Patents

Literature

19860 results about "Heat conducting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat conduction. Heat conduction, or thermal conduction, is the spontaneous transfer of thermal energy through matter, from a region at higher temperature to a region at lower temperature. It thus acts to equalize temperature differences. It is also described as heat energy transferred from one material to another by direct contact.

Electronic device

ActiveUS9313915B2Improve cooling efficiencyPump componentsDigital data processing detailsHeat conductingElectron device

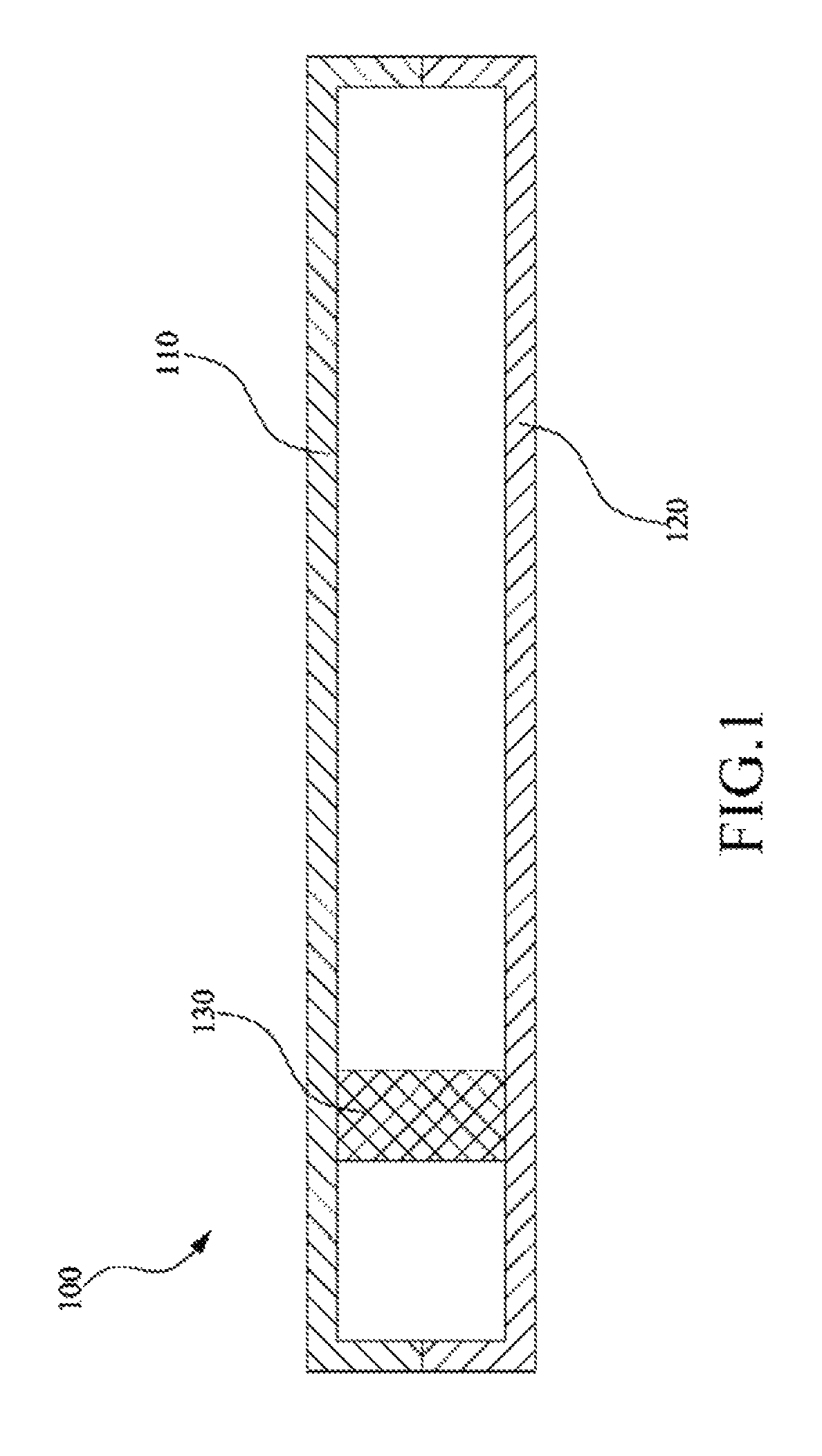

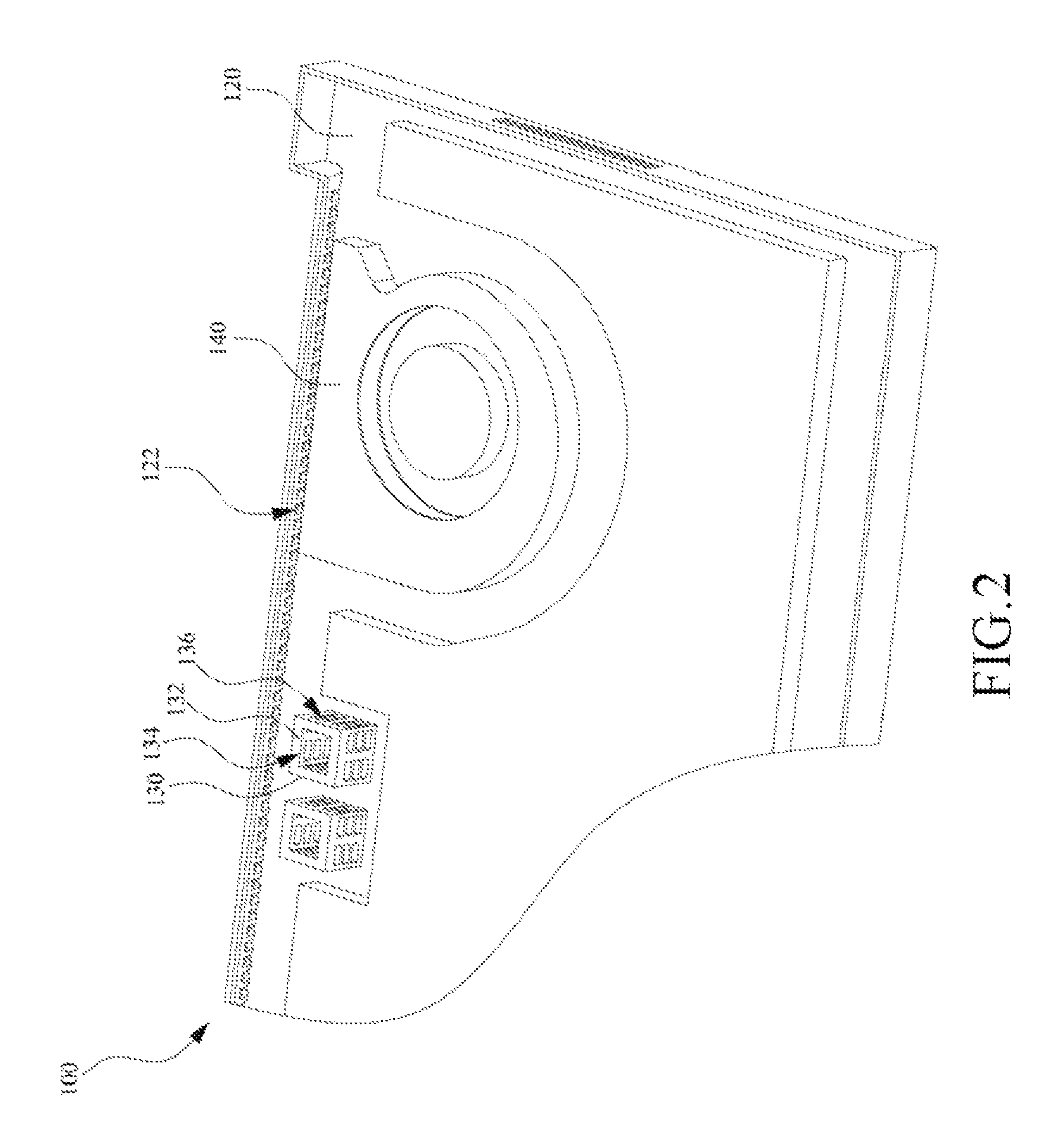

An electronic device includes an upper cover, a lower cover combined with the upper cover, and a heat conducting pillar. An accommodating space is formed by the upper cover and the lower cover. The heat conducting pillar is disposed in the accommodating space and physically connected with the upper cover and the lower cover to balance the temperature of the upper cover and the lower cover.

Owner:ASUSTEK COMPUTER INC

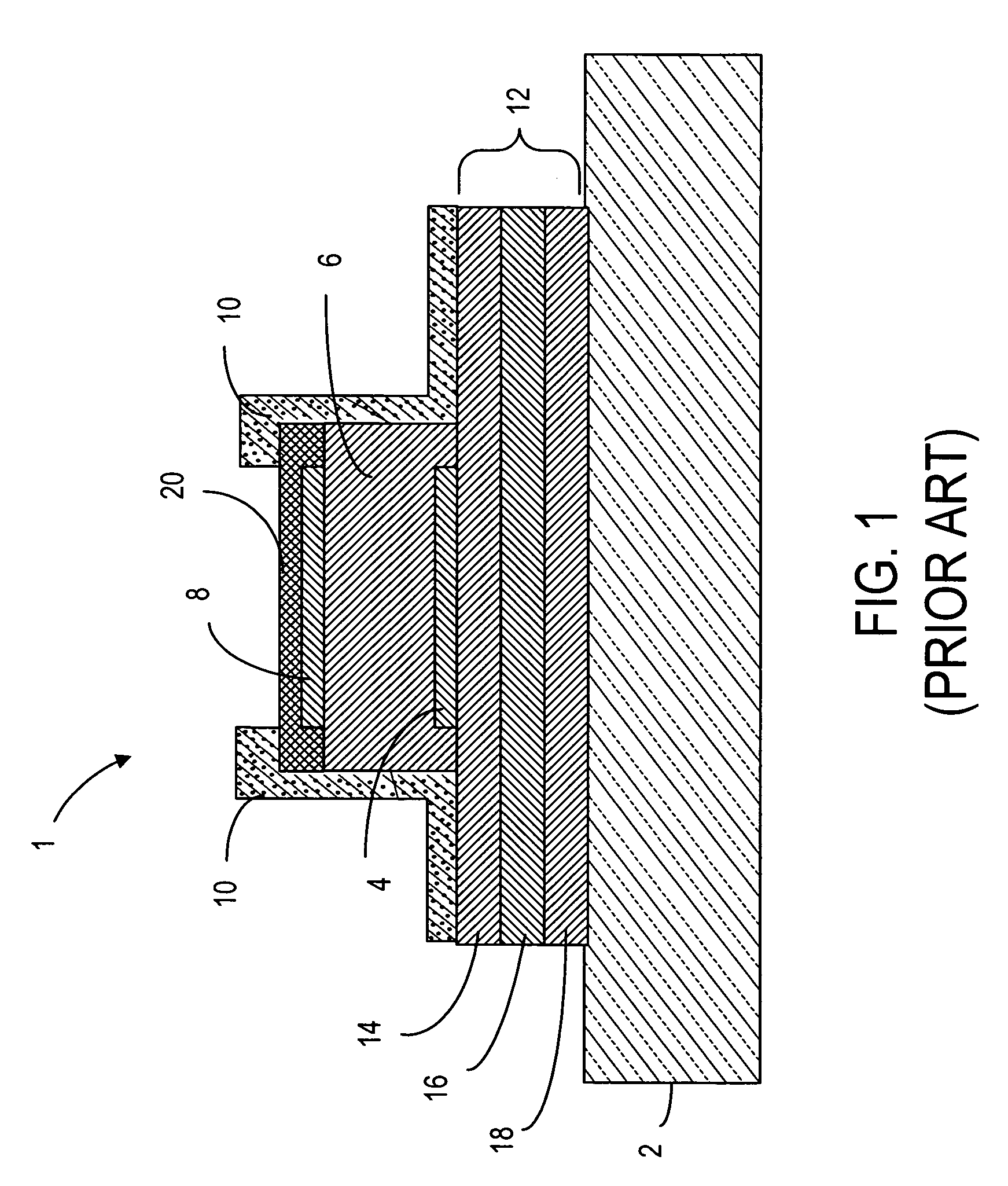

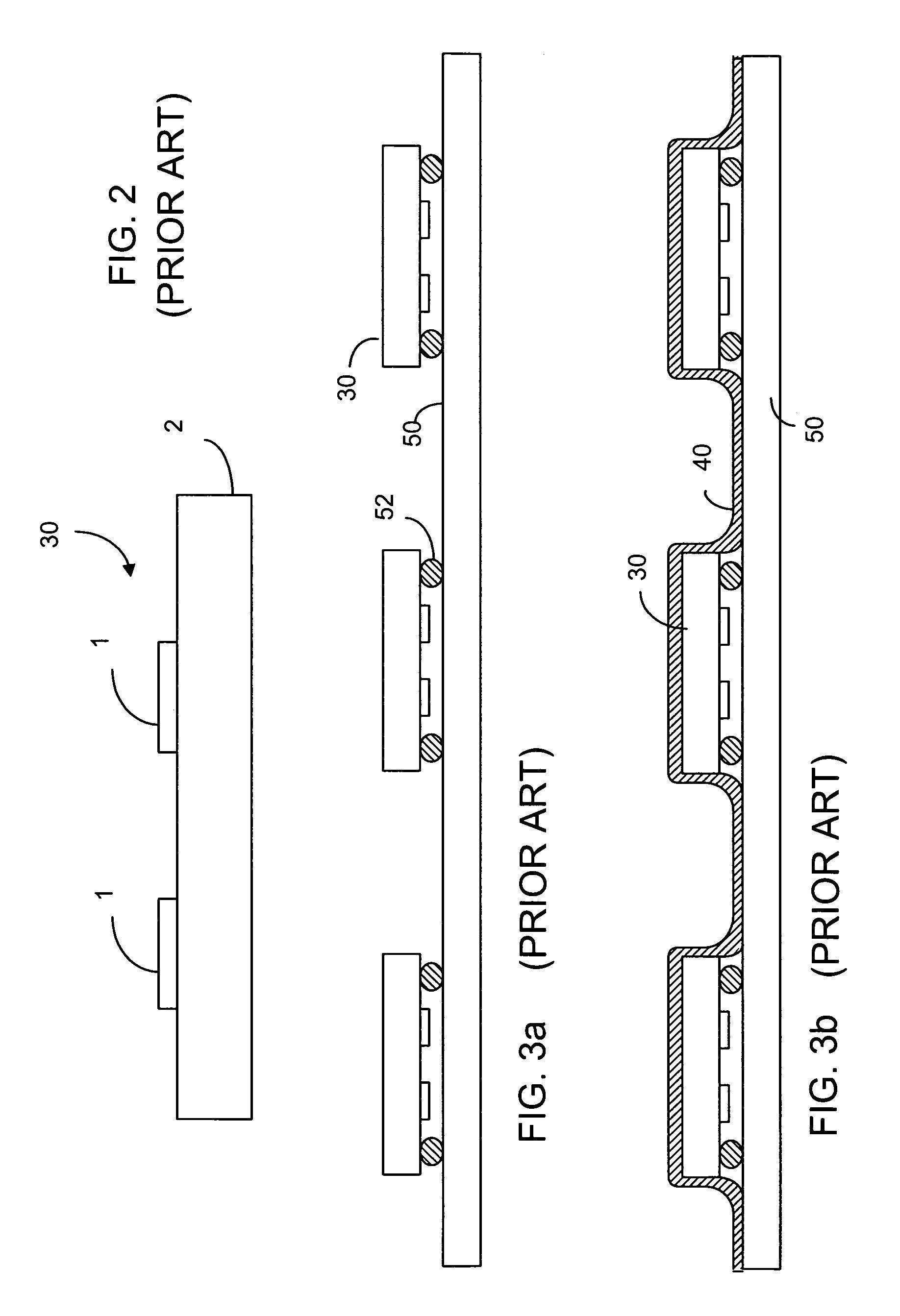

Encapsulated electronics device with improved heat dissipation

ActiveUS6992400B2Improve cooling effectImpedence networksSemiconductor/solid-state device detailsHermetic sealHeat conducting

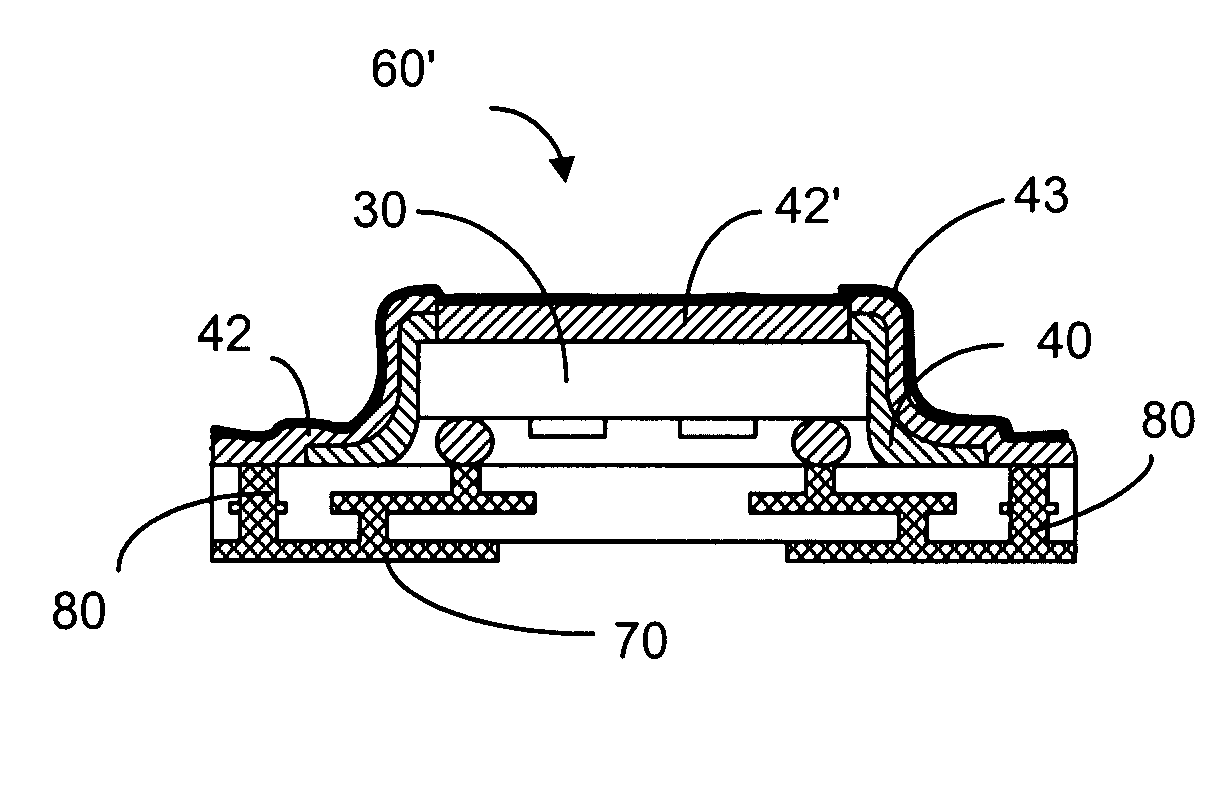

A method for improving heat dissipation in an encapsulated electronic package usually referred to as a chip-size SAW package. The package comprises one or more acoustic-wave components fabricated on a die, which is disposed on an electrically non-conductive carrier separated by electrically conducting bumps. The top of the package is covered by a laminate and a hermetic seal layer. Heat dissipation can be improved by removing a part of the laminate and then depositing a layer of thermal conducting material on the package, and by providing one or more heat conducting paths through the carrier.

