Patents

Literature

16737 results about "Thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal expansion is the tendency of matter to change its shape, area, and volume in response to a change in temperature. Temperature is a monotonic function of the average molecular kinetic energy of a substance. When a substance is heated, the kinetic energy of its molecules increases. Thus, the molecules begin vibrating/moving more and usually maintain a greater average separation. Materials which contract with increasing temperature are unusual; this effect is limited in size, and only occurs within limited temperature ranges (see examples below). The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of thermal expansion and generally varies with temperature.

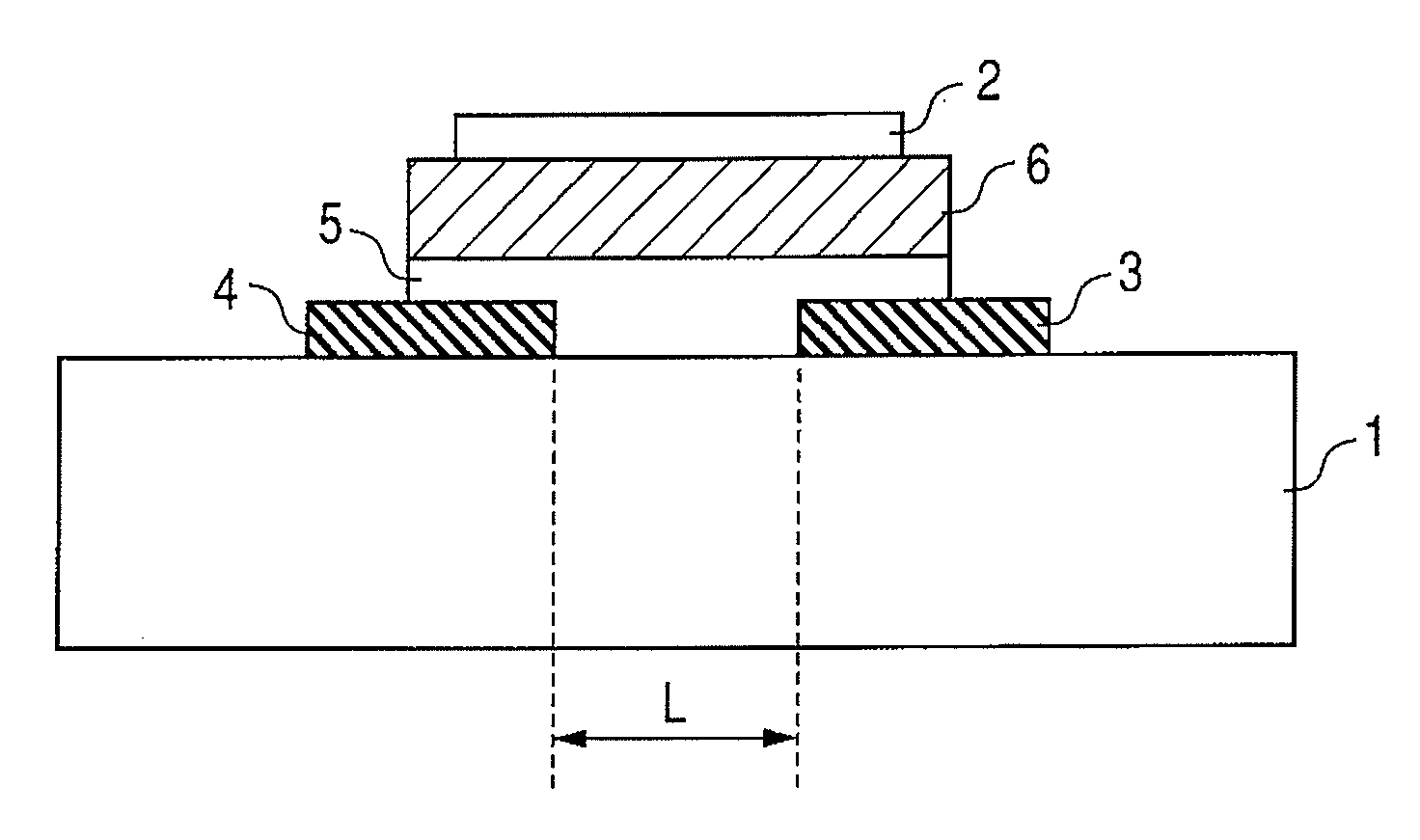

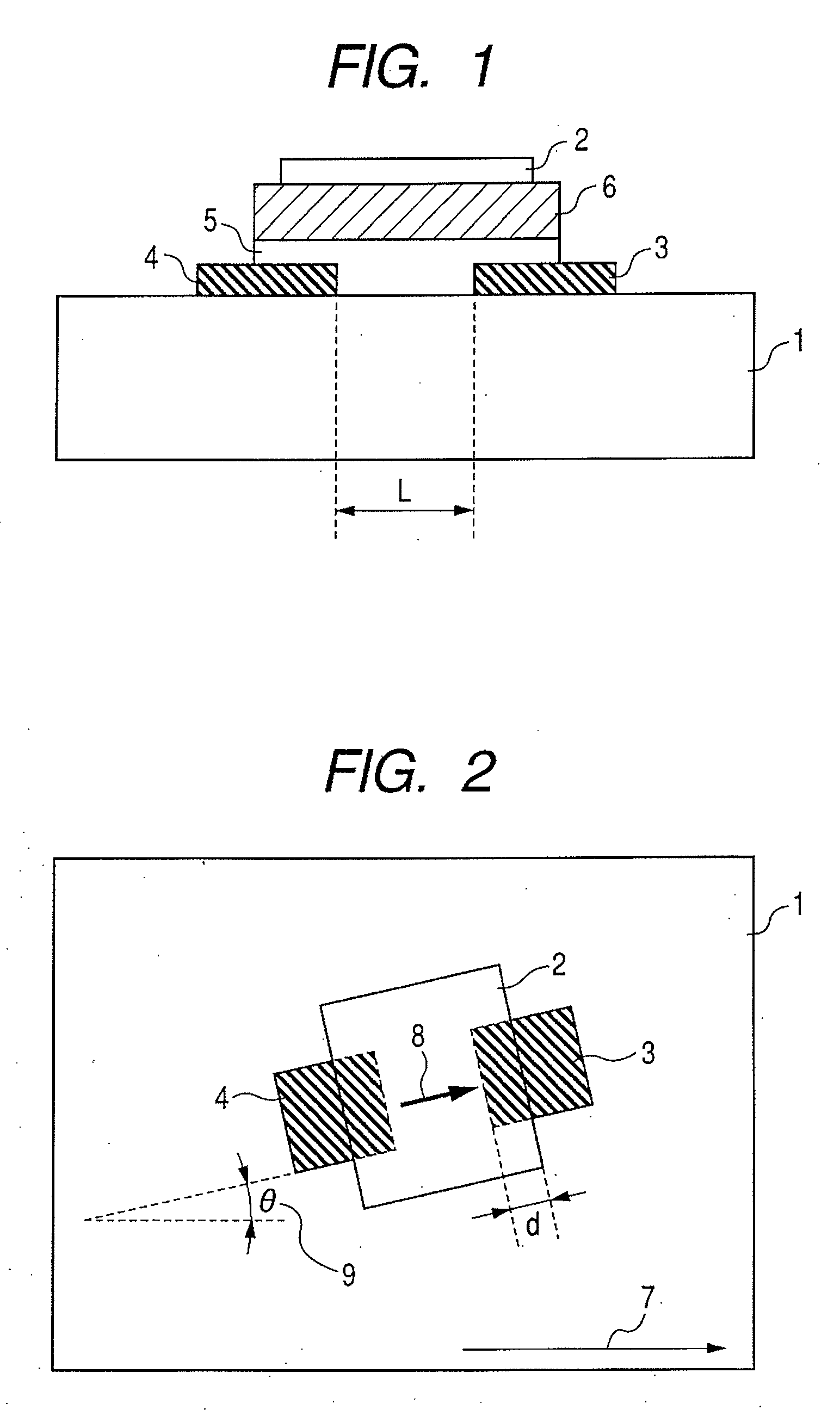

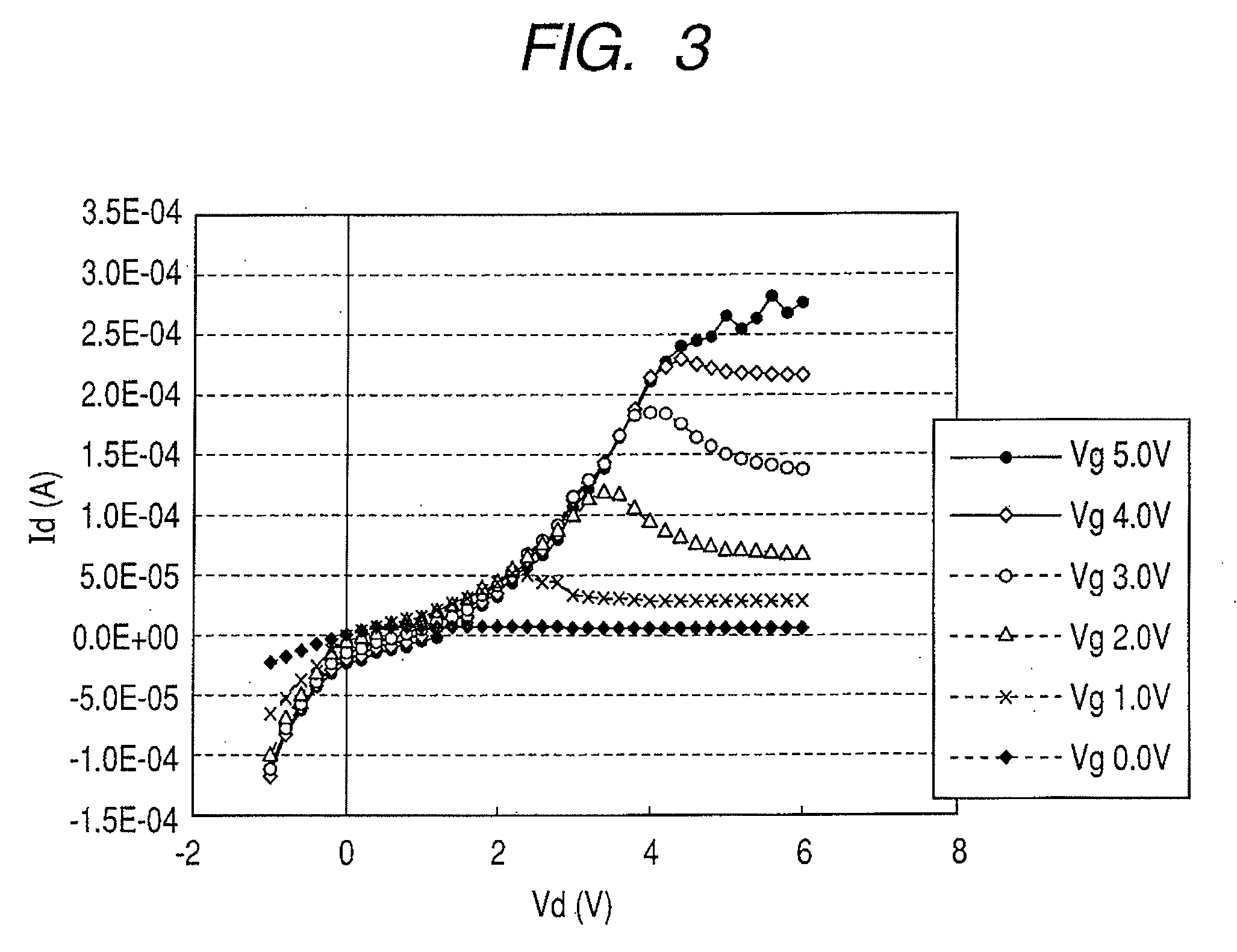

Semiconductor device

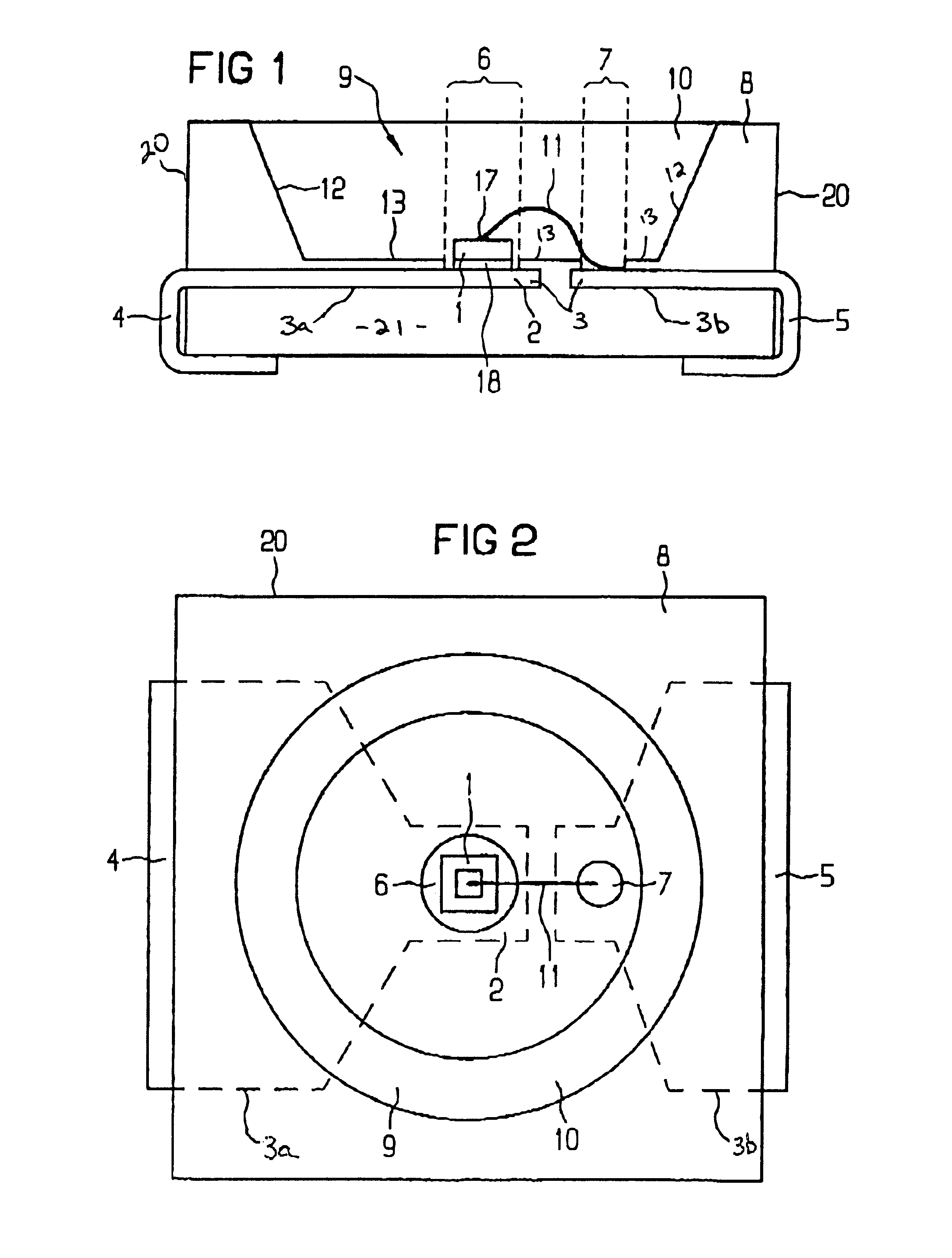

InactiveUS20090114910A1Uniform and high stabilityIncrease productionTransistorSolid-state devicesIn planeDevice material

In the present invention, a thin film transistor is formed on a plastic film substrate (1) having anisotropy of thermal shrinkage rate or coefficient of thermal expansion in in-plane directions of the substrate. A channel is formed such thatthe direction (7) in which the thermal shrinkage rate or the coefficient of thermal expansion of the substrate is largest is nonparallel tothe direction (8) of a current flowing through the channel of the thin film transistor. Then, a thin film transistor having stable and uniform electrical characteristics, which is formed on the plastic film substrate, is provided.

