Patents

Literature

13387 results about "Vacuum chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum chamber is a rigid enclosure from which air and other gases are removed by a vacuum pump. This results in a low-pressure environment within the chamber, commonly referred to as a vacuum. A vacuum environment allows researchers to conduct physical experiments or to test mechanical devices which must operate in outer space (for example) or for processes such as vacuum drying or vacuum coating. Chambers are typically made of metals which may or may not shield applied external magnetic fields depending on wall thickness, frequency, resistivity, and permeability of the material used. Only some materials are suitable for vacuum use.

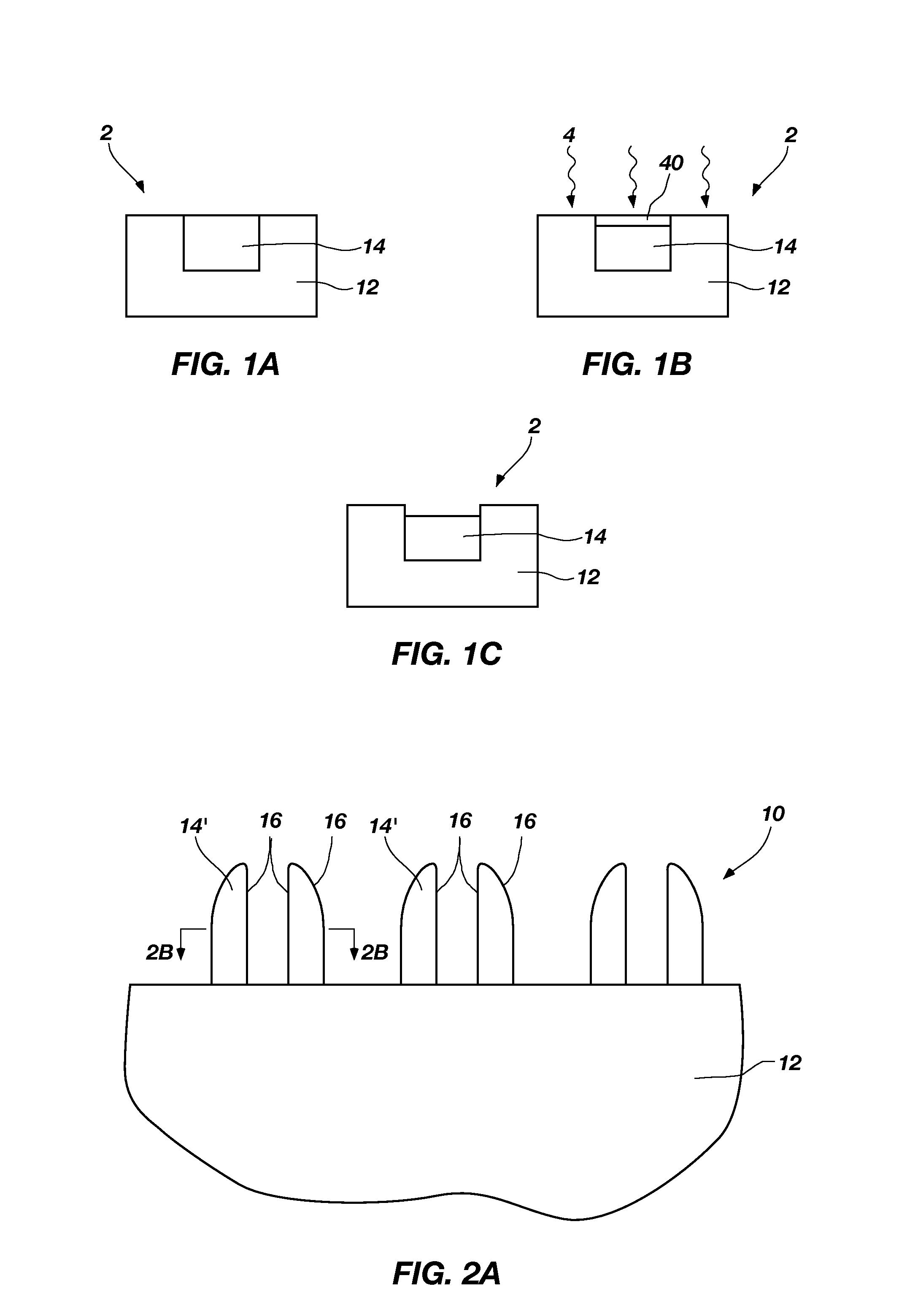

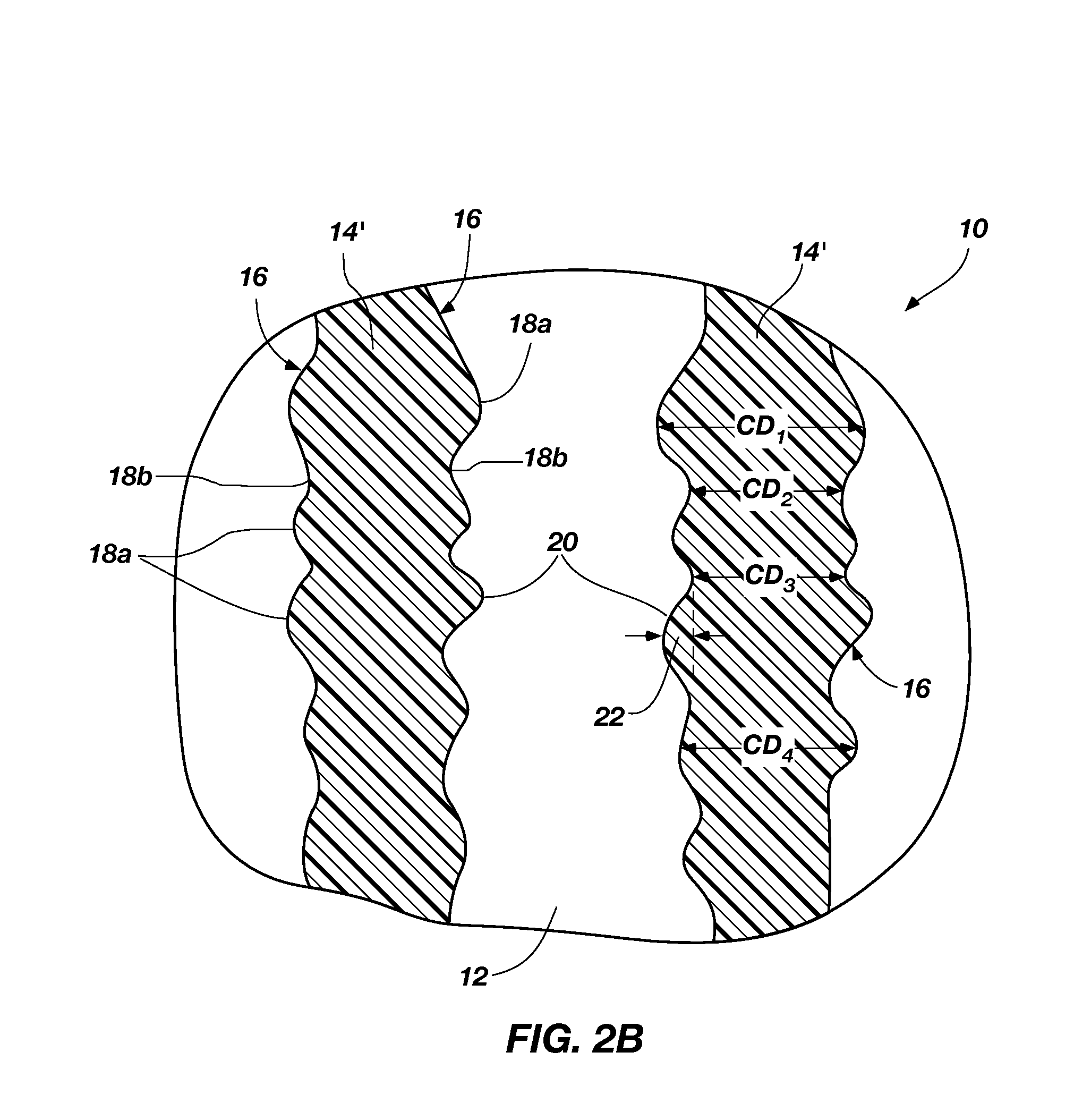

Process and apparatus for organic vapor jet deposition

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

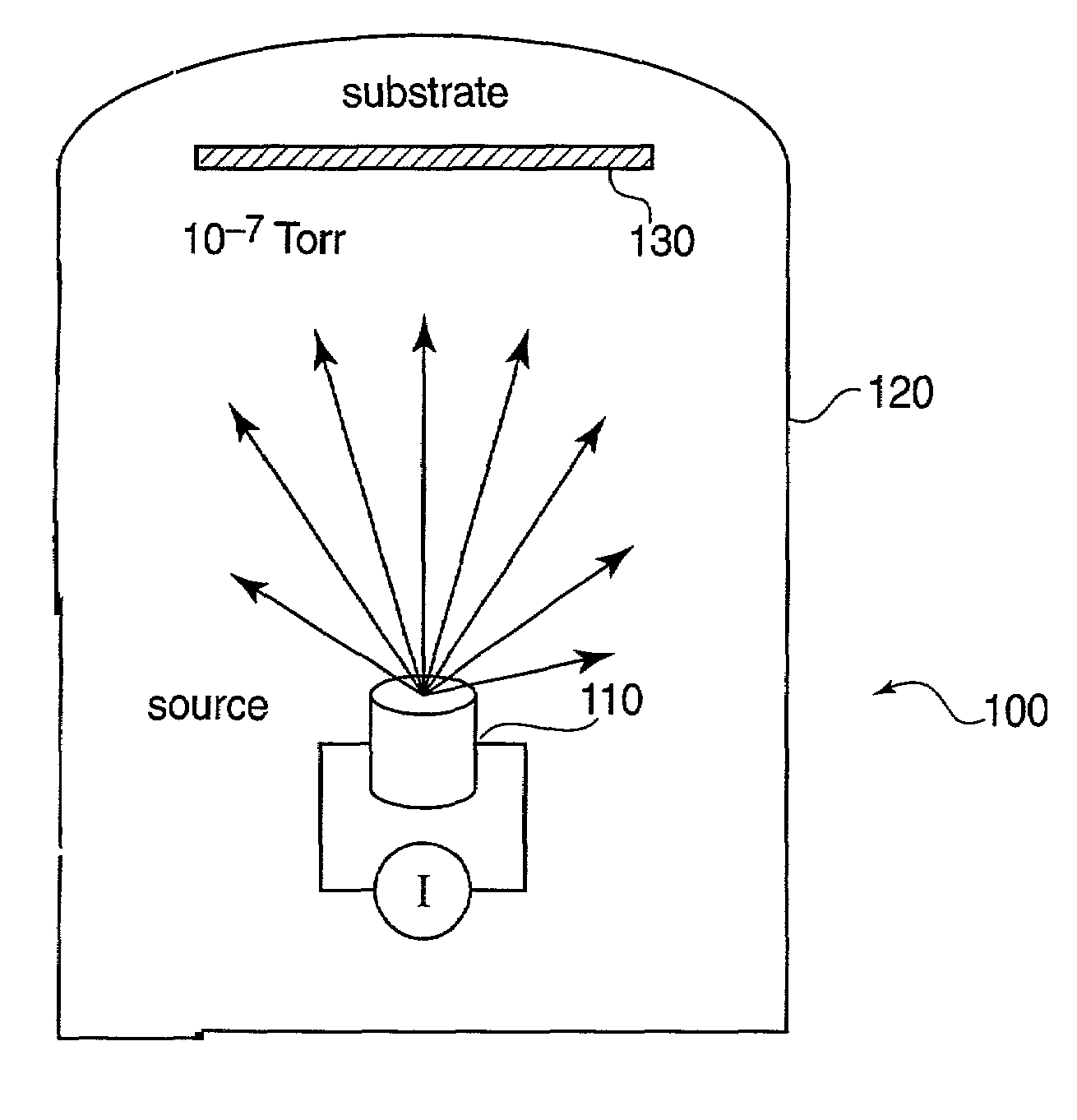

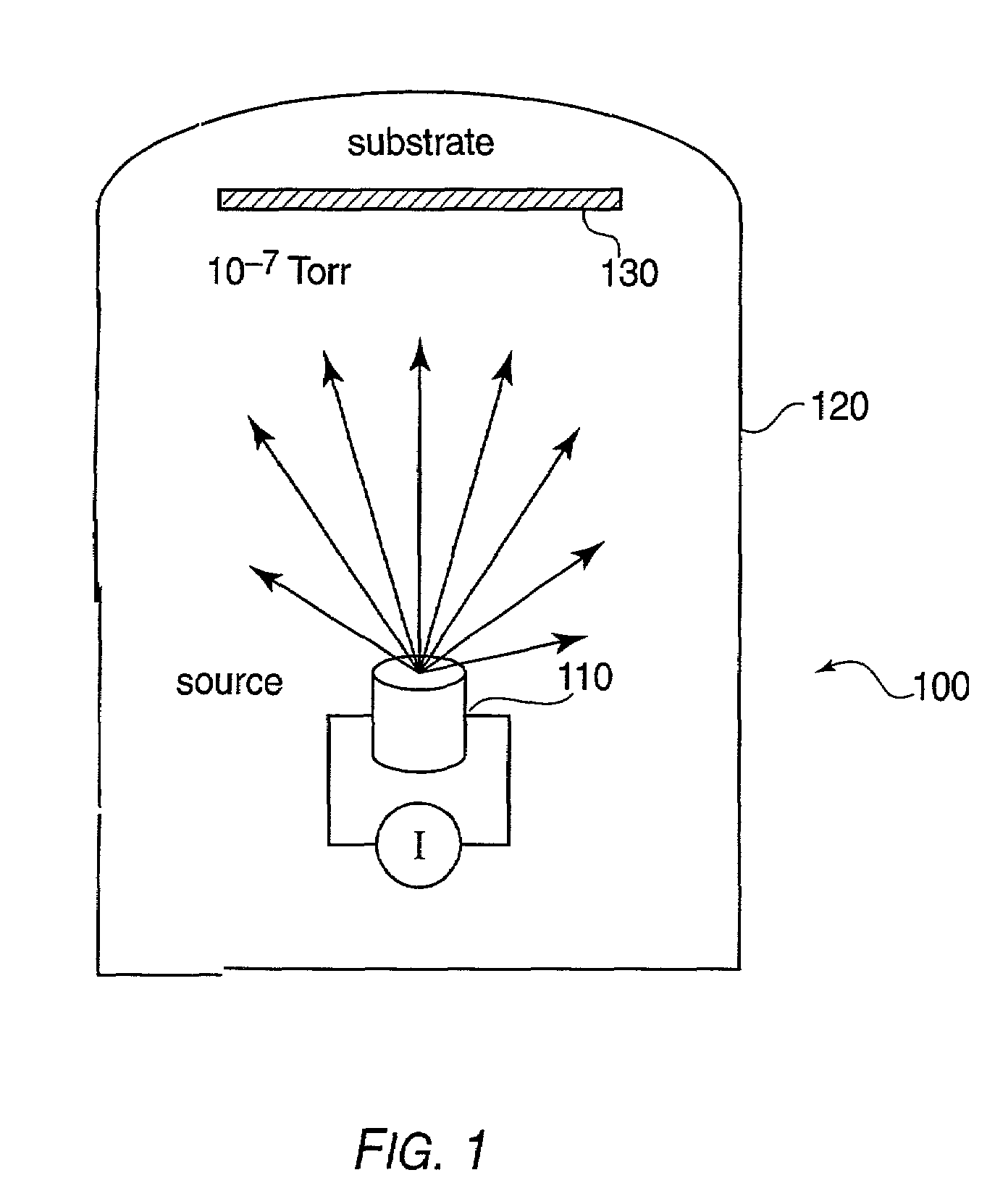

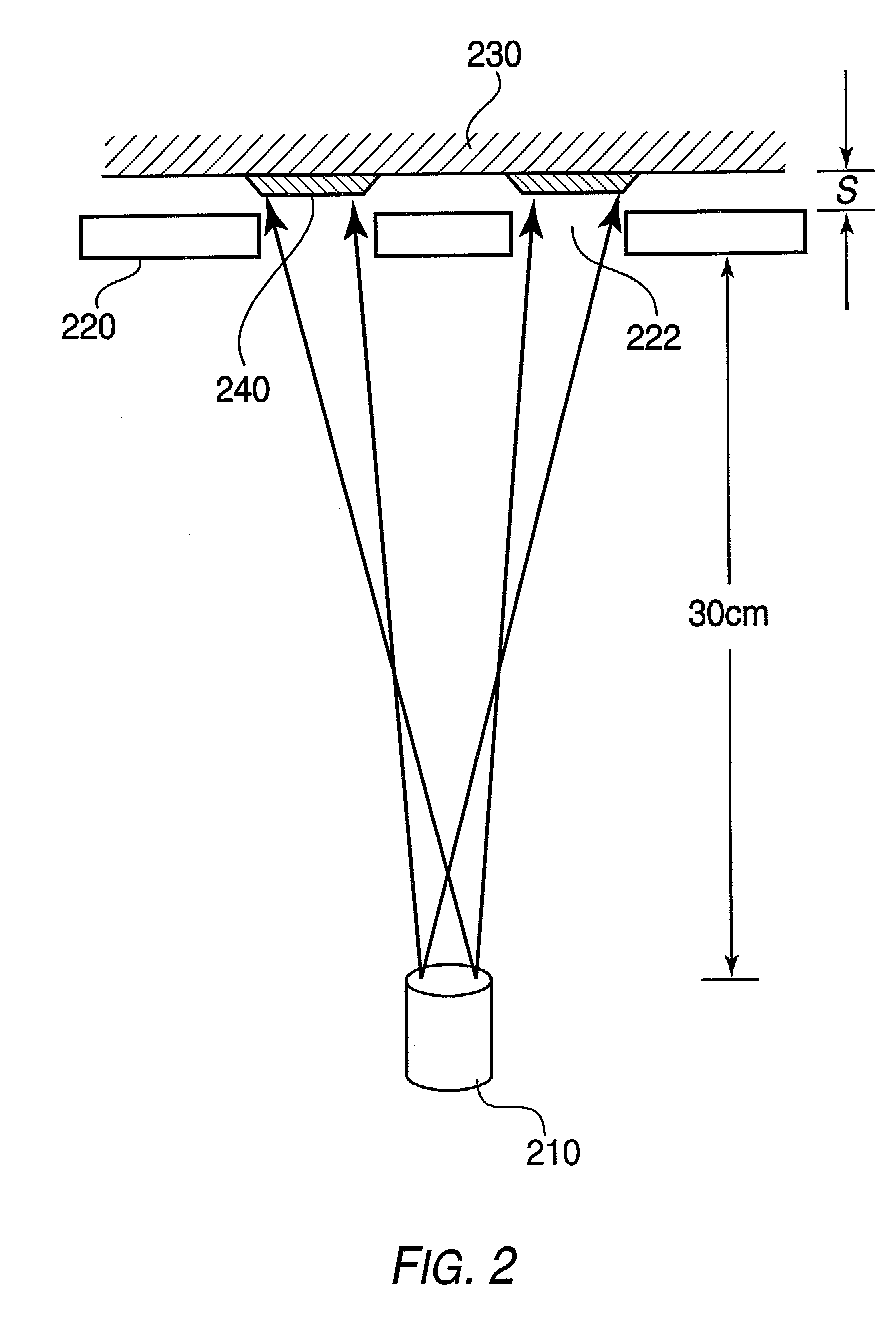

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Methods of removing silicon oxide and gaseous mixtures for achieving same

ActiveUS20090275205A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical treatmentPartial oxidation

