Patents

Literature

1866results about "Turbine/propulsion fuel supply systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

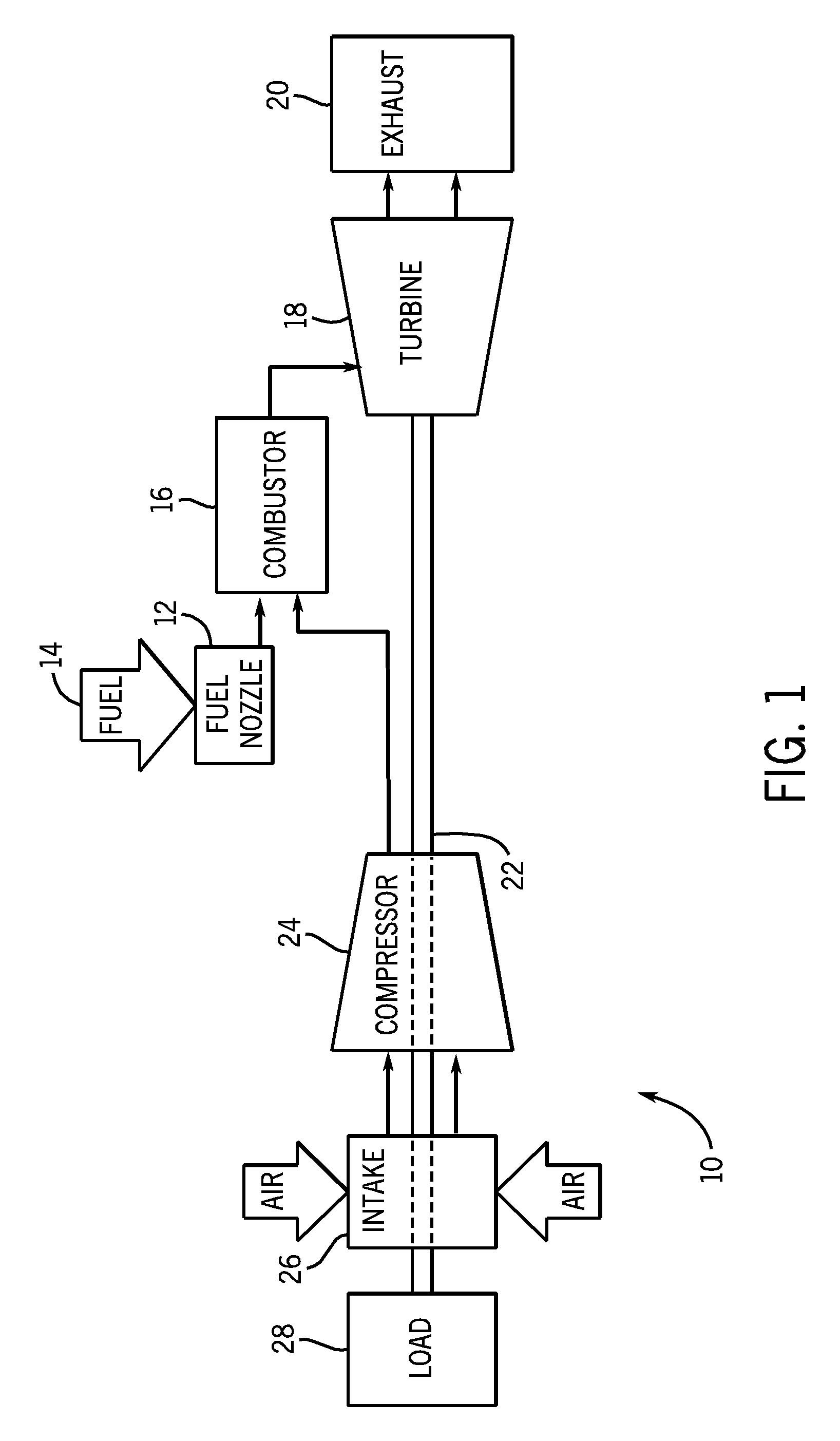

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

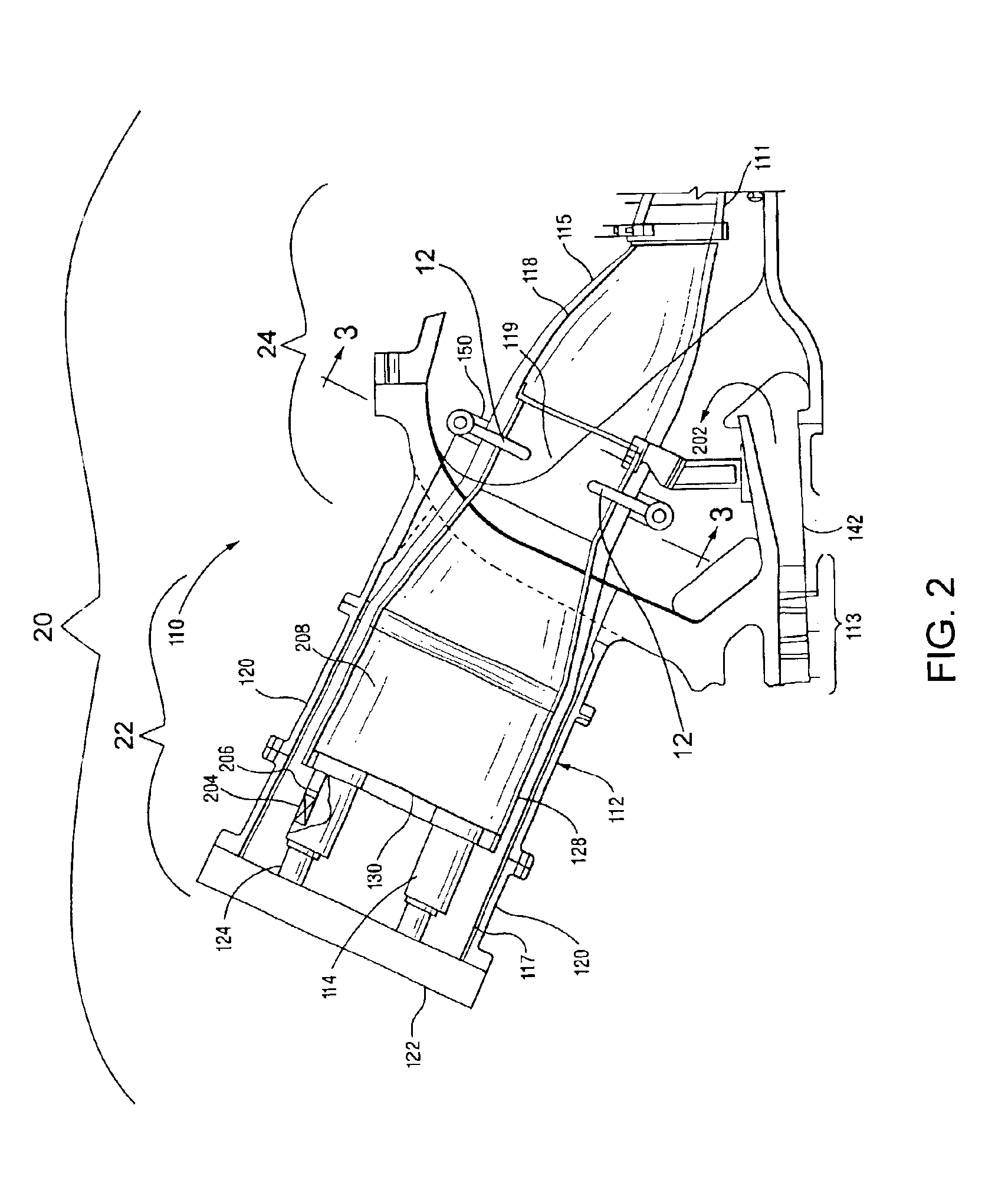

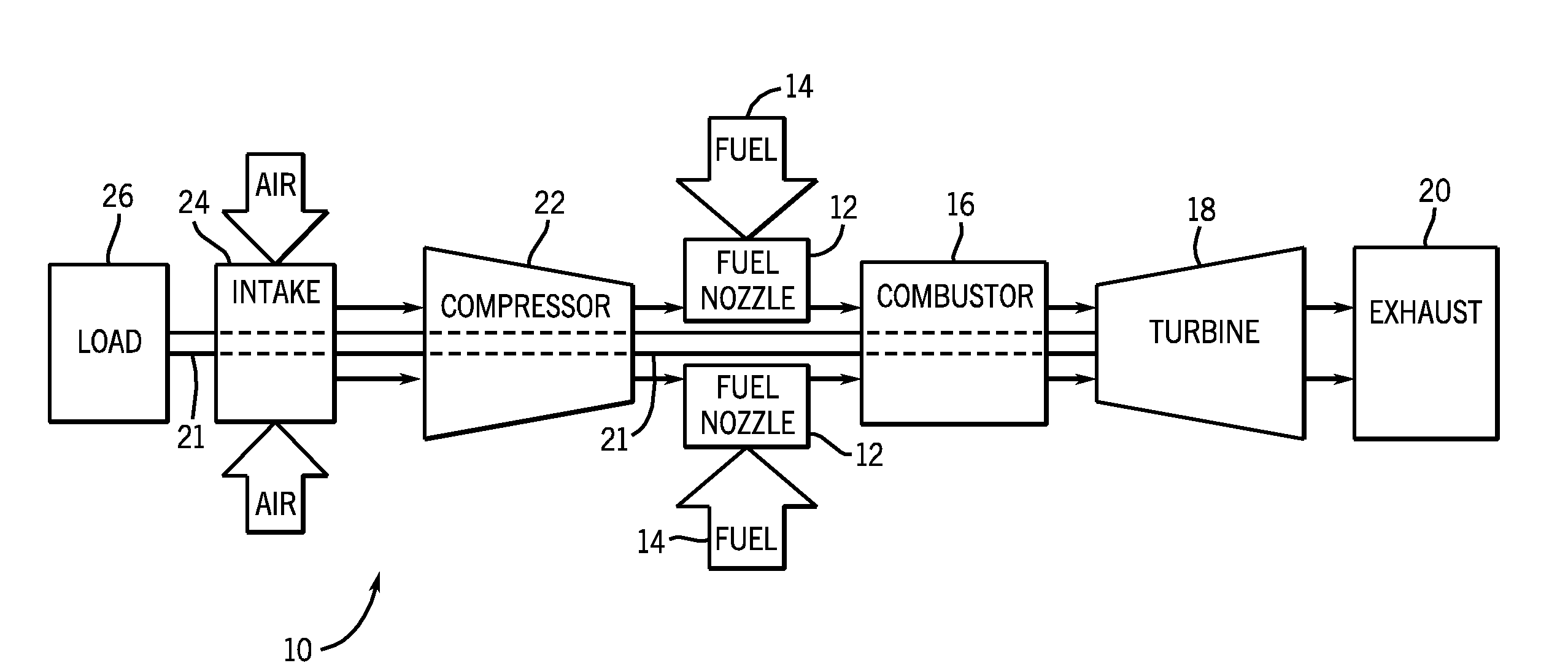

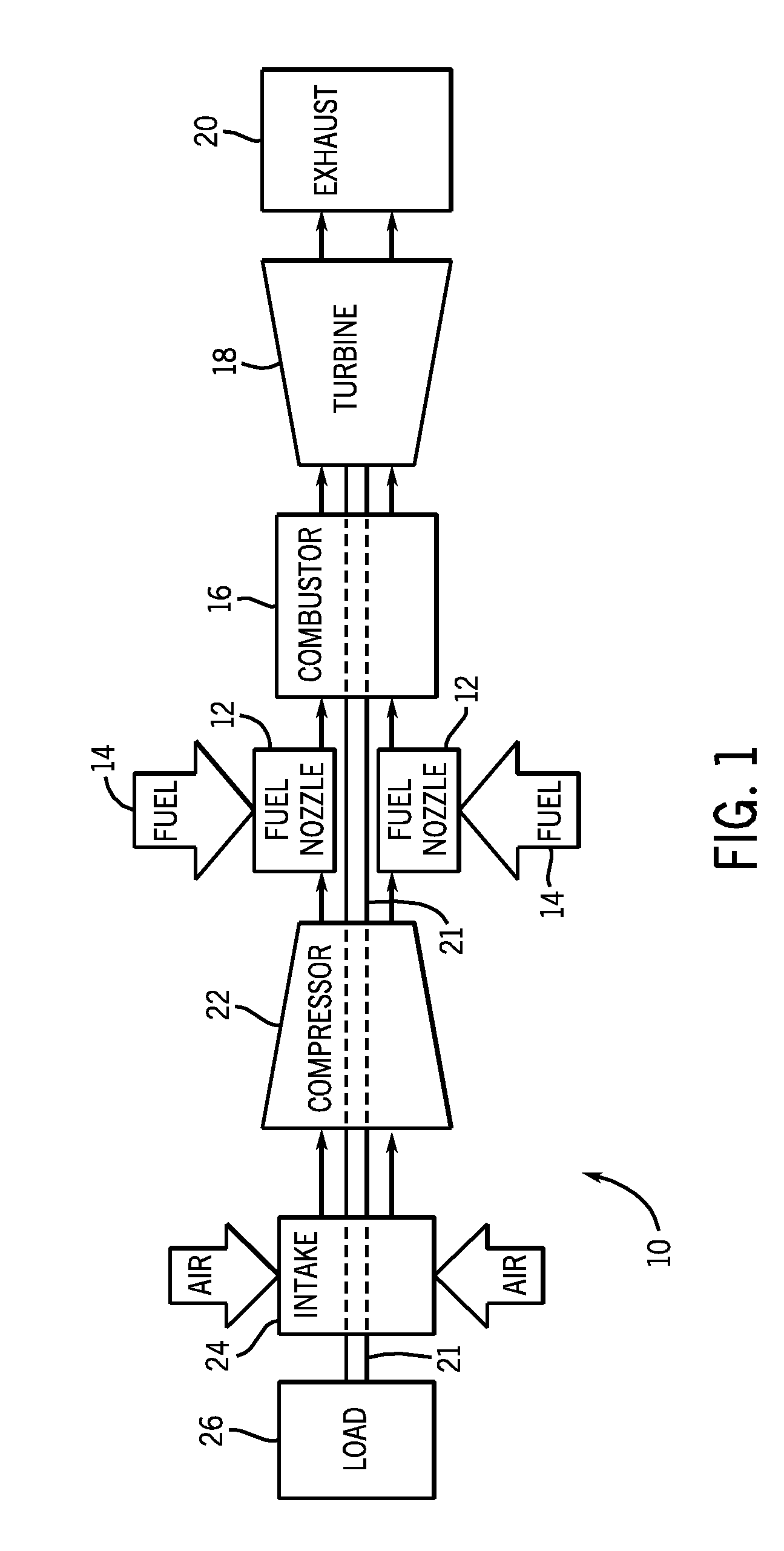

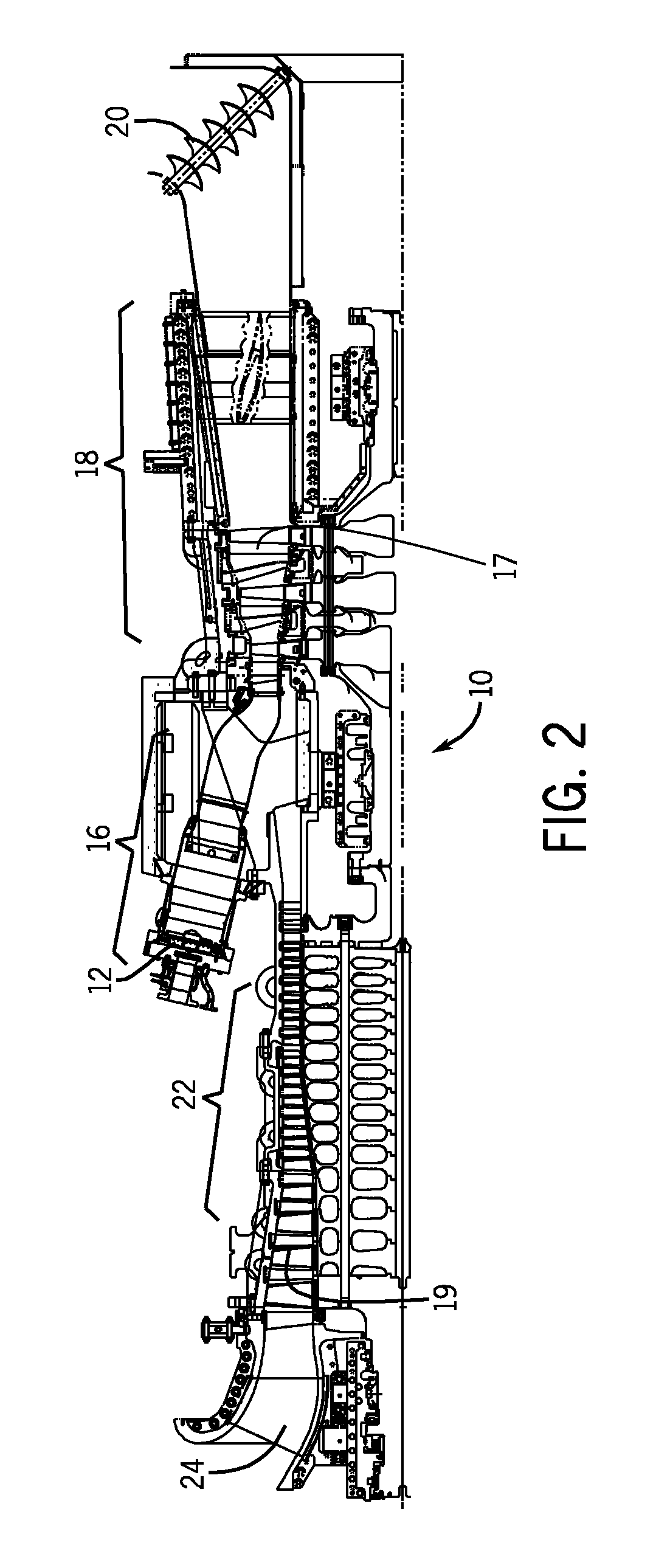

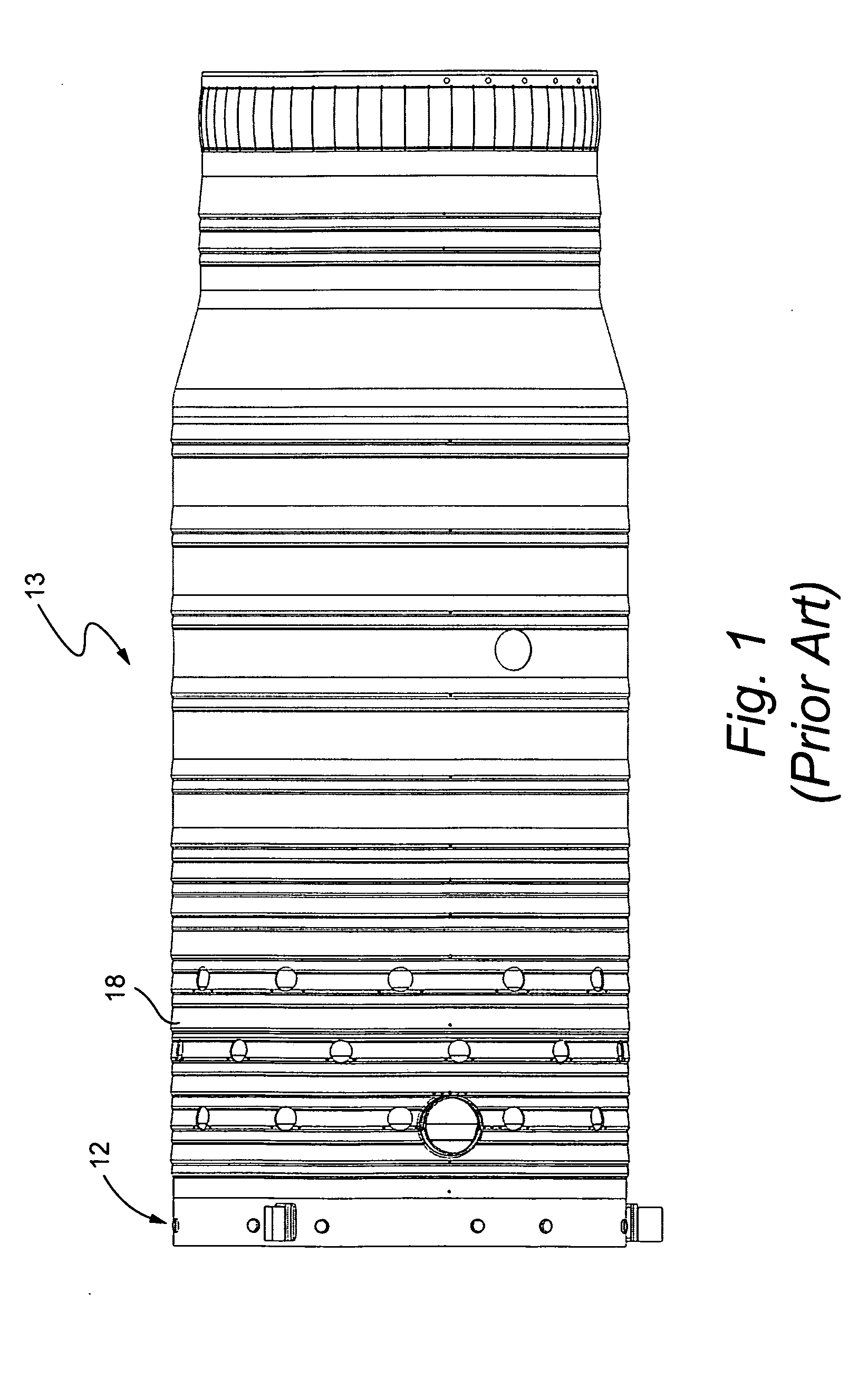

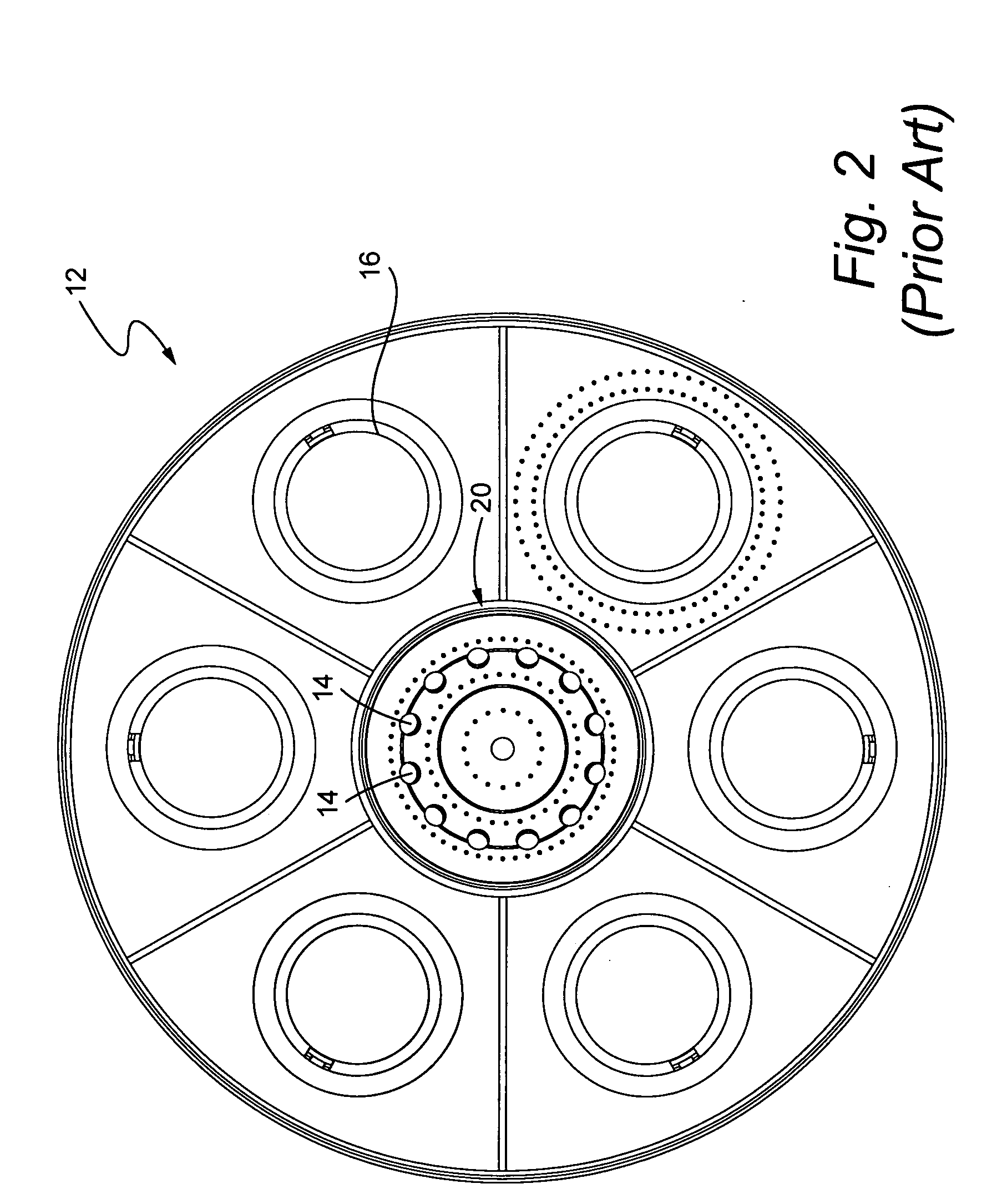

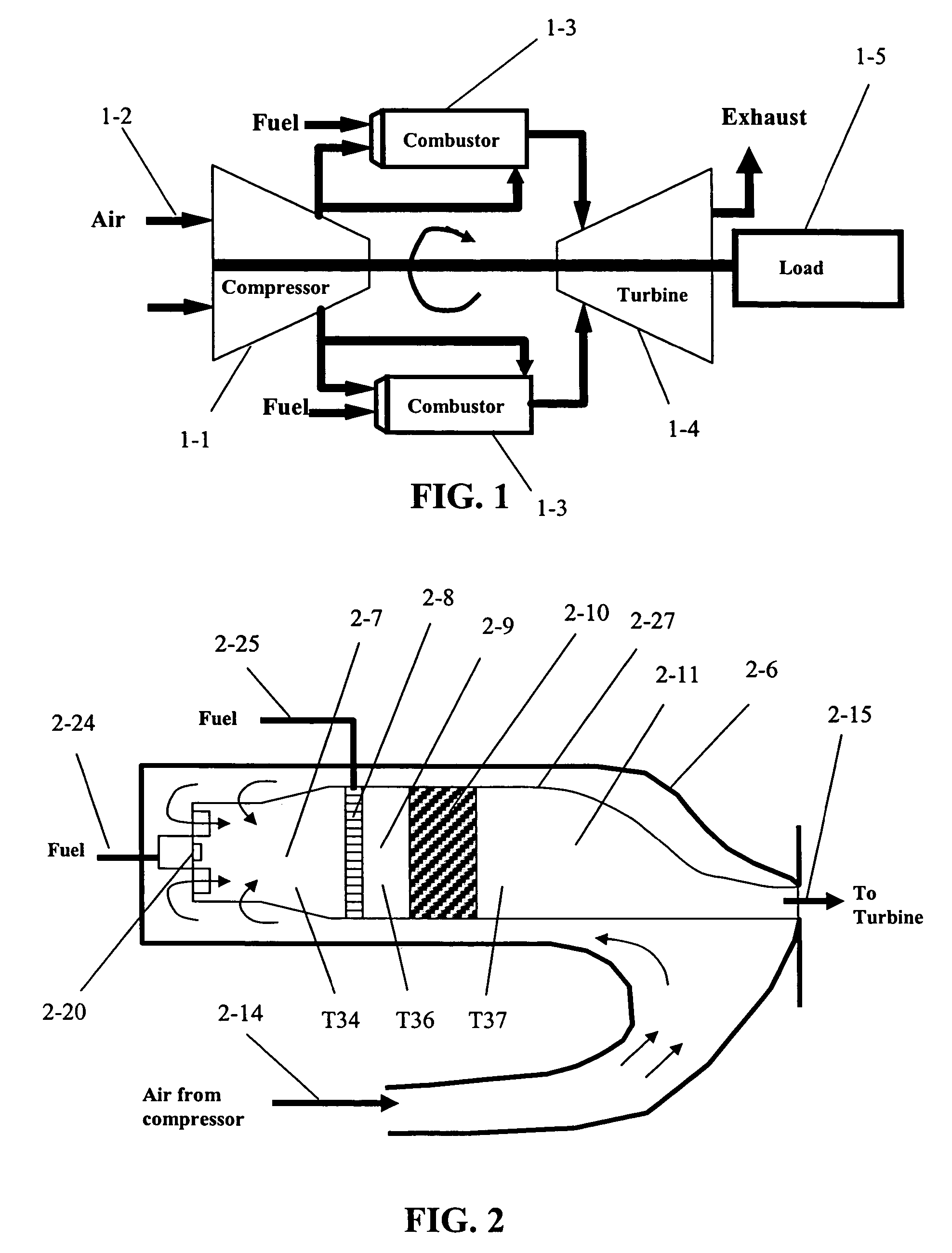

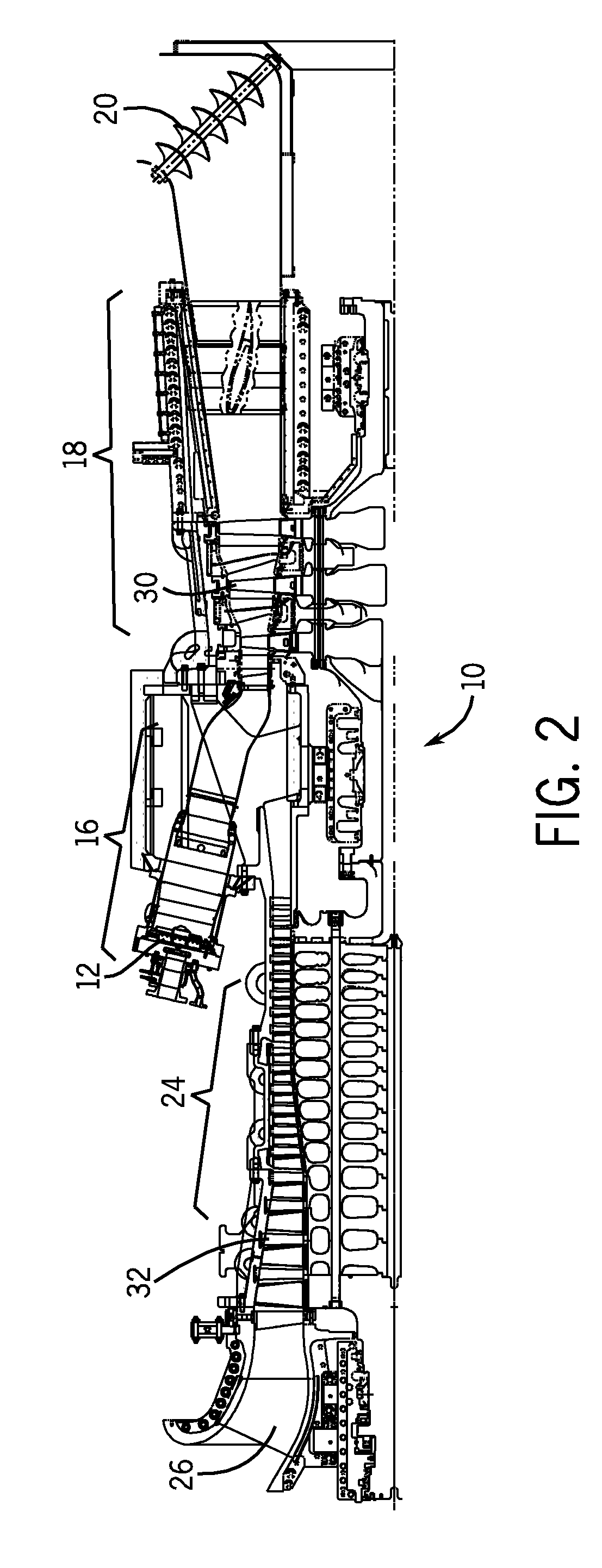

Turbine containing system and an injector therefor

A turbine containing system is disclosed. The system includes an intake section, a compressor section downstream from the intake section, a combustor section having a primary combustion system downstream from the intake section, a secondary combustion system downstream from the primary combustion system, a turbine section, an exhaust section and a load. The secondary combustion system includes an injector for transversely injecting a secondary fuel into a stream of combustion products of the primary combustion system. The injector including a coupling, a wall defining an airfoil shape circumscribing a fuel mixture passage, and at least one exit for communication between said fuel mixture passage and said stream of primary combustion products.

