Patents

Literature

2486 results about "Cogeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time. Trigeneration or combined cooling, heat and power (CCHP) refers to the simultaneous generation of electricity and useful heating and cooling from the combustion of a fuel or a solar heat collector. The terms cogeneration and trigeneration can be also applied to the power systems generating simultaneously electricity, heat, and industrial chemicals – e.g., syngas or pure hydrogen (article: combined cycles, chapter: natural gas integrated power & syngas (hydrogen) generation cycle).

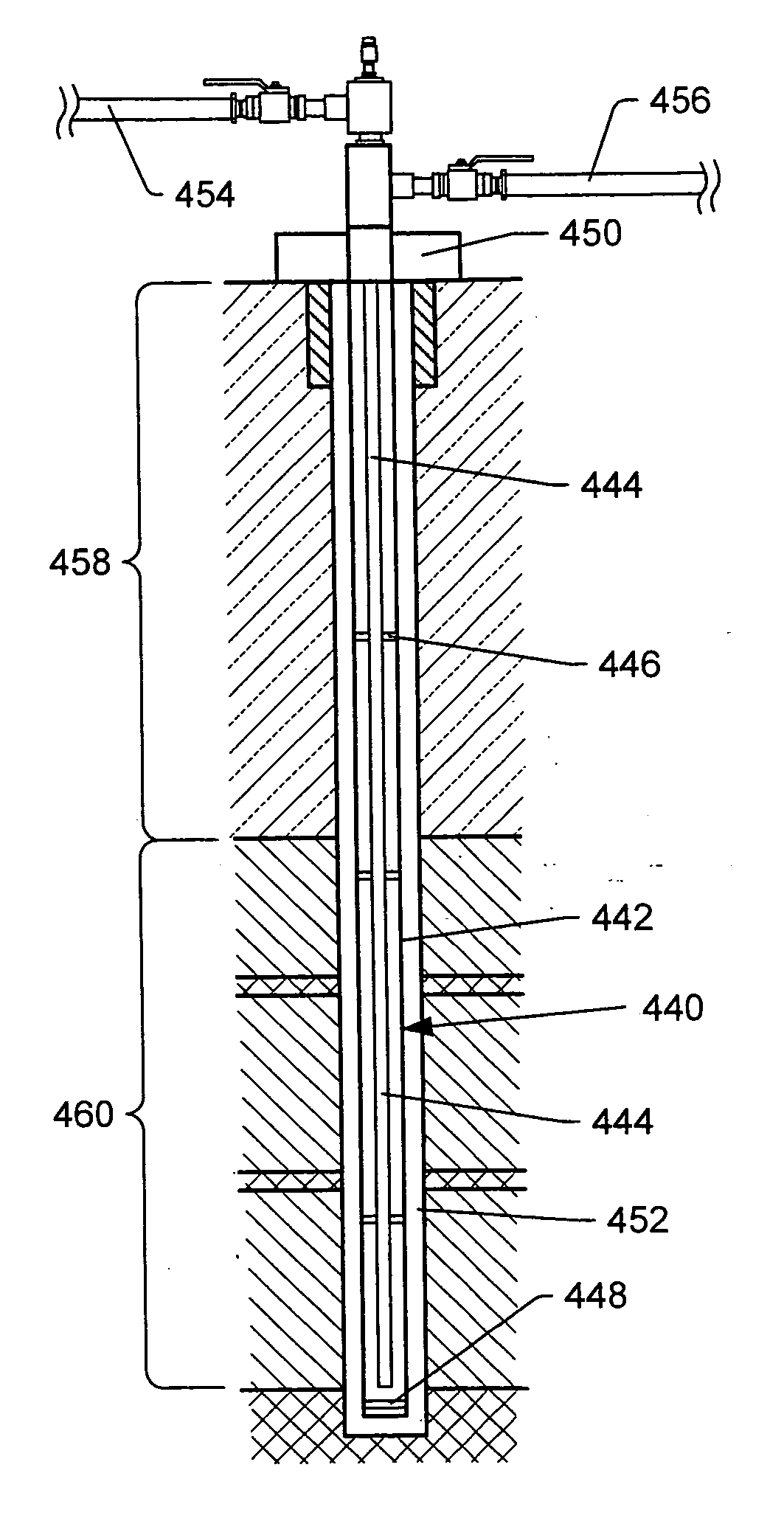

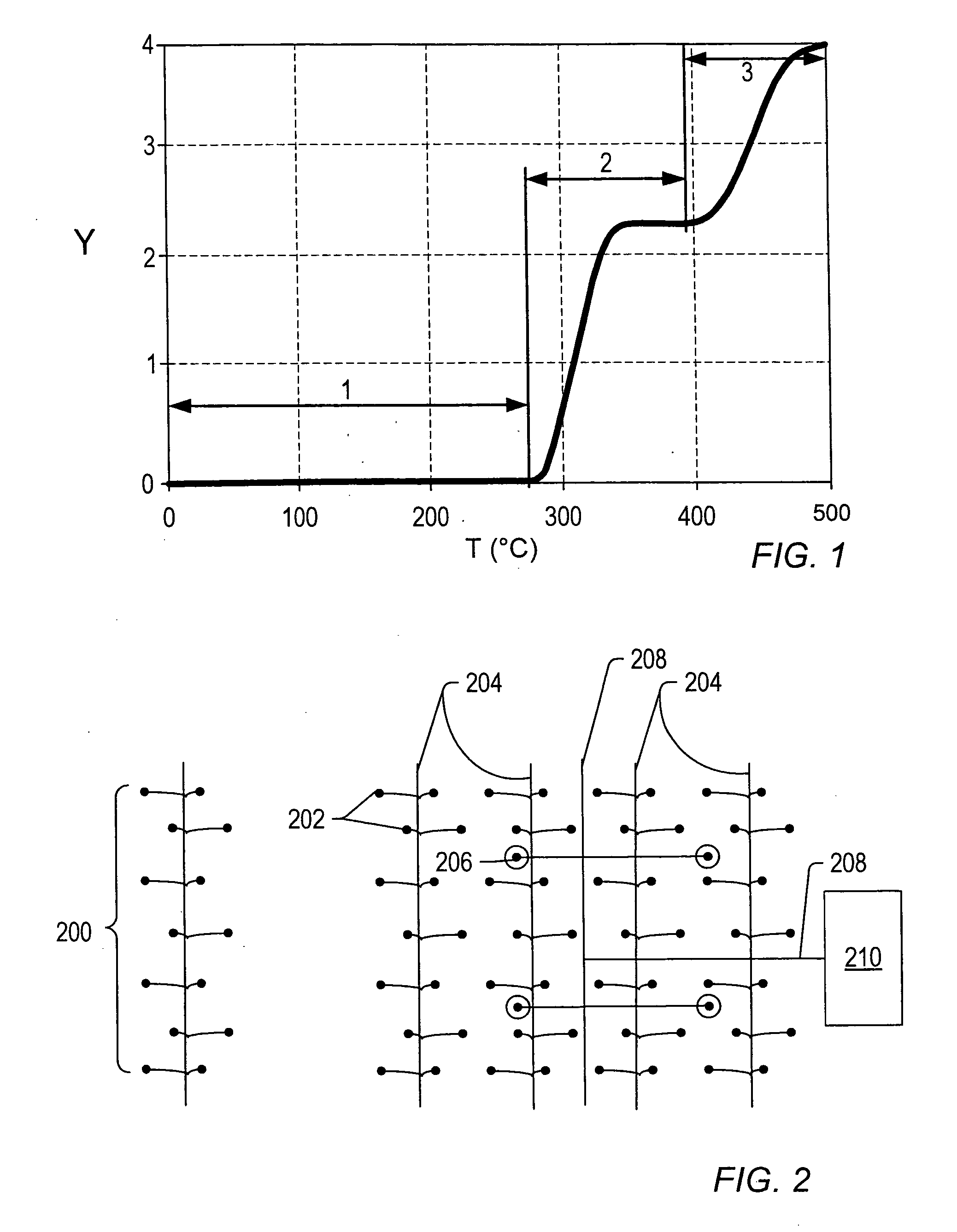

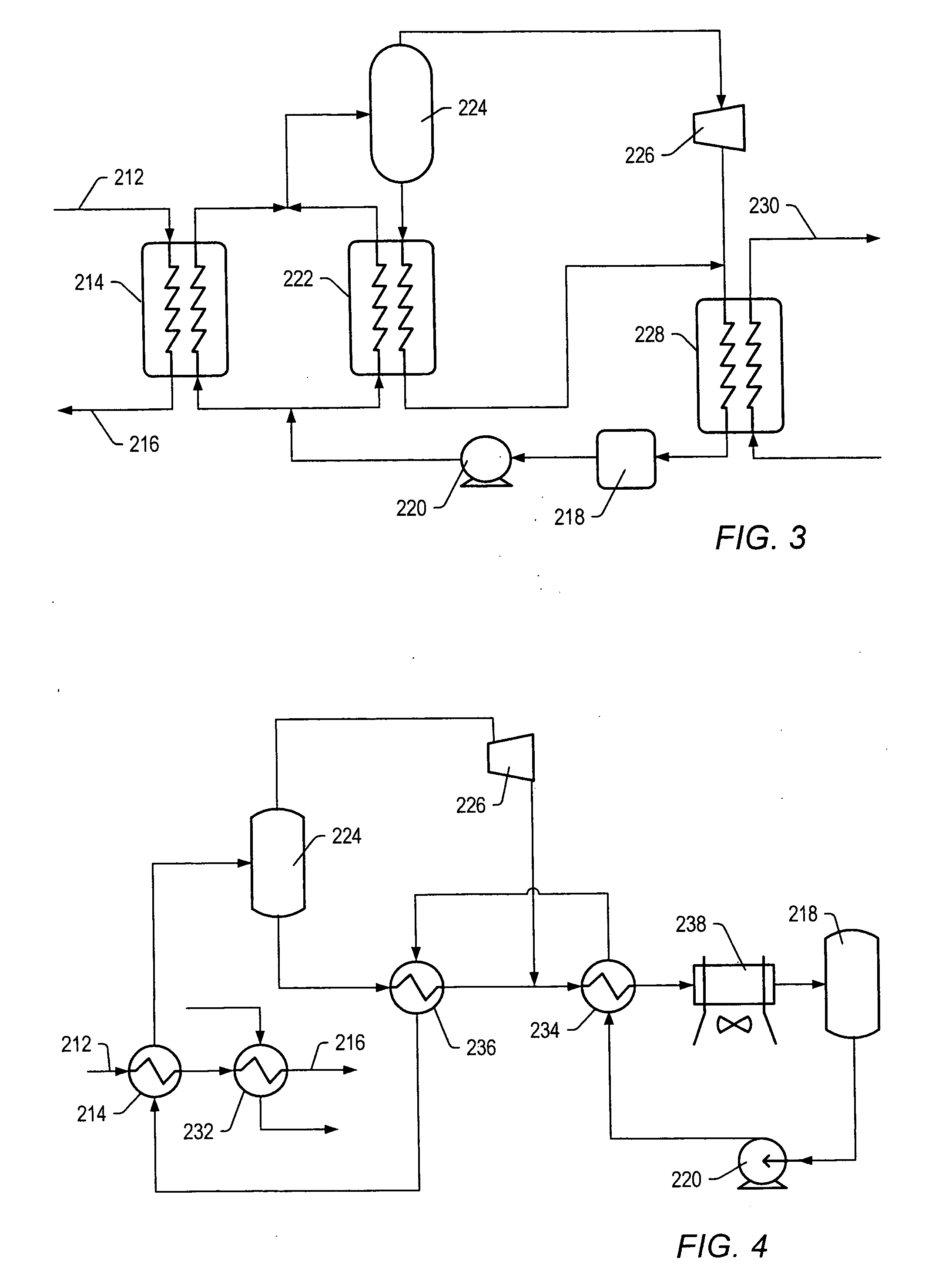

Cogeneration systems and processes for treating hydrocarbon containing formations

InactiveUS20070095536A1Thermal non-catalytic crackingCatalytic crackingElectricityNuclear engineering

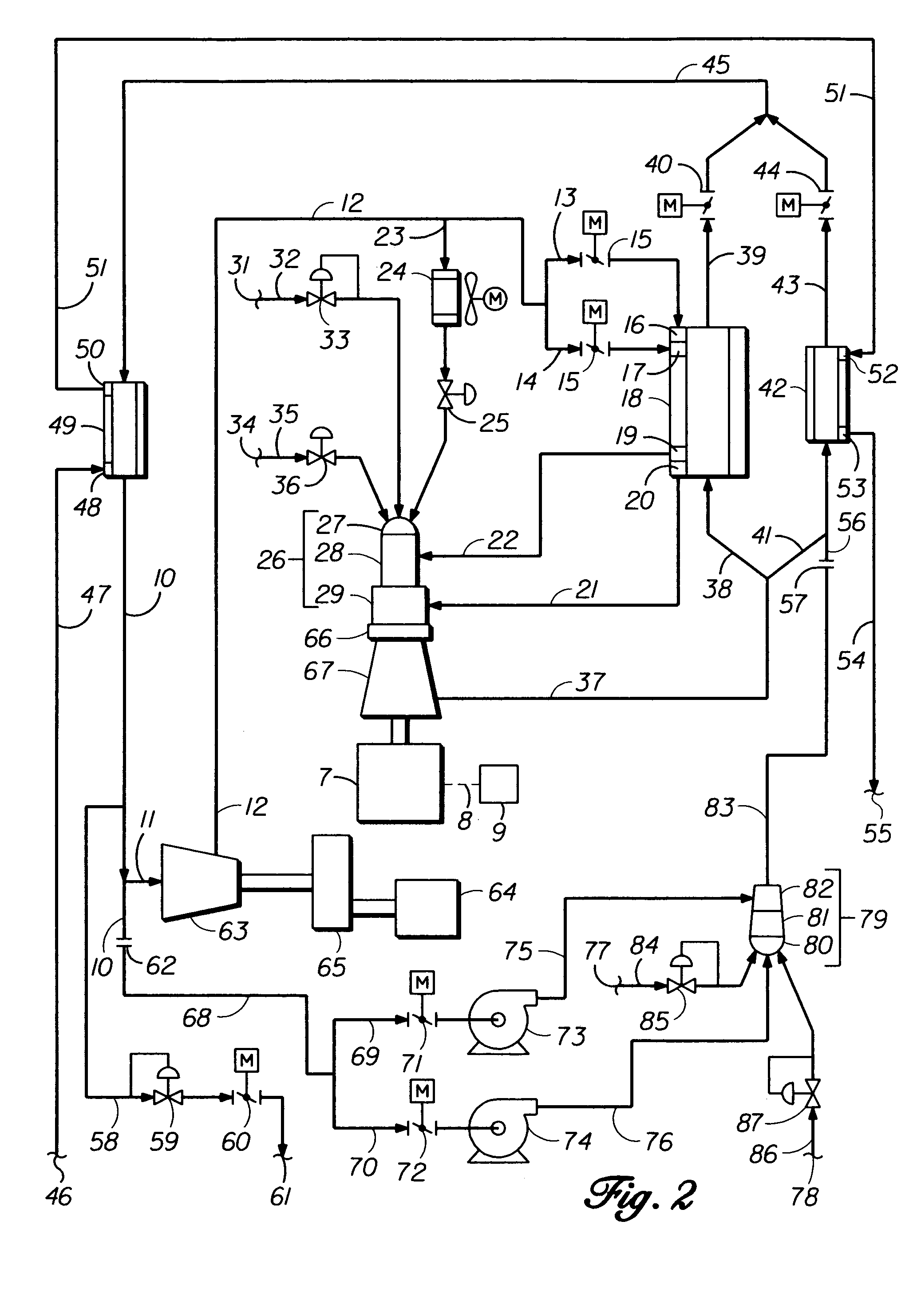

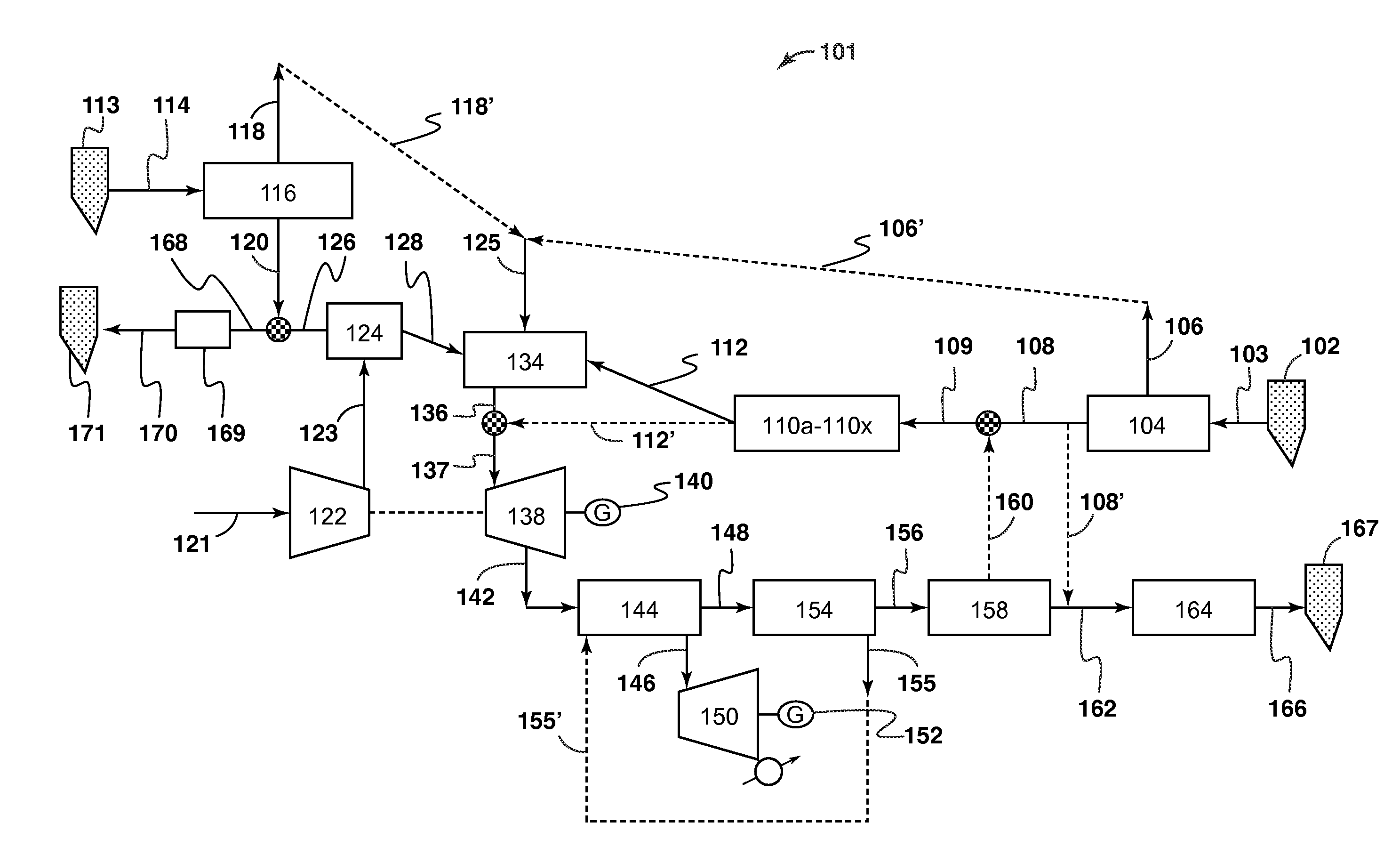

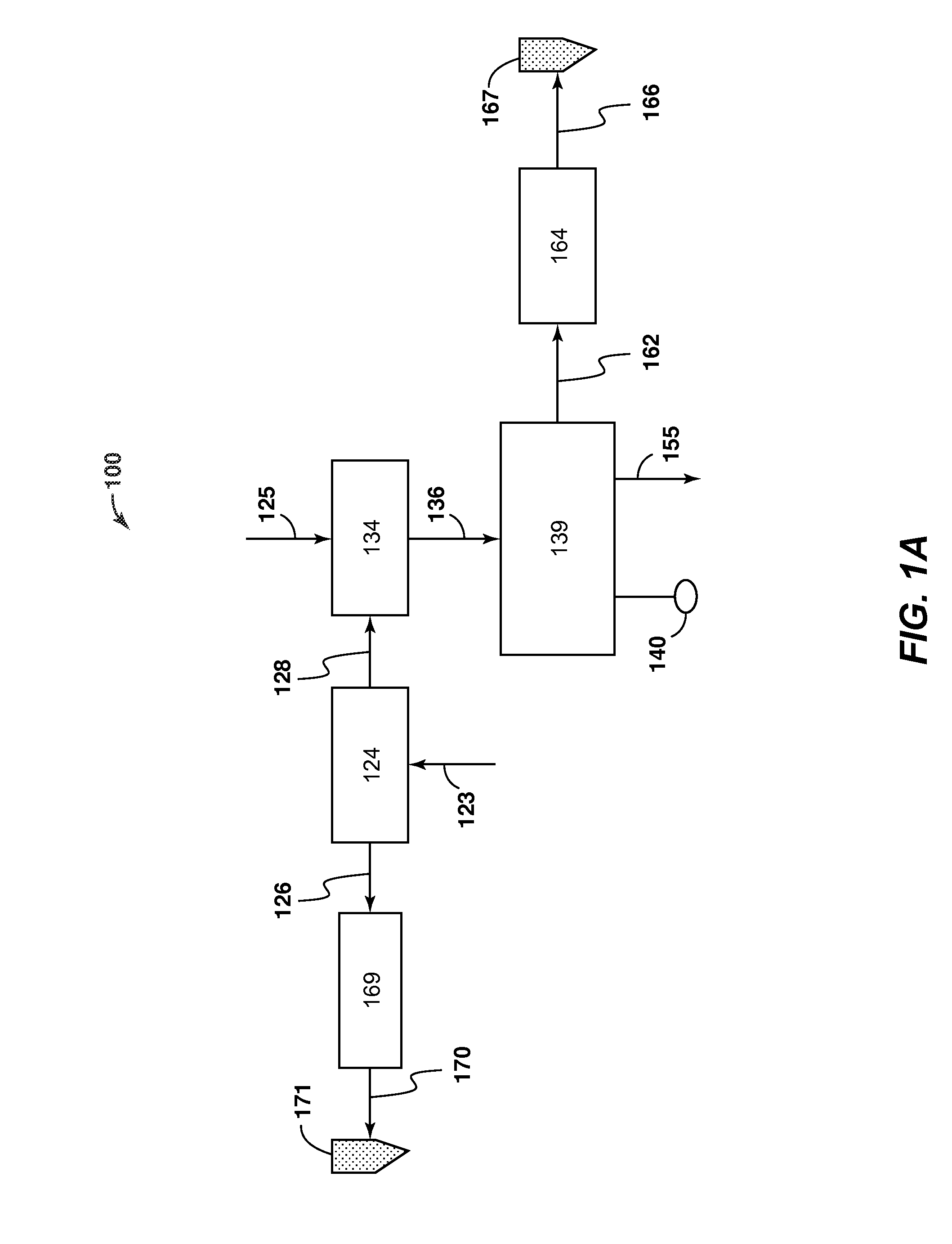

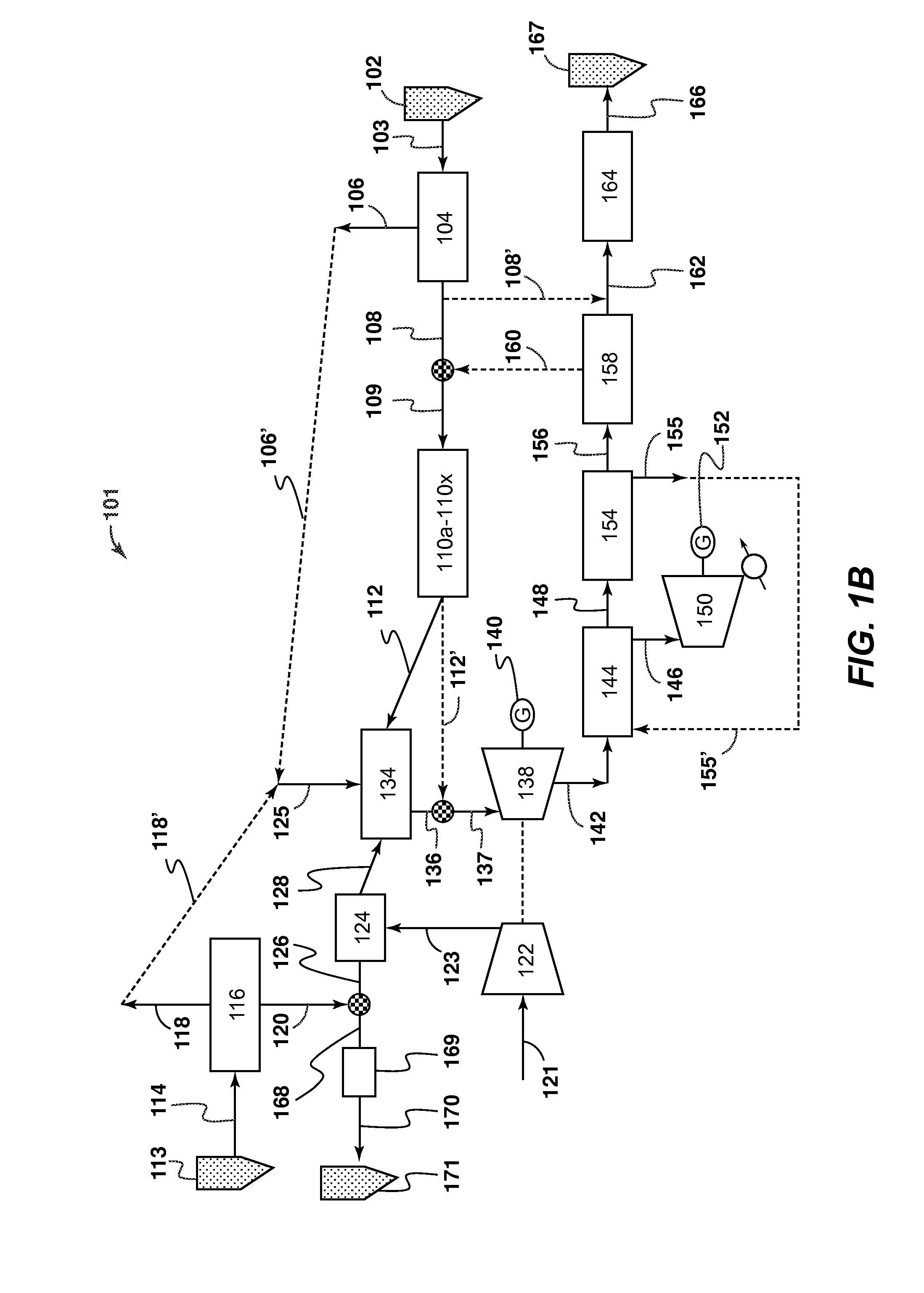

A system for treating a hydrocarbon containing formation includes a steam and electricity cogeneration facility. At least one injection well is located in a first portion of the formation. The injection well provides steam from the steam and electricity cogeneration facility to the first portion of the formation. At least one production well is located in the first portion of the formation. The production well in the first portion produces first hydrocarbons. At least one electrical heater is located in a second portion of the formation. At least one of the electrical heaters is powered by electricity from the steam and electricity cogeneration facility. At least one production well is located in the second portion of the formation. The production well in the second portion produces second hydrocarbons. The steam and electricity cogeneration facility uses the first hydrocarbons and / or the second hydrocarbons to generate electricity.

Owner:SHELL OIL CO

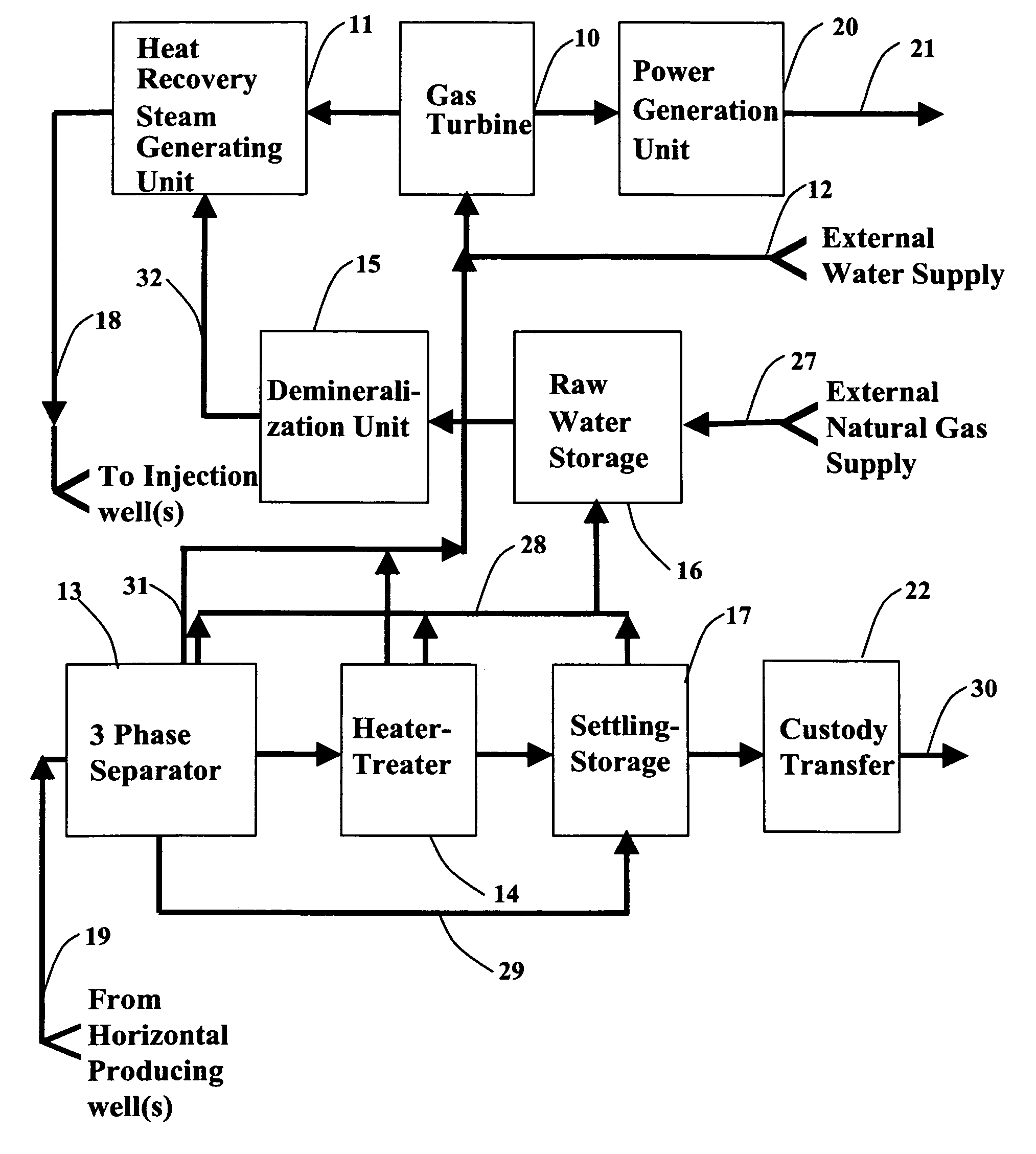

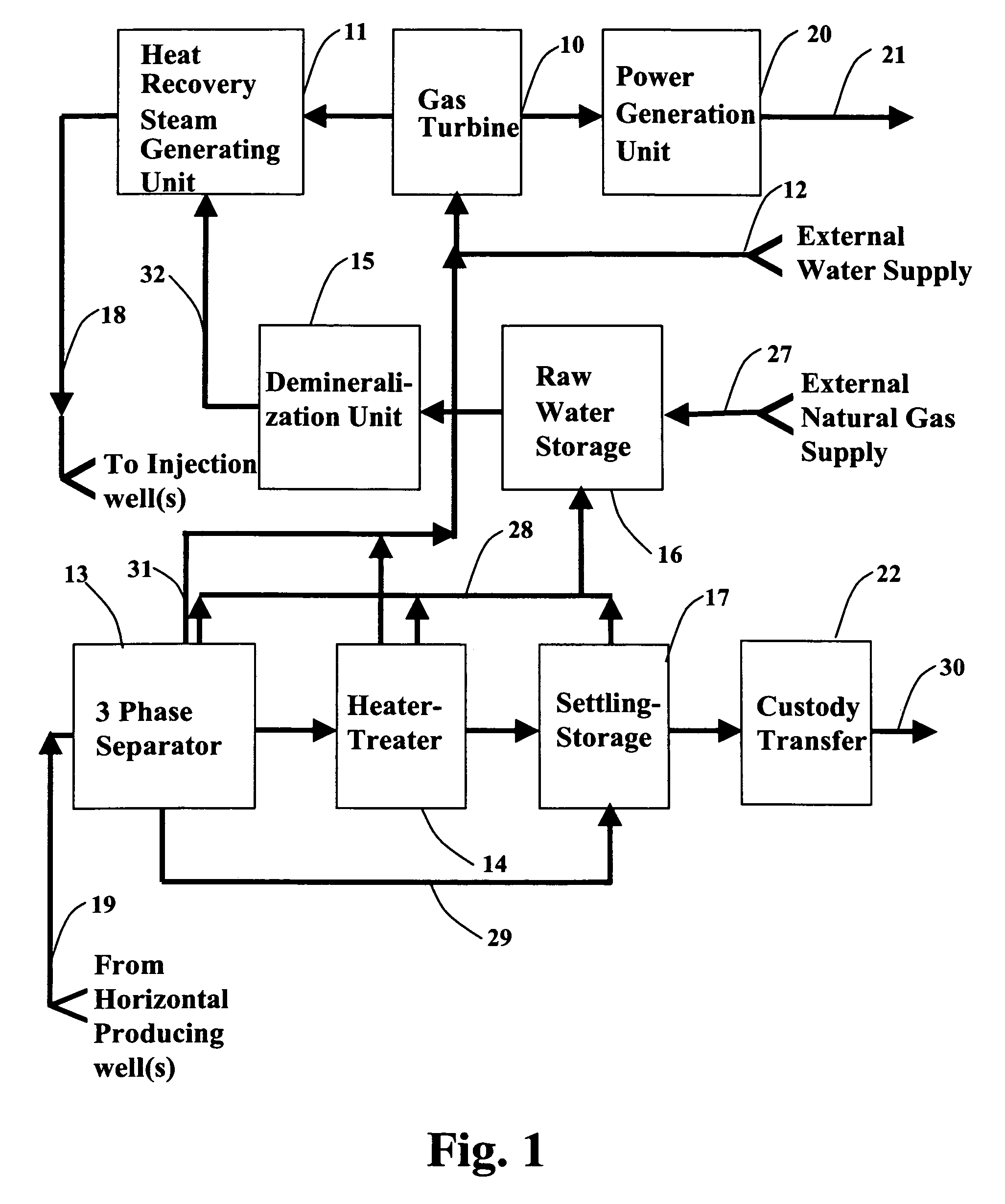

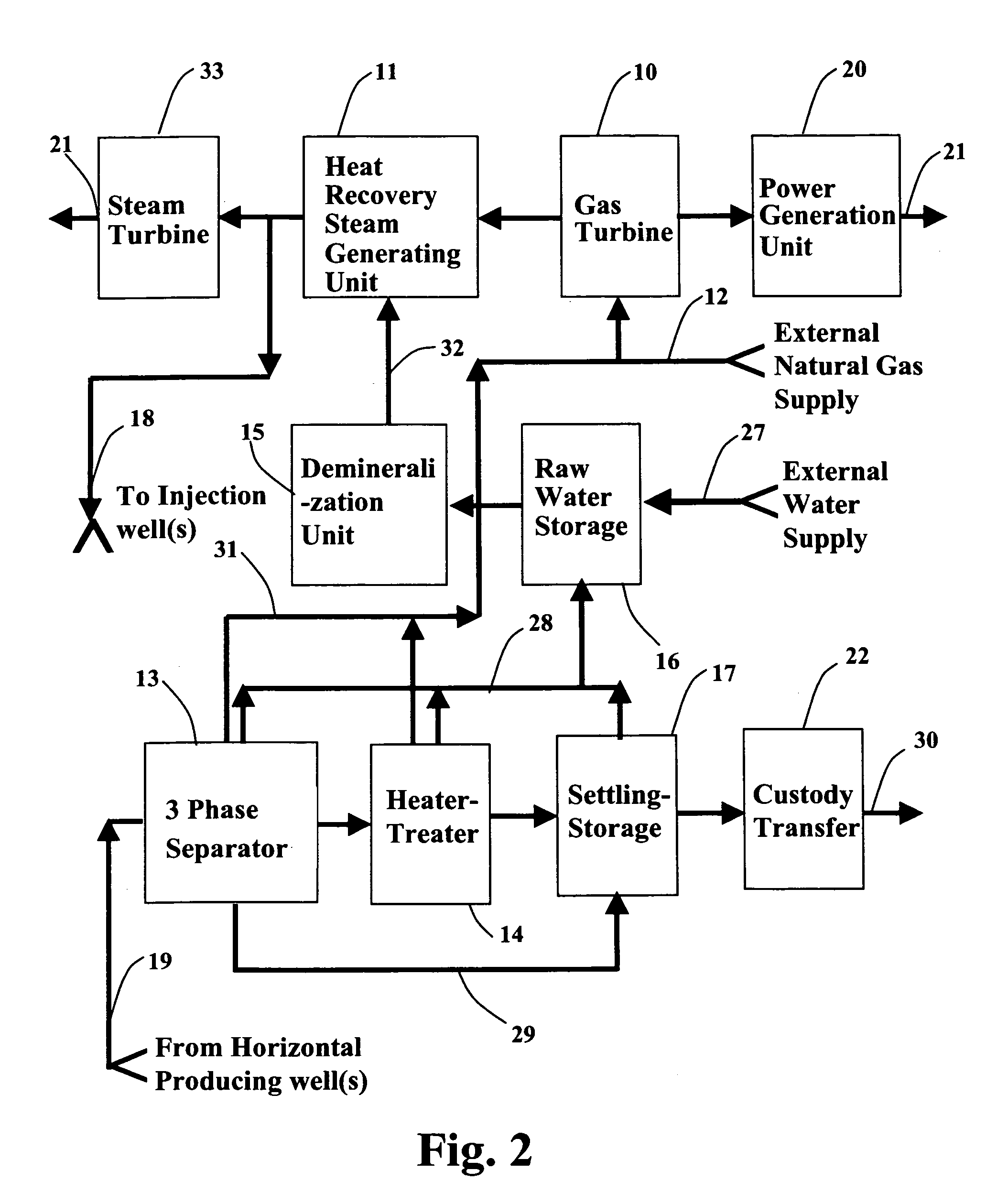

SAGD-plus

A combination of SAGD with cogeneration technology for exploiting shallow heavy oil and bitumen reservoirs under primary, secondary and tertiary thermal recovery. Superheated steam is generated by the heat recovery from the exhaust of an above-ground hydrocarbon powered turbine driven electric generator cogeneration plant and is injected through well bores into the hydrocarbon bearing reservoir that is traversed by at least one horizontal producing well bore and one injection well bore to heat the reservoir formation and to induce gravity drainage of the hydrocarbons and allowing their recovery from the horizontal producing well bore. Electrical power that is generated is sold to the electric grid and can be used to offset the fuel costs for the above ground hydrocarbon turbine-driven elector generators.