Owner:MICRON TECH INC

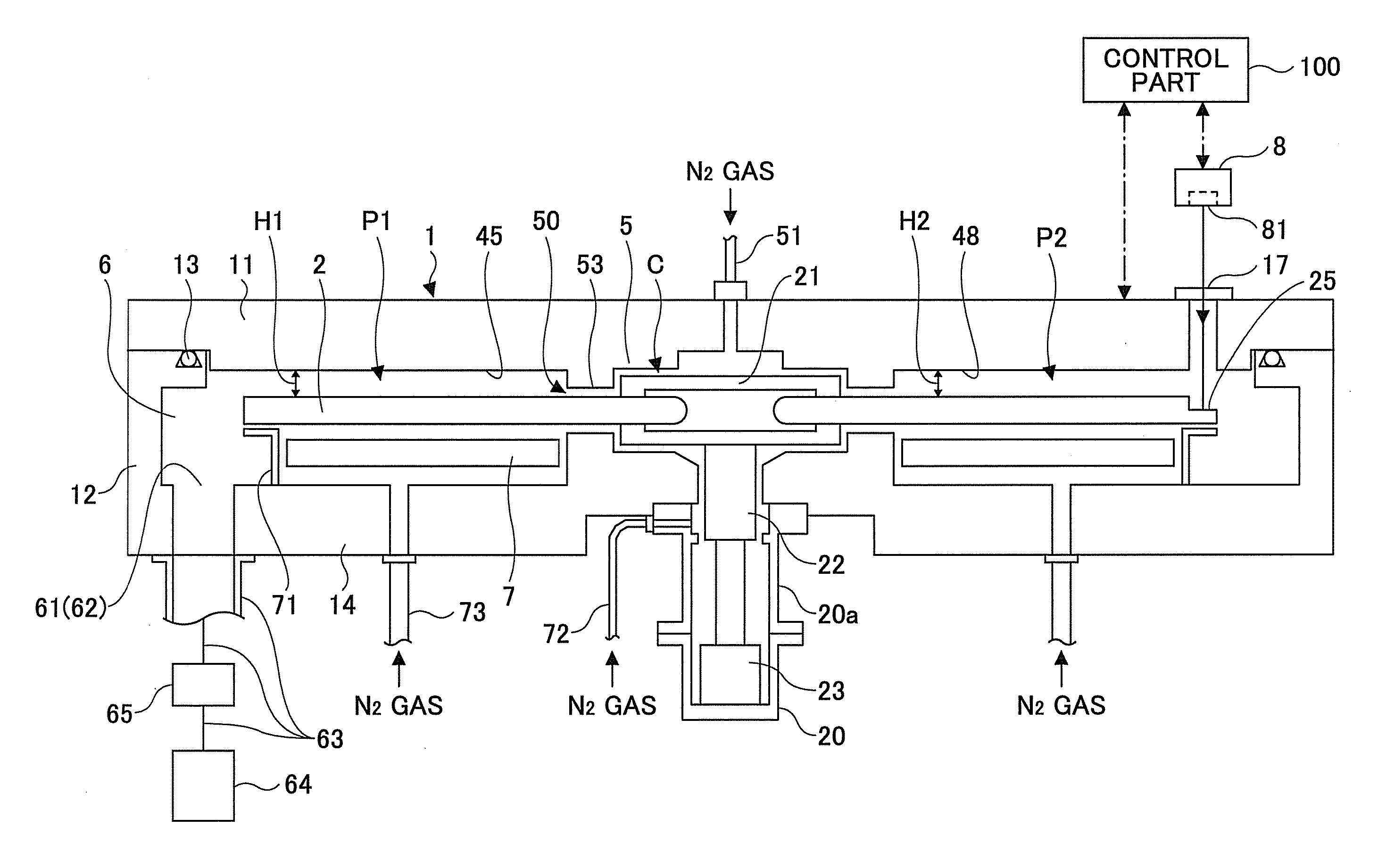

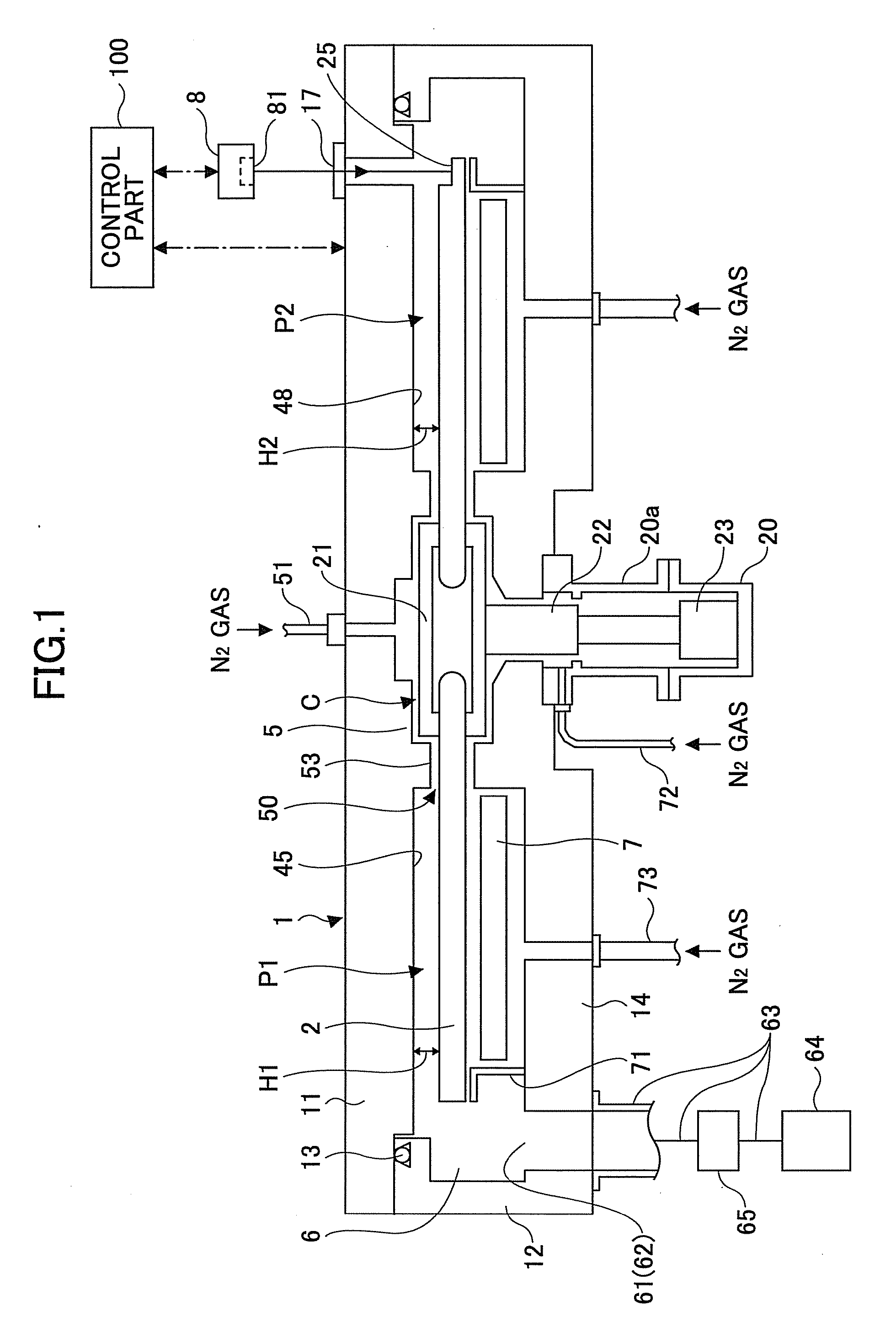

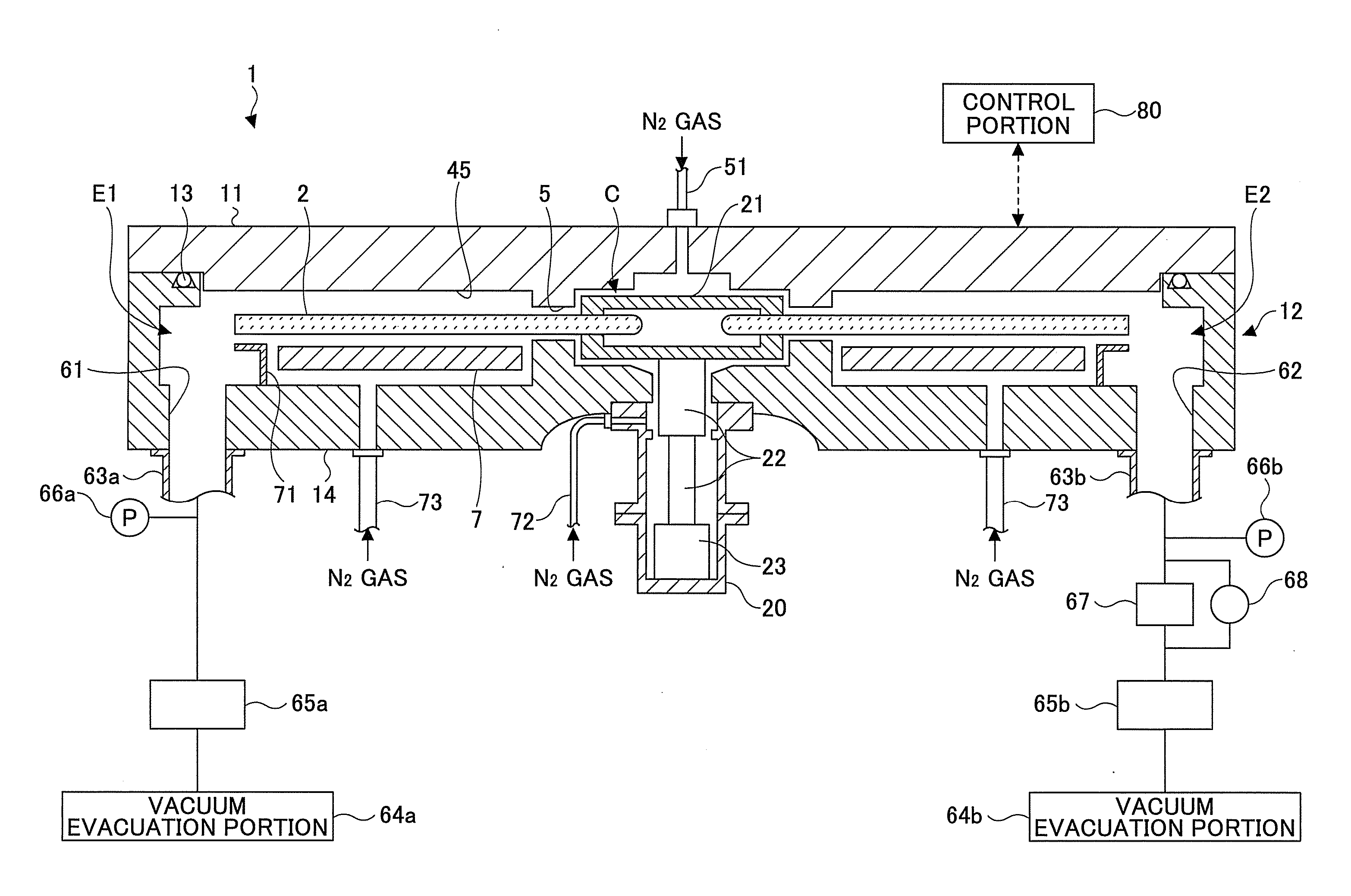

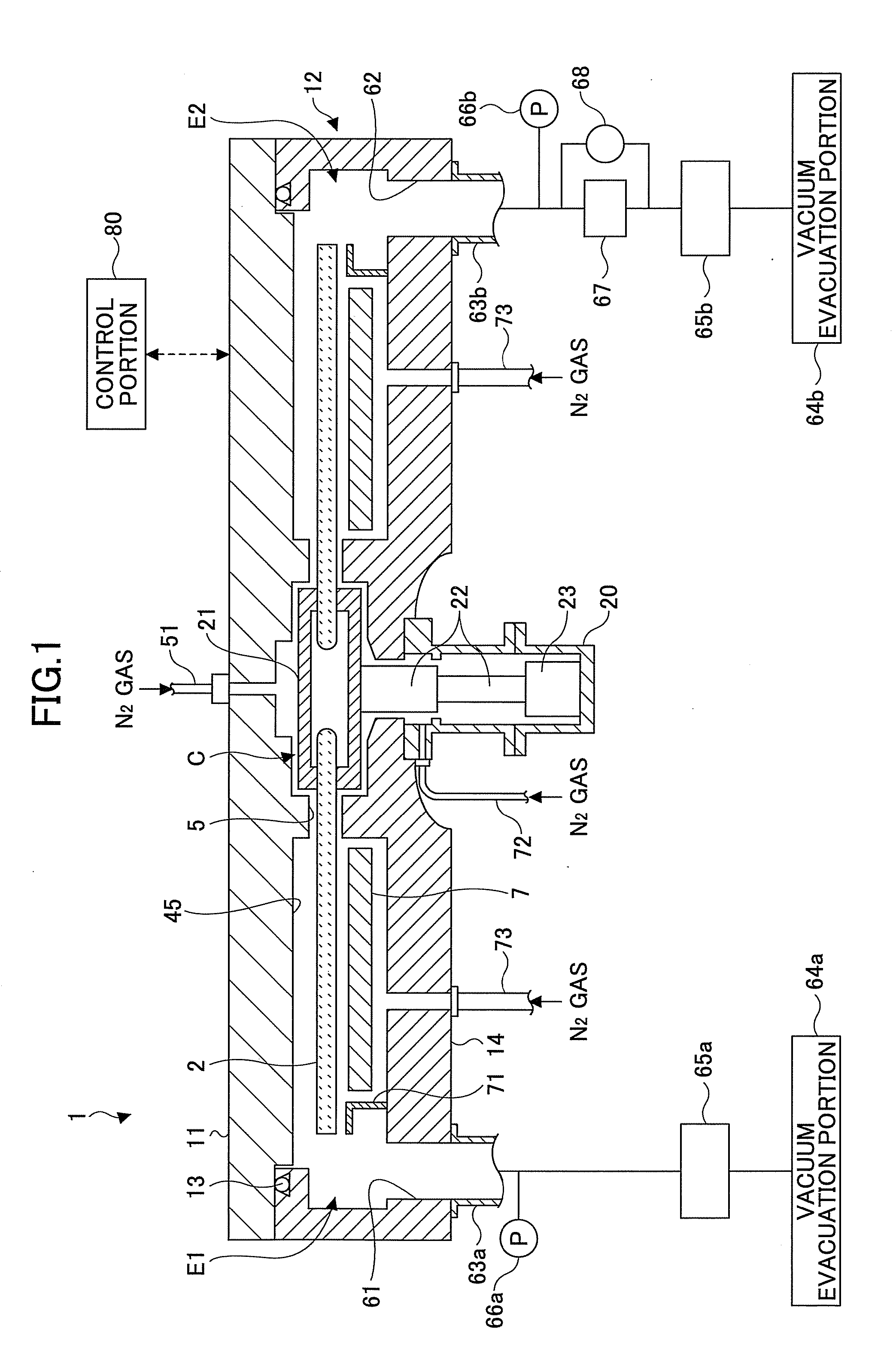

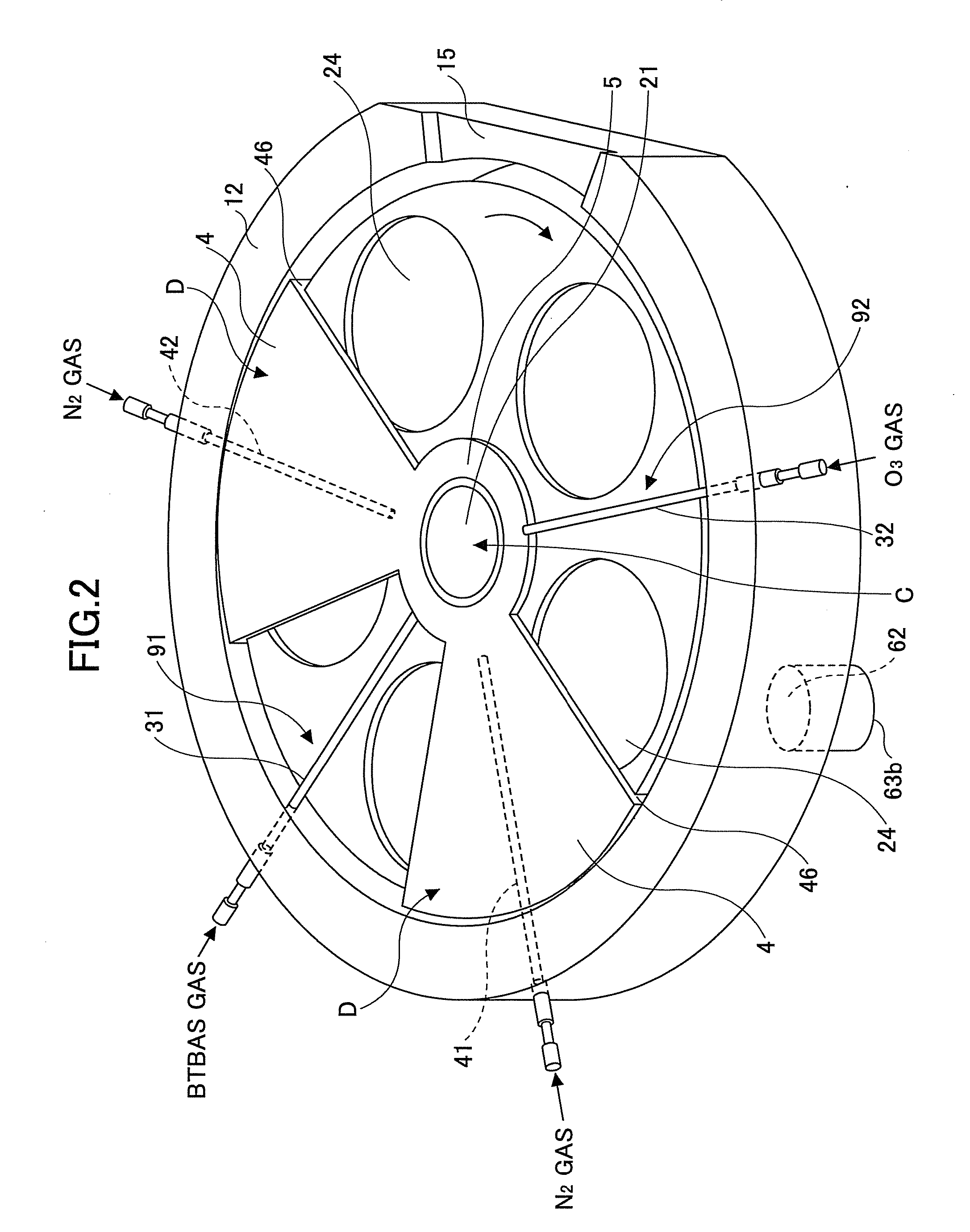

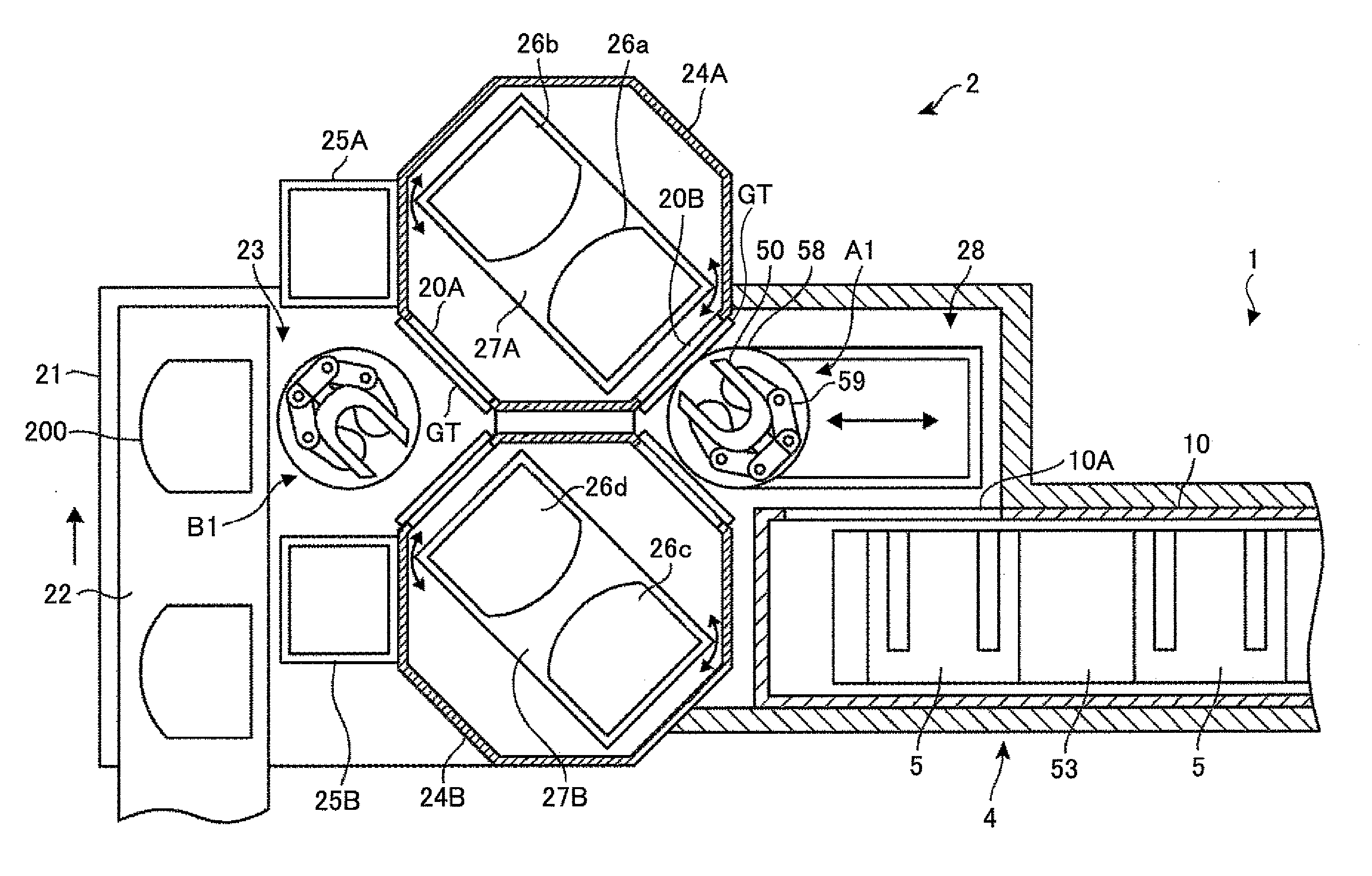

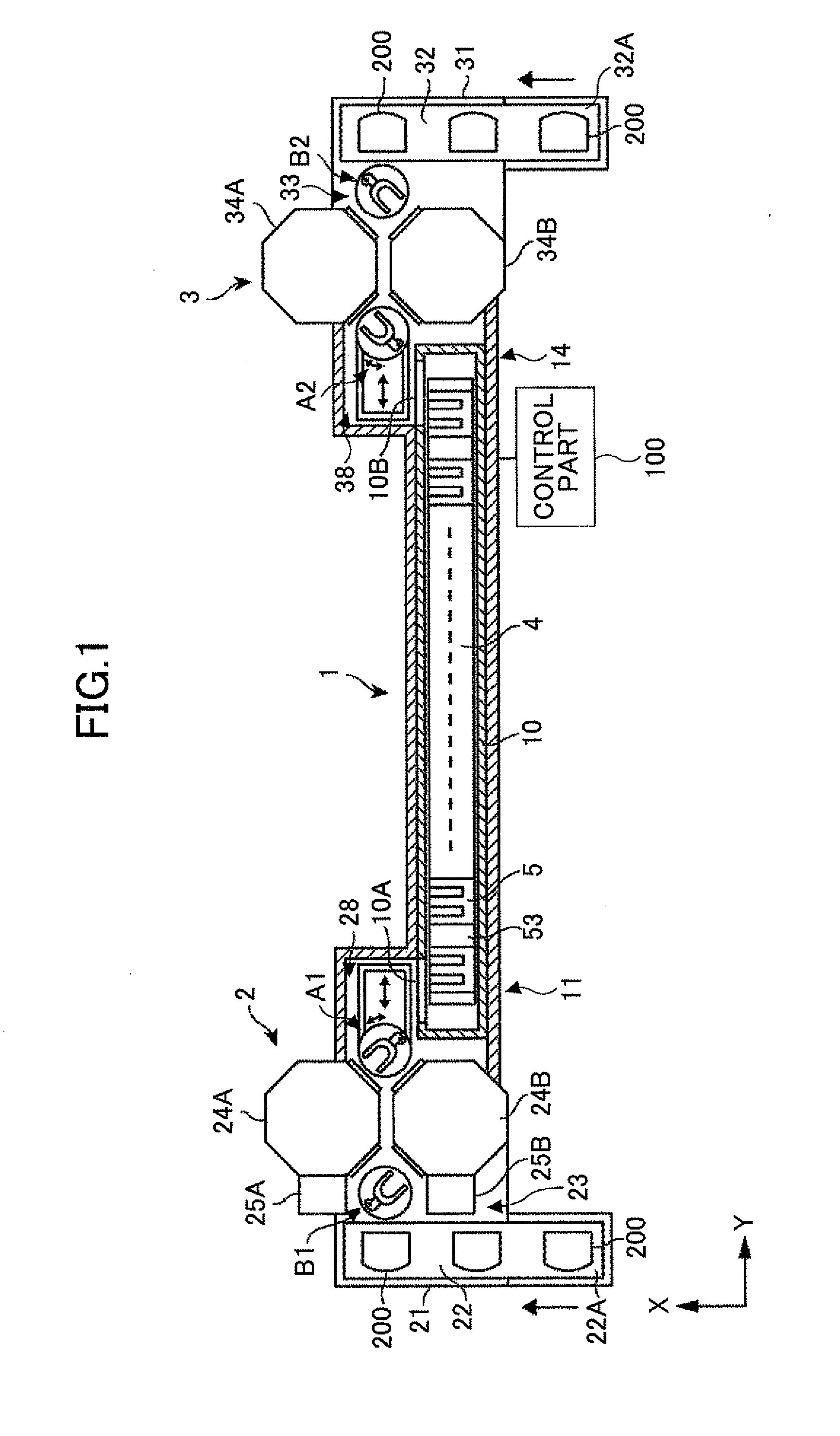

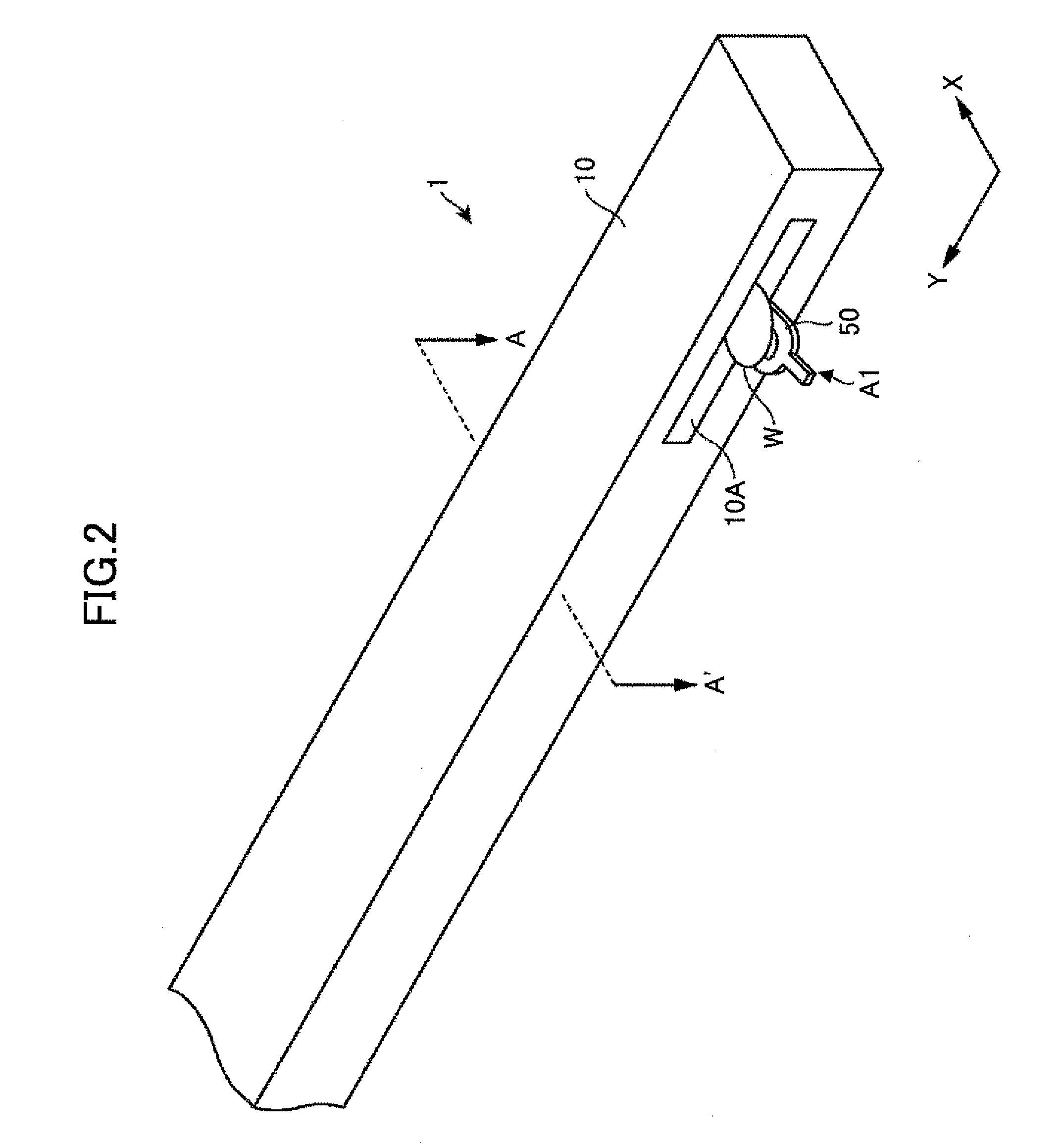

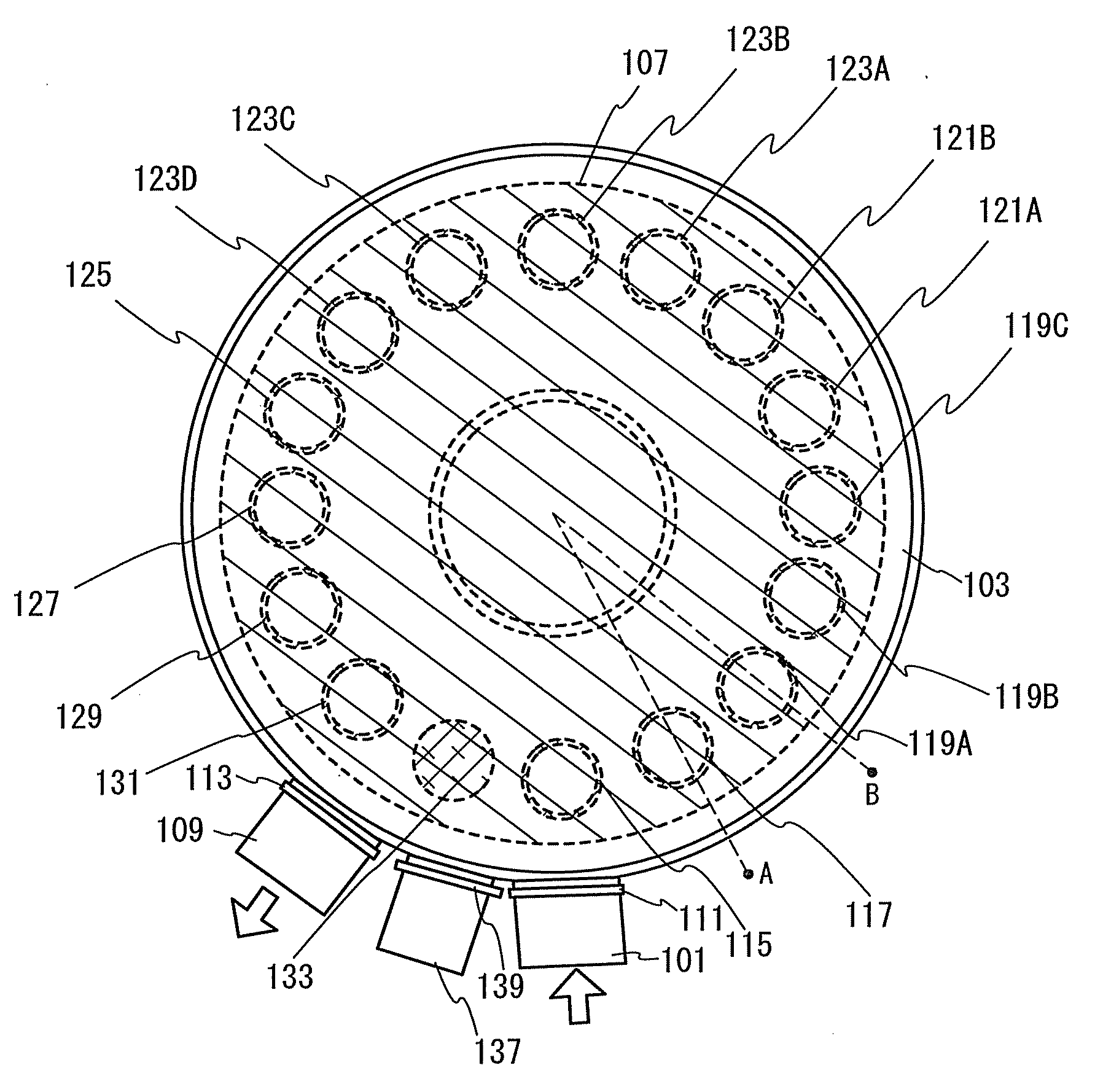

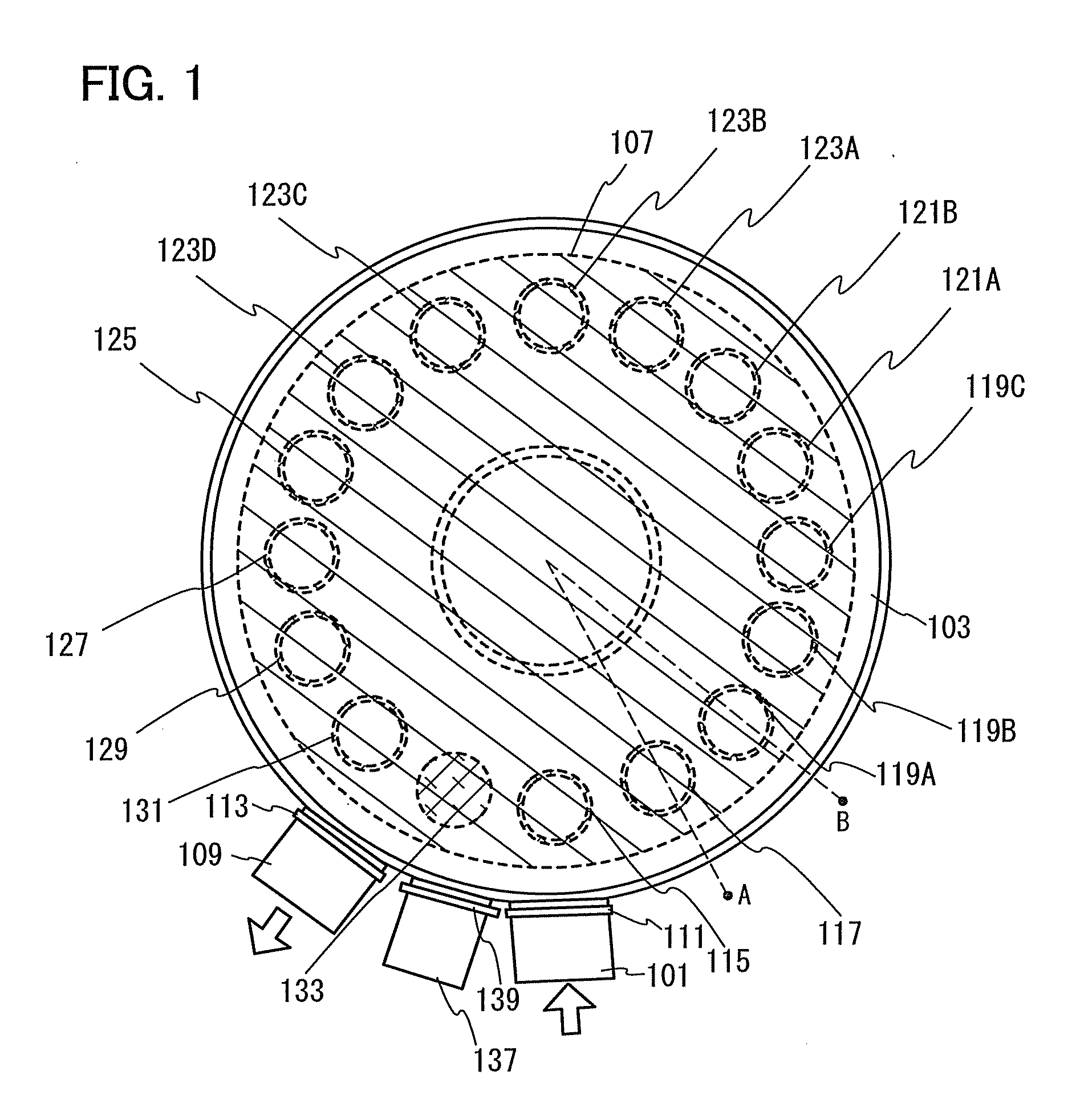

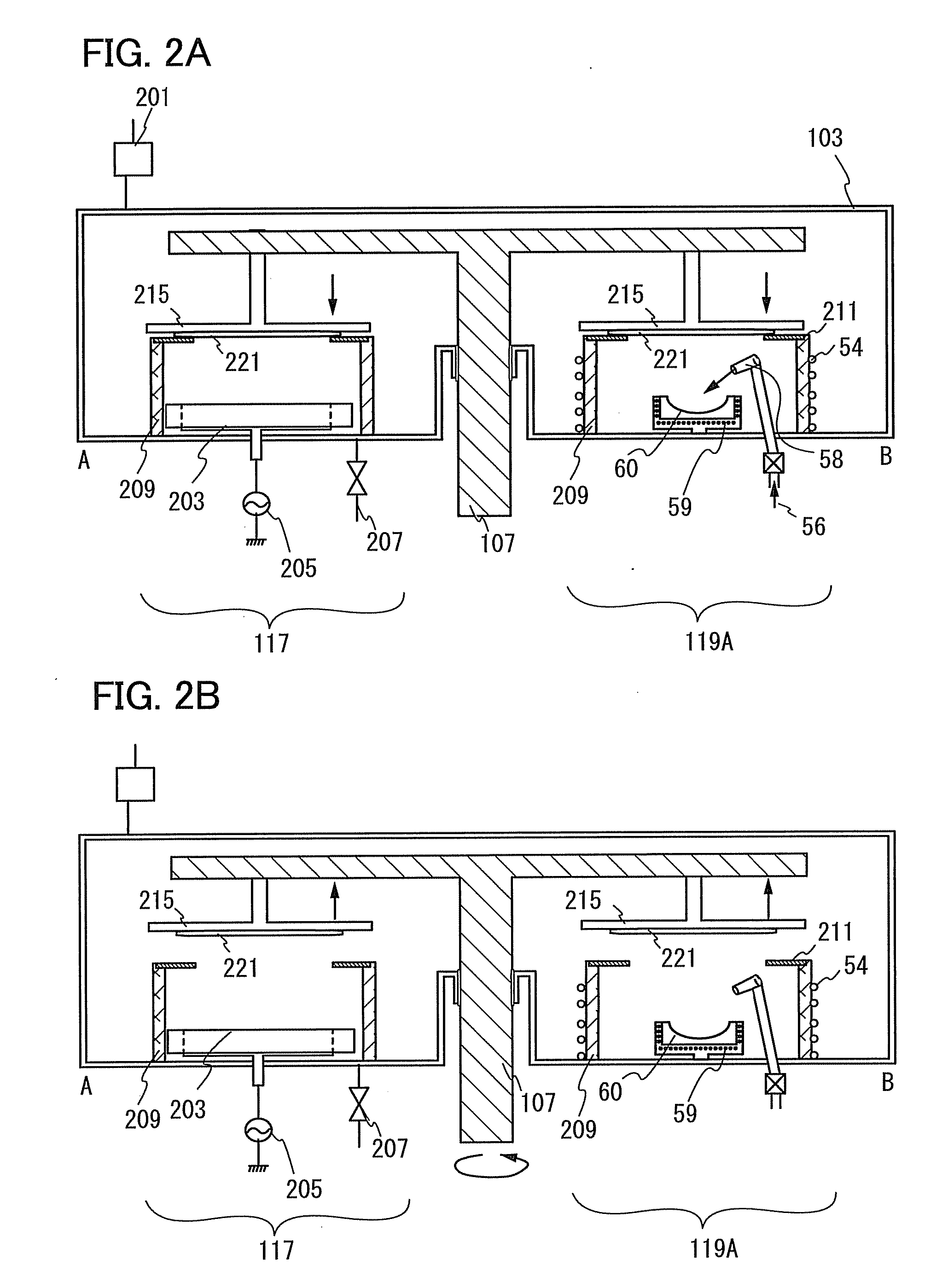

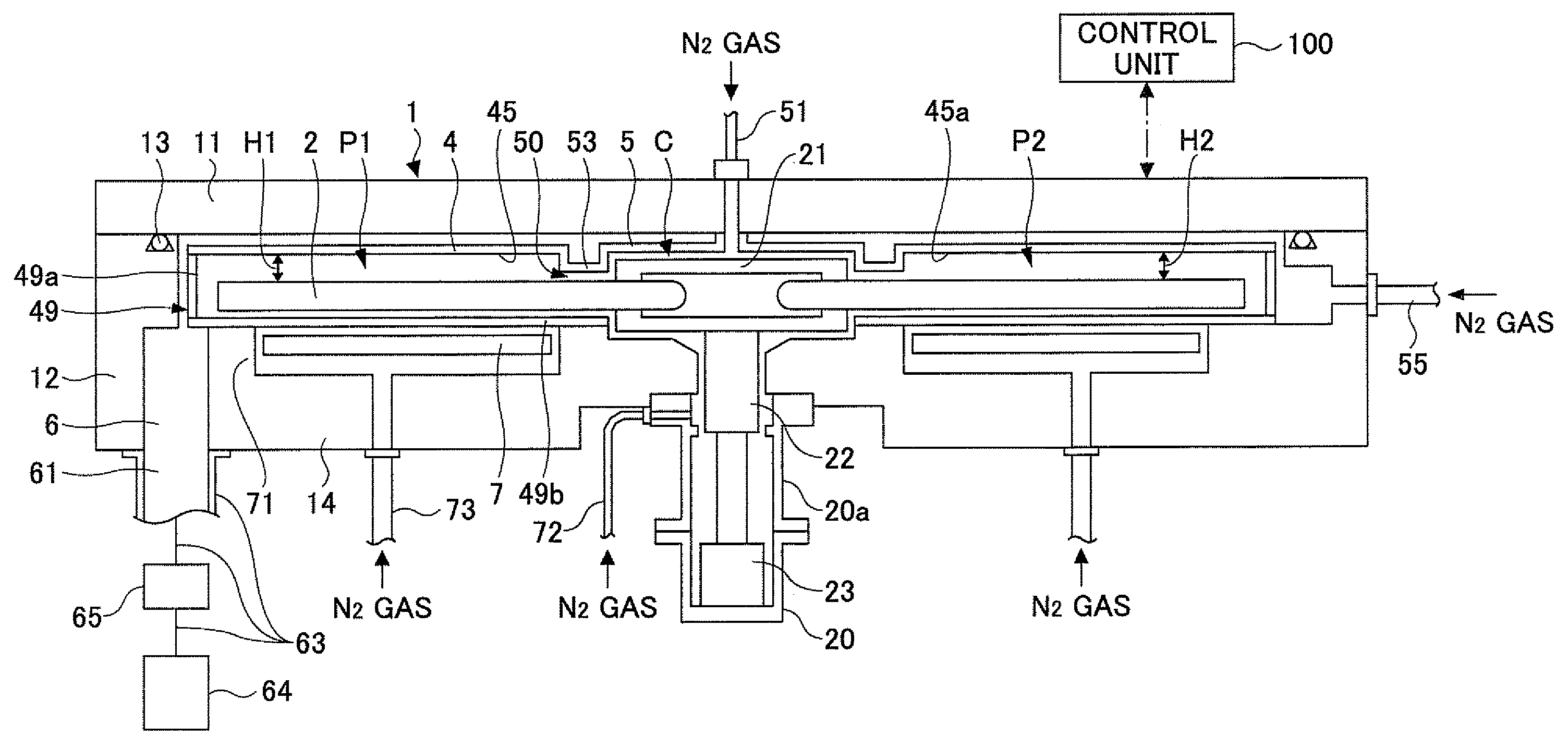

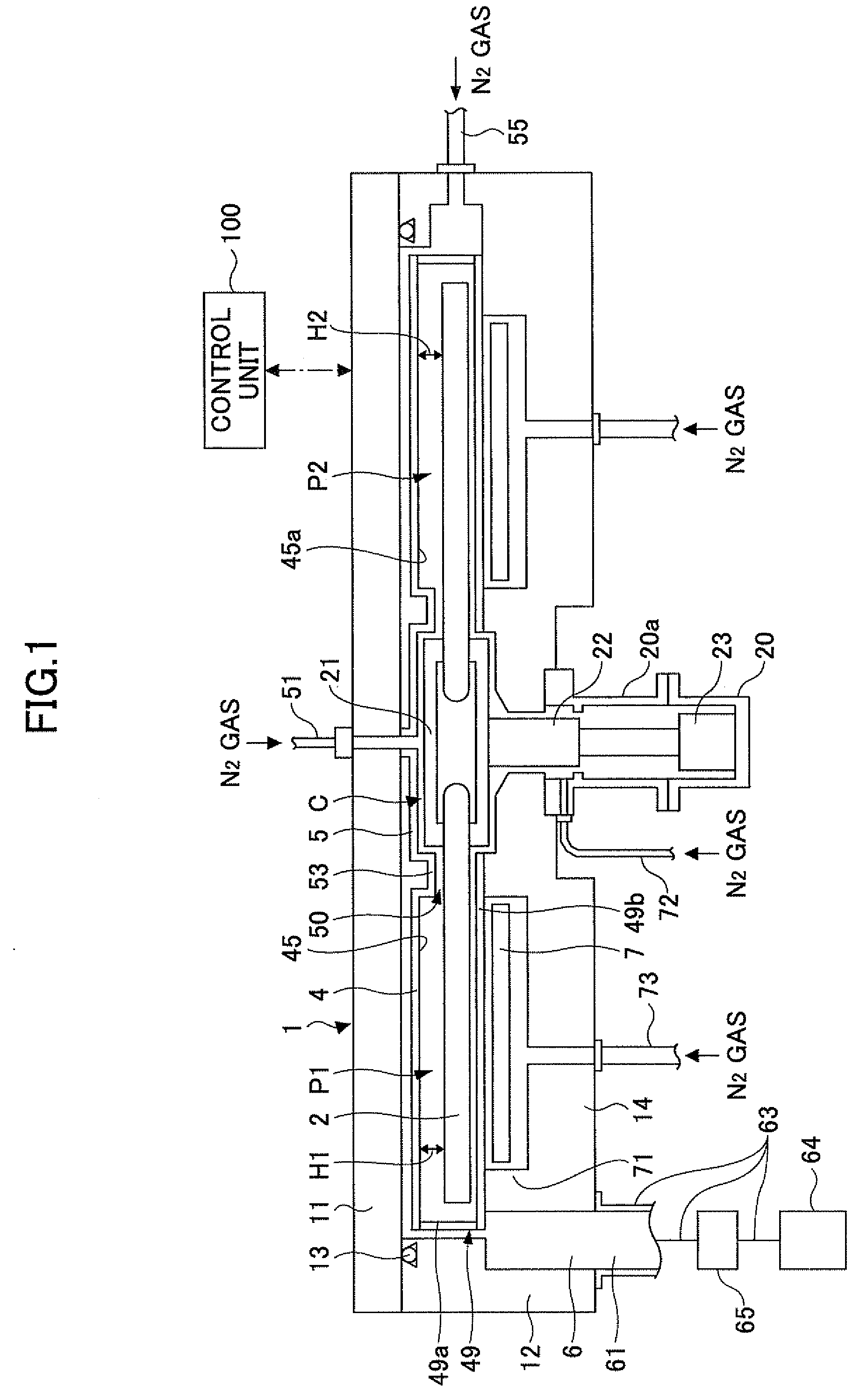

Film deposition apparatus, substrate processing apparatus, film deposition method, and computer-readable storage medium

InactiveUS20100055312A1Accurate detectionAccurate correctionLiquid surface applicatorsVacuum evaporation coatingReactive gasEngineering