Owner:GENERAL ELECTRIC CO

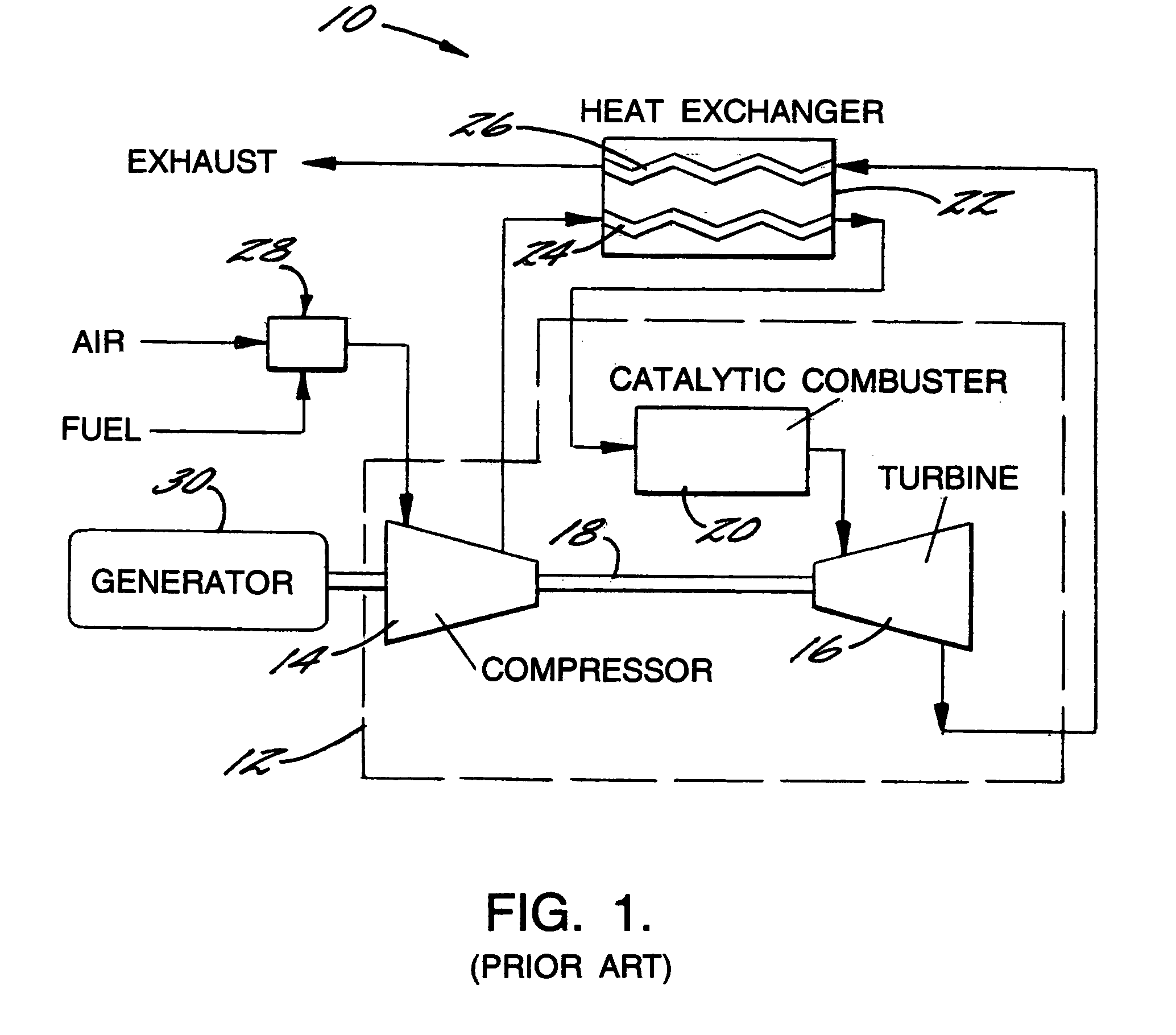

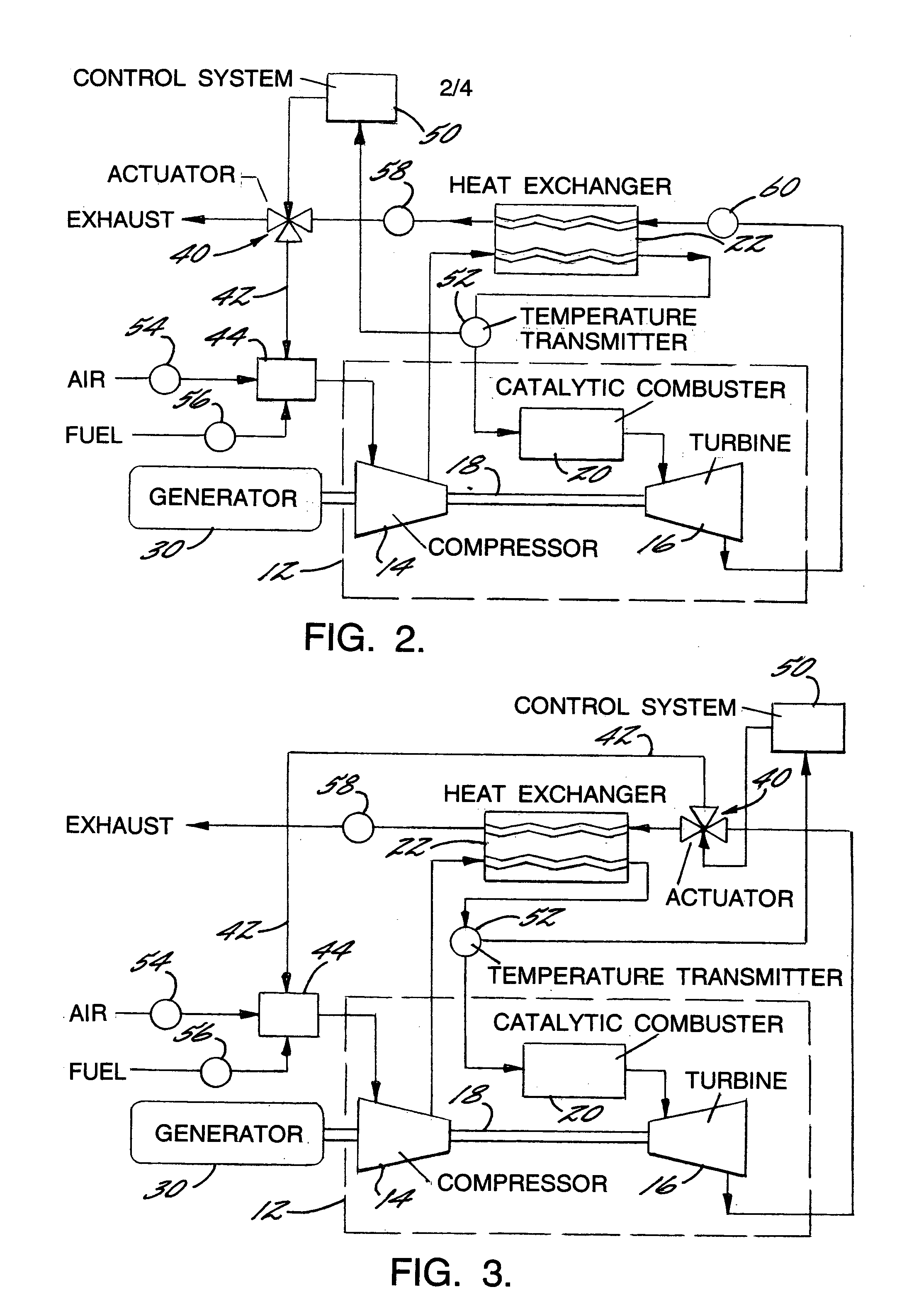

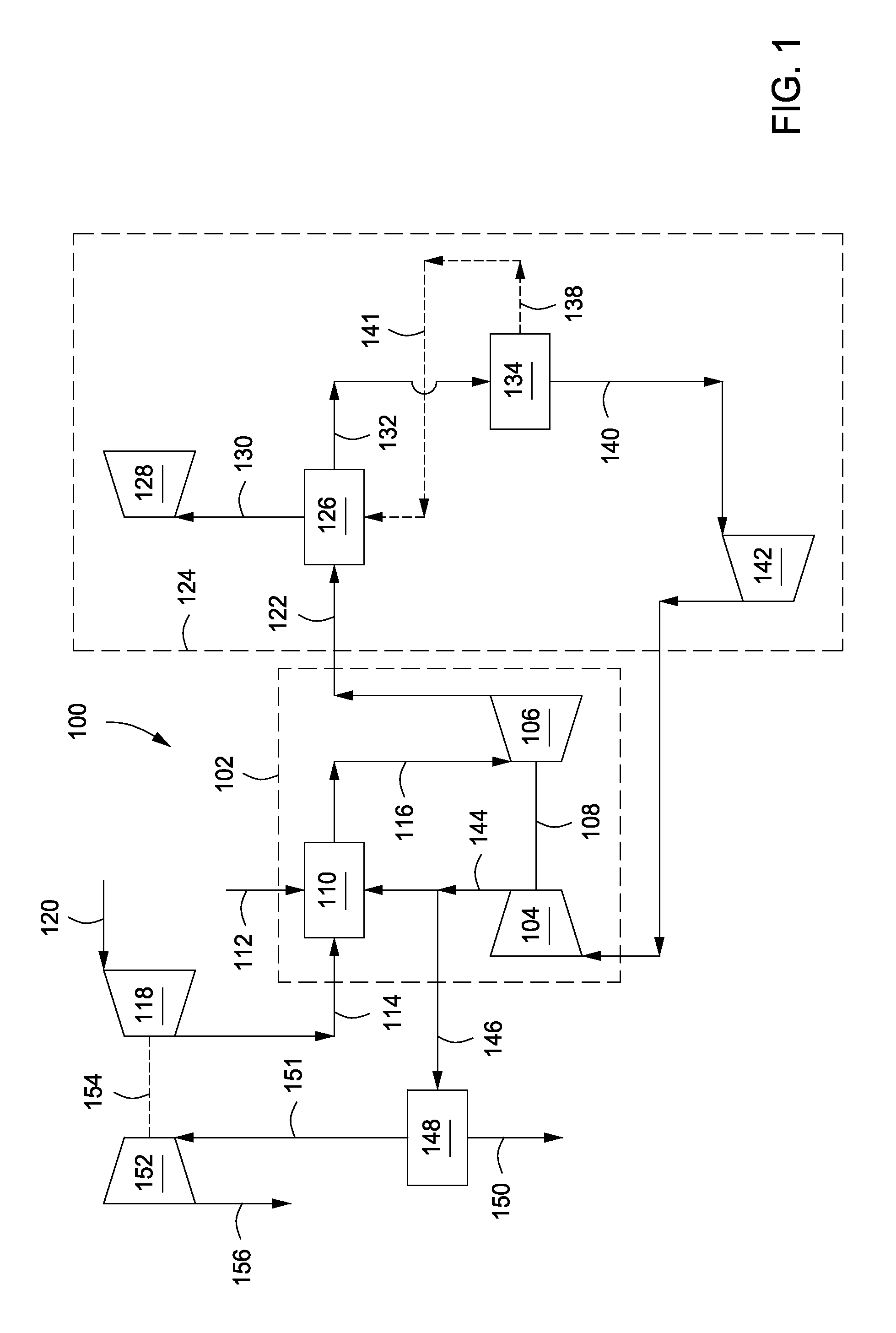

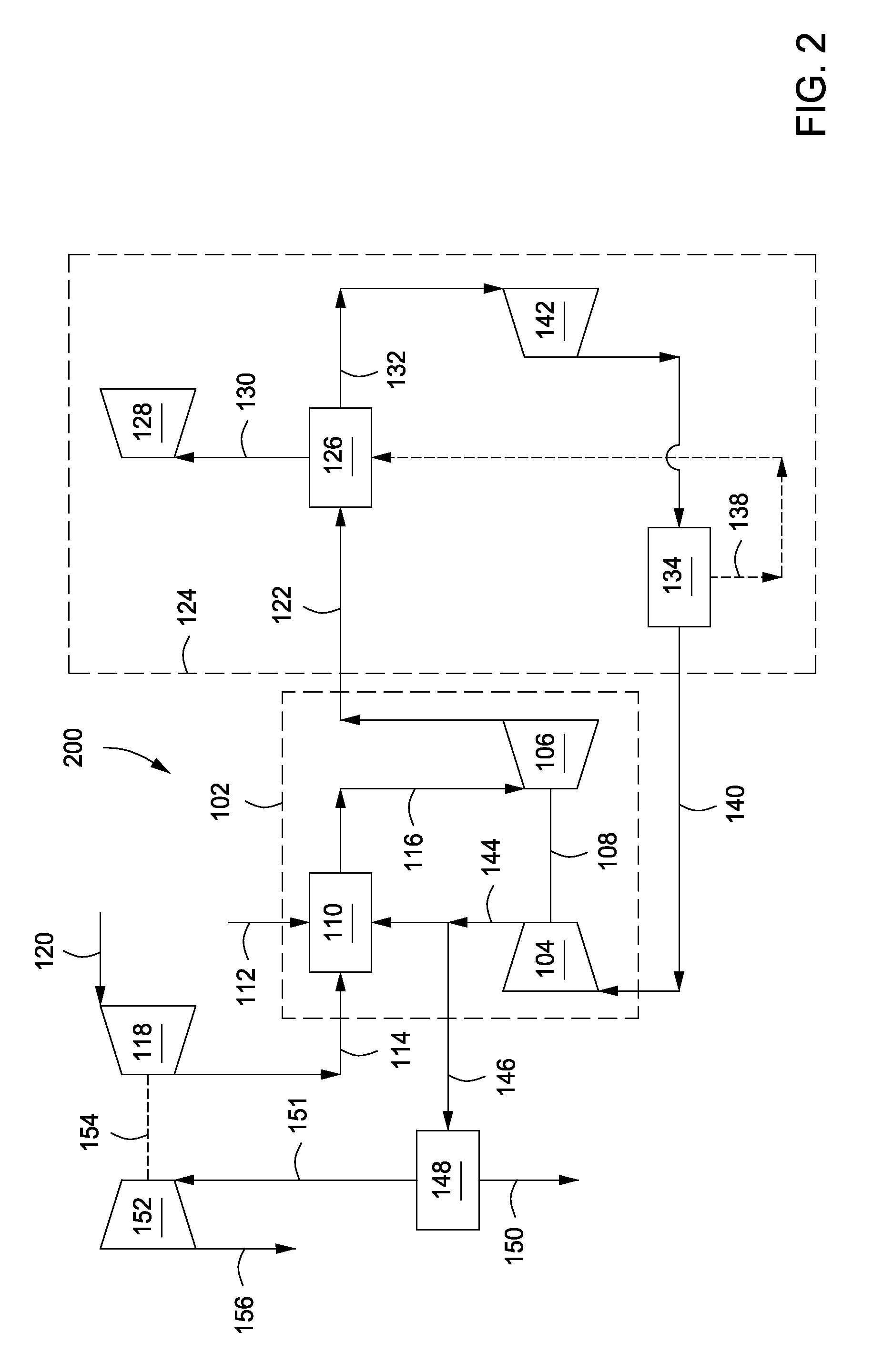

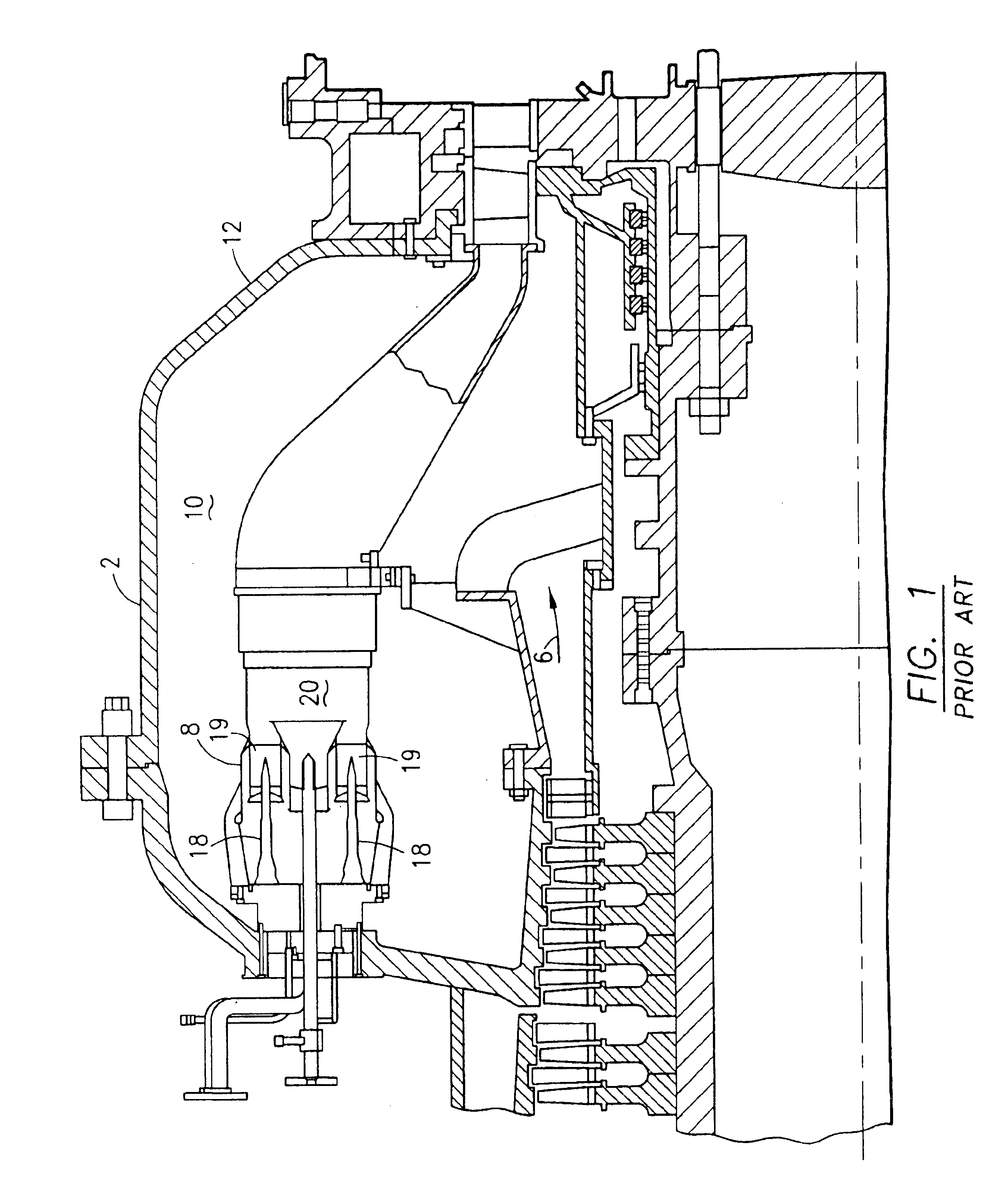

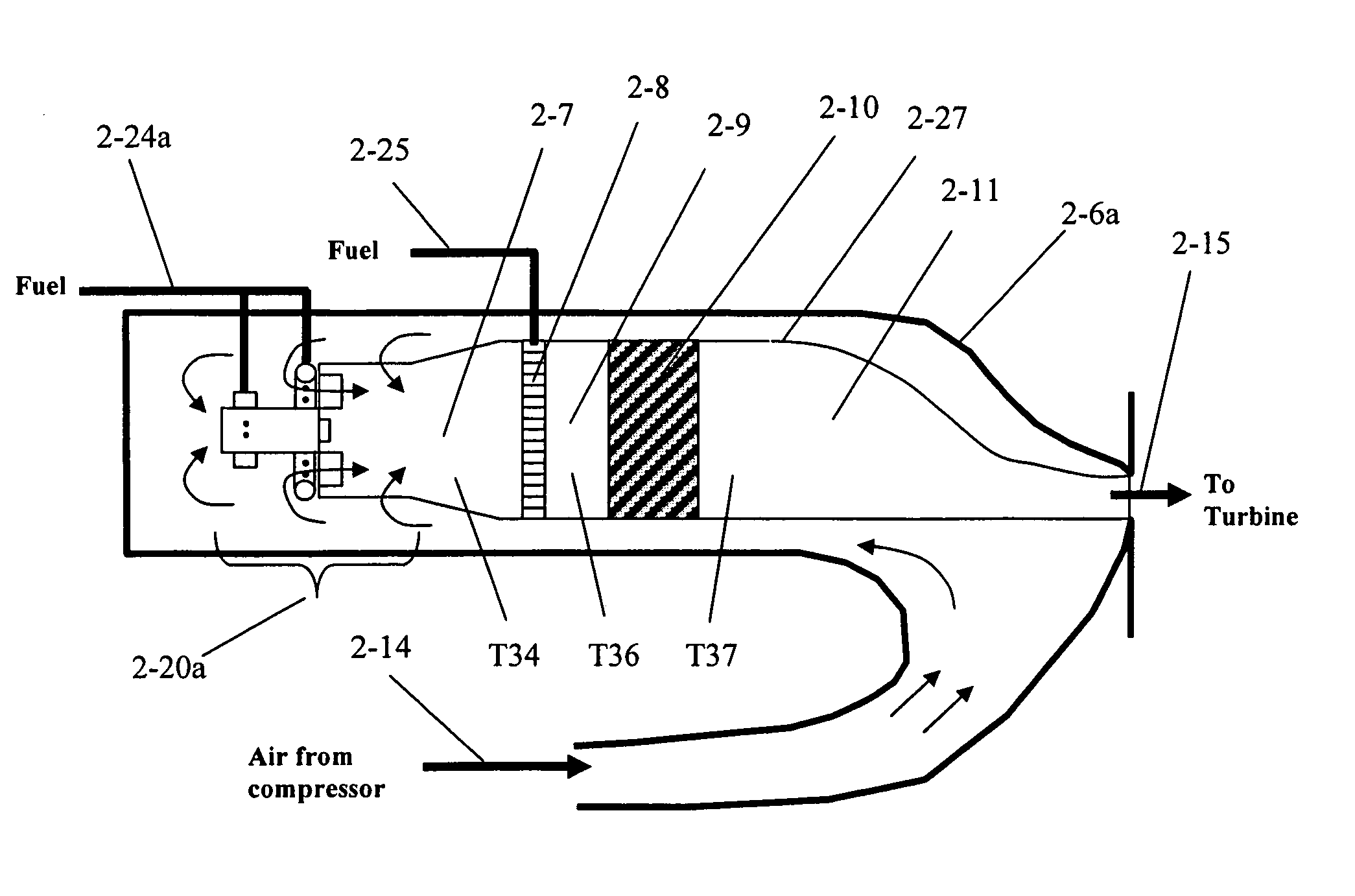

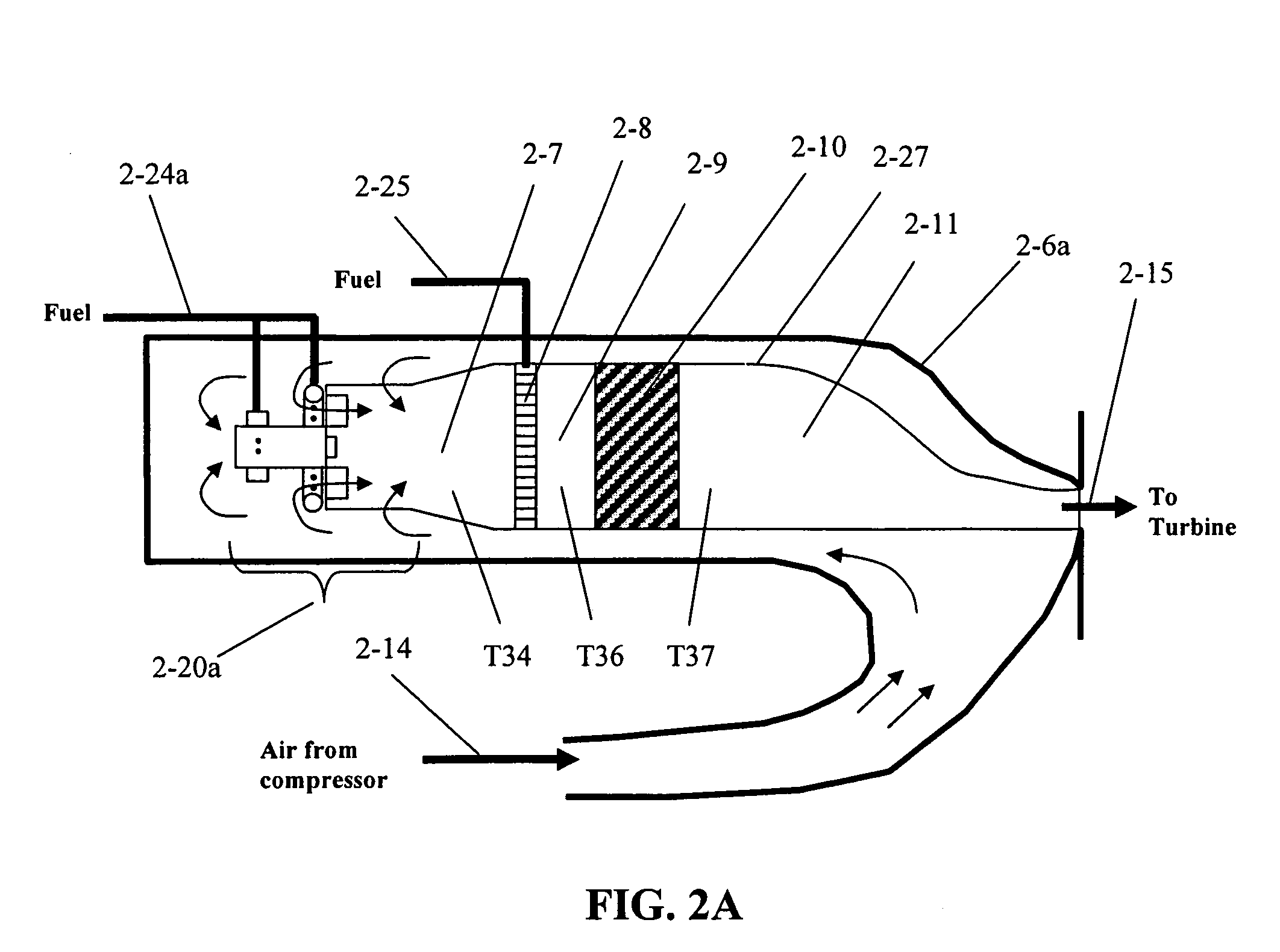

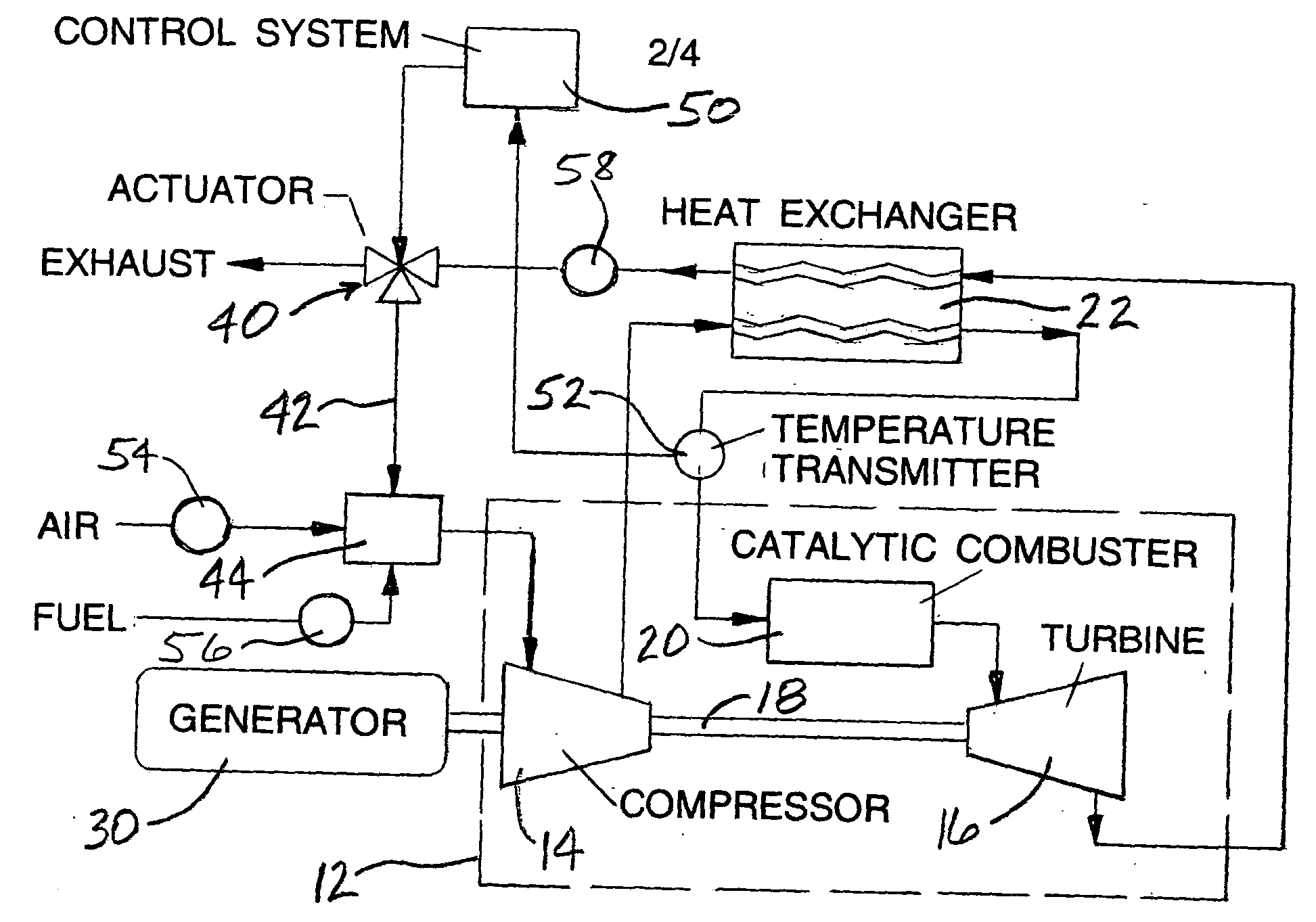

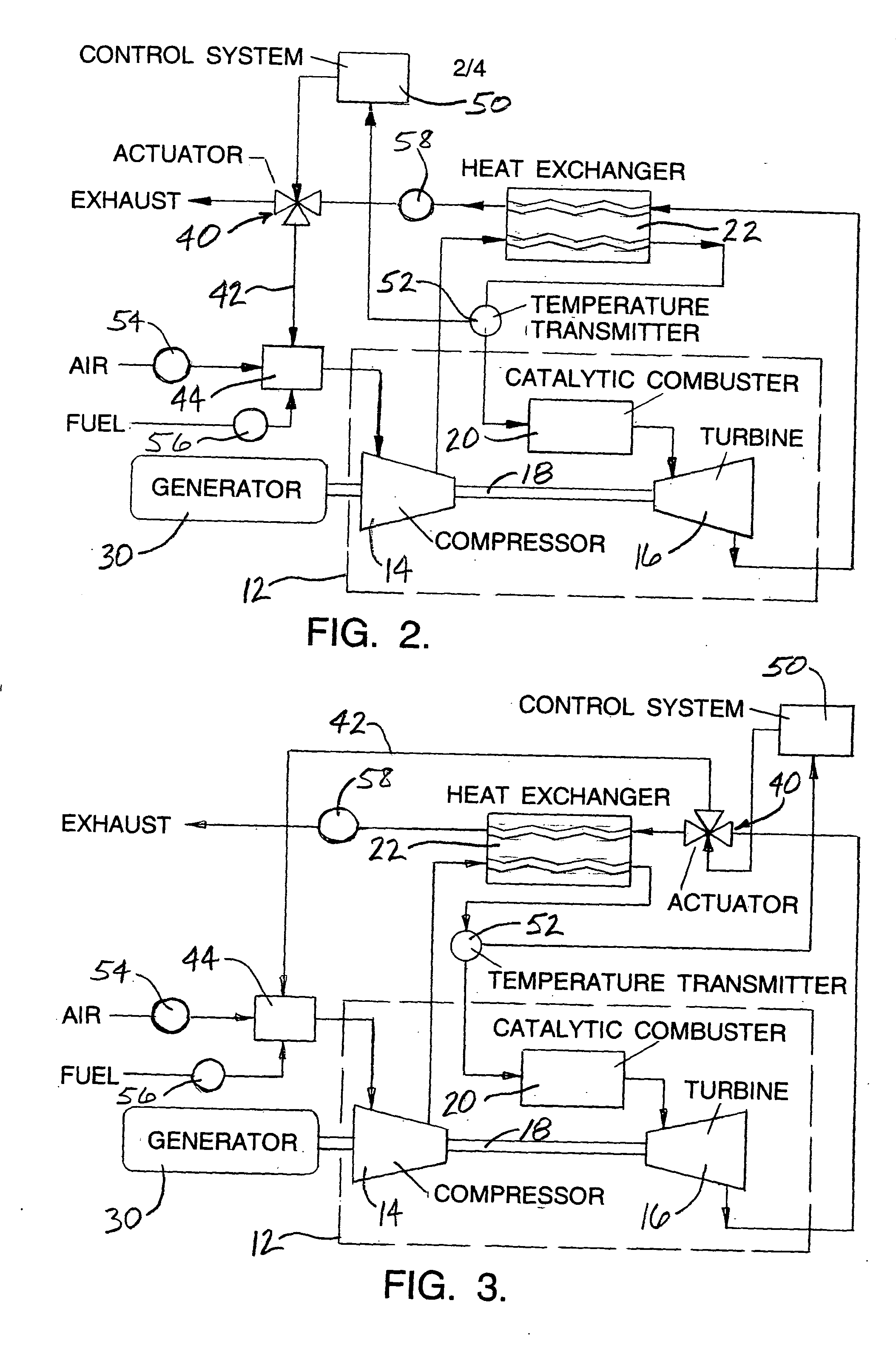

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

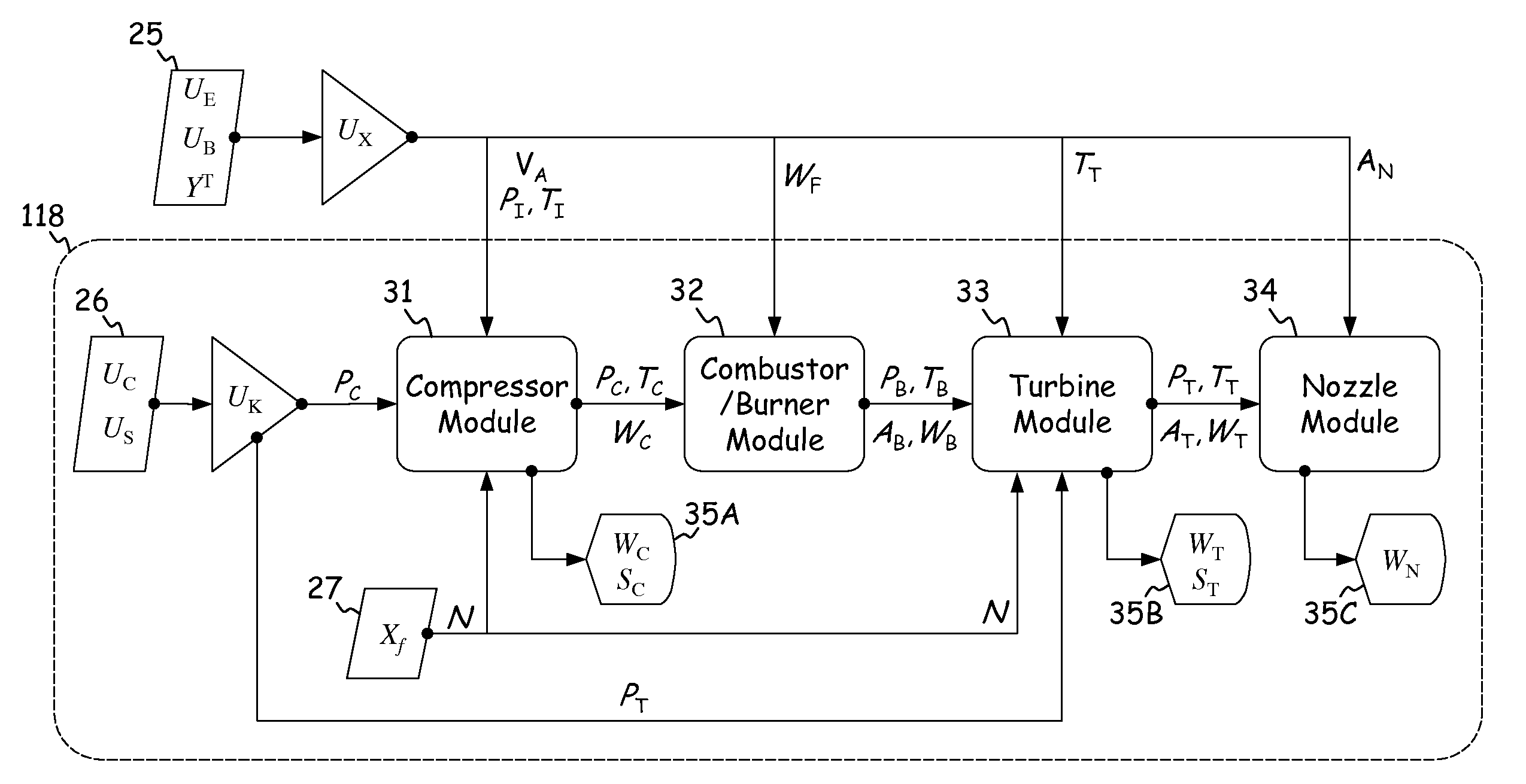

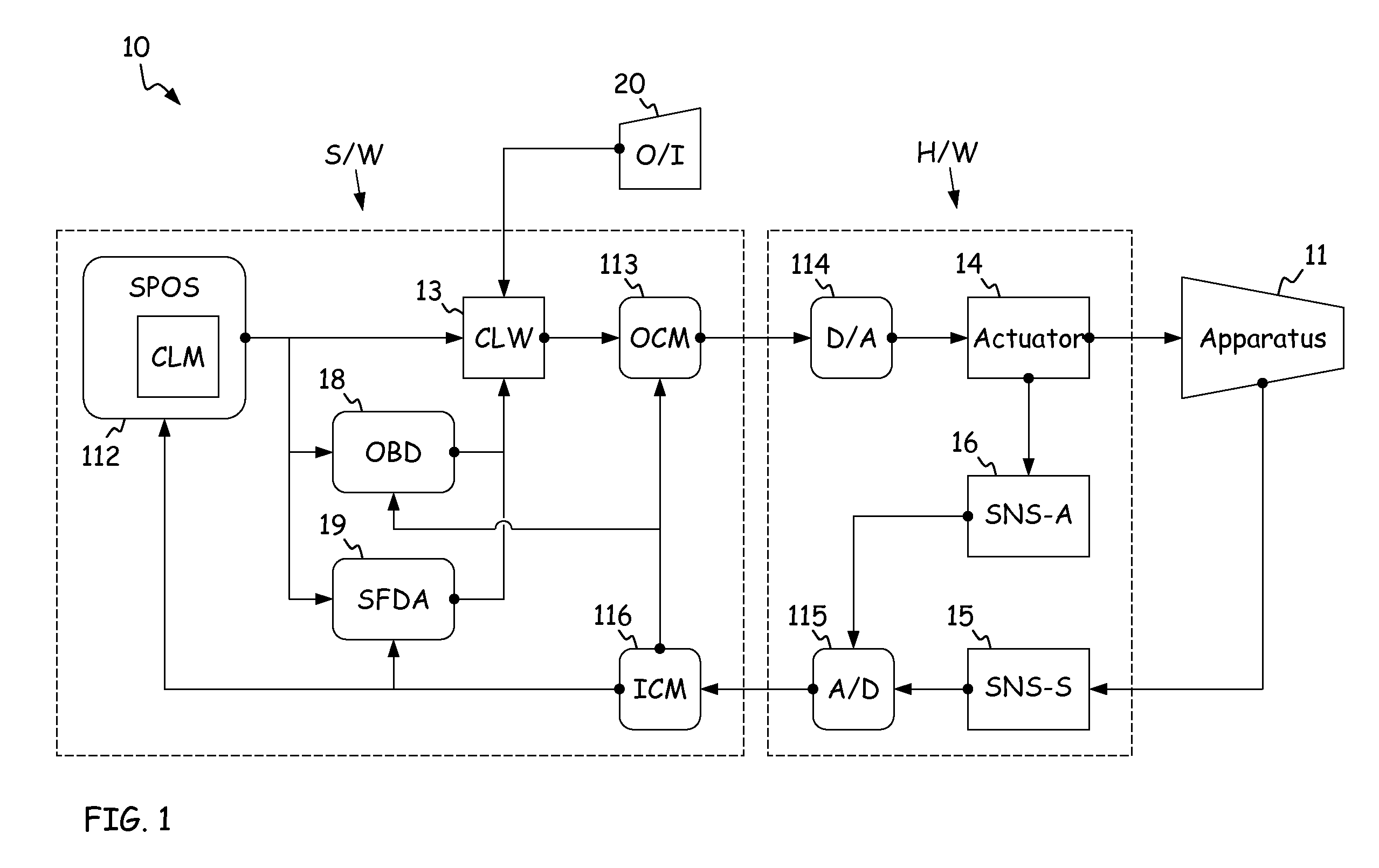

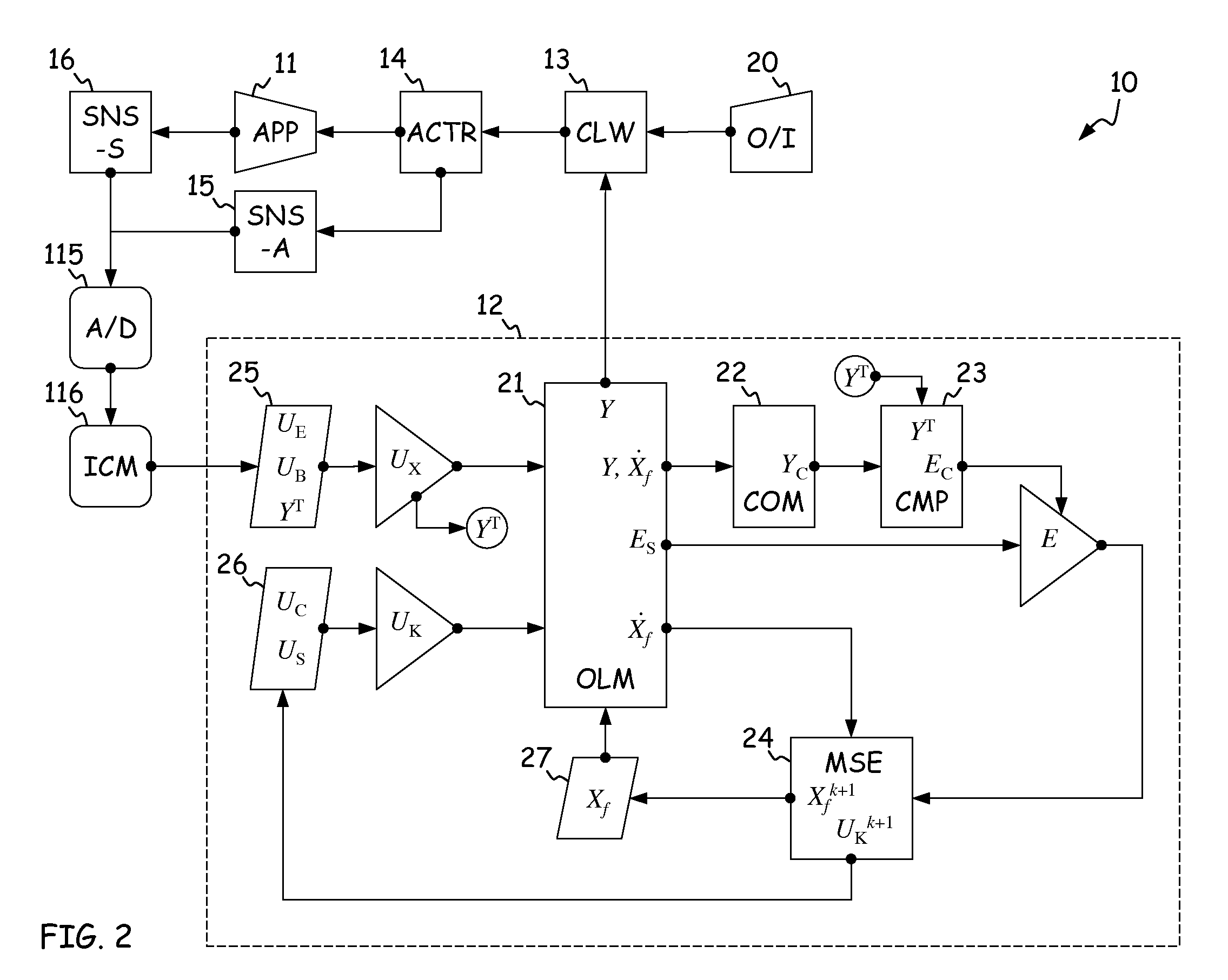

High fidelity integrated heat transfer and clearance in component-level dynamic turbine system control

ActiveUS20110054704A1Turbine/propulsion fuel supply systemsTemperatue controlControl flowEngineering

A system comprises a rotary apparatus, a control law and a processor. The rotary apparatus comprises a rotor and a housing forming a gas path therebetween, and the control law controls flow along the gas path. The processor comprises an output module, a plurality of temperature modules, a thermodynamic module, a comparator and an estimator. The output module generates an output signal as a function of a plurality of rotor and housing temperatures defined along the gas path, and the temperature modules determine time derivatives of the rotor and housing temperatures. The thermodynamic module models boundary conditions for the gas path, and the comparator determines errors in the boundary conditions. The estimator estimates the rotor and housing temperatures based on the time derivatives, such that the errors are minimized and the flow is controlled.