Owner:BABCOCK JOHN A

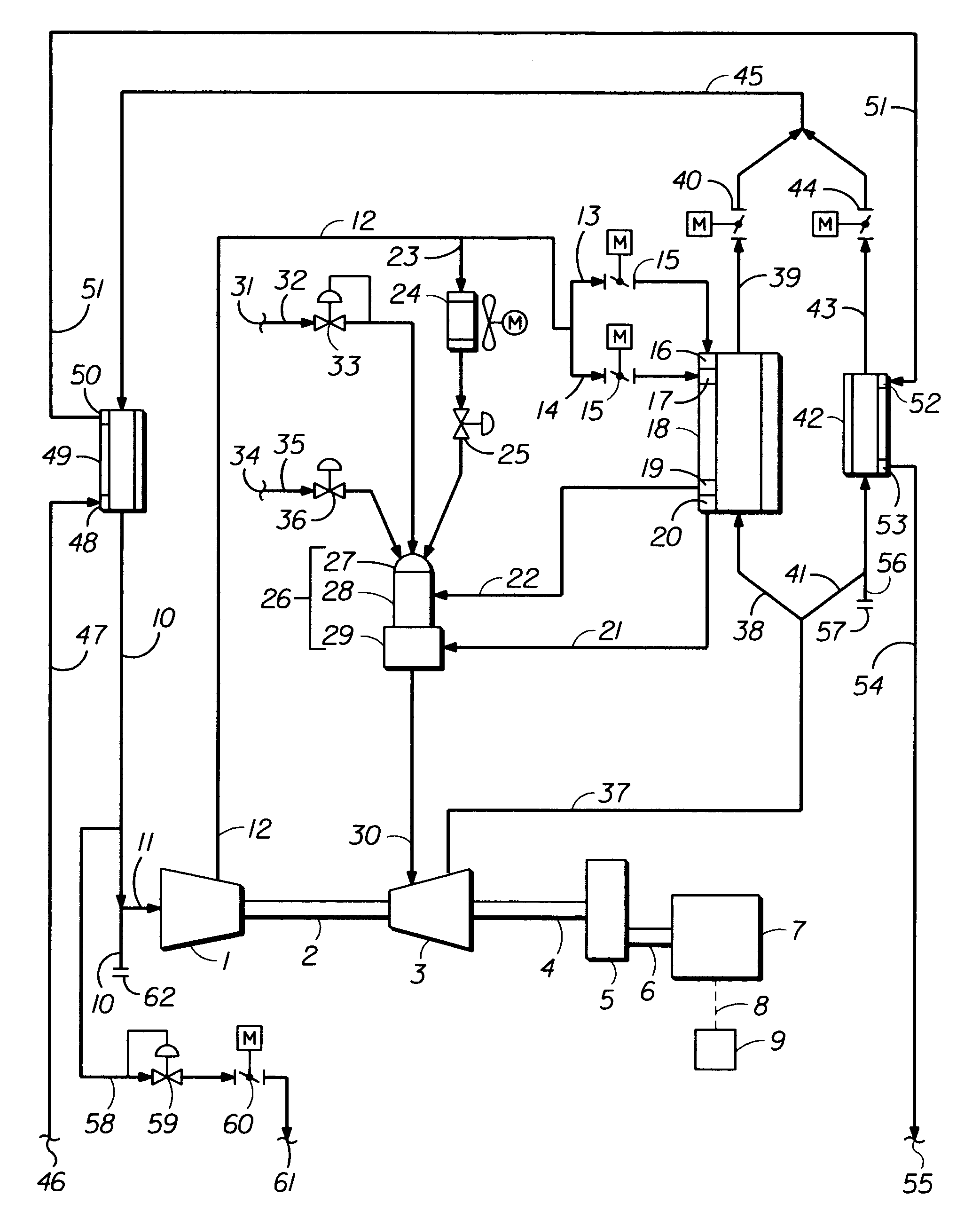

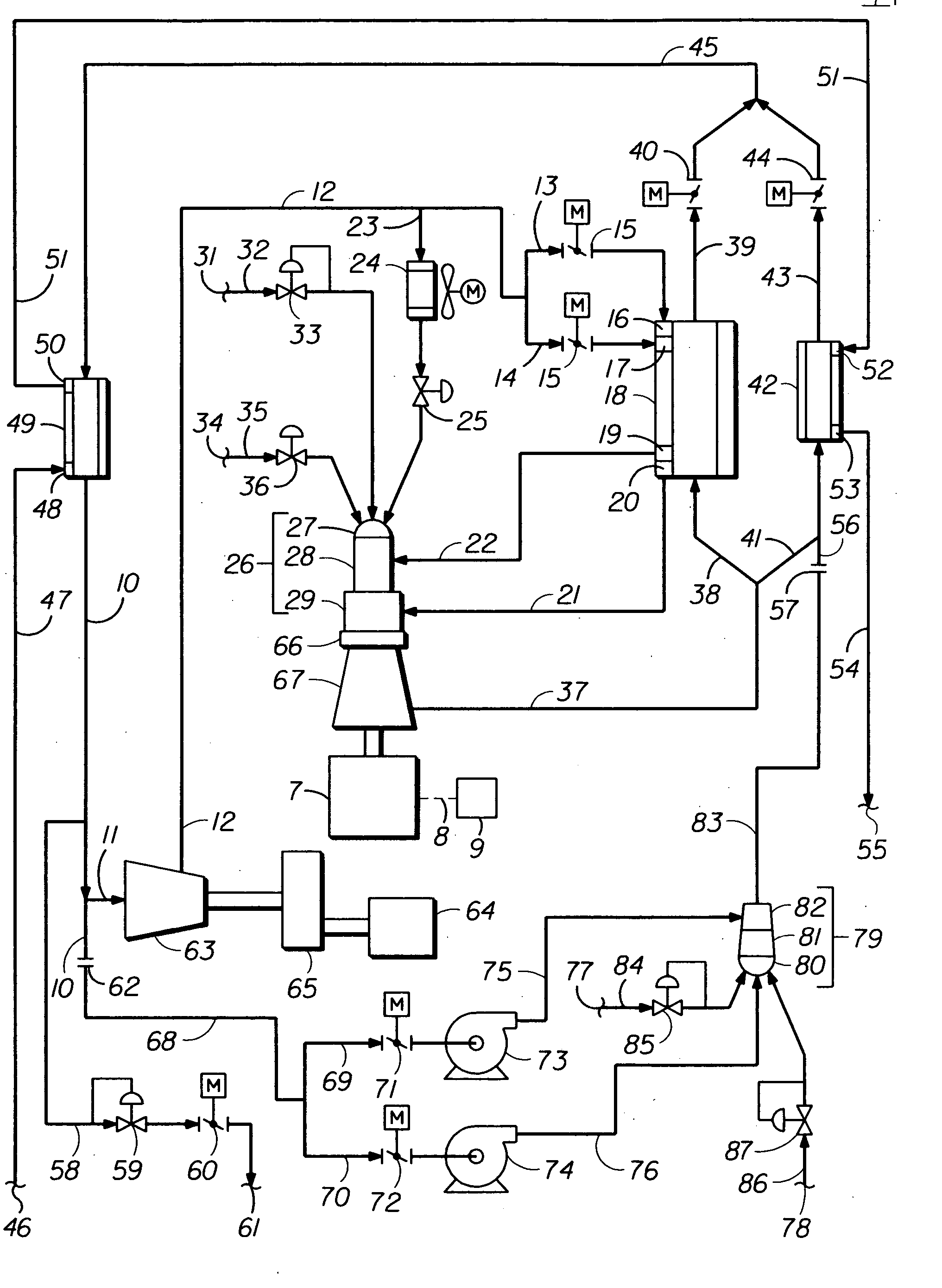

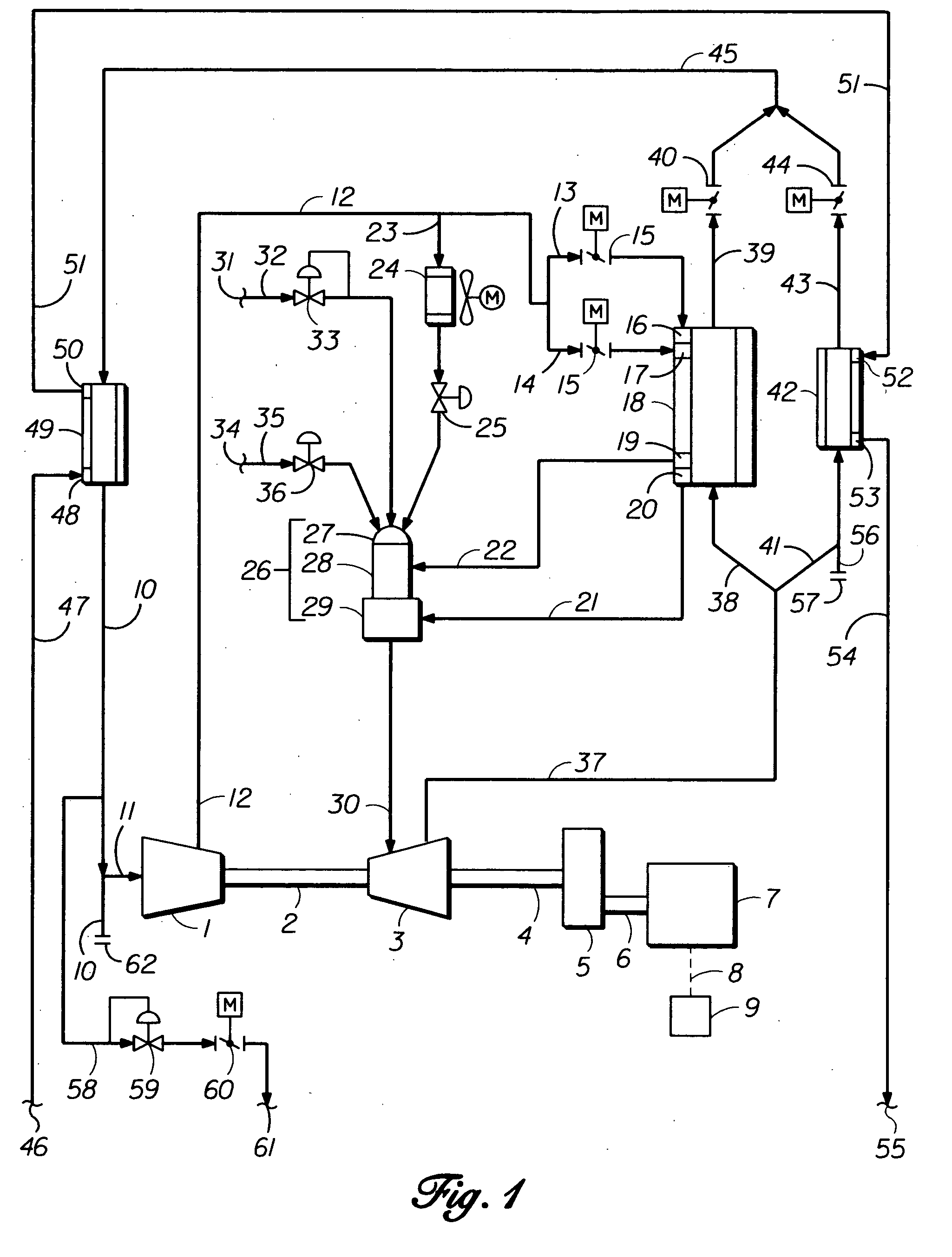

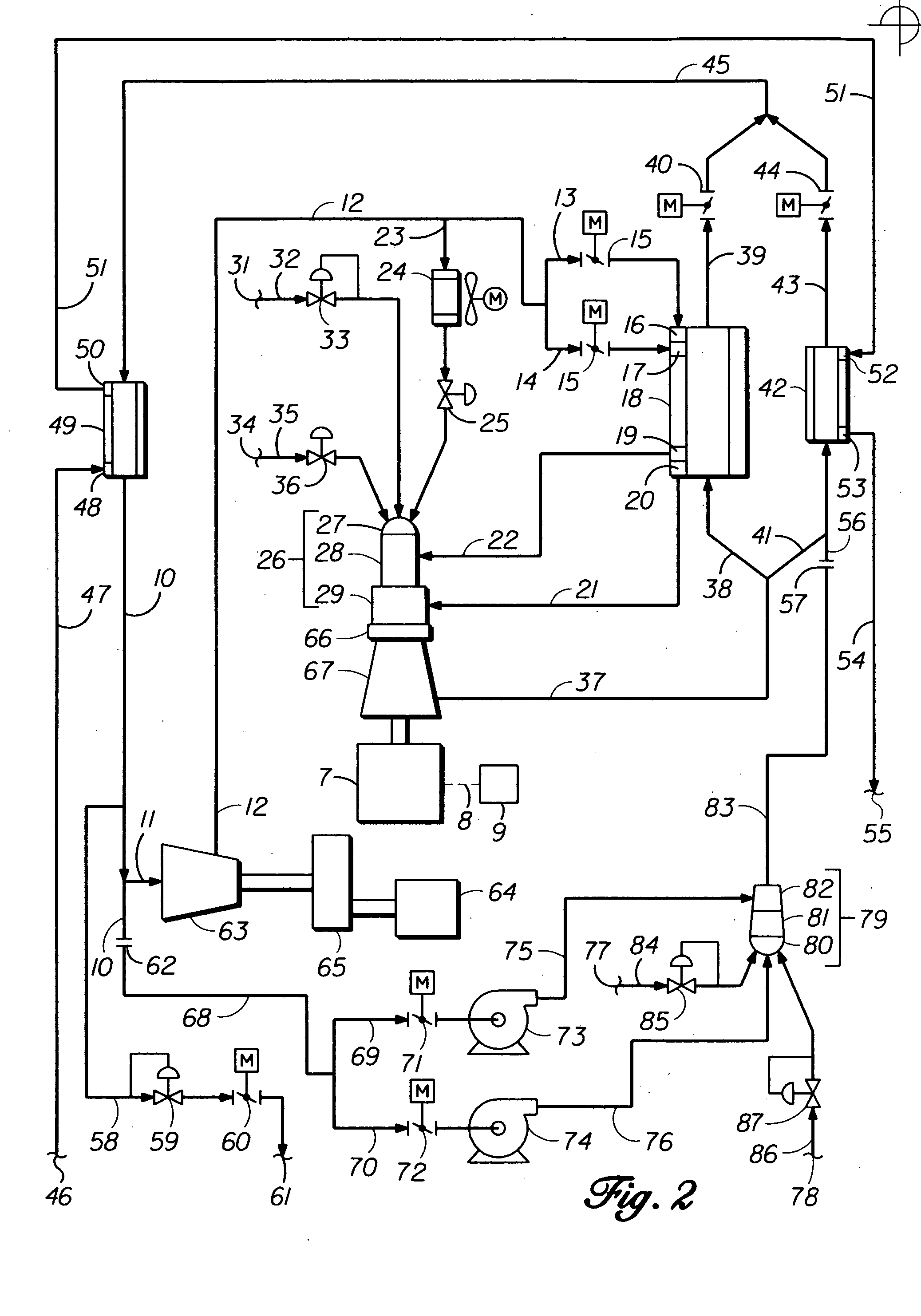

Power cogeneration system and apparatus means for improved high thermal efficiencies and ultra-low emissions

InactiveUS7124589B2Improve thermal efficiencyGas turbine plantsCombined combustion mitigationThermal energyCogeneration

A power cogeneration system employing a partially-open gaseous fluid cycle method and apparatus devices for oxy-fuel combustion conversion of a given hydrocarbon composition fuel's heat-value energy into mechanical or electrical power energy, and transferred useful heat energy, with accompanying large reductions of consumed fuel and undesirable exhaust emissions.

Owner:AES DEV CO

Oxidant control in co-generation installations

InactiveUS6247315B1Steam regenerationIndirect carbon-dioxide mitigationControl system designCogeneration

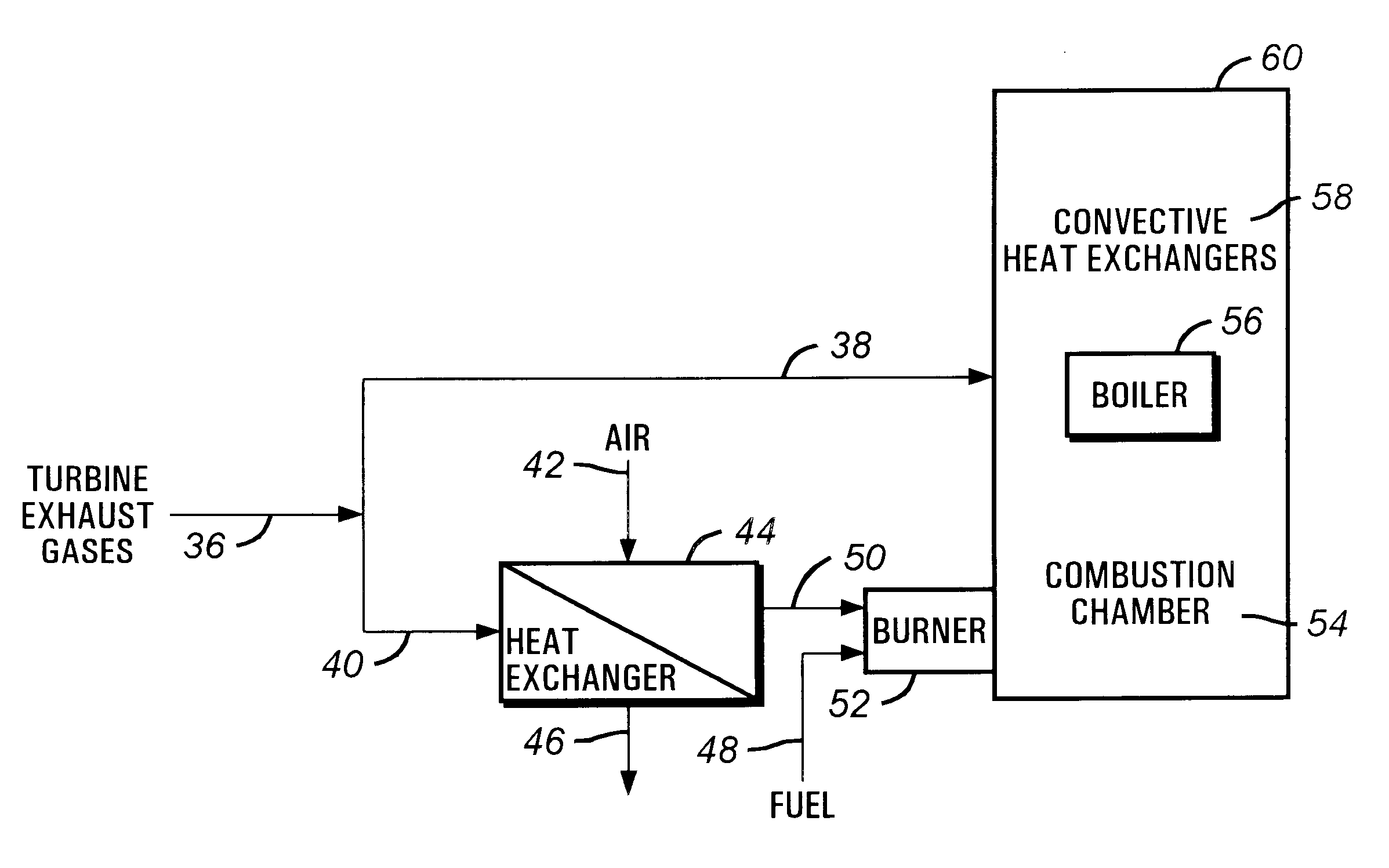

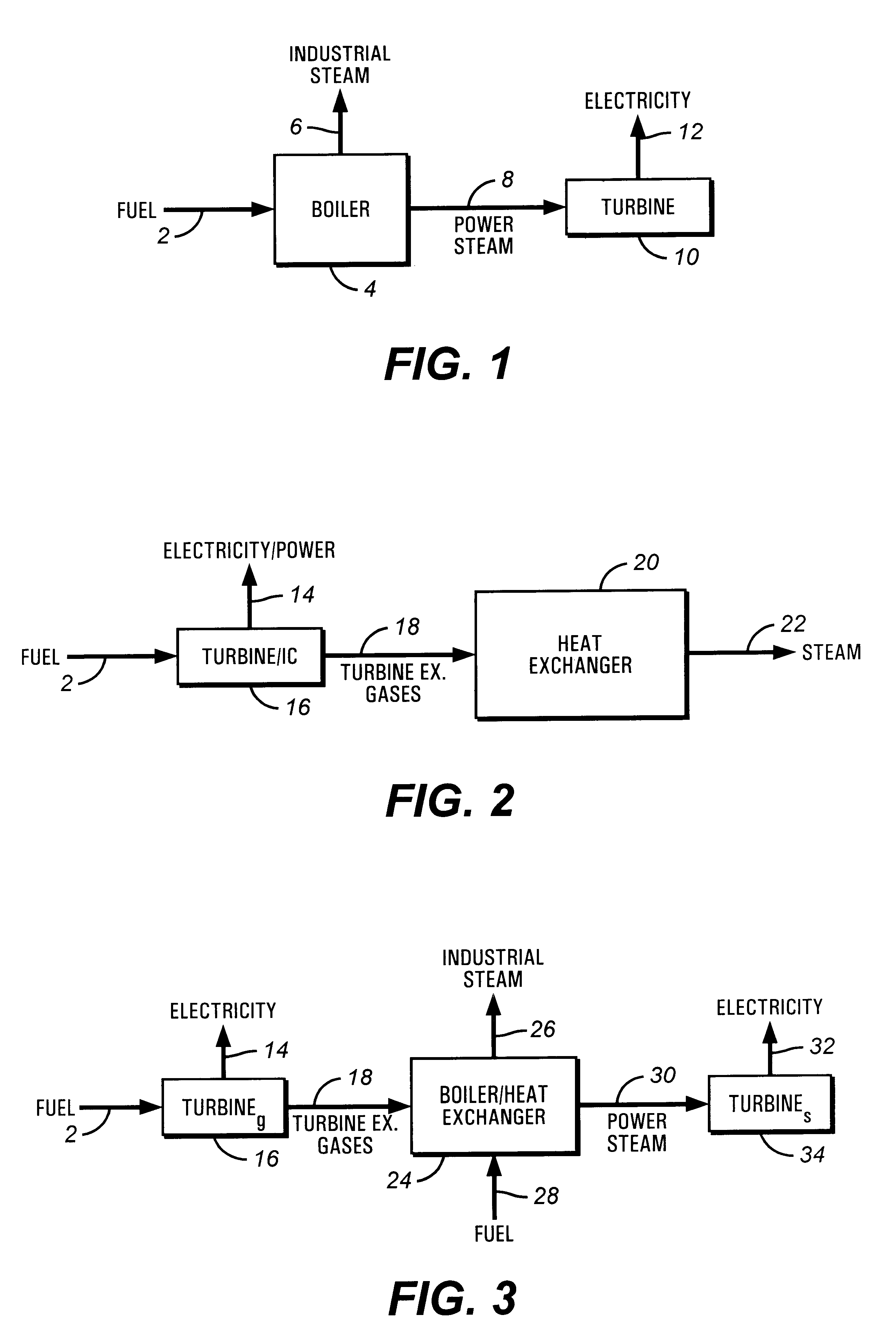

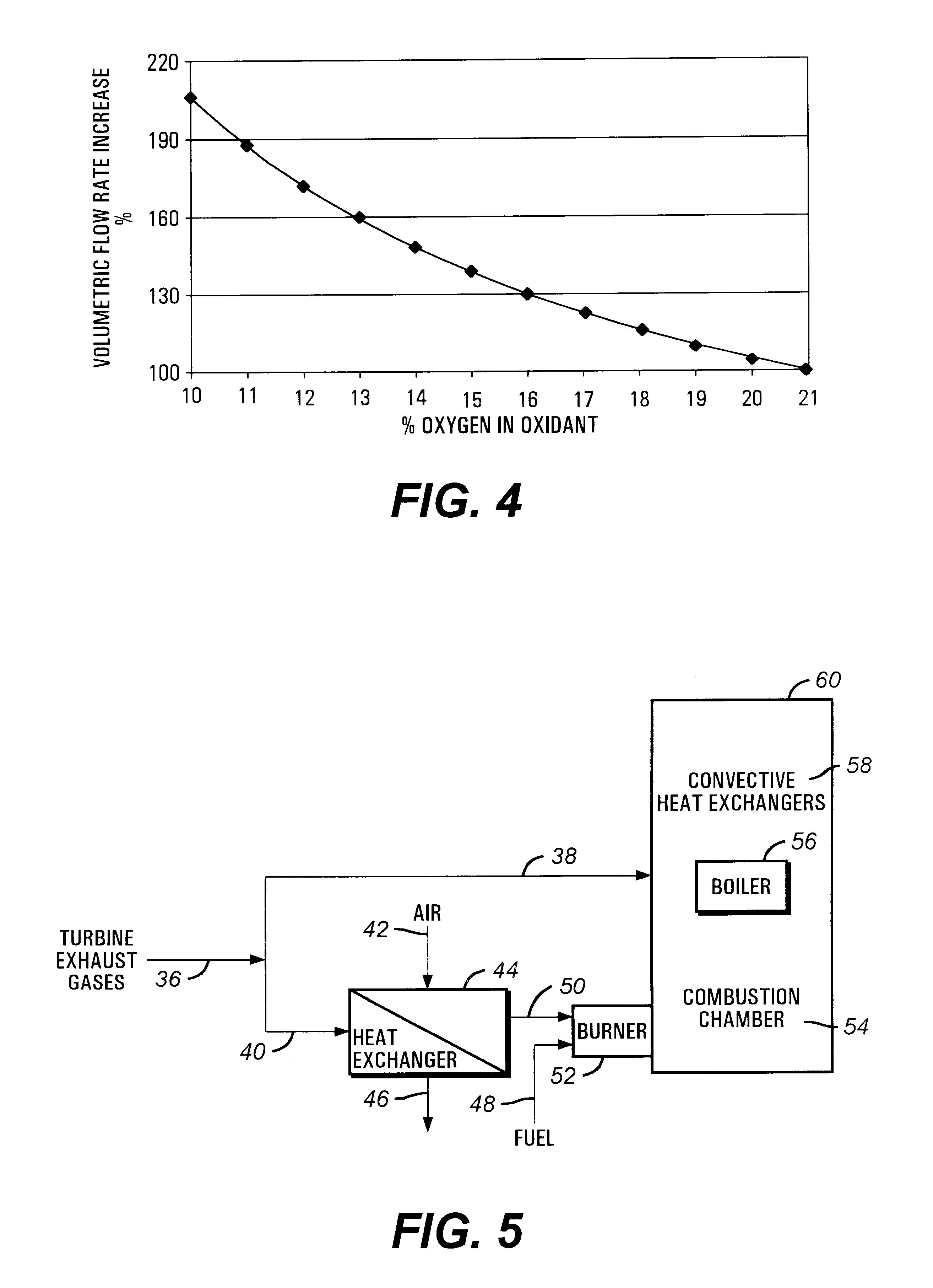

This invention is related to so-called combined cycle co-generation installations, and it addresses present concerns of the industry. Among these, combustion stability, corrosion (due to large water content in the flue gases), large heat transfer areas, and the like. In some embodiments, an additional heat exchanger is added to heat combustion air with a portion of the exhaust gases resulting from an engine, preferably a gas turbine. As a result, the efficiency of the cycle will improve, the oxidant will be enriched by above 50% oxygen, the combustion process will be enhanced, and the dimensions of the boiler may be reduced. It is considered that the combustion air will require between 10% and 80% of the total flue gas volume, more preferably between 20% and 40%. This is the portion of the flue gases sent through the heat exchanger. A control system designed to optimize the flow of the different streams is also presented. Other inventive embodiments forego heat exchanges in lieu of precise control of two flows of exhaust gas, with preferred addition of additional oxidant to the boiler bumers.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Low Emission Power Generation and Hydrocarbon Recovery Systems and Methods

ActiveUS20110000221A1Enhanced recovery of hydrocarbonEnhanced overall recoveryTurbine/propulsion fuel supply systemsOther gas emission reduction technologiesCogenerationDrug Substitution

Methods and systems for low emission power generation in hydrocarbon recovery processes are provided. One system includes integrated pressure maintenance and miscible flood systems with low emission power generation. An alternative system provides for low emission power generation, carbon sequestration, enhanced oil recovery (EOR), or carbon dioxide sales using a hot gas expander and external combustor. Another alternative system provides for low emission power generation using a gas power turbine to compress air in the inlet compressor and generate power using hot carbon dioxide laden gas in the expander. Other efficiencies may be gained by incorporating heat cross-exchange, a desalination plant, co-generation, and other features.

Owner:EXXONMOBIL UPSTREAM RES CO

High power density combined cycle power plant

InactiveUS6230480B1Reduce installation costsService degradationEnergy industryGas turbine plantsPower stationCogeneration

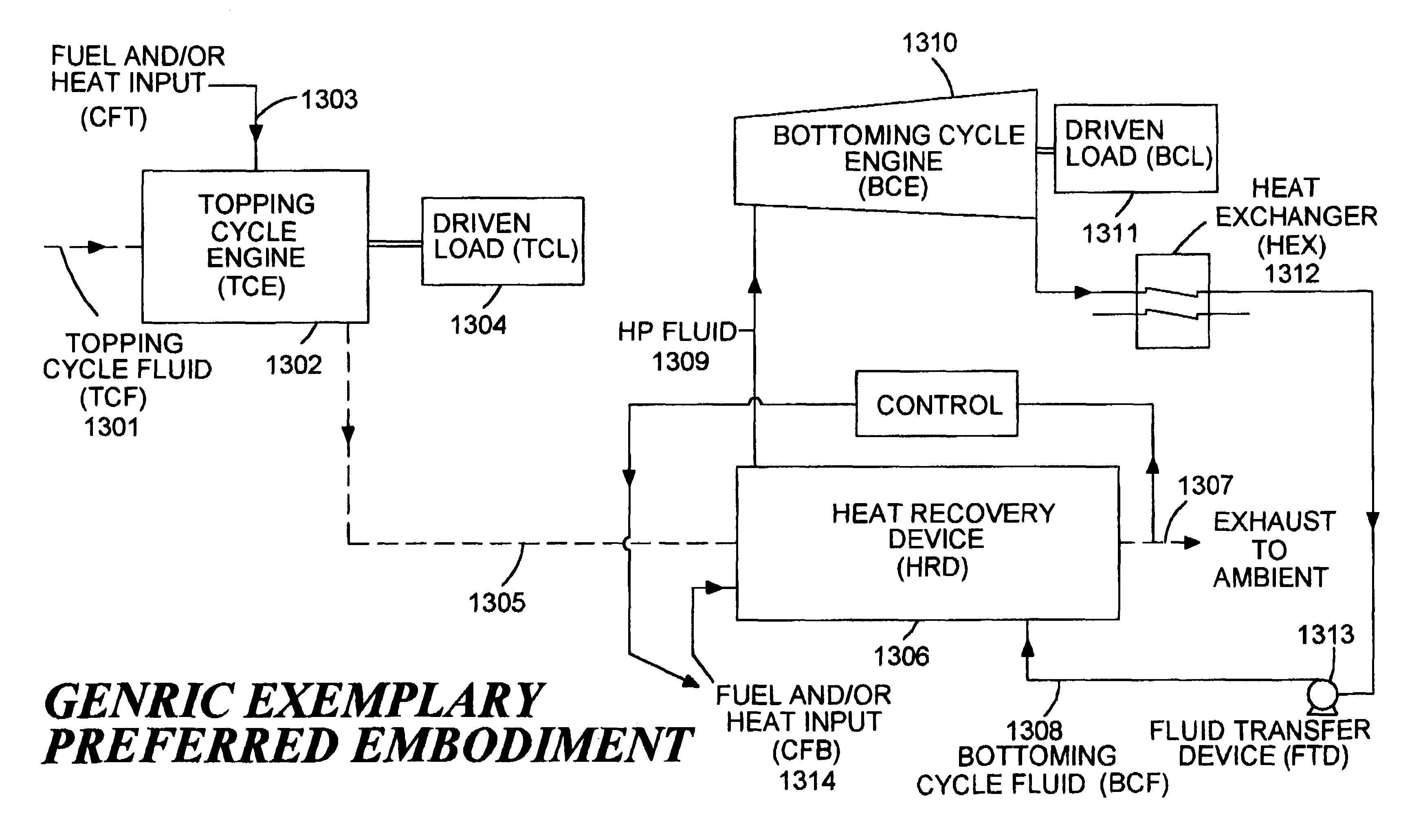

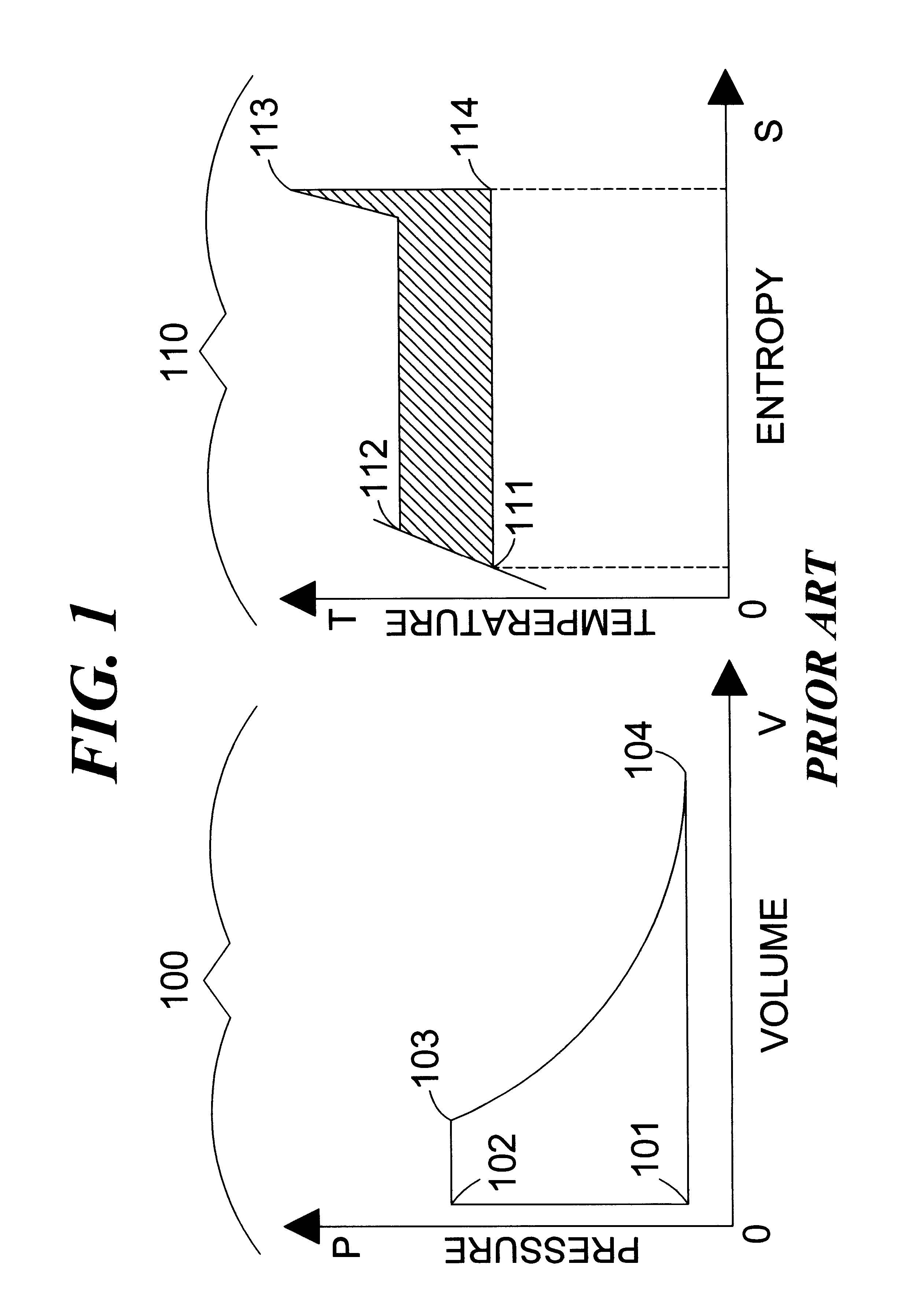

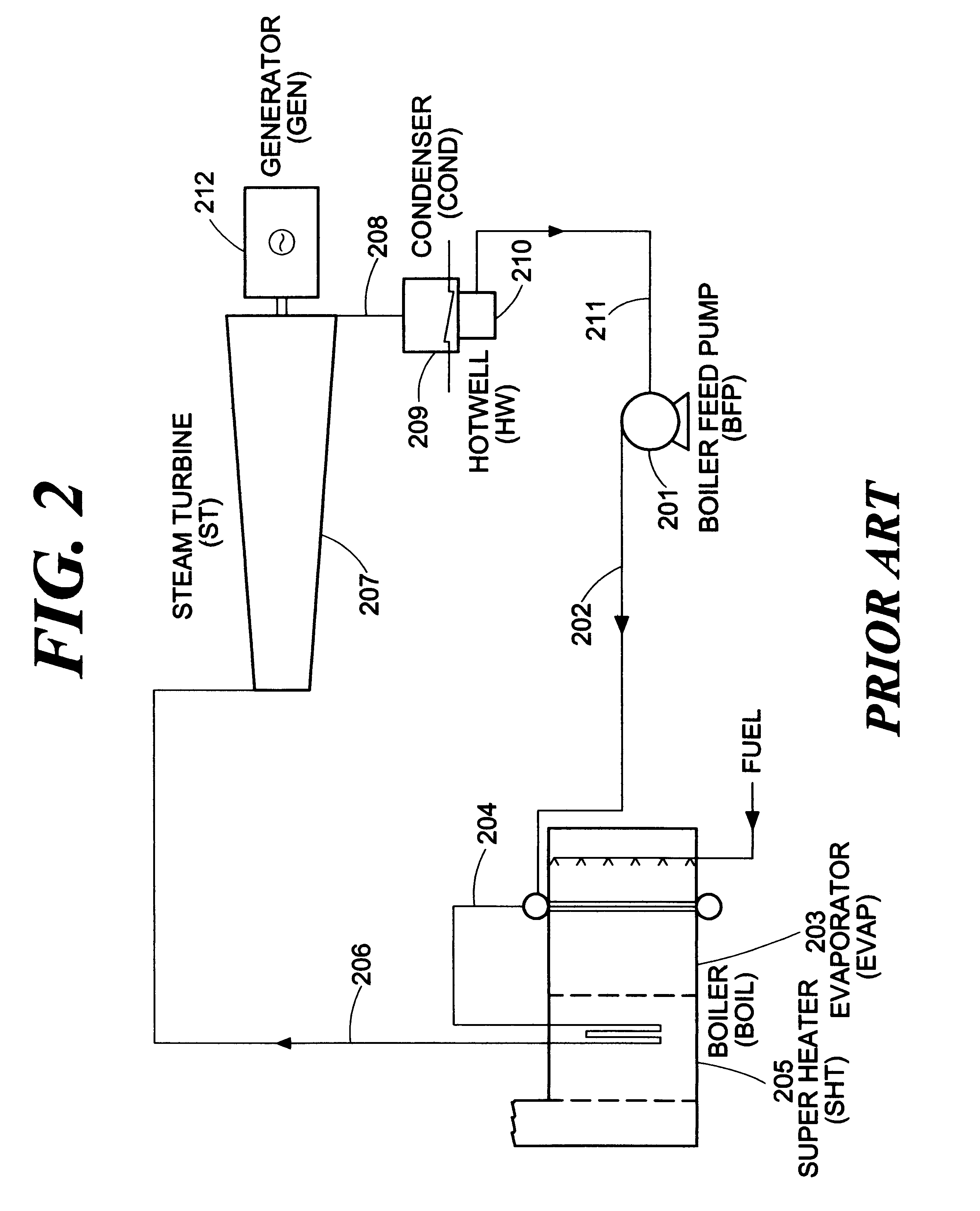

A system and method for increasing the specific output of a combined cycle power plant and providing flexibility in the power plant rating, both without a commensurate increase in the plant heat rate, is disclosed. The present invention demonstrates that the process of upgrading thermal efficiencies of combined cycles can often be accomplished through the strategic use of additional fuel and / or heat input. In particular, gas turbines that exhaust into HRSGs, can be supplemental fired to obtain much higher steam turbine outputs and greater overall plant ratings, but without a penalty on efficiency. This system and method by in large defines a high efficiency combined cycle power plant that is predominantly a Rankine (bottoming) cycle. Exemplary embodiments of the present invention include a load driven by a topping cycle engine (TCE), powered by a topping cycle fluid (TCF) which exhausts into a heat recovery device (HRD). The HRD is fired with a supplementary fuel or provided an additional heat source to produce more energetic and / or a larger quantity of the bottoming cycle fluid (BCF) which is used to power a bottoming cycle engine, (BCE) which drives a load (potentially the same load as the topping cycle engine). Energy contained in either the TCF or BCF is used to power the TCE and BCE respectively, but these fluids, and / or their respective engine exhausts, may also be used to support a wide variety of cogeneration applications.

