Patents

Literature

15196results about "Gaseous fuel burner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

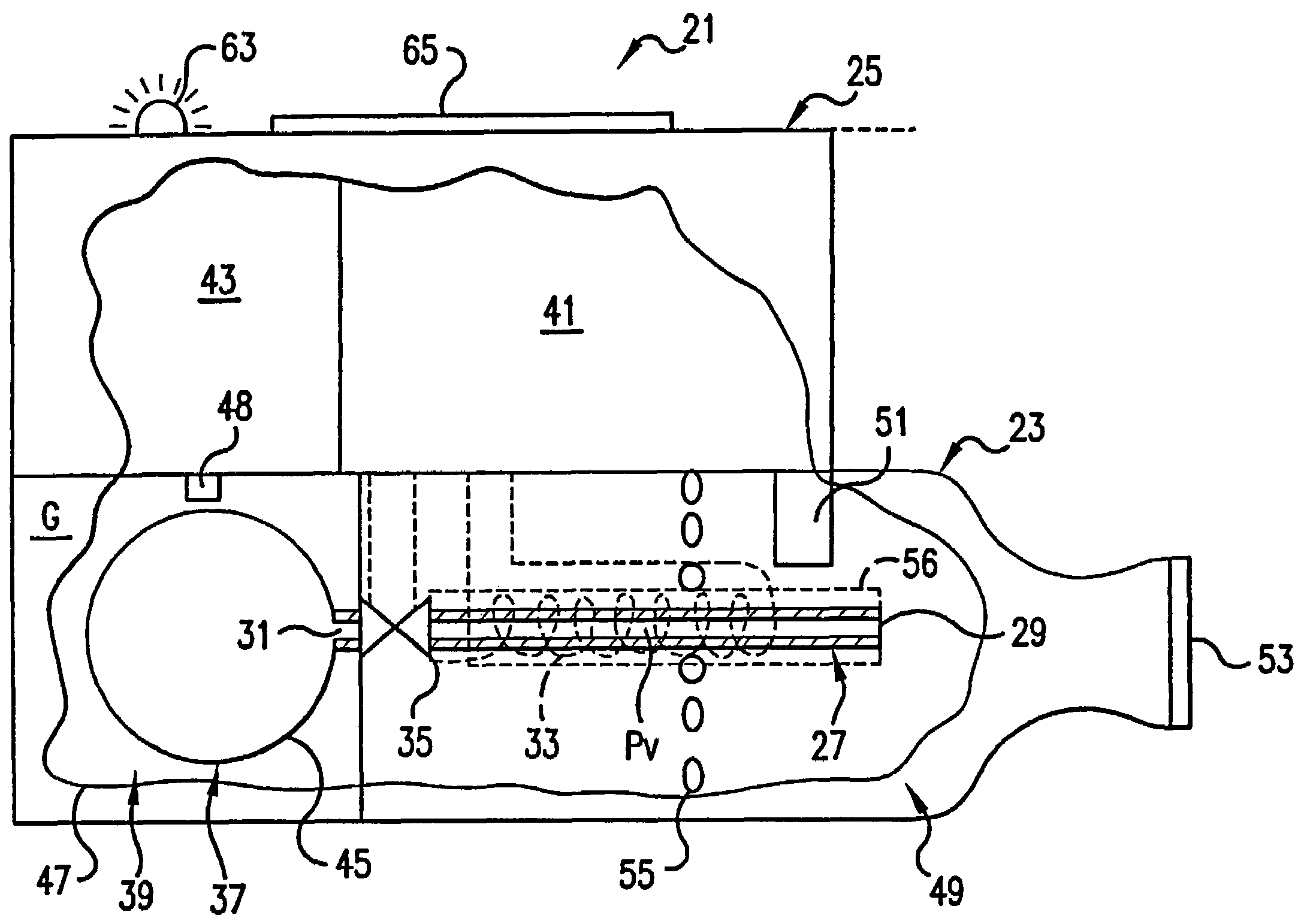

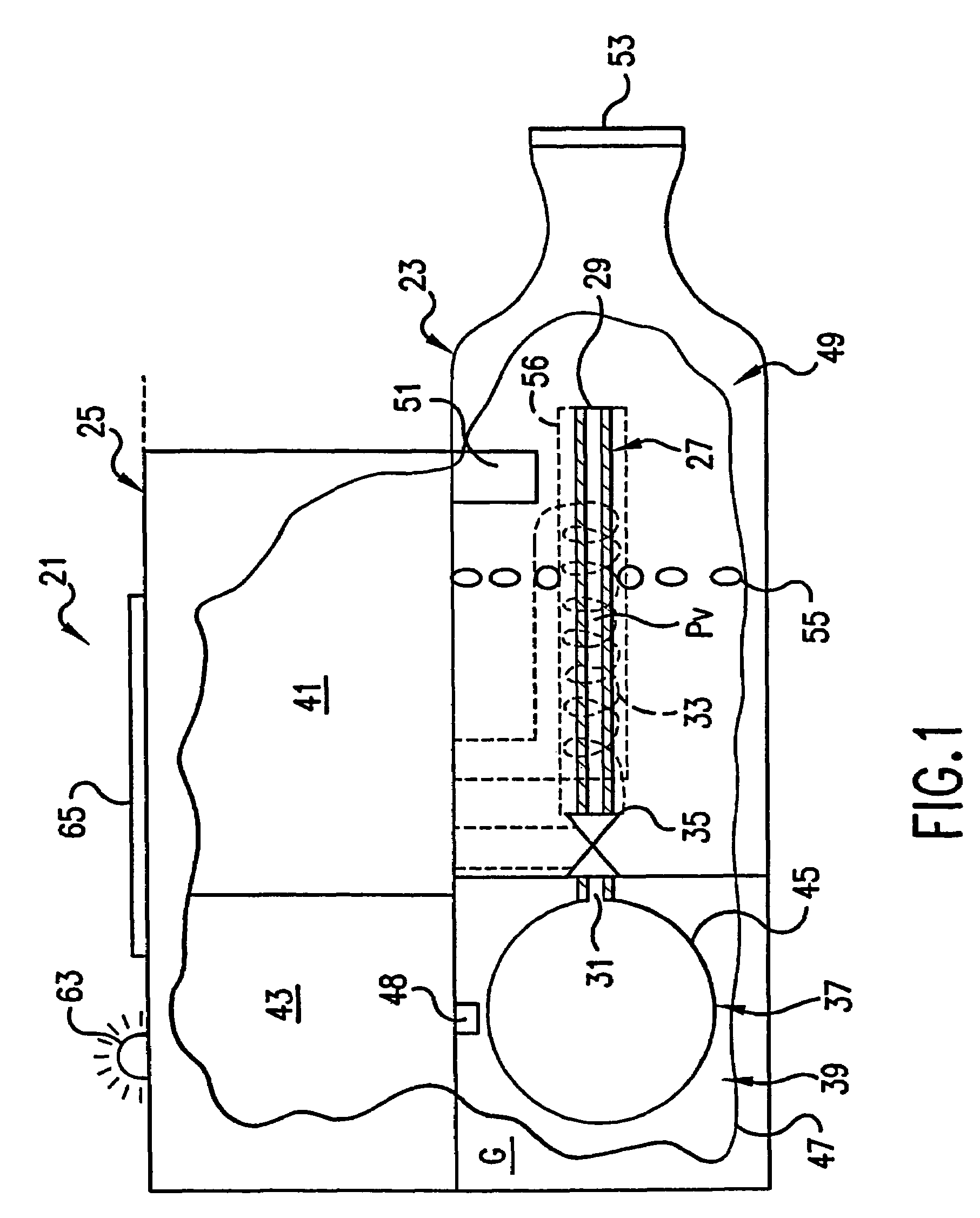

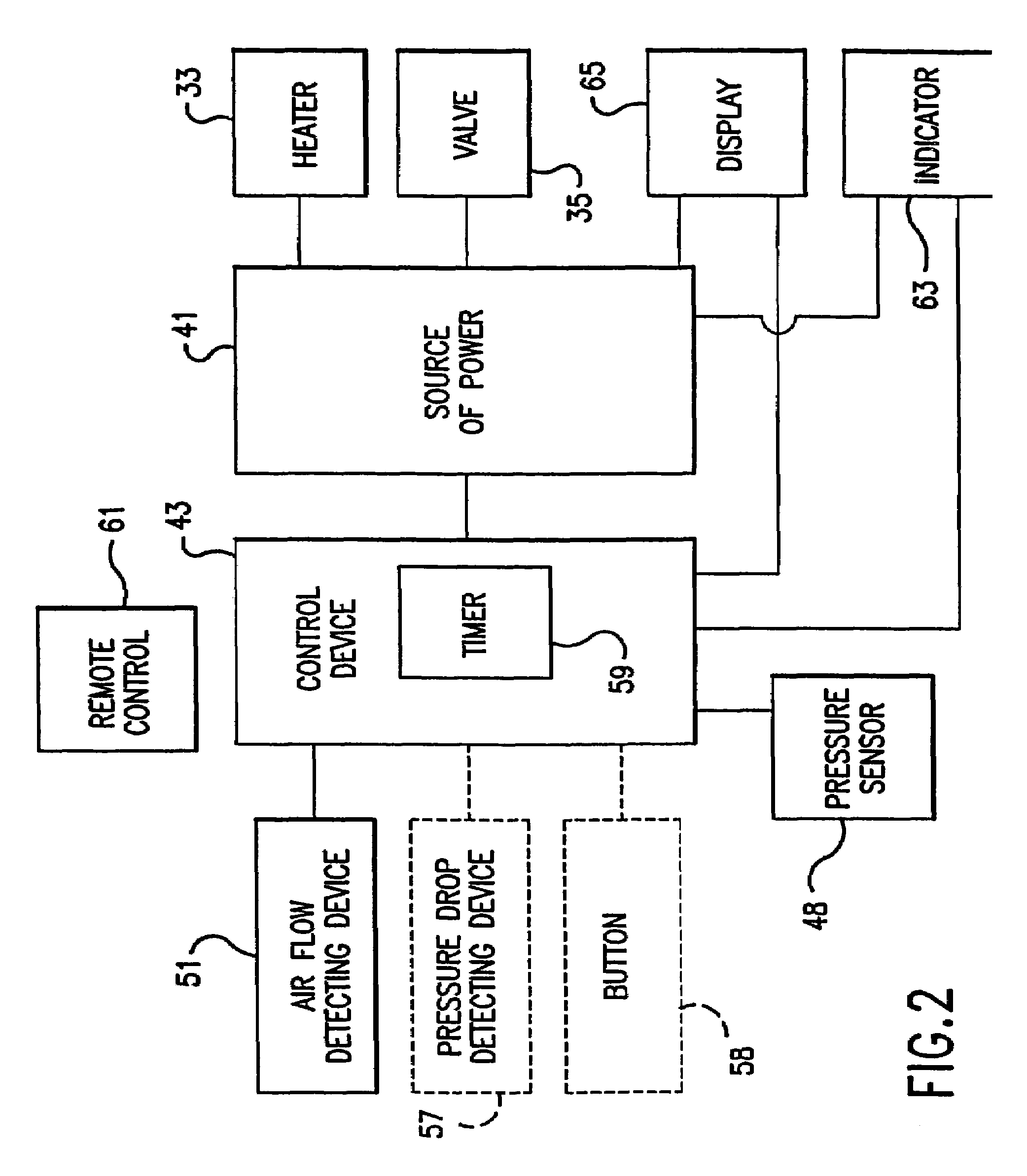

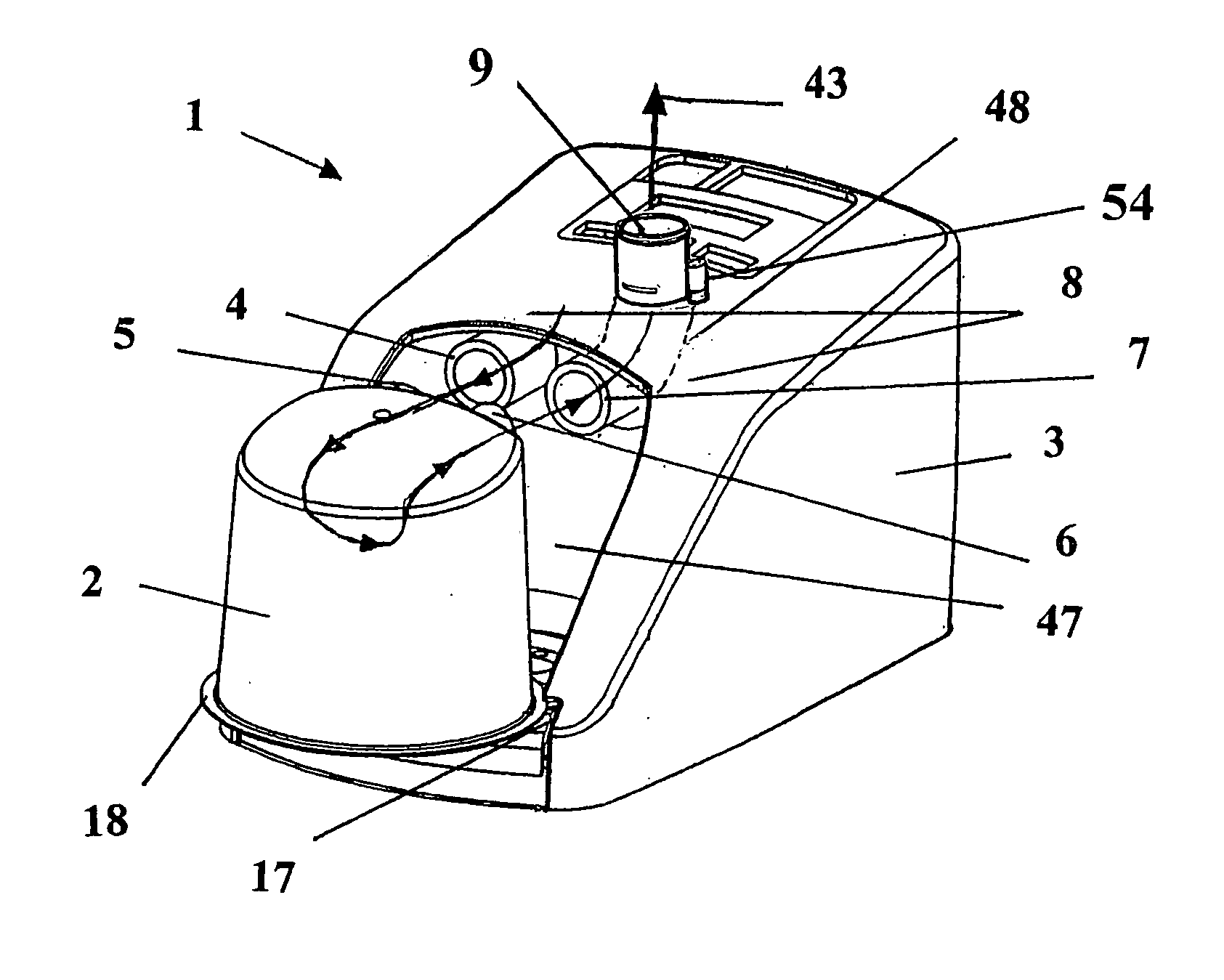

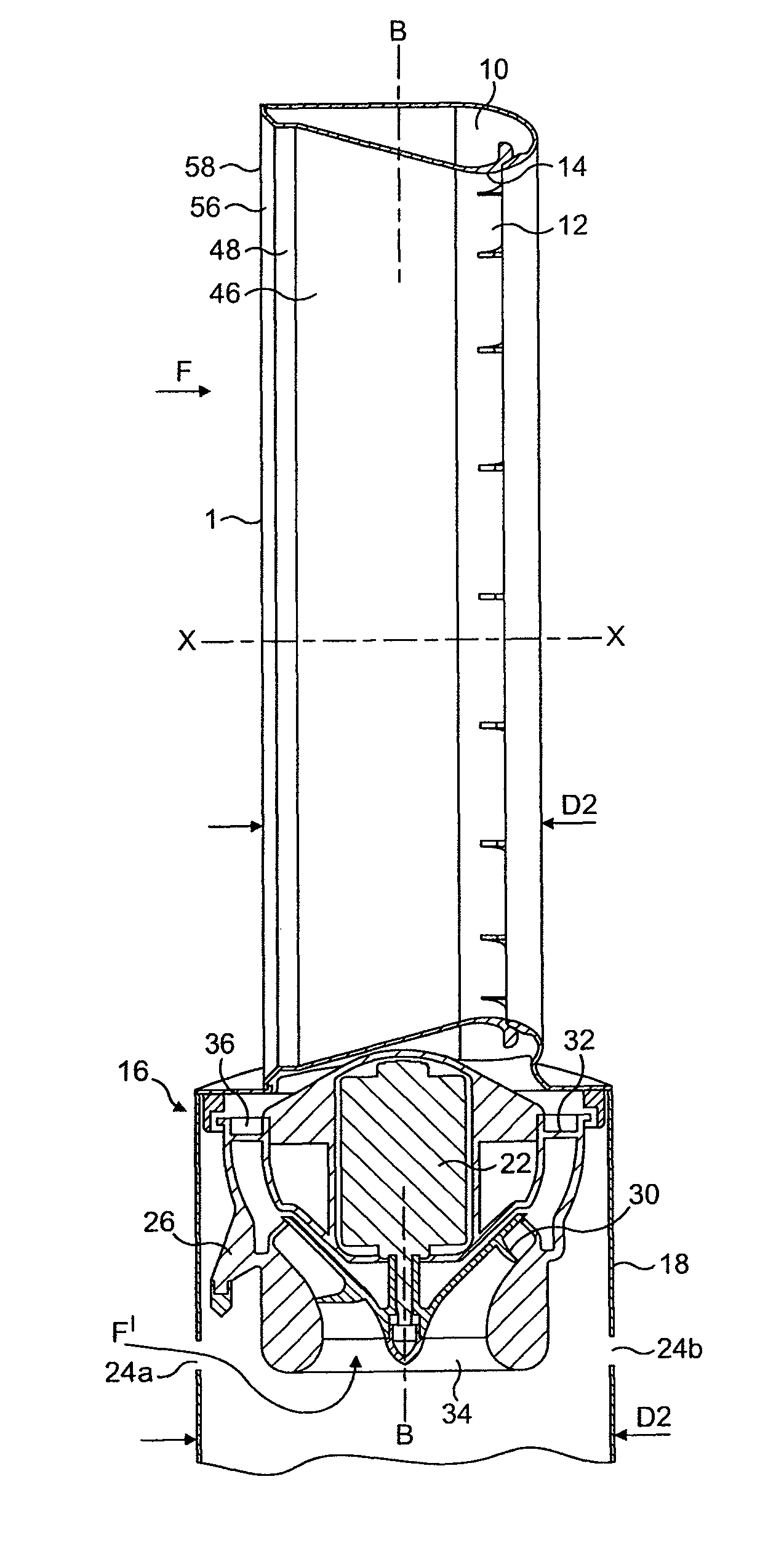

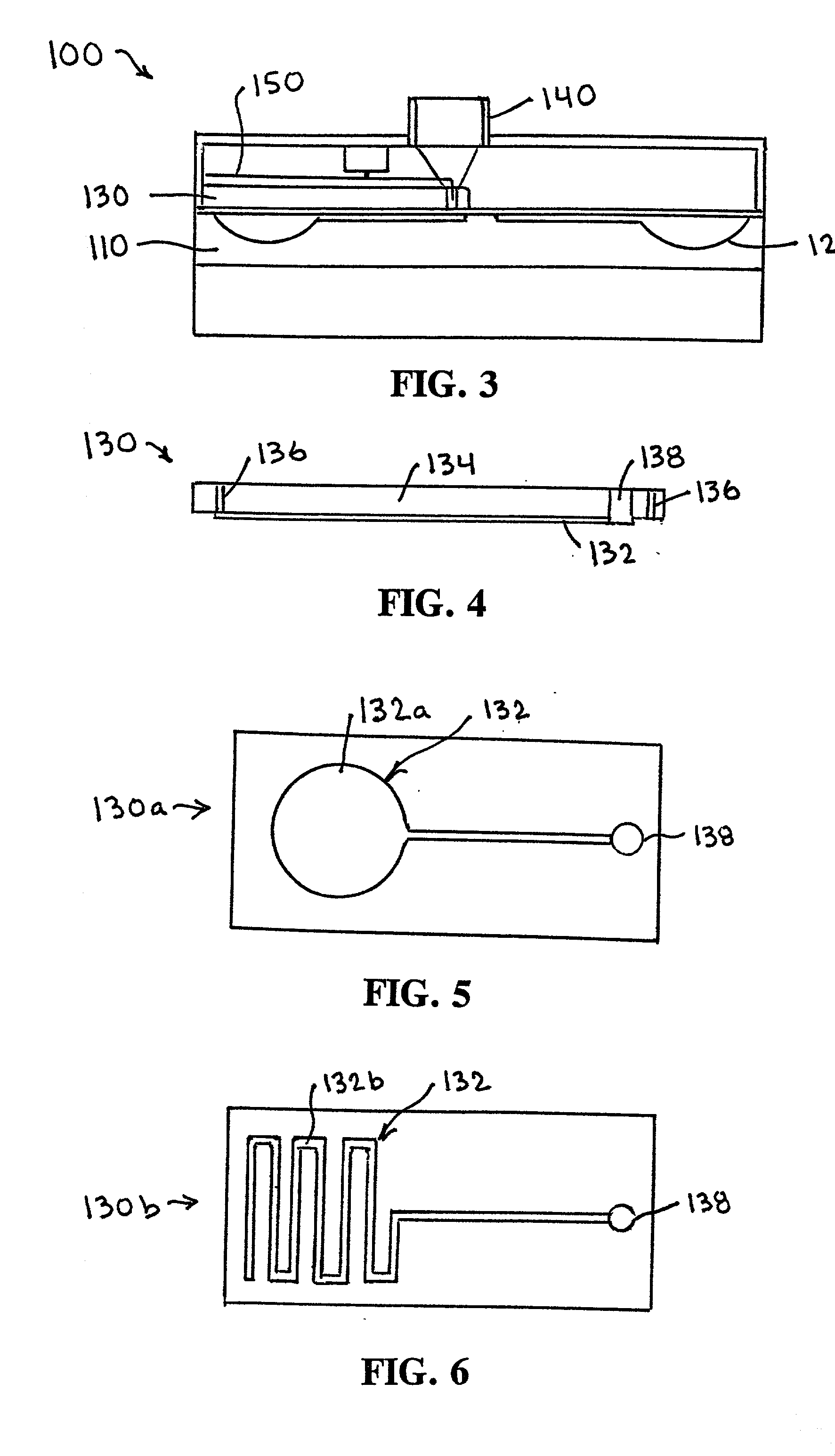

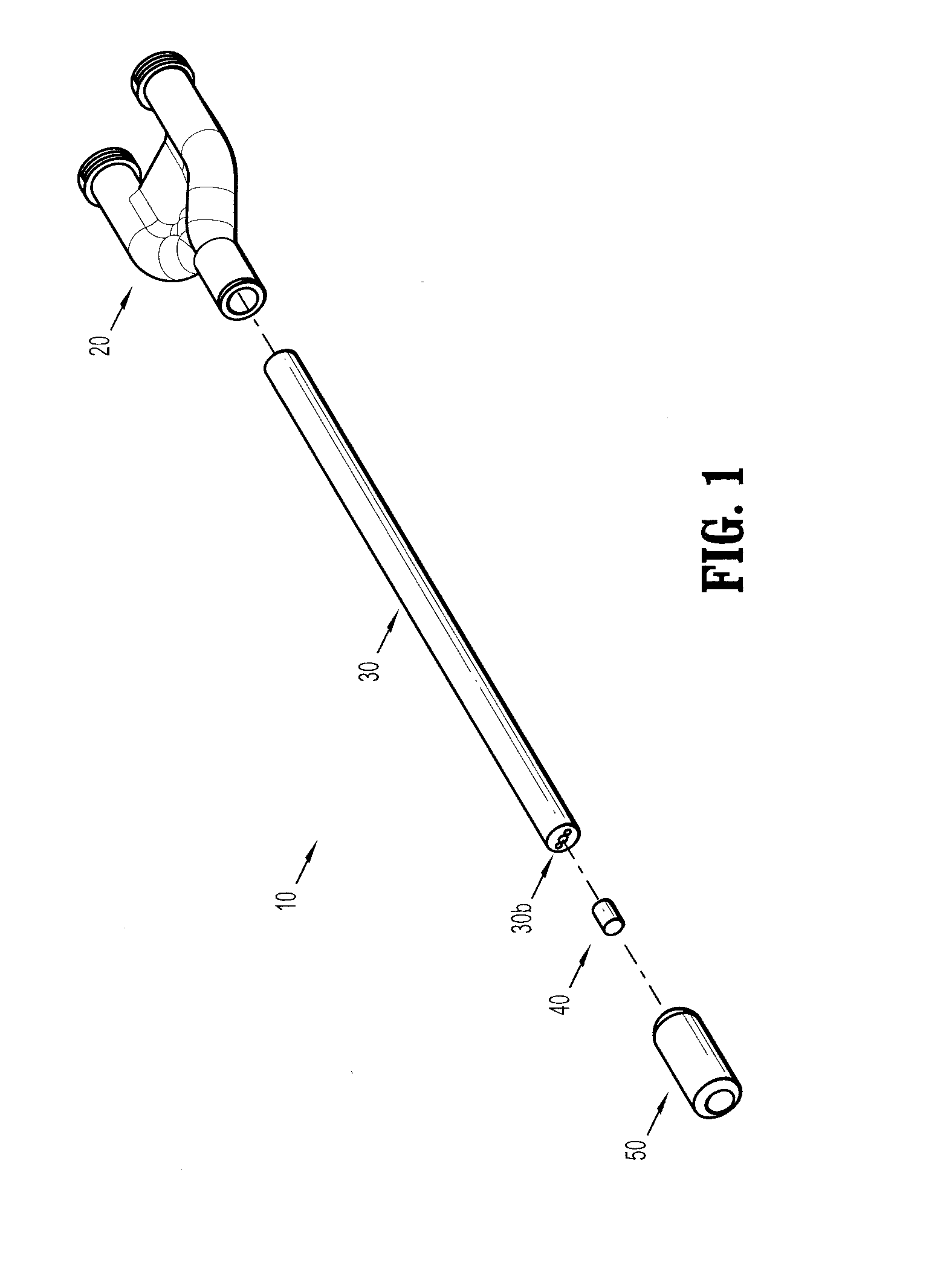

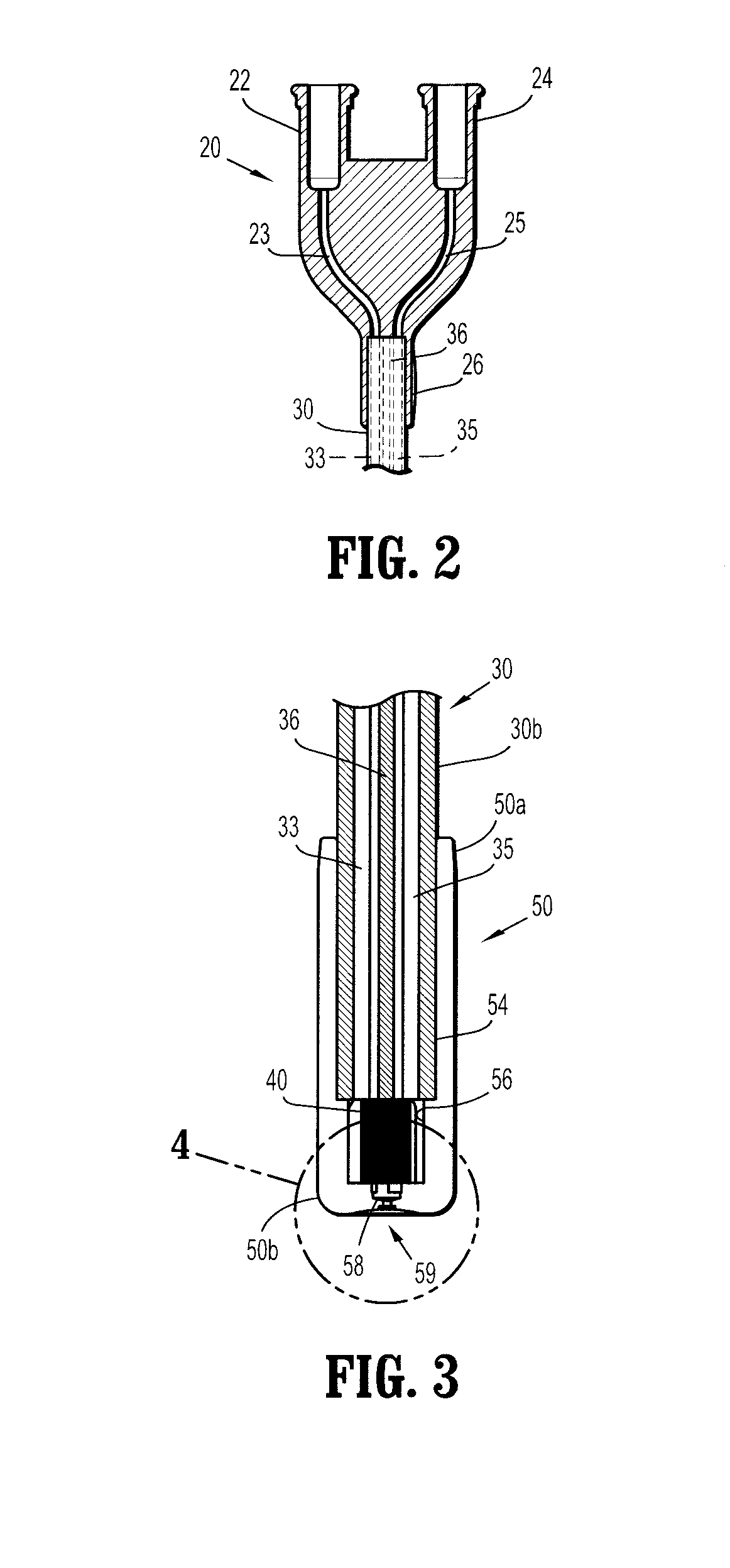

Aerosol generator and methods of making and using an aerosol generator

InactiveUS7117867B2Easy to useEasy to moveRespiratorsControlling ratio of multiple fluid flowsRotary valveEngineering

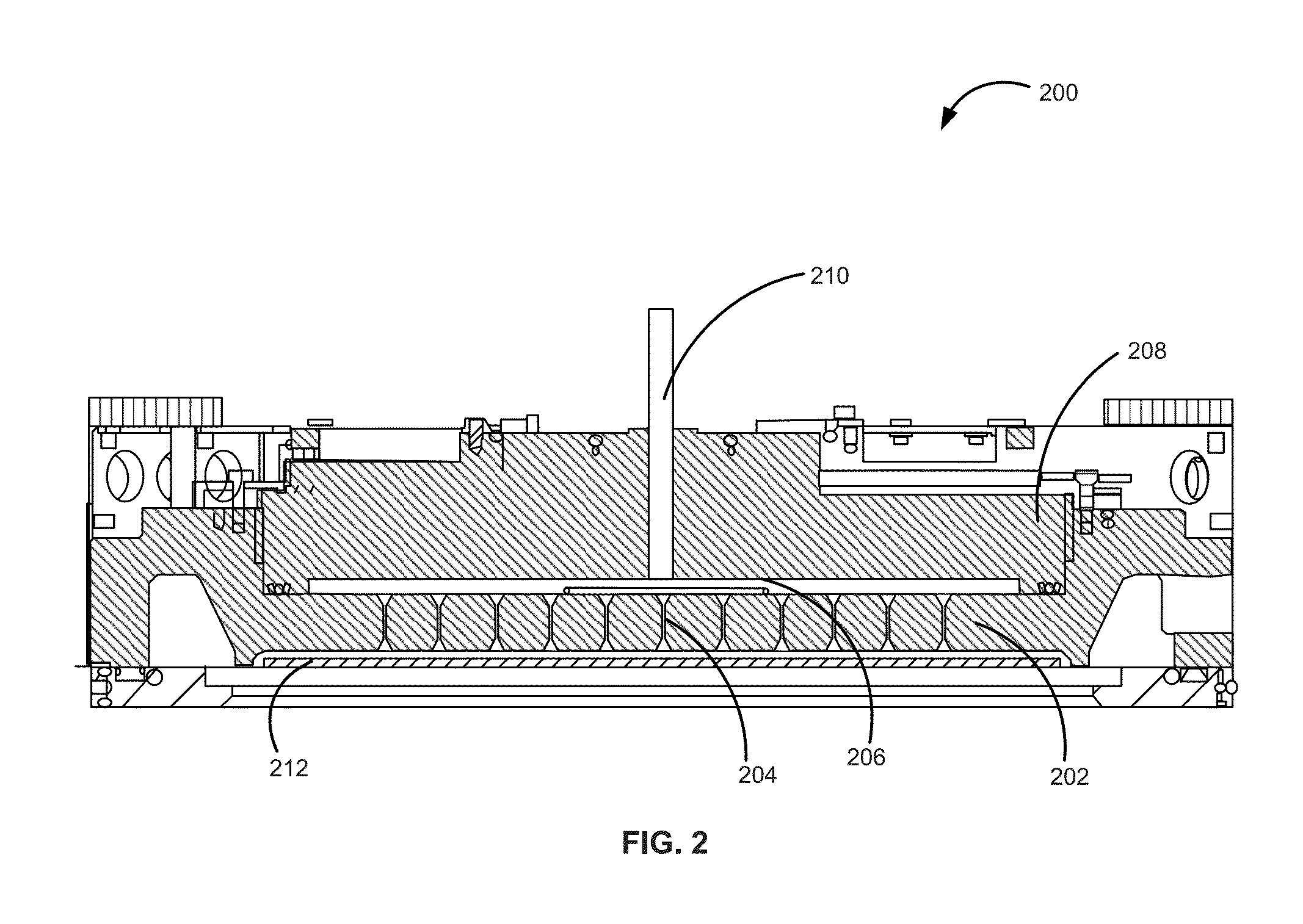

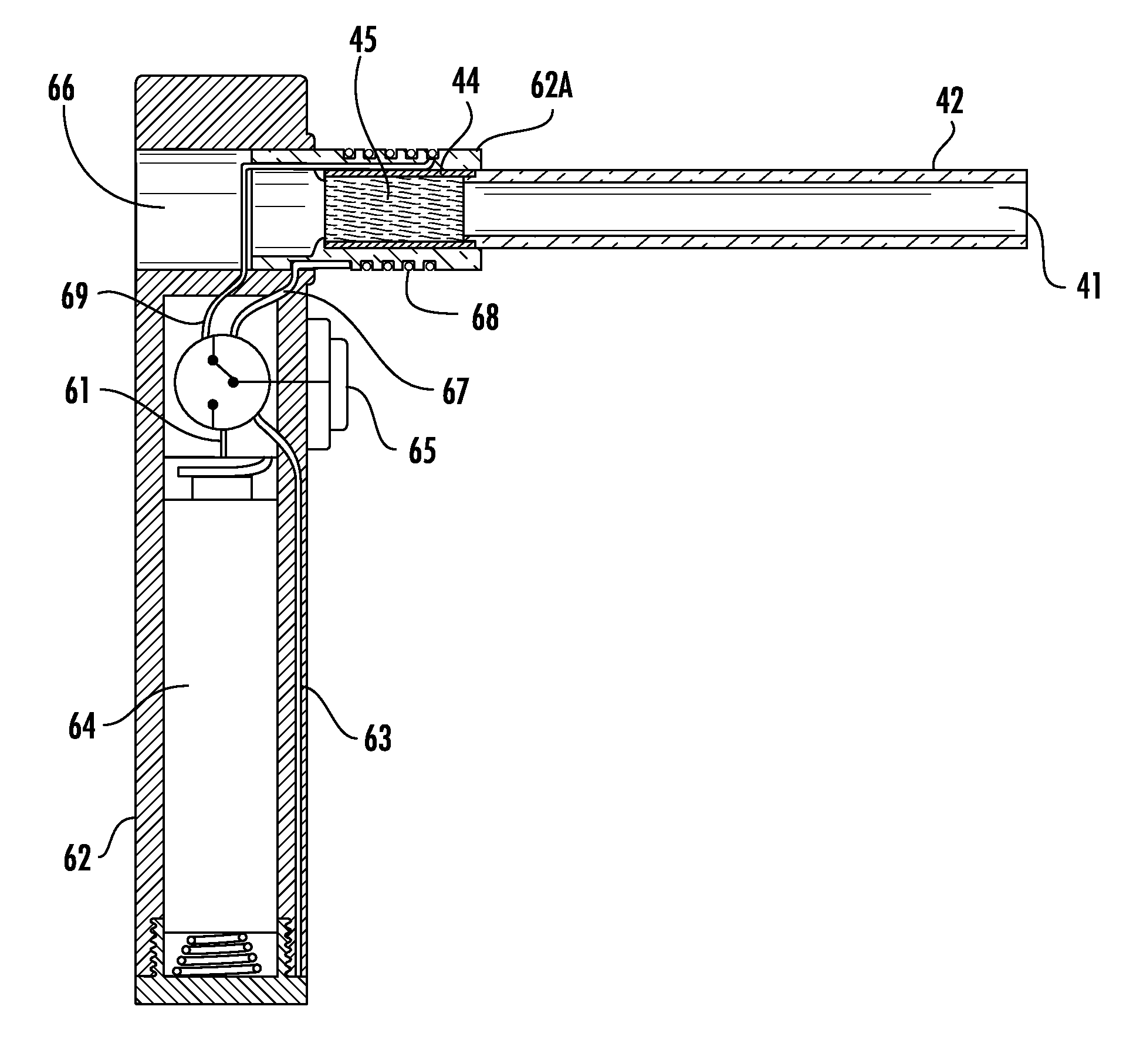

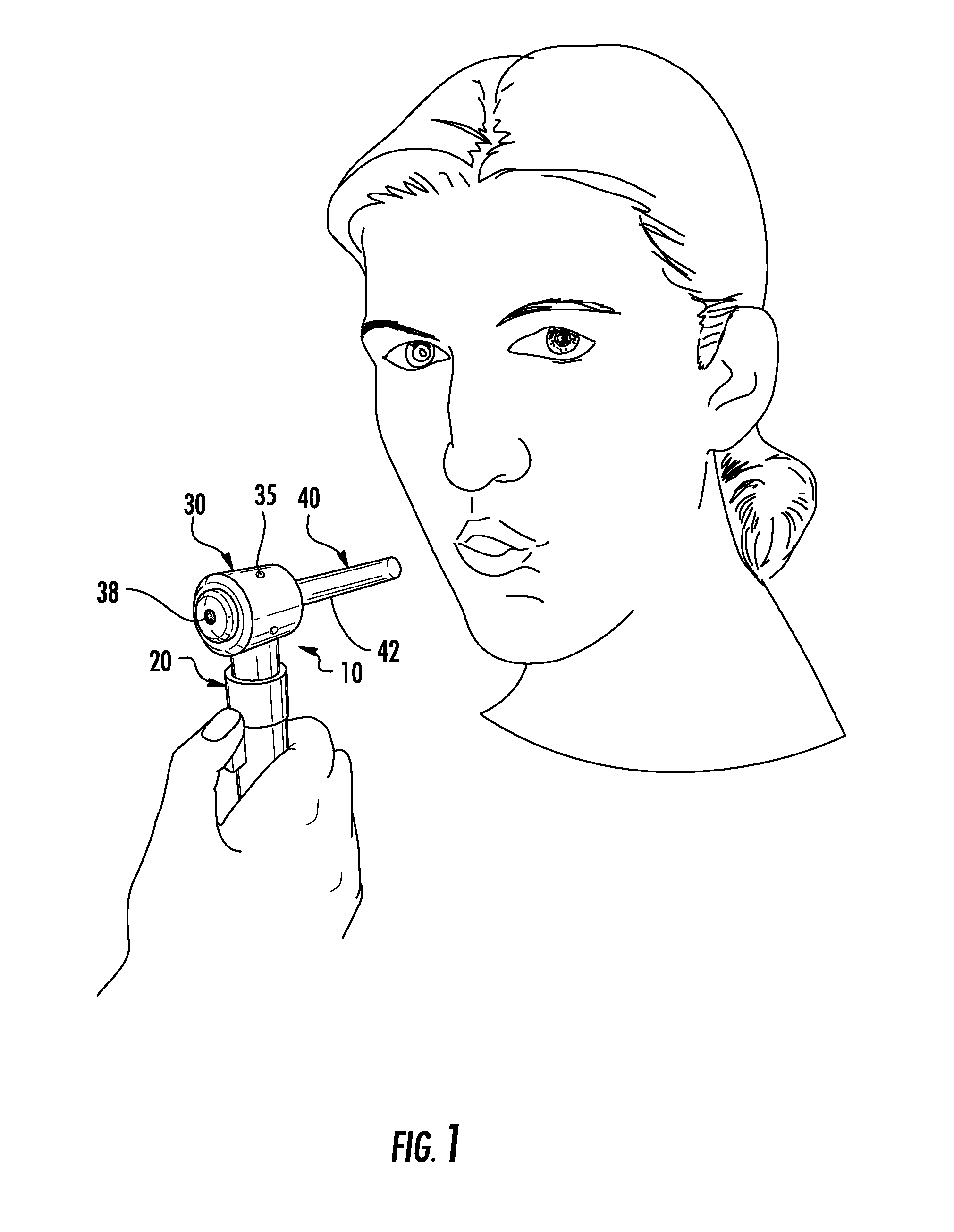

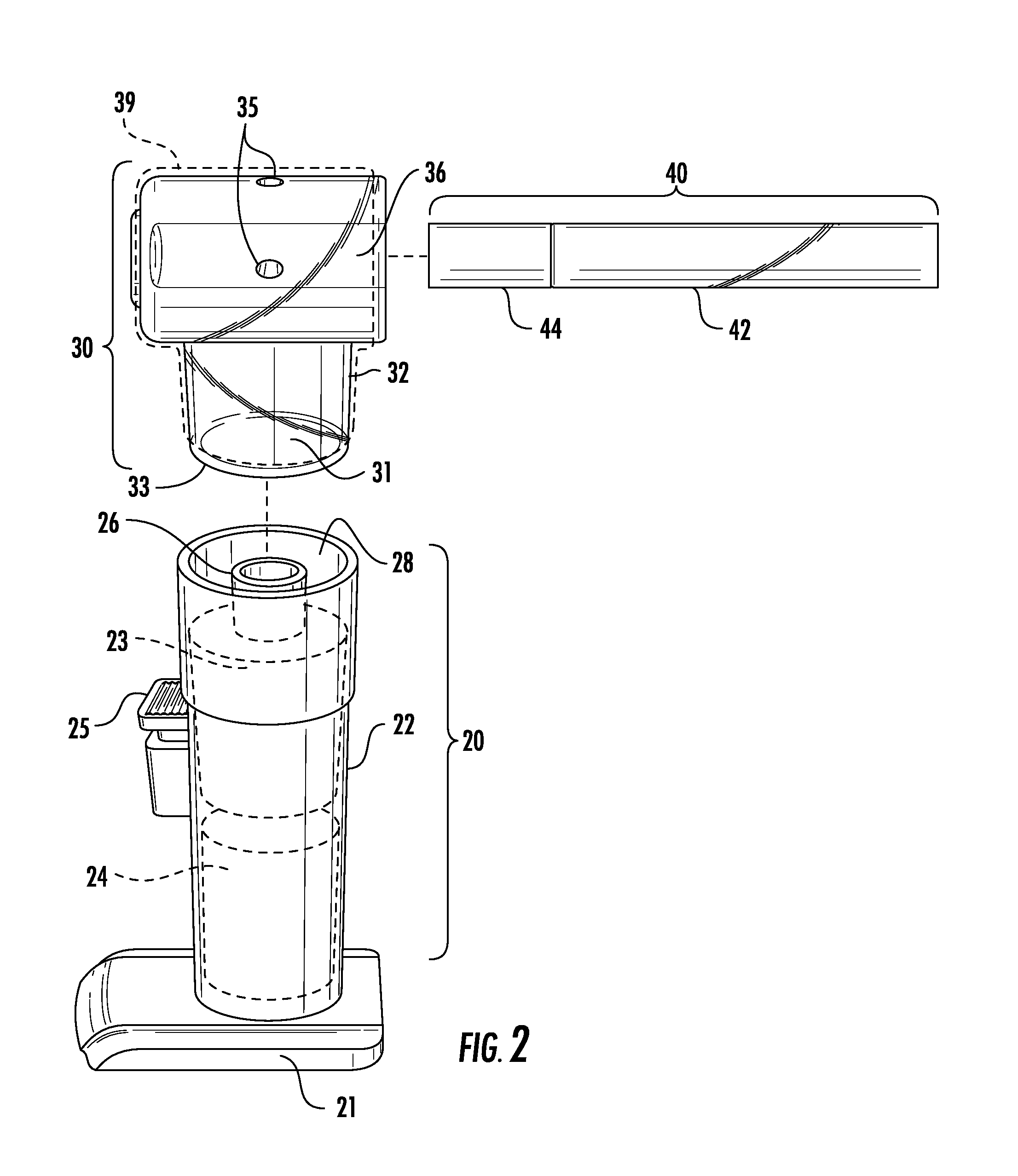

An aerosol generator includes a flow passage having an inlet and an outlet, a heater arranged relative to the flow passage for heating the flow passage, a source of material to be volatilized in communication with the inlet of the flow passage, a valve to open and close communication between the source of material and the inlet of the flow passage, and a pressurization arrangement for causing material in the source of material to be introduced into the flow passage when the valve is in an open position. The aerosol generator further includes a source of power for operating the heater and the valve, and a control device for controlling supply of power from the source of power to the heater and the valve. A metering device in an inhaler includes a pressurized source of medicated fluid and a metering chamber configured to deliver a predetermined volume of fluid to a heated flow passage in the inhaler. The metering chamber can be part of a rotary valve having a bore and a displacement member moveable within the bore from a first position where the fluid is loaded into the bore to a second position where the predetermined volume is ejected out of the bore. Another metering chamber has an elastic portion of a delivery passage in fluid communication with the pressurized source of liquid and the elastic portion of the delivery passage is deformed to eject the predetermined volume.