Owner:NOKIA CORP

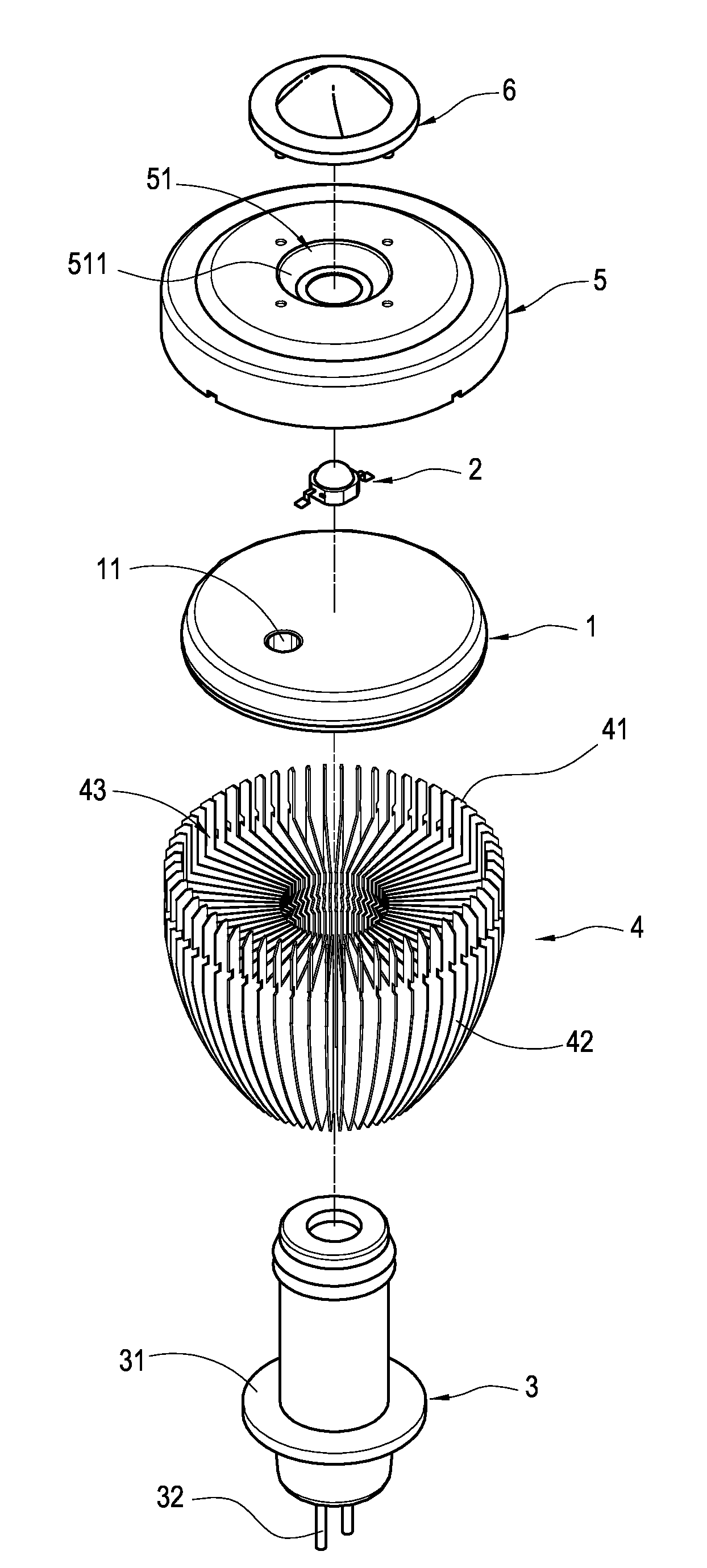

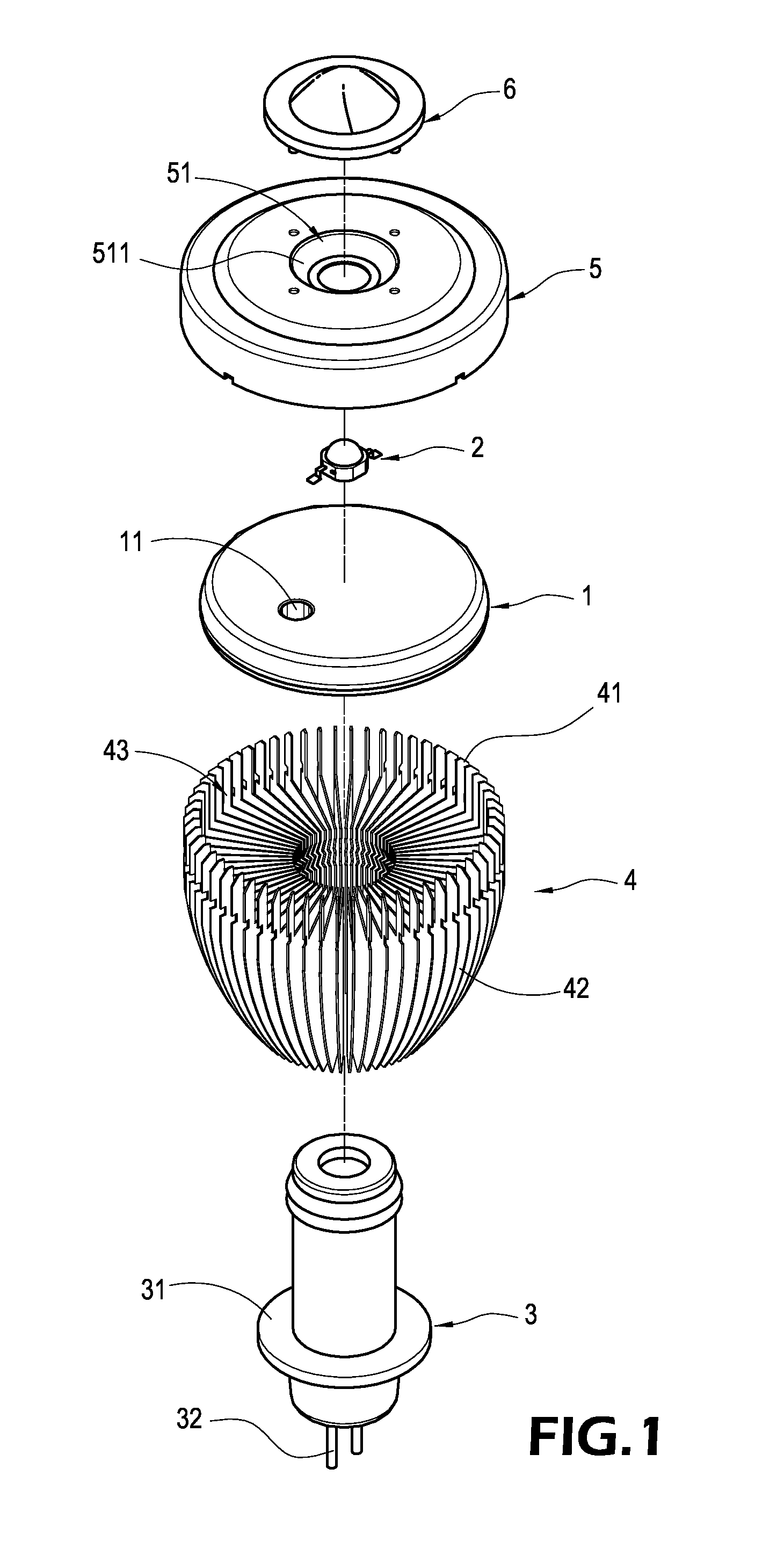

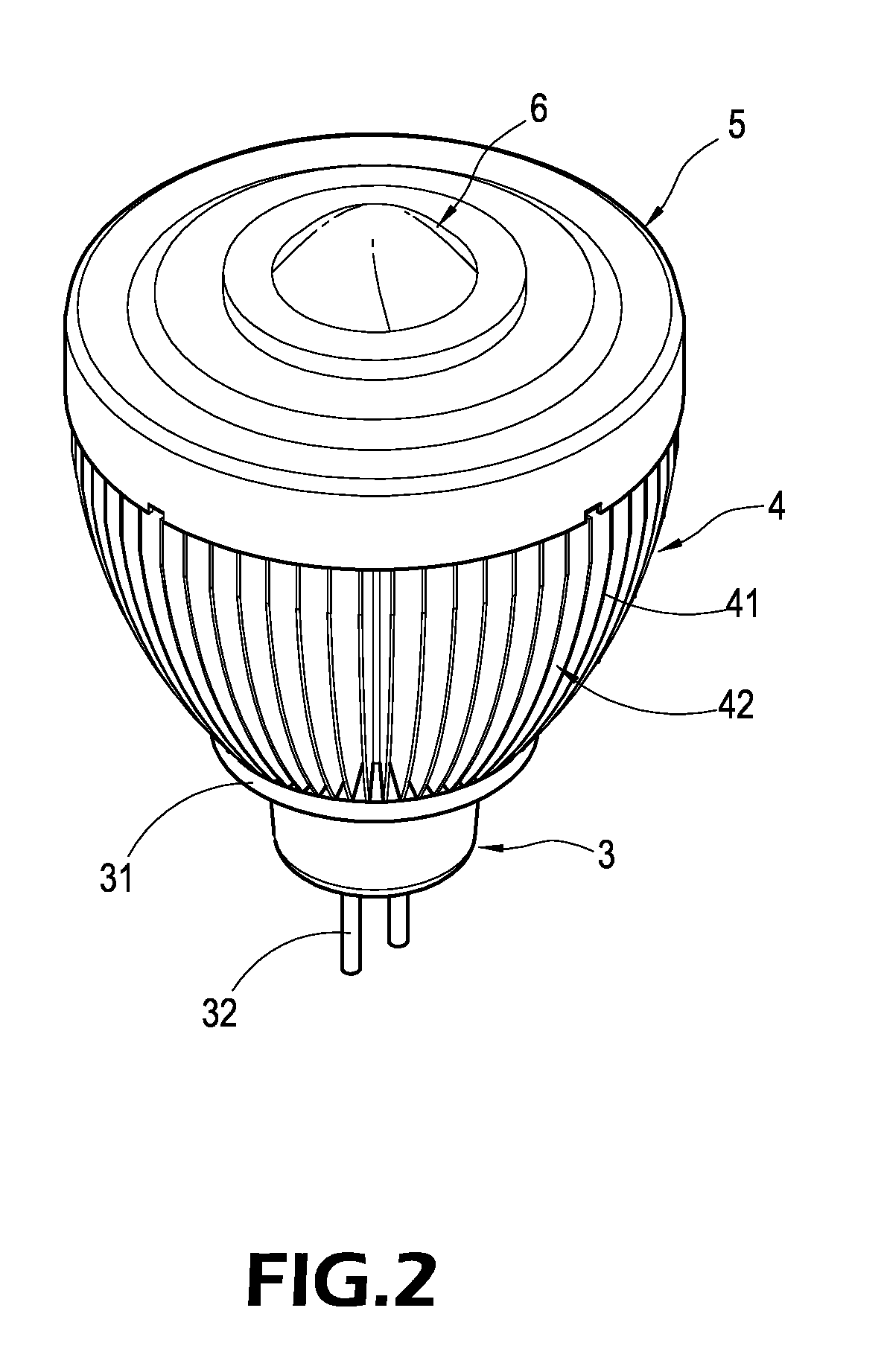

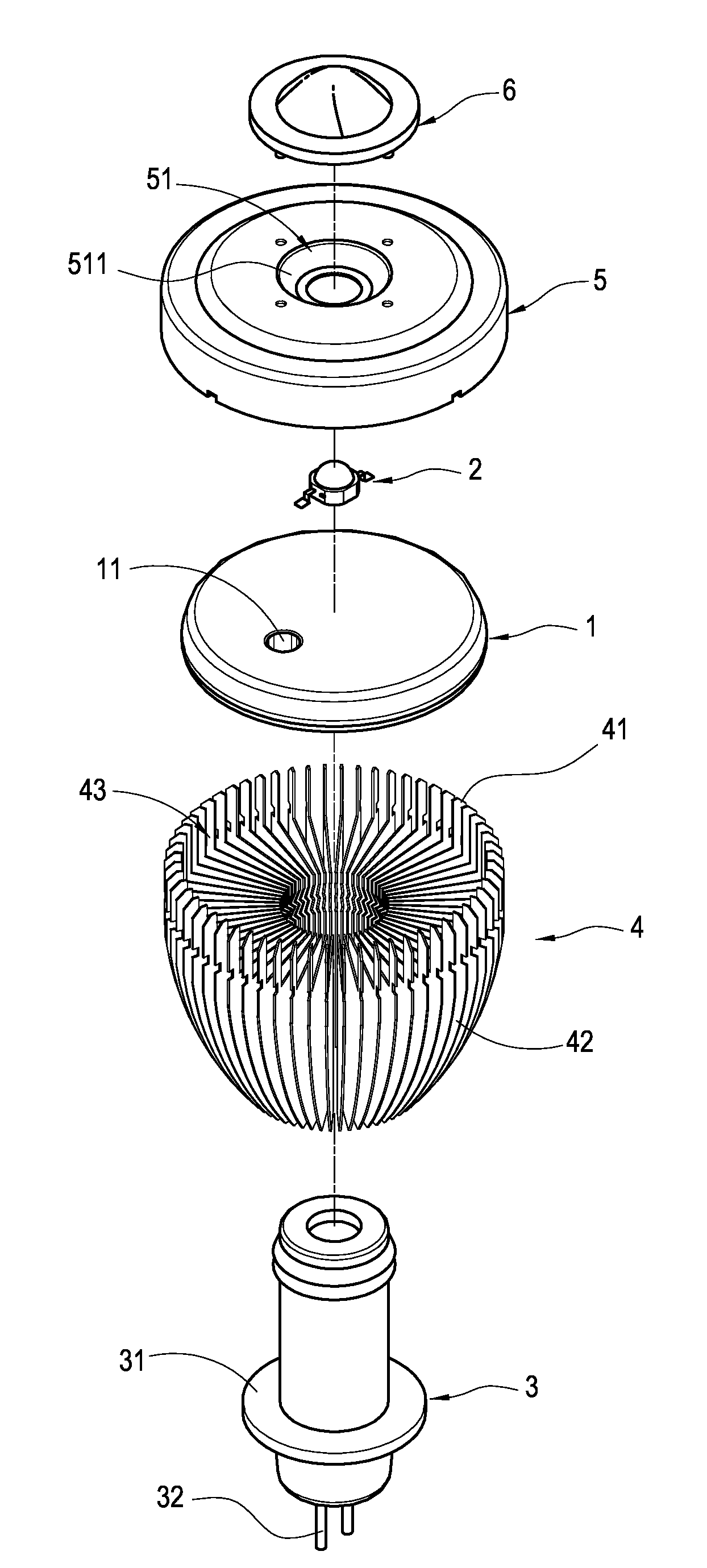

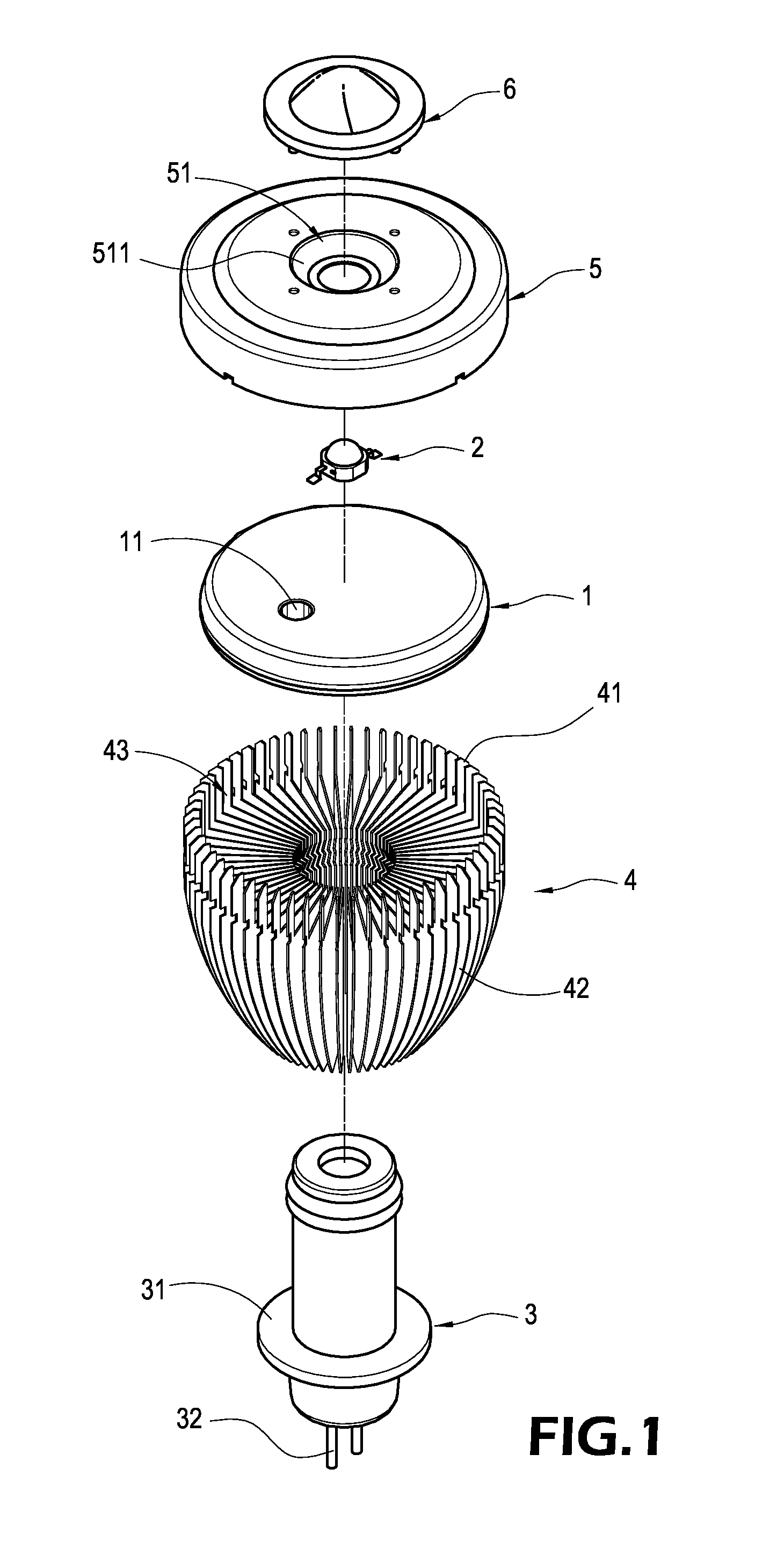

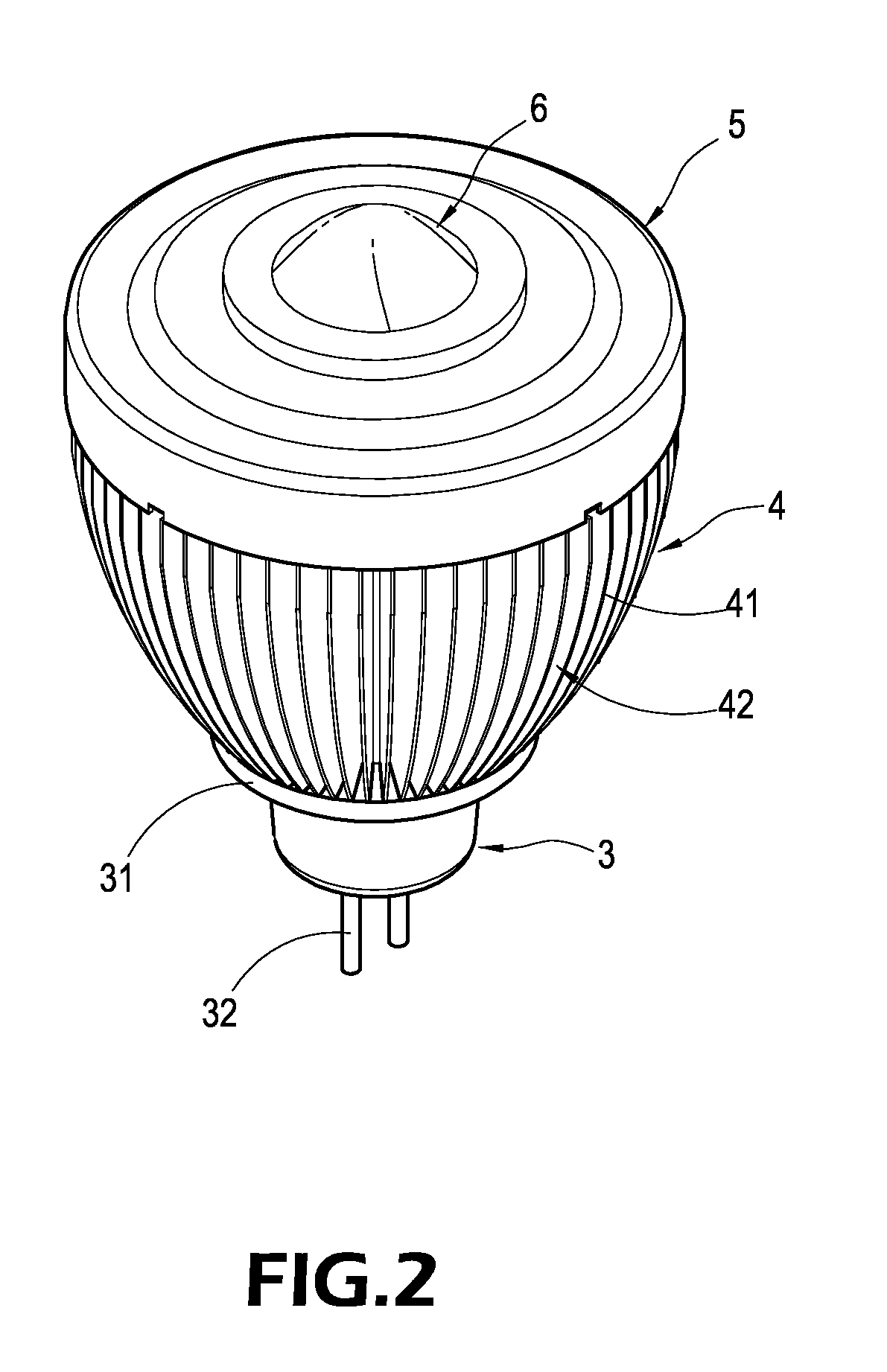

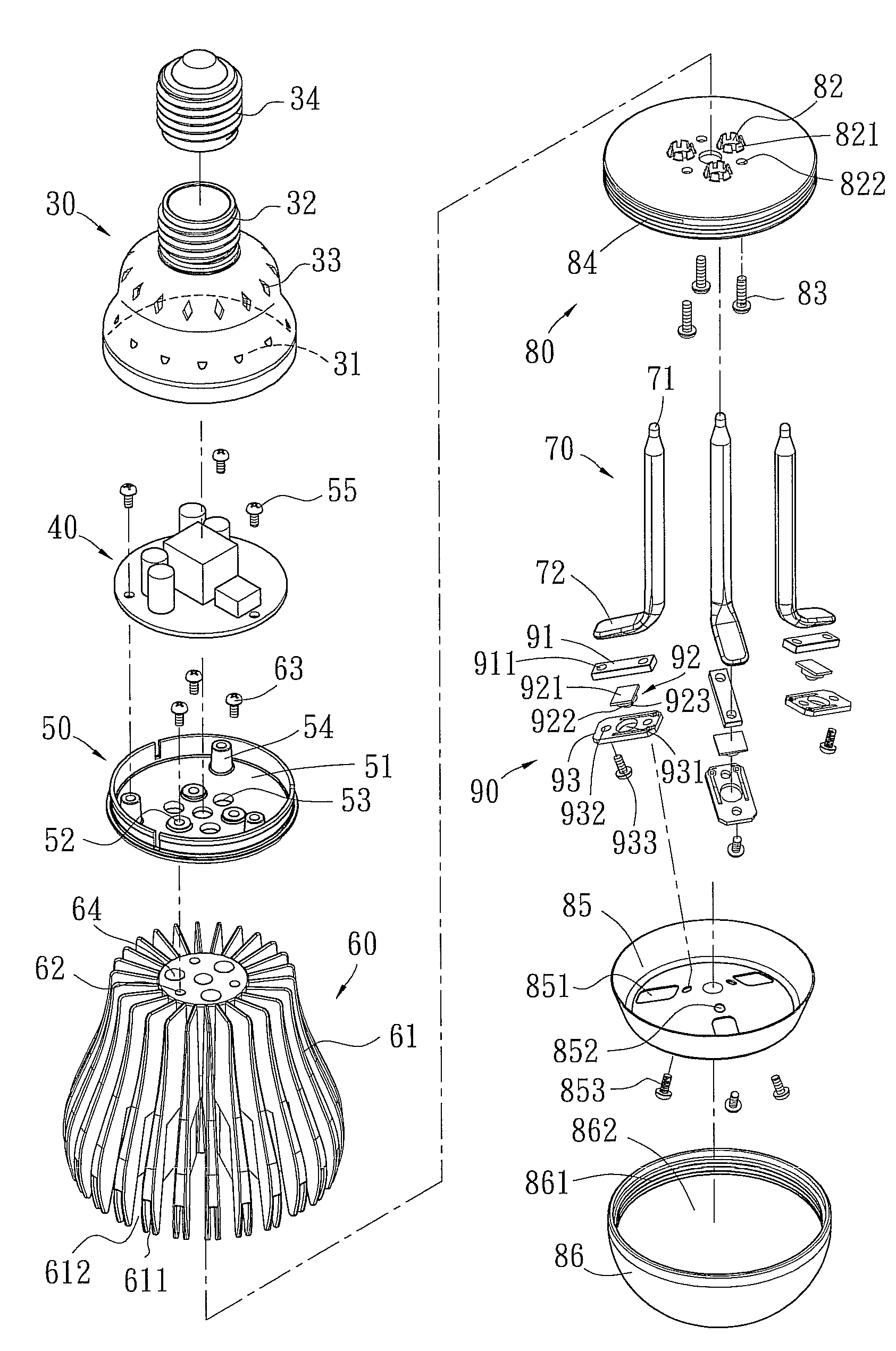

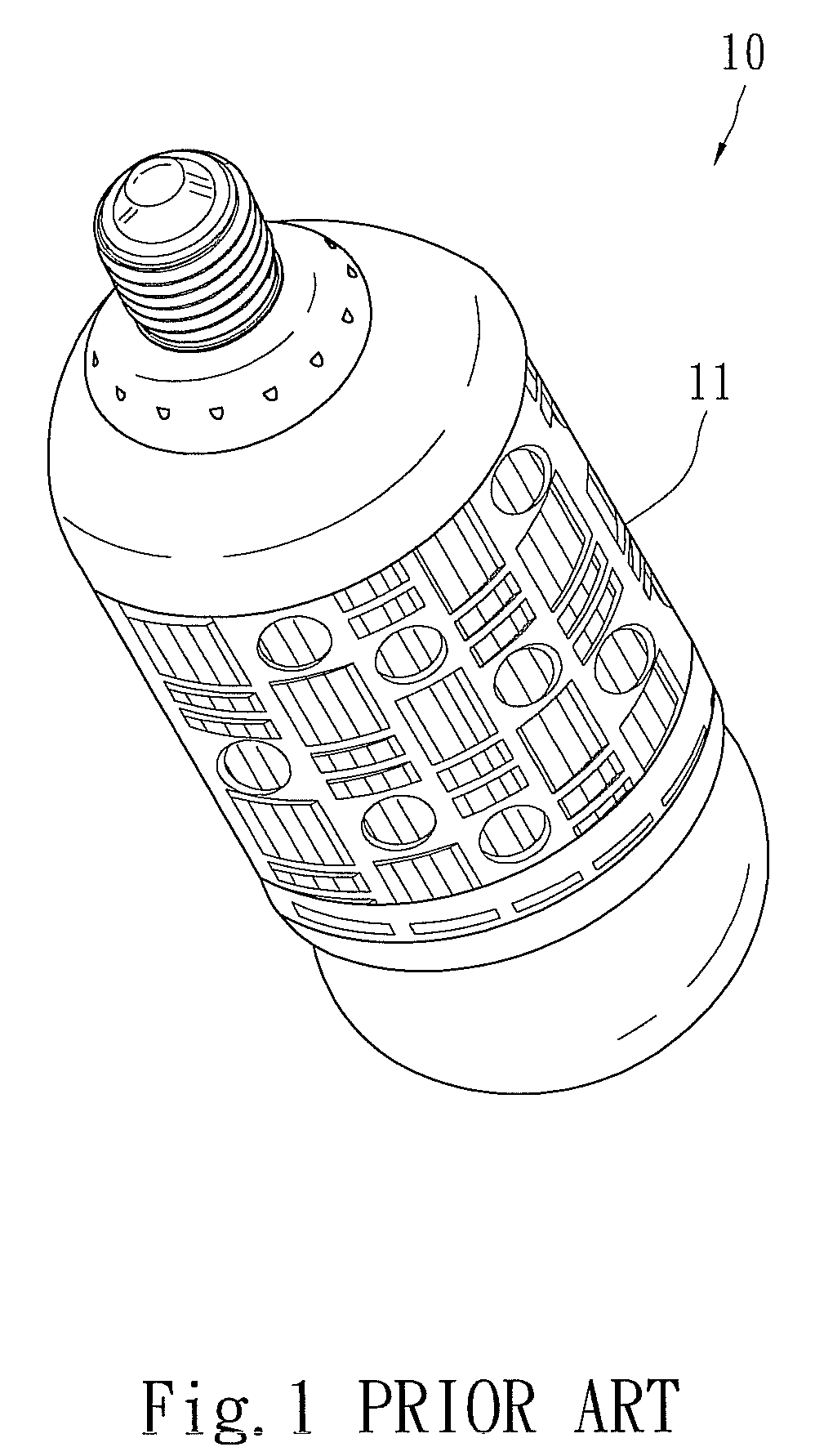

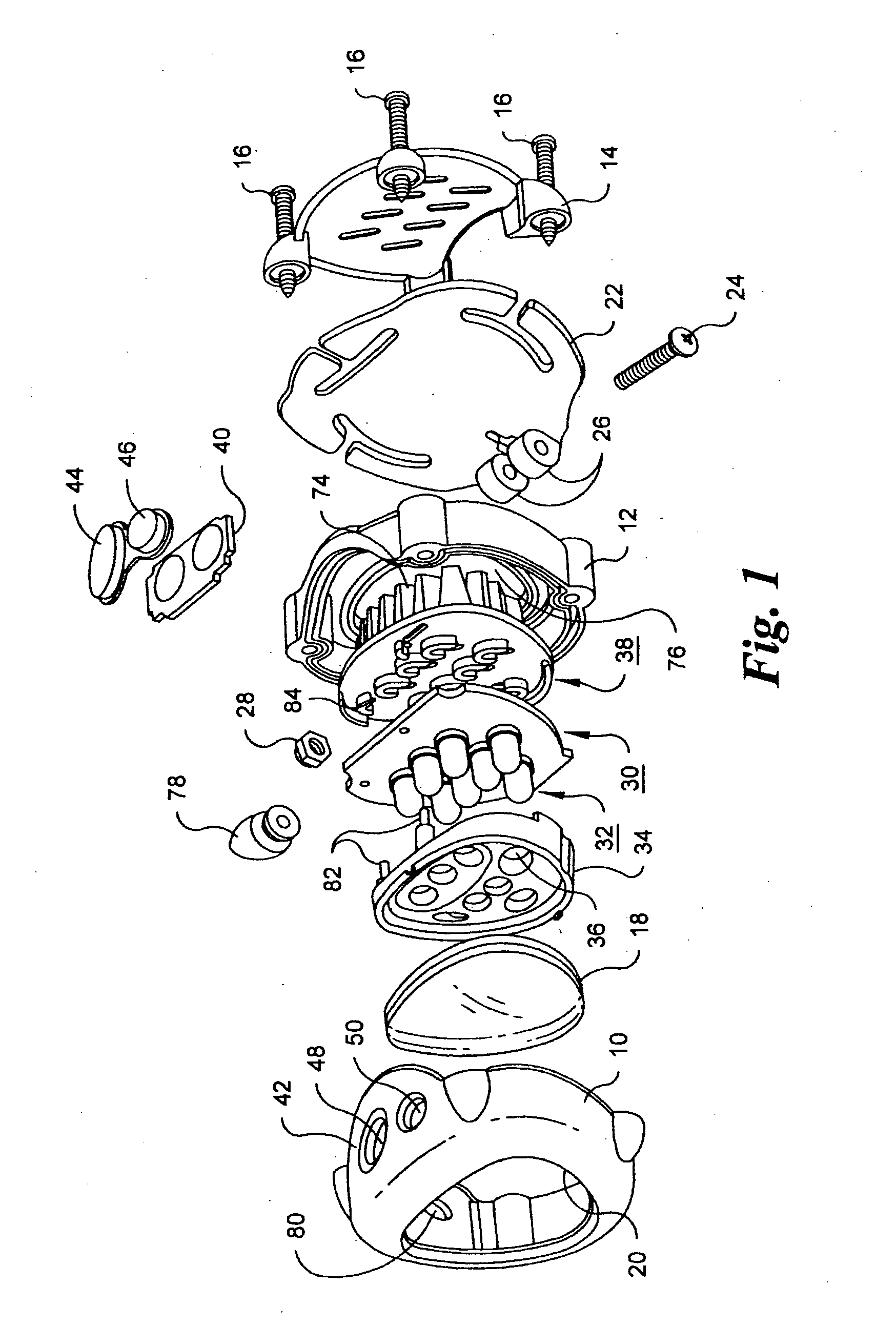

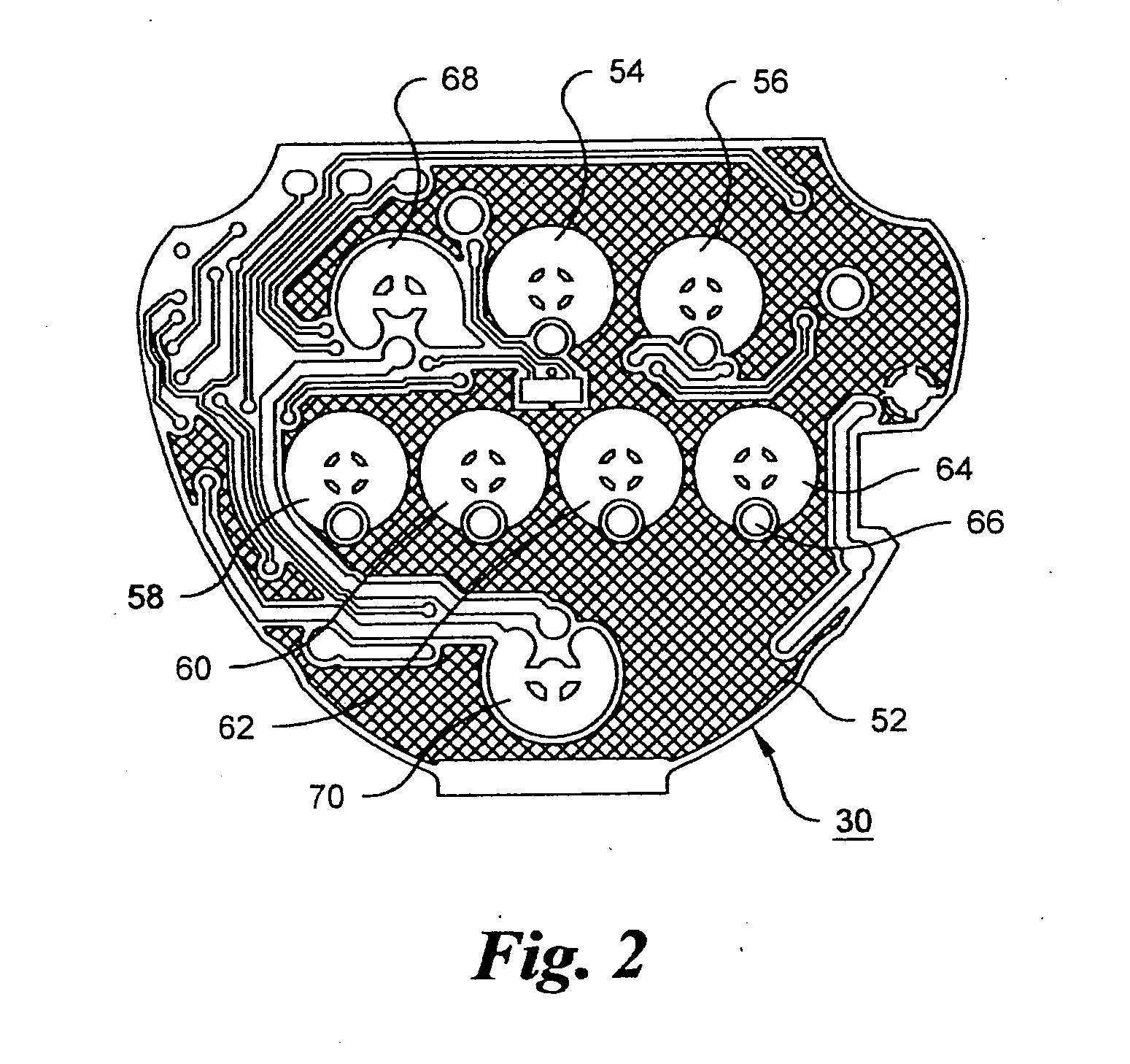

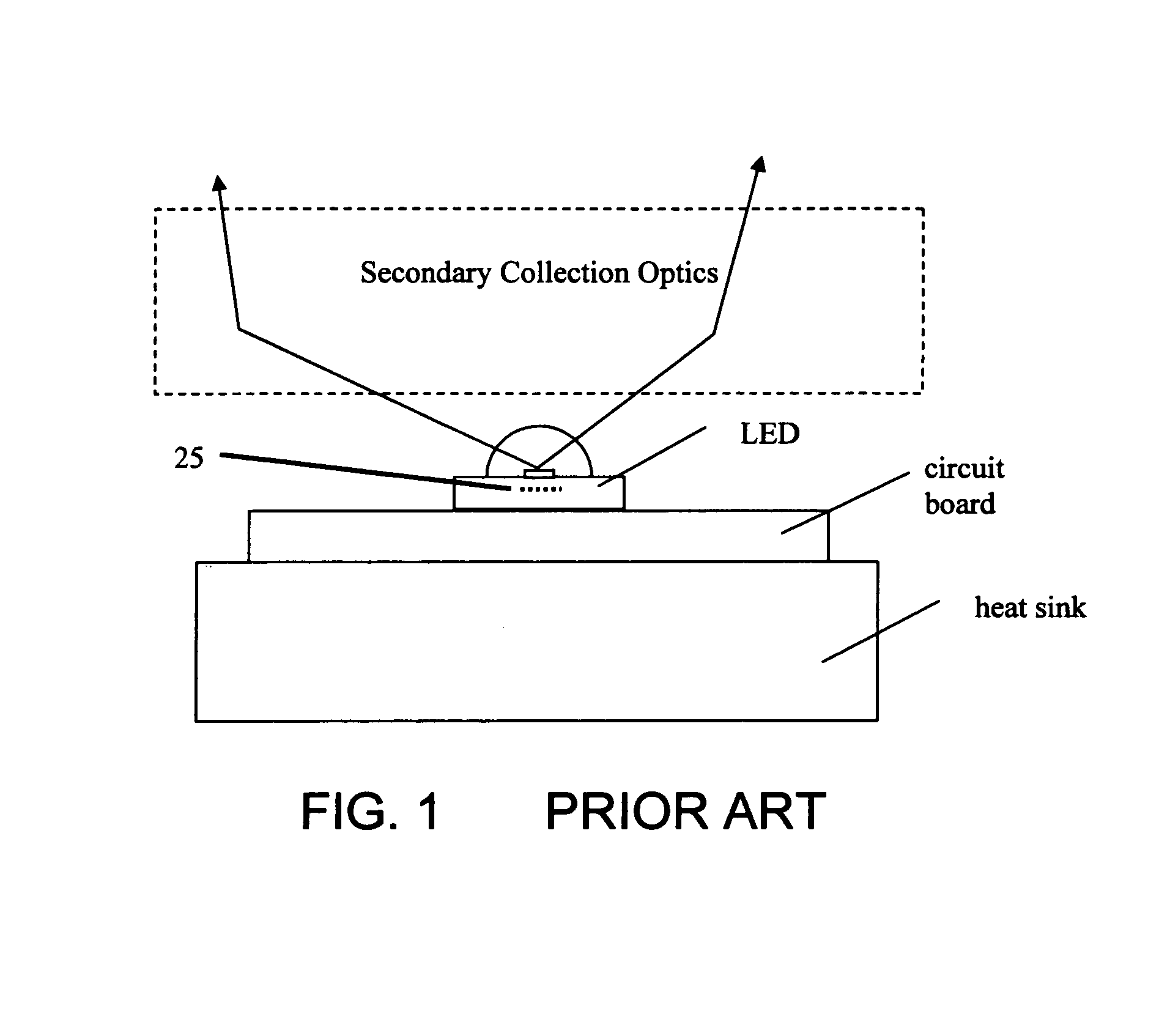

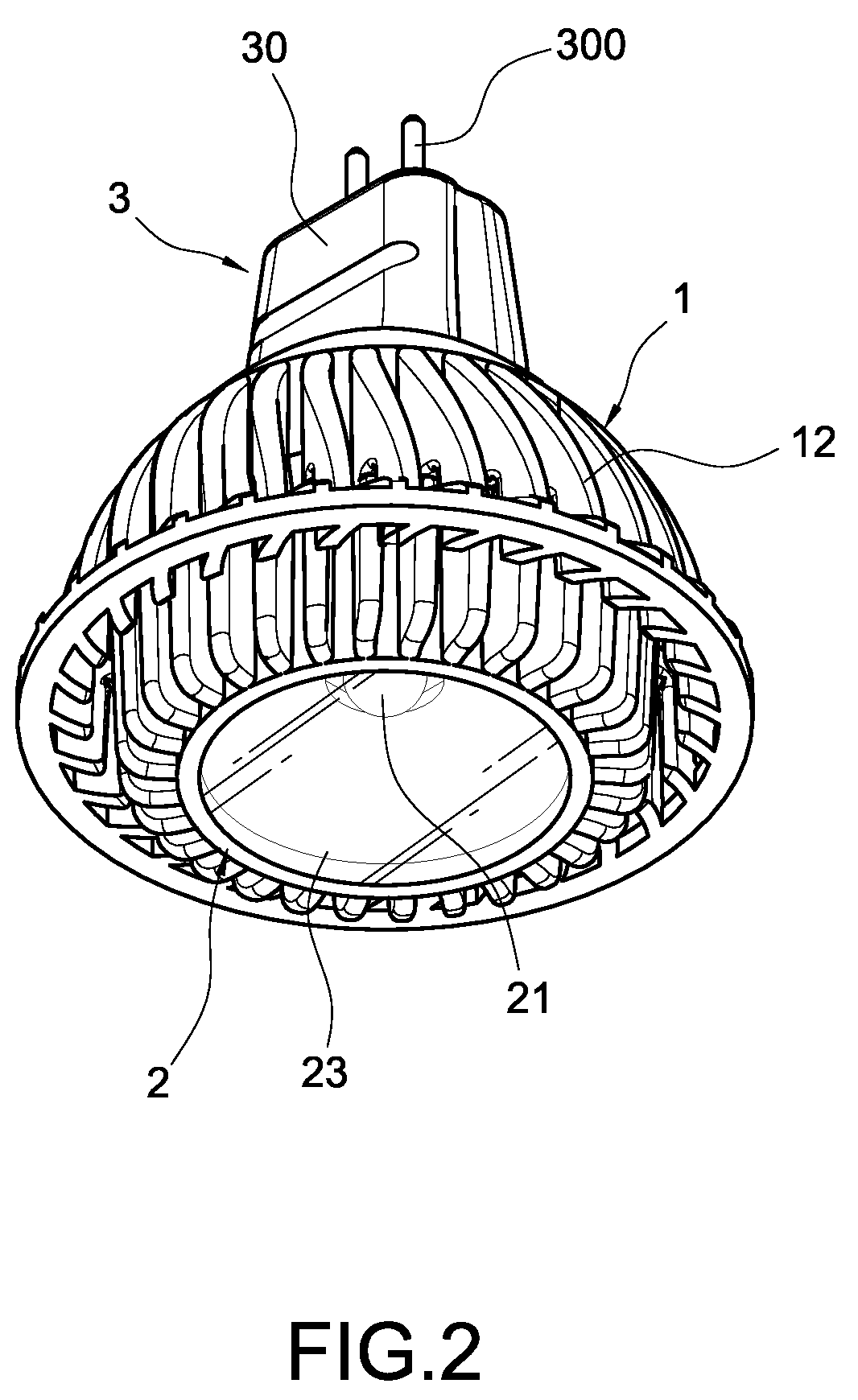

Heat dissipating LED signal lamp source structure

InactiveUS7396146B2Heat dissipationEnhances light emitting efficiency and life expectancy of light emittingPoint-like light sourceElectric circuit arrangementsHeat conductingEngineering

A heat dissipating LED signal lamp emitting structure includes an isothermal board, a light emitting unit on the isothermal board, a heat conducting cylinder connected to the bottom of the isothermal board, a heat dissipating body around the periphery of the heat conducting cylinder and comprised of heat sinks, a circular cover body above the isothermal board for covering the isothermal board, a reflecting groove at the center of the cover body for passing through the light emitting unit, and a transparent lid on the cover body for covering the light emitting unit. With the heat dissipating effect of the heat dissipating body, the operating heat produced by the light emitting unit can be dissipated to the outside. The invention not only uses a single light emitting unit as a signal lamp emitting source, but also enhances the light emitting efficiency and the life expectancy of the light emitting unit.

