Patents

Literature

331results about "Tongue/grooves making apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical locking of floor panels

ActiveUS20090193748A1Avoid vertical displacementReduce vertical frictionTongue/grooves making apparatusWallsEngineeringTongue and groove

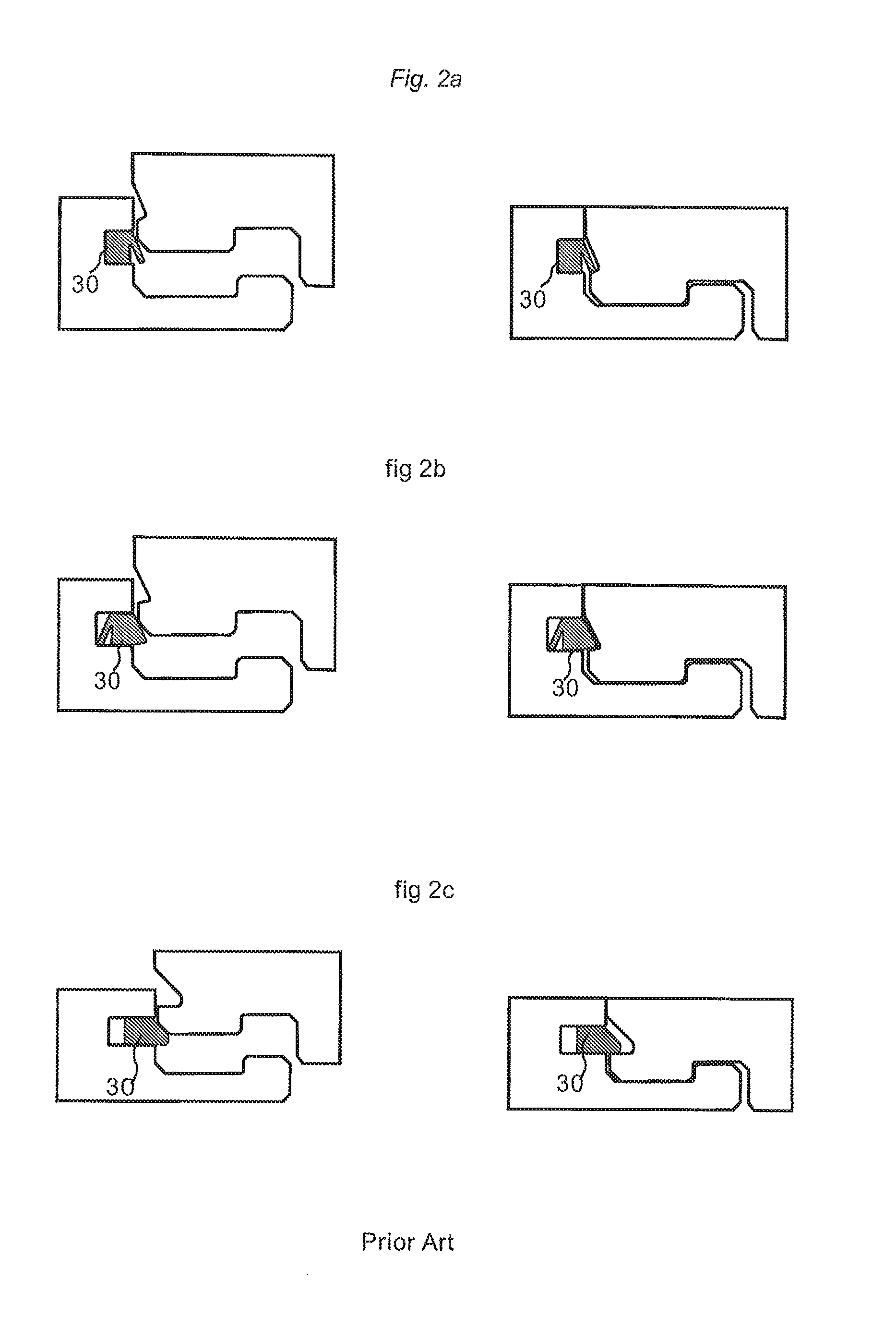

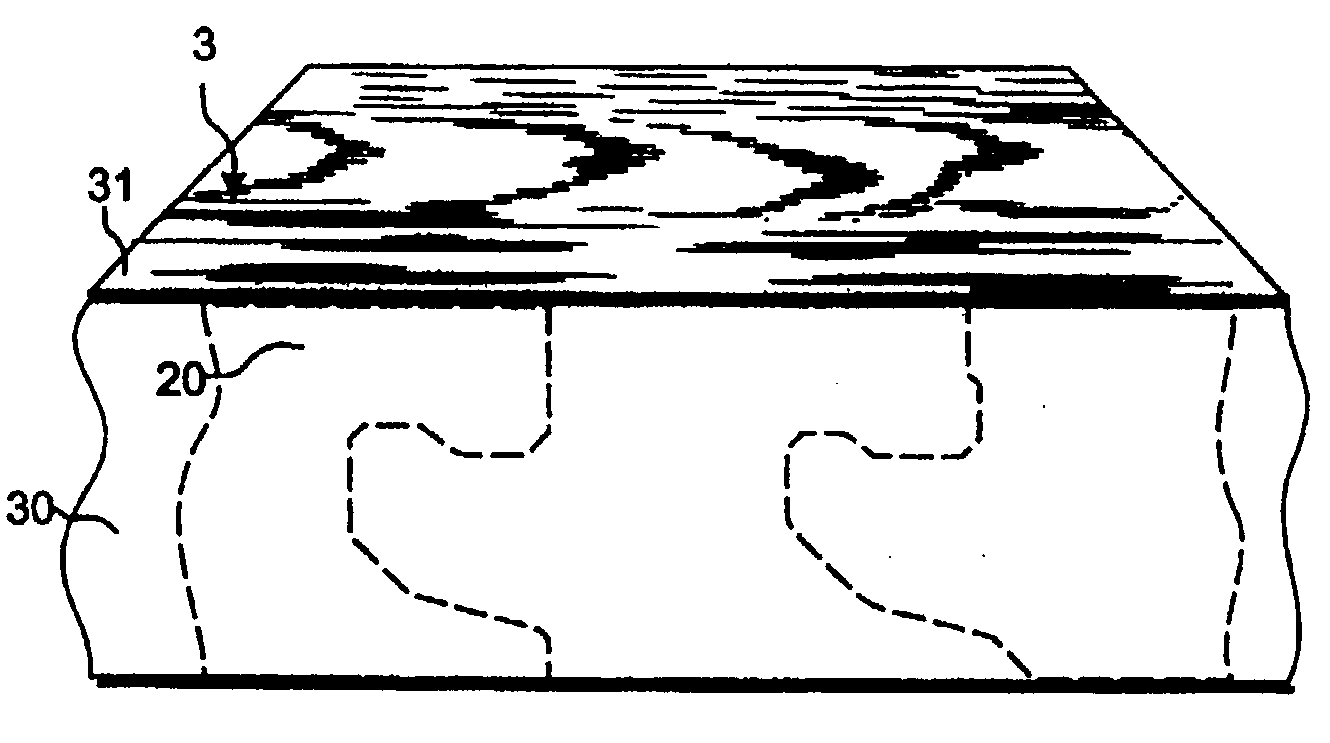

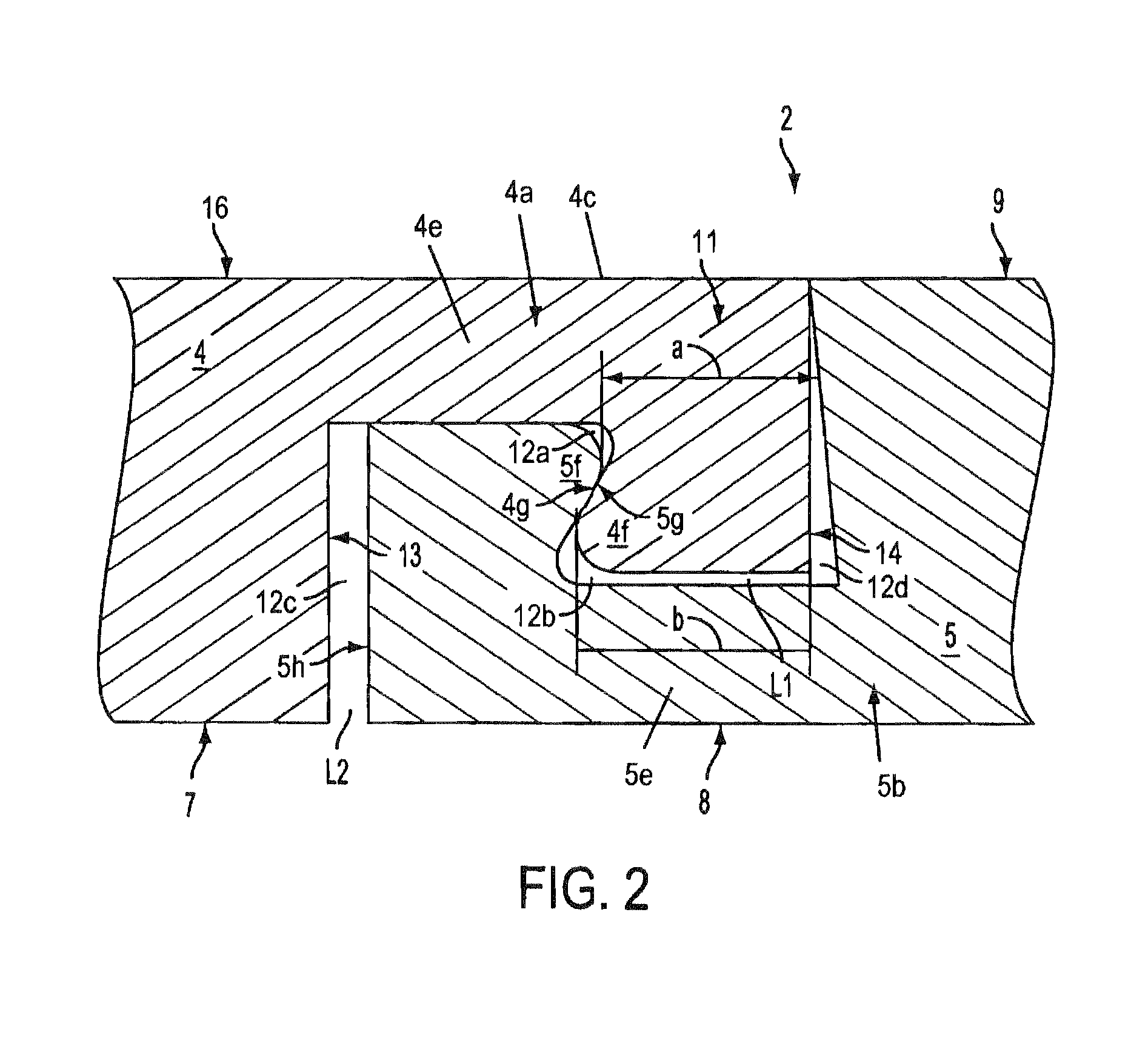

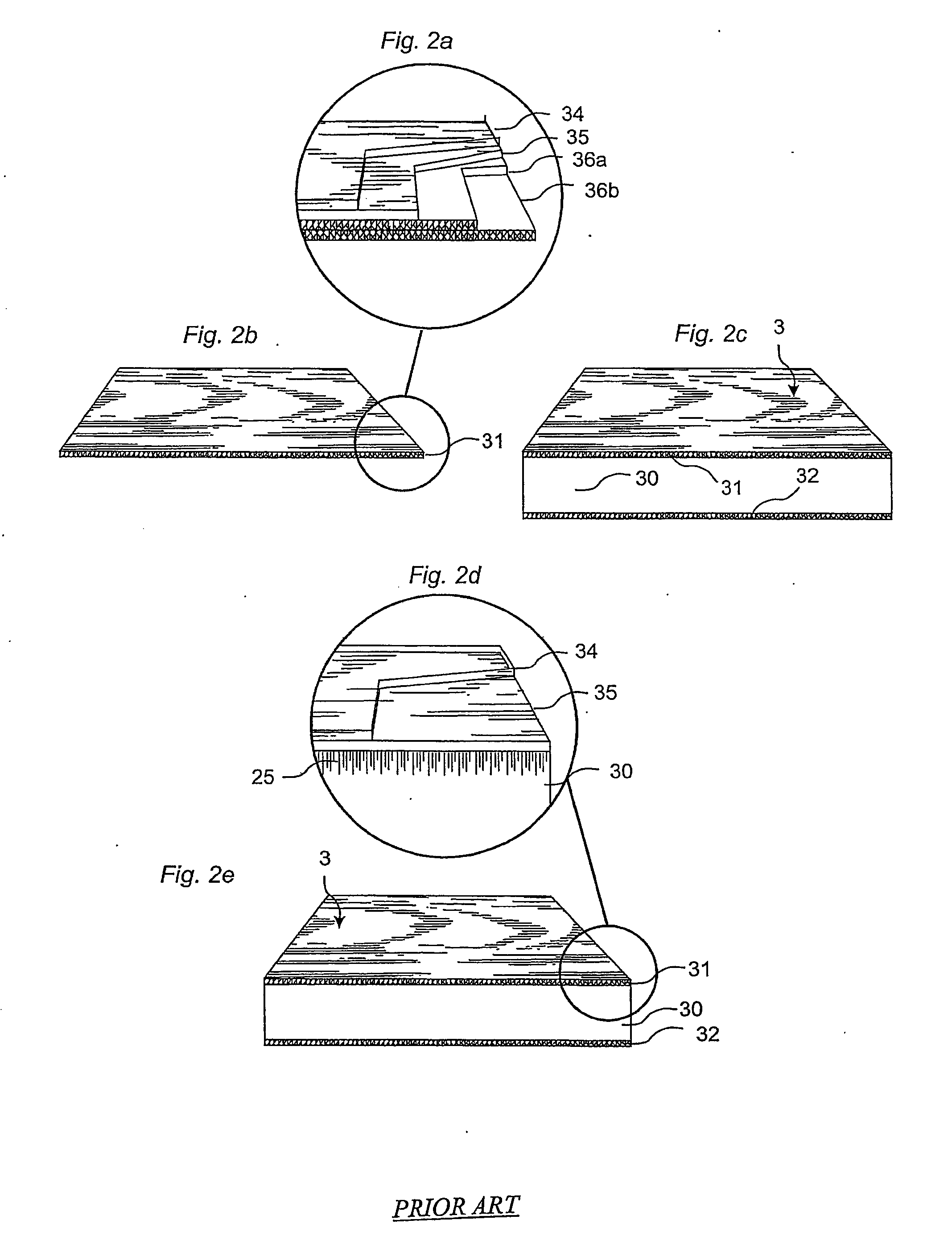

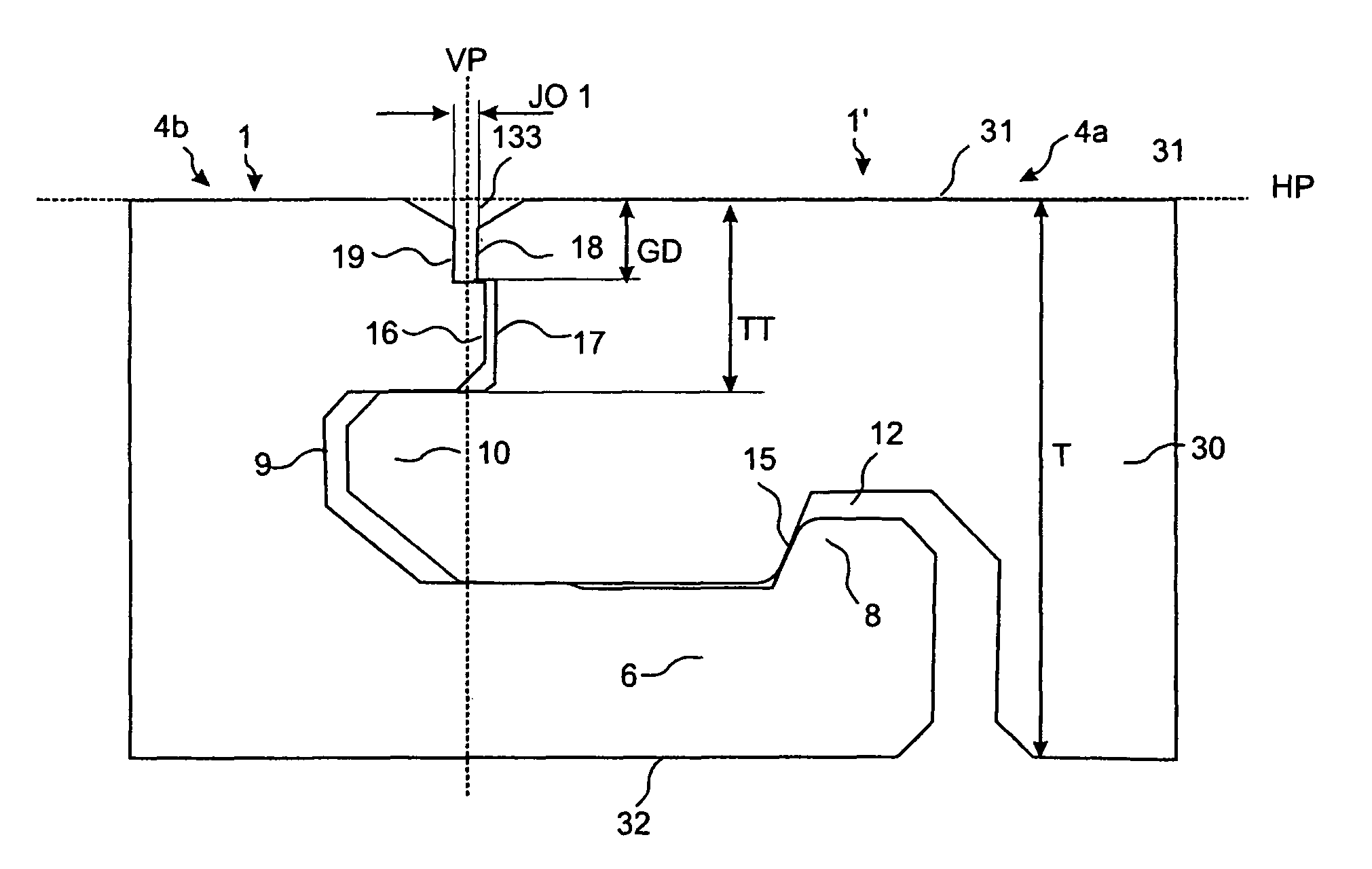

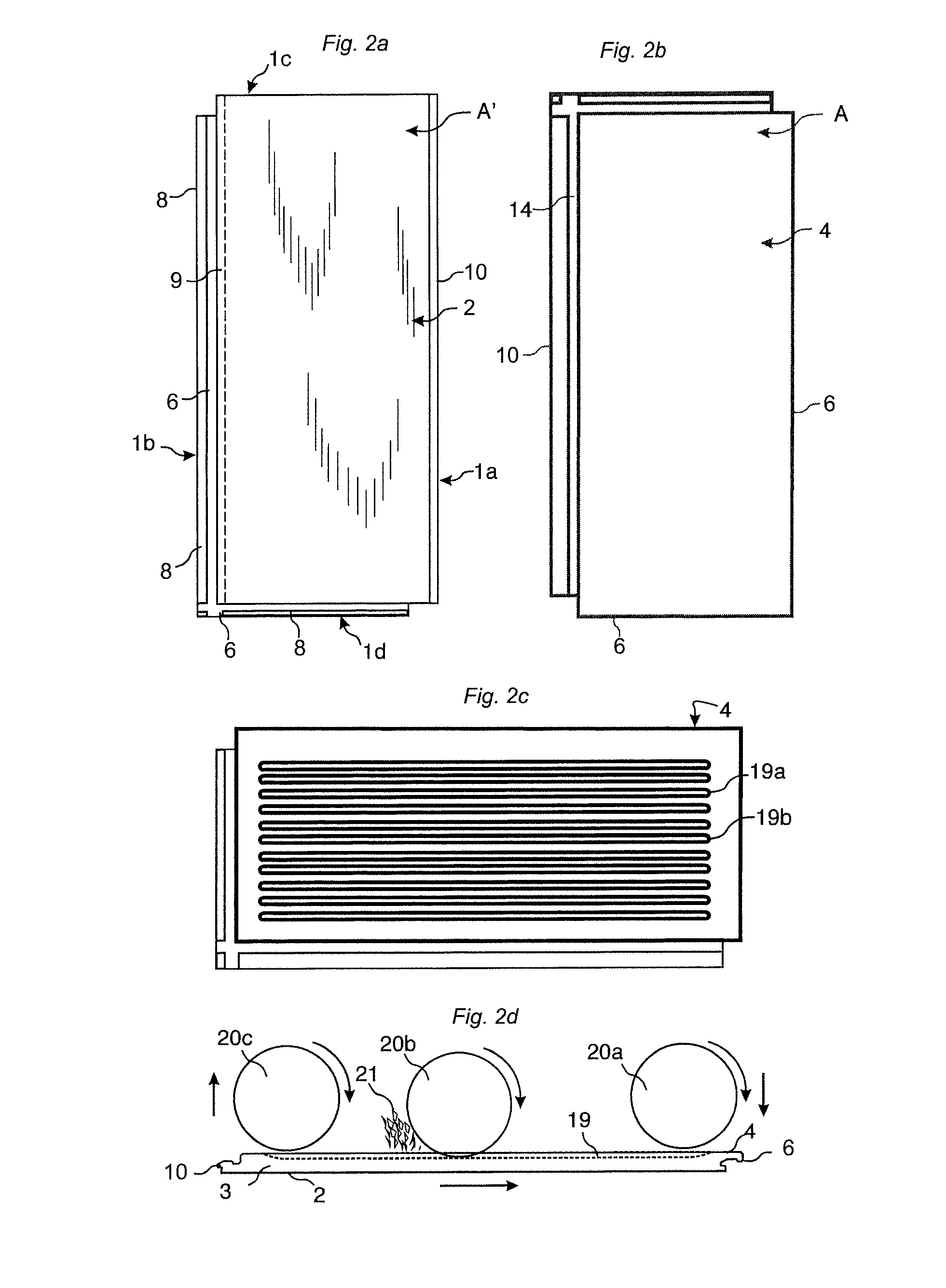

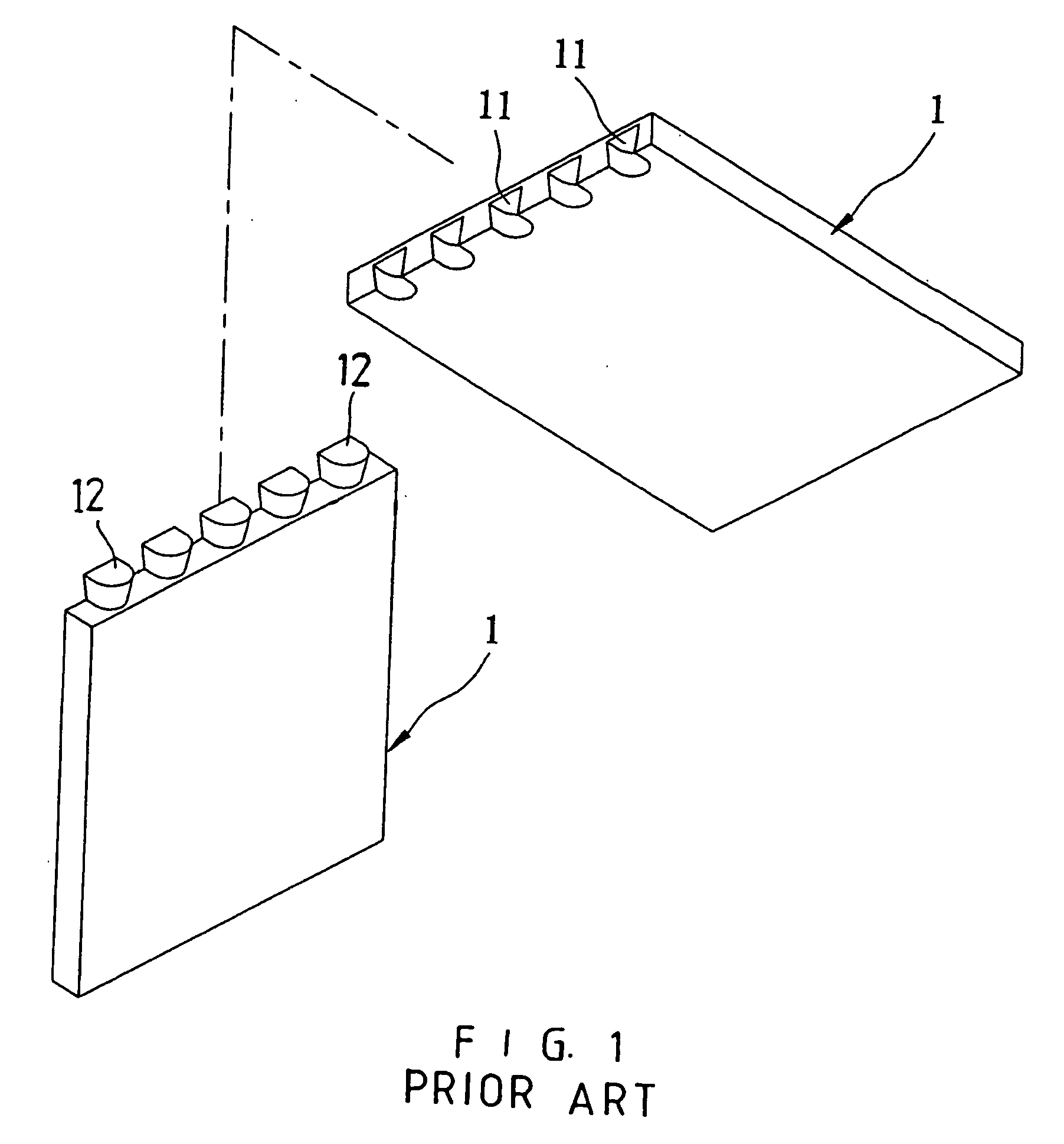

Floor panels are shown, which are provided with a mechanical locking system having tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

