Patents

Literature

9321 results about "Differential pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Differential Pressure. Differential pressure is a pressure that is measured relative to the pressure in the atmosphere around it. The other type of pressure is absolute pressure, which is measured against absolute zero, but is not often used to measure pressure in real-life scenarios.

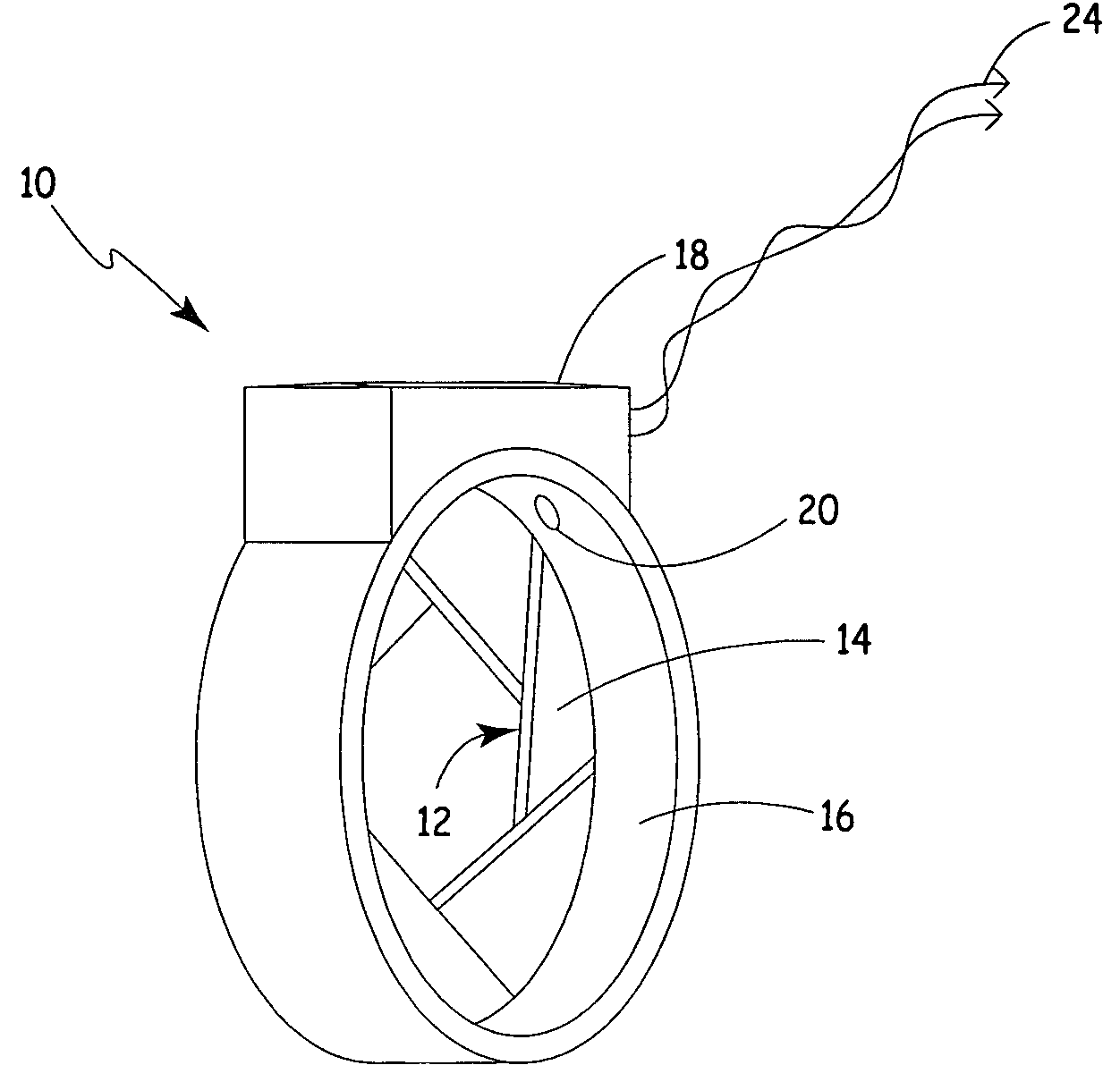

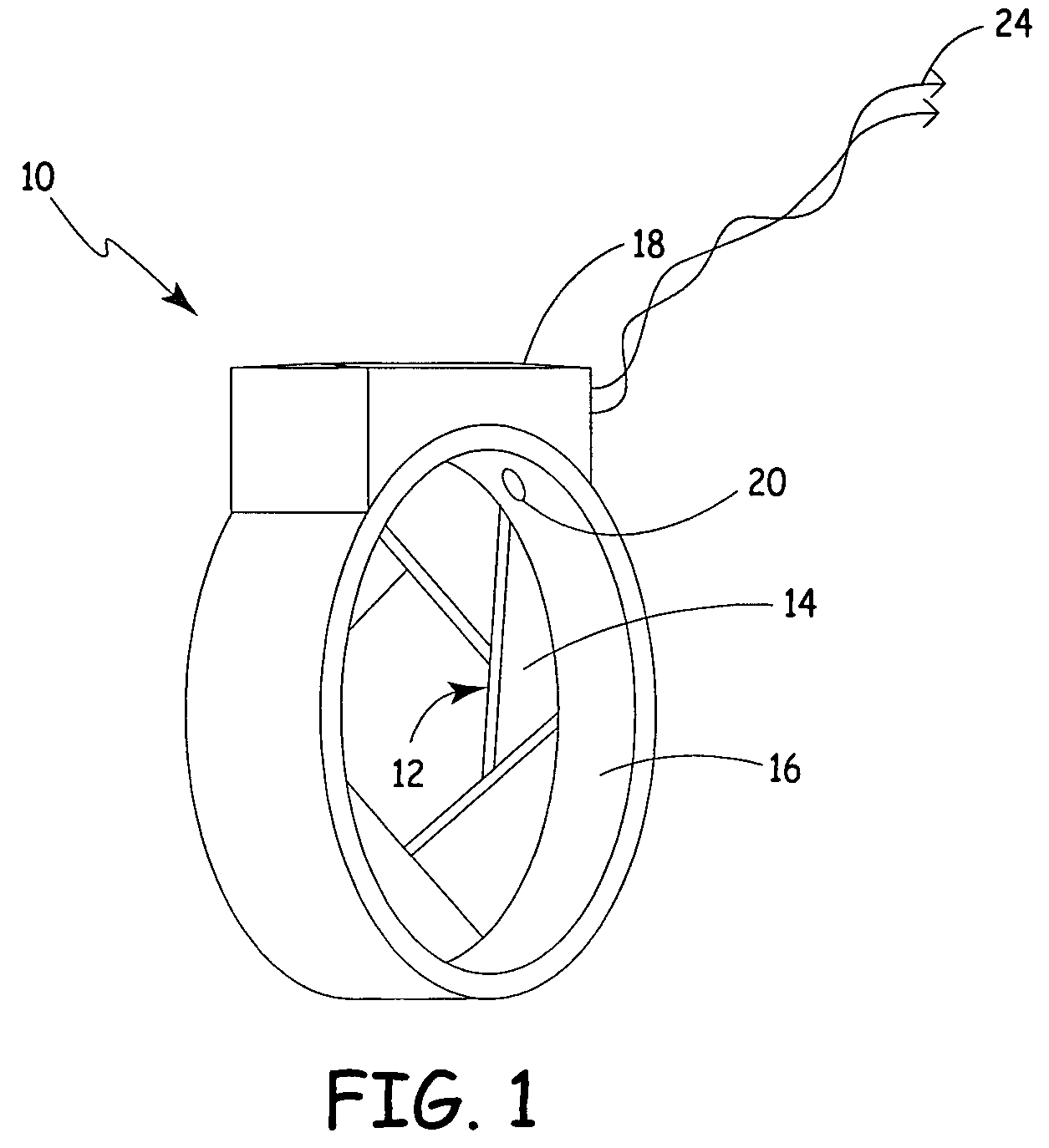

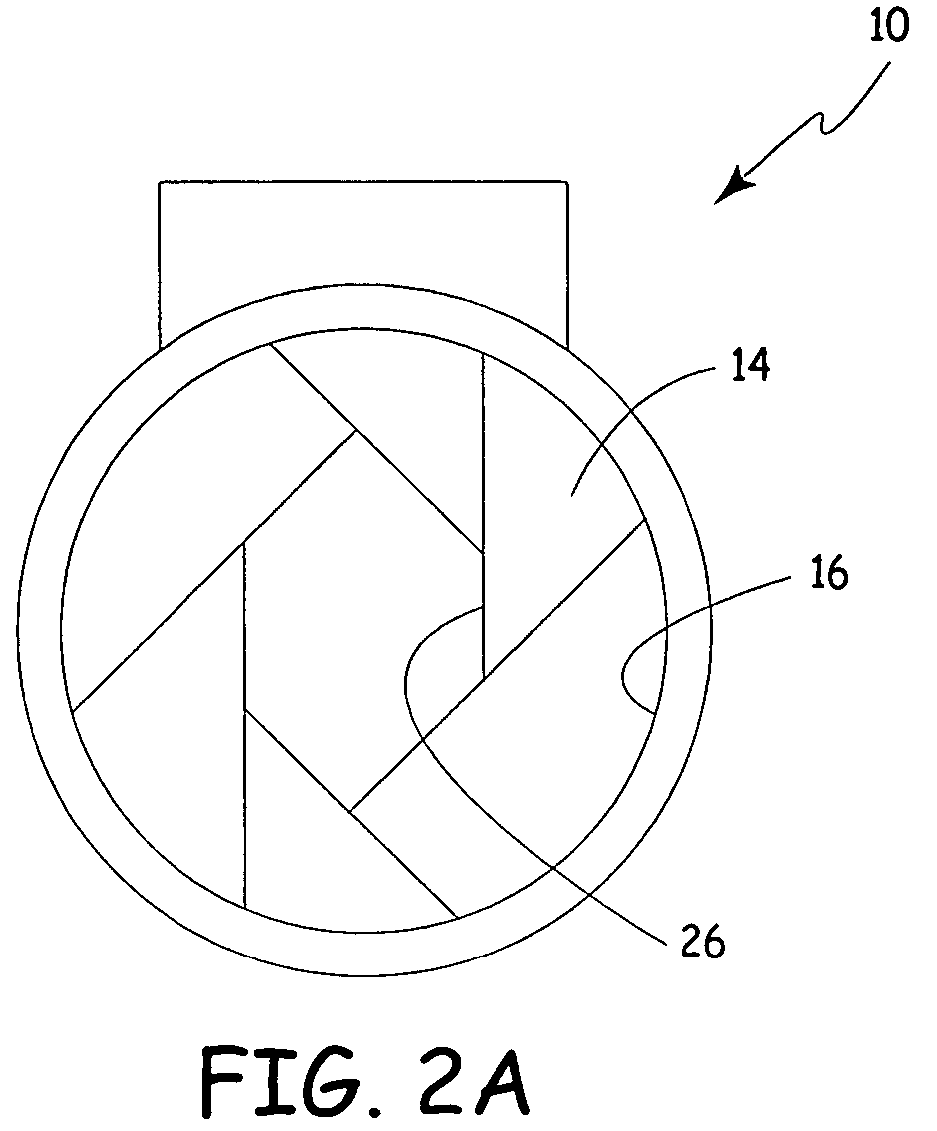

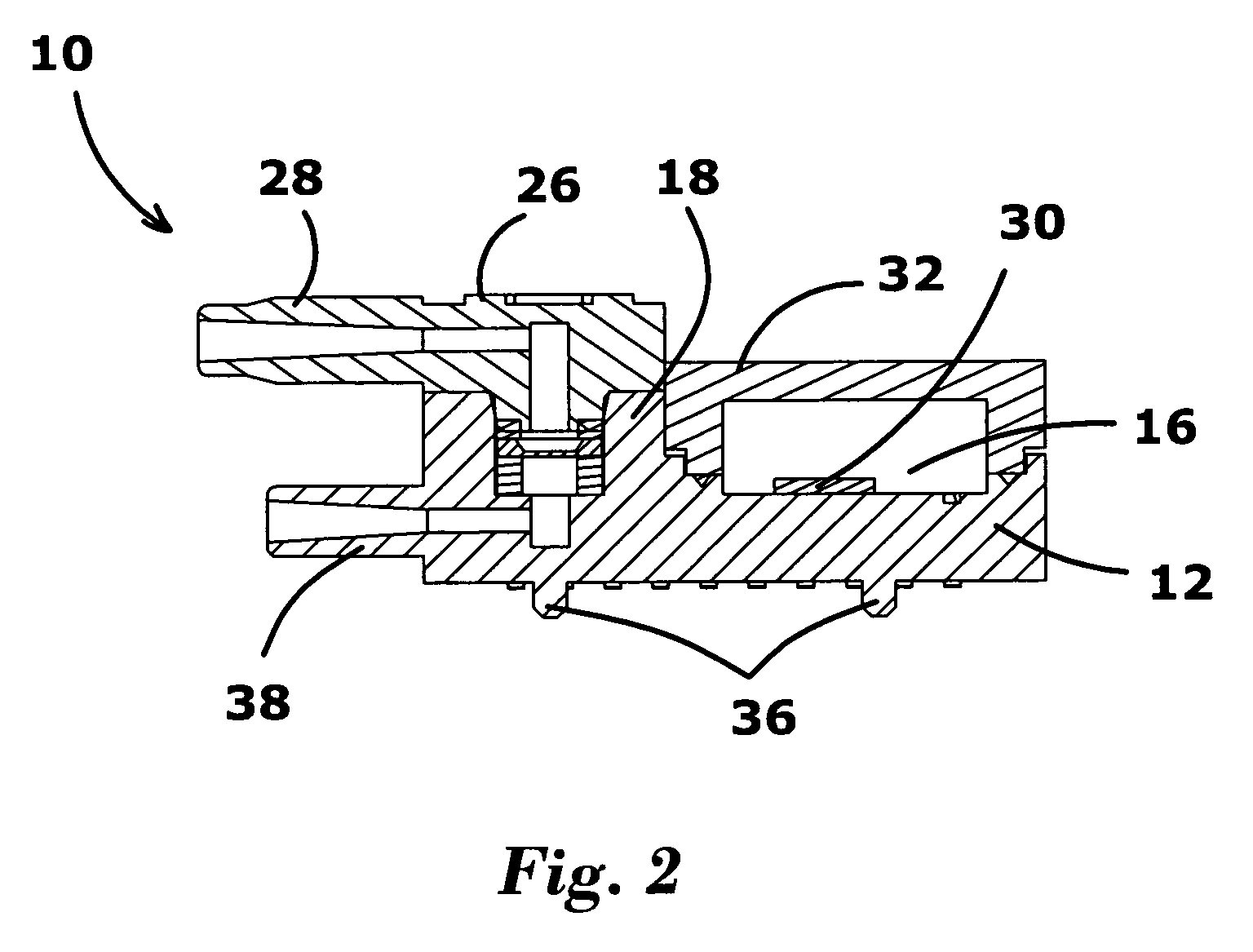

Process fluid flow device with variable orifice

A process device providing total fluid flow control is provided. The device includes a closure mechanism disposed in a flow conduit. The closure mechanism, which is preferably an iris-type diaphragm, provides a variable internal diameter. The device includes a differential pressure sensor for sensing the differential pressure on opposite sides of the diaphragm. A controller receives an indication of differential pressure and generates a control signal to an actuator that actuates the closure mechanism. The closure mechanism, differential pressure sensor and controller create a closed-loop flow controller in a single process device.

