Patents

Literature

9405results about "Catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroalkylation of aromatic hydrocarbons

InactiveUS6037513AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07.

Owner:MOBIL OIL CORP

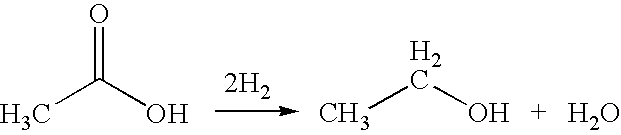

Ethylene production from acetic acid utilizing dual reaction zone process

A process for selective formation of ethylene from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with a first catalytic composition including a suitable hydrogenating catalyst in a first reaction zone to form an intermediate mixture including ethanol and ethyl acetate; and subsequently reacting the intermediate mixture over a suitable dehydrating and / or cracking catalyst in a second reaction zone to form ethylene. Selectivities of ethylene of over 80% are achieved.

Owner:CELANESE INT CORP

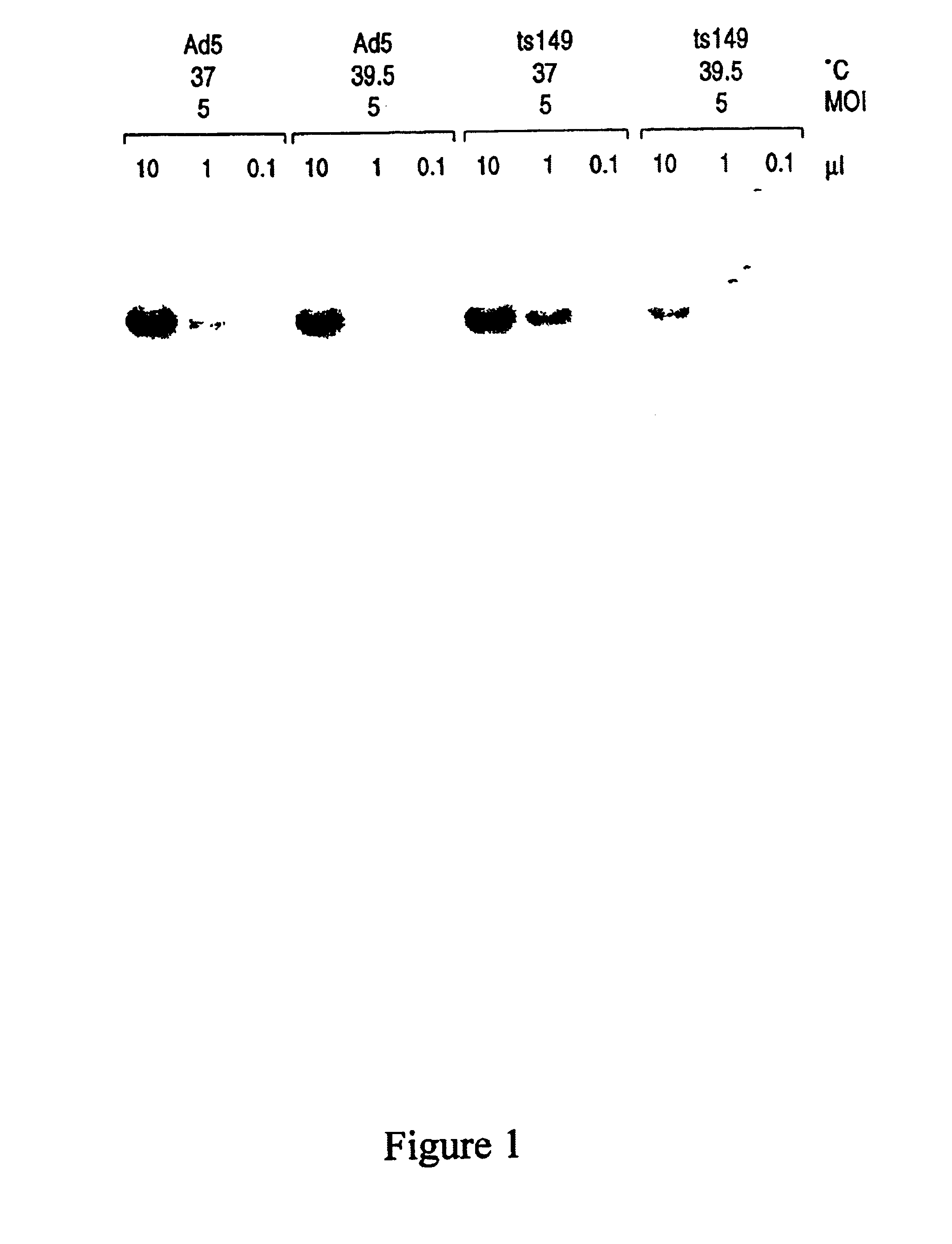

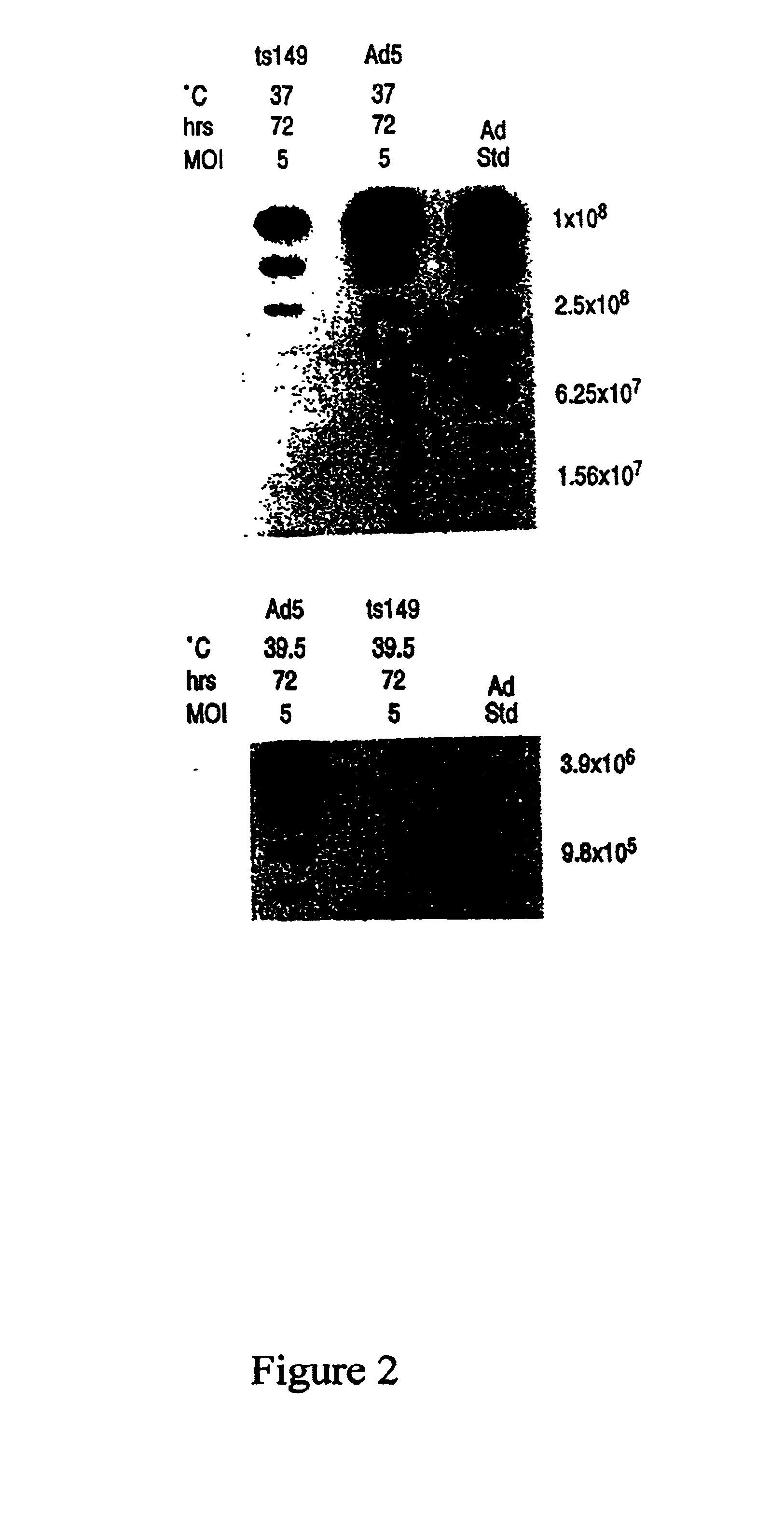

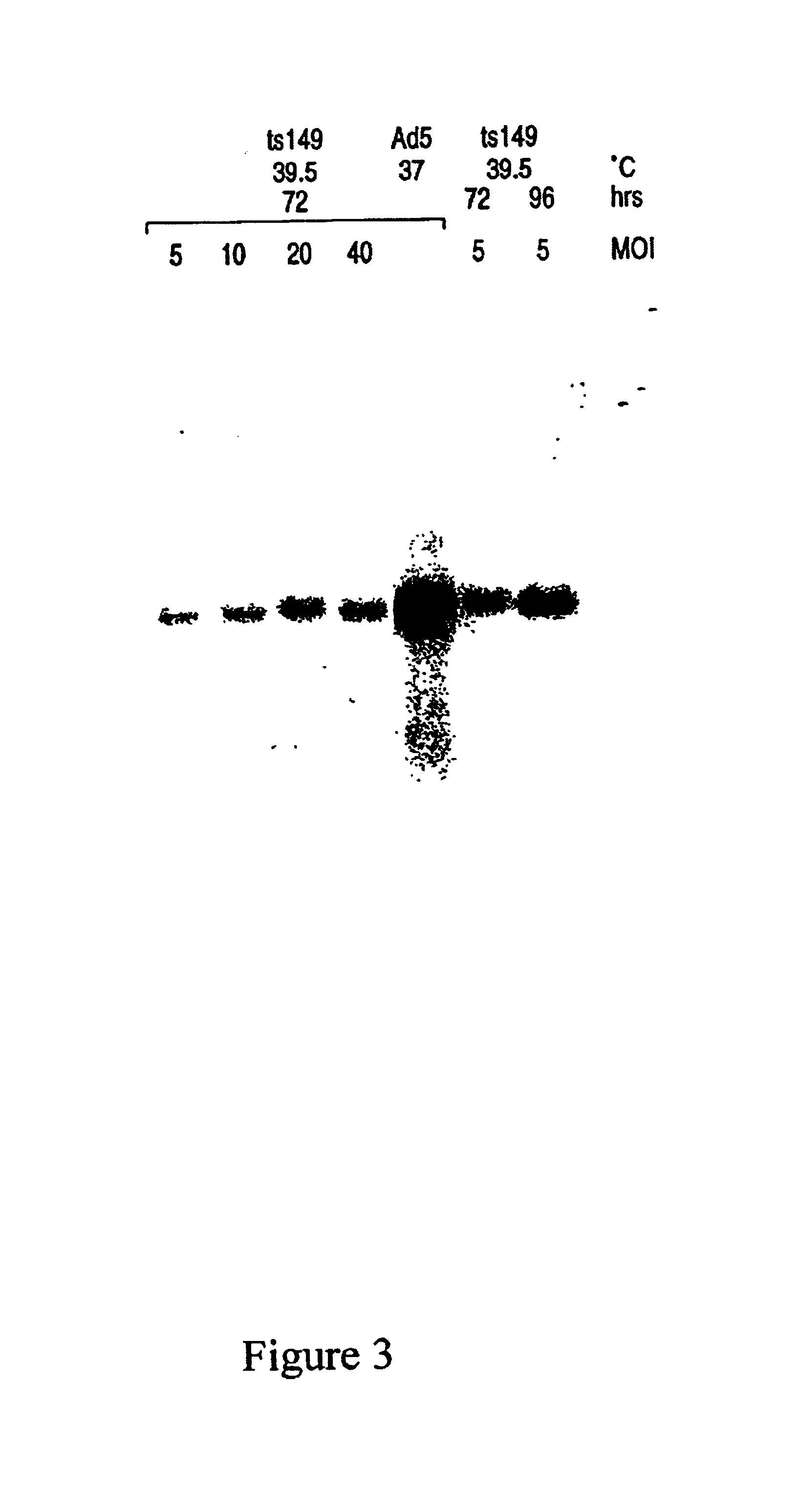

Methods for generating high titer helper-free preparations of released recombinant AAV vectors

InactiveUS6989264B2Genetic therapy composition manufactureGroup 5/15 element organic compoundsGene deliveryHeterologous

This invention provides methods and compositions for producing high titer, substantially purified preparations of recombinant adeno-associated virus (AAV) that can be used as vectors for gene delivery. At the onset of vector production, AAV producer cells of this invention typically comprise one or more AAV packaging genes, an AAV vector comprising a heterologous (i.e. non-AAV) transgene of interest, and a helper virus such as an adenovirus. The AAV vector preparations produced are generally replication incompetent but are capable of mediating delivery of a transgene of interest (such as a therapeutic gene) to any of a wide variety of tissues and cells. The AAV vector preparations produced according to this invention are also substantially free of helper virus as well as helper viral and cellular proteins and other contaminants. The invention described herein provides methods of producing rAAV particles by culturing producer cells under conditions, such as temperature and pH, that promote release of virus. Also provided is a quantitative, high-throughput assay useful in the assessment of viral infectivity and replication, as well as in the screening of agent that affect viral infectivity and / or replication.