Owner:PYROSWIFT HOLDING CO LIMITED

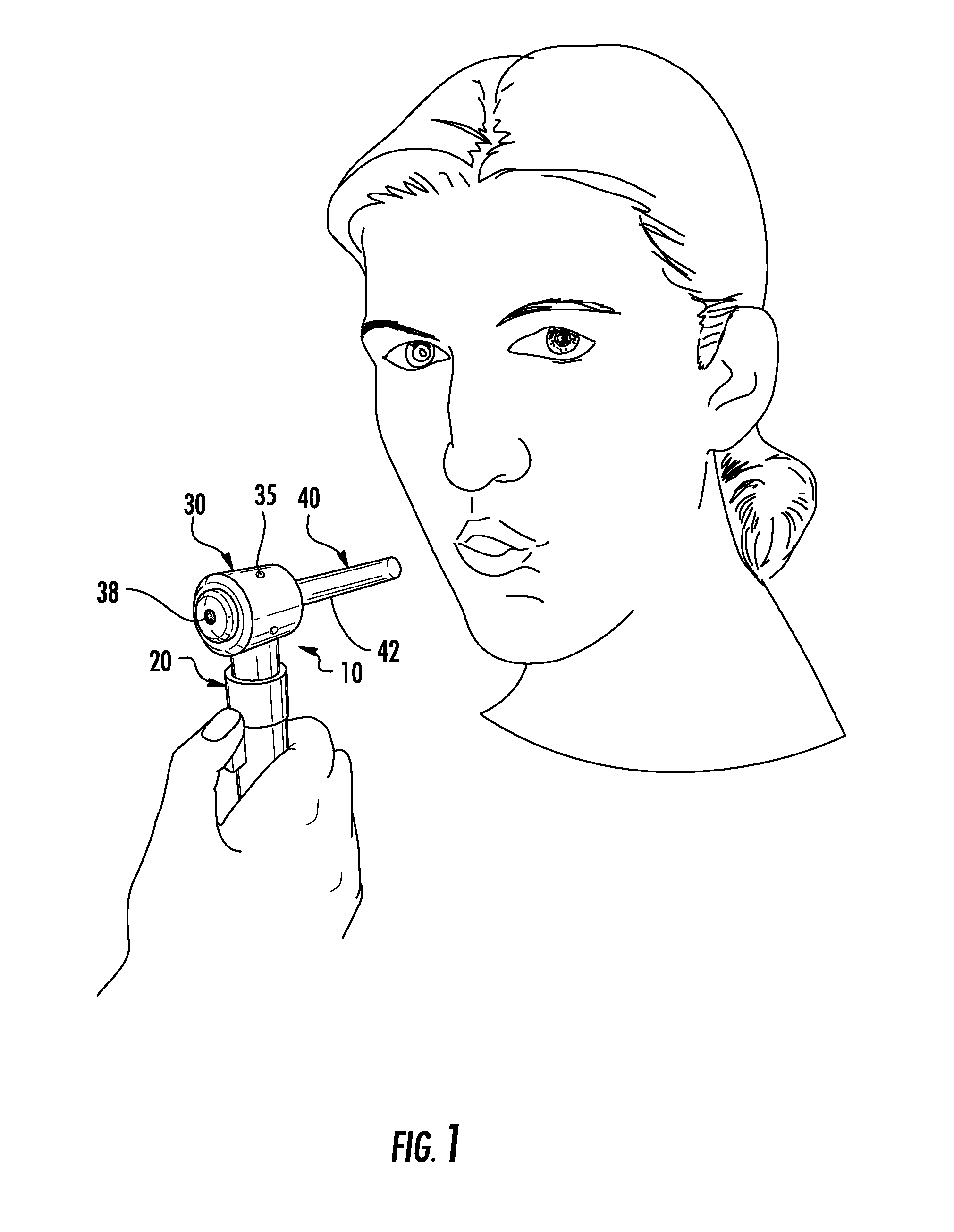

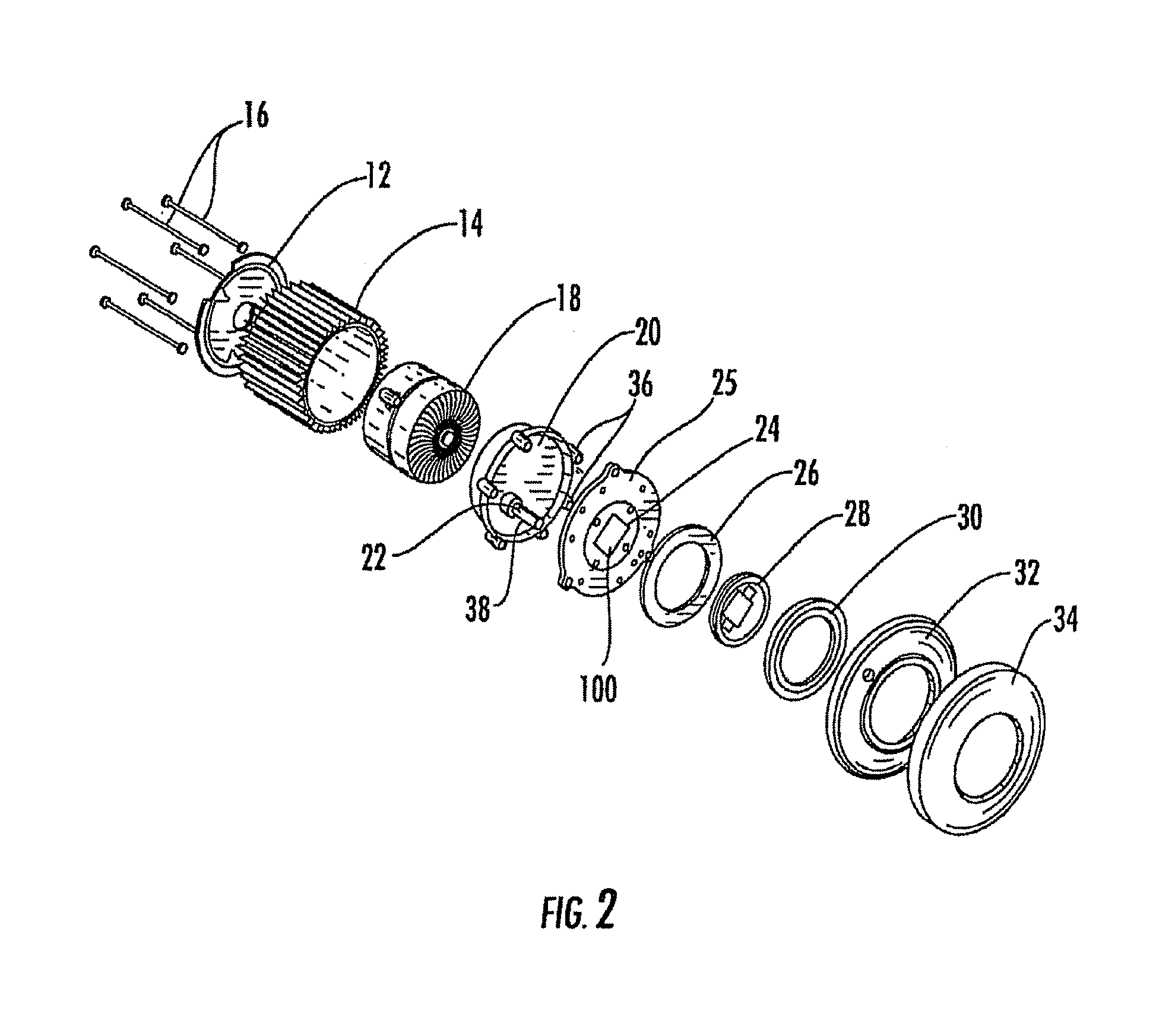

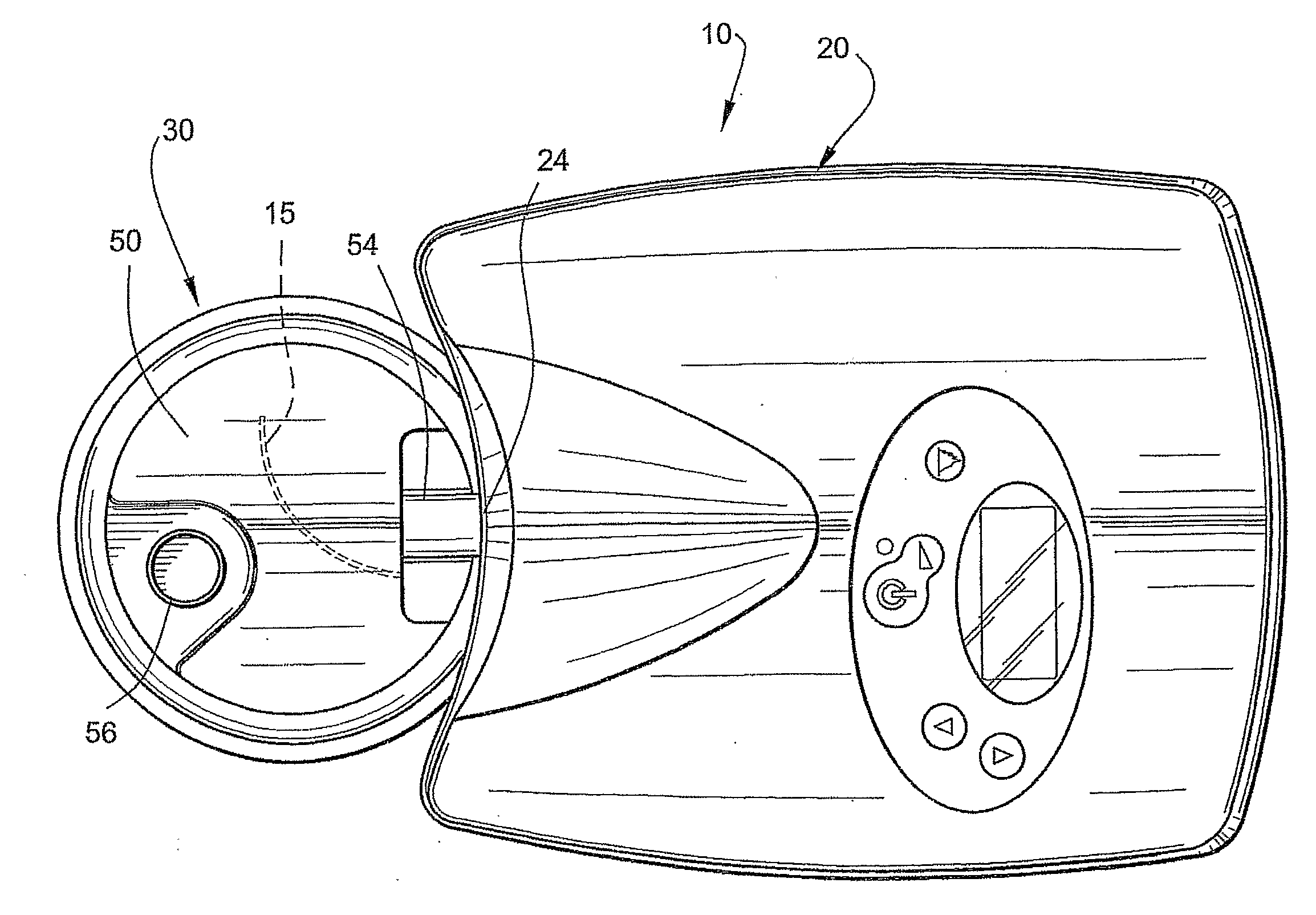

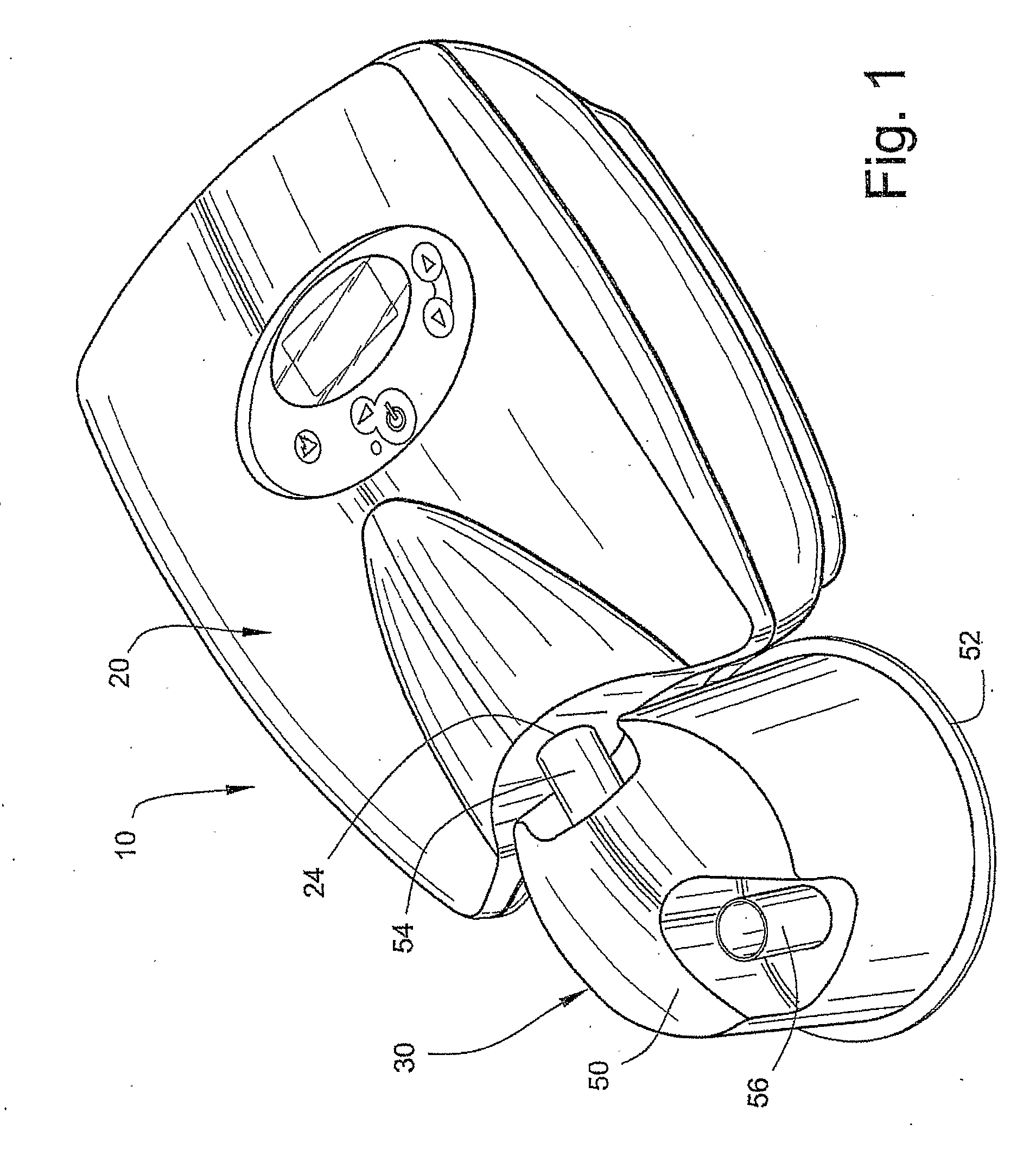

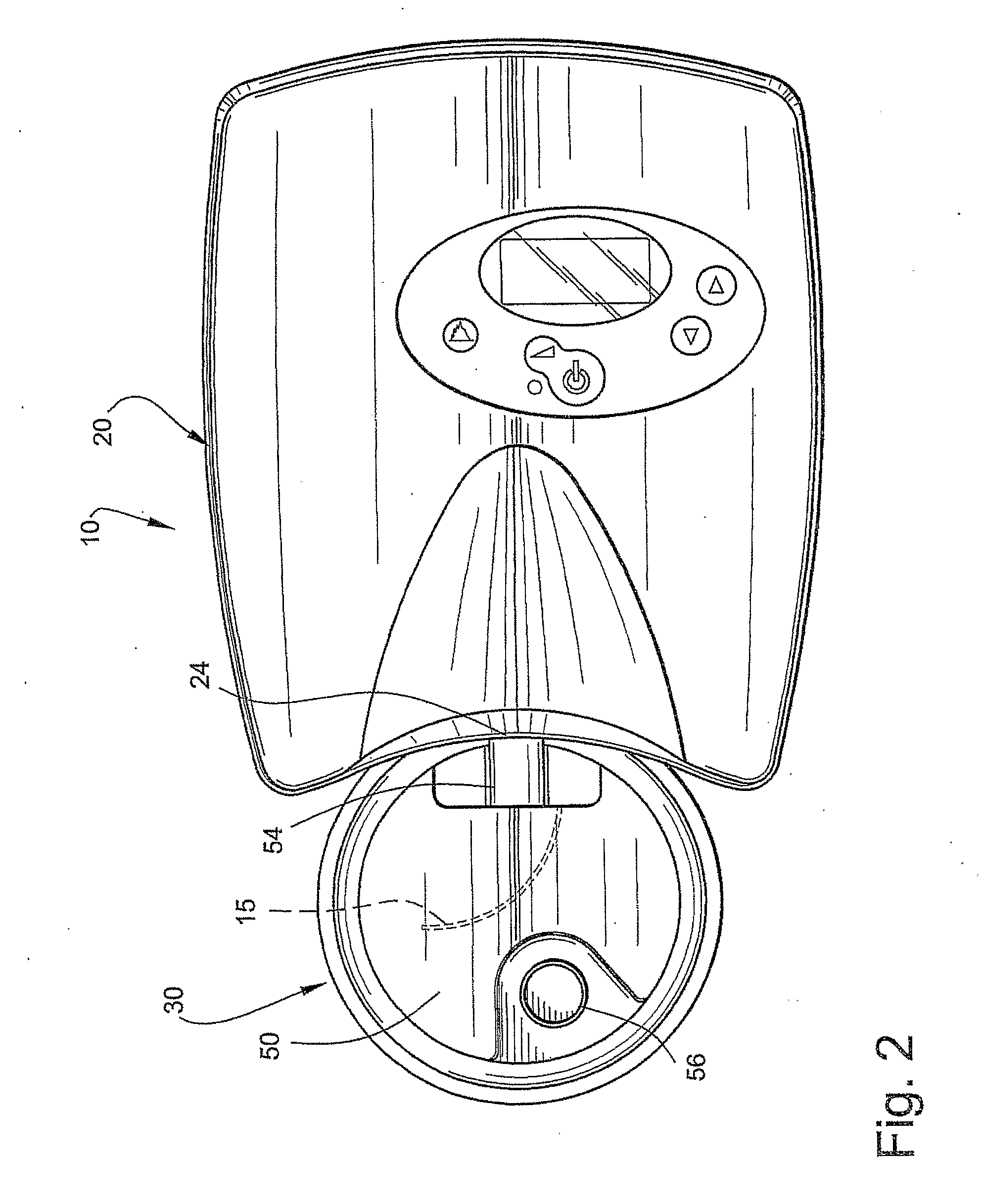

Digital controller for surgical handpiece

The present disclosure generally pertains to a digital controller for surgical handpieces. The controller is programmable and configurable by software which may be used with a variety of types of handpieces. The controller is equipped with environmental sensors that detect pressure, humidity and temperature, and operational sensors that detect the angle and placement of the rotor of a motor. These sensors provide data used for testing and evaluating the function of the handpiece. A filter program is provided which removes electronic noise from collected data. The controller includes an electronic memory writer and reader to download firmware, control parameters for handpiece operation and read logged data from sensors to determine motor function. The sensor includes a hermetic enclosure constructed from a heat conducting material and that is non-ferromagnetic to allow communication between the trigger and controller.

Owner:INTEGRATED MEDICAL SYST INT INC

Heat Dissipating LED Signal Lamp Source Structure

InactiveUS20080037255A1Improve light emission efficiencyEnhance life expectancyPoint-like light sourceElectric circuit arrangementsHeat conductingEngineering

A heat dissipating LED signal lamp emitting structure includes an isothermal board, a light emitting unit on the isothermal board, a heat conducting cylinder connected to the bottom of the isothermal board, a heat dissipating body around the periphery of the heat conducting cylinder and comprised of heat sinks, a circular cover body above the isothermal board for covering the isothermal board, a reflecting groove at the center of the cover body for passing through the light emitting unit, and a transparent lid on the cover body for covering the light emitting unit. With the heat dissipating effect of the heat dissipating body, the operating heat produced by the light emitting unit can be dissipated to the outside. The invention not only uses a single light emitting unit as a signal lamp emitting source, but also enhances the light emitting efficiency and the life expectancy of the light emitting unit.

Owner:PYROSWIFT HOLDING CO LIMITED

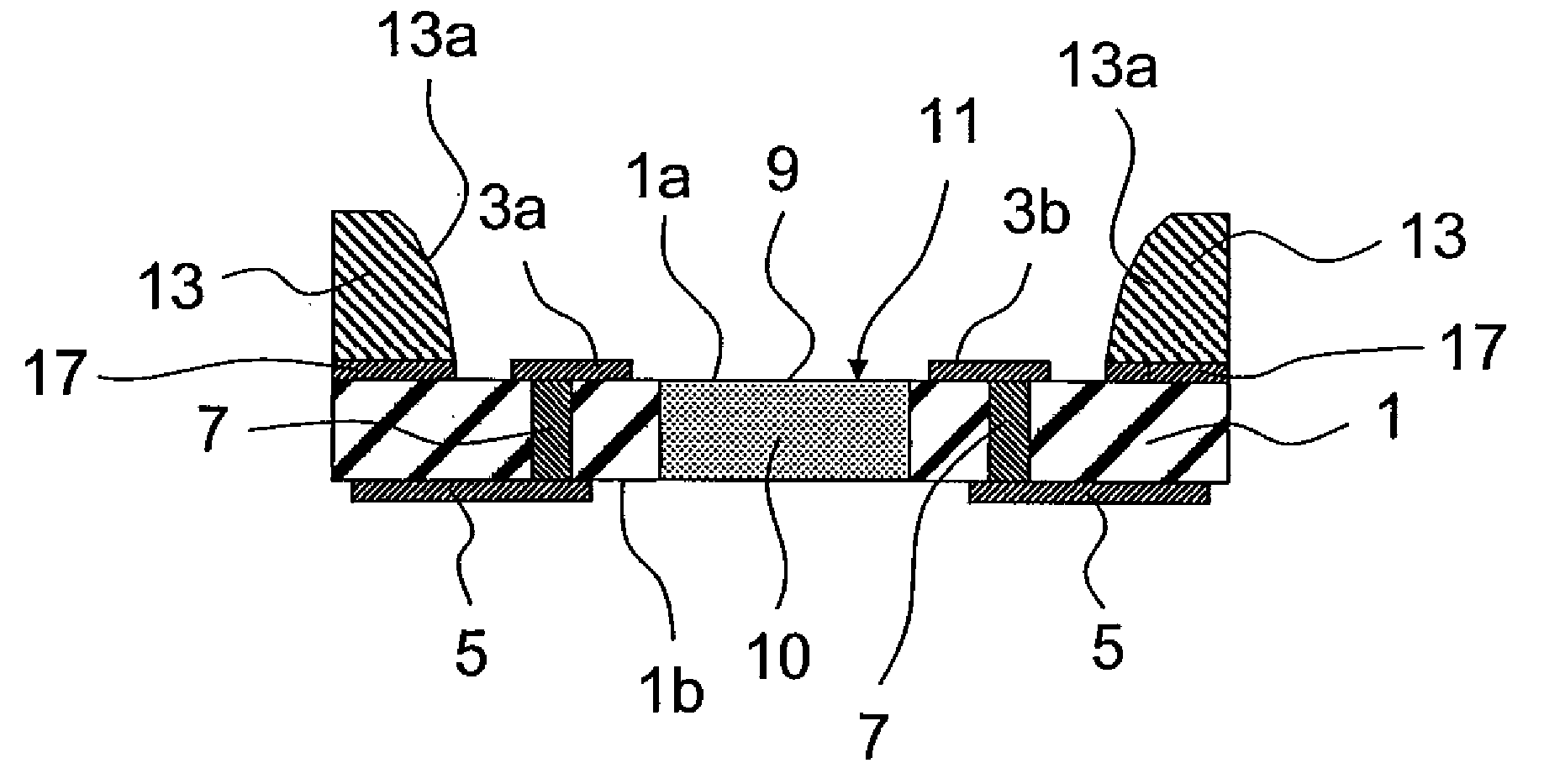

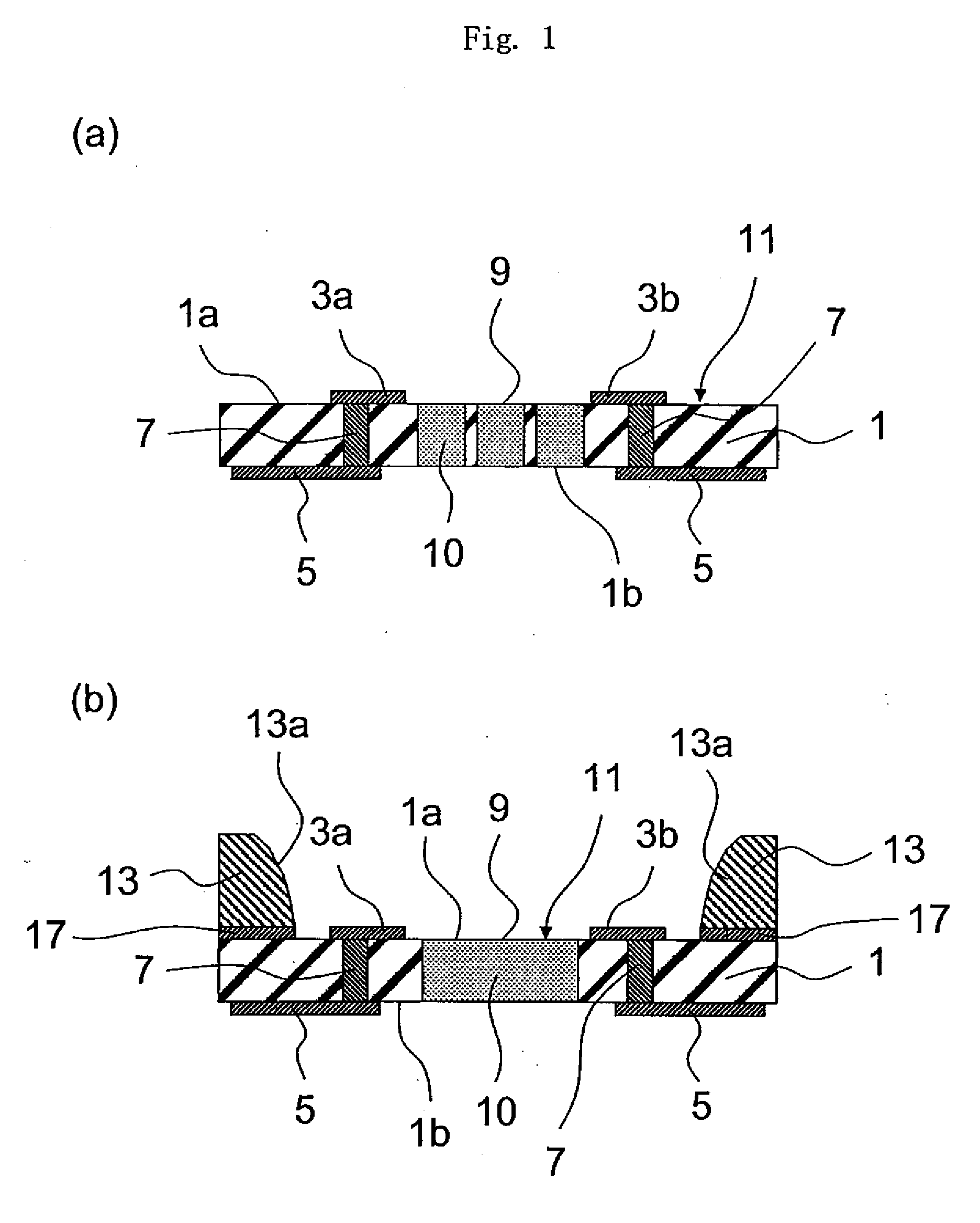

Wiring Board for Light-Emitting Element

InactiveUS20080043444A1InhibitionHigh bonding strengthPrinted circuit aspectsSolid-state devicesElectrical conductorHeat conducting

A wiring board for light-emitting element, comprising a ceramic insulating substrate, and a conductor layer formed on the surface or in the inside of the insulating substrate, and having a mounting region mounting a light-emitting element on one surface of the insulating substrate; wherein the insulating substrate is provided with a heat-conducting pole-like conductor having a thermal conductivity higher than that of said insulating substrate; and the heat-conducting pole-like conductor is extending through the insulating substrate in the direction of thickness thereof from the light-emitting element mounting region of the insulating substrate, and is formed by the co-firing with the insulating substrate. The wiring board is produced inexpensively by co-firing, features excellent heat-radiating performance, is capable of quickly radiating the heat from the light-emitting element when the light-emitting element is mounted, and effectively prevents a decrease in the brightness of the light-emitting element caused by the heat.

Owner:KYOCERA CORP

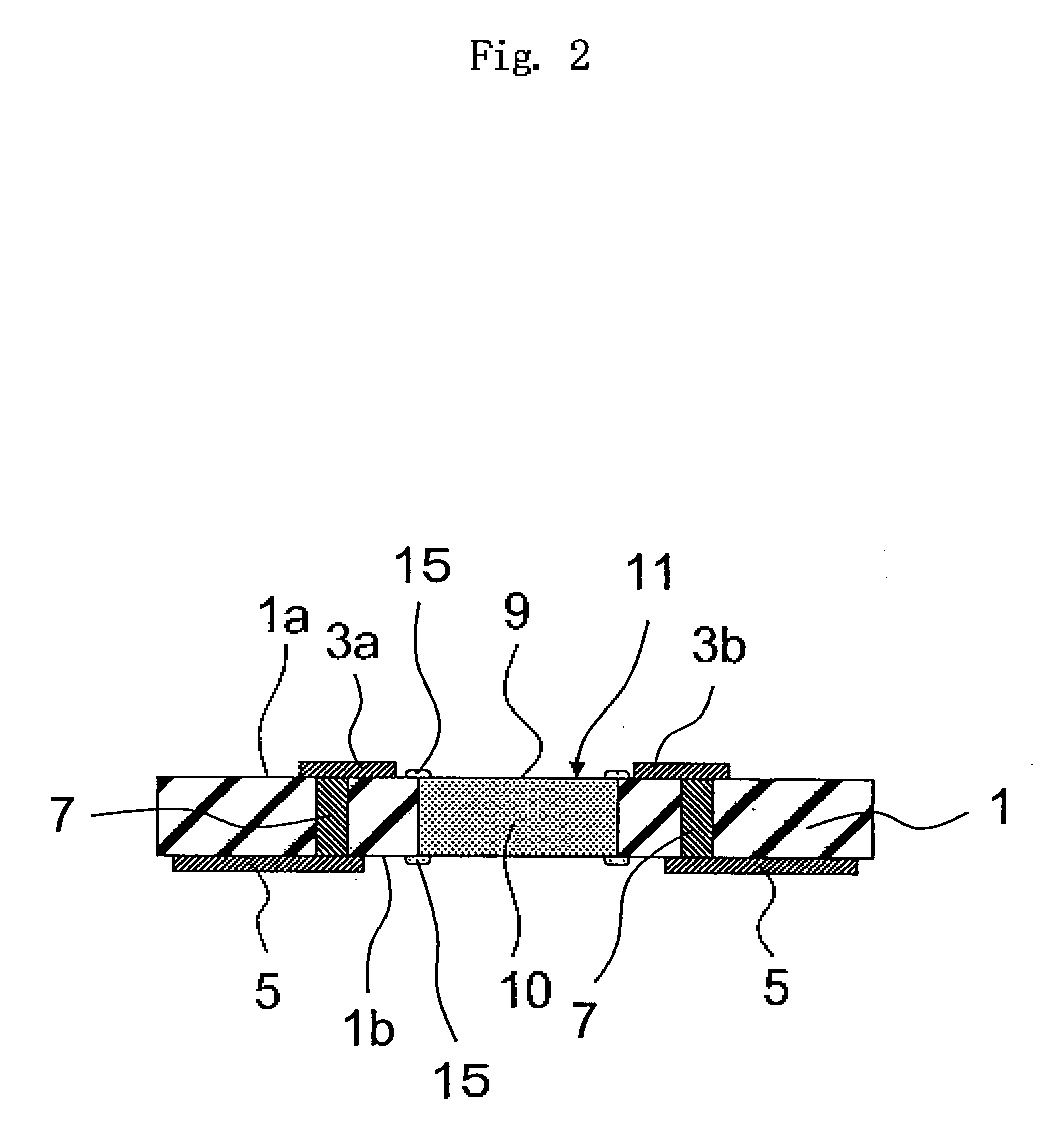

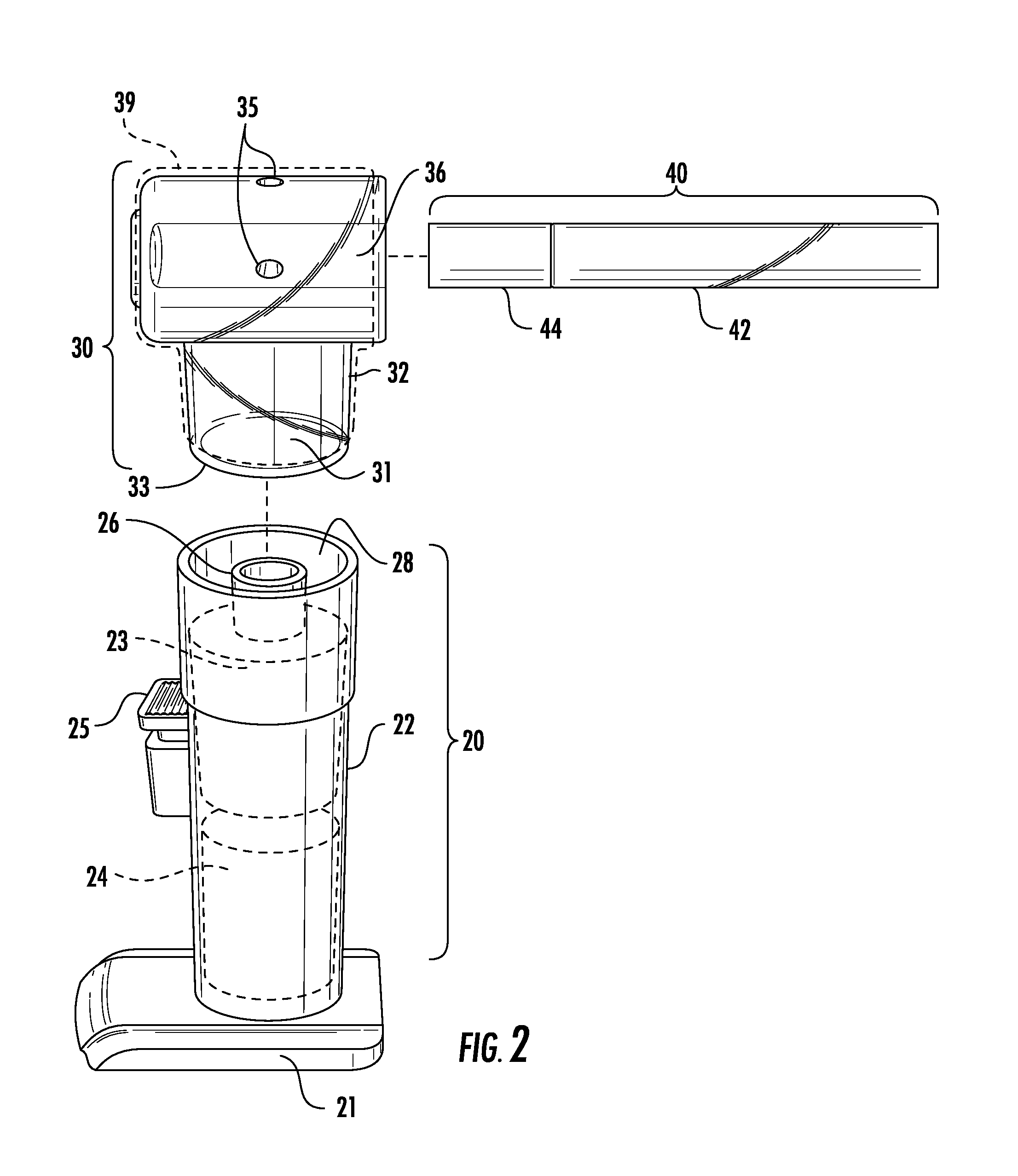

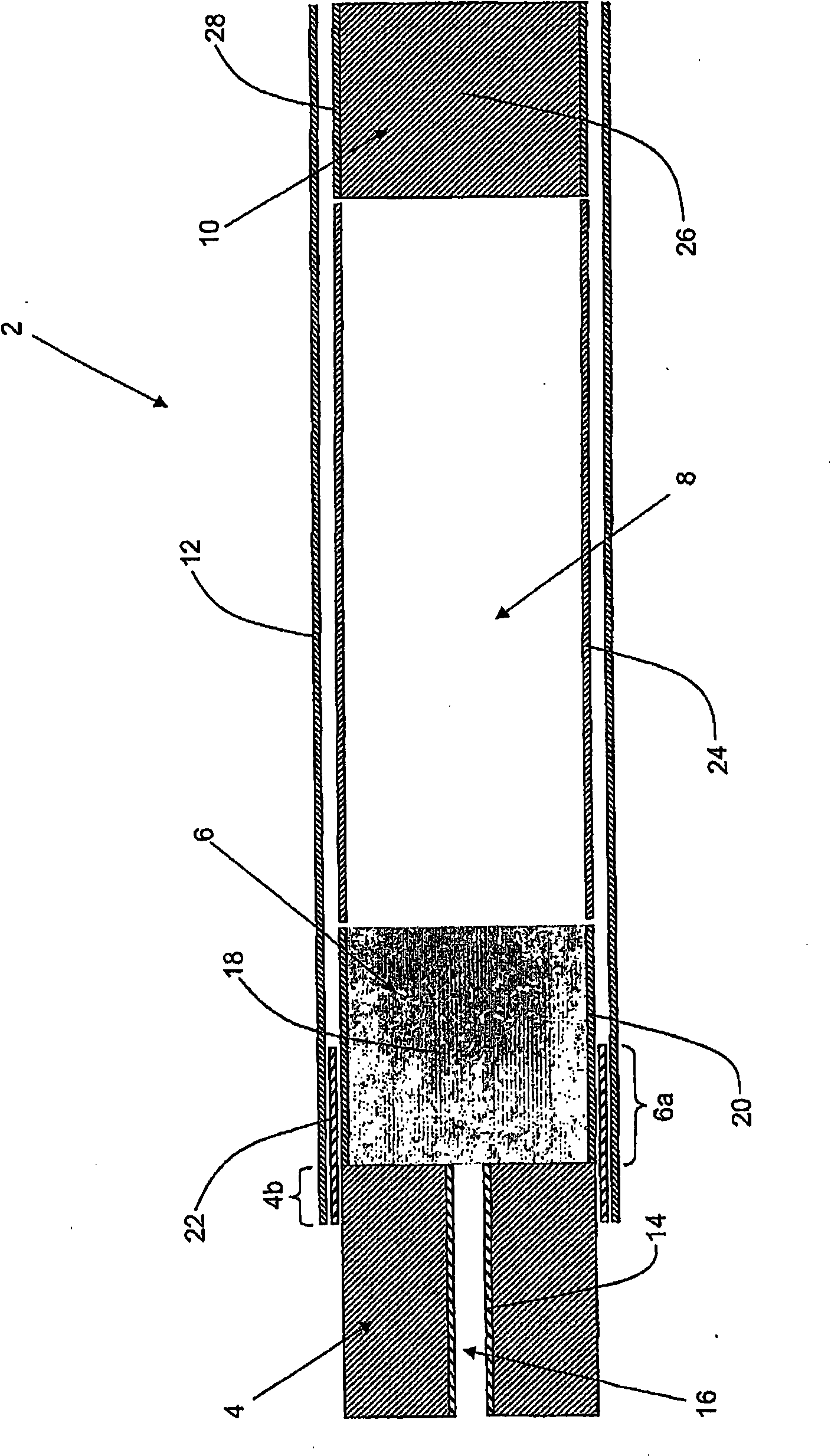

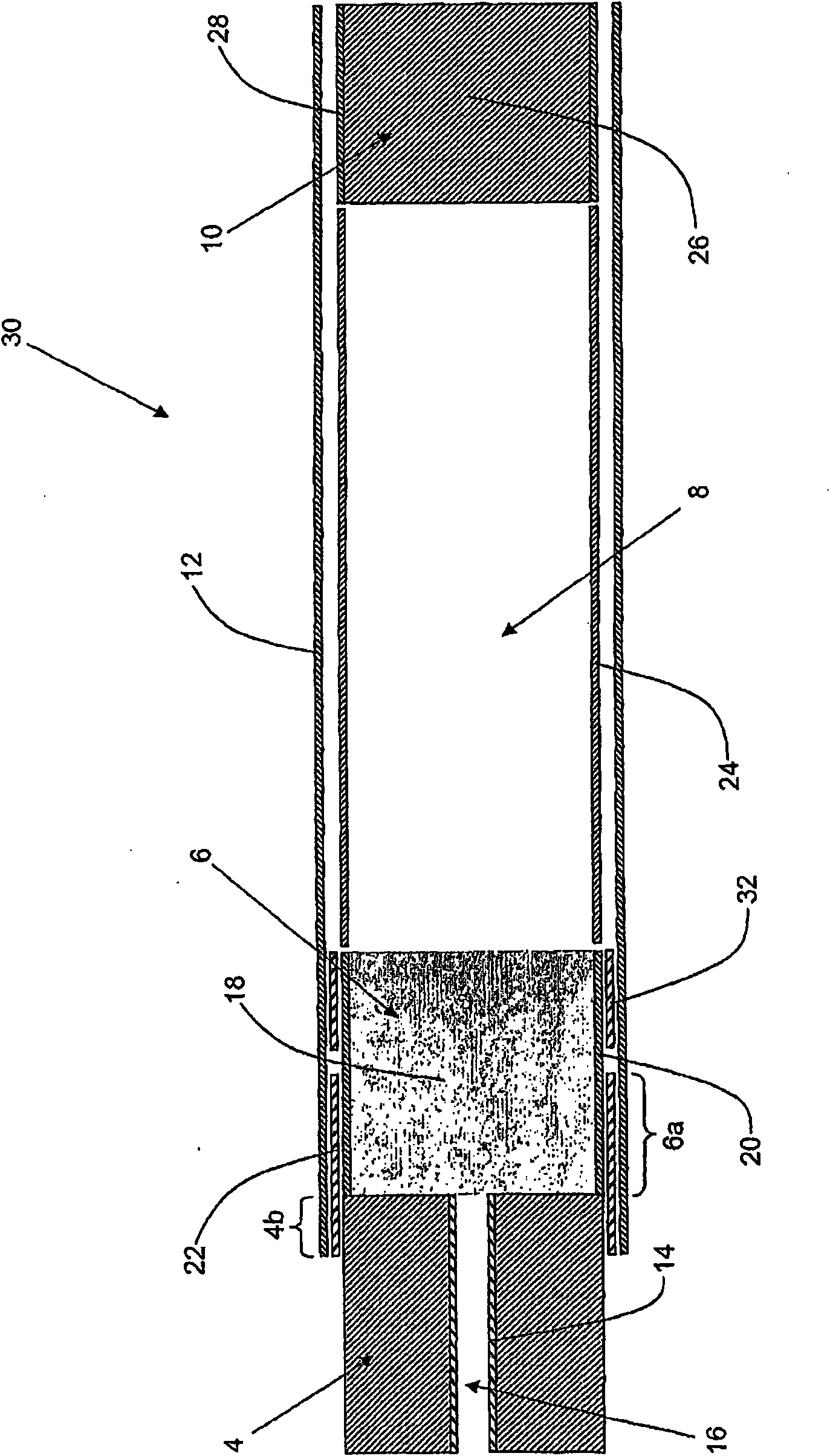

Devices for vaporizing and delivering an aerosol agent

ActiveUS20150101606A1Effective and convenient and easy to useRespiratorsMedical devicesElectricityElectrical conductor

A device for vaporizing and delivering an aerosol agent includes a heat generator, a heat conductor in fluid (airflow) communication with the heat generator, and a substrate holder in heat conducting relation with the heat conductor. The heat generator is a handheld, portable torch and the heat conductor defines an annular heat conducting chamber surrounding a substrate disposed within the substrate holder that supports the aerosol agent and an aerosol forming agent. Another device is a handheld, battery-powered heat generator including a heating element in heat conducting relation with a substrate holder. The heating element is a nichrome heating coil wound about the substrate disposed within the substrate holder and electrically coupled to the battery. Another device further includes an auxiliary heat generator having an auxiliary heating element formed by a finely woven wire mesh positioned adjacent the substrate and electrically coupled to the battery.