Owner:CANON KK

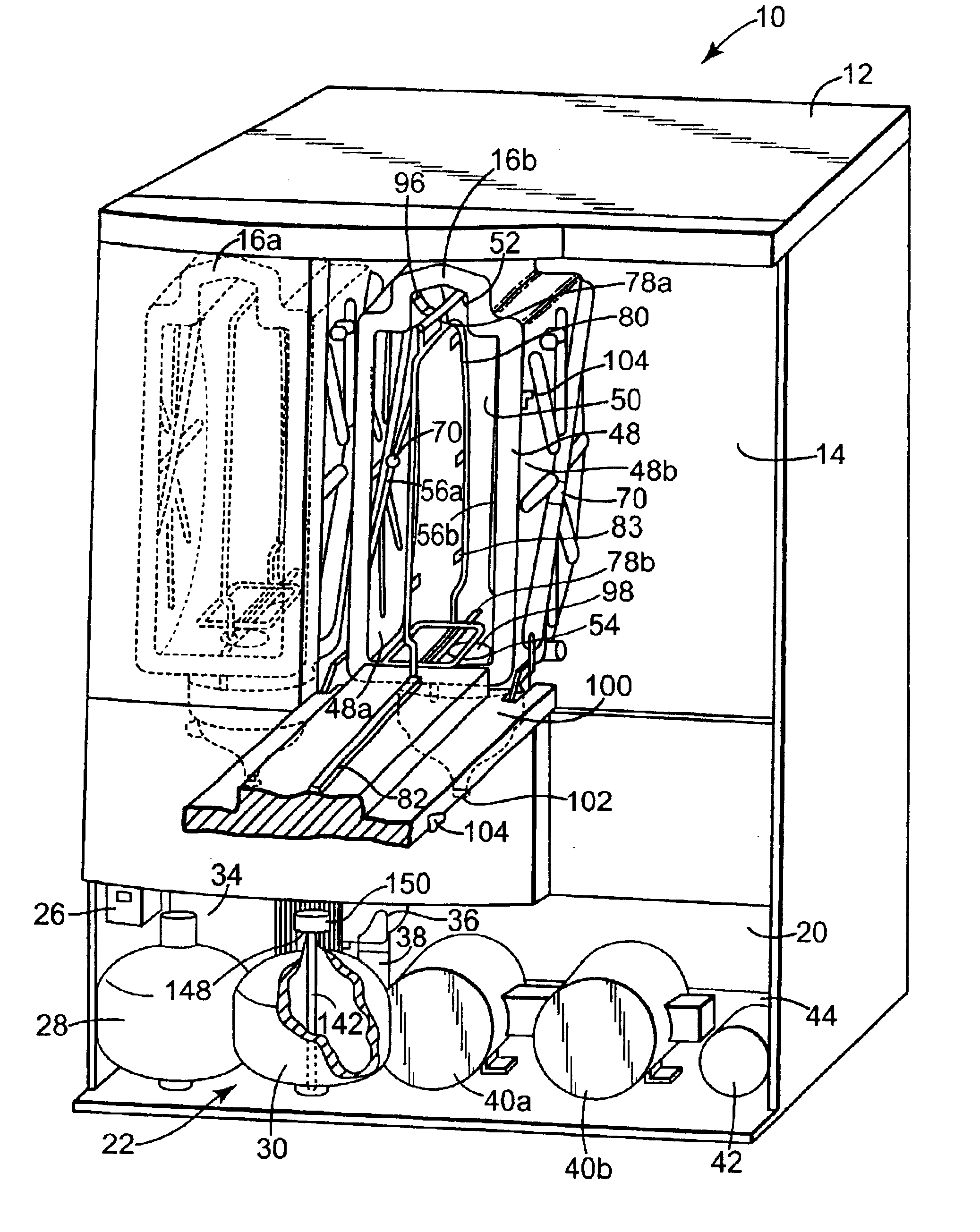

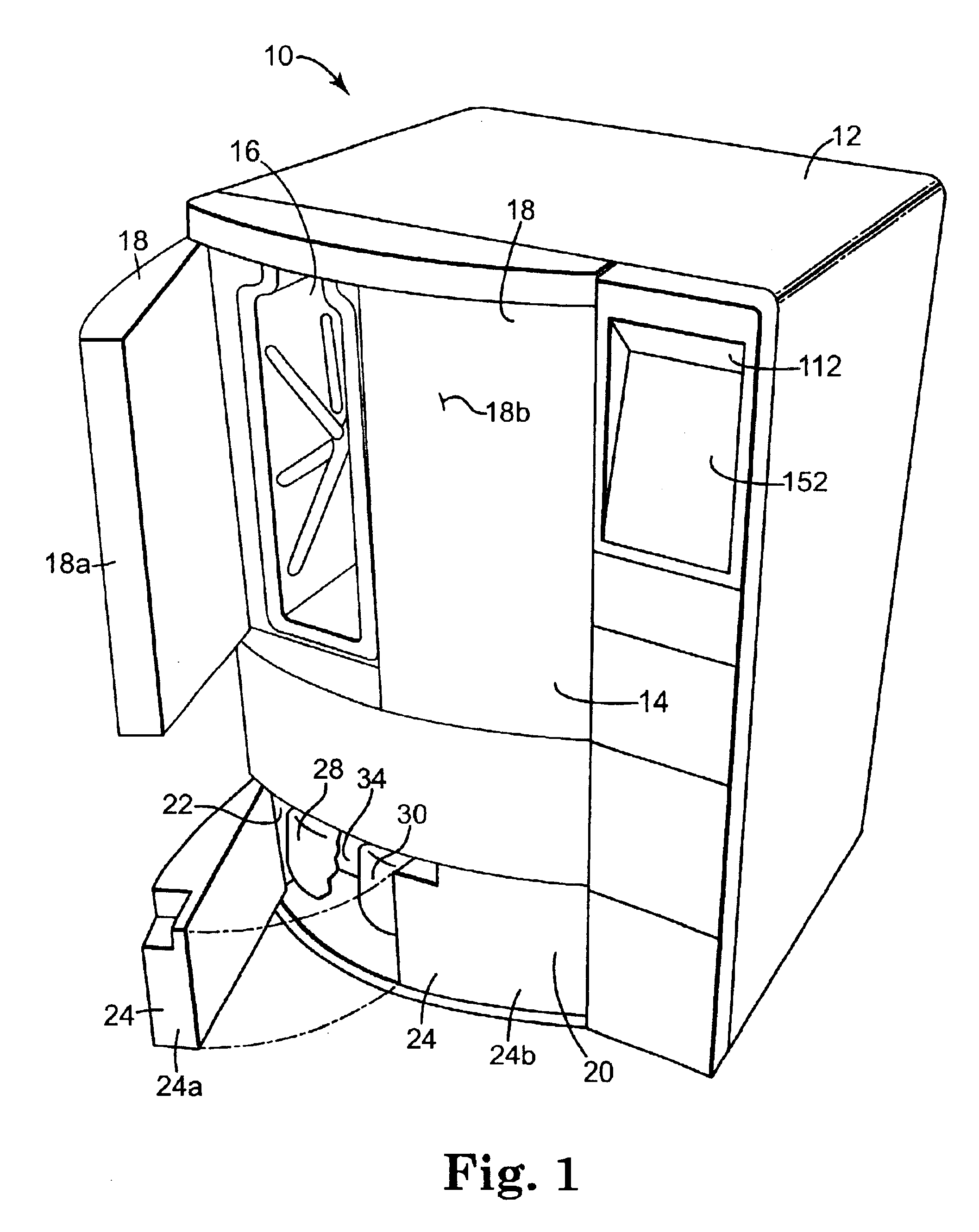

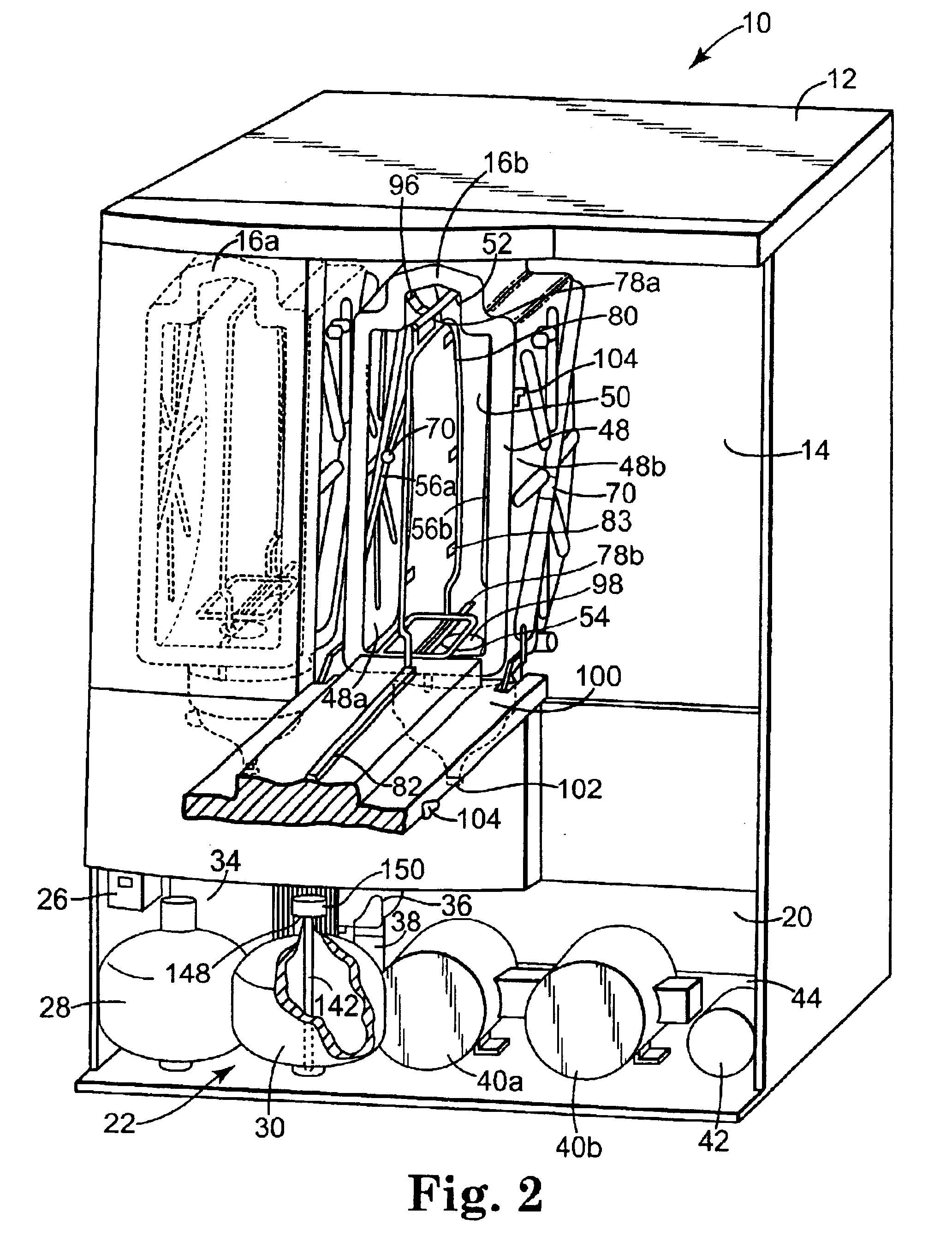

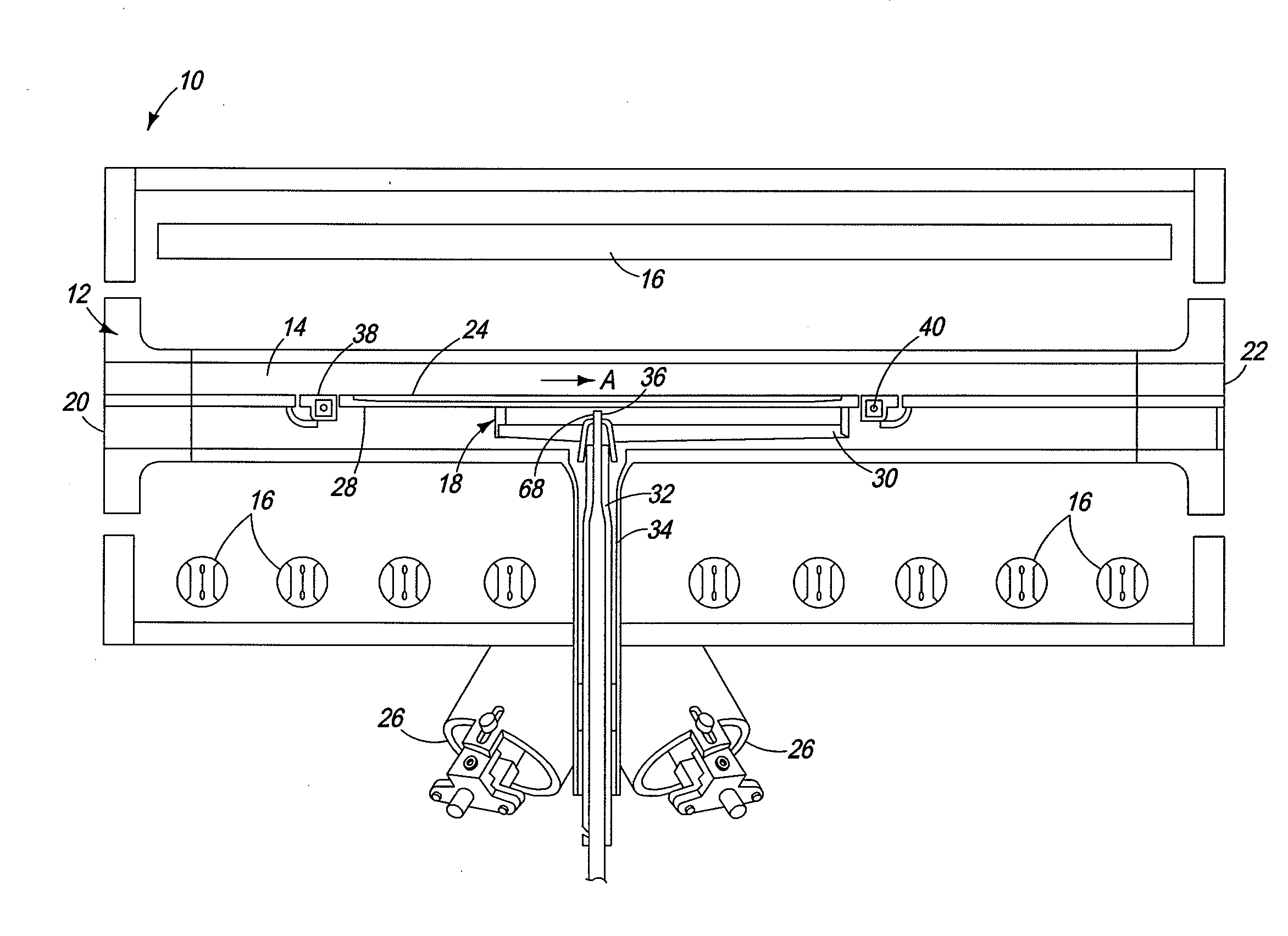

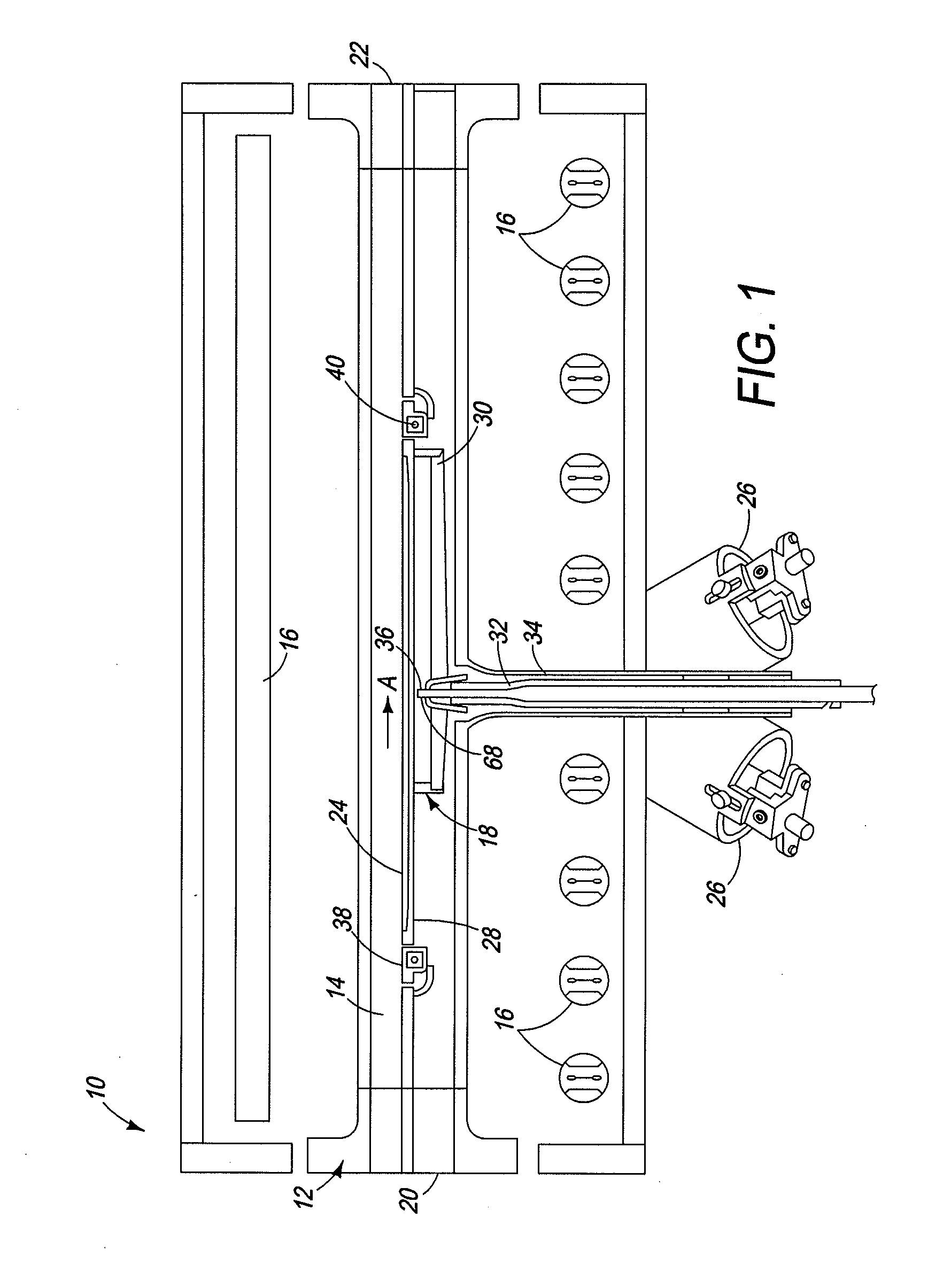

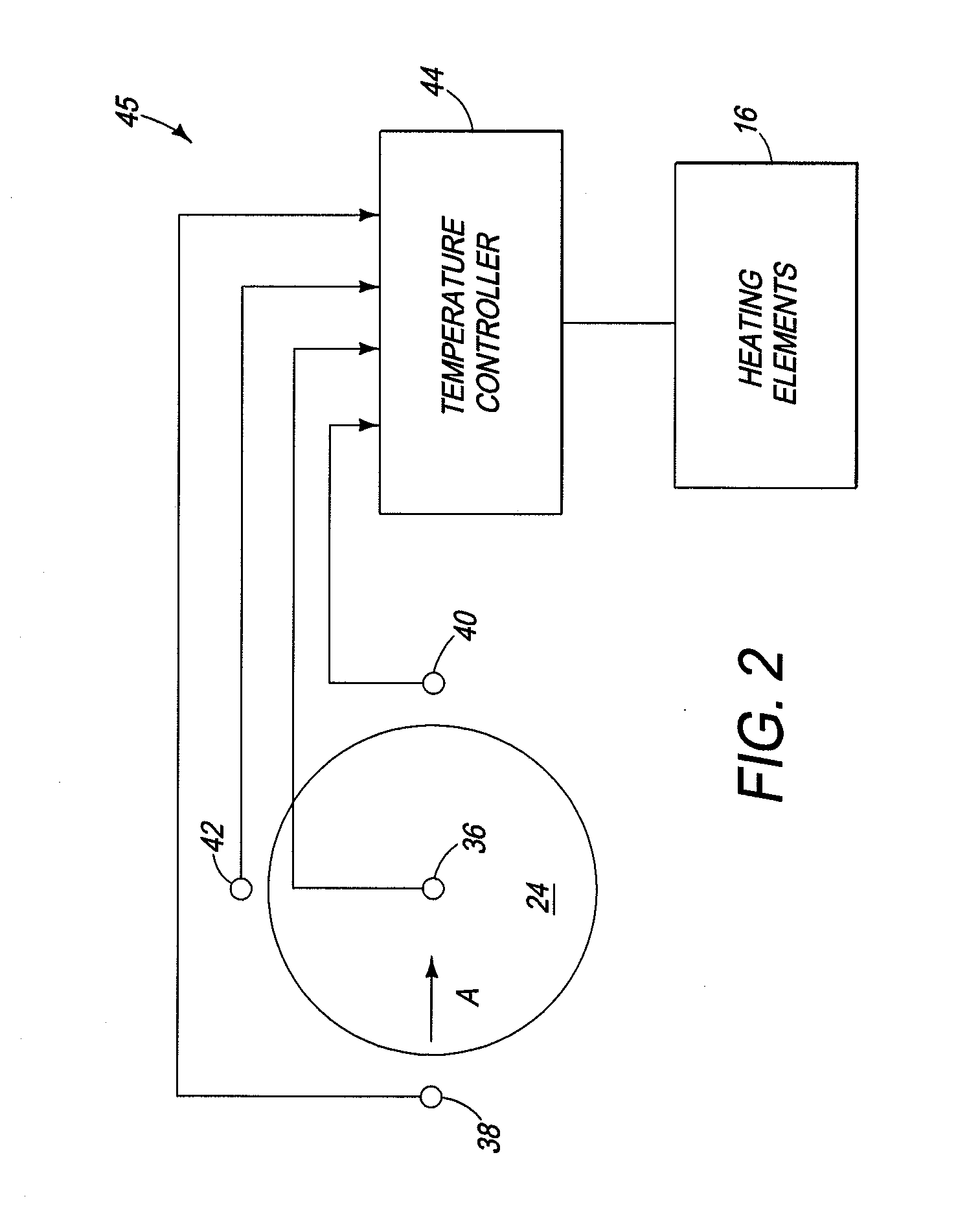

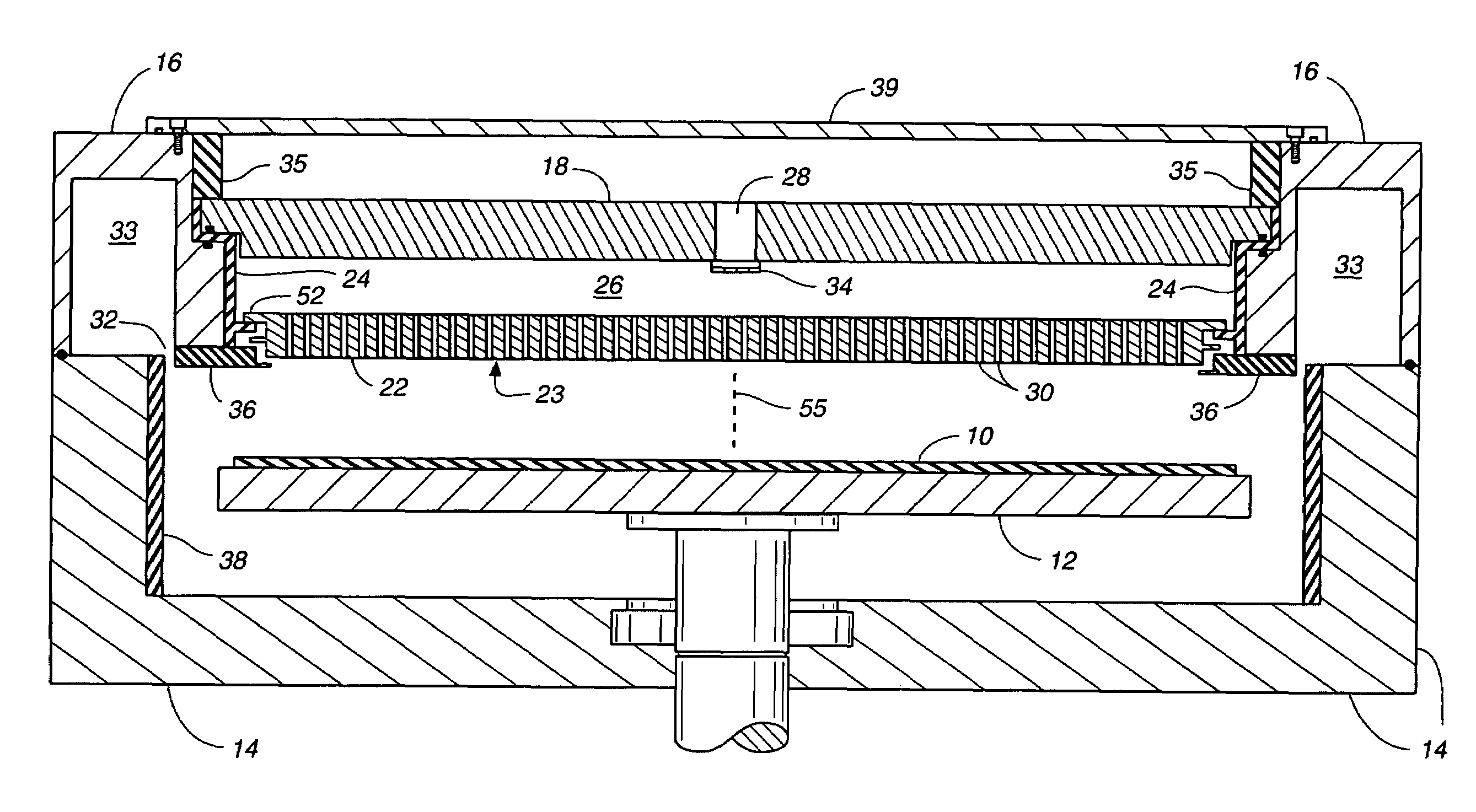

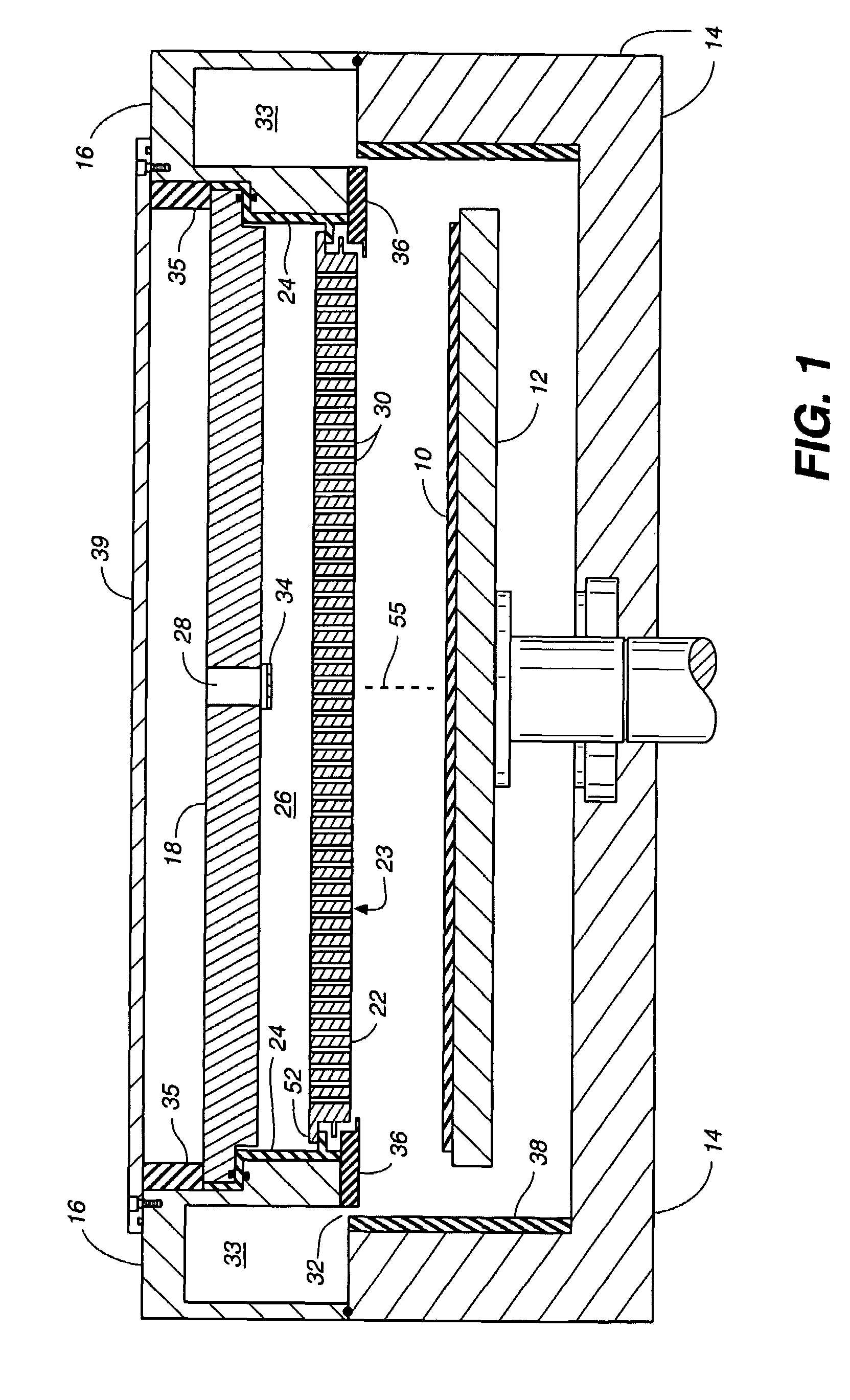

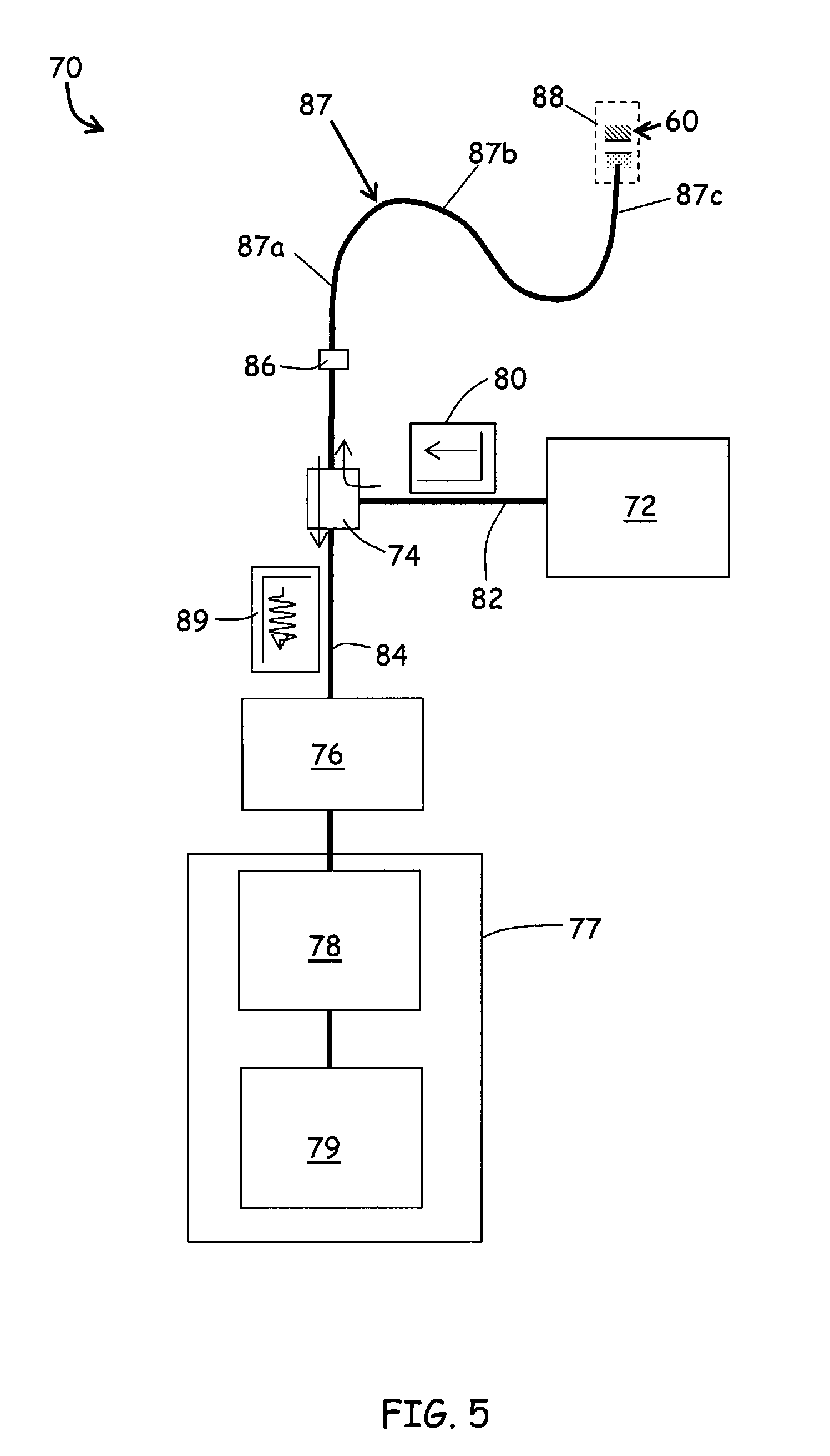

Apparatus and method for steam reprocessing flexible endoscopes

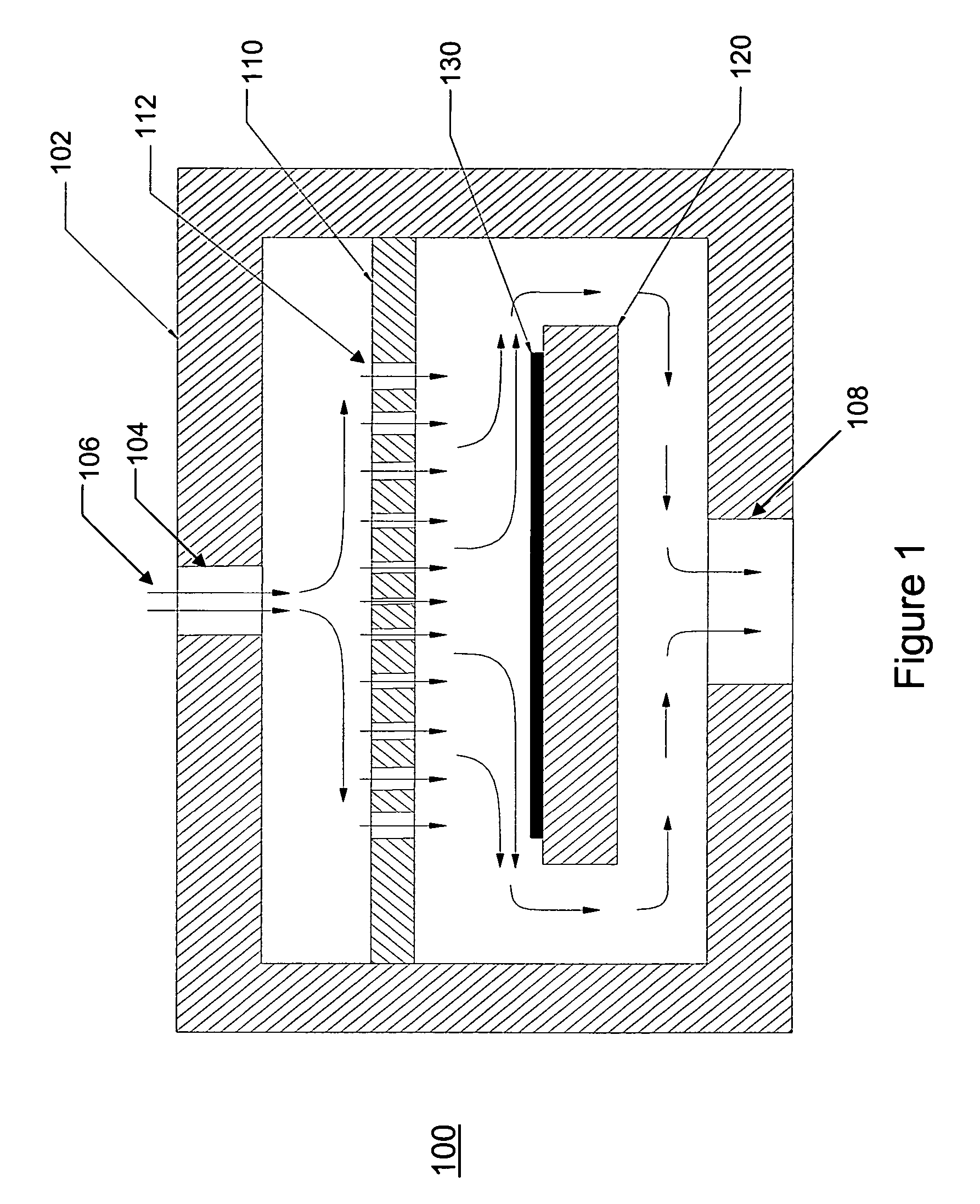

A system for reprocessing flexible endoscopes having lumen therein. The reprocessing system deploys steam to disinfect and / or sterilize the endoscopes, and designs, components, and methods for reducing or balancing the reprocessing cycle time and the effects of thermal expansion and contraction on the endoscopes.

Owner:MEDIVATORS INC

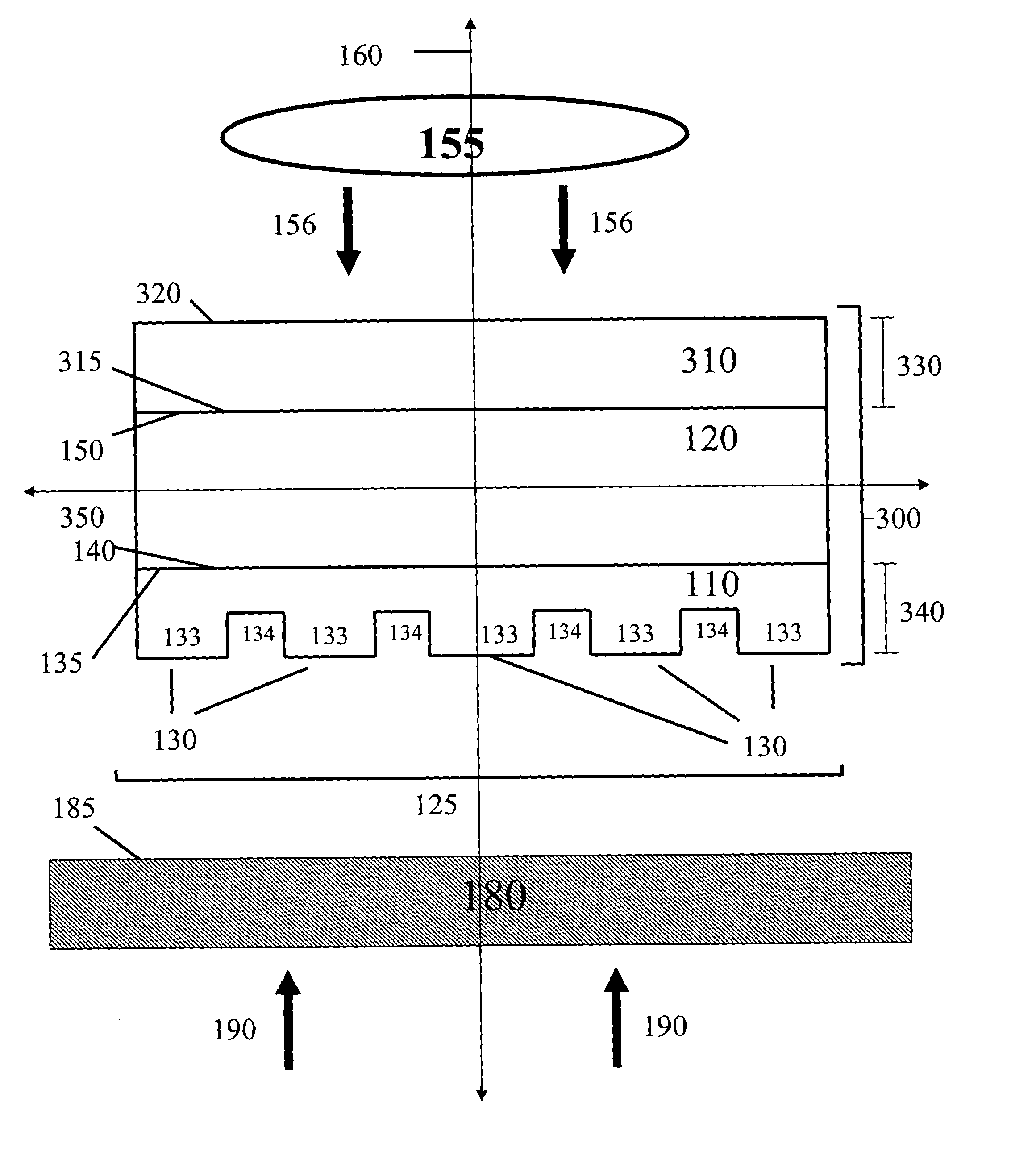

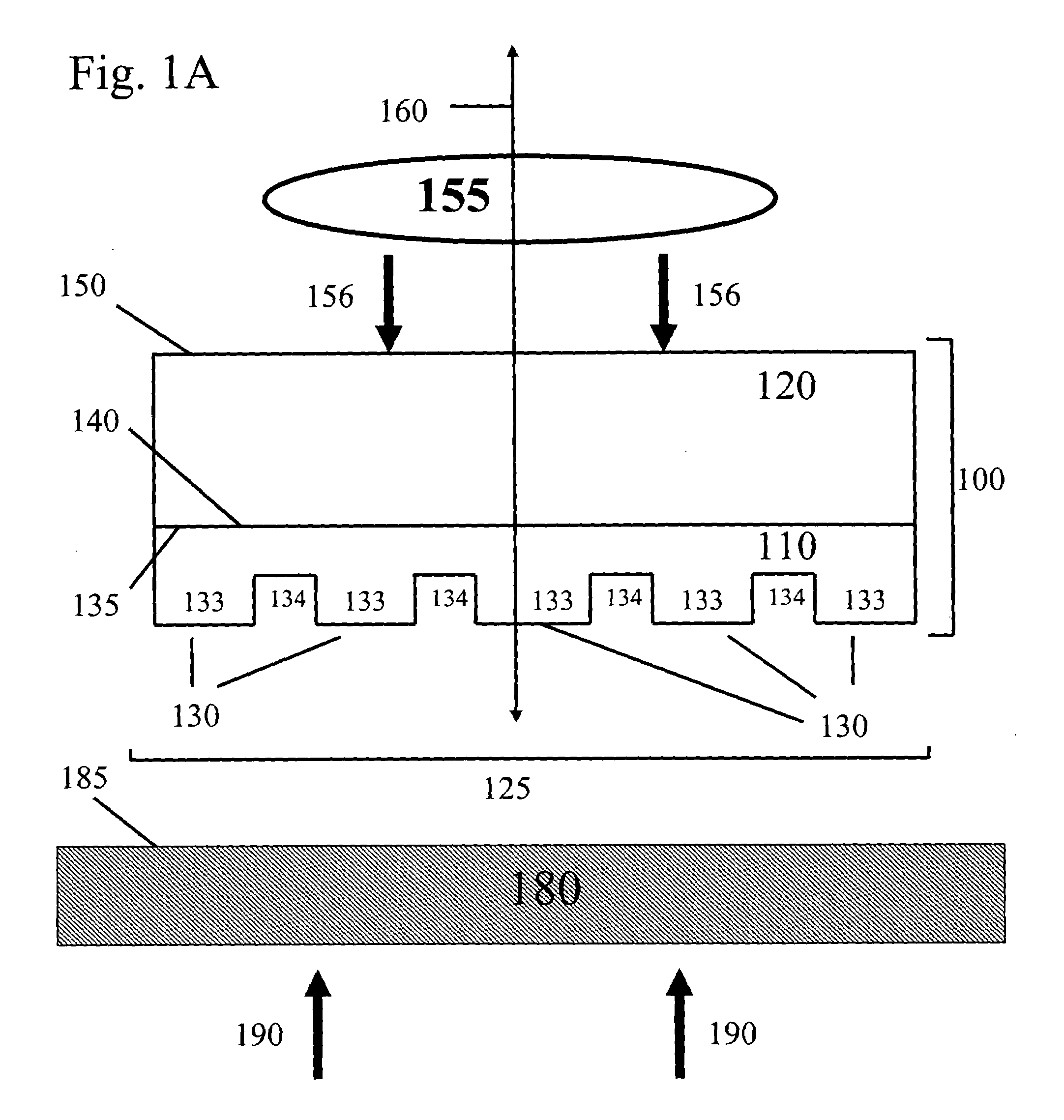

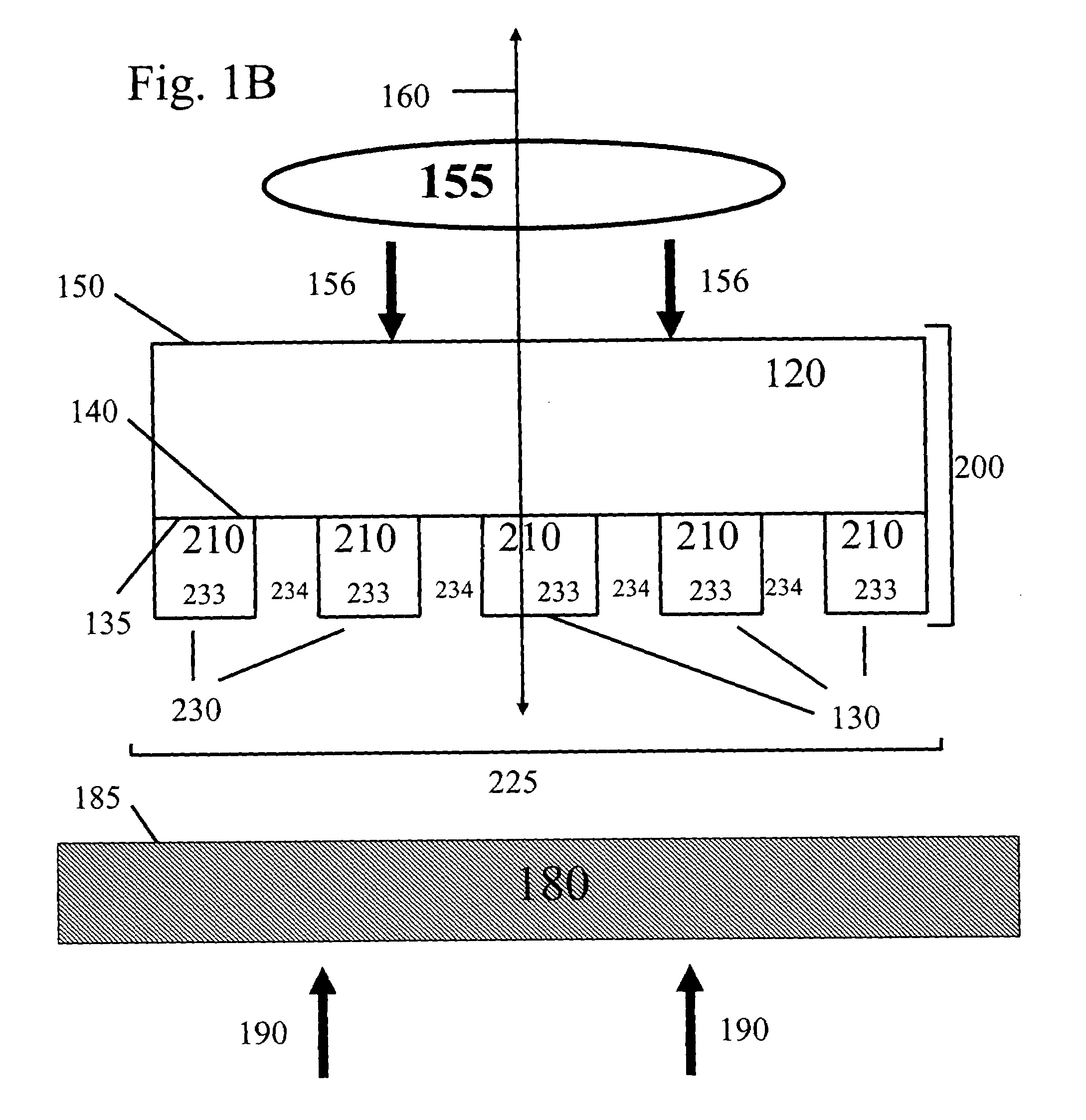

Composite patterning devices for soft lithography

ActiveUS7195733B2Improve fidelityIncrease resistanceMaterial nanotechnologyNanoinformaticsNano sizeYoung's modulus