Owner:TARGETED GENETICS CORPORTION

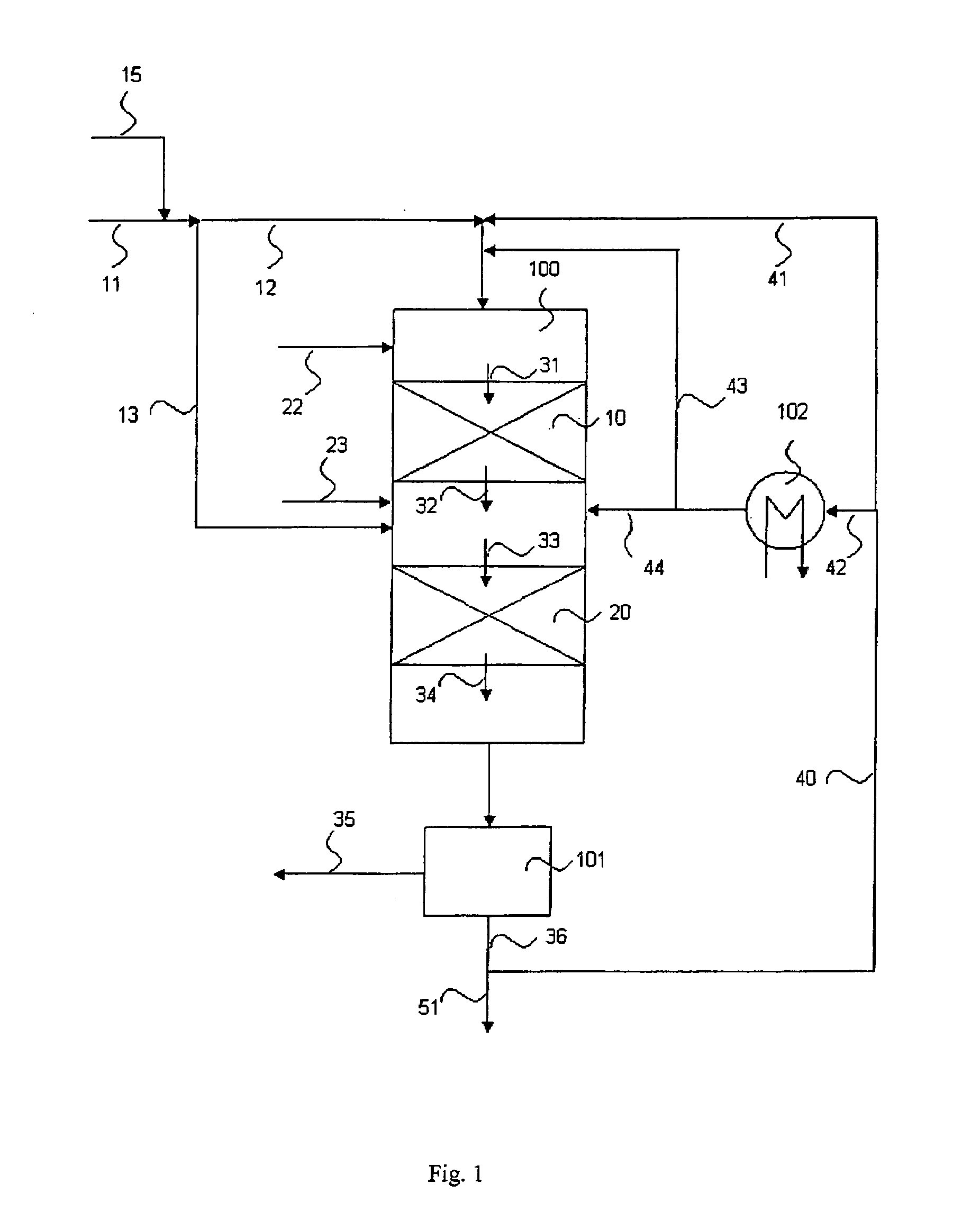

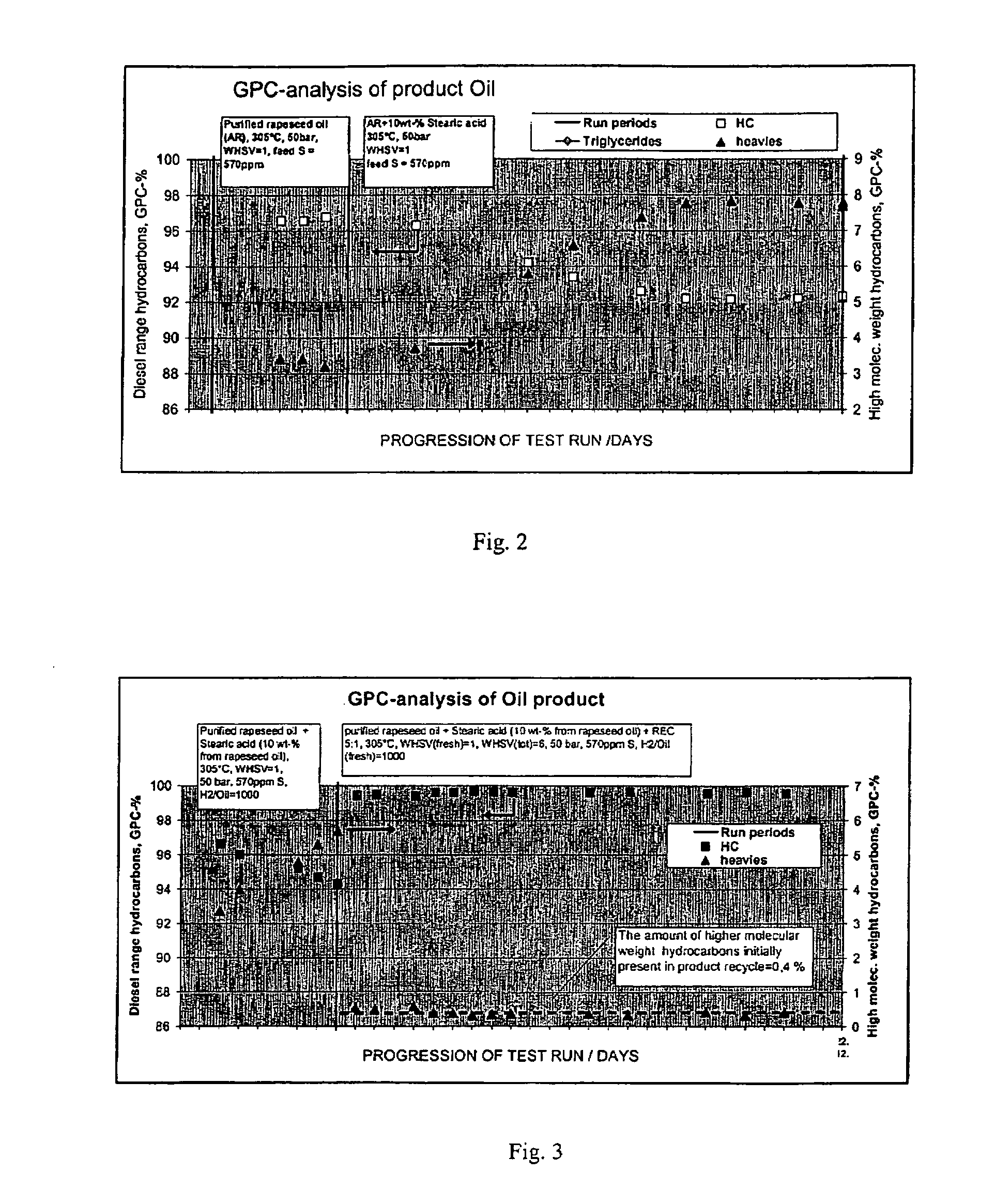

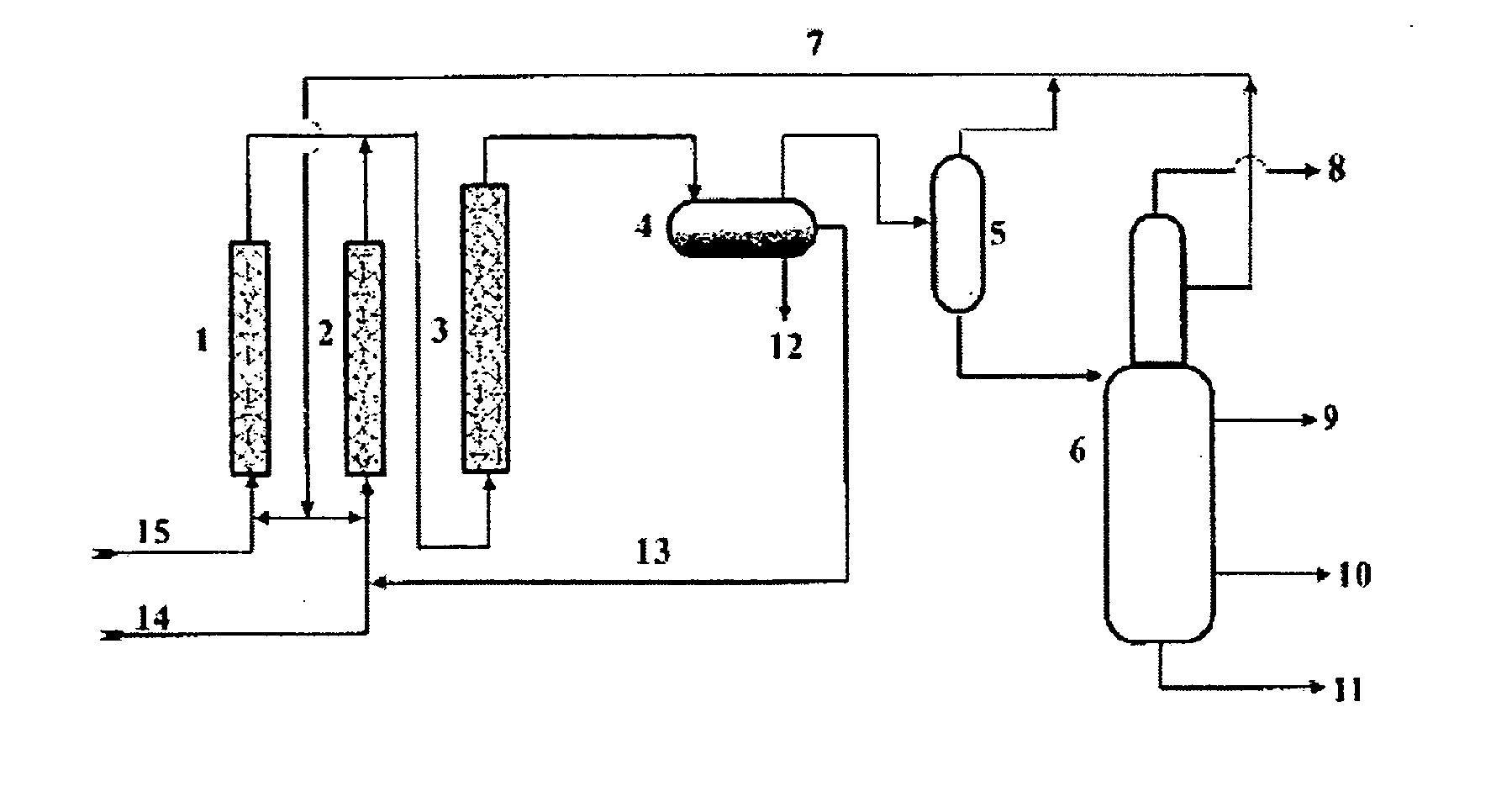

Process for the manufacture of diesel range hydrocarbons

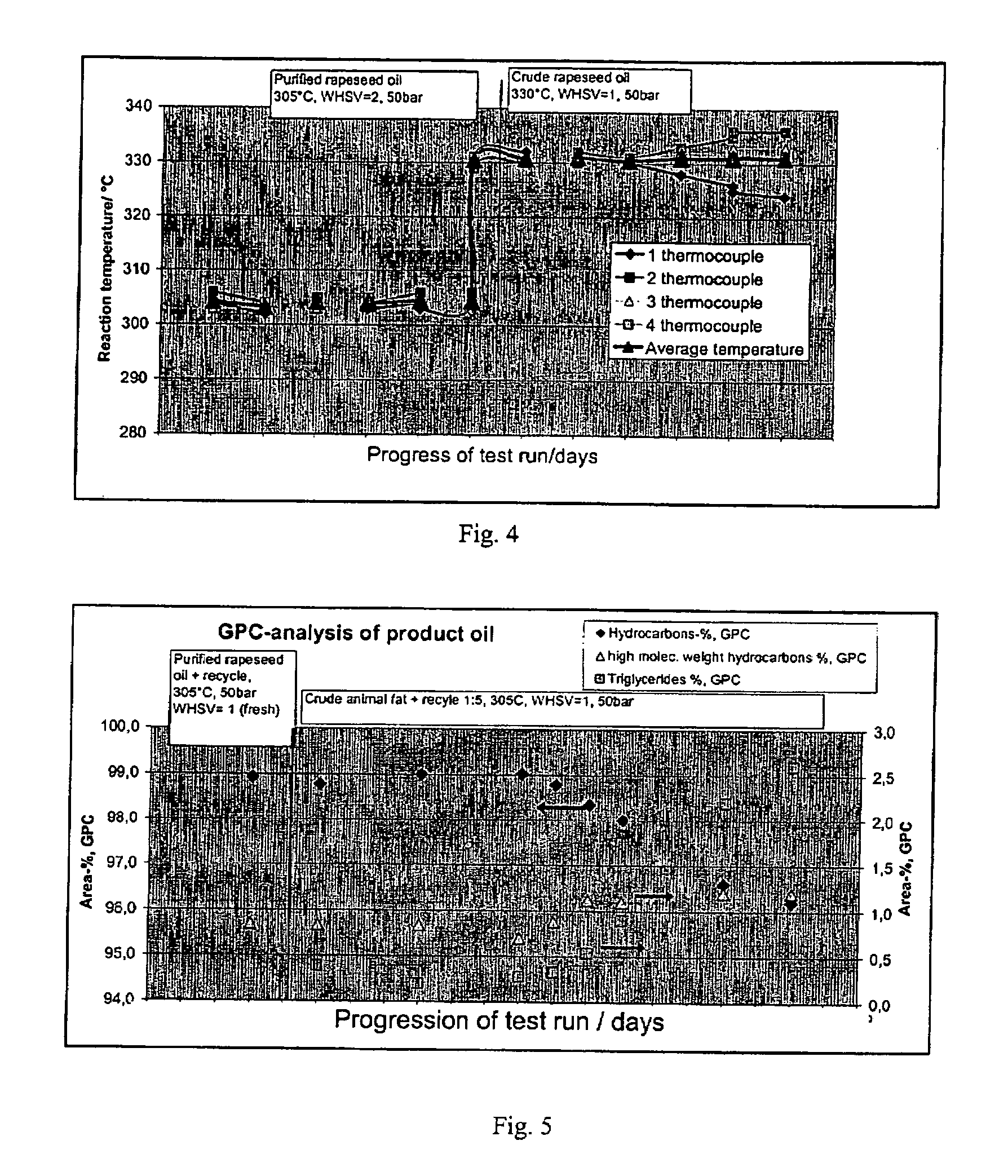

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

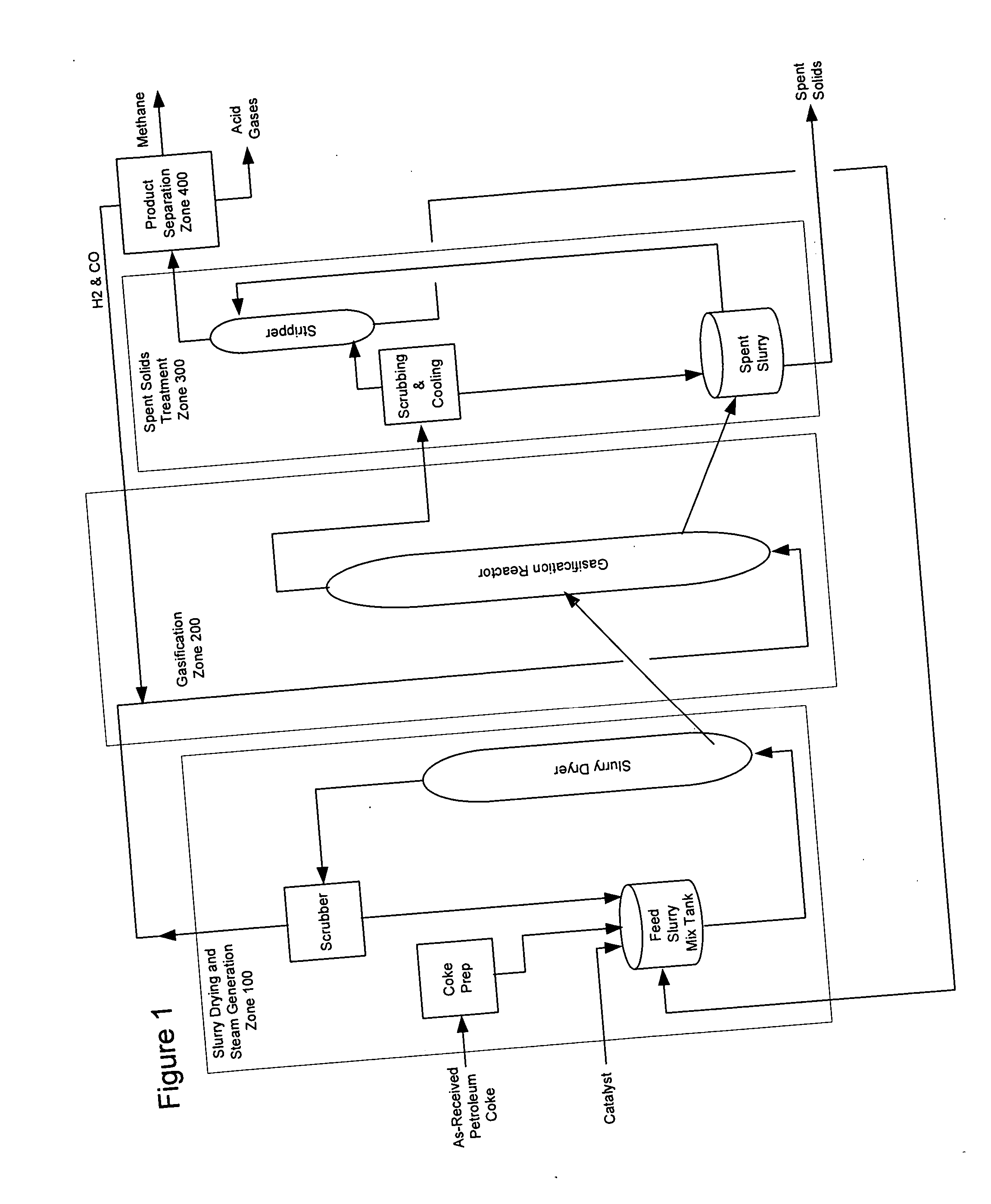

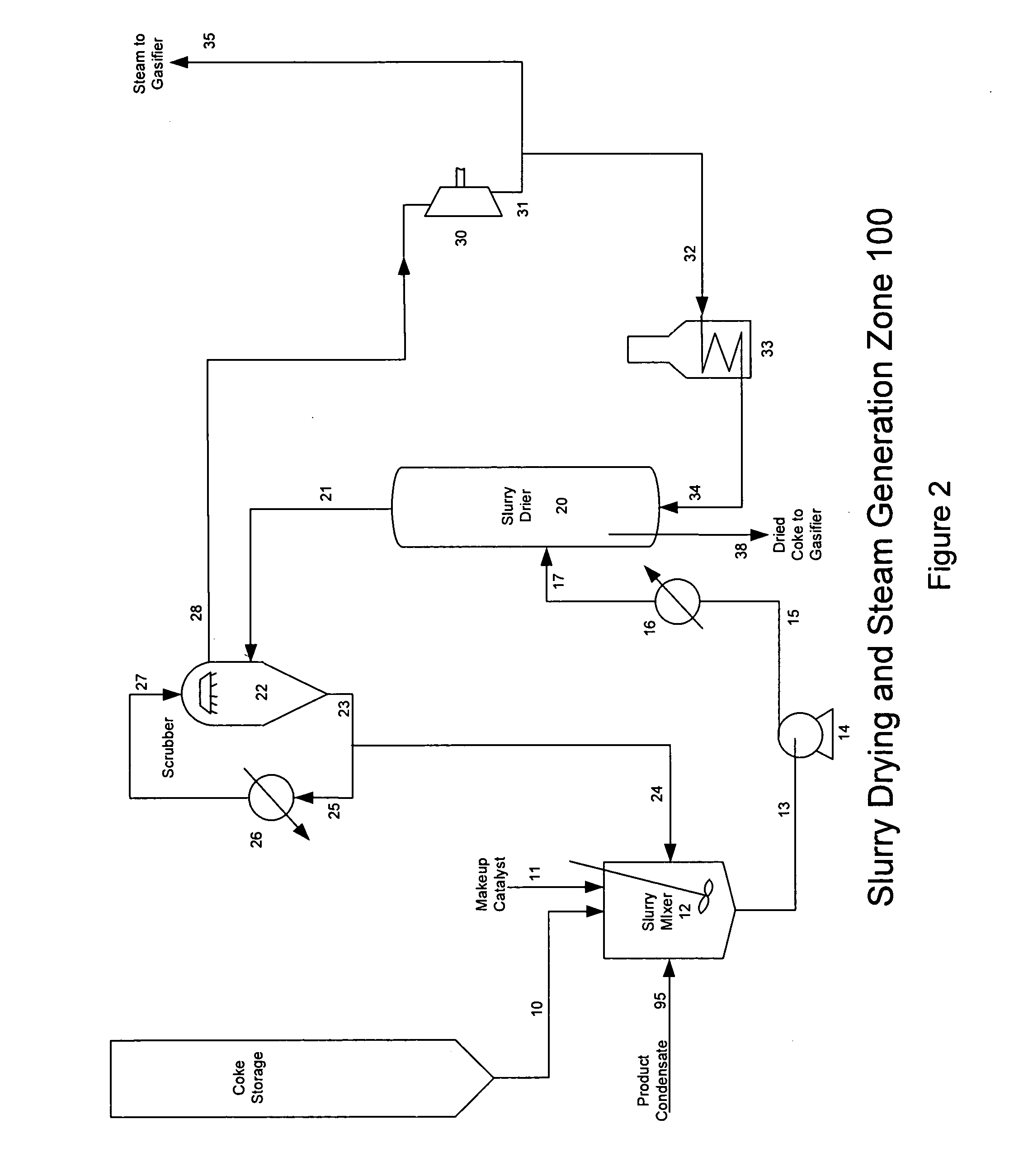

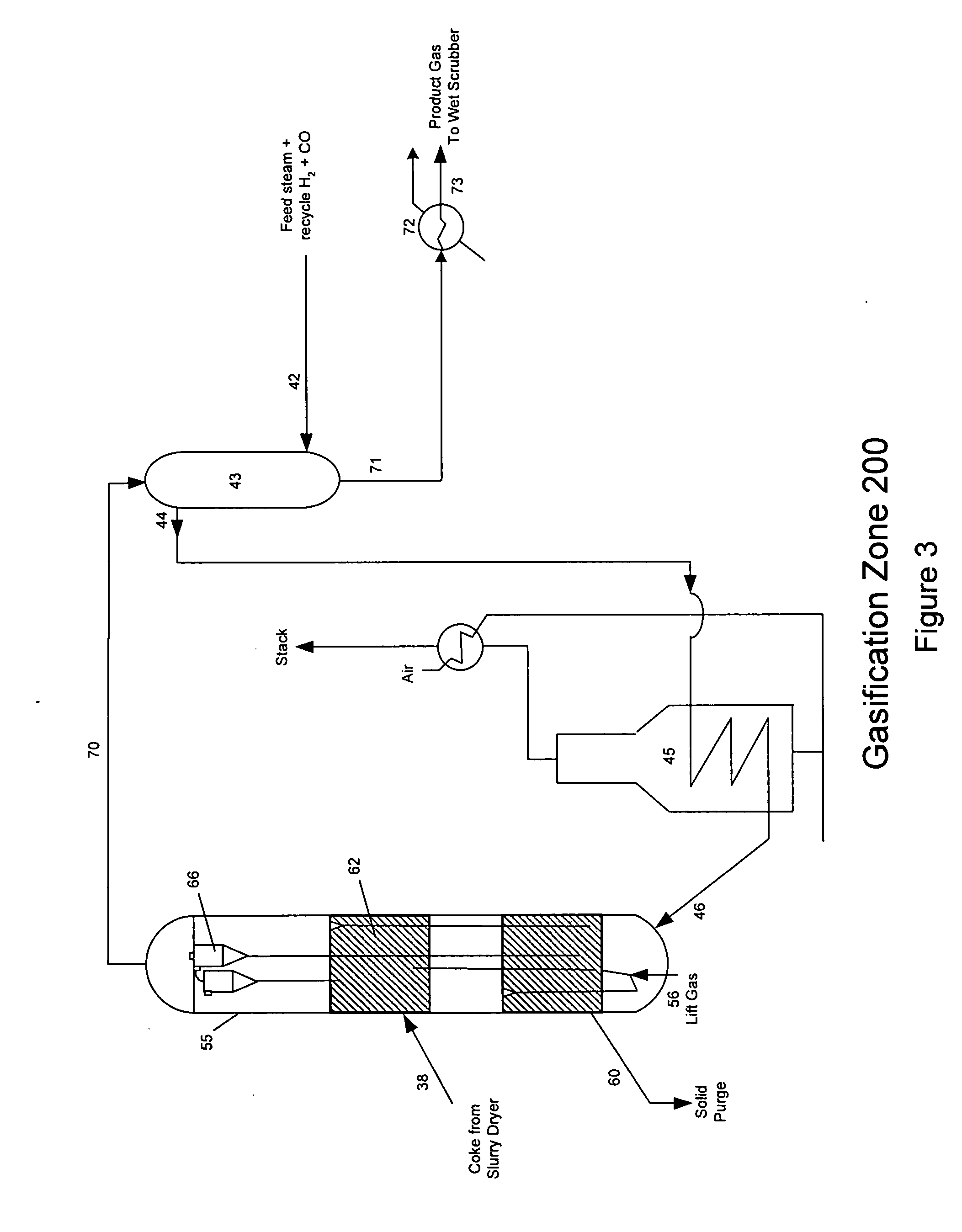

Catalytic steam gasification of petroleum coke to methane

The present invention provides a catalytic steam gasification process for gasifying petroleum coke. The solids composition within the gasification reactor of the disclosed invention is maintained by controlling the catalyst composition of the feed. The process utilizes sour water from the raw gasification product gases to recover and recycle catalyst. Fine particles generated in the handling of coke are advantageously utilized to increase the efficiency of the process.

Owner:SURE CHAMPION INVESTMENT LTD

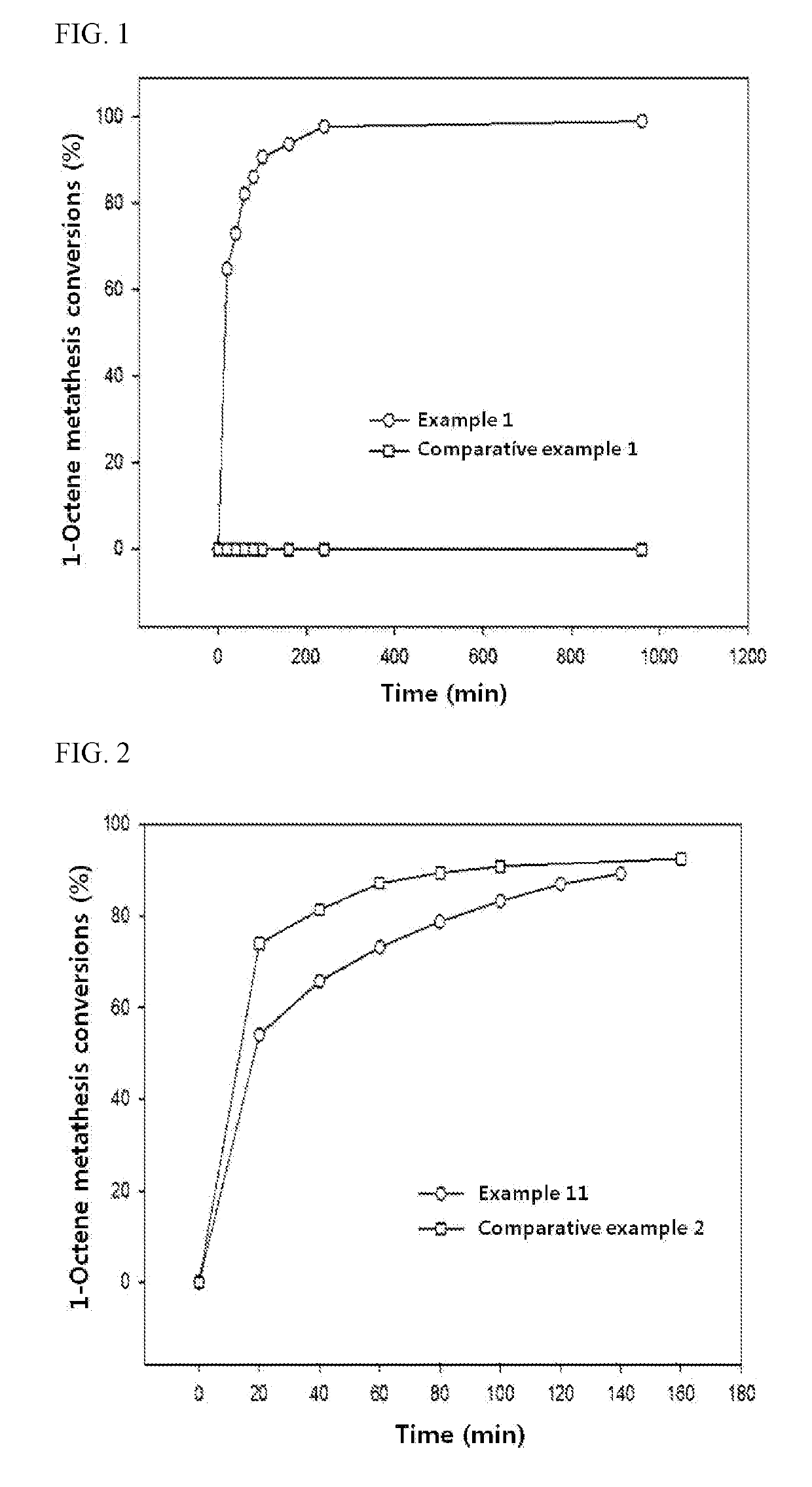

Olefin metathesis reaction catalyst and preparation method therefor

ActiveUS20190217277A1Separated/recovered readilyEasy to useMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumUnsaturated hydrocarbon

The present invention relates to an olefin metathesis reaction catalyst where rhenium (Re) oxide or molybdenum (Mo) oxide is supported, as a catalyst main component, on a surface-modified mesoporous silica or mesoporous alumina support, and a preparation method therefor. The olefin metathesis reaction catalyst of the present invention allows highly efficient metathesis of long-chain unsaturated hydrocarbons having at least eight carbons at a low temperature of 150° C. or lower. The catalyst can be separated readily from reaction solution, regenerated at a low temperature of 400° C. or lower by removing toxins accumulated on it during the metathesis reaction, and used repeatedly in metathesis reaction many times, thereby being made good use in commercial olefin metathesis processes.