Owner:PATHFINDER INNOVATIONS LLC

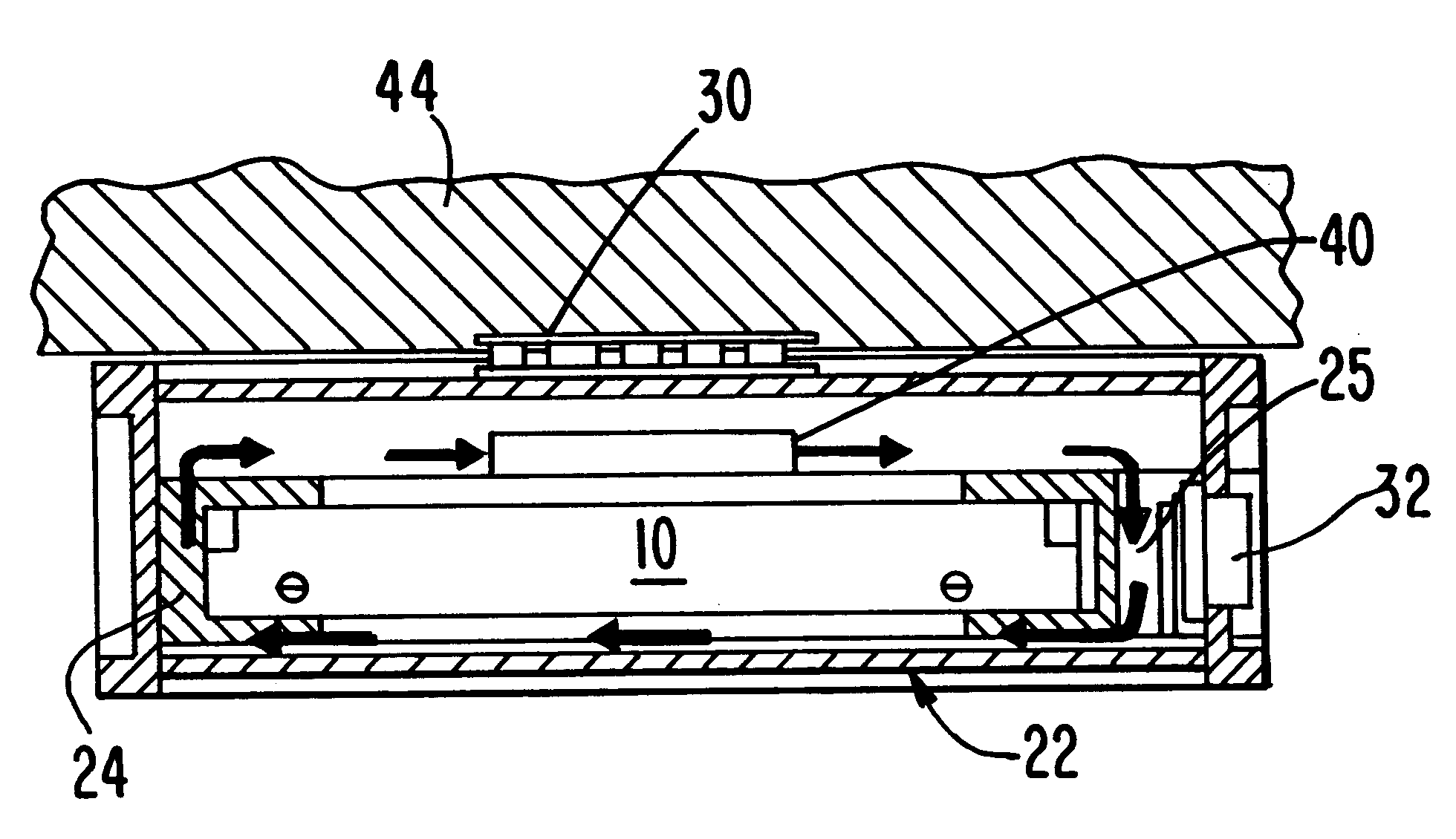

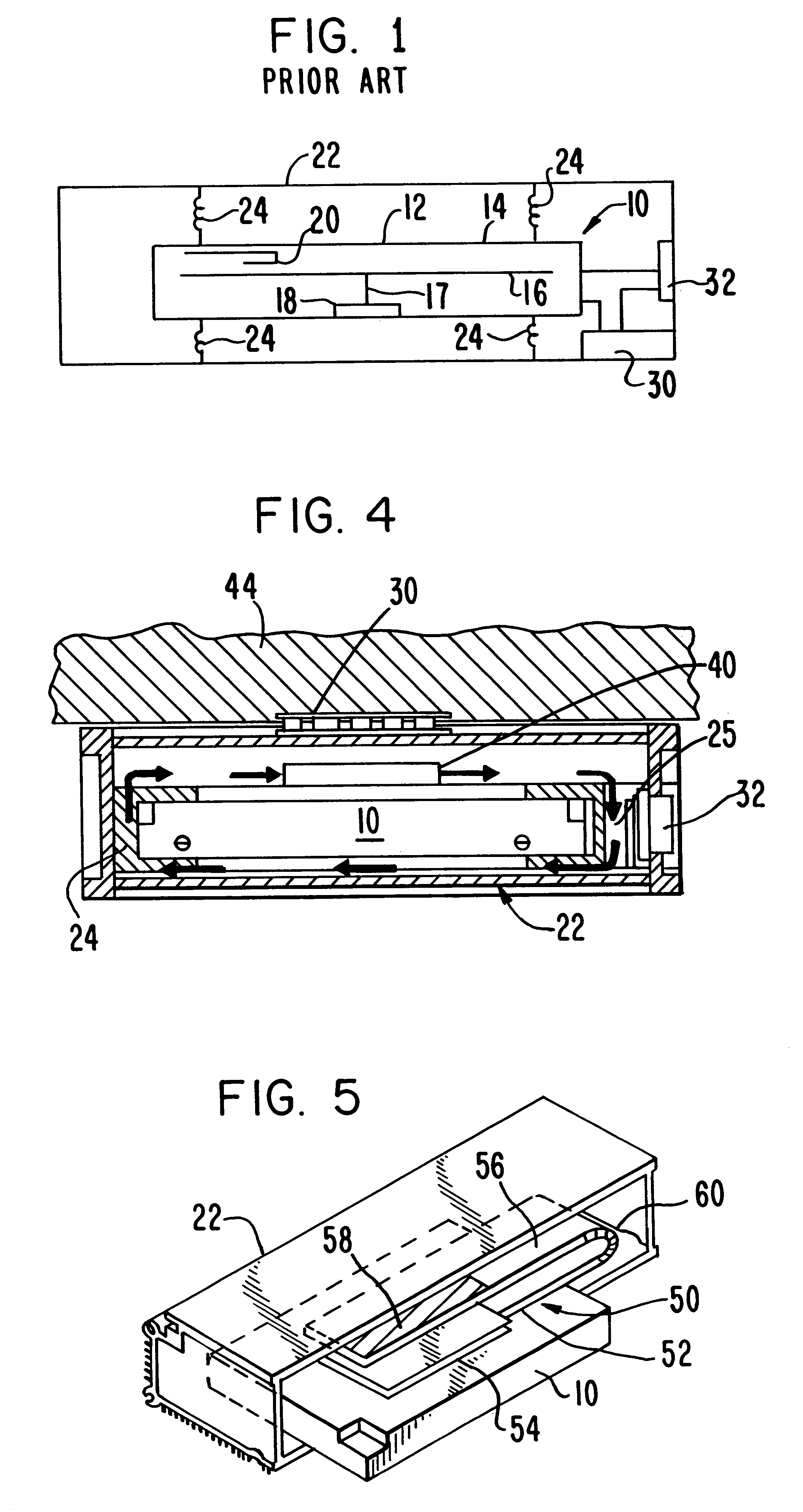

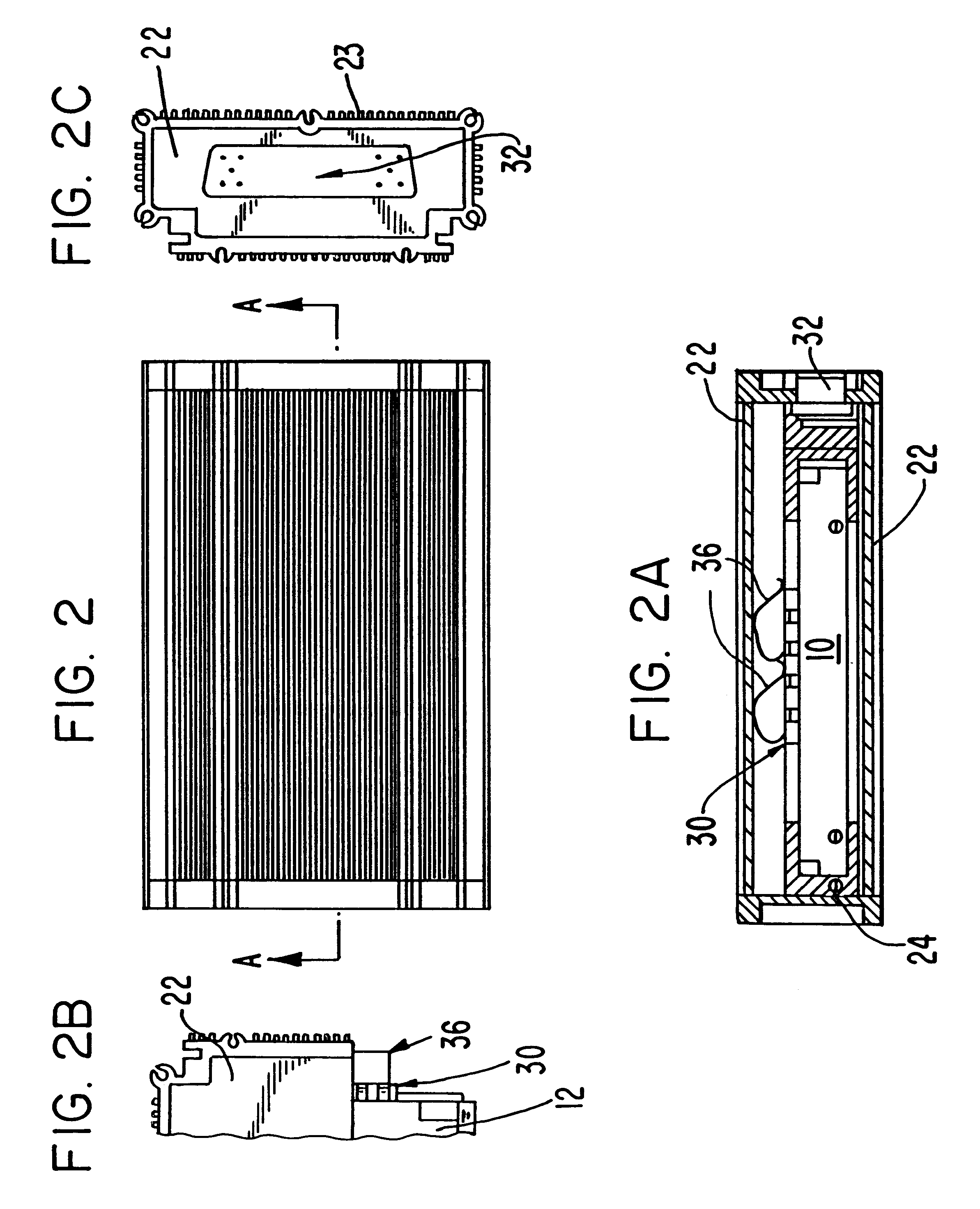

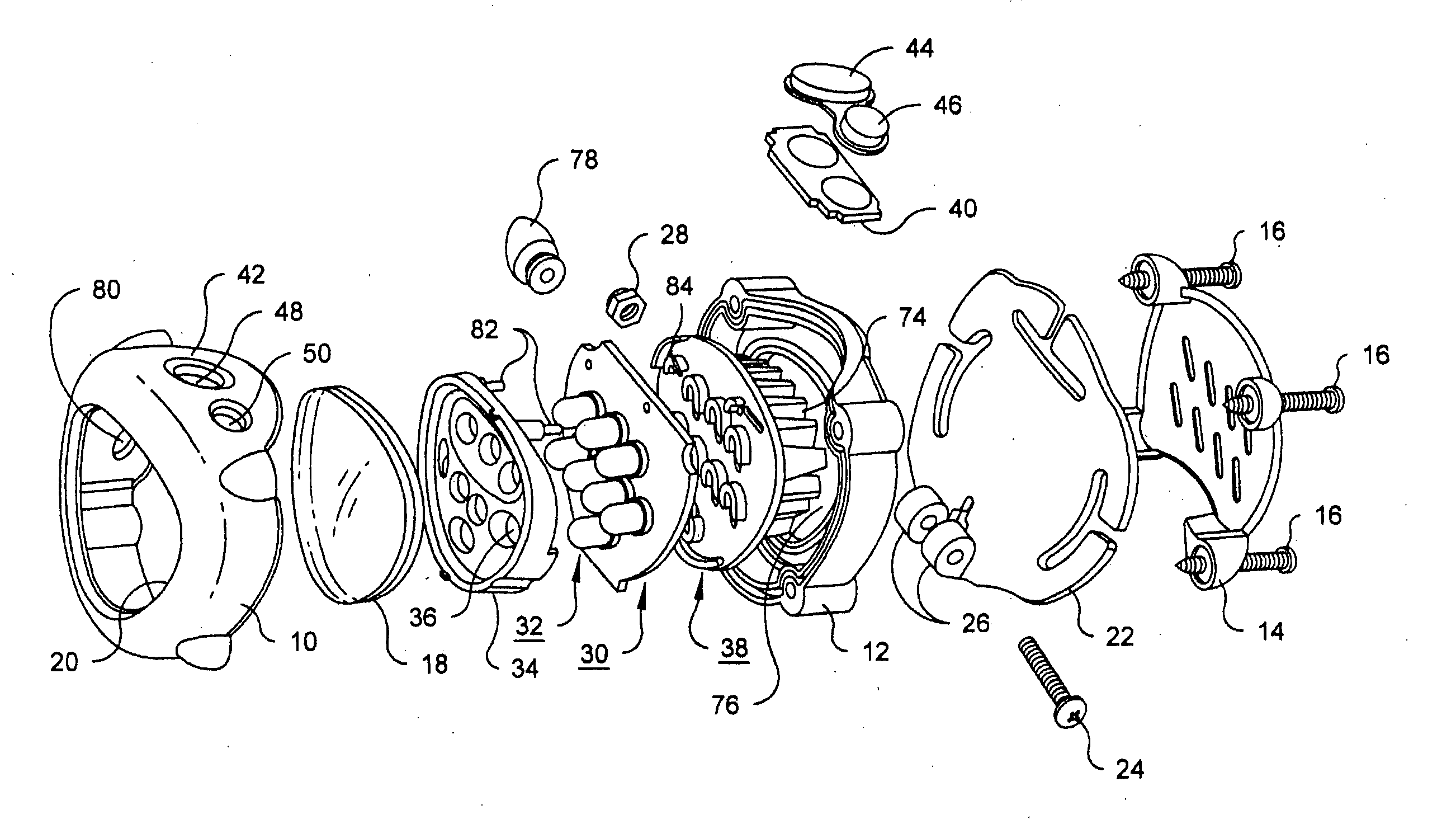

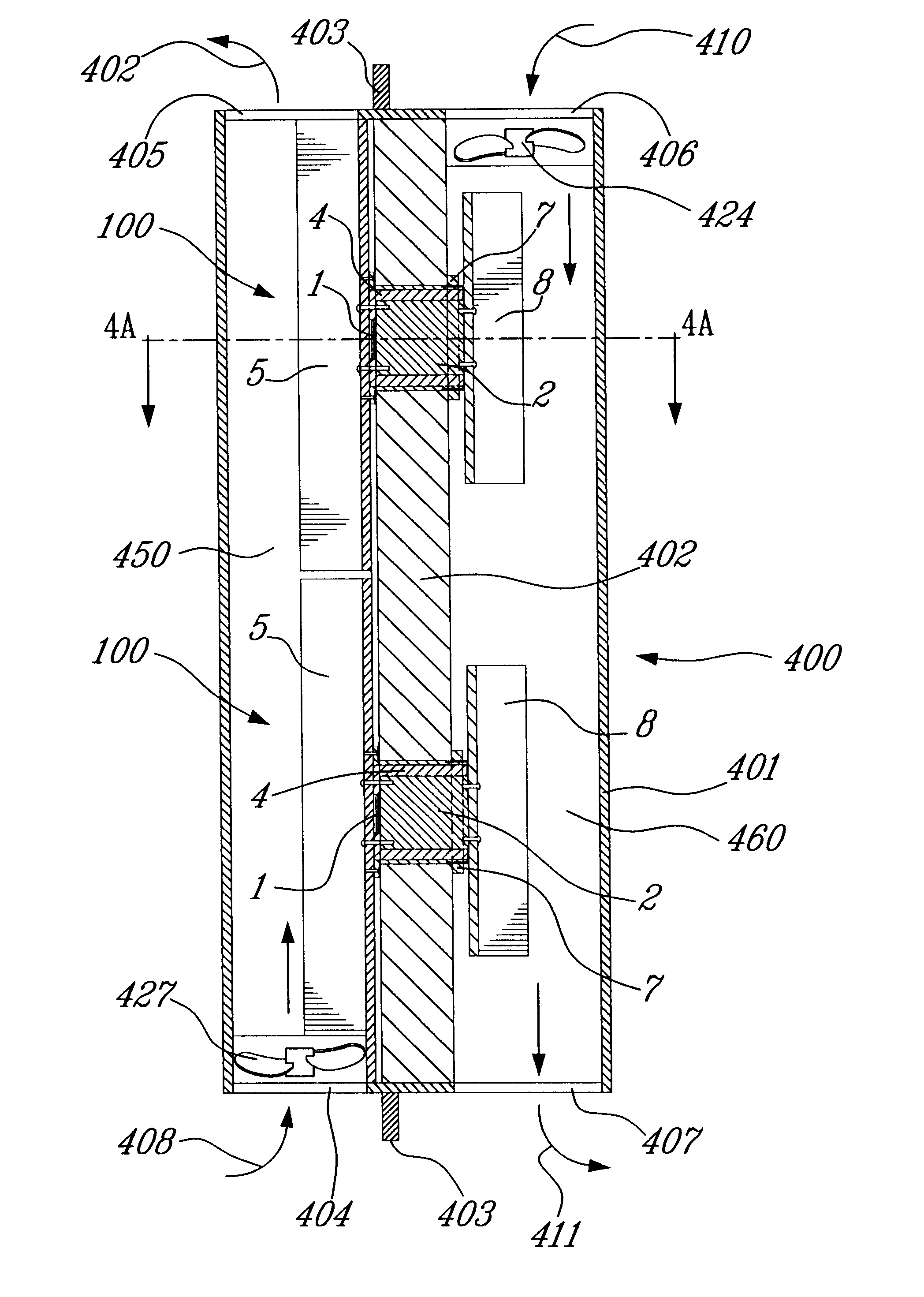

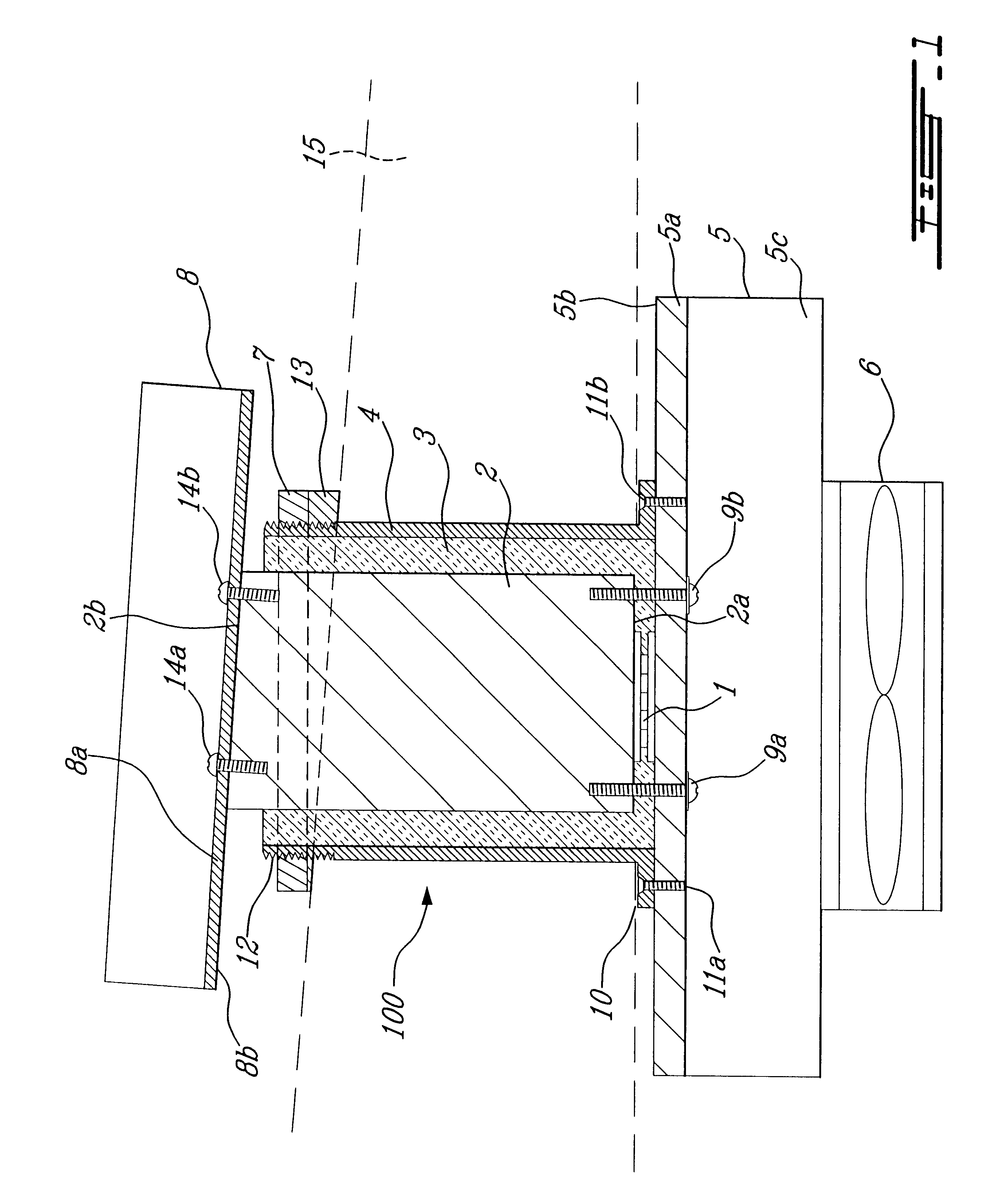

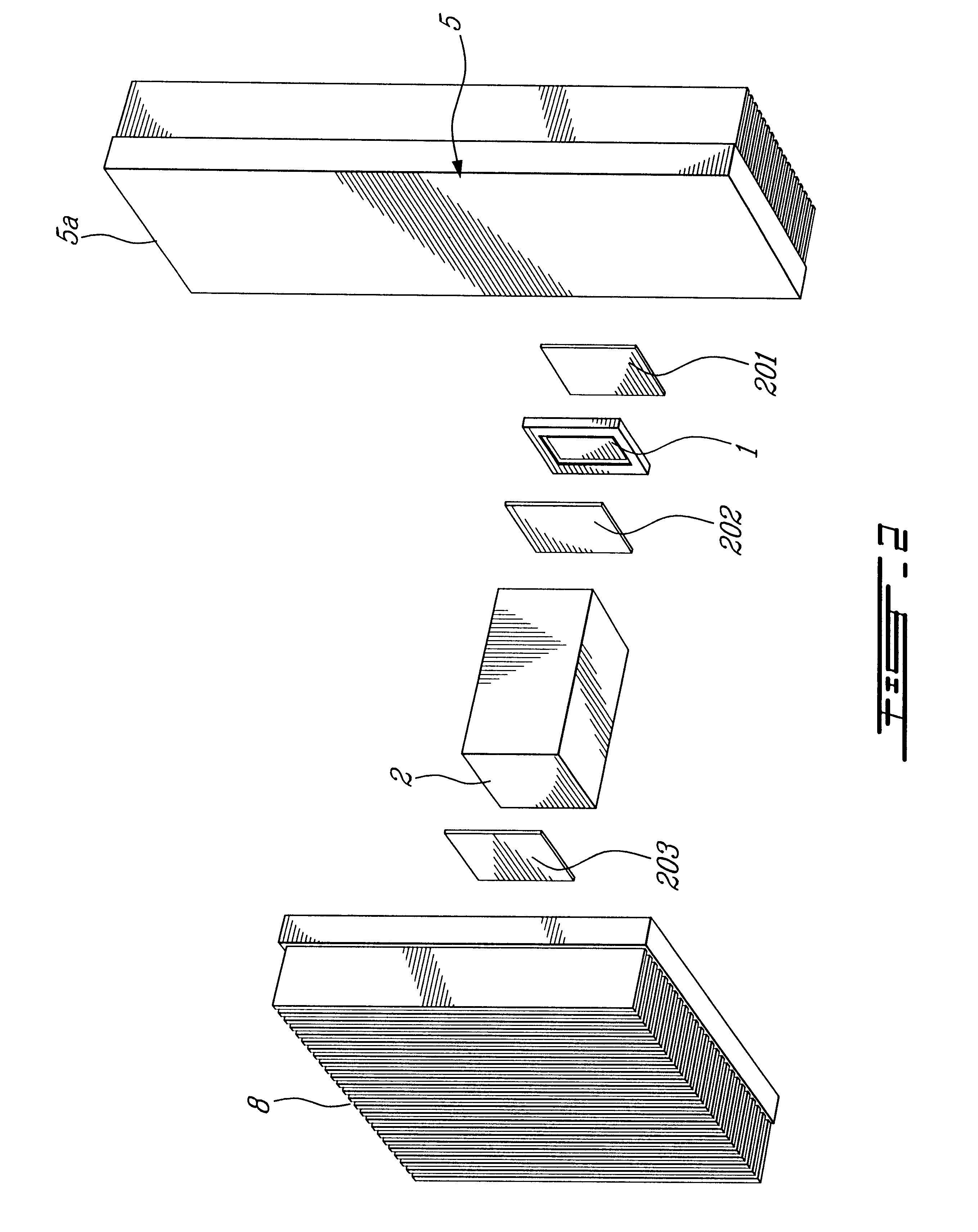

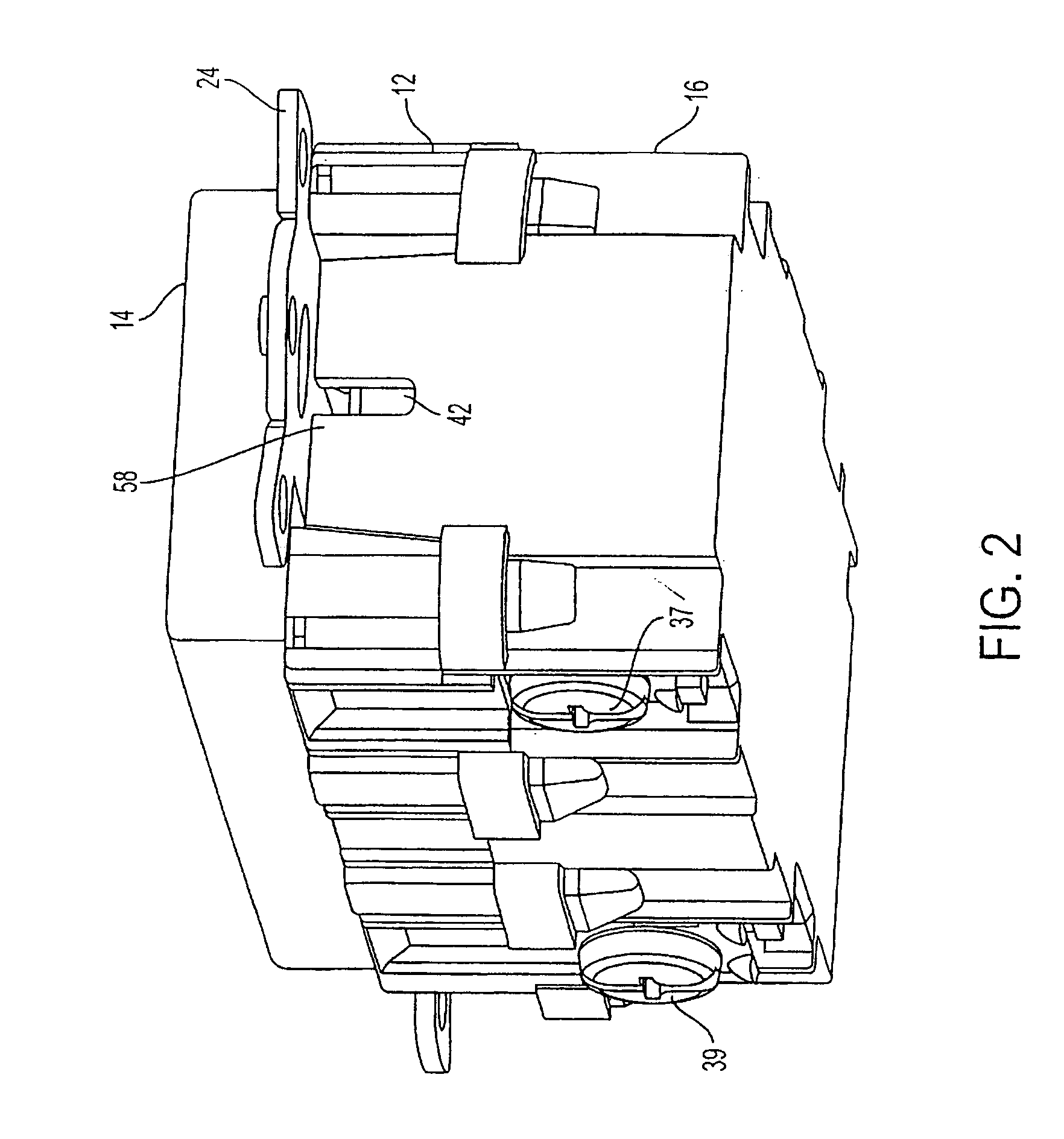

Environmental system for rugged disk drive

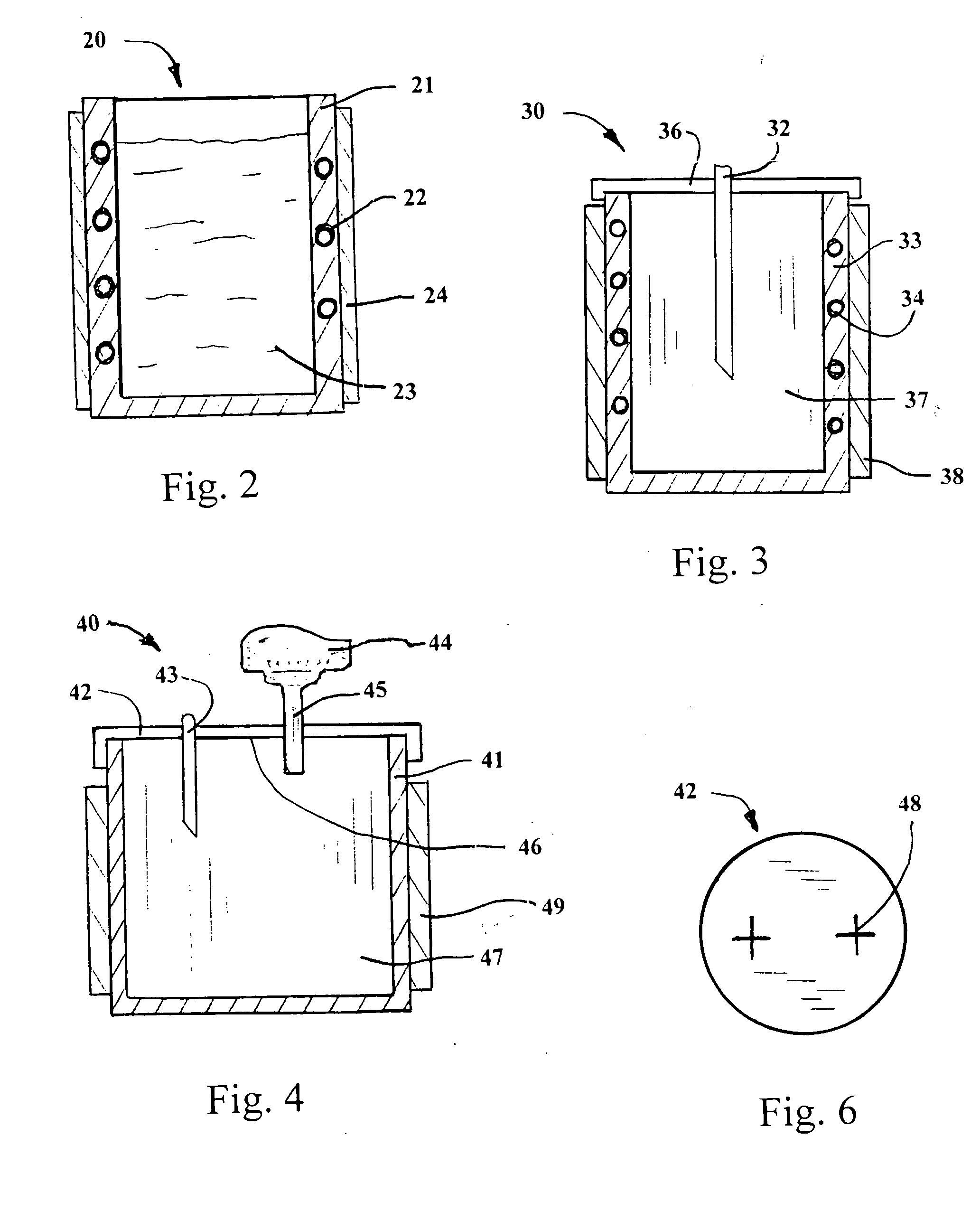

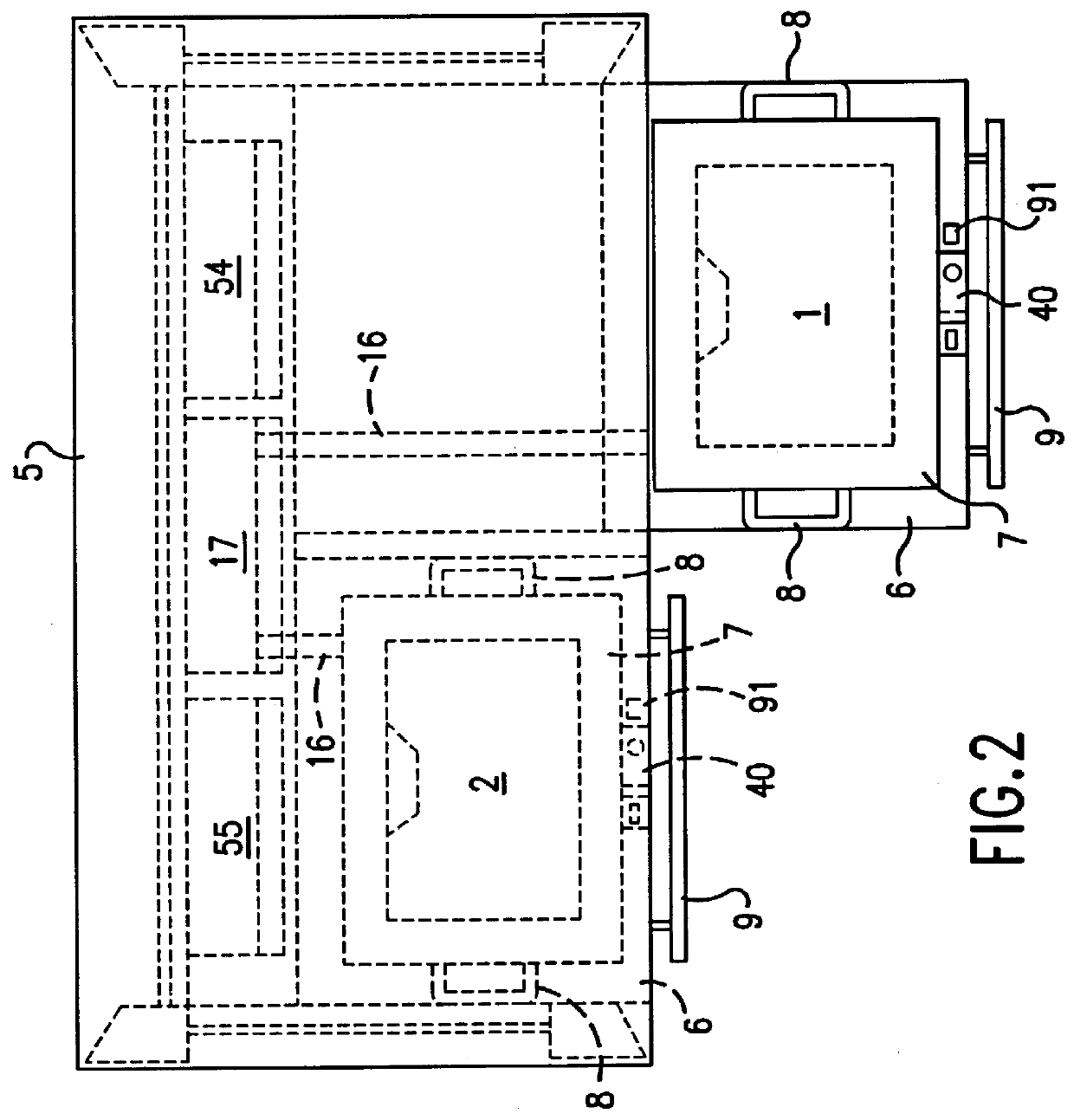

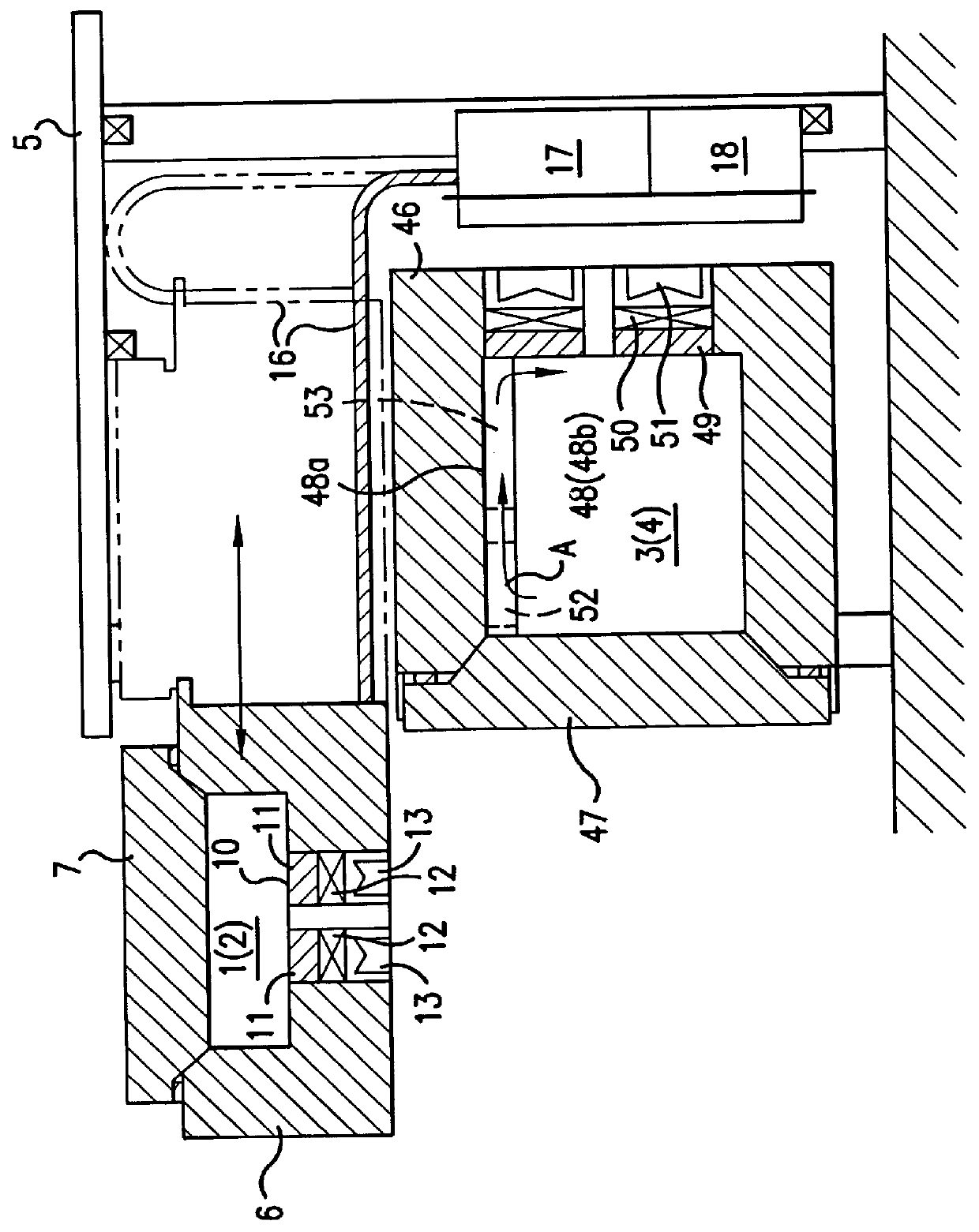

InactiveUS6289678B1Reducing temperature influence on carrierDigital data processing detailsCold sideShock mount

A hard disk system having a disk housing shock mounted in an environmental housing employs a device to transfer heat from the disk housing while avoiding any mechanical connection that would impose significant rigidity between the disk housing and the environment housing so as to defeat the shock mounting. In one embodiment, a Peltier effect heat pump has a cold side in contact with the disk housing and a hot side in contact with heat-conducting spring fingers contacting the environmental housing. In another embodiment, a fan is positioned in a space between the outside of the disk housing and the inside of the environmental housing to circulate air around the disk housing, while a Peltier effect heat pump moves heat to the environmental housing. In yet another embodiment, the fan is positioned in the space between the disk housing and the environmental housing, and the Peltier effect heat pump has a cold side in contact with an exterior surface of the environmental housing and a hot side in contact with a heat sink. In still another embodiment, a flexible heat pipe comprising a shell containing a low vapor-point liquid is positioned in the space between the outside of the disk housing and the inside of the environmental housing with respective ends in contact with each of the housings.

