Patents

Literature

3571 results about "Alkyl transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jump to navigation Jump to search. Alkylation is the transfer of an alkyl group from one molecule to another. The alkyl group may be transferred as an alkyl carbocation, a free radical, a carbanion or a carbene (or their equivalents).

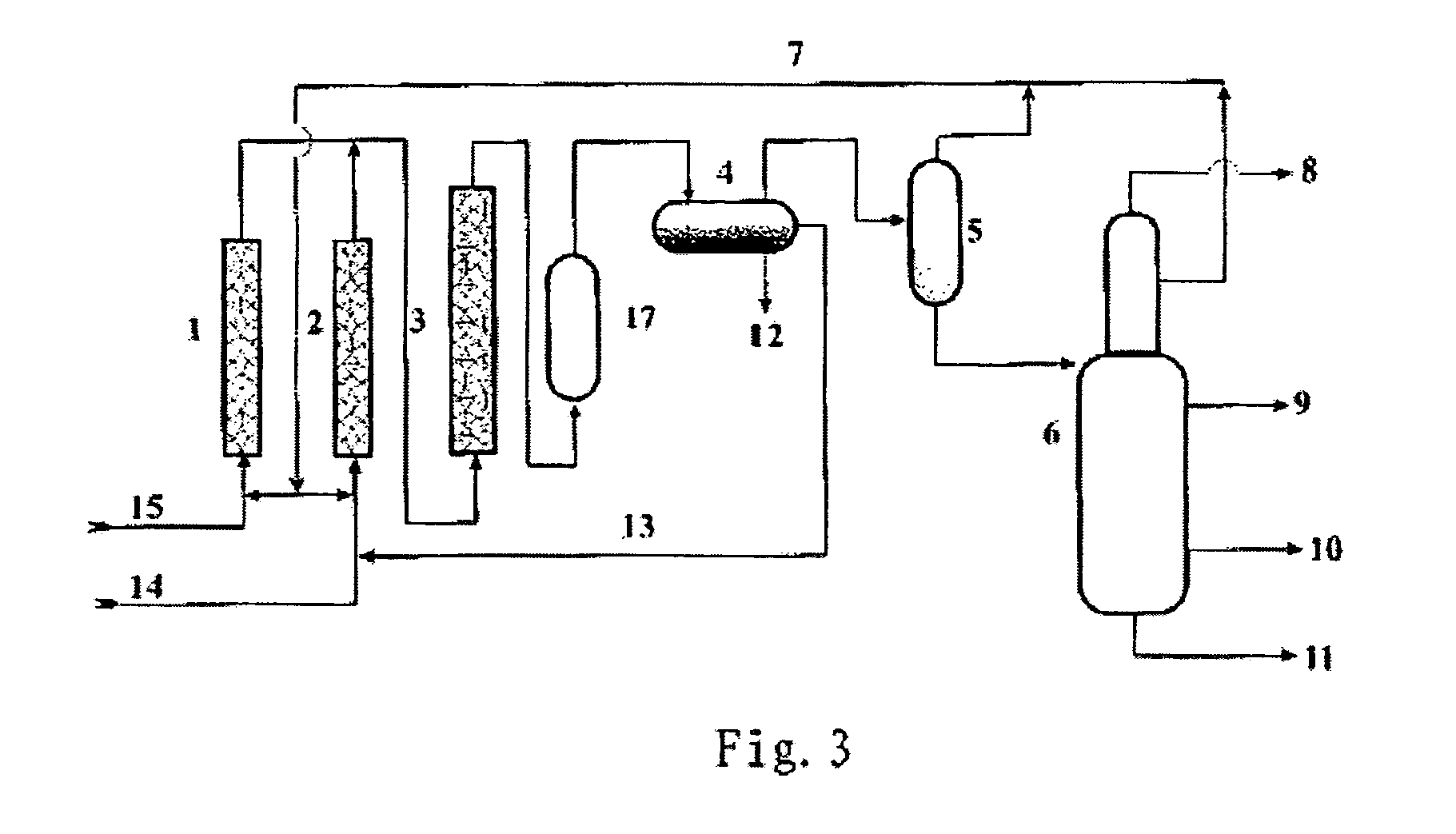

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

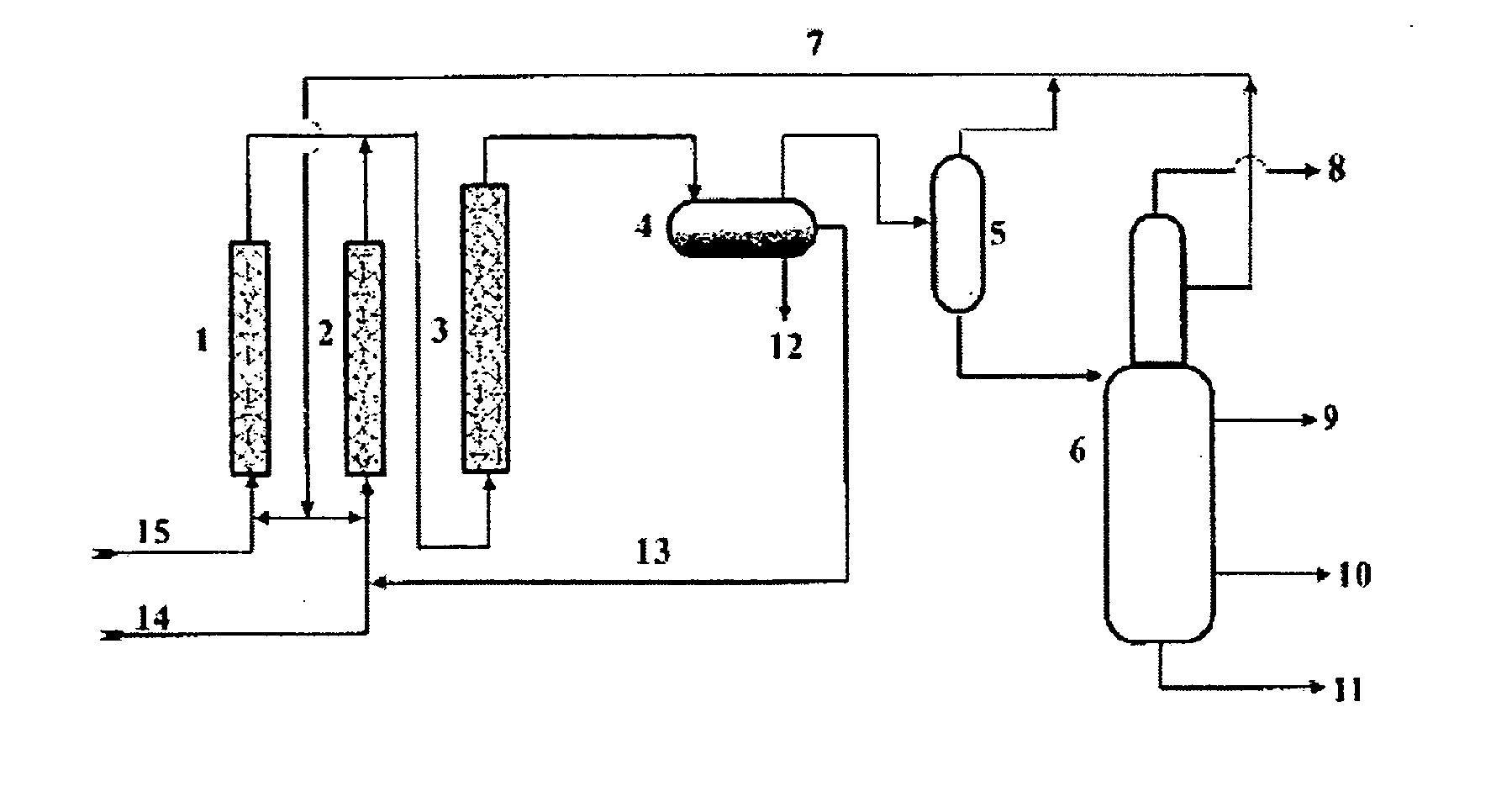

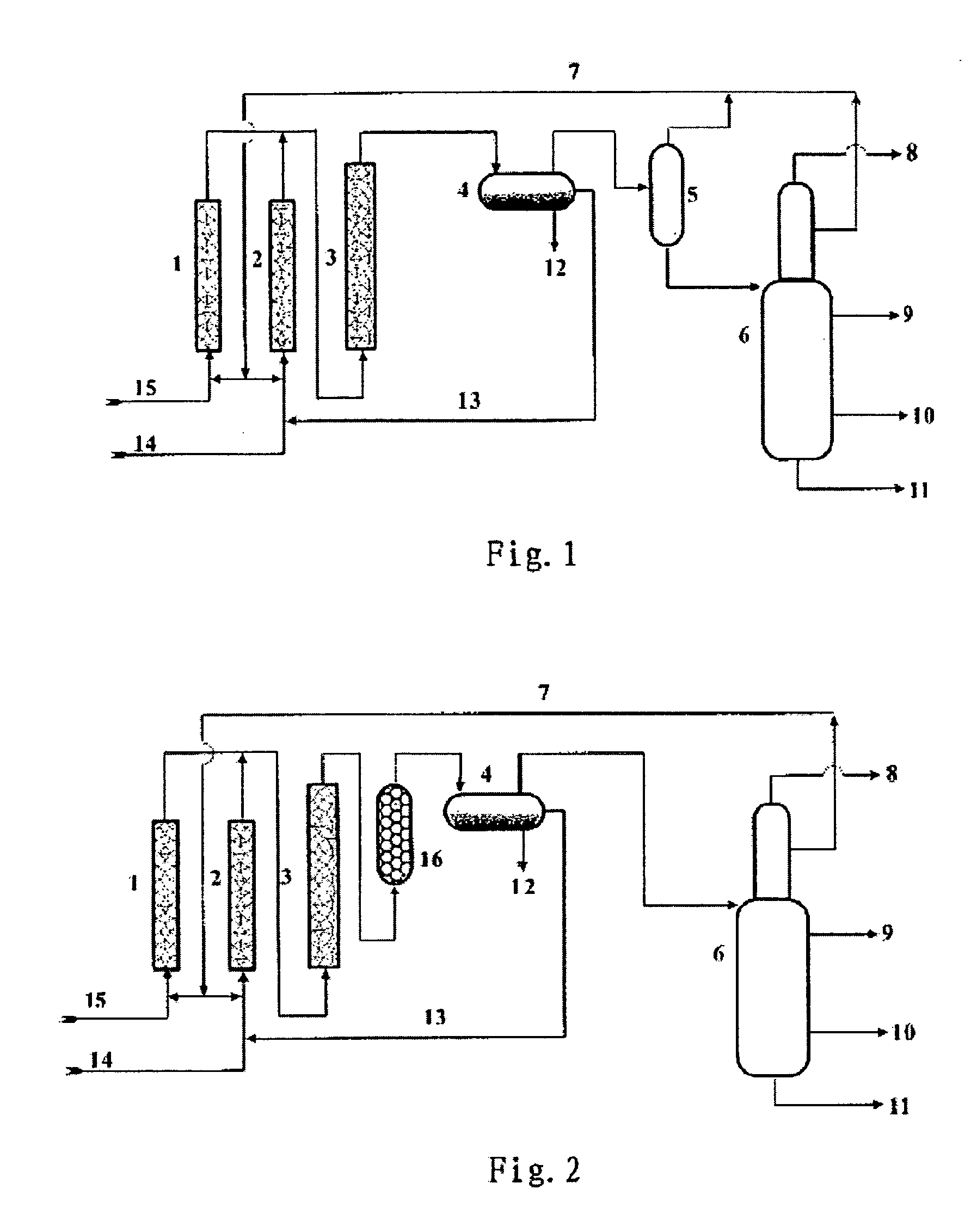

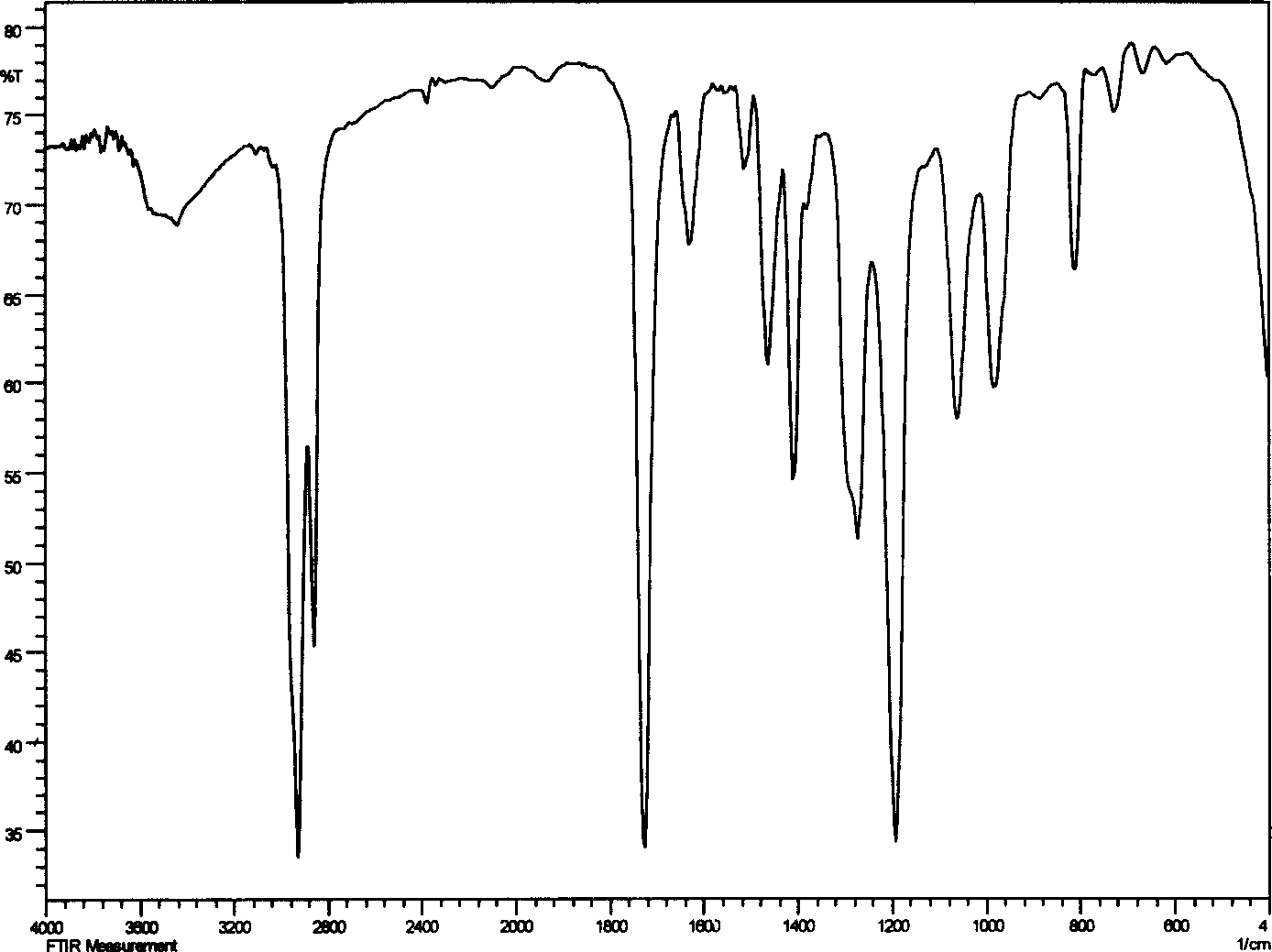

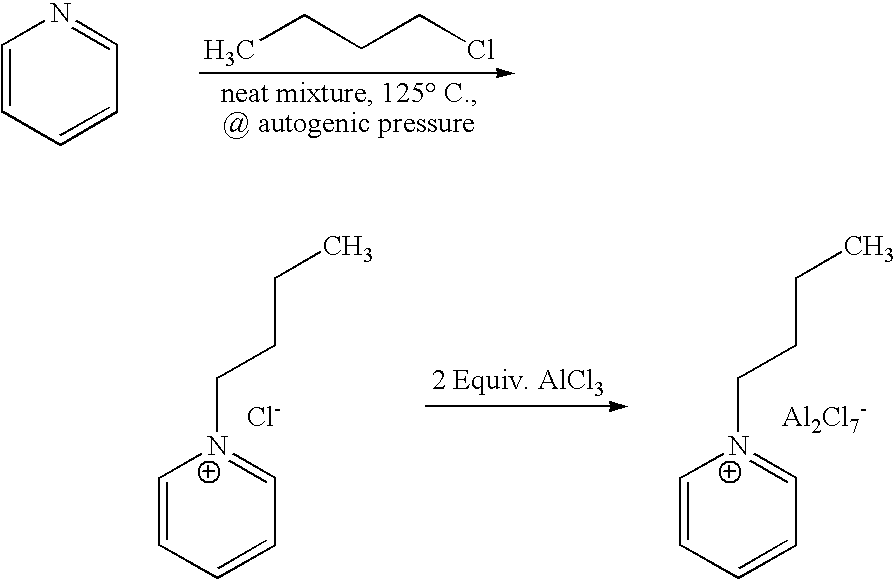

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

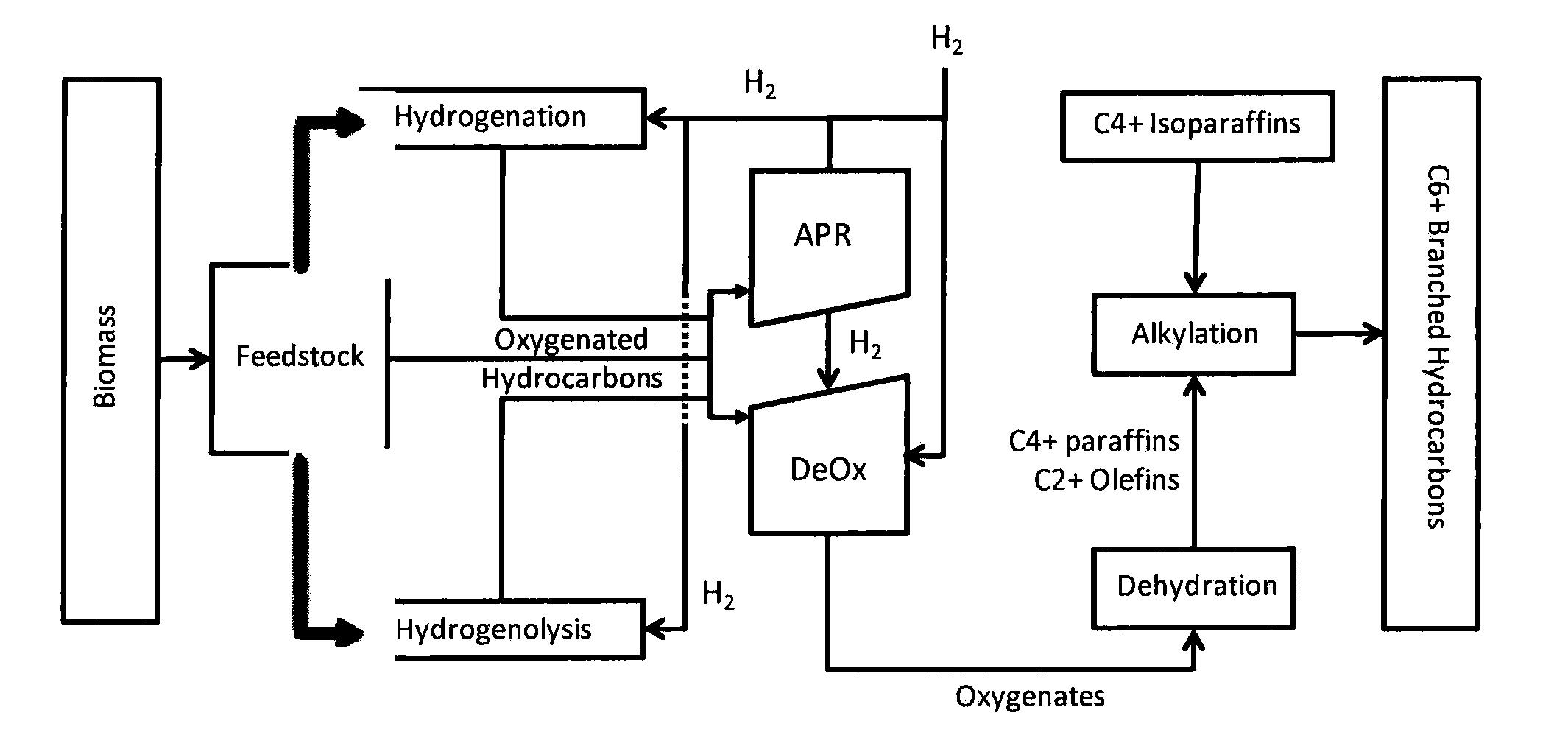

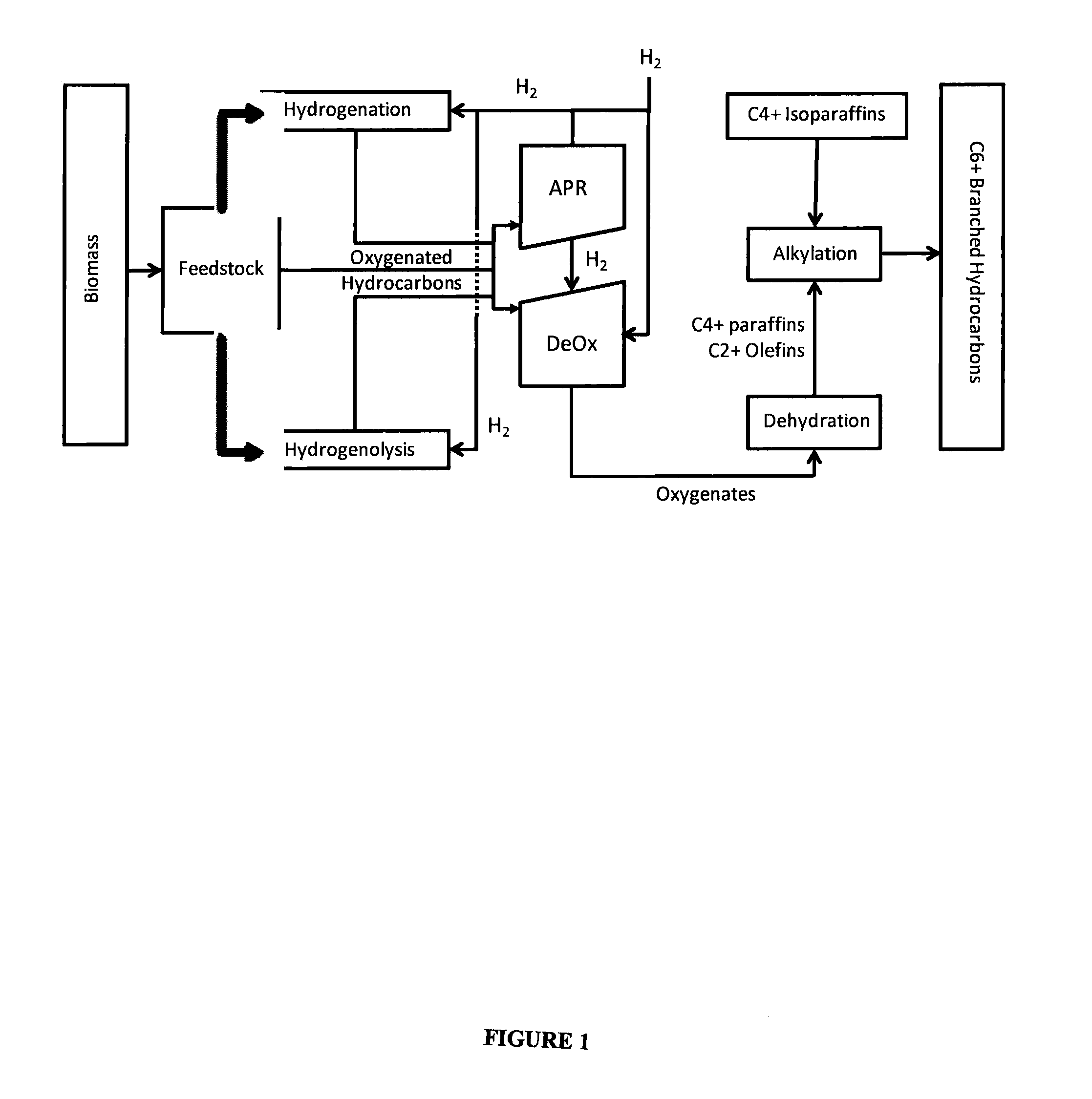

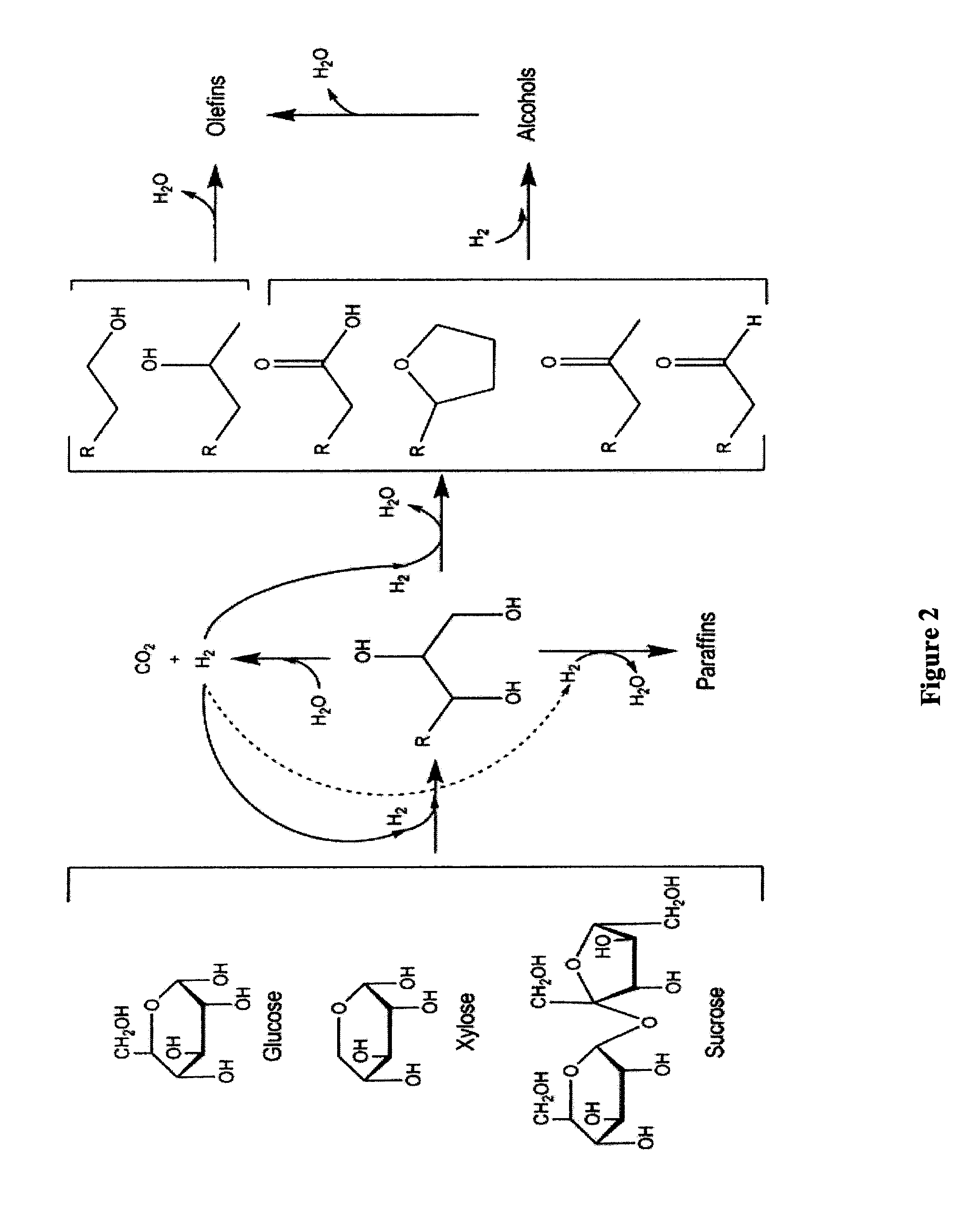

Synthesis of liquid fuels from biomass

ActiveUS20100076233A1Hydrocarbon by metathesis reactionLiquid hydrocarbon mixture productionFuranAlkane

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to paraffins useful as liquid fuels. The process involves the conversion of water soluble oxygenated hydrocarbons to oxygenates, such as alcohols, furans, ketones, aldehydes, carboxylic acids, diols, triols, and / or other polyols, followed by the subsequent conversion of the oxygenates to paraffins by dehydration and alkylation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

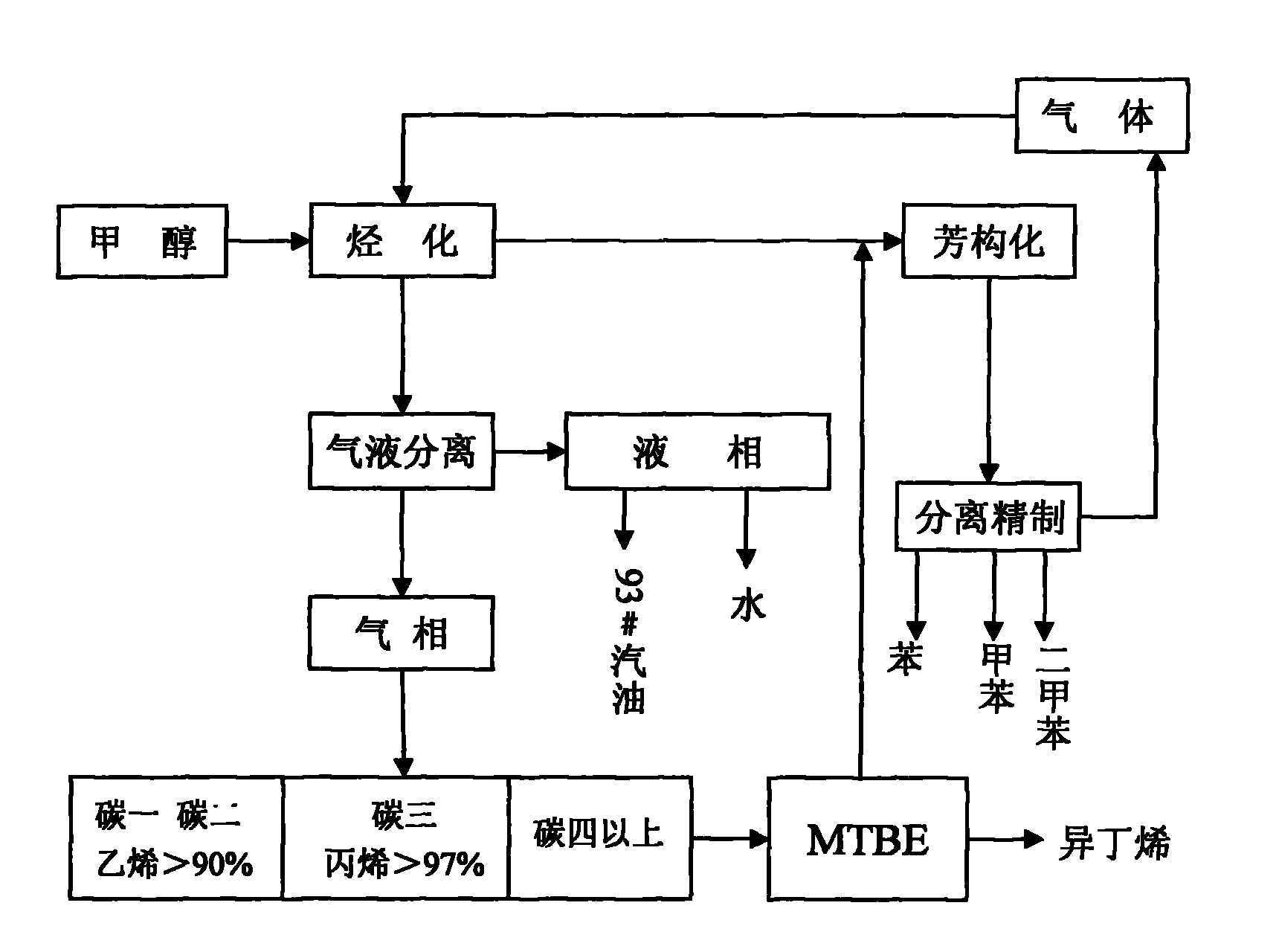

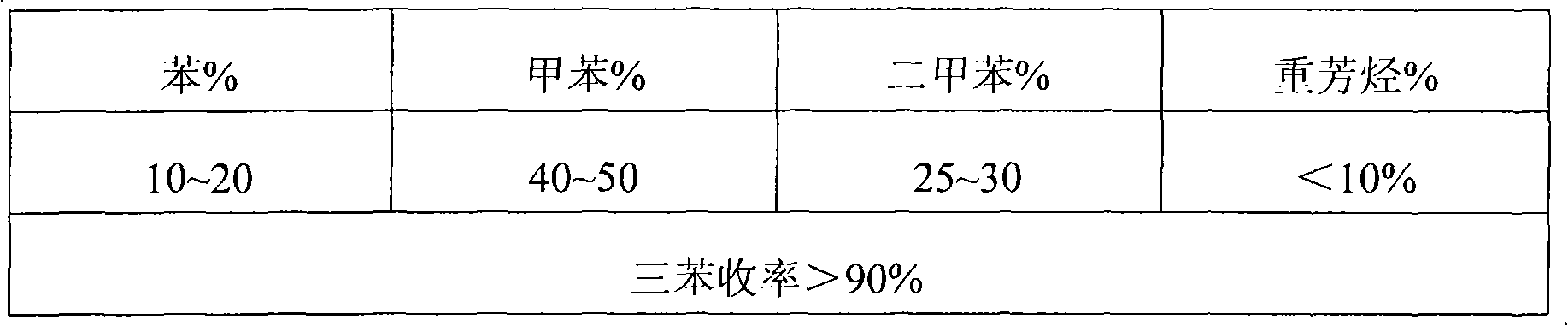

Process for preparing dimethylbenzene by aromatization of methanol

ActiveCN101671226AHigh yieldExtend the life cycleHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAlkyl transfer

A process for preparing dimethylbenzene by aromatization of methanol relates to a process for preparing dimethylbenzene by conducting aromatization reaction in a methanol aromatization reactor with methanol and hydrocarbon as raw materials. The process uses a metal-modified molecular sieve composite material as catalyst and causes the mixture of methanol and one or a plurality of C1-C12 hydrocarbons to conduct aromatization reaction in the methanol aromatization reactor. By adjusting the ratio between methanol and hydrocarbons in the raw material, the process regulates and controls the coordination between aromatization and alkylation reaction and realizes the purposes of effectively improving the yield of the target product dimethylbenzene and prolonging the service cycle of catalyst.