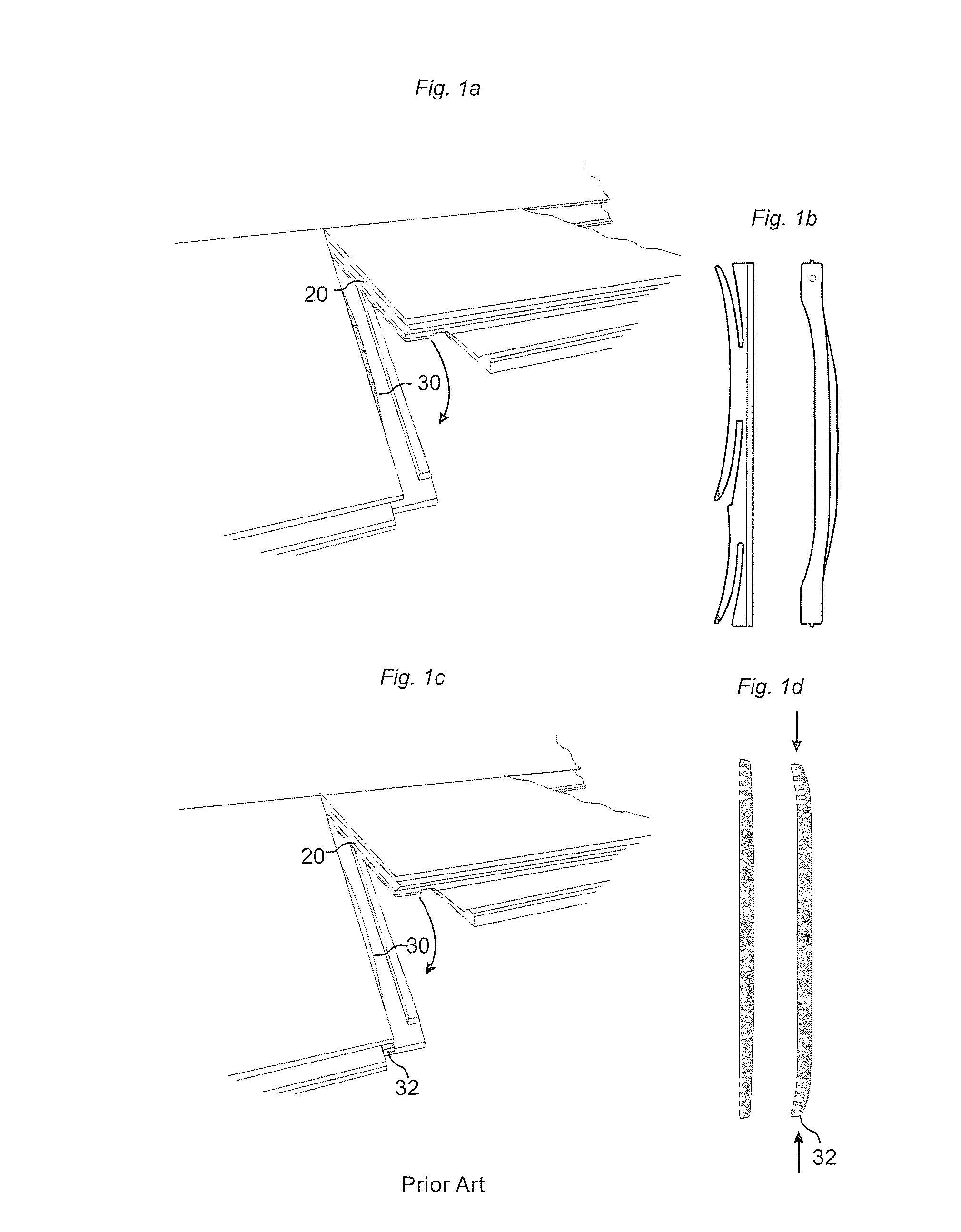

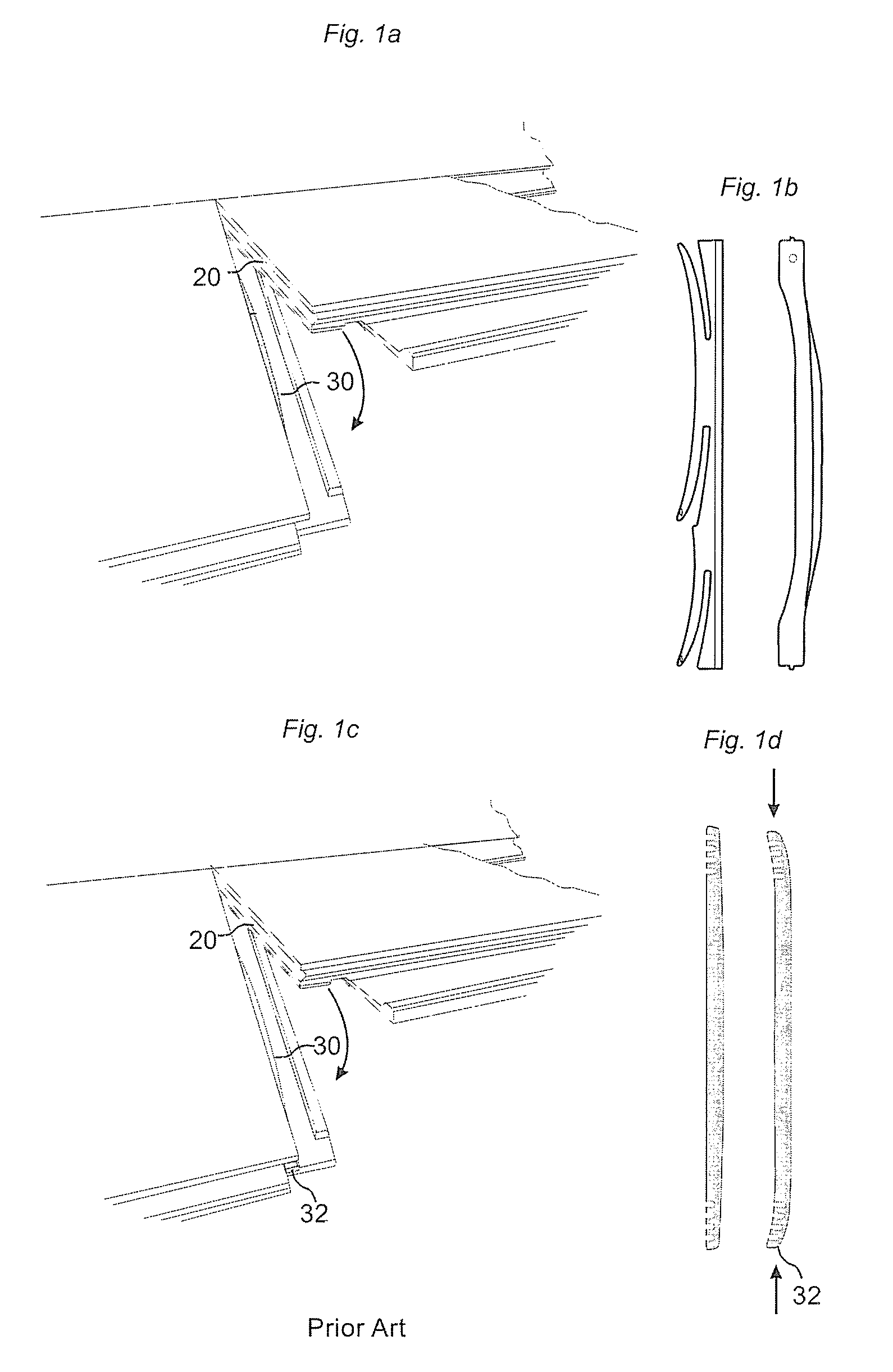

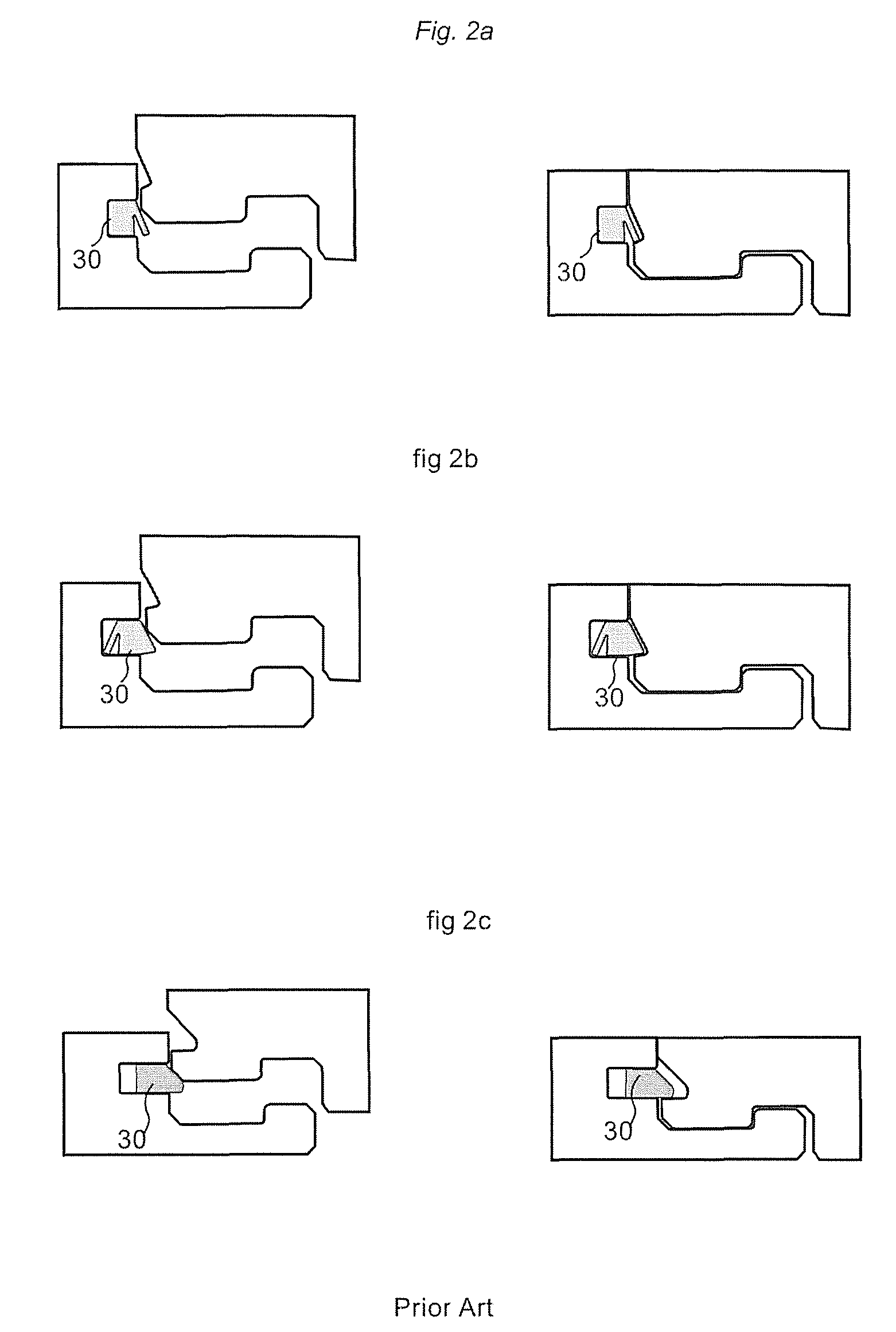

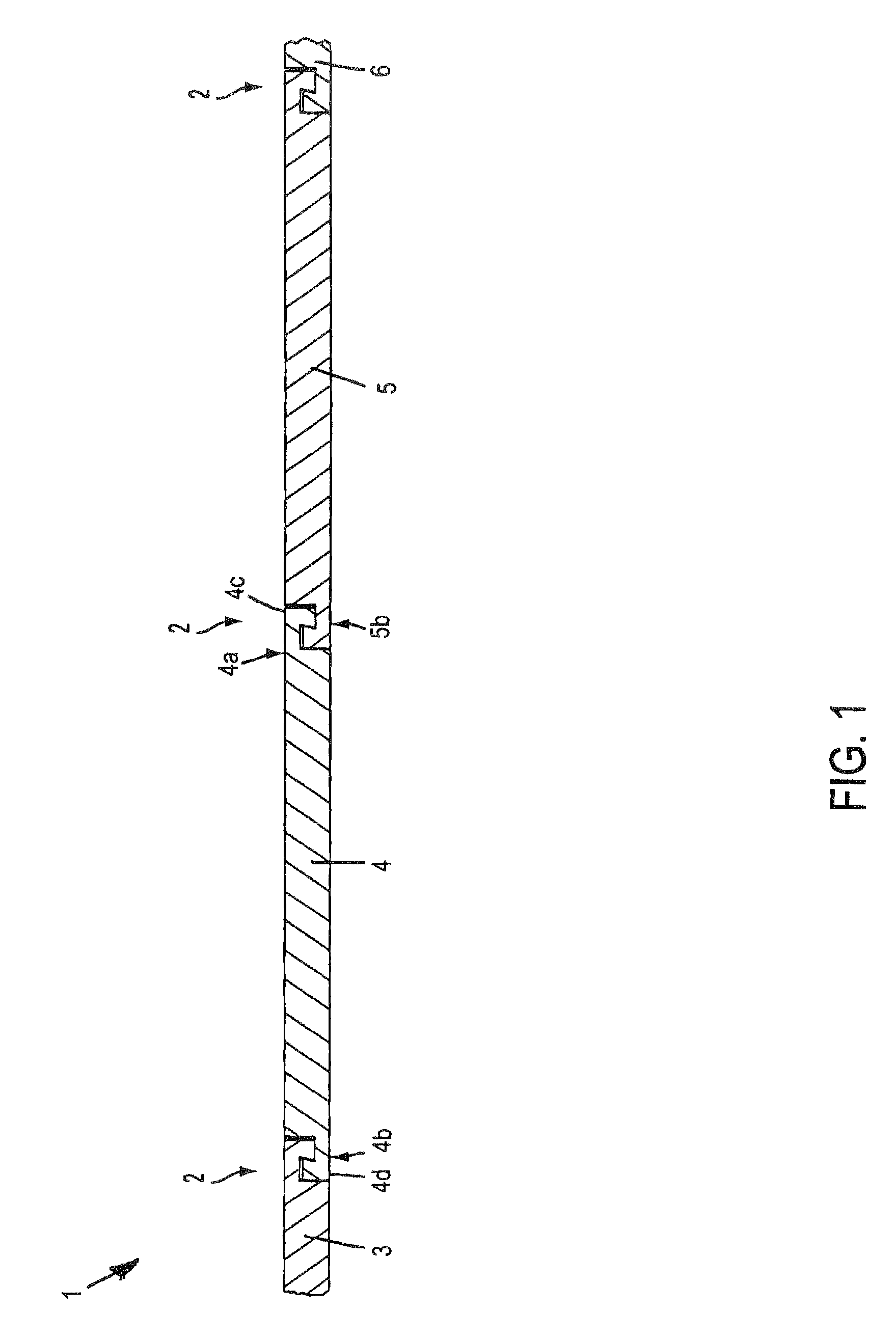

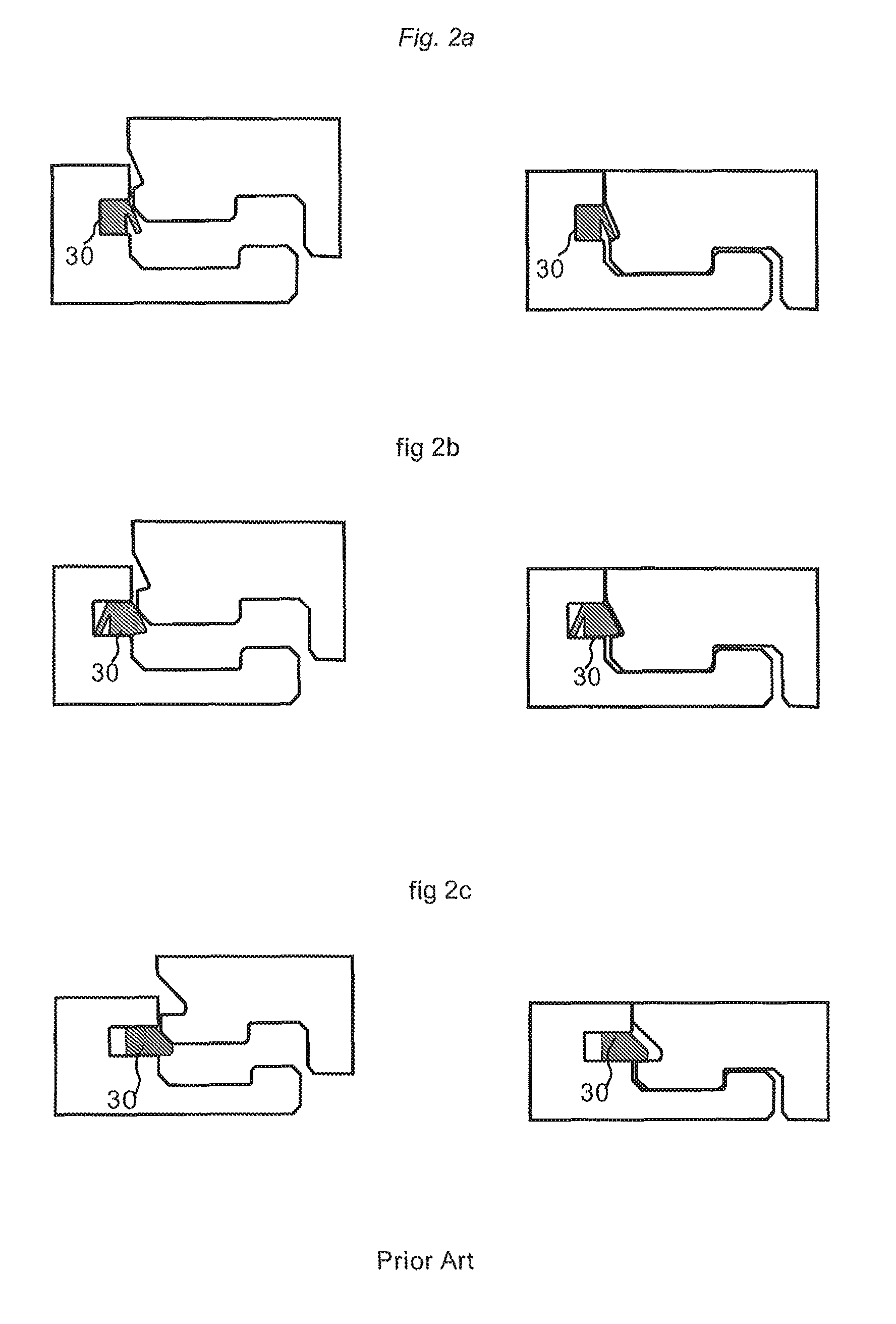

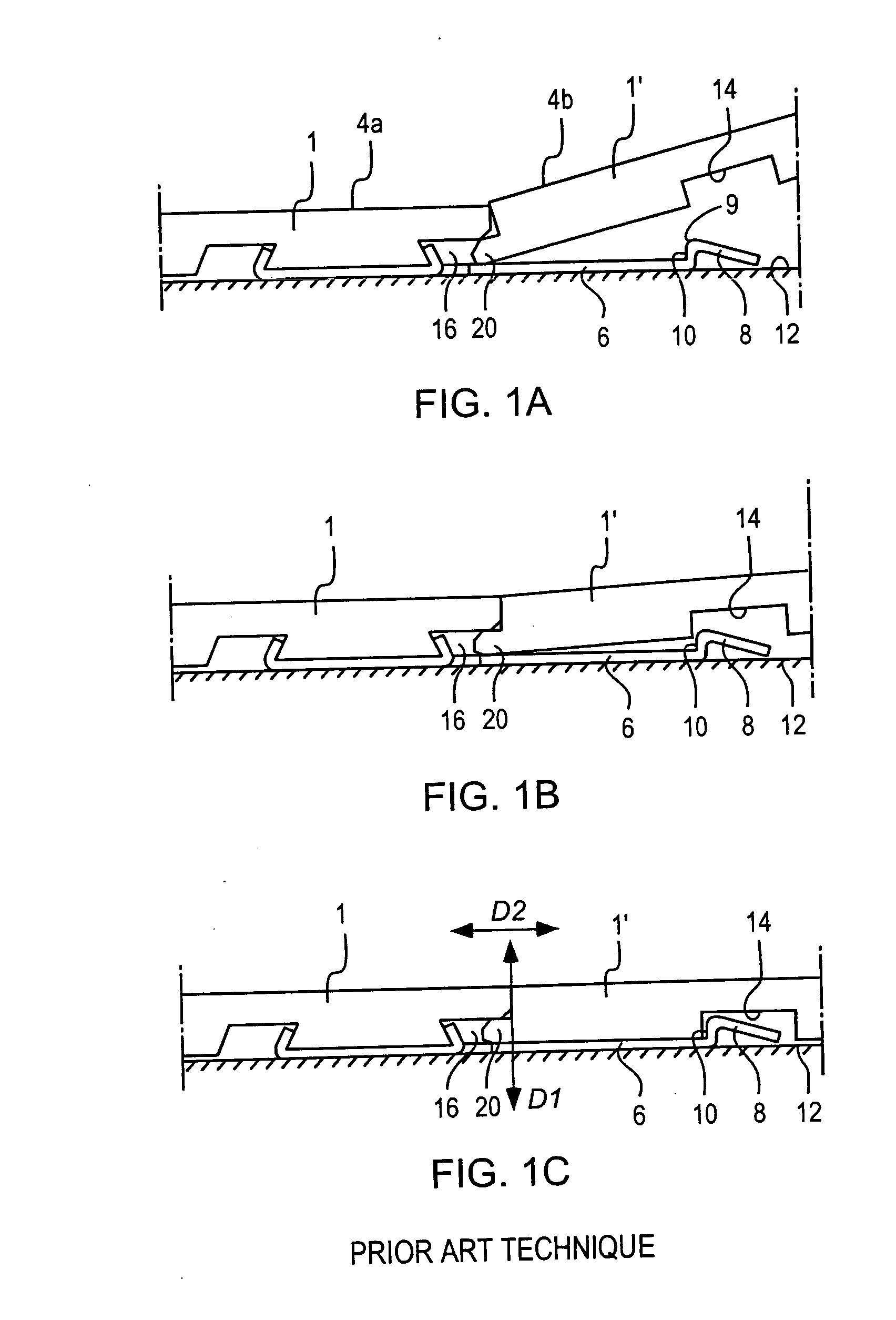

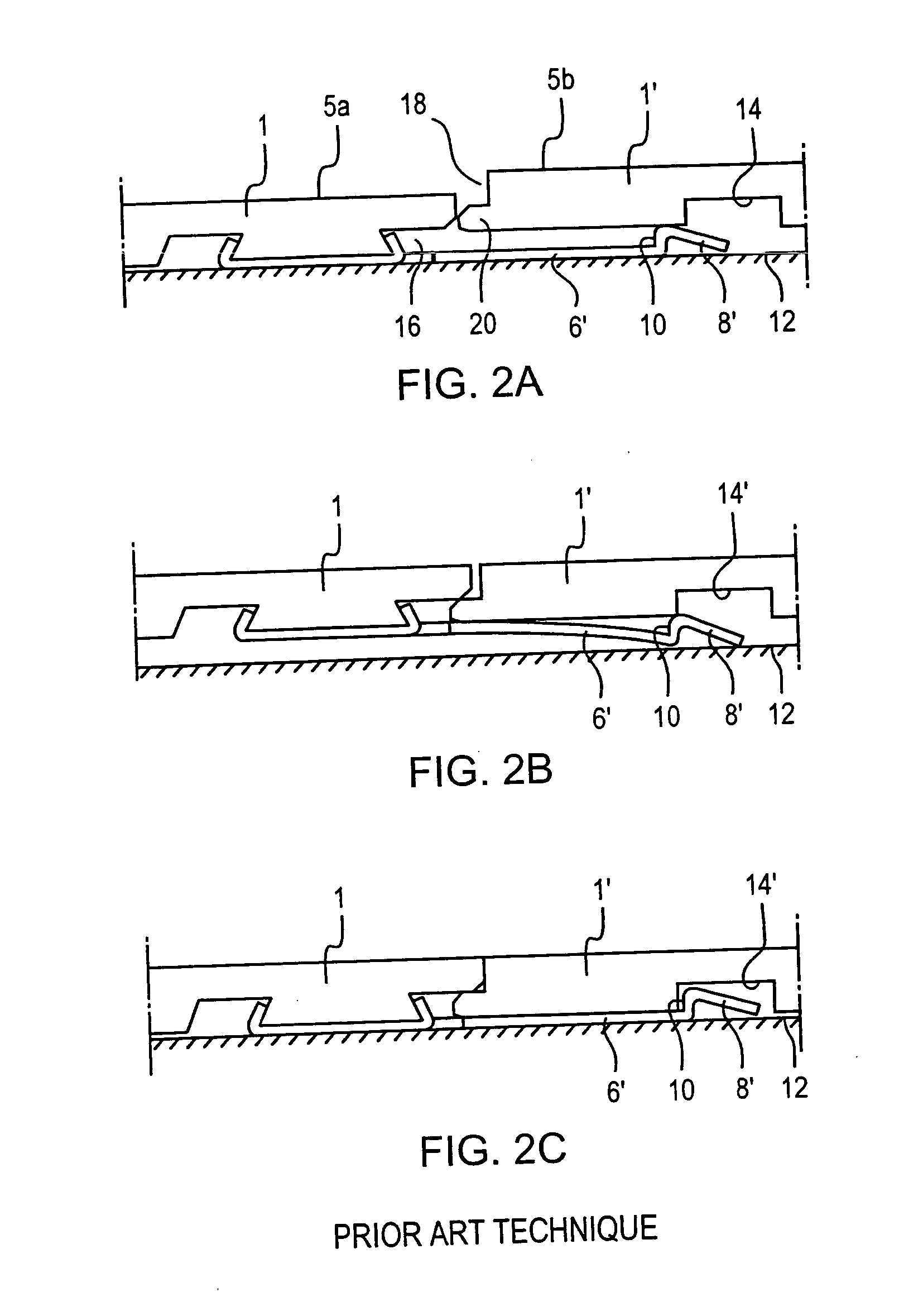

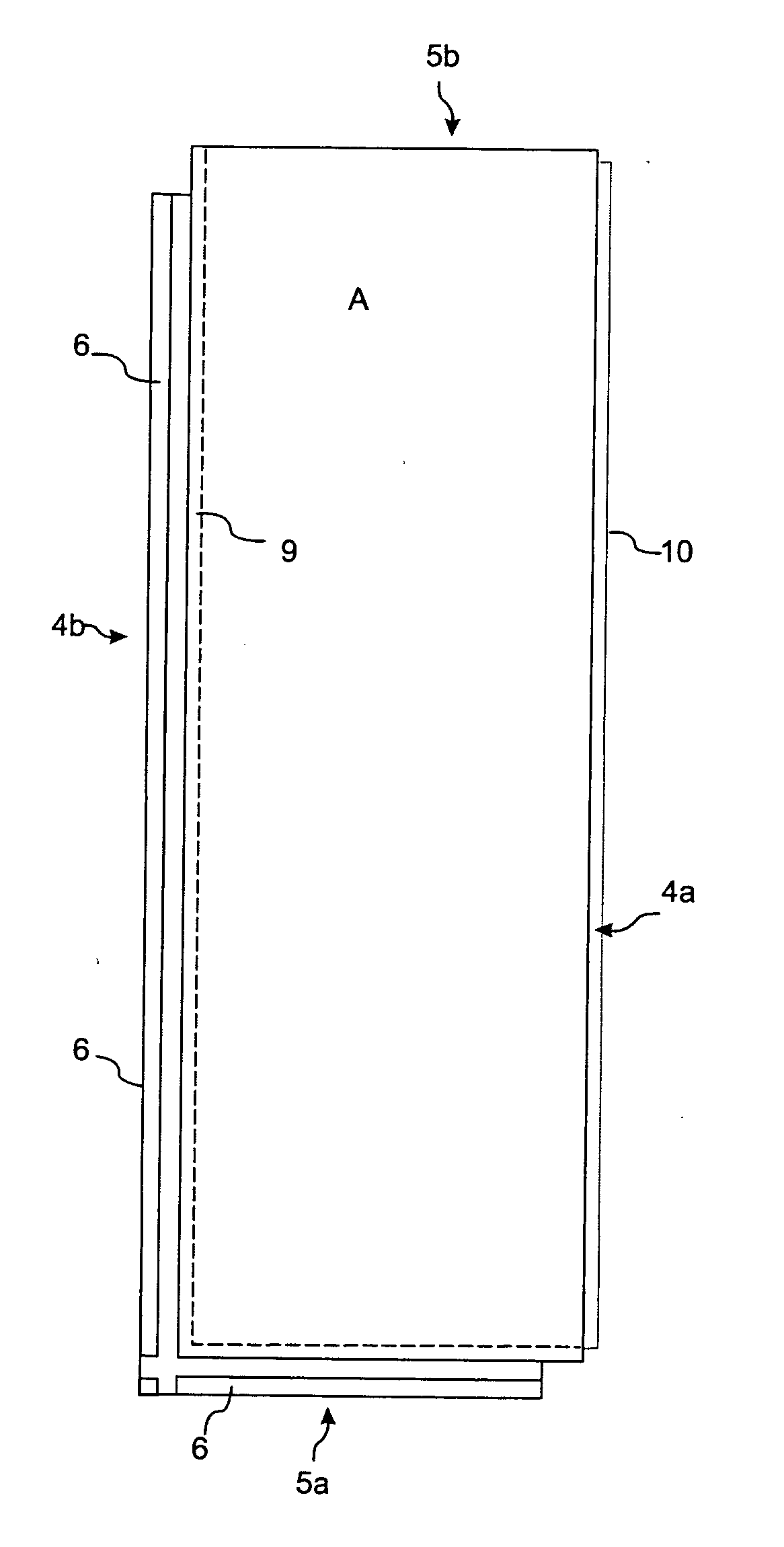

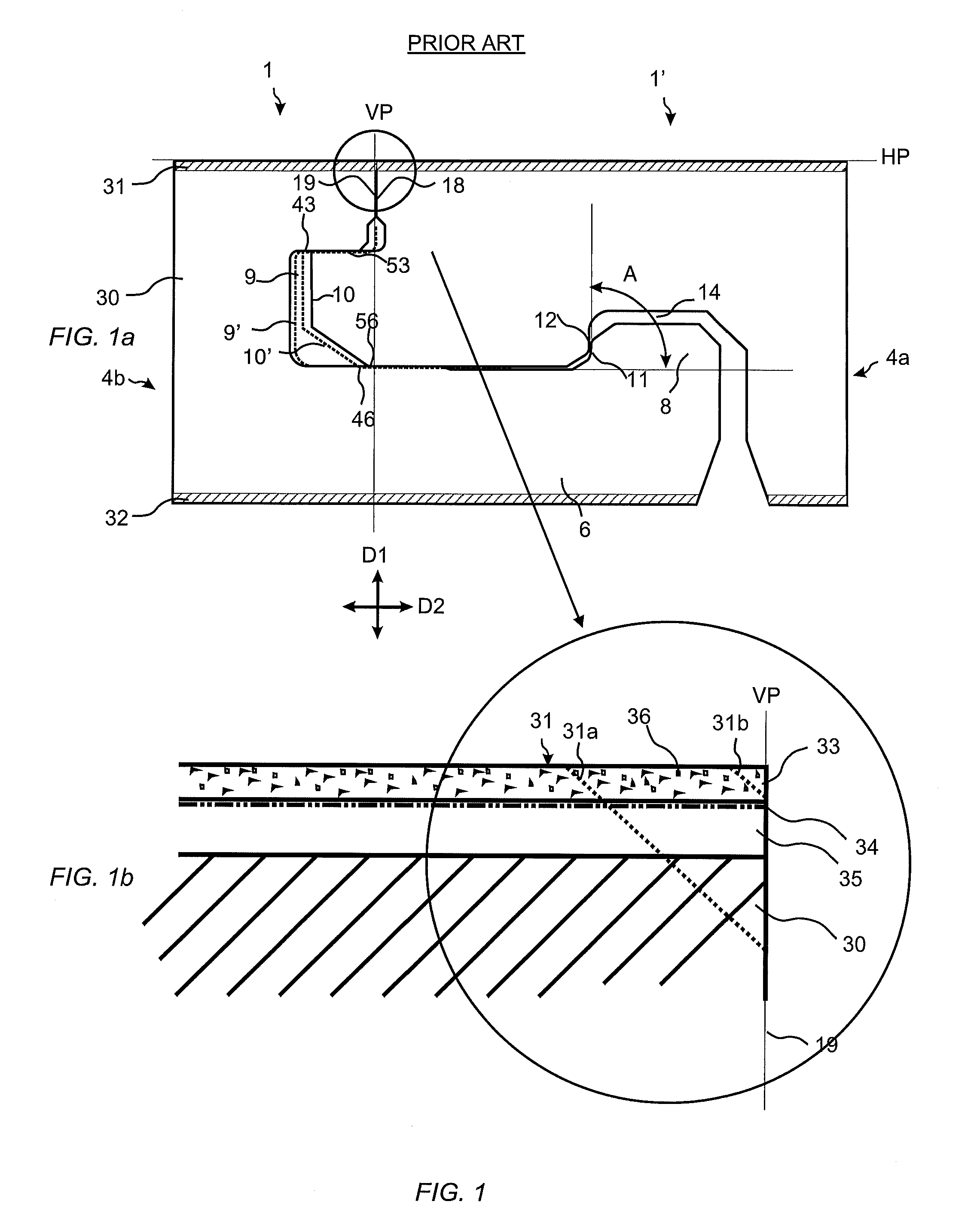

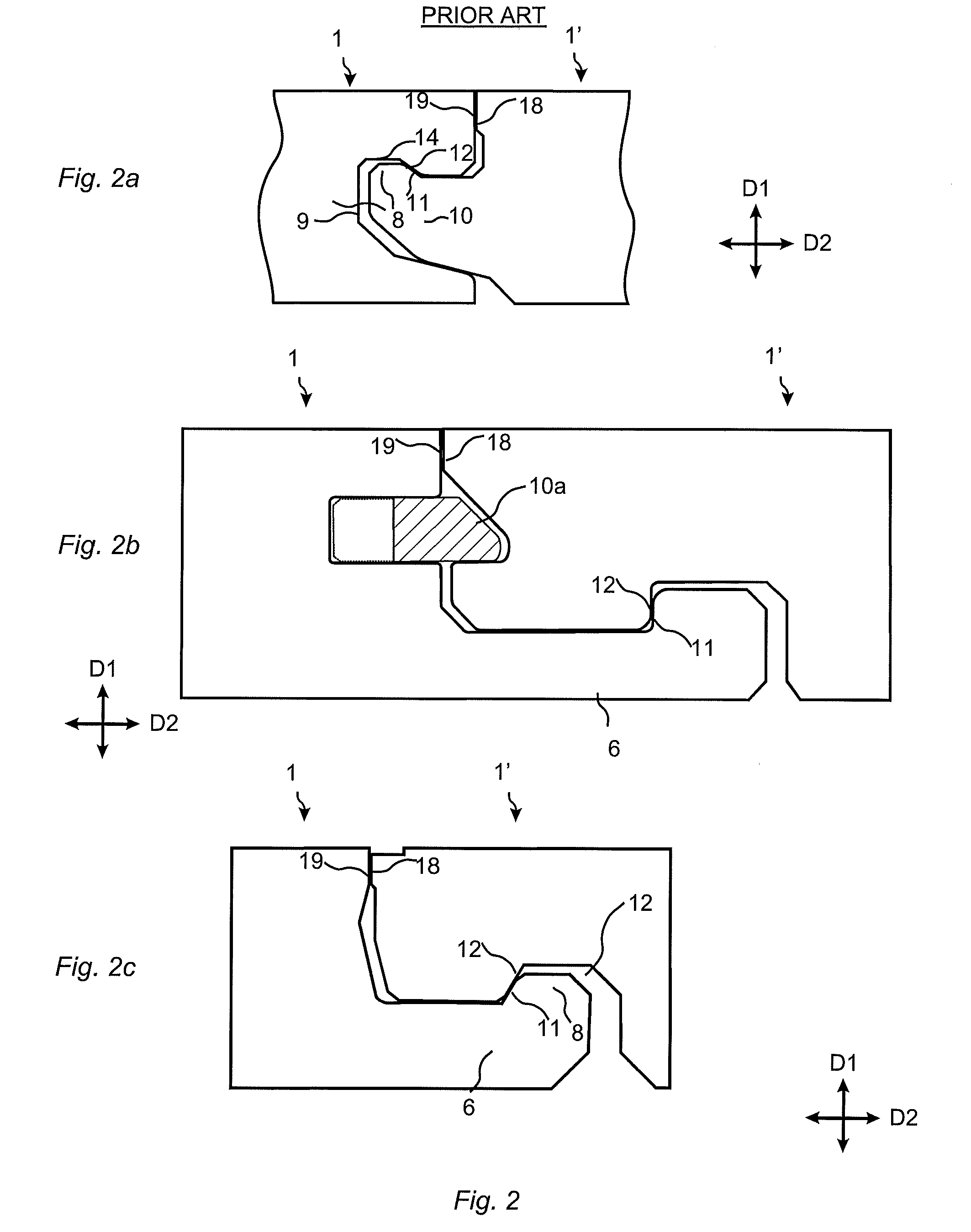

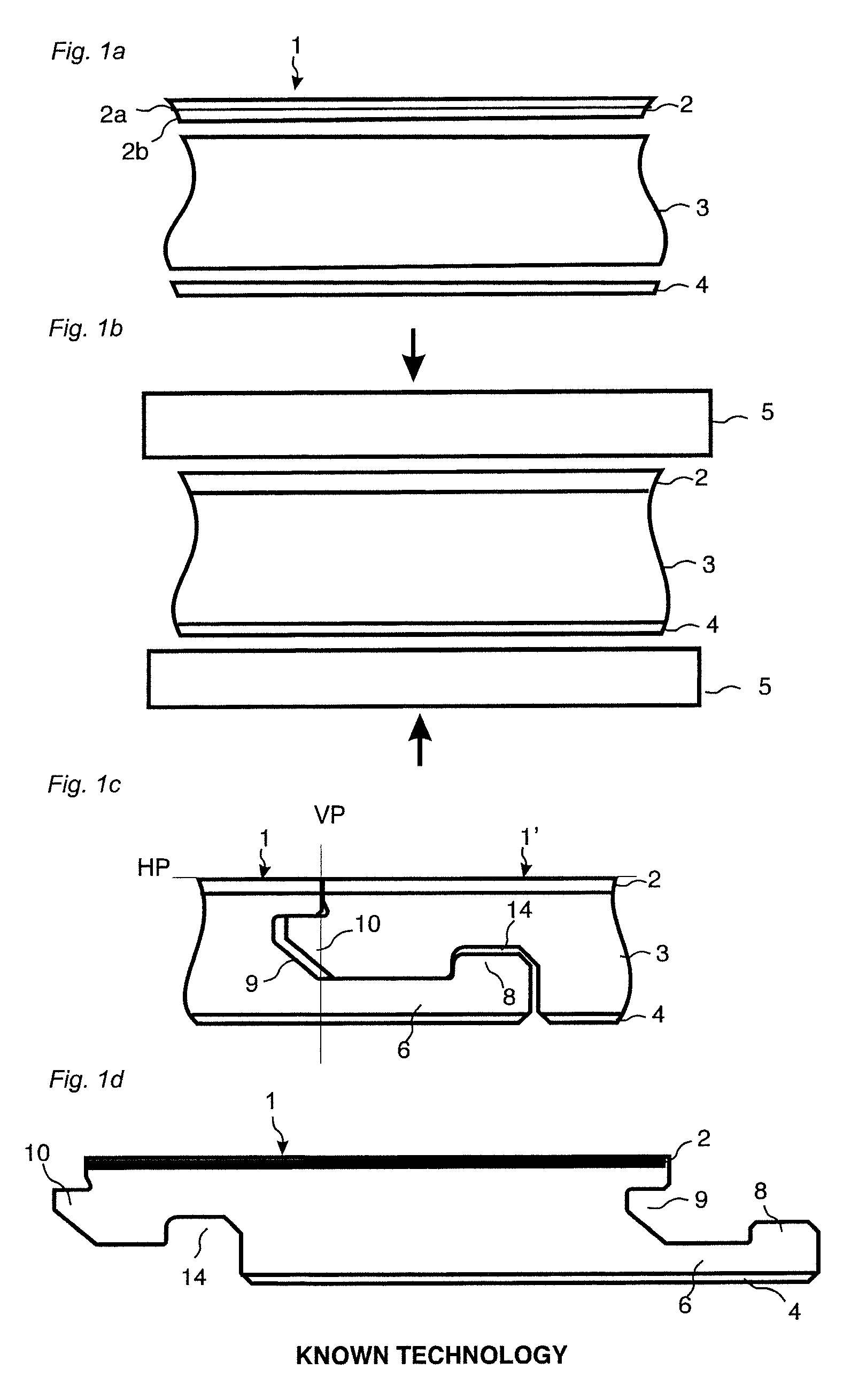

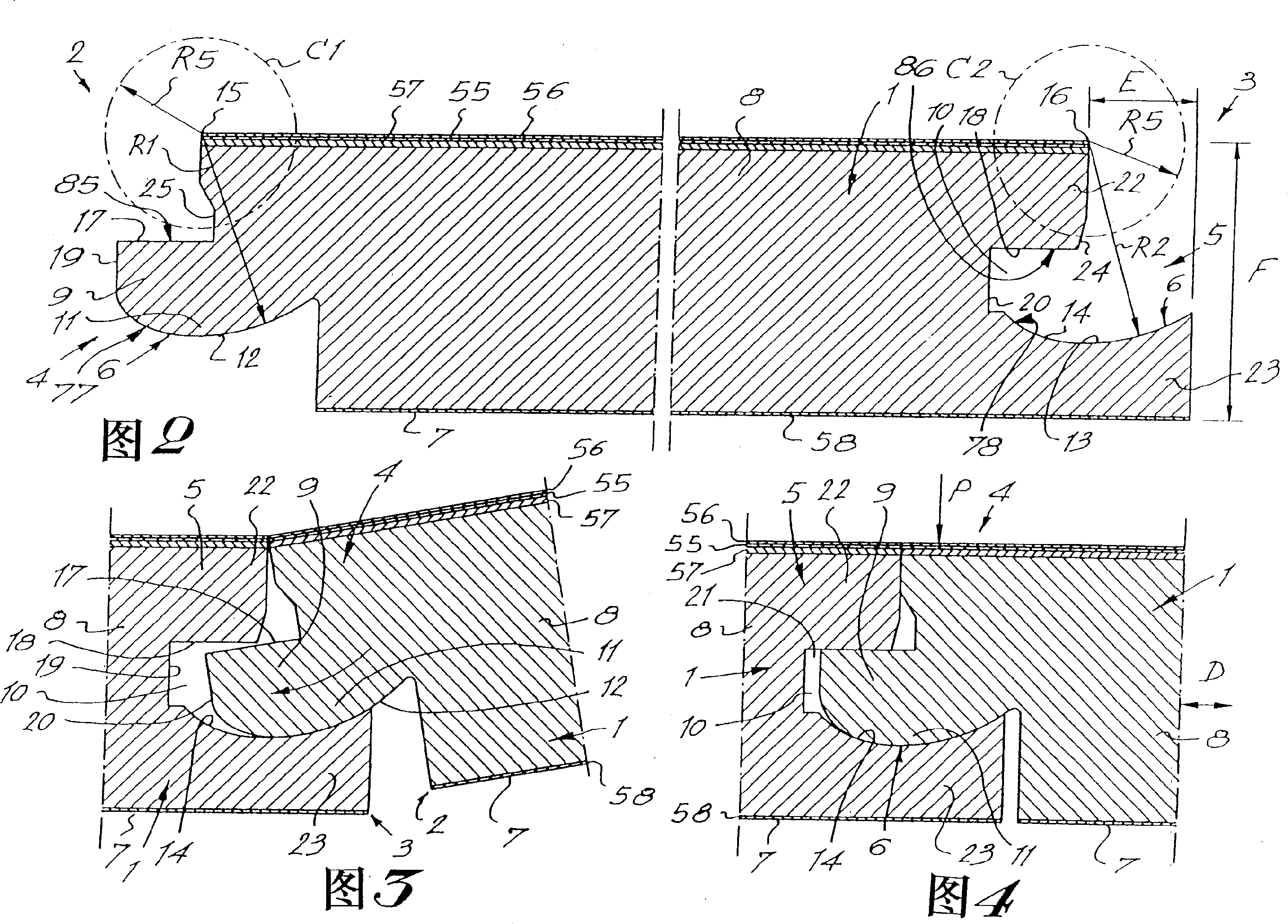

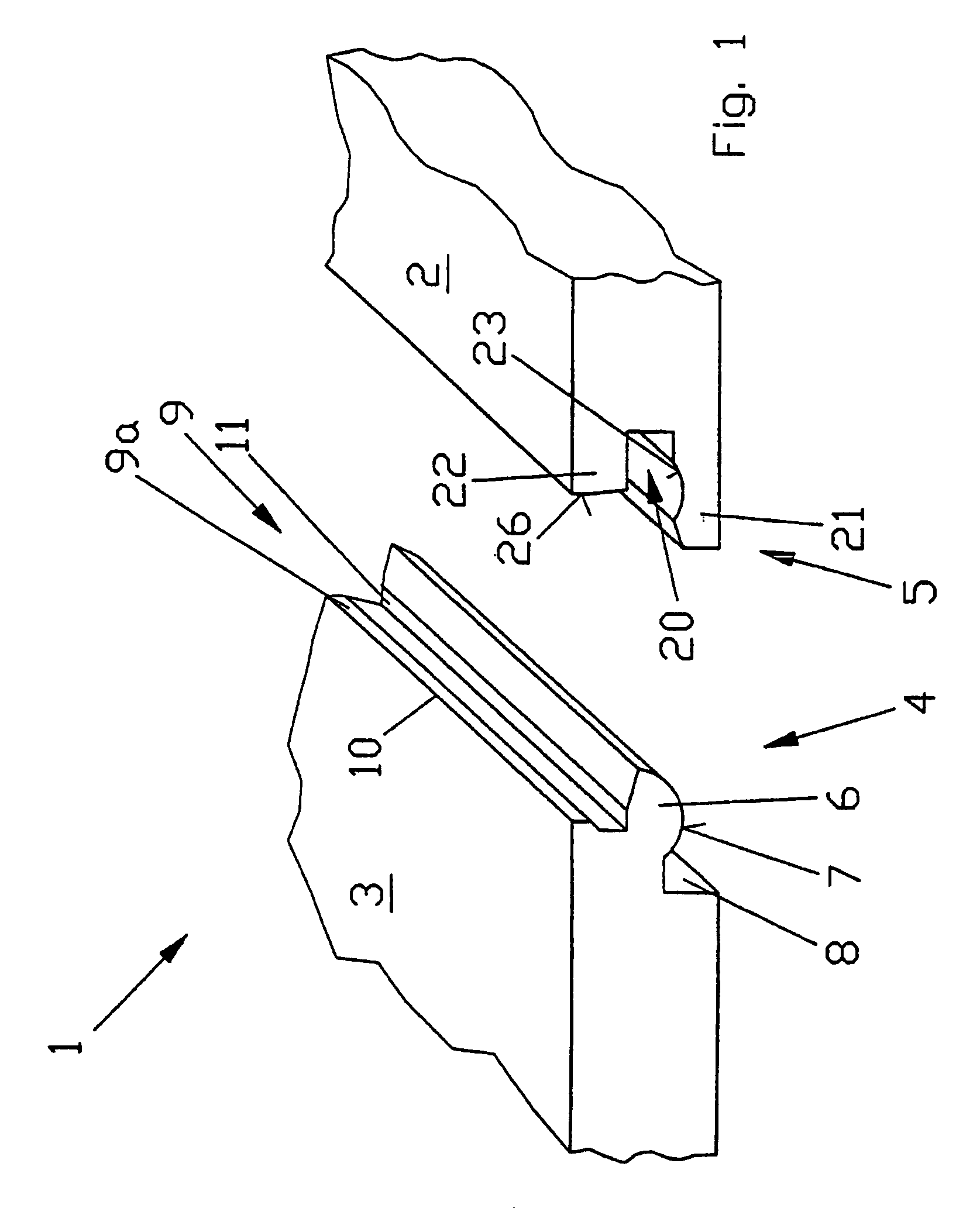

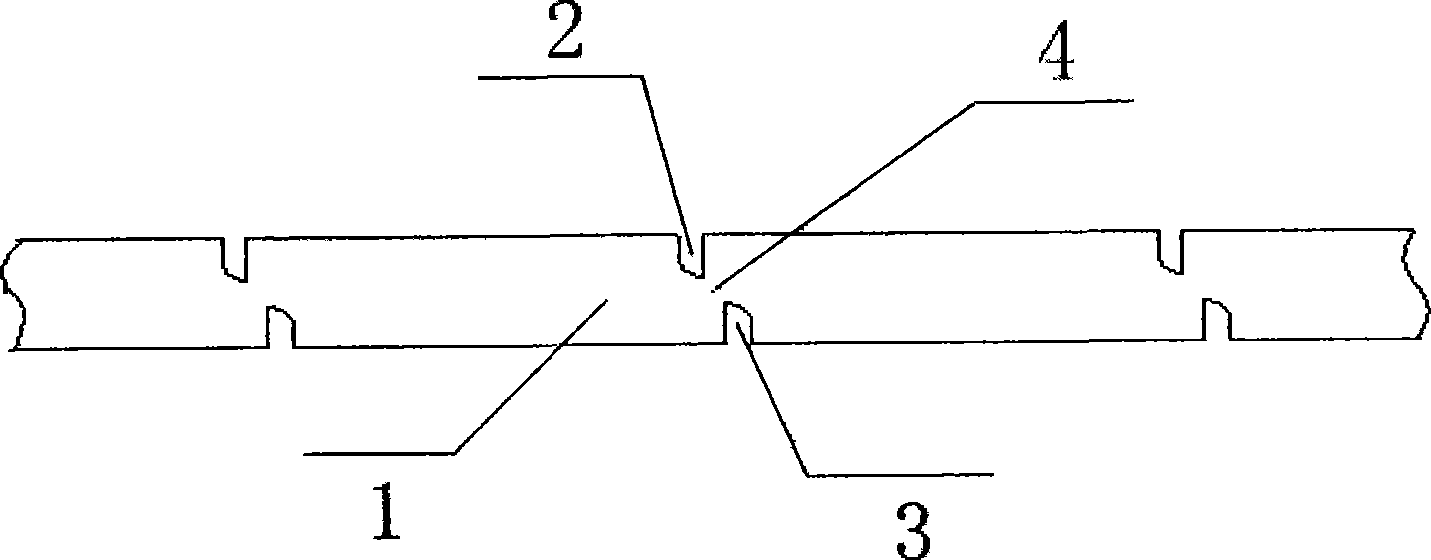

Mechanical locking system for floorboards

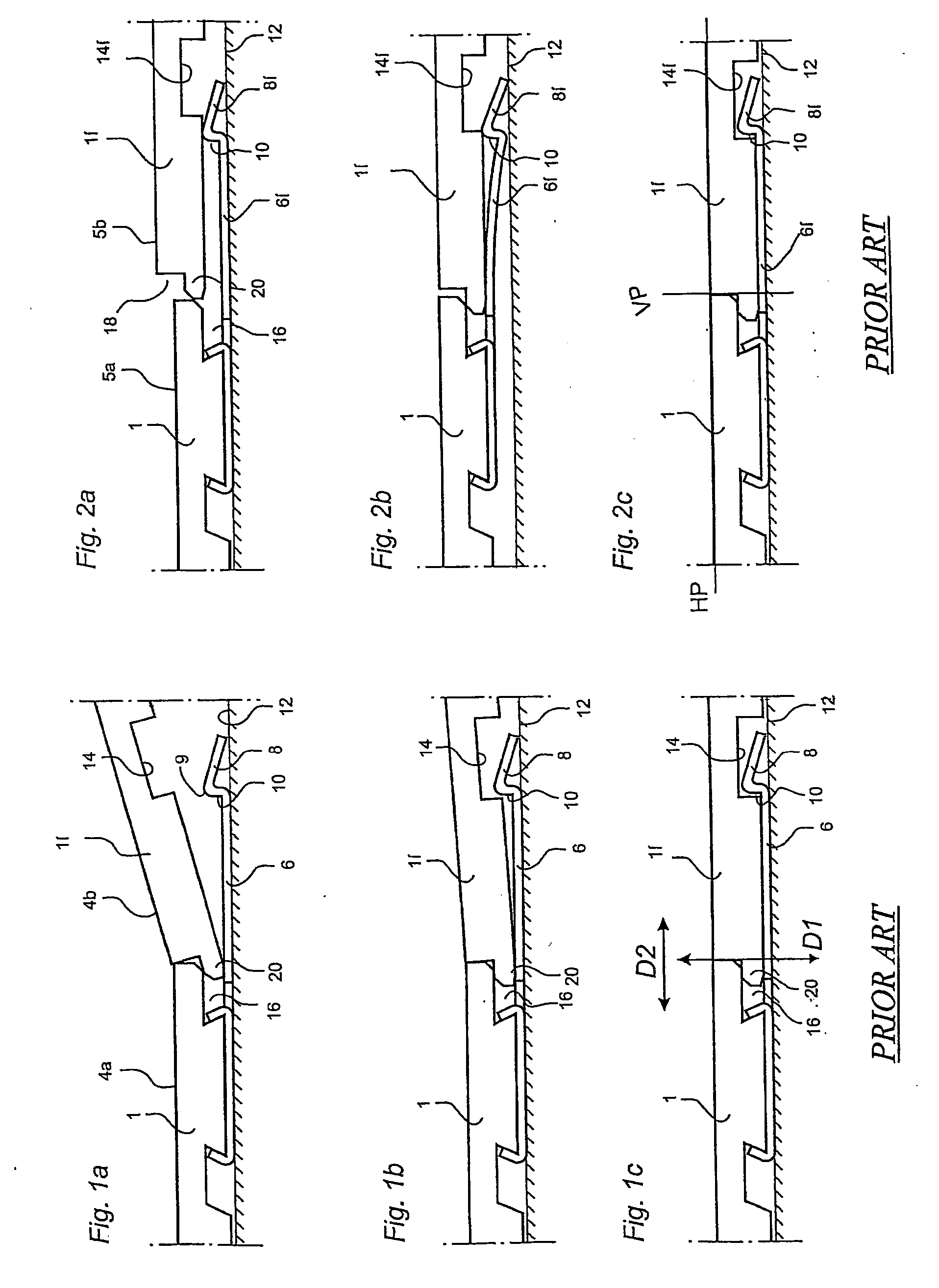

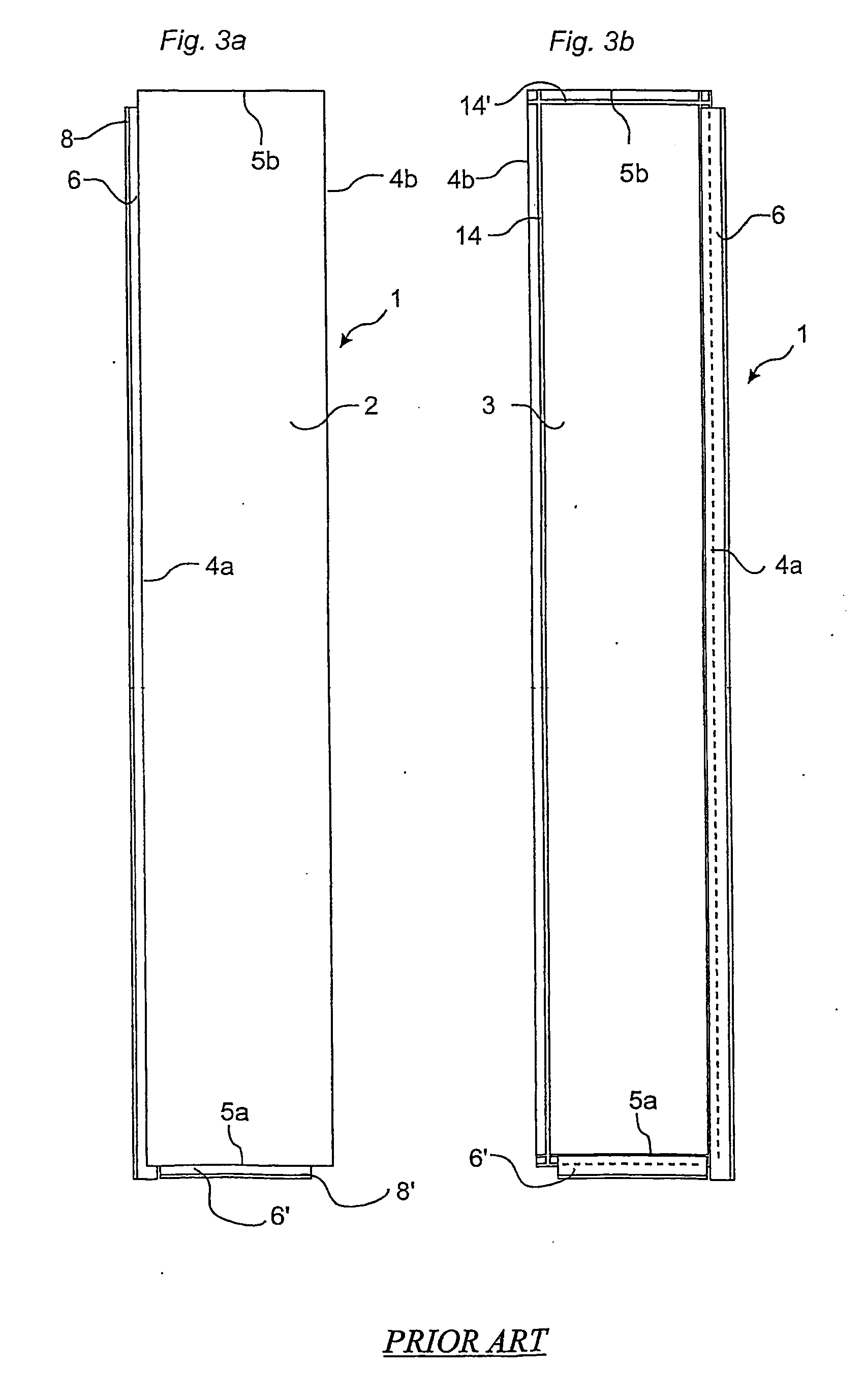

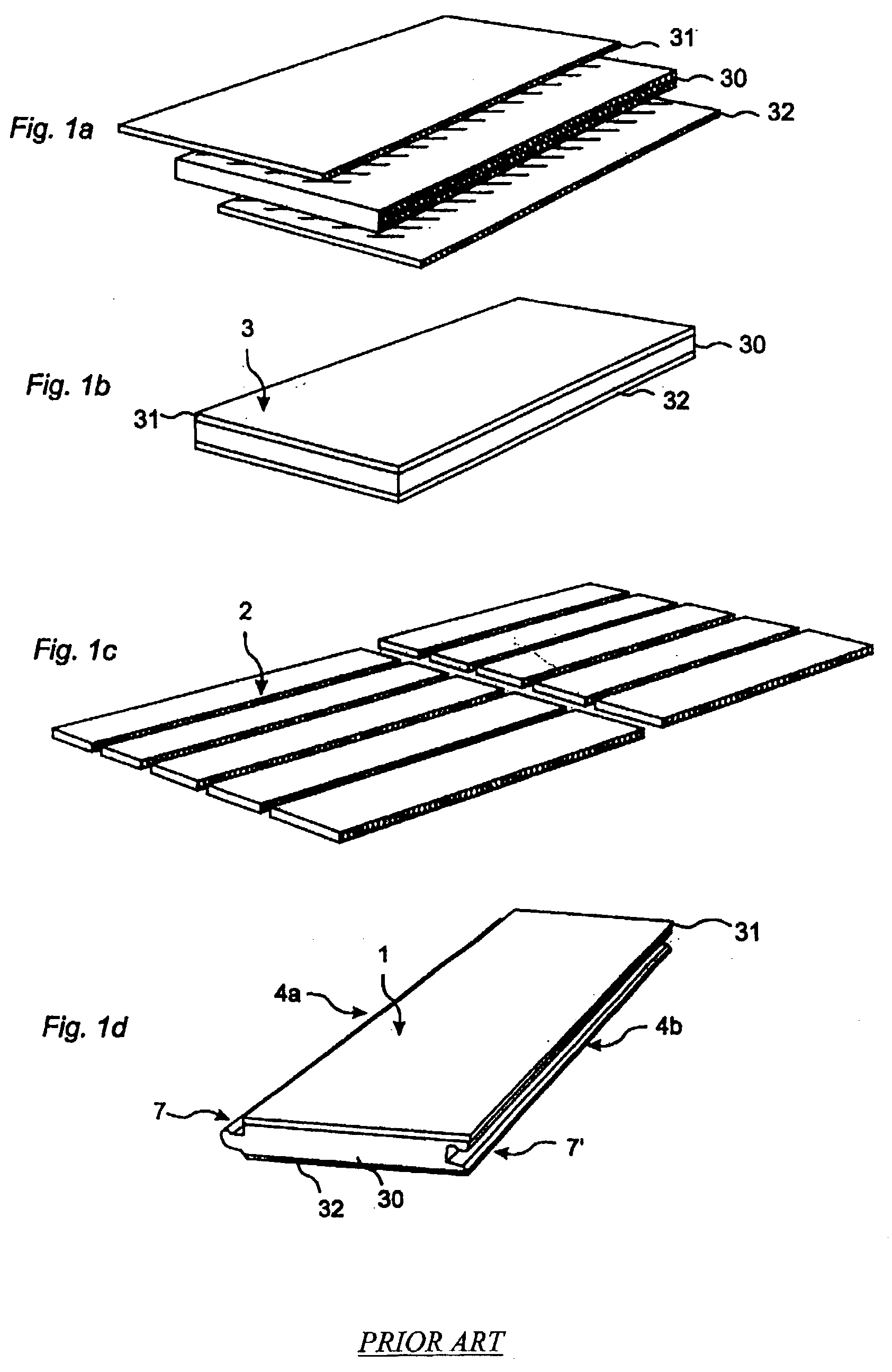

InactiveUS20060070333A1High strength requirementsCost advantageTongue/grooves making apparatusWallsEngineeringMechanical engineering