Owner:KOREA RES INST OF CHEM TECH

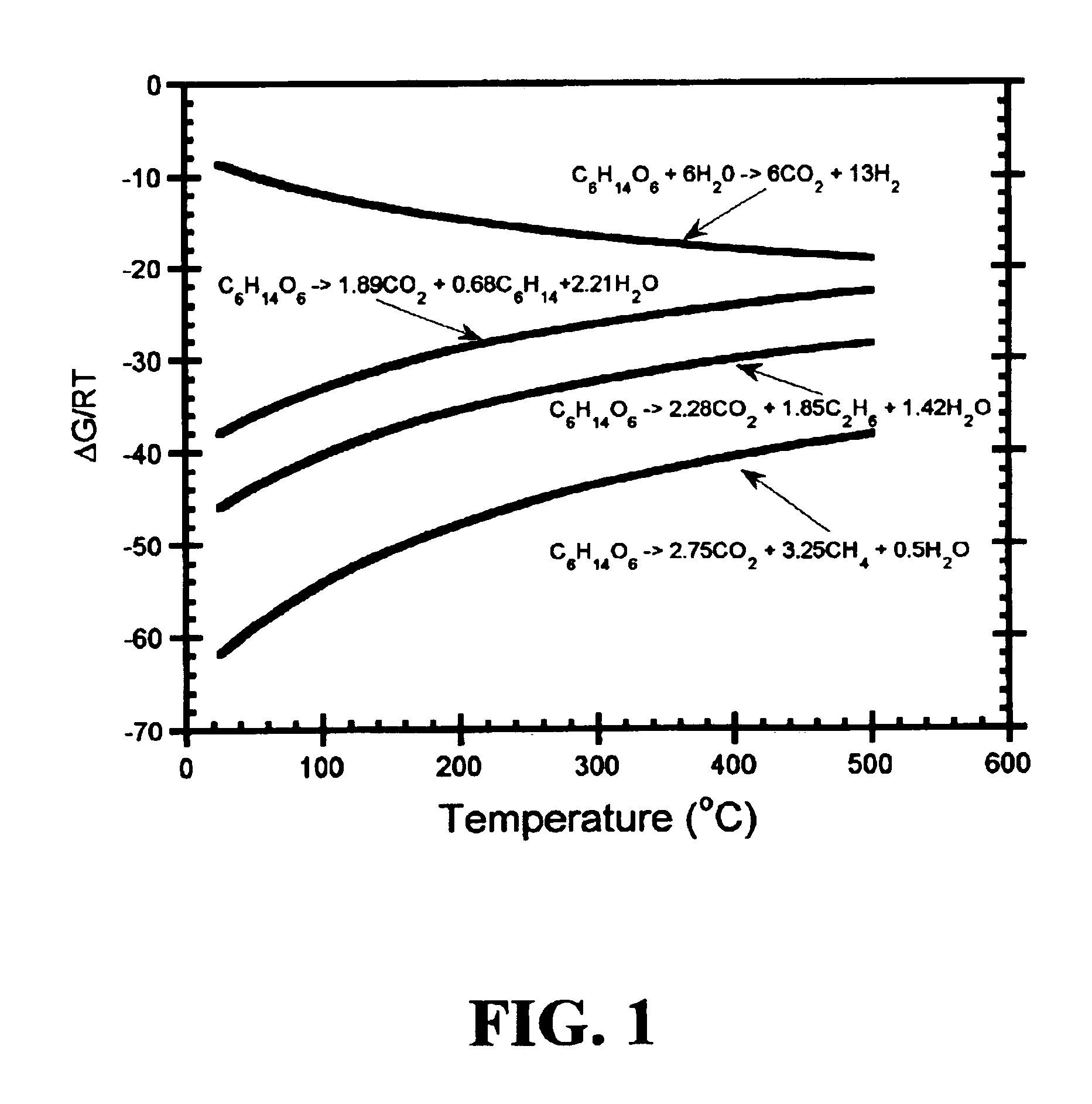

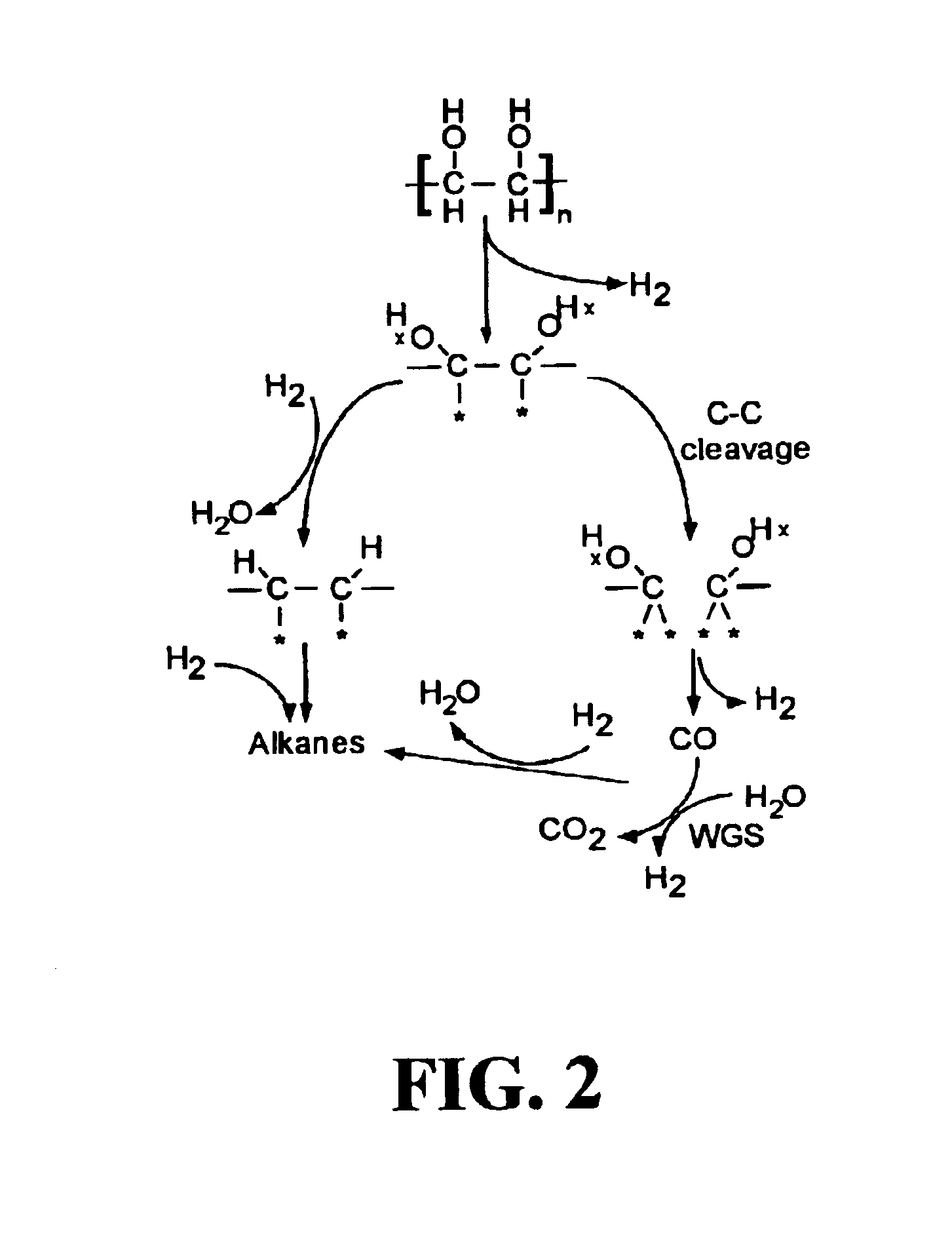

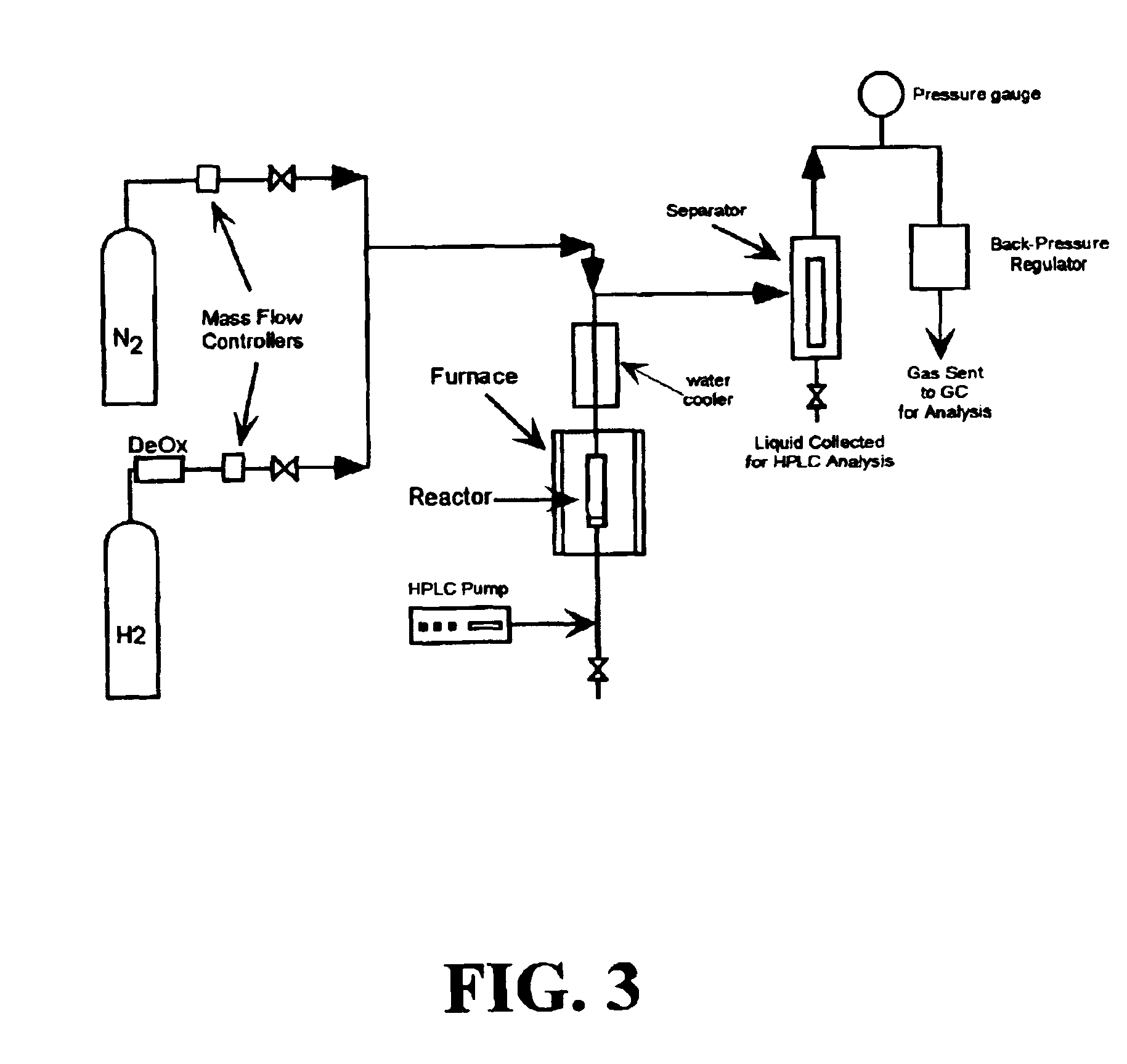

Low-temperature hydrocarbon production from oxygenated hydrocarbons

Disclosed is a method of producing hydrocarbons from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase (preferably in the condensed liquid phase). The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. These metals are supported on supports that exhibit acidity or the reaction is conducted under liquid-phase conditions at acidic pHs. The disclosed method allows the production of hydrocarbon by the liquid-phase reaction of water with biomass-derived oxygenated compounds.

Owner:WISCONSIN ALUMNI RES FOUND

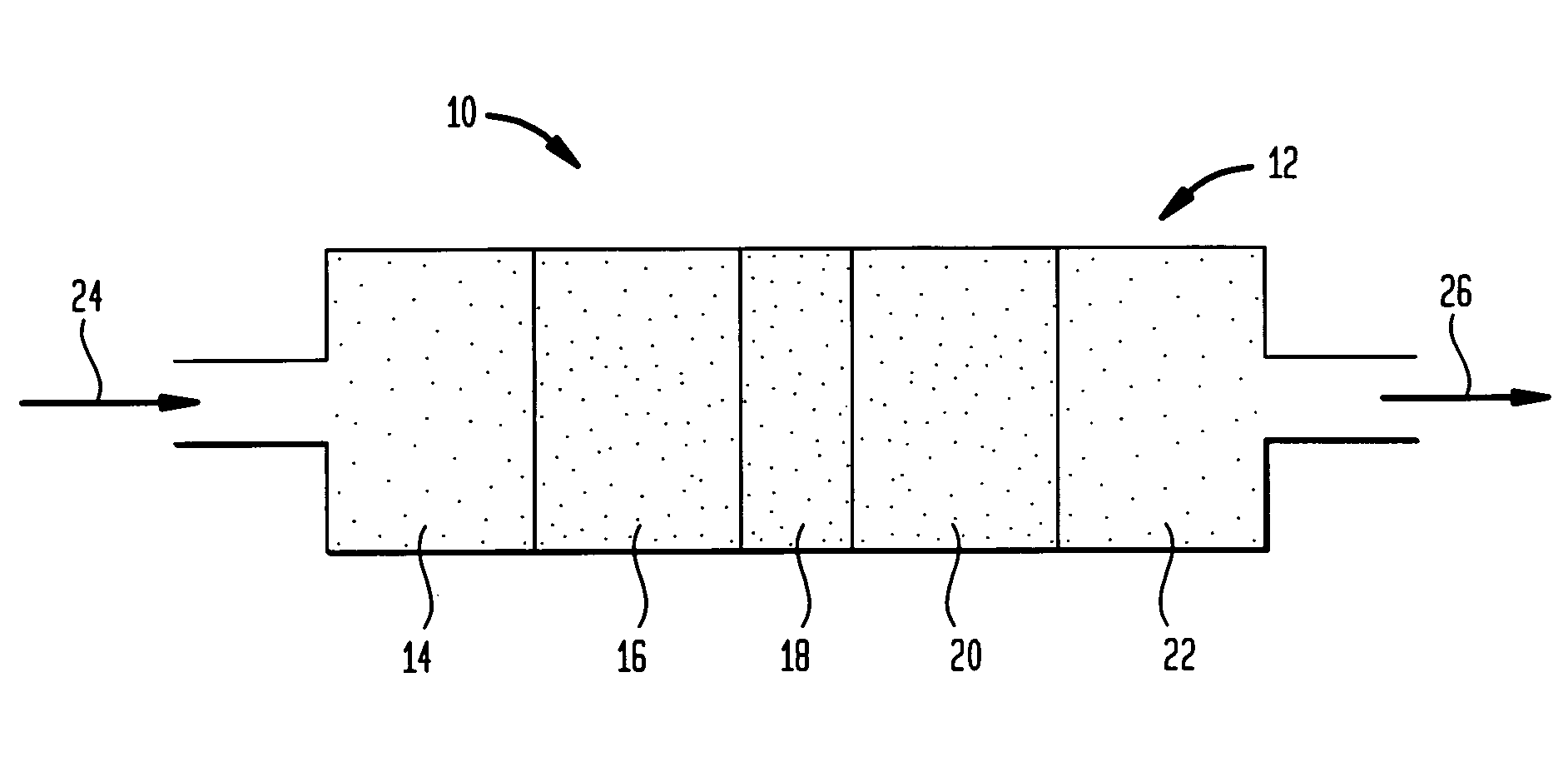

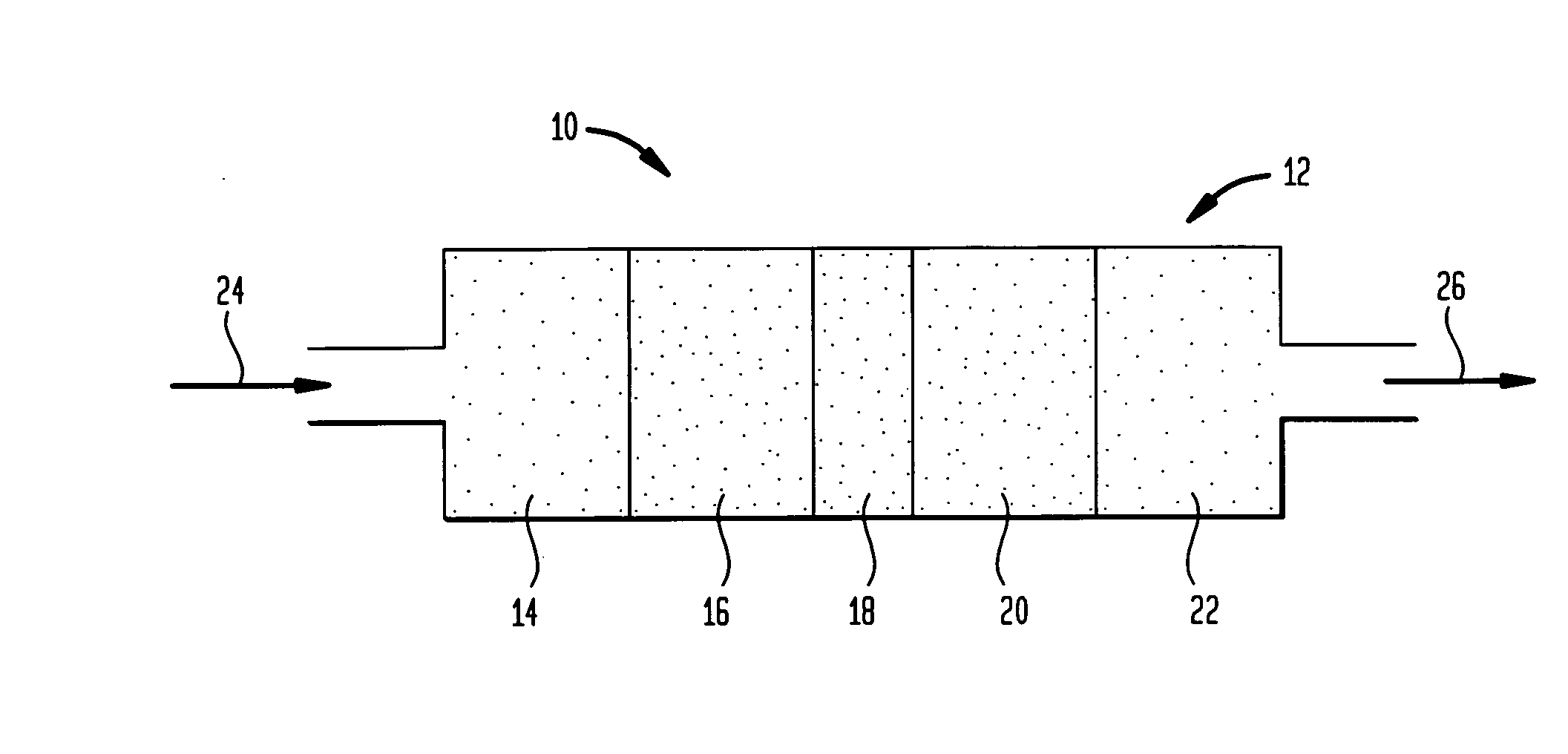

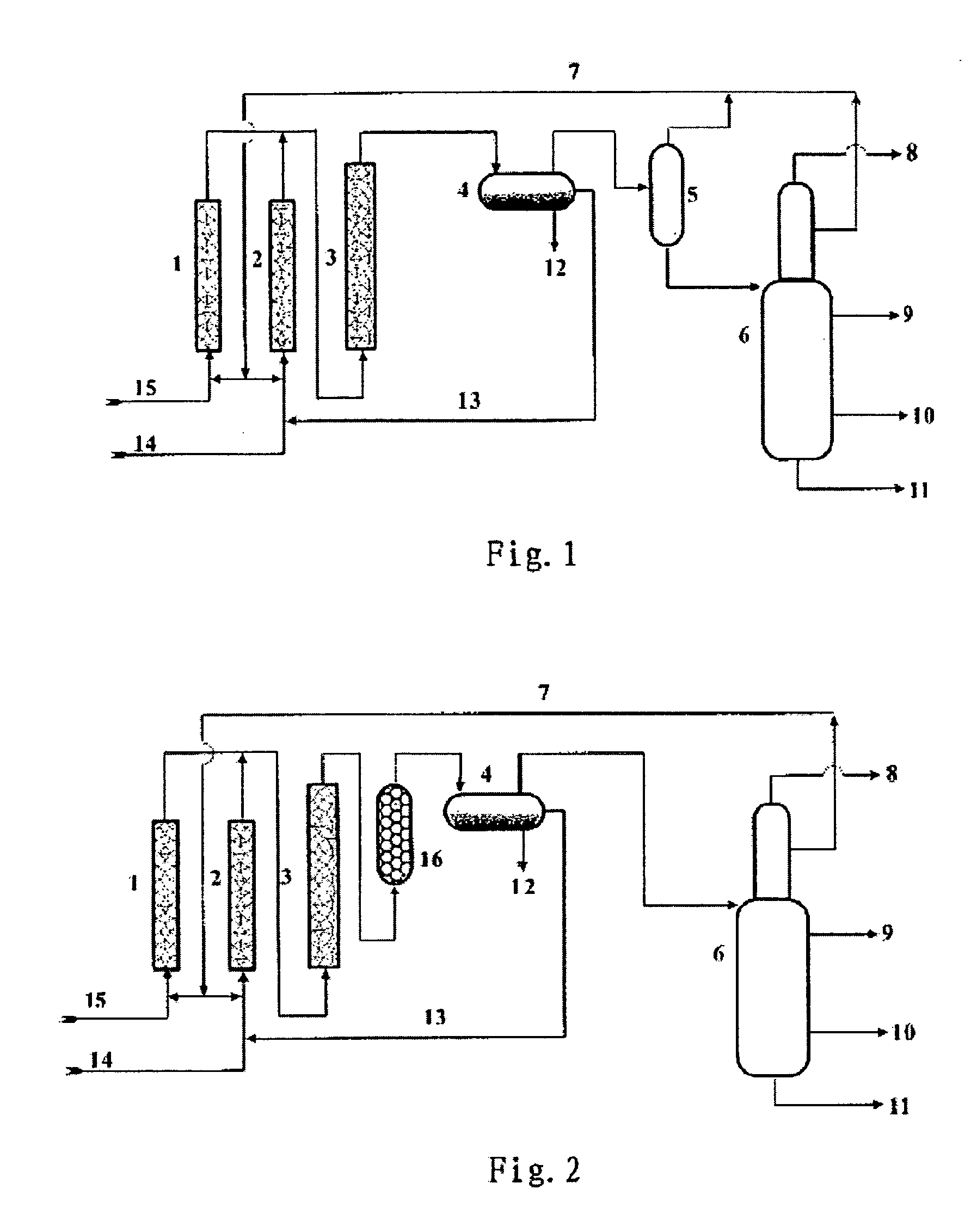

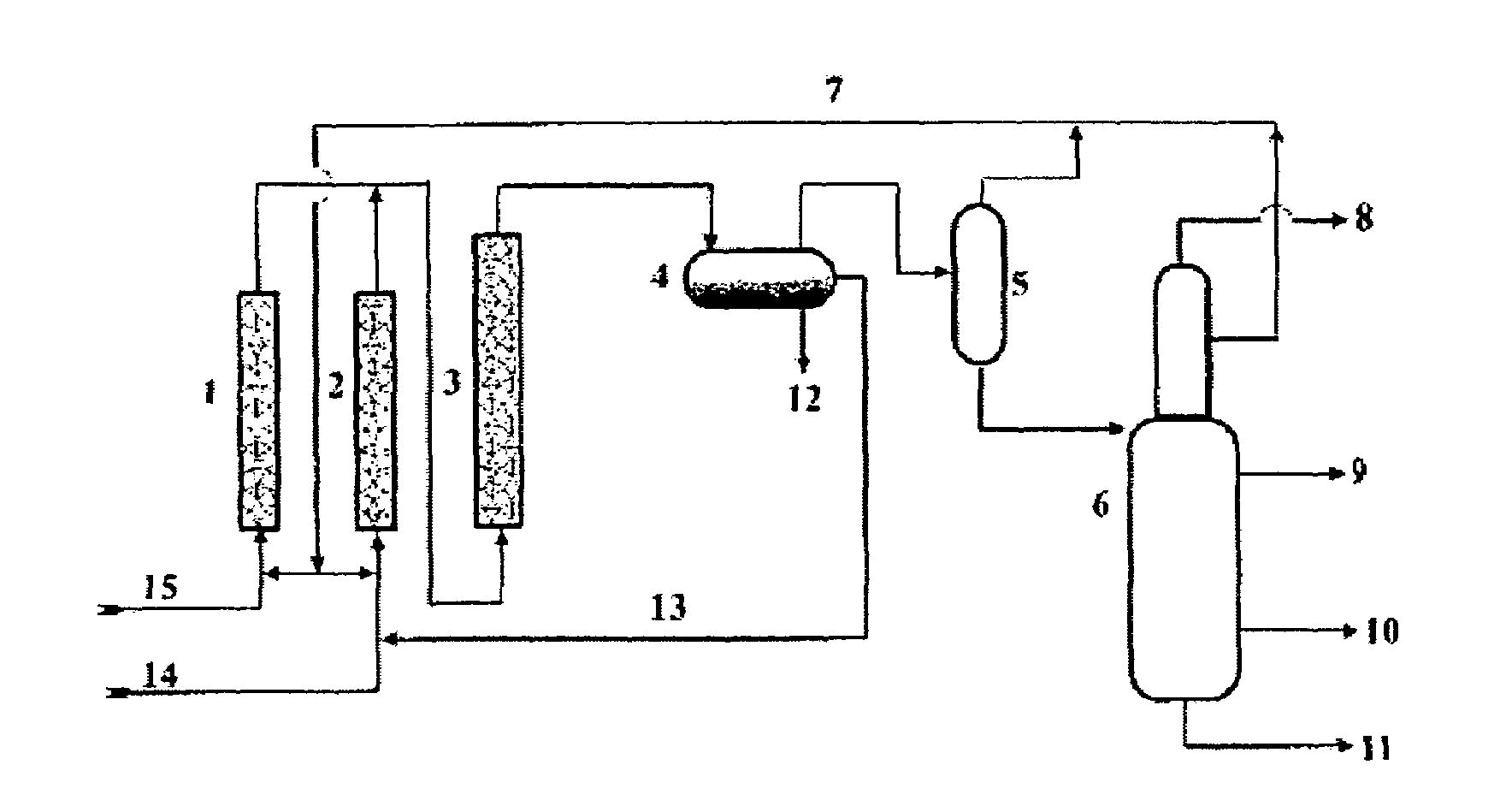

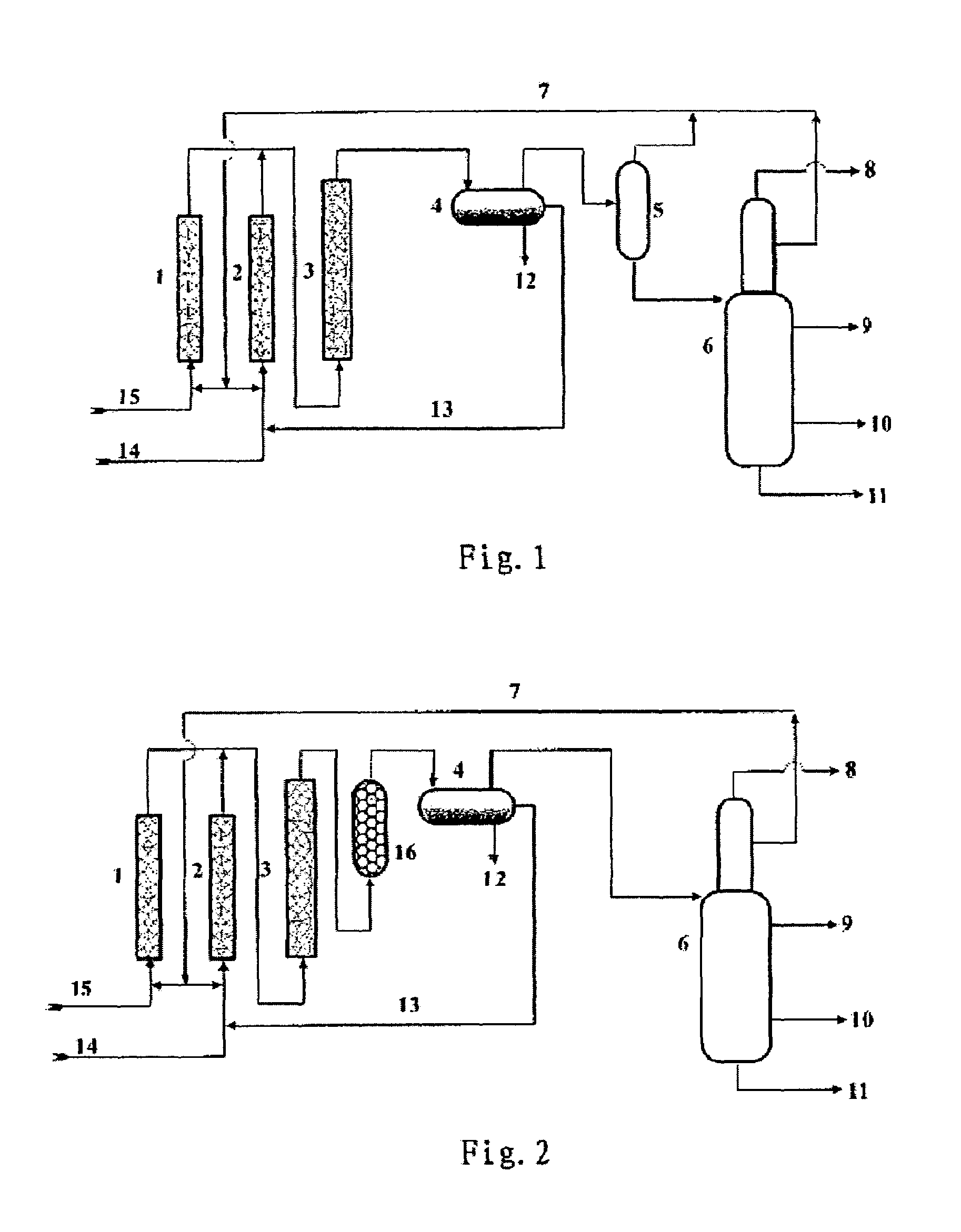

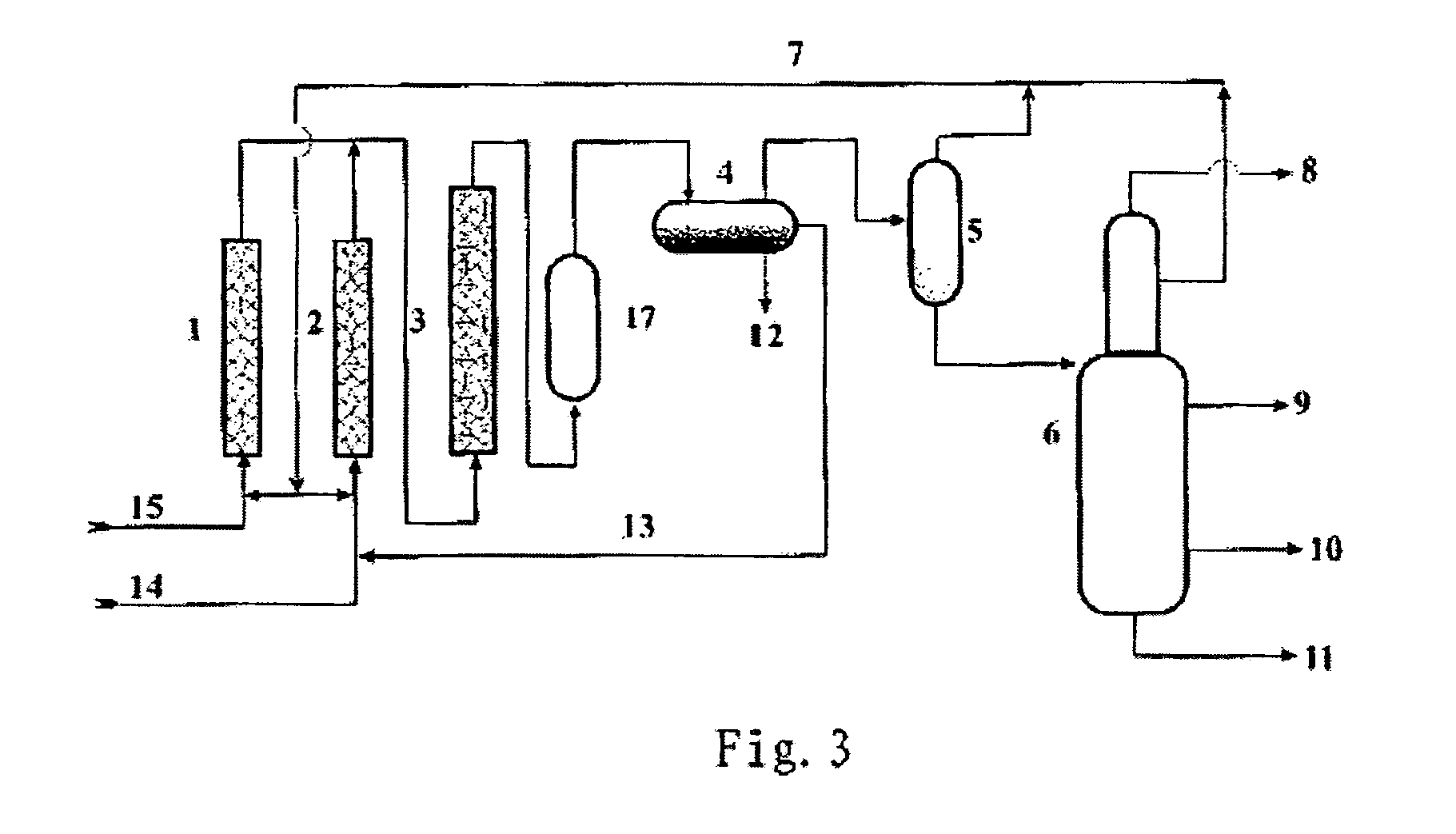

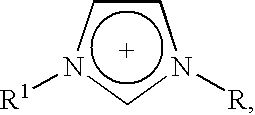

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Manufacture of alpha -olefins