Owner:ROLLINS III WILLIAM SCOTT

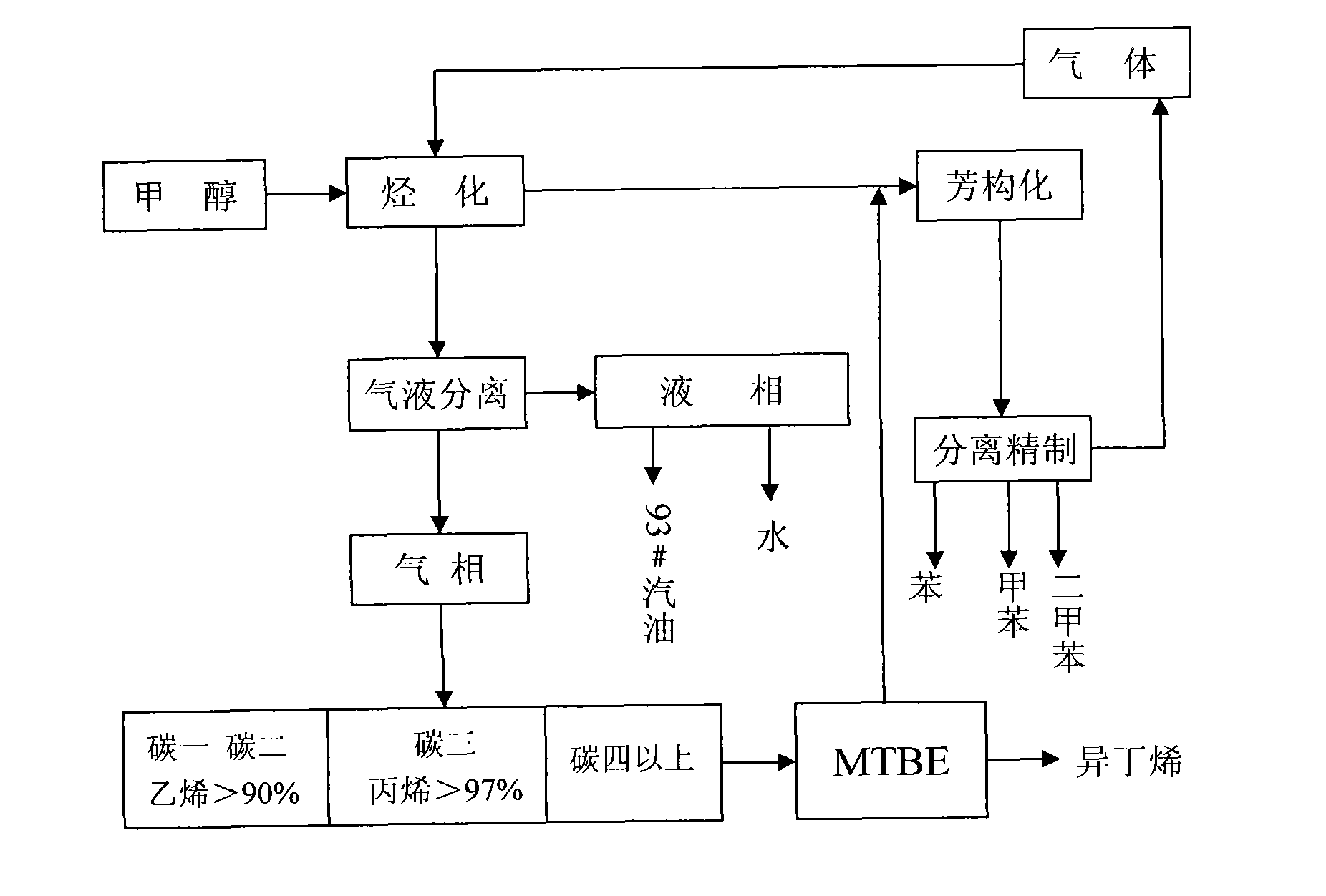

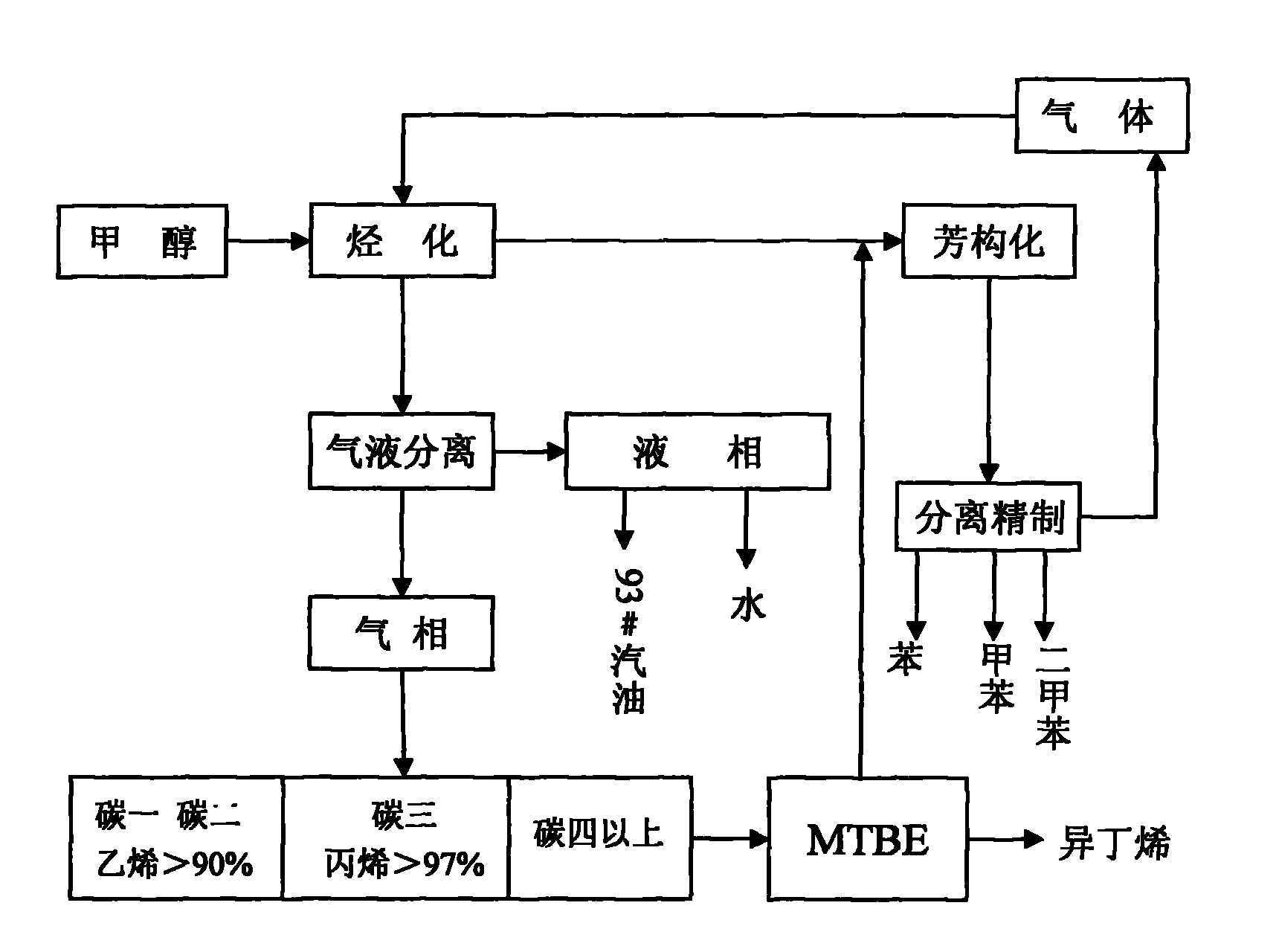

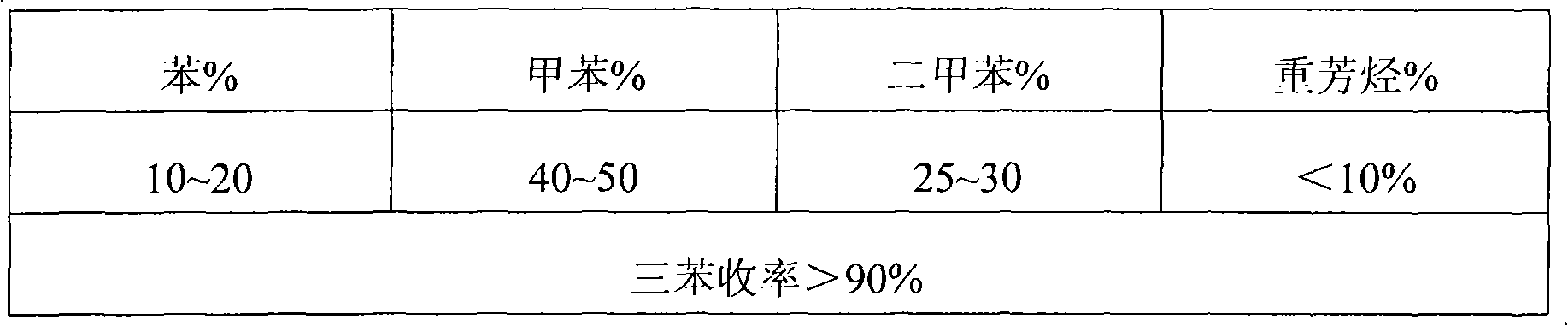

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

InactiveCN102146010ALow costReduce energy consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionEnvironmental resistanceCogeneration

The invention discloses a process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as a raw material. In the process, the methanol is used as the raw material and a molecular sieve catalyst is adopted to produce the low carbon olefin and arene parallel cogeneration gasoline by a methanol alkylation reaction and aromatization. In the process, the coal-based methanol is used as the raw material and can replace the conventional petroleum raw material to cogenerate a basis organic chemical raw material, and thus, the dependence degree of the conventional petrochemical industry on the petroleum can be reduced. Meanwhile, the process is also beneficial for reducing the foreign dependence degree of national petroleum, the strategic safety of energy and resources is improved, the production process of the process has low discharge, low pollution and low energy consumption, the requirements on green and environment protection are met, and the process has the advantages of low production cost and strong market competitiveness.

Owner:江苏煤化工程研究设计院有限公司 +2

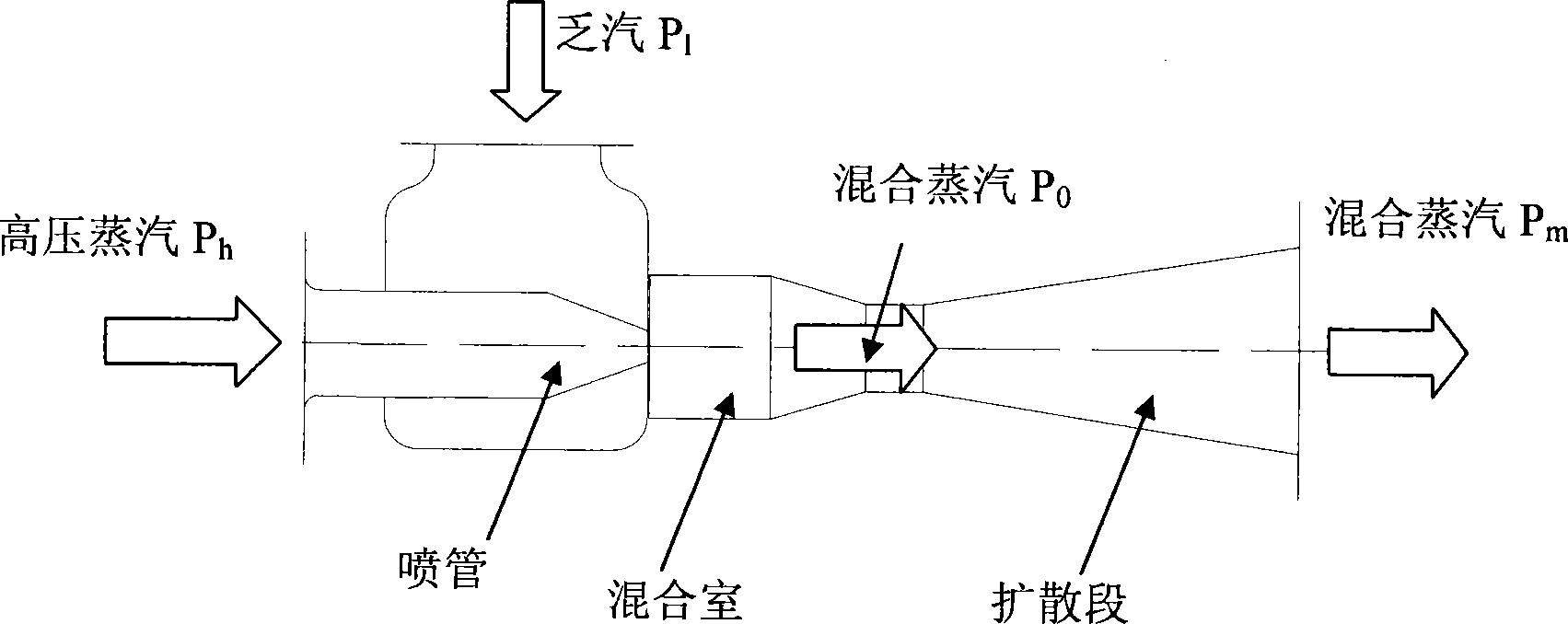

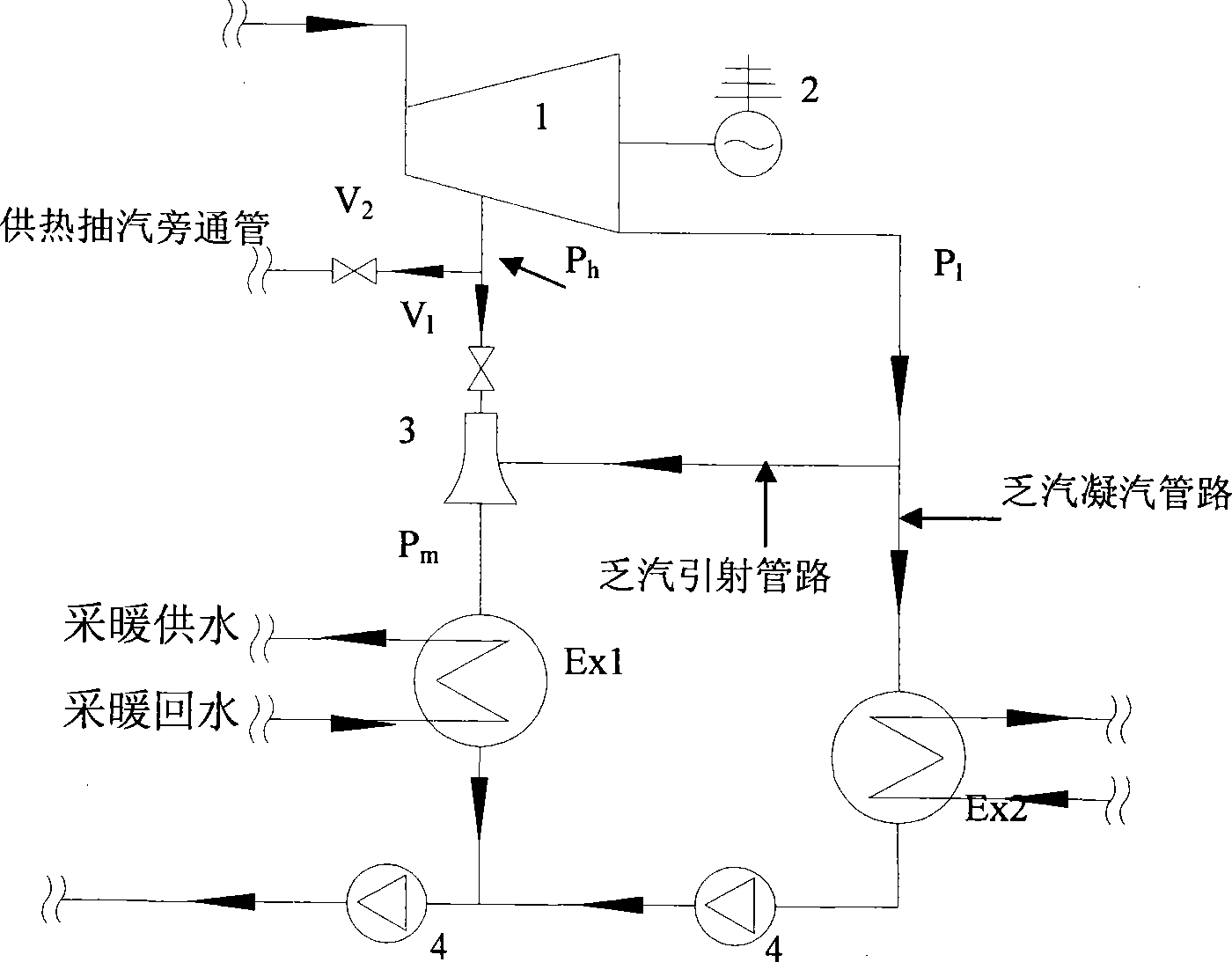

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

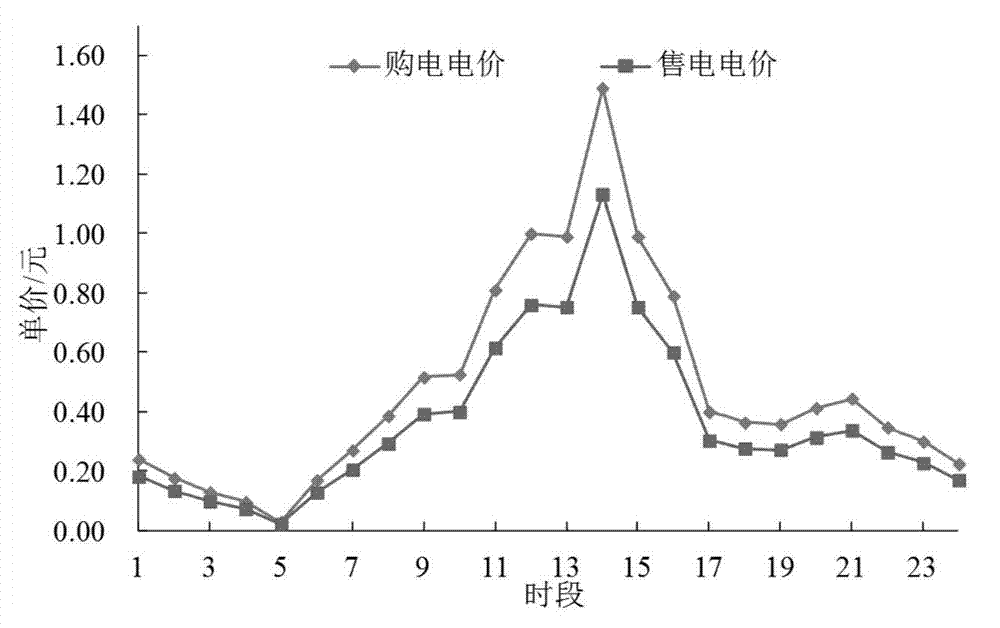

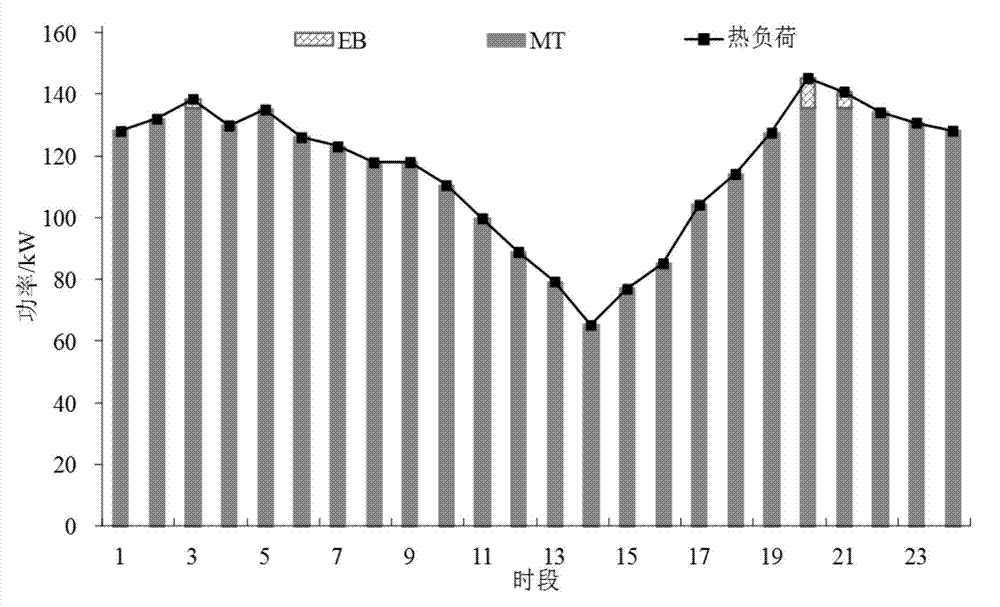

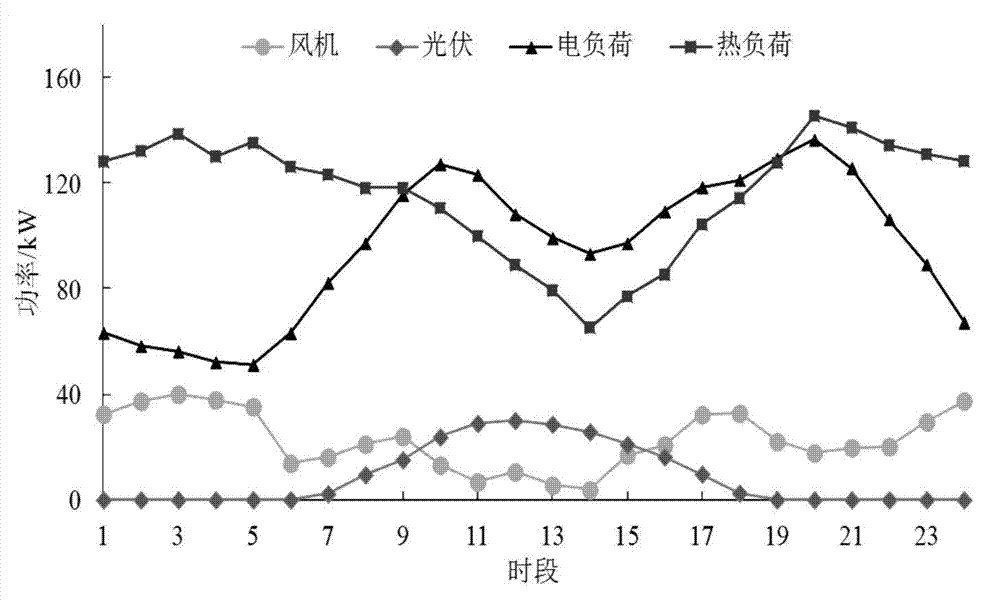

Microgrid running optimization system and method based on power and heat combined dispatching

ActiveCN104734168AIncrease profitLow running costEnergy storageAc network load balancingDistributed generatorInteger non linear programming

The invention discloses a microgrid running optimization system and method based on power and heat combined dispatching. Running restrains such as the output force characteristic, start, stop and climbing of a distributed type generator set and the charge and discharge characteristics of power and heat energy storage are comprehensively considered, a microgrid power and heat combined dispatching model containing a fan, a photovoltaic cell, a combined heat and power generation system, an electric boiler, a fuel cell and an energy storage (electrical energy storage and heat energy storage) is built, the 0-1 mixed integer nonlinear programming method is adopted for solving the optimal output force and total running cost of all units in the network, and power and heat dispatching contrastive analysis is carried out on the system and a traditional separated generation and combined generation optimization model. In addition, the influences of the heat and power reliability difference on the running are analyzed and discussed, and therefore the heat and power dispatching module is more reasonable, comprehensive and universal.