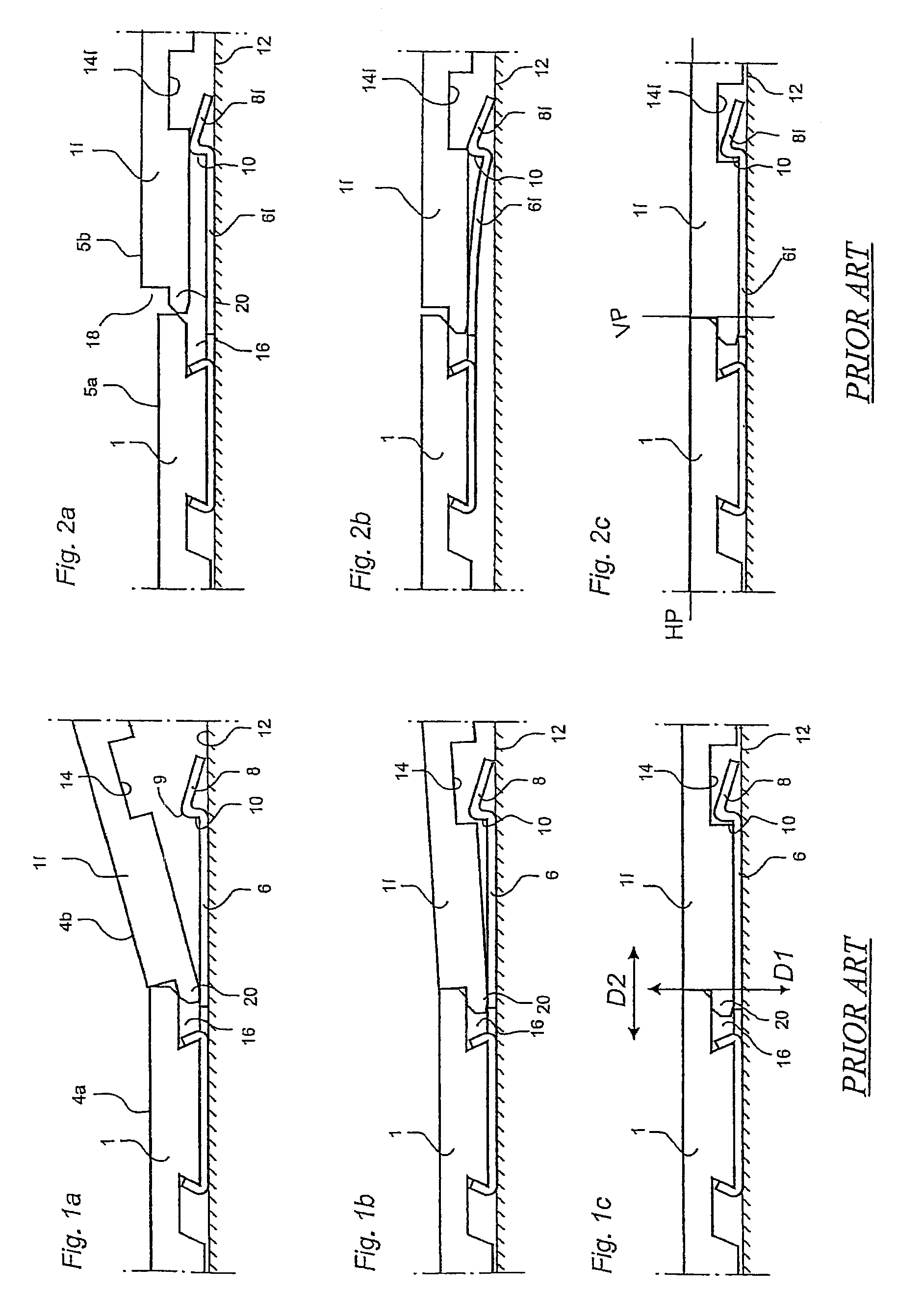

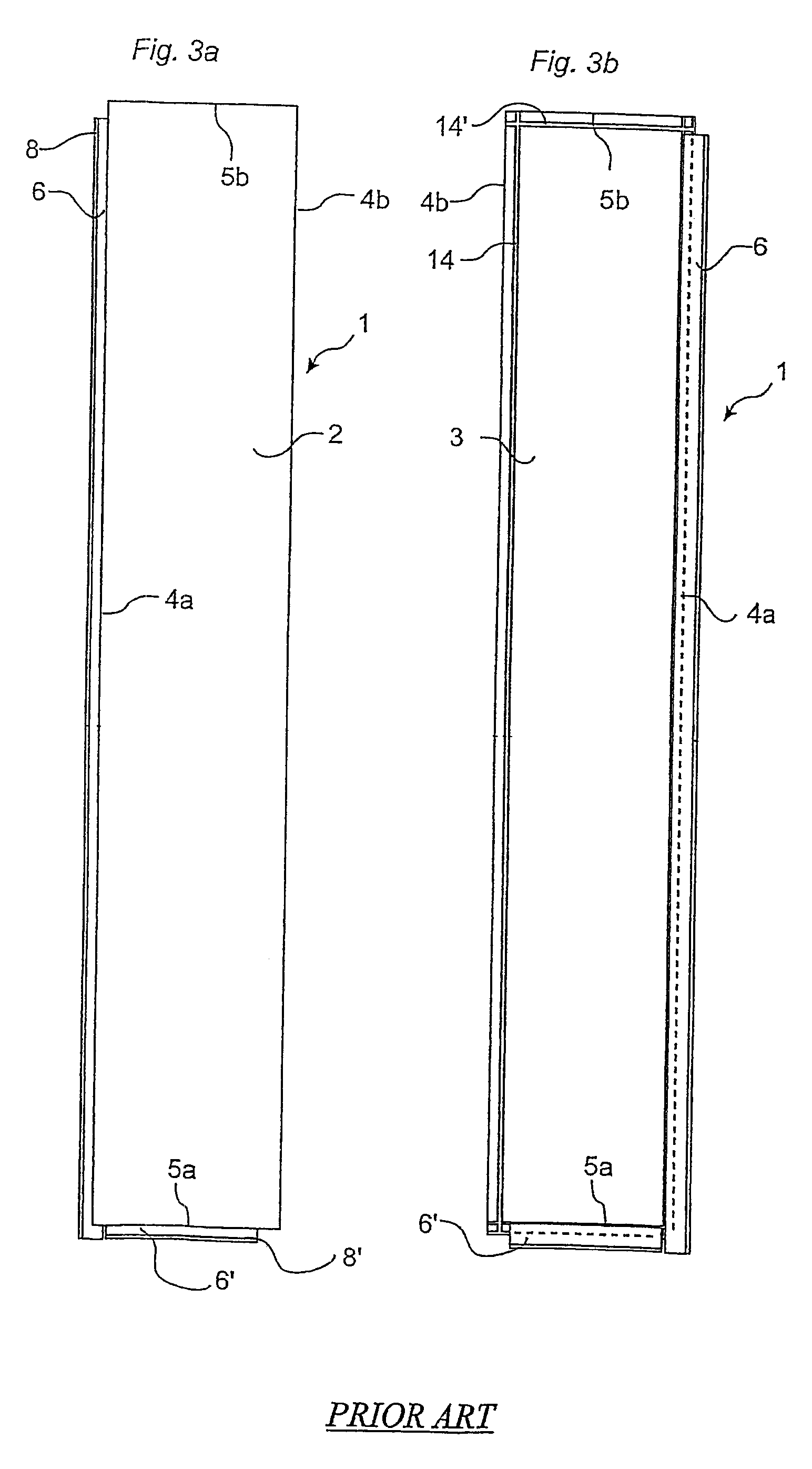

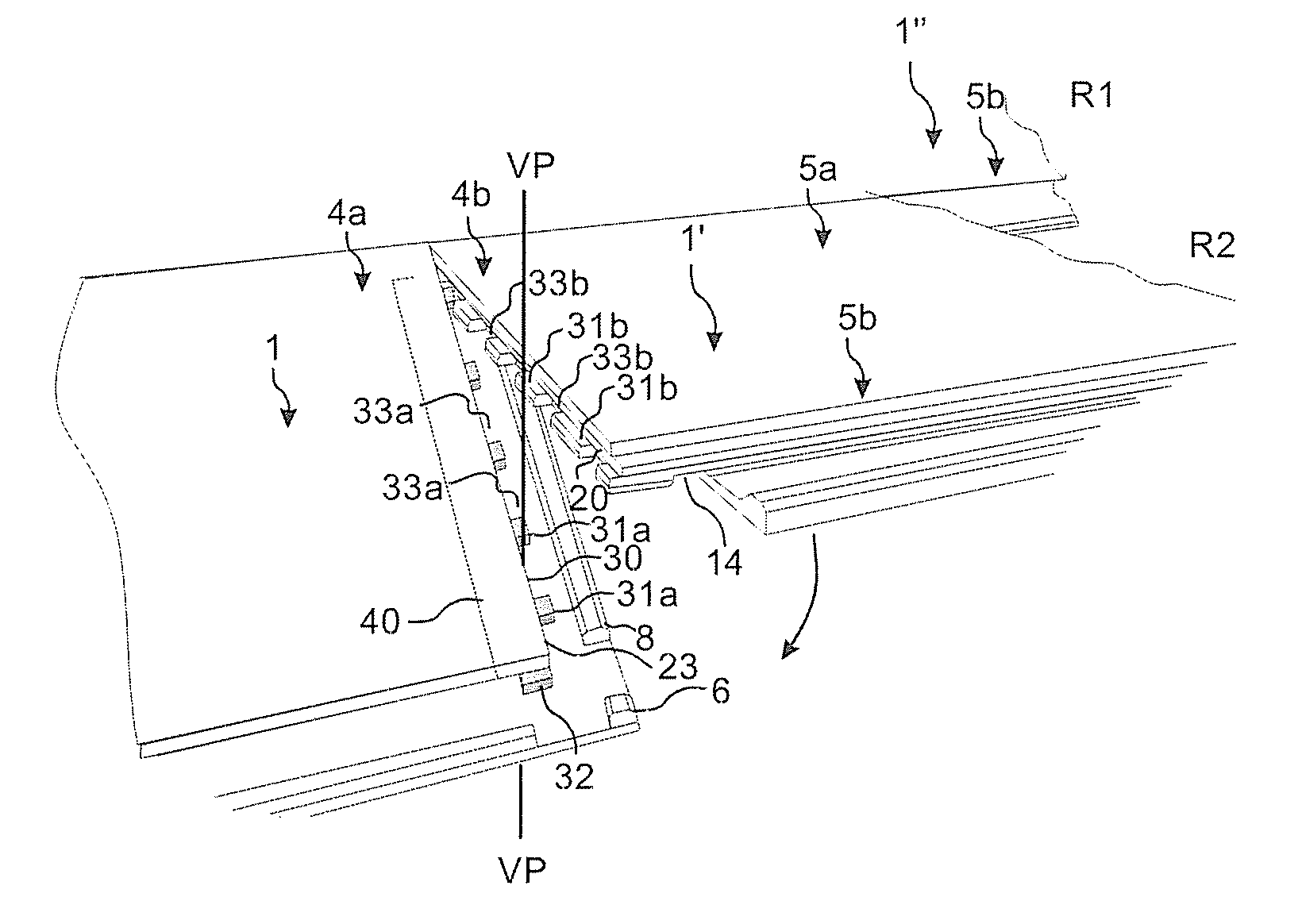

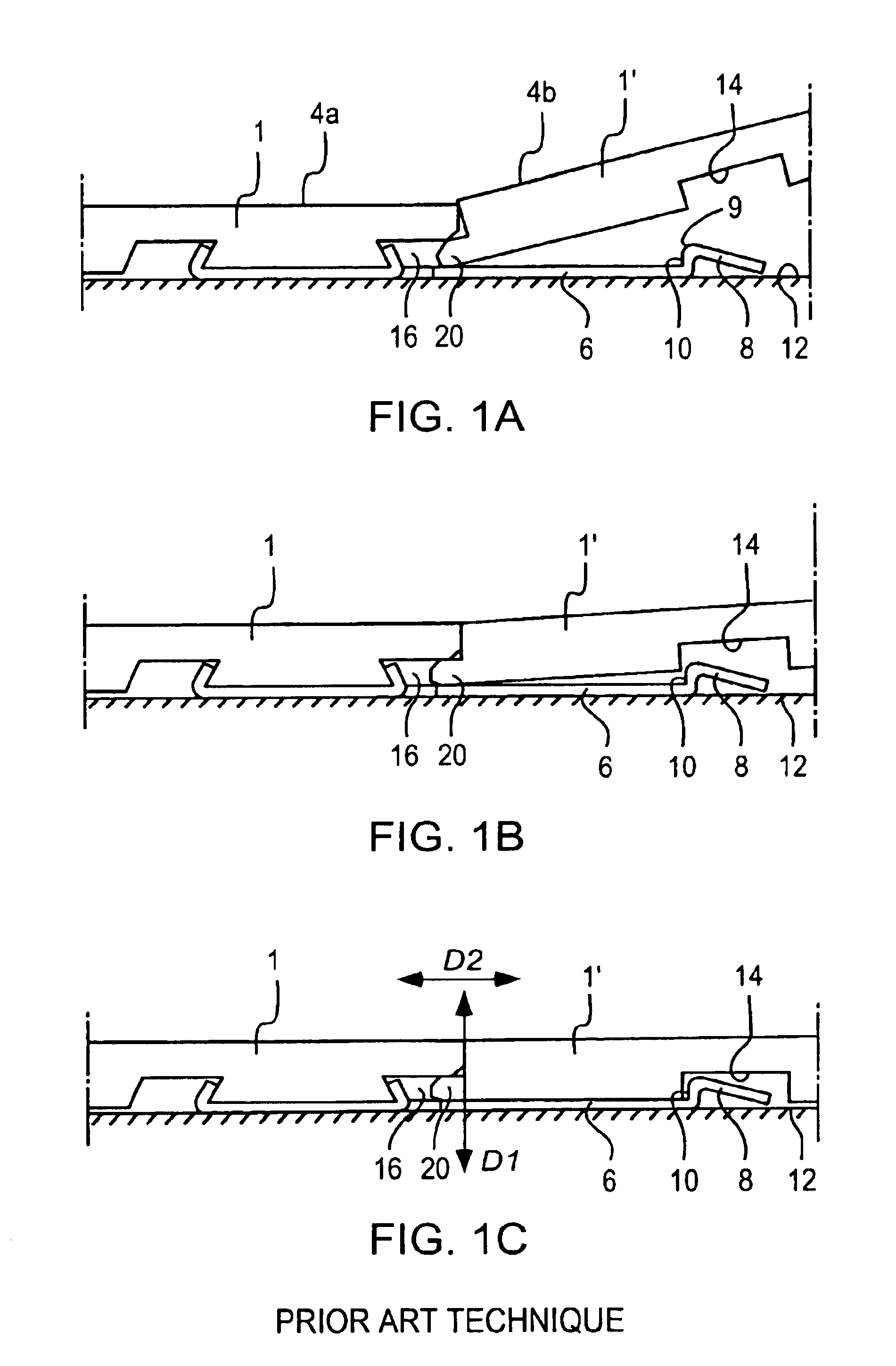

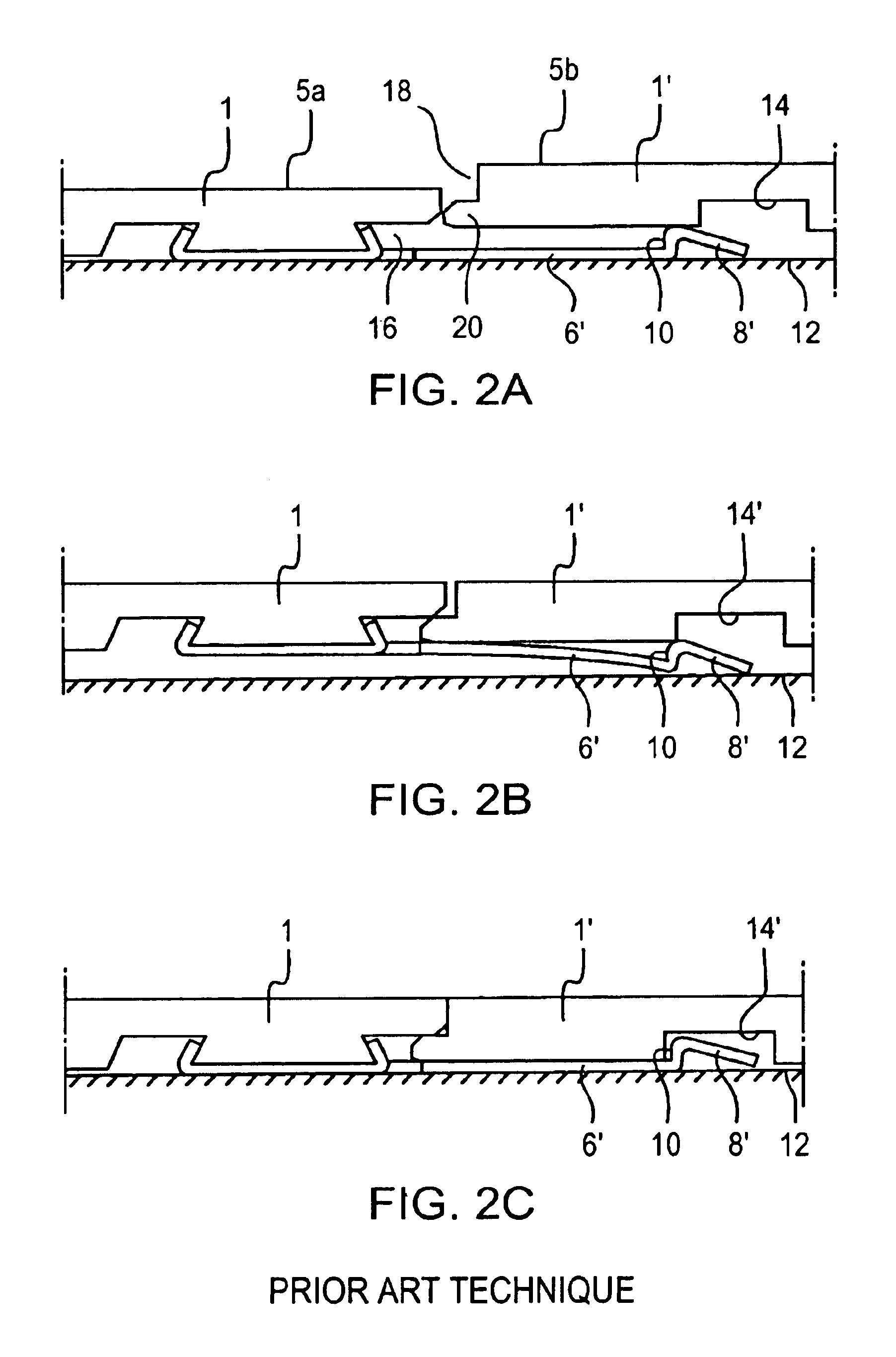

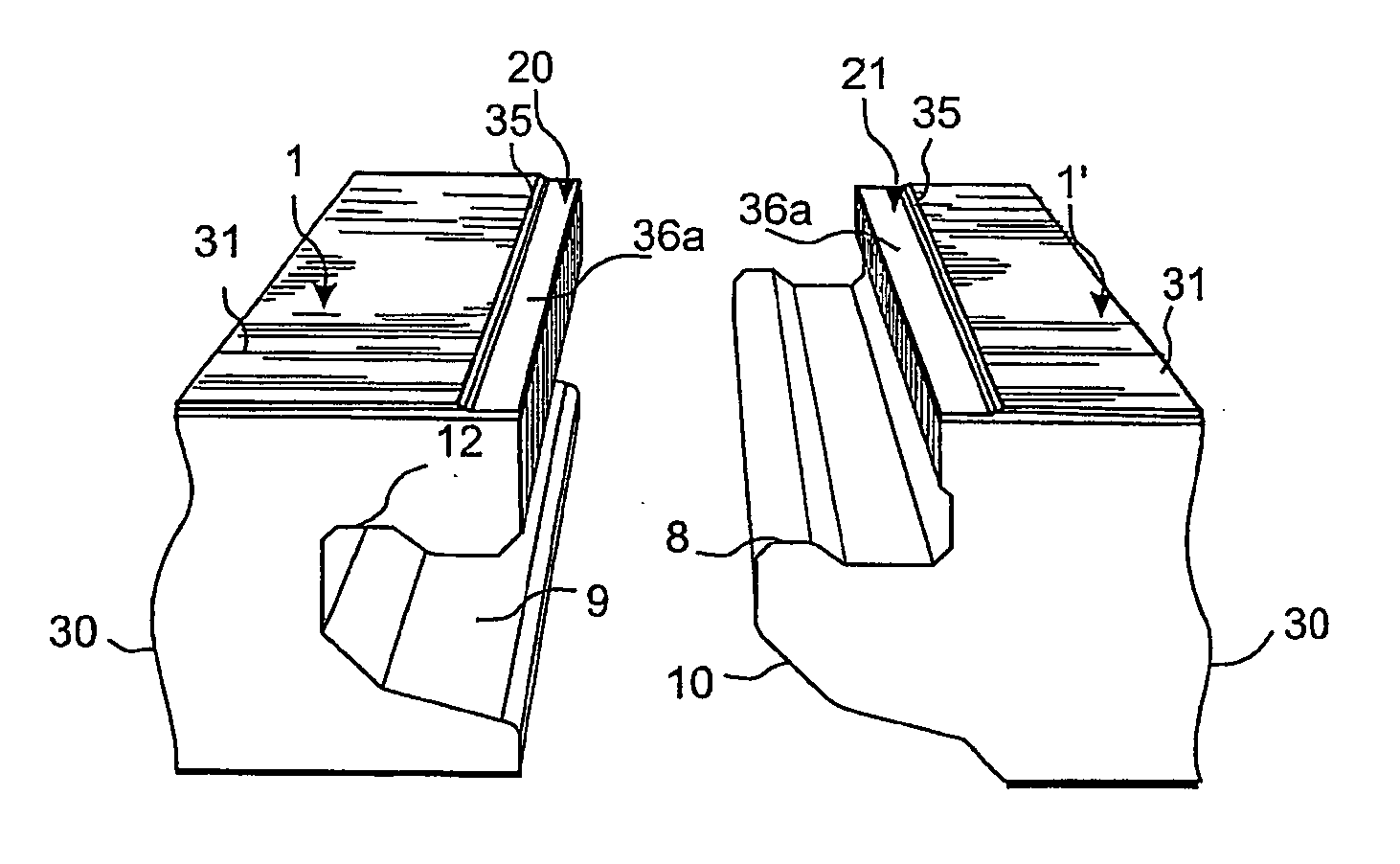

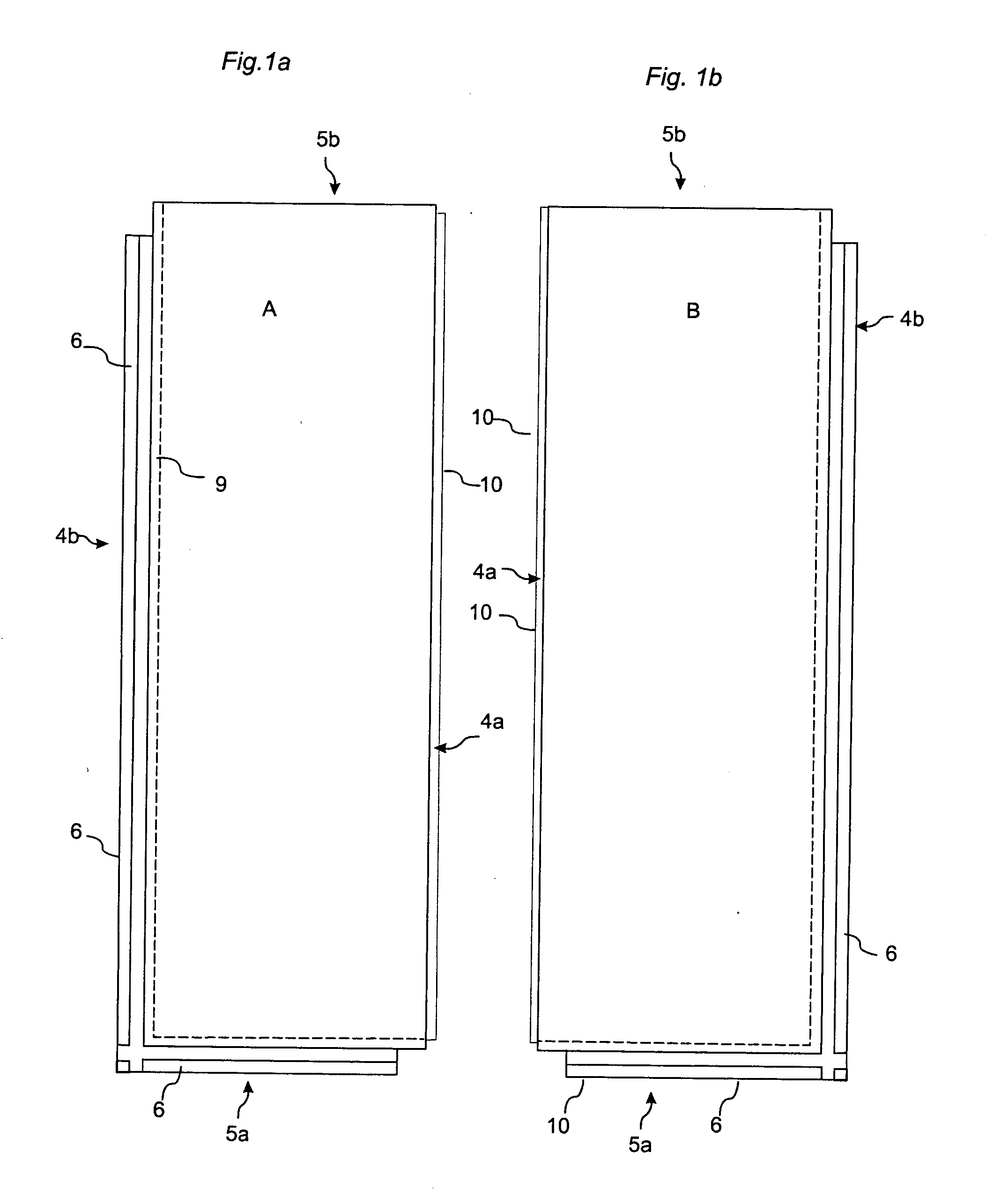

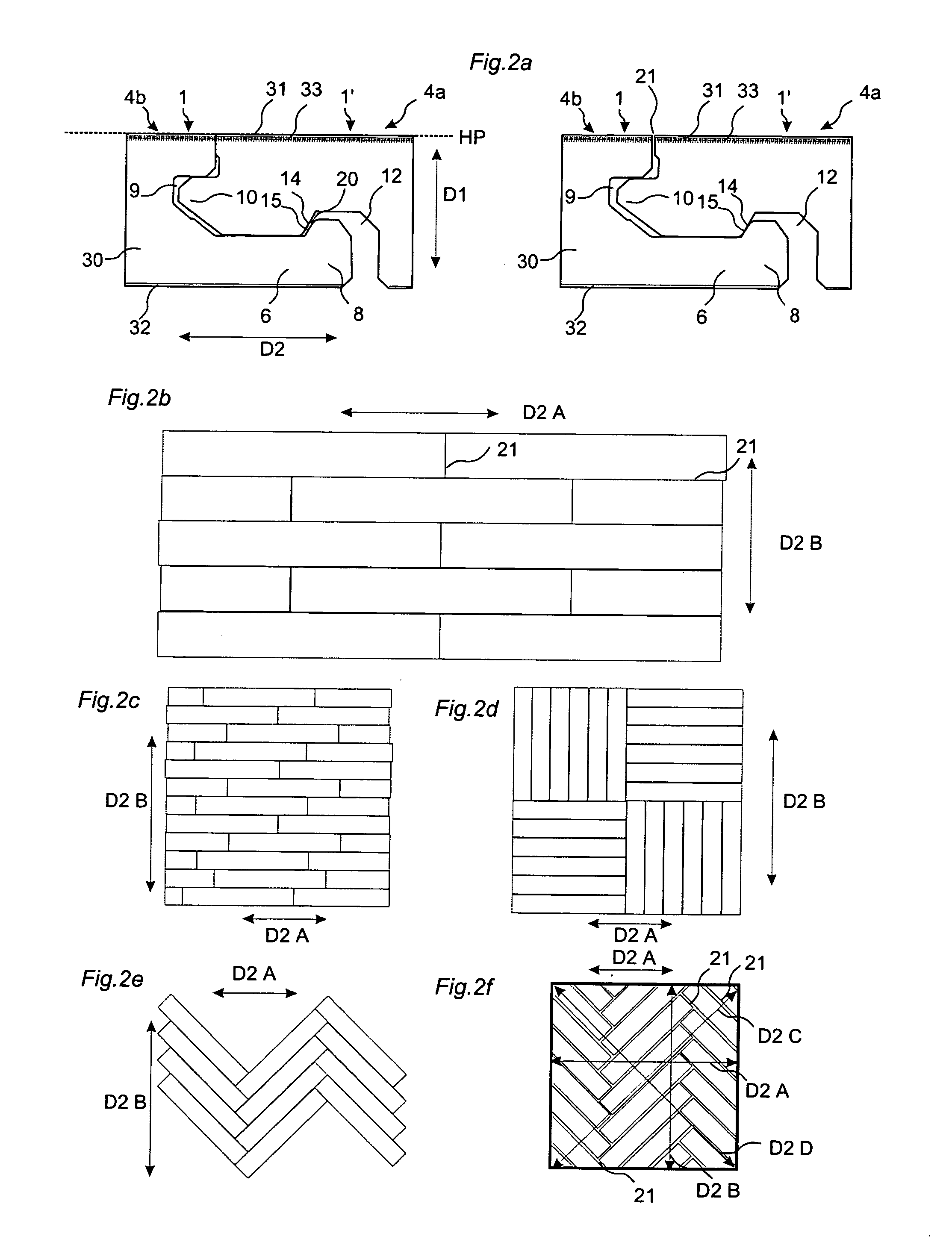

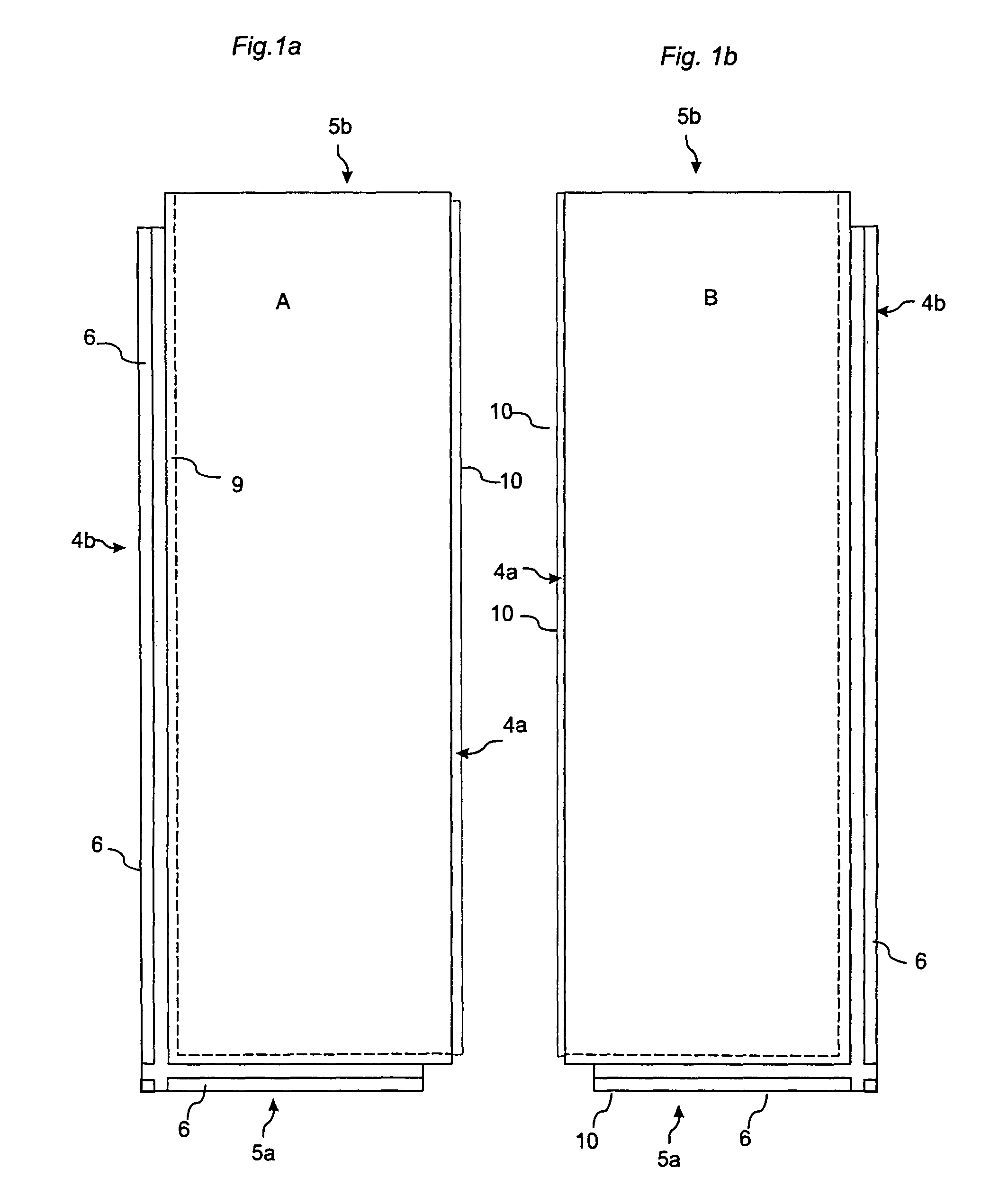

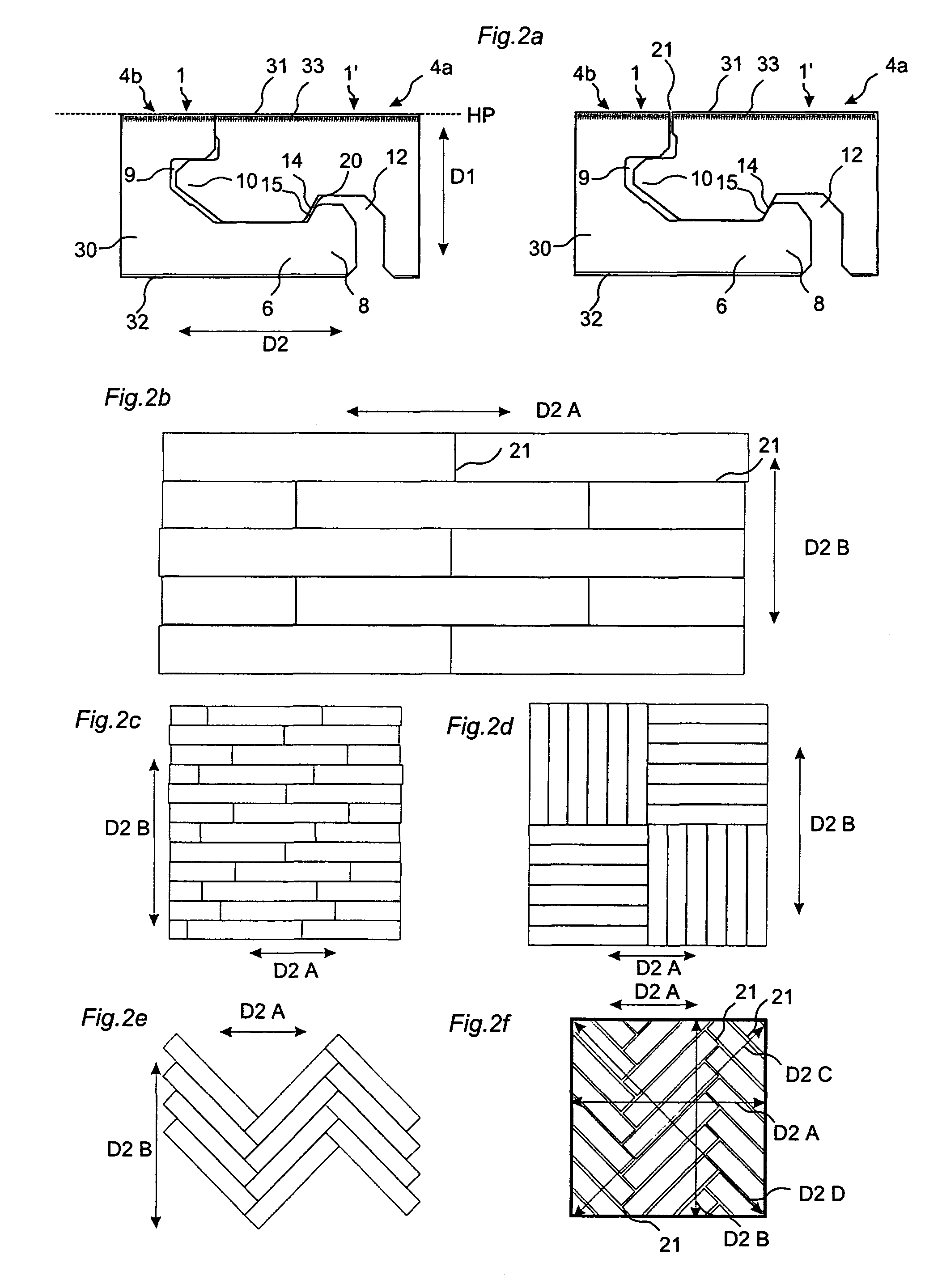

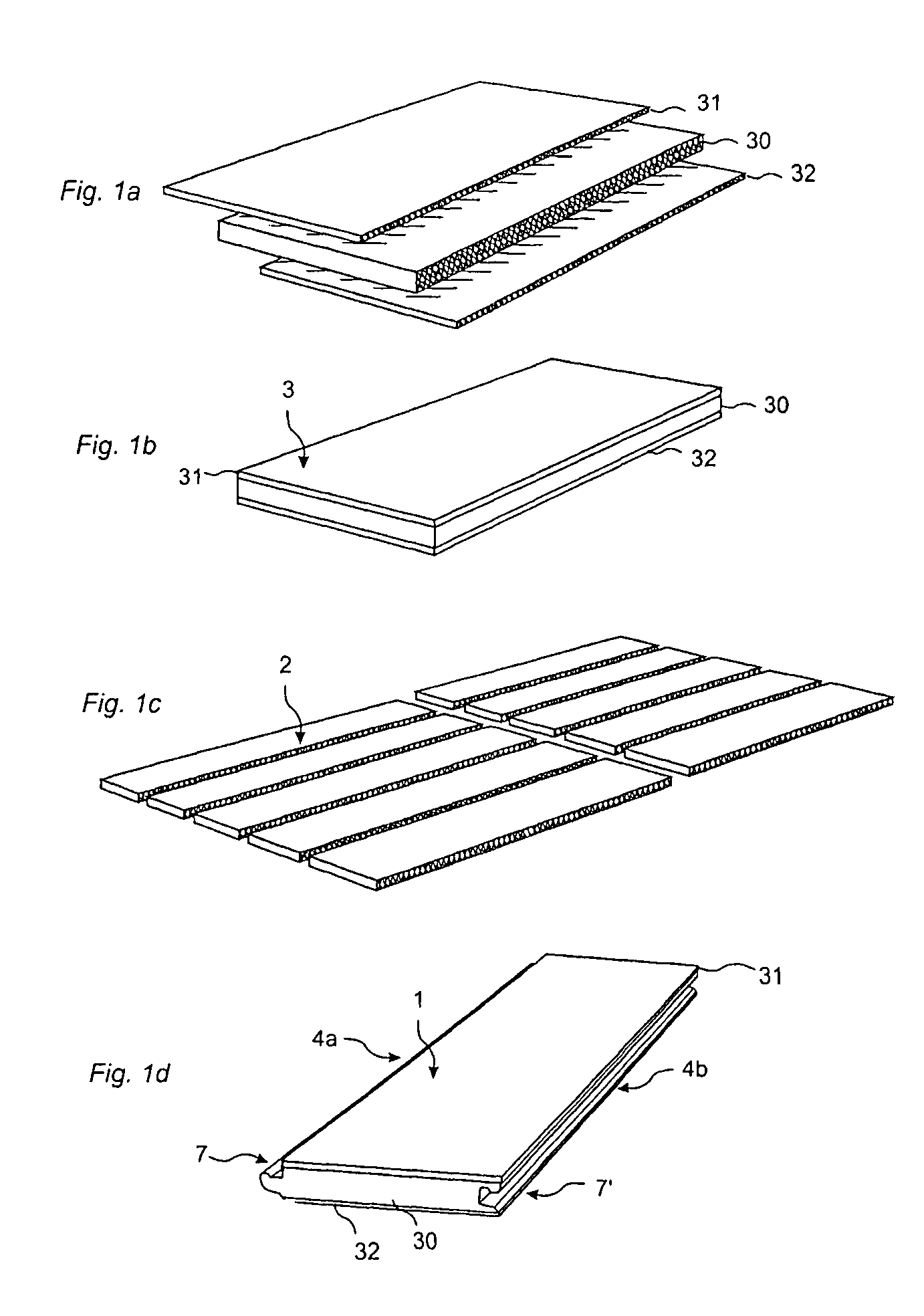

Floorboards (1, 1′) are shown, which are provided with a mechanical locking system consisting of a separately machined locking strip (6) which is mechanically joined with the floorboard (1), the locking strip (6) being designed for mechanical fixing to the floorboard (1) by means of a joint, which is operable by snapping-in and / or inward angling, and the locking strip (6) being designed to connect the floorboard (1) with the essentially identical floorboard (1′) by at least inward angling. Moreover, a locking strip, a strip blank, a set of parts for making a floorboard and methods for manufacturing a floorboard and a locking strip, respectively, are shown.

