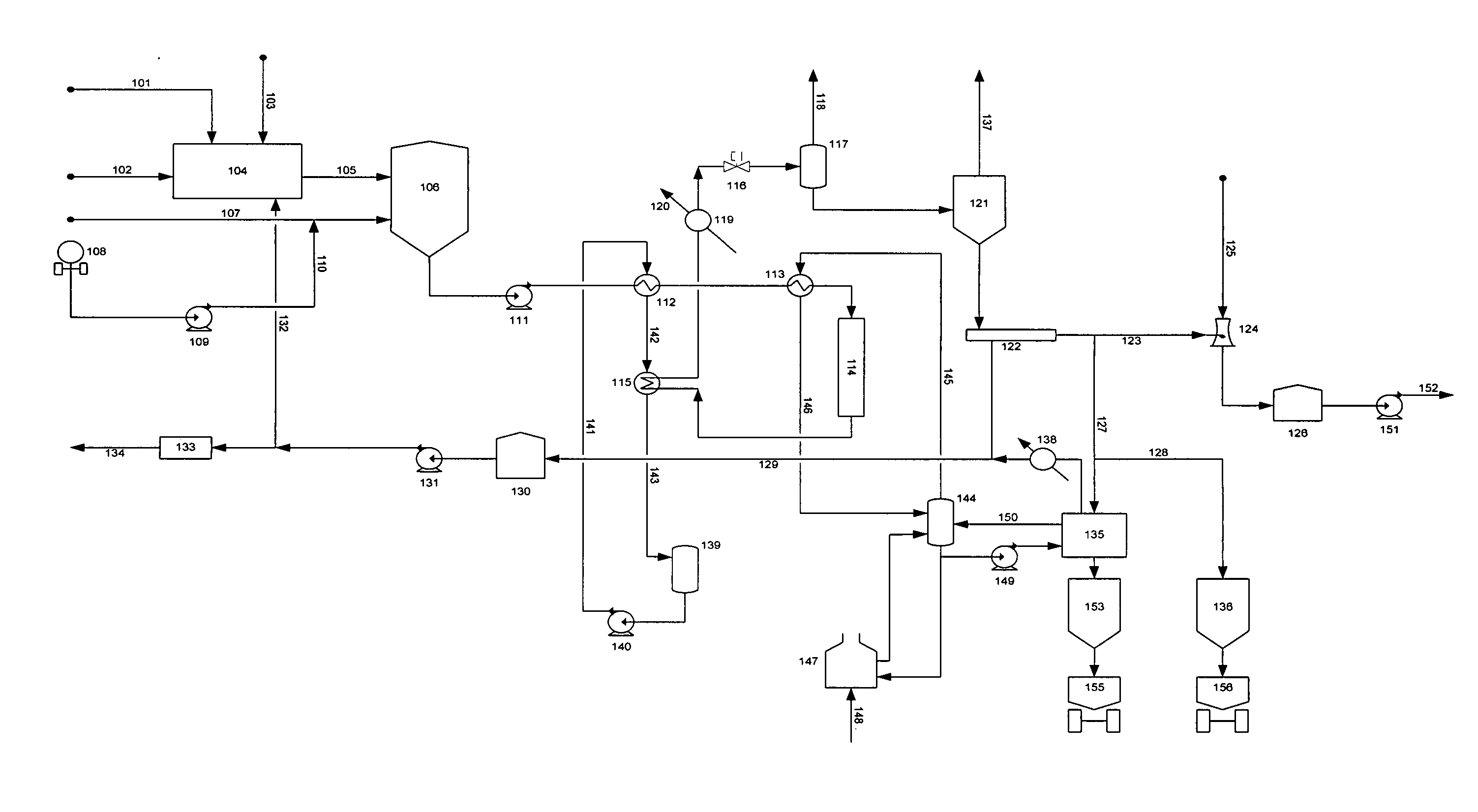

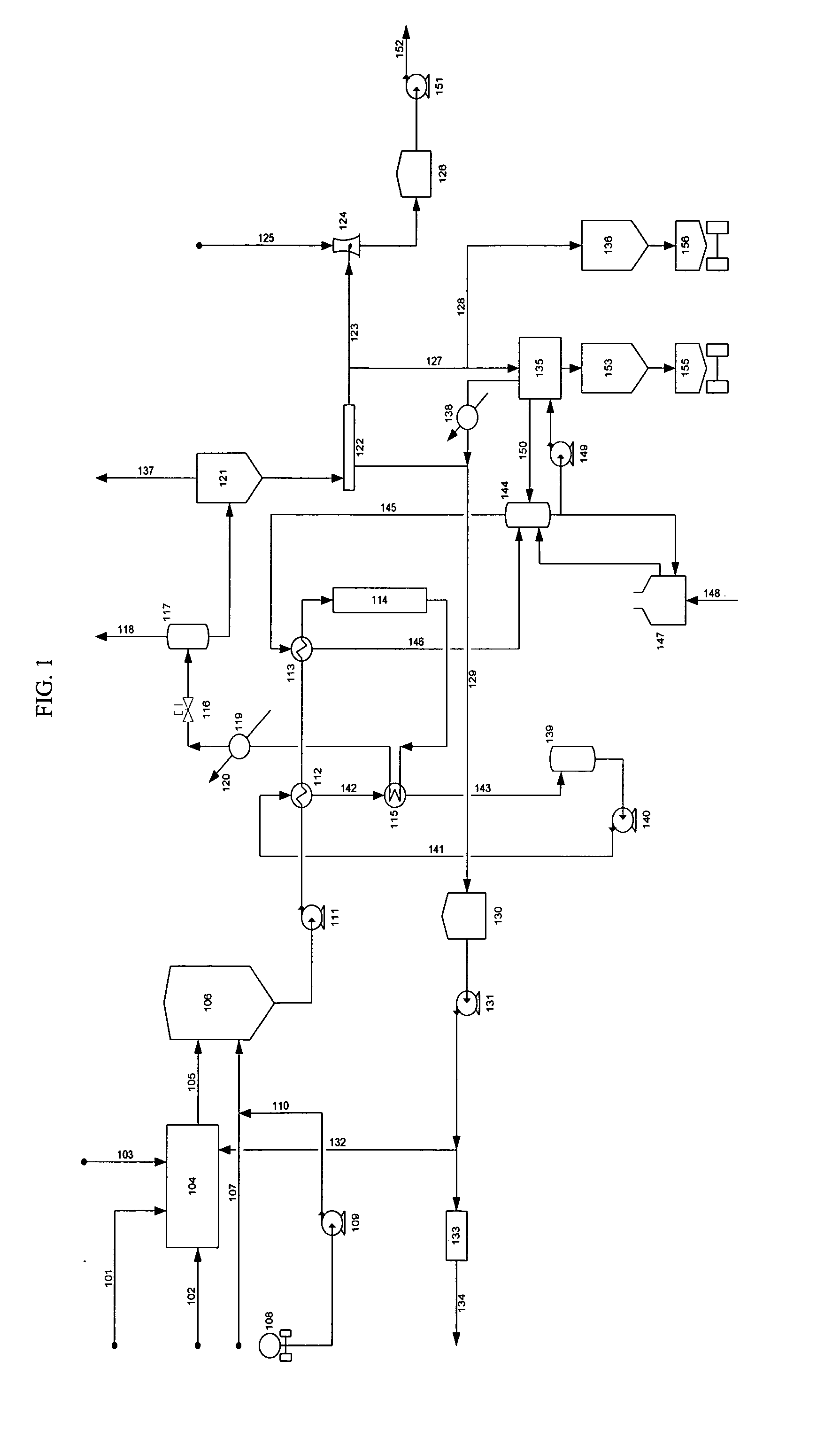

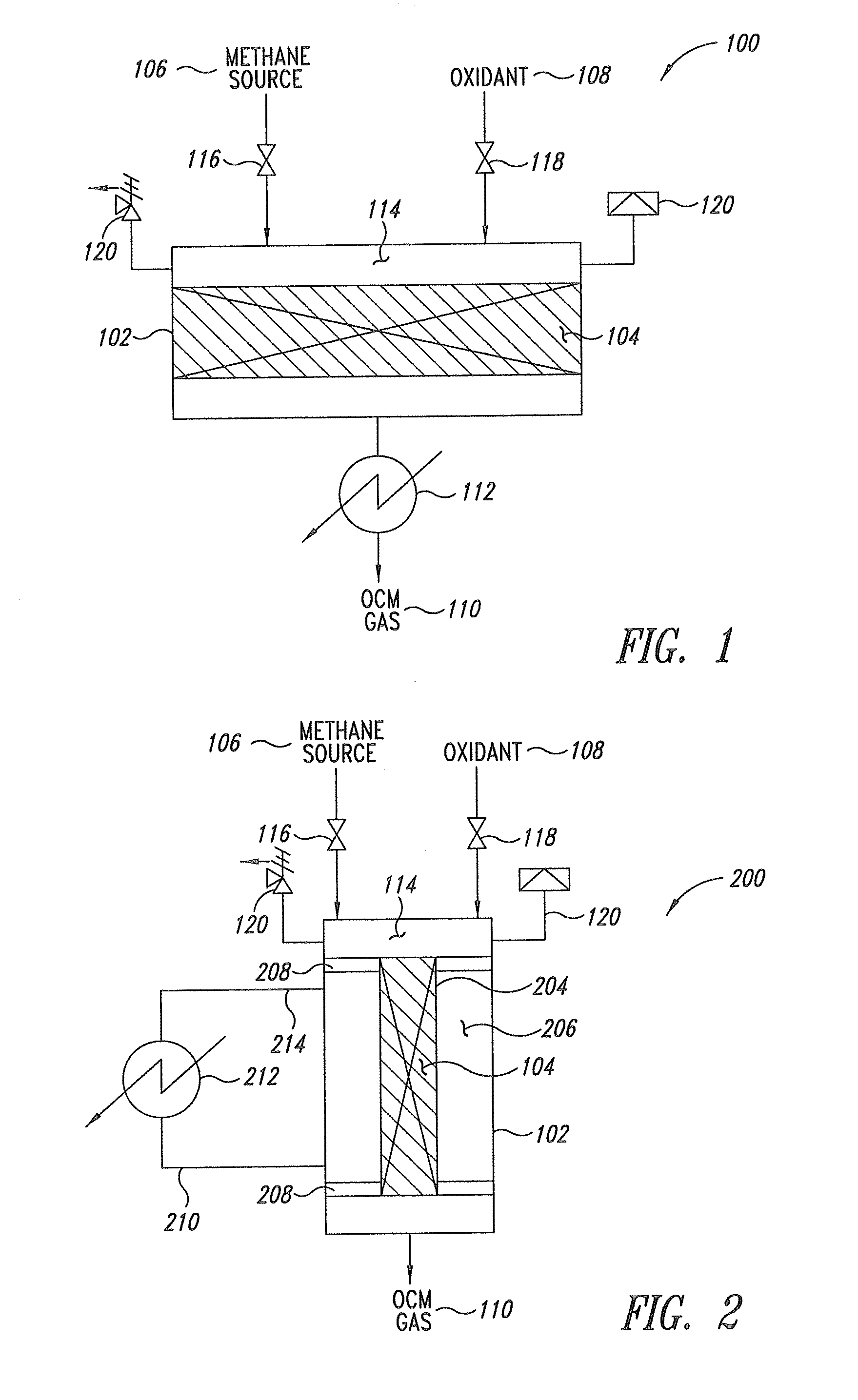

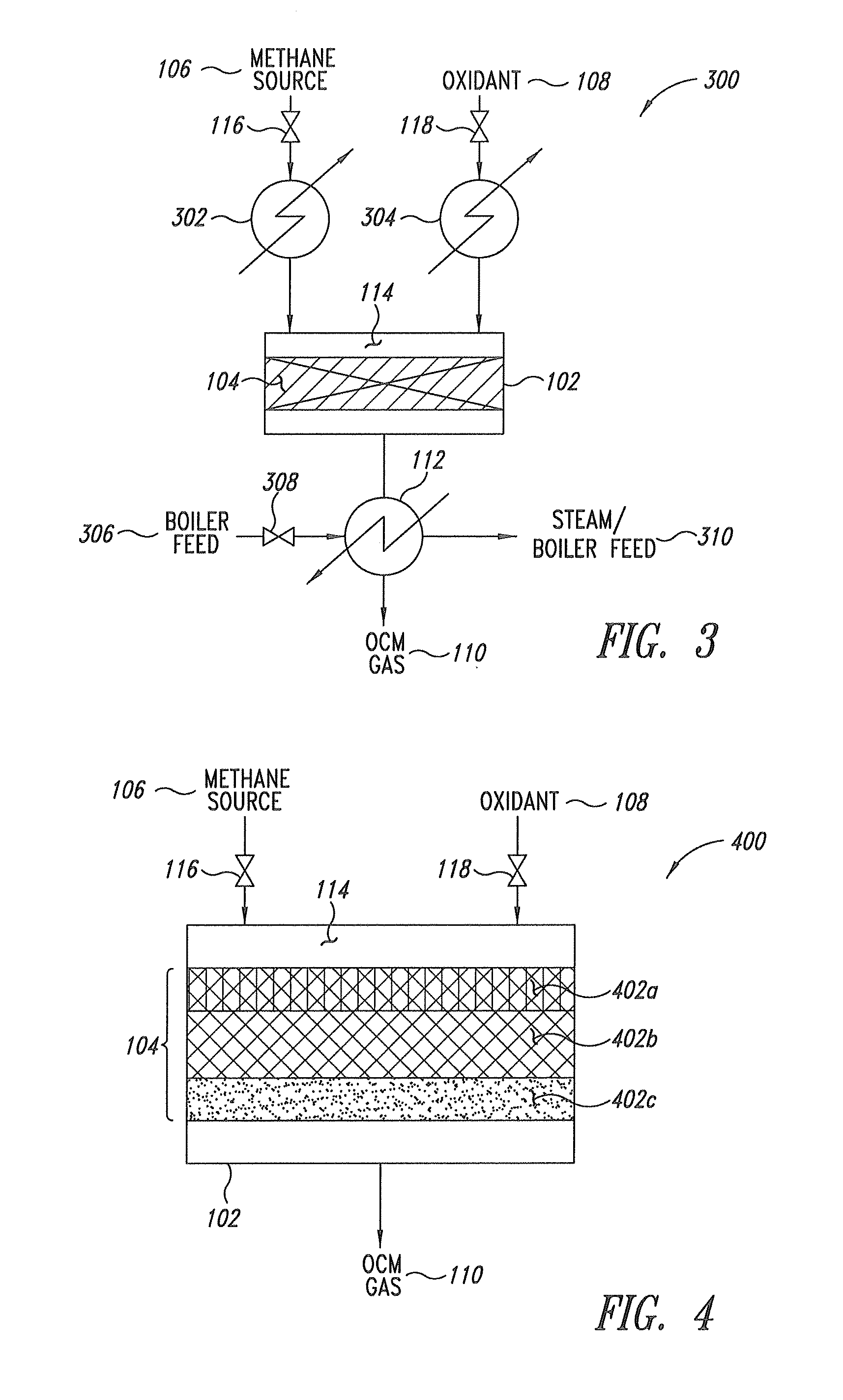

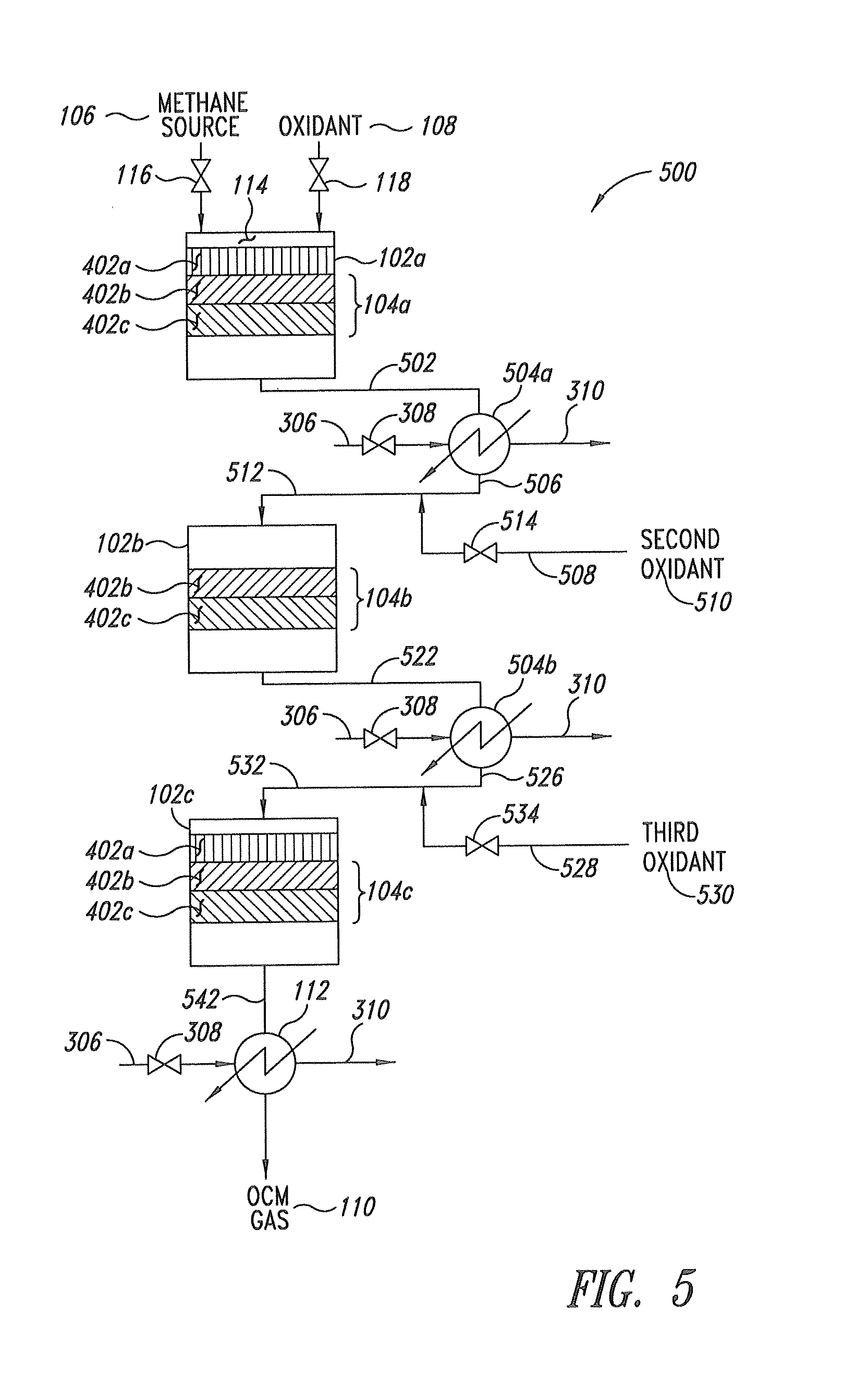

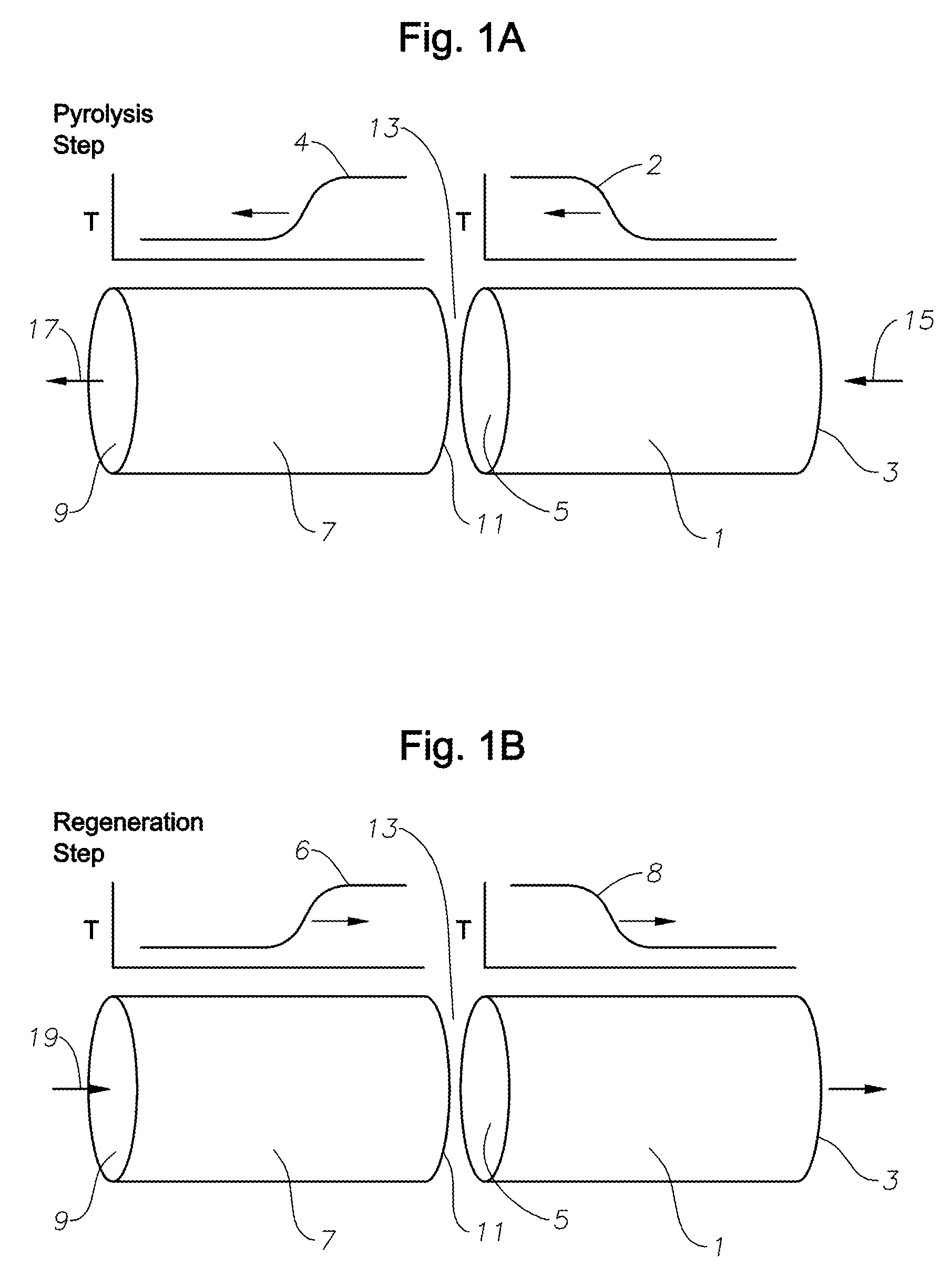

Oxidative coupling of methane systems and methods

ActiveUS20140107385A1Maintain temperatureTemperatue controlLiquid hydrocarbon mixtures productionChemical compositionPhysical form

Systems and methods conducive to the formation of one or more alkene hydrocarbons using a methane source and an oxidant in an oxidative coupling of methane (OCM) reaction are provided. One or more vessels each containing one or more catalyst beds containing one or more catalysts each having similar or differing chemical composition or physical form may be used. The one or more catalyst beds may be operated under a variety of conditions. At least a portion of the catalyst beds may be operated under substantially adiabatic conditions. At least a portion of the catalyst beds may be operated under substantially isothermal conditions.

