Patents

Literature

2752 results about "Upper joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

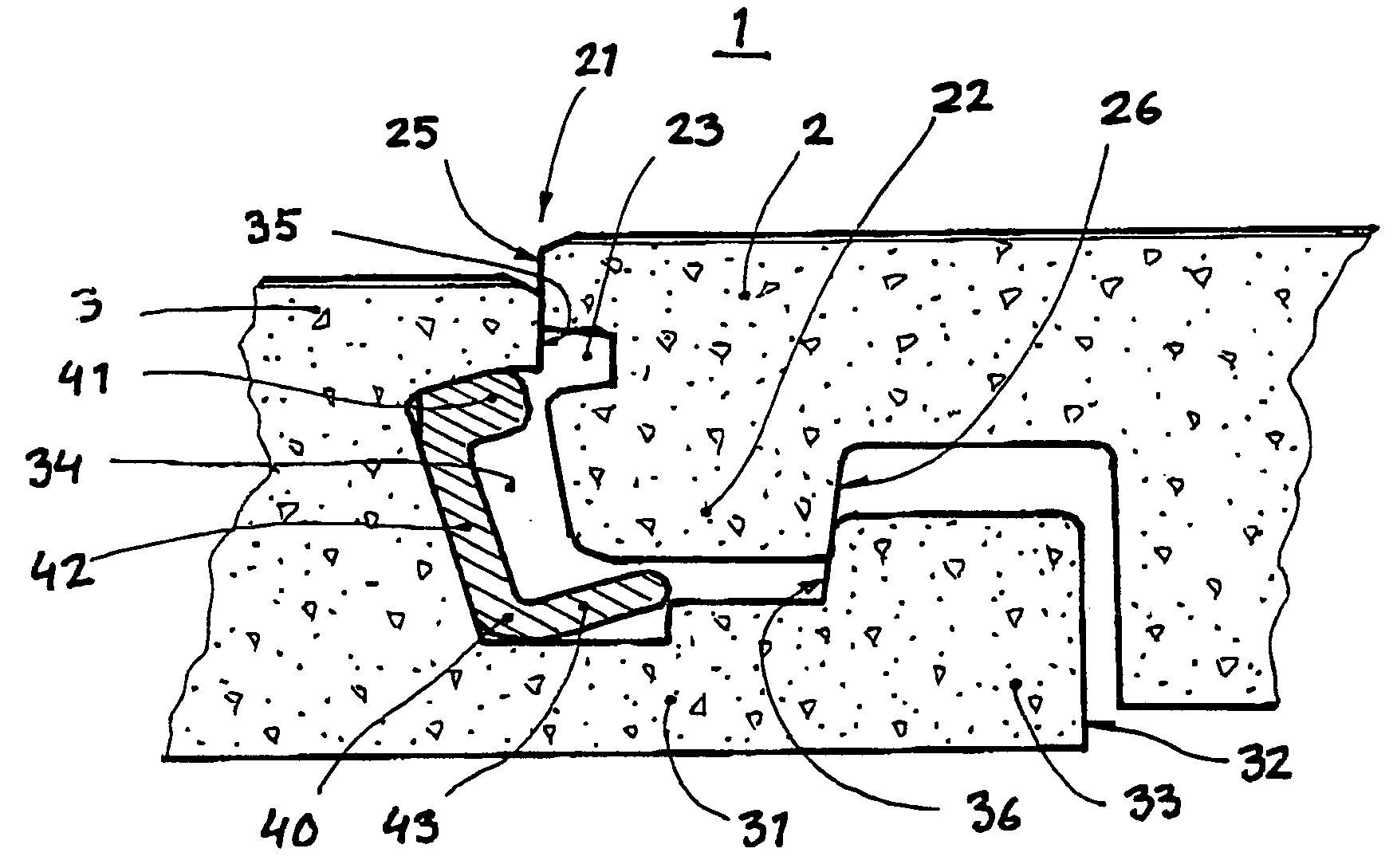

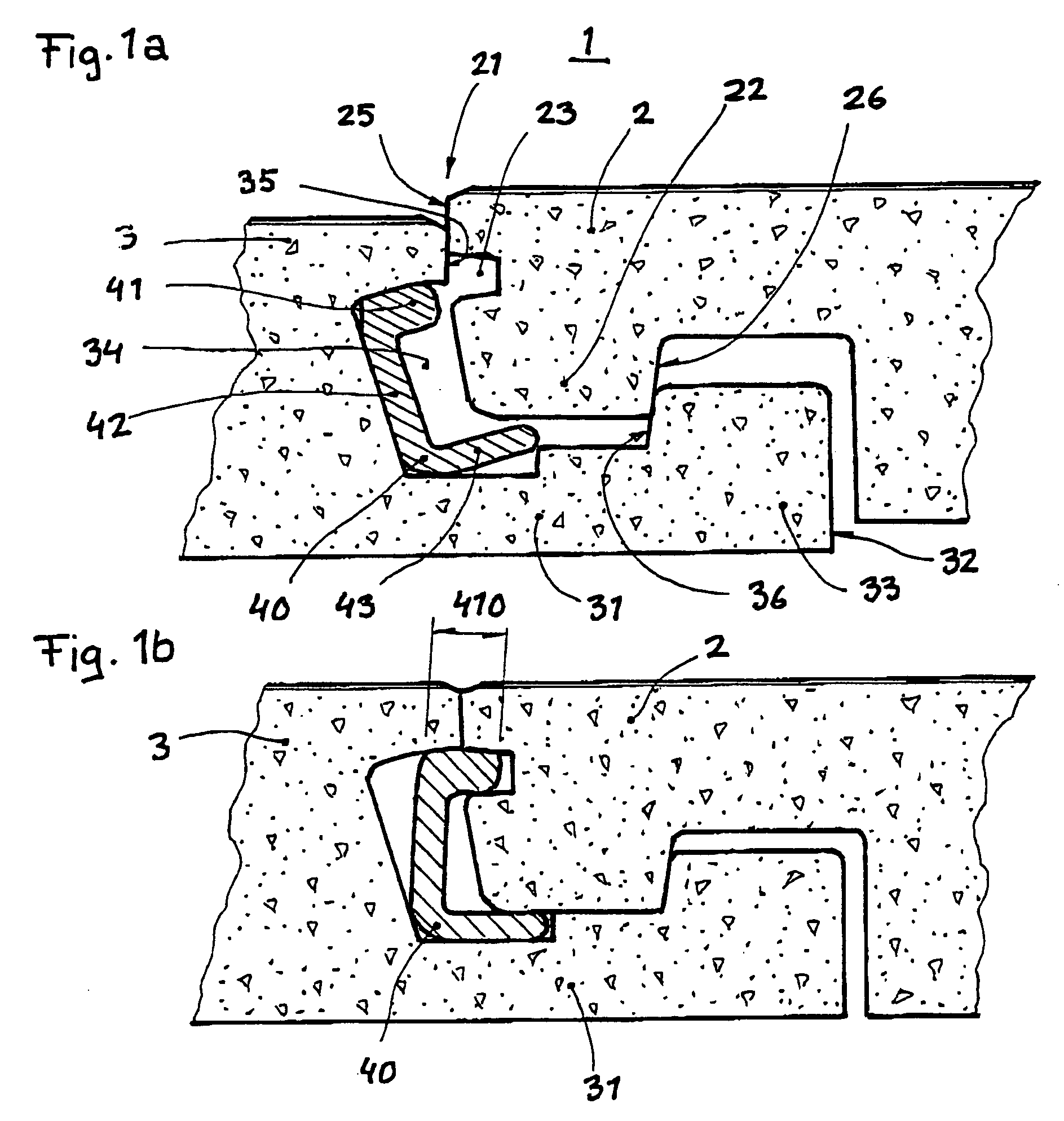

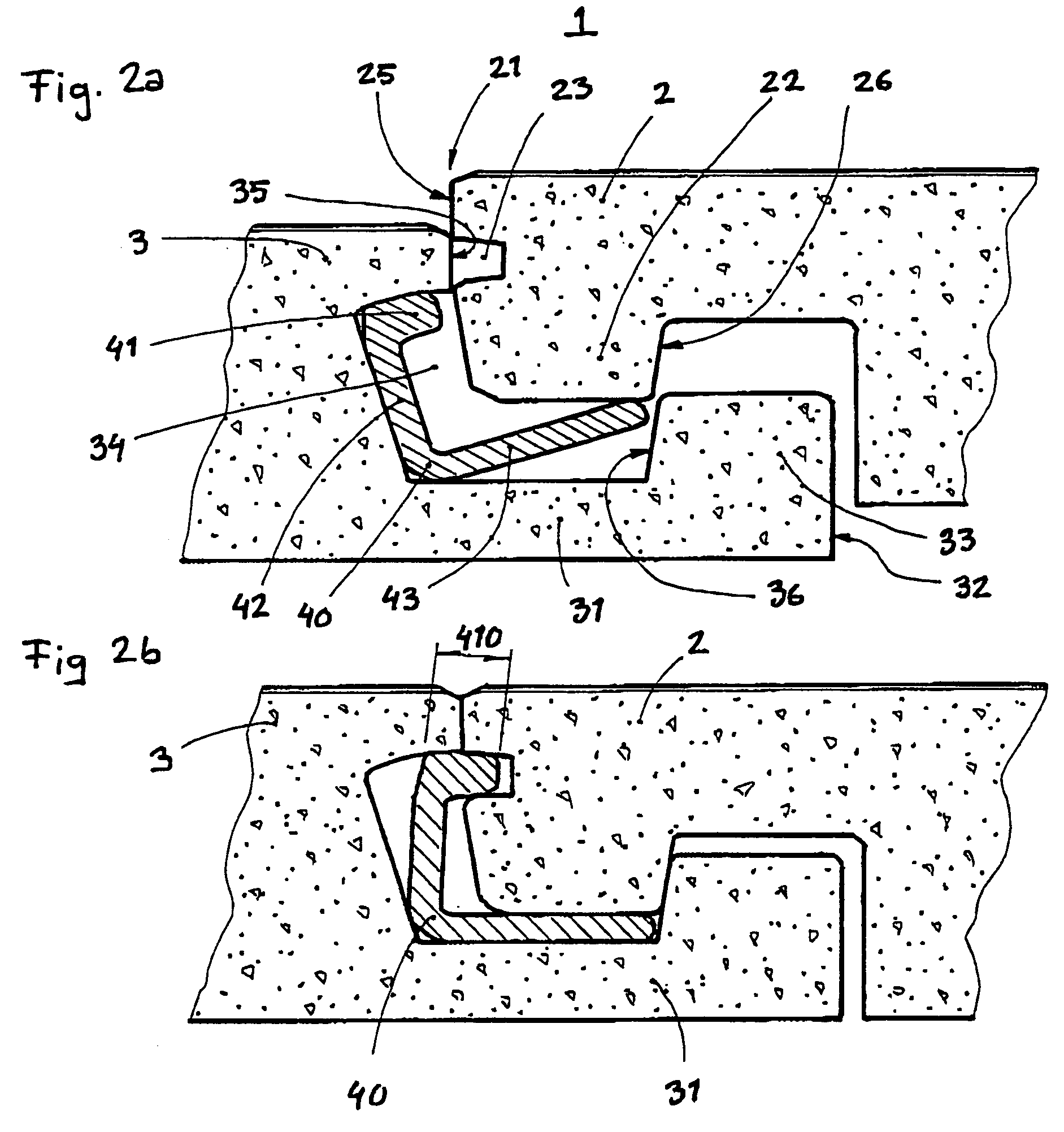

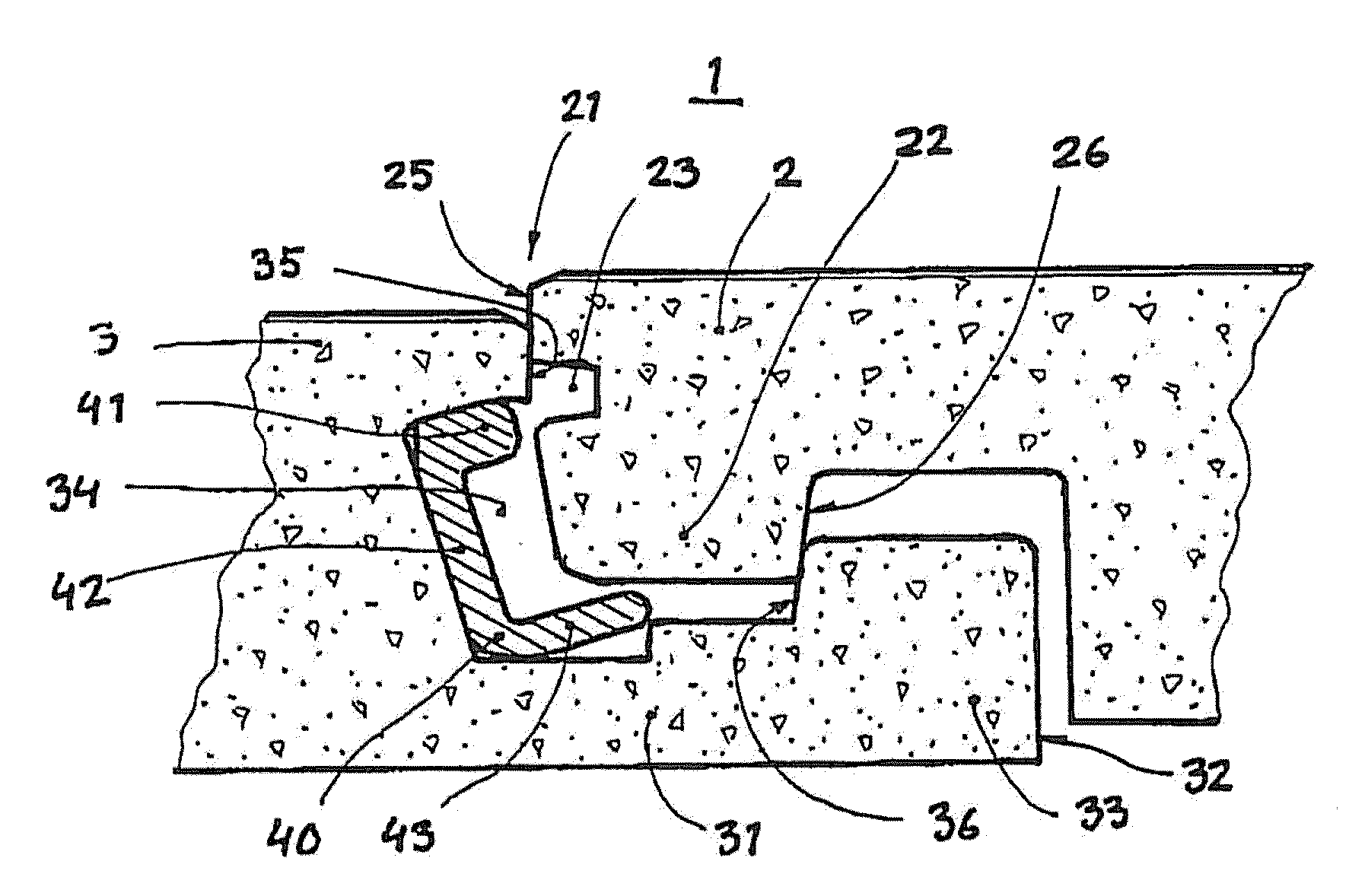

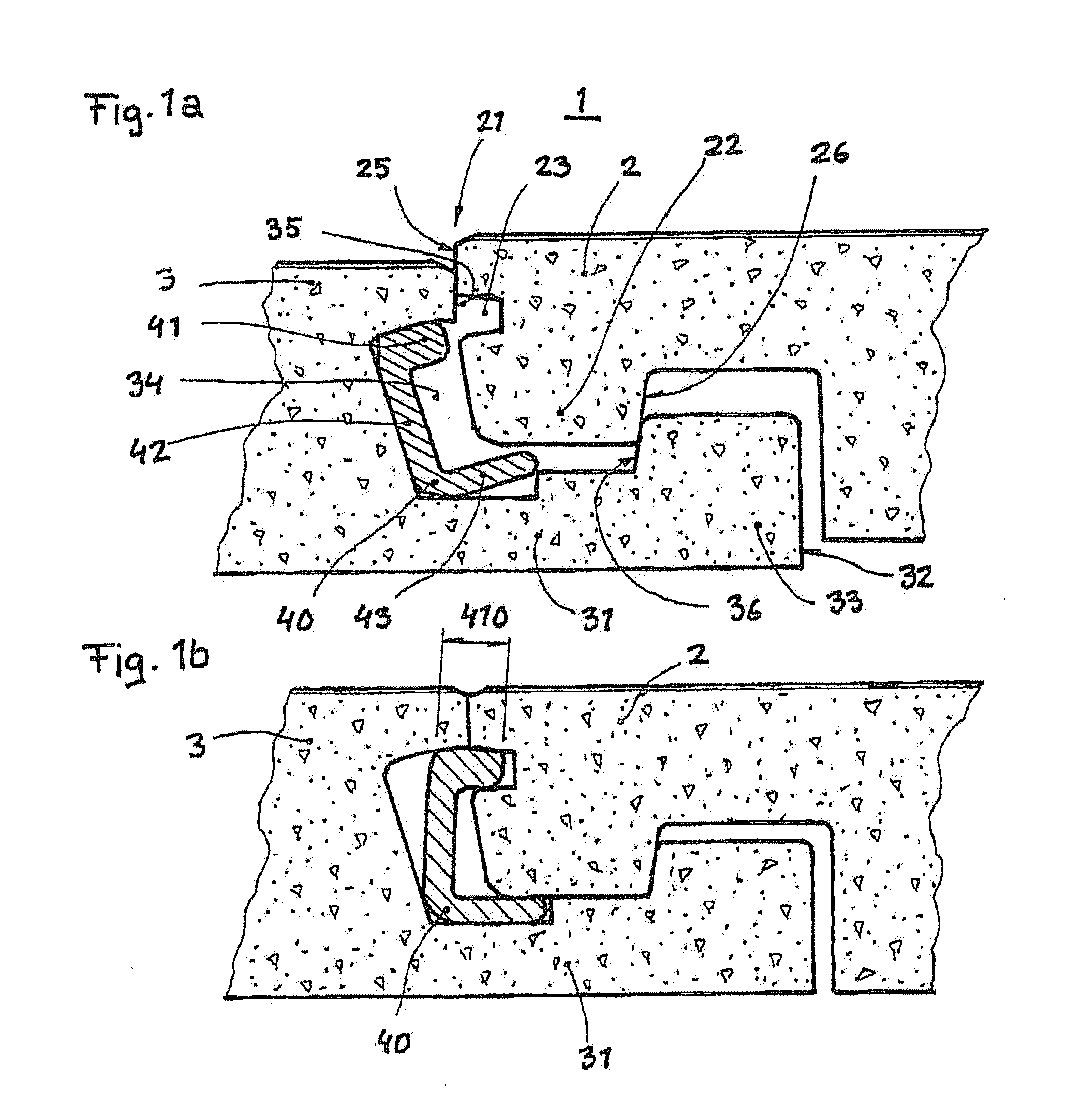

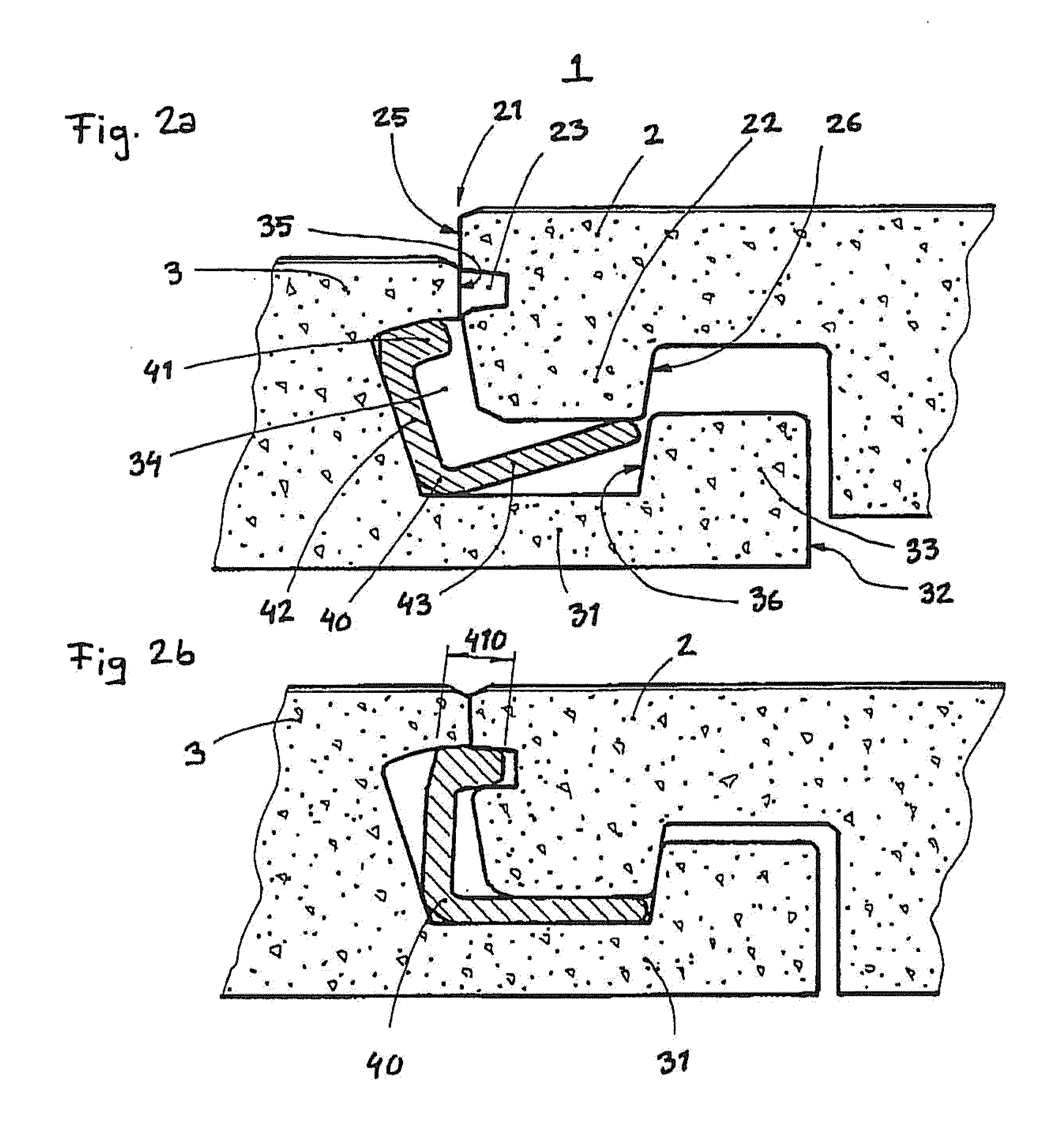

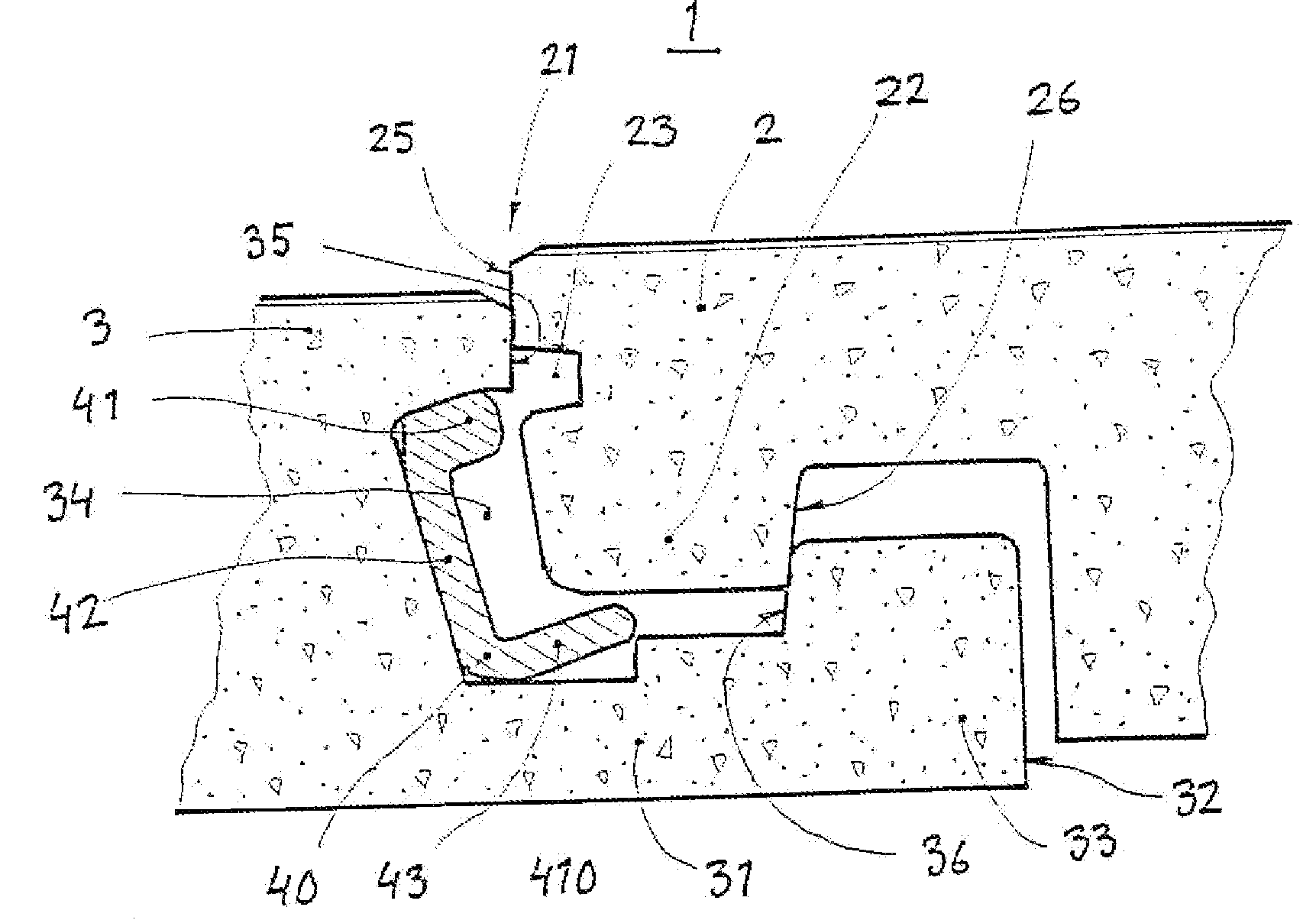

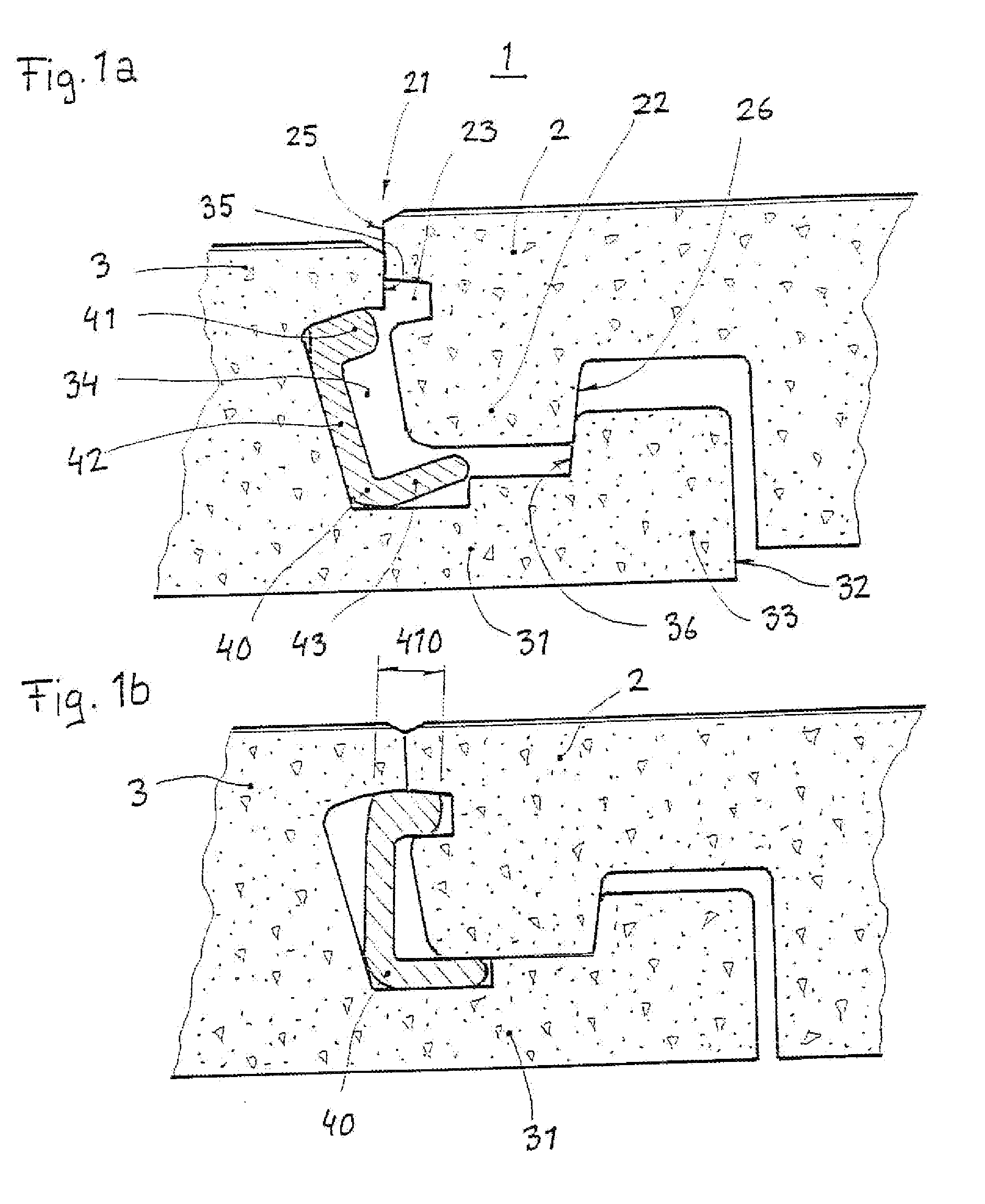

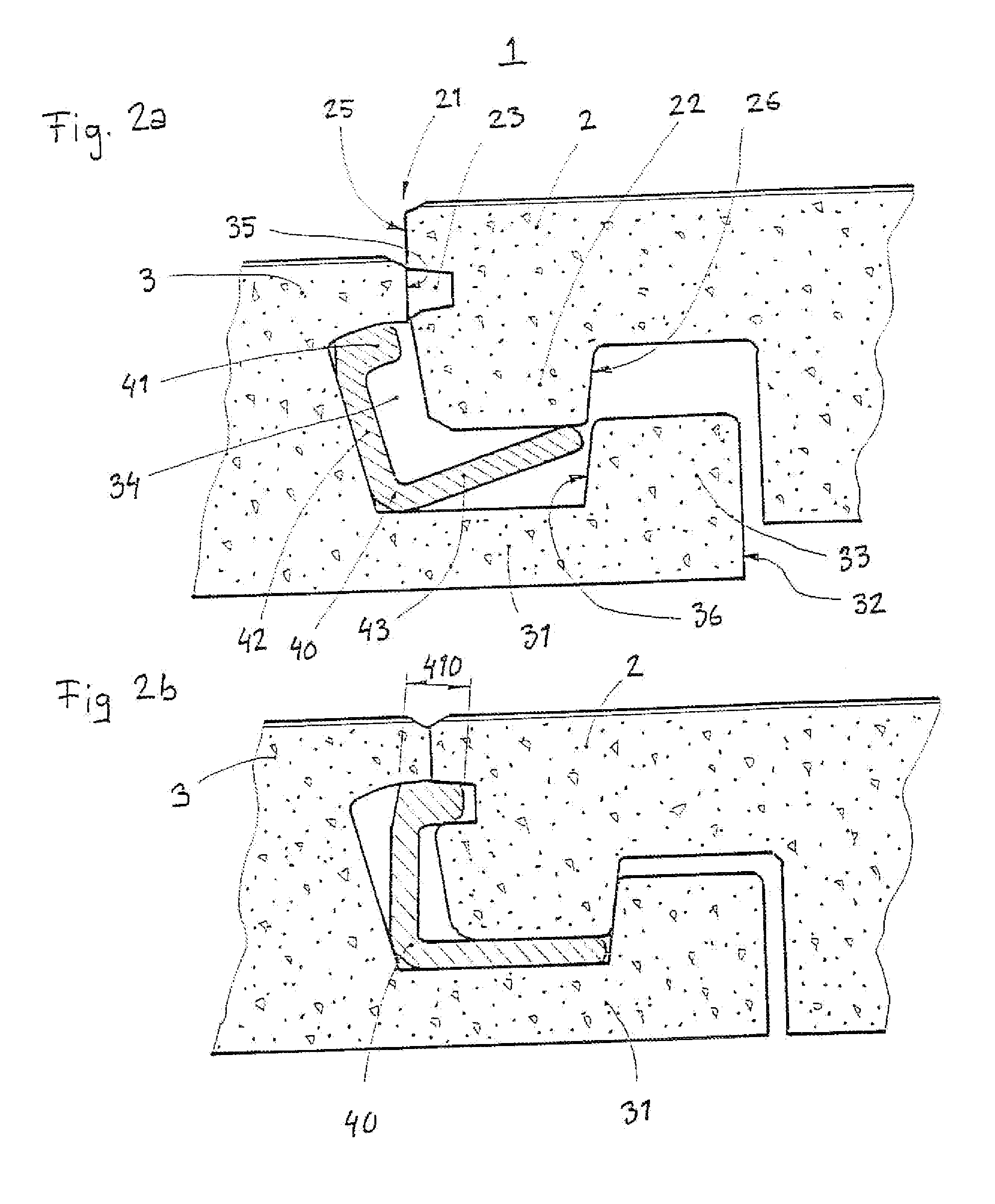

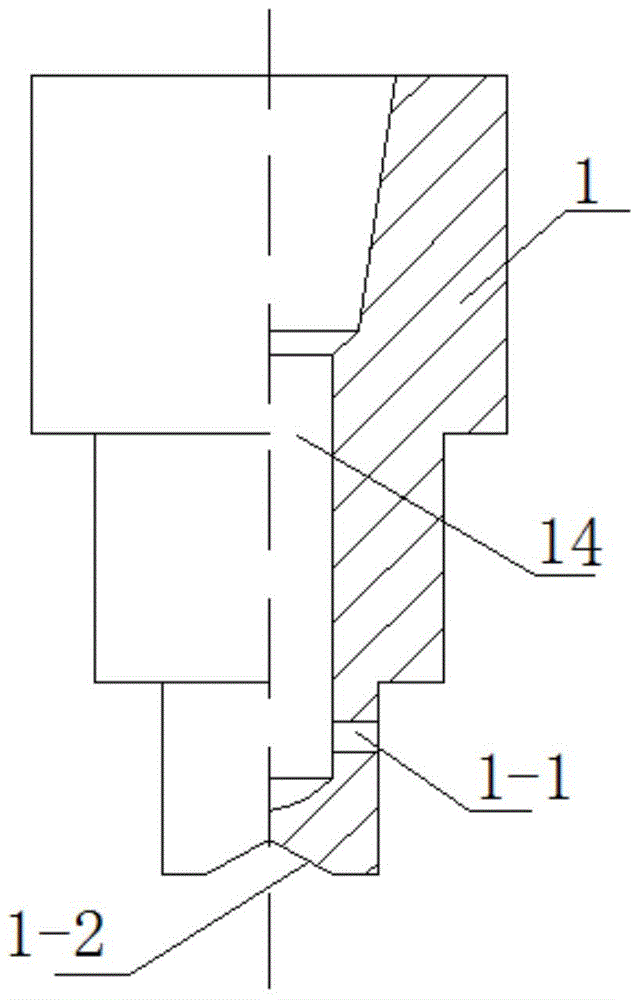

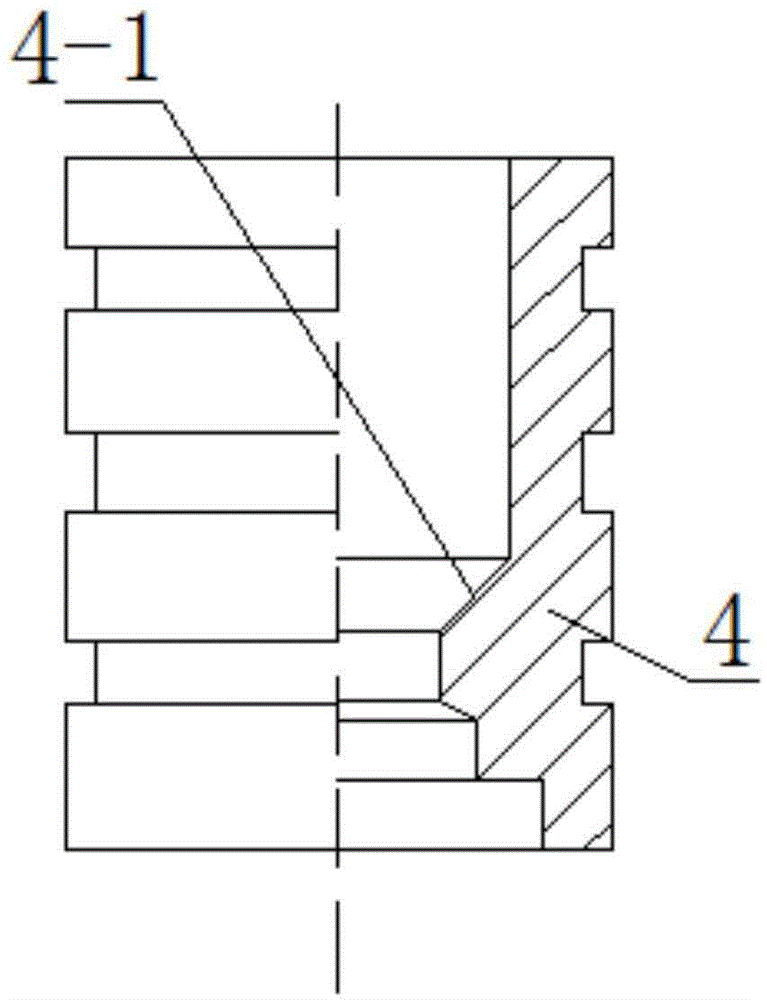

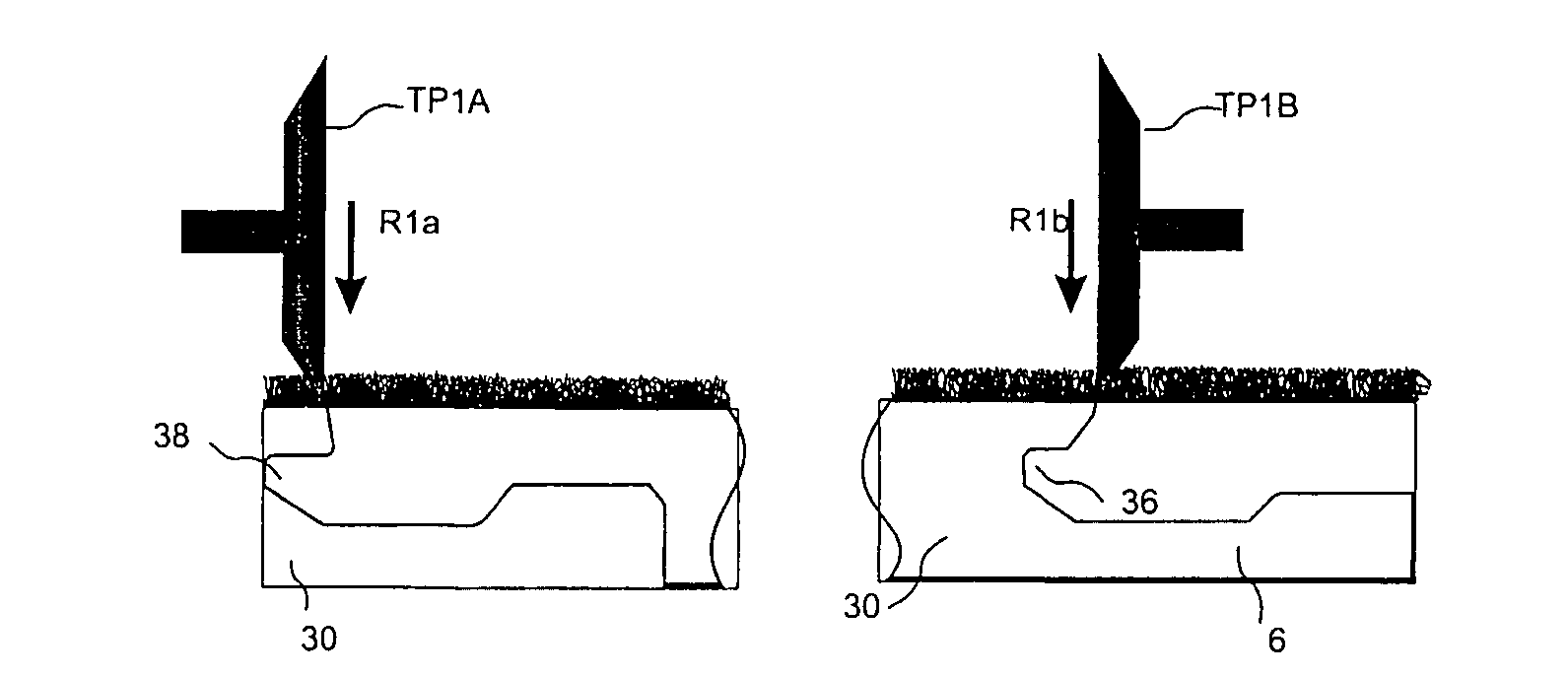

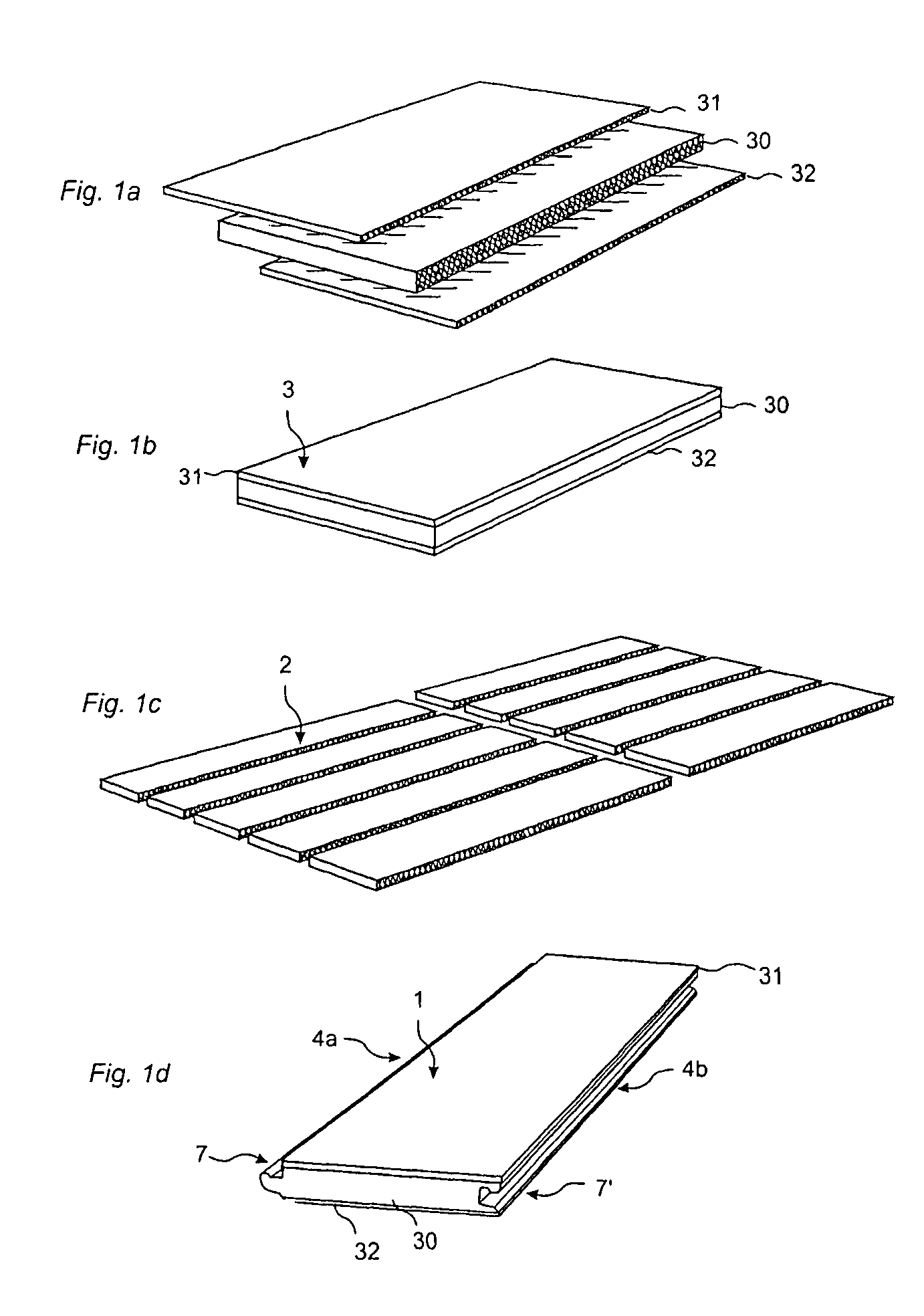

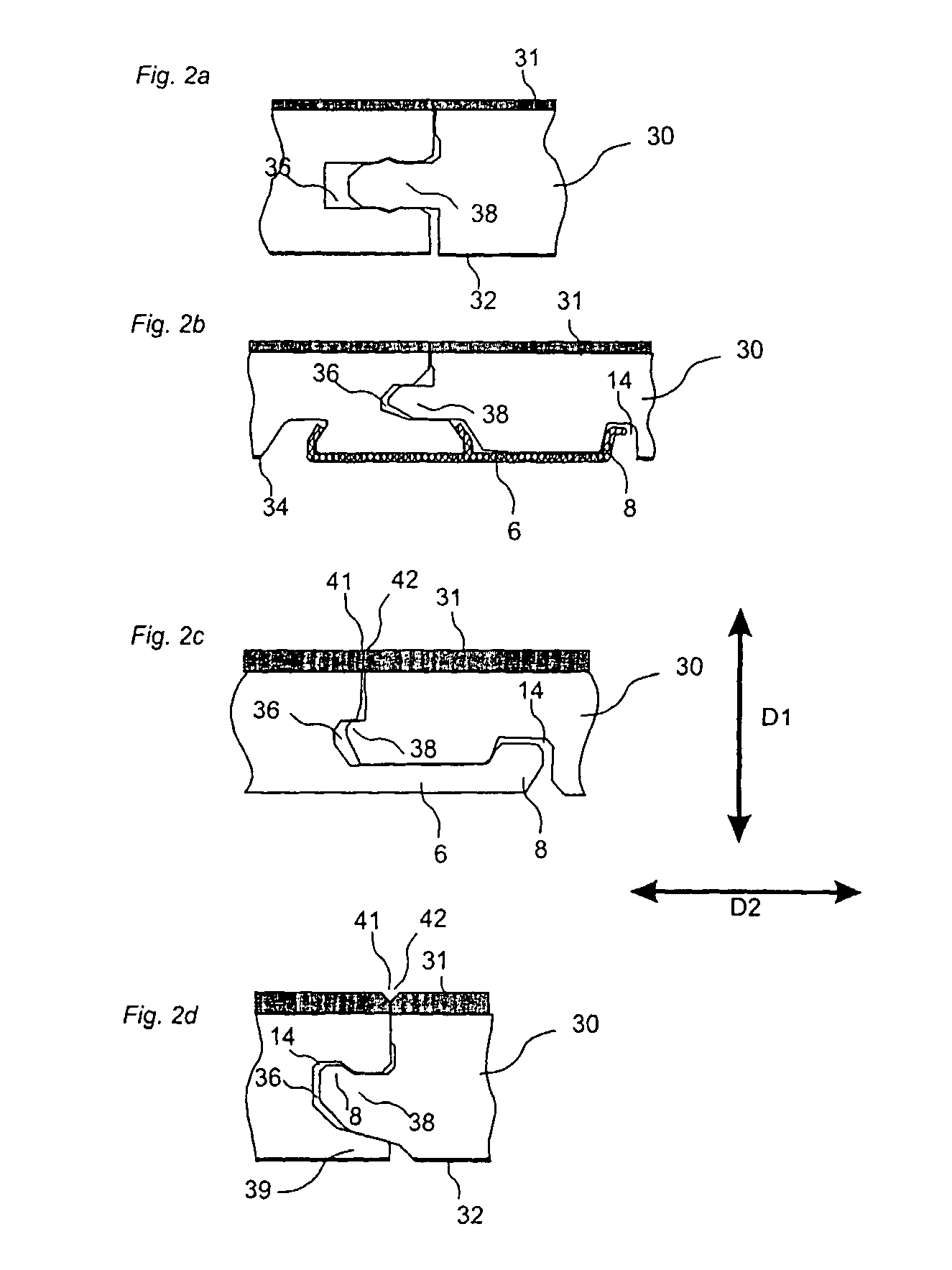

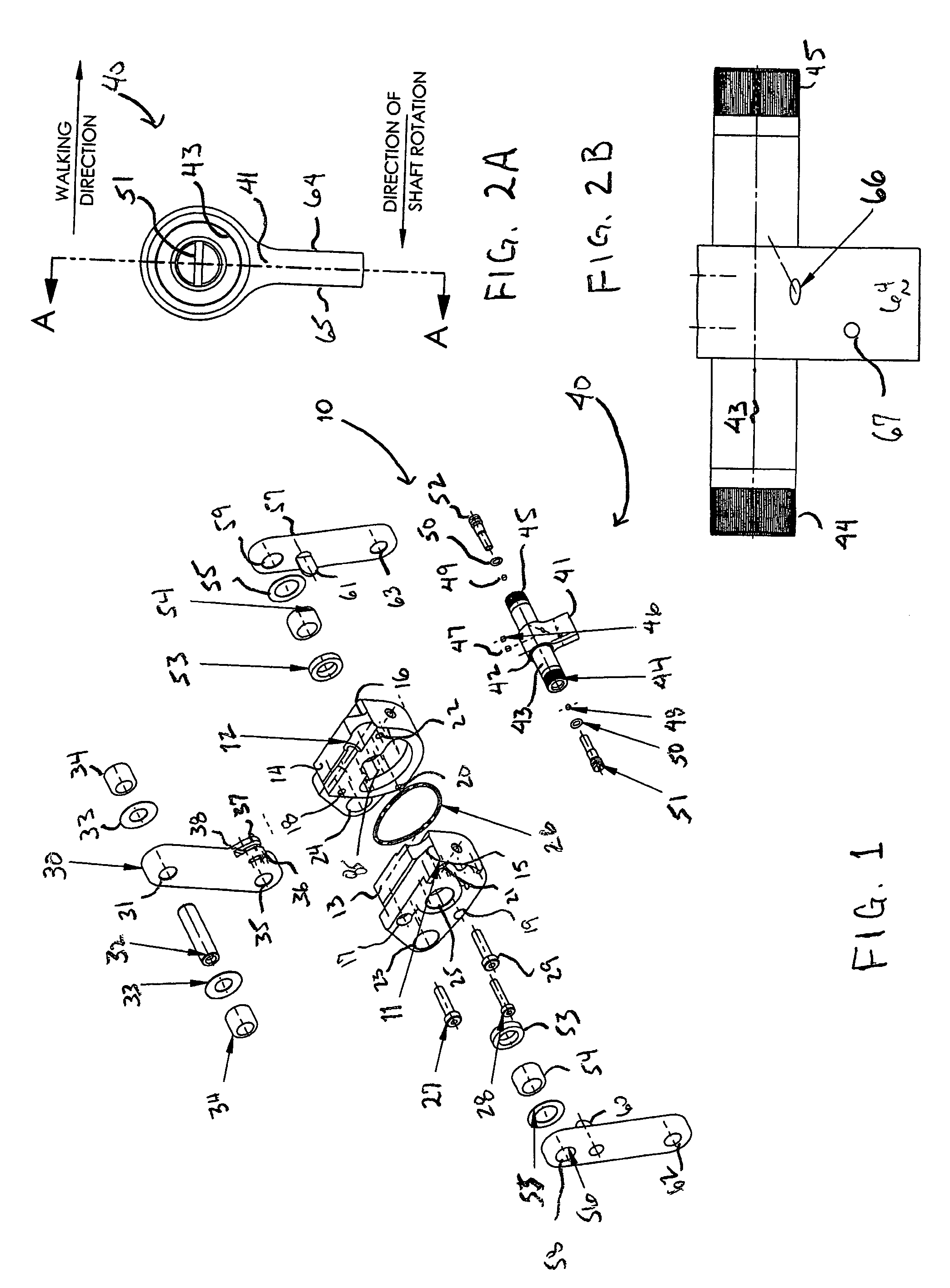

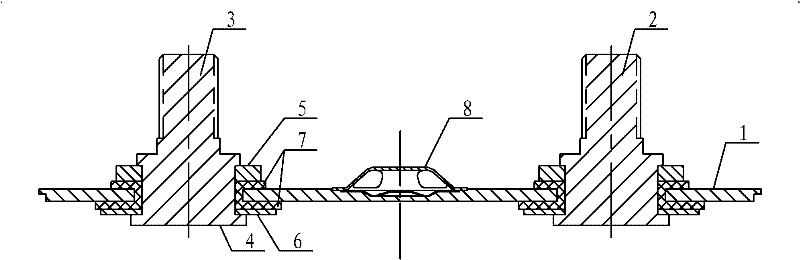

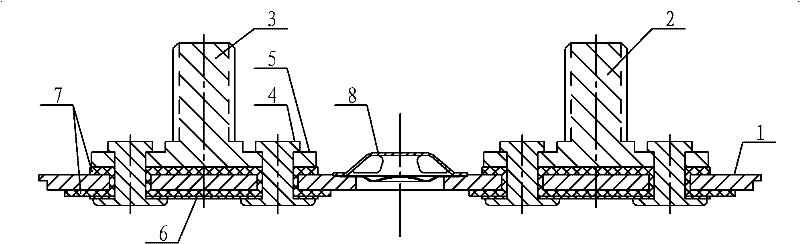

Joint for panels

A joint (1) having a first edge (2) and a second edge (3), the first edge (2) being provided with a distal edge (21) and a downwards protruding heel (22) The distal edge (21) is further provided with an upper joint edge (25) beneath which a groove (23) is arranged. The second edge (3) is provided with lower cheek (31) having a distal end (32) at which an upwards protruding lower cheek heel (33) is arranged. The second edge (3) is further provided with an upper joining edge (35) beneath which an undercut (34) is arranged. A moveable locking element (40) is arranged in the space created by the undercut (34). The moveable locking element (40) have a locking tongue (41), a locking tongue leg (42) and a manoeuvring leg (43).

Owner:PERGO

Joint for panels

A joint (1) having a first edge (2) and a second edge (3), the first edge (2) being provided with a distal edge (21) and a downwards protruding heel (22). The distal edge (21) is further provided with an upper joint edge (25) beneath which a groove (23) is arranged. The second edge (3) is provided with lower cheek (31) having a distal end (32) at which an upwards protruding lower cheek heel (33) is arranged. The second edge (3) is further provided with an upper joining edge (35) beneath which an undercut (34) is arranged. A moveable locking element (40) is arranged in the space created by the undercut (34). The moveable locking element (40) have a locking tongue (41), a locking tongue leg (42) and a maneuvering leg (43).