Owner:PHILIP MORRIS USA INC

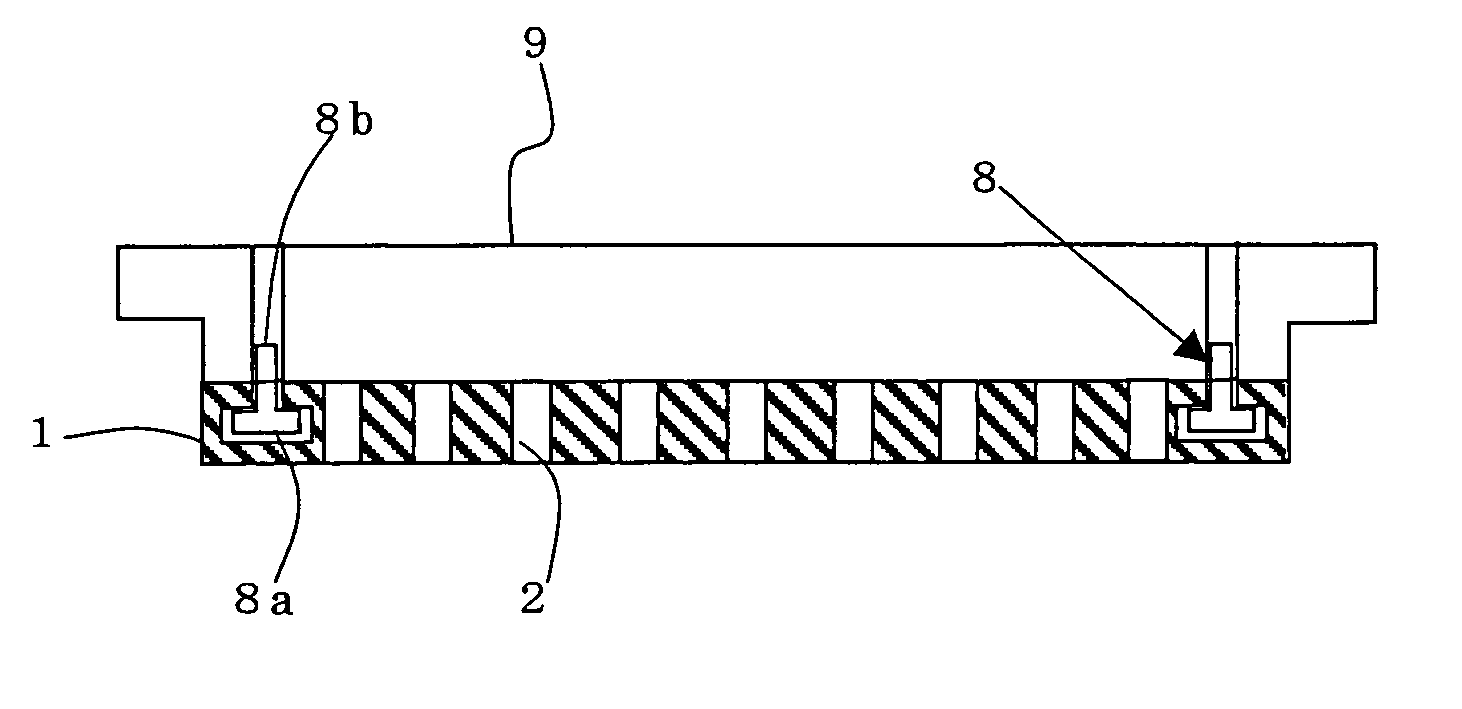

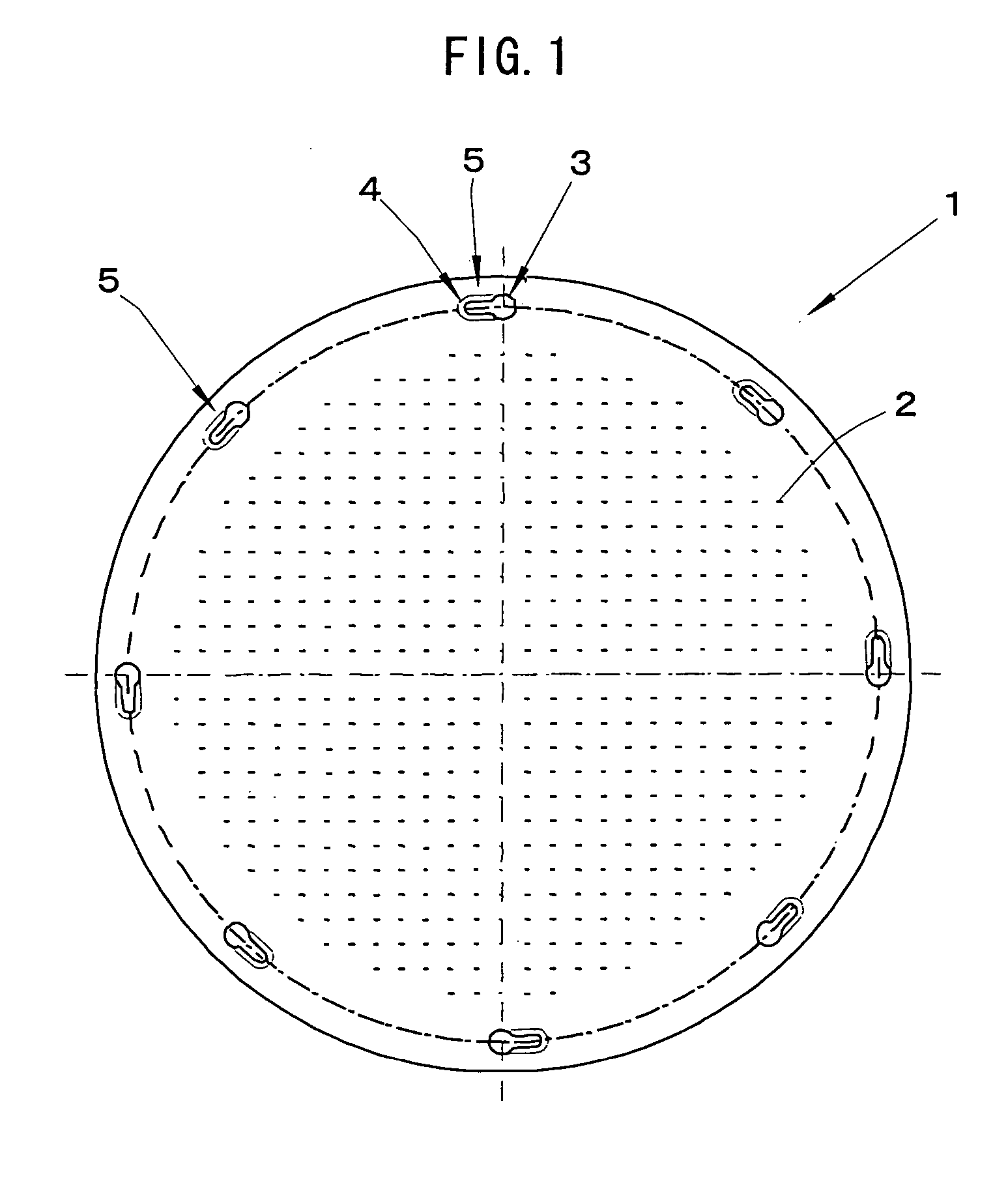

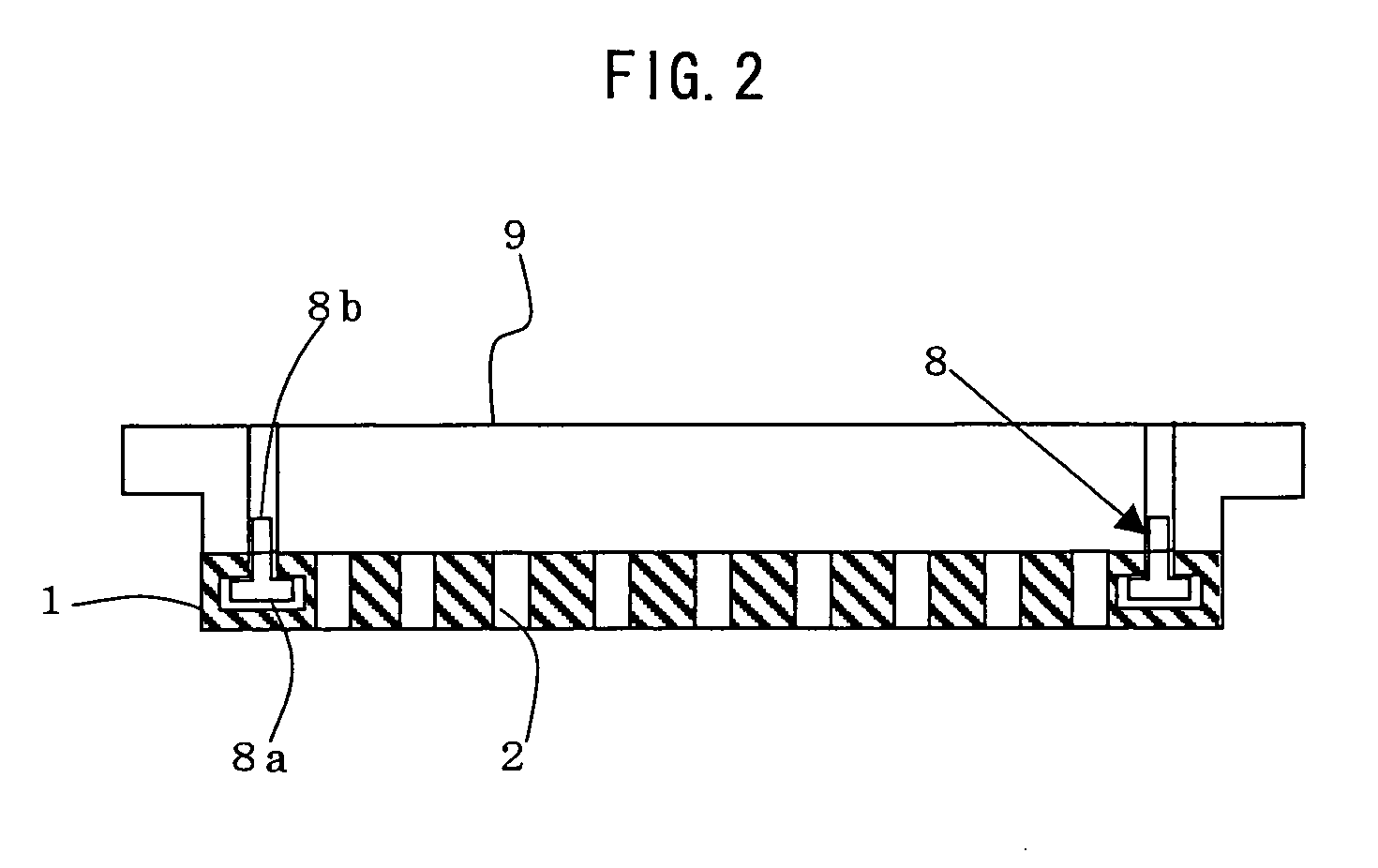

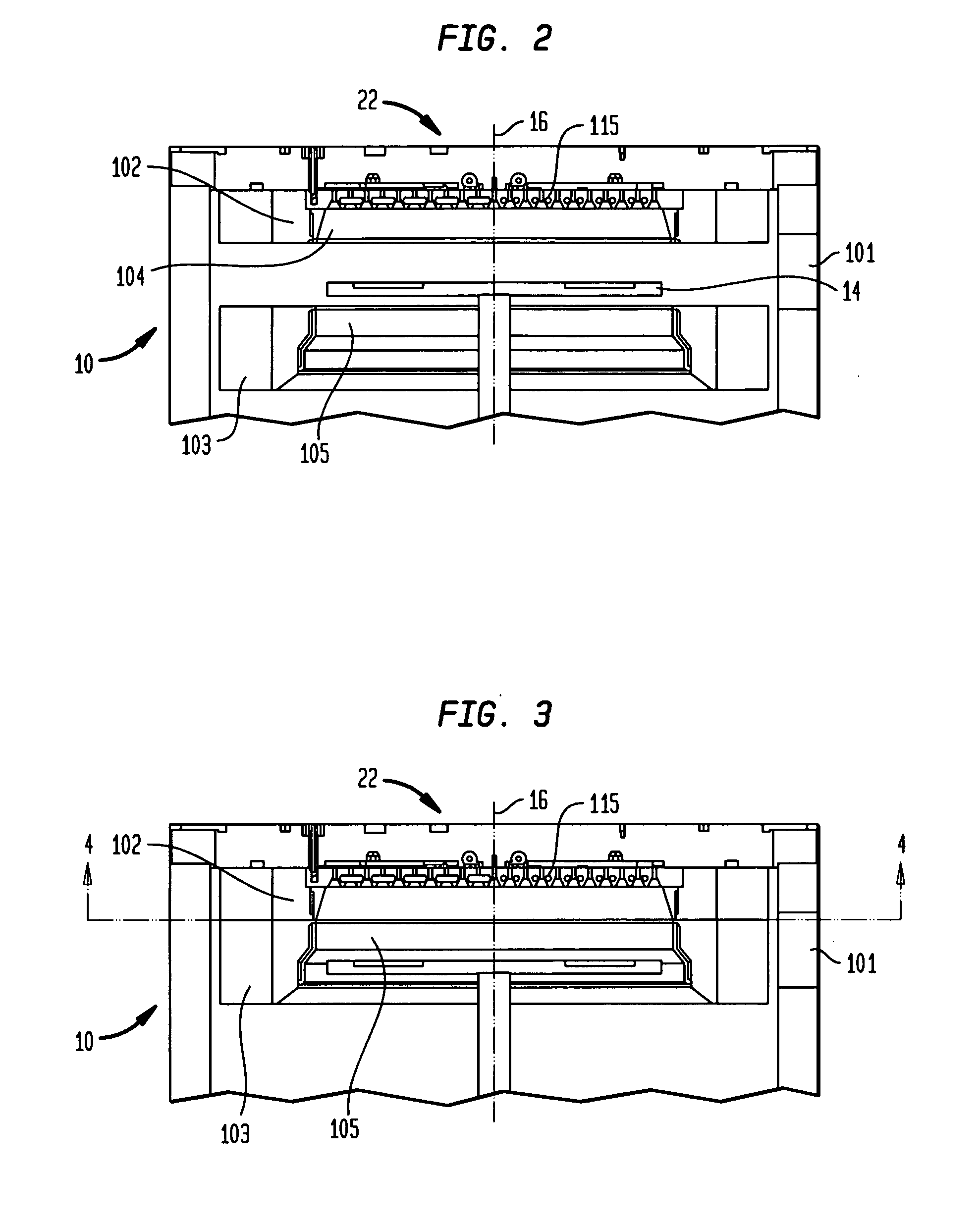

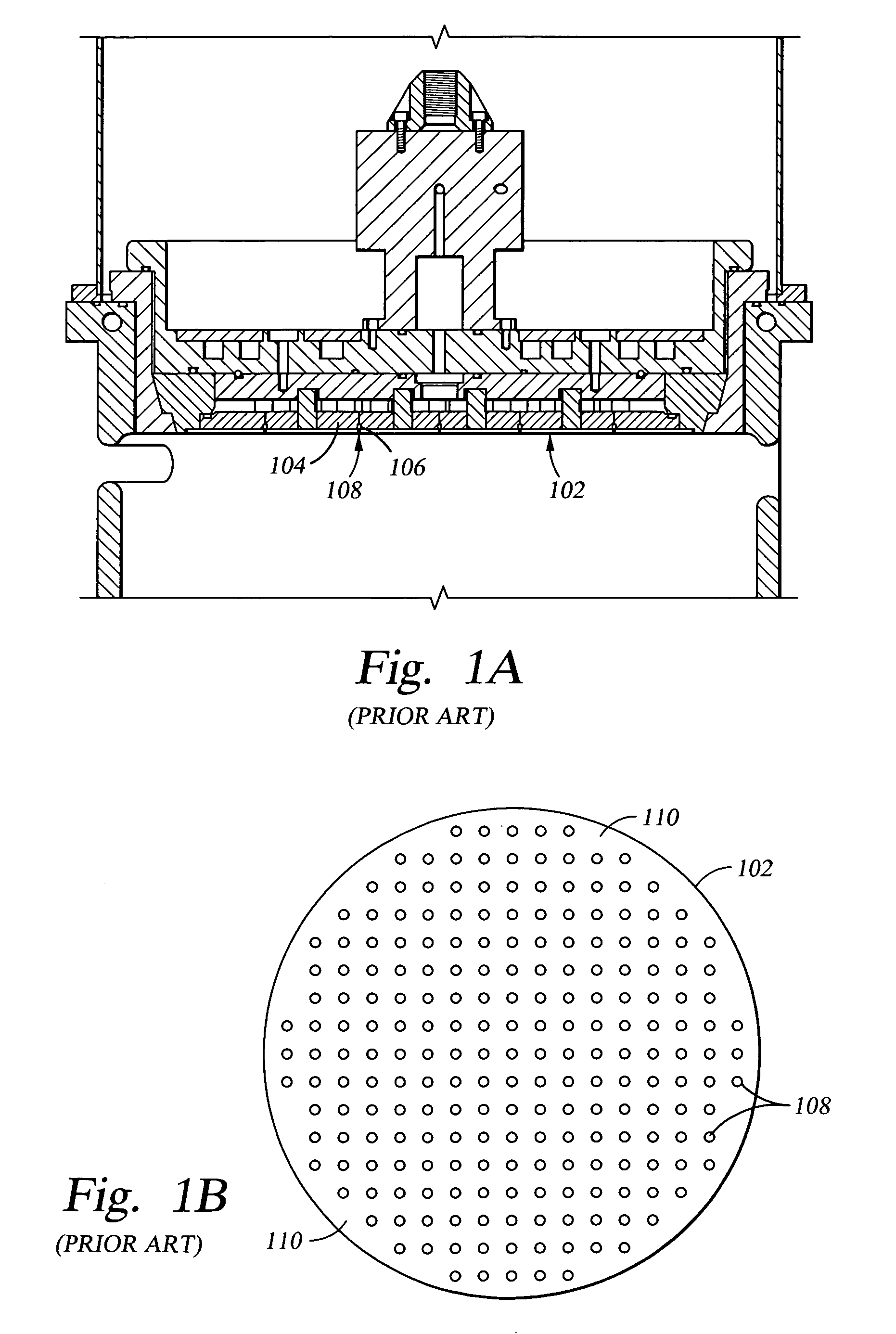

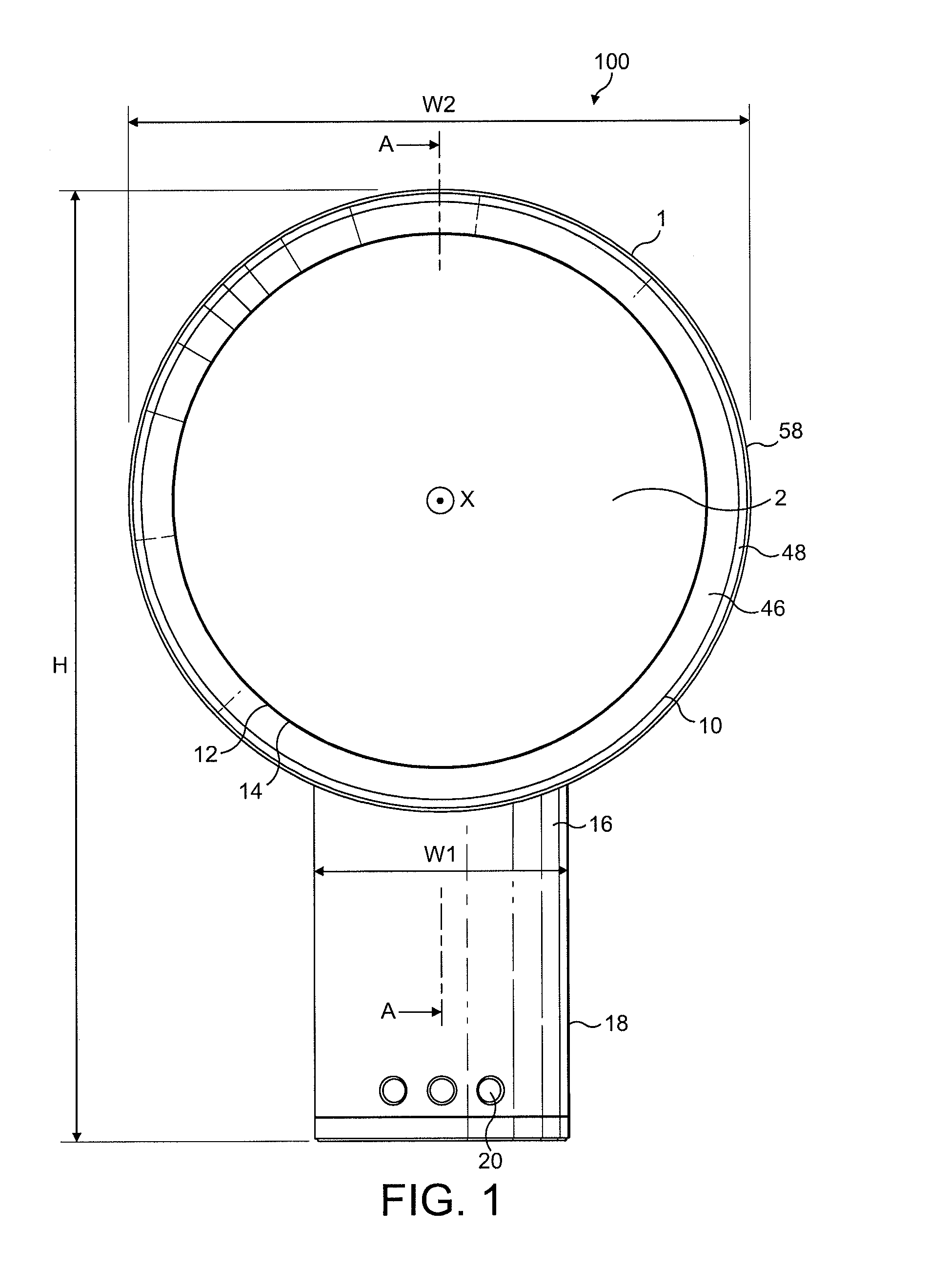

Shower plate for plasma processing apparatus and plasma processing apparatus

InactiveUS20050258280A1Easy to manufactureAvoid pollutionElectric discharge tubesMovable spraying apparatusEngineeringContamination

There is disclosed a shower plate 1, wherein the shower plate has a plurality of holes 3 for inserting the head of the fastening member and holes 4 for fitting the head are formed integrally along a concentric circle in the outside region of the gas feeding holes 2 on a side facing the supporting member, each hole for fitting extending in one direction of the concentric circle from each hole for insertion, each hole for fitting has a groove portion 4b through which the shank of the fastening member is to pass and a fitting portion 4a which is wider than the groove portion and in which the head of the fastening member is to be fitted, and the head of the fastening member fixed in the supporting member is inserted into the hole for insertion of the shower plate and the shower plate is turned so that the head of the fastening member is fitted in the fitting portion, and thereby the shower plate is supported by the supporting member without exposure of the fastening member. There can be provided a shower plate for a plasma processing apparatus, wherein effective diameter is large enough, contamination of a substrate to be treated can be prevented, it is easy to manufacture, and it is easy to fix to a supporting member.