Owner:LUMMUS TECH LLC

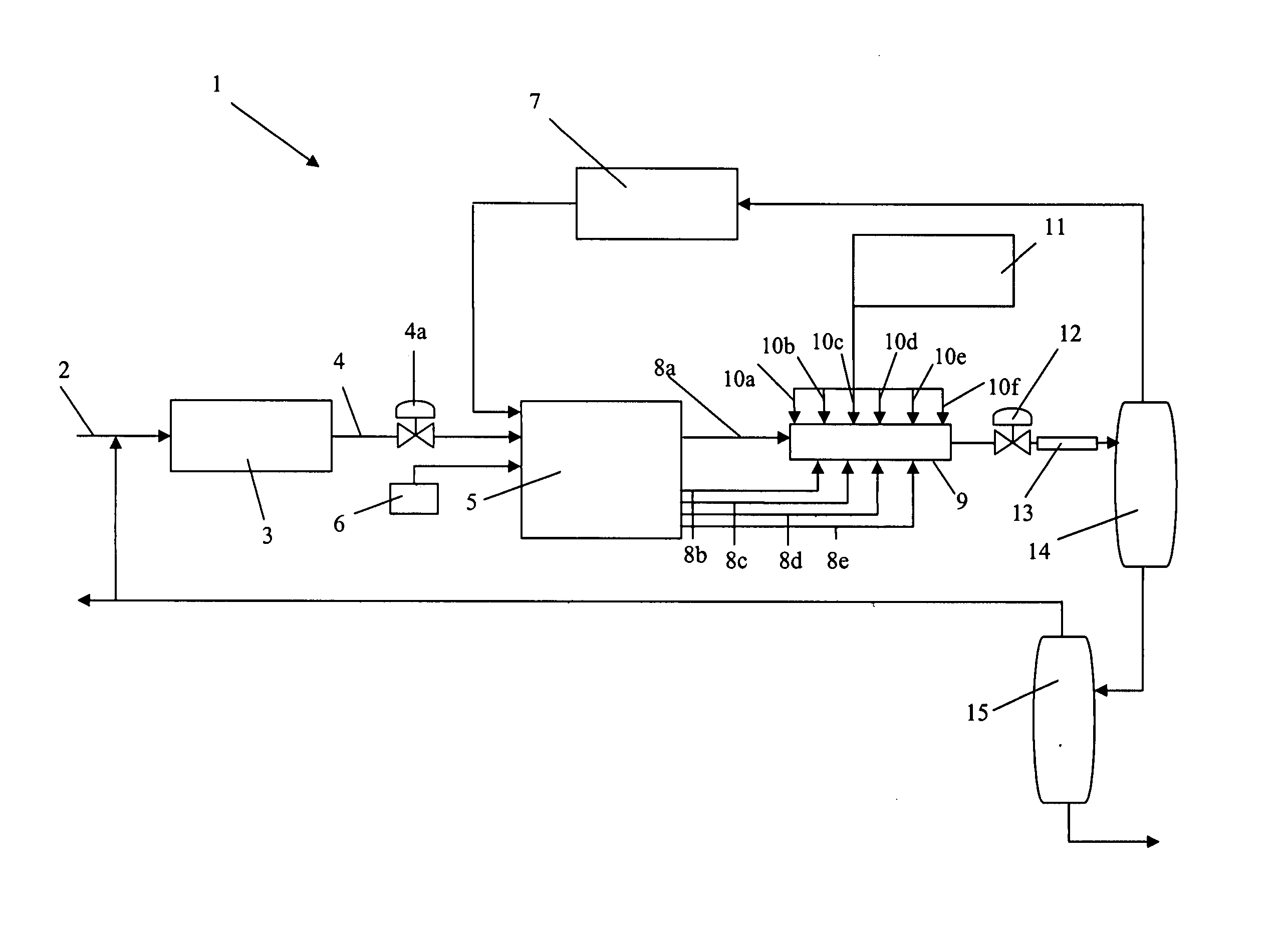

Process and apparatus for manufacturing ethylene polymers and copolymers

InactiveUS20070032614A1Efficient and reliableSpeed up the conversion processEthylene productionChemical/physical/physico-chemical stationary reactorsTonnePolymer science

The invention relates to a process for the manufacture of ethylene polymers and copolymers in which ethylene is compressed in a primary compressor at a throughput of at least 55 tonnes / hour, mixed with recycled ethylene and further compressed in a two-stage reciprocating secondary compressor having at least 14 cylinders to a pressure of at least 2300 bar at a throughput of at least 120 tonnes / hour, heating at least a portion of that ethylene to a temperature of at least 95° C. and introducing it into a tubular reactor of diameter at least 65 mm and a length of at least 1500 m, introducing initiator in at least three reaction zones to give a conversion of at least 28% and maintaining a pressure drop over the reactor to maintain a flow velocity of at least 6 m / s.

Owner:EXXONMOBIL CHEM PAT INC

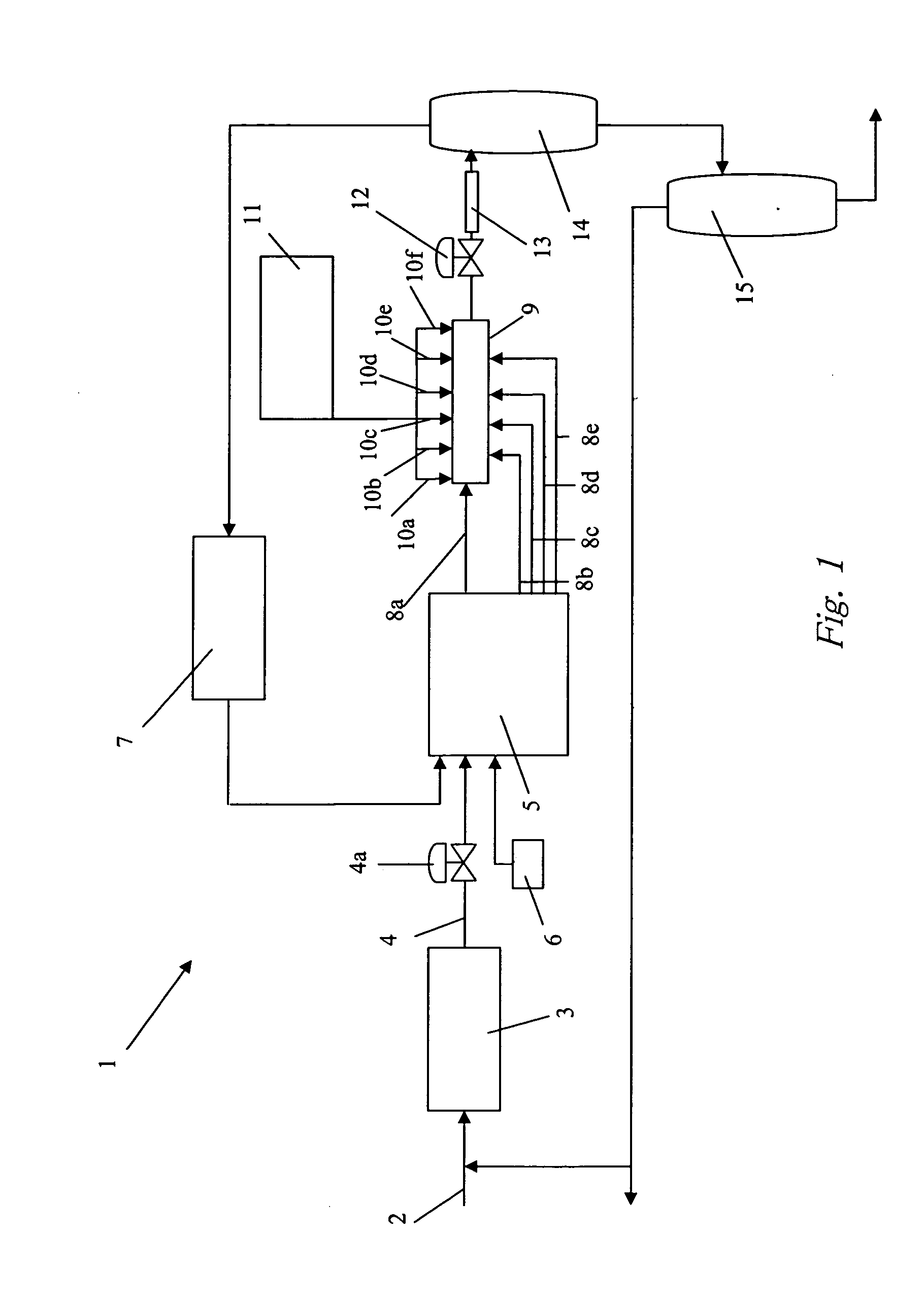

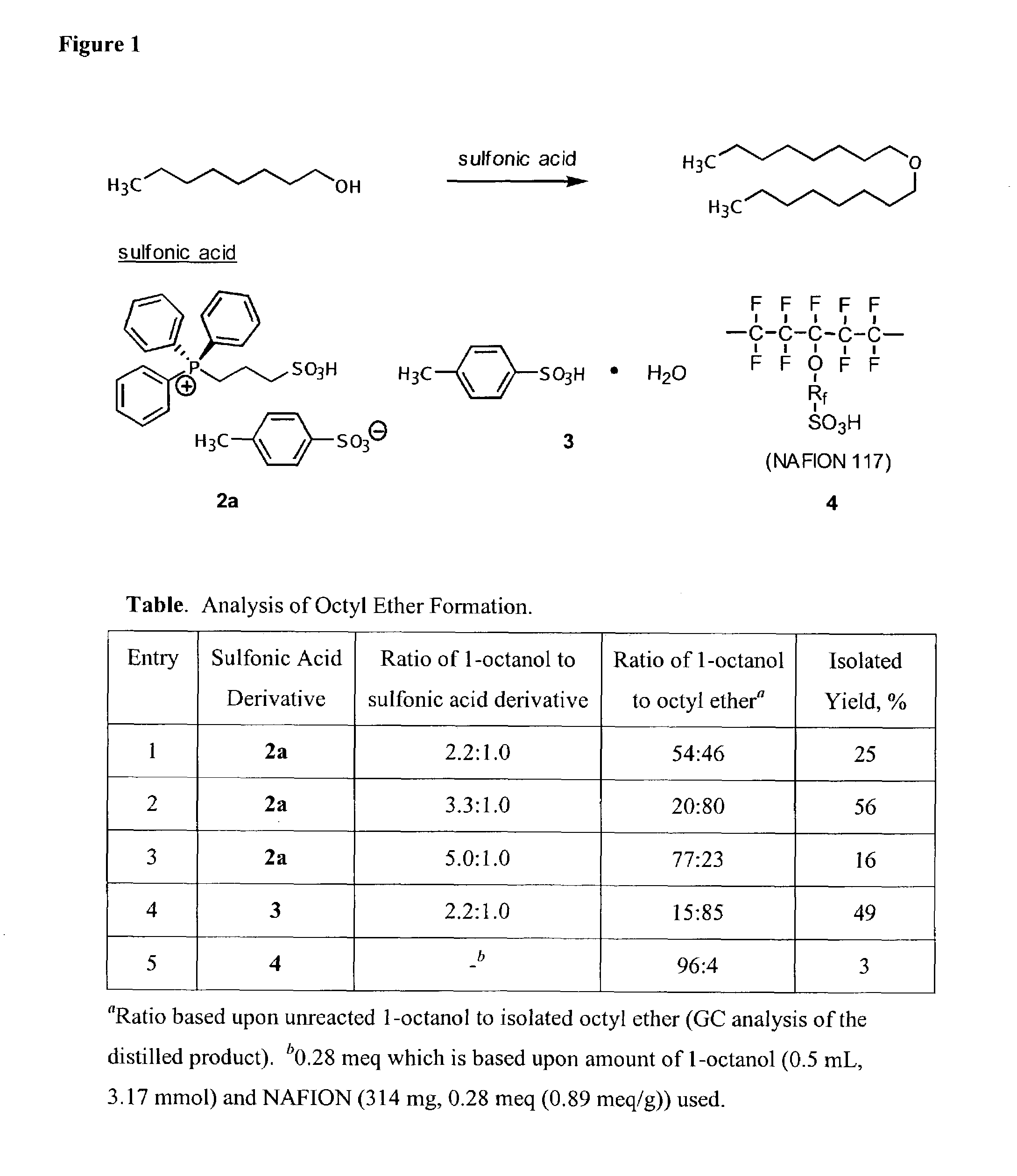

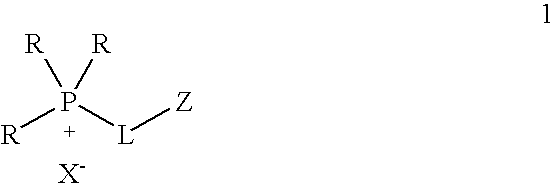

Functionalized ionic liquids, and methods of use thereof

One aspect of the present invention relates to ionic liquids comprising a pendant Bronsted-acidic group, e.g., a sulfonic acid group. Another aspect of the present invention relates to the use of an ionic liquid comprising a pendant Bronsted-acidic group to catalyze a Bronsted-acid-catalyzed chemical reaction. A third aspect of the present invention relates to ionic liquids comprising a pendant nucleophilic group, e.g., an amine. Still another aspect of the present invention relates to the use of an ionic liquid comprising a pendant nucleophilic group to catalyze a nucleophile-assisted chemical reaction. A fifth aspect of the present invention relates to the use of an ionic liquid comprising a pendant nucleophilic group to remove a gaseous impurity, e.g., carbon dioxide, from a gas, e.g., sour natural gas.