Owner:PERGO

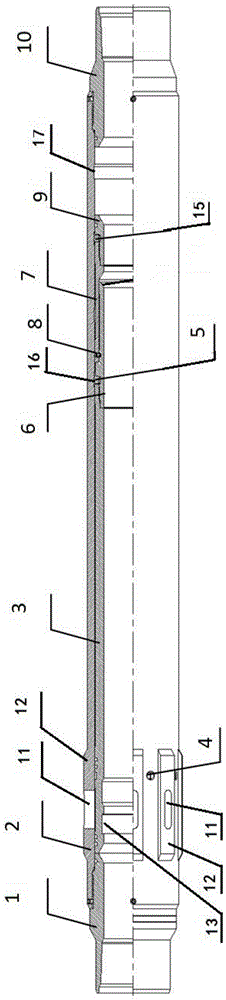

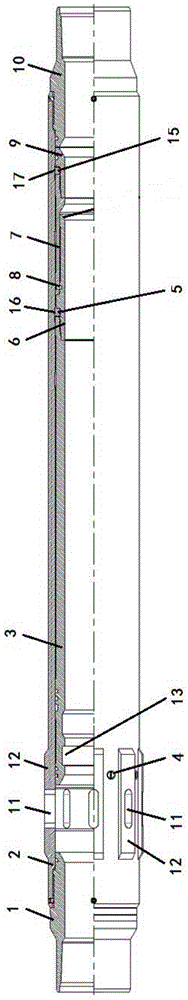

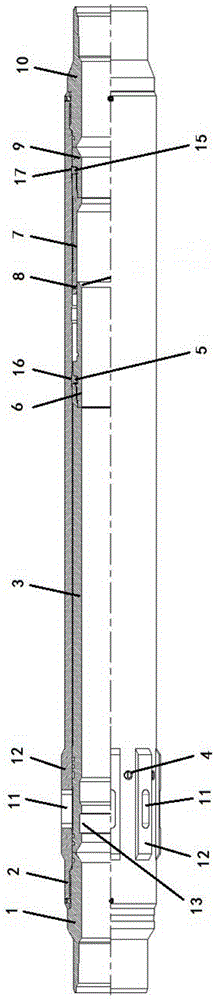

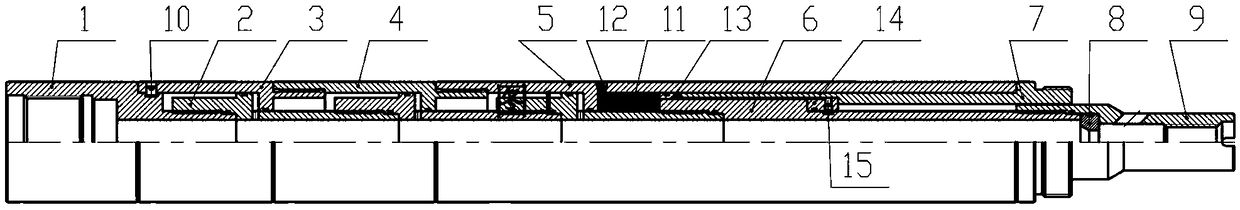

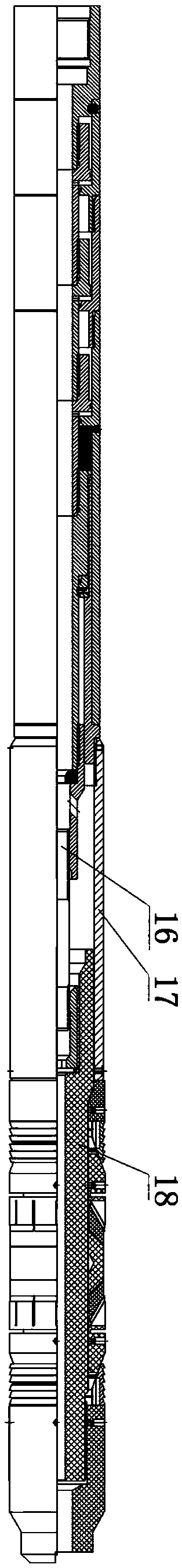

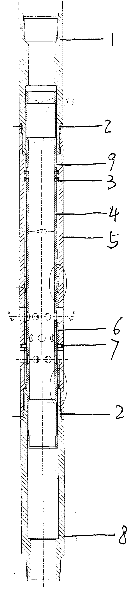

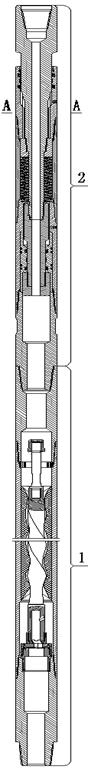

Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A switchable well cementation sliding sleeve based on fracturing of separate layers comprises an outer barrel, an upper joint and a lower joint are installed at the upper end and the lower end of the barrel respectively, a fracturing port is formed in the side wall of the upper portion of the outer barrel, and an upper center pipe, an upper connection sleeve, a lower center pipe and a lower connection sleeve are installed inside the outer barrel. The switchable well cementation sliding sleeve based on fracturing of the separate layers is not provided with a ball seat, so a full bore of the inner wall can be maintained, fracturing fluid can flow back in time, and the construction period is shortened. The well cementation sliding sleeve is set in the upper center pipe through a bottom packer, downward pushing force big enough can be generated in the process of annular or continuous tubing pressing, so the upper center pipe can overcome shearing force of corresponding shearing dowels and move downwards, and therefore the fracturing port of the well cementation sliding sleeve can be opened.

Owner:JEREH ENERGY SERVICES

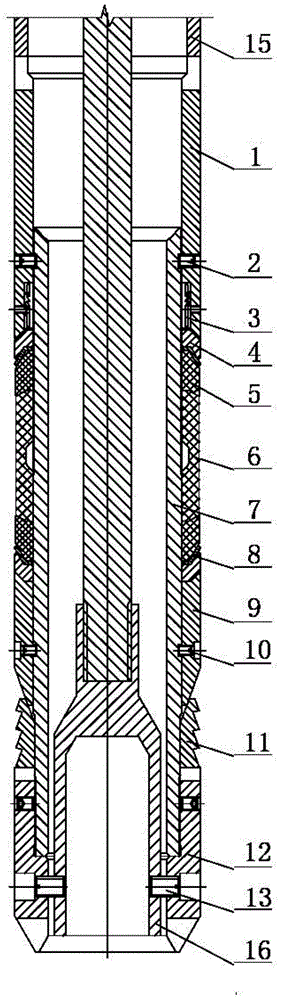

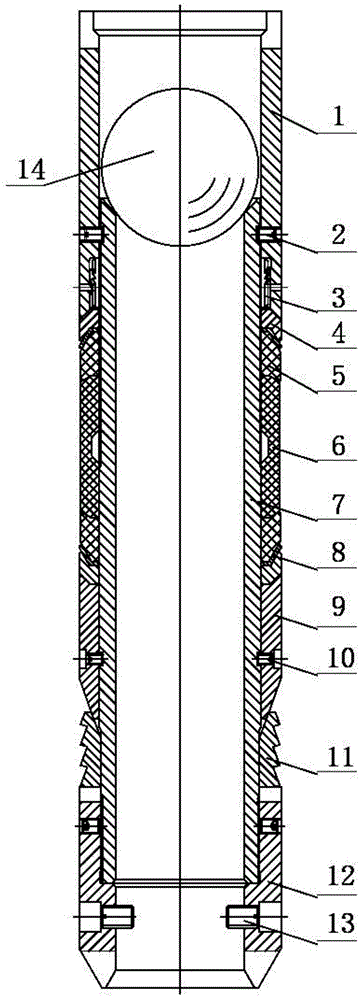

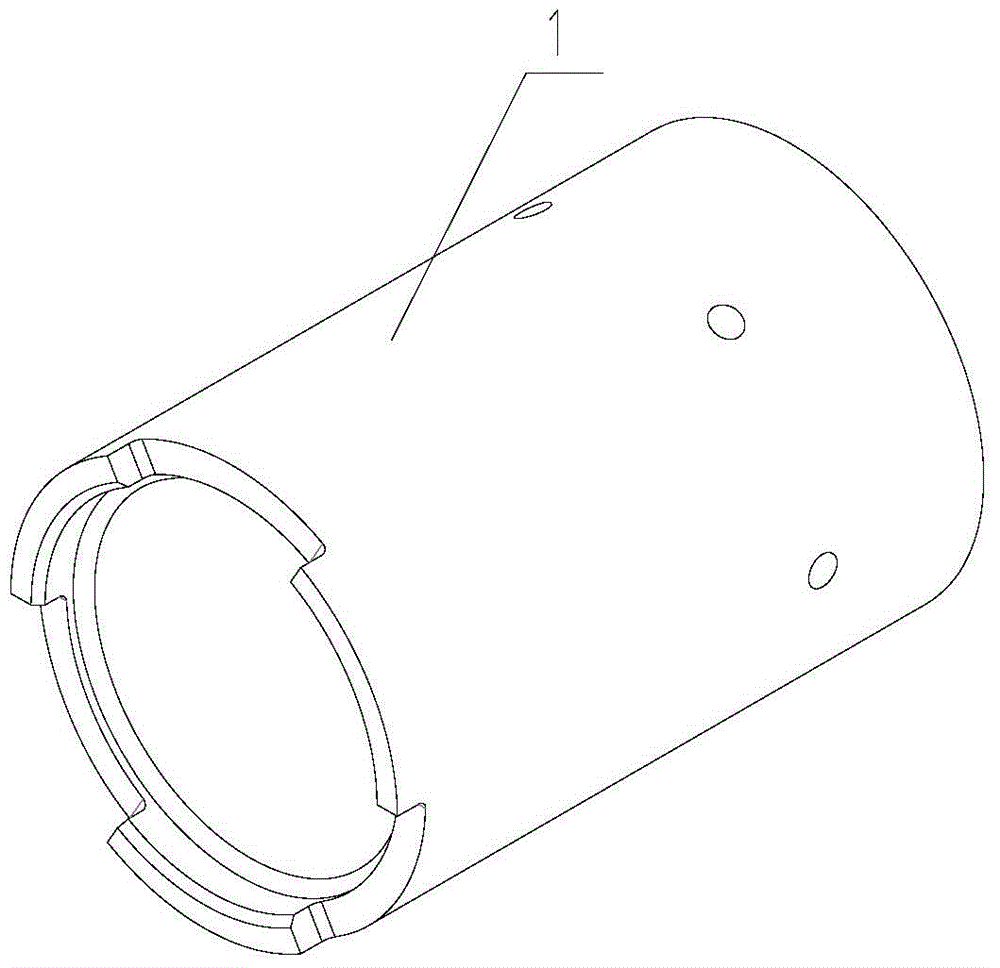

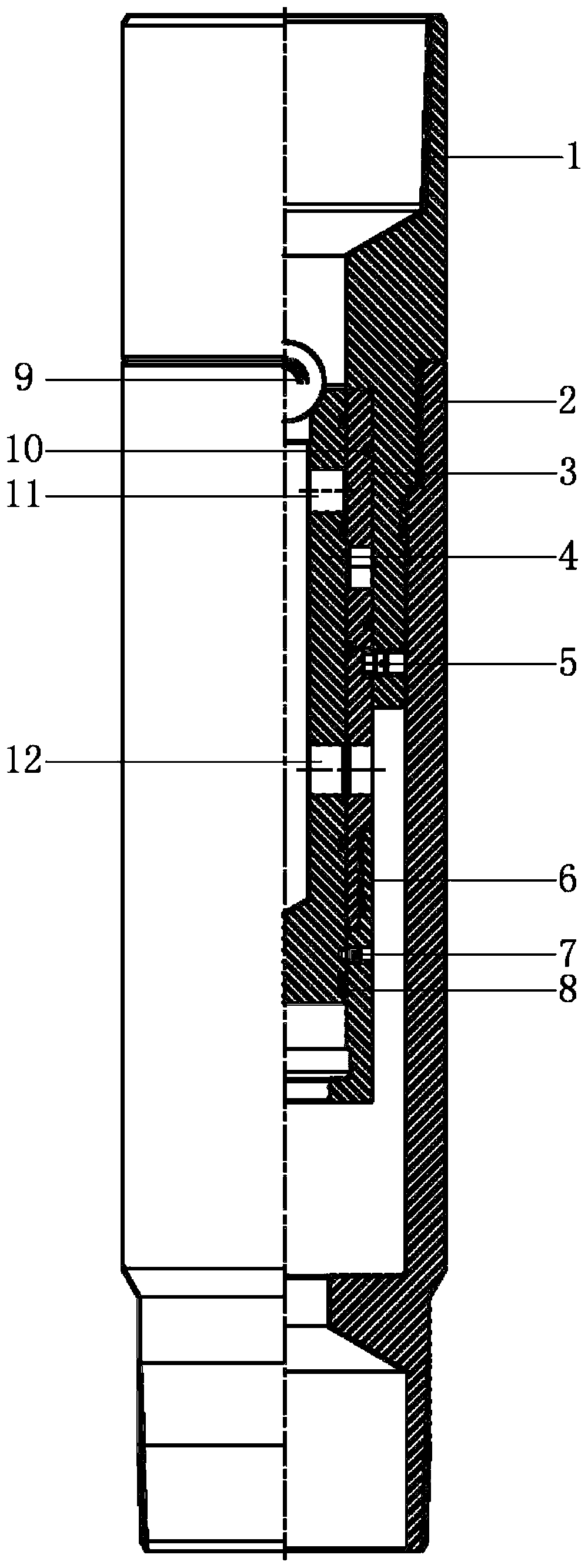

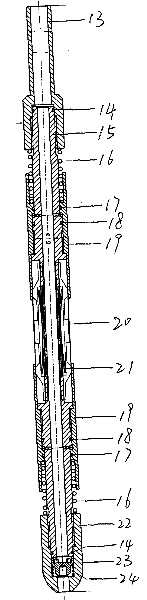

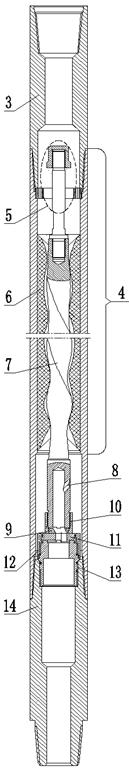

Bridge plug with large drift diameter and setting method of bridge plug

The invention discloses a bridge plug with a large drift diameter. The bridge plug comprises an upper joint, a central tube, a guiding shoe head and a bridge plug assembly; the upper joint is an annular part and is fixedly connected with the outer side of one end of the central tube in a sleeving mode; the central tube is a metal central tube, a soluble ball base is arranged at the end, close to the upper joint, of the central tube, and the central tube is a drillable metal part; the guiding shoe head is an annular part, is fixedly connected with the outer side of the other end of the central tube in a sleeving mode and is provided with a device used for being fixedly connected with a pull rod which is arranged in the bridge plug in a sleeved mode; the middle section of the central tube is sleeved with the bridge plug assembly which is located between the upper joint and the guiding shoe head. The invention further discloses a setting method of the bridge plug with the large drift diameter. The drilling polishing procedure of the bridge plug with the large drift diameter can be omitted, the problems of a long construction period, high operation cost and high construction risk brought by drilling polishing are solved, and the bridge plug is easier and more convenient to use and faster to construct.

Owner:JEREH ENERGY SERVICES

Joint guard for panels

A joint guard (100) provided with means for protecting, and stabilizing portions in the edge region of a panel, said portions being selected from the group consisting of; a distal edge (21), a downwards protruding heel (22), a upper joint edge (25), a groove (23), a lower cheek (31), a distal end (32), an upwards protruding lower cheek heel (33), an upper joining edge (35), an undercut (34), a moveable locking element (40), a locking tongue (41), a locking tongue leg (42) and a maneuvering leg (43).

Owner:PERGO

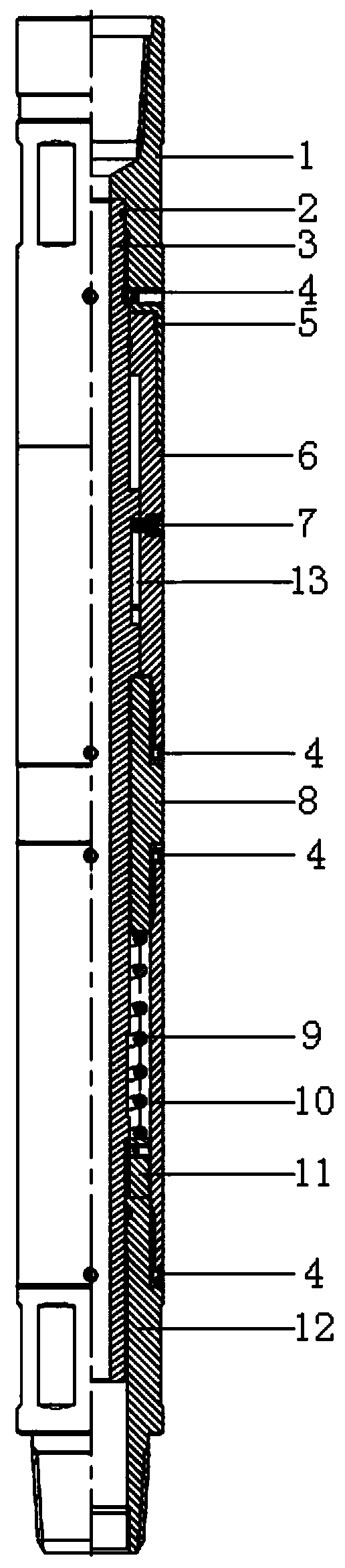

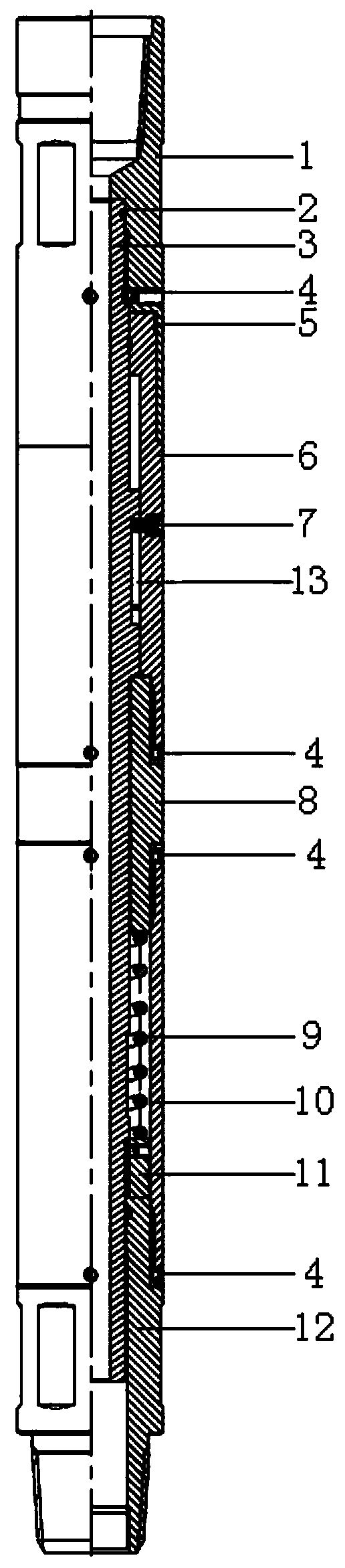

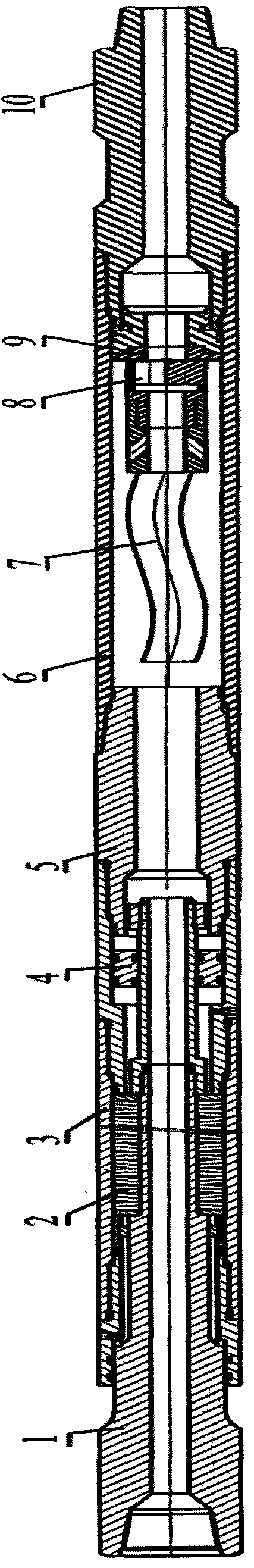

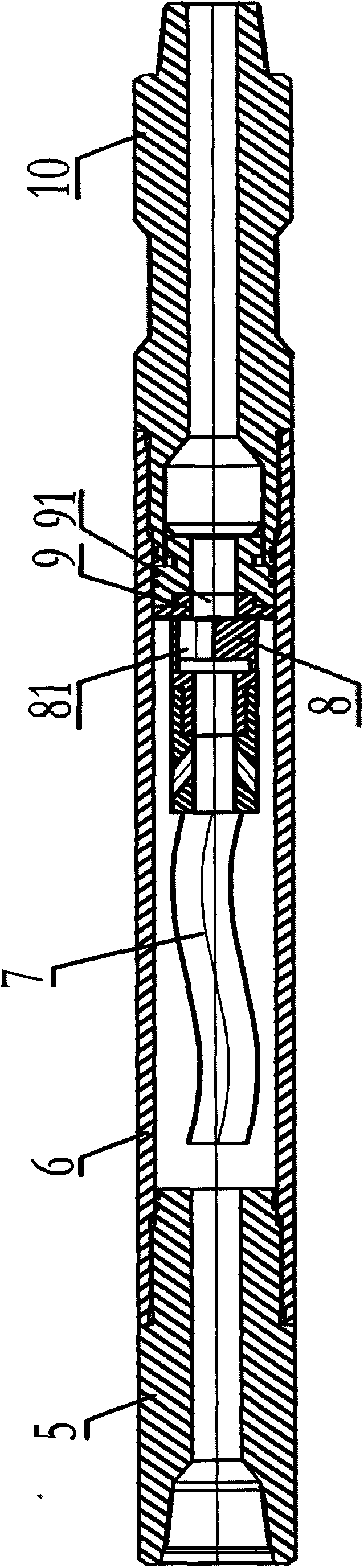

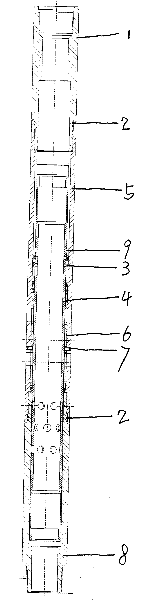

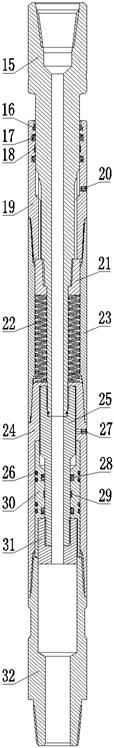

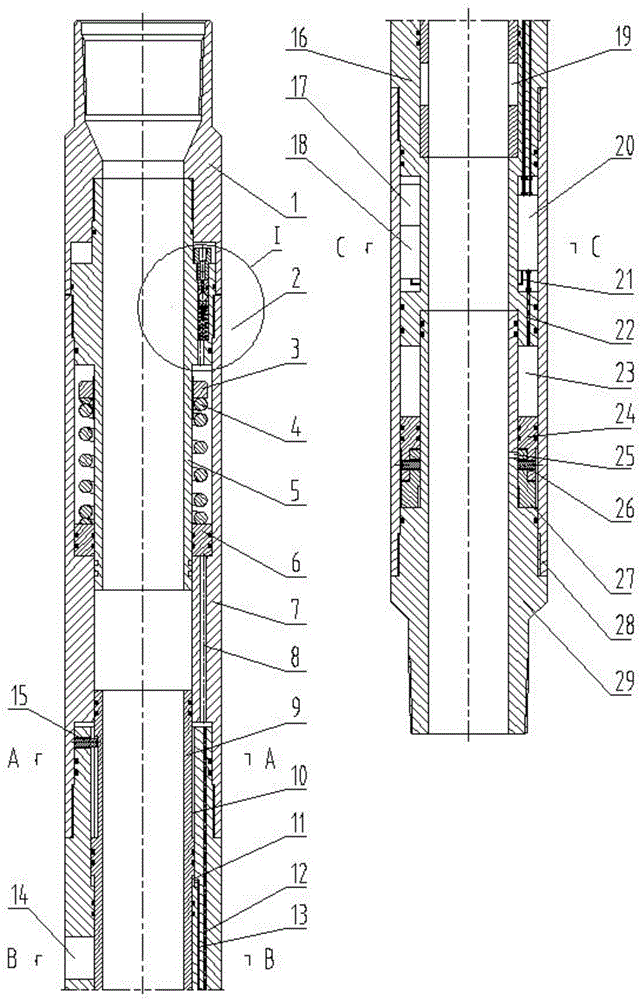

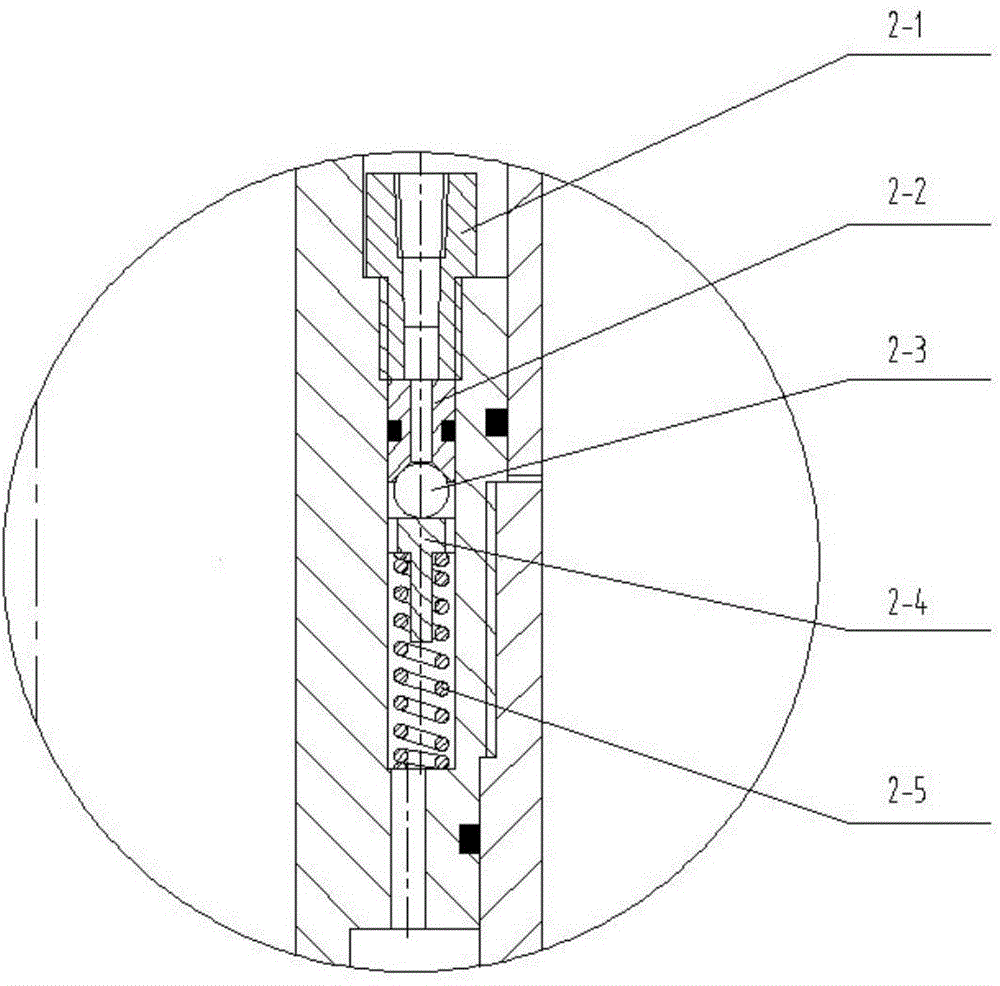

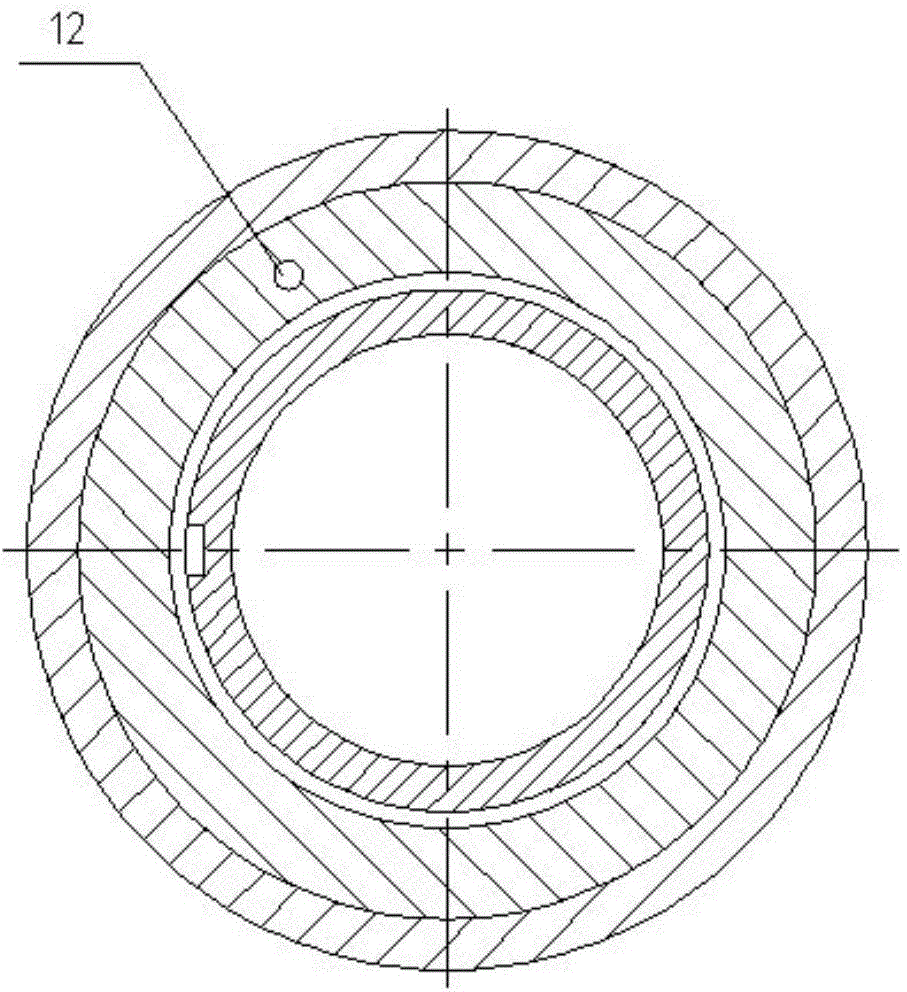

Continuous shocking tool

ActiveCN104563938AAvoid repeated lifting and loweringAvoid damageBorehole/well accessoriesUpper jointEngineering

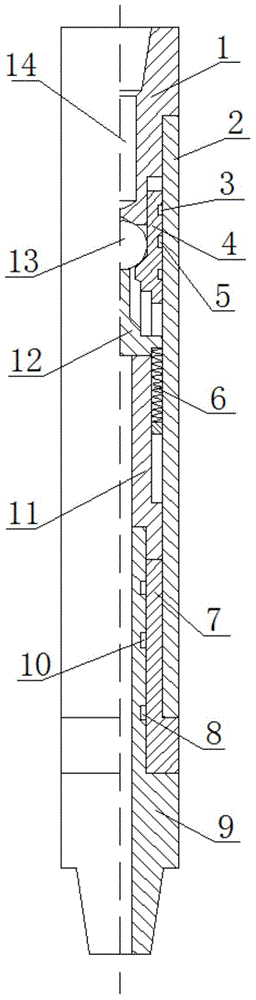

The invention relates to a shocking tool, and specifically relates to a continuous shocking tool. The continuous shocking tool comprises an upper joint, an outer sleeve equipped with a medium hole, a piston, a shuttle key, an inserting rod, a sliding sleeve equipped with another medium hole, and a lower joint; the upper joint is inserted from the middle part of the sleeve into the central hole of the outer sleeve; a flowing groove is vertically formed in the top part of the upper joint; a guide hole which communicates with the central hole in the outer sleeve is formed in the sidewall of the flowing groove; a tapered groove is formed in the bottom part of the upper joint; the piston is vertically sealed and arranged in the central hole of the outer sleeve; the bottom part of the upper joint is inserted into an inner cavity of the piston; a sealing ball is arranged in the inner cavity of the piston; the shuttle key is positioned in the central hole of the outer sleeve; the inserting rod is positioned in the central hole of the outer sleeve; a bulge is fixedly arranged on the inner wall of the outer sleeve and below the shuttle key; a compression spring is arranged between the bulge and the base; the sliding sleeve is inserted from the bottom part of the outer sleeve into the outer sleeve; the lower joint passes through the central hole of the sliding sleeve from the bottom part of the sliding sleeve; one end of the lower joint, passing through the sliding sleeve is fixedly connected with the bottom part of the inserting rod. The continuous shocking tool has the beneficial effects of being good in shocking effect and high in shocking efficiency.