Owner:VÄLINGE INNOVATION AB

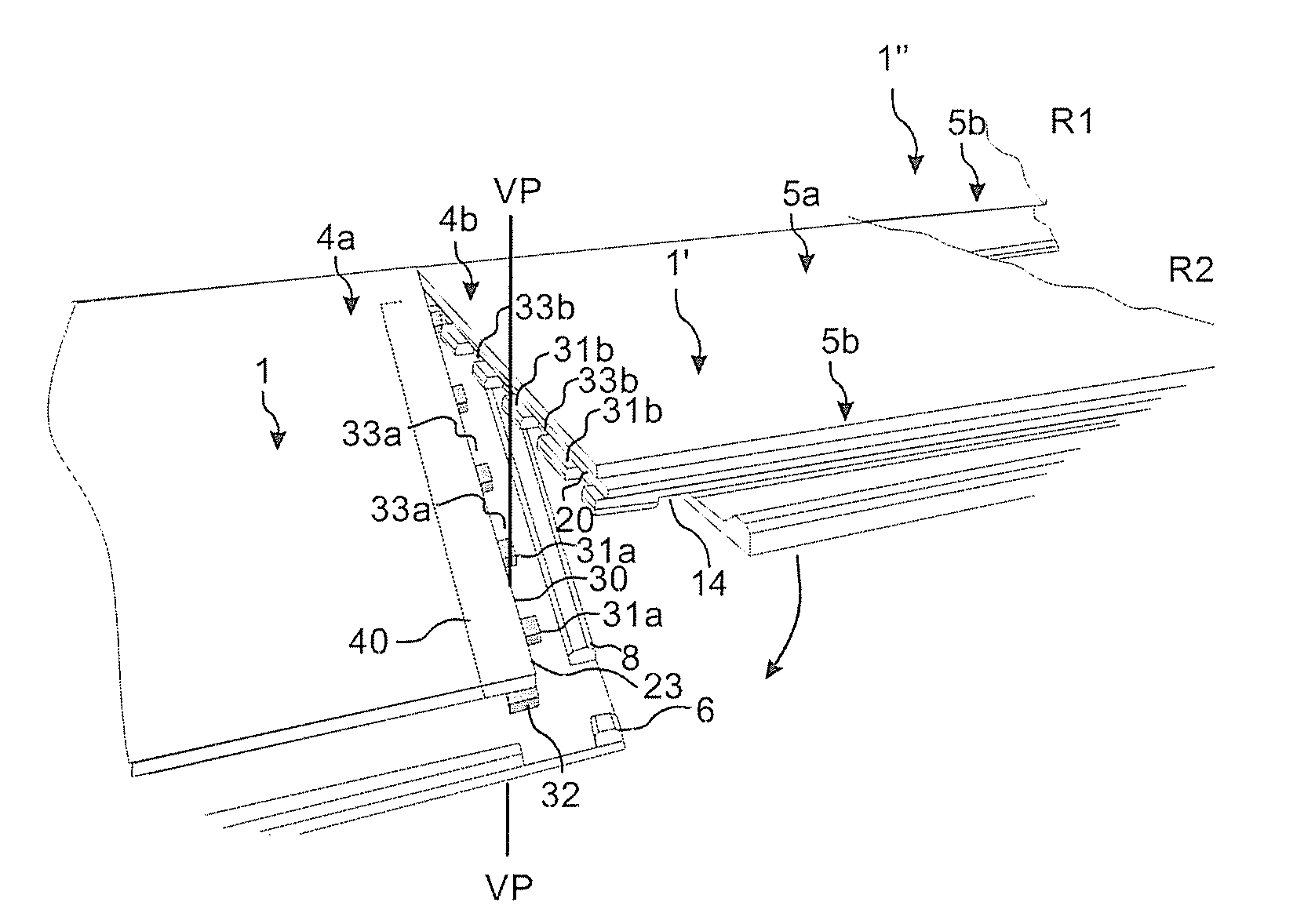

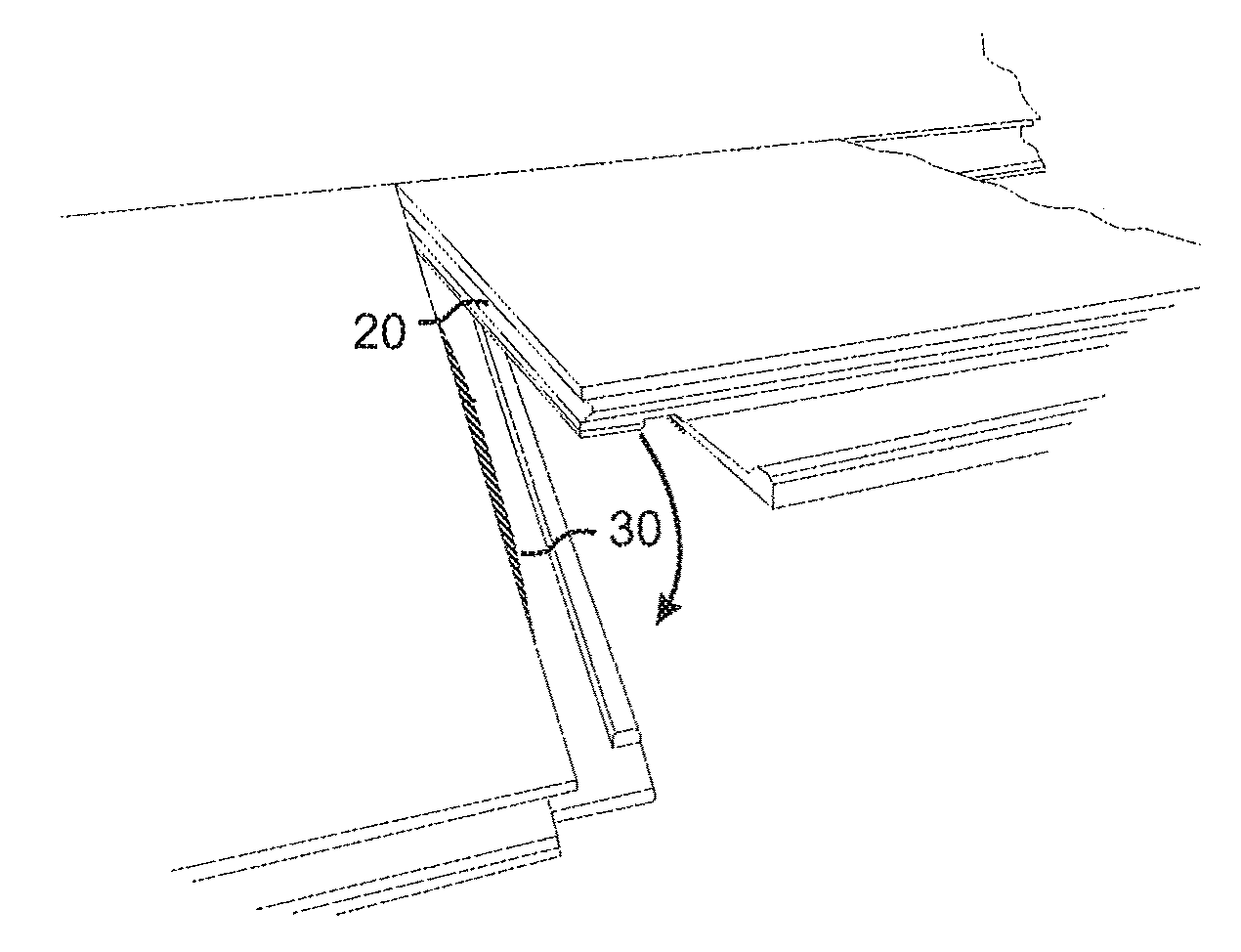

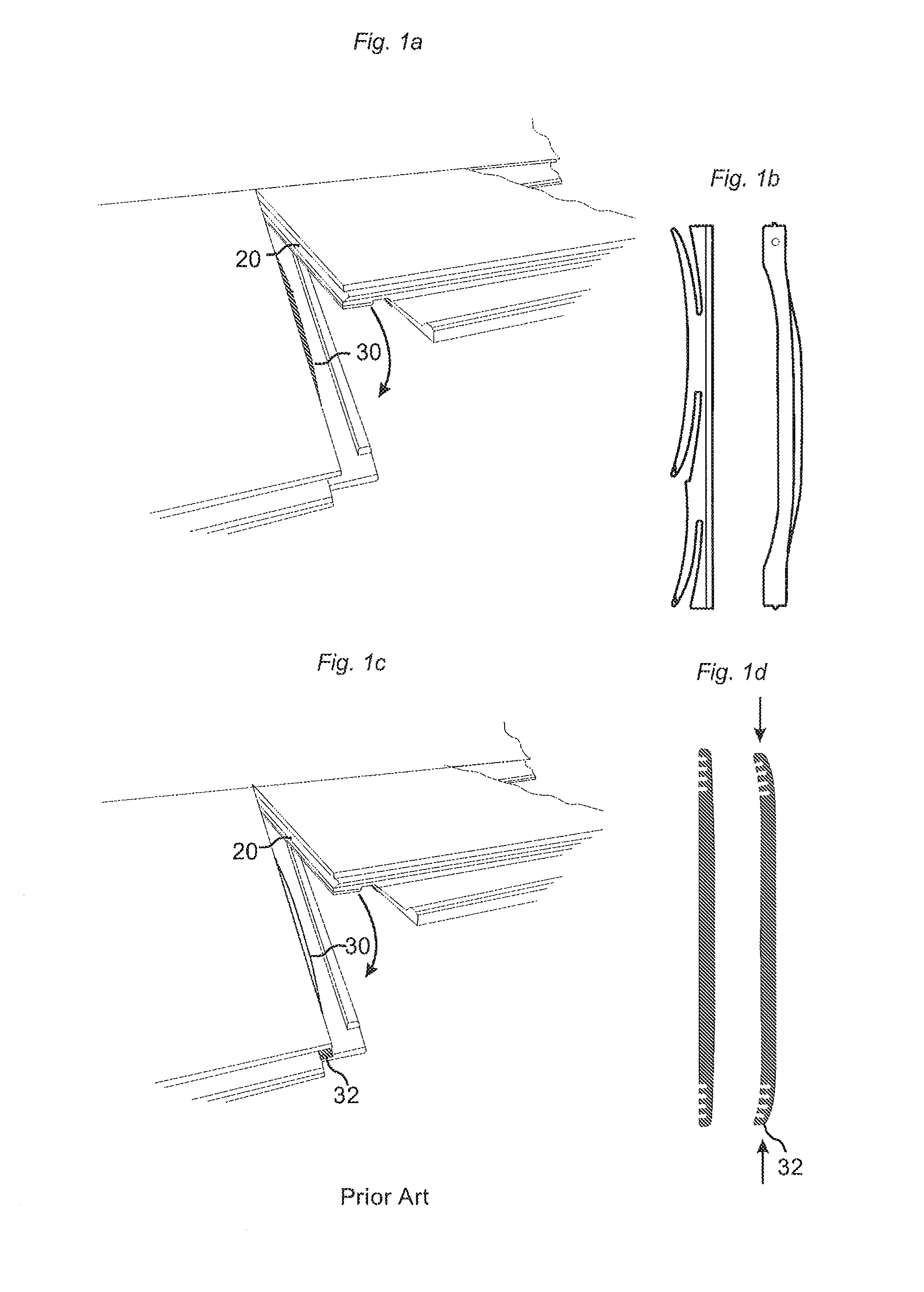

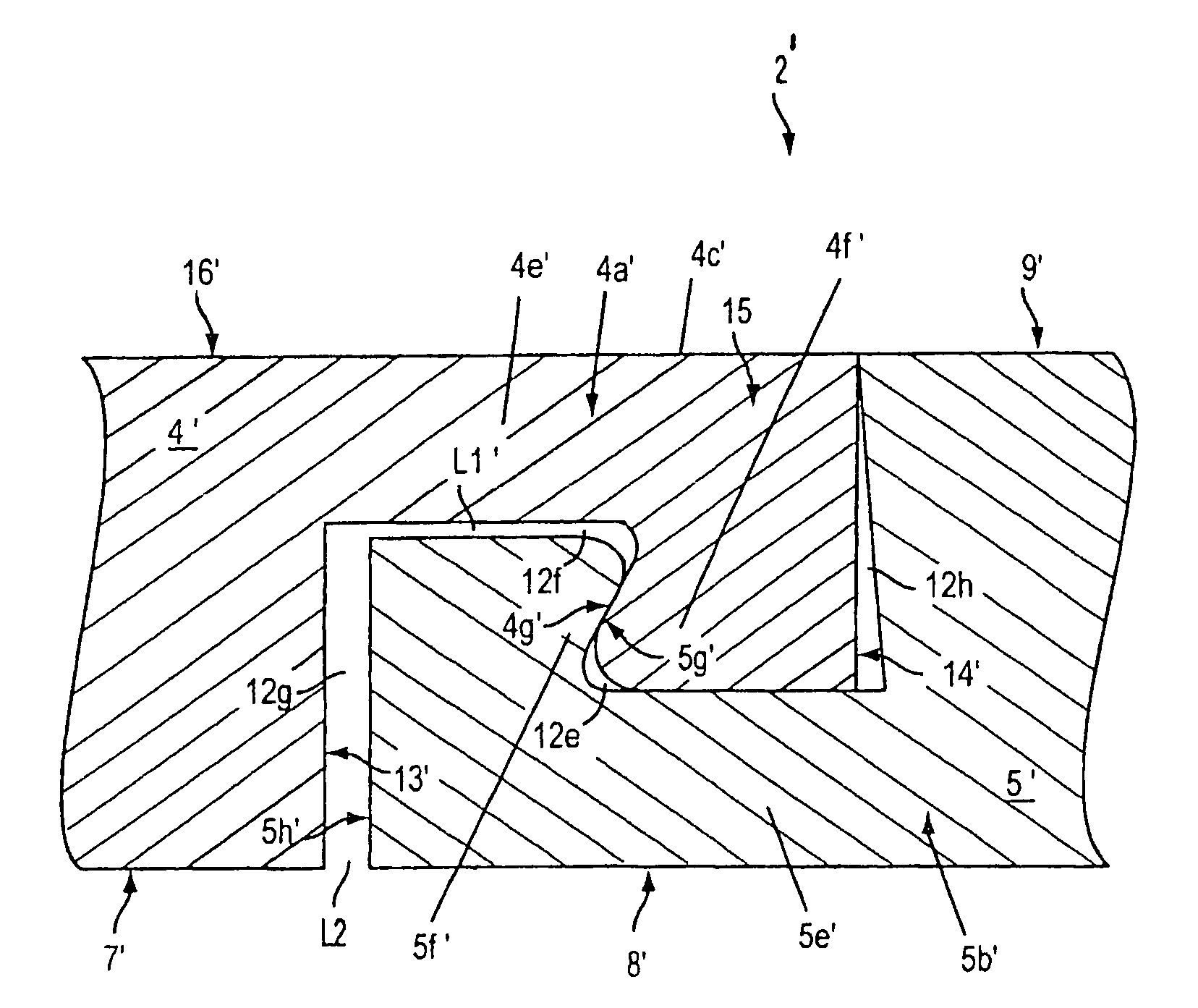

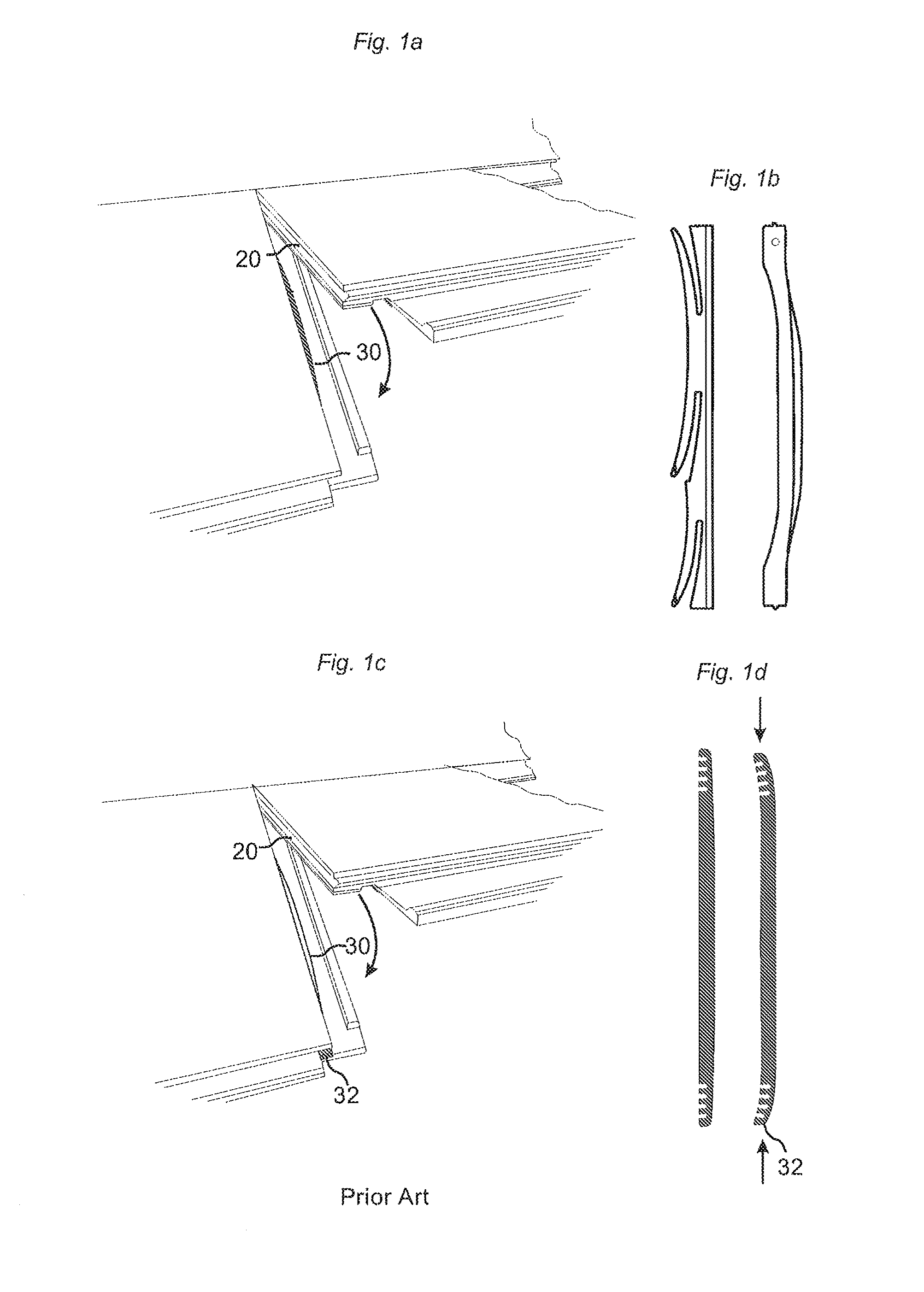

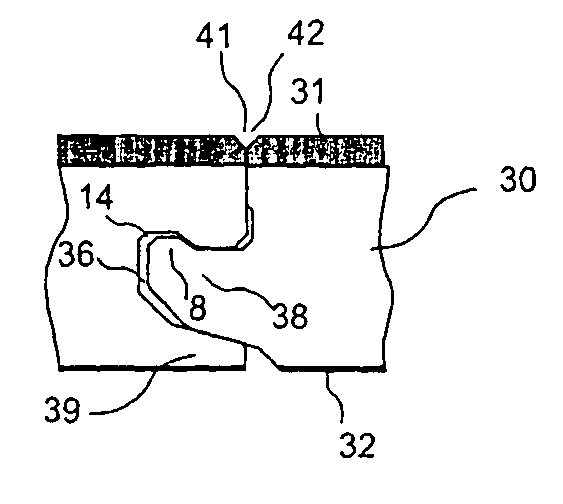

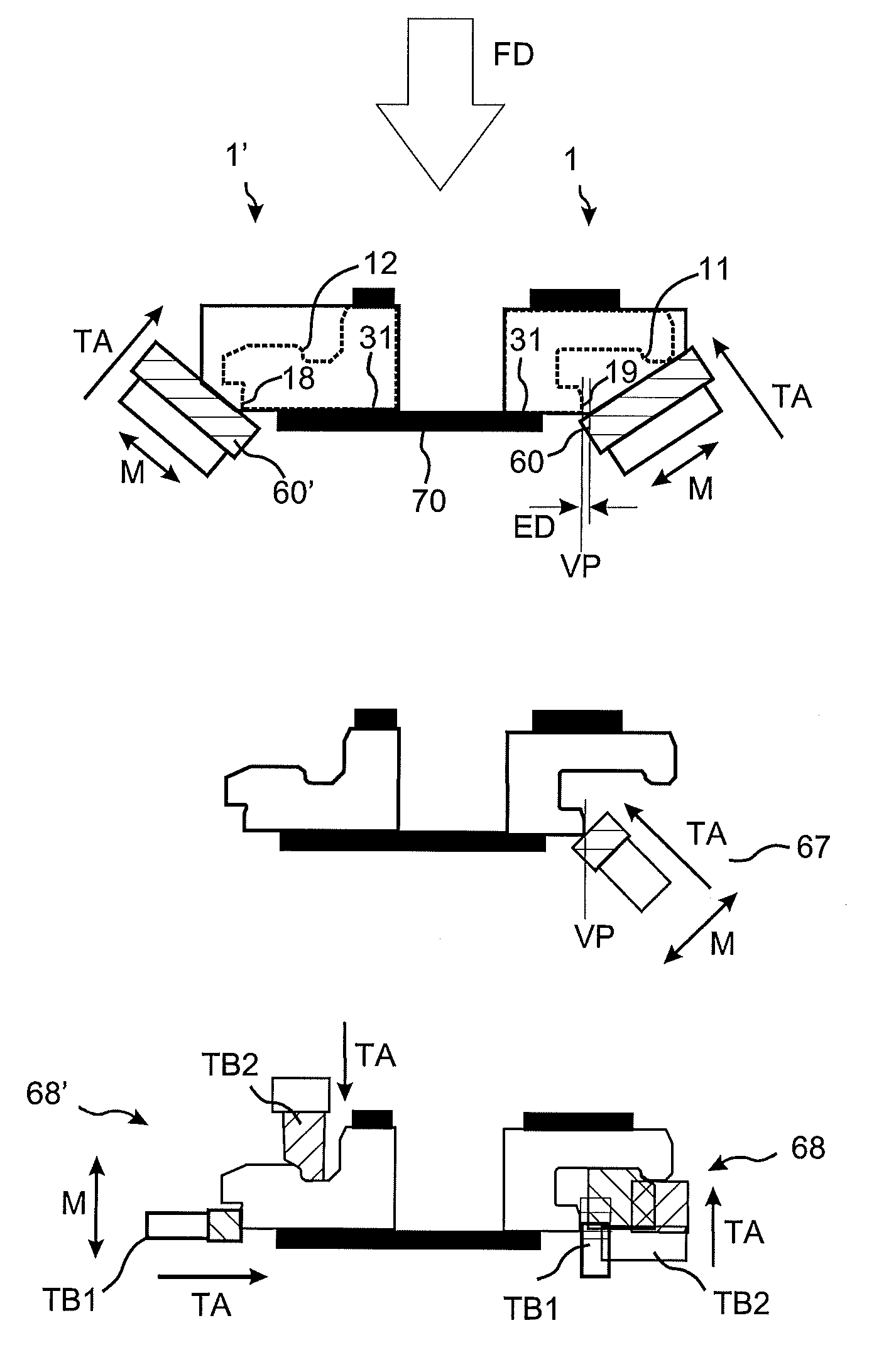

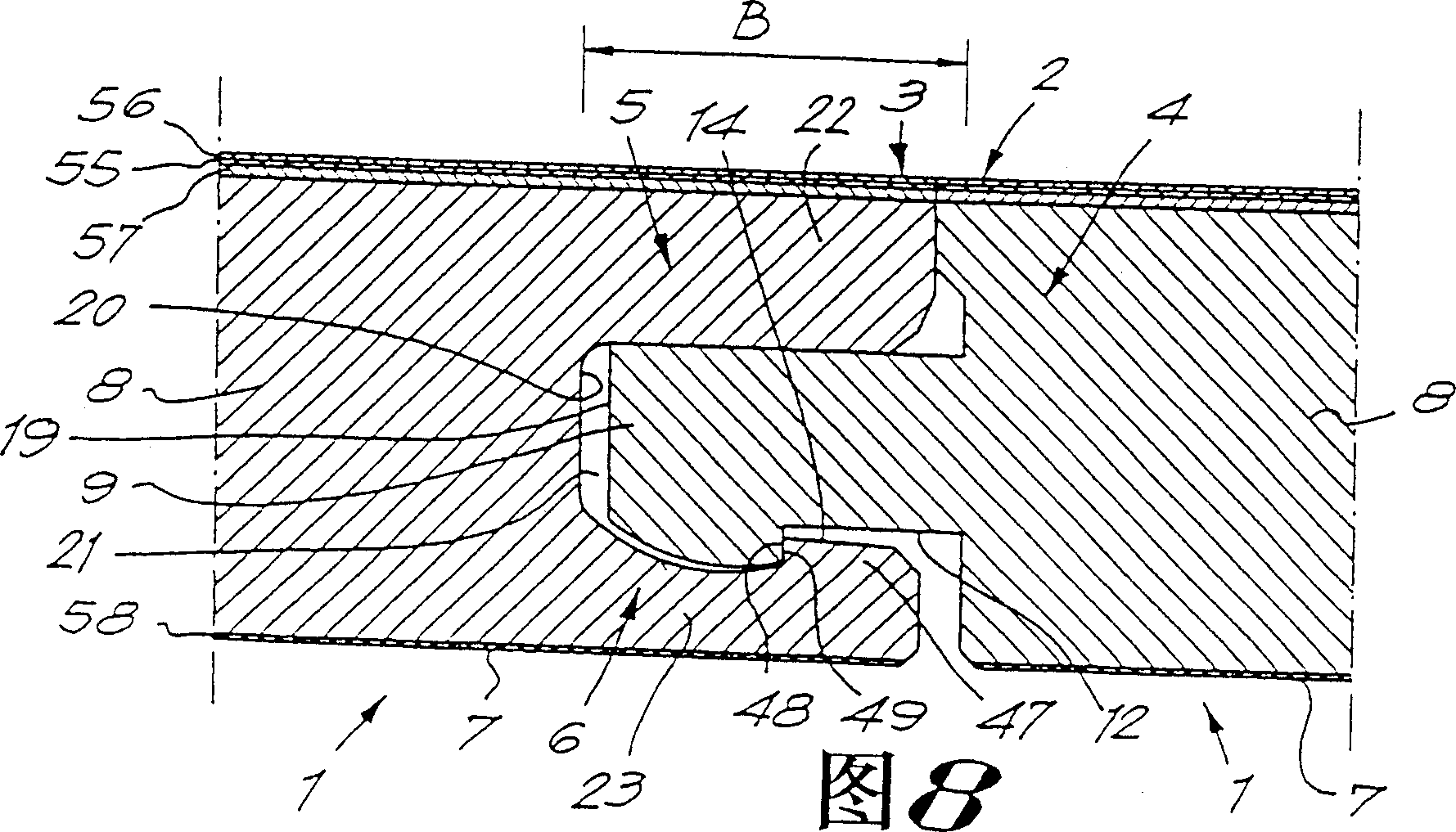

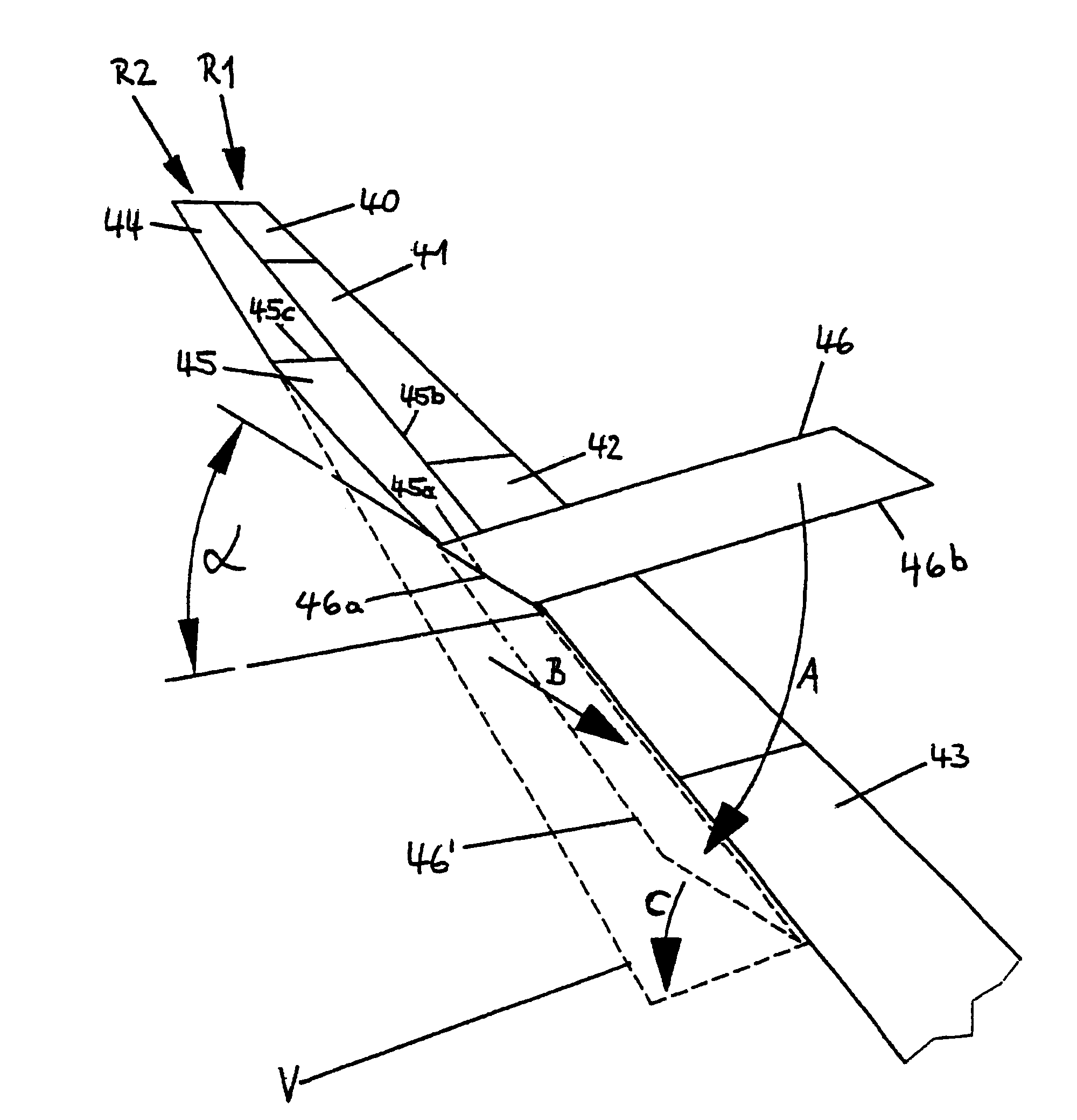

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Mechanical locking system for floorboards

InactiveUS20080041008A1Rational and cost-efficientTongue/grooves making apparatusFloorsClassical mechanicsEngineering

Floorboards (1, 1′) are shown, which are provided with a mechanical locking system consisting of a separately machined locking strip (6) which is mechanically joined with the floorboard (1), the locking strip (6) being designed for mechanical fixing to the floorboard (1) by means of a joint, which is operable by snapping-in and / or inward angling, and the locking strip (6) being designed to connect the floorboard (1) with the essentially identical floorboard (1′) by at least inward angling. Moreover, a locking strip, a strip blank, a set of parts for making a floorboard and methods for manufacturing a floorboard and a locking strip, respectively, are shown.

Owner:VÄLINGE INNOVATION AB

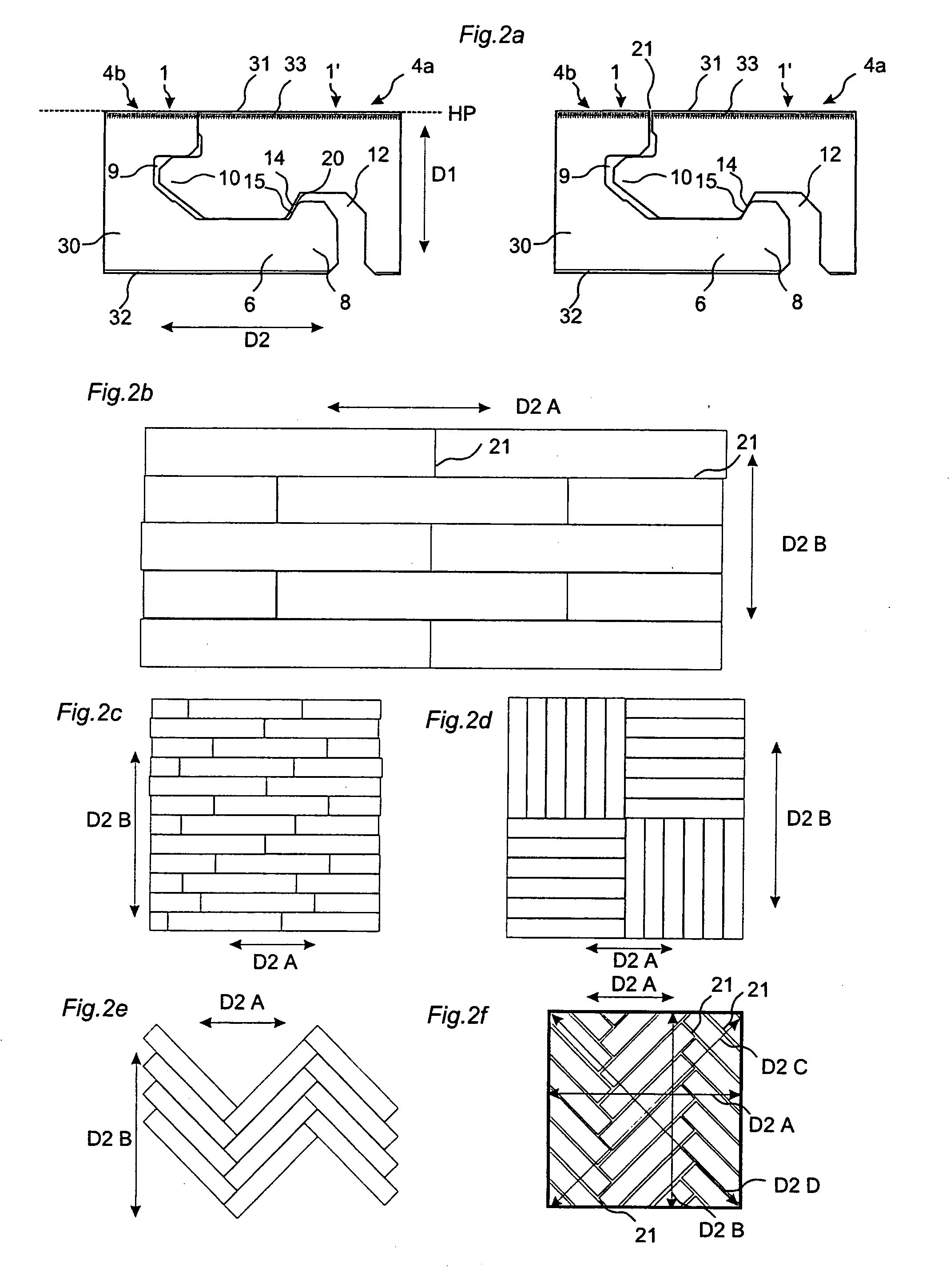

Floorboards with decorative grooves

InactiveUS20040035078A1Provides appearance and durabilityNatural appearanceCovering/liningsTongue/grooves making apparatusSurface layerEngineering

Floorboards consisting of a core and a surface layer with decorative joint edge portions which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels

ActiveUS8505257B2Easy to installImprove installation and strength and quality and production costTongue/grooves making apparatusWallsTongue and grooveEngineering

Owner:VÄLINGE INNOVATION AB

Panel and panel fastening system

InactiveUS7896571B1Reduce the amount requiredLower elastic deformabilityFlanged jointsTongue/grooves making apparatusFront edgeEngineering

A panel fastening system, especially for floor panels. The floor panels are fitted with retaining profiles on their edges, whereby the retaining profile of a front edge and the retaining profile of the opposite back edge and the retaining profile of a left edge and the retaining profile of the opposite right edge of a panel match each other in such a way that similar panels can be fixed to one another. The mutually matching retaining profiles have complementary hook elements that can be hooked into one another and the hook elements have retaining surfaces by means of which the panels are held against each other when mounted in such a way that a gap-free surface is obtained.