Owner:UNIV OF SOUTH ALABAMA

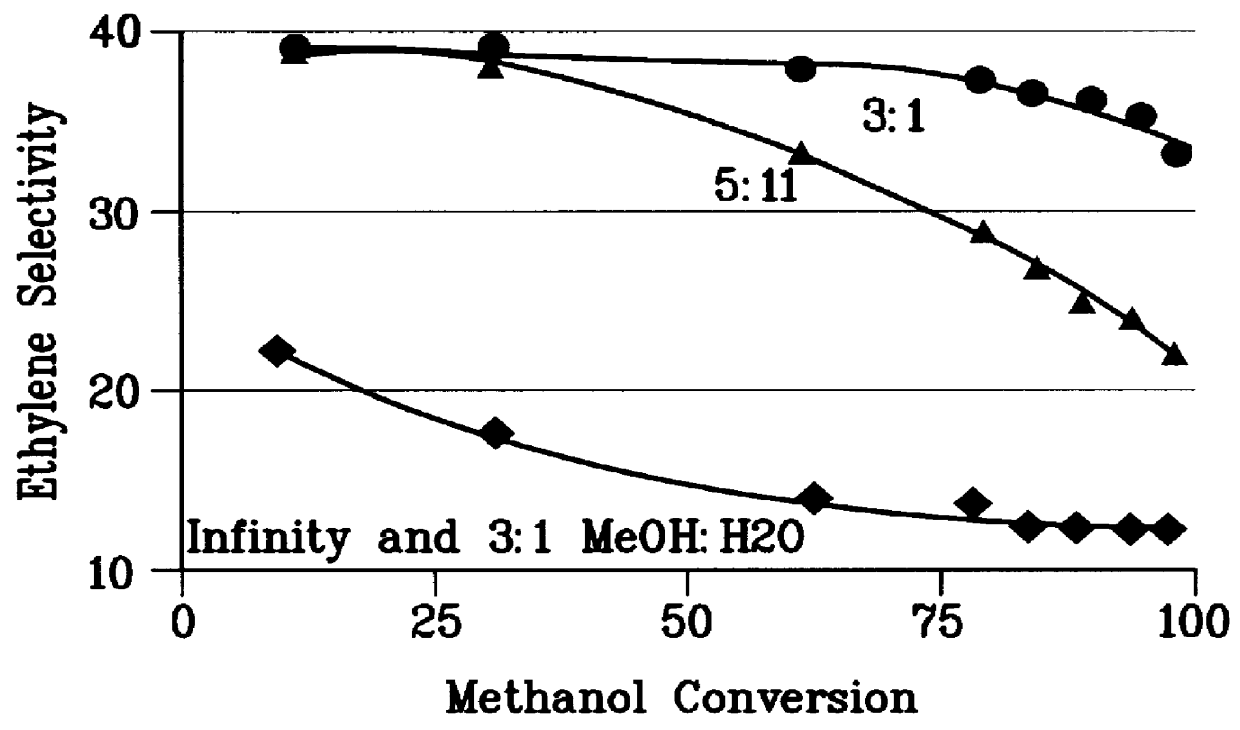

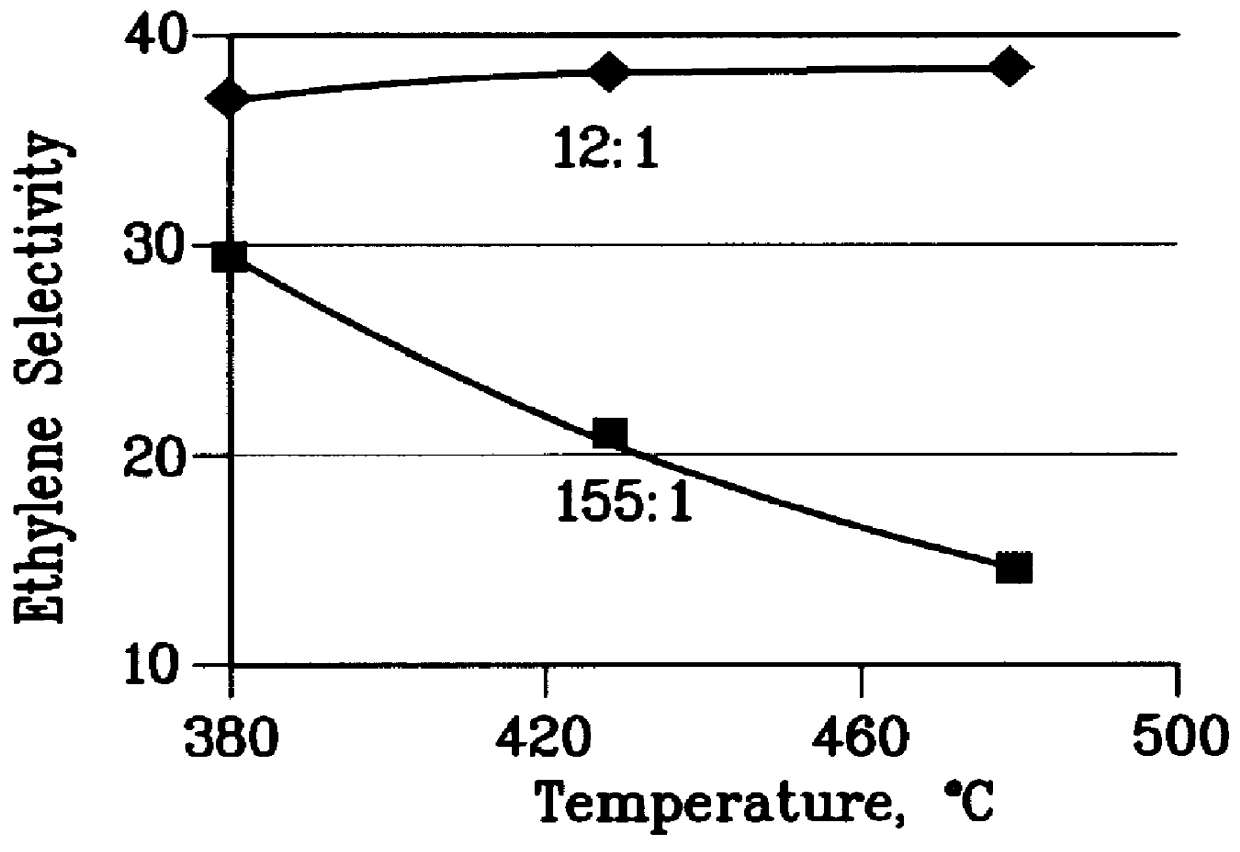

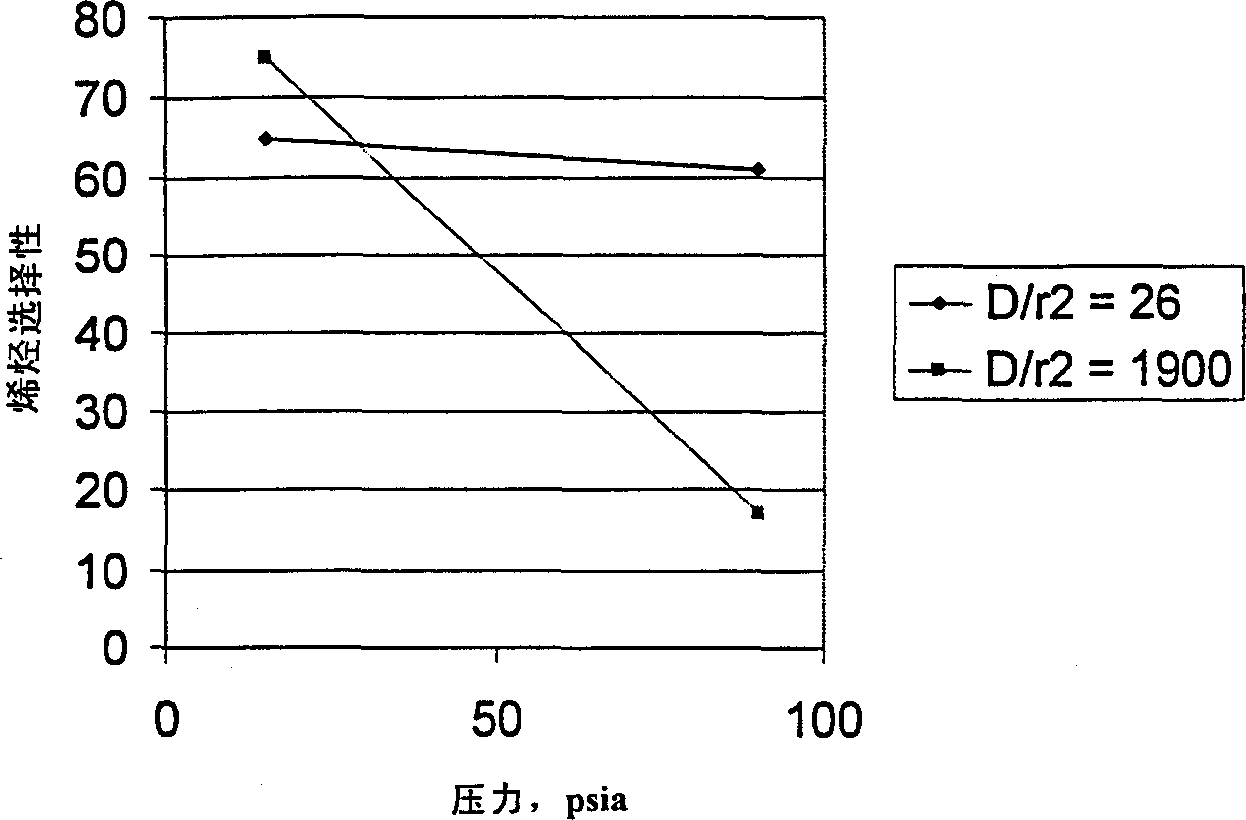

Process for producing light olefins

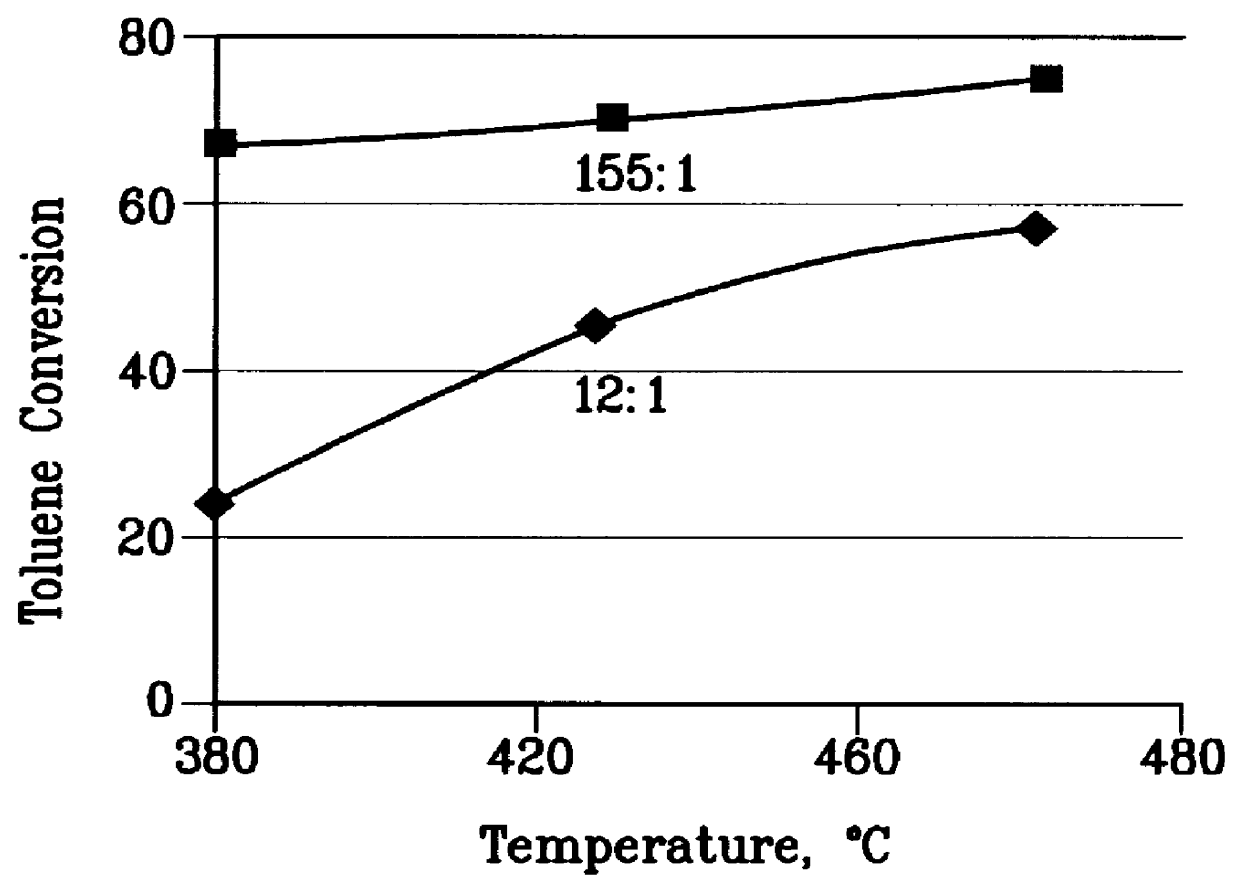

InactiveUS6046372AMolecular sieve catalystsMolecular sieve catalystAlkyl transferCrystalline materials

There is provided a process for converting methanol and / or dimethyl ether to a product containing C2 to C4 olefins which comprises the step of contacting a feed which contains methanol and / or dimethyl ether with a catalyst comprising a porous crystalline material, said contacting step being conducted in the presence of an aromatic compound under conversion conditions including a temperature of 350 DEG C. to 480 DEG C. and a methanol partial pressure in excess of 10 psia (70 kPa), said porous crystalline material having a pore size greater than the critical diameter of the aromatic compound and the aromatic compound being capable of alkylation by the methanol and / or dimethyl ether under said conversion conditions.

Owner:MOBIL OIL CORP

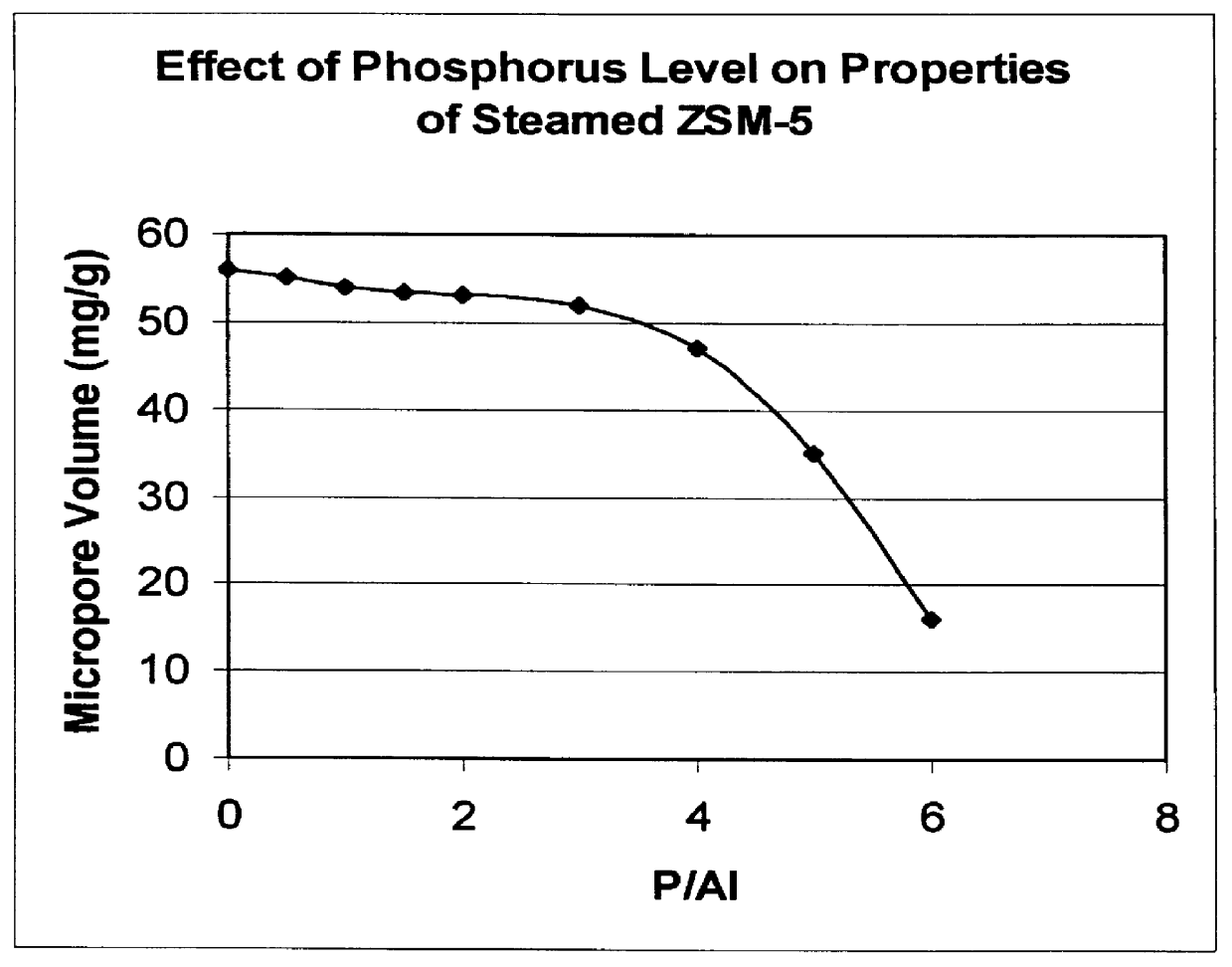

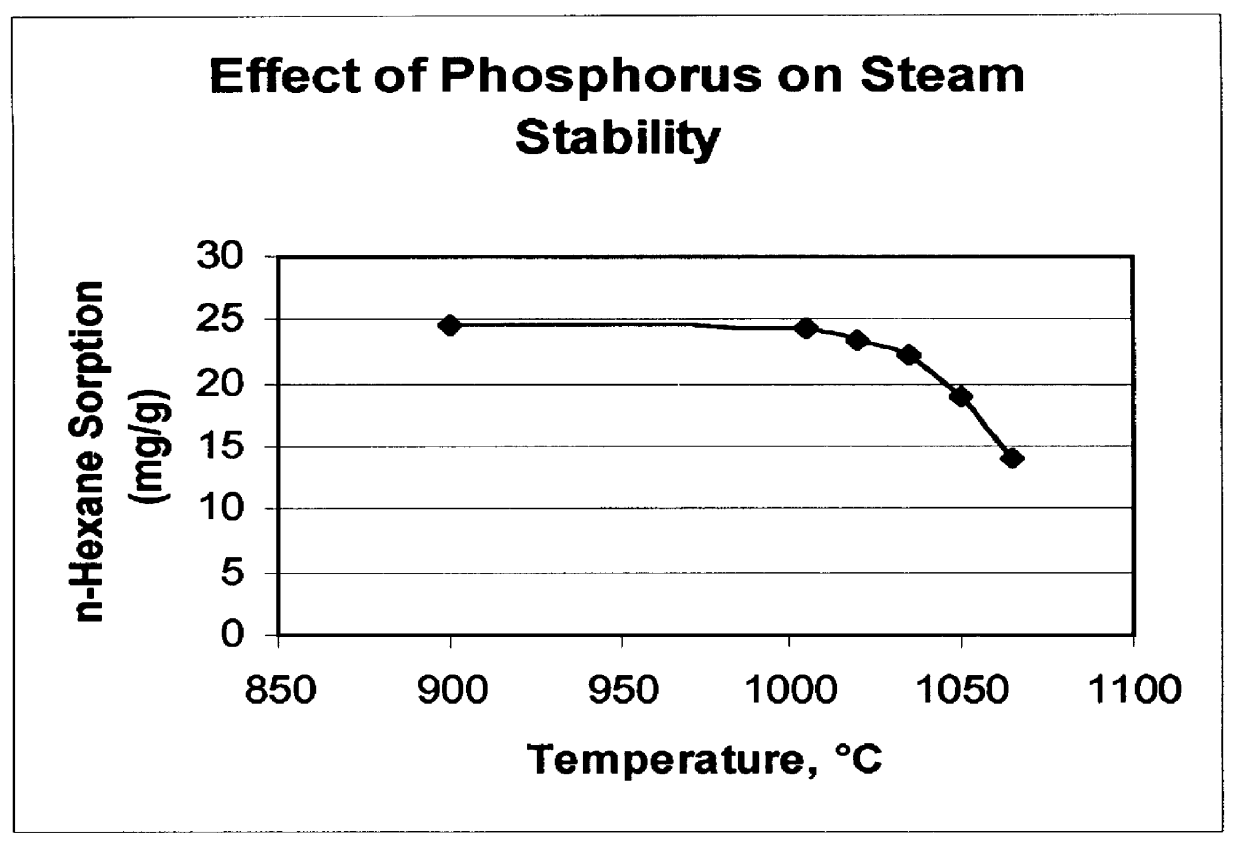

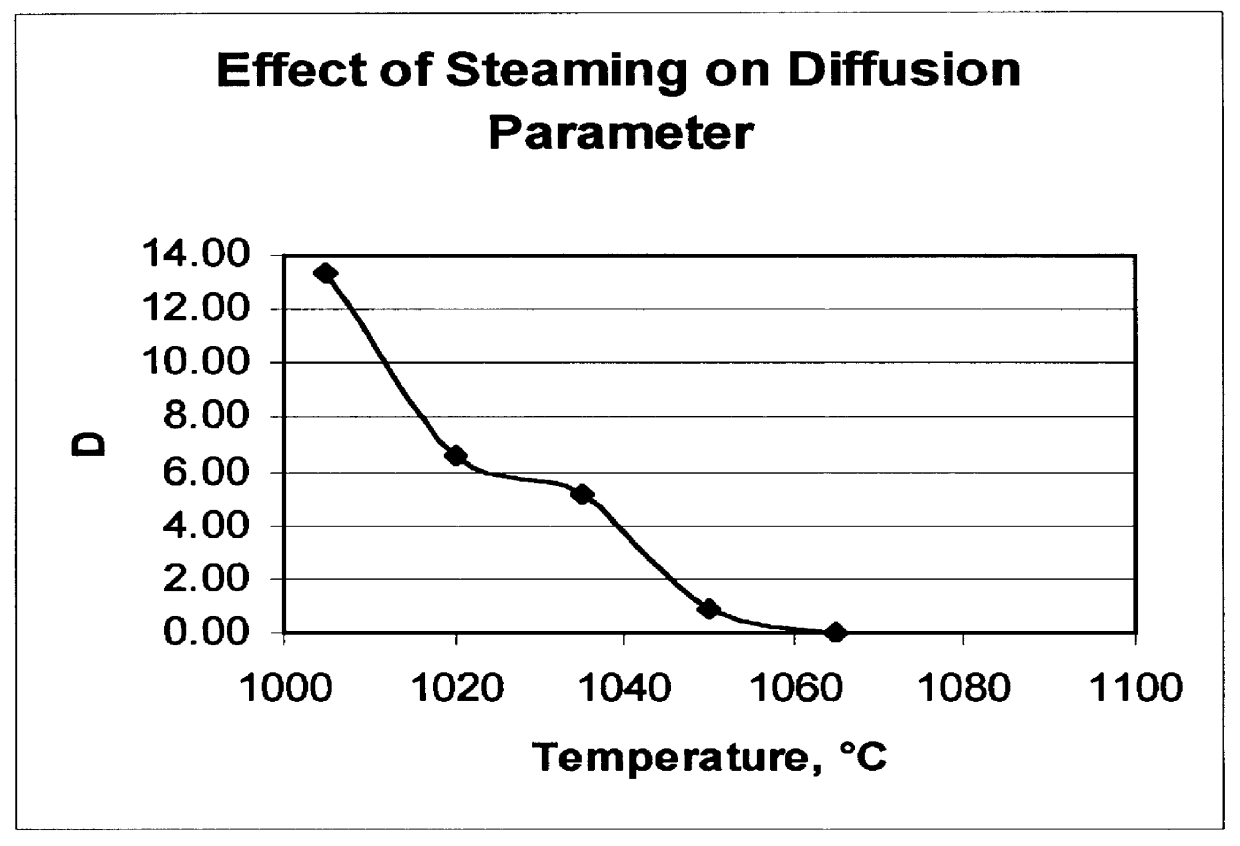

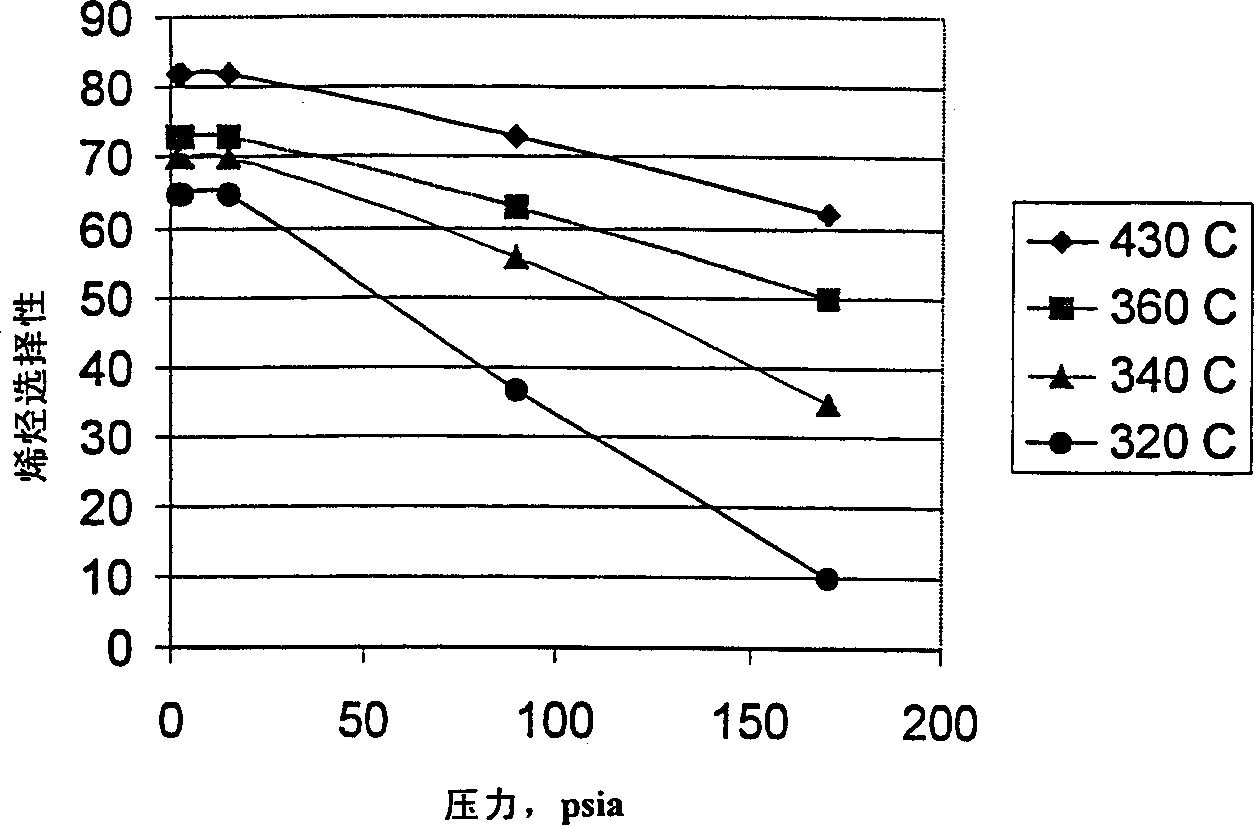

Catalyst and process for converting methanol to hydrocarbons

InactiveUS6048816AMolecular sieve catalystsMolecular sieve catalystCrystalline materialsDimethyl ether

There is provided a catalyst and a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins. The catalyst comprises a porous crystalline material having a Diffusion Parameter for 2,2-dimethylbutane of about 0.1-20 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). In addition, the catalyst is characterized by a hydrothermal stability such that, after steaming the catalyst at 1025 DEG C. for 45 minutes in 1 atmosphere steam, the catalyst exhibits a methanol conversion activity of at least 50% when contacted with methanol at a methanol partial pressure of 1 atmosphere, a temperature of 430 DEG C. and 0.5 WHSV. The porous crystalline material is preferably a medium-pore zeolite, particularly ZSM-5, which contains phosphorus and has been severely steamed at a temperature of at least 950 DEG C.