Owner:JEREH ENERGY SERVICES

Hydraulic bridge plug setting tool and bridge plug setting method

PendingCN108868675ARealize the purpose of setting bridge plugShorten the lengthSealing/packingUpper jointShort length

The invention discloses a hydraulic bridge plug setting tool, which comprises an upper joint, a shear pin a, a front drive device, a lower center rod, a push cylinder connection sleeve, a sealing plug, a push ring, a composite ring, a shear pin b, a ball seat, a conversion joint, wherein the upper joint is connected to the front drive device by the shear pin a, the push cylinder connection sleeveand the lower center rod sleeve fitly and snugly the front drive device, and a containing sealed cavity for holding fluid is defined among the front drive device, the lower center rod and the push cylinder connection sleeve; the push ring and the push cylinder connection sleeve are movable backwards, and the containing sealed cavity is formed between the front drive device and the lower center rodafter the movement; the composite ring is connected to the lower center rod through the shear pin b, the sealing plug is arranged on the front drive device, the conversion joint is connected with thelower center rod, and the ball seat is arranged in the inner cavity of the conversion joint. The tool has the advantages of shorter length, convenient use, connection, and maintenance, lower cost, reusability and more efficient bridge plugging. The invention further discloses a bridge plug setting method.

Owner:JEREH ENERGY SERVICES

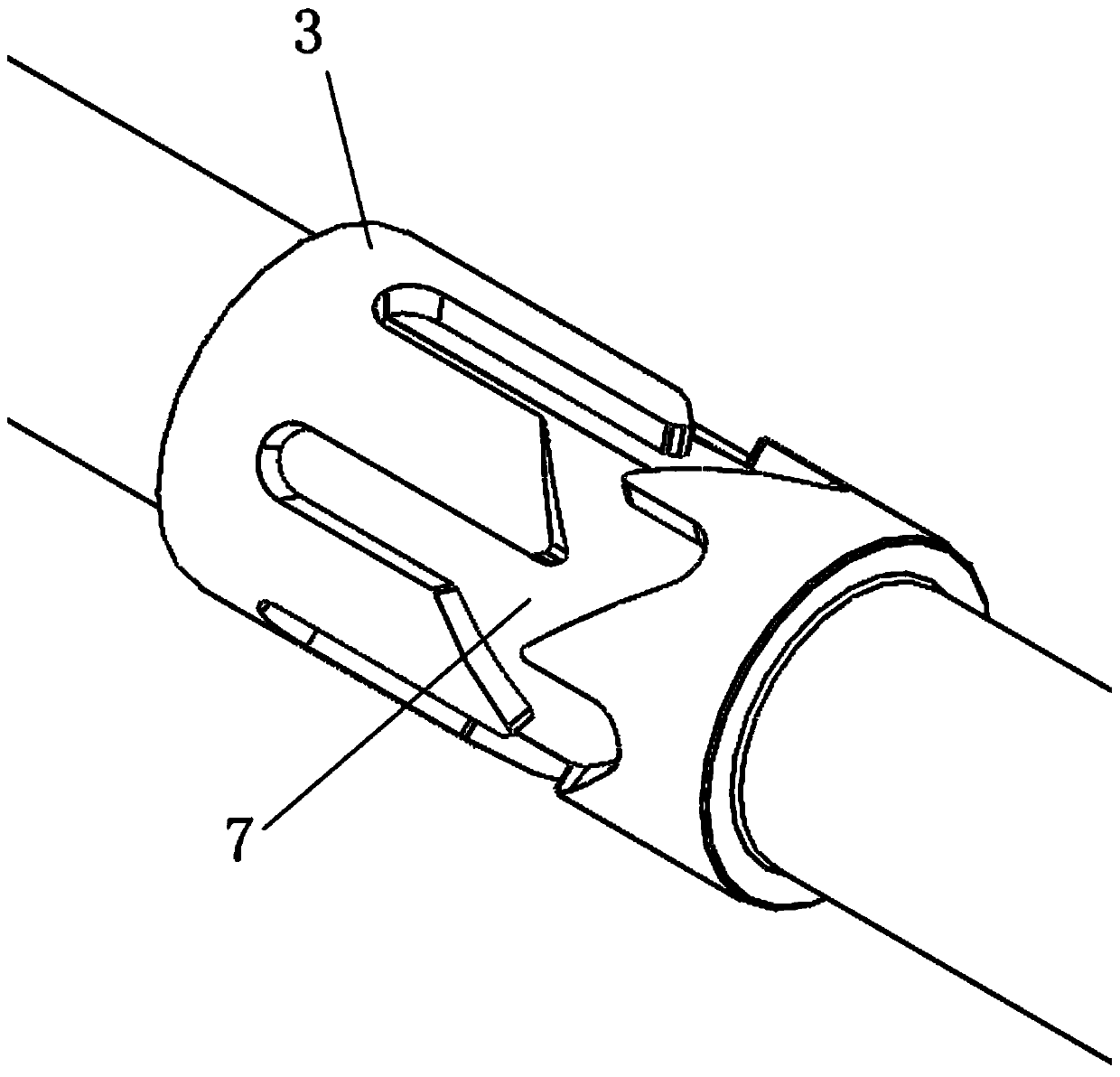

Starting pup joint with second-time opening function

PendingCN110080707AWith secondary opening functionAvoid resetFluid removalUpper jointDifferential pressure

The invention discloses a starting pup joint with a second-time starting function. The starting pup joint comprises a core shaft and a setting ball. The core shaft is connected with a sliding sleeve,the setting ball is connected with the core shaft, the sliding sleeve is connected with an outer sleeve, the outer sleeve is connected with the core shaft through a first-stage shear pin, a groove isformed in the core shaft, a baffle ring can be embedded into the groove, the baffle ring is in contact with the outer sleeve, the sliding sleeve is connected with an upper joint, the upper joint is connected with a lower joint, the upper joint, the sliding sleeve and the core shaft are sequentially connected in a step mode, the core shaft is provided with a fluid channel and a fracturing channel,and the sliding sleeve is provided with a fluid channel and a fracturing channel. Setting of a packer can be achieved when the packer is opened for the first time, and when the differential pressure sliding sleeve cannot be opened normally, the starting pup joint is started for the second time, and the fracturing channel is opened.

Owner:JEREH ENERGY SERVICES

Hydraulic reversing mechanism

PendingCN111167769ASimple structureAchieve Rotary JettingFlushingCleaning using liquidsUpper jointEngineering

The invention discloses a hydraulic reversing mechanism. The hydraulic reversing mechanism comprises an upper joint, a center shaft, a guide ring, an upper shell, a guide pin, a connection nipple, a compression spring, a lower shell, a limiting sleeve and a lower joint, wherein the upper joint is connected with the center shaft, the guide ring is arranged between the upper joint and the upper shell, and the upper shell, the connection nipple, the lower shell and the lower joint can be slidably arranged on the outer side of the center shaft. The guide pin is arranged on the upper shell, a guidegroove is formed in the portion, corresponding to the guide pin, of the center shaft, the guide pin can rotate in the guide groove, a compression cavity is defined by the connection nipple, the lowershell, the lower joint and the center shaft, and the compression spring and the limiting sleeve are arranged in the compression cavity. The hydraulic reversing mechanism has the benefits that the hydraulic reversing mechanism can be used for rotational reversing of a sand washing tool, the washing operation is more sufficient, no atomization is generated, and the washing capacity is ensured. According to the hydraulic reversing mechanism, reversing is achieved under the hydraulic action, the structure is simple, and convenience is brought to installation, disassembly and maintenance. The large-discharge-capacity cleaning work can be met, and rotary jetting to the washing tool can be achieved.

Owner:JEREH ENERGY SERVICES

High-temperature resistant vibration tool for horizontal well

ActiveCN104234651AHigh working reliabilityImprove high temperature resistanceVibration devicesUpper jointTemperature resistance

The invention relates to a high-temperature resistant vibration tool for a horizontal well. The high-temperature resistant vibration tool for the horizontal well comprises a shell assembly and a vibration assembly arranged in the shell assembly and is characterized in that the shell assembly comprises an upper joint, an upper joint sleeve, a connection sleeve, a cover and a lower joint which sleeve from top to bottom in sequence; the vibration assembly comprises an upper end turbine, an eccentric shaft and a lower end turbine which are connected in sequence from top to bottom; the vibration assembly is arranged in the shell assembly by an upper end bearing and a lower end bearing; the upper end bearing and the lower end bearing respectively sleeve two end shafts of the eccentric shaft; an upper thrust ring and a lower thrust ring are respectively arranged at two ends of the vibration assembly and are respectively arranged in the upper joint sleeve and the lower joint; a channel for allowing fluid to flow is arranged in each of the shell assembly and the vibration assembly. The high-temperature resistant vibration tool for the horizontal well has the beneficial effects that the work reliability and high temperature resistance of the tool are improved, the deepening depth is increased, and enough drilling and pressing effects are applied.

Owner:JEREH ENERGY SERVICES

Method for manufacturing floorboard having surface layer of flexible and resilient fibers

ActiveUS8112891B2Reduce sound levelAttractive appearanceTongue/grooves making apparatusWallsFiberMoving floor

Owner:VÄLINGE INNOVATION AB

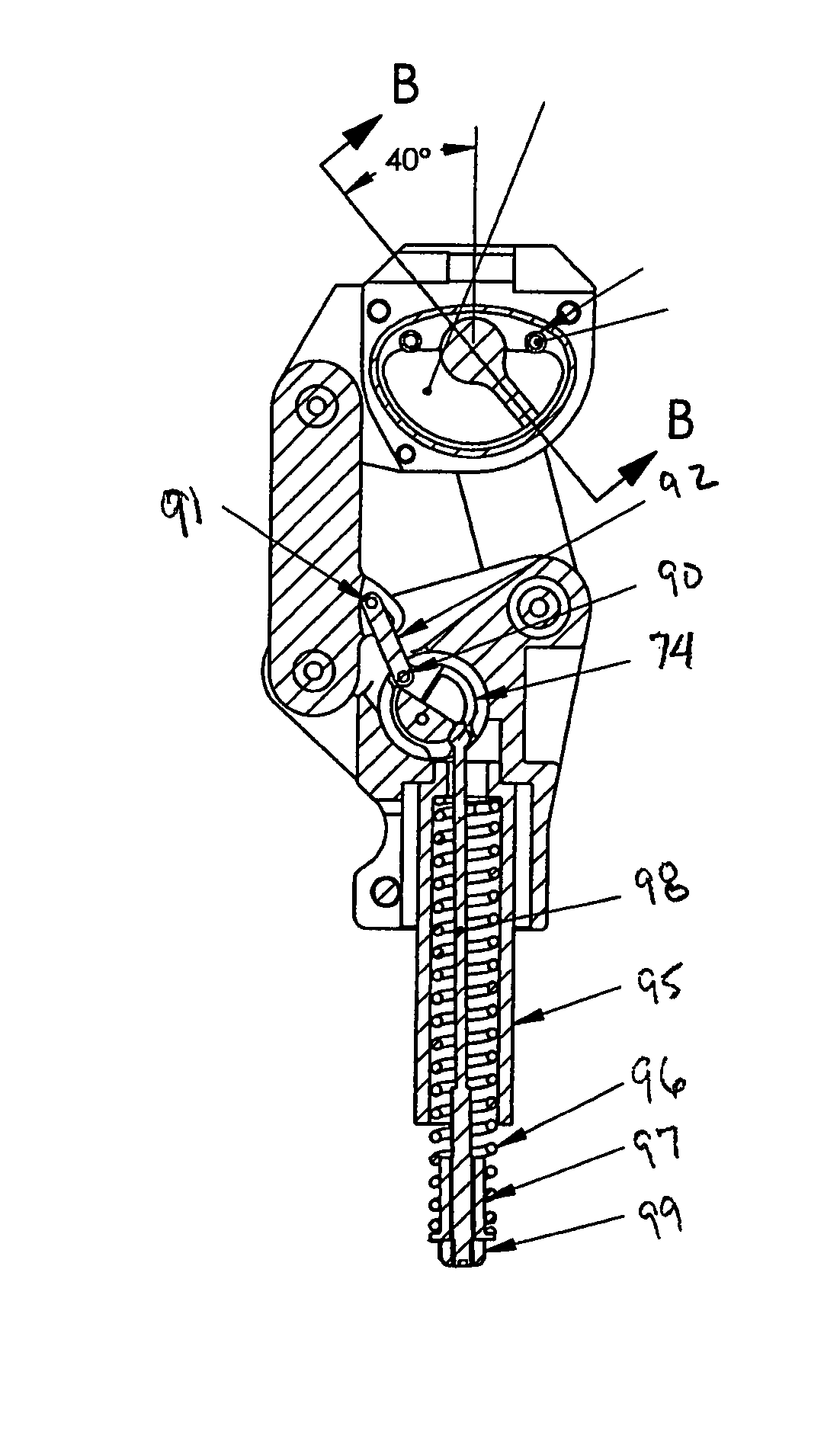

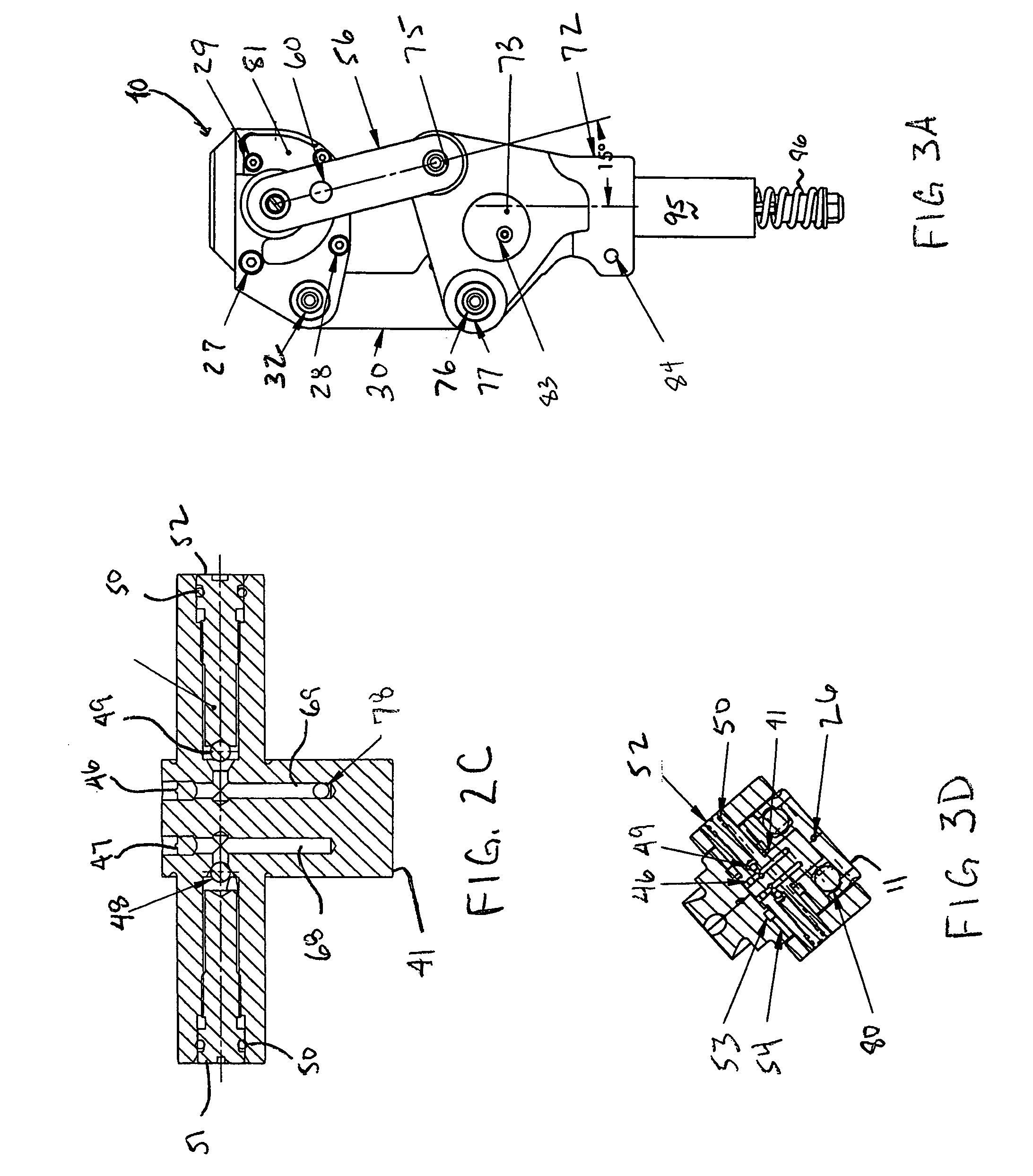

Prosthetic knee and rotary hydraulic chamber

An improved prosthetic knee joint utilizes a rotary hydraulic chamber with internal flow control and positioned with hydraulic chamber opposite the upper joint section. A polycentric knee joint is provided with a forward flexion bumper and a cable extension assist for improved gait performance.

Owner:HOSMERDORRANCE CORP

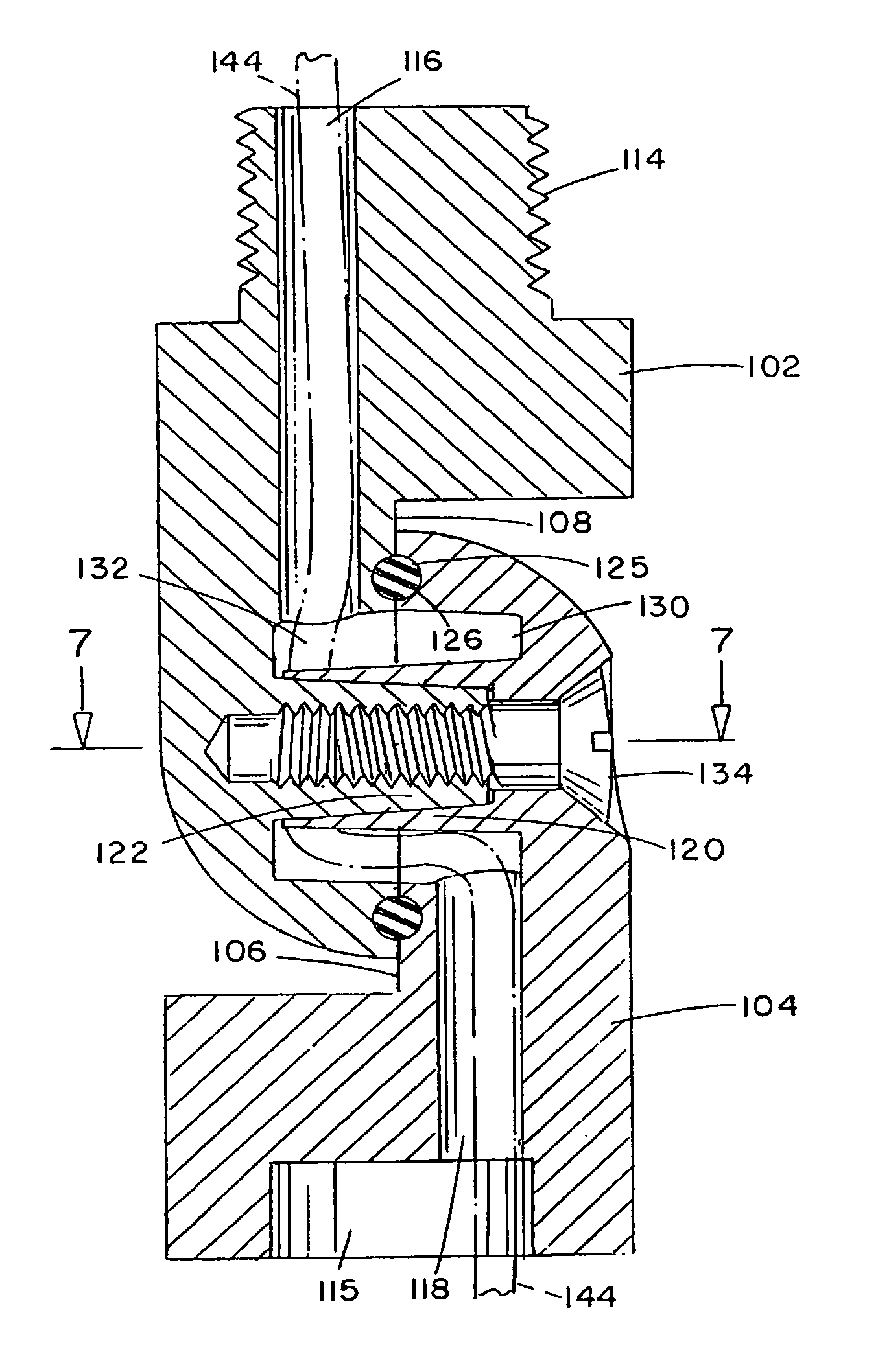

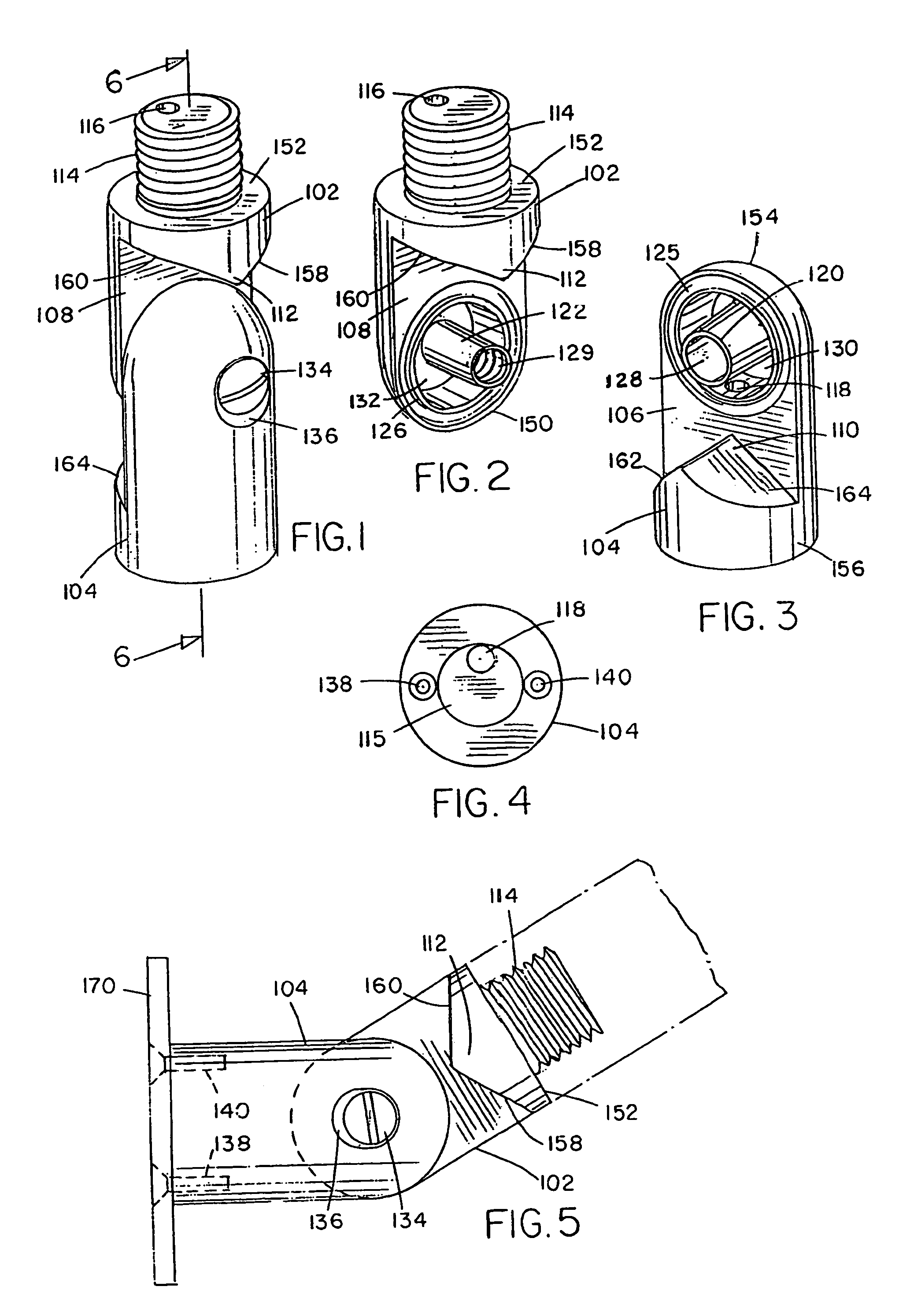

Contaminant-resistant pivot joint for outdoor lighting fixture

InactiveUS6902200B1Space minimizationLighting support devicesAdjustable jointsCircular cavityPivot joint

The pivoting knuckle joint for an outdoor lighting fixture comprises a base knuckle, a top knuckle and a fastener for locking the base and top knuckles in position. Each of the base knuckle and top knuckle has a generally cylindrical body with a domed top, a portion of which is cut-away to form a flattened face, and circular cavity formed in the flattened face with a tapered ferrule formed in and extending from the cavity. The ferrule of one of the knuckles has a smaller diameter than the other, so that the smaller ferrule fits within the larger ferrule, forming a pivot point. The relative diameters are adapted to closely fit such that friction is generated between the interfitting ferrules to form a taper lock, resisting rotation of one knuckle relative to the other. In the preferred embodiment, the smaller ferrule has an internal thread formed therein for receiving a locking screw inserted through the body of the knuckle with the larger ferrule, permitting the position of the joint to be locked in place after adjustment. Bores are formed through the base and top knuckles to provide a conduit for an electrical wire to pass through the assembly.