Owner:RTX CORP

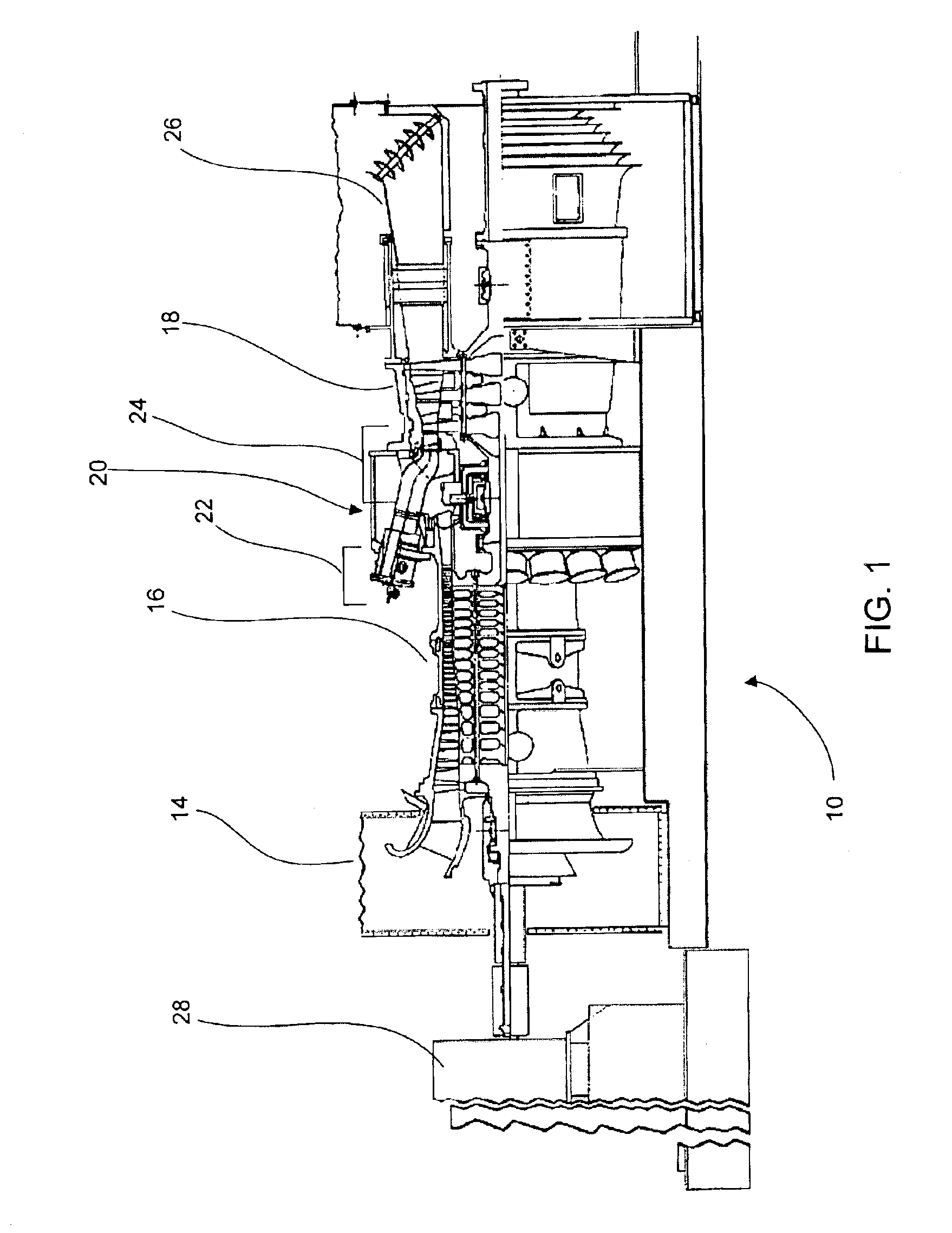

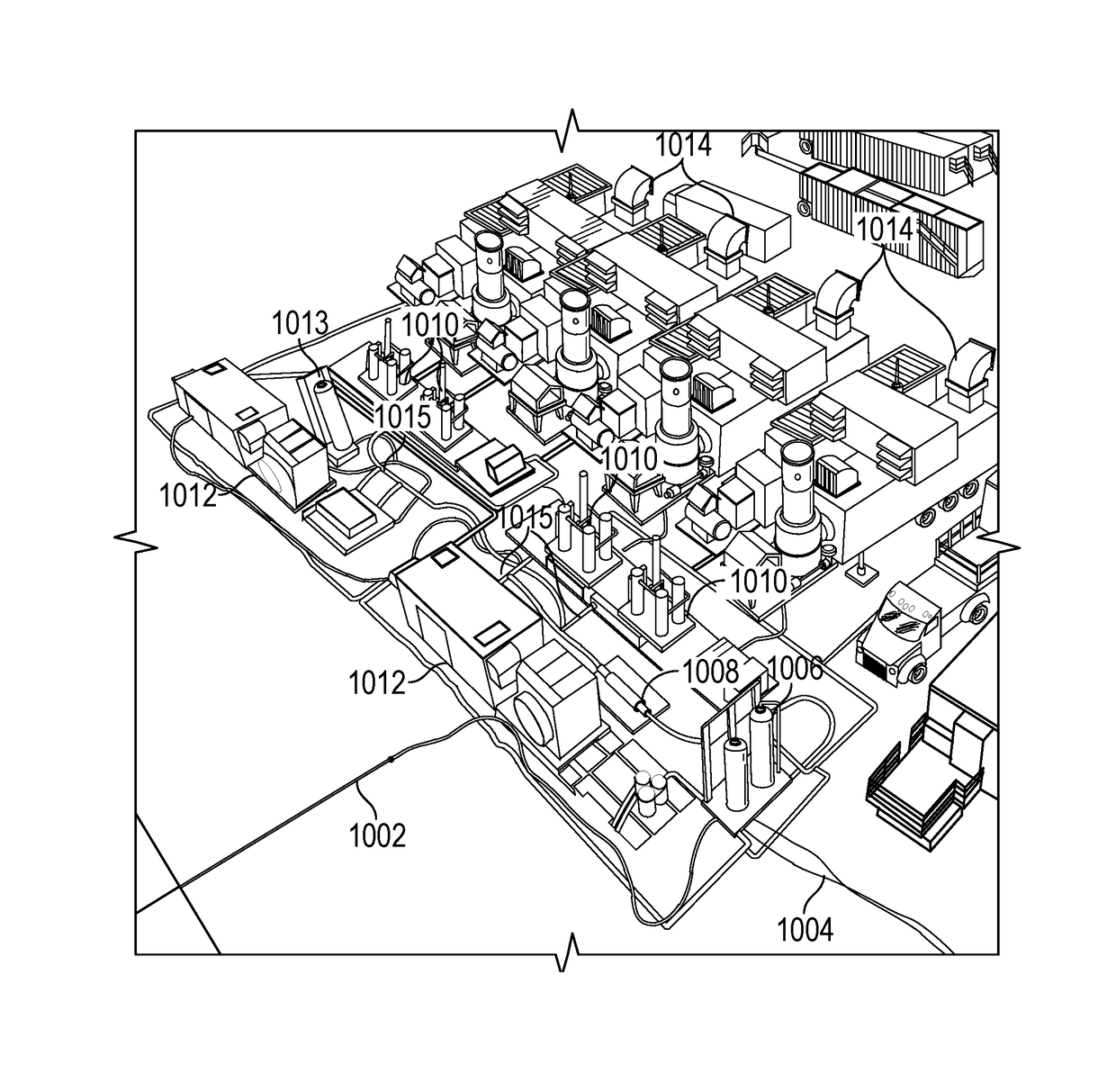

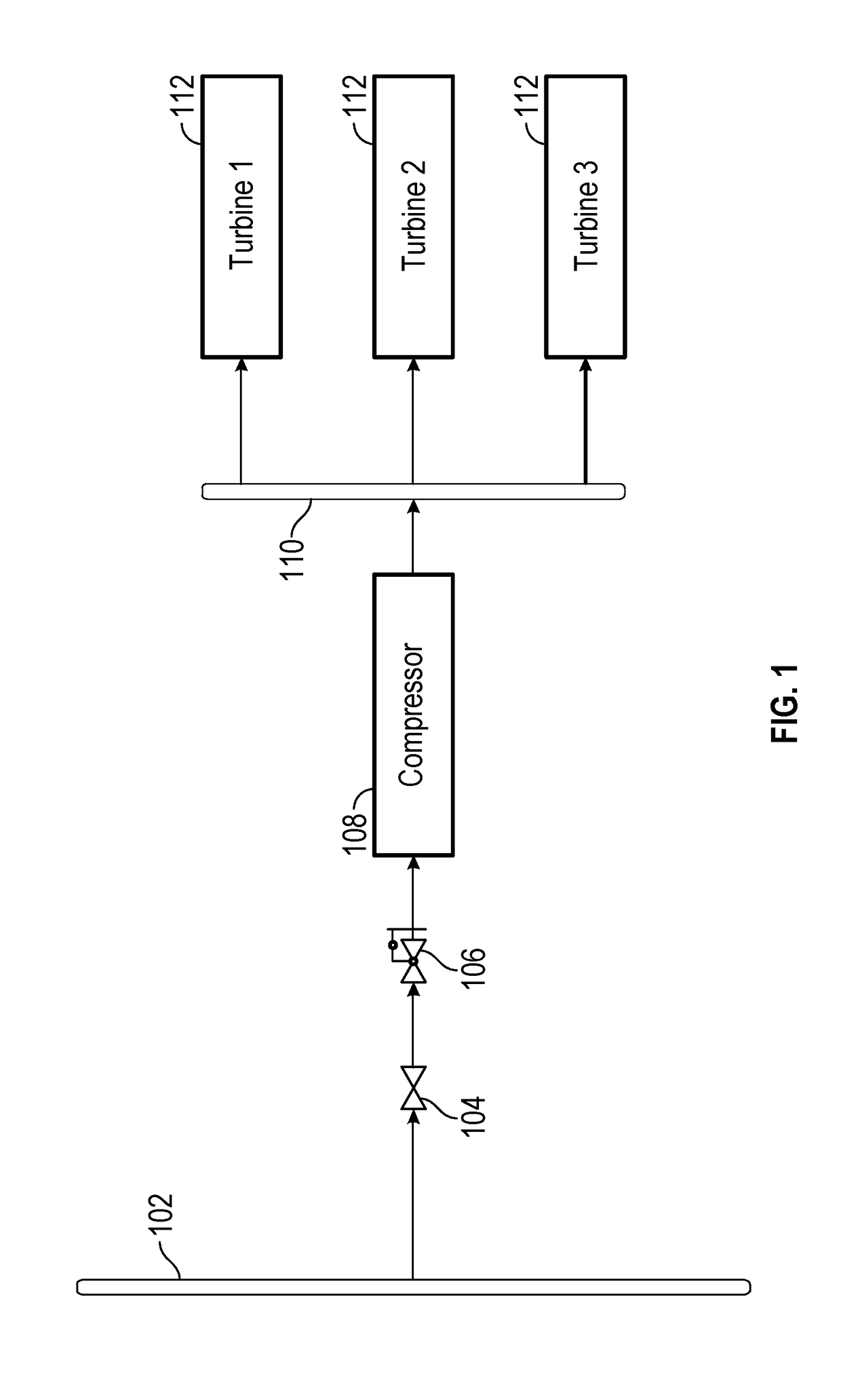

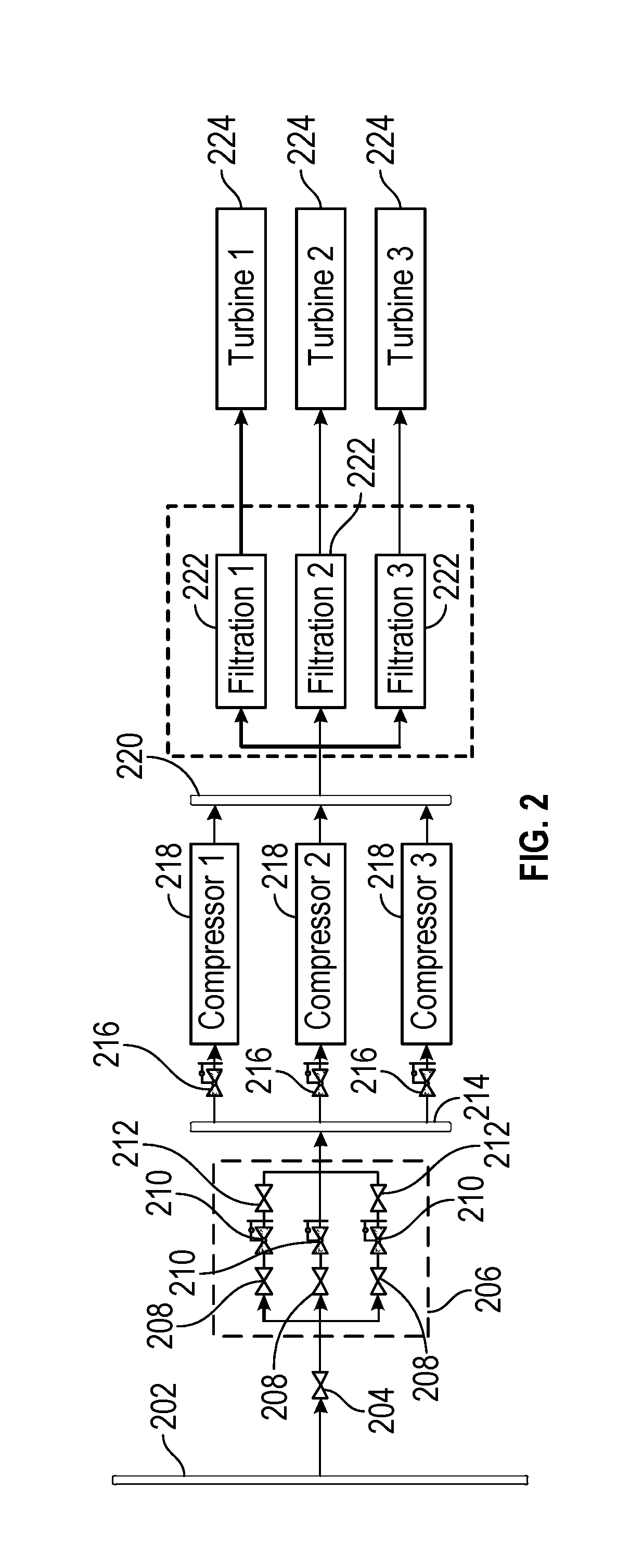

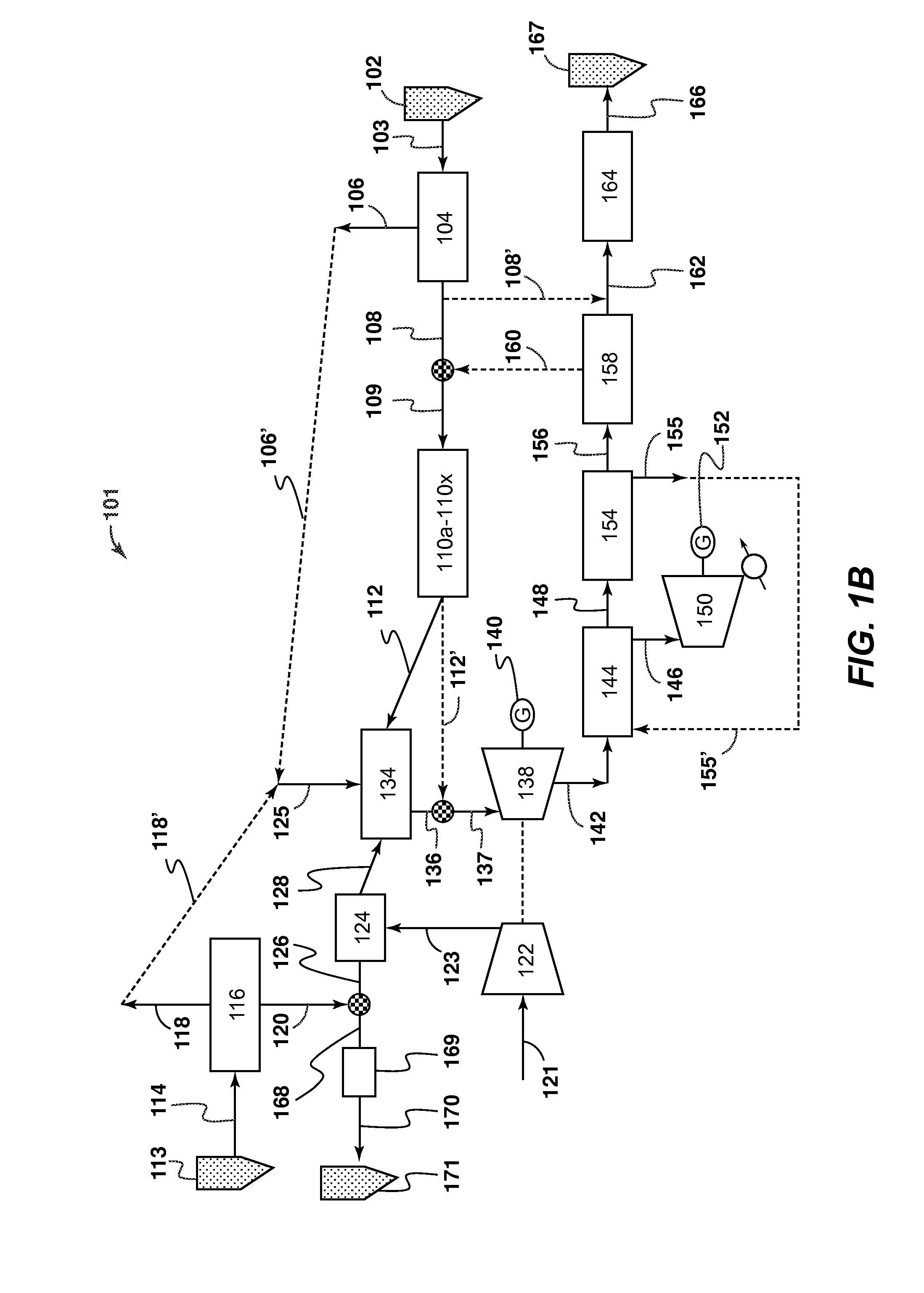

System for gas compression on electric hydraulic fracturing fleets

PendingUS20170145918A1Reduce pressureTurbine/propulsion fuel supply systemsGas turbine plantsElectricityGas compressor

Embodiments relate to hydraulic fracturing equipment powered by one or more natural gas turbine generators. Natural gas from a supply line is released via a valve into a turbine gas line. The turbine gas line includes one or more regulators to reduce the pressure of the natural gas stream in the turbine gas line to a pressure or pressure range optimum for one or more gas compressors. The gas compressors increase the pressure of the natural gas stream, which is then directed to one or more natural gas turbine generators. The natural gas turbine generators combust the natural gas to produce electricity, which powers electric hydraulic fracturing equipment.

Owner:US WELL SERVICS LLC

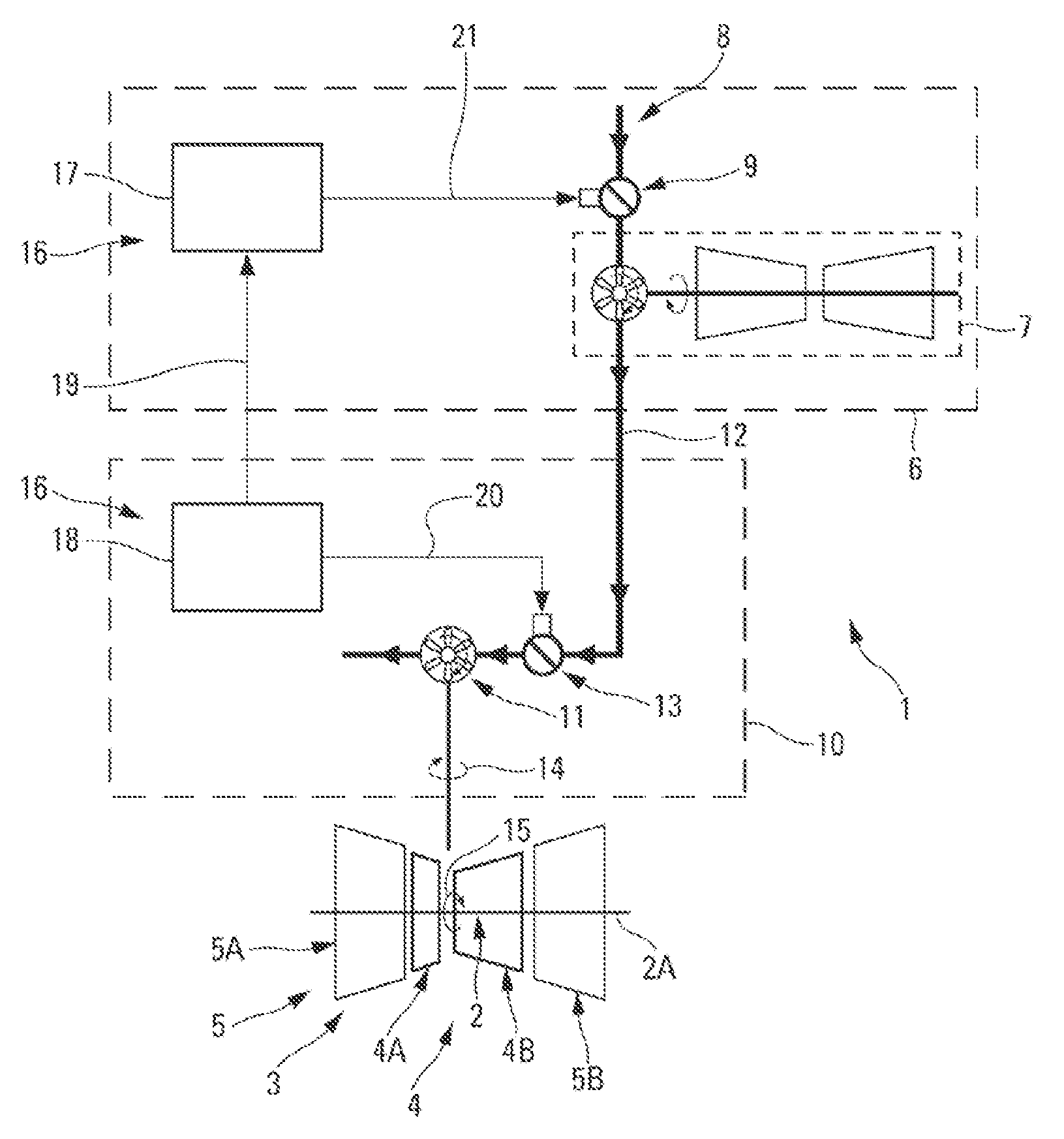

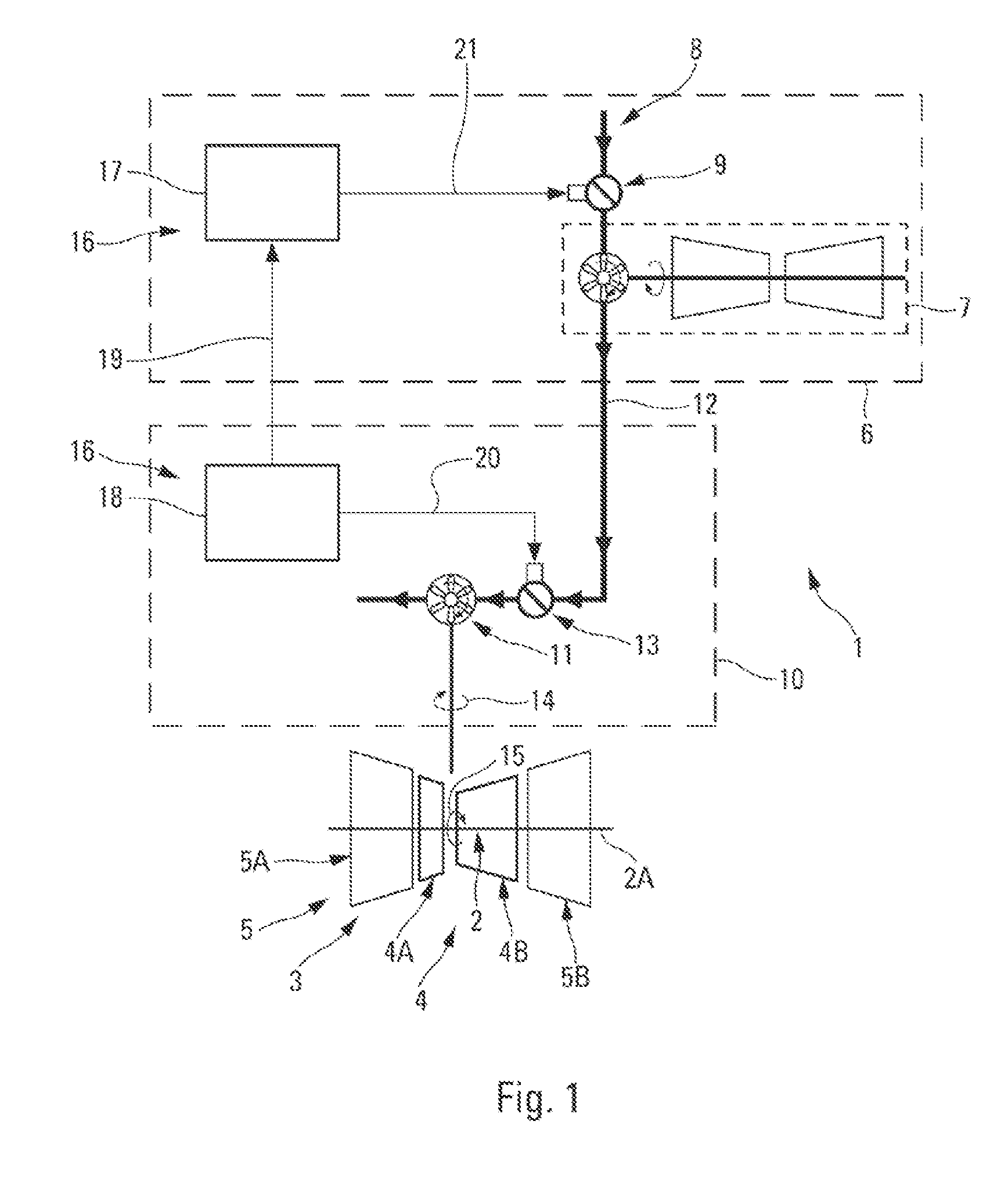

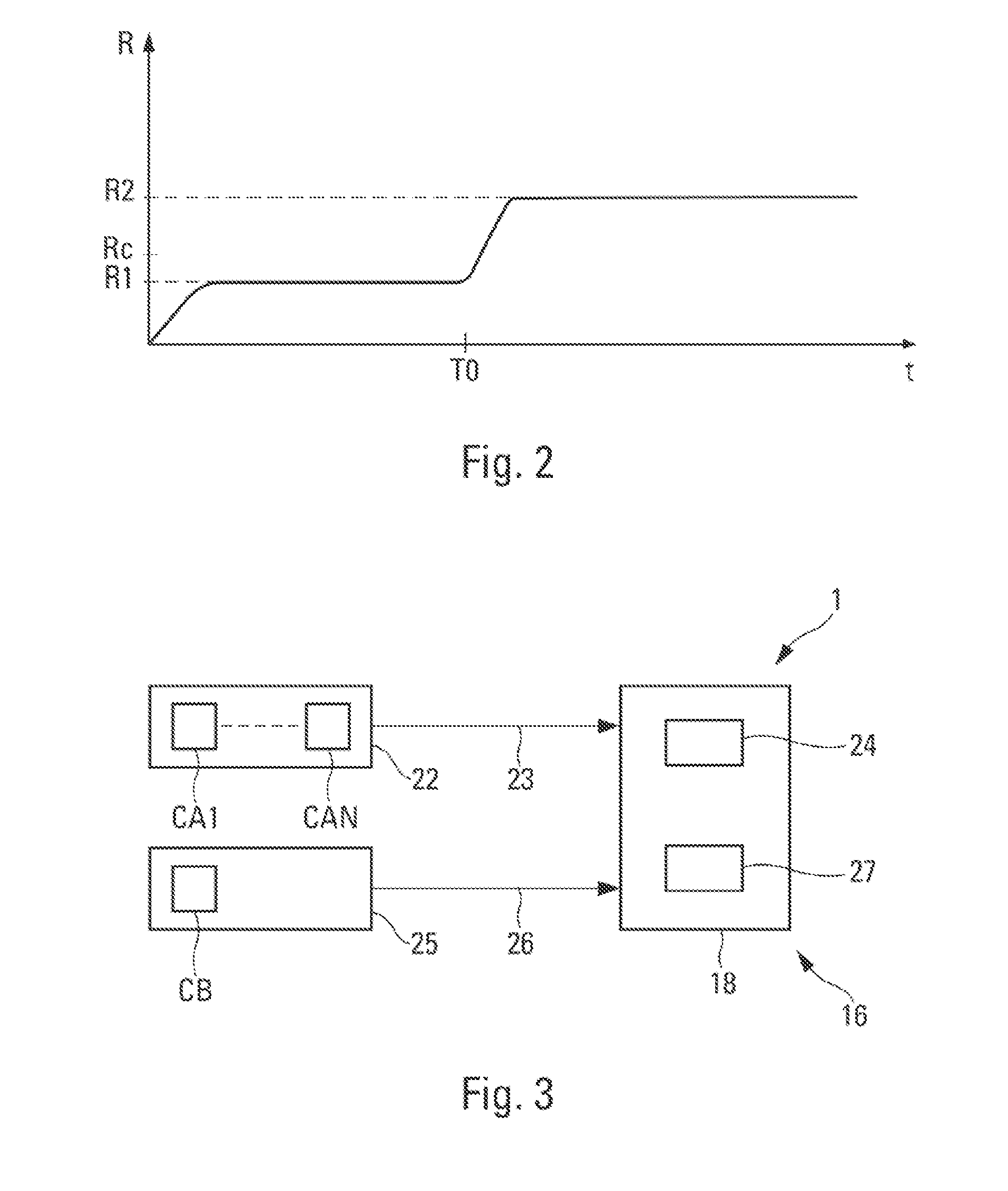

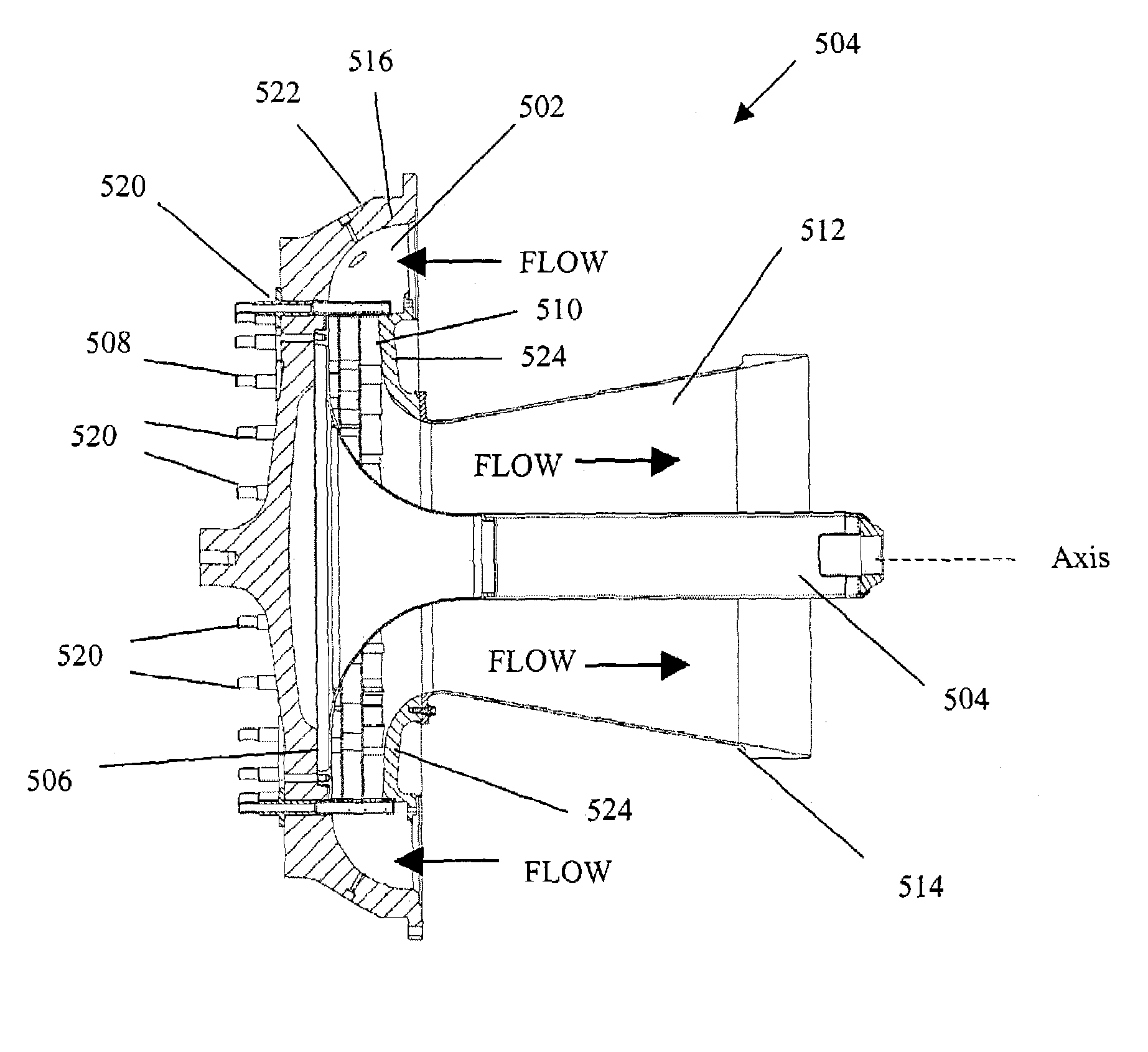

Method and system for starting up an aircraft turbomachine

ActiveUS20140373553A1Avoid vibrationTurbine/propulsion fuel supply systemsEngine fuctionsAirplaneStart up

A start-up system including a control system controlling a partial opening of an air intake valve of a start-up turbine during a first phase of the start-up. The start-up turbine is capable of turning a rotor of the turbomachine for the purpose of the start-up, so as to prevent the rotor from encountering critical frequencies of the turbomachine

Owner:AIRBUS OPERATIONS (SAS) +1

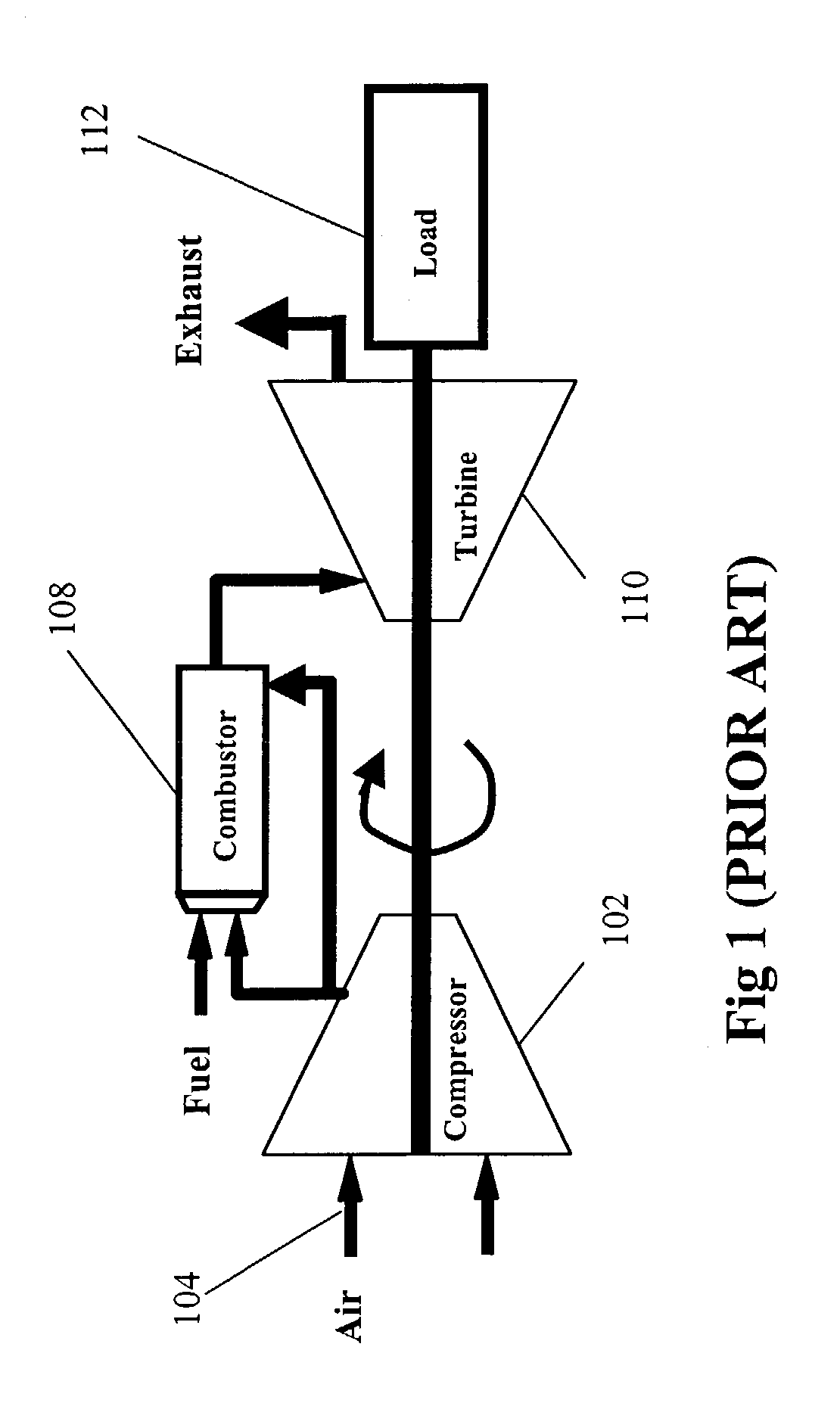

Fuel-air premixing system for a catalytic combustor

InactiveUS7093445B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemHybrid system

Disclosed is a unique fuel and air premixing system for a gas turbine catalytic combustion system. The mixer utilizes a multi-channel counter-rotating swirler with aerodynamically shaped fuel pegs located upstream of the swirler. The premixing system provides the downstream catalyst with a fuel-air mixture sufficiently uniform for proper catalyst operation and wide operating limits. Features have been incorporated in the system to make it resistant to flameholding.

Owner:KAWASAKI HEAVY IND LTD

Low Emission Triple-Cycle Power Generation Systems and Methods

Methods and systems for low emission power generation in combined cycle power plants are provided. One system includes a gas turbine system that stoichiometrically combusts a fuel and an oxidant in the presence of a compressed recycle stream to provide mechanical power and a gaseous exhaust. The compressed recycle stream acts as a diluent to moderate the temperature of the combustion process. A boost compressor can boost the pressure of the gaseous exhaust before being compressed into the compressed recycle stream. A purge stream is tapped off from the compressed recycle stream and directed to a C02 separator which discharges C02 and a nitrogen-rich gas which can be expanded in a gas expander to generate additional mechanical power.

Owner:EXXONMOBIL UPSTREAM RES CO

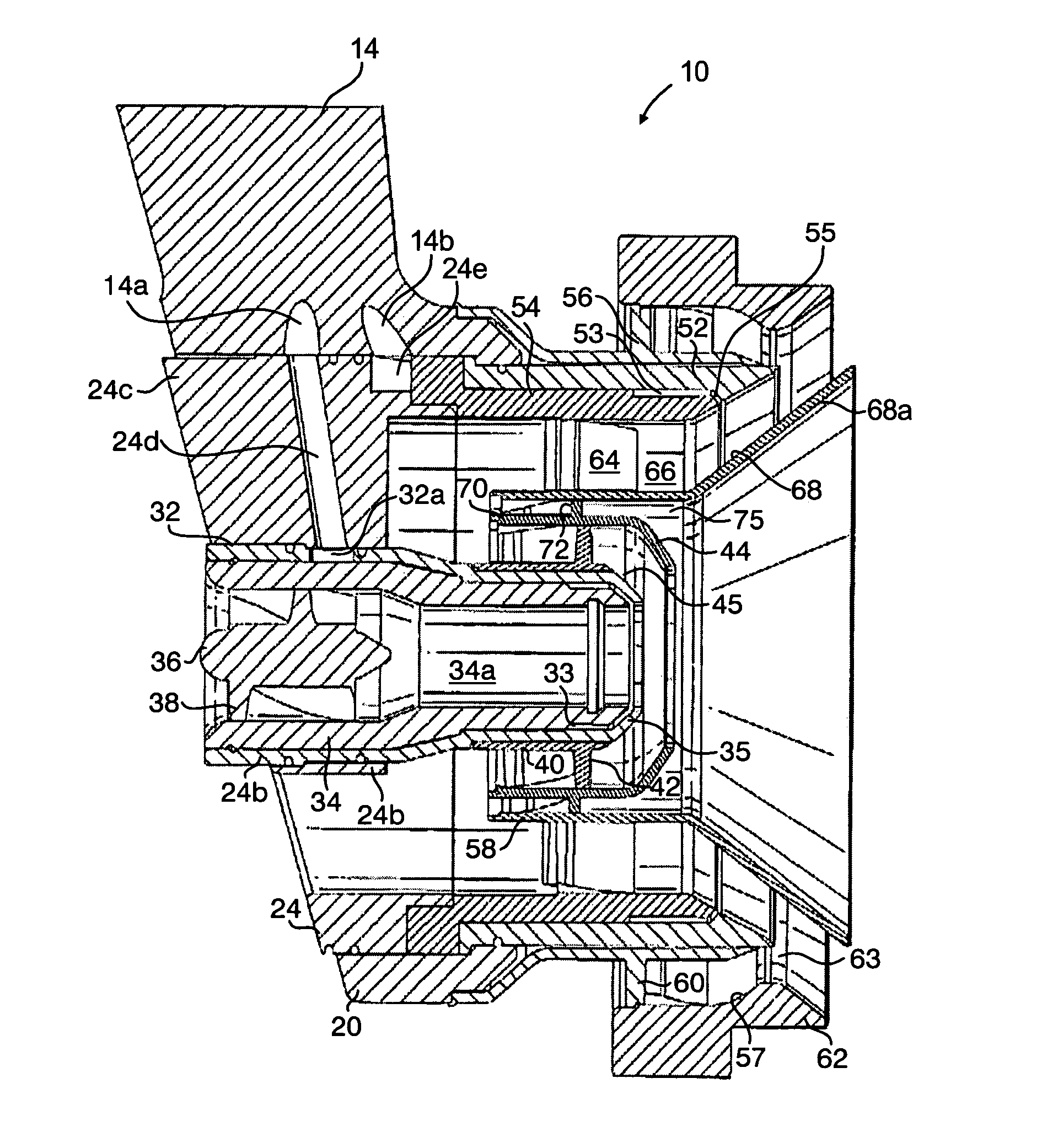

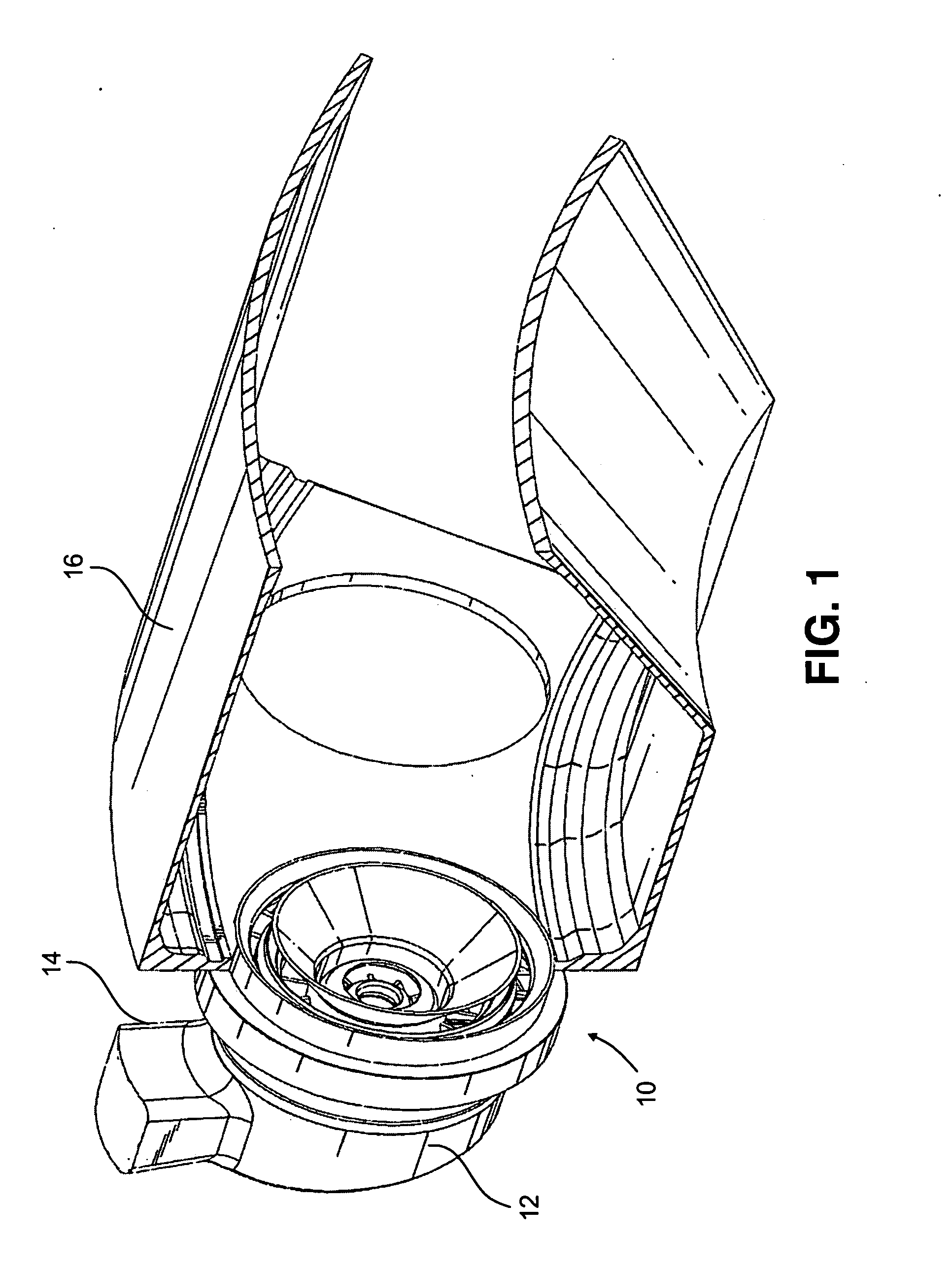

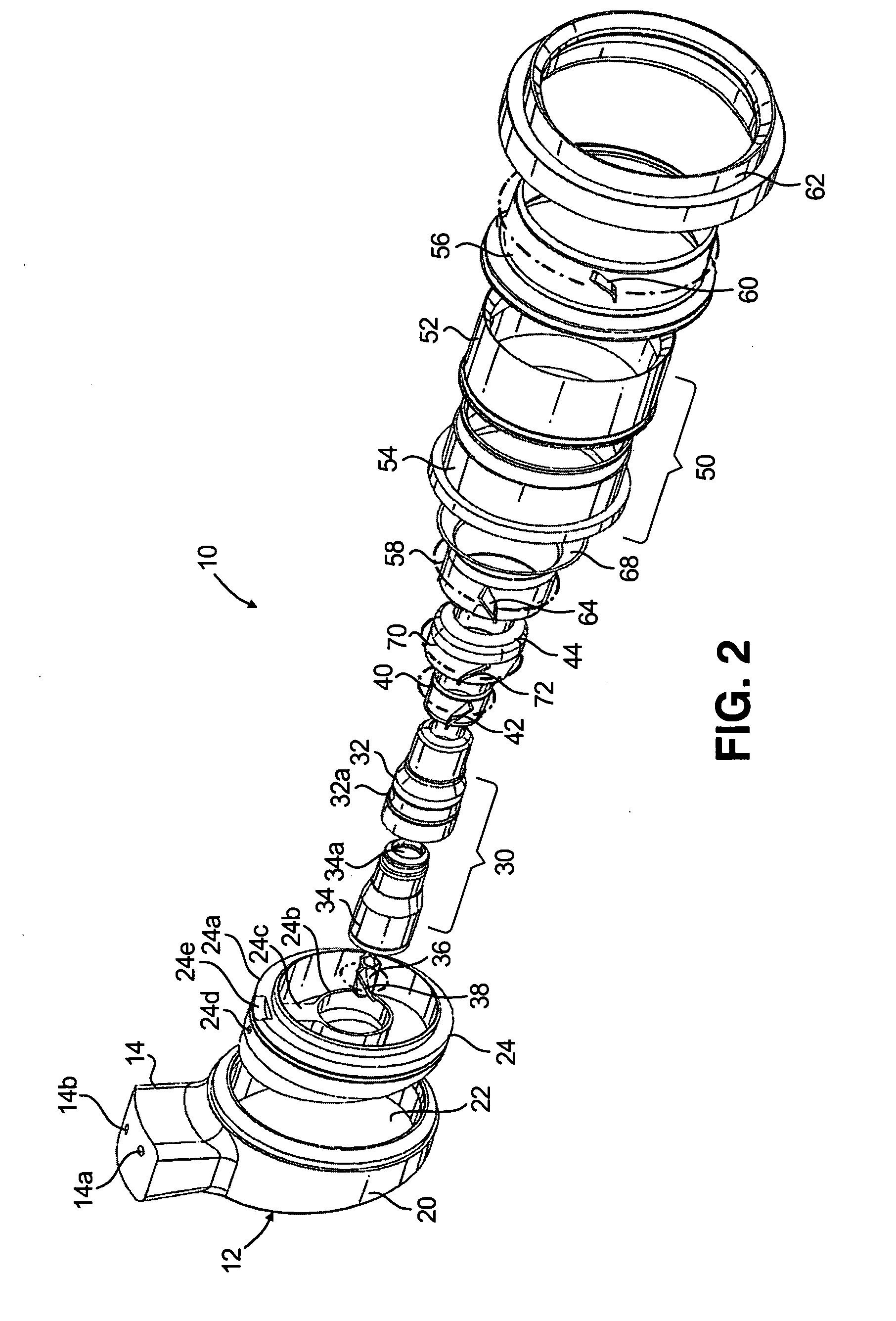

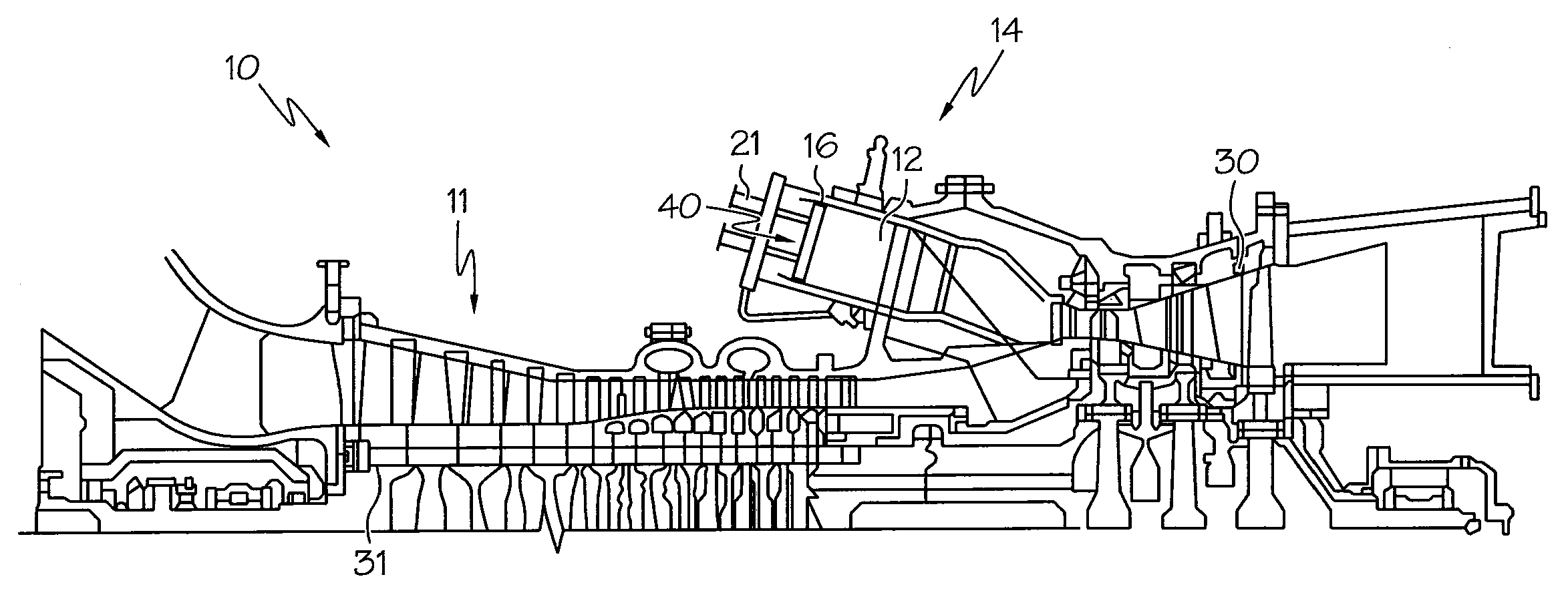

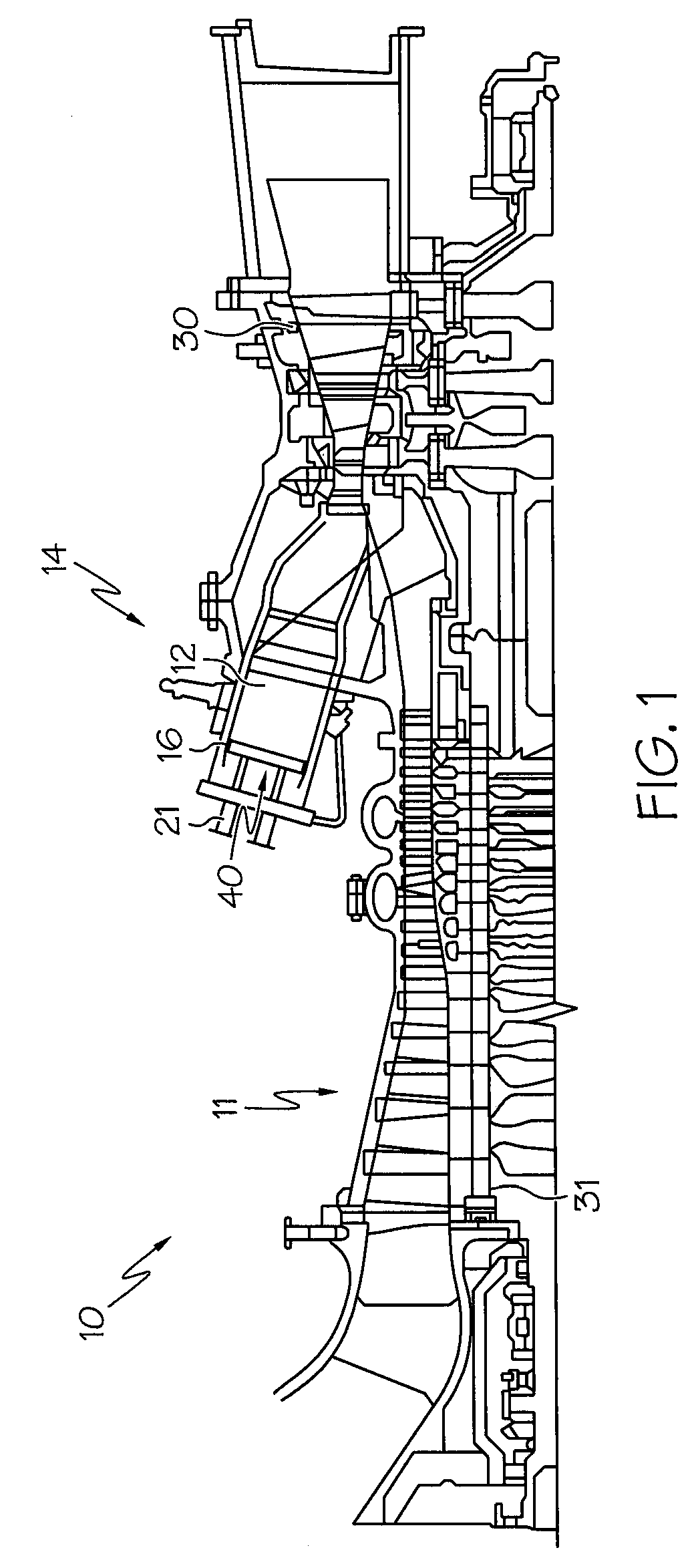

Lean direct injection atomizer for gas turbine engines

ActiveUS20060248898A1Increase pressureBurnersContinuous combustion chamberGas turbinesDelivery system

A lean direct injection fuel nozzle for a gas turbine is disclosed which includes a radially outer main fuel delivery system including a main inner air swirler defined in part by a main inner air passage having a radially inner wall with a diverging downstream surface, an intermediate air swirler radially inward of the main inner air swirler for providing a cooling air flow along the downstream surface of the radially inner wall of the main inner air passage, and a radially inner pilot fuel delivery system radially inward of the intermediate air swirler.