Owner:PHOENIX GROUP

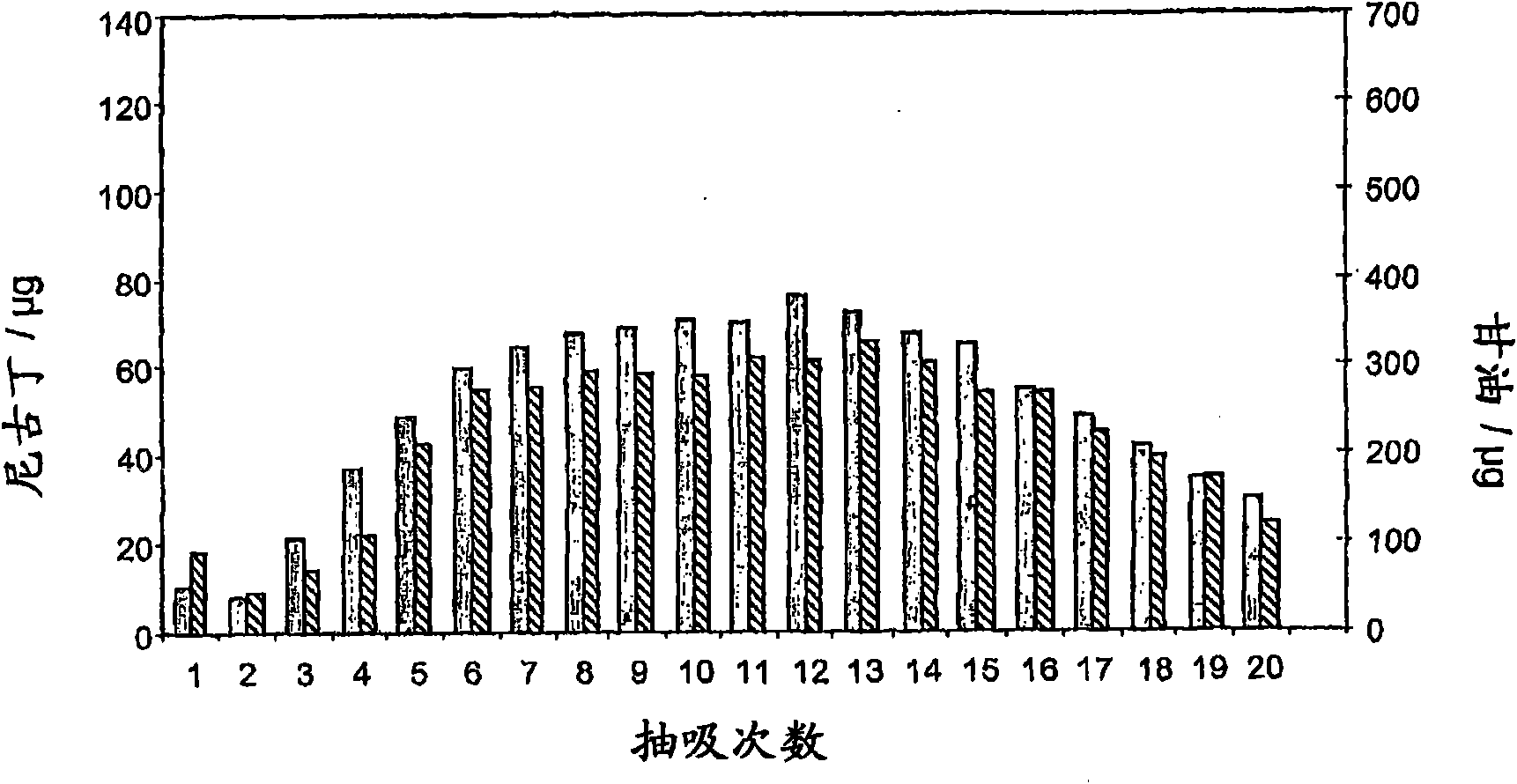

Distillation-based smoking article

Owner:PHILIP MORRIS PROD SA

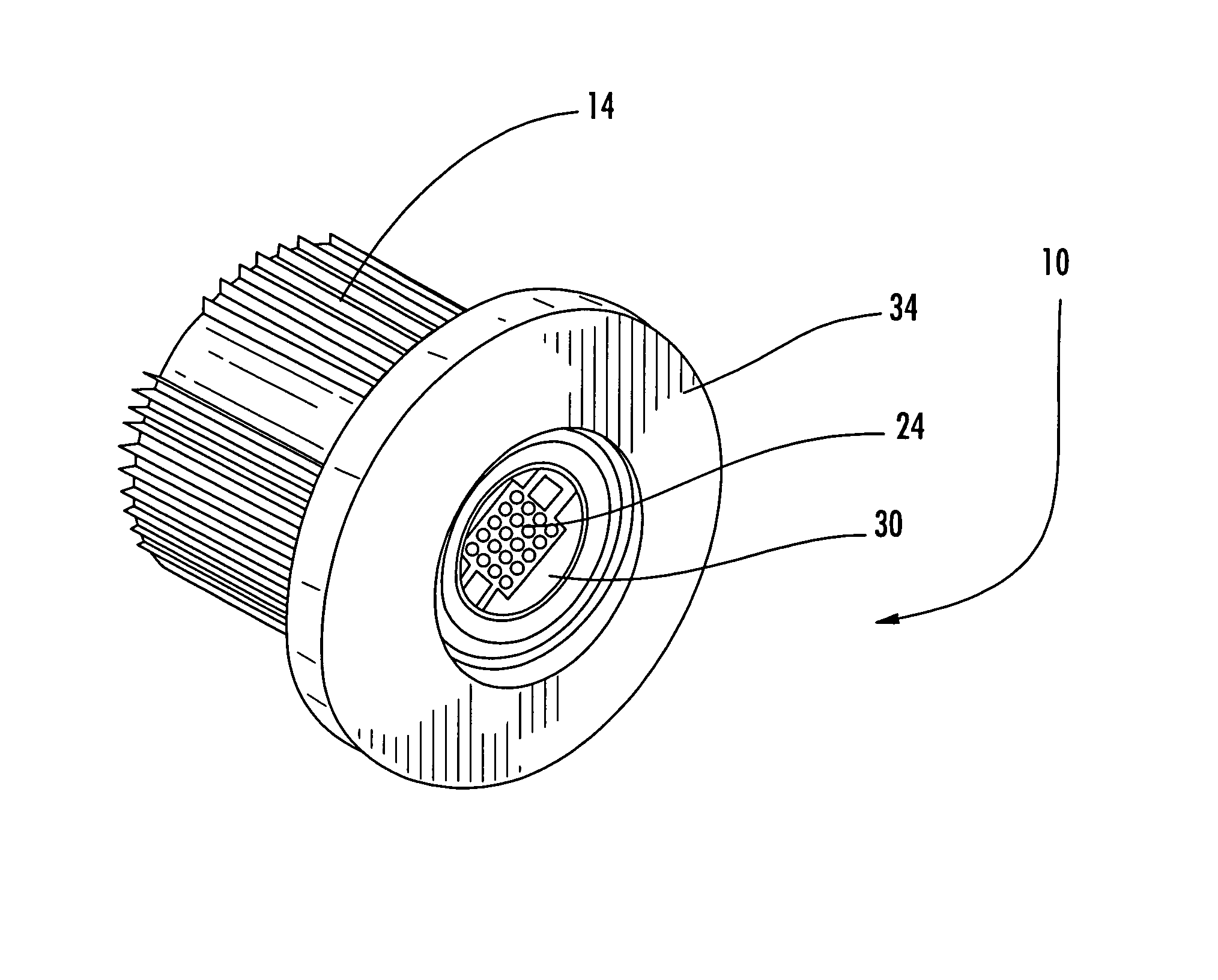

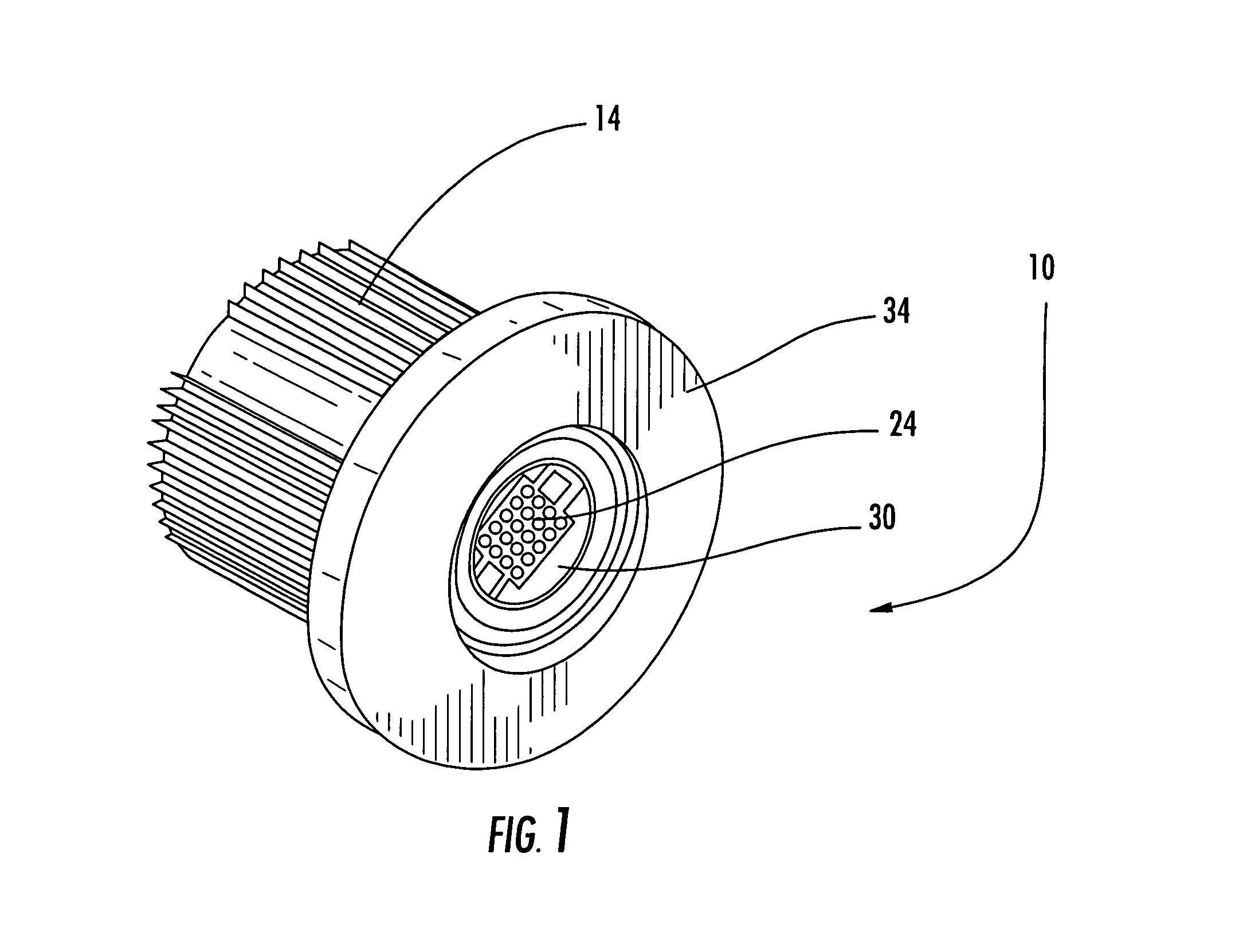

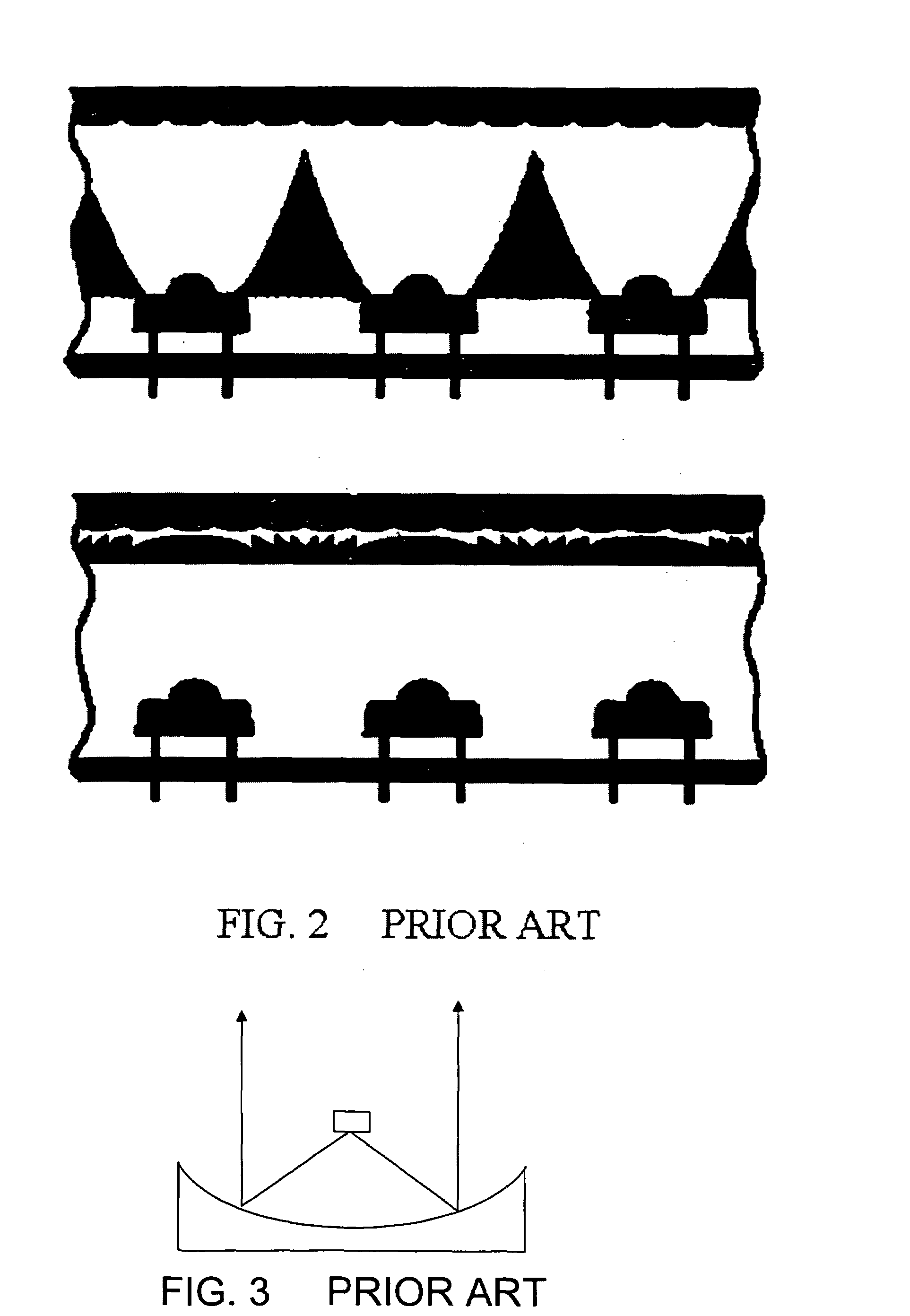

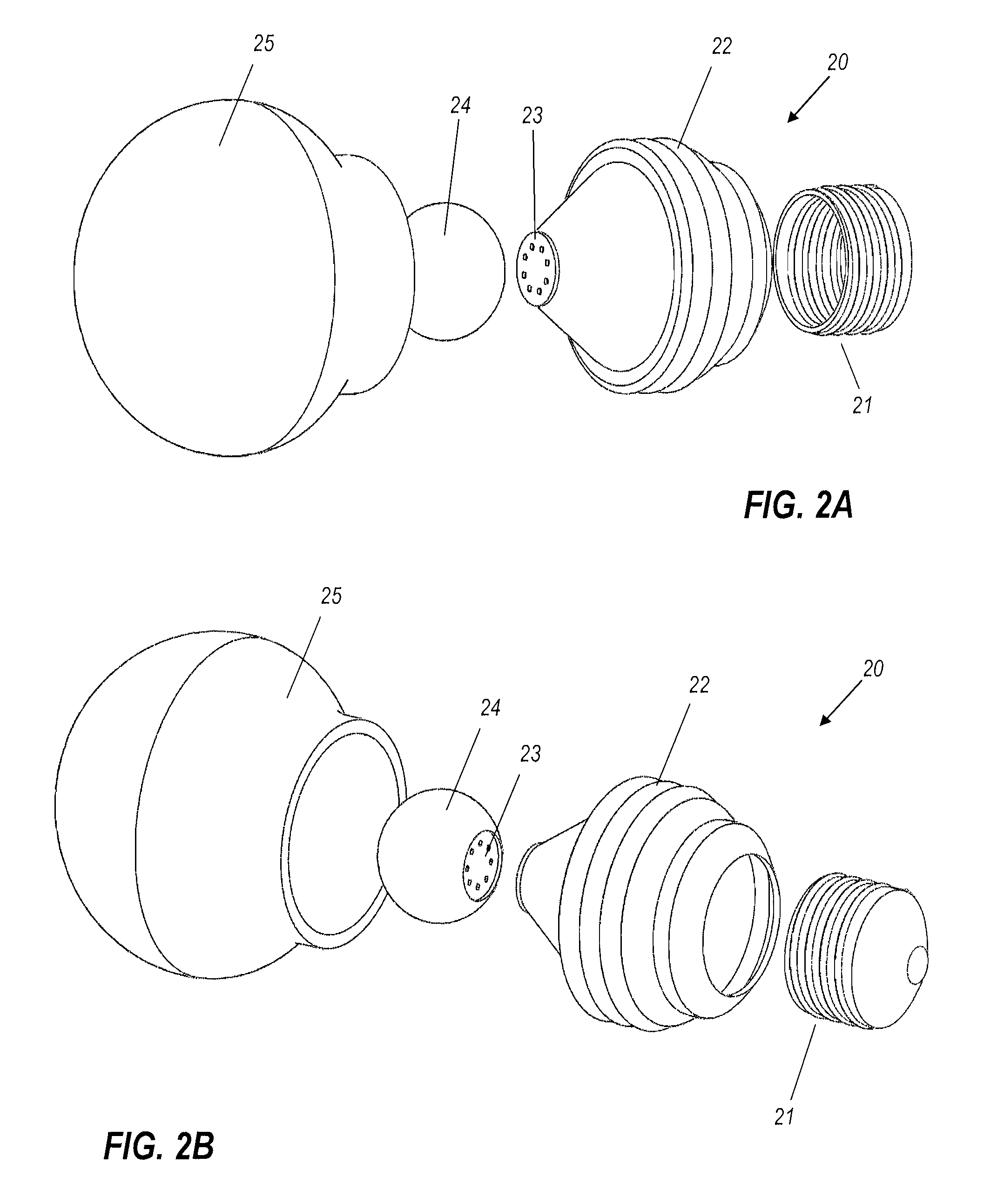

LED lamp bulb structure

InactiveUS7748870B2Effective dispersionGood dispersionPoint-like light sourceElectric circuit arrangementsHeat conductingEngineering

A LED lamp bulb structure is disclosed, wherein a lamp controller is installed inside a lamp head and the bottom surface thereof is fixed by an upper cover. At the bottom surface of the upper cover, a heat dispersing fin set, which has at least a heat conducting tube installed therein, and a lower cover are fixed therein. Furthermore, a bulb housing, which has a tray mounted therein, is screwed around the peripheral edge of the lower cover, and at the bottom of the tray, plural LED lamp sets corresponding to plural heat conducting tubes are outwardly extended. Therefore, the heat produced by the LED lamp set can have a heat exchange through plural heat conducting tubes and heat dispersing fin set for achieving a better heat dispersing efficiency and for more effectively dispersing the heat.

Owner:LI HONG TECHNOLOGICAL

Portable light

ActiveUS20060067077A1Adequate heat dissipationGuaranteed uptimePoint-like light sourceLighting elementsElectrical conductorHeat conducting

A portable personal headlamp utilizes an array of light-emitting diodes on the front face of a circuit board. Arc-shaped projections on the front face of a finned heat sink are in heat-conducting relationship with printed conductors on the rear face of the circuit board, which partially surround one lead of each light-emitting diode.

Owner:PRINCETON TECTONICS

Submersible LED light fixture

Owner:NEXXUS LIGHTING +1

Assembling structure for LED road lamp and heat dissipating module

InactiveUS7329030B1Fast heat conductionImprove life expectancyMechanical apparatusPoint-like light sourceEngineeringHeat conducting

In an assembling structure for LED road lamp and heat dissipating module, the LED road lamp includes a partition board, an upper casing, a light transmitting lens and an LED lamp set. The upper casing and the light transmitting lens are set separately on upper and lower sides of the partition board. Each LED lamp set is contained in a space enclosed by the partition board and the light transmitting lens. The partition board has a plurality of through holes, and the LED lamp set includes a frame body and an LED module. The heat dissipating module includes a heat dissipating body, a heat pipe and an isothermal board. The heat dissipating body is set in a space enclosed by the partition board and the upper casing, and the heat pipe has a heat discharging end passing through and connecting the partition board and the heat dissipating body and a heat receiving end forming the bottom of the partition board. The isothermal board is fixed onto a frame body of the LED lamp and has two planes separately attached onto the heat receiving end and the LED module, so as to significantly enhance the overall heat conducting and dissipating performance, drive an LED to emit light at a lower temperature, and extend the life expectancy of the LED.

Owner:PYROSWIFT HOLDING CO LIMITED

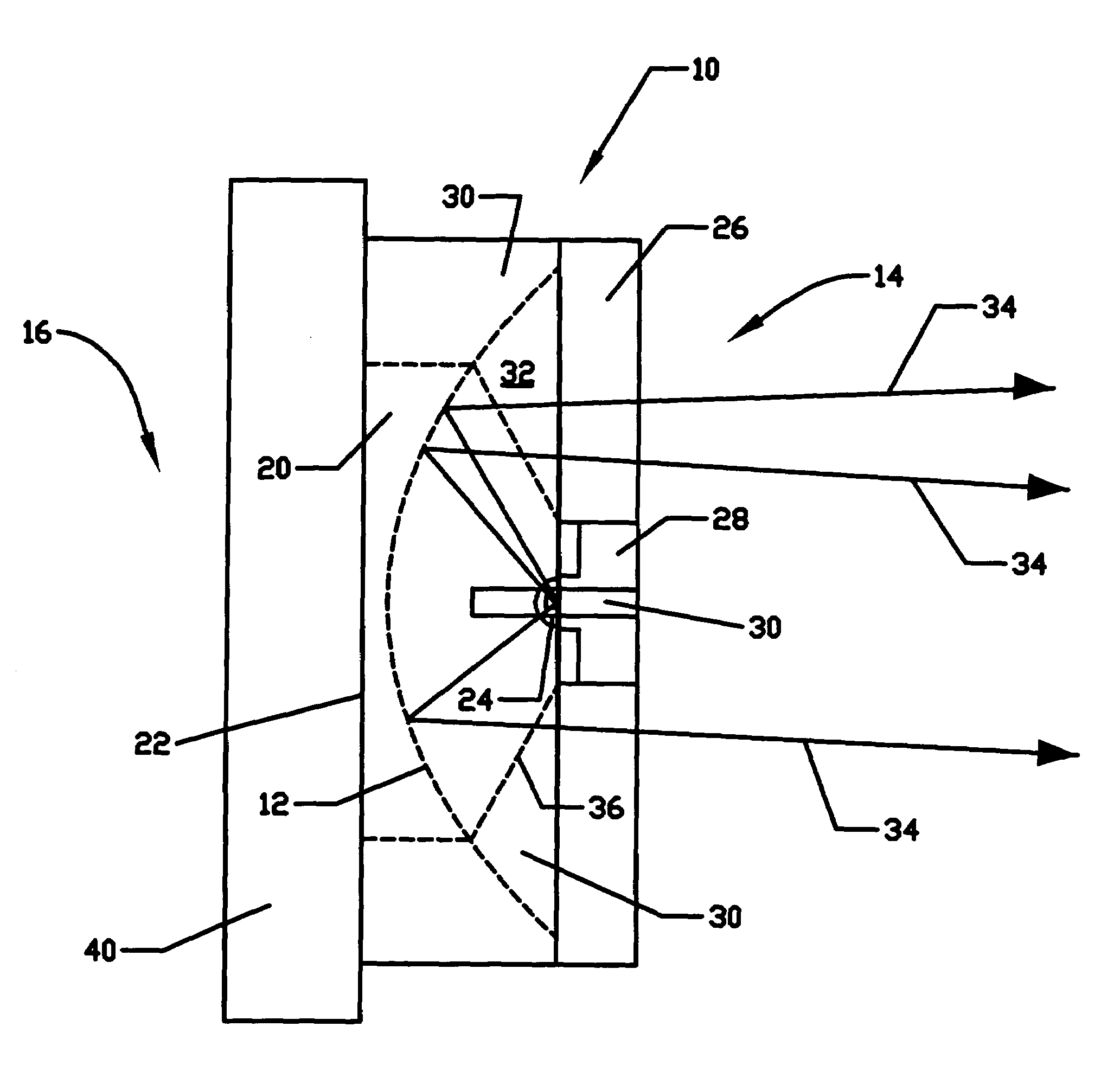

Back-reflecting LED light source

ActiveUS7246921B2Reduce thermal resistancePoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

An LED light source using back-reflecting collection optics with a supporting structure and heat sink to block only a small amount of light. A reflector has a front and back side with an LED positioned on the front side of the reflector. A heat conducting body is positioned at least partially between the reflector and the LED. The heat conducting body provides a pathway for heat to flow from the LED toward the back side of the reflector.