Owner:HUNTER INDUSTRIES

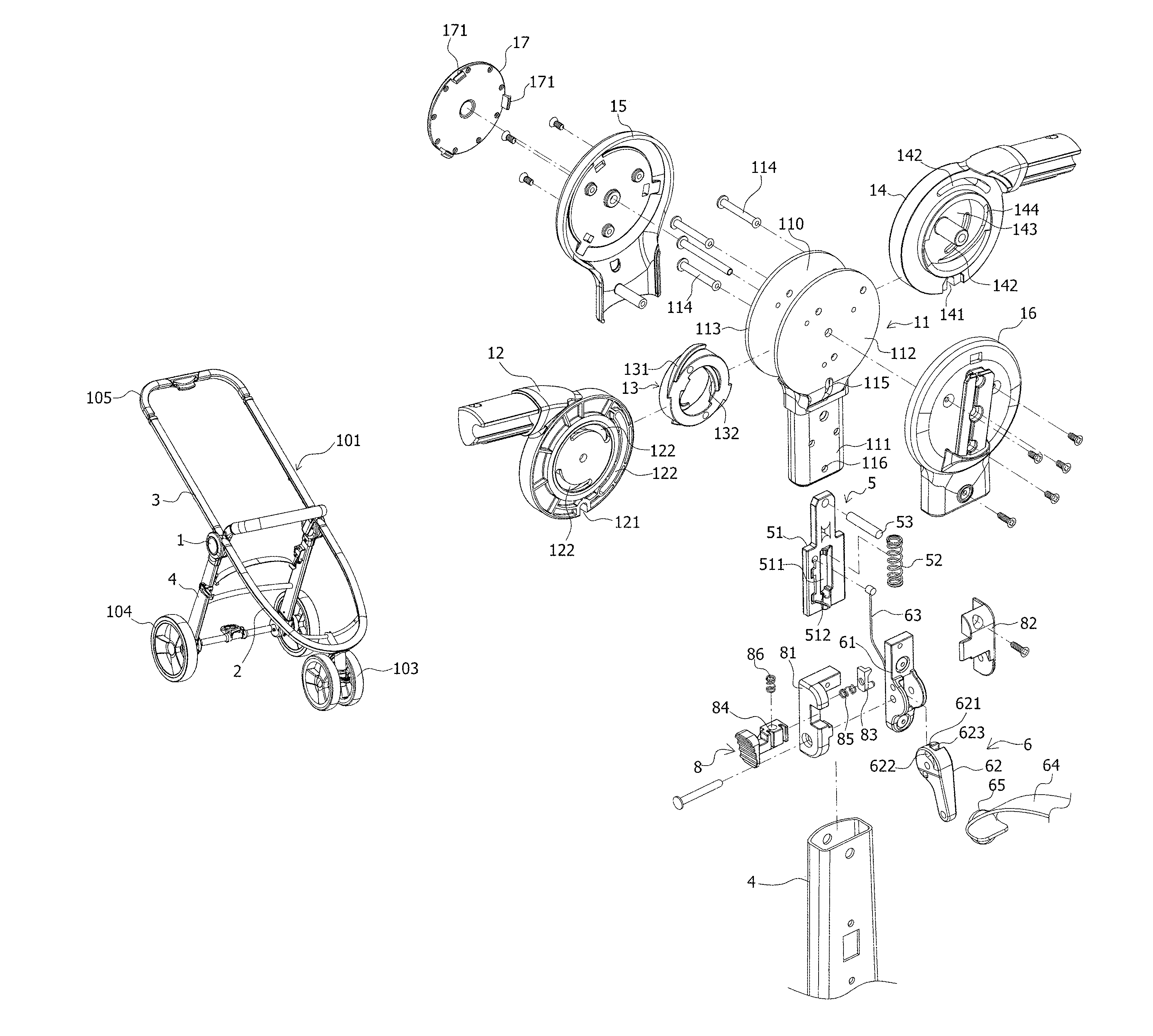

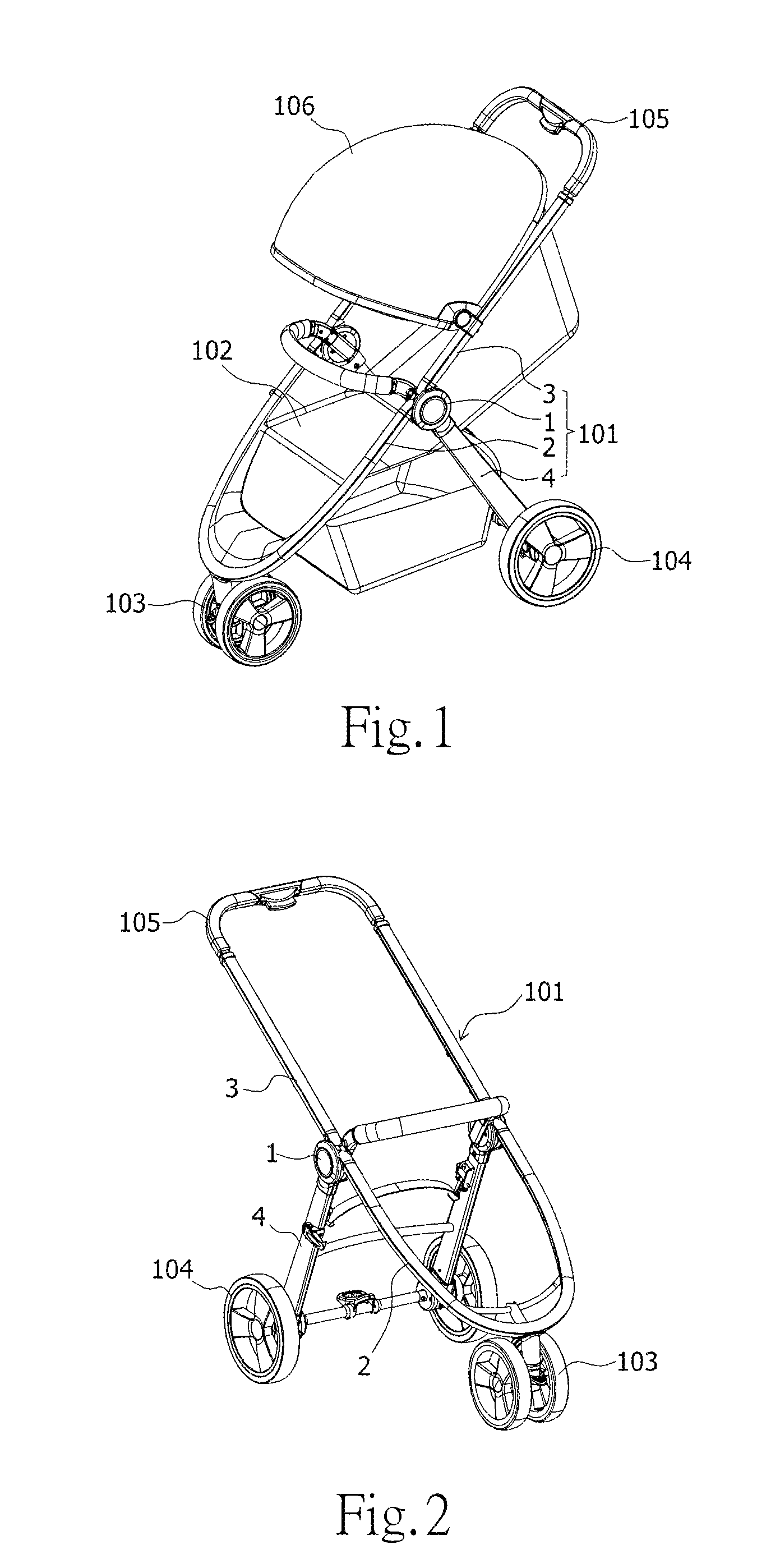

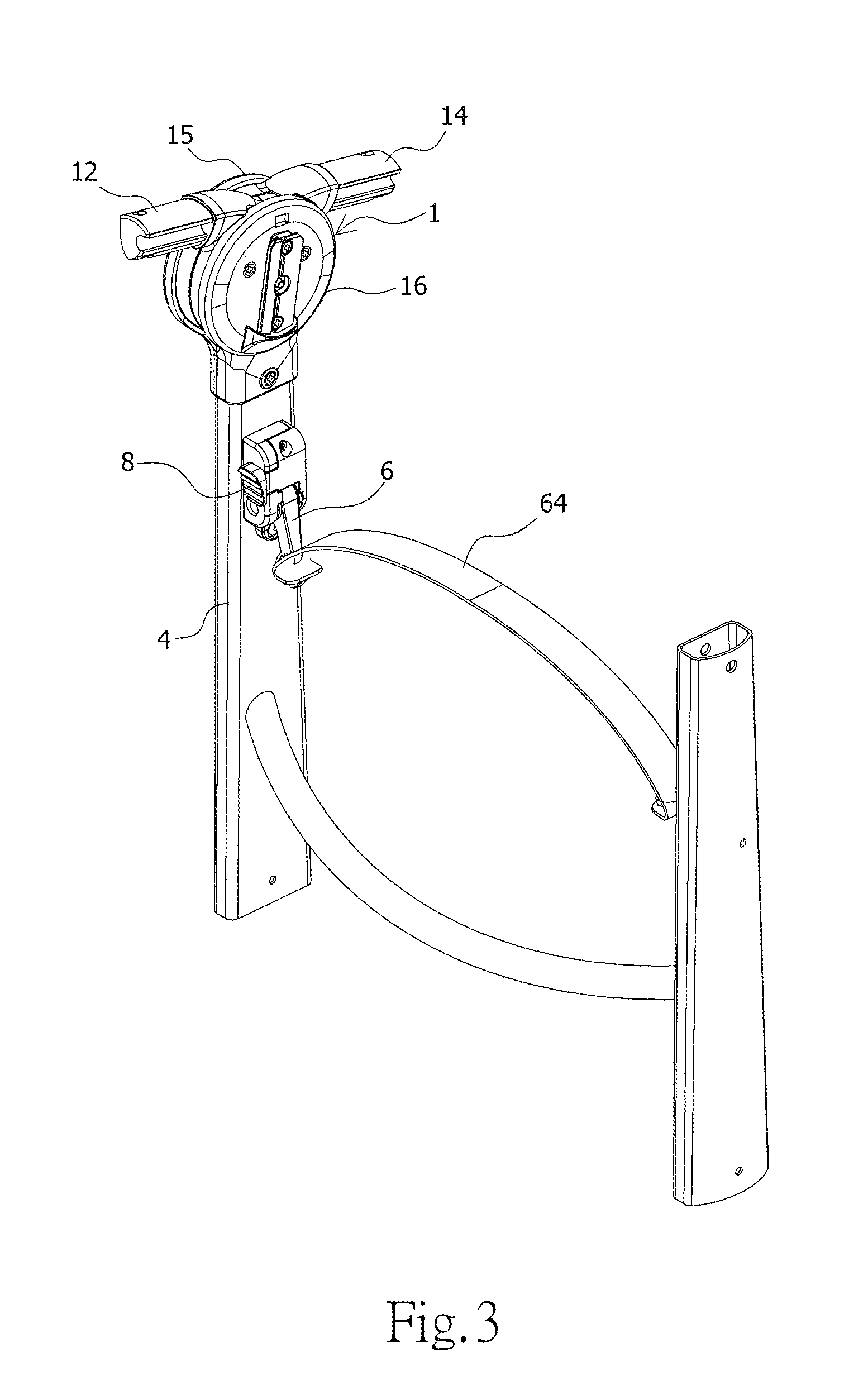

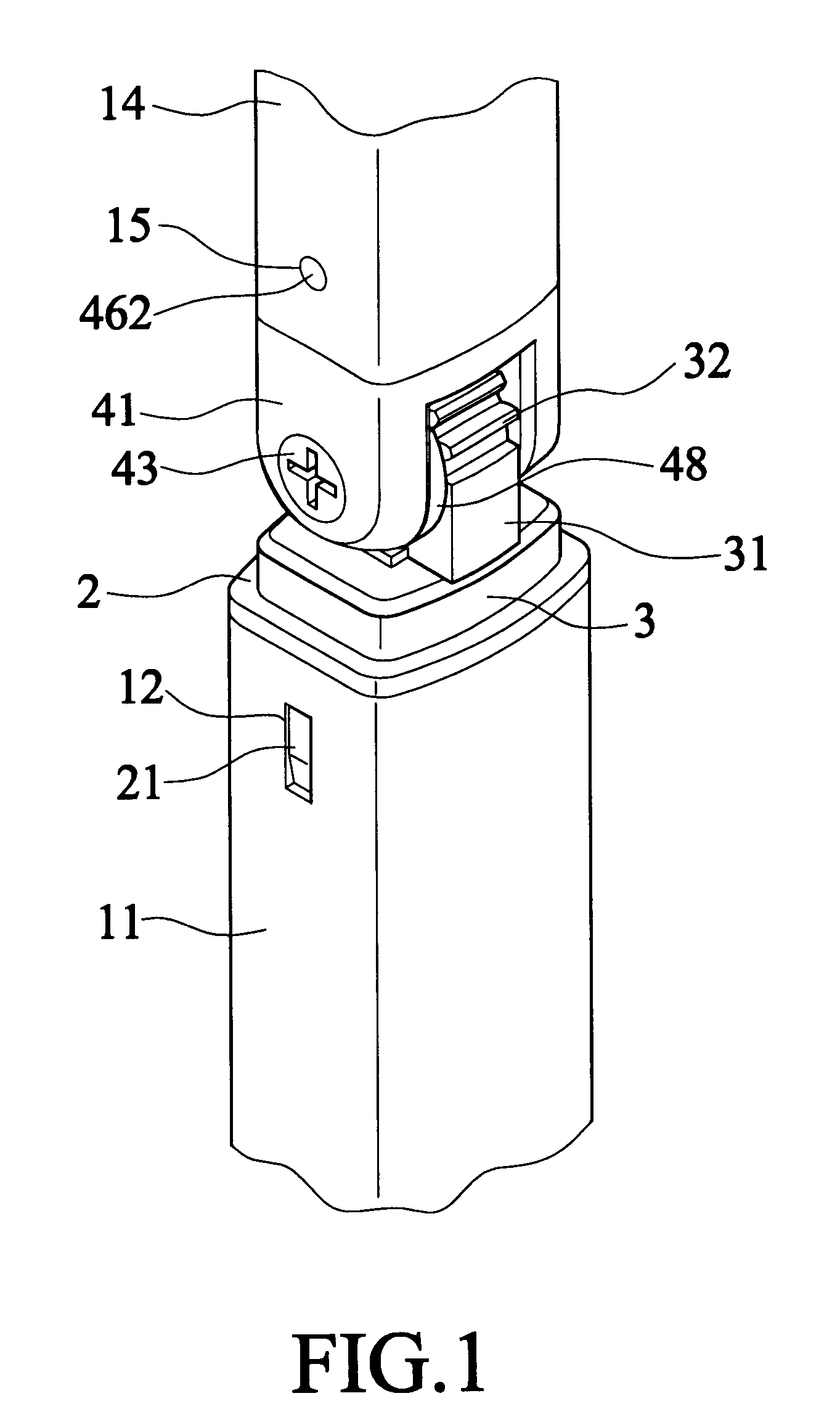

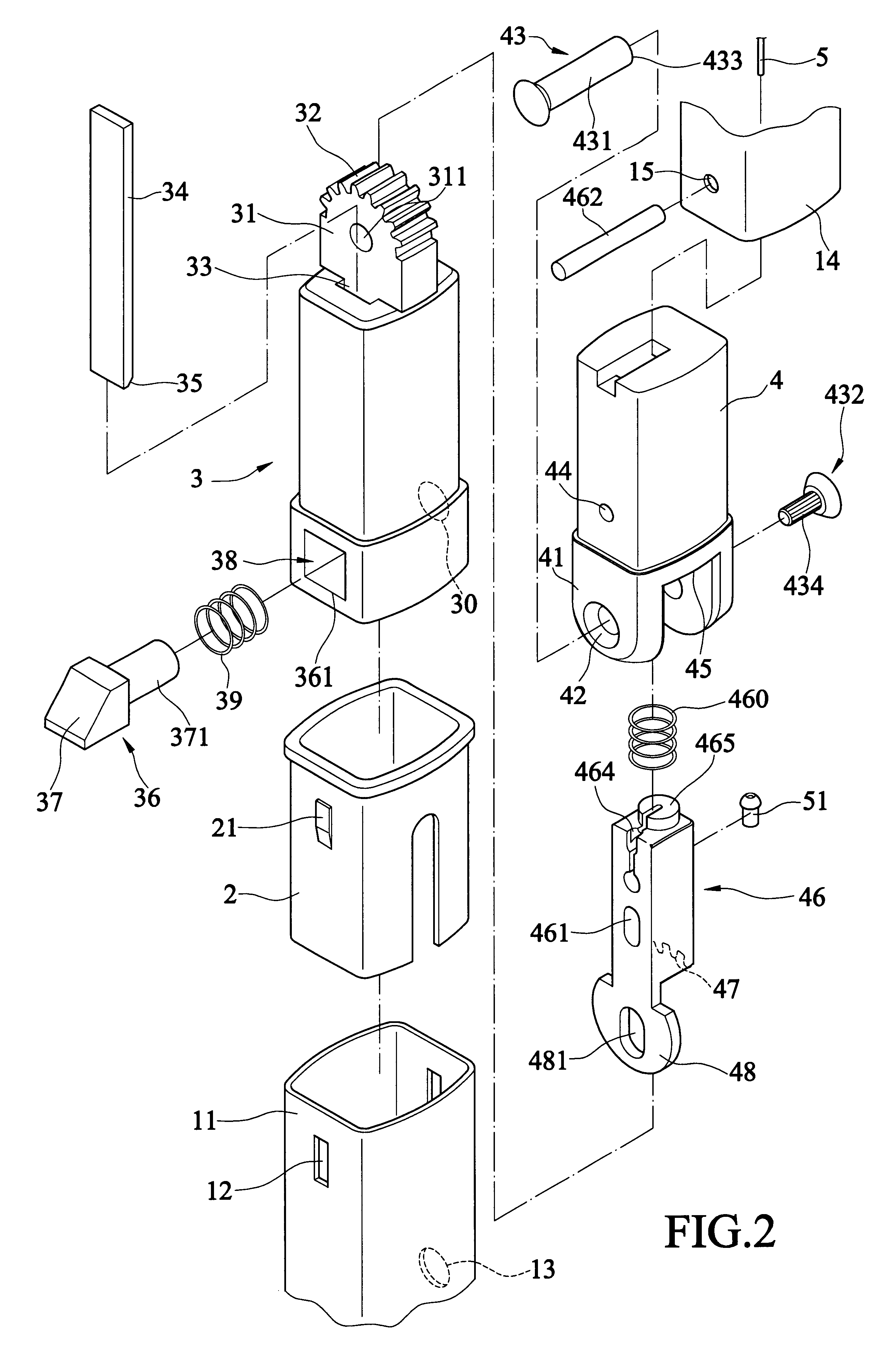

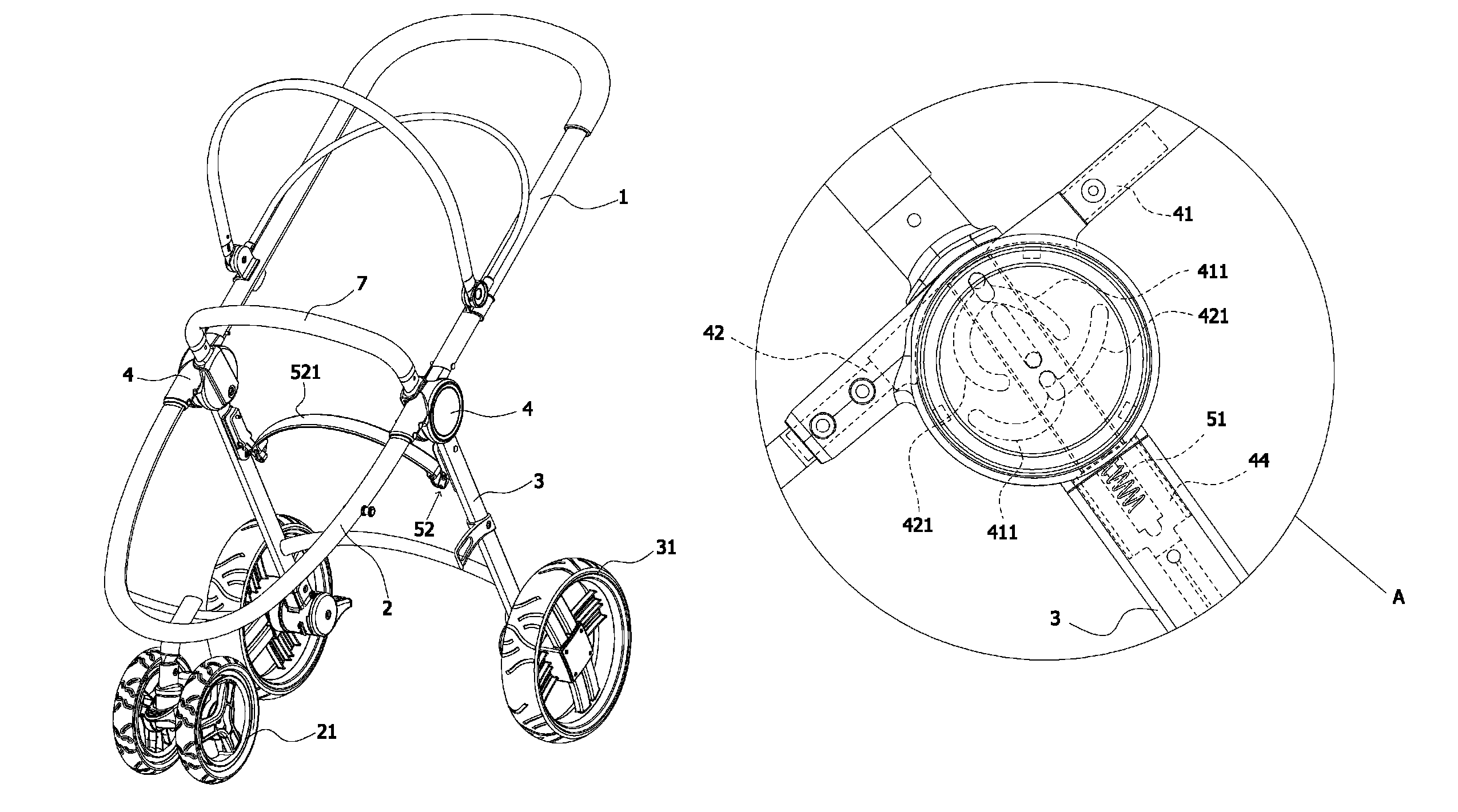

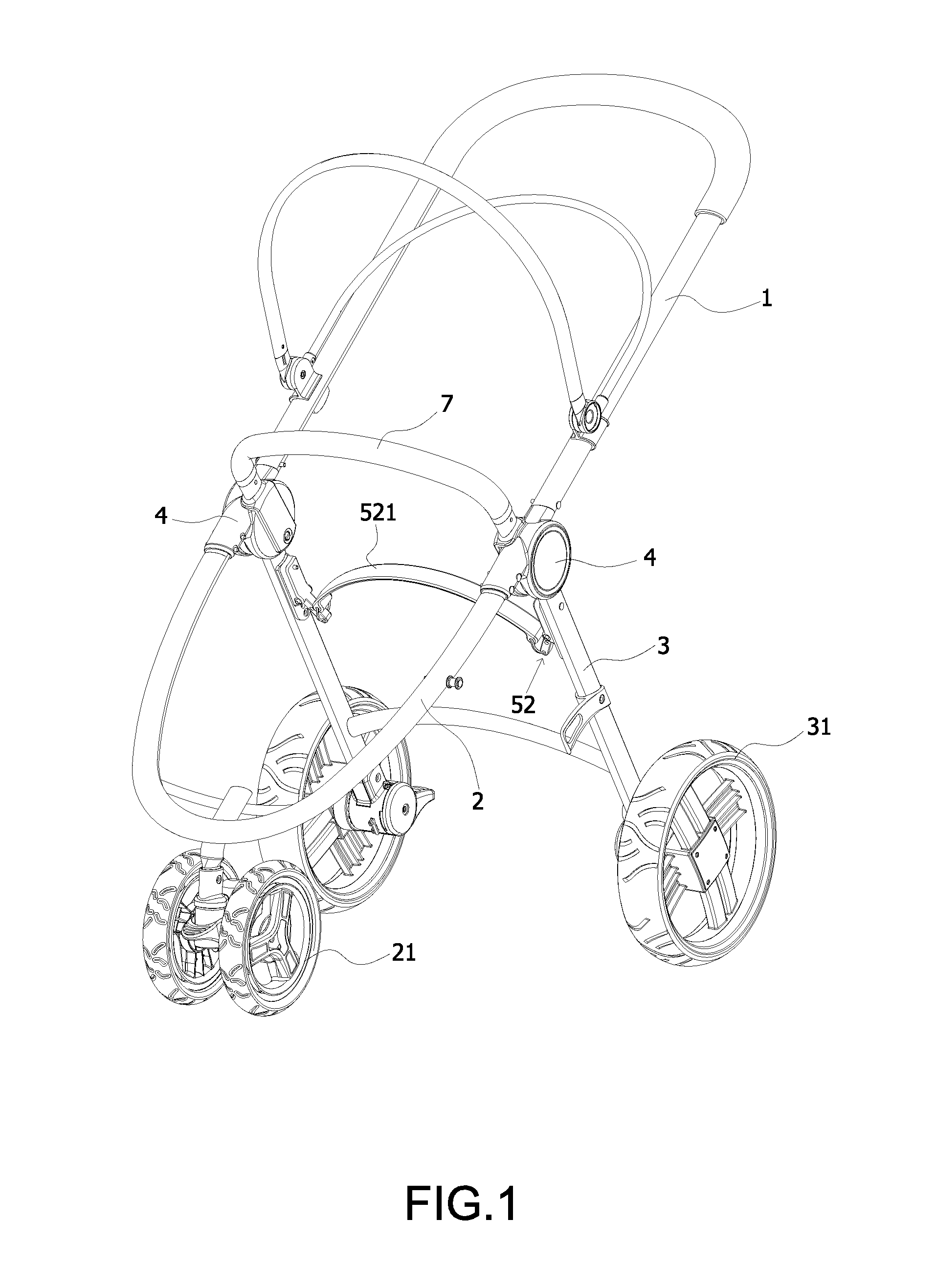

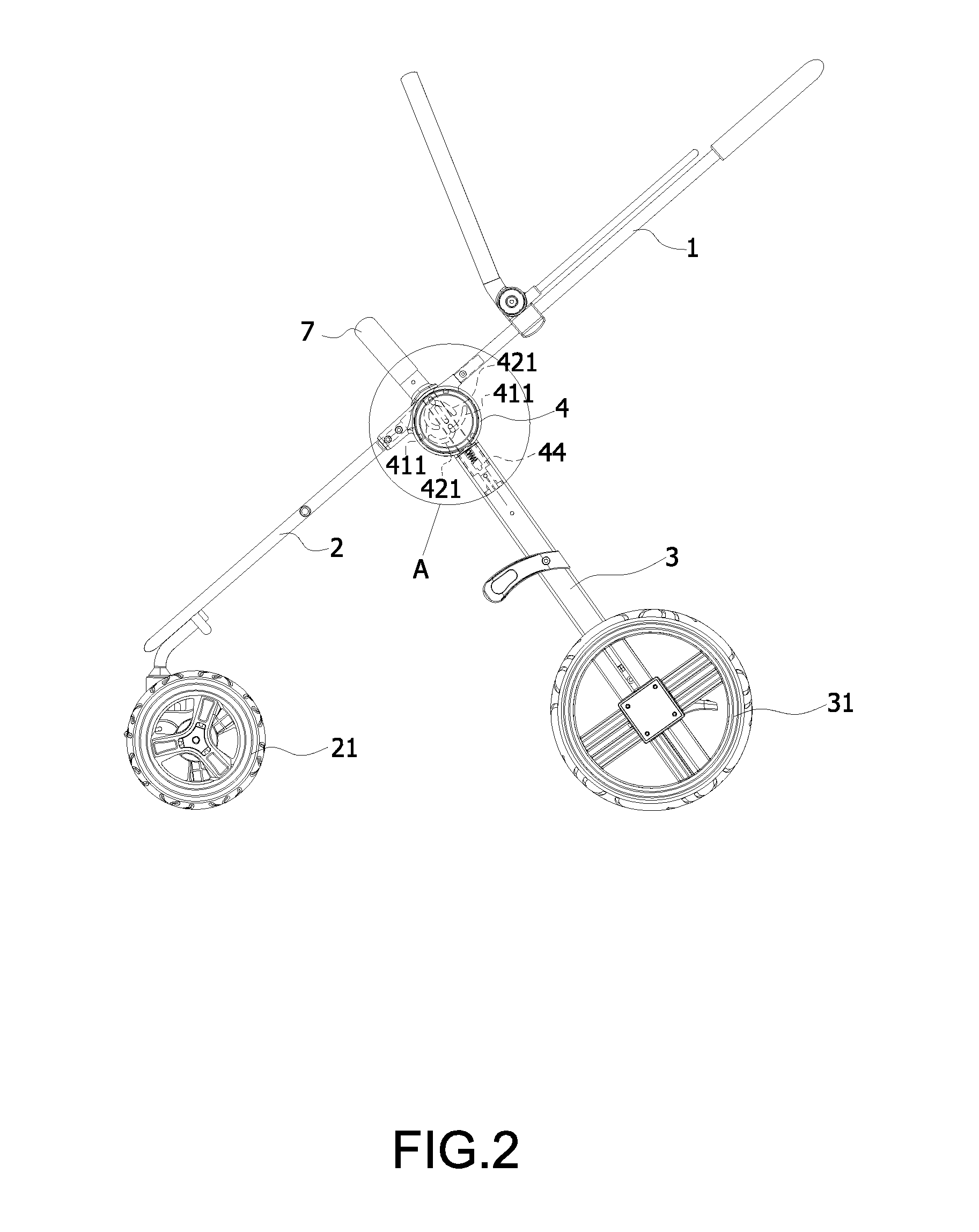

Baby stroller capable of being folded with one hand

InactiveUS8985616B1Convenient and flexible and effortless in operationEasy to foldCarriage/perambulator accessoriesSledgesUpper jointEngineering

The utility model provides a baby stroller capable of be folded with one hand, which comprises a comprise a joint seat, an upper joint, a lower joint, an annular pressing block, a lock device being used in the lower joint and the upper joint to avoid rotating among the lower joint, a folding device being used to control the lock device for locking or releasing the upper joint and the lower joint, wherein the folding device comprises a connecting seat, a lever, a wire and a lifting belt; the connecting seat is provided with first release components to control and lock the lever in case of movement. The present invention can fold the baby stroller by one hand, and the operation is very convenient, flexible, and effortless.