Owner:SHIN ETSU CHEM IND CO LTD

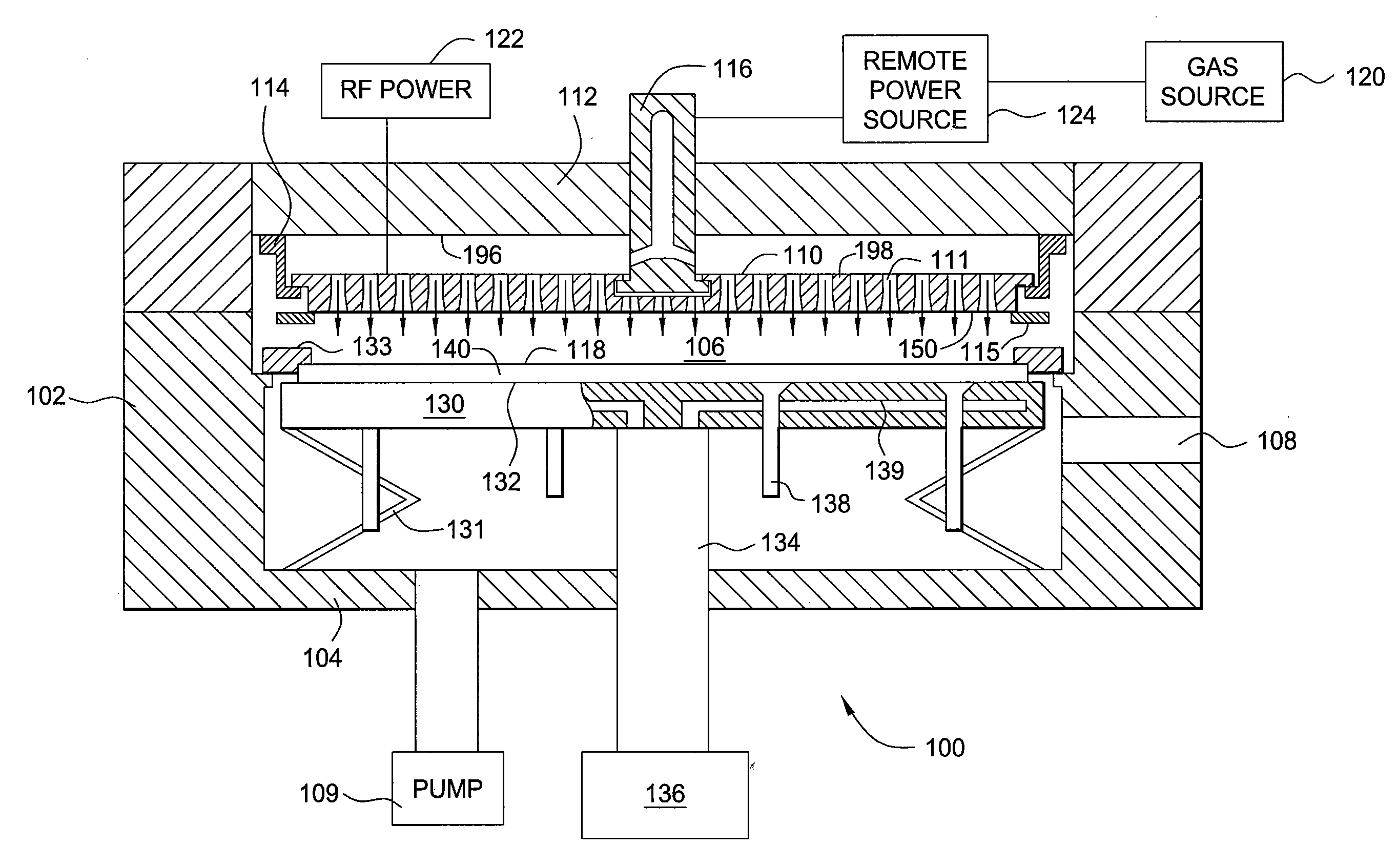

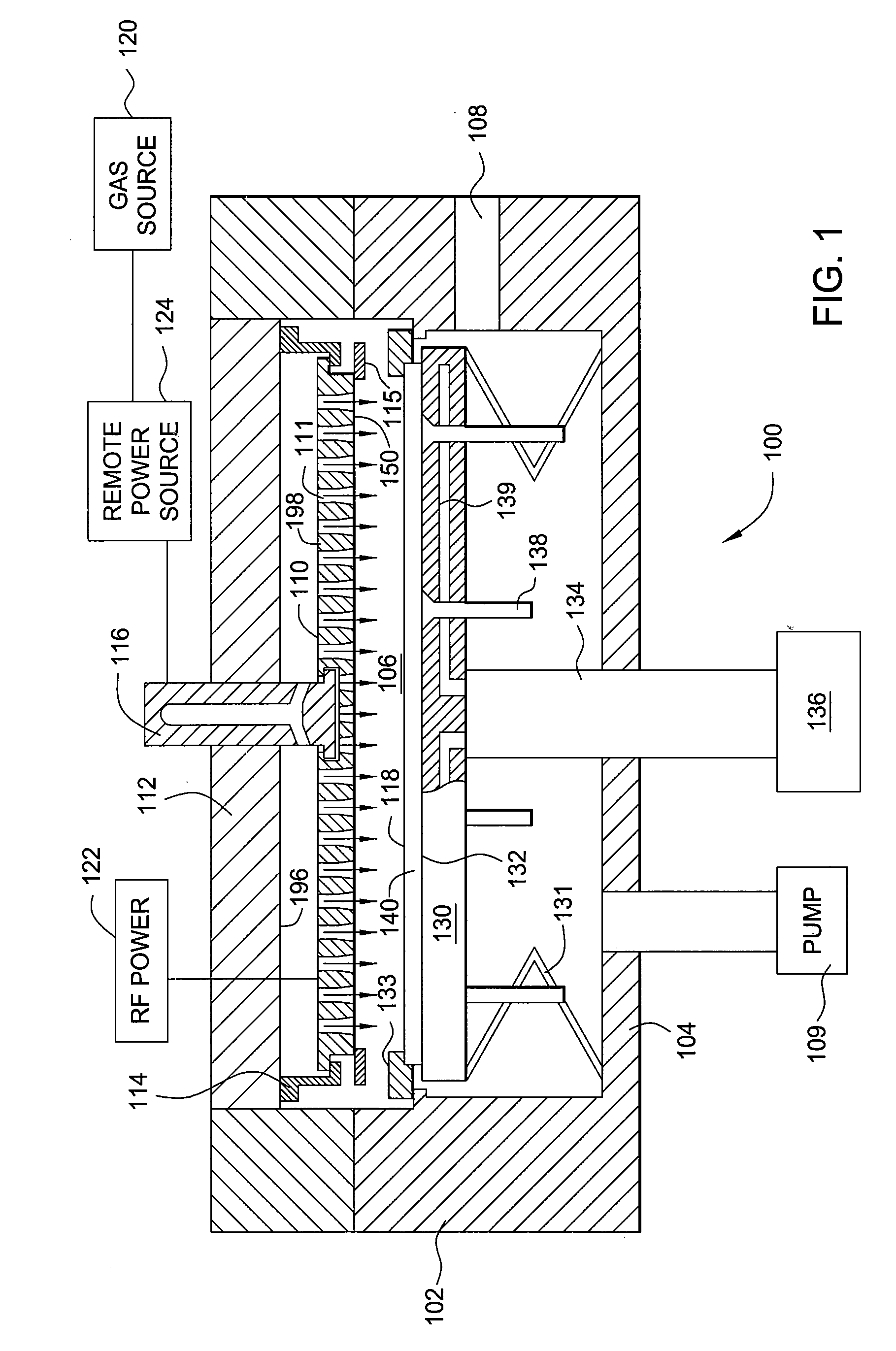

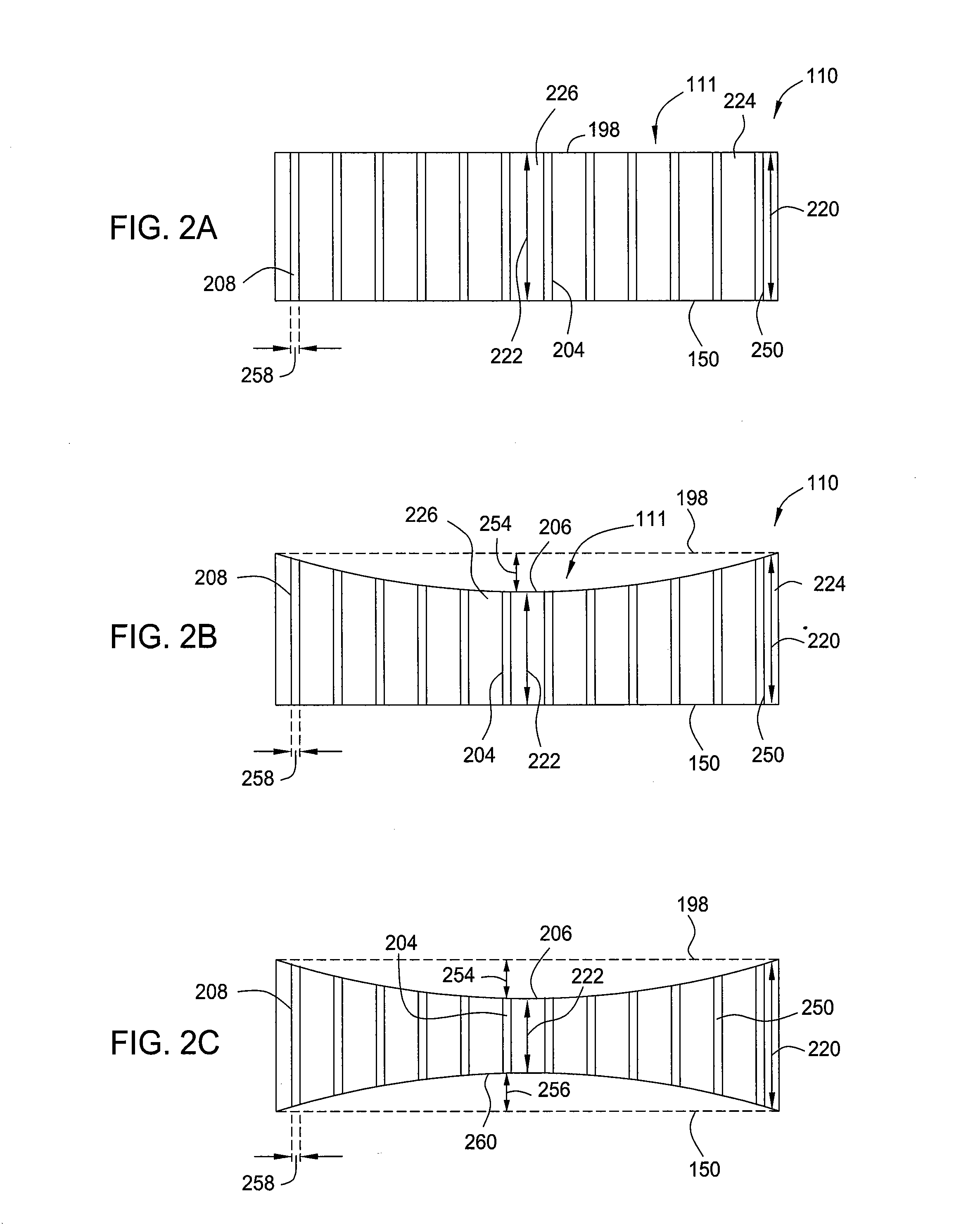

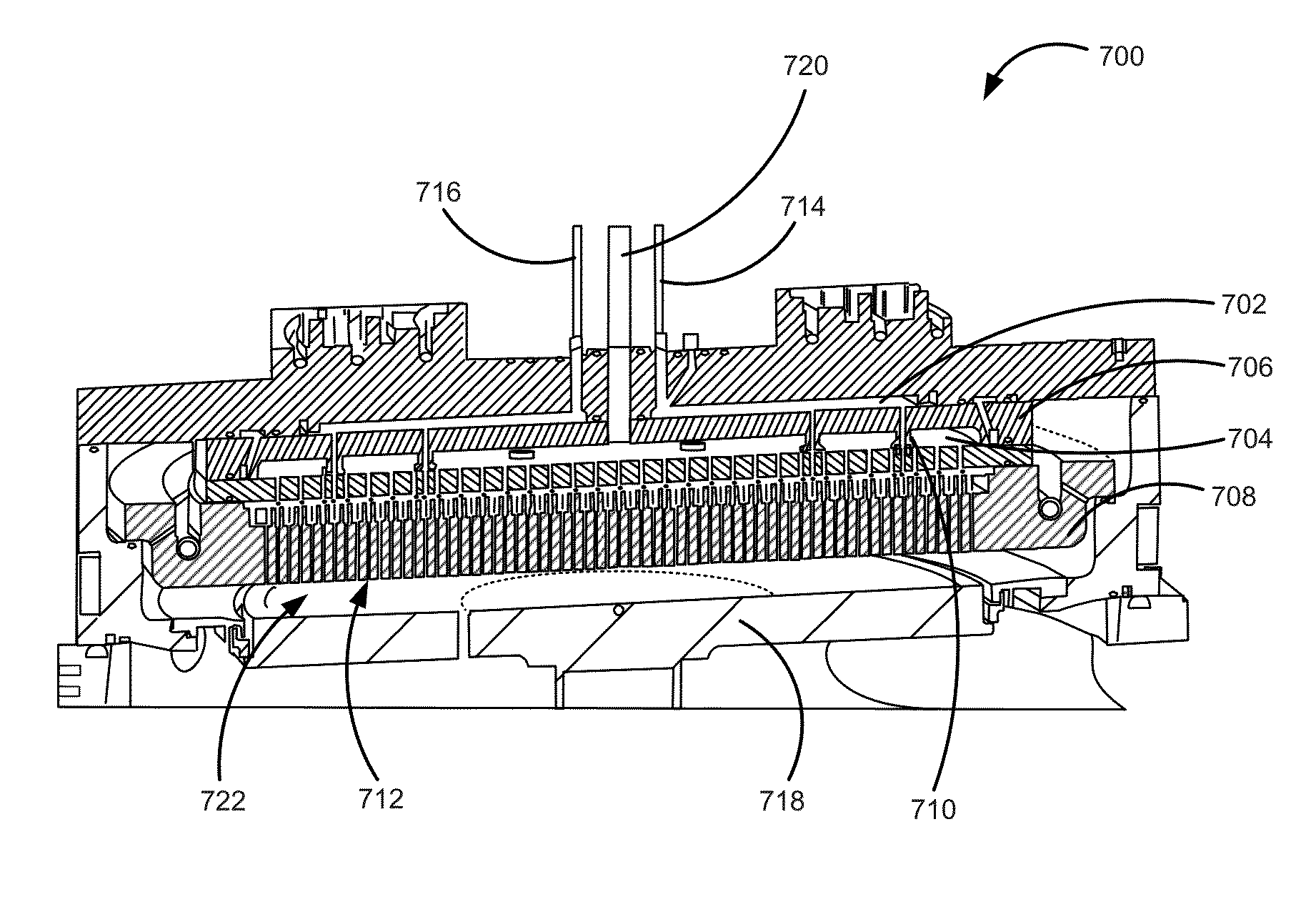

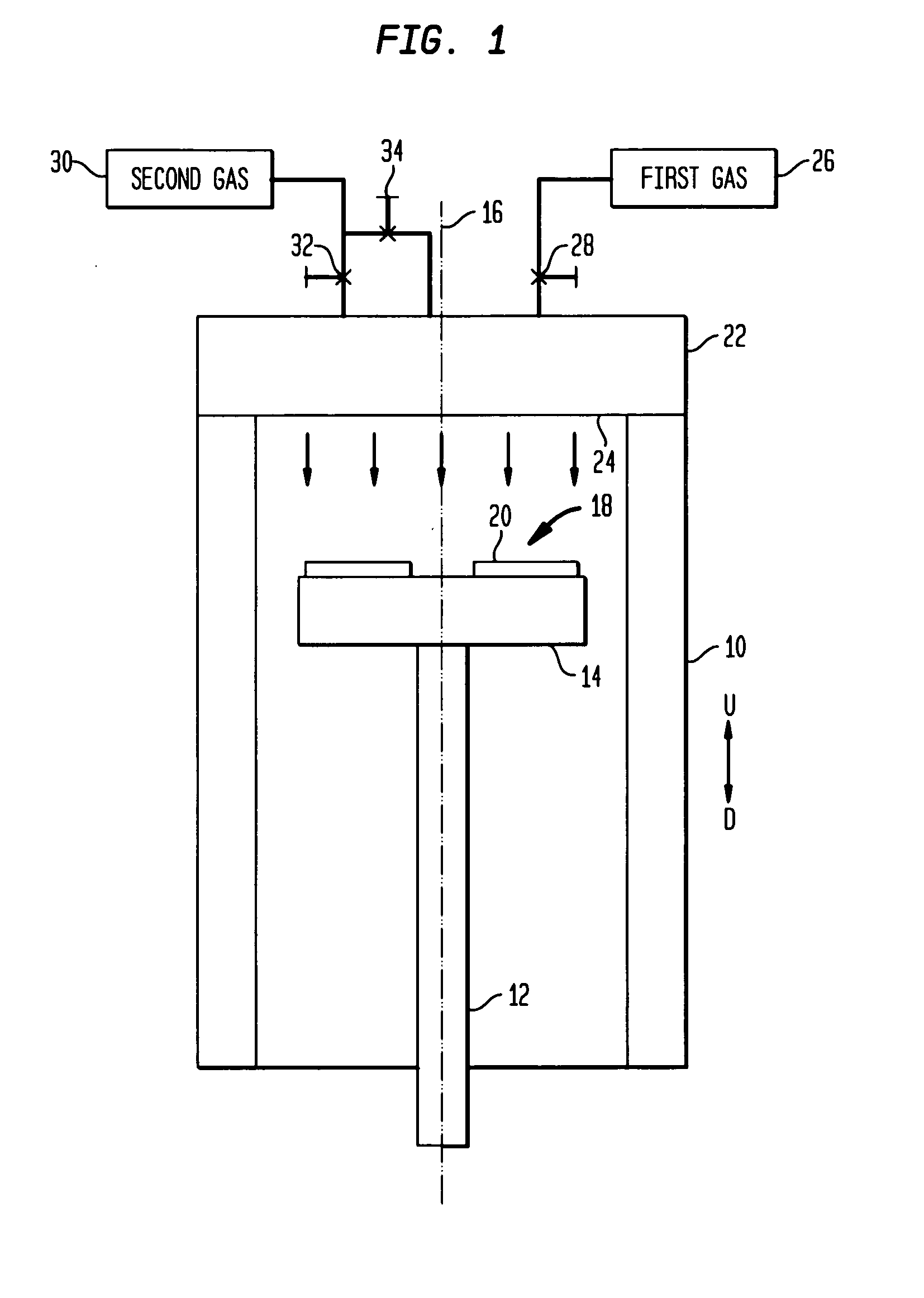

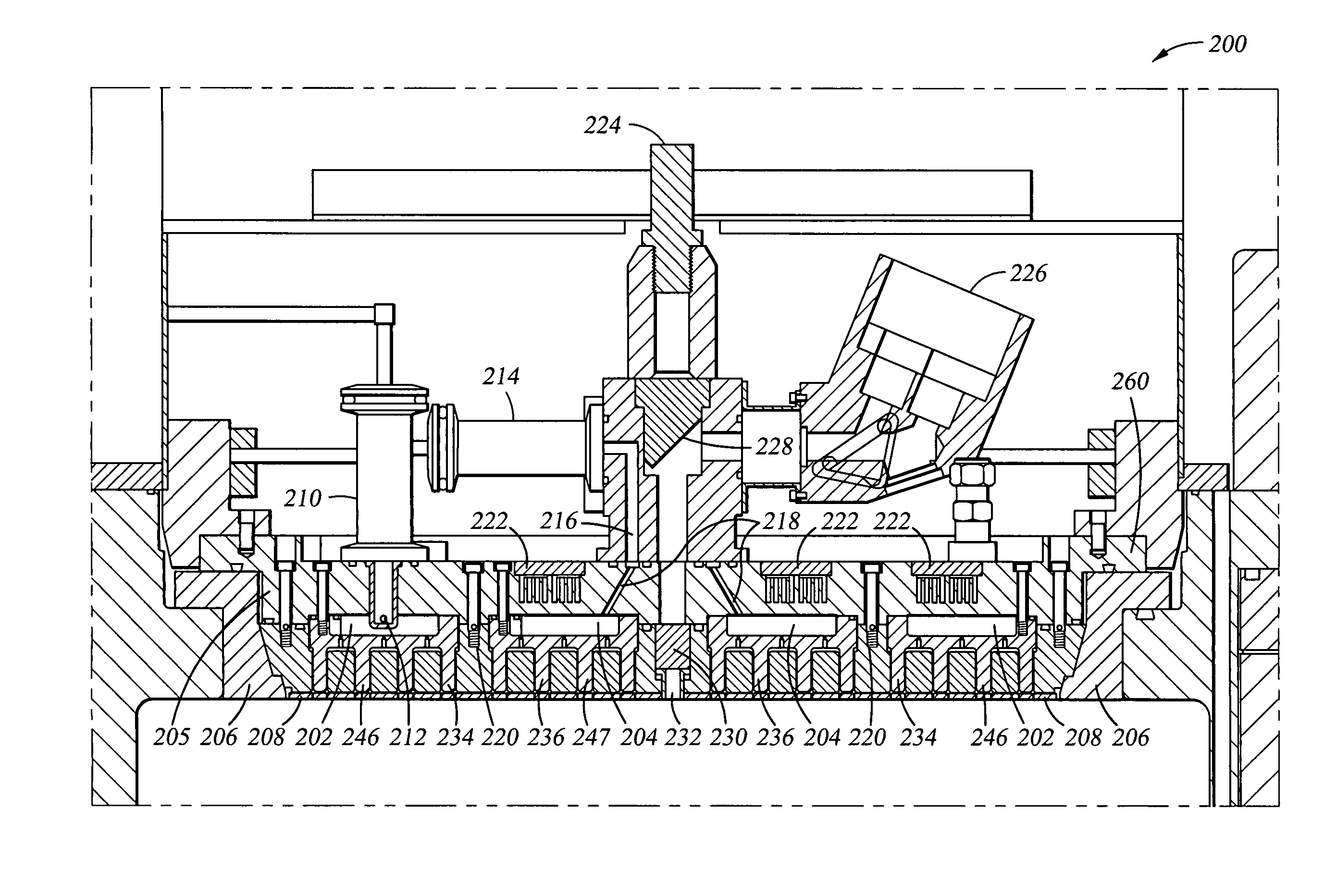

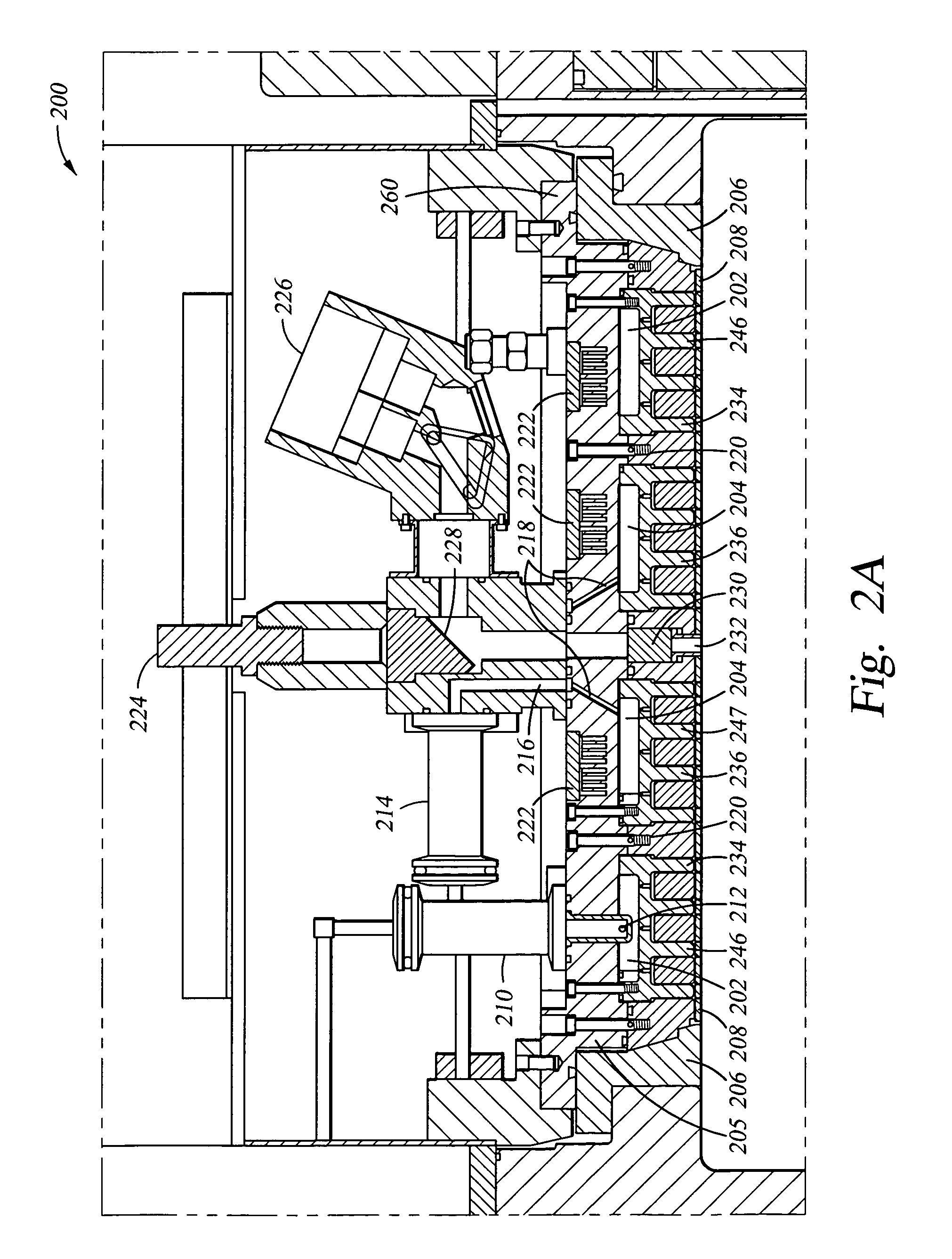

Methods and apparatus for depositing a uniform silicon film with flow gradient designs

Methods and apparatus having a flow gradient created from a gas distribution plate are provided. In one embodiment, the method and apparatus are particularly useful for, but not limited to, depositing a silicon film for solar cell applications. The apparatus for depositing a uniform film for solar cell applications includes a processing chamber, and a quadrilateral gas distribution plate disposed in the processing chamber and having at least four corners separated by four sides. The gas distribution plate further includes a first plurality of chokes formed through the gas distribution plate, the first plurality of chokes located in the corners, and a second plurality of chokes formed through the gas distribution plate, the second plurality of chokes located along the sides of the gas distribution plate between the corner regions, wherein the first plurality of chokes have a greater flow resistance than that of the second plurality of chokes.

Owner:APPLIED MATERIALS INC

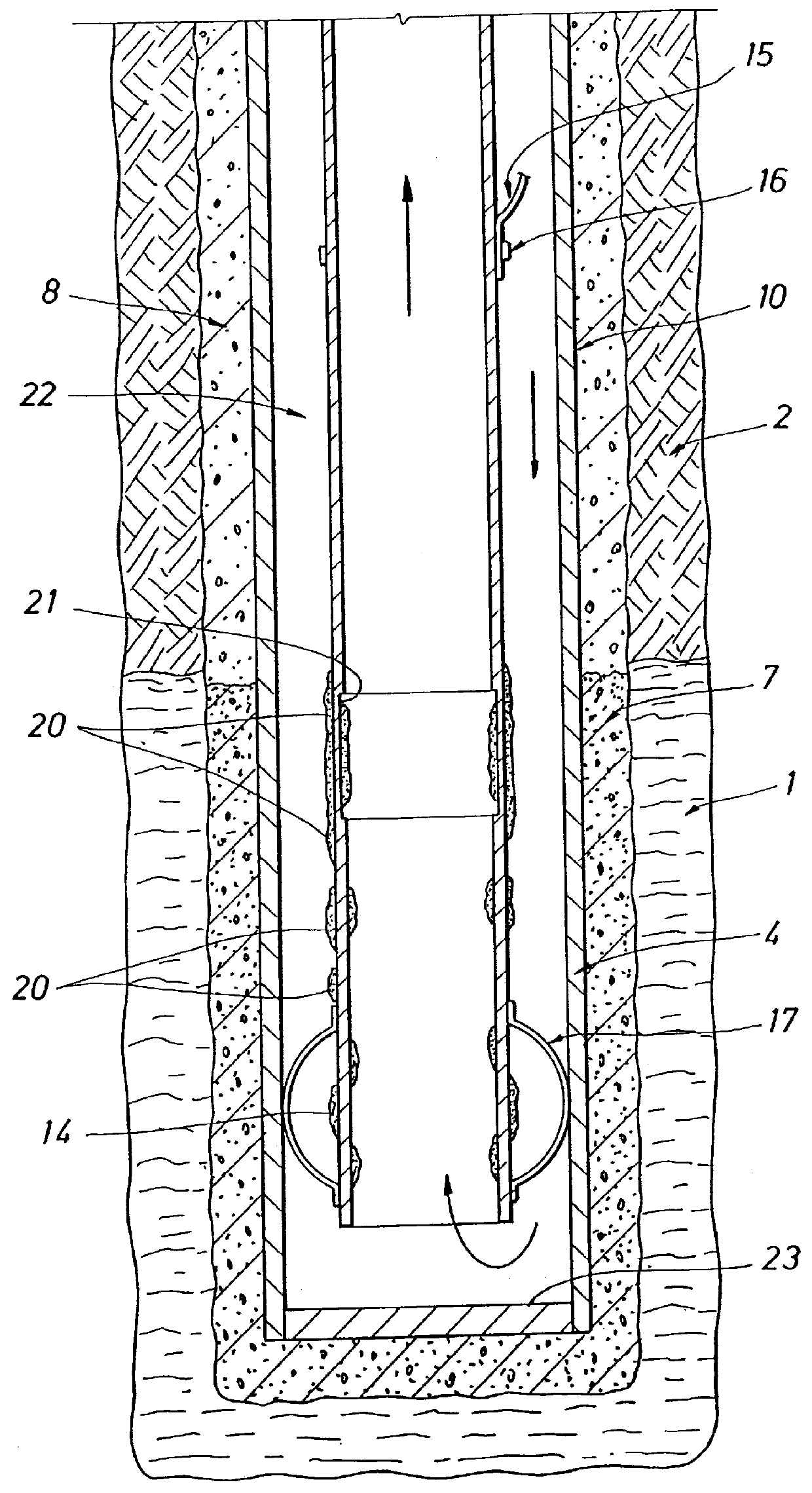

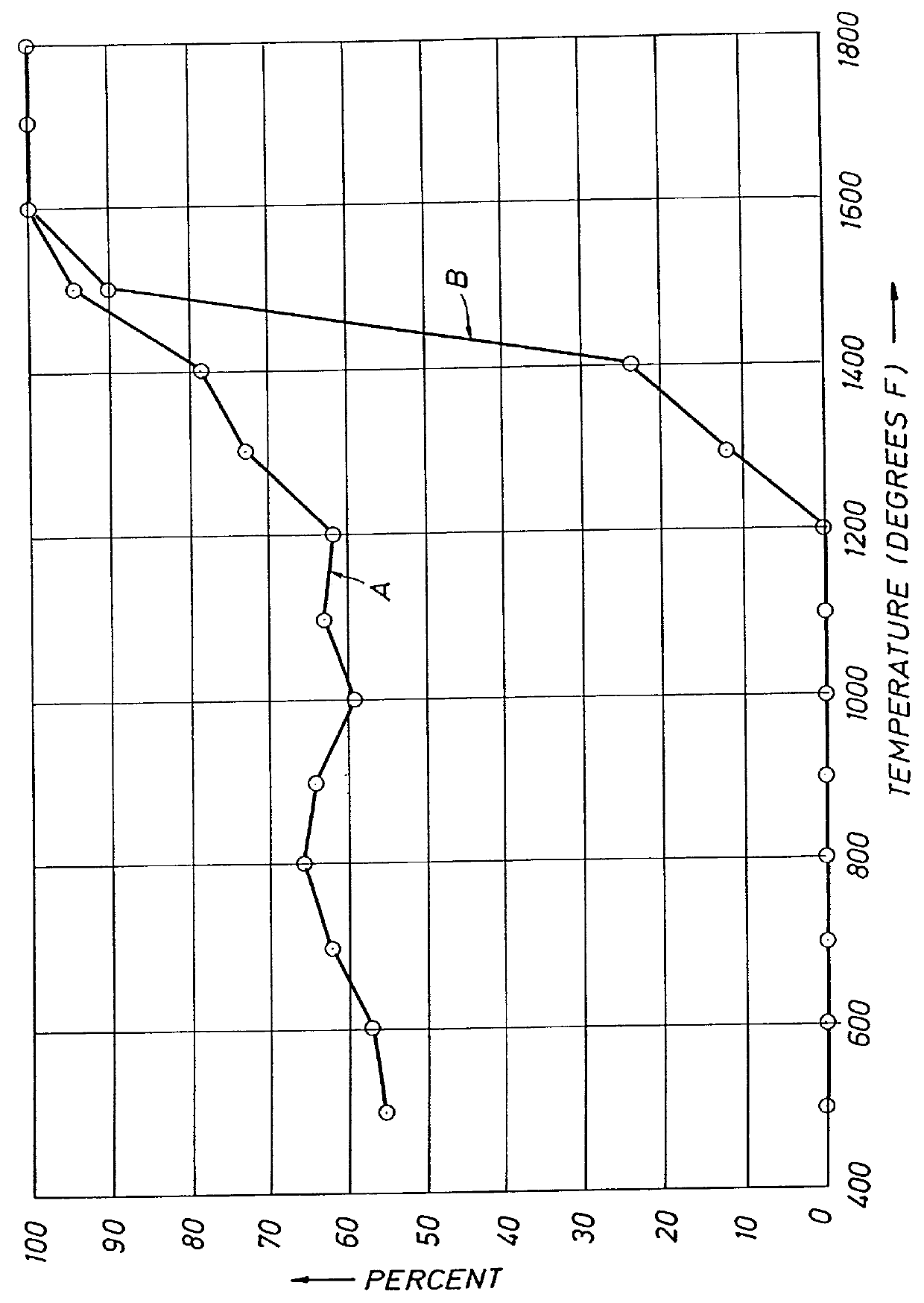

Flameless combustor

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

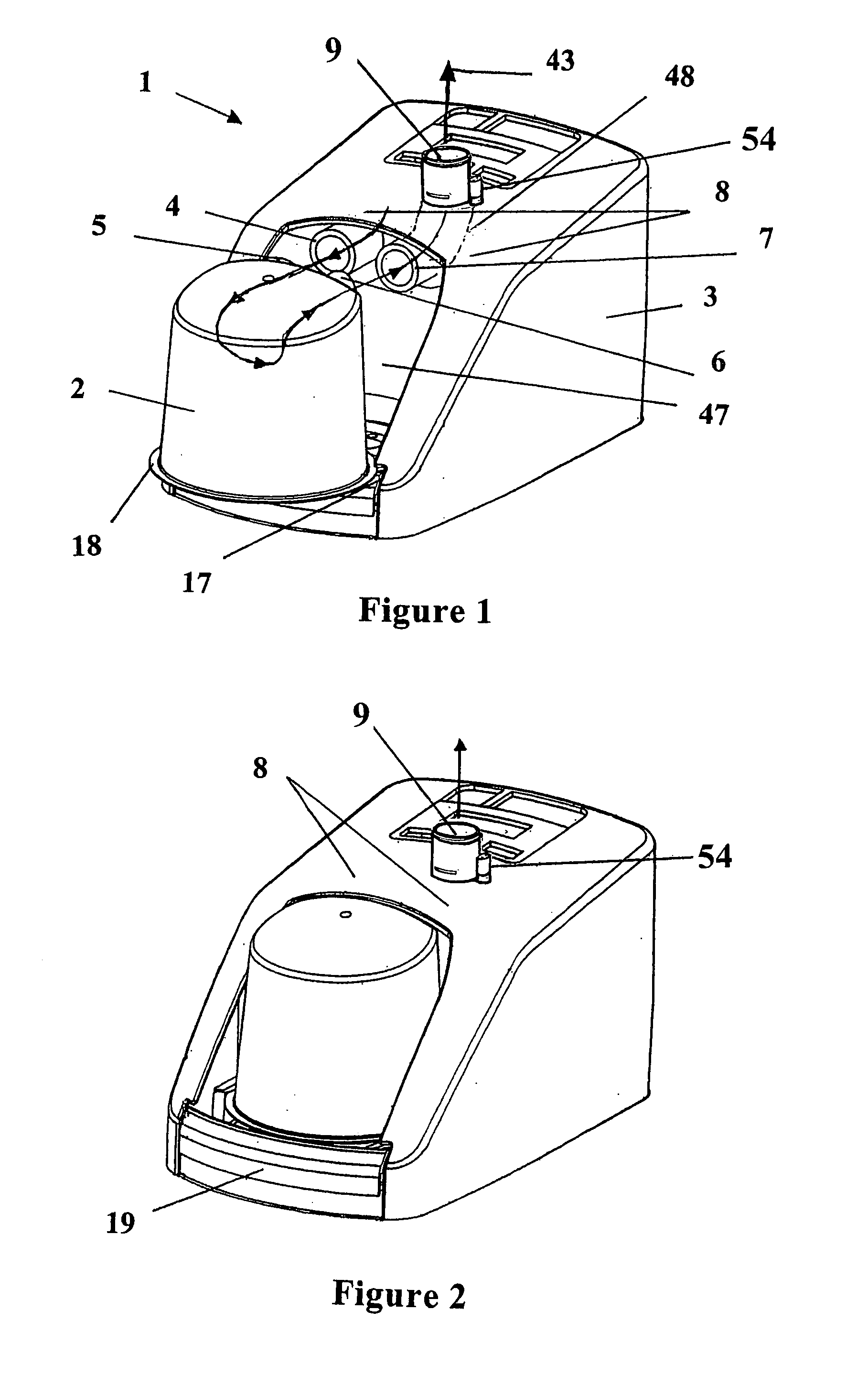

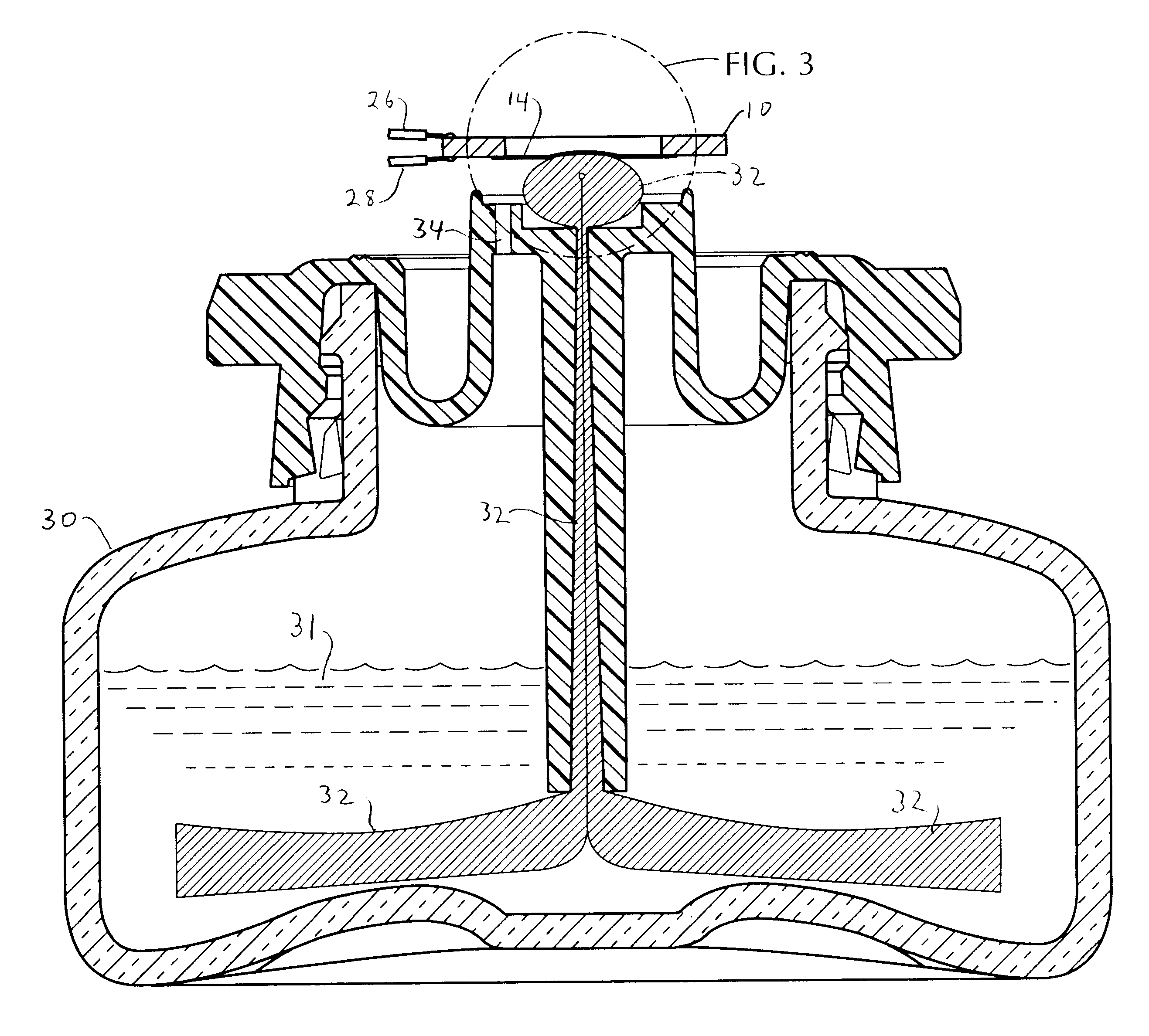

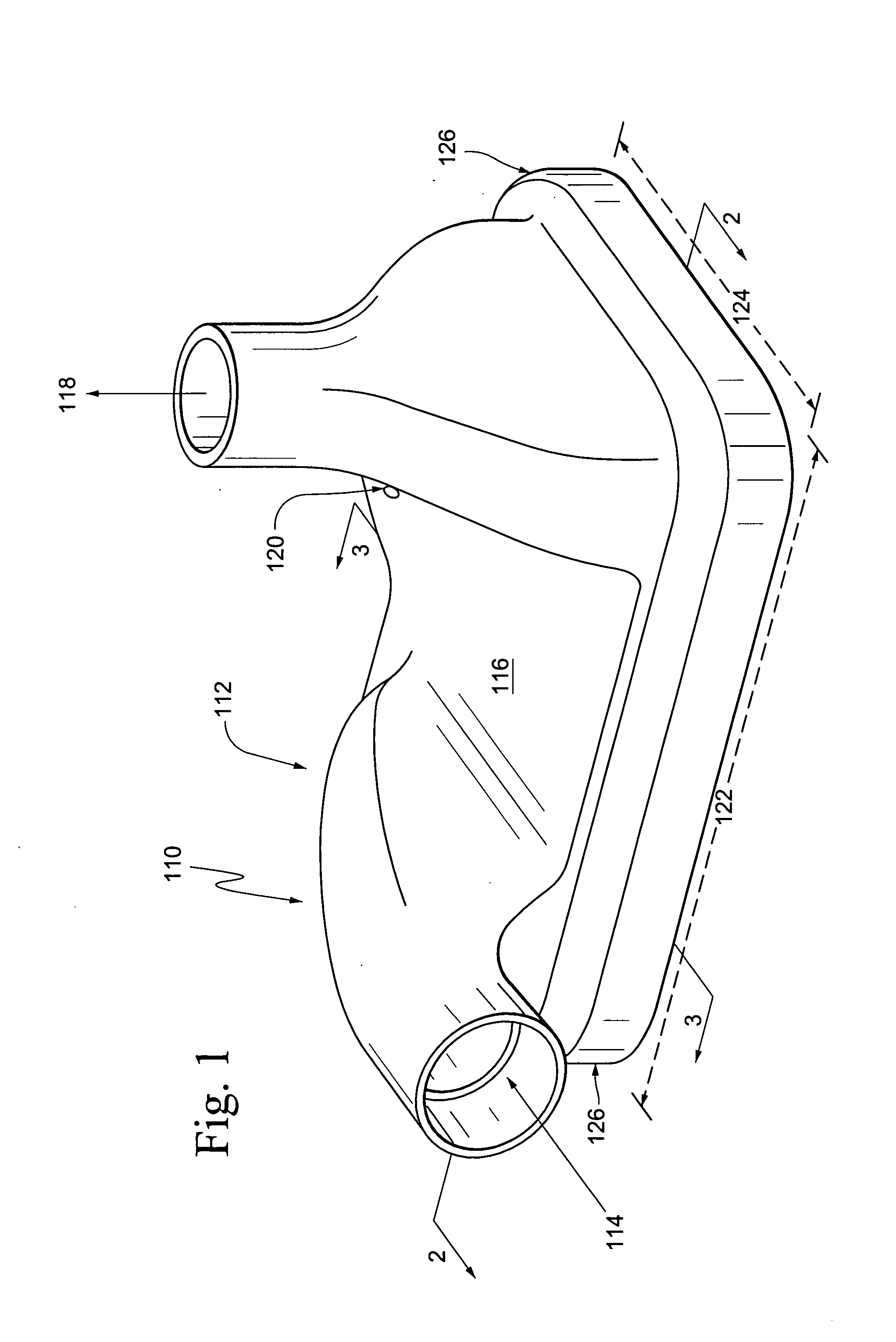

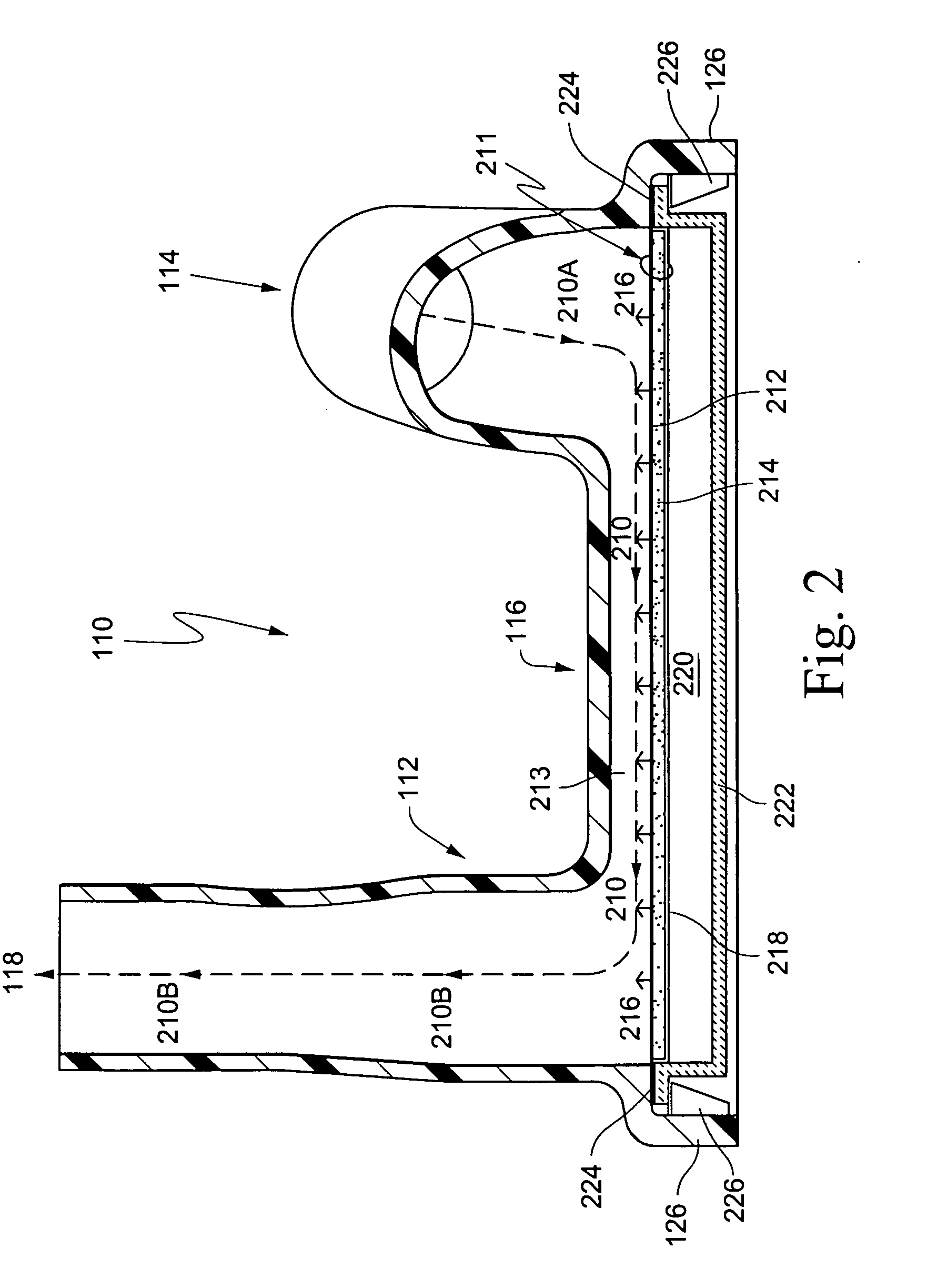

Humidifier for respiratory apparatus

ActiveUS20080105257A1Increasing patient comfortElectrocardiographyRespiratory masksWater vaporBreathing gas

A respiratory apparatus for delivering breathable gas to a patient includes a flow generator that generates a supply of pressurised gas to be delivered to the patient; a humidifier for vaporising water and delivering water vapor to humidify the gas; a gas flow path leading from the flow generator to the humidifier and from the humidifier to a patient interface; and a heater in thermal contact with the gas and / or the water, wherein the heater comprises an elongate heating filament in the form of a tape. A humidifier for respiratory apparatus includes a first respiratory gas passage for receiving gas from a flow generator, a humidifier chamber, a second respiratory gas passage for delivering humidified gas to a patient interface, and a heater in thermal contact with the gas and / or the water, wherein the heater comprises an elongate heating filament extending along at least part of both said first and second respiratory gas passages. A conduit for use in a respiratory apparatus for delivering breathable gas to a patient includes a tube; a helical rib on an outer surface of the tube; and a plurality of wires supported by the helical rib in contact with the outer surface of the tube.