Owner:ROLLS ROYCE PLC

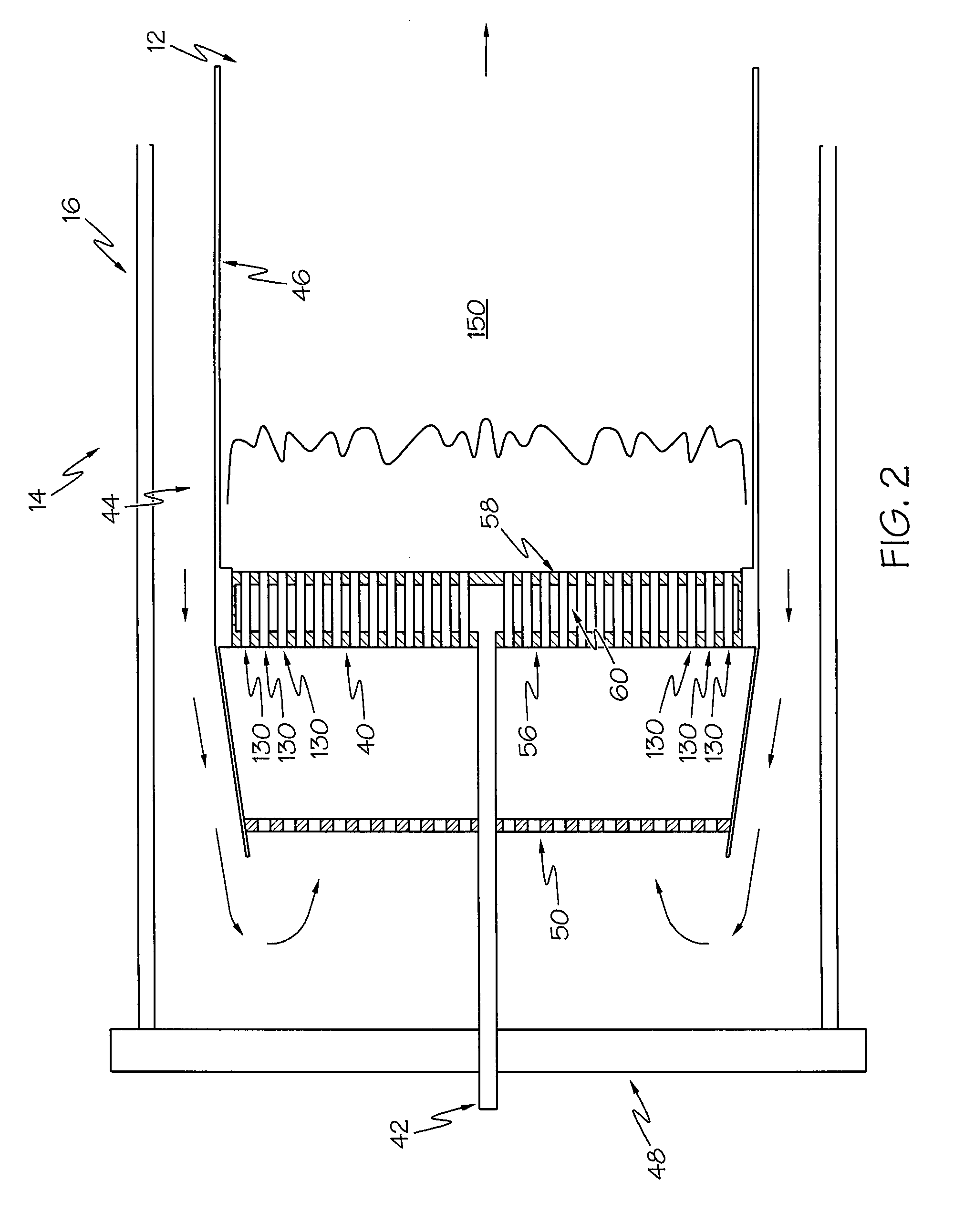

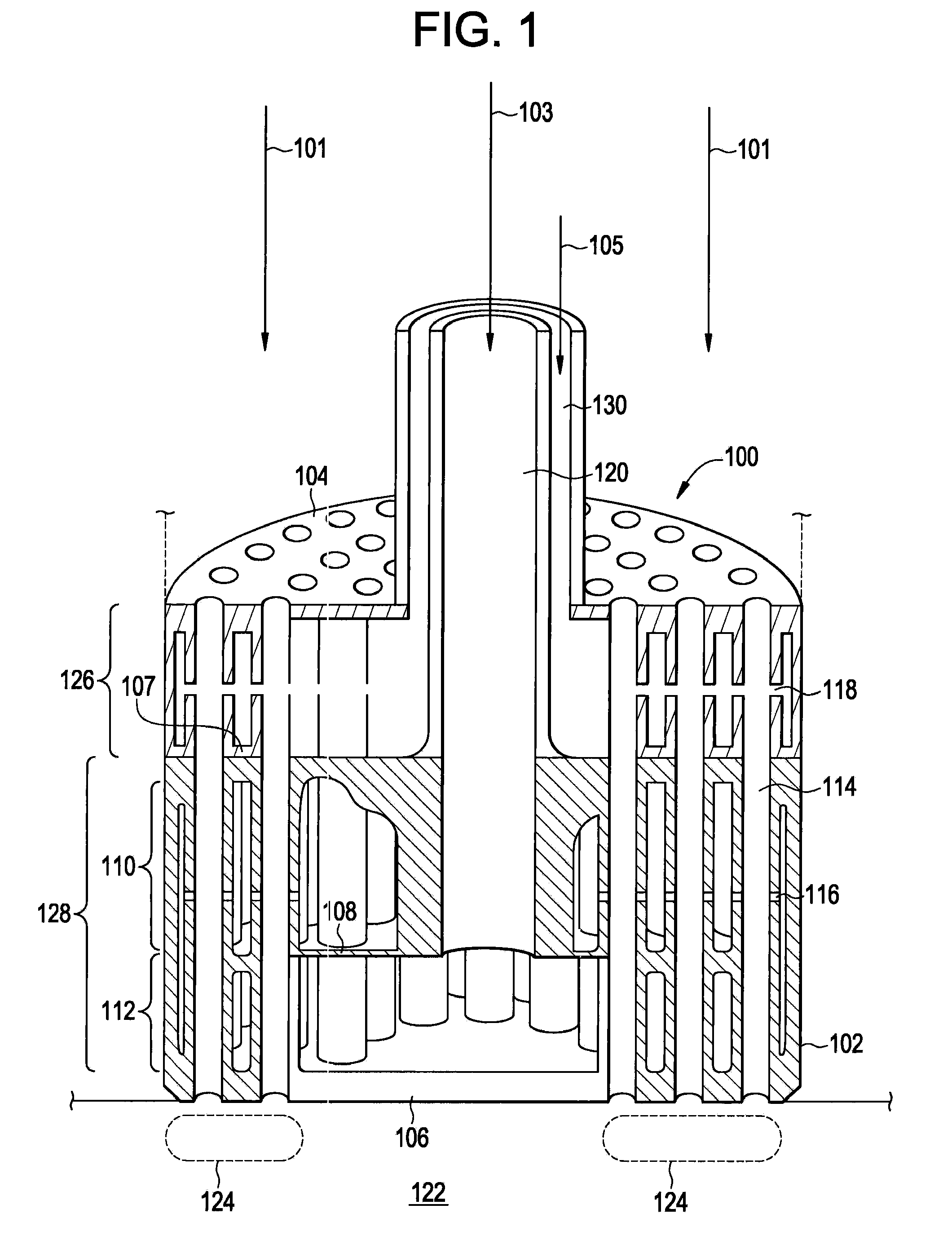

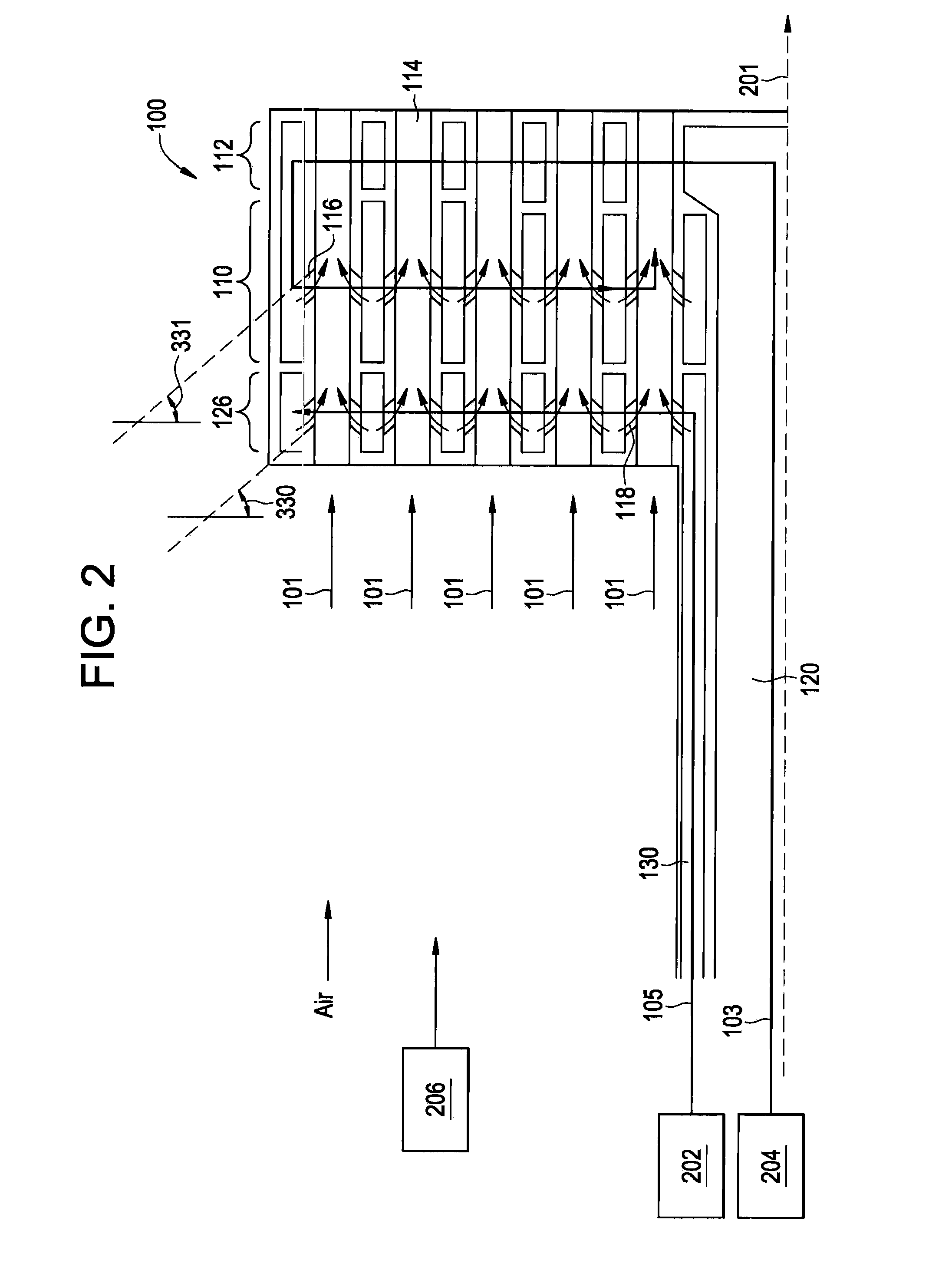

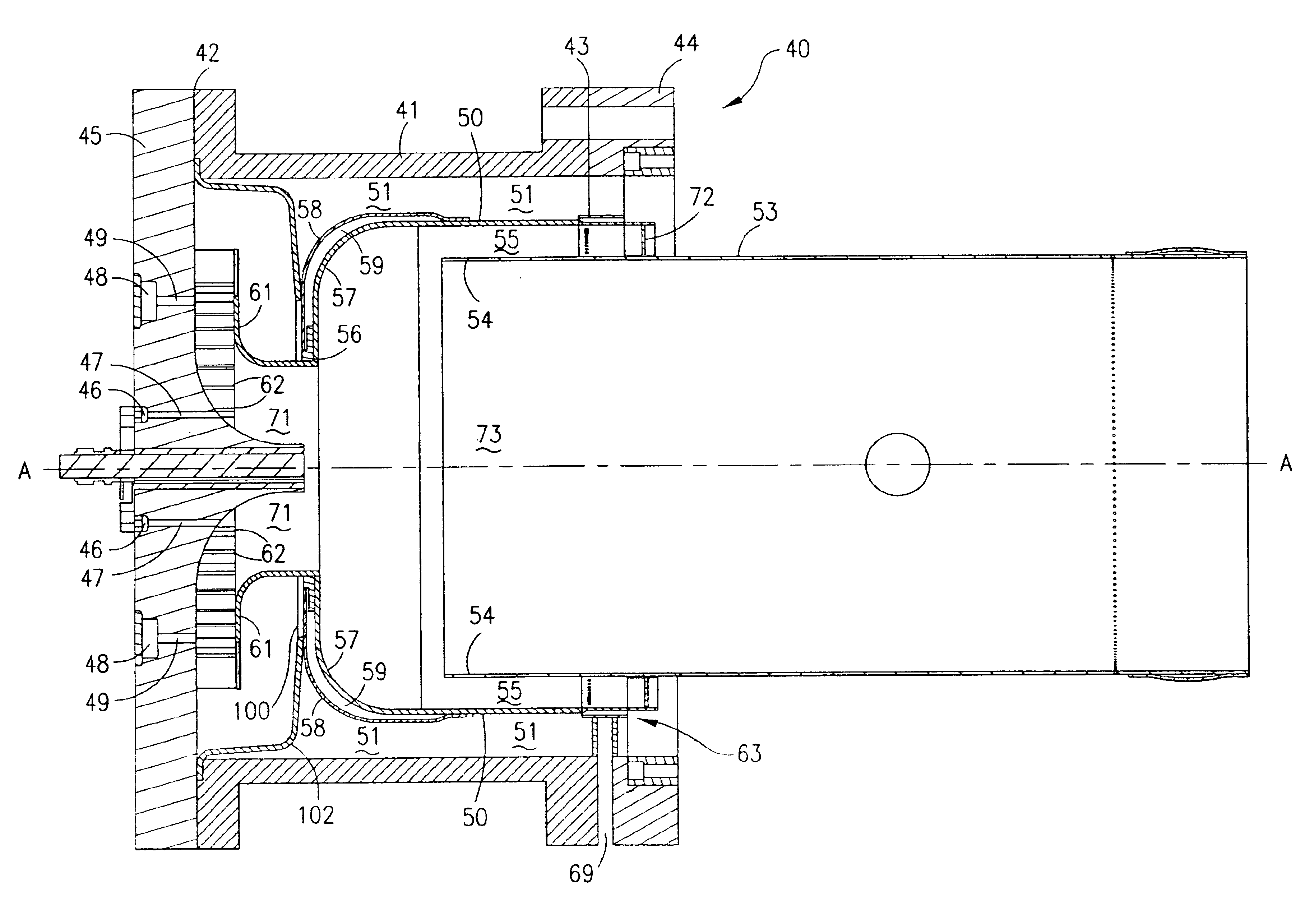

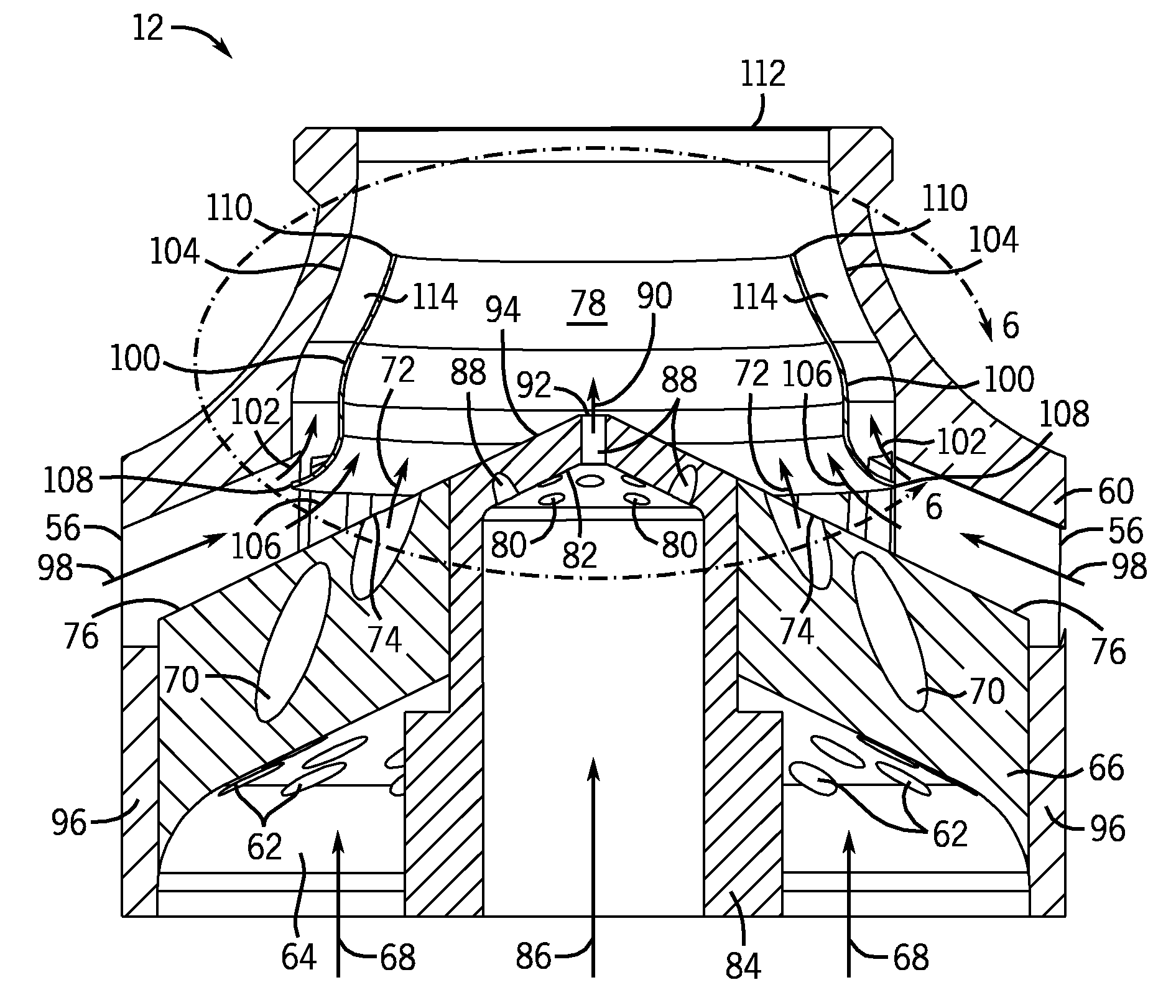

Premixed direct injection disk

ActiveUS20100218501A1Reduce riskAir mix wellBurner safety arrangementsContinuous combustion chamberCombustorEngineering

A fuel / air mixing disk for use in a fuel / air mixing combustor assembly is provided. The disk includes a first face, a second face, and at least one fuel plenum disposed therebetween. A plurality of fuel / air mixing tubes extend through the pre-mixing disk, each mixing tube including an outer tube wall extending axially along a tube axis and in fluid communication with the at least one fuel plenum. At least a portion of the plurality of fuel / air mixing tubes further includes at least one fuel injection hole have a fuel injection hole diameter extending through said outer tube wall, the fuel injection hole having an injection angle relative to the tube axis. The invention provides good fuel air mixing with low combustion generated NOx and low flow pressure loss translating to a high gas turbine efficiency, that is durable, and resistant to flame holding and flash back.

Owner:GENERAL ELECTRIC CO

Low Emission Power Generation and Hydrocarbon Recovery Systems and Methods

ActiveUS20110000221A1Enhanced recovery of hydrocarbonEnhanced overall recoveryTurbine/propulsion fuel supply systemsOther gas emission reduction technologiesCogenerationDrug Substitution

Methods and systems for low emission power generation in hydrocarbon recovery processes are provided. One system includes integrated pressure maintenance and miscible flood systems with low emission power generation. An alternative system provides for low emission power generation, carbon sequestration, enhanced oil recovery (EOR), or carbon dioxide sales using a hot gas expander and external combustor. Another alternative system provides for low emission power generation using a gas power turbine to compress air in the inlet compressor and generate power using hot carbon dioxide laden gas in the expander. Other efficiencies may be gained by incorporating heat cross-exchange, a desalination plant, co-generation, and other features.

Owner:EXXONMOBIL UPSTREAM RES CO

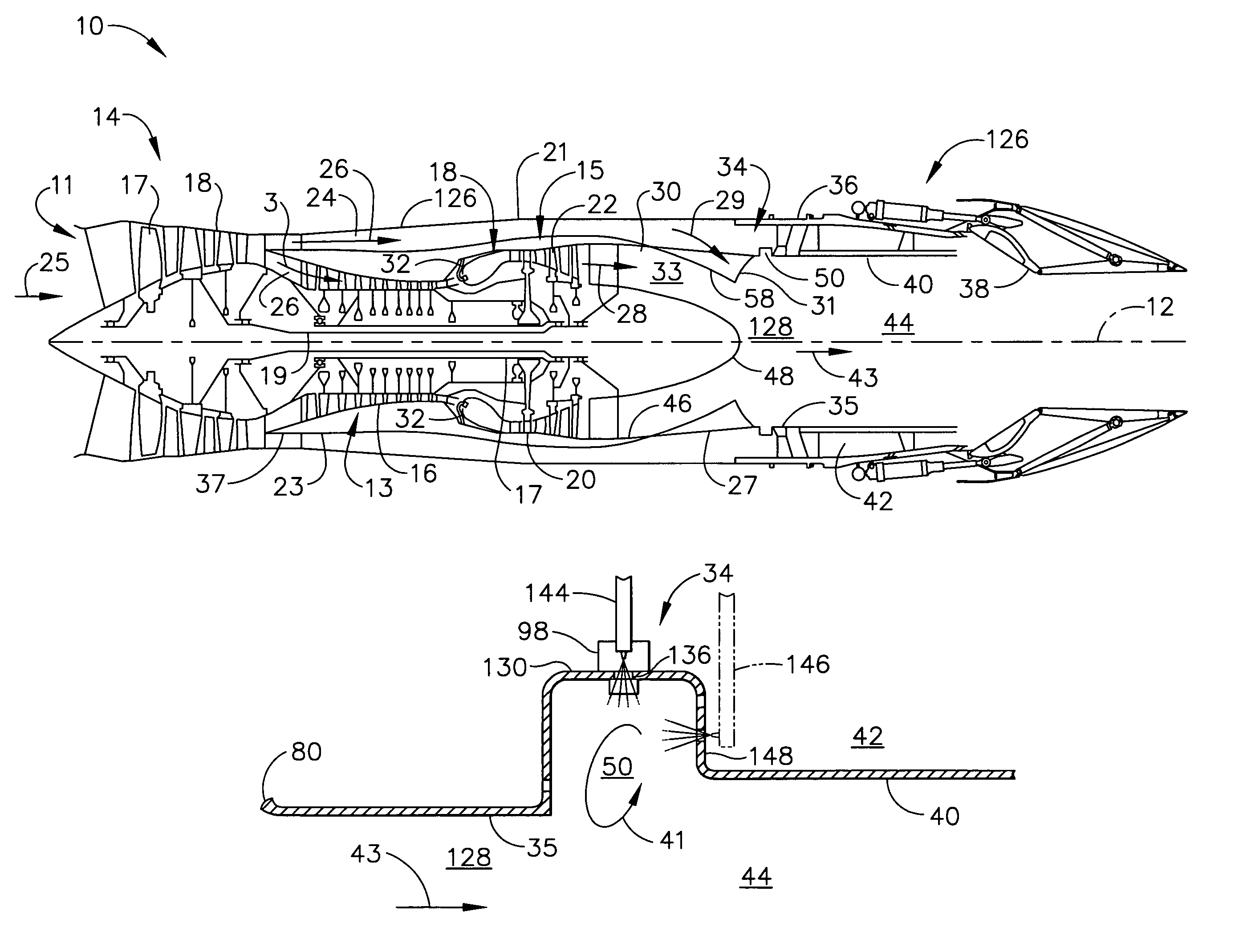

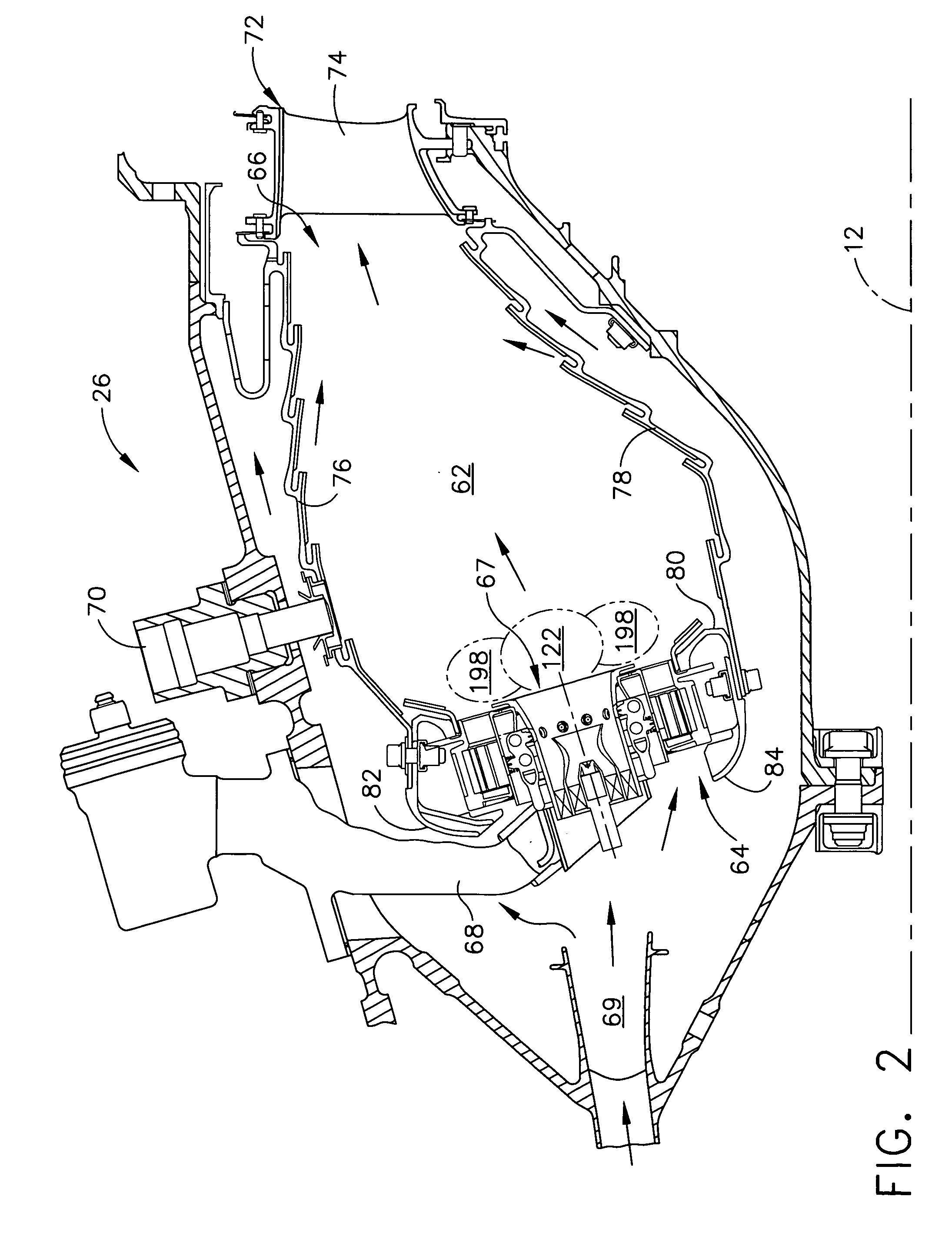

Method and apparatus for fuel injection in a turbine engine

InactiveUS20100170253A1Increase flexibilityReduce morbidityBurnersTurbine/propulsion fuel supply systemsEngineeringTurbine

In one embodiment, a turbine system, may include a fuel nozzle, that includes a plurality of fuel passages and a plurality of air passages offset in a downstream direction from the fuel passages. In the embodiment, an air flow from the air passages is configured to intersect with a fuel flow from the fuel passages at an angle to induce swirl and mixing of the air flow and the fuel flow downstream of the fuel nozzle.