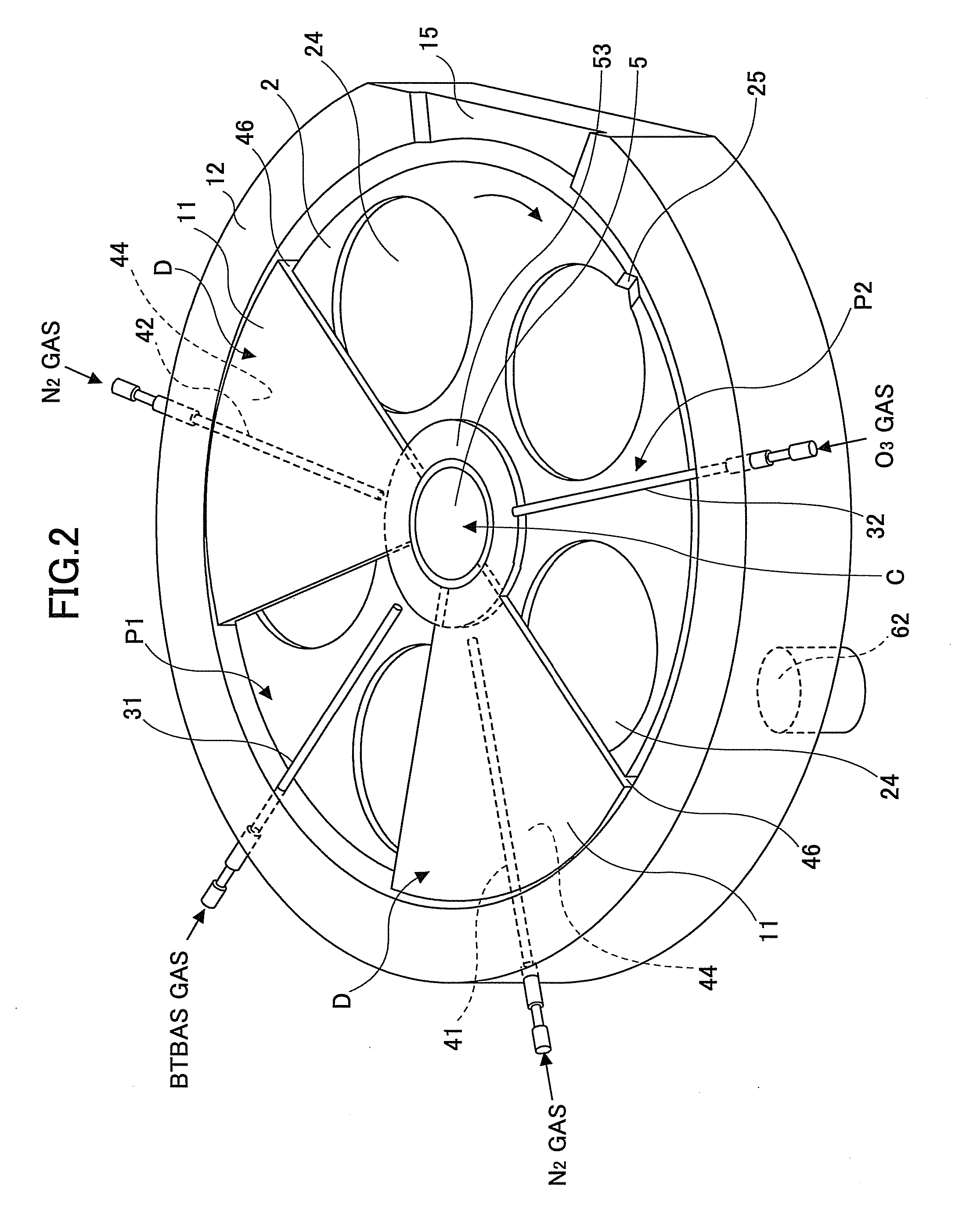

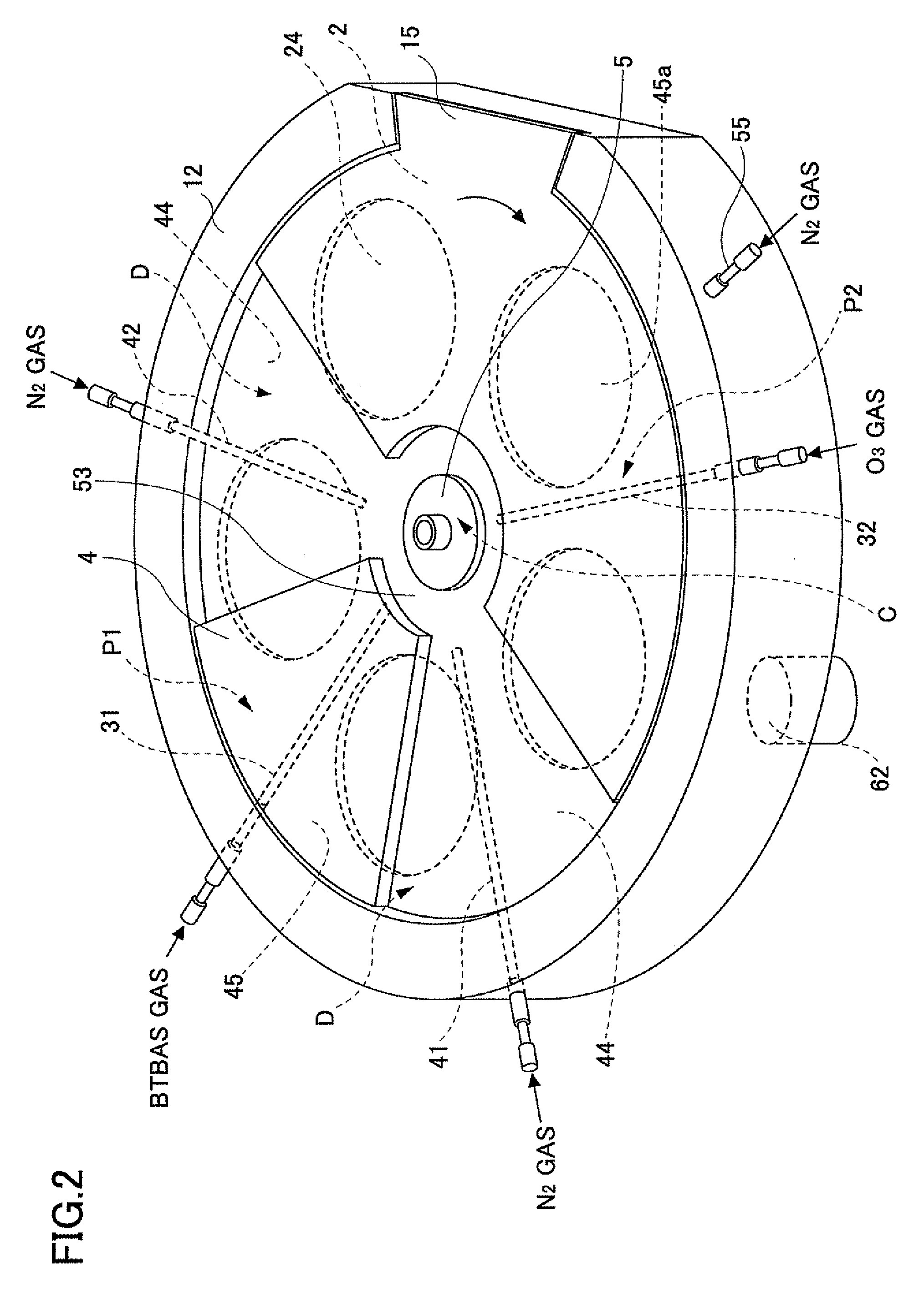

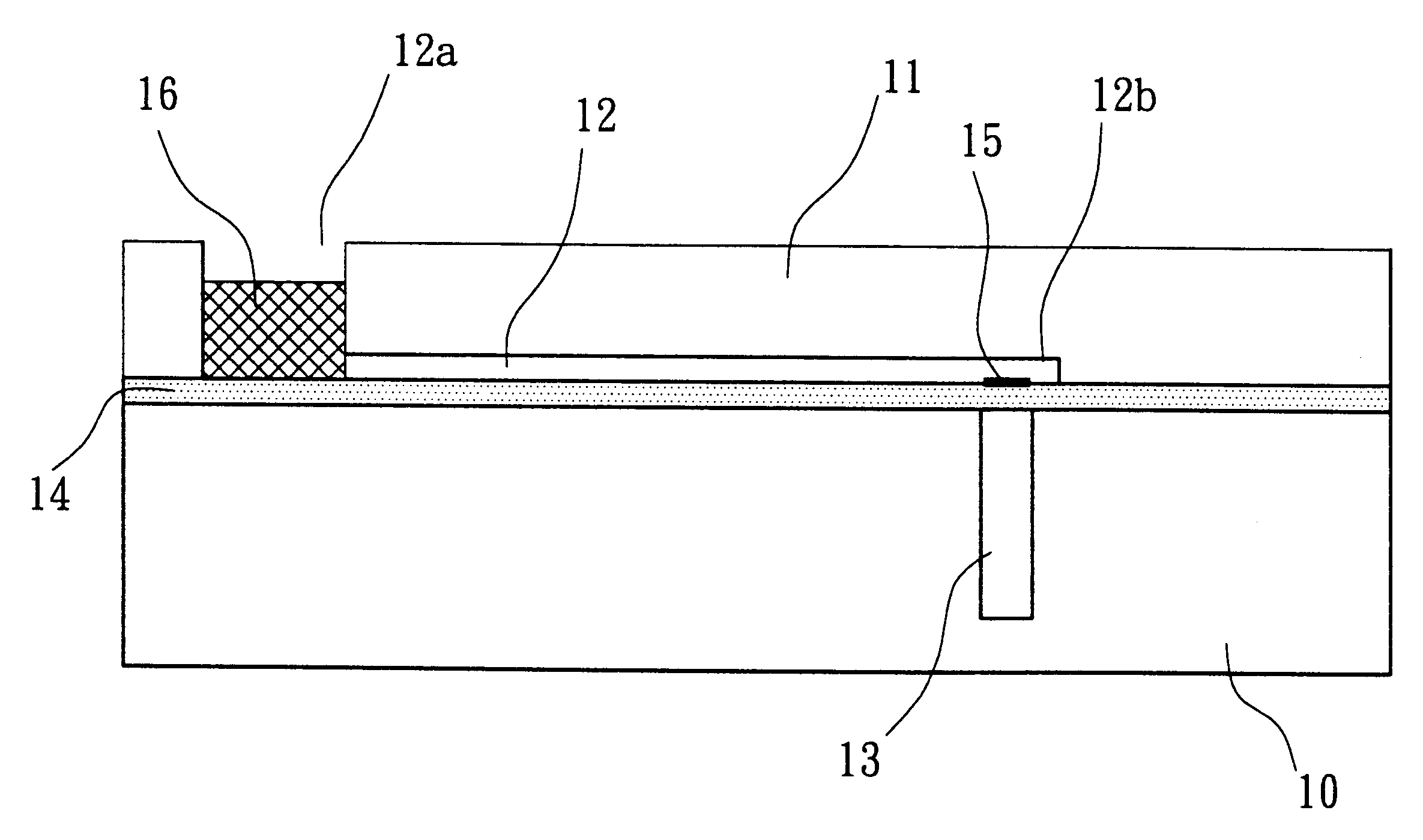

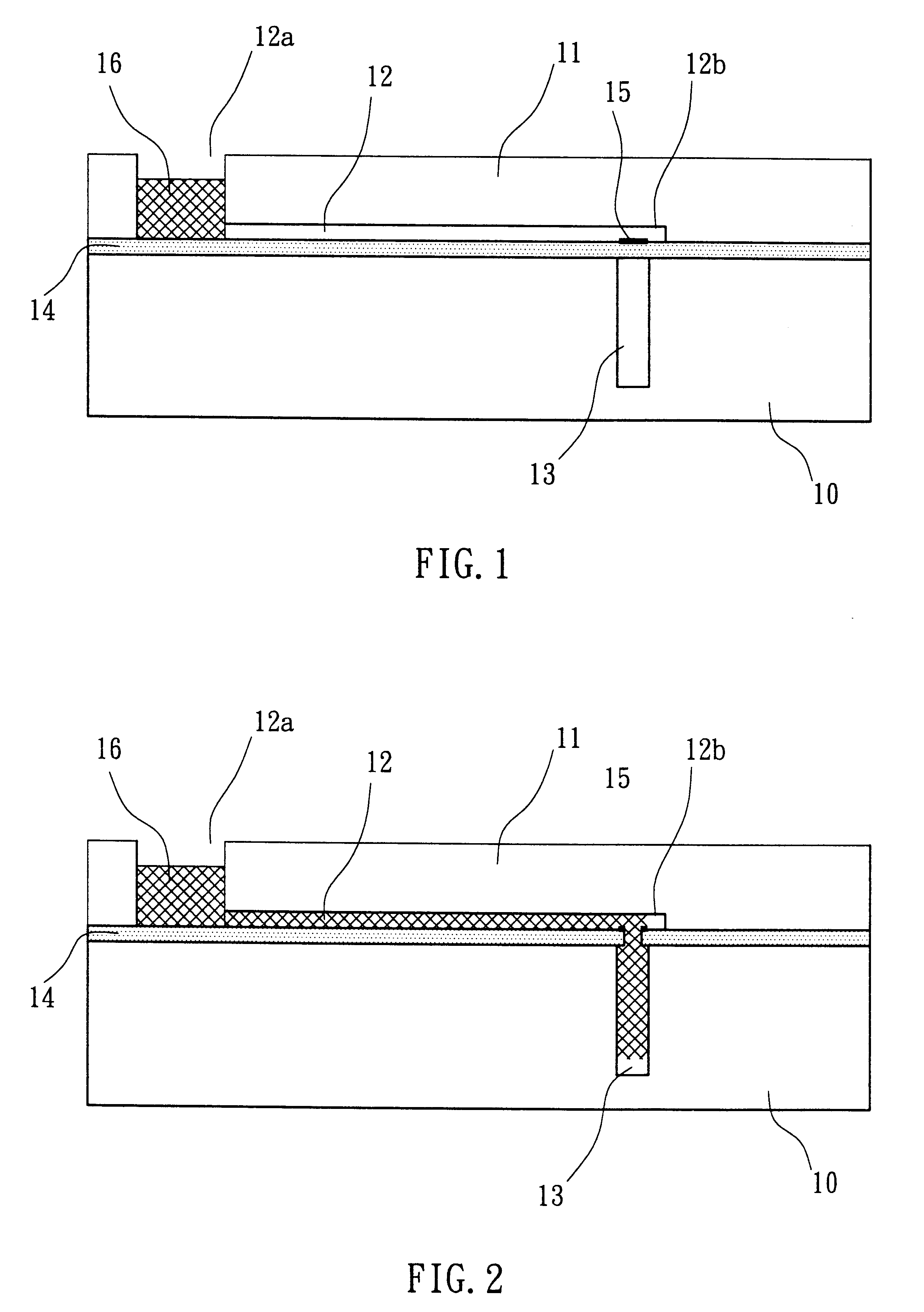

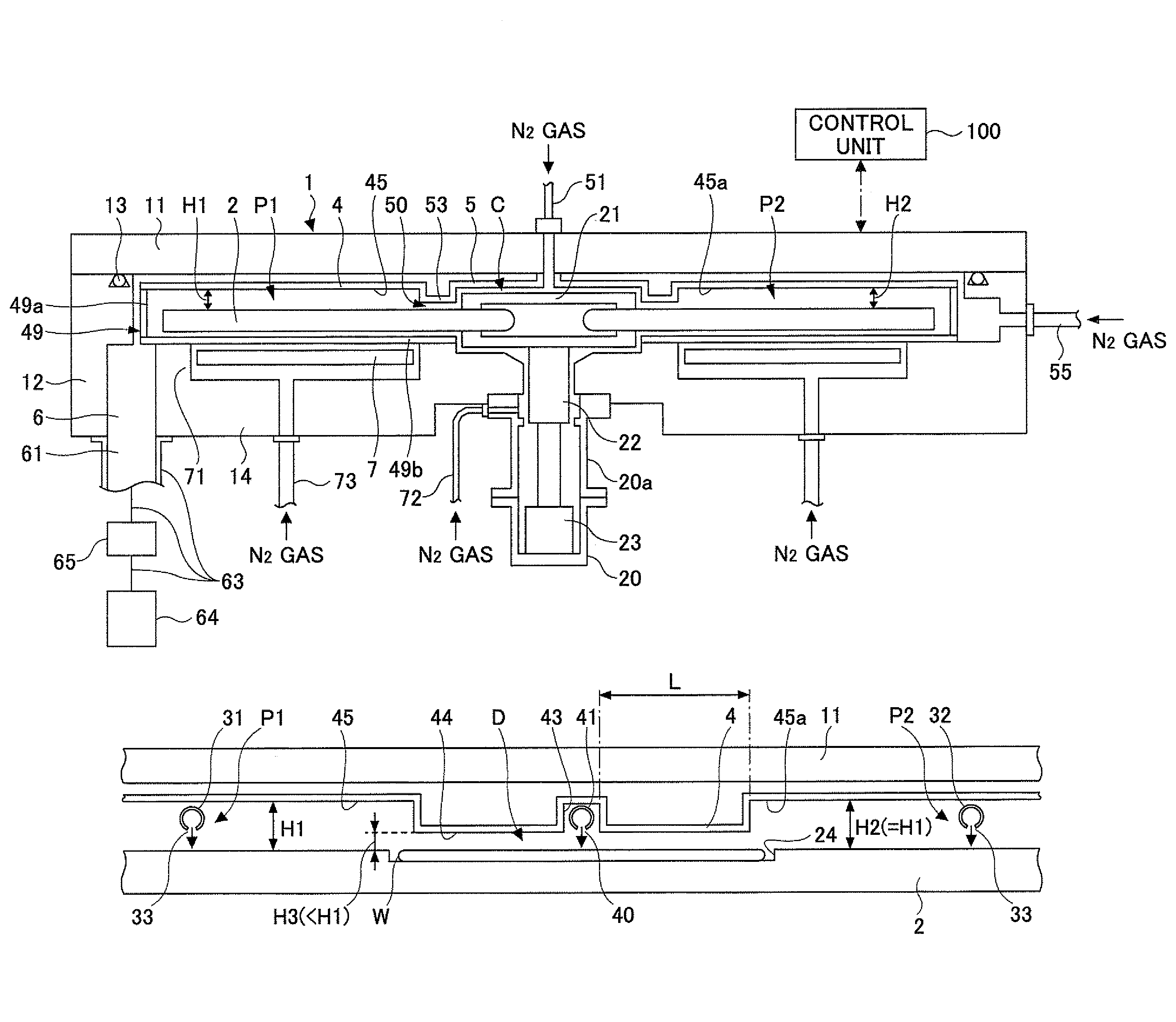

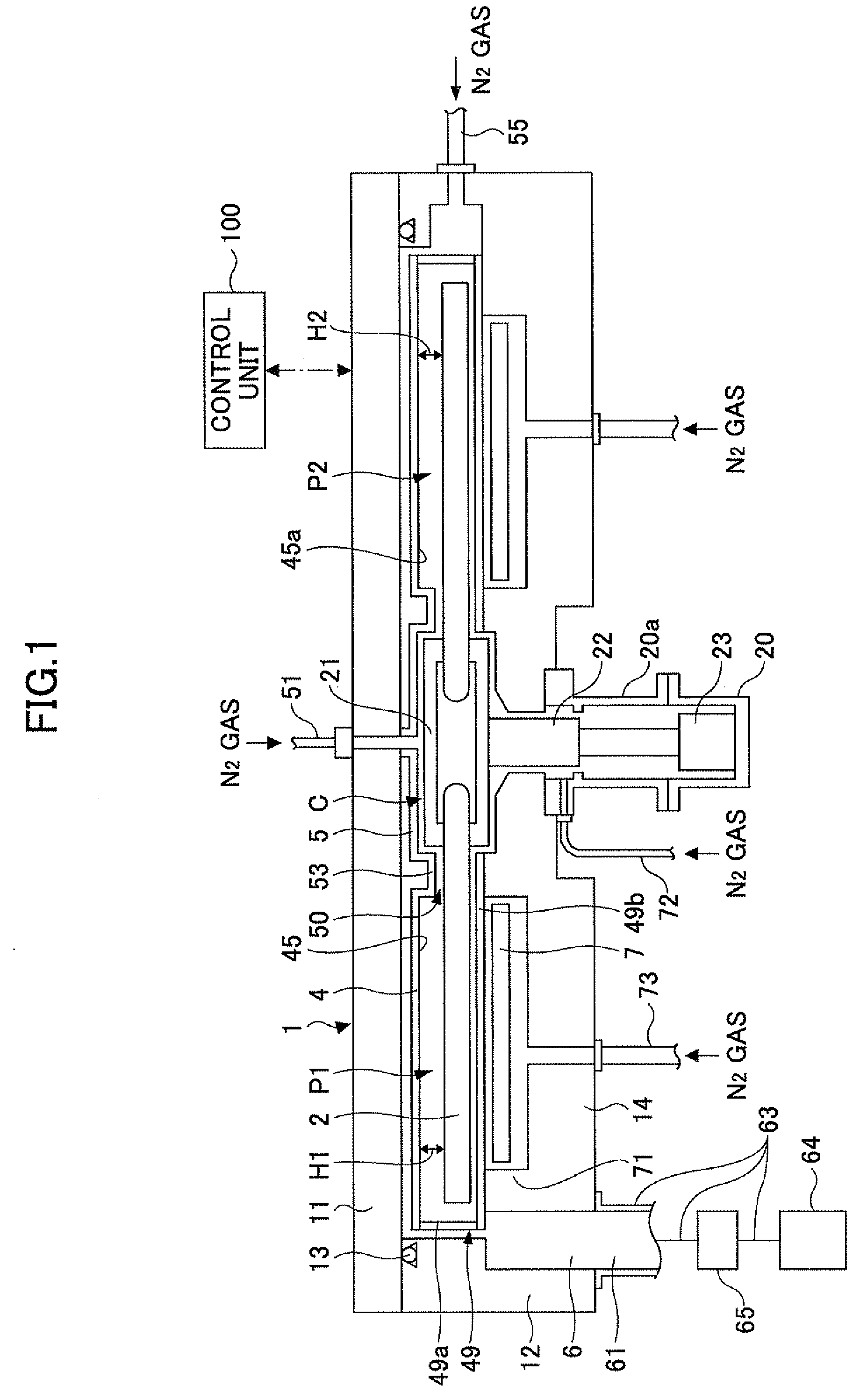

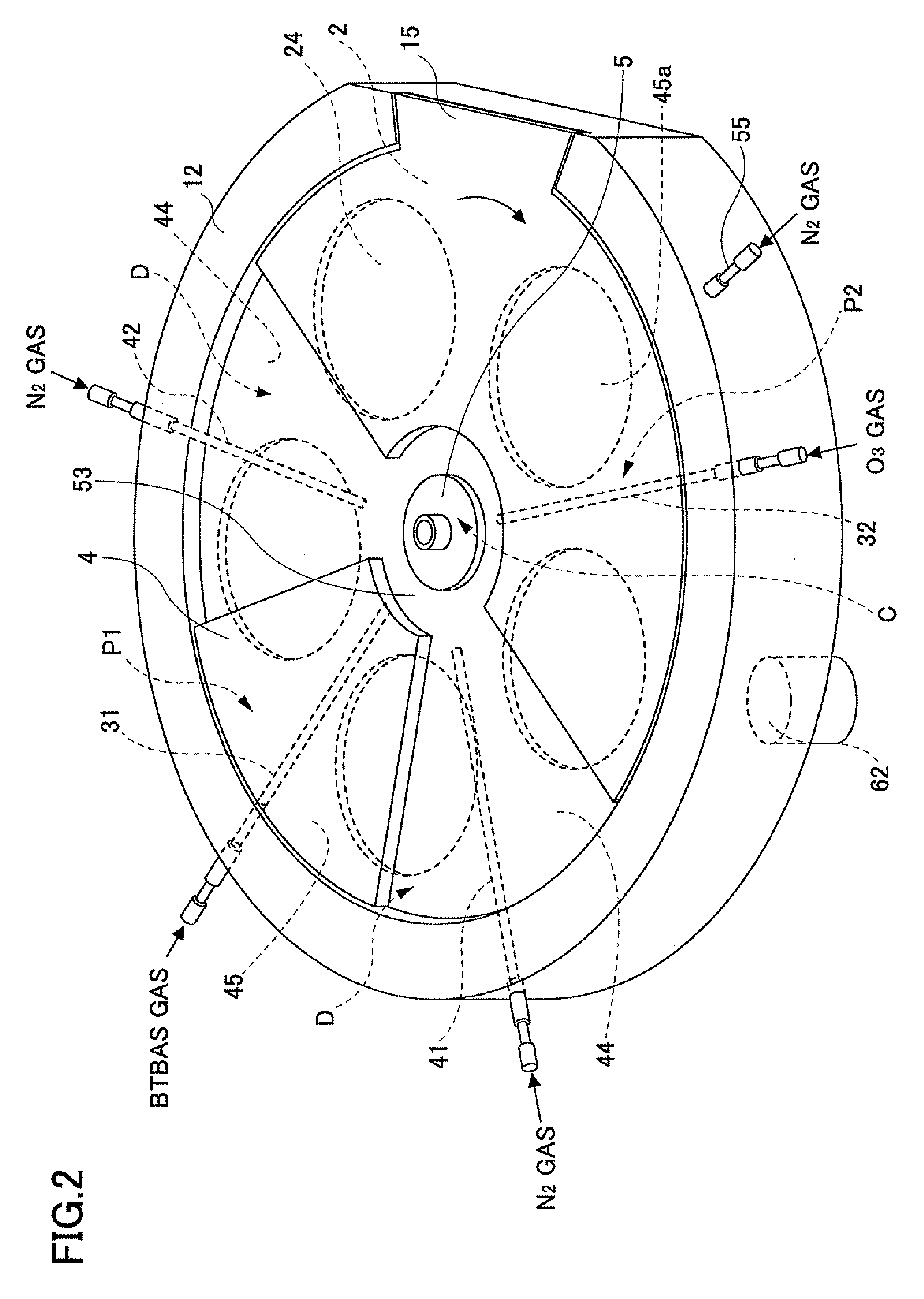

In a film deposition apparatus which deposits a thin film on a substrate by supplying first and second reactive gases in a vacuum chamber, there are provided a turntable, a first reactive gas supplying portion and a second reactive gas supplying portion which are arranged to extend from circumferential positions of the turntable to a center of rotation of the turntable, a first separation gas supplying portion arranged between the first and second reactive gas supplying portions, a first space having a first height and including the first separation gas supplying portion, a second space having a second height and including the second reactive gas supplying portion, a third space having a height lower than the first height and the second height and including the first separation gas supplying portion, a position detecting unit detecting a rotation position of the turntable, and a detection part arranged at a circumferential portion of the turntable and detected by the position detecting unit.

Owner:TOKYO ELECTRON LTD

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

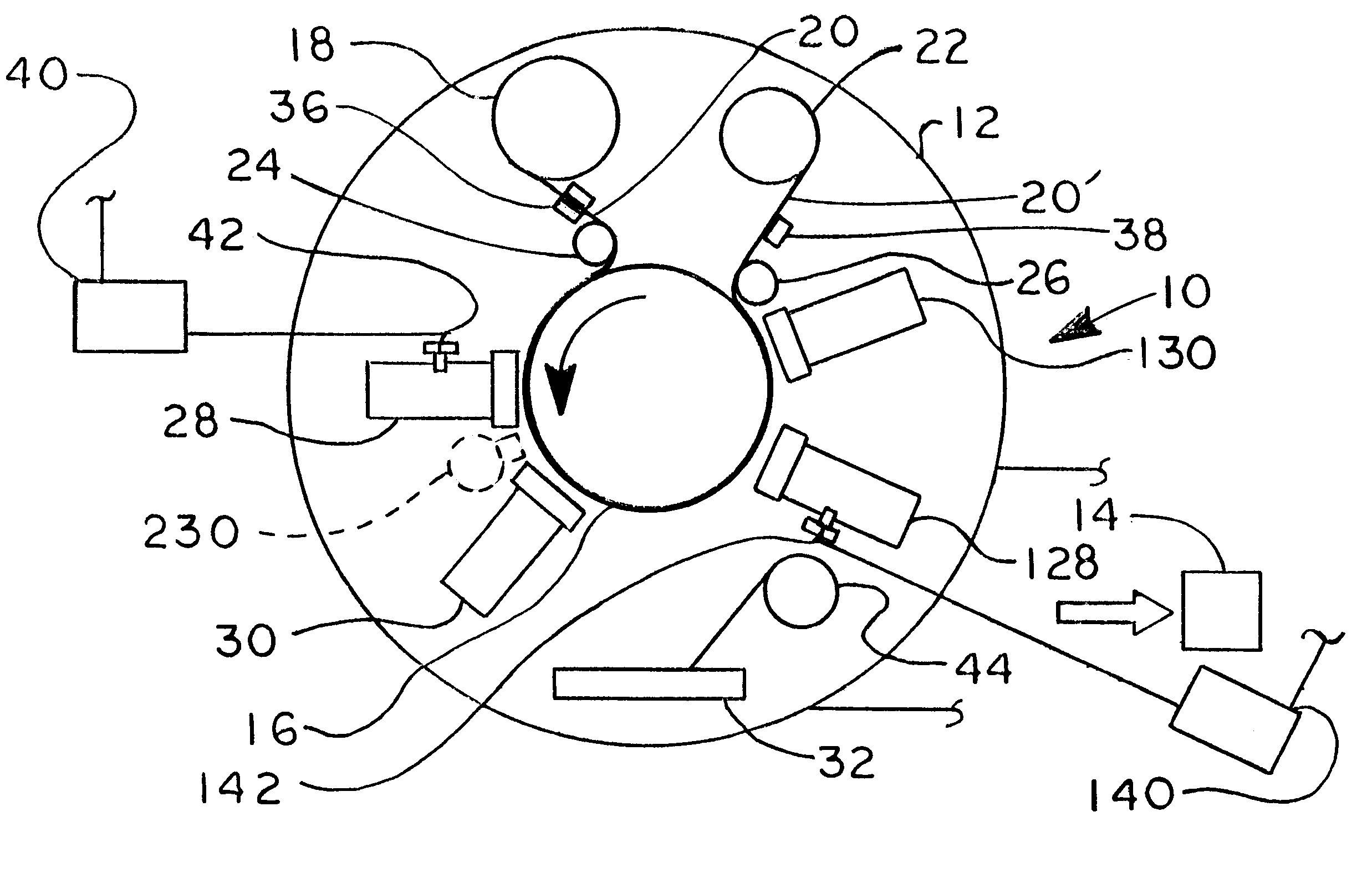

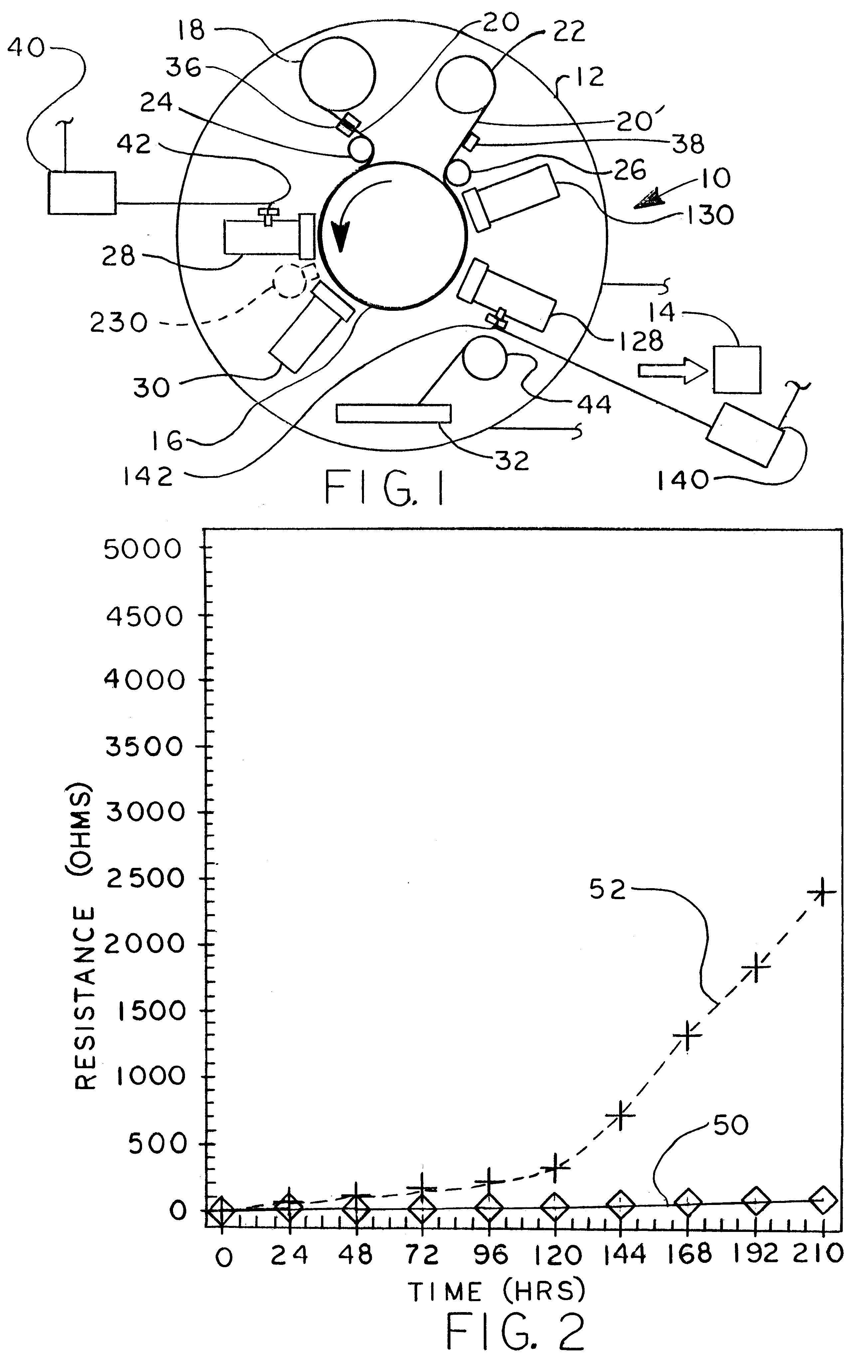

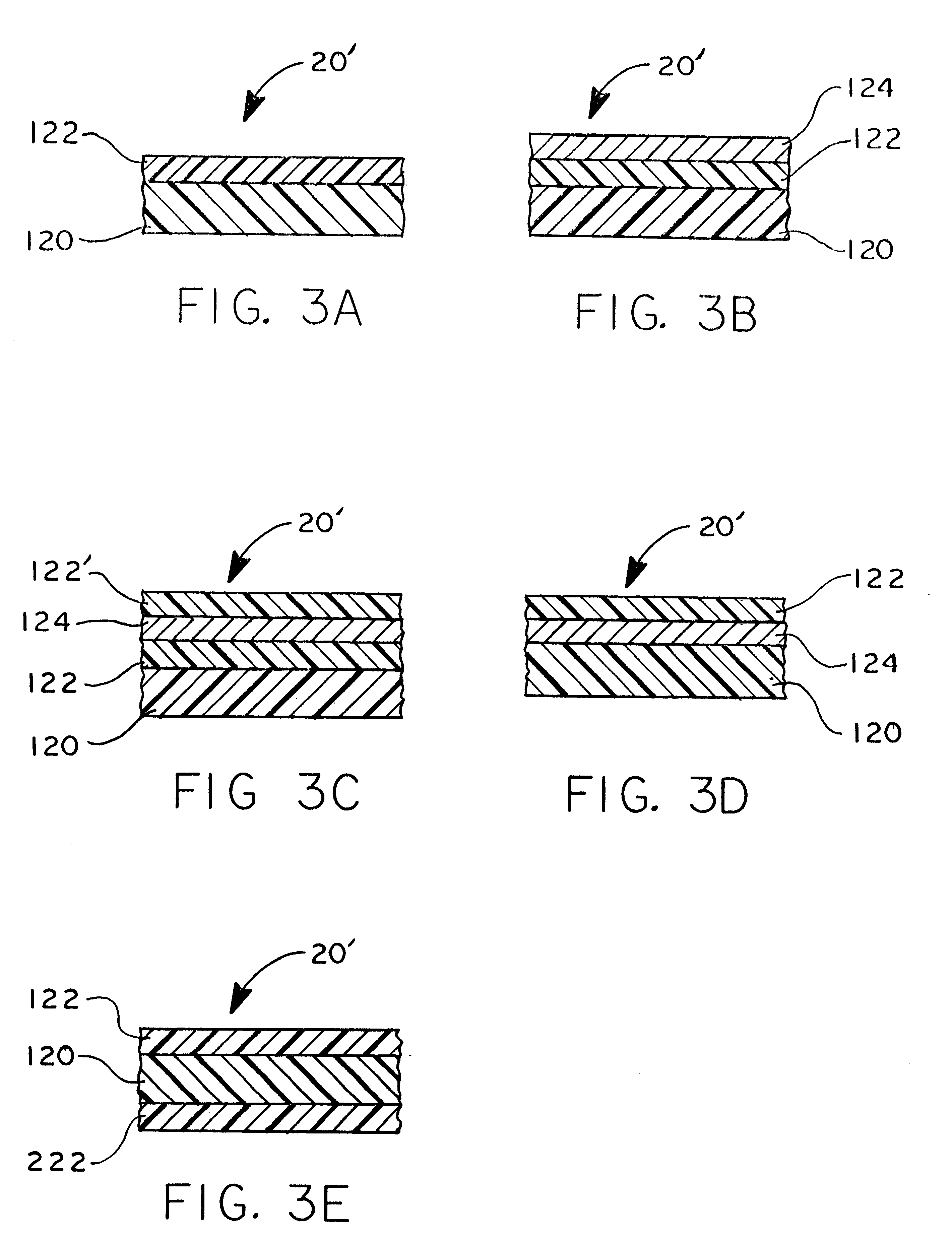

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

Method of cleaning etching apparatus

ActiveUS20060191555A1Clean interiorMaintain repeatabilityHollow article cleaningElectrostatic cleaningBoron trichlorideOxygen

To provide a cleaning method for an etching apparatus for a metal film that efficiently removes an etching residue deposited in an etching process chamber, assures the reproducibility of the etching performance, and keeps the etching process chamber in a low-dust-emission condition. Each time one workpiece with a metal film is etched (S1), the interior of the vacuum chamber is cleaned by replacing the workpiece with a dummy substrate (S2), performing a first step of plasma processing using oxygen (O2) and carbon tetrafluoride (CF4) to remove a carbon-based deposit pile (S3), and performing a second step of plasma processing using boron trichloride (BCl3) and chlorine (Cl2) to remove a residue that could not be removed by the first step and an etching residue of the metal film (S4).

Owner:HITACHI HIGH-TECH CORP

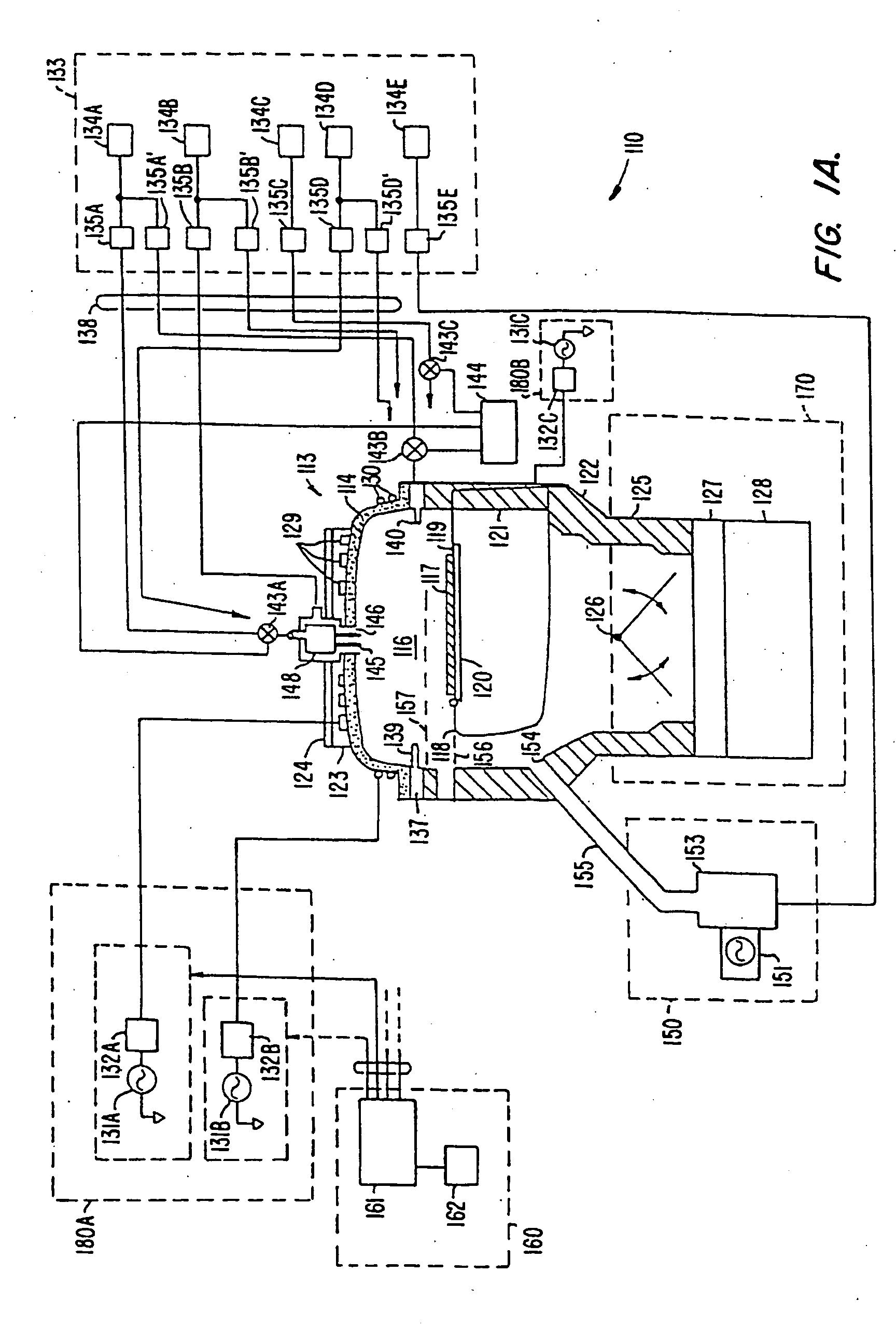

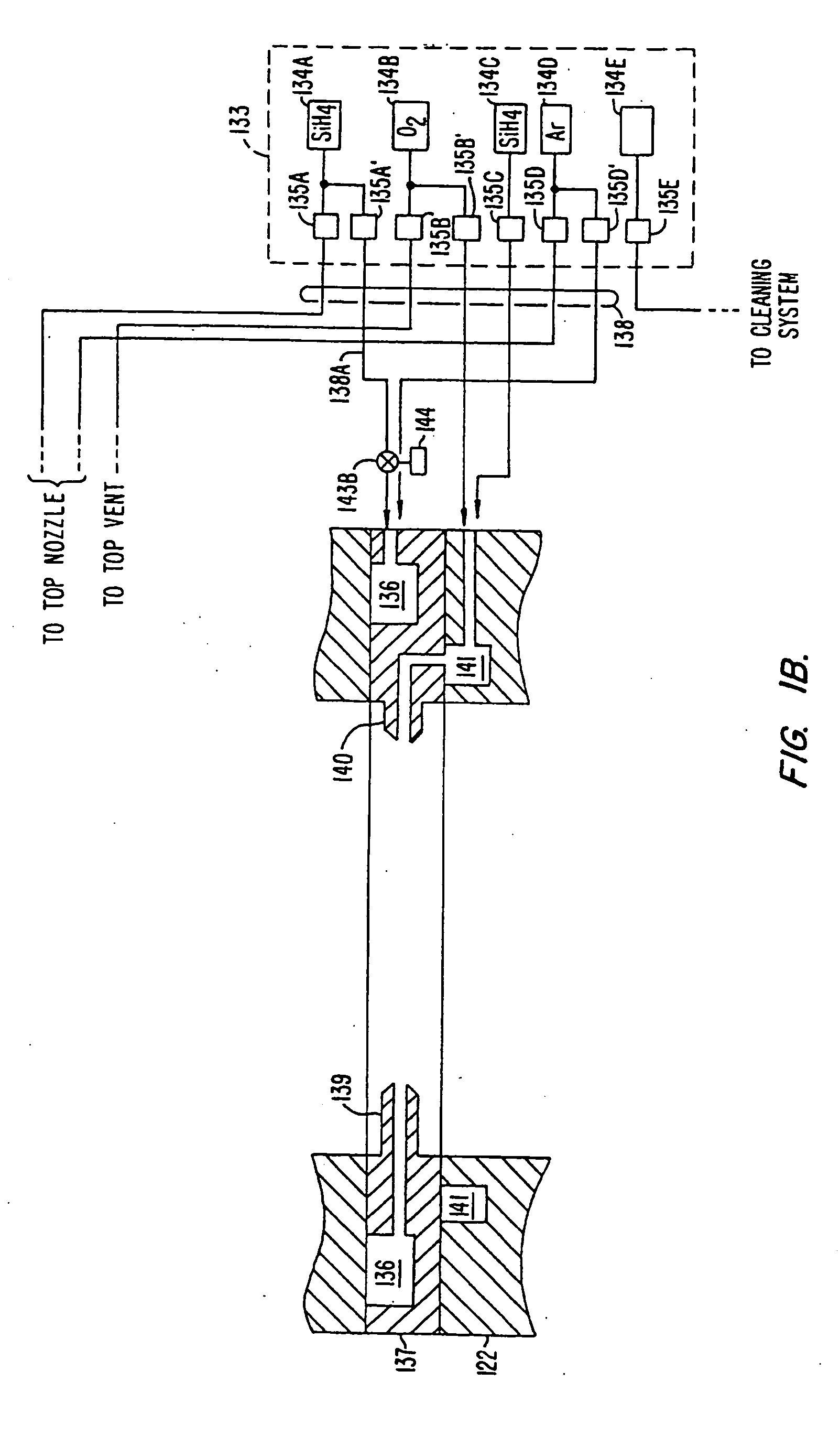

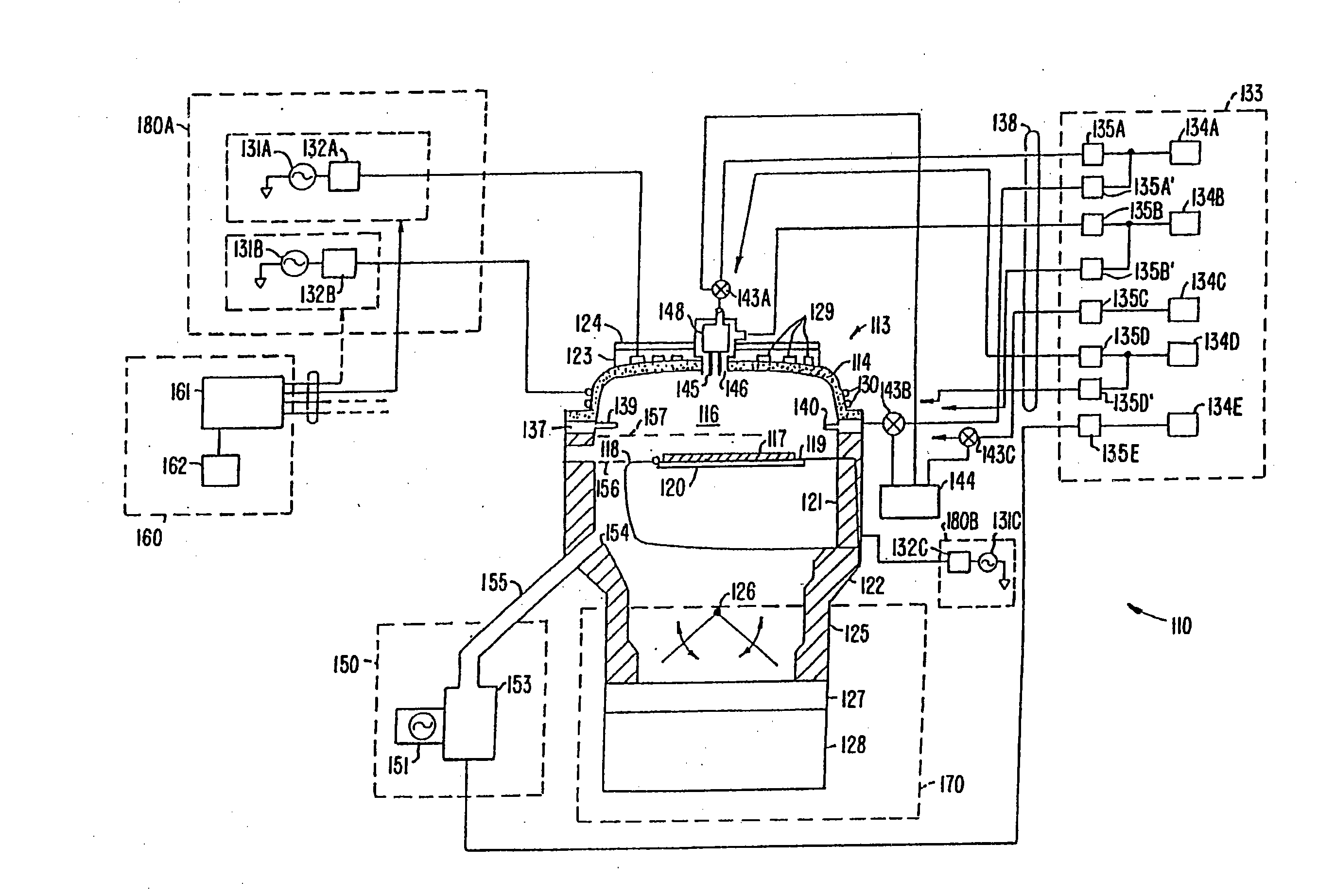

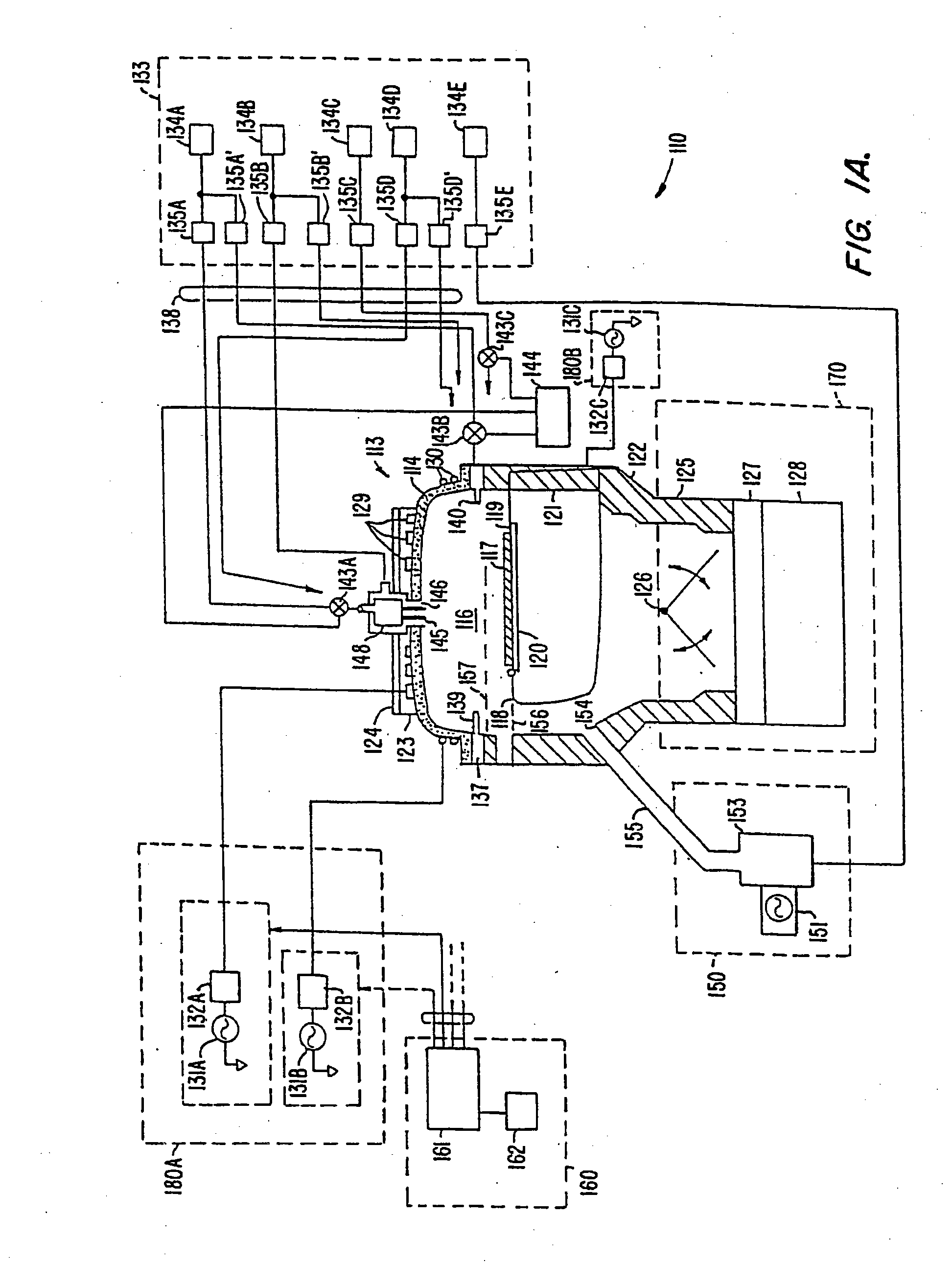

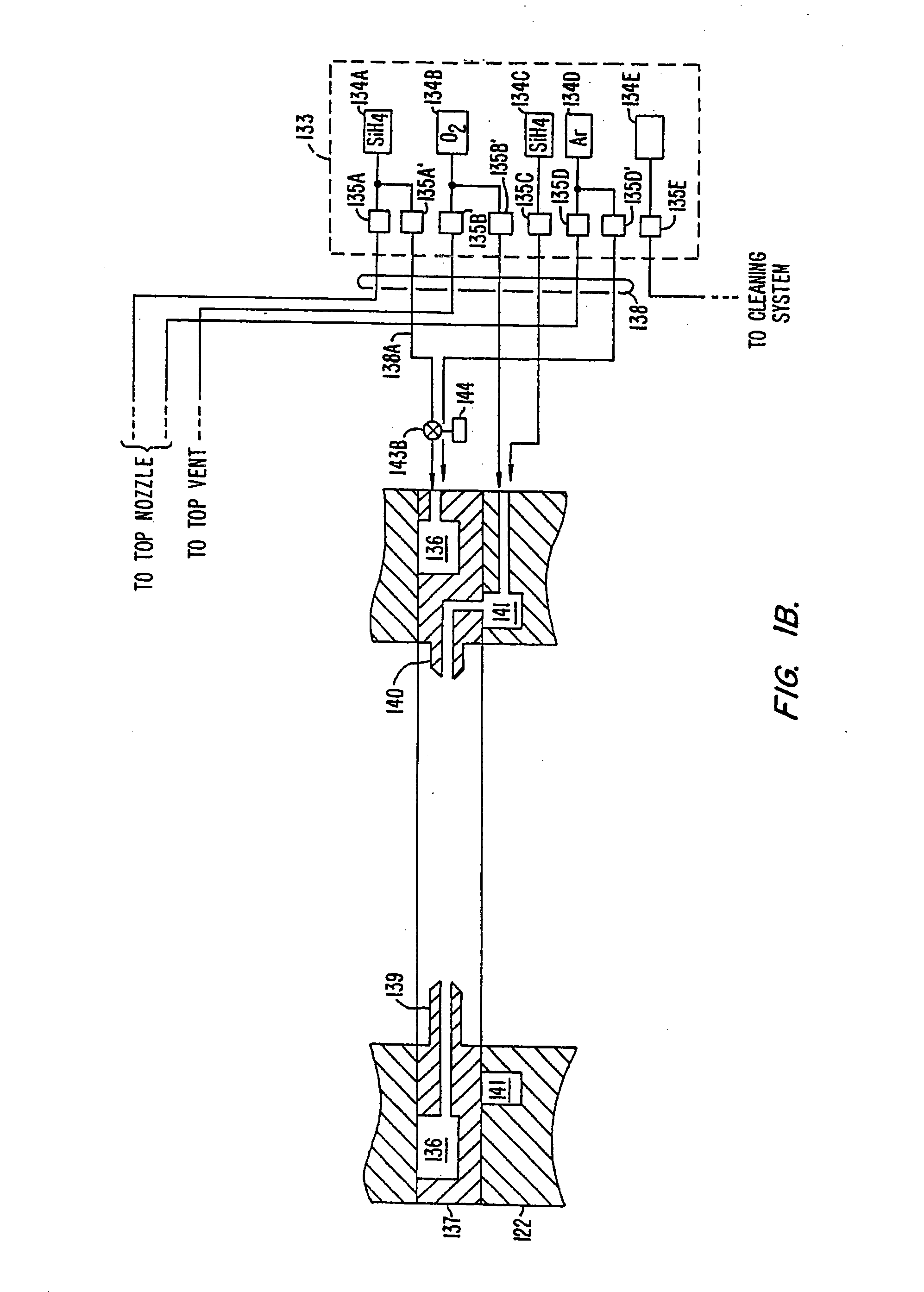

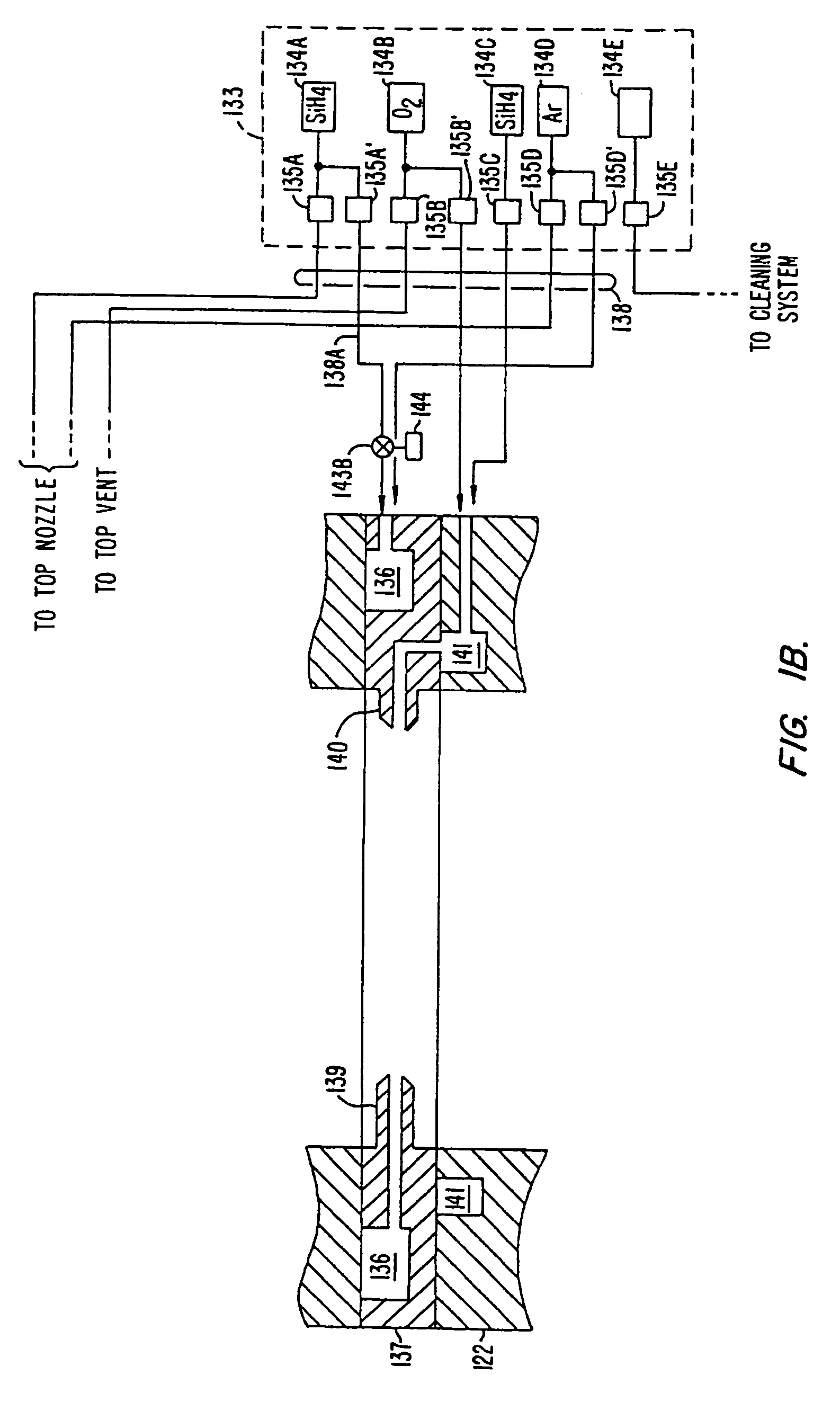

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS20050250340A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