Owner:MOBIL OIL CORP

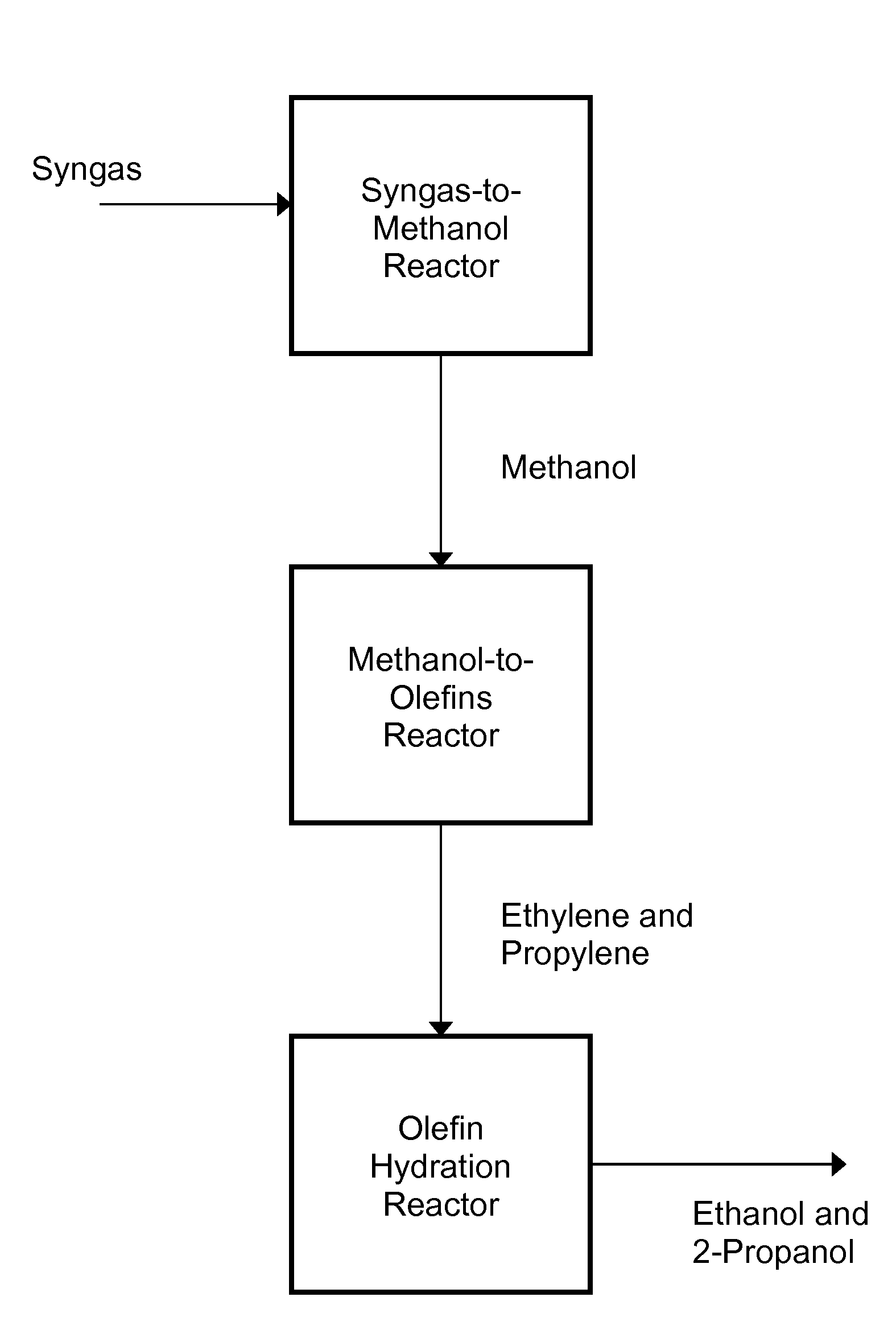

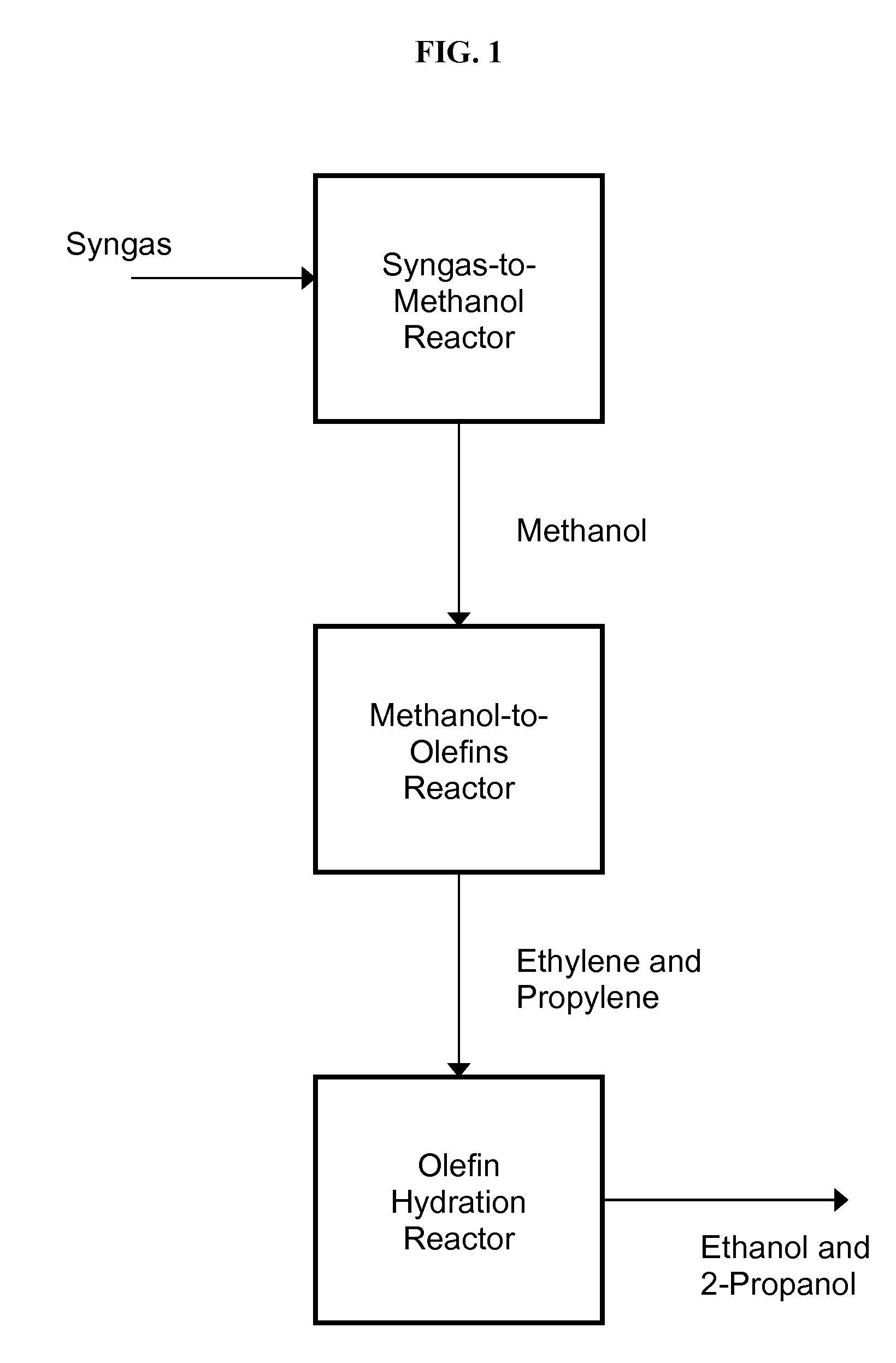

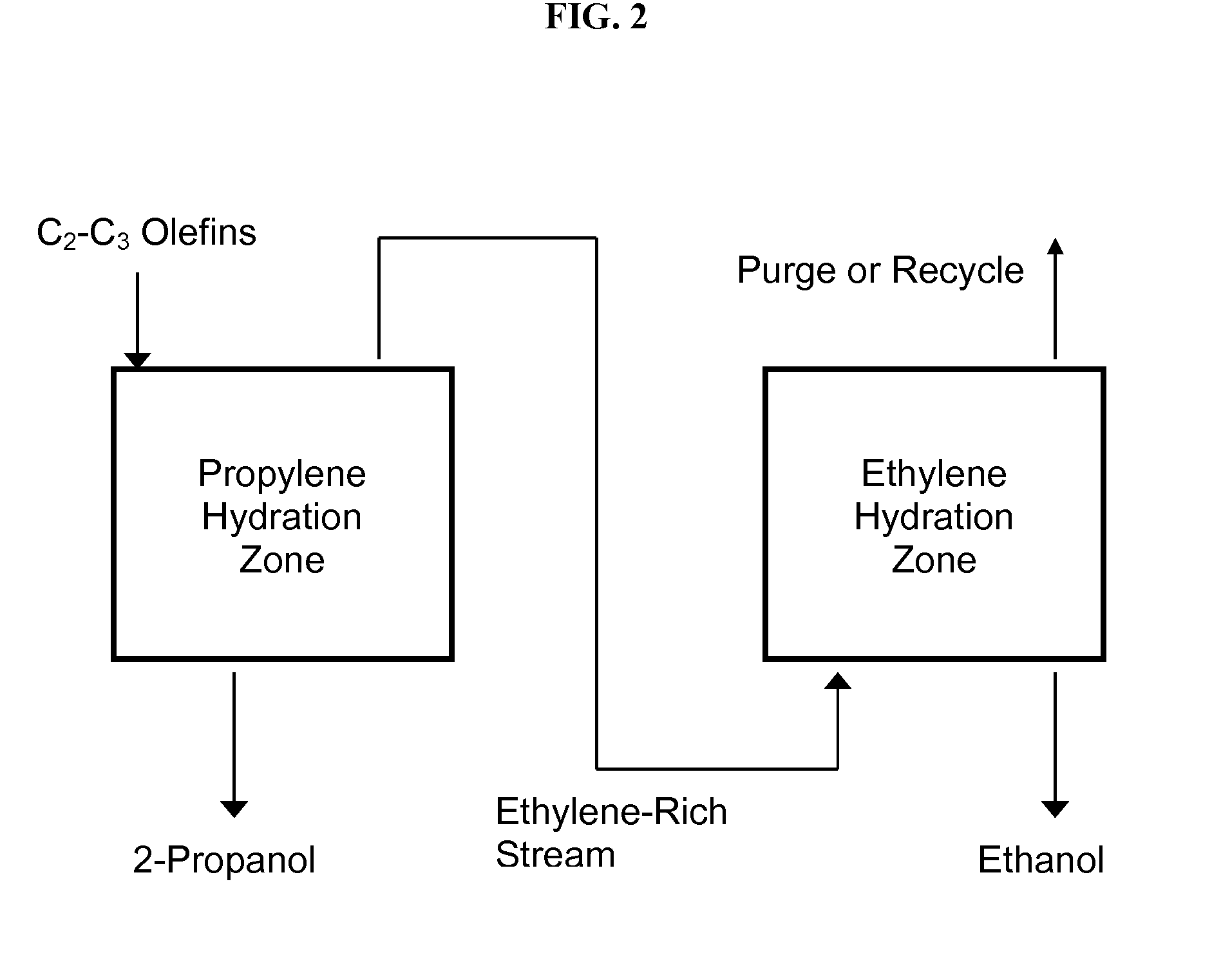

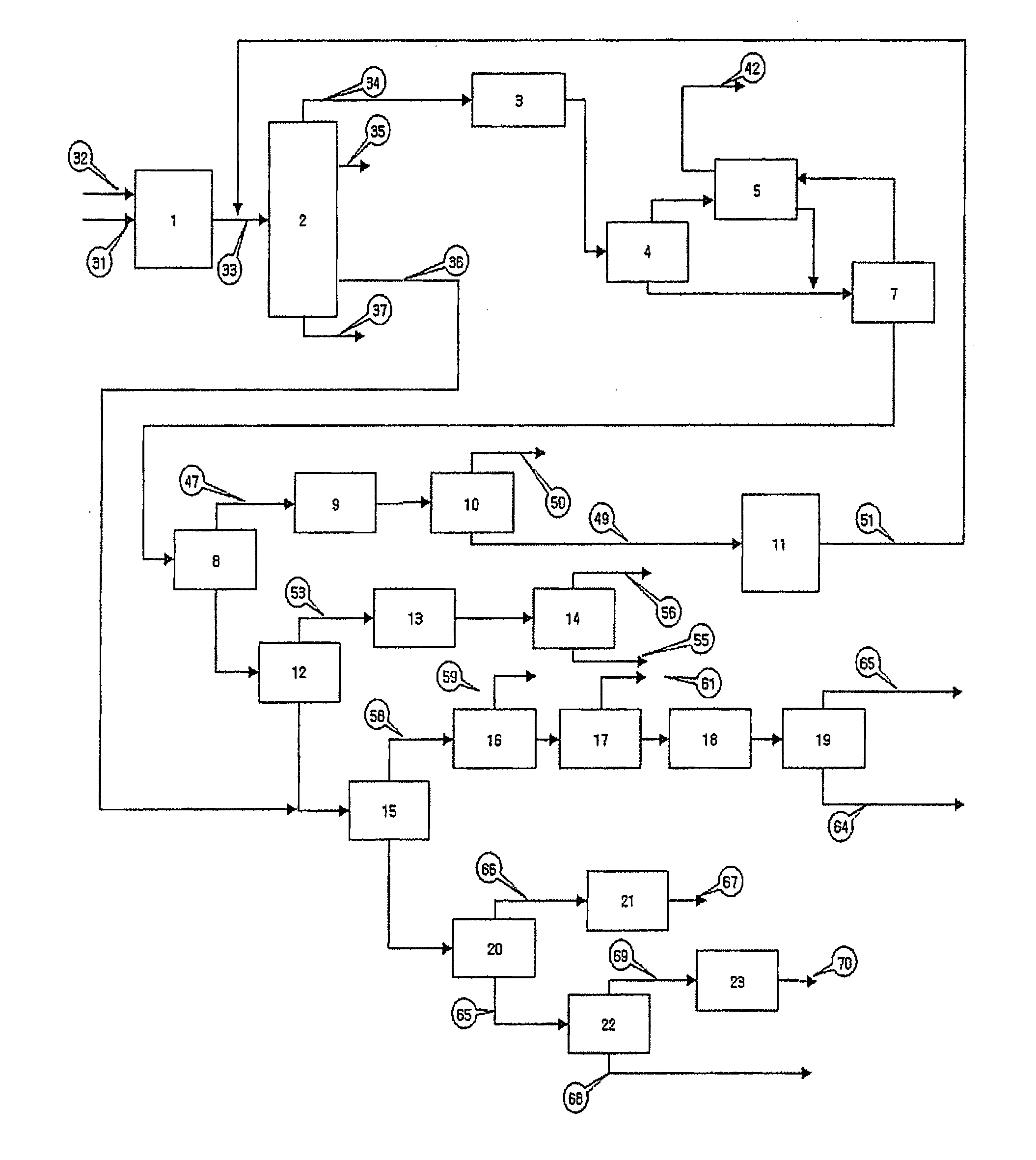

Methods and apparatus for synthesis of alcohols from syngas

This invention provides a method for producing ethanol and 2-propanol from syngas, the method comprising: (a) converting syngas into methanol using a methanol-synthesis catalyst; (b) converting methanol into ethylene and propylene using a methanol-to-olefins catalyst; and (c) hydrating ethylene into ethanol and propylene into 2-propanol. As taught herein, the combined yield of the ethanol and the 2-propanol from biomass can be at least 100 gallons per dry ton biomass. In certain embodiments, the yield of ethanol is at least 100 gallons per dry ton biomass. In some embodiments, the yield of 2-propanol is at least 50 gallons per dry ton biomass.

Owner:ALBEMARLE CORP +1

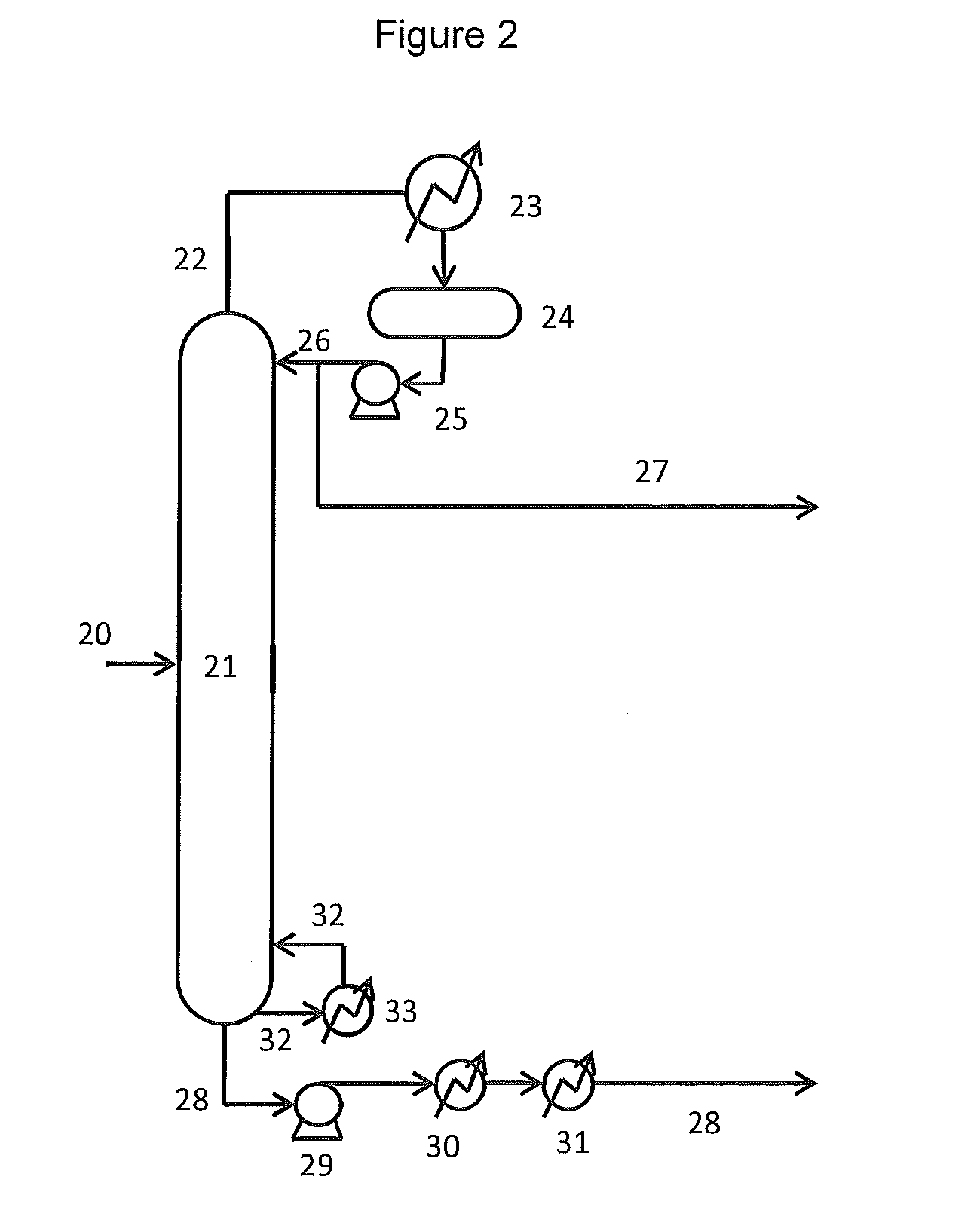

Process for increasing production of light olefins from hydrocarbon feedstock in catalytic cracking

ActiveUS20070083071A1Increase productionEconomical efficiencyTreatment with plural serial cracking stages onlyCatalytic crackingProduction ratePhotochemistry

Disclosed is a process for increasing production of light olefinic hydrocarbons from hydrocarbon feedstock by catalytic cracking. In the process, an effective separation process structure and recycle method of light olefins are used not only to increase the productivity and efficiency of an overall process, thus effectively increasing the production of light olefins, but also to simplify the overall process.