Owner:SHANDONG UNIV

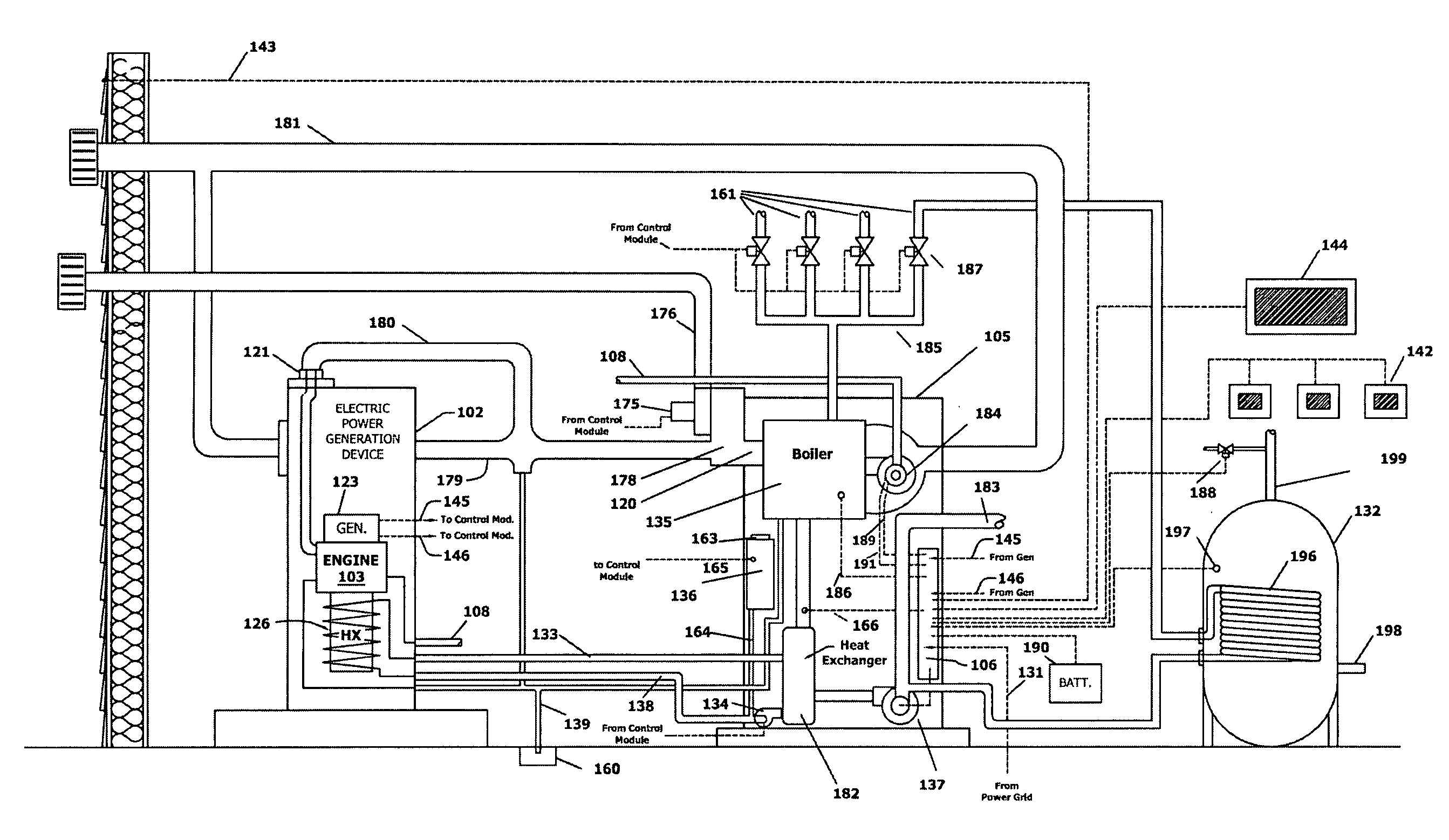

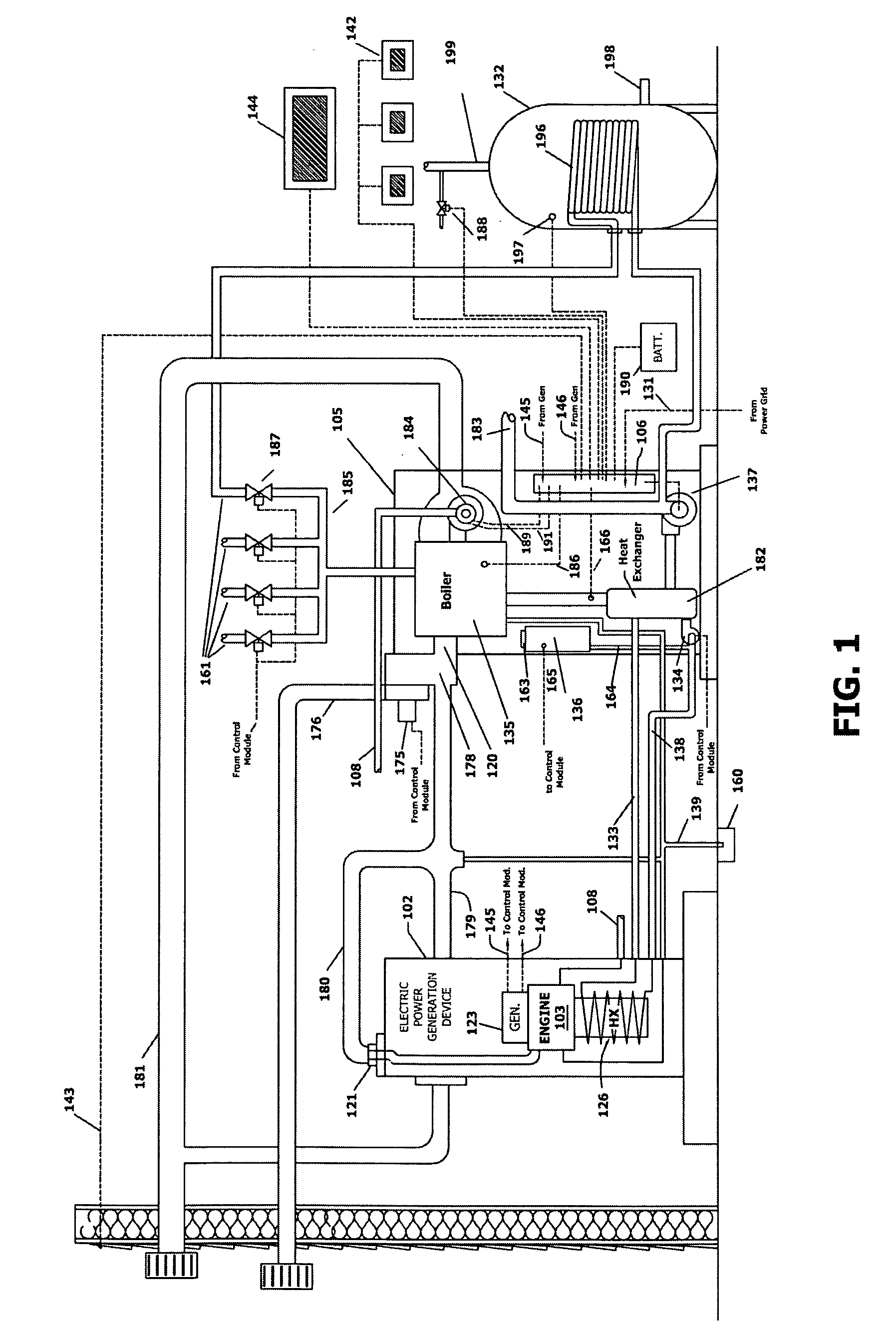

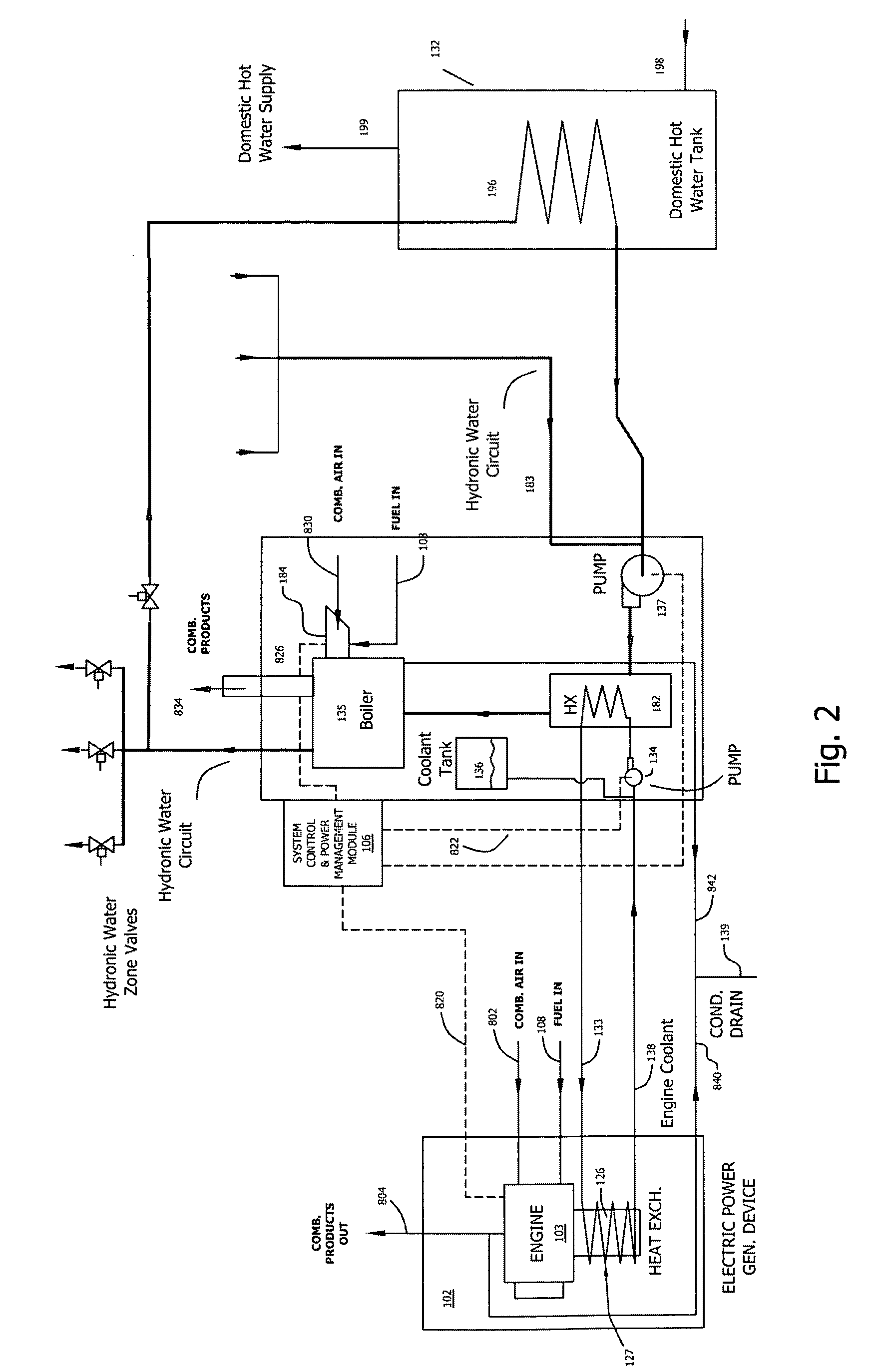

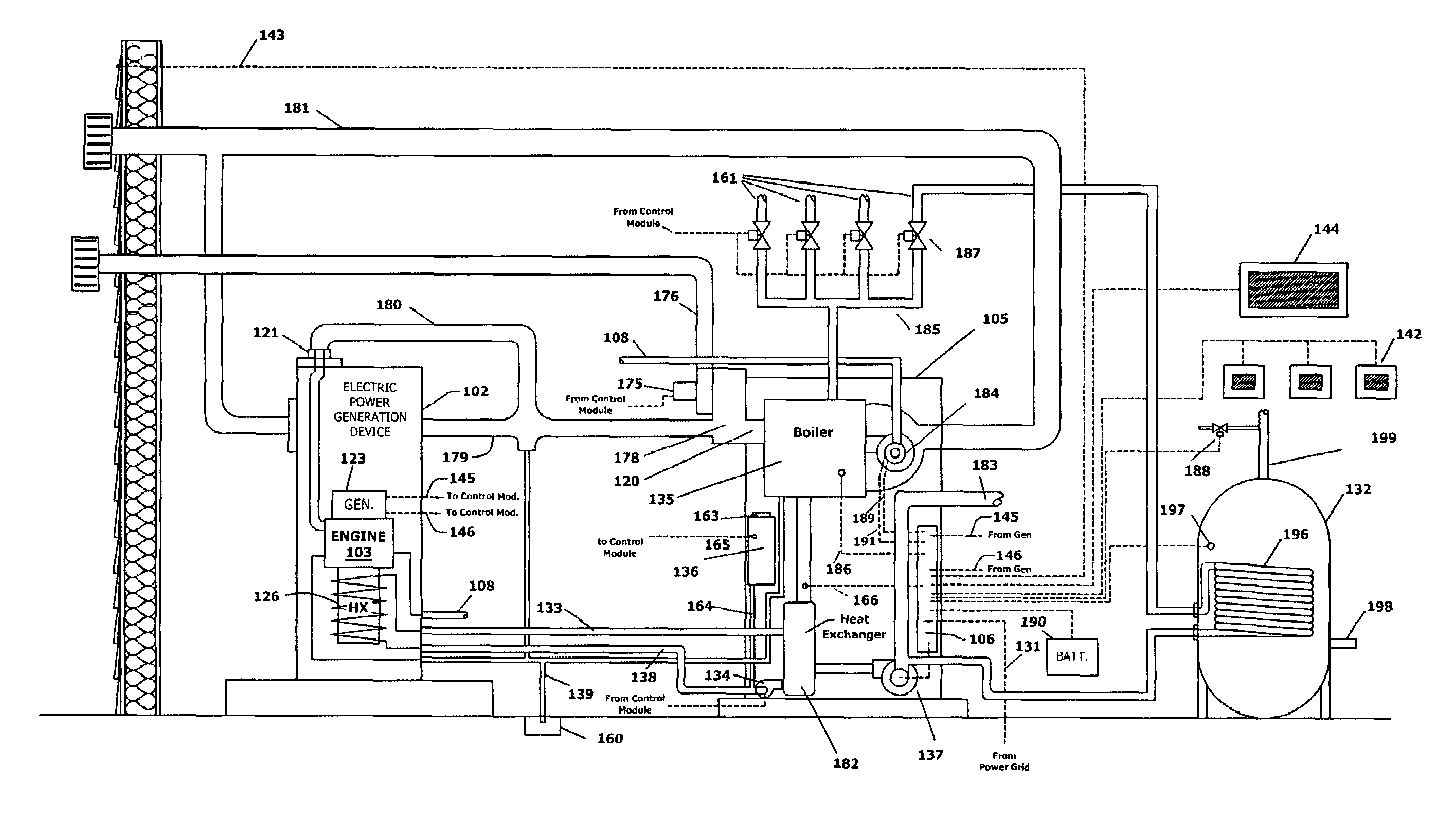

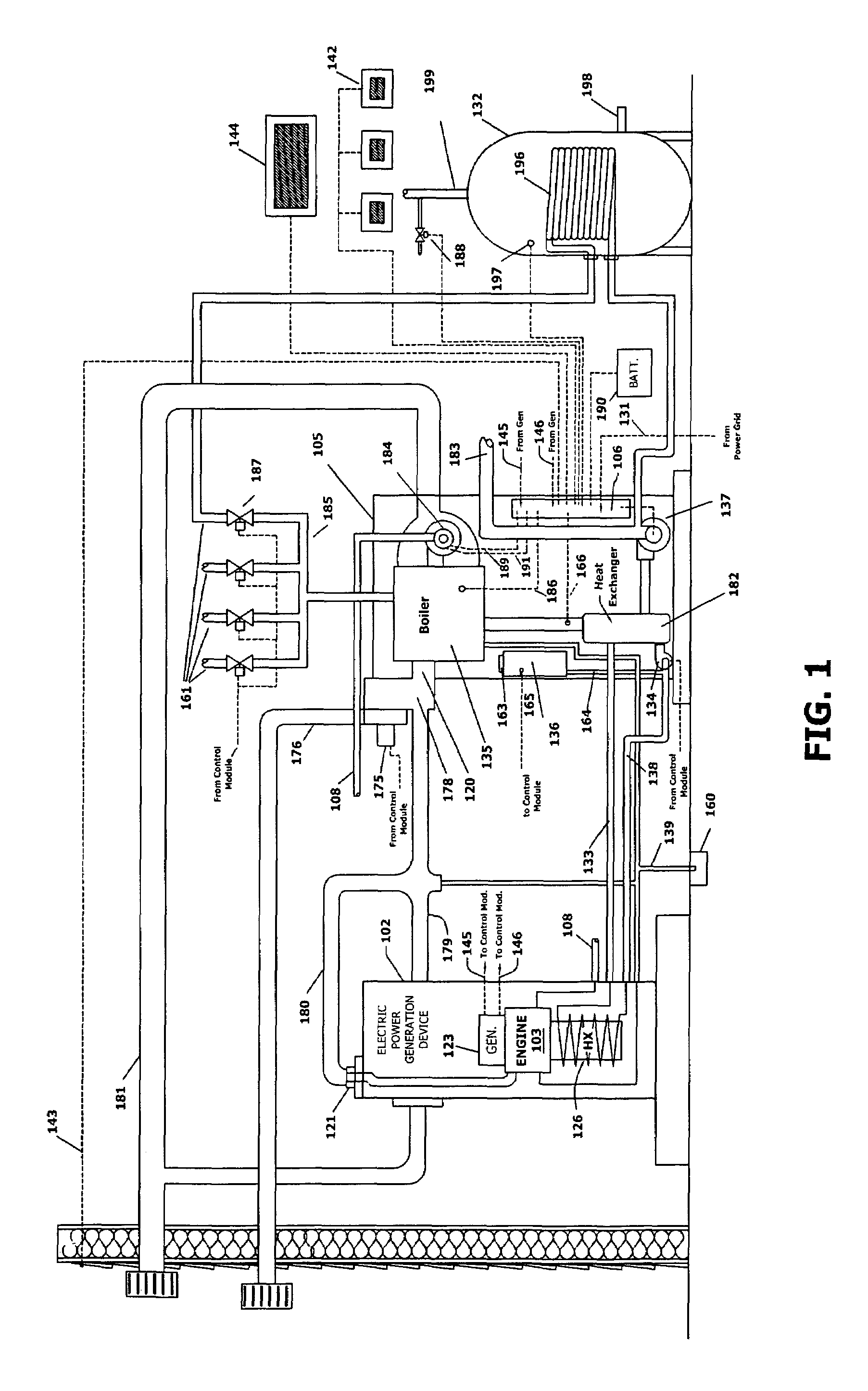

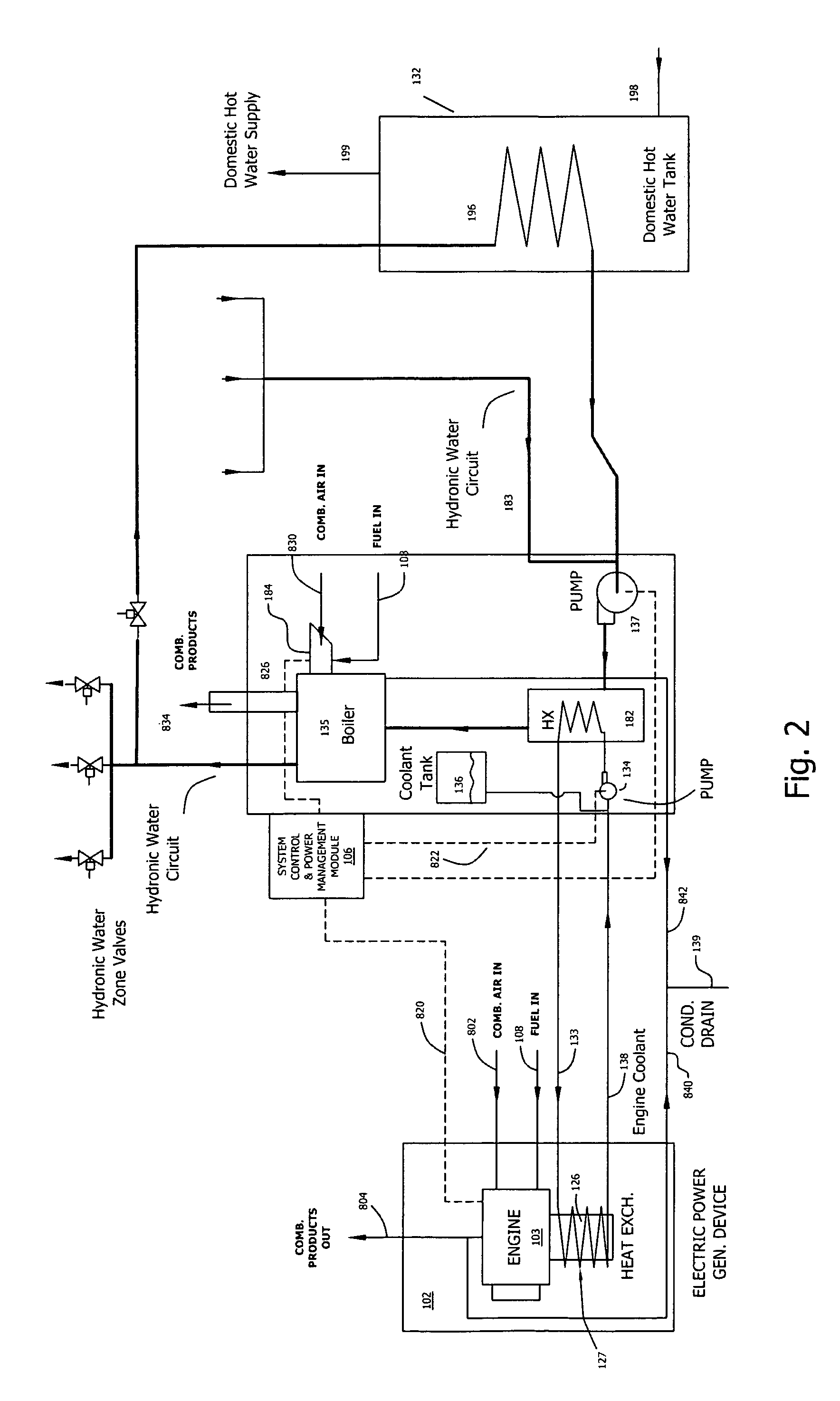

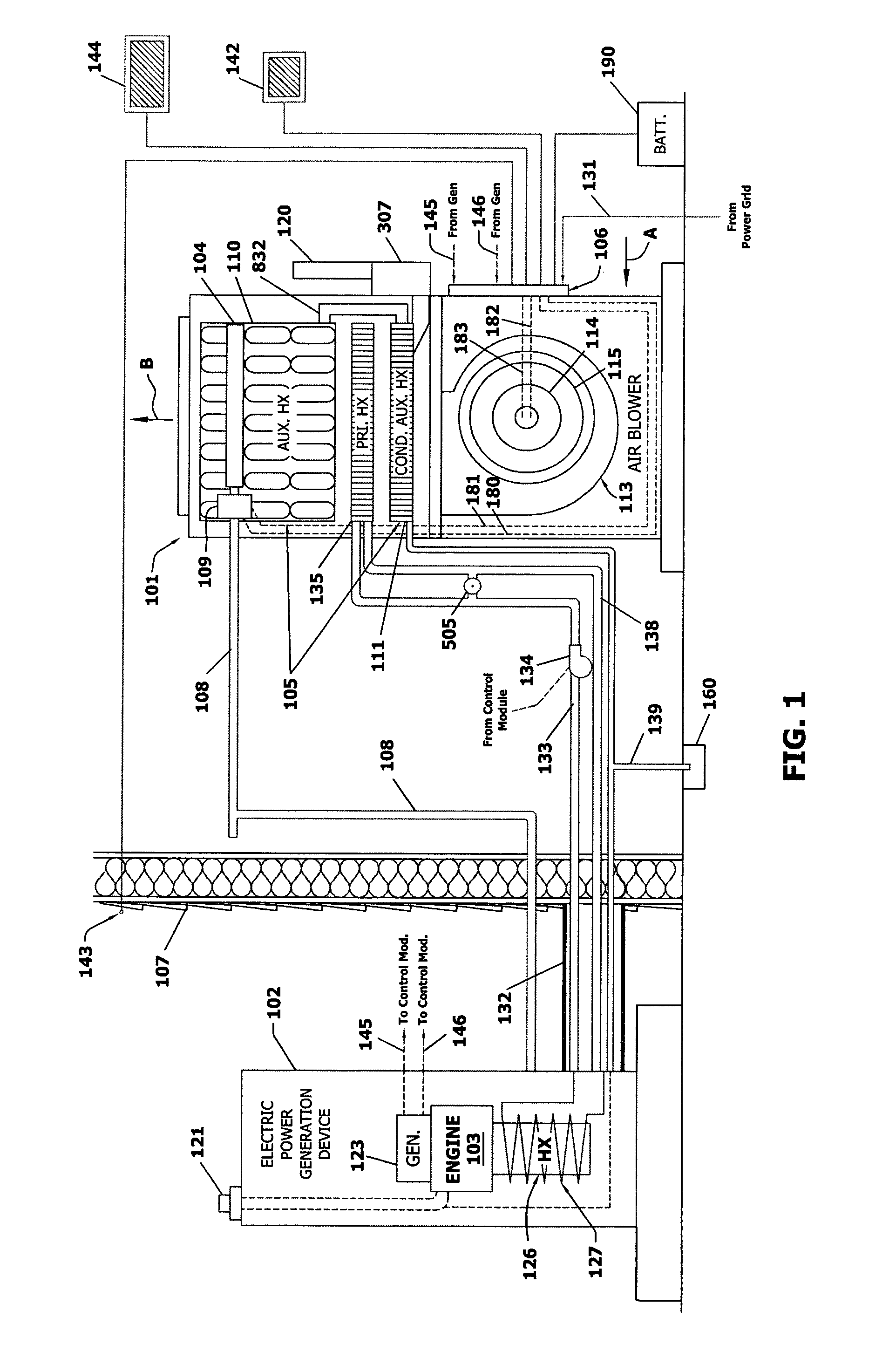

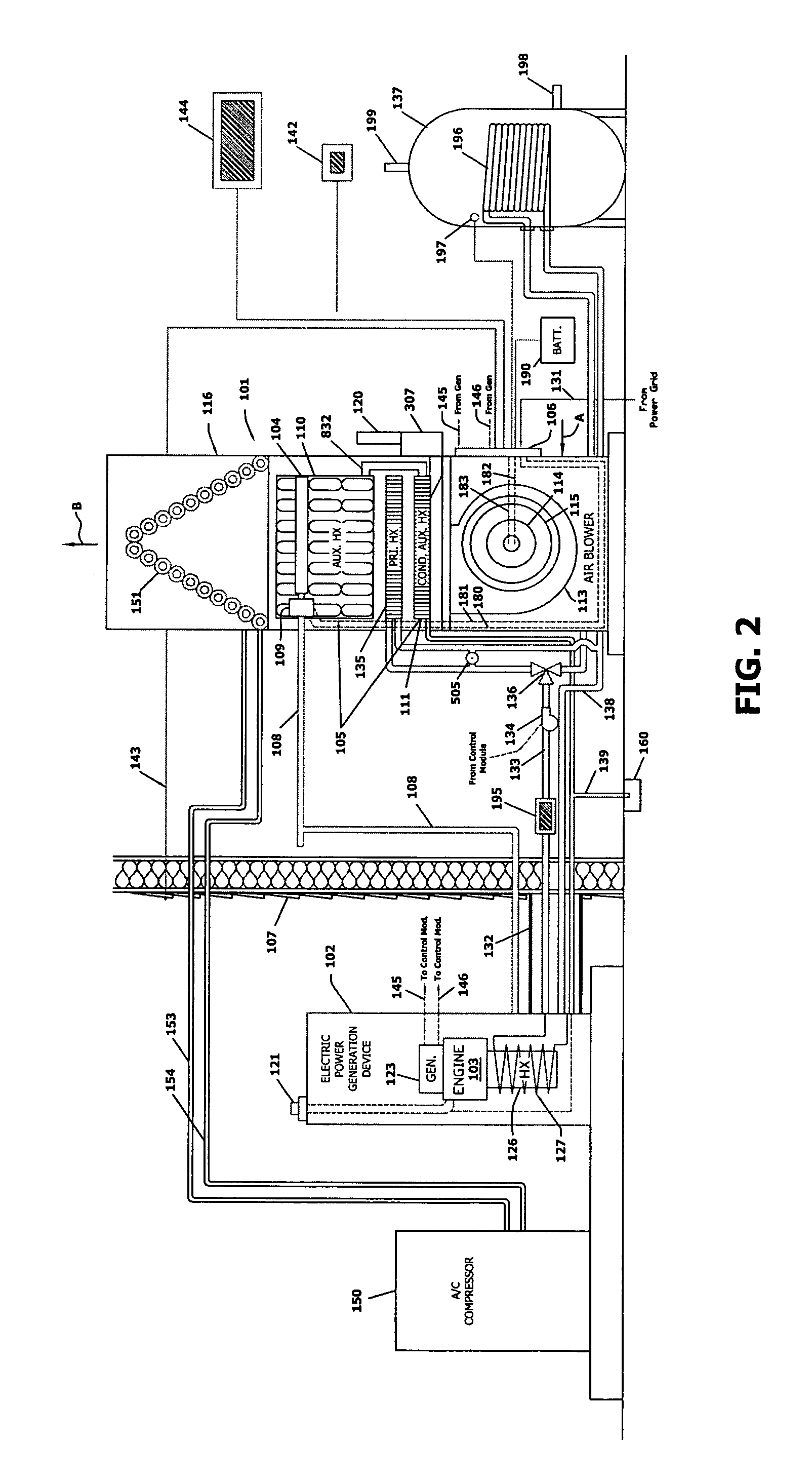

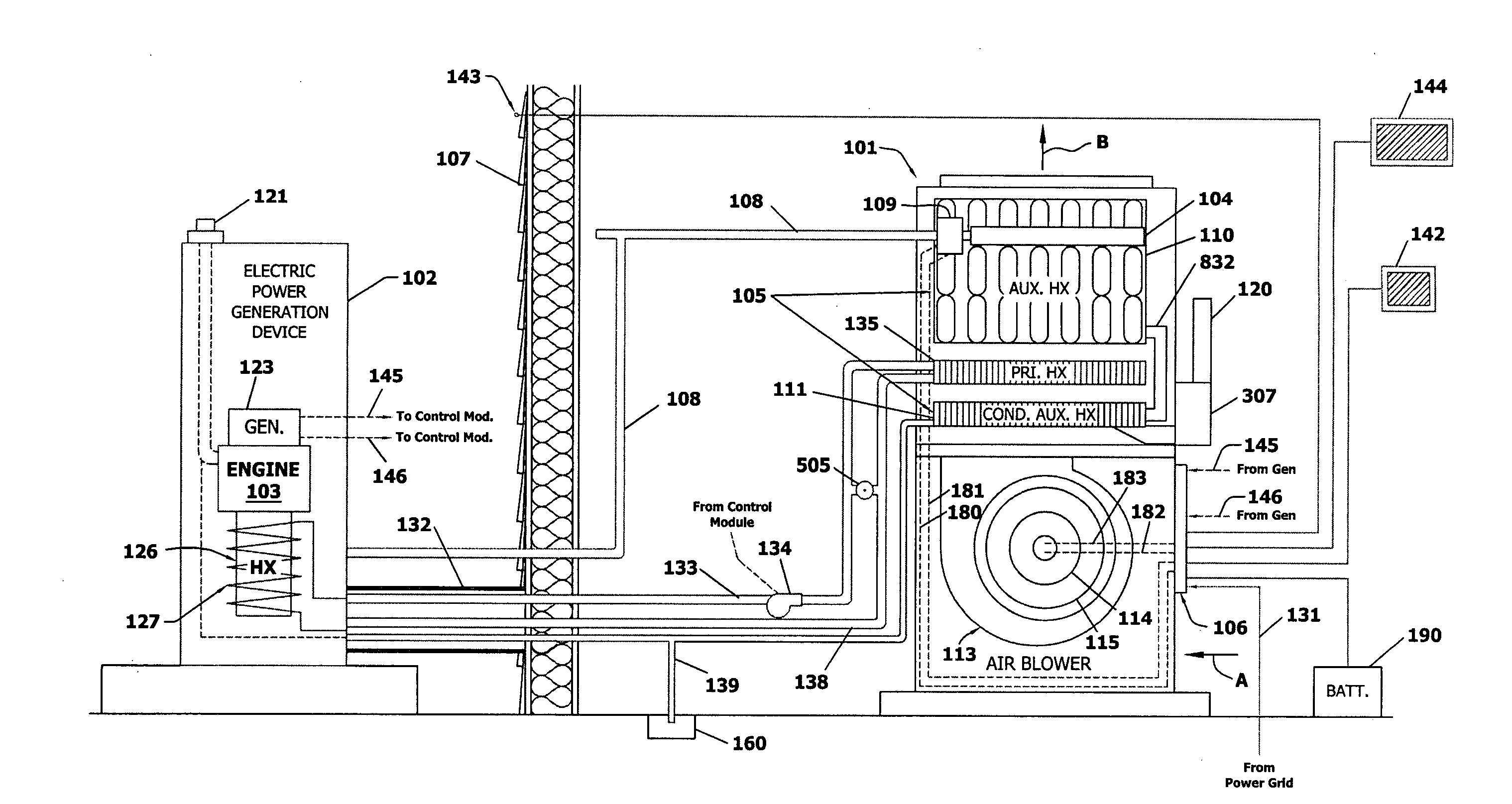

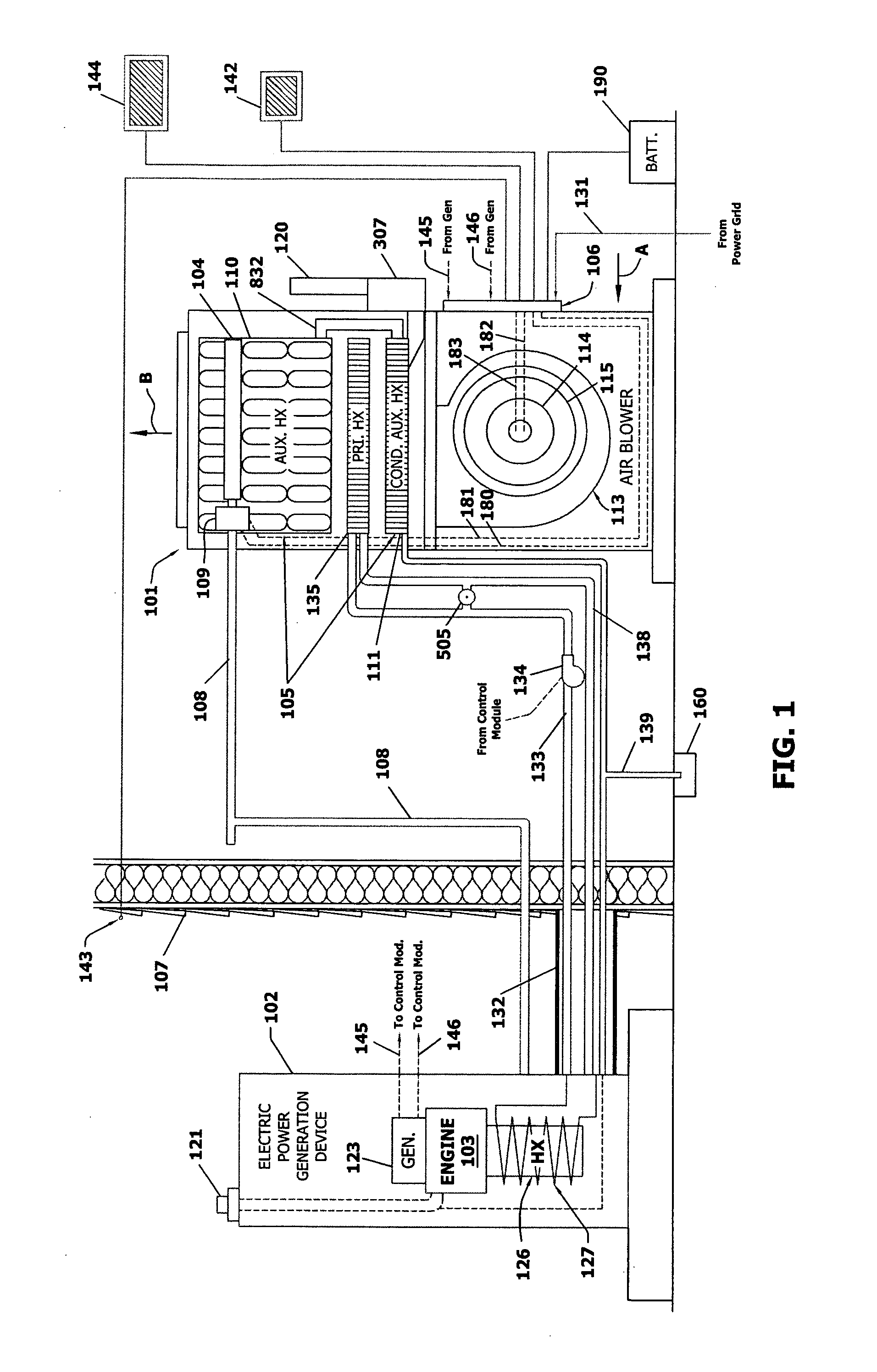

System and method for hydronic space heating with electrical power generation

ActiveUS20050161521A1Easy to useMaximizing run timeInternal combustion piston enginesWaste gas energyCogenerationEngineering

This invention provides a system and method for cogeneration of electric power and building heat that efficiently interfaces a liquid-cooled electric power generator with a multi-zone forced hot water (hydronic) space heating system. The system and method utilizes an electric generator with an electric output capacity (kW) that is near the time-averaged electric power consumption rate for the building and with a heat generation capacity that is useful for meeting building heating needs. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building, with the intent of running the generator for long periods of time and generating a total amount of electric energy (kWhs) that is significant in comparison to the total electric energy consumption of the building over time. The actual onsite time-variable power demand (kW) is met by a combination of the cogenerated electric power produced on site and quantities of electric power from the public electric power grid or another external power source. Hence, useful electric power is generated on site as a by-product of the required generation of heat for space or water heating. The generator is run at a speed / operating condition that is appropriate to maintaining a long operational life.

Owner:CLIMATE ENERGY

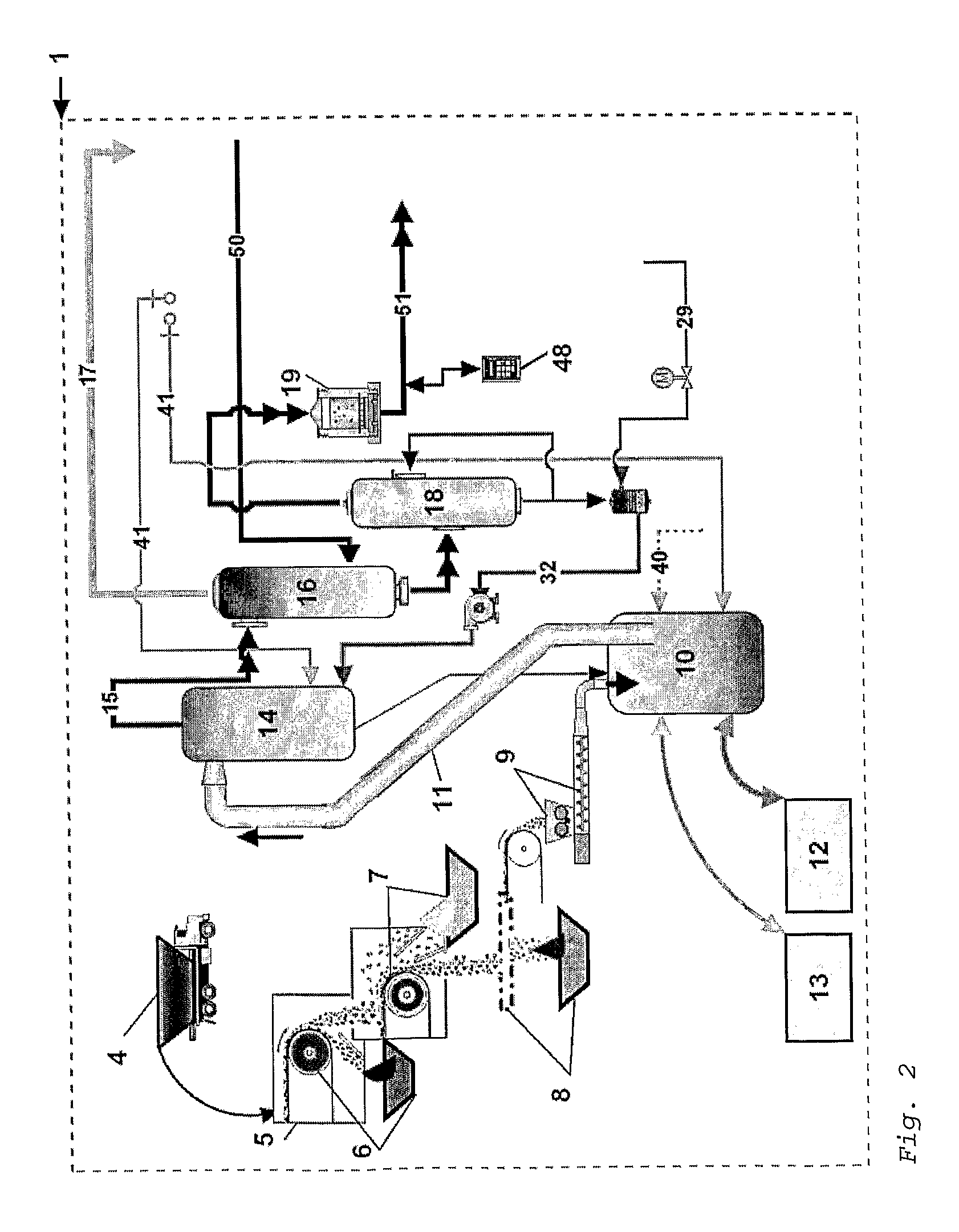

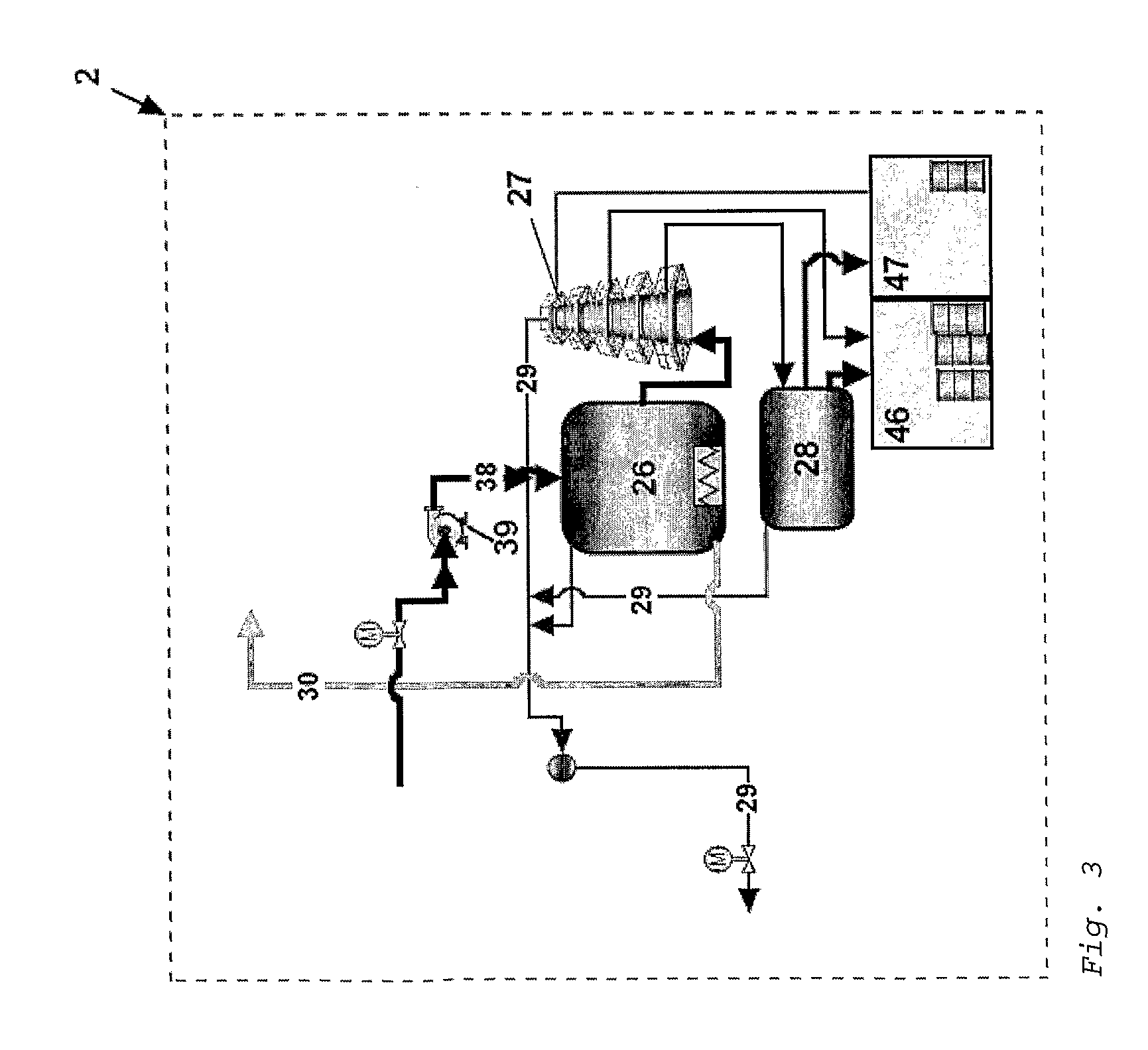

Comprehensive utilization process of wood cellulose

The invention discloses a comprehensive utilization process of wood cellulose, which comprises the processes of comprehensive treatment, oligosaccharide preparation, lignin preparation, fiber ethanol preparation and the like. The invention has the advantages of decomposing a biomass macromolecular natural compact structure by using a high-pressure instant steam exploding technology, being beneficial to the separation and the extraction of the lignin, the cellulose and the cellulose, reducing the consumption of the energy sources and the materials, such as acid, alkali, heat, catalyst and the like for preprocessing, reducing the emission of pollutants and lightening the pollution of the environment. Secondly, the cogeneration of oligosaccharide and lignin realizes the comprehensive utilization of the energy sources, especially the application of the steam exploding technology ensures that the quality of the two products of the oligosaccharide and the lignin is greatly improved and the yield is greatly increased; and alcohol and the lignin of production fuels of sugar residues can be extracted irrespective of the order.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

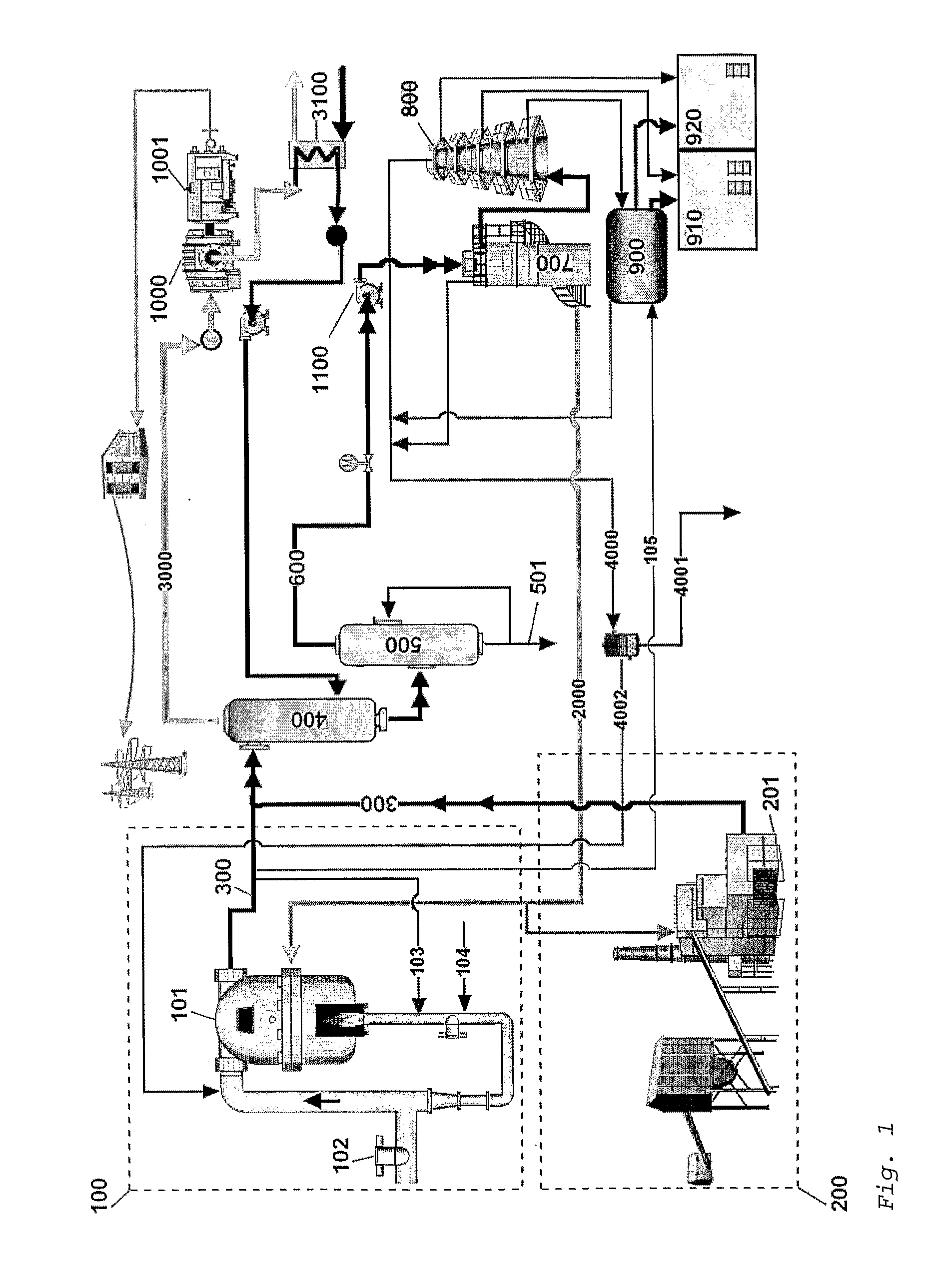

Waste to liquid hydrocarbon refinery system

InactiveUS20110158858A1Eliminate concernsReduce dependenceDirect heating destructive distillationCombustible gas catalytic treatmentLiquid wasteCogeneration

A Waste to Liquid Hydrocarbon Refinery System that transforms any municipal solid wastes and hazardous industrial wastes, Biomass or any carbon containing feedstock into synthetic hydrocarbon, particularly, but not exclusively, diesel and gasoline and / or electricity and co-generated heat, comprising three major subsystems: i) the Pyro-Electric Thermal Converter (PETC) (10) and Plasma Arc (PA) waste and biomass gasification subsystem (1); ii) the hydrocarbon synthesis subsystem (2); and iii) the electricity generation and heat co-generation subsystem (3).