Owner:ROSEMOUNT INC

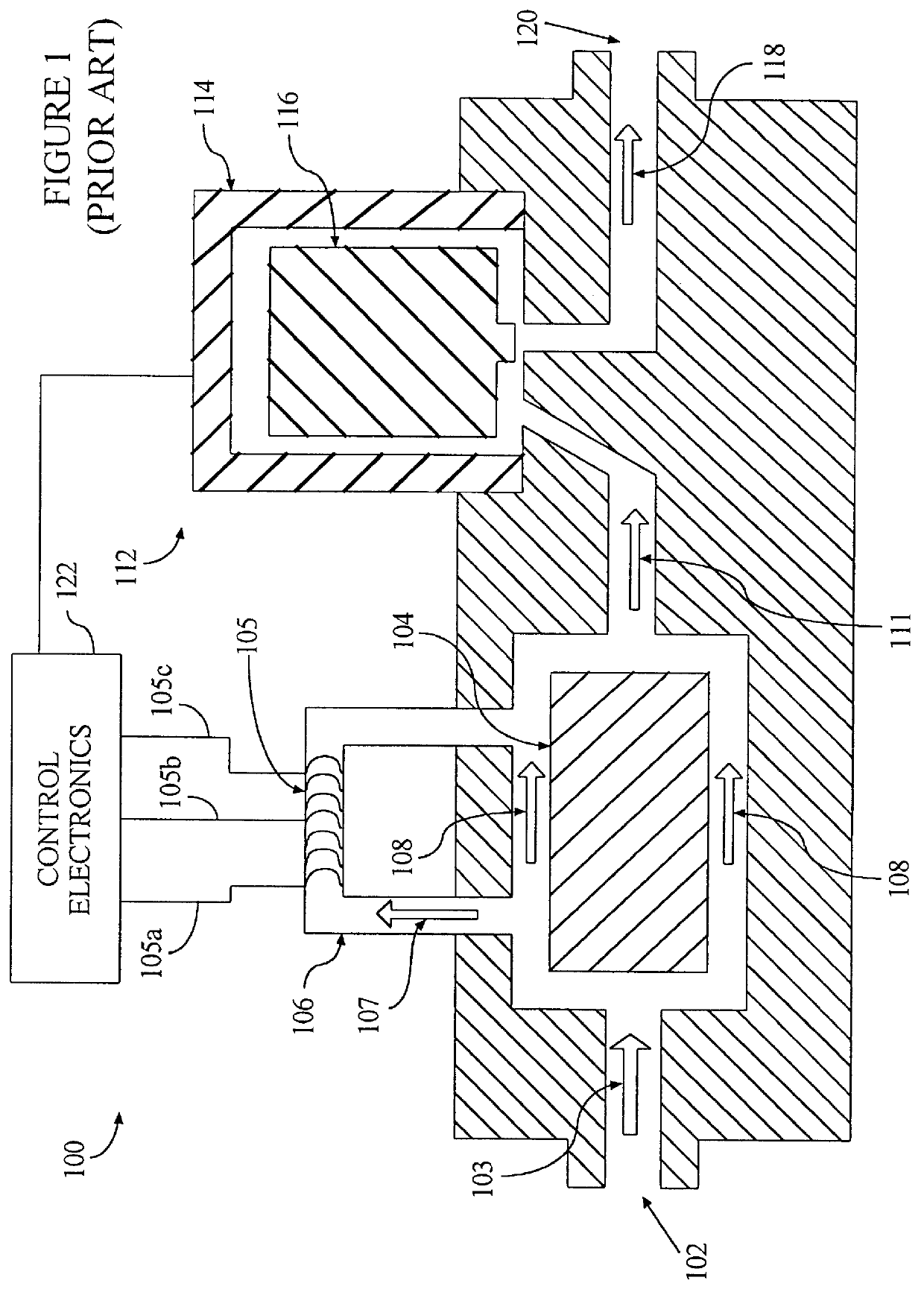

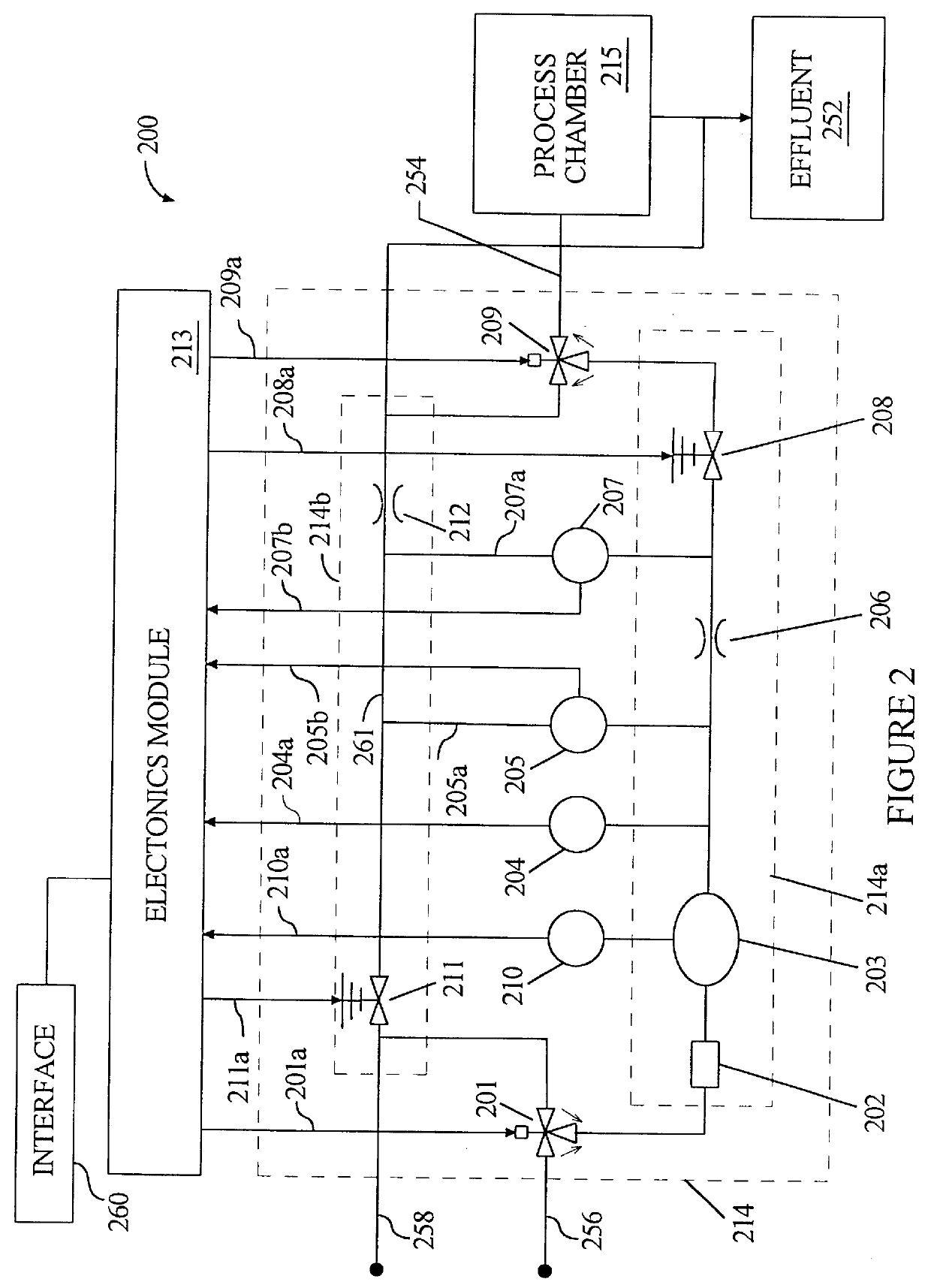

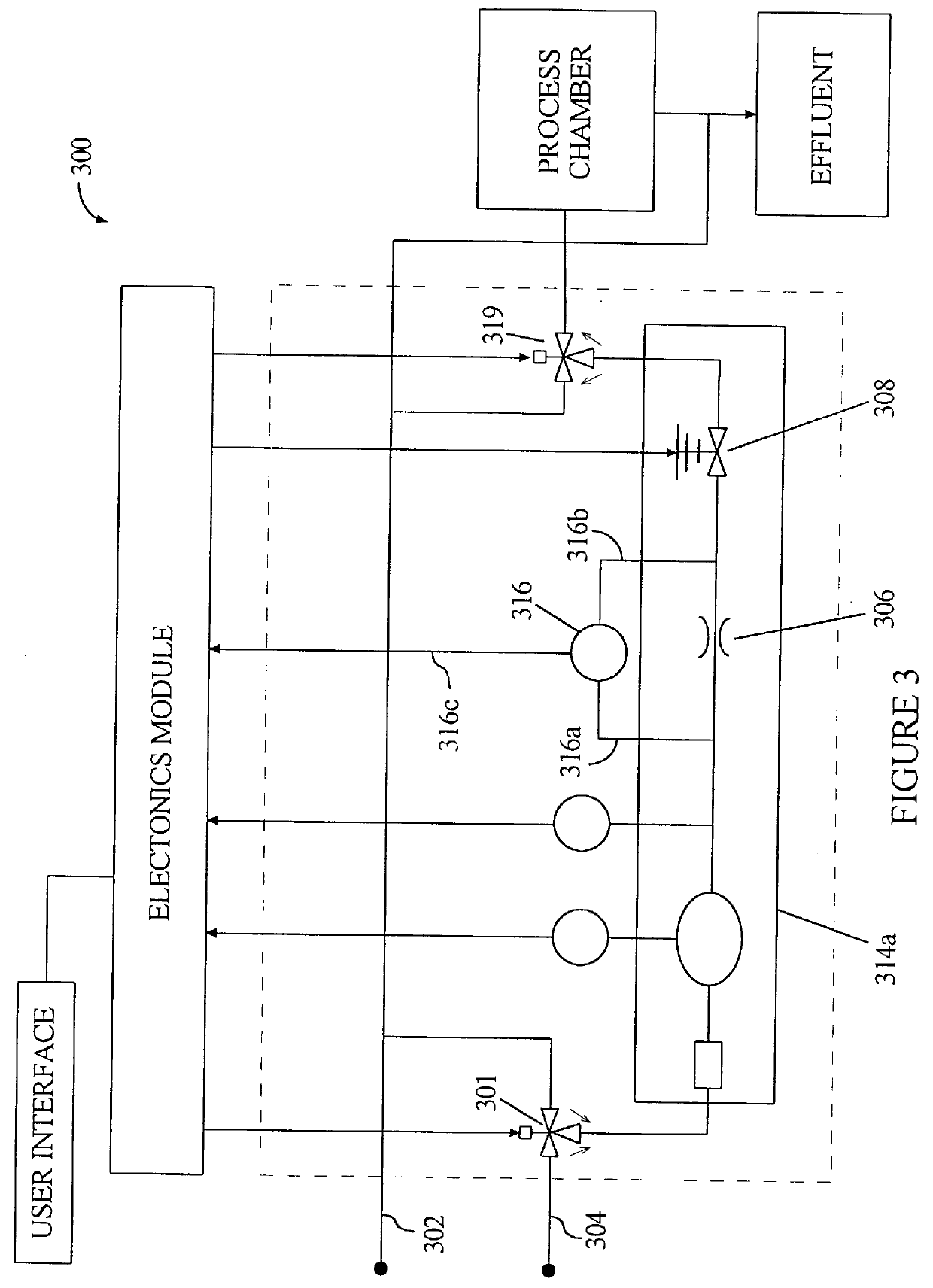

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

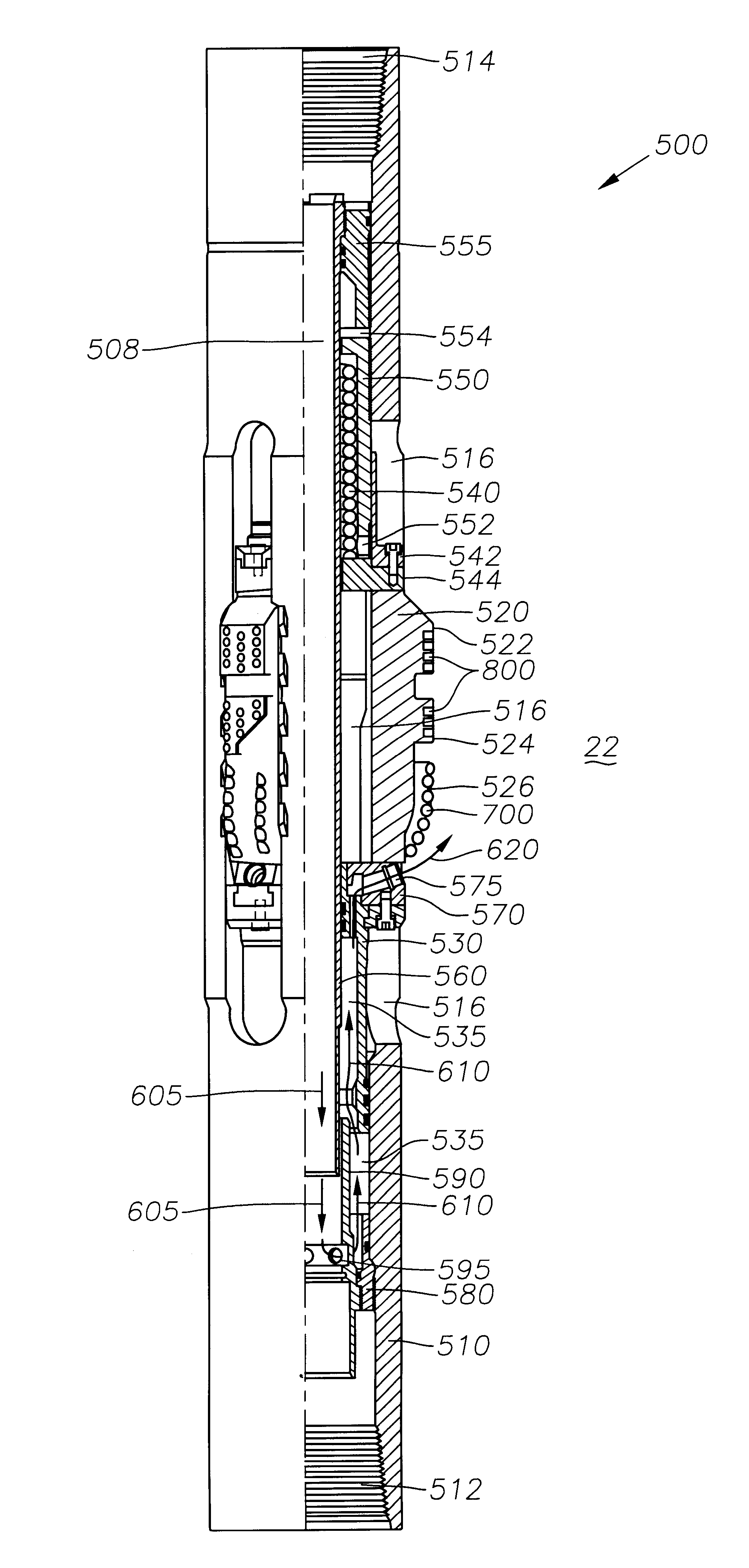

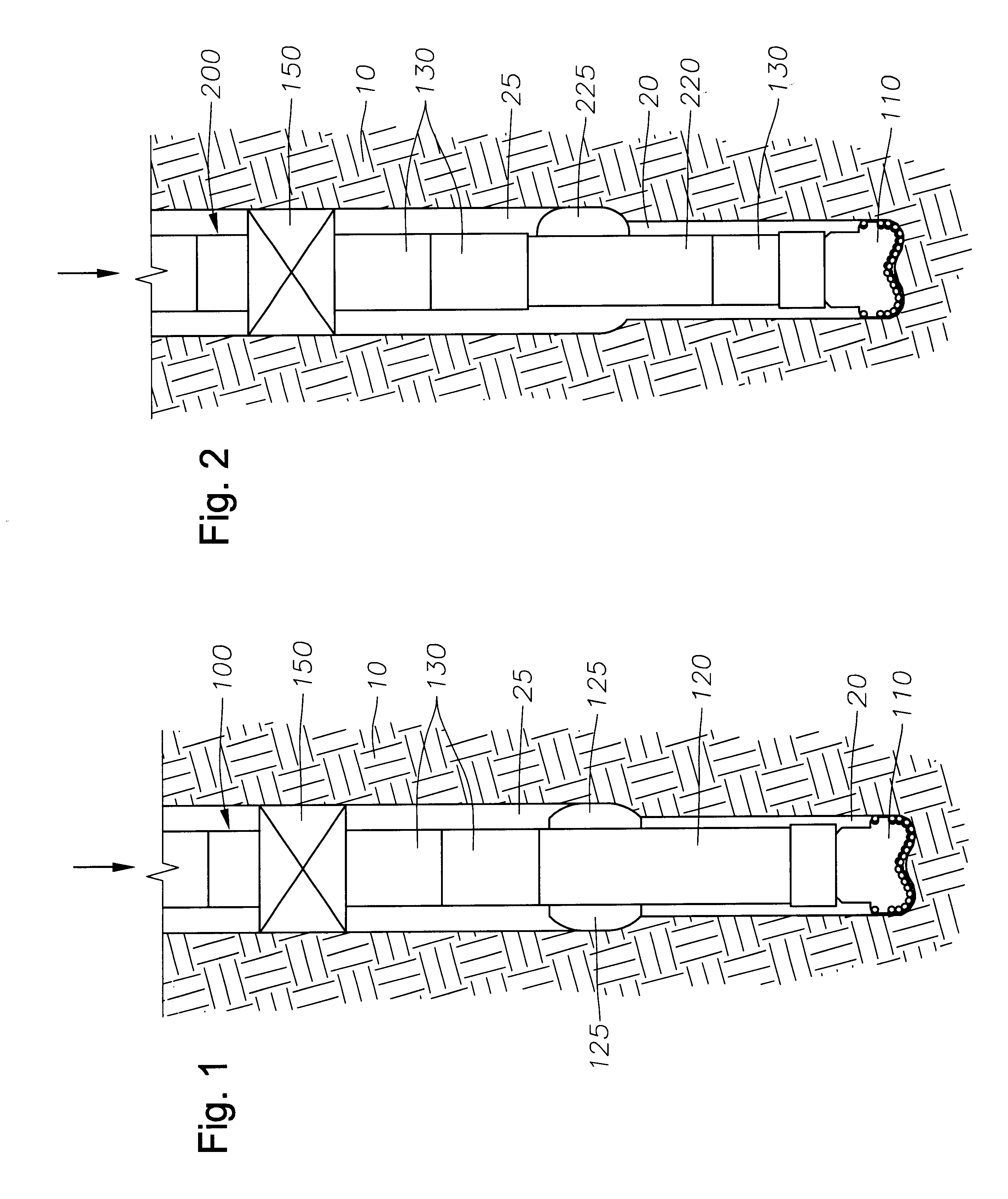

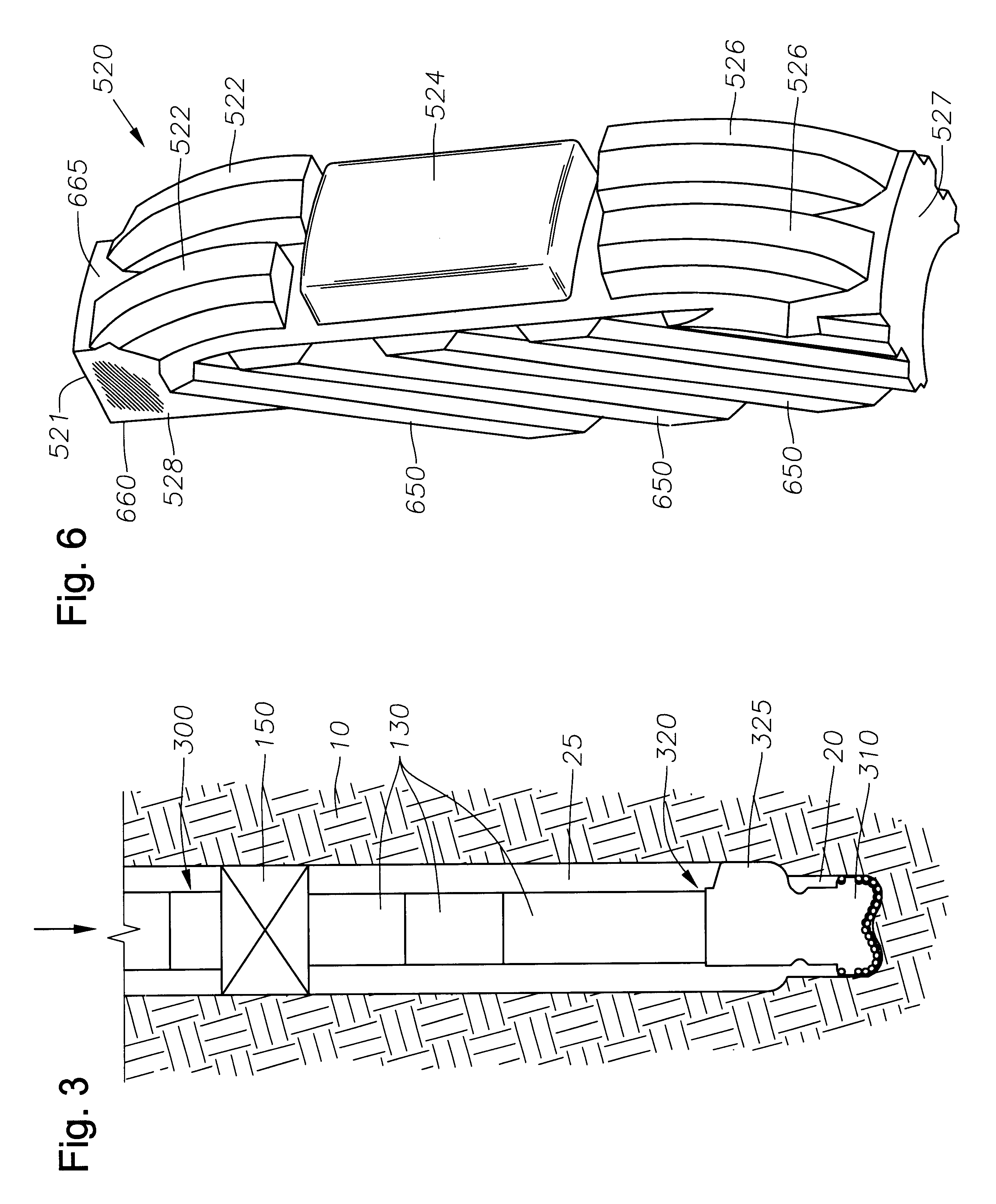

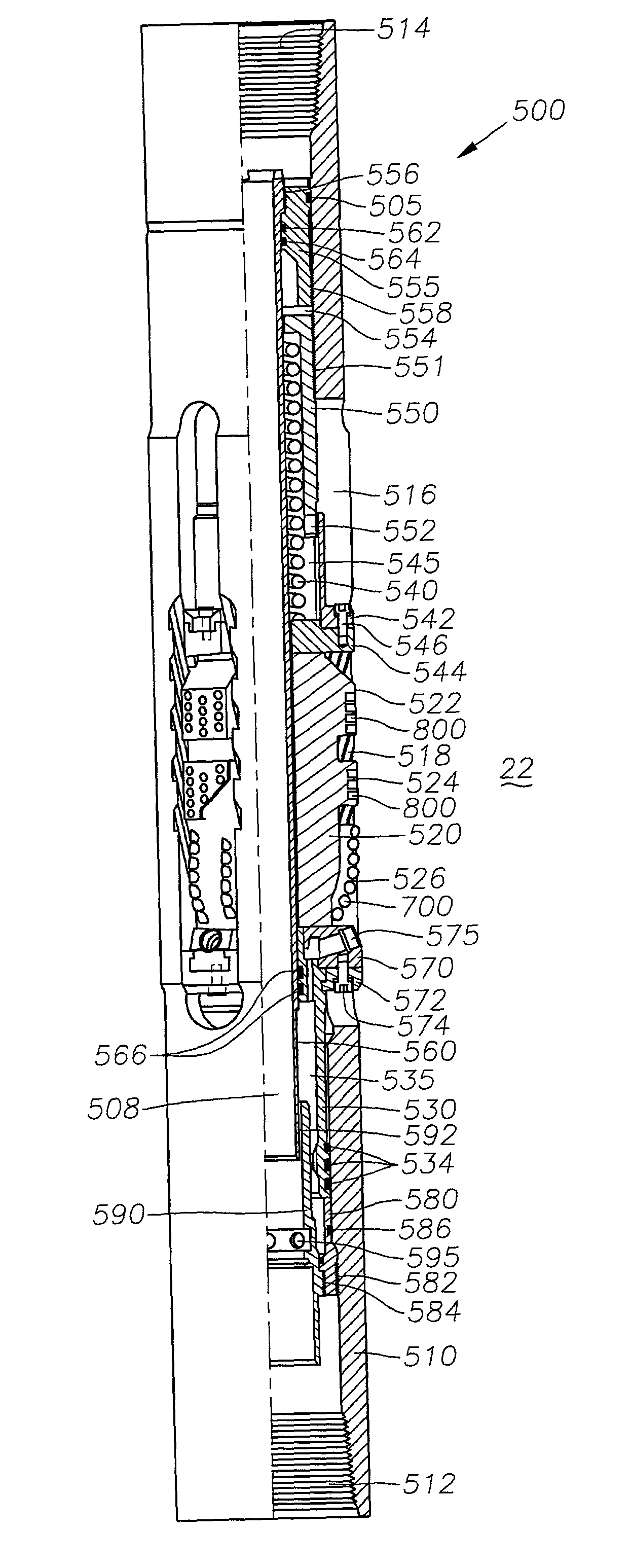

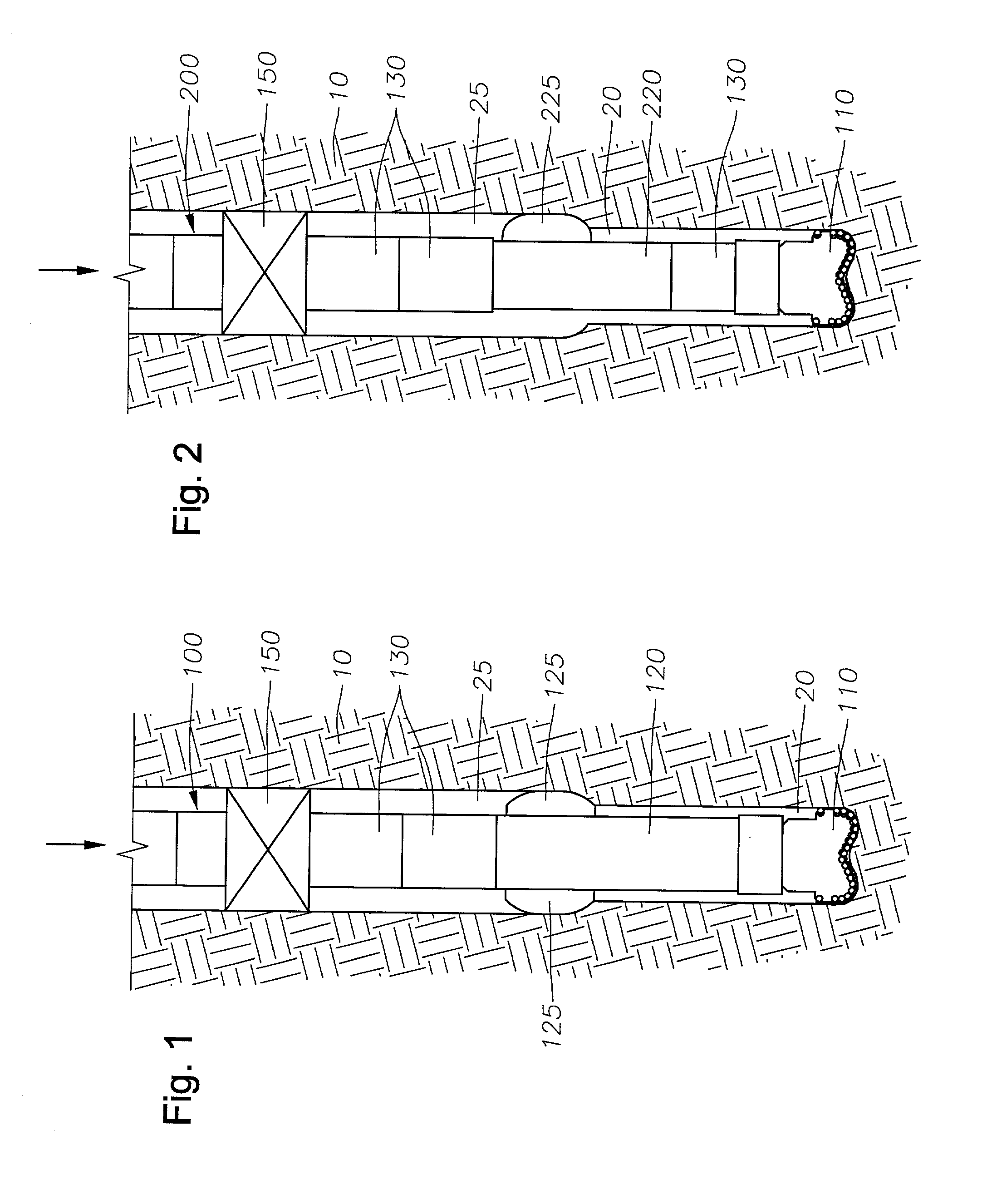

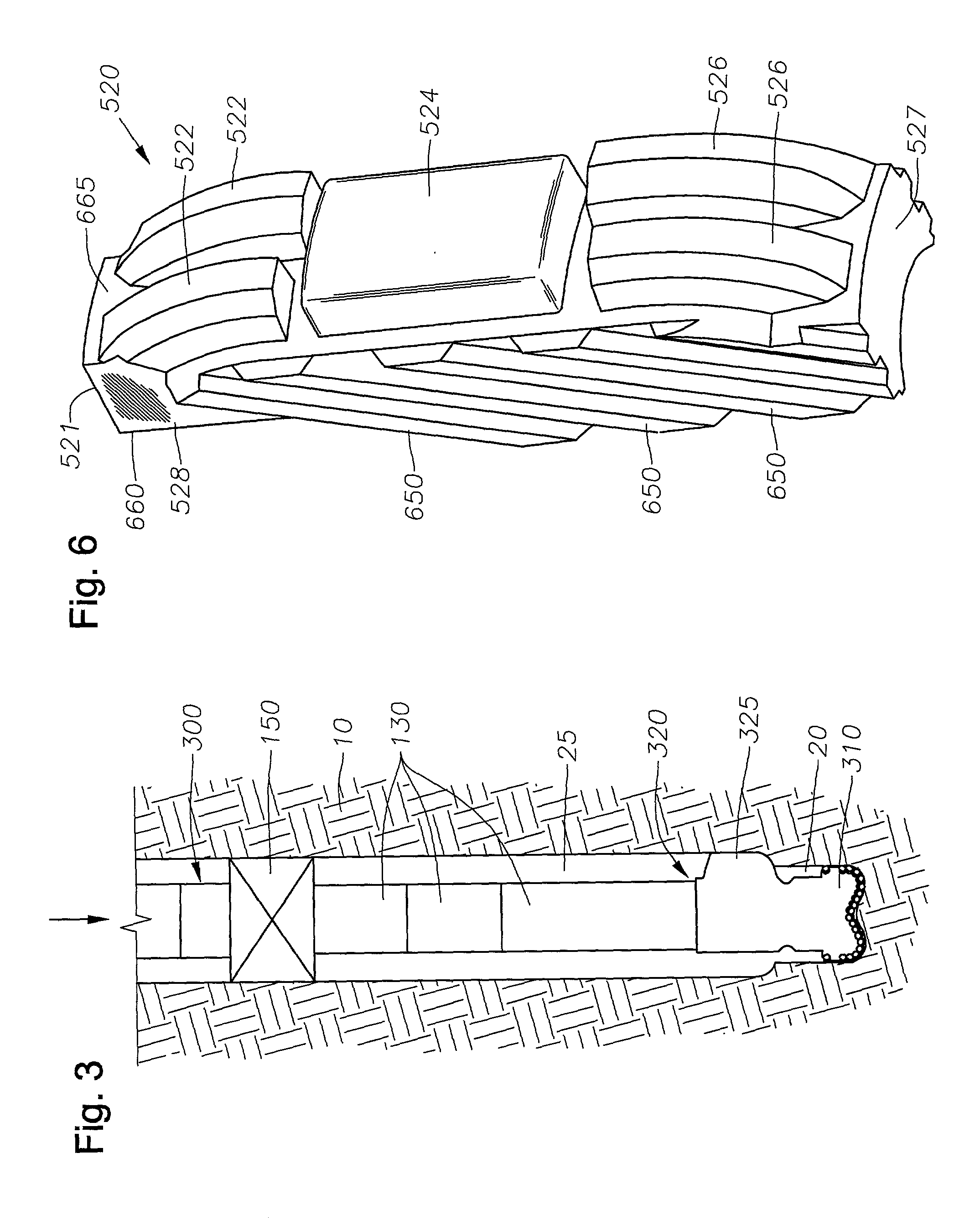

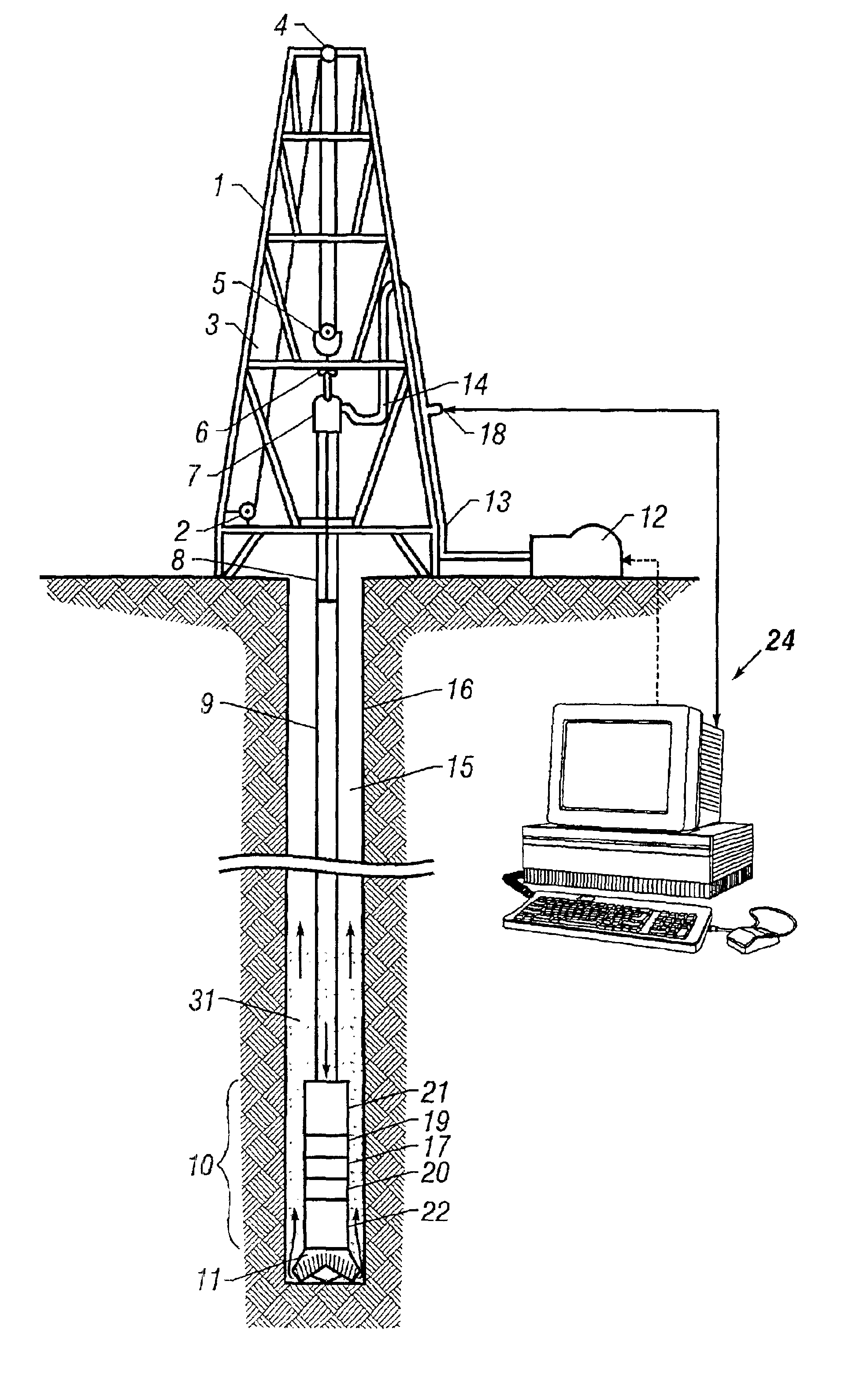

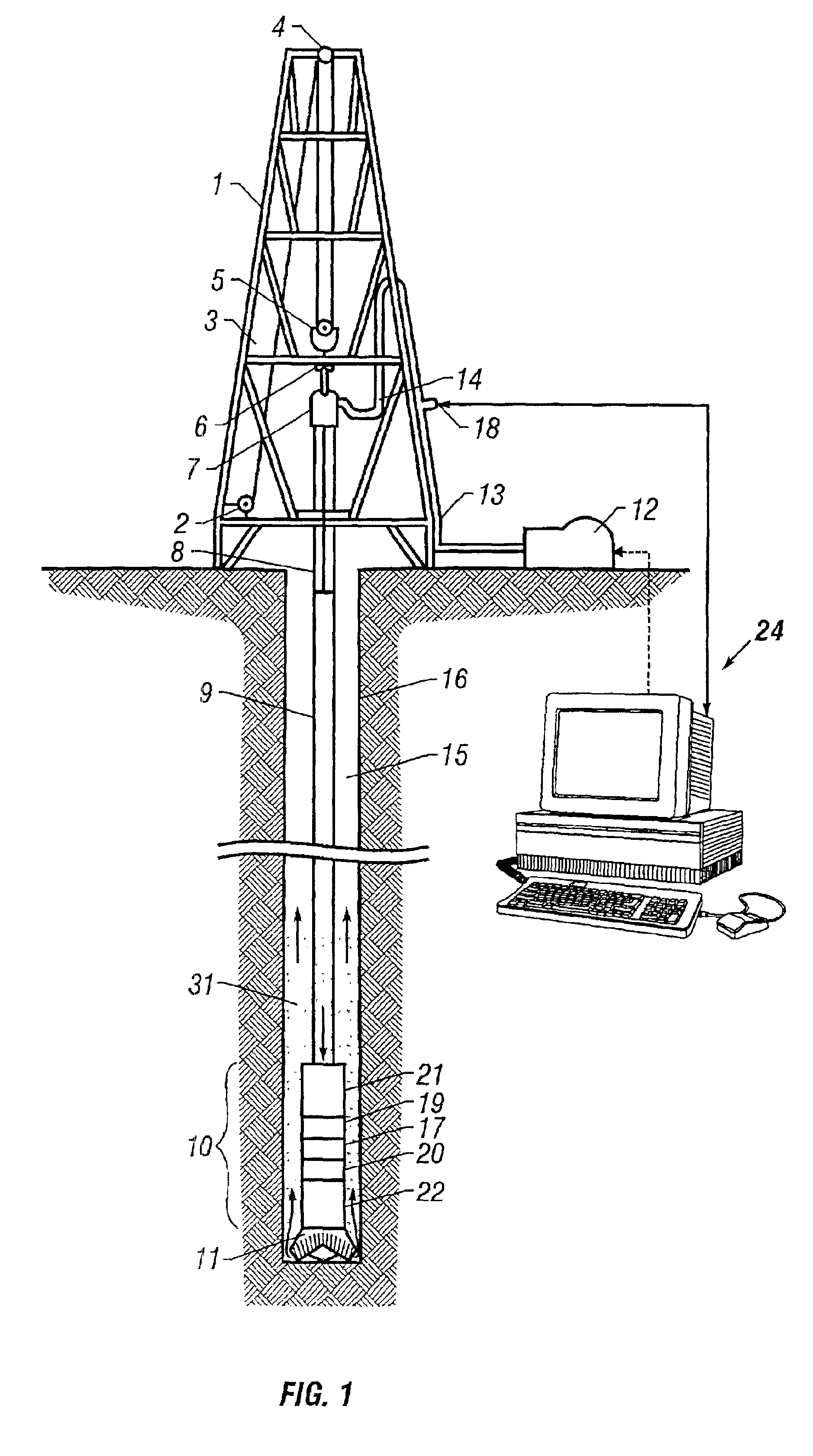

Expandable underreamer/stabilizer

A downhole tool that functions as an underreamer, or alternatively, as a stabilizer in an underreamed borehole. The tool includes one or more moveable arms disposed within a body having a flowbore therethrough in fluid communication with the wellbore annulus. The tool alternates between collapsed and expanded positions in response to differential fluid pressure between the flowbore and the wellbore annulus. In one embodiment, the tool moves automatically in response to differential pressure. In a second embodiment, the tool must be selectively actuated before it is moveable. When the tool expands, the arms are preferably translated axially upwardly, while simultaneously being extended radially outwardly from the body. The expanded tool diameter is adjustable at the surface without changing components. The arms may include borehole engaging pads that comprise cutting structures or wear structures or both, depending upon the function of the tool.

Owner:SMITH INT INC

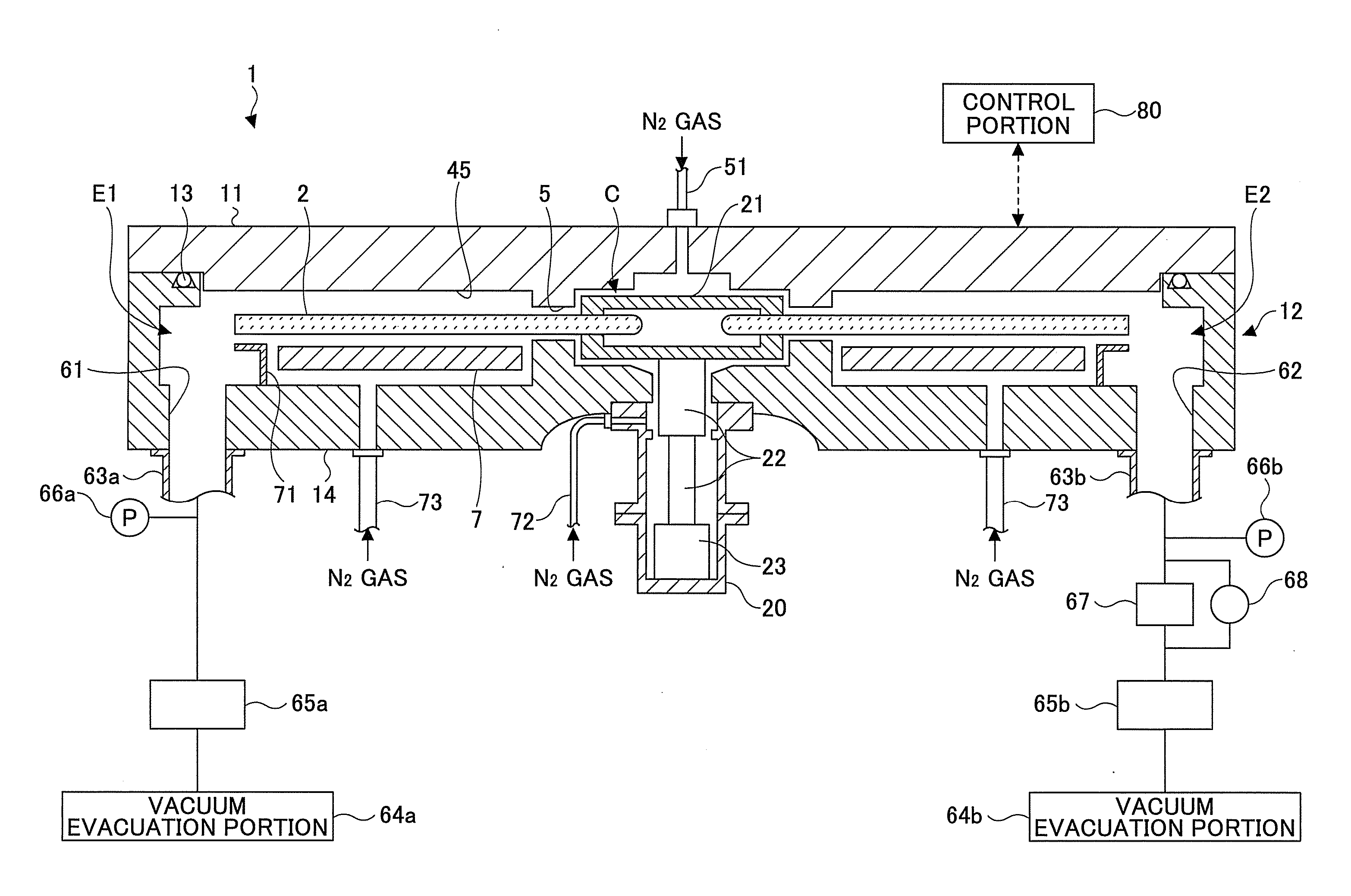

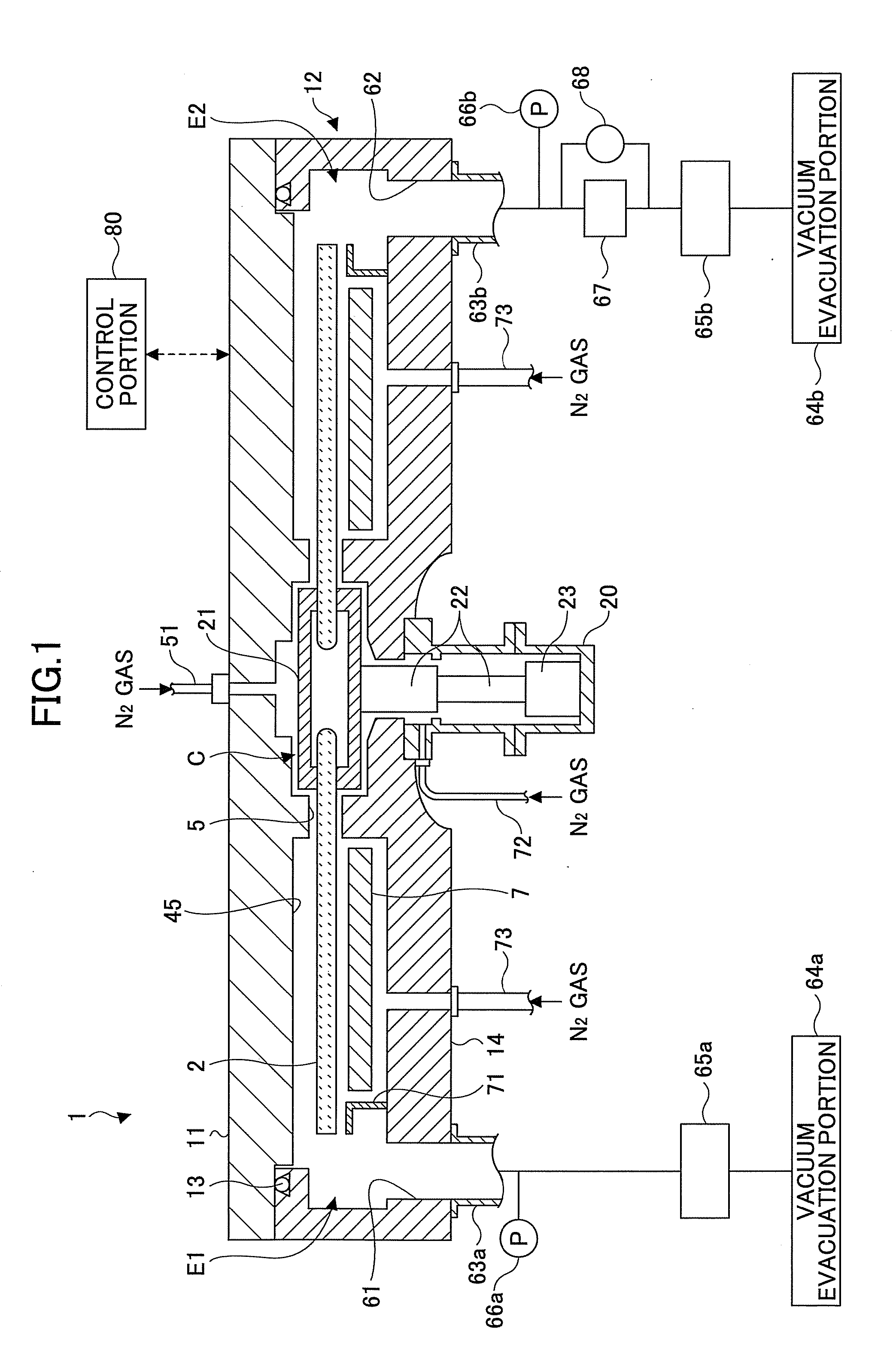

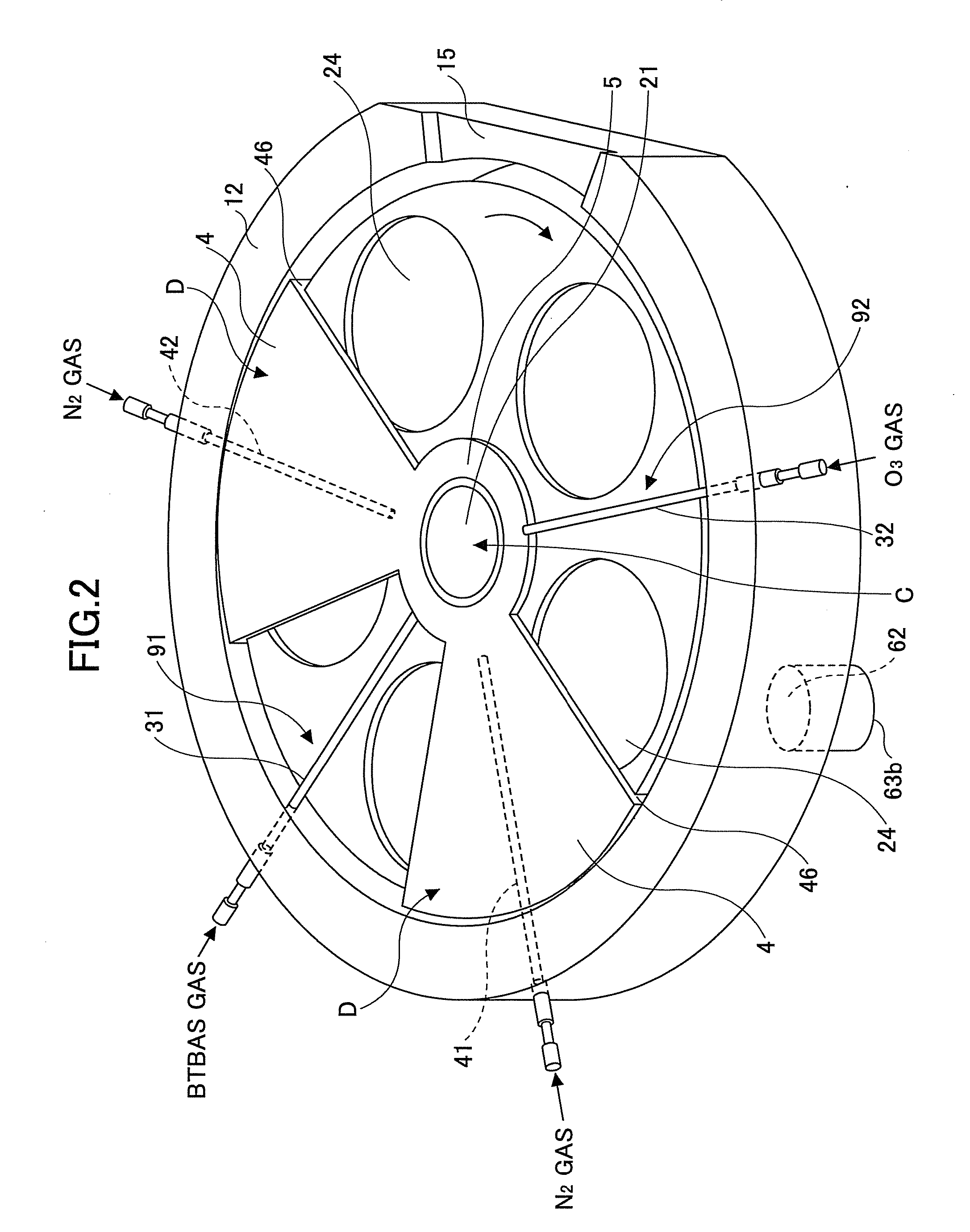

Substrate process apparatus, substrate process method, and computer readable storage medium

ActiveUS20110100489A1Servomotor componentsSemiconductor/solid-state device manufacturingDifferential pressureEngineering

A vacuum chamber is evacuated through a first evacuation passage provided with a first valve and a second evacuation passage provided with a second valve. An opening degree of the first valve is adjusted so that a pressure in the vacuum chamber becomes substantially equal to a process pressure P; an opening degree of a butterfly valve further provided in the second evacuation passage is adjusted to substantially equal to a set value determined by a table in order to set flow rates of gases to be evacuated through the first evacuation passage and the second evacuation passage to be substantially equal to corresponding set values determined by the recipe; and an opening degree of the second valve is adjusted so that a measurement value of a differential pressure gauge further provided in the second evacuation passage becomes substantially equal to a differential pressure written in the table.