Owner:GENERAL ELECTRIC CO

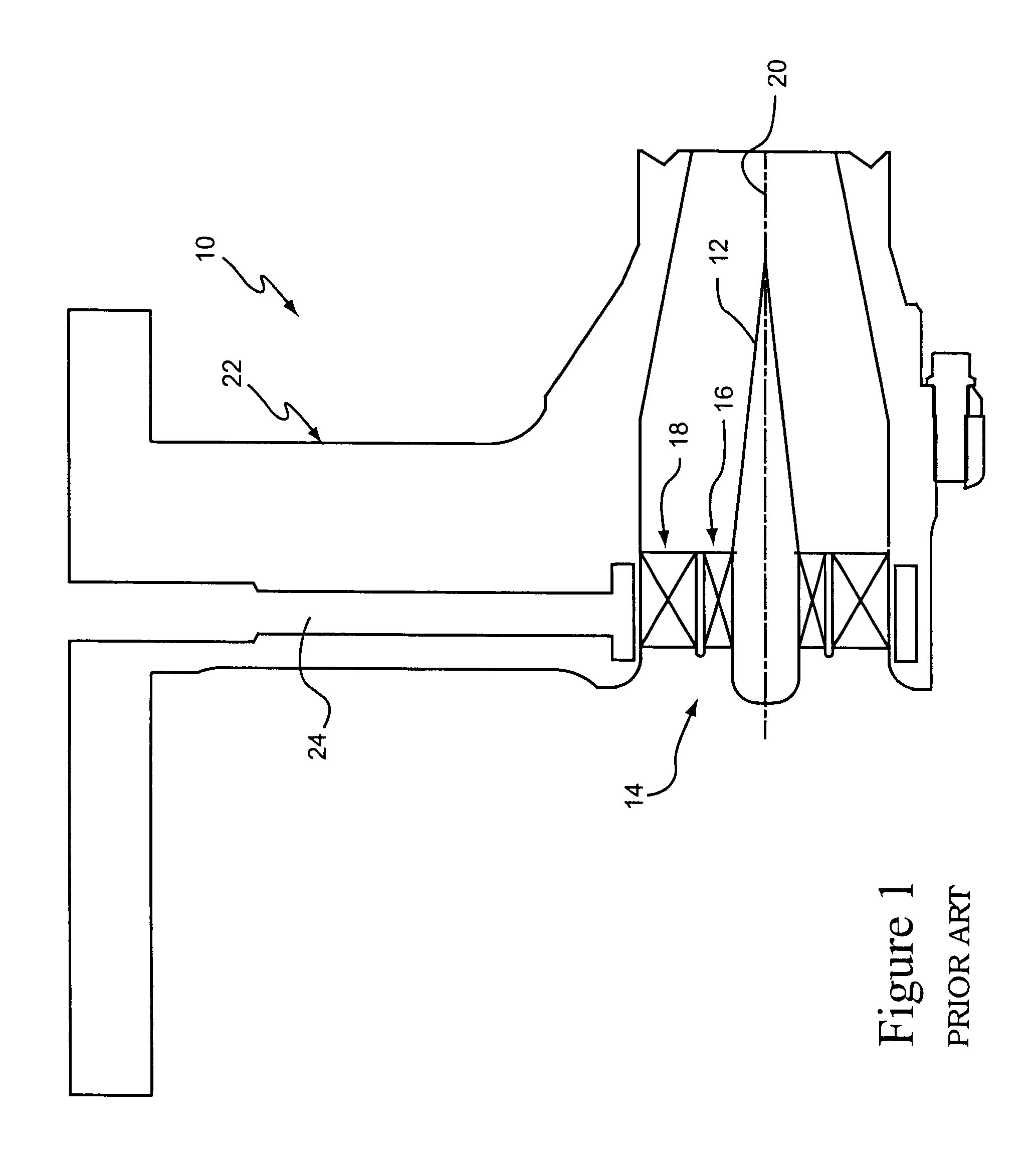

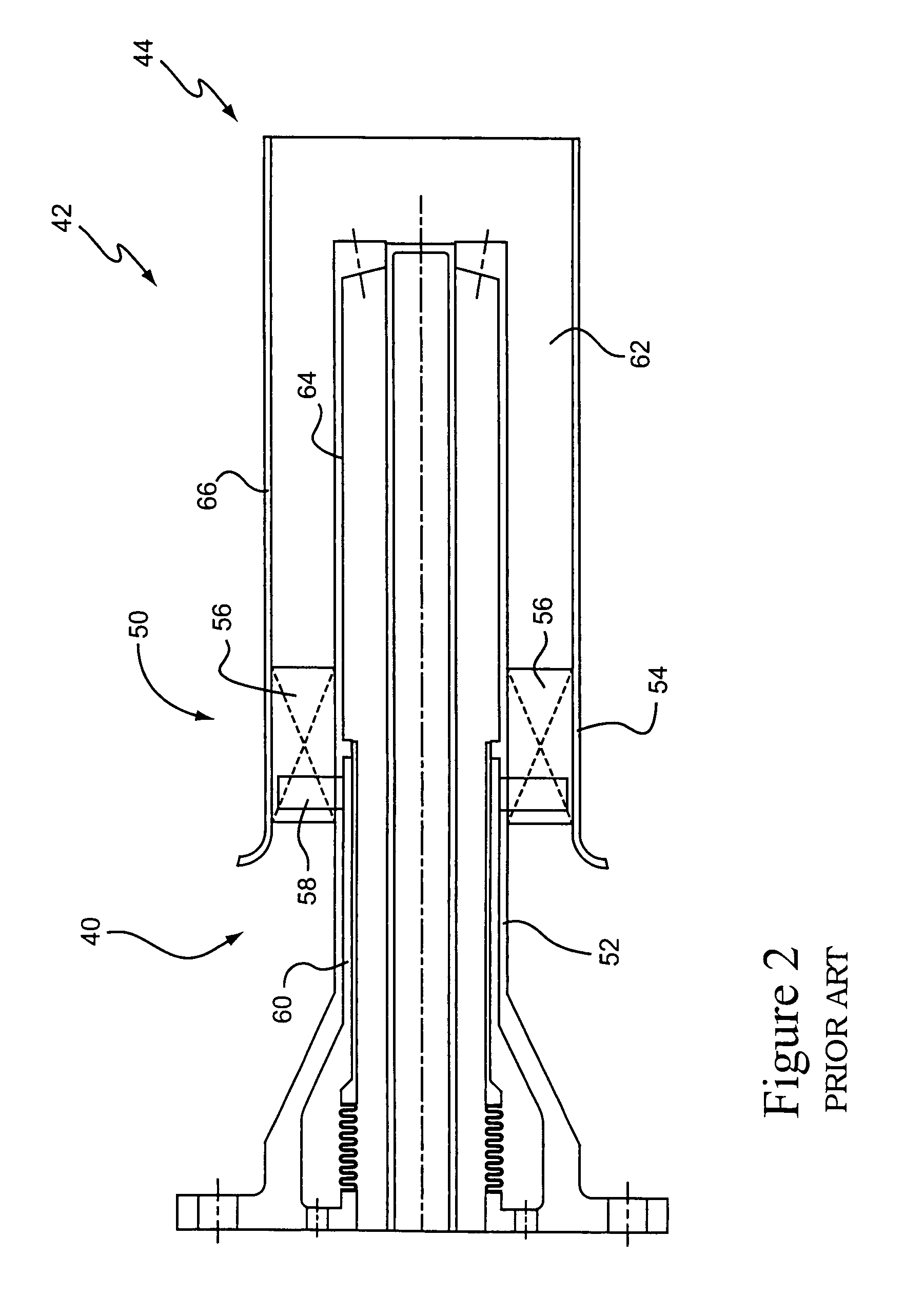

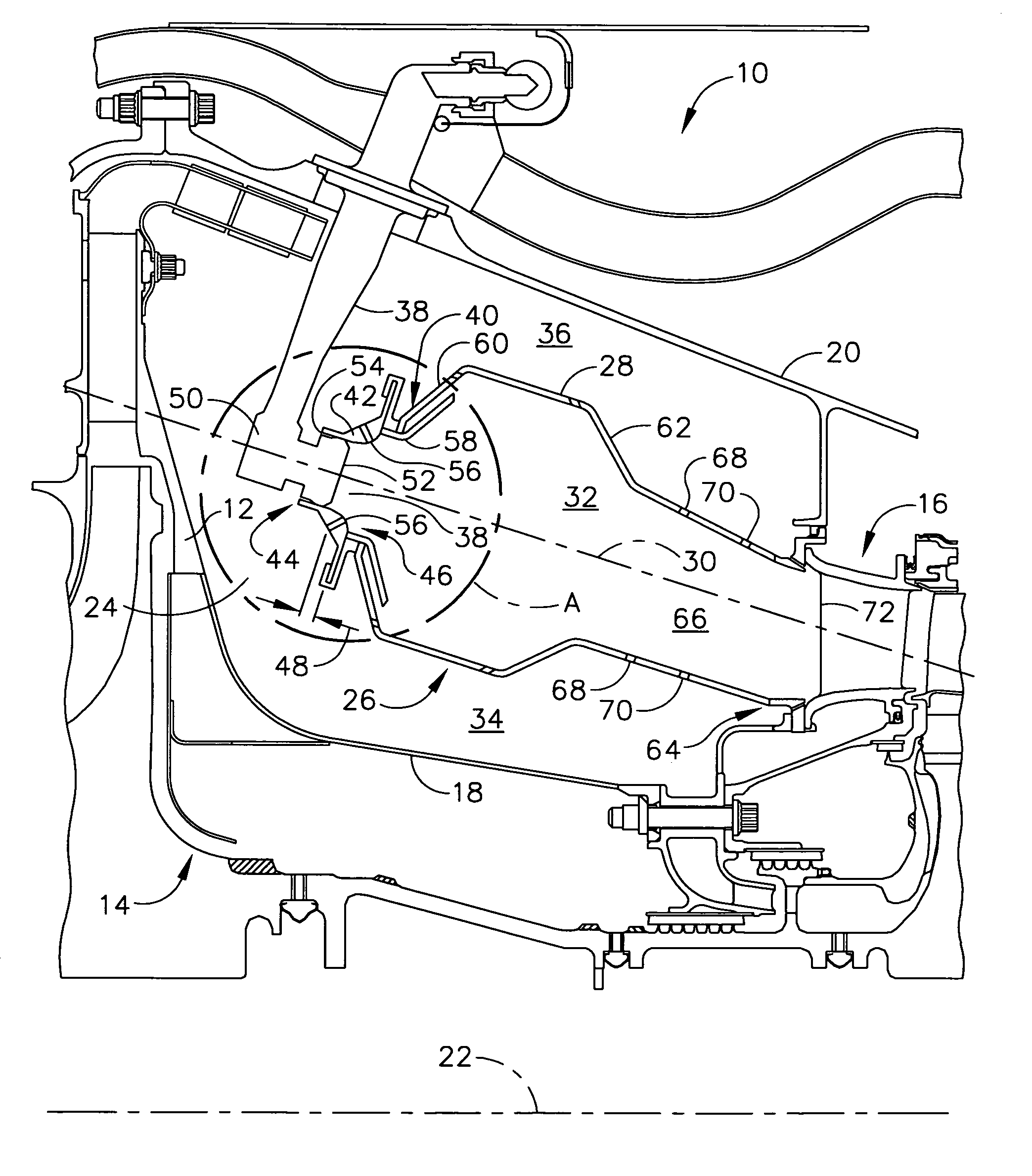

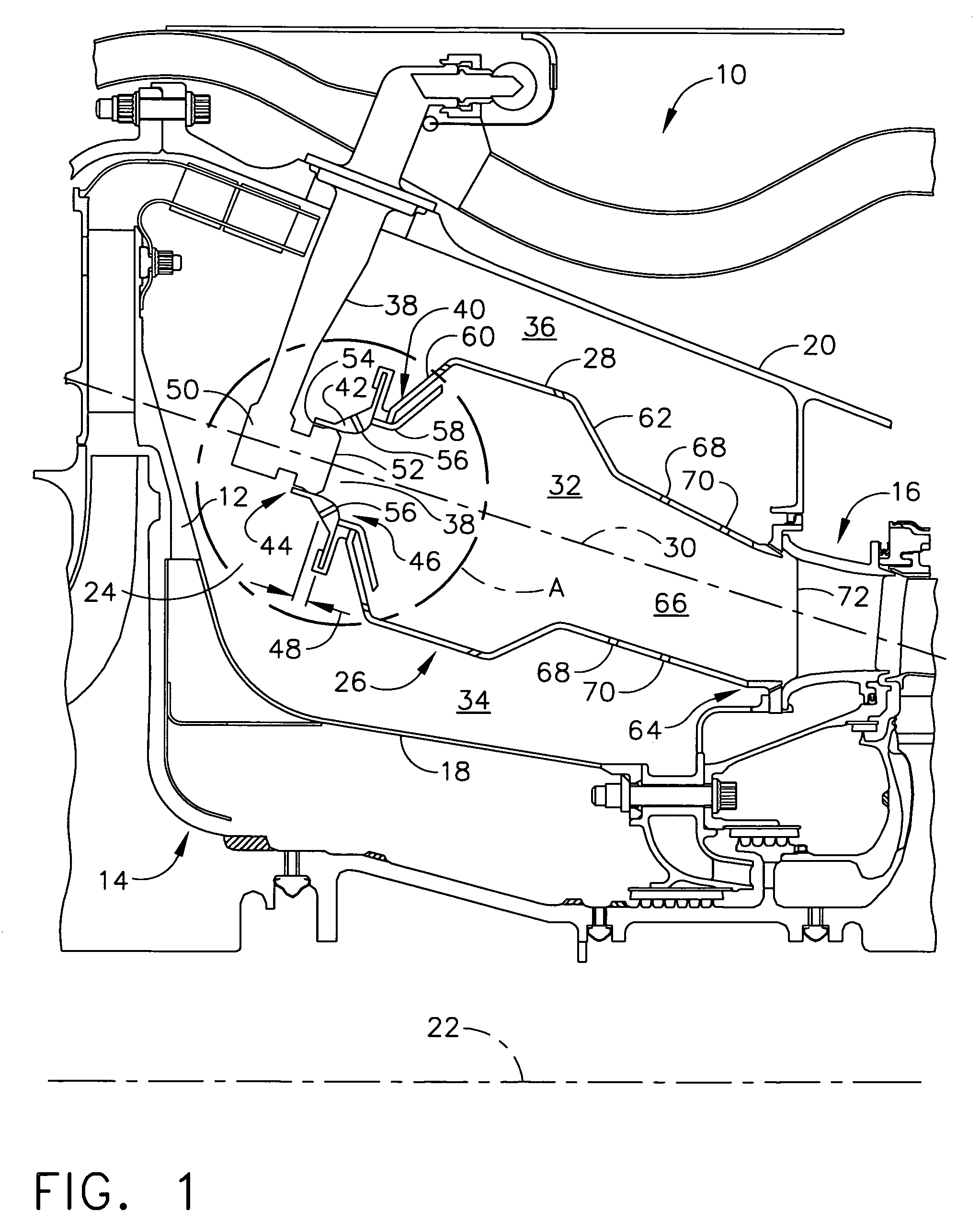

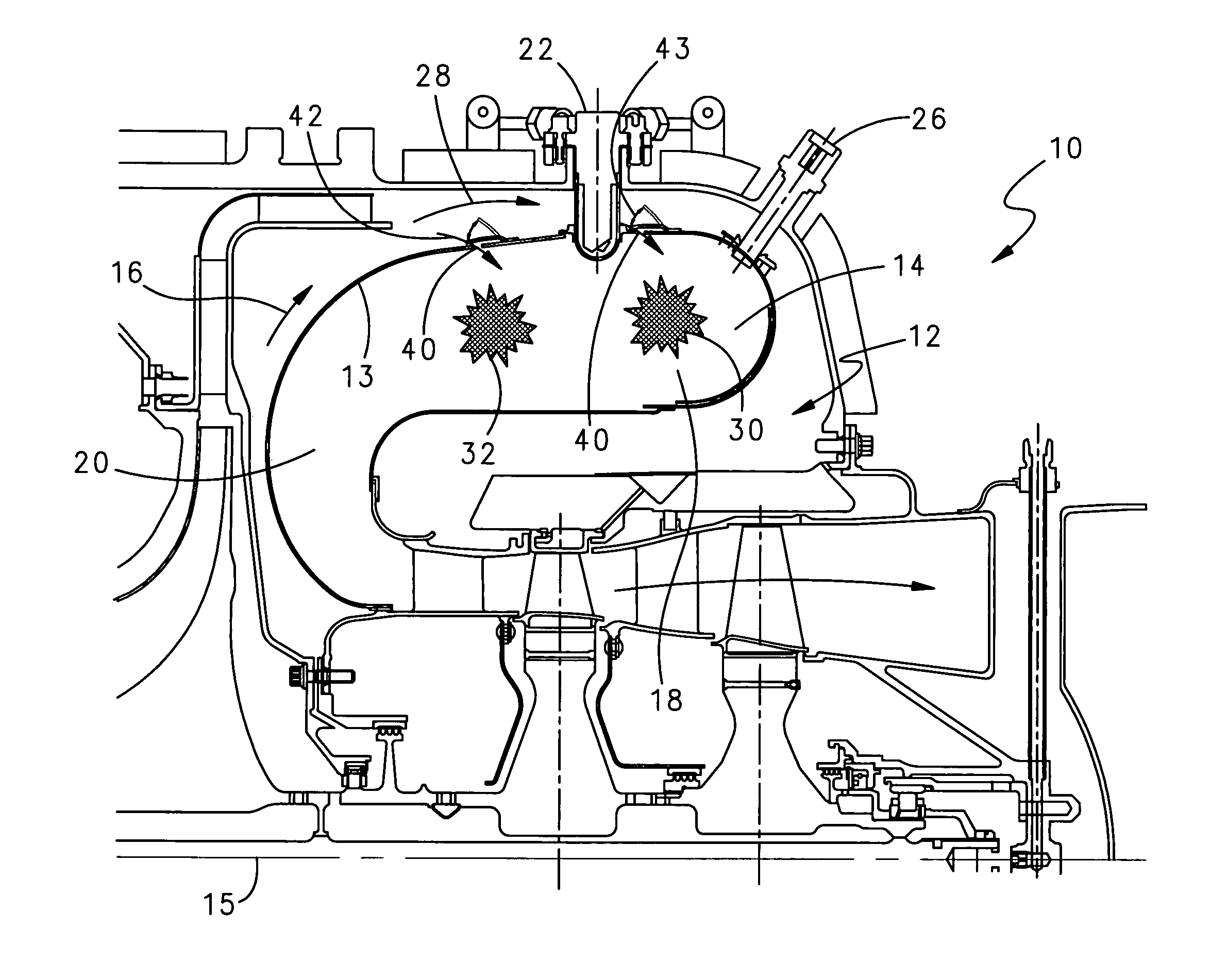

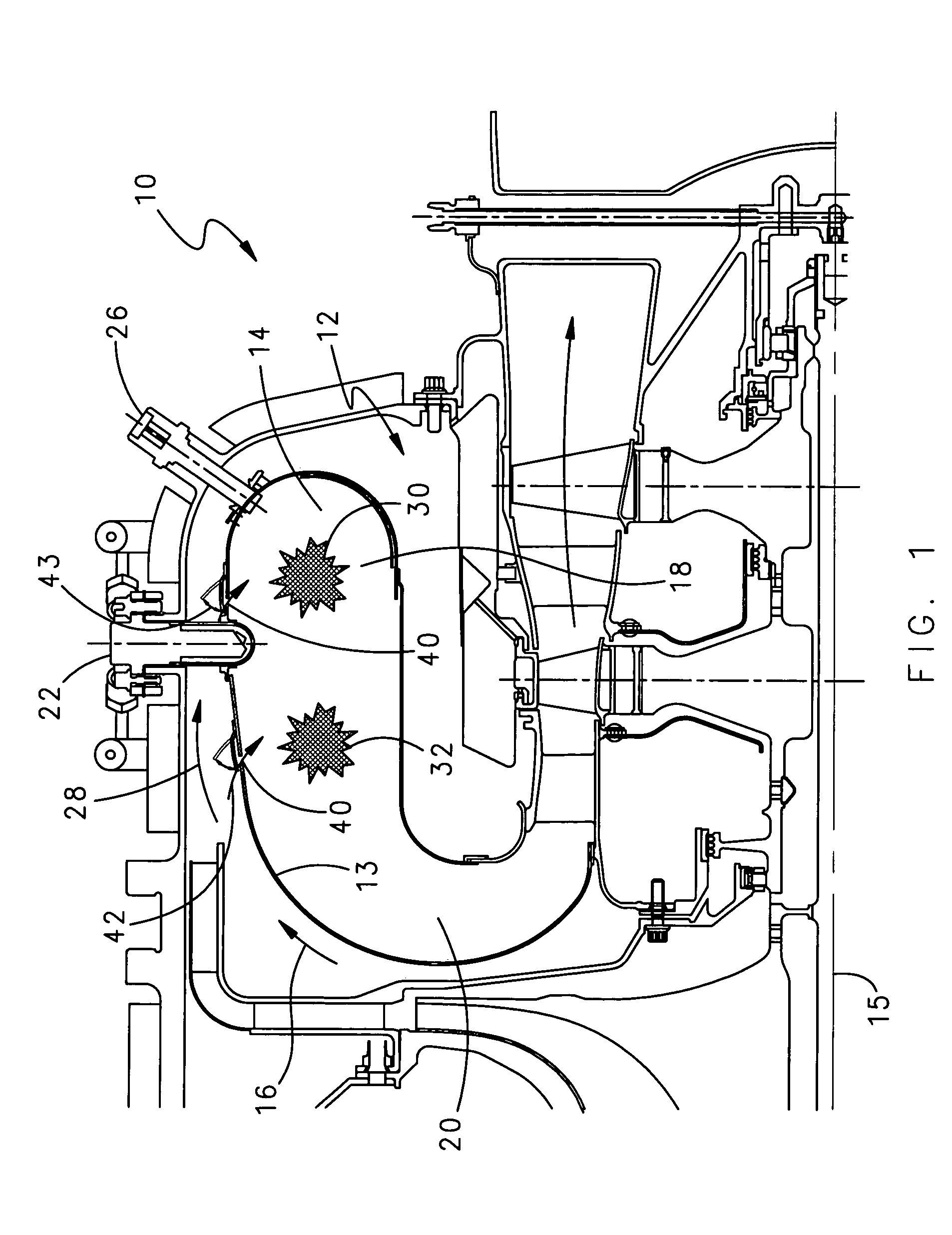

Controlled pilot oxidizer for a gas turbine combustor

InactiveUS7752850B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCombustion chamber

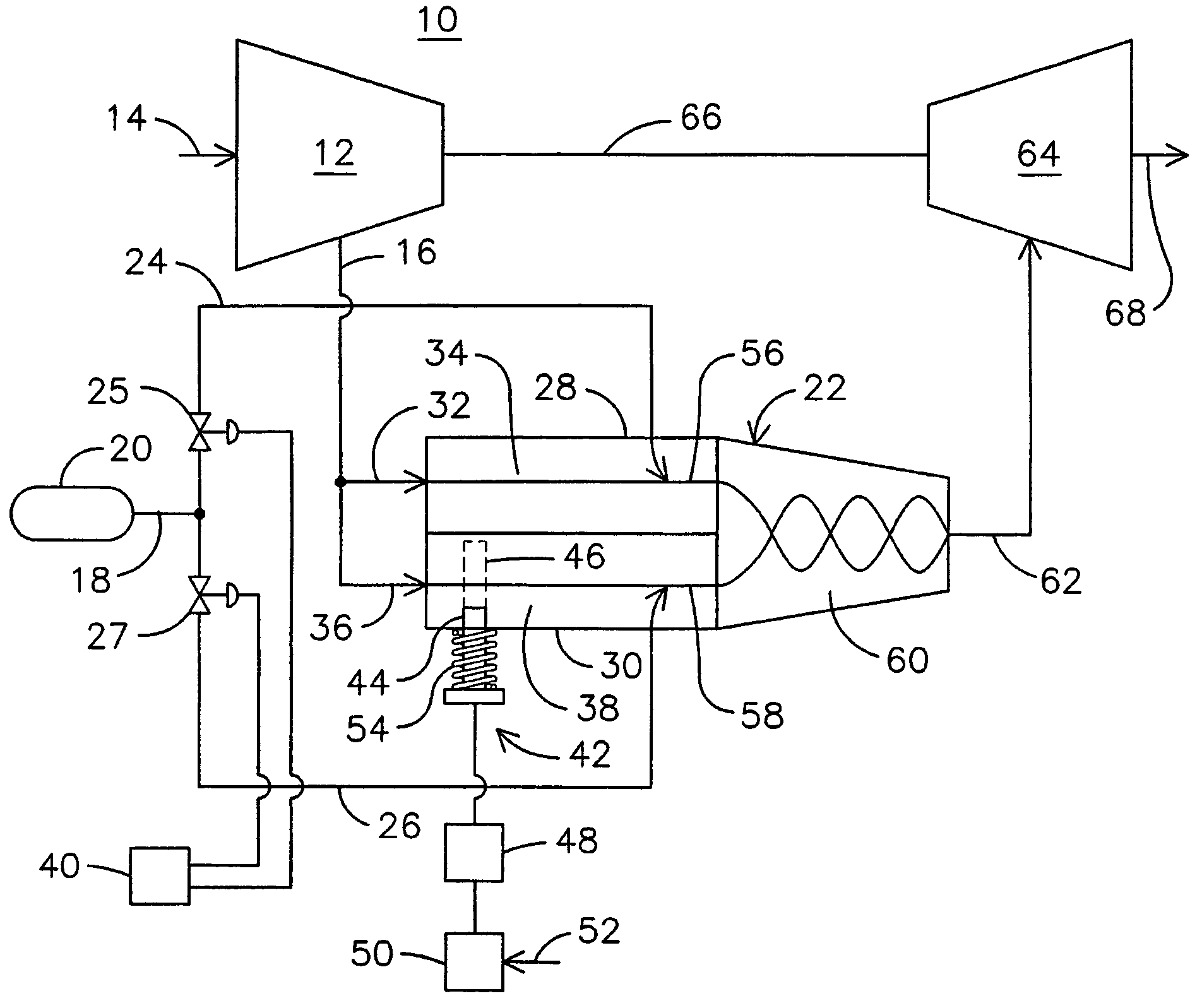

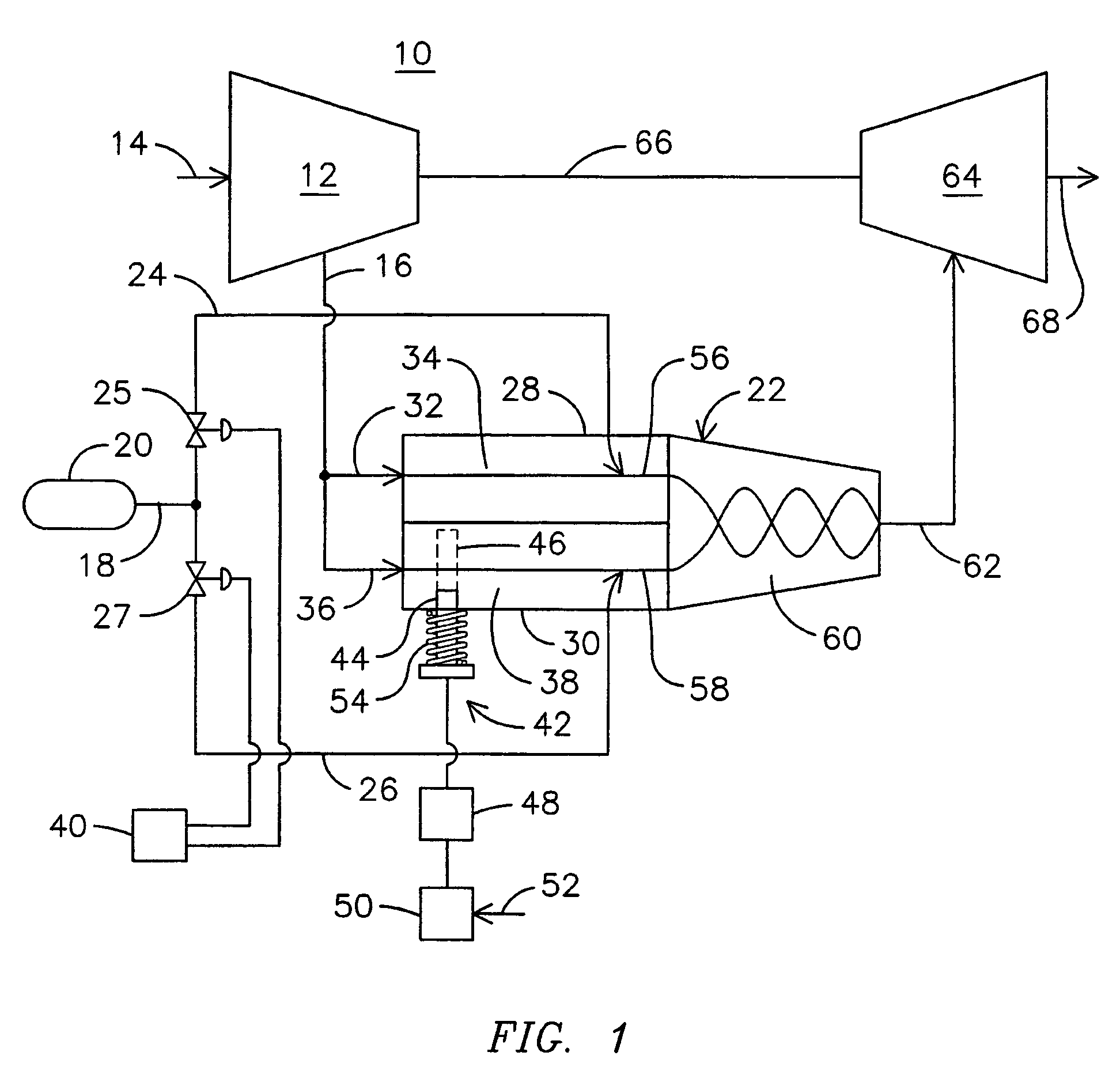

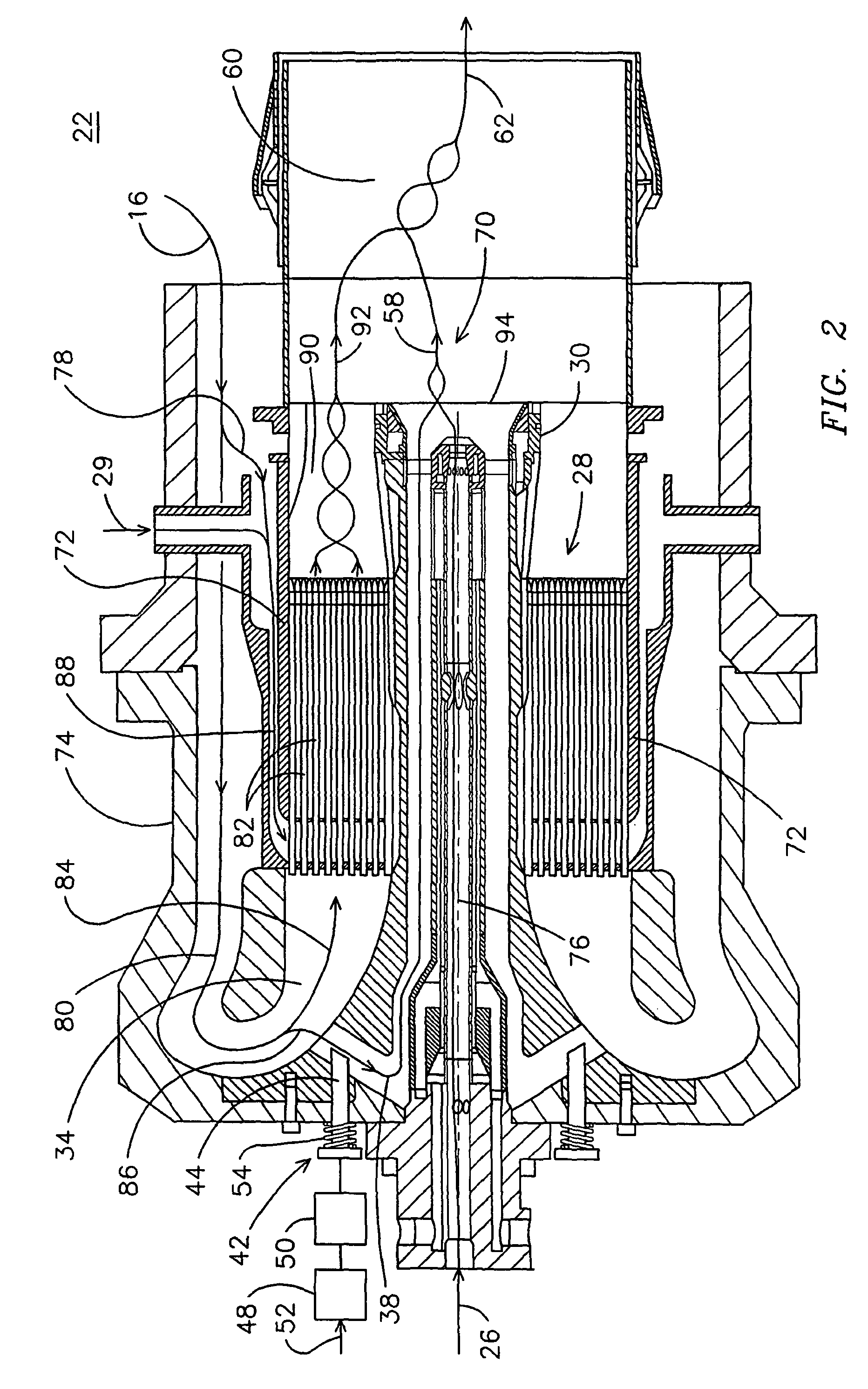

A combustor (22) for a gas turbine (10) includes a main burner oxidizer flow path (34) delivering a first portion (32) of an oxidizer flow (e.g., 16) to a main burner (28) of the combustor and a pilot oxidizer flow path (38) delivering a second portion (36) of the oxidizer flow to a pilot (30) of the combustor. The combustor also includes a flow controller (42) disposed in the pilot oxidizer flow path for controlling an amount of the second portion delivered to the pilot.

Owner:SIEMENS ENERGY INC

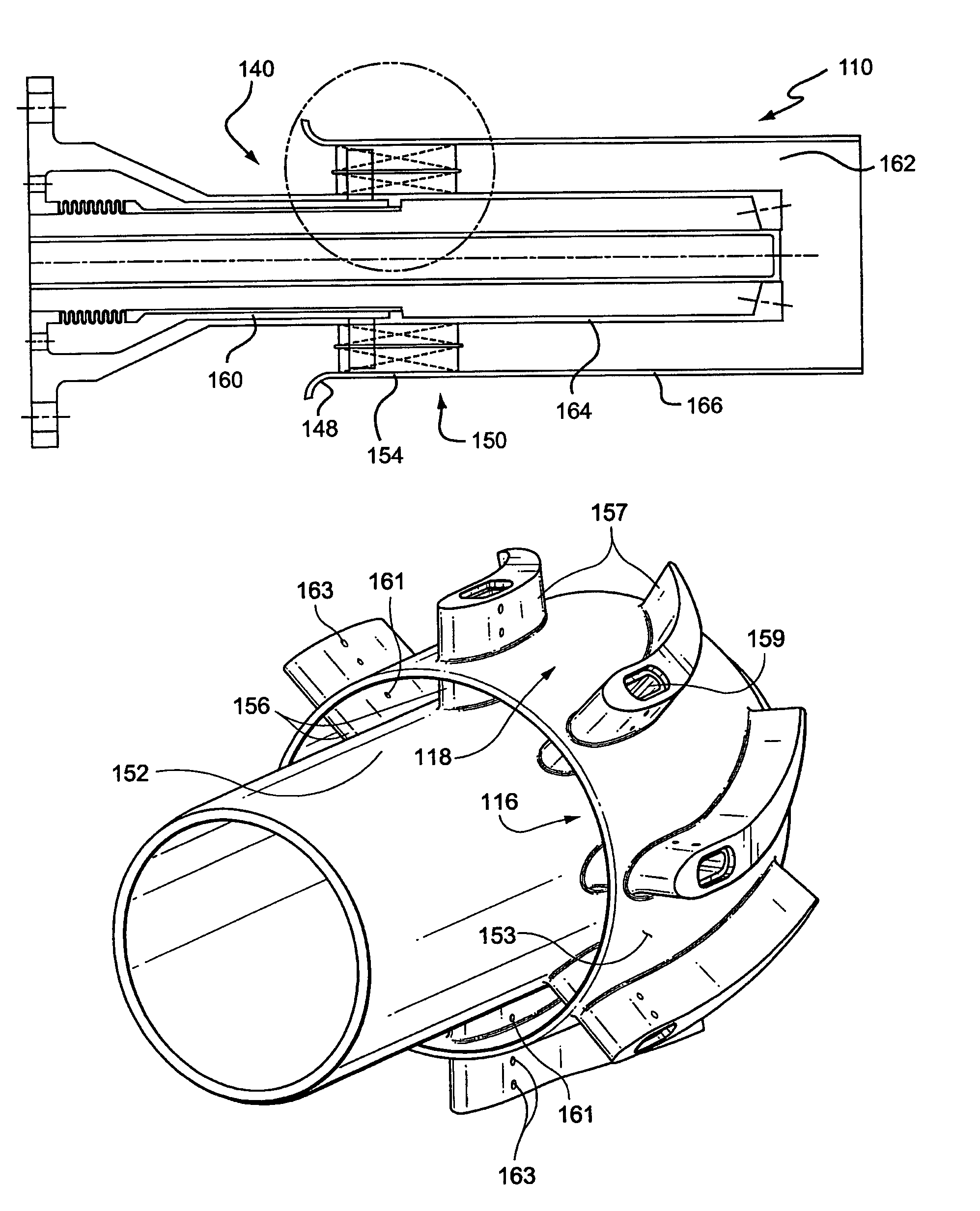

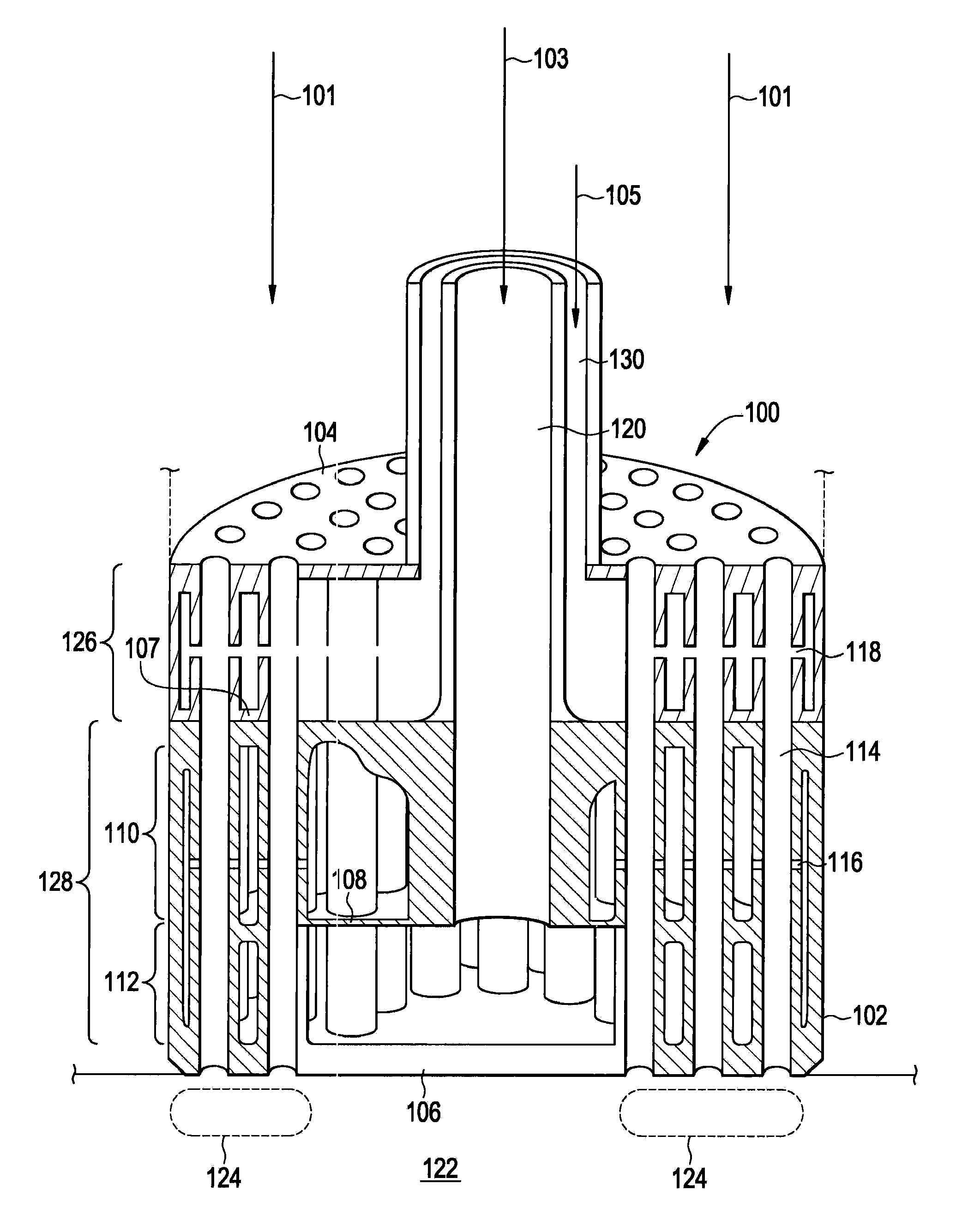

Staged Multi-Tube Premixing Injector

ActiveUS20110083439A1Continuous combustion chamberTurbine/propulsion fuel supply systemsFuel injectionInjector

A fuel injection nozzle includes a body member having an upstream wall opposing a downstream wall, and an internal wall disposed between the upstream wall and the downstream wall, a first chamber partially defined by the an inner surface of the upstream wall and a surface of the internal wall, a second chamber partially defined by an inner surface of the downstream wall and a surface of the internal wall a first gas inlet communicative with the first chamber operative to emit a first gas into the first chamber, a second gas inlet communicative with the second chamber operative to emit a second gas into the second chamber, and a plurality of mixing tubes, each of the mixing tubes having a tube inner surface, a tube outer surface, a first inlet communicative with an aperture in the upstream wall operative to receive a third gas.

Owner:GENERAL ELECTRIC CO

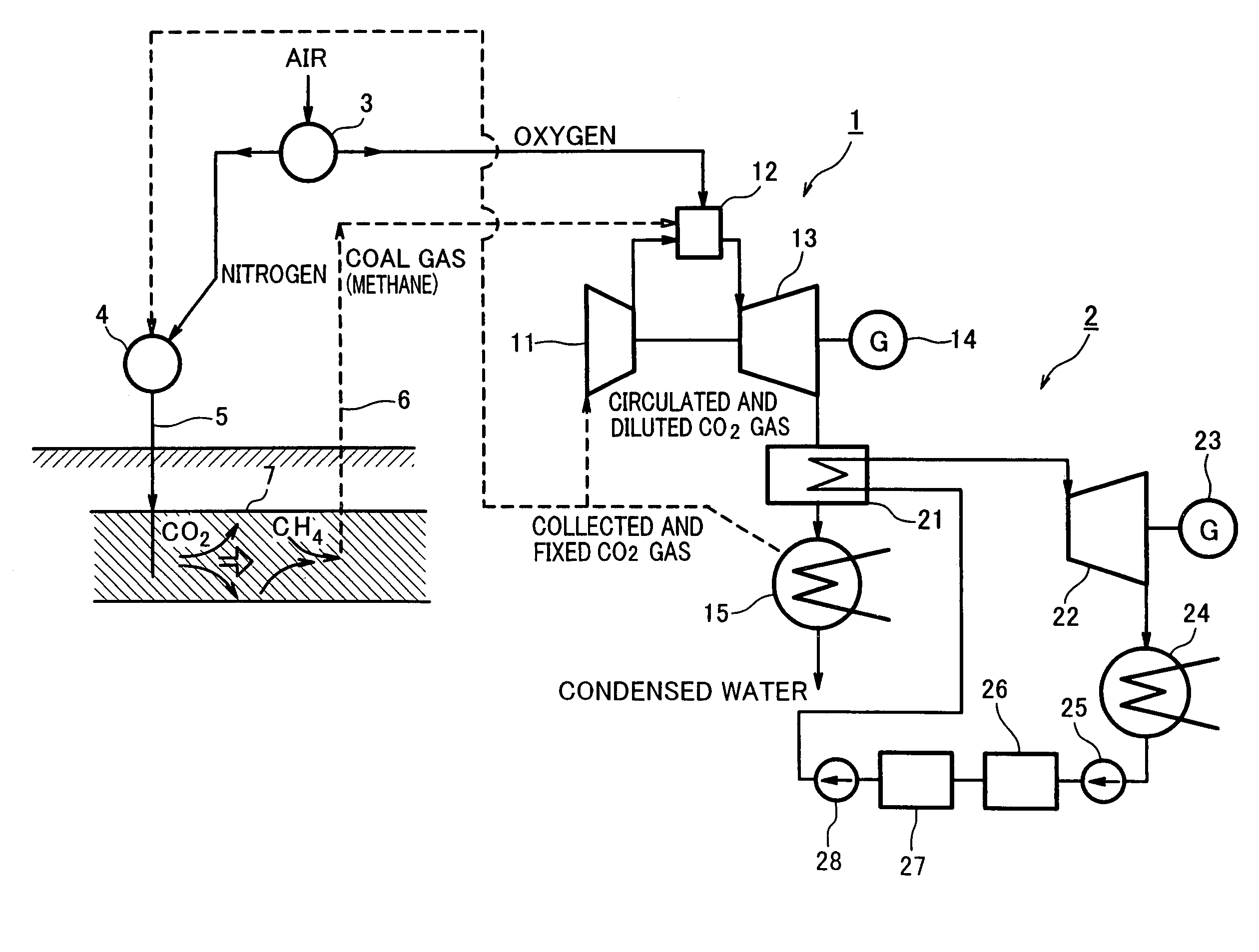

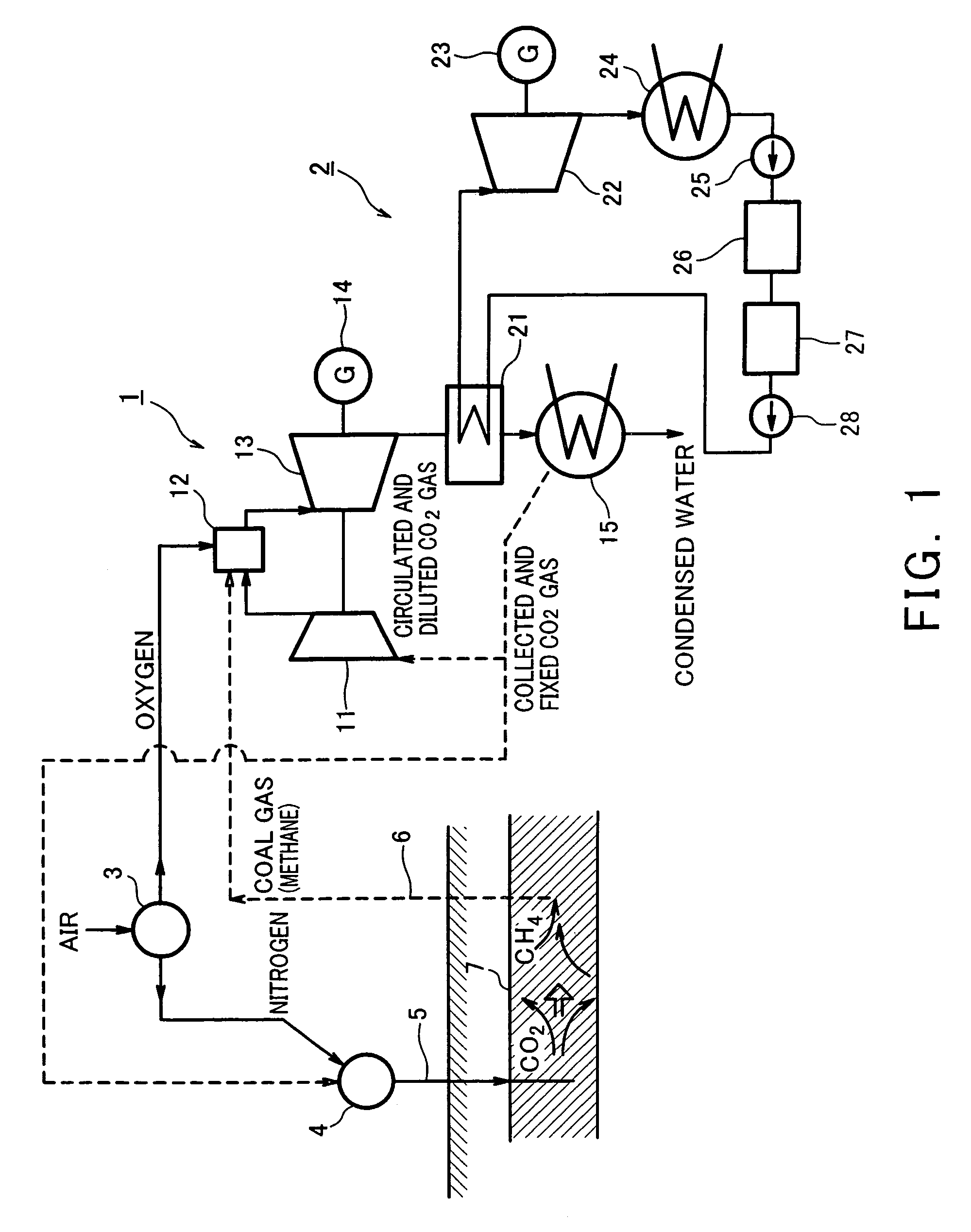

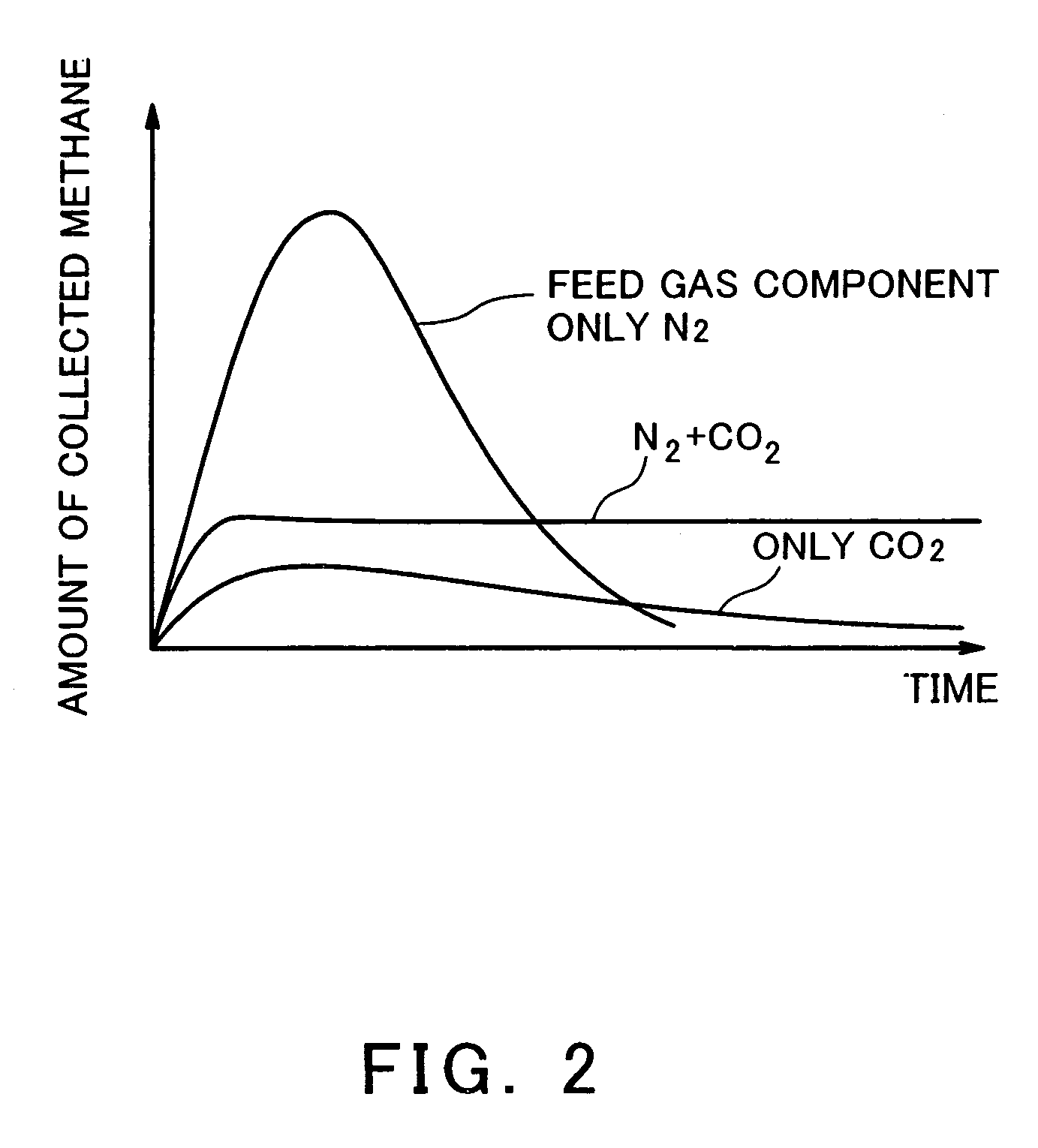

Gas turbine system comprising closed system of fuel and combustion gas using underground coal layer

InactiveUS7143572B2Inhibition releaseTurbine/propulsion fuel supply systemsWorking fluid for enginesCombustionProduct gas

A gas turbine system is configured to inhibit release of carbon dioxide to the atmosphere in such a manner that methane is combusted with oxygen that has been separated from air by an oxygen generator to allow an oxygen combustion type gas turbine to be driven. Carbon dioxide emitted from the turbine is fed under pressure into an underground coal bed along with an air component after separating the oxygen from the air and fixed into the coal bed, and the coal bed methane is collected above the ground by a gas drive action of the gas and supplied to the gas turbine as fuel.