InactiveUS6103946AOrganic chemistry methodsIron group organic compounds without C-metal linkagesAlpha-olefinAlkene

Alpha-olefins are manufactured in high yield and with very high selectivity by contacting ethylene with an iron complex of a selected 2,6-pyridinedicarboxaldehyde bisimine or a selected 2,6-diacylpyridine bisimine, and in some cases a selected activator compound such as an alkyl aluminum compound. Novel bisimines and their iron complexes are also disclosed. The alpha -olefins are useful as monomers and chemical intermediates.

Owner:EI DU PONT DE NEMOURS & CO +1

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydroalkylation of aromatic hydrocarbons

InactiveUS6730625B1High activityHigh selectivityMolecular sieve catalystsMolecular sieve catalystBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07.

Owner:EXXONMOBIL CORP (US)

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly cumene, comprising the step of contacting a polyalkylated aromatic compound with an alkylatable aromatic compound under at least partial liquid phase conditions and in the presence of a transalkylation catalyst to produce the monoalkylated aromatic compound, wherein the transalkylation catalyst comprises a mixture of at least two different crystalline molecular sieves, wherein each of said molecular sieves is selected from zeolite beta, zeolite Y, mordenite and a material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst and process of paraffin hydrocarbon conversion

InactiveUS20040077914A1Improve solubilityEasy to useHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkanePtru catalyst

A catalyst composition and process for the conversion of linear and / or branched paraffin hydrocarbons based on the use of an ionic liquid catalyst in combination with a Brønsted Acid, which provides a catalytic composition with an increased activity compared with said ionic liquid. Under suitable reaction conditions this conversion is leading to paraffin hydrocarbon fraction with higher octane number.

Owner:HALDOR TOPSOE AS

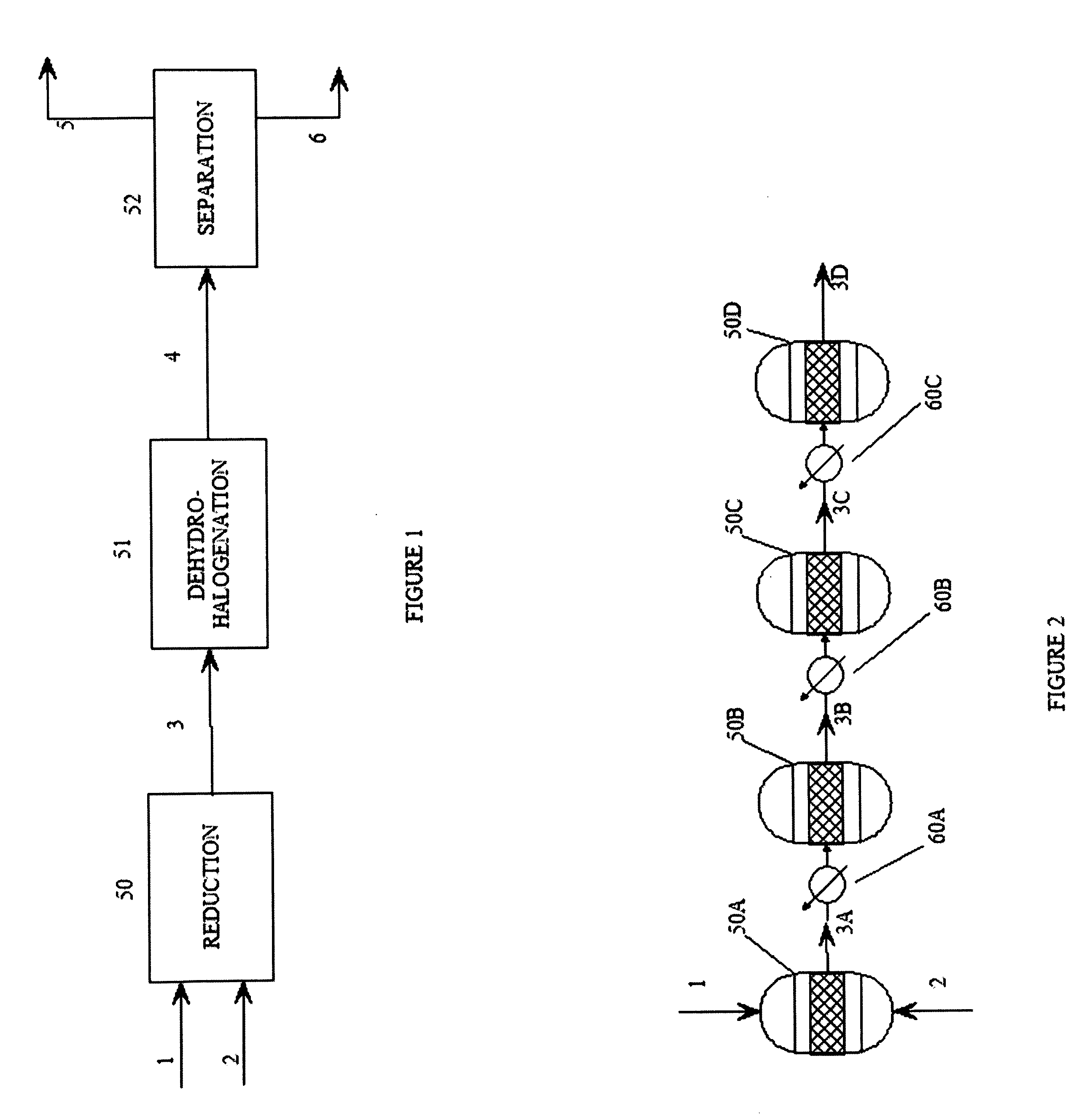

Process for manufacture of fluorinated olefins

A process for the production of fluorinated olefins, preferably fluorinated propenes, by contacting a feed stream containing a fluorinated olefin and hydrogen with a first amount of catalyst to produce the hydrofluorocarbon, wherein a first exit stream contains unreacted fluorinated olefin and hydrogen; contacting the first exit stream with a second amount of catalyst to produce a hydrofluorocarbon, wherein the second amount of catalyst is preferably greater than the first amount of catalyst; and contacting the hydrofluorocarbon with a catalyst for dehydrohalogenation to produce a product stream of fluorinated olefin.