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

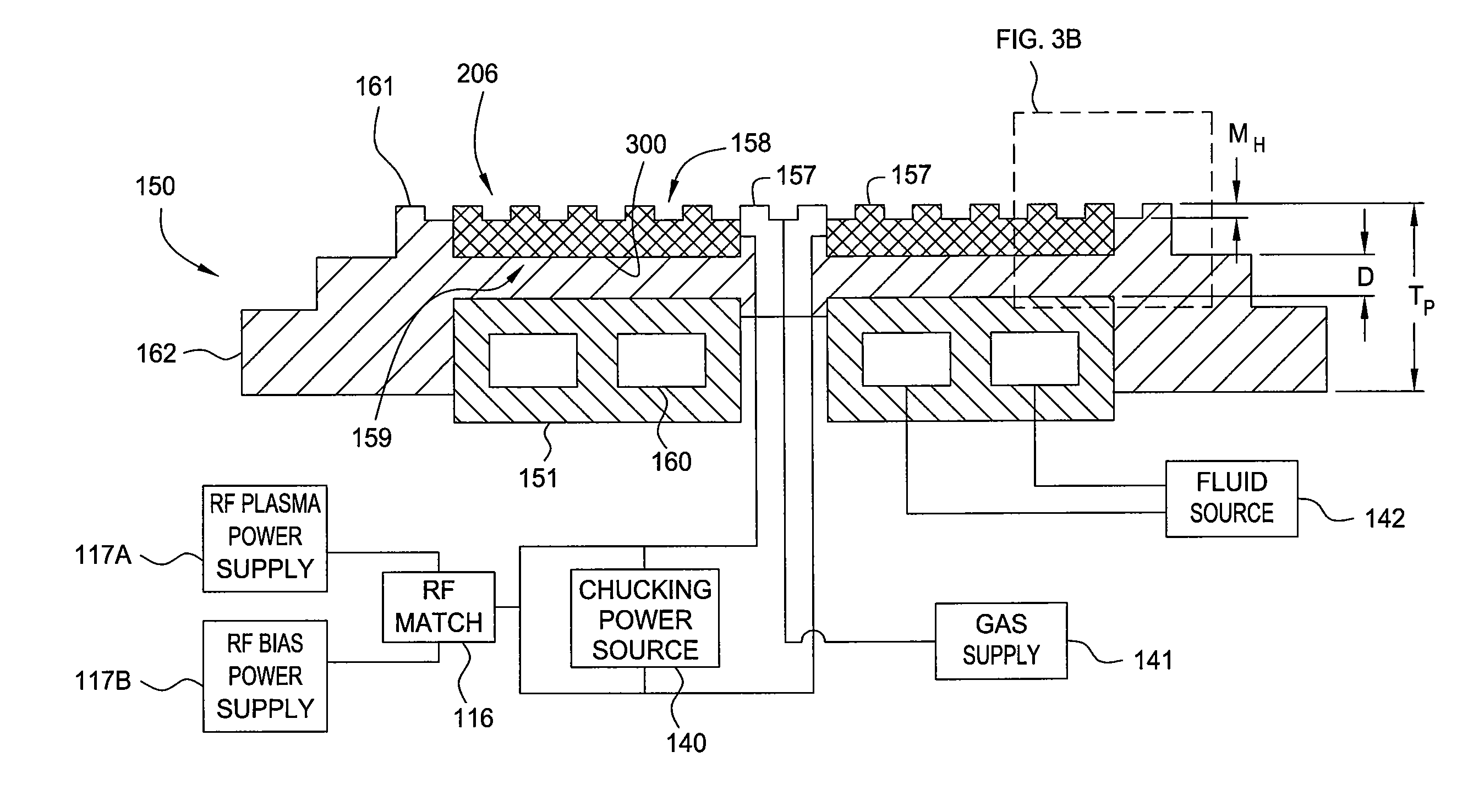

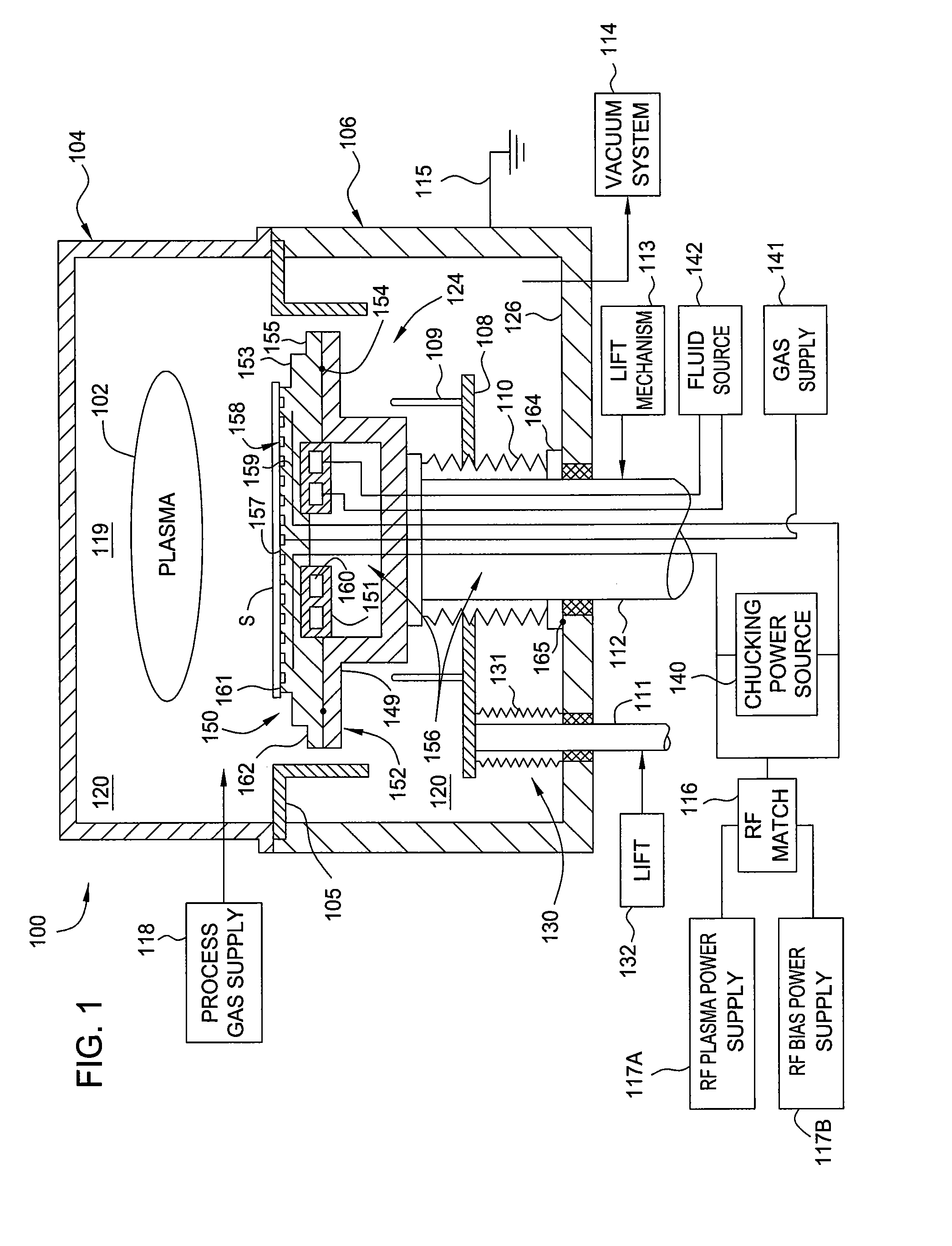

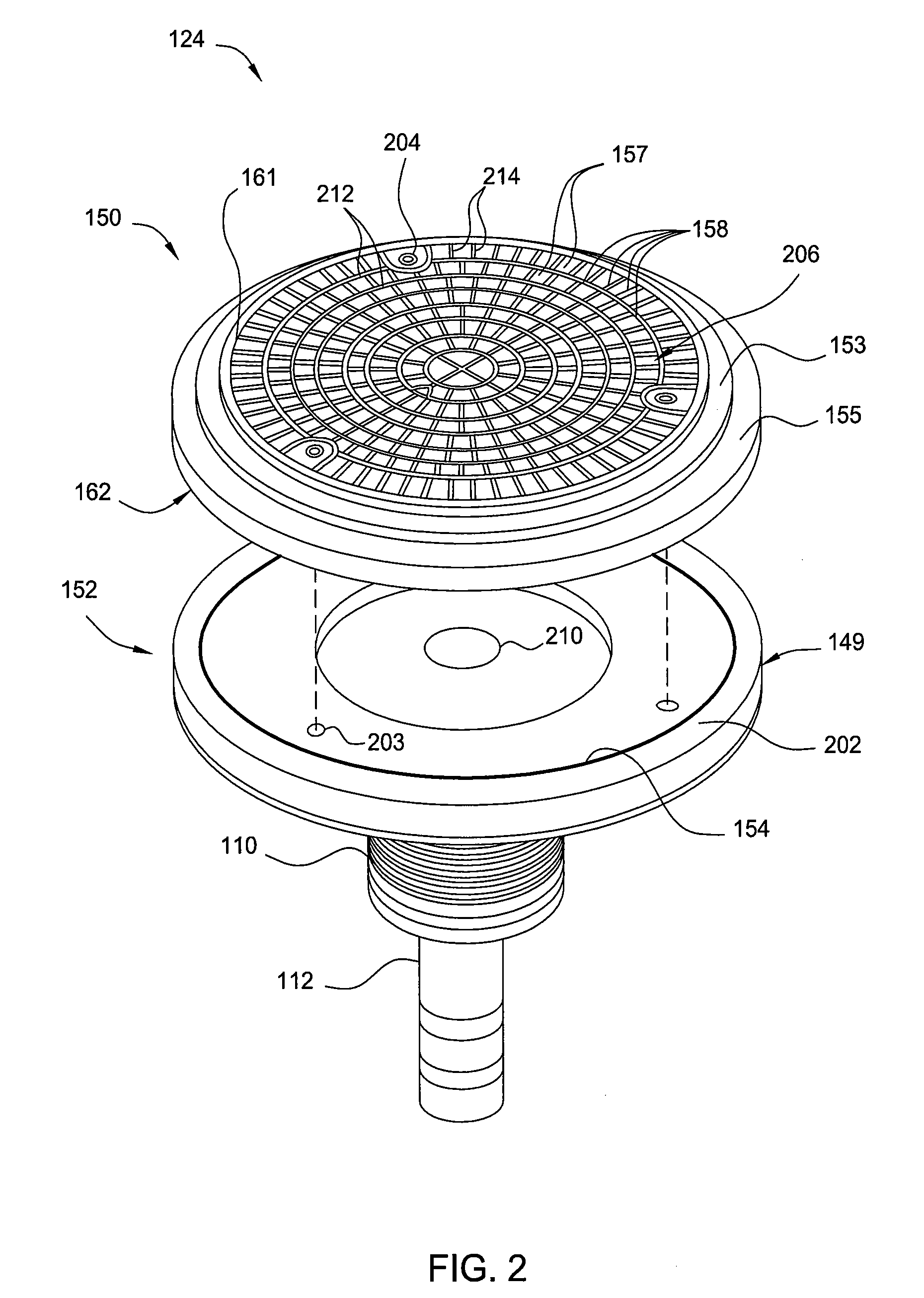

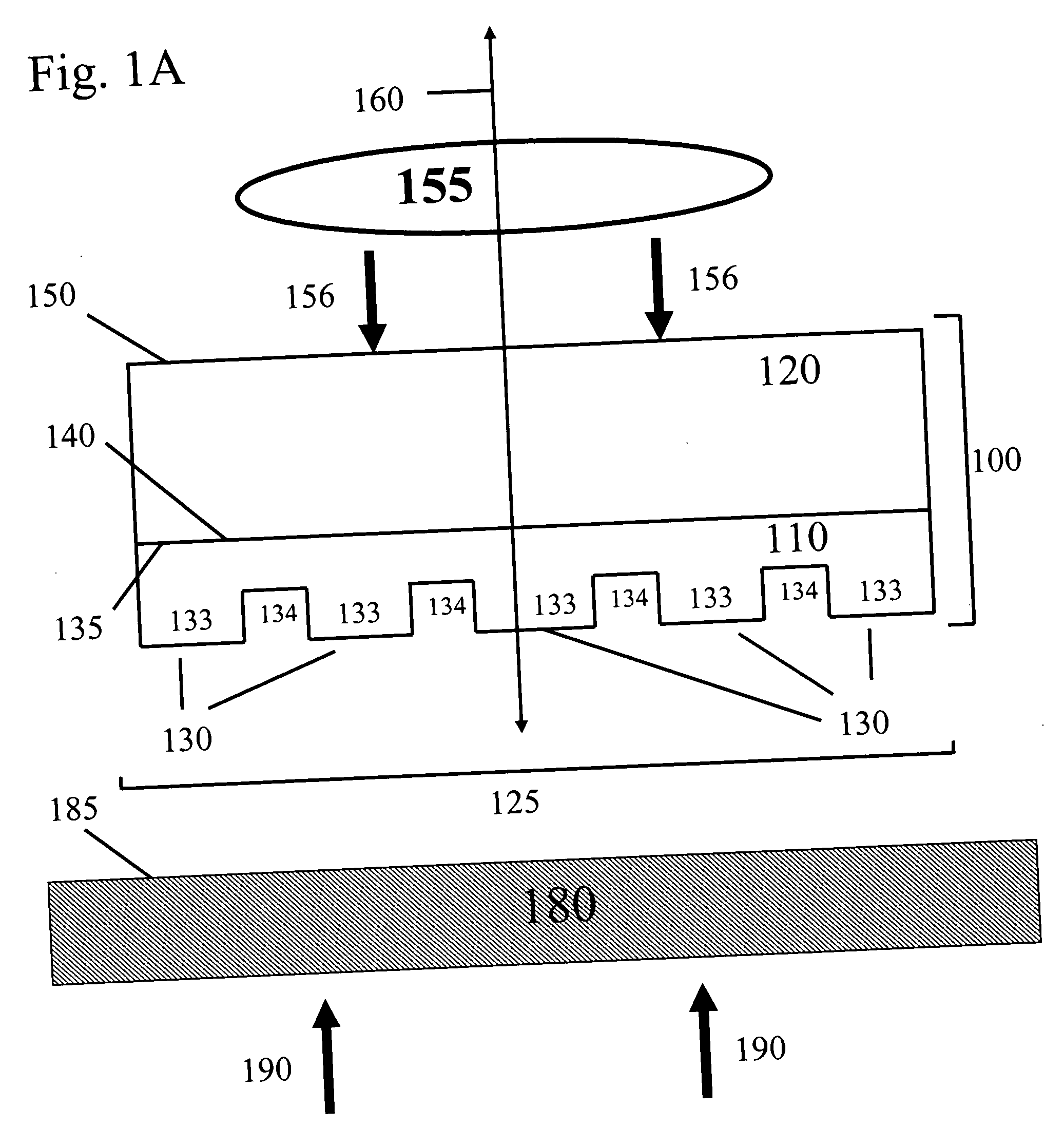

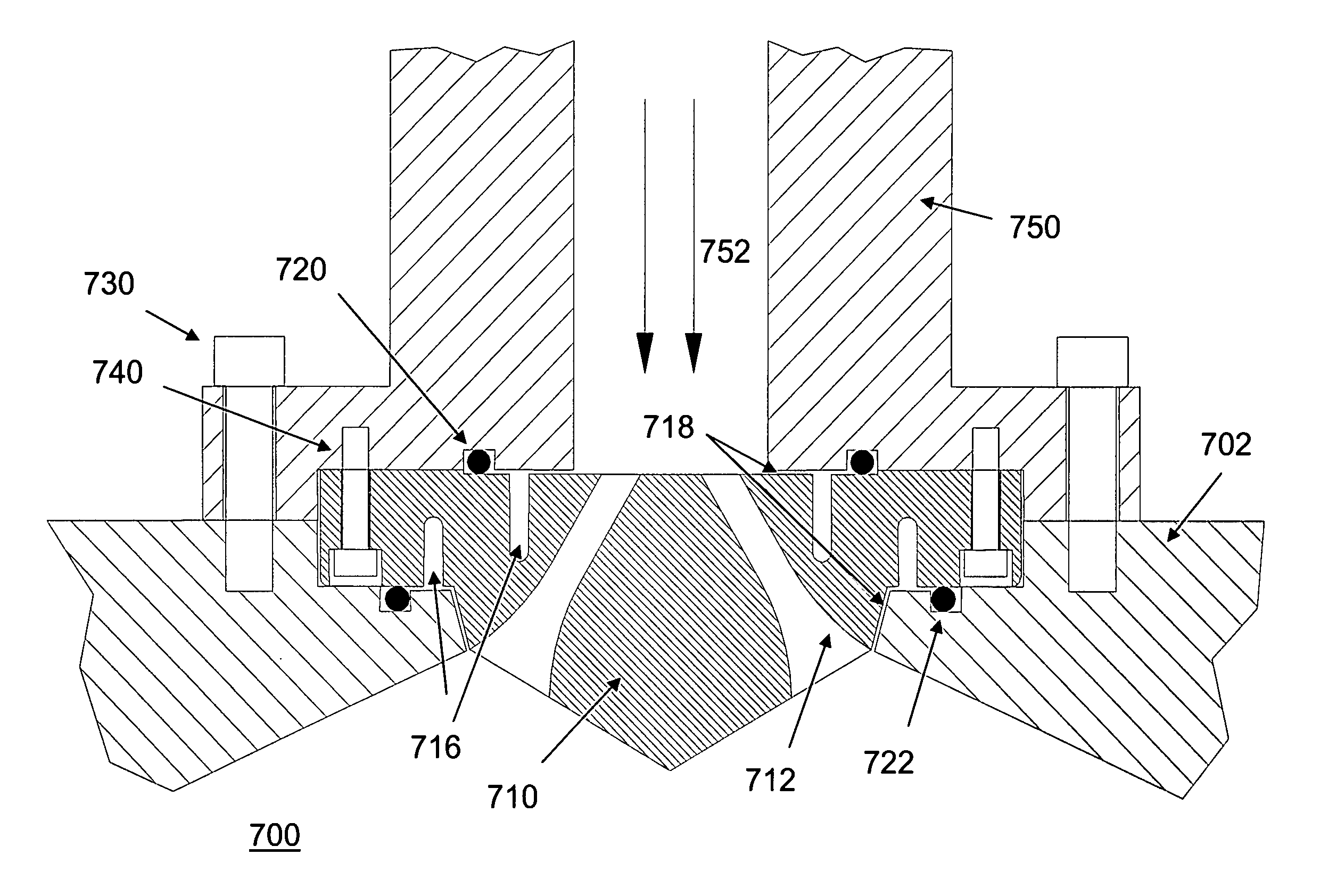

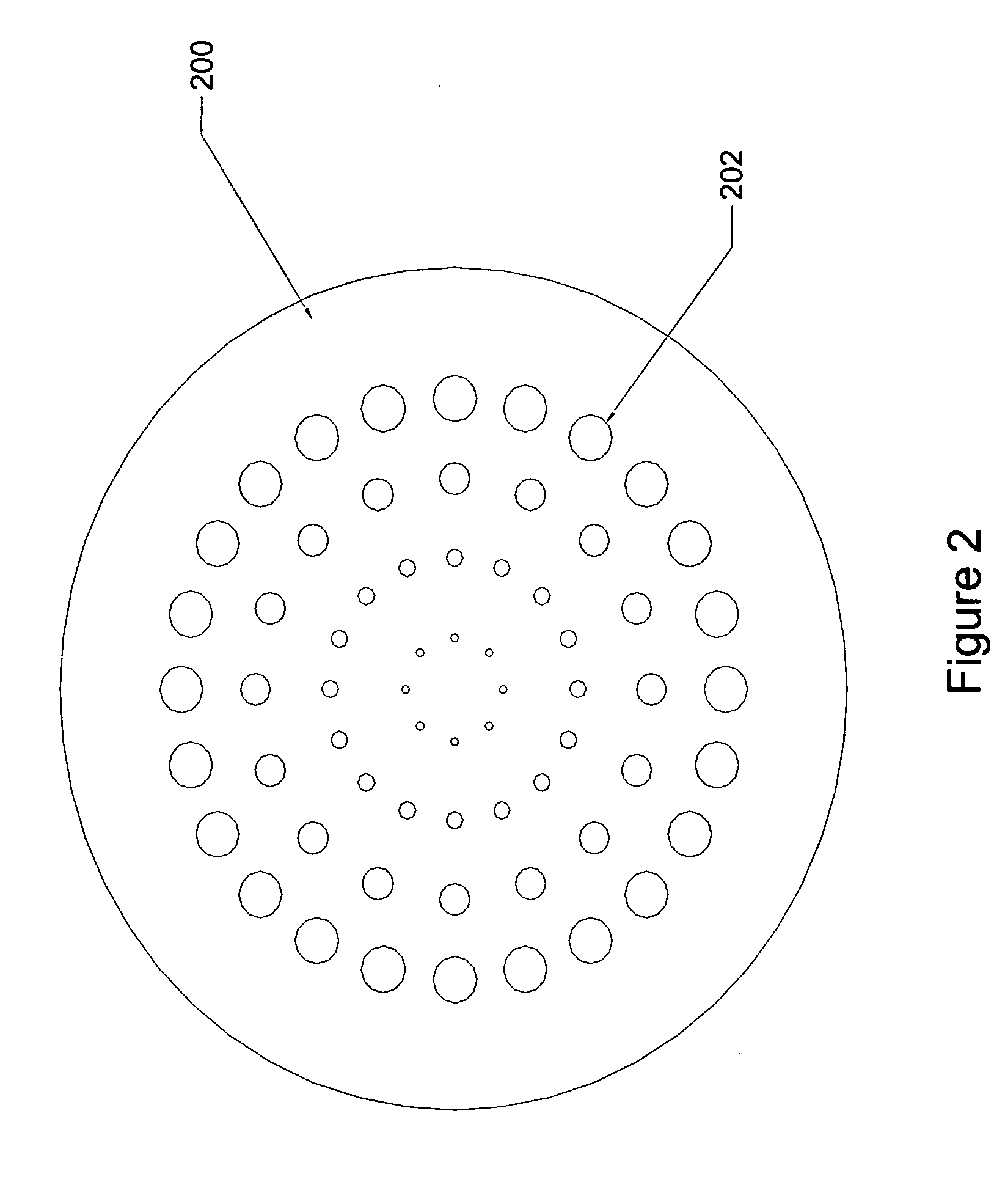

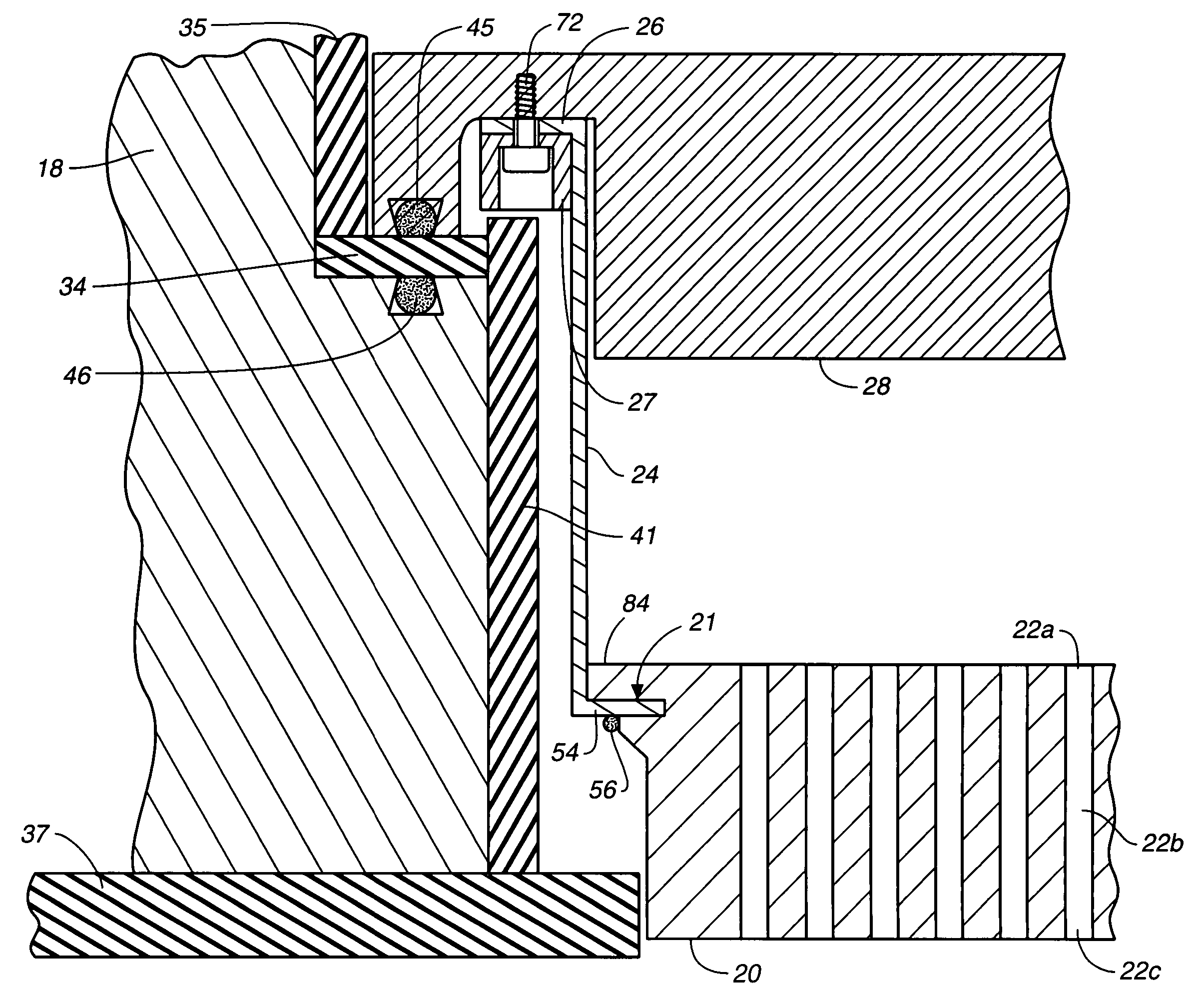

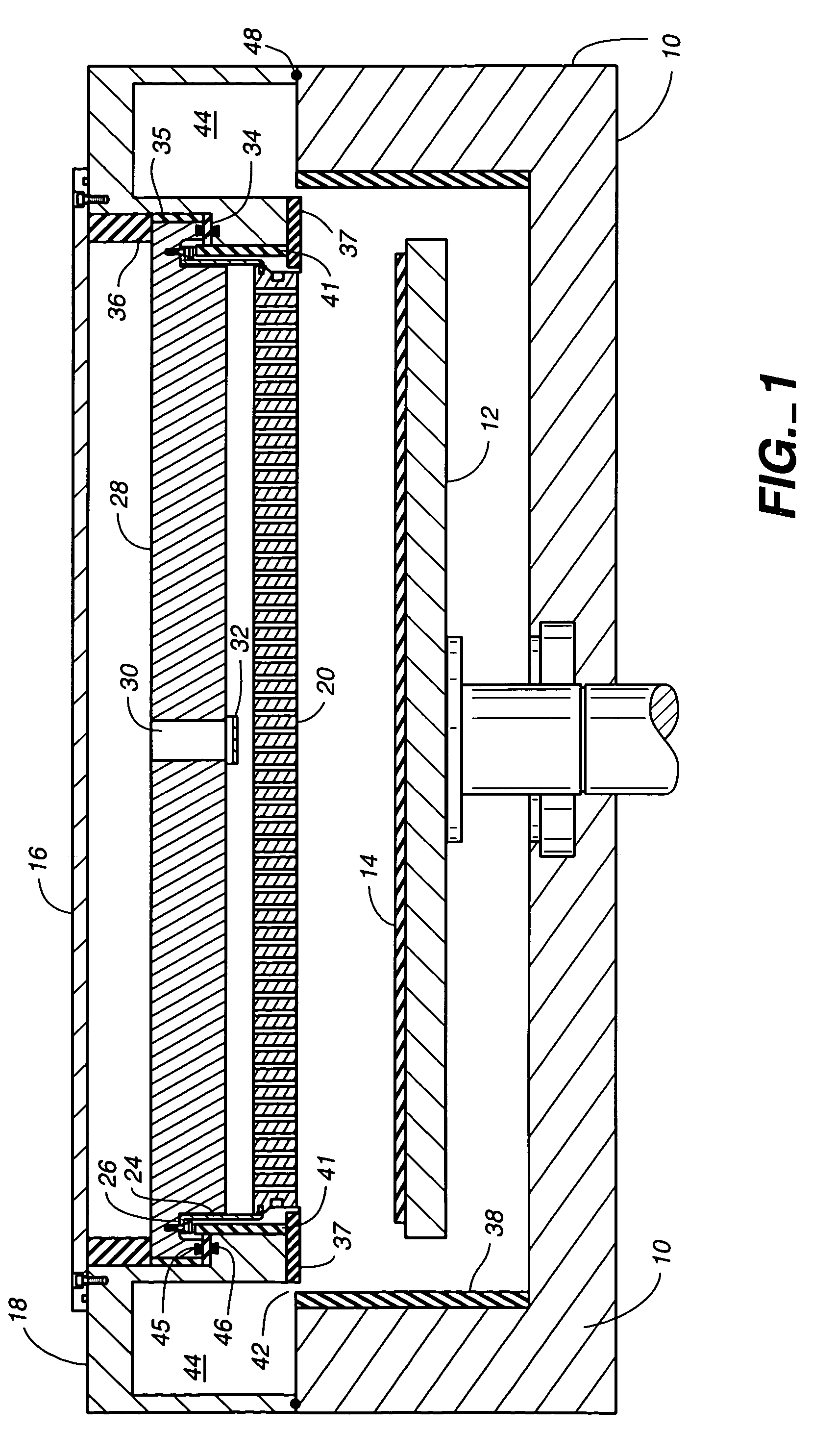

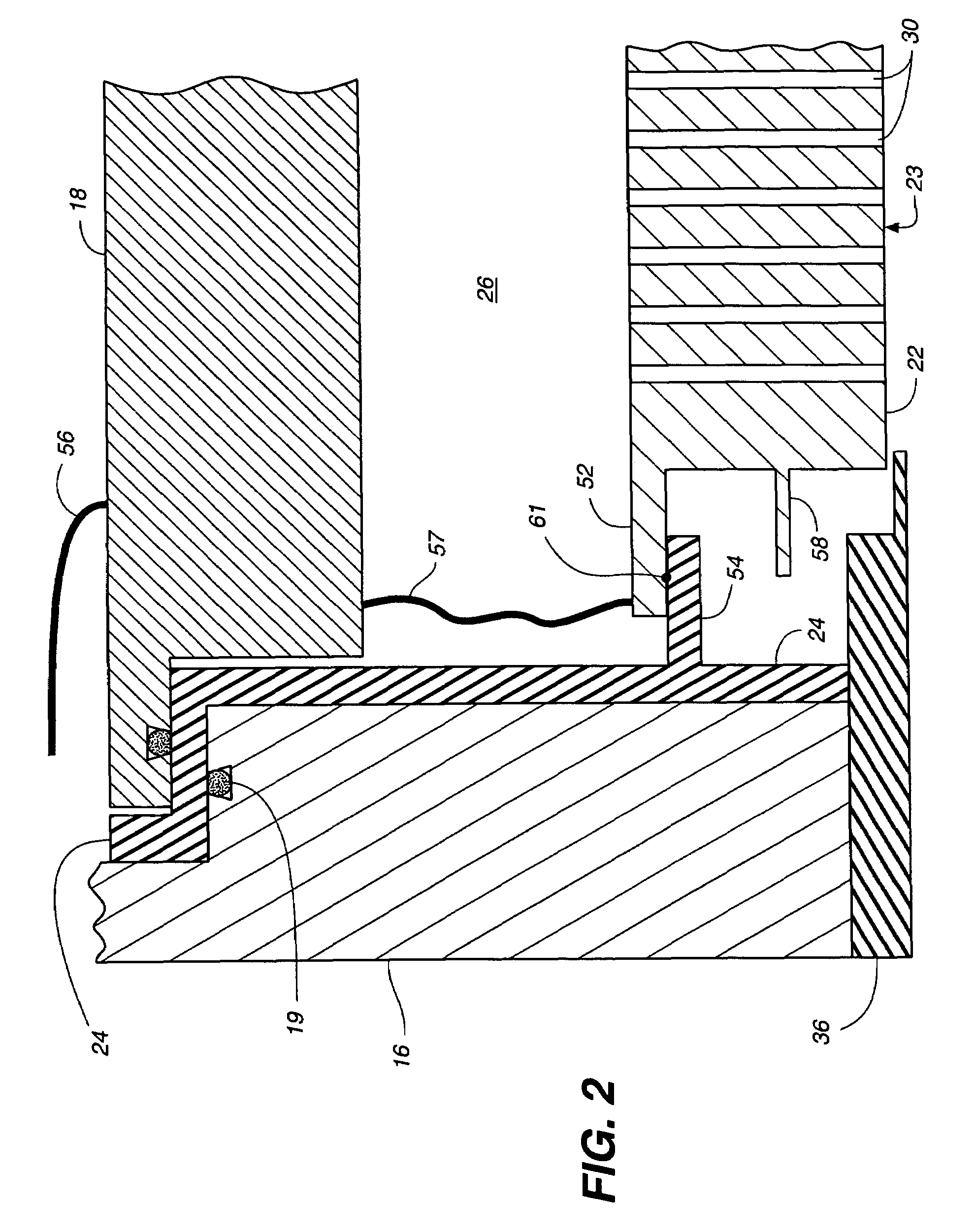

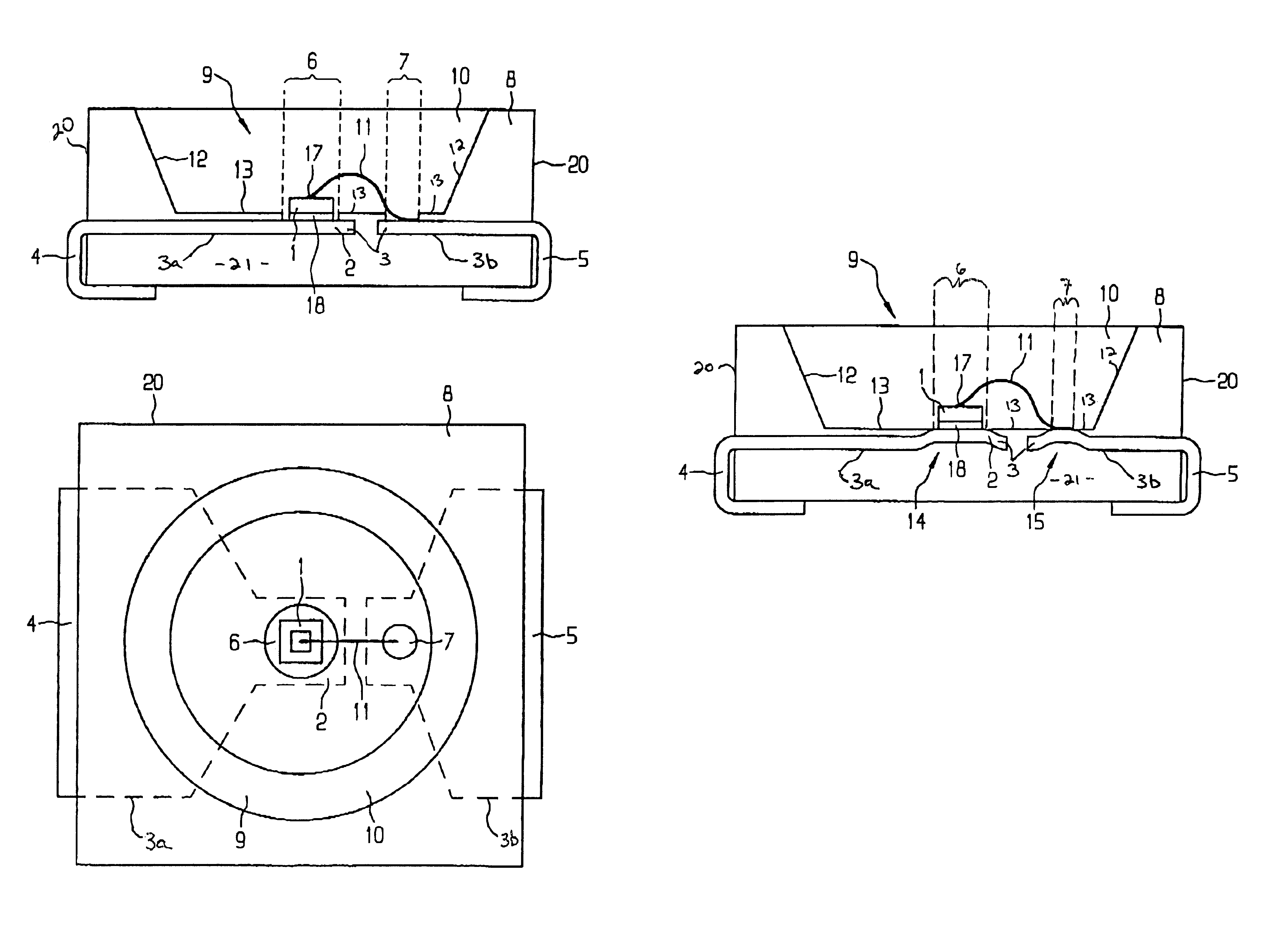

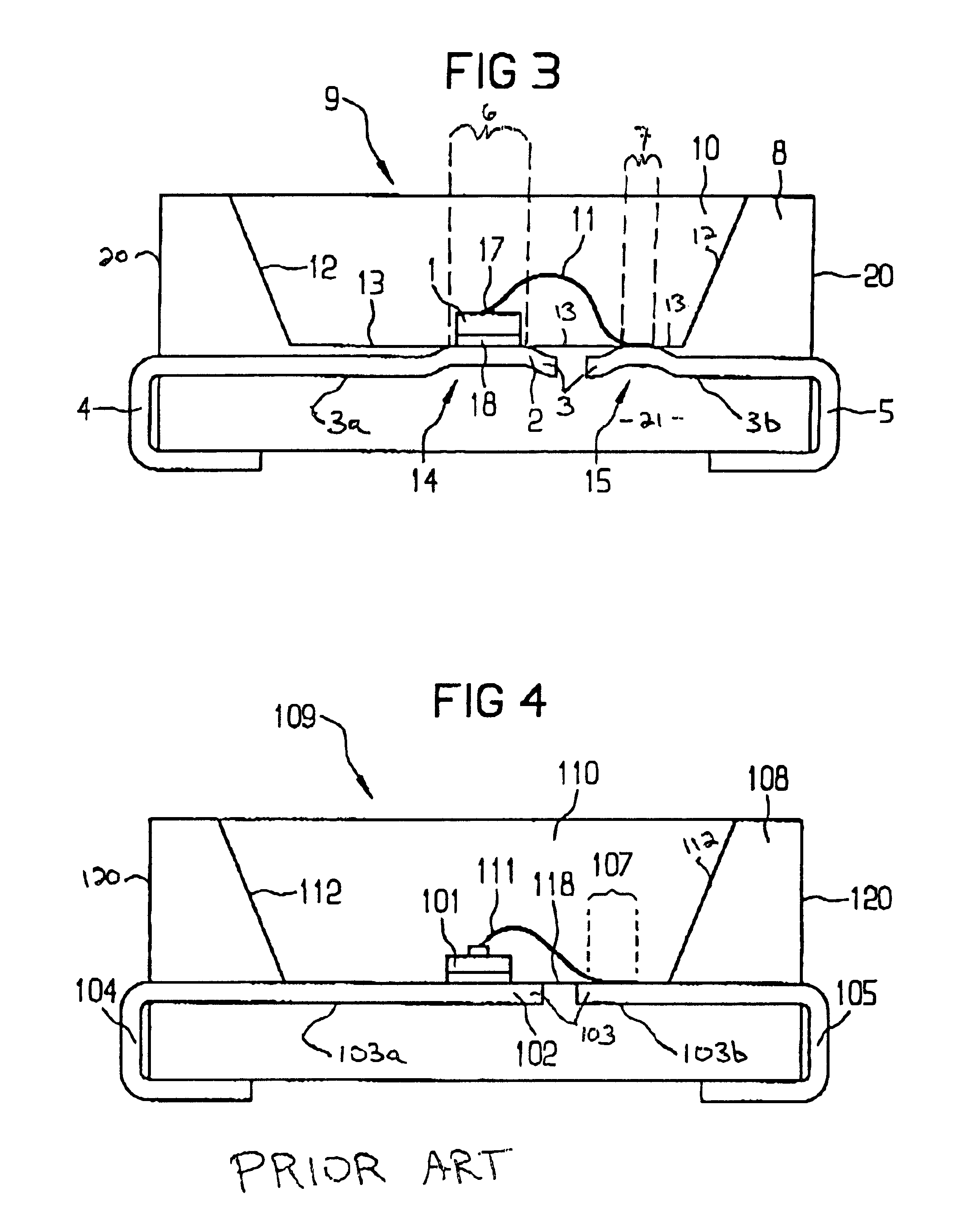

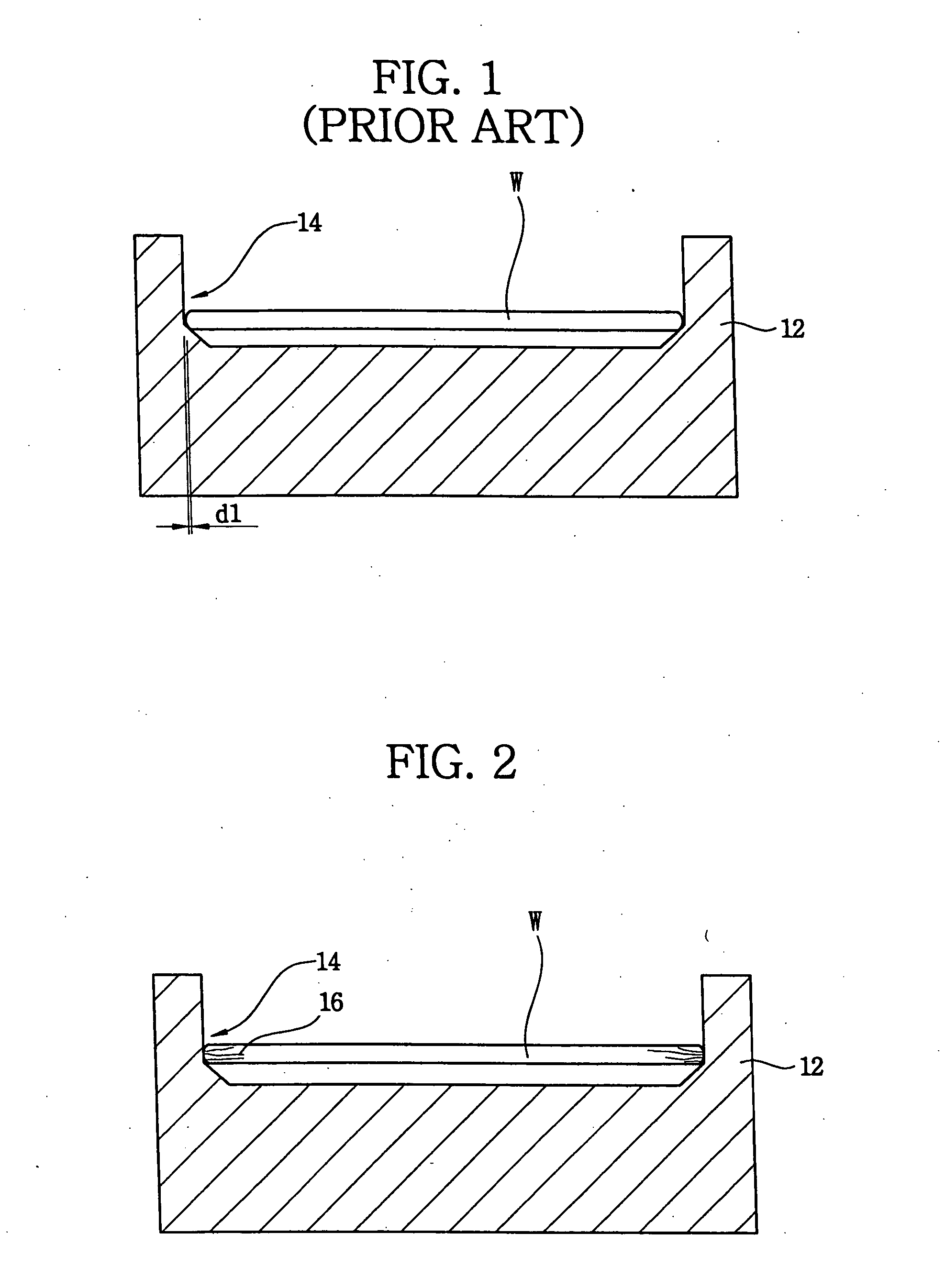

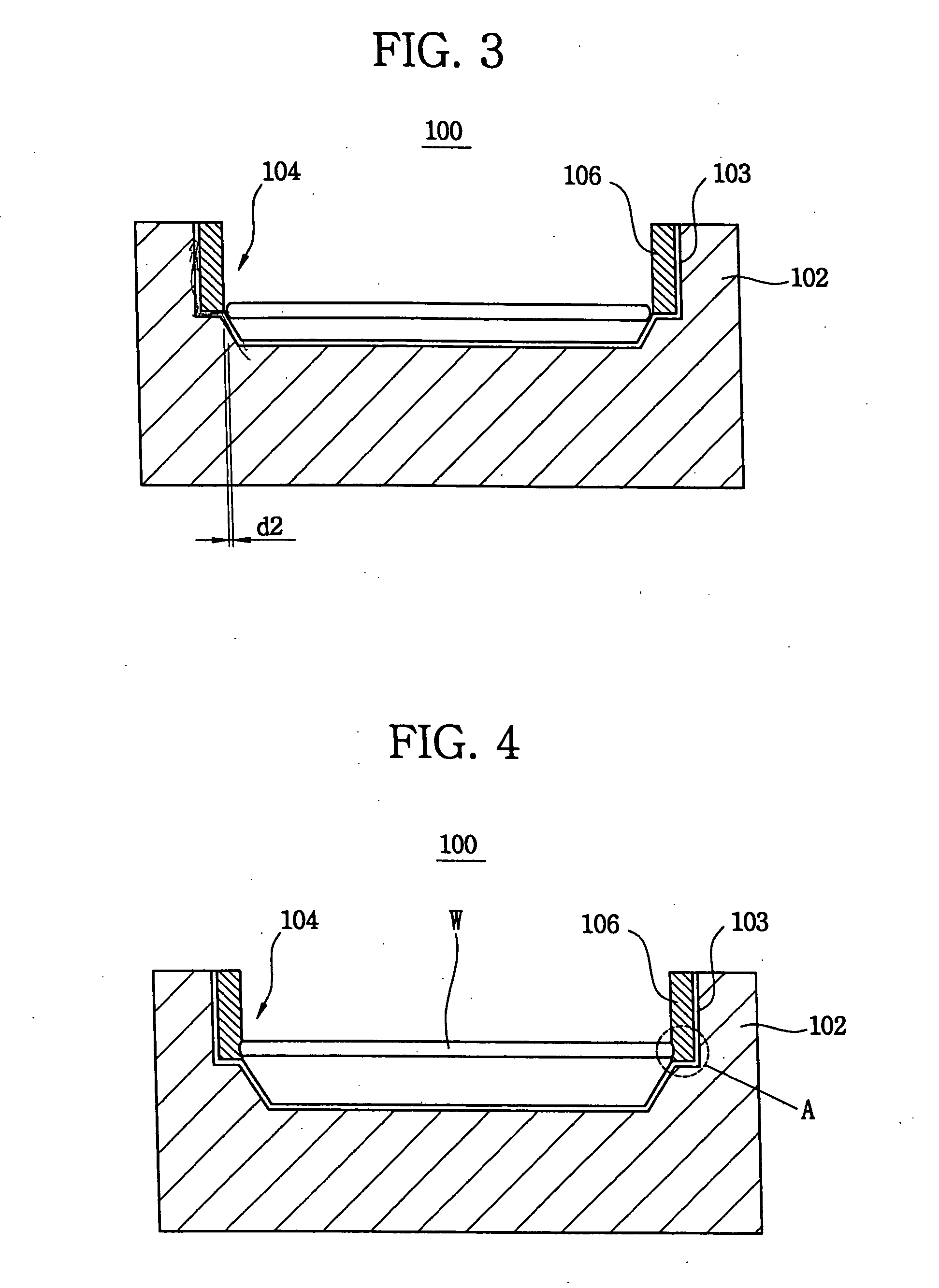

Showerhead mounting to accommodate thermal expansion

InactiveUS20050183827A1Minimize and eliminate distortionGreat thermal expansion coefficientElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringThermal expansion

Methods and apparatus for accommodating thermal expansion of a showerhead. In a first aspect of the invention, the showerhead is movably supported by resting a rim of the showerhead on a support shelf. In a second aspect, the showerhead is suspended from the chamber wall by a plurality of hangers that are connected to the showerhead, the chamber wall, or both by pins that slide within slots so as to permit the hangers to slide radially to accommodate thermal expansion of the showerhead in the radial direction. In a third aspect, the showerhead is suspended from the wall of the vacuum chamber by a plurality of rods or flexible wires. In a fourth aspect, the showerhead is connected near its perimeter to a second material having a greater thermal expansion coefficient than the showerhead. In a fifth aspect, a heater is mounted behind the showerhead to reduce the termperature differential between the top and bottom surfaces of the showerhead or to reduce heat transfer from the workpiece to the showerhead.