Owner:AKZENTA PANEELE PROFILE GMBH

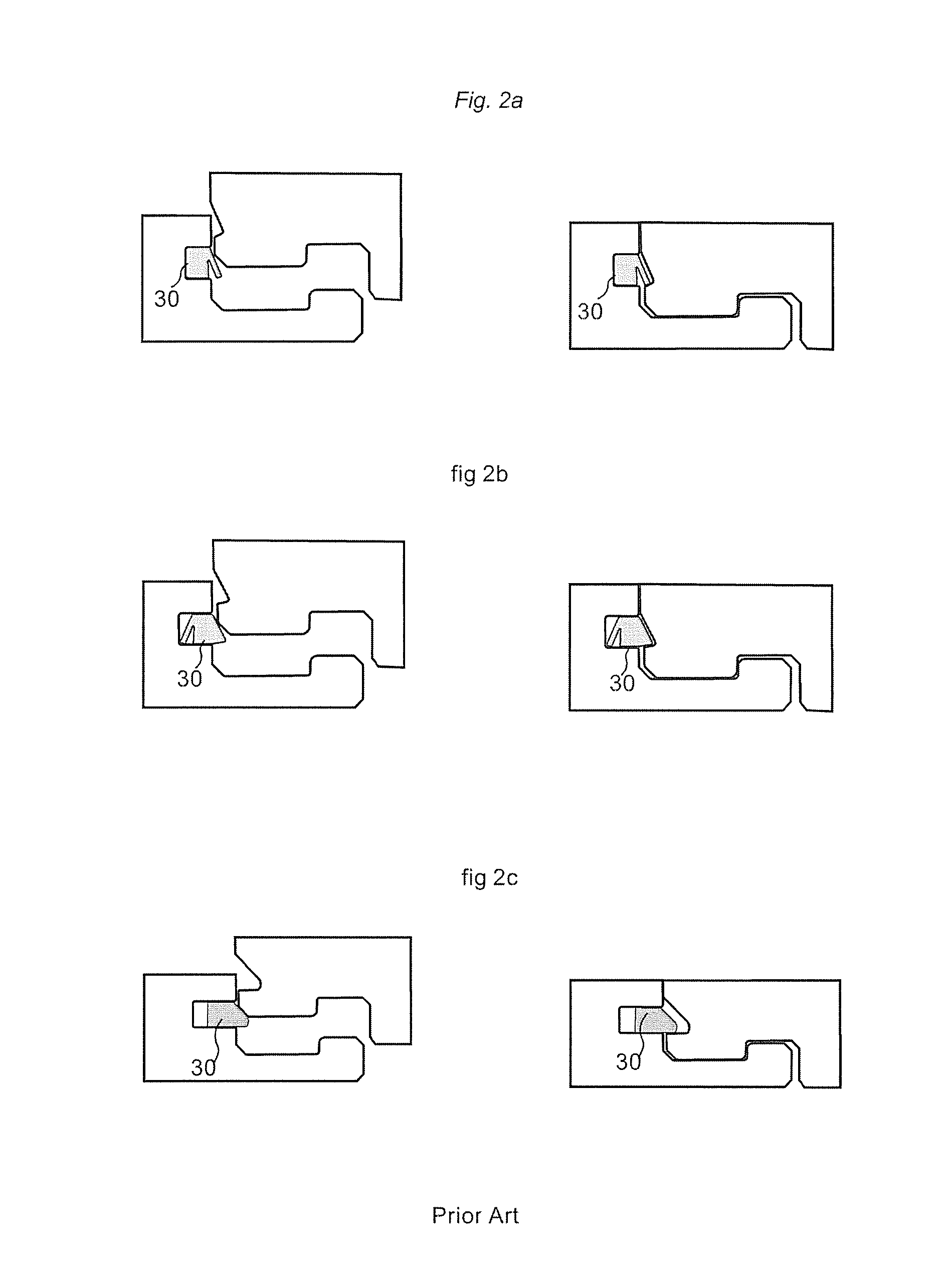

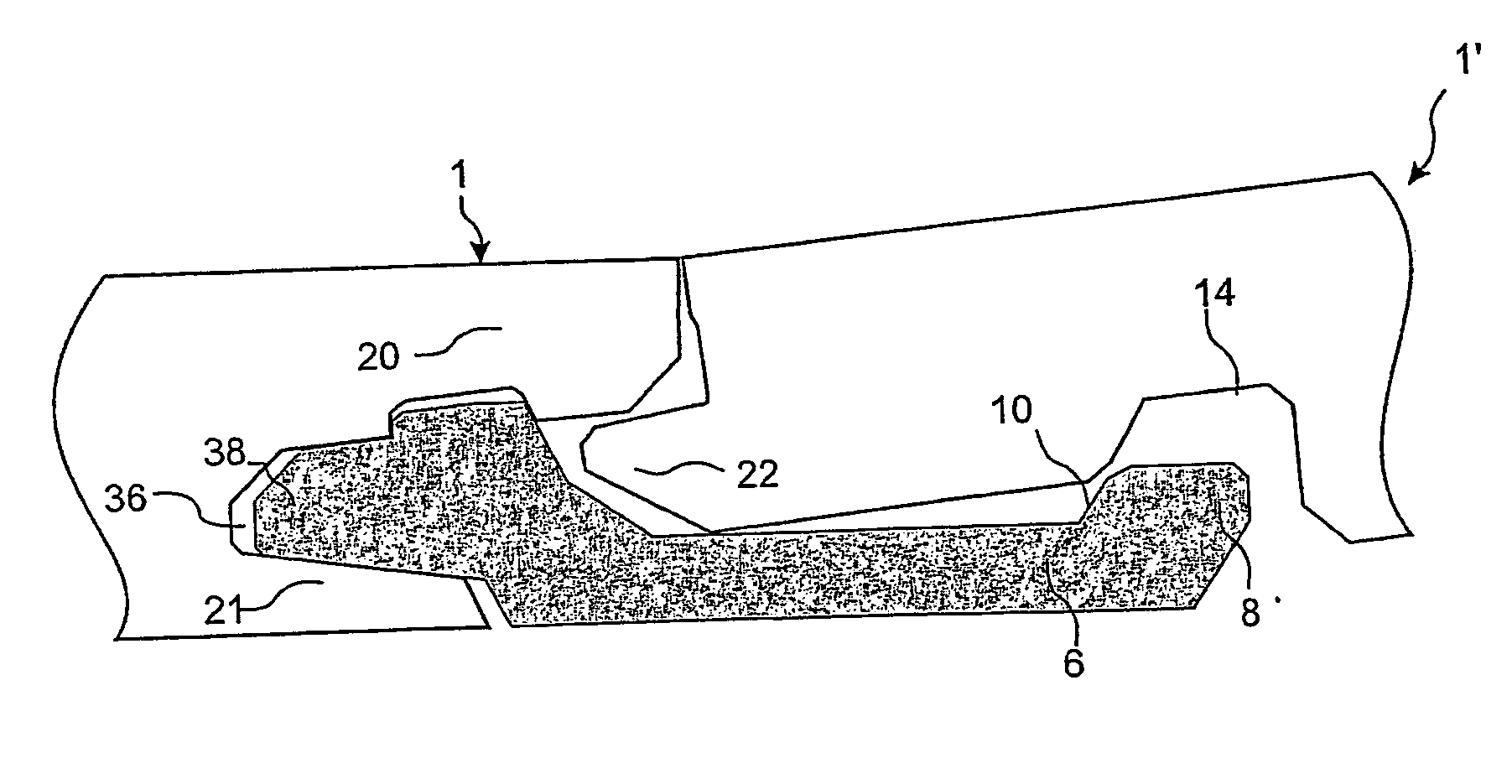

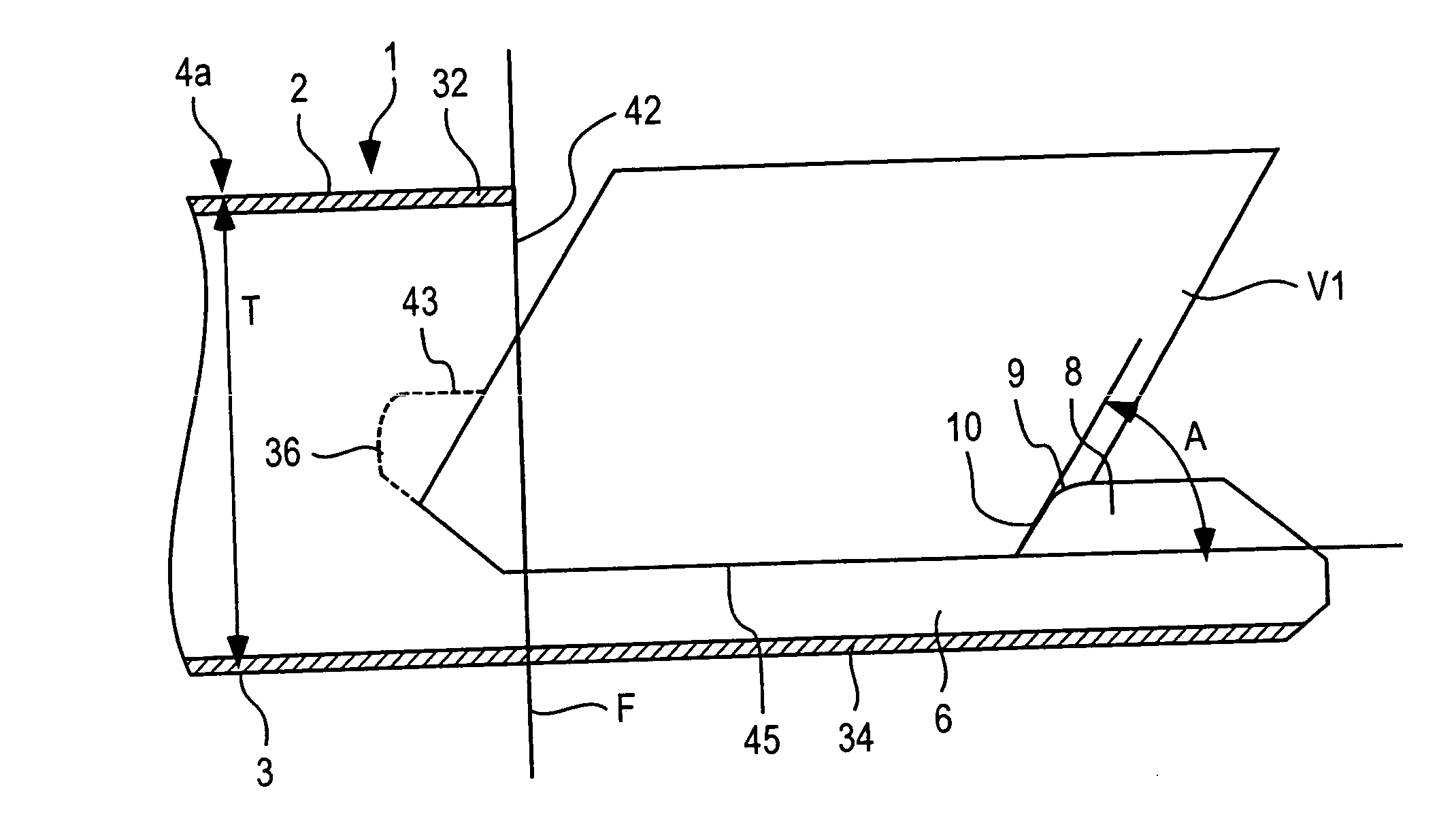

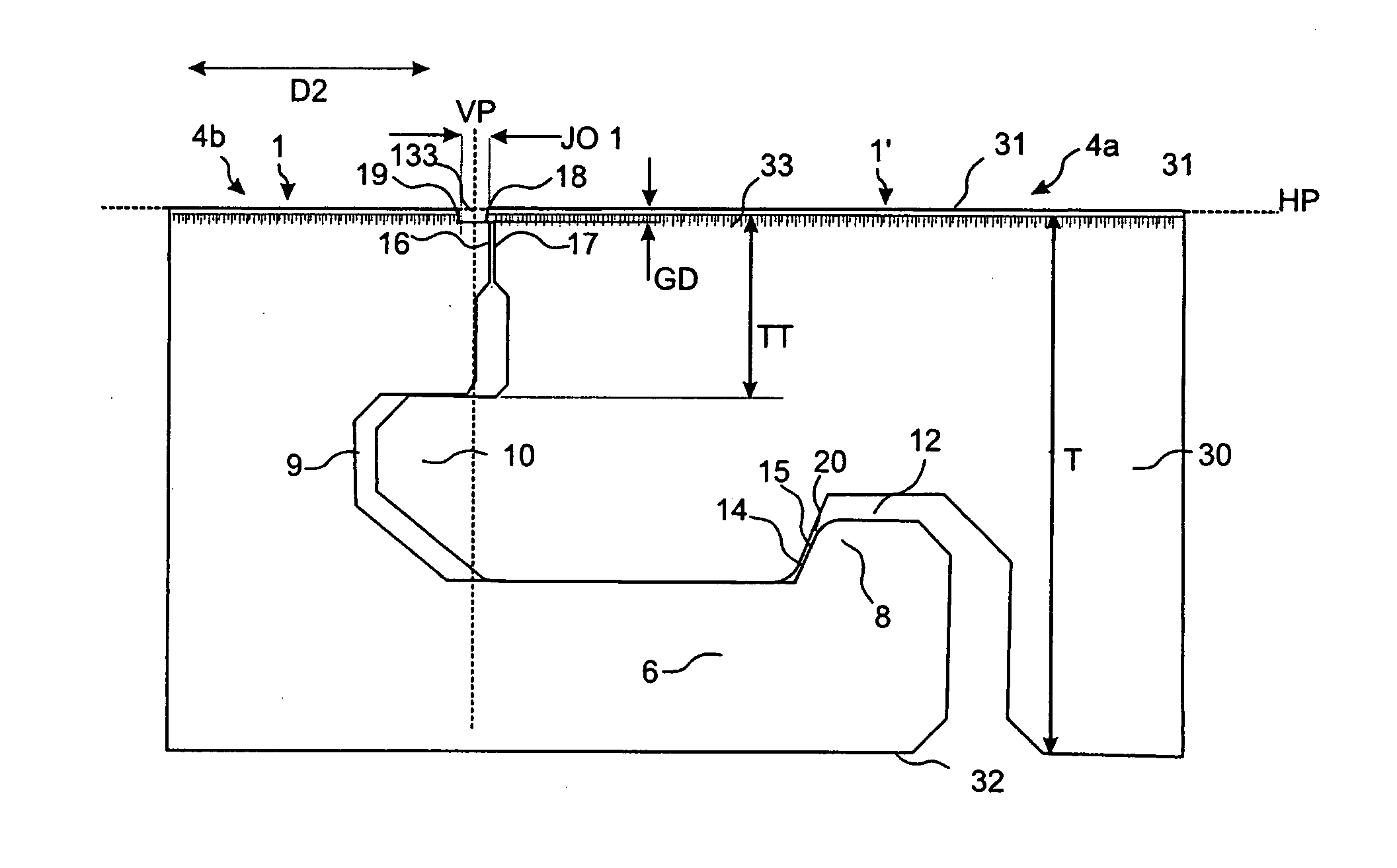

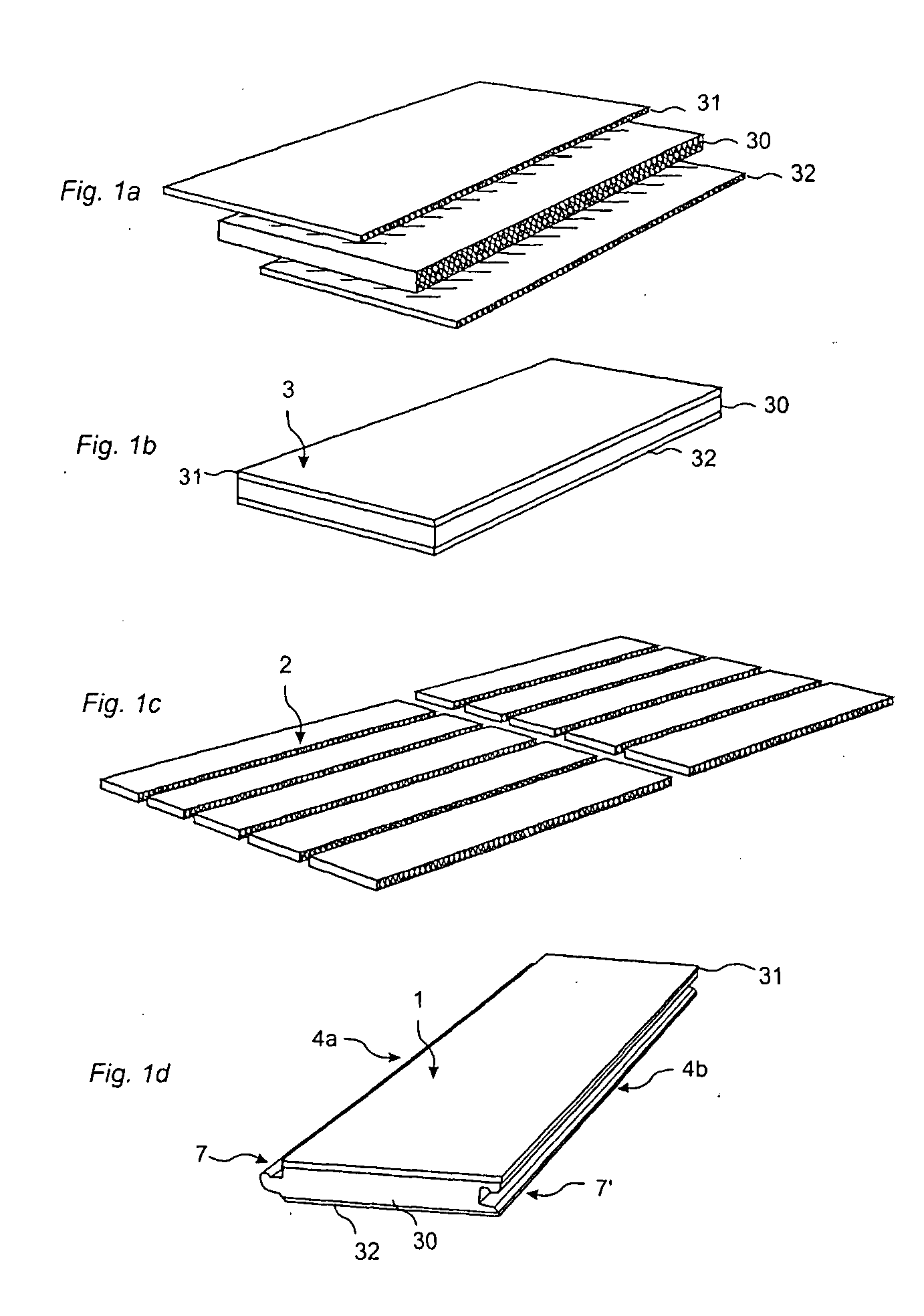

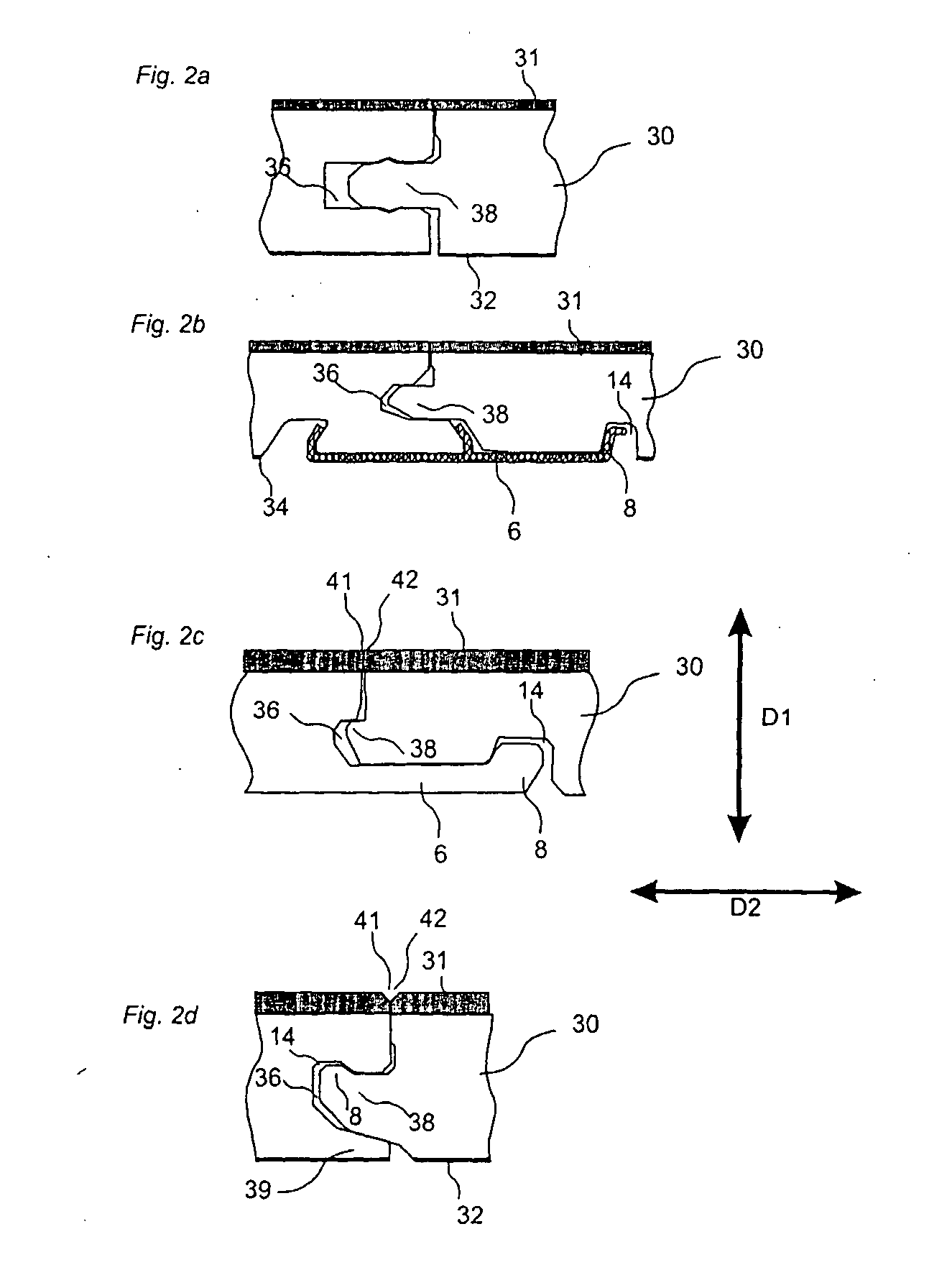

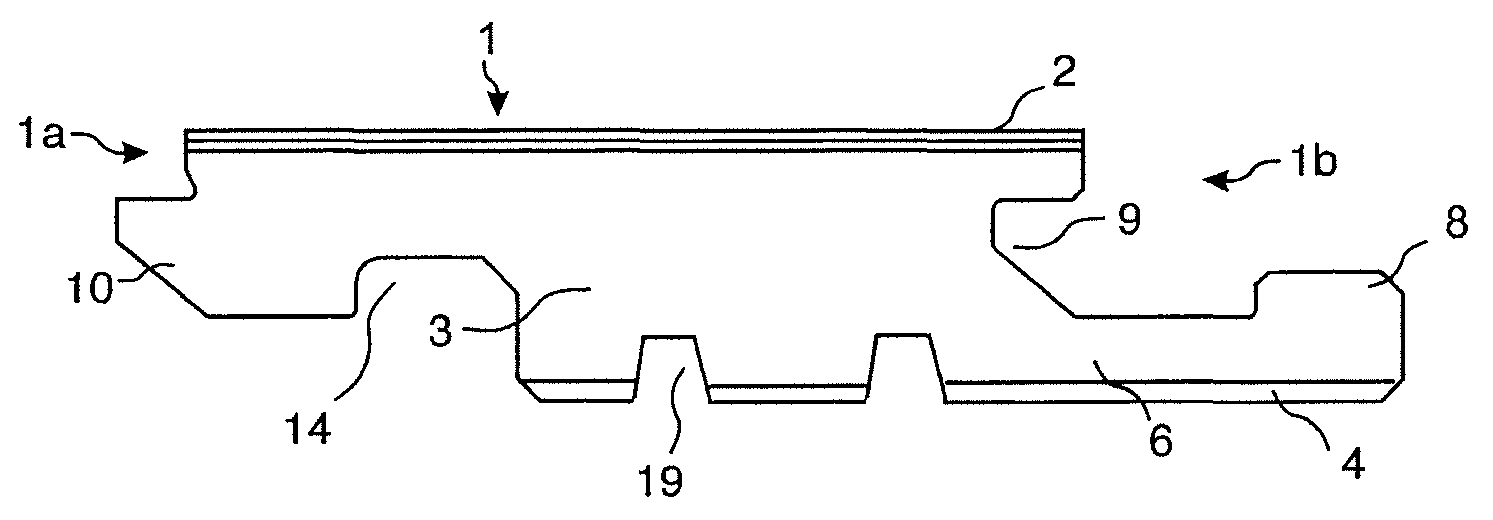

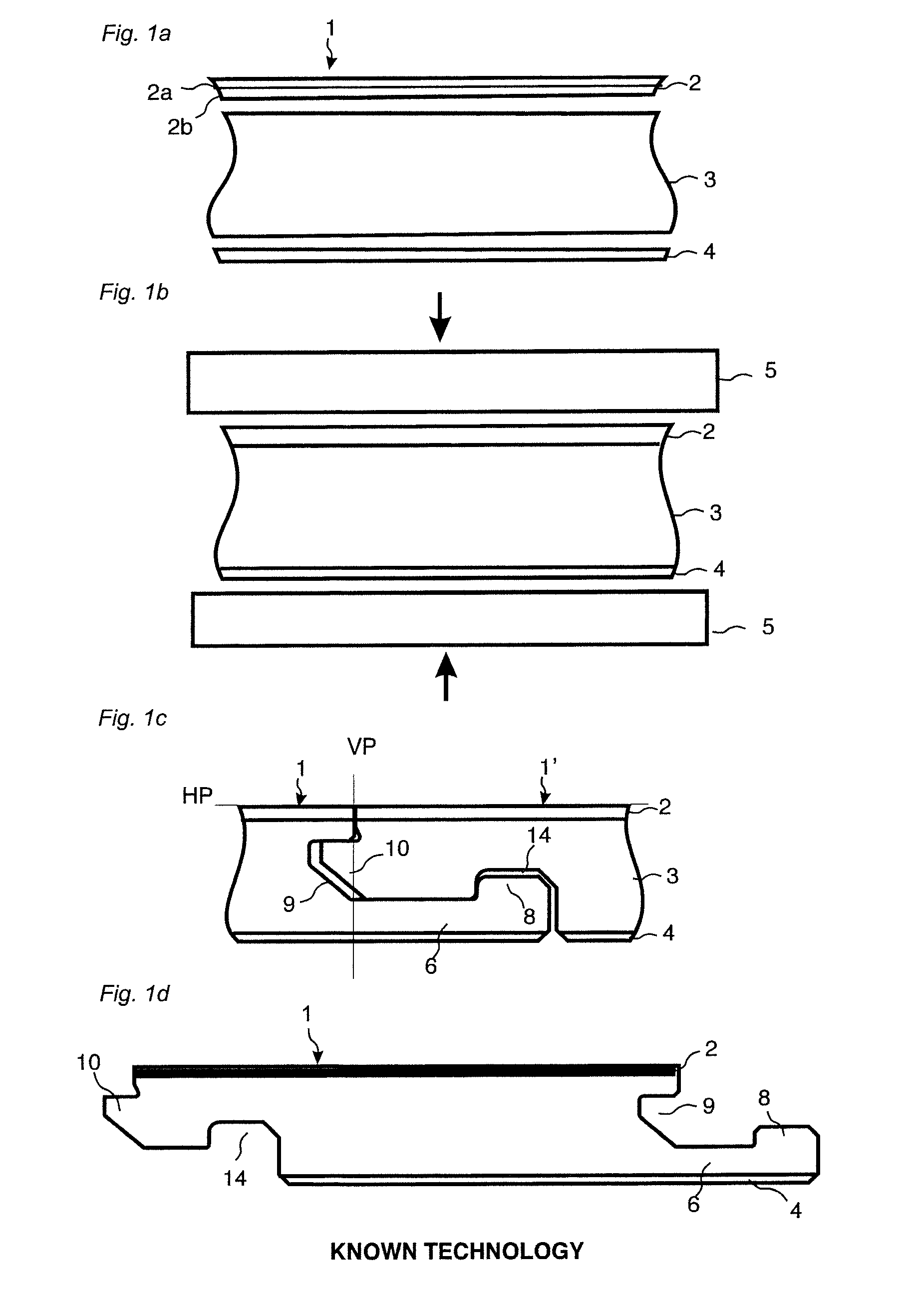

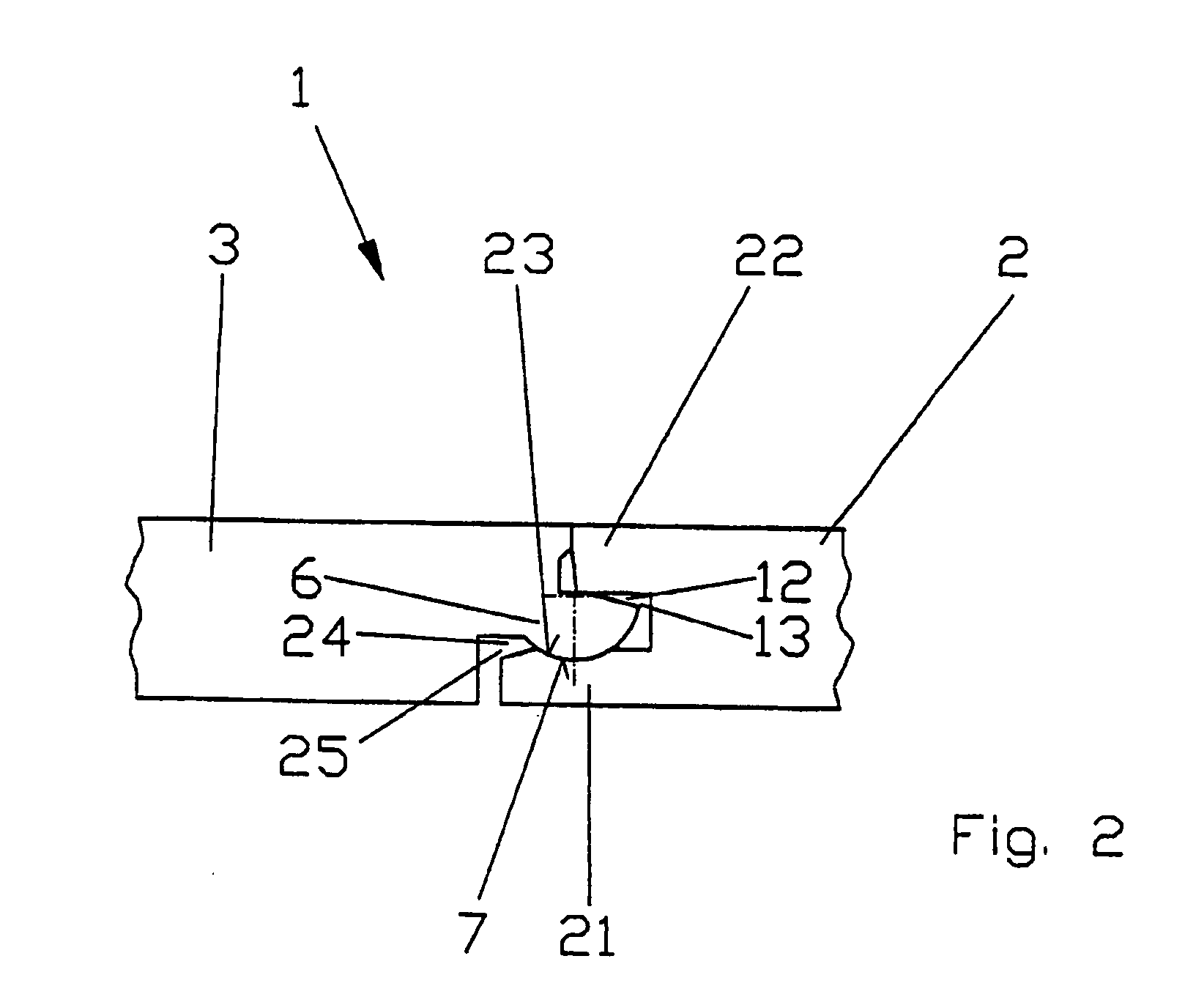

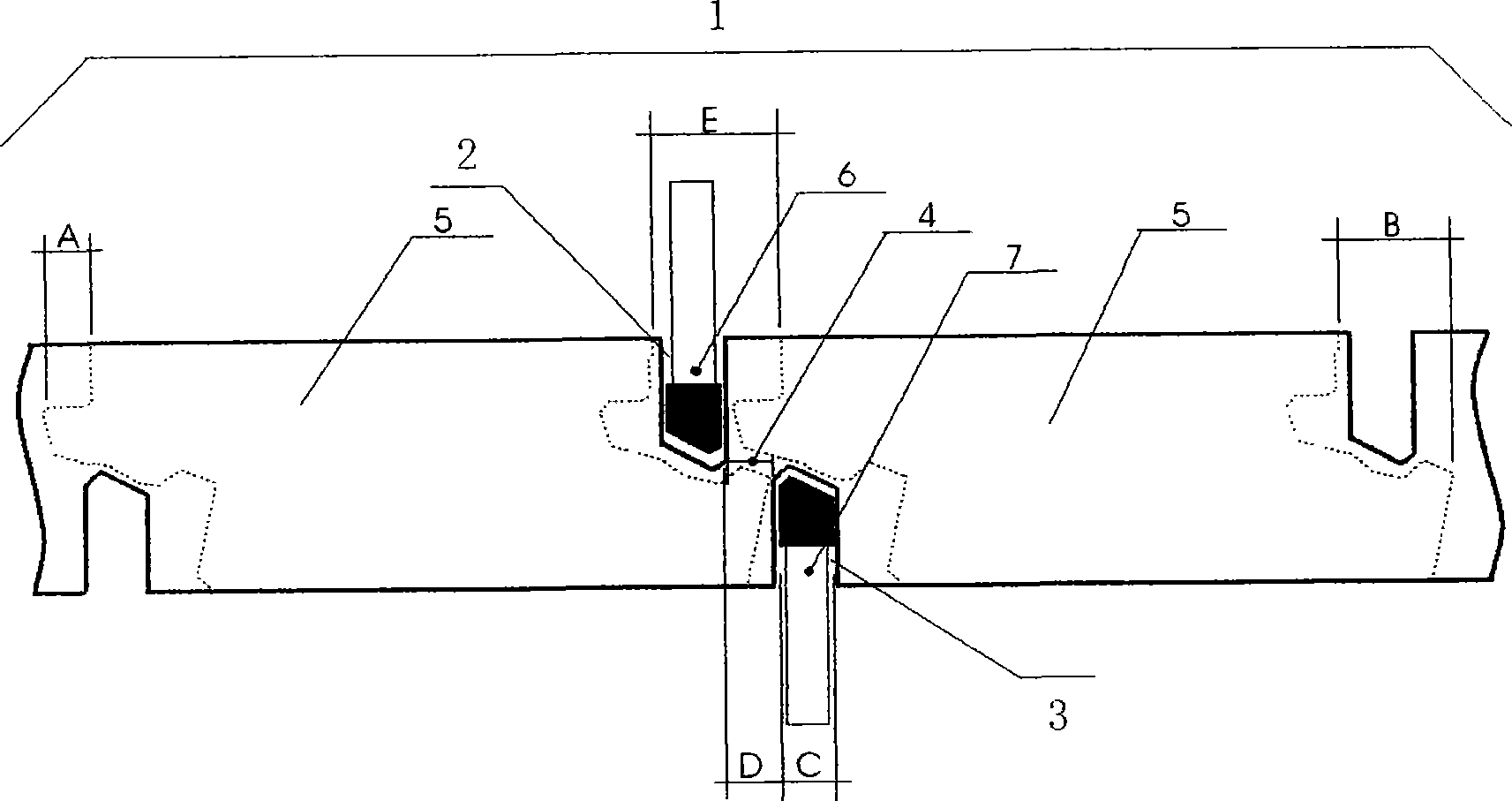

Locking system for mechanical joining of floorboards and method for production thereof

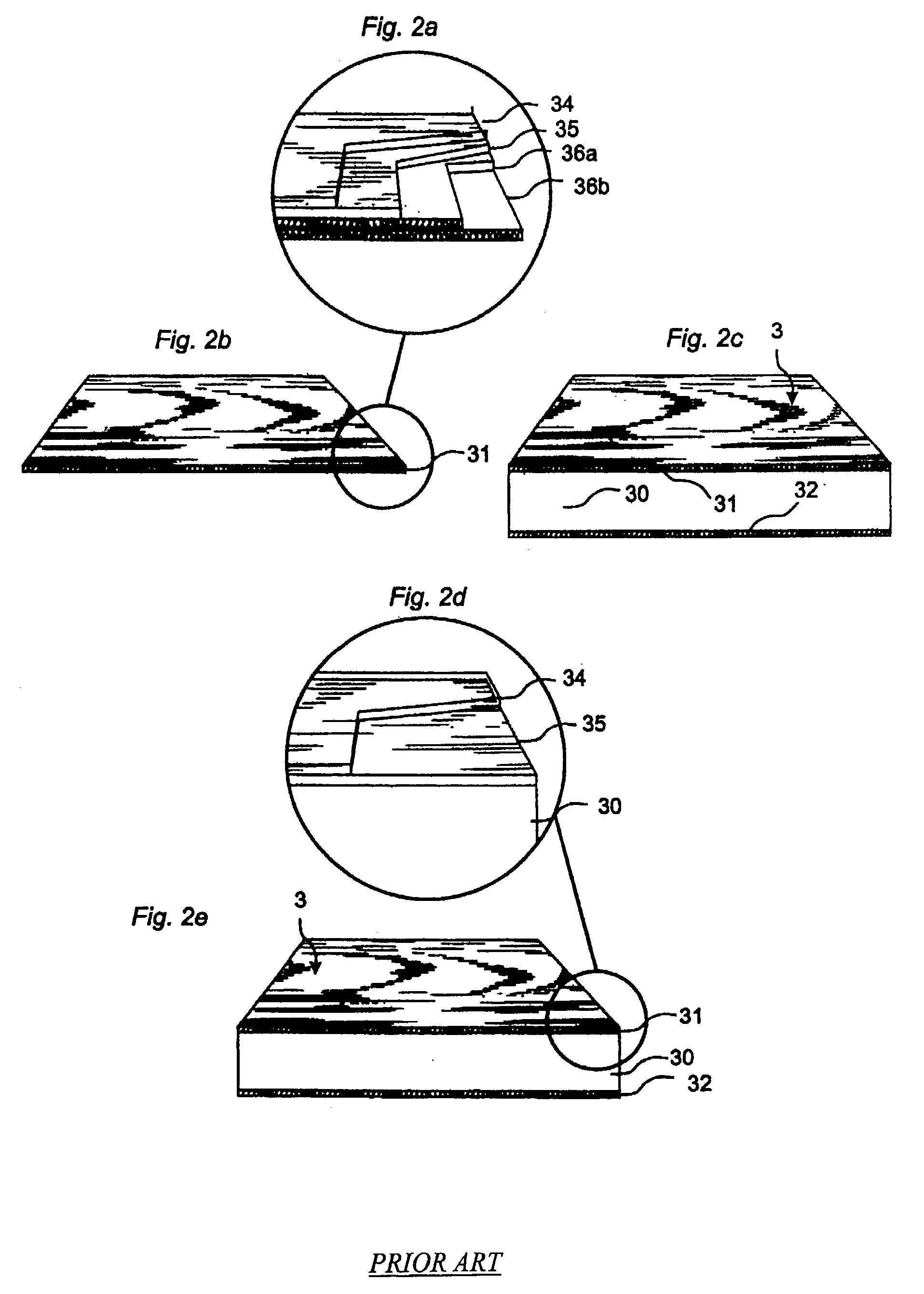

InactiveUS6898913B2High strengthFunction increaseCovering/liningsTongue/grooves making apparatusSurface layerEngineering