Owner:CHEN YONG XIANG

Joint for panels

A joint (1) having a first edge (2) and a second edge (3), the first edge (2) being provided with a distal edge (21) and a downwards protruding heel (22) The distal edge (21) is further provided with an upper joint edge (25) beneath which a groove (23) is arranged. The second edge (3) is provided with lower cheek (31) having a distal end (32) at which an upwards protruding lower cheek heel (33) is arranged. The second edge (3) is further provided with an upper joining edge (35) beneath which an undercut (34) is arranged. A moveable locking element (40) is arranged in the space created by the undercut (34). The moveable locking element (40) have a locking tongue (41), a locking tongue leg (42) and a maneuvering leg (43).

Owner:PERGO

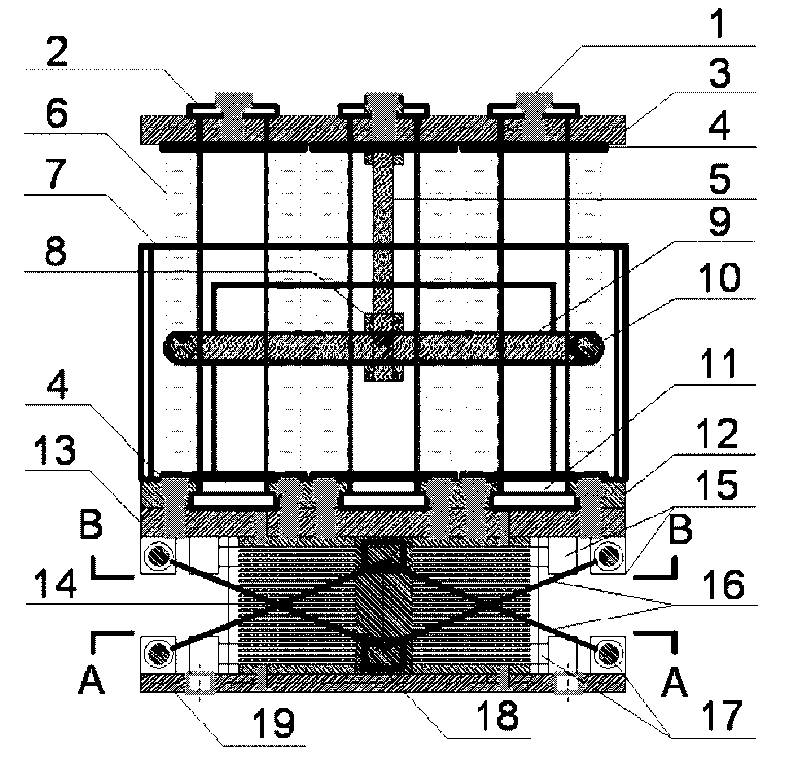

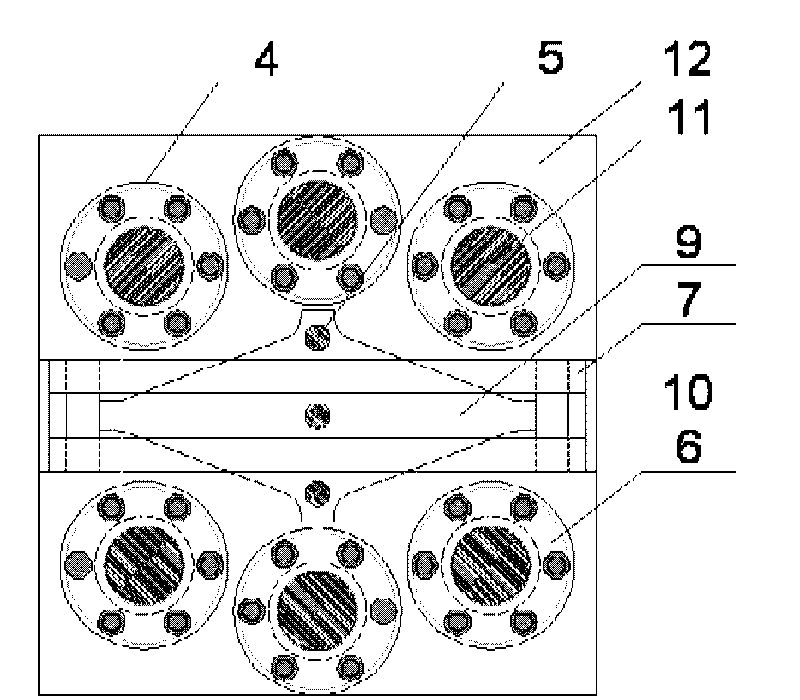

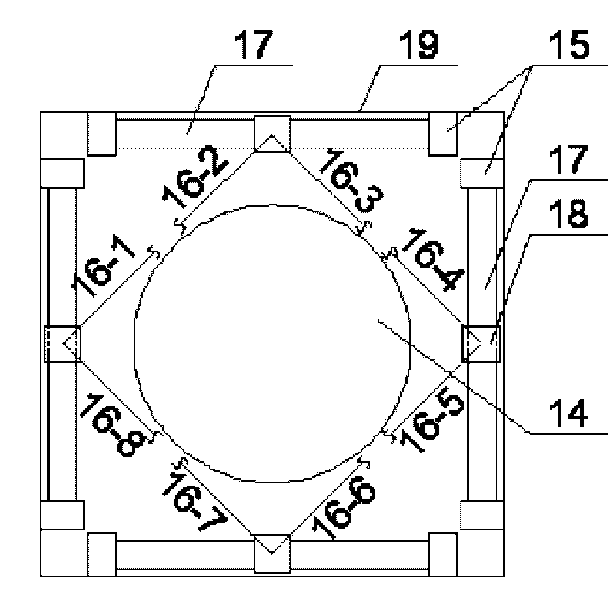

Three-dimensional isolation device

InactiveCN101761147ASufficient vertical bearing capacityAppropriate vertical load capacityShock proofingVibration controlUpper joint

The invention provides a three-dimensional isolation device, which belongs to the field of the vibration control of a civil engineering structure. The three-dimensional isolation device is characterized by mainly comprising a lead-laminated rubber shock isolator, a combined disc spring, a guiding shaft of the combined disc spring, a diamond steel plate damper and the like, wherein the lead-laminated rubber shock isolator is positioned at the lower part of the device, and a lower joint plate and a middle joint plate of the device are both fixed with a slide guide, a slide block and a crossed high-strength cable respectively; a fixed steel plate at the lower end of the guiding shaft of the disc spring is fixed on the middle joint plate by a bolt, the compound combined disc spring is sleeved on the guide shaft and the top end of the guide shaft is provided with an anti-pull baffle and an anti-pull bolt; and the diamond steel plate damper is positioned horizontally, and the two ends thereof are supported on a steel plate support bracket which is fixed on a fixed steel plate of the guiding shaft of the disc spring, and the middle of the diamond steel plate is fixed on an upper joint plate of the three-dimensional isolation device by a screw and a nut. The three-dimensional isolation device has enough vertical bearing force and provides proper vertical and horizontal rigidity and dampness; and key parts are connected reliably and horizontal limiting and vertical anti-pull measurements are provided.

Owner:DALIAN UNIV OF TECH

Swivel draw bar structure of a suitcase

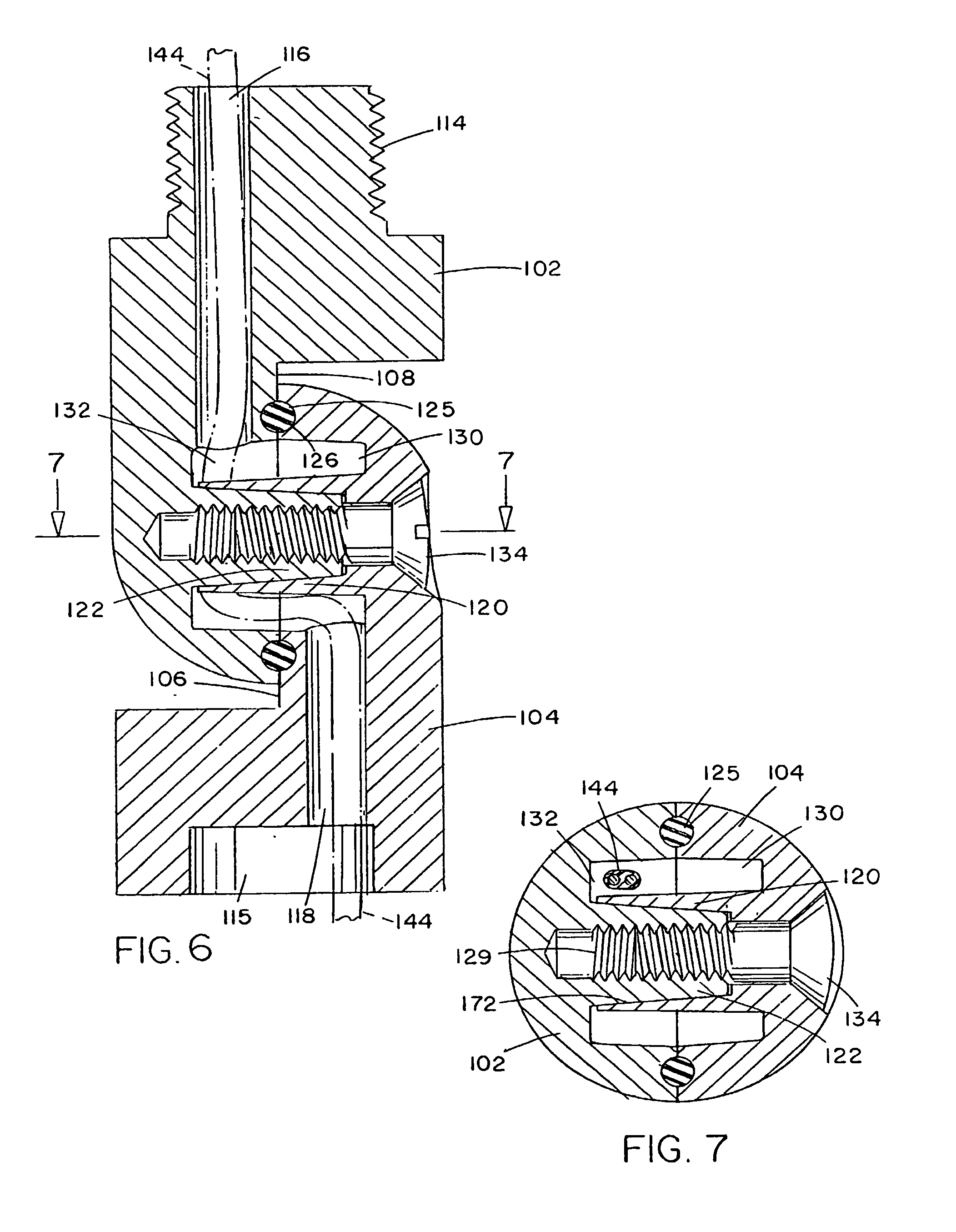

InactiveUS6409207B1Precise rotationCarriage/perambulator accessoriesOther accessoriesUpper jointEngineering

A swivel draw bar structure of a suitcase. A fixing sleeve is installed at the top end of the lower joint tube of the draw bar. A projective arc plate is joined at the center of the top surface of the fixing sleeve. A plurality of teeth are formed on the top surface of the arc plate. A downward straight groove is formed on the top surface of the fixing sleeve. A slide sheet is inserted in the straight groove. The bottom end of the slide sheet is a bevel joined with a bevel of a retractable button so that the retractable button can slide in a transversal groove of the fixing sleeve. The projective part of the retractable button can penetrate through the transversal groove and protrude out of a hole of the fixing sleeve to be locked in a hole of the lower joint tube. A swivel sleeve seat is joined at the bottom end of the upper joint tube. A pair of auriform sheets having holes extend downwards from the swivel sleeve seat. The holes of the auriform sheets are joined a central hole of the arc plate via a spindle. An upward longitudinal groove is formed on the bottom surface of the swivel sleeve seat for insertion of a slide retaining element. The slide retaining element is connected to the swivel sleeve seat through pin connection. The top end of the slide retaining element is joined with a drive element to drive the slide retaining element to move upwards or downwards. A tooth part is formed on the bottom surface of the slide retaining element to mesh with the teeth of the arc plate. A retaining sheet extends from the bottom surface of the slide retaining element. The bottom end of the retaining sheet contacts with the top end of the slide sheet to push the retractable button to be positioned in the lower joint tube.

Owner:CHAW KHONG TECH

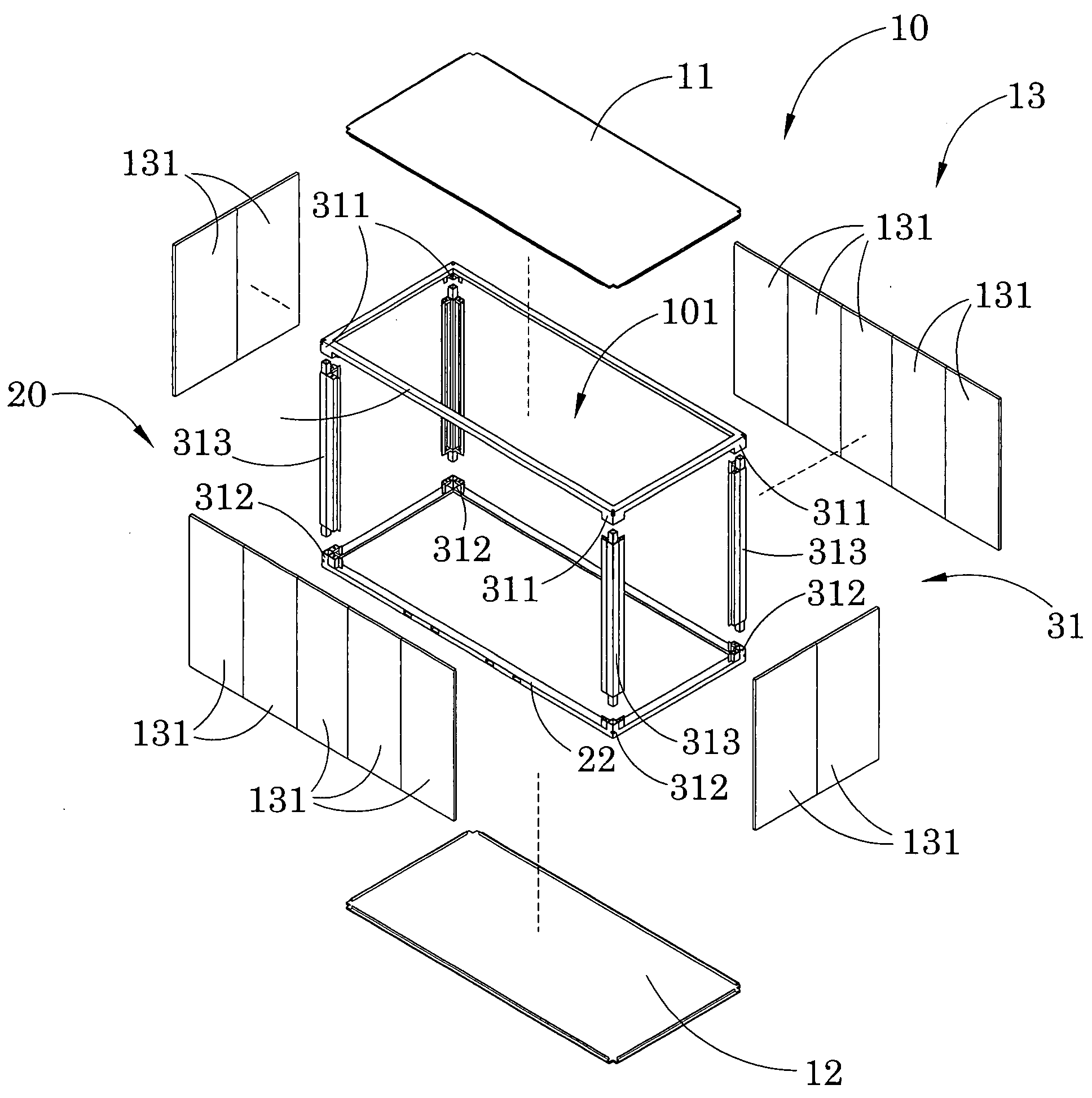

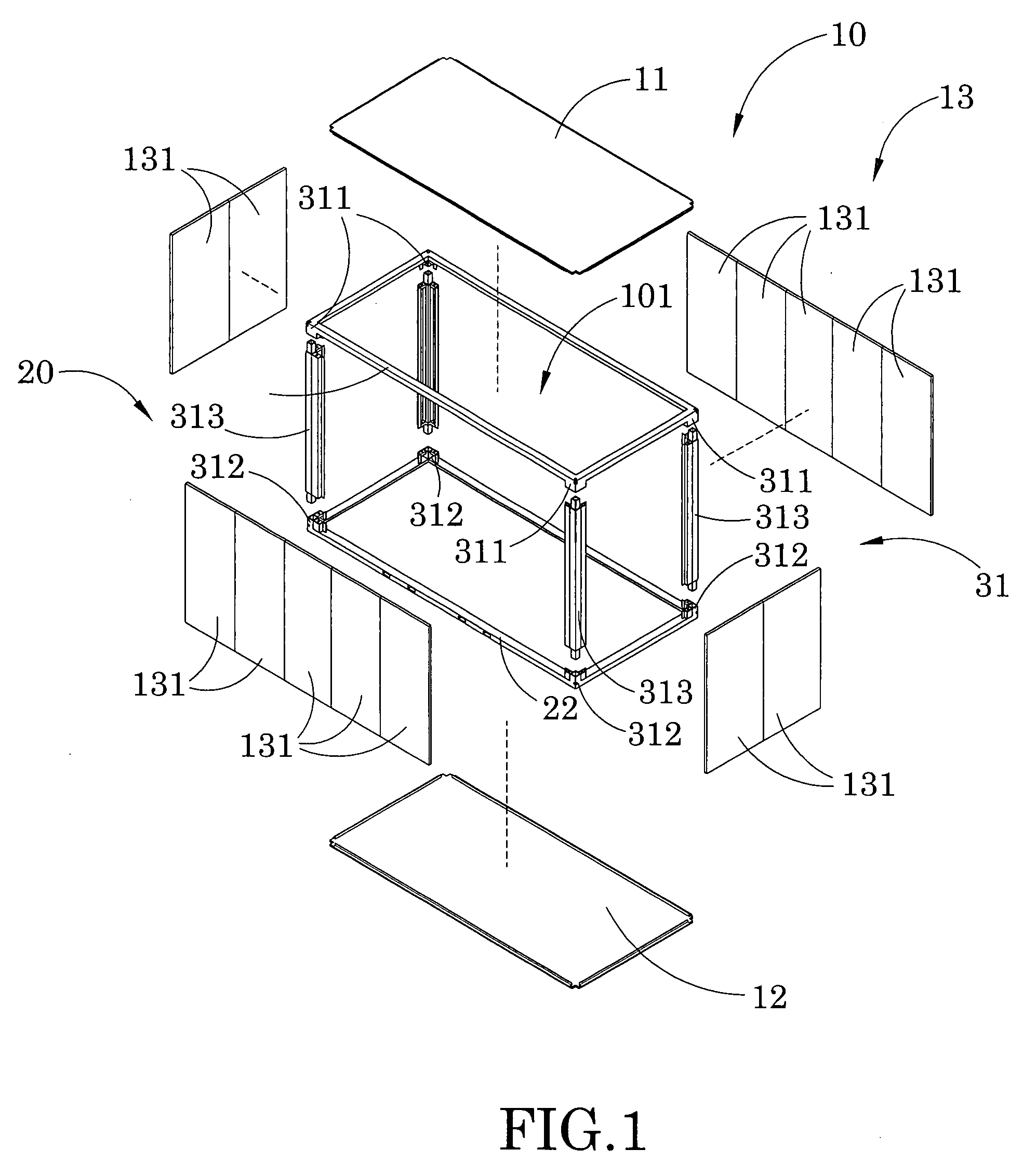

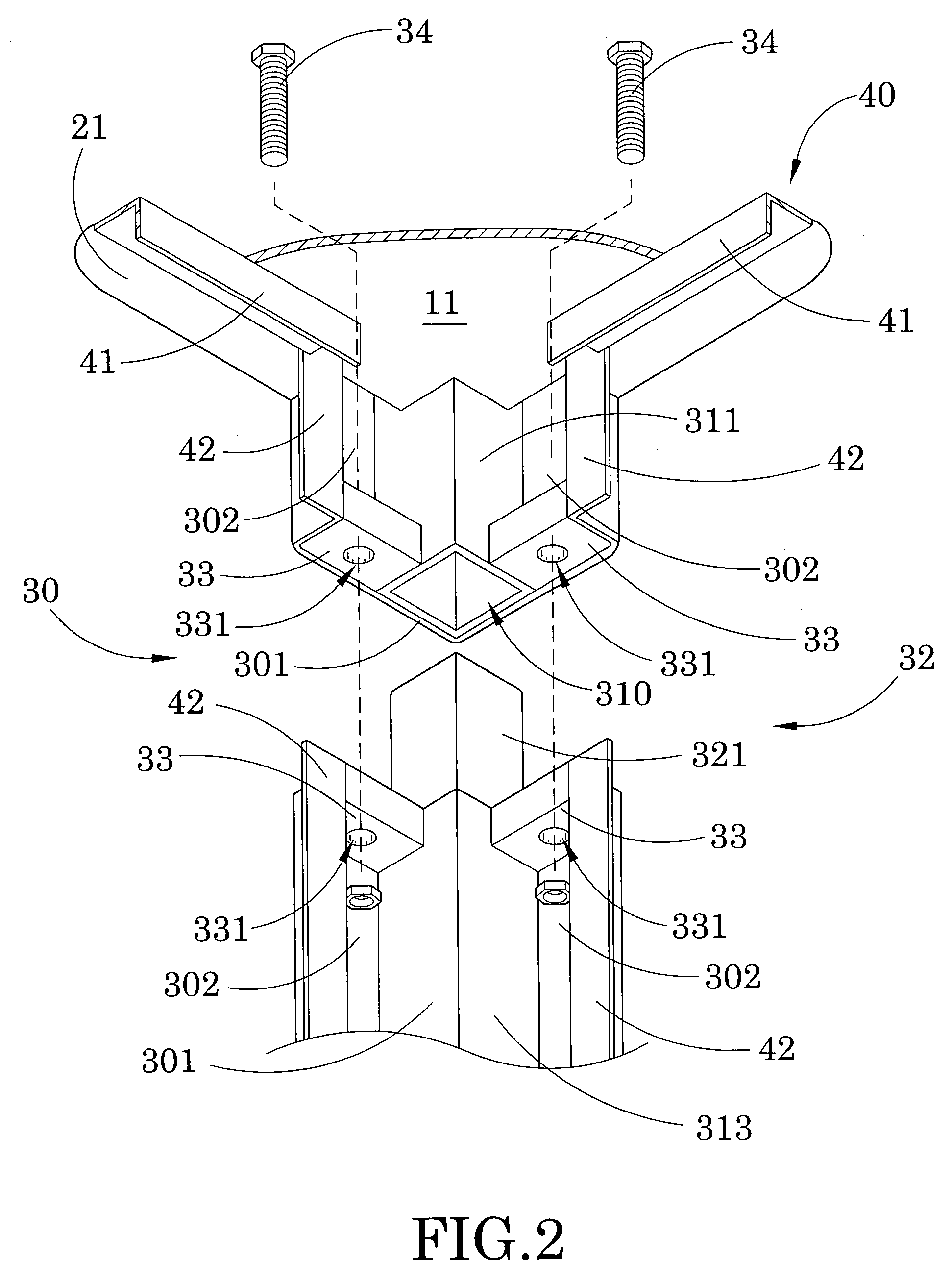

Joint structure for portable work and storage container

InactiveUS20090032530A1Improve the rigidity of the structureDisassemble storageLarge containersBuilding constructionsUpper jointEngineering

A joint structure for portable work and storage container includes a plurality of joint members and a plurality of reinforcing shafts. Each joint member includes an upper joint extended from a top retention frame, a lower joint extended from a bottom retention frame, and a shaft holder alignedly mounting between the upper and lower joints to form a reinforcement channel. The reinforcing shafts are disposed within the reinforcement channels and coupling between the upper and lower joints through the shaft holders respectively, wherein each of the reinforcing shafts has an upper portion received in a respective upper socket of the upper joint, a lower portion received in a respective lower socket of the lower joint, and a mid-portion received within the respective shaft holder such that the joint structure reinforces the a strength between the top and bottom retention frames to rigidly support the wall frame.