Owner:ALVES RAMALHO GOMES MARIO LUIS

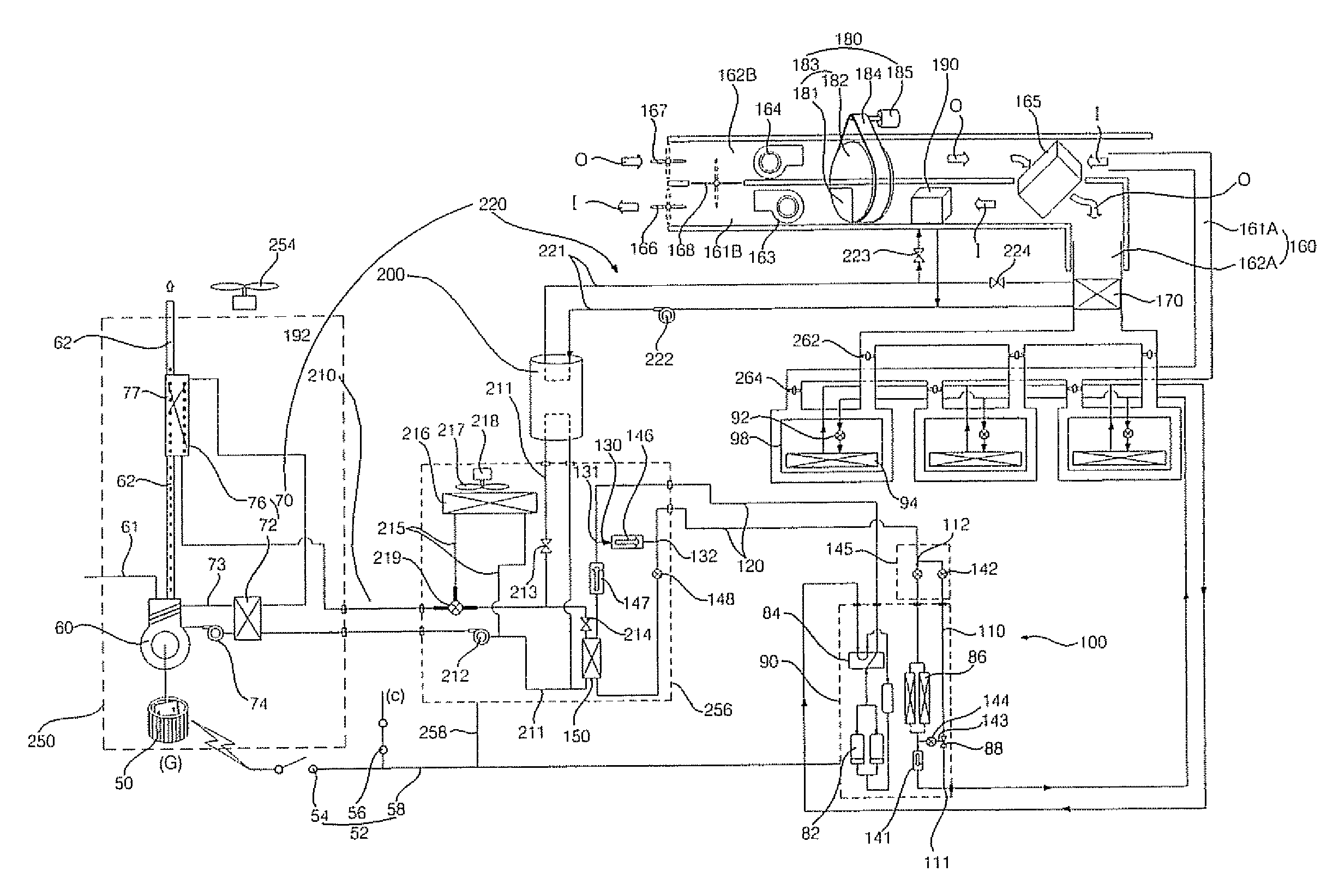

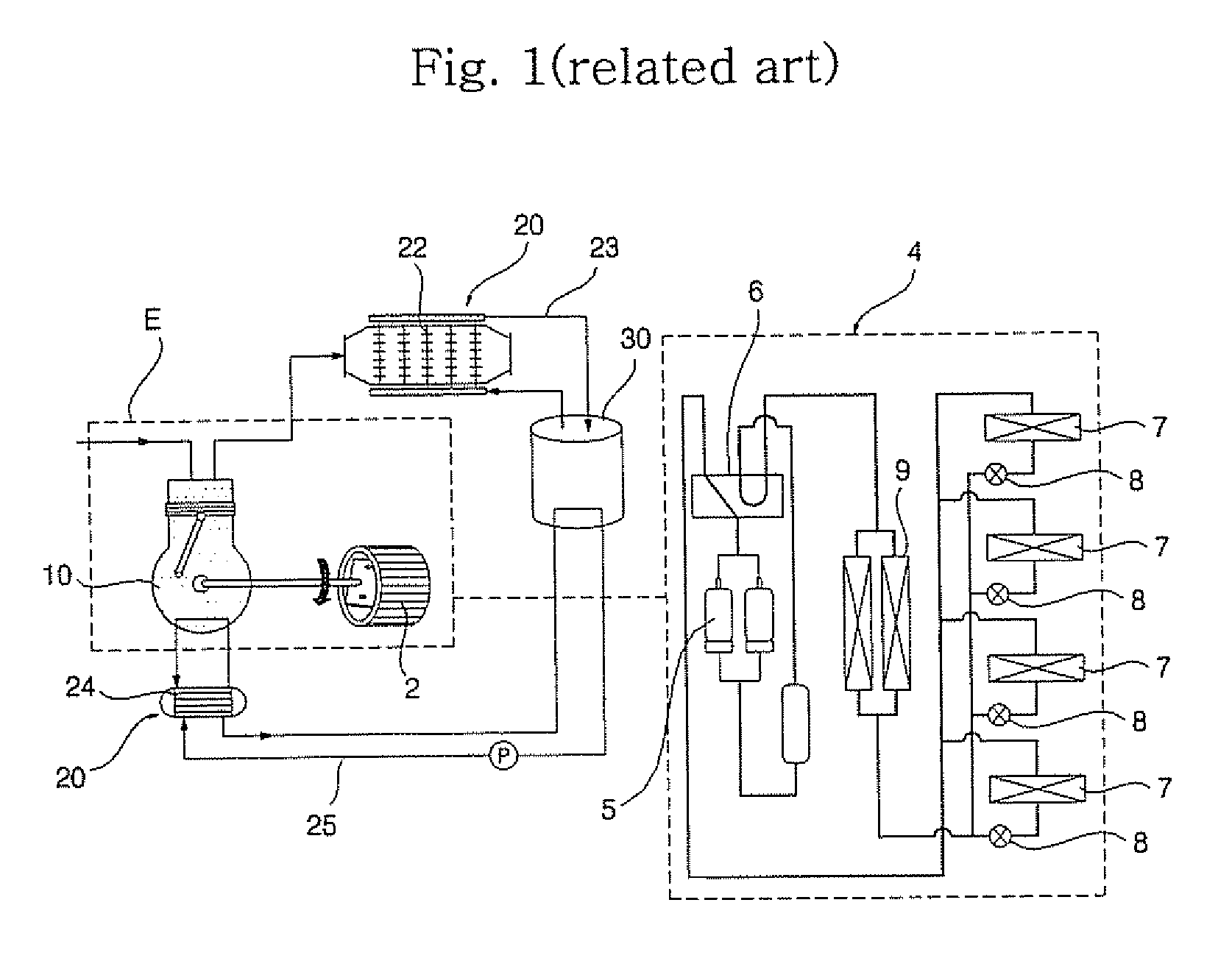

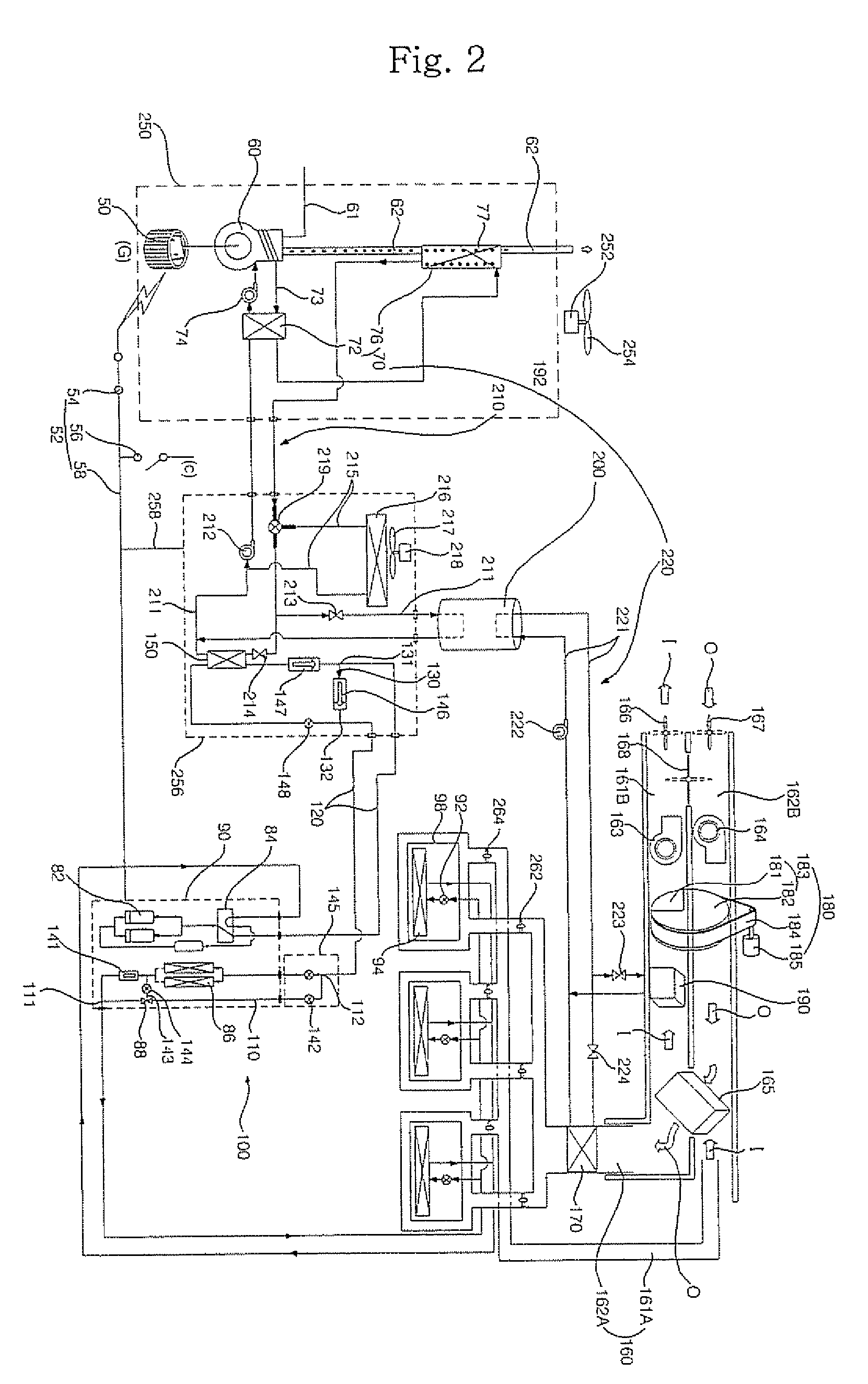

Cogeneration system

InactiveUS20060283967A1Maximum energy efficiencyImprove the heating effectMechanical apparatusHeat pumpsCogenerationProcess engineering

A cogeneration system is disclosed which includes a generator, a drive source for driving the generator, a waste heat supplying heat exchanger for enhancing the heating performance of a heat pump type air conditioner, an auxiliary heating heat exchanger using the waste heat of the drive source as a heat source for heating indoor air, and a regeneration heat supplying heat exchanger using the waste heat of the drive source as a heat source for regenerating a dehumidifier. The cogeneration system can use the waste heat of the drive source for diverse purposes in accordance with the indoor environment, and can have a maximal efficiency.

Owner:LG ELECTRONICS INC

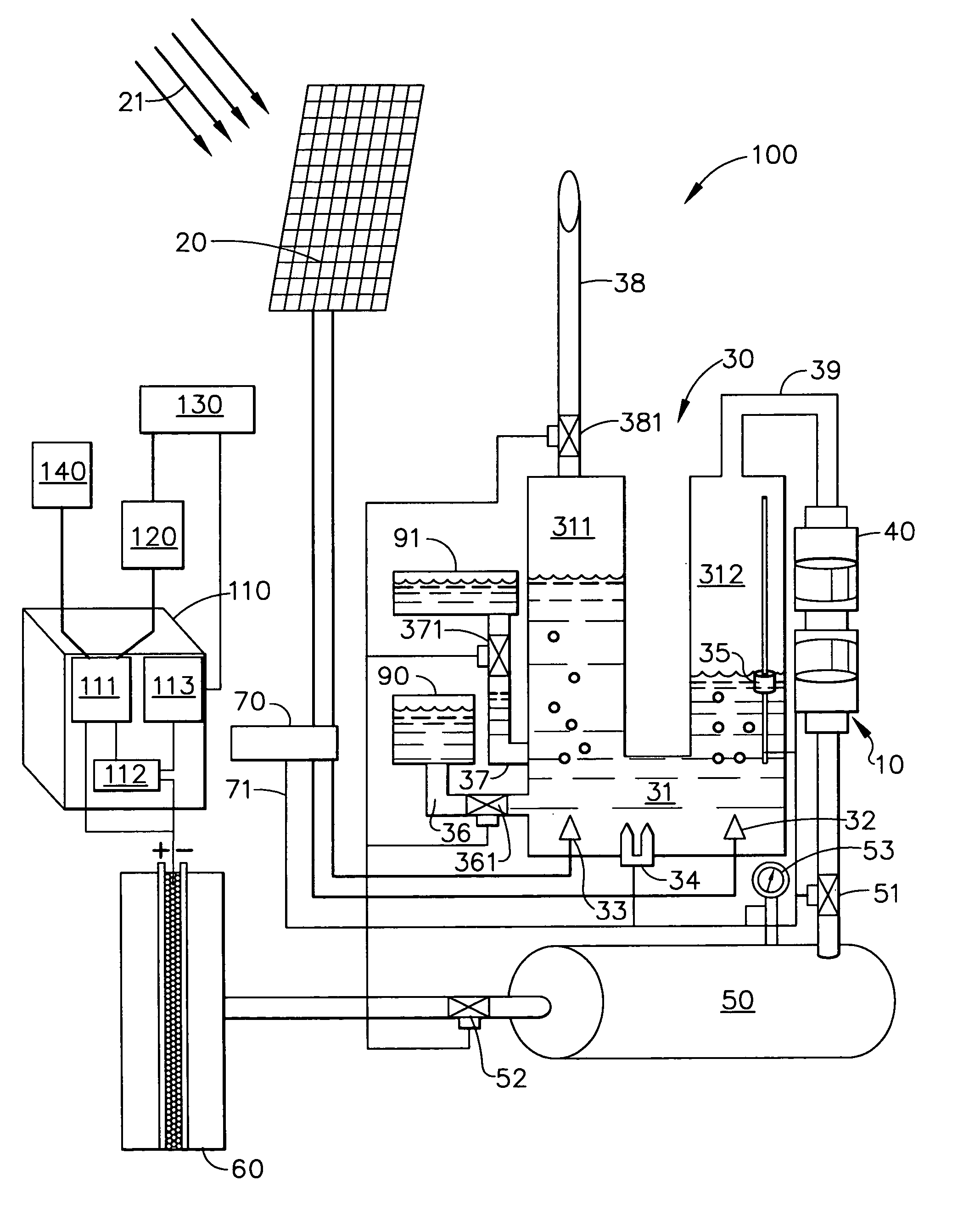

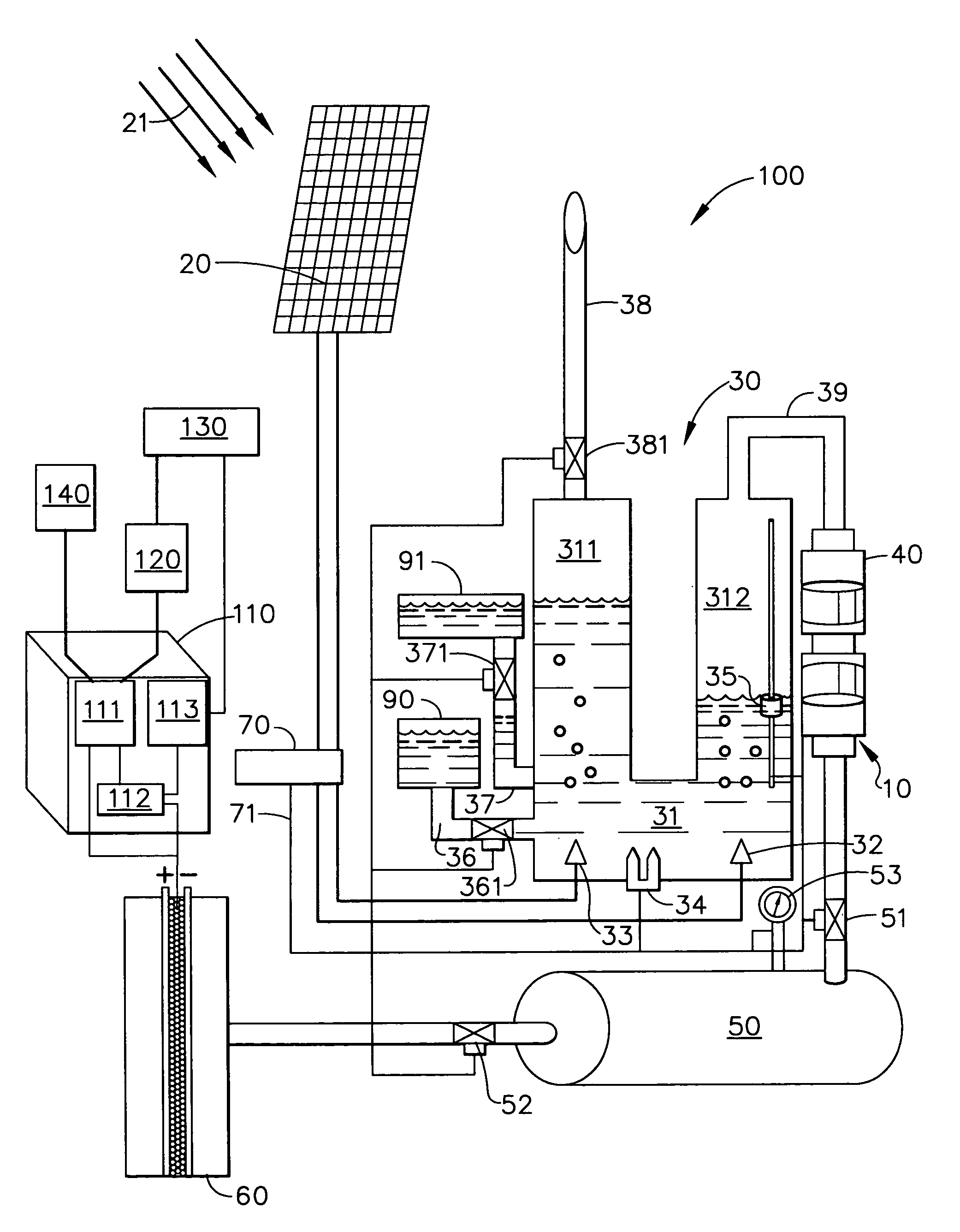

Solar electrolysis power co-generation system

A solar electrolysis power co-generation system includes a solar electrolysis source and a control unit. The solar electrolysis source includes a solar panel, an electrolysis unit, a hermetically sealed compressor, a hydrogen tank, and a hydrogen-powered fuel cell and produces, compresses, and stores hydrogen gas that is used to fuel the fuel cell. The control unit includes an inverter, a microprocessor, and a modem. The control unit connects the solar electrolysis power source with a power grid and with an individual consumer having an electrical load. The power co-generation system utilizes the electrolysis of water and solar energy to power a fuel cell. The energy produced with the fuel cell may be provided to an existing power gird as well as to an individual consumer. Further a method for decentralized power co-generation includes the step of providing a plurality of solar electrolysis power co-generation systems.

Owner:THE BOEING CO

System and method for hydronic space heating with electrical power generation

ActiveUS7284709B2Minimizing starting and stoppingMaximizing run timeInternal combustion piston enginesGas turbine plantsCogenerationElectric generator

This invention provides a system and method for cogeneration of electric power and building heat that efficiently interfaces a liquid-cooled electric power generator with a multi-zone forced hot water (hydronic) space heating system. The system and method utilizes an electric generator with an electric output capacity (kW) that is near the time-averaged electric power consumption rate for the building and with a heat generation capacity that is useful for meeting building heating needs. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building, with the intent of running the generator for long periods of time and generating a total amount of electric energy (kWhs) that is significant in comparison to the total electric energy consumption of the building over time. The actual onsite time-variable power demand (kW) is met by a combination of the cogenerated electric power produced on site and quantities of electric power from the public electric power grid or another external power source. Hence, useful electric power is generated on site as a by-product of the required generation of heat for space or water heating. The generator is run at a speed / operating condition that is appropriate to maintaining a long operational life.