Owner:RESMED LTD

Showerhead assembly and components thereof

Owner:ASM IP HLDG BV

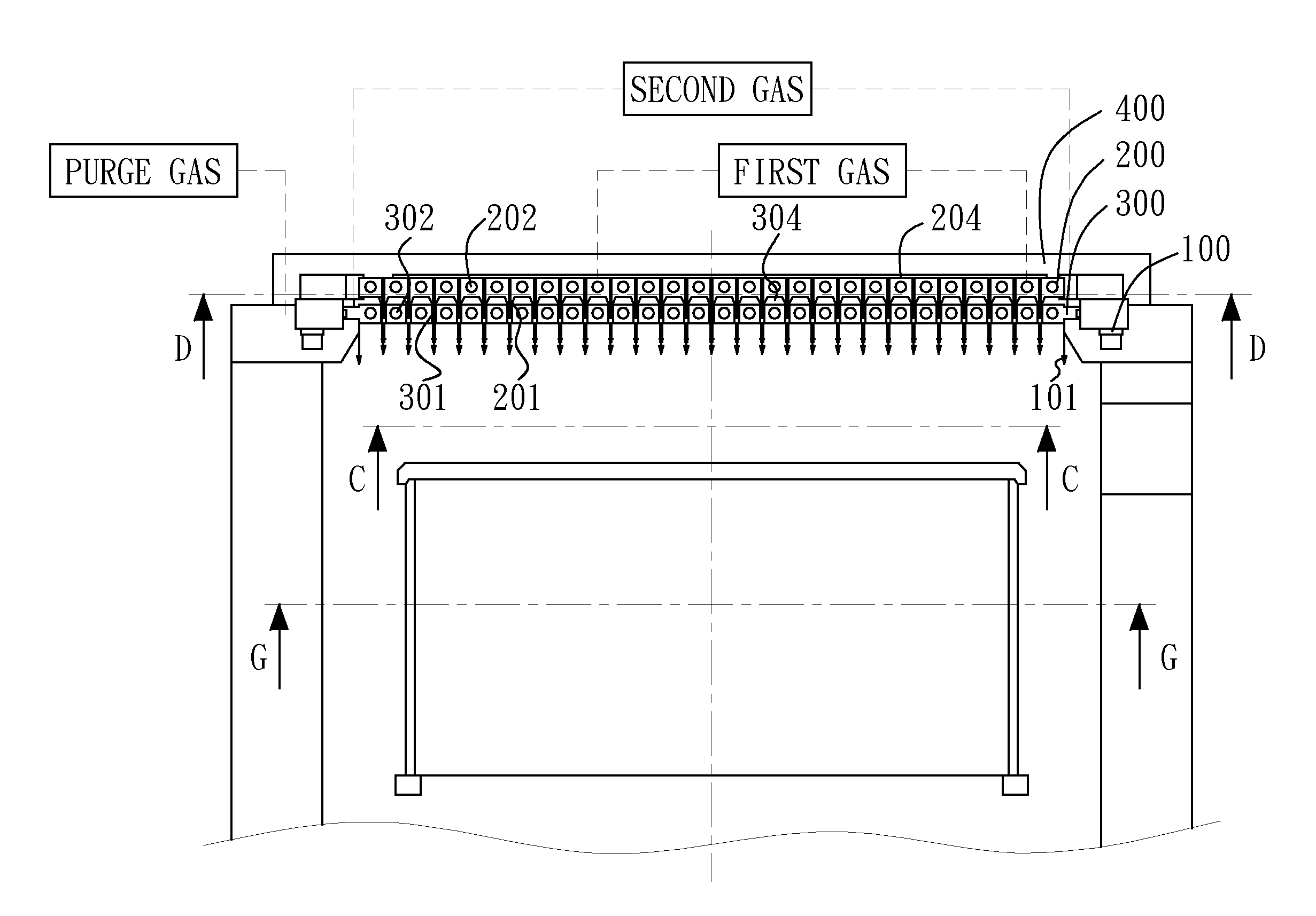

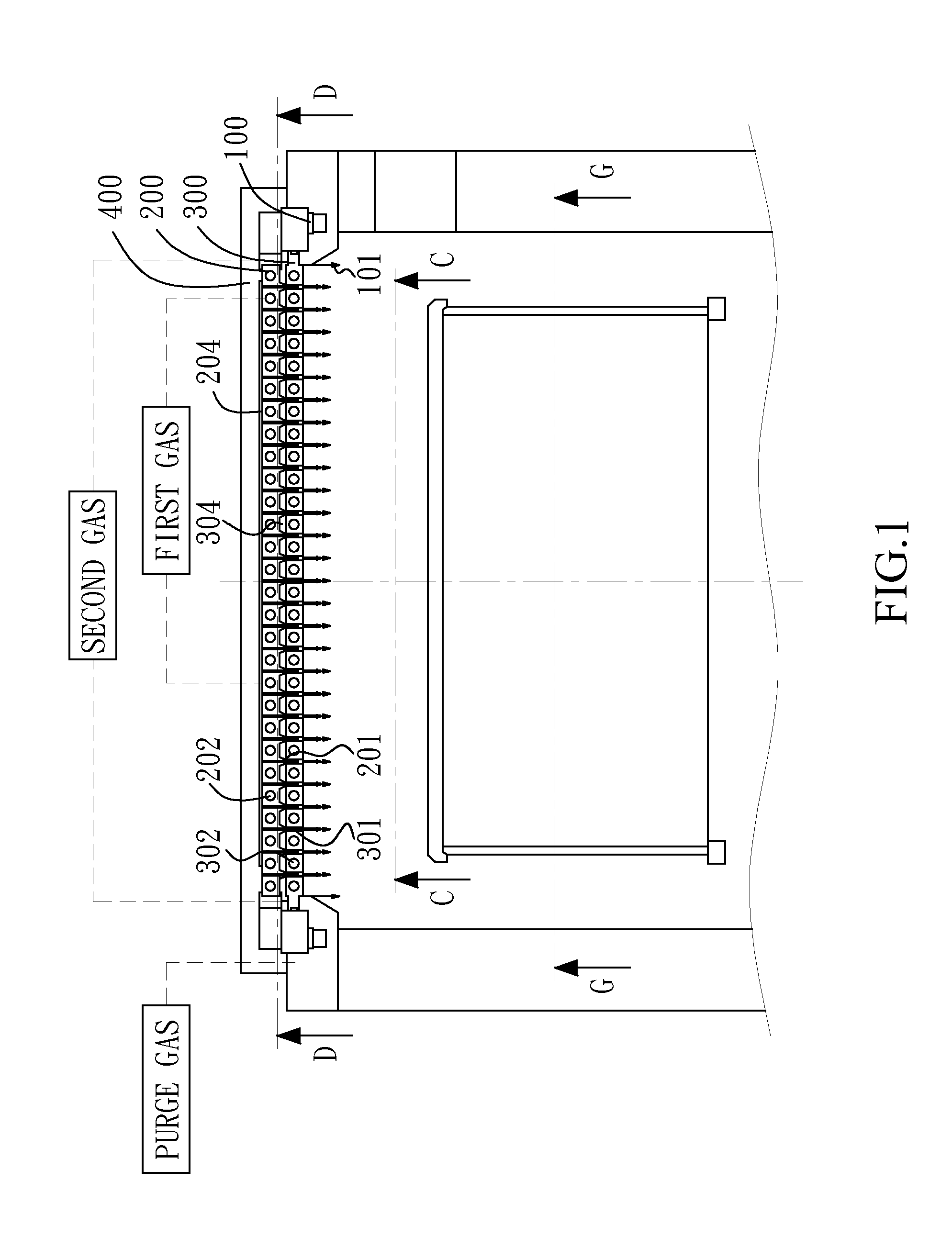

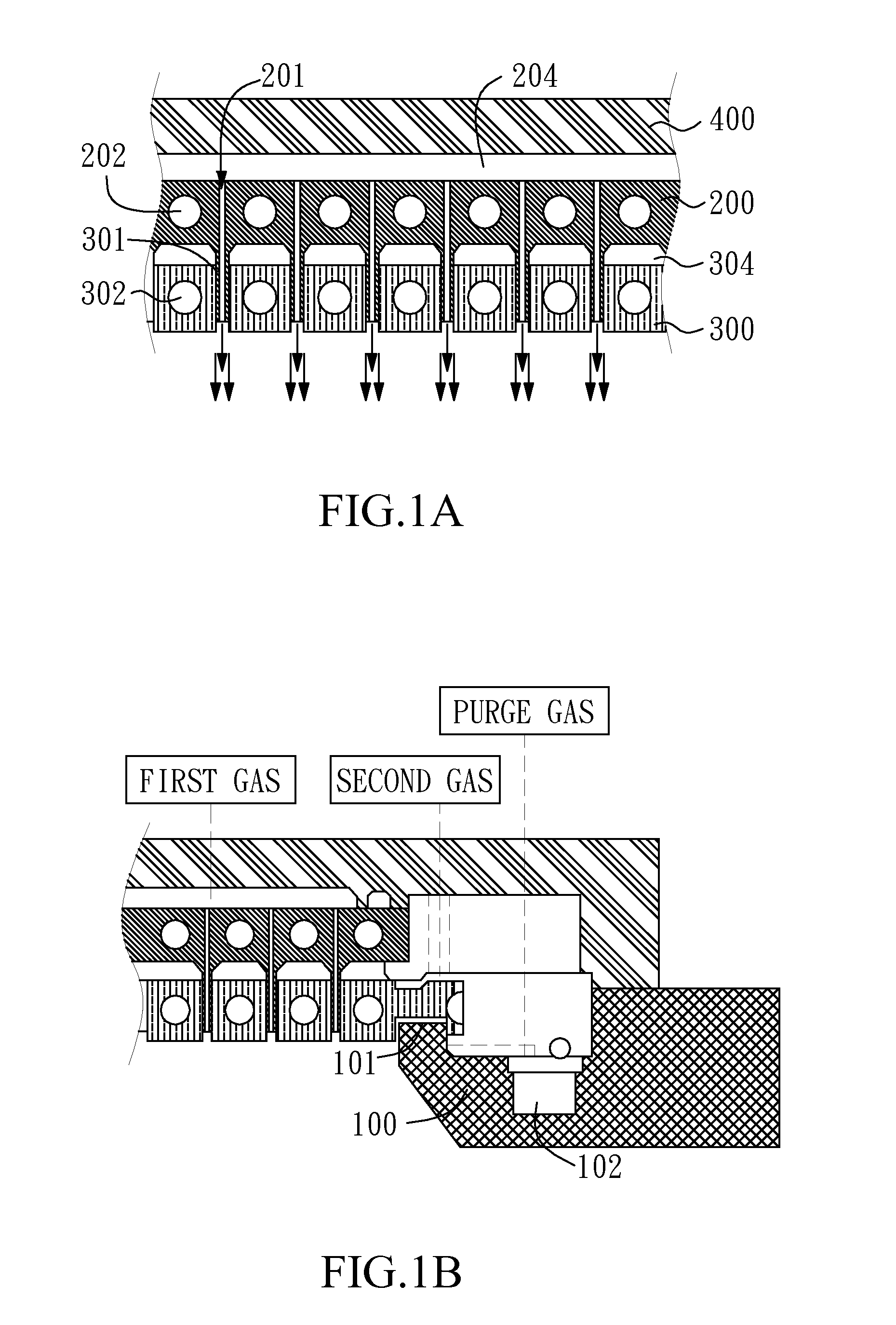

Showerhead for film depositing vacuum equipment

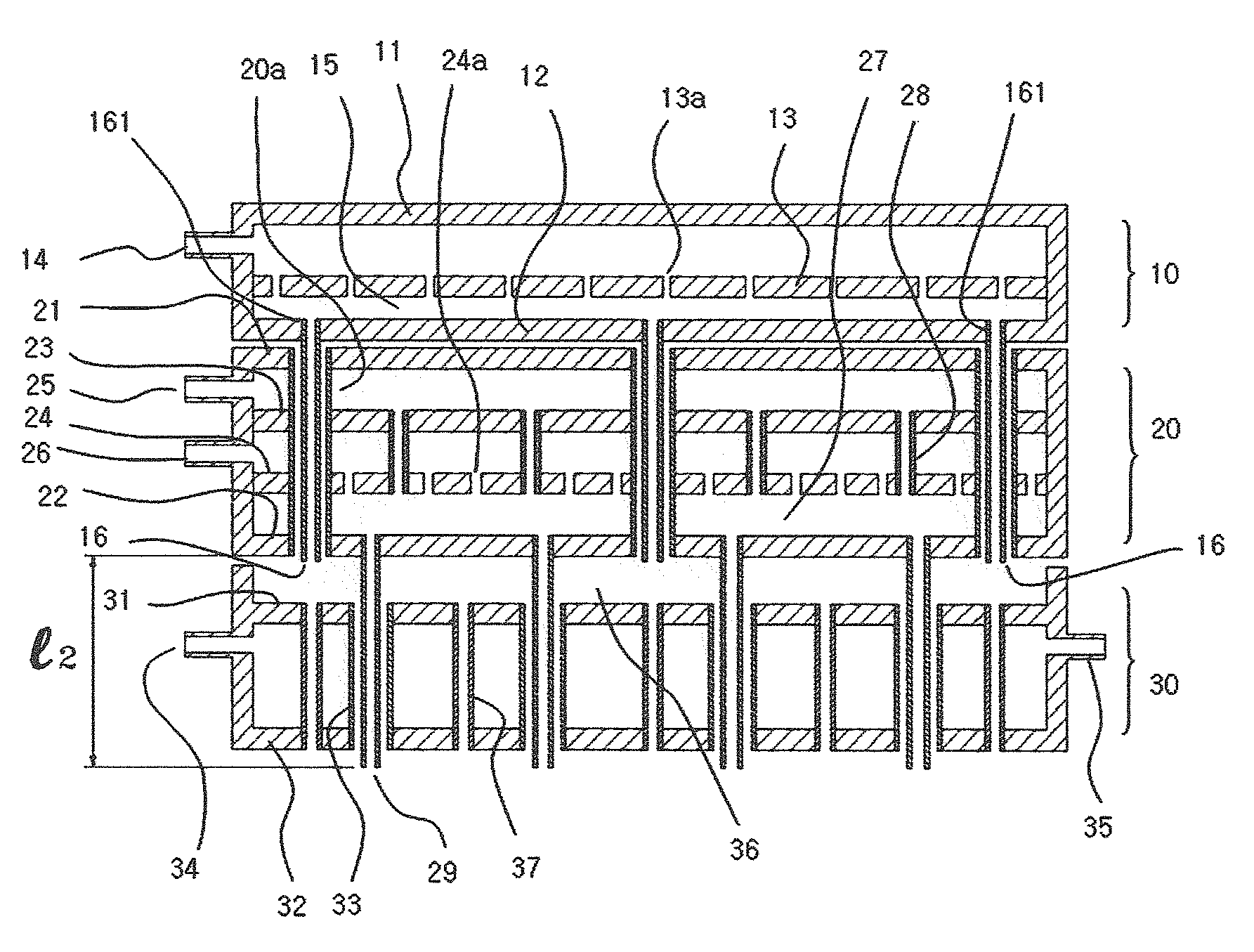

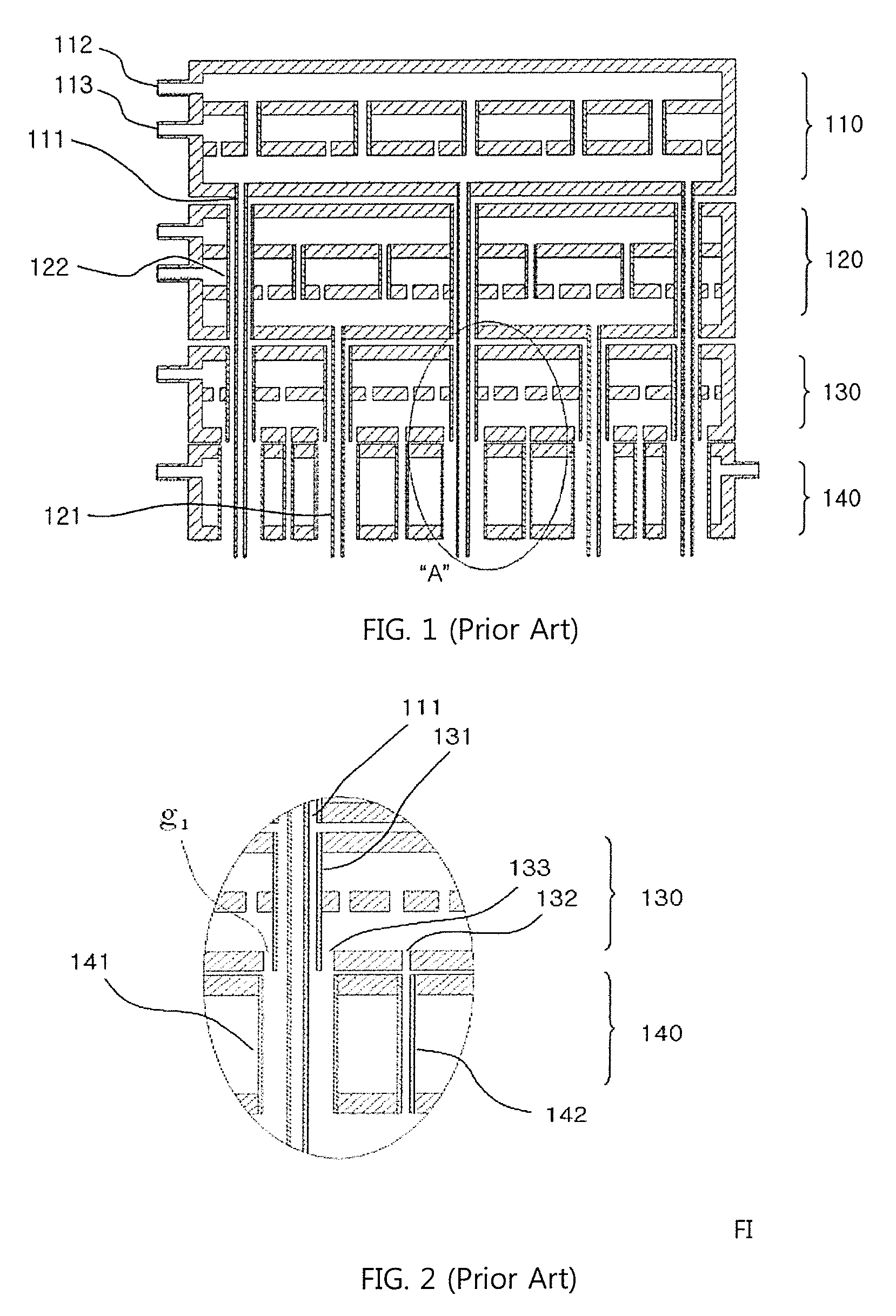

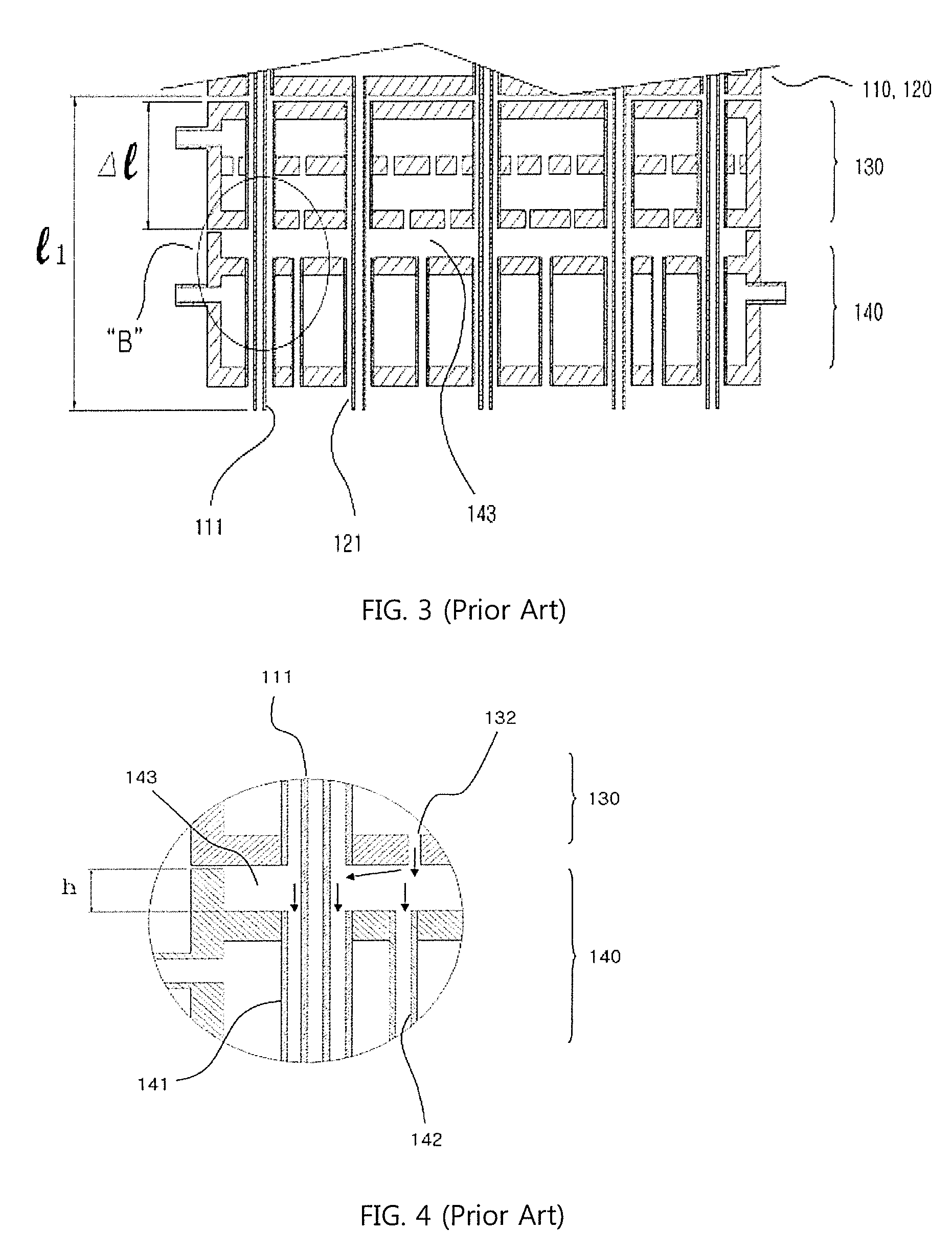

ActiveUS9315897B2Shorten the lengthAccurate supplySpraying apparatusSemiconductor/solid-state device manufacturingReactive gasMixed gas

A showerhead for film-depositing vacuum equipment having an effect shortening the length of injection tubes for a reactive gas is presented. The injection tubes extend from the bottom of a reactive gas showerhead module, and two different kinds of reactive gases are mixed with an injection support gas within a reactive showerhead module so as to inject the mixed gas. The showerhead for film-depositing vacuum equipment includes the reactive gas showerhead module above a cooling jacket and a purge gas showerhead module above the reactive gas showerhead module. The injection tubes of the reactive gas showerhead module pass through the cooling jacket disposed below the reactive gas showerhead module, and the injection tubes of the purge gas showerhead module pass through the reactive gas showerhead module disposed below the purge gas showerhead module, thereby enabling the purge gas to flow into a purge gas redistribution space defined above the cooling jacket.

Owner:KOREA INST OF IND TECH

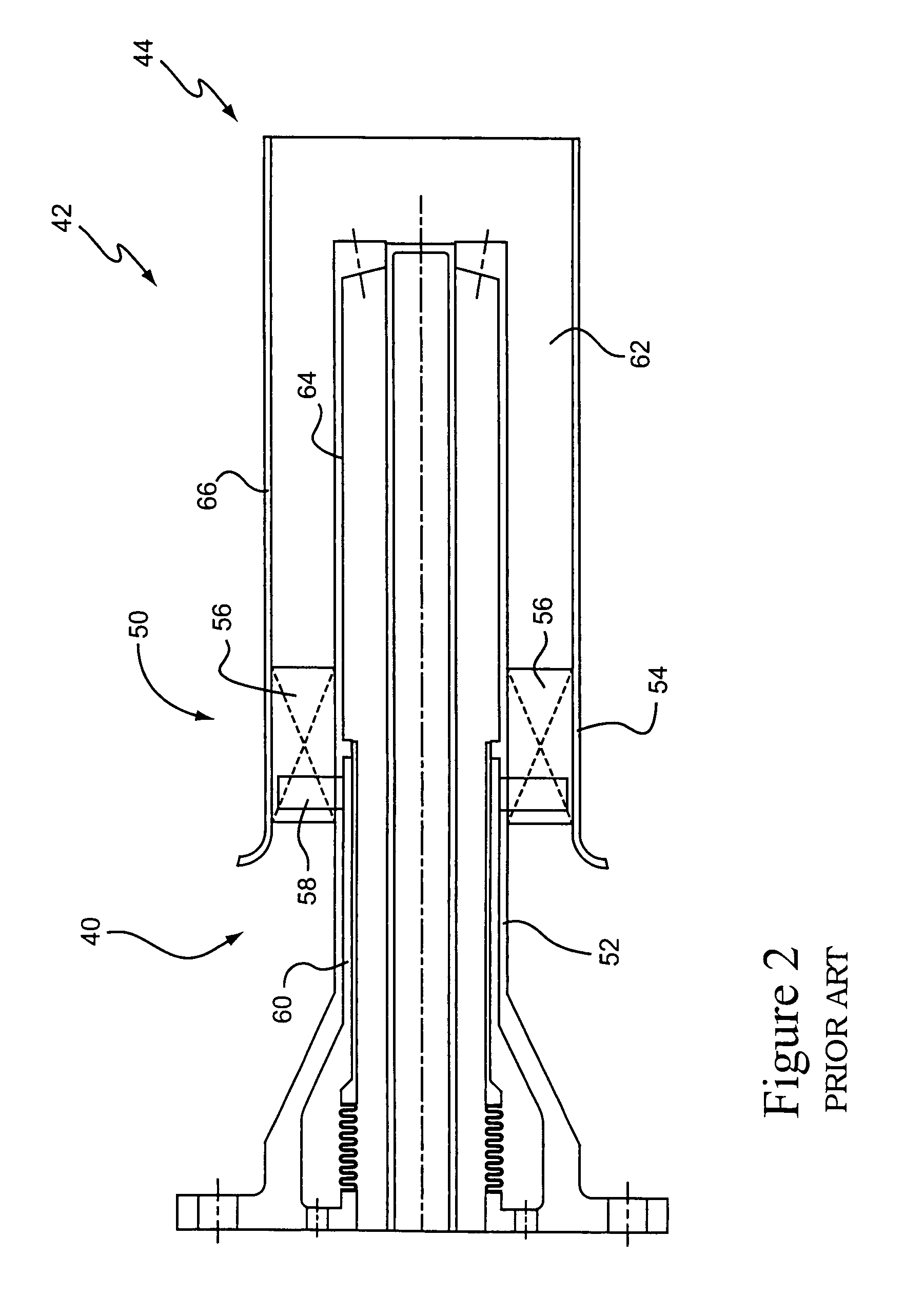

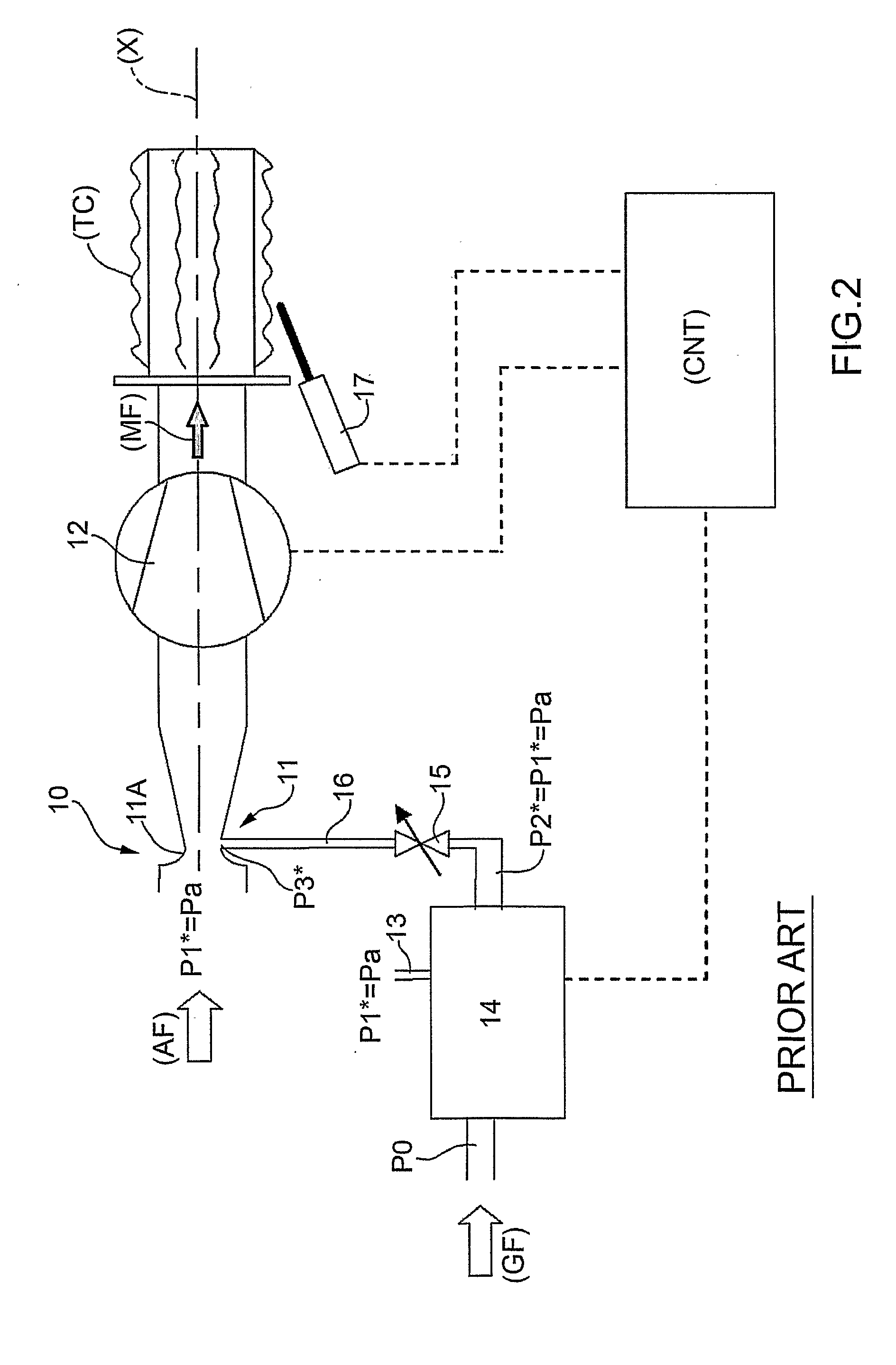

Gas Treatment Apparatus with Surrounding Spray Curtains

Owner:HERMES EPITEK

Apparatus for delivering humidified gases

An apparatus for delivering humidified gases has a connection manifold adapted to connect with inlet and outlet ports of a slide on water chamber in a single slide on motion. Connection of the gases inlet and gases outlet ports as well as any additional electrical and / or pneumatic connections are all made in the same slide on motion. The water chamber may include inwardly extending elongate extension tubes with one of the extension tubes having an air bleed aperture to aid filling of the chamber.

Owner:FISHER & PAYKEL HEALTHCARE LTD

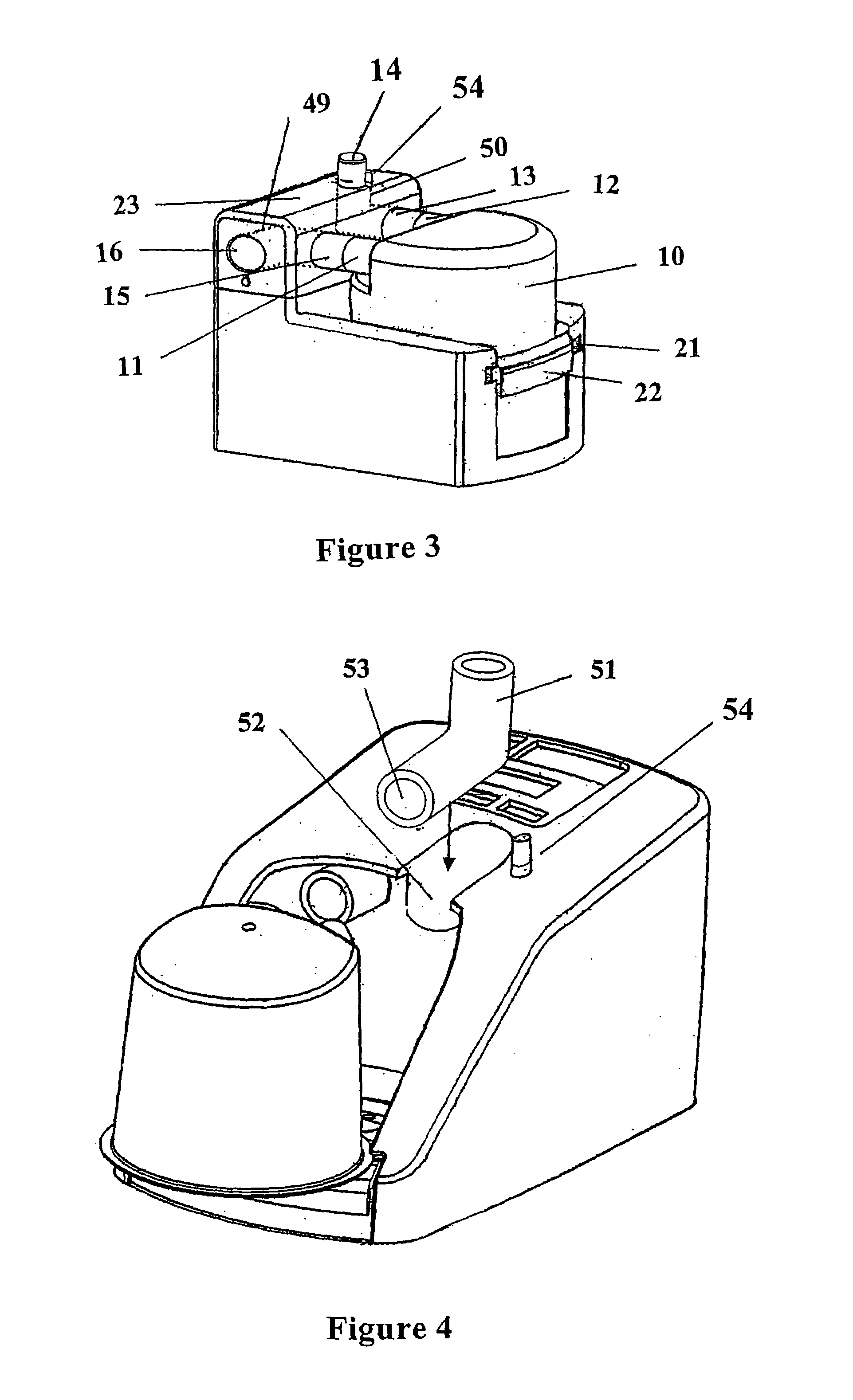

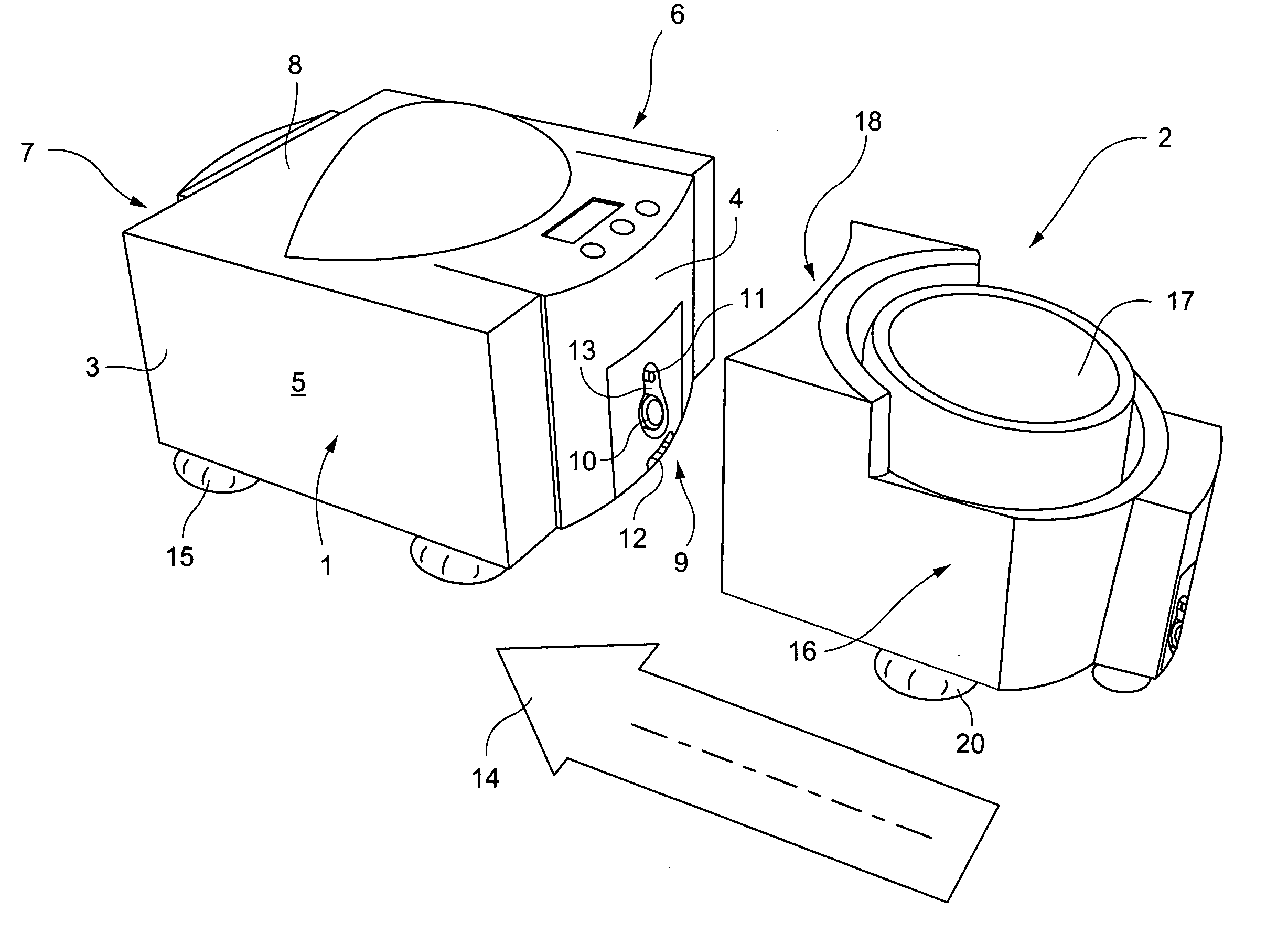

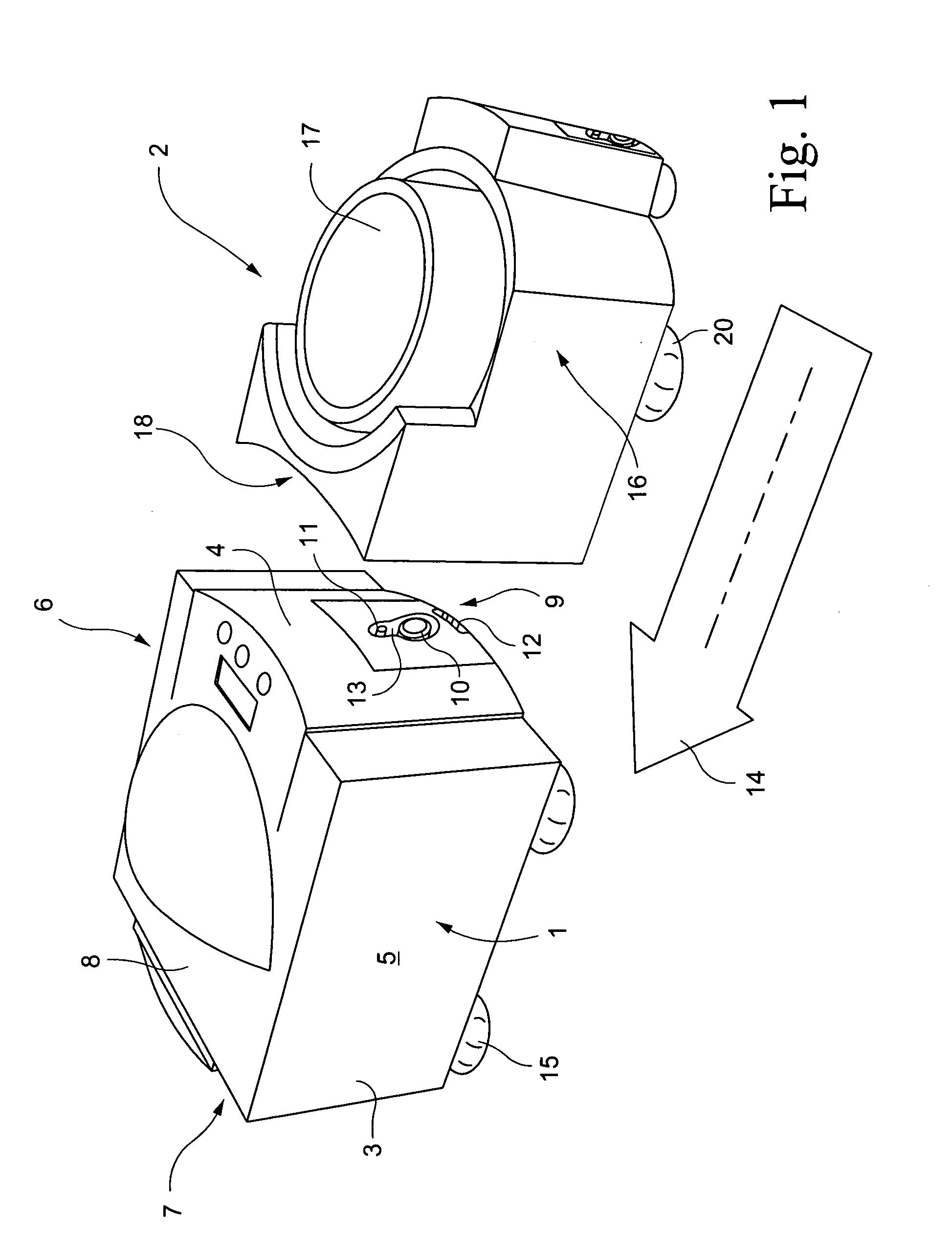

Device for supplying respiratory gas

An apparatus for supplying a respiratory gas includes a blowing device for delivering the respiratory gas, a housing device having a bottom region, a top surface region and a side region extending upwardly between the top surface region and the cover region, as well as a connecting device for connecting a humidifying apparatus. The connecting device is arranged in the side region of the apparatus in such a way that the humidifying apparatus can be laterally coupled thereto. The humidifying apparatus may include a partial amount discharge device for passing a partial amount of the liquid pre-stored in a liquid storage space into a humidifying region. A respiration tube includes a connecting plug structure which has both a respiratory gas connecting portion and a pressure measuring tube connecting portion.