Owner:TSINGHUA UNIV +1

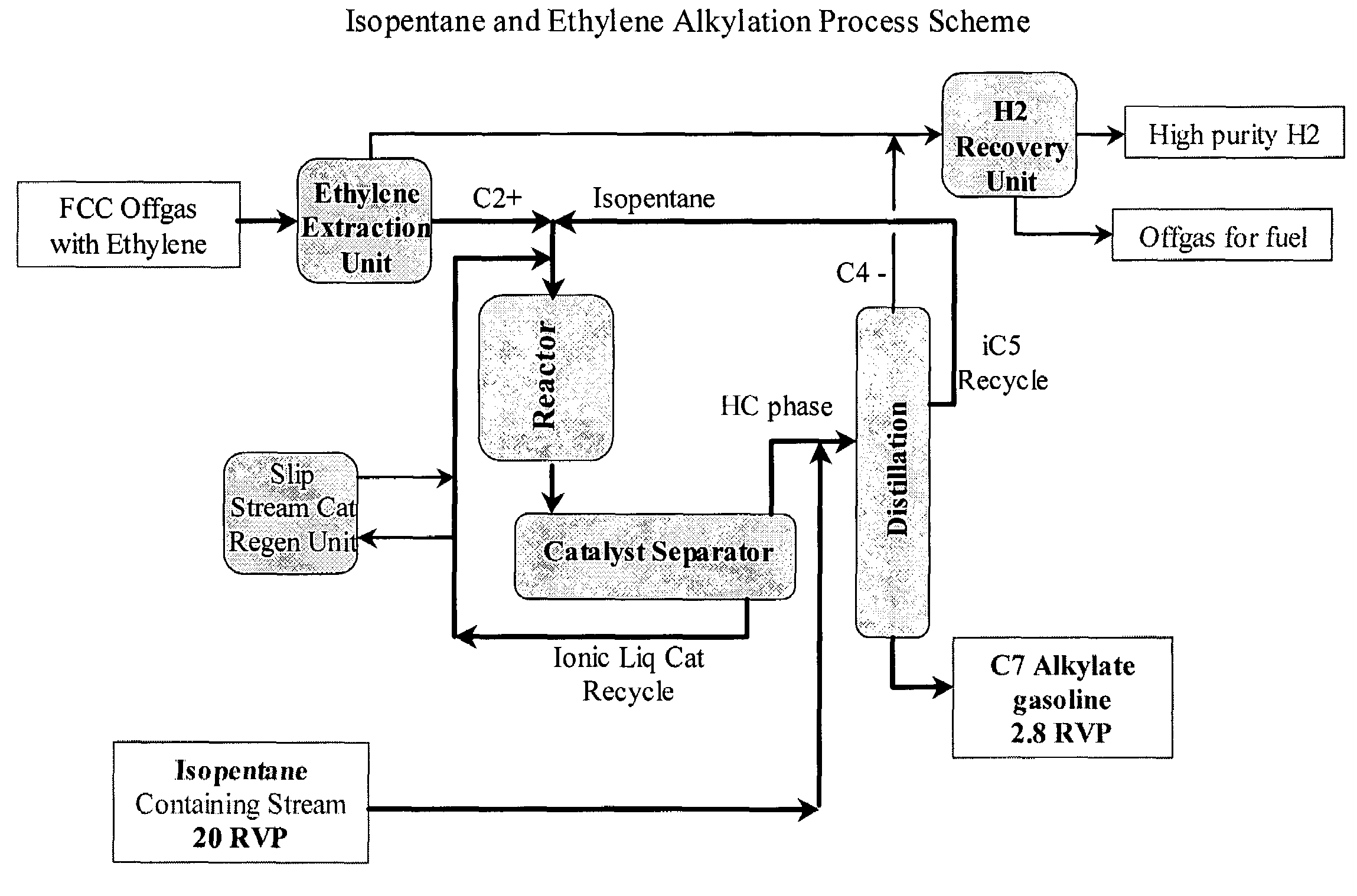

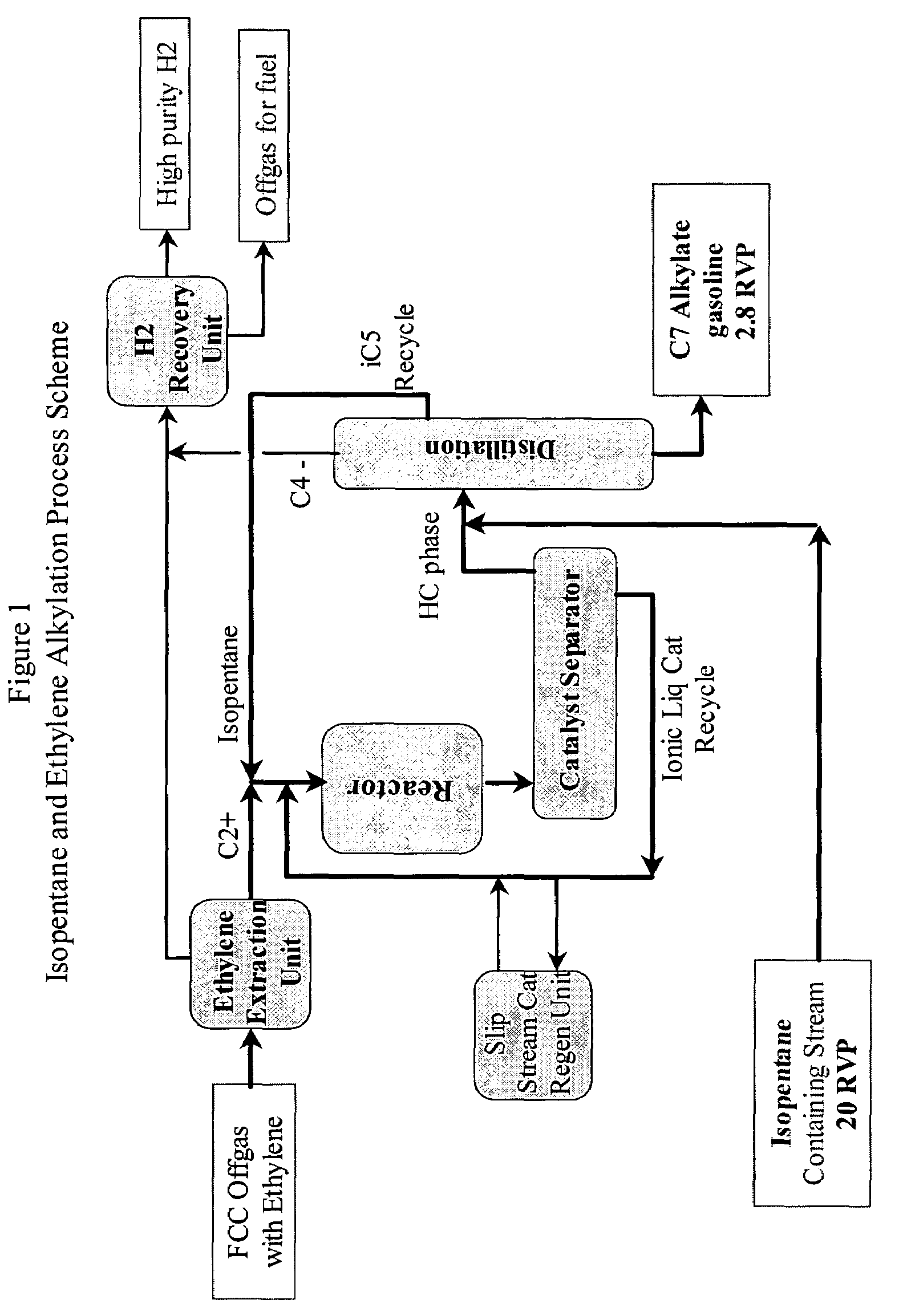

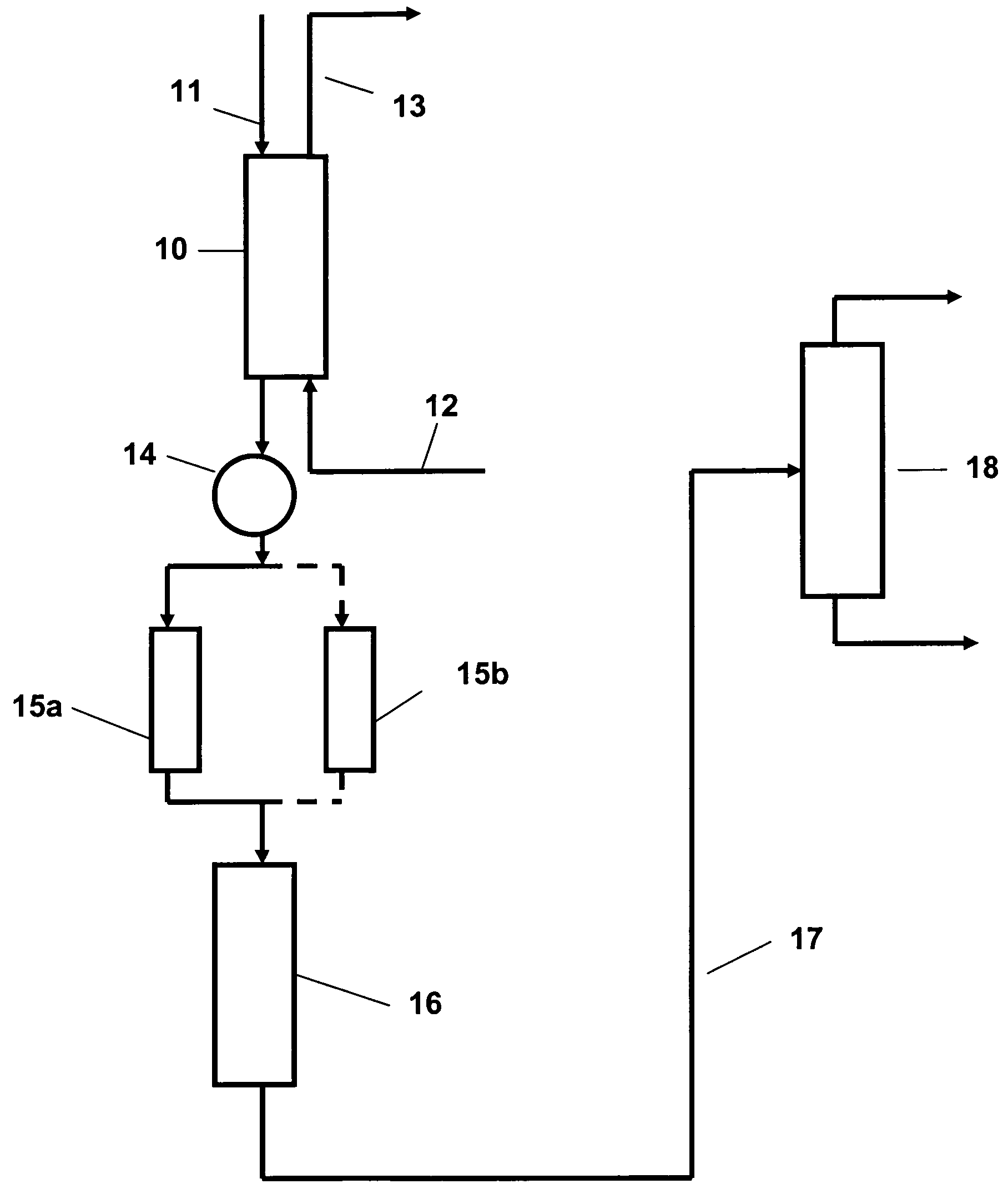

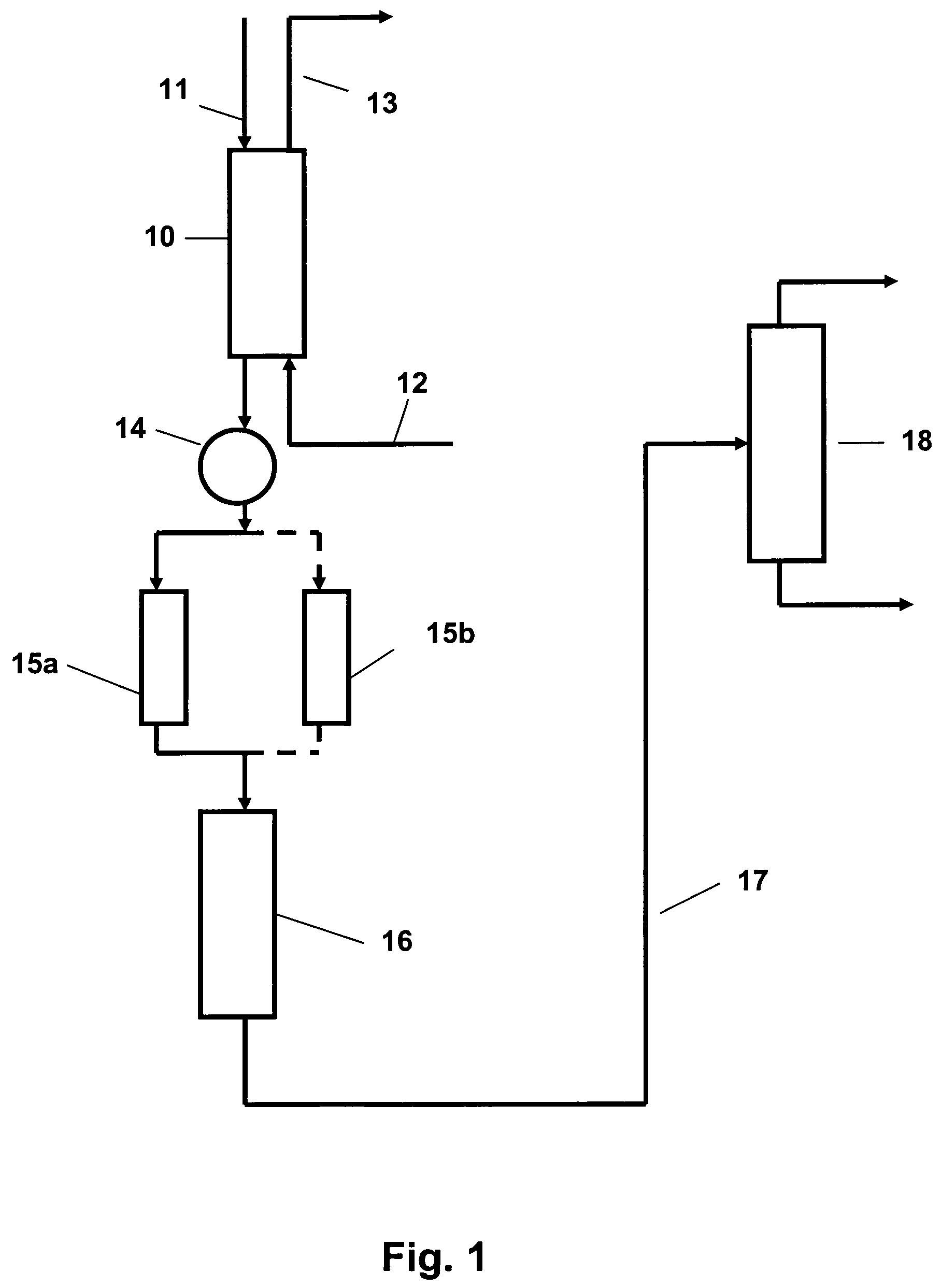

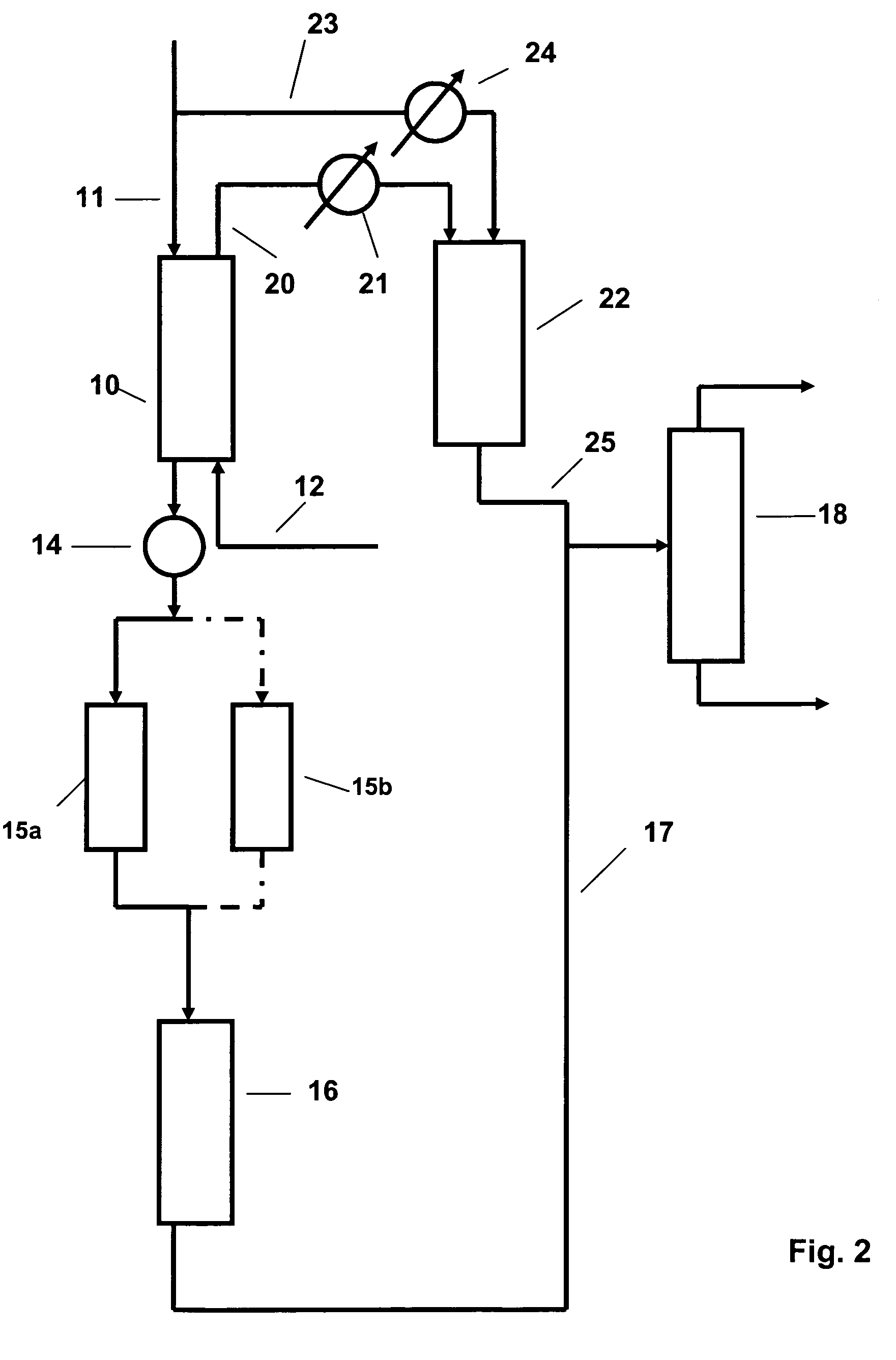

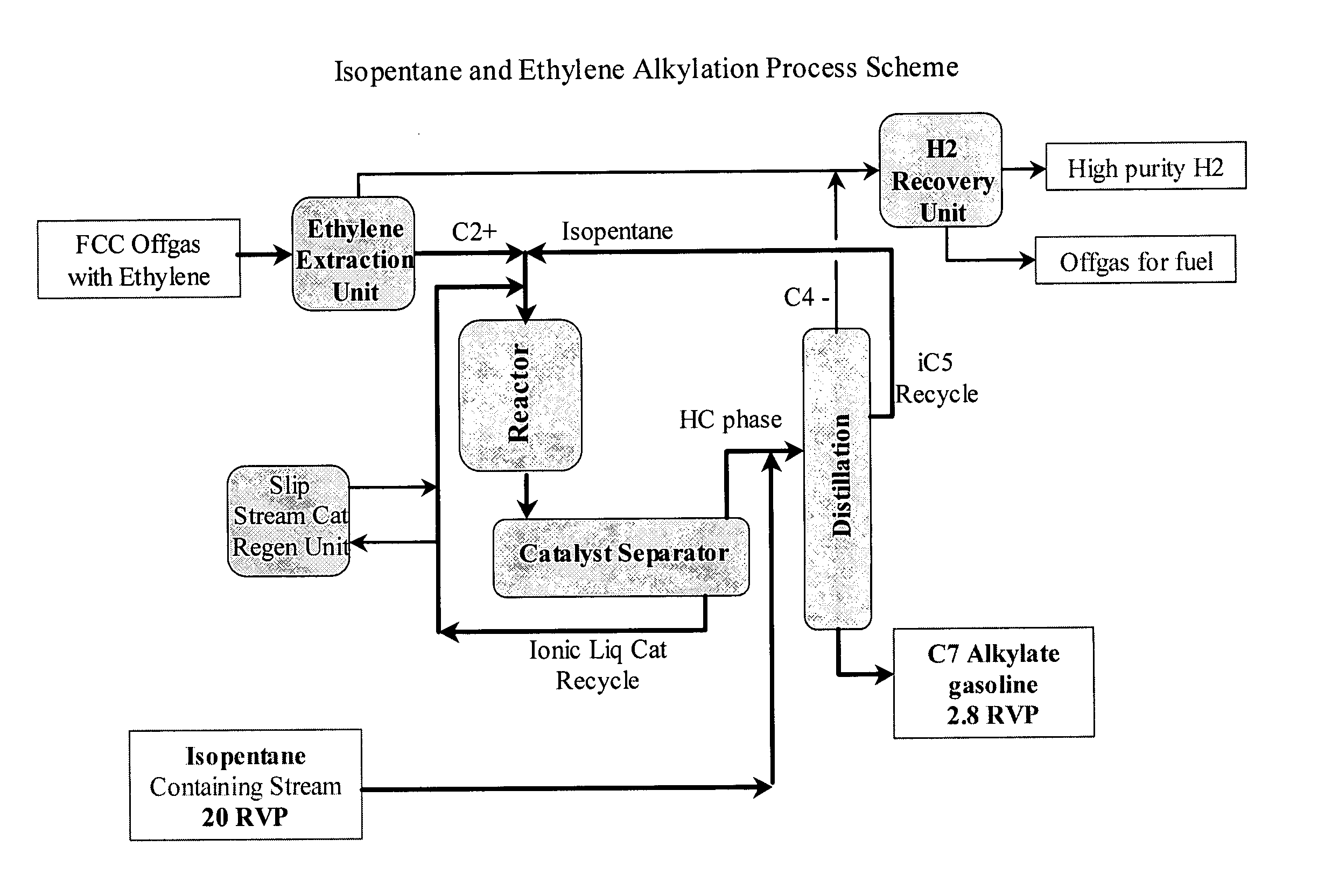

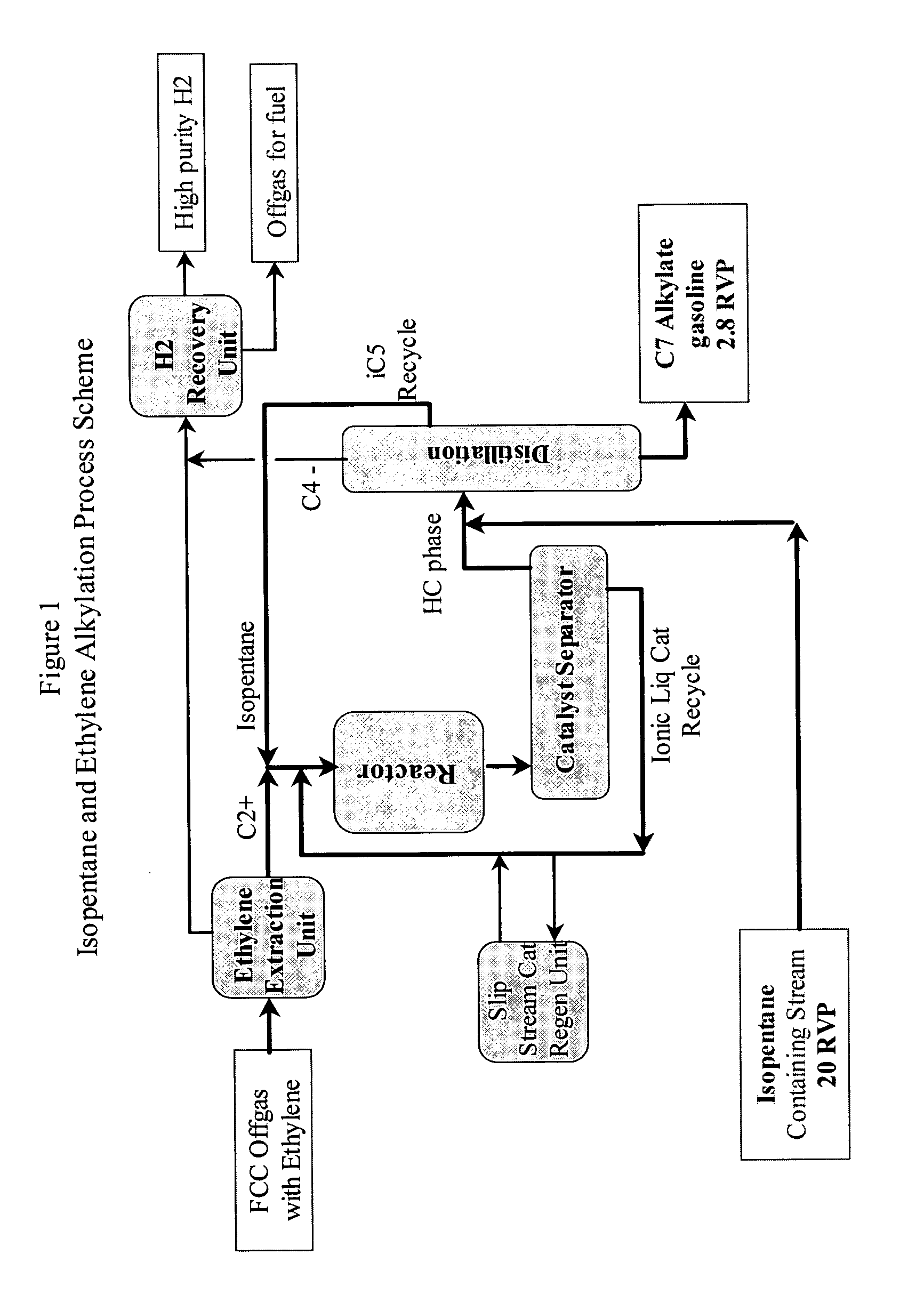

Integrated alkylation process using ionic liquid catalysts

ActiveUS7432408B2Easy to operateReduce gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