Owner:HONEYWELL INT INC

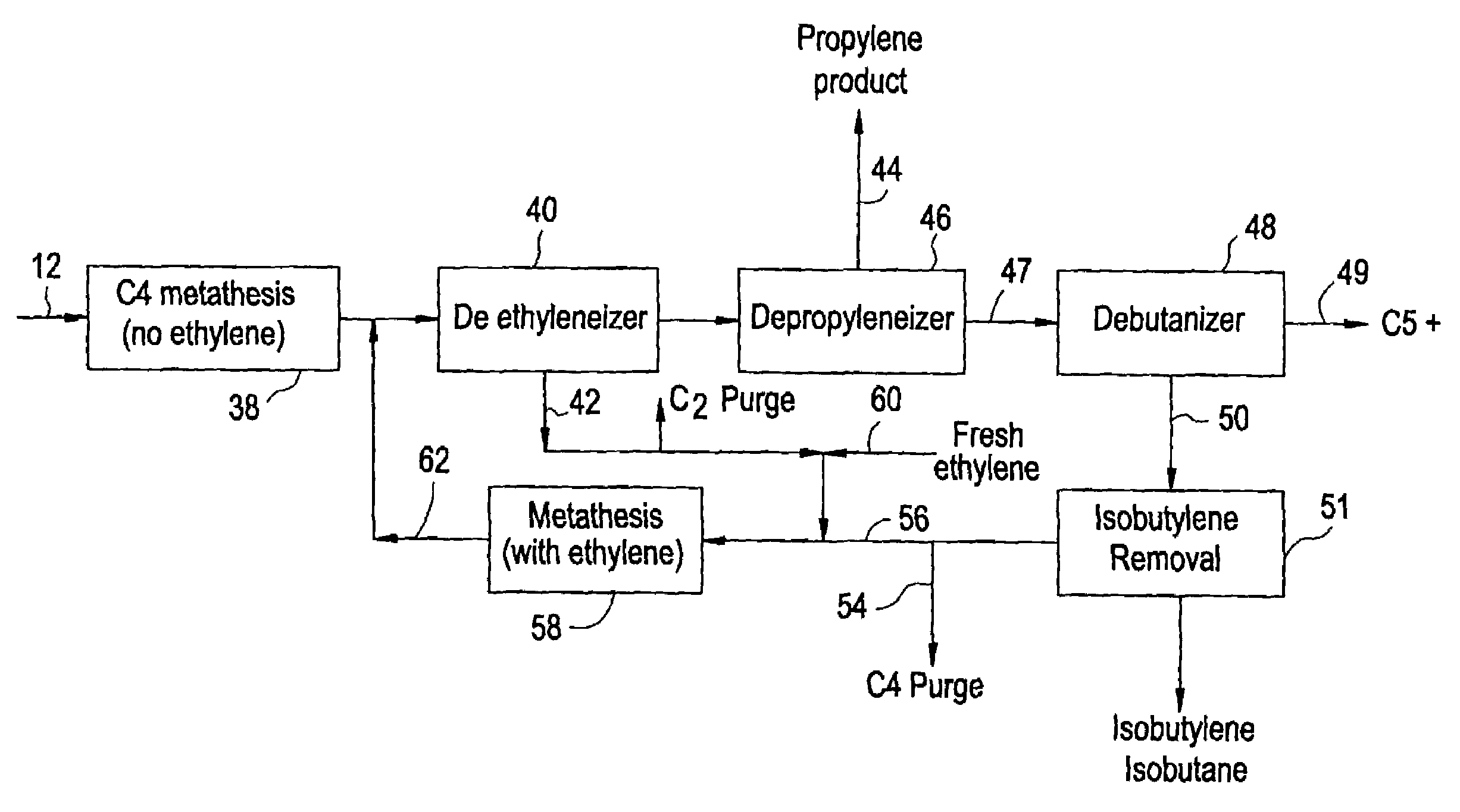

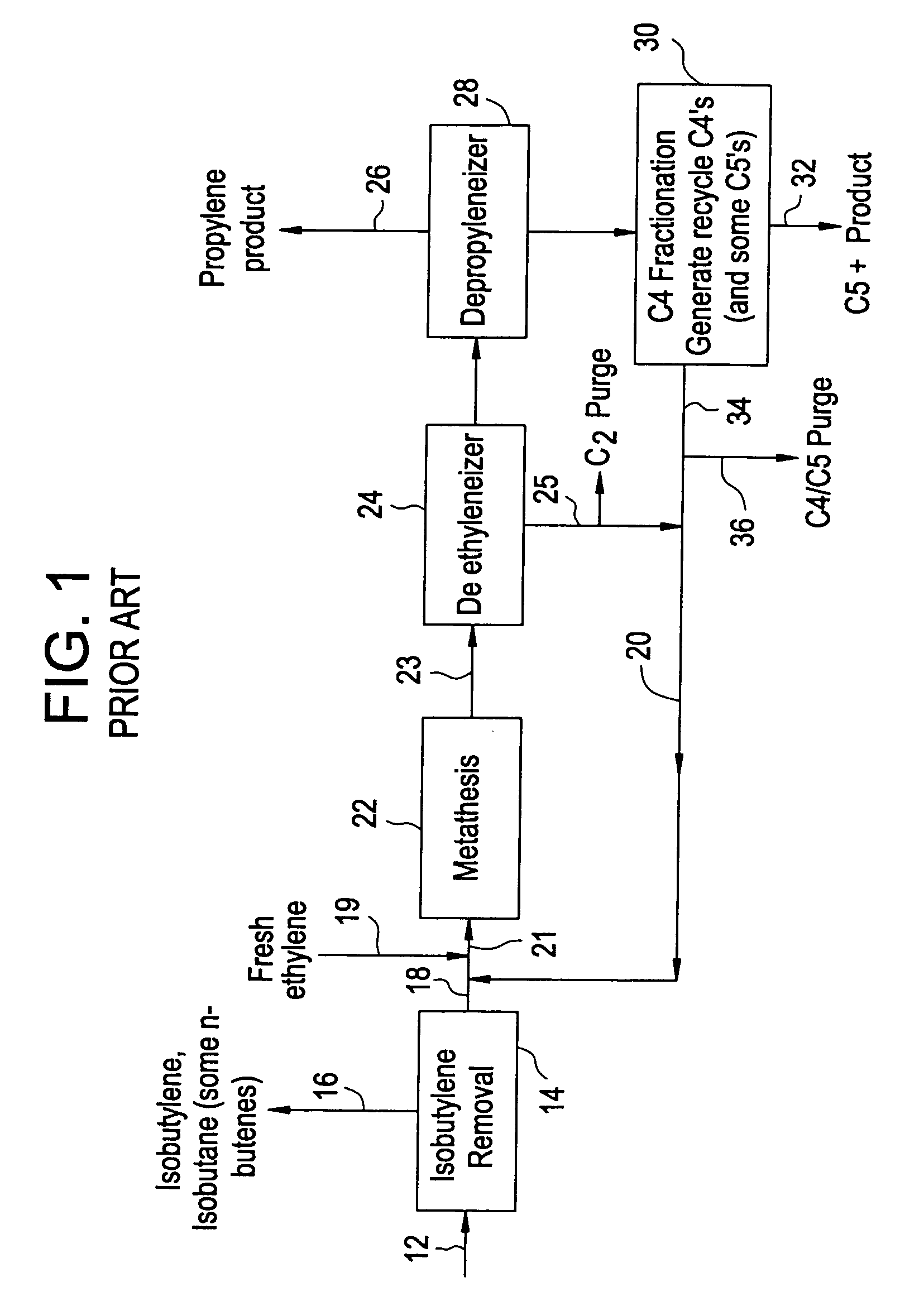

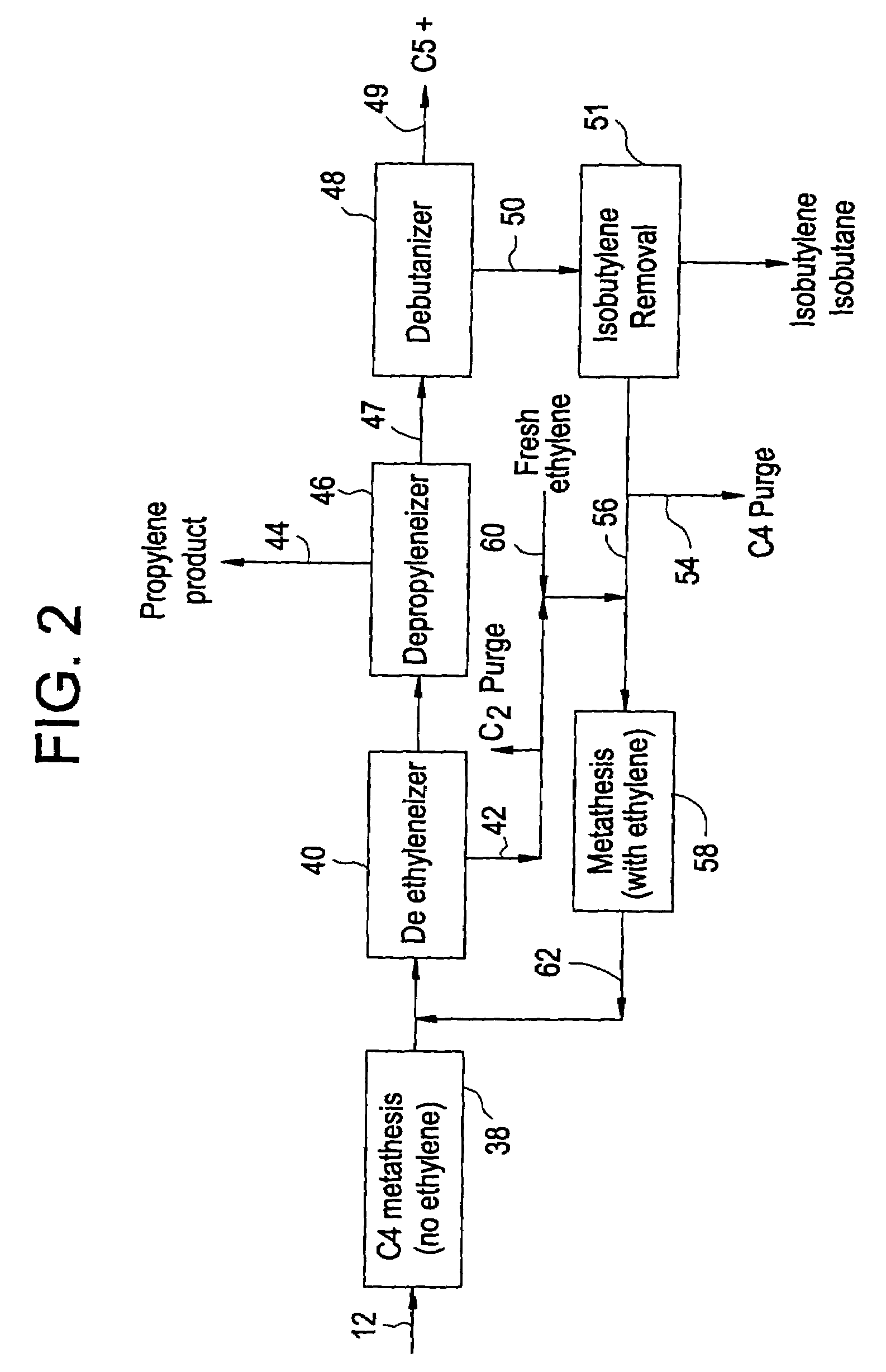

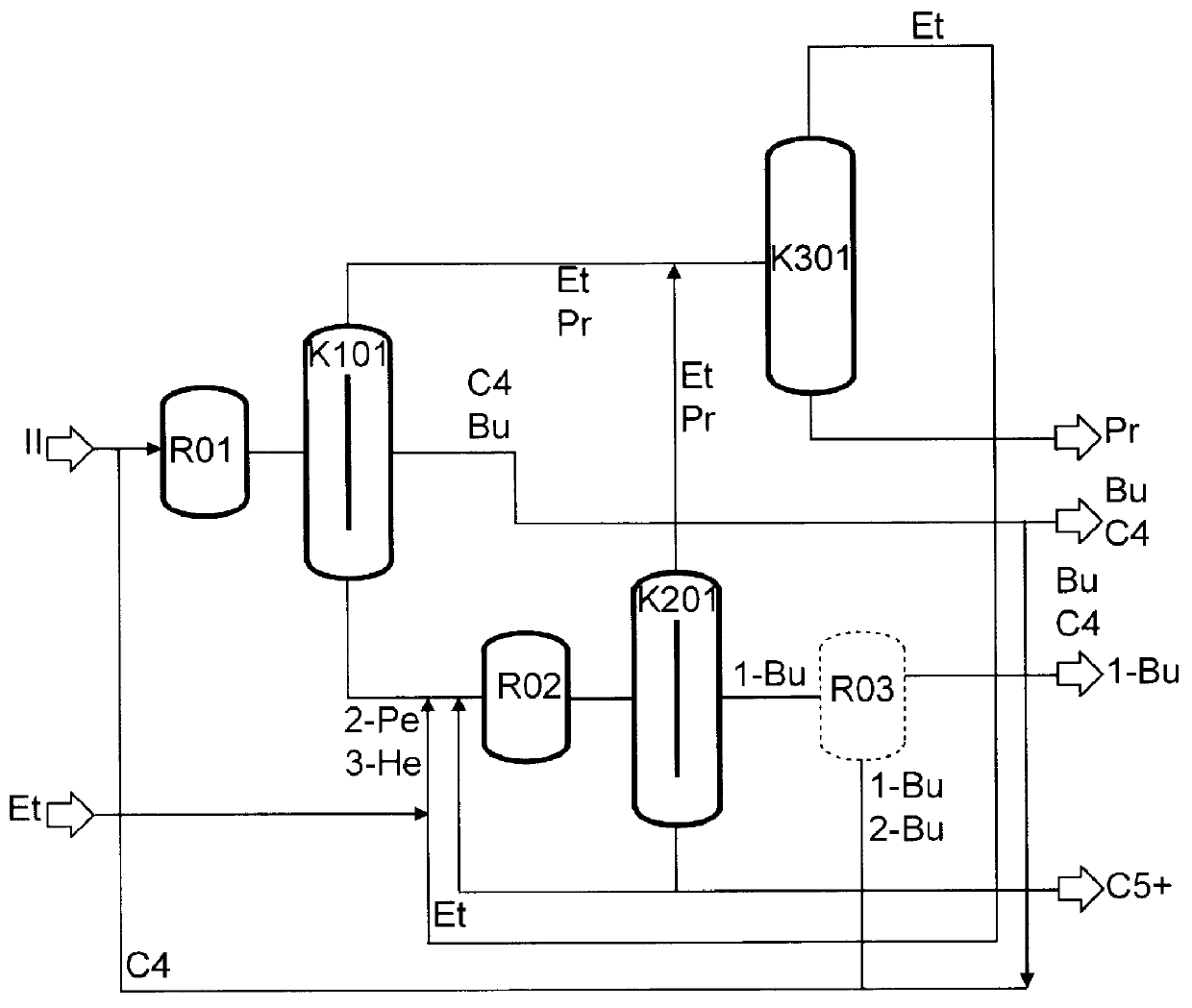

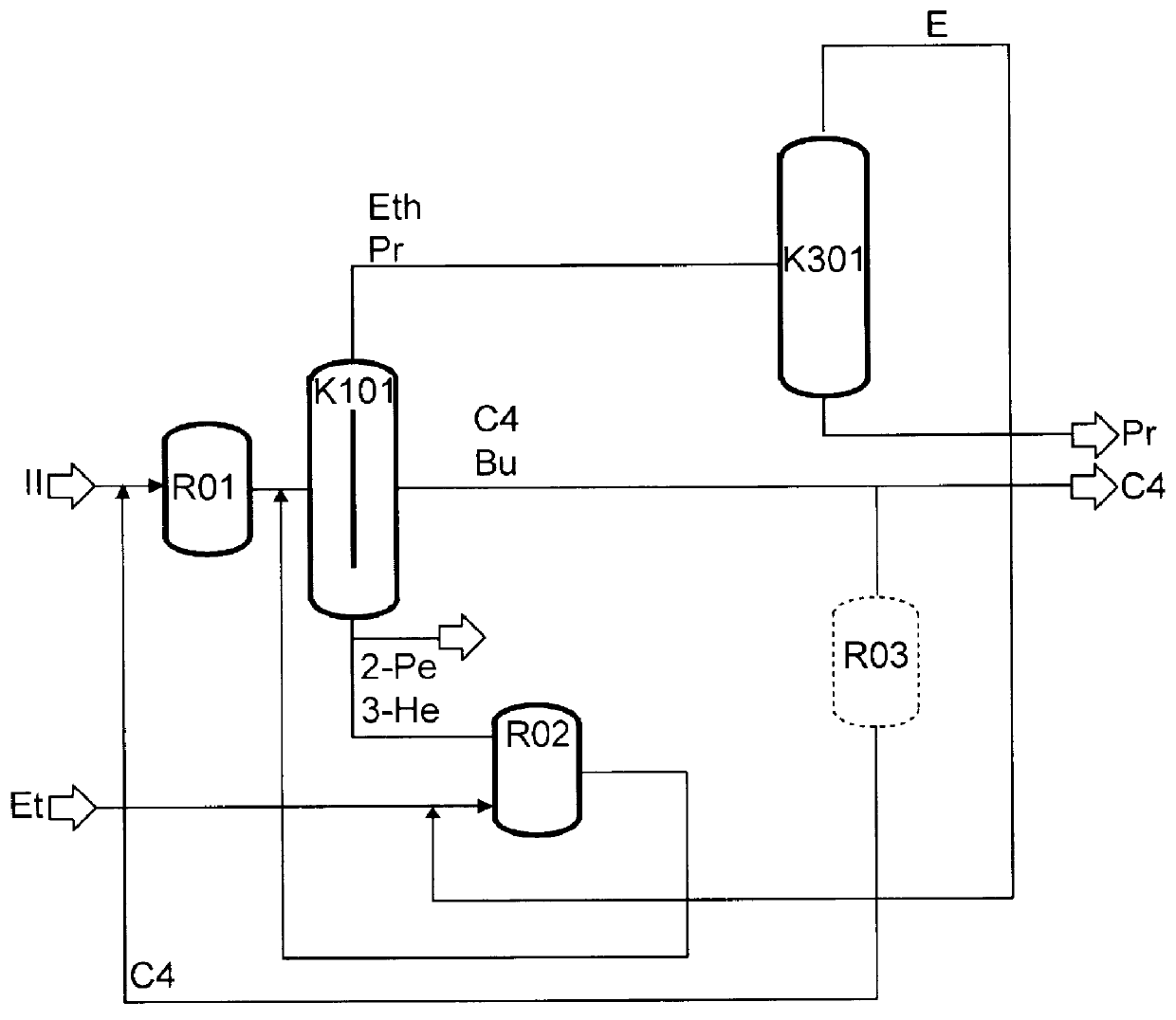

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

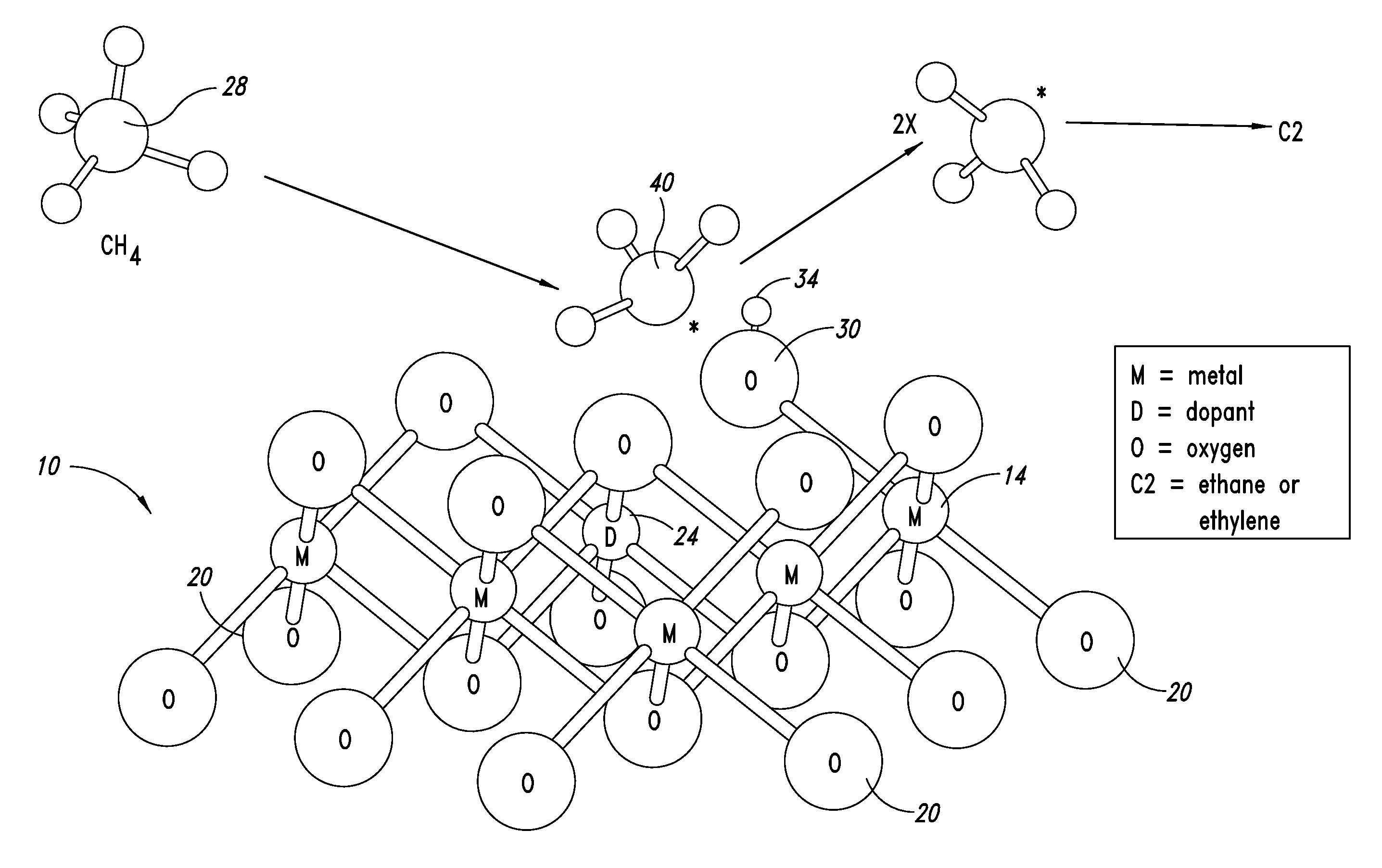

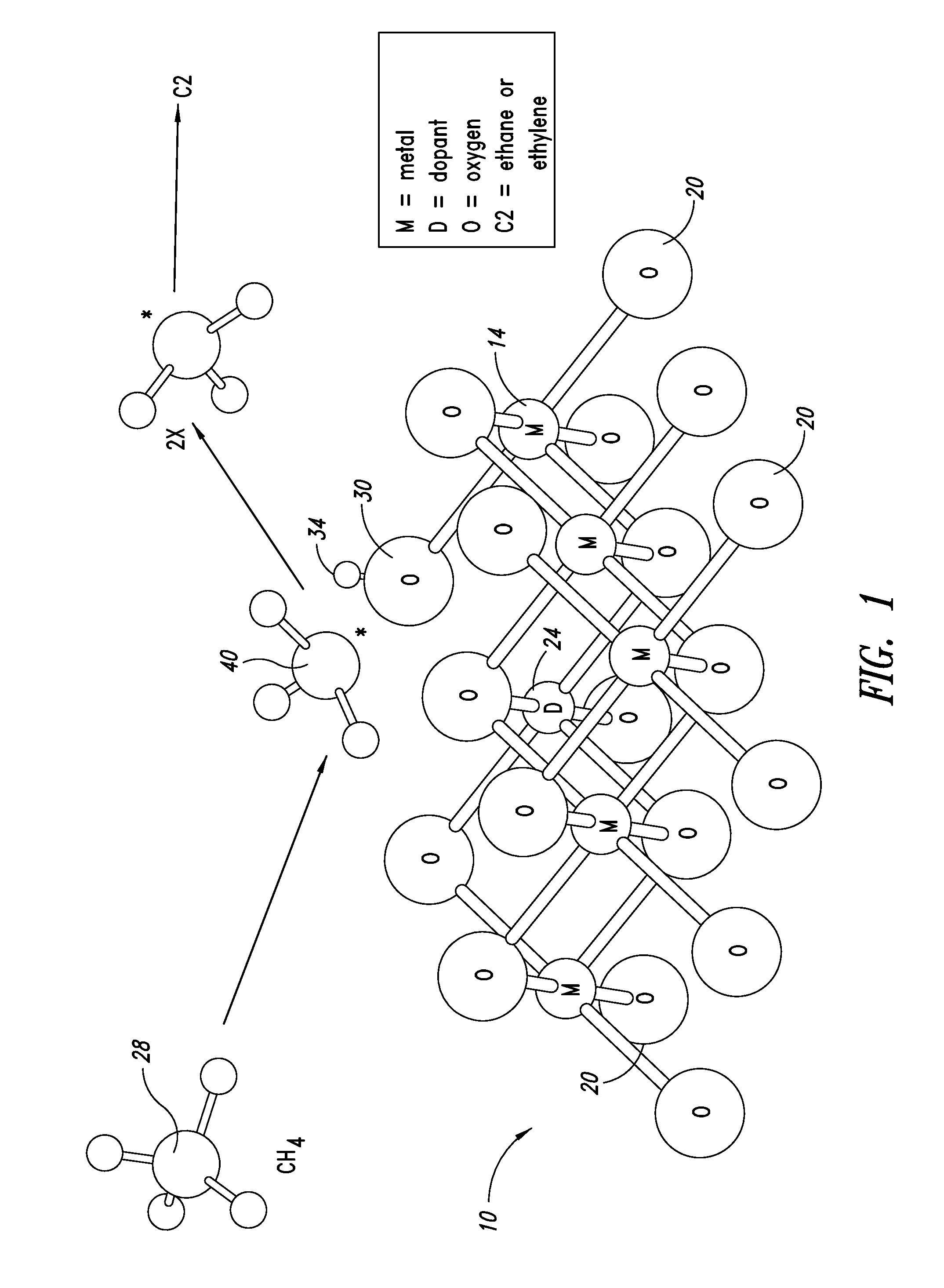

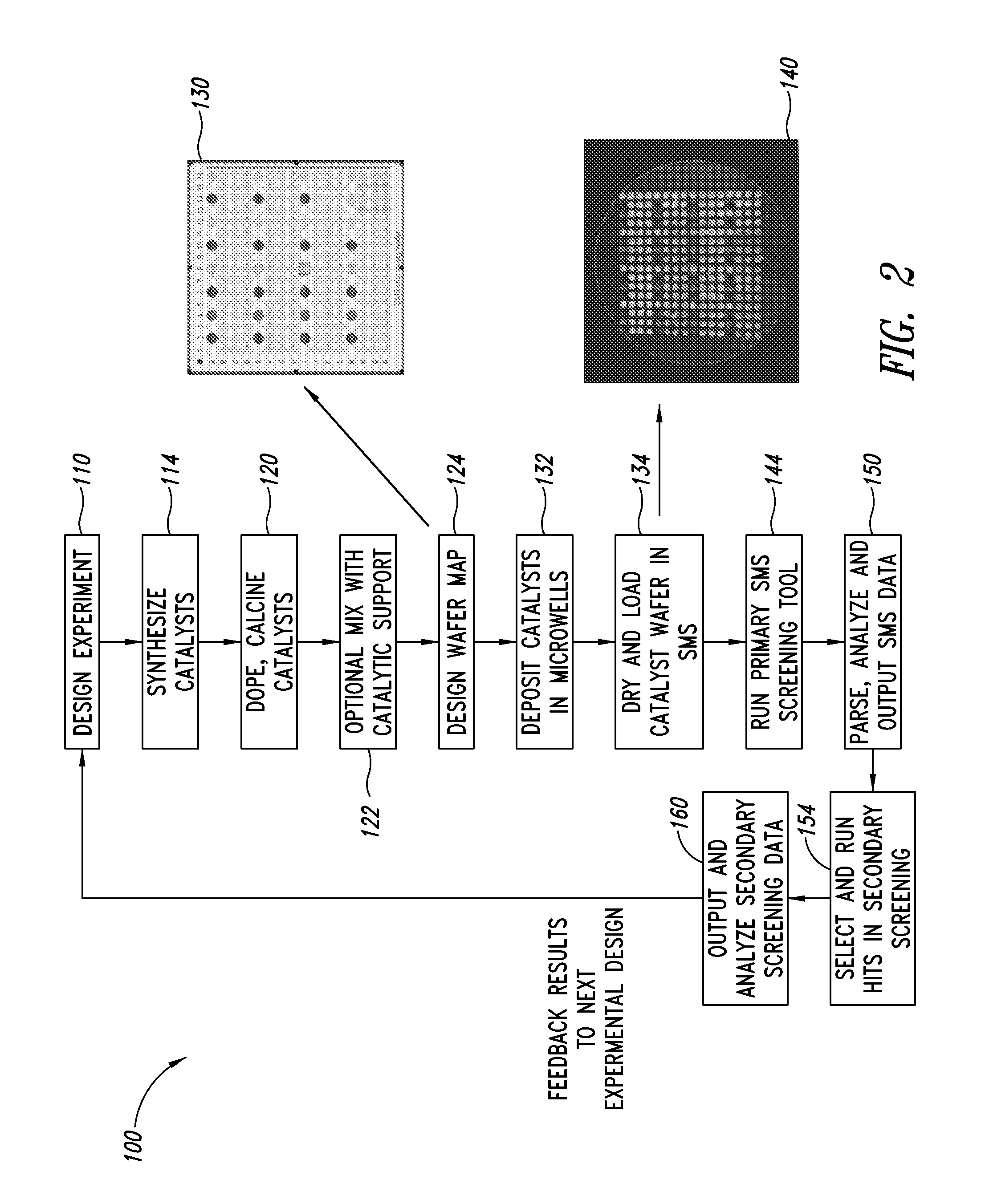

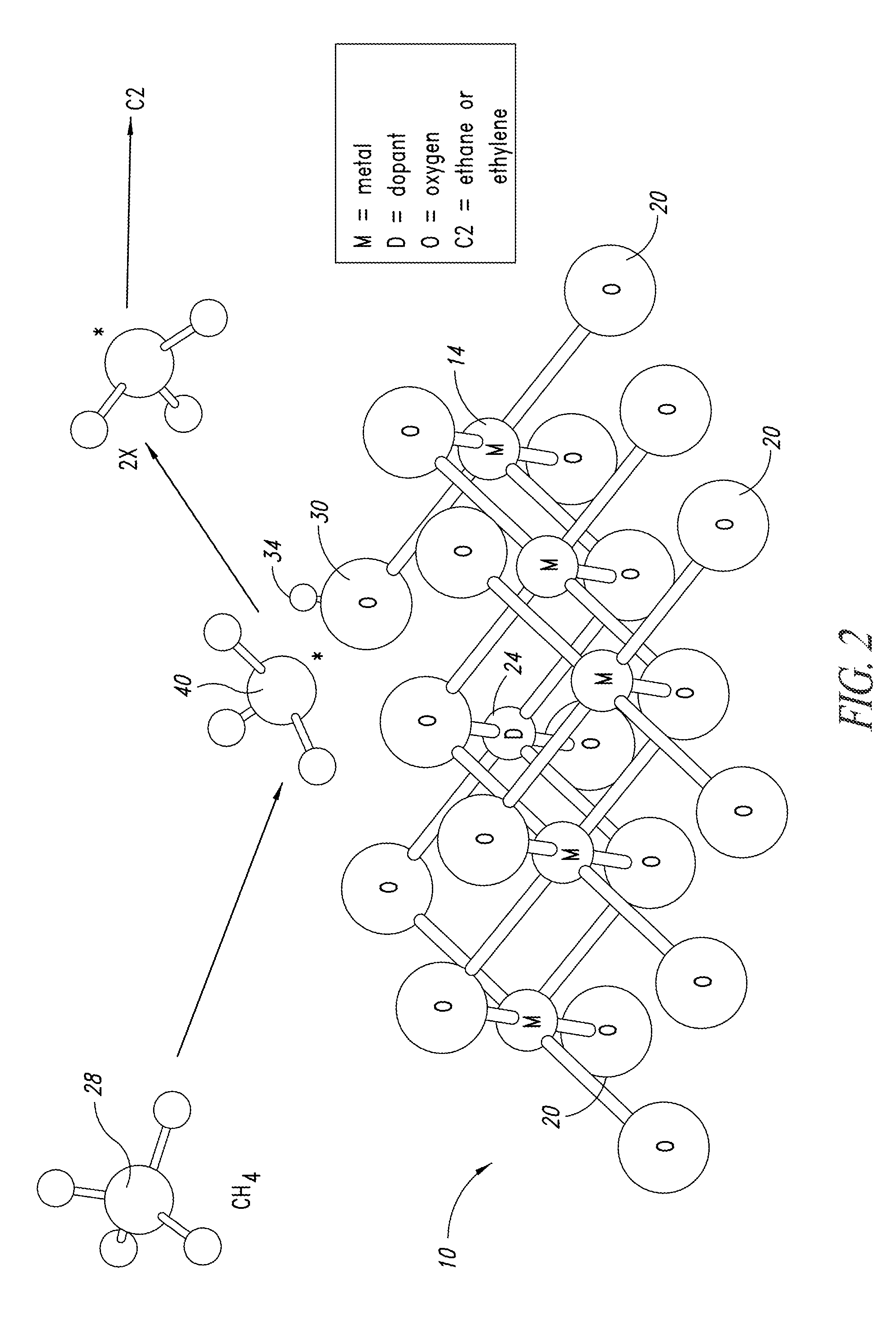

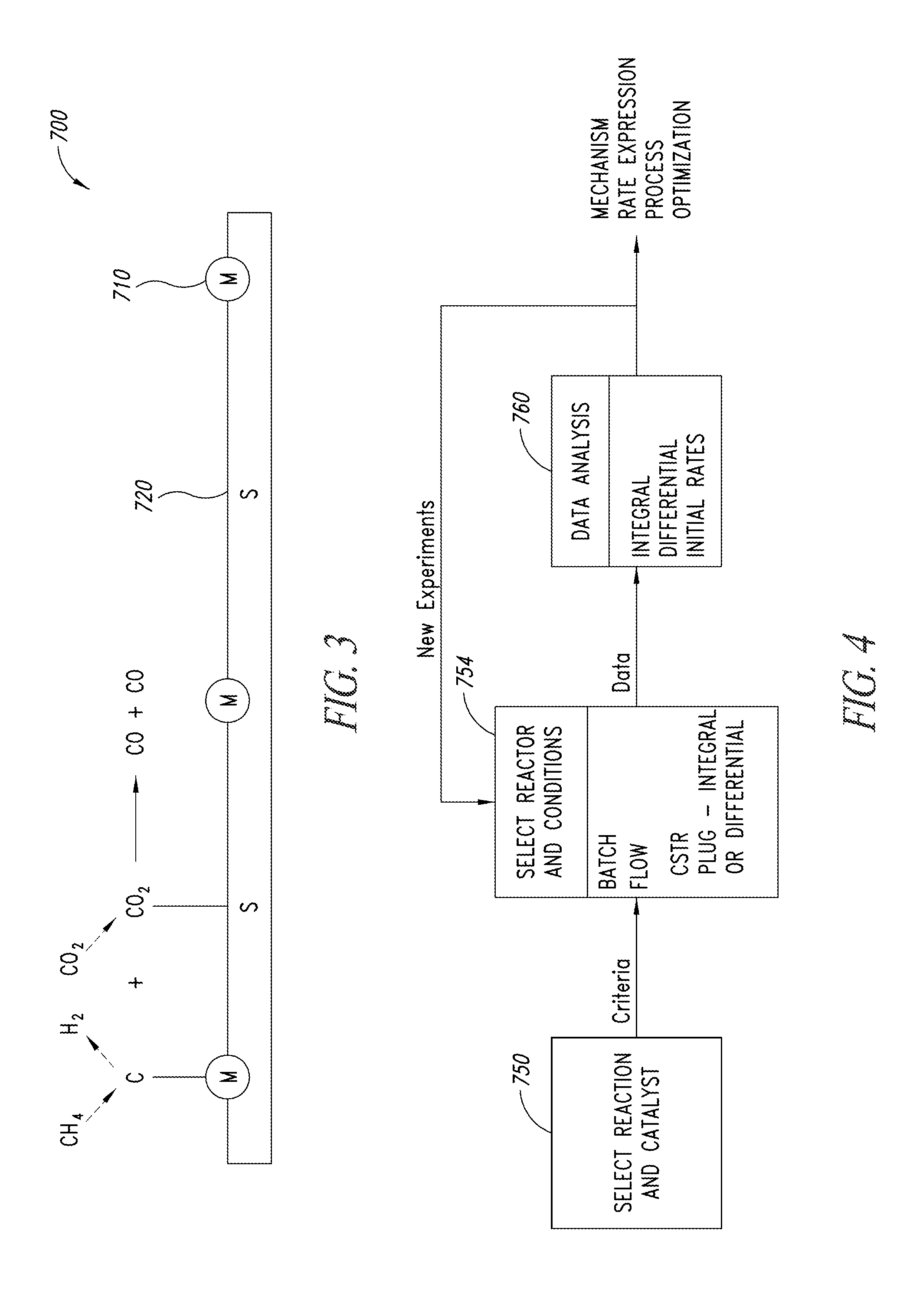

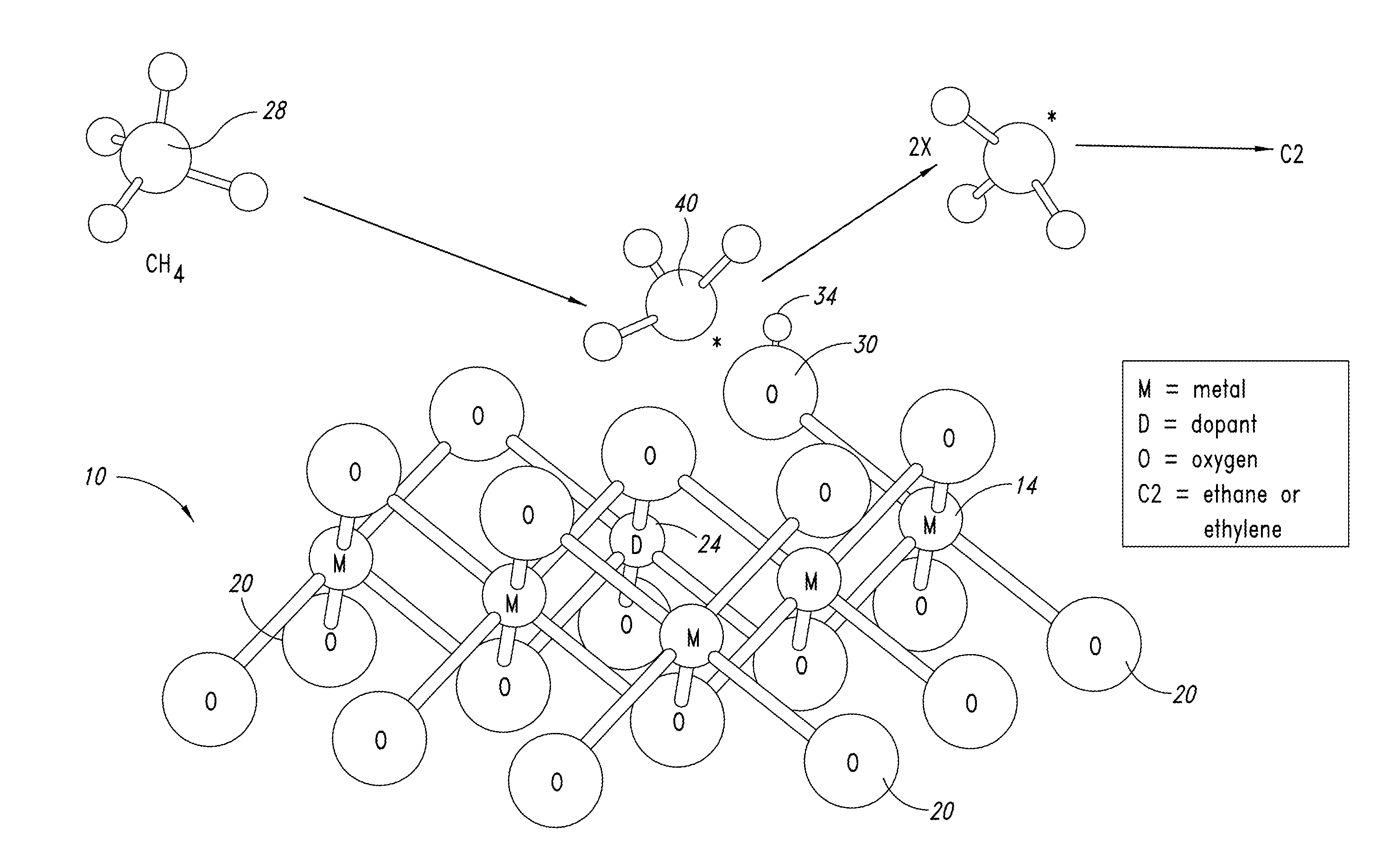

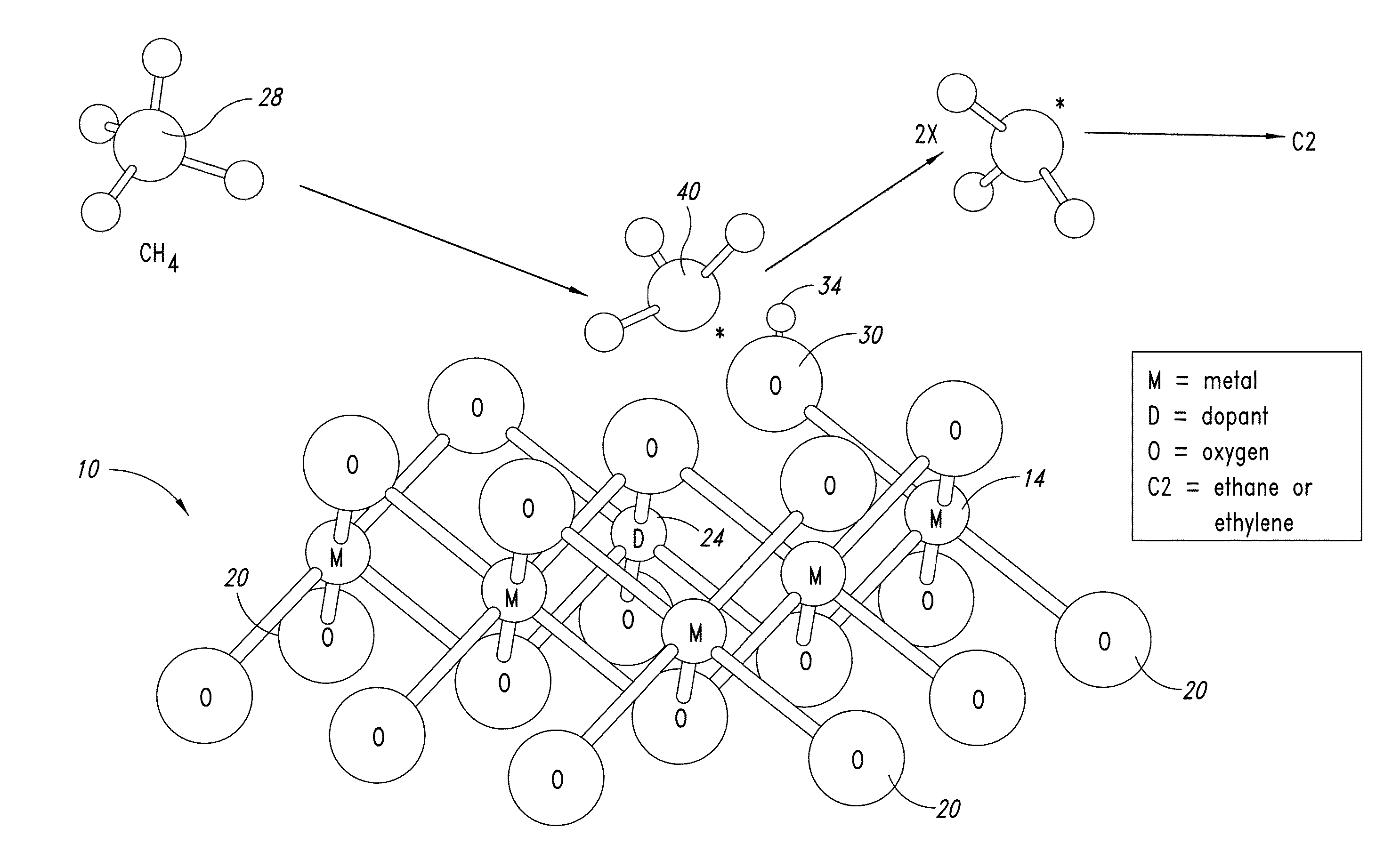

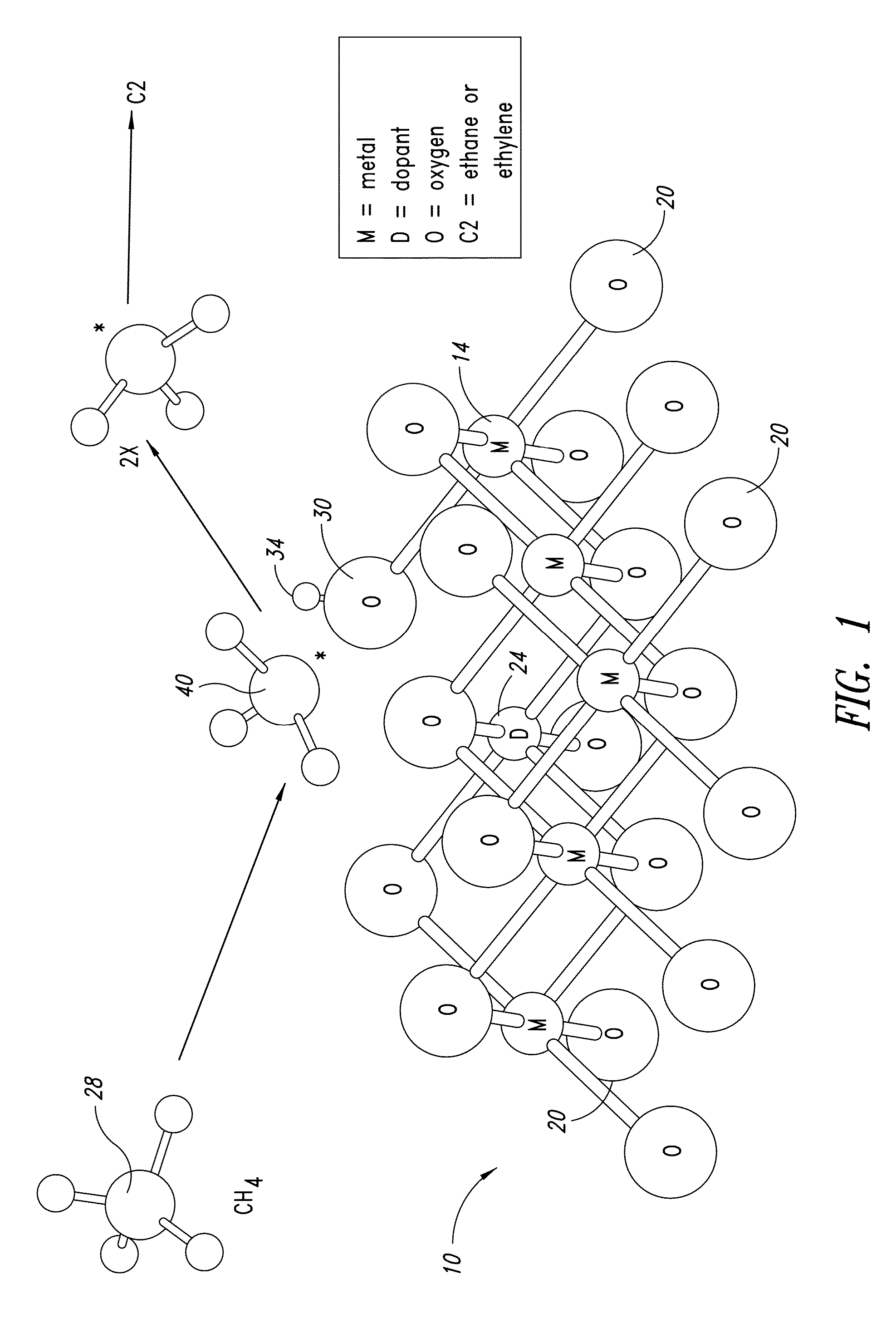

Catalysts for petrochemical catalysis

ActiveUS20130023709A1Sequential/parallel process reactionsManganese oxides/hydroxidesDopantPetrochemical

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Preparation of olefins

The preparation of olefins from steam cracker or refinery C4 streams is carried out by selective hydrogenation of butadienes and acetylenic impurities in the steam cracker or refinery C4 stream, with simultaneous or subsequent, at least partial isomerization of 1-butene to 2-butene, followed by removal of i-butene from the C4 stream by reaction with an alcohol to form an ether, followed by removal of oxygen-containing impurities from the C4 stream using adsorber materials, followed by two-stage metathesis of the butenes in the C4 stream by conversion of 1-butene and 2-butene present in the C4 stream into propene and 2-pentene and subsequent reaction of the 2-pentene with ethene in the presence of a metathesis catalyst to form propene and 1-butene. Optionally, butadiene may be removed from the C4 stream by extractive distillation in a preliminary step.

Owner:BASF AG

Process of paraffin hydrocarbon isomerisation catalysed by an ionic liquid in the presence of a cyclic hydrocarbon additive

InactiveUS6797853B2High selectivityHigh degree of branchingHydrocarbon by isomerisationCatalytic crackingAlkaneIonic liquid

Owner:HALDOR TOPSOE AS

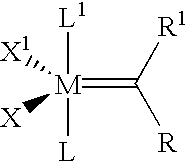

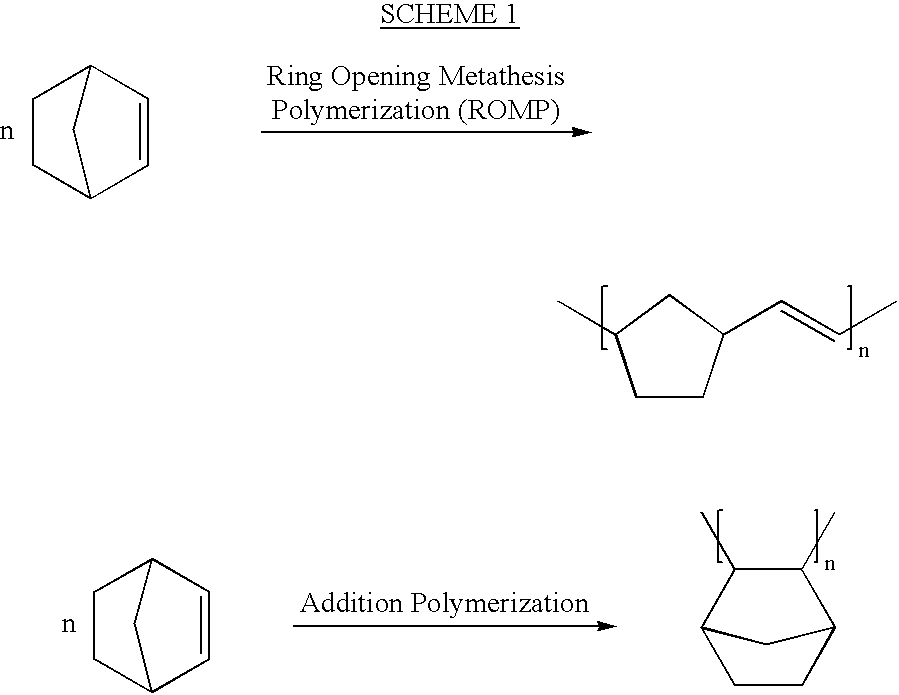

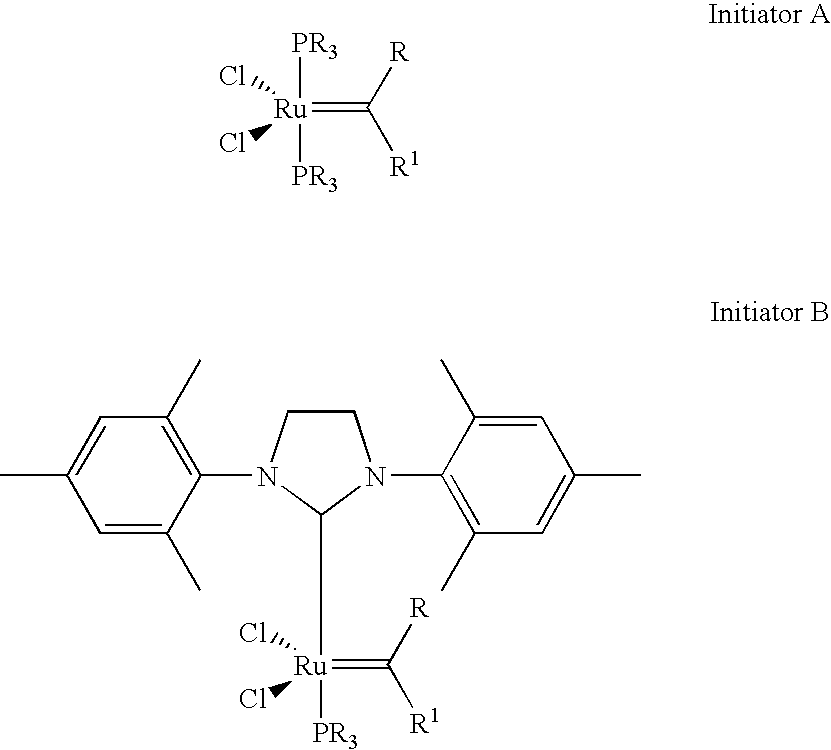

High activity metal carbene metathesis catalysts generated using a thermally activated N-heterocyclic carbene precursor