Owner:RESMED HUMIDIFICATION TECH

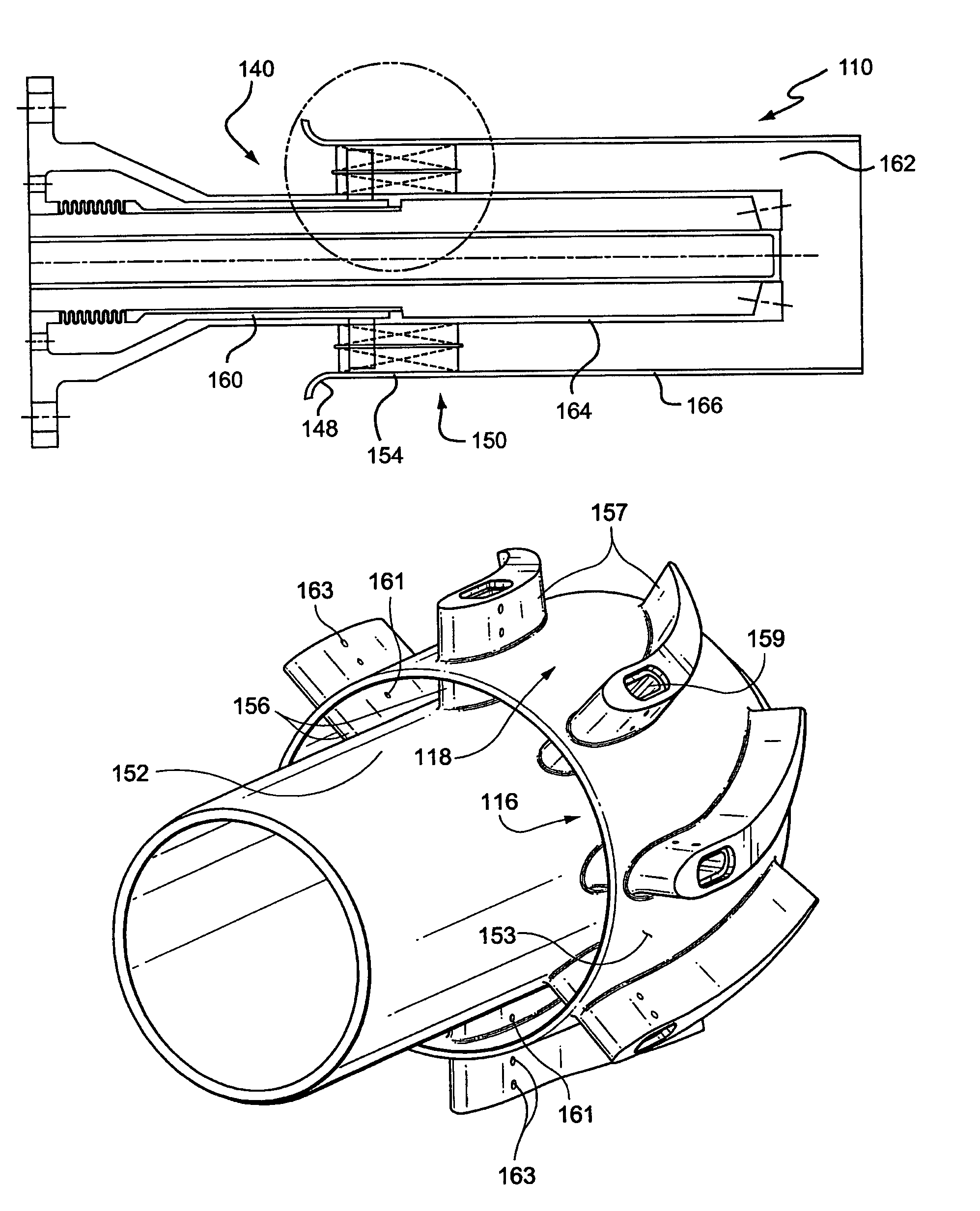

Gas treatment systems

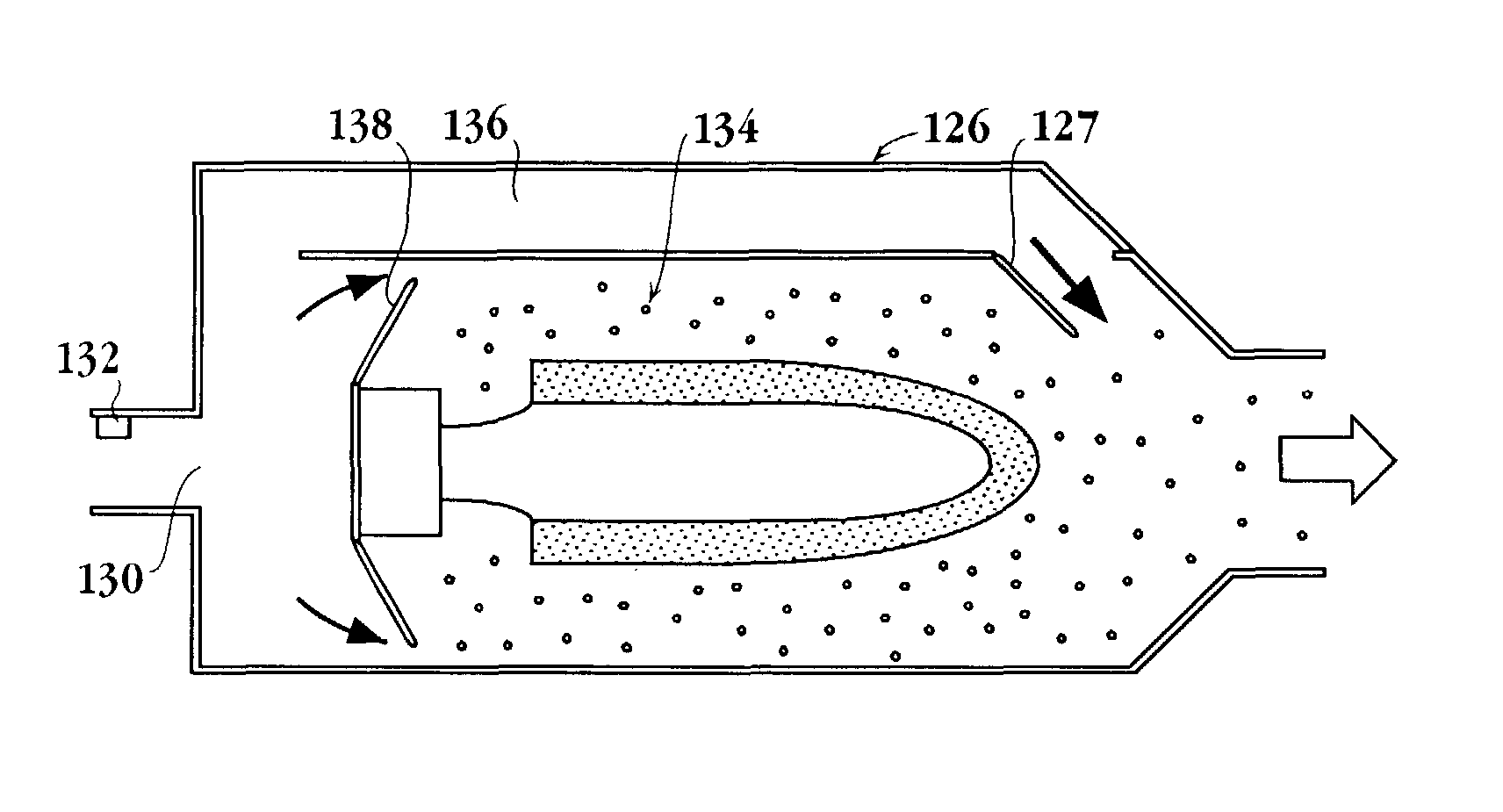

ActiveUS20080173735A1Suppress unwanted depositionDust removalFire preventionNuclear engineeringProduct gas

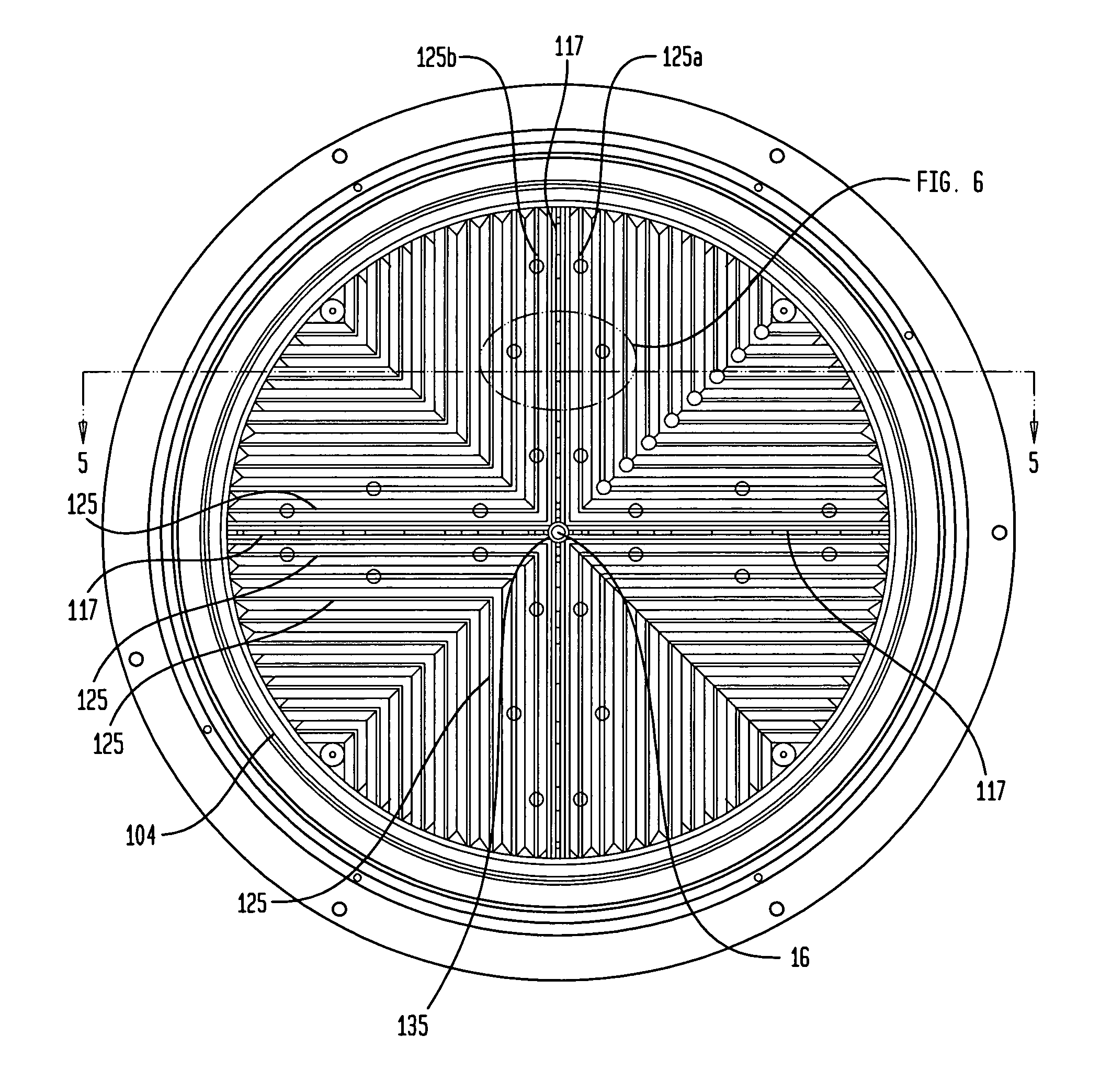

An MOCVD reactor such as a rotating disc reactor (10) is equipped with a gas injector head having diffusers (129) disposed between adjacent gas inlets. The diffusers taper in the downstream direction. The injector head desirably has inlets (117) for a first gas such as a metal alkyl disposed in radial rows which terminate radially inward from the reactor wall to minimize deposition of the reactants on the reactor wall. The injector head desirably also has inlets (125) for a second gas such as ammonia arranged in a field between the rows of first gas inlets, and additionally has a center inlet (135) for the second gas coaxial with the axis of rotation.

Owner:VEECO INSTR

Breathing assistance apparatus

A humidifier and humidity sensor for use with a breathing assistance apparatus. The humidity sensor senses absolute humidity, relative humidity and / or temperature at both the patient end and humidifier end. The humidifier may also include provision to both control independently the humidity and temperature of the gases. Further, a chamber manifold facilitates easy connection of the humidifier to various outlets, inlets and sensors. A heated conduit provides a more effective temperature profile along its length.

Owner:FISHER & PAYKEL HEALTHCARE LTD

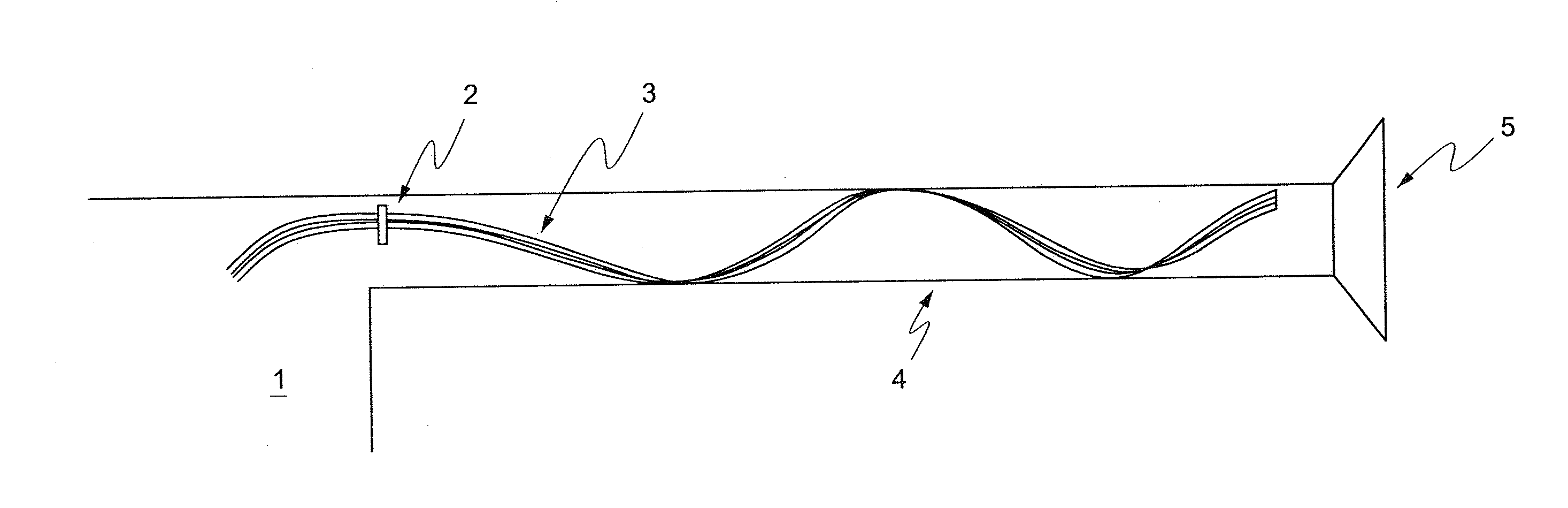

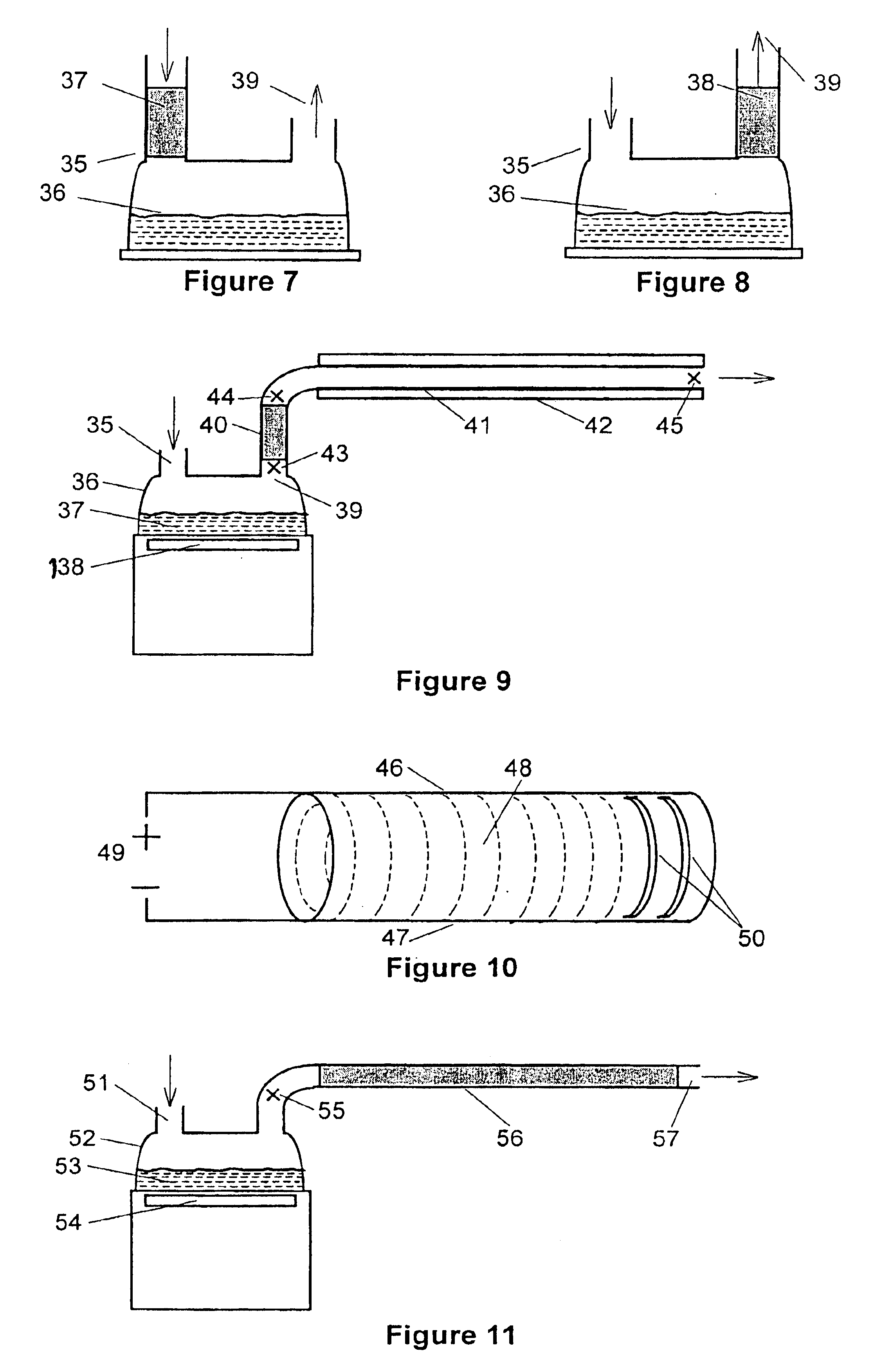

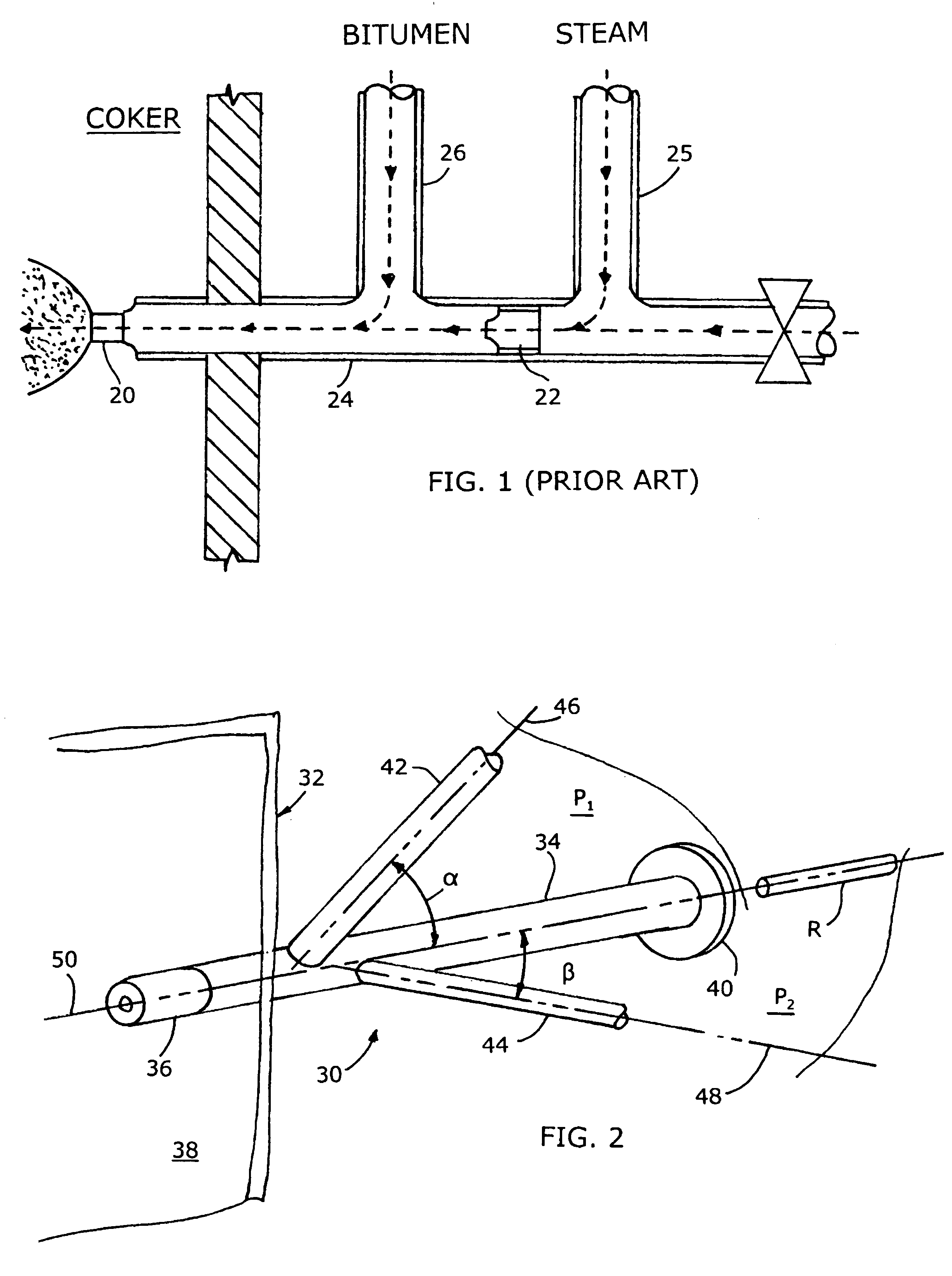

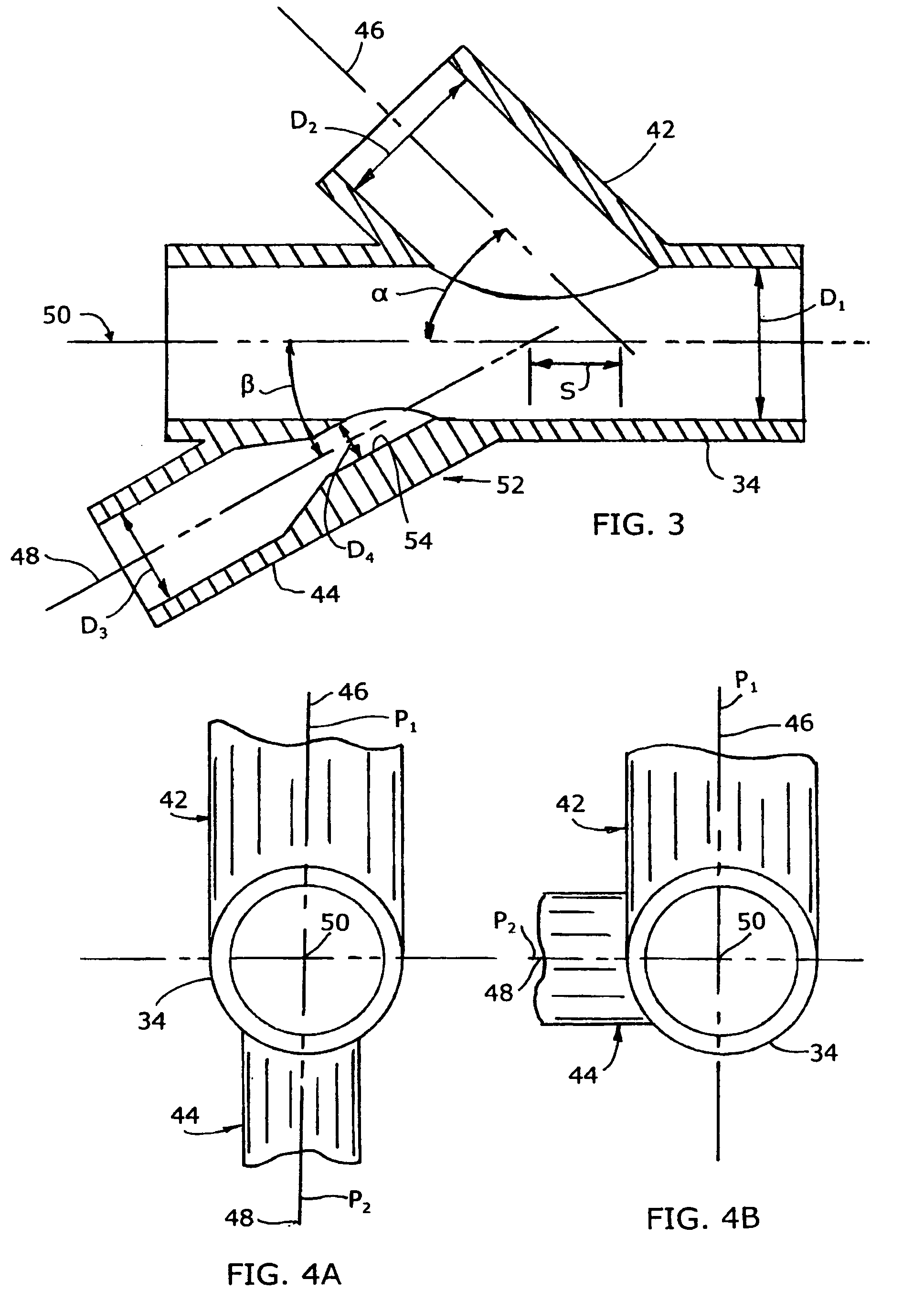

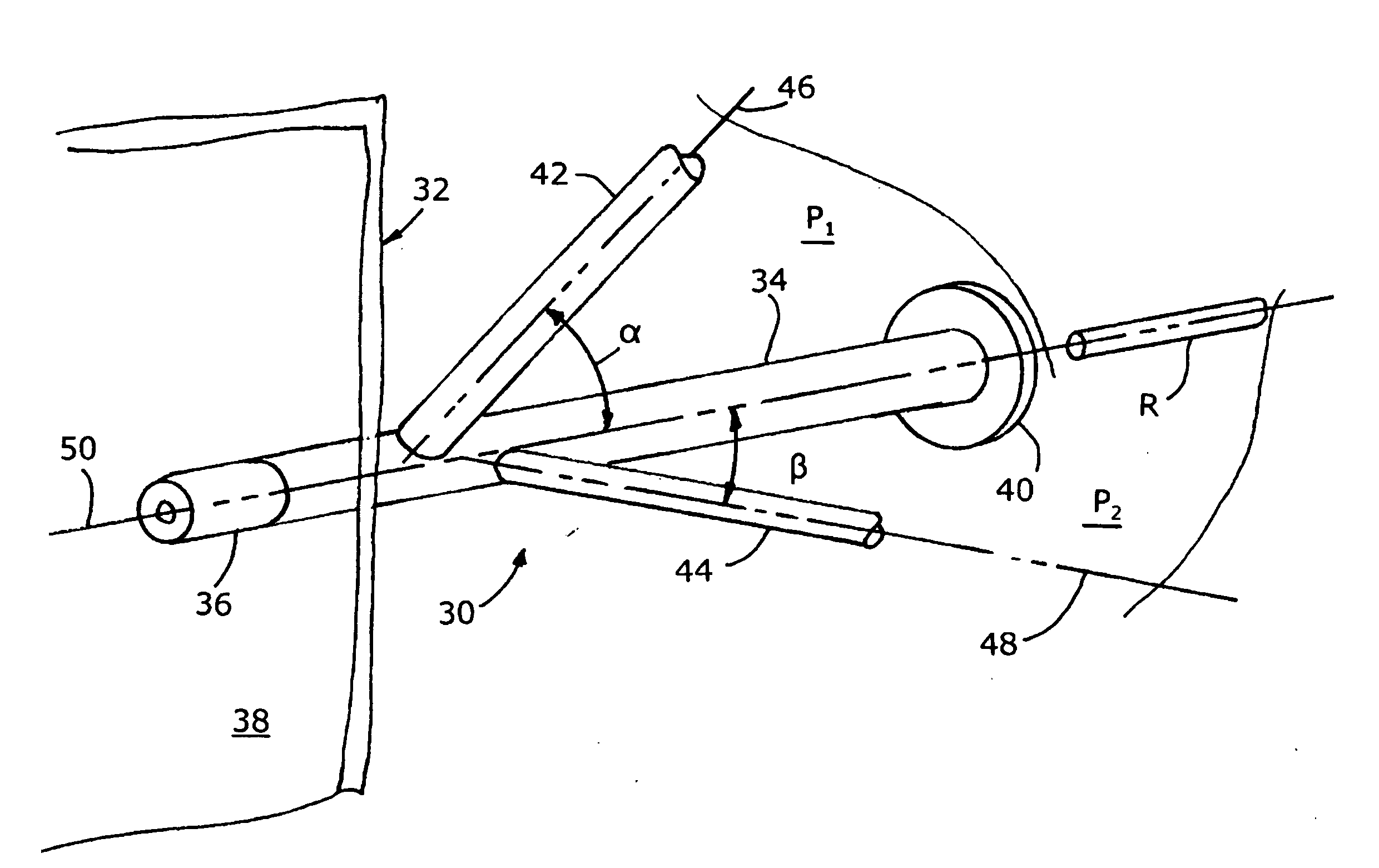

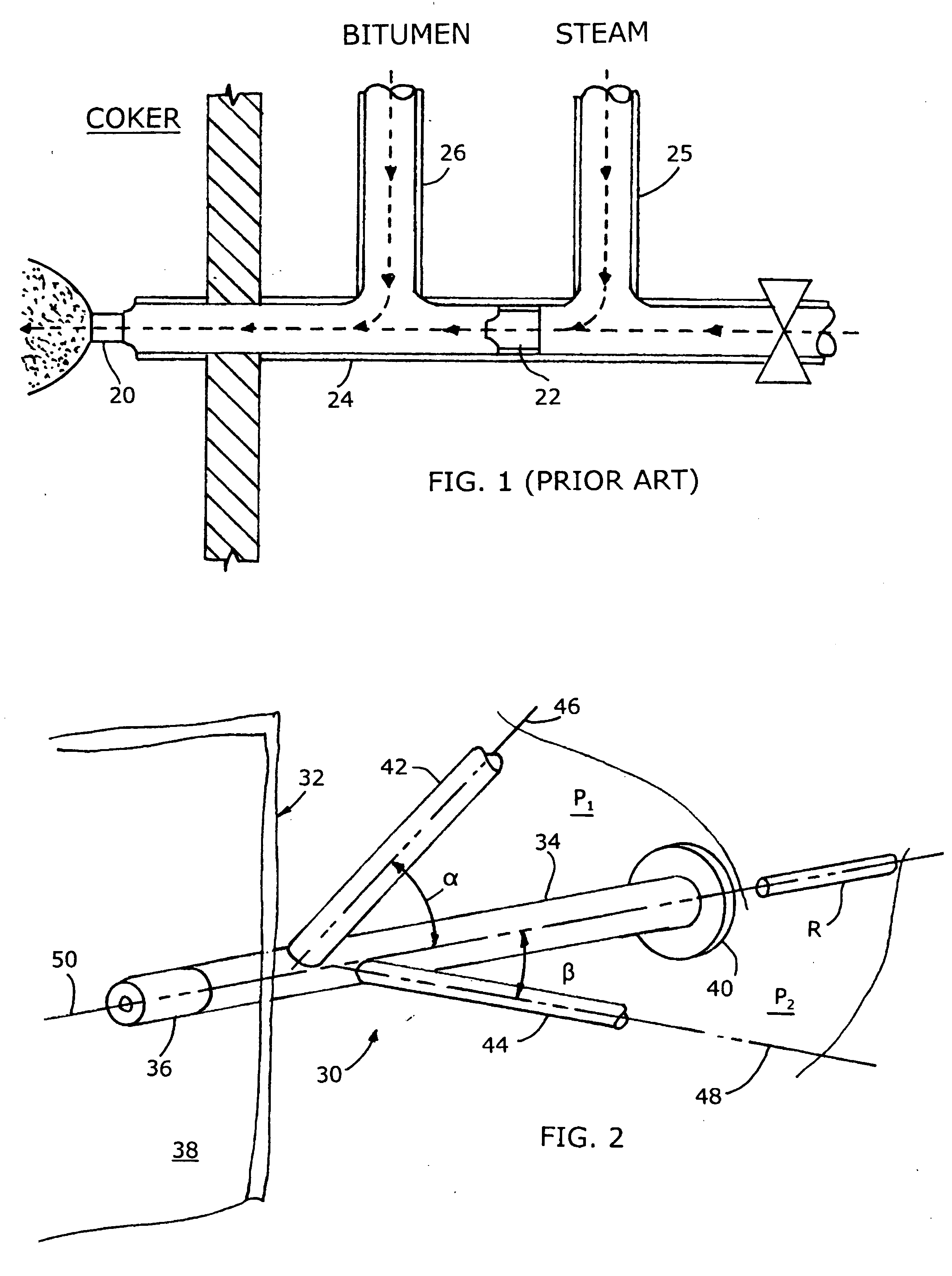

Mixing arrangement for atomizing nozzle in multi-phase flow

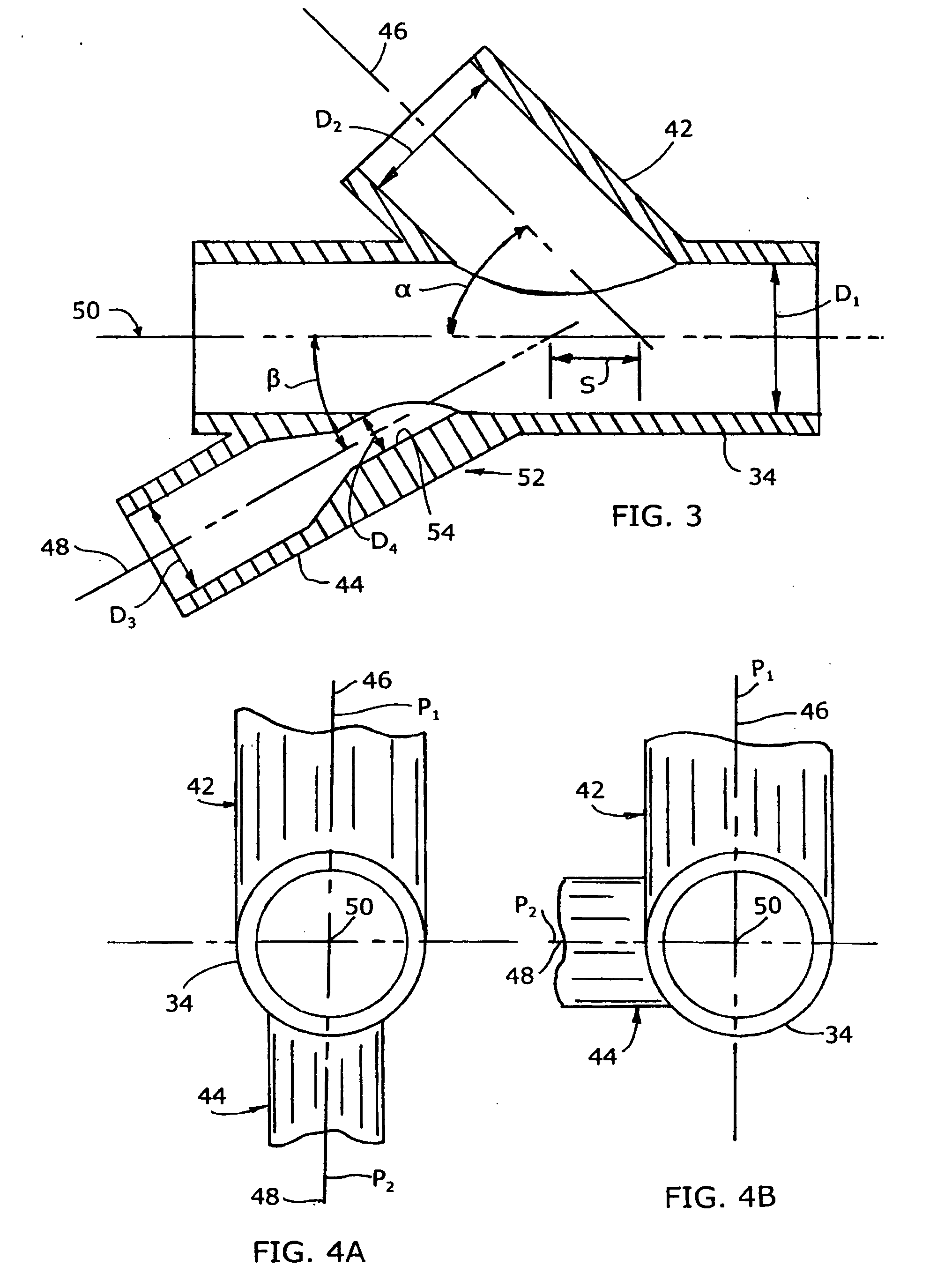

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

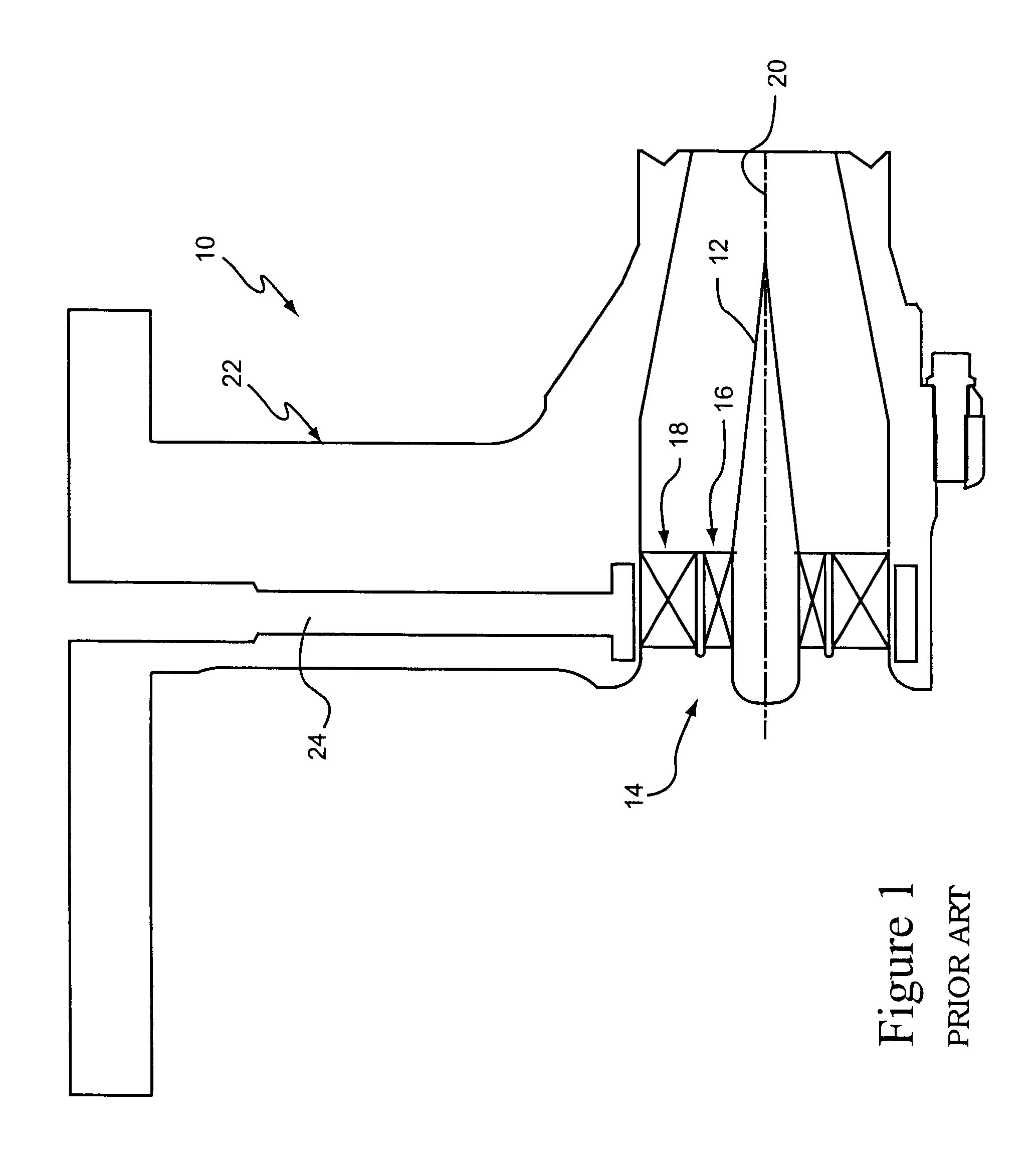

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

Method and apparatus for maintaining control of liquid flow in a vibratory atomizing device

Liquid to be atomized is supplied from a wick to the underside of a vibrating orifice plate which pumps the liquid up through atomizing orifices in the plate and ejects the liquid from is upper side; and liquid which is pumped up through the orifices in an elevated region of the plate, but which has not been ejected, is directed back down through larger openings in a lower region of the plate. The liquid also flows back onto the wick which places the liquid in capillary communication along the underside of the plate with the atomizing orifices for reputing and ejection.

Owner:SC JOHNSON & SON INC

Gas distribution showerhead for semiconductor processing

ActiveUS6983892B2Easy to disassembleAvoid ignitionSelf-acting watering devicesSpray nozzlesGas passingEngineering

Owner:APPLIED MATERIALS INC

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS20050001062A1Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned downstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit. The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

Nozzle and nozzle head

InactiveUS20150004318A1Simple structureCompact structureElectric discharge tubesDust removalEngineeringWaste management

A nozzle and nozzle head arranged to subject a surface of a substrate to gaseous precursors. The nozzle includes an output face via which the precursor is supplied, a longitudinal precursor supply element for supplying precursor and a longitudinal discharge channel open to and along the output face for discharging at least a fraction of the precursor supplied from the precursor channel. The precursor supply element is arranged to extend inside the discharge channel such that the precursor supply element divides the discharge channel in the longitudinal direction to a first discharge sub-channel and a second discharge sub-channel on opposite sides of the precursor supply element for supplying precursor through the discharge channel.