Process for producing light olefins

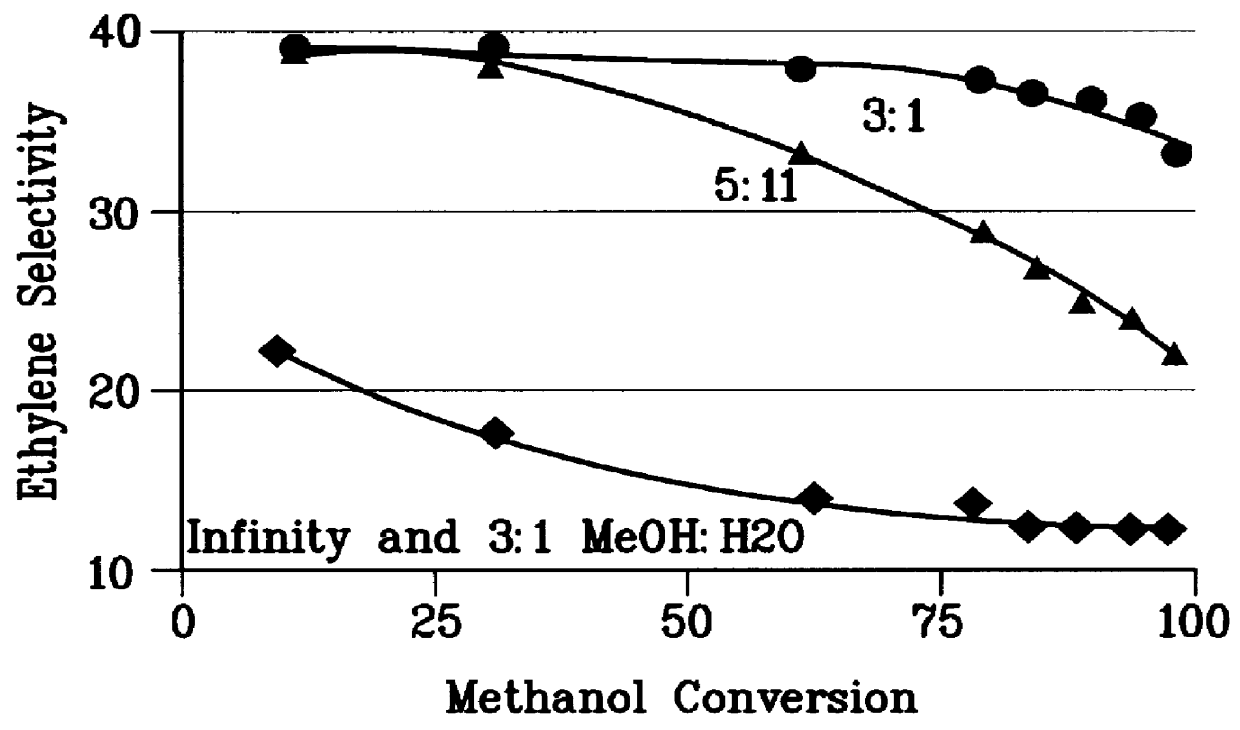

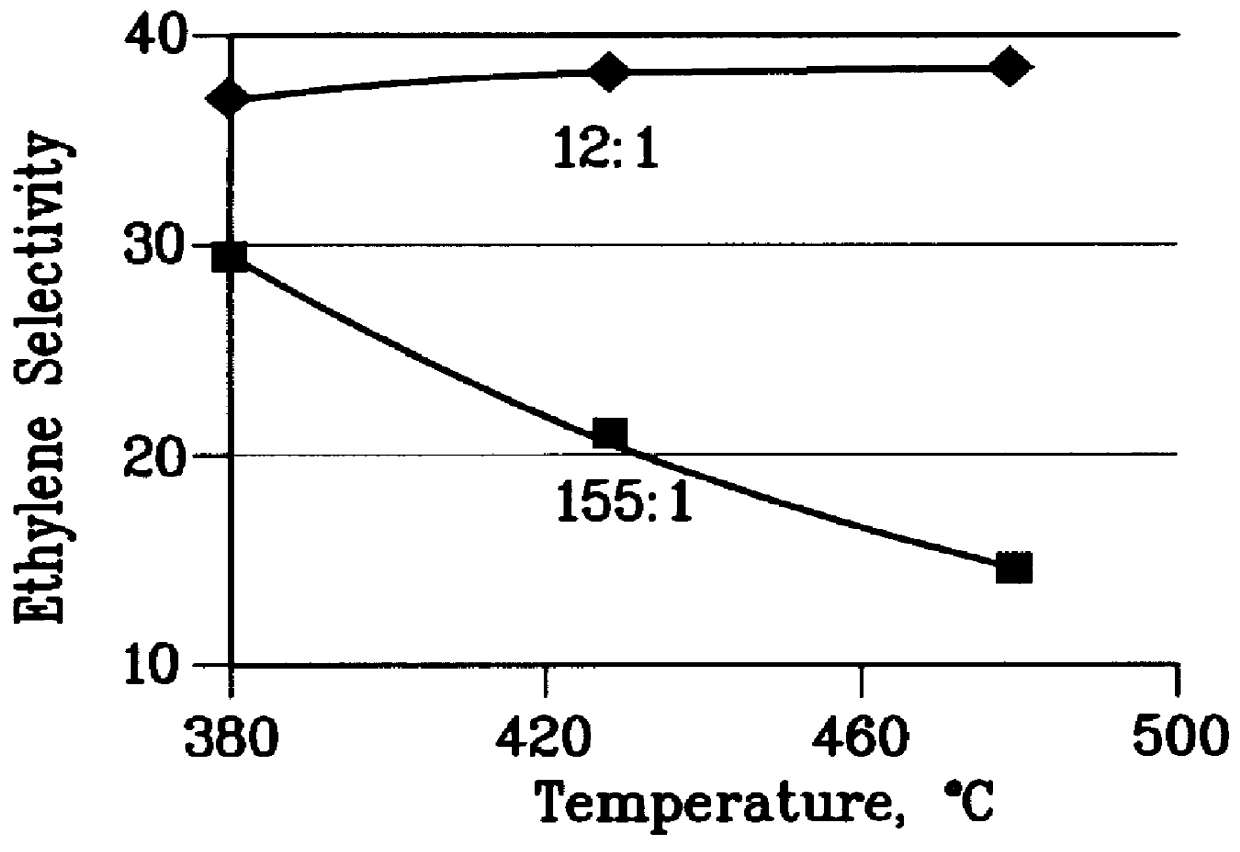

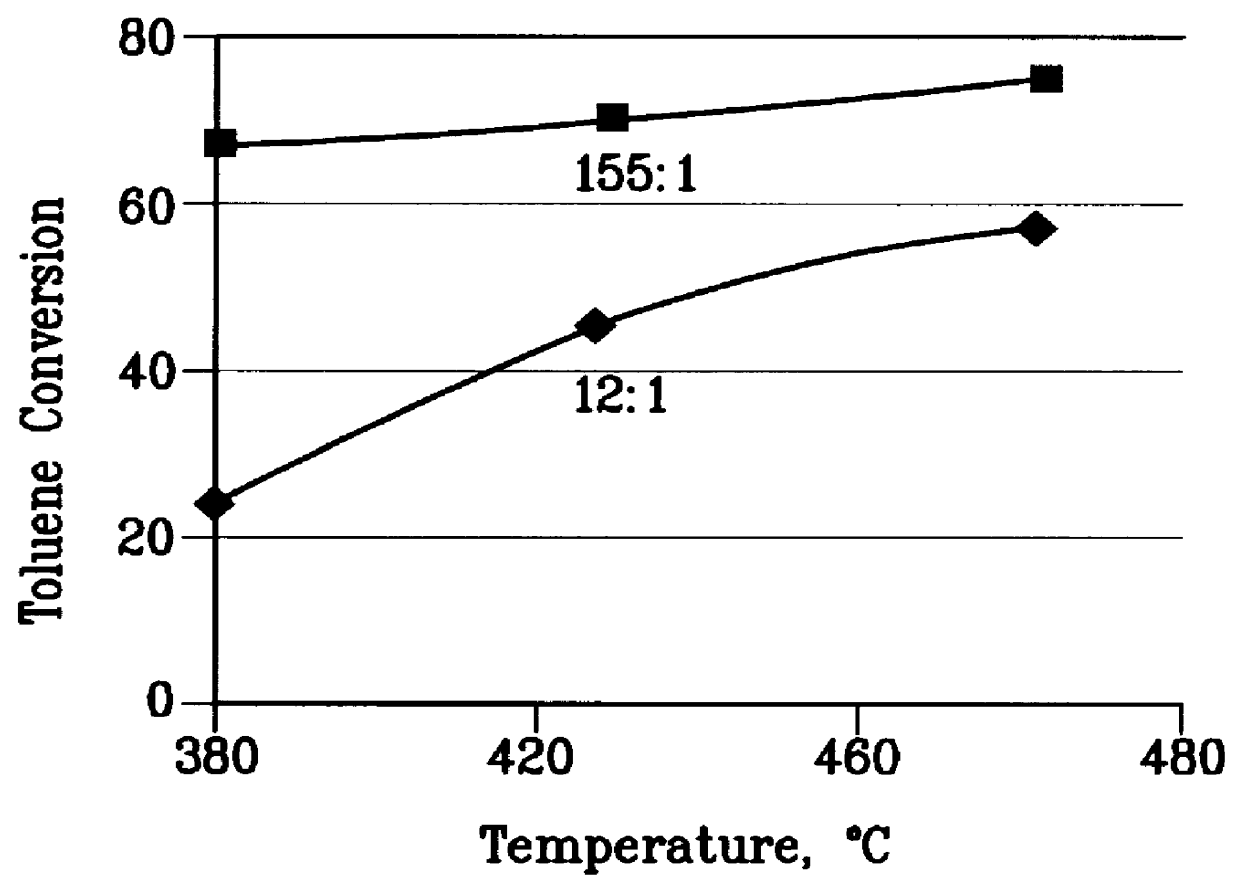

InactiveUS6046372AMolecular sieve catalystsMolecular sieve catalystAlkyl transferCrystalline materials

There is provided a process for converting methanol and / or dimethyl ether to a product containing C2 to C4 olefins which comprises the step of contacting a feed which contains methanol and / or dimethyl ether with a catalyst comprising a porous crystalline material, said contacting step being conducted in the presence of an aromatic compound under conversion conditions including a temperature of 350 DEG C. to 480 DEG C. and a methanol partial pressure in excess of 10 psia (70 kPa), said porous crystalline material having a pore size greater than the critical diameter of the aromatic compound and the aromatic compound being capable of alkylation by the methanol and / or dimethyl ether under said conversion conditions.