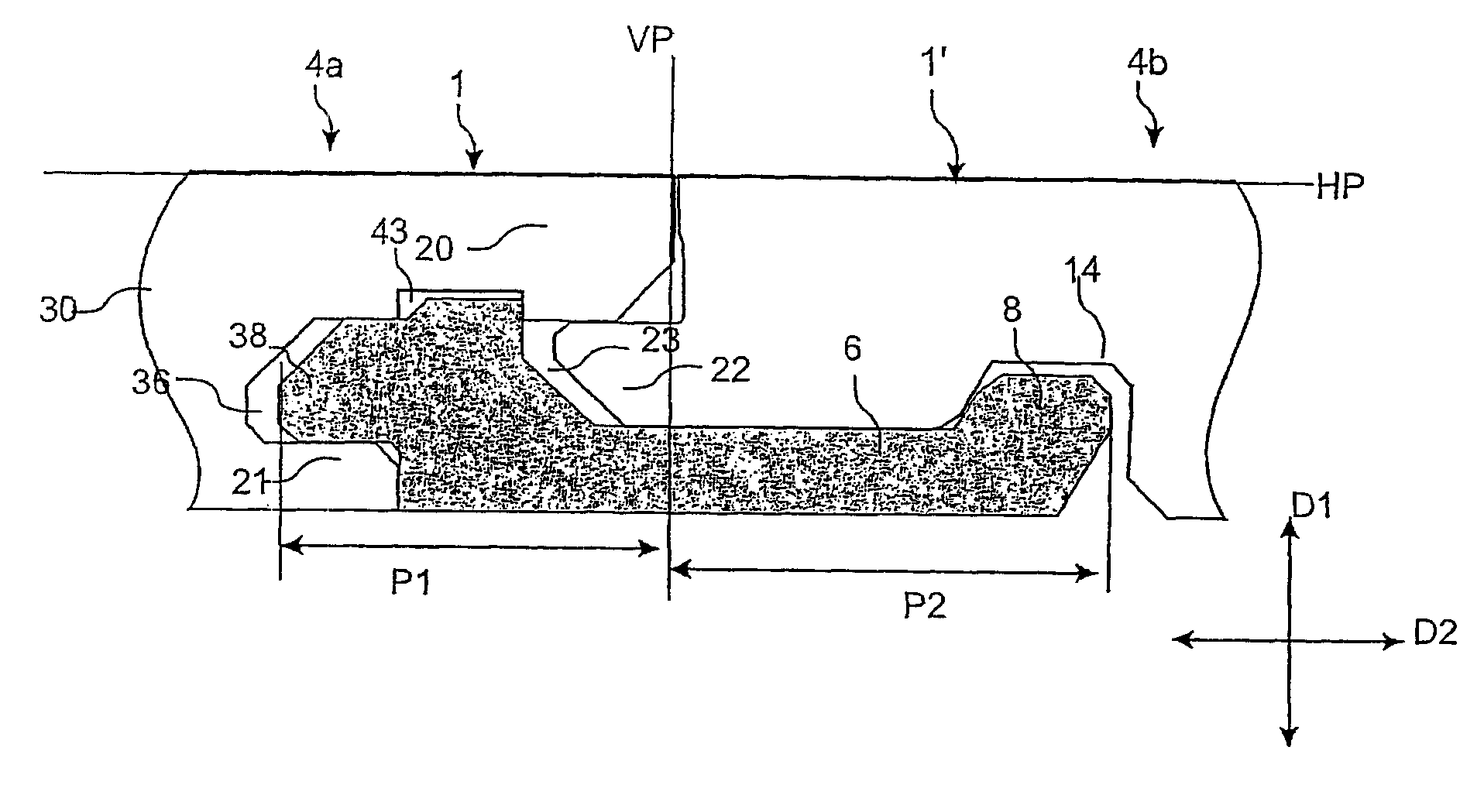

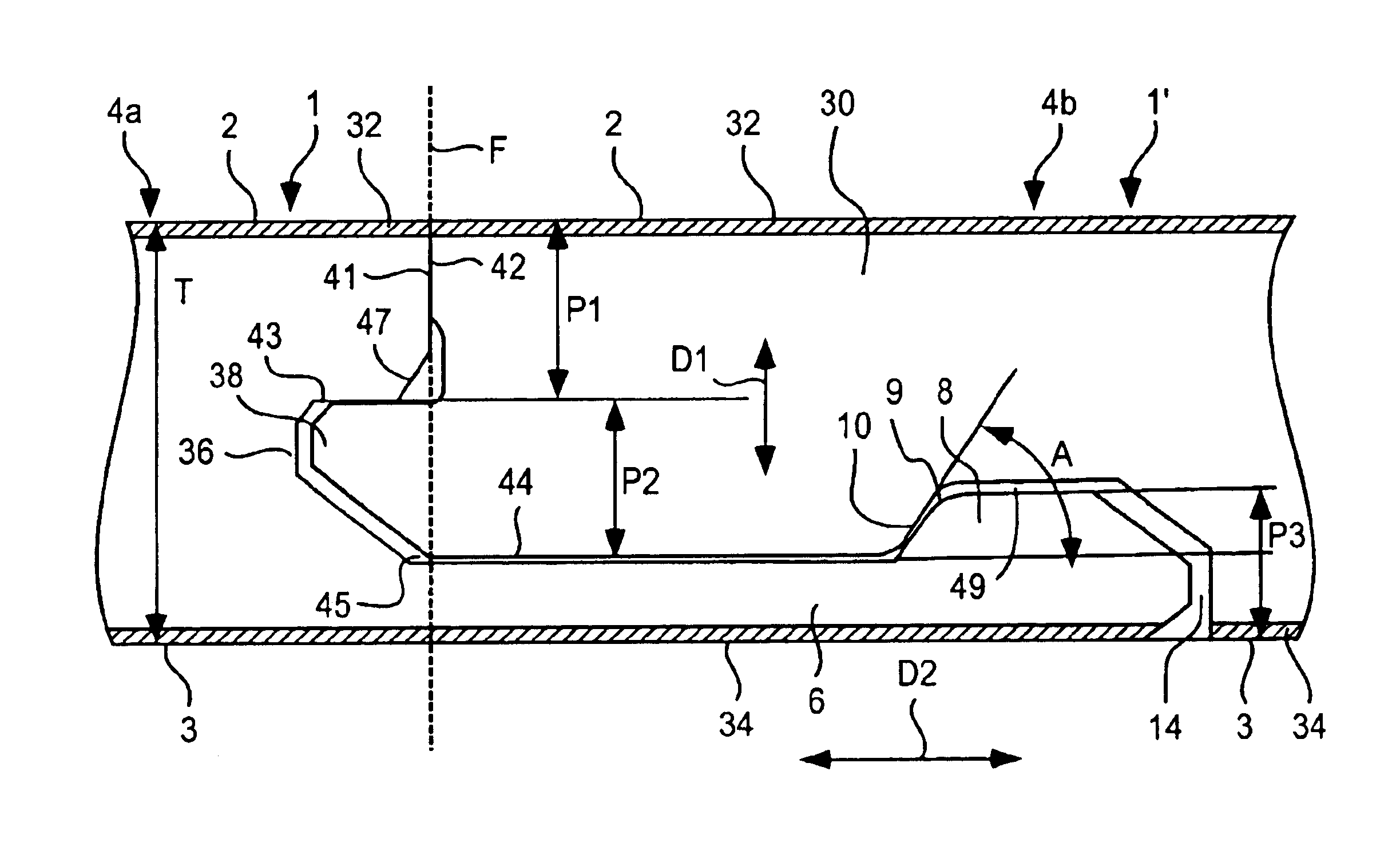

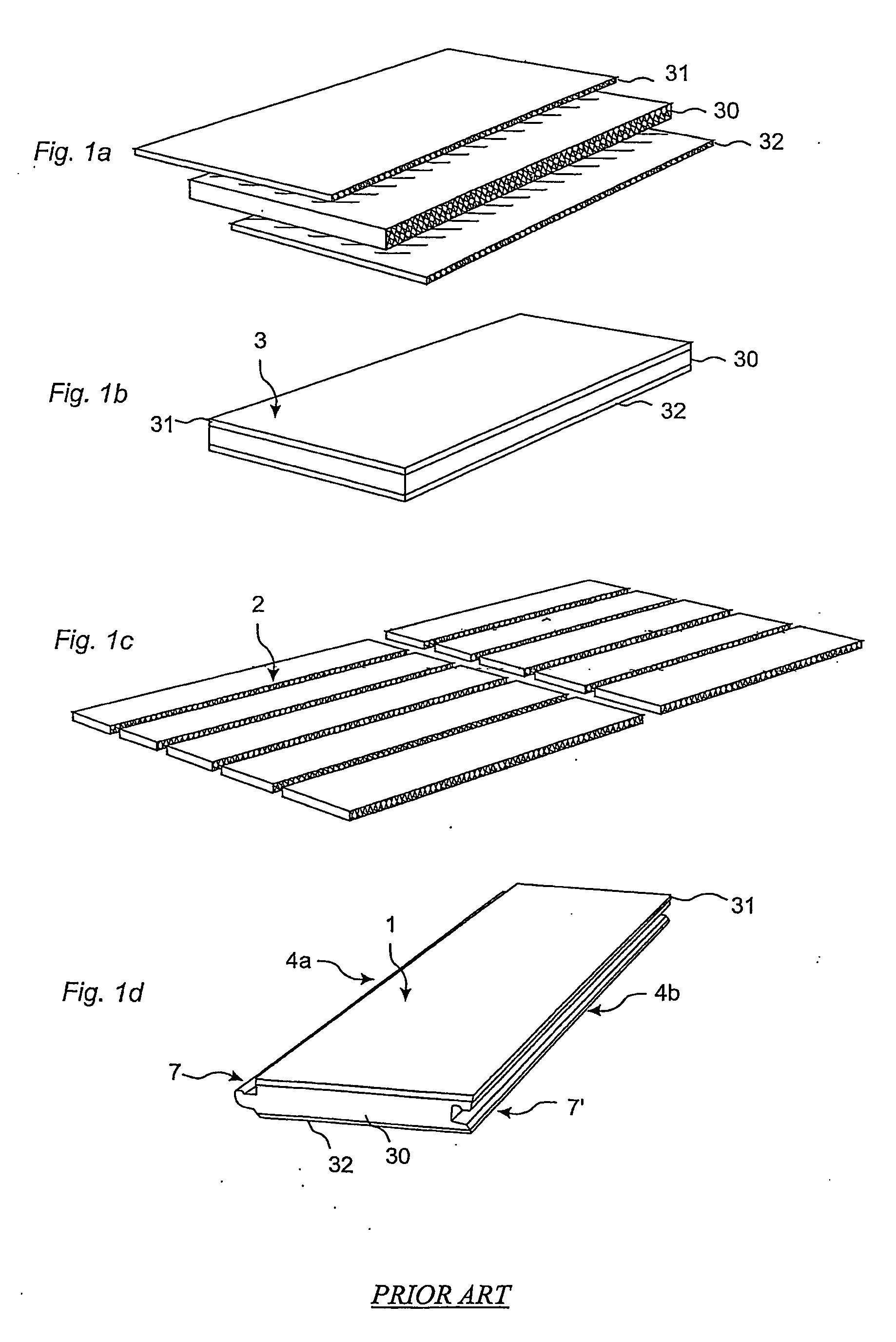

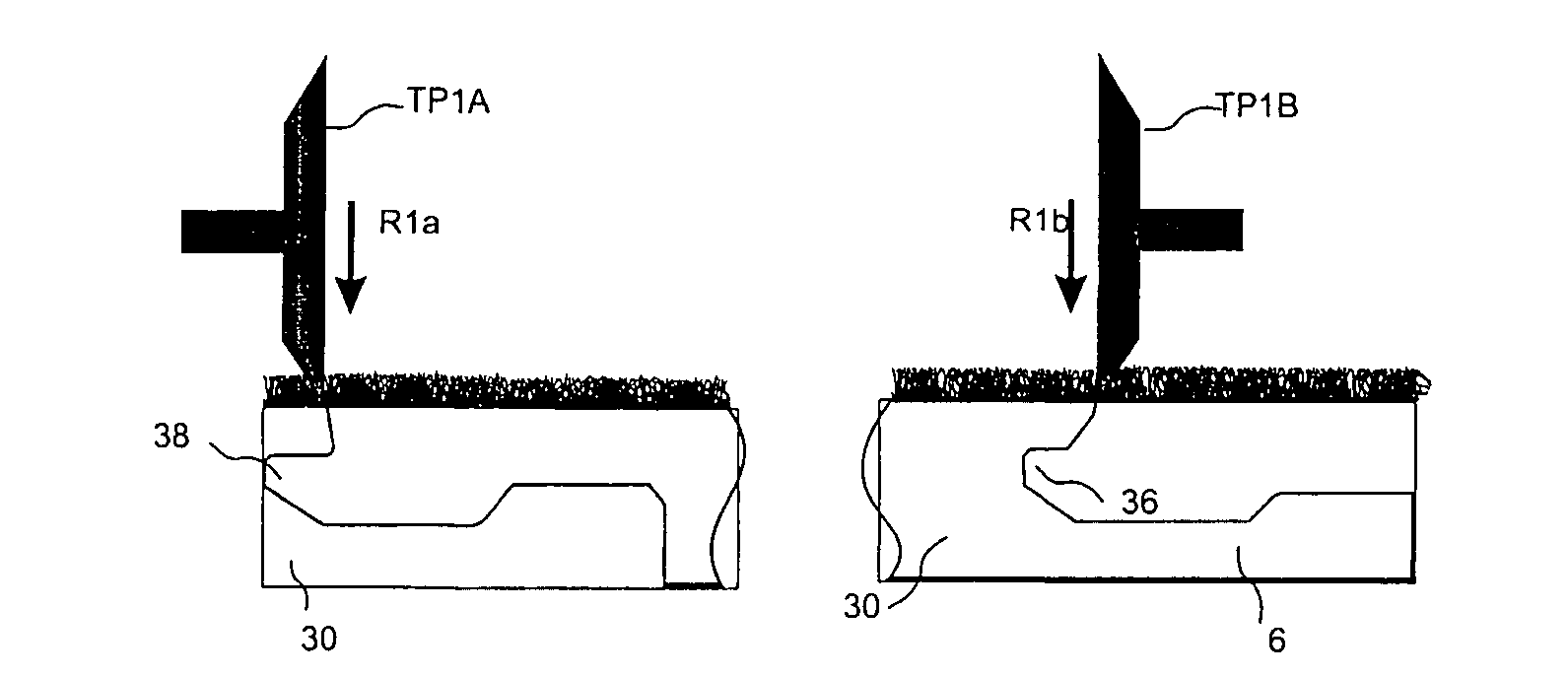

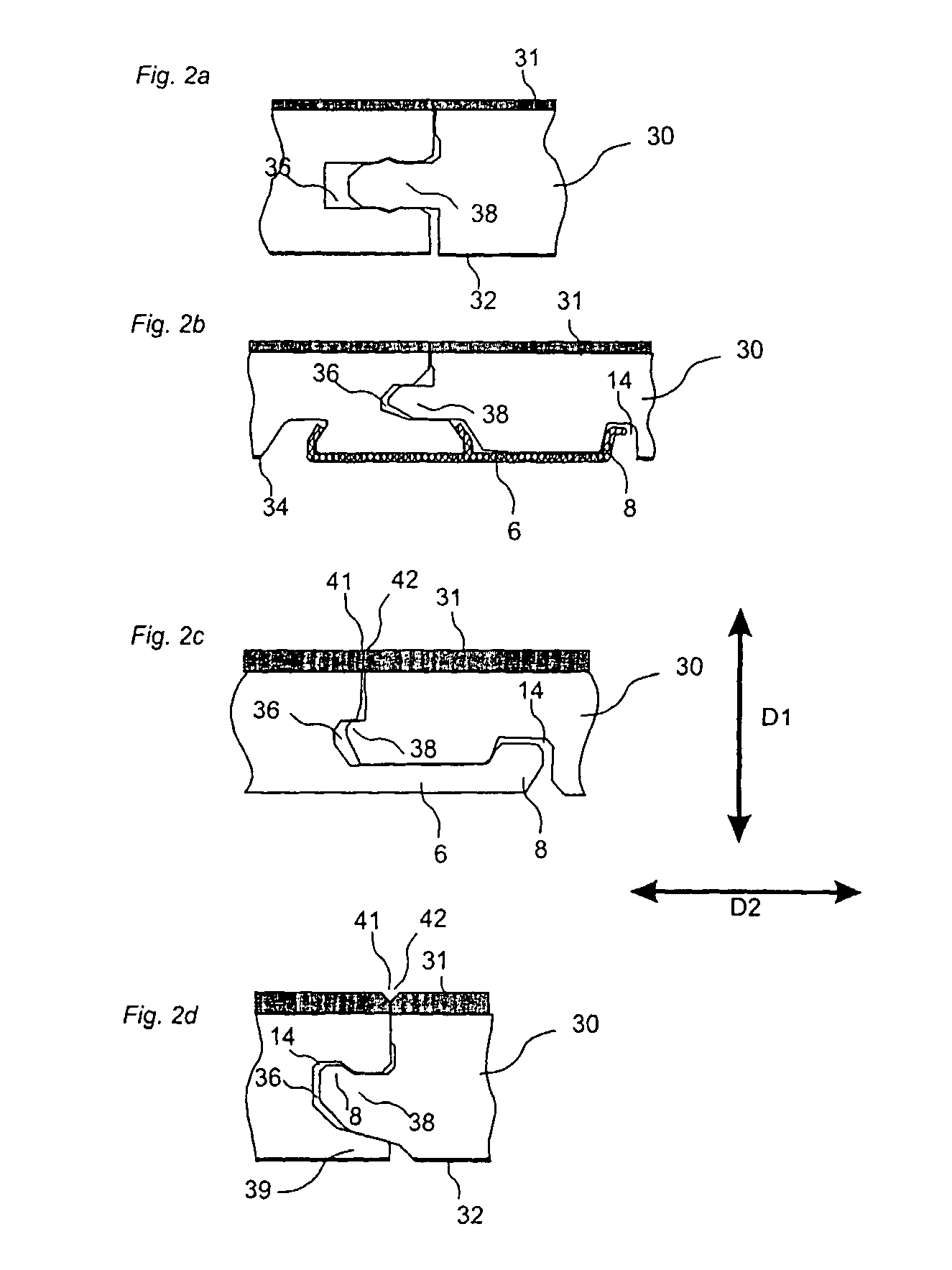

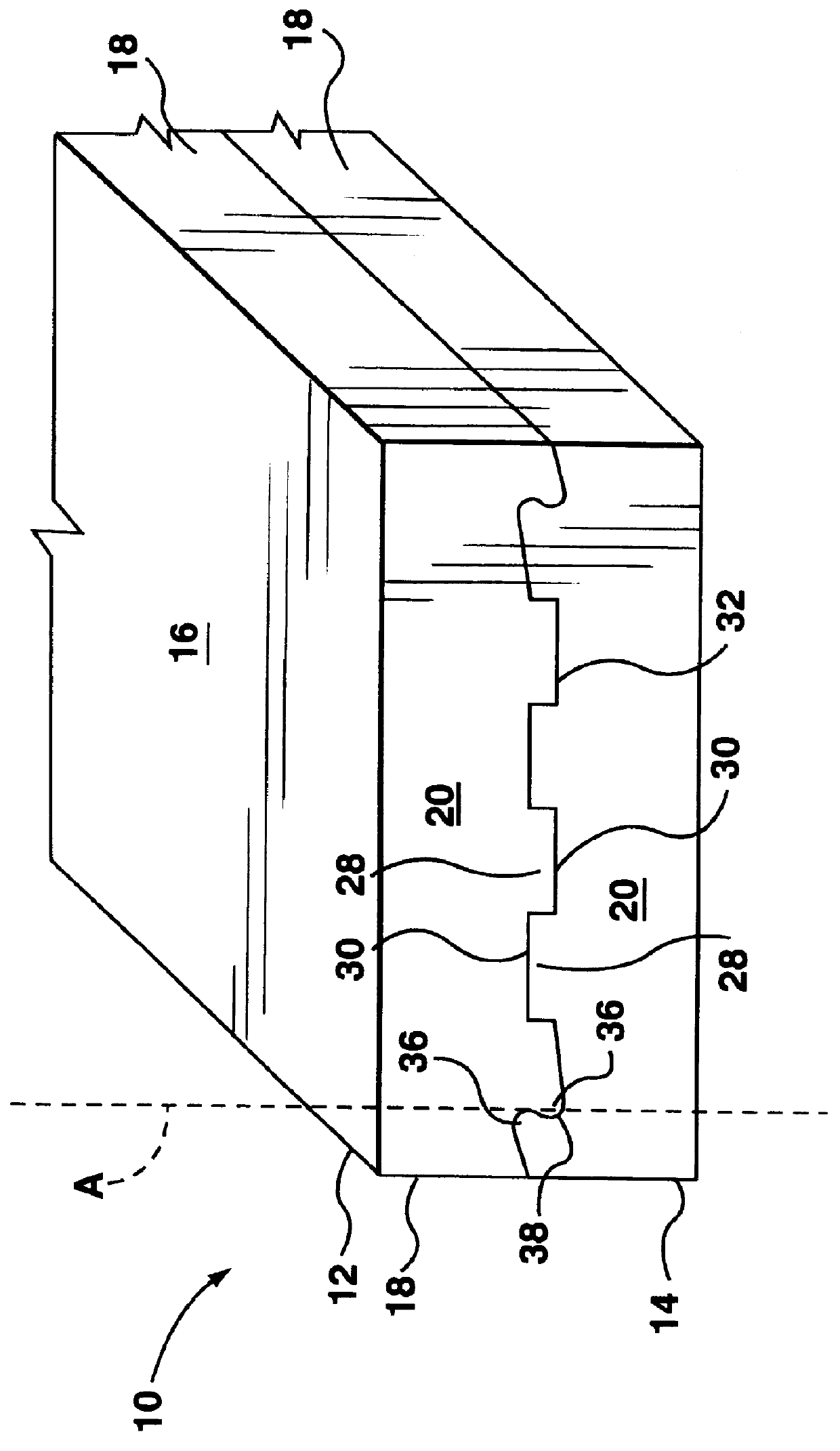

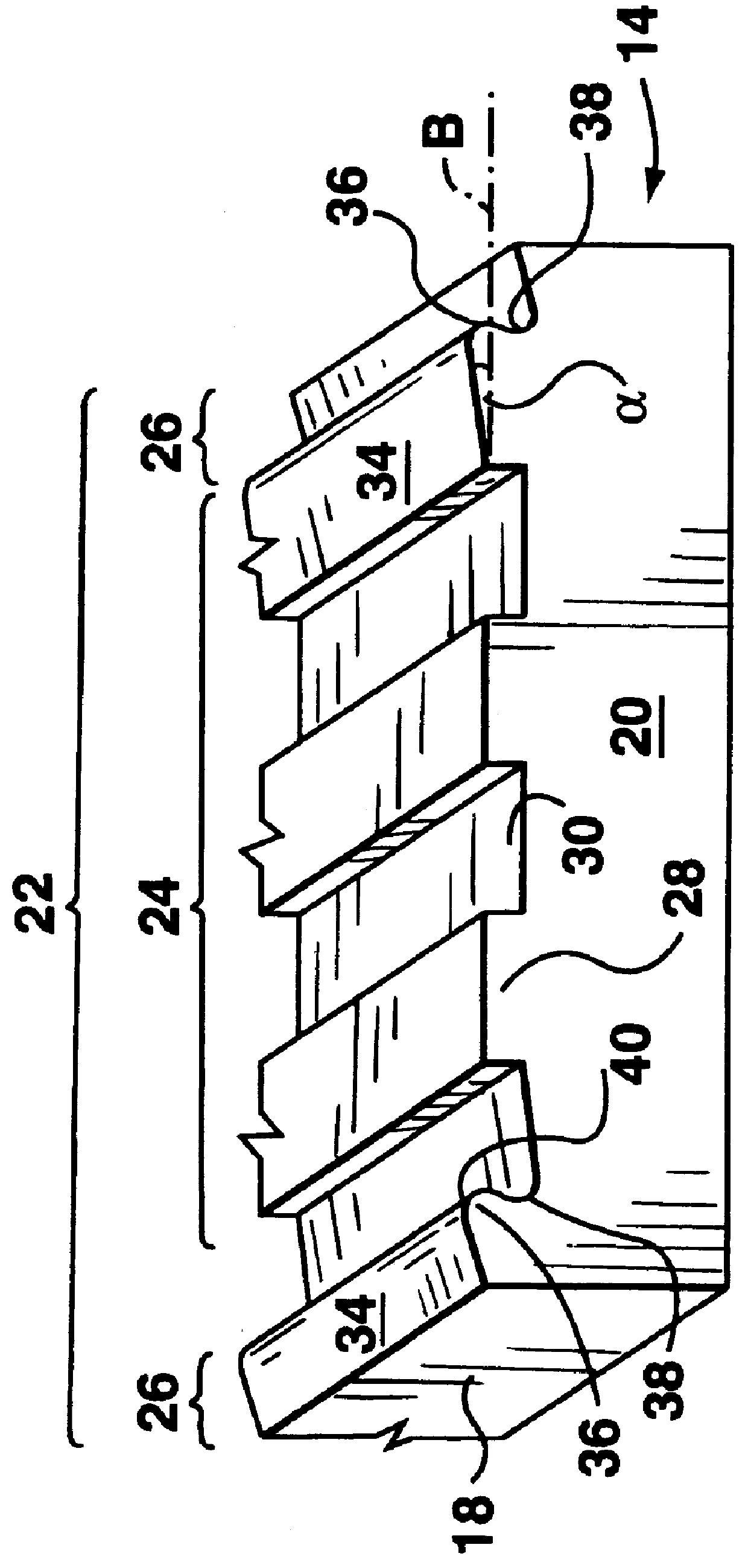

The invention relates to a locking system for mechanical joining of floorboards (1, 1′) which have a body (30), a lower balancing layer (34) and an upper surface layer (32). A strip (6) is integrally formed with the body (30) of the floorboard (1) and extends under an adjoining floorboard (1′). The strip (6) has a locking element (8), which engages a looking groove (14) in the underside of the adjoining floorboard (1′) and forms a horizontal joint. A tongue (38) and a tongue groove (36) form a vertical joint between upper and lower plane-parallel contact surfaces (43, 45) and are designed in such manner that the lower contact surfaces (45) are on a level between the upper side of the locking element (8) and a plane containing the underside (3) of the floorboard. The invention also relates to a floorboard having such a locking system, a floor made of such floorboards, as well as a method for making such a locking system.

Owner:VÄLINGE INNOVATION AB

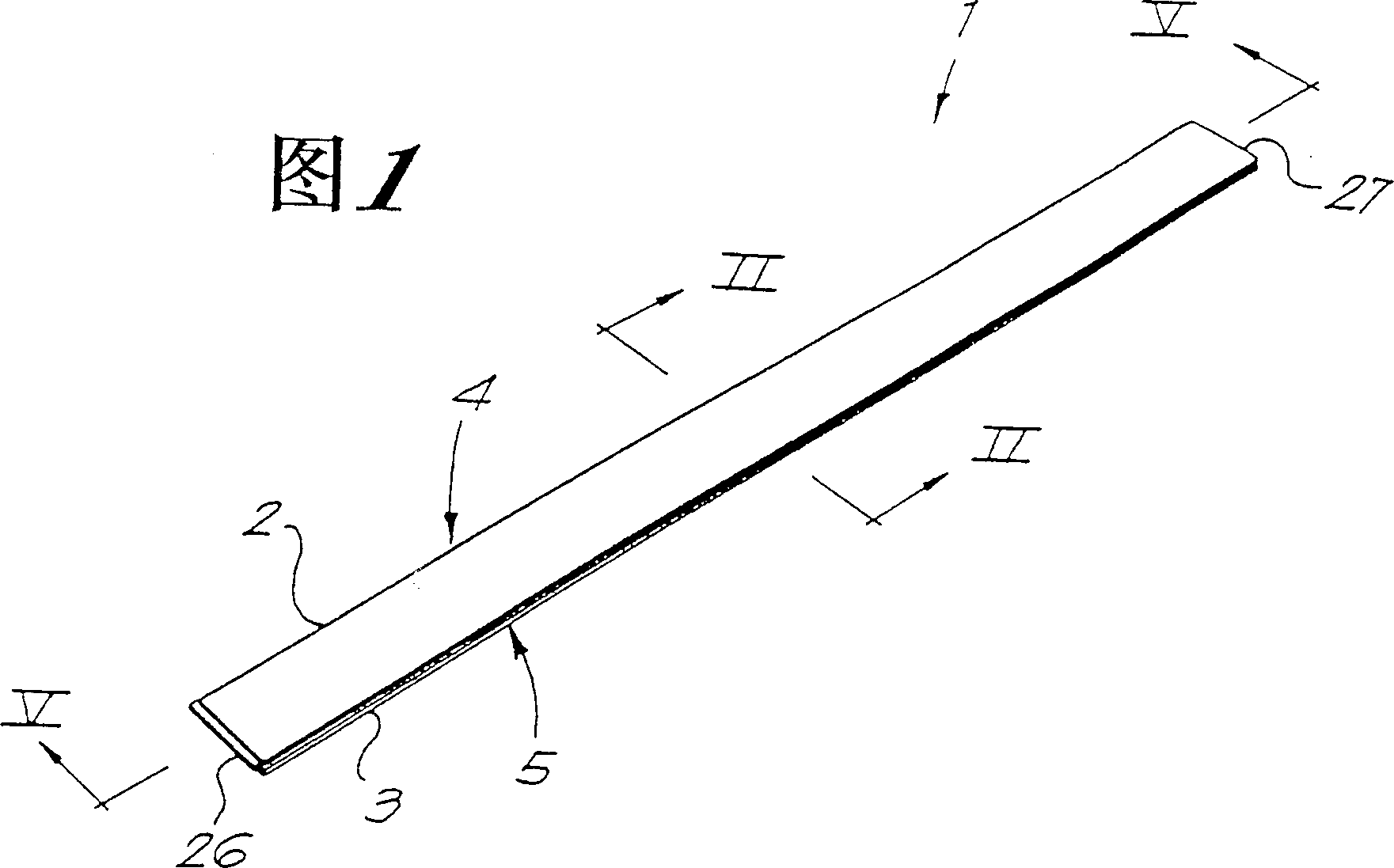

Floorboards with decorative grooves

ActiveUS20060048474A1Rational and cost-efficientEasy to cleanTongue/grooves making apparatusWallsSurface layerEngineering

Floorboards are shown, which consist of a core and a surface layer and are provided with decorative joint edges which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Locking system for mechanical joining of floorboards and method for production thereof

InactiveUS20050034404A1Reduce riskReduce thicknessRoof covering using tiles/slatesStrutsSurface layerEngineering

The invention relates to a locking system for mechanical joining of floorboards (1, 1′) which have a body (30), a lower balancing layer (34) and an upper surface layer (32). A strip (6) is integrally formed with the body (30) of the floorboard (1) and extends under an adjoining floorboard (1′). The strip (6) has a locking element (8), which engages a looking groove (14) in the underside of the adjoining floorboard (1′) and forms a horizontal joint. A tongue (38) and a tongue groove (36) form a vertical joint between upper and lower plane-parallel contact surfaces (43, 45) and are designed in such manner that the lower contact surfaces (45) are on a level between the upper side of the locking element (8) and a plane containing the underside (3) of the floorboard. The invention also relates to a floorboard having such a locking system, a floor made of such floorboards, as well as a method for making such a locking system.

Owner:VÄLINGE INNOVATION AB

Floor covering and locking systems

ActiveUS20080168737A1Remove changeChange shapeTongue/grooves making apparatusWallsEngineeringMechanical engineering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Floorboard and method for manufacturing thereof

ActiveUS20080000188A1Reduce sound levelAttractive appearanceTongue/grooves making apparatusWallsEngineeringMechanical engineering

Floorboards with a surface of flexible fibers for laying a mechanically joined floating floor, and methods for manufacturing and profloorings containing such floorboards.

Owner:VÄLINGE INNOVATION AB

Floor covering and locking systems

InactiveUS20050166516A1Remove changeChange shapeTongue/grooves making apparatusWallsEngineeringMechanical engineering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Floor covering and locking systems

ActiveUS8495849B2Remove changeChange shapeTongue/grooves making apparatusWallsMechanical engineeringFloor covering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Method for manufacturing floorboard having surface layer of flexible and resilient fibers

ActiveUS8112891B2Reduce sound levelAttractive appearanceTongue/grooves making apparatusWallsFiberMoving floor

Owner:VÄLINGE INNOVATION AB

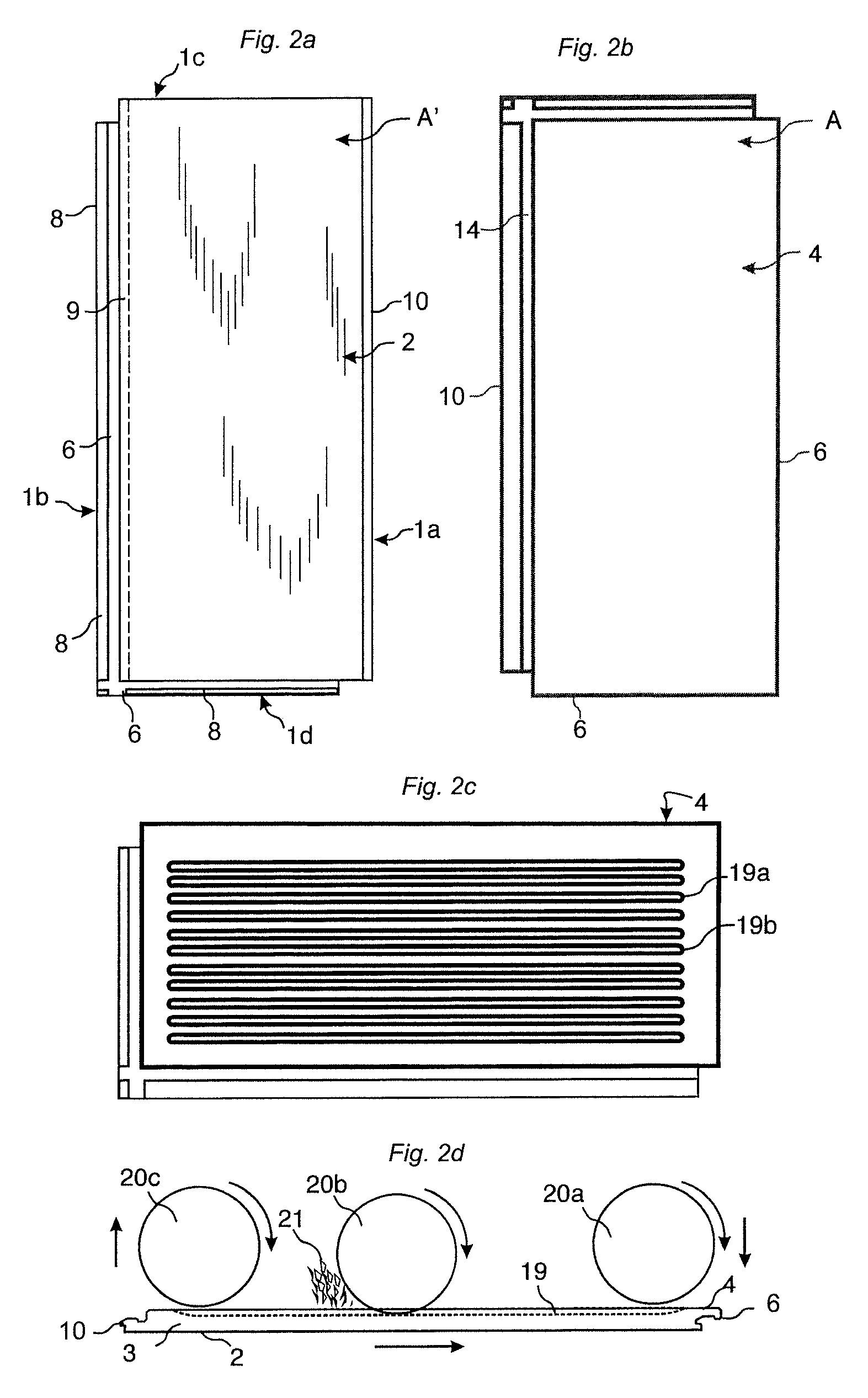

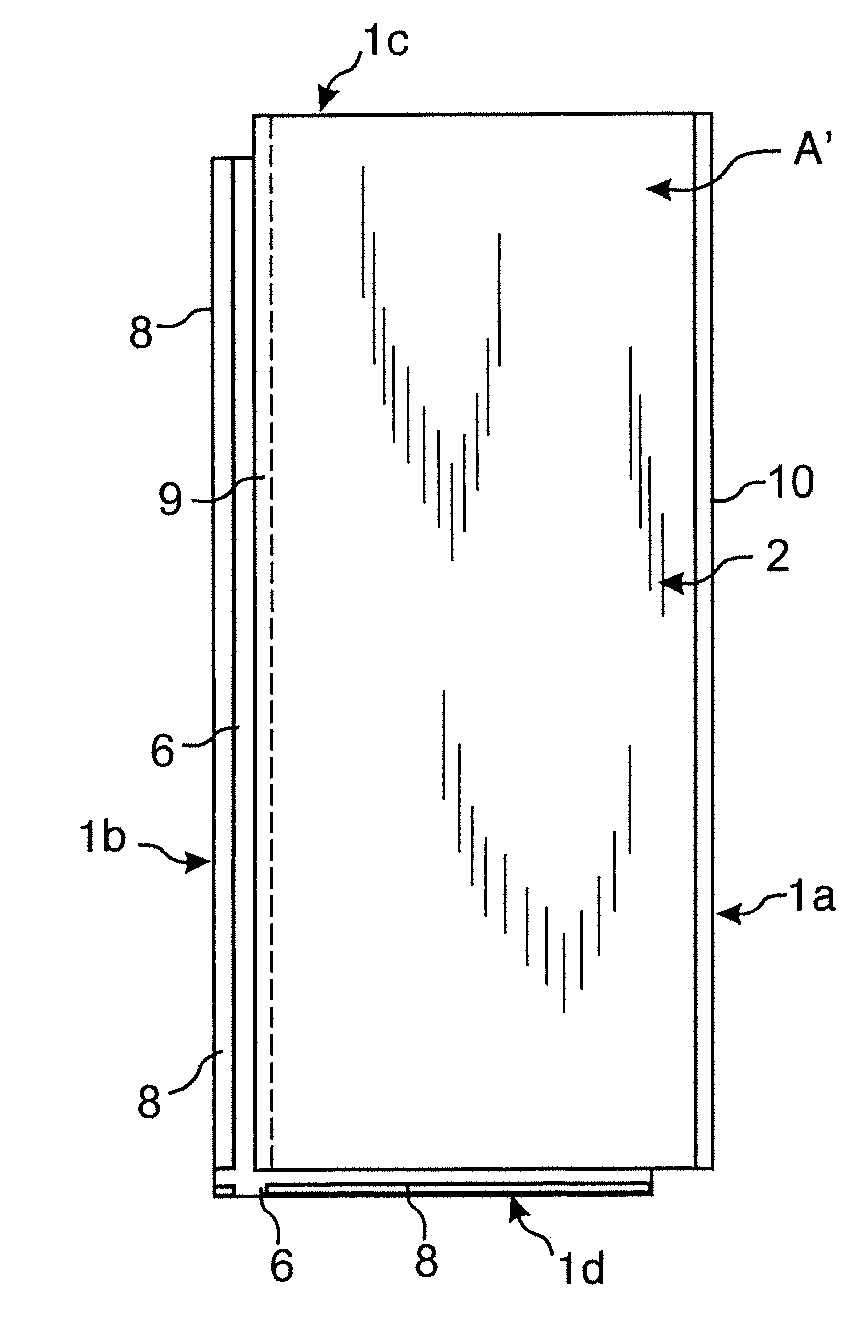

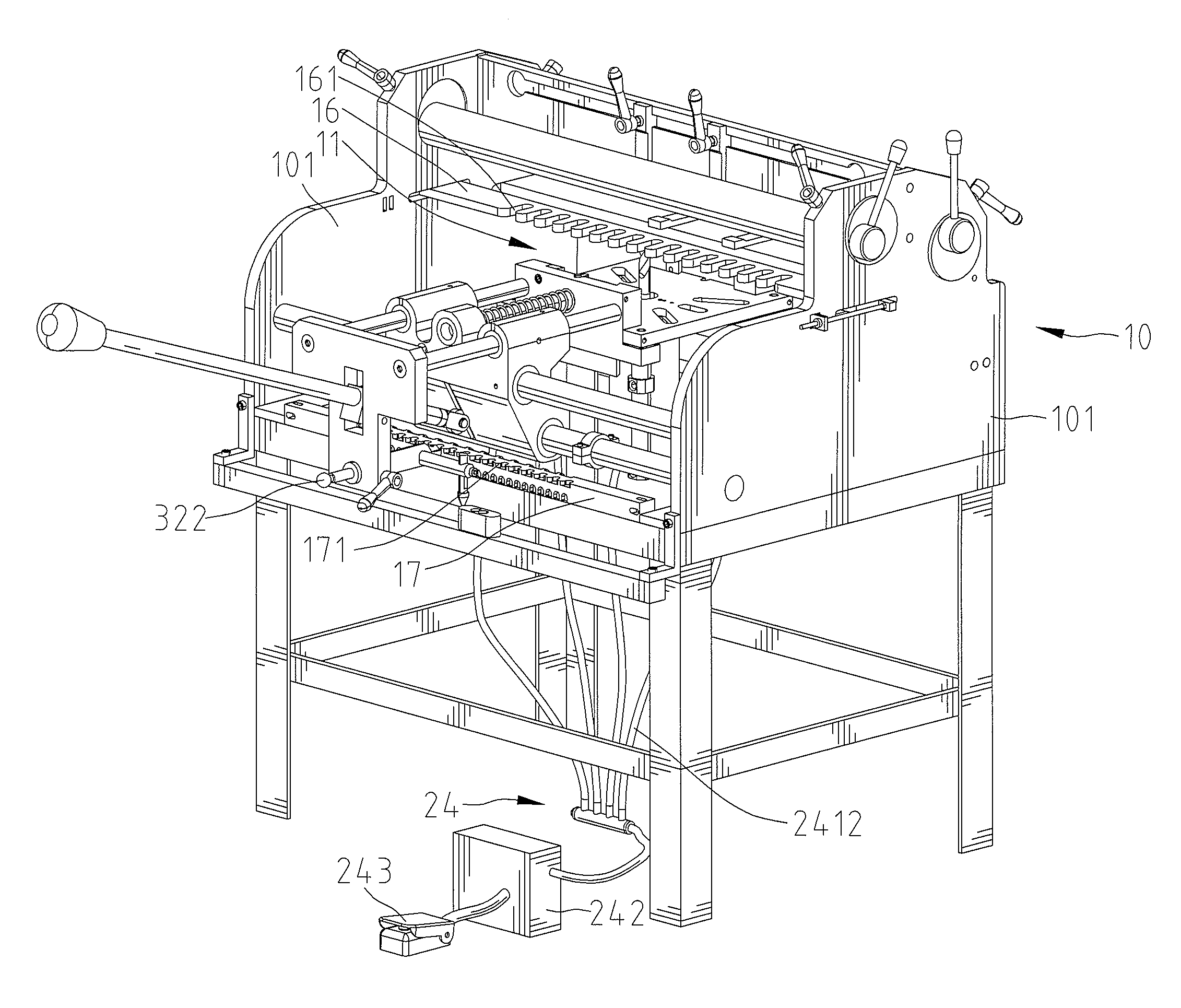

Methods and arrangements relating to edge machining of building panels

ActiveUS20110023303A1Reduce negative impactTongue/grooves making apparatusDomestic articlesSurface layerStructural engineering