Owner:APPLIED MATERIALS INC

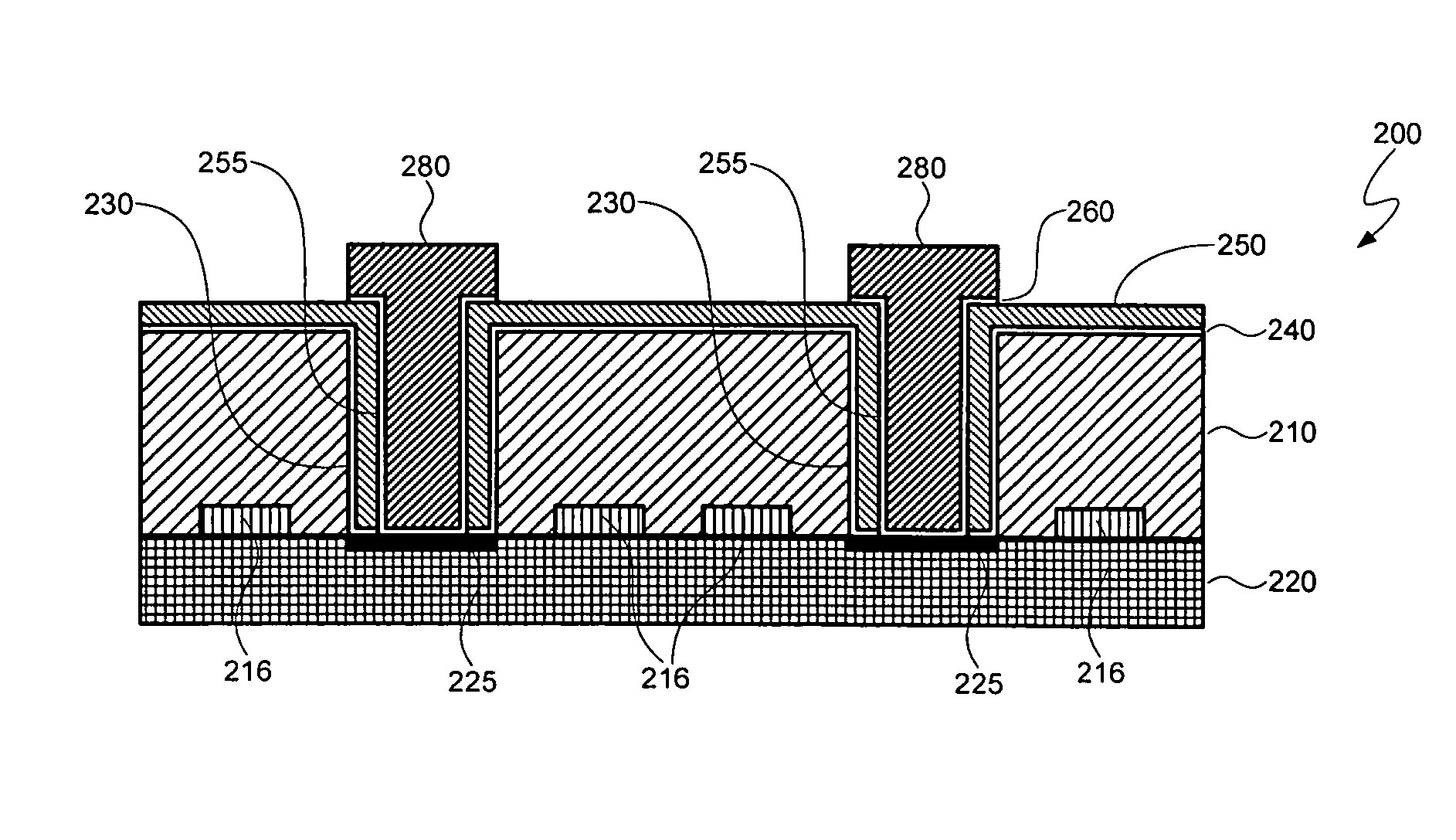

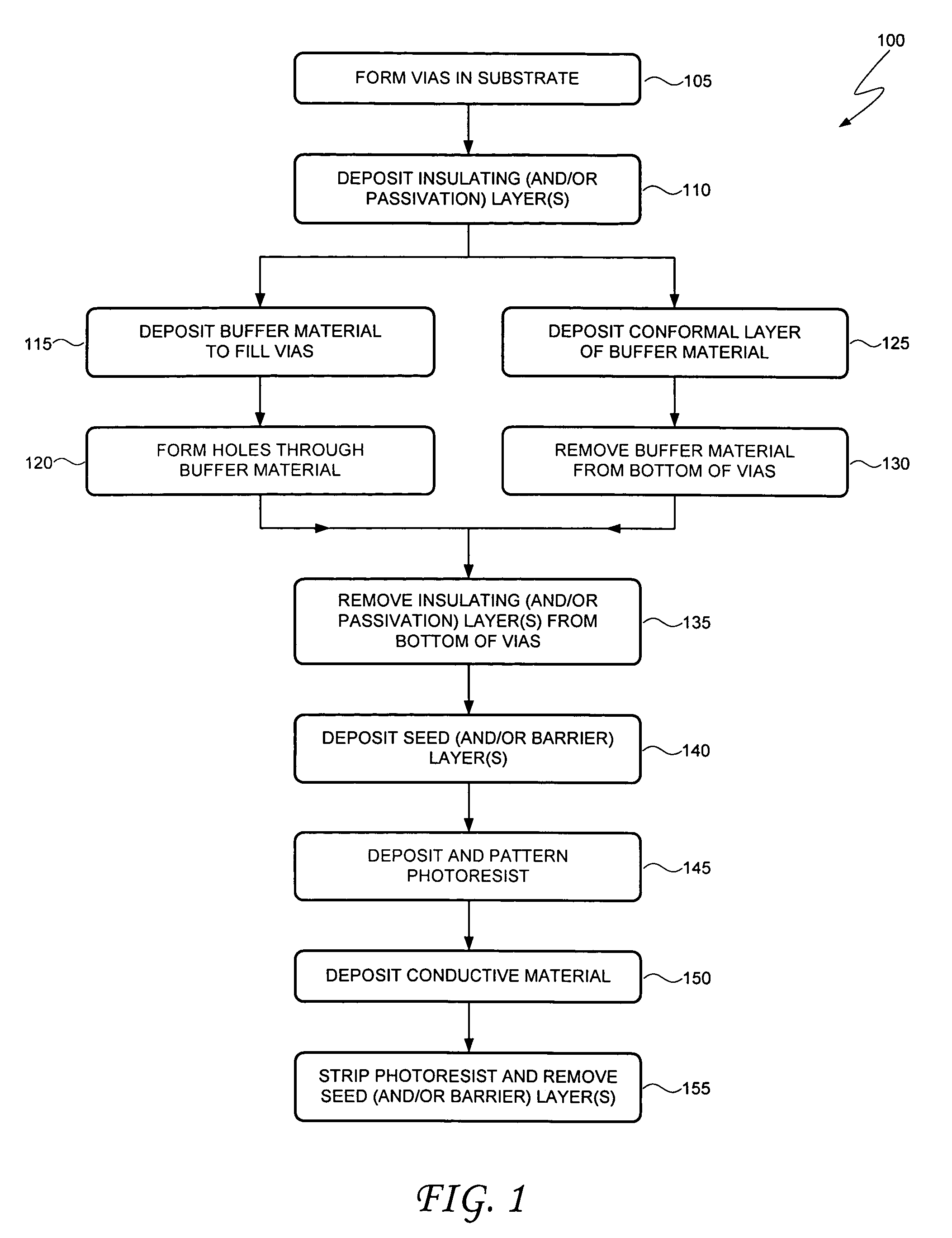

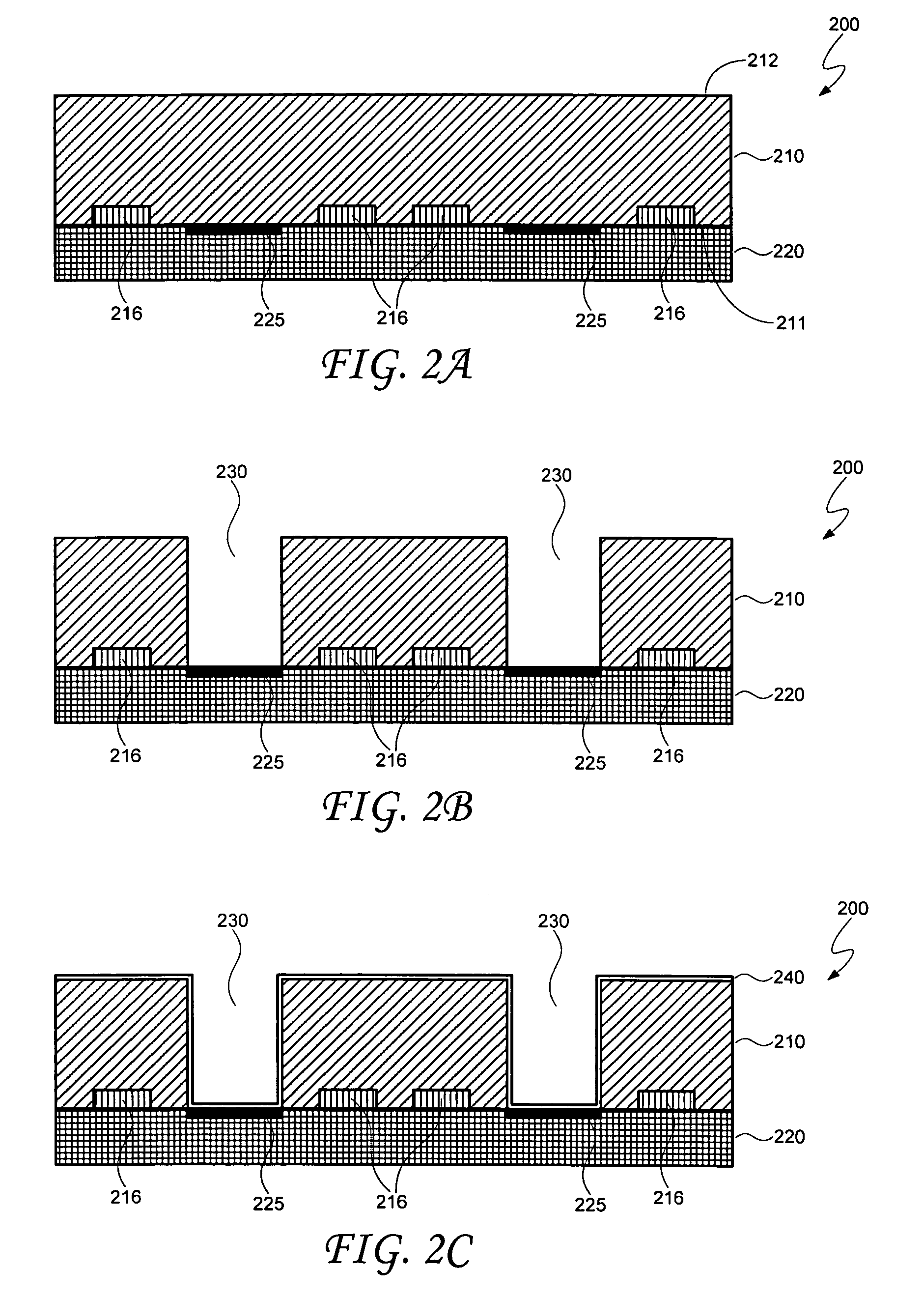

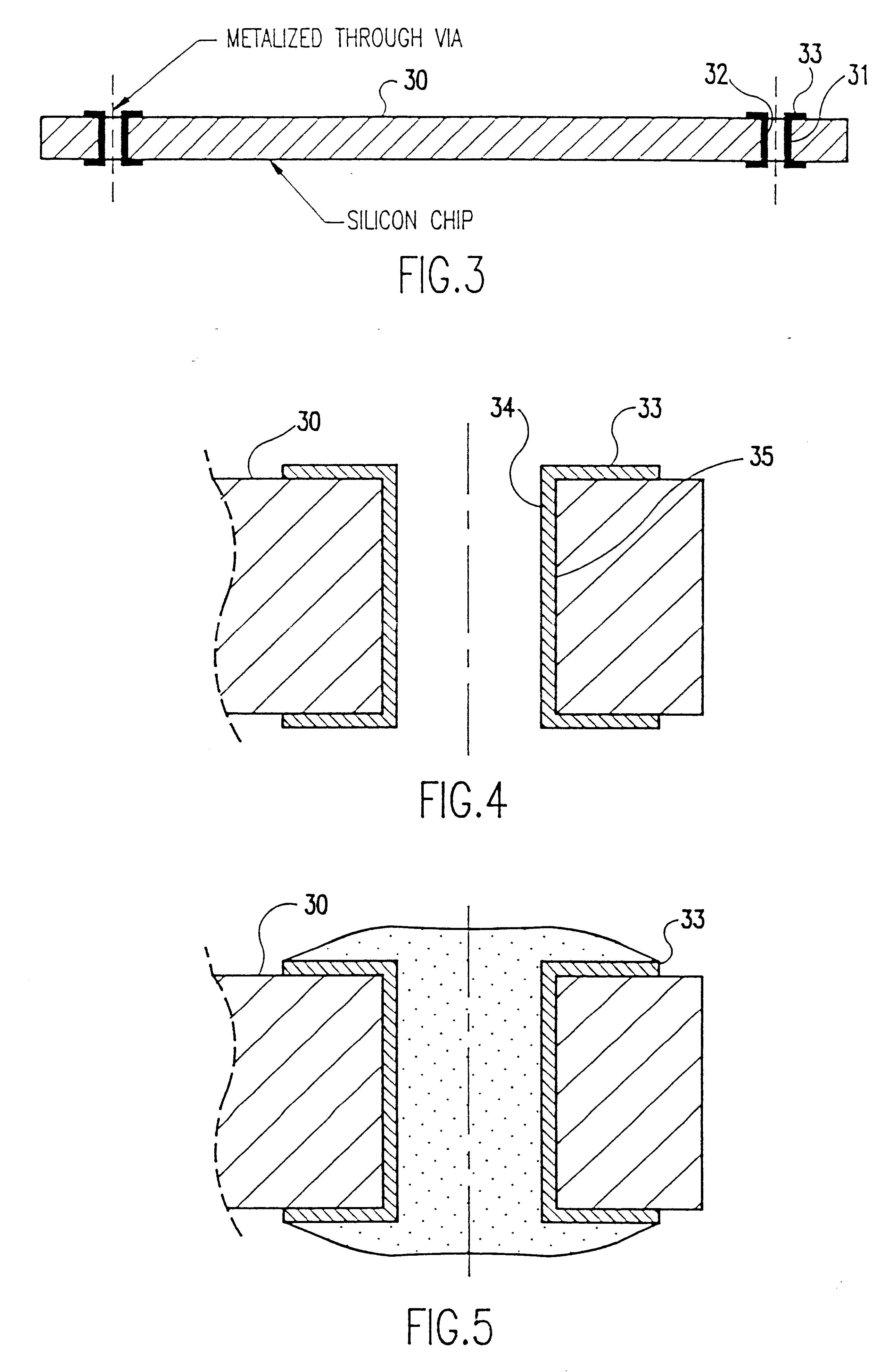

Method of forming through-silicon vias with stress buffer collars and resulting devices

InactiveUS7402515B2Semiconductor/solid-state device detailsSolid-state devicesThermal expansionSilicon

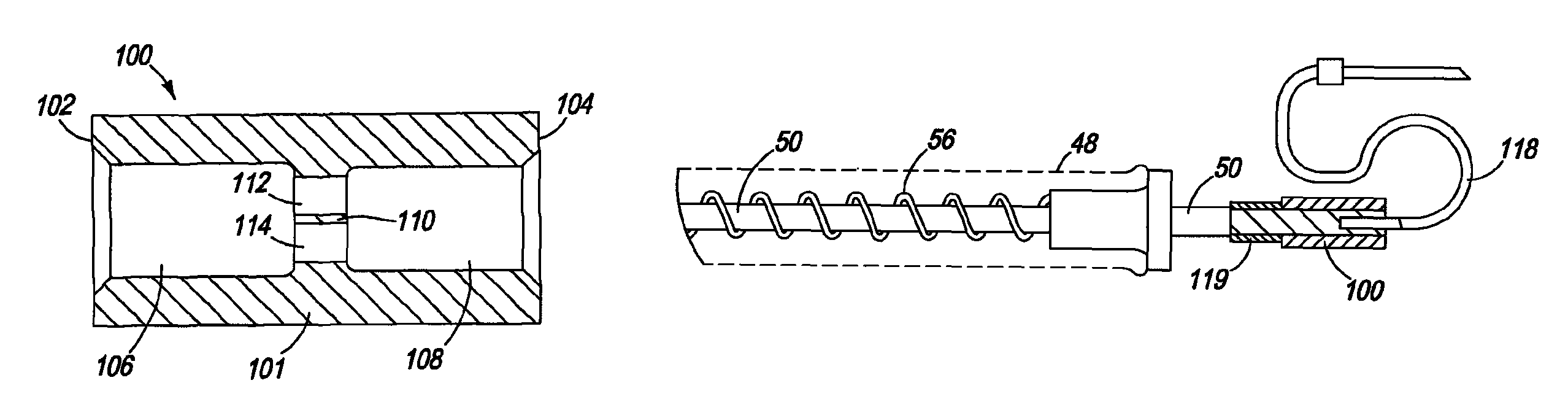

A method of forming a via having a stress buffer collar, wherein the stress buffer collar can absorb stress resulting from a mismatch in the coefficients of thermal expansion of the surrounding materials. Other embodiments are described and claimed.

Owner:INTEL CORP

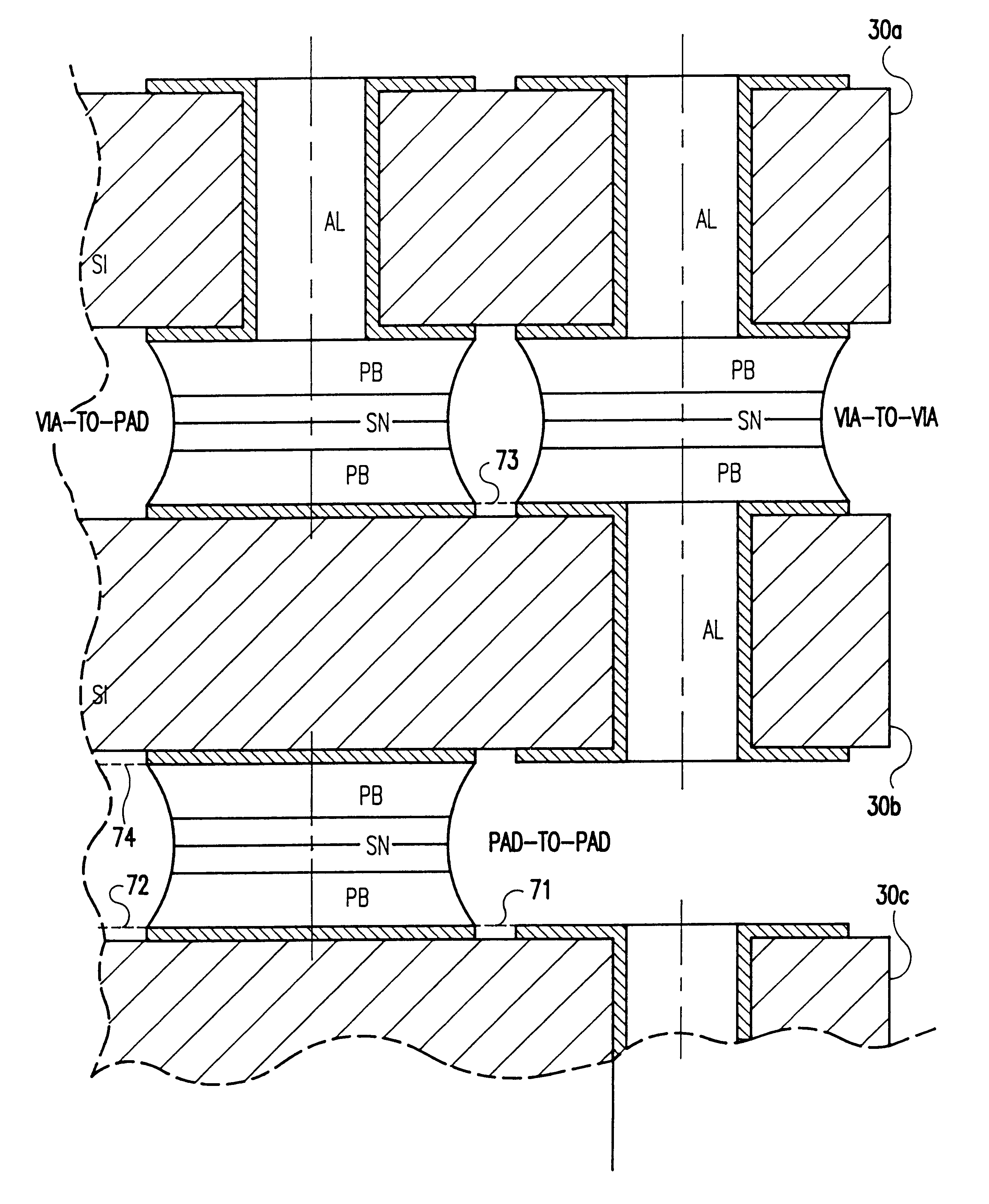

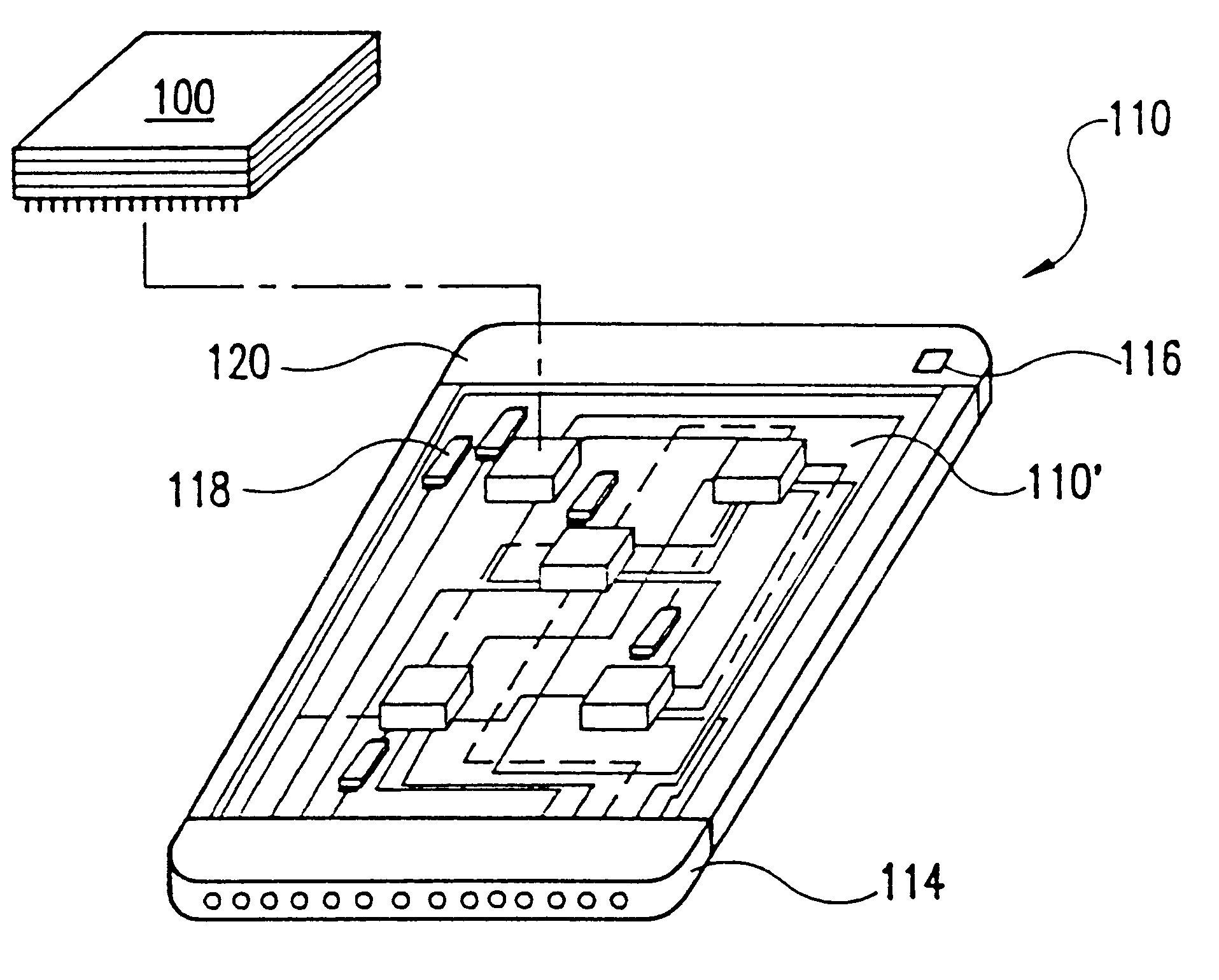

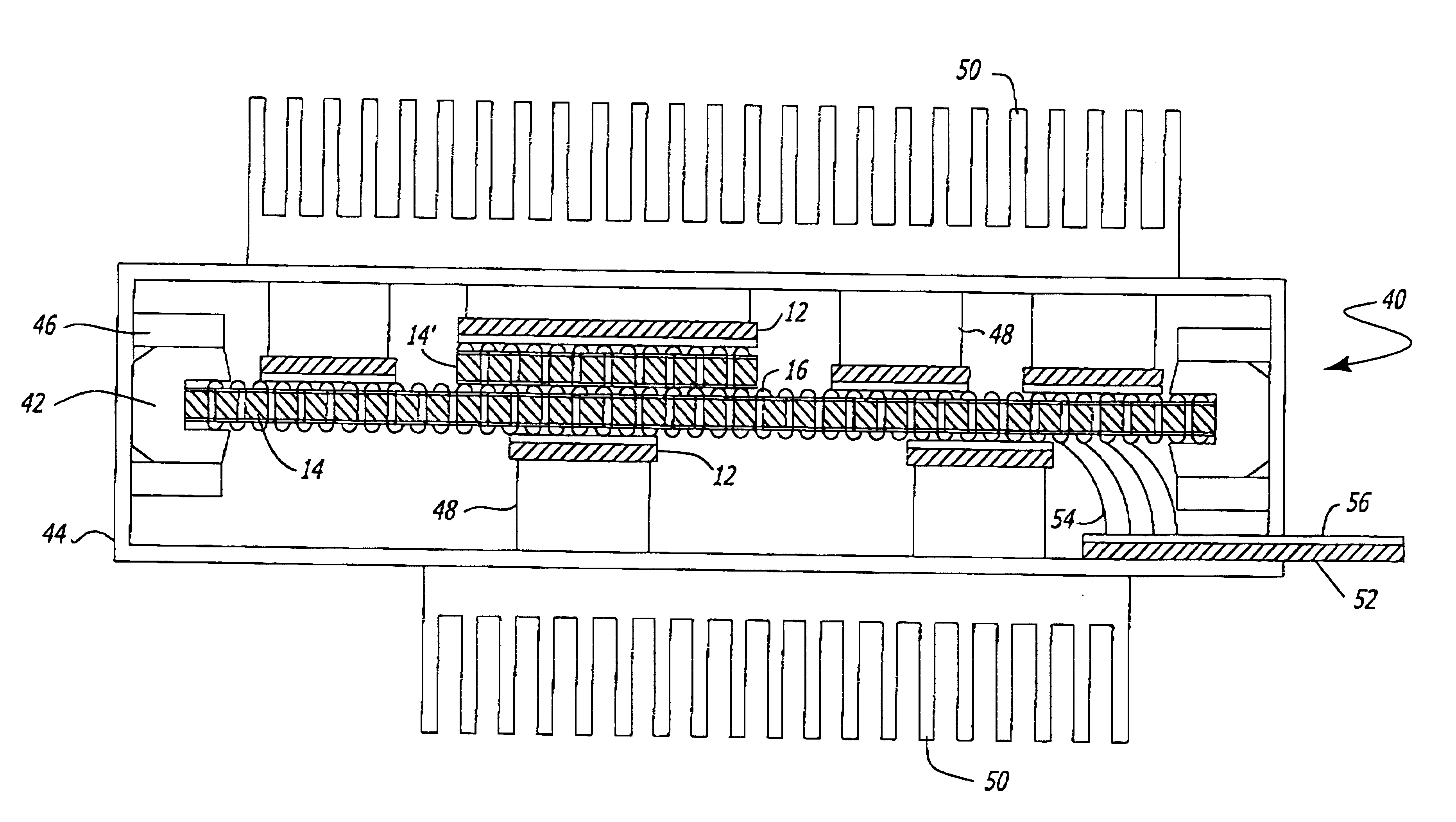

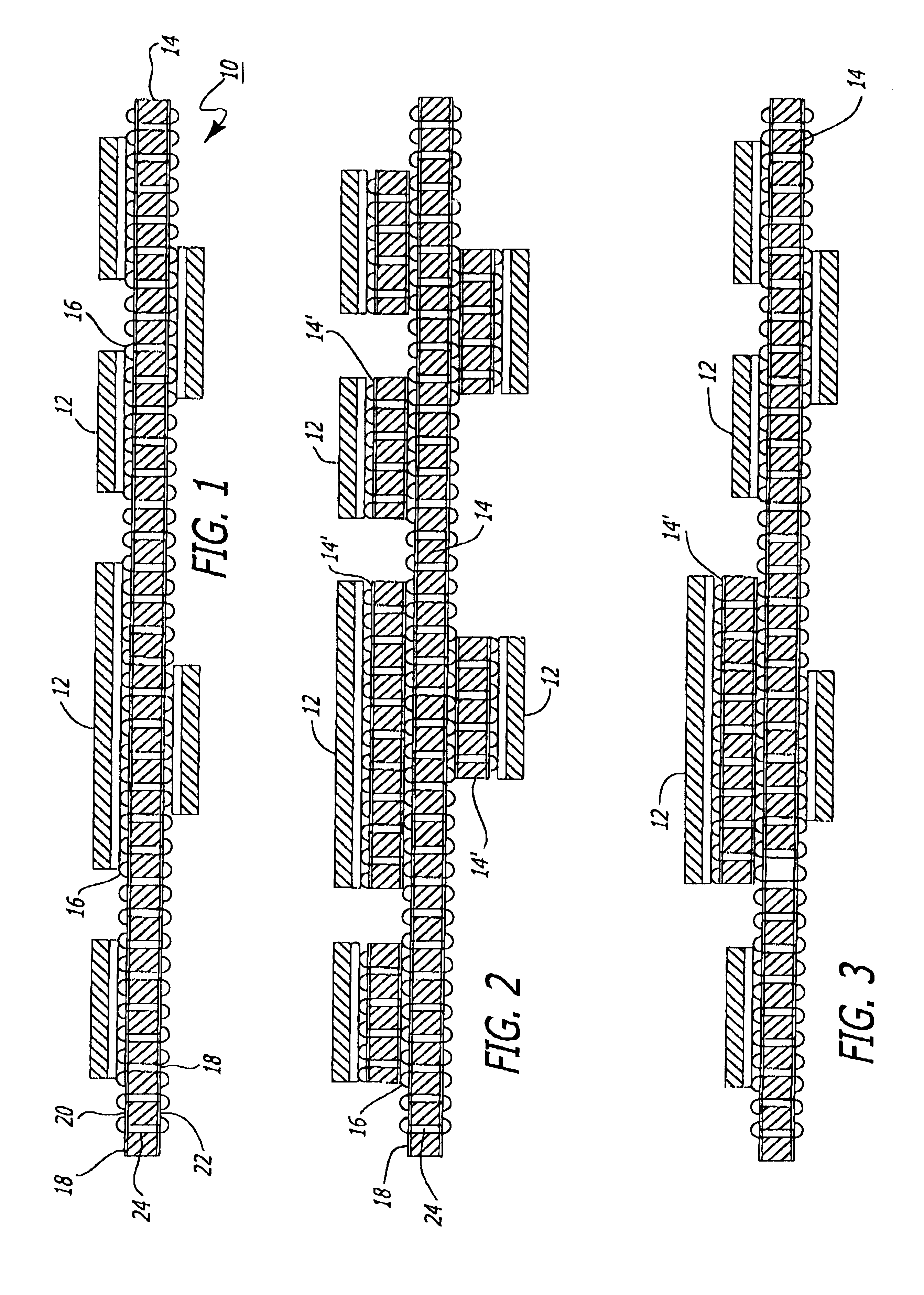

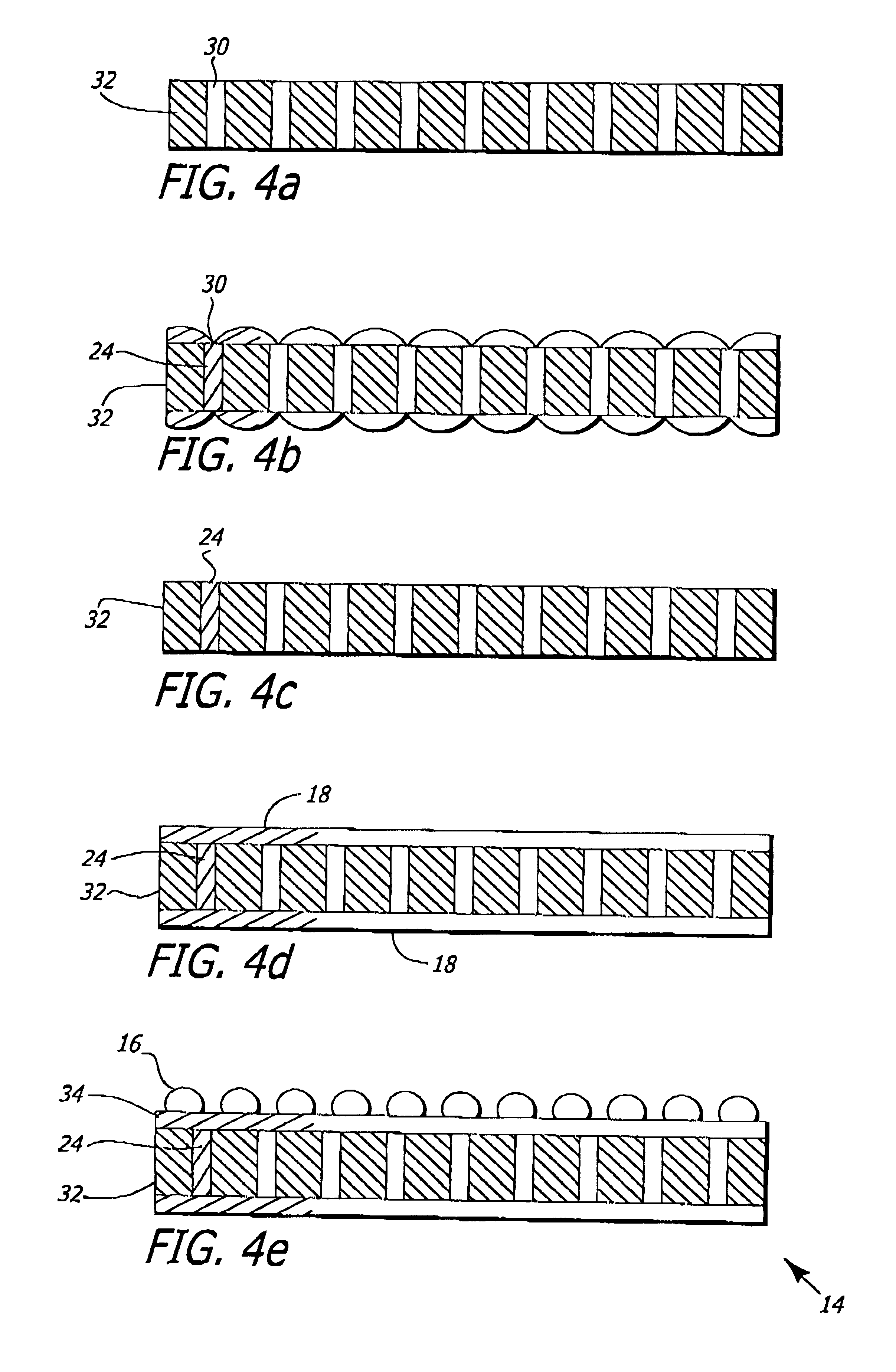

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

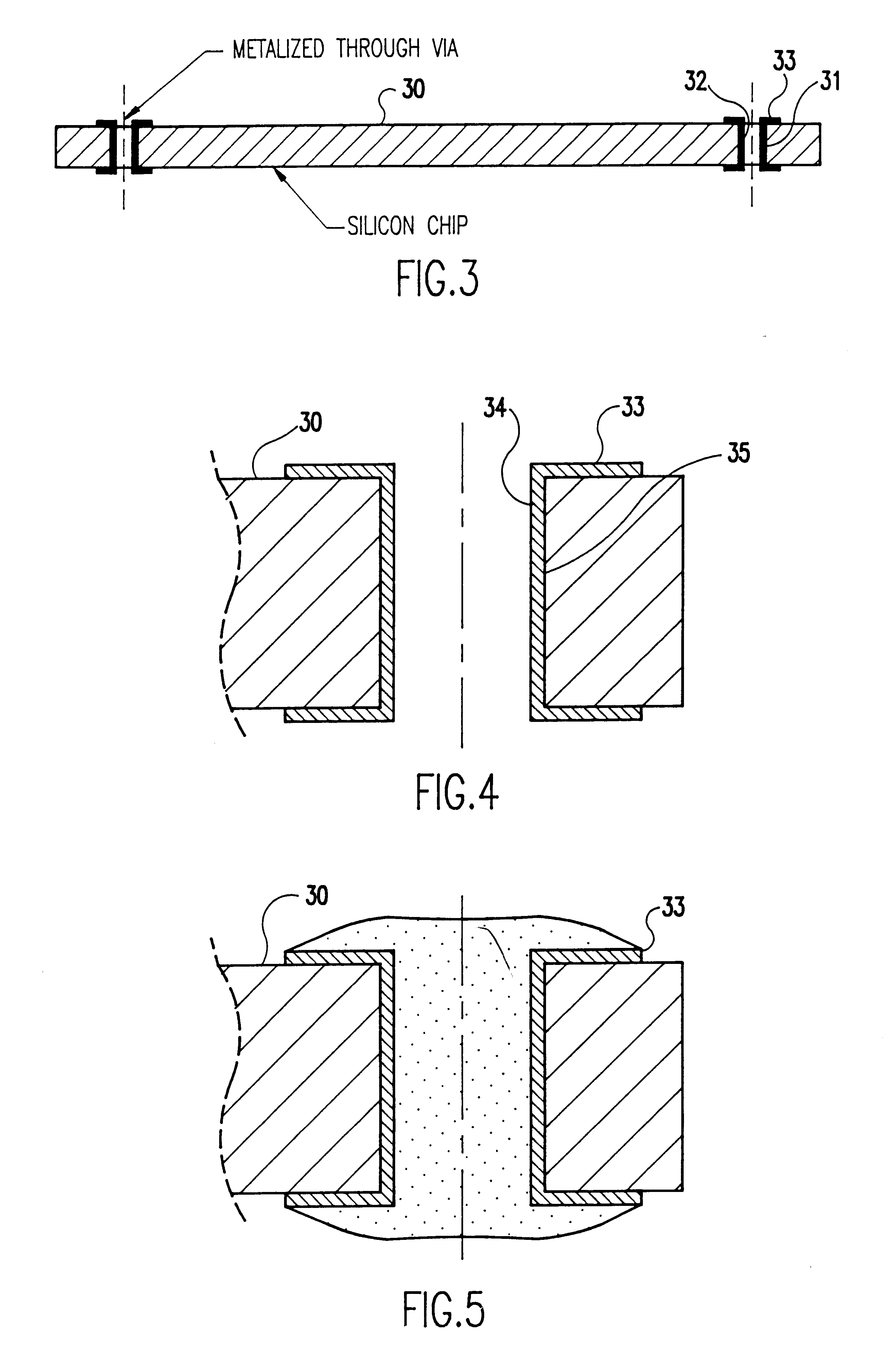

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

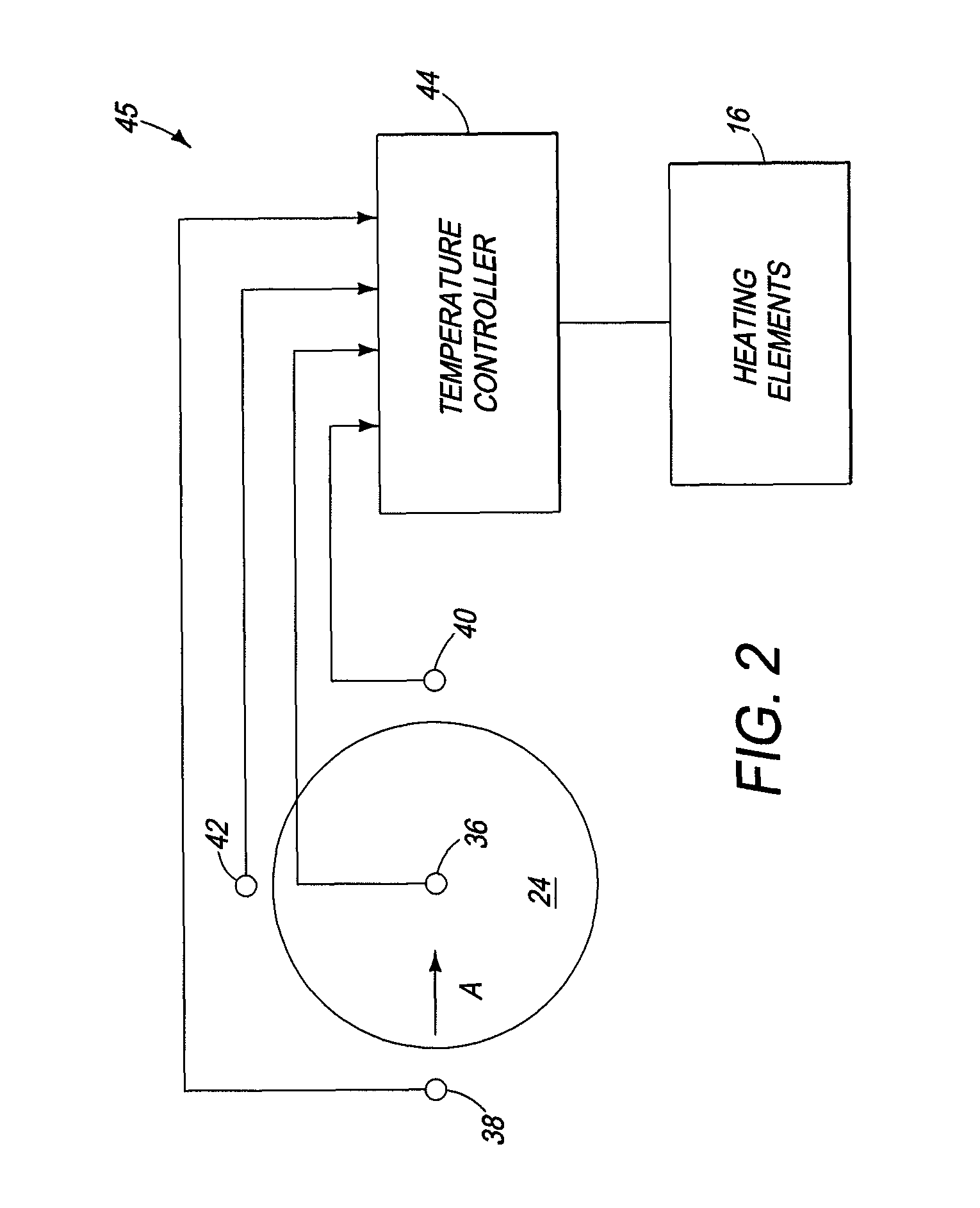

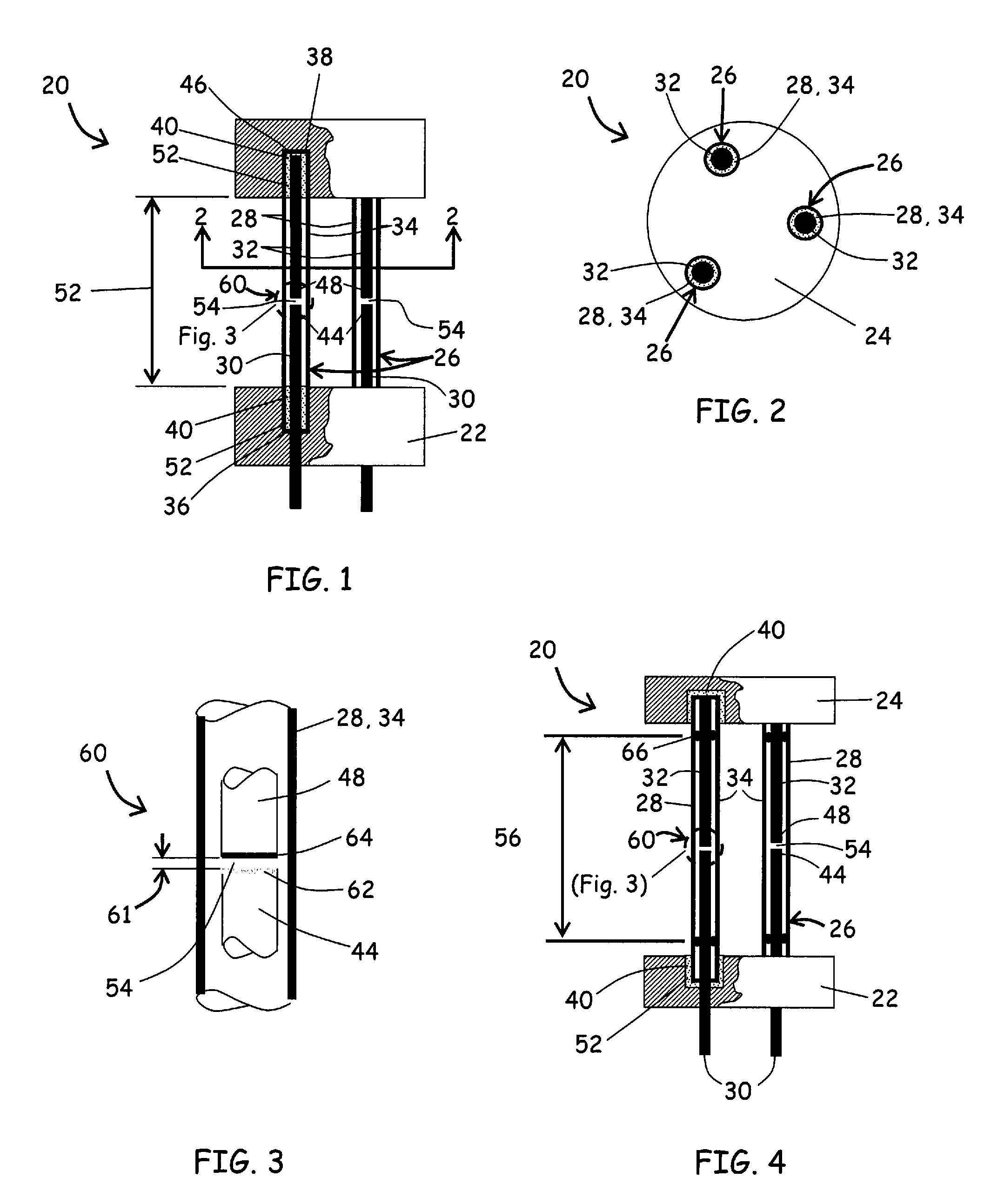

Thermocouple

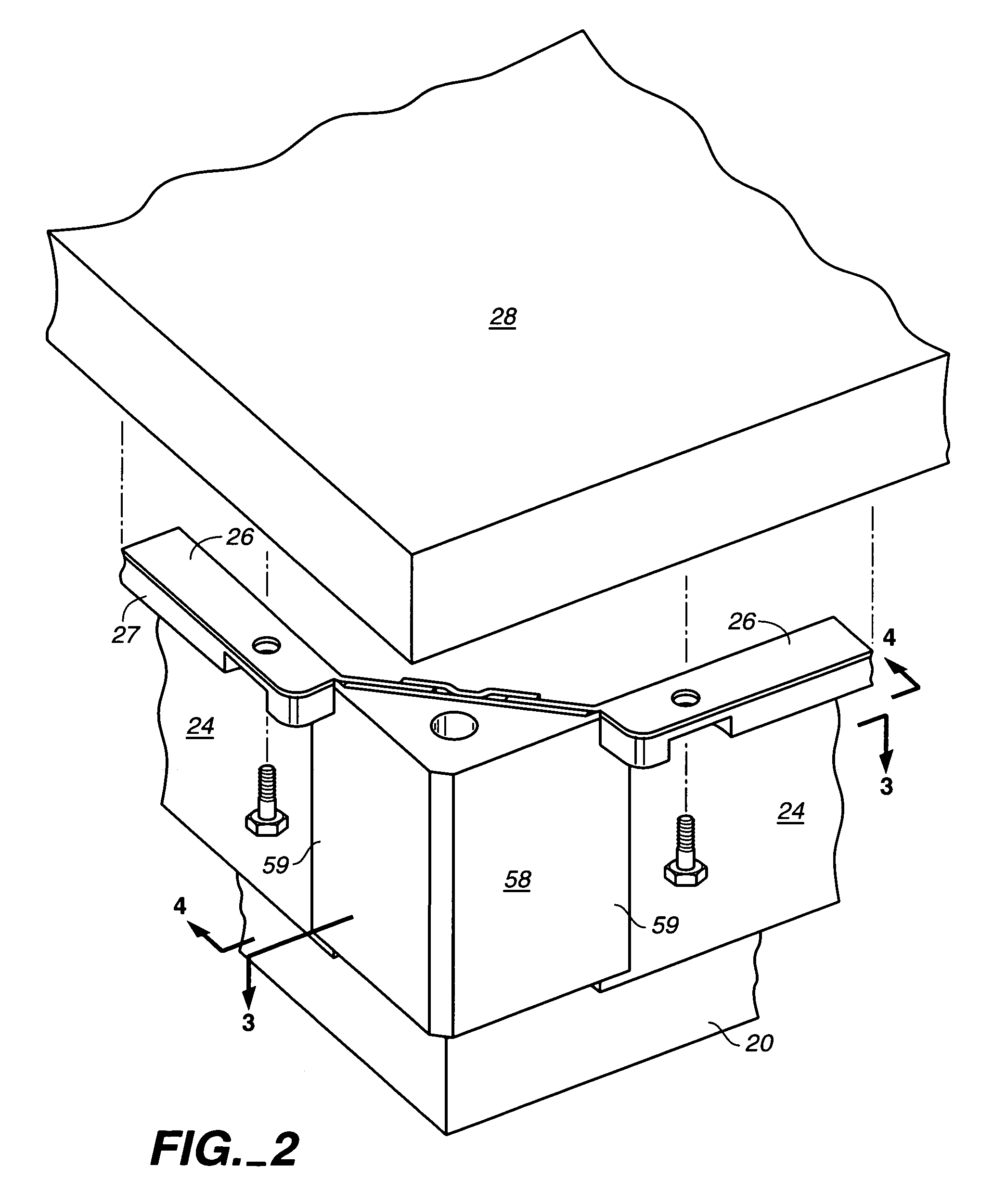

ActiveUS7874726B2Thermometer detailsThermometers using electric/magnetic elementsThermal expansionEngineering