Owner:TOKYO ELECTRON LTD

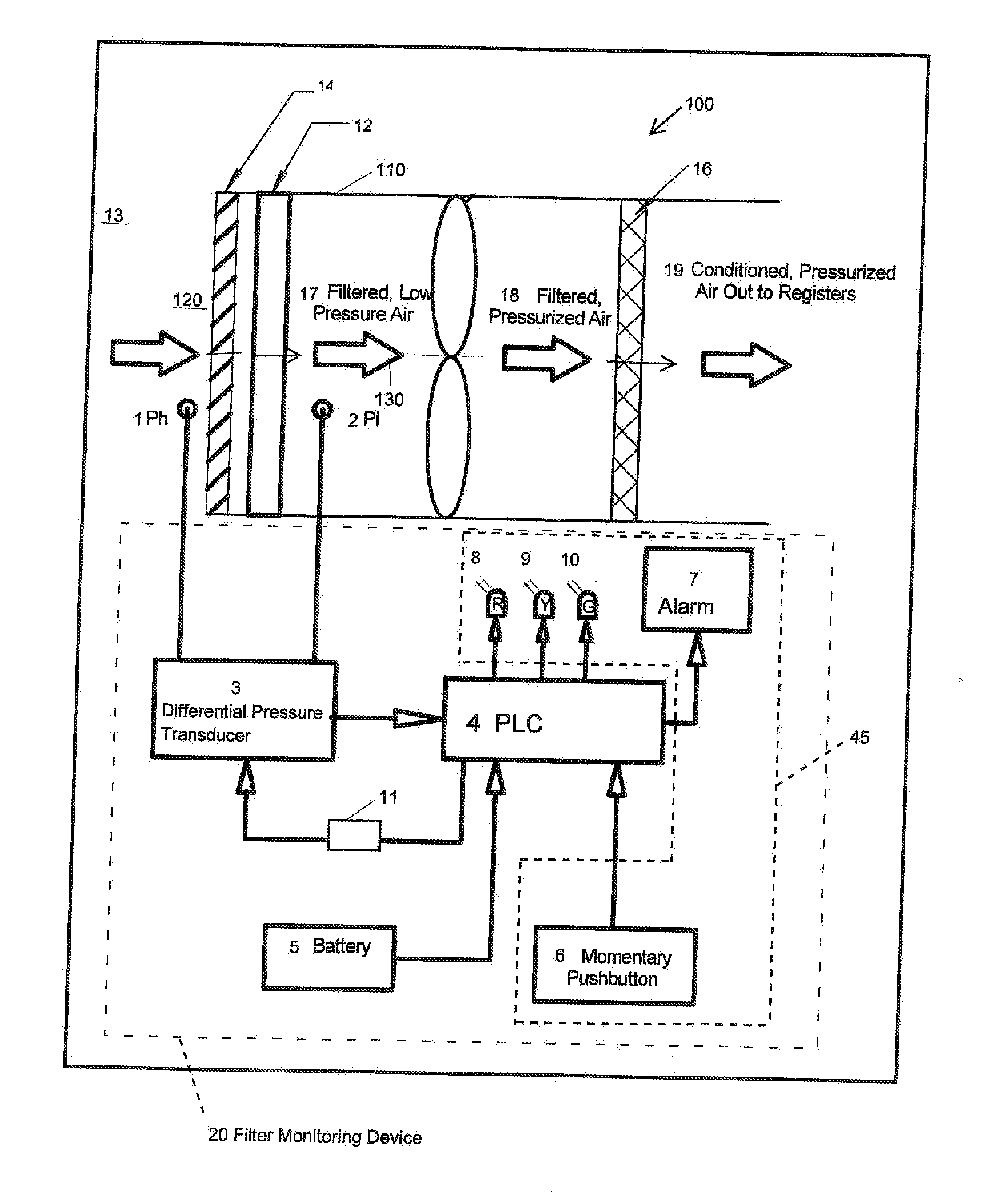

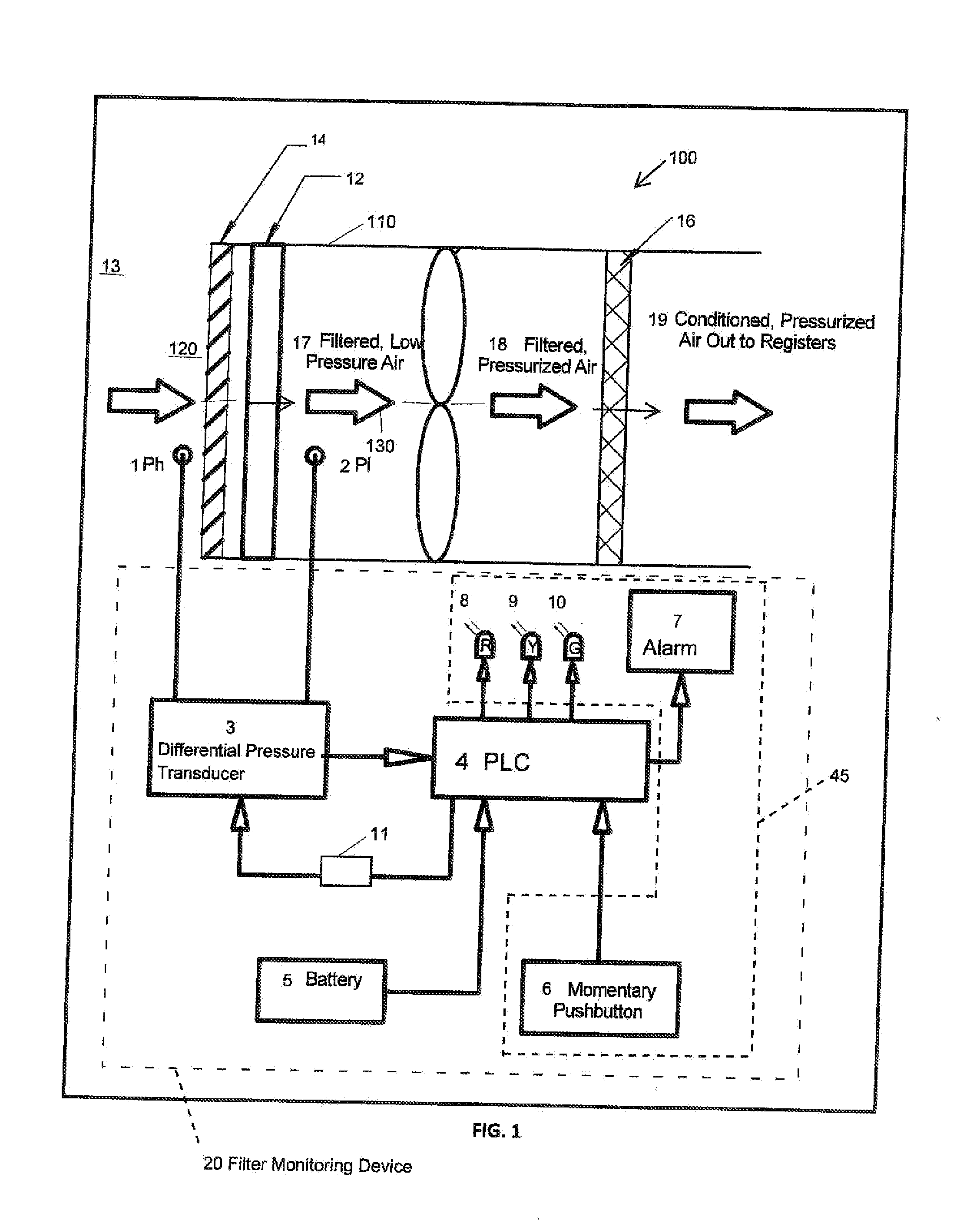

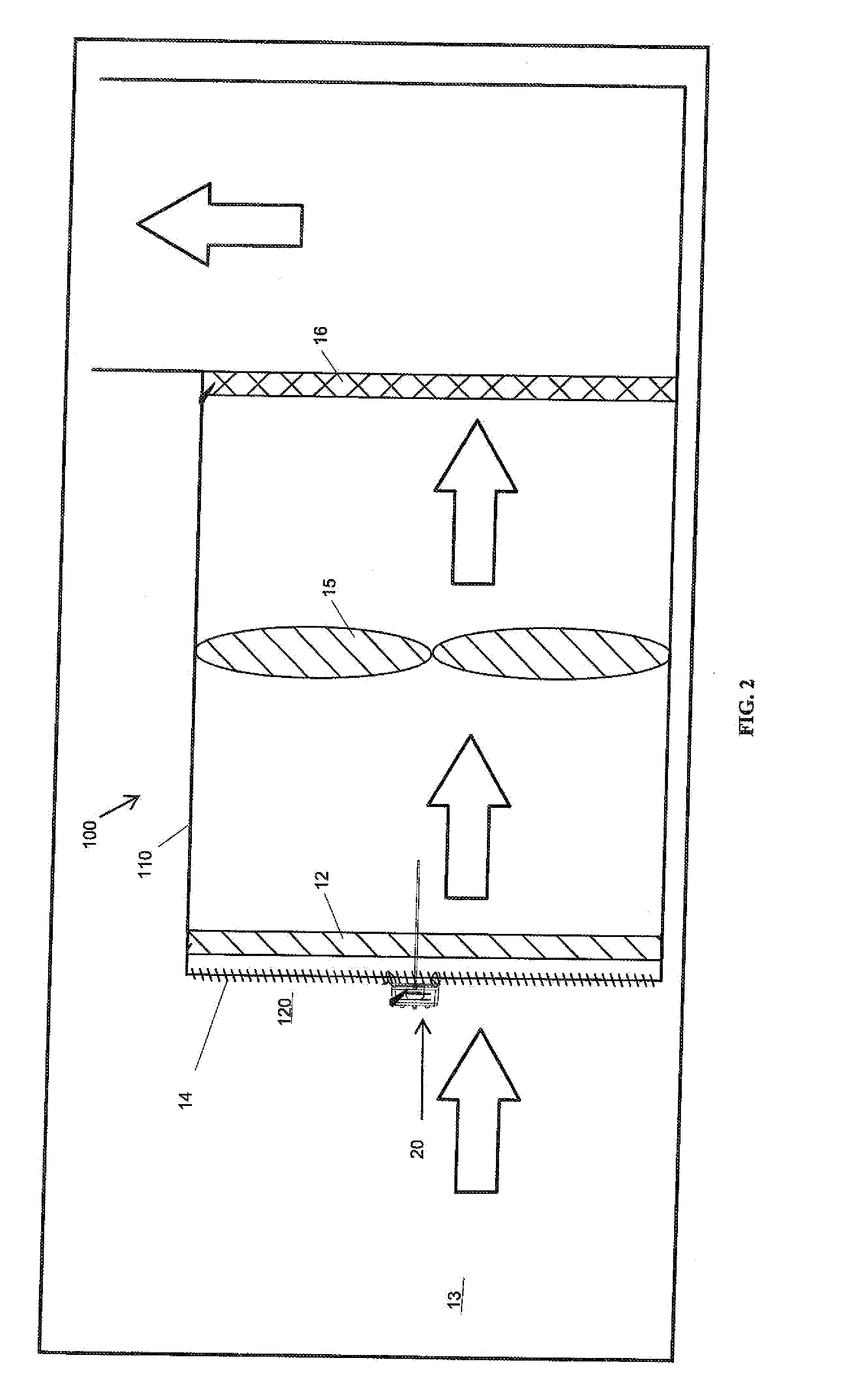

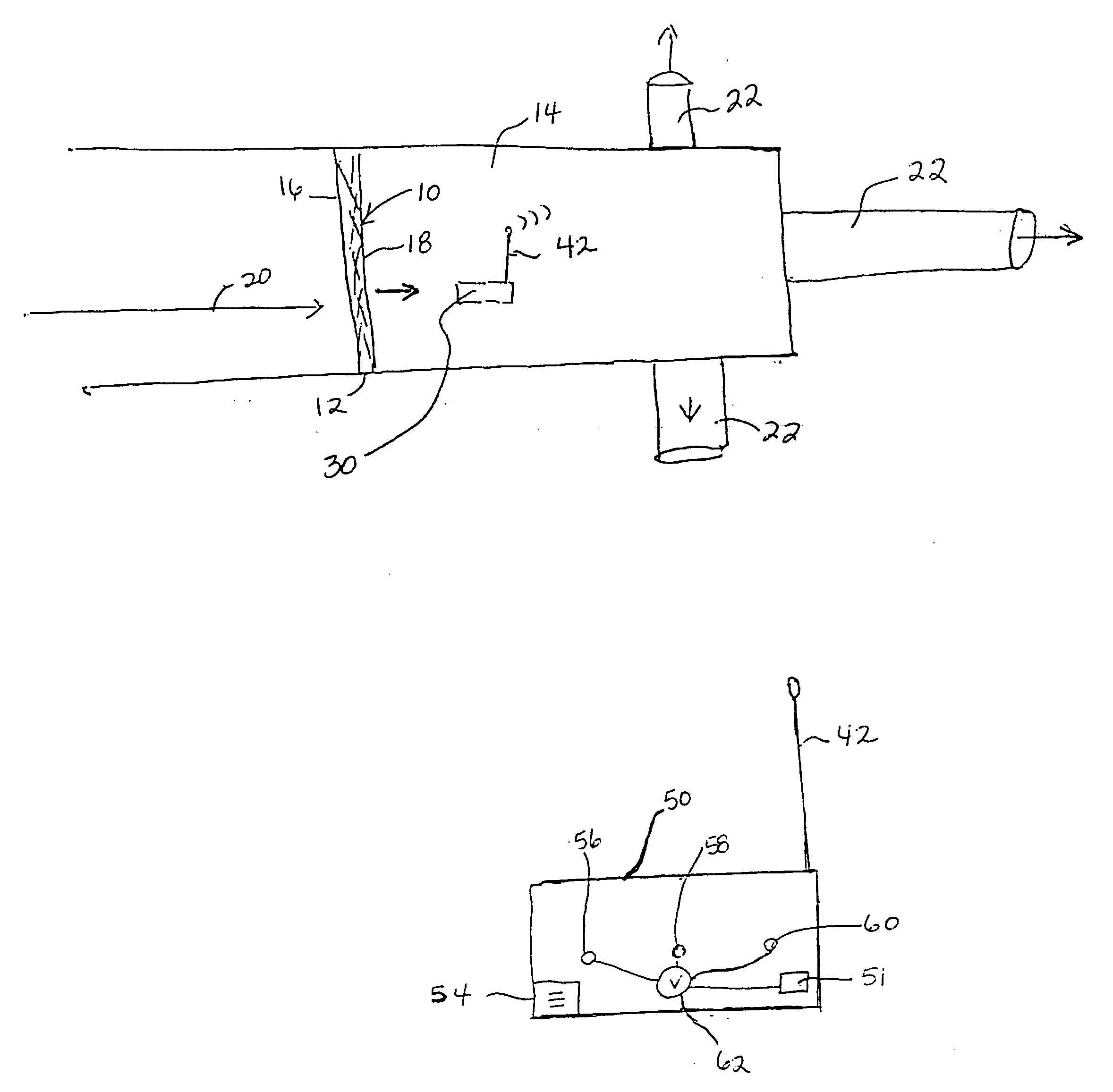

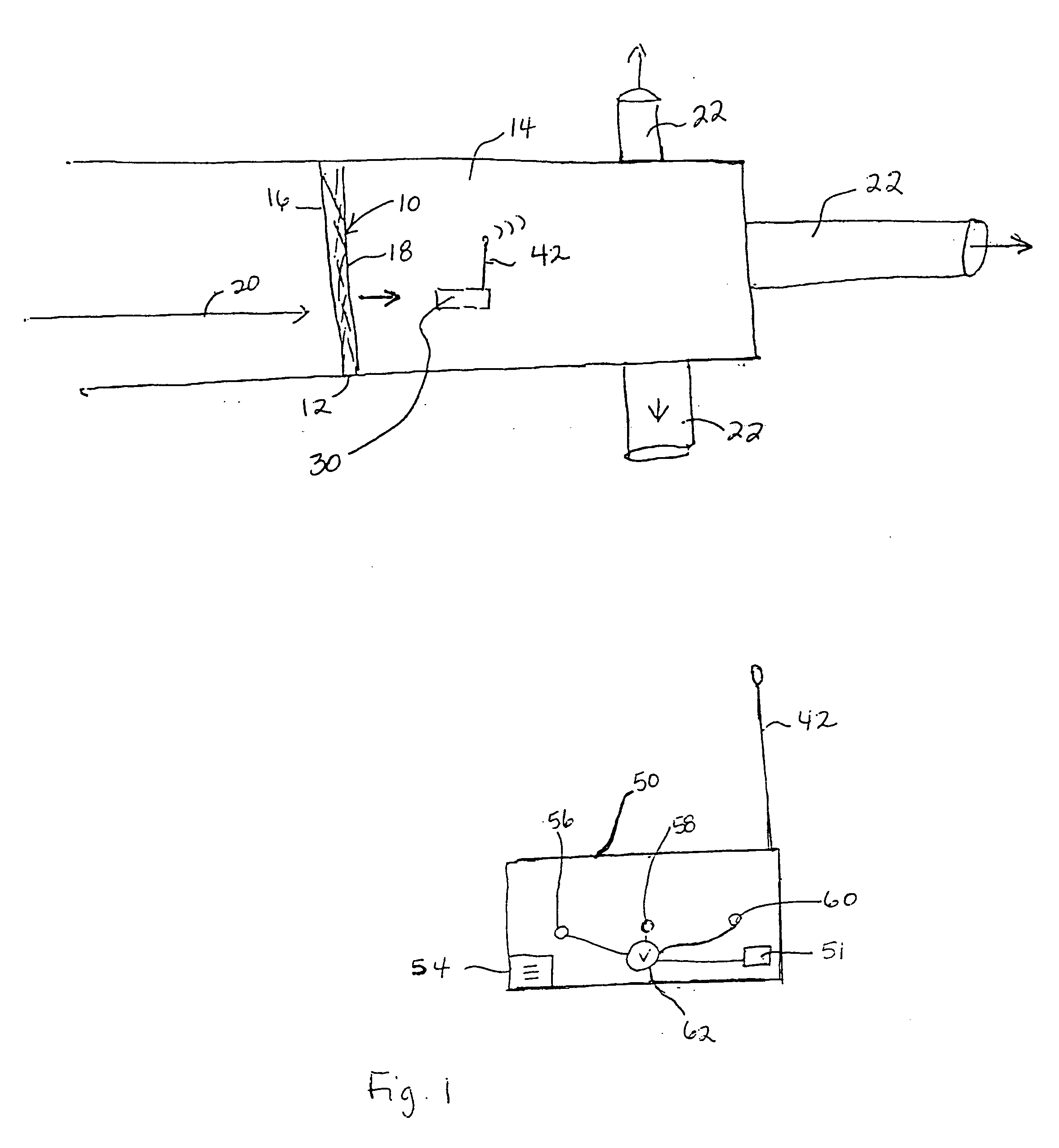

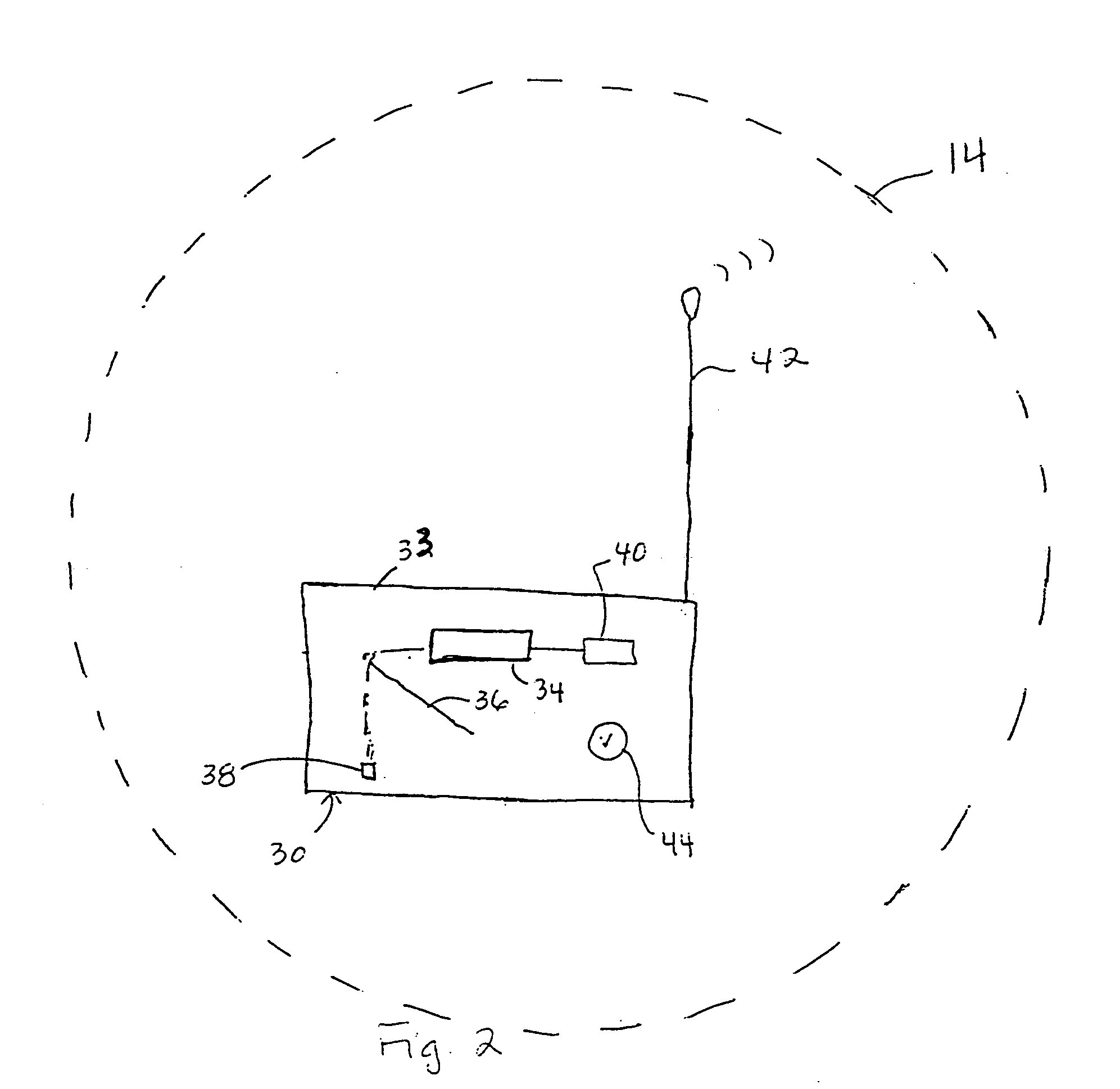

Filter apparatus and method of monitoring filter apparatus

Methods, systems, and products for monitoring an air filter. Methods involve determining a difference between a baseline pressure differential and a current pressure differential, the differential pressure between pressure at an upstream side of the filter and pressure at a downstream side of the filter. The baseline pressure differential may be set automatically or by a user. Reaching or exceeding a predetermined threshold triggers an indication of a clogged condition. The method also includes monitoring the air filter condition intermittently. The filter monitor may operate for extended periods in a sleep state and intermittently power up to a wake state to measure the current pressure differential and compare the current pressure differential with a baseline pressure differential.

Owner:FREEN PAUL

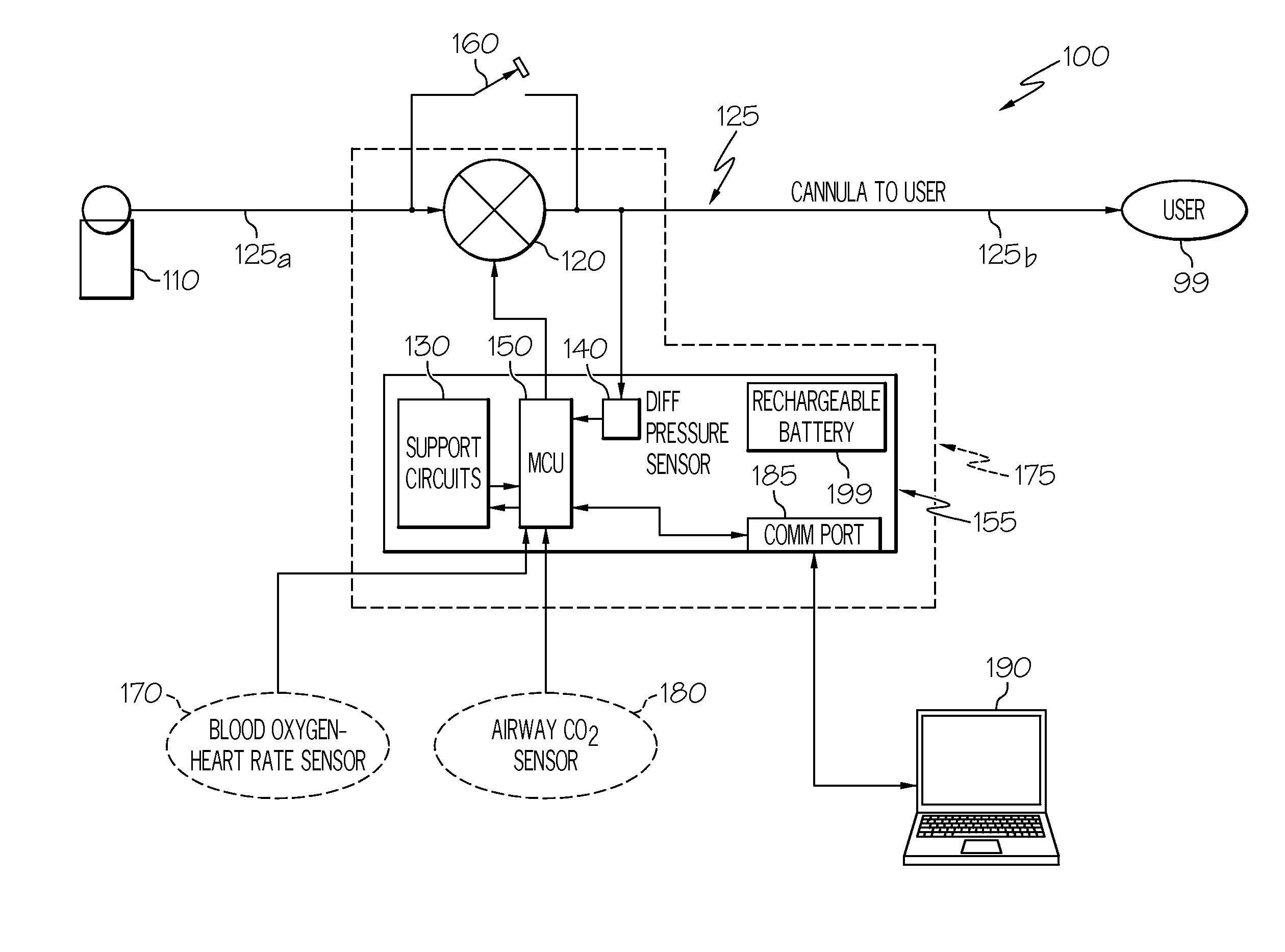

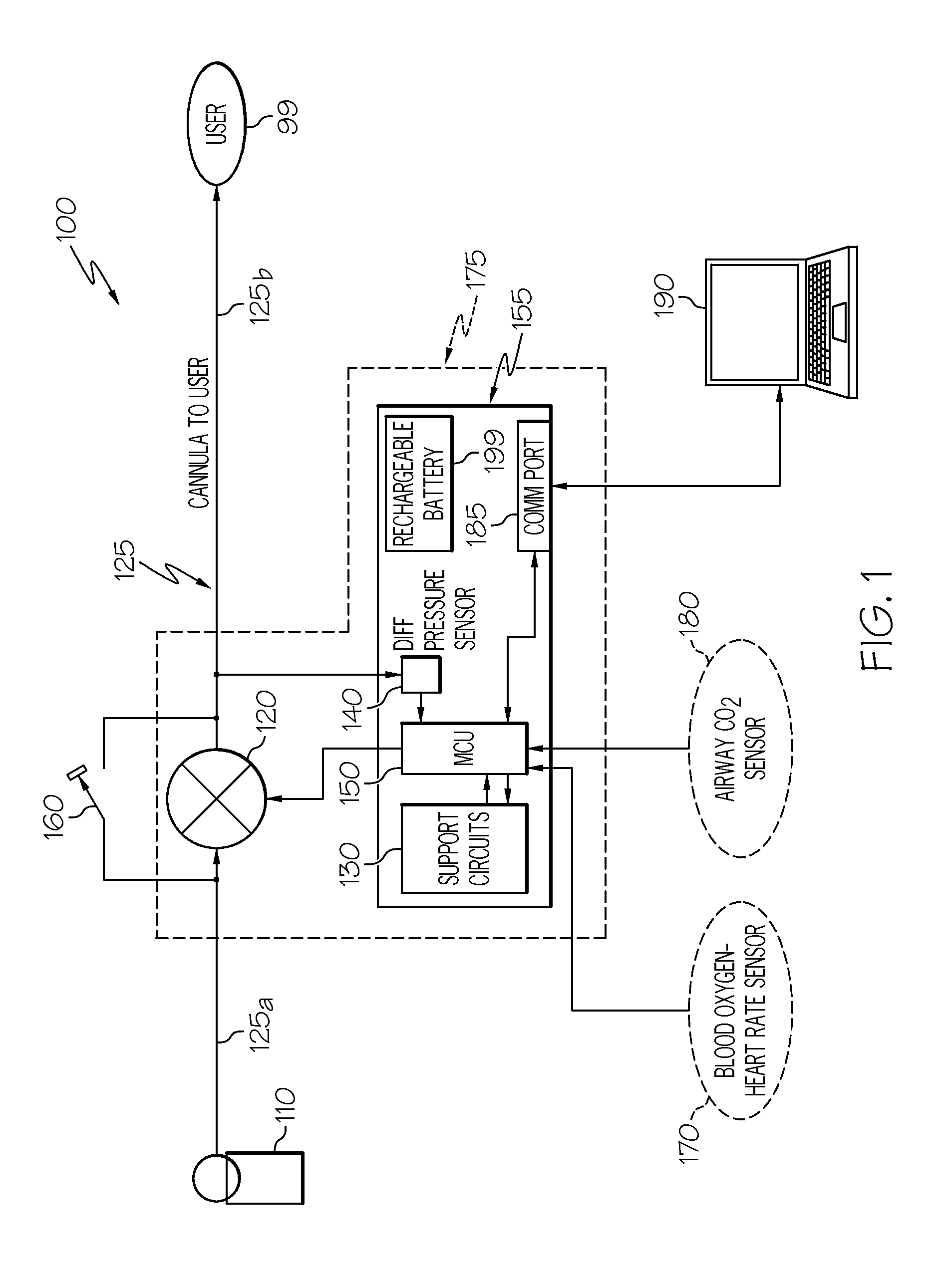

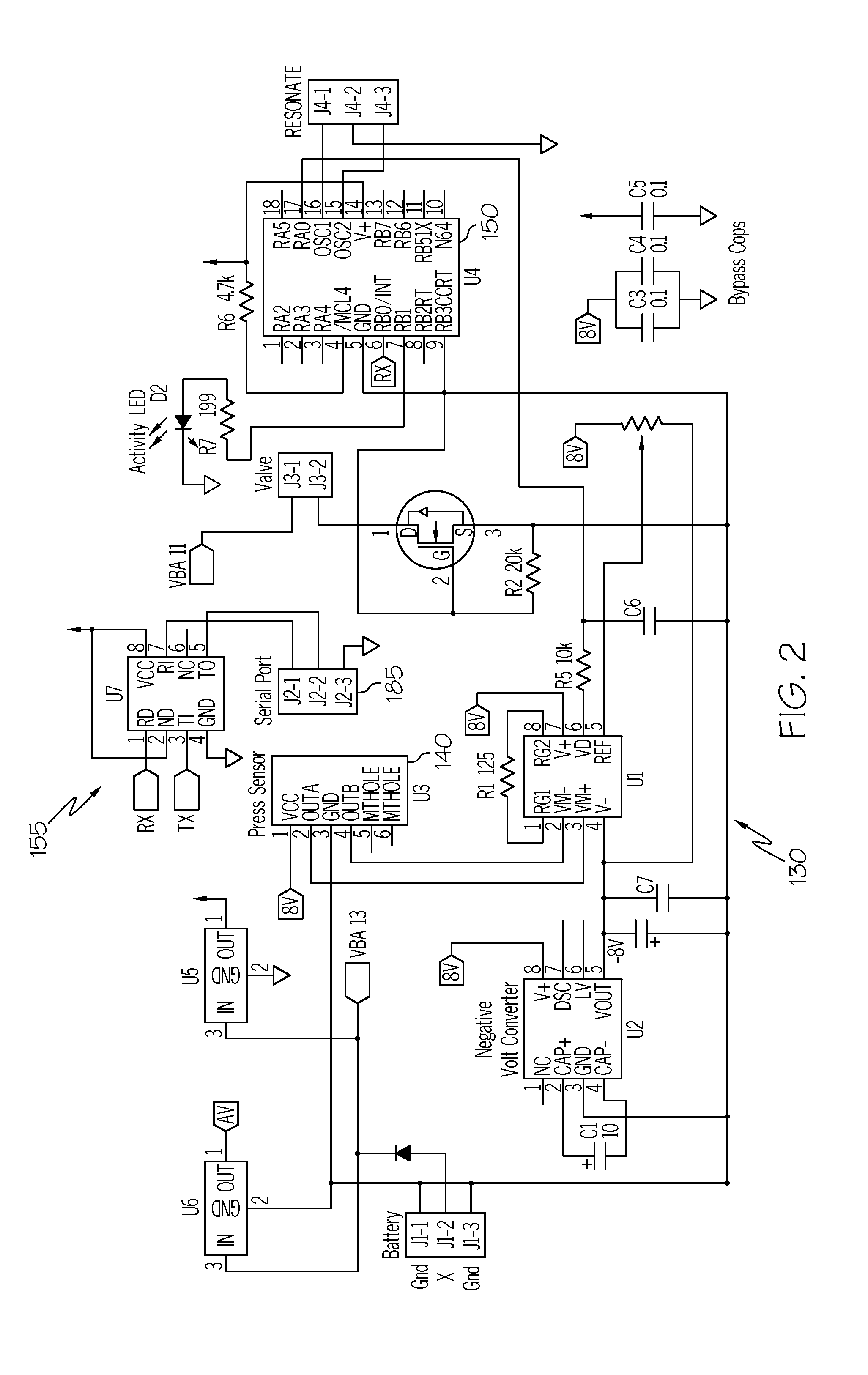

Automated fluid delivery system and method

InactiveUS20130152933A1Convenient amountRespiratorsOperating means/releasing devices for valvesDifferential pressureEngineering

An automated fluid delivery system and method are disclosed. The system includes distensible tubing, a flow controller, and a fluid flow adjustment module. The fluid flow adjustment module may be configured to detect differential pressure in the tubing and adjust the flow controller to provide an amount of fluid through the tubing during inhalation.

Owner:RGT UNIV OF CALIFORNIA

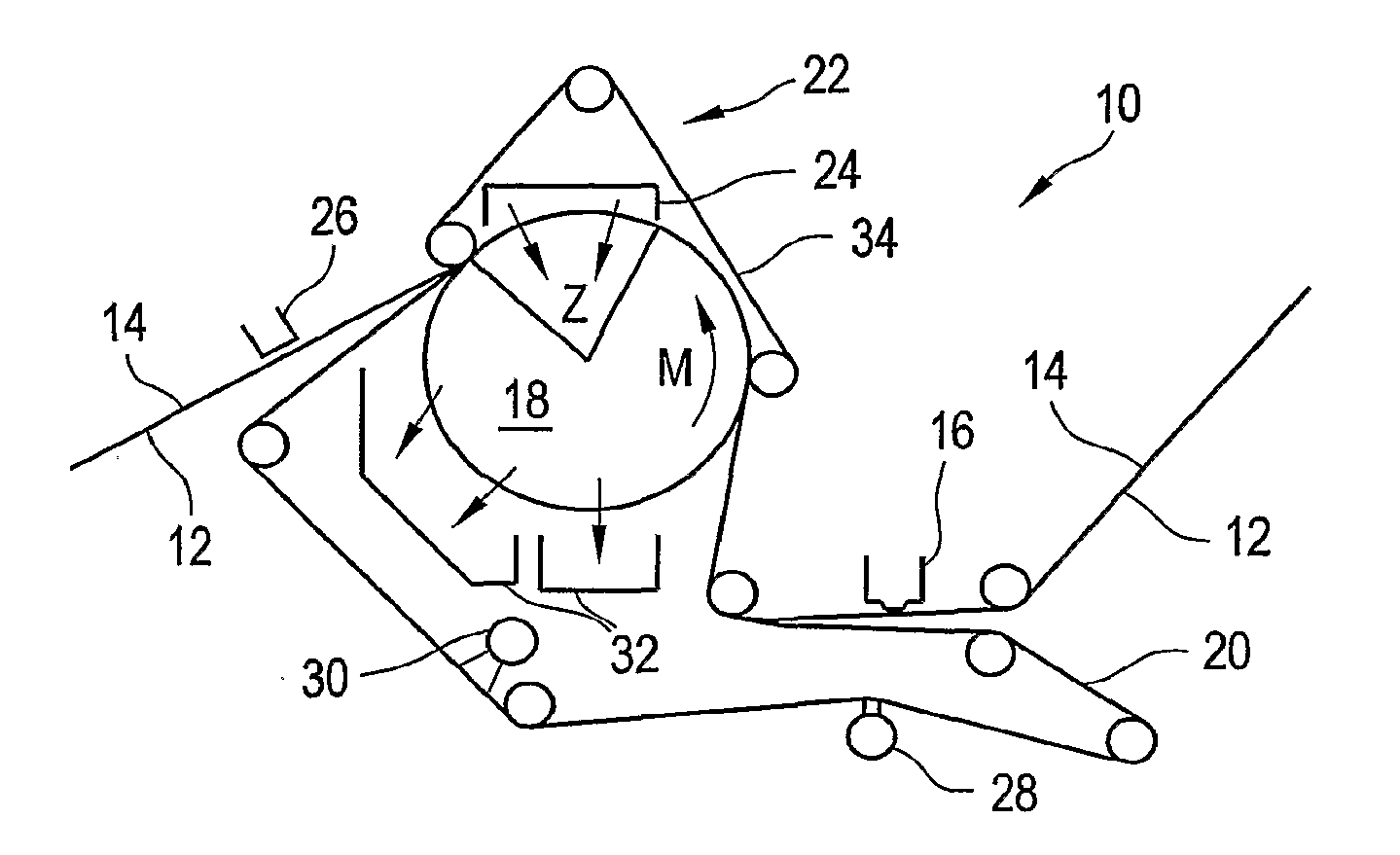

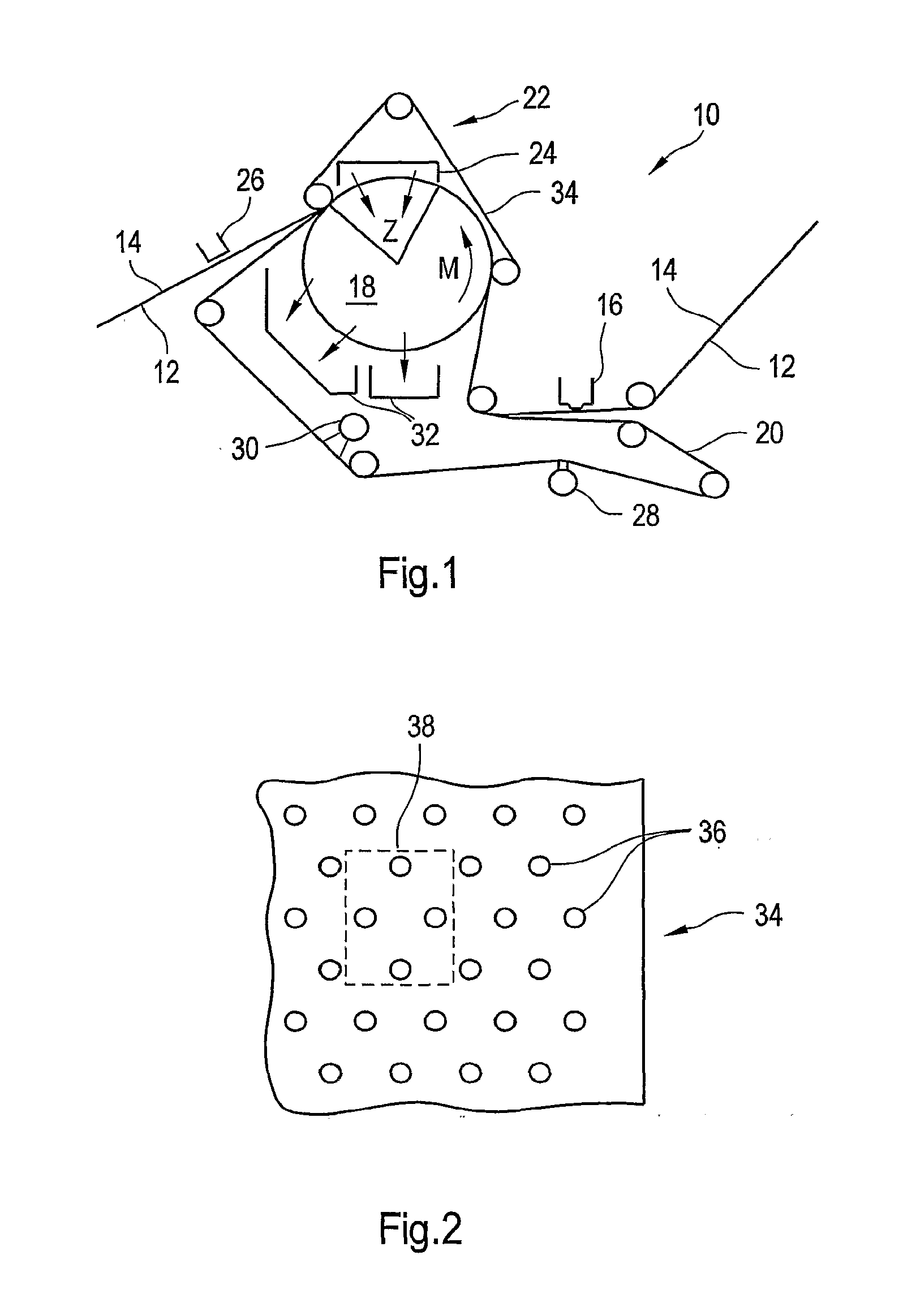

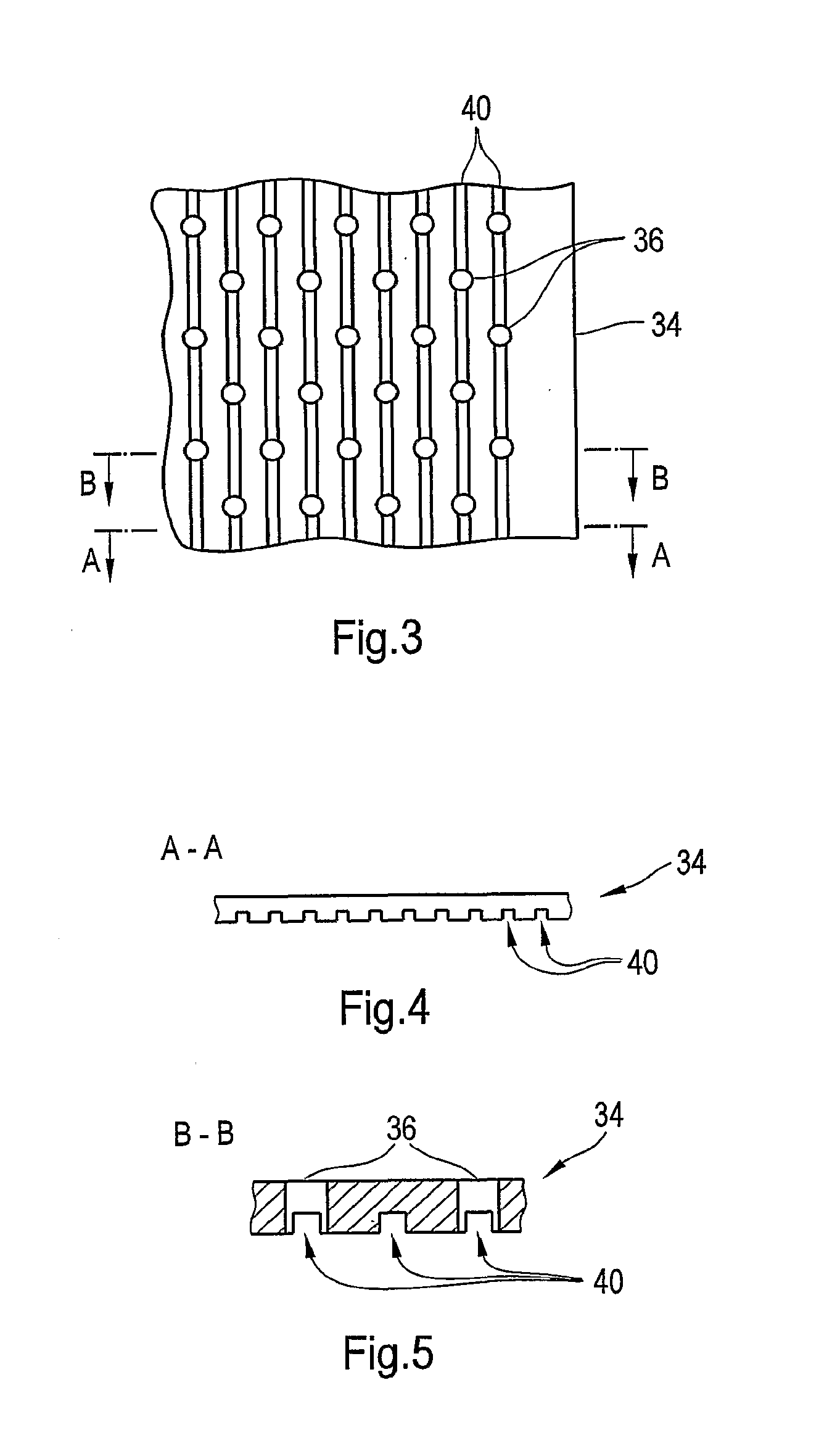

Press section and permeable belt in a paper machine

InactiveUS20100170651A1Large tensionIncrease the opening areaPress sectionDifferential pressureMechanical pressure

A pressing arrangement including at least one first fabric and second fabric both being permeable. A paper web is disposed between the first fabric and the second fabric. A pressure producing element is in contact with the first fabric. A support surface of a supporting structure is in contact with the second fabric. A differential pressure is provided between the first fabric and the support surface that acts on the first fabric, the paper web, and the second fabric, whereby the paper web is subjected to mechanical pressure and experiences a predetermined hydraulic pressure so as to cause water to be drained from the paper web. The pressing arrangement is structured and arranged to allow air to flow in a direction from the first fabric through the paper web and through the second fabric.