Owner:BENEQ OY

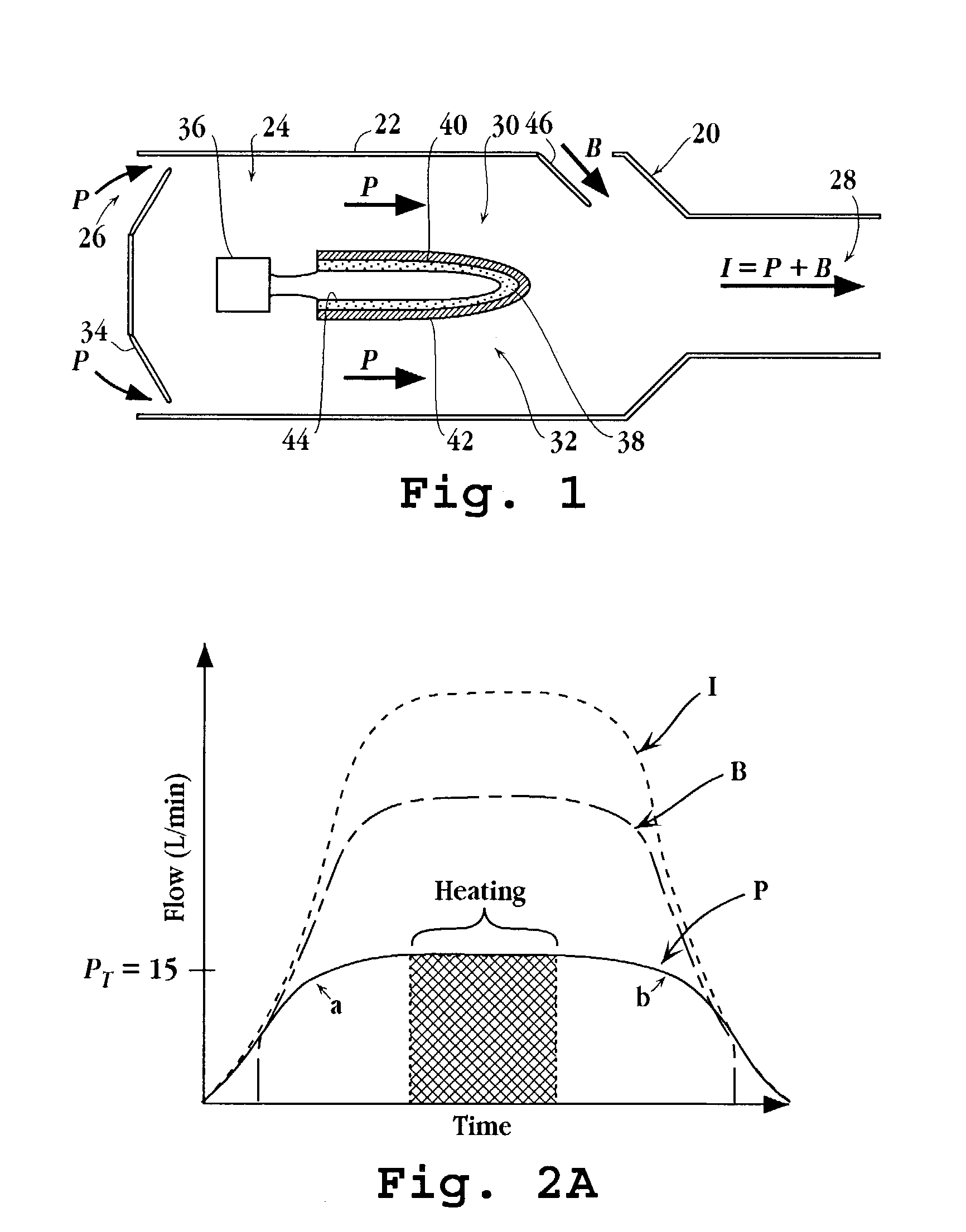

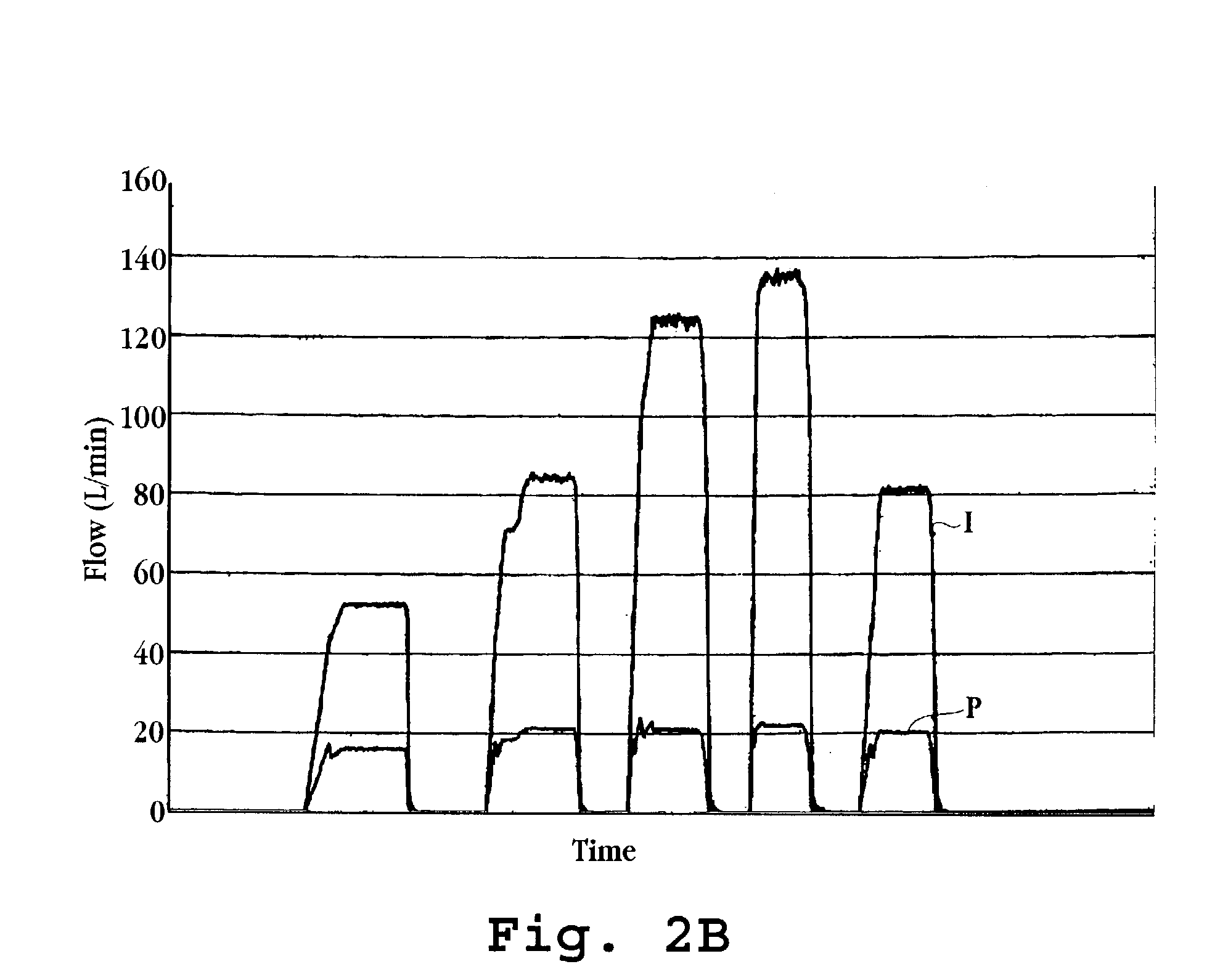

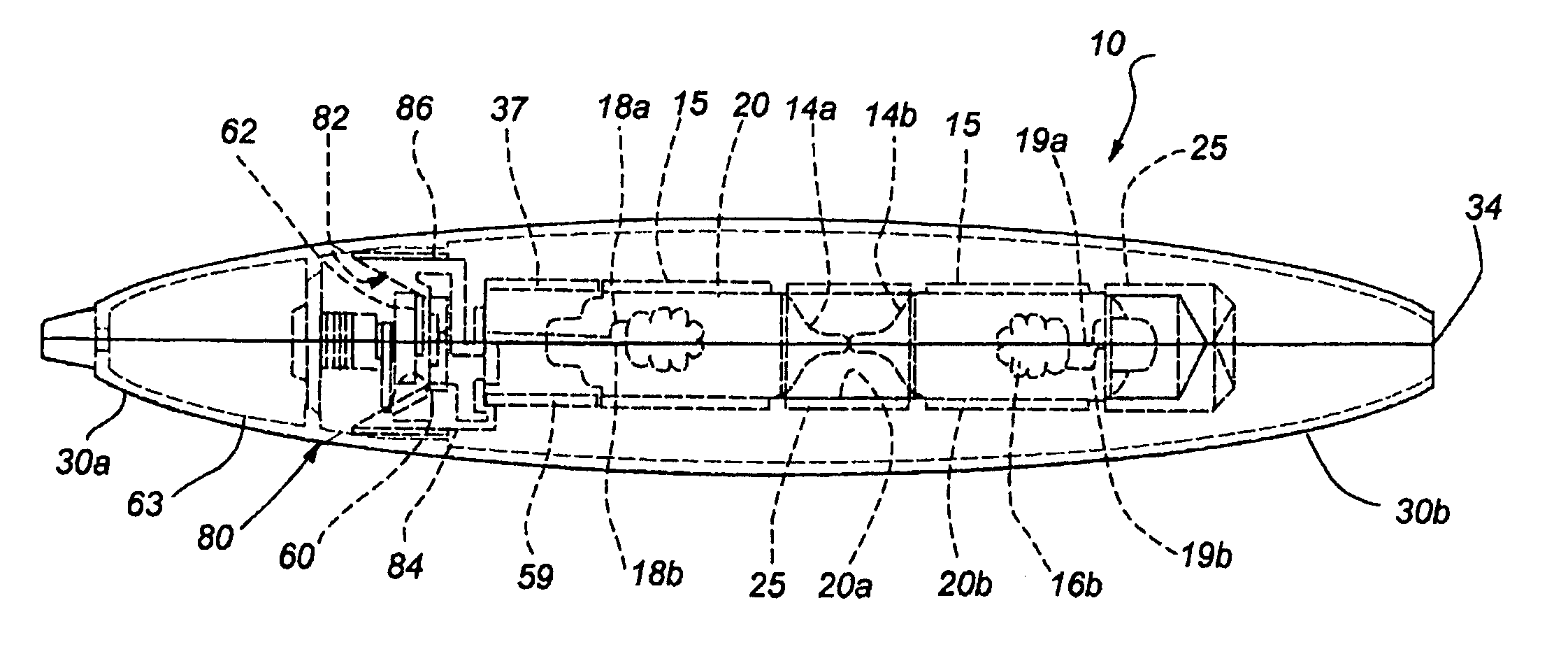

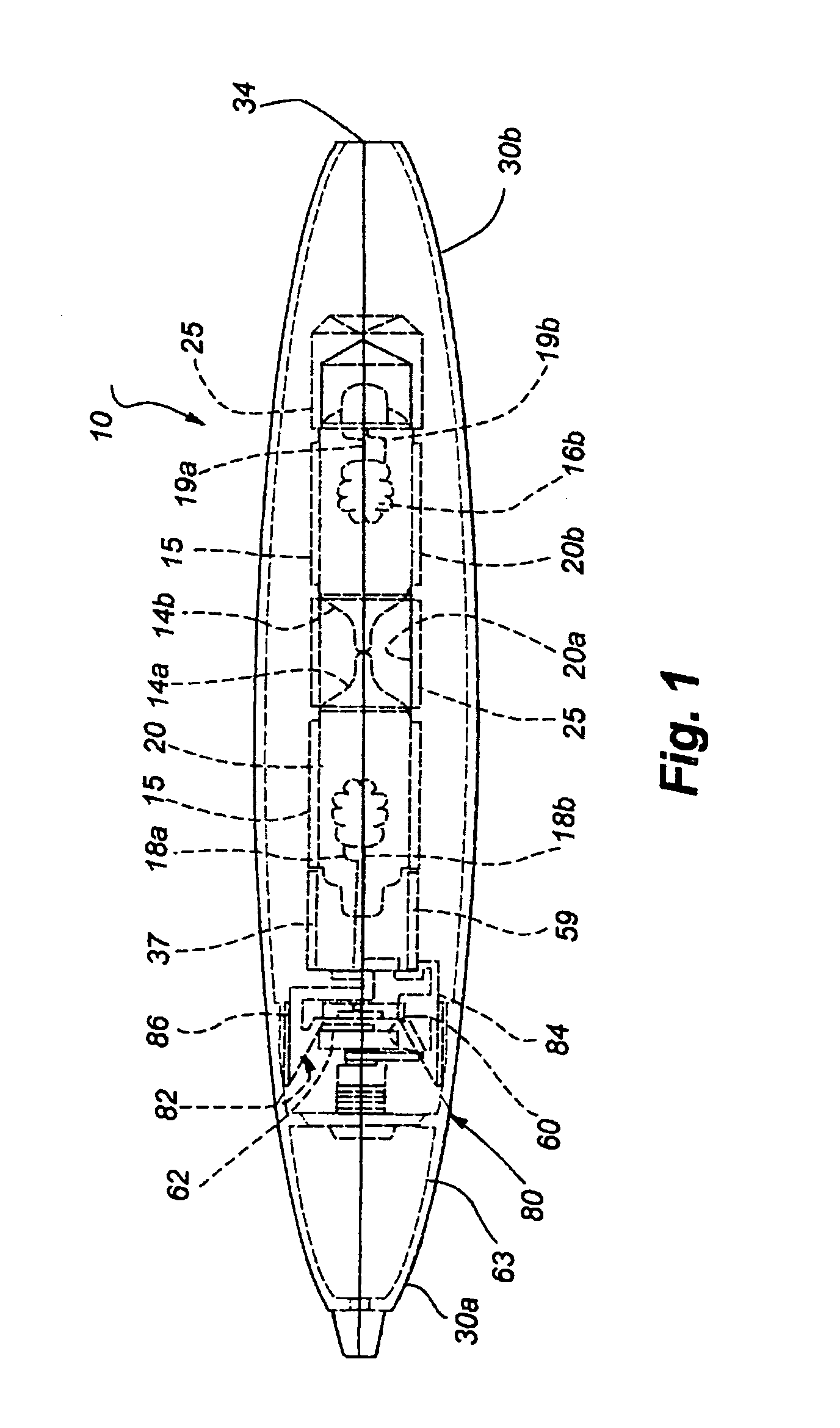

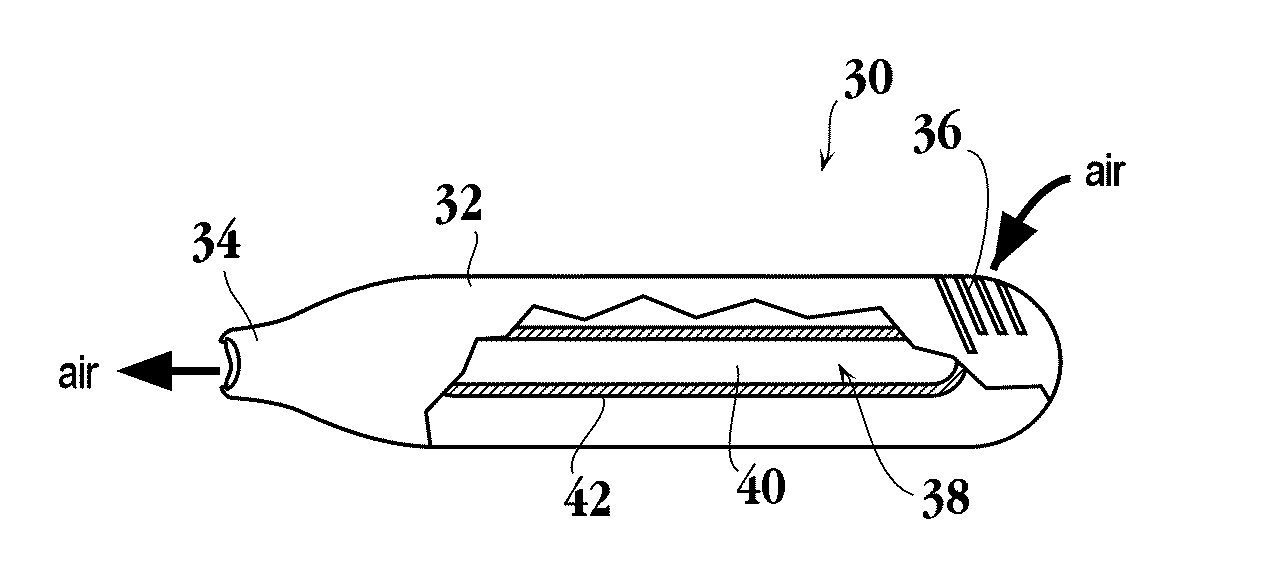

Inhalation device for producing a drug aerosol

A device for delivering a drug by inhalation is disclosed. The device includes a body defining an interior flow-through chamber having upstream and downstream chamber openings, and a drug supply unit contained within the chamber for producing, upon actuation, a heated drug vapor in a condensation region of the chamber. Gas drawn through the chamber region at a selected gas-flow rate is effective to form drug condensation particles from the drug vapor having a selected MMAD between 0.02 and 0.1 MMAD or between 1 and 3.5 μm. A gas-flow control valve disposed upstream of the unit functions to limit gas-flow rate through the condensation region to the selected gas-flow rate. An actuation switch in the device activates the drug-supply unit, such that the drug-supply unit can be controlled to produce vapor when the gas-flow rate through the chamber is at the selected flow rate.

Owner:ALEXZA PHARMA INC

Silicone spray tip

Owner:CONFLUENT SURGICAL

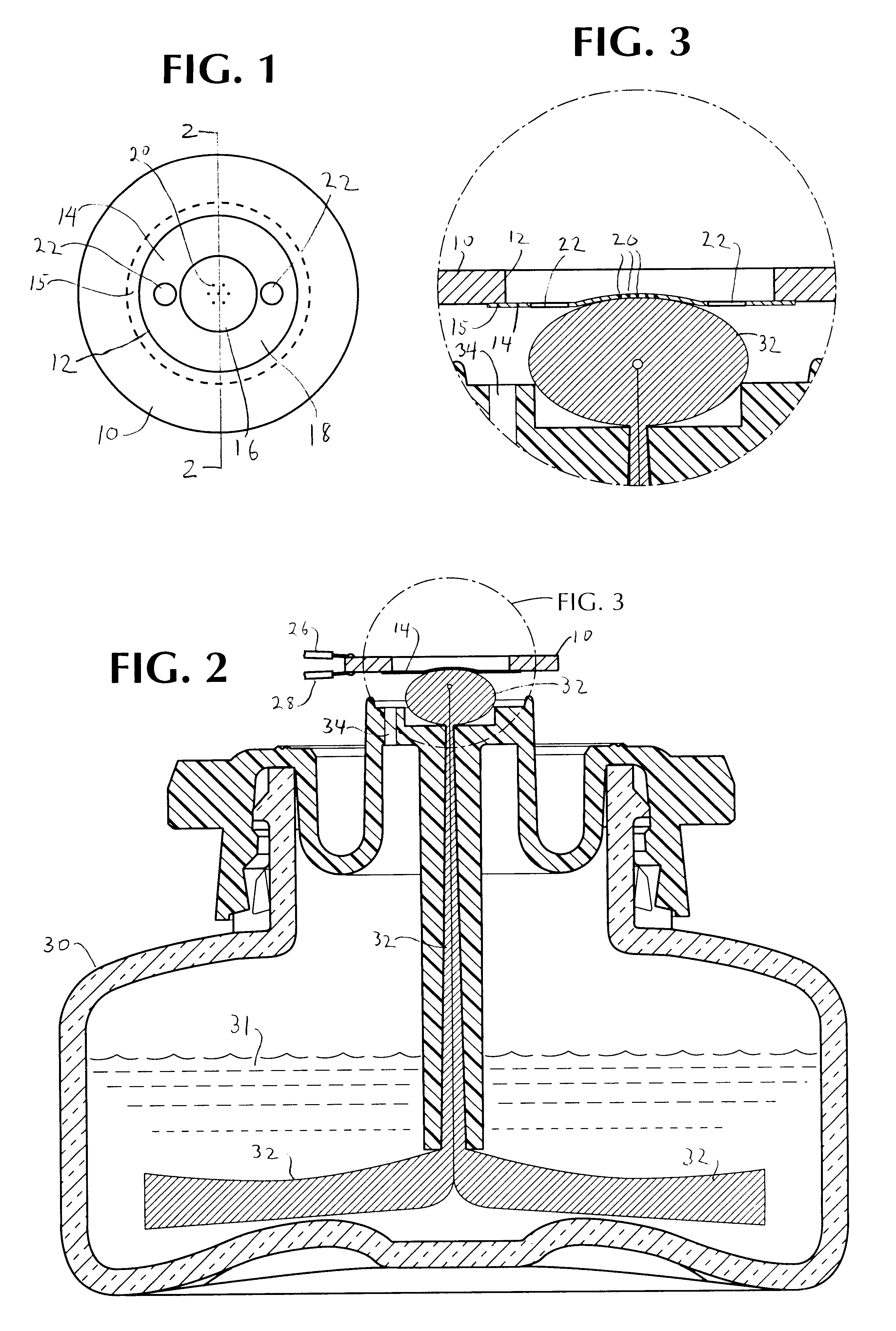

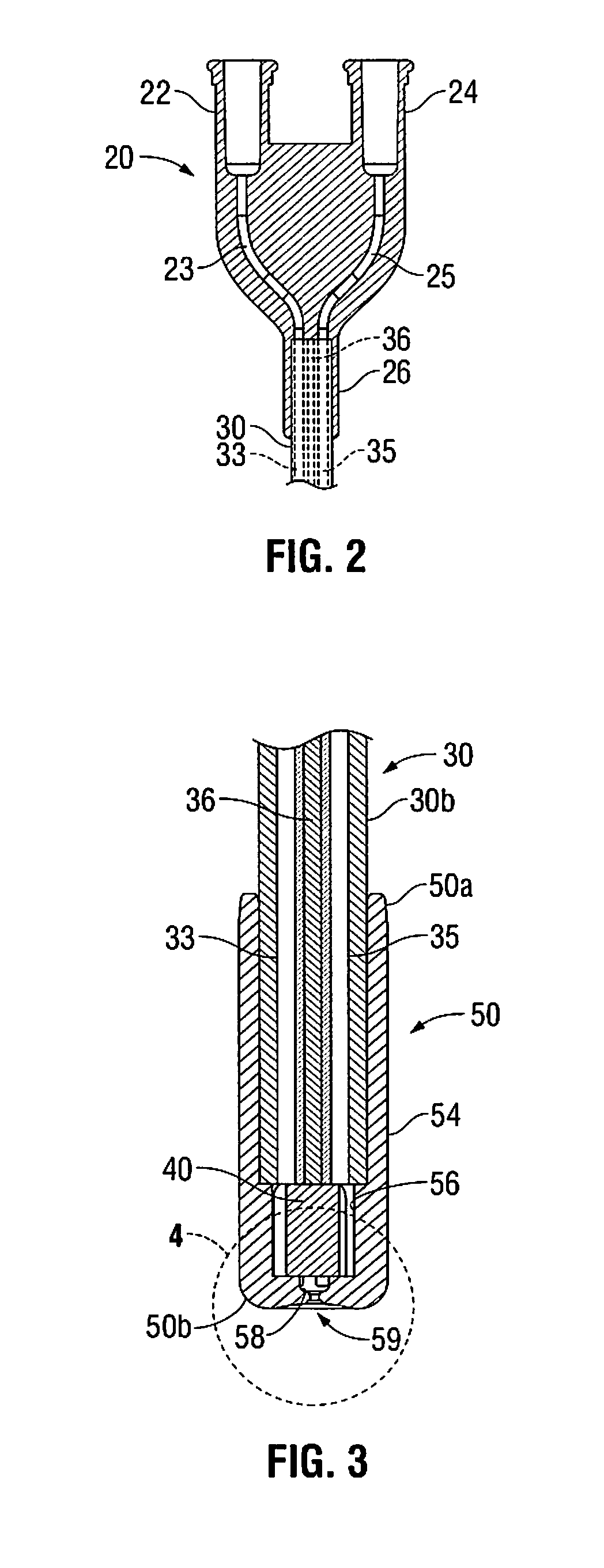

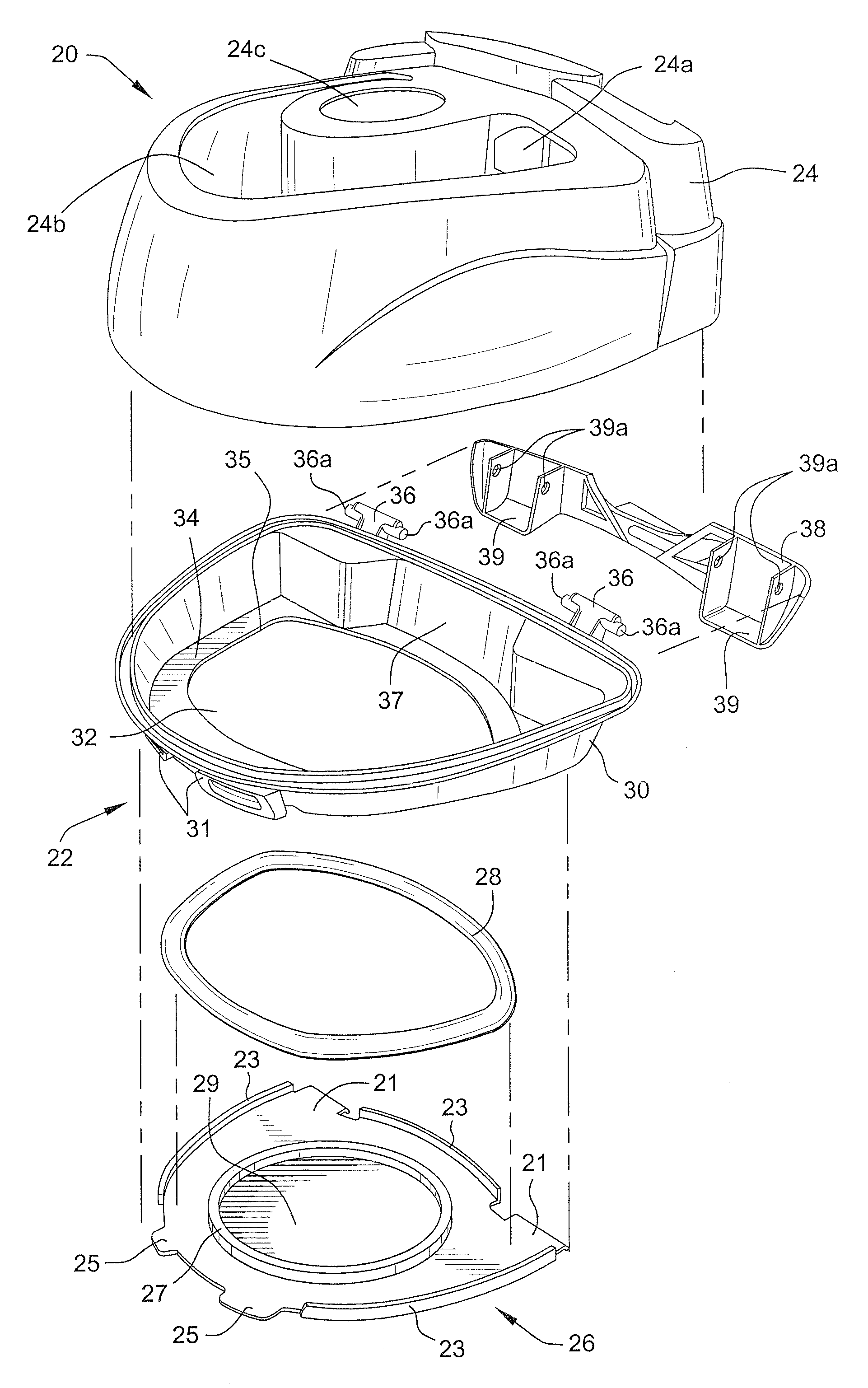

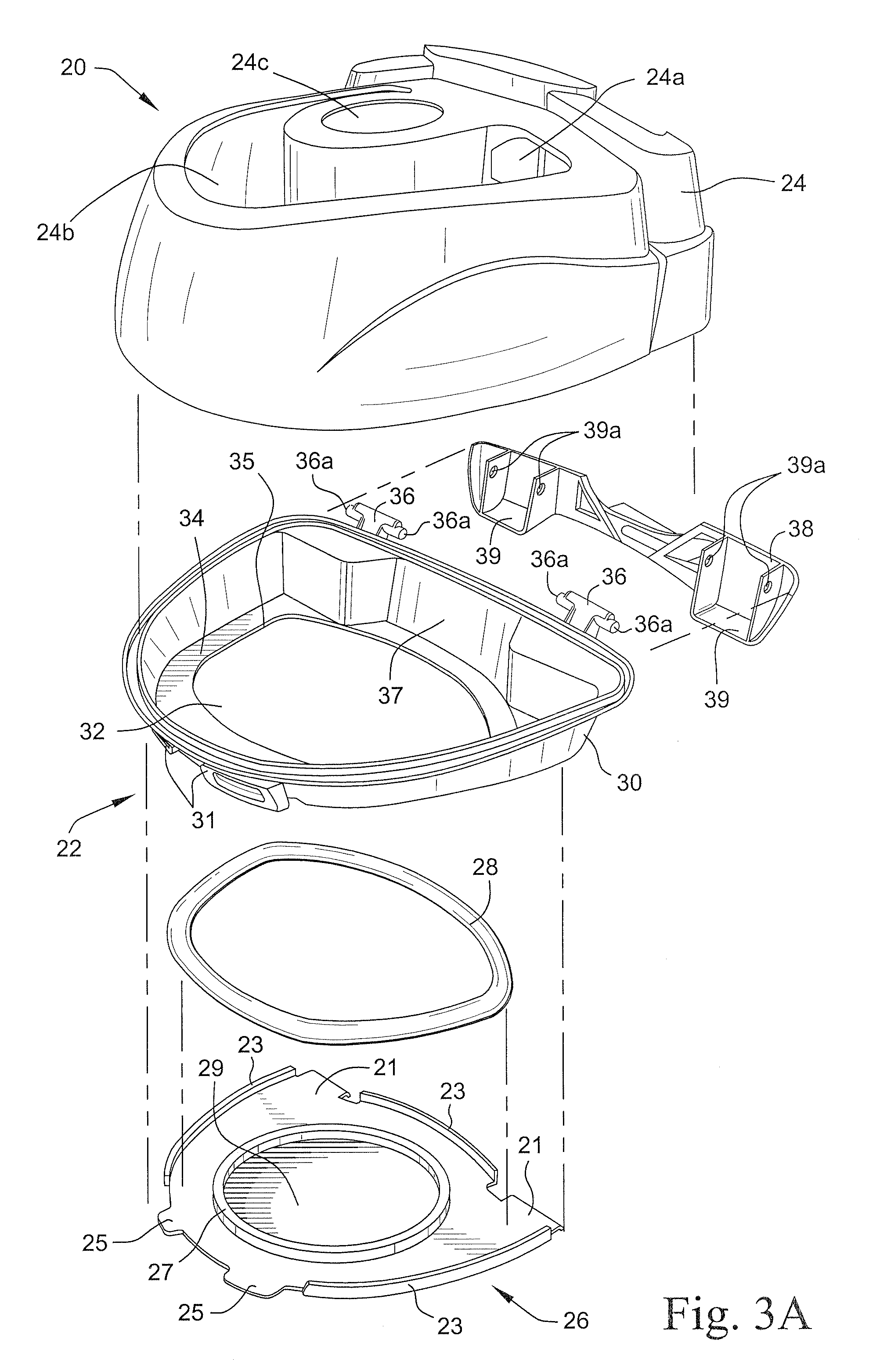

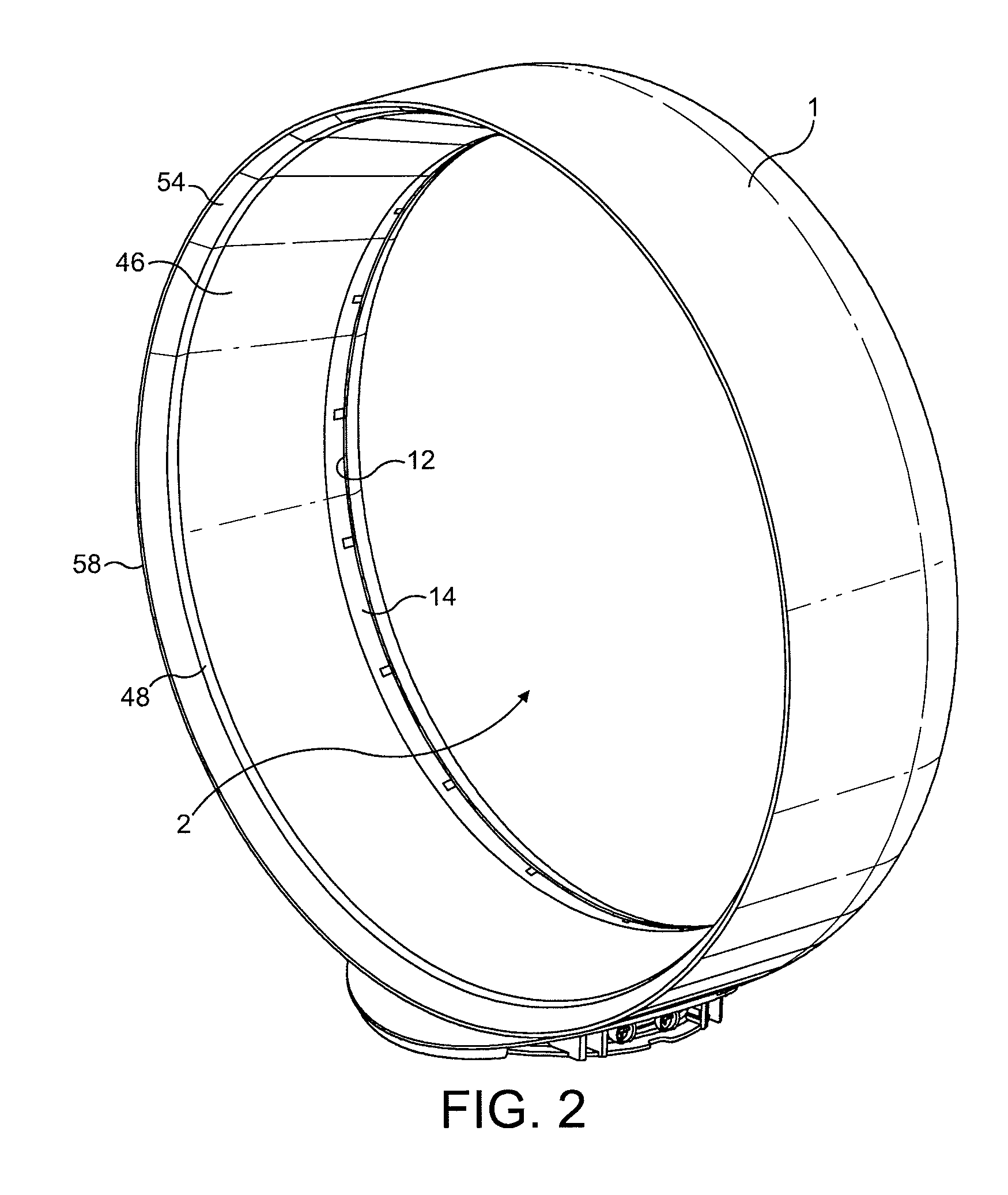

Tub for humidifier

A humidifier includes a tub. The tub includes a base plate; a tub base; a seal between the base plate and the tub base; and a latch mechanism that connects the base plate to the tub base so that the base plate is engaged with the seal. The latch mechanism may include an overcenter latch pivotably attached to the tub base and latch tabs formed on the base plate, the overcenter latch engaging the latch tabs in the connected position to connect the base plate to the tub base. The latch mechanism may alternatively include resilient tabs on the tub base, the resilient tabs elastically biasing the base plate toward the tub base upon connection of the base plate to the tub base. The resilient tabs may include tamper evident projections that indicate that the base plate has been disconnected from the tub base. The base plate may be stainless steel and be formed by stamping. The base plate may include a stamped ring. The humidifier further includes a tub lid configured to cover the tub to form a water container. A cradle receives the water container. A hinged lid on the cradle is pivotable between an open position permitting insertion of the water container into the cradle and a closed position covering the inserted water container. A heating element contacts the base plate when the water container is inserted into the cradle. The humidifier is connectable to a flow generator of a CPAP device.

Owner:RESMED LTD

Removable and/or replaceable humidifier

ActiveUS20090000620A1Improved vaporizationUsing liquid separation agentMedical devicesWater vaporEngineering

Humidifier apparatus for a respiratory apparatus includes a housing providing a gas flow path, a heater apparatus, and a water supply distribution member configured and arranged to deliver water vapour to the gas flow path. The water distribution member is provided to the housing and in thermal communication with the heater apparatus.

Owner:RESMED LTD

Devices for vaporizing and delivering an aerosol agent

ActiveUS20150101606A1Effective and convenient and easy to useRespiratorsMedical devicesElectricityElectrical conductor

A device for vaporizing and delivering an aerosol agent includes a heat generator, a heat conductor in fluid (airflow) communication with the heat generator, and a substrate holder in heat conducting relation with the heat conductor. The heat generator is a handheld, portable torch and the heat conductor defines an annular heat conducting chamber surrounding a substrate disposed within the substrate holder that supports the aerosol agent and an aerosol forming agent. Another device is a handheld, battery-powered heat generator including a heating element in heat conducting relation with a substrate holder. The heating element is a nichrome heating coil wound about the substrate disposed within the substrate holder and electrically coupled to the battery. Another device further includes an auxiliary heat generator having an auxiliary heating element formed by a finely woven wire mesh positioned adjacent the substrate and electrically coupled to the battery.

Owner:PATHFINDER INNOVATIONS LLC

Method and apparatus for vaporizing a compound

ActiveUS7458374B2Heating fastBurn quicklyOther heat production devicesAerosol deliveryInhalationMedicine

Disclosed is a method and device for rapid heating of a coated substance which preferably includes a drug to vaporized for inhalation therapy. A device in accordance with the present invention preferably includes a substrate which has an interior surface surrounding an interior region and an exterior surface upon which the coated substance is to be adhered. Though the substrate is preferably metallic, it does not need to be. A combustible element is placed in the interior region of the rigid substrate and an igniter is connected to the combustible element. The igniter is for initiating oxidation of the combustible element. Preferably, the coated substance is vaporized inside of a housing to allow the vaporized drug to aerosolize and be inhaled by a user.

Owner:ALEXZA PHARMA INC

Fan

A fan assembly for creating an air current is described. The fan assembly includes a nozzle mounted on a base housing a device for creating an air flow through the nozzle. The nozzle includes an interior passage for receiving the air flow from the base, a mouth through which the air flow is emitted, the mouth being defined by facing surfaces of the nozzle, and spacers for spacing apart the facing surfaces of the nozzle. The nozzle extends substantially orthogonally about an axis to define an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The fan provides an arrangement producing an air current and a flow of cooling air created without requiring a bladed fan. The spacers can provide for a reliable, reproducible nozzle of the fan assembly and performance of the fan assembly.