Owner:IDEAL IND LIGHTING LLC

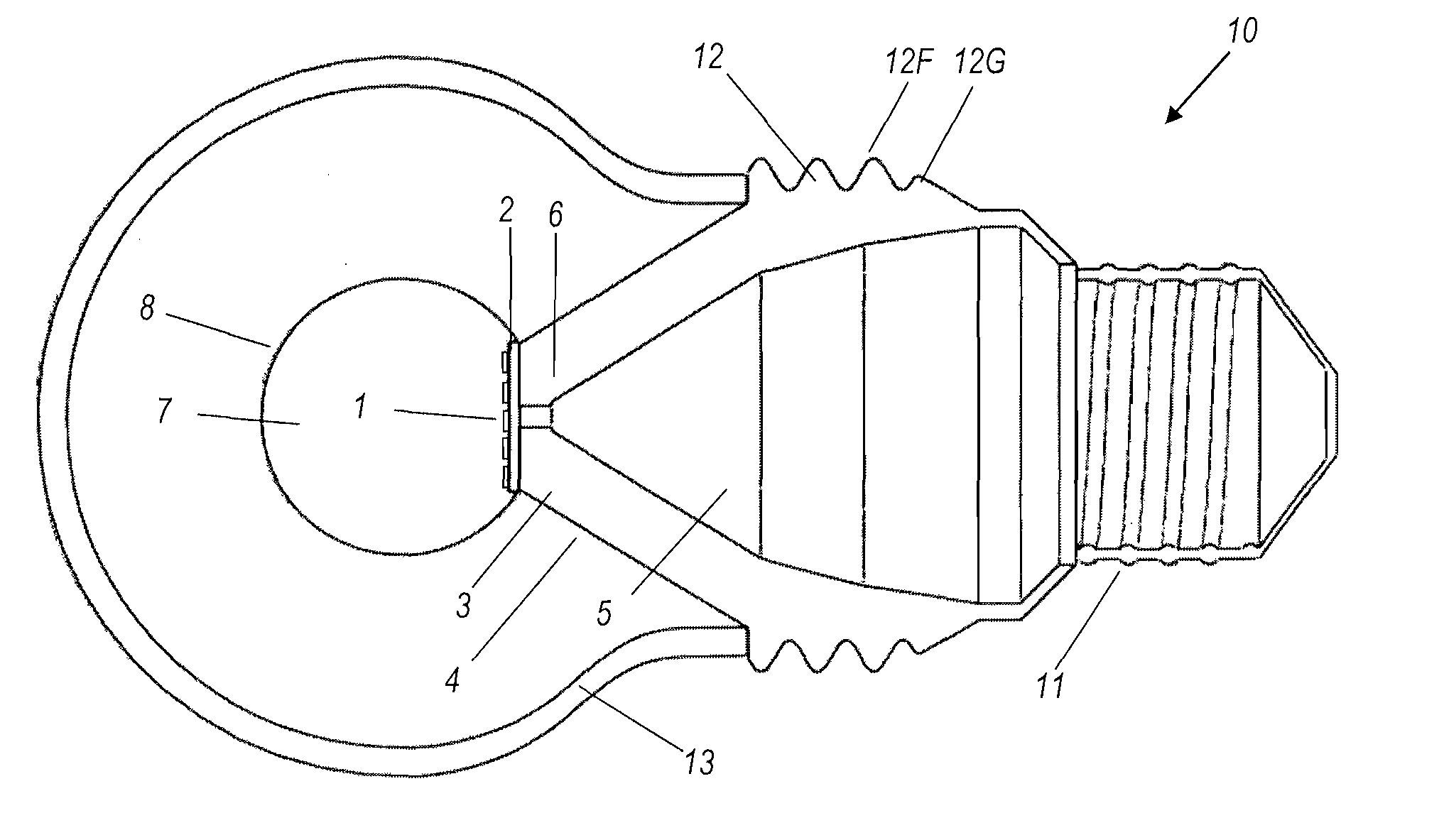

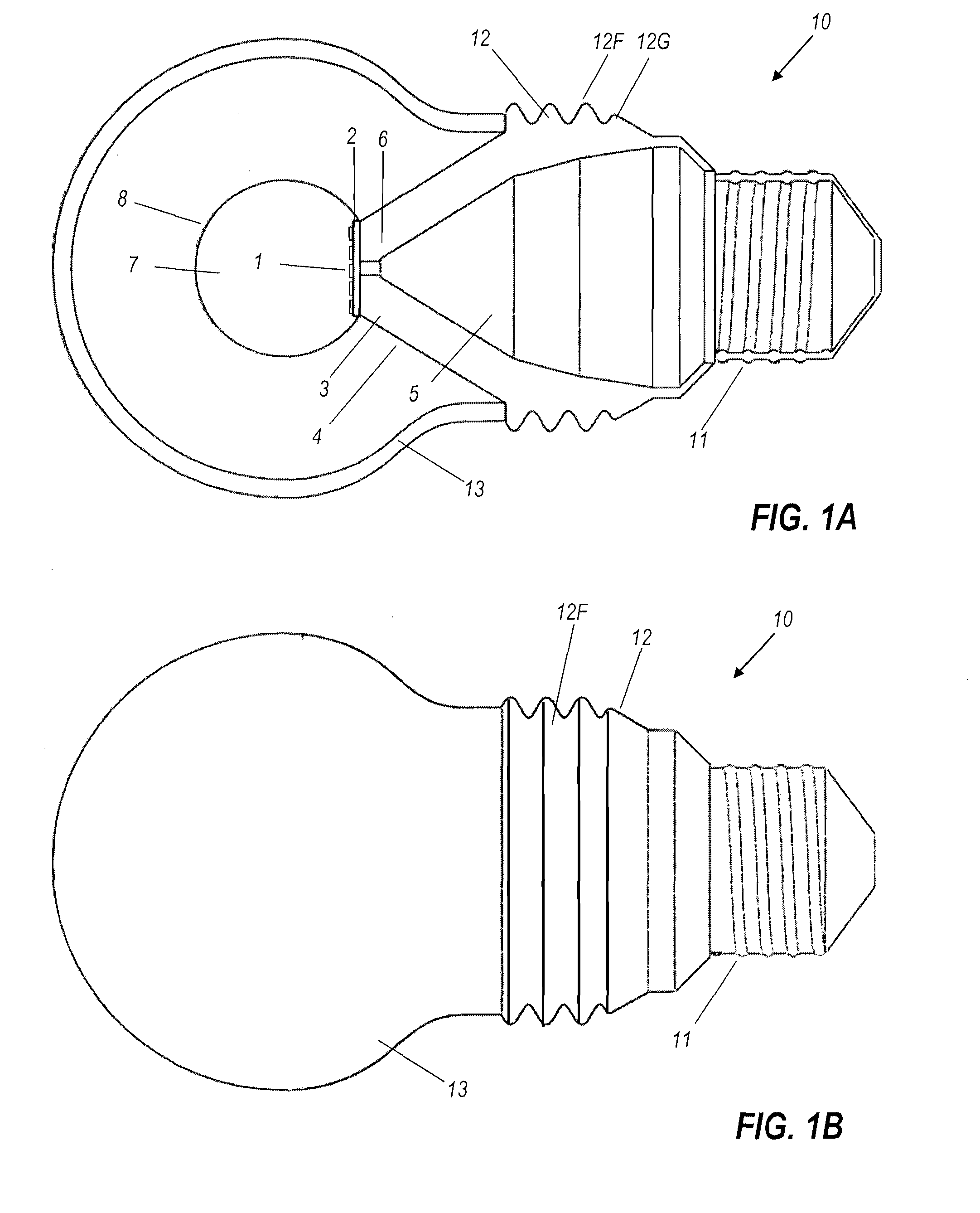

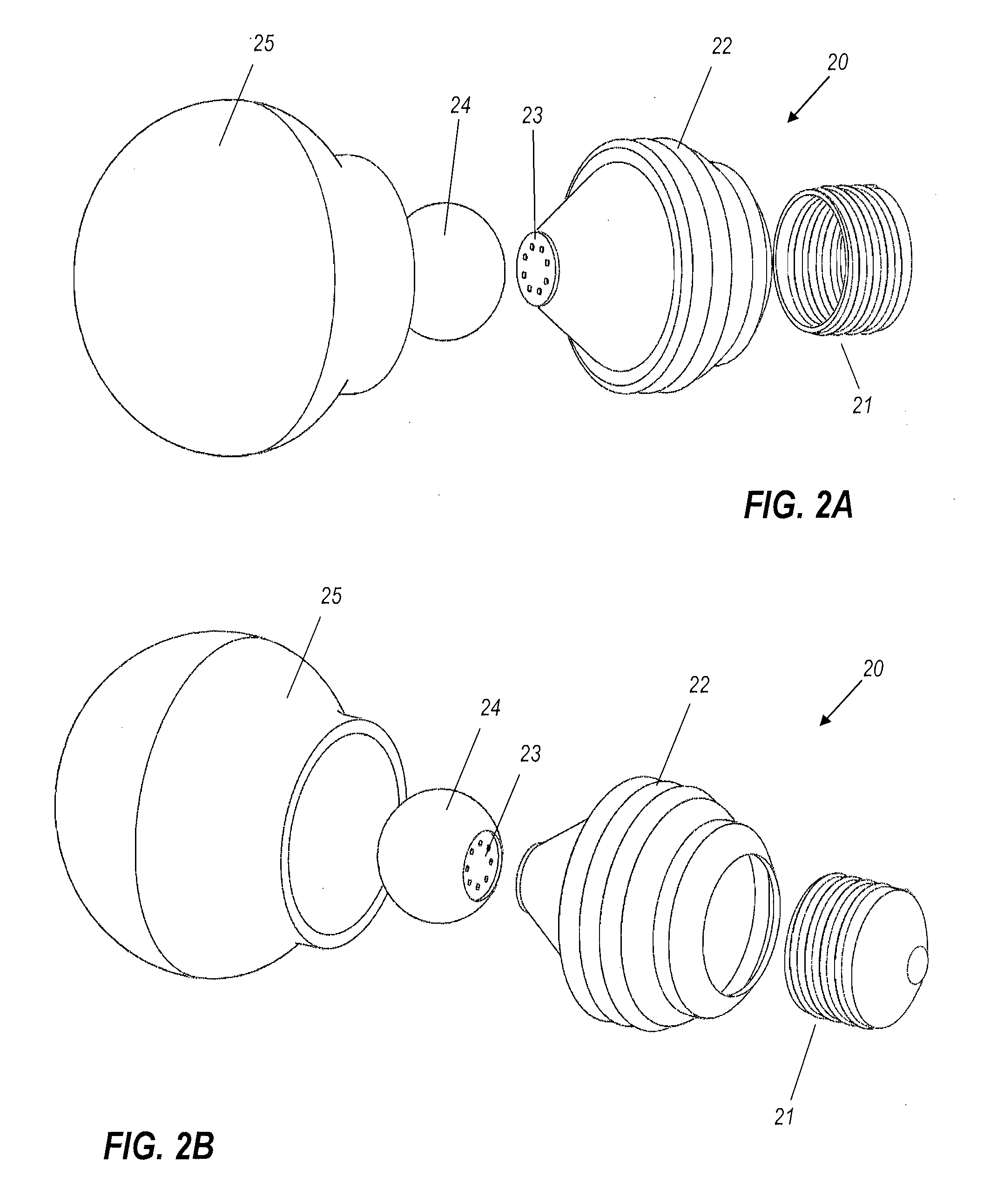

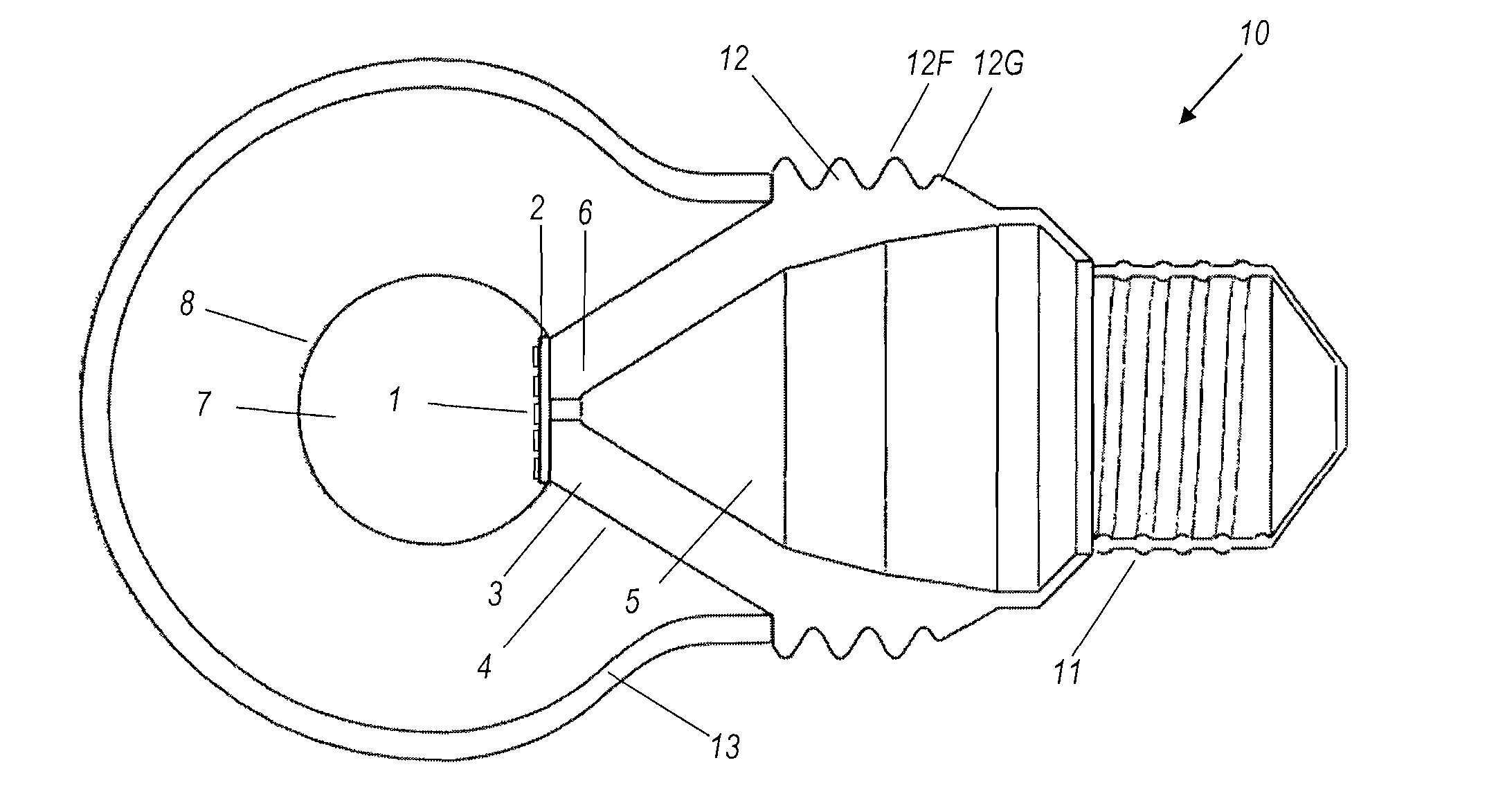

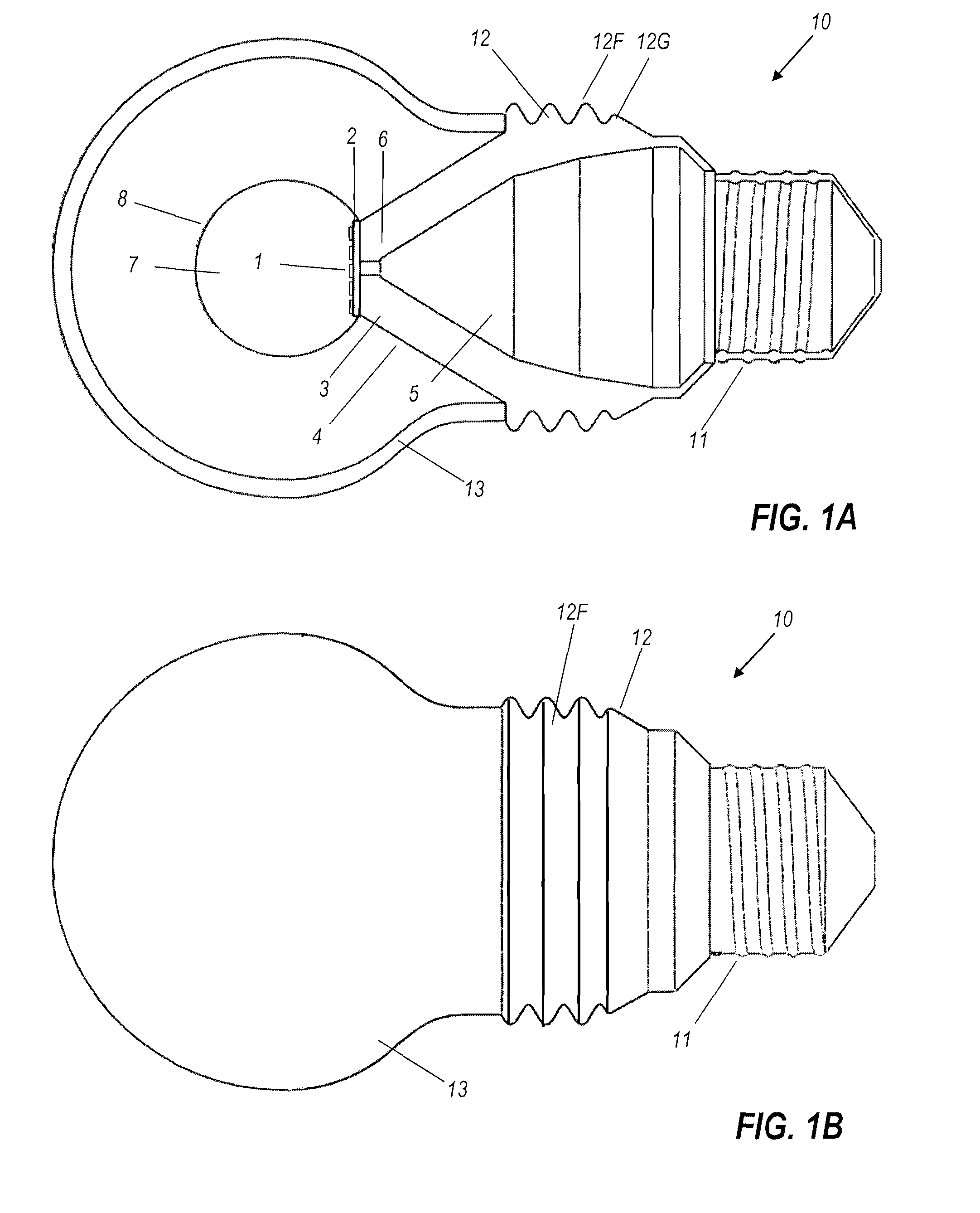

Solid-state light bulb

InactiveUS20110095686A1Reduce decreaseAvoid problemsLight source combinationsLighting support devicesHeat conductingLed array

An example of this light bulb has a light emitting element (which may be an LED array) mounted on a circuit board. The circuit board is mounted on one end of a heat-conducting frame. An Edison screw or other suitable connector, for attaching the light bulb electrically and mechanically to a receptacle, is mounted on the other end of the frame. A transparent phosphor-coated ball has a flat chord face optically bonded to said array. A light-permeable globular enclosure is mounted on the frame, surrounding the ball and both homogenizing the white light output of the bulb but also concealing the yellowing unlit appearance of the remote phosphor ball centrally located within it.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

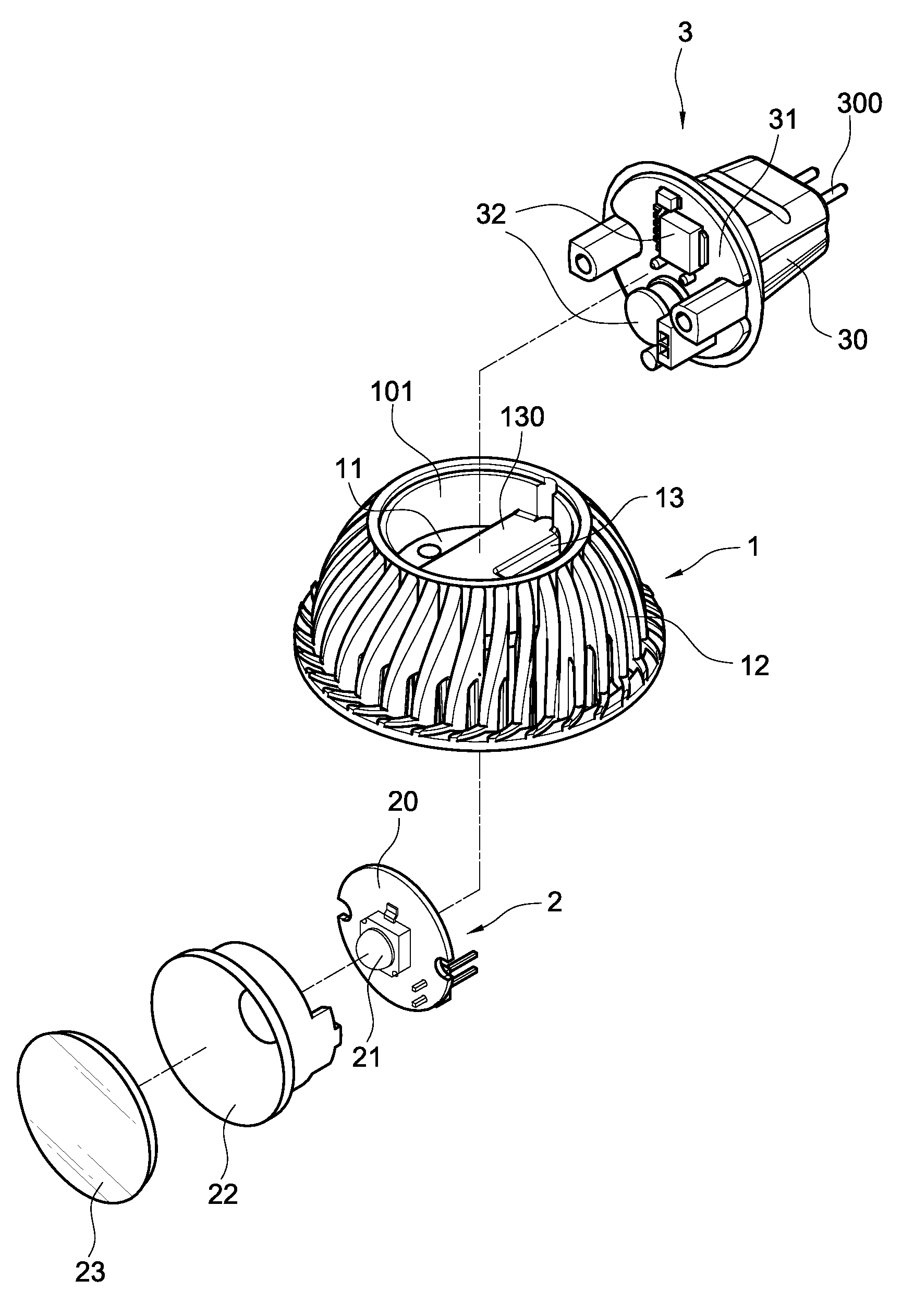

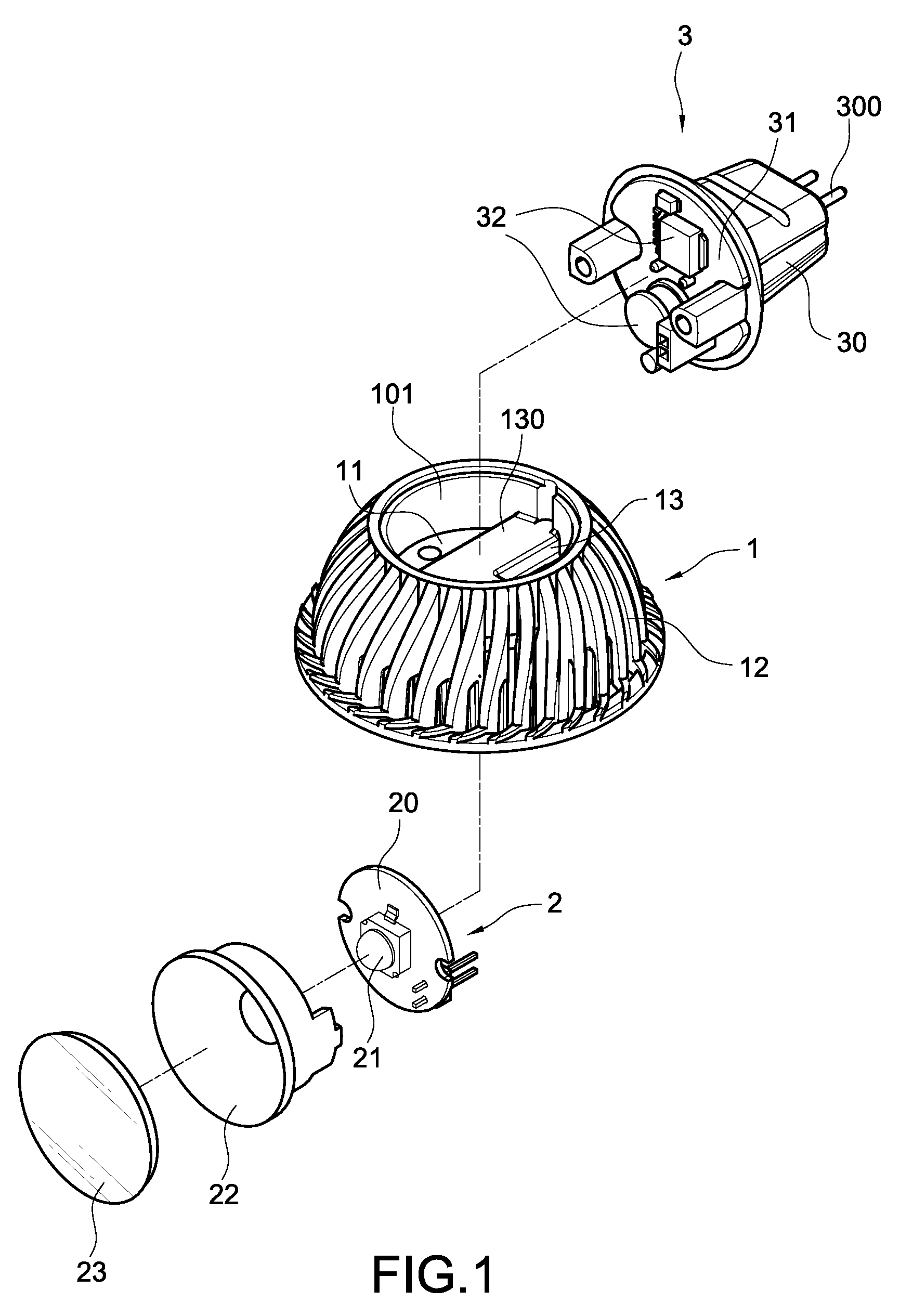

Lamp with heat conducting structure and lamp cover thereof

ActiveUS20090141508A1Heat dissipationIncrease heatCoupling device connectionsPoint-like light sourceHeat conductingEngineering

A lamp with heat conducting structure includes a lamp cover made of heat dissipating material. The lamp cover has a hollow configuration therein. An interlayer is horizontally arranged in the lamp cover. The lamp cover is divided into a first space and a second space therein by the interlayer. A LED lamp assembly is disposed in the first space of the lamp cover. A power plug is disposed in the second space of the lamp cover. The power plug has a control circuit board in the second space. The control circuit board has an electronic element disposed thereon. A heat conducting tab protrudes from the interlayer of the lamp cover towards the second space. The heat conducting tab has a heat conducting surface corresponding to the electronic element to thermally contact with the electronic element.

Owner:CHEMTRON RES

Graphene heat conducting membrane and preparation method thereof

Owner:CHANGZHOU FUXI TECH CO LTD

Solid-state light bulb

InactiveUS8322896B2Reduce heat loadAccelerated dissipationLight source combinationsLighting support devicesPhosphorLed array

An example of this light bulb has a light emitting element (which may be an LED array) mounted on a circuit board. The circuit board is mounted on one end of a heat-conducting frame. An Edison screw or other suitable connector, for attaching the light bulb electrically and mechanically to a receptacle, is mounted on the other end of the frame. A transparent phosphor-coated ball has a flat chord face optically bonded to said array. A light-permeable globular enclosure is mounted on the frame, surrounding the ball and both homogenizing the white light output of the bulb but also concealing the yellowing unlit appearance of the remote phosphor ball centrally located within it.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

Protection of electro-optic displays against thermal effects

InactiveUS20140078024A1Reduction factorHollow inflatable ballsStatic indicating devicesElectrophoresisHeat conducting

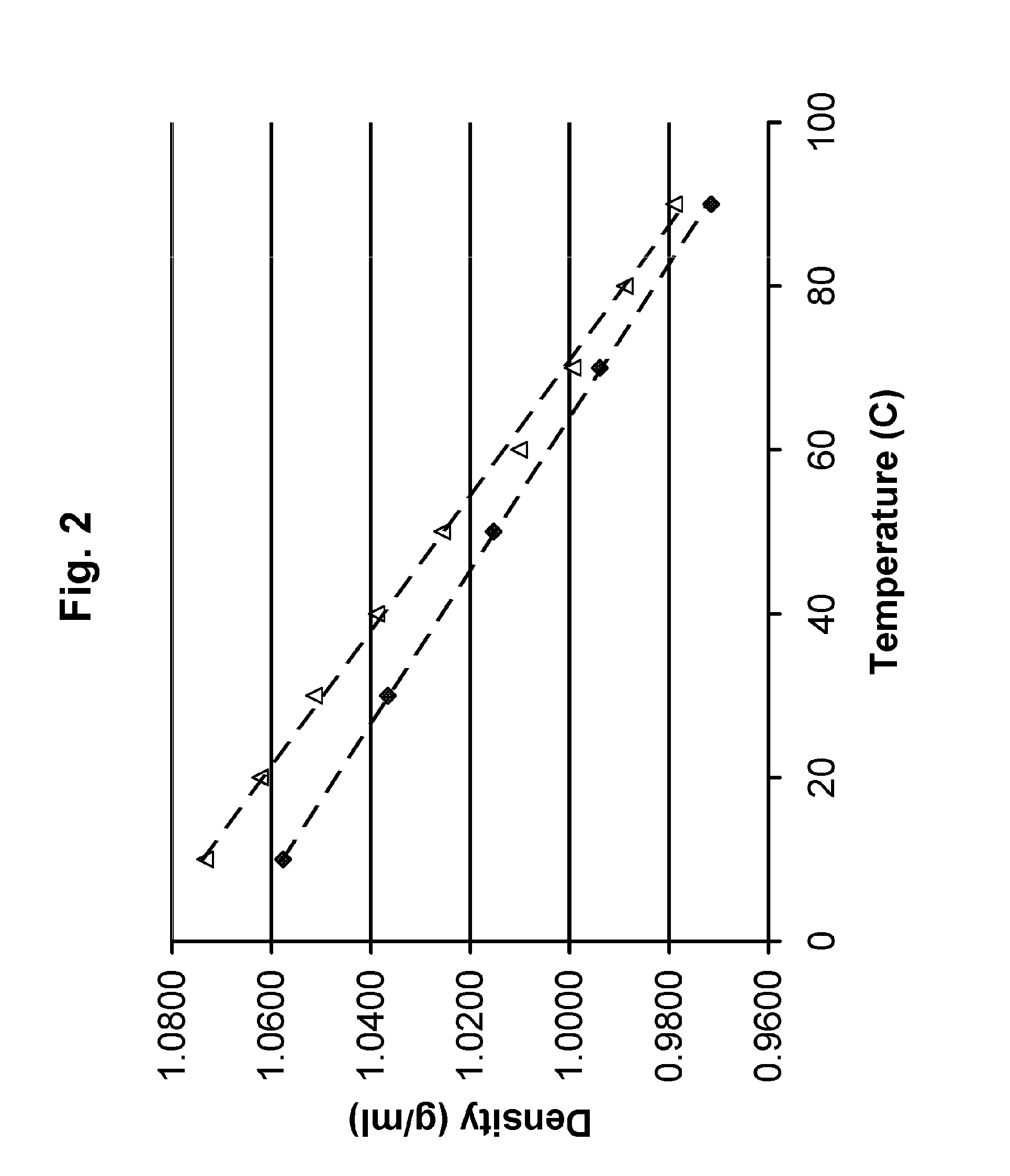

An electro-optic display comprises a layer of reflective electro-optic material capable of changing its optical state on application of an electric field, an electrode, a heat generating component in heat conducting relationship with the electro-optic material, and a heat shield disposed between the heat generating component and the electro-optic material, the heat shield comprising a layer of thermally insulating material and a layer of thermally conducting material, the thermally conducting material being disposed between the thermally insulating material and the electro-optic material. The invention also provides an electrophoretic medium comprising a suspending fluid and a plurality of electrically charged particles suspended in the suspending fluid and capable of moving therethrough upon application of an electrical field to the electrophoretic medium, the suspending fluid containing a compatibilizer to reduce its coefficient of thermal expansion.

Owner:E INK CORPORATION

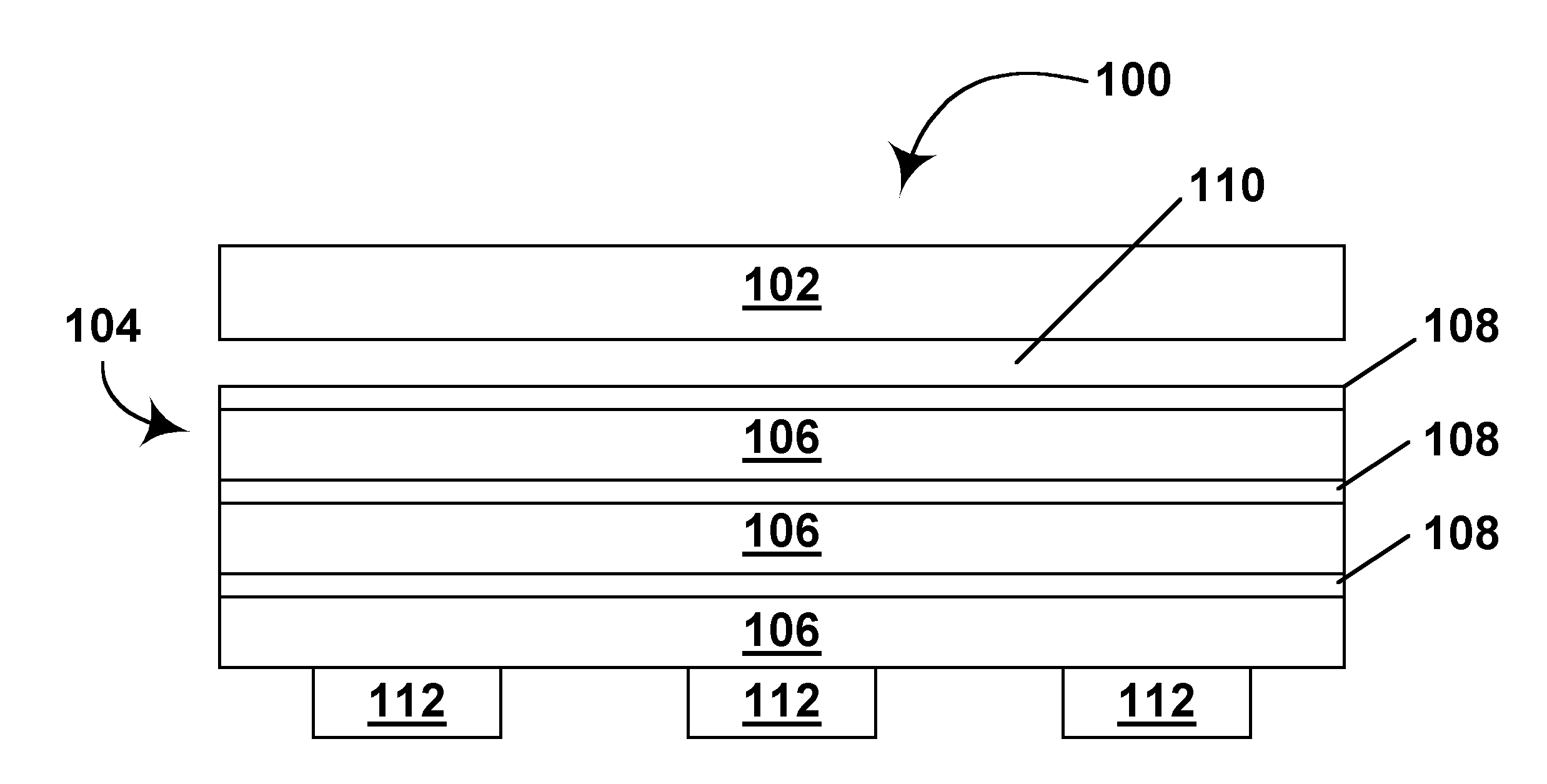

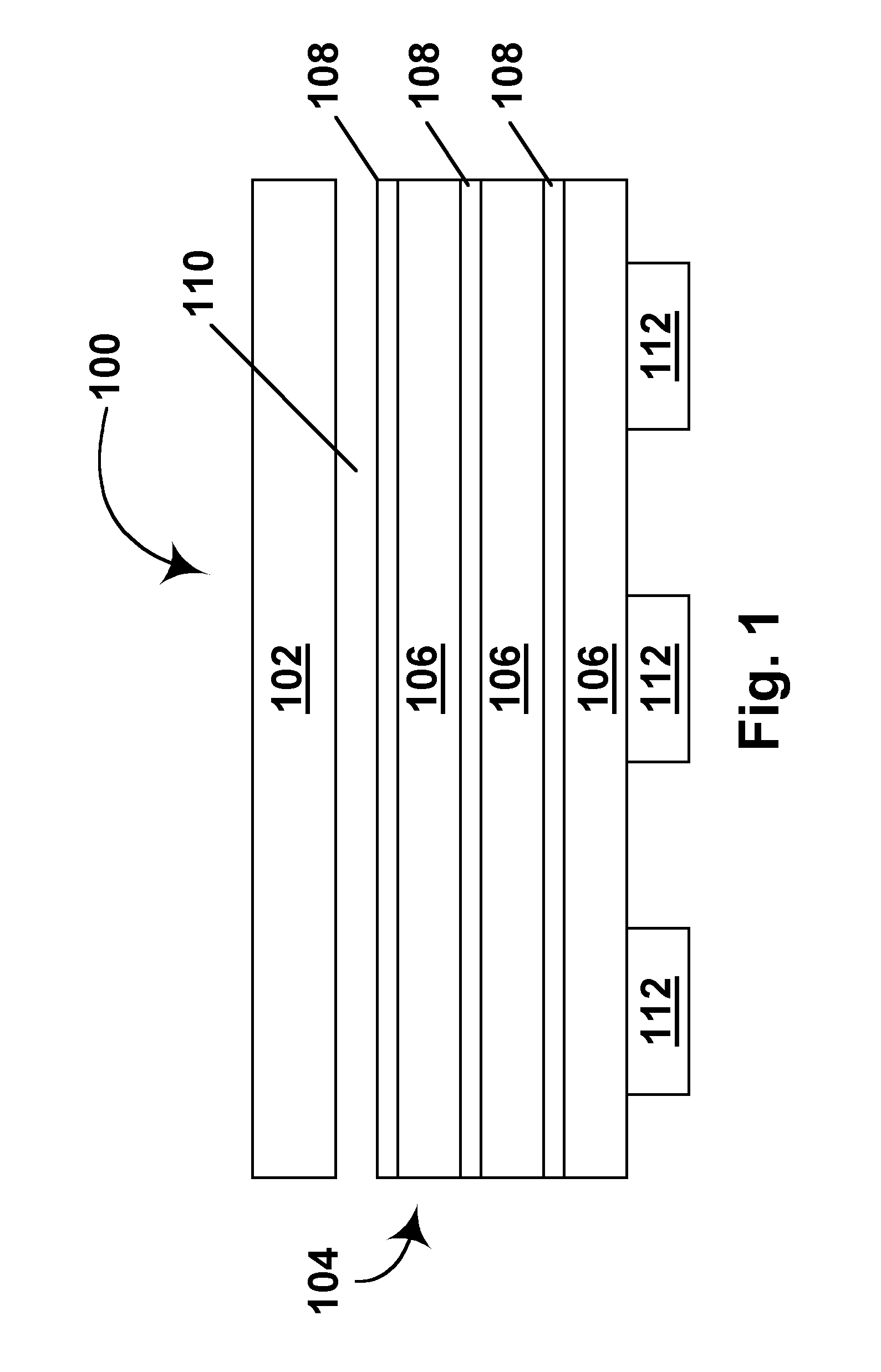

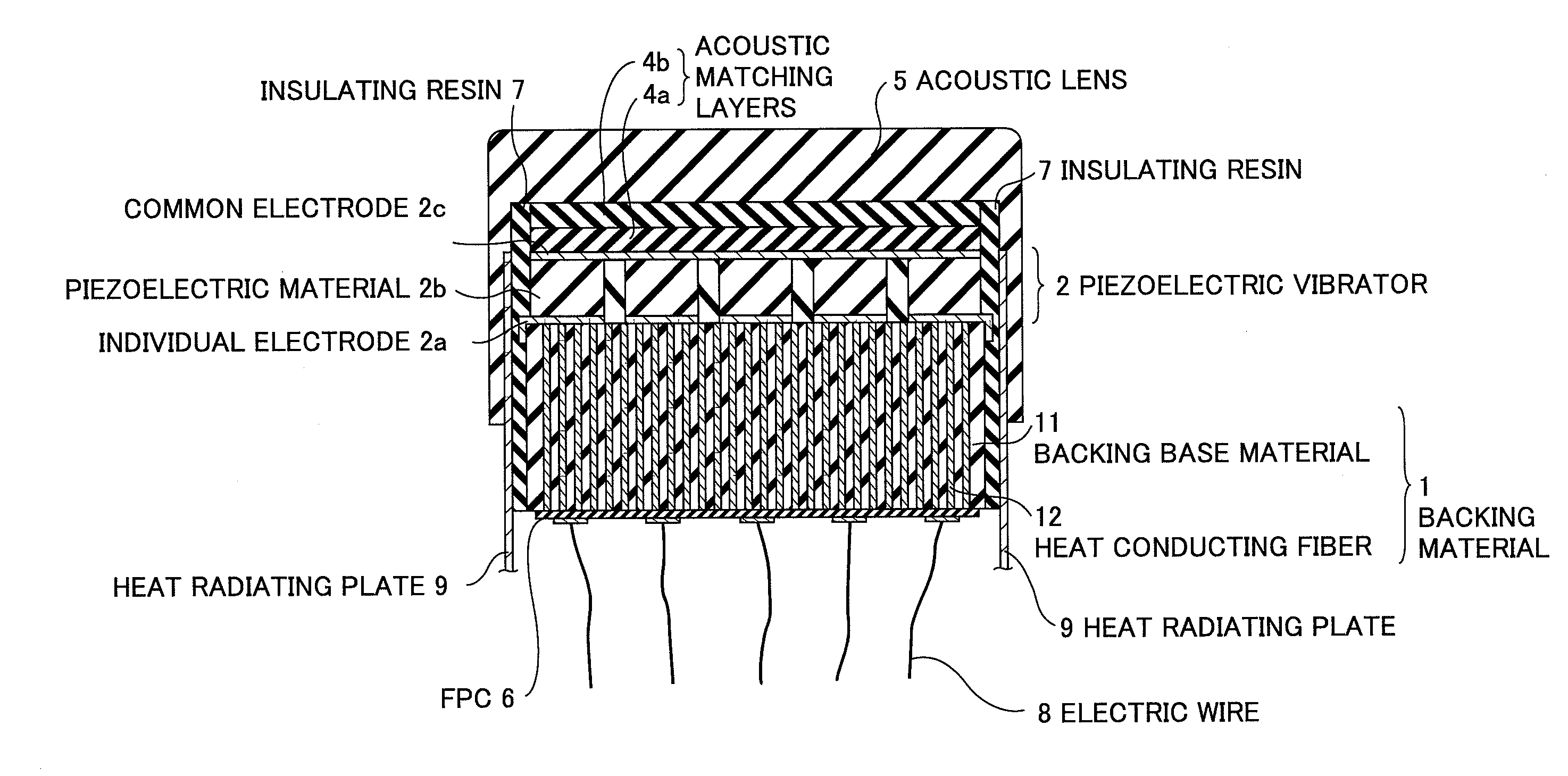

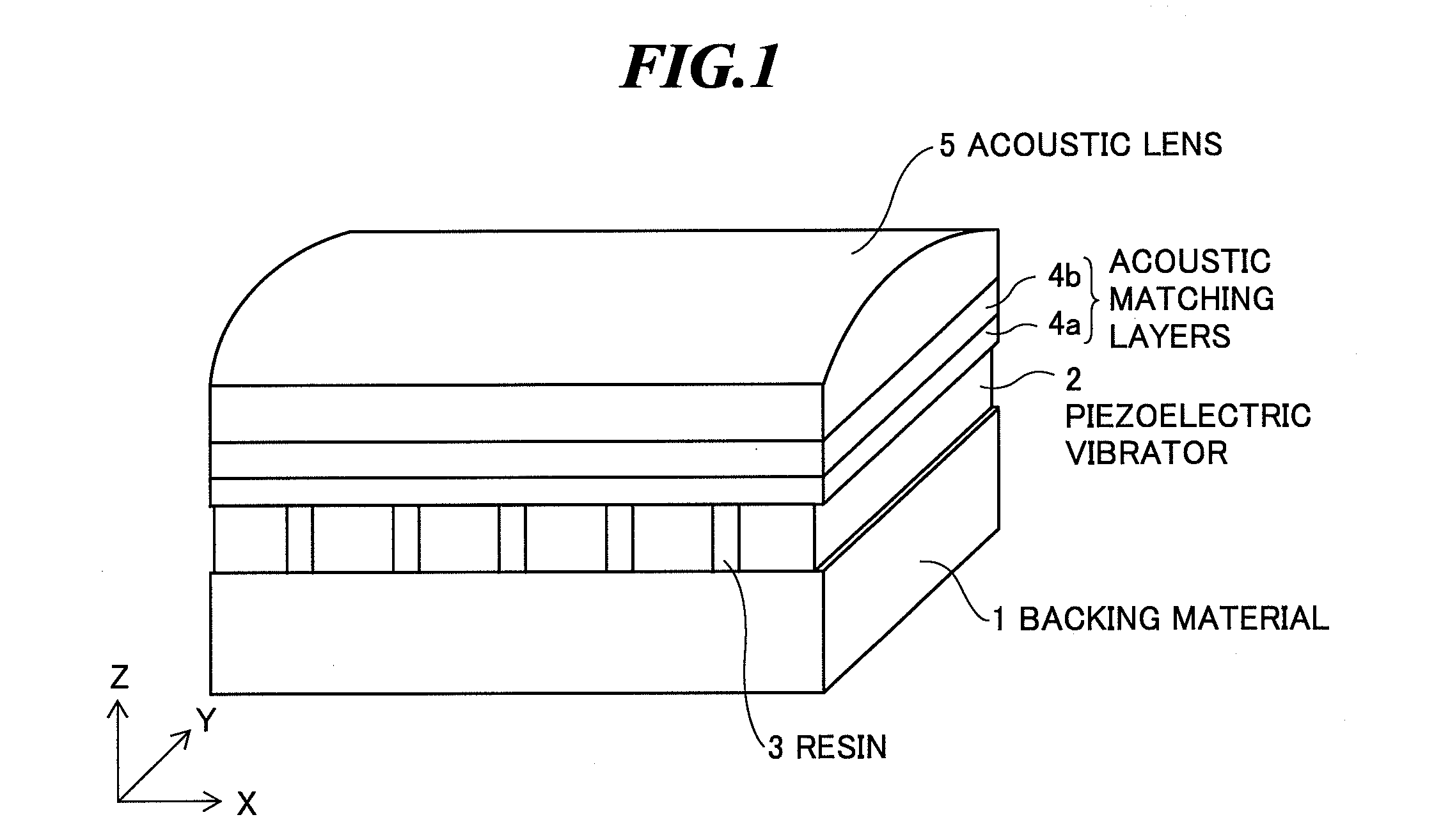

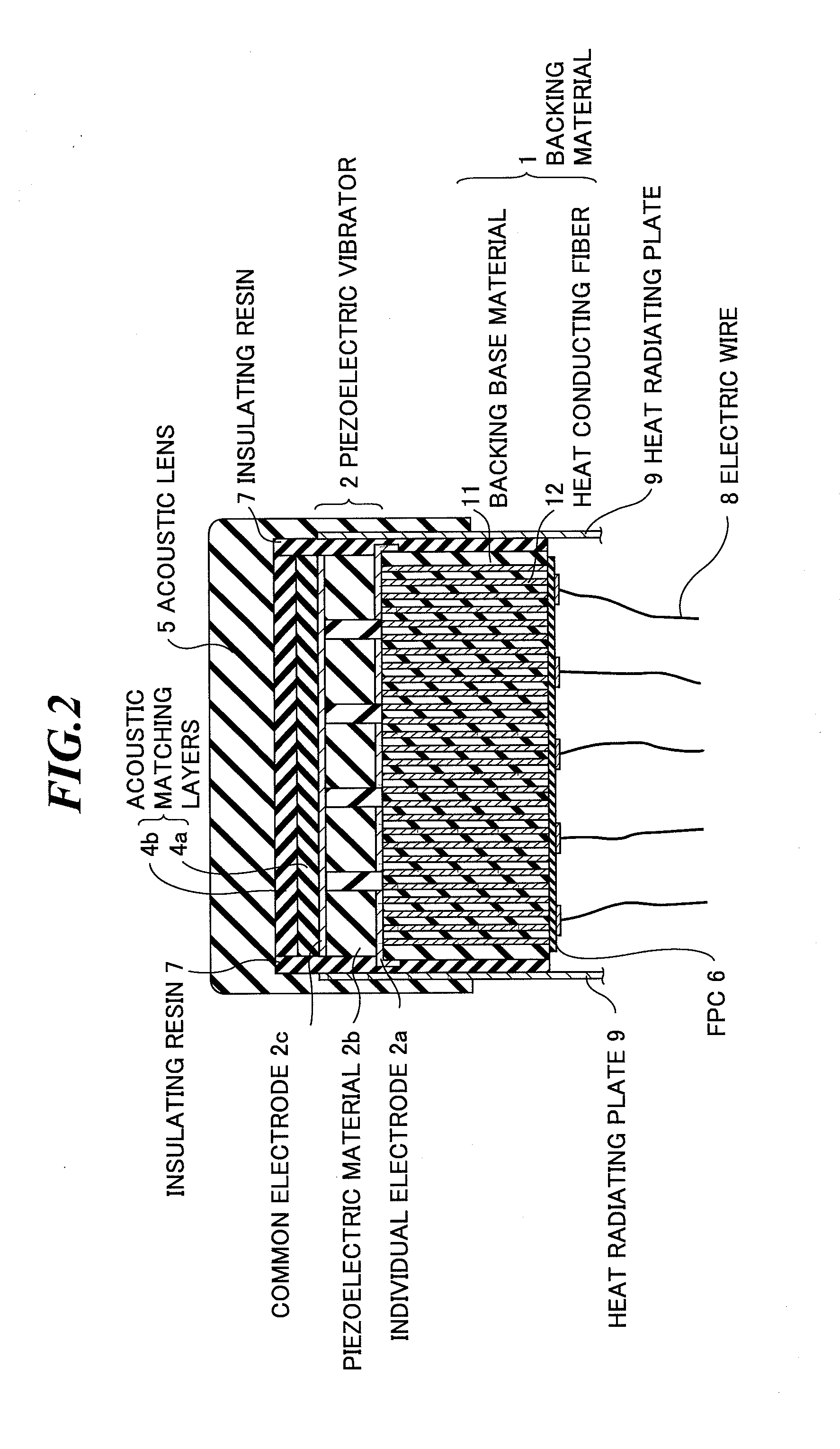

Backing material, ultrasonic probe, ultrasonic endoscope, ultrasonic diagnostic apparatus, and ultrasonic endoscopic apparatus

InactiveUS20090062656A1Reduce surface temperatureEasily and reliably drawn outUltrasonic/sonic/infrasonic diagnosticsCatheterFiberHeat conducting

A backing material for suppressing the surface temperature rise of an ultrasonic probe. This backing material is provided on a back face of at least one vibrator for transmitting and / or receiving ultrasonic waves in an ultrasonic probe, and includes: a backing base material containing a polymeric material; and a heat conducting fiber provided in the backing base material, having a larger coefficient of thermal conductivity than that of the backing base material, and running through without disconnection from a first face of the backing material in contact with the at least one vibrator to a second face different from the first face.