Owner:KAWASAKI HEAVY IND LTD +1

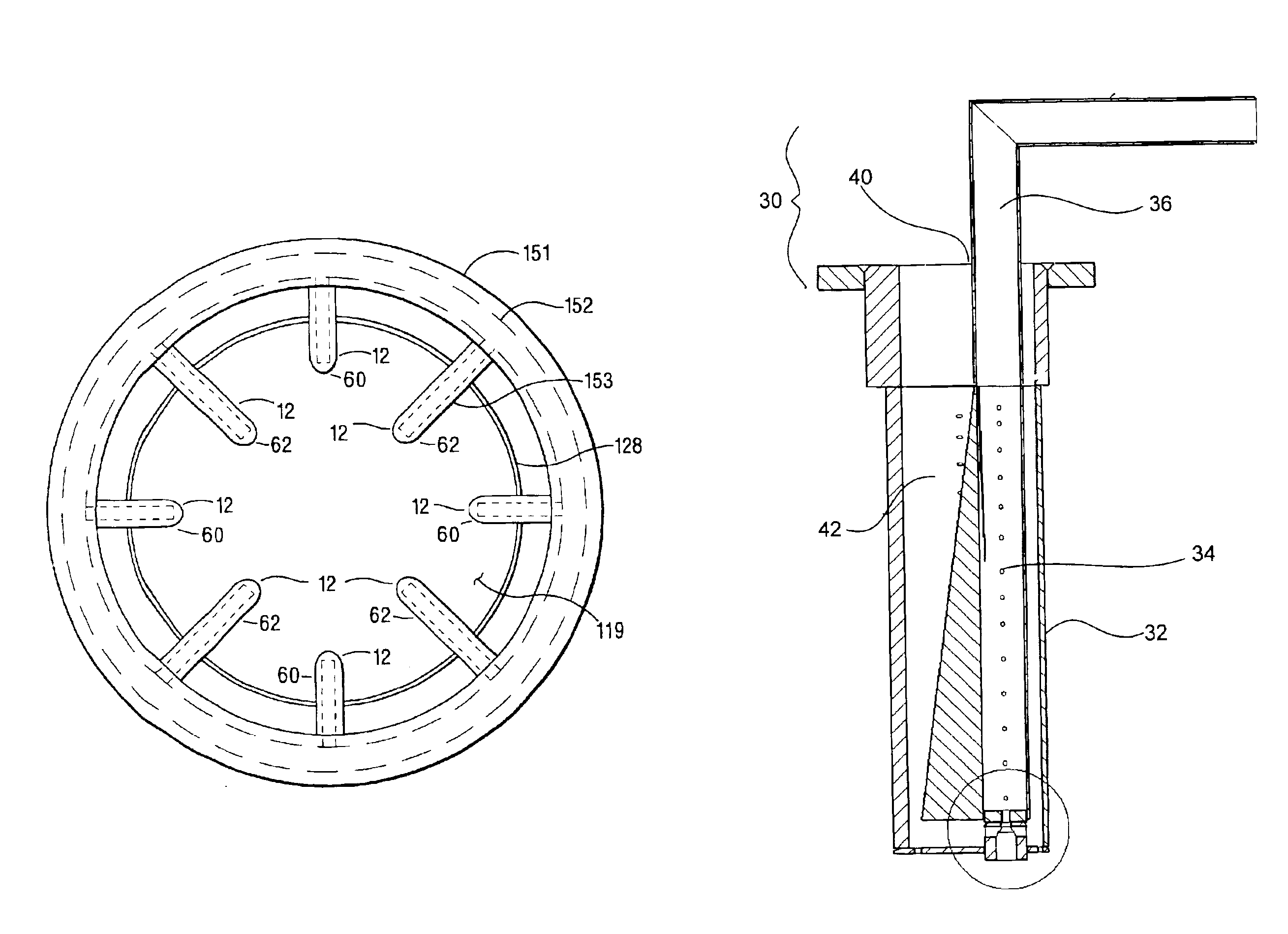

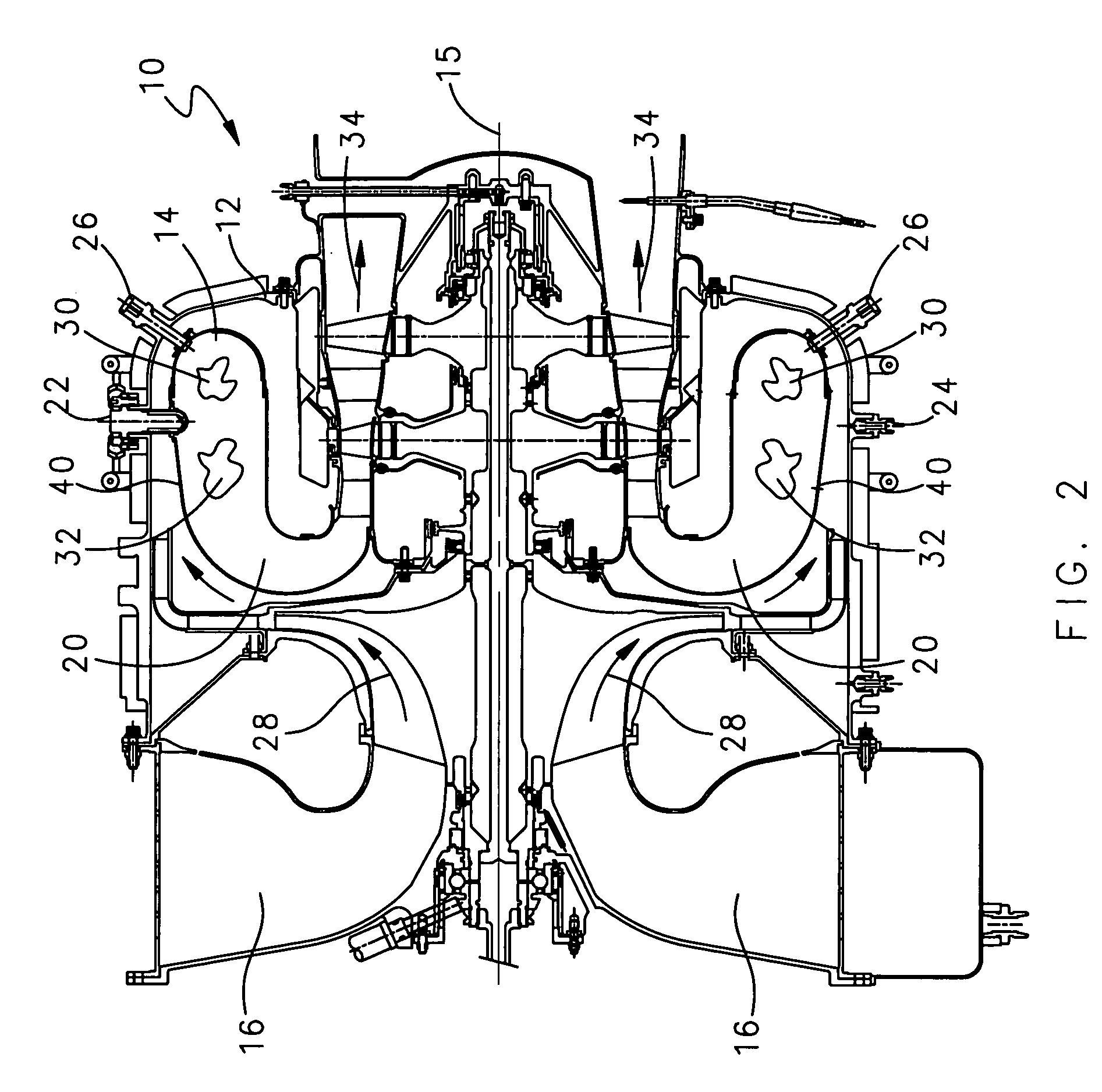

Rich quick mix combustion system

ActiveUS7185497B2Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemEngineering

A premix chamber for a combustor of a gas turbine engine comprises a cylindrical chamber having a premix chamber wall, the cylindrical chamber having a chamber inlet end longitudinally separated from a chamber outlet end along a central axis, a chamber inlet plate in communication with the premix chamber wall at the chamber inlet end, the chamber inlet plate having a fuel nozzle inlet hole disposed through the chamber inlet plate, the chamber inlet plate further comprising a plurality of swirler passages disposed through the chamber inlet plate, and the chamber outlet end being open. A method of producing turbine gas is also disclosed.

Owner:HONEYWELL INT INC

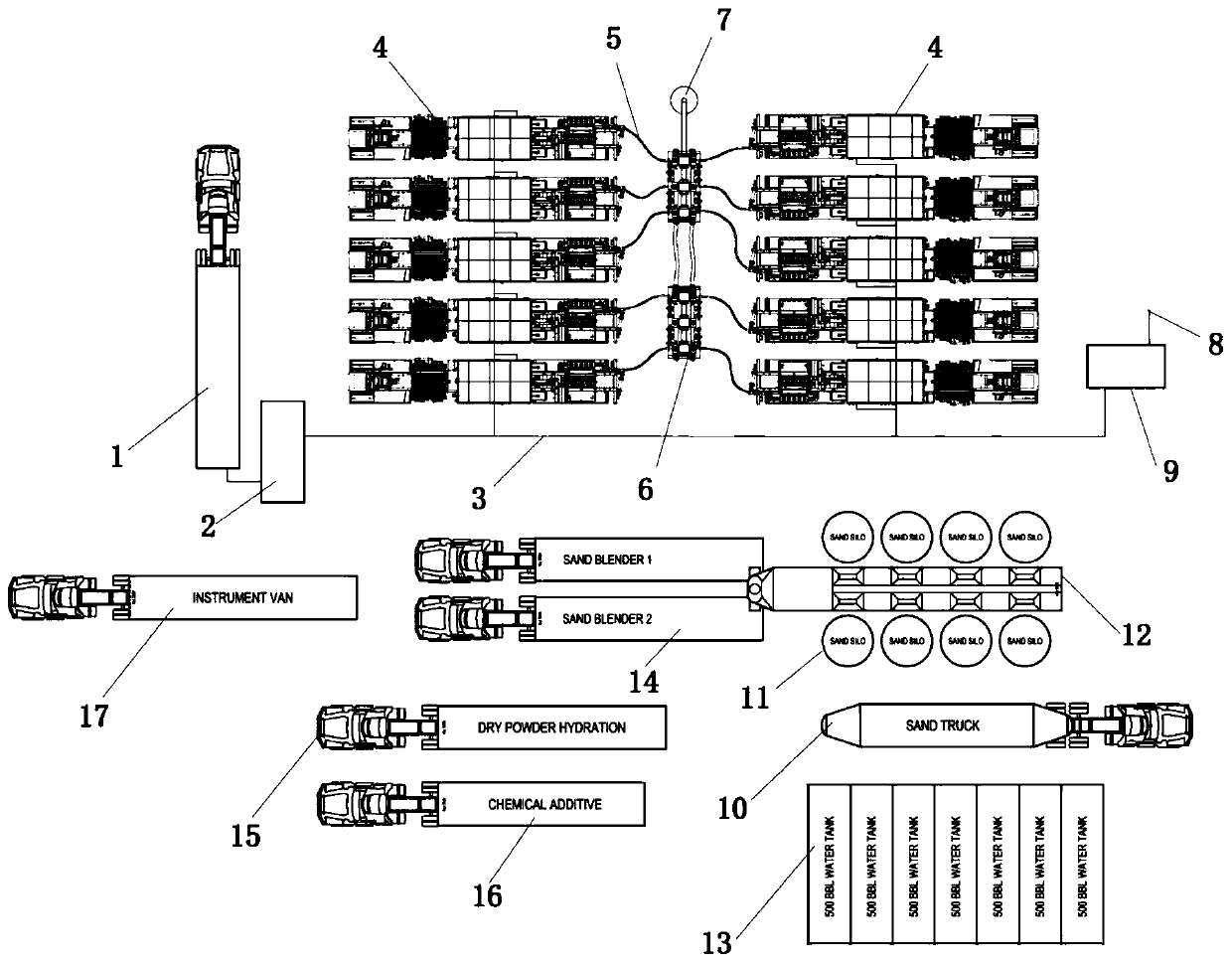

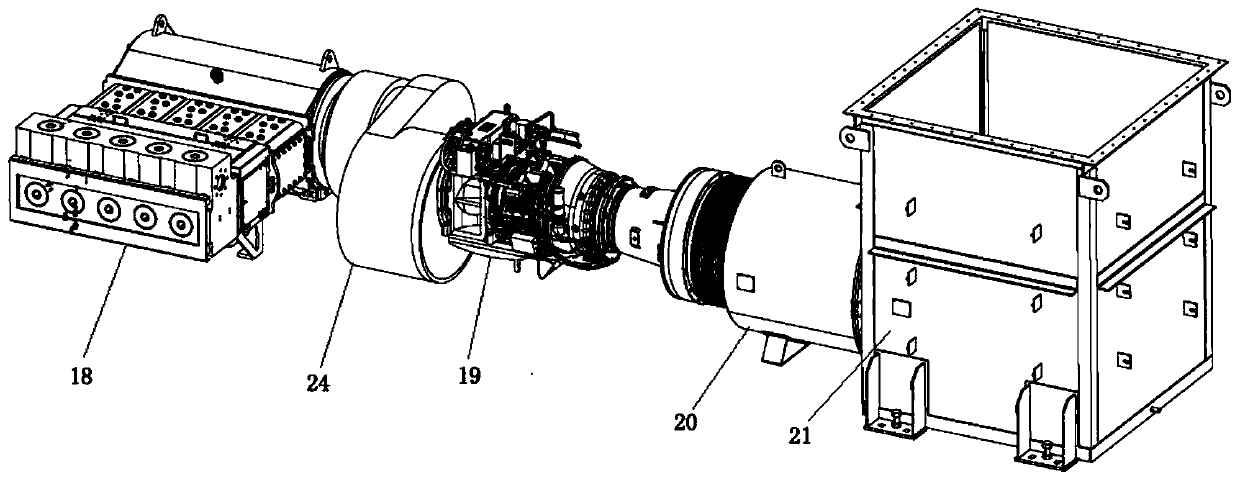

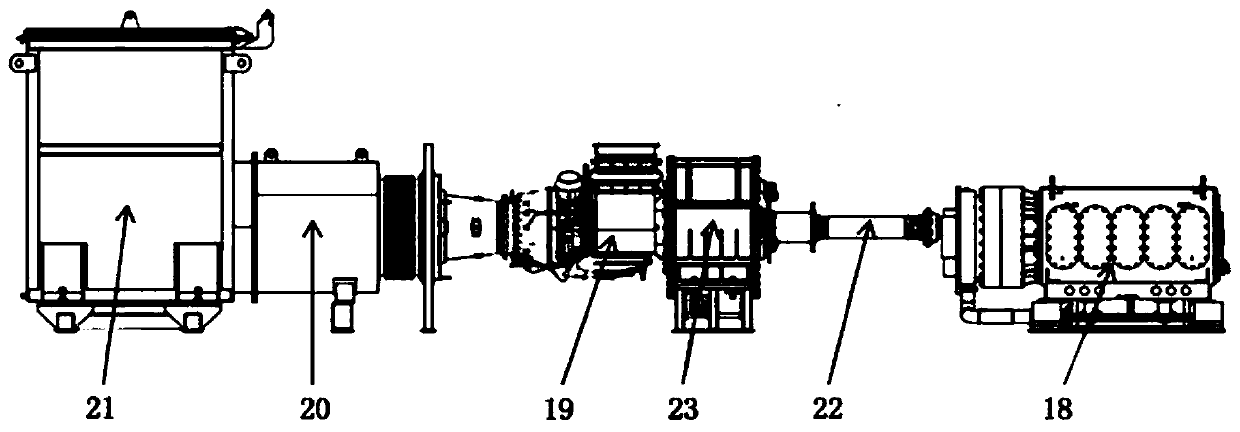

Hydraulic fracturing system for driving plunger pump by using turbine engine

PendingCN110469314ASolve driveTroubleshoot motor drivesTurbine/propulsion fuel supply systemsTransportation and packagingEngineeringHydraulic fracturing

The invention discloses a hydraulic fracturing system for driving a plunger pump by using a turbine engine. The fracturing system comprises a fracturing device, a high-low pressure pipe joint, a mixing device, a sand blender and the like, a power source of the fracturing device is the turbine engine, fuel of the turbine engine is natural gas or diesel, the plunger pump is driven by the turbine engine, the problems of existing diesel driving and electromotor driving are solved, fuel supply of the turbine engine adopting a dual-fuel system is diverse and is not limited, especially, the cost is more saved when the natural gas serves as the fuel. The gas source supply modes of the natural gas are diverse in the whole hydraulic fracturing system, requirements for more clients can be better met,the whole fracturing device is arranged on a straight line in the direction of power transmission, the whole gravity center of the fracturing device is better lowered, and the stability and safety ofthe operation and transferring states of the fracturing device are improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

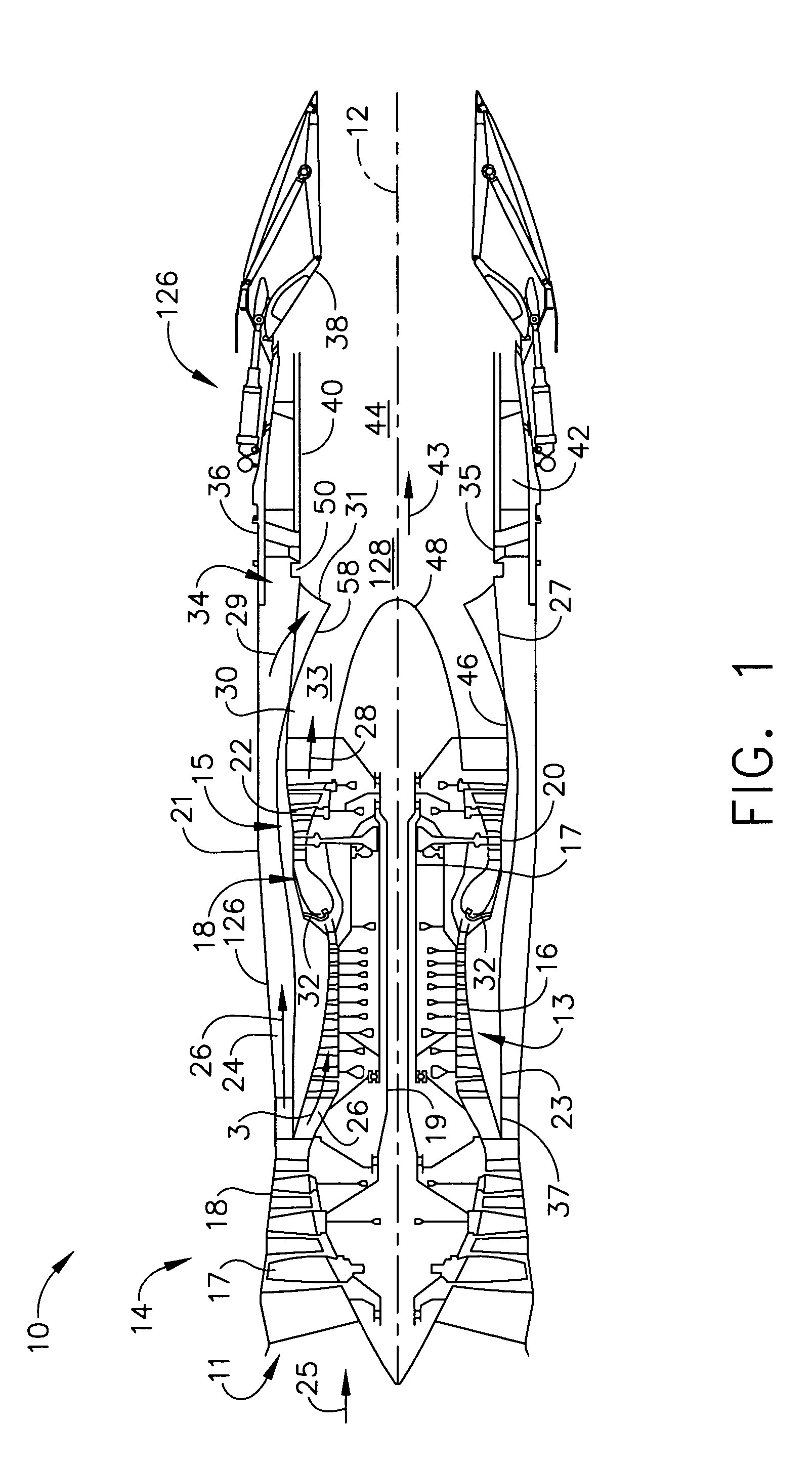

Trapped vortex cavity afterburner

ActiveUS7225623B2Continuous combustion chamberTurbine/propulsion fuel supply systemsTrailing edgeDegree Fahrenheit

A trapped vortex cavity afterburner includes one or more trapped vortex cavity stages for injecting a fuel / air mixture into a combustion zone. The trapped vortex cavity afterburner is operable to provide all thrust augmenting fuel used for engine thrust augmentation. Each stage has at least one annular trapped vortex cavity. The trapped vortex cavity afterburner may be a multi-stage afterburner having two or more trapped vortex cavity stages ganged for simultaneous ignition or operable for sequential ignition. One embodiment of the annular trapped vortex cavity is operable to raise a temperature of an exhaust gas flow through the afterburner about 100 to 200 degrees Fahrenheit. Each of the trapped vortex cavity stages may be operable to produce a single or a different amount of temperature rise of the exhaust gas flow through the afterburner. A chevron shaped trapped vortex cavity and having zig-zag shaped leading and trailing edges may be used.

Owner:GENERAL ELECTRIC CO

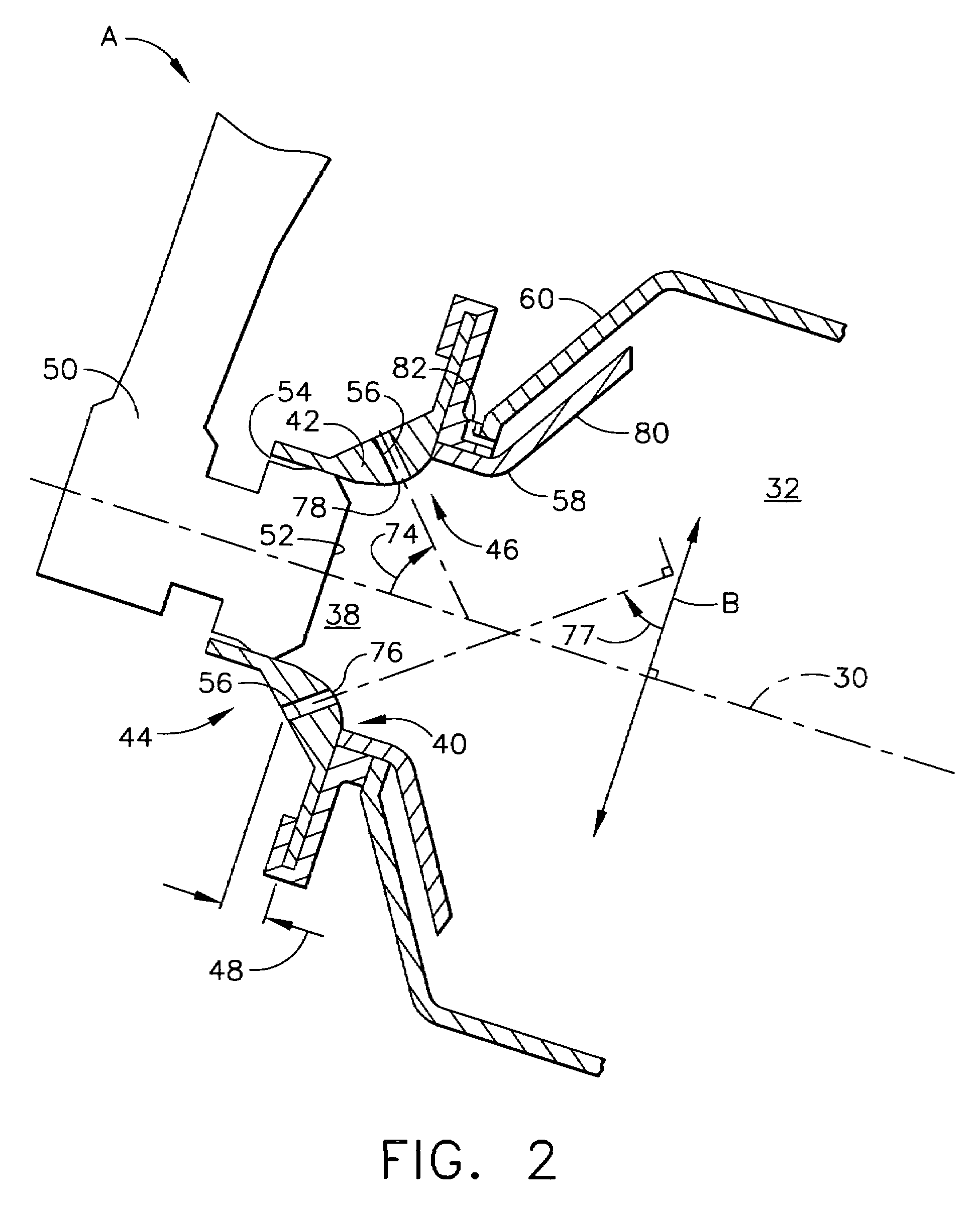

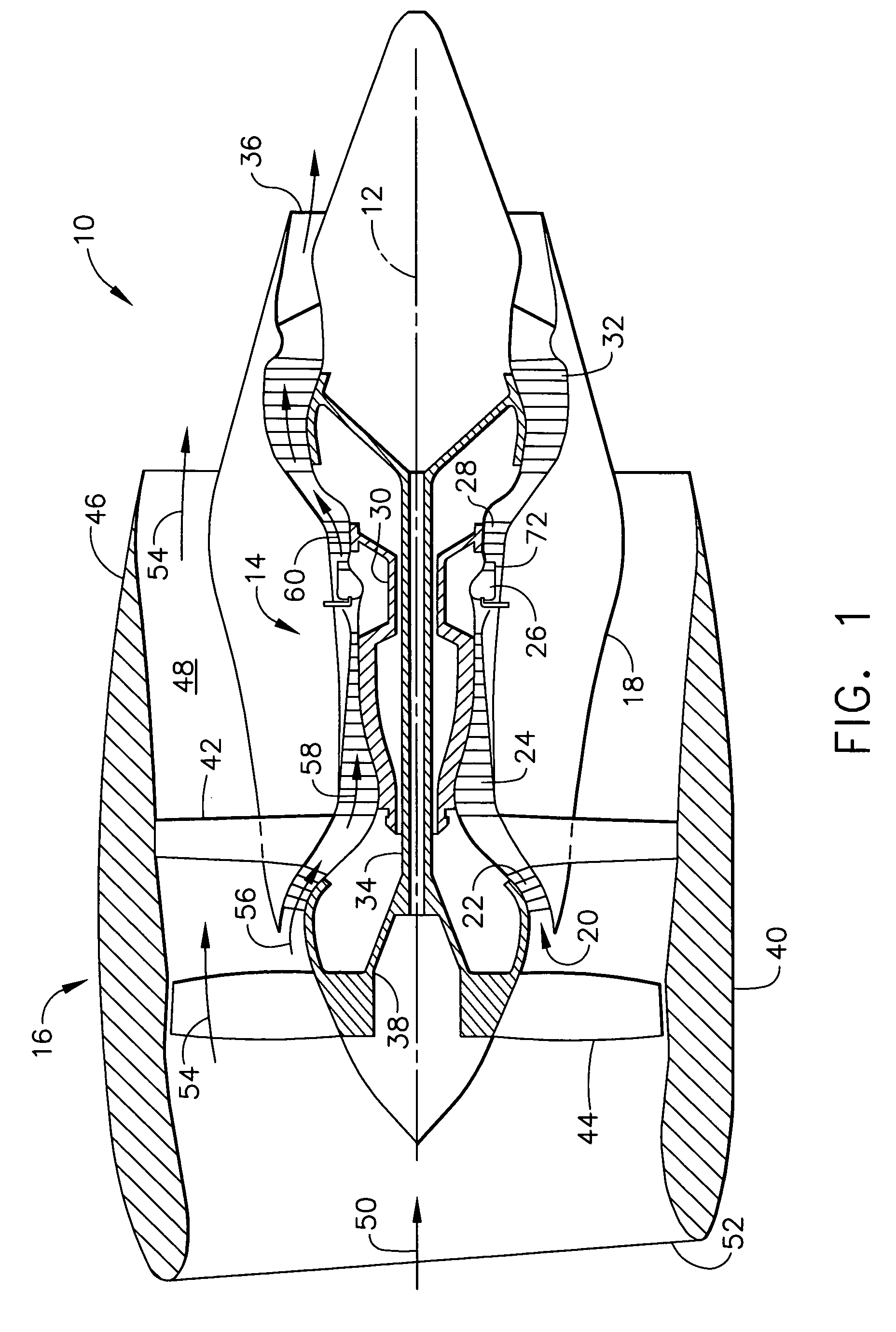

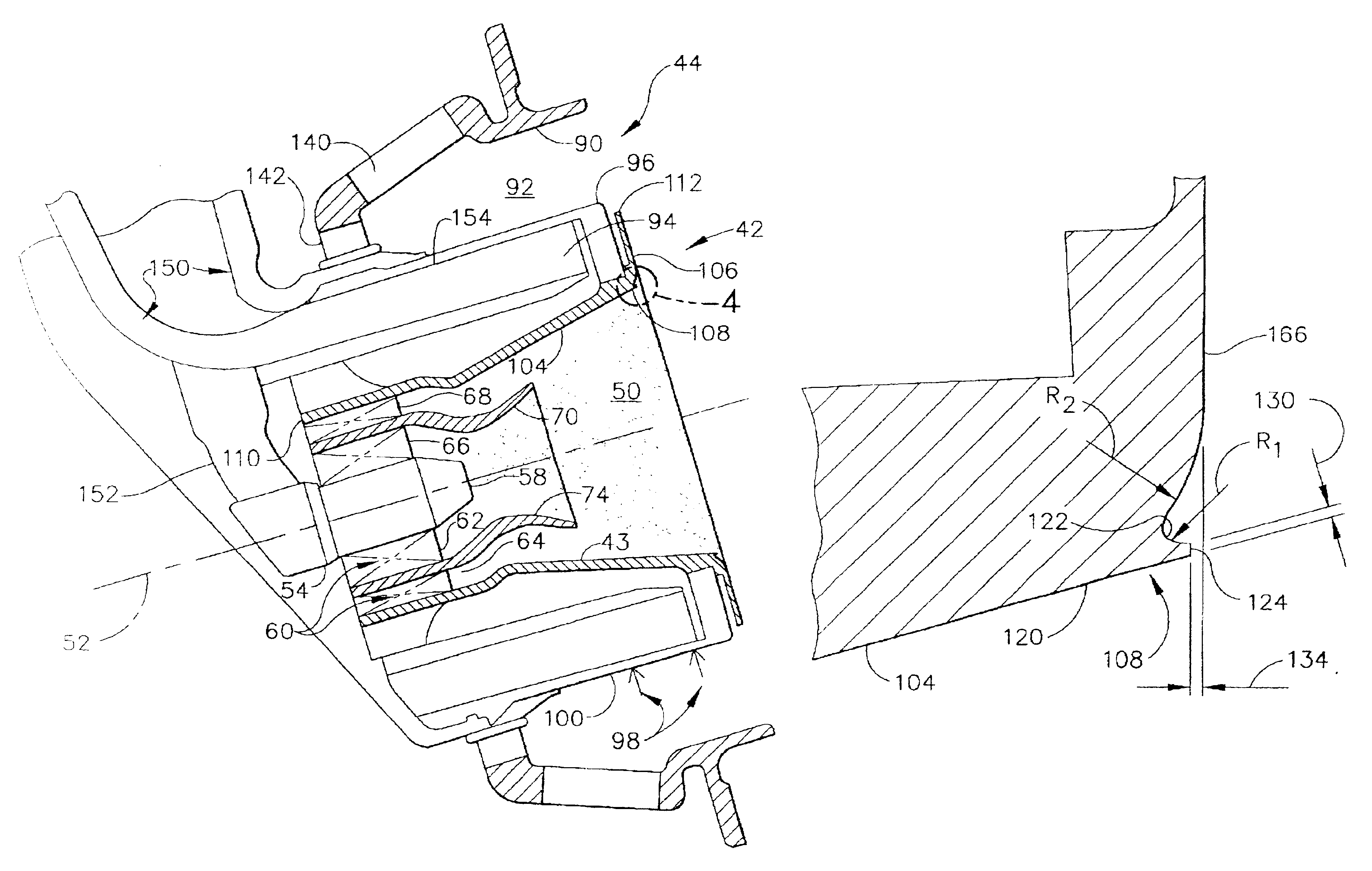

Pilot mixer for mixer assembly of a gas turbine engine combustor having a primary fuel injector and a plurality of secondary fuel injection ports

ActiveUS20090113893A1Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCombustion chamber

A mixer assembly for use in a combustion chamber of a gas turbine engine including a pilot mixer, a main mixer, and a fuel manifold. The pilot mixer includes: an annular pilot housing having a hollow interior; a primary fuel injector mounted in the pilot housing and adapted for dispensing droplets of fuel to the hollow interior of the pilot housing; a plurality of axial swirlers positioned upstream from the primary fuel injector, each of the plurality of swirlers having a plurality of vanes for swirling air traveling through the respective swirler to mix air and the droplets of fuel dispensed by the primary fuel injector; and, a plurality of secondary fuel injection ports for introducing fuel into the hollow interior of the pilot housing. The main mixer further includes: a main housing surrounding the pilot housing and defining an annular cavity; a plurality of fuel injection ports for introducing fuel into the cavity; and, at least one swirler positioned upstream from the plurality of fuel injection ports, each of the main mixer swirlers having a plurality of vanes for swirling air traveling through the respective swirler to mix air and the droplets of fuel dispensed by the main mixer fuel injection ports. The fuel manifold is in flow communication with the plurality of secondary fuel injection ports in the pilot mixer and the plurality of fuel injection ports in the main mixer.

Owner:GENERAL ELECTRIC CO

Method and apparatus to decrease combustor emissions

A method for operating a gas turbine engine facilitates reducing an amount of emissions from a combustor. The combustor includes a mixer assembly including a pilot mixer, a main mixer, and a centerbody that extends therebetween. The pilot mixer includes a pilot fuel nozzle and a plurality of axial swirlers. The main mixer includes a main swirler and a plurality of fuel injection ports. The method comprises injecting fuel into the combustor through the pilot mixer, such that the fuel is discharged downstream from the pilot mixer axial swirlers, and directing flow exiting the pilot mixer with a lip extending from the centerbody into a pilot flame zone downstream from said pilot mixer.

Owner:GENERAL ELECTRIC CO

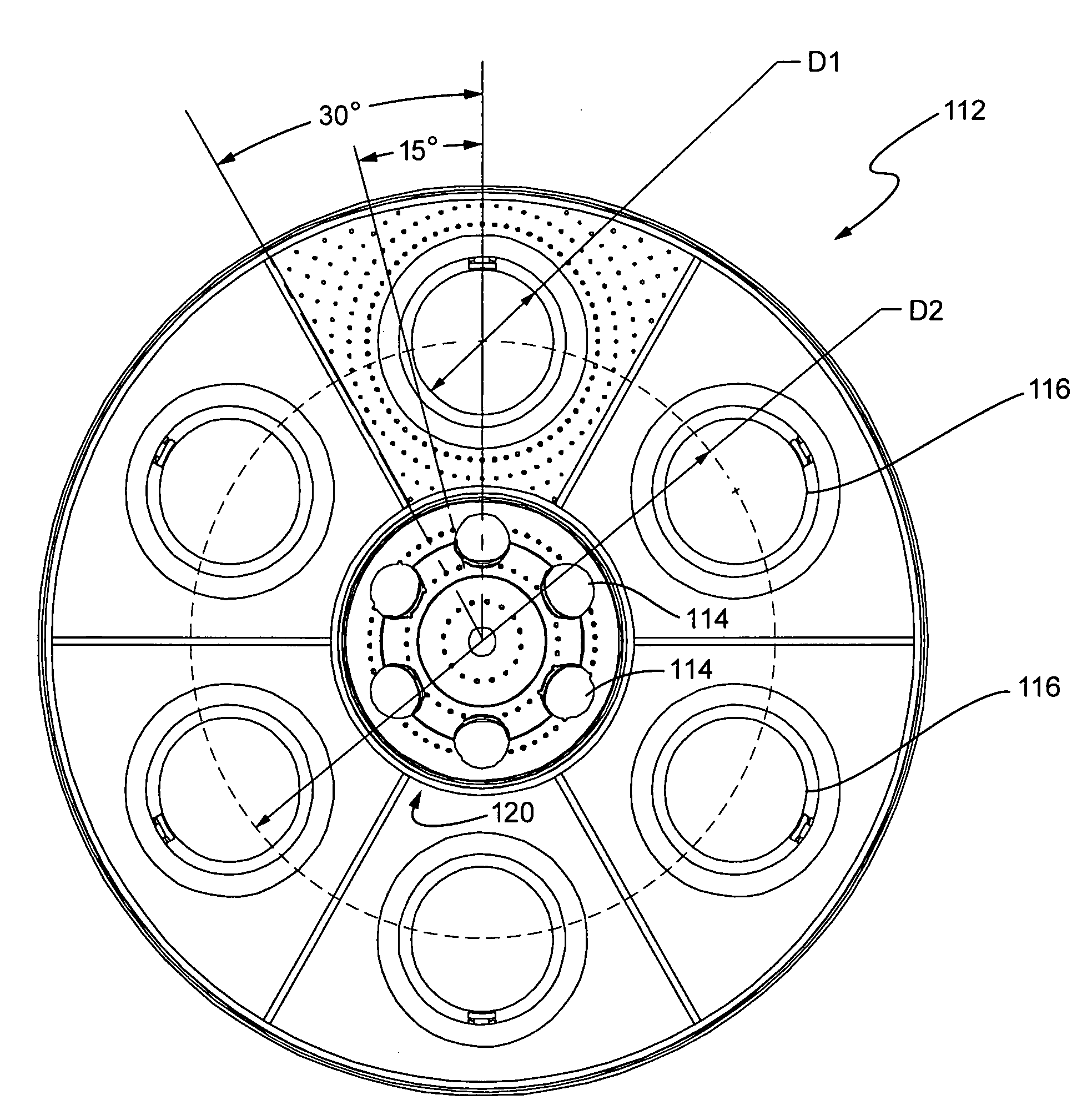

Flamesheet combustor

InactiveUS6935116B2Well mixedEmission reductionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemCombustion chamber

A gas turbine combustion system having reduced emissions and improved flame stability at multiple load conditions is disclosed. The improved combustion system accomplishes this through complete premixing, a plurality of fuel injector locations, combustor geometry, and precise three dimensional staging between fuel injectors. Axial, radial, and circumferential fuel staging is utilized including fuel injection proximate air swirlers. Furthermore, strong recirculation zones are established proximate the introduction of fuel and air premixture from different stages to the combustion zone. The combination of the strong recirculation zones, efficient premixing, and staged fuel flow thereby provide the opportunity to produce low emissions combustion at various load conditions.

Owner:H2 IP UK LTD

Combustion cap with crown mixing holes

InactiveUS20090223227A1Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEngineering

A combustor liner cap including a cap center body portion and a fuel nozzle portion defined peripherally of the cap center body portion. A plurality of fuel nozzle ports are defined through the fuel nozzle portion and a plurality of air jet holes are defined through the cap center body portion, and each air jet hole is aligned along a radius of the liner cap with a respective fuel nozzle port.