The invention provides a method for converting a less active or slower to initiate system to a higher activity system so that at the end of a polymerization the most active species is present in the system. The invention generally relates to a process for converting a less active or slower to initiate catalyst system to a higher activity catalyst system wherein the process comprises contacting a protected N-heterocyclic carbene with a metathesis catalyst and an olefin in the presence of energy. One of the benefits of the invention is that the amount of catalyst required is less than or lowered in the presence of the protected N-heterocyclic carbene as compared to the amount of catalyst required in the absence of the protected N-heterocyclic carbene. The protected N-heterocyclic carbene can be unsaturated or saturated. In addition, the invention describes novel ruthenium initiators and methods of making the same.

Owner:CALIFORNIA INST OF TECH +1

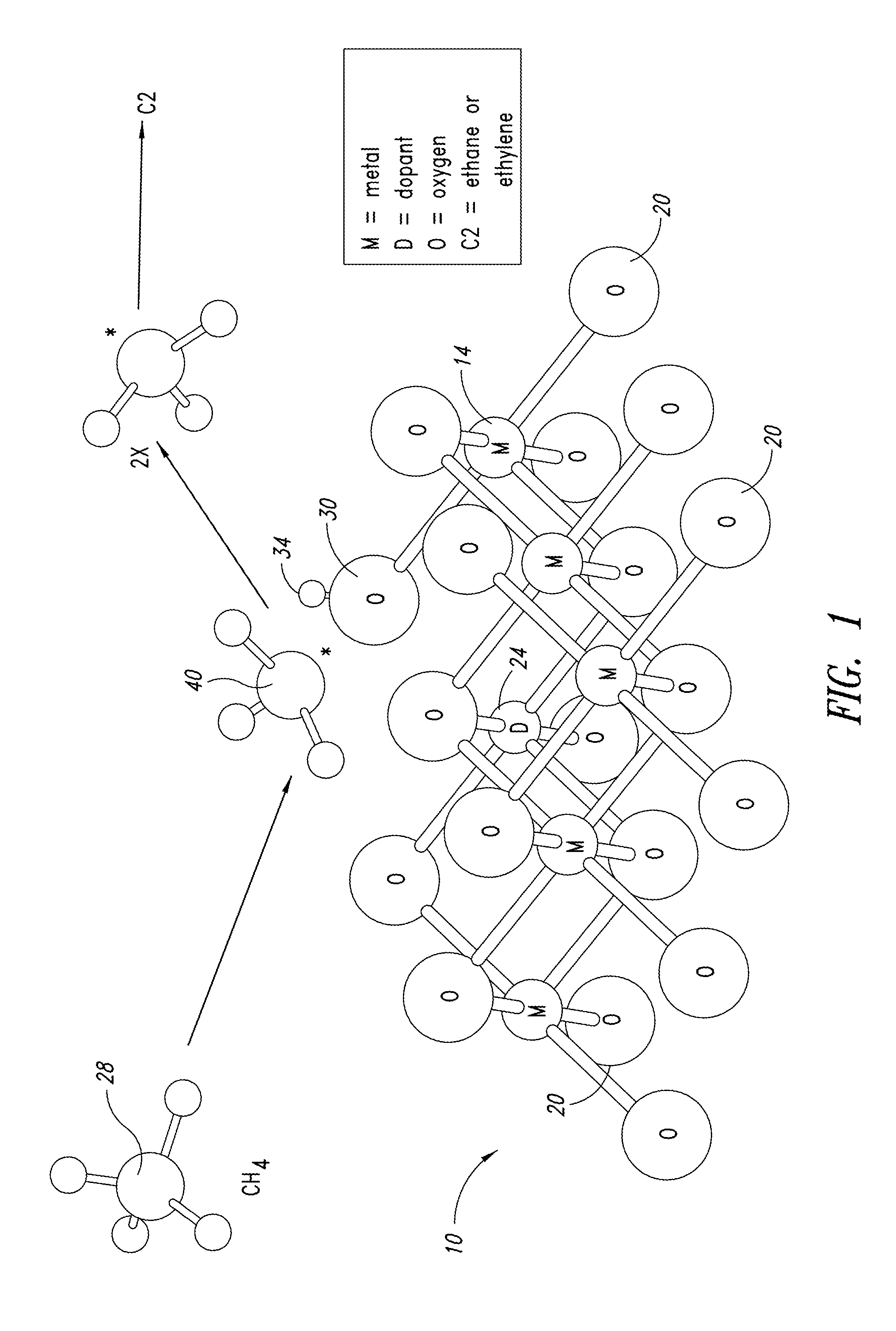

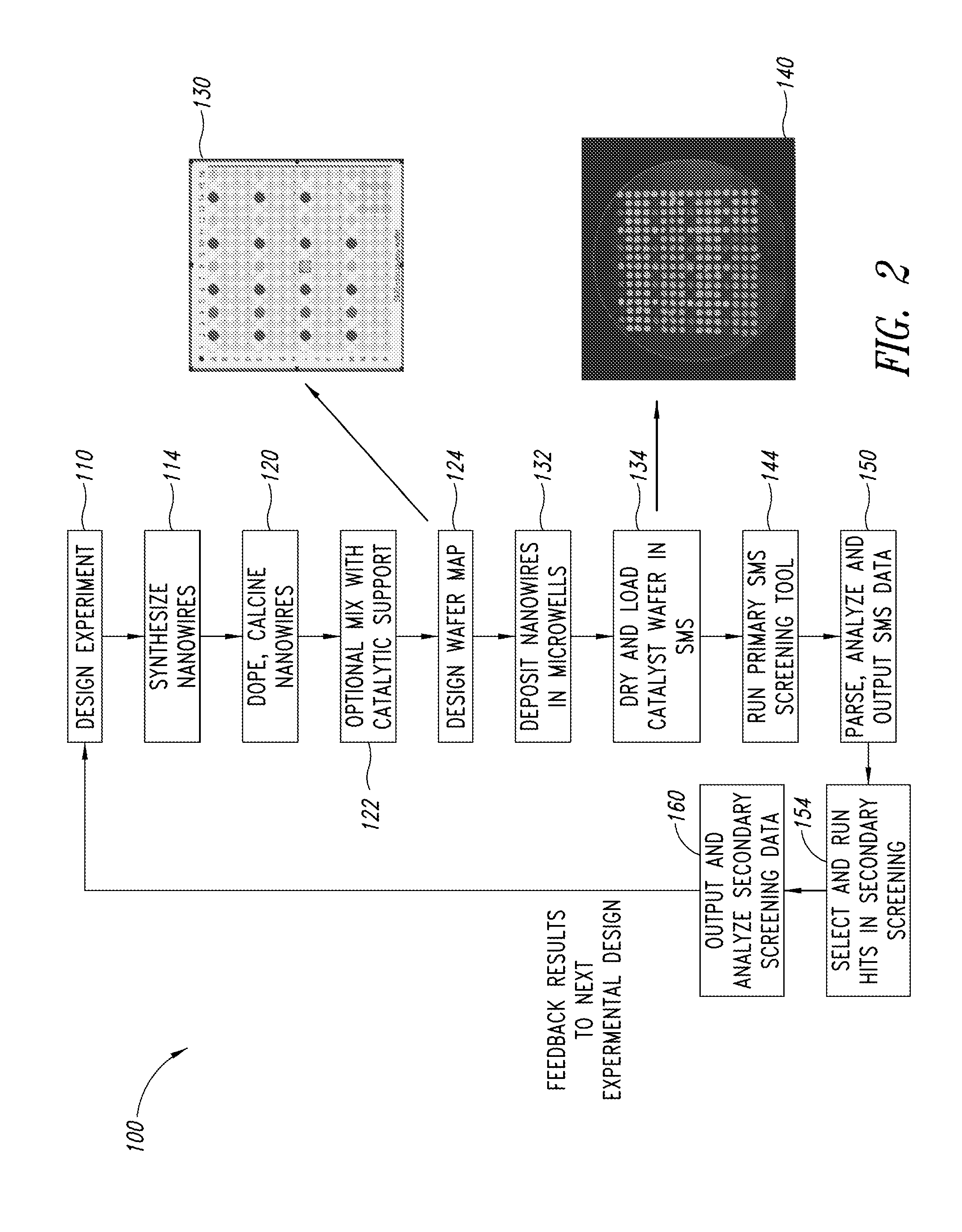

Catalytic forms and formulations

InactiveUS20140121433A1Material nanotechnologyMolecular sieve catalystsOxidative coupling of methaneChemistry

Catalytic forms and formulations are provided. The catalytic forms and formulations are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

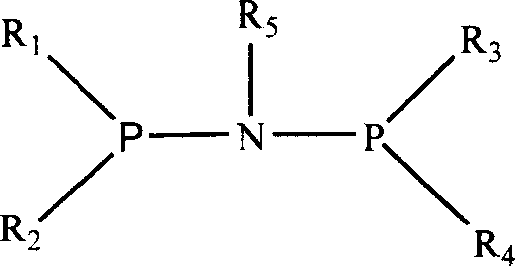

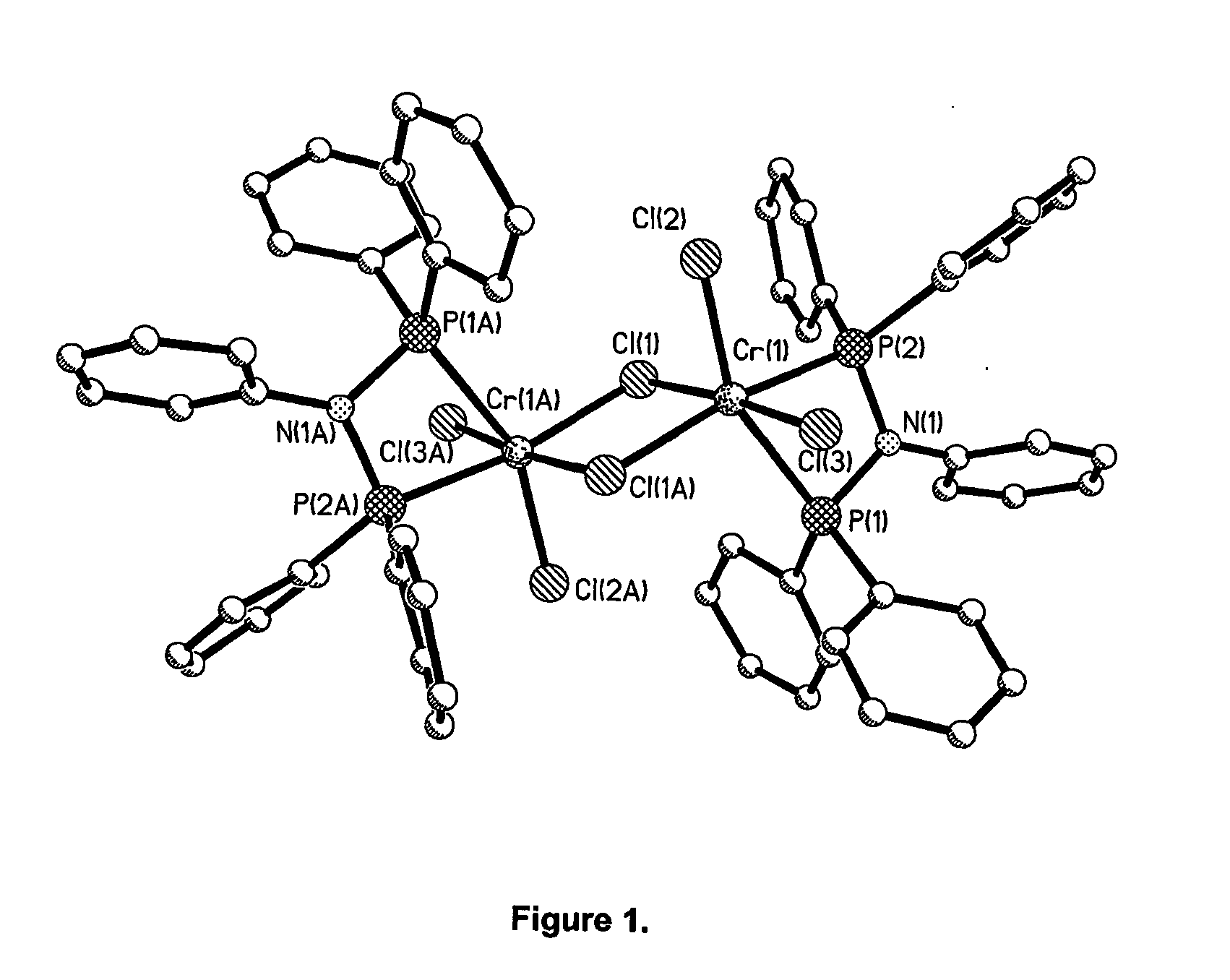

Catalyst composition of ethylene oligomerization and the application

ActiveCN101032695AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAryl1-Octene

The present invention relates to catalyst composition for oligomerizing ethylene and its application. The catalyst composition includes complex of acetylacetone chromium, tetrahydrofuran chromium chloride and / or chromium isooctanate; ligand containing P and N; activator of methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; and promoter of X1R6X2, where, each of X1 and X2 is F, Cl, Br, I or alkoxyl, and R6 is alkyl or aryl group; with the molar ratio of the complex, the ligand, the activator and the promoter being 1 to 0.5-10 to 50-3000 to 0.5-10. The catalyst composition is used in oligomerizing reaction of ethylene to prepare 1-octene, and has high catalytic activity and high 1-octene selectivity.