Owner:VOITH PATENT GMBH

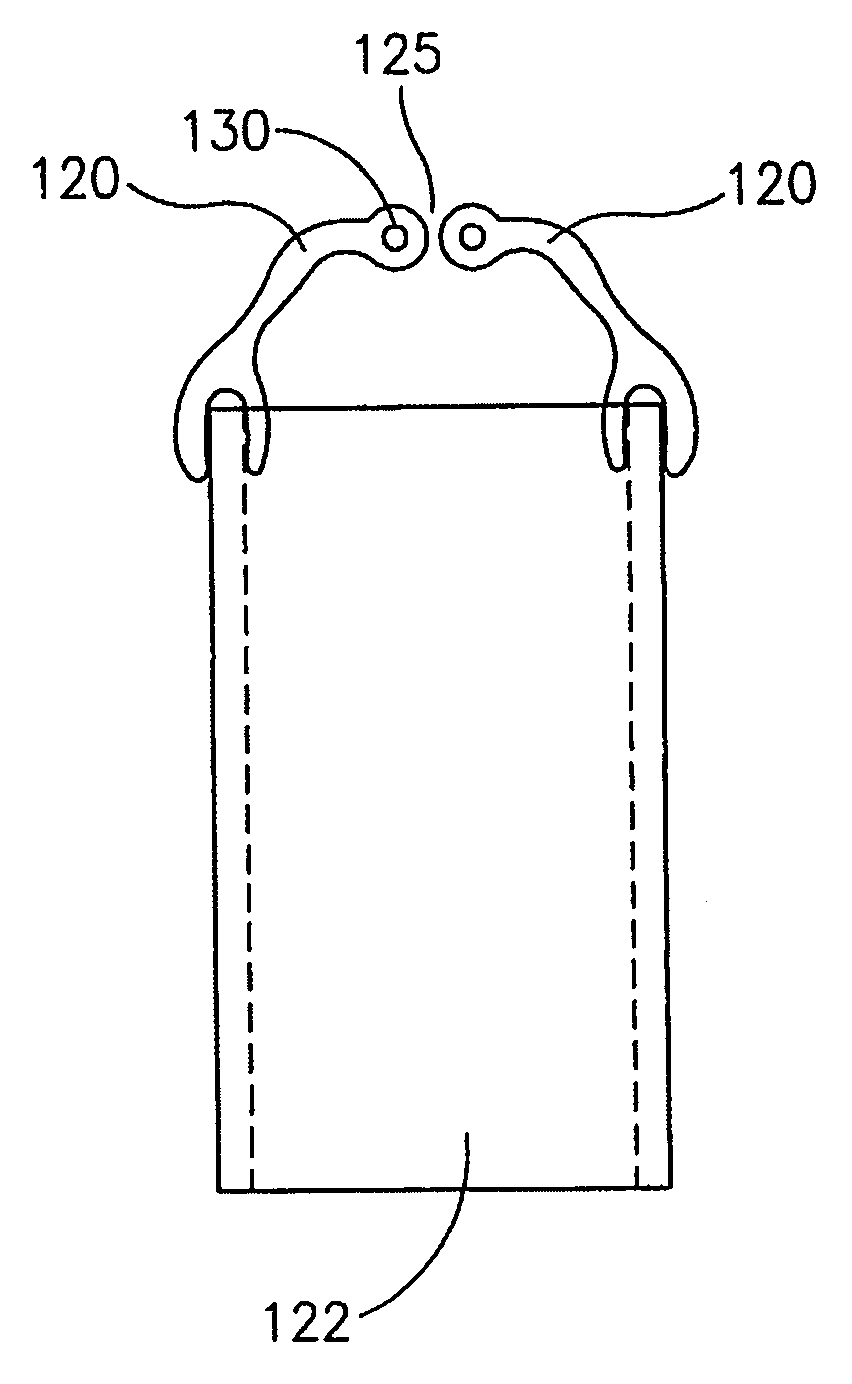

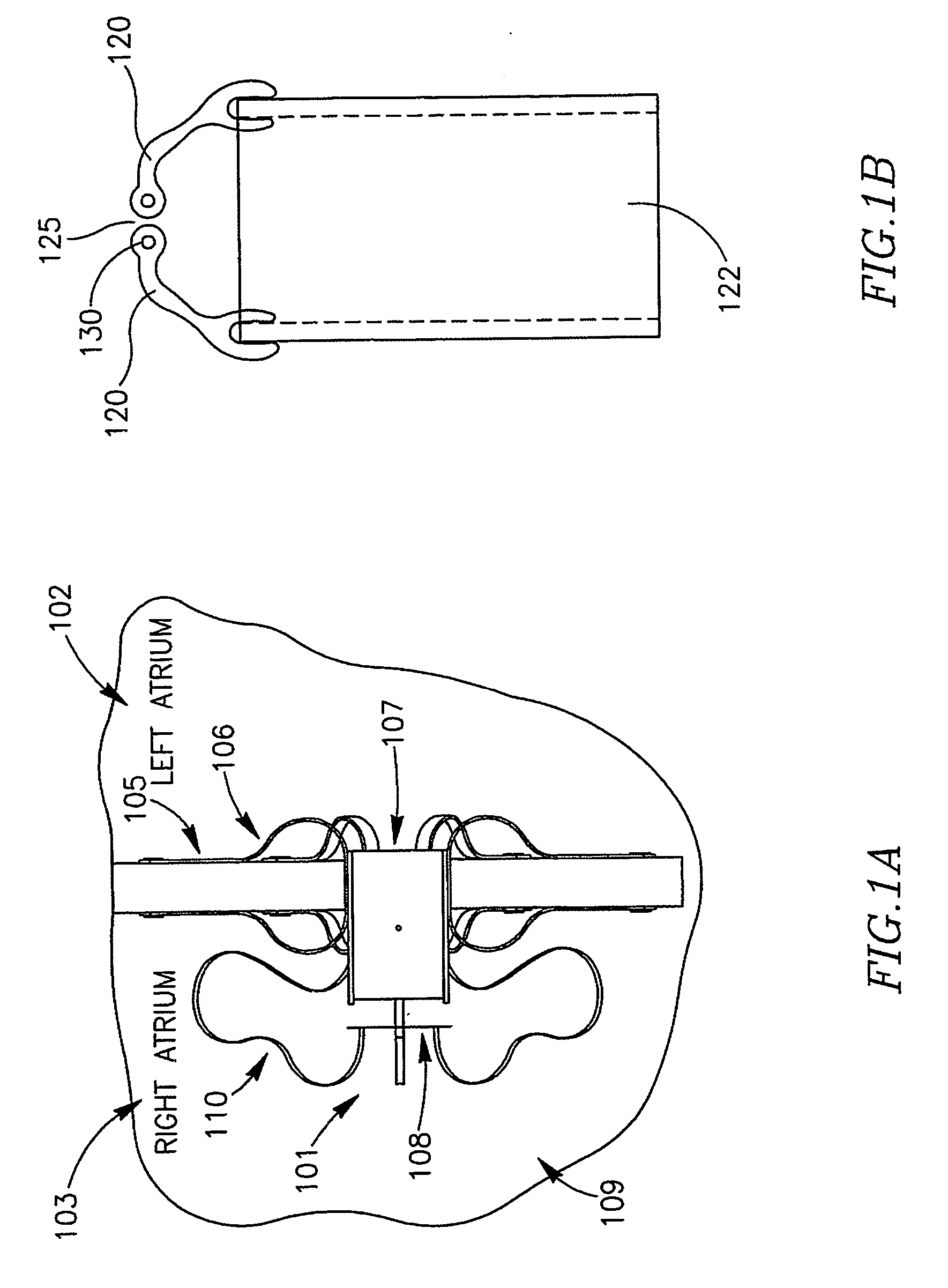

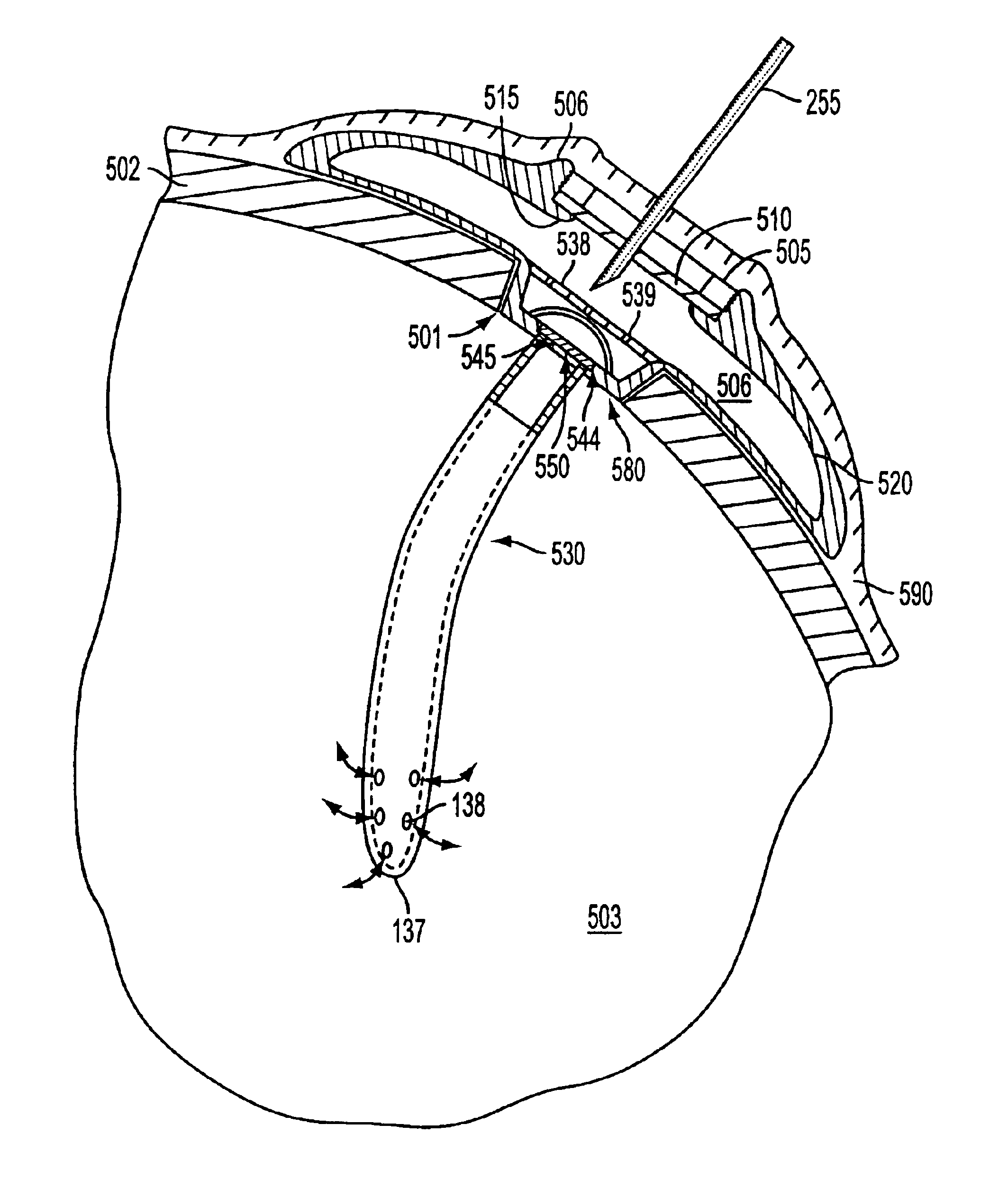

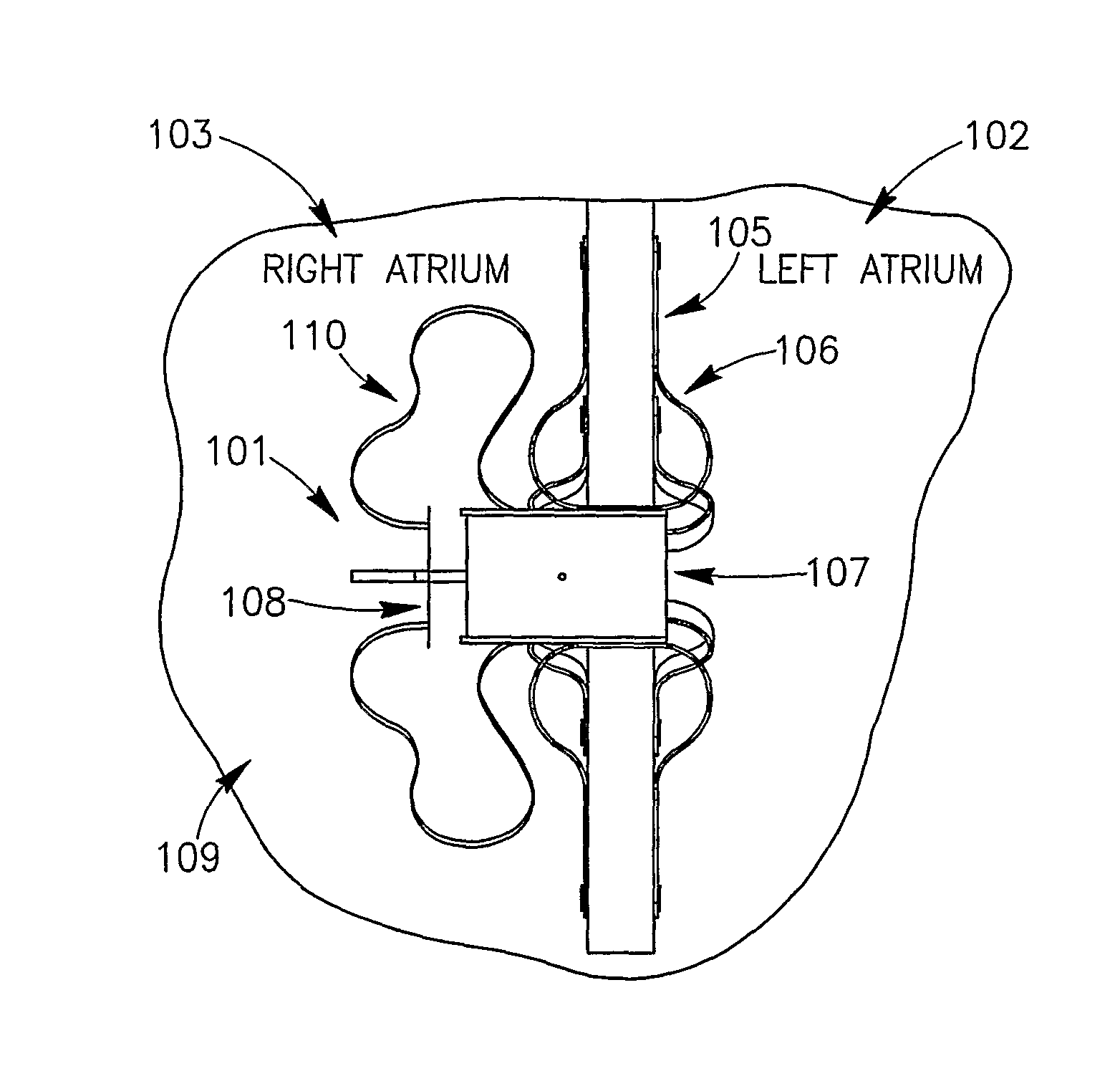

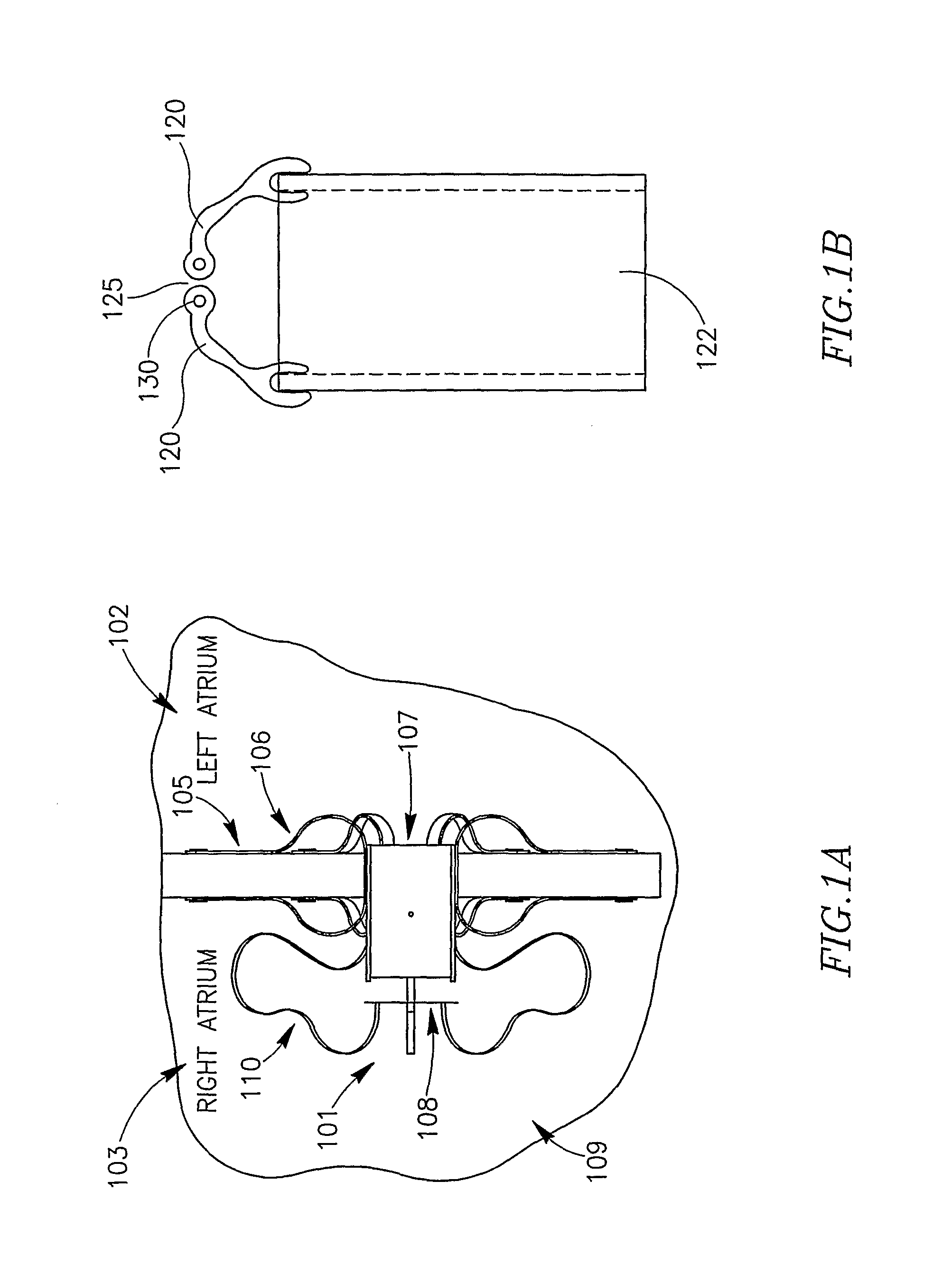

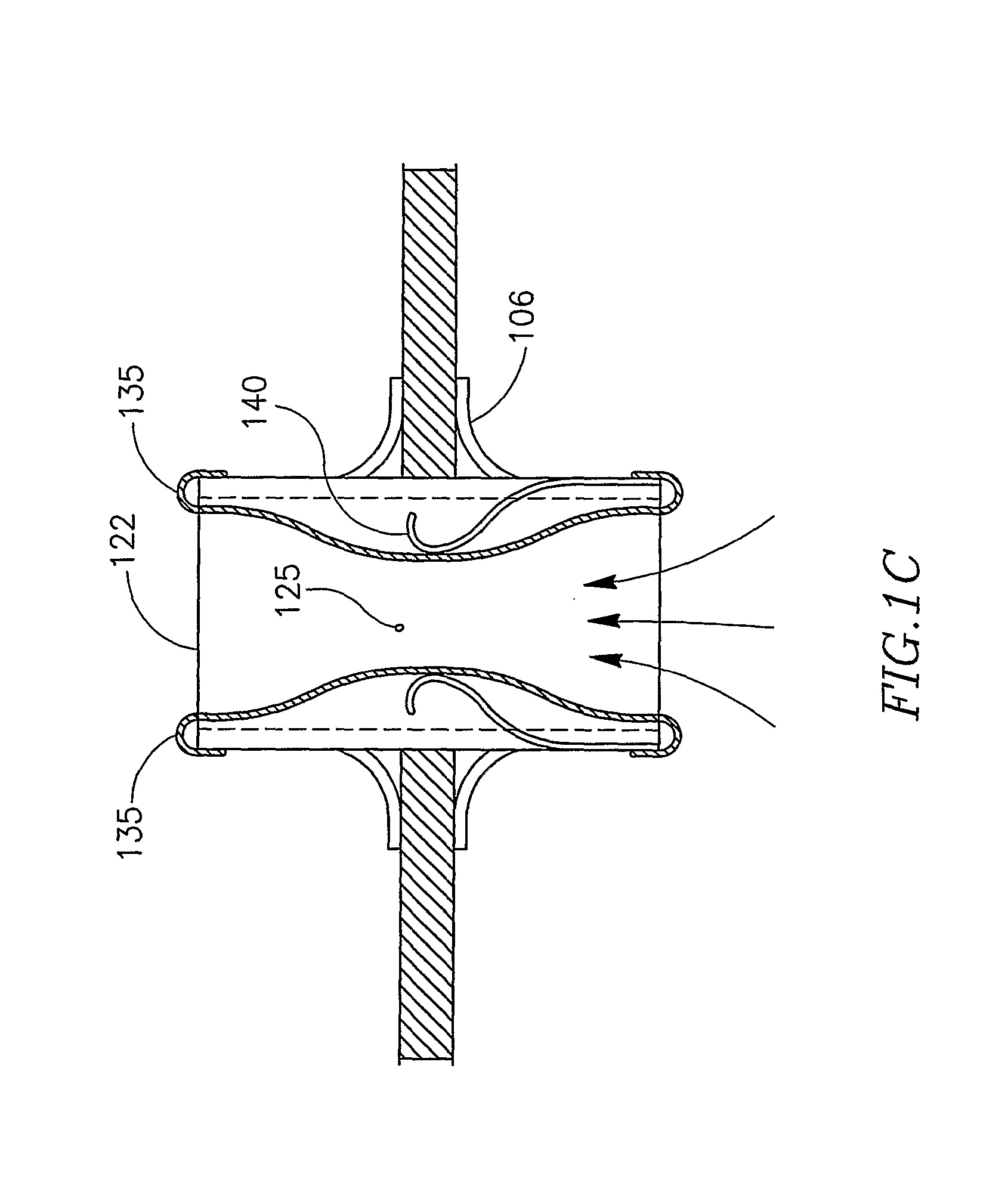

Device and method for controlling in-vivo pressure

A differential pressure regulating device is provided for controlling in-vivo pressure in a body, and in particular in a heart. The device may include a shunt being positioned between two or more lumens in a body, to enable fluids to flow between the lumens, and an adjustable flow regulation mechanism being configured to selectively cover an opening of the shunt, to regulate the flow of fluid through the shunt in relation to a pressure difference between the body lumens. In some embodiments a control mechanism coupled to the adjustable flow regulation may be provided, to remotely activate the adjustable flow regulation mechanism.

Owner:ATRIA MEDICAL

Detection device for air filter

InactiveUS20070013534A1Mechanical apparatusSpace heating and ventilation safety systemsDifferential pressureAir filter

A wireless sensor unit detects an out-of-range condition of an air filter in a HVAC system by sensing the air flow passing across the filter or by pressure differential across the air filter. A The sensor unit sends a signal to a receiver unit that can be positioned a distance from the sensor unit to process the signal sent by the sensor unit and provide audio and / or visual warning of the air filter condition.

Owner:DIMAGGIO EDWARD G

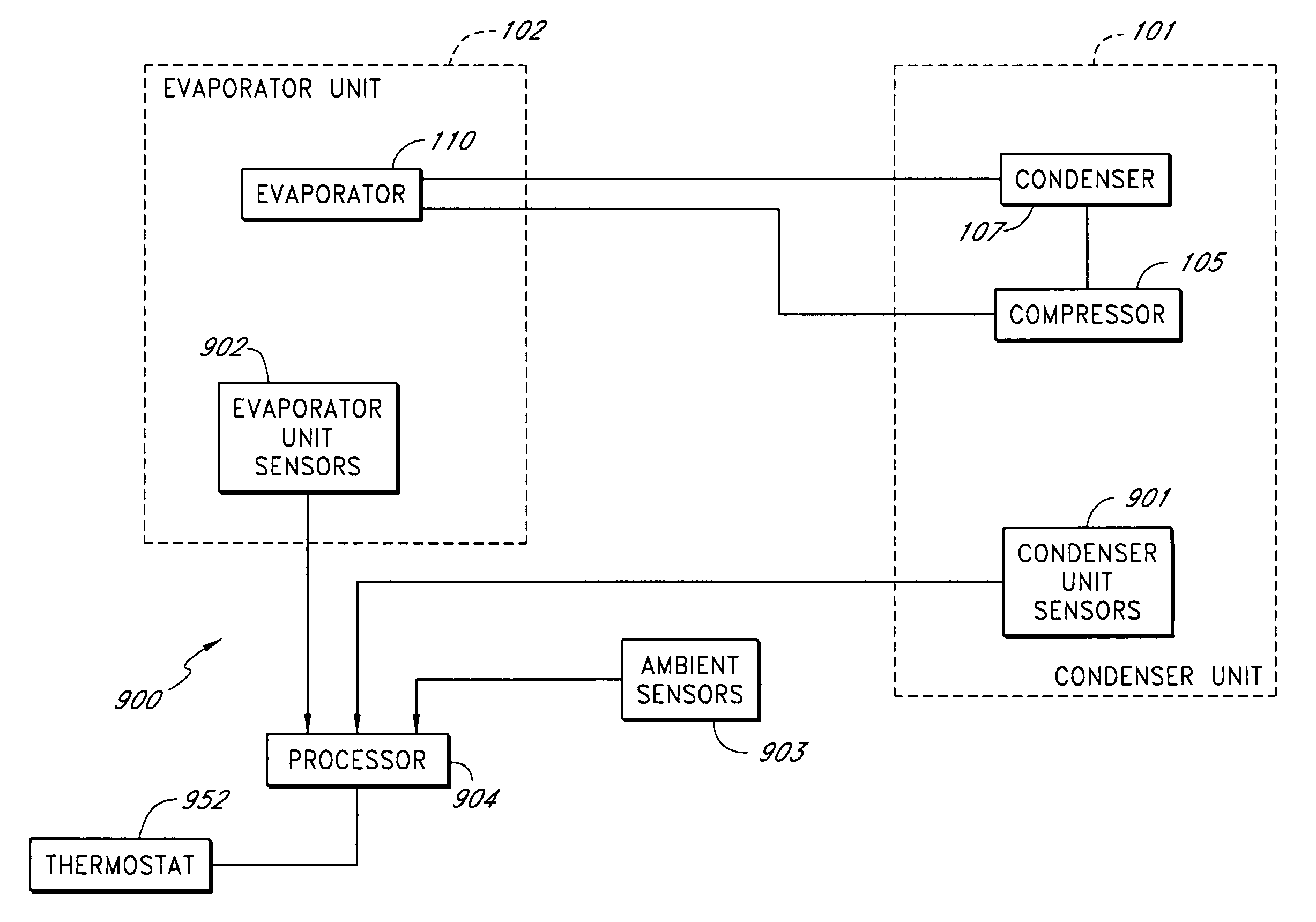

Air filter monitoring system

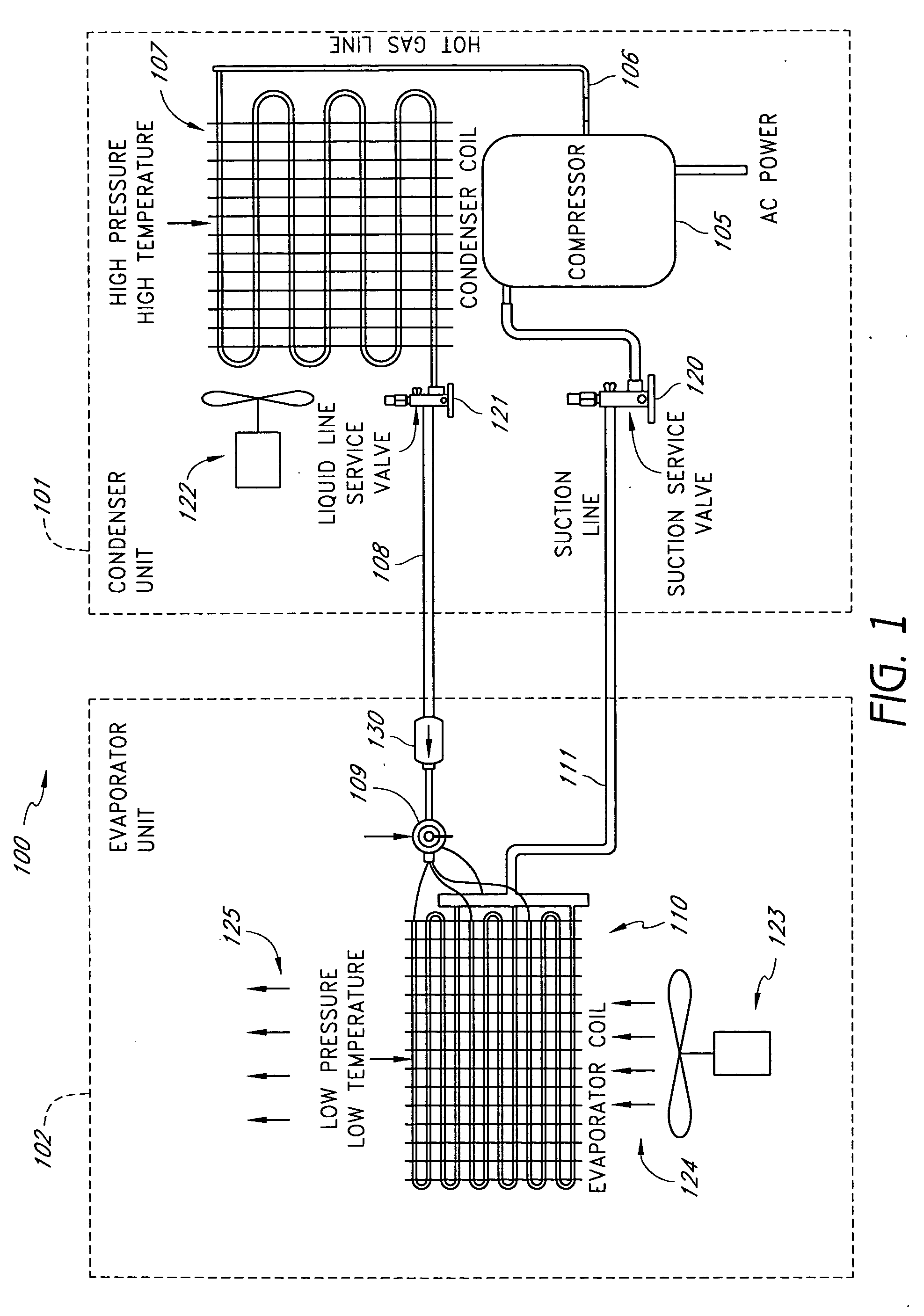

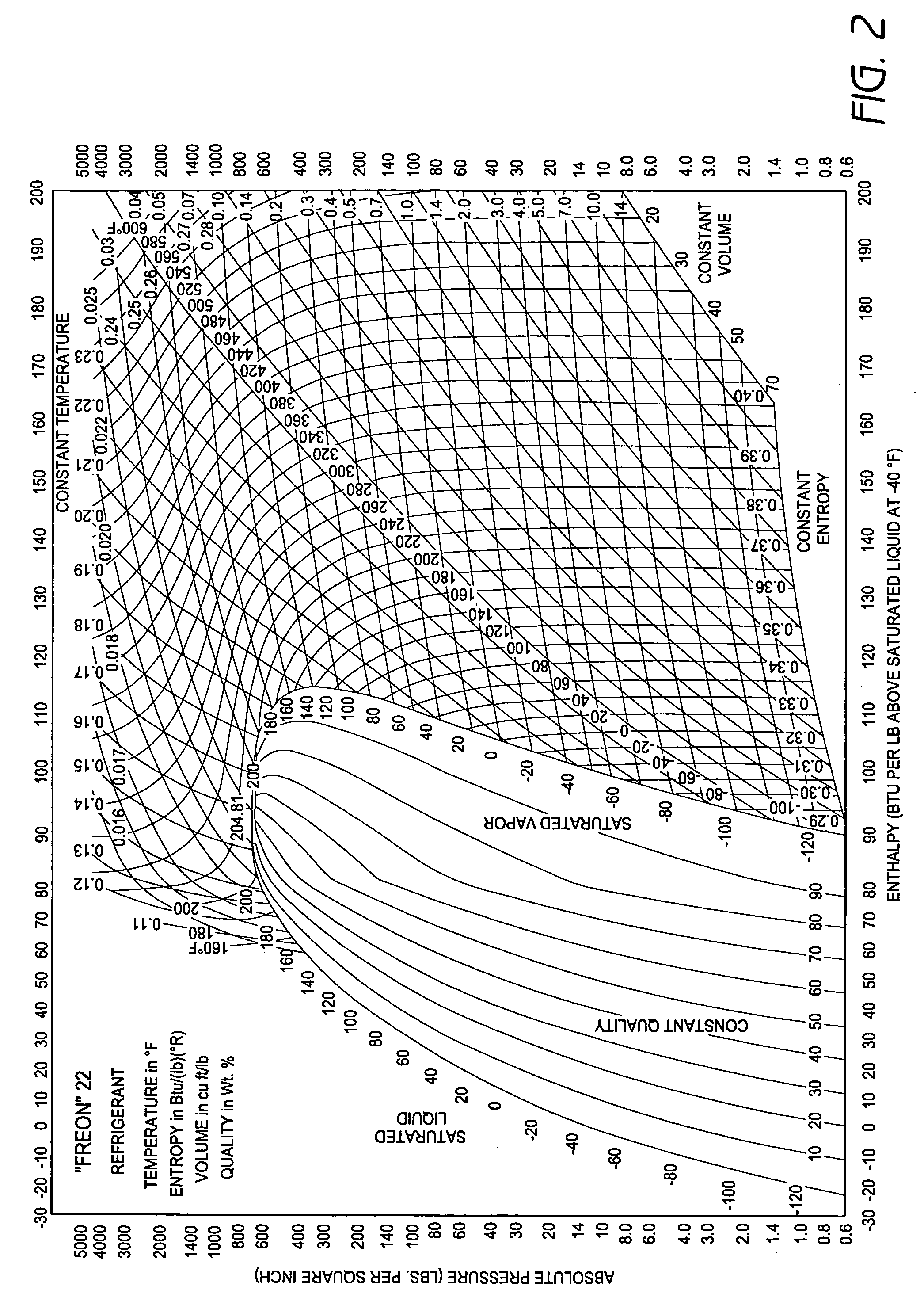

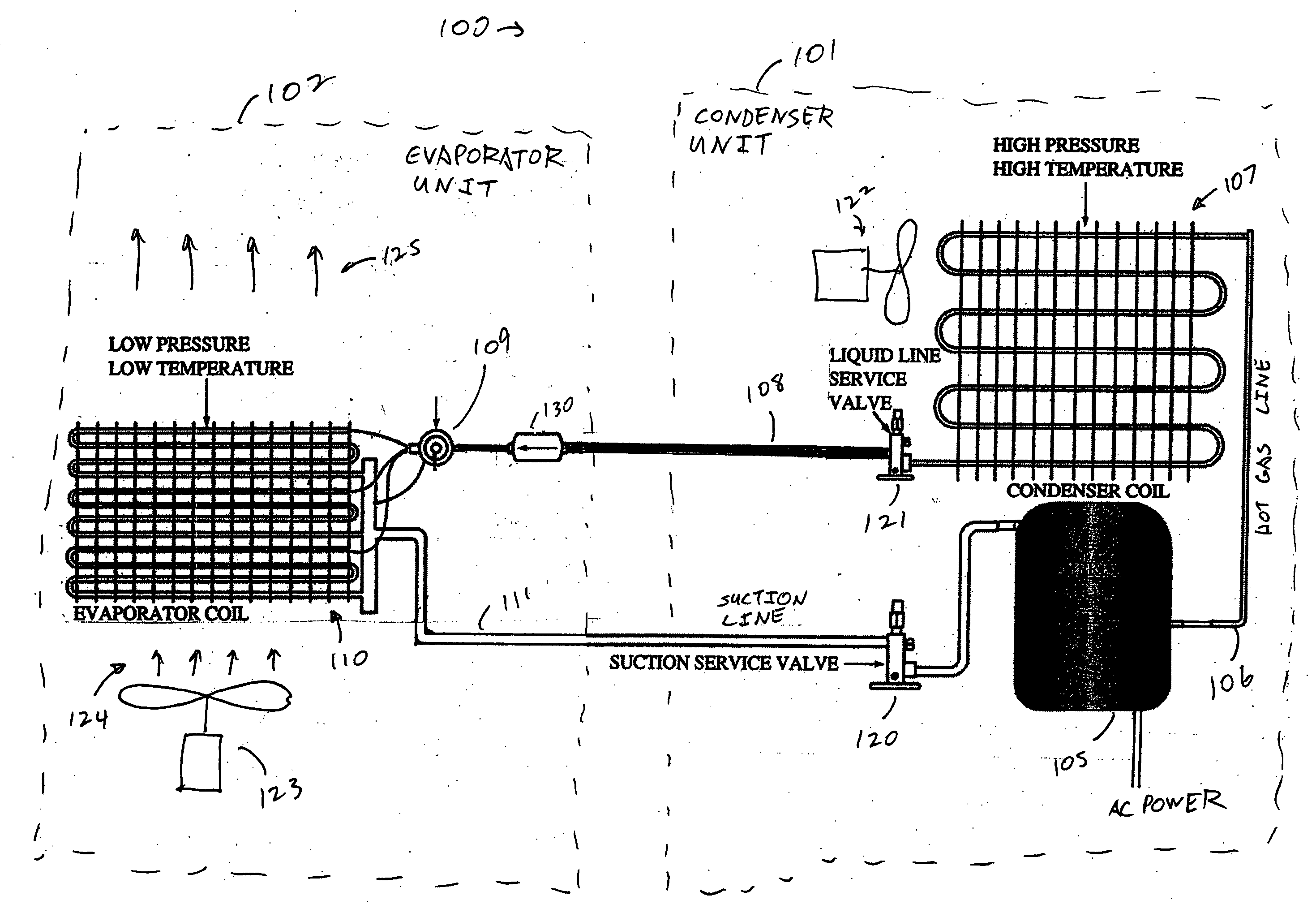

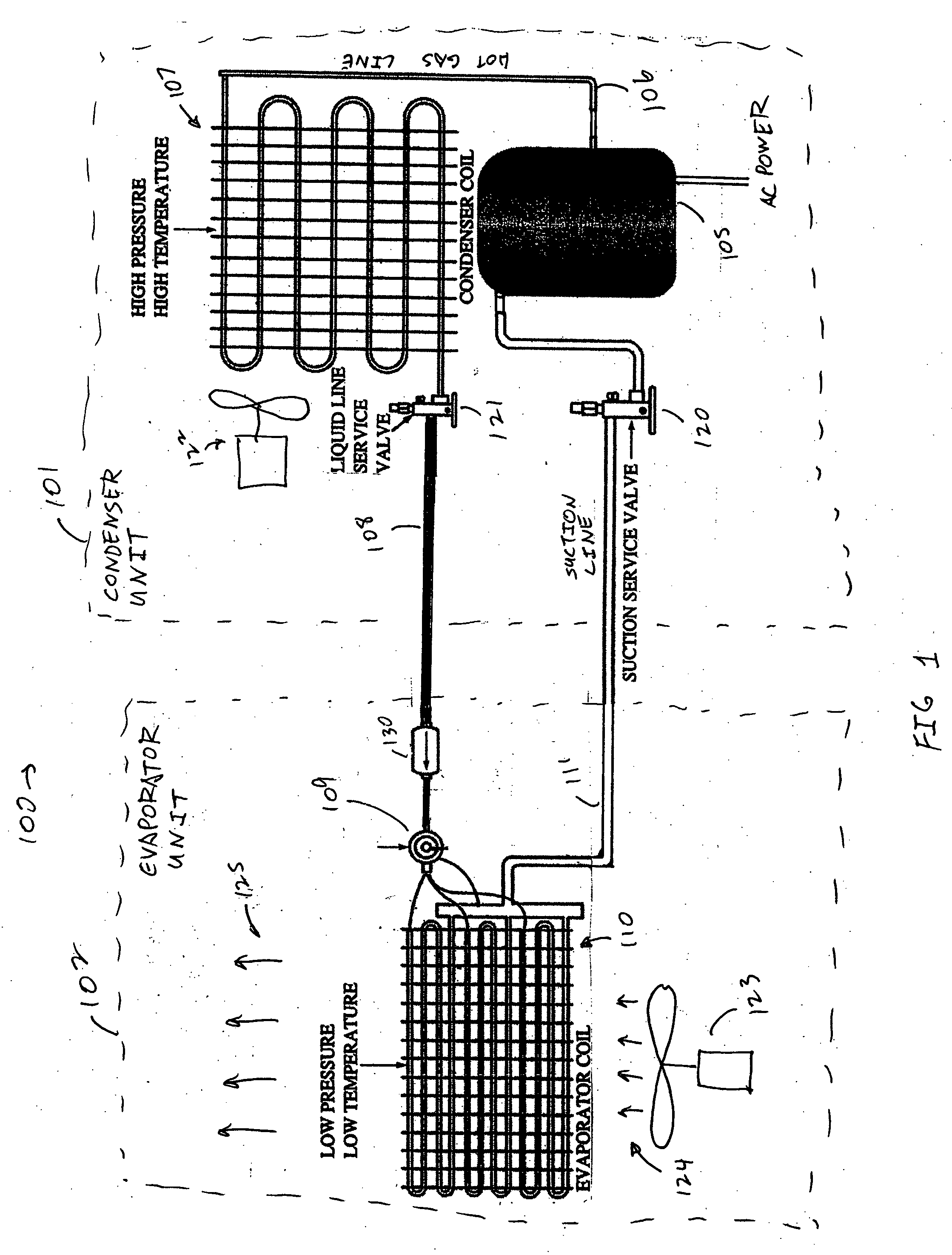

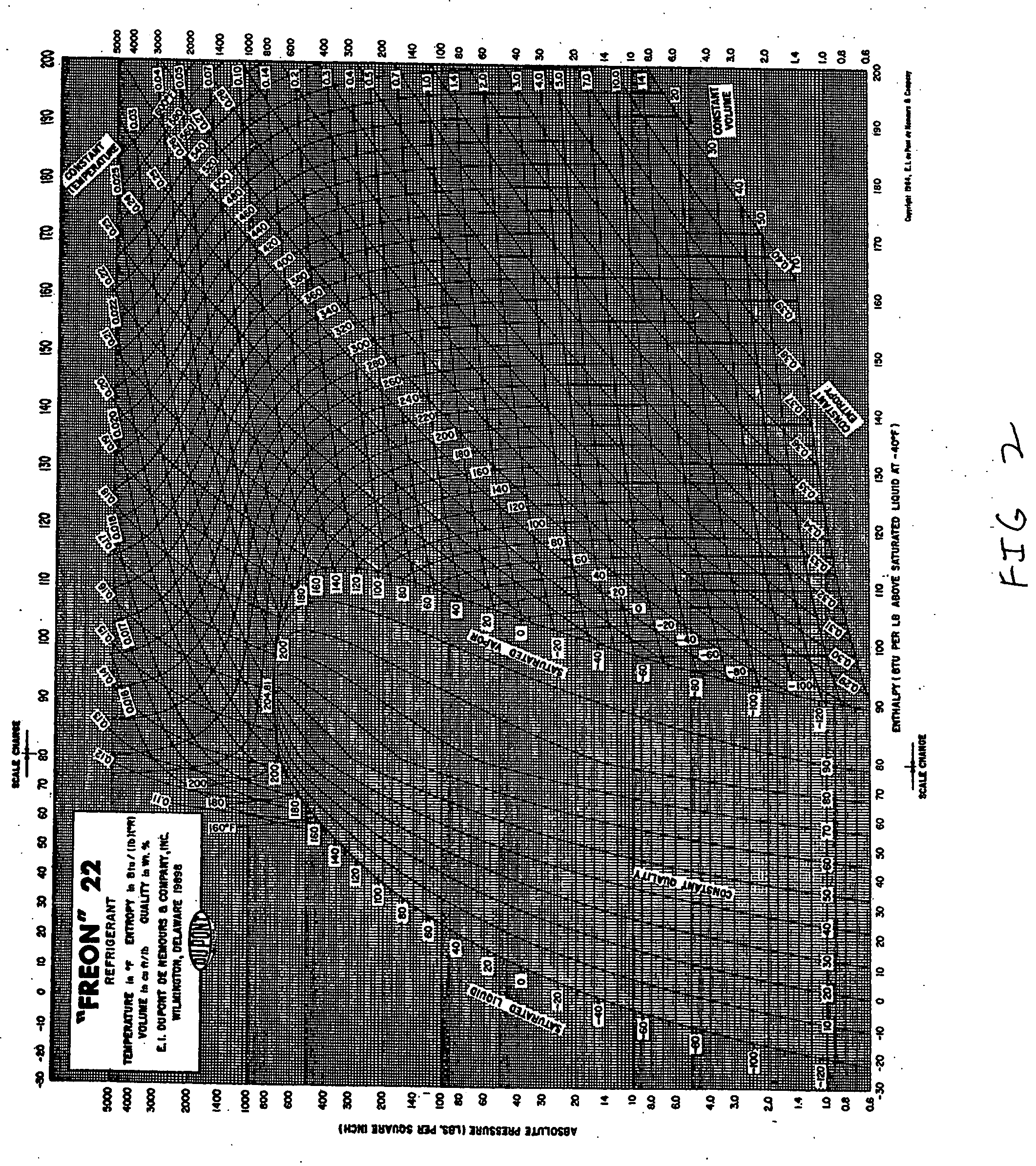

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:EMERSON CLIMATE TECH INC

Method and apparatus for monitoring refrigerant-cycle systems

ActiveUS20060032245A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

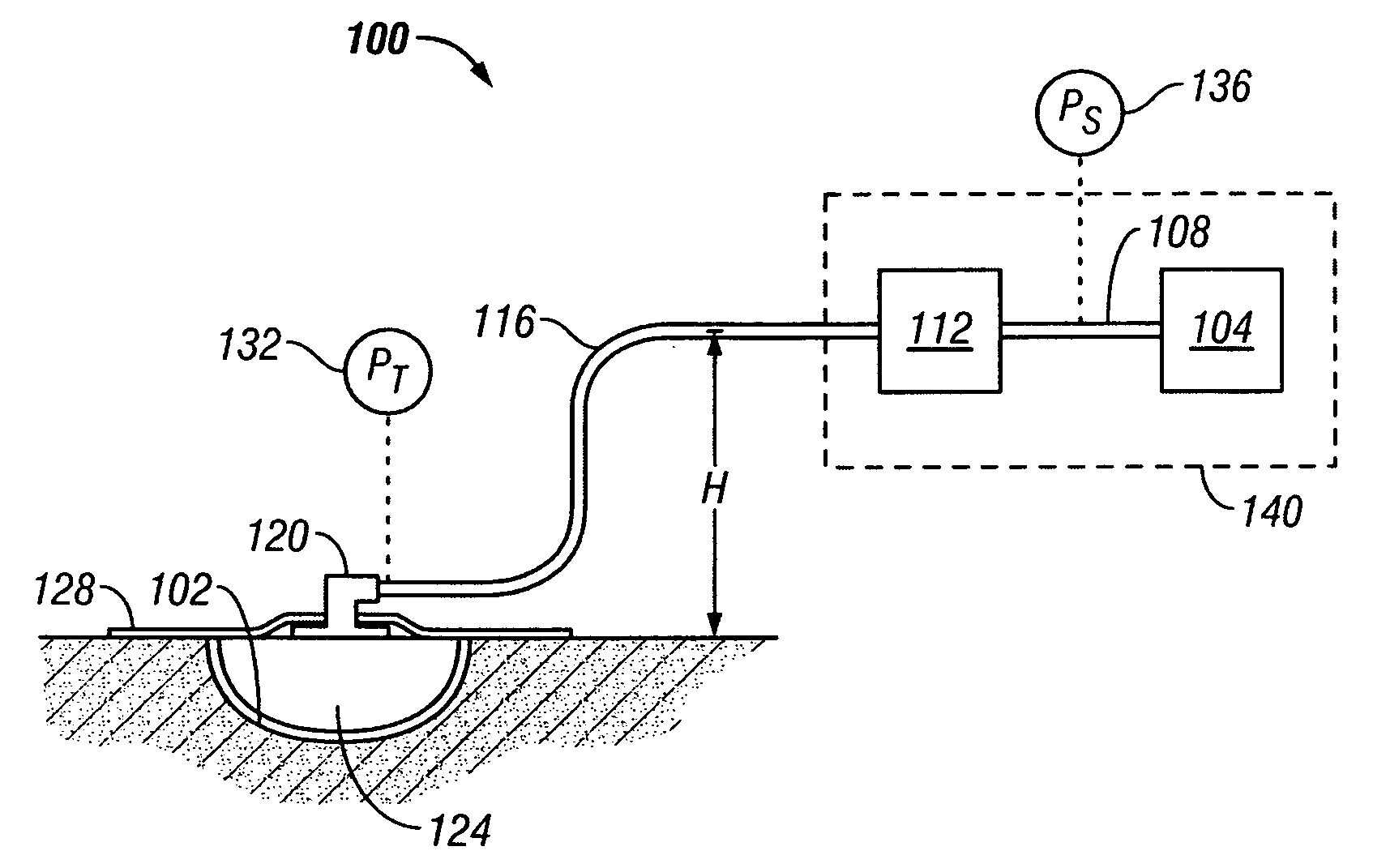

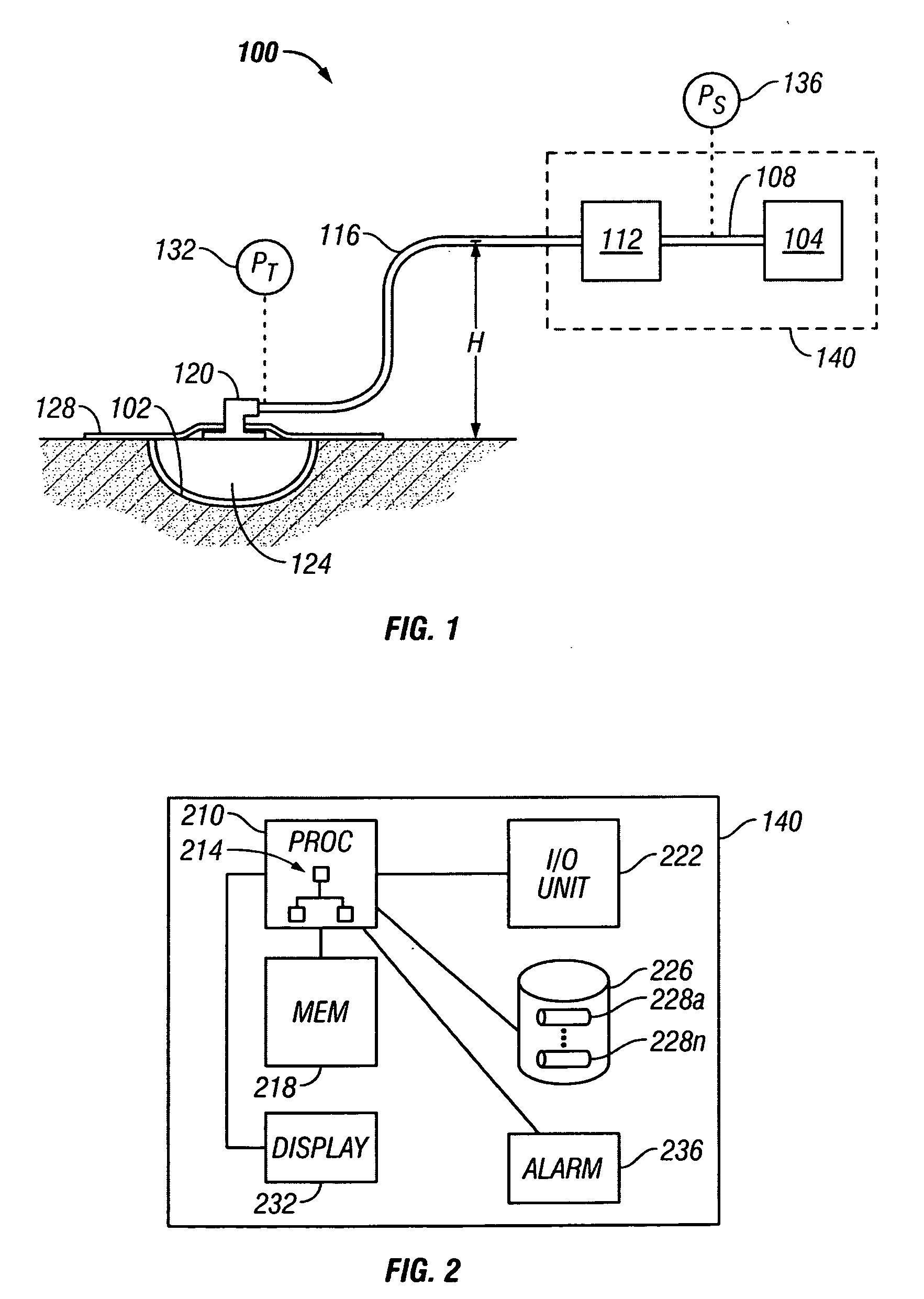

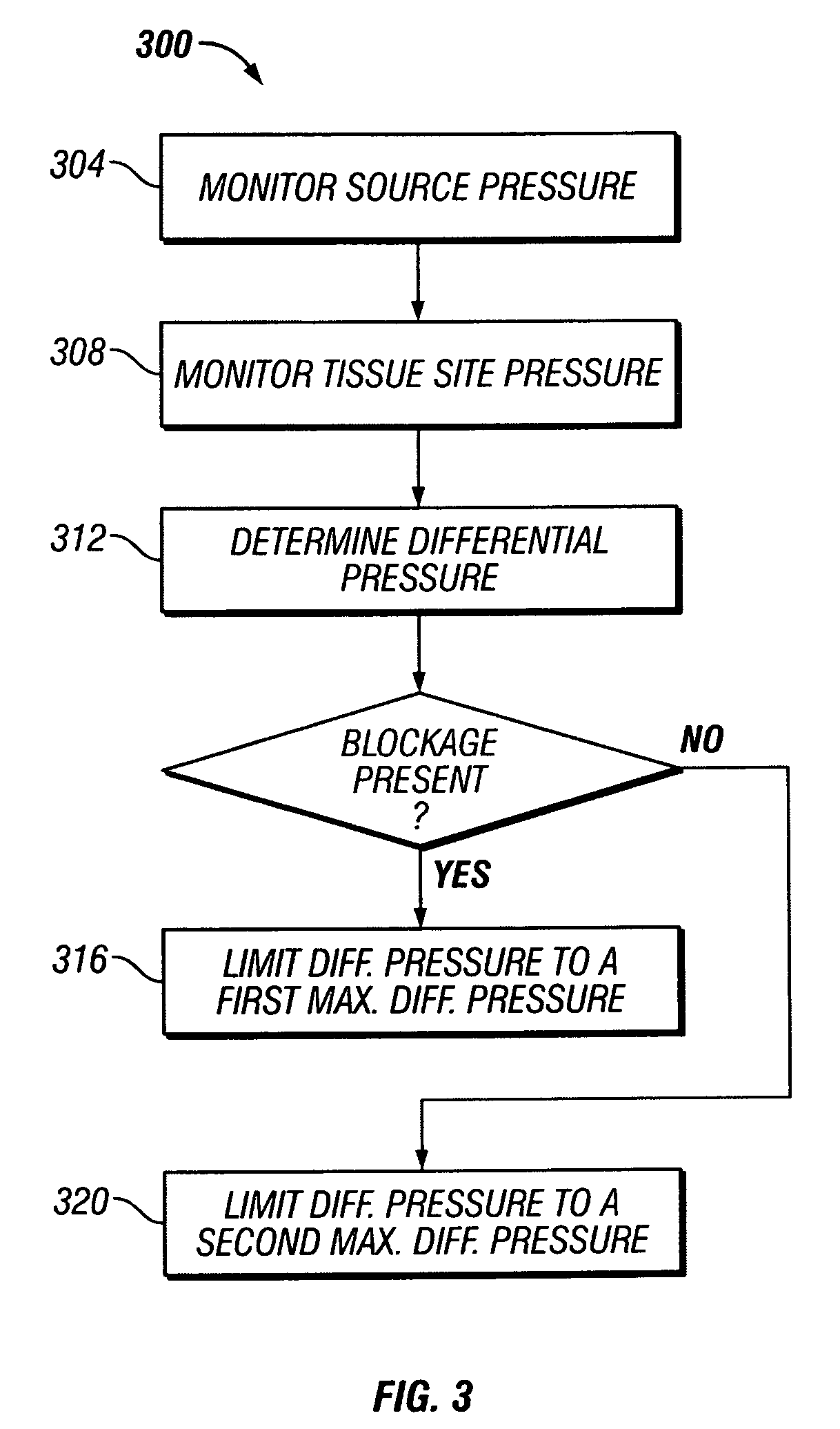

Reduced pressure treatment system having blockage clearing and dual-zone pressure protection capabilities

A method of treating a tissue site is provided. The method includes applying a reduced pressure to a tissue site with a reduced pressure source. A source pressure is monitored at the reduced pressure source, and a differential pressure is determined between the source pressure and the desired tissue site pressure. If a blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a first maximum differential pressure. If no blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a second maximum differential pressure.