Owner:SK INNOVATION CO LTD

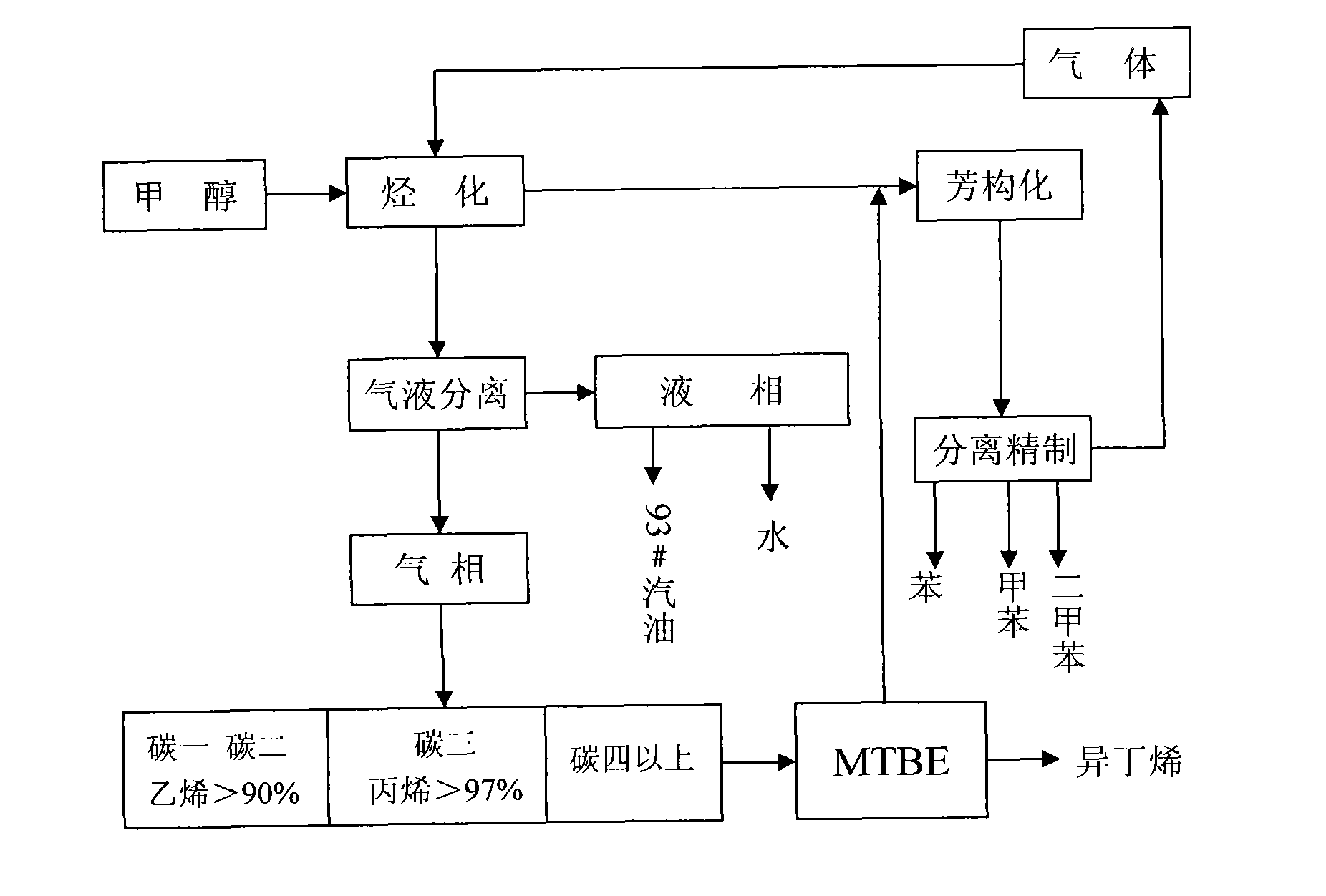

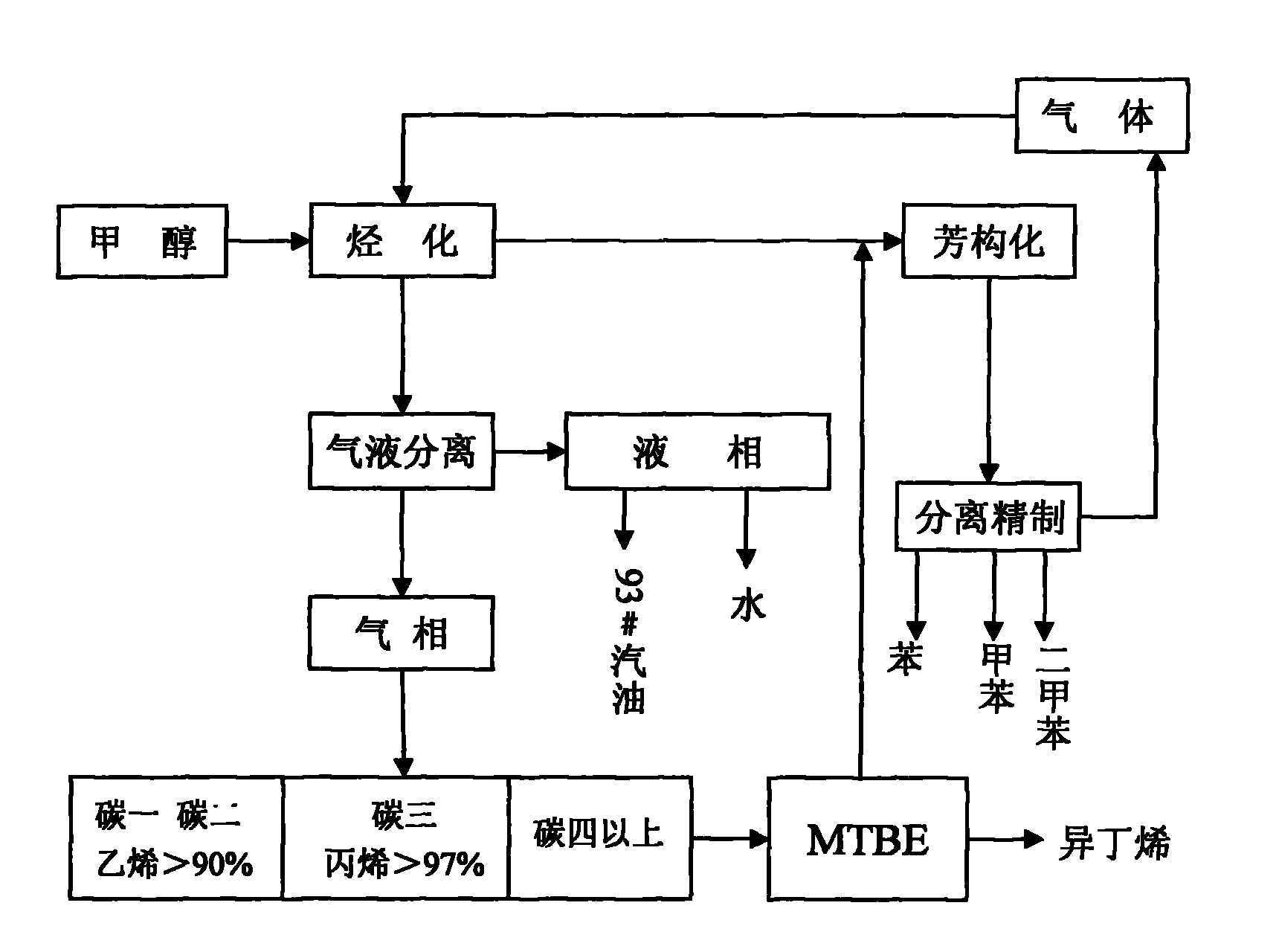

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

InactiveCN102146010ALow costReduce energy consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionEnvironmental resistanceCogeneration

The invention discloses a process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as a raw material. In the process, the methanol is used as the raw material and a molecular sieve catalyst is adopted to produce the low carbon olefin and arene parallel cogeneration gasoline by a methanol alkylation reaction and aromatization. In the process, the coal-based methanol is used as the raw material and can replace the conventional petroleum raw material to cogenerate a basis organic chemical raw material, and thus, the dependence degree of the conventional petrochemical industry on the petroleum can be reduced. Meanwhile, the process is also beneficial for reducing the foreign dependence degree of national petroleum, the strategic safety of energy and resources is improved, the production process of the process has low discharge, low pollution and low energy consumption, the requirements on green and environment protection are met, and the process has the advantages of low production cost and strong market competitiveness.

Owner:江苏煤化工程研究设计院有限公司 +2

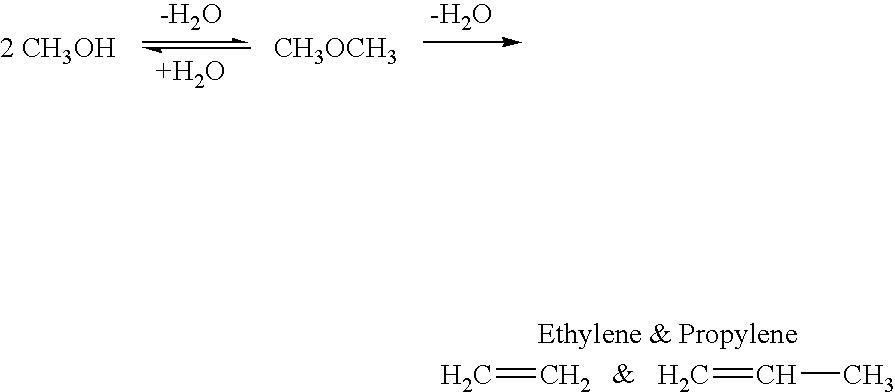

Processes for converting oxygenates to olefins at reduced volumetric flow rates

InactiveUS20060020155A1Reduction in effluent volumetric flow rateMolecular sieve catalystCatalystsSyngasMolecular sieve

This invention provides processes for forming light olefins from methanol and / or from syngas through a dimethyl ether intermediate. Specifically, the invention is to converting methanol and / or syngas to dimethyl ether and water in the presence of a first catalyst, preferably comprising γ-alumina, and converting the dimethyl ether to light olefins and water in the presence of a second catalyst, preferably a molecular sieve catalyst composition.

Owner:EXXONMOBIL CHEM PAT INC

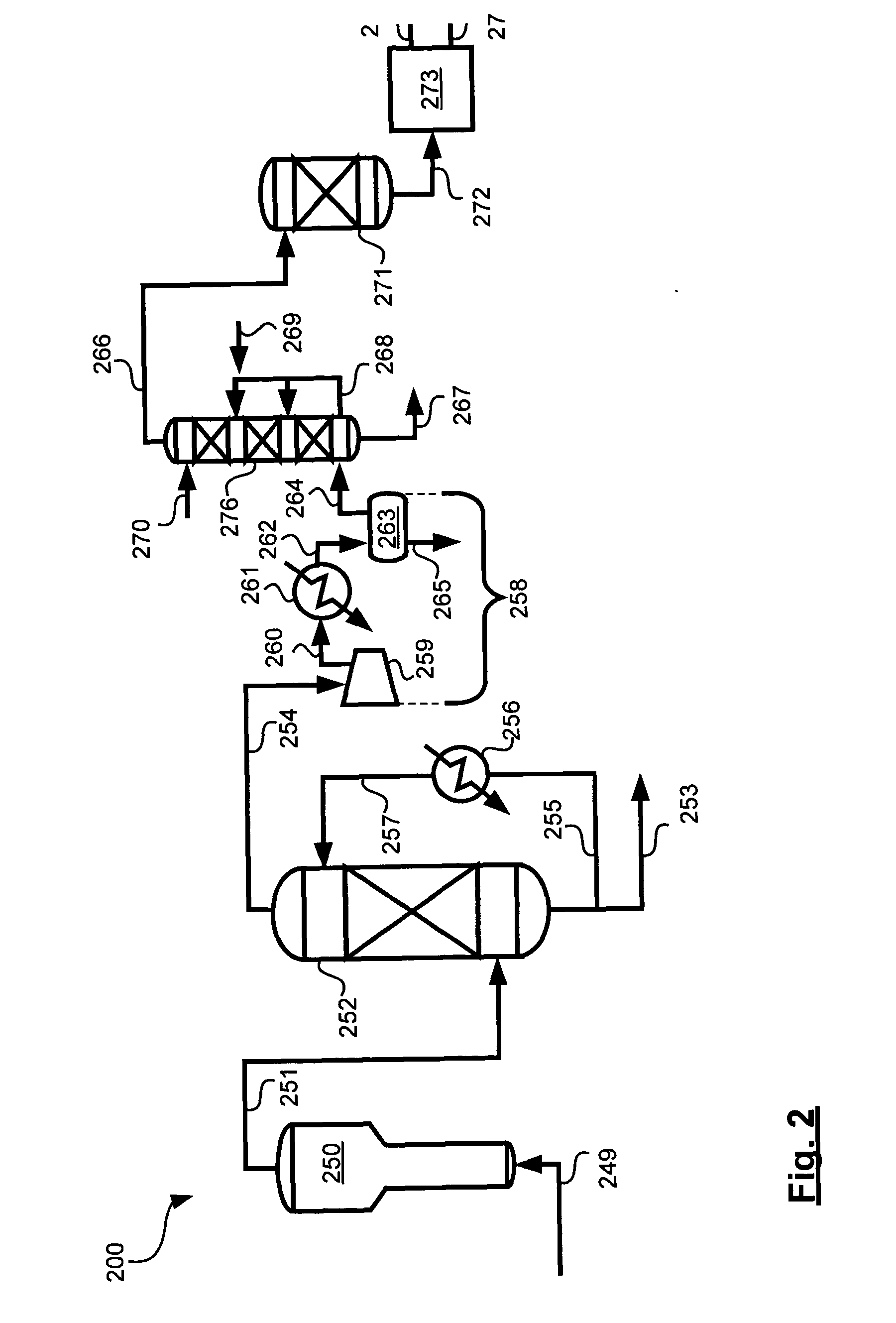

Process for producing liquid fuel from carbon dioxide and water

ActiveUS20070244208A1Combustible gas chemical modificationOrganic compounds purification/separation/stabilisationHydrocotyle bowlesioidesLiquid fuel