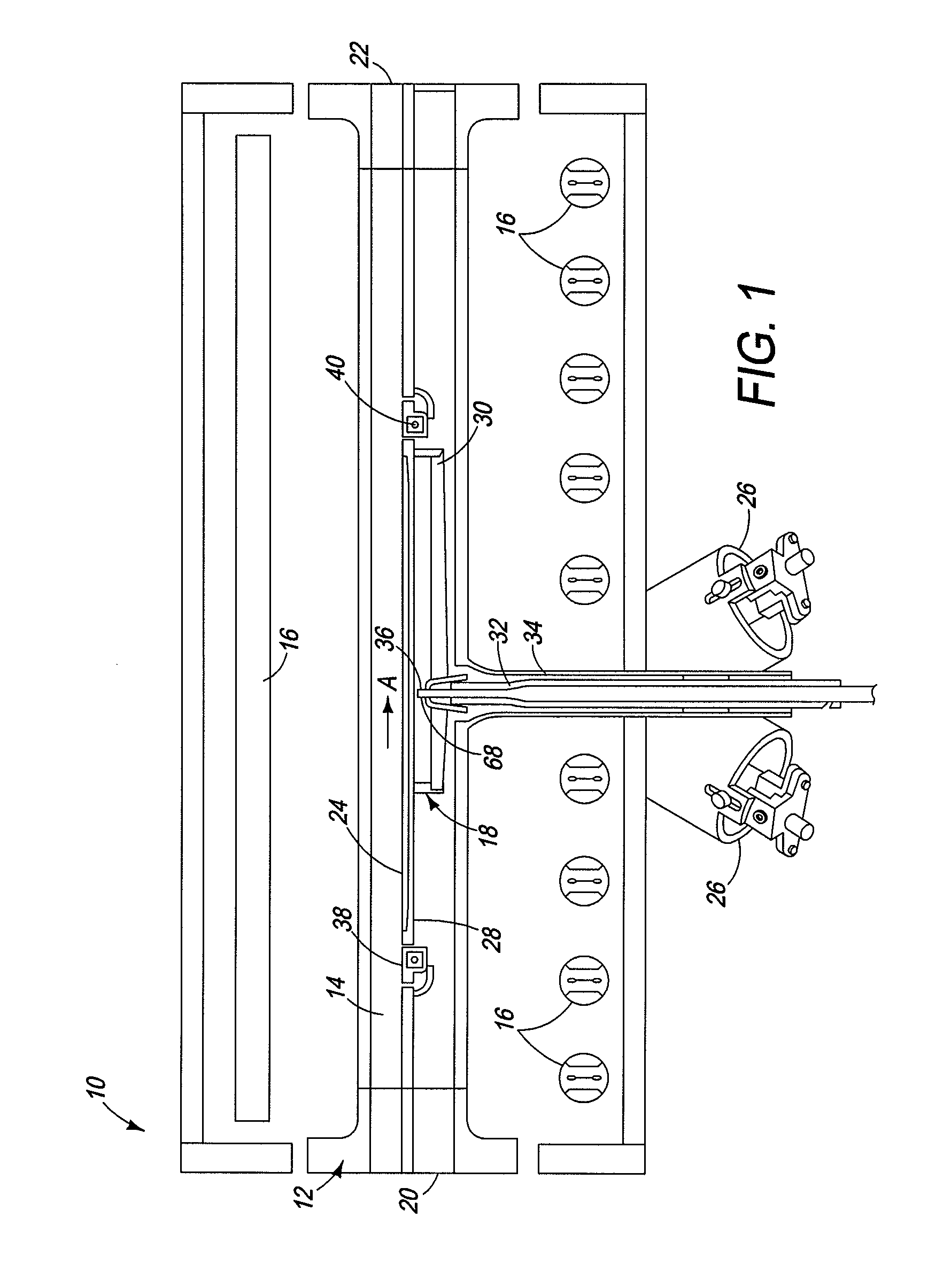

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Electrostatic chuck assembly

ActiveUS20100039747A1Efficient couplingCost effectiveElectric discharge tubesSolid-state devicesUltra-high vacuumThermal expansion

Embodiments of the present invention provide a cost effective electrostatic chuck assembly capable of operating over a wide temperature range in an ultra-high vacuum environment while minimizing thermo-mechanical stresses within the electrostatic chuck assembly. In one embodiment, the electrostatic chuck assembly includes a dielectric body having chucking electrodes which comprise a metal matrix composite material with a coefficient of thermal expansion (CTE) that is matched to the CTE of the dielectric body.

Owner:APPLIED MATERIALS INC

Thermocouple

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Composite patterning devices for soft lithography

ActiveUS20050238967A1High resolutionImprove placement accuracyMaterial nanotechnologyNanoinformaticsEngineeringThermal expansion

The present invention provides methods, devices and device components for fabricating patterns on substrate surfaces, particularly patterns comprising structures having microsized and / or nanosized features of selected lengths in one, two or three dimensions. The present invention provides composite patterning devices comprising a plurality of polymer layers each having selected mechanical properties, such as Young's Modulus and flexural rigidity, selected physical dimensions, such as thickness, surface area and relief pattern dimensions, and selected thermal properties, such as coefficients of thermal expansion, to provide high resolution patterning on a variety of substrate surfaces and surface morphologies.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

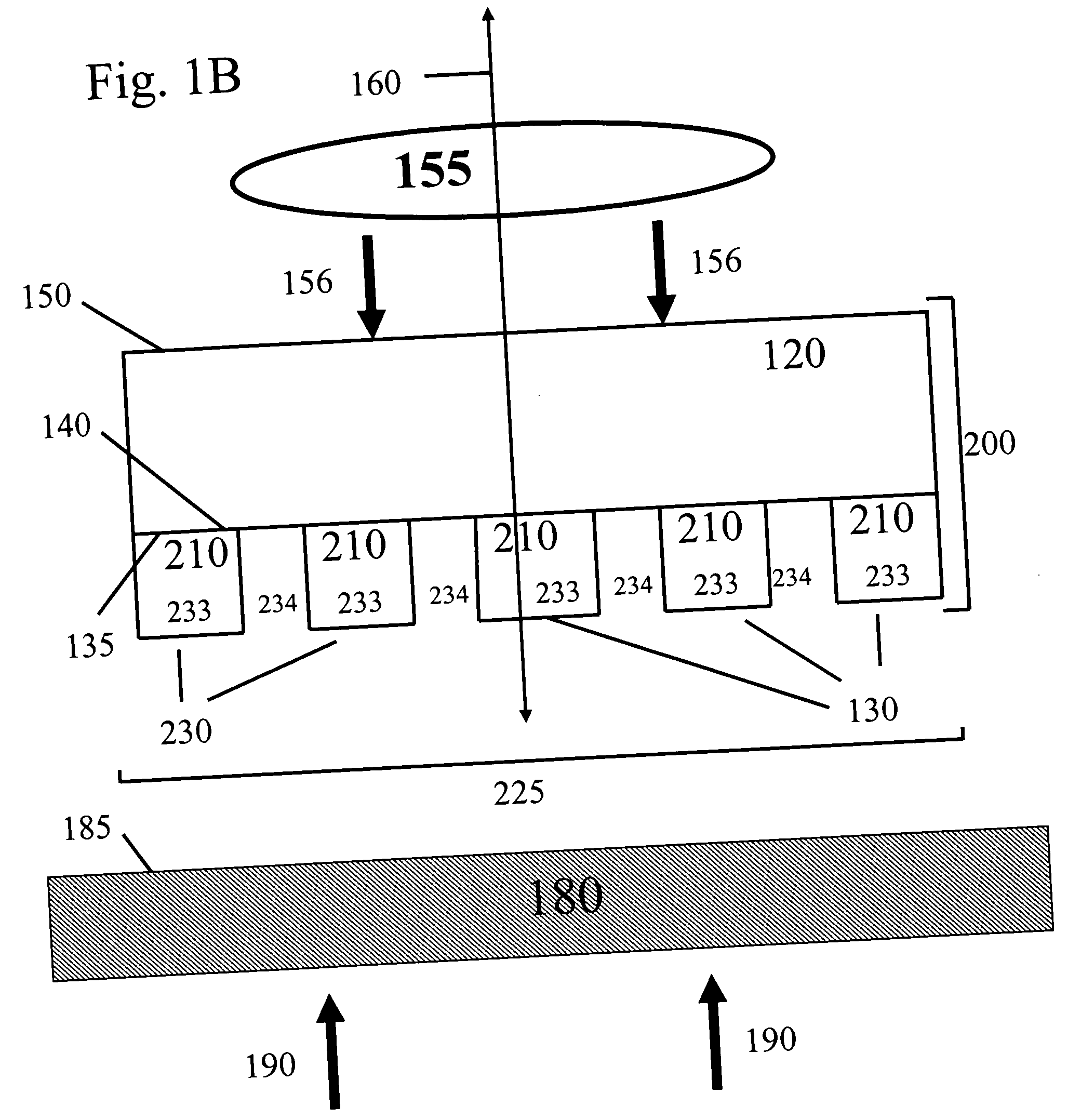

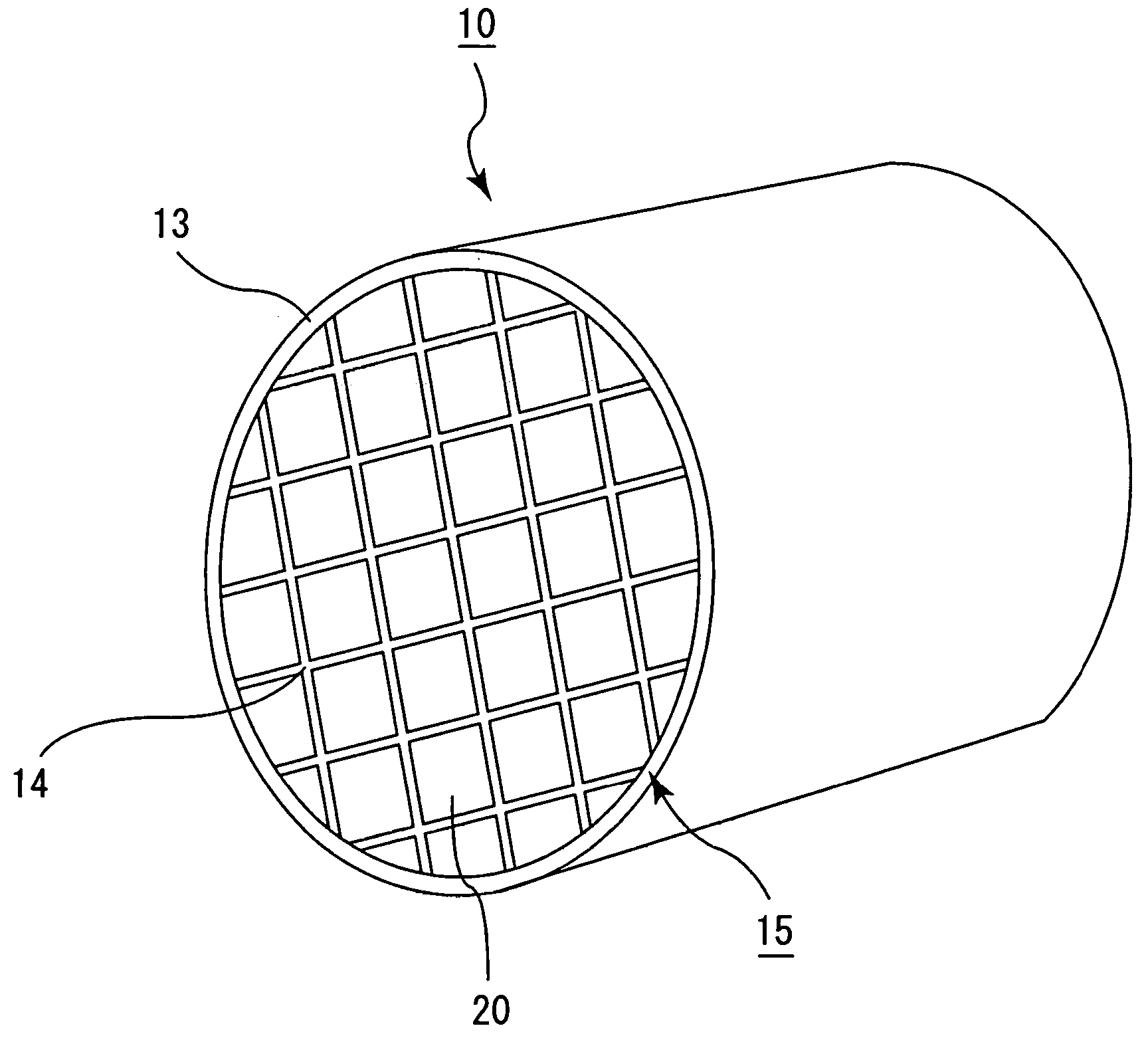

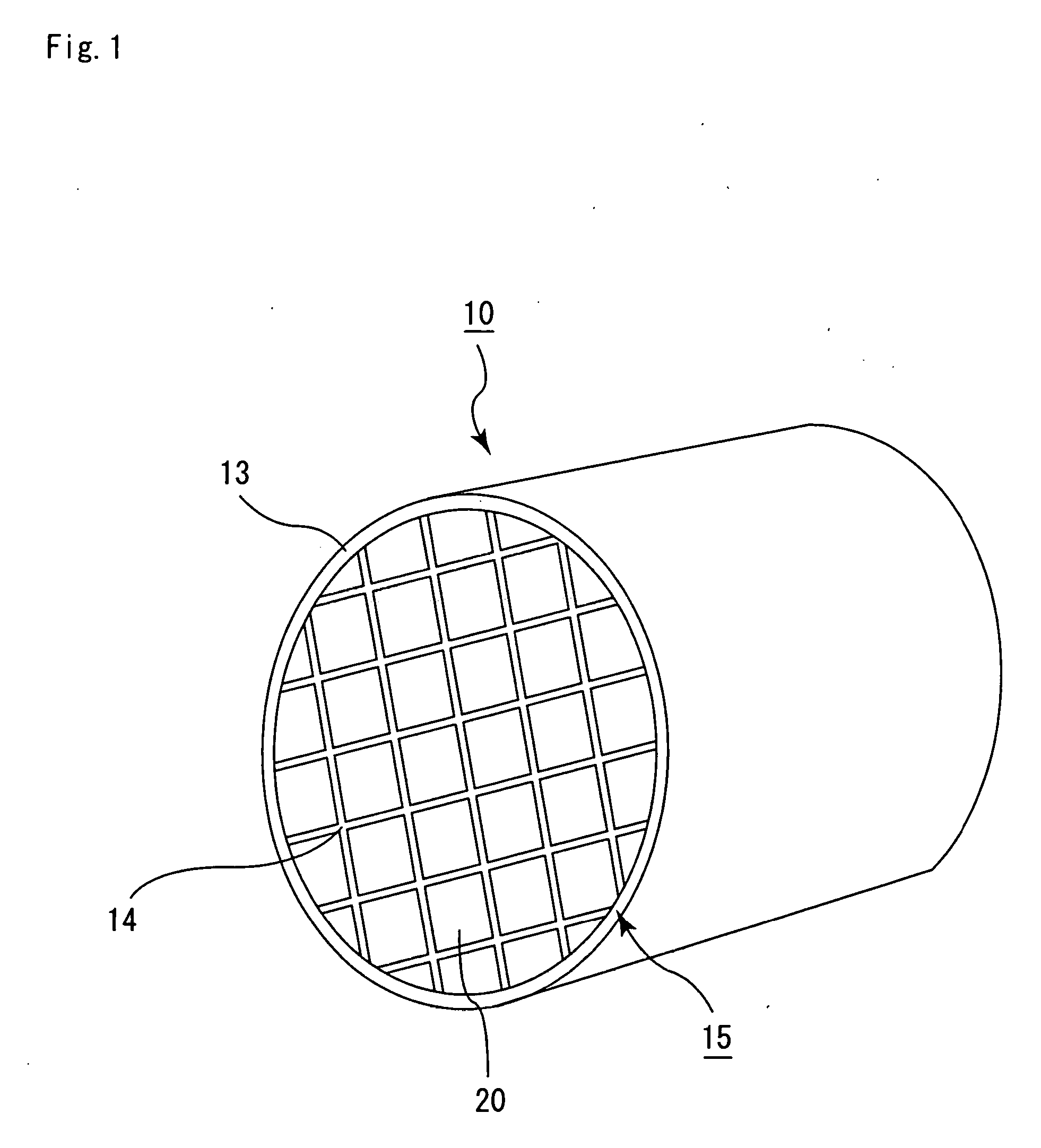

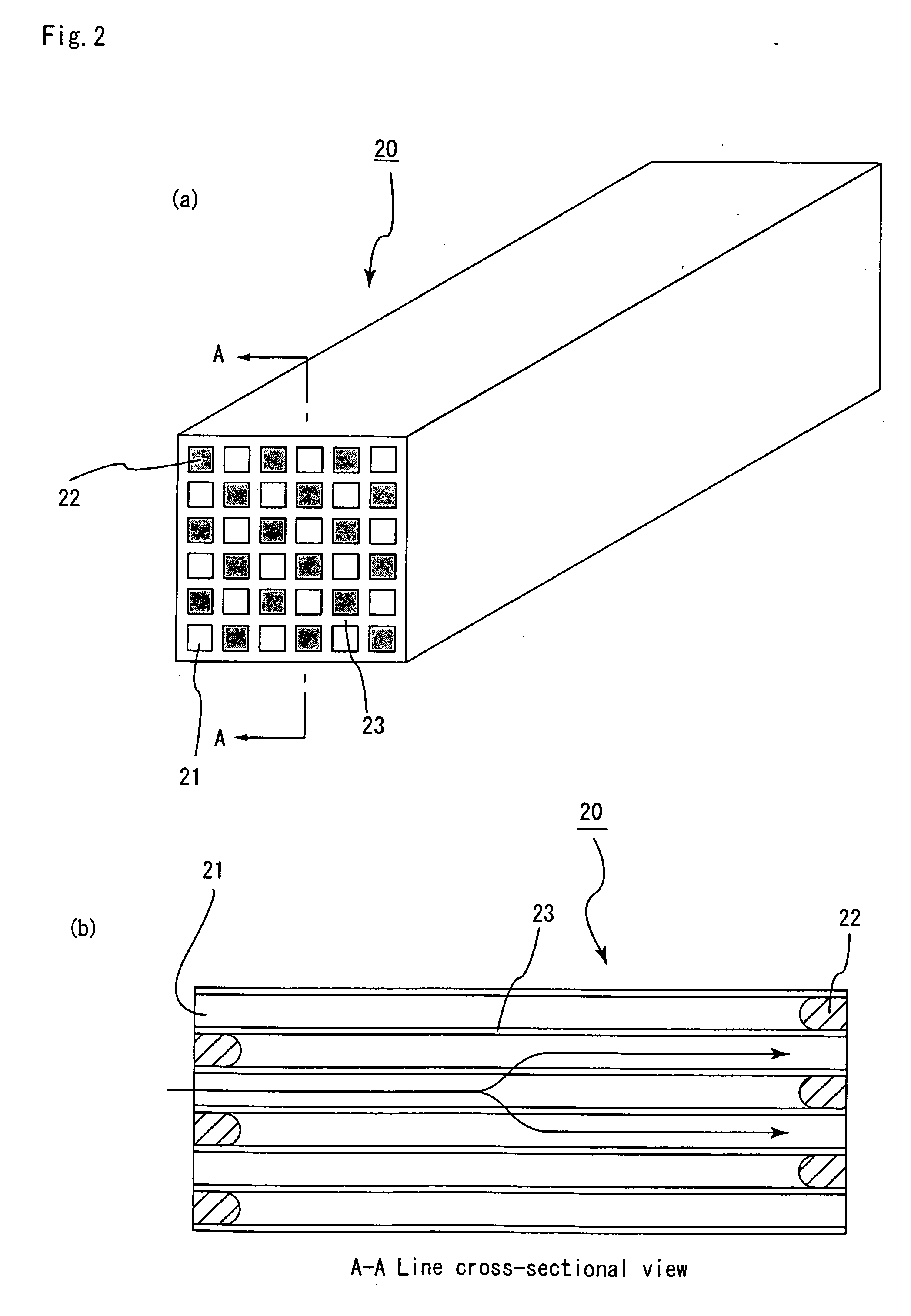

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

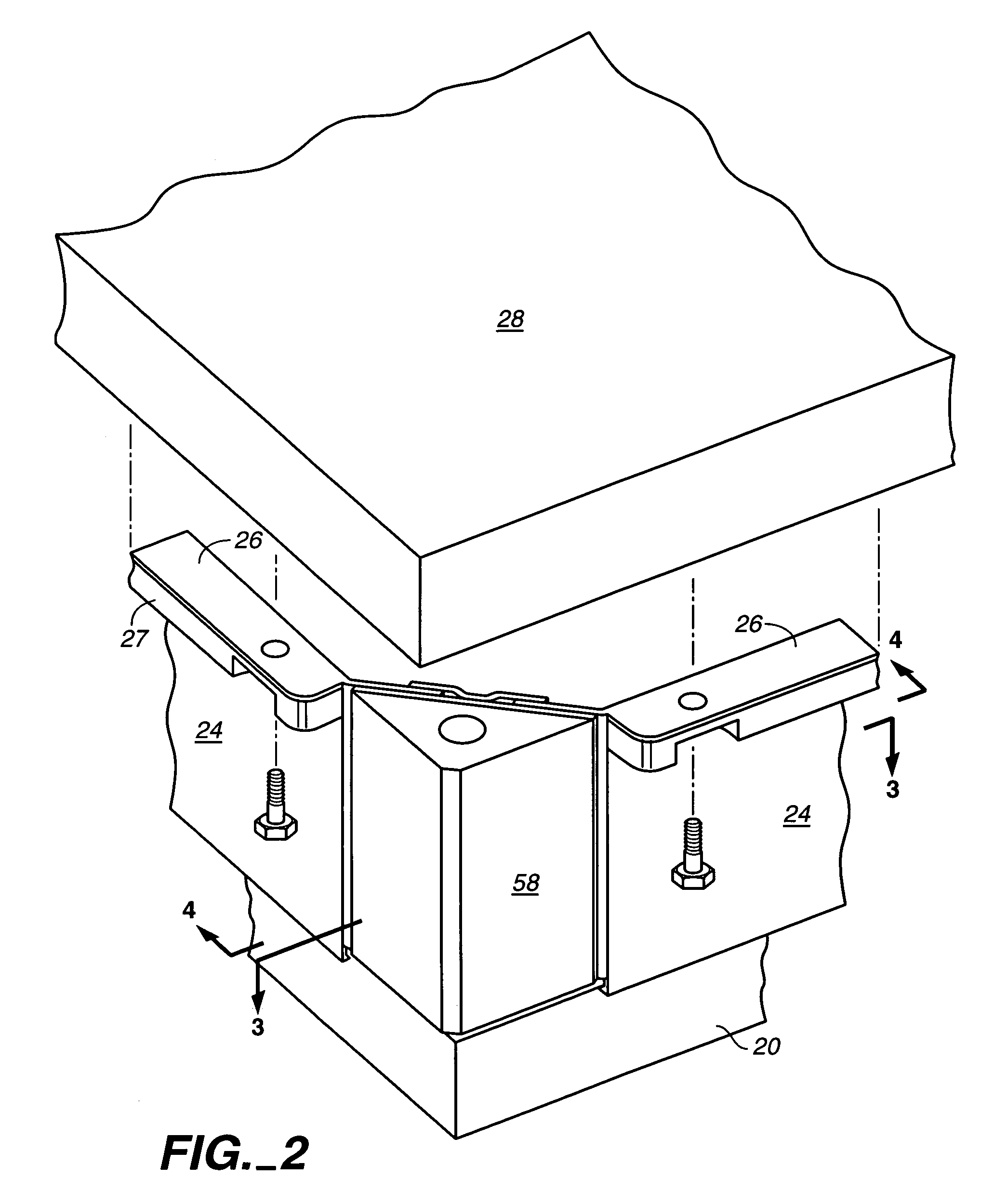

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

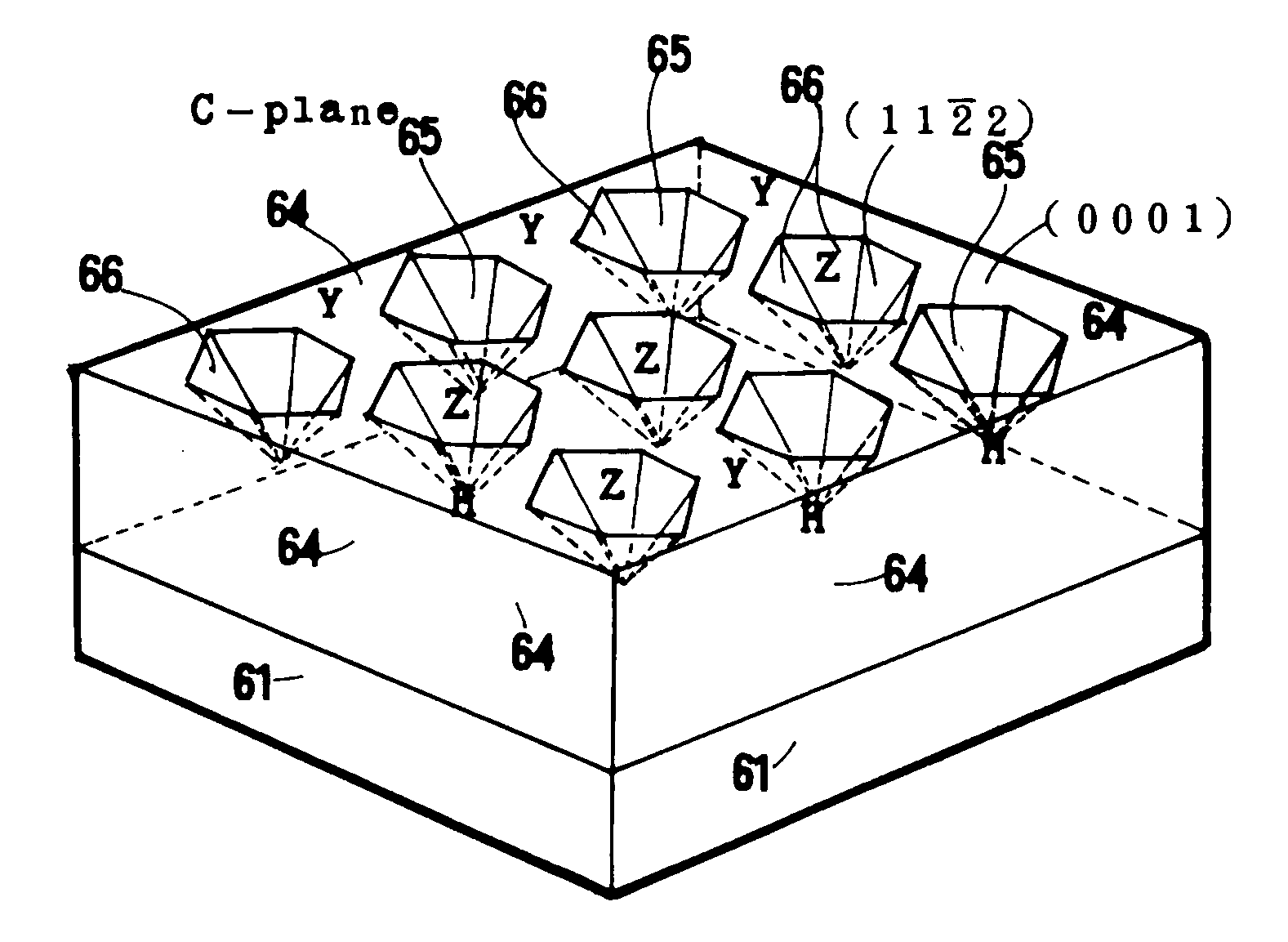

Method of growing GaN crystal, method of producing single crystal GaN substrate, and single crystal GaN substrate

InactiveUS7303630B2Resist invasionImprove stabilityPolycrystalline material growthFrom chemically reactive gasesSeed ImplantRegular pattern

Owner:SUMITOMO ELECTRIC IND LTD

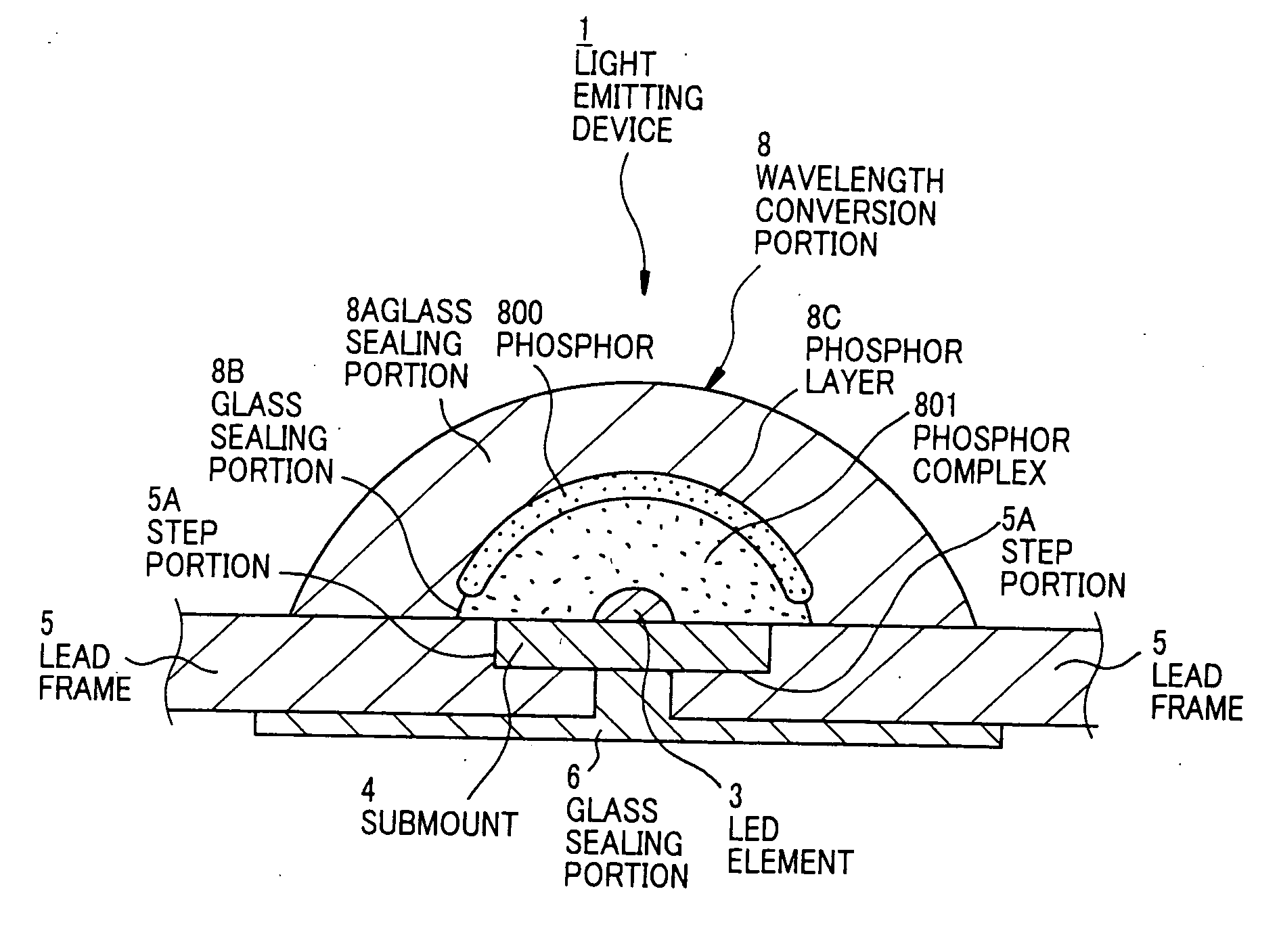

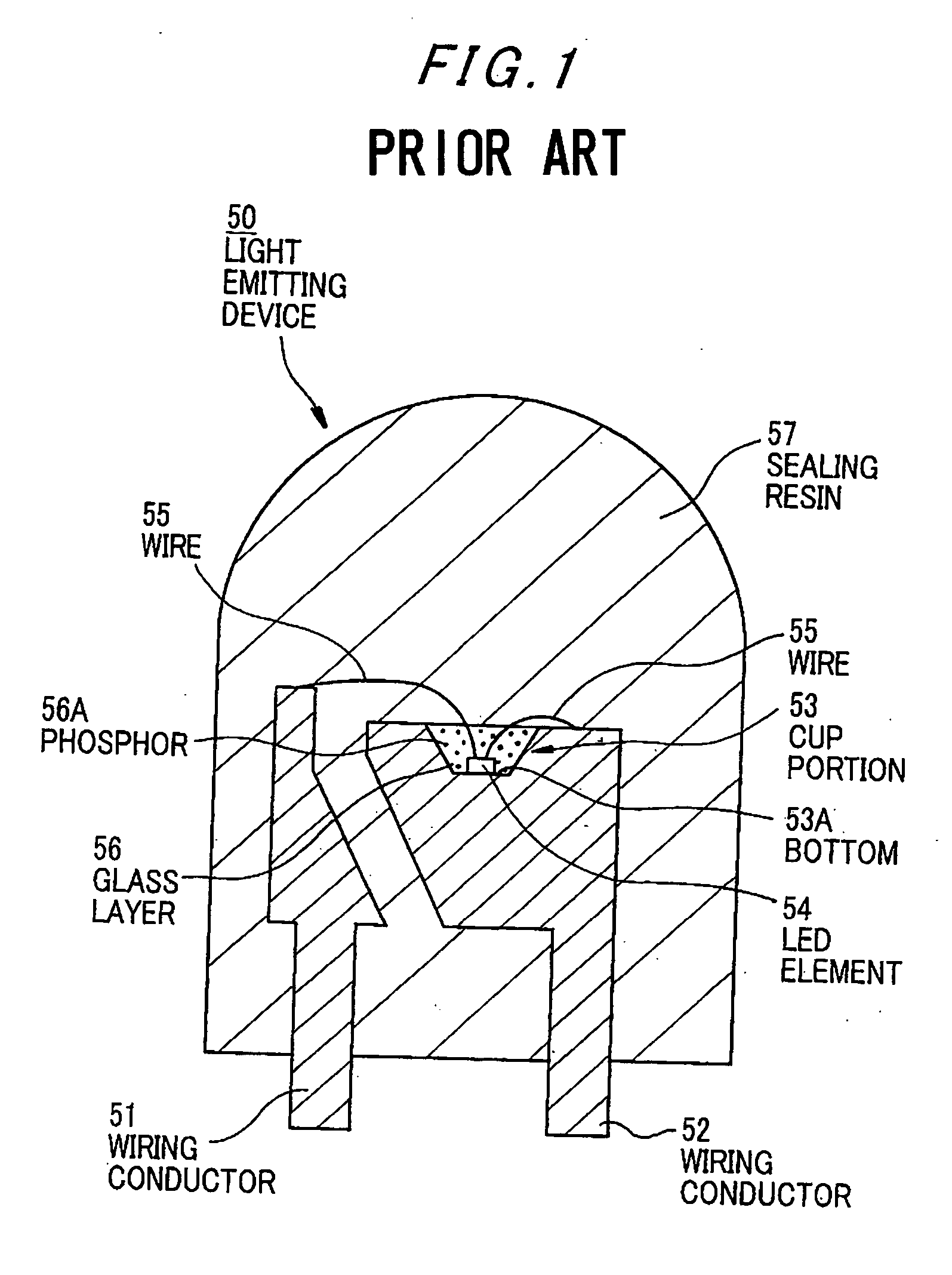

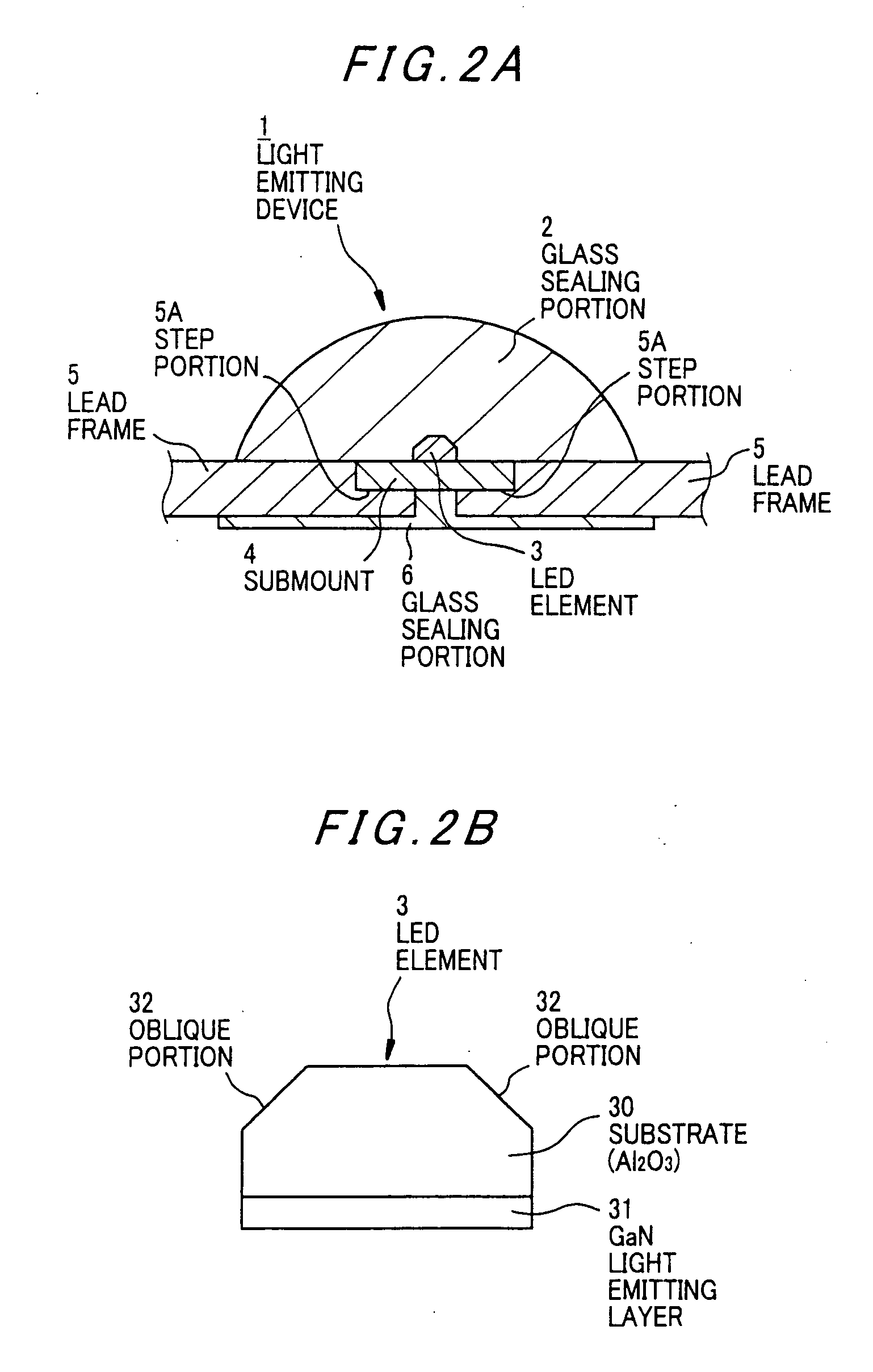

Light emitting device

ActiveUS20060012299A1Avoiding pressure injuriesDifference in stressDischarge tube luminescnet screensElectroluminescent light sourcesThermal expansionLight emitting device

A light emitting device has: a light emitting element; a lead that is electrically connected to the light emitting element at its one end and serves as a terminal to supply a power source to the light emitting element; a metal base that the light emitting element is mounted thereon and radiates heat of the light emitting element; and a sealing member that is of transparent resin or glass and covers the light emitting element. The lead is secured to the metal base by a heat-resisting insulating member with a thermal expansion coefficient nearly equal to that of the metal base.