Owner:3M INNOVATIVE PROPERTIES CO

Expandable underreamer/stabilizer

A downhole tool is disclosed that functions as an underreamer, or alternatively, as a stabilizer in an underreamed borehole. An embodiment of the tool includes one or more moveable arms disposed within a body having a flowbore therethrough in fluid communication with the wellbore annulus. The tool alternates between collapsed and expanded positions in response to differential fluid pressure between the flowbore and the wellbore annulus. In one embodiment, the tool moves automatically in response to differential pressure. In a second embodiment, the tool must be selectively actuated before it is moveable. When the tool expands, the arms are preferably translated axially upwardly, while simultaneously being extended radially outwardly from the body. The expanded tool diameter is adjustable at the surface without changing components. The arms may include borehole engaging pads that comprise cutting structures or wear structures or both, depending upon the function of the tool.

Owner:SMITH INT INC

Implantable refillable and ported controlled release drug delivery device

InactiveUS6852106B2Prevent leakageEnhanced advantageSurgeryMedical devicesRate limitingDifferential pressure

An implantable, refillable, rate controlled drug delivery device is disclosed that includes a base structure having at least a first opening and a second opening, the base structure defining a chamber, a septum covering the first opening and configured to substantially prevent leakage from the first opening to an exterior of the device, a drug delivery tube comprising a first and second distal end, wherein the first distal end of the tube communicates with the chamber through the second opening, and at least one rate-limiting permeable membrane disposed across a passage between the base structure and the second distal end of the drug delivery tube, which membrane passively regulates drug delivery. The drug delivery device is used to provide controlled drug delivery to an internal portion of the body and is advantageously leak-proof and does not rely on a pressure differential to drive the drug from the device.

Owner:CONTROL DELIVERY SYST

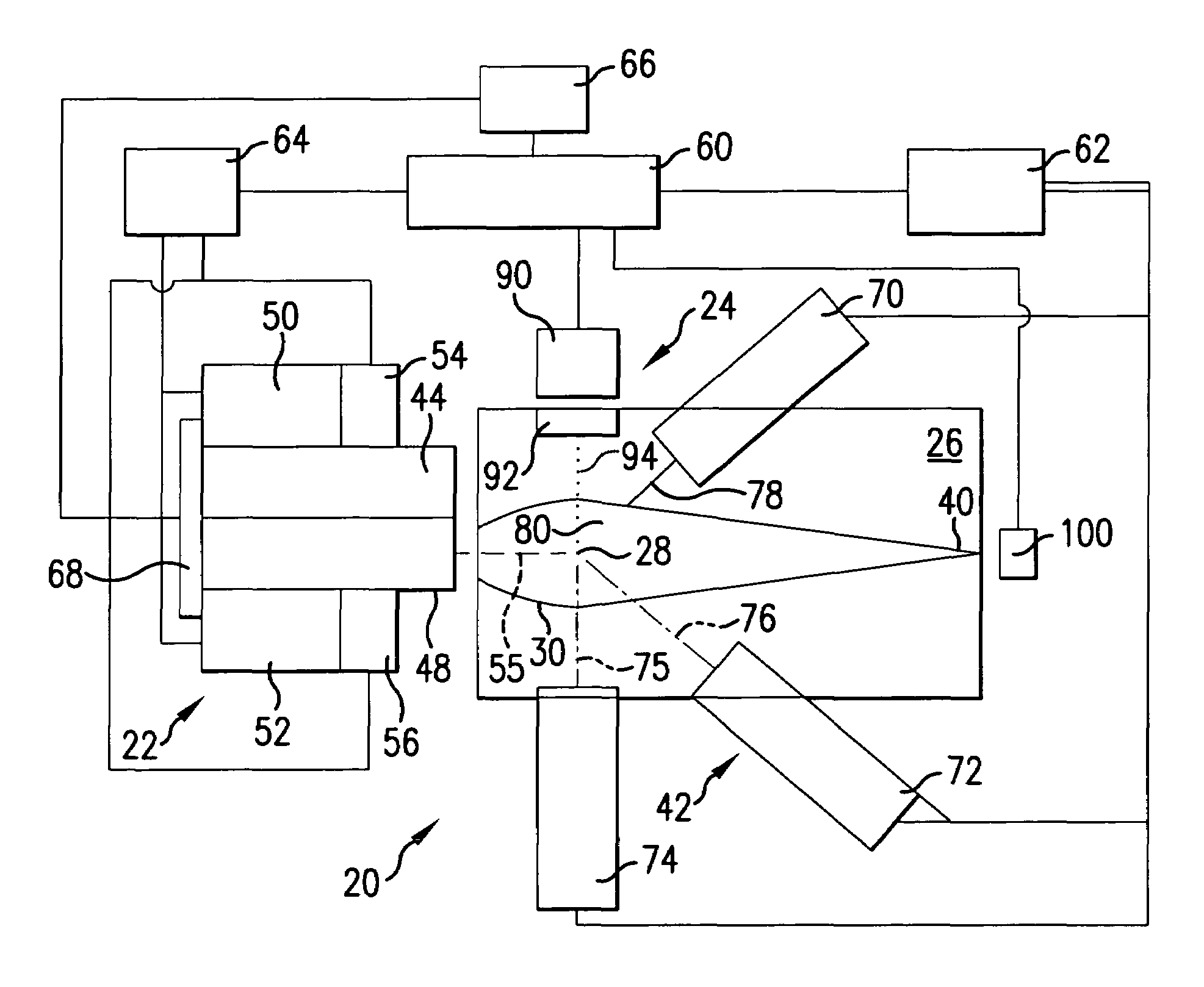

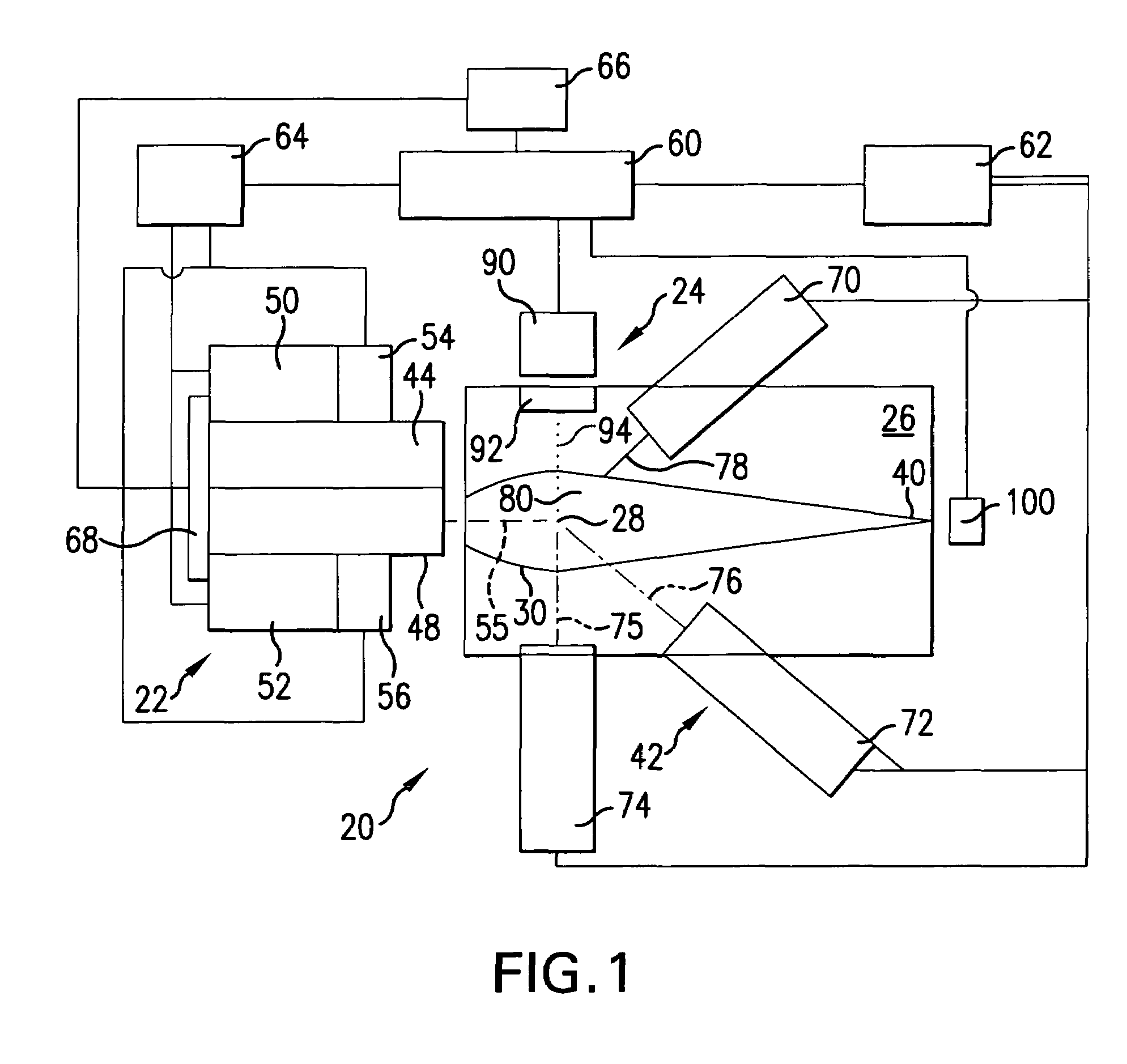

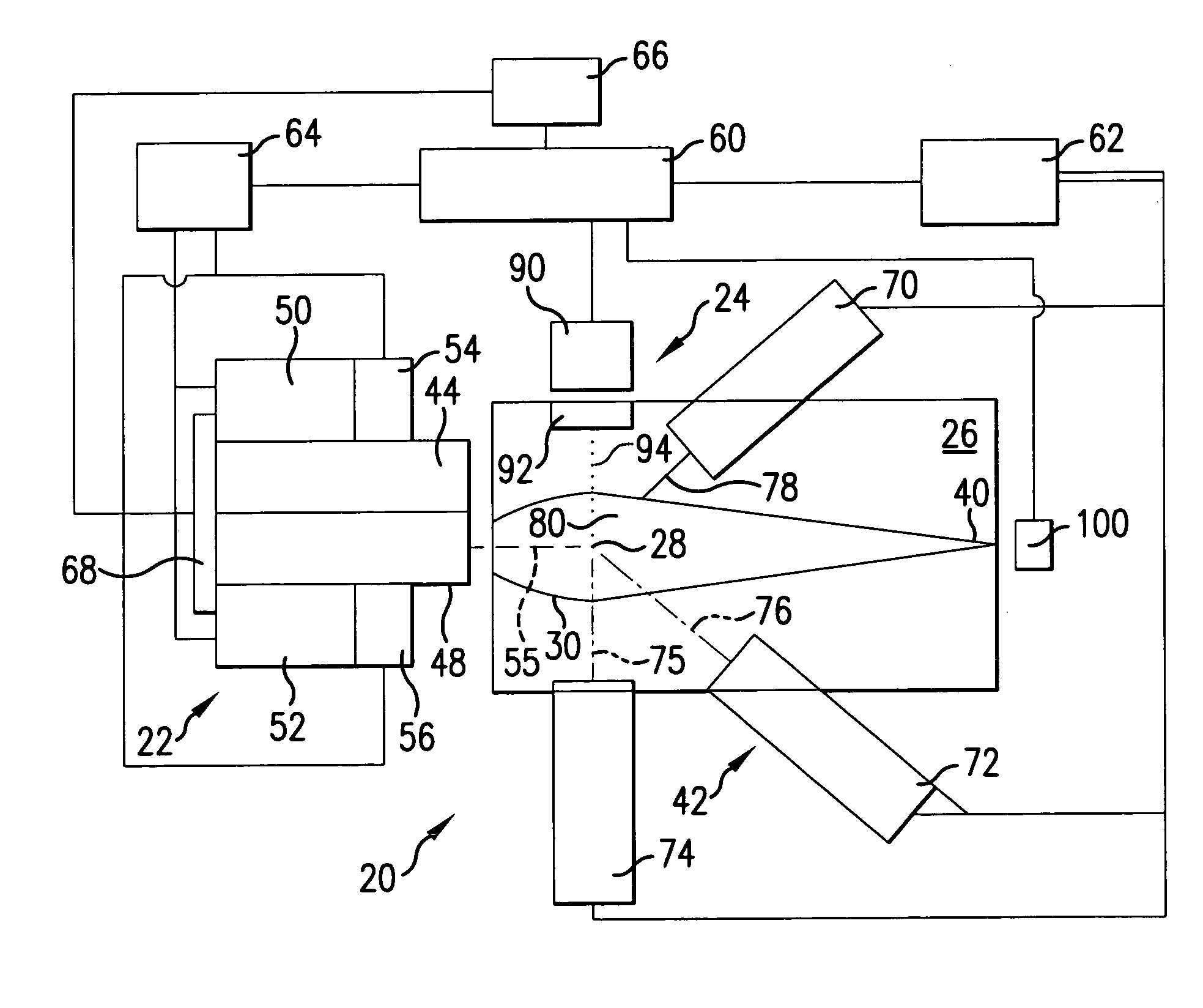

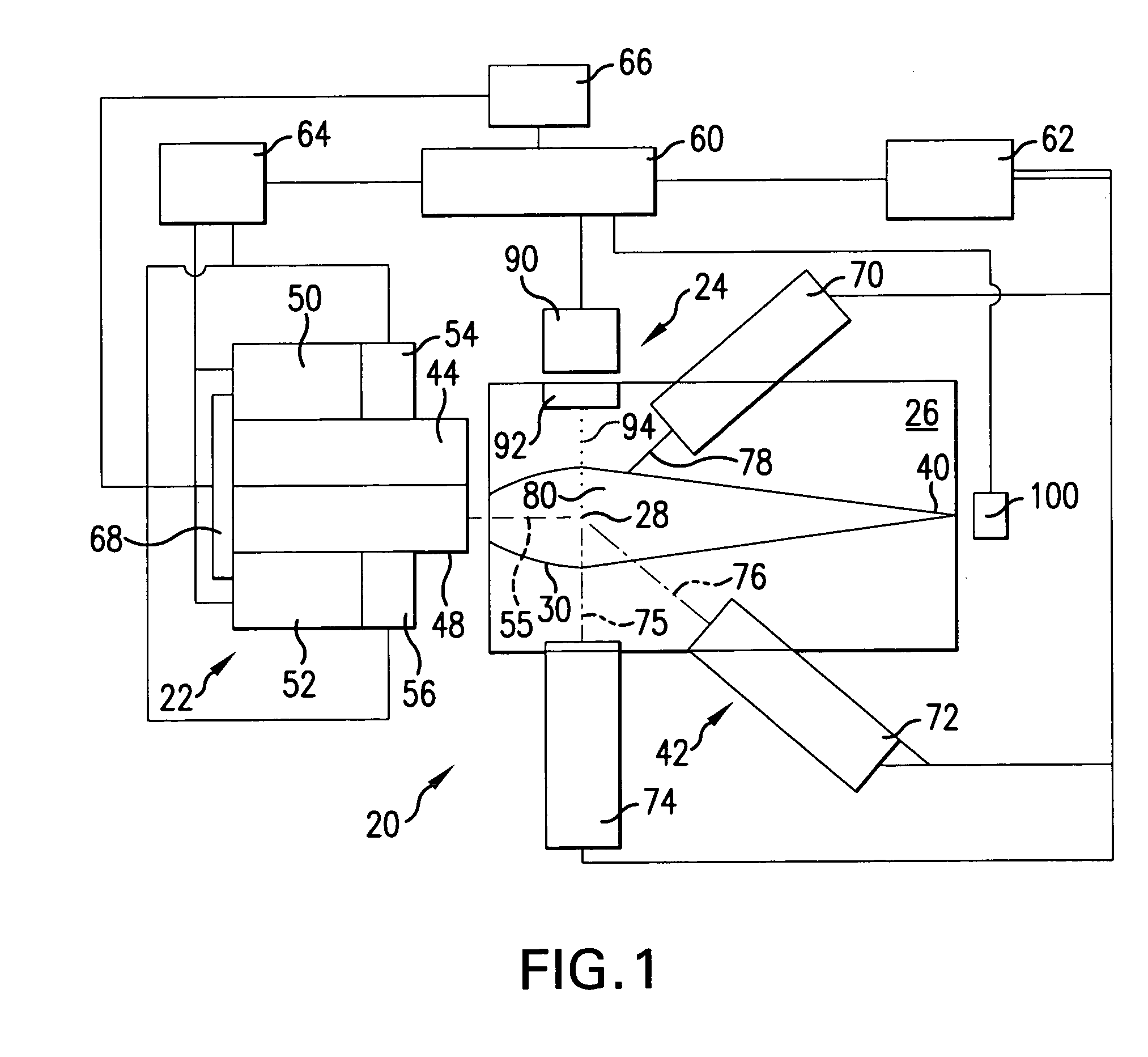

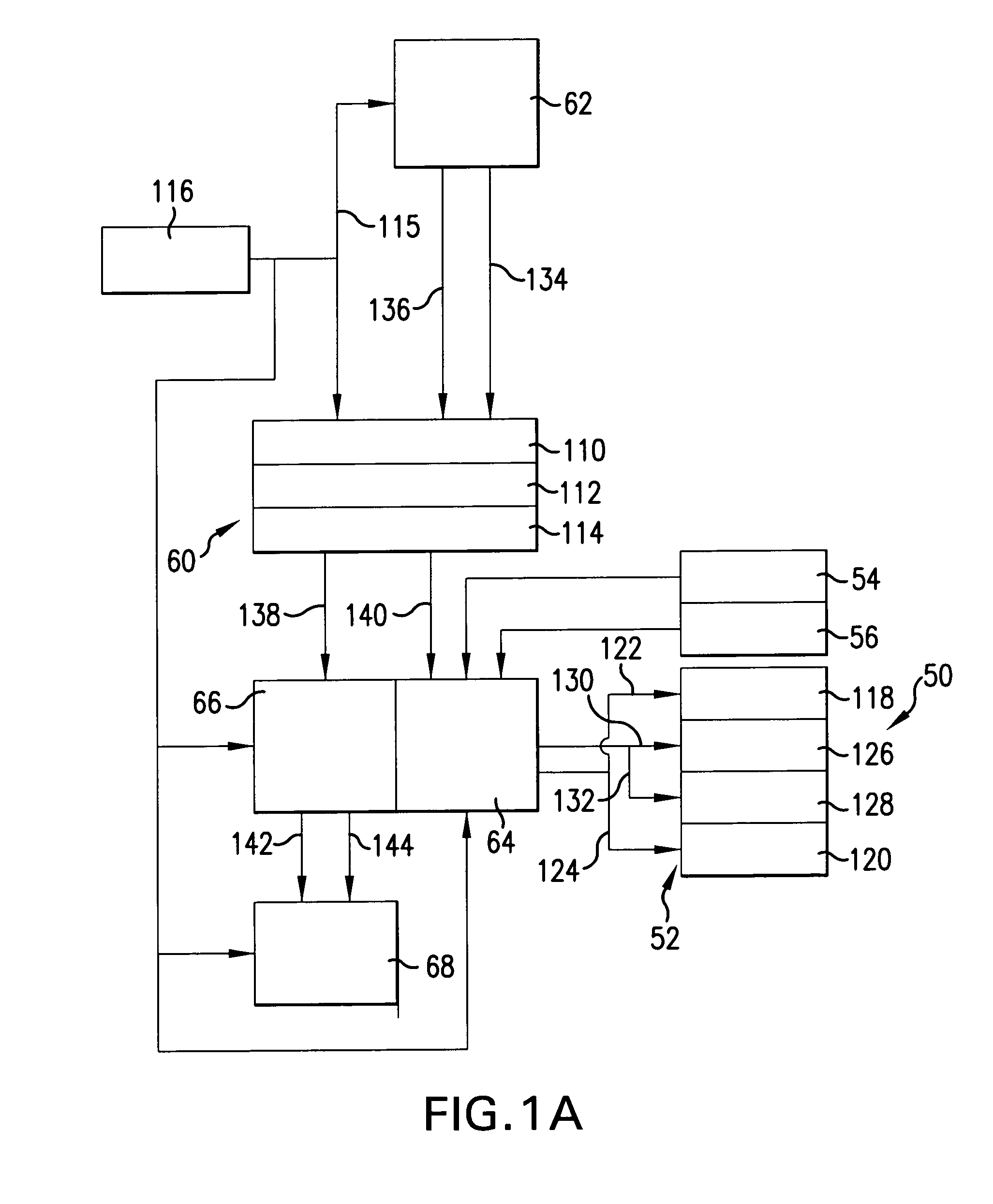

High repetition rate laser produced plasma EUV light source

An EUV light source apparatus and method are disclosed, which may comprise a pulsed laser providing laser pulses at a selected pulse repetition rate focused at a desired target ignition site; a target formation system providing discrete targets at a selected interval coordinated with the laser pulse repetition rate; a target steering system intermediate the target formation system and the desired target ignition site; and a target tracking system providing information about the movement of target between the target formation system and the target steering system, enabling the target steering system to direct the target to the desired target ignition site. The target tracking system may provide information enabling the creation of a laser firing control signal, and may comprise a droplet detector comprising a collimated light source directed to intersect a point on a projected delivery path of the target, having a respective oppositely disposed light detector detecting the passage of the target through the respective point, or a detector comprising a linear array of a plurality of photo-sensitive elements aligned to a coordinate axis, the light from the light source intersecting a projected delivery path of the target, at least one of the which may comprise a plane-intercept detection device. The droplet detectors may comprise a plurality of droplet detectors each operating at a different light frequency, or a camera having a field of view and a two dimensional array of pixels imaging the field of view. The apparatus and method may comprise an electrostatic plasma containment apparatus providing an electric plasma confinement field at or near a target ignition site at the time of ignition, with the target tracking system providing a signal enabling control of the electrostatic plasma containment apparatus. The apparatus and method may comprise a vessel having and intermediate wall with a low pressure trap allowing passage of EUV light and maintaining a differential pressure across the low pressure trap. The apparatus and method may comprise a magnetic plasma confinement mechanism creating a magnetic field in the vicinity of the target ignition site to confine the plasma to the target ignition site, which may be pulsed and may be controlled using outputs from the target tracking system.