Owner:PETROCHINA CO LTD

Tetramerization of olefins

ActiveUS20060229480A1Stabilise the catalyst systemImprove catalytic performanceHydrocarbon by dehydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsAlkeneTetramer

The invention describes a process for tetramerisation of olefins wherein the product stream of the process contains more than 30% of the tetramer olefin. The process includes the step of contacting an olefinic feedstream with a catalyst system containing a transition metal compound and a heteroatomic ligand.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

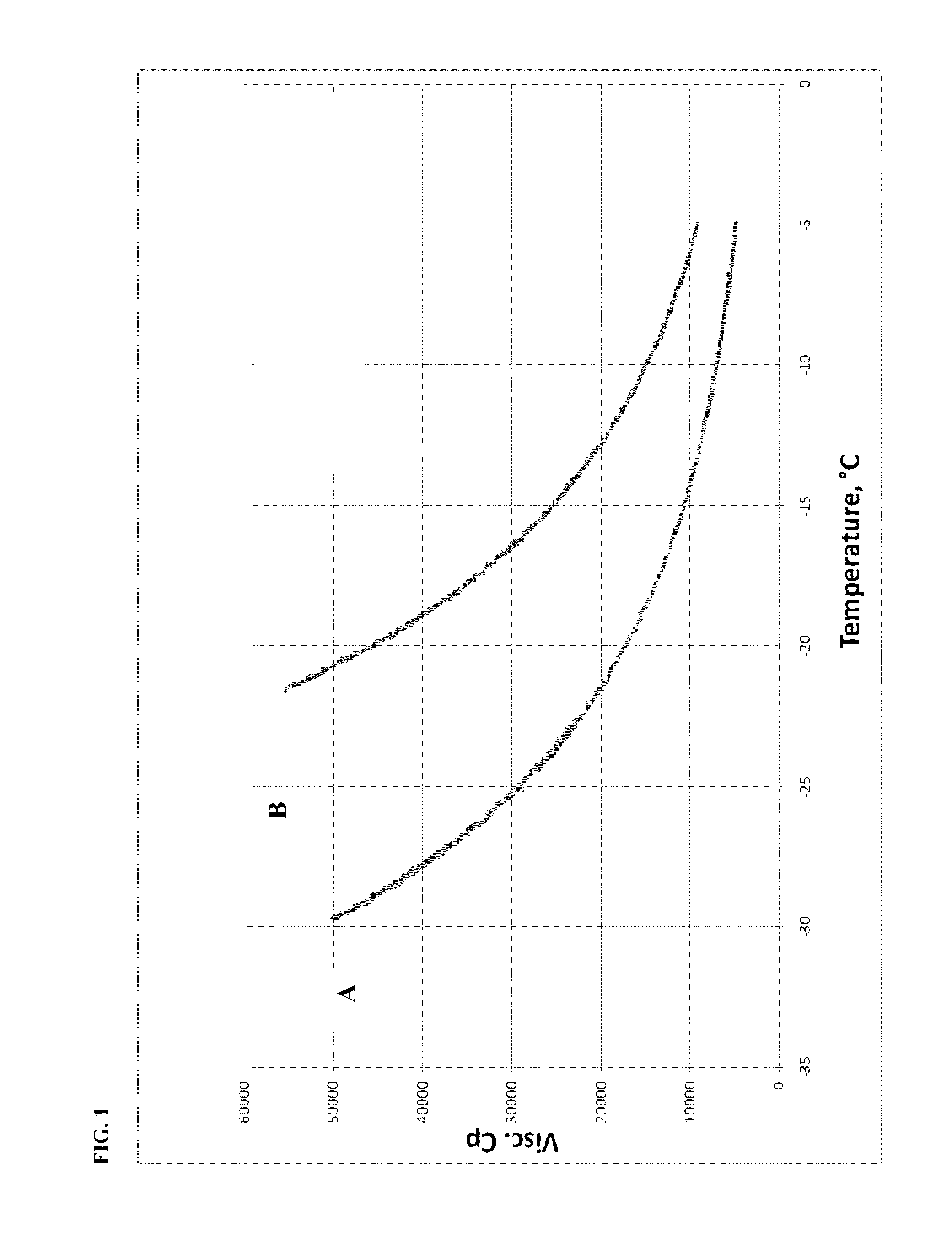

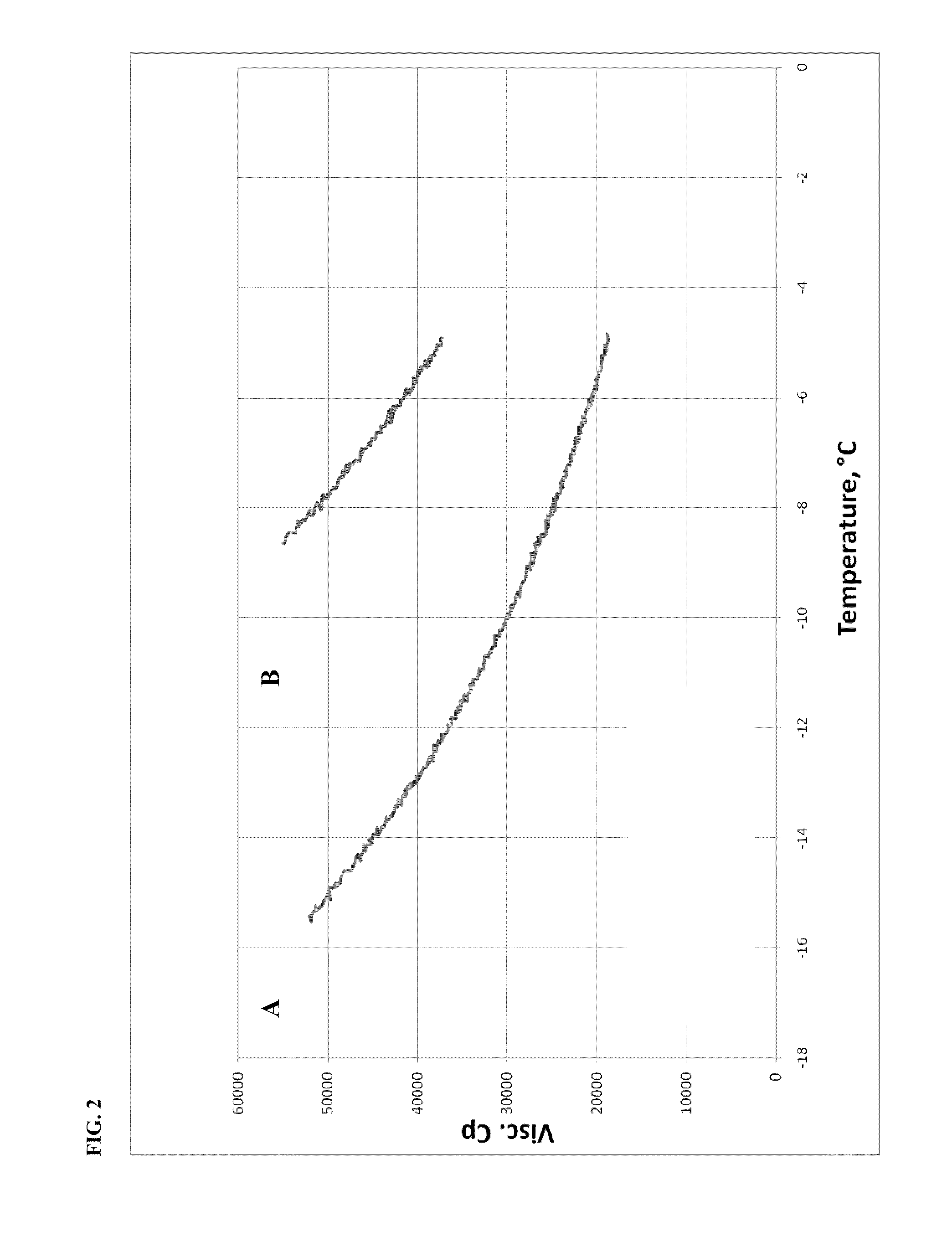

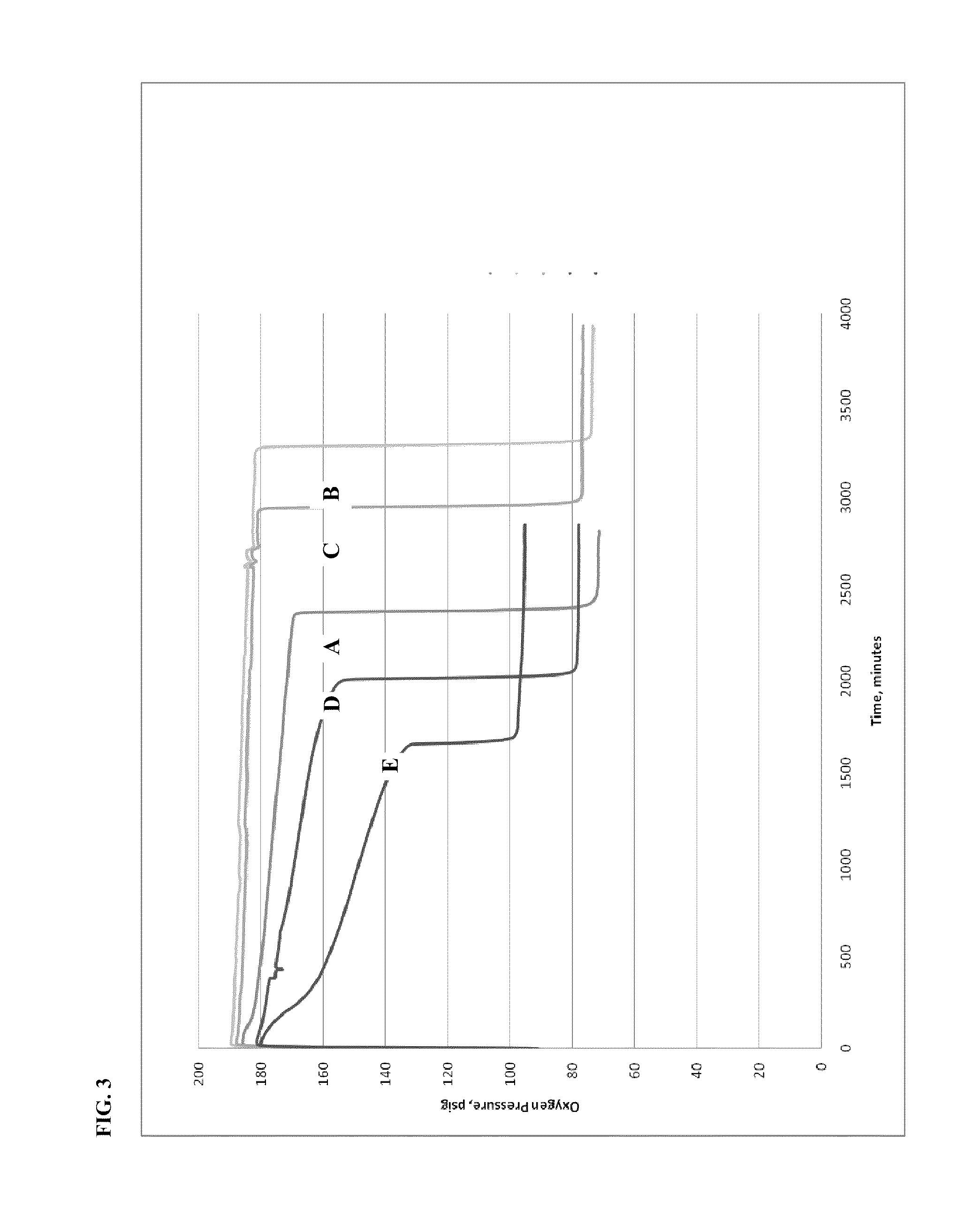

Oligomerization of alpha olefins using metallocene-ssa catalyst systems and use of the resultant polyalphaolefins to prepare lubricant blends

ActiveUS20100317904A1Improve productivityHydrocarbon by hydrogenationAdditivesOligomerViscosity index

This disclosure provides for alpha olefin oligomers and polyalphaolefins (or PAOs) and methods of making the alpha olefin oligomers and PAOs. This disclosure encompasses metallocene-based alpha olefin oligomerization catalyst systems, including those that include at least one metallocene and an activator comprising a solid oxide chemically-treated with an electron withdrawing anion. The alpha olefin oligomers and PAOs prepared with these catalyst systems can have a high viscosity index combined with a low pour point, making them particularly useful in lubricant compositions and as viscosity modifiers.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

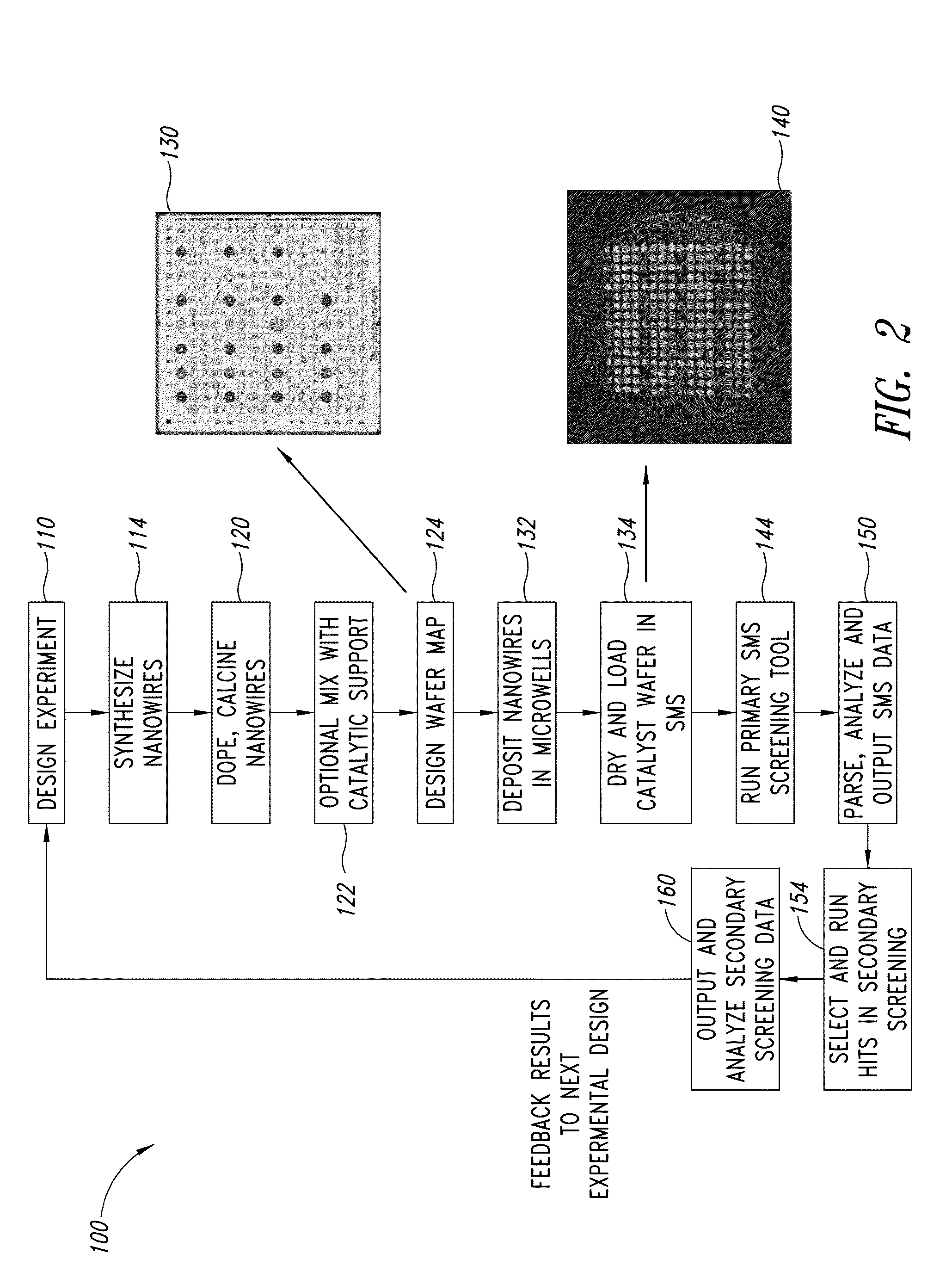

Nanowire catalysts and methods for their use and preparation

ActiveUS20130165728A1Material nanotechnologyManganese oxides/hydroxidesNanowireOxidative coupling of methane