Owner:TOYODA GOSEI CO LTD

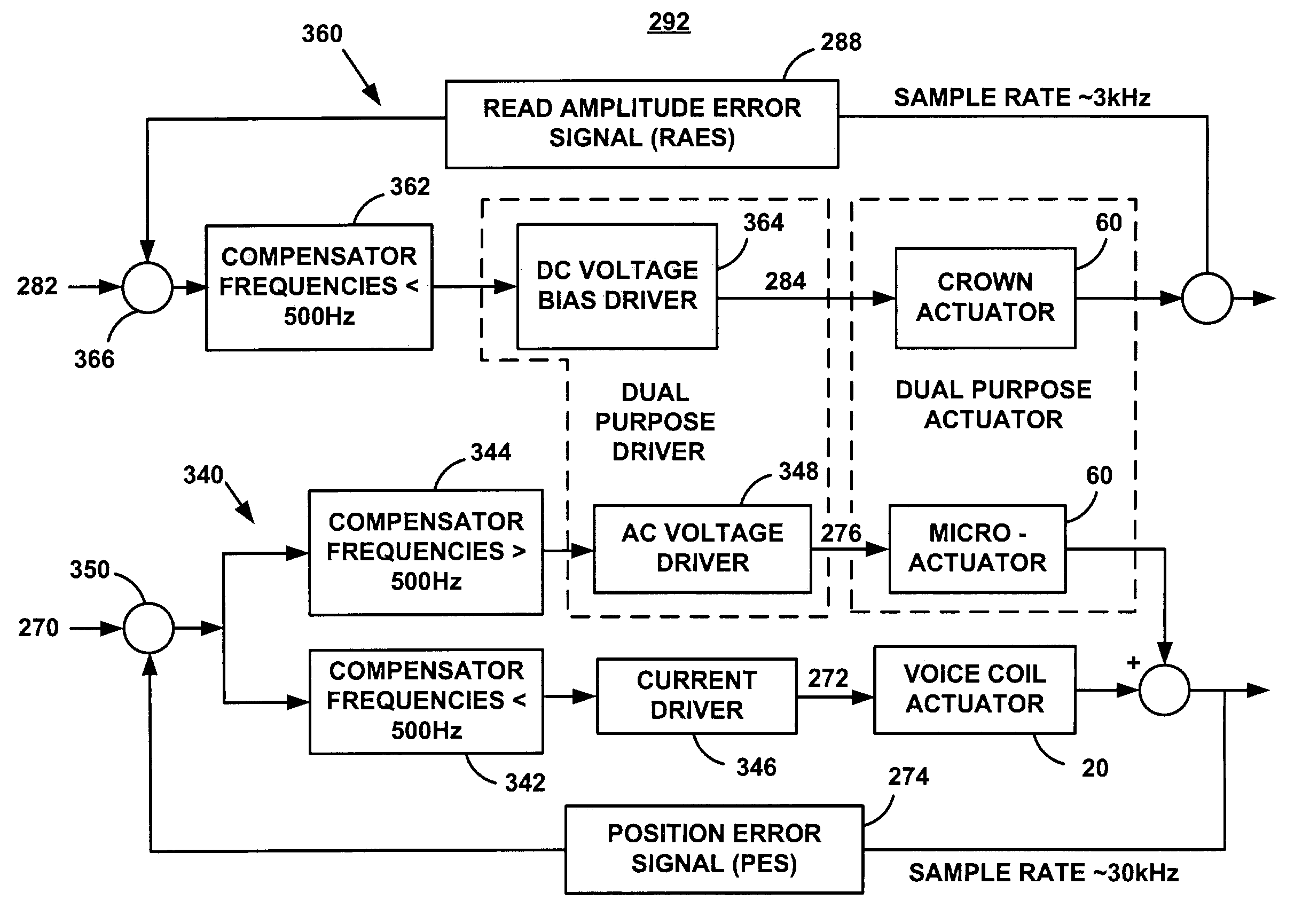

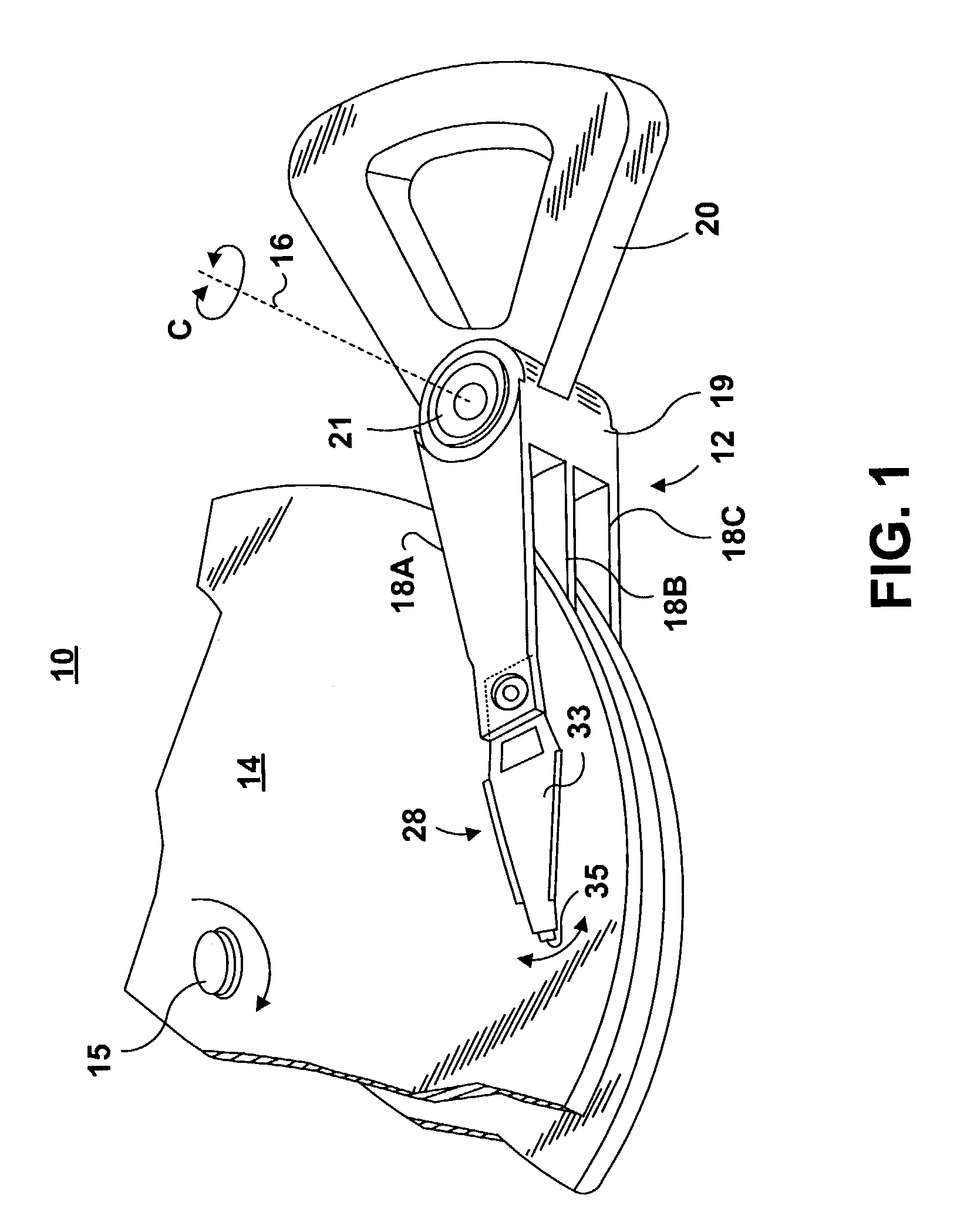

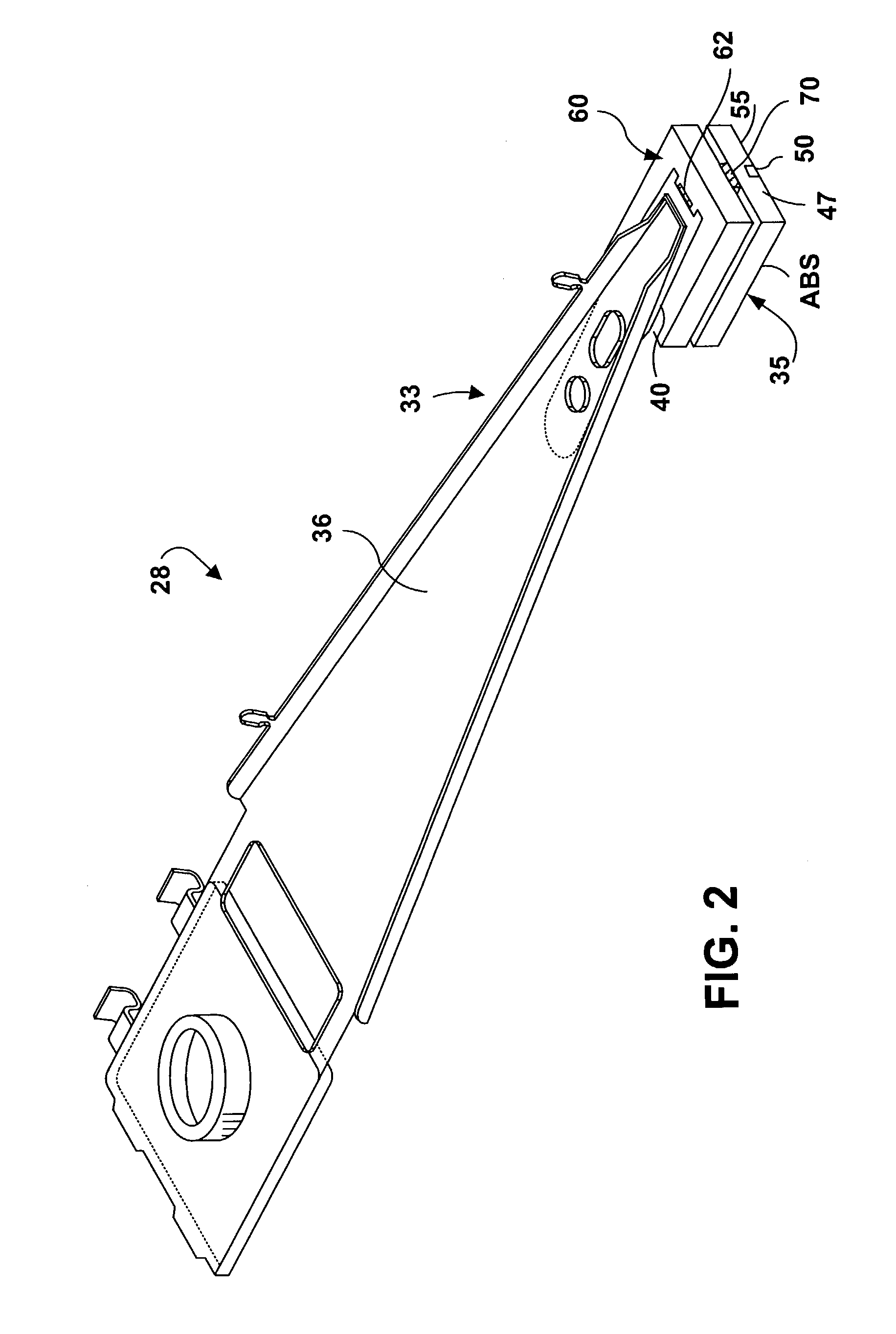

Active fly height control crown actuator

InactiveUS6950266B1Improve production efficiencyReduced altitude sensitivityAnalogue recording/reproducingDriving/moving recording headsData integrityMicro actuator

A micro-actuator is comprised of a piezoelectric motor mounted on a flexure tongue with offsetting hinges, to perform a fine positioning of the magnetic read / write head. The substantial gain in the frequency response greatly improves the performance and accuracy of the track-follow control for fine positioning. The simplicity of the enhanced micro-actuator design results in a manufacturing efficiency that enables a high-volume, low-cost production. The micro-actuator is interposed between a flexure tongue and a slider to perform an active control of the fly height of the magnetic read / write head. The induced slider crown and camber are used to compensate for thermal expansion of the magnetic read / write head, which causes the slider to be displaced at an unintended fly height position relative to the surface of the magnetic recording disk. The enhanced micro-actuator design results in reduced altitude sensitivity, ABS tolerances, and reduced stiction. The controlled fly height of the magnetic read / write head prevents a possibility of a head crash, while improving the performance and data integrity.

Owner:WESTERN DIGITAL TECH INC

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6187678B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionPrism

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:IBM CORP

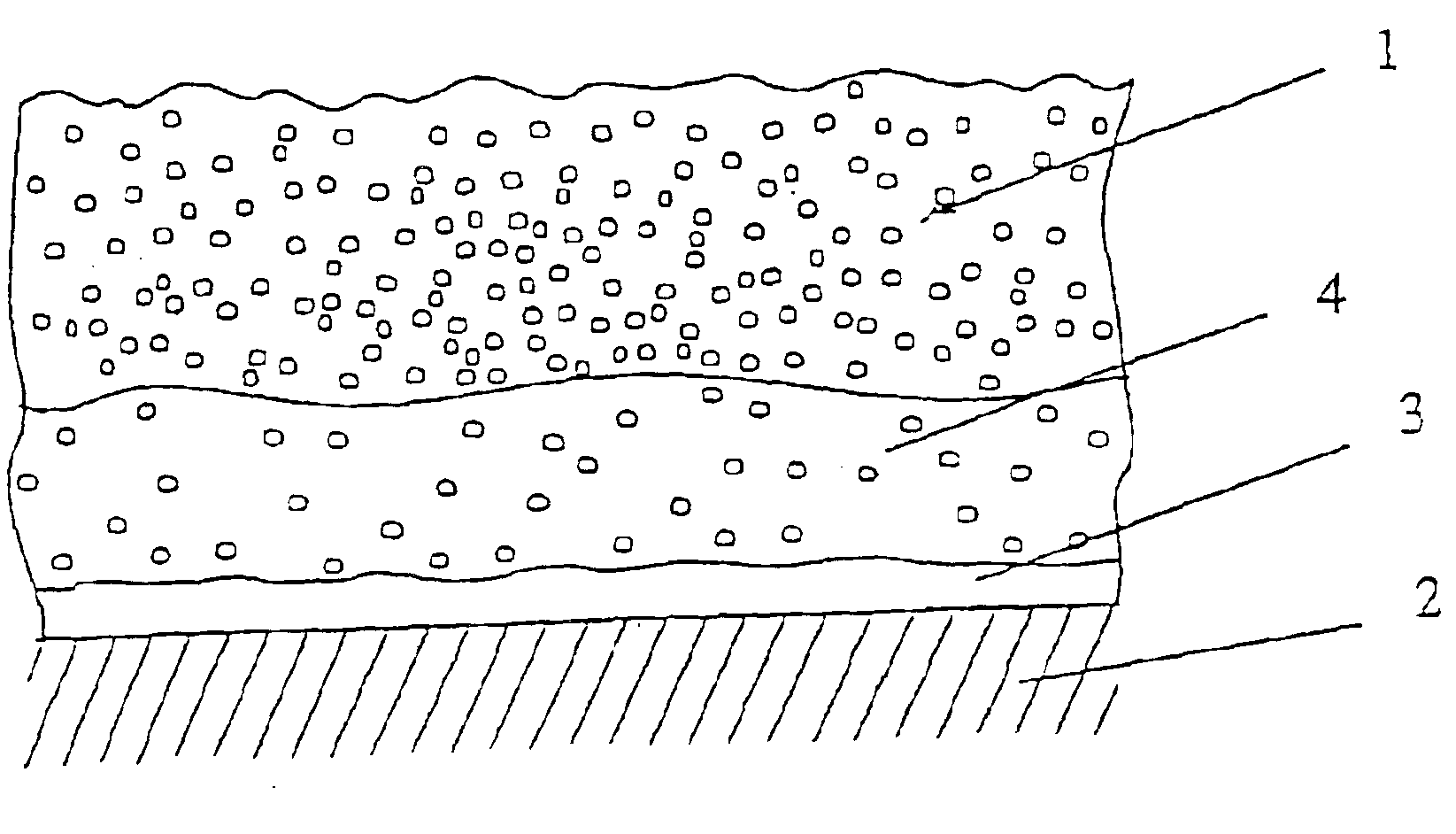

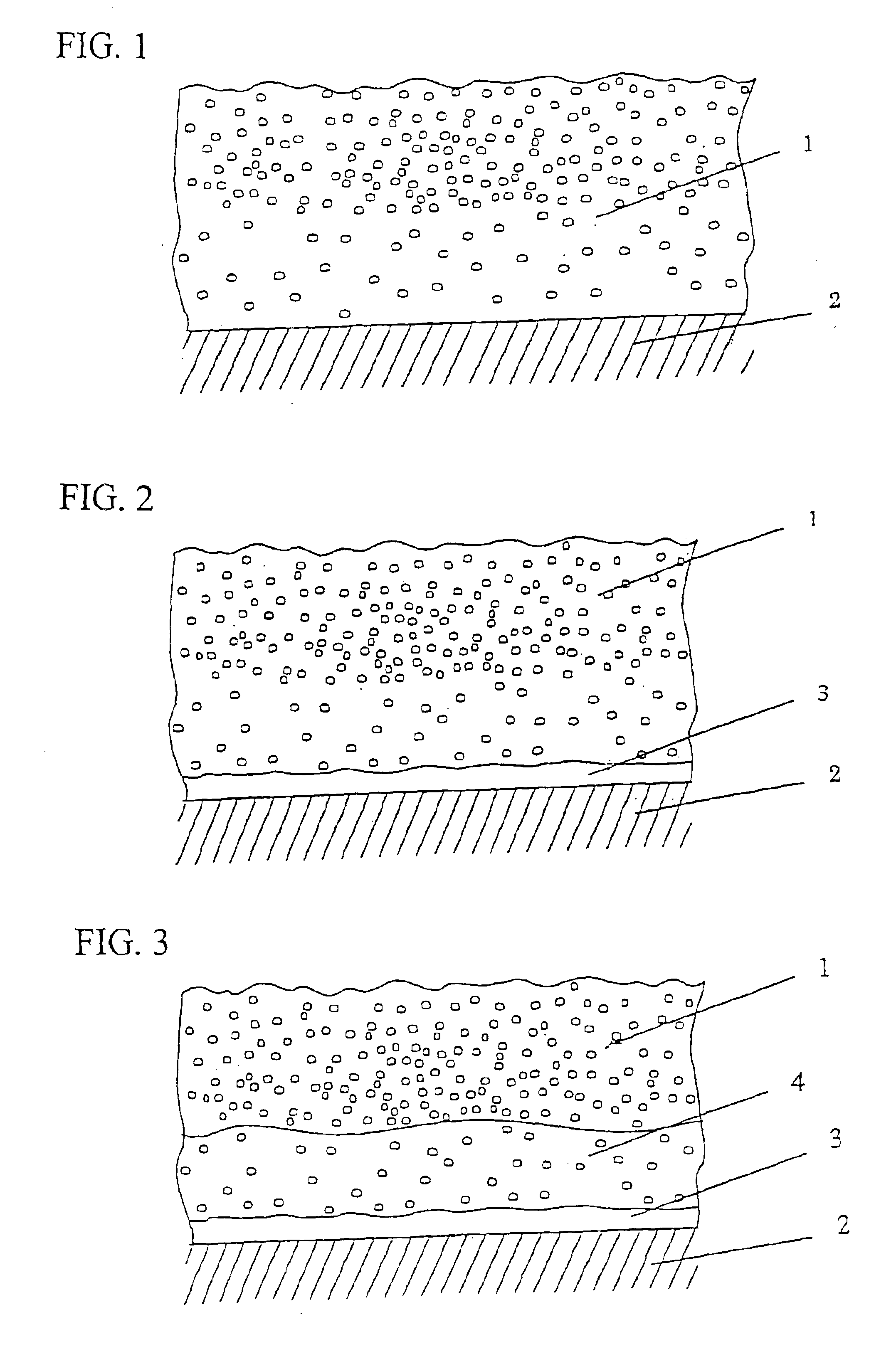

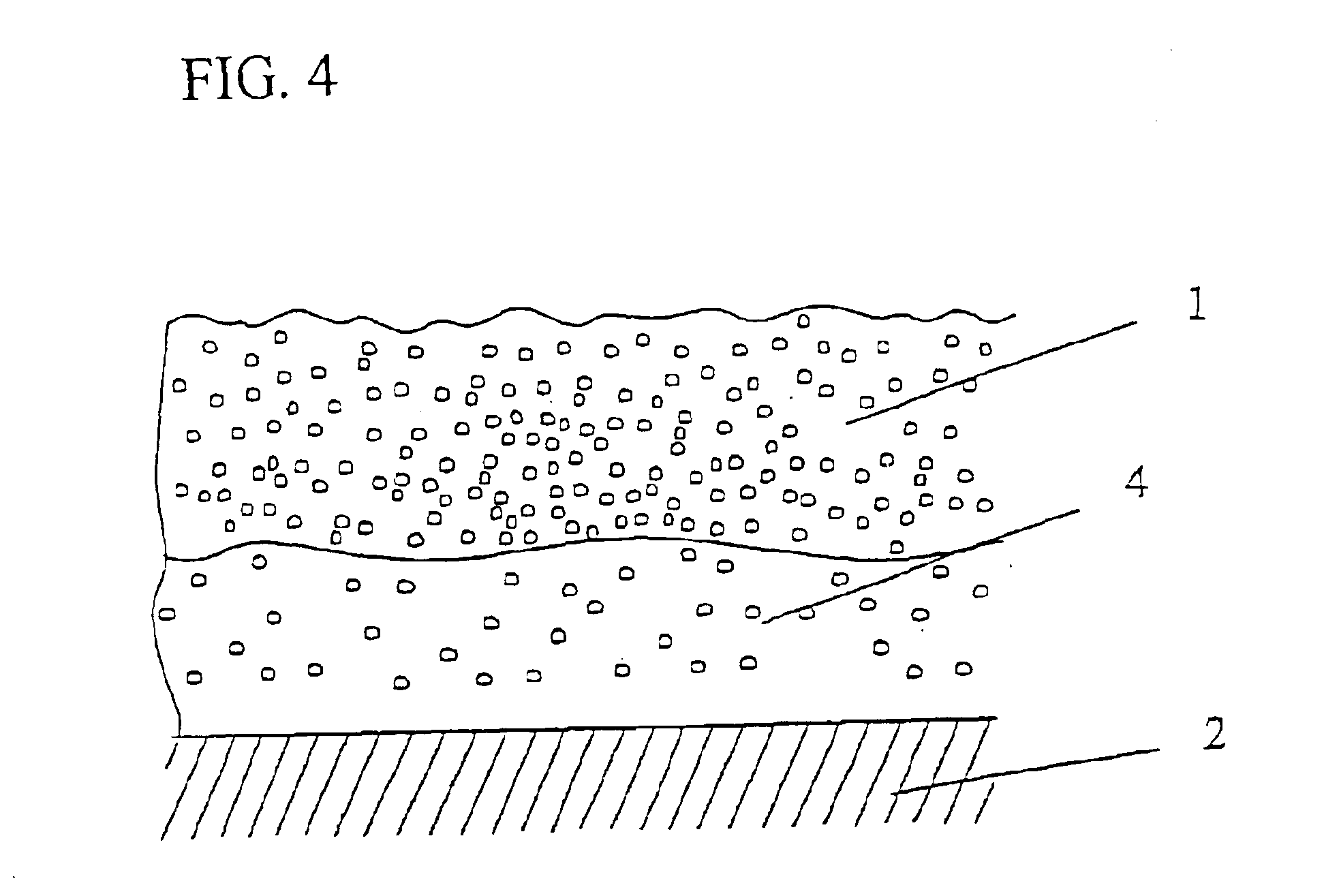

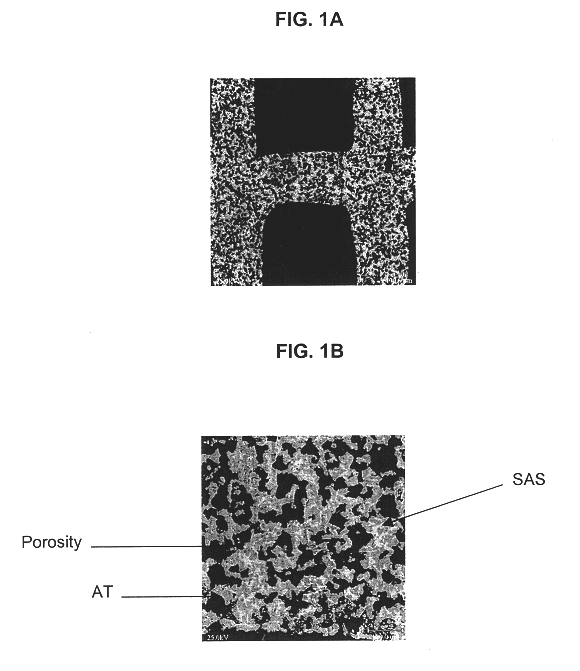

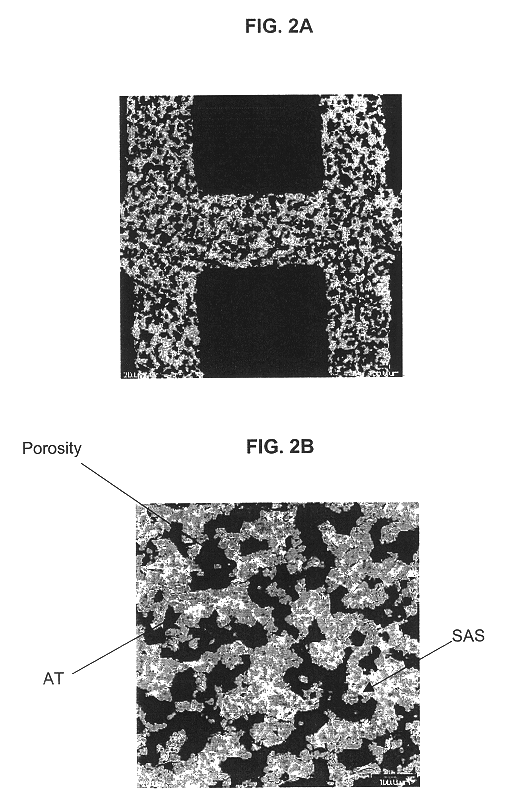

Method for coating internal surface of plasma processing chamber

InactiveUS6875477B2Improve the immunityMinimize thermal expansionLiquid surface applicatorsMolten spray coatingThermal expansionAlloy

The present invention comprises an aluminum base material 2 constituting the plasma processing chamber of the plasma processing apparatus, a bonding layer 3 deposited on the base material consisting of a transition metal or transition metal alloy that modifies the difference in thermal expansion coefficient of the base material and the material constituting a plasma contact surface, and the plasma contact surface 1 formed of a material selected from a group consisting of La2O3, LaAlO3, MgLaAl11O19, and a mixture of La2O3 and Al2O3 being a metal oxide including at least La and O deposited on the bonding layer 3 via a thermal spray process.

Owner:HITACHI HIGH-TECH CORP

Silicon interposer and multi-chip-module (MCM) with through substrate vias

InactiveUS6562653B1Semiconductor/solid-state device detailsSolid-state devicesSilicon interposerEngineering

An integrated circuit package which includes an integrated circuit that is connected to a silicon substrate. The silicon substrate may have a via. The package may further include a solder bump that is attached to both the integrated circuit and the silicon subtstrate. The silicon substrate has a coefficient of thermal expansion that matches the coefficient of thermal expansion of the integrated circuit.