Owner:PACIFIC CONTAINER NETWORK

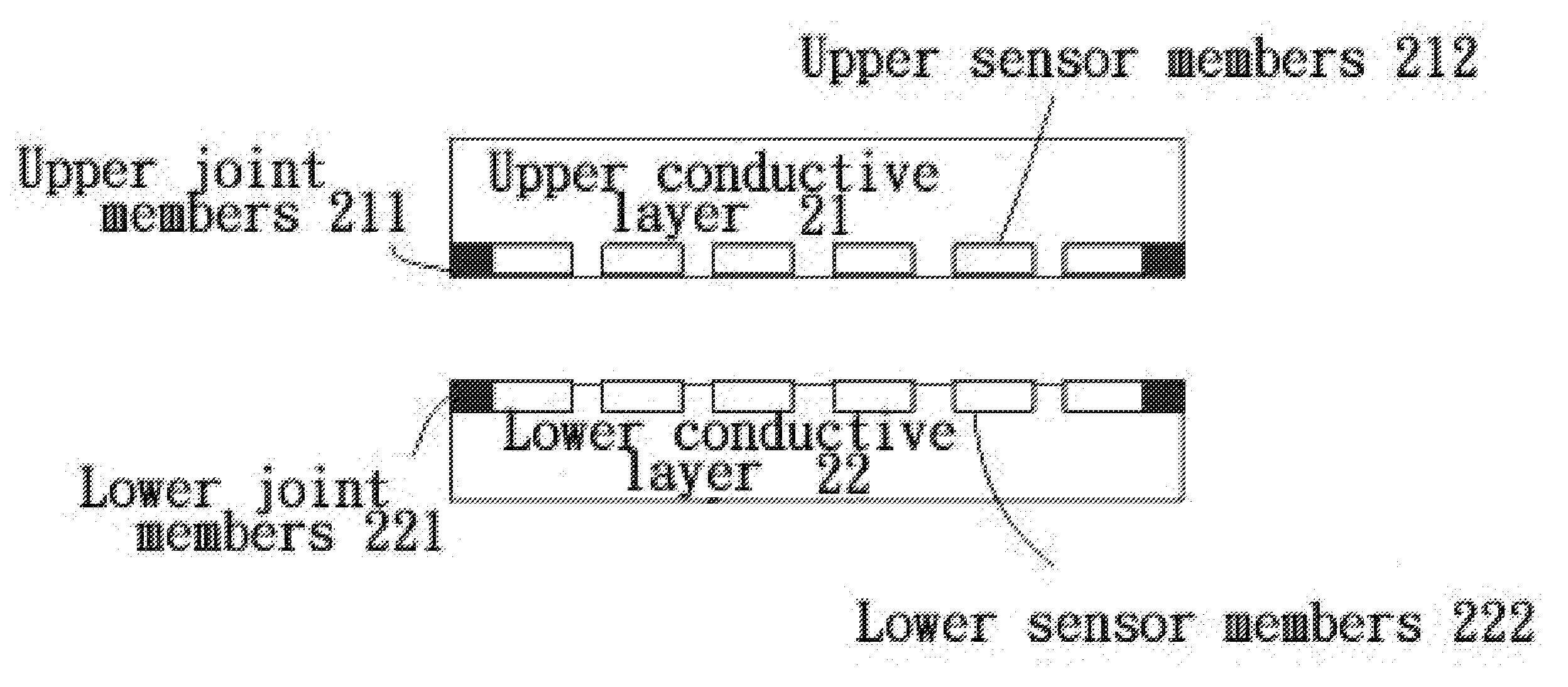

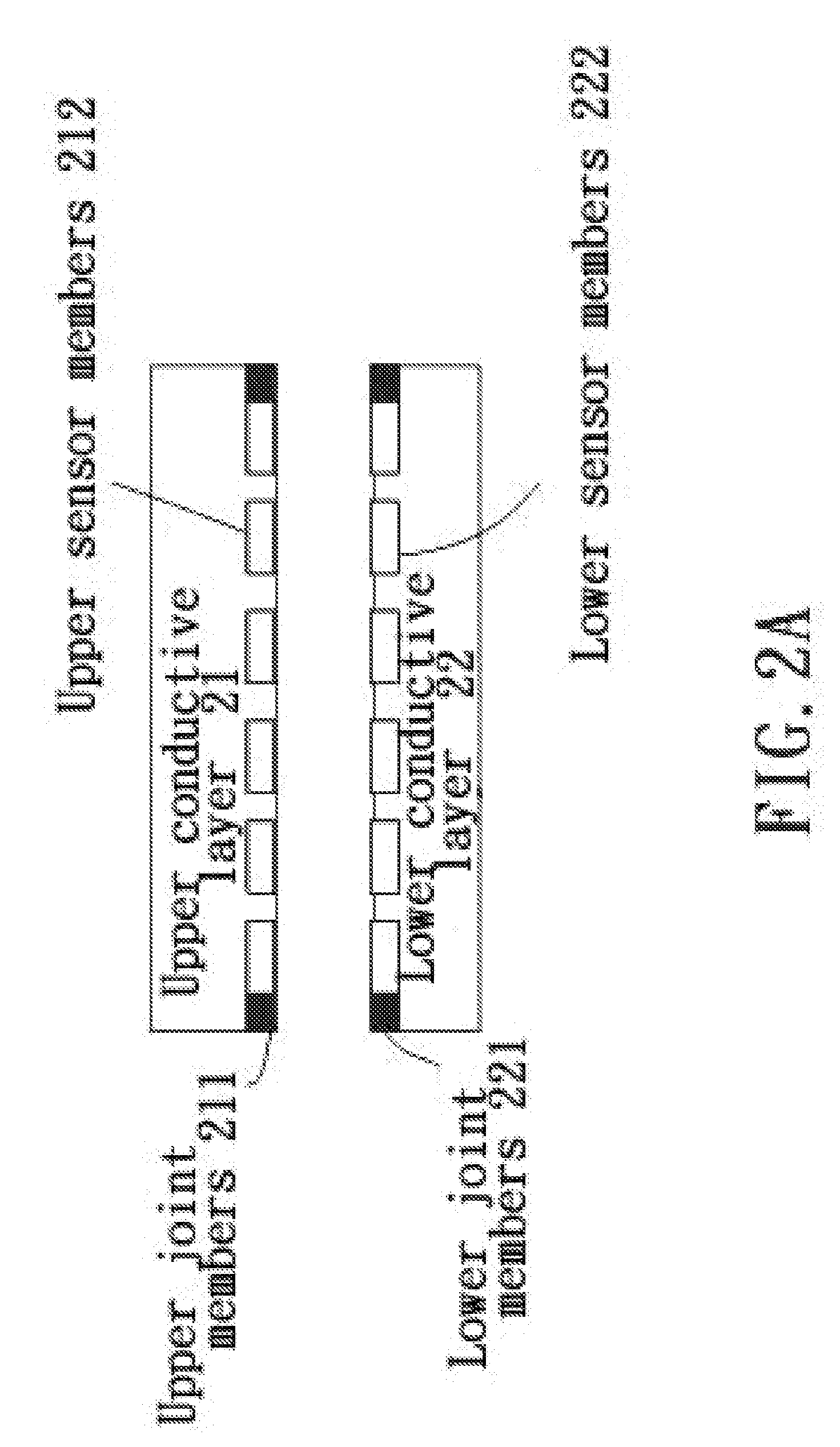

Touch pad for multiple sensing

InactiveUS20100231530A1Overcome limitationsInput/output processes for data processingCapacitanceElectrical conductor

A touch pad for multiple sensing configured to receive touch and pressed-pressure made from at least one finger, conductor or object, comprising an upper conductive layer and a lower conductive layer underneath the upper conductive layer. The upper conductive layer has a plurality of upper sensor members and a plurality of upper joint members. The lower conductive layer has a plurality of lower sensor members and a plurality of lower joint members. The distance-related capacitance on upper sensor members and lower sensor members are detected through the electrically coupled upper joint members and the electrically coupled lower joint members respectively. Besides, an overlapped portion of the upper sensor members and the lower sensor members are electrically conducted by the pressed-pressure. Meanwhile, at least one electrical signal is generated from voltage difference between the upper joint members or between the lower joint members, which the strength of electrical signal is related to the distance of pressed-pressure from the upper joint members or from the lower joint members.

Owner:MEMSOR CORP

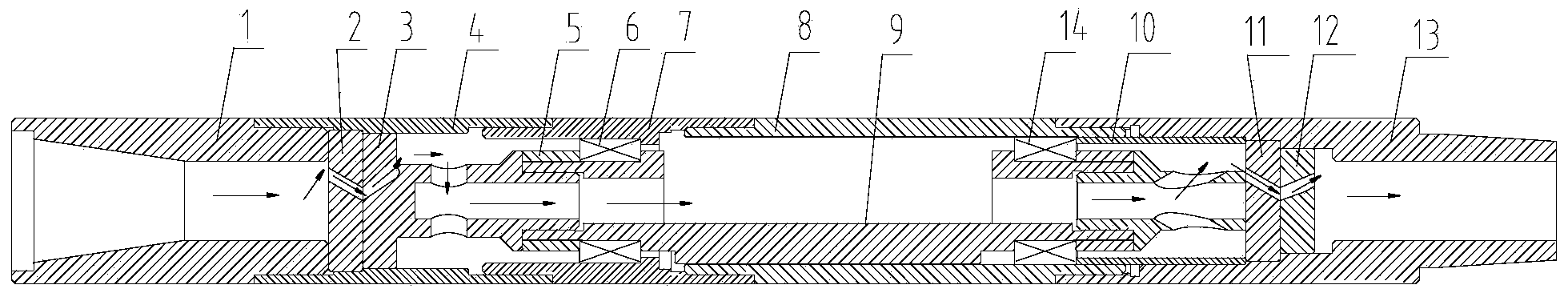

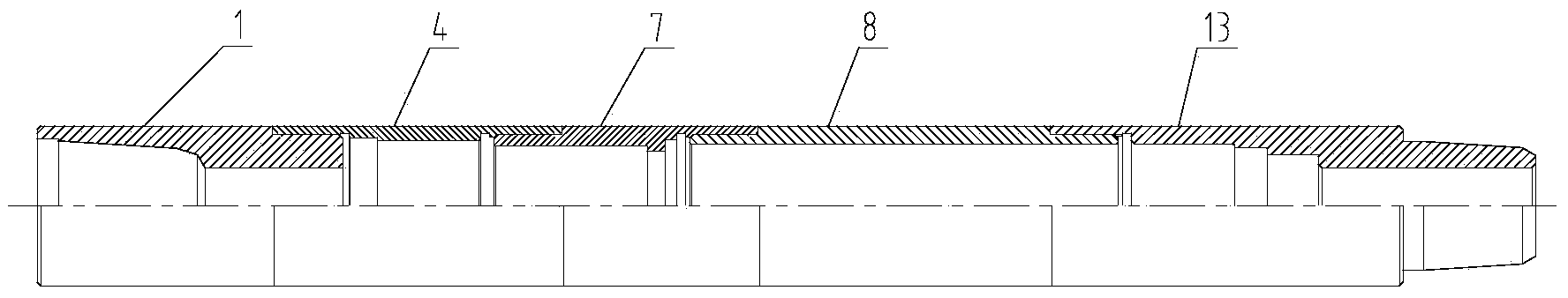

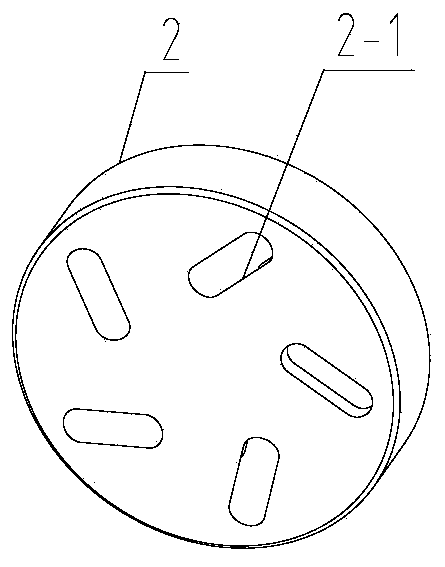

Hydraulic oscillator for well drilling

InactiveCN103696693AReduce frictionImprove drilling efficiencyVibration drillingUpper jointWell drilling

The invention relates to the technical field of well drilling tools and discloses a hydraulic oscillator for well drilling. The hydraulic oscillator comprises an axial oscillator mechanism and a power assembly, the axial oscillator mechanism comprises a joint, a disc spring, a shell and a piston, the joint is mounted on the rear portion of the shell in a sleeve manner, the disc spring is connected between the shell and the joint in a clamped manner, the piston is arranged at the front end of the shell, the power assembly comprises an upper joint, a stator, a rotor, an upper valve piece, a lower valve piece and a lower joint, the rotor is arranged inside the stator and can rotate in the stator, one end of the stator is connected with the axial oscillator mechanism through the upper joint while the other end of the same is connected with a drilling tool through the lower joint, the upper valve piece is connected with the rotor, the lower valve piece is fixedly connected inside the stator below the upper valve piece, an eccentric hole is arranged on the upper valve piece, and a central hole is arranged on the lower valve piece. In the process of horizontal well drilling, the hydraulic oscillator can generate certain oscillating frequency, so that effect of reducing friction resistance of the drilling tool in the process of horizontal well drilling and improving working efficiency in well drilling is realized.

Owner:SHANDONG LUHAI GASOLINEEUM EQUIP

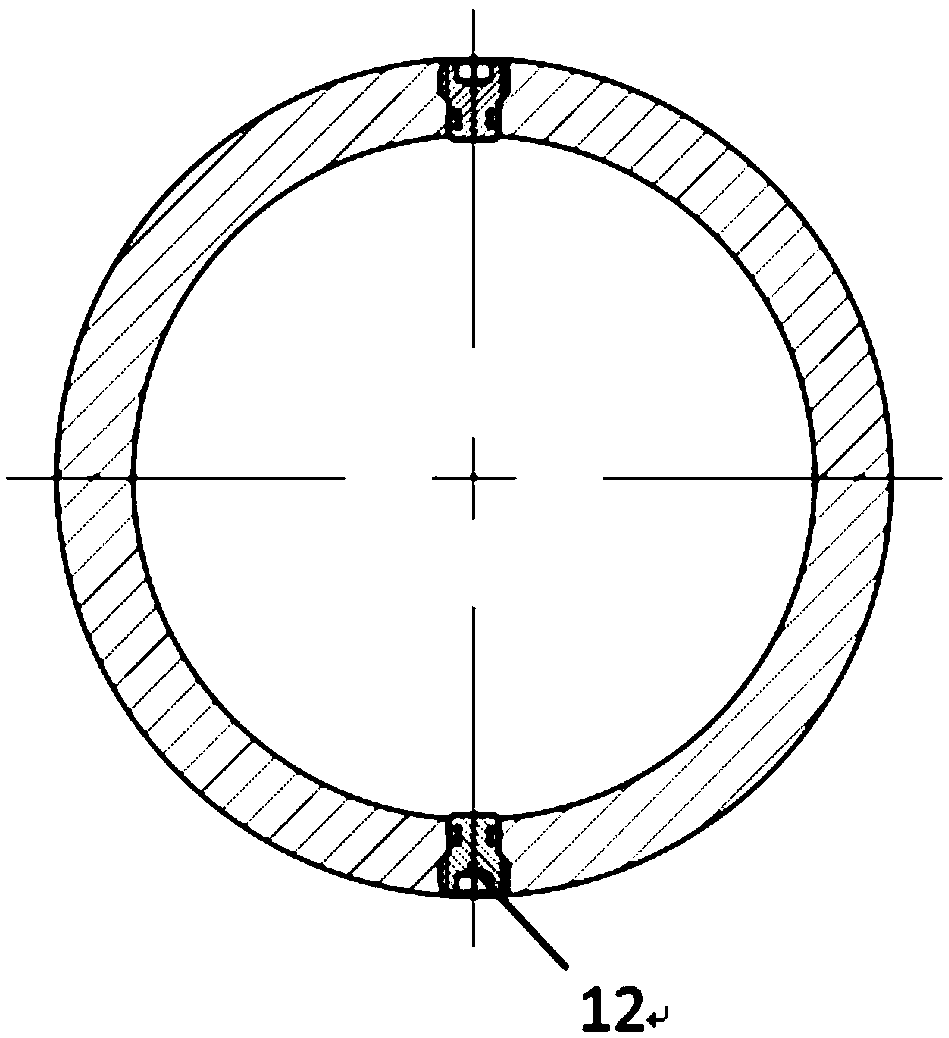

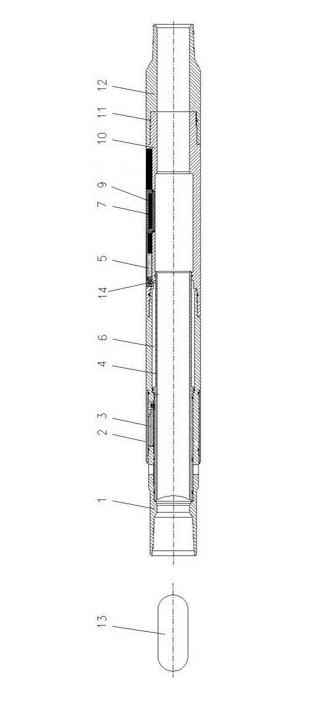

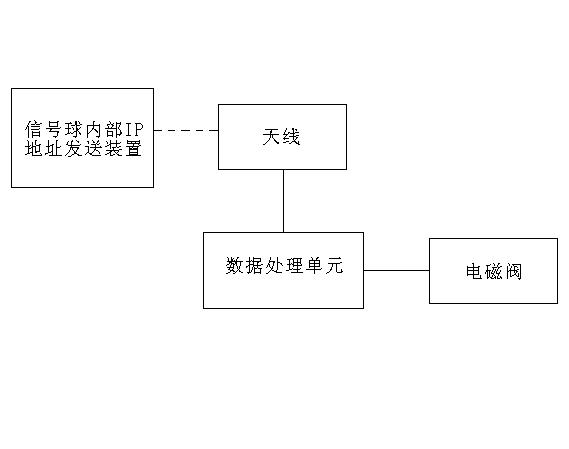

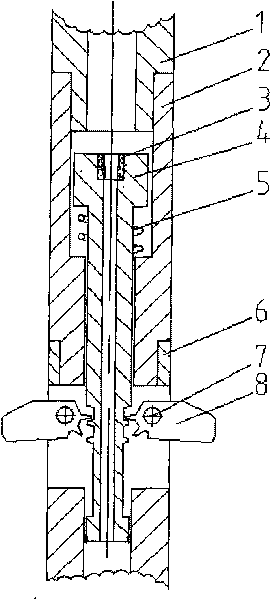

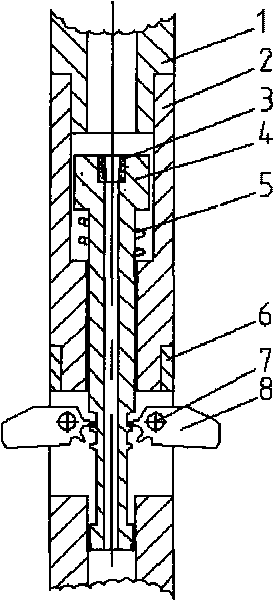

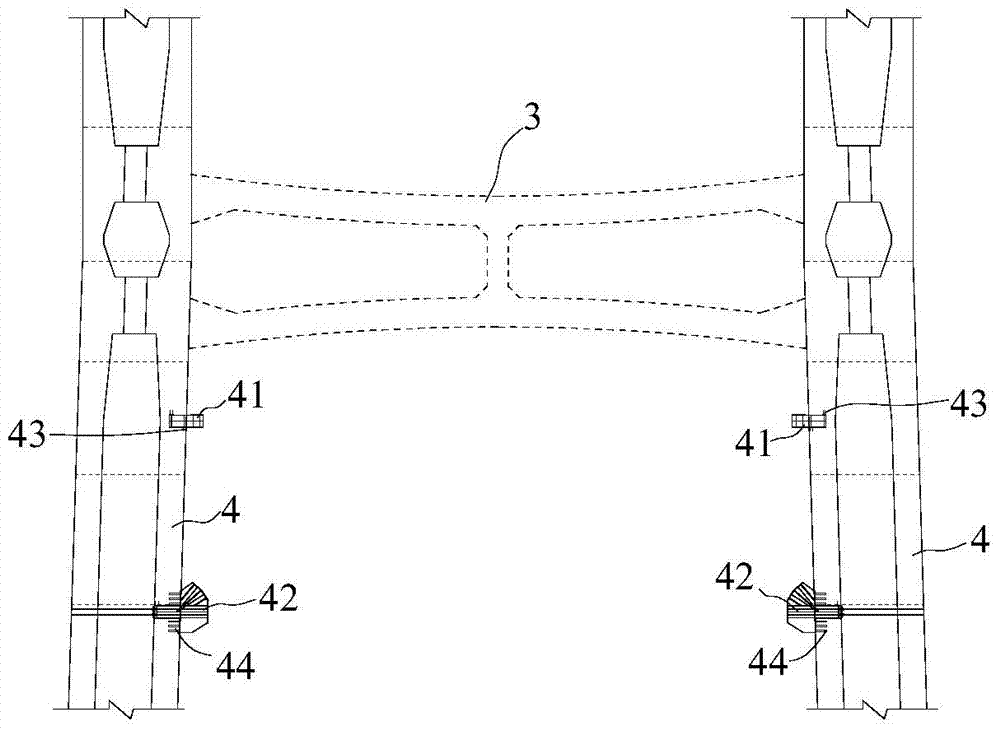

Unlimited-layer electrically controlled fracturing sliding sleeve

The invention relates to a fracturing tool, and provides an unlimited-layer electrically controlled fracturing sliding sleeve for conventional and unconventional exploitation processes of oil, natural gas, coal bed gas, shale gas and the like. The fracturing sliding sleeve comprises an outer cylinder sleeve, an inner sliding sleeve and a signal ball, wherein the outer cylinder sleeve is formed by sequentially sleeving an upper joint, a middle joint and a lower joint; a fracturing runner hole is formed in the upper joint; a signal transmitting device for transmitting specific IP addresses is arranged in the signal ball; a sealed chamber is formed between the upper joint and the inner sliding sleeve, hydraulic oil is prefilled in the chamber, and the sealed chamber is provided with a pressure relief hole; an electromagnetic valve for controlling the opening and closing of the pressure relief hole and an electric control device of the electromagnetic valve are arranged on the middle joint; and a valve plate is arranged on the inner side of the upper joint through a torsion spring. The fracturing sliding sleeve is simple in structure and convenient to use, improves the fracturing effect and the operating efficiency, and solves the problem that the fracturing level is limited.

Owner:四机赛瓦石油钻采设备有限公司

Drill-following reamer

A drill-following reamer comprises an upper joint, a reamer body, a piston nozzle, a piston, a compression spring, a blade, a pin shaft and a limit stop. The upper part of the whole set of device is connected with a drilling tool through the upper joint, while the lower part is connected with a drill bit through a screw thread. During drill-following reaming operation, the liquid piston nozzle pumped on the ground produces pressure drop to push the piston to move downwards, a groove on the piston pushes a gear structure on the blade to rotate the blade outwards by using the pin shaft as the center when the piston moves downwards till the blade is limited by the limit stop, and then the blade is expanded to reach the maximum outside diameter to start the drill-following reaming operation. 78.6 percent of drill hole expansion rate can be achieved by using the drill-following reamer, so the drill hole expansion rate is high; the blade has the mechanical locking function and is not retracted due to the extrusion of the well wall, so the diameter of the reamed drill hole is regular; and because the drilling and the reaming are carried out at the same time, the drilling cost is saved.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

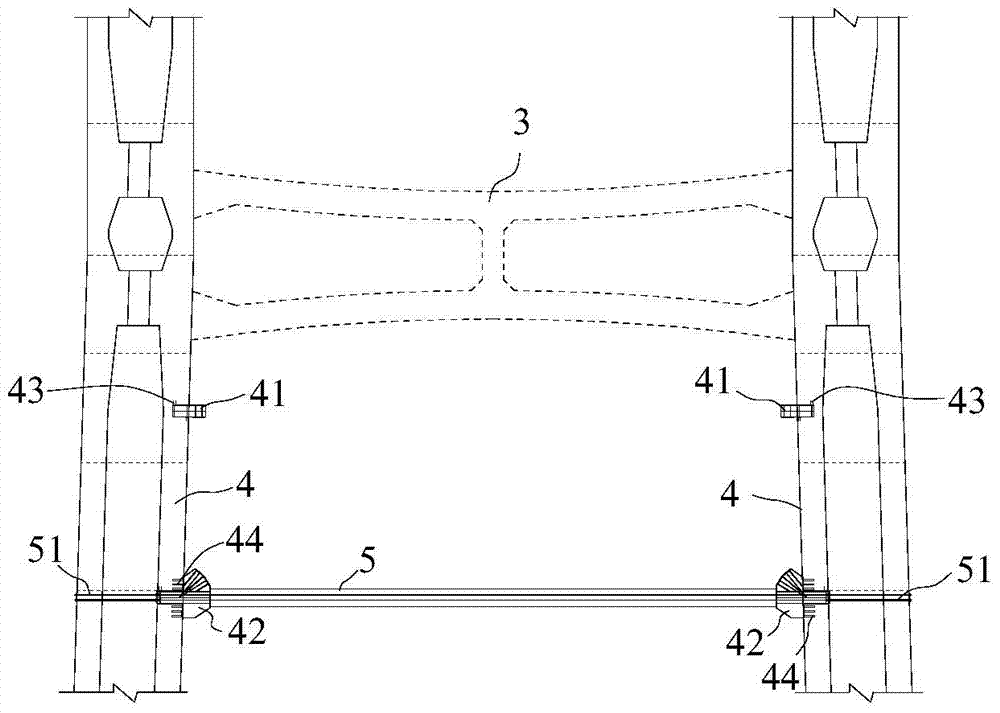

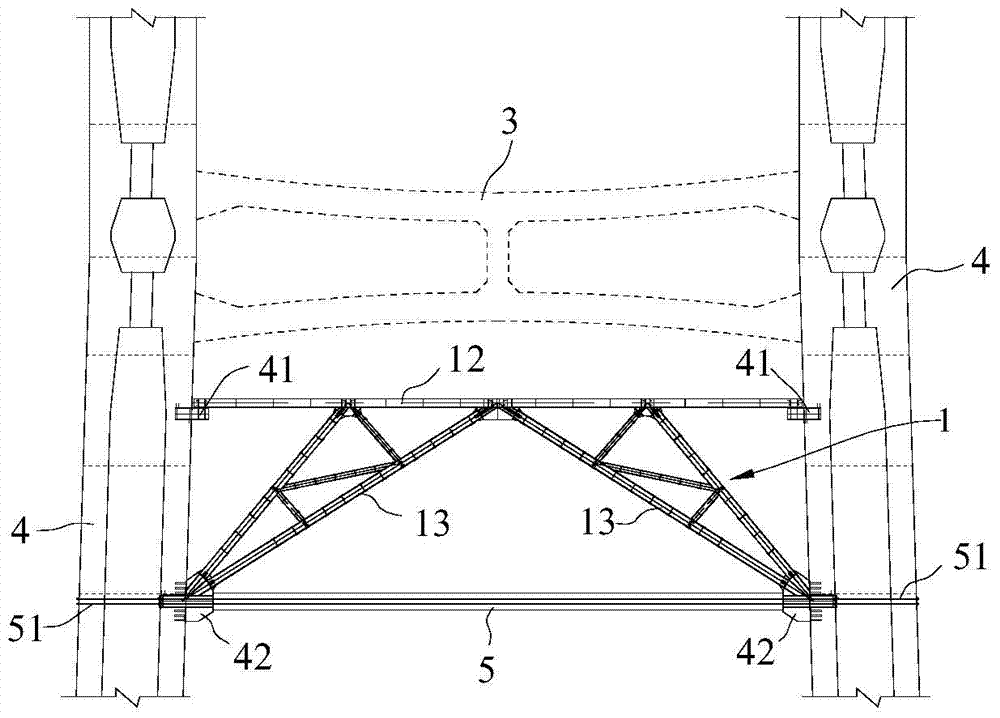

Method for construction of high upper beam steel oblique leg prestress support of H-shaped cable bent tower of cable-stayed bridge

ActiveCN103898836AAvoid installationAvoid demolitionCable-stayed bridgeBridge erection/assemblyUpper jointCable stayed

The invention discloses a method for construction of a high upper beam steel oblique leg prestress support of an H-shaped cable bent tower of a cable-stayed bridge and belongs to the field of bridge construction. According to the method, a steel oblique leg bracket and a lagging jack are adopted for construction of a beam, installation and dismantling of a large number of steel pipe supports when a high support construction method in the prior art is adopted are avoided, the workload of pre-buried piece installation during cable bent tower construction and the workload of repair in the later stage are reduced, the high-altitude welding workload and materials are reduced, the risk of aloft work is greatly reduced, and the problem that the reserved compression amount of the high support and the camber of a pre-buried bracket support are difficult to set is solved; stress of the steel oblique leg bracket is clear, an upper joint transmits a vertical load to the cable bent tower, the horizontal outward component force of obliquely-downward force on a lower joint is counteracted by prestressing force pre-applied by a prestress wire close to a horizontal tie bar, and the vertical component force of the obliquely-downward force on the lower joint is borne by the cable bent tower. In addition, the cable bent tower and the beam are constructed asynchronously, a cable bent tower formwork does not need to be constructed on the side provided with the beam, high-altitude dismantling and installation of a climbing fame are omitted, the safety risk is lowered, and the construction cycle is shortened.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