Owner:MOBIL OIL CORP

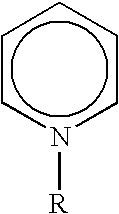

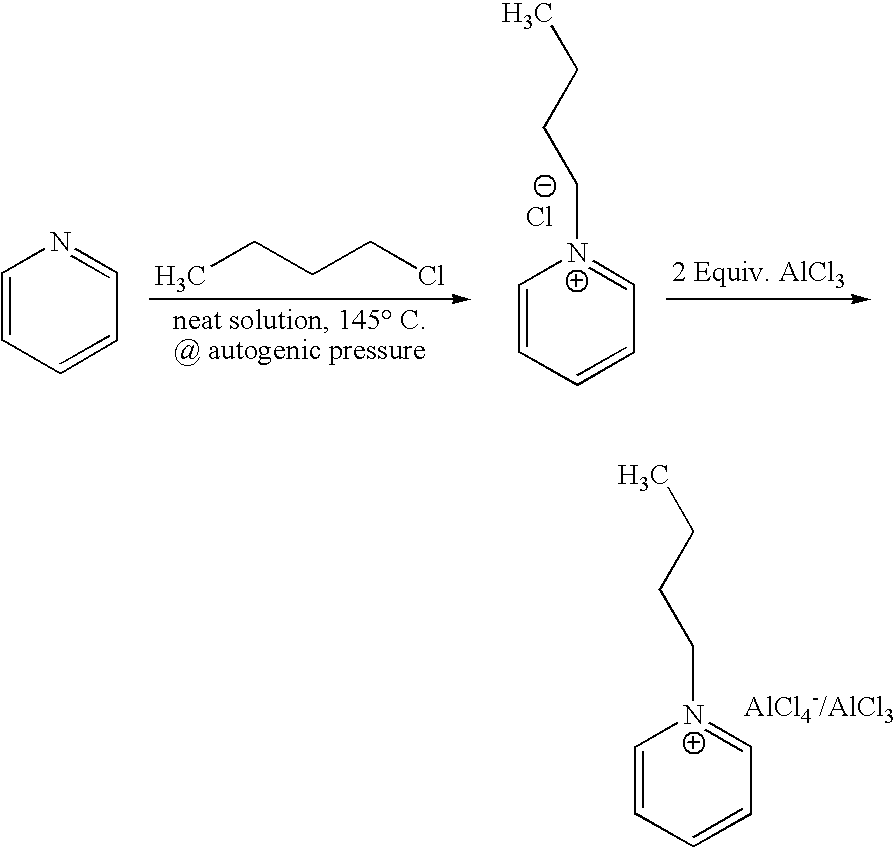

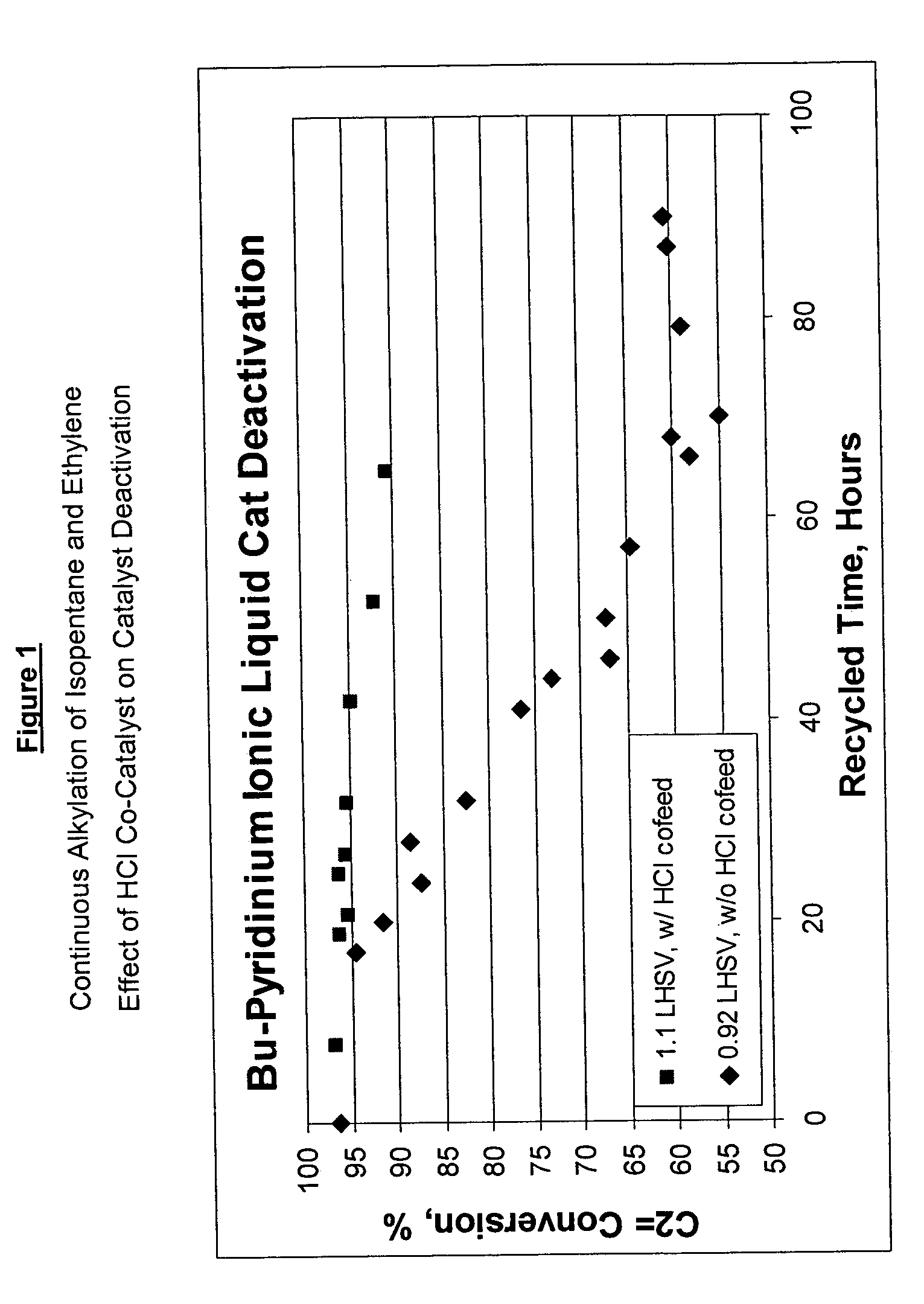

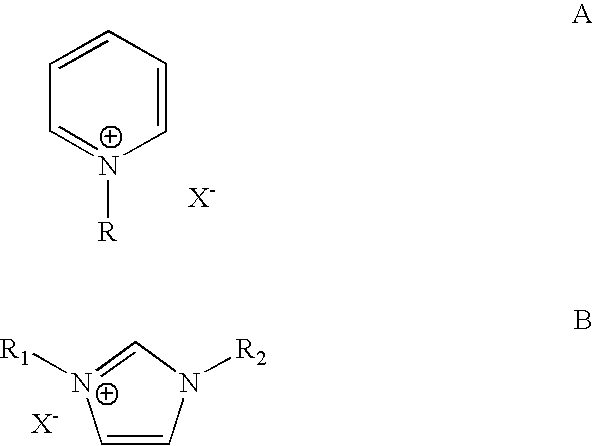

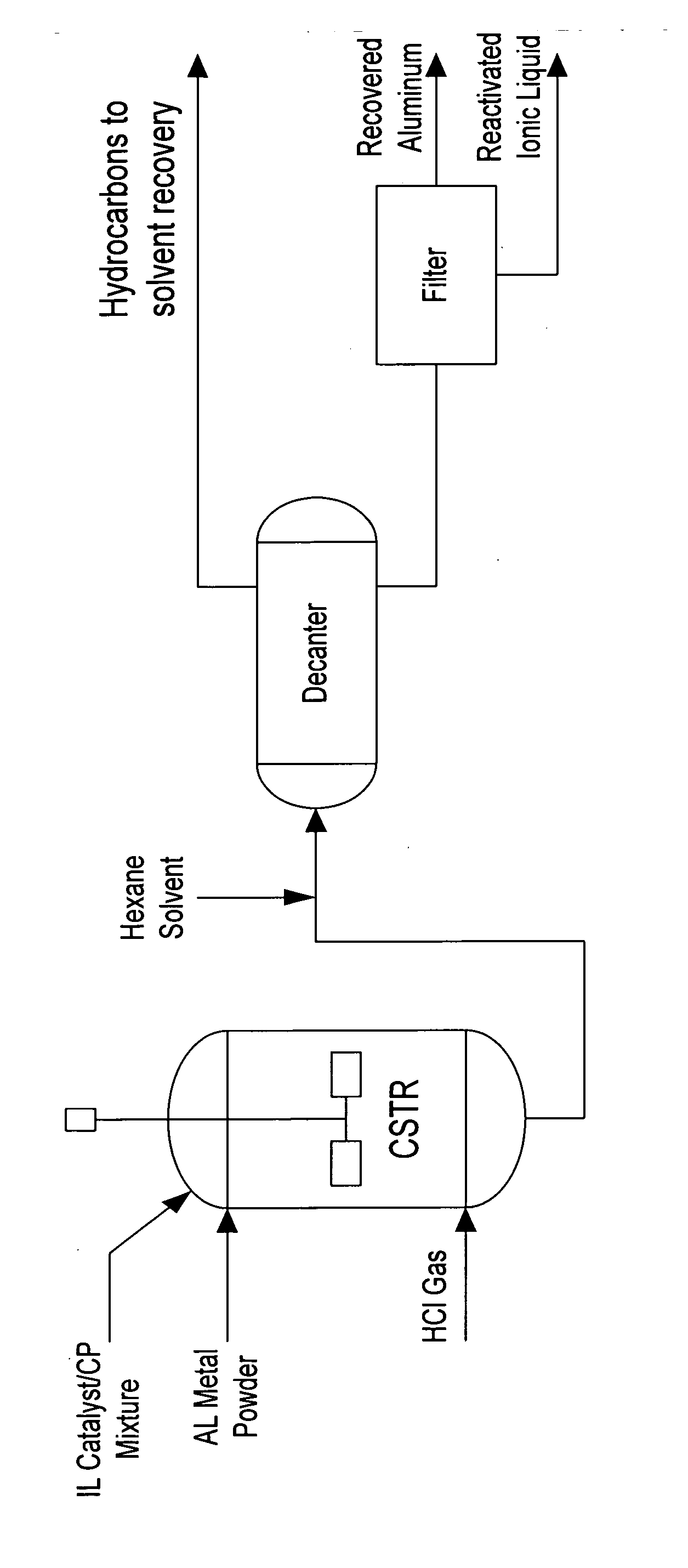

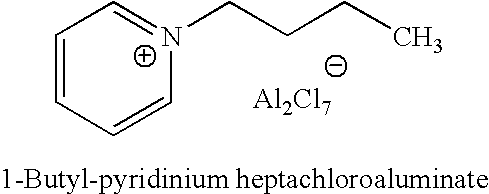

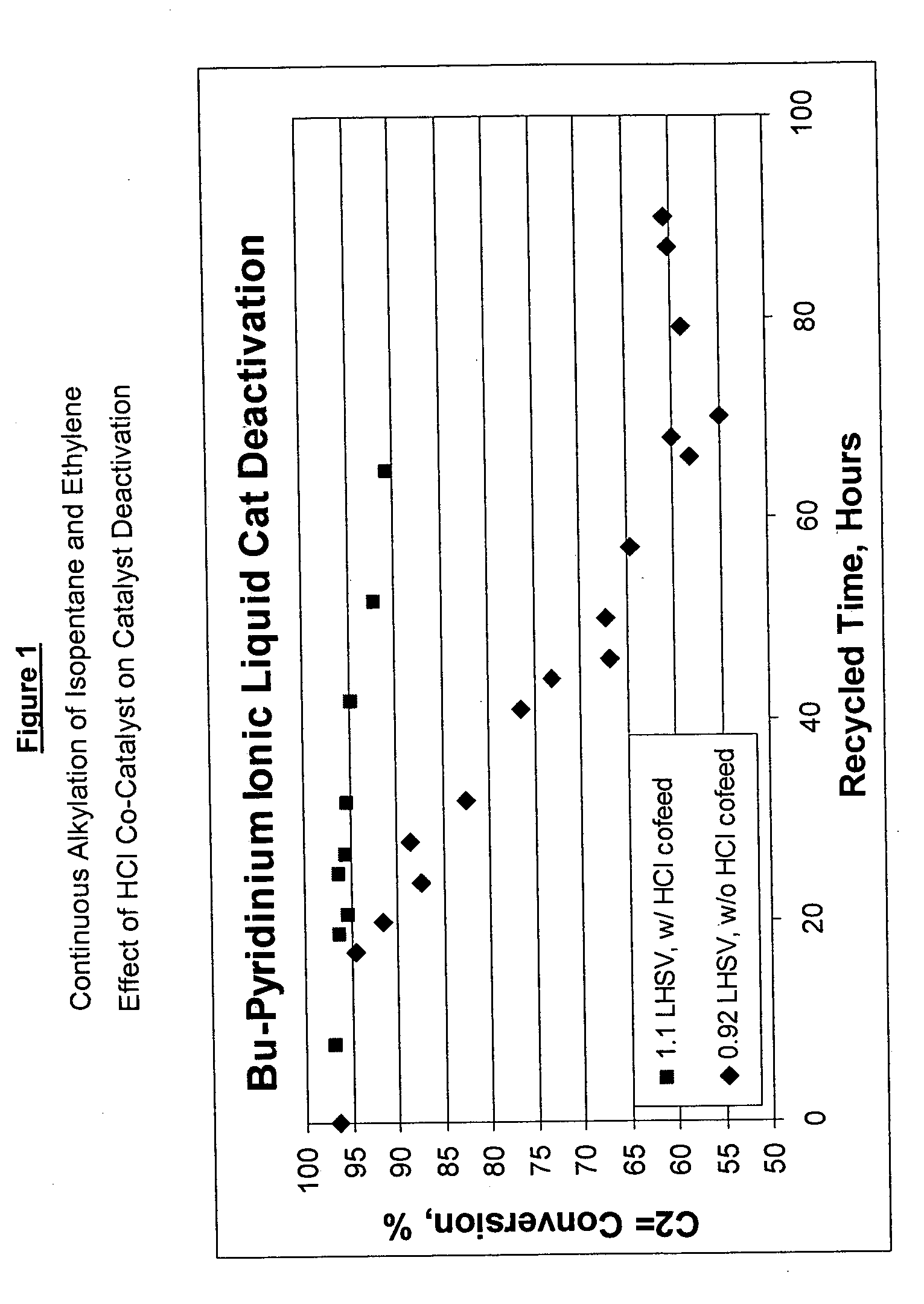

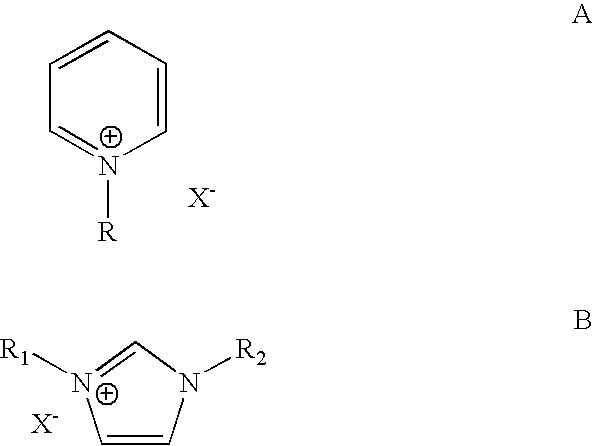

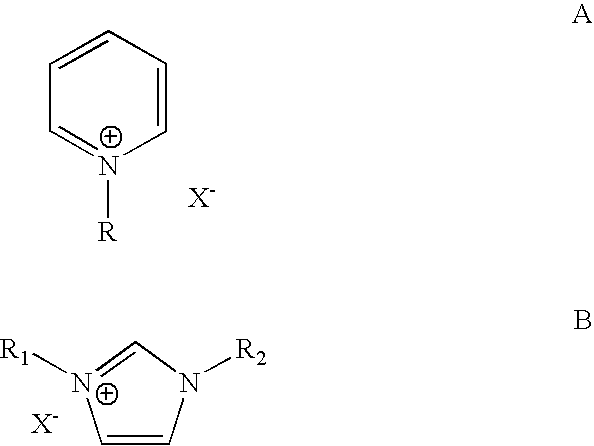

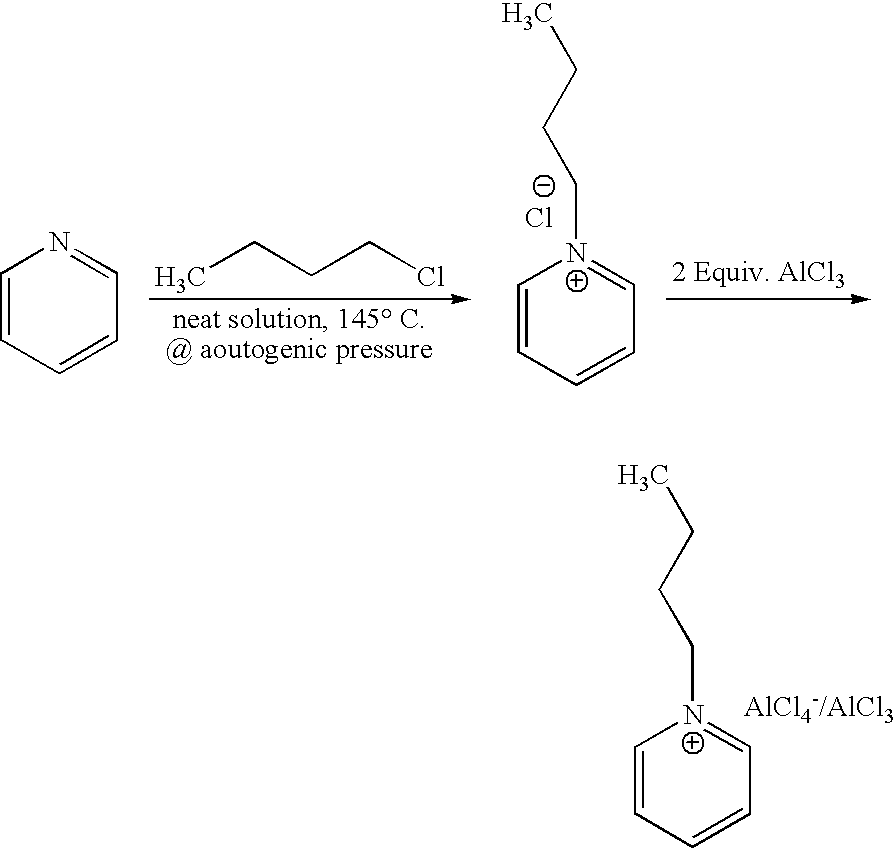

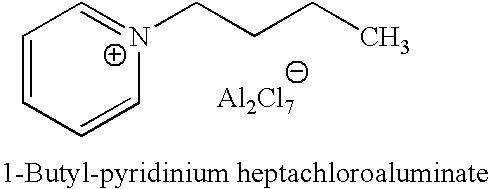

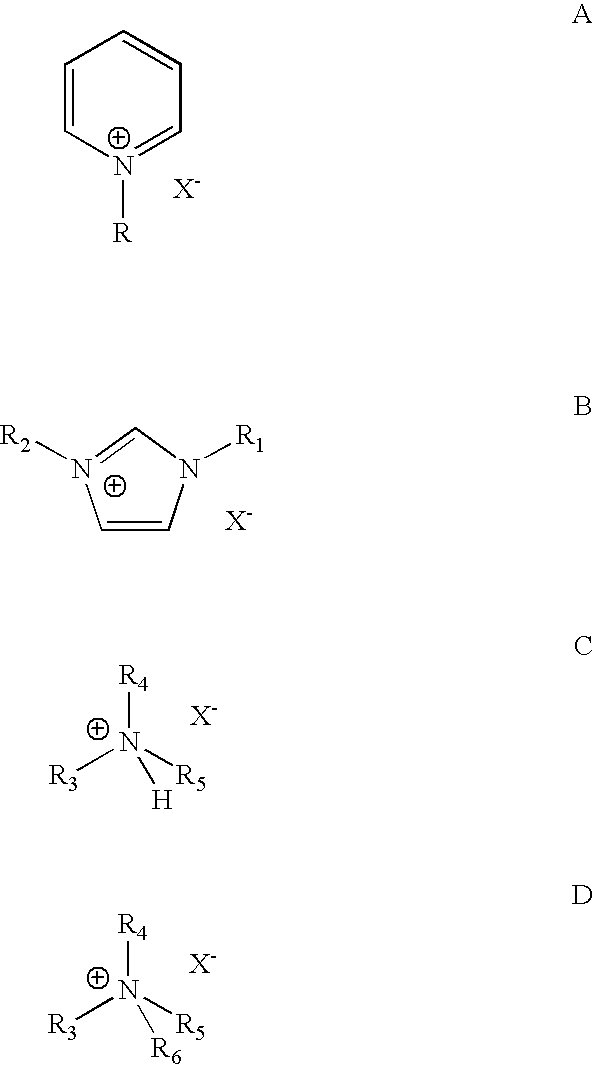

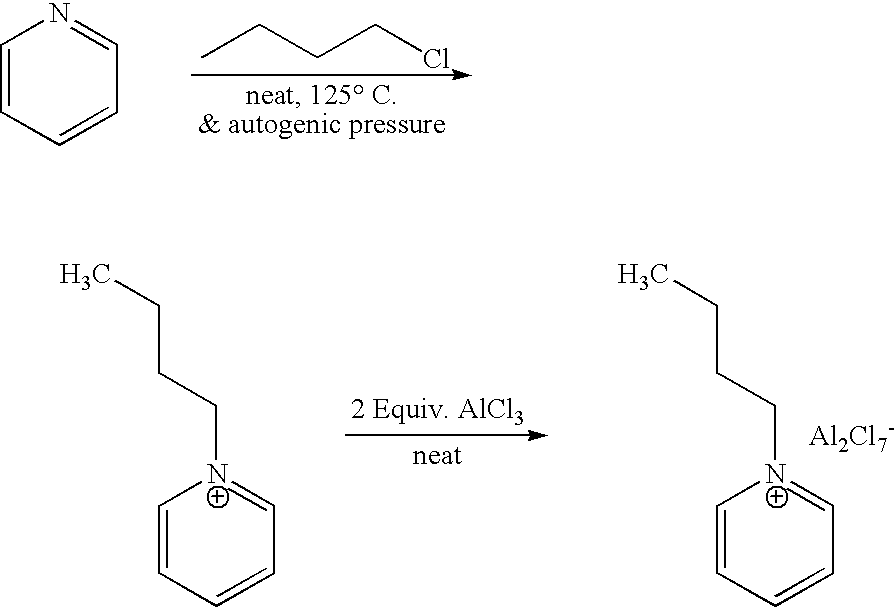

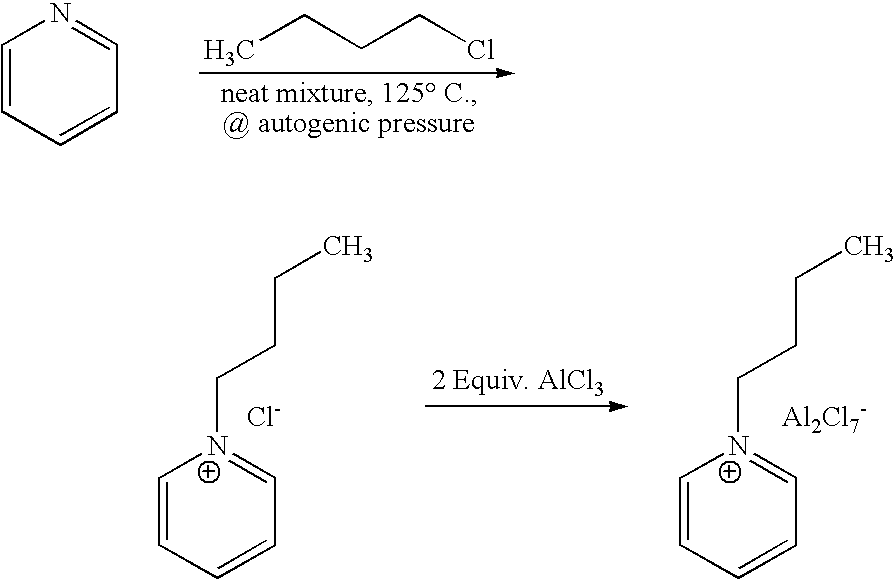

Alkylation process using an alkyl halide promoted ionic liquid catalyst

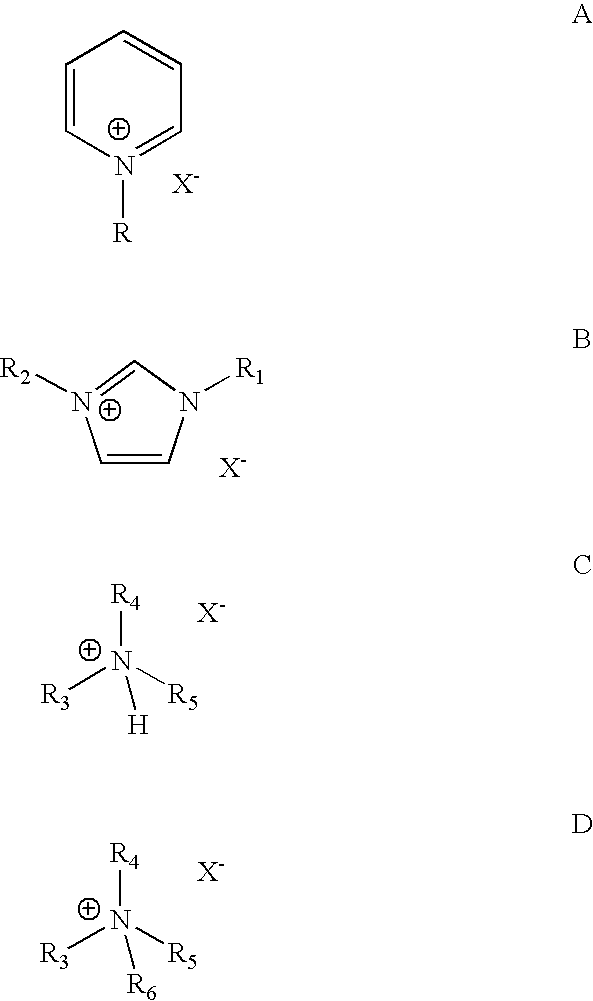

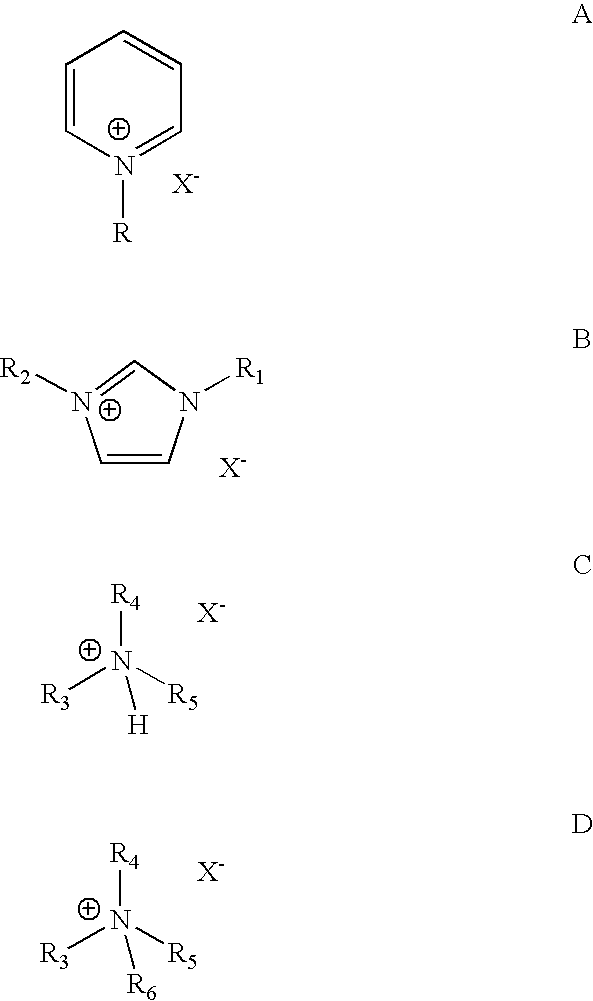

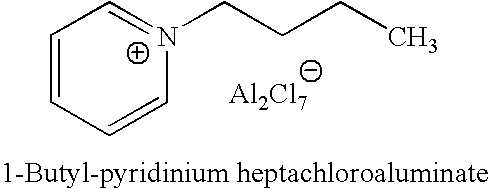

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. In one embodiment, the acidic ionic liquid is chloroaluminate ionic liquid prepared by mixing aluminum trichloride (AlCl3) and a hydrocarbyl substituted pyridinium halide, a