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

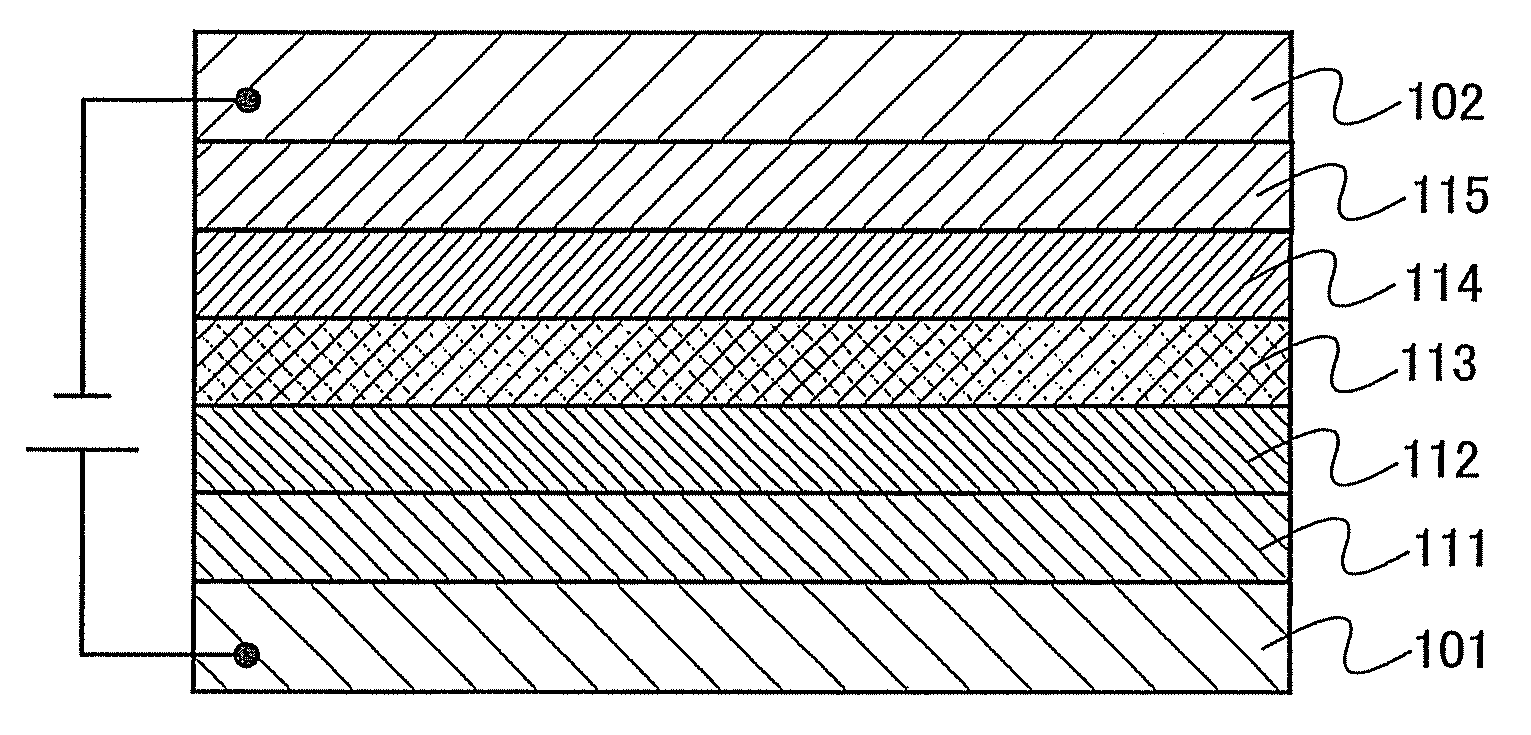

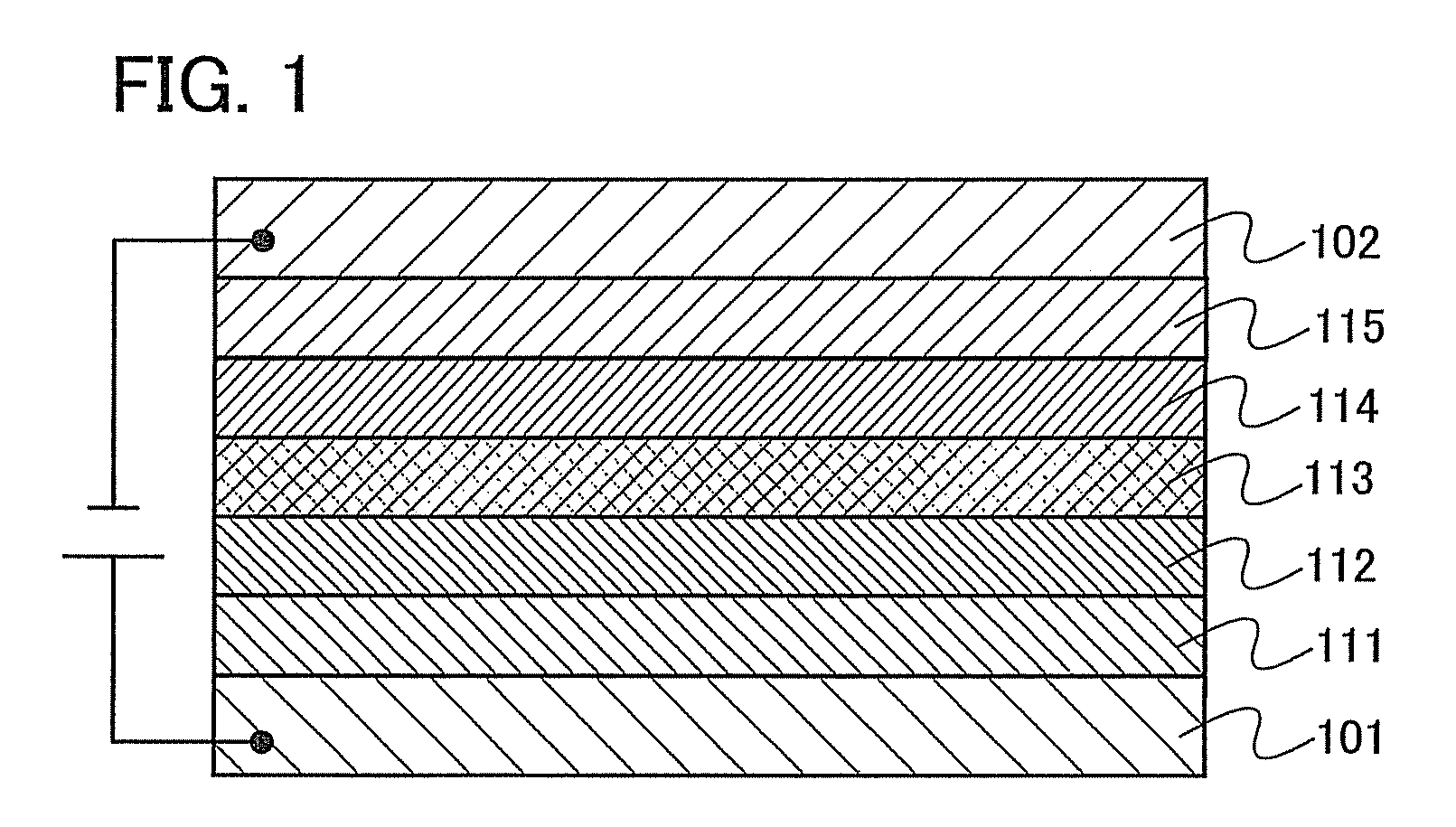

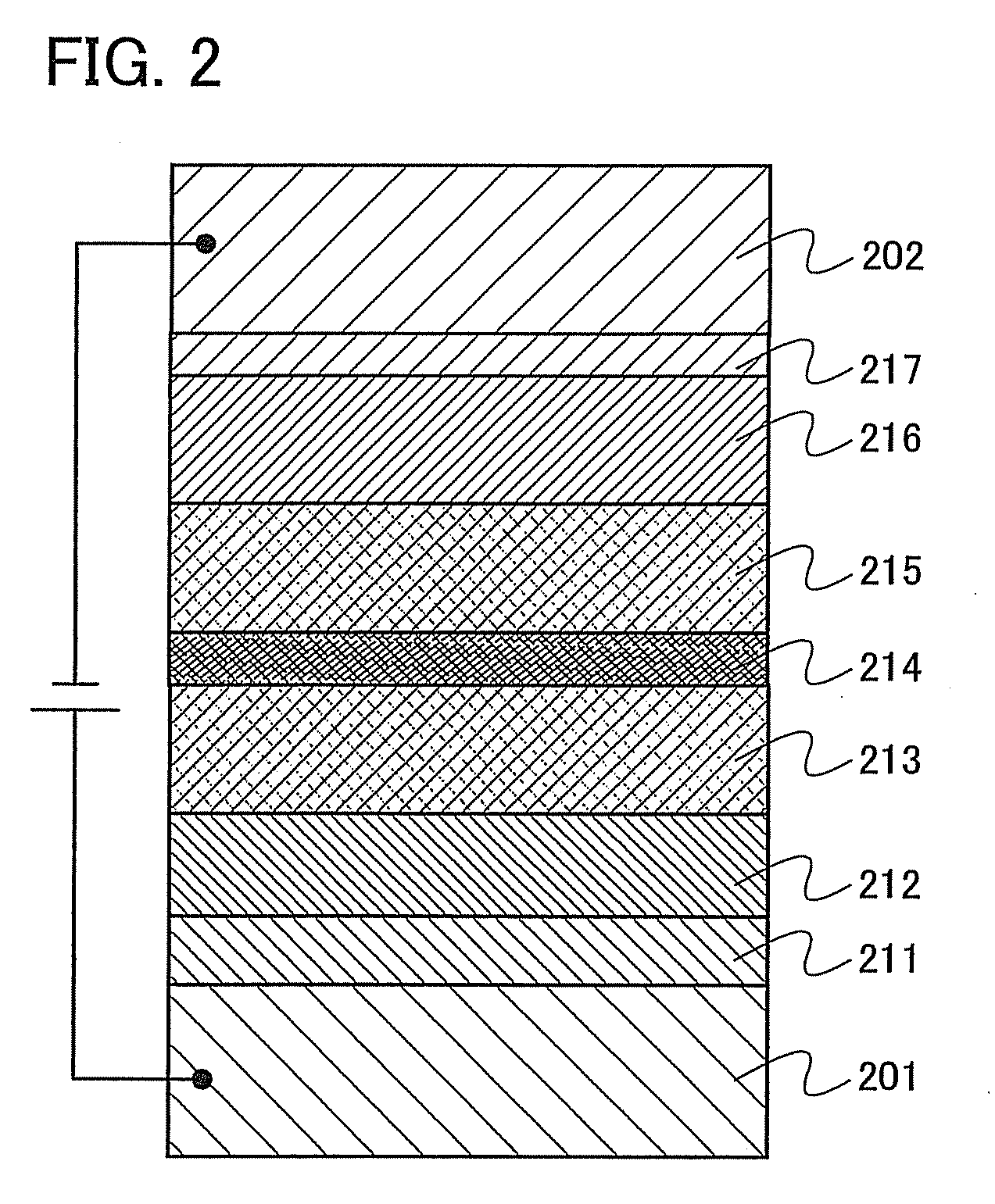

Organometallic Complex and Light-Emitting Element, Light-Emitting Device, and Electronic Device Using the Same

InactiveUS20100145044A1Easy to synthesizeSharp emission spectrumGroup 5/15 element organic compoundsSolid-state devicesHydrogenAlkoxy group

An organometallic complex having a structure represented by the general formula (G1) is synthesized and applied to a light-emitting element.In the formula, R3 represents either an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, or an alkoxycarbonyl group having 1 to 5 carbon atoms; R2 and R3 each show either hydrogen or an alkyl group 1 to 4 carbon atoms; Ar represents an arylene group having 6 to 25 carbon atoms; M is a center metal selected from Group 9 element and Group 10 element.

Owner:SEMICON ENERGY LAB CO LTD

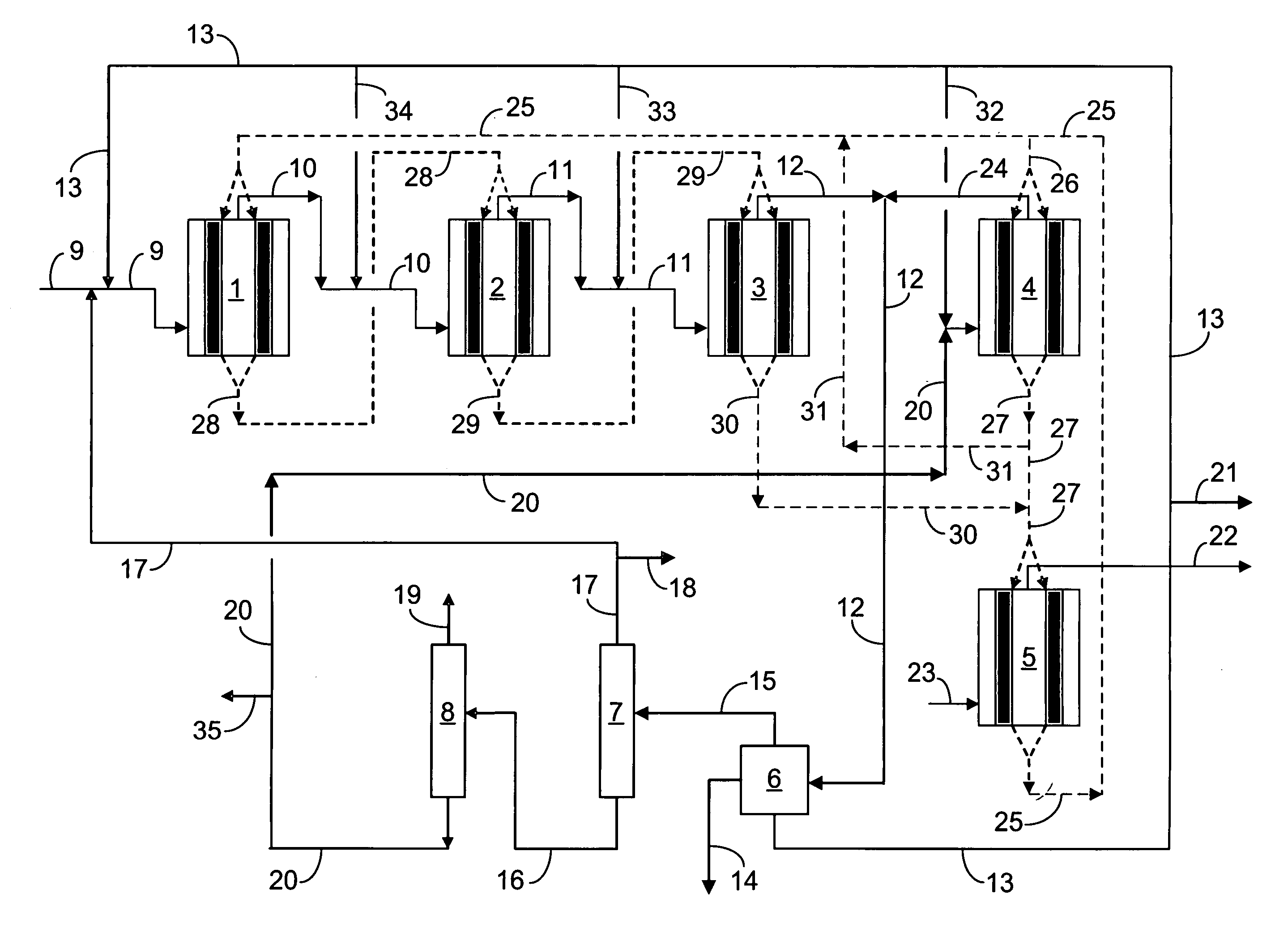

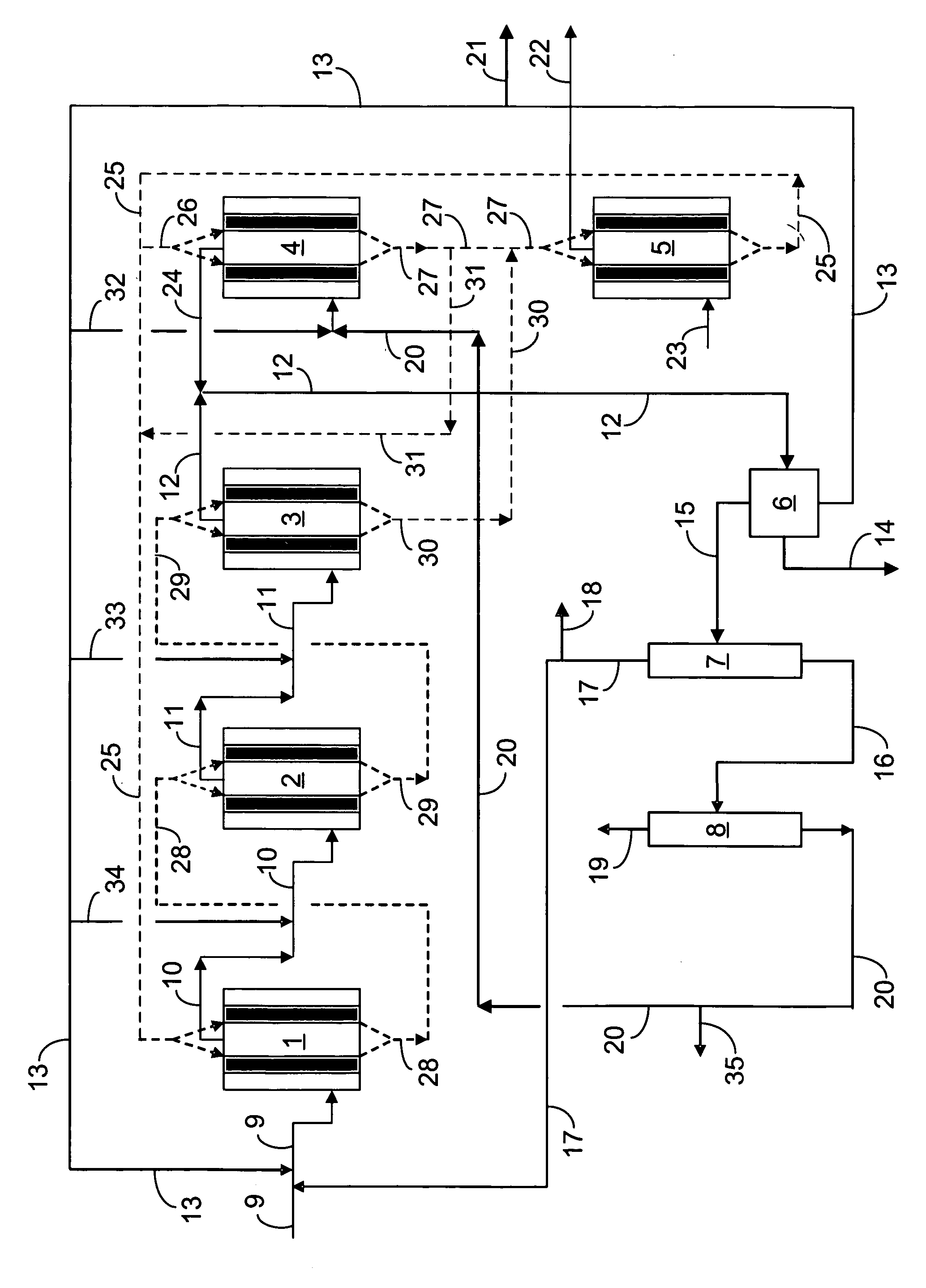

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

Polymer templated nanowire catalysts

InactiveUS20130158322A1Improve drawing legibilityMaterial nanotechnologyManganese oxides/hydroxidesNanowirePolymer science

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are prepared by polymer templated methods and are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethane and / or ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Process for removing polar impurities from hydrocarbons and mixtures of hydrocarbons

InactiveUS7553406B2Improve efficiencyMild process conditionsOrganic compounds purification/separation/stabilisationSolvent extractionHydrocotyle bowlesioidesIonic liquid

This invention relates to a process for removing polarizable impurities from hydrocarbons and mixtures of hydrocarbons using ionic liquids as an extraction medium. By way of extraction, the degree of contamination of the hydrocarbon or mixture of hydrocarbons is reduced to a low or very low level. The specific ionic liquids are compounds of the Formula 1, which are organic salts that are liquid or can be melted to form a liquid and that can form at least a biphasic mixture with a hydrocarbon. The process is suitable for purifying a wide range of hydrocarbons under a wide range of process conditions.

Owner:MERCK PATENT GMBH

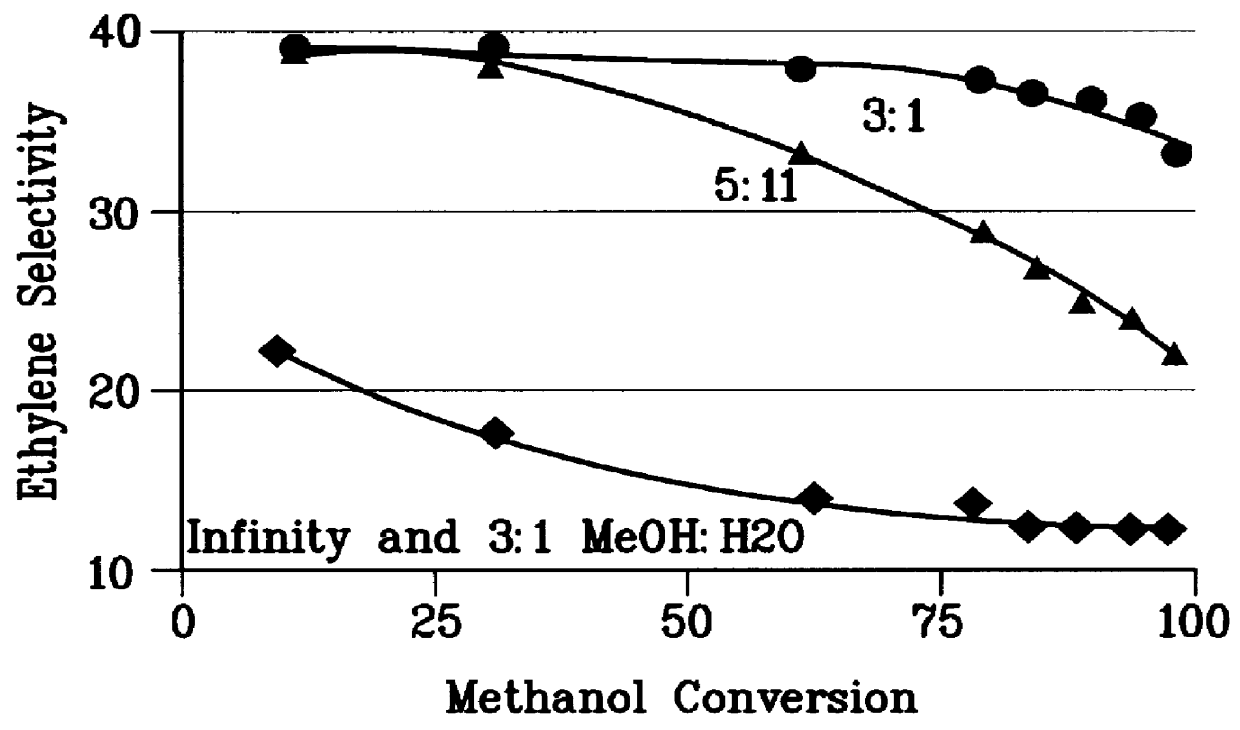

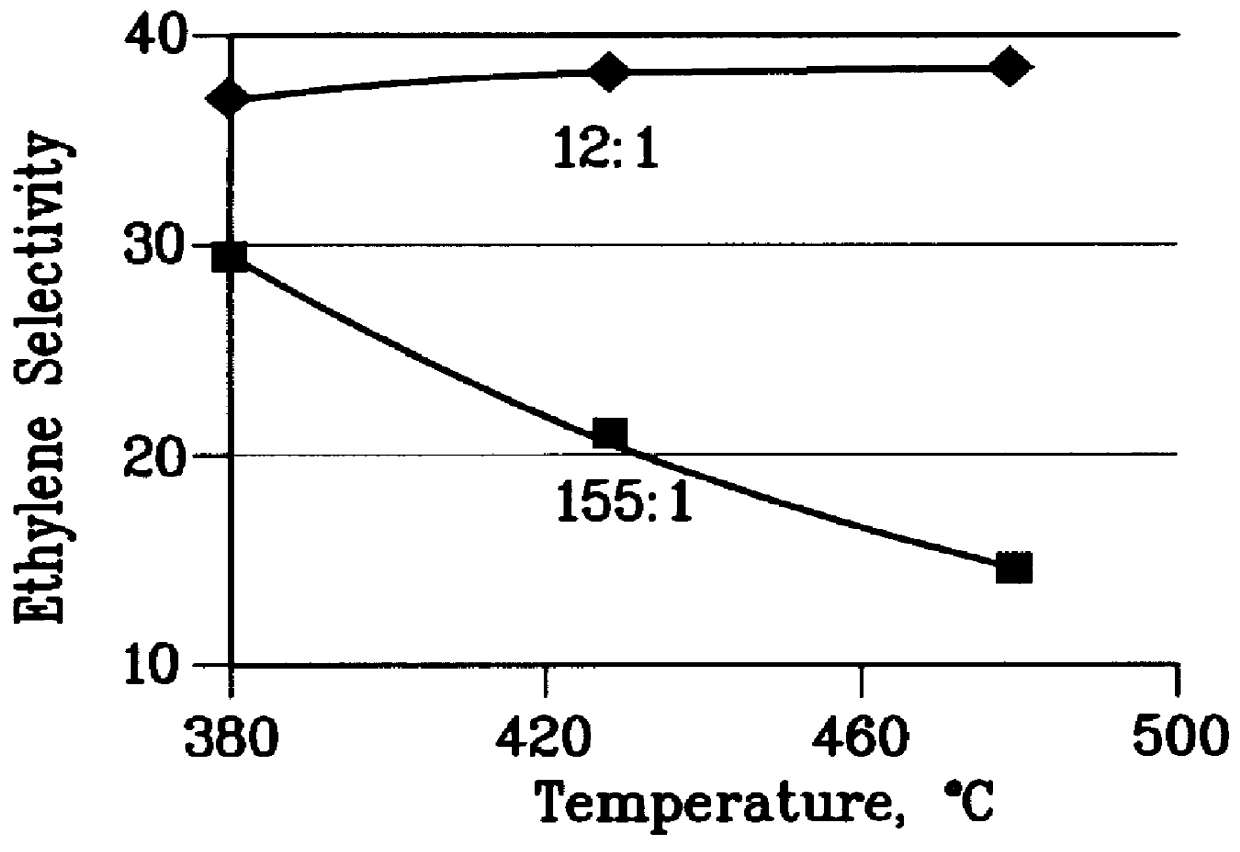

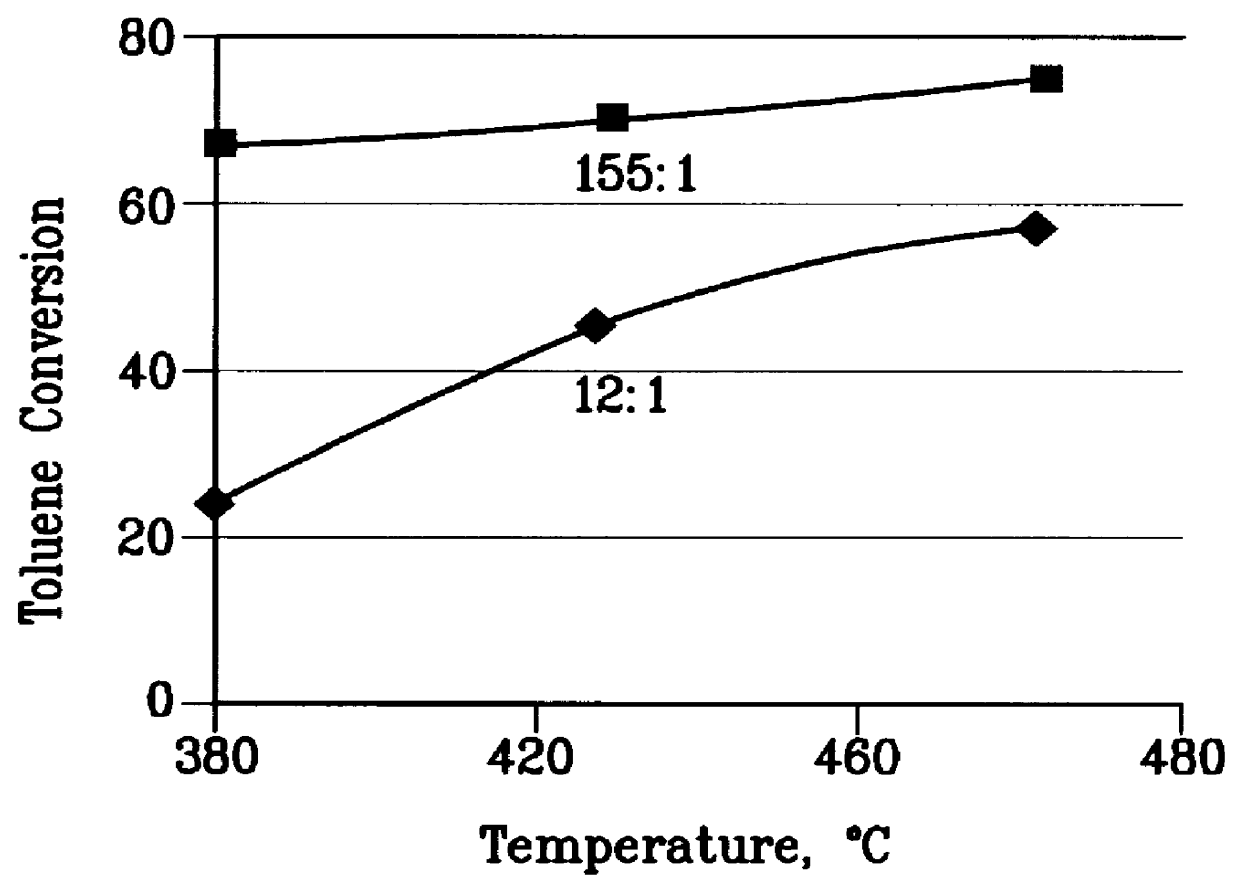

Process for producing light olefins

InactiveUS6046372AMolecular sieve catalystsMolecular sieve catalystAlkyl transferCrystalline materials

There is provided a process for converting methanol and / or dimethyl ether to a product containing C2 to C4 olefins which comprises the step of contacting a feed which contains methanol and / or dimethyl ether with a catalyst comprising a porous crystalline material, said contacting step being conducted in the presence of an aromatic compound under conversion conditions including a temperature of 350 DEG C. to 480 DEG C. and a methanol partial pressure in excess of 10 psia (70 kPa), said porous crystalline material having a pore size greater than the critical diameter of the aromatic compound and the aromatic compound being capable of alkylation by the methanol and / or dimethyl ether under said conversion conditions.

Owner:MOBIL OIL CORP

Catalytic process for the oligomerization of olefinic monomers

InactiveCN101351424AGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilylene1-Octene

A process for the simultaneous trimerization and tetramerization of olefinic monomers , wherein the process comprises contacting at least one olefinic monomer with catalyst system comprising : a) a source of chromium, molybdenum or tungsten; b) a ligand having the general formula (I) ; (R<1>)2P-X-P (R<1>)m(R<2>)n wherein : X is a bridging group of the formula -N(R<3>)-, wherein R<3> is selected from hydrogen, a hydrocarbyl group, a substituted hydrocarbyl group, a heterohydrocarbyl group, a substituted heterohydrocarbyl group, a silyl group or derivative thereof; the R<1> groups are independently selected from an optionally substituted aromatic group bearing a polar substituent on at least one of the ortho-positions; and the R<2> groups are independently selected from hydrocarbyl, substituted hydrocarbyl, heterohydrocarbyl and substituted heterohydrocarbyl groups and c) a cocatalyst. The present invention further relates to a process for the simultaneous trimerization and tetramerization of ethylene to 1-hexene and 1-octene.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Popular searches

Hydrocarbon from oxygen organic compounds Hydrocarbons Hydrocarbon by hydrocarbon and non-hydrocarbon condensation Hydrocarbon by addition and hydrogenation Hydrocarbon preparation catalysts Metal/metal-oxides/metal-hydroxide catalysts Bulk chemical production Virus peptides Nickel organic compounds Fermentation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com