Owner:UNIVERSAL SAFETY RESPONSE INC +1

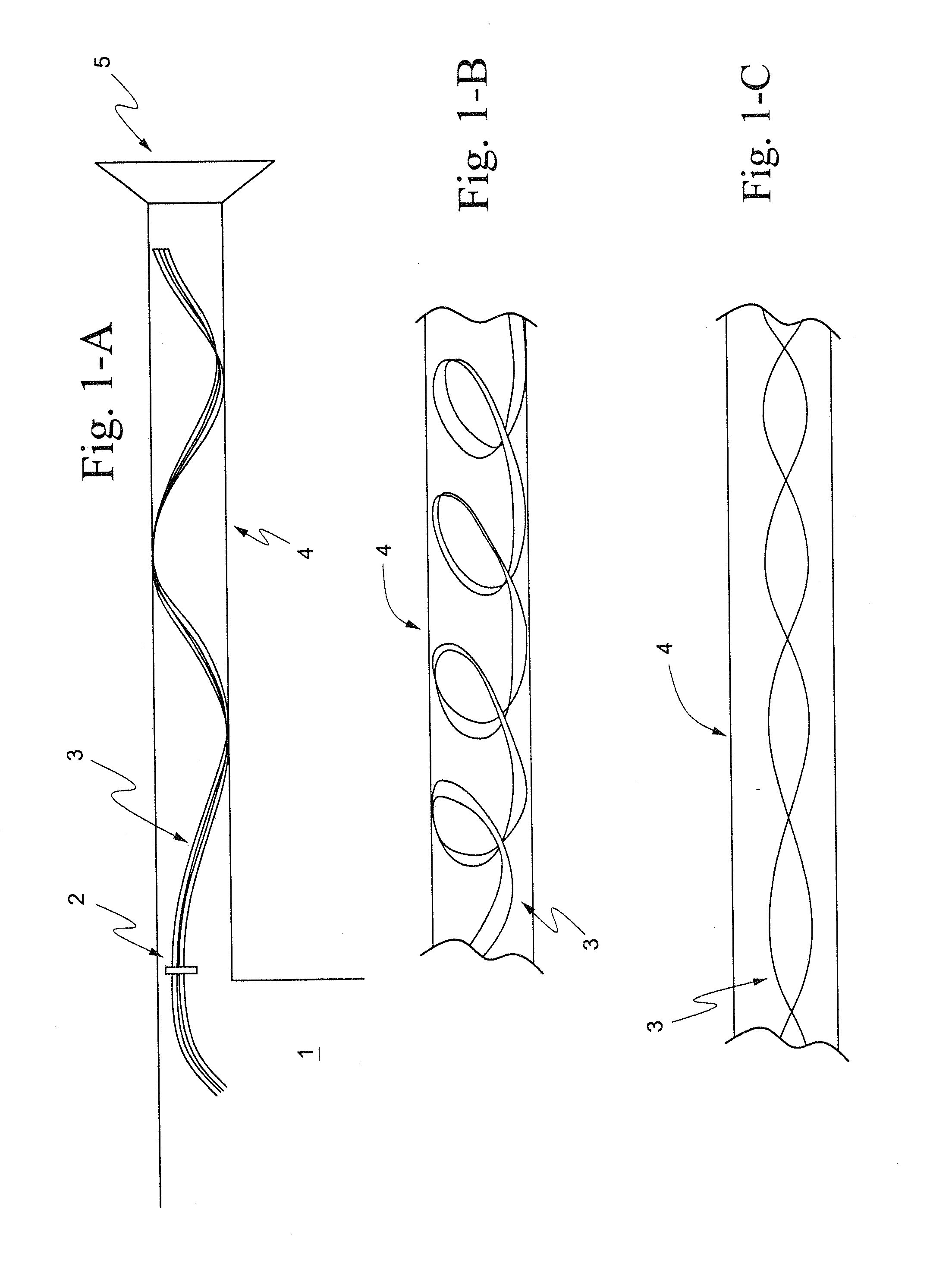

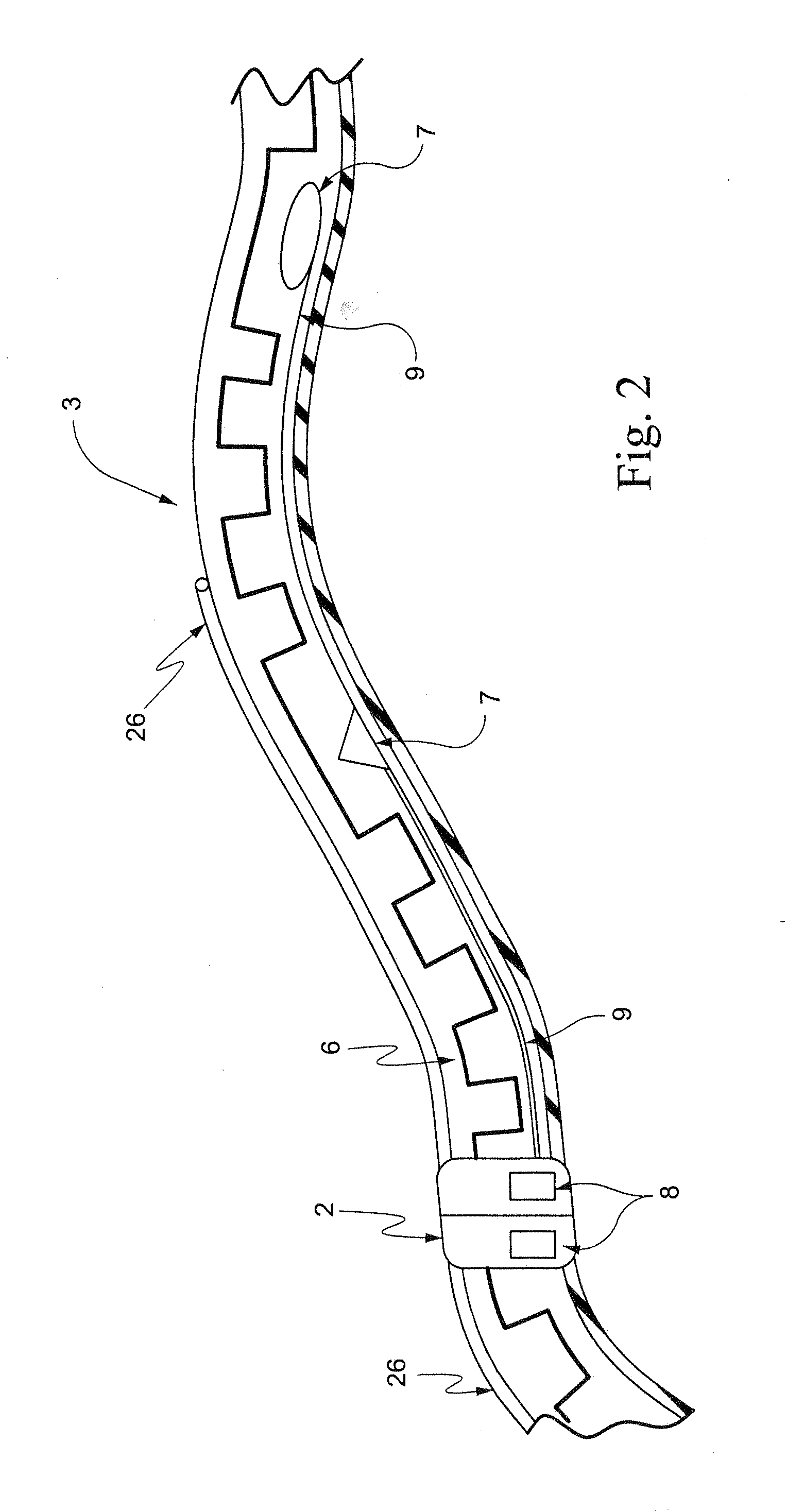

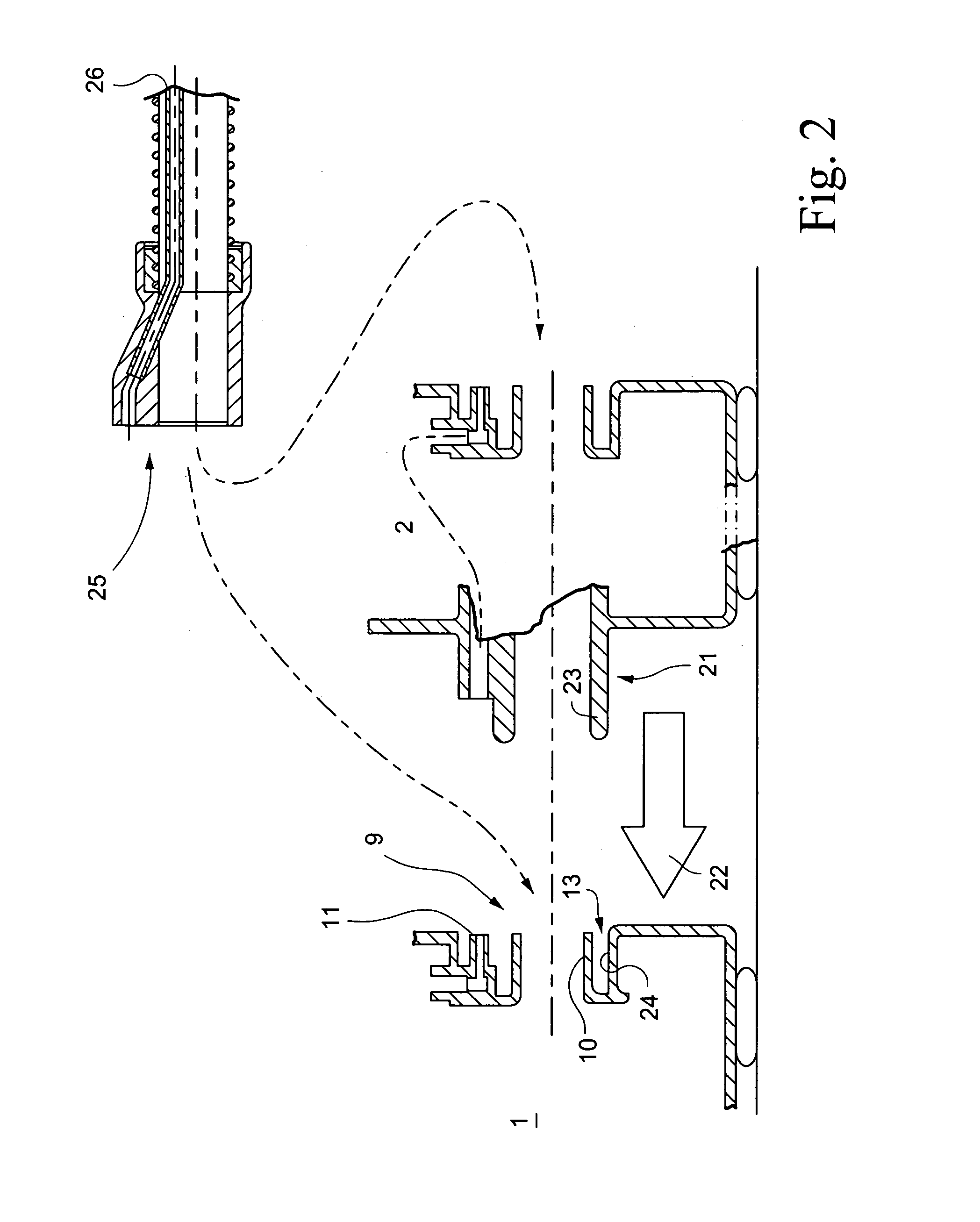

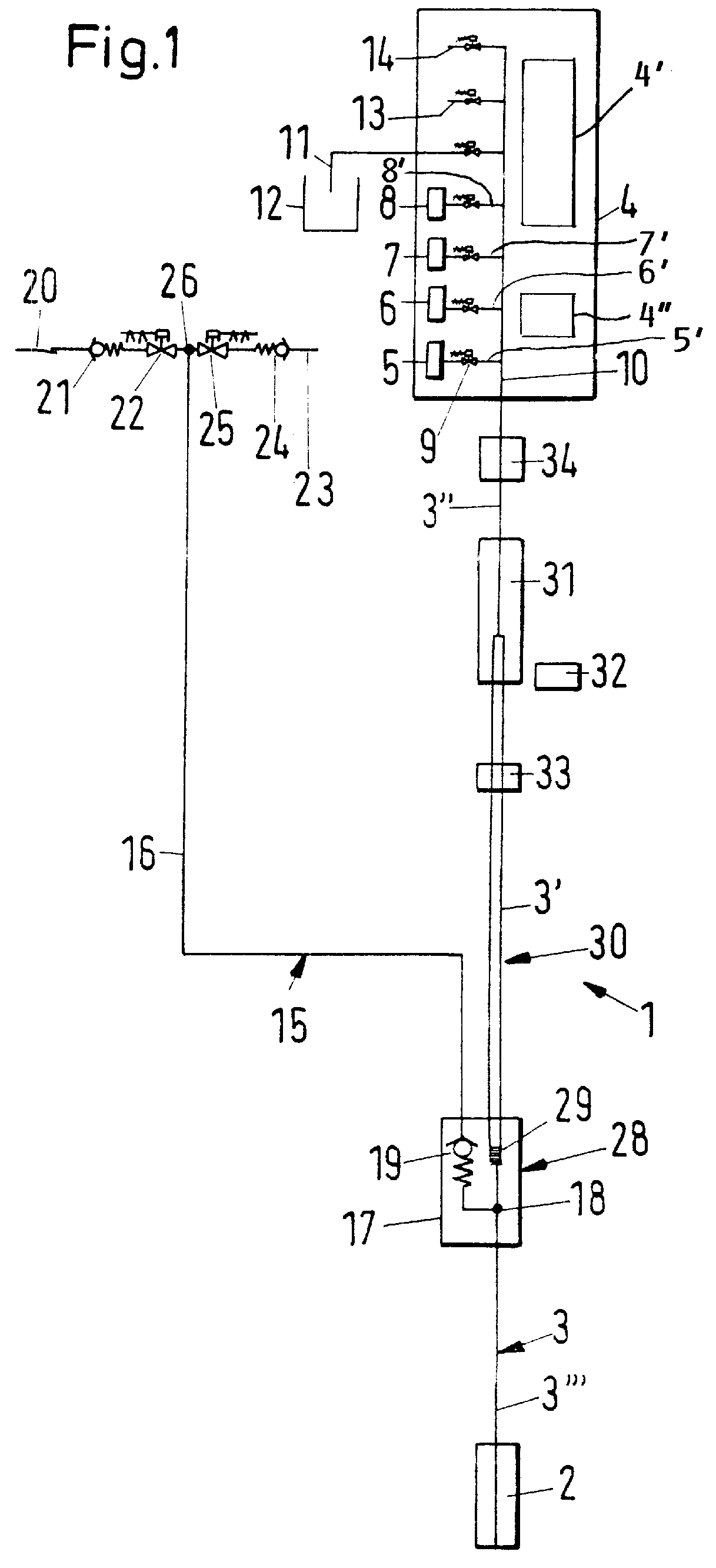

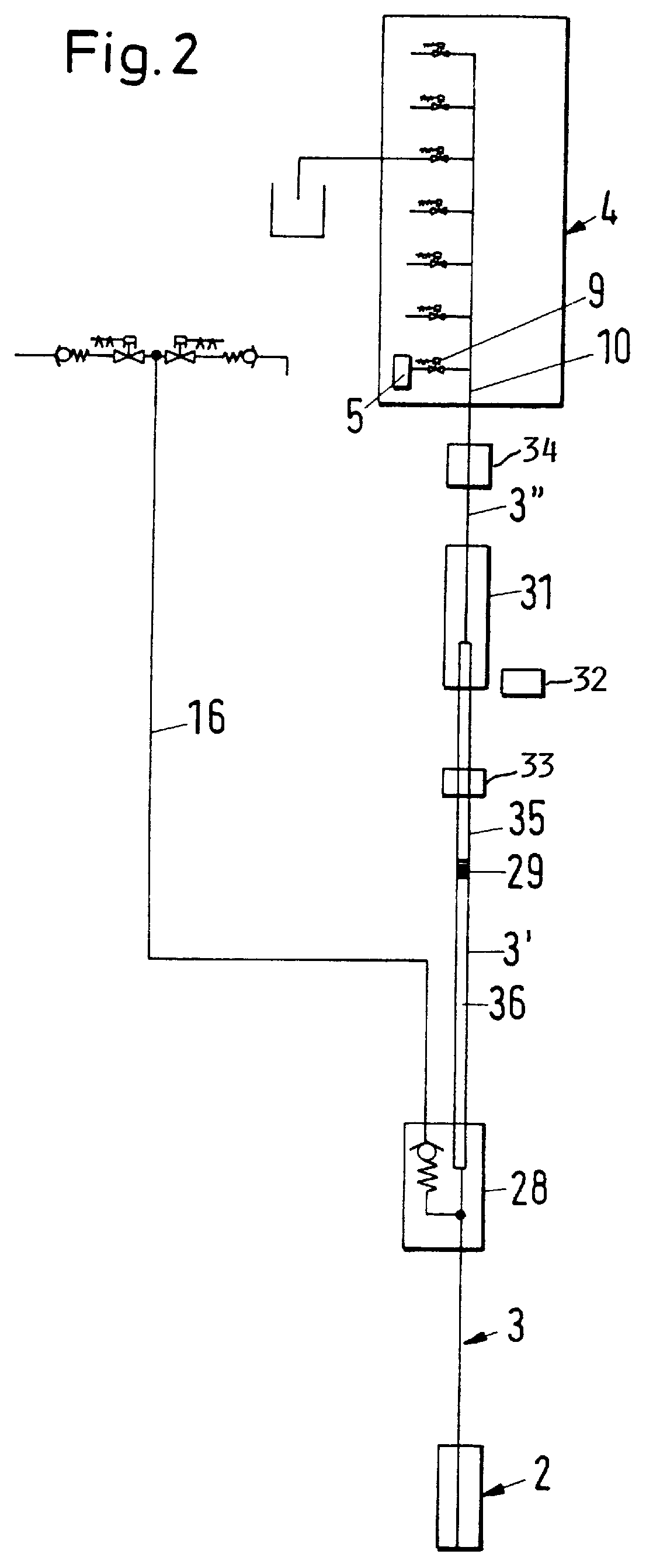

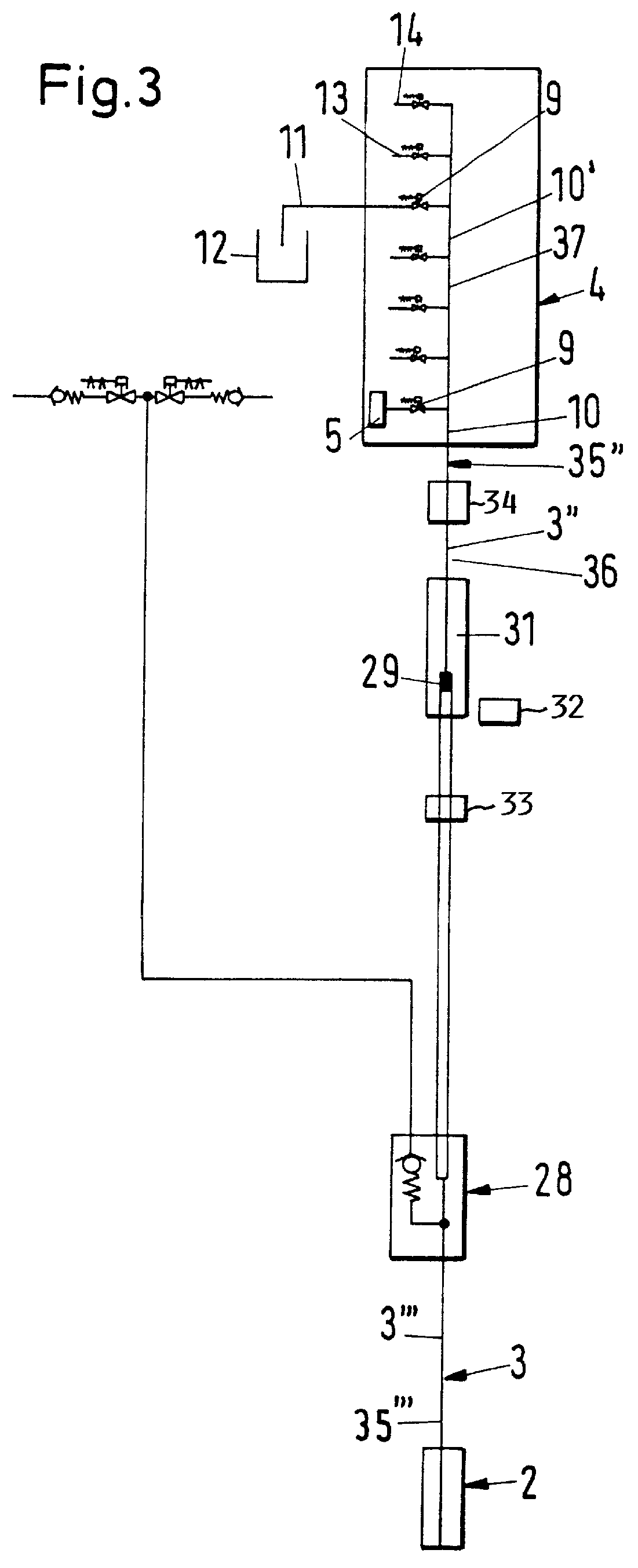

Paint spraying equipment and method of cleaning the same

InactiveUS6037010ALow costReduce the amount of wastePretreated surfacesLiquid spraying apparatusSpray nozzleEngineering

In a method of cleaning a paint application system when switching between two different types or colors of paint, at least a predominant portion of the first paint (35) remaining in a paint line (3) is caused to flow back into its paint supply container (5). Then the entire paint line is flushed out using a flushing medium, before supplying the second paint through the paint line. In this manner, the paint remaining in the painting system at the end of a painting cycle is not wasted, but rather is saved to later be reused. A paint application apparatus includes a paint supply switching device (4), at least two paint supply containers (5 to 8), a paint spray nozzle (2), and a paint line (3) connecting the color switching device (4) to the spray nozzle (2). Two receiver stations (28) and (31) are interposed in the paint line (3), and a shuttle element in the form of a pipe cleaner swab (29) is arranged in the paint line (3) so as to be able to shuttle back and forth between the two receiver stations. A pressure medium or flushing medium can be introduced into the paint line (3) between the first receiver station (28) and the spraying nozzle (2), so as to push the pipe cleaner swab (29) through the paint line (3) to the second receiver station (31). Thereby, the paint remaining in the paint line (3) is pushed back into the paint supply container.