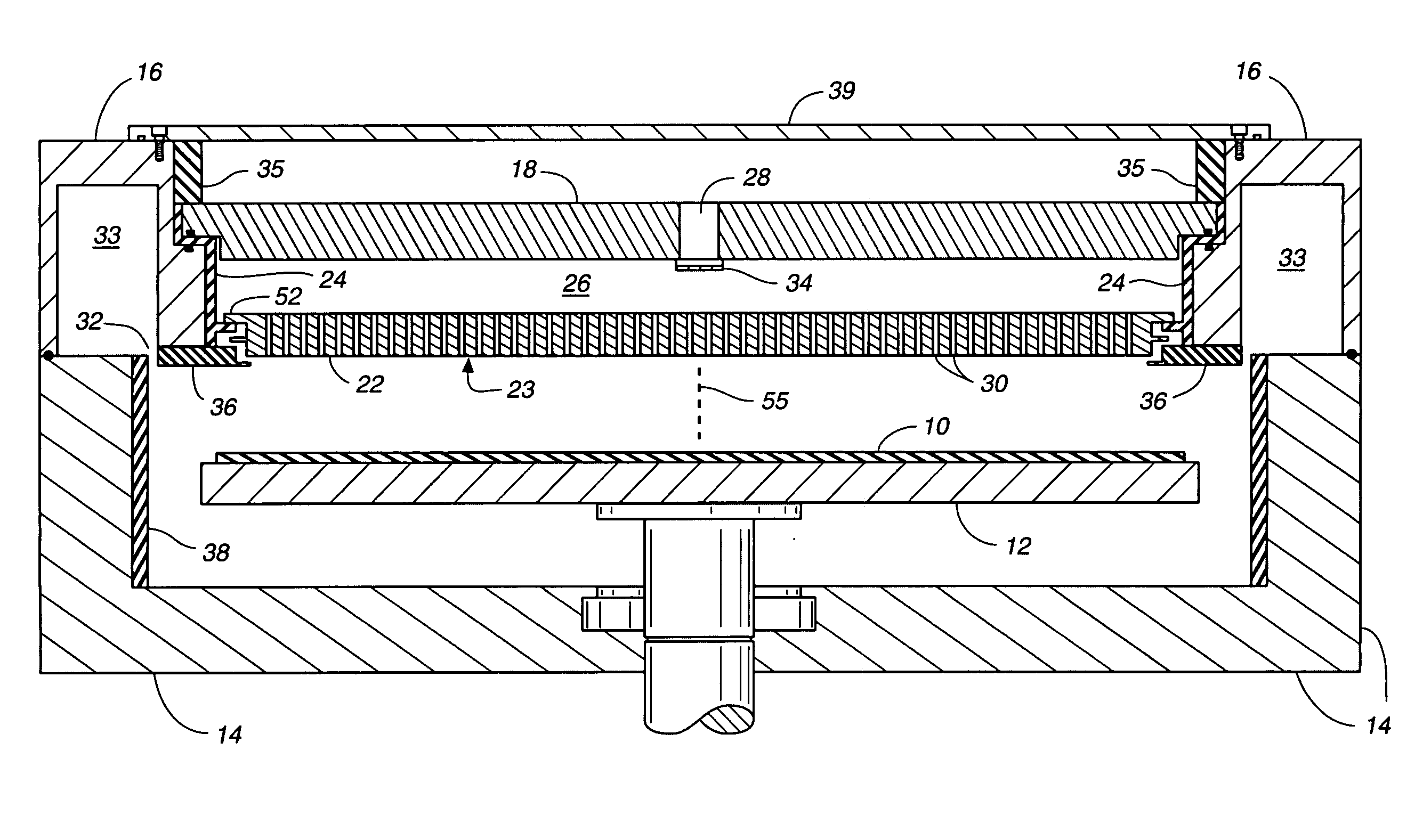

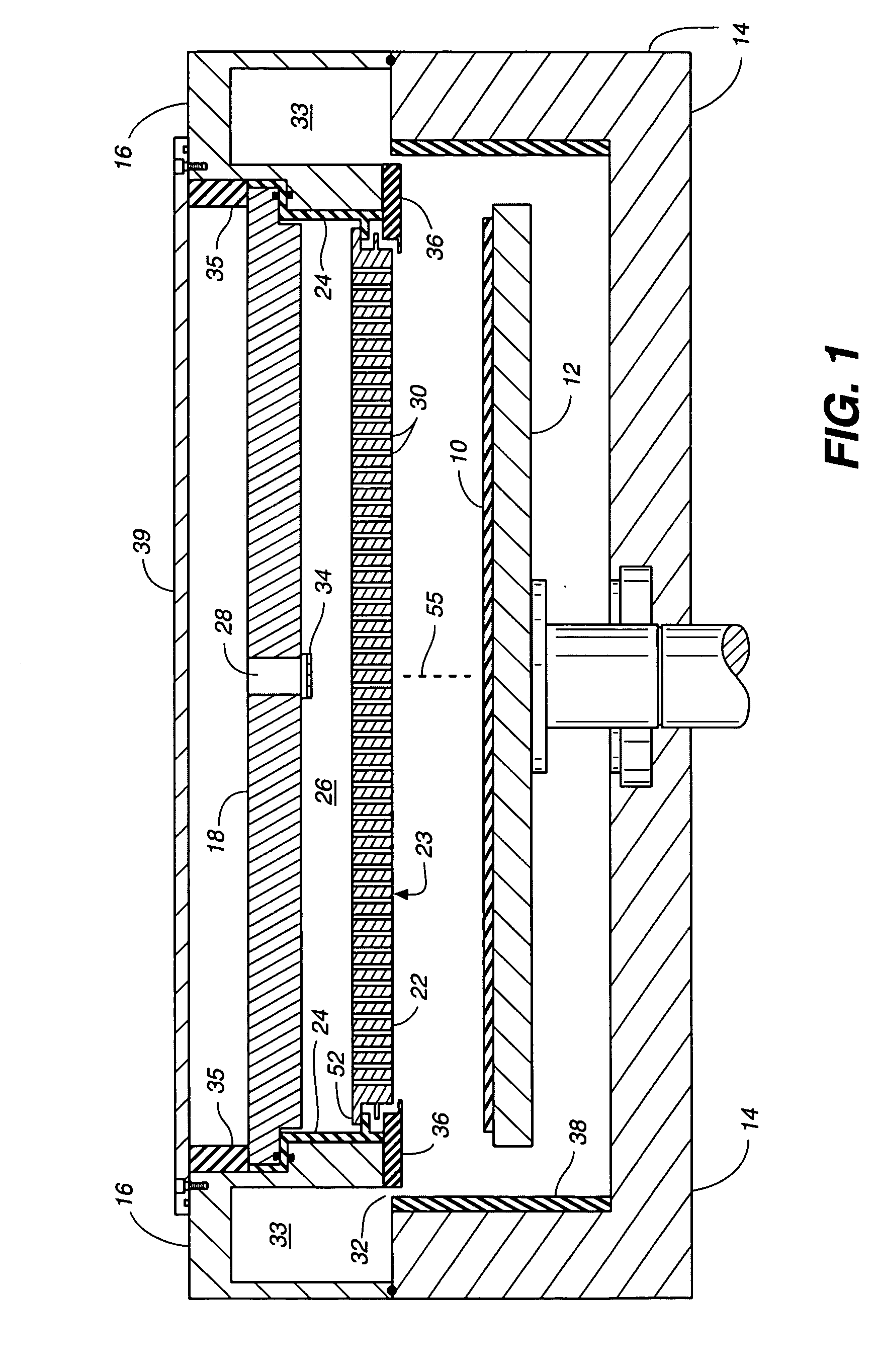

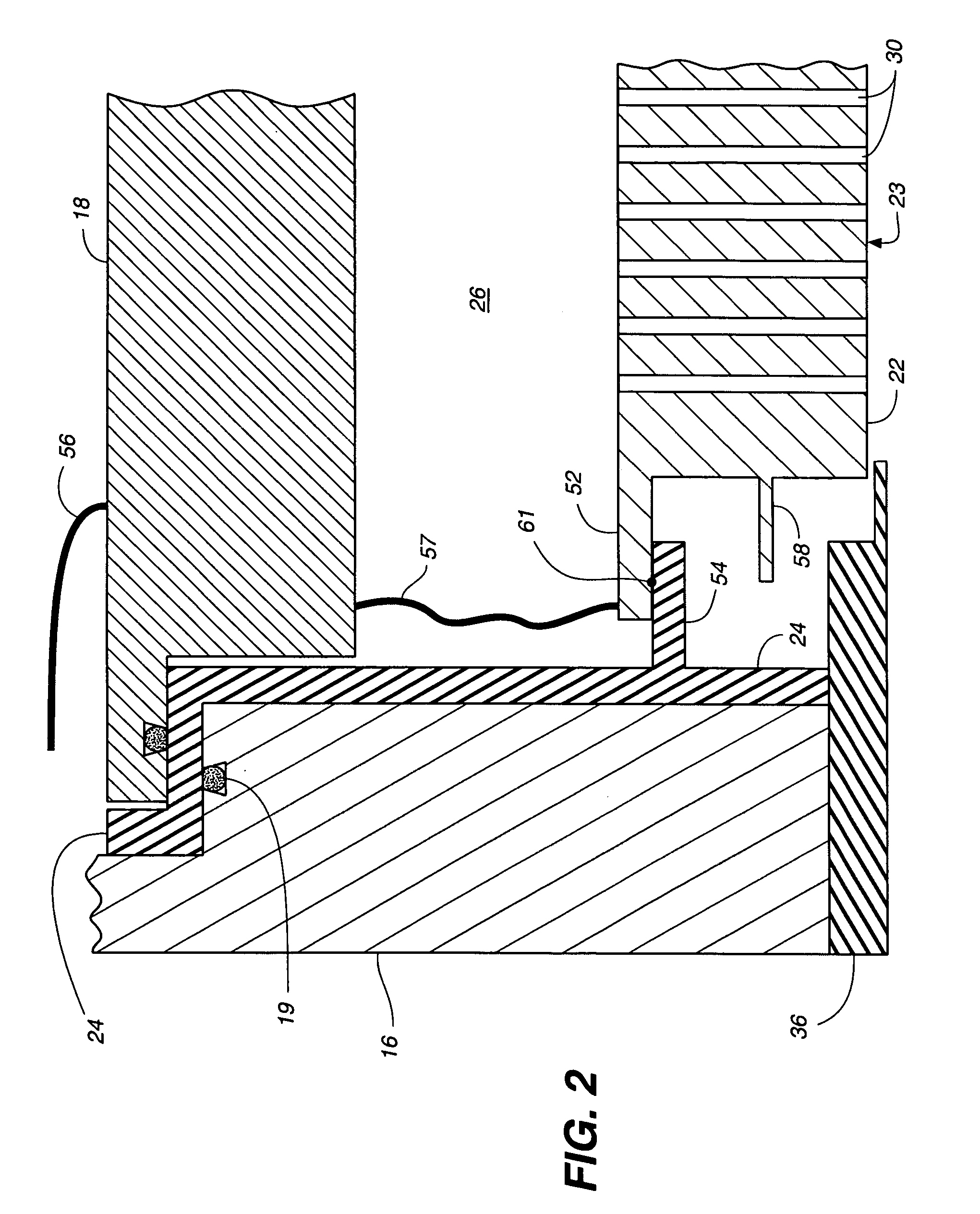

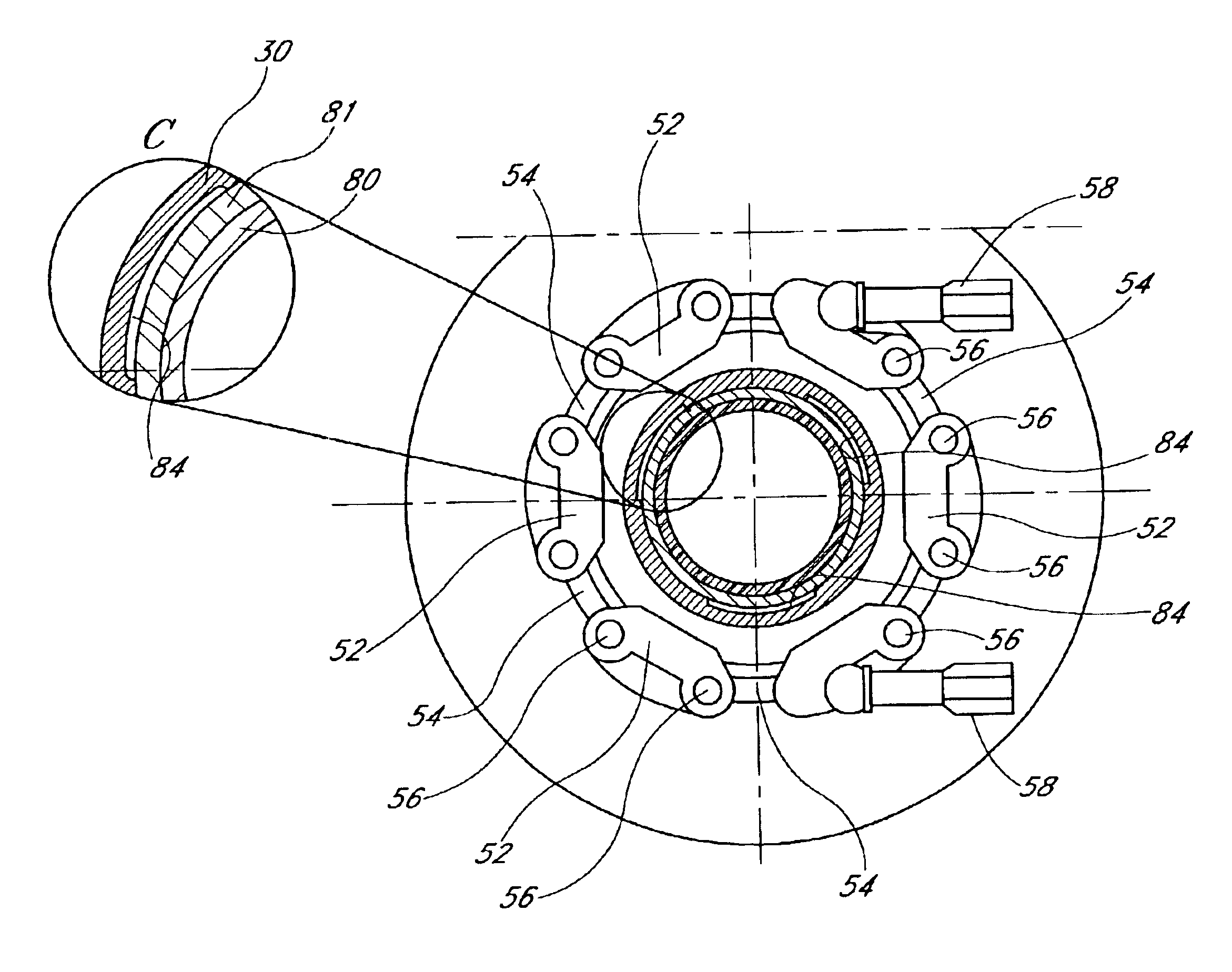

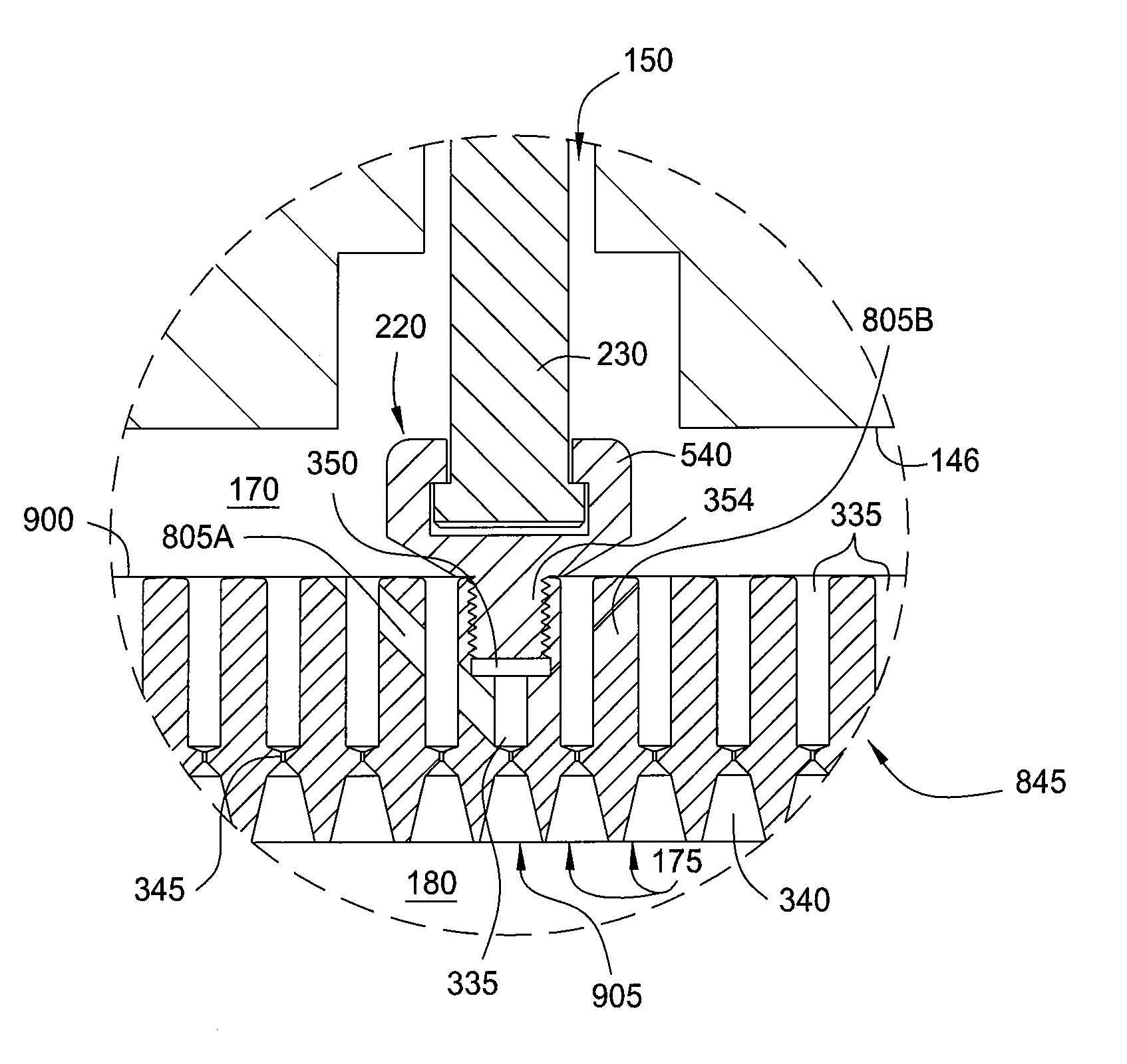

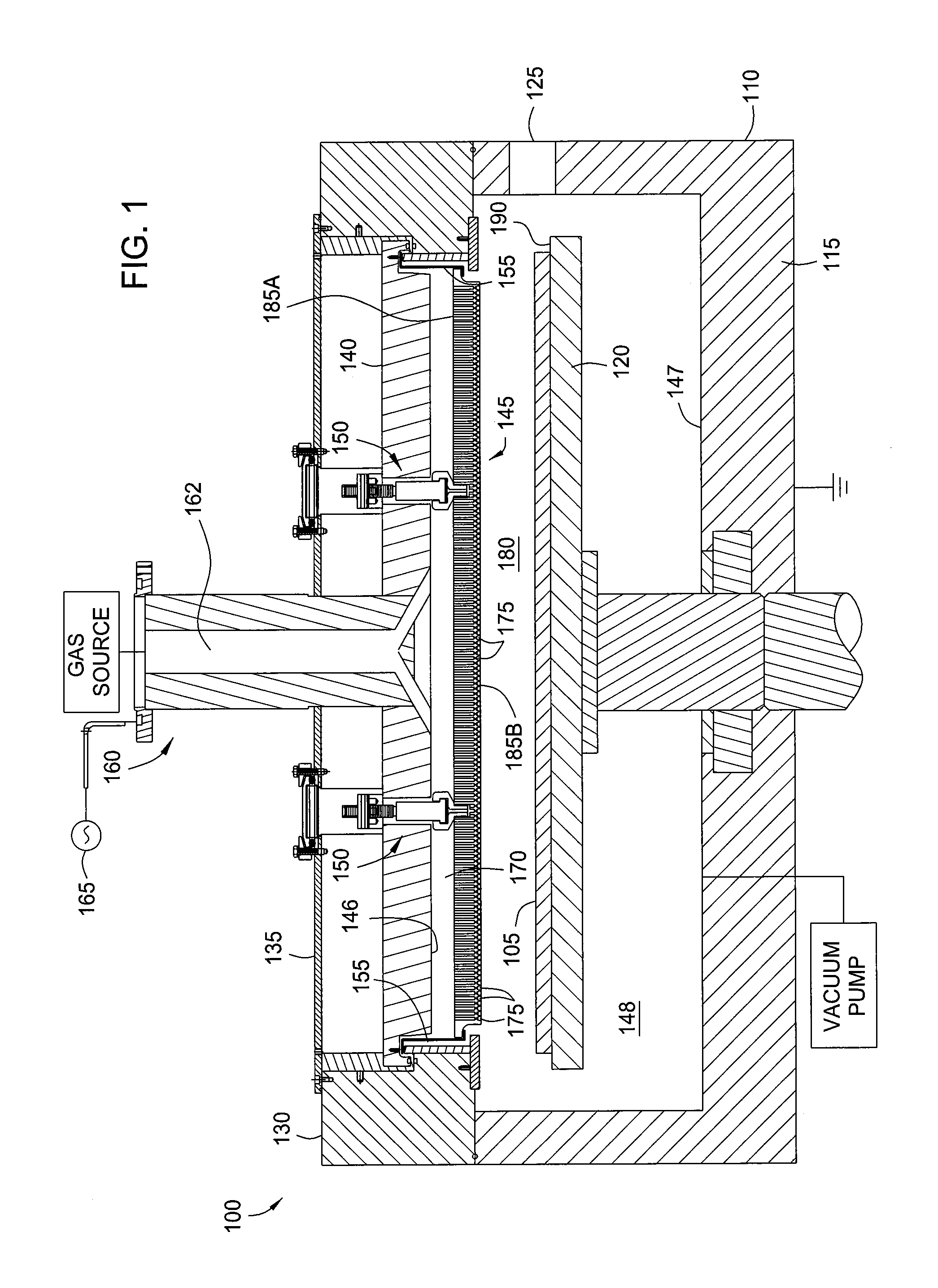

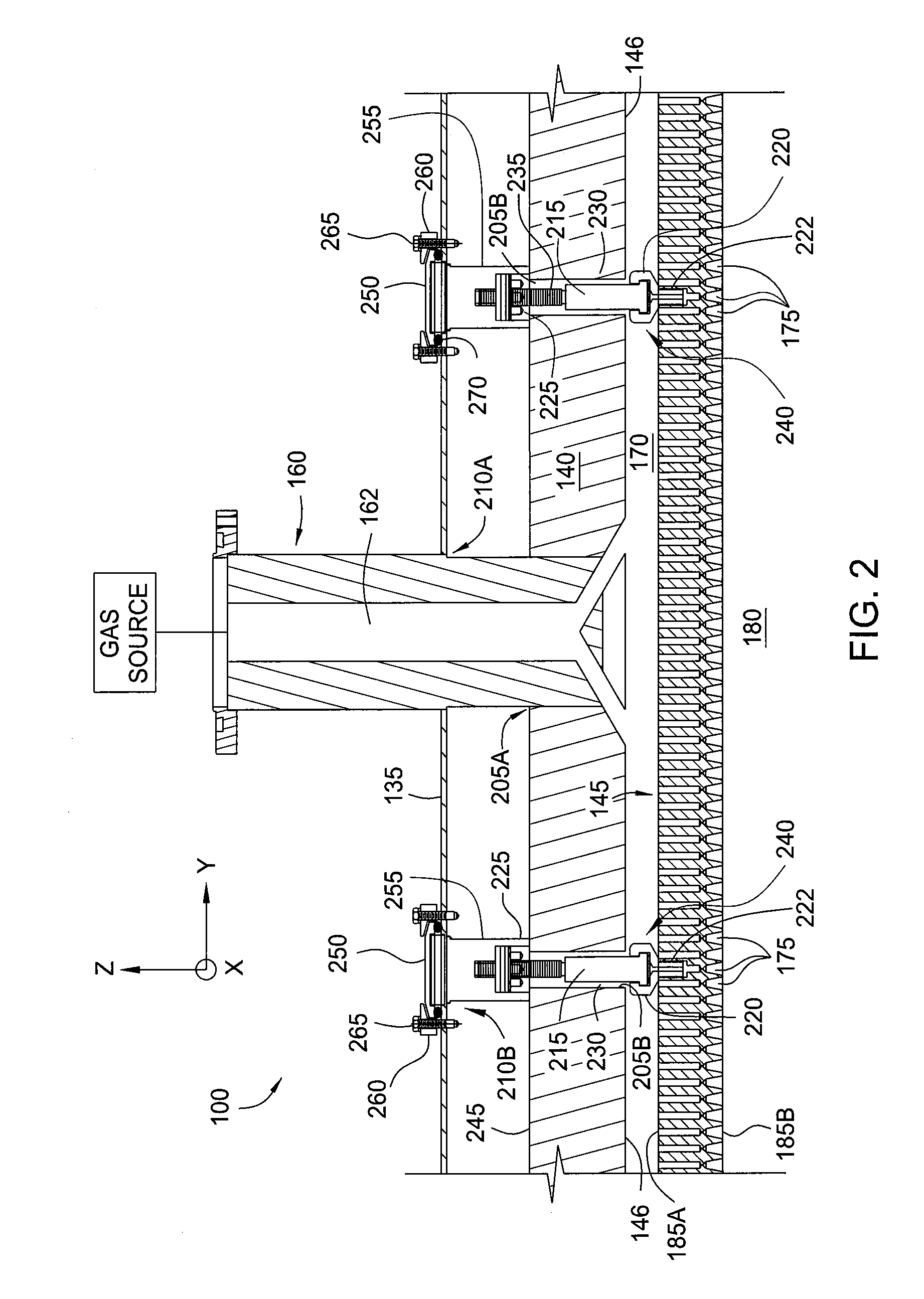

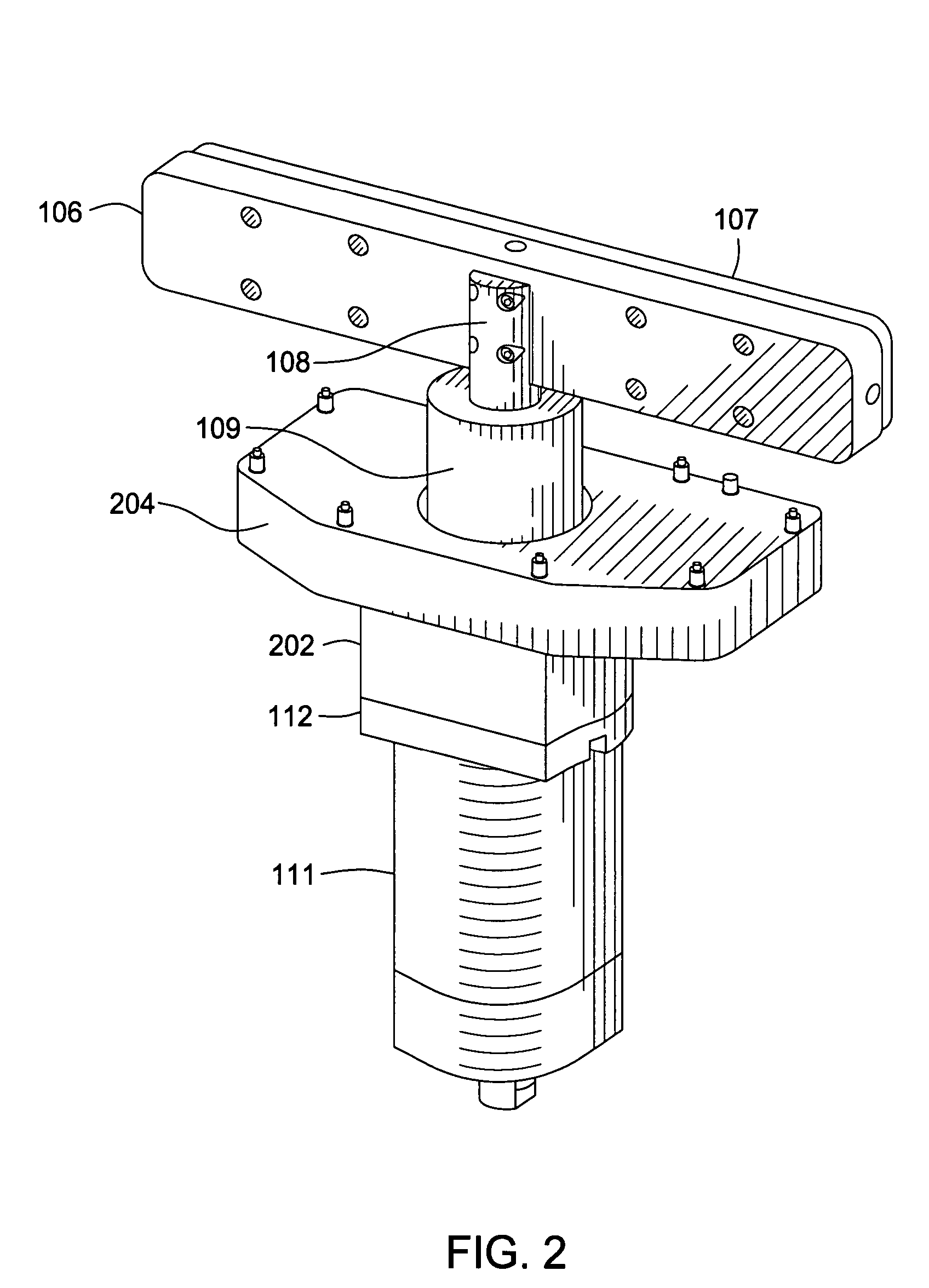

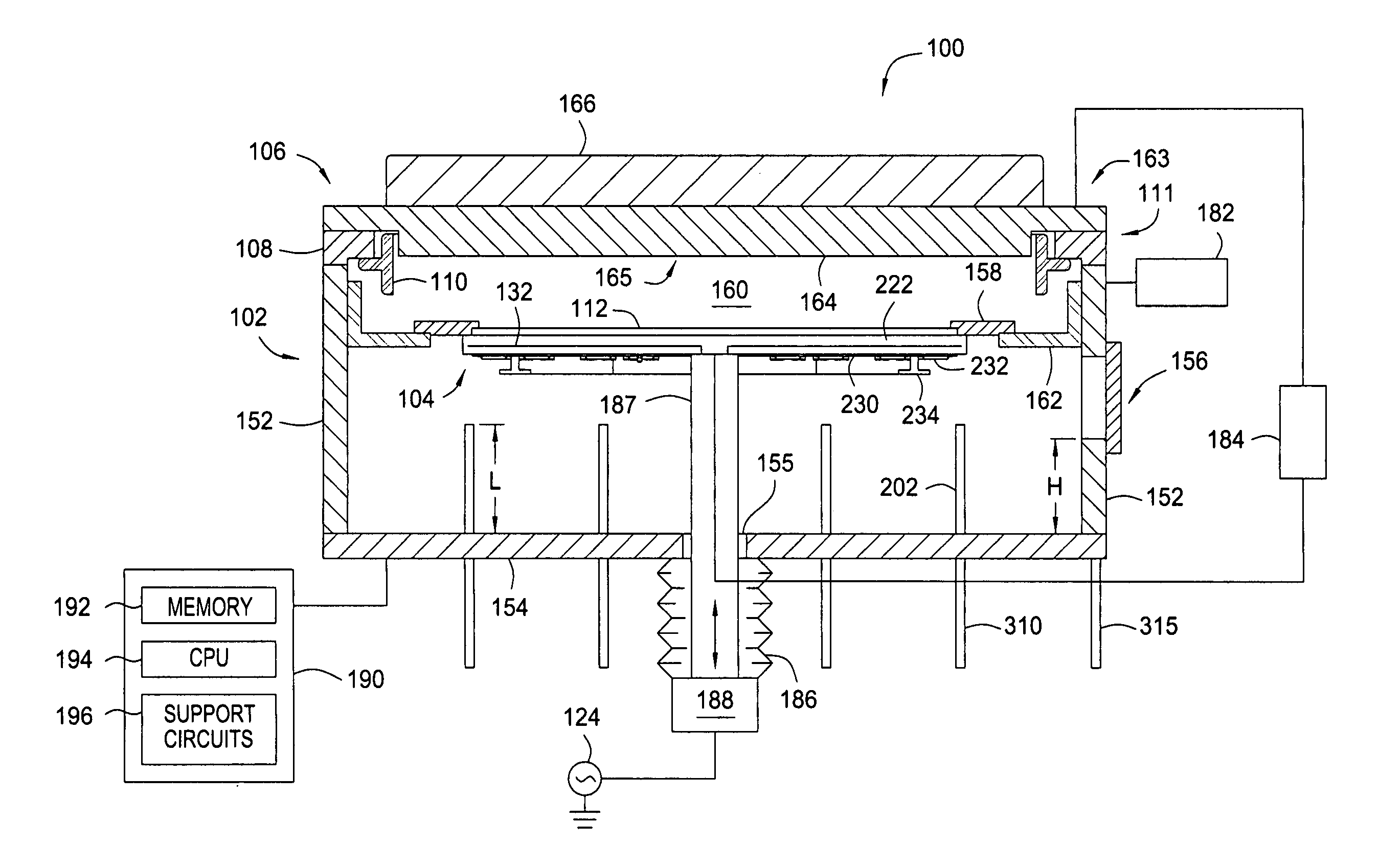

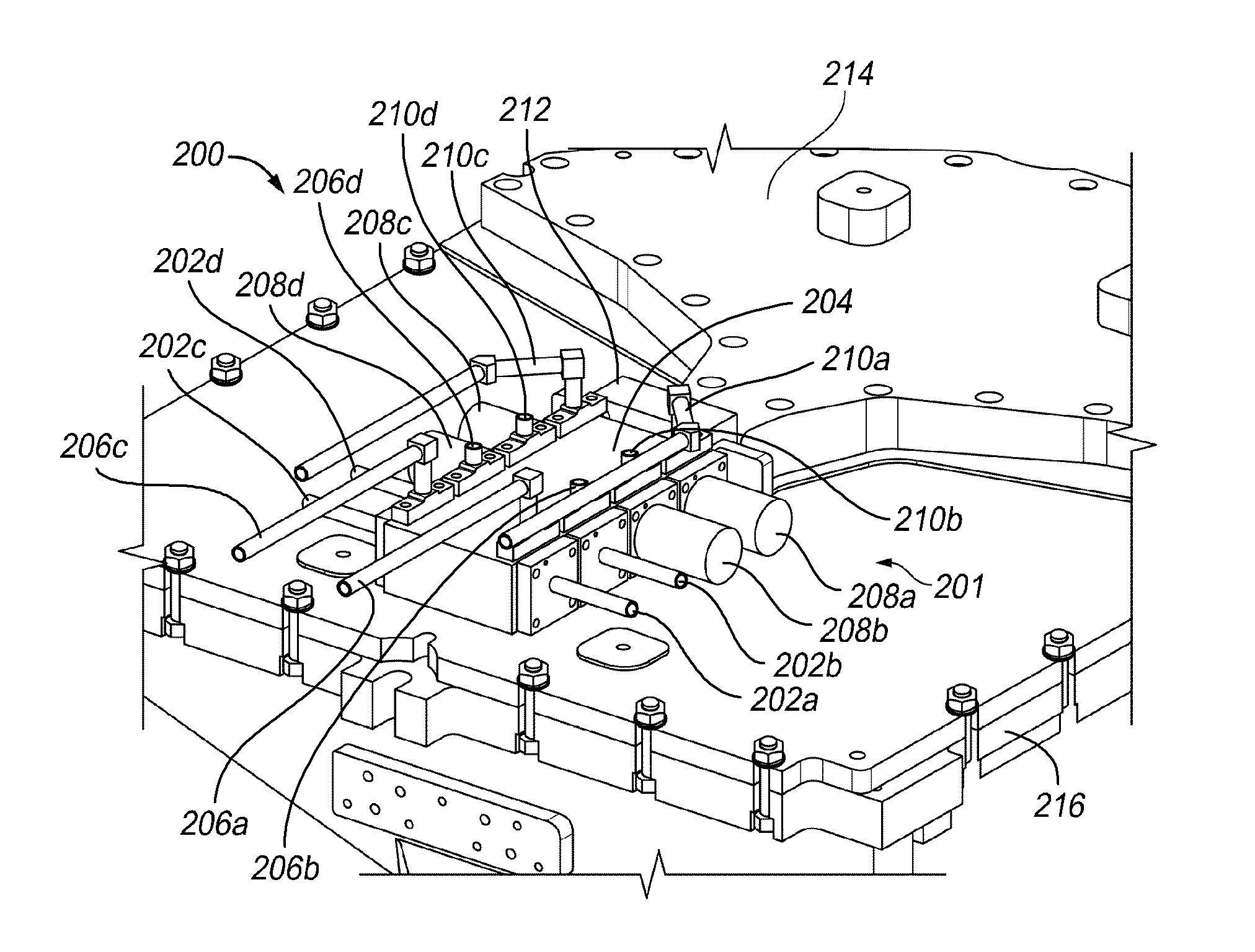

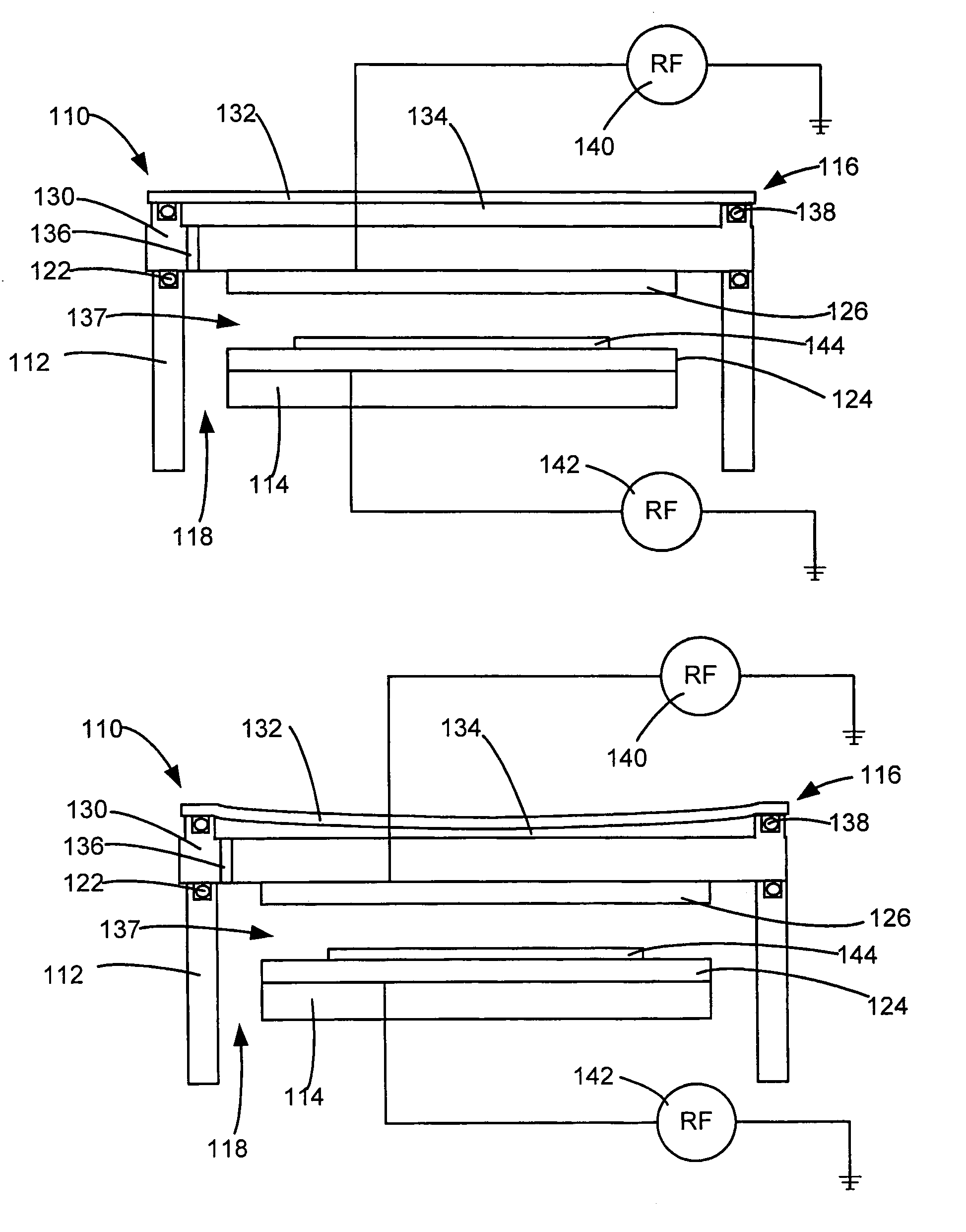

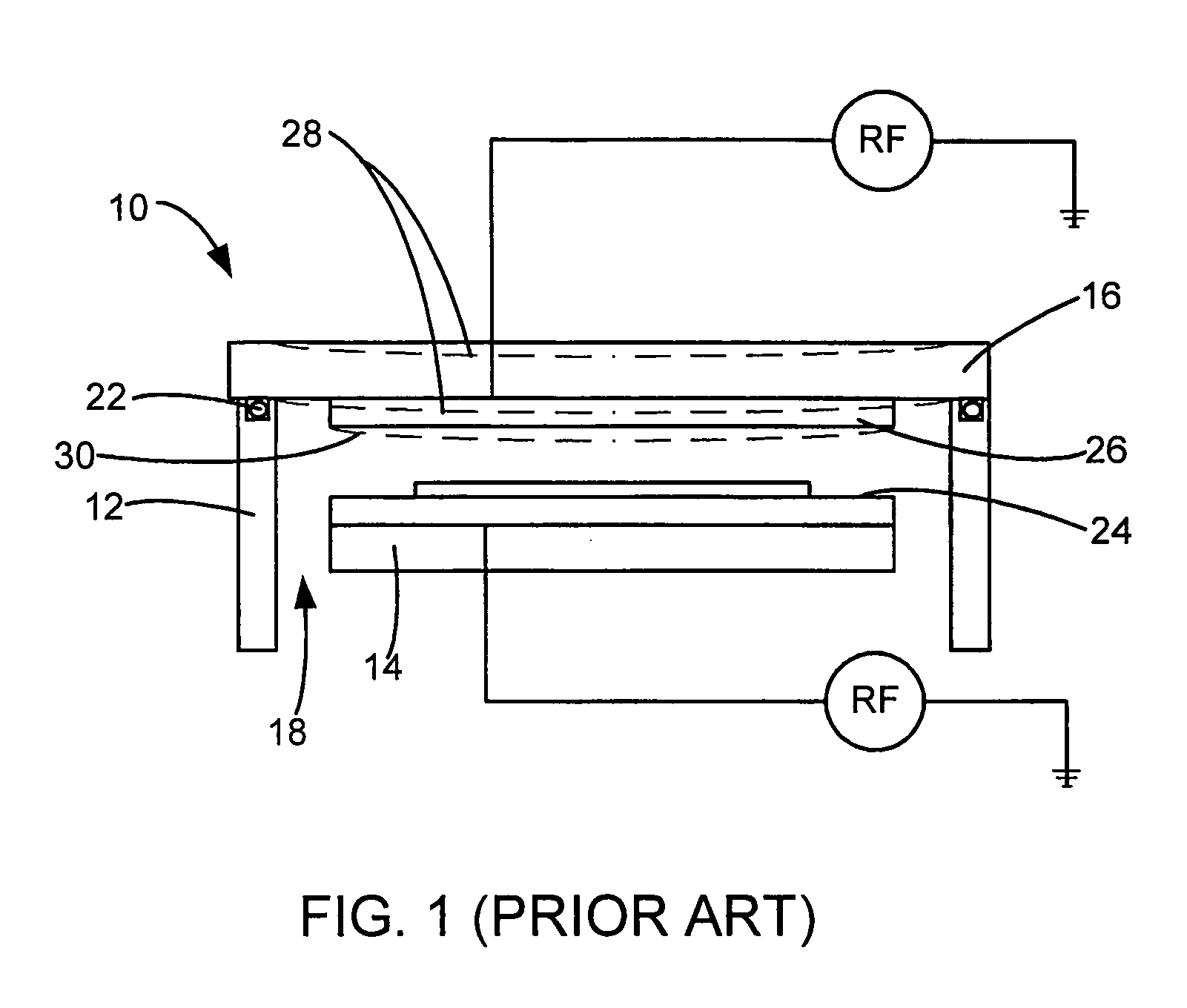

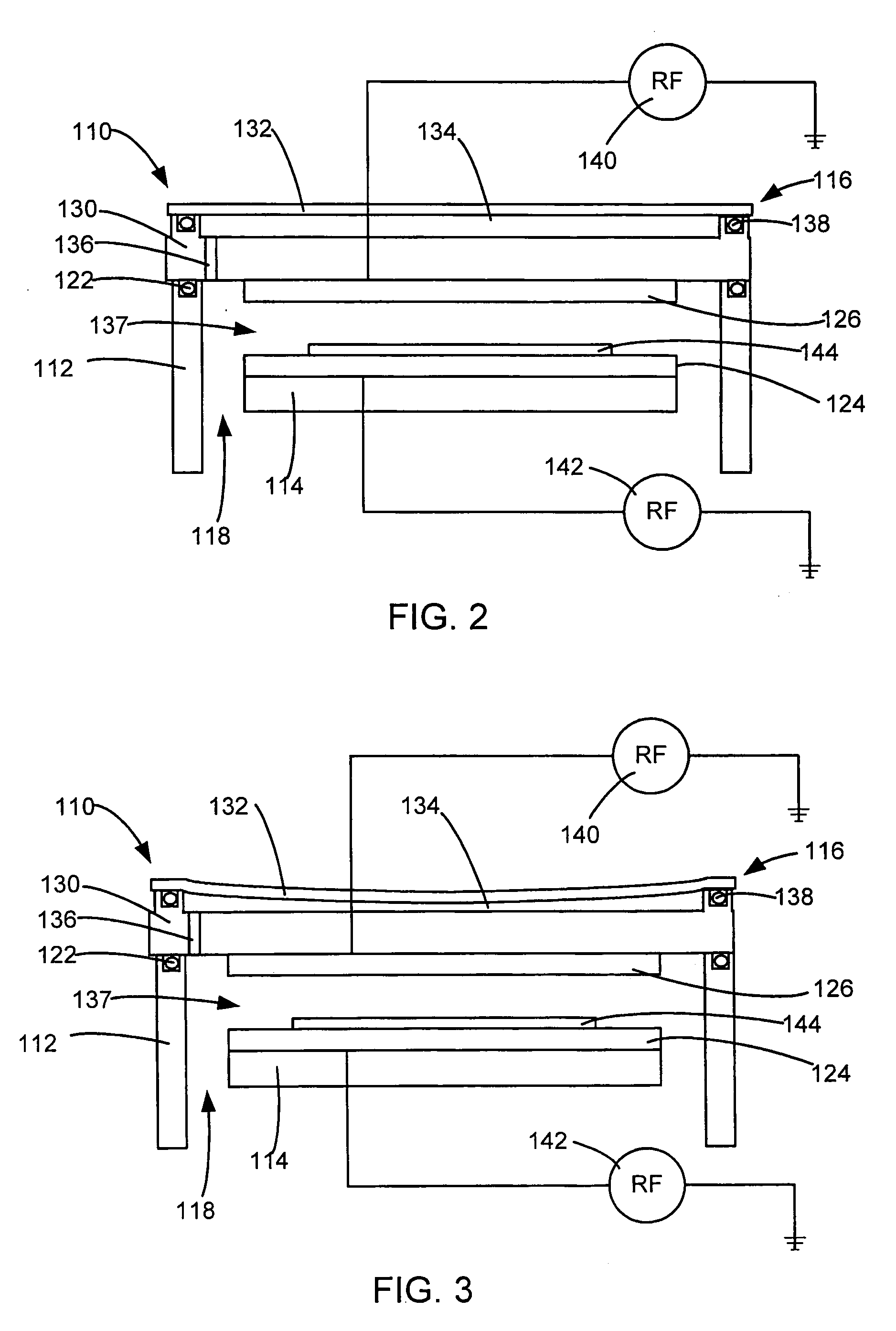

Showerhead mounting to accommodate thermal expansion

InactiveUS20050183827A1Minimize and eliminate distortionGreat thermal expansion coefficientElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringThermal expansion

Methods and apparatus for accommodating thermal expansion of a showerhead. In a first aspect of the invention, the showerhead is movably supported by resting a rim of the showerhead on a support shelf. In a second aspect, the showerhead is suspended from the chamber wall by a plurality of hangers that are connected to the showerhead, the chamber wall, or both by pins that slide within slots so as to permit the hangers to slide radially to accommodate thermal expansion of the showerhead in the radial direction. In a third aspect, the showerhead is suspended from the wall of the vacuum chamber by a plurality of rods or flexible wires. In a fourth aspect, the showerhead is connected near its perimeter to a second material having a greater thermal expansion coefficient than the showerhead. In a fifth aspect, a heater is mounted behind the showerhead to reduce the termperature differential between the top and bottom surfaces of the showerhead or to reduce heat transfer from the workpiece to the showerhead.

Owner:APPLIED MATERIALS INC

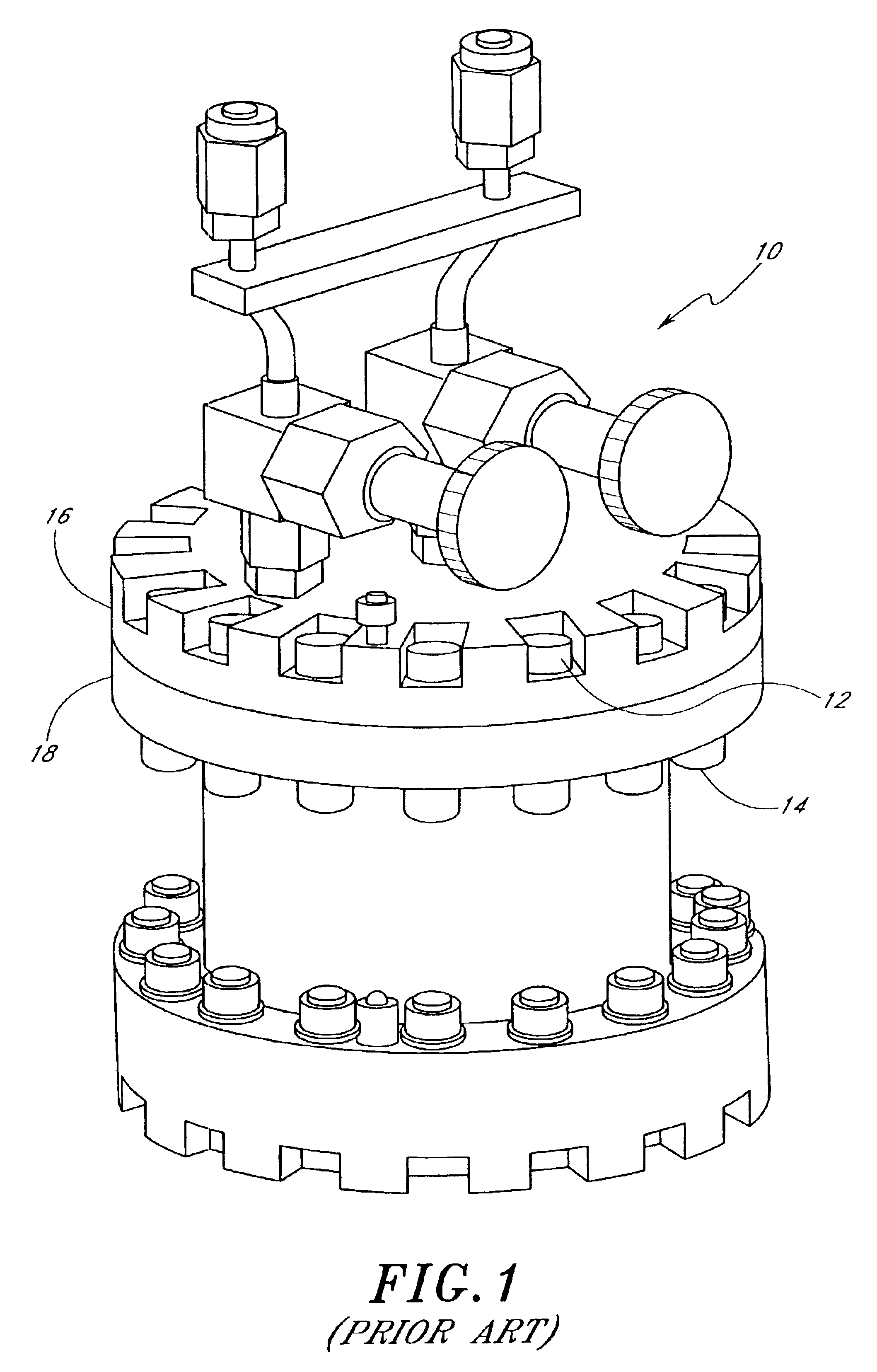

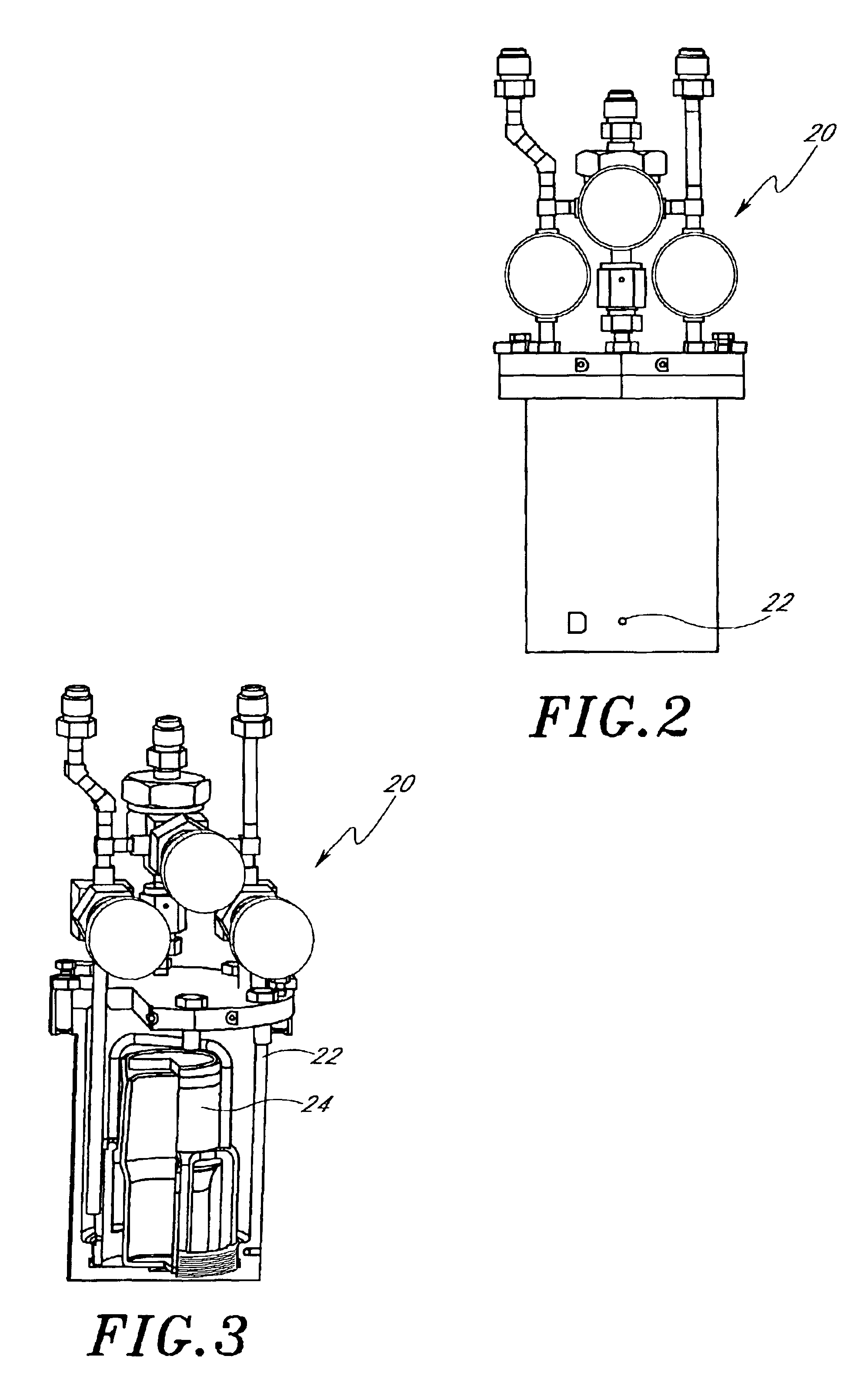

Source chemical container assembly

InactiveUS6889864B2Improve sealingHigh compression forceSleeve/socket jointsFlanged jointsVacuum chamberMechanical engineering

The invention relates to a source chemical container assembly, comprising a metal container functioning as a vacuum chamber and provided with a removable closure, which removable closure seals against the metal container with a metal seal. In order to facilitate easy recharging of the container assembly, compressive force is applied to the metal seal through a tension chain. In a preferred embodiment of the invention the metal seal and the tension chain are provided along a circumference of said metal container. The assembly can comprise an inner container in which the source chemical is contained.