Owner:GENERAL ELECTRIC CO

Lean-staged pyrospin combustor

ActiveUS7302801B2High power outputIncrease powerBurnersTurbine/propulsion fuel supply systemsCombustorCombustion chamber

Owner:HAMILTON SUNDSTRAND CORP

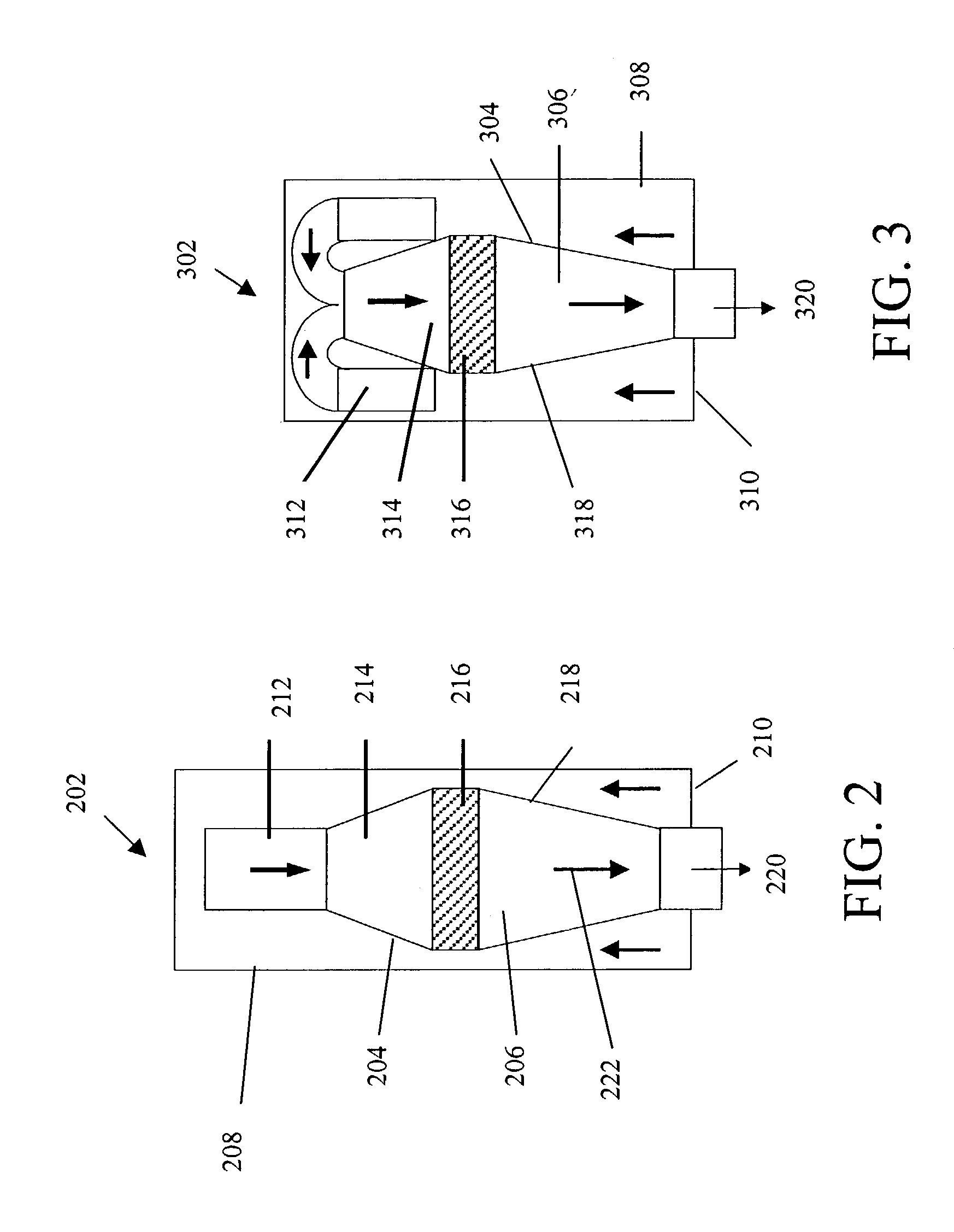

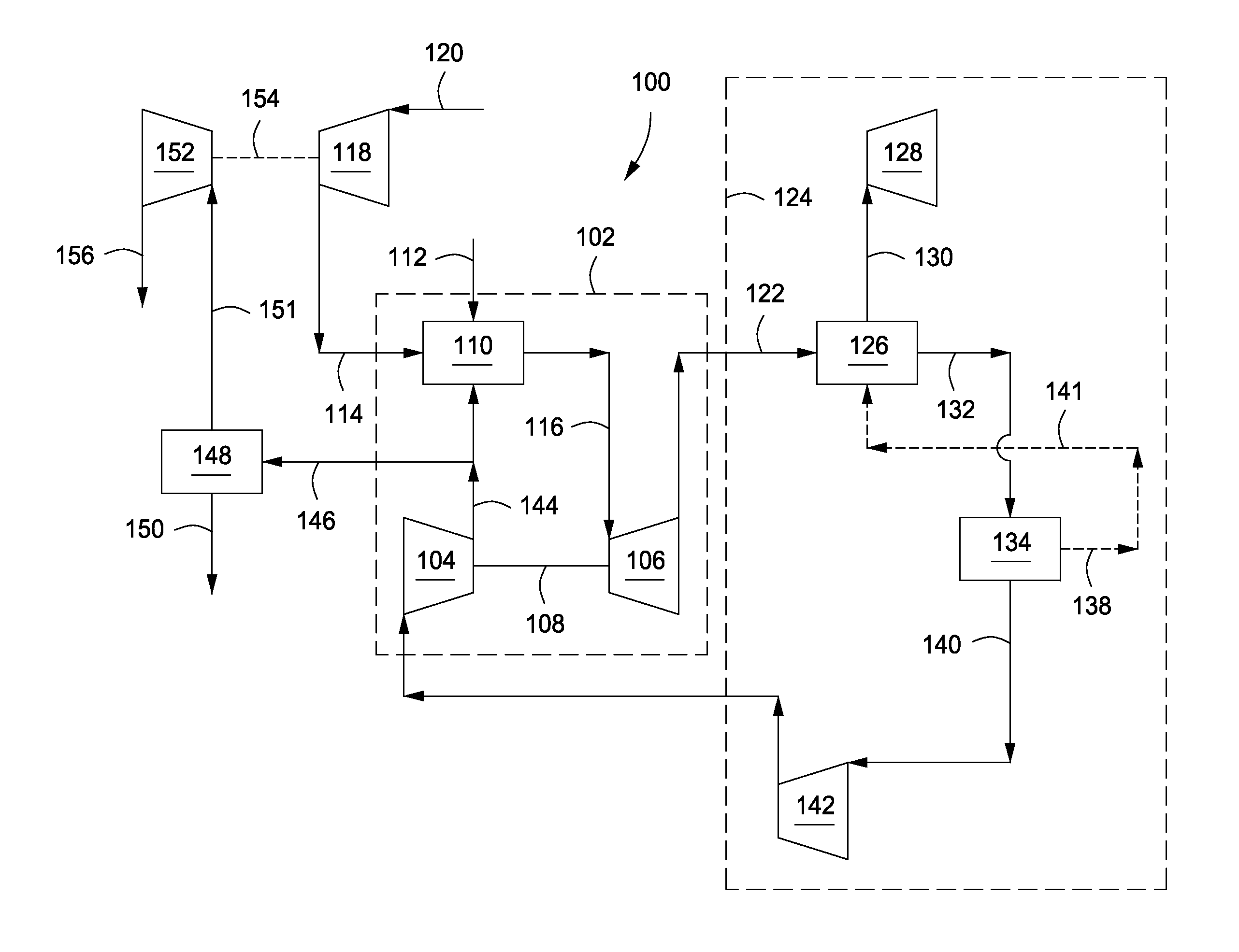

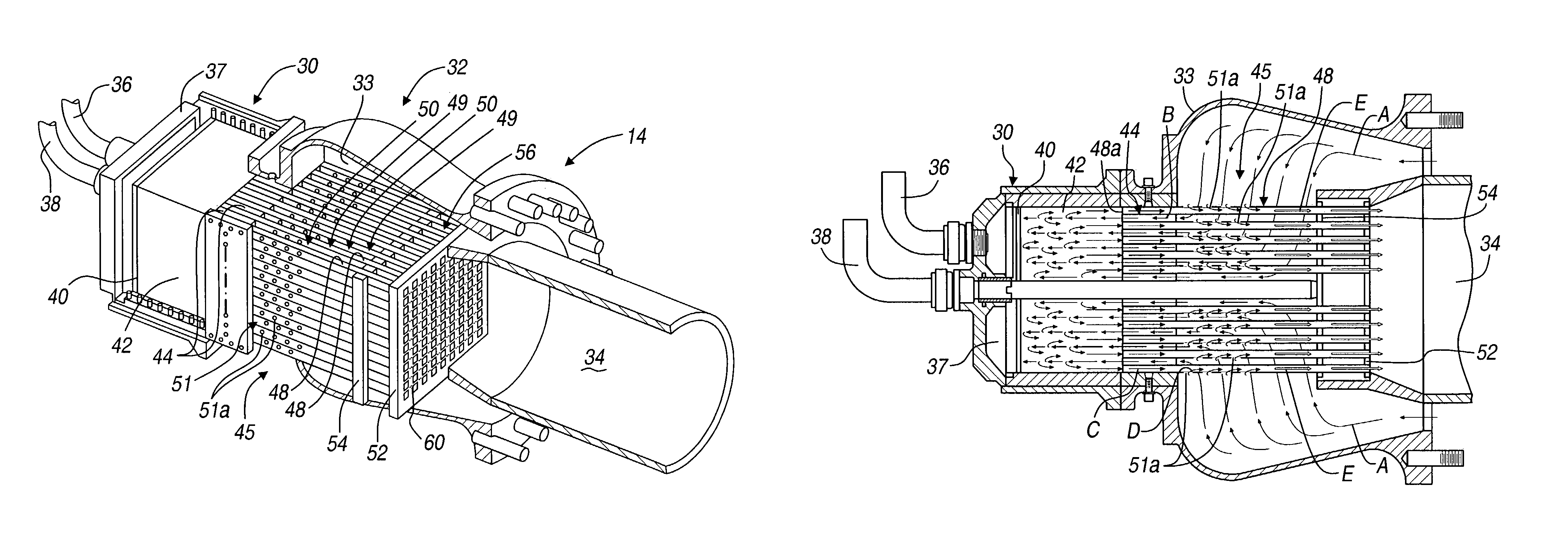

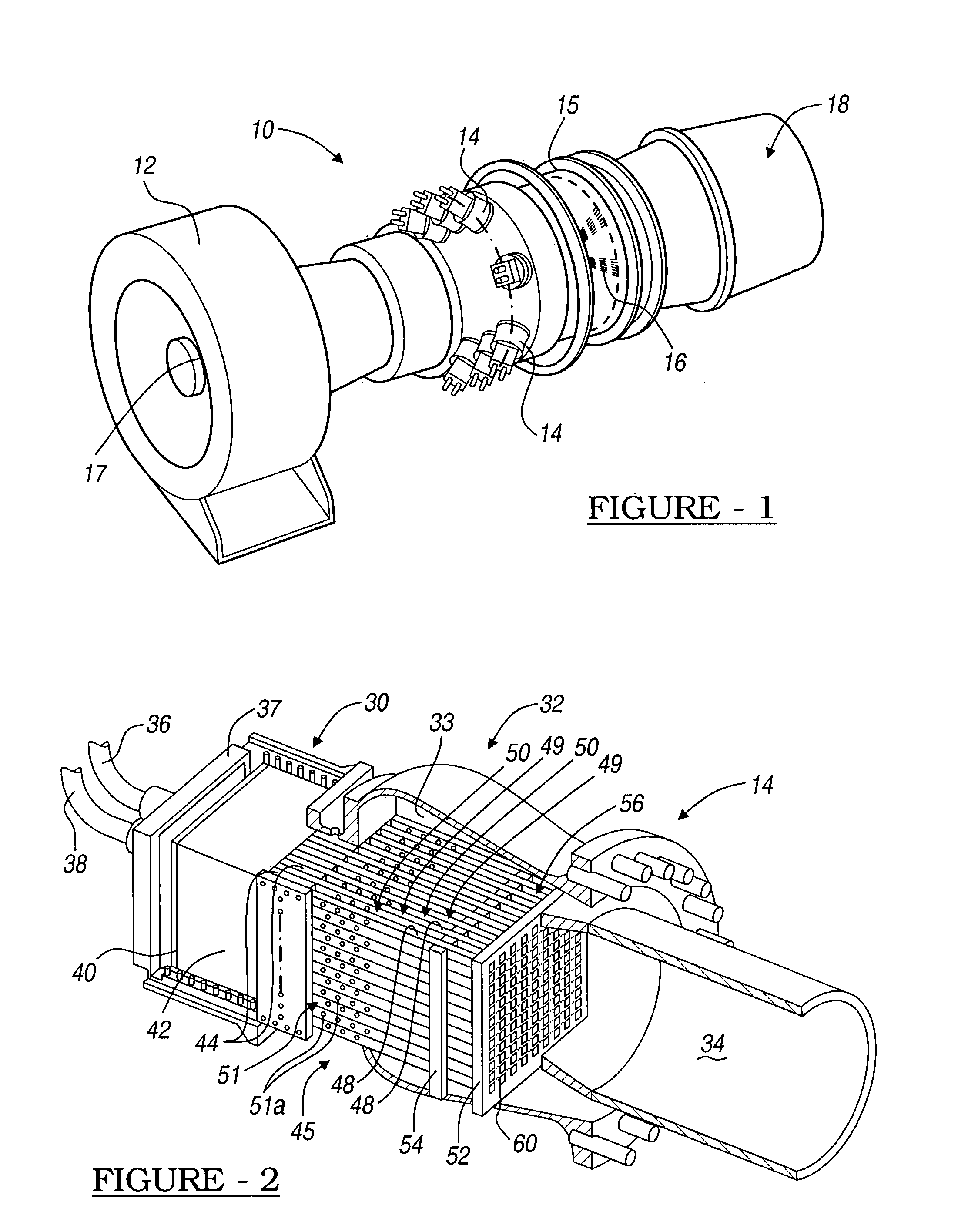

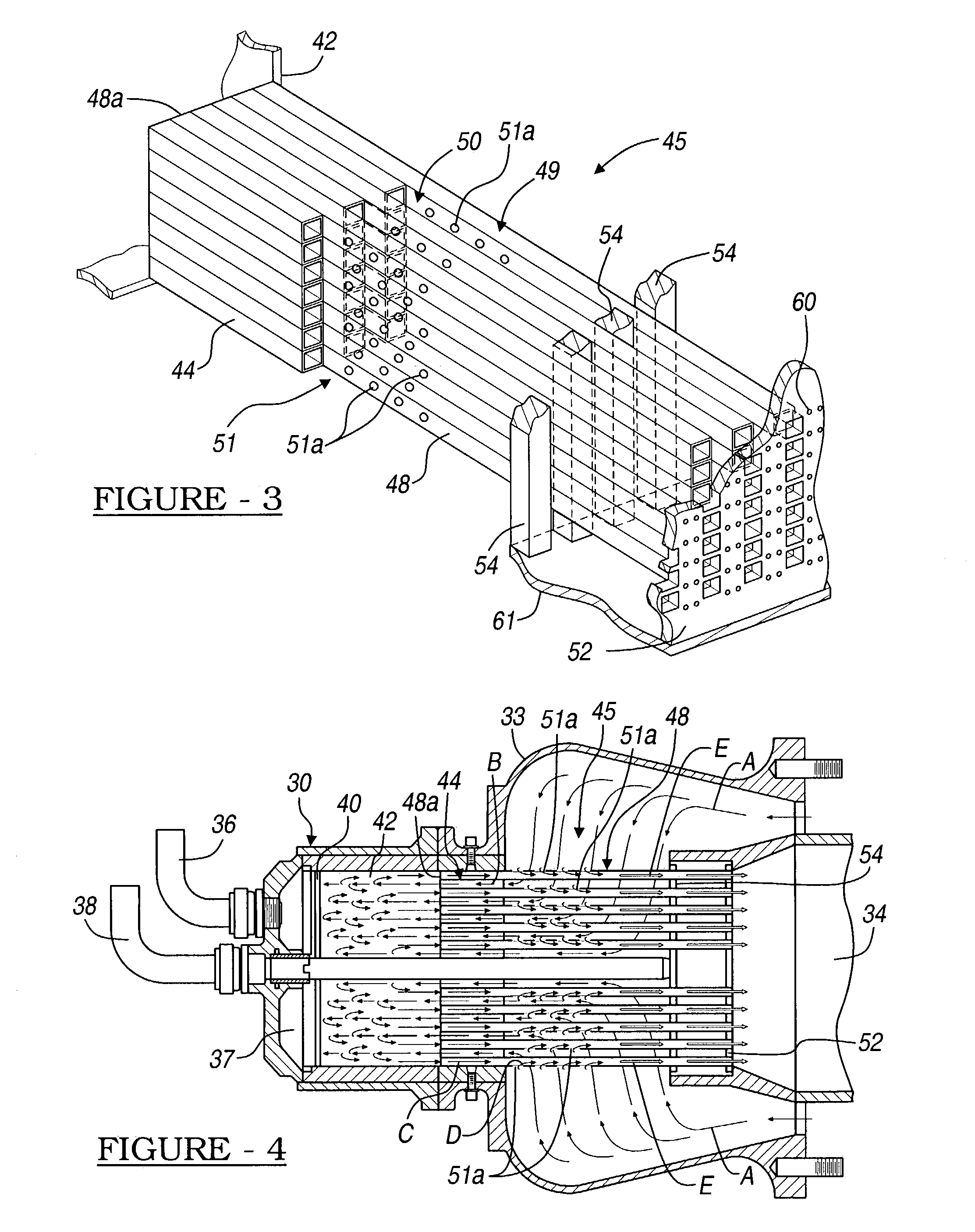

Apparatus and method for selecting a flow mixture

InactiveUS7007486B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCounter flowChemical species

A counter-flow system for use in a turbine for selecting various mixtures of fluids for use with the system. The system may be used for a combustor for a gas powered turbine which employs a heat exchanger to combust a fuel without the emission of undesired chemical species. A gas powered turbine requires expanding gases to power the turbine blades. Fuel is combusted to produce the required gases. An oxidizer is introduced into the counter-flow system in a first direction before a first portion of fuel is introduced into the oxidizer. The fuel and oxidizer mixture is then flowed through a second pathway wherein the fuel and oxidizer mixture obtains a selected amount of thermal energy. Moreover, in a second pathway an equivalence ratio of the fuel and oxidizer mixture may be altered from the original fuel and oxidizer mixture.

Owner:UNITED TECH CORP +1

Integrated Combustor and Stage 1 Nozzle in a Gas Turbine and Method

ActiveUS20100115953A1Shorten flame lengthContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberCombustor

An integrated combustor and stage one nozzle in a gas turbine includes a combustion chamber that receives premixed fuel and air from at least one fuel nozzle group at separate axial locations. The combustion chamber includes a liner and a transition piece that deliver hot combustion gas to the turbine. The stage one nozzle, the liner and the transition piece are integrated into a single part. At least one of the axial locations of the one or more fuel nozzle groups includes a plurality of small scale mixing devices that concentrate heat release and reduce flame length.

Owner:GENERAL ELECTRIC CO

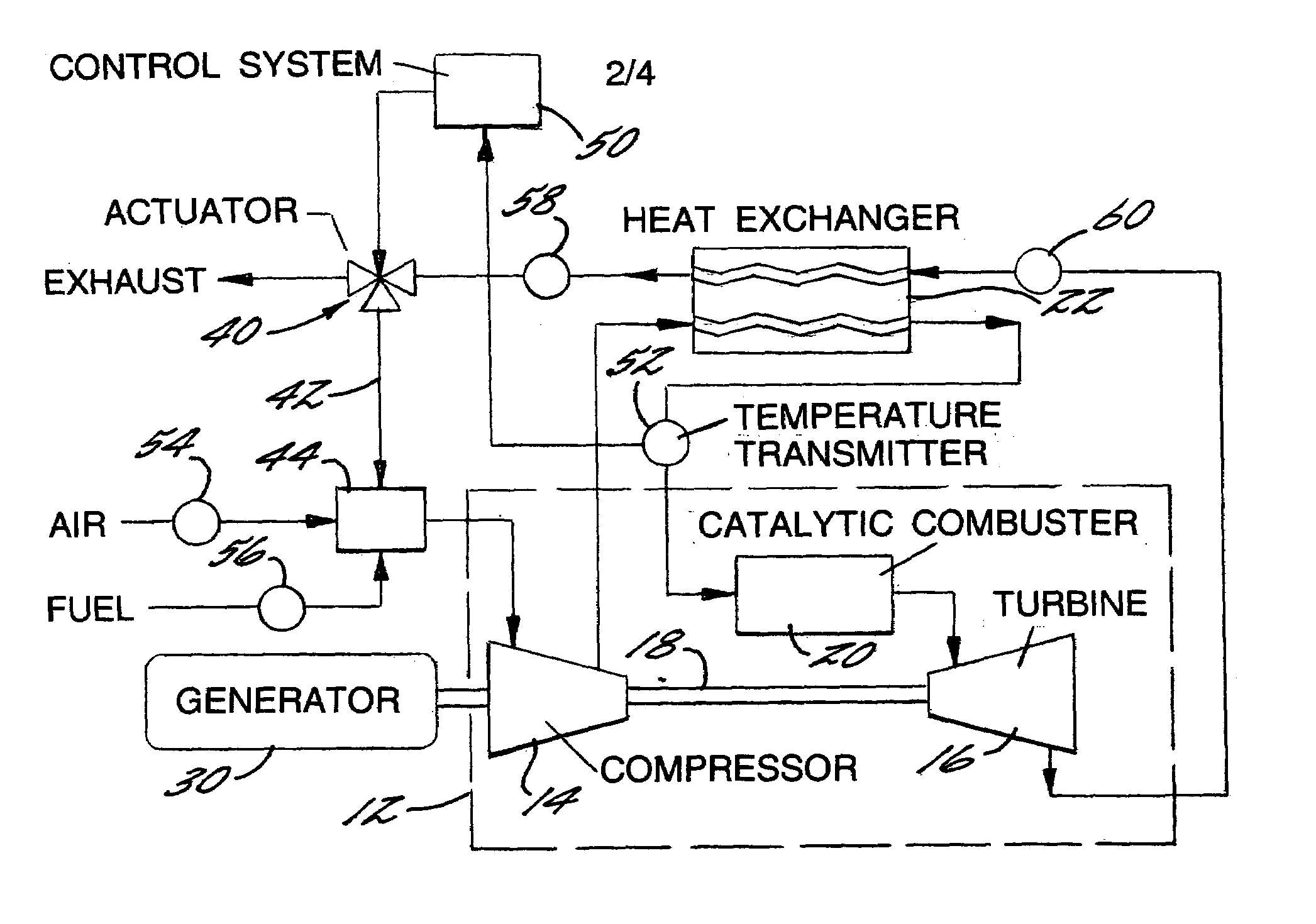

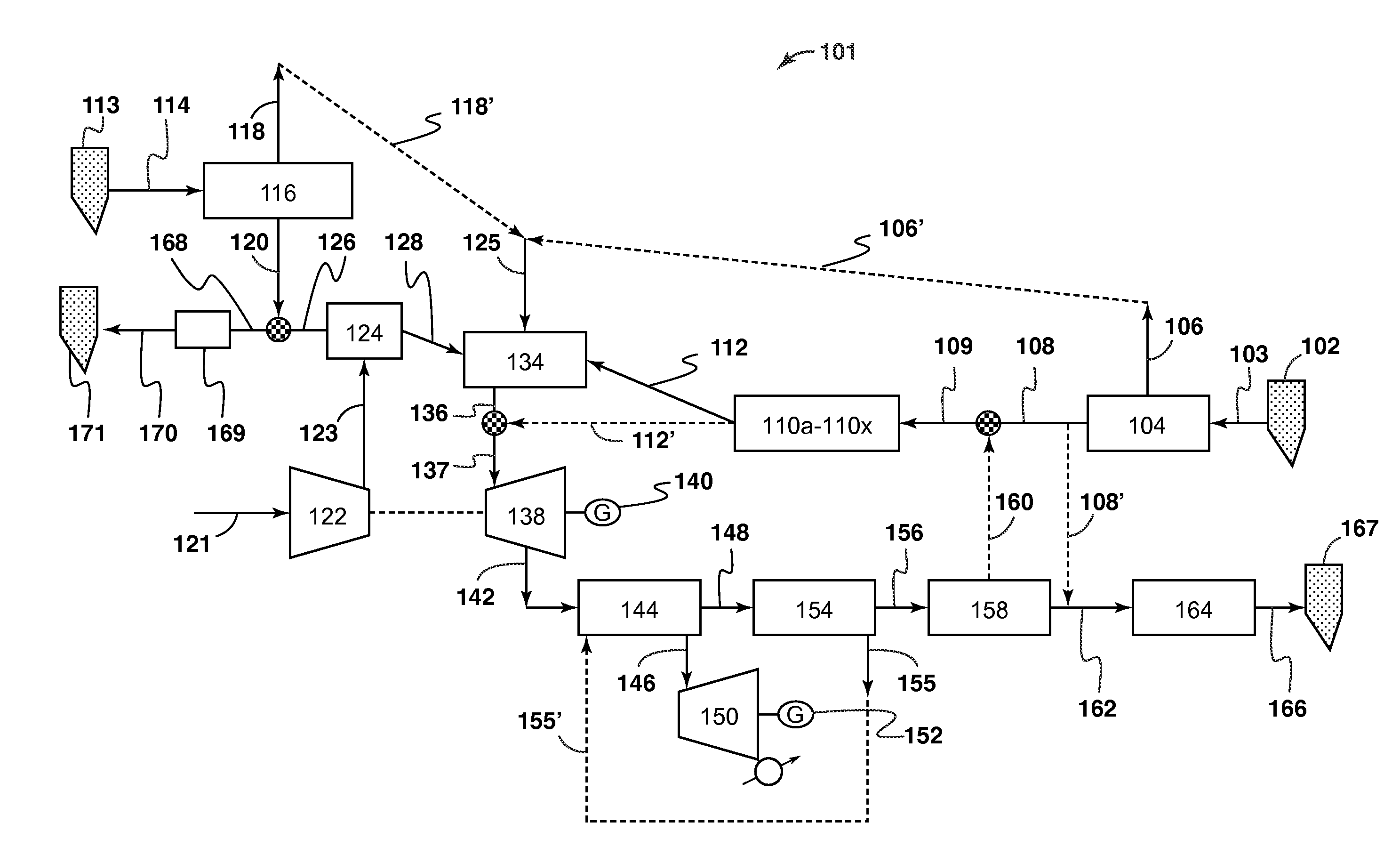

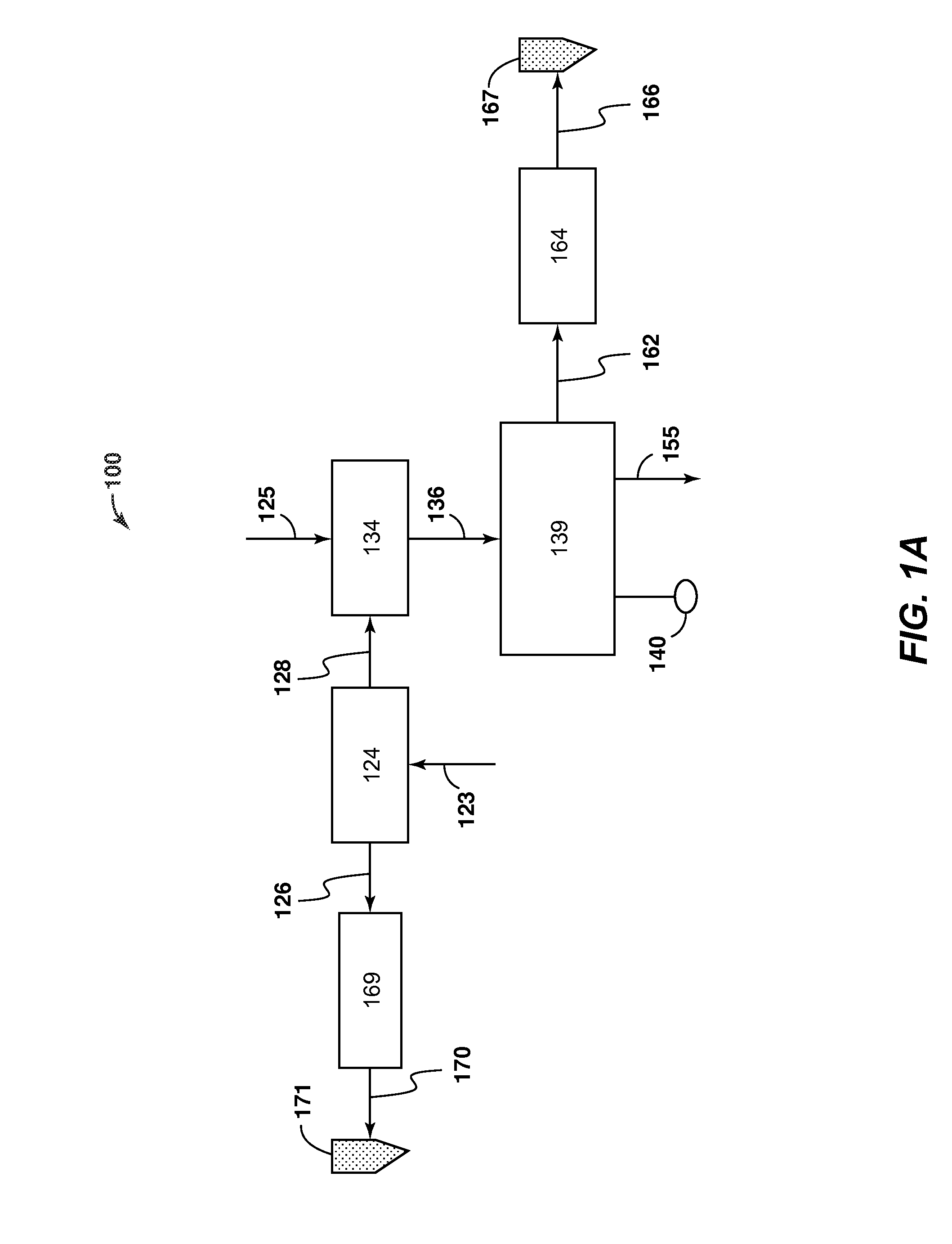

Dynamic control system and method for multi-combustor catalytic gas turbine engine

InactiveUS7152409B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemControl system

According to one aspect, a method of controlling a multi-combustor catalytic combustion system is provided for determining a characteristic of a fuel-air mixture downstream of a preburner associated with a catalytic combustor and adjusting the fuel flow to the preburner based on the characteristic. The characteristic may include, for example, a measurement of the preburner or catalyst outlet temperature or a determination of the position of the homogeneous combustion wave in the burnout zone of the combustor.

Owner:KAWASAKI HEAVY IND LTD

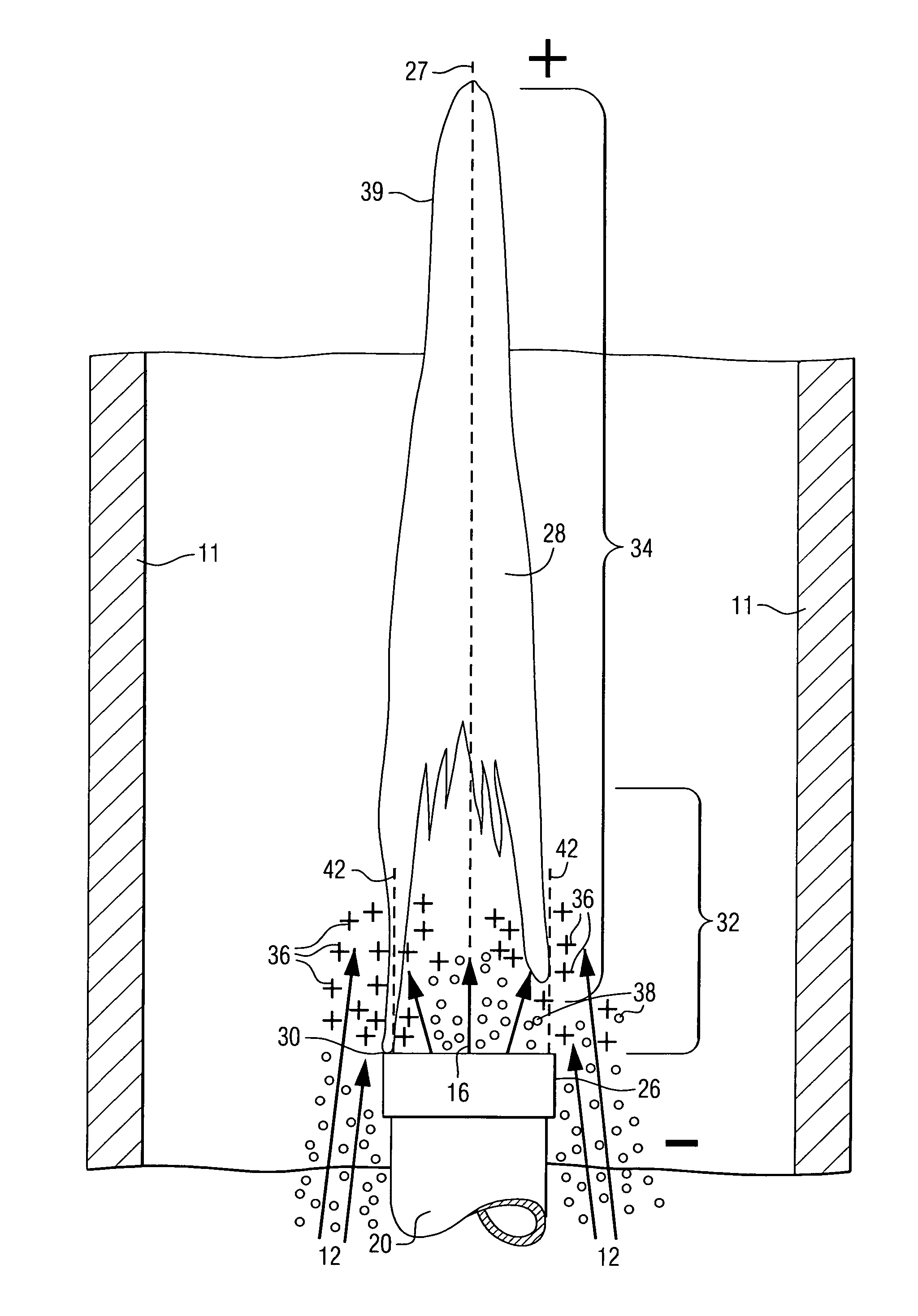

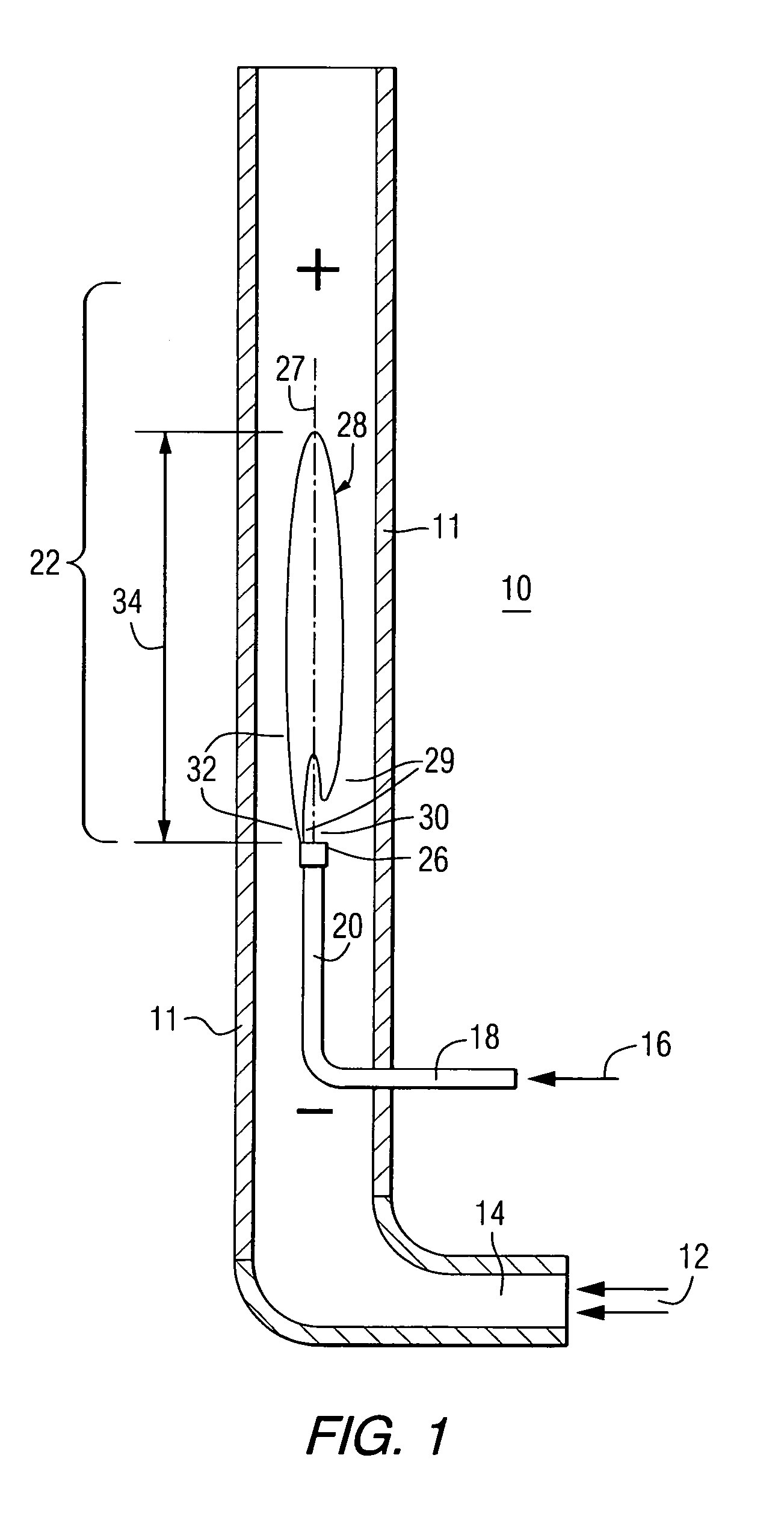

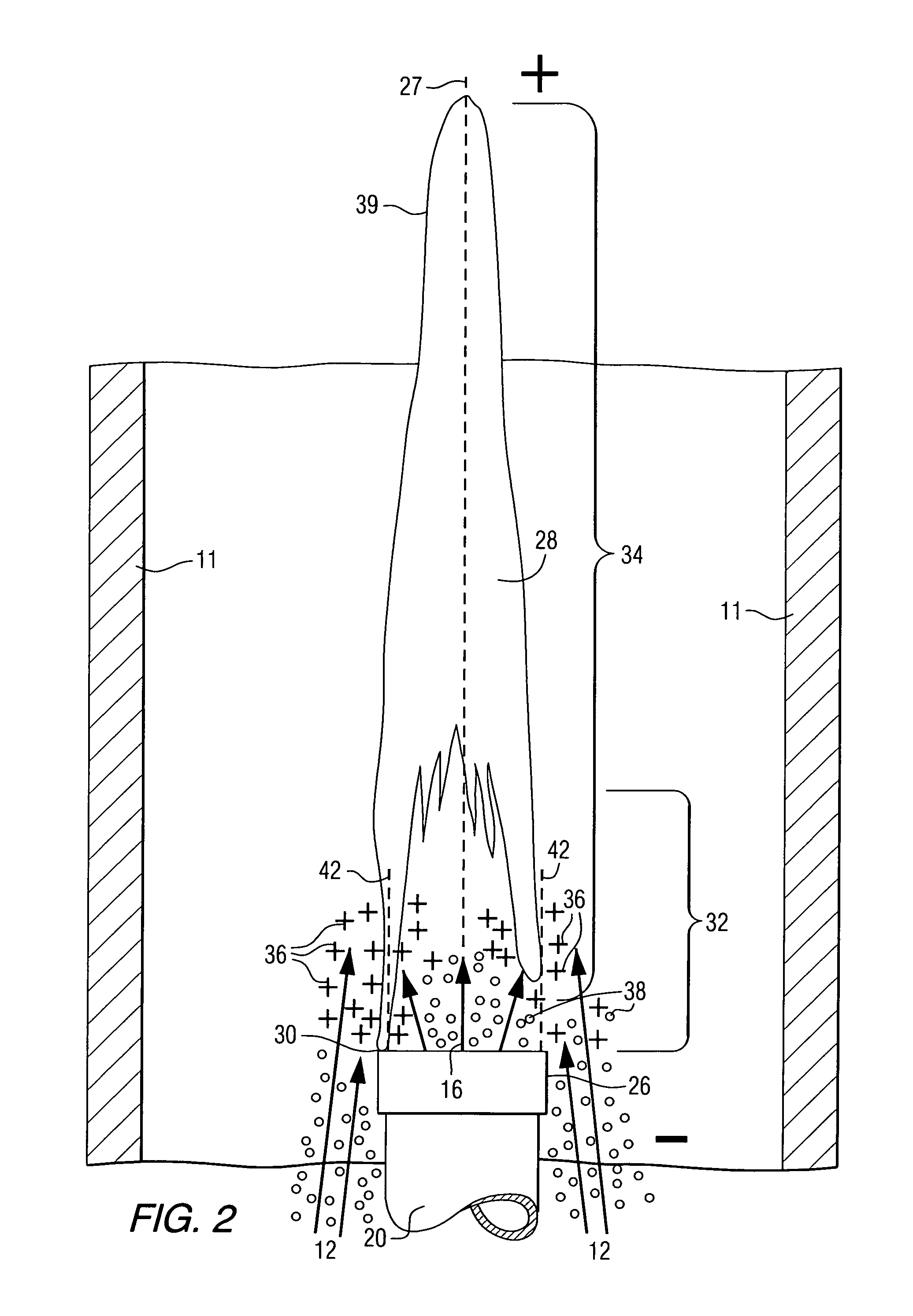

Electric flame control using corona discharge enhancement

InactiveUS7243496B2Increased ionizationPromote combustionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionElectricityCombustor

A method of operating a combustor (10), to provide intimately mixed hot combusted gas (44) for a gas turbine (46), includes feeding gaseous oxidant (12) and gaseous fuel (16) into the combustor (10) near a combustion flame (28) which has a tip end (39) and a root end (29), where corona discharge occurs through adjustment of an electric field (34), and where the corona discharge causes ionized particles (36) to form and also causes intimate turbulent mixing of the gases.