Owner:CLIMATE ENERGY

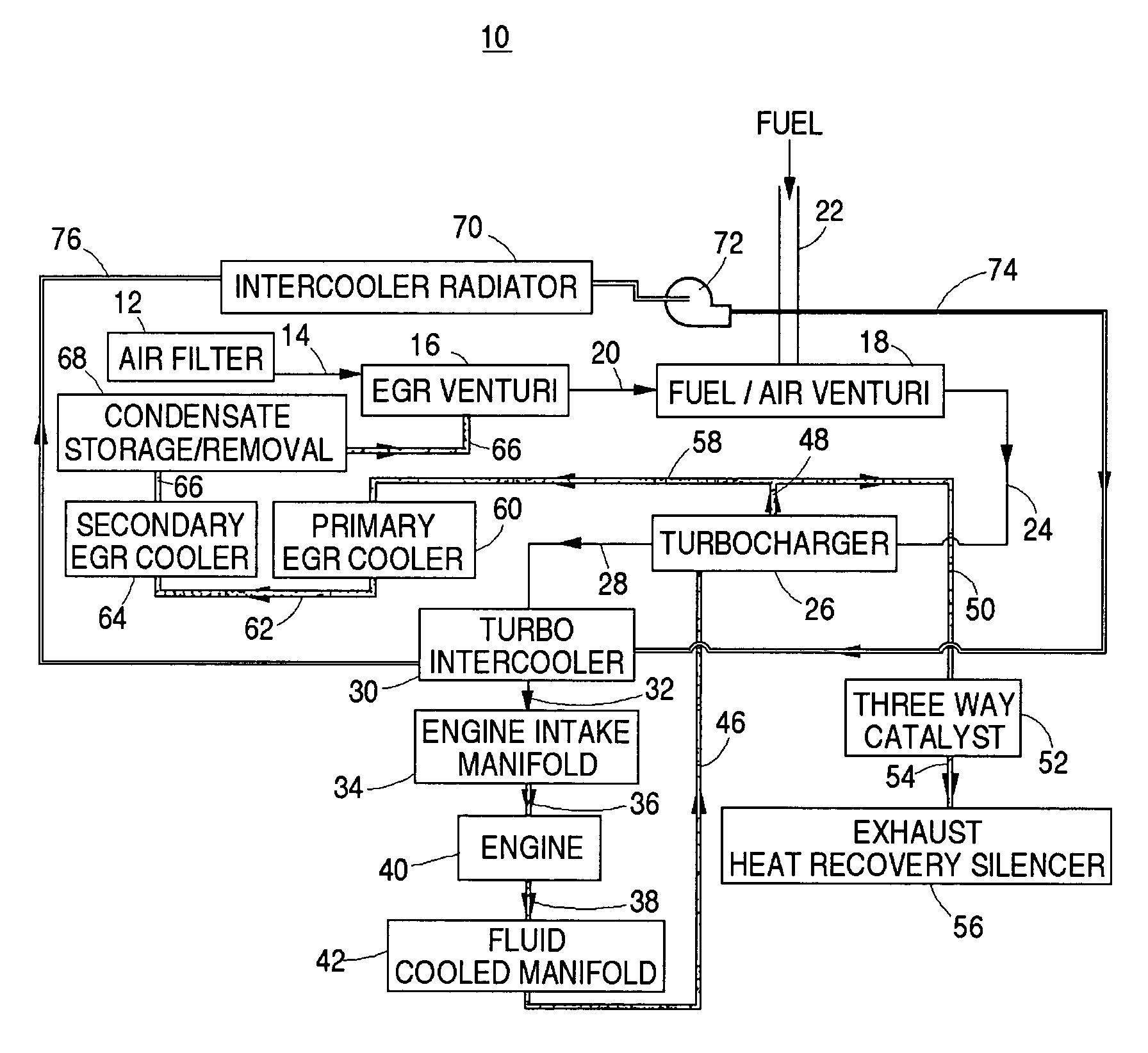

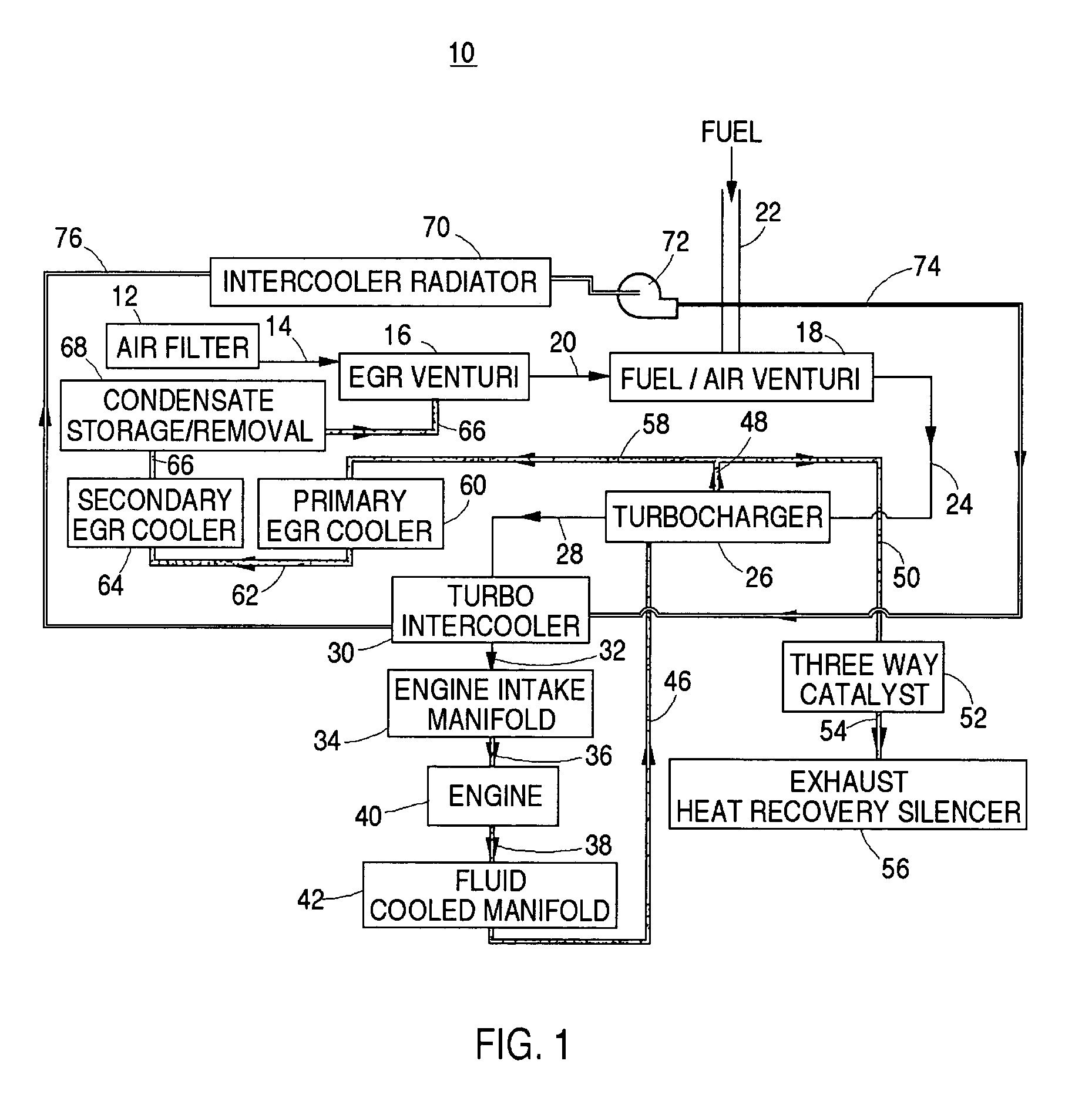

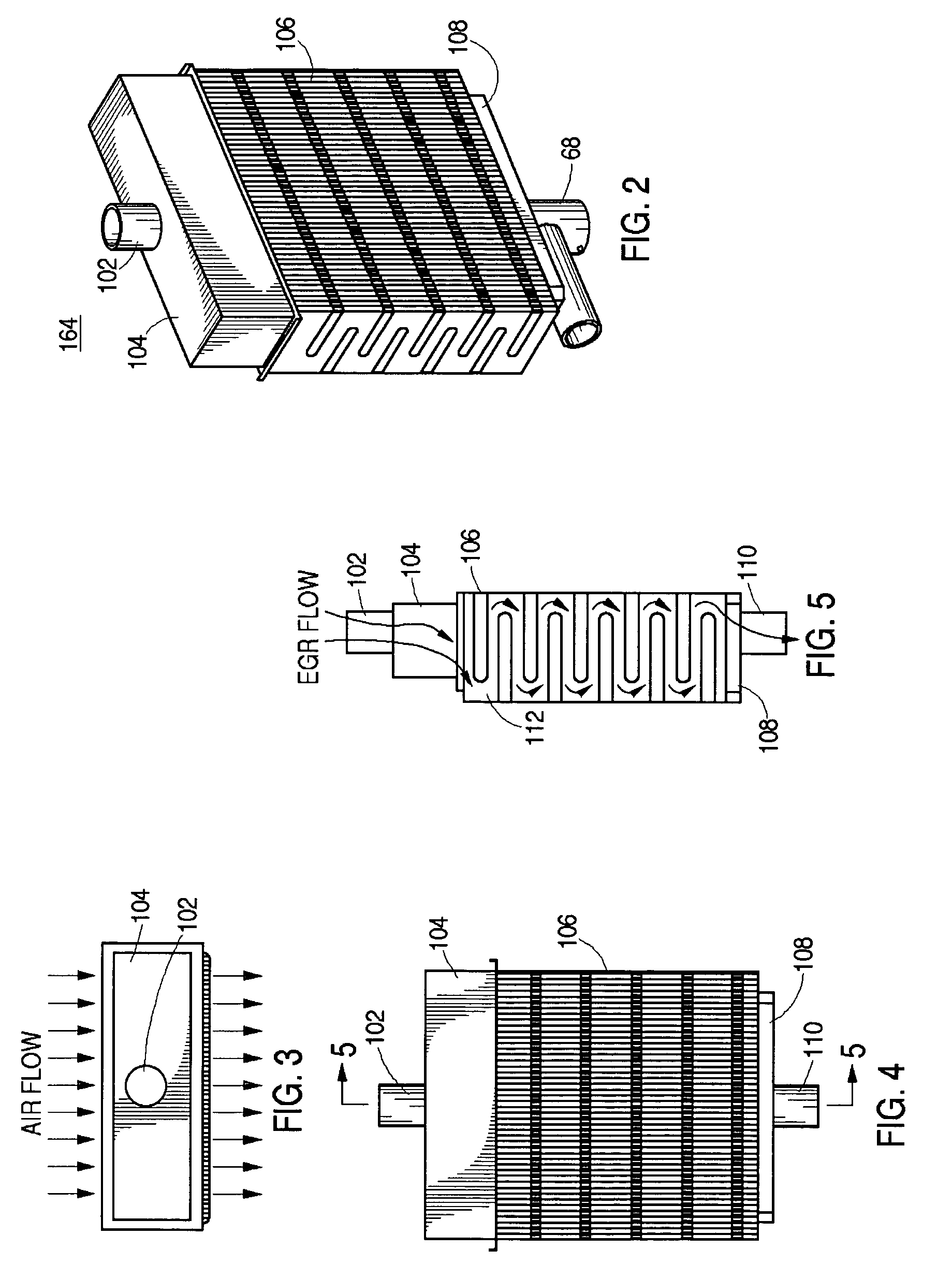

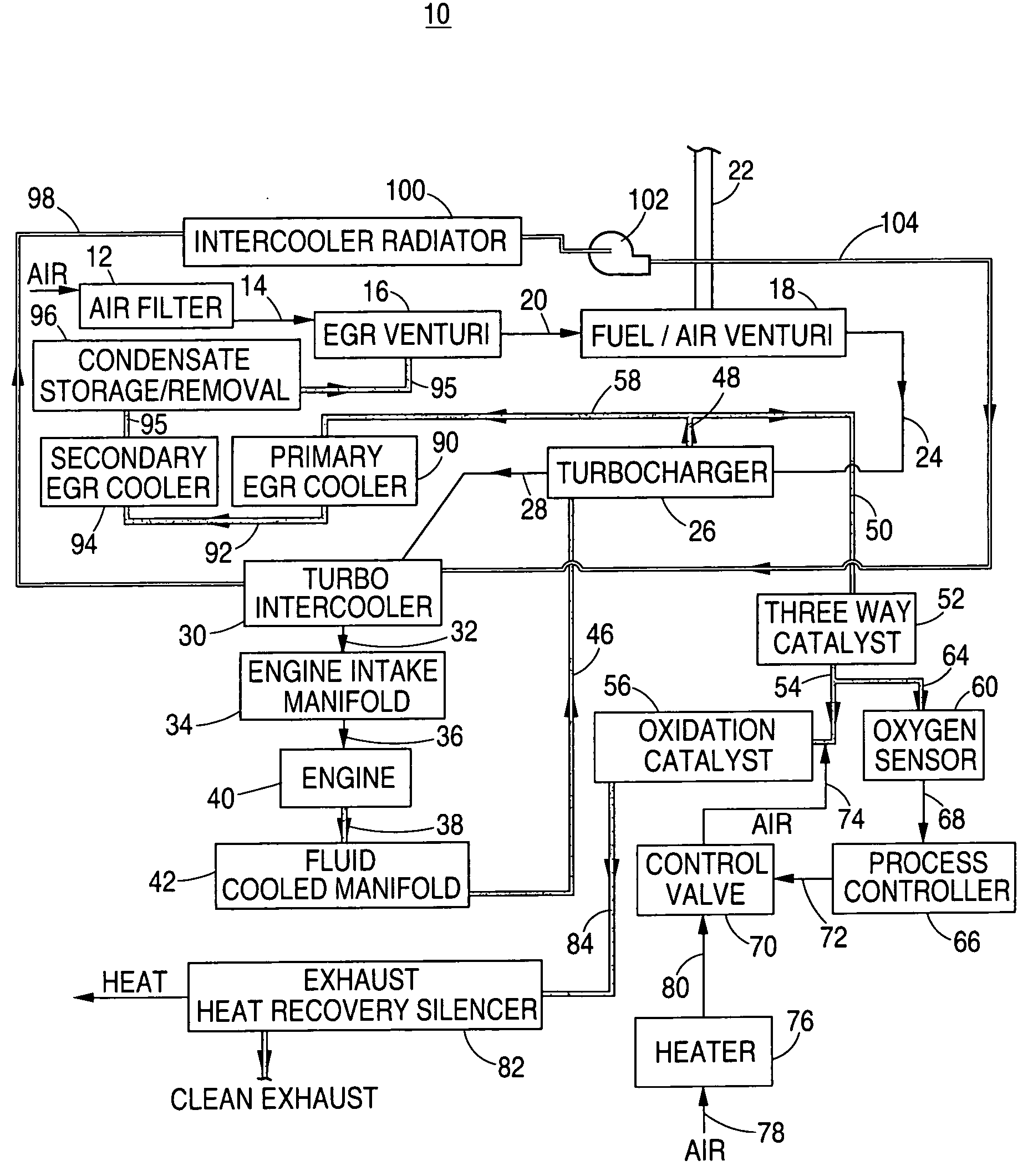

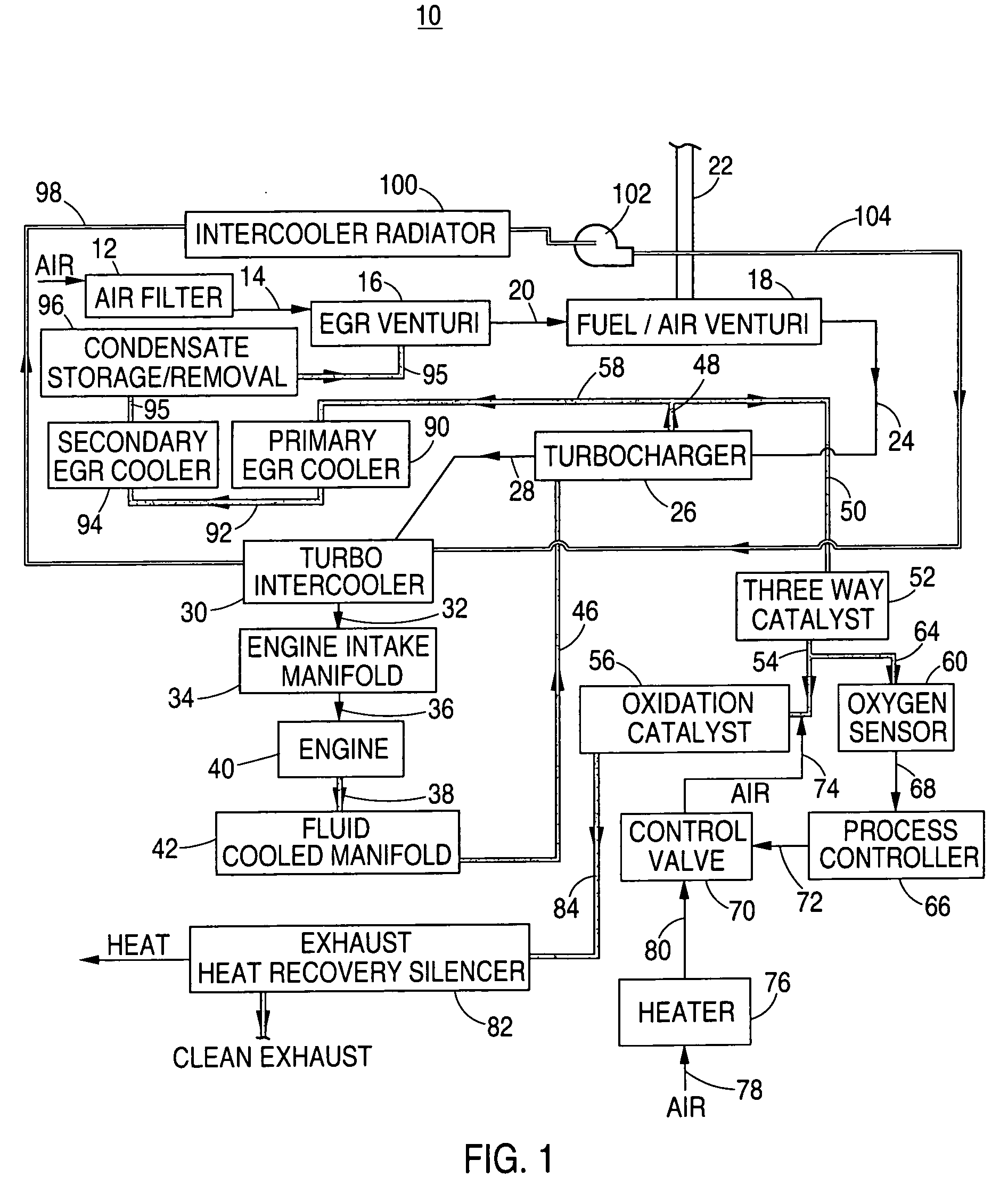

EGR cooling and condensate regulation system for natural gas fired co-generation unit

InactiveUS6978772B1Improve efficiencyReduce condensationNon-fuel substance addition to fuelInternal combustion piston enginesWater vaporCogeneration

A recycled exhaust gas cooling and condensate regulation system for a natural gas fired internal combustion engine driven co-generation plant, which allows efficient exhaust recycled gas combustion while maintaining lower head temperatures to reduce thermal NOx emissions and delivering increased process / utility heat to a proximate co-generation client, is provided. The recycled exhaust gas cooling and condensate regulation system has primary and secondary, air-to-gas, exchanger units, coupled in series, such that the first unit, designed to take exhaust gas exiting the engine, cools the gas to a first exhaust gas temperature effectively super saturating the water vapor in the cooled exhaust gas; and, the second unit, designed to handle lower inlet temperatures, condenses the water vapor and super cools the exhaust gas to <130 F. In one embodiment, the engine intake mixture including the exhaust gas is supercharged. In another embodiment, a separate intercooler circuit is used to cool the compressed intake charge containing the recycled gas prior to entry into the intake engine manifold to further reduce head temperatures and control thermal NOx emissions.

Owner:CHAPEAU

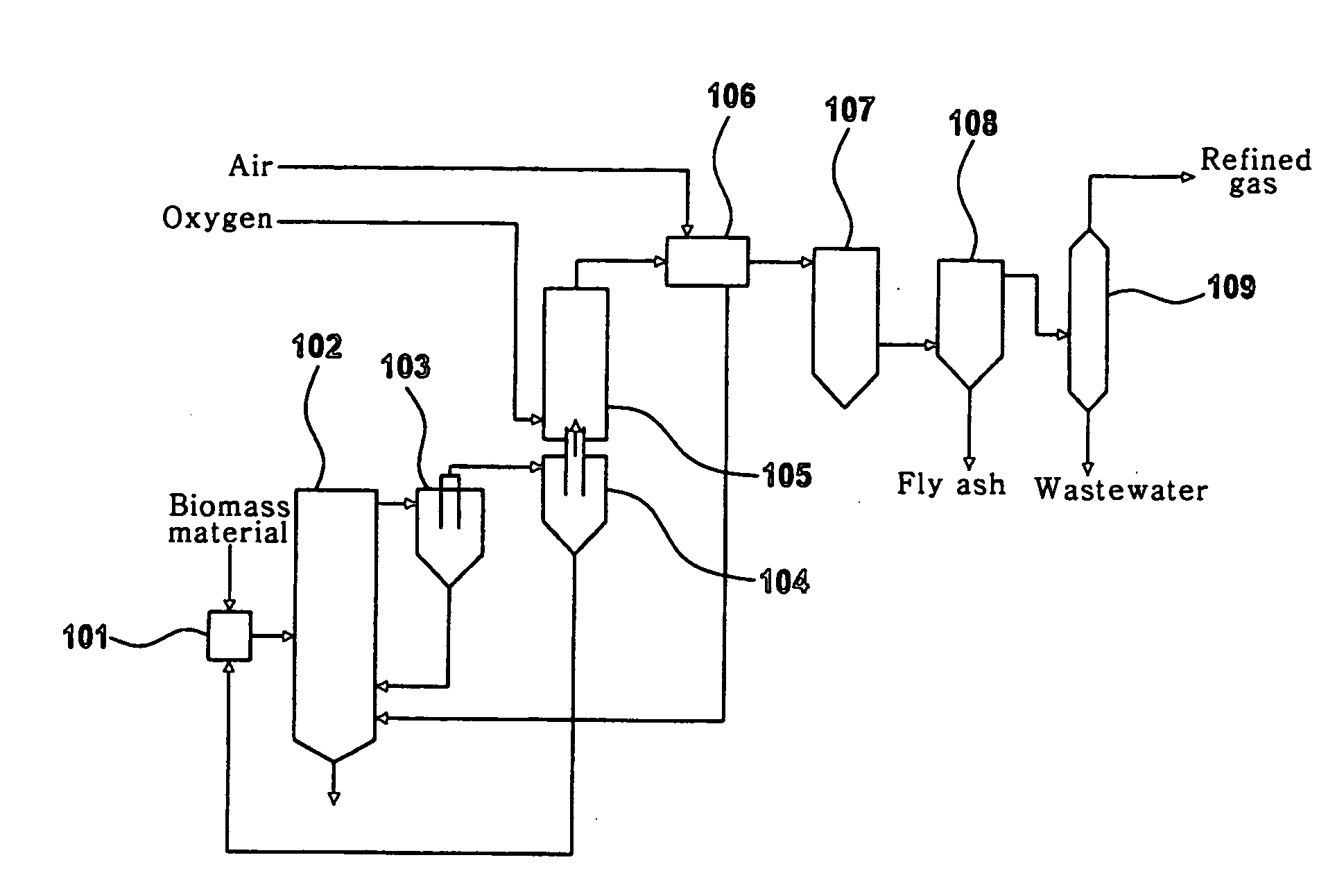

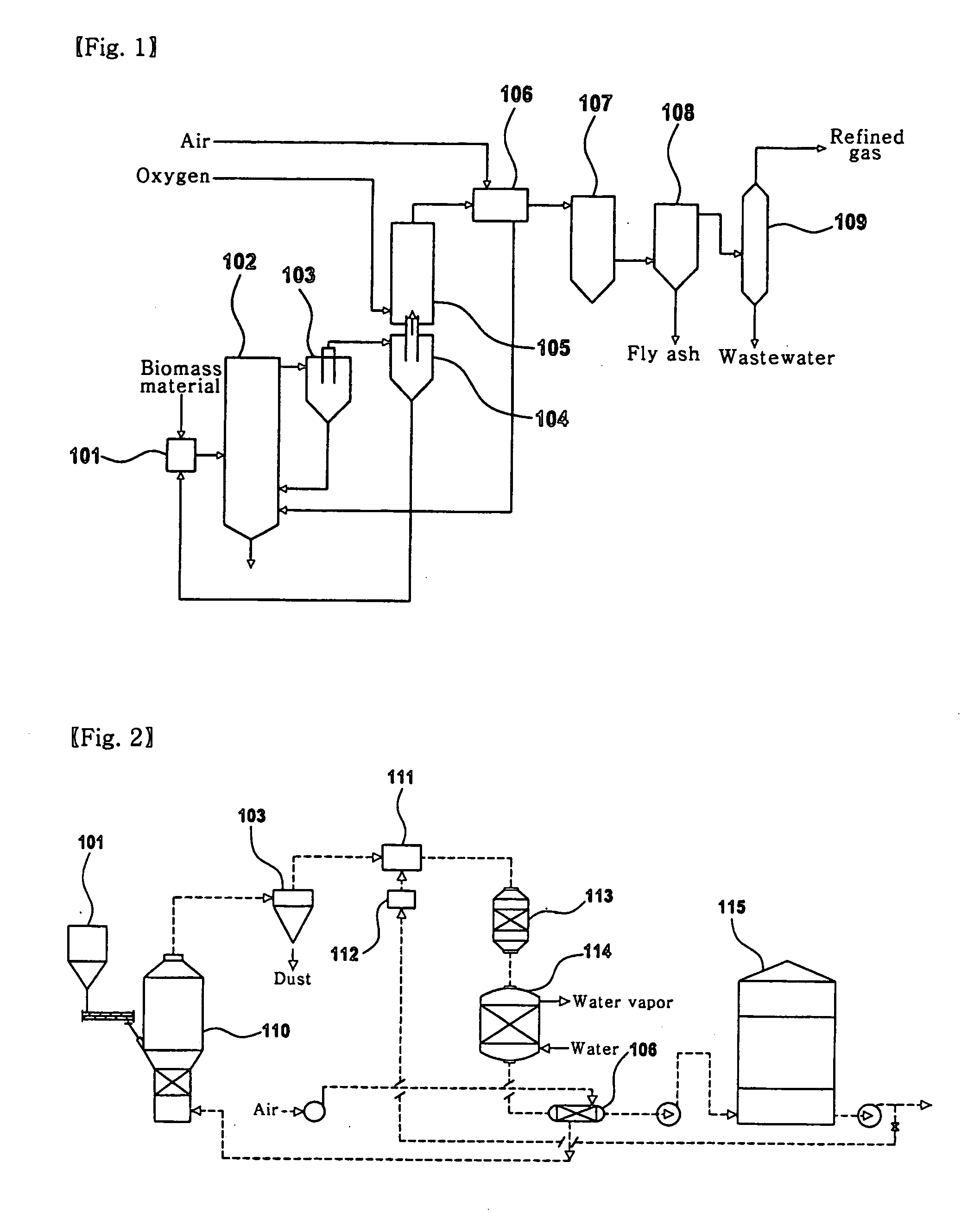

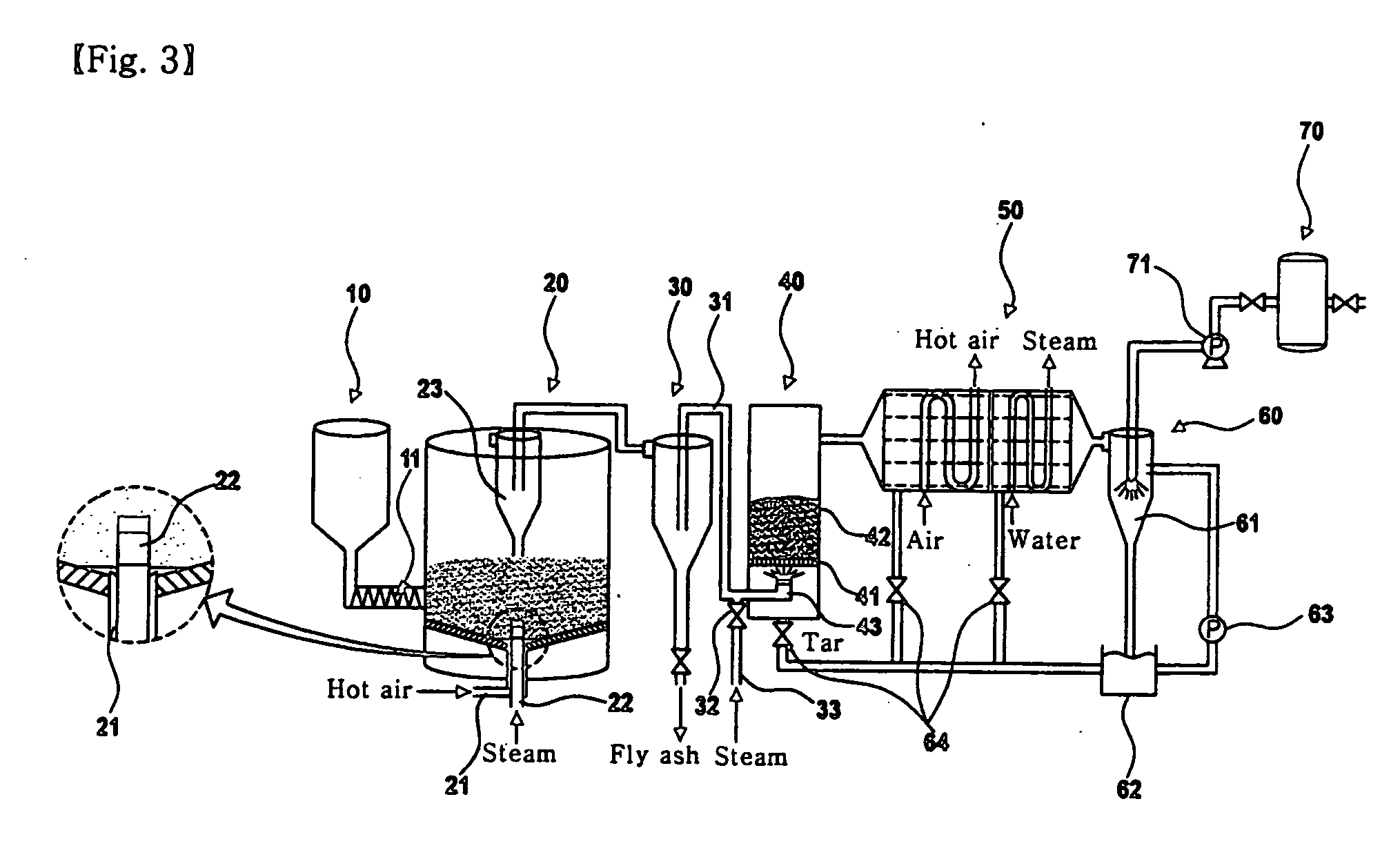

Apparatus of catalytic gasification for refined biomass fuel at low temperature and the method thereof

InactiveUS20070094929A1Low production costCompactCombustible gas catalytic treatmentLiquid hydrocarbon mixture productionCatalytic reformingFluidized bed

Disclosed is a gasification technique for converting biomass, which is difficult to treat, into clean gas fuel able to be burned in a cogeneration system. The gasification technique includes first stage fluidized-bed catalytic gasification, and second stage gasification of tar and catalytic reforming to convert nitrogen in tar, and HCN in a flammable gas into NH3, unlike conventional gasification techniques. In addition, since the temperature of a total gasification process is lower than a melting point of ash, powdery ash is generated and thus easily treated. Also, little heat is released due to the low process temperature, and therefore, a compact reactor may be designed to produce gas having a high caloric value. Further, the generated tar is recovered and reused in other processes, and the gas fuel contains a small amount of ammonia.

Owner:KOREA INST OF ENERGY RES

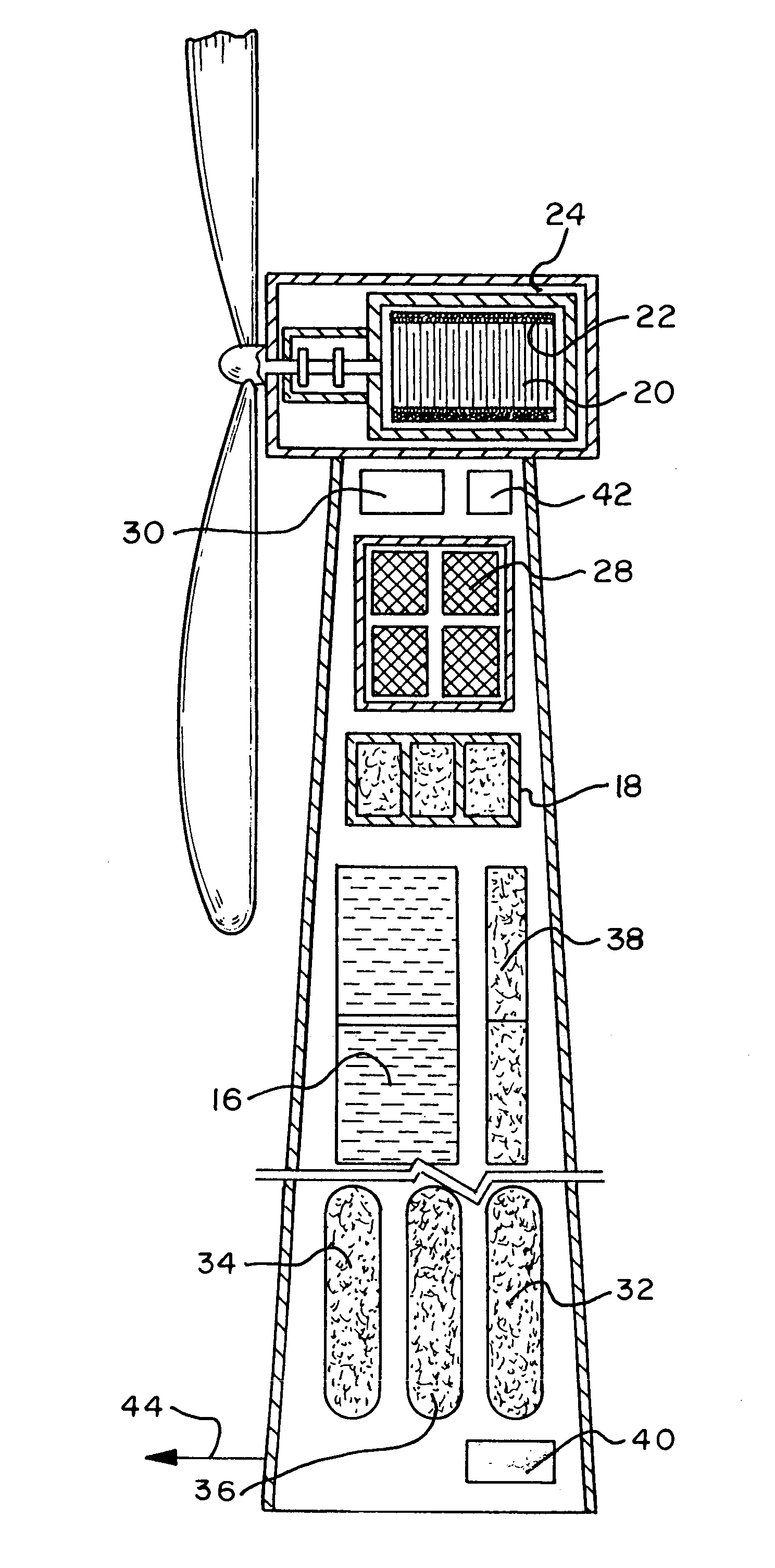

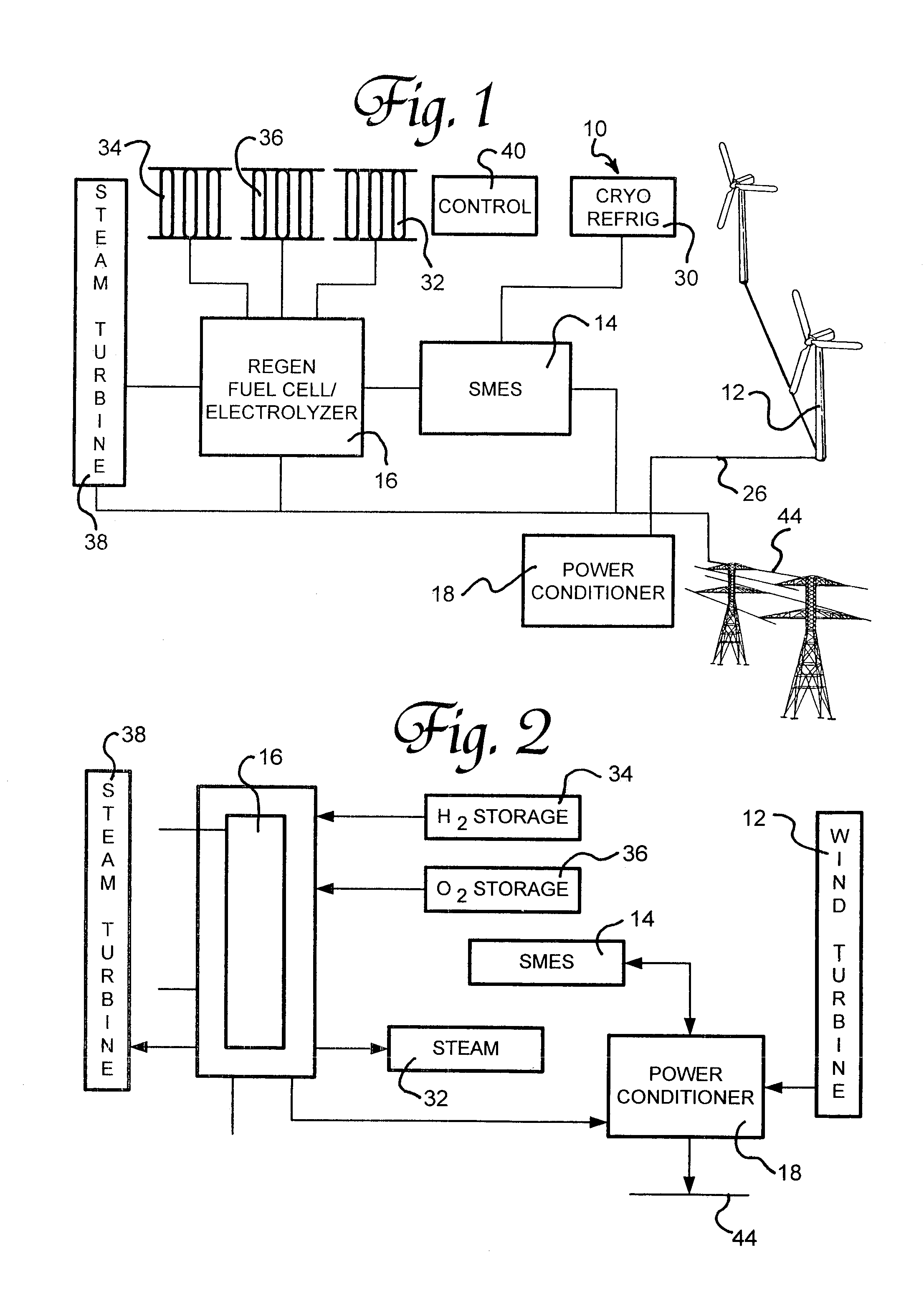

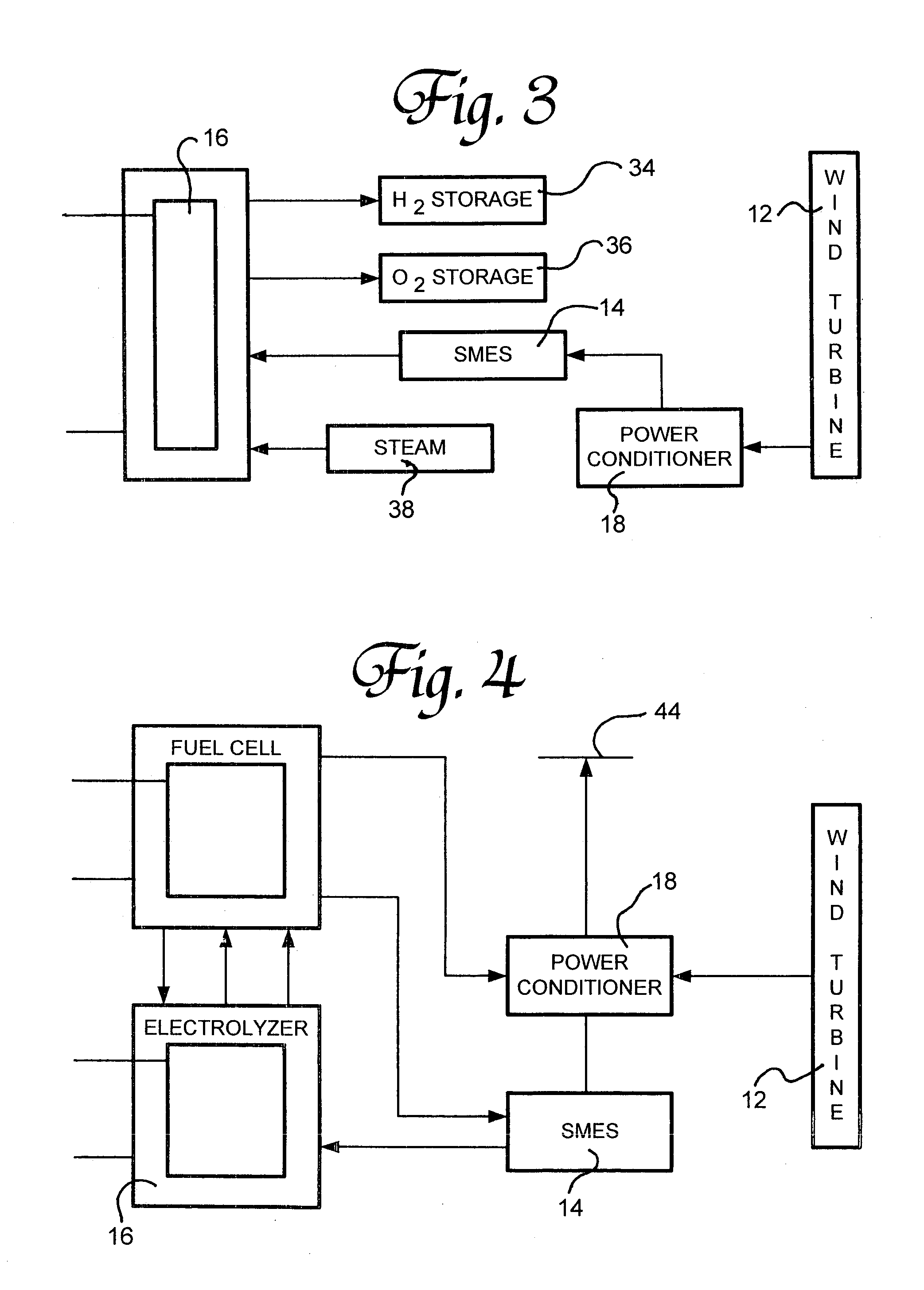

Renewable energy electric power generating system

InactiveUS7233079B1Large capacityEasy to useMachines/enginesWind energy generationElectrolysisMagnetic storage

A renewable electric power system includes a high temperature superconducting wind turbine using high temperature superconducting yttrium-barium-copper oxide for the rotor and stator windings as well as a superconducting bearing. Power from the turbine is stored in a high temperature superconducting magnetic storage system that also uses HTS YBCO. Also included is a regenerative solid oxide fuel cell / electrolyzer with steam turbine cogeneration. The system operates on a managed day / night cycle. During daytime, the energy produced by the wind turbines and fuel cells is transmitted to the grid. During nocturnal hours, the wind turbine is used to provide low cost electricity to the reversible fuel cells operating in the electrolysis mode producing hydrogen and oxygen that is stored for later use. Alternatively, the fuel cells can remain in electrolysis mode producing hydrogen and oxygen for the market. A modified interactive system generates power on a continuous twenty-four hour cycle.