Owner:ASM INTERNATIONAL

Hdp-cvd seasoning process for high power hdp-cvd gapfil to improve particle performance

InactiveUS20060219169A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

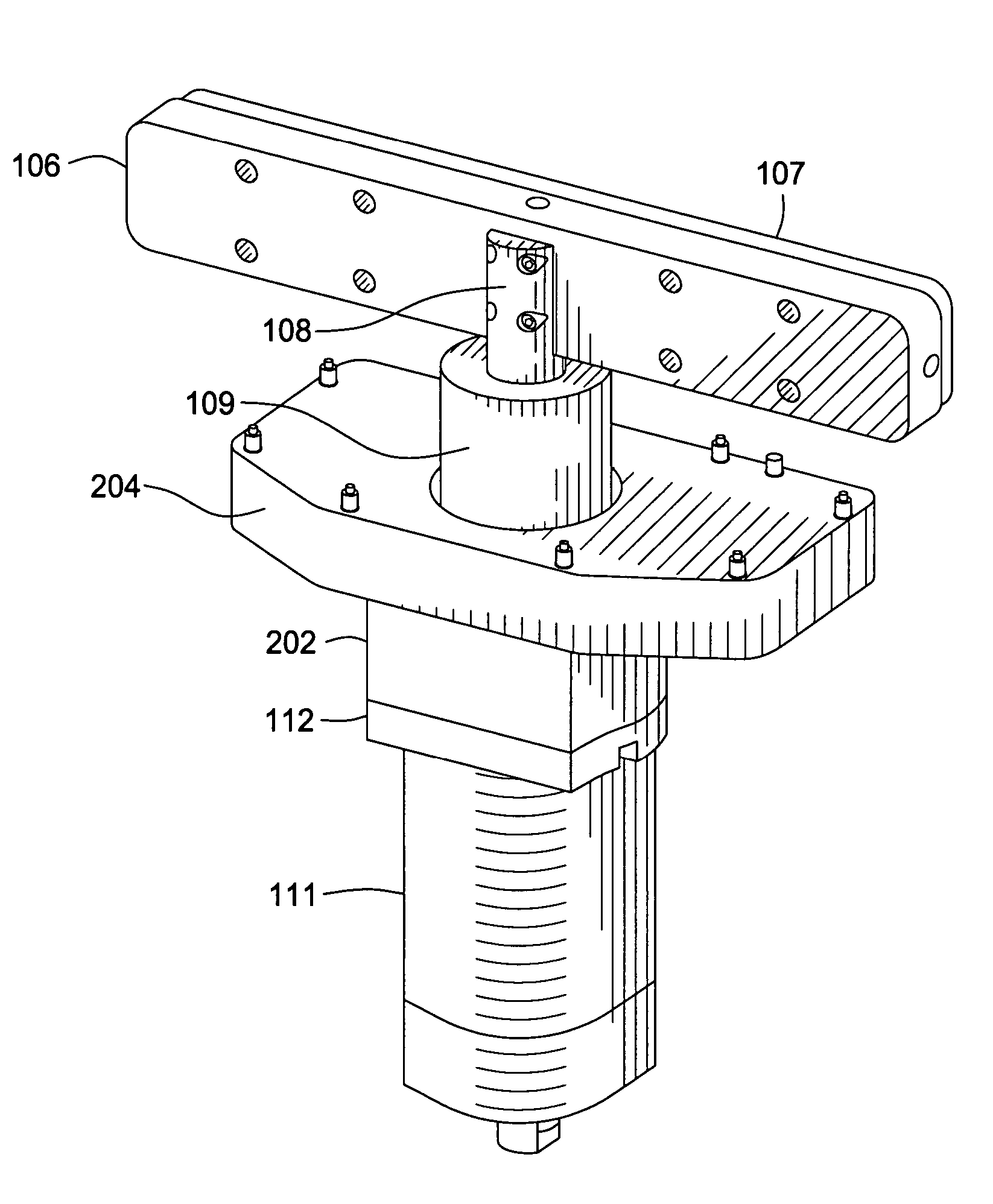

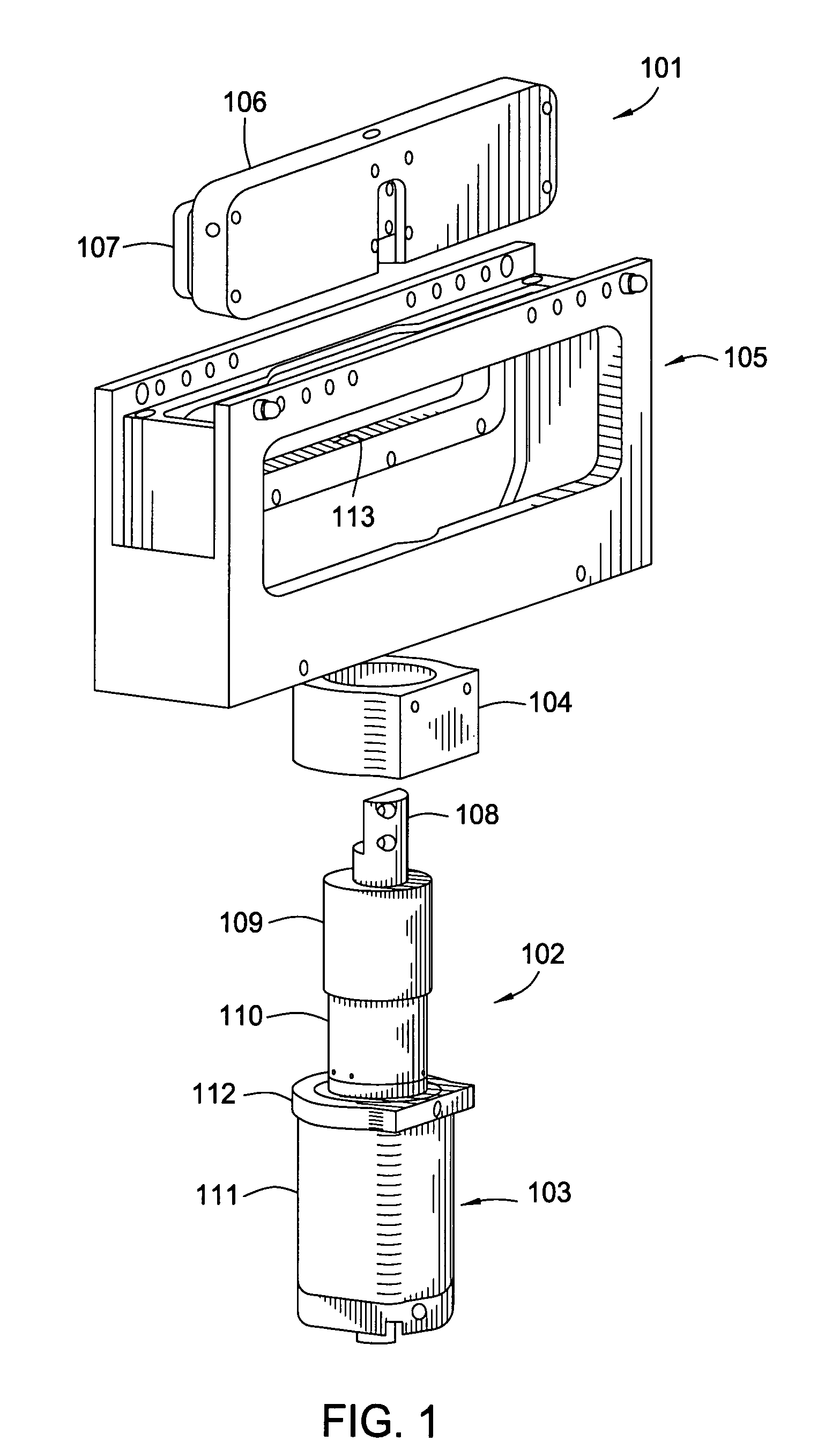

Showerhead support structure for improved gas flow

ActiveUS8721791B2Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

Embodiments of the present invention generally provide apparatus and methods for supporting a gas distribution showerhead in a processing chamber. In one embodiment, a gas distribution showerhead for a vacuum chamber is provided. The gas distribution showerhead comprises a body having a first side and a second side opposite the first side, and a plurality of gas passages formed through the body, the gas passages comprising a first bore formed in the first side that is fluidly coupled to a second bore formed in the second side by a restricting orifice, and a suspension feature formed in the first bore of at least one of the gas passages.

Owner:APPLIED MATERIALS INC

Single-sided inflatable vertical slit valve

Owner:APPLIED MATERIALS INC

Substrate process apparatus, substrate process method, and computer readable storage medium

ActiveUS20110100489A1Servomotor componentsSemiconductor/solid-state device manufacturingDifferential pressureEngineering

A vacuum chamber is evacuated through a first evacuation passage provided with a first valve and a second evacuation passage provided with a second valve. An opening degree of the first valve is adjusted so that a pressure in the vacuum chamber becomes substantially equal to a process pressure P; an opening degree of a butterfly valve further provided in the second evacuation passage is adjusted to substantially equal to a set value determined by a table in order to set flow rates of gases to be evacuated through the first evacuation passage and the second evacuation passage to be substantially equal to corresponding set values determined by the recipe; and an opening degree of the second valve is adjusted so that a measurement value of a differential pressure gauge further provided in the second evacuation passage becomes substantially equal to a differential pressure written in the table.