Owner:ASML NETHERLANDS BV

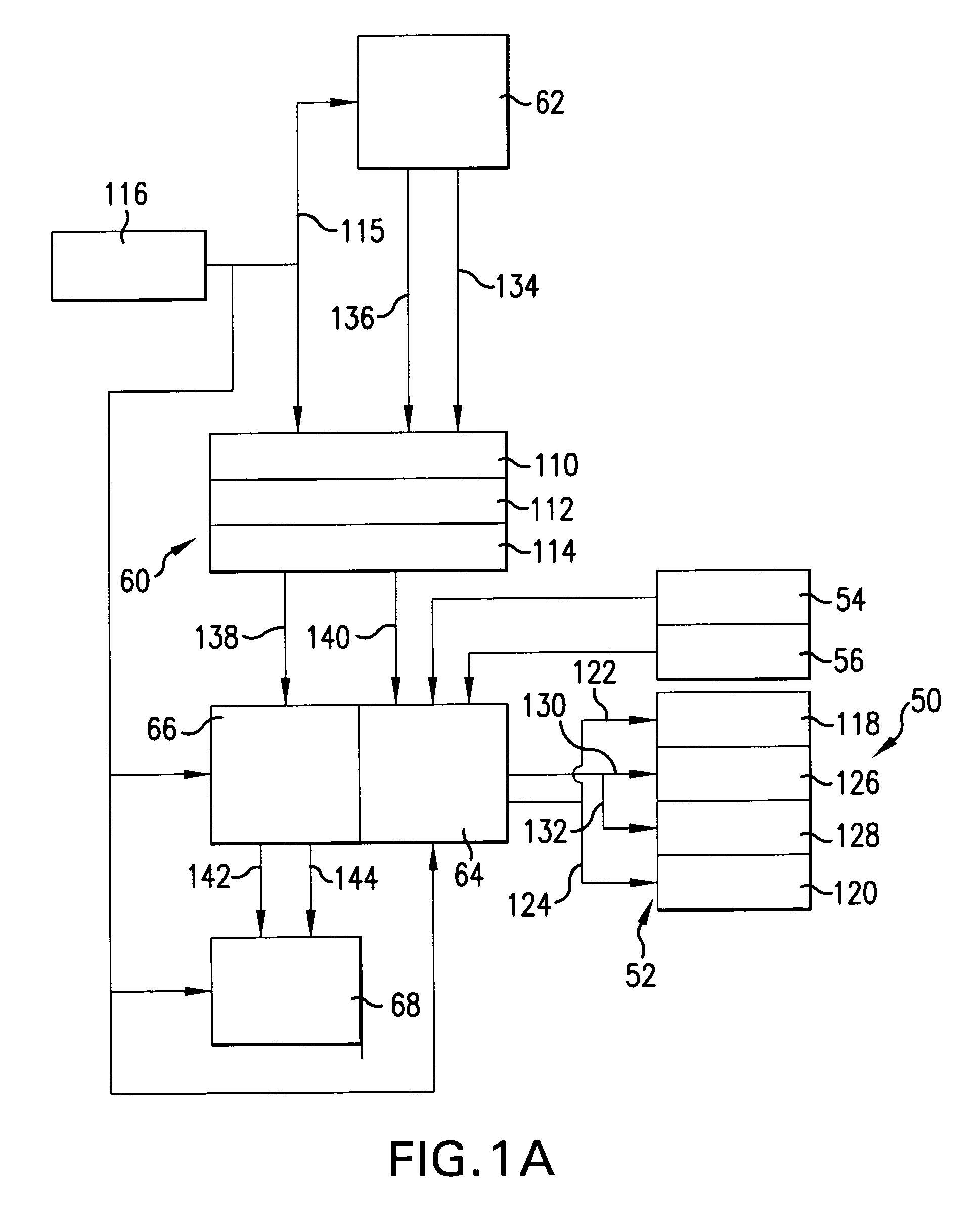

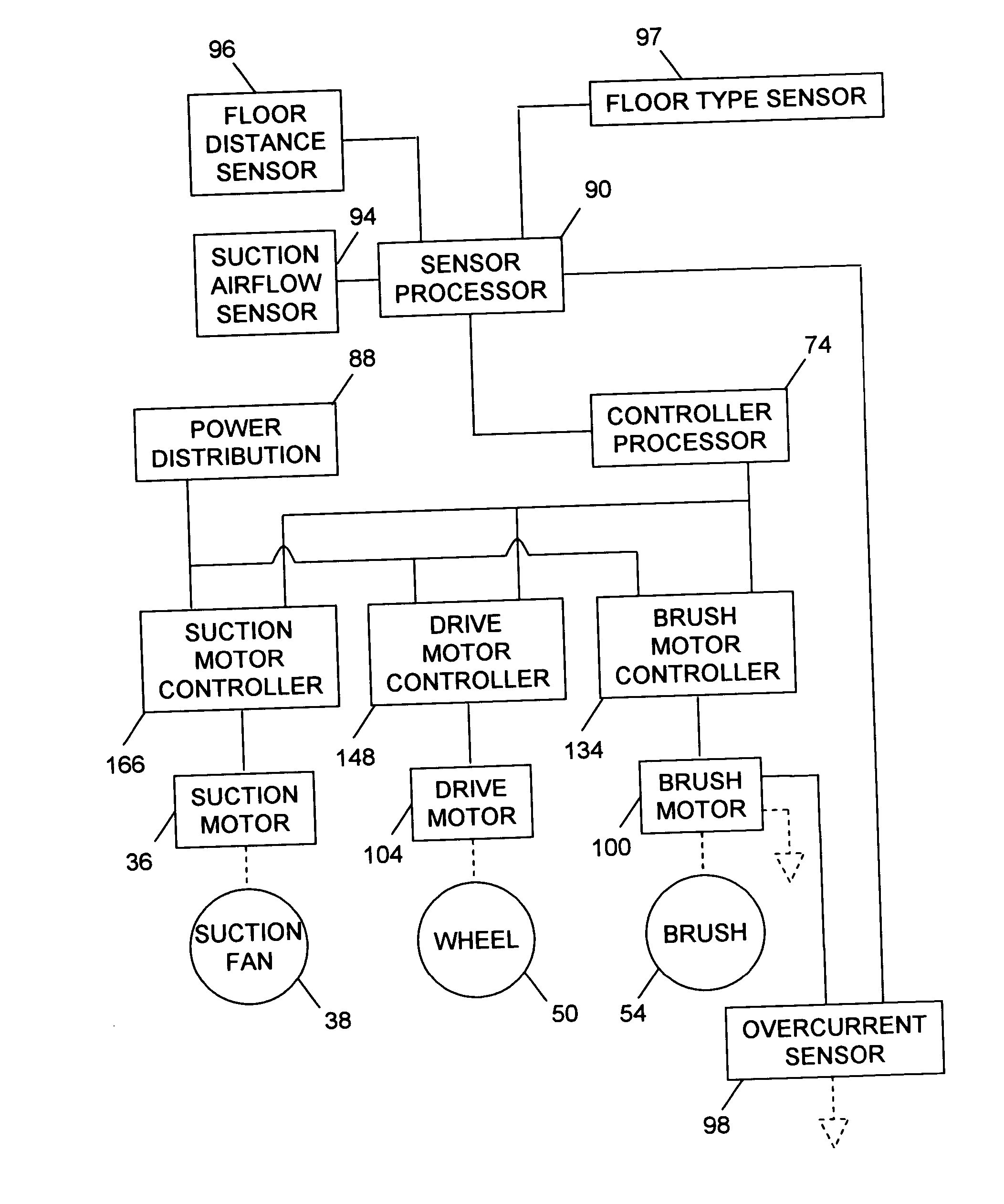

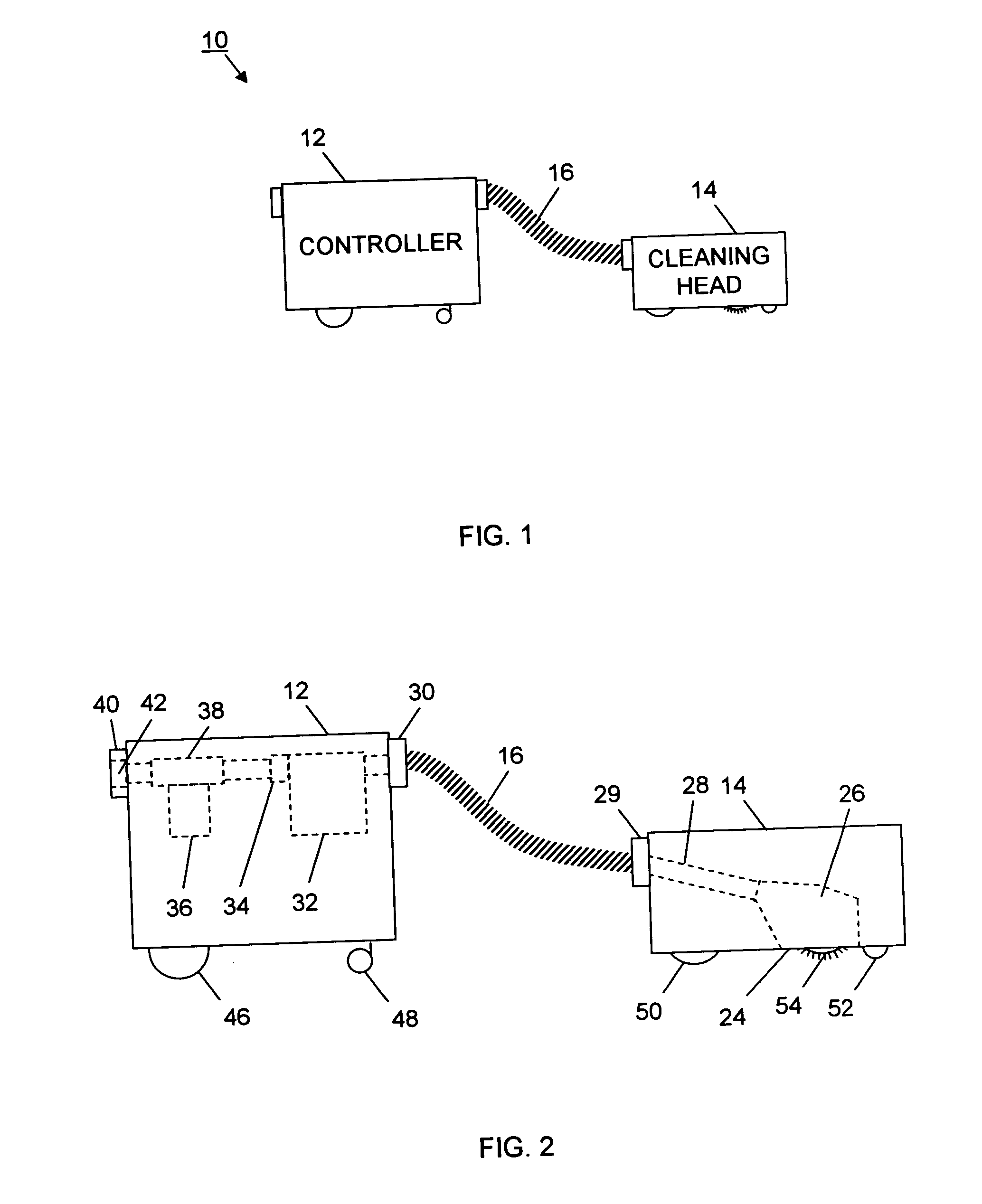

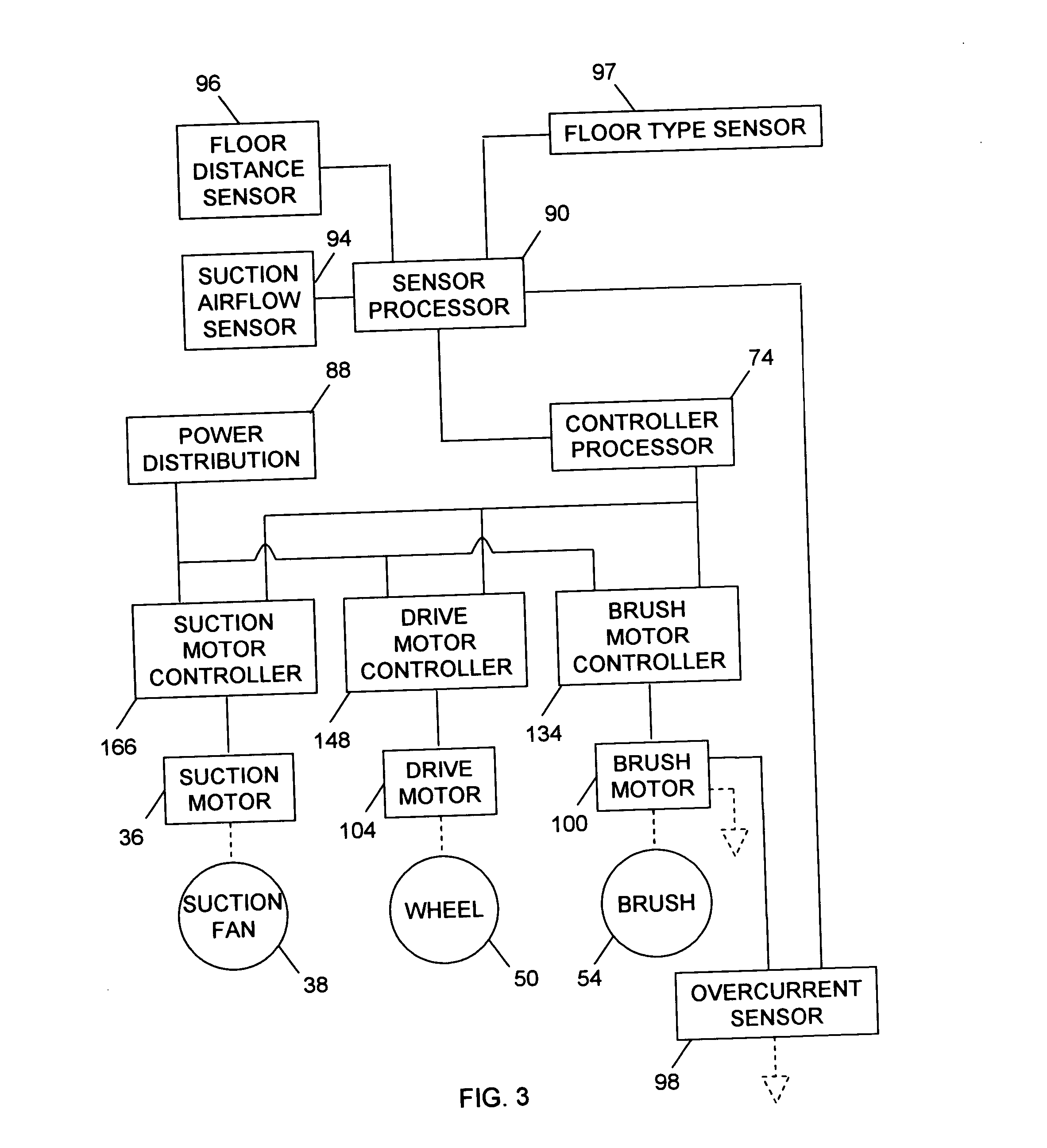

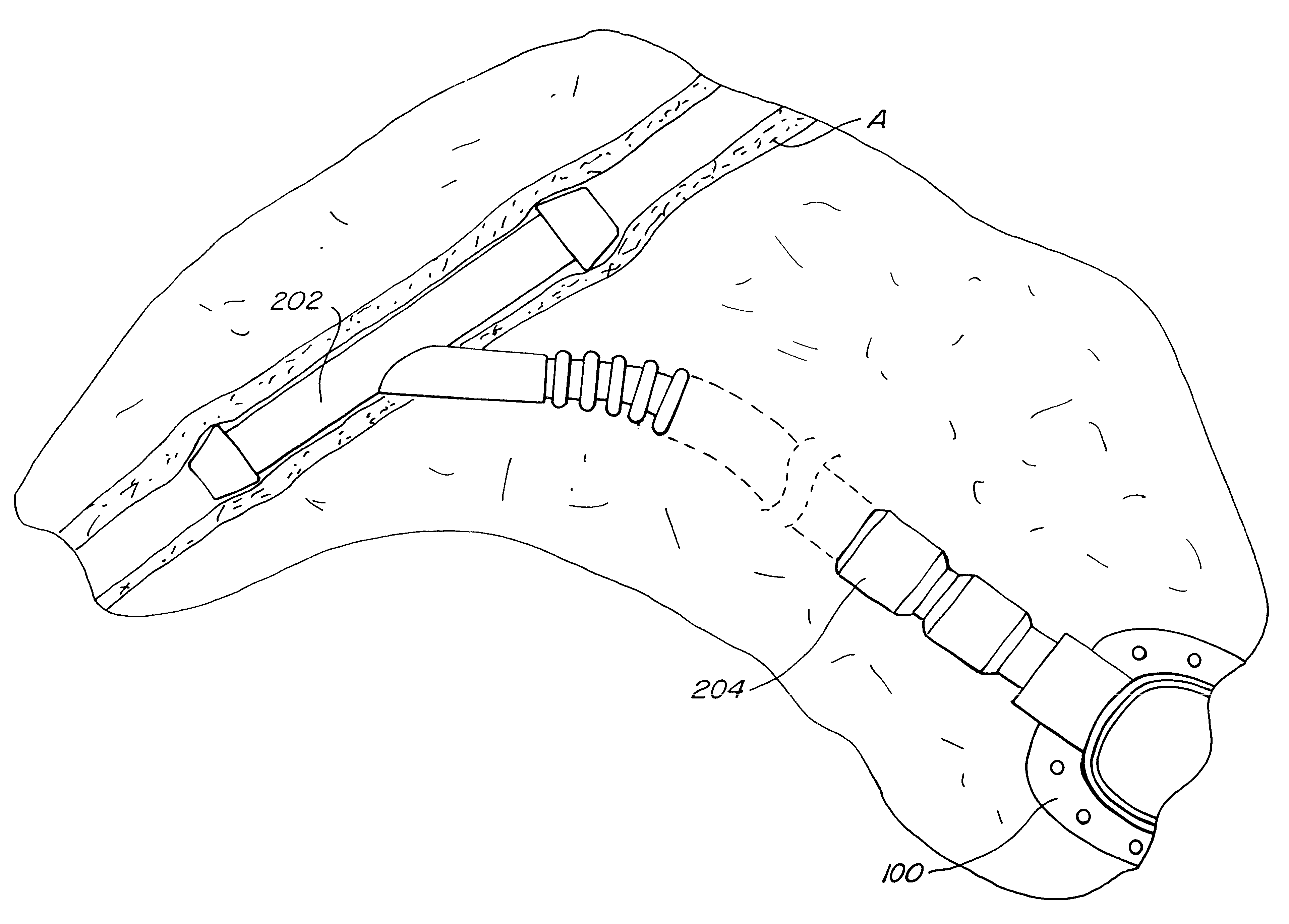

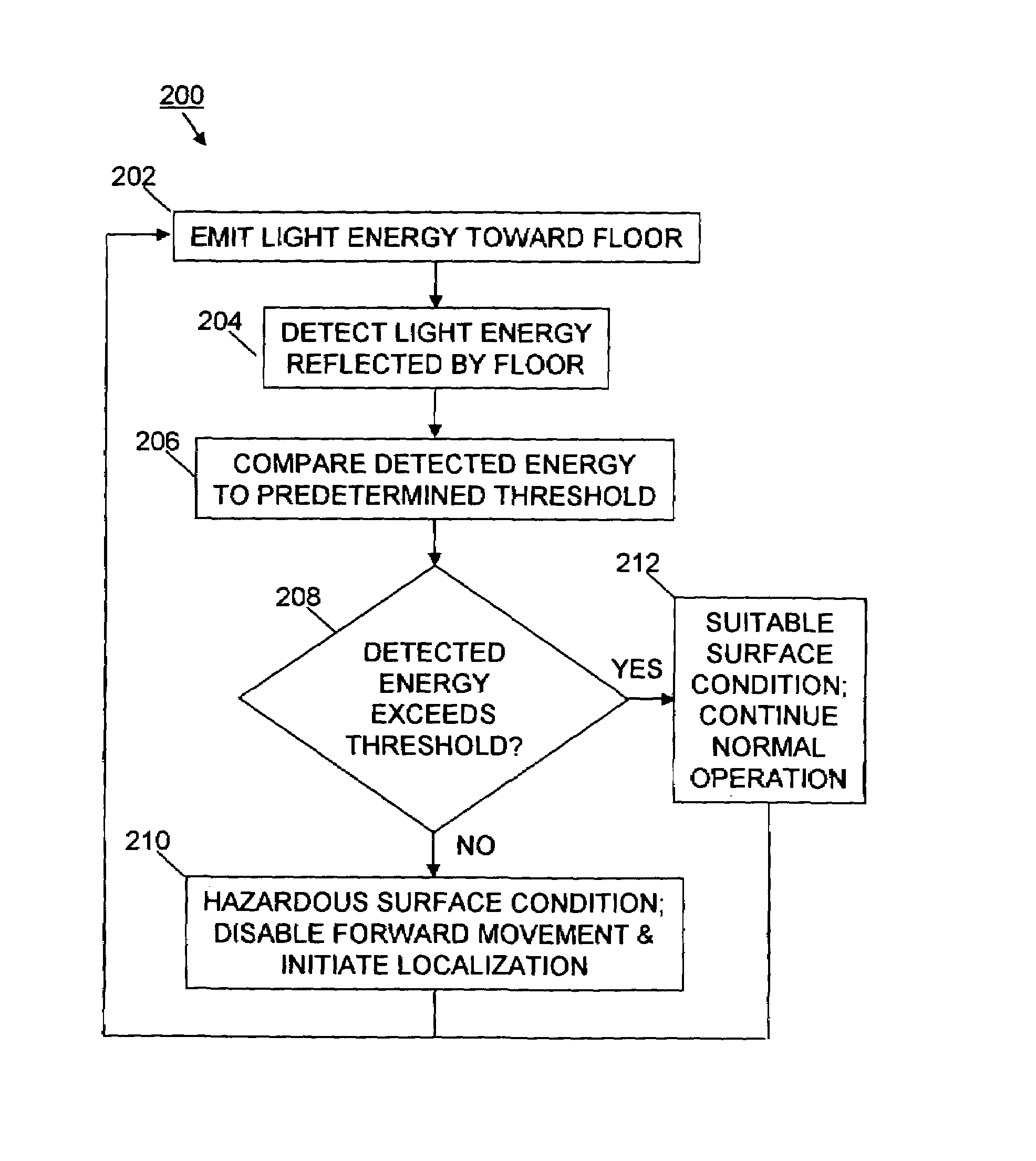

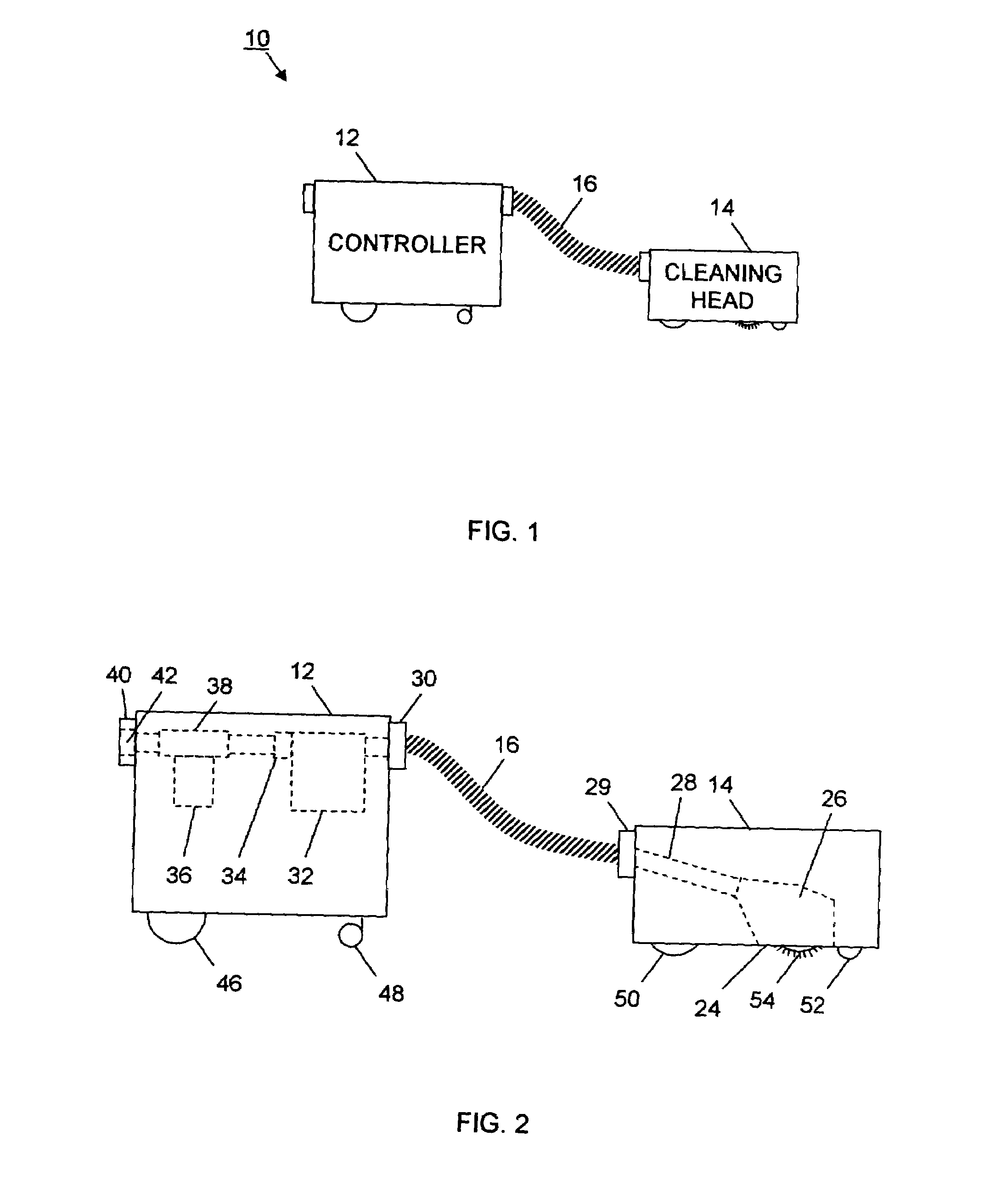

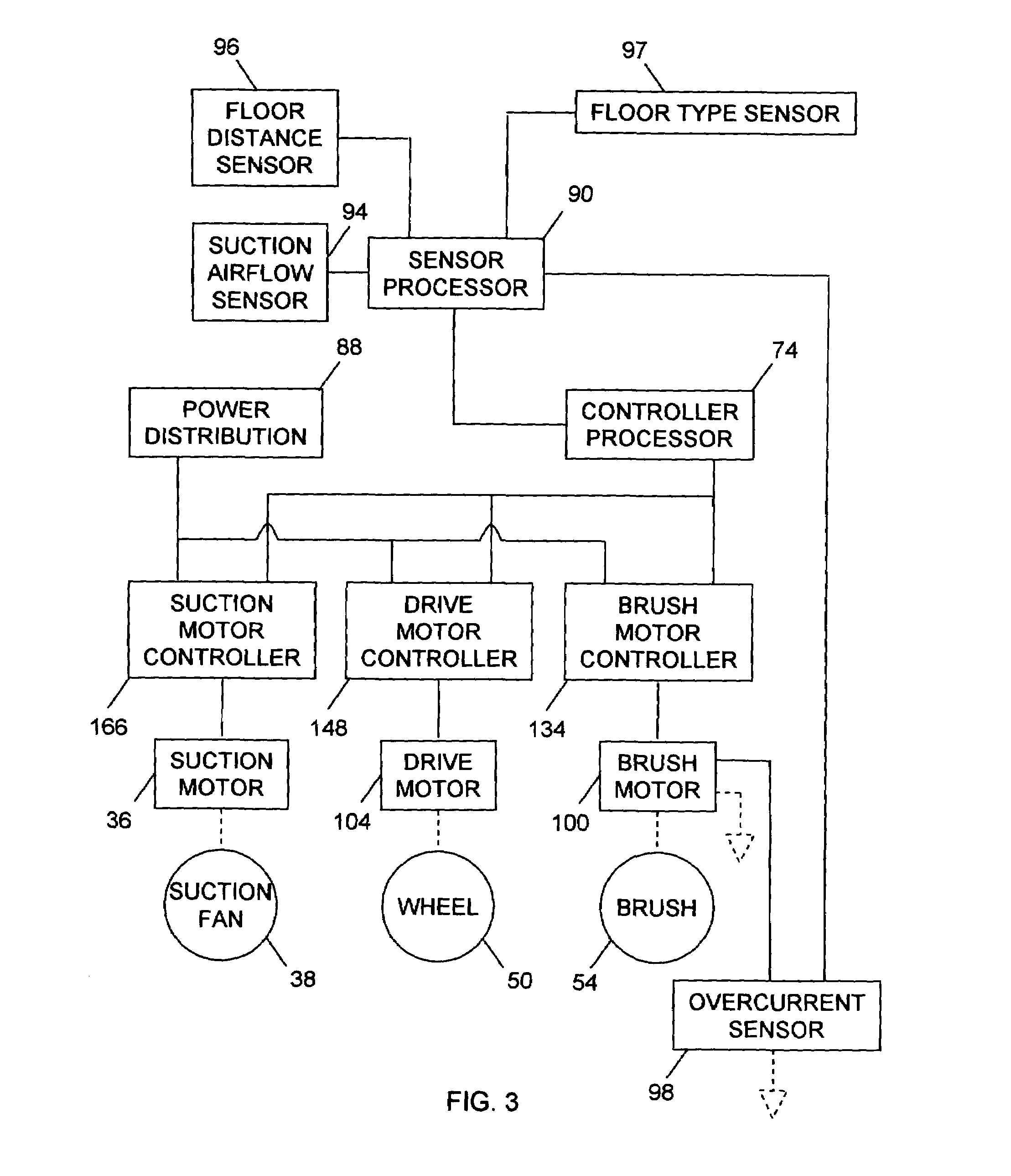

Sensors and associated methods for controlling a vacuum cleaner

Several methods of controlling a vacuum cleaner (10) using various types of sensors (94, 96, 97, 98) are provided. One method is based on a differential pressure between a suction airflow path and ambient air and includes: detecting the differential pressure, comparing the detected differential pressure to a predetermined threshold, and, when the detected differential pressure is less than the predetermined threshold, initiating a predetermined control procedure. A status indicator (164) is updated based on the detected differential pressure. Another method is based on a level of electrical current flowing through a brush motor (100). Still another method is based on a type or condition of the floor being traversed. Yet another method is based on a distance to a surface of a floor over which the vacuum cleaner is advancing. In another aspect of the invention, a vacuum cleaner is provided. In various combinations, the vacuum cleaner includes a vacuum source (36, 38), a brush motor (100), a drive motor (104), a controller processor (74), a sensor processor (90), an overcurrent sensor (98), a suction airflow sensor (94), a floor type sensor (97), and a floor distance sensor (96).

Owner:ROYAL APPLIANCE MFG

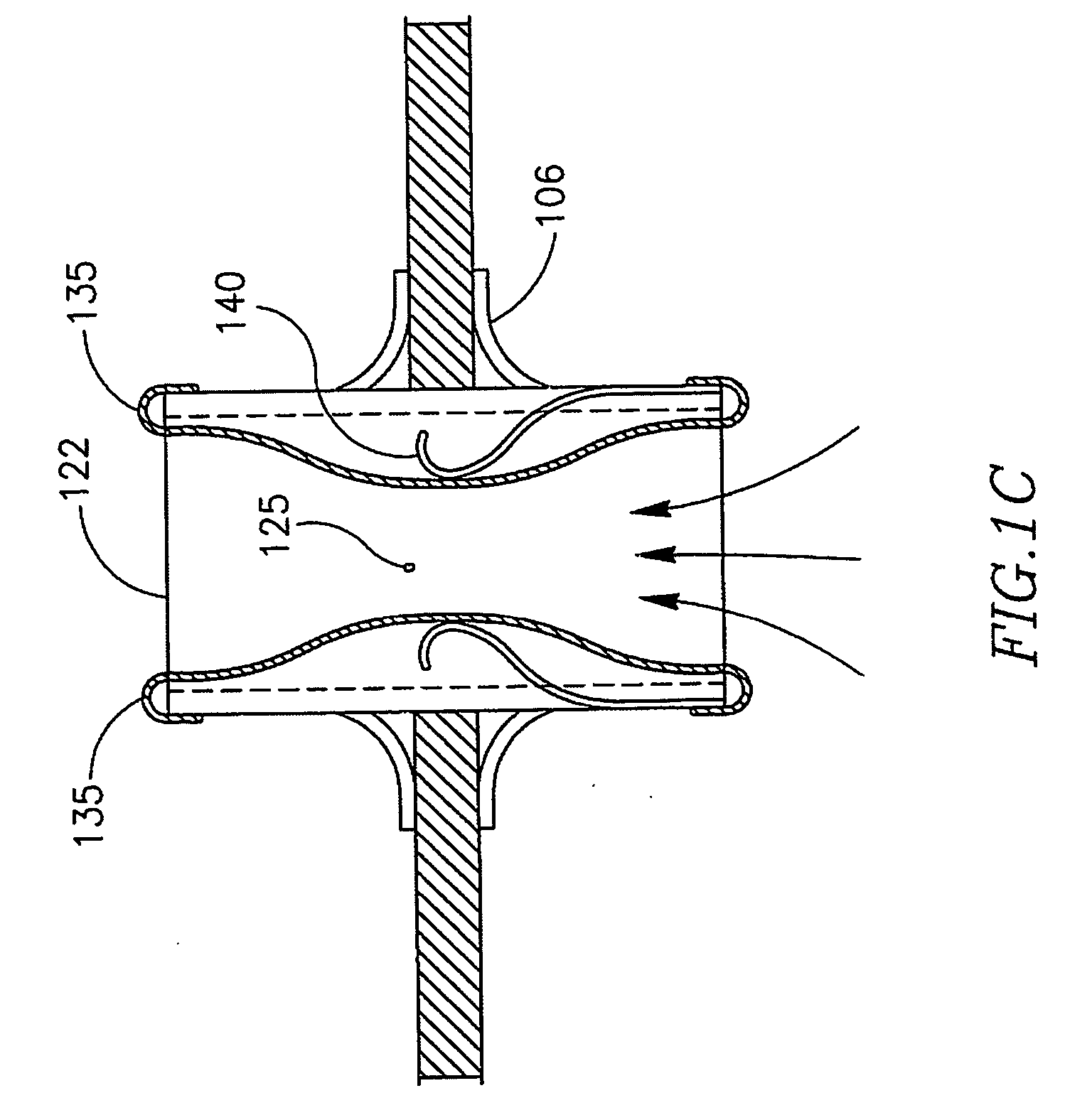

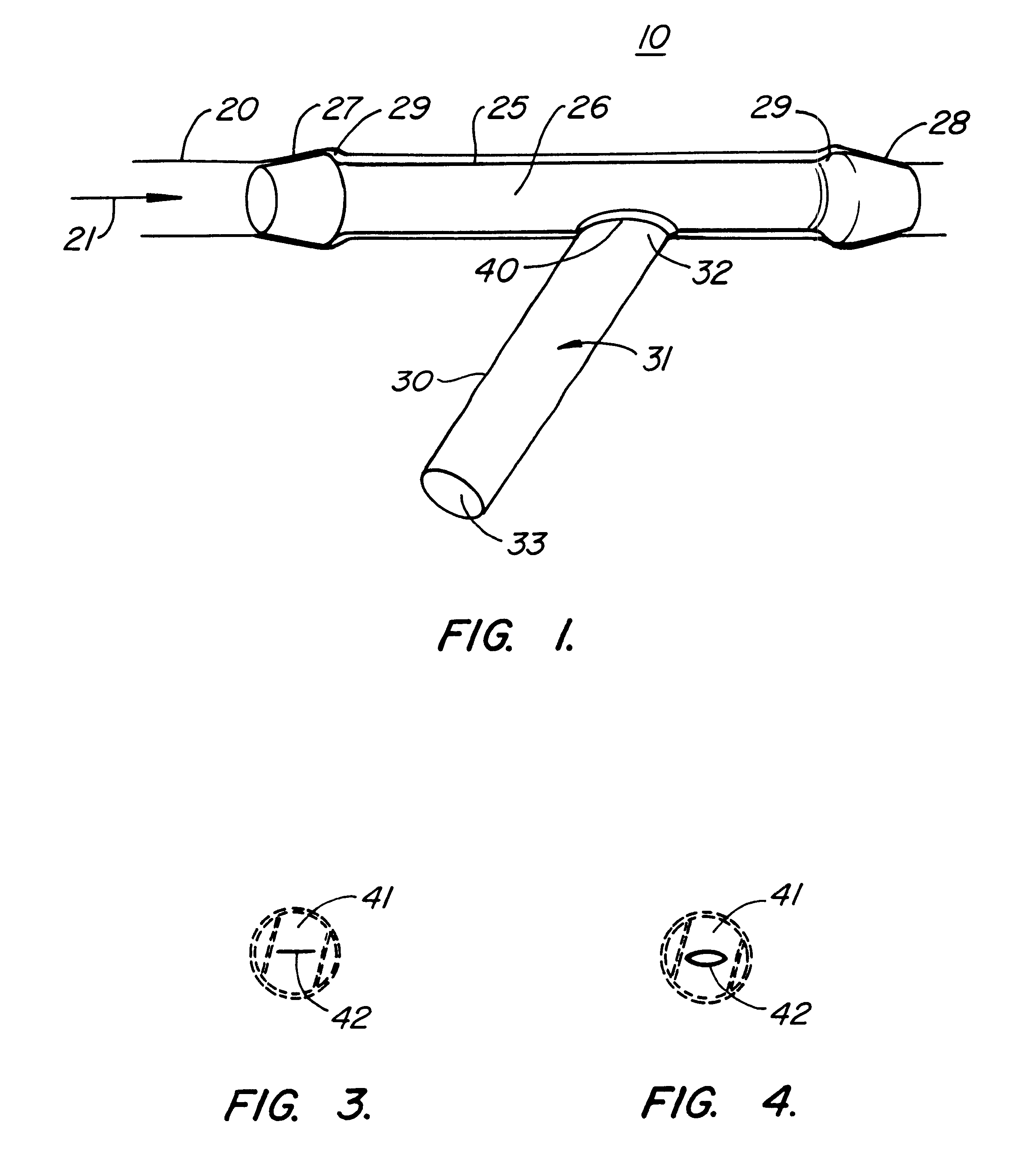

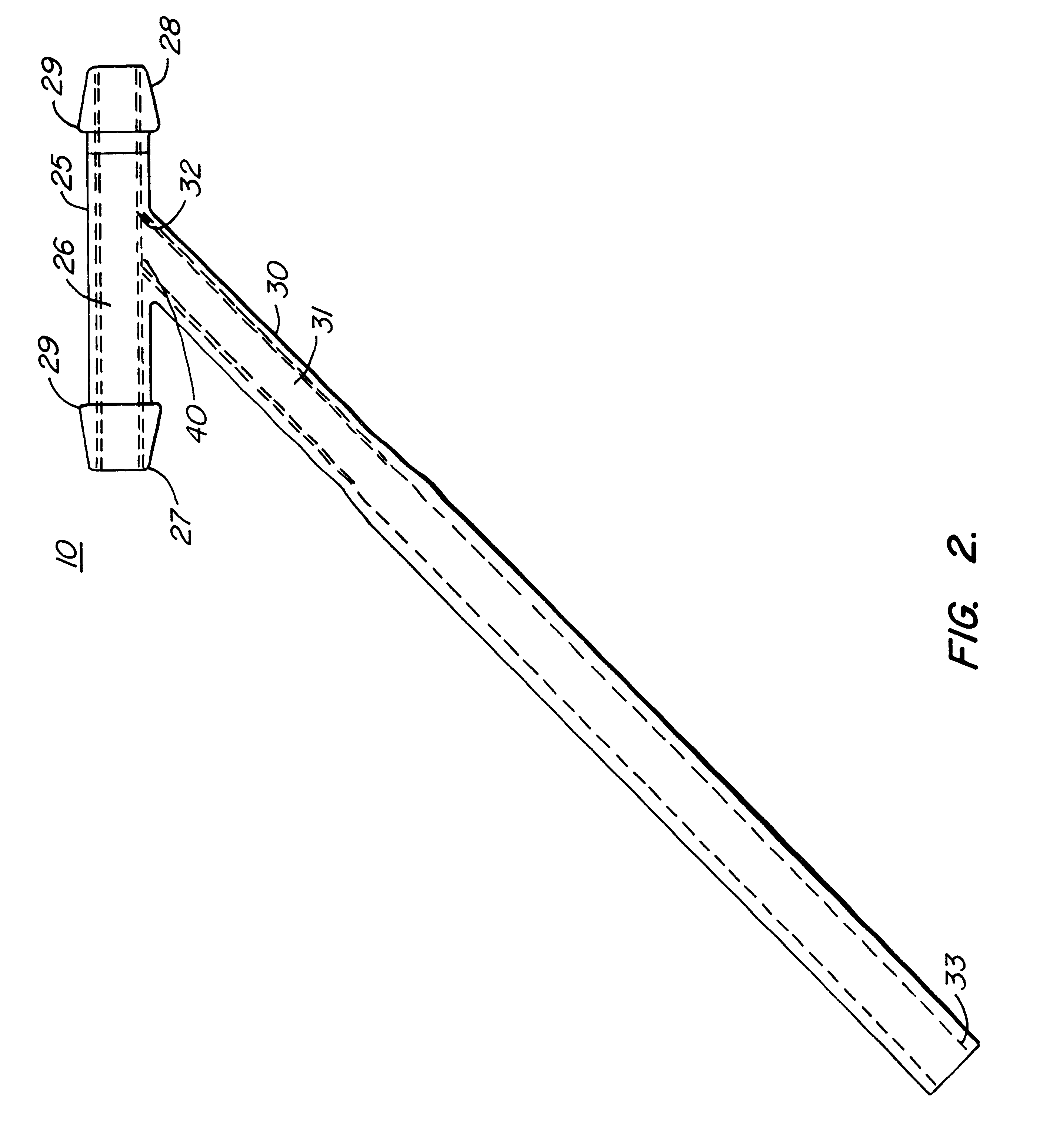

Subcutaneously implanted cannula and method for arterial access

InactiveUS6398764B1Avoid blood lossReduce exerciseMedical devicesCatheterDifferential pressureSubcutaneous implantation

A catheter with valve for implantation in a vascular structure of a living being. The catheter is in the general shape of a "T" with the top of the "T" implanted within the lumen of a vascular structure, and the leg of the "T" extending out of the vascular structure through an incision in the vascular structure. The lumen of the implanted portion of the catheter completely occupies the lumen of the vascular structure, causing all blood flow through the vascular structure to be directed through the implanted portion of the catheter. A valve is placed in the wall of the implanted portion of the catheter which opens into the lumen of the leg of the "T" of the catheter upon application of sufficient differential pressure between the lumens of the two portions of the catheter. The leg of the "T" is connected to the side wall of the implant portion of the catheter at an angle, such that the axis of the lumen of the leg of the "T" intersects the axis of the lumen of the implanted portion of the catheter at approximately a 45 degree angle.

Owner:VASCA

Sensors and associated methods for controlling a vacuum cleaner

Owner:ROYAL APPLIANCE MFG

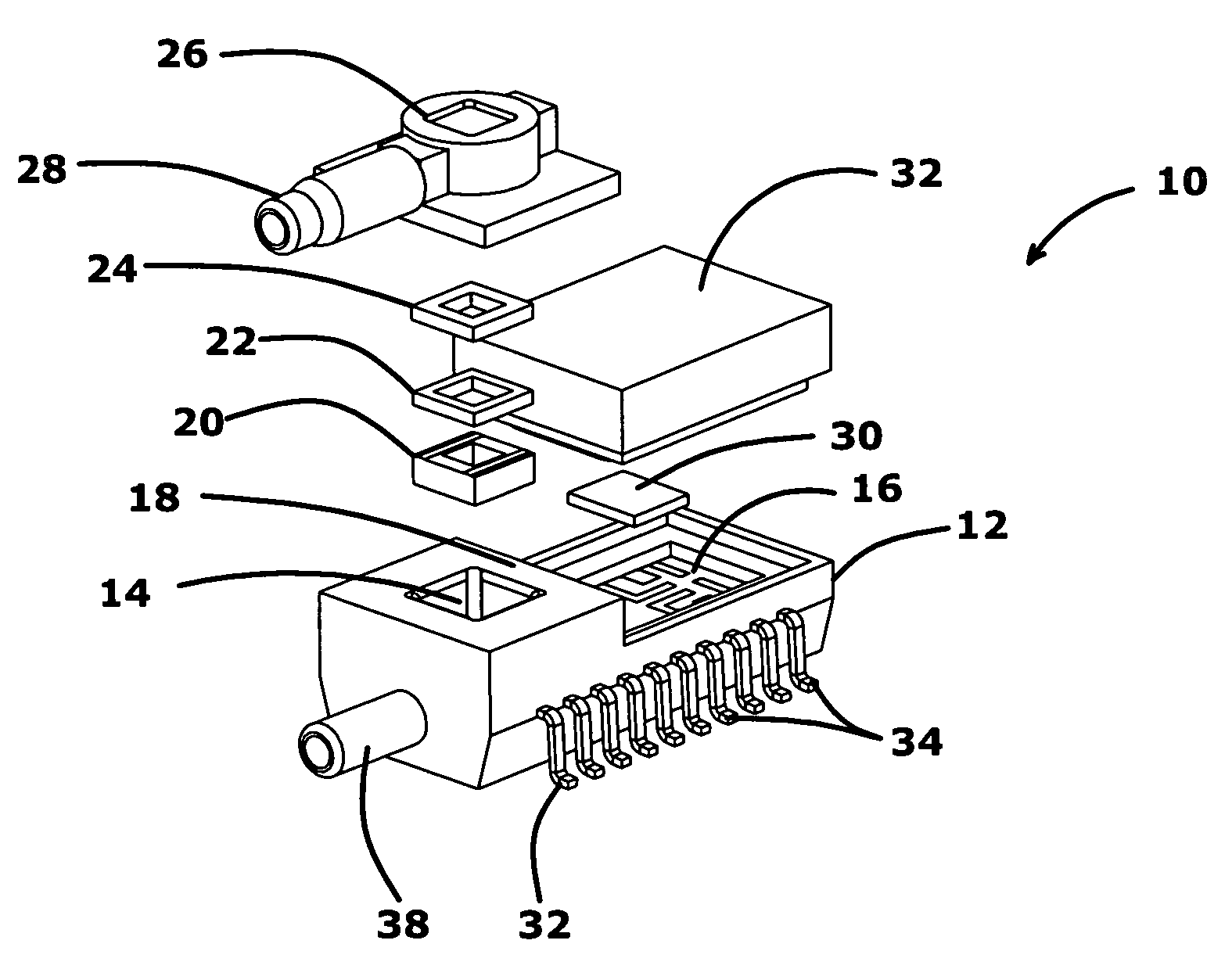

Design of a wet/wet amplified differential pressure sensor based on silicon piezoresistive technology

InactiveUS7162927B1Fluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsAudio power amplifierHermetic seal

The invention provides pressure sensors for use in wet environments. A pressure sensor package according to the invention has a housing having a pair of cavities separated by a wall member. Sequentially contained within one cavity is a conductive elastomeric seal pad, a pressure sensor and an elastomeric media seal. A pressure cap is attached to the housing such that the pressure cap and the housing together form a hermetic seal. The pressure cap has a port for admitting a gas under pressure into the first cavity. A signal amplifier is positioned within the second cavity and a cover encloses the signal amplifier within the second cavity. An electrical connector through the wall member forms an electrical connection between the pressure sensor and the signal amplifier. A lead frame extends through the housing and forms electrical connections with the pressure sensor and the signal amplifier.

Owner:HONEYWELL INT INC

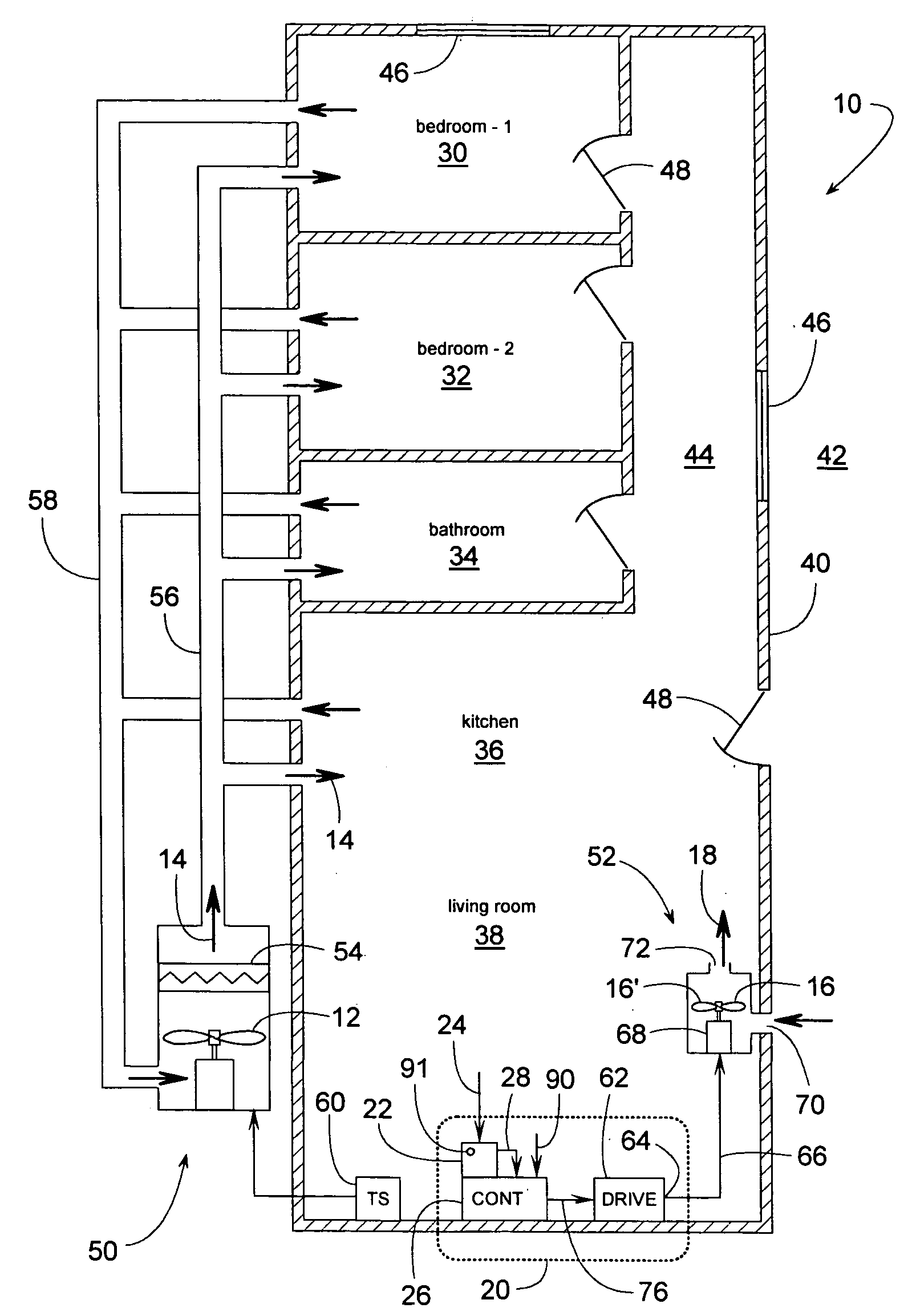

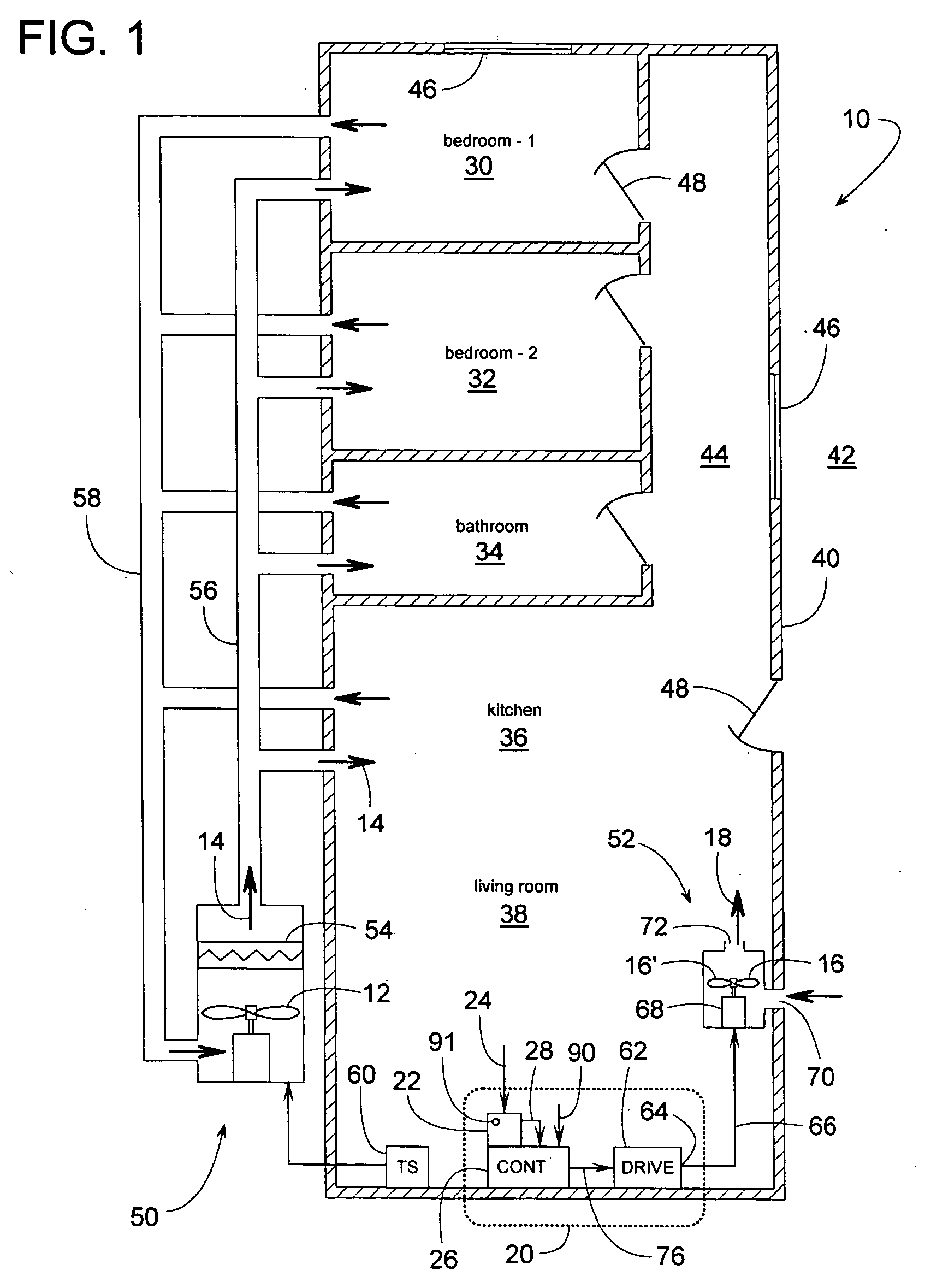

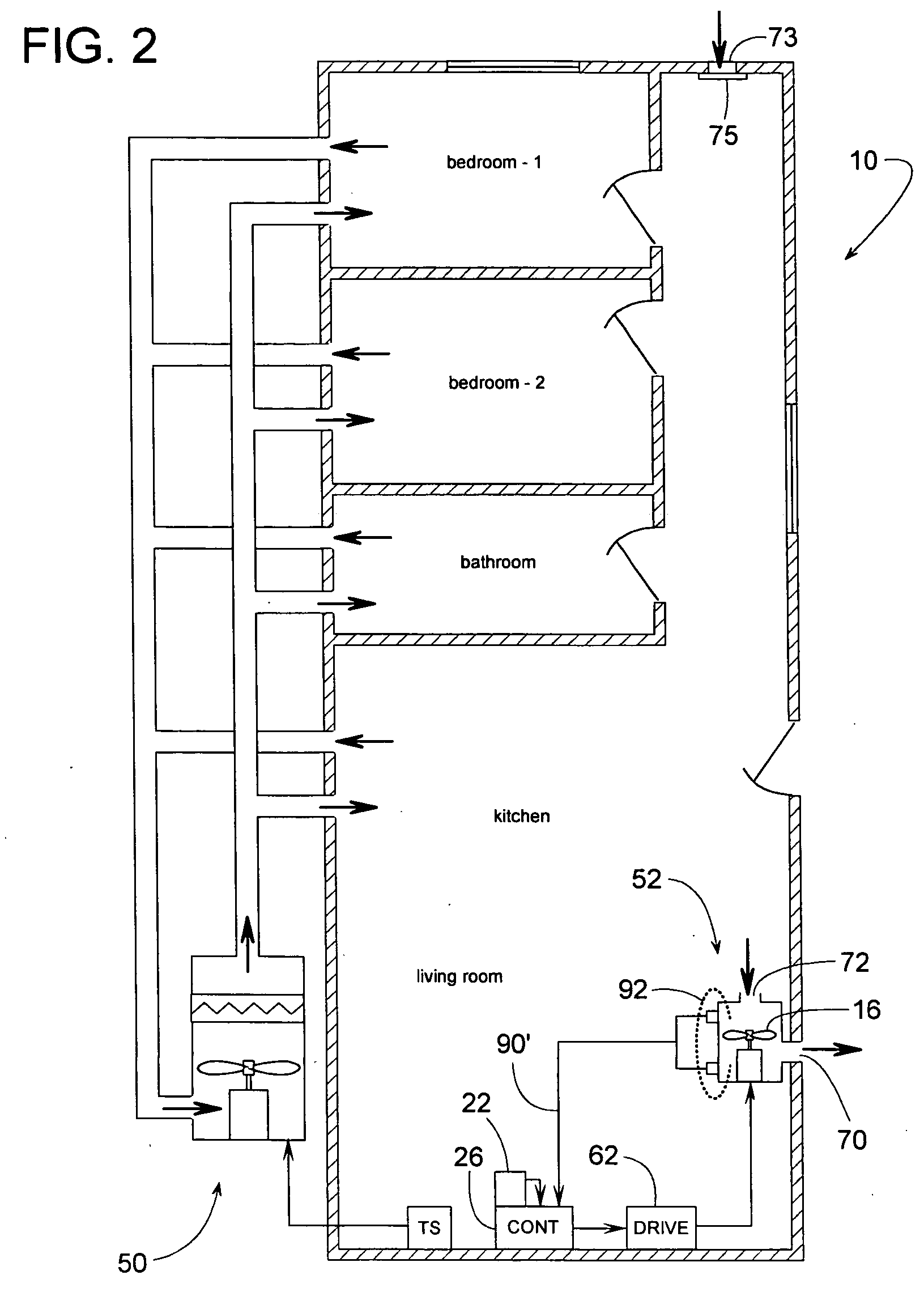

Ventilation controller

ActiveUS20060117769A1OptimizationMechanical apparatusSpace heating and ventilation safety systemsDifferential pressureFresh air

A ventilation system for a building in some cases includes a main HVAC blower for moving temperature-conditioned air through the building plus a smaller ventilation blower for providing fresh air. A controller regulates the ventilation blower's speed to provide a target ventilation flow rate regardless of changes in the pressure differential between the indoor and outdoor air. To ensure that the target rate is appropriate for a particular building, the target flow rate is determined based on a ventilation setting that reflects a specified number of bedrooms and a specified amount of floor space of the building.