Owner:SIEMENS ENERGY INC

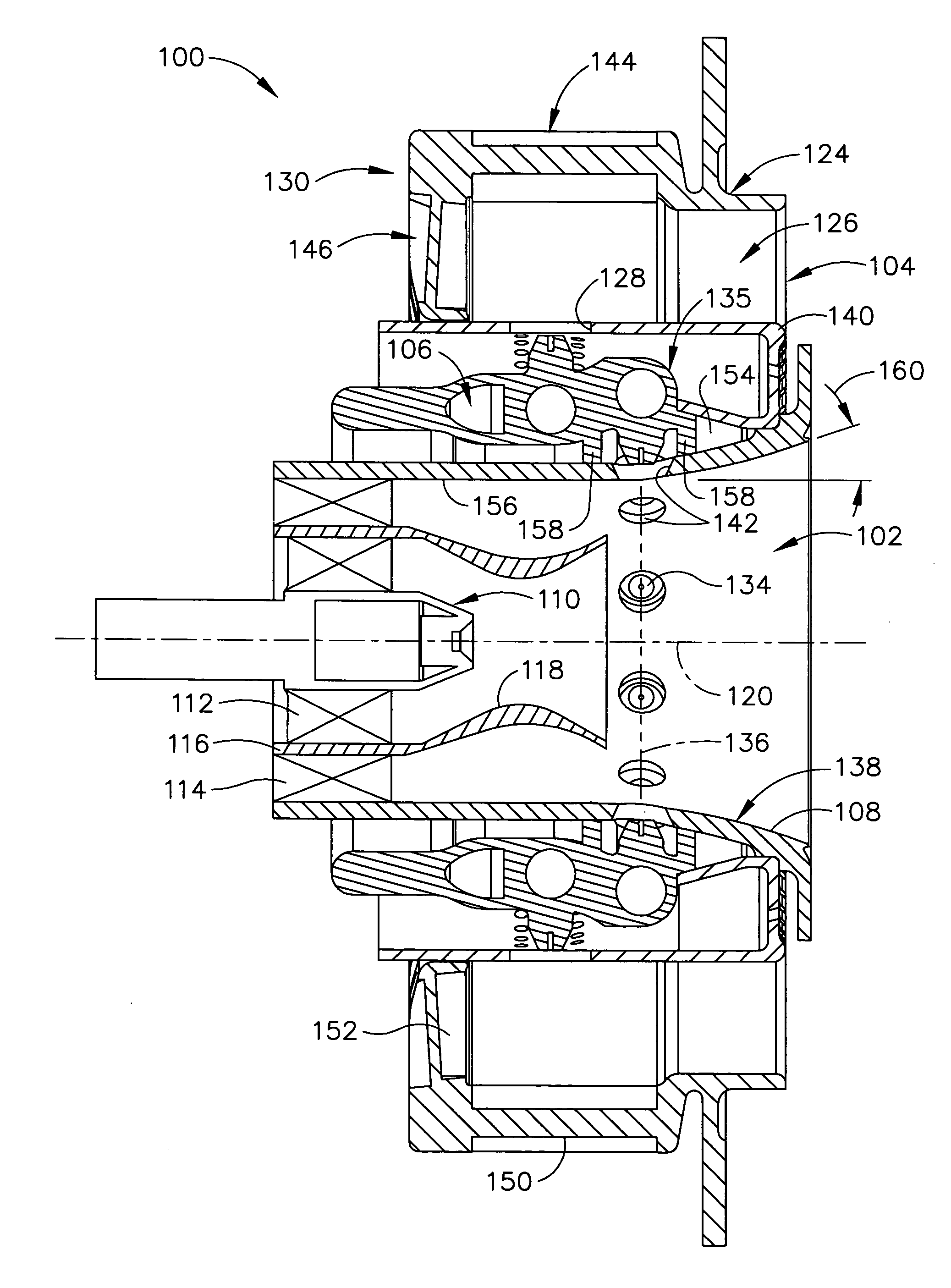

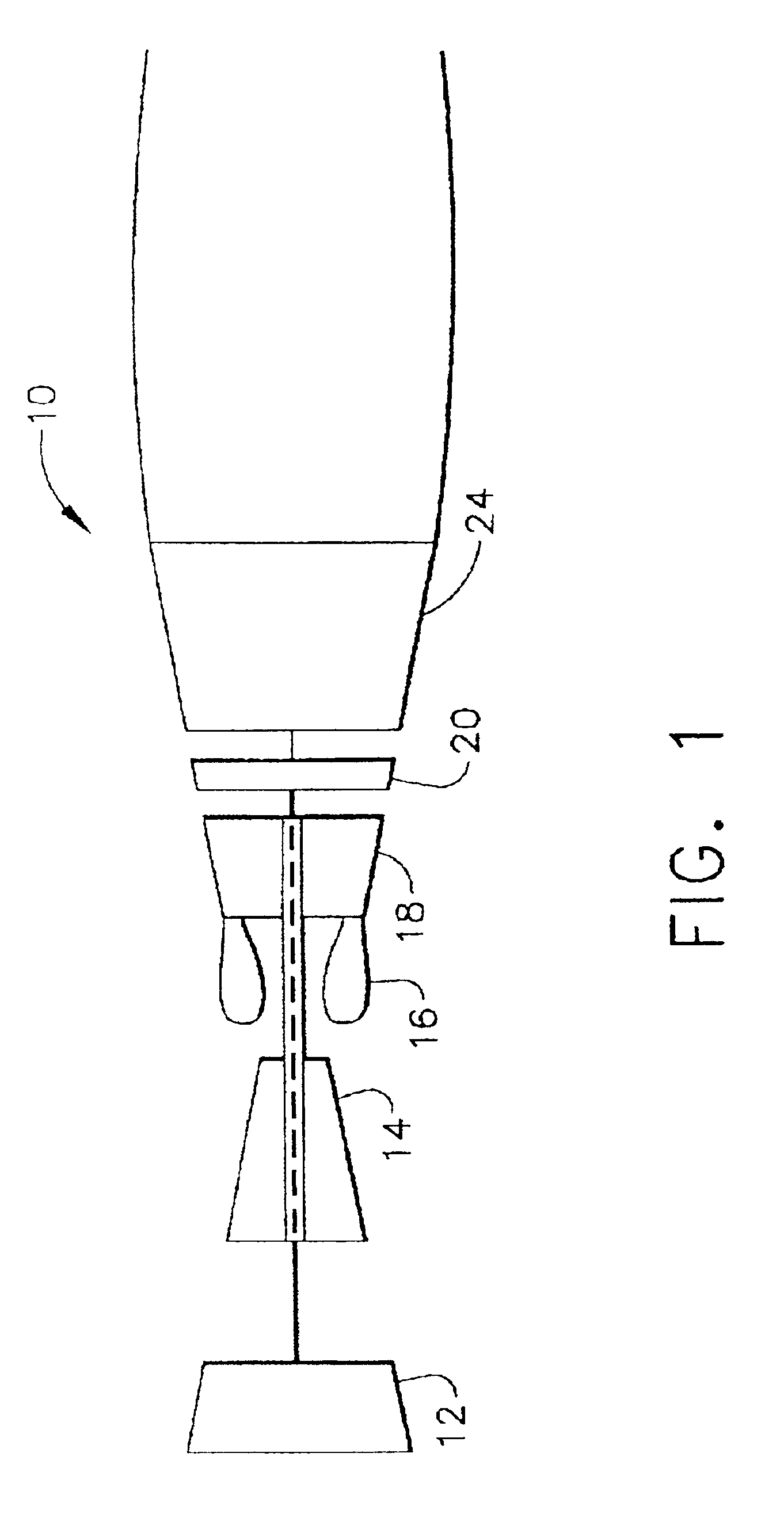

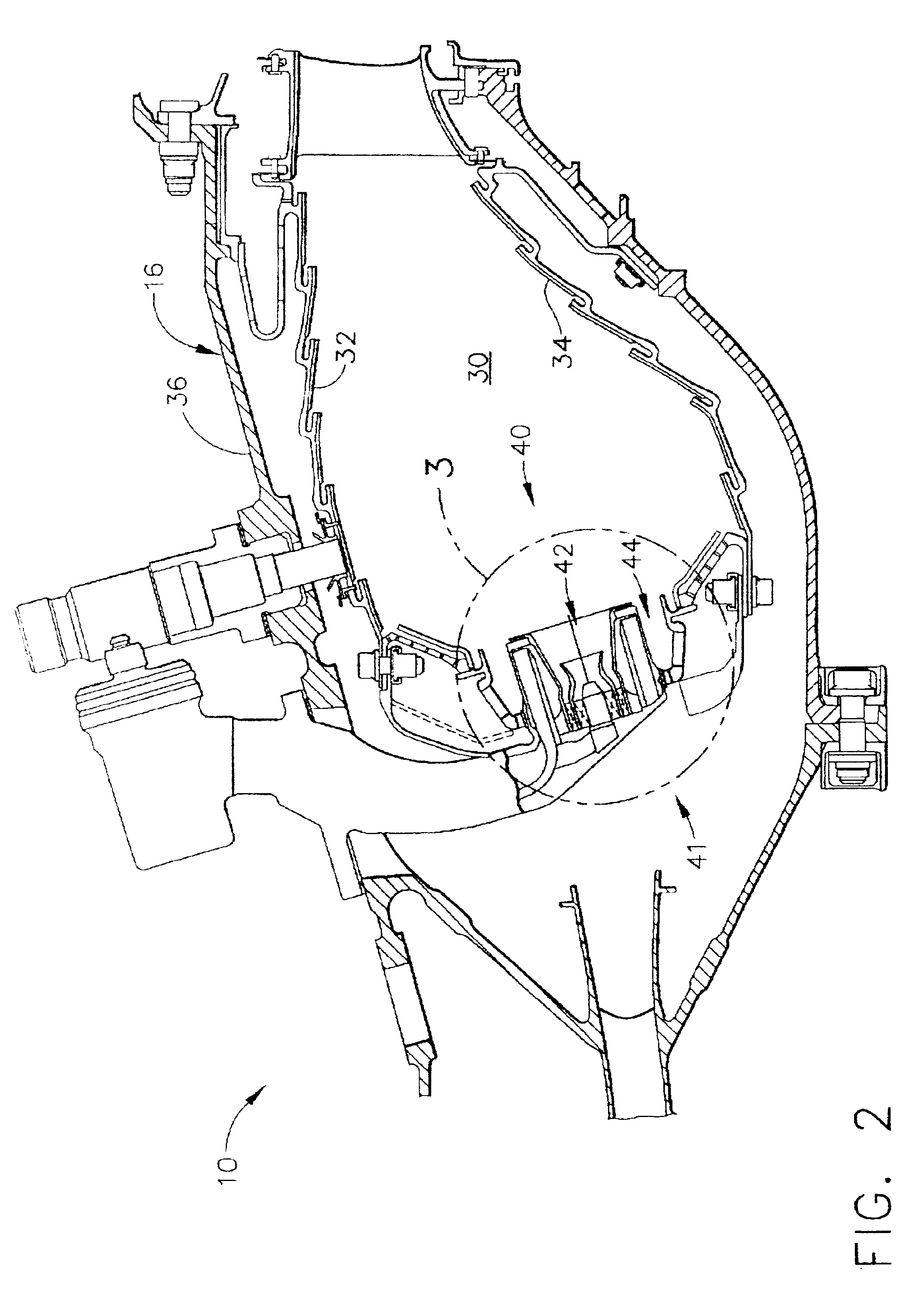

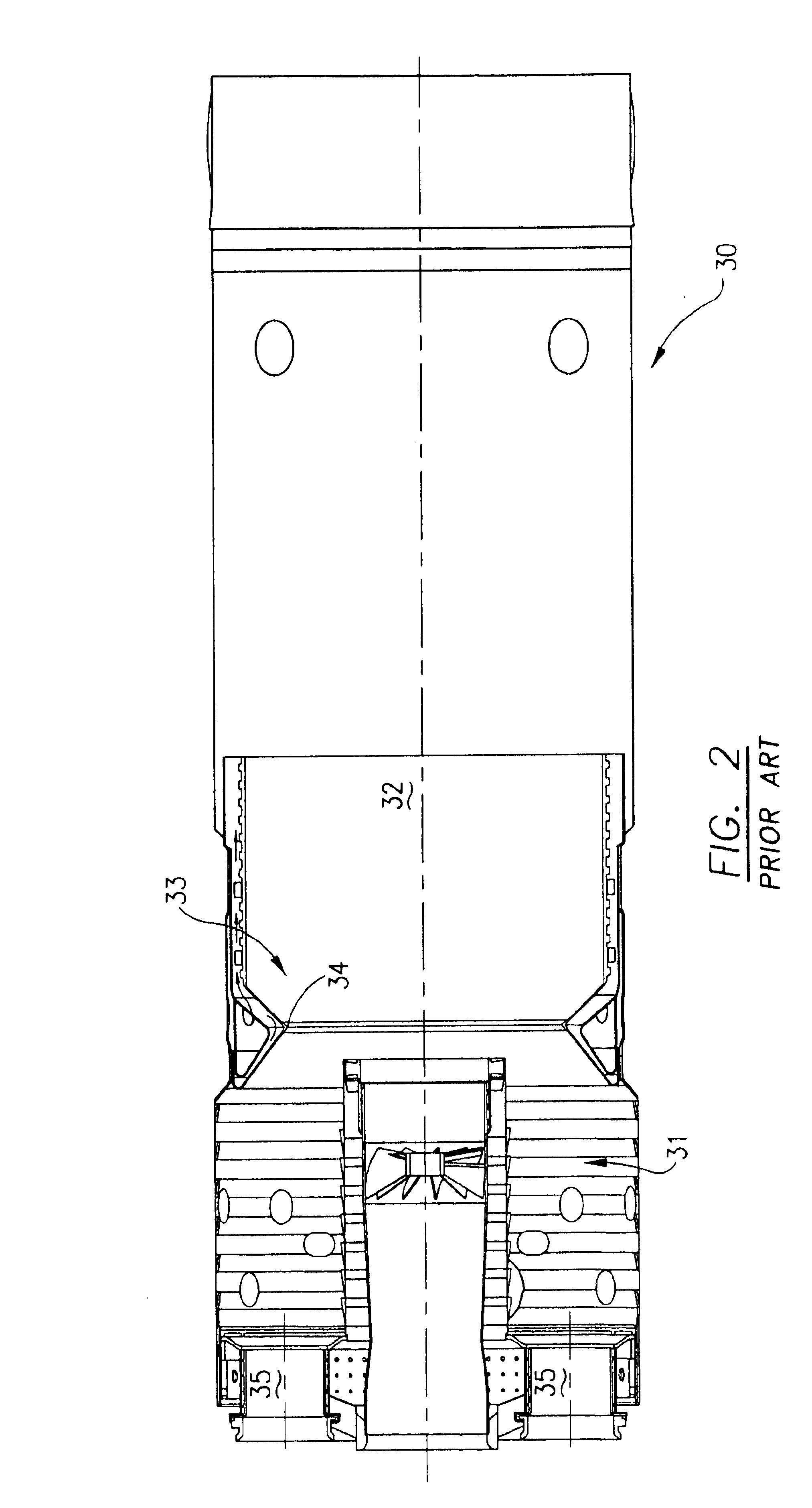

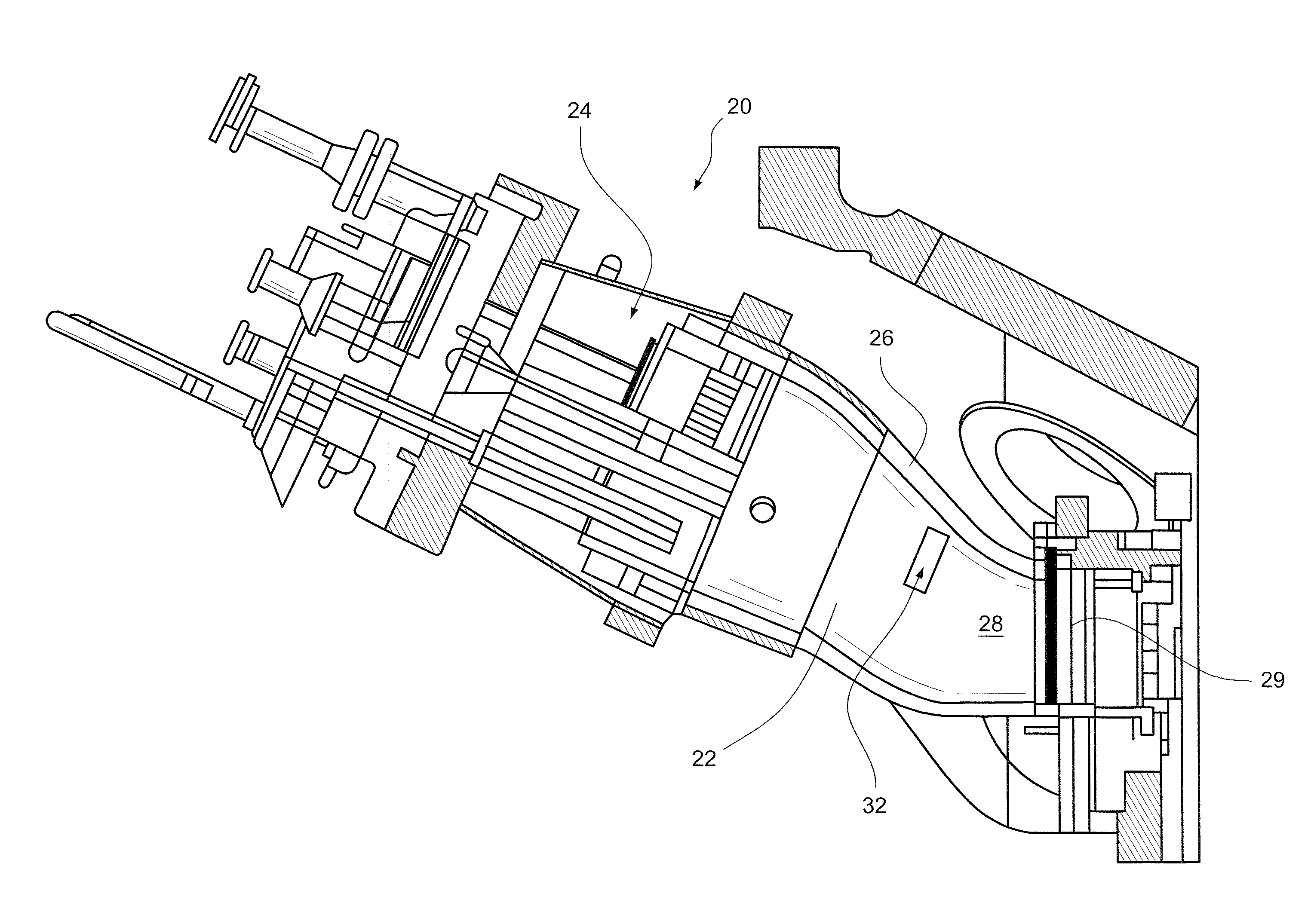

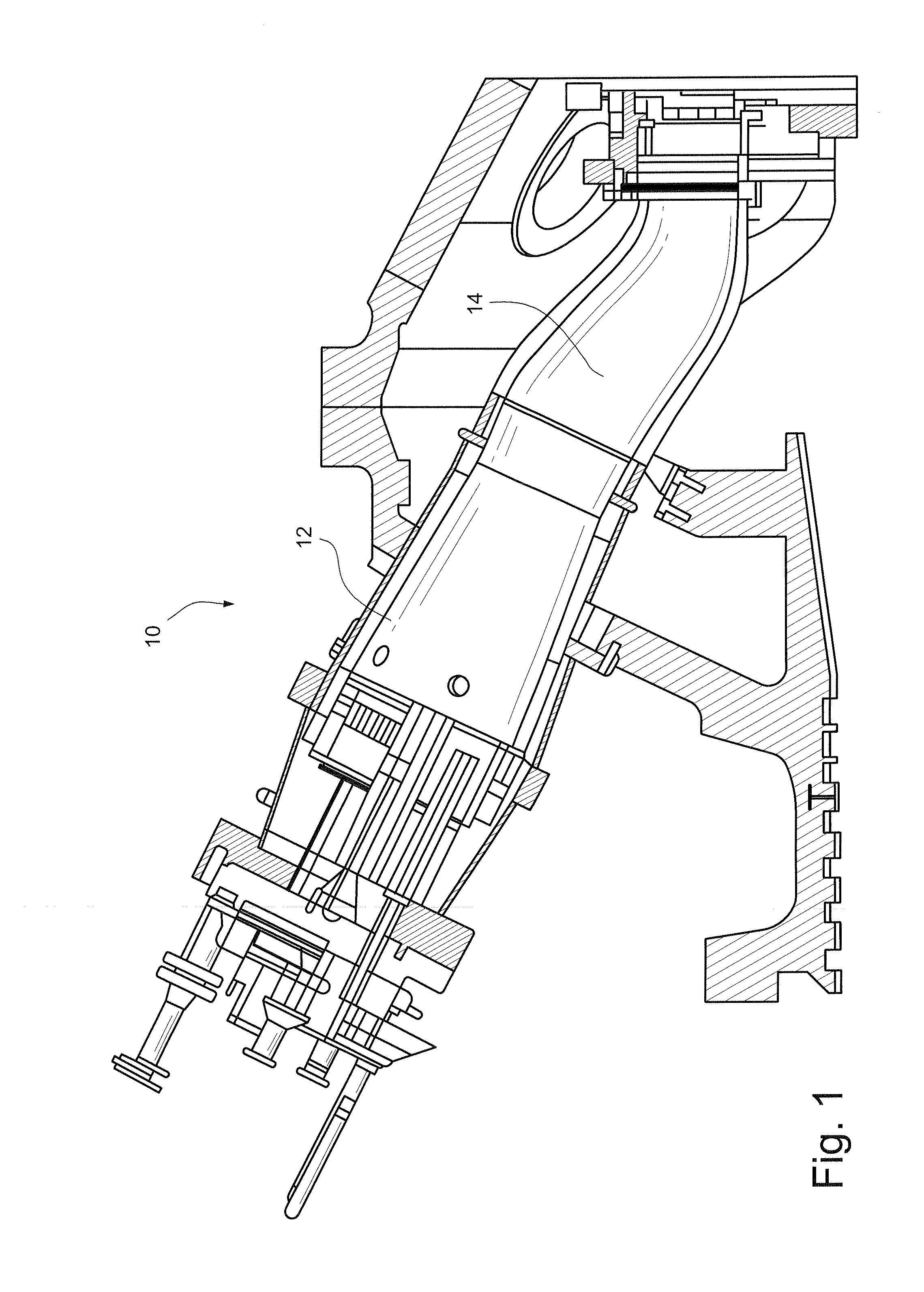

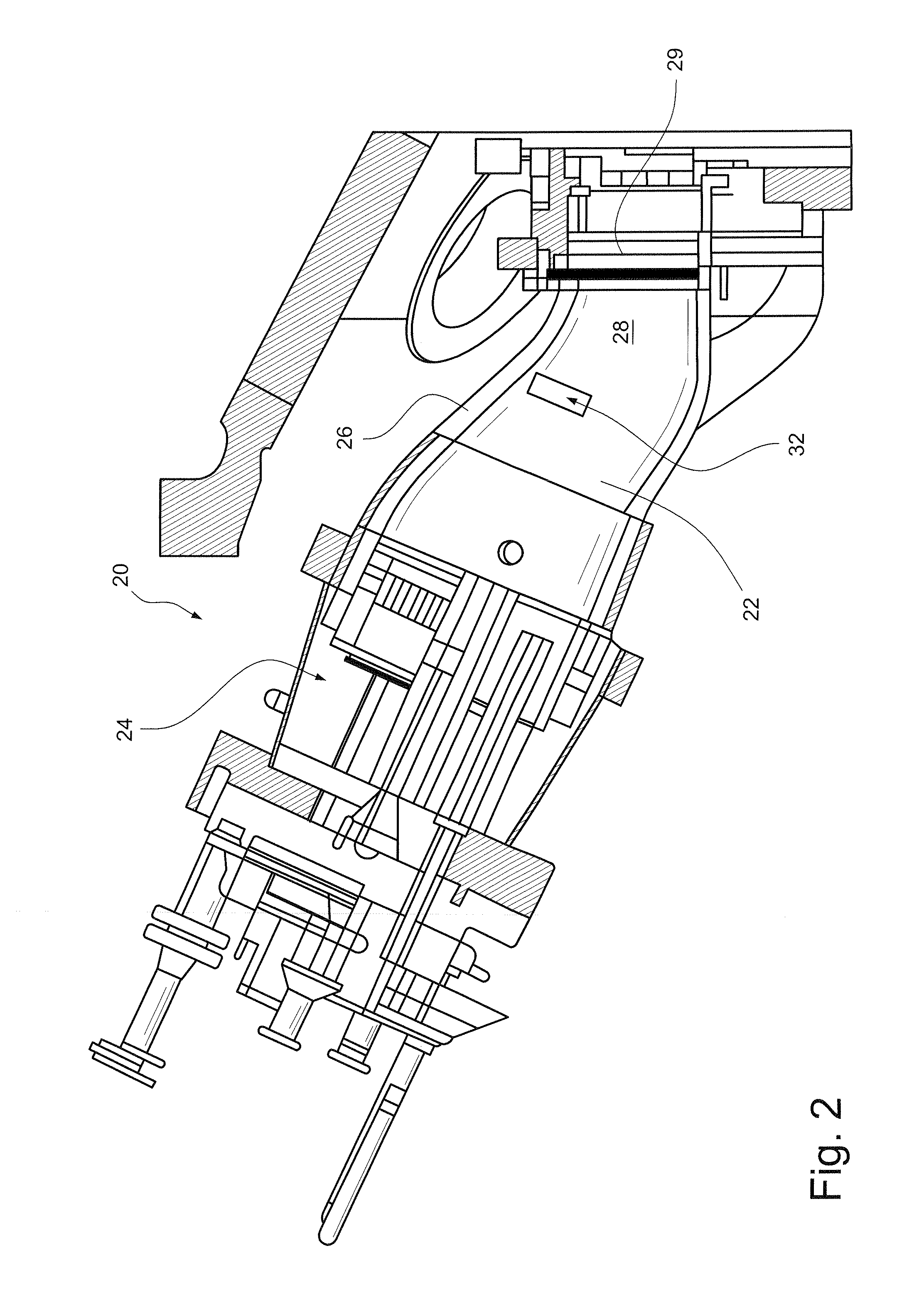

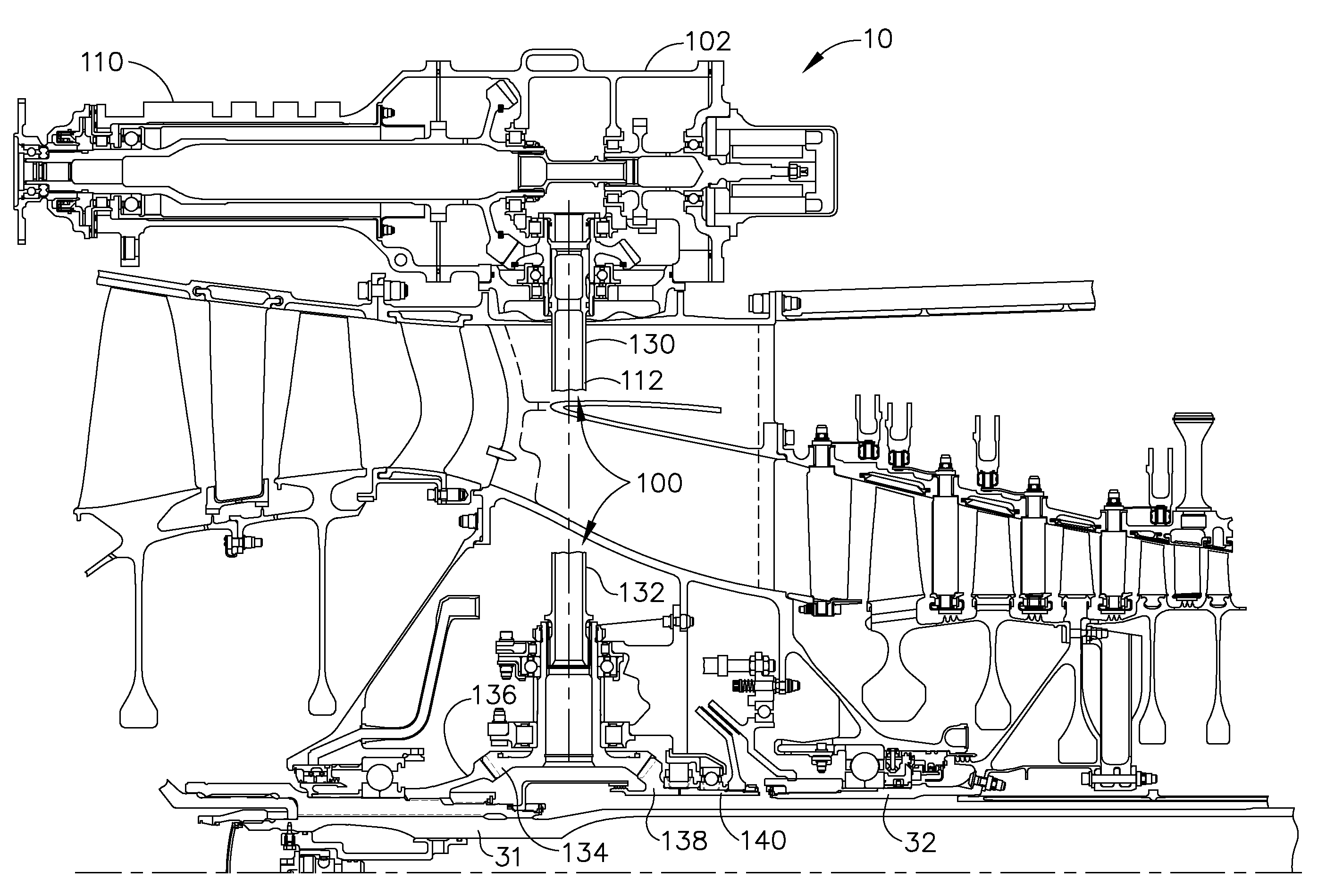

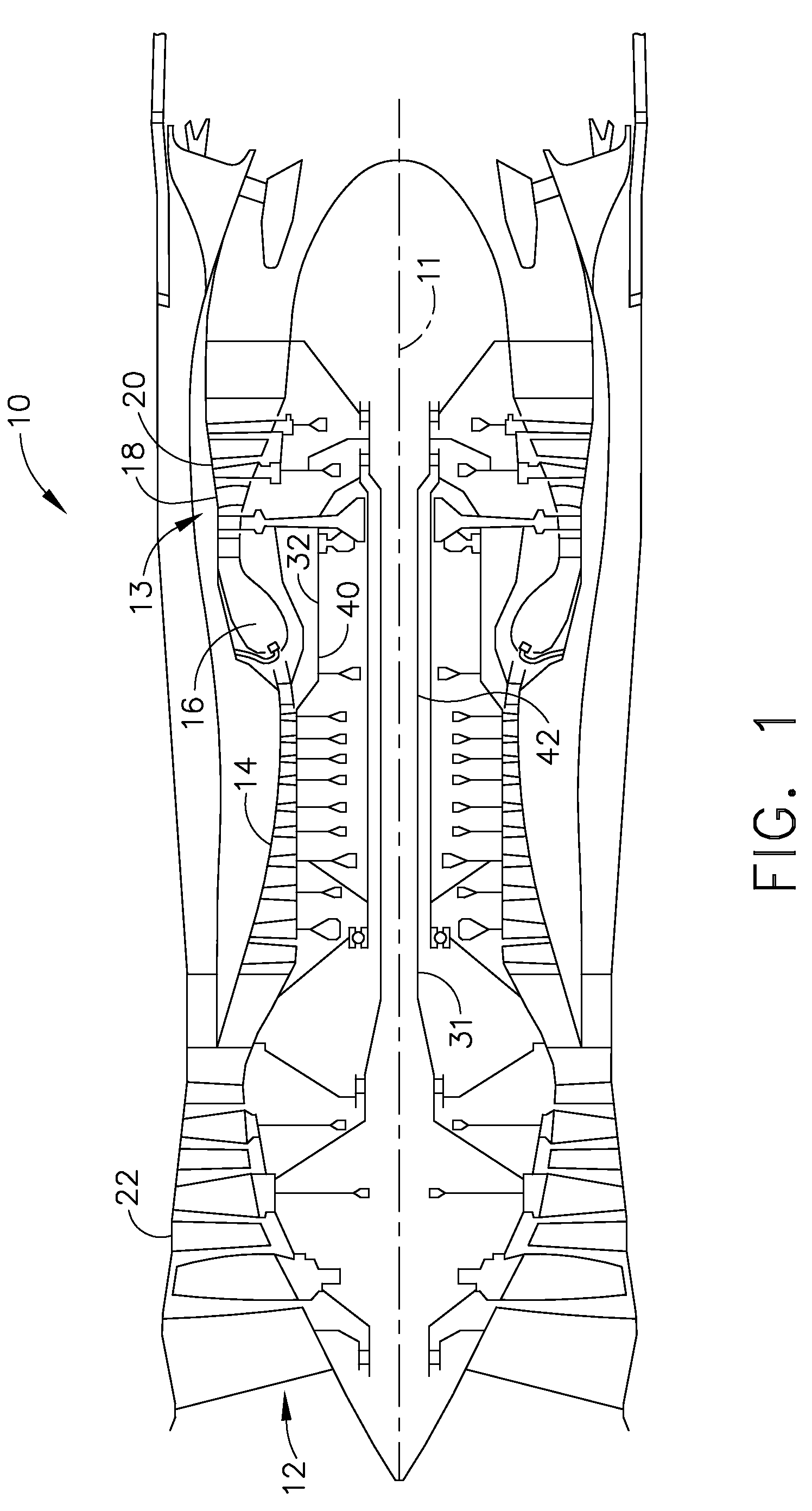

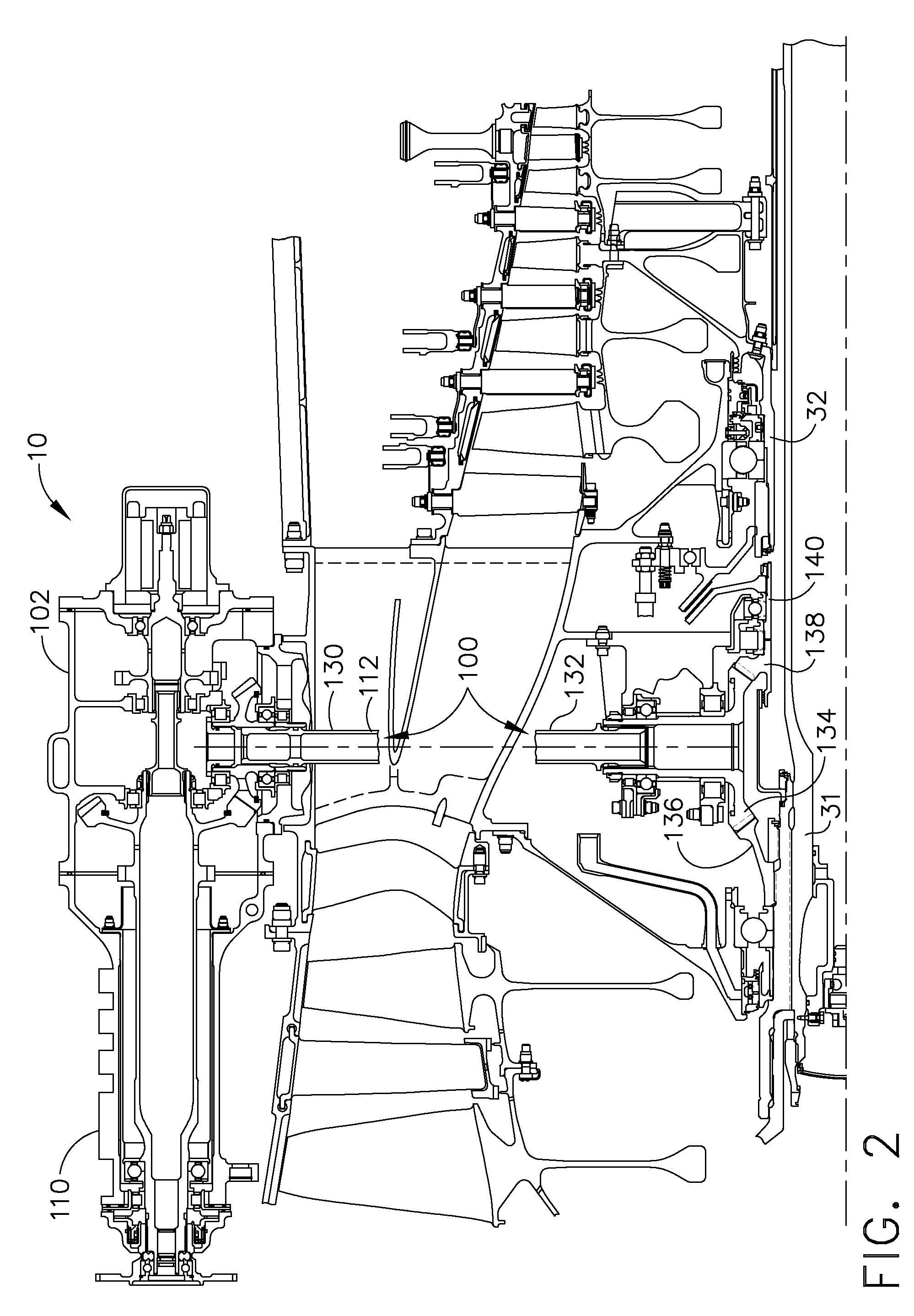

Power take-off system and gas turbine engine assembly including same

ActiveUS8015828B2Turbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionPower take-offGas turbines

A power take-off system for a gas turbine engine includes a starter coupled to a second spool, and a clutch assembly coupled between the starter and a first spool, the clutch assembly configured to couple the first spool to the starter when starting the gas turbine engine assembly. A method of assembling a gas turbine engine assembly that includes the power take-off system, and a gas turbine engine assembly including the power take-off system are also described.

Owner:GENERAL ELECTRIC CO

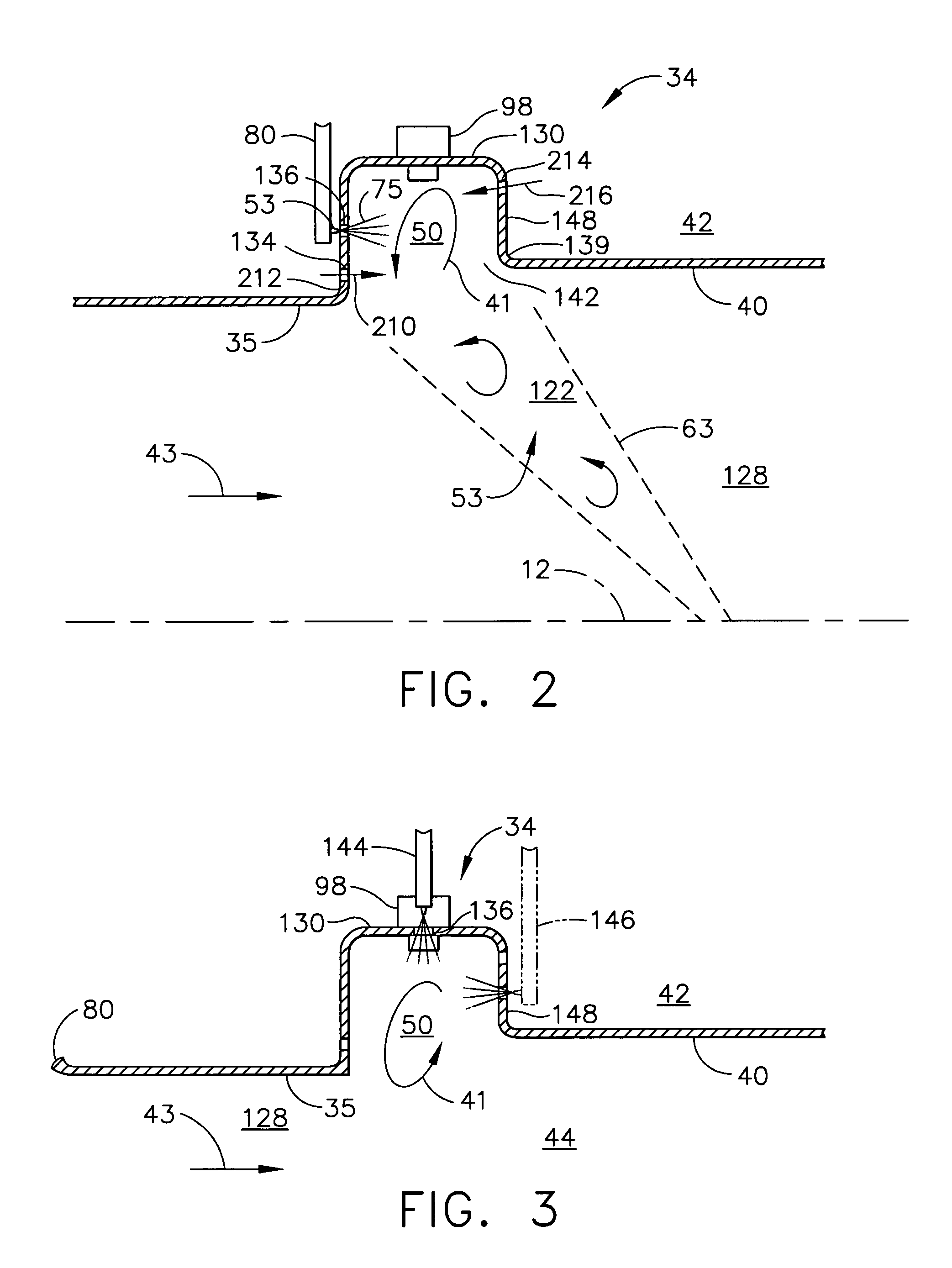

Method and apparatus for air and fuel injection in a turbine

InactiveUS20100300102A1Reduce the possibilityTurbine/propulsion fuel supply systemsContinuous combustion chamberTurbineFuel injection

A method includes receiving fuel and air into a cup of a turbine fuel nozzle. The method also includes mixing the fuel and air at least partially within the cup. In addition, the method includes directing a fuel air mixture toward a turbine combustor. The method also includes shielding an inner wall of the cup with a blanket of a protective fluid flow to reduce the possibility of flame holding along the inner wall. The protective fluid flow excludes a combustible mixture of fuel and air.

Owner:GENERAL ELECTRIC CO

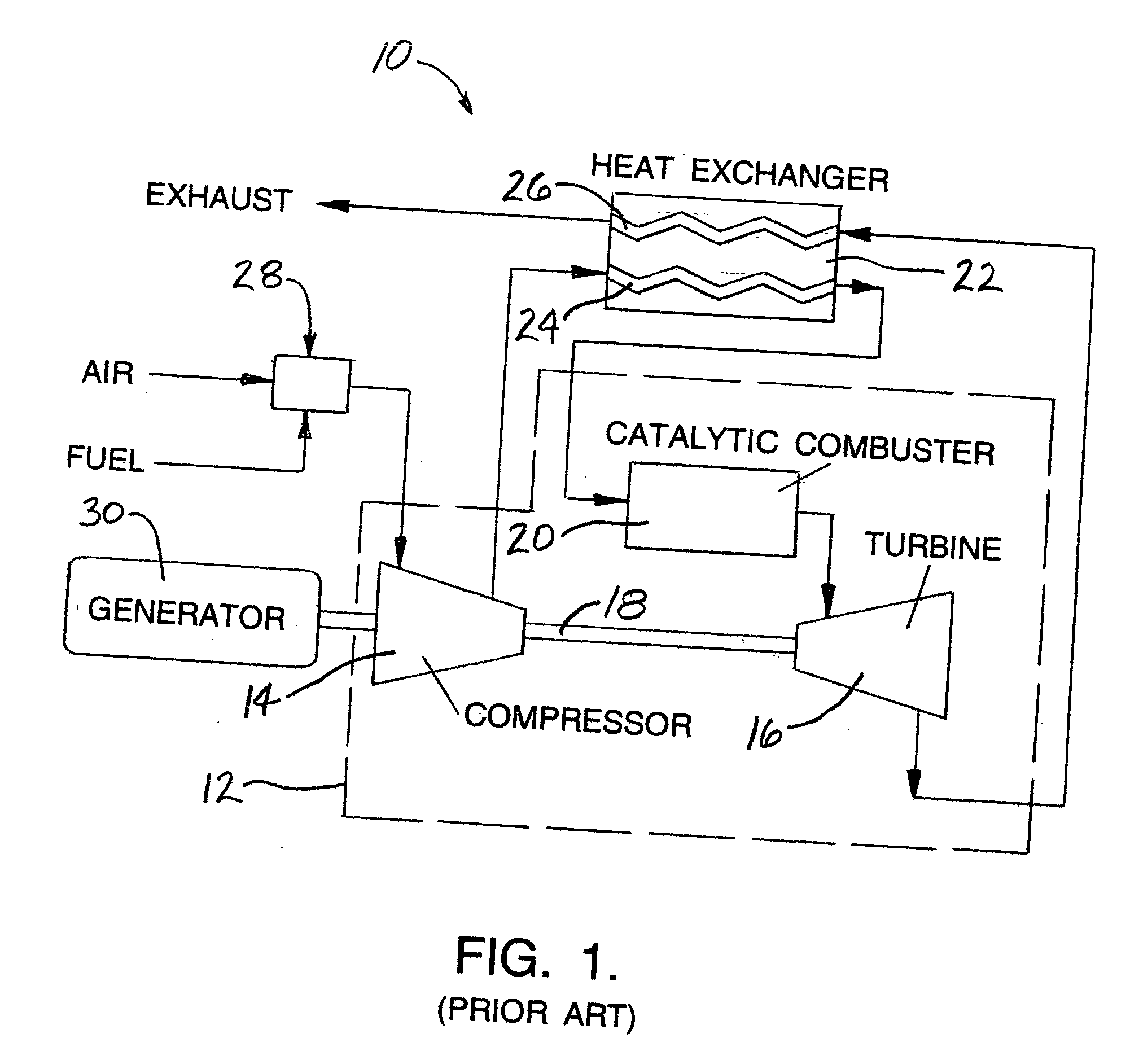

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com