Owner:TOKYO ELECTRON LTD

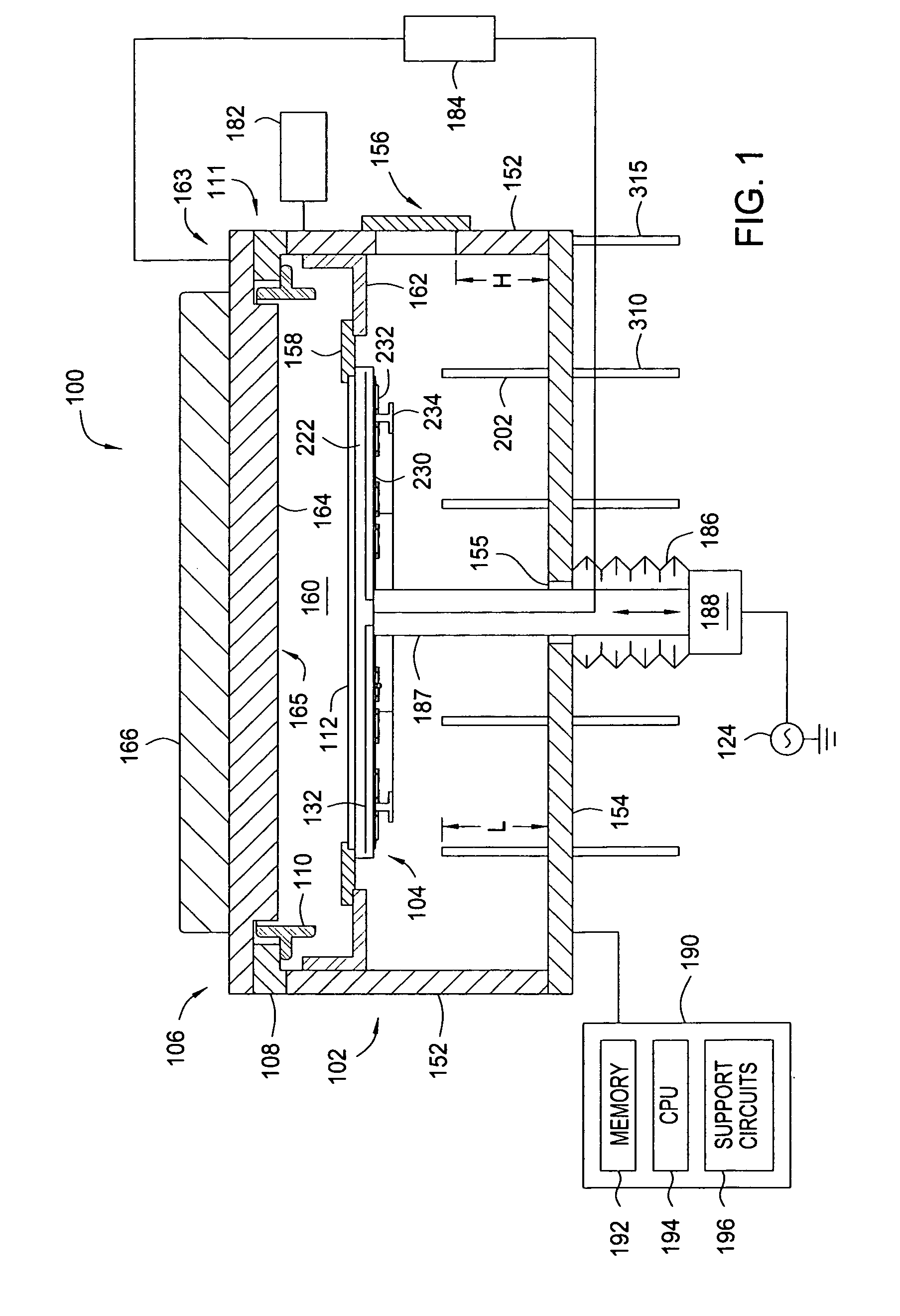

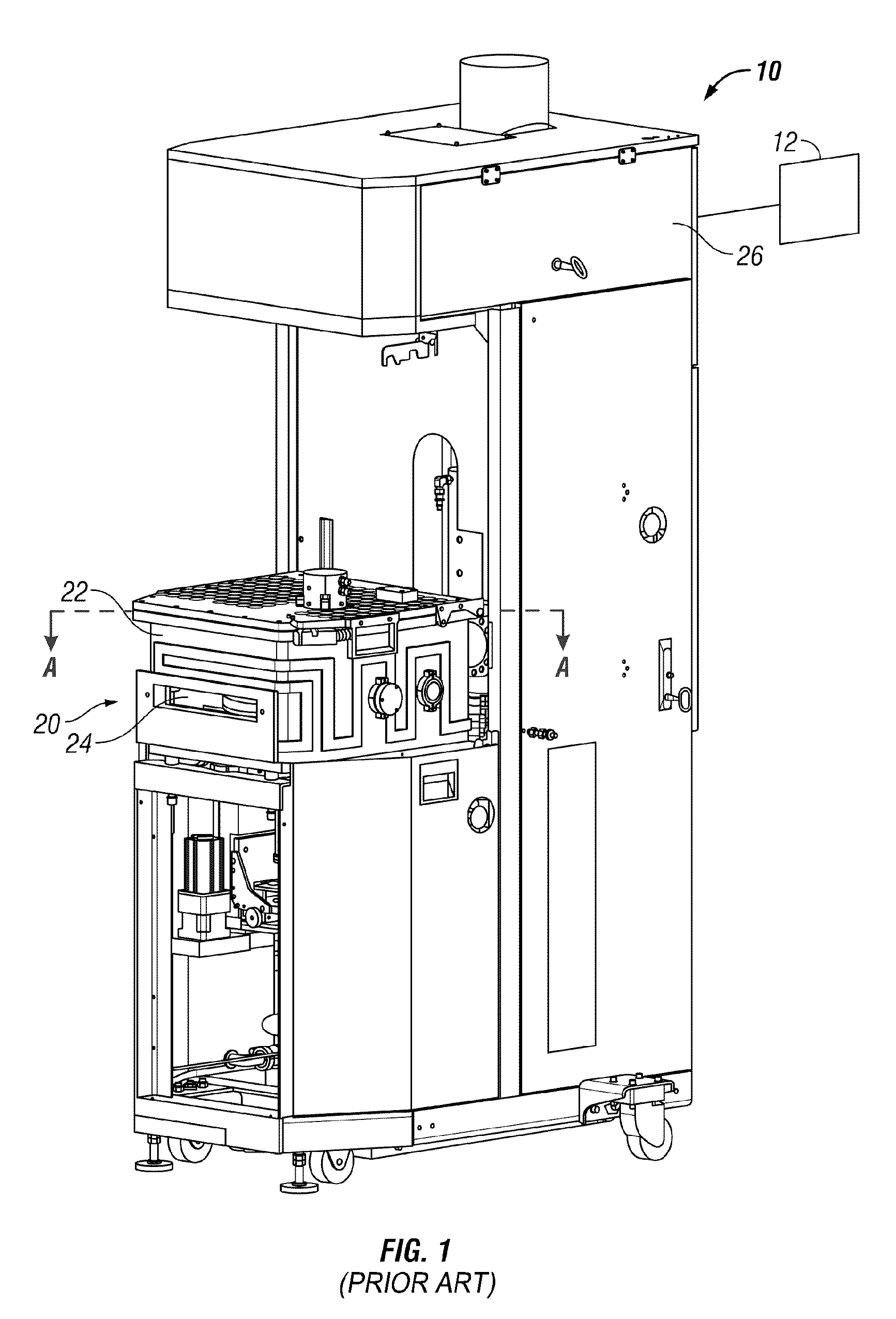

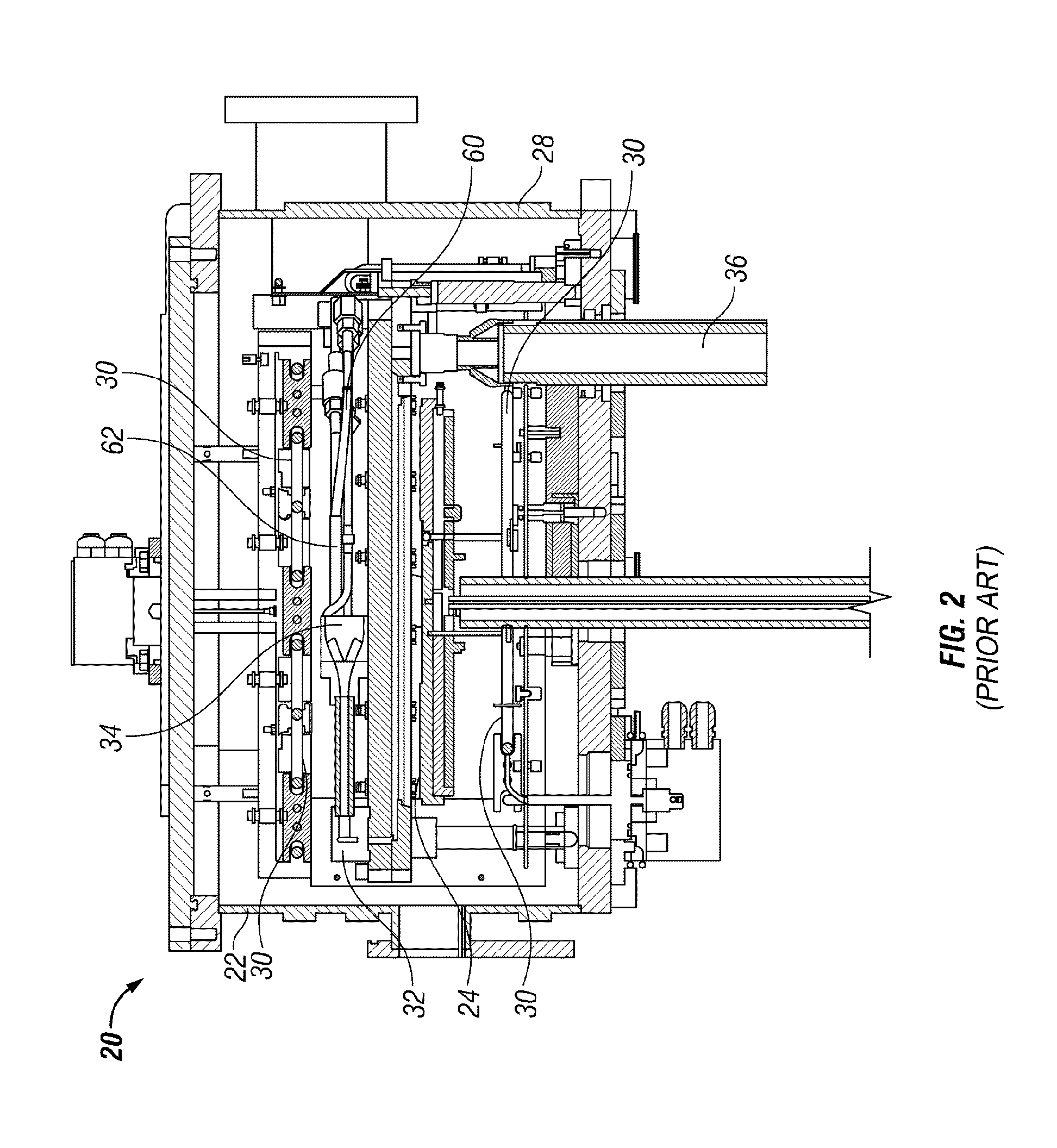

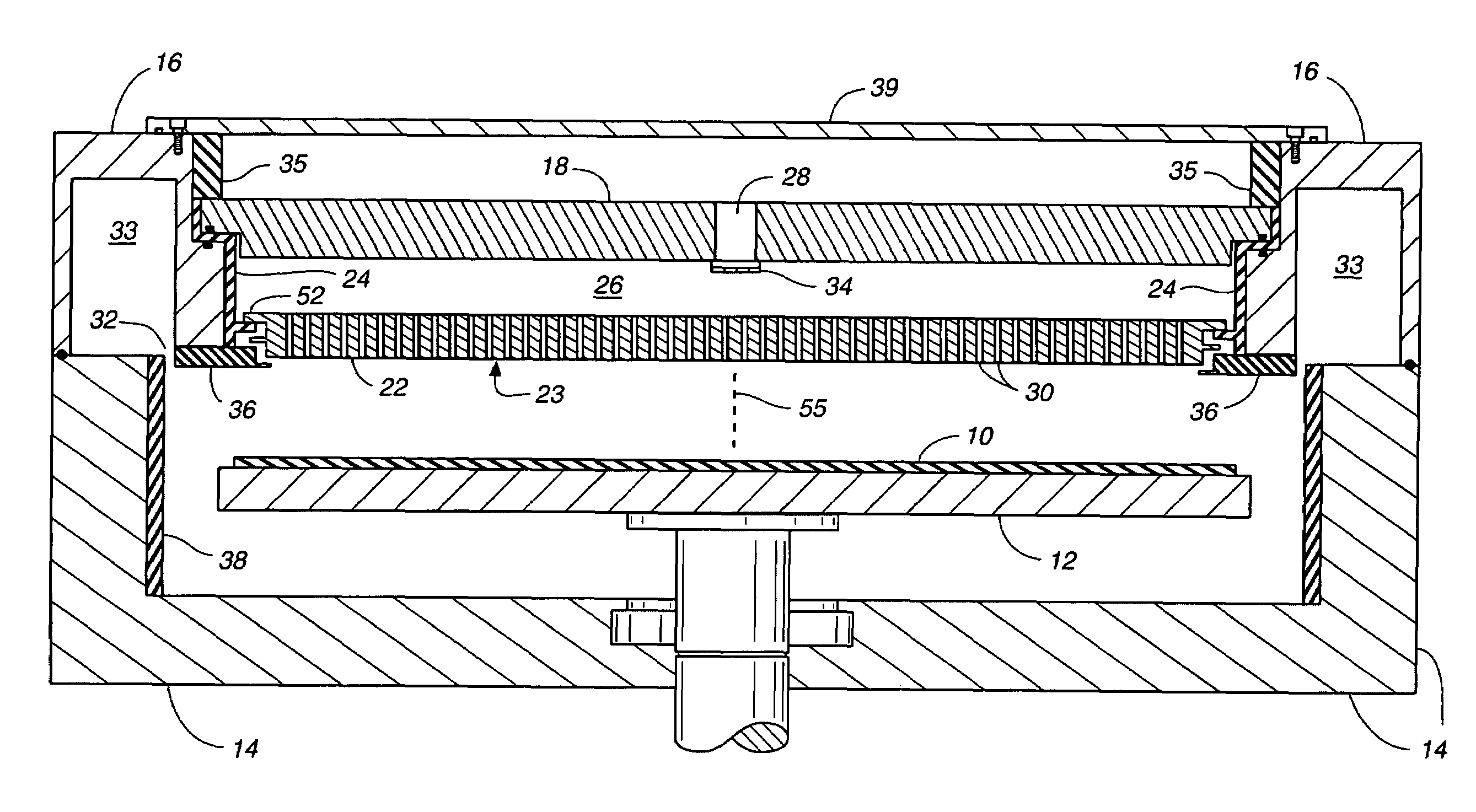

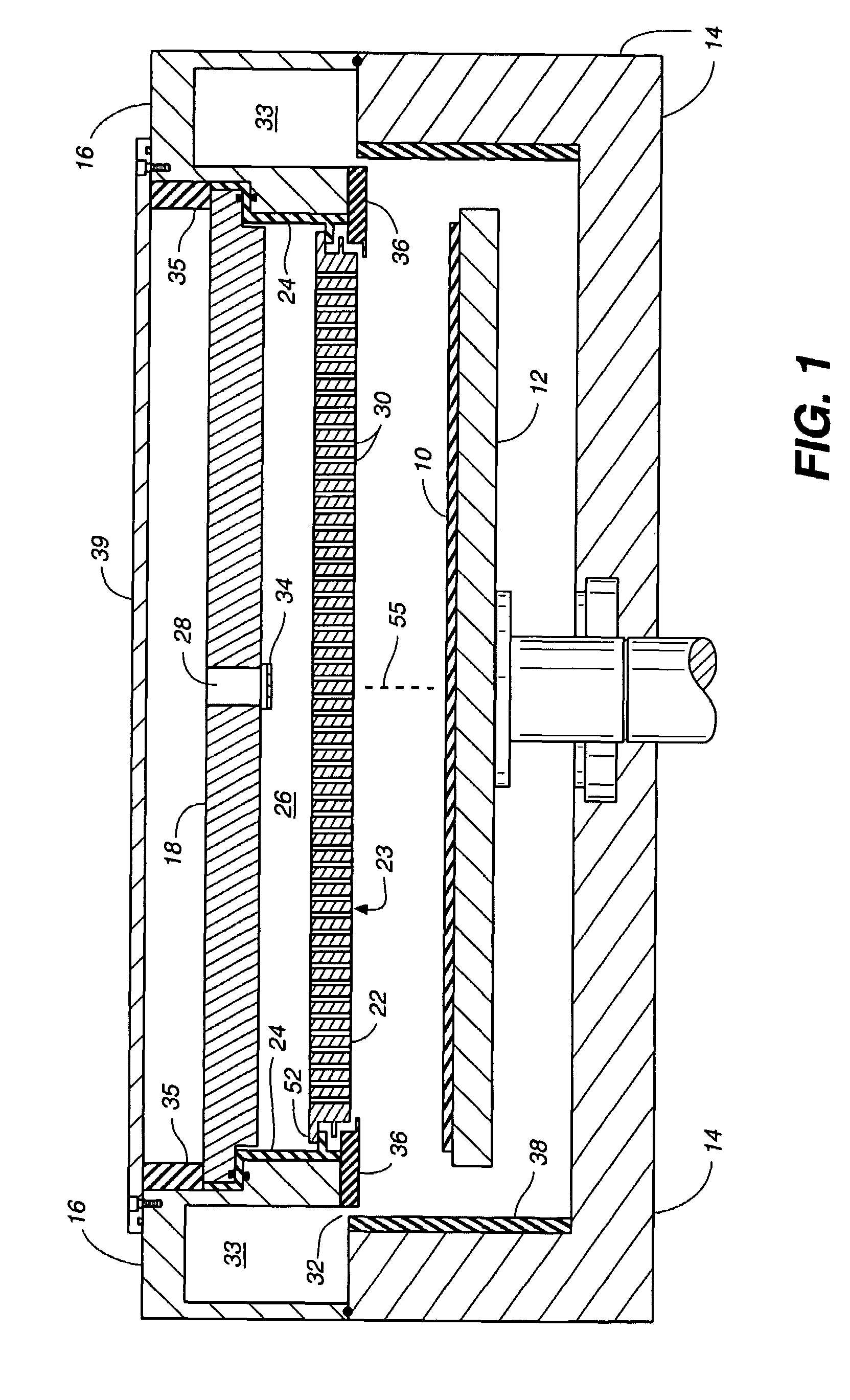

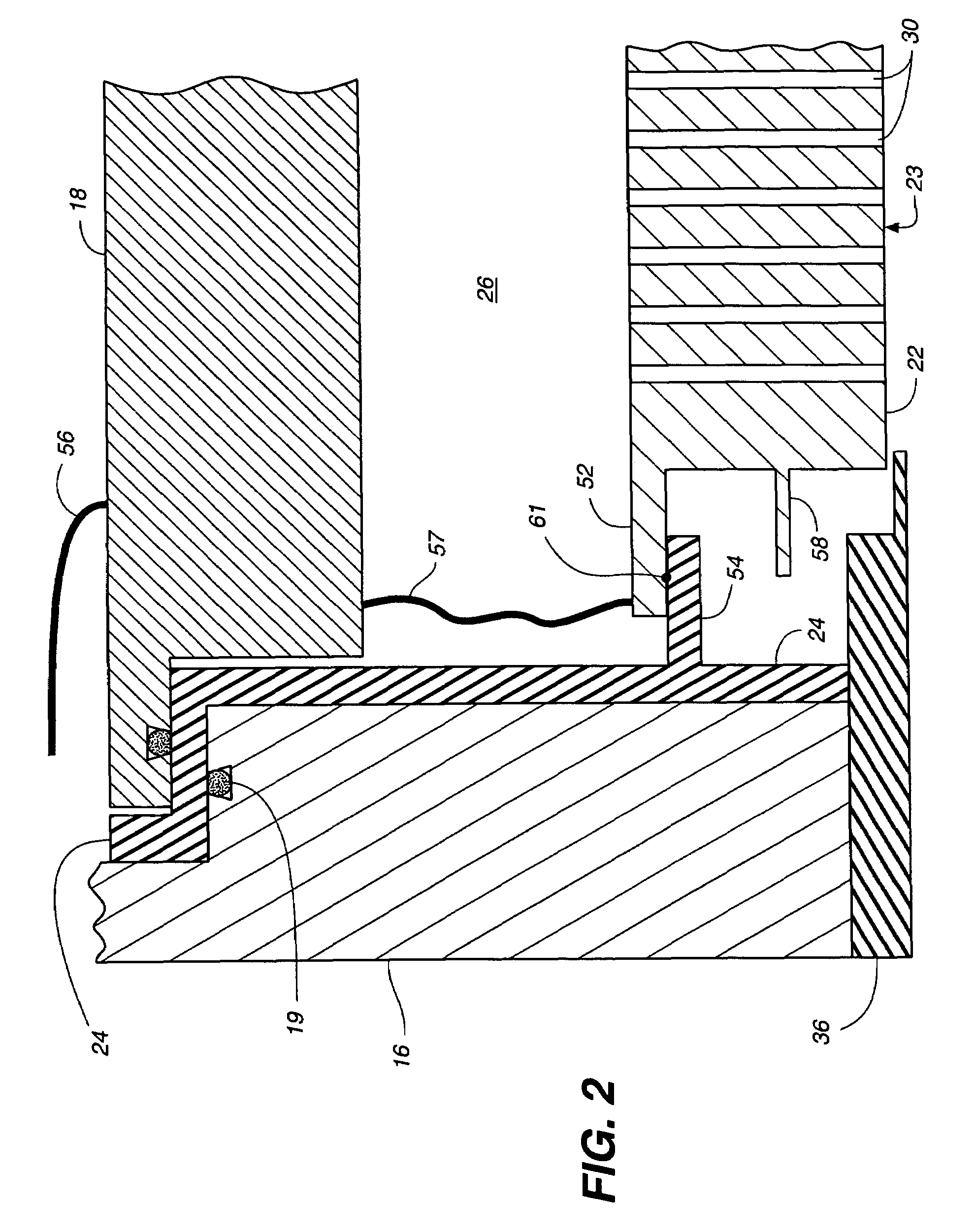

Vacuum chamber bottom

InactiveUS20070028842A1Electric discharge tubesChemical vapor deposition coatingEngineeringVacuum chamber

A process chamber having an reinforced chamber body is provided. The reinforced chamber body may include one or more chamber walls, a chamber bottom, and a chamber support assembly attached to an exterior side of the chamber bottom. The chamber support assembly may include one or more elongated base support structures and one or more lateral support structures connected to the one or more elongated base support structures. The process chamber may also include a plurality of substrate support pins attached to an interior side of the chamber bottom and adapted to support a large area substrate thereon.

Owner:APPLIED MATERIALS INC

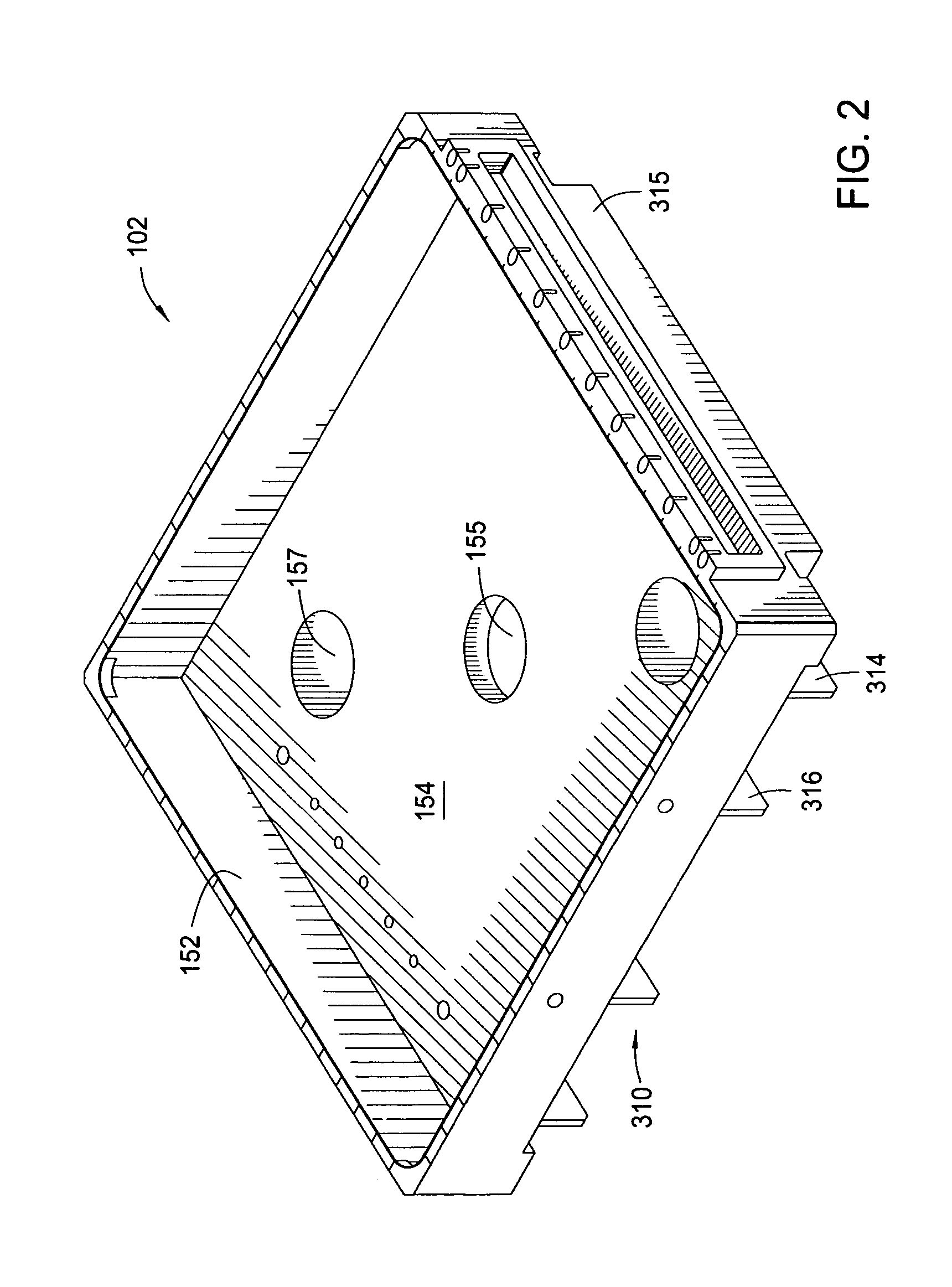

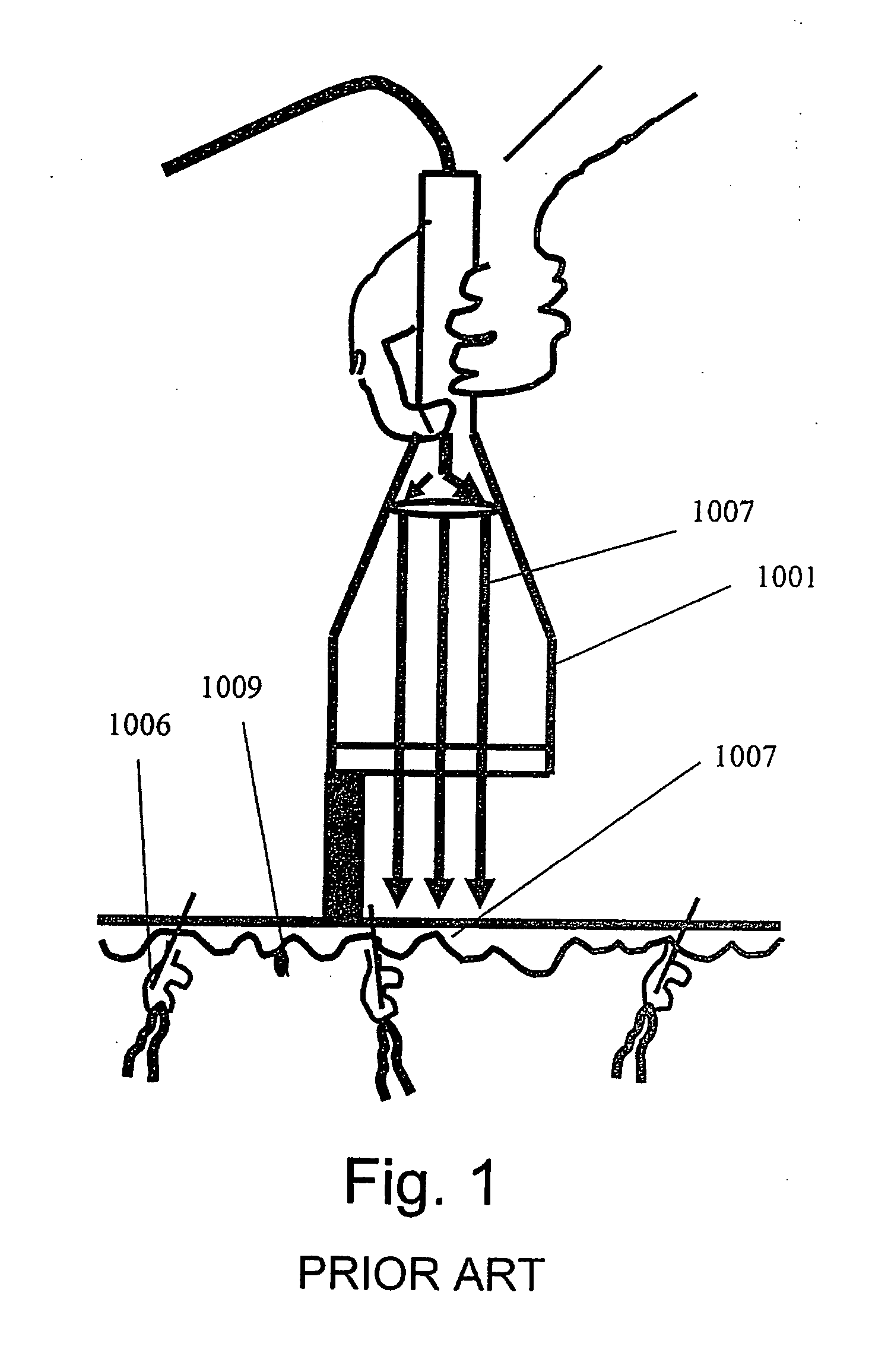

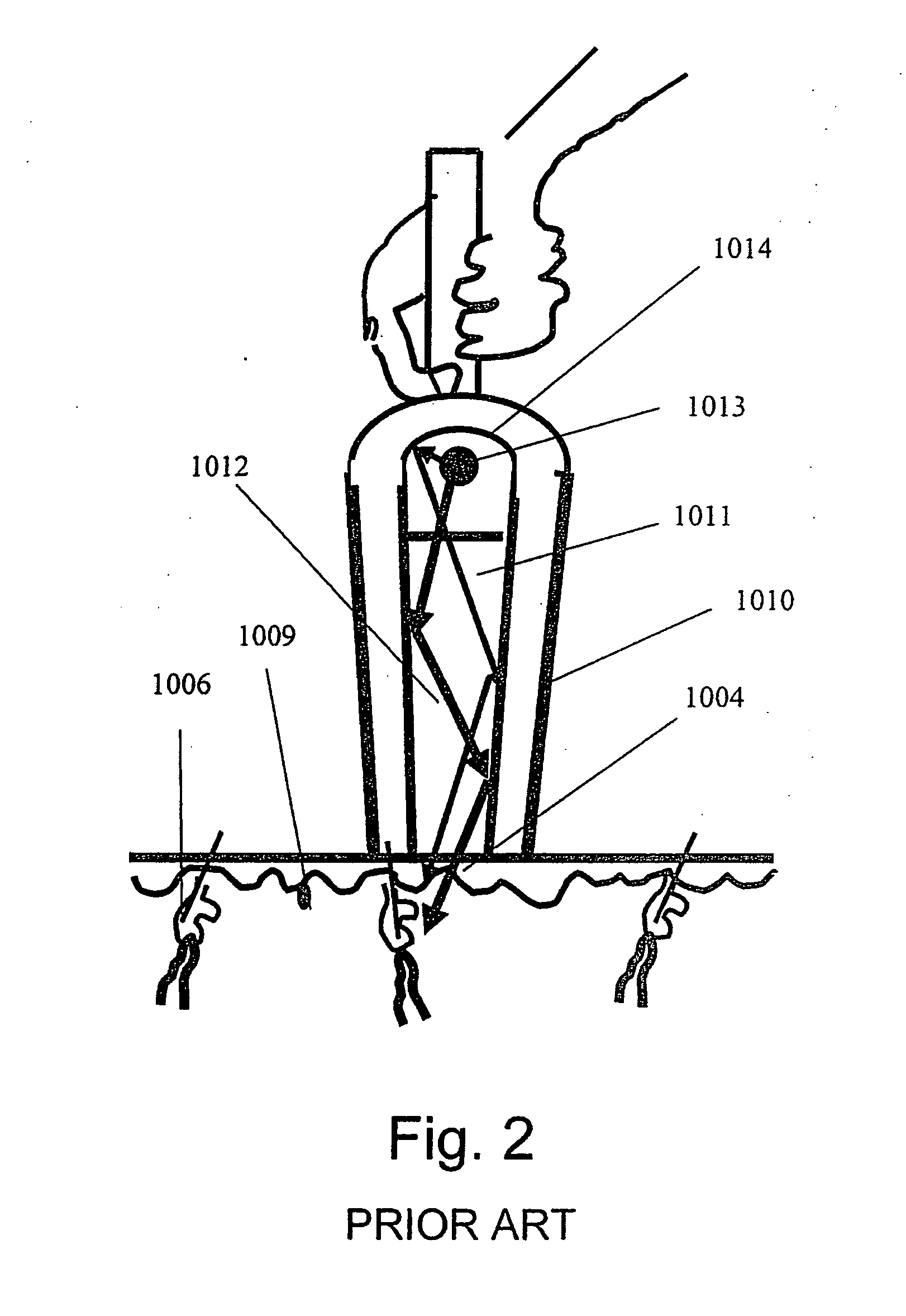

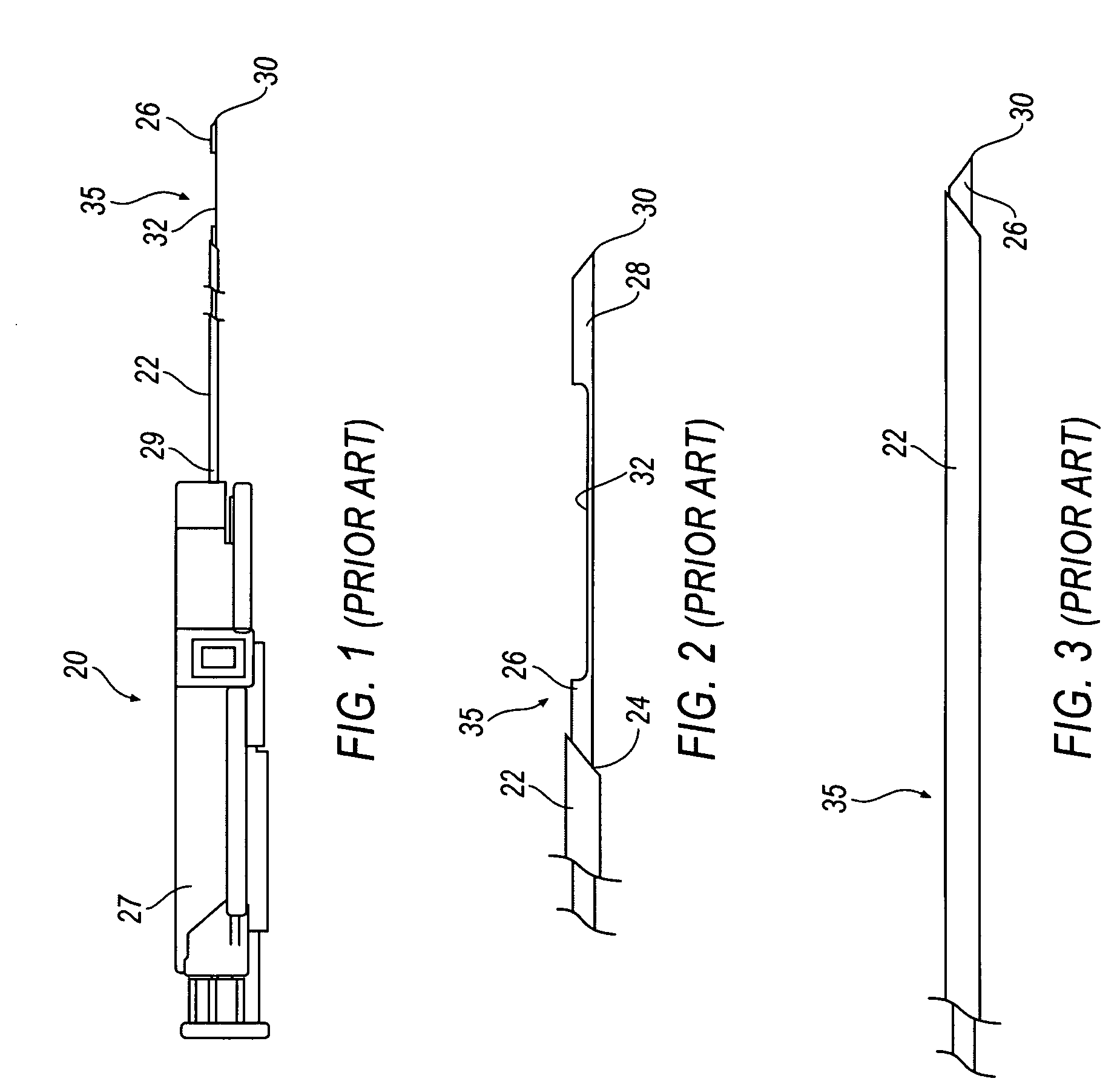

Method and apparatus for vacuum-assisted light-based treatments of the skin

InactiveUS20060259102A1Efficacy and utilityUltrasound therapyPneumatic massageVacuum assistedThree vessels

A method and apparatus are disclosed for enhancing the absorption of light in targeted skin structures and for the inhibition of pain transmission during light based treatments of the skin. After applying a vacuum to a vacuum chamber placed on a skin target and modulating the applied vacuum, the concentration of blood and / or blood vessels is increased within a predetermined depth below the skin surface of the skin target. Optical energy associated with light directed in a direction substantially normal to a skin surface adjoining the skin target is absorbed within the predetermined depth. The apparatus is suitable for treating vascular lesions with a reduced treatment energy density level than that of the prior art and for evacuating condensed vapors produced during the cooling of skin. The vacuum chamber may also have a skin flattening transmitting element which inhibits pain transmission upon applying a sufficiently high vacuum.

Owner:CANDELA CORP

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS7109114B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

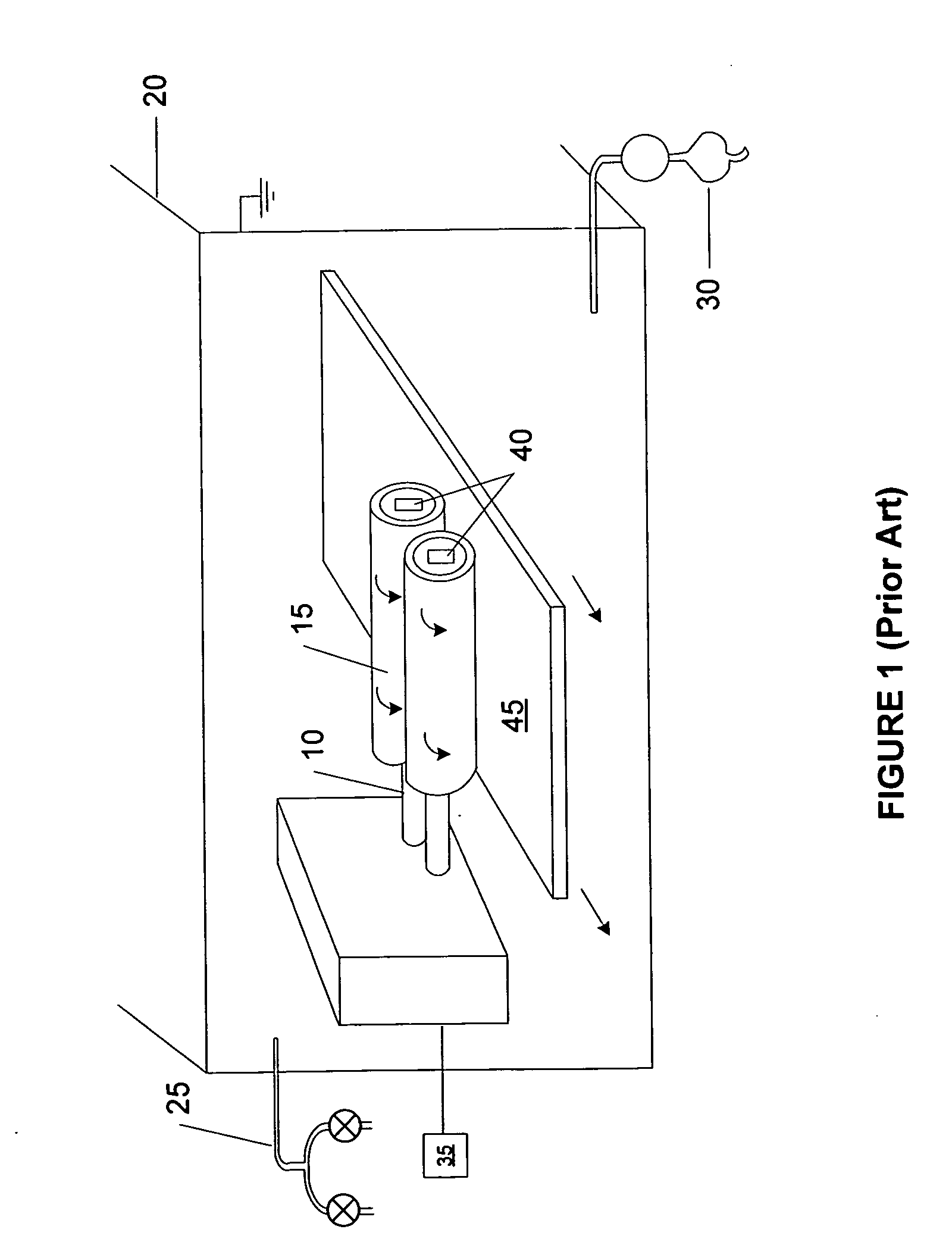

System and method for modulating power signals to control sputtering

One embodiment includes a sputtering system that includes a vacuum chamber; a substrate transport system configured to transport a substrate through the vacuum chamber; a cathode for supporting a sputtering target, the cathode at least partially inside the vacuum chamber; and a power supply configured to supply power to the cathode and the power supply configured to output a modulated power signal. Depending upon the implementation, the power supply can be configured to output an amplitude-modulated power signal; a frequency-modulated power signal; a pulse-width power signal; a pulse-position power signal; a pulse-amplitude modulated power signal; or any other type of modulated power or energy signal.

Owner:APPLIED MATERIALS INC

Vapor flow control apparatus for atomic layer deposition

A device for performing ALD includes a housing having a vacuum chamber that surrounds a horizontal flow reactor. The device further includes a gas distribution system for delivering gases to the reactor. The gas distribution system includes at least one of a high temperature valve and a high temperature filter disposed inside the vacuum chamber. The high temperature valve (and / or filter) controls (and / or filters) a supply of a precursor / reactant gas, inert gas, or precursor / reactant and inert gas mixture before it enters the horizontal flow reactor.

Owner:ASM IP HLDG BV

Film deposition device and substrate processing device

InactiveUS20110265725A1Improve throughputLow gas consumptionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReactive gasGas supply

A film deposition device includes a substrate transporting device arranged in a vacuum chamber to include a circulatory transport path in which substrate mounting parts arranged in a row are transported in a circulatory manner, the circulatory transport path including a linear transport path in which the substrate mounting parts are transported linearly. A first reactive gas supplying part is arranged along a transporting direction in which the substrate mounting parts are transported in the linear transport path, to supply a first reactive gas to the substrate mounting parts. A second reactive gas supplying part is arranged alternately with the first reactive gas supplying part along the transporting direction, to supply a second reactive gas to the substrate mounting parts. A separation gas supplying part is arranged to supply a separation gas to a space between the first reactive gas supplying part and the second reactive gas supplying part.