Owner:FUJIFILM CORP

Instrument for heating and cooling

InactiveUS7666664B2Bioreactor/fermenter combinationsBiological substance pretreatmentsHeat conductingBiomedical engineering

An instrument and method is provided that conveniently allows rapid amplification of nucleic acids. The instrument comprises in the following order at least one substantially flat temperature sensor element; a heat conducting substrate and a heater layer, whereby the heat conducting substrate comprises one or more channels permeable for fluid.

Owner:ROCHE MOLECULAR SYST INC

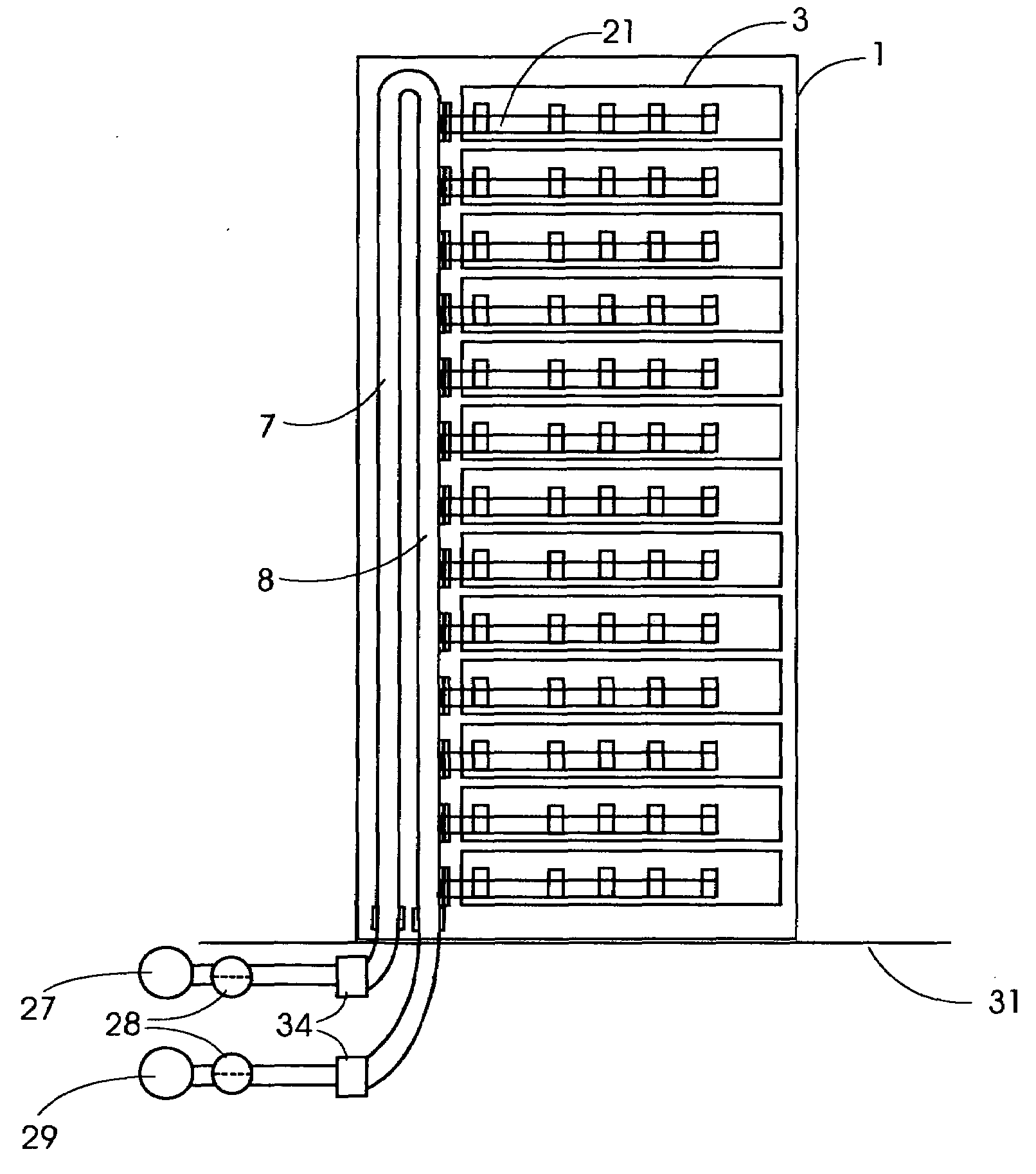

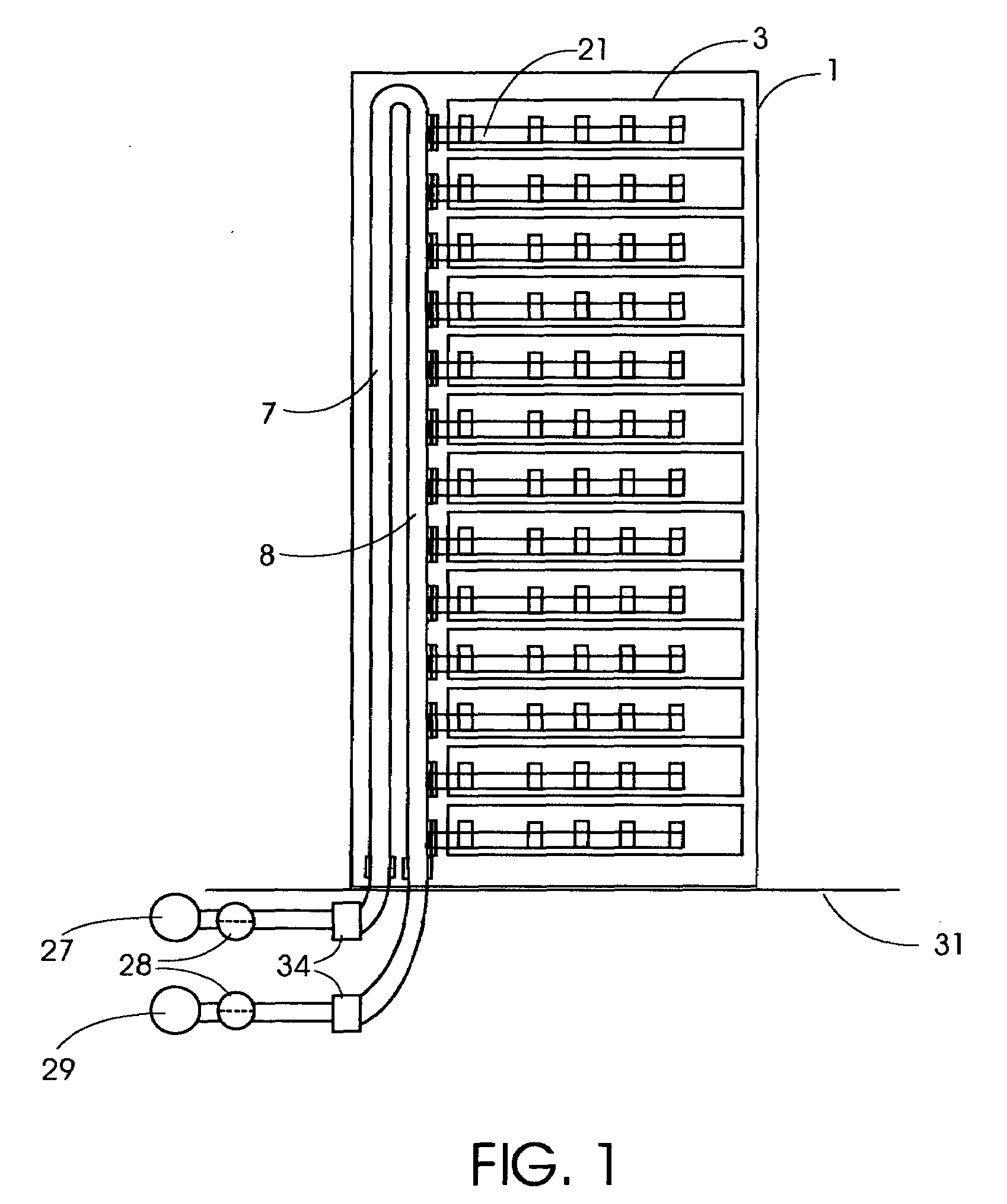

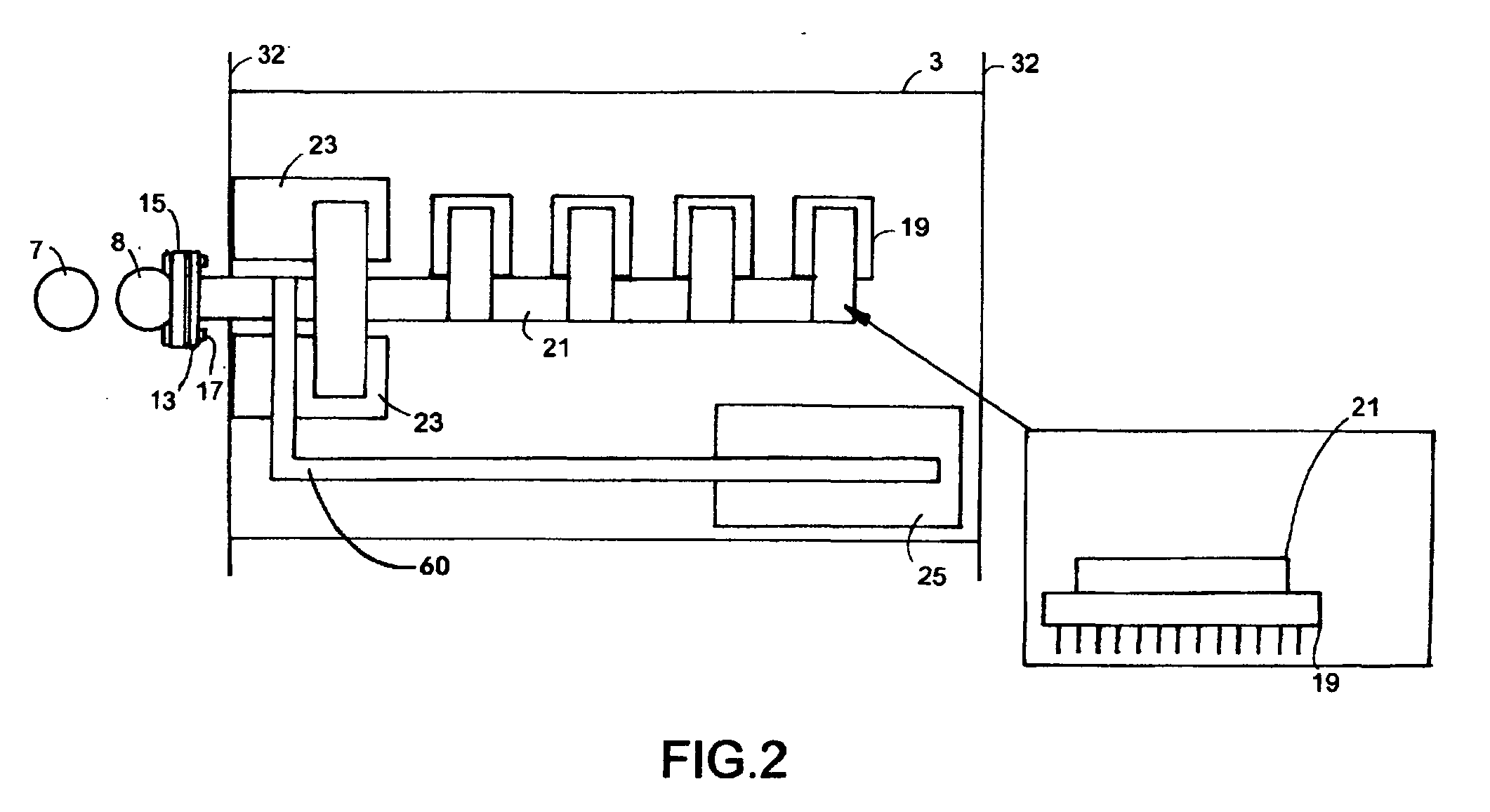

High efficiency heat removal system for rack mounted computer equipment

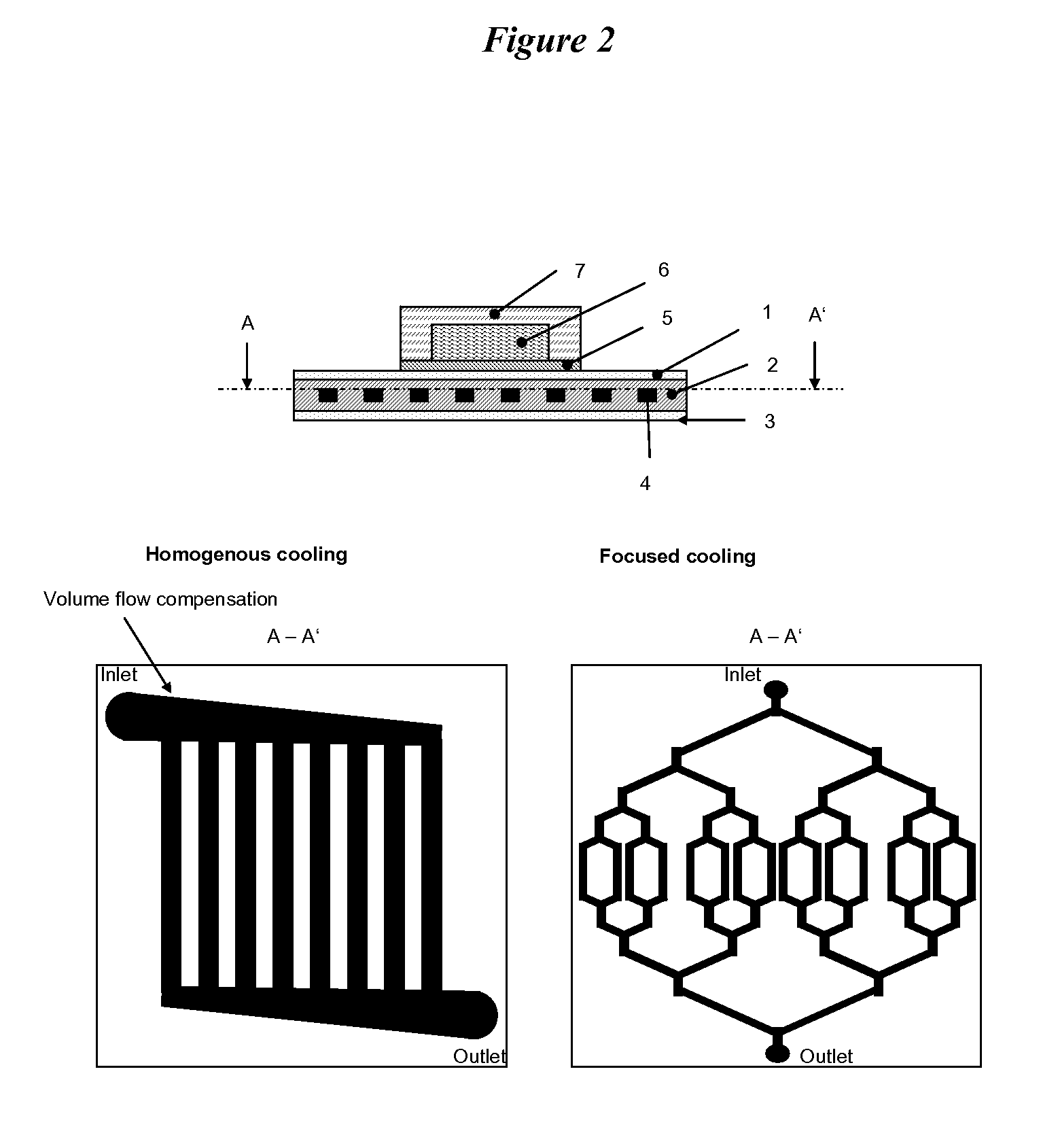

InactiveUS20090262495A1Minimize energy usageEfficient transportDomestic cooling apparatusDigital data processing detailsHeat conductingEngineering

An efficient method of heat removal from rack mounted computer equipment, network gear and other electronic equipment, consisting of solid heat conducting components in direct contact with the heat generating sources. In particular, this invention is primarily focused on the ability to efficiently and effectively cool computer equipment in standard computer rack cabinets.This invention utilizes a design that retains the general existing form factor of the rack mounted computer equipment, but uses direct contact heat transfer to a metal heat transfer conduit (Copper, Aluminum or other metal or efficient heat conducting material) contained within the computer equipment chassis. Furthermore, it is thermally coupled to an external rack mounted solid-to-fluid heat exchanger as an efficient method of heat transfer and removal. This is much more efficient than air as heat transfer medium which it the common method of heat removal from existing standardized rack mounted computer equipment.This invention covers the design of the heat transfer components within the chassis of rack mounted computer server and the heat transfer system components external to the server within rack enclosure, as well as the external cooling system components necessary to connect to existing fluid based heat transfer and removal systems and processes.

Owner:NEUDORFER JULIUS

Conductive heat-conductive graphene slurry and coating

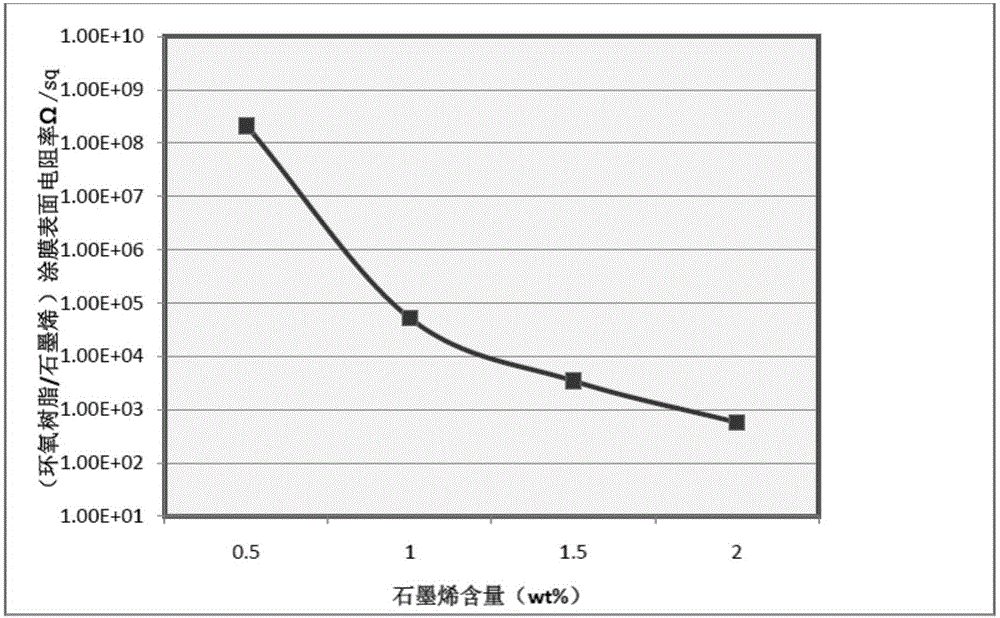

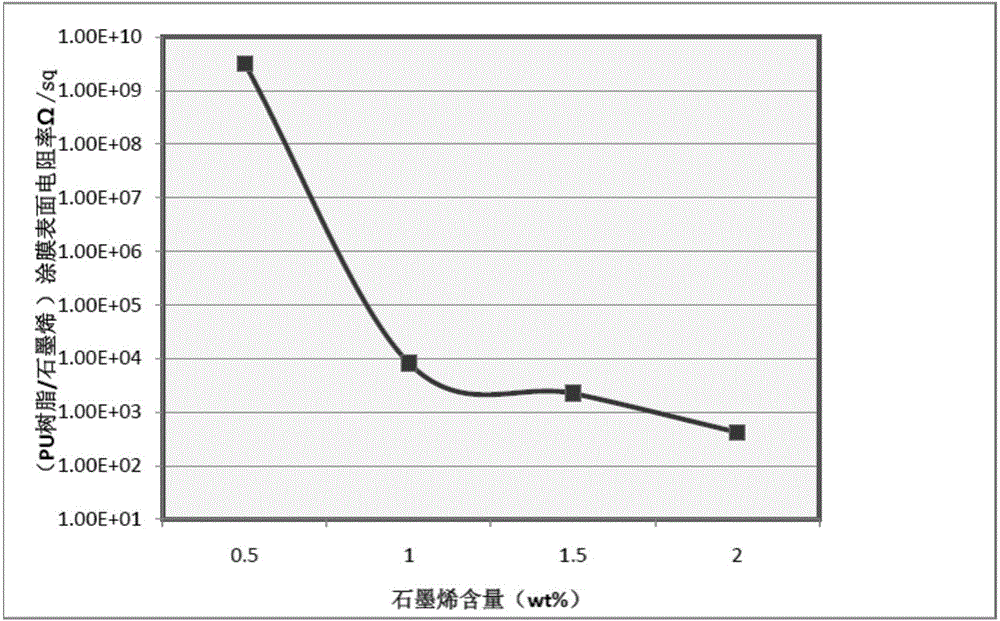

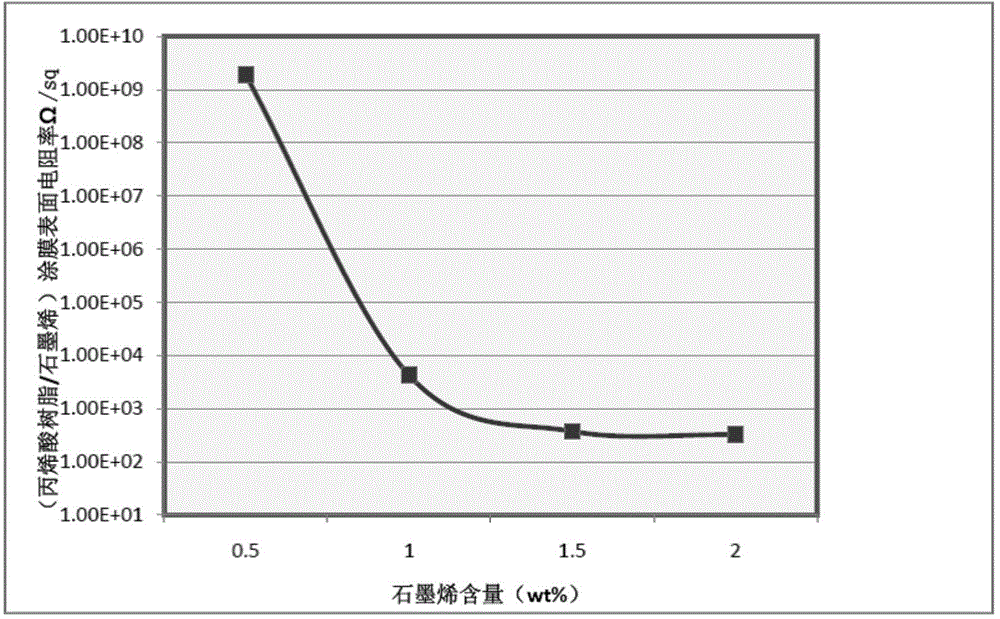

InactiveCN104163928AAdd lessReduce pollutionPolyurea/polyurethane coatingsEpoxy resin coatingsHeat conductingConductive materials

The invention relates to a conductive heat-conductive graphene slurry and a coating. The conductive heat-conductive graphene slurry comprises the following raw materials: 0.1-90wt% of conductive heat-conductive graphene slurry ( consisting of 3-20wt% of less graphene, 0-80wt% of base solvent, 0-80wt% of base resin), 0-60wt% of filler, 0-10% of dispersing agent, 10-60wt% of resin, 10-60wt% of curing agent, and 30-70wt% of solvent, wherein not only can the graphene slurry be antistatic, conductive and heat-conducting despite of less addition amount, but also the surface of a coated article is smoother and finer, firmer and more durable; compared with the addition amount of the existing conductive material, the conductive heat-conductive graphene slurry is lower in addition amount and can also reach lower resistivity.

Owner:SUPERCDONGGUAN TECH

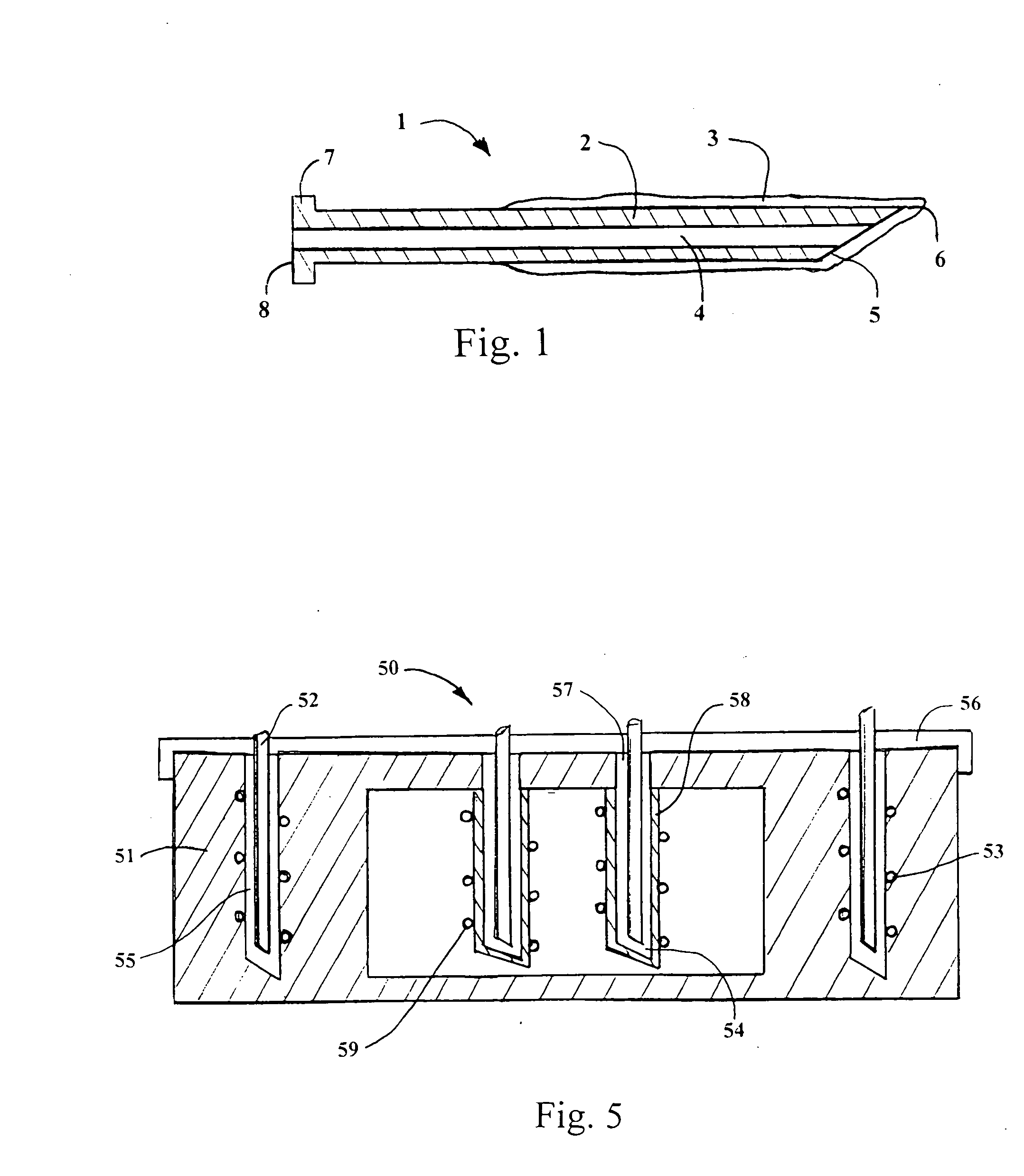

Modular thermoelectric unit and cooling system using same

InactiveUS6463743B1Thermoelectric device with peltier/seeback effectDomestic refrigeratorsThermoelectric coolingHeat conducting

A modular thermoelectric cooling / heating unit is installed through an opening in a wall separating first and second temperature zones. This modular thermoelectric cooling / heating unit comprises a thermoelectric device including a cold surface, a hot surface, and a cooling / heating member between an electrical power supply and the cold and hot surfaces. A heat conducting block has a proximal end for thermally contacting with a first one of the cold and hot surfaces, and a distal end. A first heatsink thermally contacts with a second one of the cold and hot surfaces, a second heatsink thermally contacts with the distal end of the heat conducting block, and a thermally insulated housing covers at least a portion of the heat conducting block between the proximal and distal ends of this block. In operation, the first heatsink is located in the first temperature zone, at least a portion of the heat conducting block and the thermally insulated housing extend through the wall opening, and the second heatsink is located in the second temperature zone. The above described modular thermoelectric cooling / heating unit can be used in a modular cooling system for retrofit into an existing refrigeration unit.

Owner:LALIBERTE JACQUES

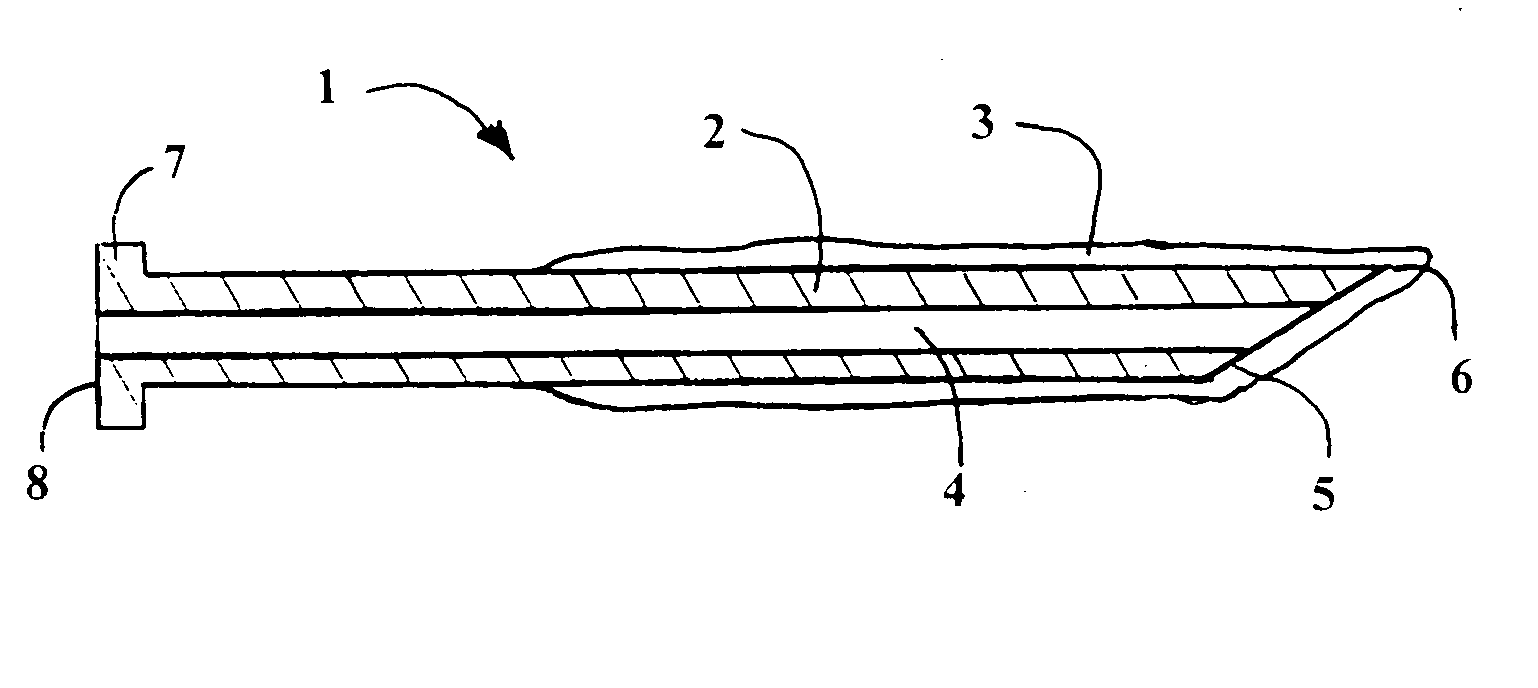

Ice coated hypodermic needle

An ice coating is placed on the hypodermic needle to cool the flesh during insertion. The ice coated front end is sharp, for penetration. The ice coating can be formed by cooling the needle and dipping it in water or molding ice onto the needle. A refrigeration chamber or cryogenic chamber can be used to cool the needle. The mold for forming an ice coating can be cooled by a cryogenic fluid or refrigerant being conducted into coils of the mold surrounding heat conducting mold walls that are used to form the ice coating on the needle. The water can be sterilized with disinfectant included.