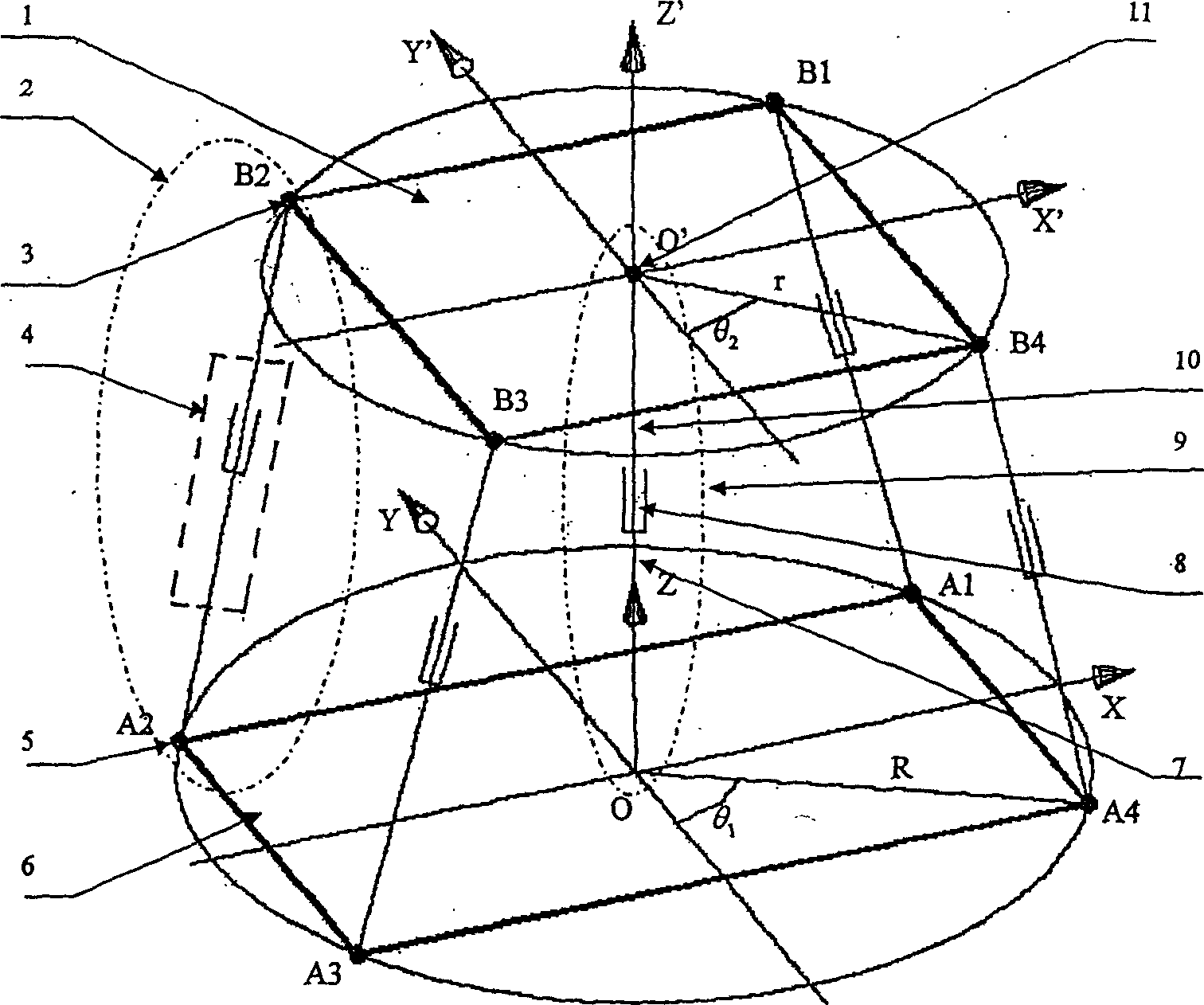

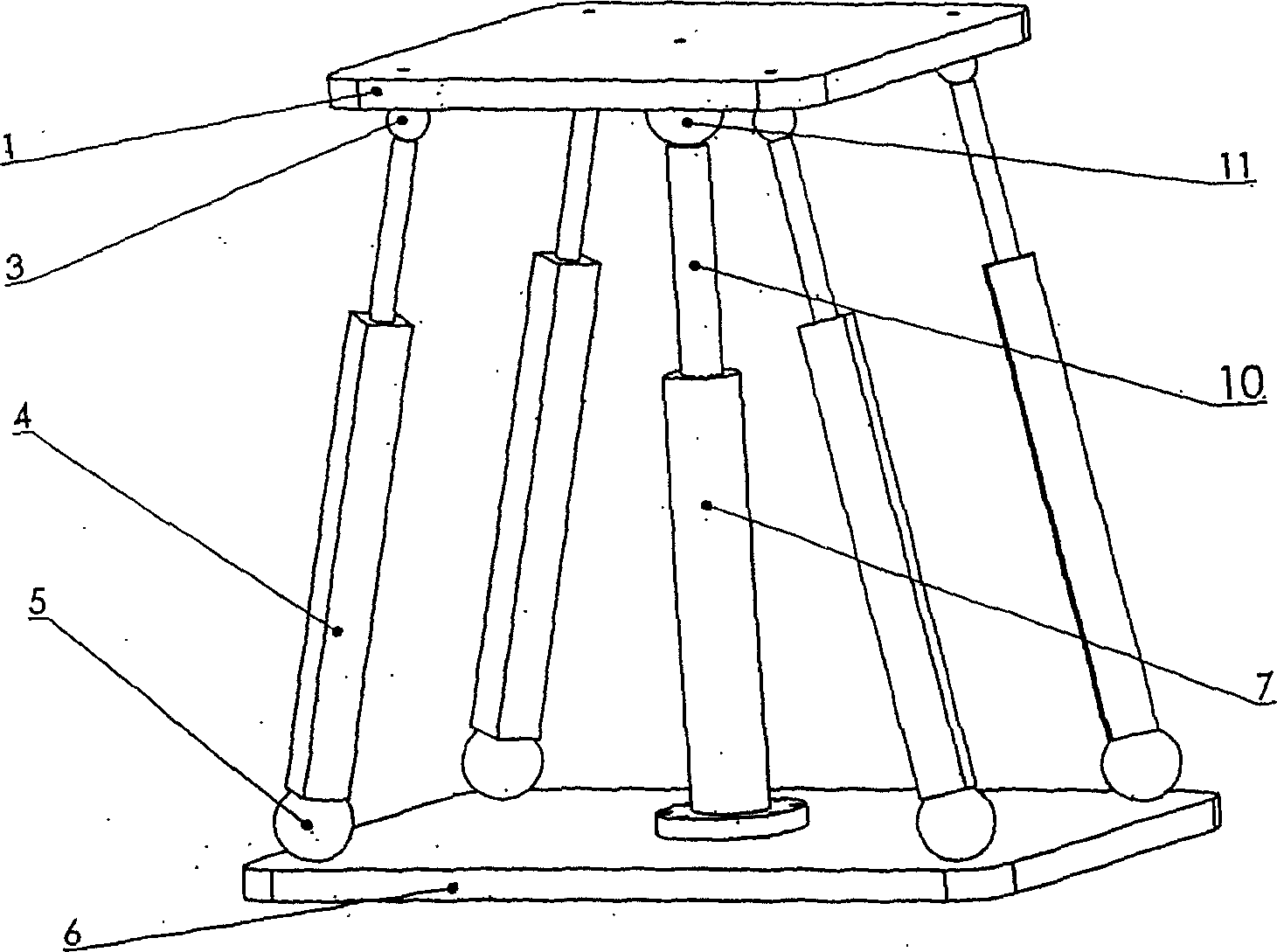

Space four freedom mechanism for realizing three rotating and one moving

InactiveCN1673606AImprove structural rigidityHigh control precisionProgramme-controlled manipulatorInstrumental componentsLinear motionUpper joint

The present invention discloses one kind of four-freedom spatial structure realizing three rotation freedoms and one translation freedom. There are four driving branch chains, each of which has upper joint connected between one corner of the upper platform and the upper end of one linear motion executor, and lower joint connected between one corner of the lower platform and the lower end of the linear motion executor, and one driven branch chain, which has upper joint connected between the upper platform and the upper end of the driven branch member and lower end member connected to the lower platform vertically. The present invention can realize the rotation of the upper platform around three spatial coordinate axes and one transition along one axis. The present invention is used in various stably tracking platform, motion simulator, shuttle butt connector, etc.

Owner:ZHEJIANG UNIV

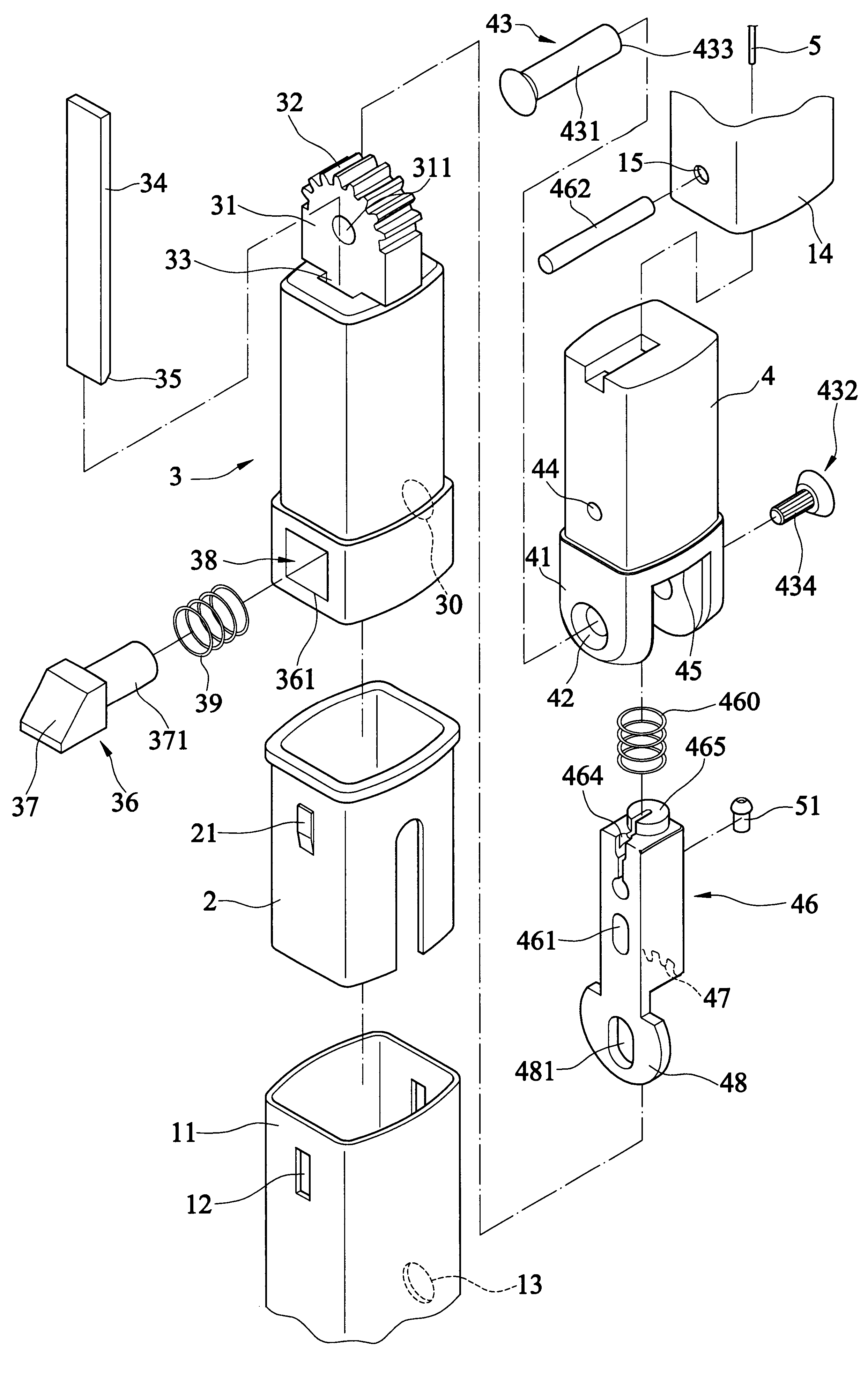

Single-hand foldable baby stroller

InactiveUS8870213B1Easy to foldThe process is convenient and fastCarriage/perambulator accessoriesSledgesJoint componentUpper joint

The present invention reveals a Single-Handedly Foldable Stroller that includes a Hand Tube, a Front Leg Tube, a Front Helm, a Rear Leg Tube, a Rear Helm, and 2 Joint Components. Said Joint Components connect the Hand Tube, the Front Leg Tube and the Rear Leg Tube with each other. Each said Joint Components includes an Upper Joint, a Lower Joint, a Sleeve, a Sleeve Limiting Pedestal and a Folding Operation Component. The Upper Joint is connected with the Hand Tube, and the Lower Joint is connected with the Front Leg Tube. One end of the Sleeve is inserted in the Sleeve Limiting Pedestal, while the other end is sleeved in the Rear Leg Tube. Moving the Sleeve through the Folding Operation Component would gradually turn the Upper Joint and the Lower Joint counter-clockwise, accomplishing the folding / expanding of the Stroller.

Owner:MASTER KIDS TOY

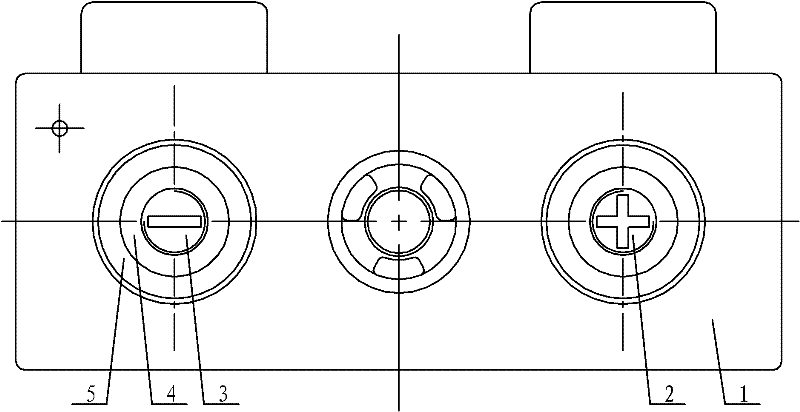

Post type lithium battery cover plate

The invention discloses a post type lithium battery cover plate which comprises a substrate, wherein the center of the substrate is provided with an explosion-proof hole, and the two sides of the substrate are respectively provided with a post installing hole; one end of a post passes through the installing holes, and the other end of the post is connected to the substrate by virtue of a rivet and an electrode pressing plate; the electrode pressing plate is arranged on the upper joint face of the rivet and the substrate, and the lower joint face of the rivet and the substrate is provided with an electrode extraction slice; and joints of the electrode pressing plate, the electrode extraction slice and the substrate are respectively provided with a sealing gasket. In the process of assembling a battery, a lug is connected with the post firstly, then the post and an electrode core connected with the post are arranged in a battery shell, and then the cover plate is sleeved on the post, and finally, the cover plate is fixedly connected with the battery shell. In the lithium battery cover plate, the length of the electrode extraction slice is not required to be increased, thereby effectively avoiding the occurrence of short-circuiting caused by the contact between the extraction slice and the battery shell; and the lithium battery cover plate has the advantages of simple structure and convenience in use.

Owner:无锡市金杨新材料股份有限公司

A multiple switch sliding sleeve device

ActiveCN102261231AGuaranteed tightnessAvoid insufficient frictionWell/borehole valve arrangementsSealing/packingUpper jointControl switch

The invention relates to a segmentally improved underground tool device, in particular to a repeated switch sliding sleeve device which comprises a switch sliding sleeve and a switch tool, wherein the switch sliding sleeve comprises a switch sliding sleeve upper joint, a sliding sleeve, an outer barrel, an opening bushing and a switch sliding sleeve lower joint which are connected with one another sequentially; the switch tool comprises a switch upper joint, a central spindle, a spring, a limiting sleeve and a tap which are connected with one another sequentially; and a switch can be placed in the sliding sleeve to control switching-on and switching-off of the switch sliding sleeve. By the repeated switch sliding sleeve device, a connection state or a disconnection state of each section of flow channel can be selected randomly, so that a full drift diameter of a pipe column is realized and the repeated switch sliding sleeve device is easy to operate.

Owner:XINJIANG SINOGASOLINEEUM ENG

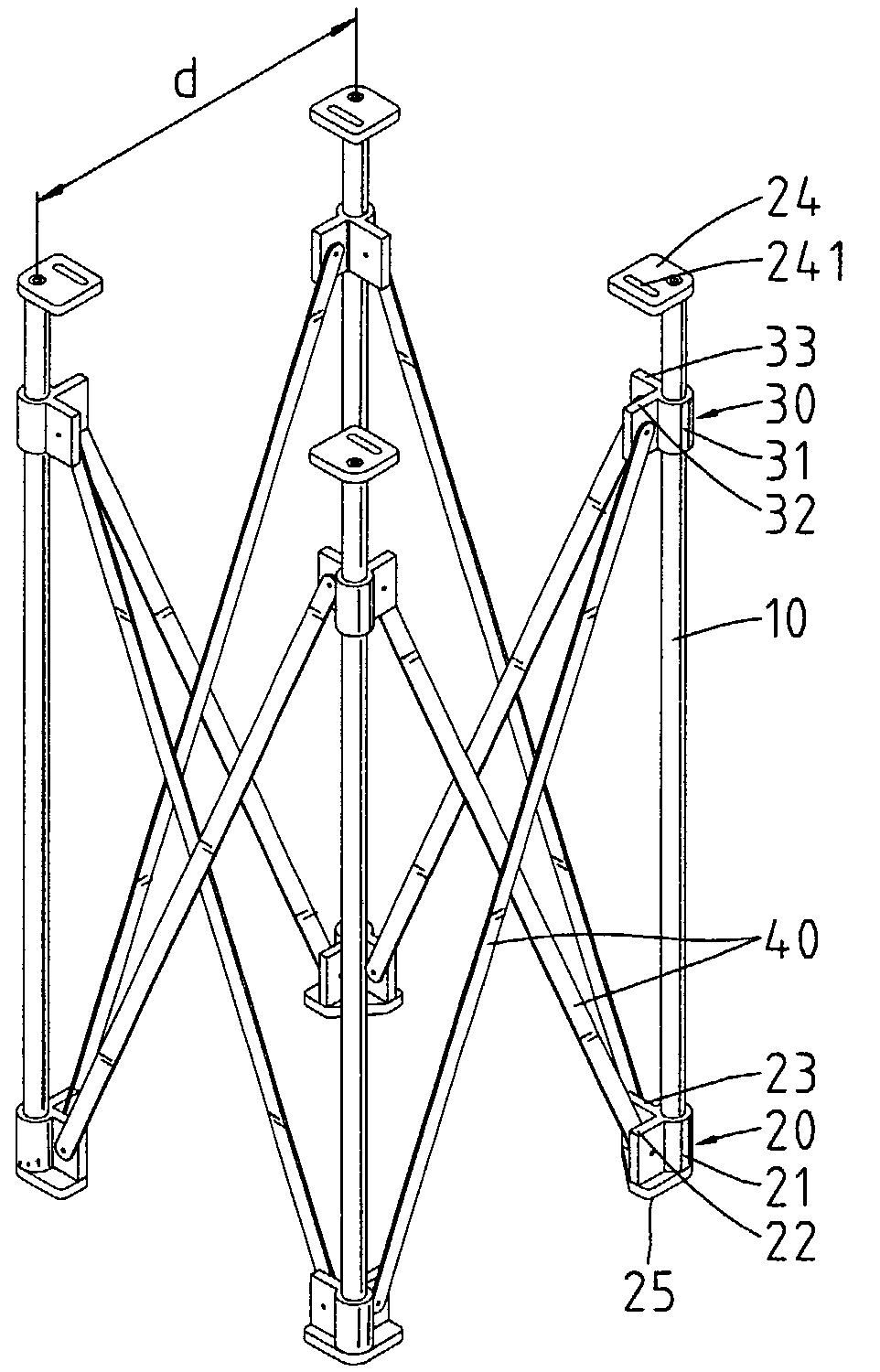

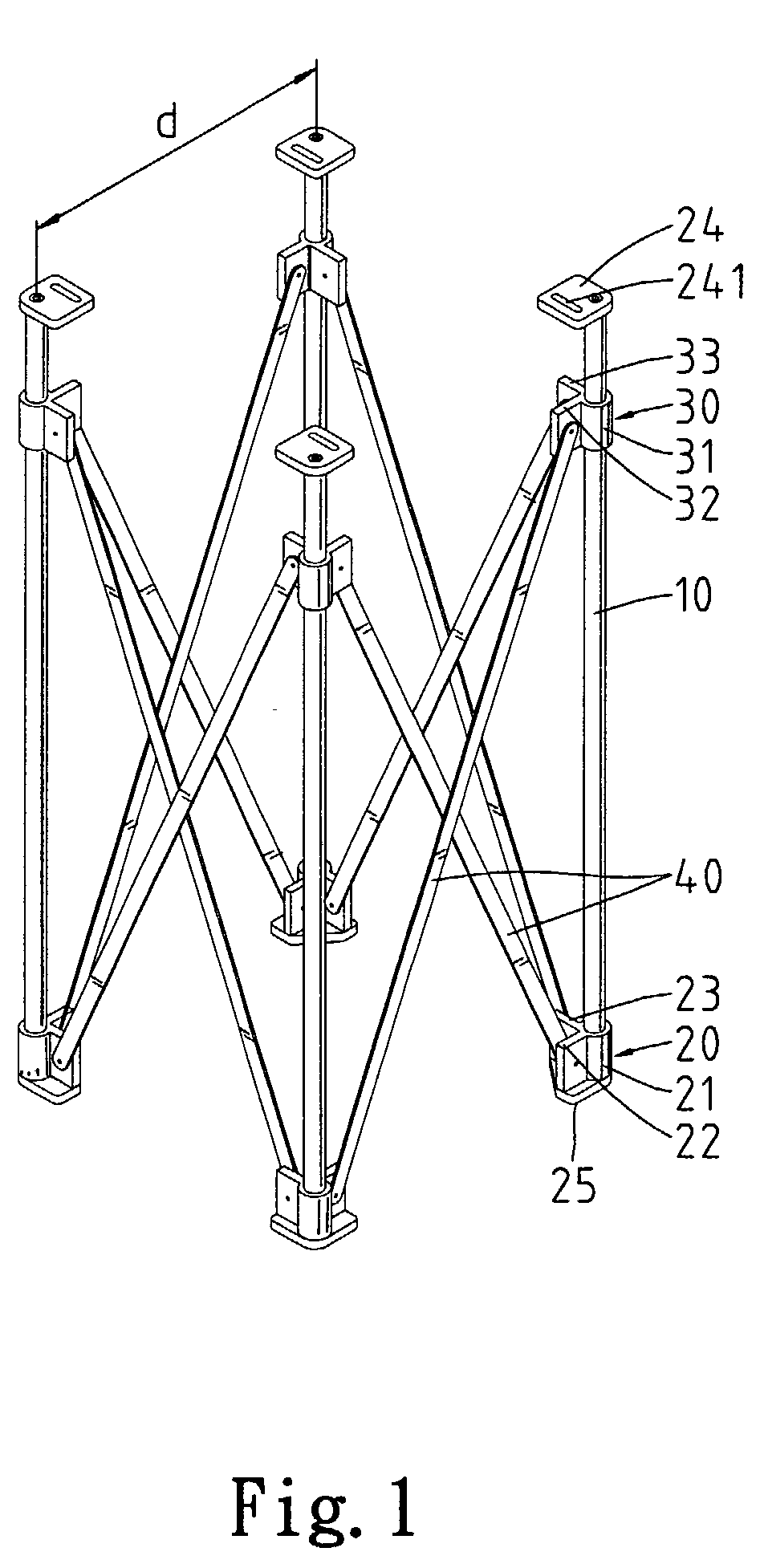

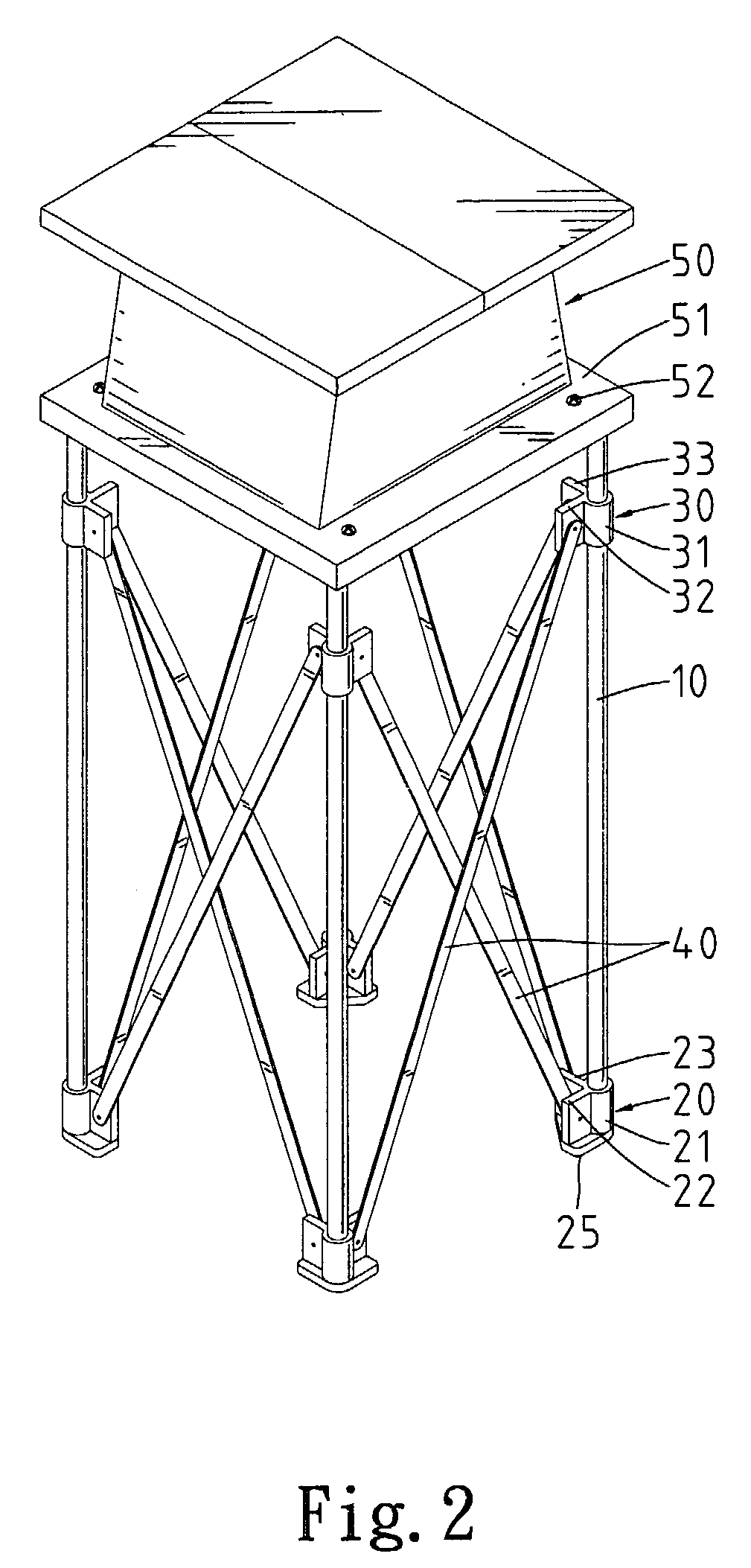

Collapsible support for workbenches

A collapsible support includes at least three legs and a corresponding number of collapsible X-shaped structures each connected between adjacent two of the legs. Each of the collapsible X-shaped structures includes two connectors each having a lower end connected with one of the legs and an upper end connected with another one of the legs. Each of the X-shaped structures includes two lower joints connected between one of the legs and the lower end of one of the connectors and two upper joint connected between one of the legs and the upper end of one of the connectors. Each of the lower joints includes a sleeve for receiving one of the legs and a tab formed on the sleeve and connected with the lower end of one of the connectors. The lower joint includes a foot attached to the lower end of each of the legs. Each of the upper joints includes a sleeve for receiving one of the legs and a tab formed on the sleeve and connected with the upper end of one of the connectors. Each of the connectors is a strip or a tube. The support includes a number of stages each secured to an upper end of one of the legs. Each of the stages defines a slot for receiving a threaded bolt extending from a workbench.

Owner:JOINERY INDAL

Pressure resistant tool for reducing frictional resistance of horizontal well section

ActiveCN102587832AStrong axial vibration capabilityEffective destructionDirectional drillingBorehole drivesUpper jointDrive shaft

The invention relates to a pressure resistant tool for reducing frictional resistance of a horizontal well section, which is used for reducing the frictional resistance of the horizontal well section and improving horizontal section extending and drilling capacity. The technical scheme includes: the pressure resistant tool for reducing the frictional resistance of a whole well consists of a pulse part and a vibration part. The pulse part mainly comprises an upper joint, a power part, an upper abrasion-resistant block, an upper fixing sleeve, a lower abrasion-resistant block, a lower fixing sleeve, a lower valve and a lower joint. The vibration part mainly comprises a spline transmission shaft, a spline righting tube, a locking nut, a disk spring, a supporting shell, a piston rod, a piston bush, a piston nut and a pulse pup joint. The vibration part is in threaded connection with the upper end of the pulse part. The overall overflowing area of a valve part driven by a motor rotor is gradually reduced, and fluid energy is converted into a series of pulse pressure to be transmitted to the vibration part. The pressure resistant tool has the advantages of high axial vibration capacity and simple structure, the frictional resistance between a drill stem and the well wall can be reduced, and the horizontal well and large-displacement well horizontal section extending and drilling capacity is improved.

Owner:SOUTHWEST PETROLEUM UNIV

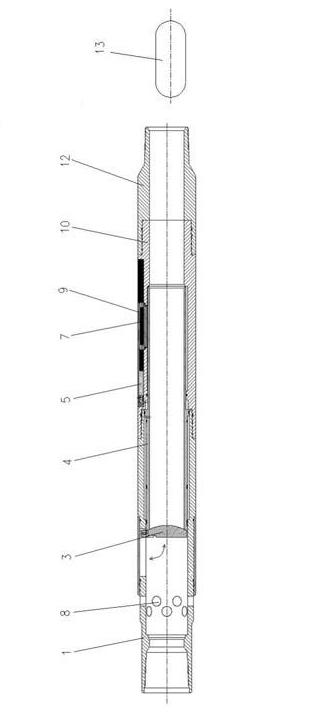

Electric-hydraulic dual-control energy storage type fracturing well completion switch and switch control method

ActiveCN105003226AGood for moving up and downGuaranteed reliabilityFluid removalWell/borehole valve arrangementsType fracturePressure transmission

The invention discloses an electric-hydraulic dual-control energy storage type fracturing well completion switch. The electric-hydraulic dual-control energy storage type fracturing well completion switch comprises an upper joint, a center pipe, a pressure transmission outer tube, a slide sleeve outer tube, an outer sheath and a lower joint which are sequentially connected from top to bottom, wherein an energy storage device is arranged on the center pipe; a slide sleeve system is arranged inside the slide sleeve outer tube; a hydraulic transmission system is arranged inside the slide sleeve outer tube and the outer sheath; each of the center pipe, the pressure transmission outer tube and the slide sleeve outer tube is provided with communicated pressure transmission holes; and the energy storage device, the slide sleeve system and the hydraulic transmission system are communicated through the pressure transmission holes. A control driving system is also arranged between the lower half part of the slide sleeve outer tube and the outer sheath. The electric-hydraulic dual-control energy storage type fracturing well completion switch solves the problems that during the conventional ball injection slide sleeve staged fracturing, due to the existence of a ball seat, the layering stage number is limited; the oil well yield is influenced; and the late-period control production and the selective production cannot be realized, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com