Owner:TOKYO ELECTRON LTD

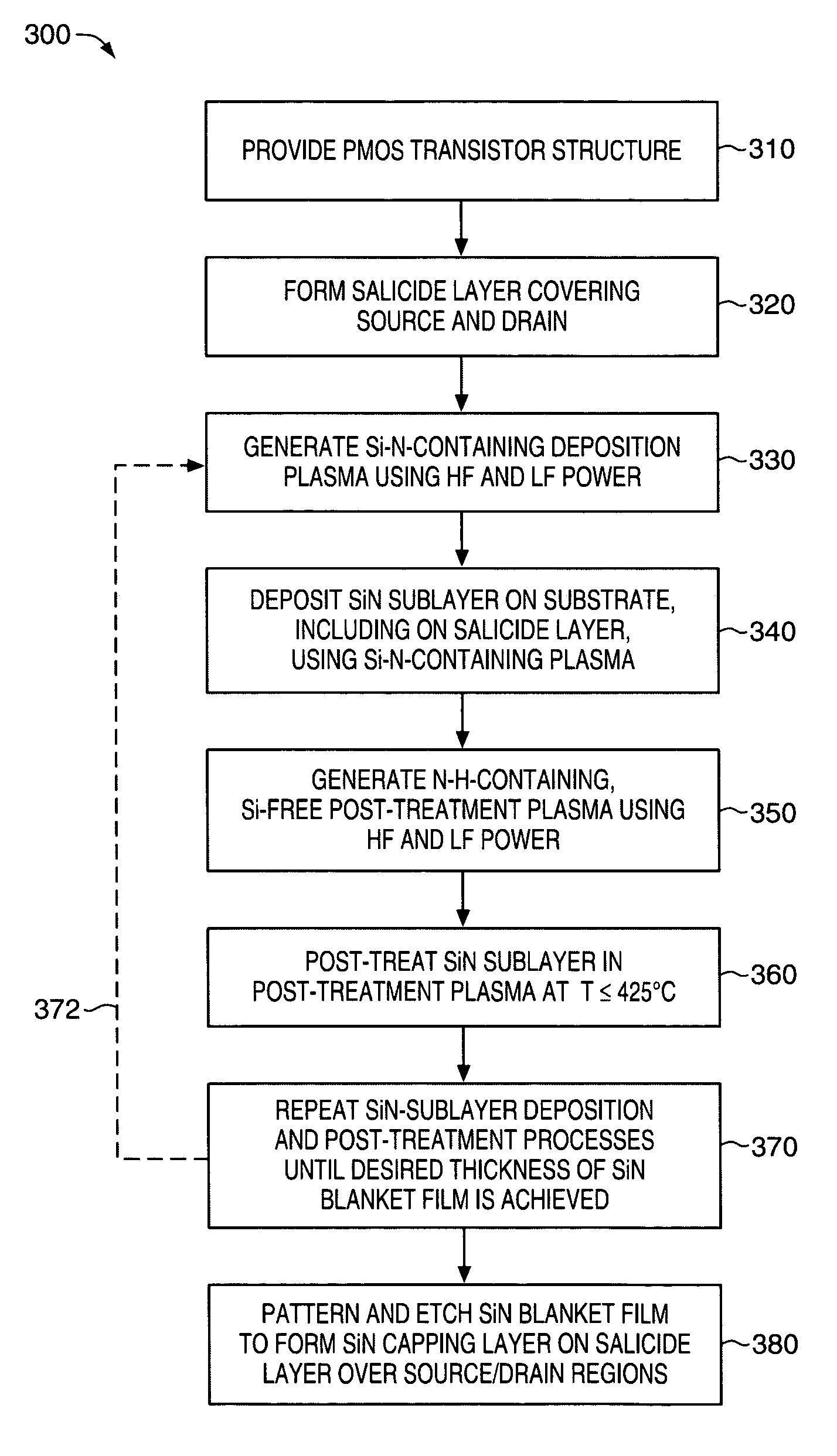

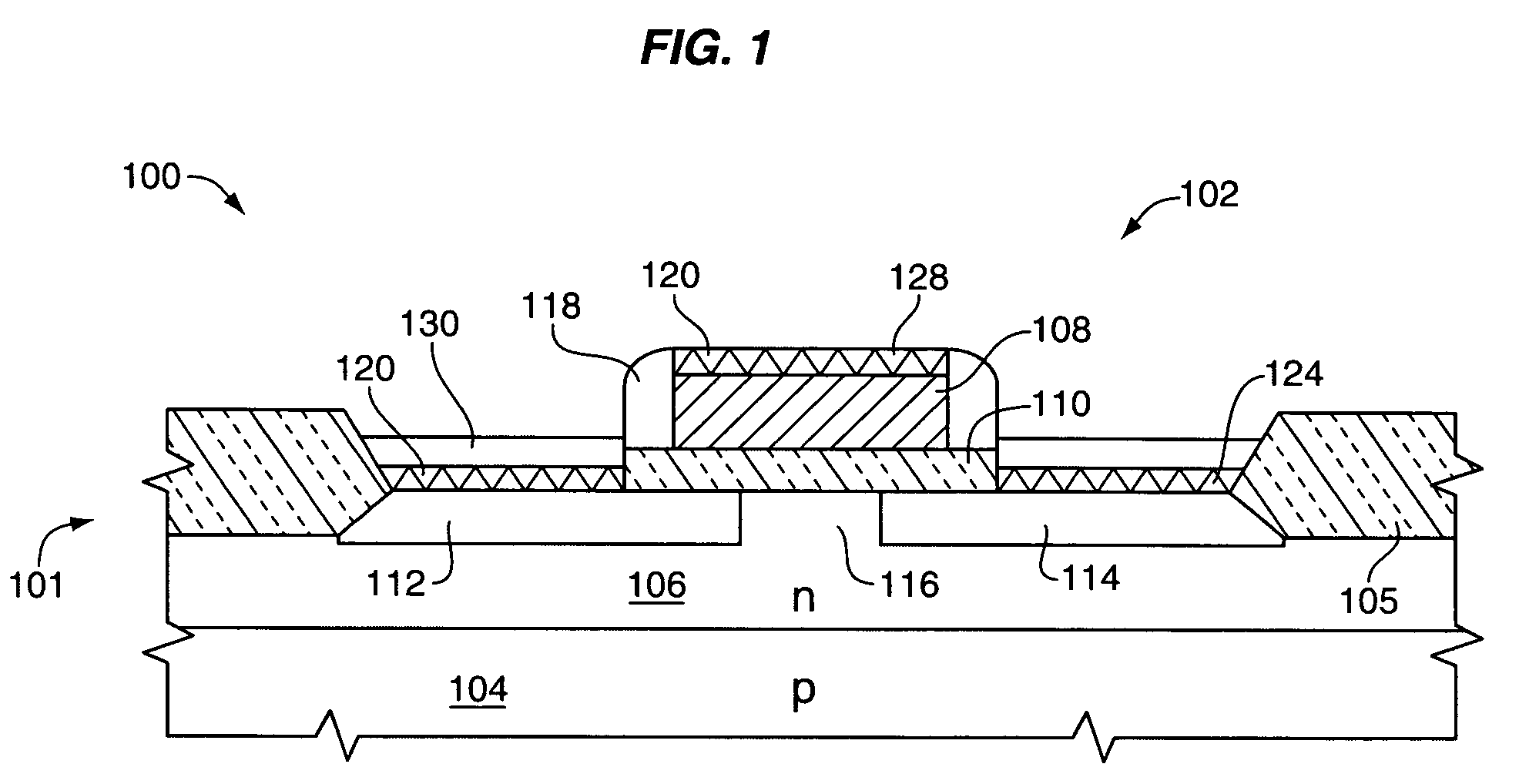

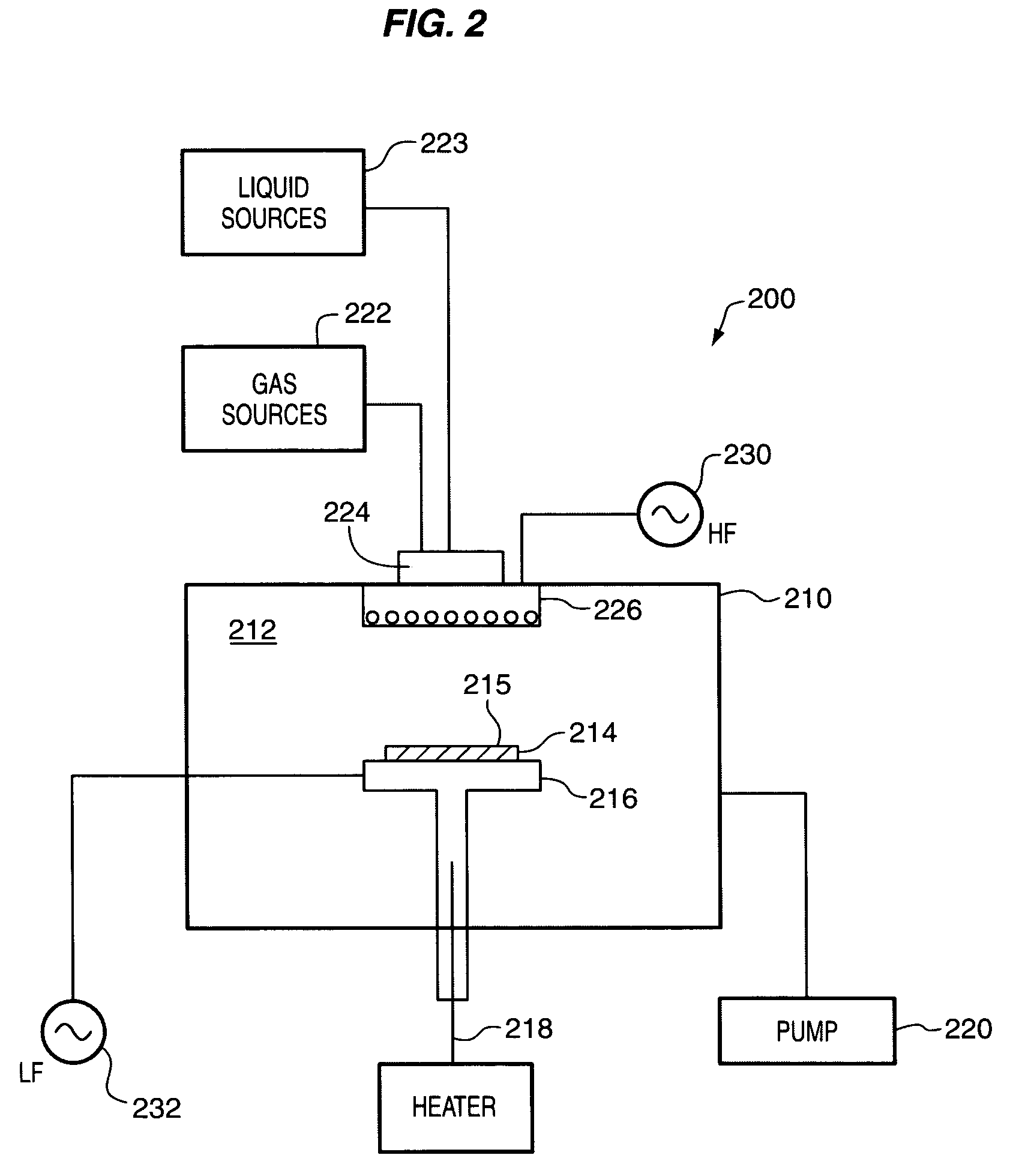

PMOS transistor with compressive dielectric capping layer

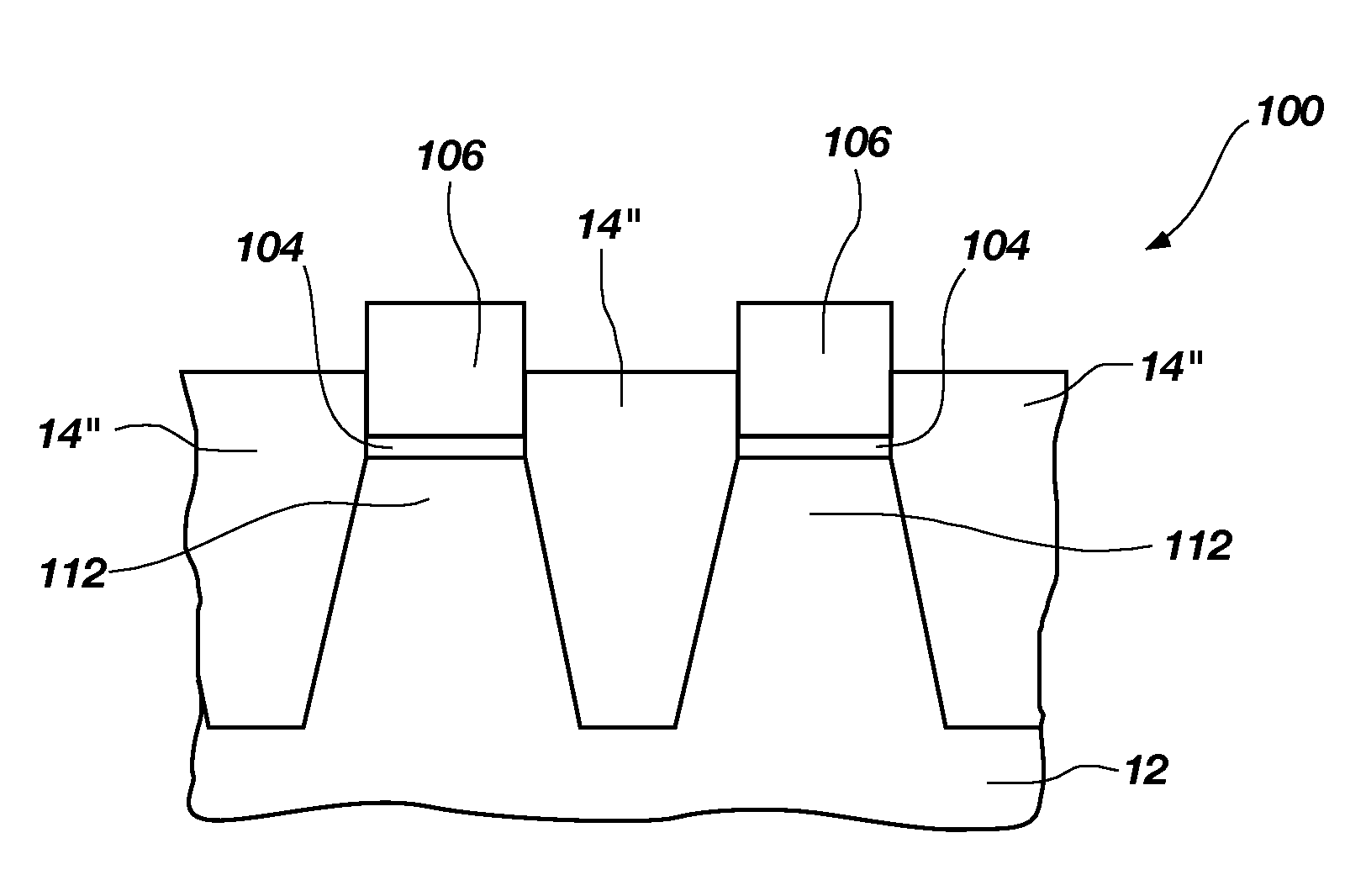

ActiveUS7214630B1Preserving material qualityImprove performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSalicideOxidation state

A salicide layer is deposited on the source / drain regions of a PMOS transistor. A dielectric capping layer having residual compressive stress is formed on the salicide layer by depositing a plurality of PECVD dielectric sublayers and plasma-treating each sublayer. Compressive stress from the dielectric capping layer is uniaxially transferred to the PMOS channel through the source-drain regions to create compressive strain in the PMOS channel. To form a compressive dielectric layer, a deposition reactant mixture containing A1 atoms and A2 atoms is provided in a vacuum chamber. Element A2 is more electronegative than element A1, and A1 atoms have a positive oxidation state and A2 atoms have a negative oxidation state when A1 atoms are bonded with A2 atoms. A deposition plasma is generated by applying HF and LF radio-frequency power to the deposition reactant mixture, and a sublayer of compressive dielectric material is deposited. A post-treatment plasma is generated by applying HF and LF radio-frequency power to a post-treatment gas that does not contain at least one of A1 atoms and A2 atoms. Compressive stress in the dielectric sublayer is increased by treating the sublayer in the post-treatment plasma. Processes of depositing a dielectric sublayer and post-treating the sublayer in plasma are repeated until a desired thickness is achieved. The resulting dielectric layer has residual compressive stress.

Owner:NOVELLUS SYSTEMS

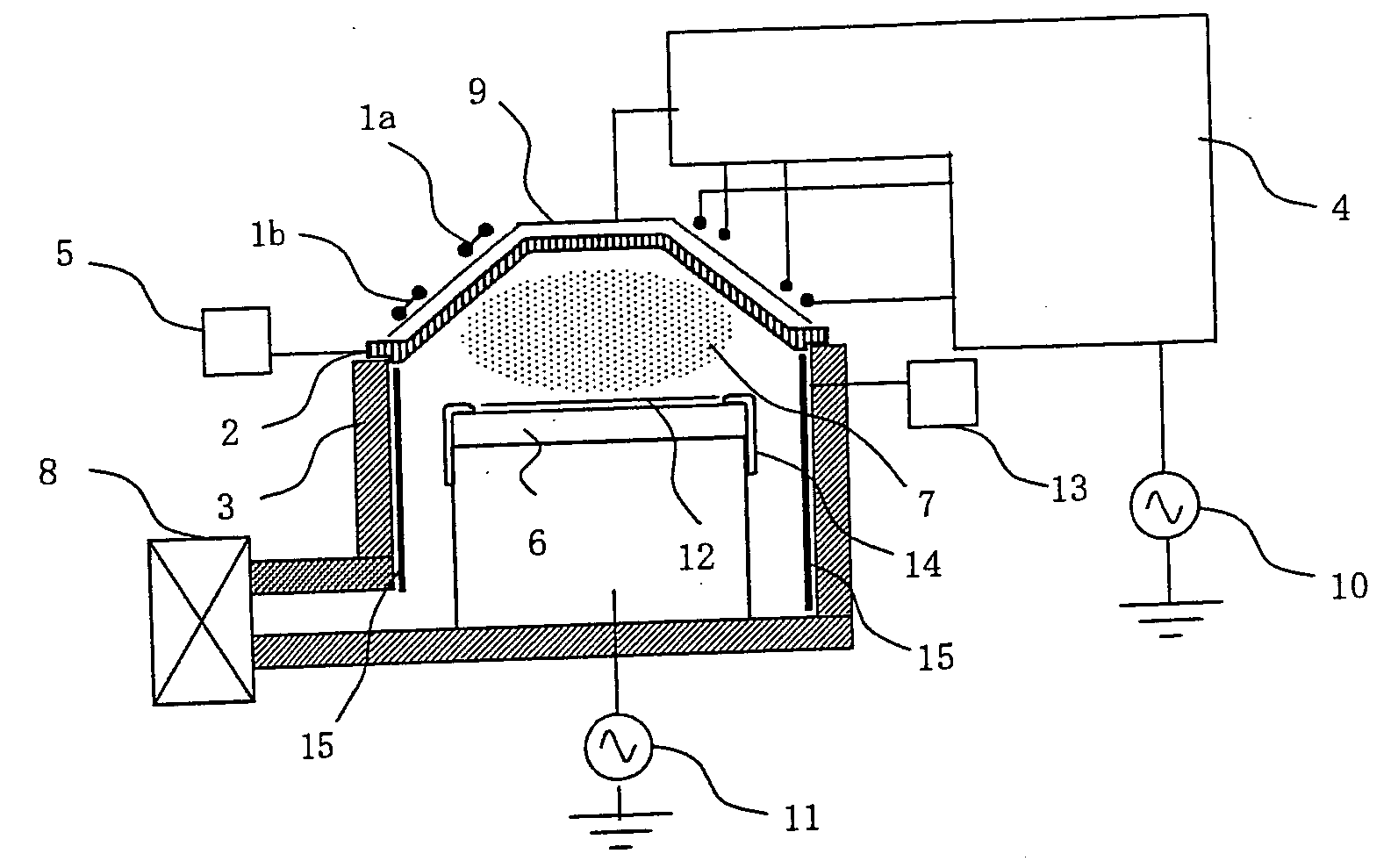

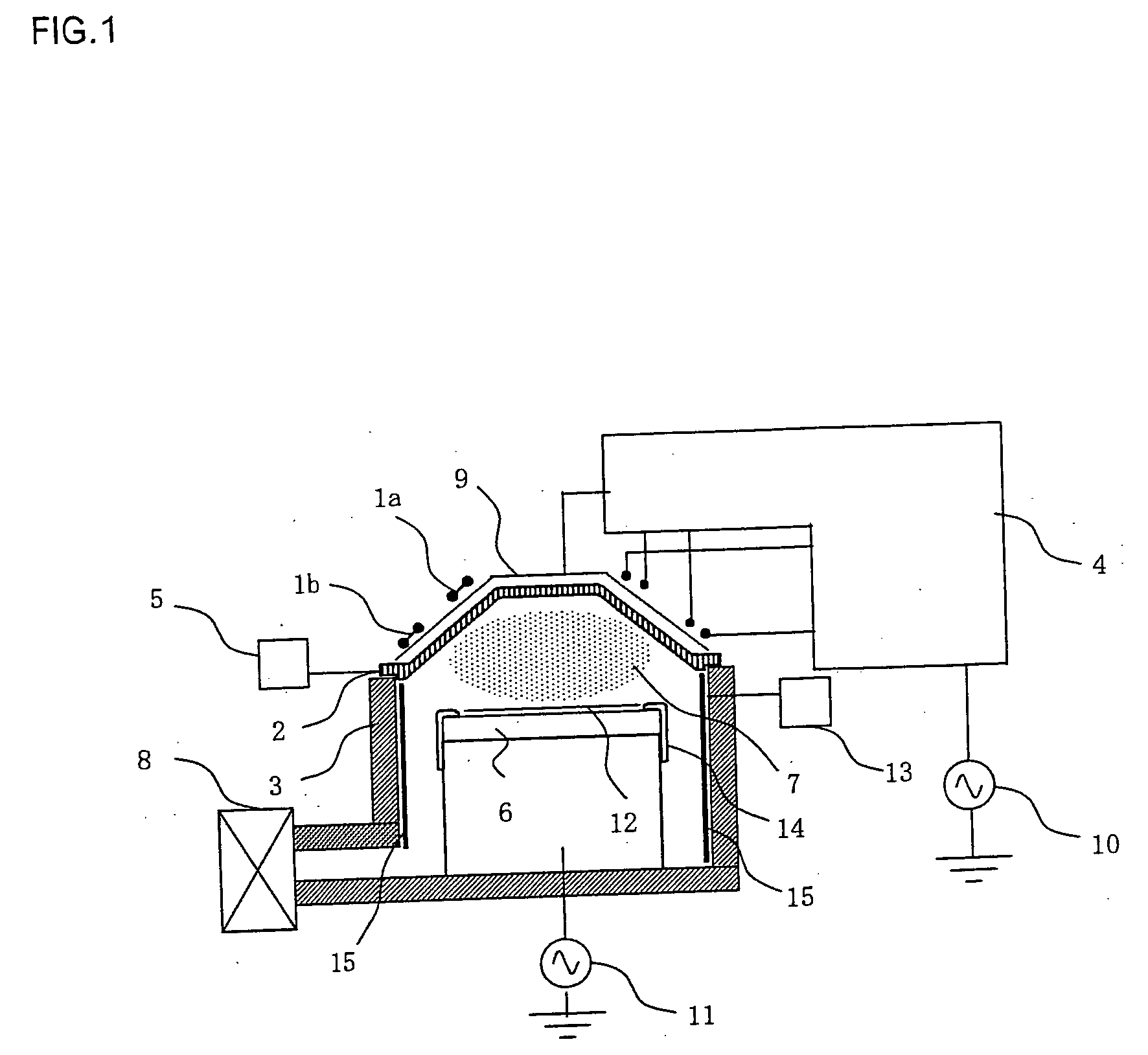

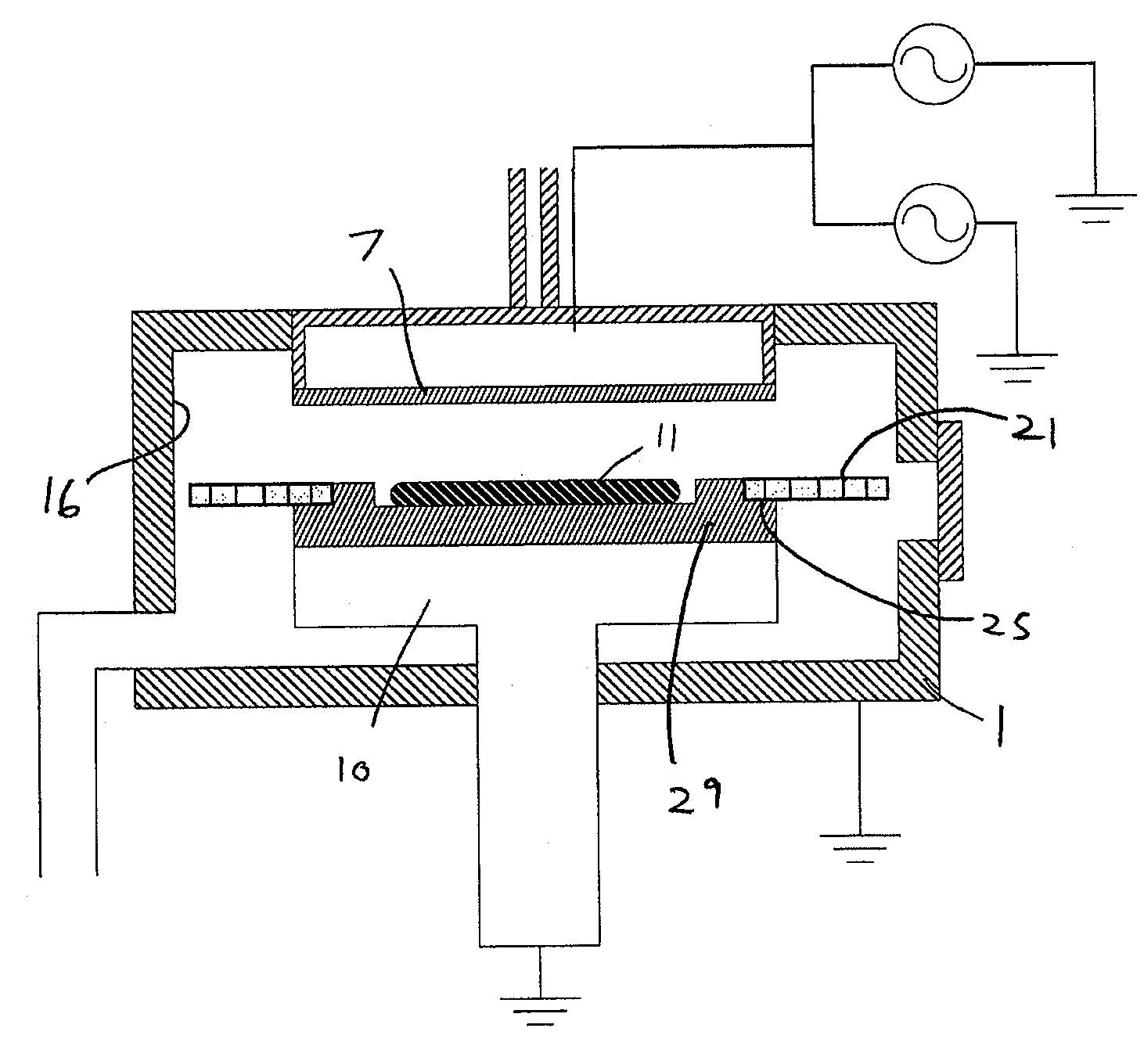

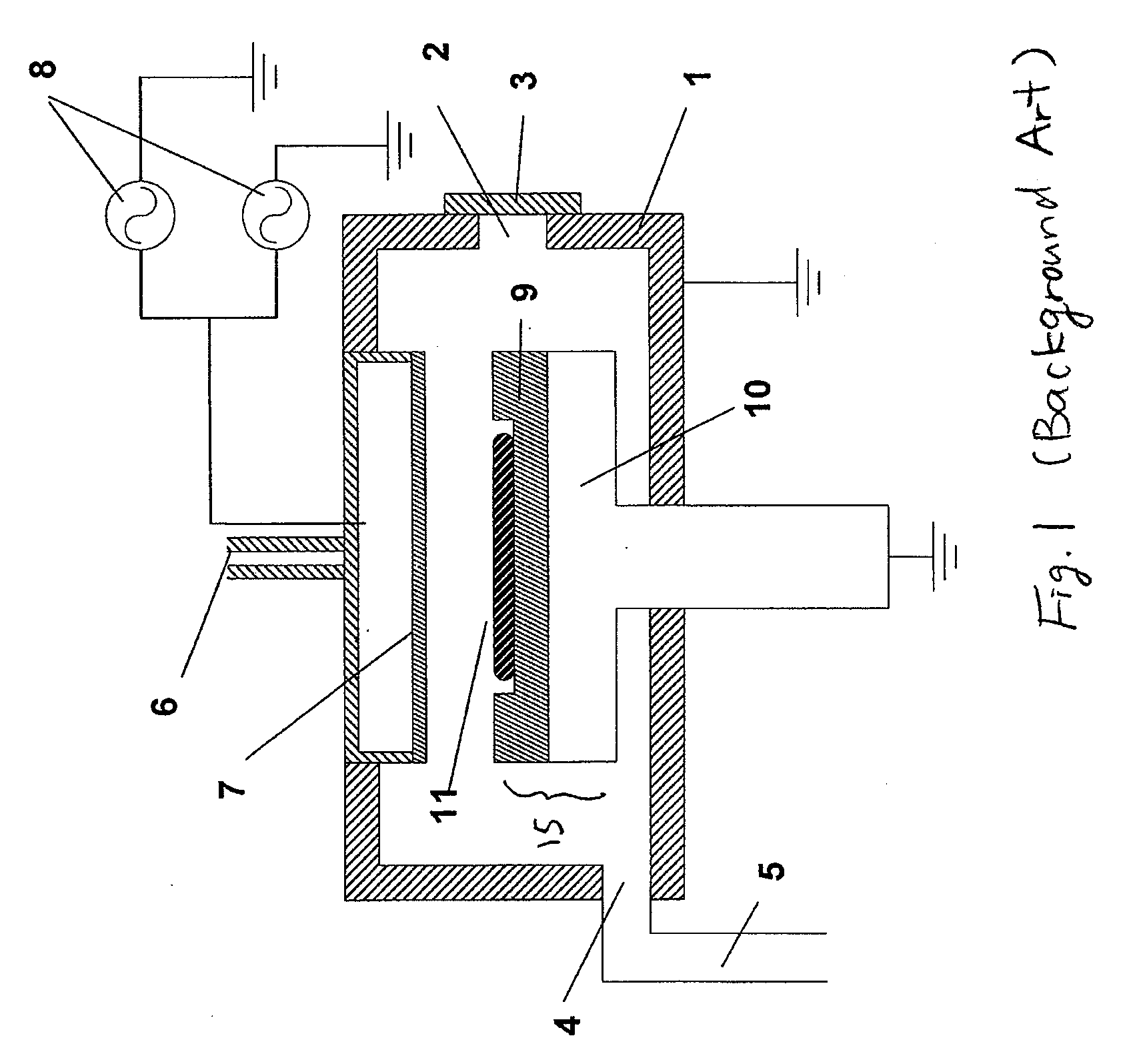

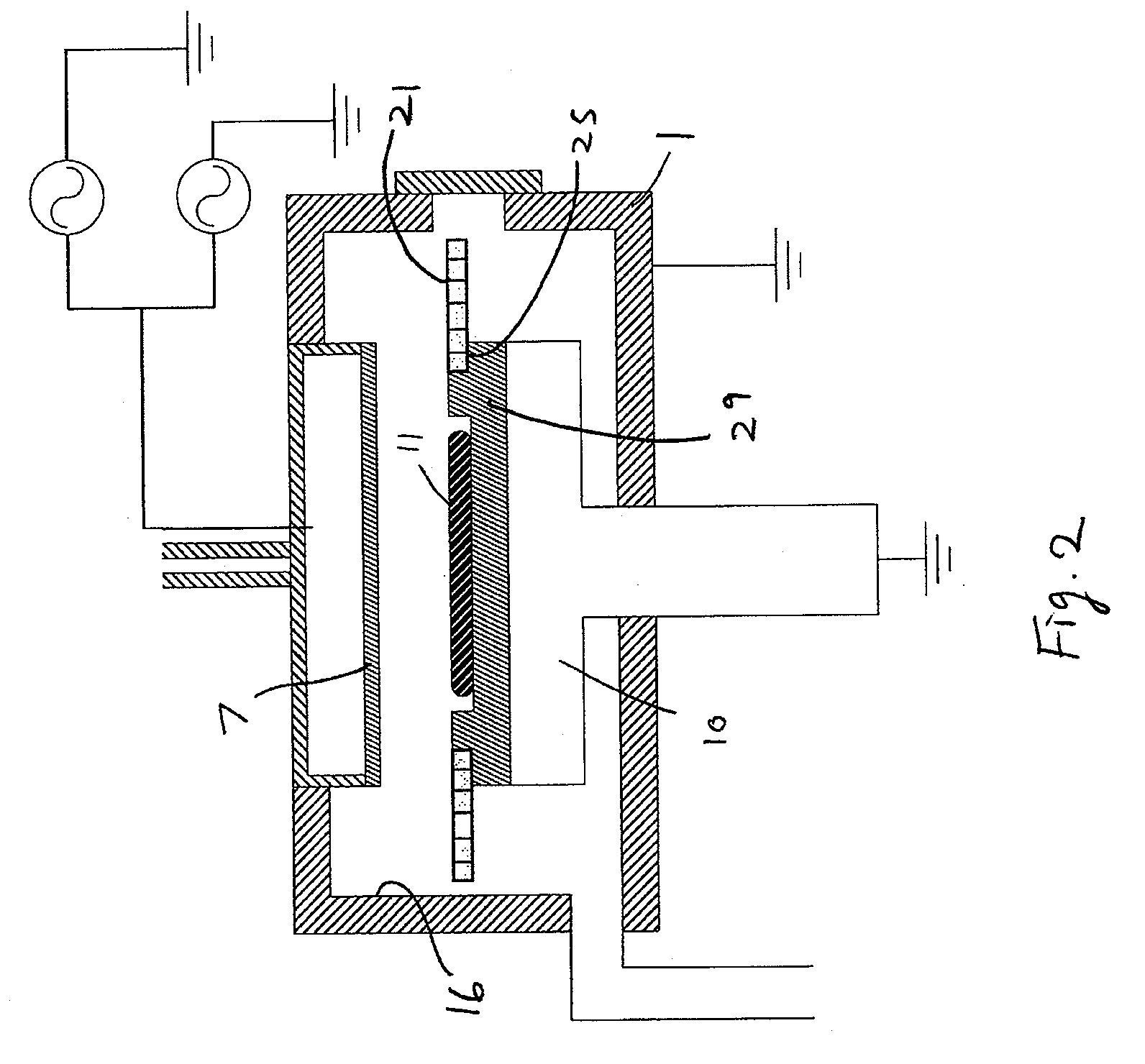

Plasma CVD apparatus equipped with plasma blocking insulation plate

InactiveUS20070266945A1Floating potentialControl areaElectric discharge tubesChemical vapor deposition coatingSusceptorEngineering

A plasma CVD apparatus for forming a thin film on a substrate includes: a vacuum chamber; an upper electrode; a susceptor as a lower electrode; and a ring-shaped insulation plate disposed in a gap between the susceptor and an inner wall of the chamber in the vicinity of or in contact with the susceptor to minimize a floating potential charged on the substrate while processing the substrate.

Owner:ASM JAPAN

Manufacturing Apparatus and Manufacturing Method of Lighting Device

InactiveUS20100236691A1Improve efficiencyReduce manufacturing costVacuum evaporation coatingSolid-state devicesInter layerManufactured apparatus

A manufacturing apparatus of a lighting device, including a vacuum chamber, an exhaust system by which the vacuum chamber is set to a reduced-pressure state, and a transfer chamber from which a substrate is transferred to the vacuum chamber is provided. The vacuum chamber of the manufacturing apparatus includes a plurality of deposition chambers in which a first electrode, a first light-emitting unit including at least a light-emitting layer, an intermediate layer, a second light-emitting unit including at least a light-emitting layer, a second electrode, a sealing film are formed, and a substrate transfer means by which the substrate is sequentially transferred to the deposition chambers.