hydrocarbyl substituted imidazolium halide, trialkylammonium hydrohalide or tetraalkylammonium halide of the general formulas A, B, C and D, respectively,where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same, and R3, R4, and R5 and R6=methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R3, R4, R5 and R6 may or may not be the same.

Owner:CHEVROU USA INC

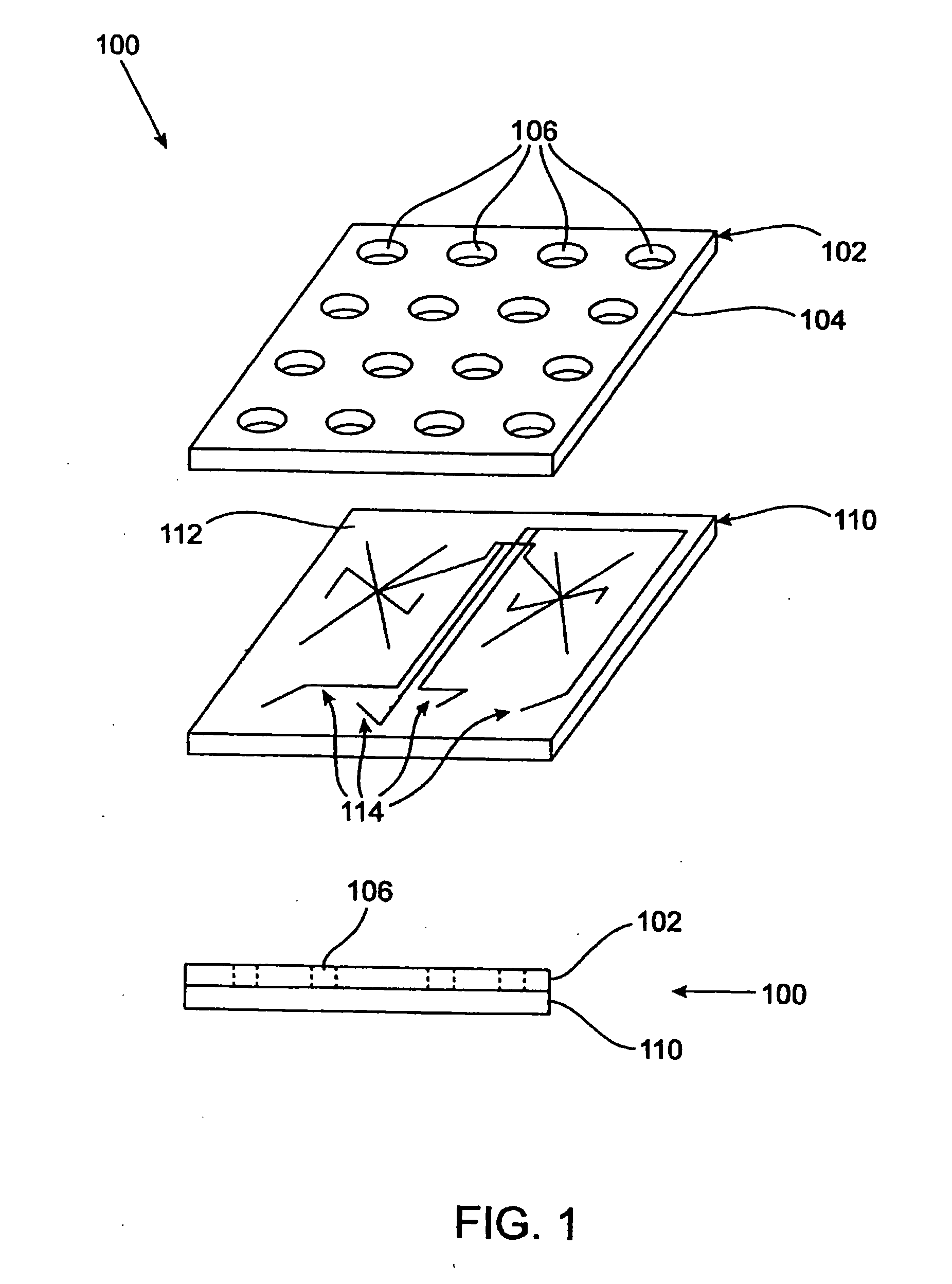

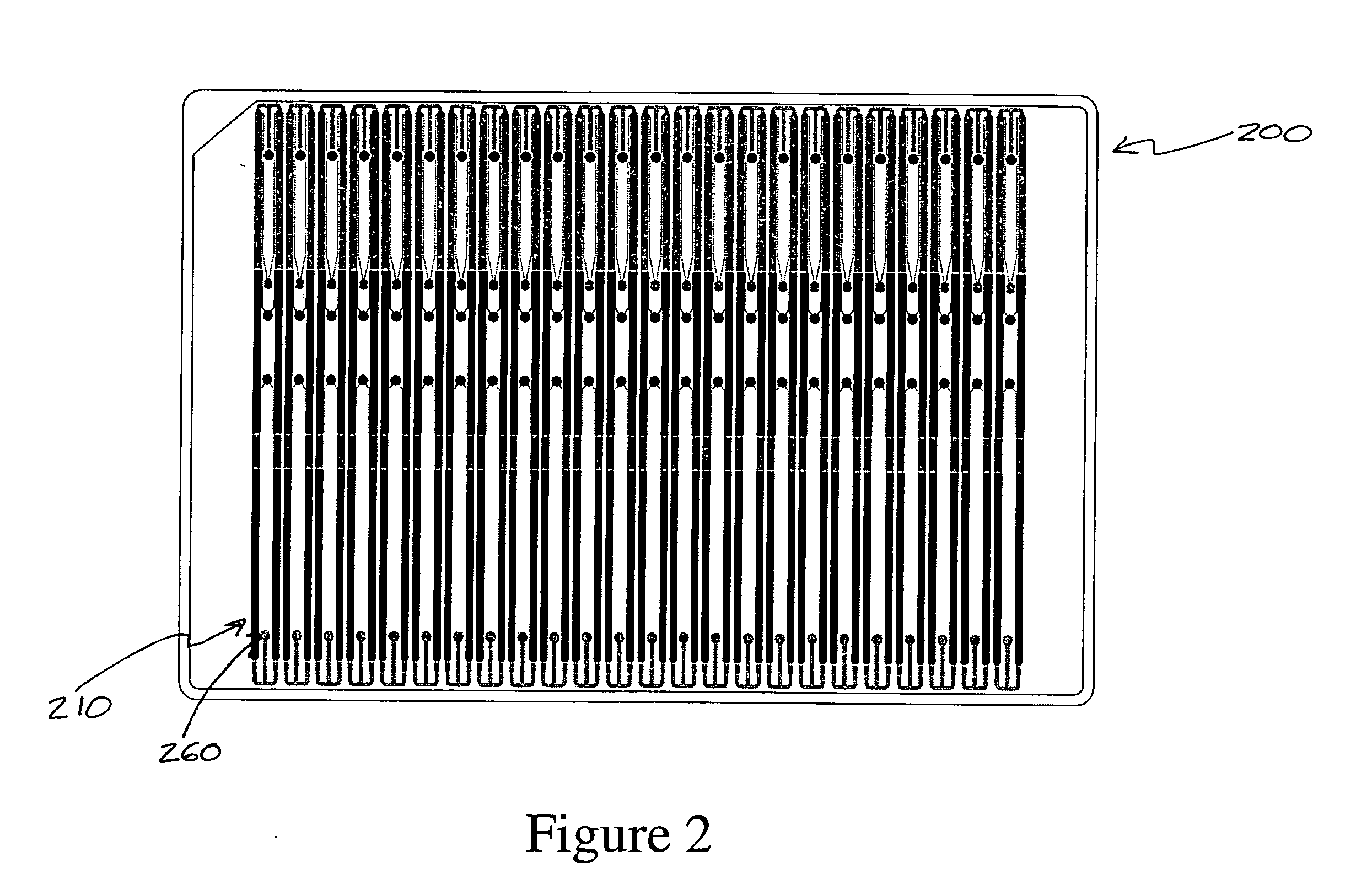

Method and apparatus for performing peptide digestion on a microfluidic device

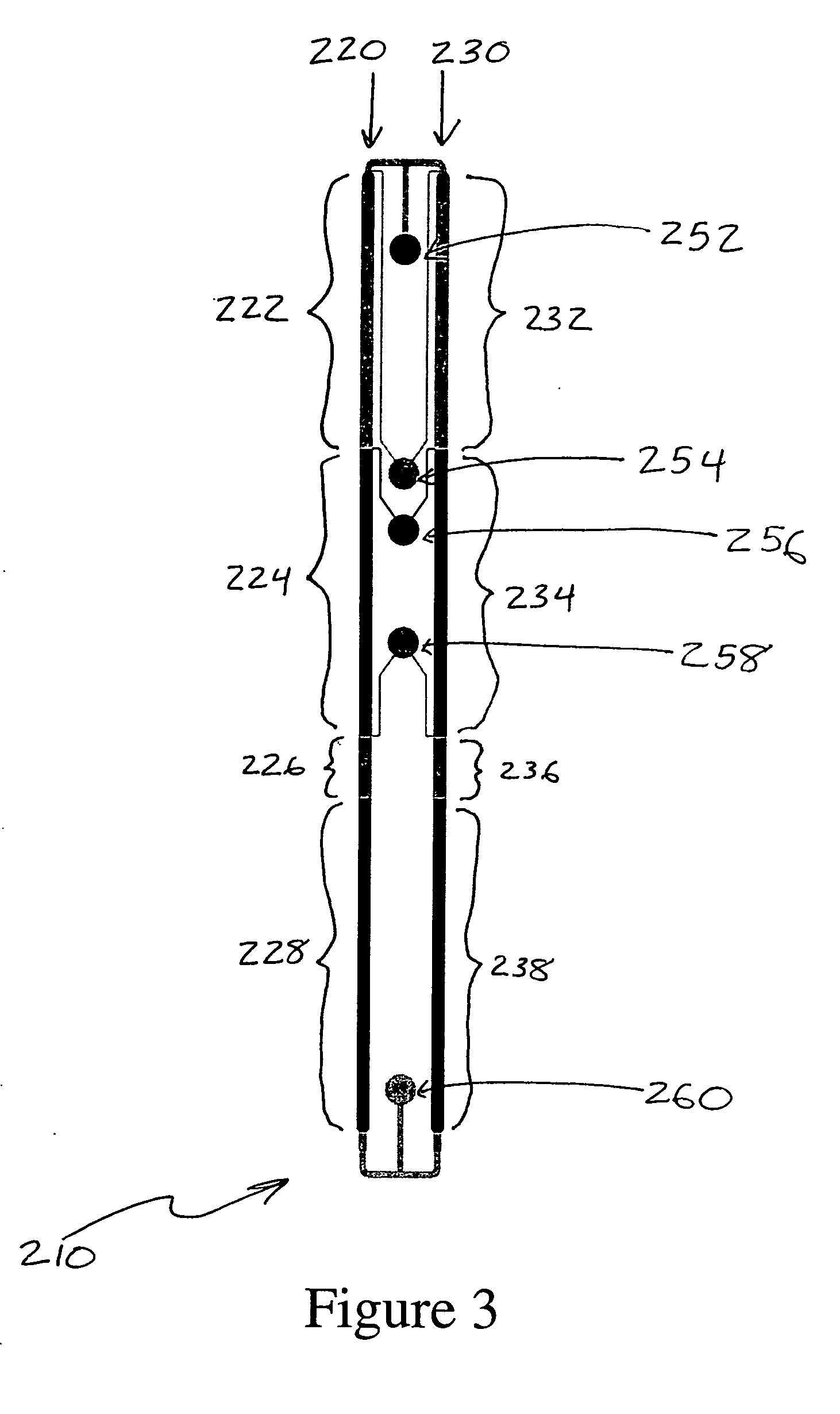

ActiveUS20060246533A1Microbiological testing/measurementMaterial analysisAlkyl transferContinuous flow

The invention provides methods and apparatuses that allow a protein sample to undergo reduction, alkylation, and digestion in a continuous flow process carried out within a microfluidic device. Methods and apparatuses in accordance with the invention can be employed as part of an automated proteomics analysis carried out in an integrated proteomics system.