Owner:COOPER WILLARD

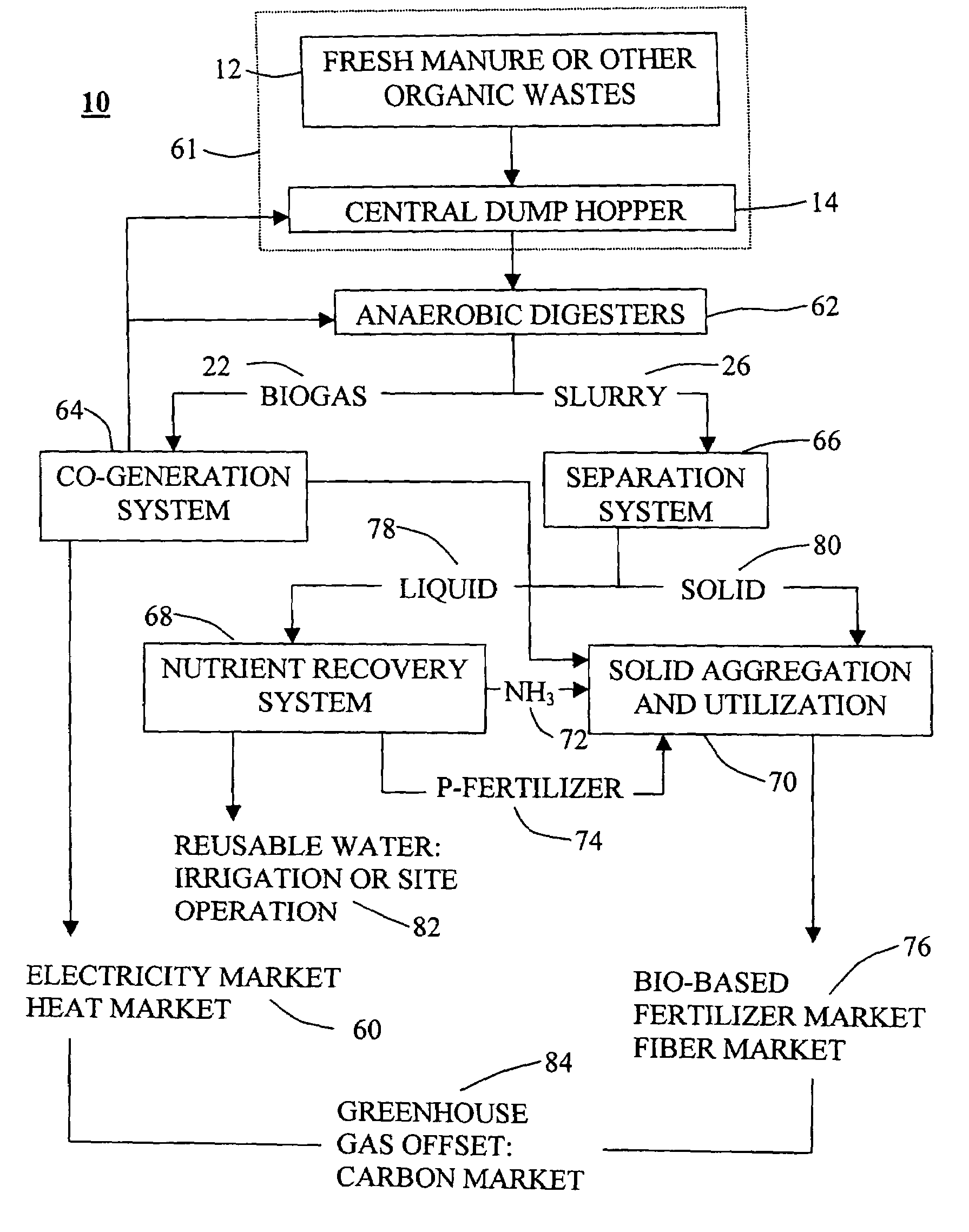

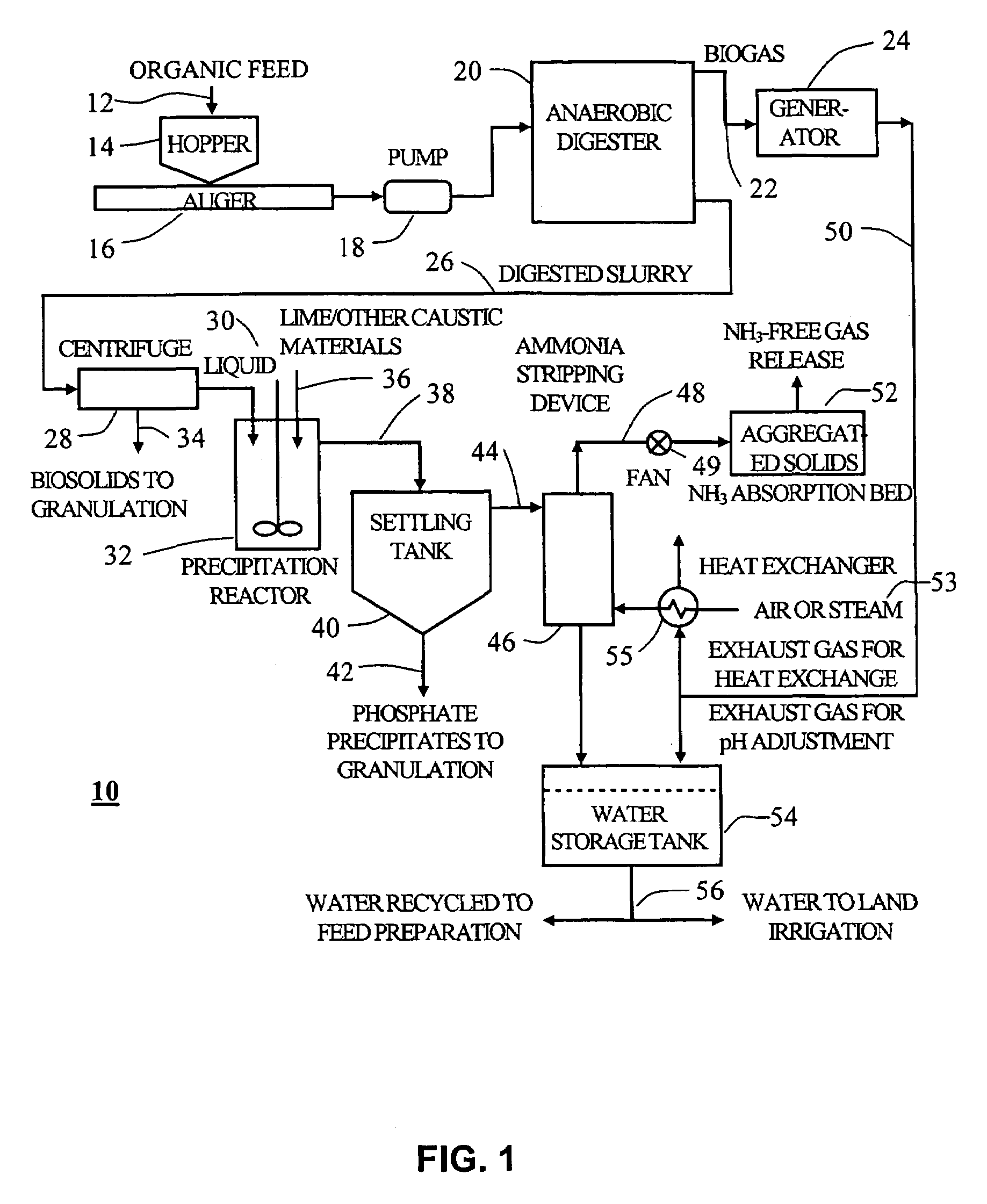

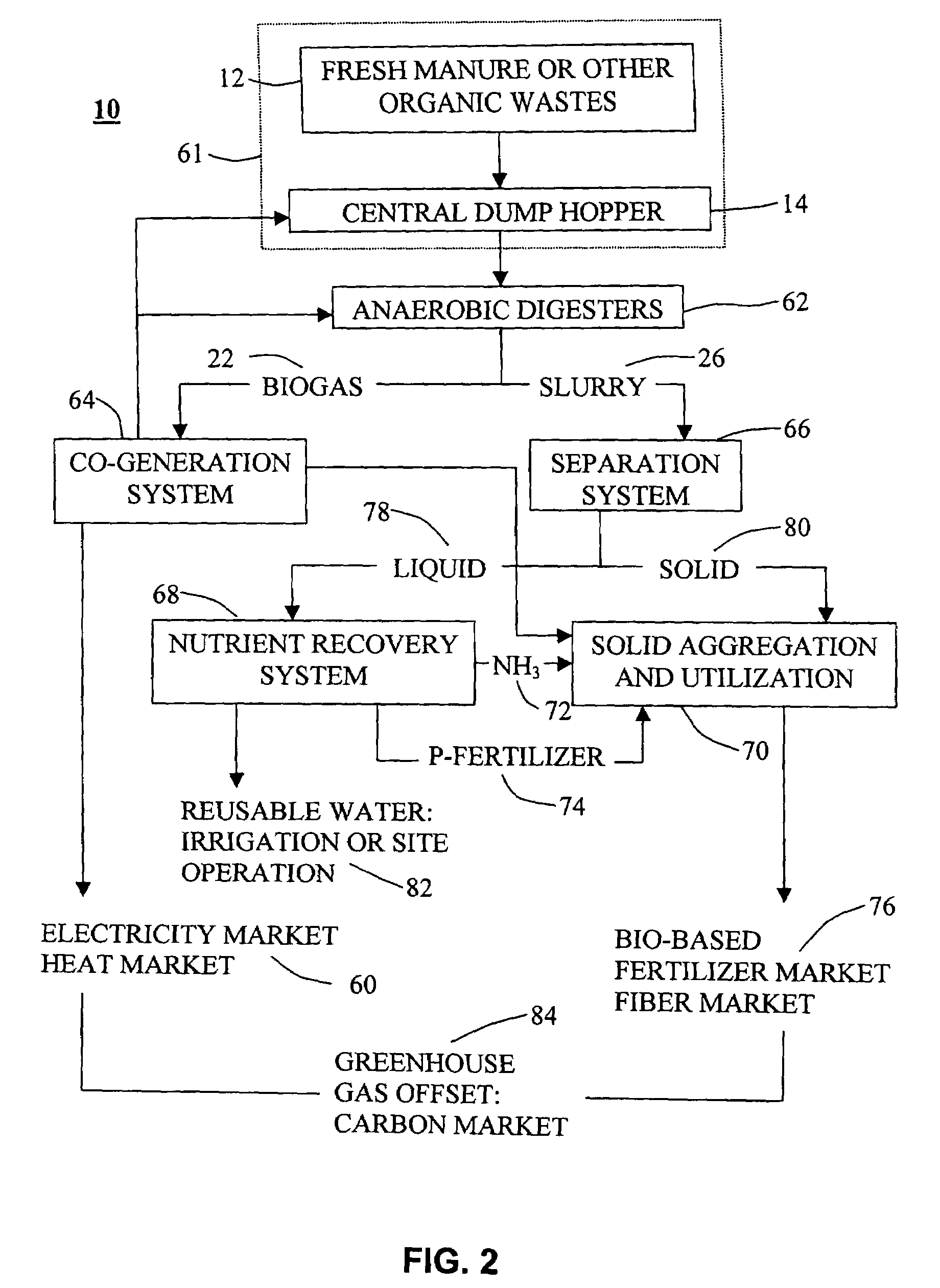

Process for removal and recovery of nutrients from digested manure or other organic wastes

InactiveUS7014768B2Eliminate the effects ofIncrease temperatureBioreactor/fermenter combinationsBio-organic fraction processingCogenerationNitrogen gas

A process for removal and recovery of nutrients and recycling of water from digested manure or other organic wastes. A first step involves separating waste from an anaerobic digester into digested liquids, digested solids, and biogas. A second step involves precipitating solids from the digested liquids. A third step involves stripping ammonia from the digested liquids. A fourth step involves injecting an exhaust stream of carbon dioxide drawn from the co-generator into the digested liquids to reduce the pH and raise the temperature of the digested liquid. A fifth step involves recycling the digested liquids back to the anaerobic digester for use in diluting in coming solid wastes. A sixth step involves passing the excess ammonia stripped from the digested liquid through the digested solids to recover nitrogen through aborption with the resultant digested solids being usable as a biofertilizer with a high nitrogen content. A seventh step involves capturing the biogas for use in a co-generation system.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

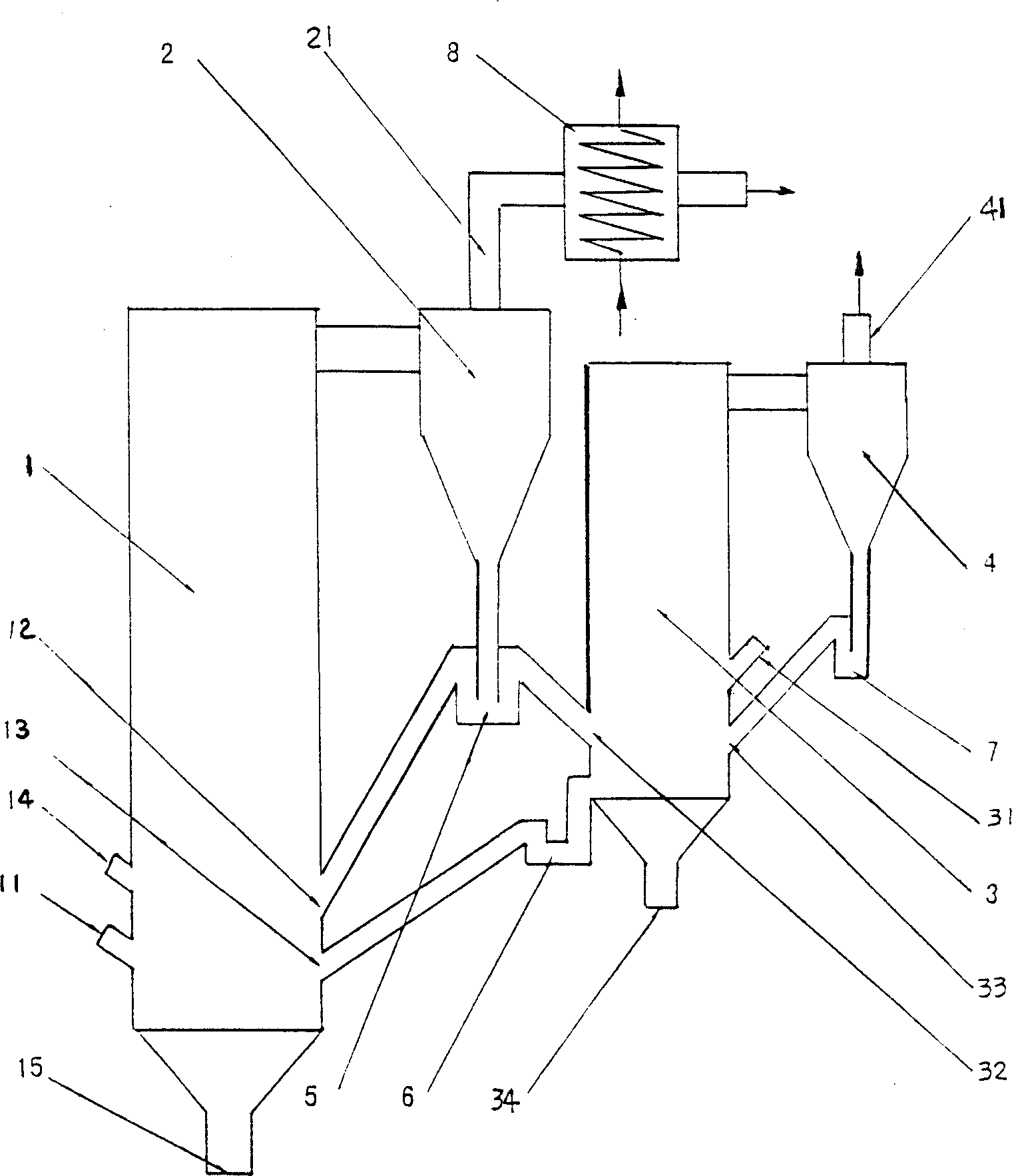

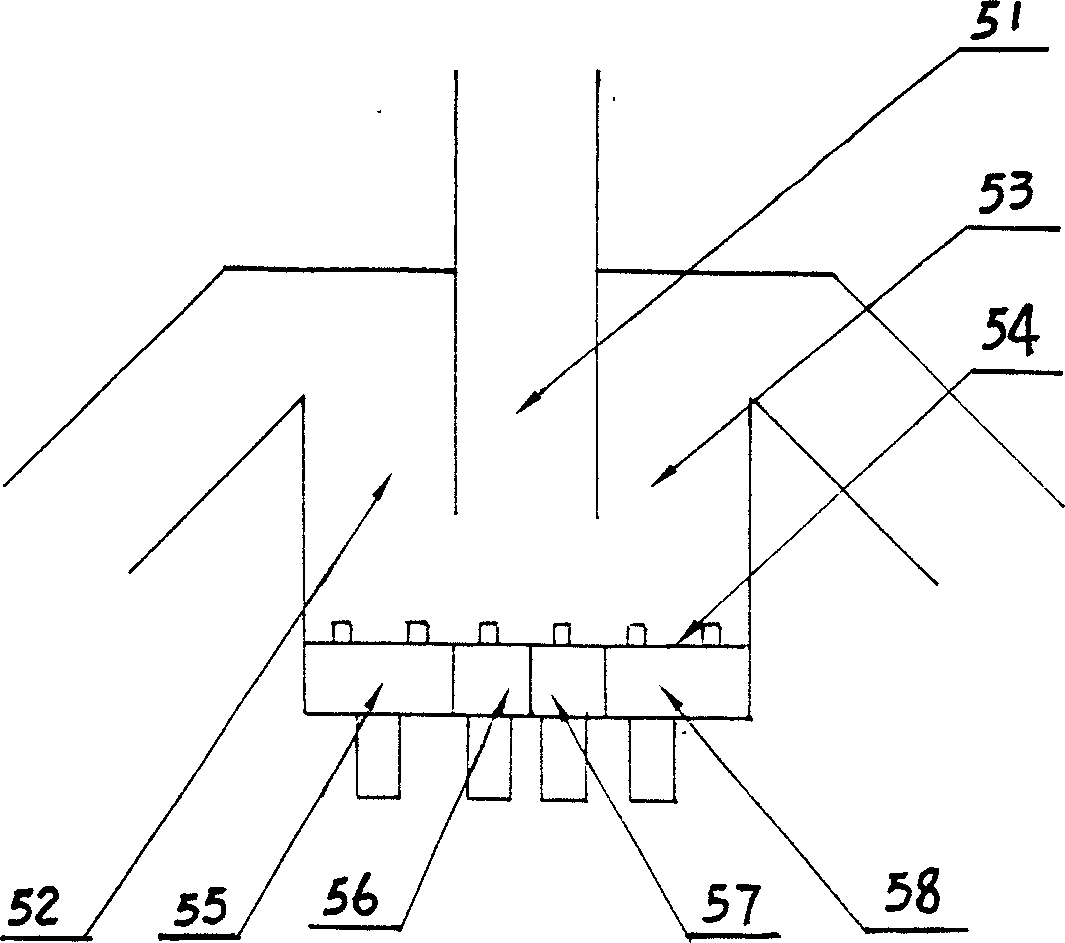

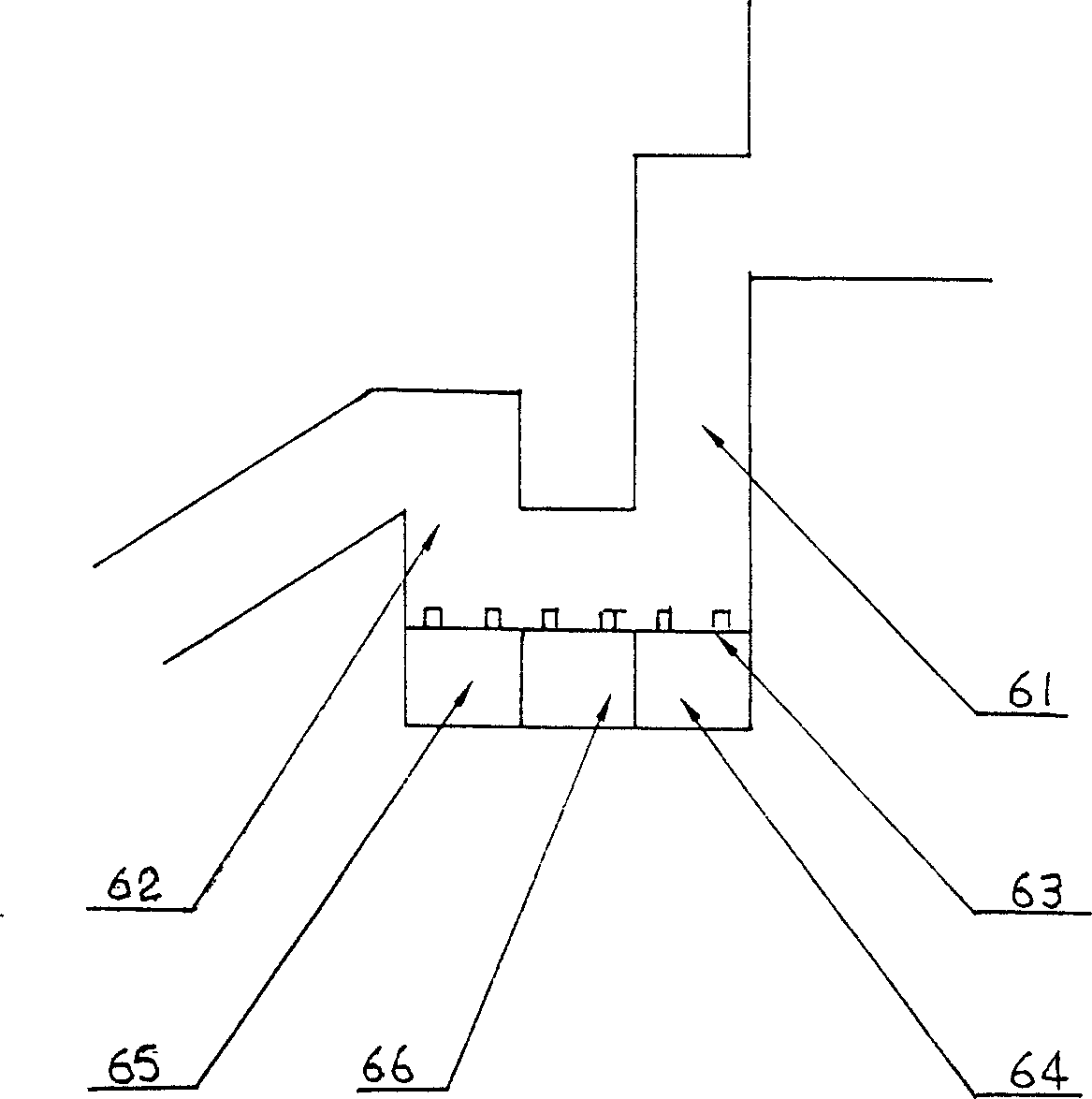

Coal gas-steam combined production method and apparatus of double-circulation fluidized bed

InactiveCN1754945AStable productionDwell time is easy to controlSteam generation plantsGranular/pulverulent flues gasificationCombustion chamberAlternative fuels

The invention relates to coal gas-steam cogeneration method and opposite furnace. Wherein, fuel burns in combustion chamber to generate smoke gas, the latter enters heat exchanger after cyclone separator to generate steam; some cycle dust collected by cyclone separator returns to chamber, other enters vaporizer; fuel takes pyrogenic gasification reaction to generate coal gas with reacted product back to chamber; the cogeneration furnace has double-cycle fluidized bed loop, wherein, the burning loop composes of a chamber, a smoke gas separator, and a refeeding device; the gasification loop composes of a gasification room, a coal gas separator, and a refeeding device; two loops are coupled by hot dust allocator and refeeding device. The running mode is flexible, and also fit to treat carbon-containing waste.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

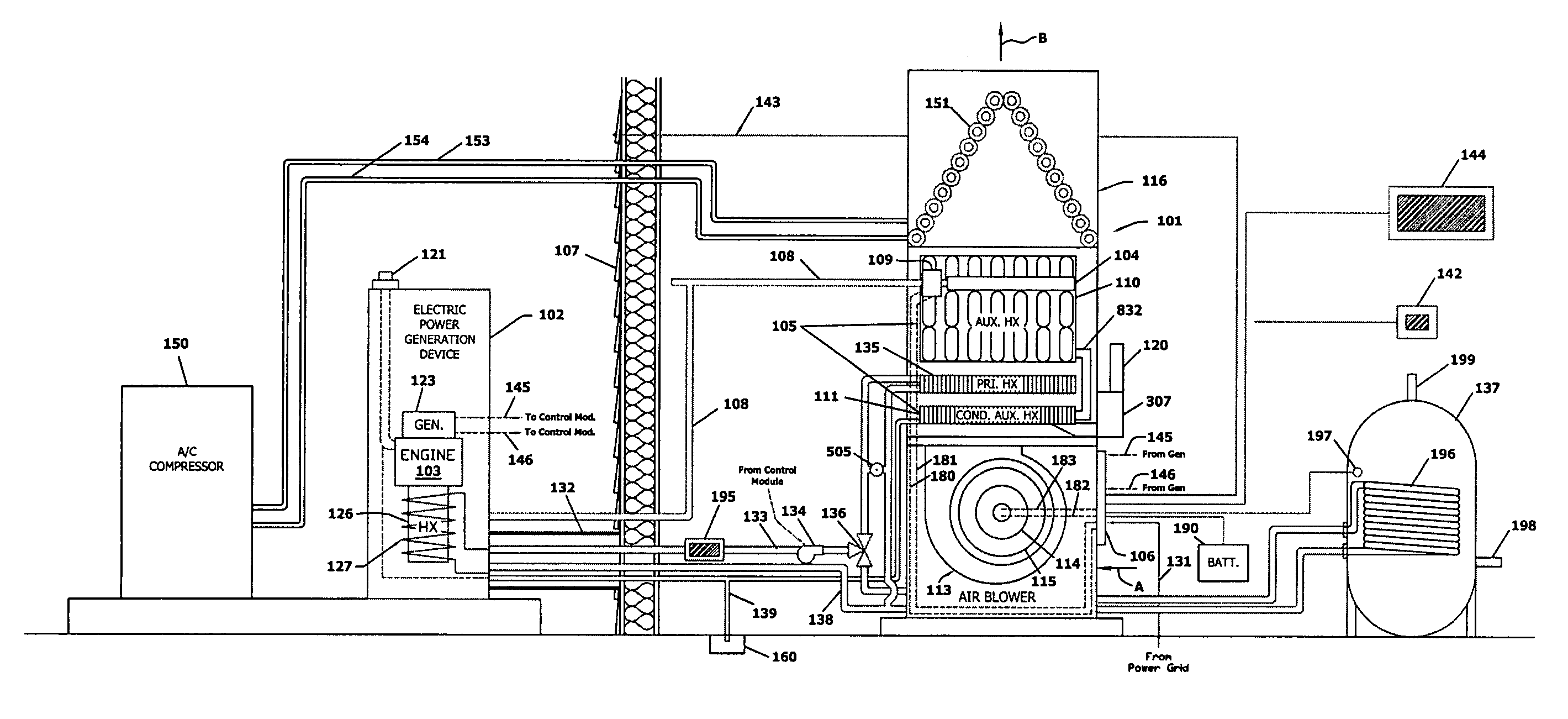

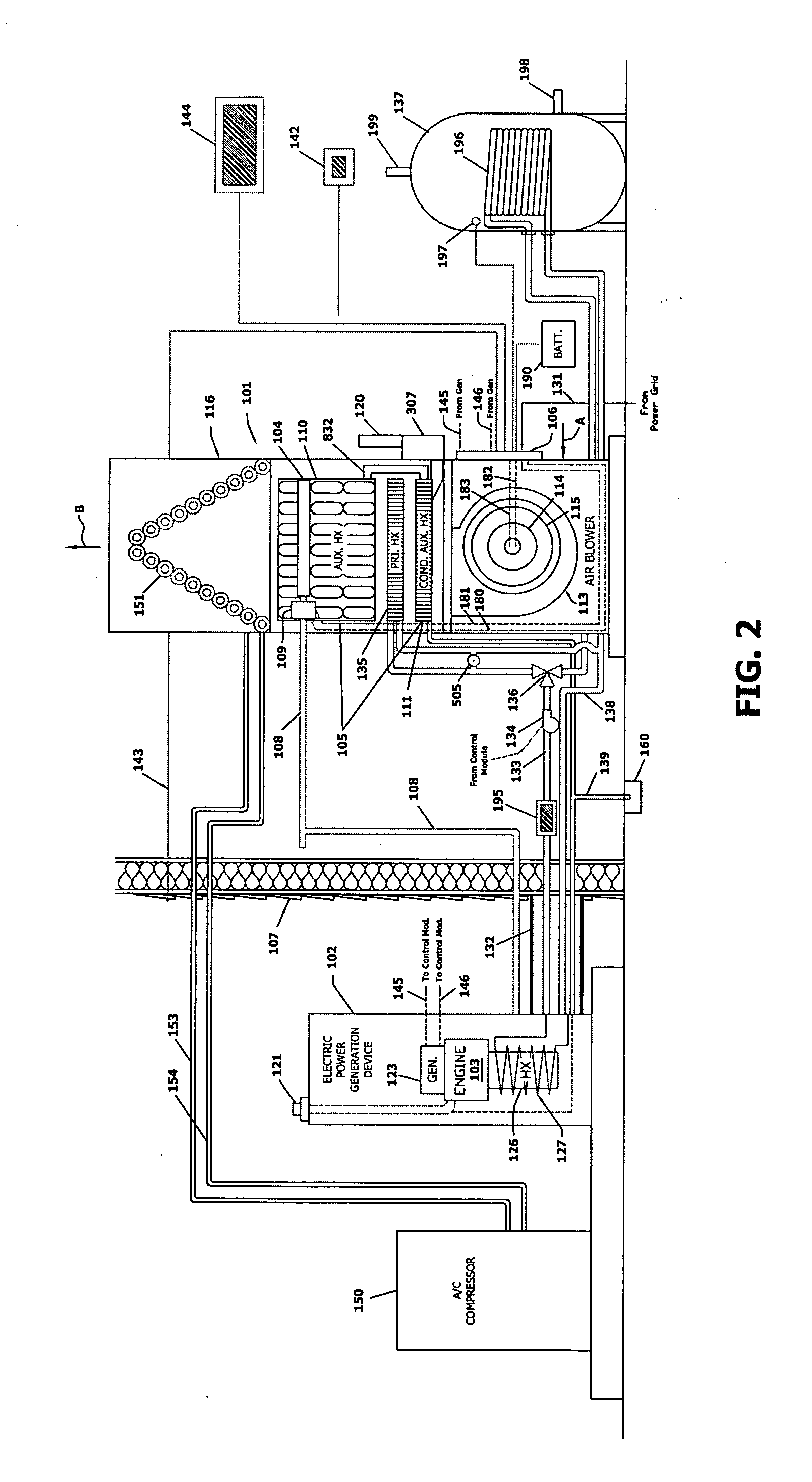

System and method for warm air space heating with electrical power generation

This invention provides a system and method for cogeneration of building heat and electric power and that efficiently interfaces a warm air heating system with a liquid-cooled electric power generator. The system and method utilizes an electric generator that is rated at near the time-averaged electric power consumption for the building. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building. In this manner, the generator can run to generate a significant part of the building's electric power but in a manner that is typically supplemented in variable quantities by power from a public power grid. The heat output is directed via a liquid coolant circuit on the generator, as needed, to the warm air heating unit for the building. The warm air heating unit blows return air through a cabinet and out to the supply duct(s). The warm liquid coolant is directed through a primary heat exchanger in the cabinet. The air is passed over this primary heat exchanger to provide heat to the building. When heat from primary heat exchanger is insufficient to heat the building fully, an auxiliary heater, operated typically by burning fuel, supplements the heat through one or more auxiliary heat exchangers arranged in line along the airflow path with the primary heat exchanger. The blower that directs the airflow is controlled variably in speed to create the most efficient use of electric power by the blower and a desirable heated air delivery temperature.

Owner:CLIMATE ENERGY

Method for cogeneration of 5-hydroxymethyl-furfural, acetylpropionic acid and formic acid by high temperature catalytic dehydration of glucose in formic acid

The invention discloses a method for coproduction of 5-hydroxymethyl furfural, an acetylpropionic acid and a formic acid through high-temperature catalysis and dehydration of the formic acid of glucose. The method specifically comprises the following steps: firstly, establishment of a formic acid reaction system, namely the glucose is added into the formic acid solution, and the weight ratio of the glucose to the formic acid in the reaction system is 0.05-0.2 to 1; and the mixture is reacted for 2 to 6 hours in the presence of the catalyst at a temperature of between 120 and 220 DEG C which is higher than the boiling temperature of the formic acid, and the reaction system is single-phase reaction or biphase reaction; and secondly, separation of products after reaction by a fractionating tower device, namely graded separation of 5-HMF, LA and the formic acid. The method can convert the glucose into the products, namely the 5-HMF, the LA and the formic acid with high added values through effective acid catalysis and dehydration, and has high conversion of reactant during the reaction process and obvious economic benefit; and the 5-HMF, the LA and the formic acid can be directly taken as chemical products to be further converted, and are good raw materials for synthesizing other chemical products.

Owner:SOUTH CHINA UNIV OF TECH

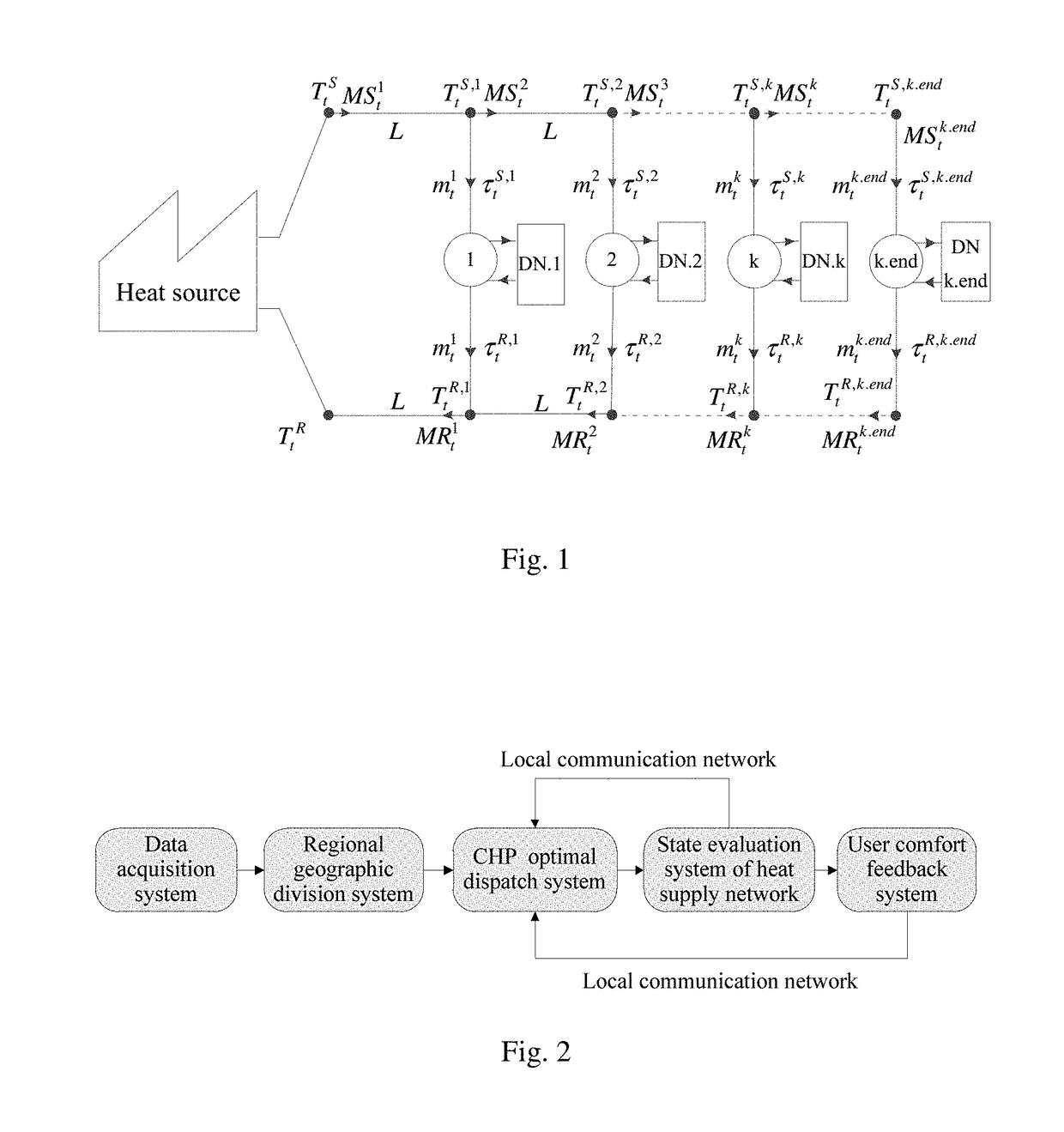

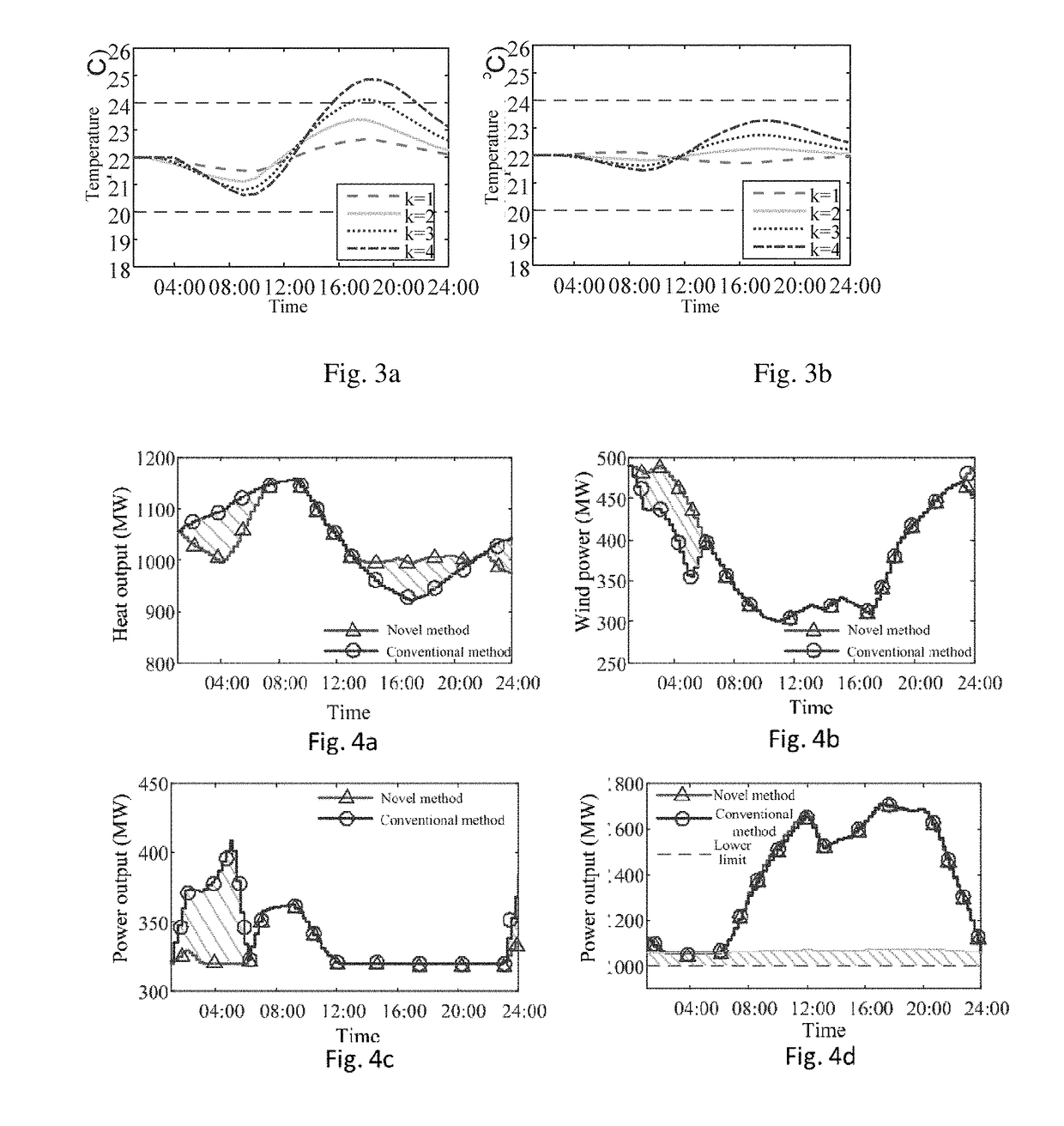

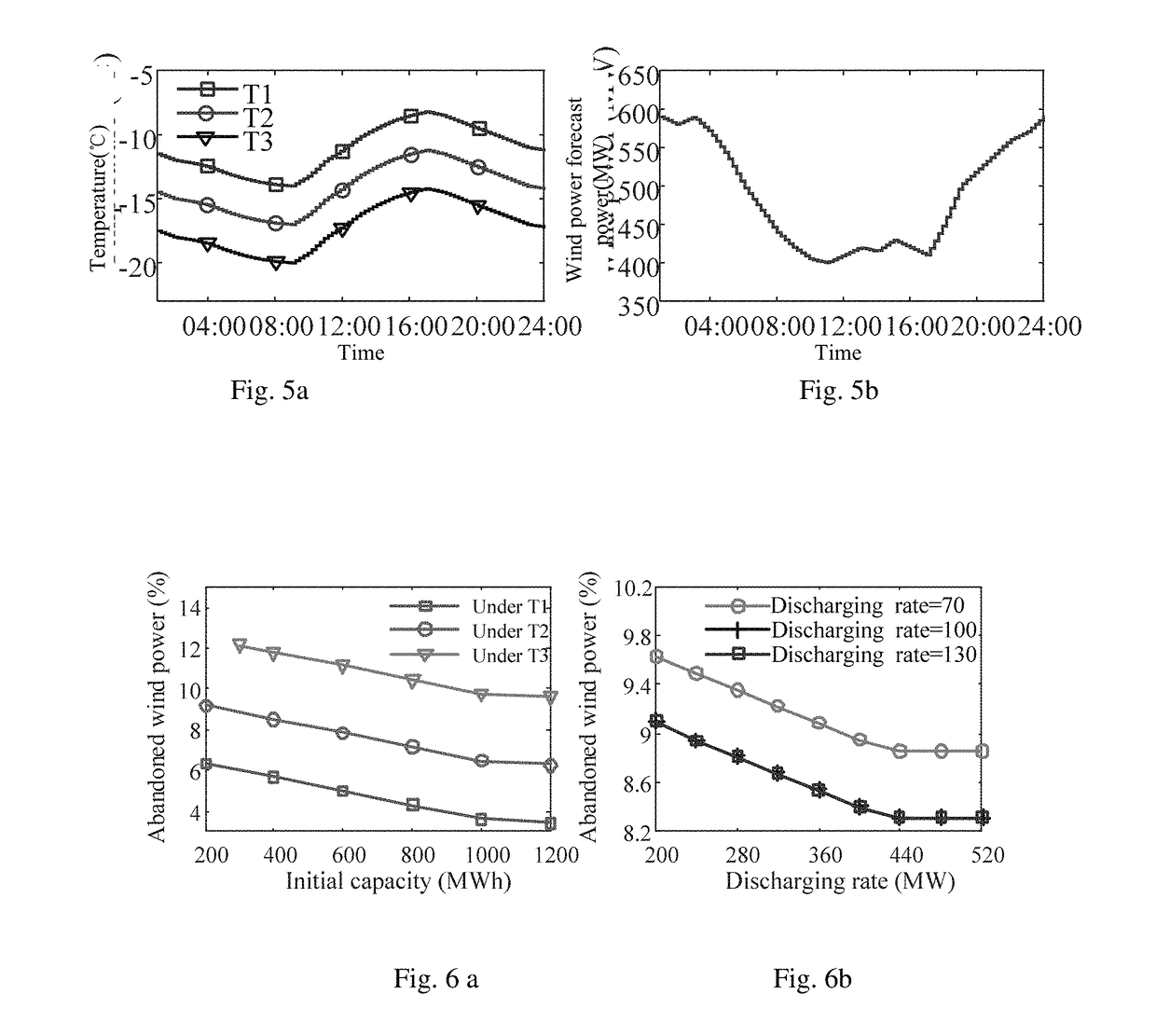

Modeling Method of Combined Heat and Power Optimal Dispatching Model

ActiveUS20180356105A1Promote absorptionSolve the real problemFuel heating with wind energySimulator controlCogenerationEngineering

A CHP optimal dispatching model is a mixed integer programming model and is used for a district heating system (DHS) comprising a heat source, a heating network and a heat load, and the heating network comprises a heat transmission network and a heat distribution network. A plurality of heating areas is divided, and one day is divided into a plurality of time periods; the heat transmission loss of the heat distribution network is omitted, and a heat transmission network model taking transmission time delay of the heating network into consideration is established according to the heat transmission network; a terminal heat consumer model capable of reflecting indoor temperature is established; and a combined optimal dispatching model comprising conventional generators, wind power units, CHP units, electric boilers and heat storage tanks is established.