Owner:TRANE INT INC

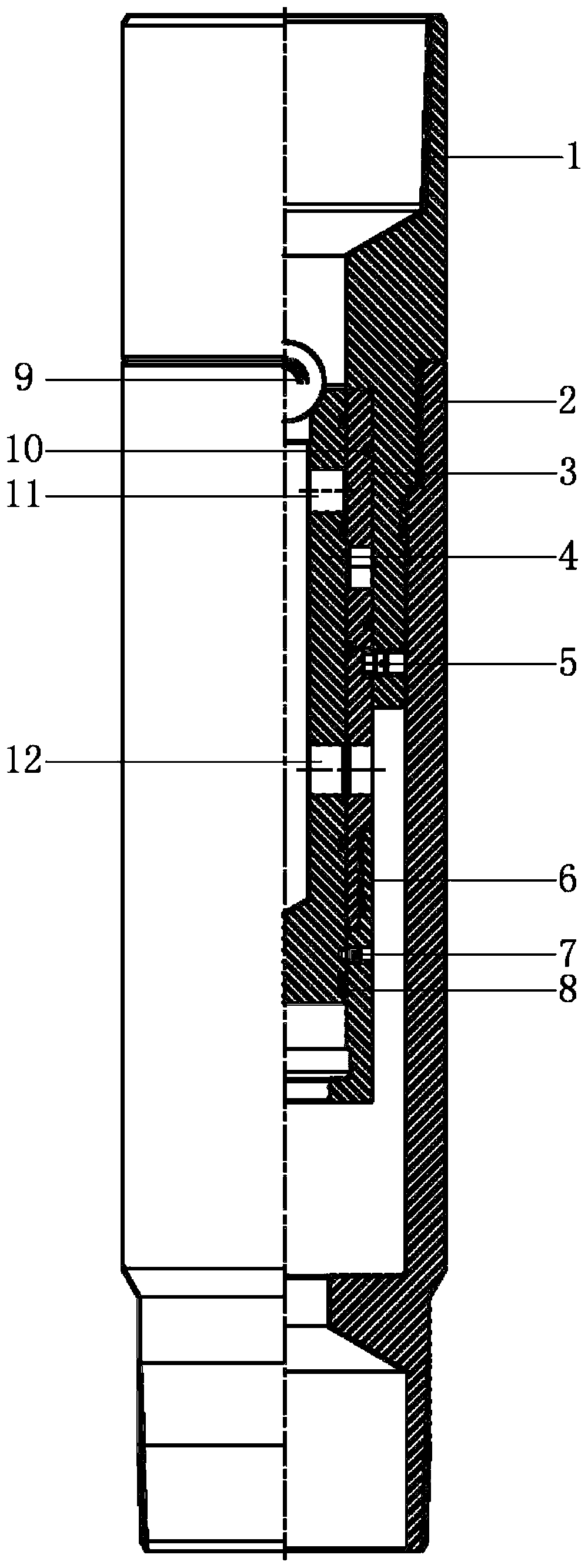

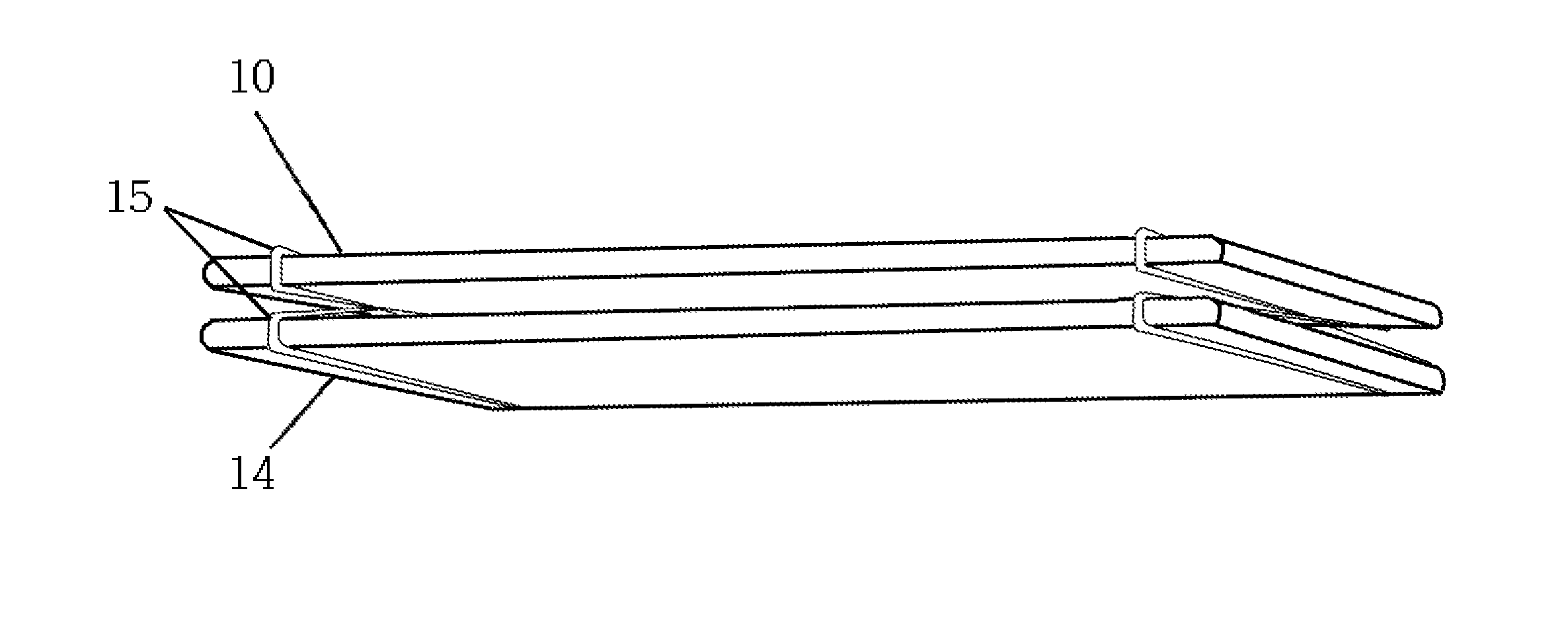

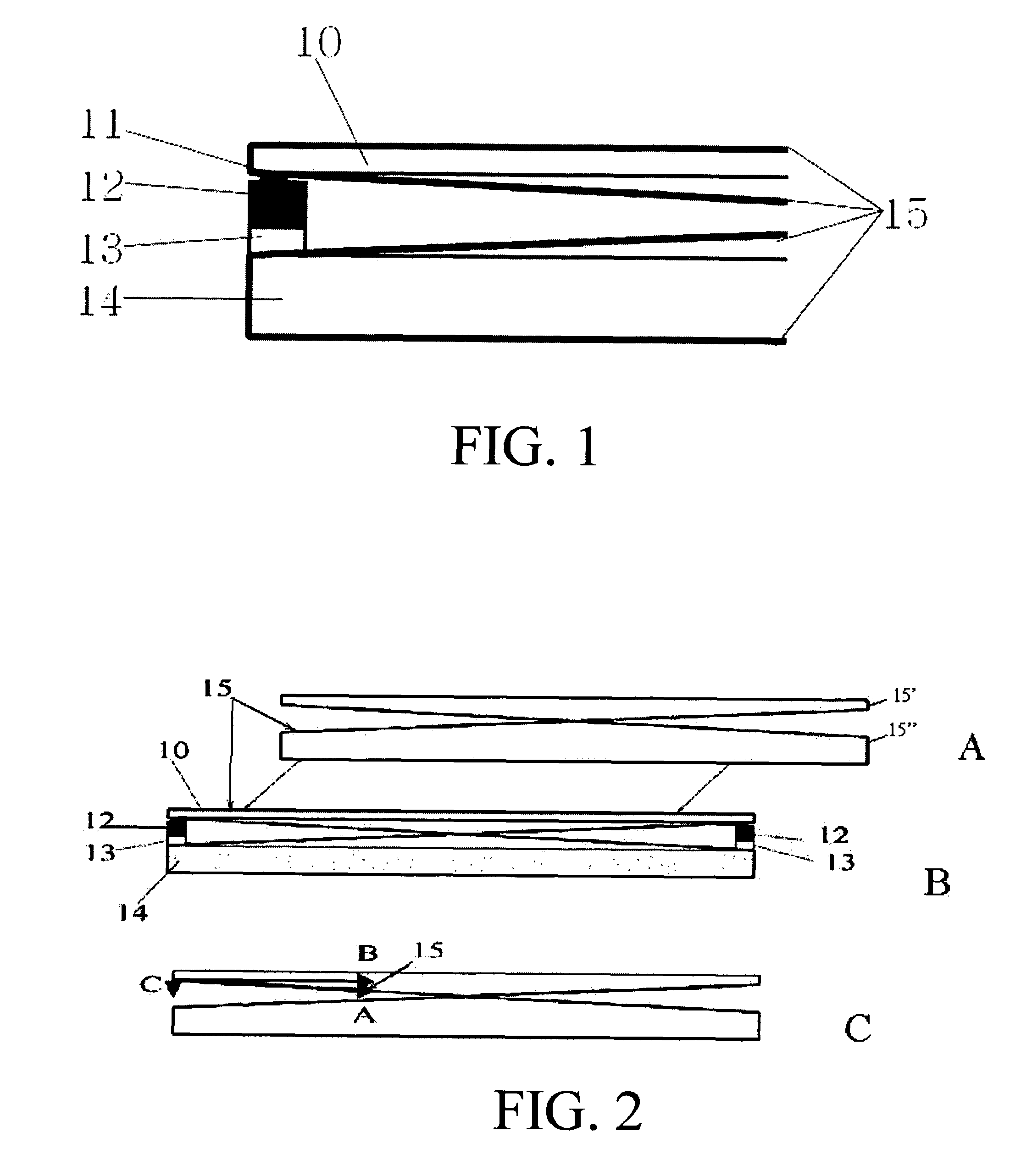

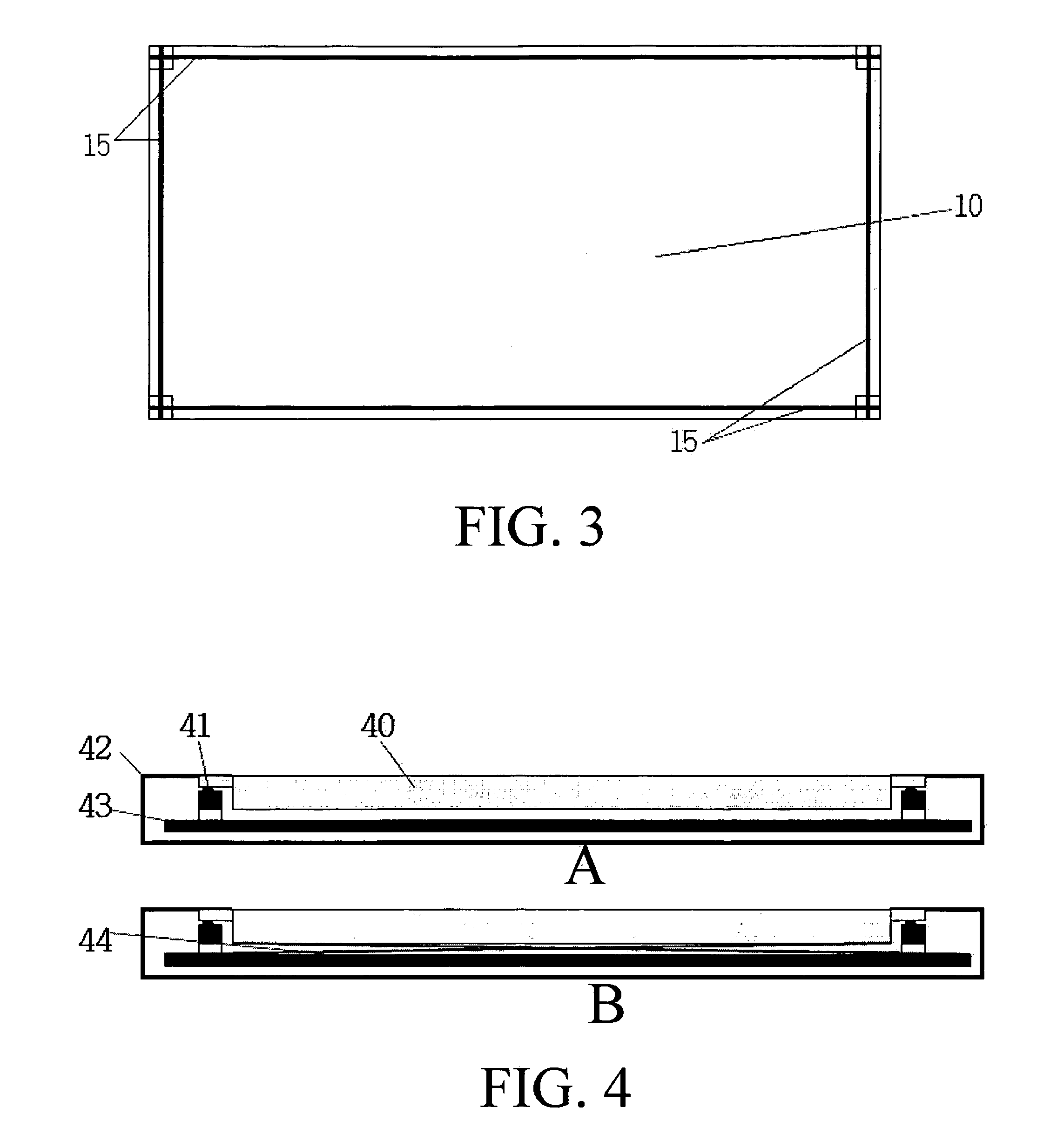

Starting pup joint with second-time opening function

PendingCN110080707AWith secondary opening functionAvoid resetFluid removalUpper jointDifferential pressure

The invention discloses a starting pup joint with a second-time starting function. The starting pup joint comprises a core shaft and a setting ball. The core shaft is connected with a sliding sleeve,the setting ball is connected with the core shaft, the sliding sleeve is connected with an outer sleeve, the outer sleeve is connected with the core shaft through a first-stage shear pin, a groove isformed in the core shaft, a baffle ring can be embedded into the groove, the baffle ring is in contact with the outer sleeve, the sliding sleeve is connected with an upper joint, the upper joint is connected with a lower joint, the upper joint, the sliding sleeve and the core shaft are sequentially connected in a step mode, the core shaft is provided with a fluid channel and a fracturing channel,and the sliding sleeve is provided with a fluid channel and a fracturing channel. Setting of a packer can be achieved when the packer is opened for the first time, and when the differential pressure sliding sleeve cannot be opened normally, the starting pup joint is started for the second time, and the fracturing channel is opened.

Owner:JEREH ENERGY SERVICES

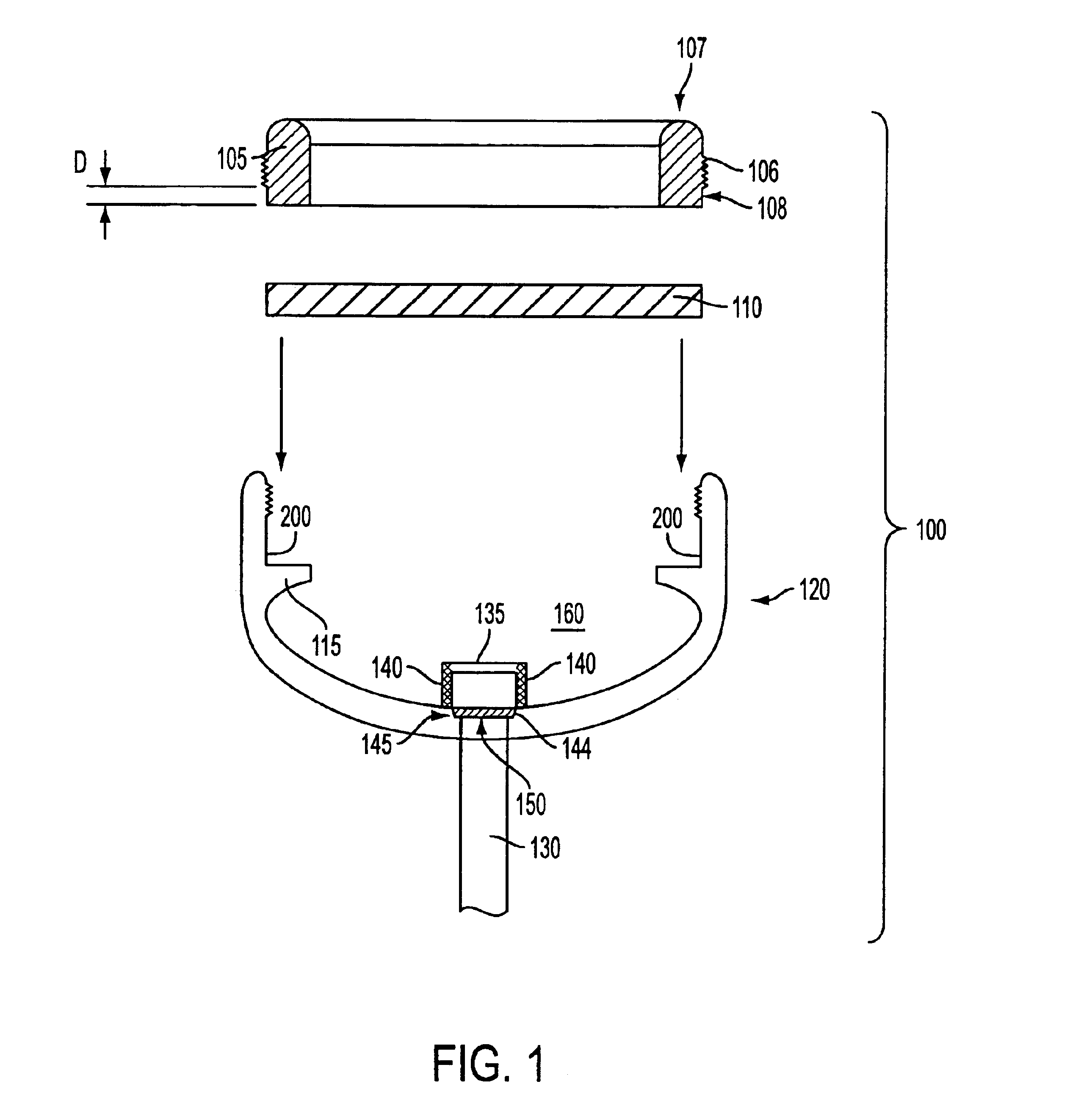

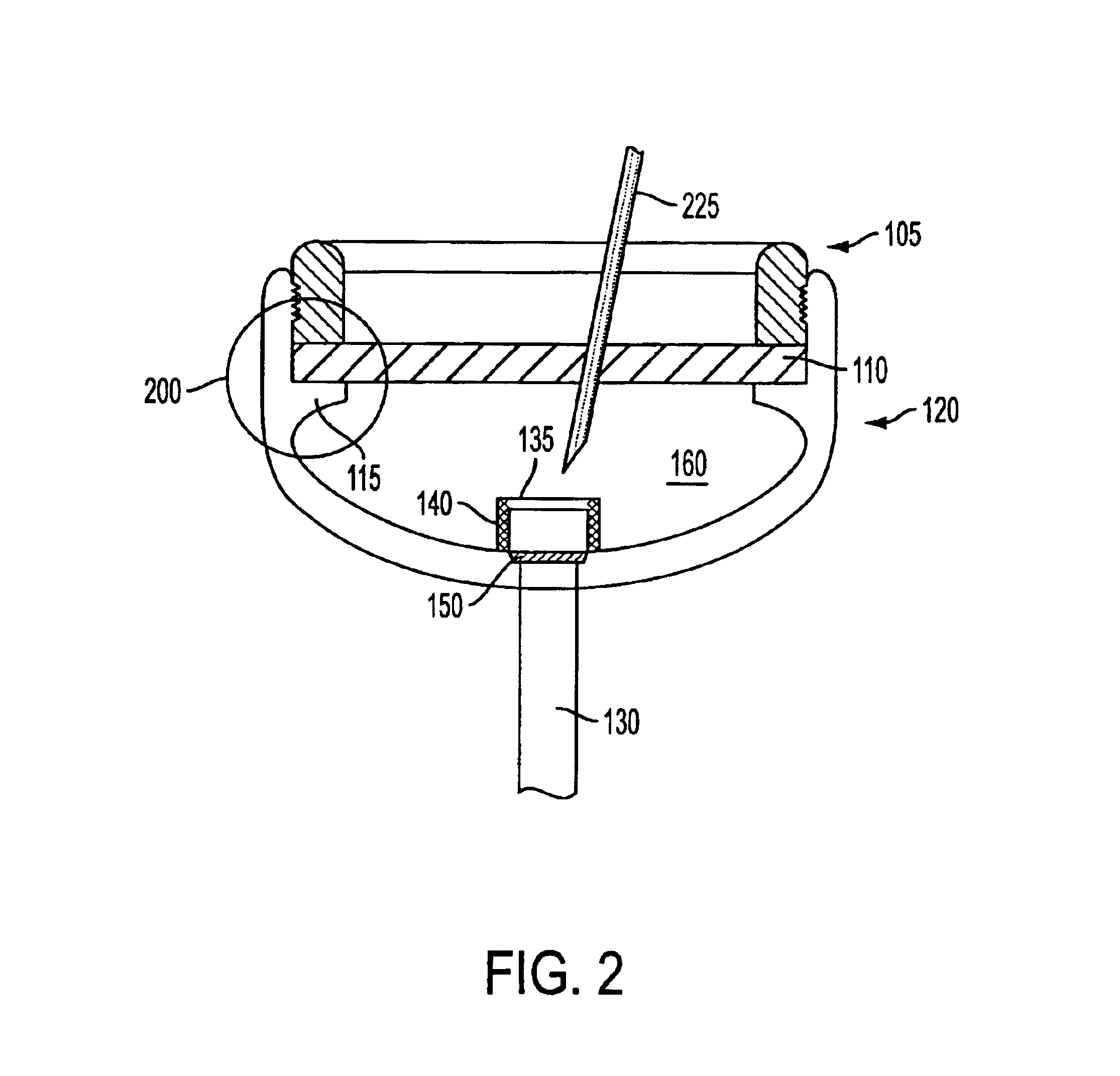

Integrated feature for friction less movement of force sensitive touch screen

ActiveUS8144453B2Reduce dependenceIncrease volumeSubstation/switching arrangement detailsDigital data processing detailsSensitive touchDifferential pressure

A suspension system for a differential-pressure touch sensitive panel suspended over force sensors, for use in either fixed or mobile devices such as point of sales terminals, kiosks, laptops, monitors, PDAs, cell phones, UMPCs and more. In one embodiment, each side of the lens is encircled and supported by a looped string, monofilament or flexible wire, which is then looped around the back cover or base plate, forming a figure-8. The figure 8-loops bring the lens into a fixed state in the xy-plane without the addition of any friction causing physical contact. Other alternative implementations include continuous suspensions, bender suspensions and 3-dimensional force suspensions. Moreover, the present invention proposes the use of a flexible padding under the force sensors to allow the sensors to be slightly preloaded, which reduces the dependency on extremely tight mechanical tolerances.

Owner:APPLE INC

Device And Method For Controlling In-Vivo Pressure

A differential pressure regulating device is provided for controlling in-vivo pressure in a body, and in particularly in a heart. The device may include a shunt being positioned between two or more lumens in a body, to enable fluids to flow between the lumens, and an adjustable flow regulation mechanism being configured to selectively cover an opening of the shunt, to regulate the flow of fluid through the shunt in relation to a pressure difference between the body lumens. In some embodiments a control mechanism coupled to the adjustable flow regulation mechanism may be provided, to remotely activate the adjustable flow regulation mechanism.

Owner:WAVE LTD V

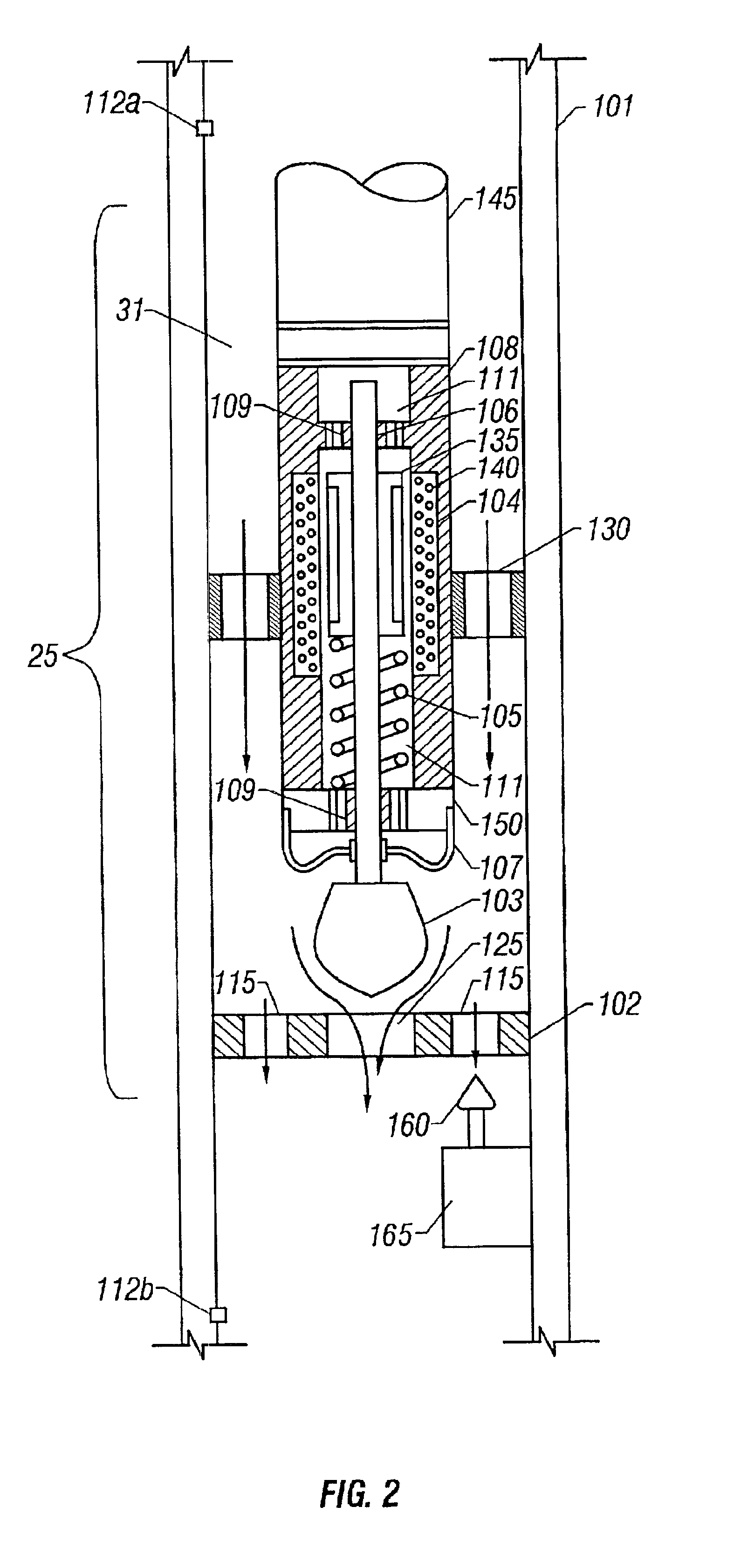

Hydraulically balanced reciprocating pulser valve for mud pulse telemetry

ActiveUS6898150B2Improve data transfer rateSurveyMultiple modulation transmitter/receiver arrangementsDifferential pressureReciprocating motion

A reciprocating pulser system for generating pressure fluctuations in a flowing drilling fluid comprising a reciprocating poppet and a stationary valve assembly with axial flow passages. The poppet reciprocates in close proximity to the valve assembly, at least partially blocking the flow through the valve assembly and generating oscillating pressure pulses. The poppet passes through two zero speed positions during each cycle, enabling rapid changes in signal phase, frequency, and / or amplitude thereby facilitating enhanced data encoding. The poppet is driven by a linear electric motor disposed in a lubricant filled housing. In one embodiment, the housing to shaft seal is a flexible bellows. In one embodiment, a force balance spring is used to essentially offset the hydraulic flow forces on the poppet. In one embodiment, a bypass poppet is used to adjust the differential pressure across the valve assembly.

Owner:BAKER HUGHES INC

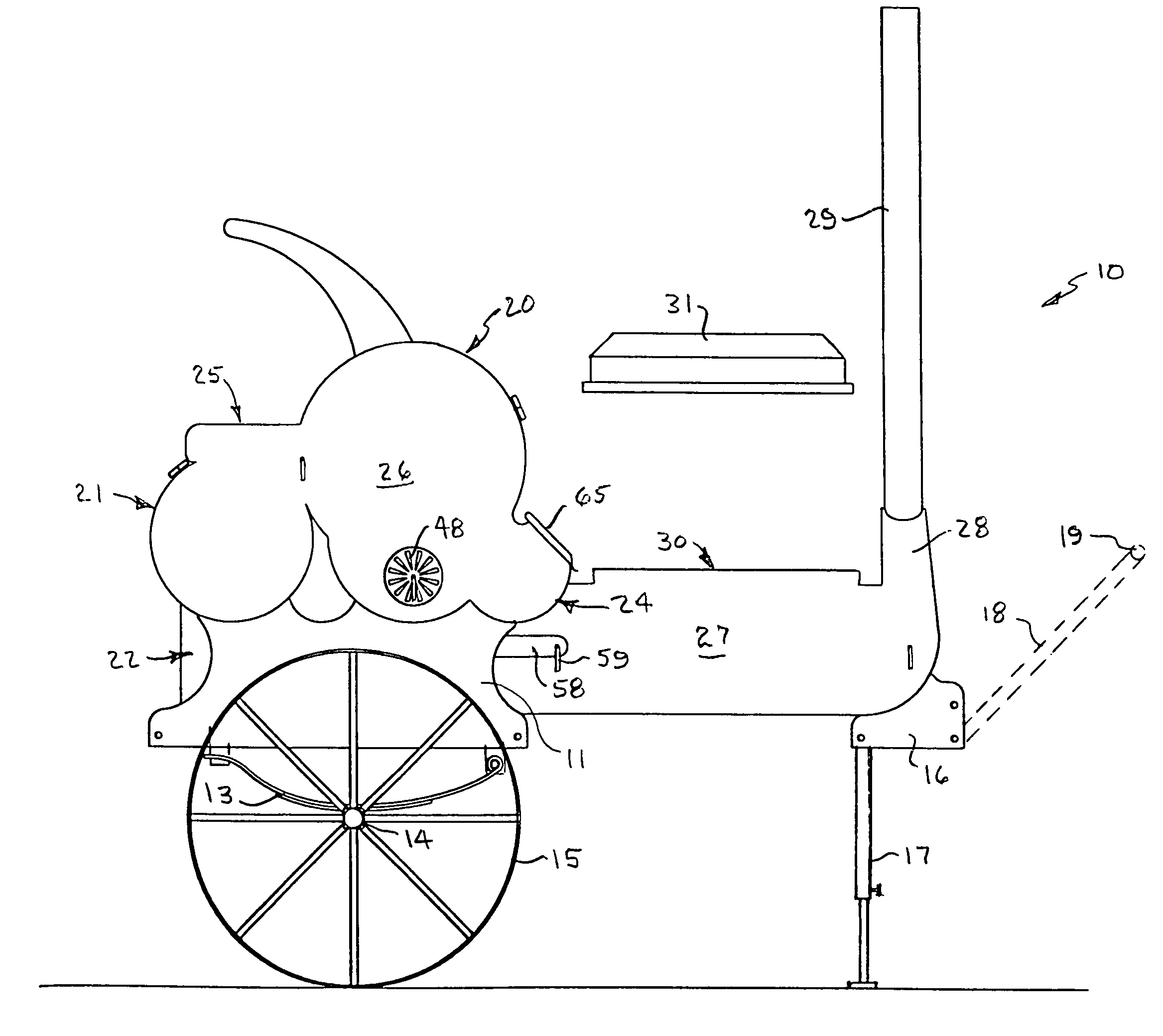

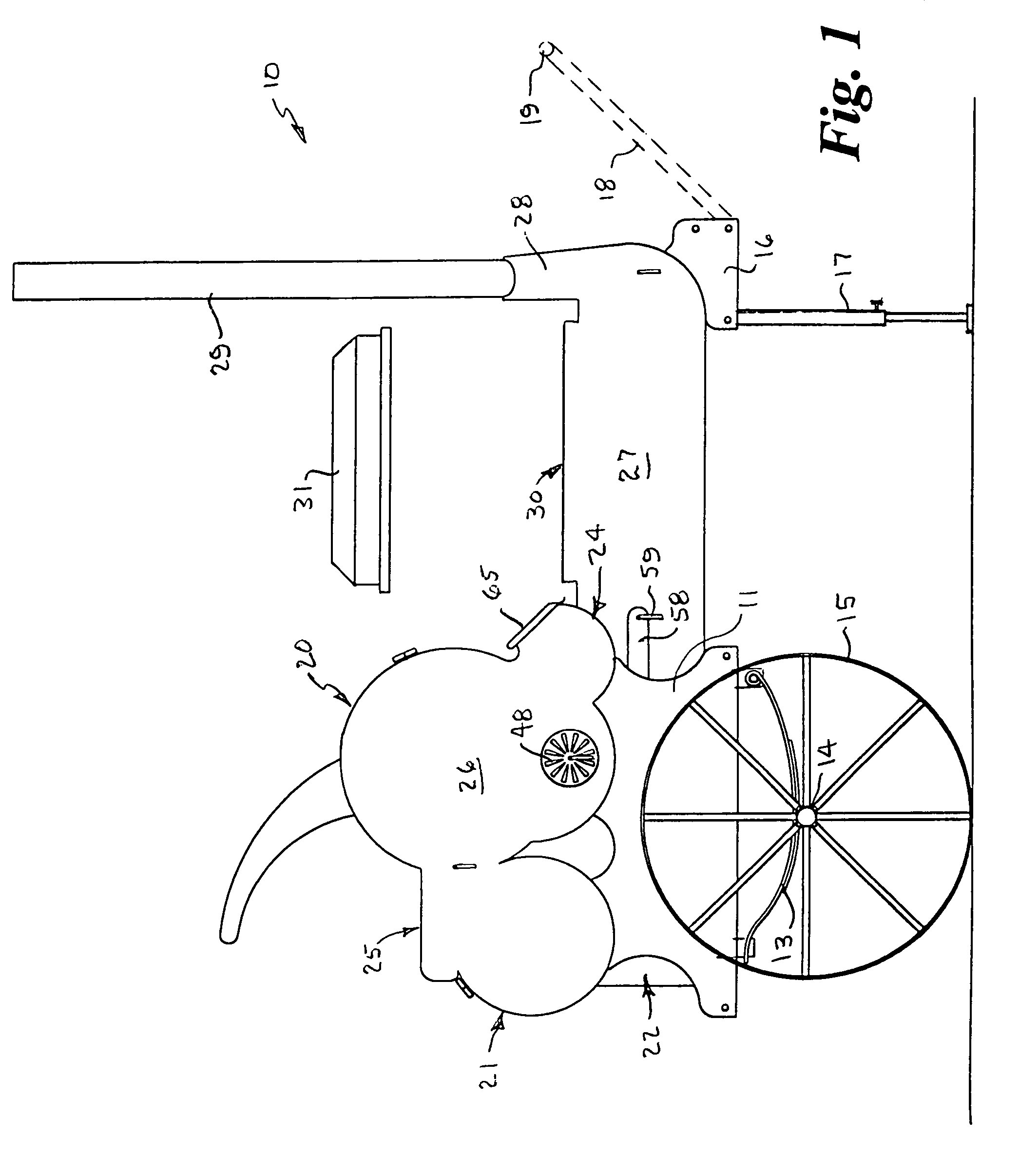

Outdoor multi-method cooker

InactiveUS7156087B1Lighting and heating apparatusStove/ranges for heating waterCombustionDifferential pressure

An outdoor multi-method cooker for preparing a wide variety of different foods at the same time using selective convection, radiant, or conduction cooking operations with or without smoke, or combinations thereof, using a single heat source. The cooker has a horizontal central longitudinal chamber with a firebox at one end and a pair of stacks at the opposed end, a main oven, a pair of lateral smokeless ovens, a warming compartment, and a griddle above the firebox, all disposed transversely on the longitudinal chamber in parallel spaced relation, and a steam table along the upper portion of the longitudinal chamber. The cooker operates on the principle of equalization of natural differential pressures caused by rising warmer air, similar to the draw created by the upper portion of a fireplace, for drafting hot gases or smoke laden hot gases from the combustion source and selectively routing it through passageways into and around the various components.