Owner:CAPLIPER LIFE SCI INC

Selectively N-alkylated peptidomimetic combinatorial libraries and compounds therein

The instant invention is directed to a single, selectively N-alkylated compound and libraries of such compounds as set forth in Formula I. Furthermore, the instant invention is directed to methods of effecting analgesia, a decrease in the postprandial rise in the blood glucose levels of a mammal after ingestion of a carbohydrate load by said mammal, and treating microbial infections, utilizing such a single compound of Formula I in conjunction with a pharmaceutically-acceptable carrier. Also, the instant invention is directed to methods for selective alkylation, positional scanning and iterative synthetic and screening technologies.

Owner:LION BIOSCIENCE AG

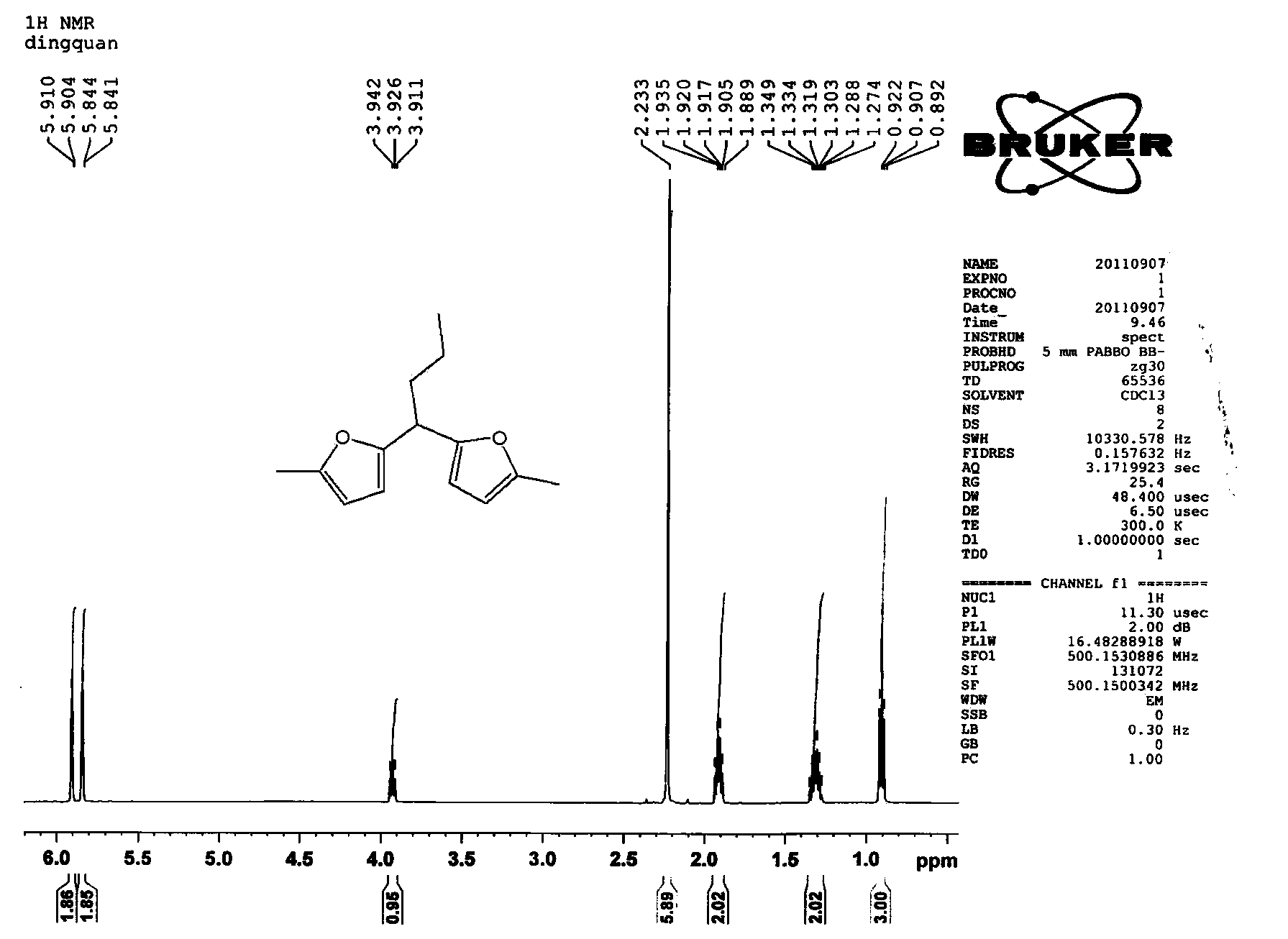

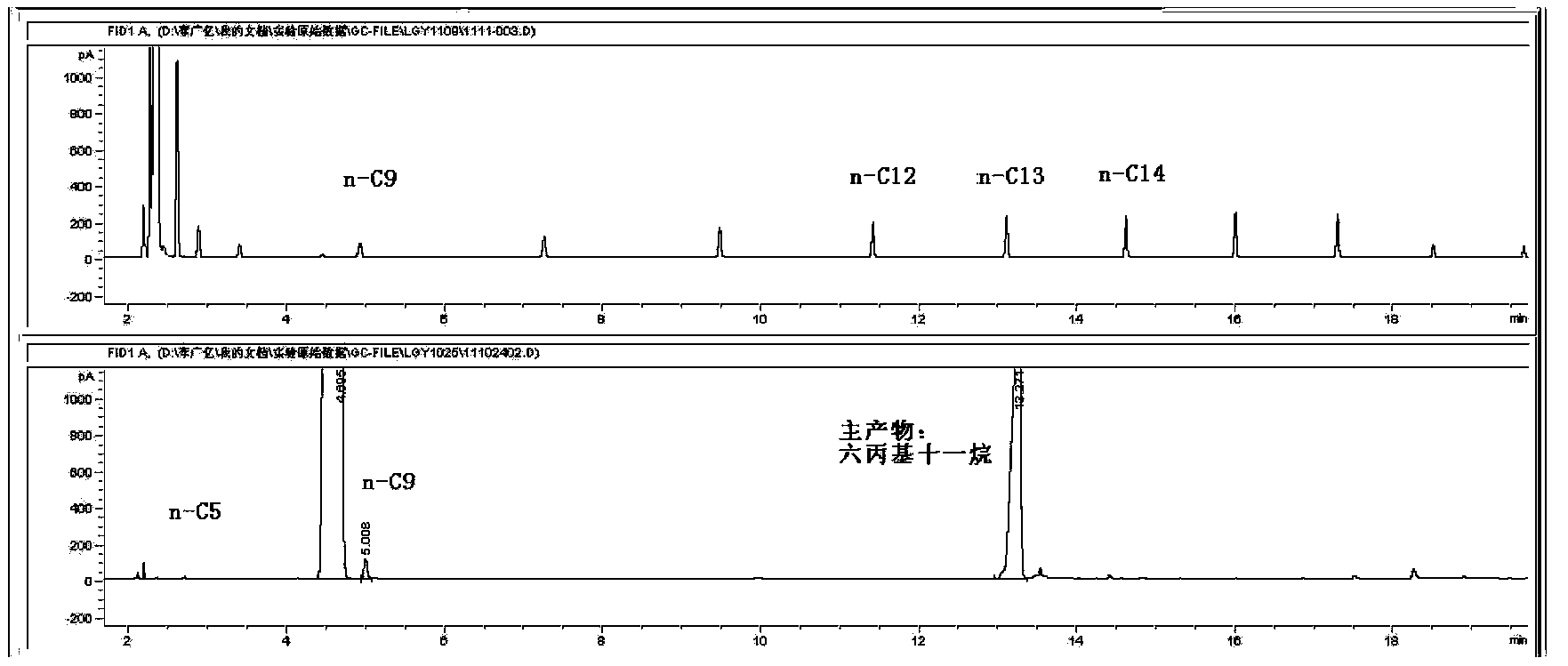

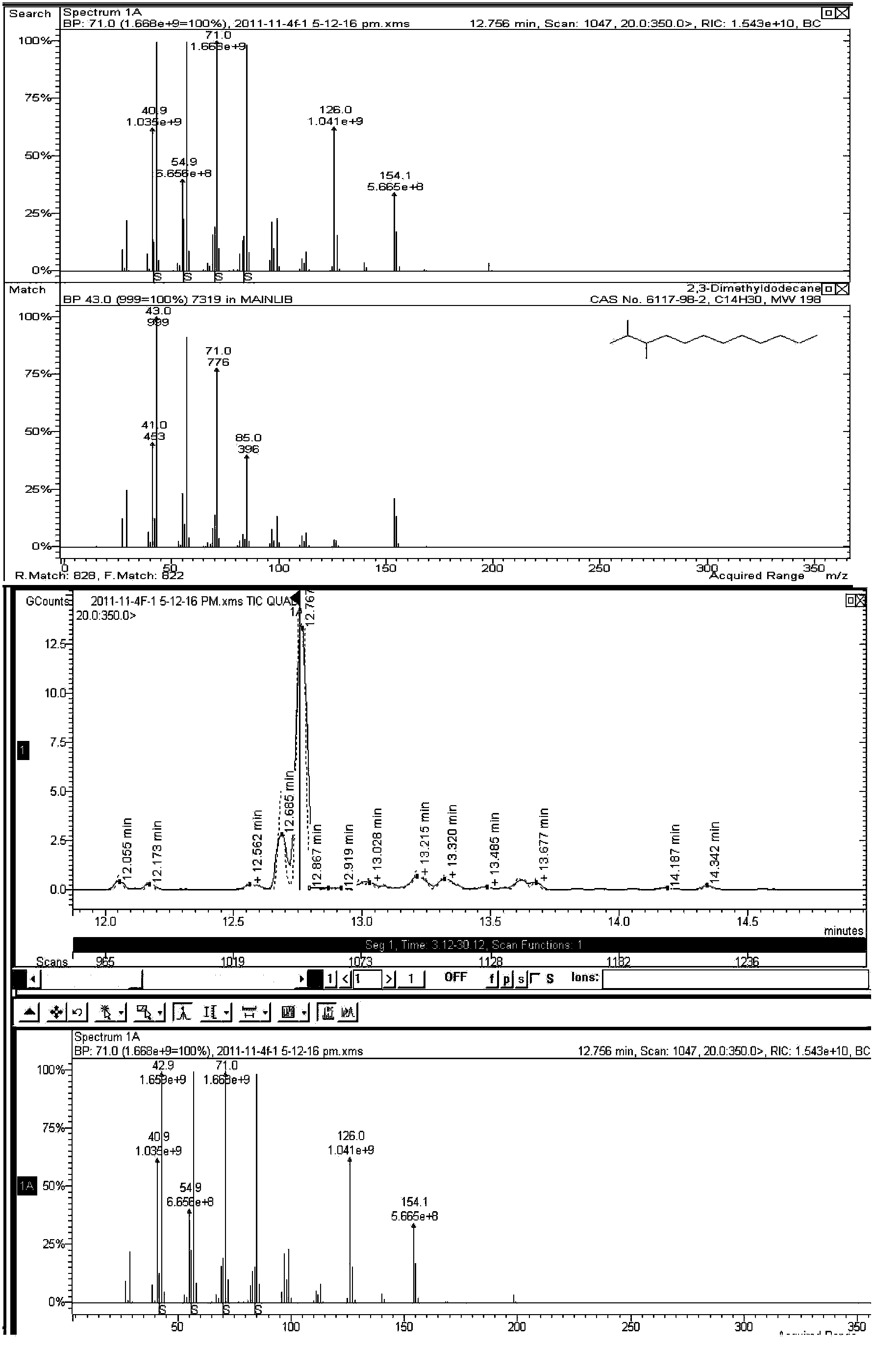

Preparation method of aviation kerosene or diesel

The present invention relates to a novel synthetic route of a liquid chain hydrocarbon fuel totally independent of fossil energy based on a lignocellulose raw material to obtain a platform compound. The method includes three parts: 1) preparing oxygen-containing organic compounds with carbon chain length of 8-16 through the acid-catalyzed alkylation reaction by taking lignocelluloses-based carbonyl-containing platform compounds and furan platform compounds as raw materials on a novel solid catalyst; 2) effectively removing carbon-carbon double bonds and carbon-oxygen double bonds to prepare saturated oxygen-containing organic compounds by hydrogenation of the alkylated product; and 3) conducting hydrodeoxygenation for the hydrogenated alkylation product by using a metal-solid acid bifunctional catalyst to obtain the biomass aviation kerosene or high grade diesel fuel with the carbon chain length of 8-16 and having a high energy density and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Liquid phase aromatics alkylation process

InactiveUS7476774B2Improve overall utilizationEasy to useLiquid carbonaceous fuelsHydrocarbonsAlkylationChemistry

A process for the production of high octane number gasoline from light refinery olefins and benzene-containing aromatic streams such as reformate. Light olefins including ethylene and propylene are extracted from refinery off-gases, typically from the catalytic cracking unit, into a light aromatic stream such as reformate containing benzene and other single ring aromatic compounds which is then reacted with the light olefins to form a gasoline boiling range product containing akylaromatics. The alkylation reaction is carried out in the liquid phase with a catalyst which preferably comprises a member of the MWW family of zeolites such as MCM-22 using a fixed catalyst bed.

Owner:EXXON RES & ENG CO

Alkylation process using chloroaluminate ionic liquid catalysts

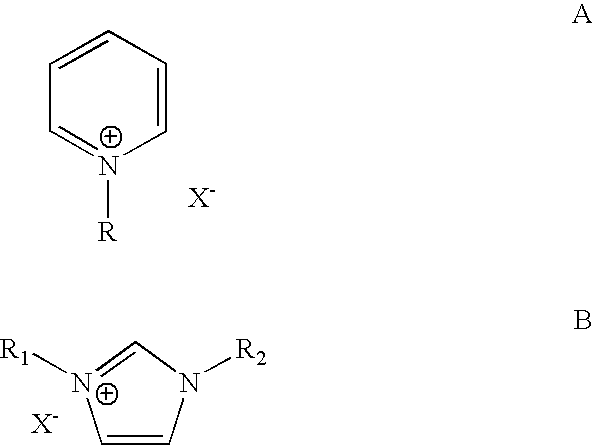

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium chloroaluminate or a hydrocarbyl substituted imidazolium chloroaluminate of the general formulas A and B, respectively.Where R═H, methlyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a chloroaluminate, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

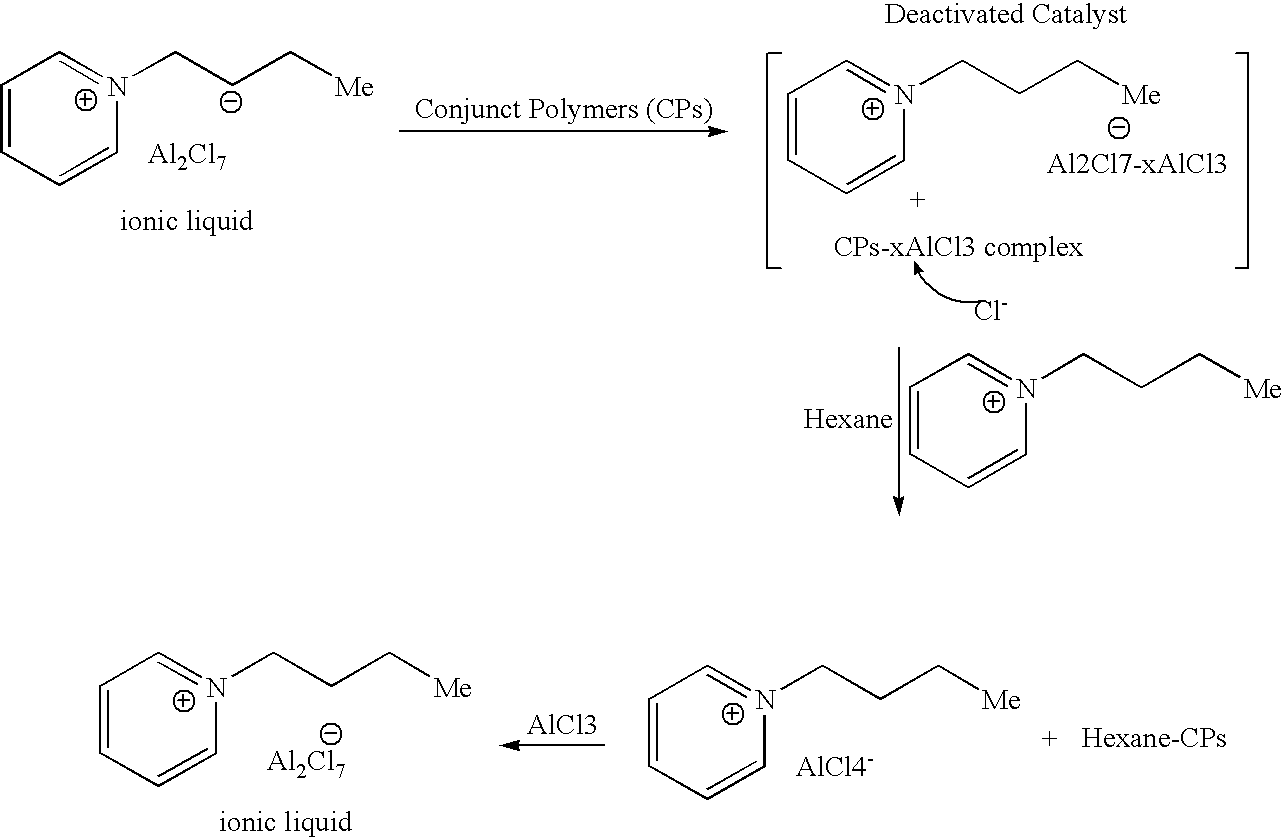

Regeneration of acidic catalysts

ActiveUS20070142213A1High activityChlorine/hydrogen-chloride purificationSulfur compoundsAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

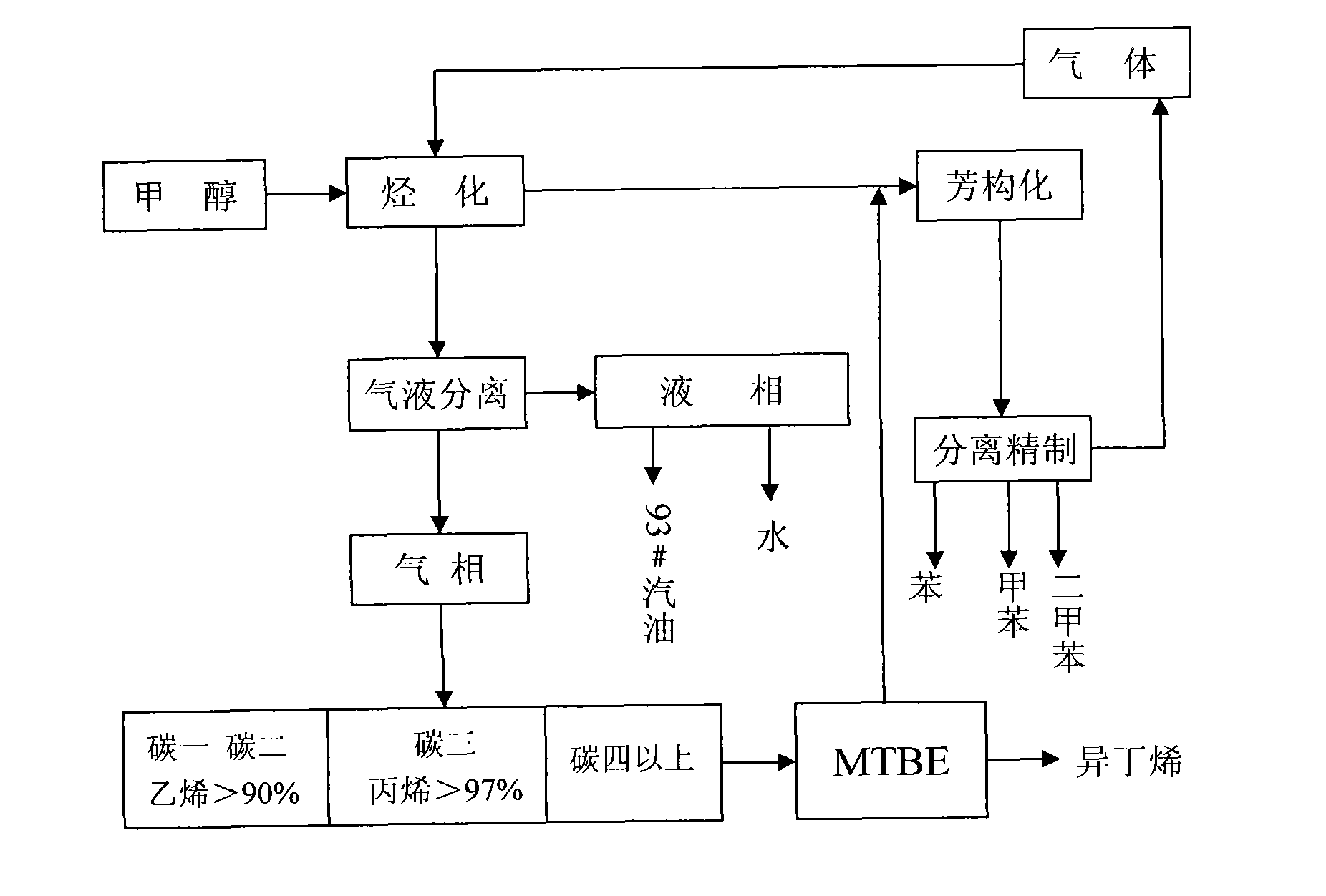

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

InactiveCN102146010ALow costReduce energy consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionEnvironmental resistanceCogeneration

The invention discloses a process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as a raw material. In the process, the methanol is used as the raw material and a molecular sieve catalyst is adopted to produce the low carbon olefin and arene parallel cogeneration gasoline by a methanol alkylation reaction and aromatization. In the process, the coal-based methanol is used as the raw material and can replace the conventional petroleum raw material to cogenerate a basis organic chemical raw material, and thus, the dependence degree of the conventional petrochemical industry on the petroleum can be reduced. Meanwhile, the process is also beneficial for reducing the foreign dependence degree of national petroleum, the strategic safety of energy and resources is improved, the production process of the process has low discharge, low pollution and low energy consumption, the requirements on green and environment protection are met, and the process has the advantages of low production cost and strong market competitiveness.