Owner:SOUTHEAST UNIV

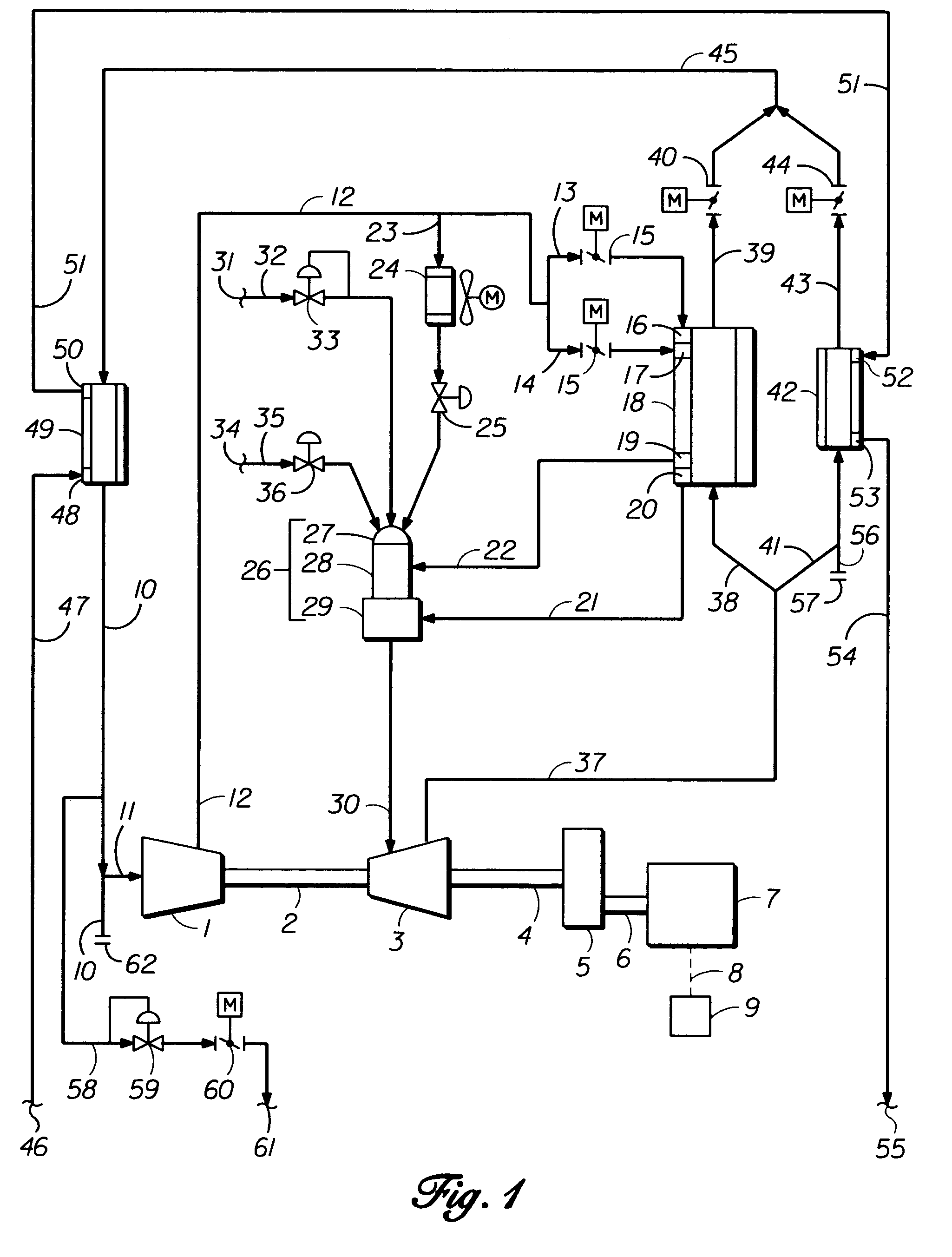

Power cogeneration system and apparatus means for improved high thermal efficiencies and ultra-low emissions

InactiveUS20050132713A1Improve thermal efficiencyMaximum efficiencyGas turbine plantsCombined combustion mitigationThermal energyCogeneration

A power cogeneration system employing a partially-open gaseous fluid cycle method and apparatus devices for oxy-fuel combustion conversion of a given hydrocarbon composition fuel's heat-value energy into mechanical or electrical power energy, and transferred useful heat energy, with accompanying large reductions of consumed fuel and undesirable exhaust emissions.

Owner:AES DEV CO

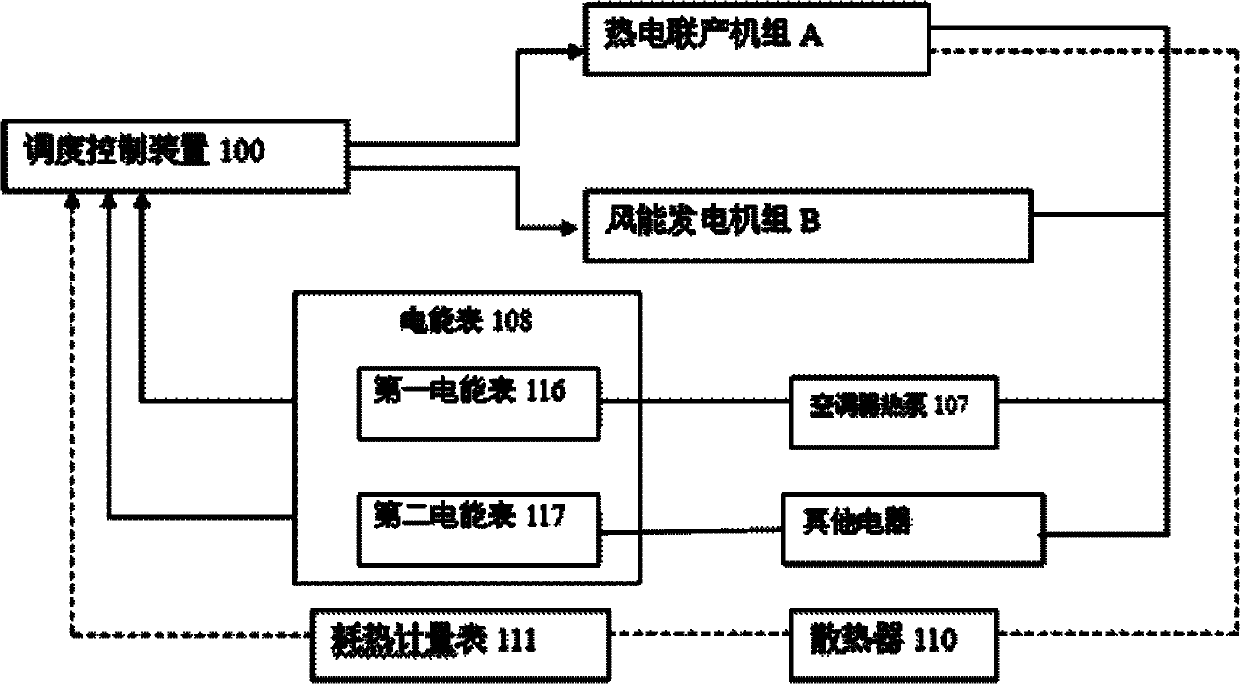

System and method for saving energy and shaving peak by coordinating cogeneration set and wind energy generator set

InactiveCN101950962AAvoid downtimeAvoid wastingLighting and heating apparatusSteam engine plantsControl signalCogeneration

The invention relates to a system and a method for saving energy and shaving the peak by coordinating a cogeneration set and a wind energy generator set. The system comprises the cogeneration set, the wind energy generator set, a conditioner heat pump, an electric energy meter, a radiator, a heat consumption gauge, and a scheduling control device, wherein the scheduling control device is used for acquiring fuel consumption, generated output and heating output of the cogeneration set, generated output of the wind energy generator set, electric power consumption of heating of the conditioner heat pump, a scheduling control signal of the heating load of the radiator in the electric load trough period according to detected electivity consumption data and heating and heat consumption data, and controlling the cogeneration set, the wind energy generator set, the conditioner heat pump, and the radiator to run according to the scheduling control signal. Through the system and the method, the distribution of the generated output of each of the cogeneration set and the wind energy generator set is optimized so as to reduce the total energy consumption, save energy and solve the problems of the forced shutdown and the waste of abandoning electricity of the wind energy generator set in the electric load trough period of the power grid.

Owner:XI AN JIAOTONG UNIV

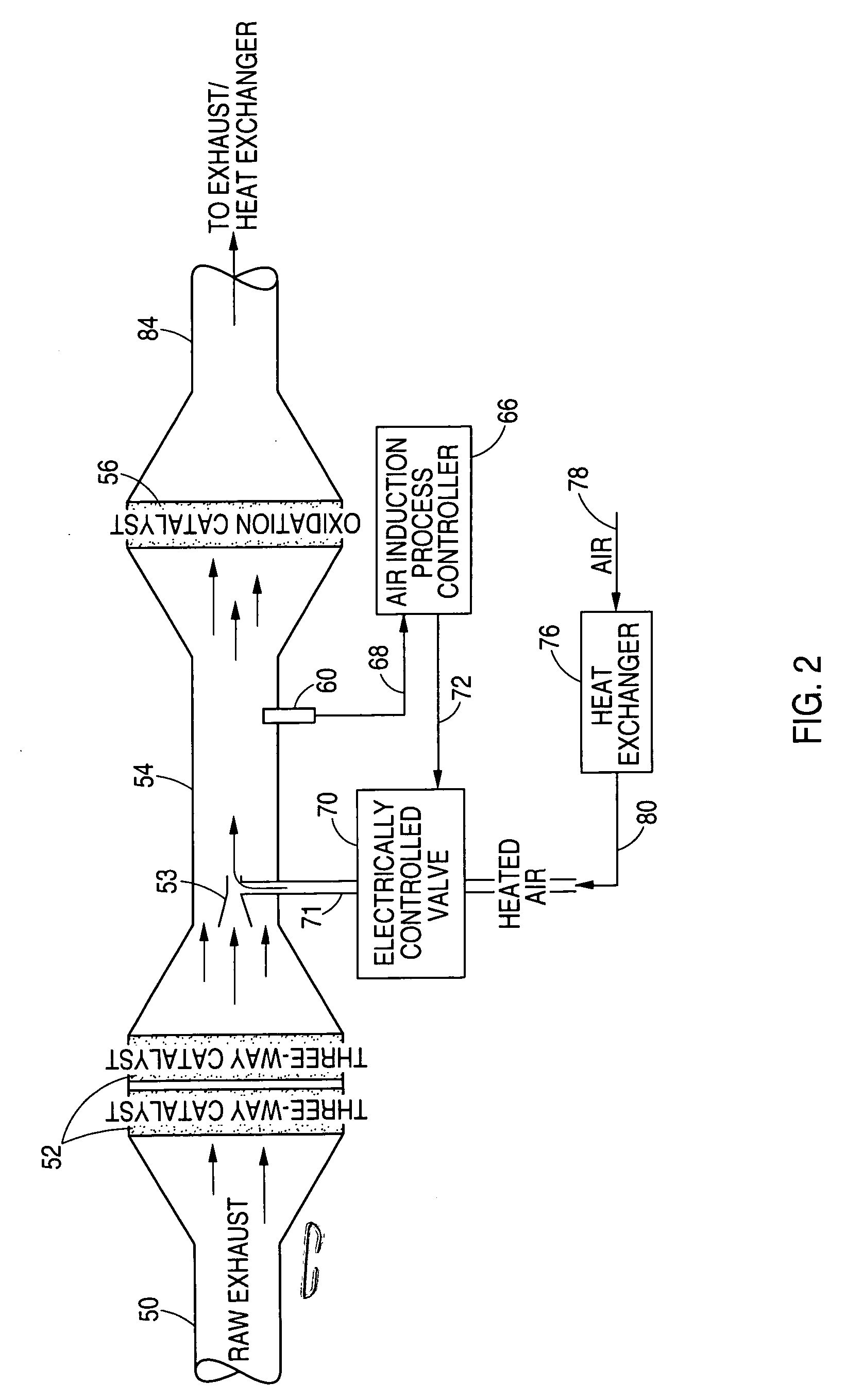

Air flow regulation system for exhaust stream oxidation catalyst

InactiveUS20060179824A1Improve oxidation capacityMinimize degradationNon-fuel substance addition to fuelInternal combustion piston enginesStream flowCogeneration

An air flow regulation system for enhancing the performance of oxidation catalyst in the exhaust stream of an internal combustion engine is provided wherein air flow into the exhaust upstream of an oxidation catalyst is dynamically controlled via a controlled feedback loop to ensure sufficient oxygen availability to induce enhanced oxidation catalyst performance while simultaneously limiting the exhaust cooling effect of the incoming air stream and the associated loss of catalytic conversion performance. The modulation of air temperature and flow into the exhaust gas stream of a reciprocating internal combustion natural gas fuel engine upstream of an oxidation catalyst is regulated such that oxidation of carbon monoxide, hydrocarbons, and ammonia is achieved to a level beyond the levels attainable and maintainable with a catalyst strategy that relies only upon pre-combustion air / fuel ratio management. In one aspect, the modulation of air flow into the exhaust is via an electronically controlled feedback loop. In another aspect, the induced air is heated to assure catalyst performance and retard the loss of recoverable heat from the exhaust stream for combined heat and power applications.

Owner:CHAPEAU

System and method for warm air space heating with electrical power generation

This invention provides a system and method for cogeneration of building heat and electric power and that efficiently interfaces a warm air heating system with a liquid-cooled electric power generator. The system and method utilizes an electric generator that is rated at near the time-averaged electric power consumption for the building. This generator is operated as the priority source of heat for the building, but normally only when there is a demand for heat in building. In this manner, the generator can run to generate a significant part of the building's electric power but in a manner that is typically supplemented in variable quantities by power from a public power grid. The heat output is directed via a liquid coolant circuit on the generator, as needed, to the warm air heating unit for the building. The warm air heating unit blows return air through a cabinet and out to the supply duct(s). The warm liquid coolant is directed through a primary heat exchanger in the cabinet. The air is passed over this primary heat exchanger to provide heat to the building. When heat from primary heat exchanger is insufficient to heat the building fully, an auxiliary heater, operated typically by burning fuel, supplements the heat through one or more auxiliary heat exchangers arranged in line along the airflow path with the primary heat exchanger. The blower that directs the airflow is controlled variably in speed to create the most efficient use of electric power by the blower and a desirable heated air delivery temperature.

Owner:CLIMATE ENERGY

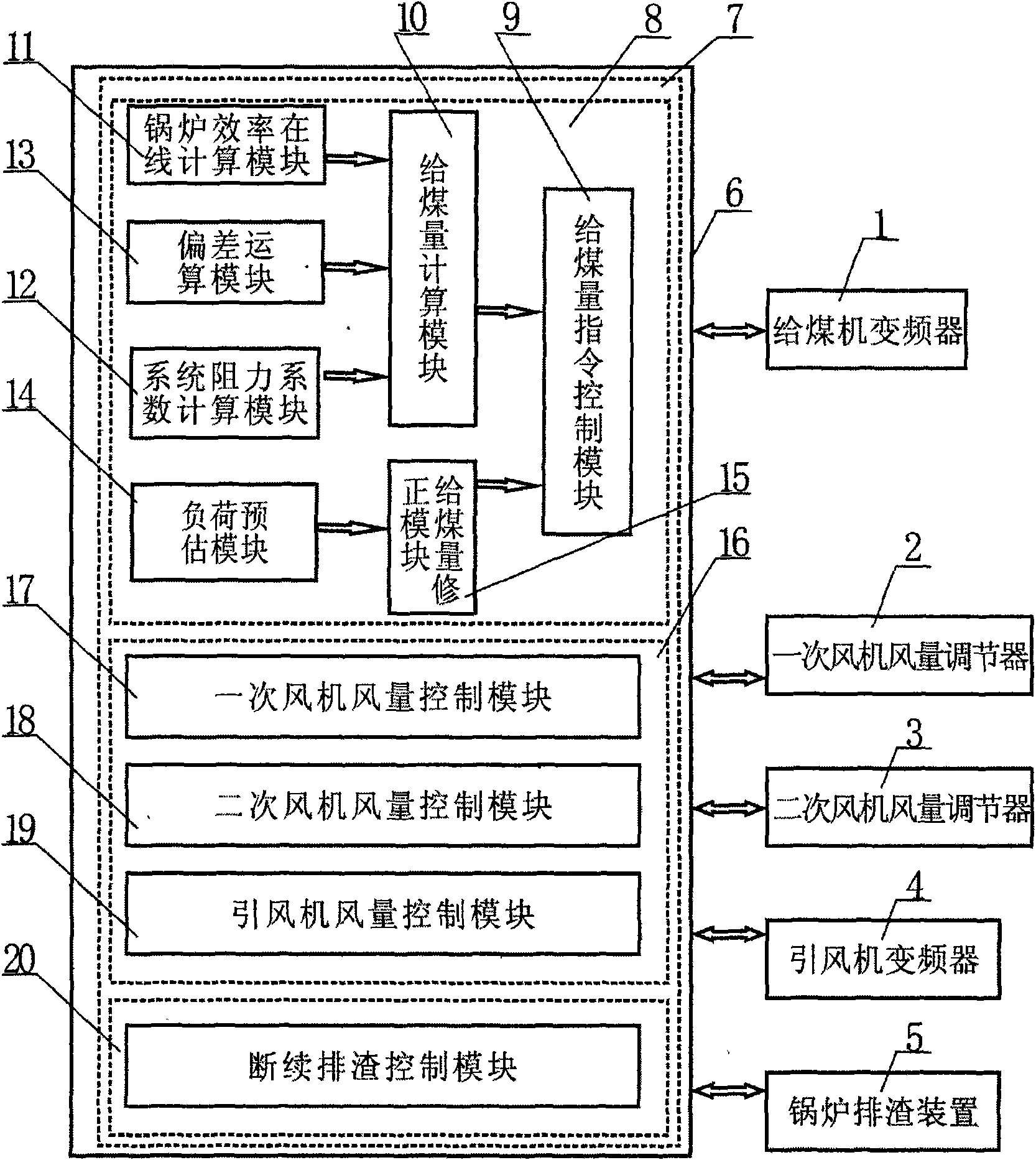

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

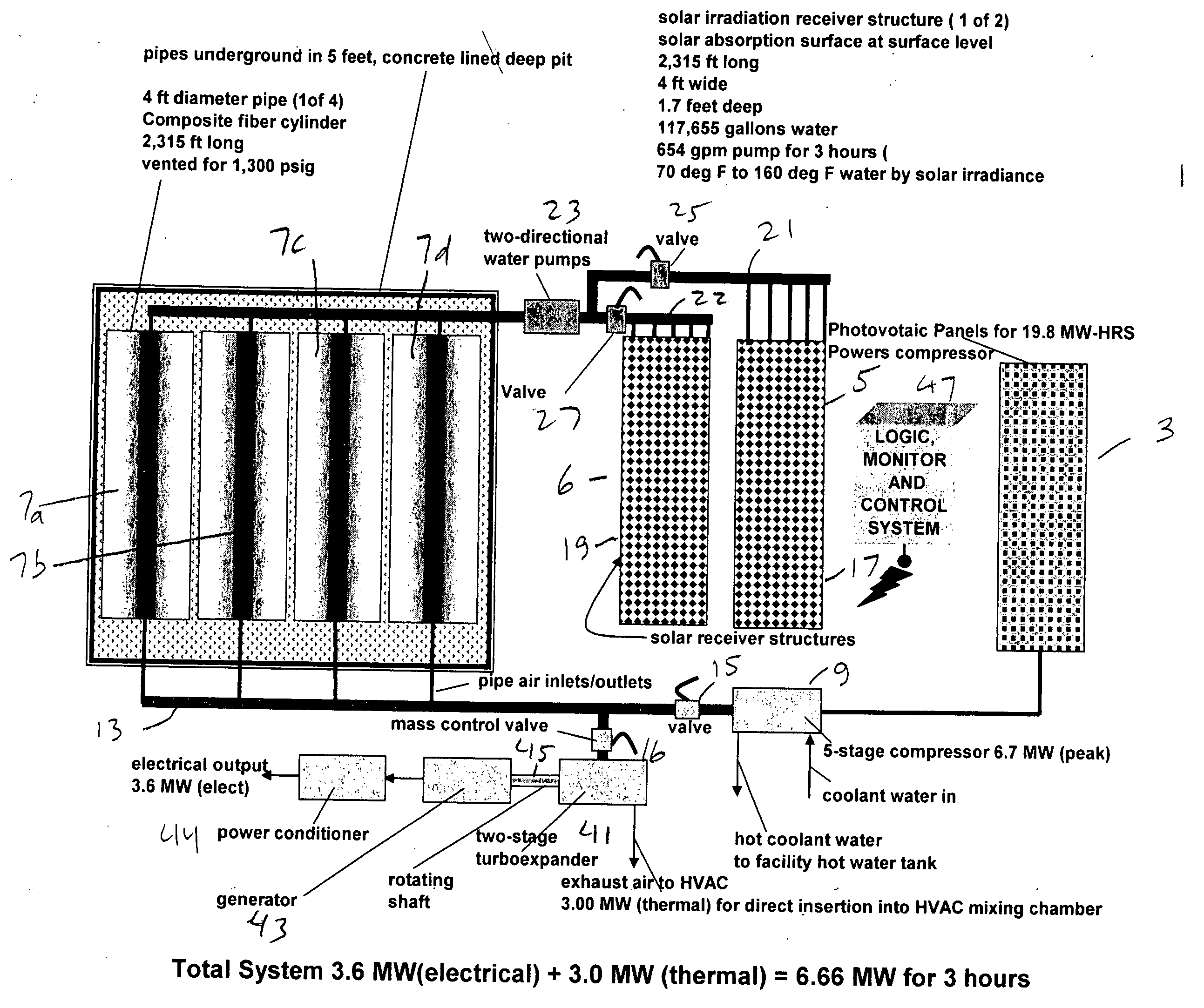

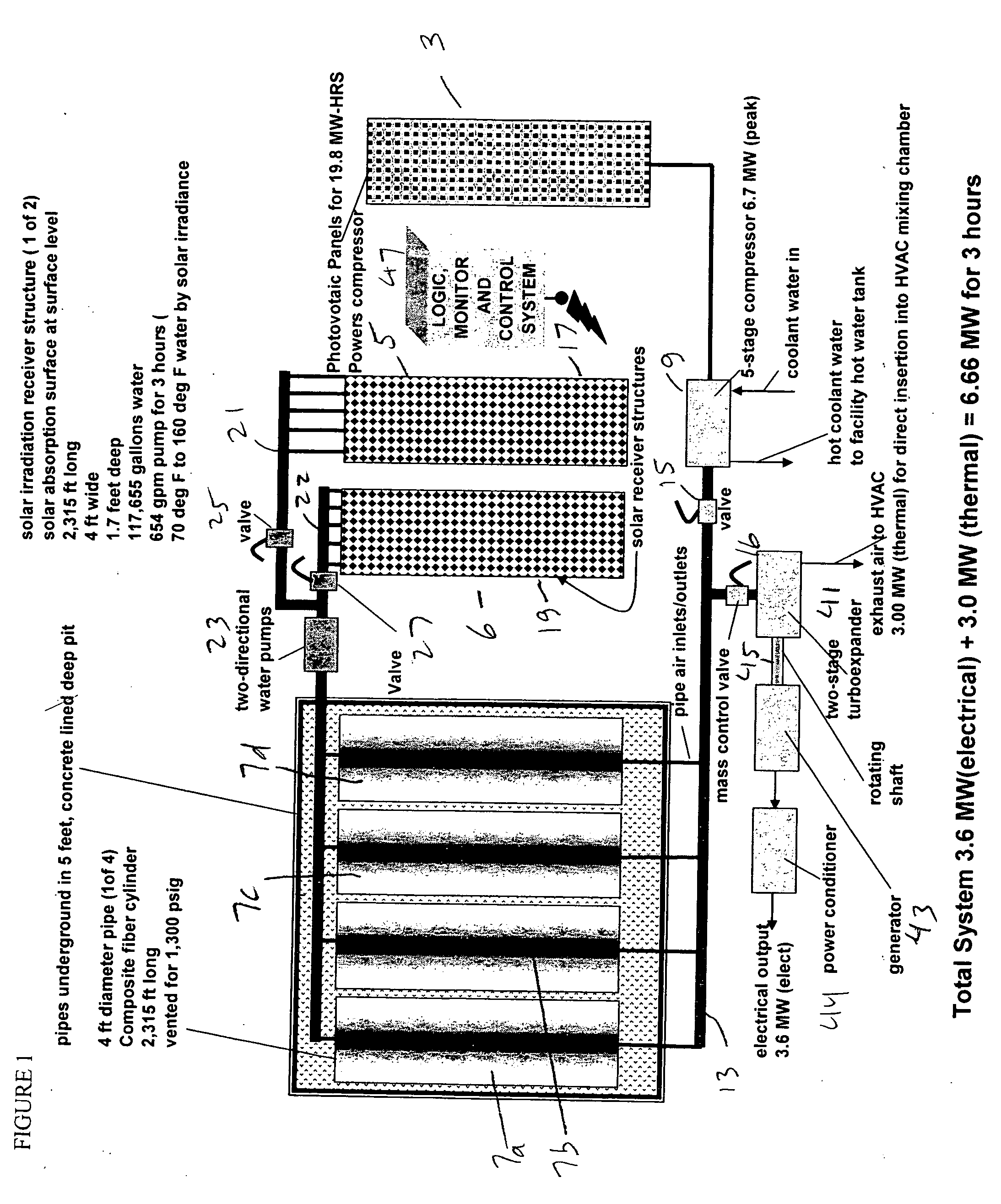

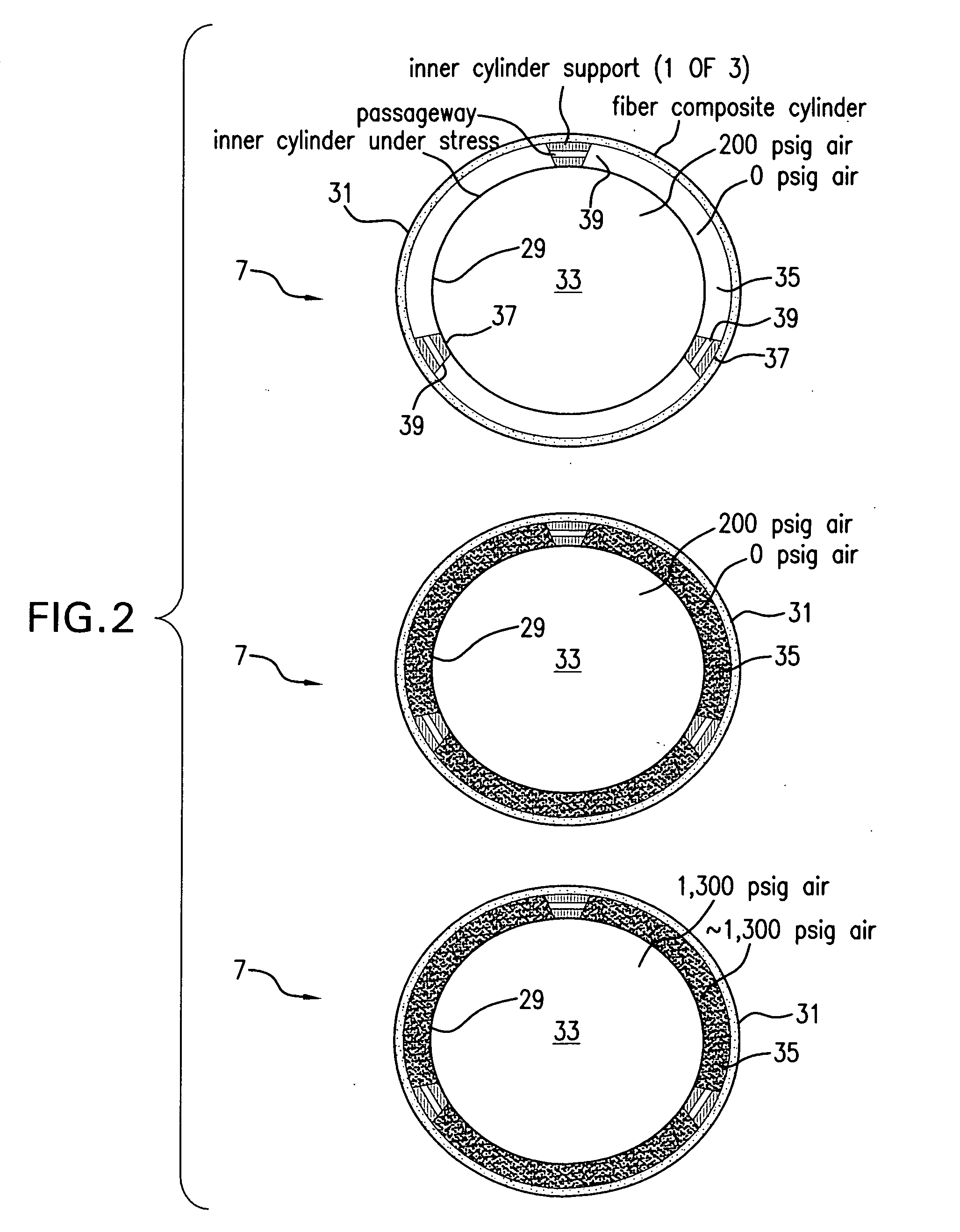

Method and apparatus for using solar energy to enhance the operation of a compressed air energy storage system

ActiveUS20090230696A1Reduce inconsistencyReduce inefficienciesSolar heating energyAuxillary drivesThermal energy storageCogeneration

The invention relates to a method and apparatus for using solar energy to enhance the efficiency of a compressed air energy storage system (and visa-versa). The apparatus comprises a photovoltaic panel to drive a compressor, which provides compressed air energy into an inner vessel housed within a storage tank. Two solar receiving panels are used to heat water which can be circulated and stored within an annulus surrounding the inner vessel, wherein the heated water can help regulate the temperature of the compressed air within the tank. This way, when air is released using a turbo expander, any excess temperature drops that can otherwise result from air expansion can be avoided. The overall system efficiency is enhanced by the chilled air by-product of the turbo expander which is used to generate more electrical power from an associated fuel-driven generator set, and / or by the waste heat from the compressor and from the generator set exhaust which is used in a Combined Heat and Power system (CHP) to power either a steam-driven generator set or an absorption chiller.

Owner:ENIS BEN M +1

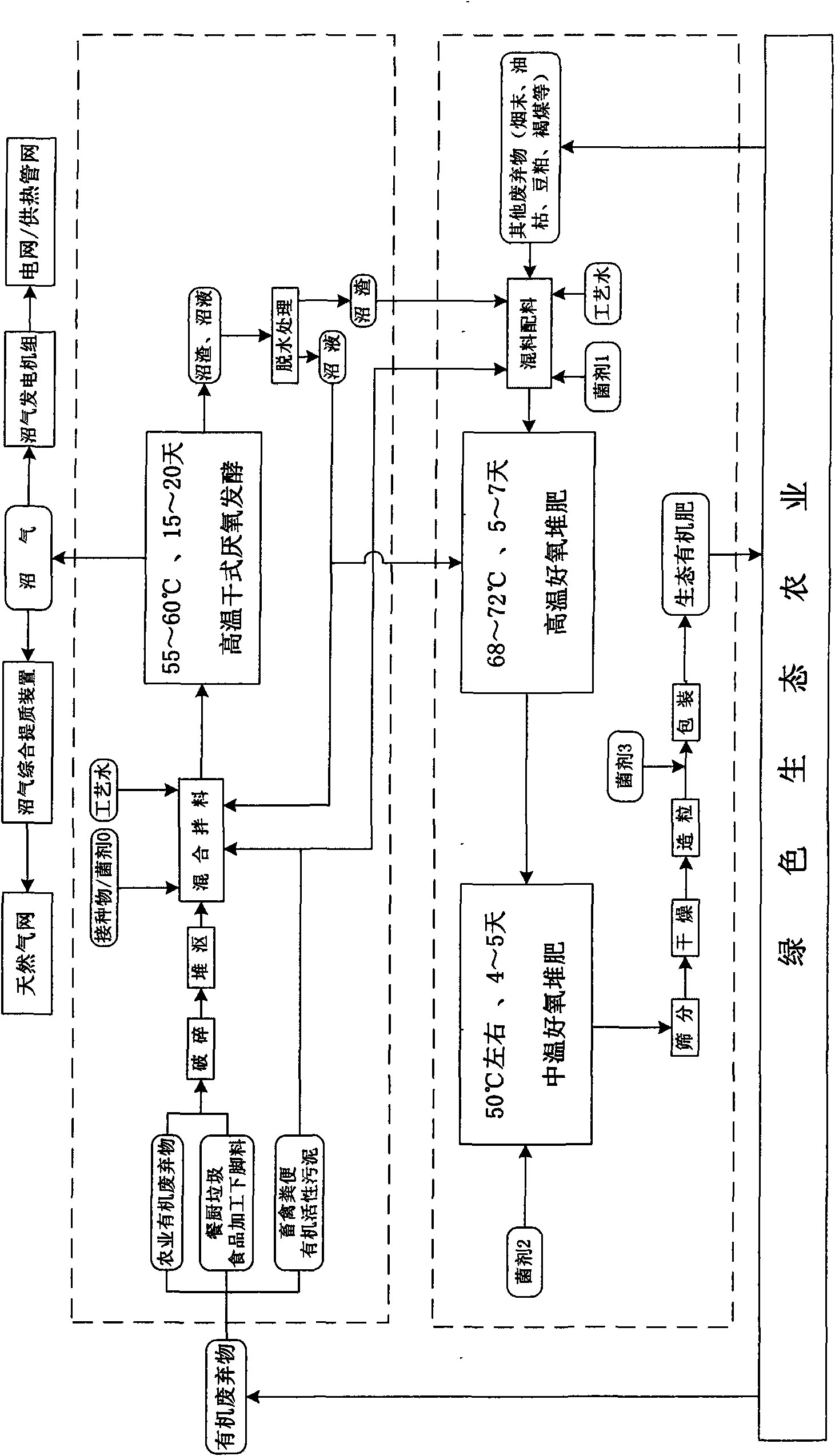

Comprehensive processing technology of organic wastes

ActiveCN101637778AImprove efficiencyStable nutrientsBio-organic fraction processingSolid waste disposalThermal energyProcess systems

The invention provides a comprehensive processing technology of organic wastes, belonging to the technical field of environmental protection, and in particular relates to resourcing comprehensive processing technology of organic wastes. The invention comprises the following steps: a. preparing materials: placing liquid or solid organic wastes into different storing tanks; b. pretreating: crashingthe organic wastes to particles with the granuality of being equal to or less than 30 mm, conveying the well-crashed materials into a stackretting tank for stackretting; c. mixing and matching variousorganic wastes and process water, wherein, the carbon nitrogen ratio (C / N) of the materials is 20-30:1, and the concentration of TS is 30%-35%; d. adding the inoculum, adopting high temperature dry anaerobic fermentation to carry out anaerobic fermentation on pretreated materials; and e. manufacturing from the biogas residues generated in step d into efficient multifungus composite ecological organic fertilizer, backflowing the generated biogas liquid to adjust the state of the anaerobic fermentation system or ensure the biogas liquid to enter the aerobic composting process flow, and introducing the generated biogas to a thermoelectricity cogeneration unit to provide electrical energy and thermal energy required by the process system. In the invention, composite microorganism agent and biogas residues and other base stocks are adopted for composite preparation, thus greatly improving fertilizer efficiency, lowering cost, having effects of diversification of nutrients, stable fertilizer efficiency and non pollution, and being suitable for being applied for various crops.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com