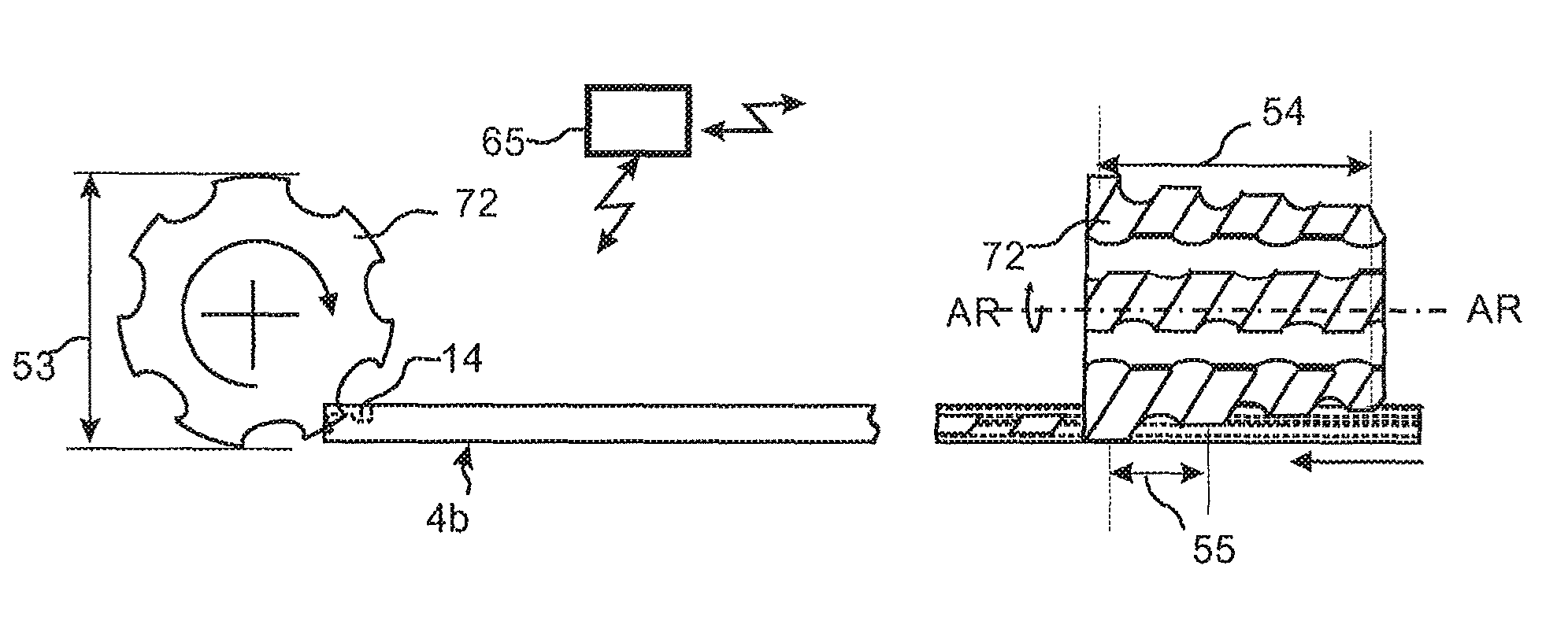

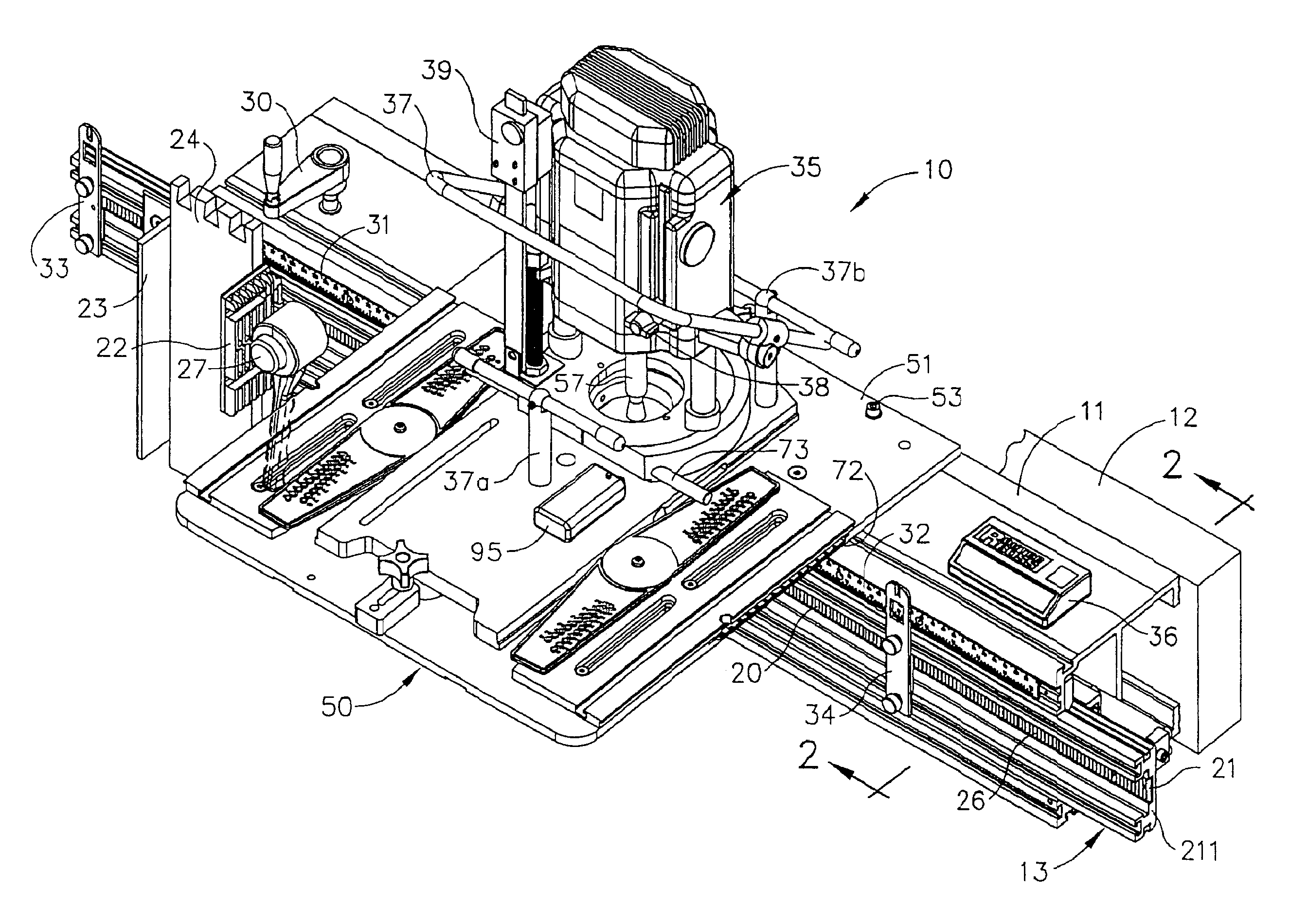

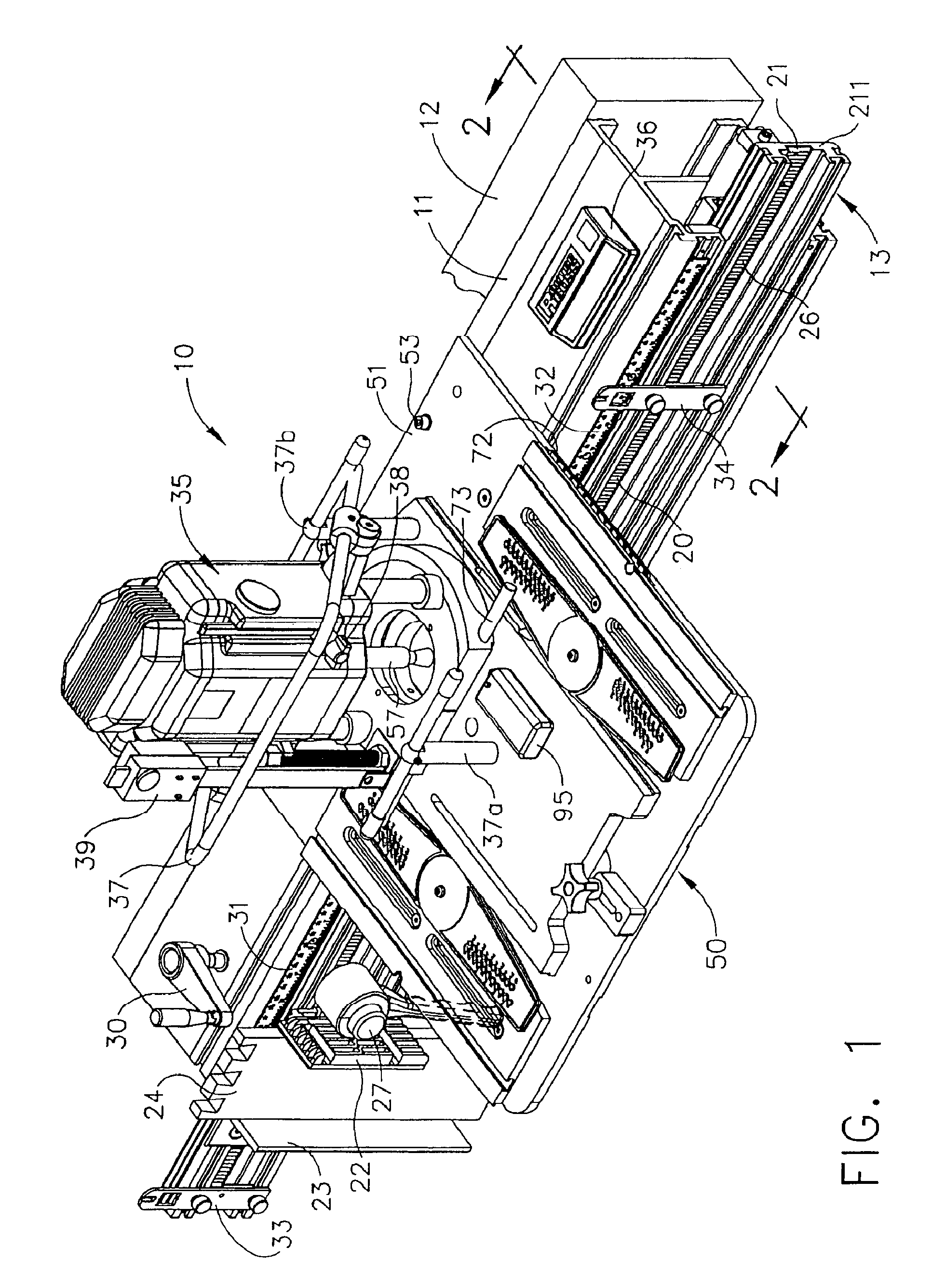

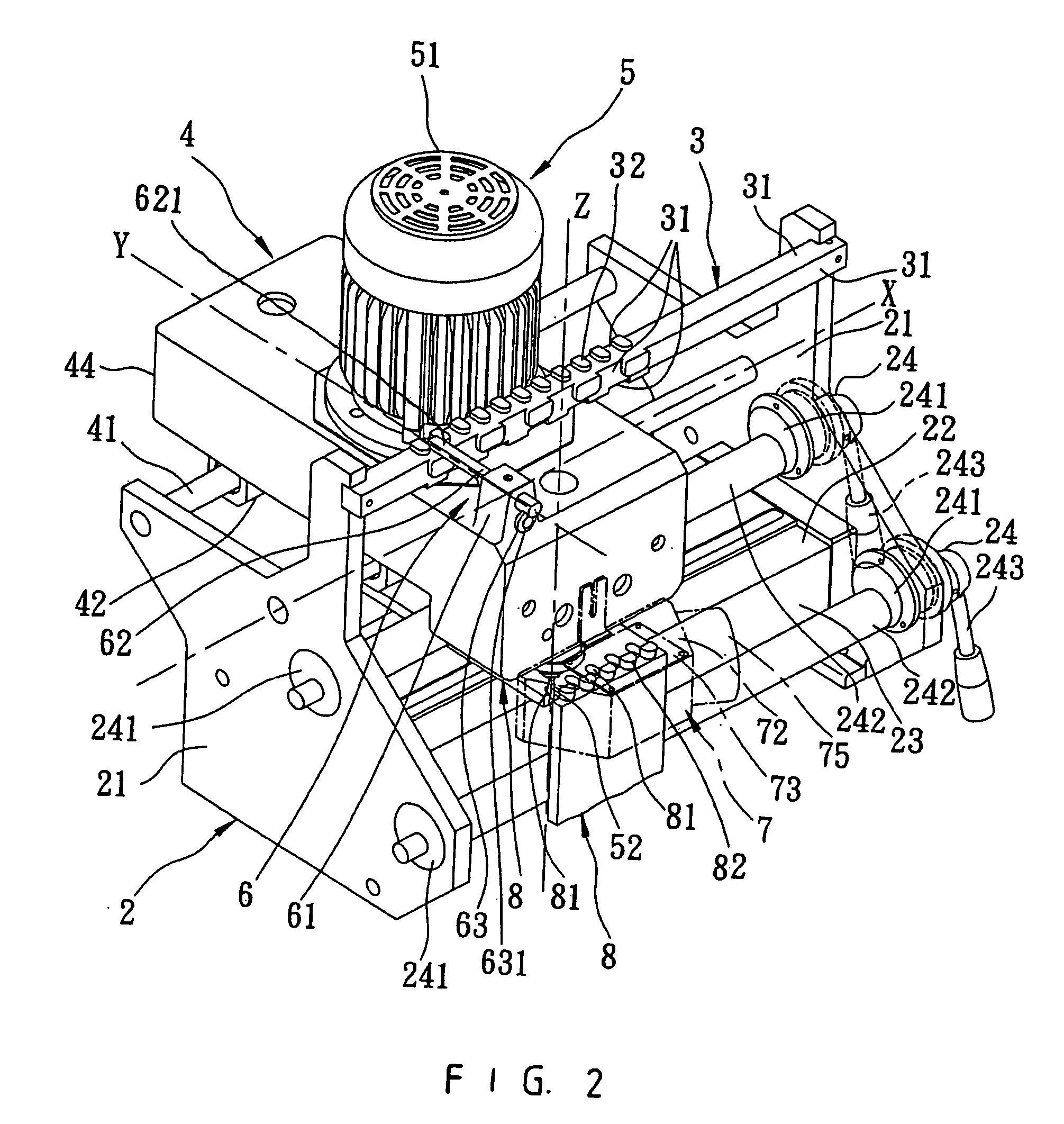

A tool configuration incorporating a preprocessing step and a method incorporating the tool configuration with its preprocessing step, producing an improved locking system of a floor panel. With the special tool configuration, and the preprocessing step changing the properties of the surface layer, certain surfaces are profiled of the joint edge of the floor panel, resulting in decreased tolerances. Further, equipment having an upper belt or chain guided in a horizontal direction, by an upper guiding device, and configured to press the floor panel vertically towards the lower chain, decreasing the tolerances of the produced floor panel as well.

Owner:VÄLINGE INNOVATION AB

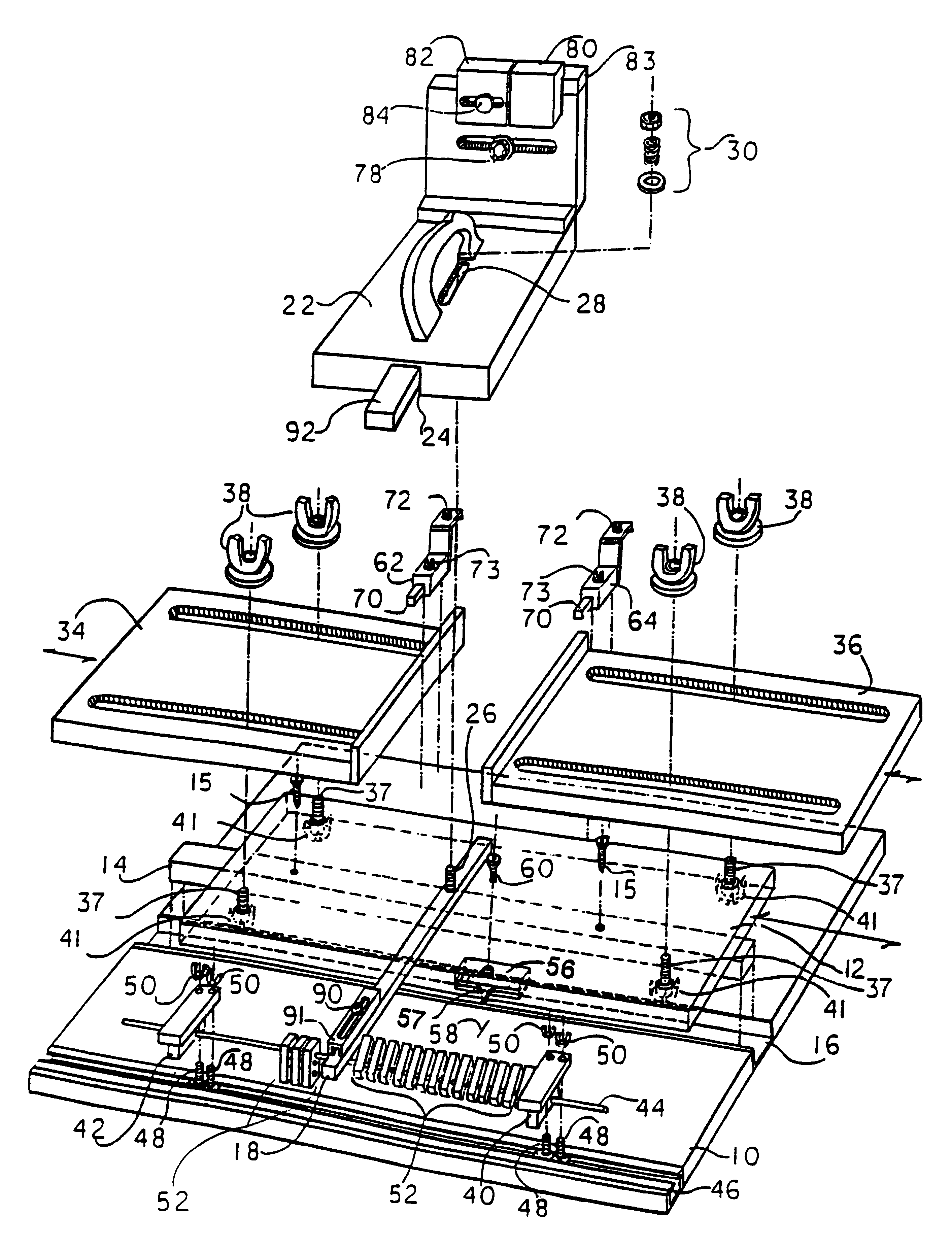

Jig system for positioning the placement of multiple cuts in a workpiece

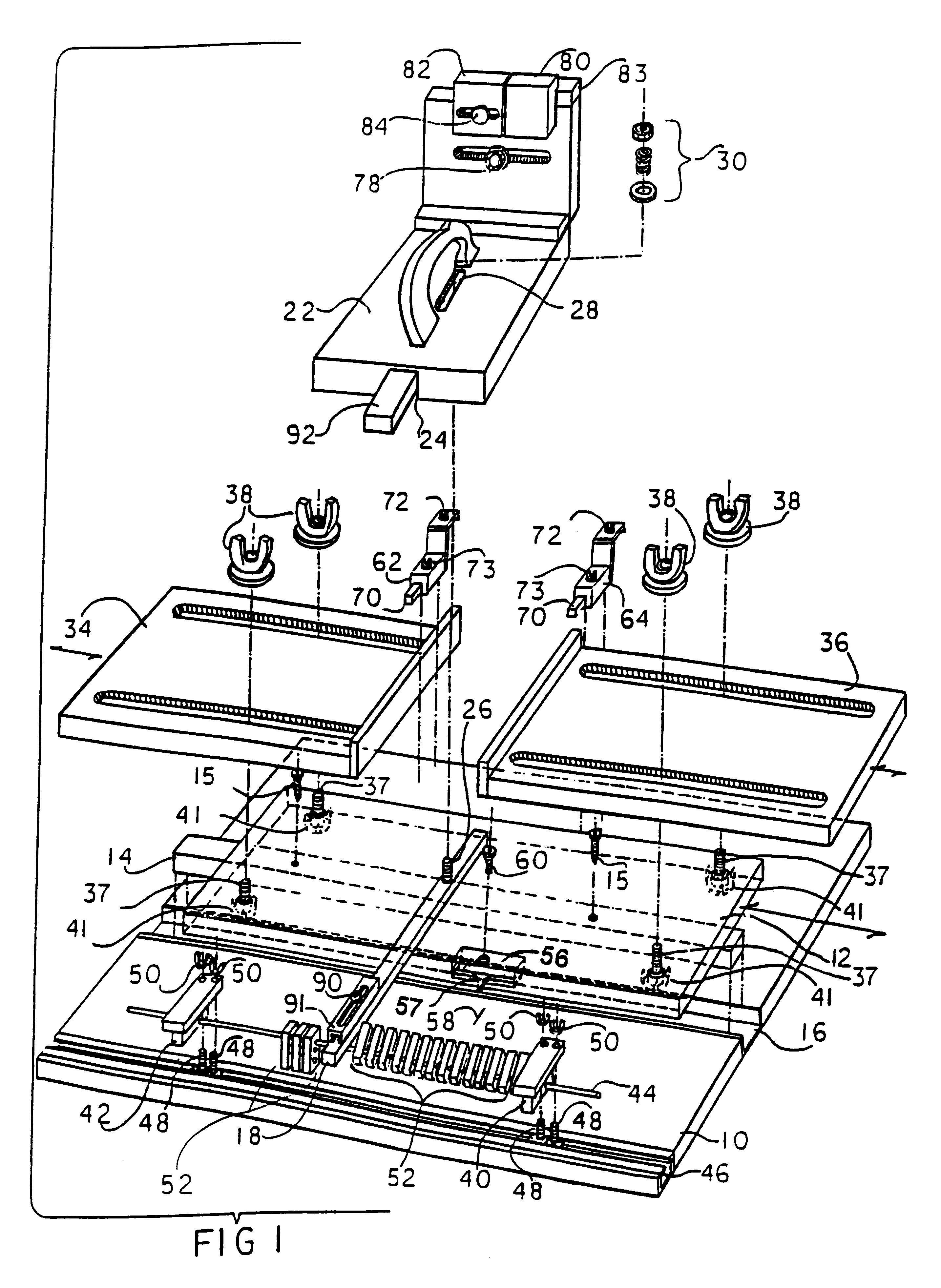

InactiveUS6206060B1Reduce lateral movementGreat accuracy positioningDrilling/boring measurement devicesTongue/grooves making apparatusEngineeringDovetail joint

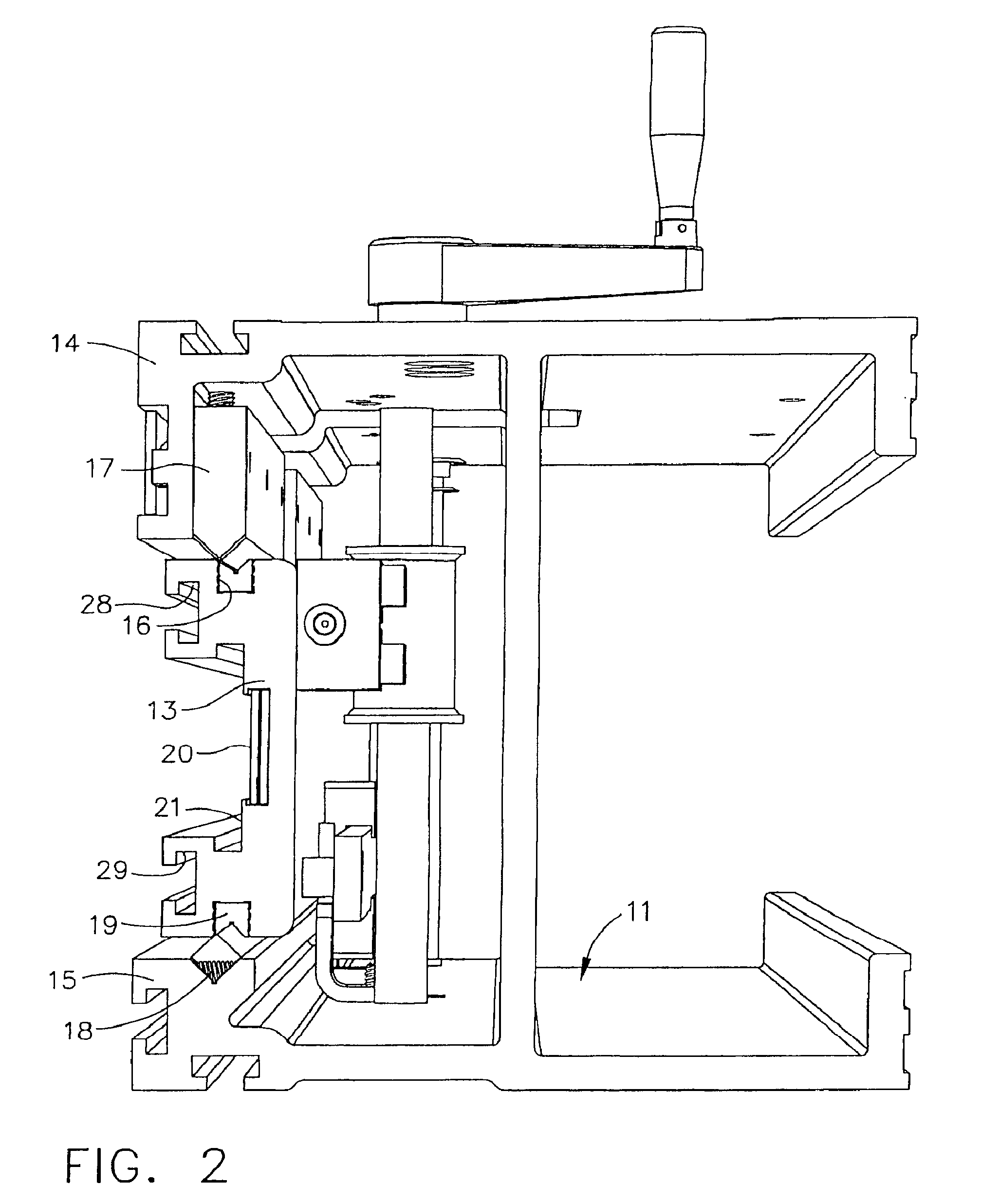

The present invention is a jig system for precisely positioning the placement of multiple cuts such as in the placement of dovetail or box joints cut in a wood panel. A row of multi-use adjustable spacers controls the indexing of a workpiece and can be used with a stationary and / or a portable cutting tool. The movability of the spacers permits a workpiece to be cut on both sides of a guide bar fence thereby assuring that the first cut will always be made on the same side of a drawer and will be esthetically pleasing regardless of the width of the workpiece. Additionally, the adjustability of the spacers accommodates any desired cutting tool height, angle and / or size. The jig system comprises: a stationary fixture; a spacer bar; a plurality of spacers engaged with the spacer bar, the spacers are adapted for lateral and rotational movement along the spacer bar thereby providing an engaged and non-engaged working mode; a sliding member adapted for lateral movement on the stationary fixture and for engaging at least one of the spacers in the engaged working mode; and means for holding the spacer bar and connecting the spacer bar to the stationary fixture while engaging with at least one of the spacers during the engaged working mode.

Owner:BLAKE F RICHARD

Apparatus for forming dovetail, box and related joints

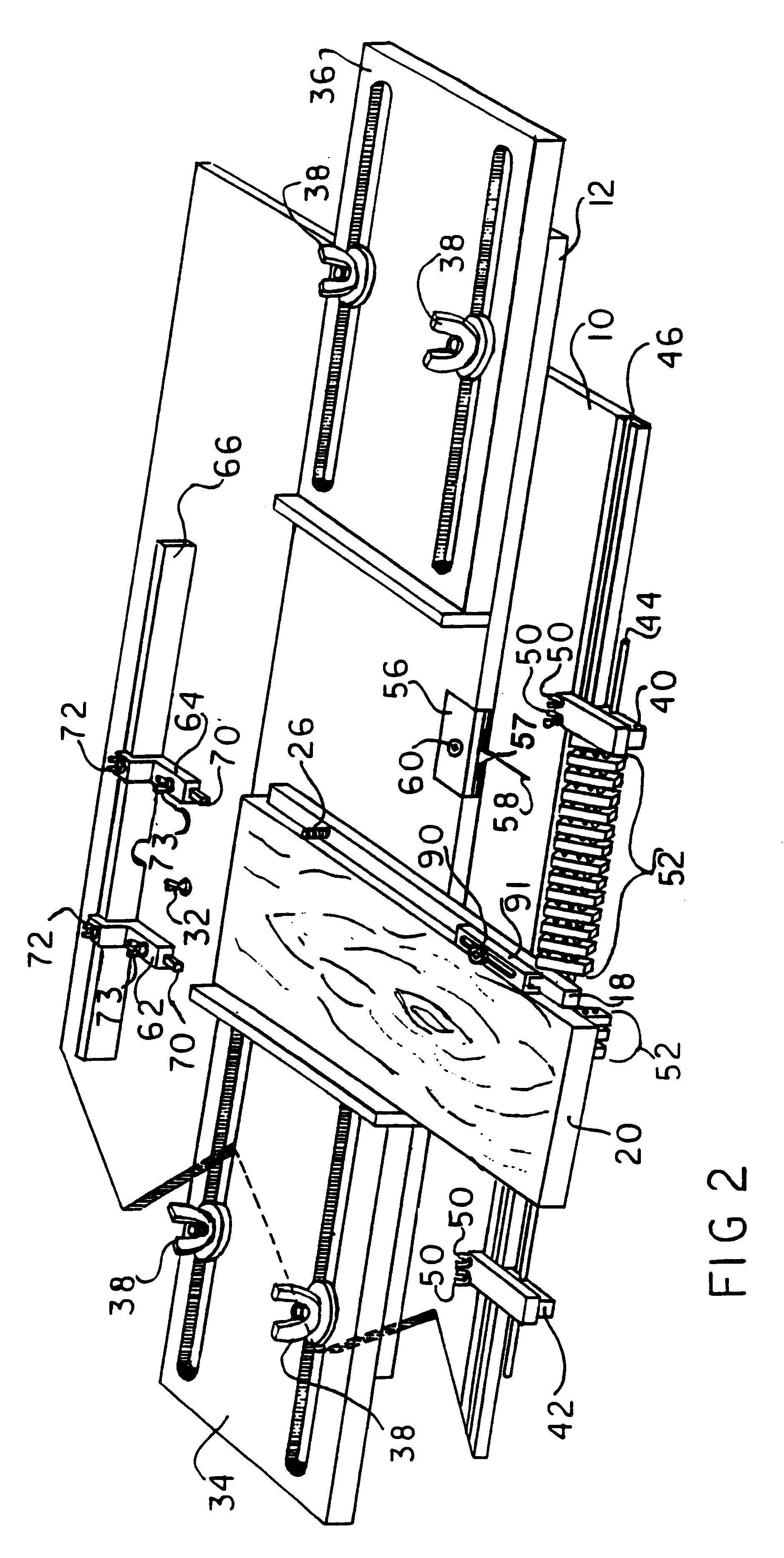

InactiveUS6076575APrecise positioningGood precisionTongue/grooves making apparatusDovetailed workEngineeringMechanical engineering

A jig used to support and guide a router has a support base to which the workpiece is clamped as well as a moveable template containing guiding surfaces for a router. The template is attached to the support base via an elongated support channel. The support channel is permanently attached to the support base and captures two square nuts used to clamp the template to said channel while cutting but allowing the template to be loosened and repositioned between cuts. A bar clamped to the underside of the template is pressed against the channel to align both in parallel and, by virtue of being attached to the template via angled slots, can be used to adjust the position of guiding surfaces in the template relative to the workpiece. The template has a variety of slots and cutouts whose sides guide the router in the making of specific cuts for dovetail, box and related joints. The template is indexed from one cutting position to another by means of a ratchet or equivalent which engages the teeth of a saw tooth rack. The pitch or distance between teeth is precise and carefully chosen in regard to a variety of factors. The jig essentially cuts tails or pins one at a time. Its adjustable nature allows wide variation in joint design including the size and spacing of joint elements.

Owner:HARKNESS RICHARD C

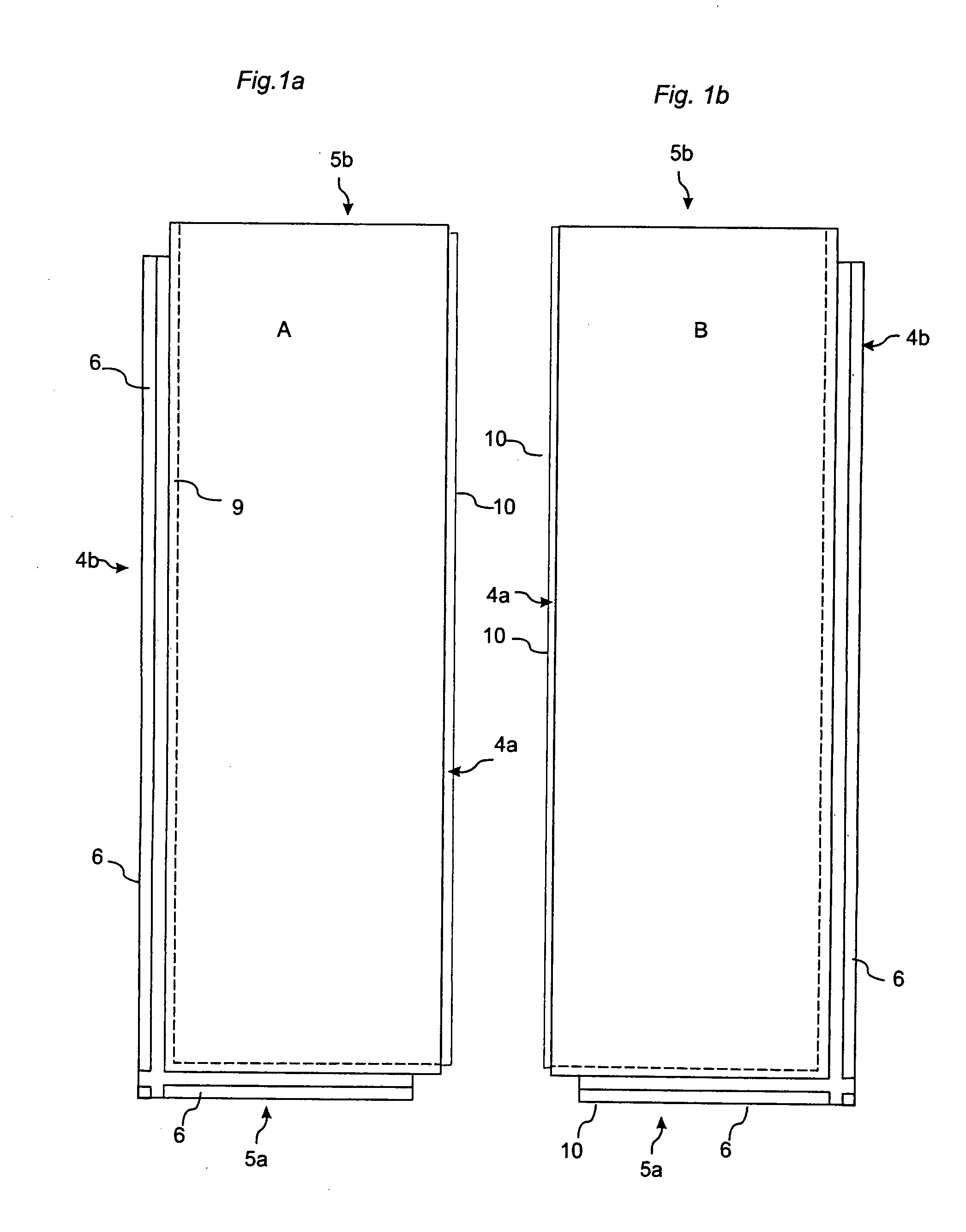

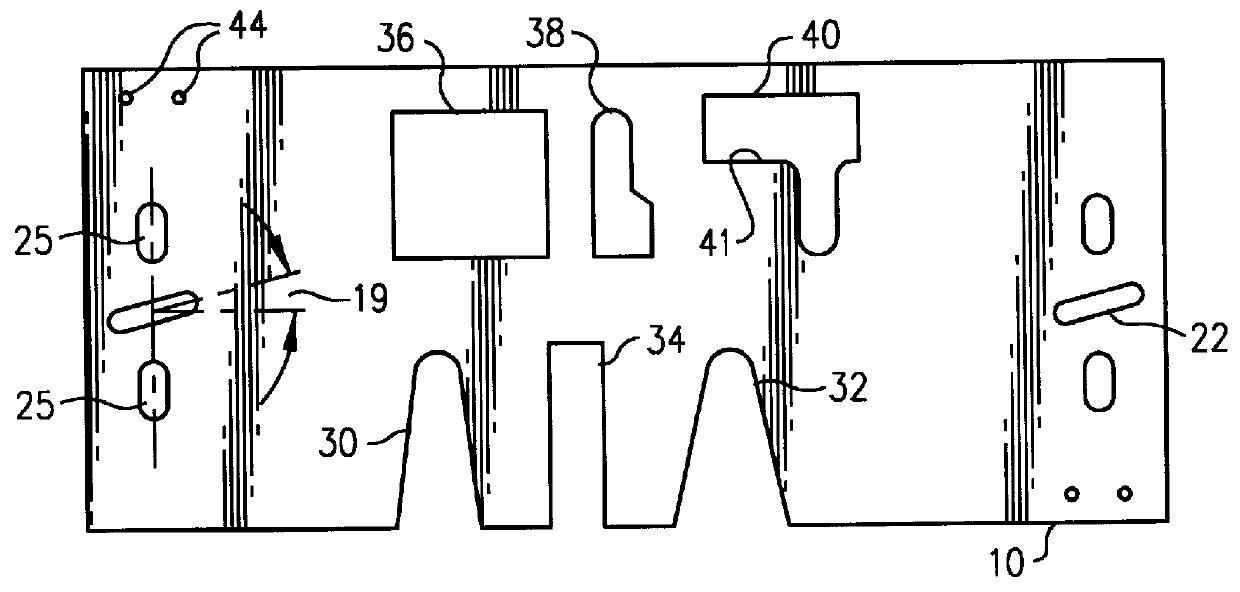

Panel forming

ActiveUS9140010B2Reduce contentReduce weightCovering/liningsTongue/grooves making apparatusDecrease weightEngineering

Building panels, especially laminated floor panels are shown, which are provided with a locking system and several core grooves at the rear side in order to save material and decrease weight.