Owner:LACTEC GESELLSCHAFT FUR MODERNE LACKIERTECHNIK GMBH

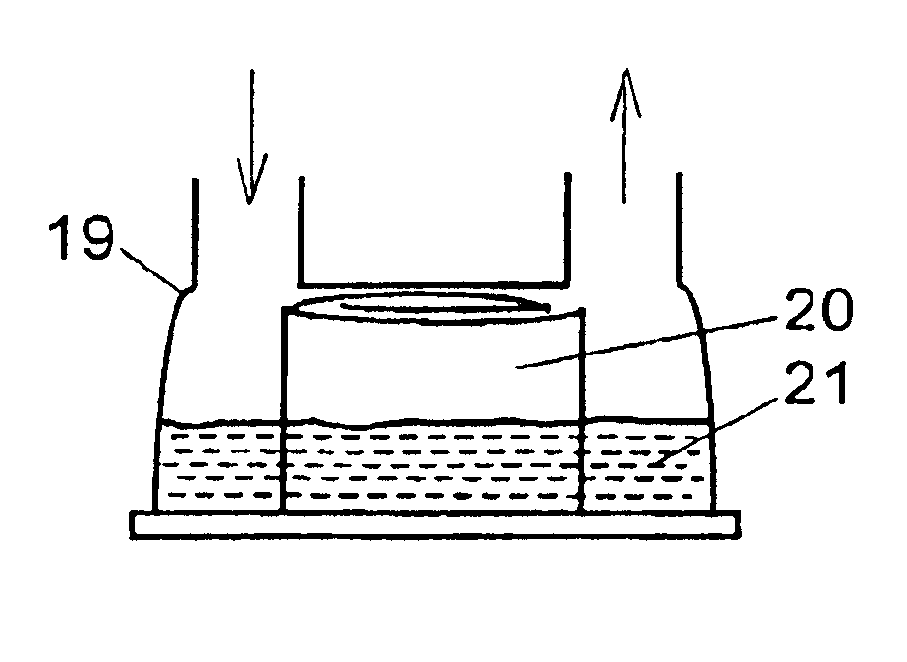

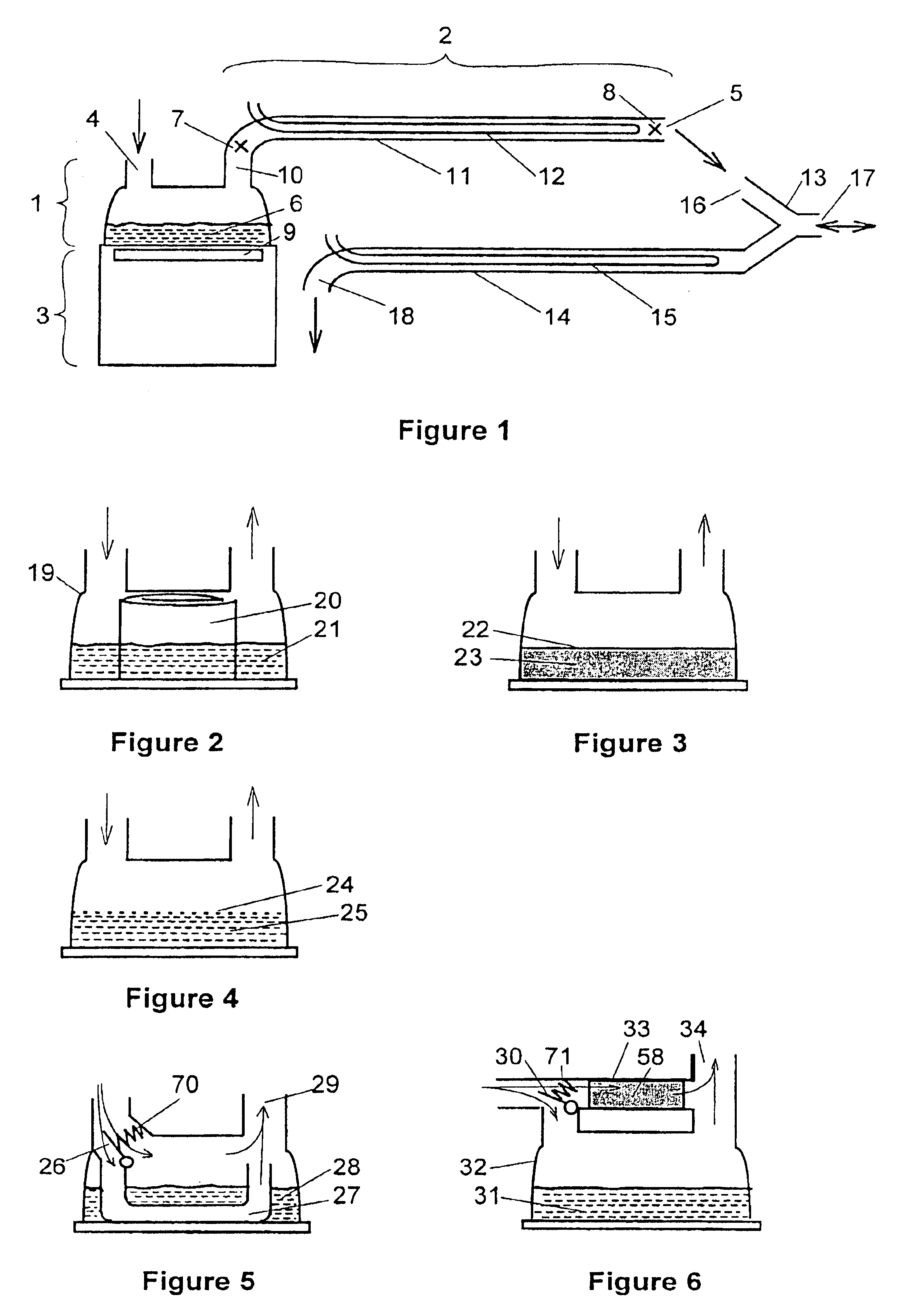

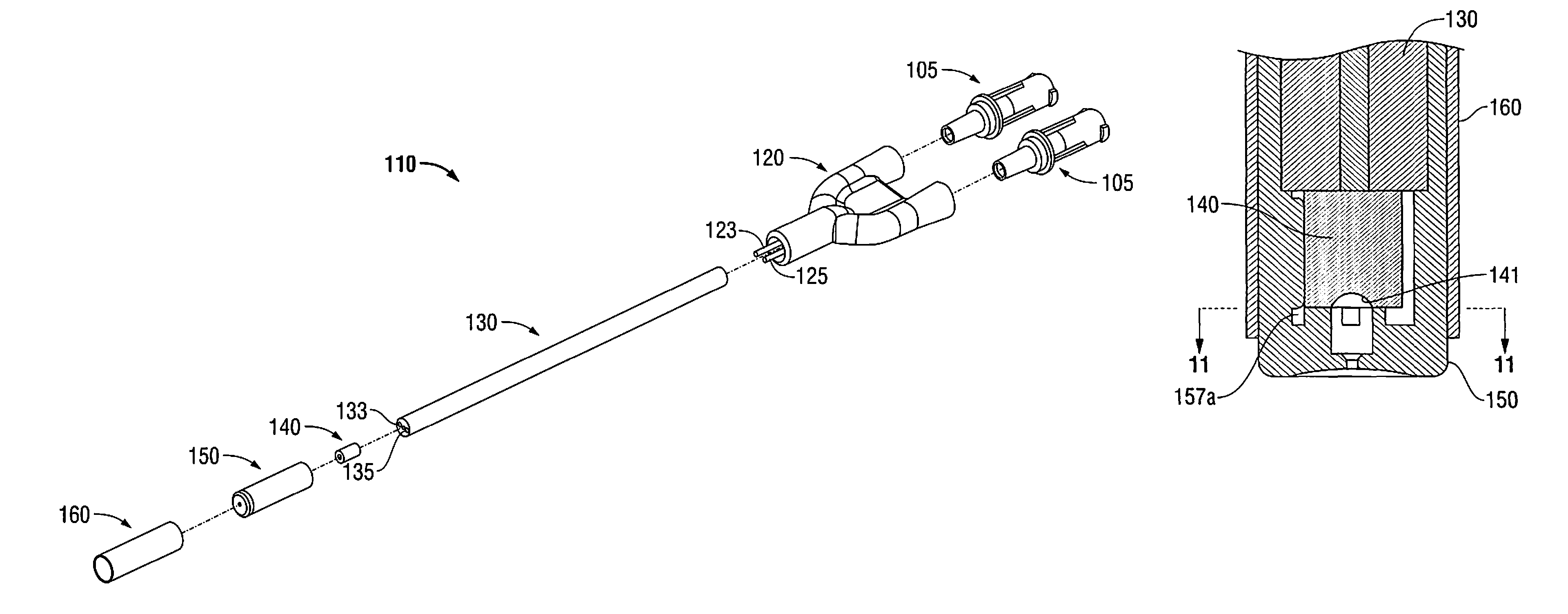

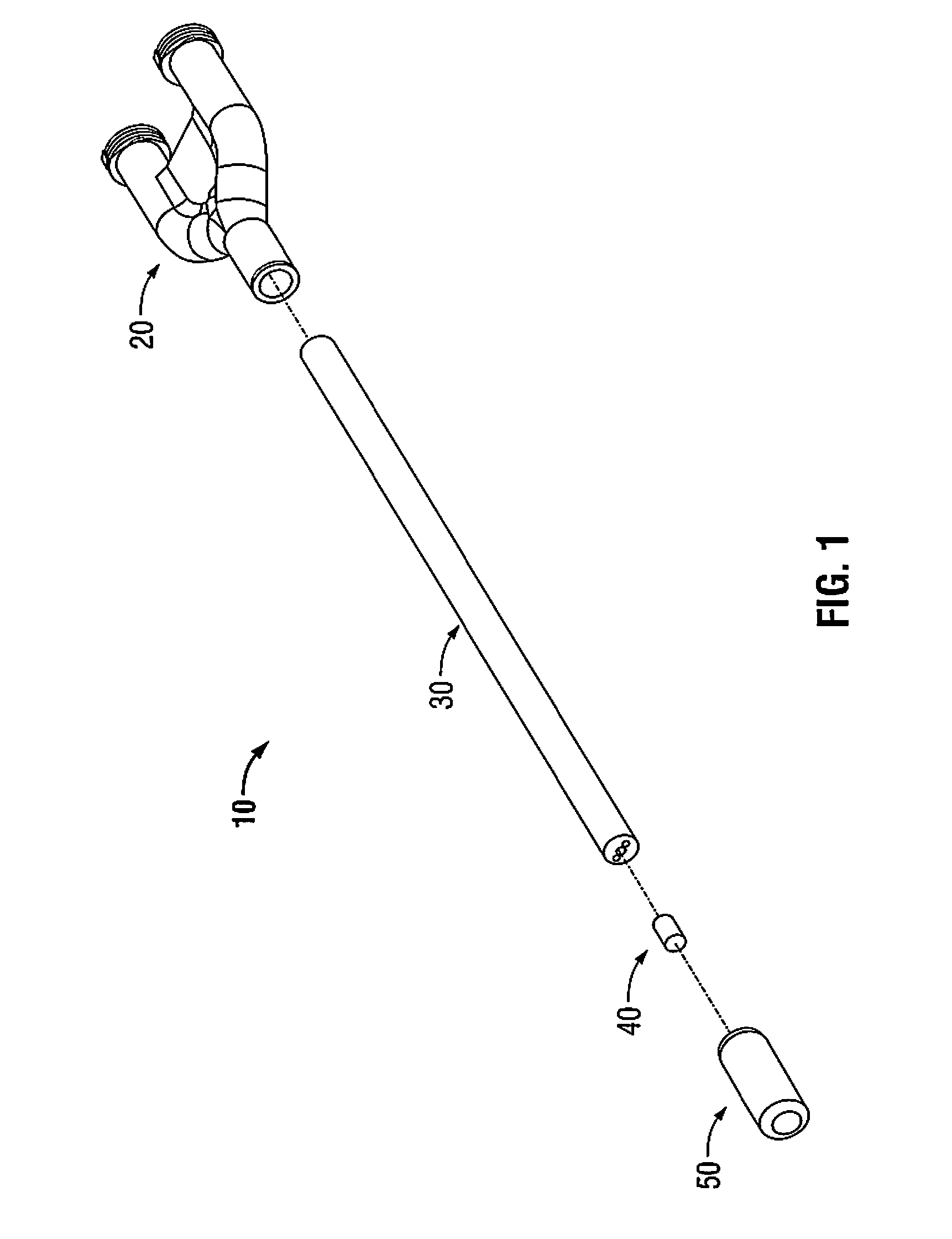

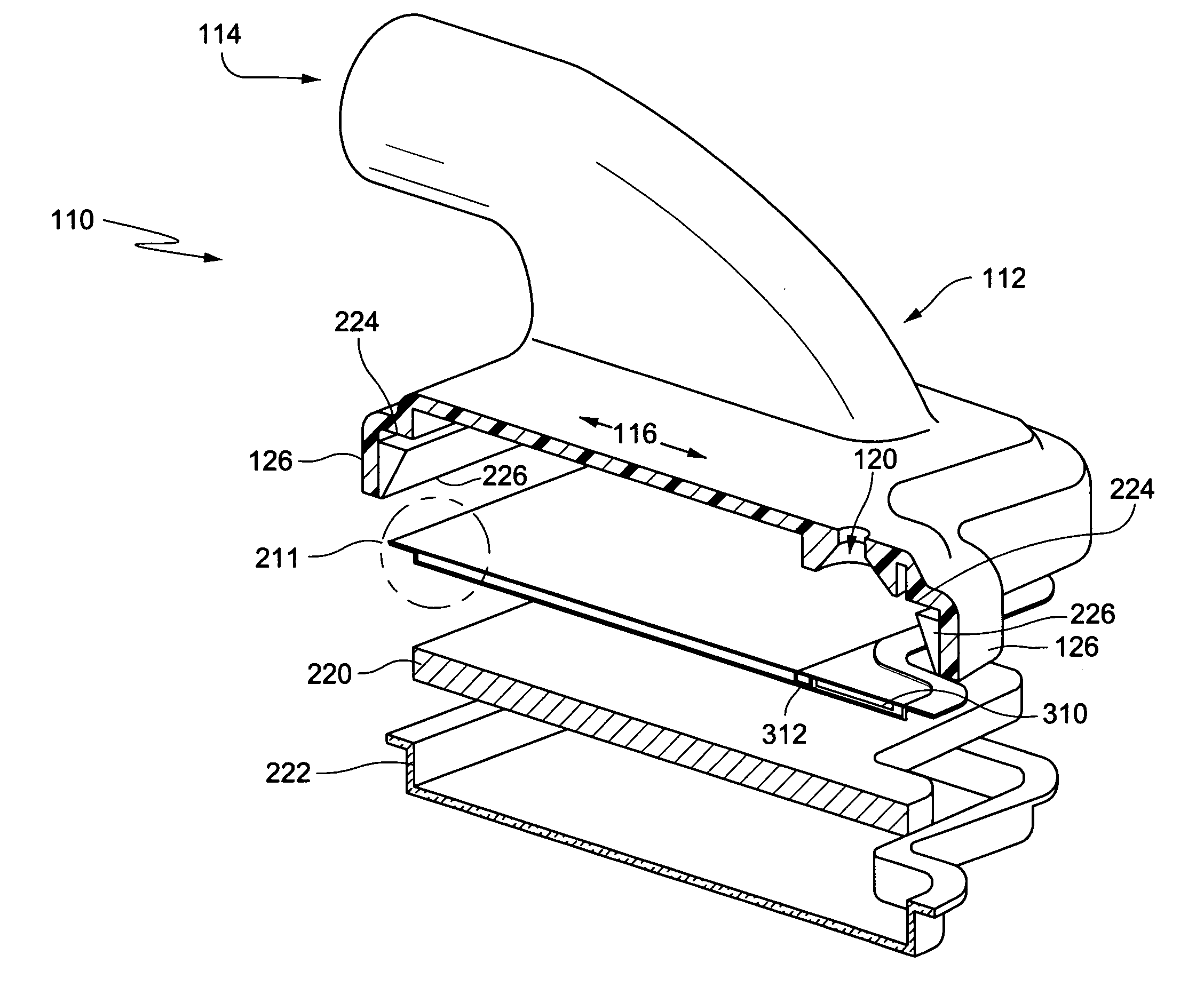

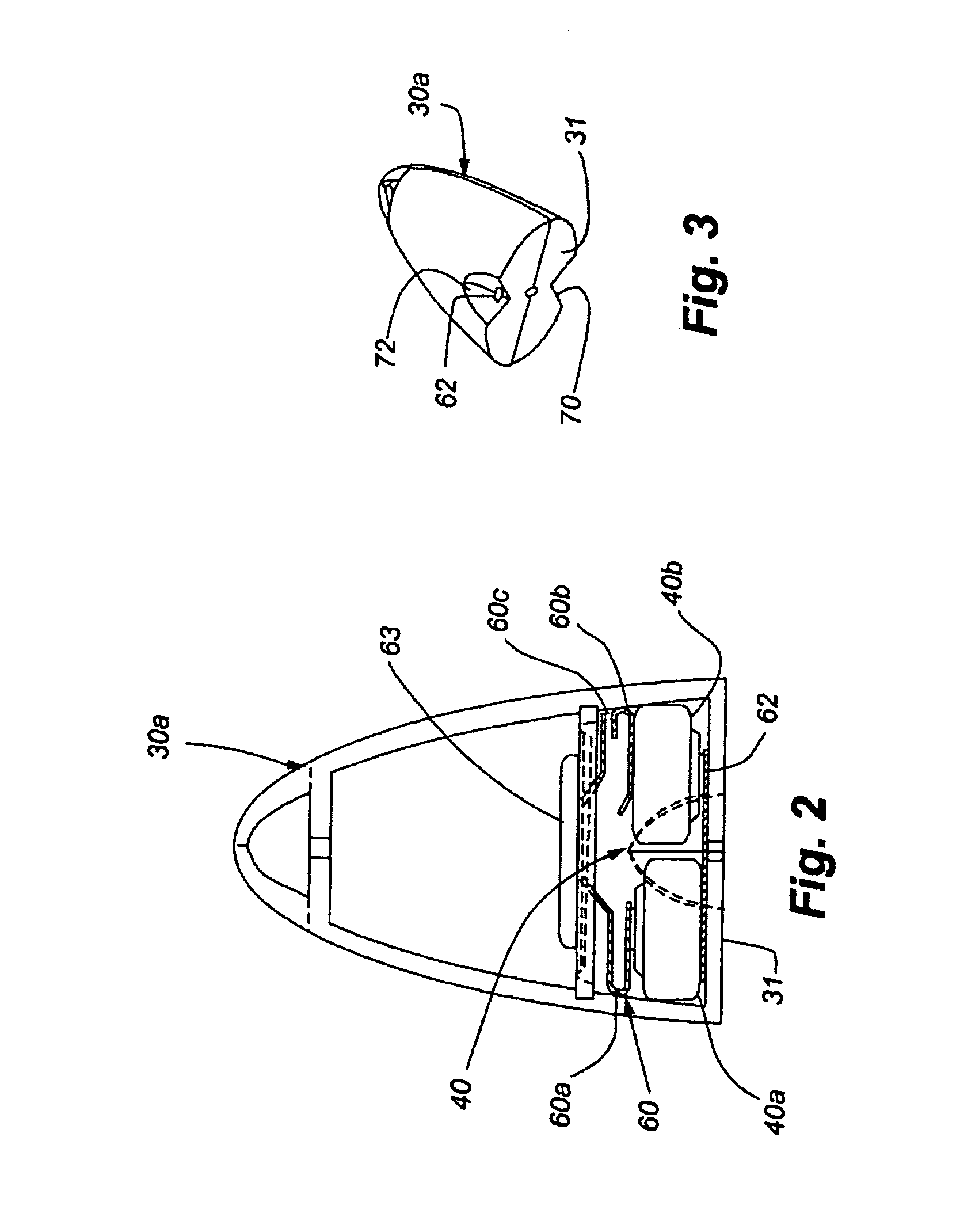

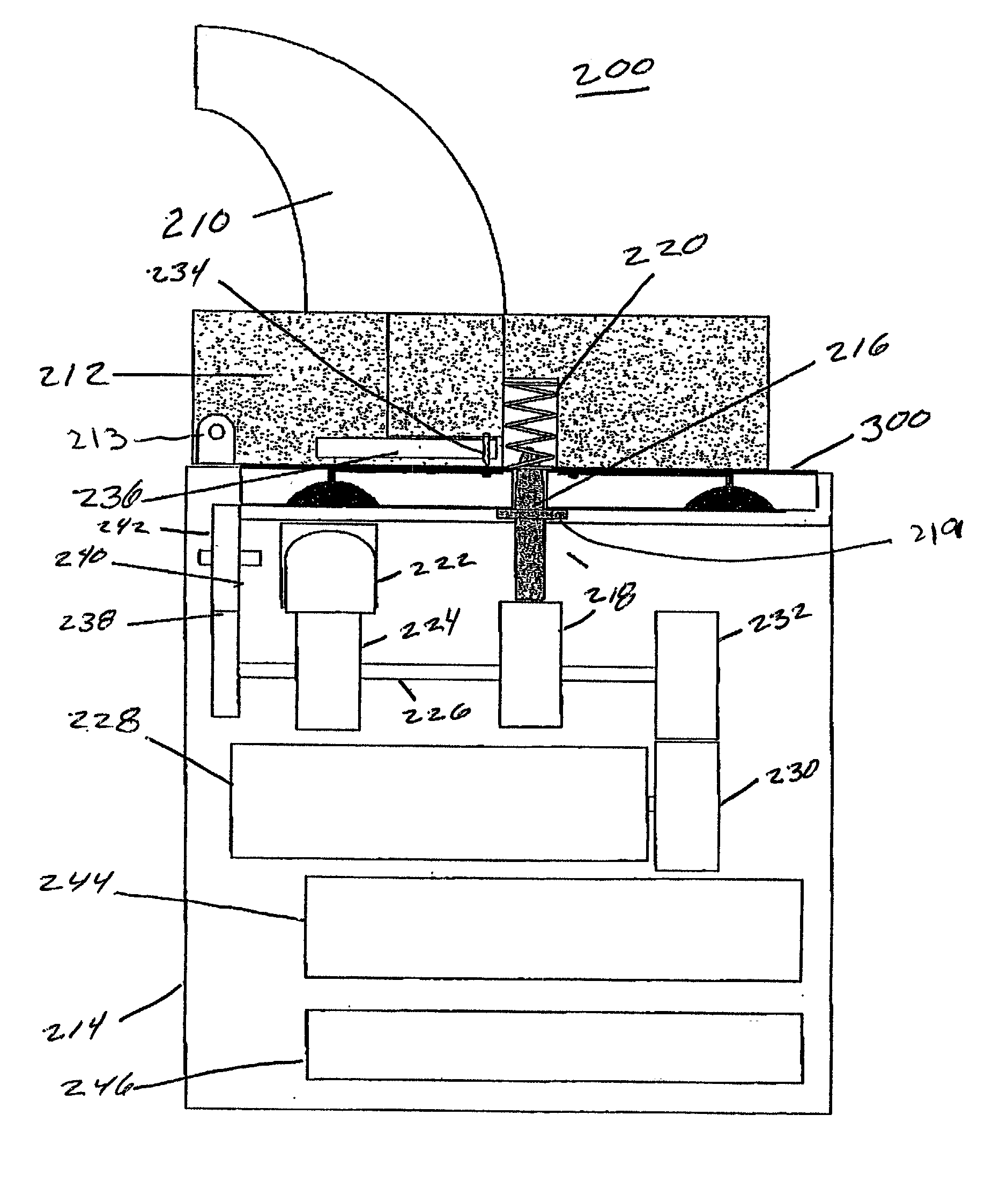

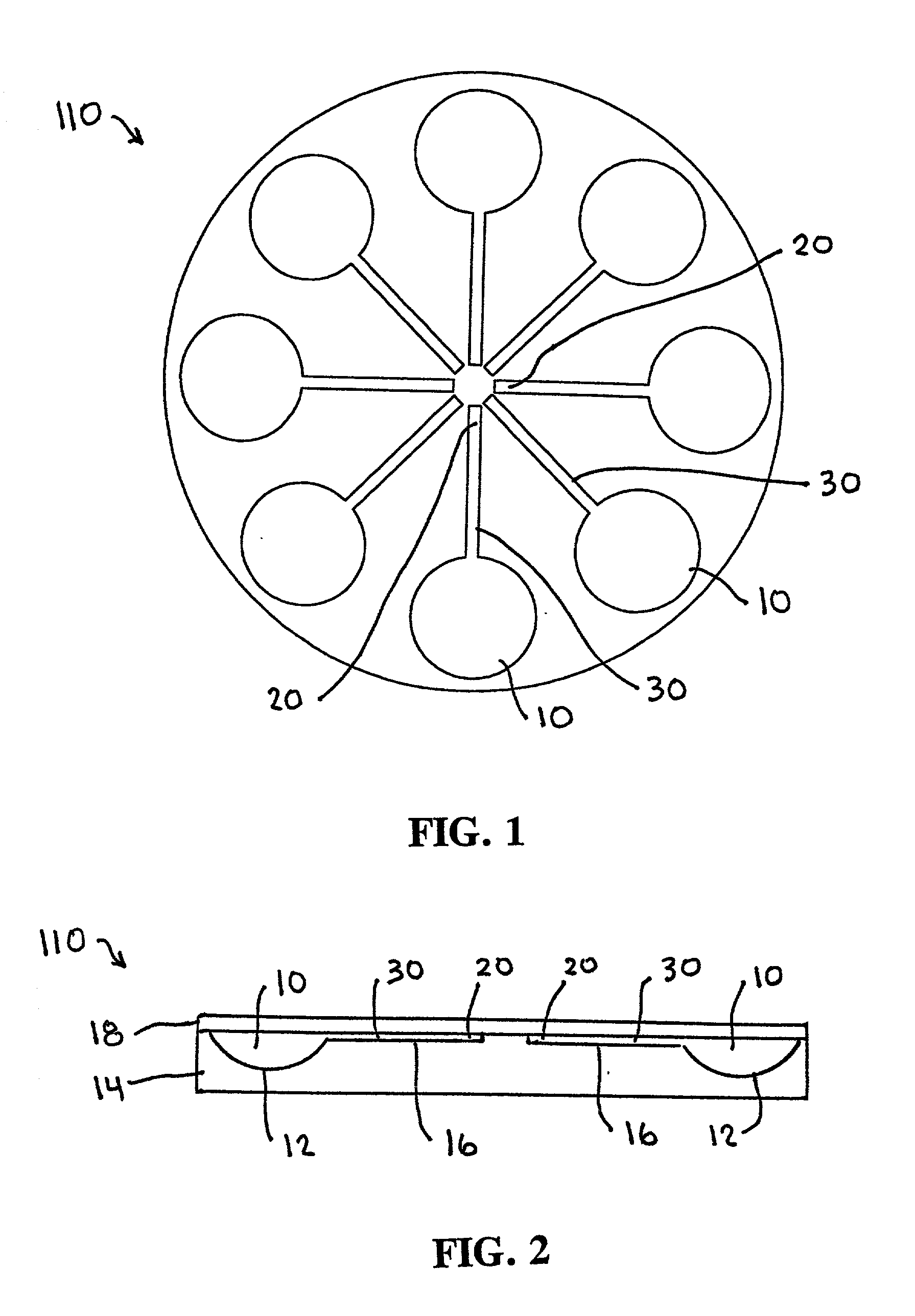

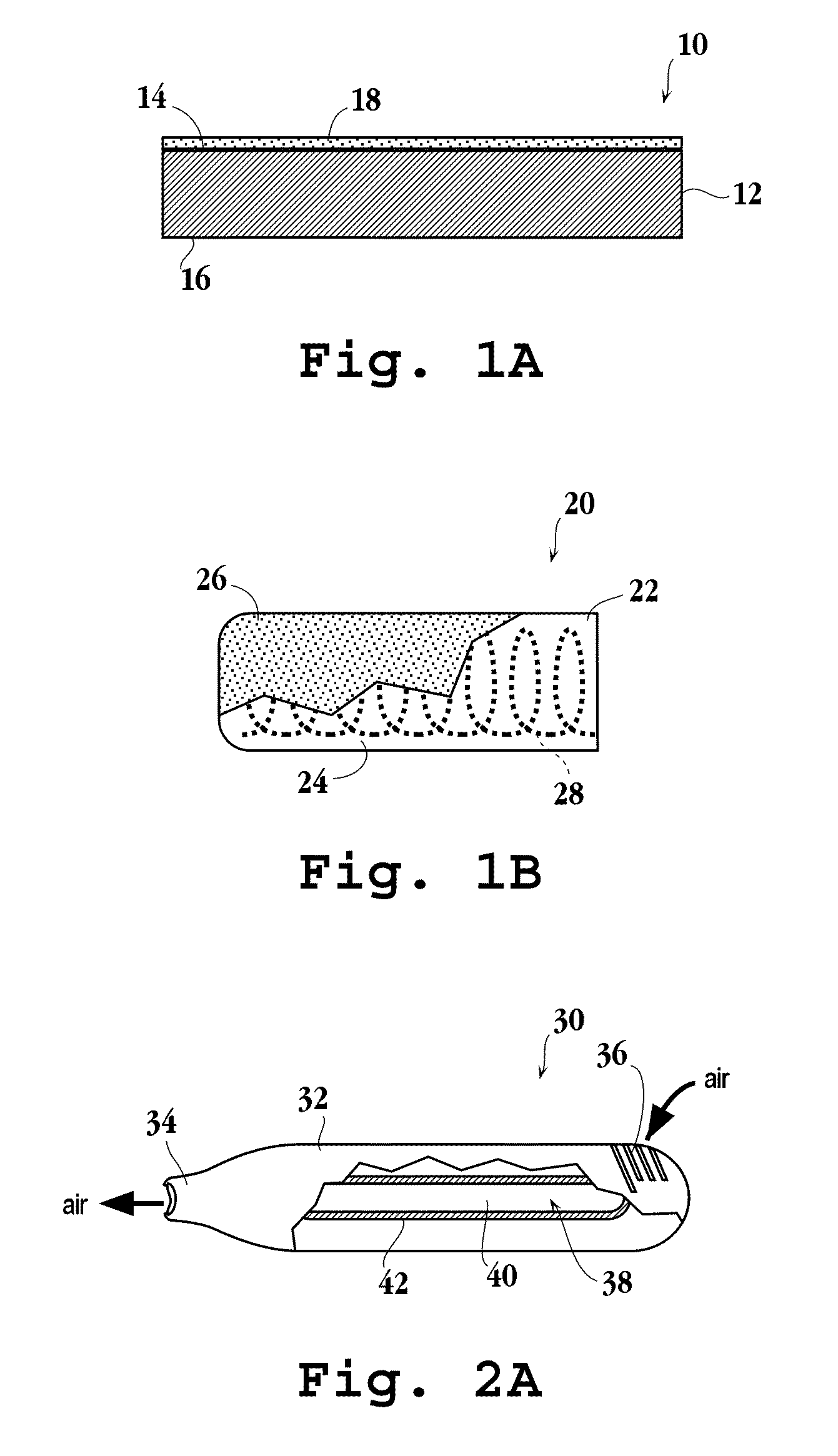

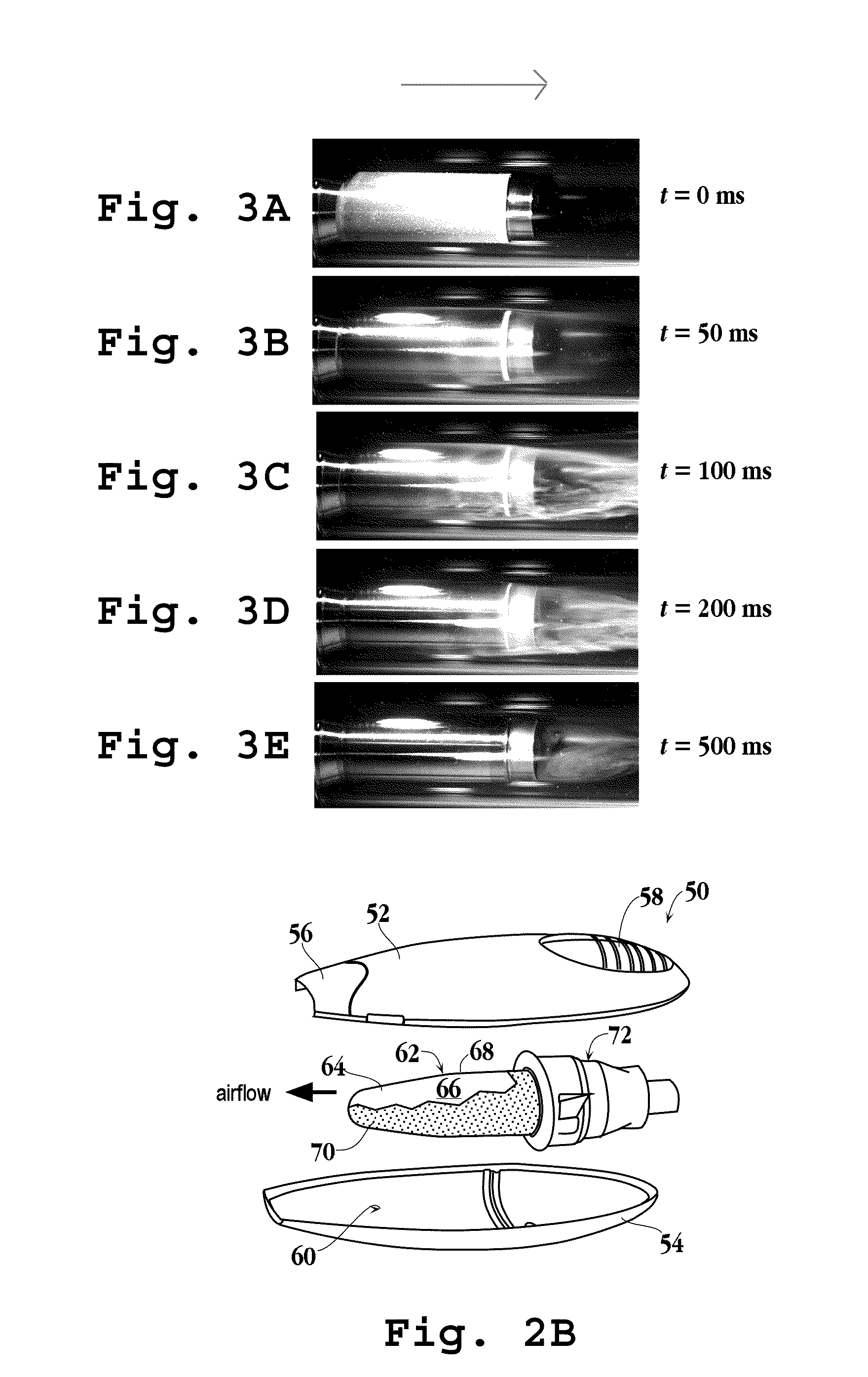

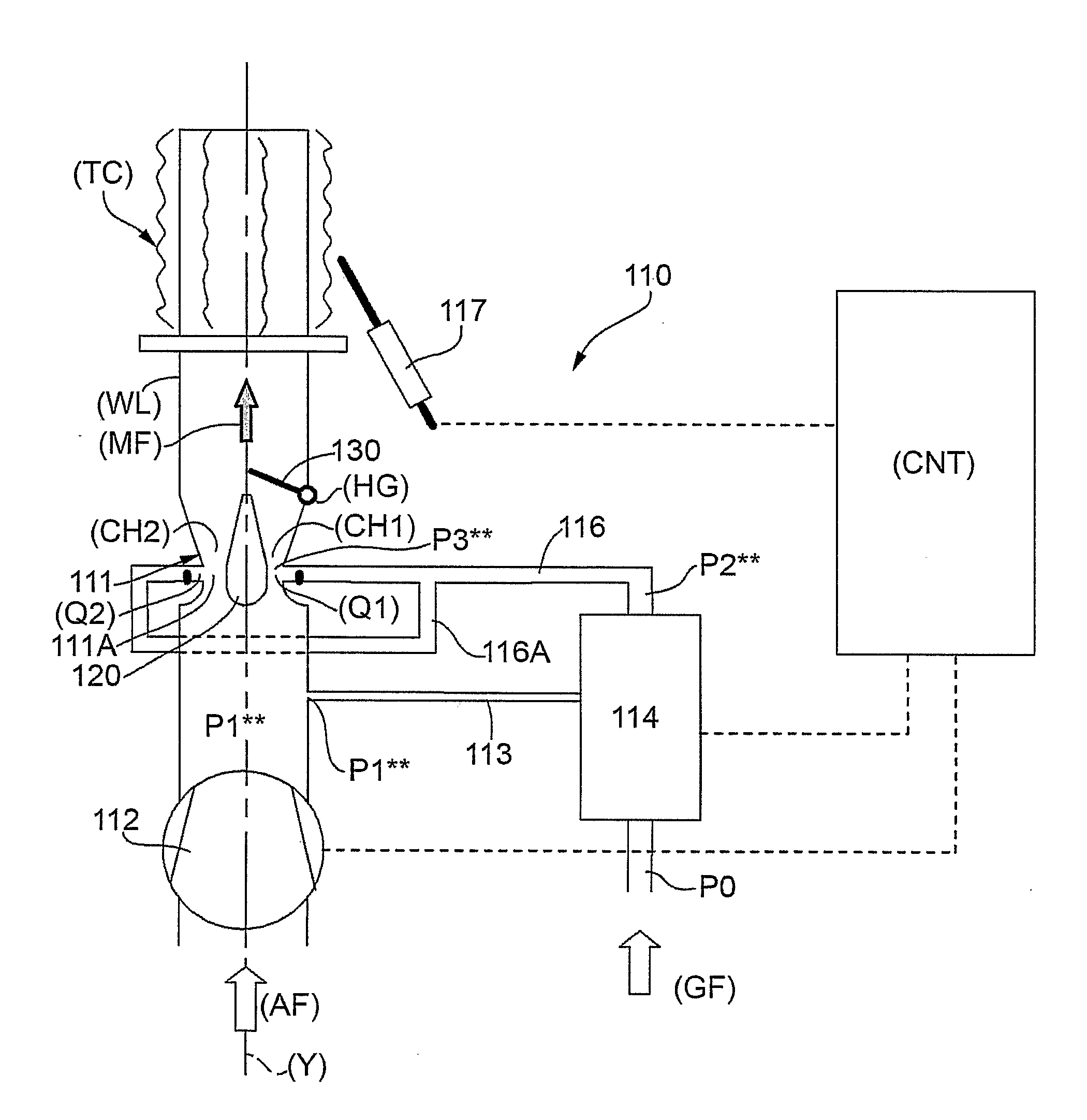

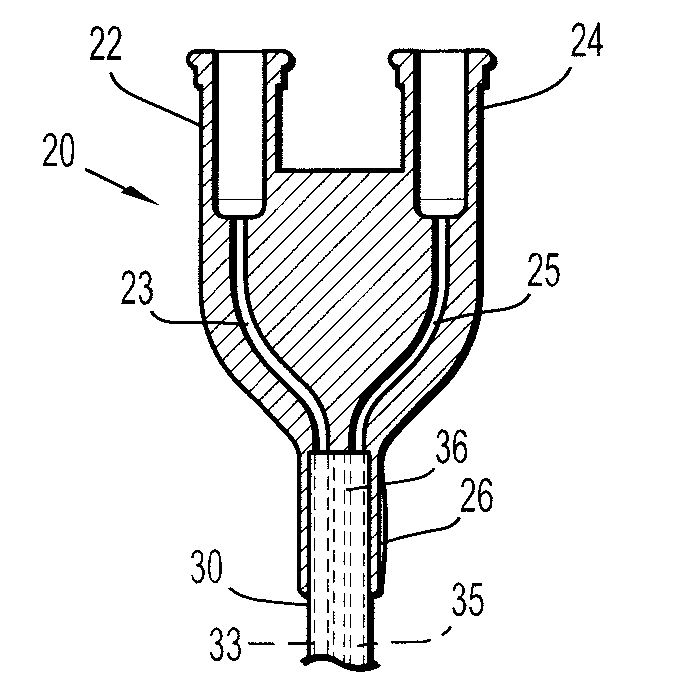

Disposable aerosol generator system and methods for administering the aerosol

InactiveUS20020078951A1Avoid contamination of fluidNegates needRespiratorsMedical devicesBiomedical engineeringAerosol generator

A disposable aerosol generator for use with an inhaler device which includes a heater adapted to volatilize fluid stored in the disposable aerosol generator and method of using the inhaler. The disposable body includes a sealed chamber and an outlet, the chamber being located between first and second layers of material. The chamber holds a predetermined volume of a fluid which is expelled through the outlet when the fluid in the chamber is volatilized by the heater. The disposable body can include a series of spaced apart aerosol generators, each of which can be advanced to a release position at which the heater can heat one of the fluid containing chambers. Prior to heating the fluid, the outlet can be formed by severing the first and / or second layer with a piercing element and the volatilized fluid can be expelled from the outlet into a passage of a dispensing member.

Owner:PHILIP MORRIS USA INC

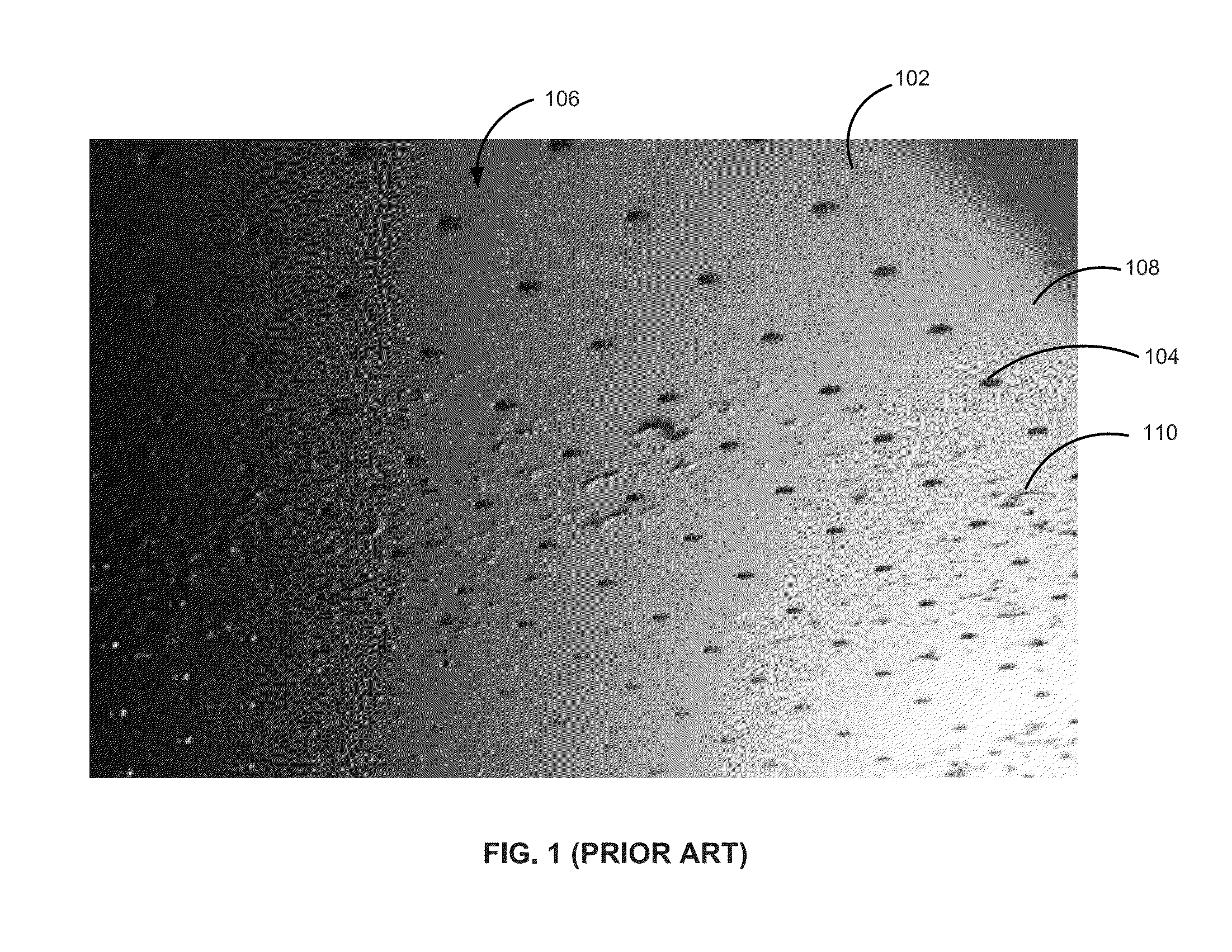

Aerosol delivery system and uses thereof

InactiveUS20100181387A1Avoid overuseReduce usageLiquid surface applicatorsSpray nozzlesMedicineAerosol delivery

A device, method, and system for producing a condensation aerosol are disclosed. The device includes a chamber having an upstream opening and a downstream opening which allow gas to flow through the chamber, and a heat-conductive substrate located at a position between the upstream and downstream openings. Formed on the substrate is a drug composition film containing a therapeutically effective dose of a drug when the drug is administered in aerosol form. A heat source in the device is operable to supply heat to the substrate to produce a substrate temperature greater than 300 oC, and to substantially volatilize the drug composition film from the substrate in a period of 2 seconds or less. The device produces an aerosol containing less than about 10% by weight drug composition degradation products and at least 50% of the drug composition of said film.

Owner:ALEXZA PHARMA INC

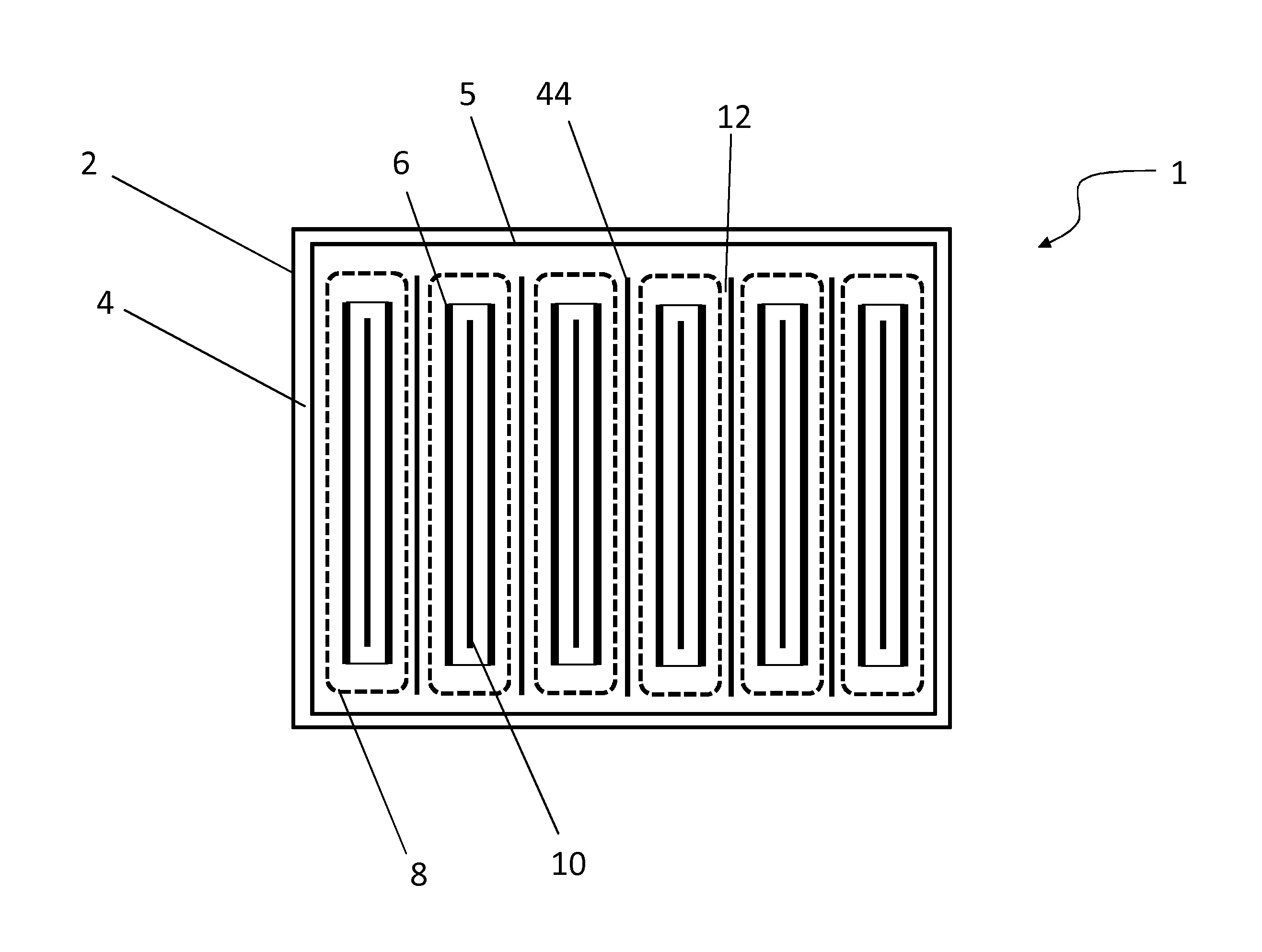

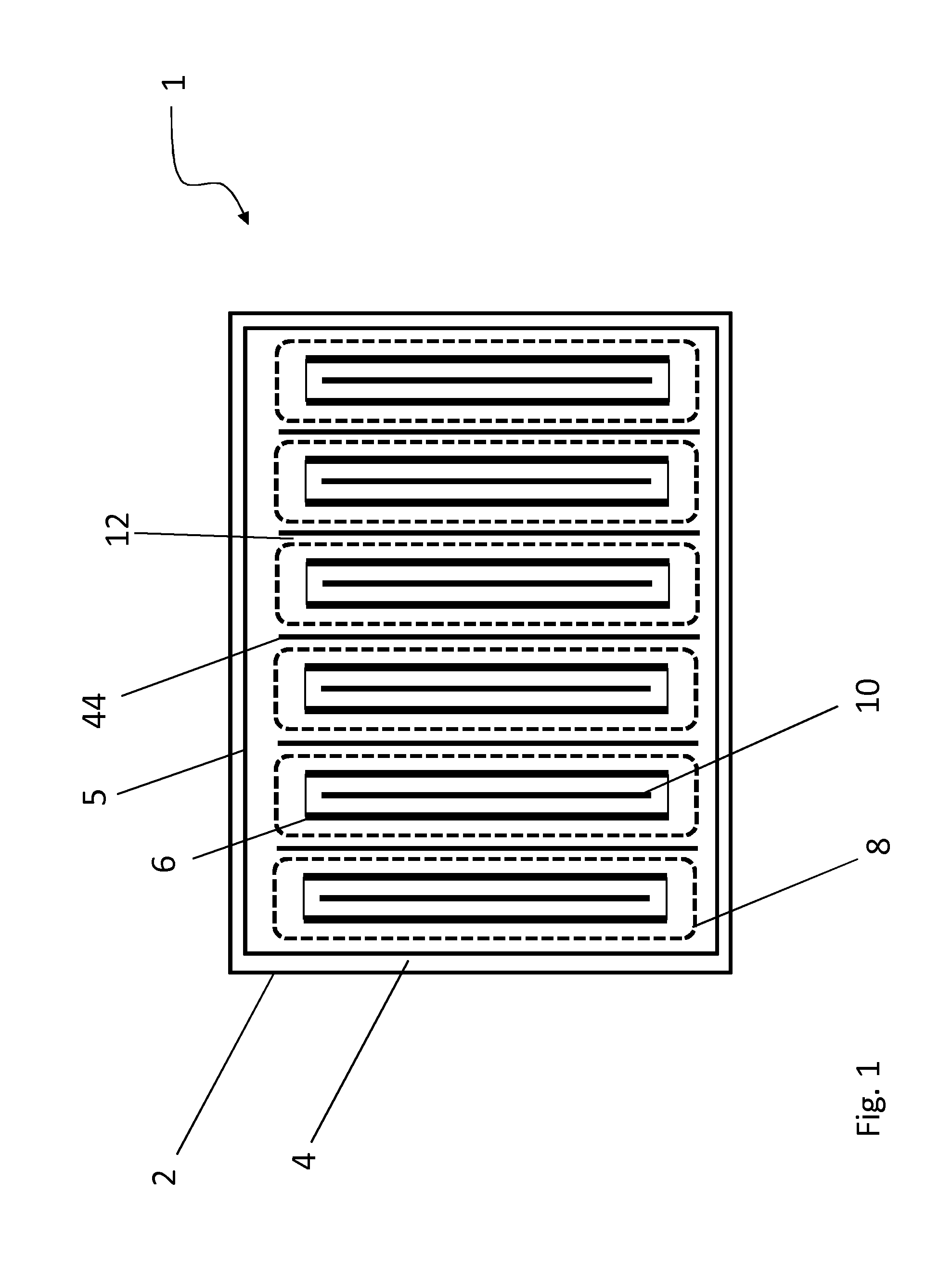

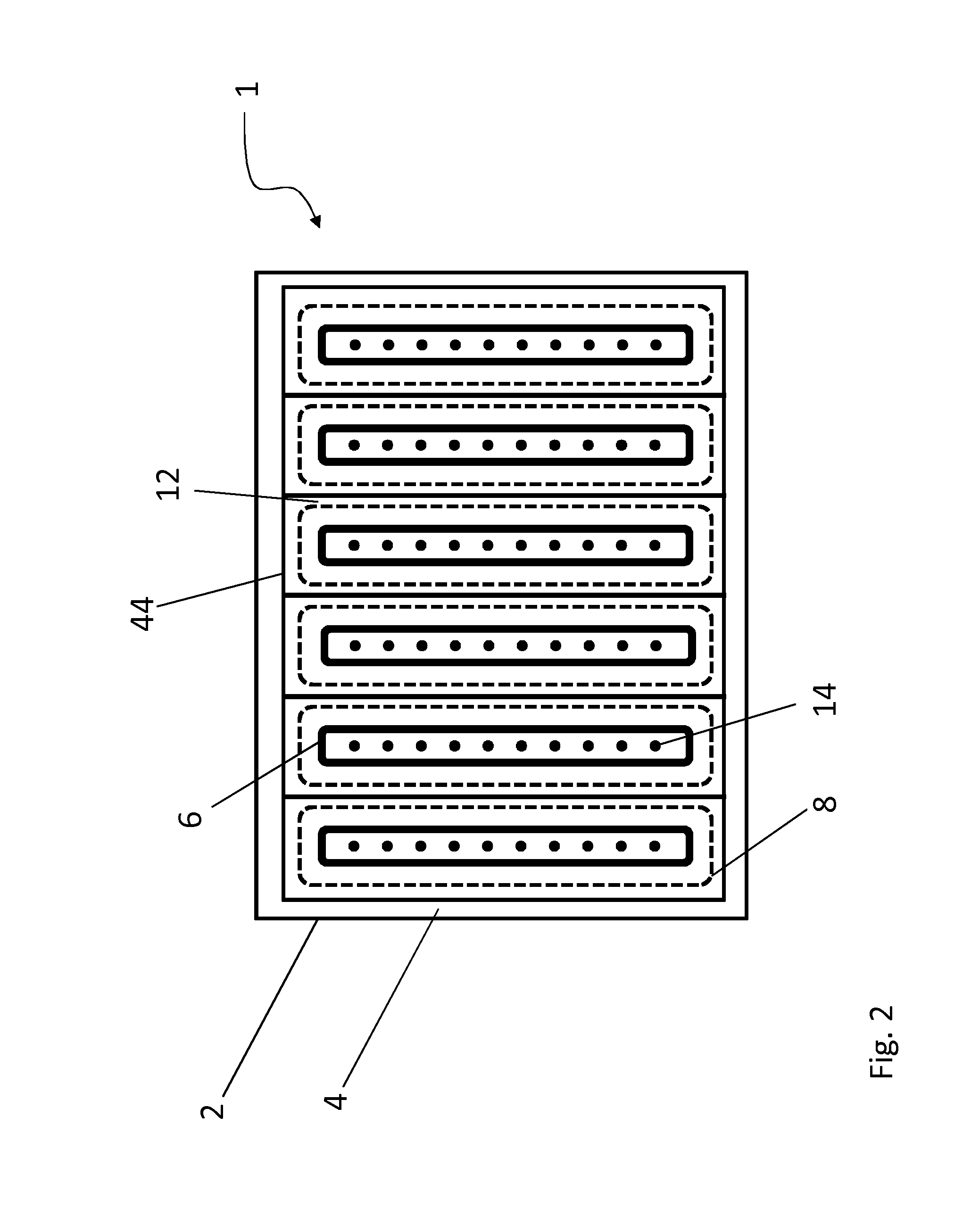

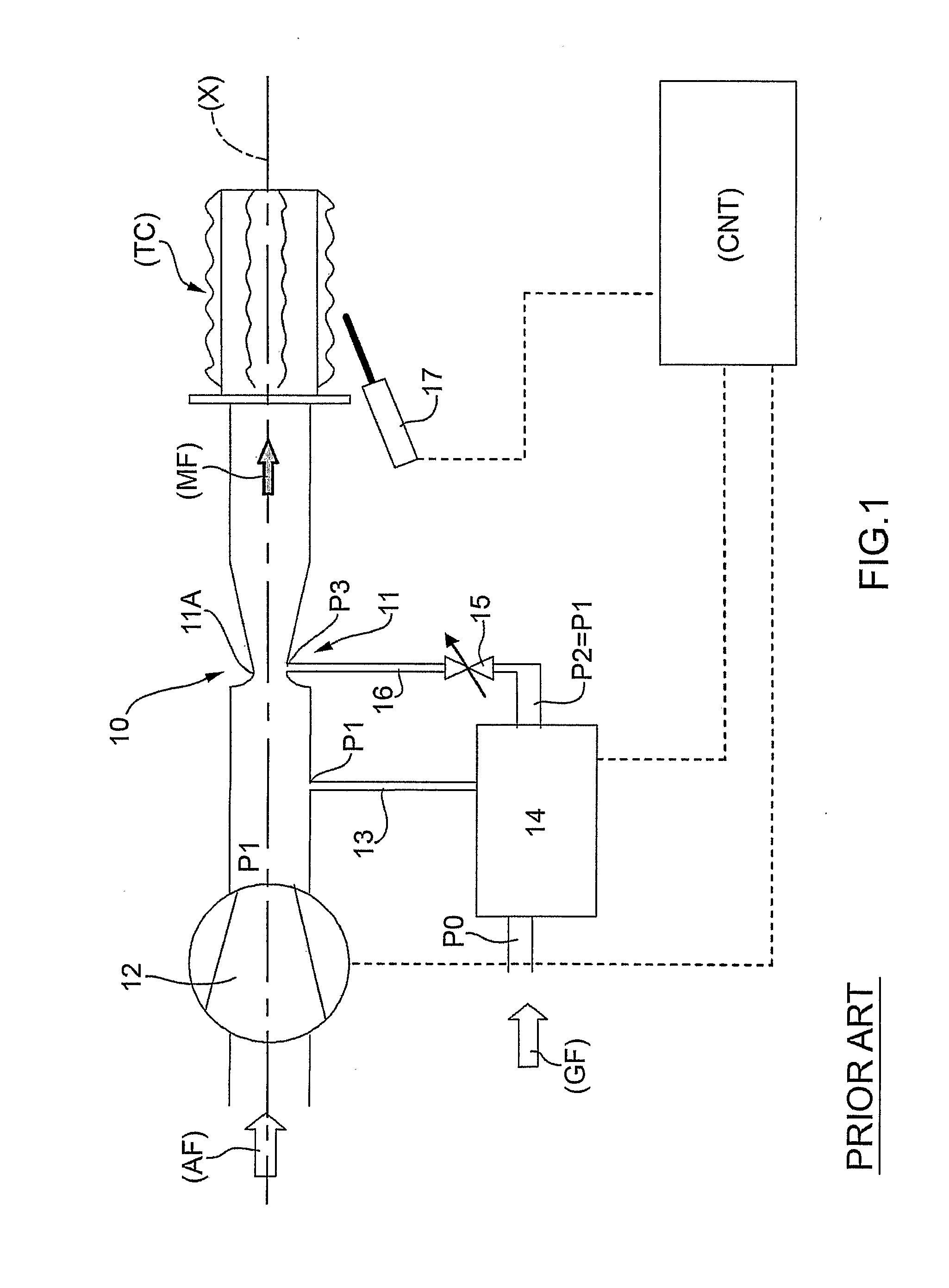

Premix gas burner

ActiveUS20110139045A1Easy and inexpensive to produceFuel supply regulationGaseous fuel burnerCombustible gasEngineering

An air / gas premix burner, comprising:a fan for sending the air / gas mixture to a combustion head;a gas valve for regulating admission of the combustible gas;an air / gas mixer, which comprises a device for localized loss of pressure; anda combustion head.The premix burner is characterized in that the air / gas mixer comprises at least two channels for mixing the air with the gas; in addition, a channel is provided with an open / close element designed to regulate the flow rate of the mixture.

Owner:GAS POINT

Self-cleaning spray tip

ActiveUS20100096481A1Clear obstructionFlow mixersTransportation and packagingBiomedical engineeringNozzle

A spray tip assembly capable of self-clearing is provided. The spray tip assembly includes a distal end including an outlet. The outlet defines at least a first configuration during a first condition and at least a second configuration during a second condition. The distal end may be configured to at least one of flex and expand such that the outlet changes from the first configuration to the second configuration.

Owner:CONFLUENT SURGICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com