Owner:SEMICON ENERGY LAB CO LTD

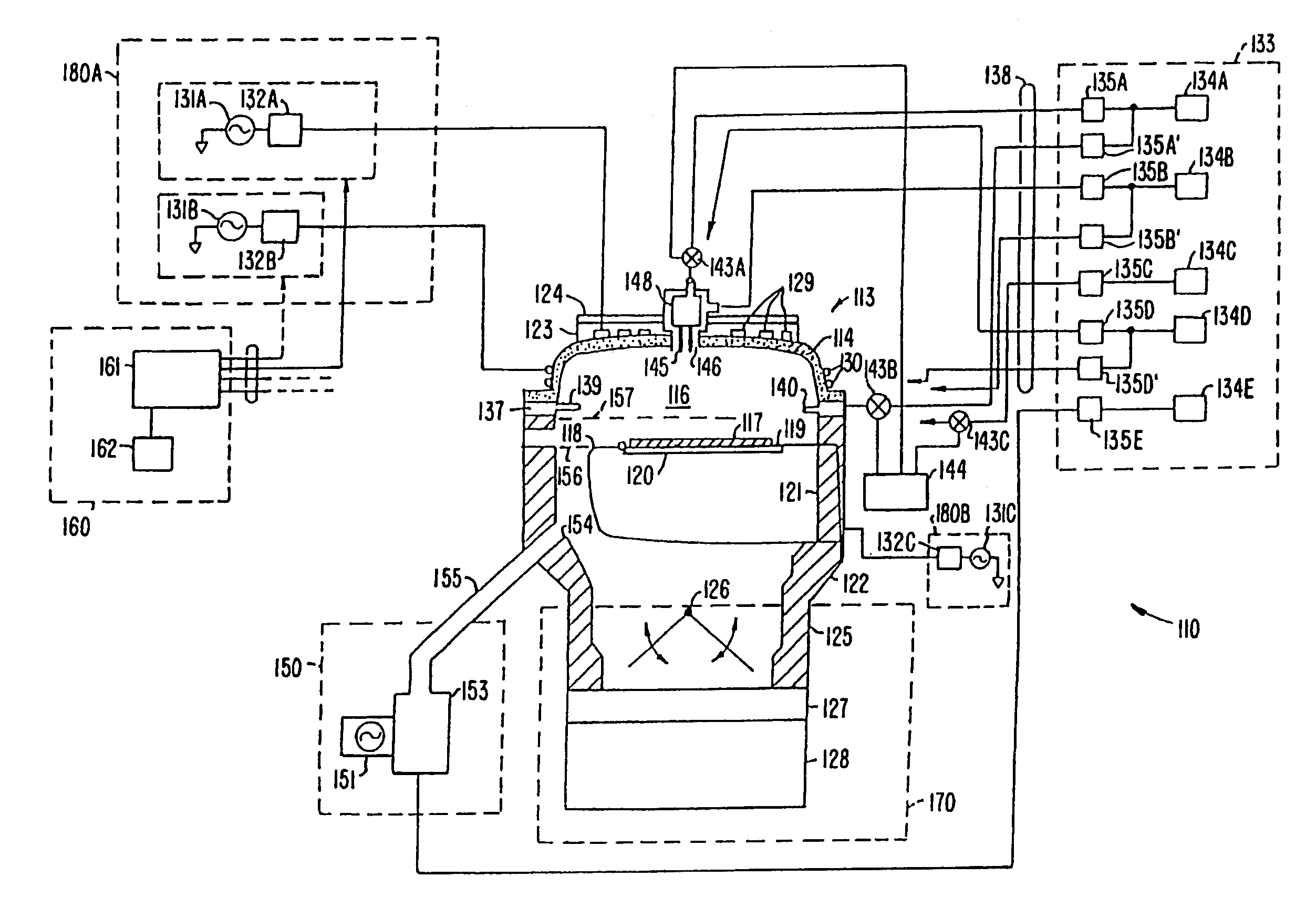

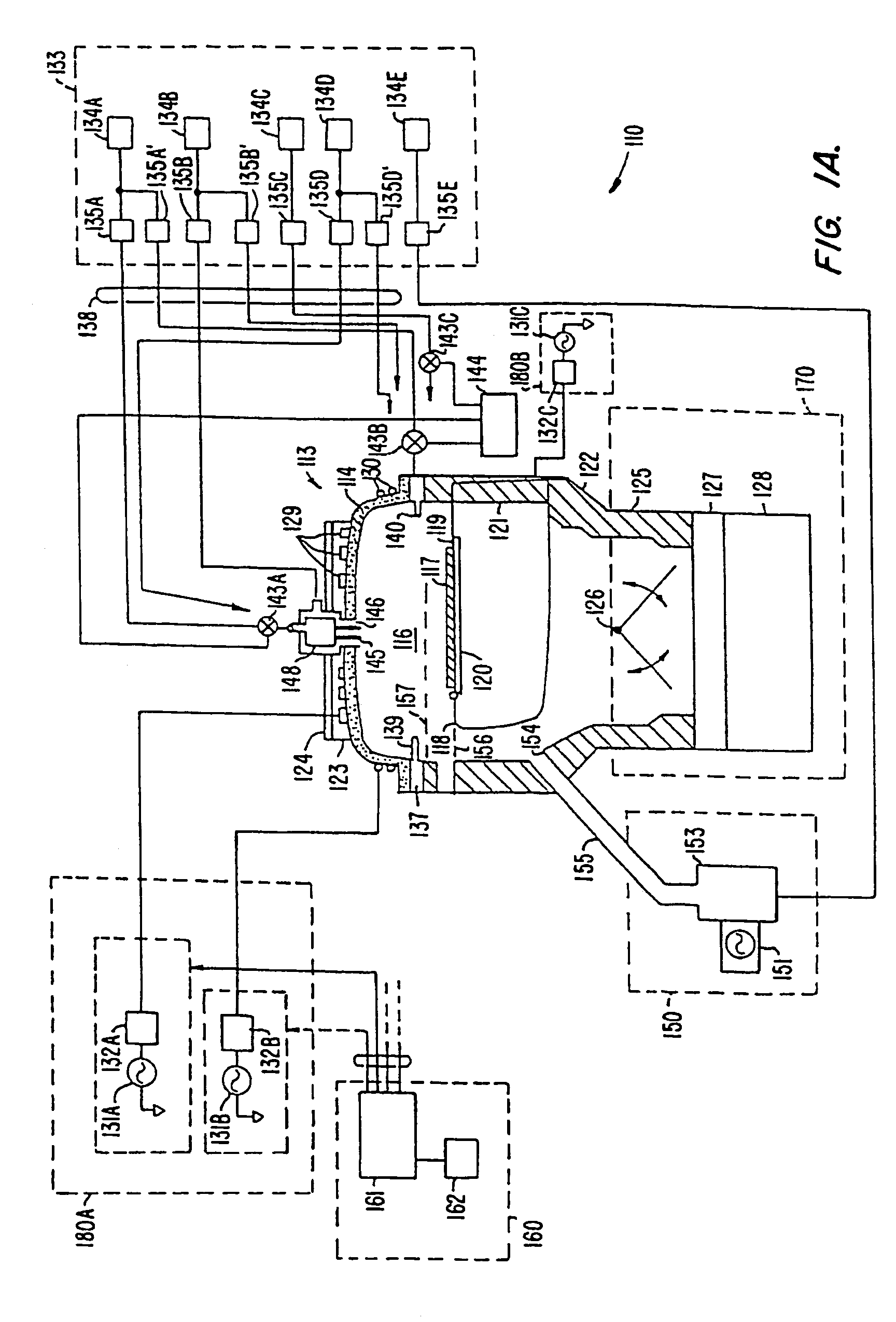

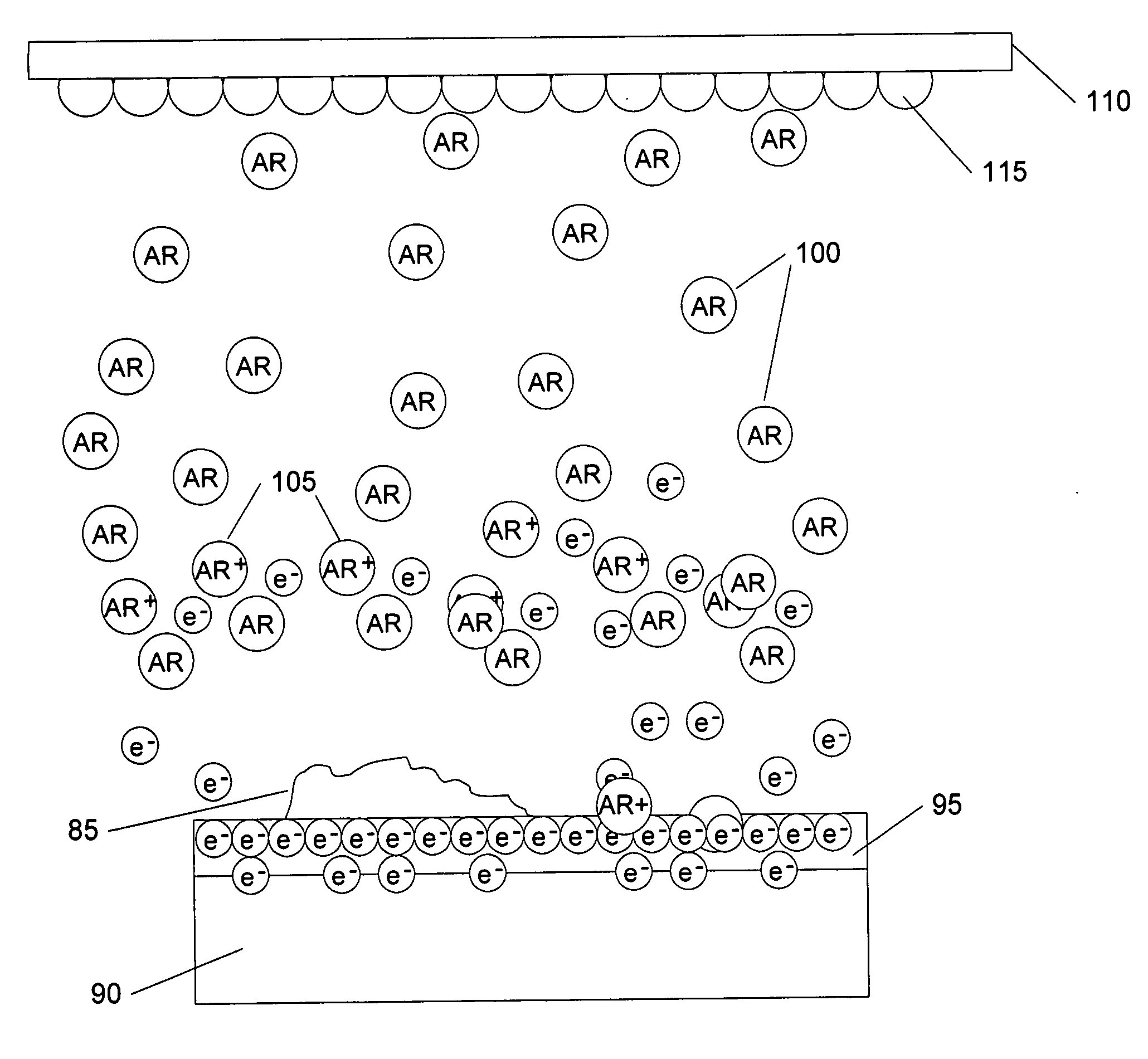

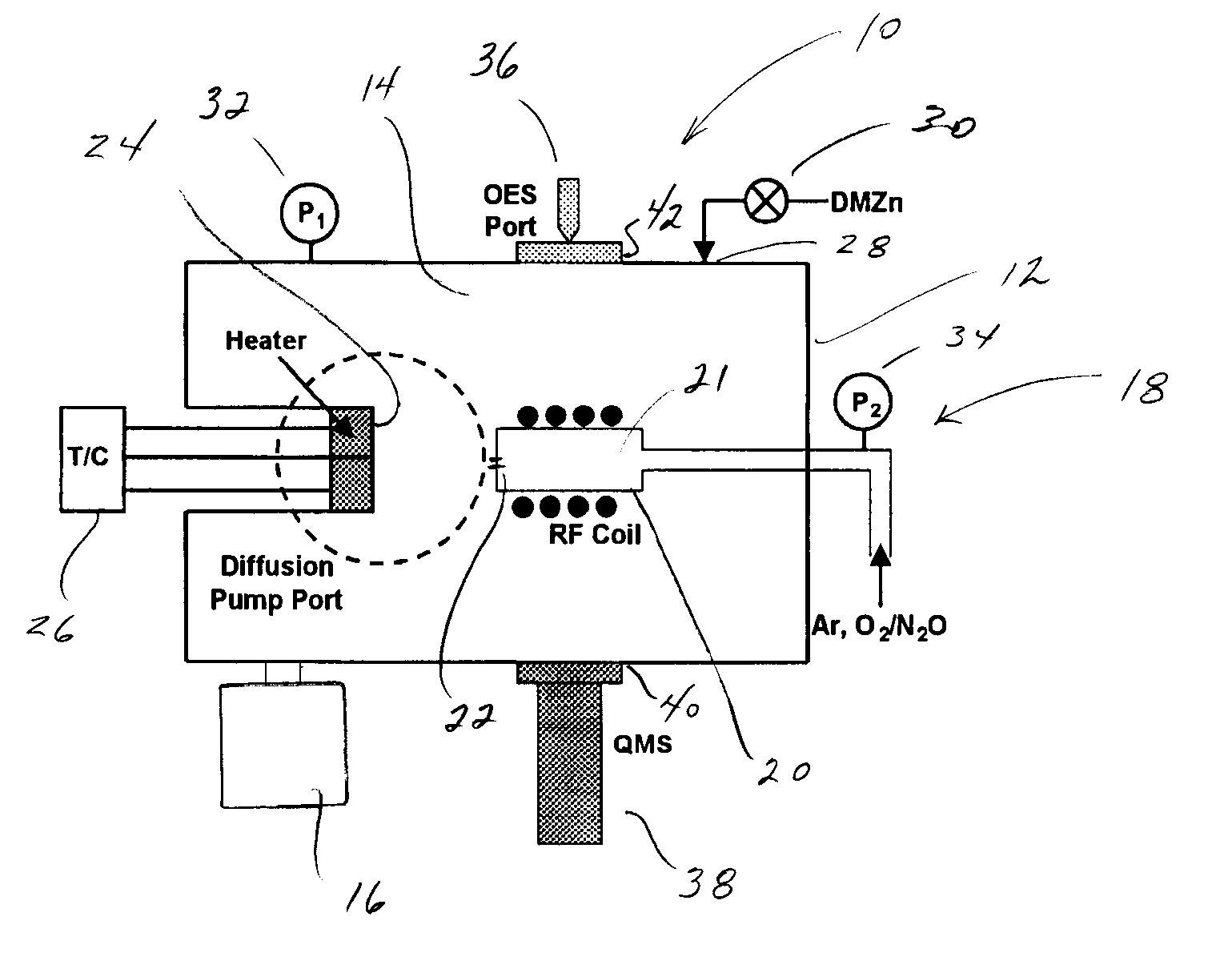

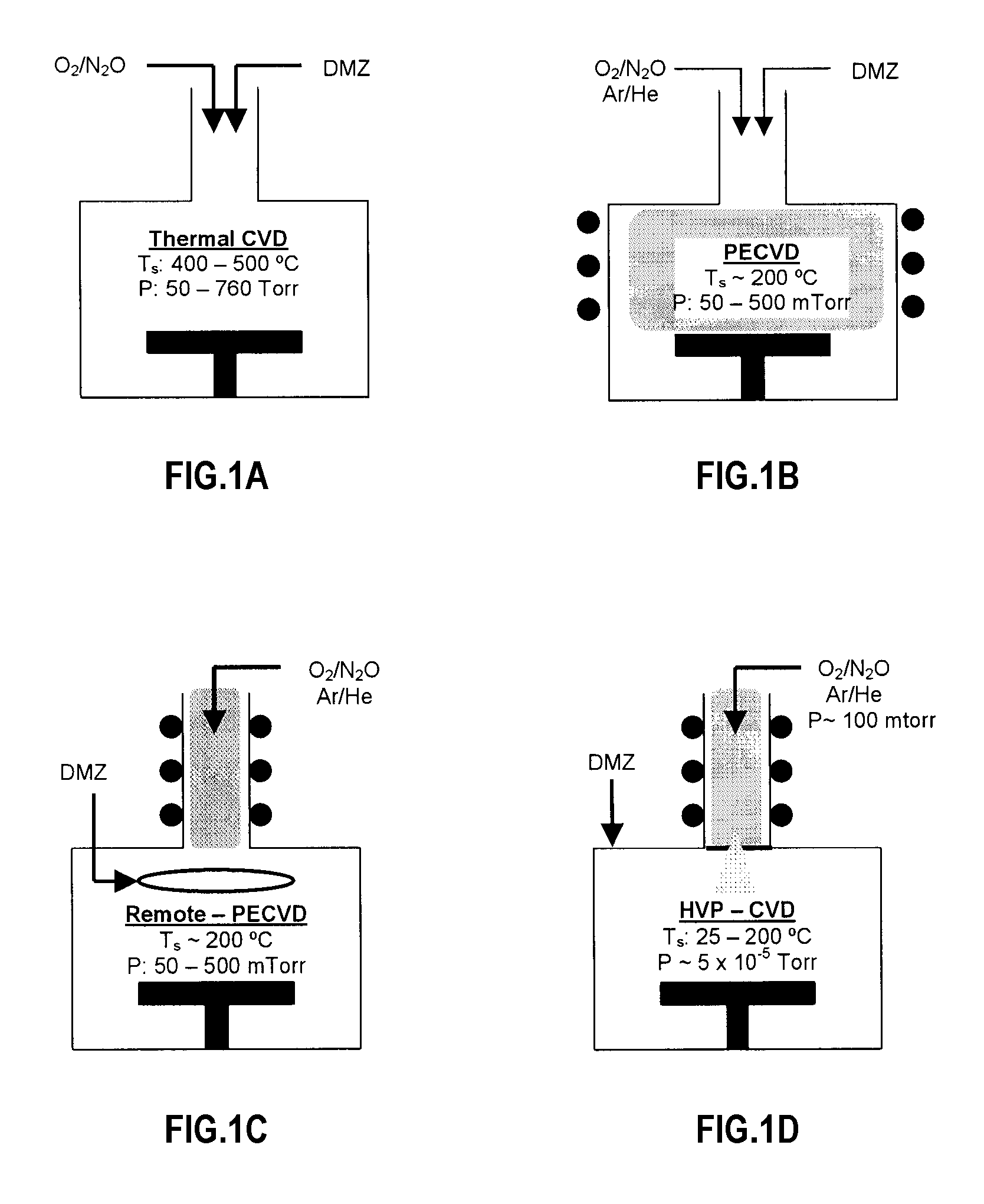

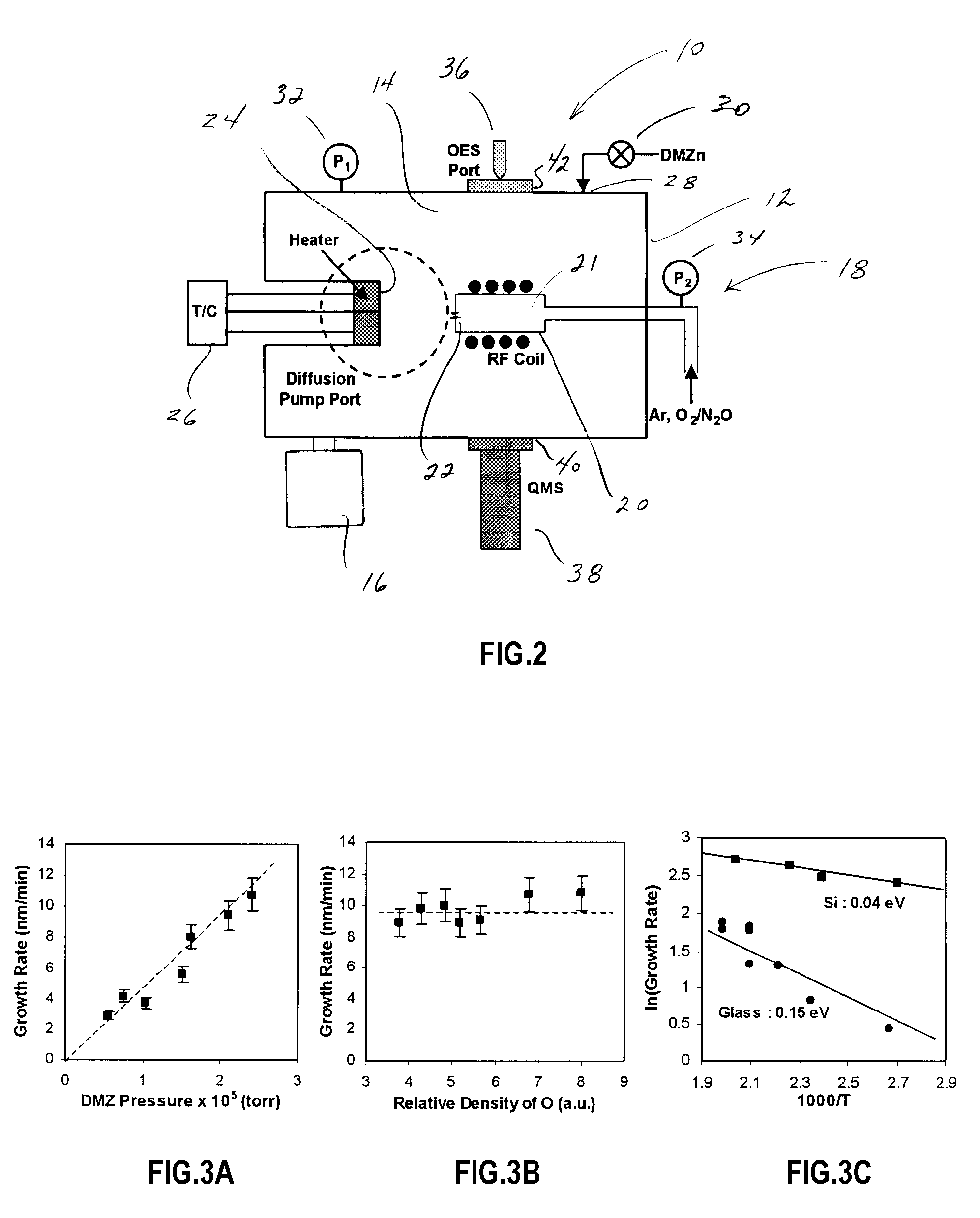

High Vacuum Plasma-Assisted Chemical Vapor Deposition System

The invention is directed to a novel approach to thin film synthesis that is described as high vacuum plasma-assisted chemical vapor deposition (HVP-CVD). In one application of HVP-CVD, atomic oxygen and organometallic precursors are simultaneously introduced into a high vacuum chamber. Gas-phase chemistry is eliminated or substantially eliminated in the collisionless or substantially collisionless environment, allowing the surface chemistry between atomic oxygen and the precursor(s) to be interrogated directly. In preliminary work it has been observed that the presence of atomic oxygen greatly accelerates the desorption of organic ligands, facilitating oxide formation. The prominent advantages of the HVP-CVD include reduced substrate temperature, significant rates, inherent uniformity, facilitated doping, and the ability to directly study these processes in-situ with high vacuum diagnostics that are not compatible with conventional CVD technologies.

Owner:COLORADO SCHOOL OF MINES

Film deposition apparatus, substrate processing apparatus, film deposition method, and storage medium

ActiveUS20100055316A1Improve throughputSatisfy processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas supplyVacuum chamber

A film deposition apparatus to form a thin film by supplying first and second reaction gases within a vacuum chamber includes a turntable, a protection top plate, first and second reaction gas supply parts extending from a circumferential edge towards a rotation center of the turntable, and a separation gas supply part provided therebetween. First and second spaces respectively include the first and second reaction gas supply parts and have heights H1 and H2. A third space includes the separation gas supply part and has a height H3 lower than H1 and H2. The film deposition apparatus further includes a vacuum chamber protection part which surrounds the turntable and the first, second and third spaces together with the protection top plate to protect the vacuum chamber from corrosion.

Owner:TOKYO ELECTRON LTD

Microfluidic actuator

InactiveUS6521188B1Easy to prepareLow costCircuit elementsPressure pumpsEngineeringAtmospheric pressure

A simple microfluidic actuator includes a sealed vacuum chamber actuated by providing a current to a thin film heater, which in turn weakens and, under the atmospheric pressure differential, breaks a diaphragm sealing said vacuum chamber whereby the vacuum inside said chamber is released. By applying the microfluidic actuator to a microfluidic network the resulting pressure differential can be used to generate a pumping force with the microfluidic network. The chamber may be prepared in a silicon, glass, or plastic substrate. The diaphragm may be a metallic gas-impermeable film. A releasing member comprising a thin-film metallic heater is then microfabricated on the diaphragm. The assembly so prepared may be bonded to a glass or plastic substrate that contains a network of microchannels. The microfluidic actuator is suited for a microfluidic platform in generating driving powers for operations including pumping, metering, mixing and valving of liquid samples.

Owner:IND TECH RES INST

Film deposition apparatus, substrate processing apparatus, film deposition method, and storage medium

ActiveUS9267204B2Improve throughputAvoid mixingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringVacuum chamber

A film deposition apparatus to form a thin film by supplying first and second reaction gases within a vacuum chamber includes a turntable, a protection top plate, first and second reaction gas supply parts extending from a circumferential edge towards a rotation center of the turntable, and a separation gas supply part provided therebetween. First and second spaces respectively include the first and second reaction gas supply parts and have heights H1 and H2. A third space includes the separation gas supply part and has a height H3 lower than H1 and H2. The film deposition apparatus further includes a vacuum chamber protection part which surrounds the turntable and the first, second and third spaces together with the protection top plate to protect the vacuum chamber from corrosion.

Owner:TOKYO ELECTRON LTD

Hybrid polymer film

InactiveUS6083628AFine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer. A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-linked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

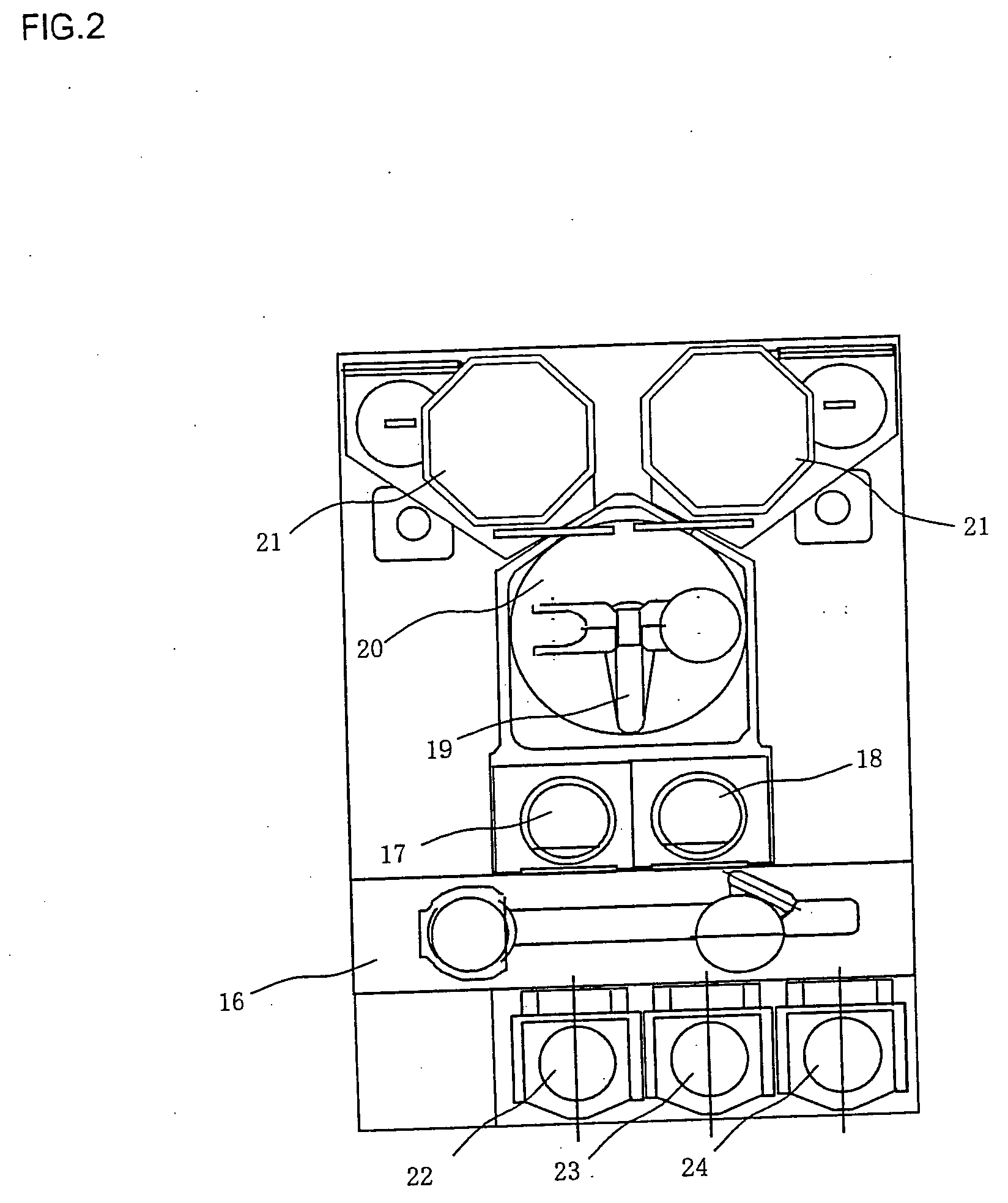

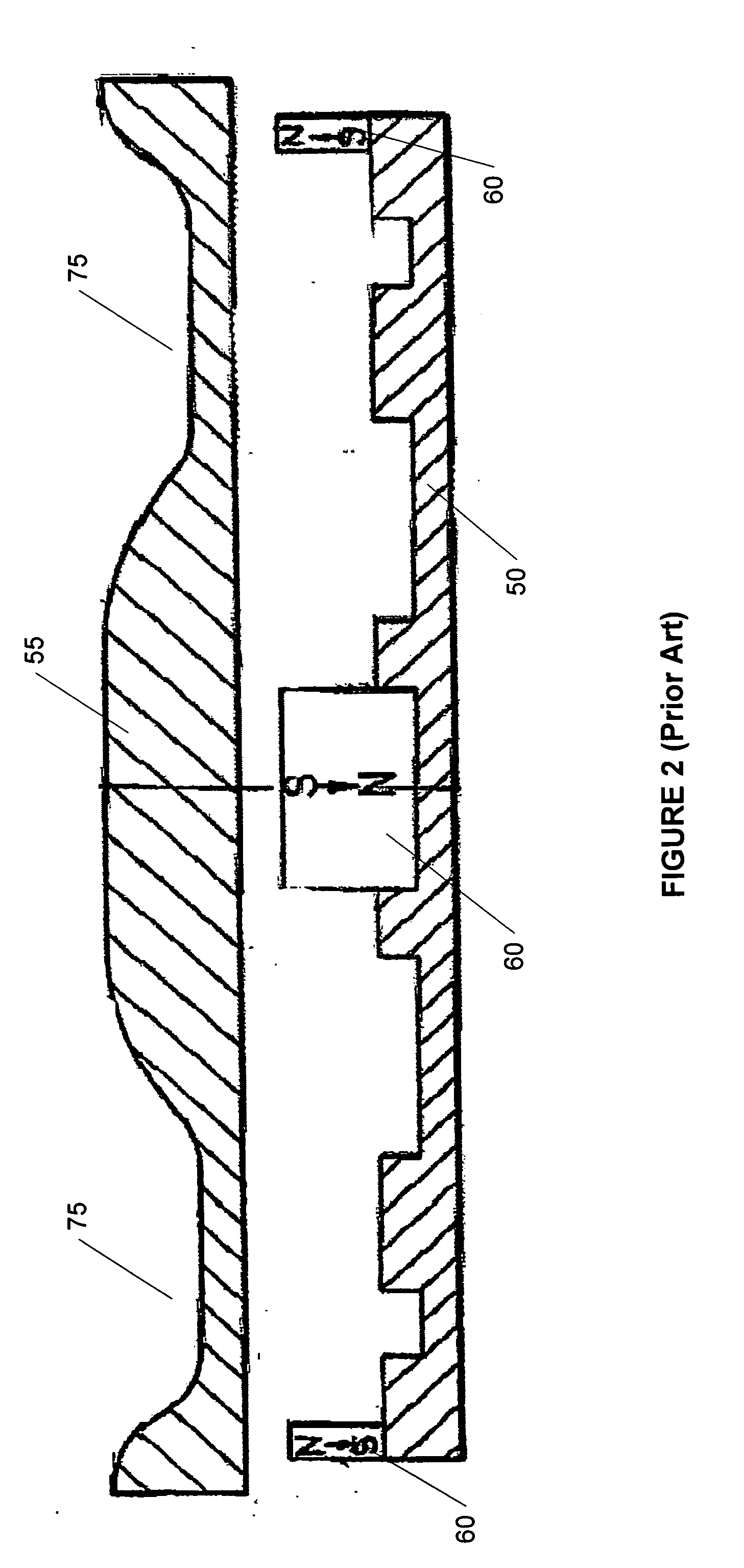

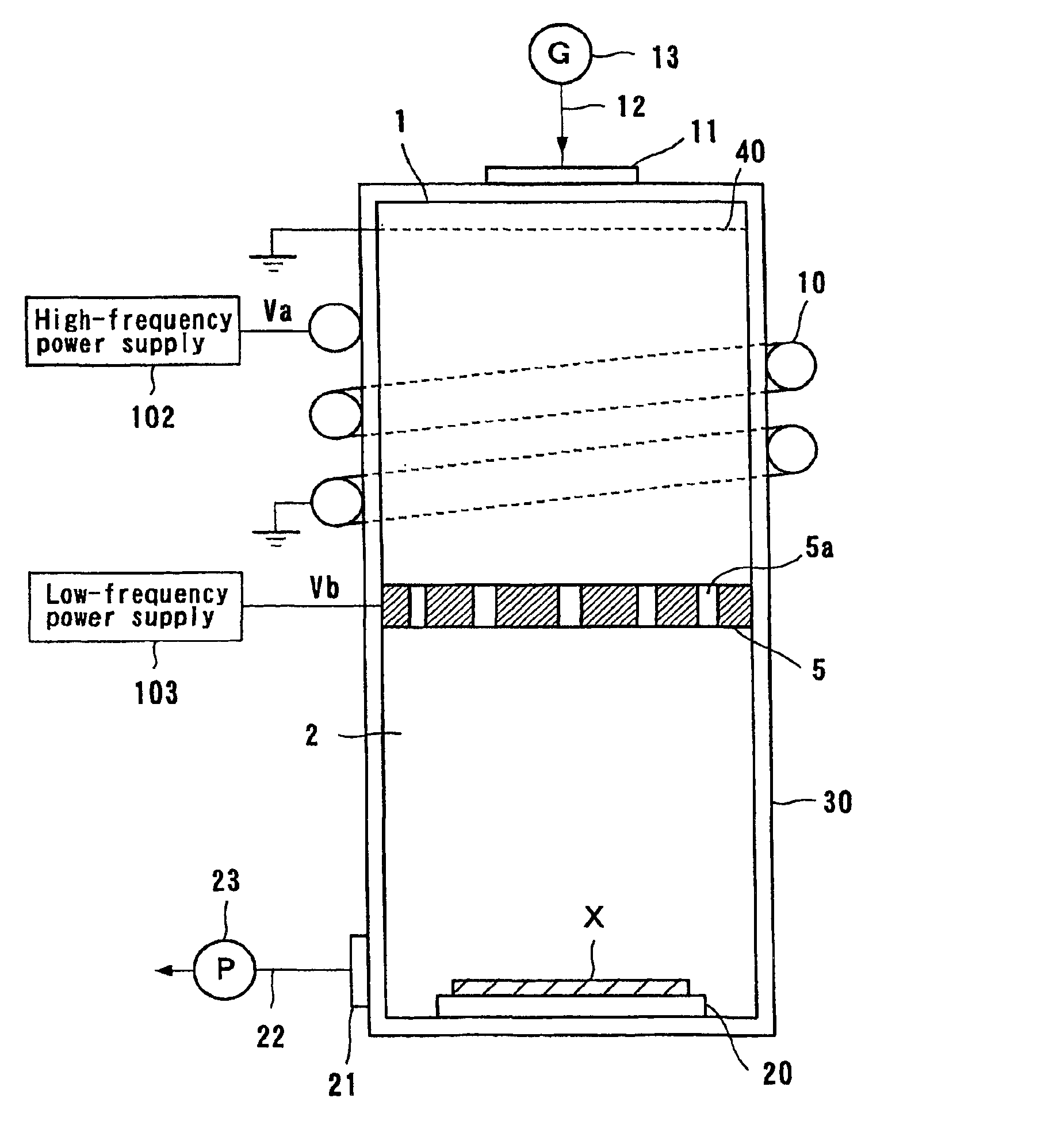

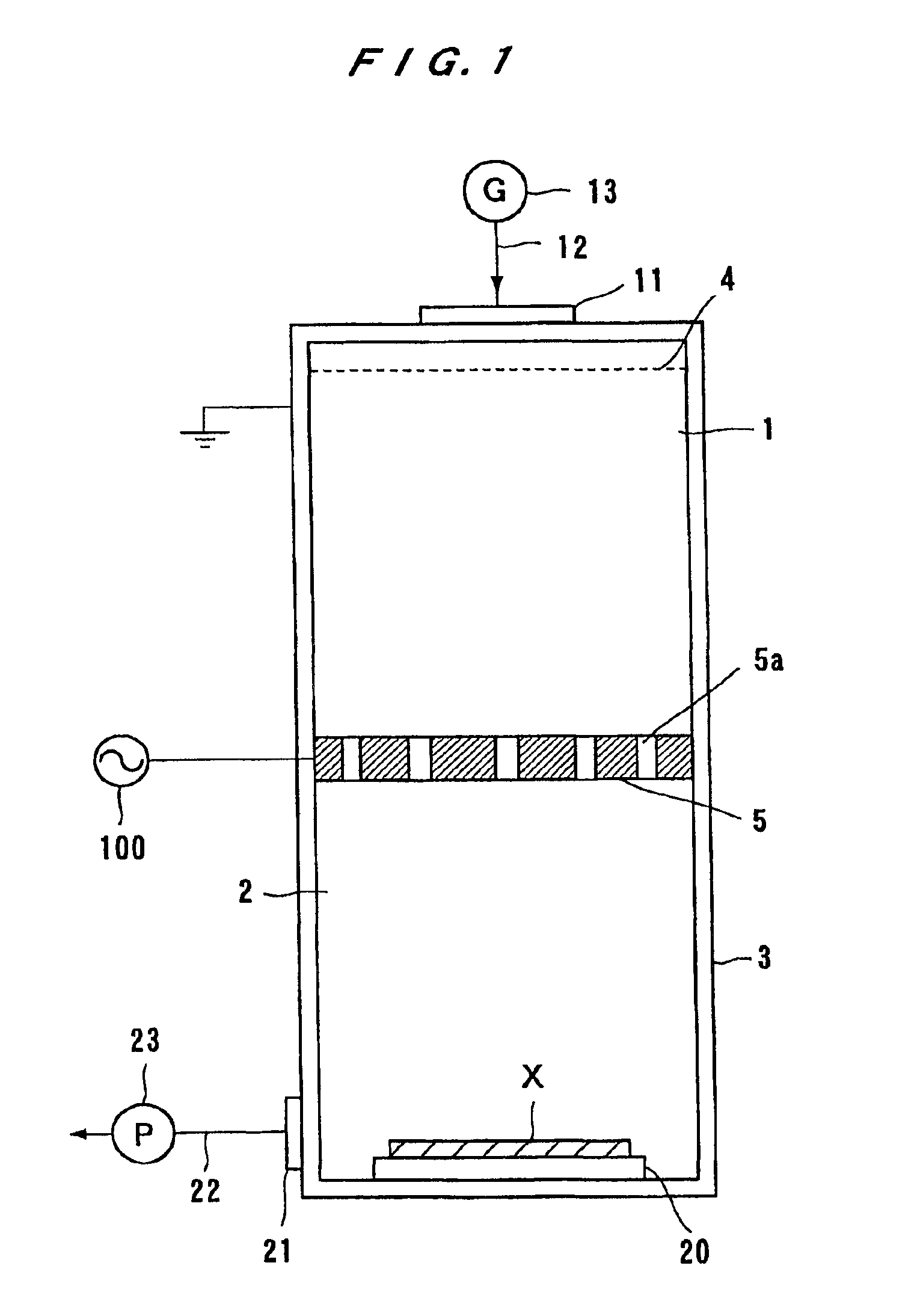

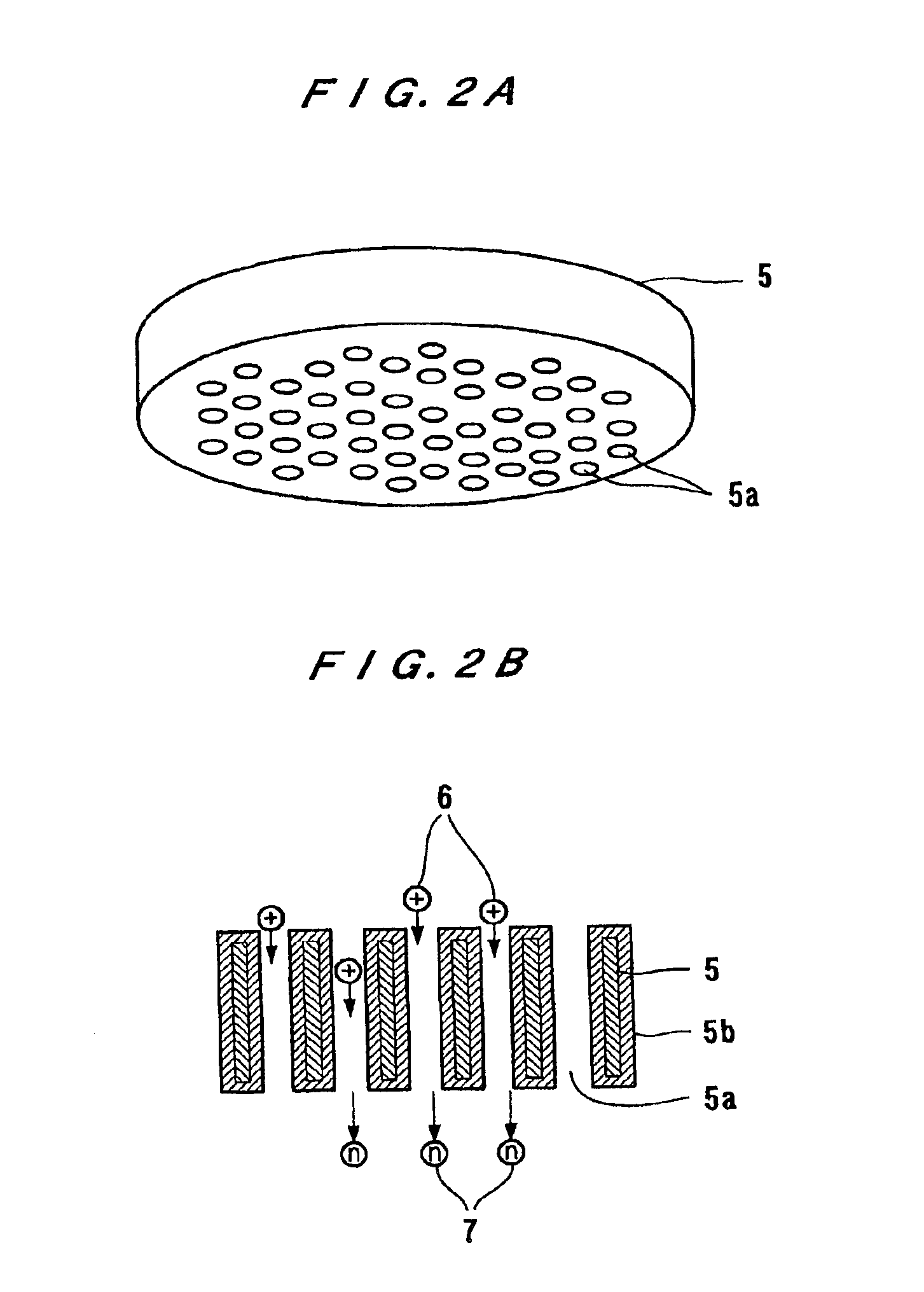

Neutral particle beam processing apparatus

InactiveUS6861642B2Inexpensive and compact structureImprove neutralization efficiencyLaser detailsVacuum evaporation coatingDielectricPlasma generator

A neutral particle beam processing apparatus comprises a workpiece holder (20) for holding a workpiece (X), a plasma generator for generating a plasma in a vacuum chamber (3), an orifice electrode (5) disposed between the workpiece holder (20) and the plasma generator, and a grid electrode (4) disposed upstream of the orifice electrode (5) in the vacuum chamber (3). The orifice electrode (5) has orifices (5a) defined therein. The neutral particle beam processing apparatus further comprises a voltage applying unit for applying a voltage between the orifice electrode (5) and the grid electrode (4) via a dielectric (5b) to extract positive ions from the plasma generated by the plasma generator and pass the extracted positive ions through the orifices (5a) in the orifice electrode (5).

Owner:ASM IP HLDG BV

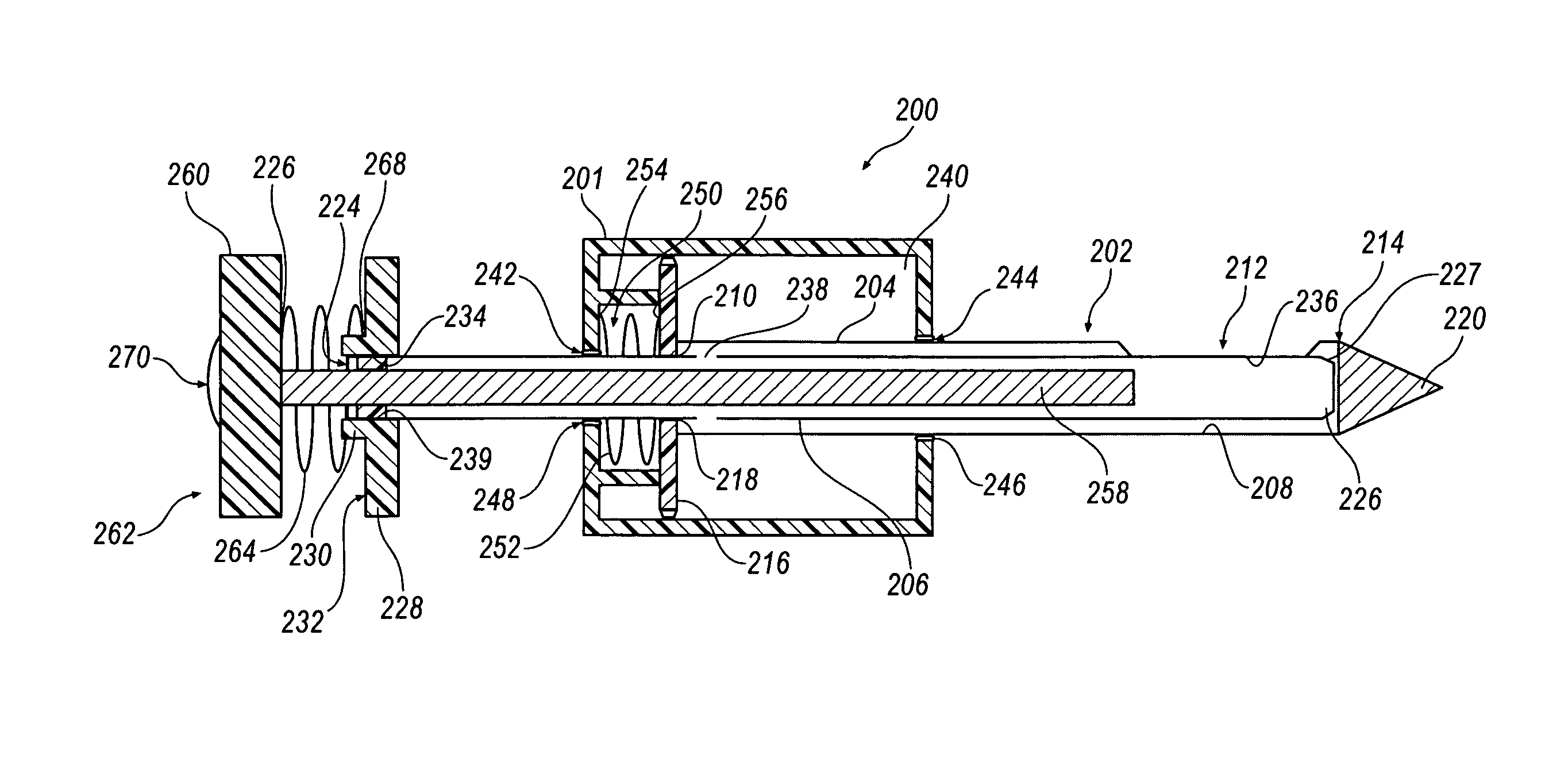

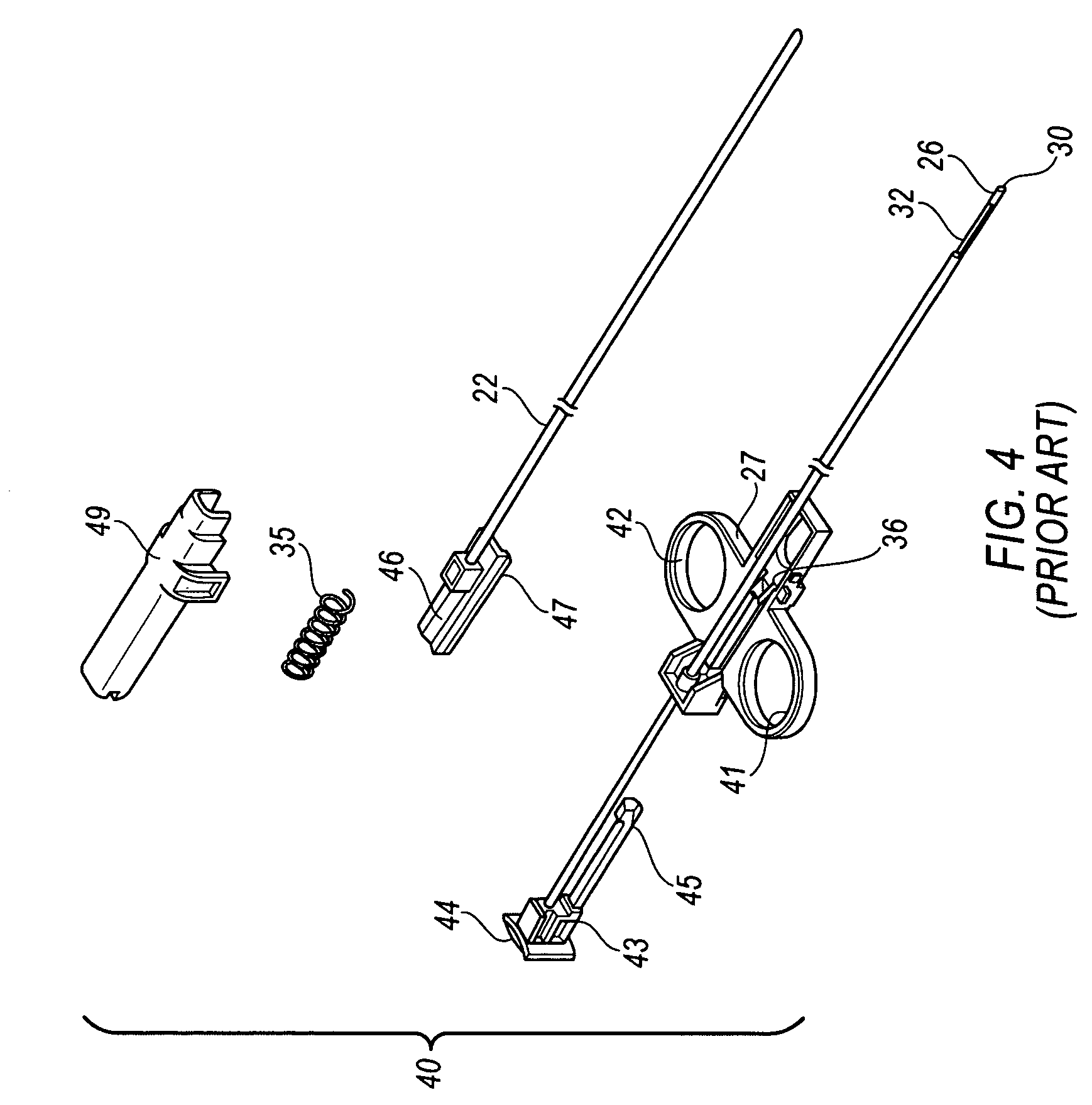

Vacuum assisted biopsy needle set

A biopsy device having a cutting element is disclosed. The cutting element includes an inner cannula having a tissue receiving aperture disposed proximate a distal end thereof and an inner lumen. The inner cannula is slidably disposed within the inner lumen of an outer cannula. A vacuum chamber is disposed about at least a portion of the cutting element and is configured to create a vacuum in the cutting element during a biopsy procedure. The inner cannula is advanced distally outwardly and to cause the vacuum to be generated in the vacuum chamber. The vacuum is delivered to the cutting element whereby tissue is drawn into the tissue receiving aperture. The outer cannula is advanced distally outwardly after the inner cannula such that tissue drawn into the tissue cutting aperture is severed.

Owner:PROMEX TECH

Deformation reduction at the main chamber

InactiveUS6949204B1Electric discharge tubesDecorative surface effectsVacuum chamberPlasma processing

A vacuum chamber with a cover with a first section, a second section, and a pocket between the first section and second section is provided. The vacuum chamber has a main cavity to which the first section is adjacent. The vacuum chamber may be used for plasma processing, which may require a critical element to be supported by the first section. The pocket is in fluid communication with the main cavity. When a vacuum is created in the main cavity, the pressure is also reduced in the pocket. As a result, the second section of the cover is deformed by the vacuum in the pocket. However, the vacuum in the pocket helps to prevent the first section from deforming, providing better support for the critical element.

Owner:LAM RES CORP

Showerhead mounting to accommodate thermal expansion

InactiveUS7722925B2Minimize and eliminate distortionGreat thermal expansion coefficientElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringThermal expansion

Methods and apparatus for accommodating thermal expansion of a showerhead. In a first aspect of the invention, the showerhead is movably supported by resting a rim of the showerhead on a support shelf. In a second aspect, the showerhead is suspended from the chamber wall by a plurality of hangers that are connected to the showerhead, the chamber wall, or both by pins that slide within slots so as to permit the hangers to slide radially to accommodate thermal expansion of the showerhead in the radial direction. In a third aspect, the showerhead is suspended from the wall of the vacuum chamber by a plurality of rods or flexible wires. In a fourth aspect, the showerhead is connected near its perimeter to a second material having a greater thermal expansion coefficient than the showerhead. In a fifth aspect, a heater is mounted behind the showerhead to reduce the temperature differential between the top and bottom surfaces of the showerhead or to reduce heat transfer from the workpiece to the showerhead.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com