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

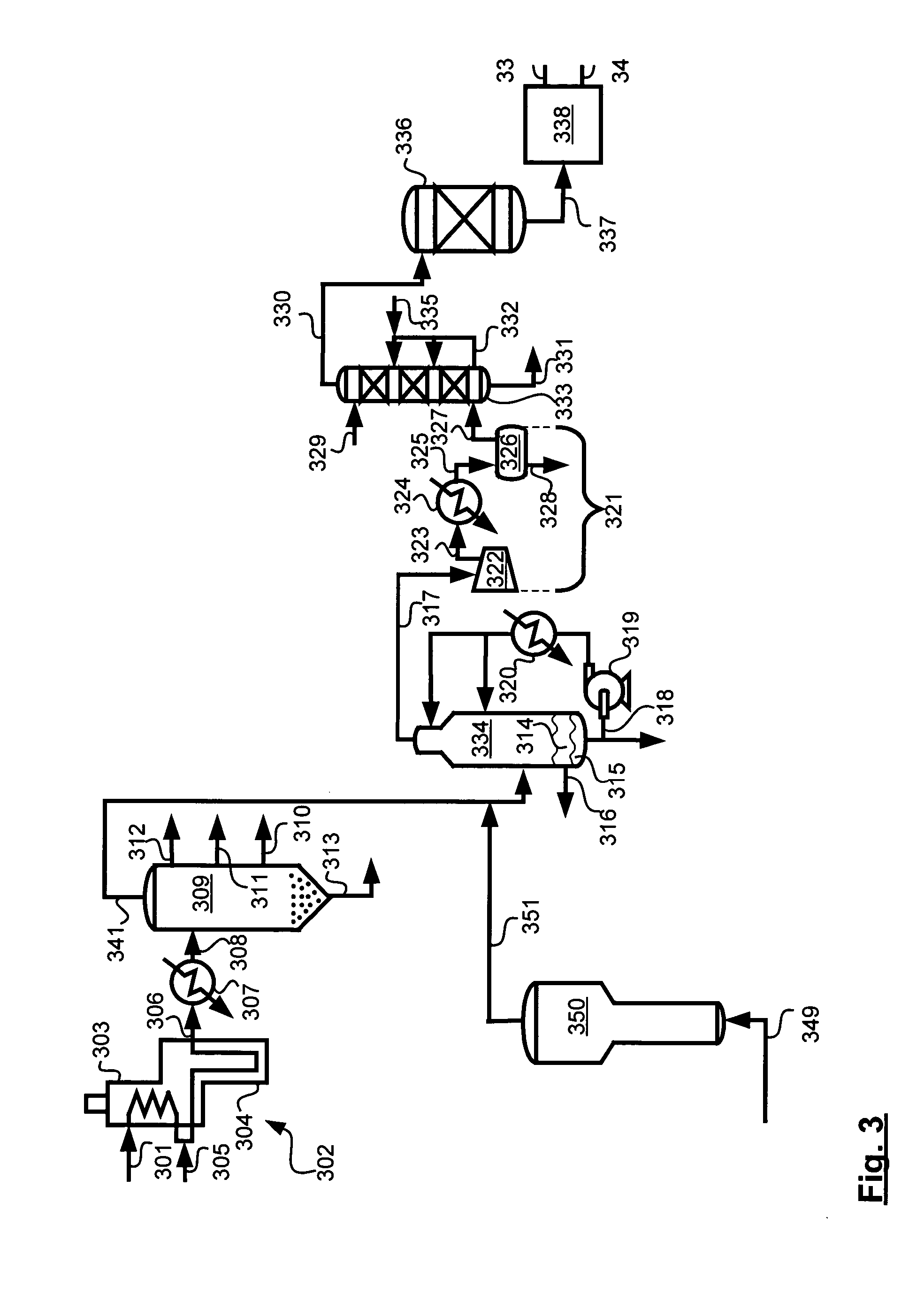

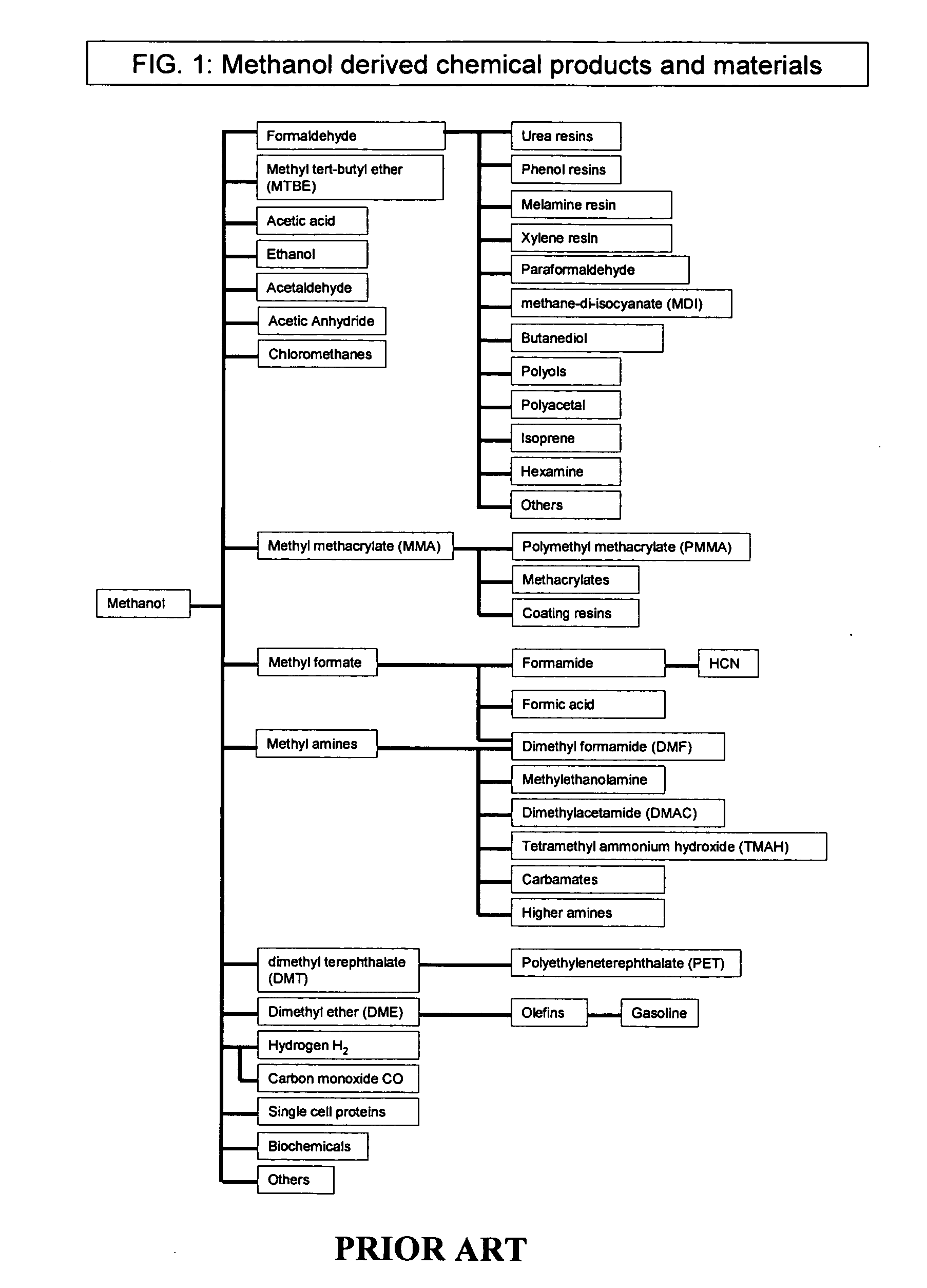

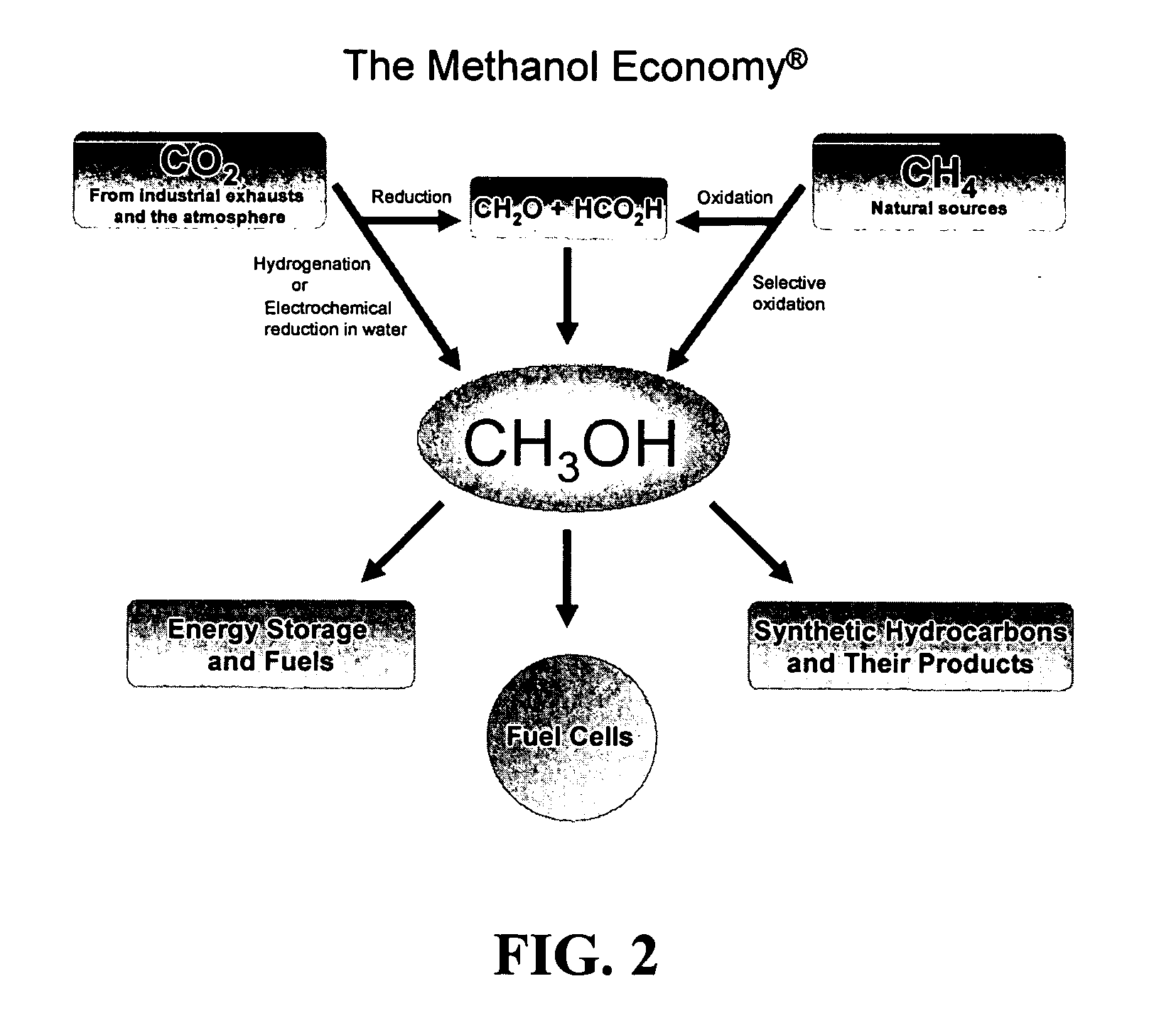

Method for producing methanol, dimethyl ether, derived synthetic hydrocarbons and their products from carbon dioxide and water (moisture) of the air as sole source material

InactiveUS7378561B2High activityImprove surface activityOrganic compound preparationOrganic chemistry methodsNano structuringWater source

A method for producing methanol and dimethyl ether using the air as the sole source of materials is disclosed. The invention relates to a method for separating the water (i.e., the moisture in the air) and carbon dioxide content of atmospheric air for their use in the subsequent production of methanol, dimethyl ether and derived synthetic hydrocarbons as products. The method includes the conversion of carbon dioxide and water under conditions sufficient to produce methanol and / or dimethyl ether. Methanol and / or dimethyl ether can be used as fuel or fuel additives or further converted to synthetic hydrocarbons and their products. Carbon dioxide is captured on a suitable absorbent, preferentially polyethyleneimine supported on nano-structured fumed silica. The process can also involve hydrogenation with hydrogen produced by electrolysis of water obtained from the air or from any other water source. Methanol can be dehydrated to produce dimethyl ether or further processed to produce synthetic hydrocarbons, polymers, and products derived from them by other known methods.

Owner:UNIV OF SOUTHERN CALIFORNIA

Method for preparing propylene and aromatic hydrocarbon by virtue of conversion of methanol

ActiveCN102190546AHigh yieldHydrocarbon from oxygen organic compoundsEthylene productionLiquid productGas phase

The invention relates to a method for preparing propylene and aromatic hydrocarbon by virtue of conversion of methanol, and the method is mainly used for solving the problem that the methanol is just converted into propylene and the aromatic hydrocarbon can not be co-produced in the prior art. The method comprises the following steps: 1) converting above 80% of methanol into dimethyl ether by virtue of pre-reaction; 2) feeding the generated diamethyl ether and residual methanol into a device for producing propylene from the methanol for reaction so as to obtain a material flow I which mainly comprises the propylene, ethylene and C4, C5, C6 and over-C6 hydrocarbons; 3) after the material flow I is separated, returning the ethylene back to the device for producing the propylene from the methanol for cycling reaction, and feeding C4 and C5 hydrocarbons into an aromatizing device for reaction so as to obtain a material flow II containing aromatic hydrocarbon; and 4) cooling the material flow II, separating a gas-phase product low-carbon hydrocarbons from a liquid-phase product, and separating the liquid product from the material flow I so as to obtain C6 and over-C6 hydrocarbons, mixing, extracting and separating so as to obtain the aromatic hydrocarbon and non-aromatic hydrocarbon. By using the technical scheme, the problem is well solved; and the method can be used in industrialproduction for preparing the ethylene and the aromatic hydrocarbon by virtue of conversion of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

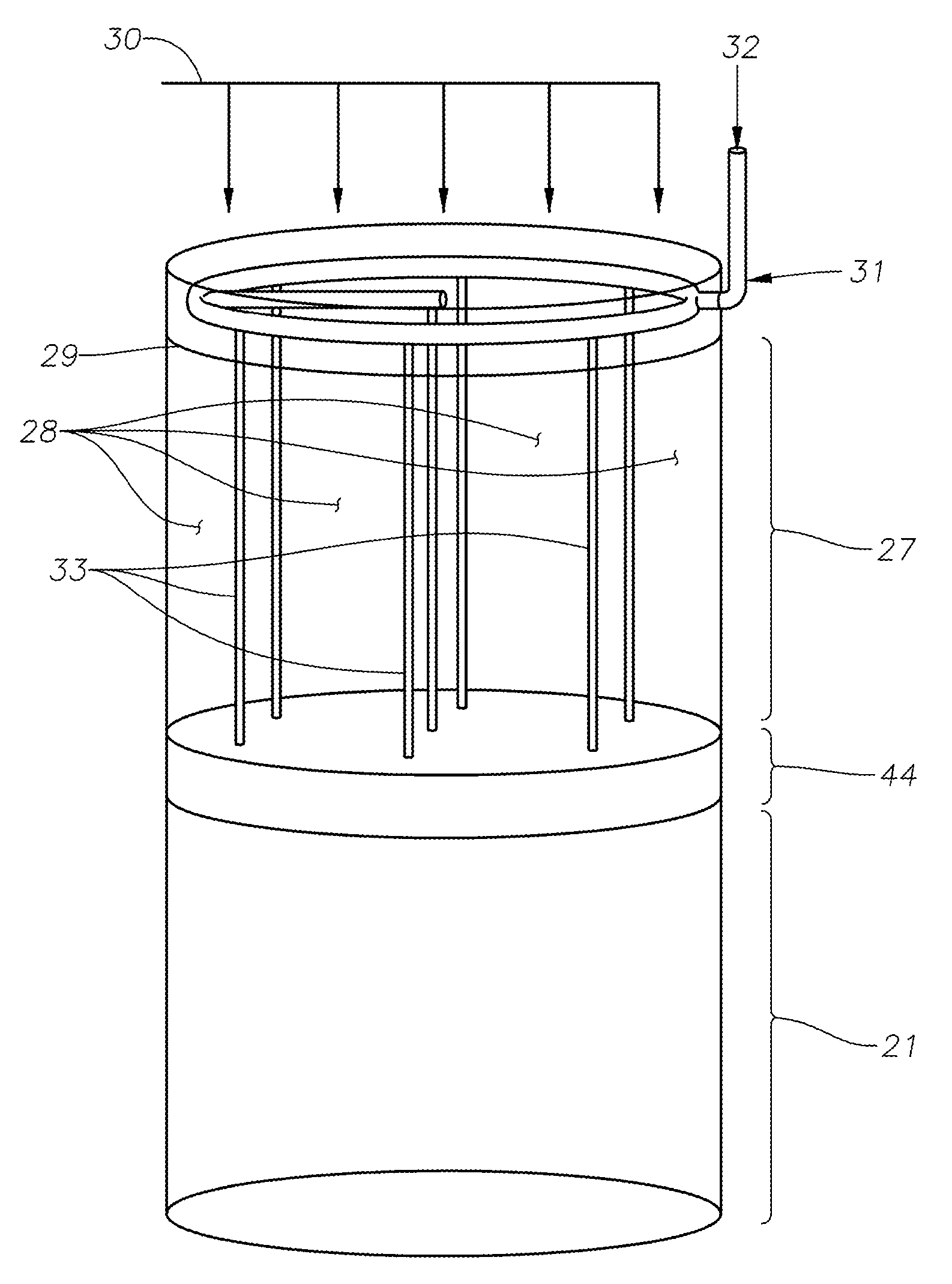

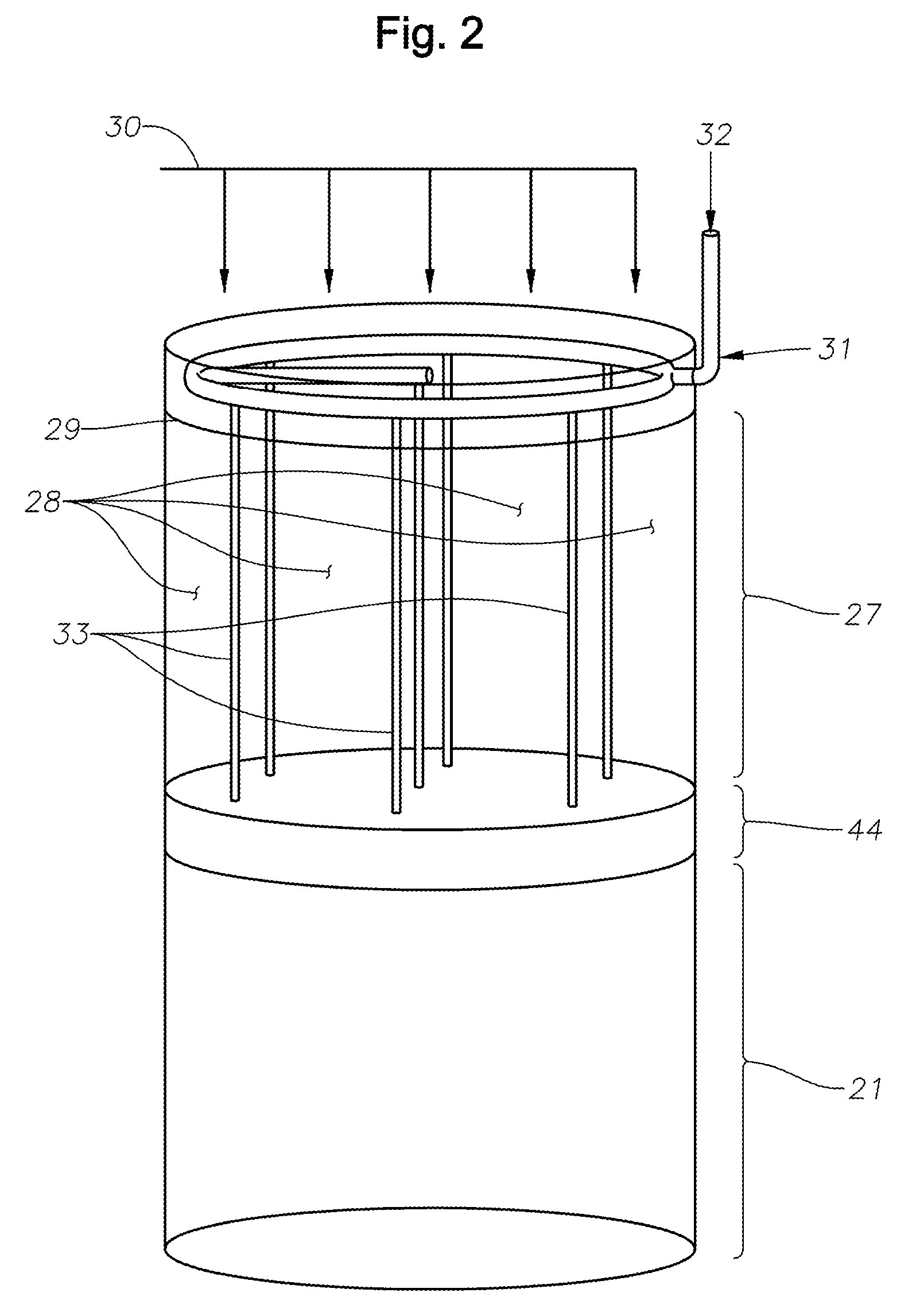

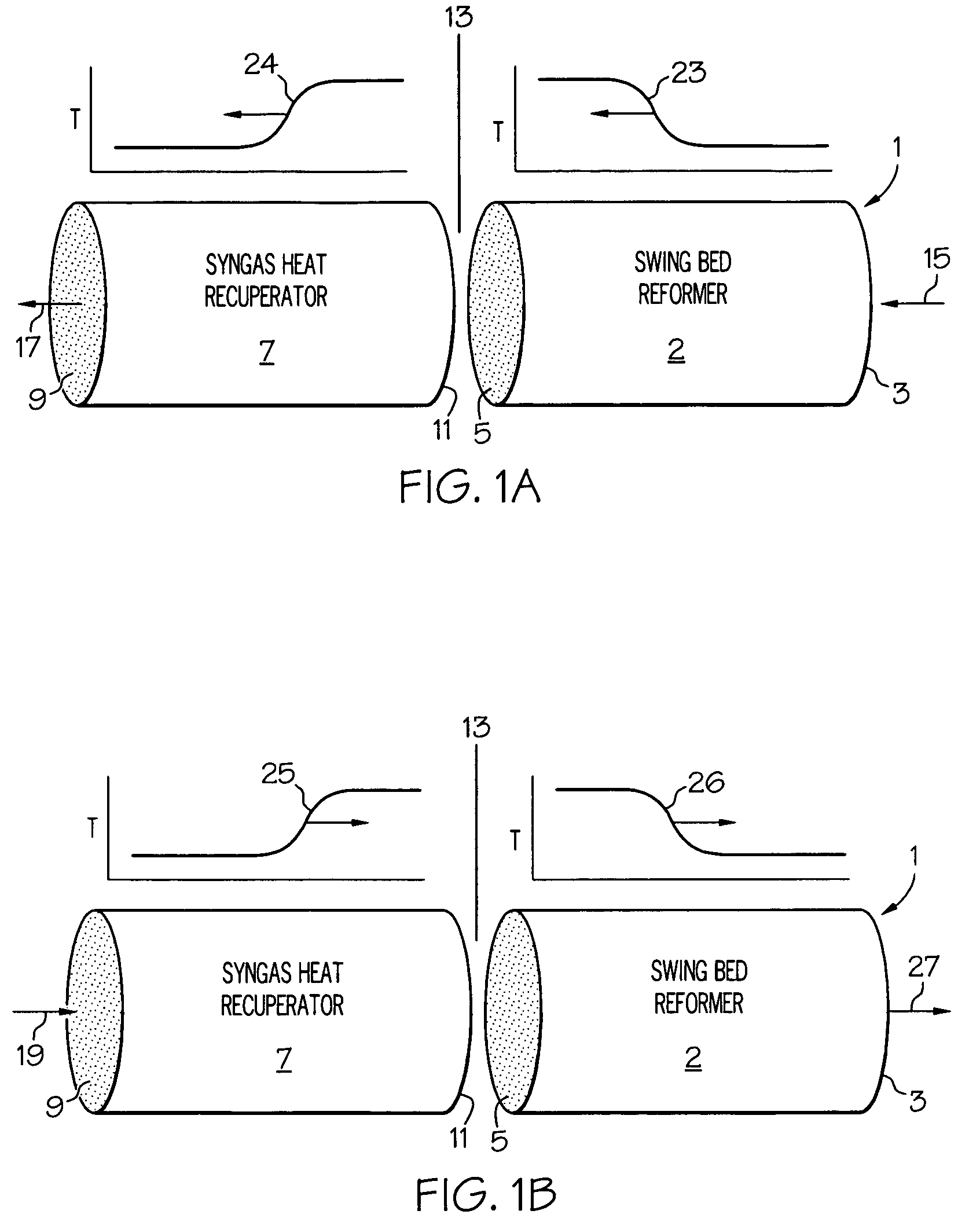

Pyrolysis reactor conversion of hydrocarbon feedstocks into higher value hydrocarbons

ActiveUS20090008292A1Thermal non-catalytic crackingCatalytic crackingReactor systemProcess engineering

In one aspect, the inventive process comprises a process for pyrolyzing a hydrocarbon feedstock containing nonvolatiles in a regenerative pyrolysis reactor system. The inventive process comprises: (a) heating the nonvolatile-containing hydrocarbon feedstock upstream of a regenerative pyrolysis reactor system to a temperature sufficient to form a vapor phase that is essentially free of nonvolatiles and a liquid phase containing the nonvolatiles; (b) separating said vapor phase from said liquid phase; (c) feeding the separated vapor phase to the pyrolysis reactor system; and (d) converting the separated vapor phase in said pyrolysis reactor system to form a pyrolysis product.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst and method for converting low molecular weight paraffinic hydrocarbons into alkenes and organic compounds with carbon numbers of 2 or more

InactiveUS20070083073A1Reduce the amount requiredPromotes oxidative couplingHydrogenHeterogenous catalyst chemical elementsCarbon numberOxygen

A catalyst and process for formation of hydrocarbons having carbon numbers of two or greater, the result of both oxidative coupling of methane (“OCM”), and other reforming reactions of OCM end products. An OCM catalyst has a structure represented by formula ABTiO3, wherein A is samarium or tin, B is barium; the reforming catalysts a composition represented by formula XYZ, wherein X is a metal from Group IA, Group IIA or Group VIIIA, or not present, Y a metal from Group VA, Group VIA, Group VIIA or Group VIIIA, Z chosen from oxygen, silica, silicalite and alumina. The inventive catalyst comprises an OCM catalyst and a reforming catalyst blended together; when used in a reactor effects an increased yield of hydrocarbons having a carbon number greater than 2 (in excess of 27%-30%, first pass rate of methane conversion about 50%) than occurs under OCM conditions alone.