Owner:江苏煤化工程研究设计院有限公司 +2

Alkylation process using chloroaluminate ionic liquid catalysts

ActiveUS20060135839A1Quality improvementLiquid hydrocarbon mixtures productionHydrocarbons2-methylbutanePyridinium

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The process includes reacting a refinery stream containing isopentane and / or isobutane with a refinery stream containing ethylene and / or propylene and butylenes under alkylation conditions in the presence of a chloroaluminate ionic liquid catalyst comprising a hydrocarbyl substituted pyridinium halide or a hydrocarbyl substituted imidazolium halide of the general formulas A and B, respectively. Where R=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and X is a halide and preferably a chloride, and R1 and R2=H, methyl, ethyl, propyl, butyl, pentyl or hexyl group and where R1 and R2 may or may not be the same.

Owner:CHEVROU USA INC

Method of producing an aromatics alkylation catalyst

This invention provides a method of producing an aromatics alkylation catalyst comprising the steps of: (a) synthesizing a layered oxide material MCM-56 in the presence of alkali and / or alkaline earth metal cations; (b) prior to any calcination of the MCM-56, subjecting the MCM-56 produced in step (a) to ammonium ion exchange so as to at least partially replace the alkaline or alkaline earth metal cations associated with the MCM-56 with ammonium ions; then (c) heating the ammonium-exchanged MCM-56 to decompose the ammonium cations and convert the MCM-56 into the hydrogen form; and (d) after step (b), forming the MCM-56 into catalyst particles. The resultant catalyst exhibits enhanced activity in the alkylation of benzene with ethylene and propylene.

Owner:MOBIL OIL CORP

Integrated alkylation process using ionic liquid catalysts

ActiveUS20060131209A1Easy to operateReducing fuel gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

Alkylation process using an alkyl halide promoted ionic liquid catalyst

ActiveUS7531707B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsHydrogen halideAlkane

A process for the production of a high quality gasoline blending components from refinery process streams by the alkylation of light isoparaffins with olefins using an ionic liquid catalyst is disclosed. The alkylation process comprises contacting a hydrocarbon mixture comprising at least one olefin having from 2 to 6 carbon atoms and at least one isoparaffin having from 3 to 6 carbon atoms under alkylation conditions, said catalyst comprising a mixture of at least one acidic ionic liquid and at least one alkyl halide. The alkylhalide by reacting to at least a portion of the olefin with a hydrogen halide.

Owner:CHEVROU USA INC

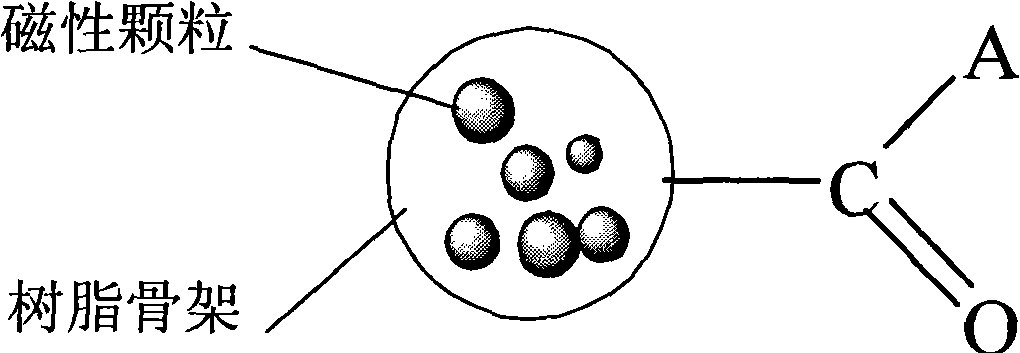

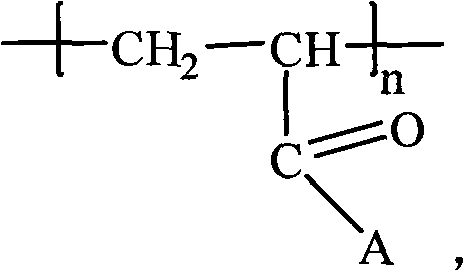

Magnetic acrylic acid series strongly basic anion exchange microballoon resin and preparation method thereof

ActiveCN101781437AIncrease switching capacityHigh base exchange capacityInorganic material magnetismAnion exchangersCross-linkIon exchange

The invention discloses a magnetic acrylic acid series strongly basic anion exchange microballoon resin and a preparation method thereof. The microballoon resin has the following structure: the resin skeleton is internally provided with magnetic particles, wherein A stands for a radical containing quaternary ammonium salt. The preparation method comprises the following steps: acrylic acid series substances serve as a monomer, the monomer is mixed with cross-linking agent and pore-forming agent to form oil phase; the oil phase is uniformly mixed with the magnetic particles and then suspension polymerization is carried out on the mixture; after going through amination and alkylation reaction, the polymerized magnetic polymer particles form the quaternary ammonium salt, namely the magnetic acrylic acid series strongly basic anion exchange microballoon resin. Exchange capacity of the resin is higher than any magnetic acrylic acid series strongly basic anion exchange microballoon resin ever found in existing literatures and reports and domestic market as well as foreign markets and can replace the traditional strongly basic anion exchange resin, thus being capable of being used for separating and removing soluble organisms in various water bodies, especially disinfection by-product precursor and multiple negative ions such as nitrate and phosphate.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

Anionic surfactants based on alkene sulfonic acid

InactiveUS6043391AIncrease productionImprove yieldGroup 3/13 element organic compoundsFlushingAlkylphenolAlpha-olefin

New anionic surfactants and methods of preparation which are derived from aromatic or substituted aromatic molecules and alkenesulfonic acid. Wherein the aryl compound is alkylated and sulfonated in one-step with an alkene sulfonic acid prior to sulfonic acid neutralization. The methods allow the functional sulfonate group to be attached to the end of the alkyl chain rather than to the aromatic ring thus allowing for selective substituted groups, either branched, linear or alkoxylated or combinations thereof to be placed on the aryl compound prior to sulfonation and alkylation. The invention uses the alkene sulfonic acid produced from thin-film sulfonation of an alpha-olefin to alkylate benzene, mono-substituted aromatic, poly-substituted aromatic, alkylbenzene, alkoxylated benzene, polycyclic aromatic, mono-substituted polycyclic aromatic, poly-substituted polycyclic aromatic, naphthalene, alkylnaphthalene, phenol, alkylphenol, alkoxylated phenol, and alkoxylated alkylphenolalkyl substituted or polysubstituted cyclic or polycyclic compounds to produce the corresponding sulfonic acid having an additional alkyl group derived from the alpha-olefin used during the thin-film sulfonation which is either linear or branched.

Owner:OIL CHEM TECH

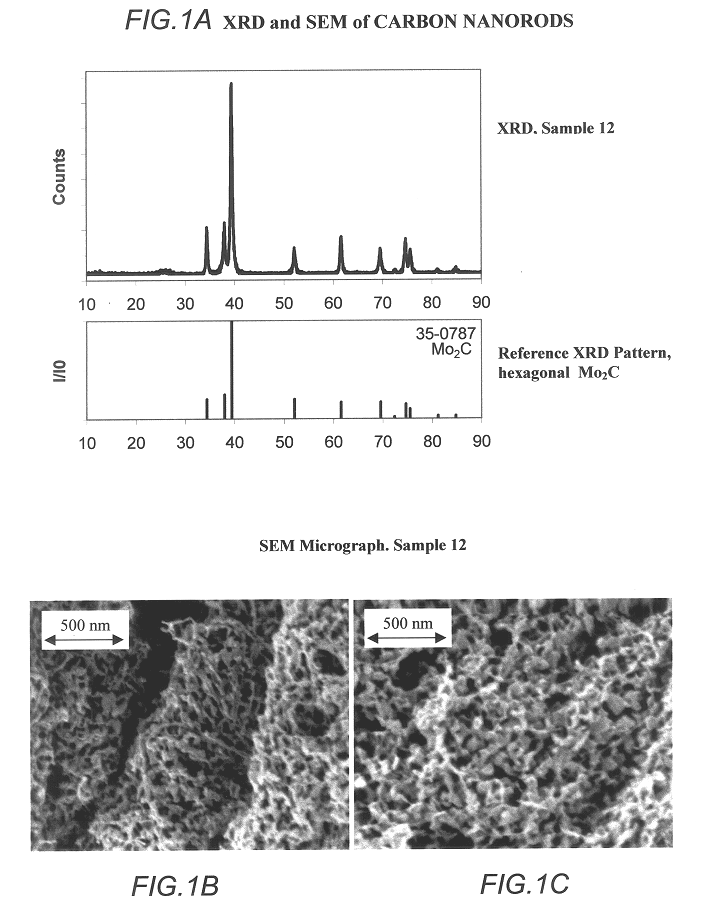

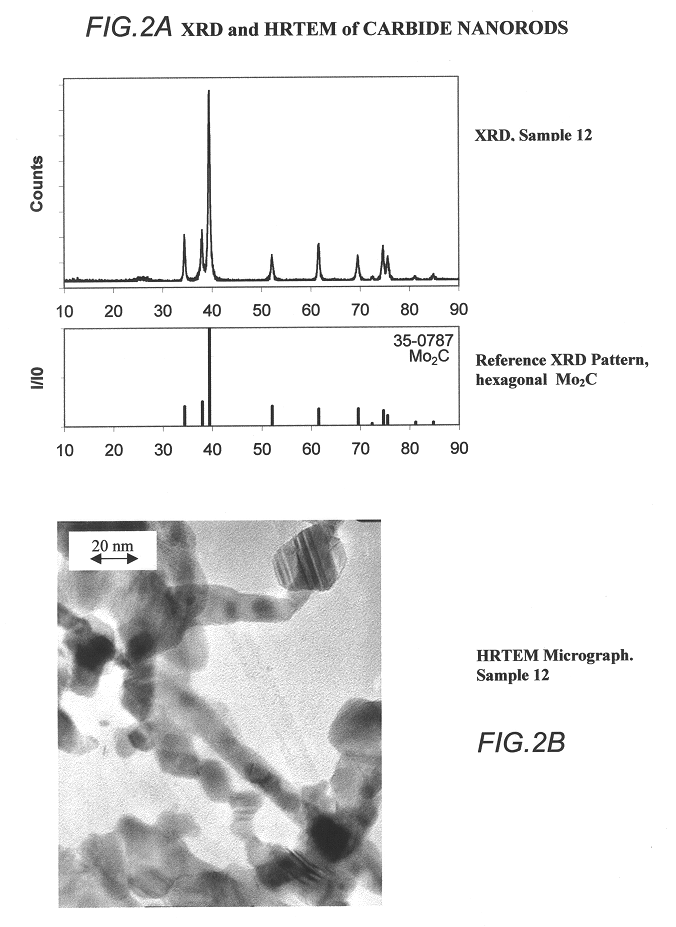

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS6514897B1Easy to diffuseSpeed up the flowMaterial nanotechnologyHydrocarbon by isomerisationIsomerizationChemical reaction

The present invention relates to compositions and rigid porous structures that contain nanorods having carbides and / or oxycarbides and methods of making and using such compositions and such rigid porous structures. The compositions and rigid porous structures can be used either as catalysts and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided. The fluid phase catalytic reactions catalyzed include hydrogenation hydrodesulfuriaation, hydrodenitrogenation, hydrodemetallization, hydrodeoxygenation, hydrodearomatization, dehydrogenation, hydrogenolyis, isomerization, alkylation, dealkylation, oxidation and transalkylation.

Owner:HYPERION CATALYSIS INT

Method for preparing styrene catalyst through toluene-methanol side chain alkylation

ActiveCN101623650AAvoid breakingImprove stabilityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferMolecular sieve

The invention relates to a method for preparing a styrene catalyst through toluene-methanol side chain alkylation, which mainly solves the problem that in the prior art, a catalyst has a vulnerable catalyst structure and poor catalyst stability. Through the technical scheme that an alkali molecular carrier is loaded with elements selected from B, P and at least one of alkali metal and alkaline-earth metal to prepare the catalyst, wherein the carrier is exchanged into an H-type molecular sieve by ammonium salt before loading, roasted, exchanged by alkali metal salt, dried, roasted and dipped with the loaded elements, the method well solves the problem of poor stability and can be used for industrial preparation of the styrene catalyst through toluene-methanol side chain alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