Owner:SUN WILLIAM Y

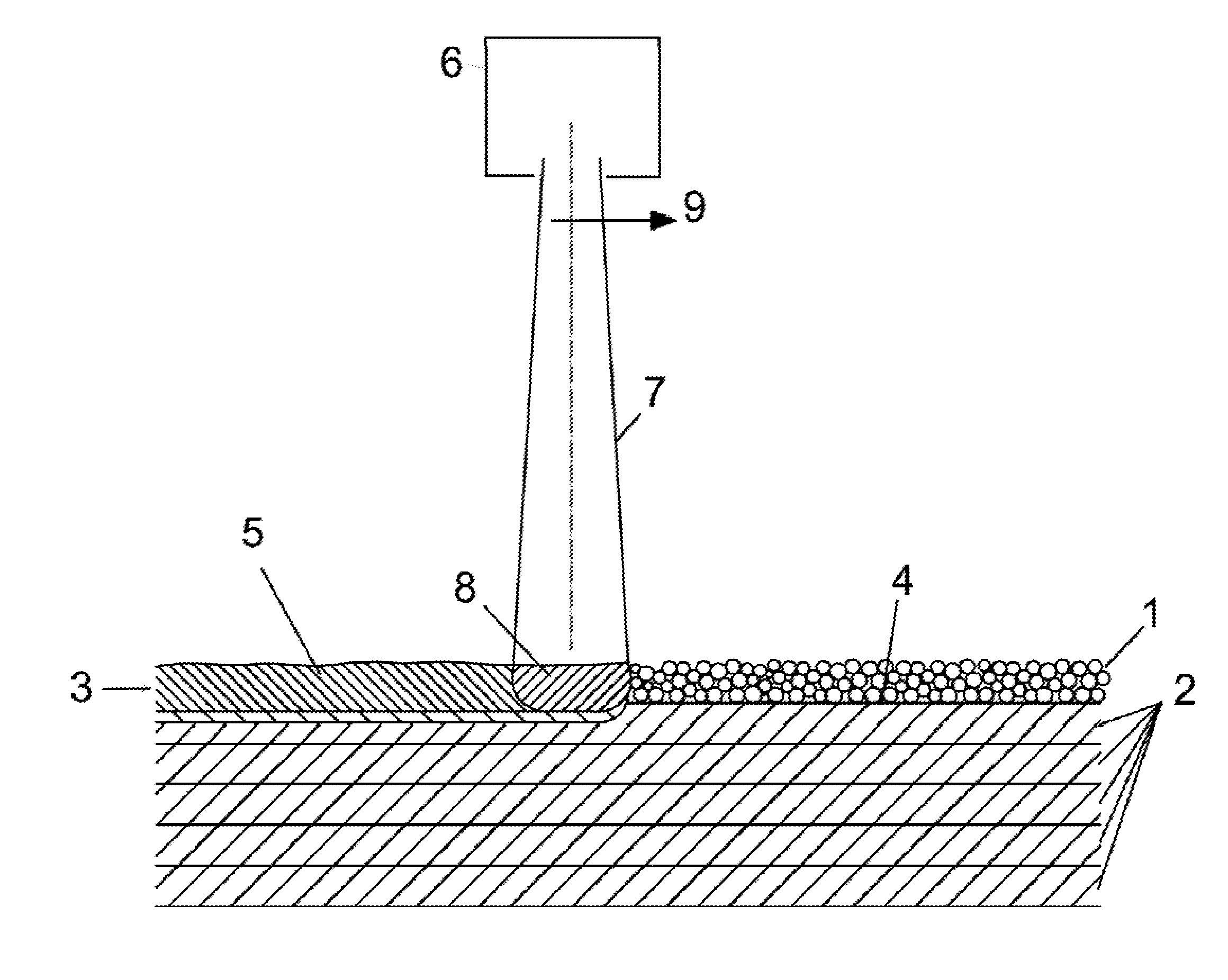

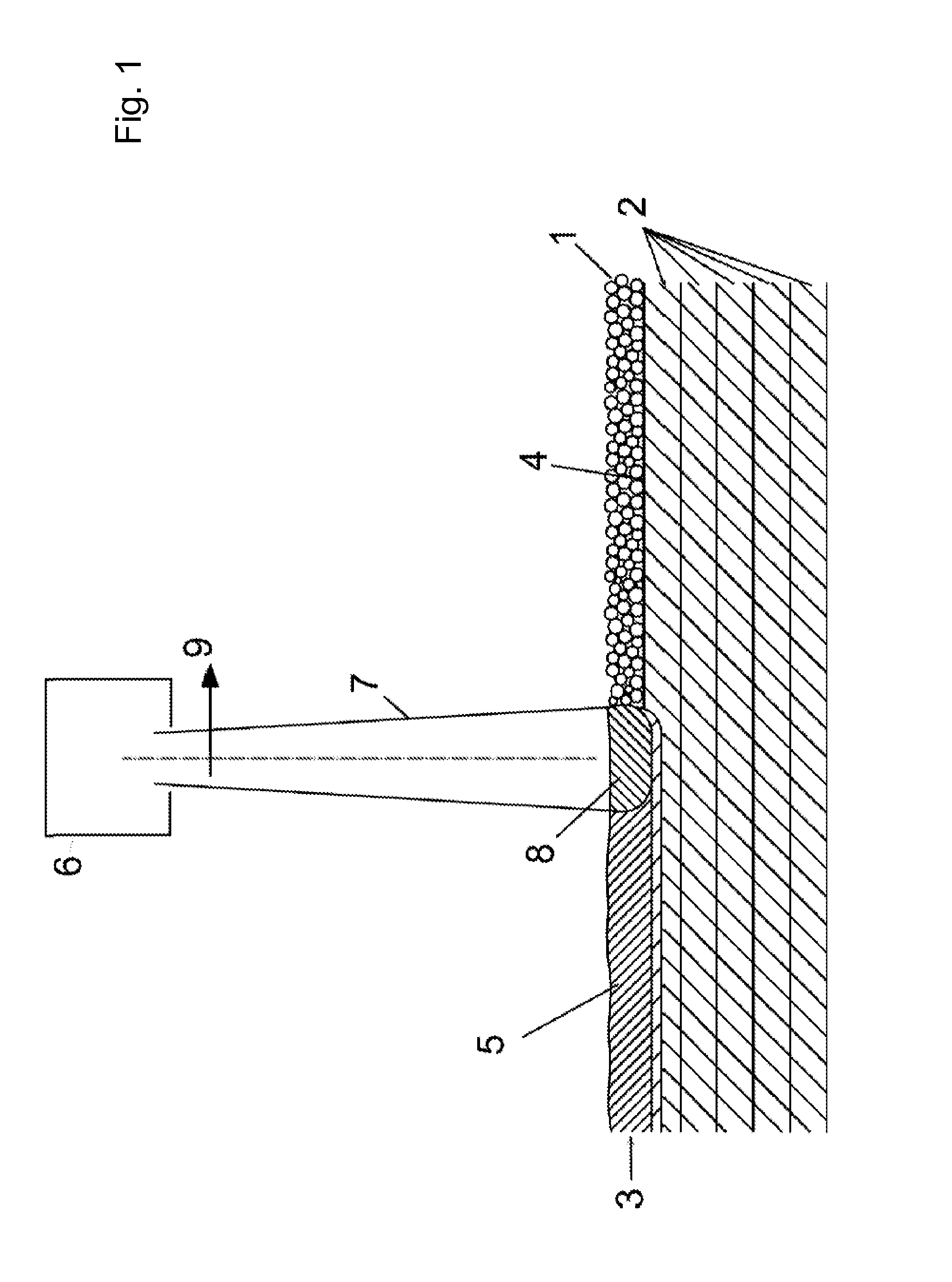

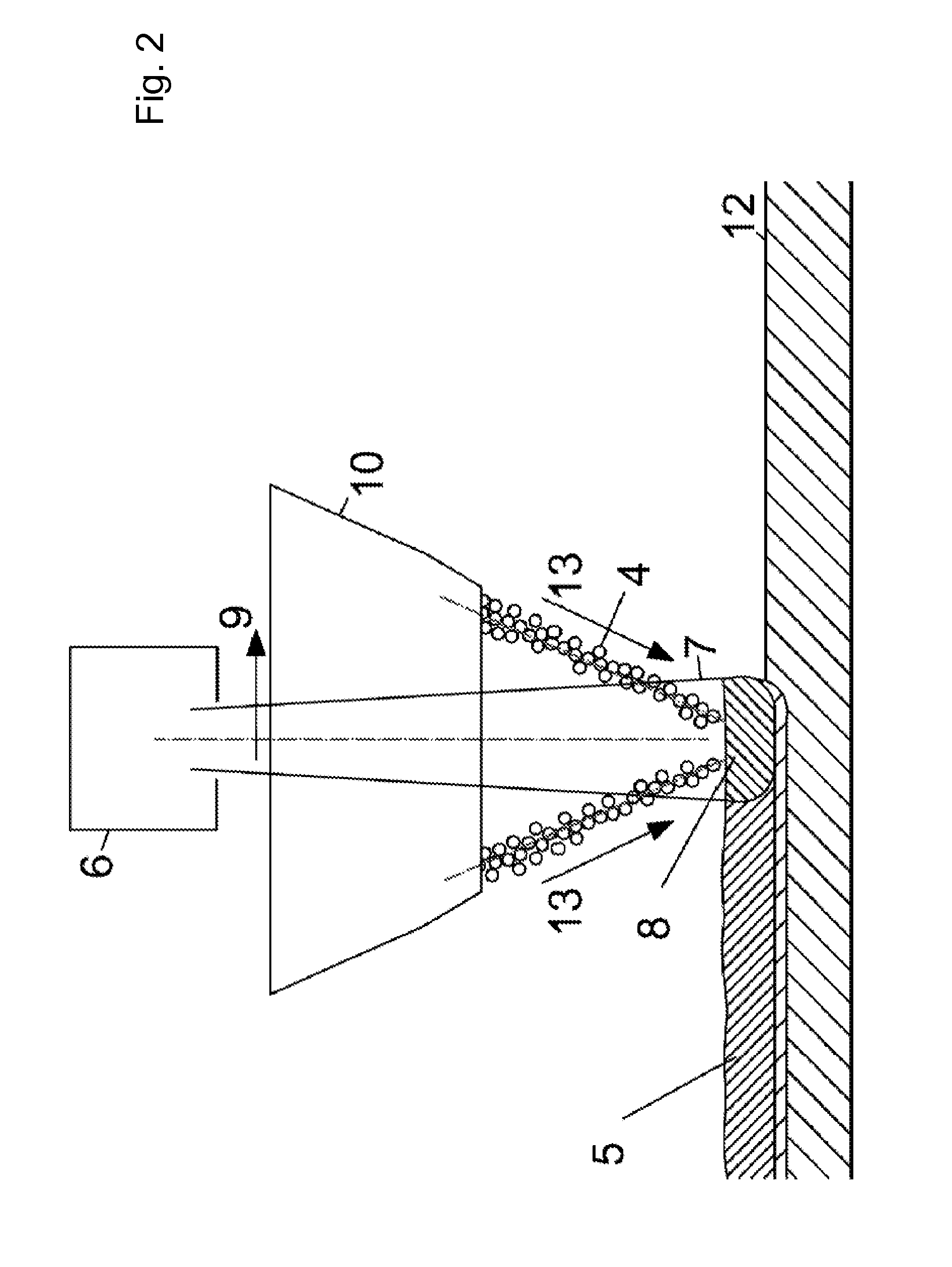

Method for Producing a Component

ActiveUS20130280547A1Additive manufacturing apparatusRadiation applicationsMetal alloyHeat conducting

A method for manufacturing a component having increased thermal conductivity through layer-by-layer construction. At least one section of the component is constructed by applying a layer section having predetermined dimensions of a composite material of a metal and / or a metal alloy and particles of a highly heat-conducting material, including diamond and / or cubic boron nitride, in a predetermined area on a base layer by melting the metal or the metal alloy a heat source, in such a way that the metal and / or metal alloy form(s) within the predetermined dimensions a cohesive matrix, in which particles of the highly heat-conducting material are embedded, and then cooling.

Owner:EADS DEUT GMBH

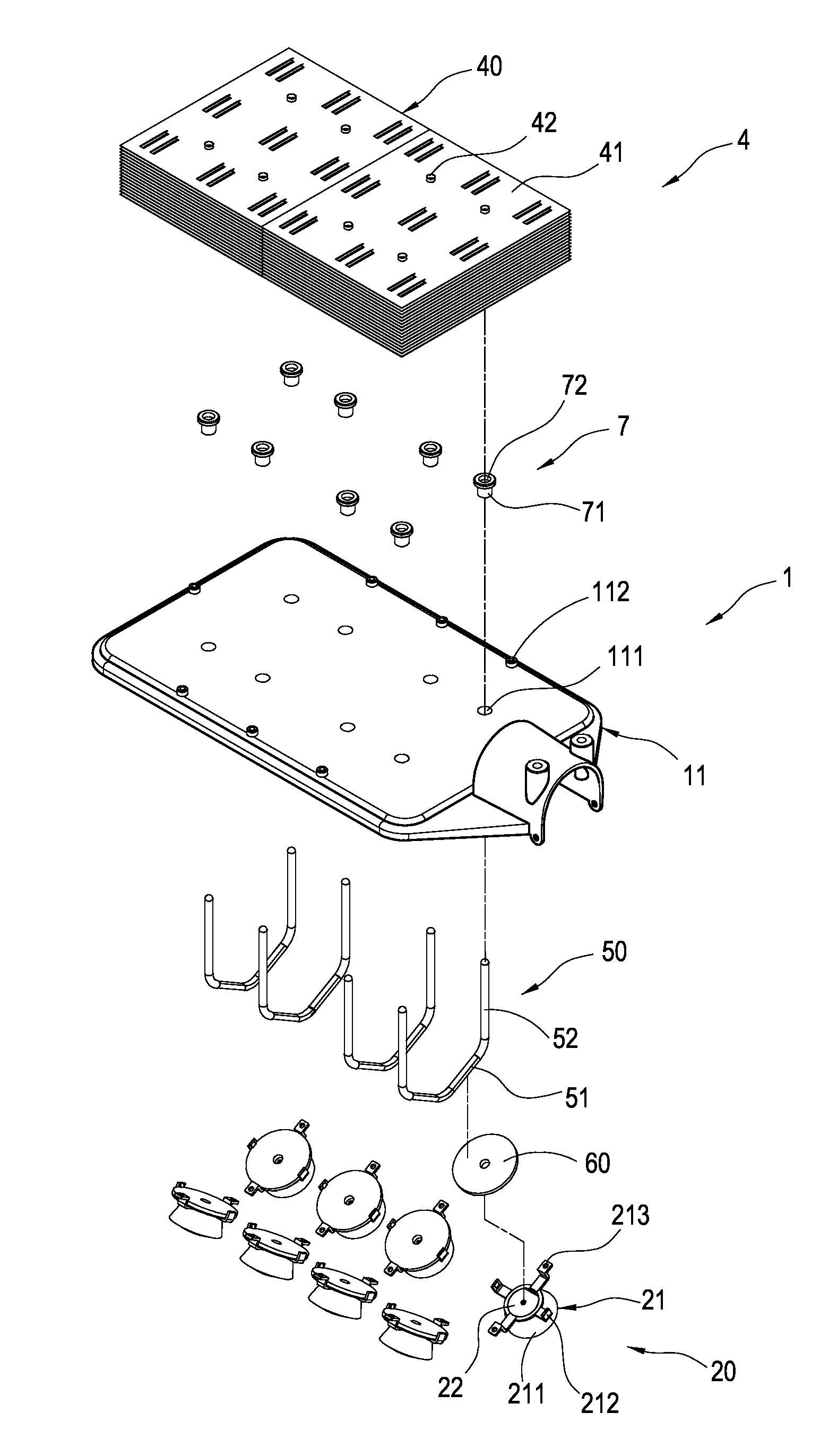

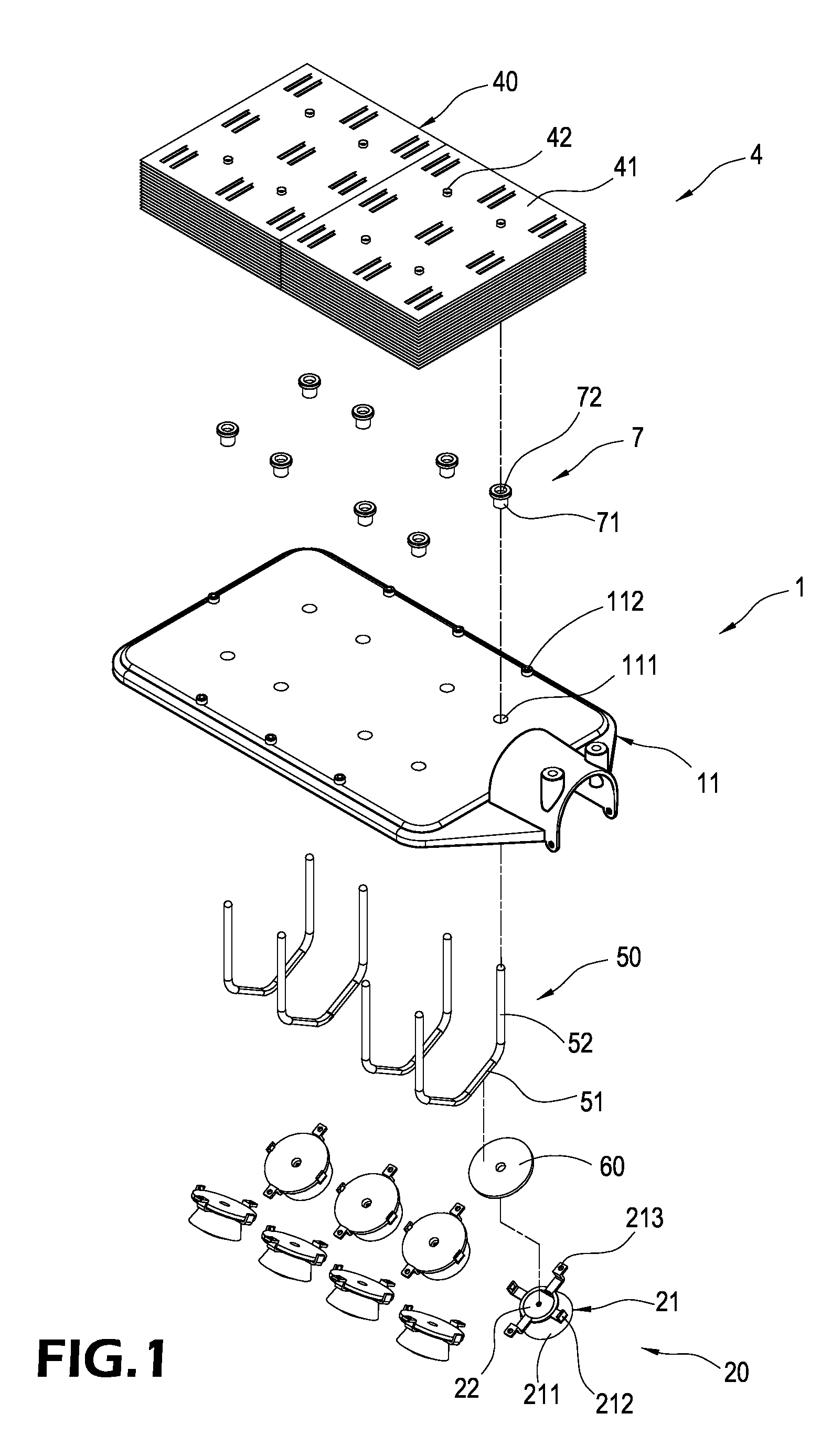

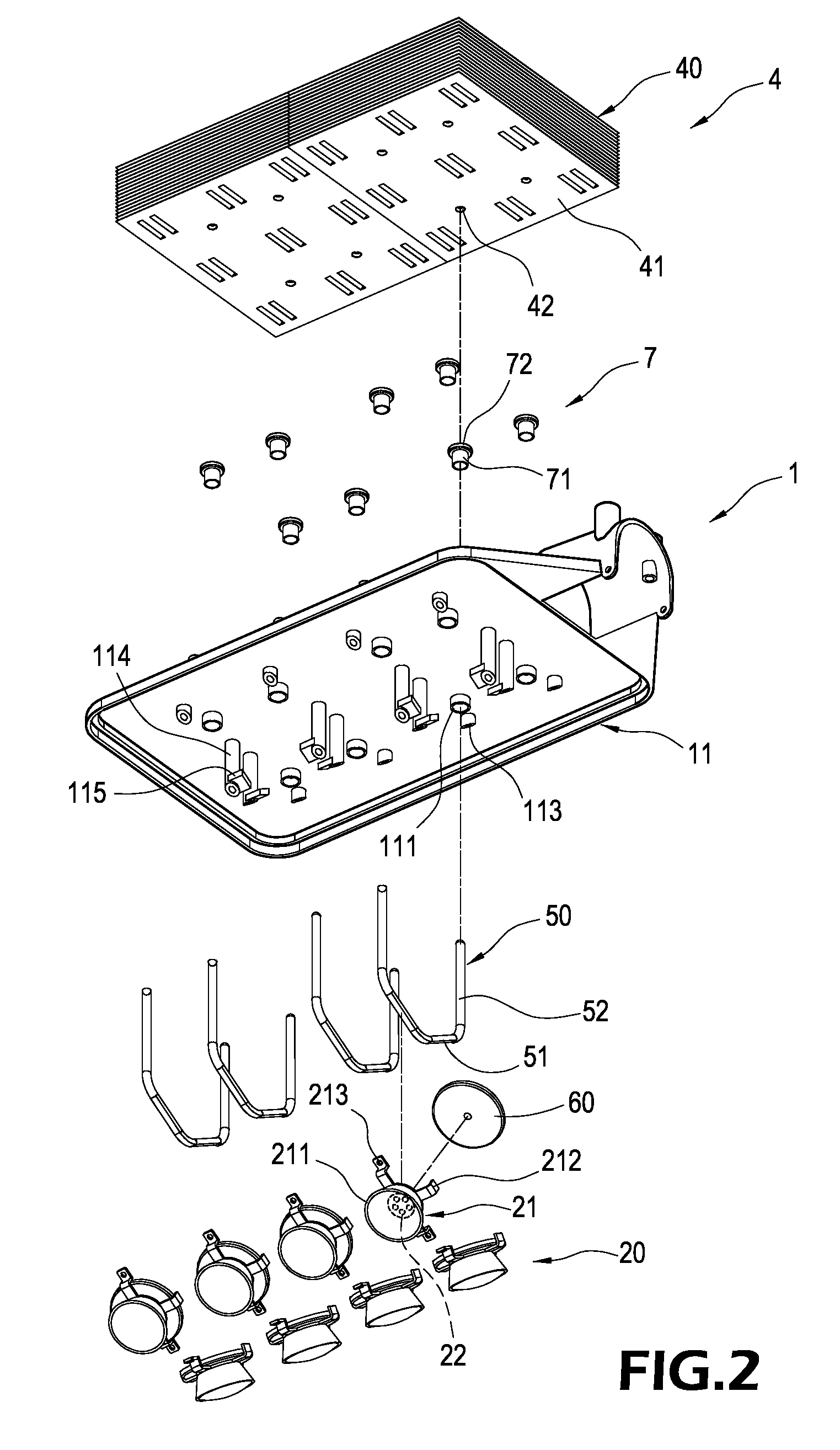

Humidifier and/or flow generator for CPAP device

ActiveUS20090194106A1Easy to understandComfortable sealRespiratorsUsing liquid separation agentHeat conductingHumidifiers

A CPAP device includes a humidifier including humidifier tub having a heat conducting base plate; and a cradle to support the humidifier tub in an operative position. The cradle may also support a flow generator in operative relation to the humidifier tub. The cradle includes a heater plate in communication with the heat conducting base plate of the humidifier tub in use. The cradle further includes a retaining mechanism to retain the humidifier tub in the cradle, the retaining mechanism being structured to force the base plate into engagement with the heater plate. The humidifier and / or flow generator may include various features to manage inadvertent back-spill of water from the humidifier to the flow generator.

Owner:RESMED LTD

Halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive and preparation method thereof

ActiveCN101735619AExcellent electrical performanceImprove flame retardant performanceOther chemical processesCross-linkHydrogen

The invention discloses a halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive and a preparation method thereof. The preparation method comprises: adding vinyl dimethicone, a reinforcing material, a heat-conducting filling material and a halogen-free flame retardant in a vacuum kneader, dehydrating and blending for 30-120 minutes at 100-150 DEG C and vacuum degree of 0.06-0.1MPa to obtain a base material, adding a cross-linking agent containing hydrogen silicone oil and a cross-linking inhibitor to the base material at the normal temperature, adequately agitating for 10-30 minutes to prepare a component A; adding a platinum catalyst to the base material, adequately agitating for 10-30 minutes to prepare a component B; taking the component A and the component B of the same parts by weight, blending uniformly, and deaerating for 5-10 minutes at the vacuum degree of 0.06-0.1MPa to obtain the halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive. The potting adhesive has good flow properties and convenient use and can be cured at the normal temperature or a high temperature, condensate has excellent flame retardant property and heat-conducting property, and the potting adhesive can be widely applied to the fields of electronic electric appliance, chip encapsulation and LED encapsulation, and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

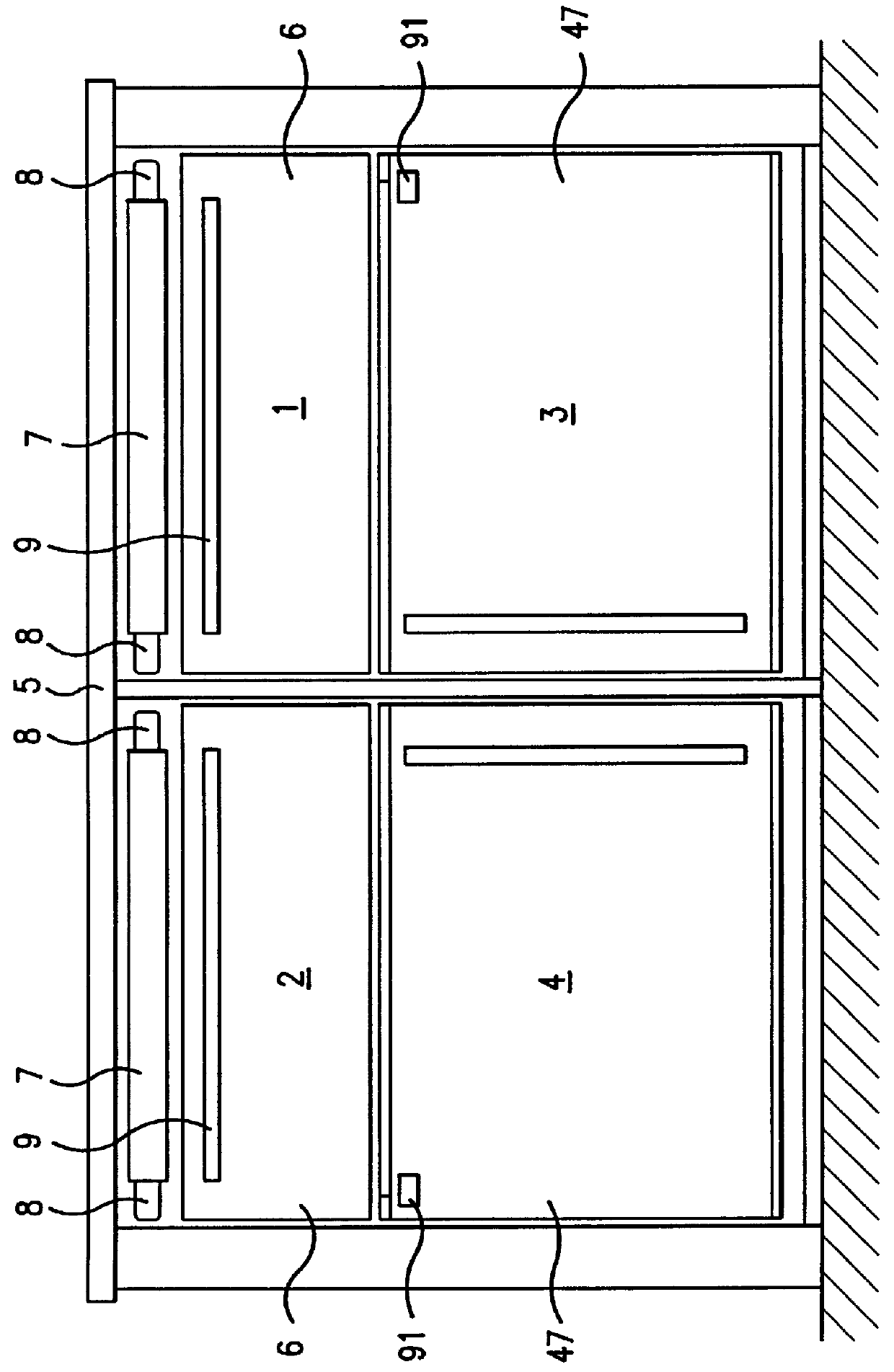

Temperature-controlled appliance

A temperature-controlled appliance is provided with mutually-independent temperature-controlled compartments arranged close to each other. Each of the compartments comprises a casing formed of a heat-insulating layer, a thermal conductor arranged in the casing and provided with a heat-conducting surface located opposite a storage space in the casing, a Peltier device thermally connected with the thermal conductor, a power supply for feeding electric power to the Peltier device, and a controller for controlling electric power to be fed to the Peltier device so that a temperature in the casing is controlled.

Owner:THERMOVONICS

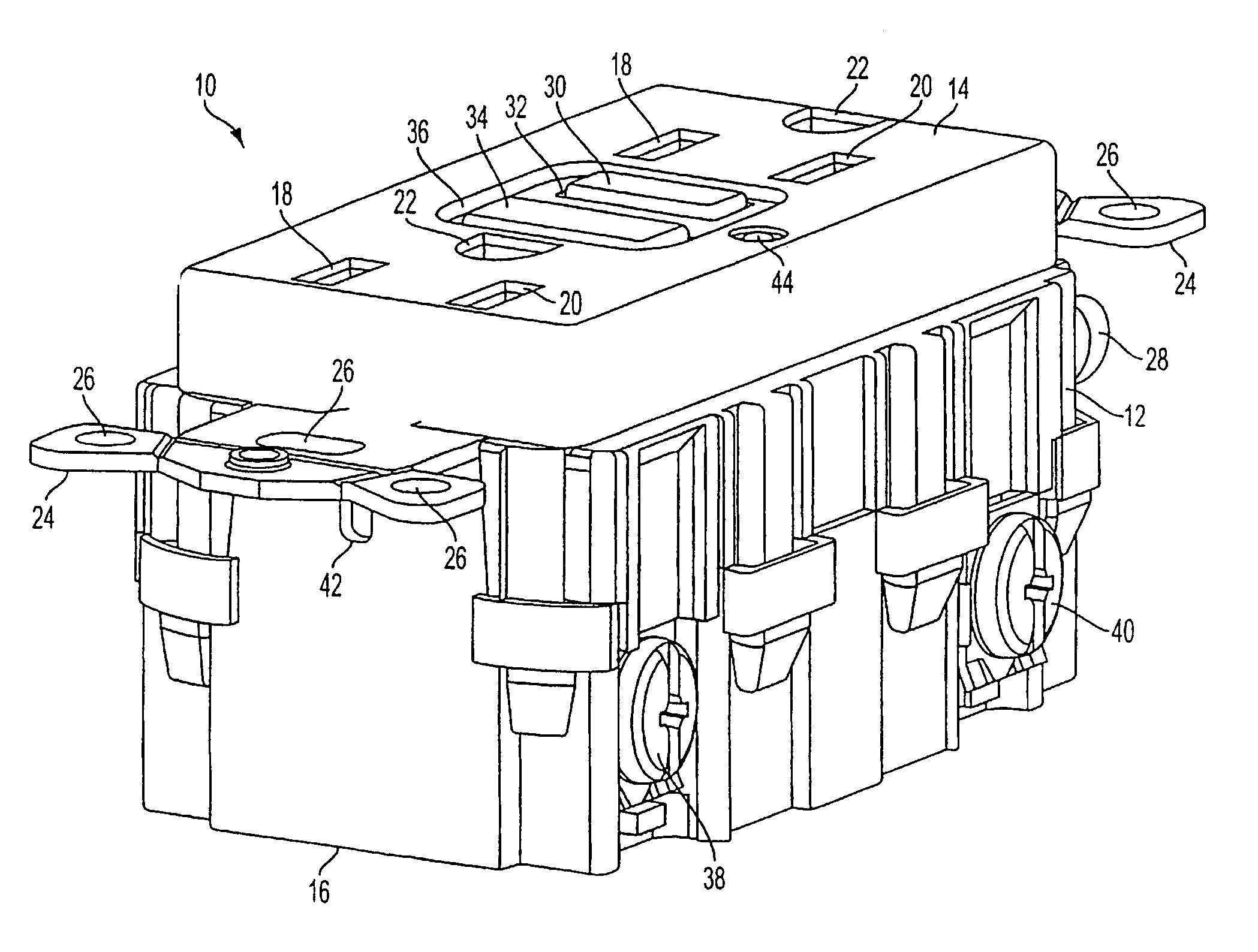

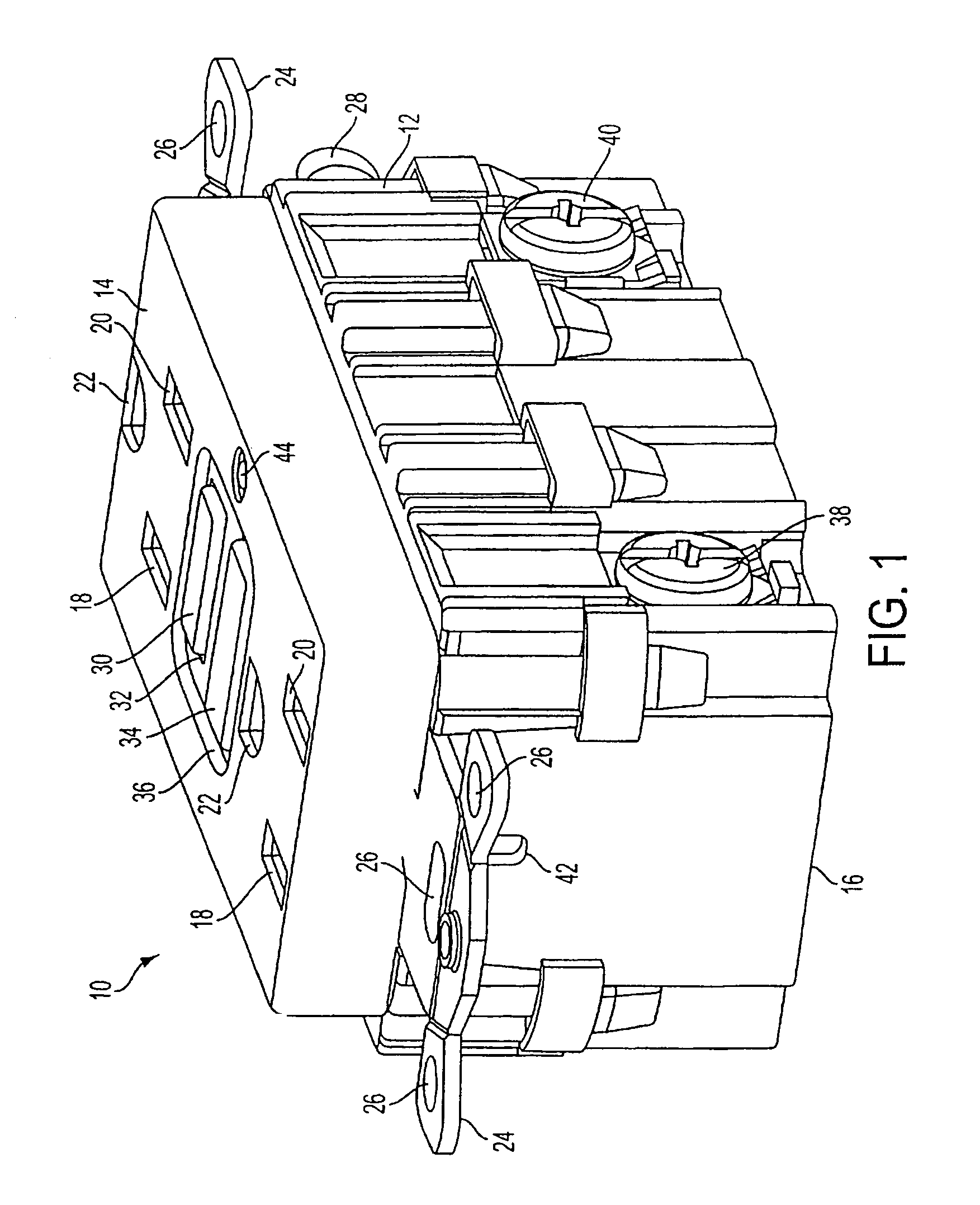

Self testing ground fault circuit interrupter (GFCI) with end of life (EOL) indicator, secondary power supply for EOL and self test circuitry, and device for opening line hot when EOL occurs

ActiveUS7315437B2Increase surface temperatureProtective switch detailsSwitch operated by earth fault currentsHeat conductingPrinted circuit board

A self test (ST) ground fault circuit interrupter (GFCI) provides a half wave rectifier for powering circuitry for determining and annunciating end of life (EOL) of the GFCI regardless of a shorted diode bridge or opening of a printed circuit board (PCB) trace. A fuse resistor is provided to open before an open PCB trace can occur. A microprocessor-controlled heat-conducting circuit is provided adjacent to a thermal fuse to controllably open the thermal fuse and remove power from face receptacle contacts and load terminals when EOL occurs.

Owner:HUBBELL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com