Owner:CERALOC INNOVATION AB

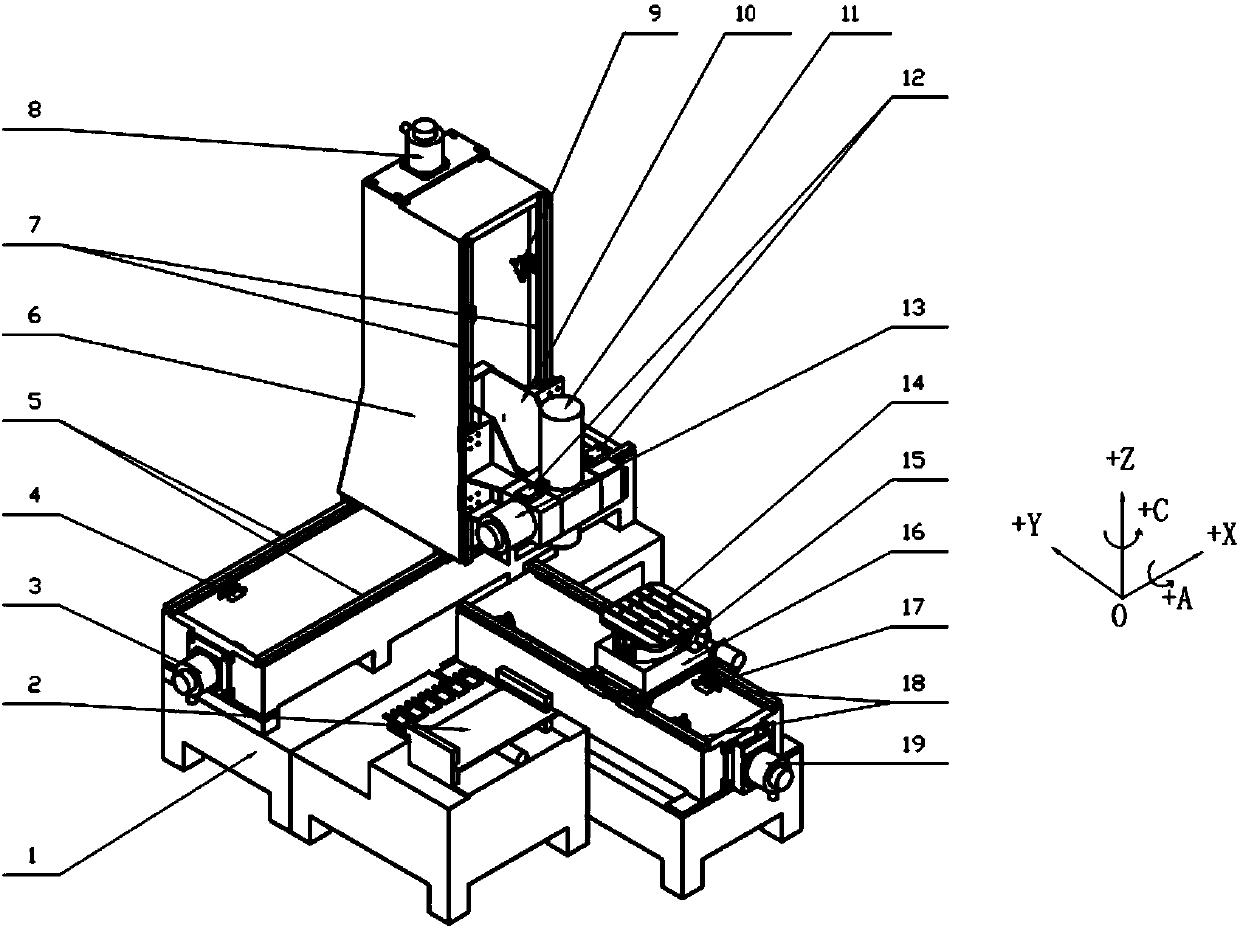

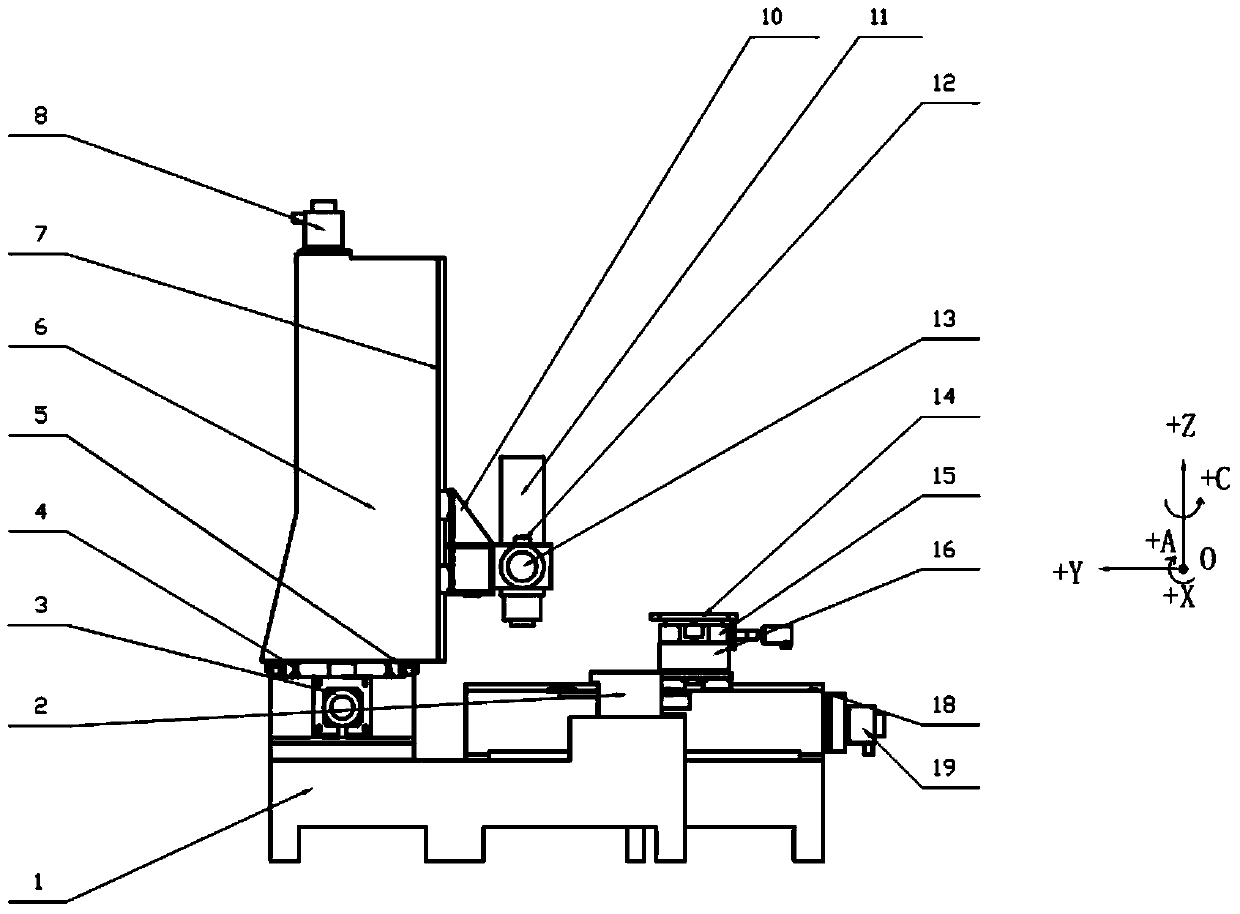

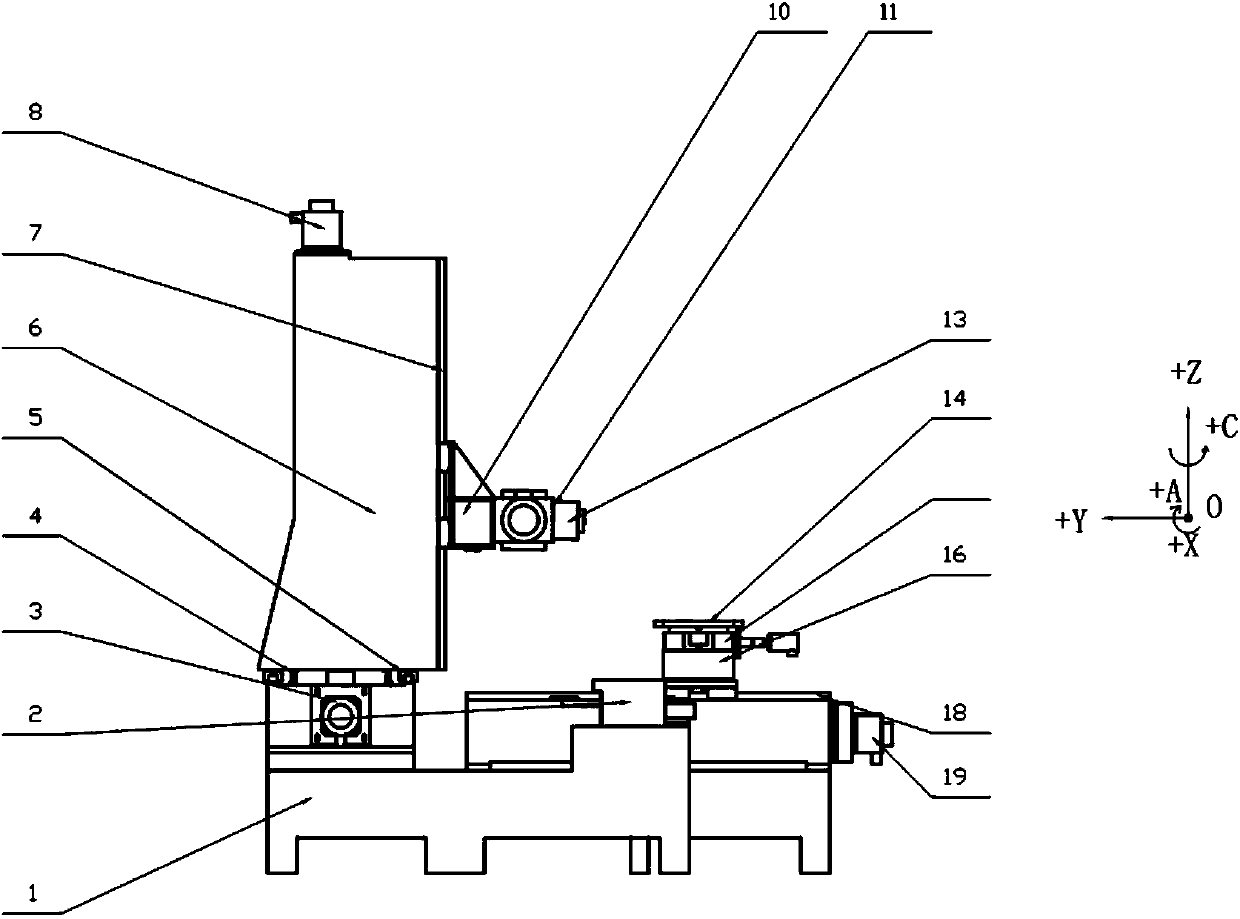

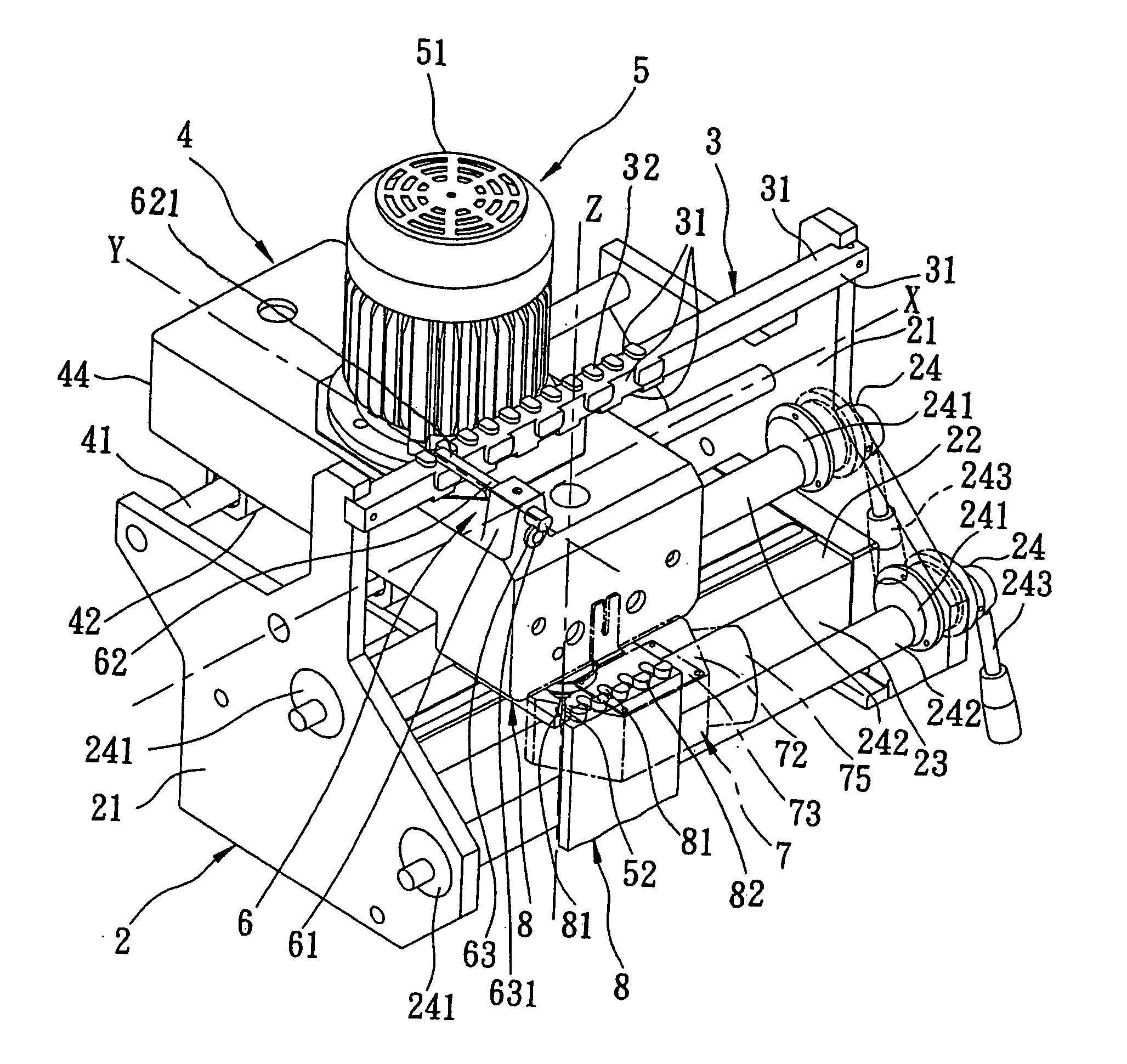

Numerical control five-axis tenon machining machine tool

InactiveCN103802180AImprove machining accuracyPracticalTongue/grooves making apparatusTenon making apparatusNumerical controlMortise and tenon

The invention discloses a numerical control five-axis tenon machining machine tool, and belongs to the technical field of machining machine tools. The numerical control five-axis tenon machining machine tool comprises a machine tool body, upright posts, a rotary positioning turntable, a main shaft component, a tool magazine and a control card used for controlling the machine tool, wherein the upright posts are connected with the machine tool body through X-axial guide rails and move along the X axes under the drive of a drive device; the rotary positioning turntable is connected with the machine tool body through a Y-axial guide rail and moves along the Y axis under the drive of the drive device; the main shaft component is connected with the upright posts through Z-axial guide rails and move along the Z axis under the drive of the drive device; an X-axial guide rail is placed on each of the two cross beams of the machine tool; the upright posts and the cross beams of the machine tool body form guide rail connection; a Y-axial guide rail is placed on each of the two longitudinal beams of the machine tool body; a Y-axial sliding plate and the longitudinal beams of the machine tool body form guide rail connection. The numerical control five-axis tenon machining machine tool can implement the three-dimensional five-axis cutting machining on a complex tenon structure, and the machining level of the machine tool is higher. According to the machine tool, the self gravity of the machine tool is greatly reduced without influencing the use precision of the machine tool.

Owner:刘岩松

Floor made of hard floor boards and production process of the floor board

InactiveCN1399051AEasy to processCooperate accuratelyTongue/grooves making apparatusWallsClipping - actionEngineering

A method for linking rigid flooring panels has interlocking edge profiles. One edge has a shaped groove in the support layer, into which is clipped a profiled lip of the adjoining panel. The lip and groove are linked by a tilt and clip action resulting in a tension grip between the lip and groove profiles. This ensures that the butting edges of the panels are pulled together at all times, even with the expansion and shrinking of the panels with weathering. The panels present a gap free fitting under all conditions, and can be lifted for repair.

Owner:UNILIN BEHEER

Panel forming

ActiveUS20140000197A1Reduce contentReduce weightCovering/liningsTongue/grooves making apparatusDecrease weightEngineering

Building panels, especially laminated floor panels are shown, which are provided with a locking system and several core grooves at the rear side in order to save material and decrease weight.

Owner:CERALOC INNOVATION AB

Wood Working Machine

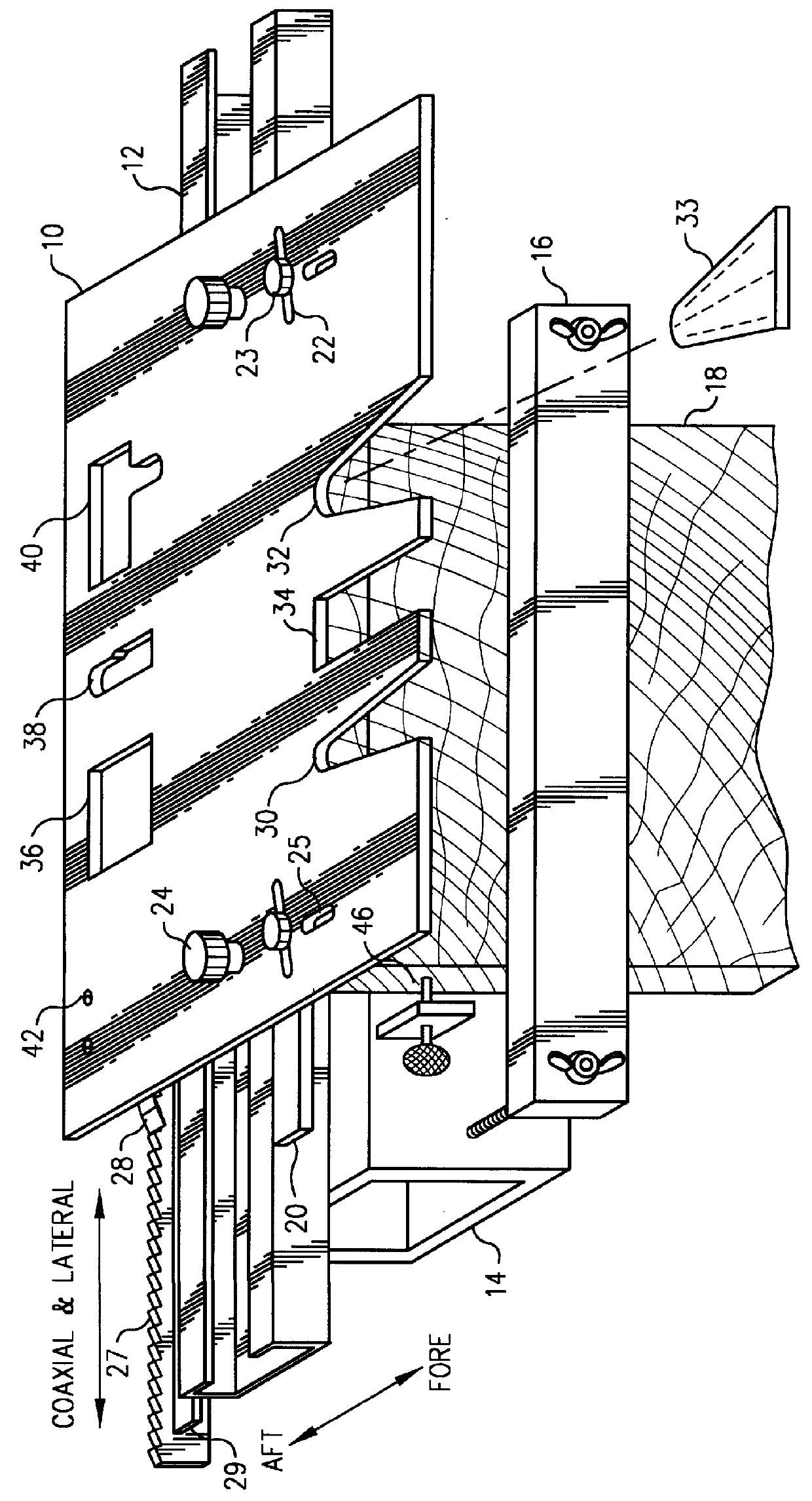

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

Method for laying and interlocking panels

InactiveUS7065935B2Easy to processImprove surface qualityTongue/grooves making apparatusWallsSlope positionSurface plate

Owner:AKZENTA PANEELE PROFILE GMBH

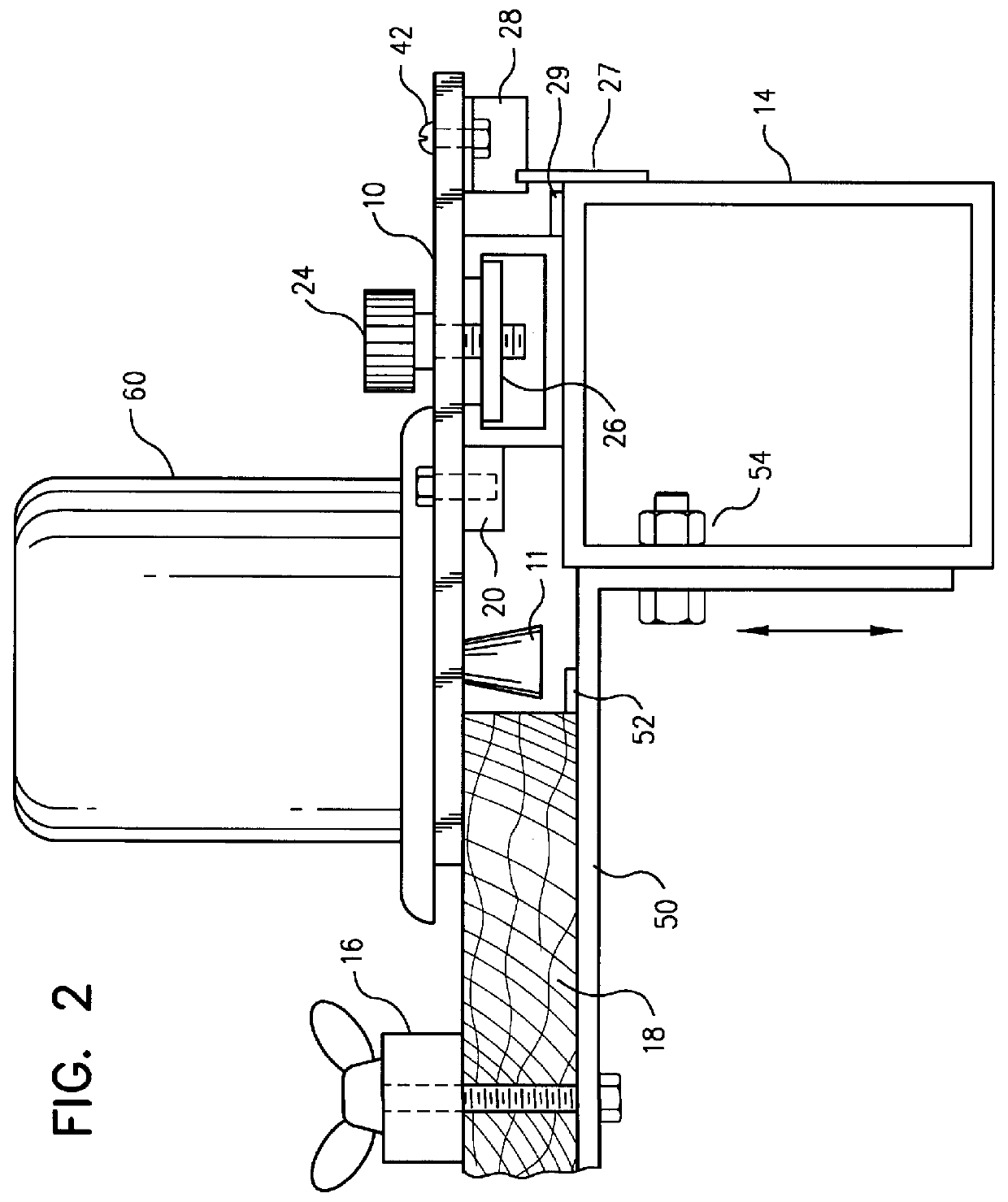

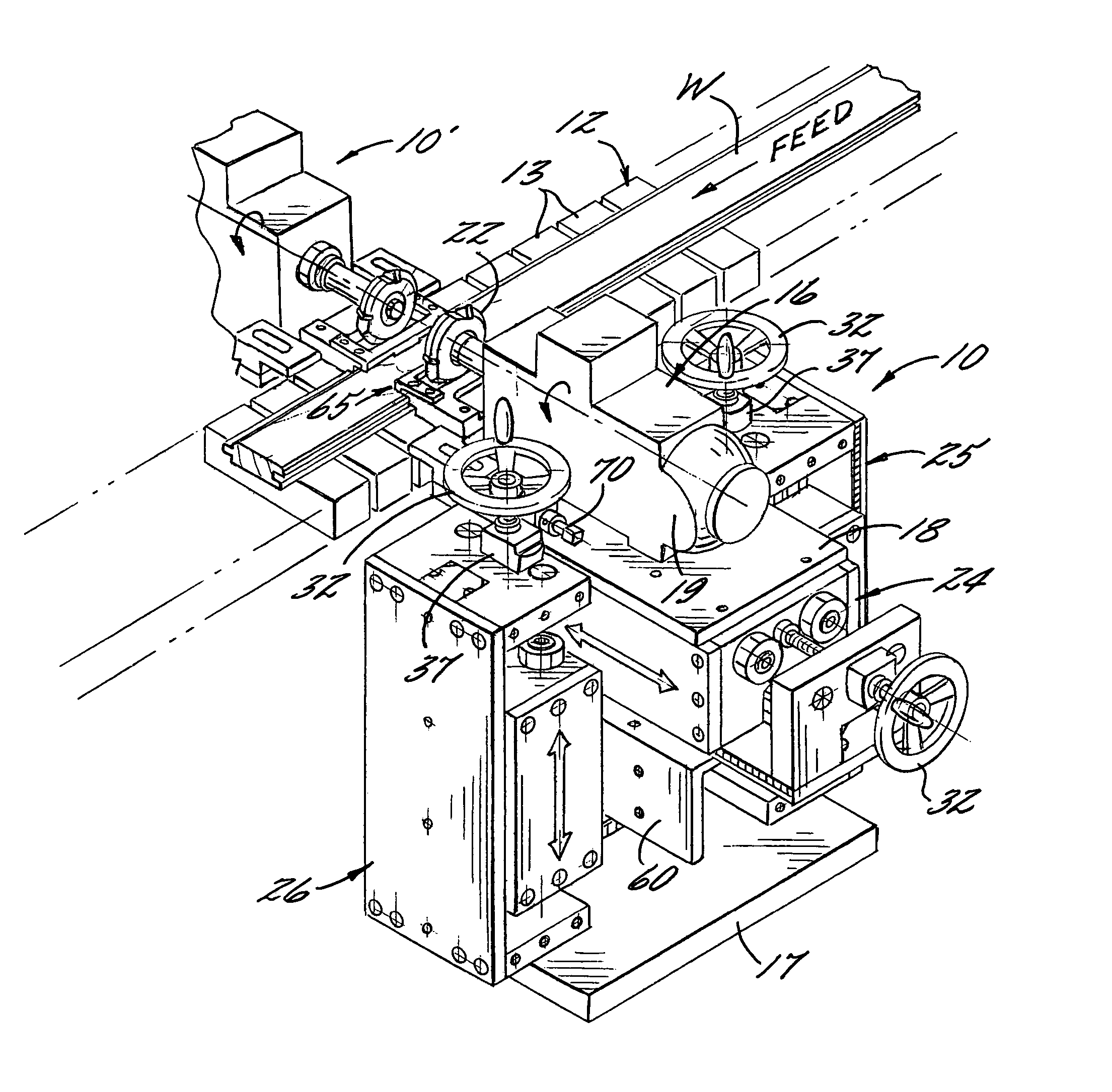

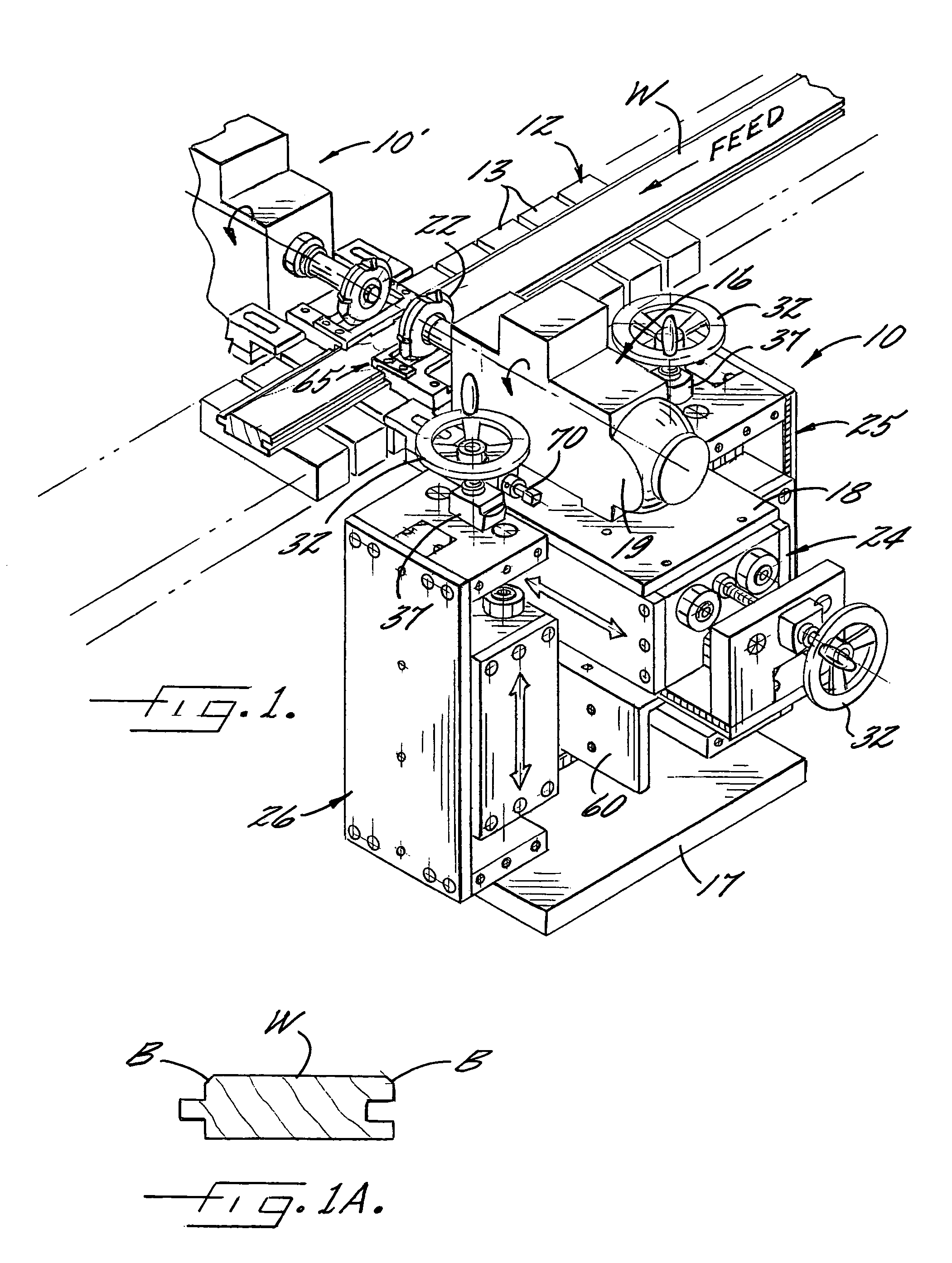

Semi-automatic mortising machine

InactiveUS20050022899A1Easy constructionReduce the possibility of failureTongue/grooves making apparatusMulti-purpose machinesMortise and tenonMortising machine

A semi-automatic mortising machine includes a support base, a support bar, a guide device, a working device, a distance adjusting device, and a dust collection box. Thus, the displacement direction can be controlled in a manual manner during the working process, and the cutting operation is performed in an automatic manner, so as to cut the mortises and tenons in the workpiece.

Owner:CHANG CHI LO

Wood article and method of manufacture

InactiveUS6125607ALow costElement becomes smallTongue/grooves making apparatusWallsAdhesiveEngineering

A wood member comprises first and second opposed members made of wood and secured together. Each of the first and second members has spaced sides and a surface extending between the sides. The surfaces include a first portion contoured to define a contact surface which extends in more than one plane, the first portions defining a space therebetween for receiving an adhesive for securing the first and second members together; a second portion contoured to restrict the flow of the adhesive to a position outward from the sides when the first and second members are brought into engagement; and, opposed engagement members configured to lockingly engage without substantial deformation of the engagement members and secure the first and second members together as the adhesive dries.

Owner:POCE JOHN DI

Energy-saving shape cutting method of composite floor

InactiveCN101391427AReduce wasteReduce lossTongue/grooves making apparatusWood mortising machinesEnvironmental resistanceHigh density

The invention belongs to a base plate cutting method of a wood-based panel lock-catch composite floor, which is used to improve the usage rate of a wood floor base plate and reduce the loss. The cutting method uses an non-corresponding upper and lower slotting and cutting as well as cutting saw blade copying technique, the cutting method is determined according to the shape of a wood floor lock catch, the cutting position is selected reasonably, the practical usable area of the wood floor base plate is increased, the method is particularly applicable to a high density impregnated paper lamination strengthening composite floor, the floor commonly uses the method of the lock catch assembling. Using the technique of the composite floor energy saving copying cutting method can save the loss by 3 to 7% under the situation that the original structure of the wood floor base plate is not changed, the width of the wood board strip produced after the cutting of the wood floor base plate before shape milling is more than or equal to the practical calculating width of the wood floor base plate being equally divided corresponding to the required specification of the finished wood floor, the method really plays the effects of saving the wood resources, reducing the cost, saving the energy and protecting the environment; the competitive advantage of the floor production enterprises is increased.

Owner:沈冬良

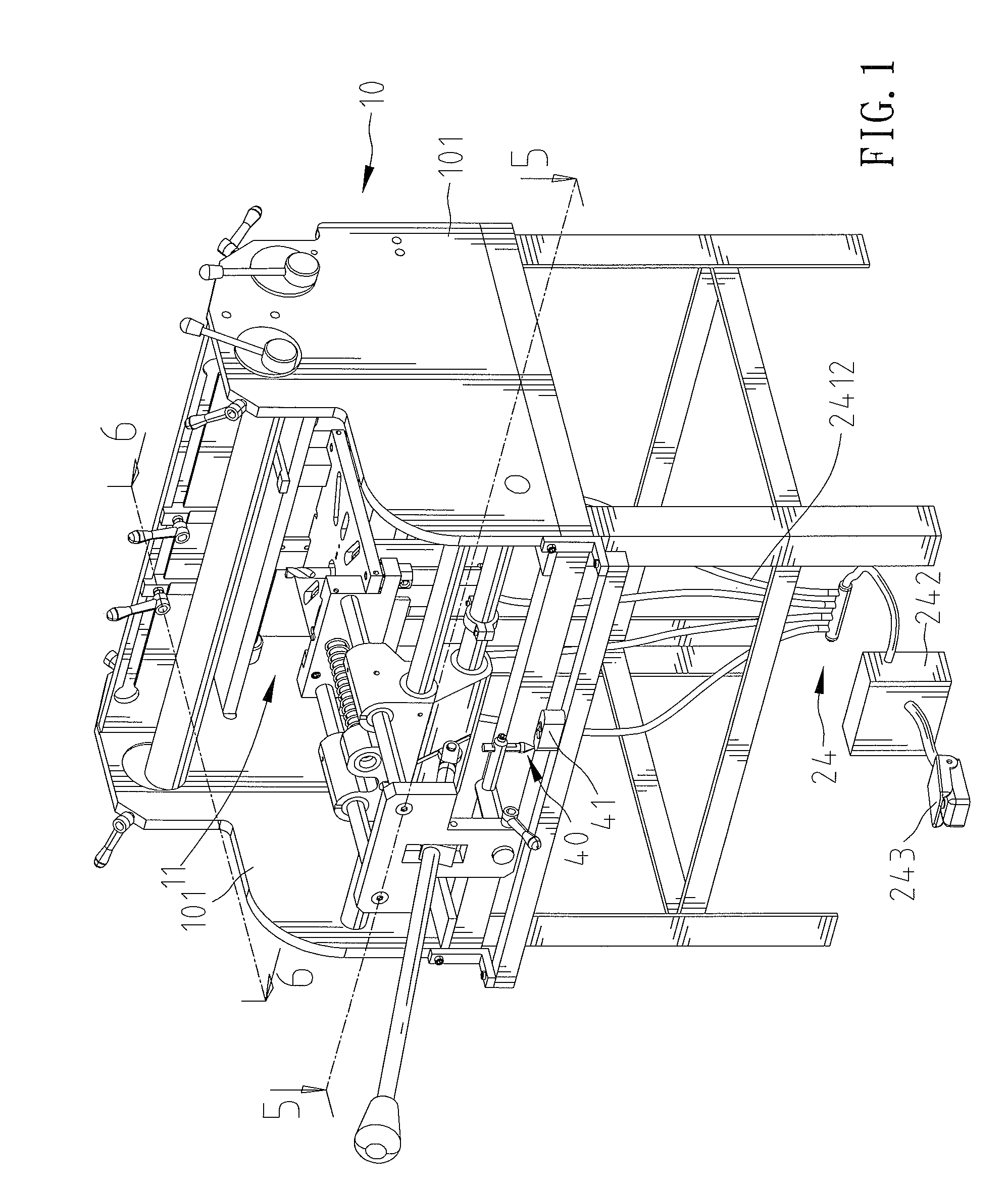

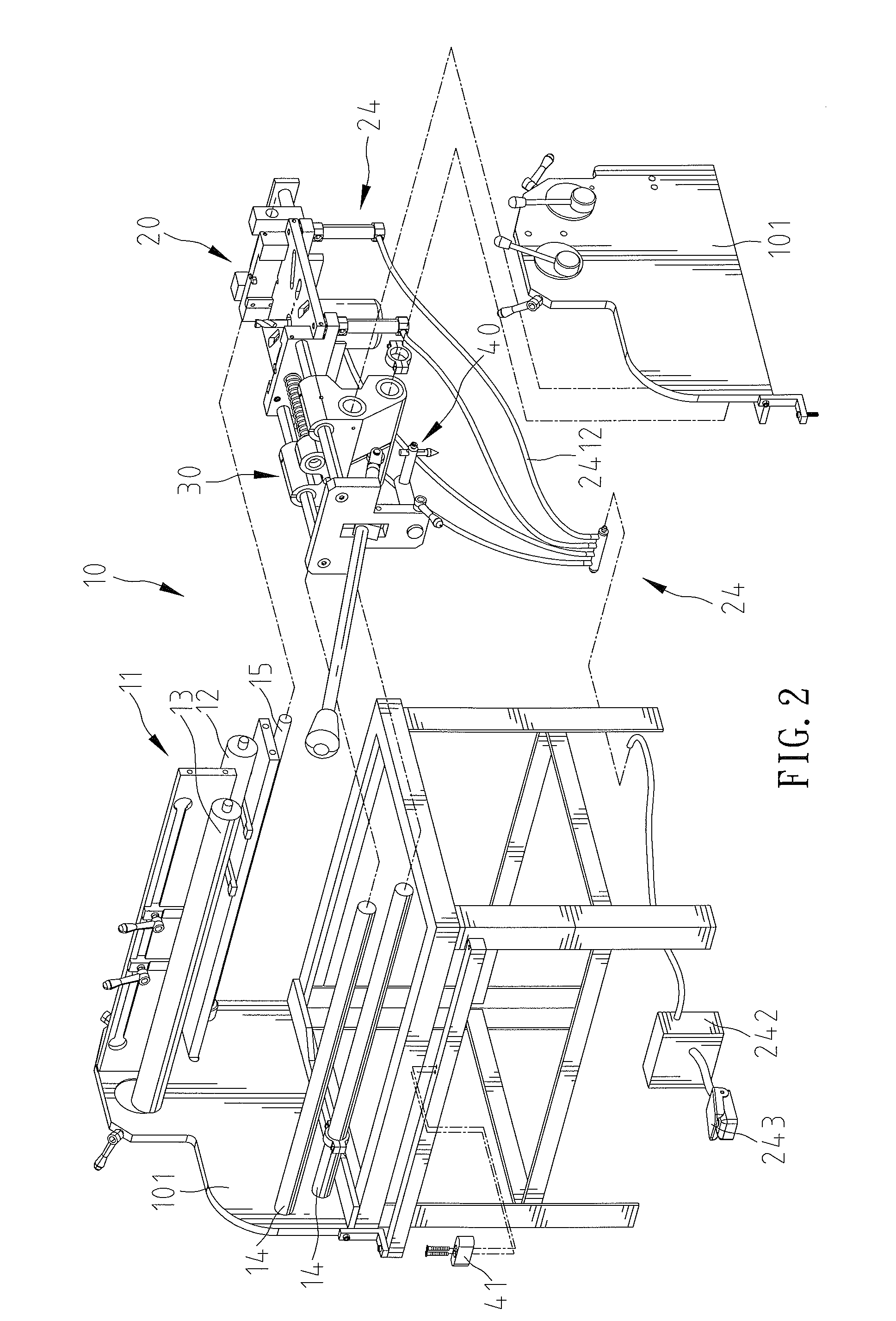

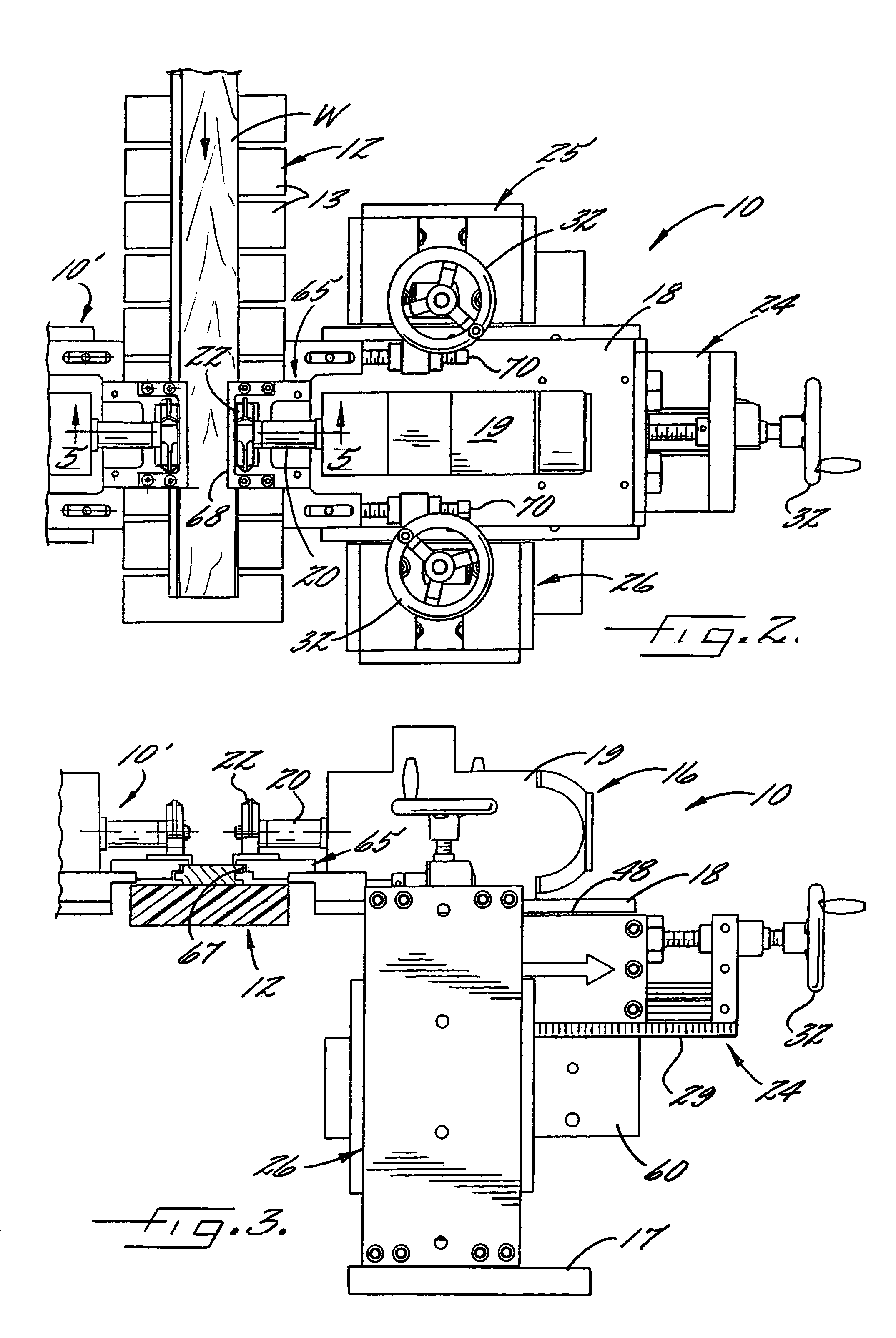

Multi-Function Mortise/Tenon Apparatus

A multi-function mortise / tenon apparatus, the apparatus comprises a chassis including a placement portion for placing a work piece horizontally / vertically and at least one transverse sliding rod; a work table including a first base member, a second base member and a lift / lower platform provided between the first and second base members; wherein the lift / lower platform and the first and second base members are driven to slide with respect to the chassis transversely / longitudinally; wherein the lift / lower platform is driven to lift / lower with respect to the chassis; and a guiding device installed to the at least one first sliding rod slideably and transversely and coupled to the work table which is driven by the guiding device to slide with respect to the chassis transversely / longitudinally.

Owner:YANG JACK

Workpiece beveling machine

Owner:HASKO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com