Owner:HRD CORP

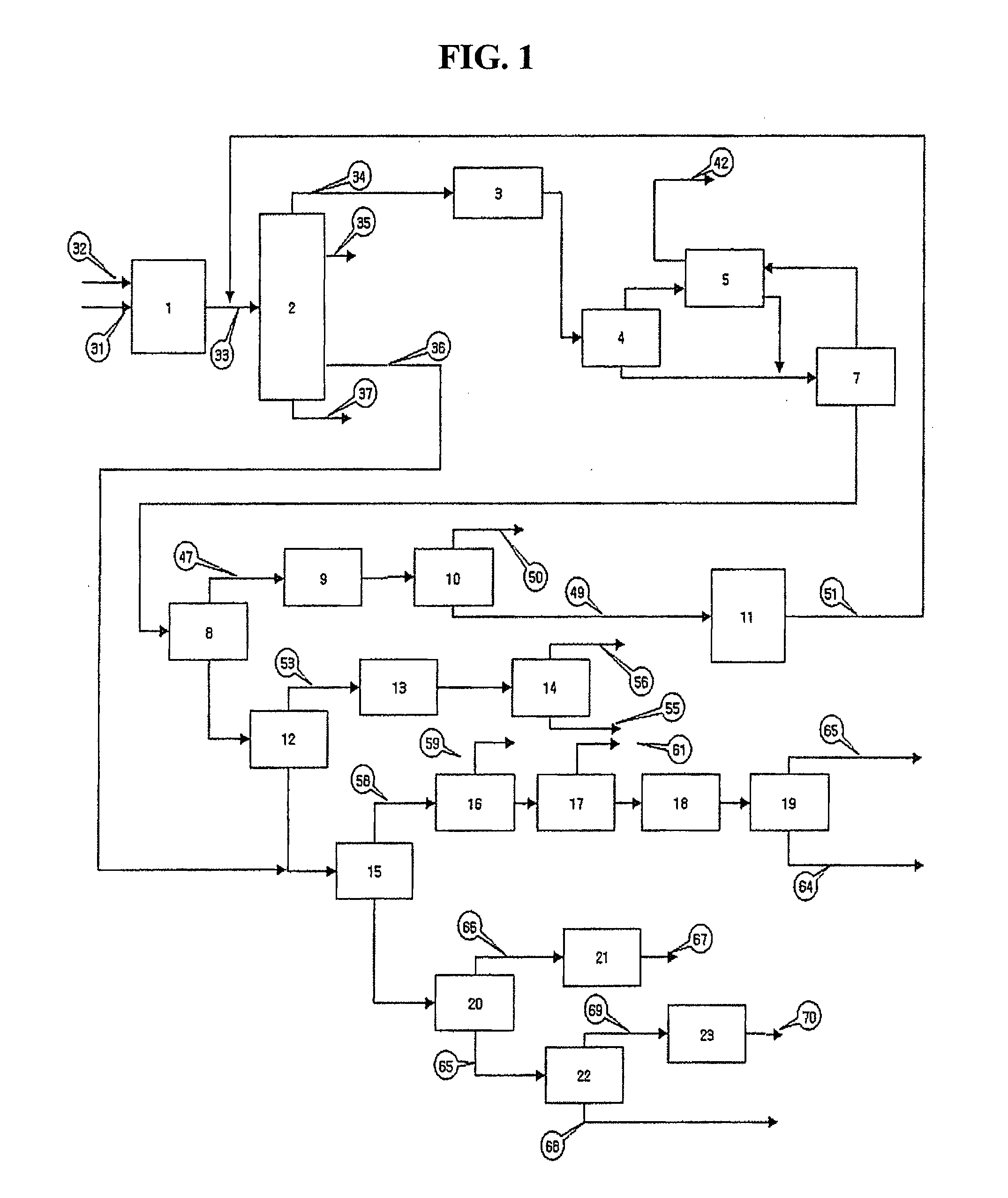

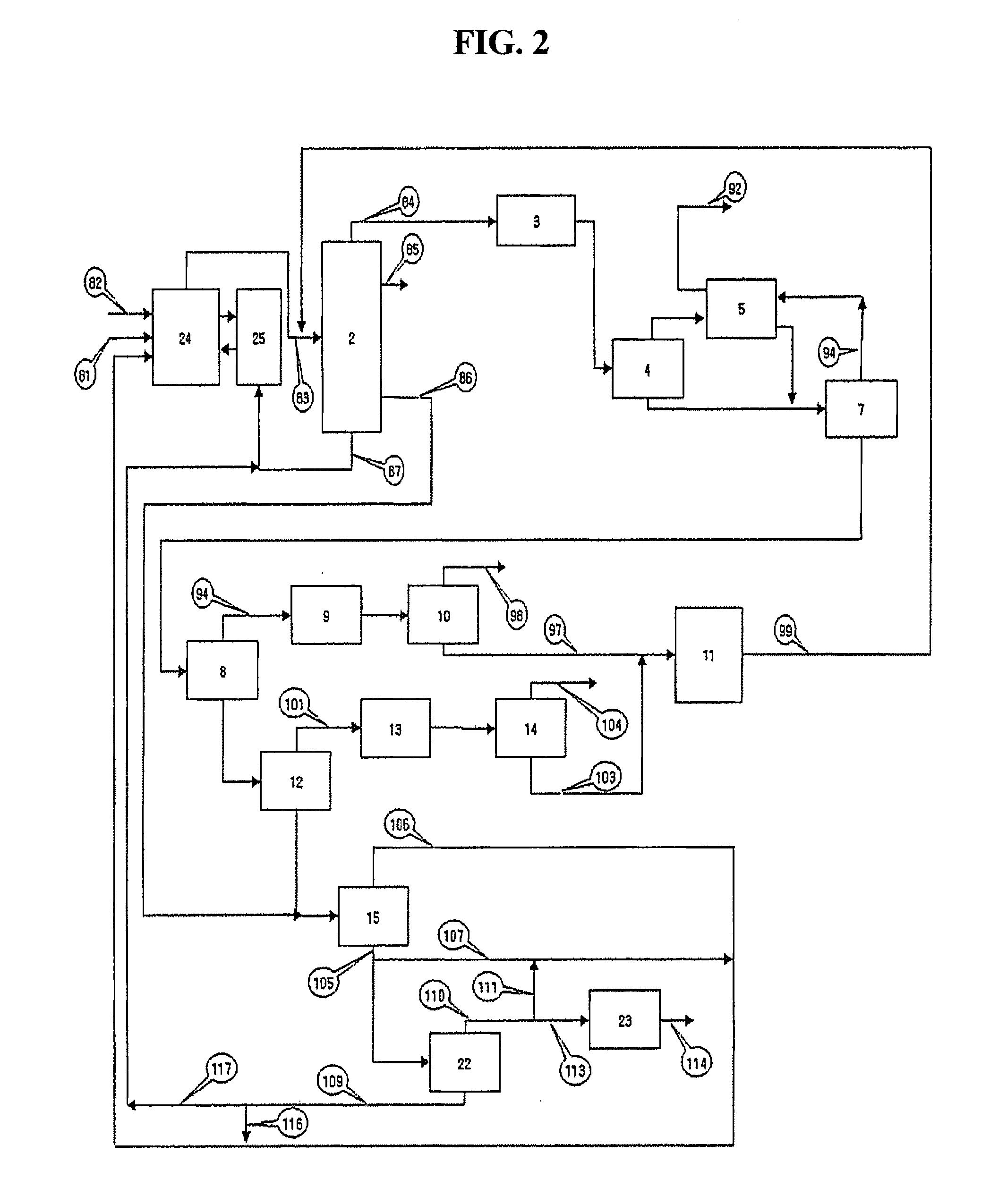

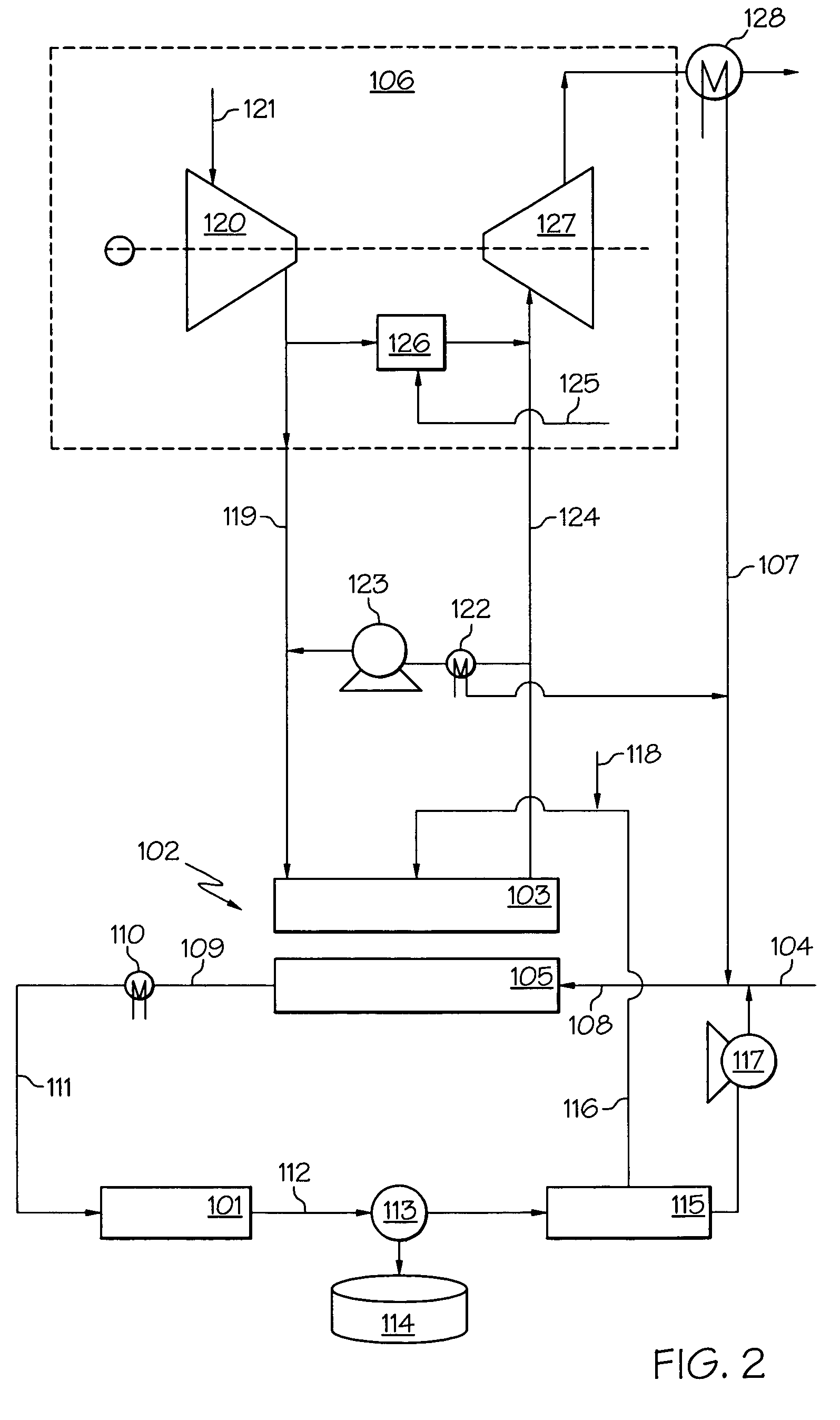

Integrating a methanol to olefin reaction system with a steam cracking system

InactiveUS20050038304A1Shorten the counting processReduce the amount requiredThermal non-catalytic crackingMolecular sieve catalystOxygenateFractionating column

The present invention provides an integrated system for producing ethylene and propylene from an oxygenate to olefin (OTO) reaction system and a steam cracking system. In a preferred embodiment, at least a portion of an effluent stream from a steam cracking furnace is combined with at least a portion of an effluent stream from an OTO reaction system. Preferably the combined effluent stream is processed by one or more quench units, compression units, and / or fractionation columns. By integrating a steam cracking system with an OTO reaction system, equipment count can be reduced at a significant commercial savings. Compressor efficiency per pound of ethylene and propylene can also be advantageously increased over conventional steam cracking systems. Moreover, the amount of pollutants produced per pound of ethylene and propylene produced can be significantly reduced over the amount of pollutants produced per pound of ethylene and propylene produced in a steam cracking system.

Owner:EXXONMOBIL CHEM PAT INC

Selective oxidative conversion of methane to methanol, dimethyl ether and derived products

ActiveUS20060235088A1Minimize or eliminate the disadvantages or dangers inherentPreparation by oxidation reactionsElectrolysis componentsFormate EstersDimethyl ether

The present invention relates to a method of producing methanol from a methane source by oxidizing methane under conditions sufficient to a mixture of methanol and formaldehyde while minimizing the formation of formic acid and carbon dioxide. The oxidation step is followed by treatment step in which formaldehyde is converted into methanol and formic acid which itself can further be converted into methanol via catalytic hydrogenation of intermediately formed methyl formate.

Owner:UNIV OF SOUTHERN CALIFORNIA

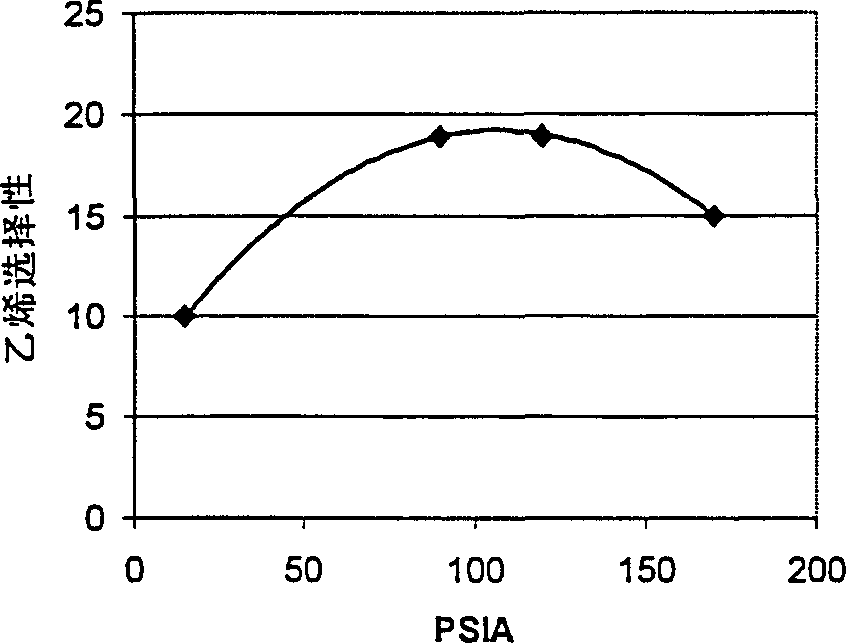

Process for converting methanol or dimethyl ether to olefins

There is provided a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins, which comprises the step of contacting a feed containing methanol or dimethyl ether with a catalyst which comprises a zeolite having 10-ring intersecting channels, such as ZSM-5, and which has a Diffusion Parameter for 2,2-dimethylbutane of less than 100 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). The contacting step is conducted at a temperature of 370 to 480 DEG C., a methanol partial pressure of 30 to 150 psia and a methanol conversion per pass of less than 95%.

Owner:EXXONMOBIL CORP (US)

Biofuels via hydrogenolysis and dehydrogenation-condensation

ActiveUS20110282115A1Easy to oxidizePromote hydrolysis reactionBiofuelsEfficient propulsion technologiesHydrogenDehydrogenation

A method comprising providing a carbohydrate feed; contacting at least a portion of the carbohydrate feed directly with hydrogen in the presence of a hydrogenolysis catalyst to produce a first reaction product comprising a stable hydroxyl intermediate; contacting at least a portion of the first reaction product comprising the stably hydroxyl intermediates with a dehydrogenation catalyst to form a second reaction product; and contacting at least a portion of the second reaction product with a condensation catalyst comprising a base functionality to form a fuel blend.