Owner:INTEL CORP

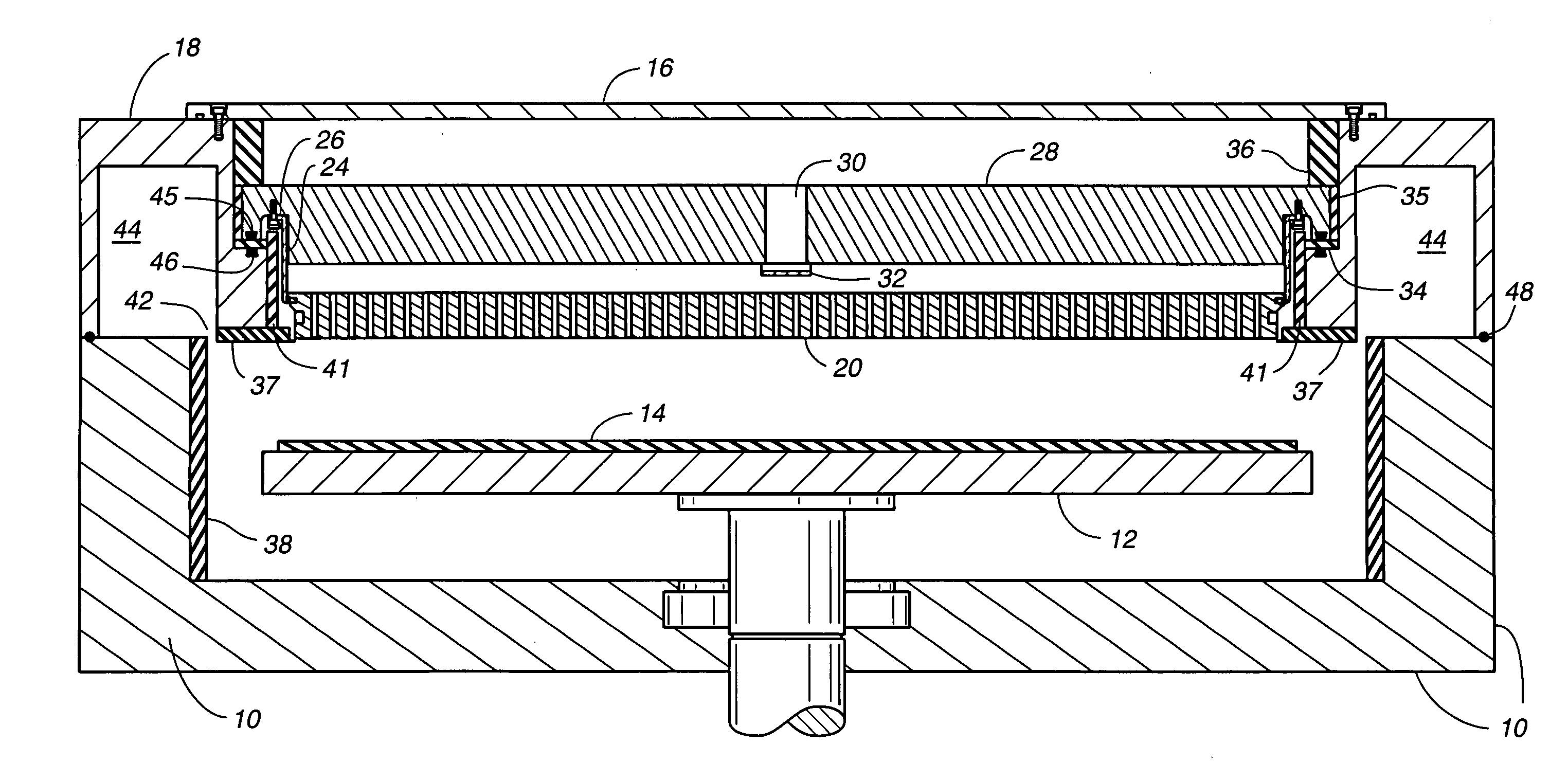

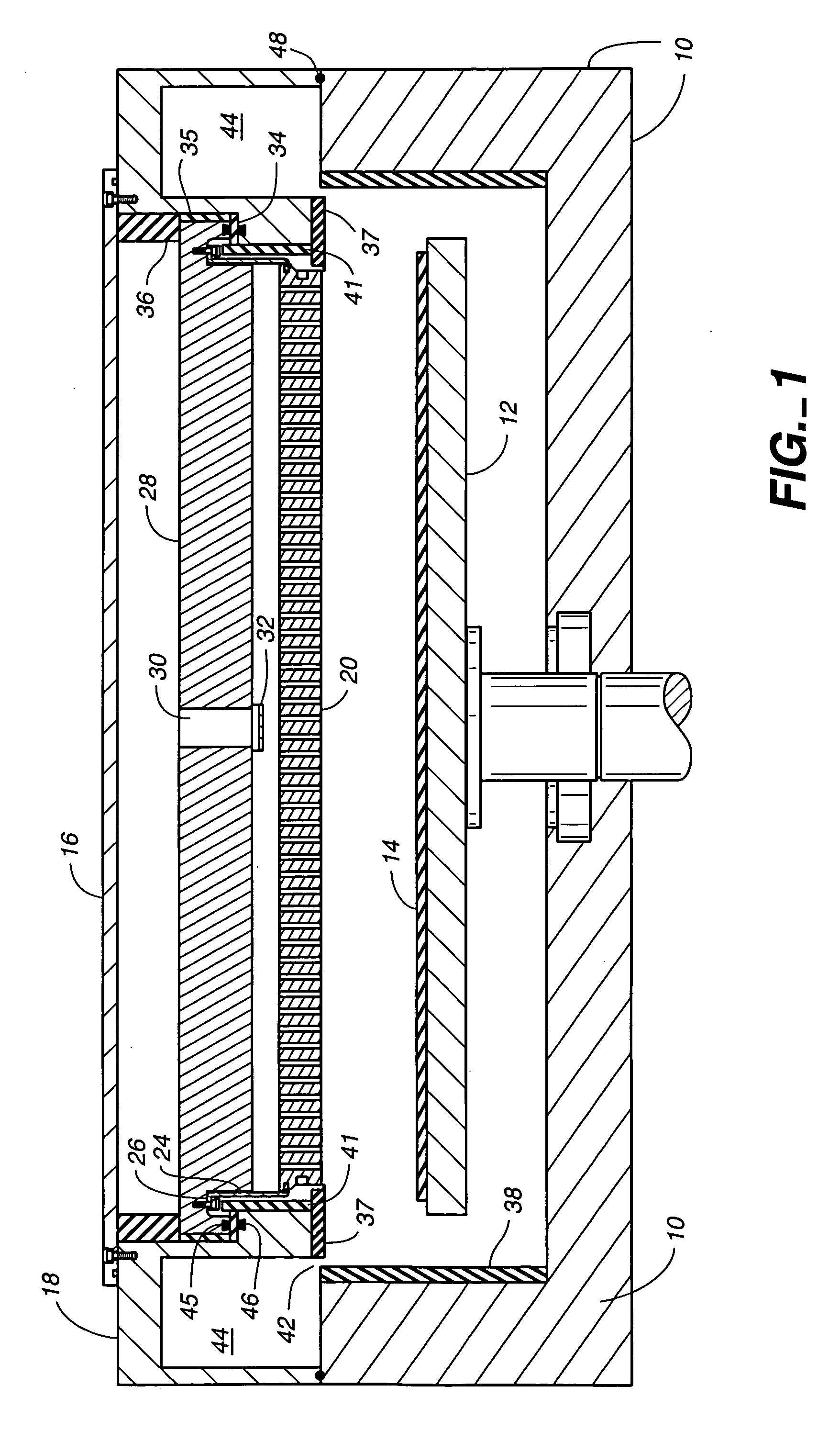

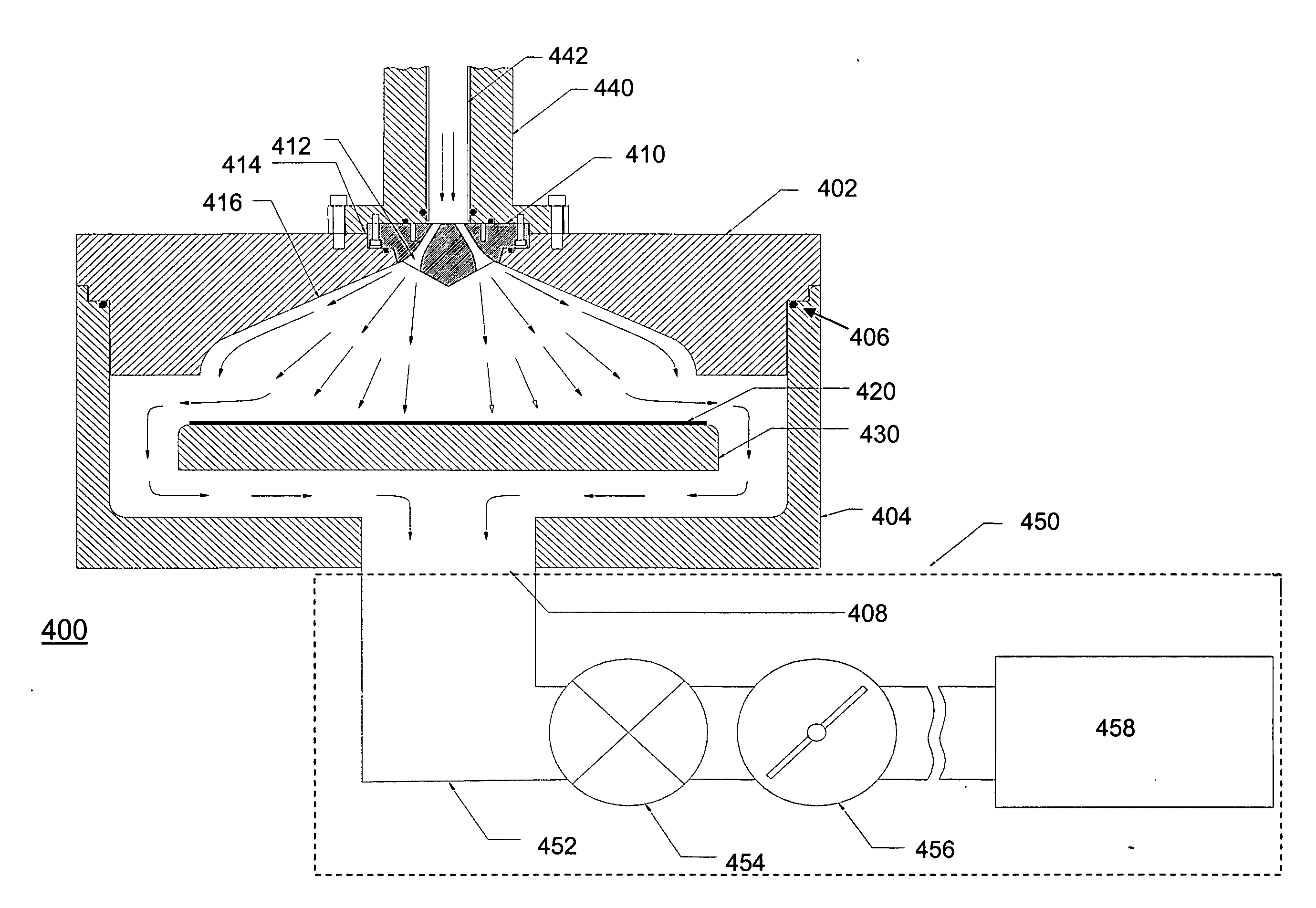

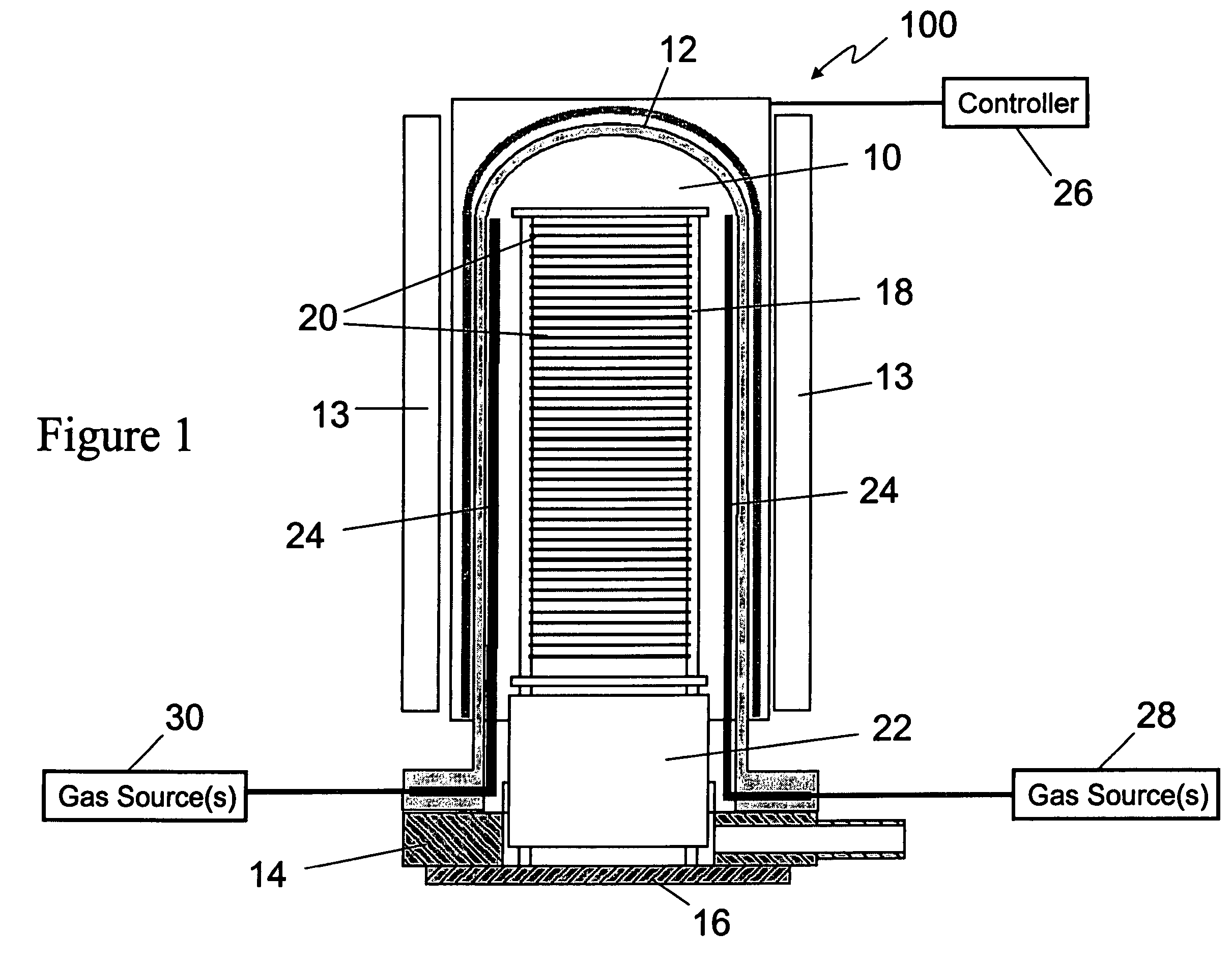

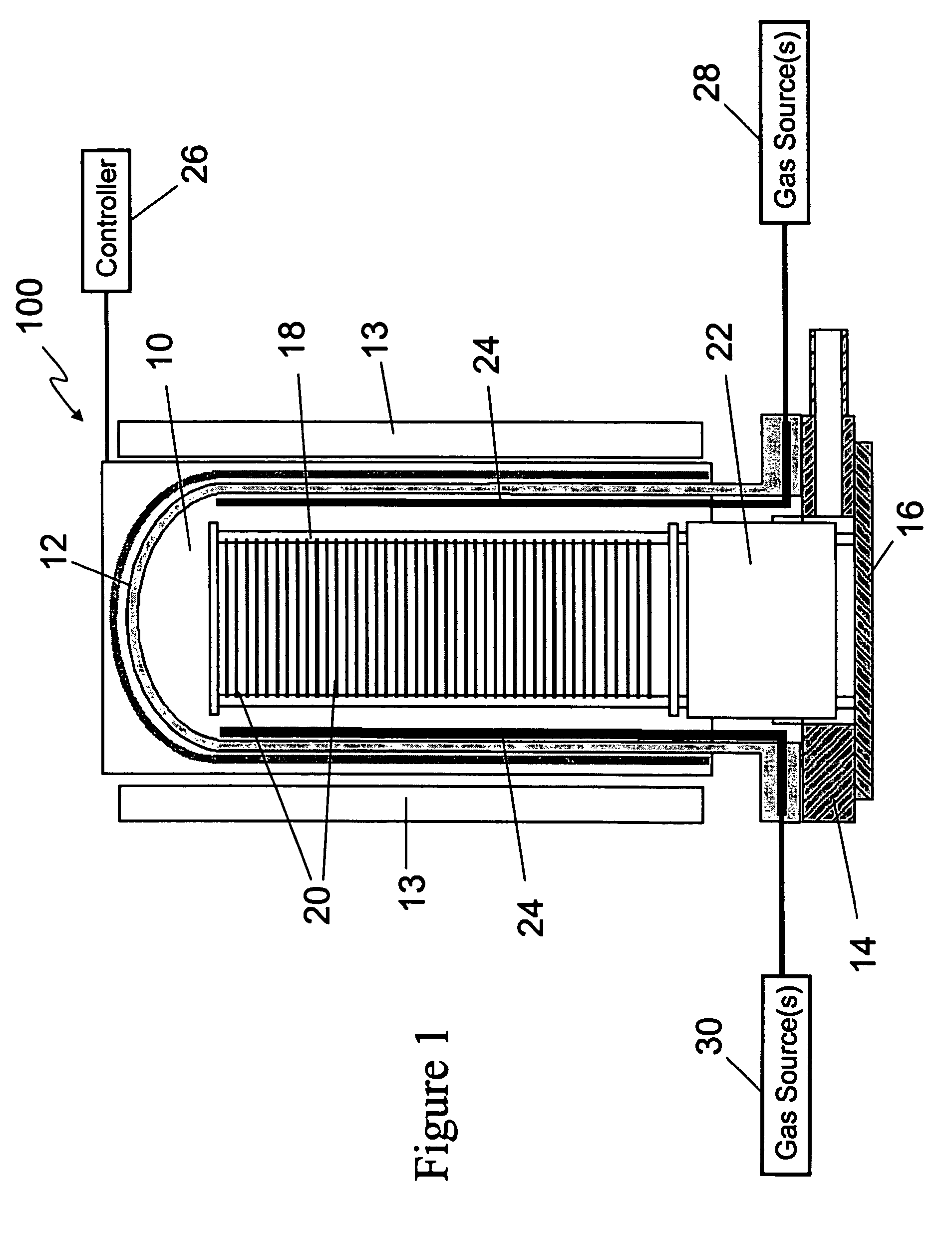

High strip rate downstream chamber

ActiveUS8298336B2Avoid radiationAbsorb thermal expansionElectric discharge tubesDecorative surface effectsSpray nozzleThermal expansion

A gas chamber contains upper and lower chamber bodies forming a cavity, a heating chuck for a wafer, a remote gas source, and an exhaust unit. Gas is injected into the cavity through channels in an injector. Each channel has sections that are bent with respect to each other at a sufficient angle to substantially eliminate entering light rays entering the channel from exiting the channel without reflection. The channels have funnel-shaped nozzles at end points proximate to the chuck. The injector also has thermal expansion relief slots and small gaps between the injector and mating surfaces of the chamber and gas source. The temperature of the injector is controlled by a cooling liquid in cooling channels and electrical heaters in receptacles of the injector. The upper chamber body is funnel-shaped and curves downward at an end of the upper chamber body proximate to the chuck.

Owner:LAM RES CORP

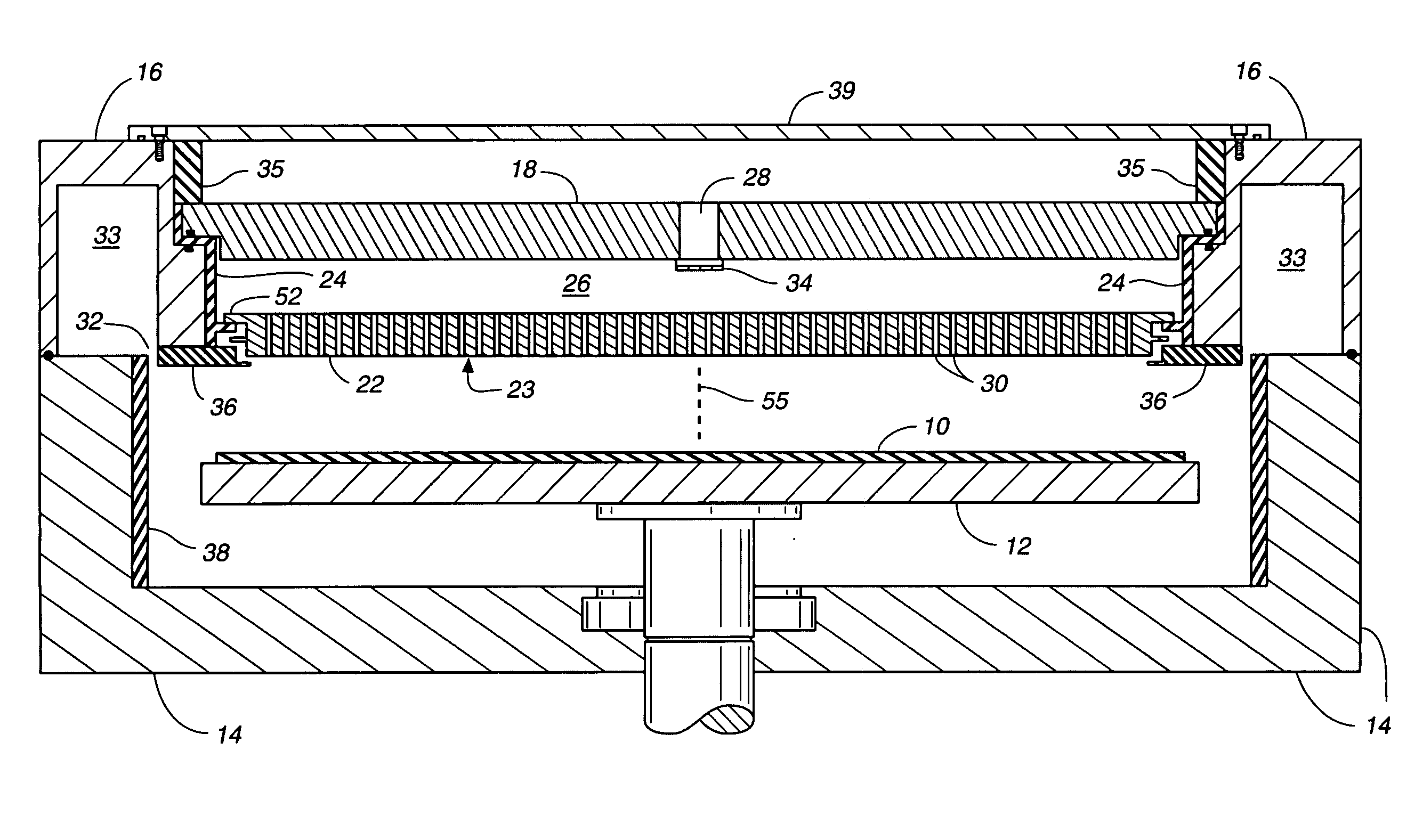

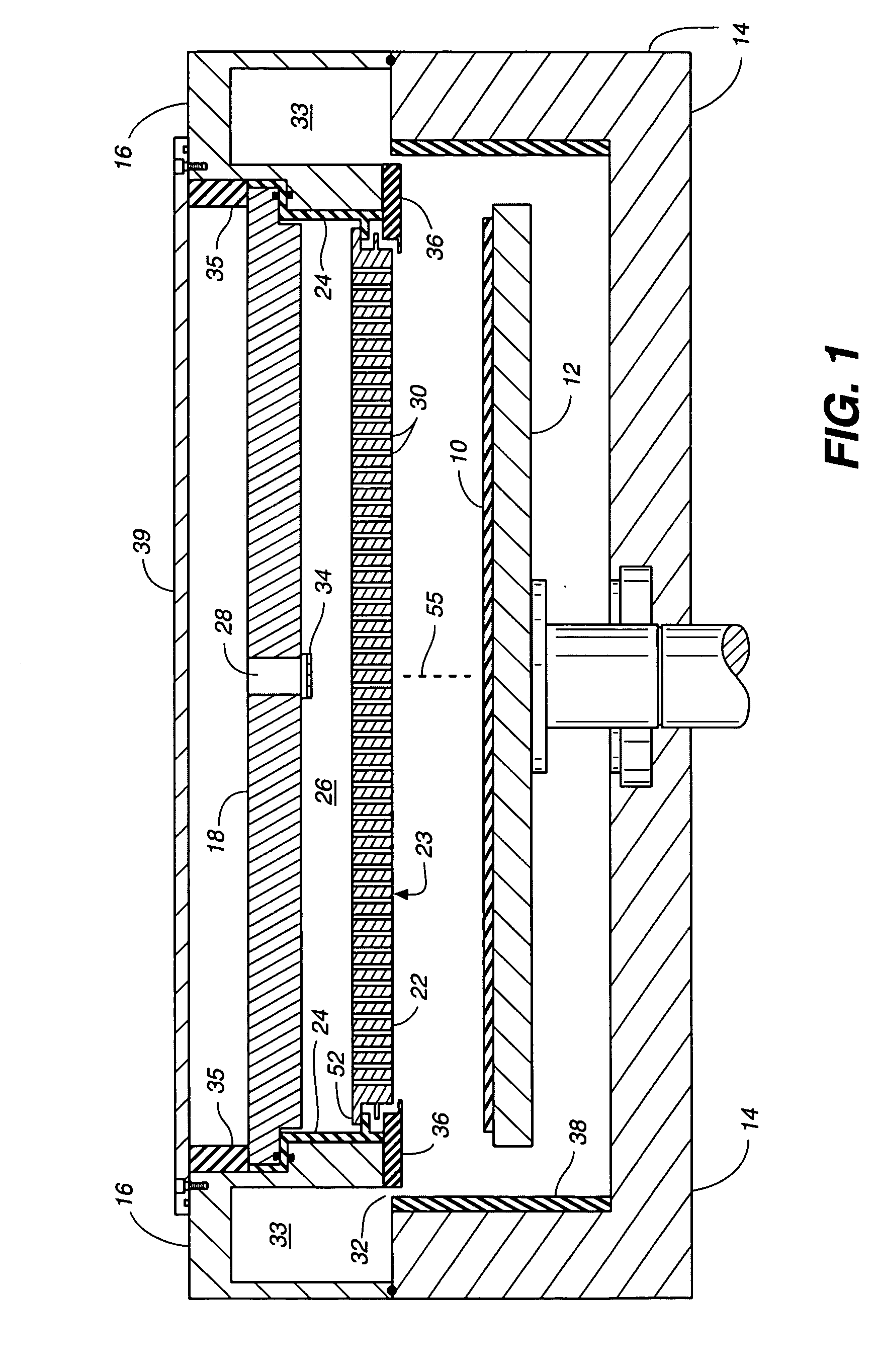

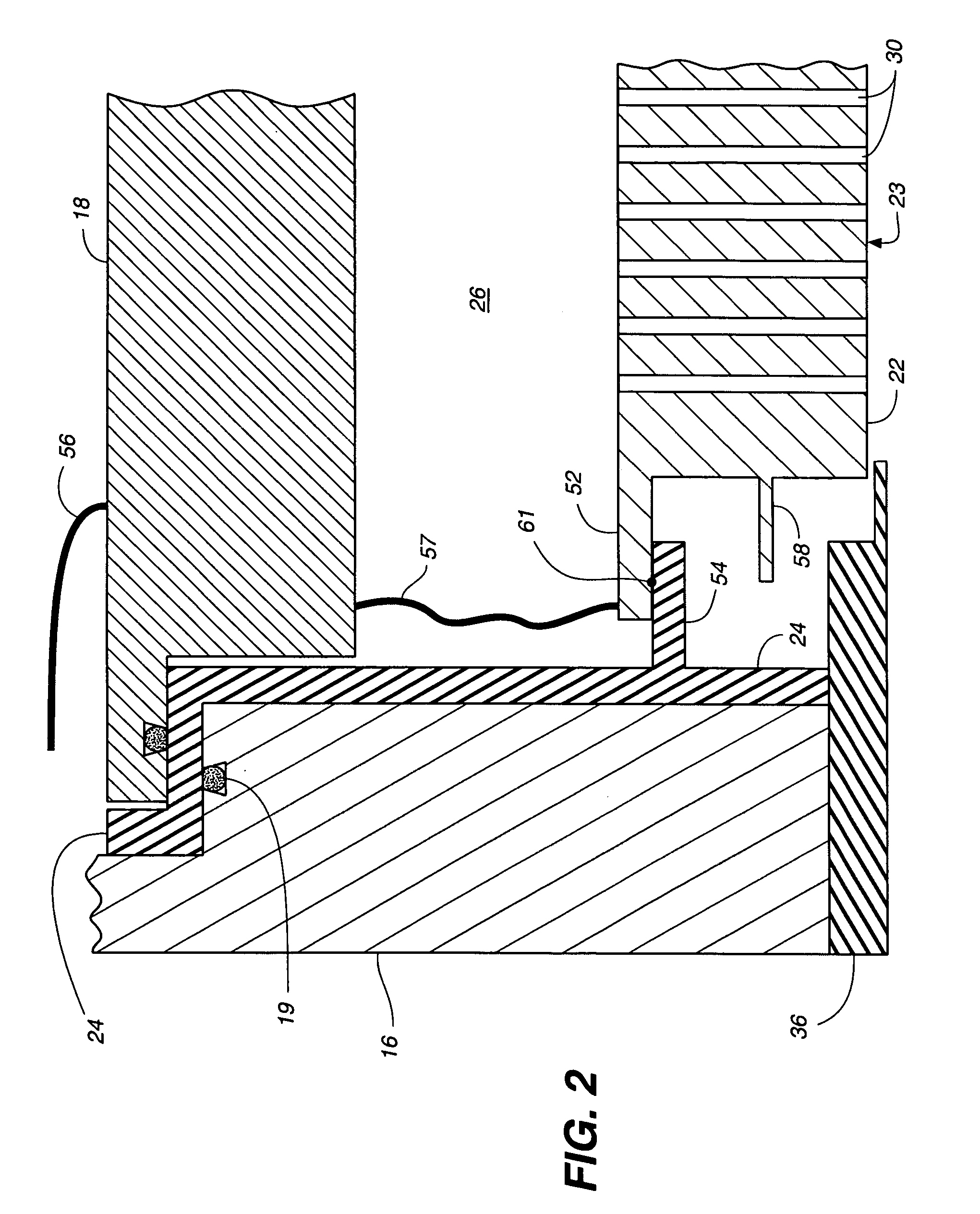

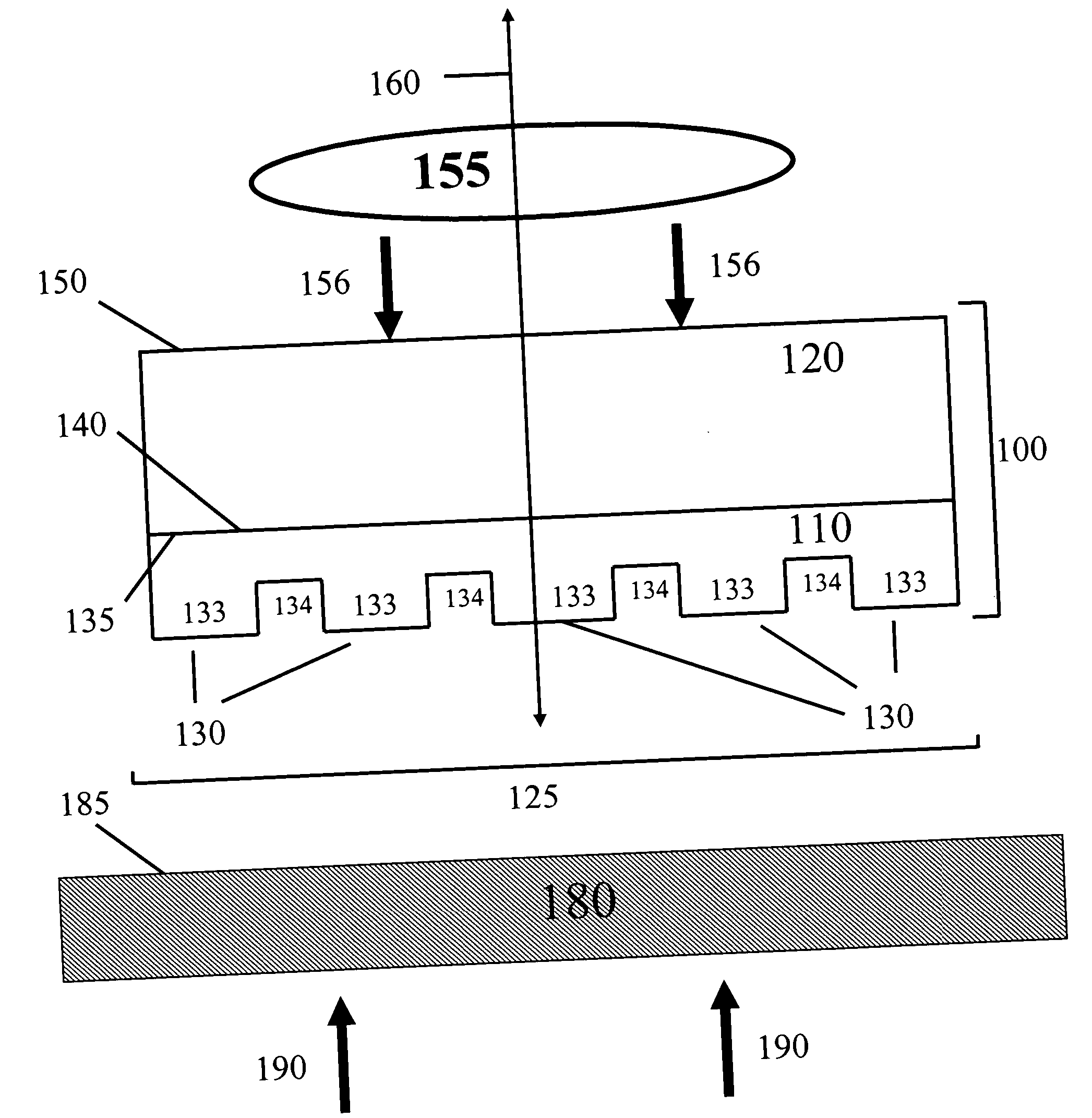

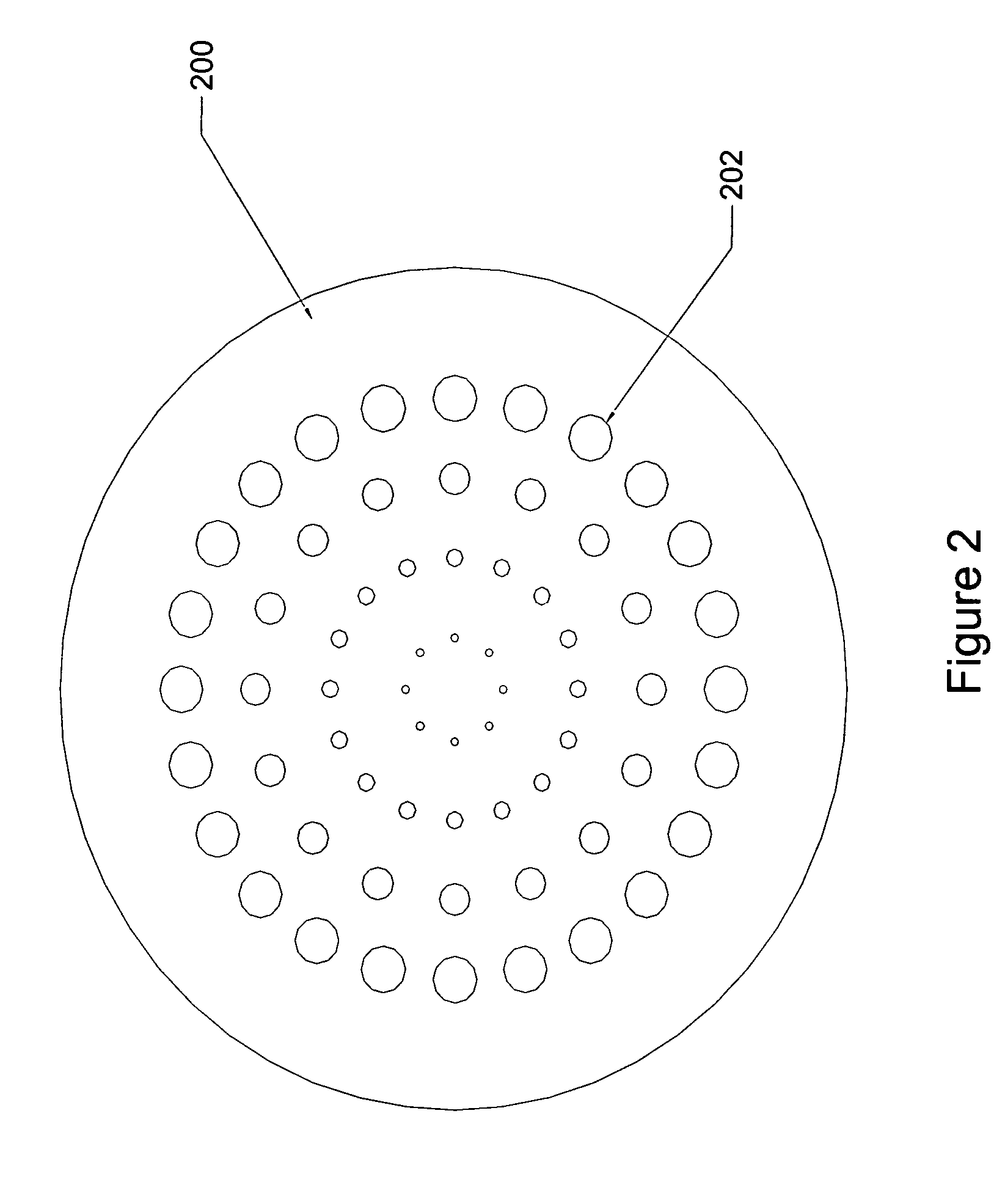

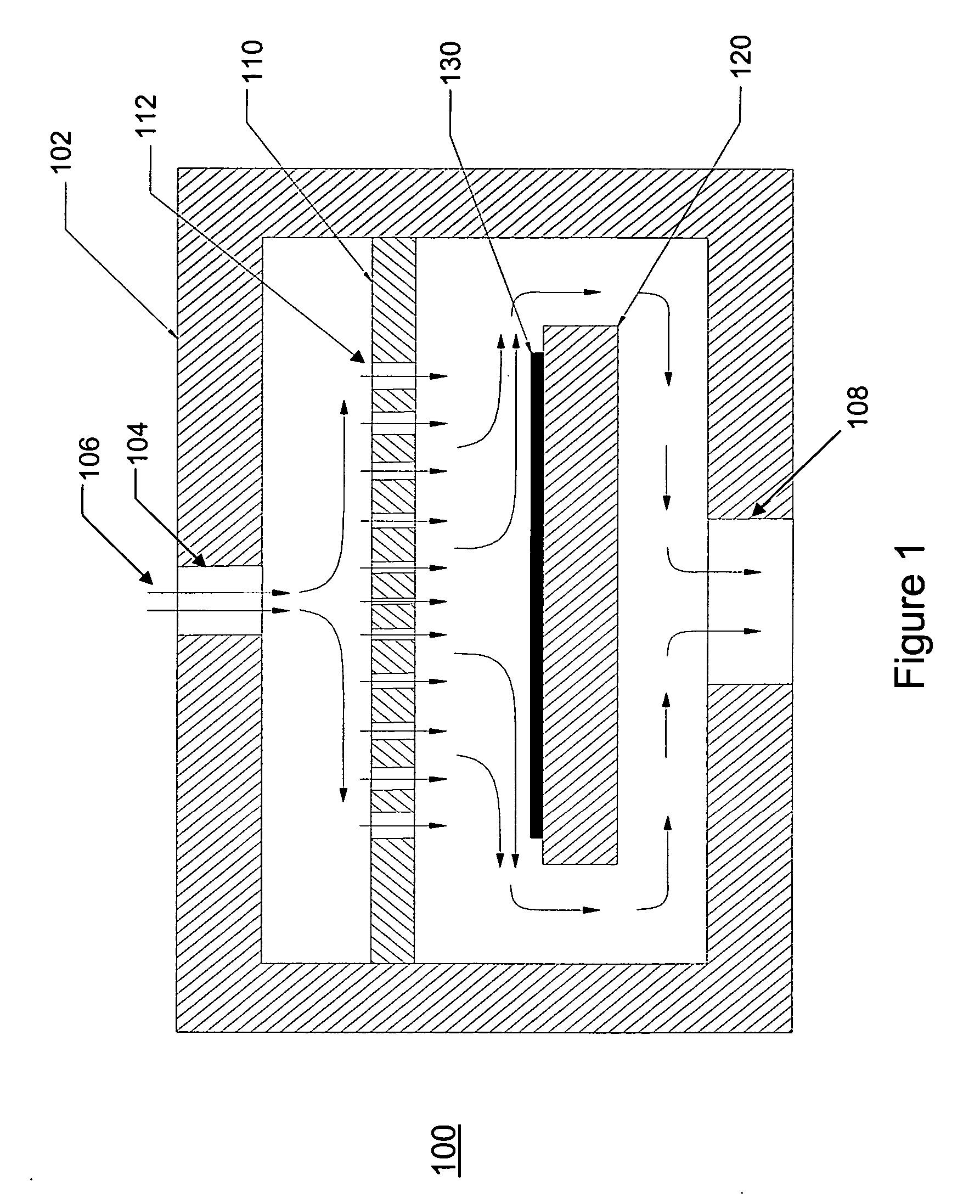

Suspended gas distribution plate

InactiveUS7017269B2Avoid distortionAvoid crackingElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationEngineering

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by flexible side walls. The flexible suspension minimizes mechanical stress due to thermal expansion of the gas distribution plate. In another aspect, the suspension provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

High strip rate downstream chamber

ActiveUS20060219361A1Avoid radiationAbsorb thermal expansionElectric discharge tubesDecorative surface effectsSpray nozzleGas passing

A gas chamber contains upper and lower chamber bodies forming a cavity, a heating chuck for a wafer, a remote gas source, and an exhaust unit. Gas is injected into the cavity through channels in an injector. Each channel has sections that are bent with respect to each other at a sufficient angle to substantially eliminate entering light rays entering the channel from exiting the channel without reflection. The channels have funnel-shaped nozzles at end points proximate to the chuck. The injector also has thermal expansion relief slots and small gaps between the injector and mating surfaces of the chamber and gas source. The temperature of the injector is controlled by a cooling liquid in cooling channels and electrical heaters in receptacles of the injector. The upper chamber body is funnel-shaped and curves downward at an end of the upper chamber body proximate to the chuck.

Owner:LAM RES CORP

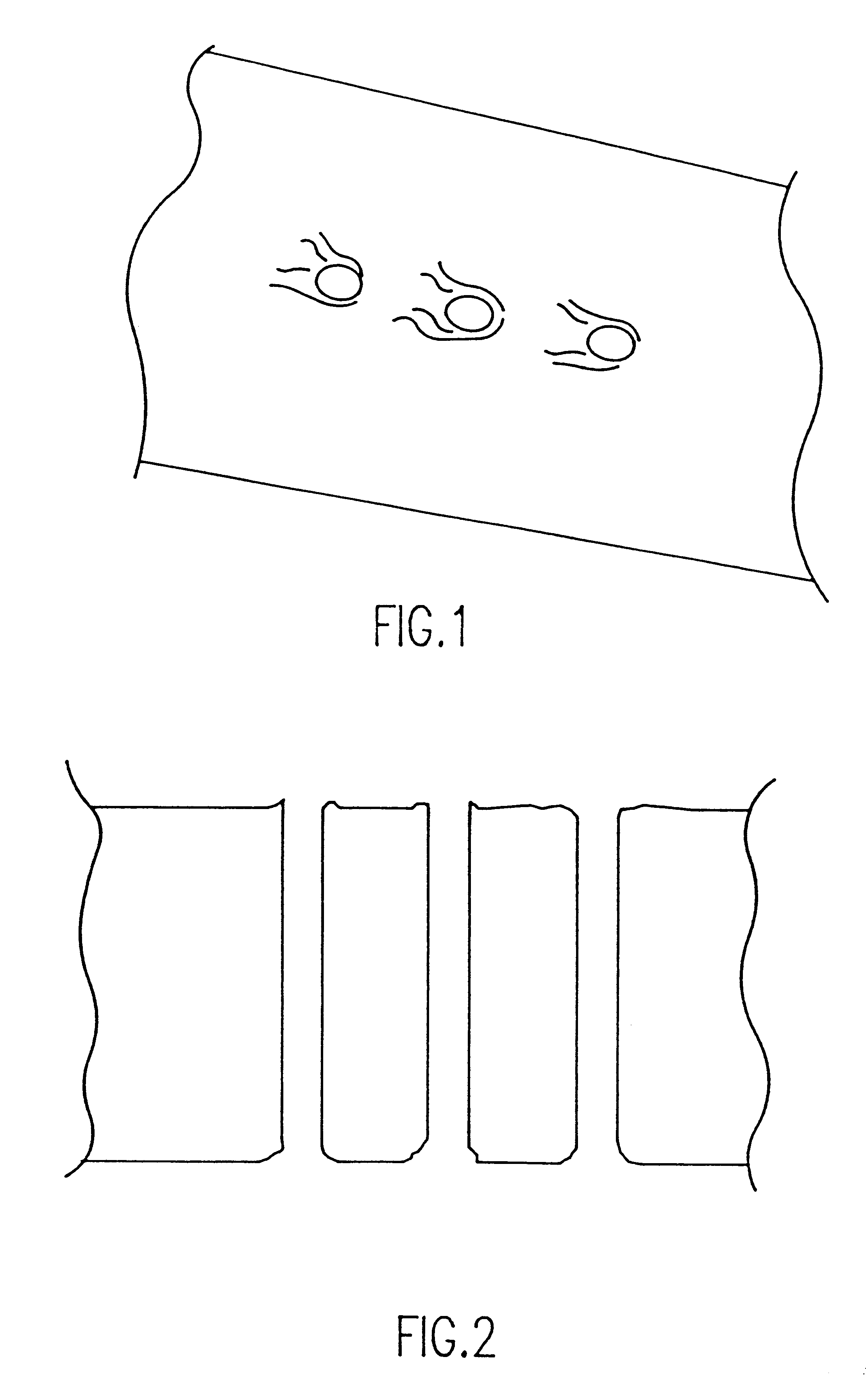

Optical fiber

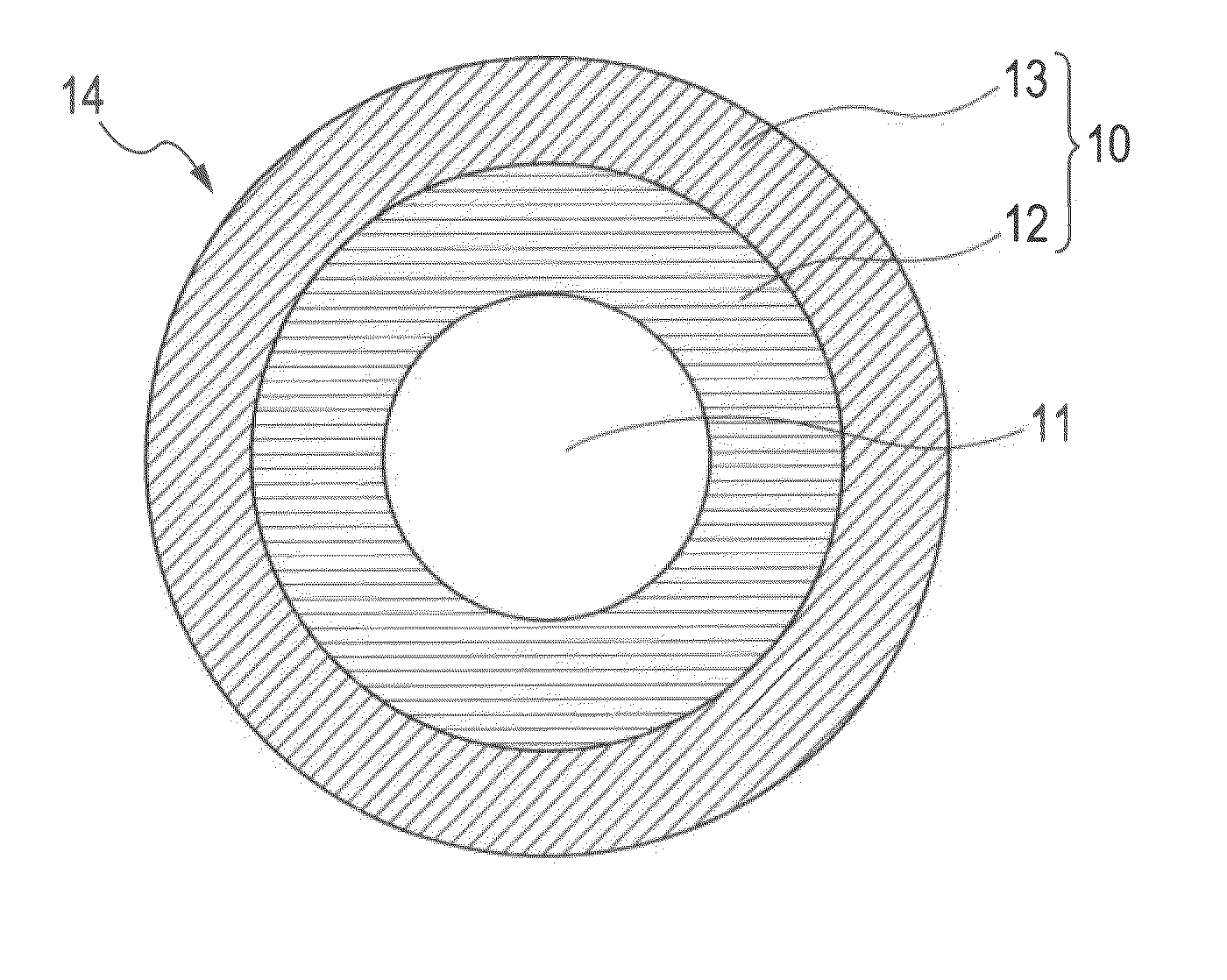

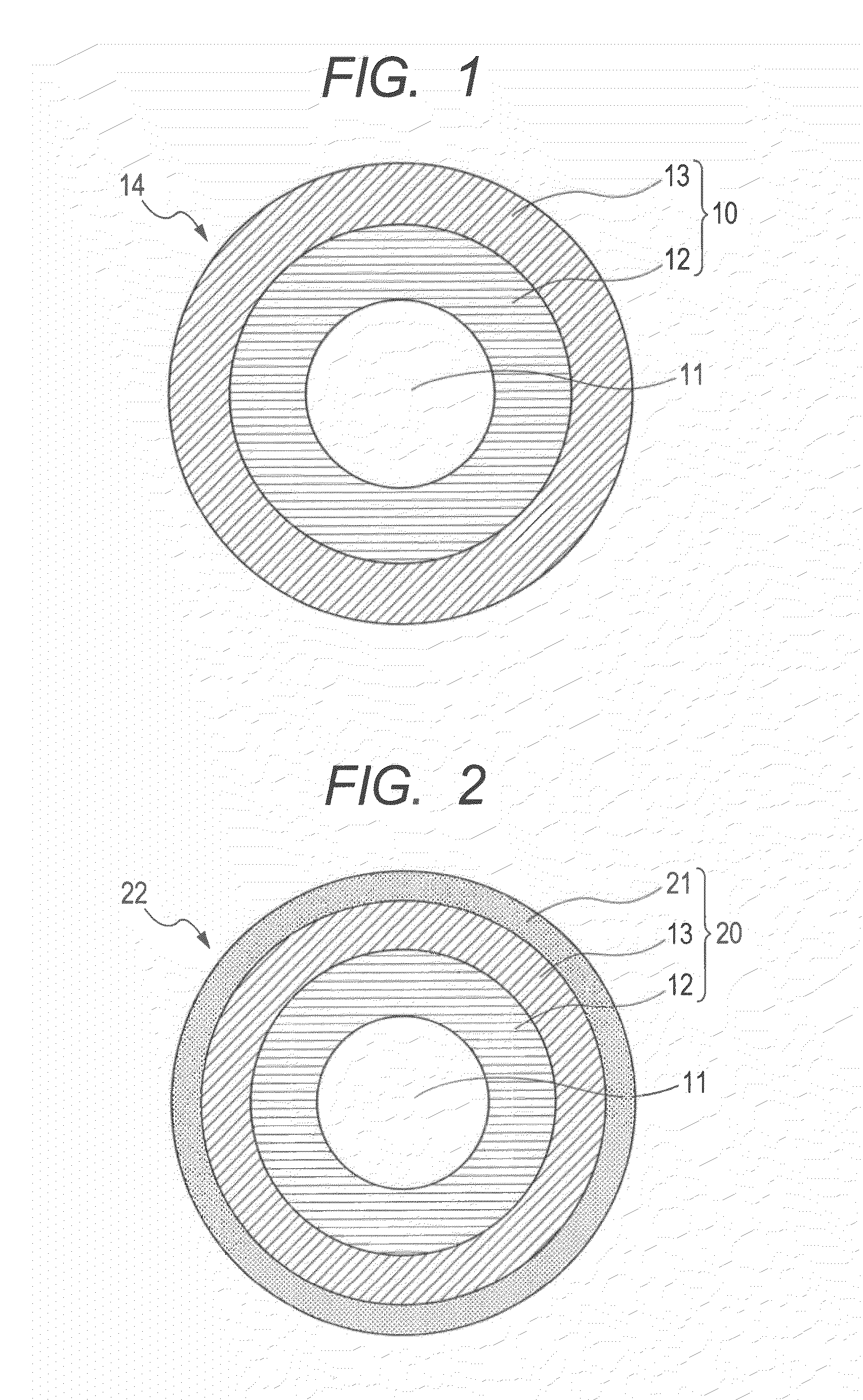

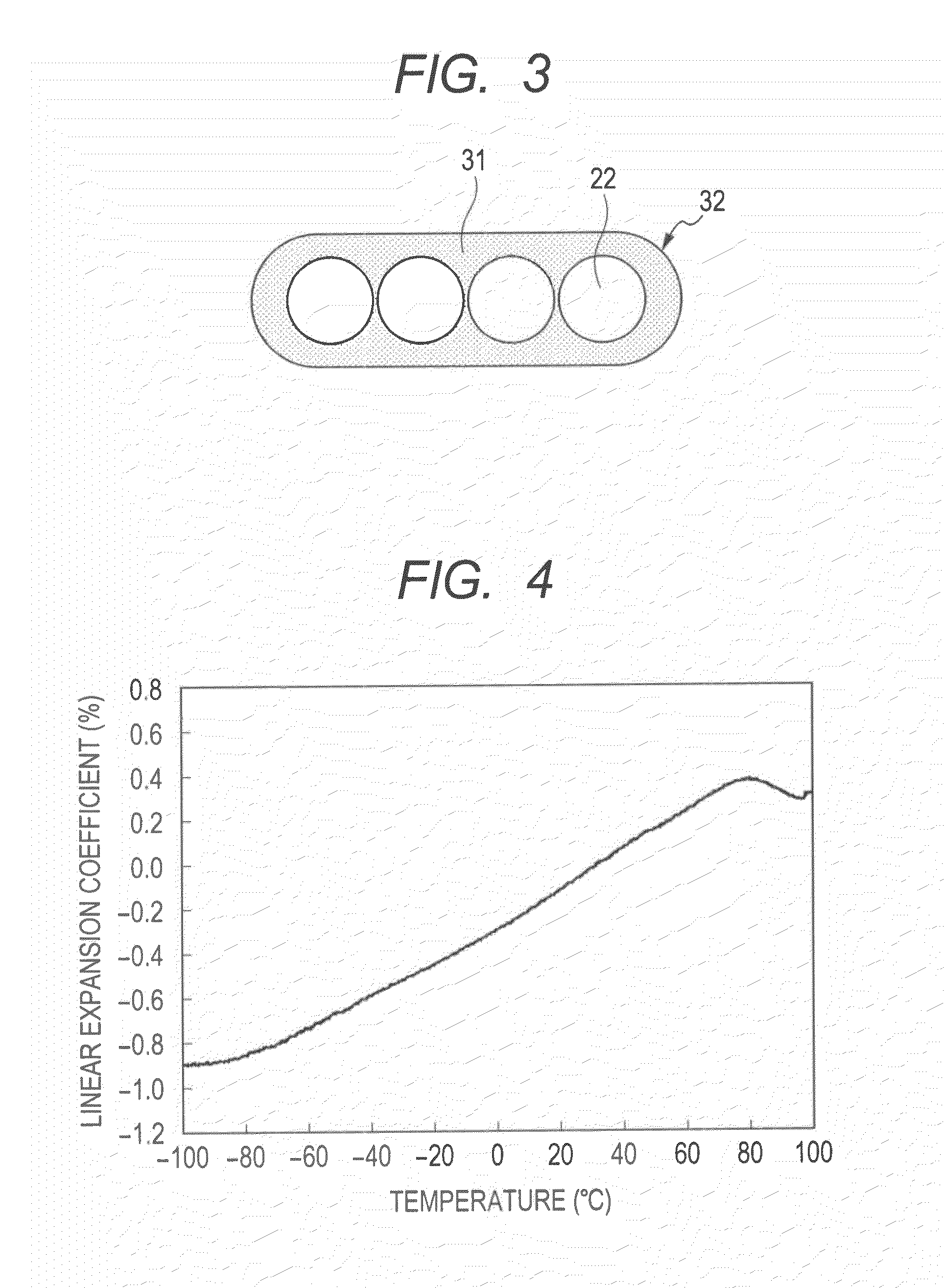

ActiveUS20110274396A1Increased transmission lossTransmission loss is hardGlass optical fibreOptical fibre with multilayer core/claddingHigh humidityThermal expansion

The present invention provides an optical fiber in which the transmission loss increase is suppressed even under a high-humidity condition or under a water-immersed condition. A colored optical fiber (22) according to an embodiment of the present invention is a colored optical fiber (22) formed by applying a colored layer to an optical fiber (14) including a glass optical fiber coated with at least a double-layered coating layer of a soft layer and a hard layer, and the ratio of thermal expansion coefficient between the coating layer after the colored layer of the colored optical fiber (22) is applied and the coating layer of the optical fiber (14) before the colored layer is applied is 0.87 or more. Furthermore, an optical fiber ribbon (32) according to another embodiment of the present invention is an optical fiber (32) formed by arranging a plurality of the colored optical fiber (22) in the form of a plane and coating them all together with a ribbon resin and the ratio of thermal expansion coefficient between the coating layer after the colored layer of the colored optical fiber (22) is applied and the coating layer of the optical fiber before the colored layer is applied is 0.90 or more.