Owner:CHURCHILL III ALBERT B +1

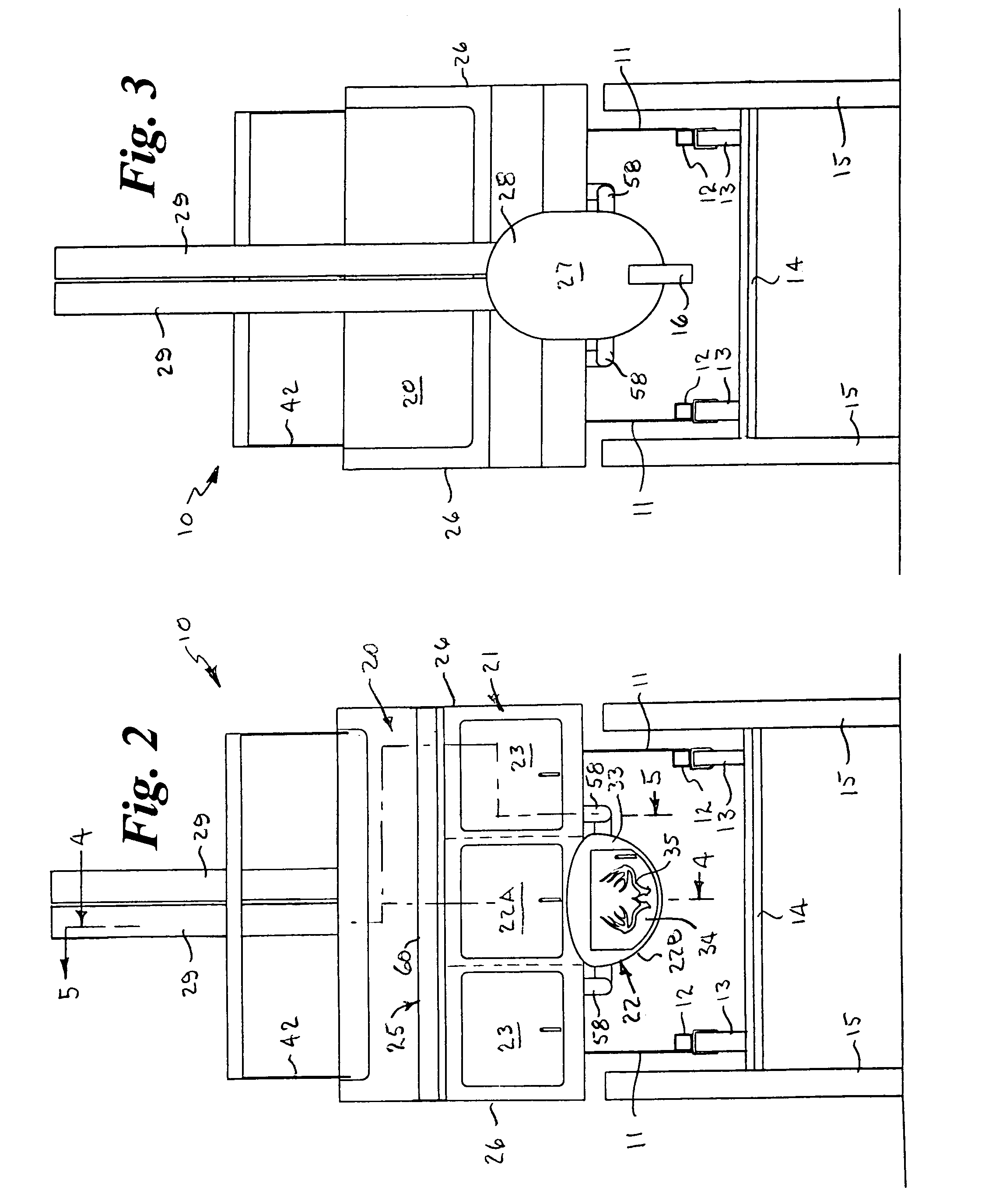

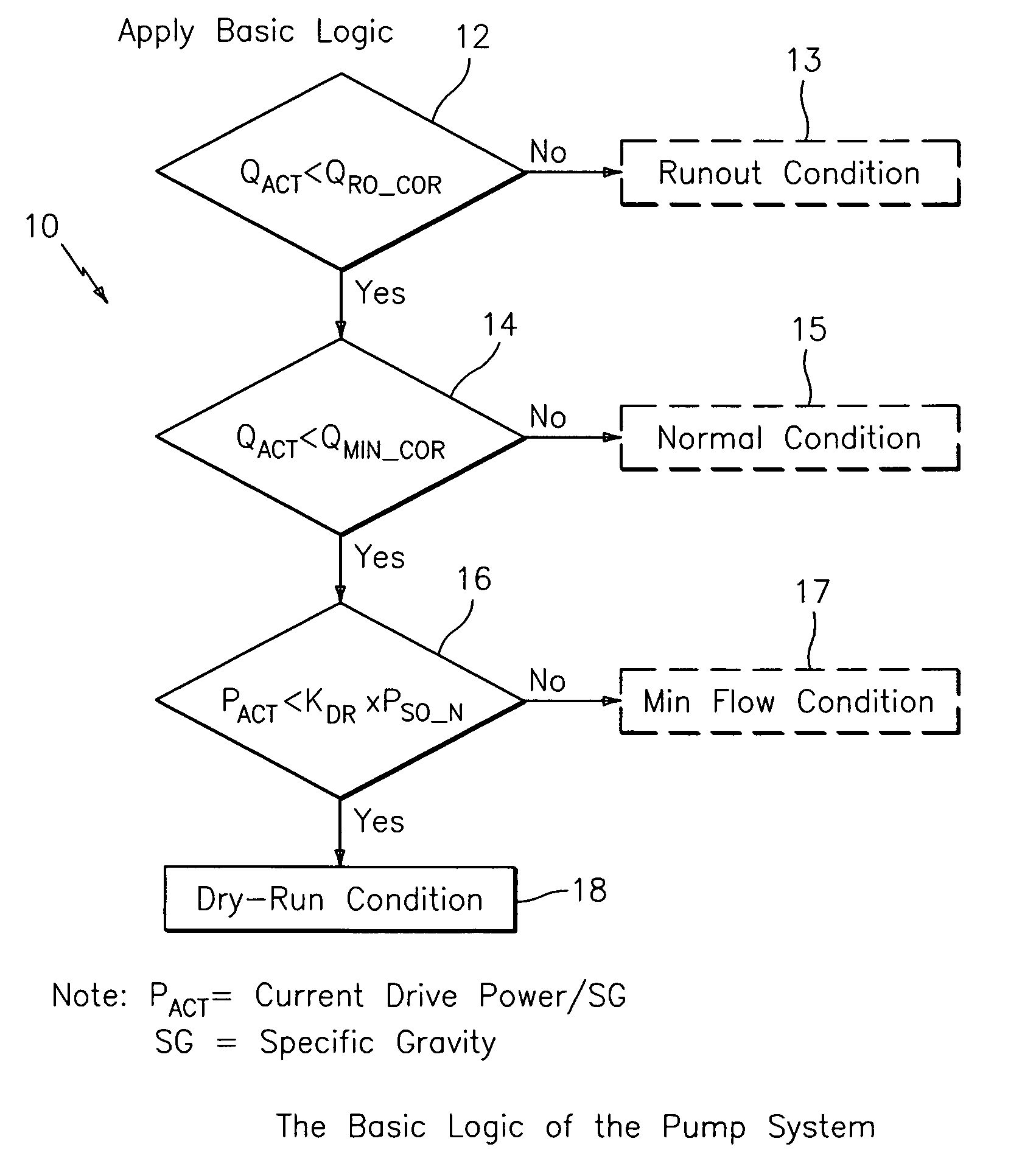

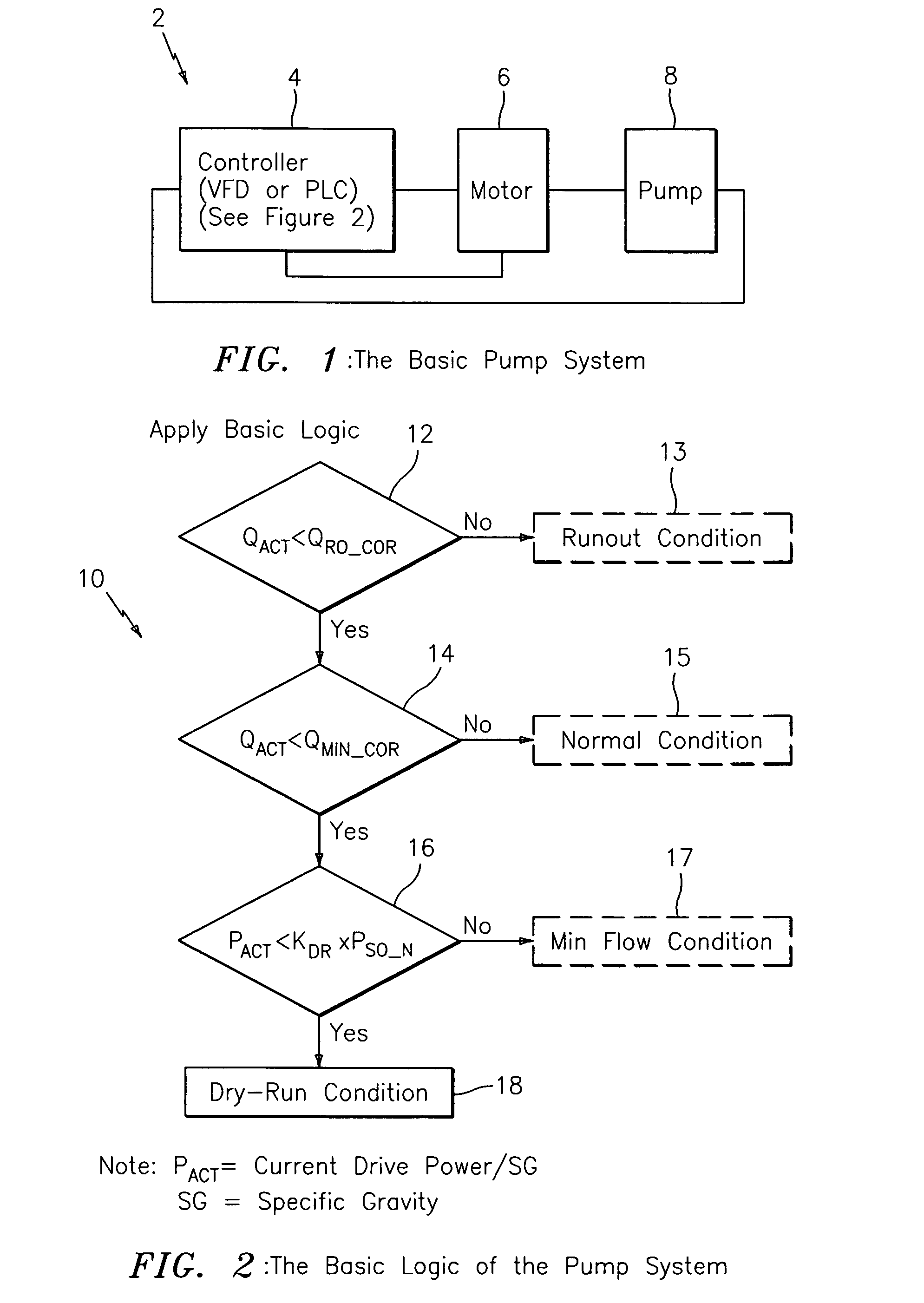

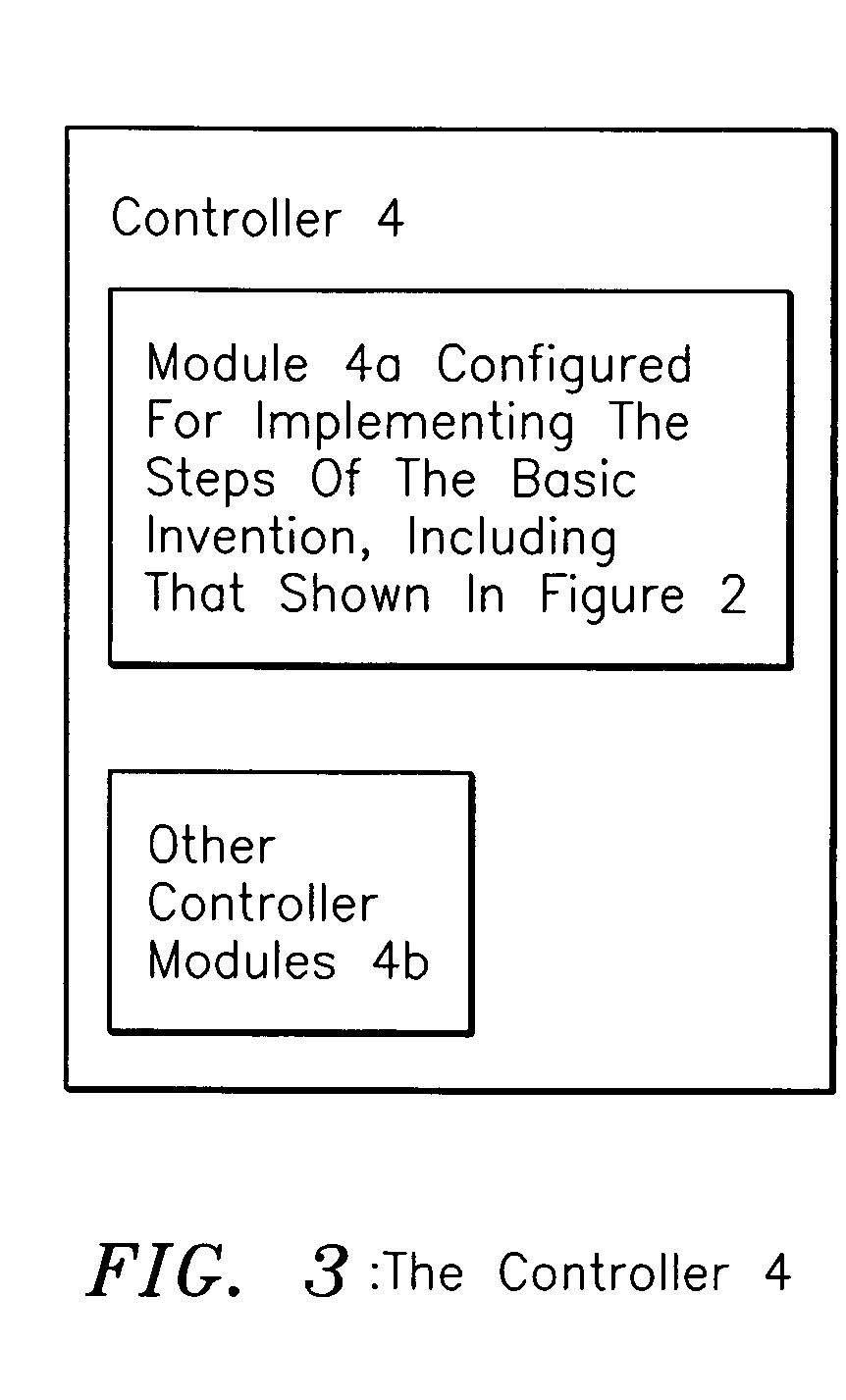

Method and apparatus for pump protection without the use of traditional sensors

ActiveUS20070212229A1Precise processAccurately determine power v flowVolume/mass flow measurementFlexible member pumpsDifferential pressureFlow curve

The present invention provides protection for centrifugal pumps while differentiating between dangerous operating conditions (e.g. dry running, minimum flow and runout) and / or conditions where transient conditions (e.g. closed valve operation) may occur and the protection can be revoked once the condition clears. The methodology utilizes a calculated flow value which can be mathematically determined from a calibrated closed valve power vs speed curve and / or various pump and motor parameters such as speed, torque, power and / or differential pressure or from calibrated flow curves stored in the evaluation device. The calculated flow value is then compared to threshold values of flow associated with these adverse operating conditions.

Owner:ITT MFG ENTERPRISES LLC

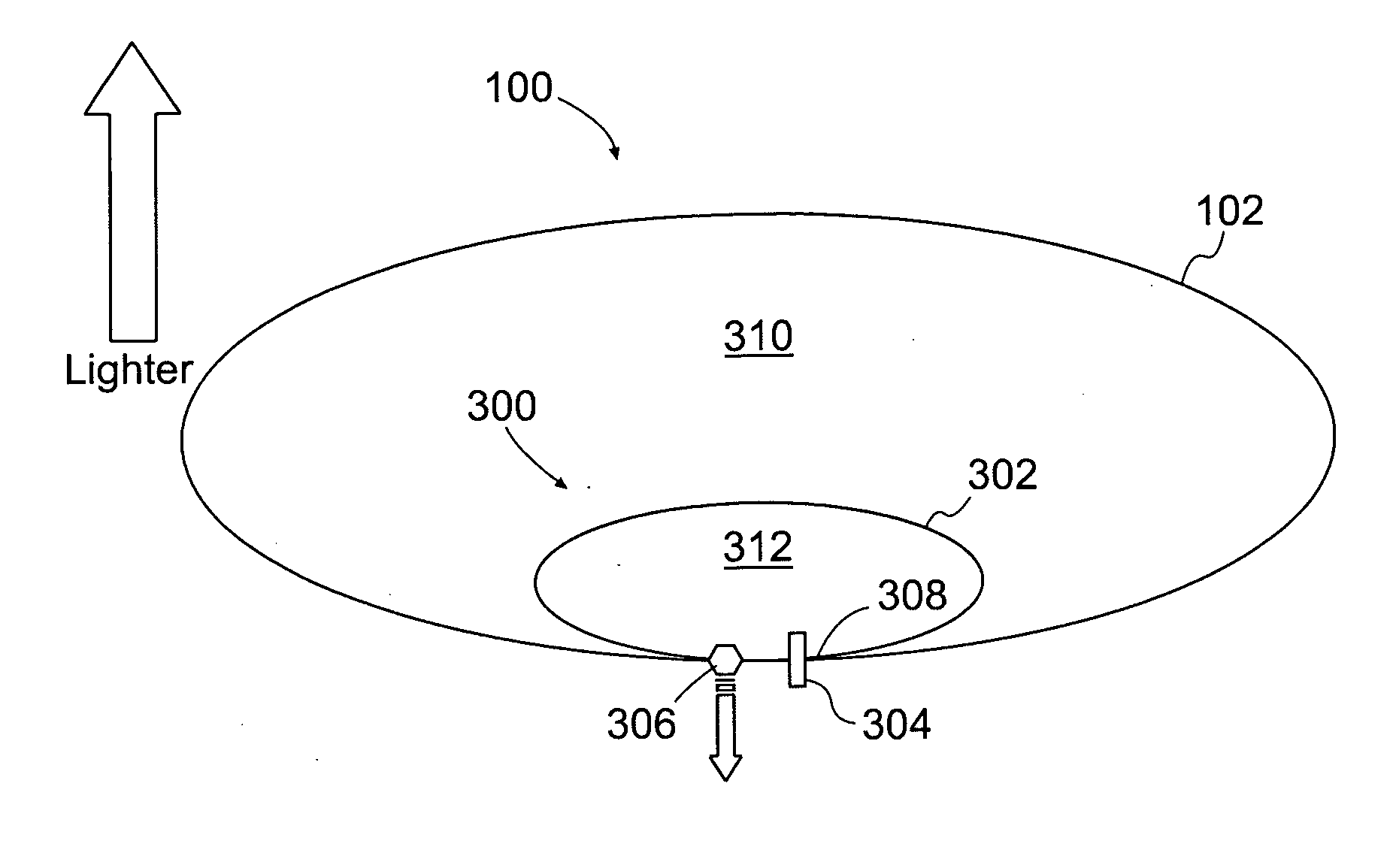

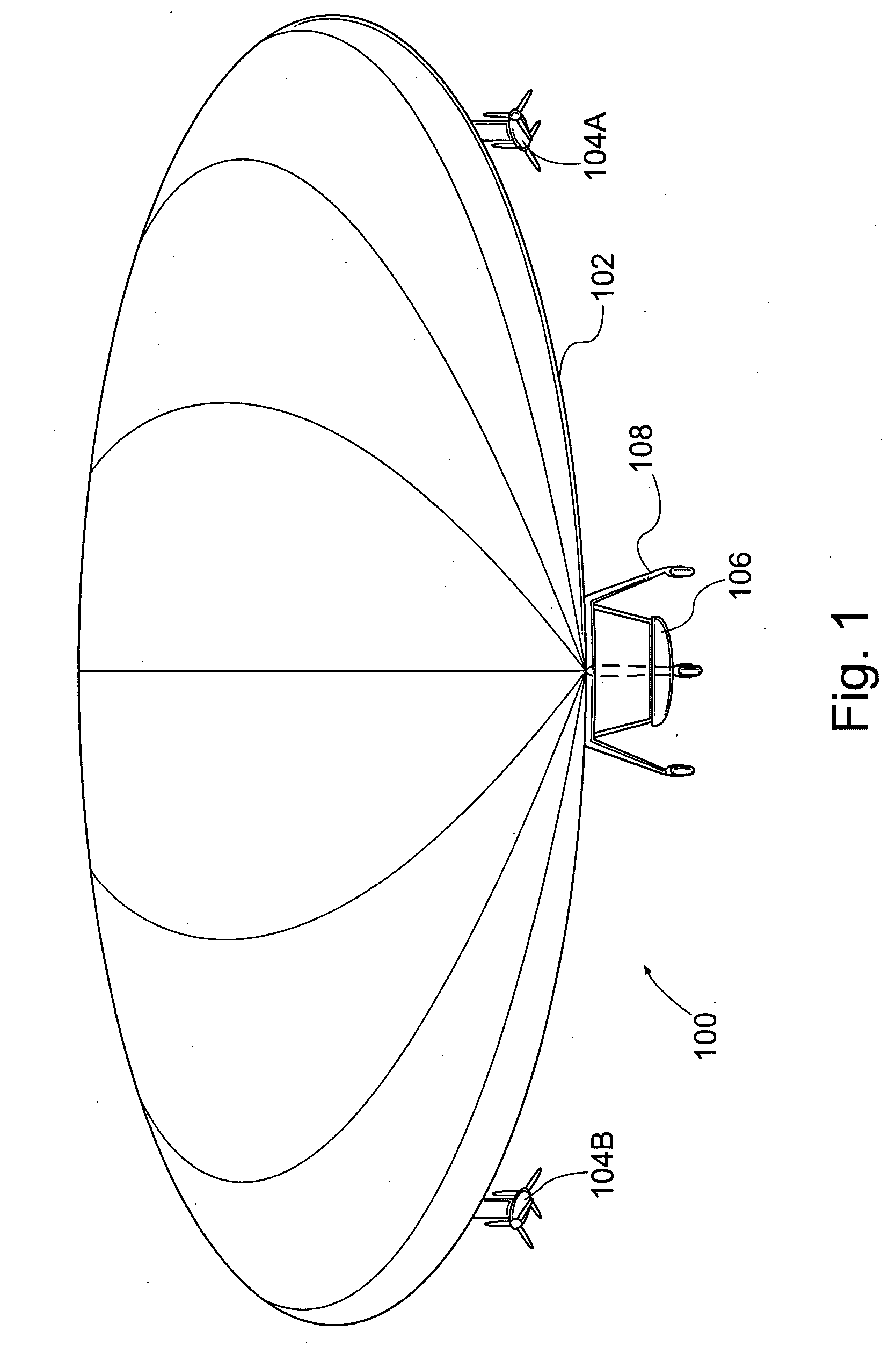

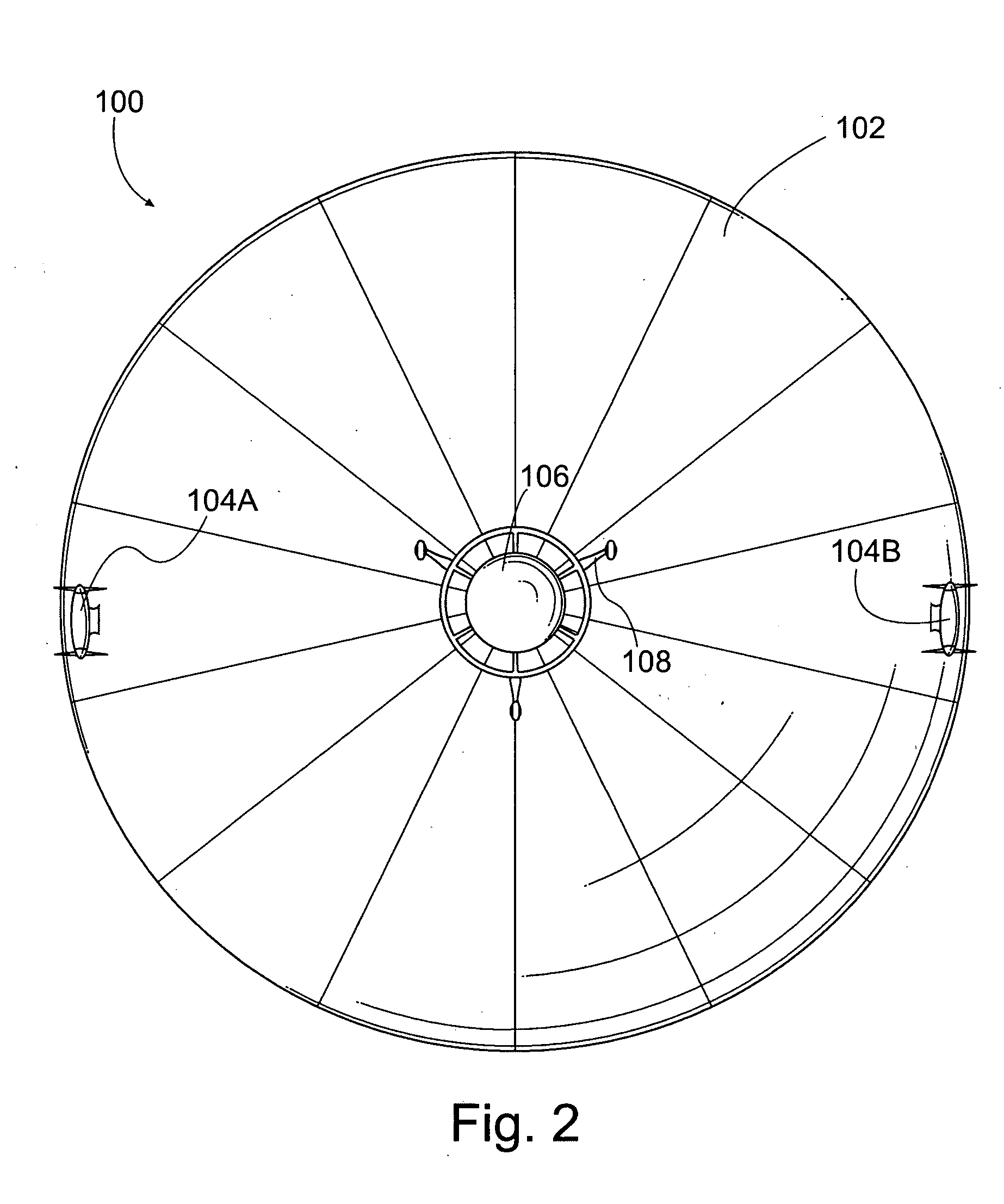

Systems for actively controlling the aerostatic lift of an airship

InactiveUS20060065777A1Statically heavyLess buoyantNon-rigid airshipsRigid airshipsInternal pressureAviation

Various embodiments of the invention relate generally to systems for providing active vertical control of an airship. More particularly, at least one embodiment of the invention relates to a system for actively controlling the aerostatic lift of an airship by manipulating the ratio of air to lifting gas contained within the airship, and thus the overall mass of the airship. This manipulation is accomplished by actively compressing and / or decompressing the lifting gas or internal air, with the resulting pressure differential borne primarily by the hull and / or an internal pressure tank depending upon the configuration.

Owner:LTAS HLDG

High repetition rate laser produced plasma EUV light source

An EUV light source apparatus and method are disclosed, which may comprise a pulsed laser providing laser pulses at a selected pulse repetition rate focused at a desired target ignition site; a target formation system providing discrete targets at a selected interval coordinated with the laser pulse repetition rate; a target steering system intermediate the target formation system and the desired target ignition site; and a target tracking system providing information about the movement of target between the target formation system and the target steering system, enabling the target steering system to direct the target to the desired target ignition site. The target tracking system may provide information enabling the creation of a laser firing control signal, and may comprise a droplet detector comprising a collimated light source directed to intersect a point on a projected delivery path of the target, having a respective oppositely disposed light detector detecting the passage of the target through the respective point, or a detector comprising a linear array of a plurality of photo-sensitive elements aligned to a coordinate axis, the light from the light source intersecting a projected delivery path of the target, at least one of the which may comprise a plane-intercept detection device. The droplet detectors may comprise a plurality of droplet detectors each operating at a different light frequency, or a camera having a field of view and a two dimensional array of pixels imaging the field of view. The apparatus and method may comprise an electrostatic plasma containment apparatus providing an electric plasma confinement field at or near a target ignition site at the time of ignition, with the target tracking system providing a signal enabling control of the electrostatic plasma containment apparatus. The apparatus and method may comprise a vessel having and intermediate wall with a low pressure trap allowing passage of EUV light and maintaining a differential pressure across the low pressure trap. The apparatus and method may comprise a magnetic plasma confinement mechanism creating a magnetic field in the vicinity of the target ignition site to confine the plasma to the target ignition site, which may be pulsed and may be controlled using outputs from the target tracking system.

Owner:ASML NETHERLANDS BV

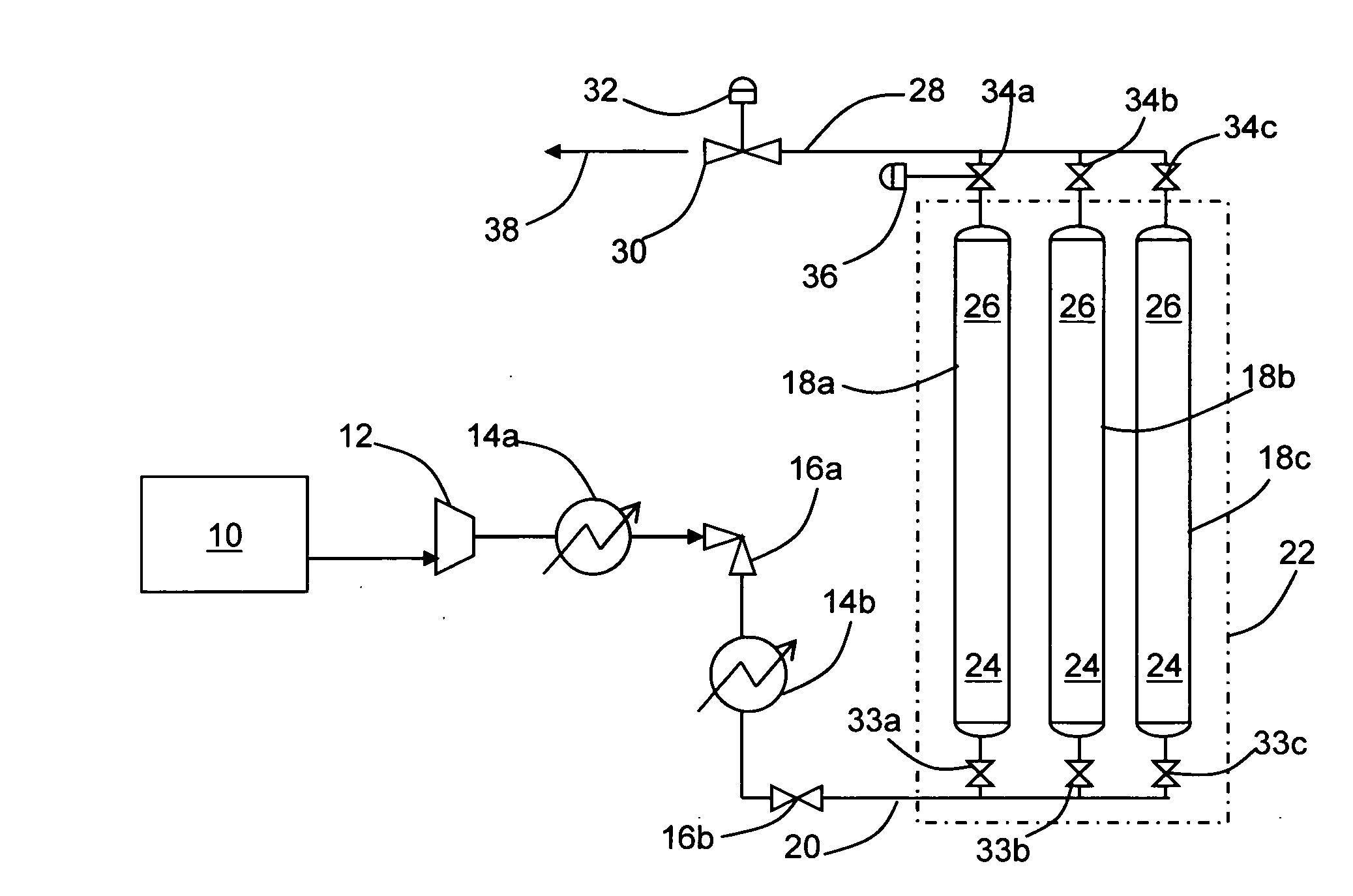

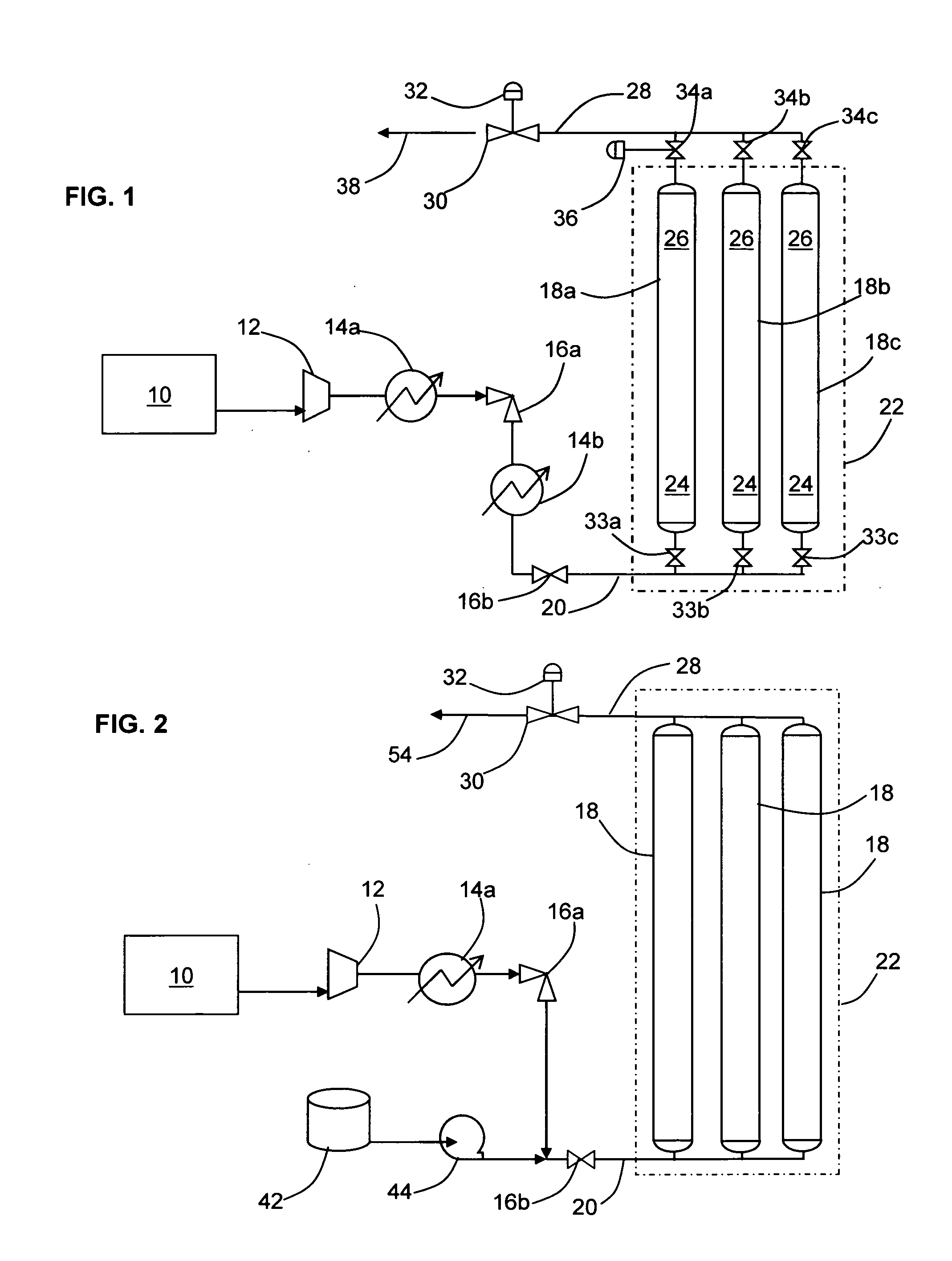

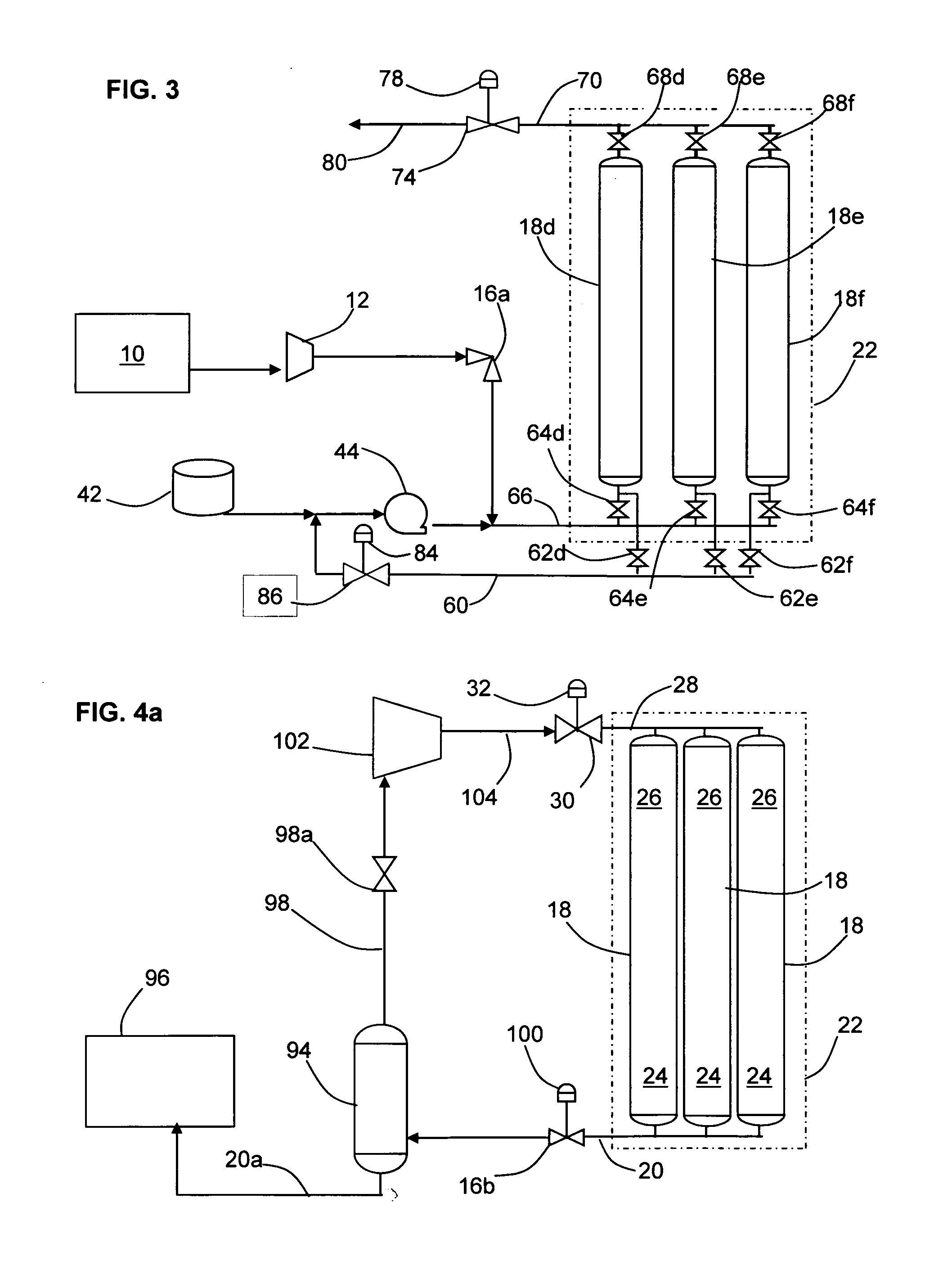

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS20080209916A1Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionCompressed fluid

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

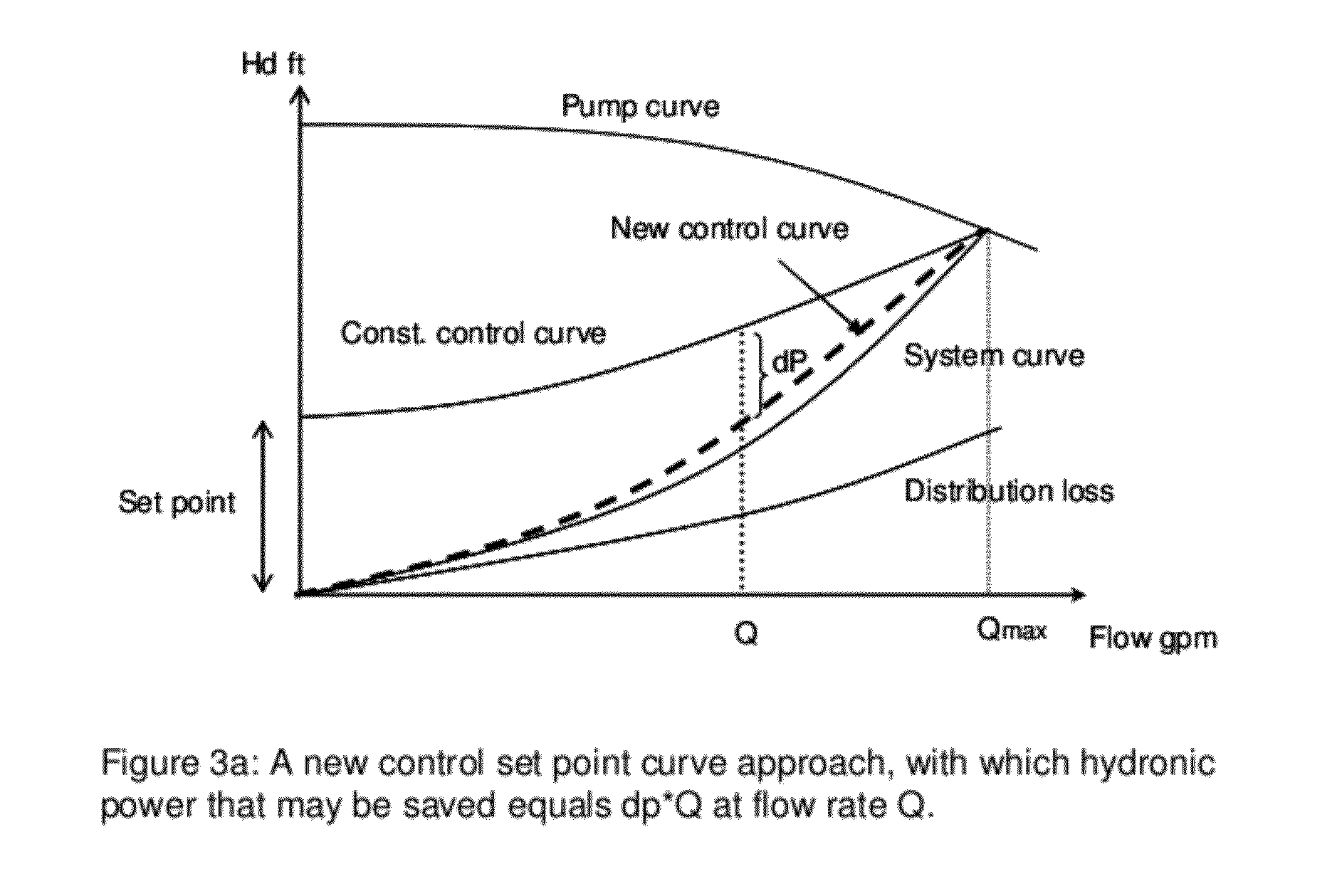

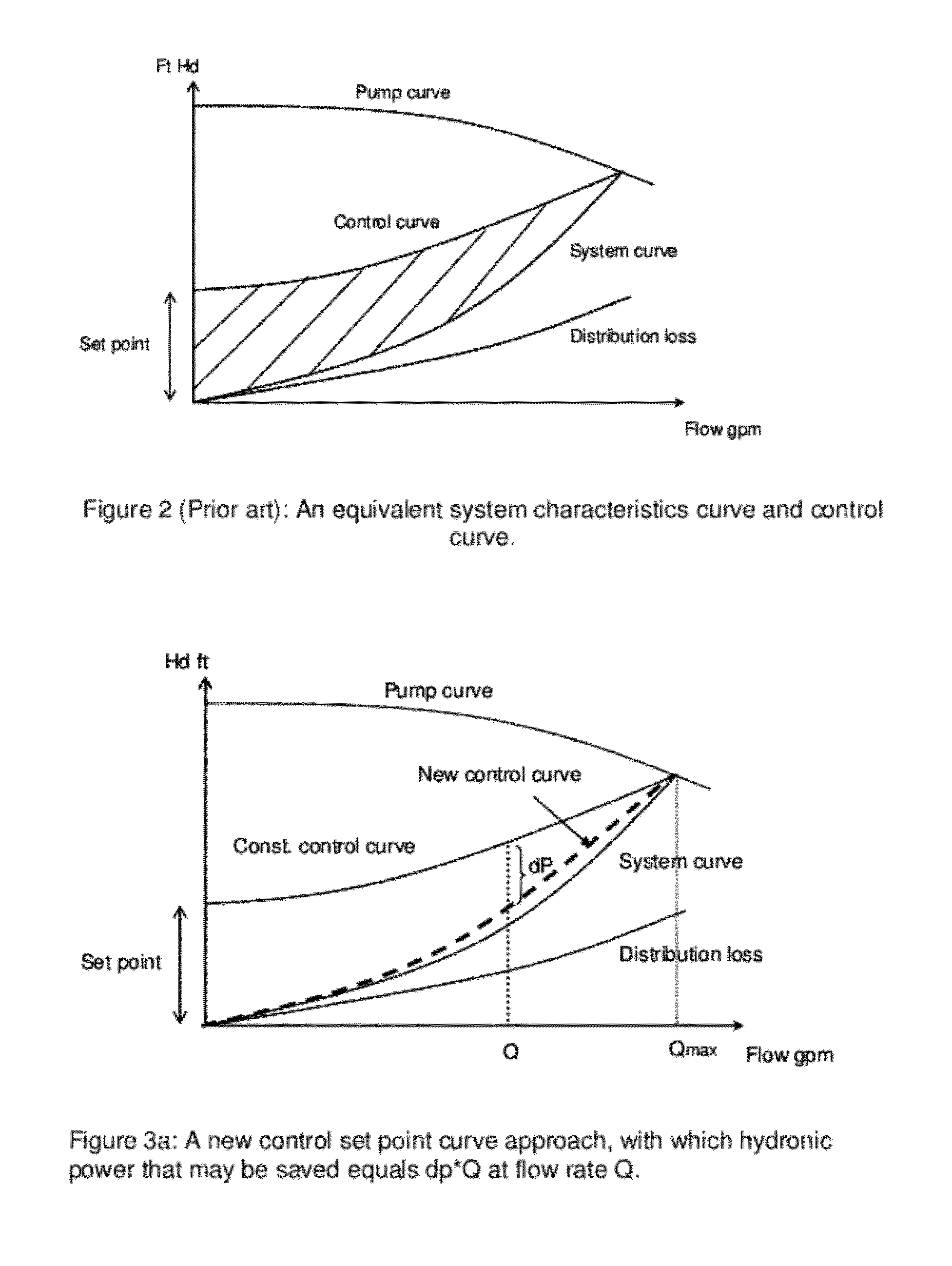

Method and Apparatus for Pump Control Using Varying Equivalent System Characteristic Curve, AKA an Adaptive Control Curve

ActiveUS20120173027A1Reduce energy consumptionReduce operating costsFlow control using electric meansFluid pressure control using electric meansMoving averageAverage filter

The present invention provides, e.g., apparatus comprising at least one processor; at least one memory including computer program code; the at least one memory and computer program code being configured, with at least one processor, to cause the apparatus at least to: respond to signaling containing information about an instant pressure and a flow rate of fluid being pumped in a pumping system, and obtain an adaptive control curve based at least partly on the instant pressure and flow rate using an adaptive moving average filter. The adaptive moving average filter may be based at least partly on a system flow equation: SAMAt=AMAF(Qt / √{square root over (ΔPt)}), where the function AMAF is an adaptive moving average filter (AMAF), and the parameters Q and ΔP are a system flow rate and differential pressure respectively. The at least one memory and computer program code may be configured to, with the at least one processor, to cause the apparatus at least to obtain an optimal control pressure set point from the adaptive control curve with respect to an instant flow rate or a moving average flow rate as SPt=MA(Qt) / SAMAt, where the function MA is a moving average filter (MA), to obtain a desired pump speed through a PID control.

Owner:FLUID HANDLING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com