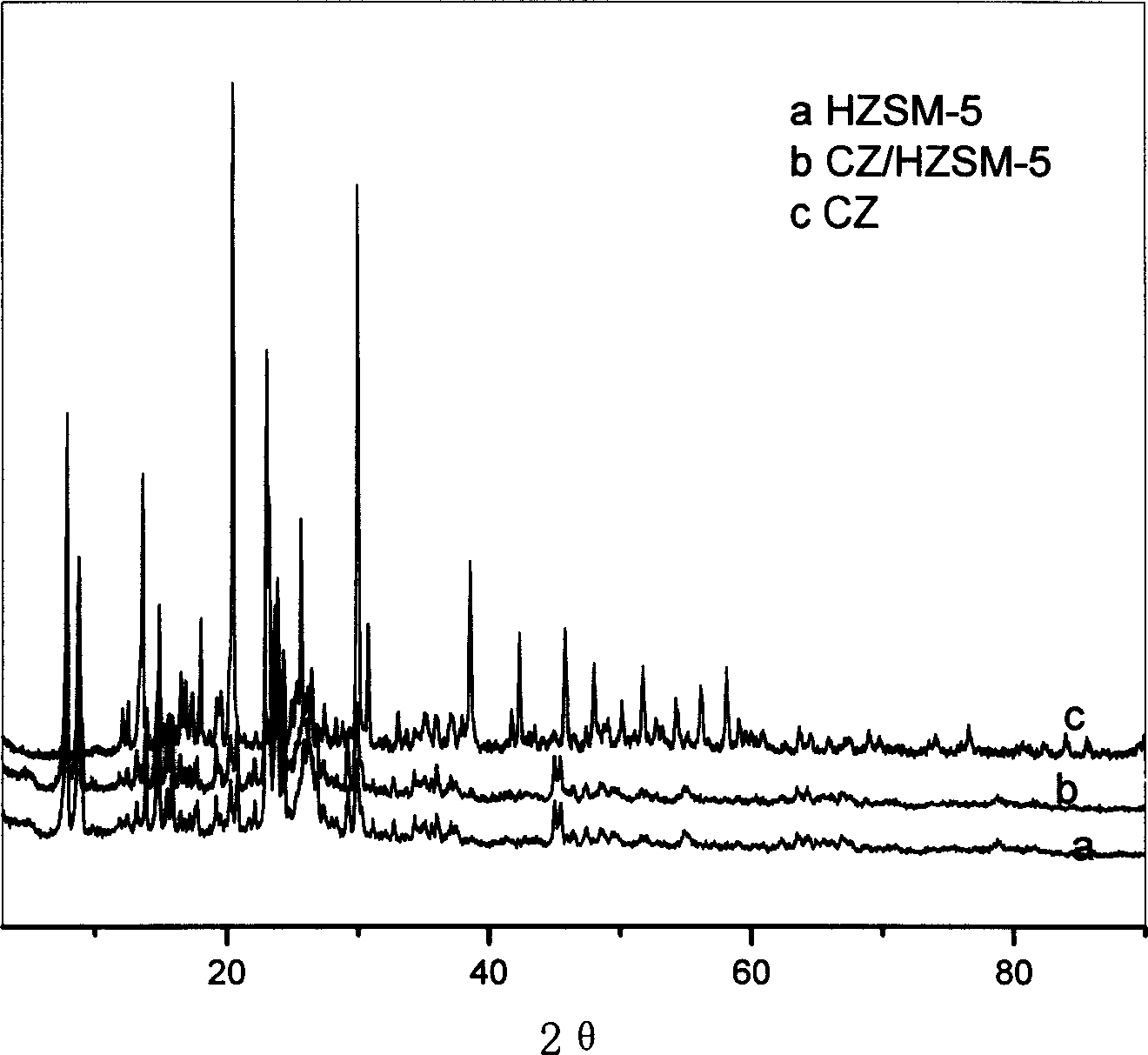

Zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:ABB LUMMUS GLOBAL INC

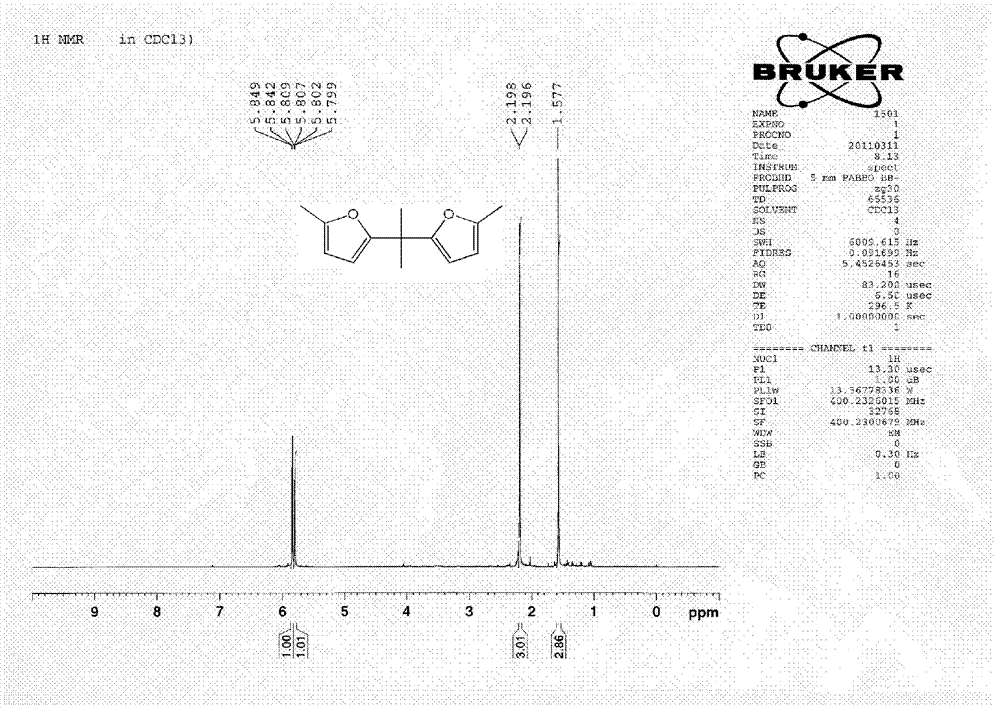

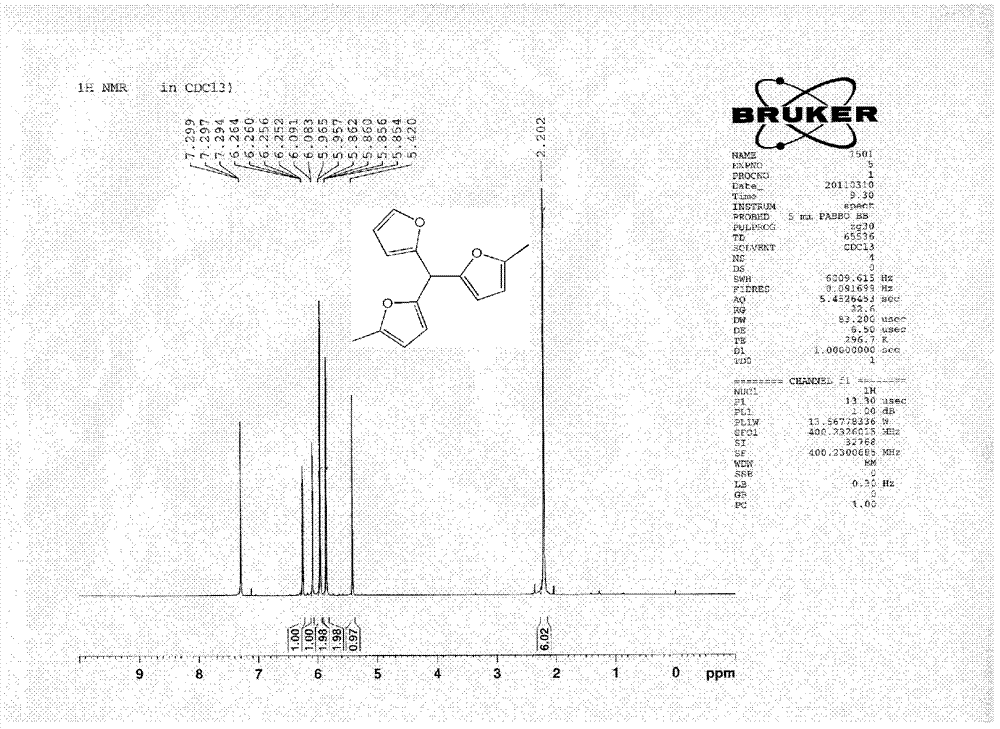

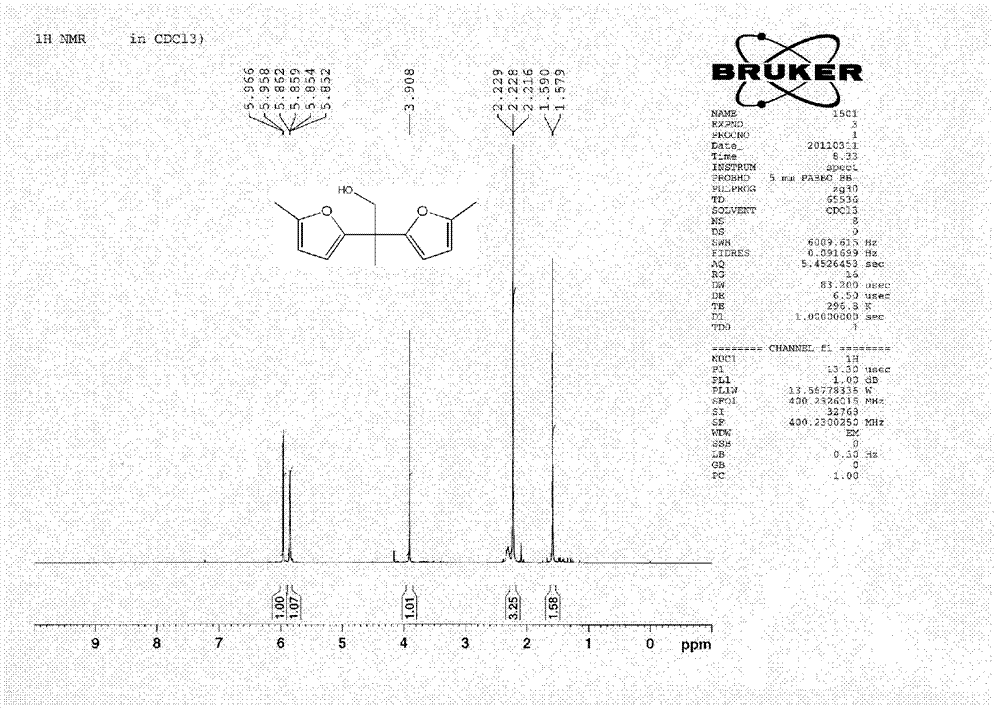

Method for preparation of aviation kerosene and diesel oil from biomass derivative

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation for hydrophobic solid acid catalyst

InactiveCN1613559AAcidicHydrophobicMolecular sieve catalystsCatalyst activation/preparationHydration reactionAlkyl transfer

A hydrophobic solid, acid catalyst for the acid catalyzing reaction, such as esterifying reaction, alkylation reaction and hydration reaction, is prepared by attaching the inorganic metal salt to the high-hydrophobicity carrier. Its advantages are high catalyst activity and selectivity, high stability, and high hydrophobicity.

Owner:BEIJING UNIV OF CHEM TECH

Process for producing cumene

InactiveUS6888037B2Hydrocarbon by isomerisationMolecular sieve catalystMolecular sieveAlkyl transfer

A process for producing cumene is provided which comprises the step of contacting benzene and propylene under at least partial liquid phase alkylating conditions with a particulate molecular sieve alkylation catalyst, wherein the particles of said alkylation catalyst have a surface to volume ratio of about 80 to less than 200 inch−1.

Owner:EXXONMOBIL CHEM PAT INC

Metal catalysts

InactiveUS6747180B2Low bulk densityHigh activityOrganic compound preparationCatalyst activation/preparationHydration reactionAlkyl transfer

Owner:DEGUSSA AG +1

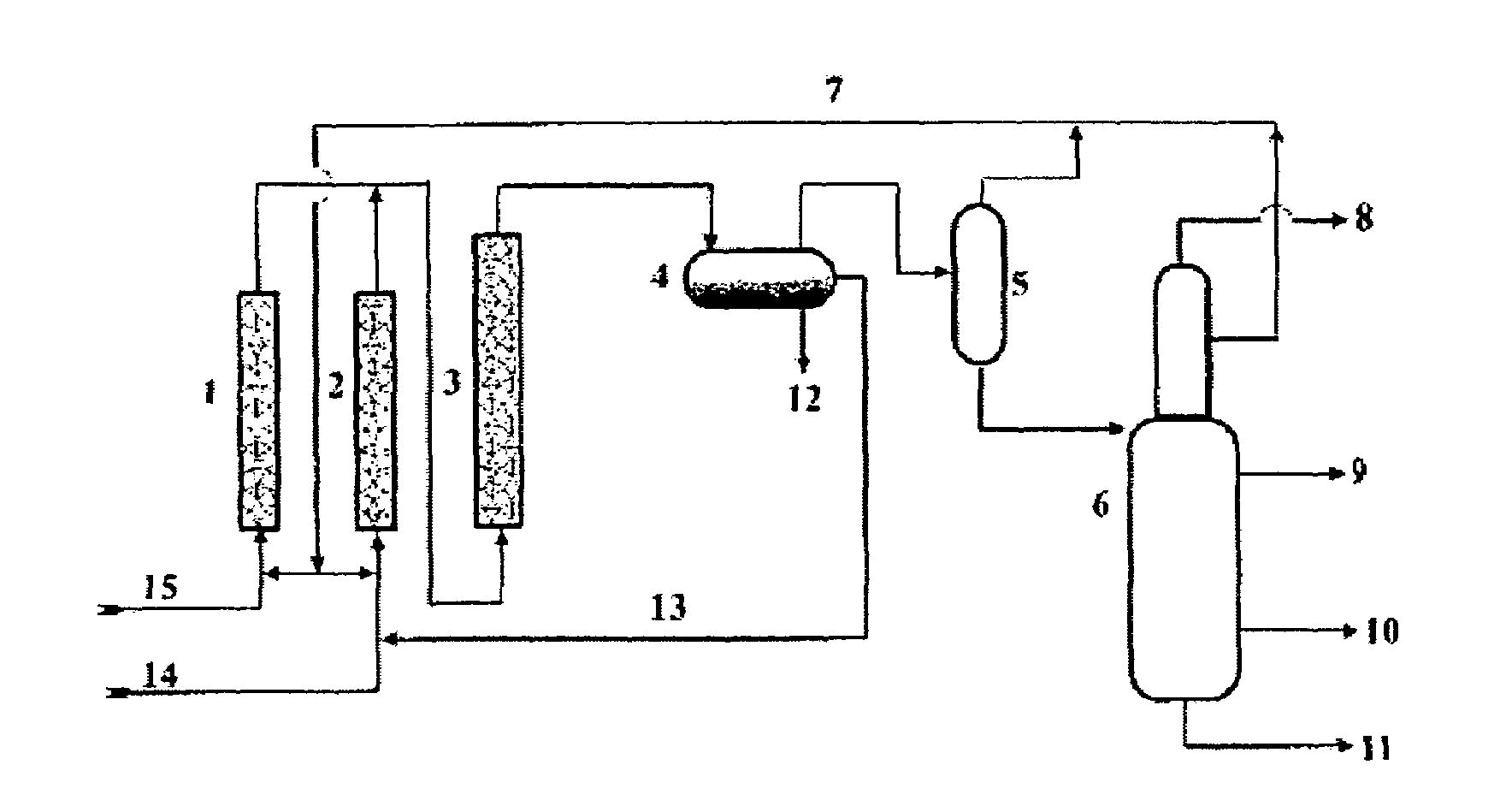

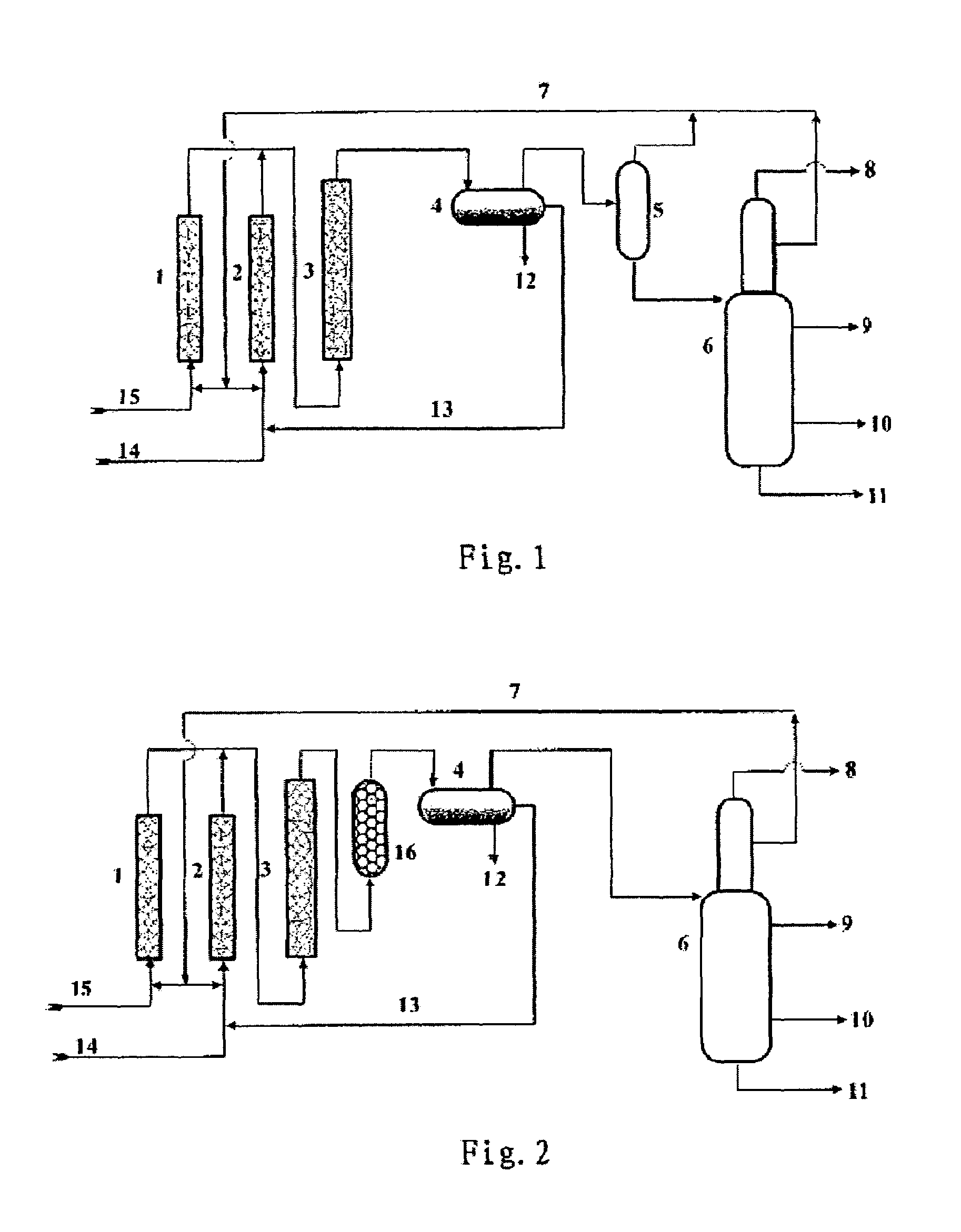

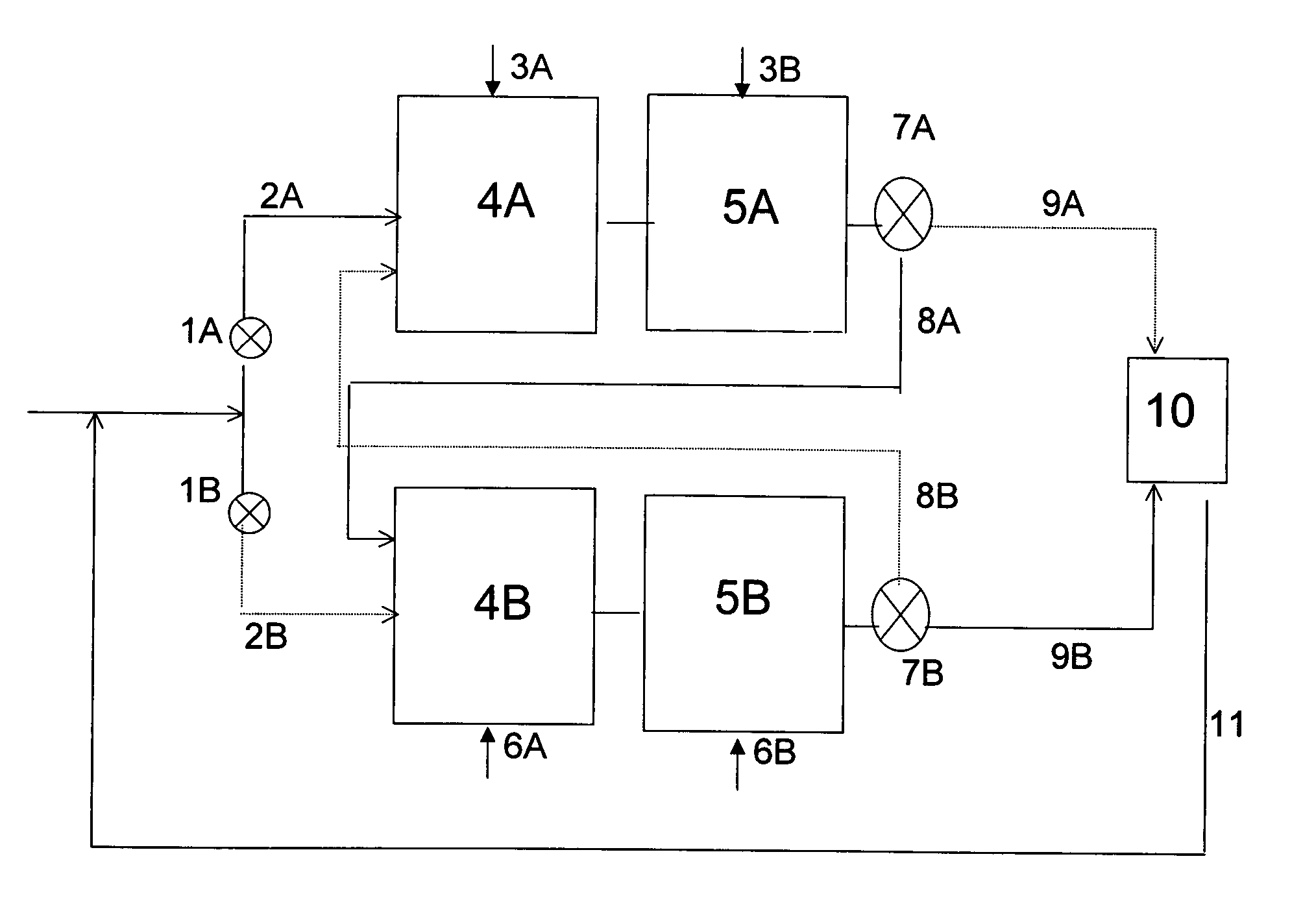

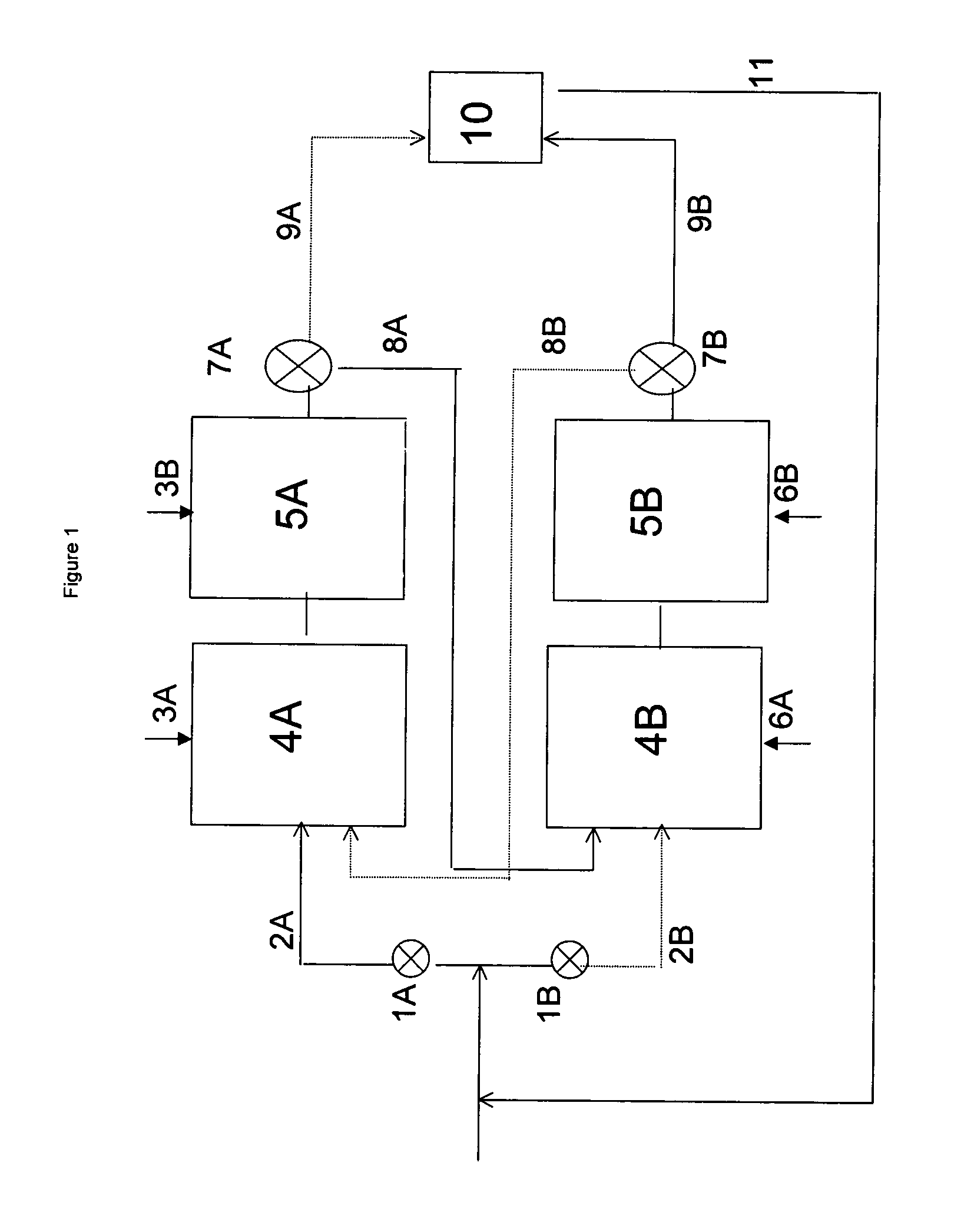

Continuous process for the alkylation of hydrocarbons

A continuous alkylation process performed in an apparatus comprising a series of at least two zone A reactors and a series of at least two zone B reactors, in which the zone A reactors and the zone B reactors cycle between alkylation mode and mild regeneration mode, and wherein the alkylation mode comprises introducing an alkylation agent into a first reactor of the zone through which the alkylatable compound passes, reacting a portion of the alkylatable compound with a portion of the alkylation agent to produce a product stream, and performing this operation at least once more in a downstream reactor in the same zone employing, instead of alkylatable compound, a stream comprising the product stream.

Owner:ALBEMARLE NETHERLANDS BV

Alkylation of olefins with isoparaffins in ionic liquid to make lubricant or fuel blendstock

ActiveUS20070142690A1Increase the degree of branchingHigh molecular weightOrganic chemistry methodsCatalystsAlkyl transferAlkane

A process and method for making a superior lubricant or distillate fuel component by the alkylation of C5+ olefins with isoparaffins to produce a “capped” (alkylated) olefin using an acidic chloroaluminate ionic liquid catalyst system. Preferably the catalyst system includes a Brönsted acid.

Owner:CHEVROU USA INC

Alkylation of olefins with isoparaffins in ionic liquid to make lubricant or fuel blendstock

ActiveUS7569740B2Degree of improvementWeight increaseOrganic chemistry methodsCatalystsAlkaneAlkyl transfer

A process and method for making a superior lubricant or distillate fuel component by the alkylation of C5+ olefins with isoparaffins to produce a “capped” (alkylated) olefin using an acidic chloroaluminate ionic liquid catalyst system. Preferably the catalyst system includes a Brönsted acid.

Owner:CHEVROU USA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com