Owner:SHELL USA INC

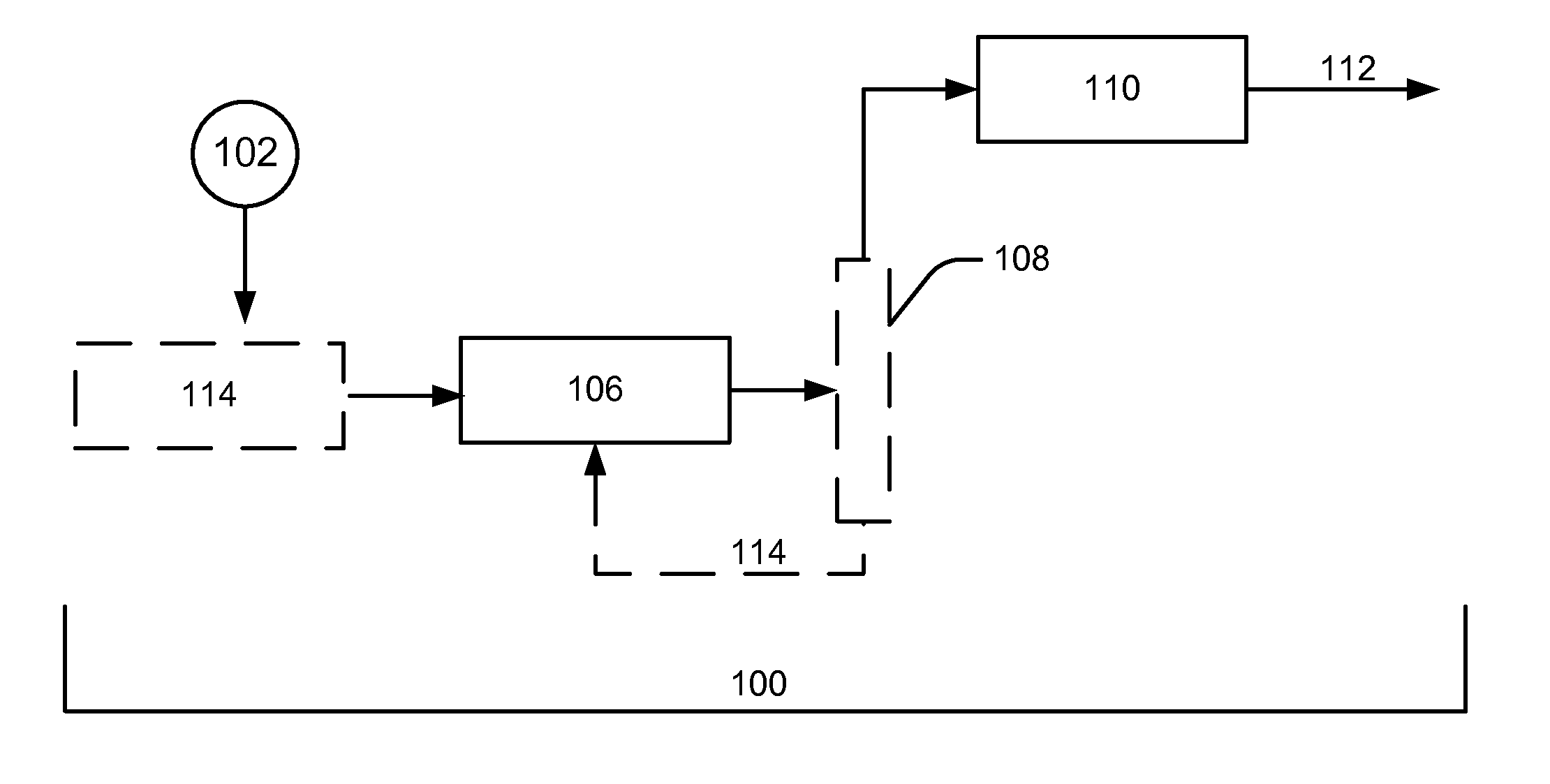

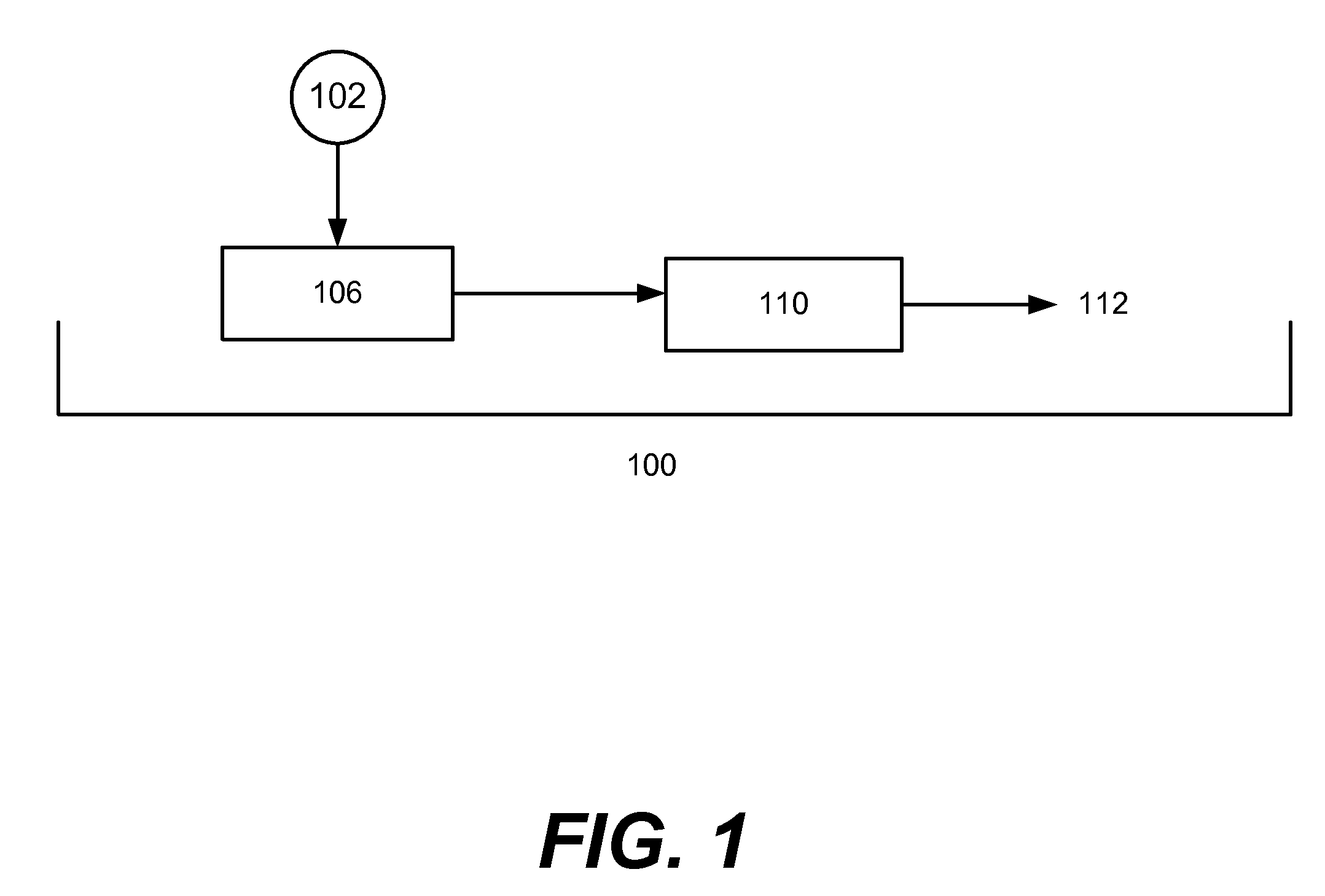

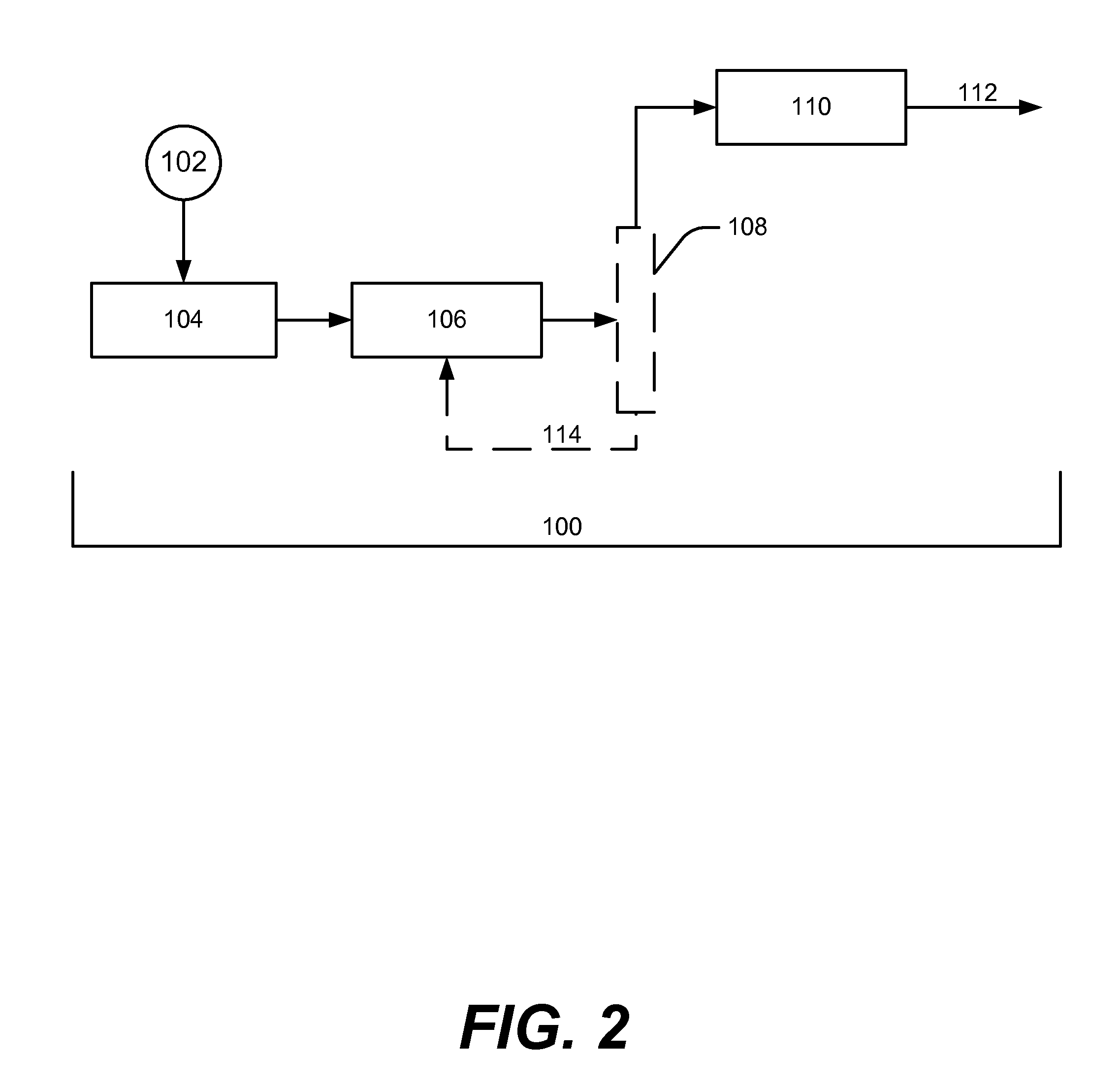

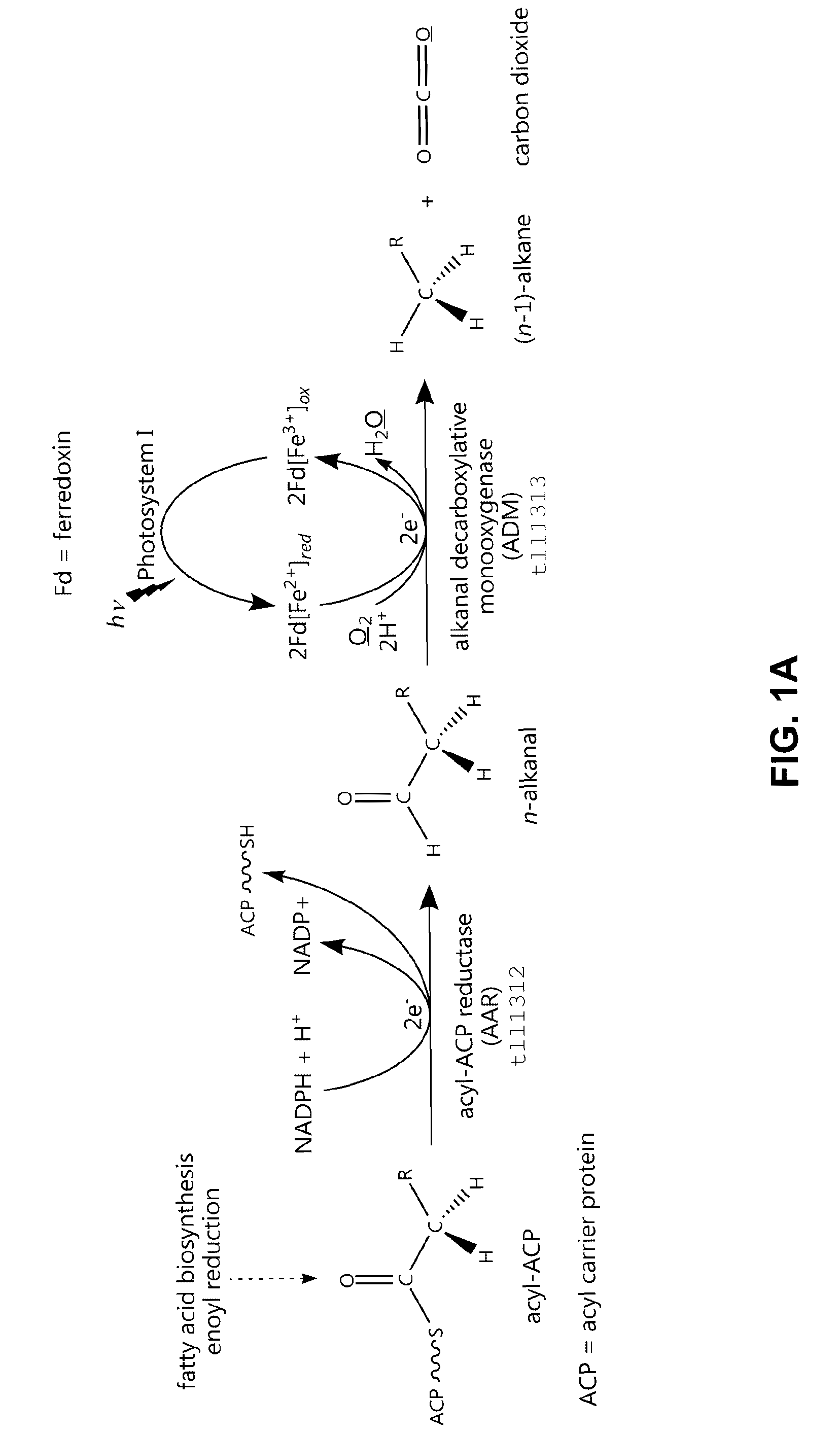

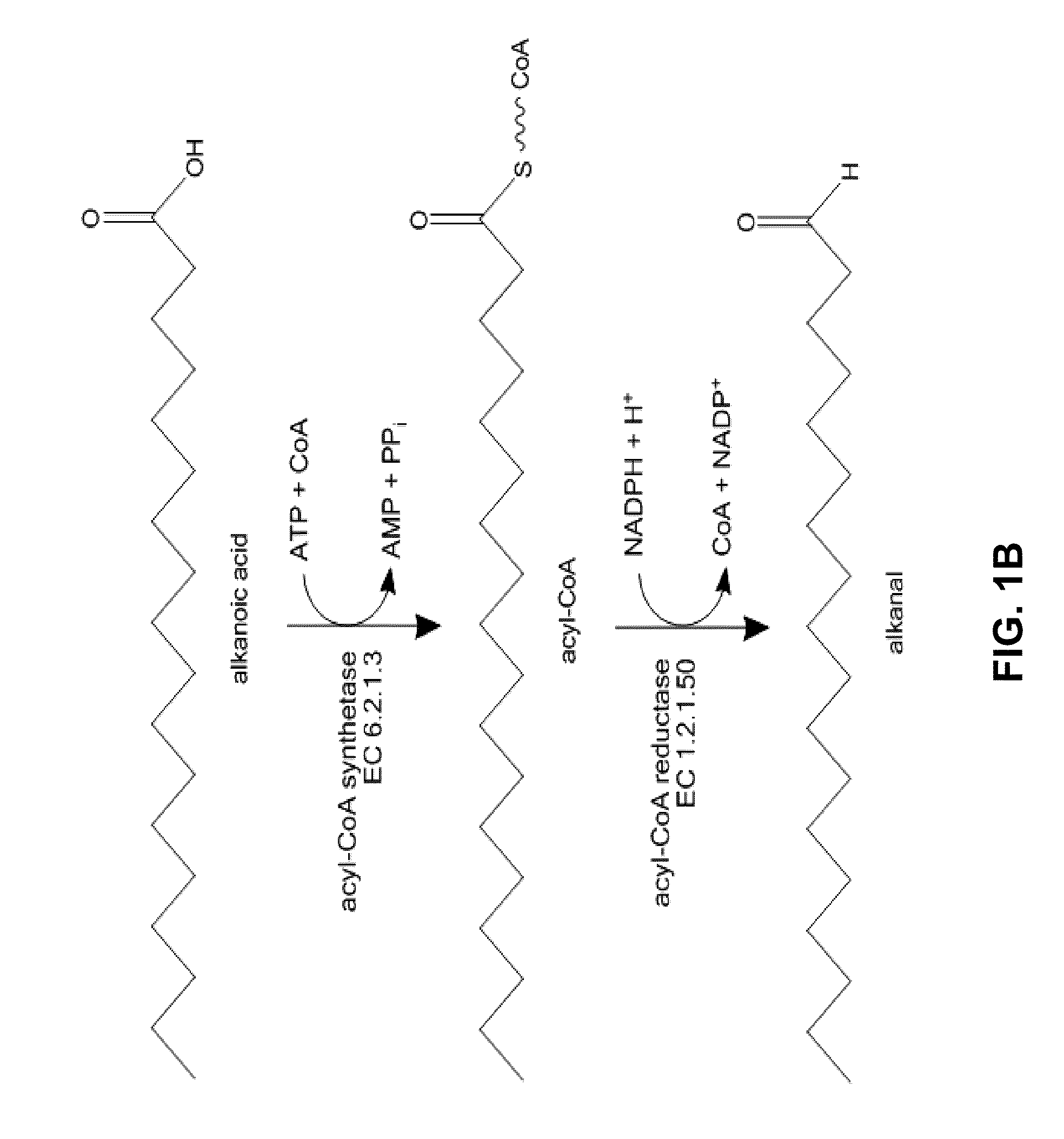

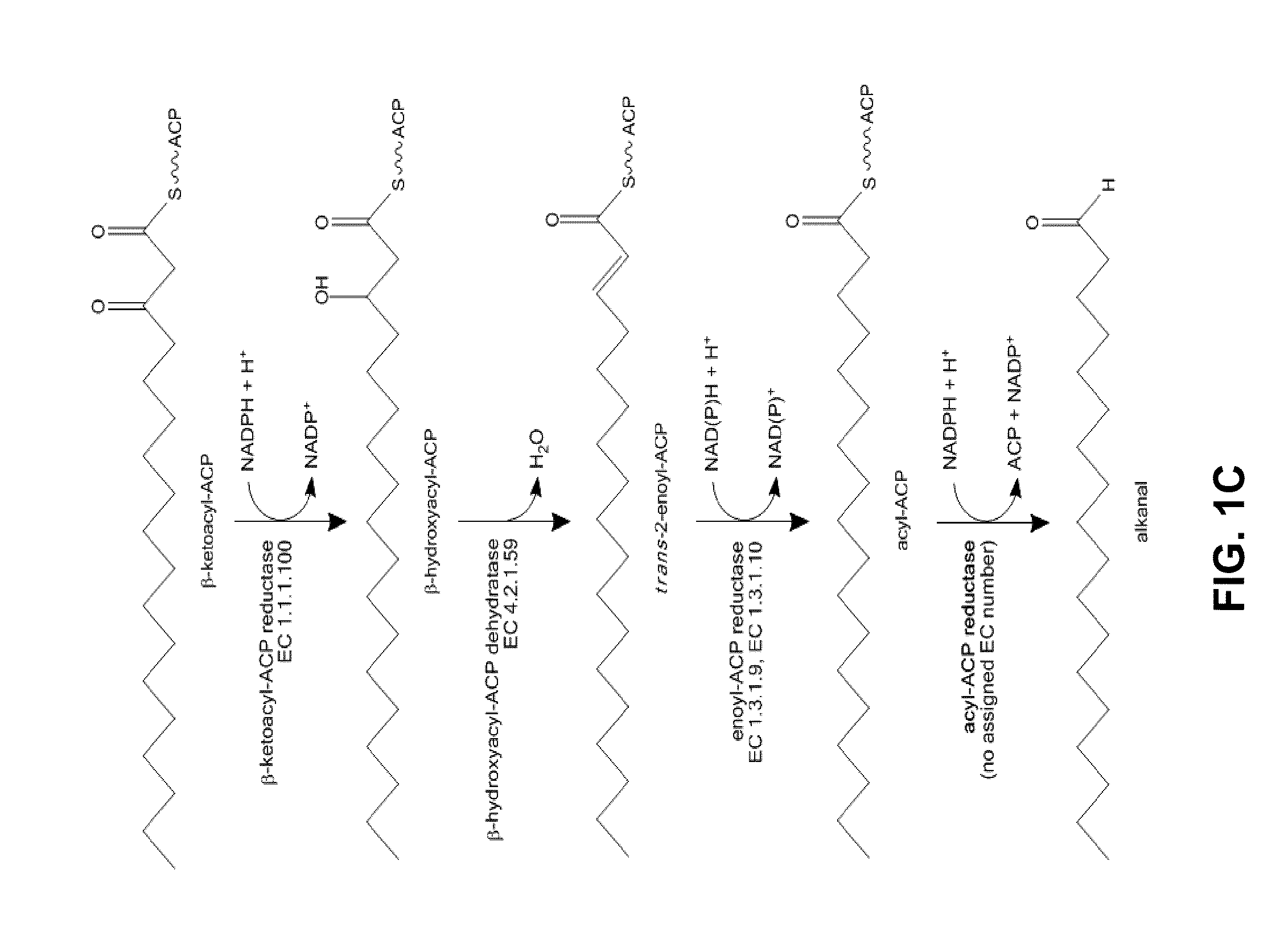

Methods and compositions for the recombinant biosynthesis of n-alkanes

InactiveUS7794969B1Improve rendering capabilitiesOrganic chemistryOxidoreductasesAlkaneAutotrophic organism

The present disclosure identifies methods and compositions for modifying photoautotrophic organisms as hosts, such that the organisms efficiently convert carbon dioxide and light into n-alkanes, and in particular the use of such organisms for the commercial production of n-alkanes and related molecules.

Owner:JOULE UNLTD TECH

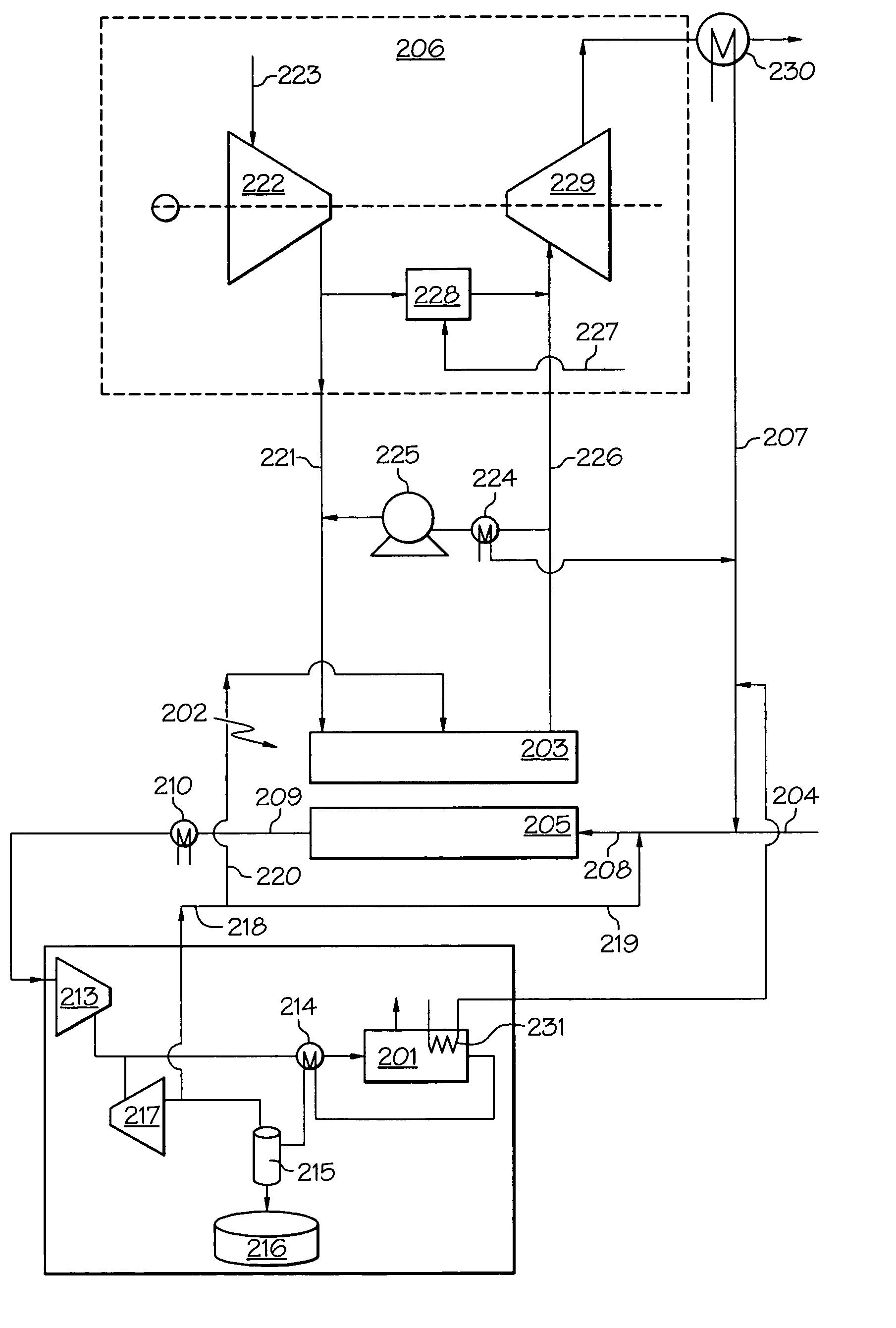

Methanol manufacture using pressure swing reforming

ActiveUS7148261B2Easy to produceIncrease pressureOrganic compound preparationOxygen compounds preparation by reductionSteam reformingHydrogen

A process for producing methanol is described in which a hydrocarbon is steam reformed in a reforming zone, and during the reforming stage, of a cyclic steam reformer having a reforming stage and a regeneration stage, the steam reforming being conducted under conditions effective to produce a first effluent stream containing synthesis gas. Fuel and an oxygen-containing gas are combusted in the regeneration stage of the reformer so as to reheat the reforming zone to a temperature sufficient for the reforming stage and generate a flue gas. At least part of the first effluent stream is contacted with a methanol synthesis catalyst under conditions effective to convert synthesis gas to methanol and form a methanol-containing stream and a tail gas stream comprising unreacted carbon monoxide and hydrogen. At least part of the tail gas stream is recycled as fuel for the regeneration stage of the cyclic steam reformer.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com