Owner:FURUKAWA ELECTRIC CO LTD

Suspended gas distribution manifold for plasma chamber

InactiveUS7484473B2Avoiding distortion and crackingImprove spatial uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationProduct gas

Owner:APPLIED MATERIALS INC

Parts for deposition reactors

ActiveUS7674726B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal expansionSemiconductor

Processing methods and internal reactor parts avoid peeling and particle generation caused by differences in the coefficients of thermal expansion (CTE's) between reactor parts and films deposited on the reactor parts in hot wall CVD chambers. Conventional materials for reactor parts have relatively low CTE's, resulting in significant CTE differences with modem films, which can be deposited on the surfaces of reactor parts during semiconductor processing. Such CTE differences can cause cracking and flaking of the deposited films, thereby leading to particle generation. Reactor parts, such as boats and pedestals, which undergo large thermal cycles even in a hot wall chamber, are made of materials having a CTE greater than about 5×10−6 K−1, in order to more closely match the CTE of deposited materials, such TiN. The decreased CTE differences decrease differences between the expansion and contraction of the reactor parts and deposited films, leading to decreased cracking, flaking and, ultimately, decreased particle generation.

Owner:ASM INTERNATIONAL

Showerhead mounting to accommodate thermal expansion

InactiveUS7722925B2Minimize and eliminate distortionGreat thermal expansion coefficientElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringThermal expansion

Methods and apparatus for accommodating thermal expansion of a showerhead. In a first aspect of the invention, the showerhead is movably supported by resting a rim of the showerhead on a support shelf. In a second aspect, the showerhead is suspended from the chamber wall by a plurality of hangers that are connected to the showerhead, the chamber wall, or both by pins that slide within slots so as to permit the hangers to slide radially to accommodate thermal expansion of the showerhead in the radial direction. In a third aspect, the showerhead is suspended from the wall of the vacuum chamber by a plurality of rods or flexible wires. In a fourth aspect, the showerhead is connected near its perimeter to a second material having a greater thermal expansion coefficient than the showerhead. In a fifth aspect, a heater is mounted behind the showerhead to reduce the temperature differential between the top and bottom surfaces of the showerhead or to reduce heat transfer from the workpiece to the showerhead.

Owner:APPLIED MATERIALS INC

Diode housing

InactiveUS6624491B2Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

A housing accommodating a semiconductor chip is set out. The housing and chip may be used for sending and / or receiving radiation. Popular applications of the housing may be in light emitting diodes. The housing includes a conductor strip that is punched into two electrically isolated portions. The housing further includes a cavity extending inwards from the top of the housing. The conductor portions include respective areas that are exposed at the bottom of the cavity. The semiconductor chip is bonded to one of the exposed areas and a wire bonds the chip to the second exposed area. The conductor portions also terminate in exposed electrodes, which allow for electrical connection of the chip with external devices. A window is formed in the cavity and the walls of the housing that form the cavity may be made of a reflective material. The electrodes remain unexposed to the window but for any residual areas about the chip and bonding wire within the first and second exposed areas. By minimizing the area of the conductor exposed to the window, delamination brought about by the different thermal expansions of the window and conductor are minimized and / or eliminated. Likewise, with a reflective housing covering the base of the cavity that accommodates the window, internal radiation reflection is increased over that which was achieved with an exposed conductor.

Owner:OSRAM GMBH

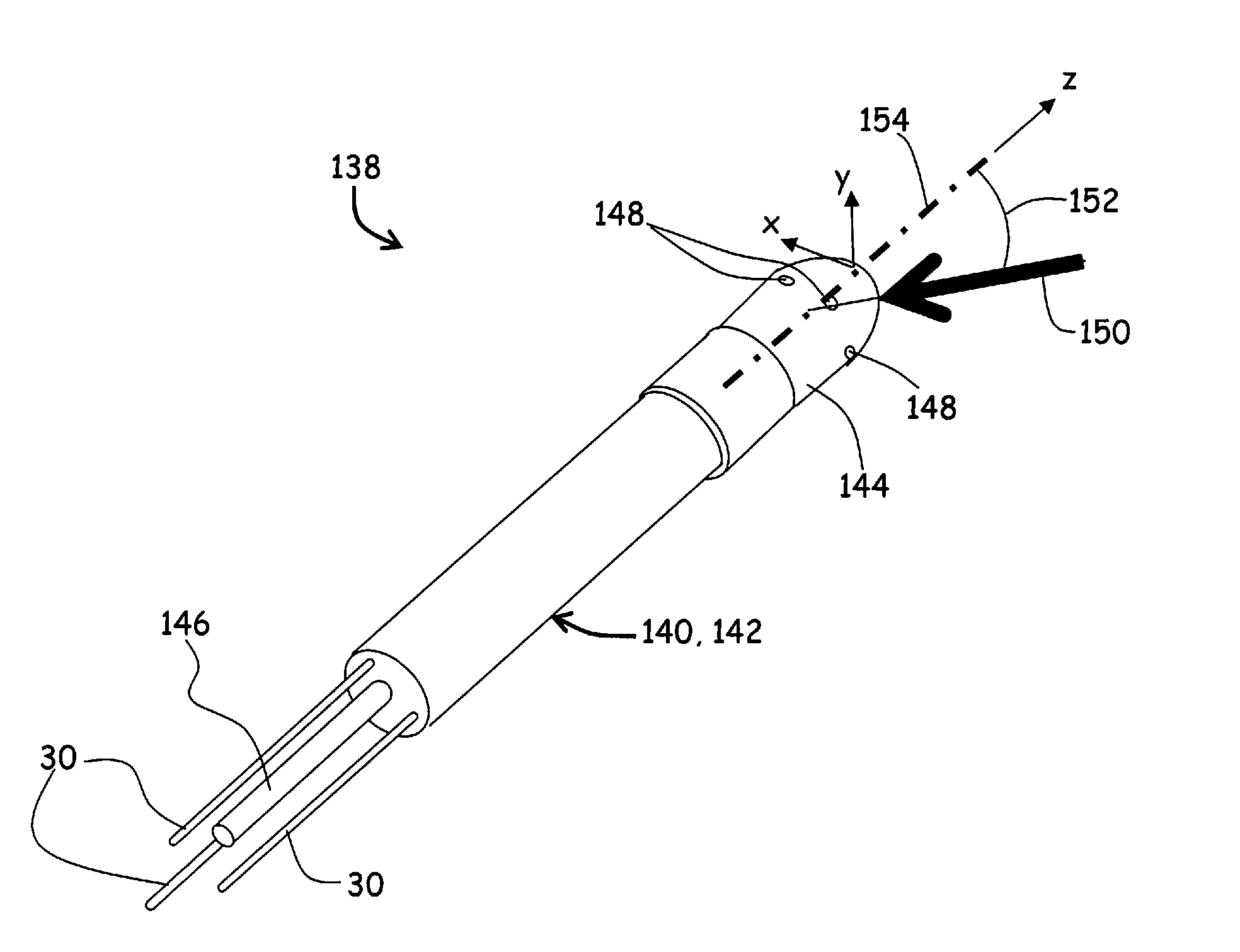

Touch Sensing Catheter

ActiveUS20080294144A1Moderate effectReduce potential temperature gradientStrain gaugeEndoscopesThermal isolationTouch Senses

A touch sensing catheter having a strain sensor assembly that may resolve the magnitude and direction of a force exerted on a distal extremity of the catheter, the strain sensor assembly being substantially insensitive to bulk temperature changes. A deformable structure having a plurality of optical fibers associated therewith that are strained by the imposition of a contact force transferred thereto. The optical fibers cooperate with the deformable structure to effect variable gap interferometers, such as Fabry-Perot resonators, that vary in operative length when a force is exerted on the deformable structure. The strain sensor assembly is rendered insensitive to bulk temperature changes by matching the coefficient of thermal expansion of the deformable body with that of the optical fibers. The strain sensor assembly may also be configured to mitigate the effects of thermal gradients using various thermal isolation techniques.

Owner:ST JUDE MEDICAL INT HLDG SARL

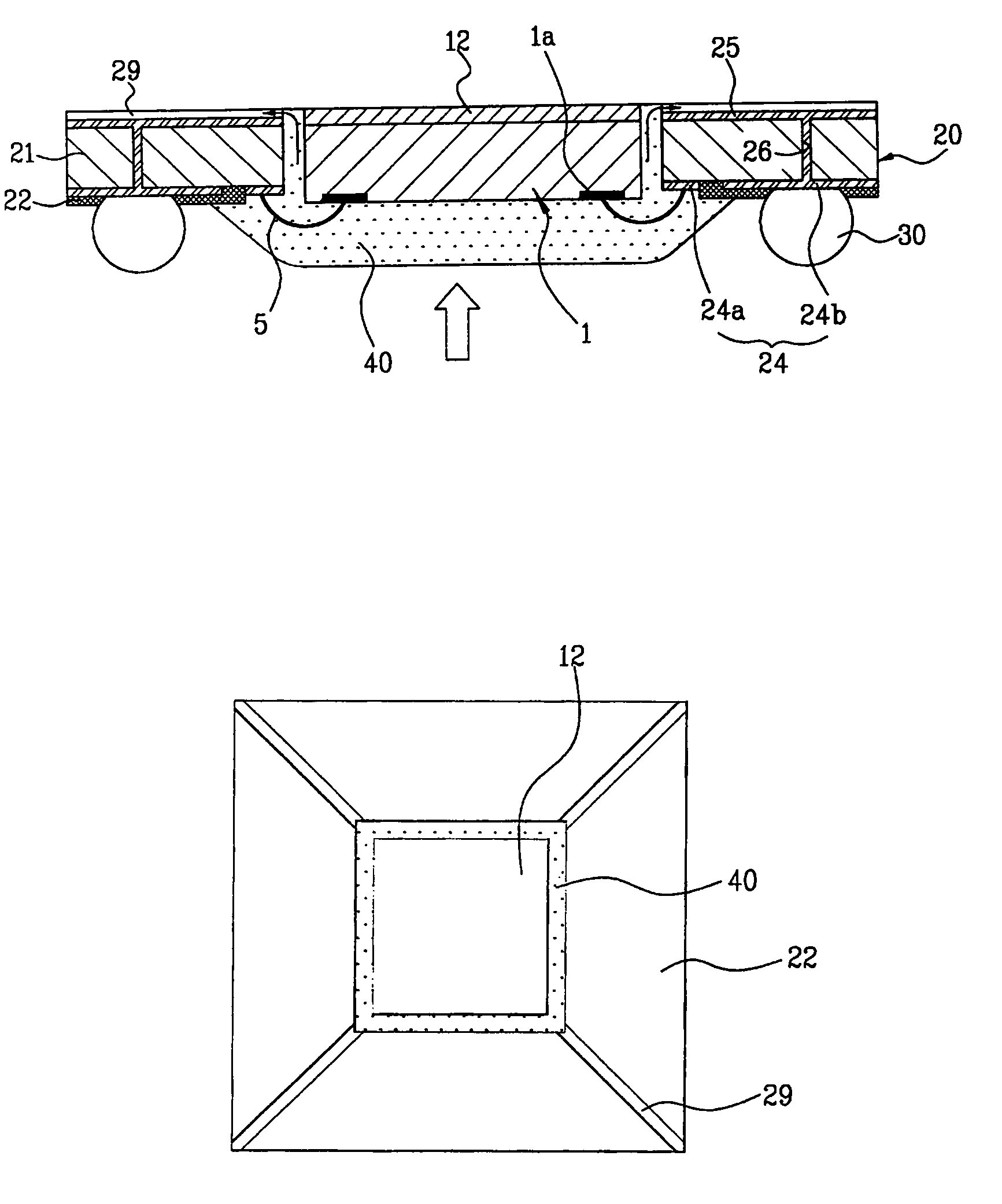

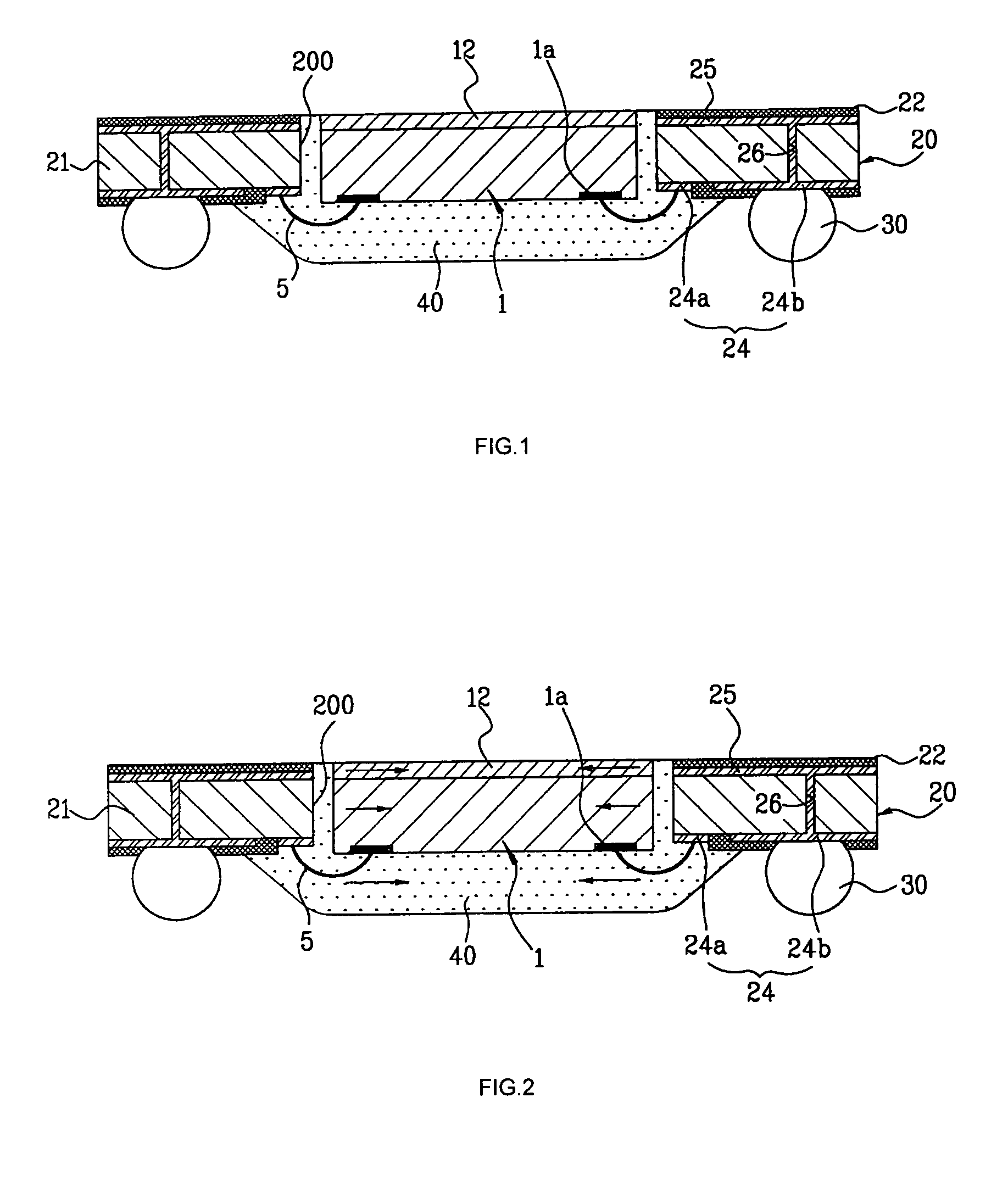

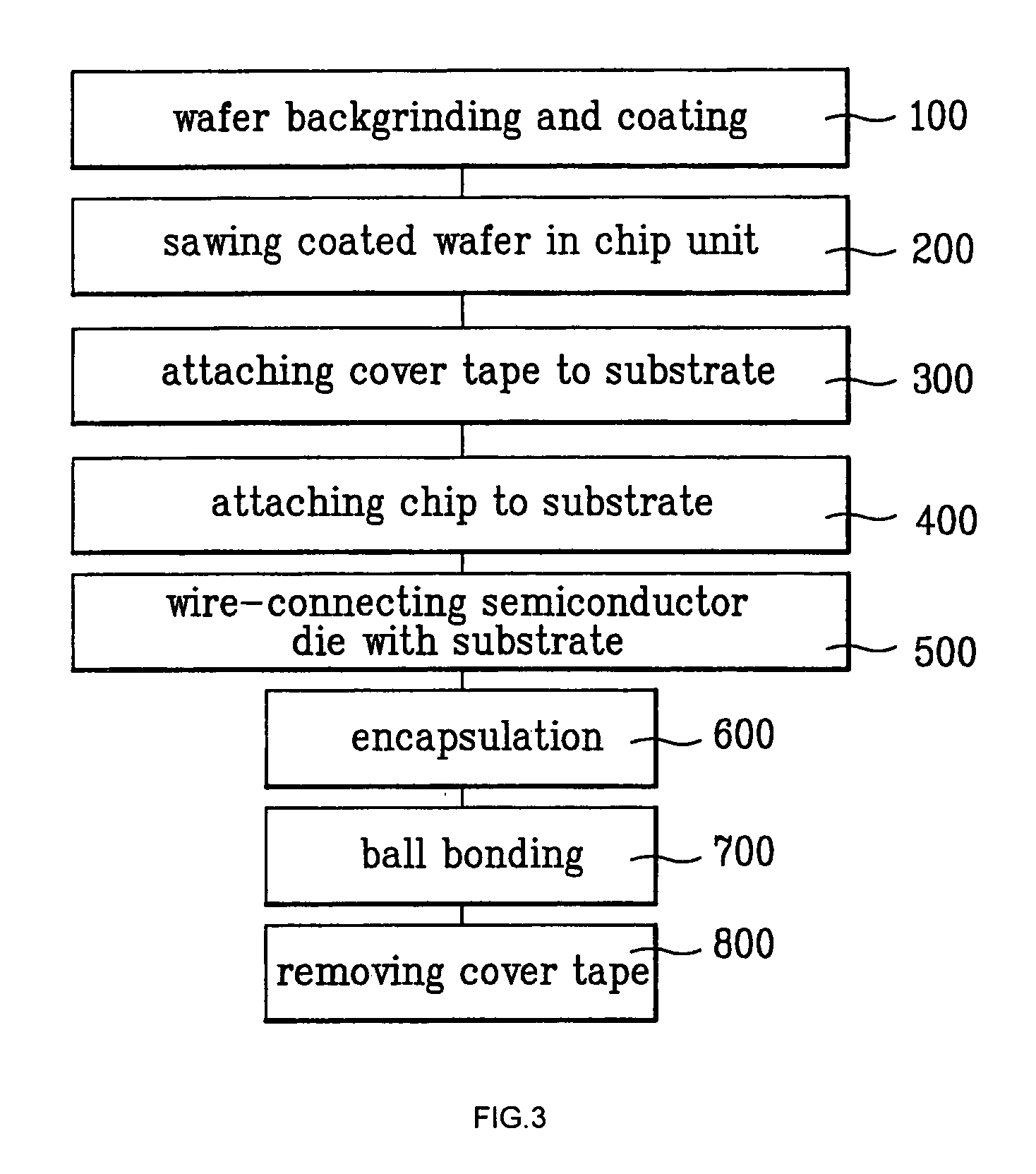

Semiconductor package and method of manufacturing the same which reduces warpage

InactiveUS7042072B1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package and method of producing the same has a semiconductor die having a first face and a second face. A coating material is coupled to the second face of the semiconductor die. A substrate having a cavity is provided wherein the semiconductor die is placed within the cavity. An encapsulant is used to encapsulate the second face of the semiconductor die placed in the cavity. Connection members are provided to couple the semiconductor die and the substrate in order to transfer signals between the semiconductor die and the substrate. Terminal members are couple to the substrate to connect the semiconductor package to an external device. In the semiconductor package, a thermal expansion coefficient of the coating material C and a thermal expansion coefficient of the encapsulant E should be approximately equal in value in order to limit the problems associated with warpage.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

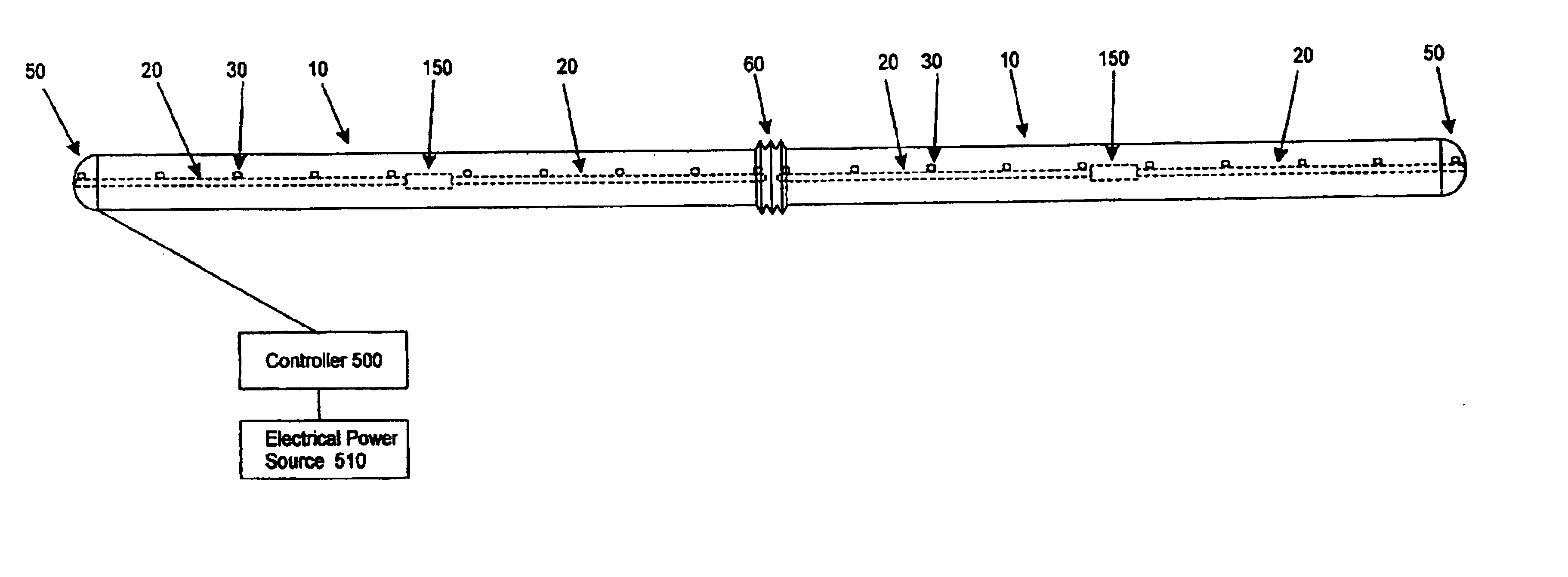

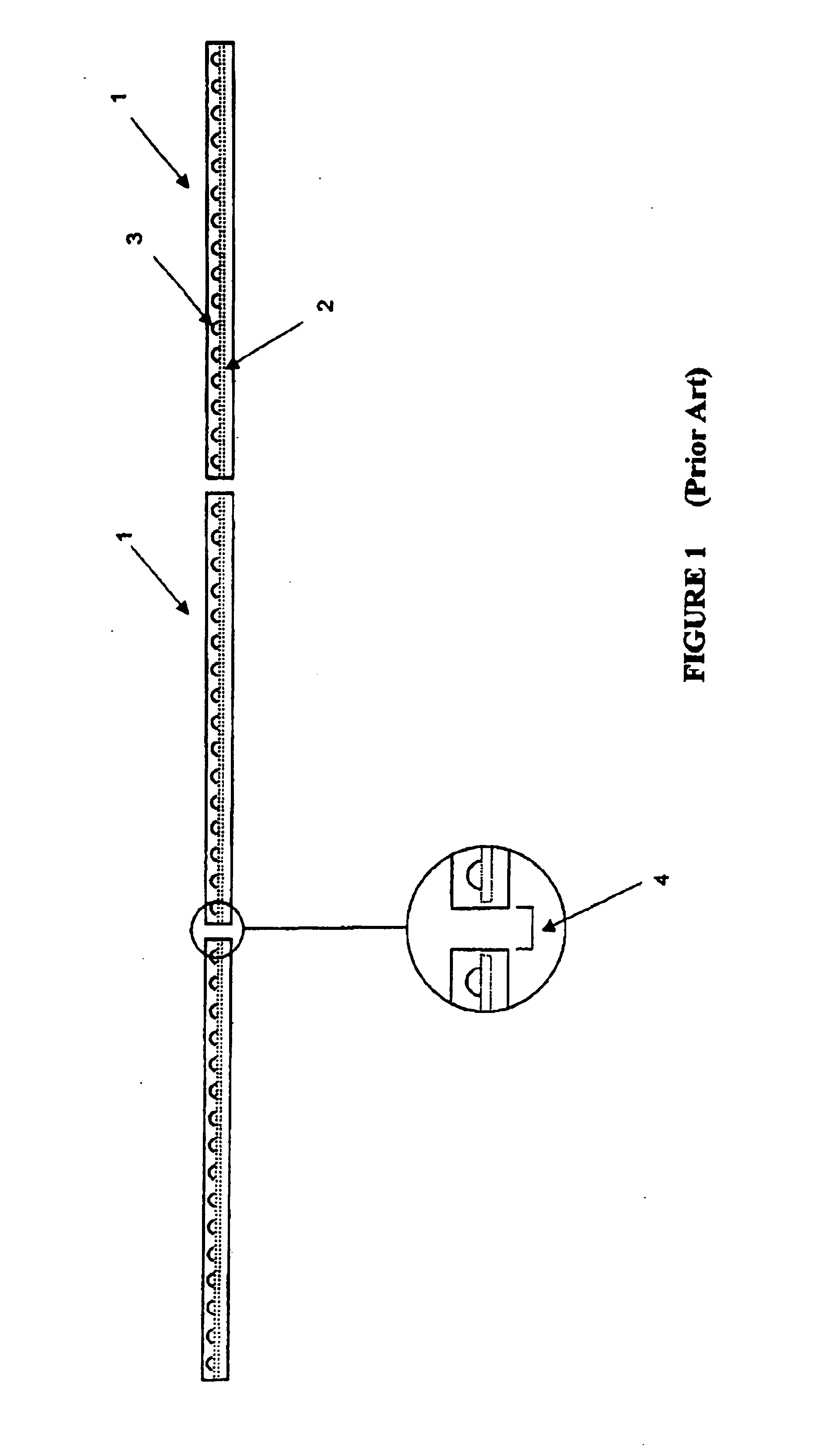

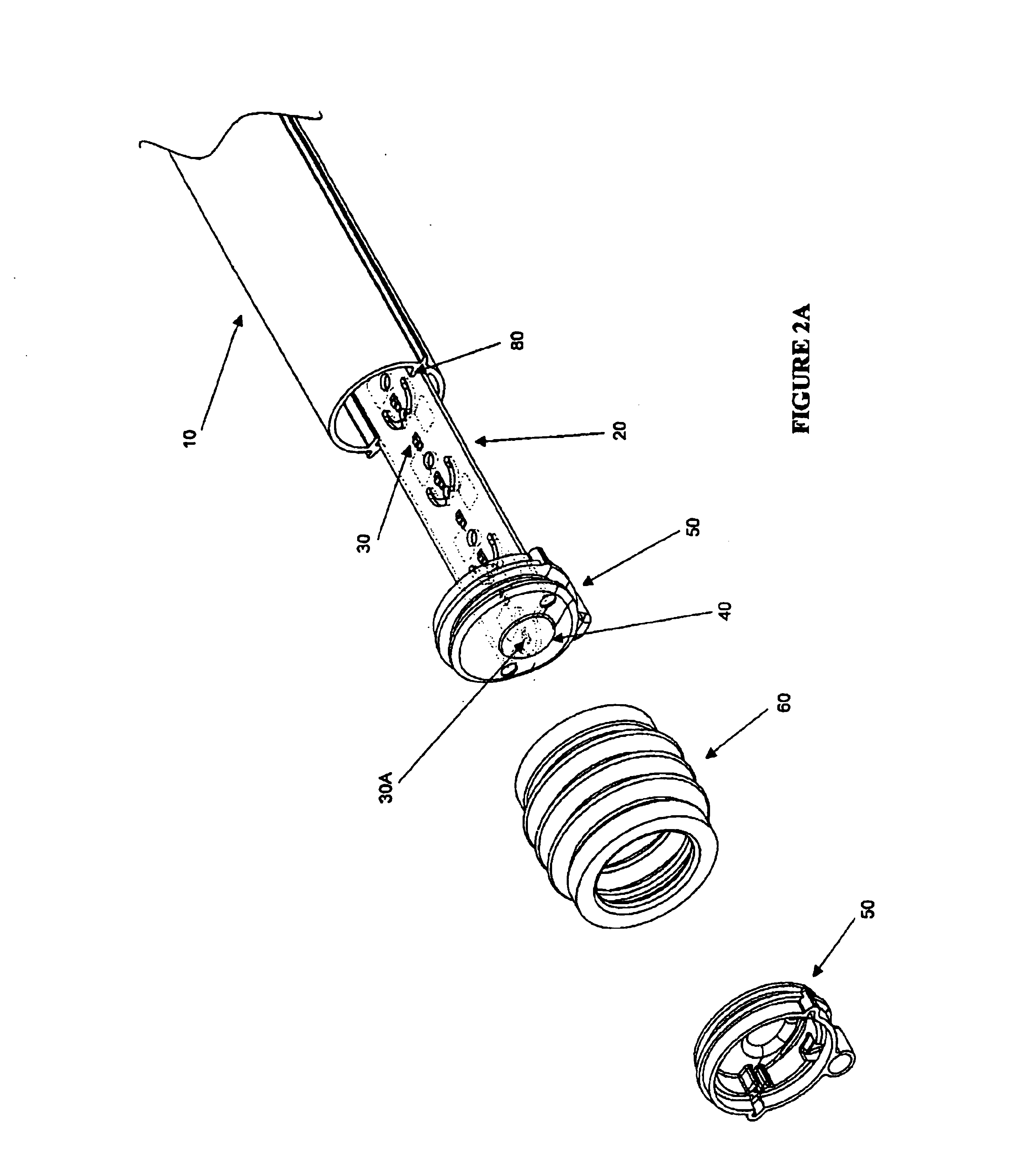

Strip lighting system incorporating light emitting devices

The invention provides an elongated lighting apparatus that can withstand temperature fluctuations. The elongated lighting apparatus comprises of the following elements: at least two elongated tubular members fabricated from translucent material. These elongated tubular members are fixed in an end-to-end configuration, separated by a region enabling for thermal expansion / contraction of the members. A substrate upon which a plurality of light emitting devices is placed, is slidably positioned inside each tubular member. End caps seal the open ends of the elongated tubular members. At least one of these end caps has a translucent protrusion that projects towards the region of separation. At least one light emitting device is positioned proximate to an end cap protrusion, thereby illuminating this region. A flexible interconnector encloses and visually conceals separating the adjacent members. The light emitting devices are electrically interconnected. An external power source provides a system to energize the light sources.

Owner:SIGNIFY HLDG BV

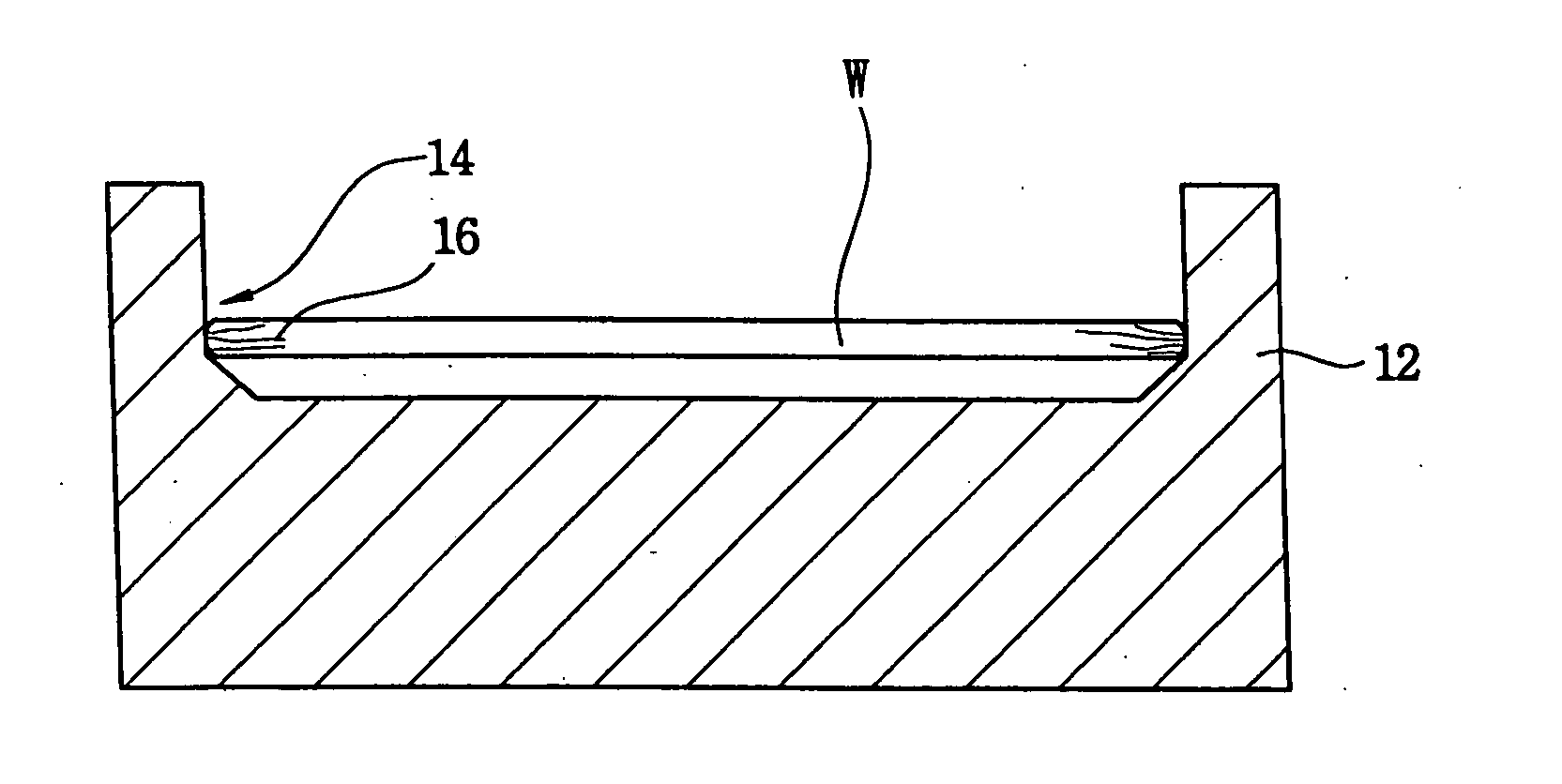

Susceptor and deposition apparatus including the same

InactiveUS20050016470A1Minimize physical impactMinimizing slip dislocationDiffusion/dopingSemiconductor/solid-state device manufacturingSusceptorEngineering

A susceptor for use in a deposition apparatus includes a recess in which a wafer is received, and a stress-reducing bumper disposed along the side of the recess. The stress-reducing bumper is of material having ductility at a relatively high temperature. Therefore, when the wafer contacts the stress-reducing bumper, such as may occur due to thermal expansion of the wafer during processing, the force of the impact on the wafer is minimized by an elastic deformation of the stress-reducing bumper. As a result, defects, such as slip dislocations at the outer peripheral edge of the wafer, are prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

Strontium feldspar aluminum titanate for high temperature applications

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com